Patents

Literature

18949 results about "Quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, quenching is the rapid cooling of a workpiece in water, oil or air to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable, and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness.

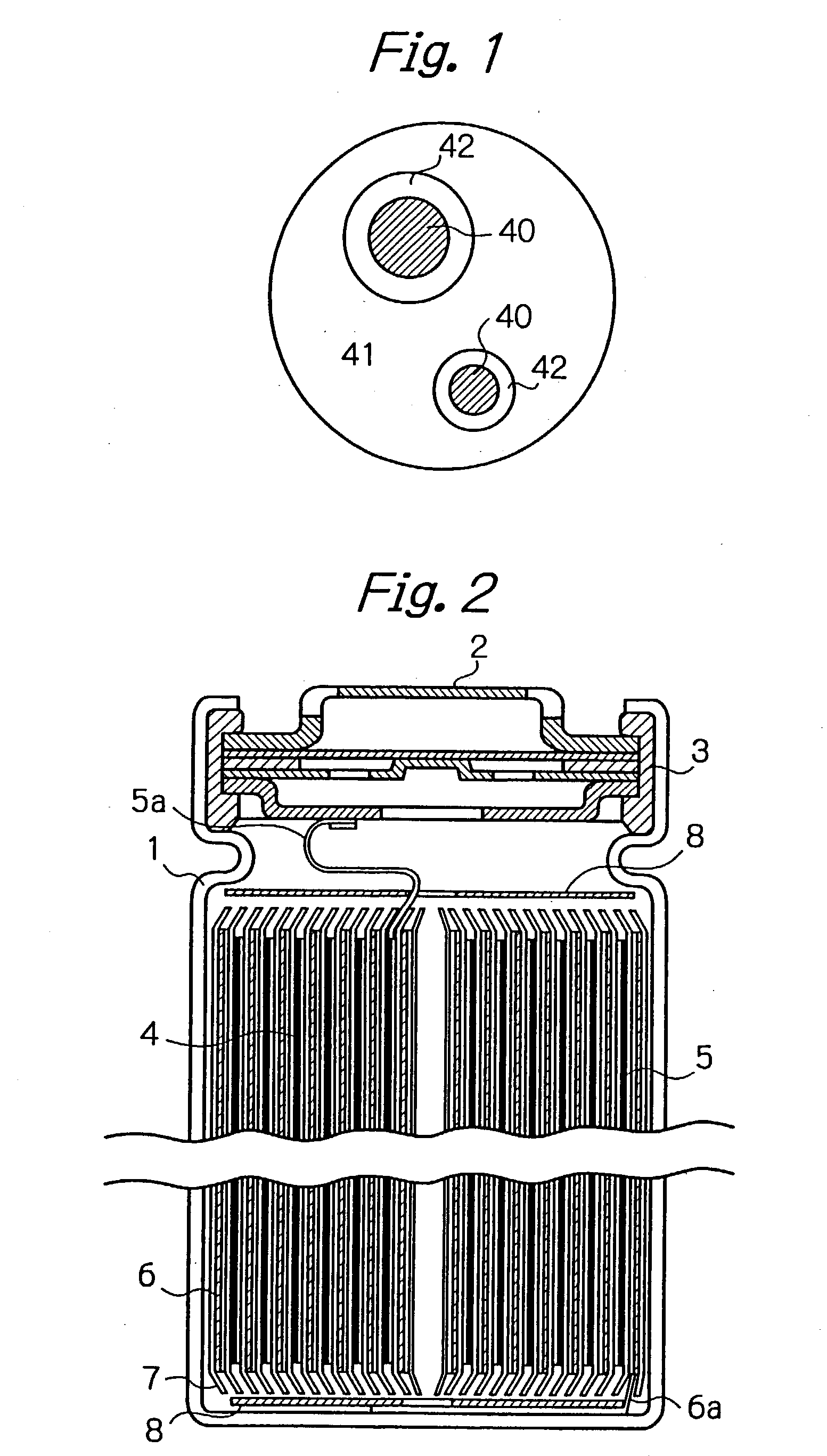

Wavelength Converter, Light-Emitting Device, Method of Producing Wavelength Converter and Method of Producing Light-Emitting Device

InactiveUS20080231170A1Reduce self-quenchingSolve low luminous efficiencyDischarge tube luminescnet screensLamp detailsPhosphorFluorescence

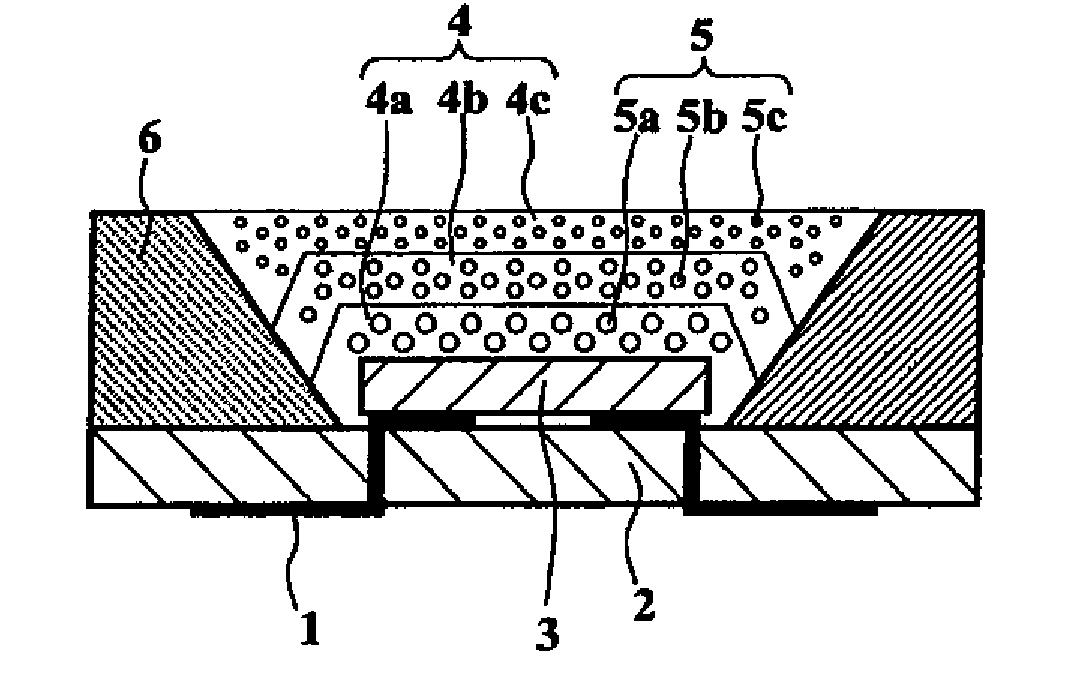

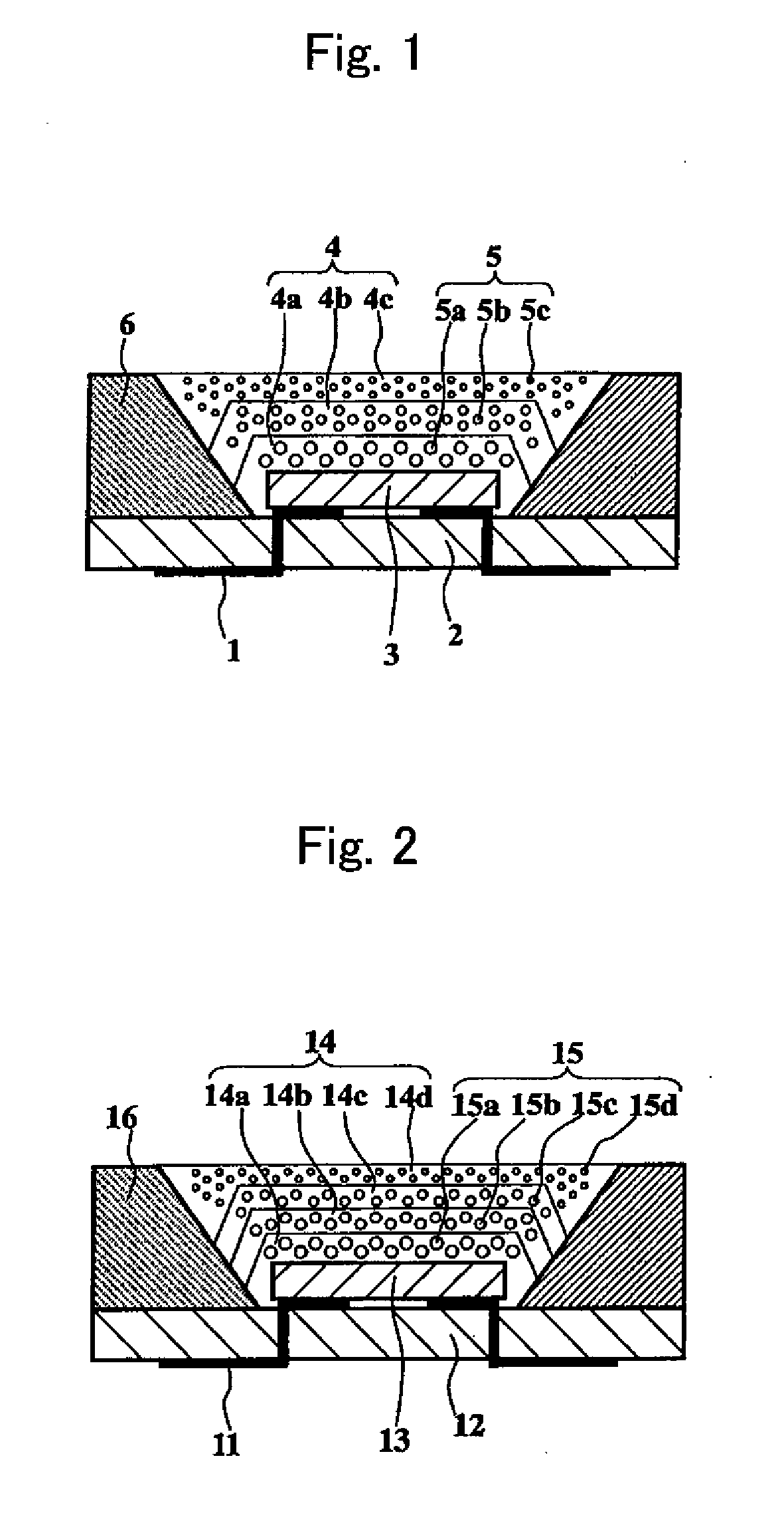

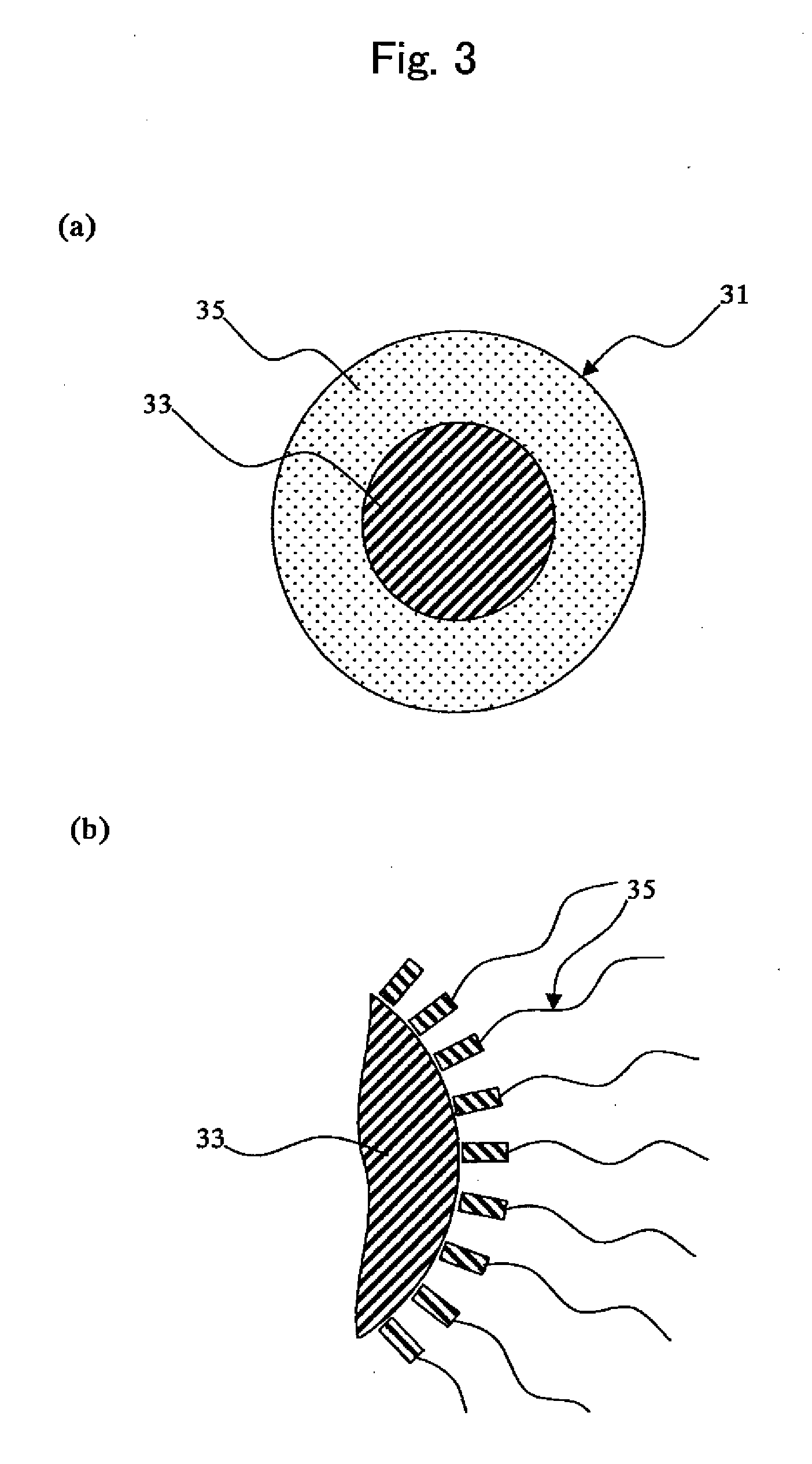

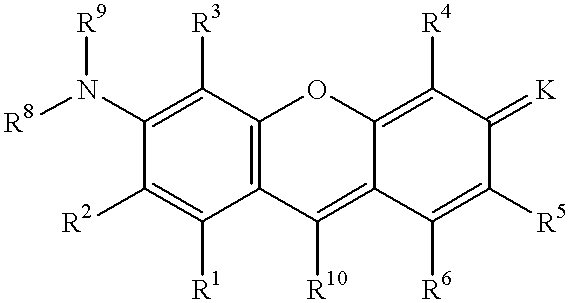

A light-emitting device comprises a light-emitting element 3 that is provided on a substrate 2 and emits excitation light, and a wavelength converter 4 that converts the excitation light into visible light. The visible light is output light. The wavelength converter 4 comprises a plurality of wavelength conversion layers 4a, 4b and 4c which respectively contain, as phosphors, at least one type of semiconductor ultrafine particles having a mean particle size of not more than 20 nm and at least one type of fluorescent substance having a mean particle size of not less than 0.1 μm in a resin matrix. Thereby, self-quenching of phosphors is reduced and high luminous efficiency is attained.

Owner:KYOCERA CORP

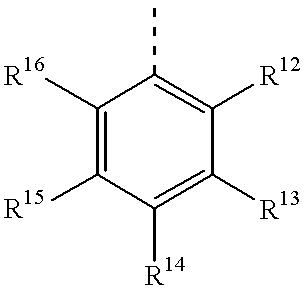

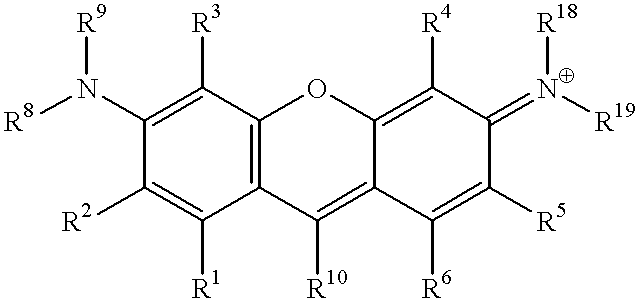

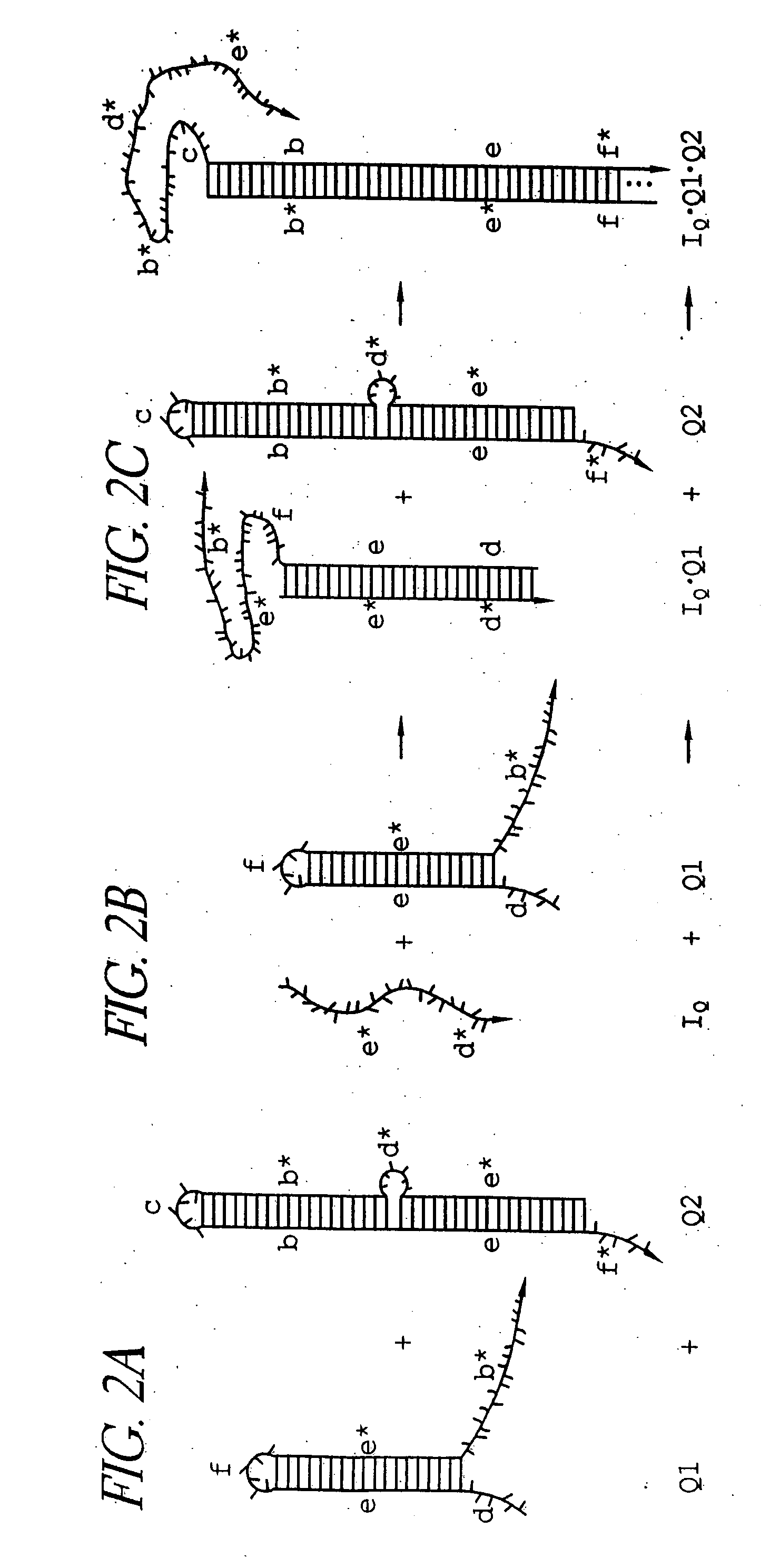

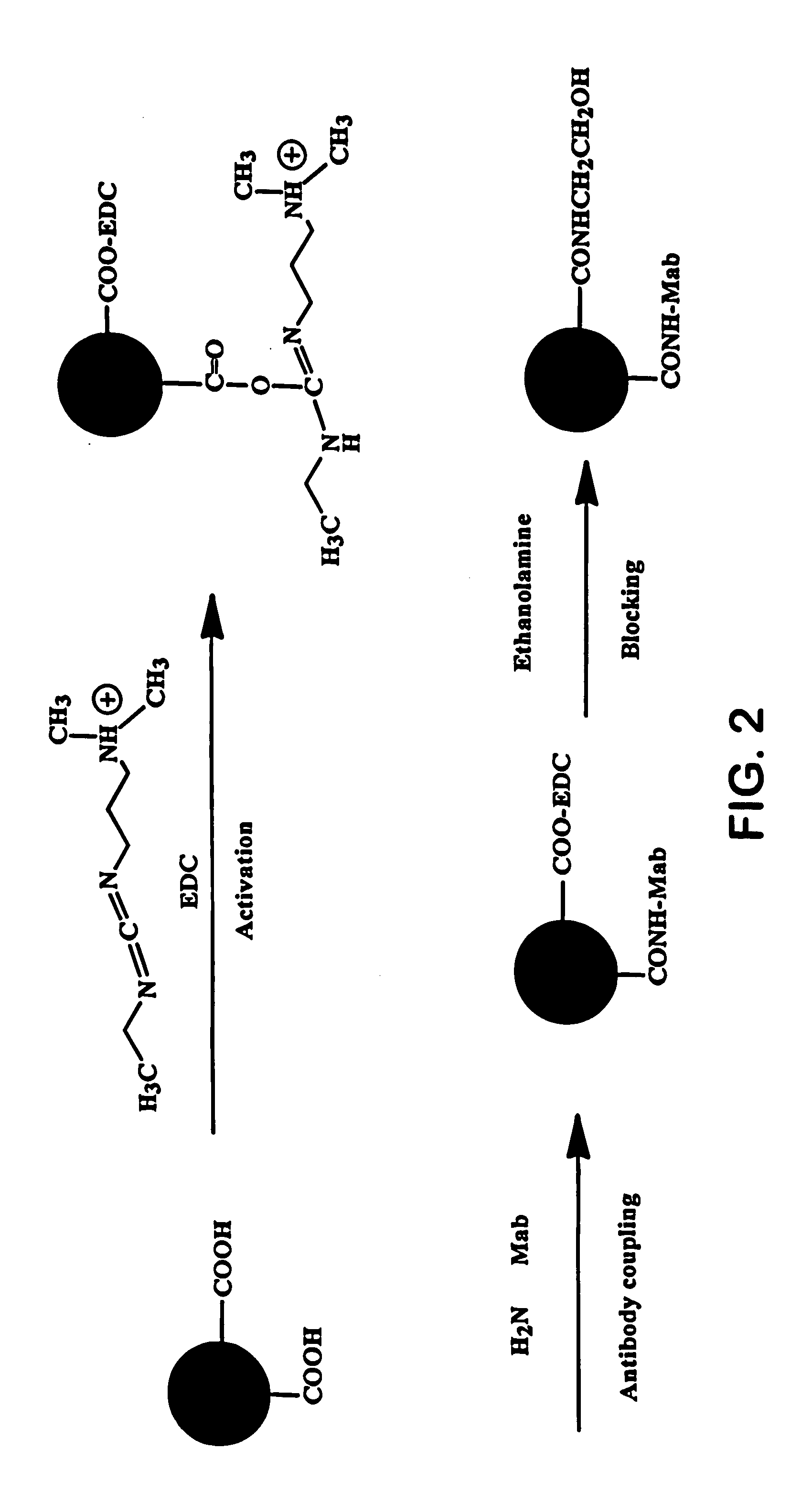

Quenching oligonucleotides

InactiveUS6323337B1Decreasing background fluorescenceReducing background fluorescenceSugar derivativesMicrobiological testing/measurementEnergy transferQuenching

The invention relates to oligonucleotides labeled with an energy transfer acceptor useful in conjunction with fluorescent nucleic acid stains. The resulting oligonucleotides are useful for decreasing background fluorescence during amplification assays and in ligation assays, and for detecting hybridization.

Owner:MOLECULAR PROBES

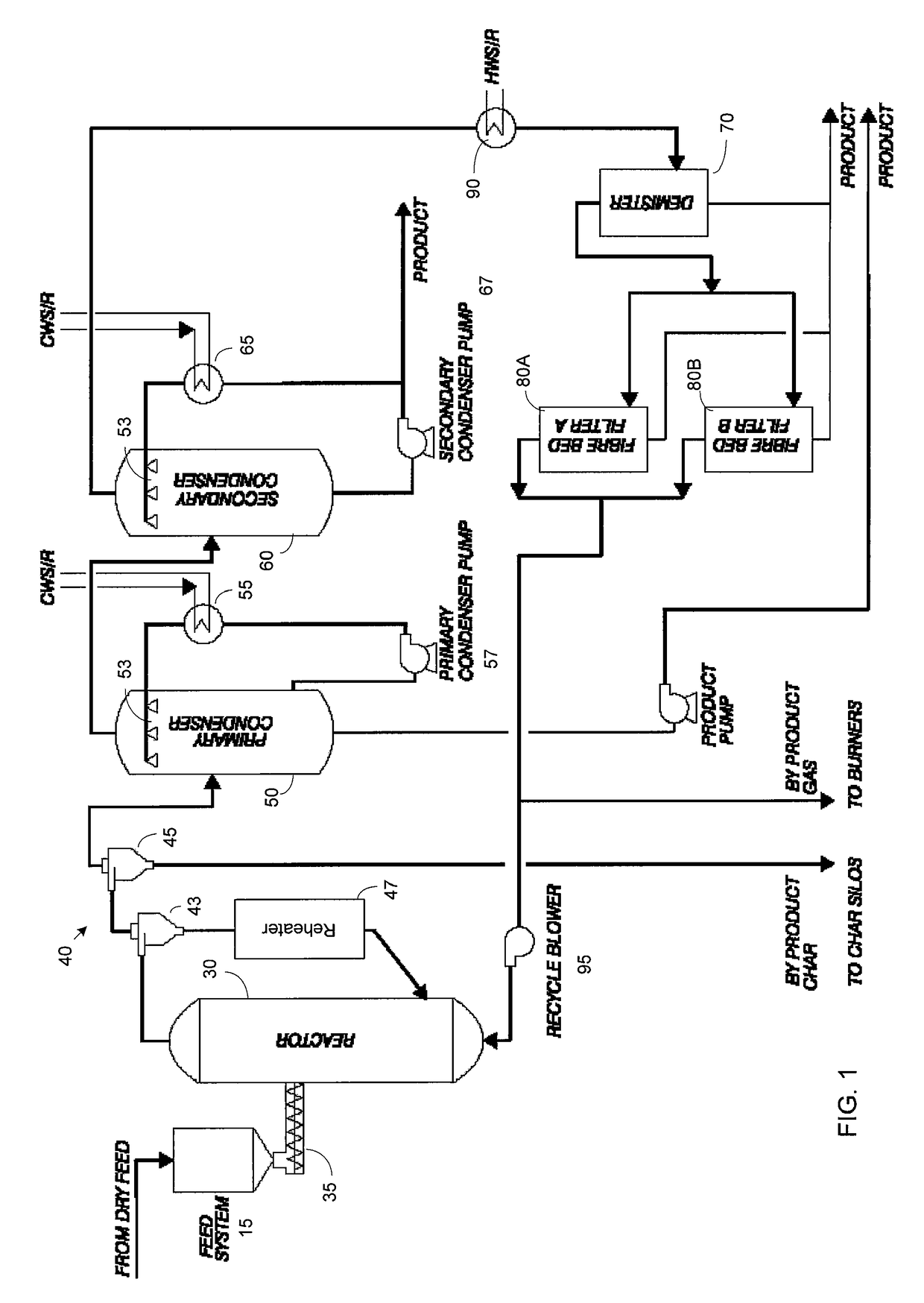

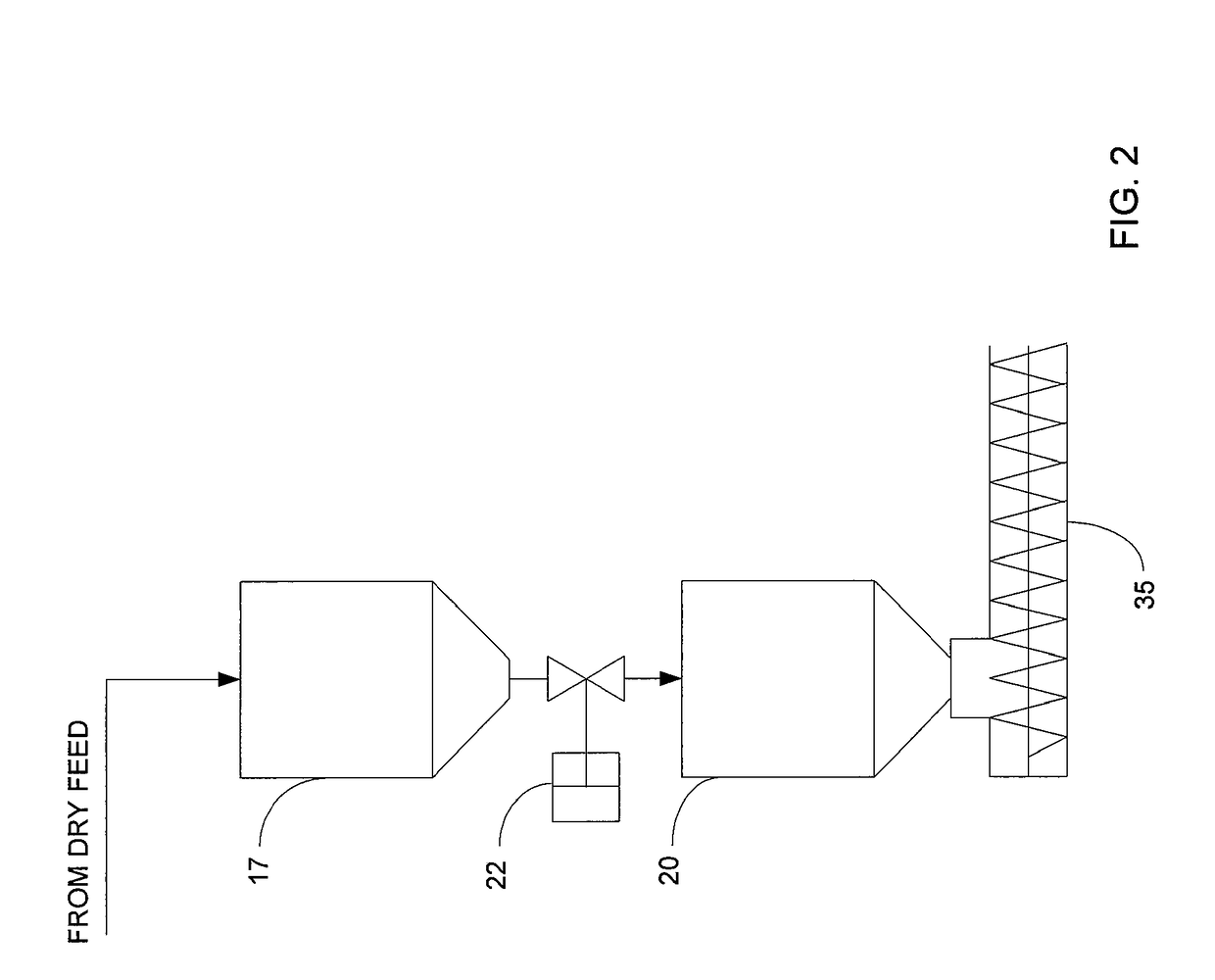

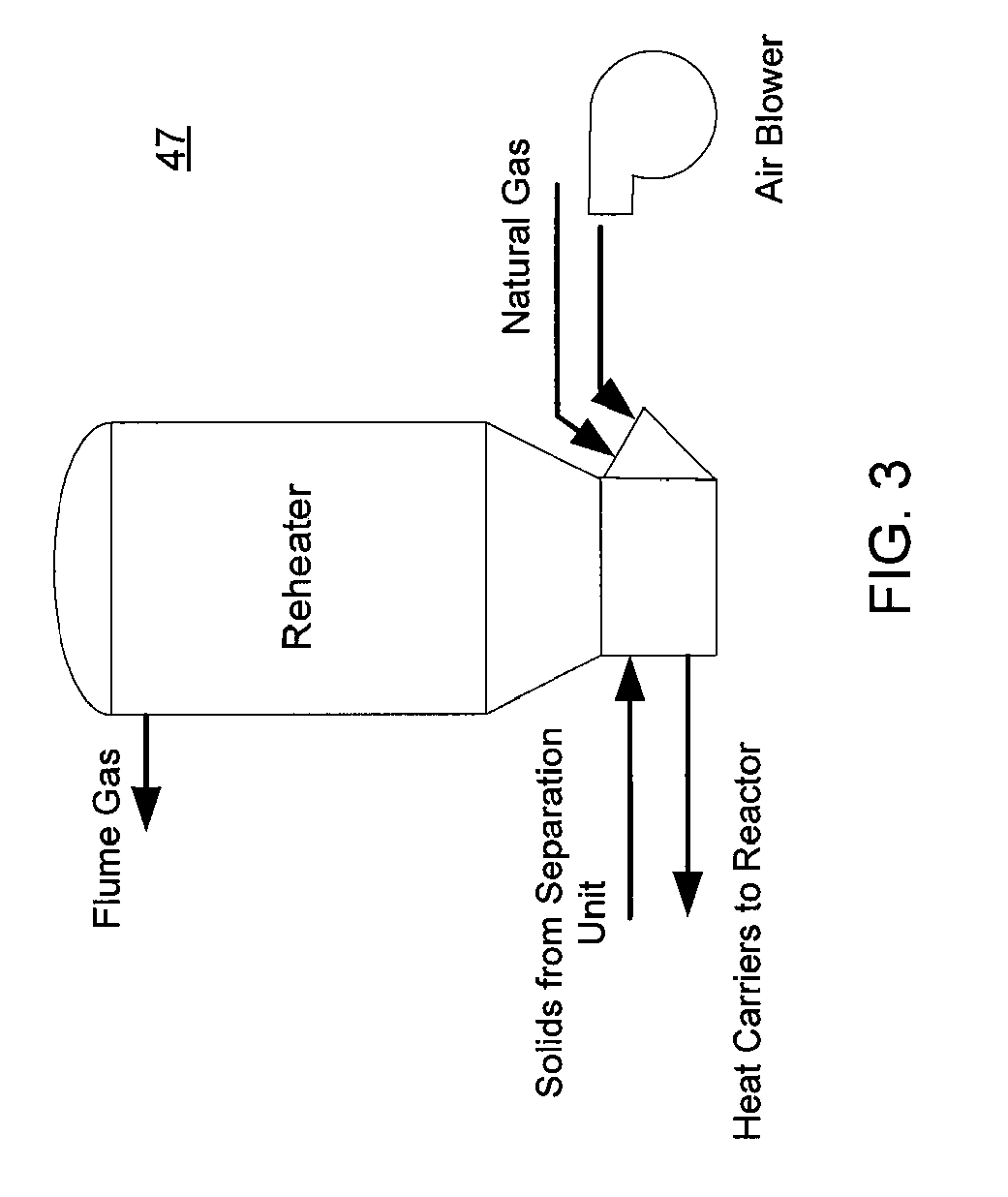

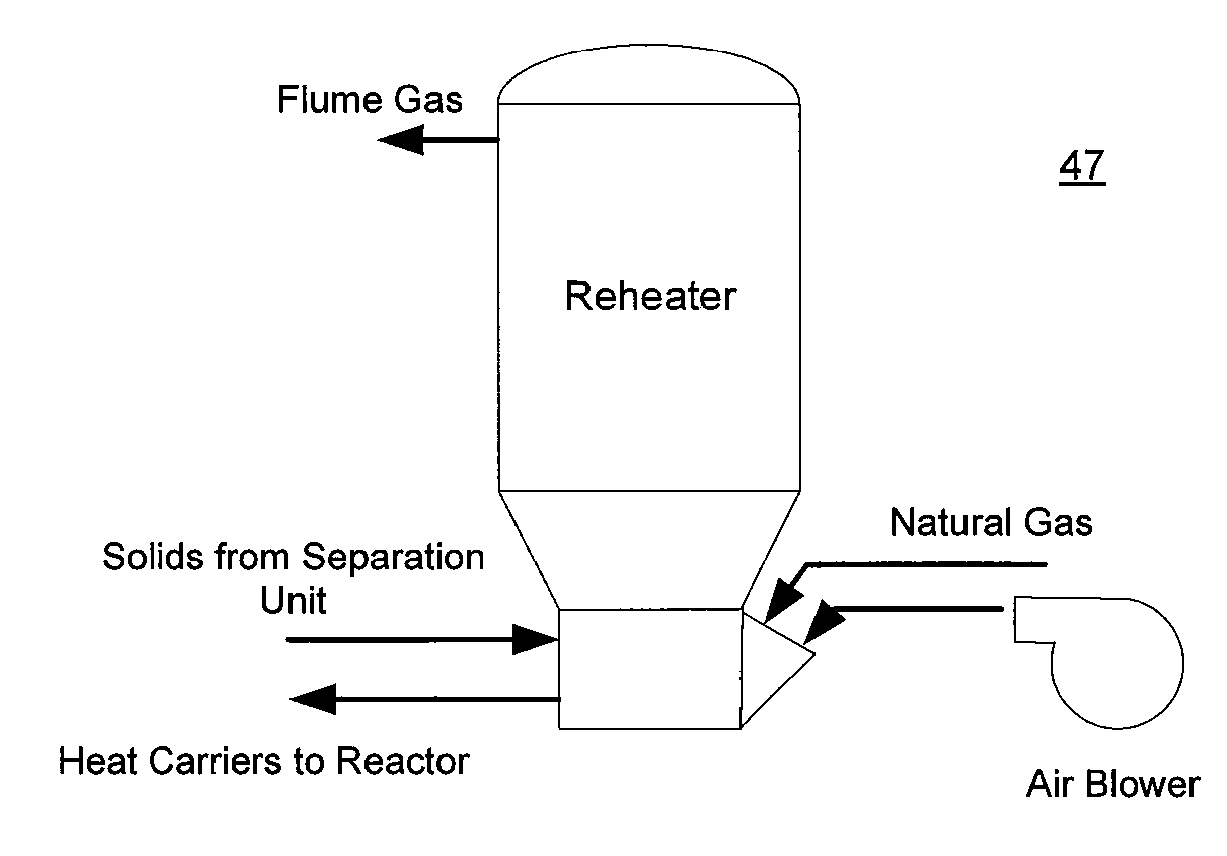

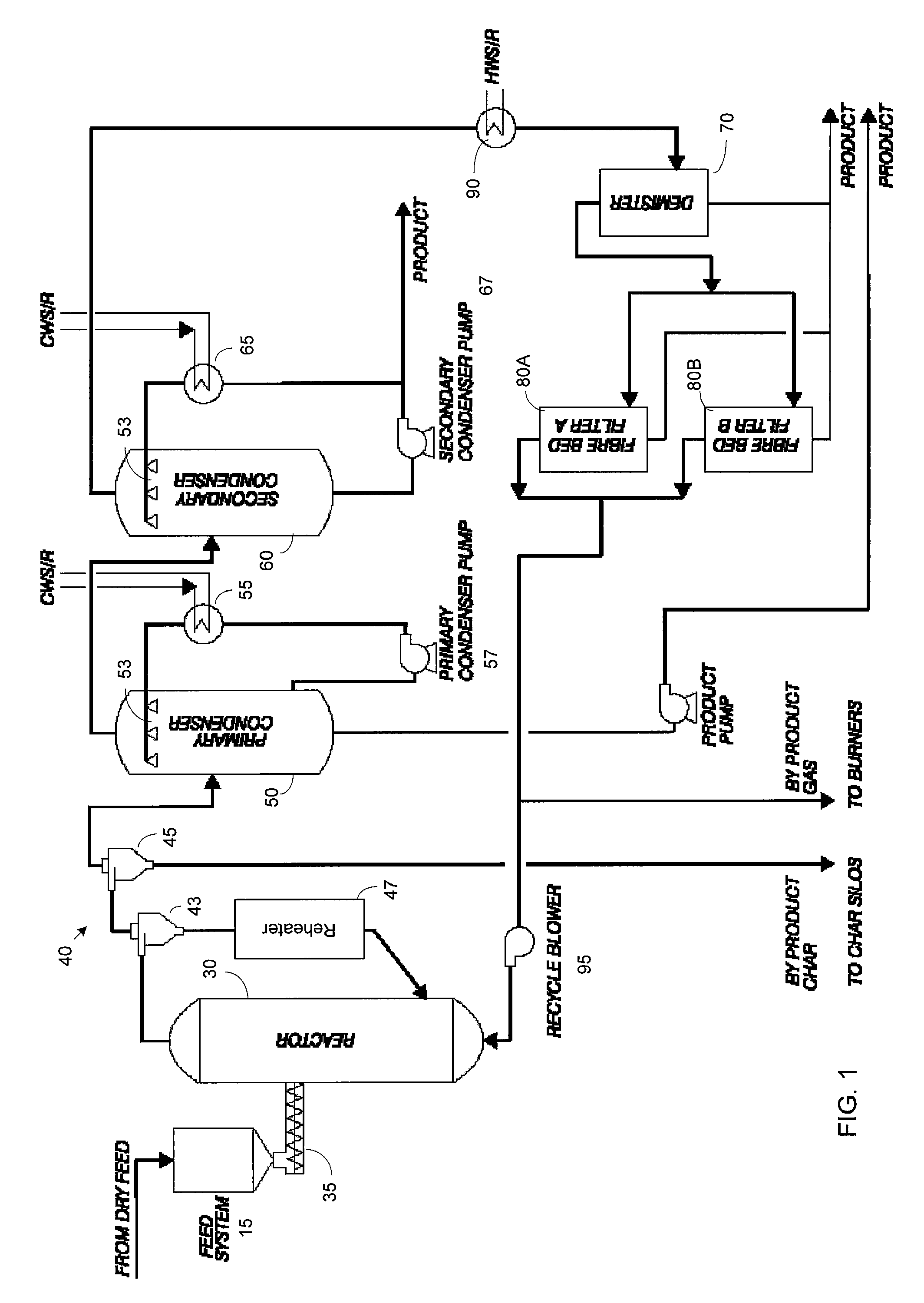

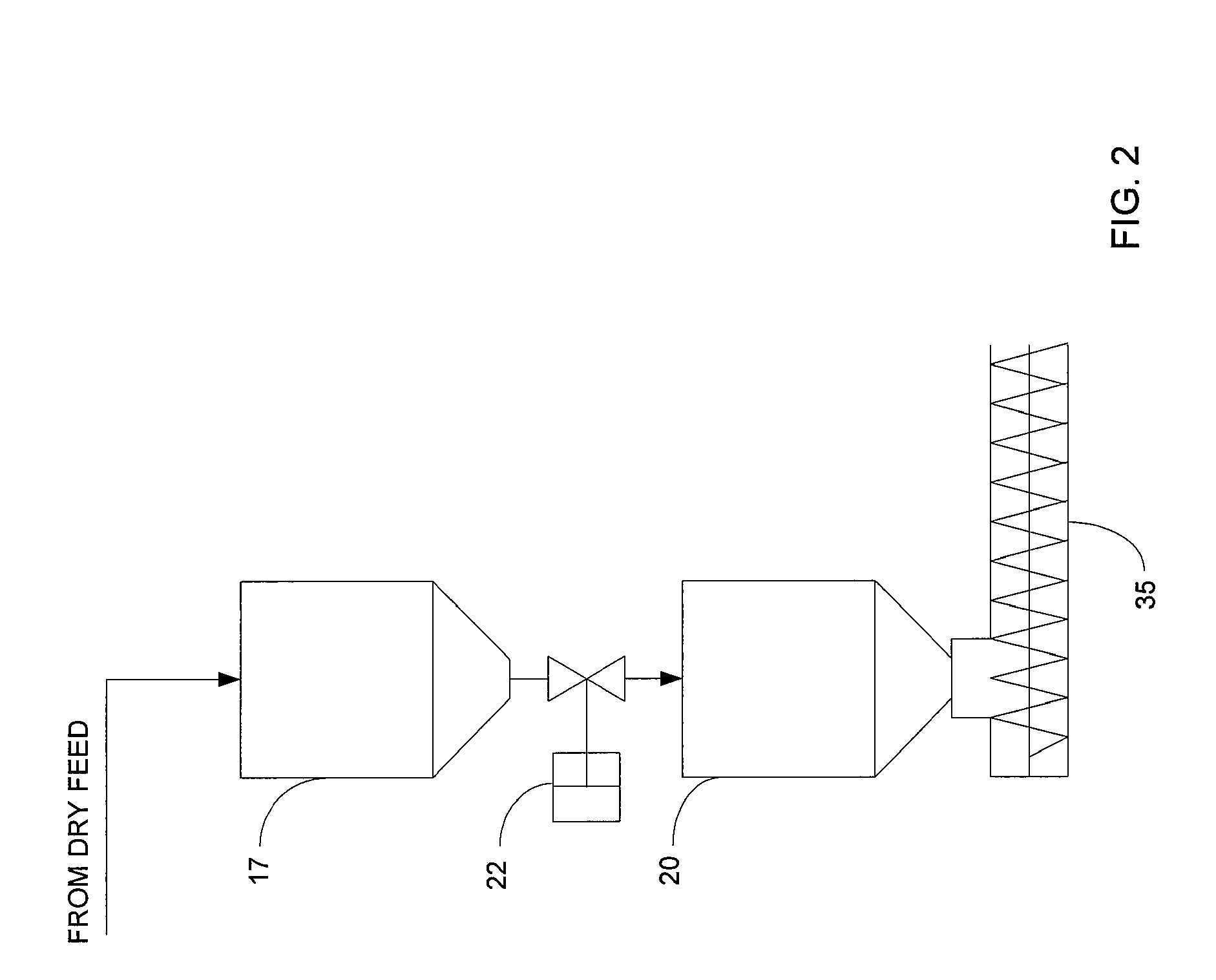

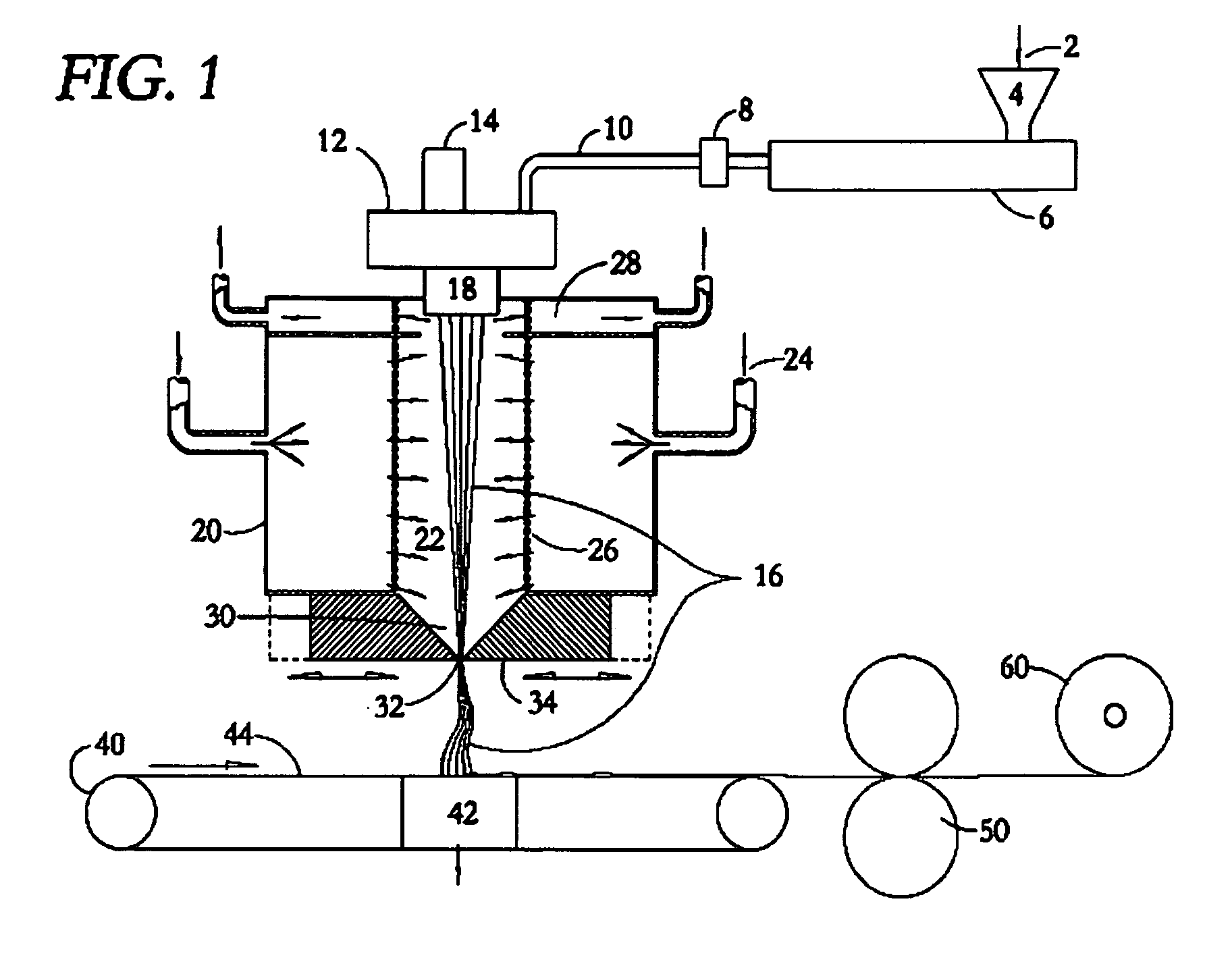

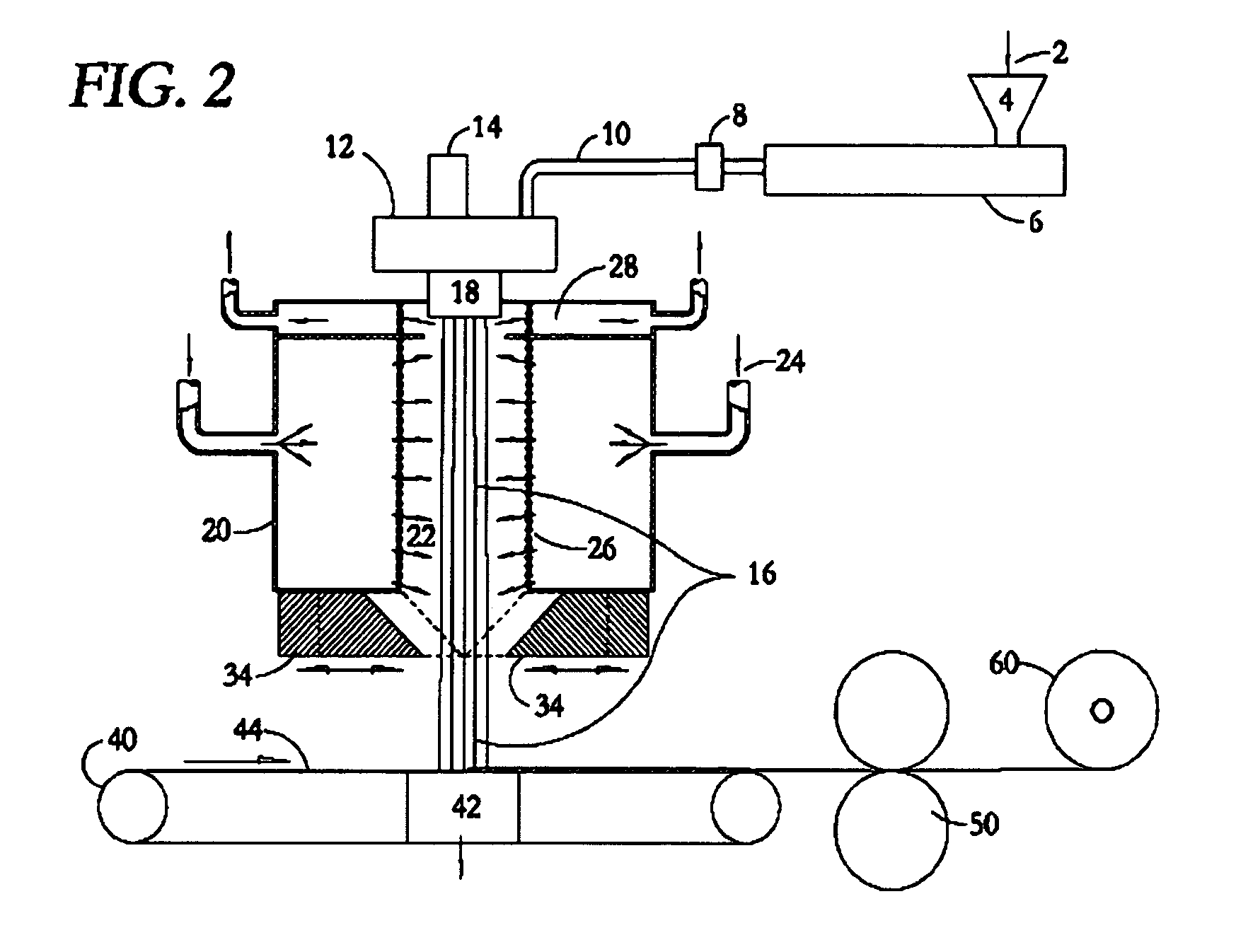

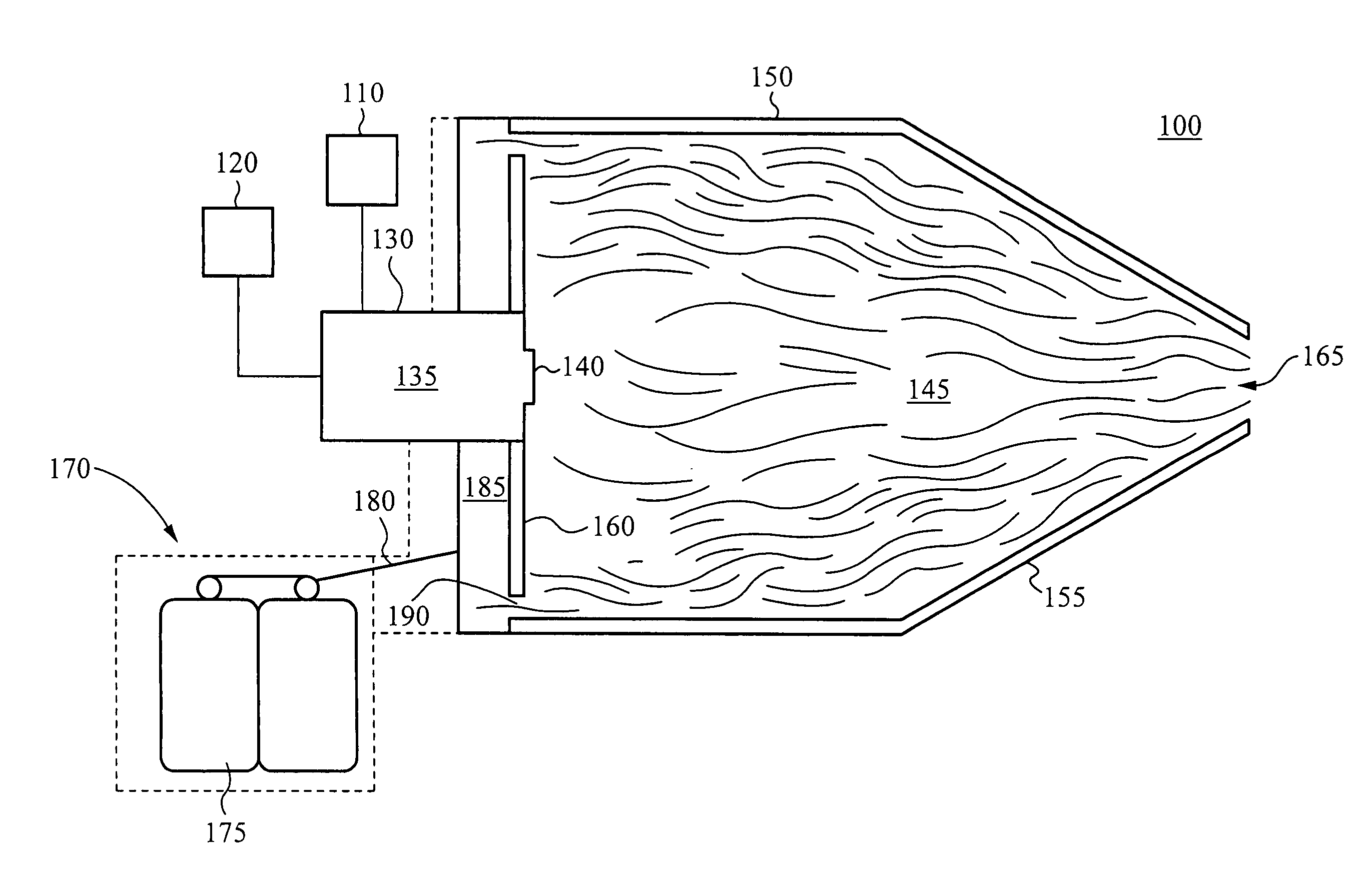

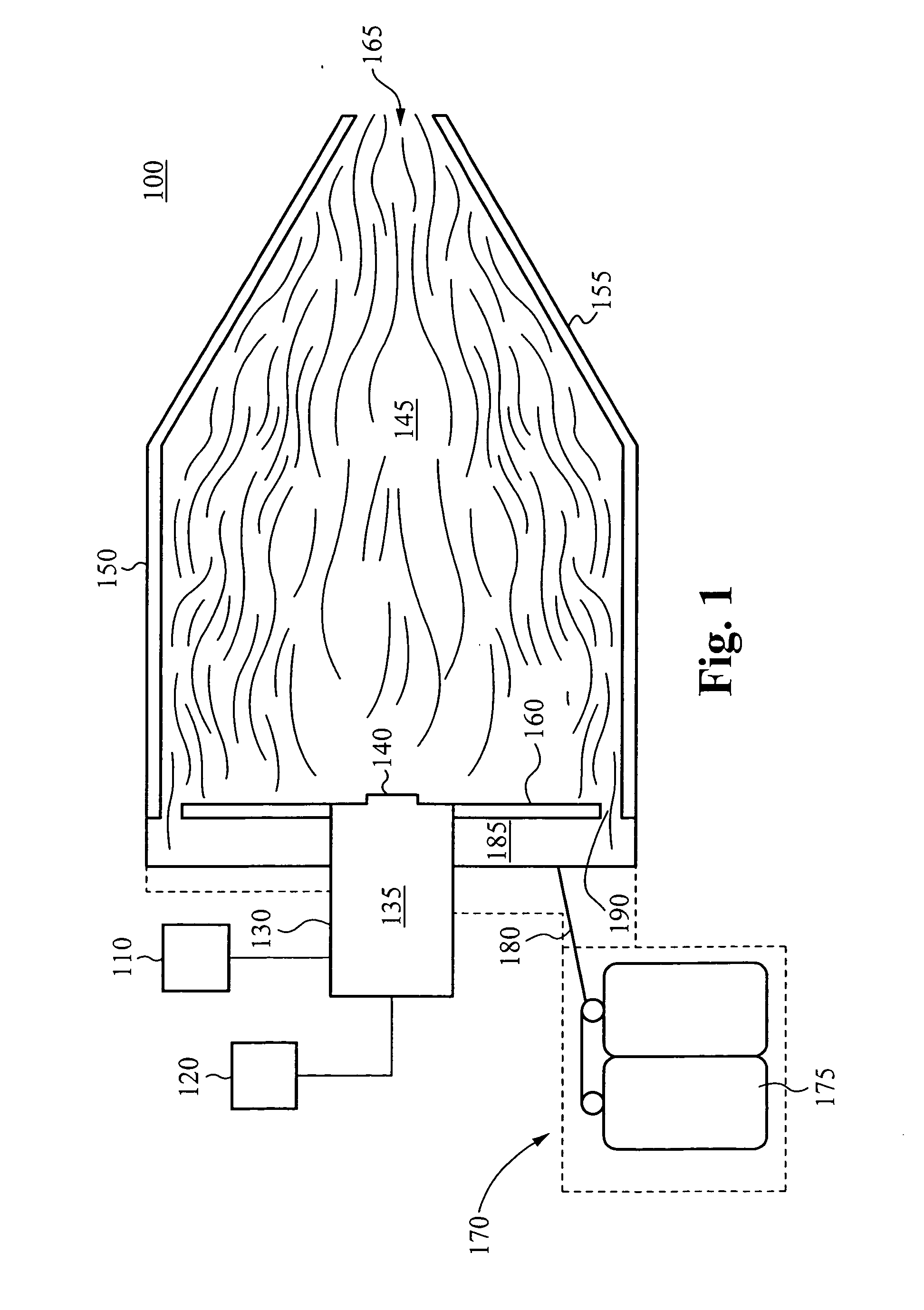

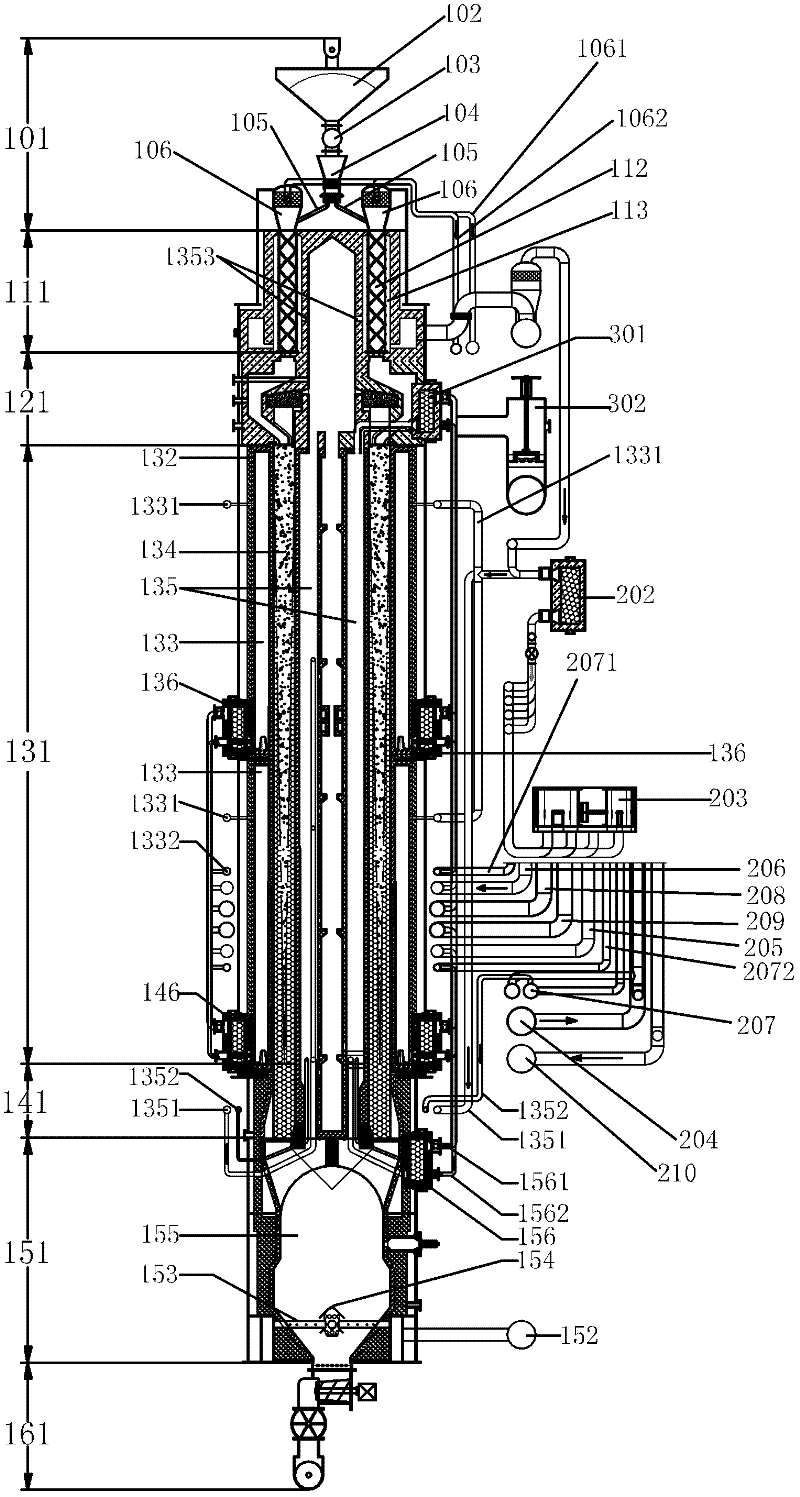

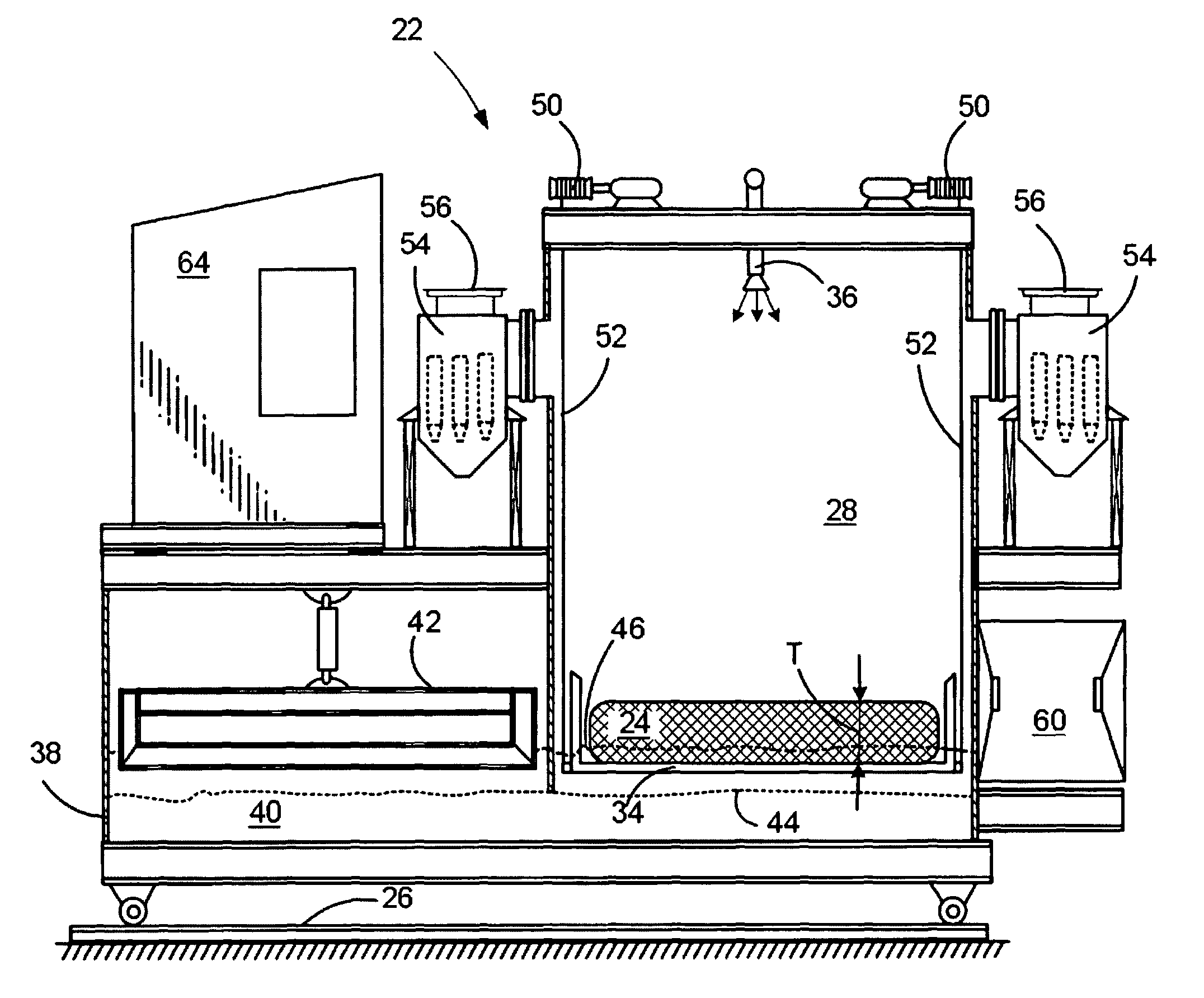

Rapid thermal conversion of biomass

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

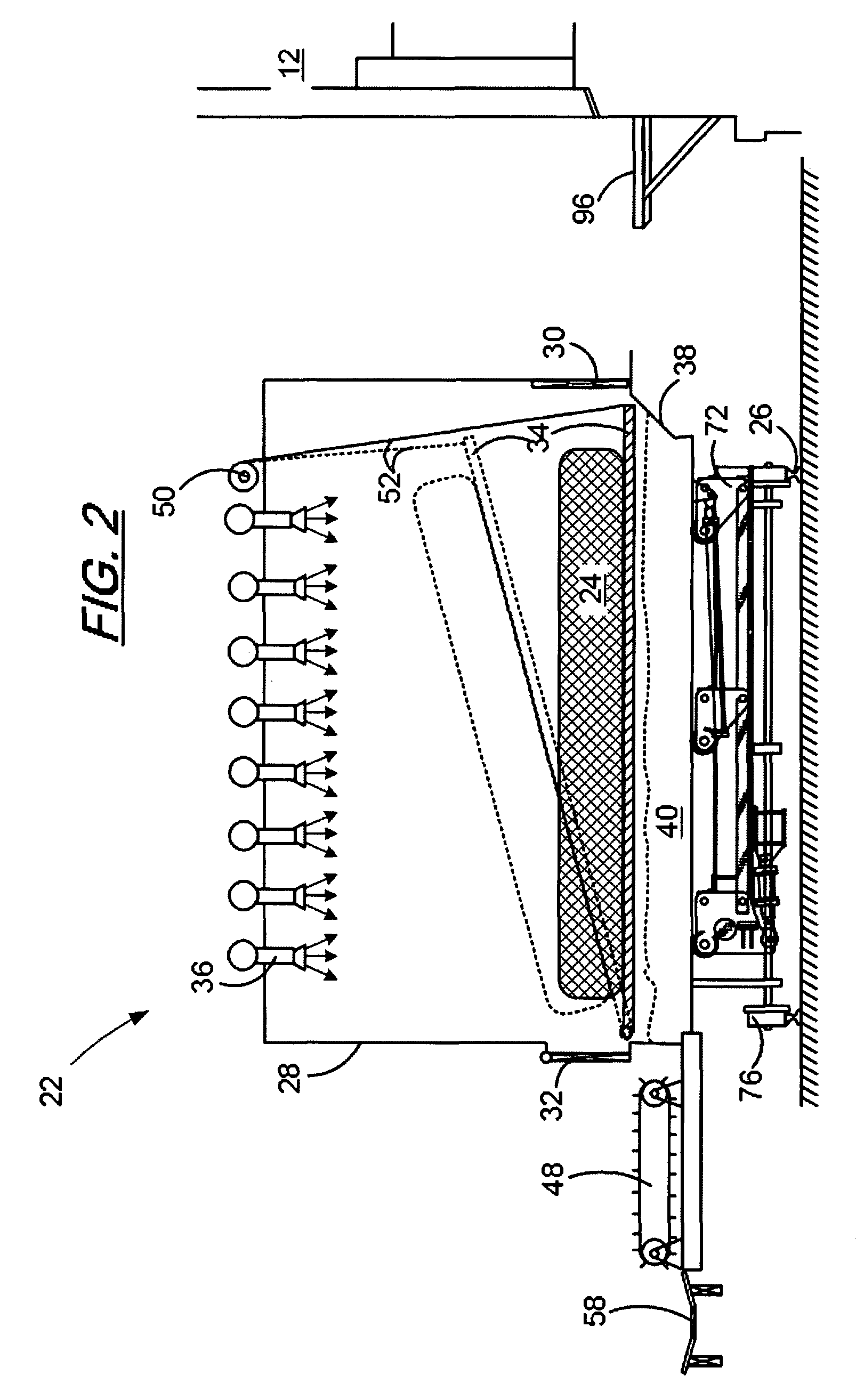

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

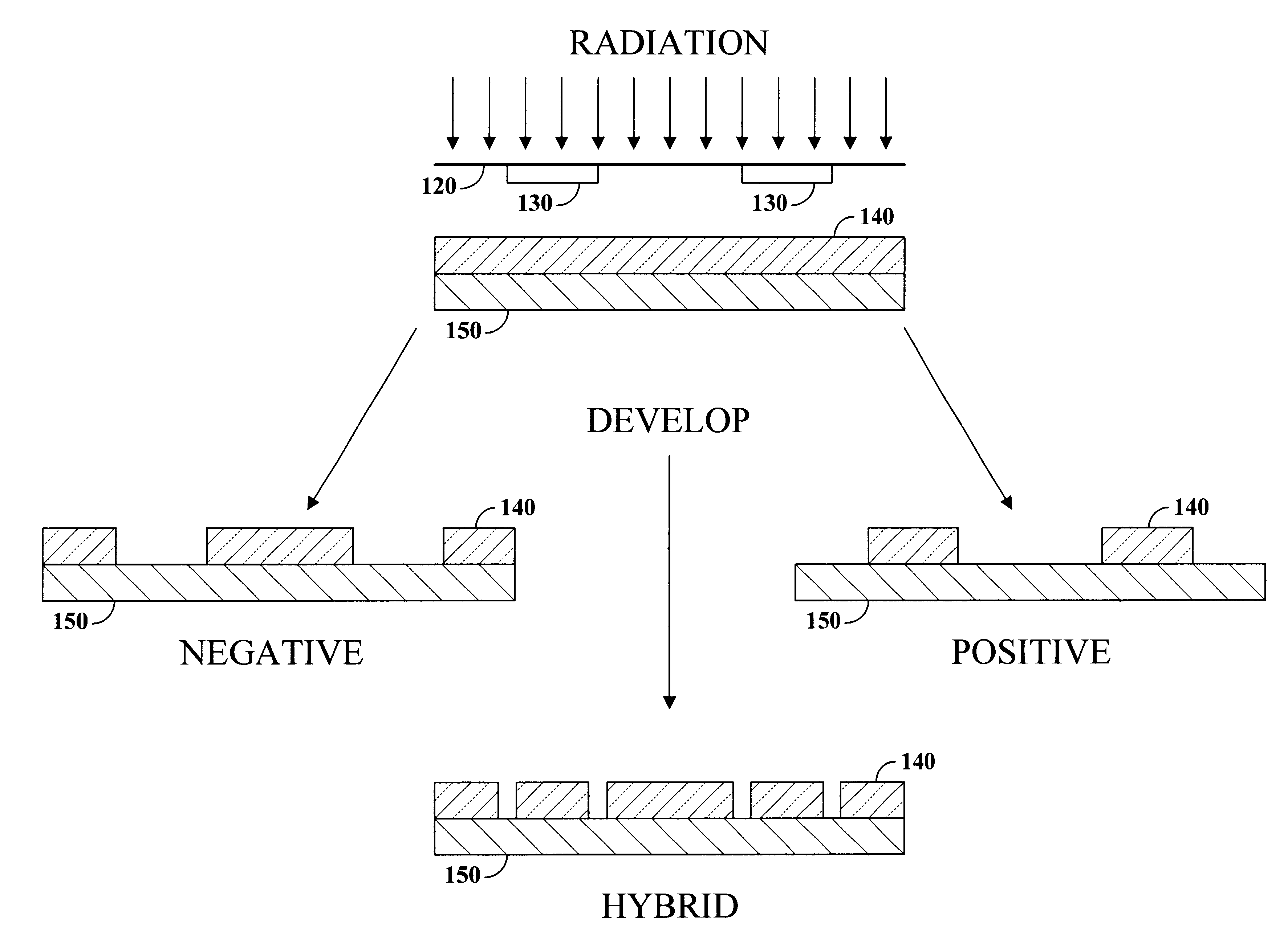

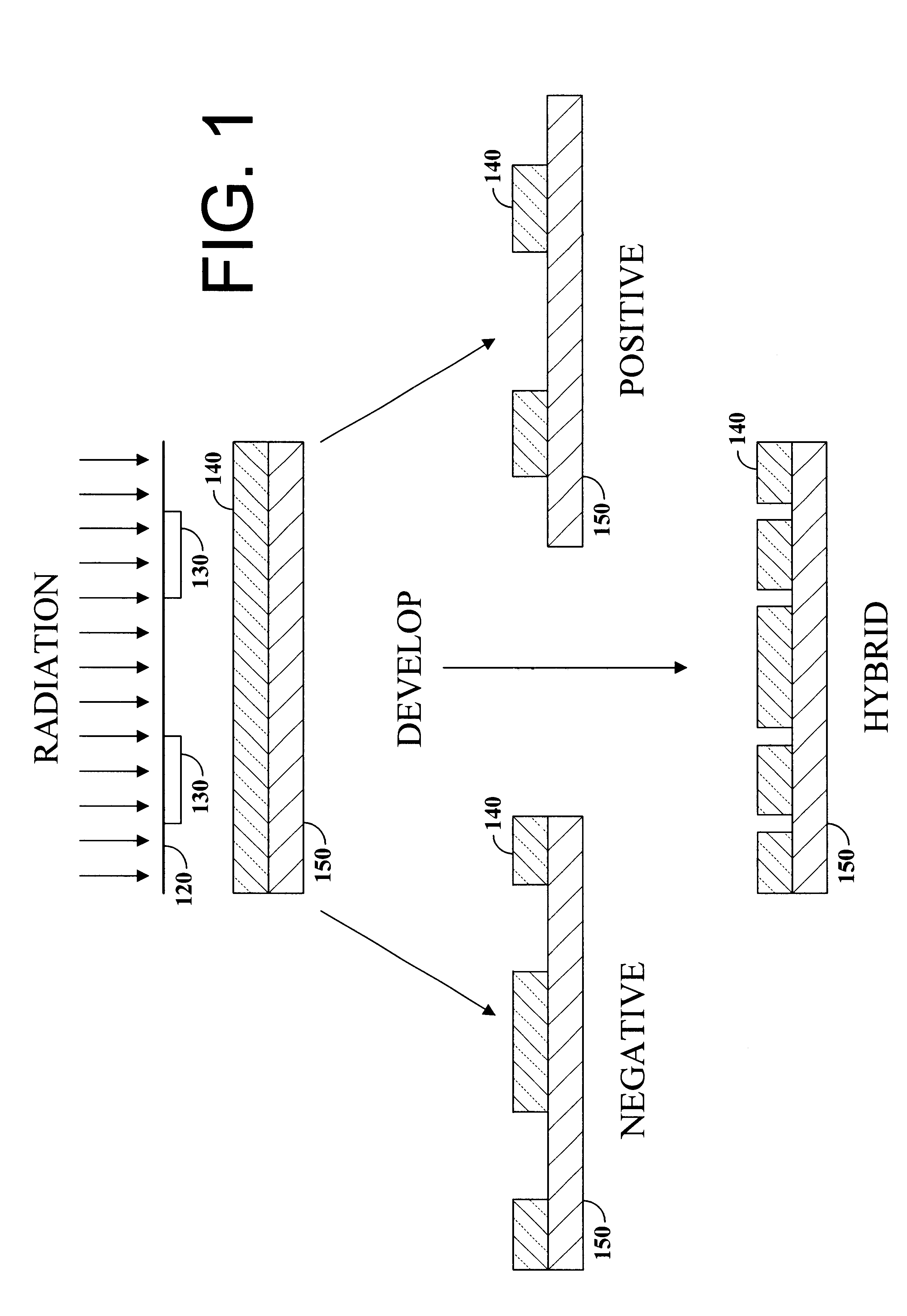

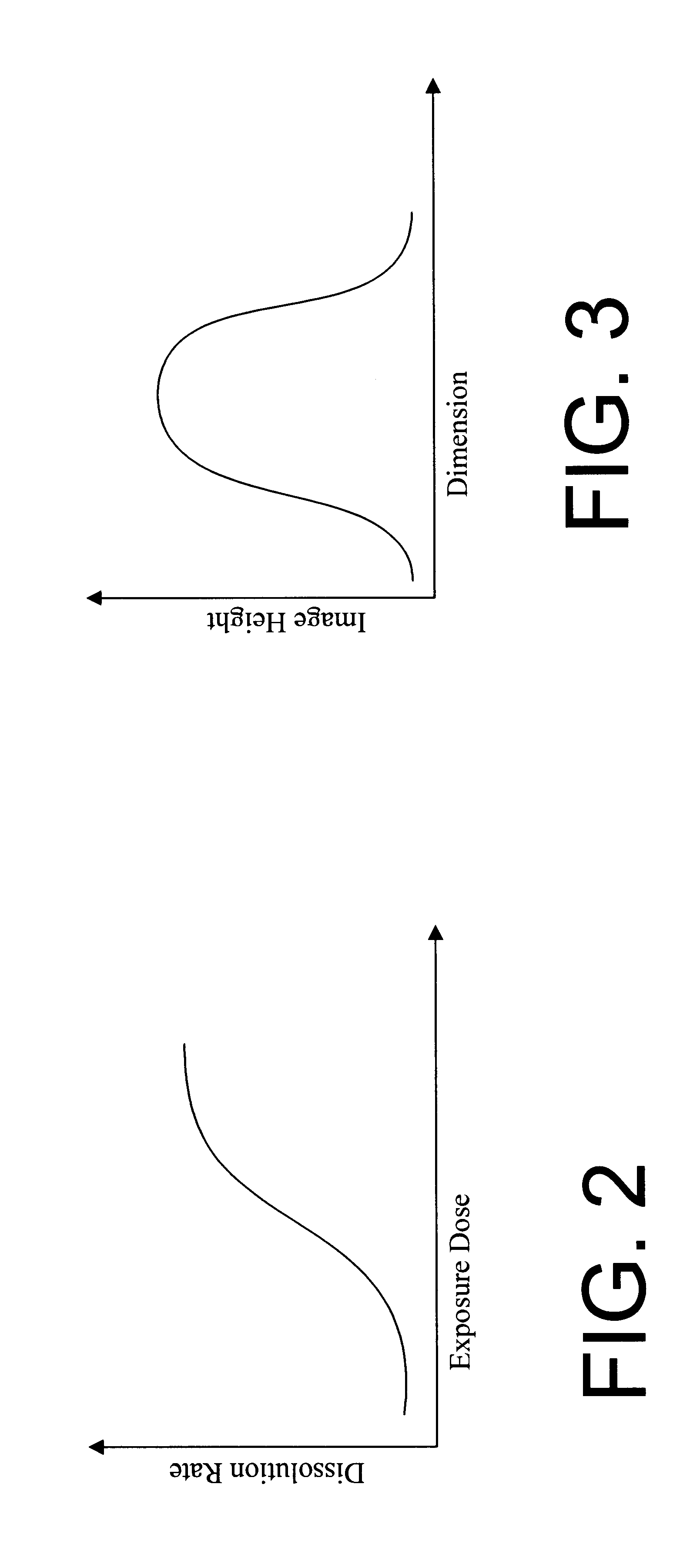

Hybrid resist based on photo acid/photo base blending

A photo resist composition contains a polymer resin, a first photo acid generator (PAG) requiring a first dose of actinic energy to generate a first photo acid, and a photo base generator (PBG) requiring a second dose of actinic energy, different from the first dose, to generate a photo base. The amounts and types of components in the photo resist are selected to produce a hybrid resist image. Either the first photo acid or photo base acts as a catalyst for a chemical transformation in the resist to induce a solubility change. The other compound is formulated in material type and loading in the resist such that it acts as a quenching agent. The catalyst is formed at low doses to induce the solubility change and the quenching agent is formed at higher doses to counterbalance the presence of the catalyst. Accordingly, the same frequency doubling effect of conventional hybrid resist compositions may be obtained, however, either a line or a space may be formed at the edge of an aerial image. Feature size may also be influenced by incorporating a quenching agent into the resist composition that does not require photo generation.

Owner:IBM CORP

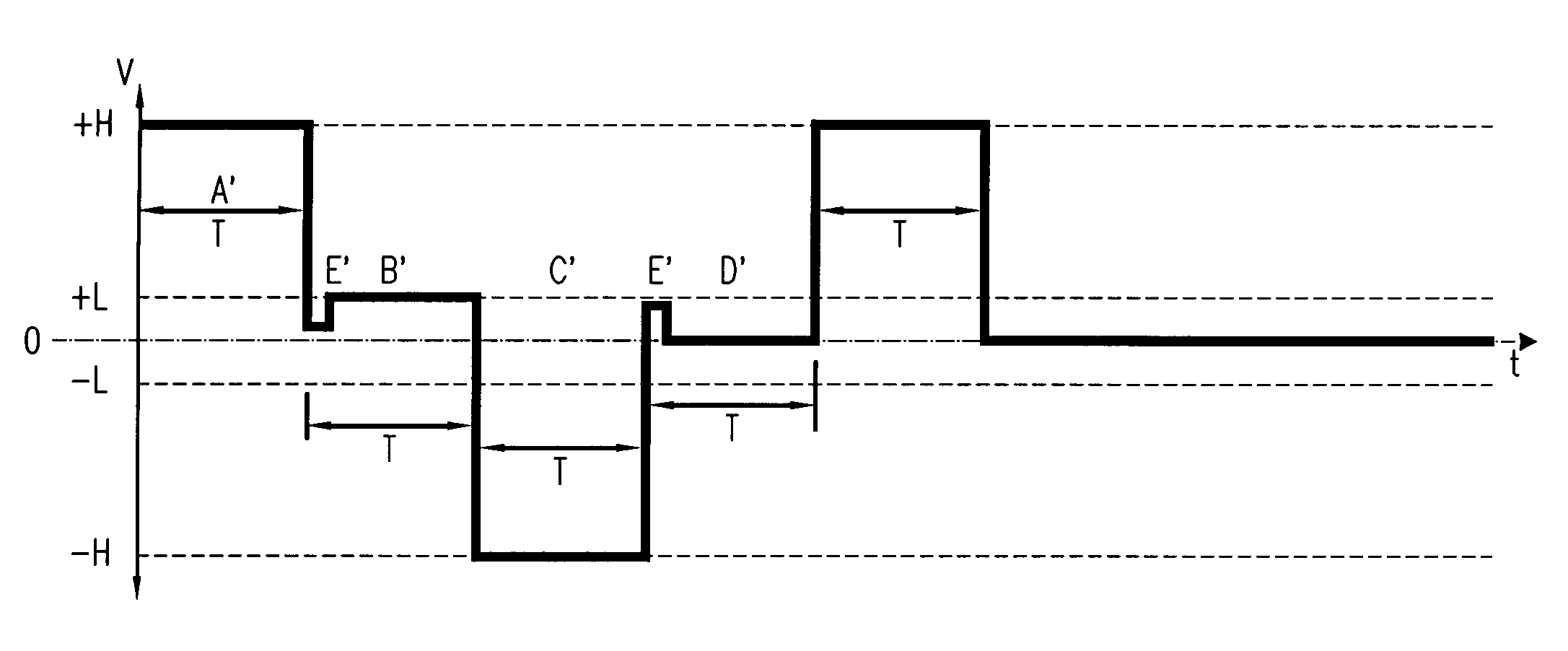

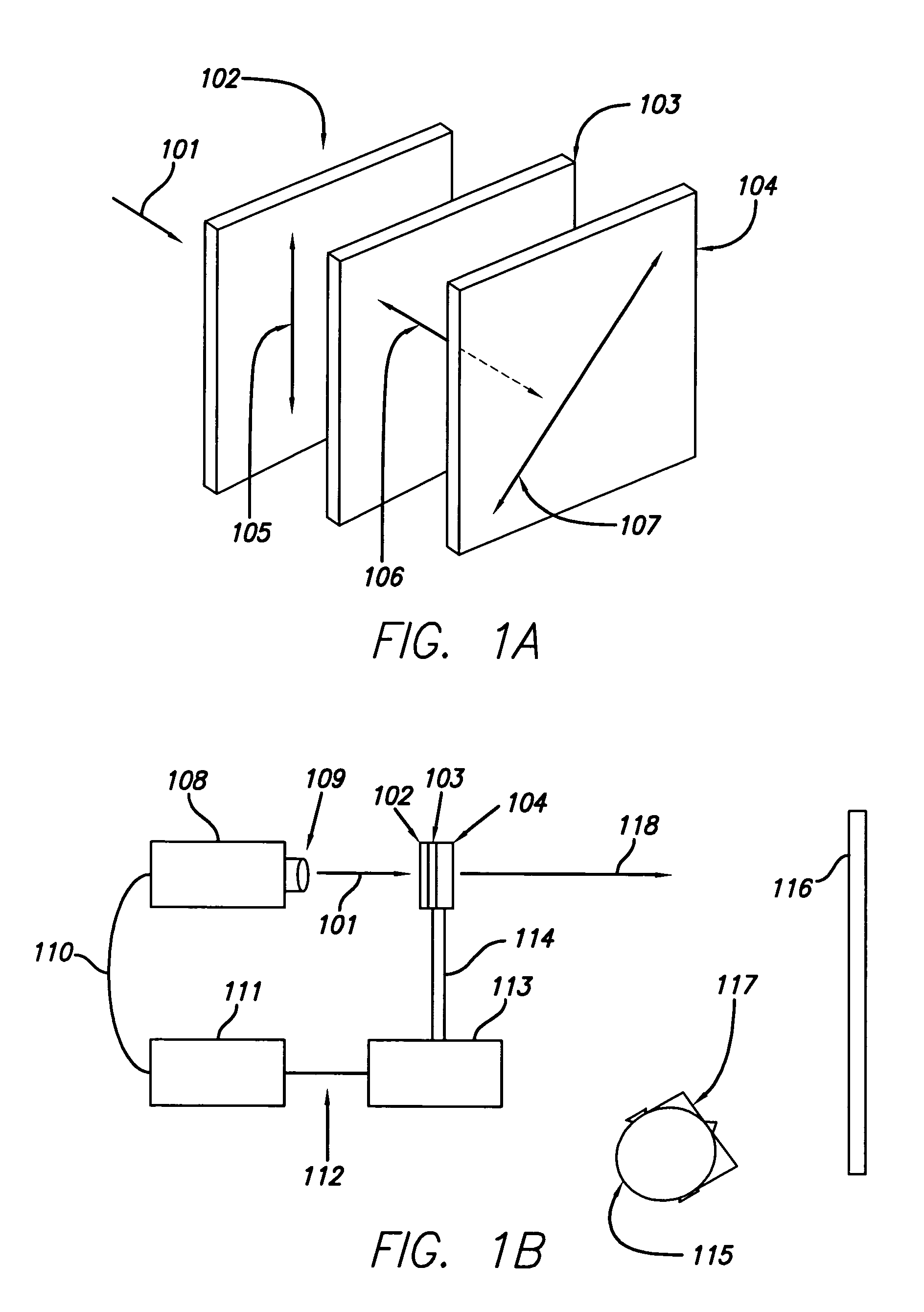

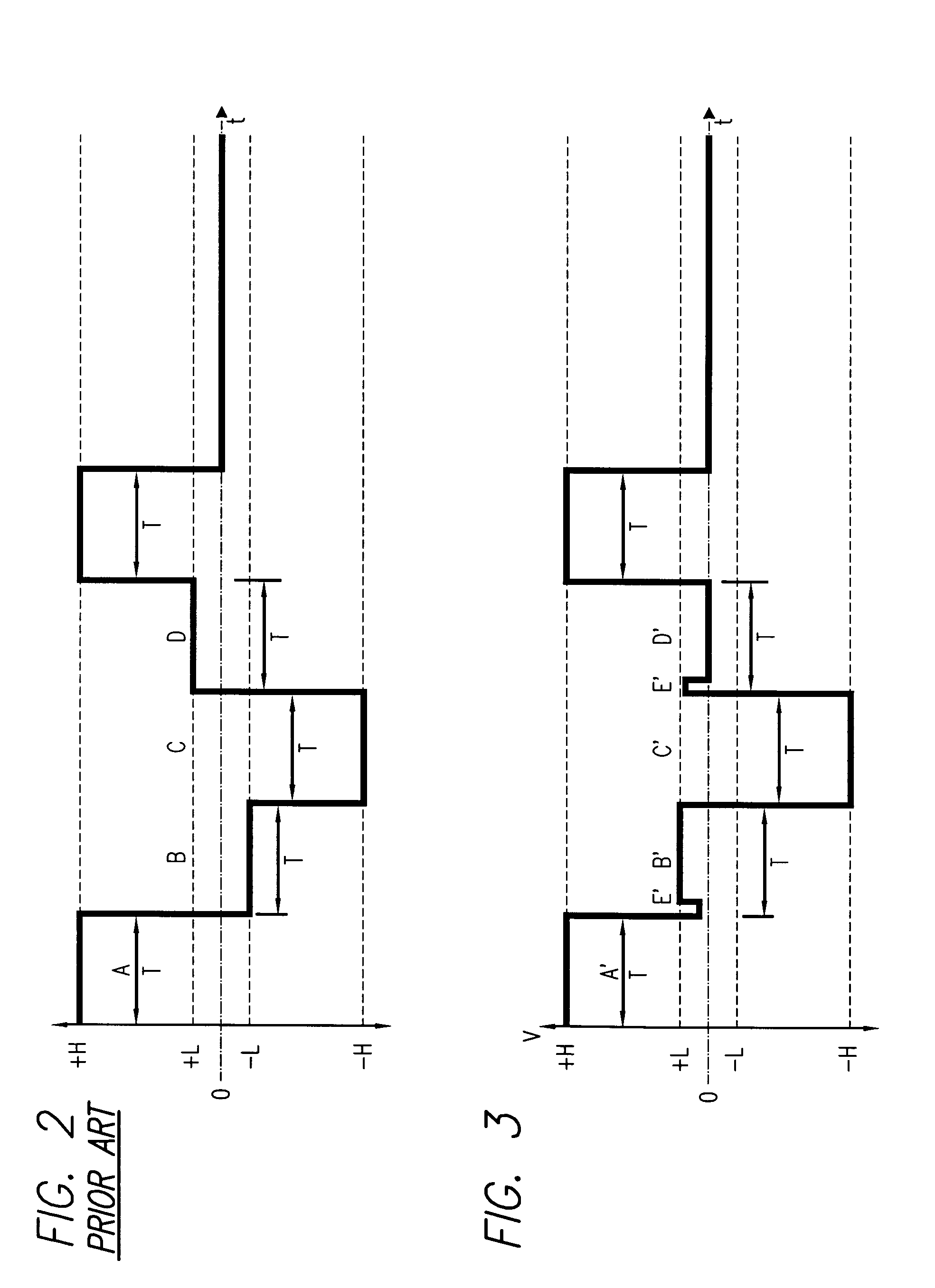

Enhanced ZScreen modulator techniques

Owner:REAID INC

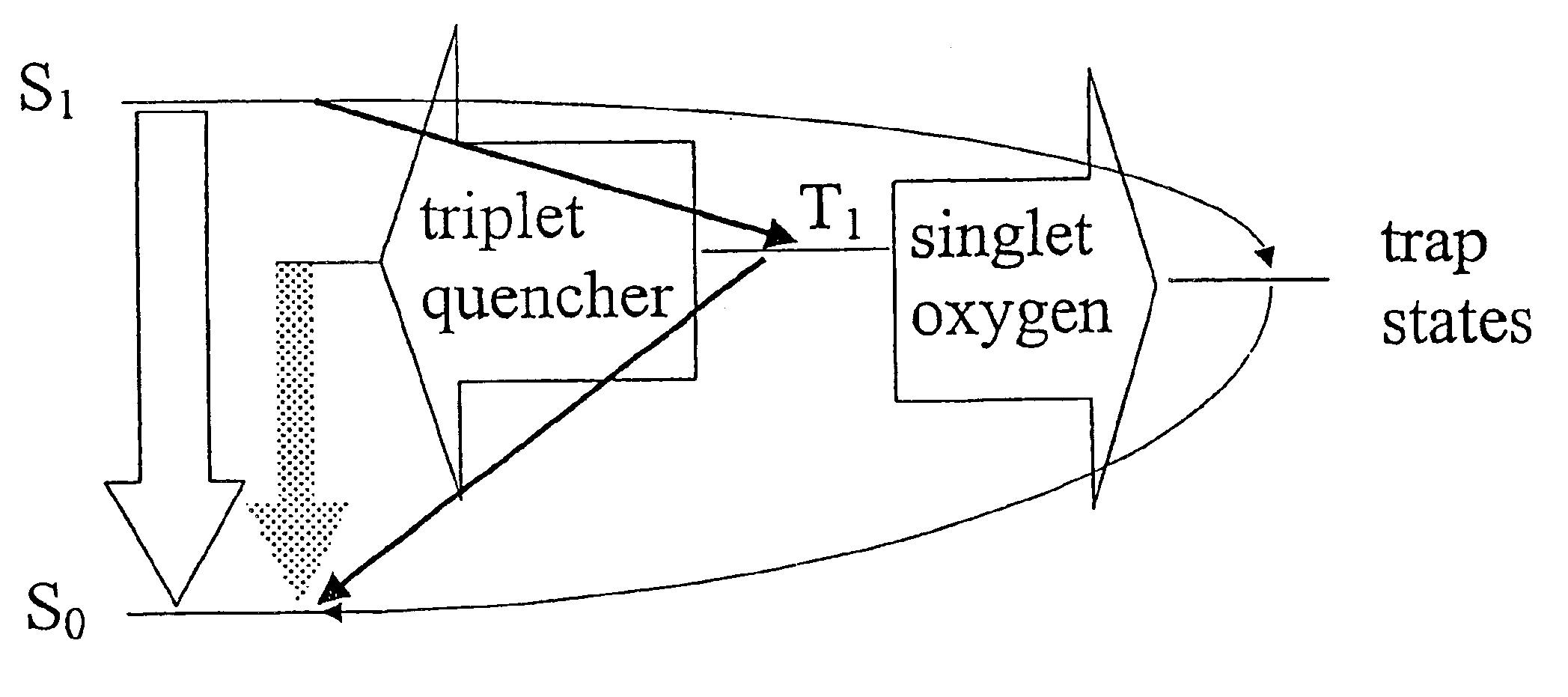

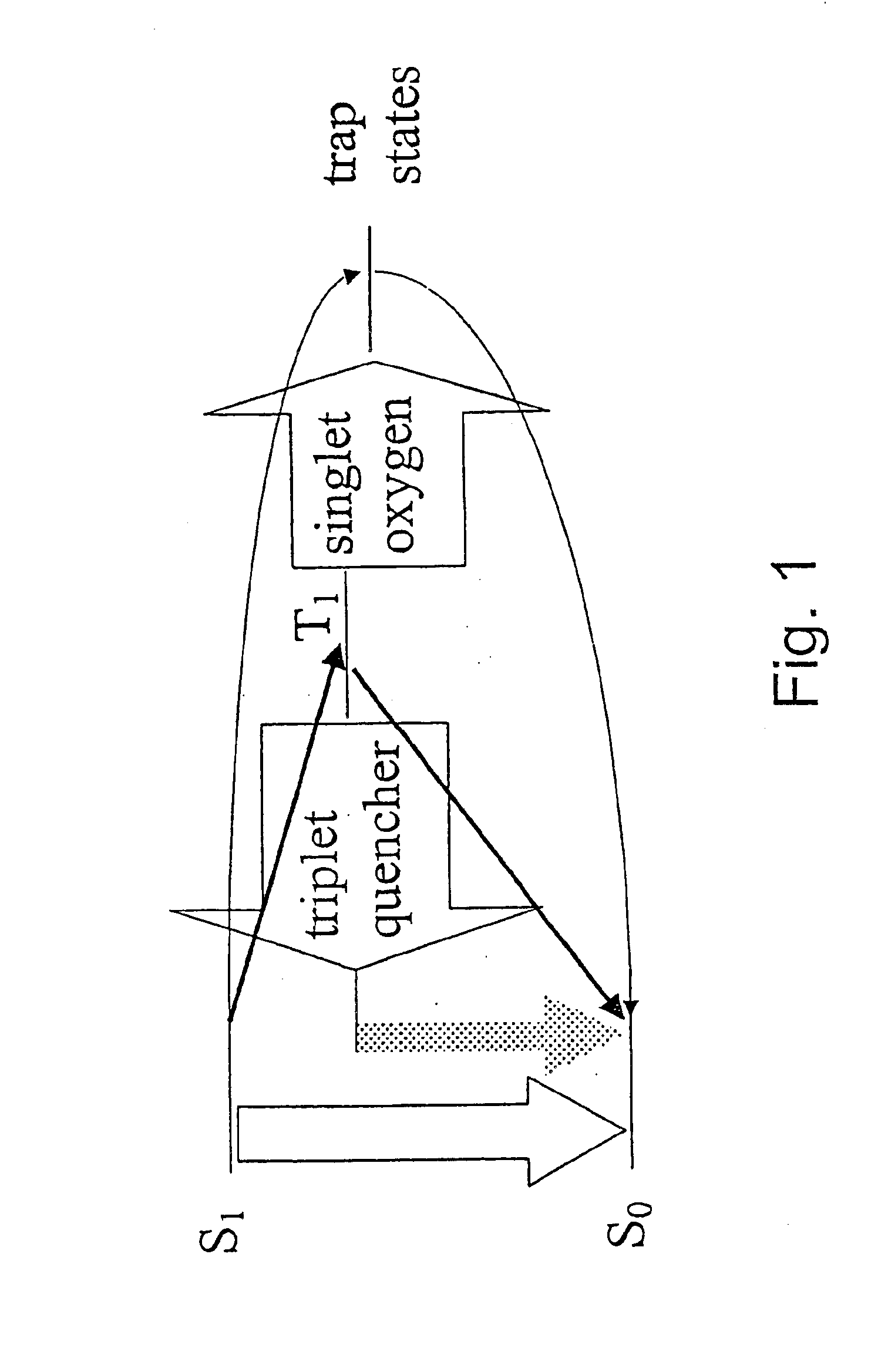

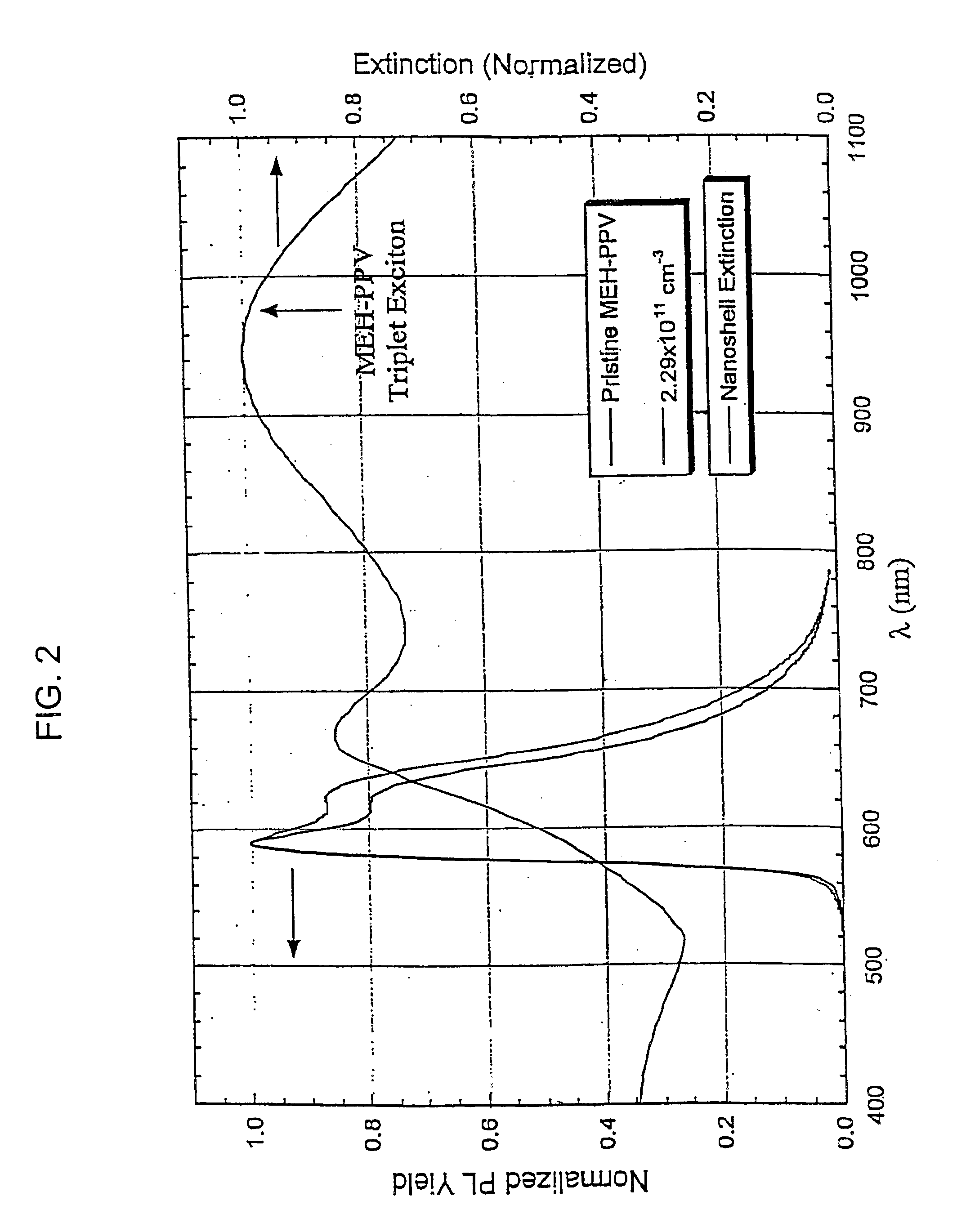

Use of metalnanoshells to impede the photo-oxidation of conjugated polymer

InactiveUS6852252B2Impede photo-oxidation processReduce degradationMaterial nanotechnologyDiffusing elementsPhoto-oxidation of polymersVolumetric Mass Density

The present invention relates to incorporating metal nanoshells specifically designed to interact with triplet excitons in polymers. By interacting with triplet excitons, the rate of photo-oxidation can be slowed and the density of luminescence-quenching traps can be reduced.

Owner:RICE UNIV

Rapid thermal conversion of biomass

ActiveUS20090139851A1Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingCoke quenchingLiquid productHeat carrier

The present invent provides improved rapid thermal conversion processes for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. In an embodiment, biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. In one embodiment, the liquid product itself is used as the quench media.

Owner:ENSYN RENEWABLES

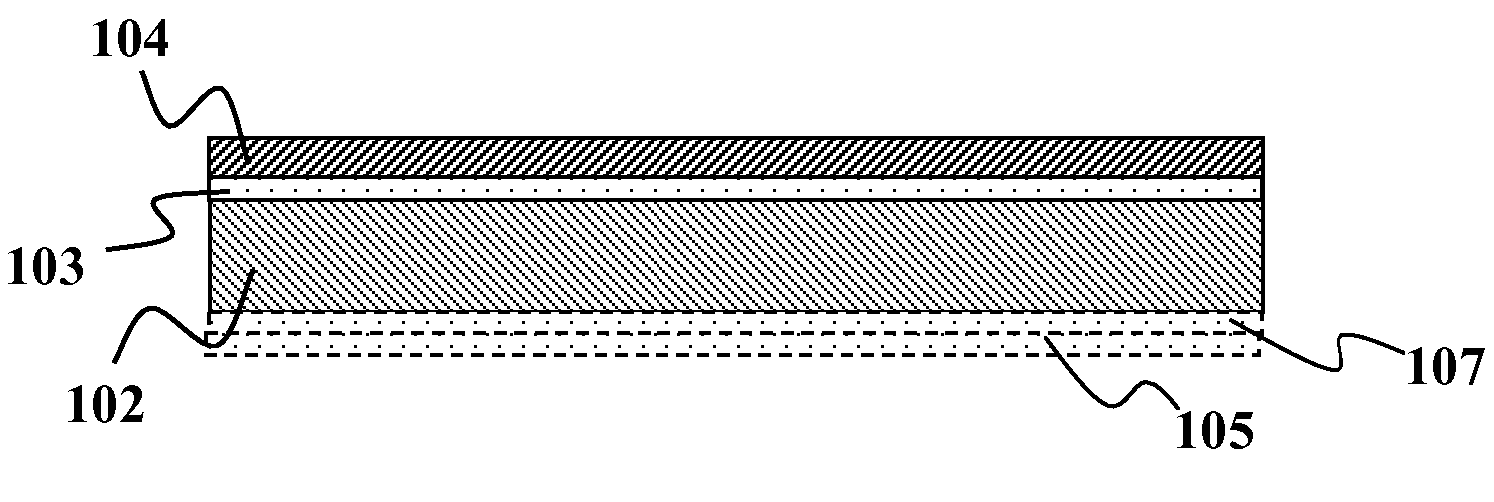

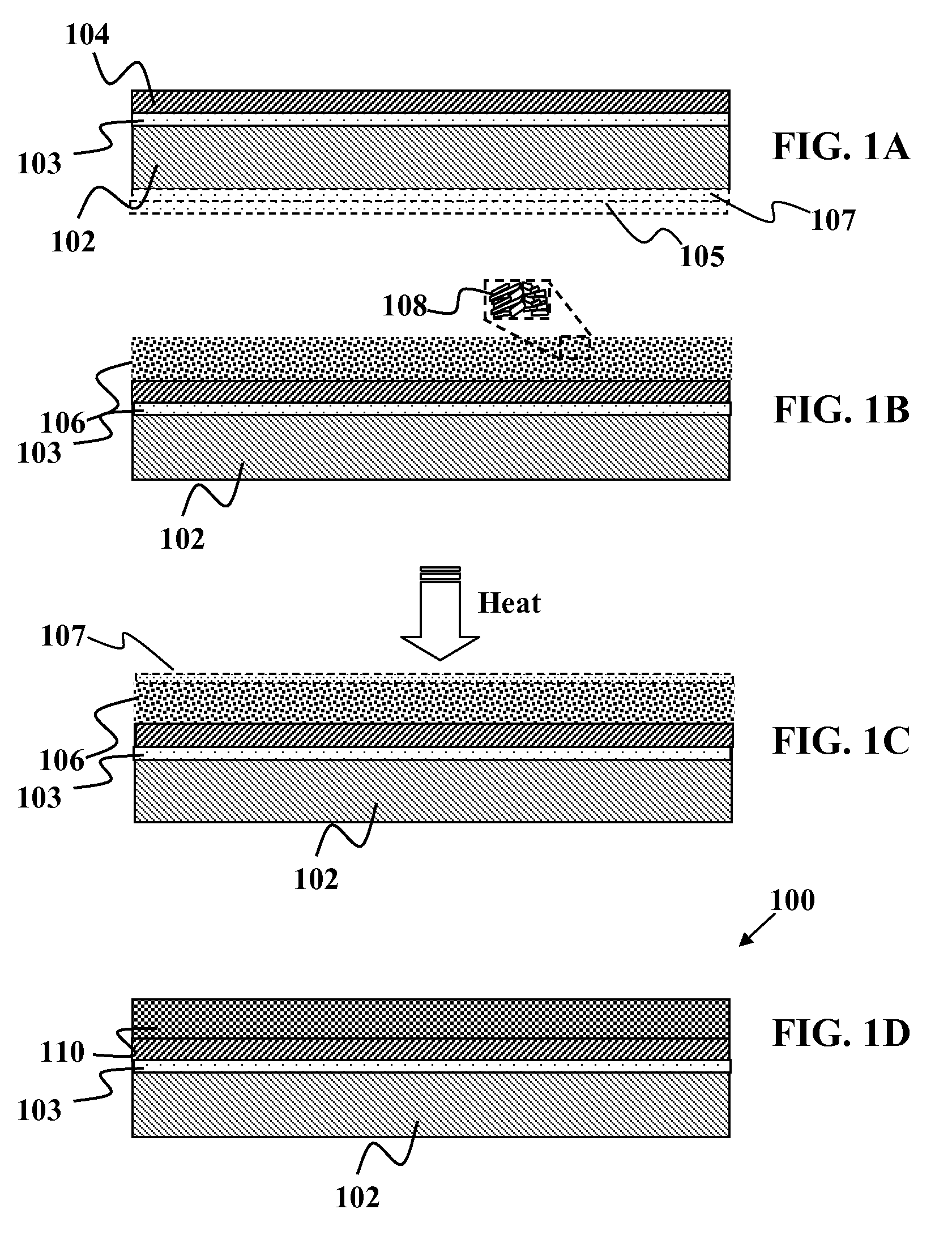

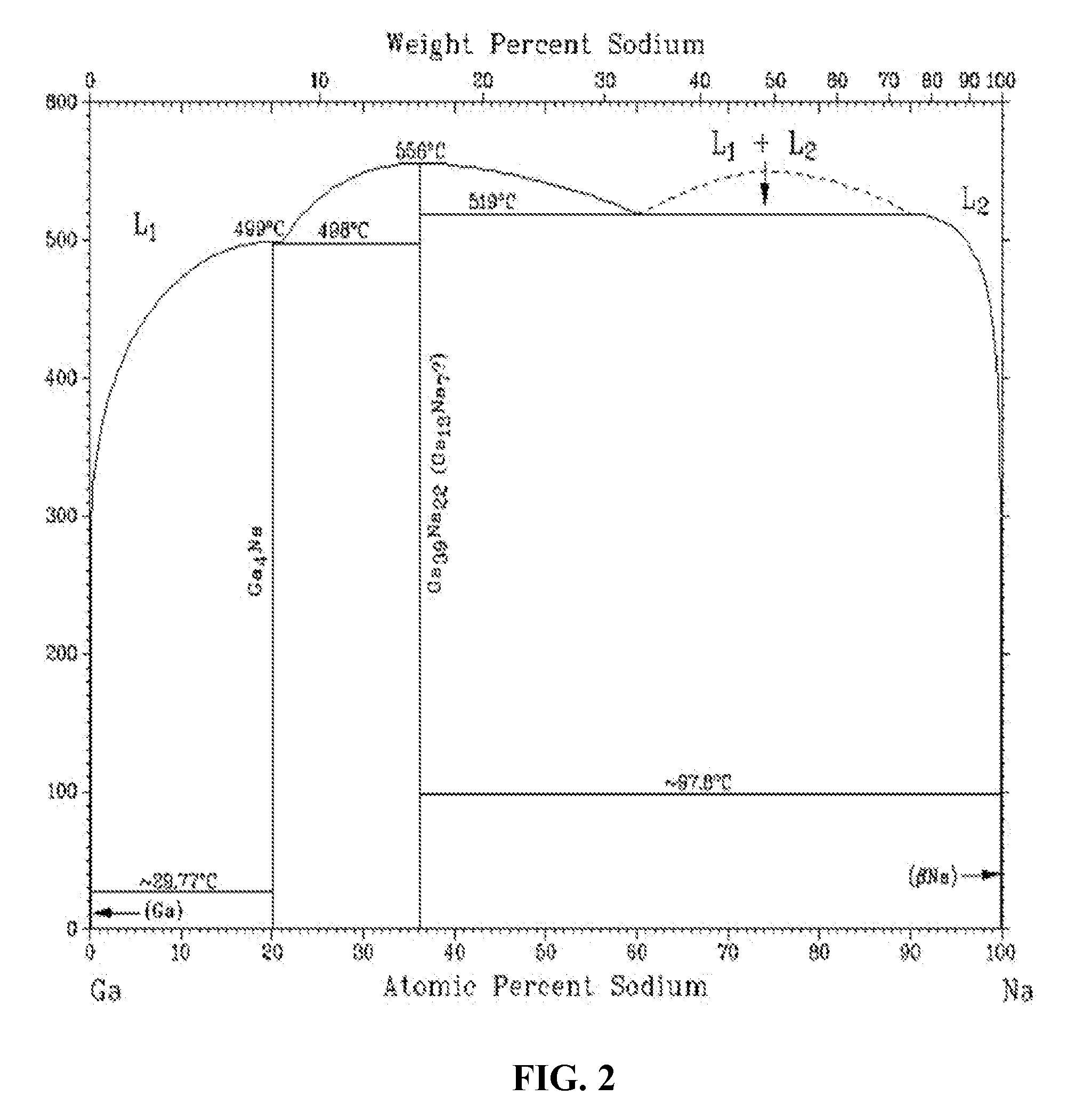

Solid group IIIA particles formed via quenching

InactiveUS20080057203A1Efficient and simplified creationPrevent leaching and phase separationPretreated surfacesCoatingsSolid particleAlloy

Methods and devices are provided for forming thin-films from solid group IIIA-based particles. In one embodiment, a process for forming solid particles is provided. The method includes providing a first suspension of solid and / or liquid particles containing at least one group IIIA element. A material may be added to substantially increase the melting point of at least one set of group IIIA-containing particles in the suspension into higher-melting solid particles comprising an alloy of the group IIIA element and at least a part of the added material. The suspension may be deposited onto a substrate to form a precursor layer on the substrate and the precursor layer is reacted in a suitable atmosphere to form a film.

Owner:NANOSOLAR

Carbon nanostructures and process for the production of carbon-based nanotubes, nanofibres and nanostructures

InactiveUS20070183959A1Enhanced interactionImprove mechanical propertiesMaterial nanotechnologyFullerenesThermal insulationNanostructure

Continuous process for the production of carbon-based nanotubes, nanofibres and nanostructures, comprising the following steps: generating a plasma with electrical energy, introducing a carbon precursor and / or one or more catalysers and / or carrier plasma gas in a reaction zone of an airtight high temperature resistant vessel optionally having a thermal insulation lining, vaporizing the carbon precursor in the reaction zone at a very high temperature, preferably 4000° C. and higher, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyser through a nozzle, whose diameter is narrowing in the direction of the plasma gas flow, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyses into a quenching zone for nucleation, growing and quenching operating with flow conditions generated by aerodynamic and electromagnetic forces, so that no significant recirculation of feedstocks or products from the quenching zone into the reaction zone occurs, controlling the gas temperature in the quenching zone between about 4000° C. in the upper part of this zone and about 50° C. in the lower part of this zone and controlling the quenching velocity between 103 K / s and 106 K / s quenching and extracting carbon-based nanotubes, nanofibres and other nanostructures from the quenching zone, separating carbon-based nanotubes, nanofibres and nanostructures from other reaction products.

Owner:ТІМКАЛ SА +1

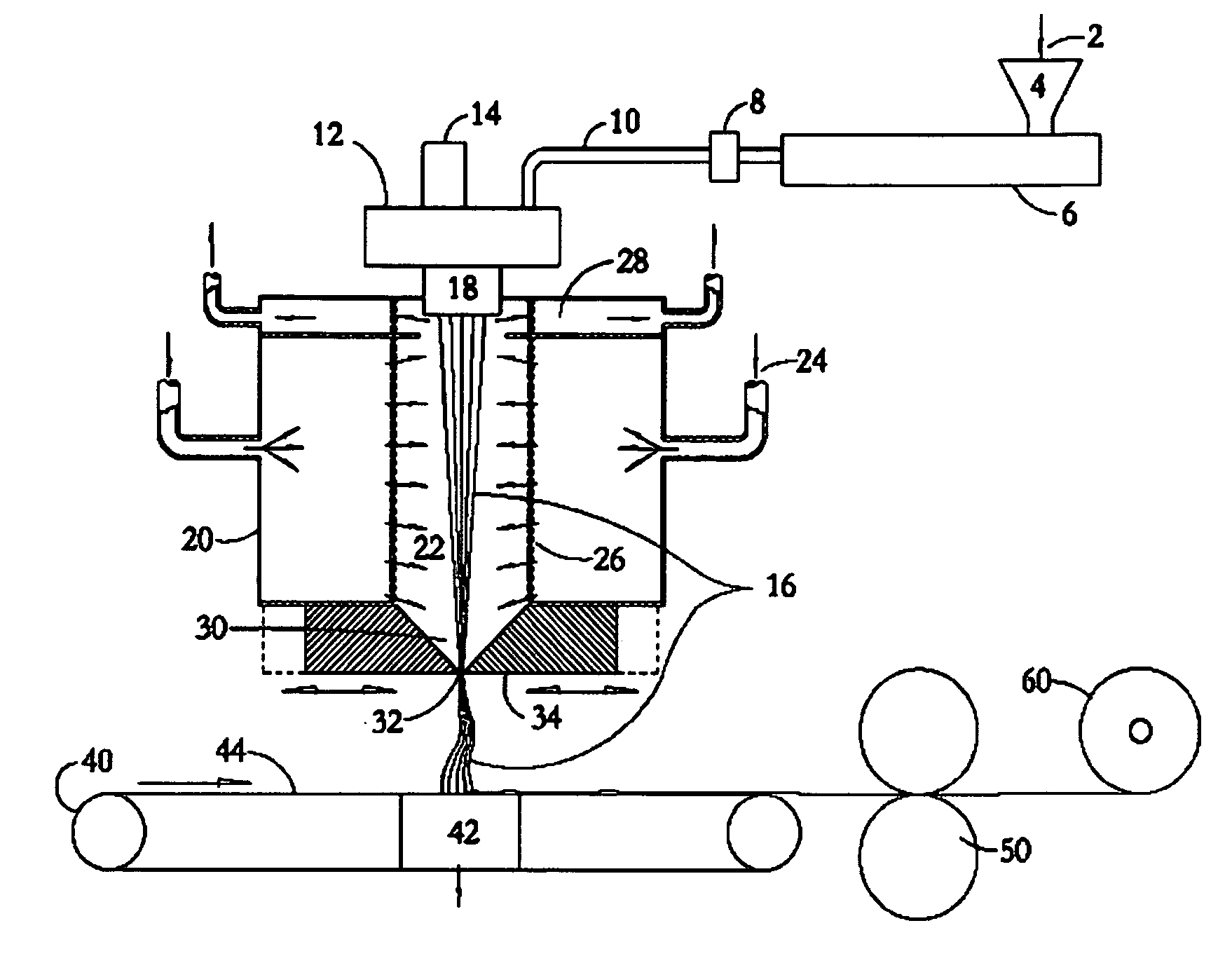

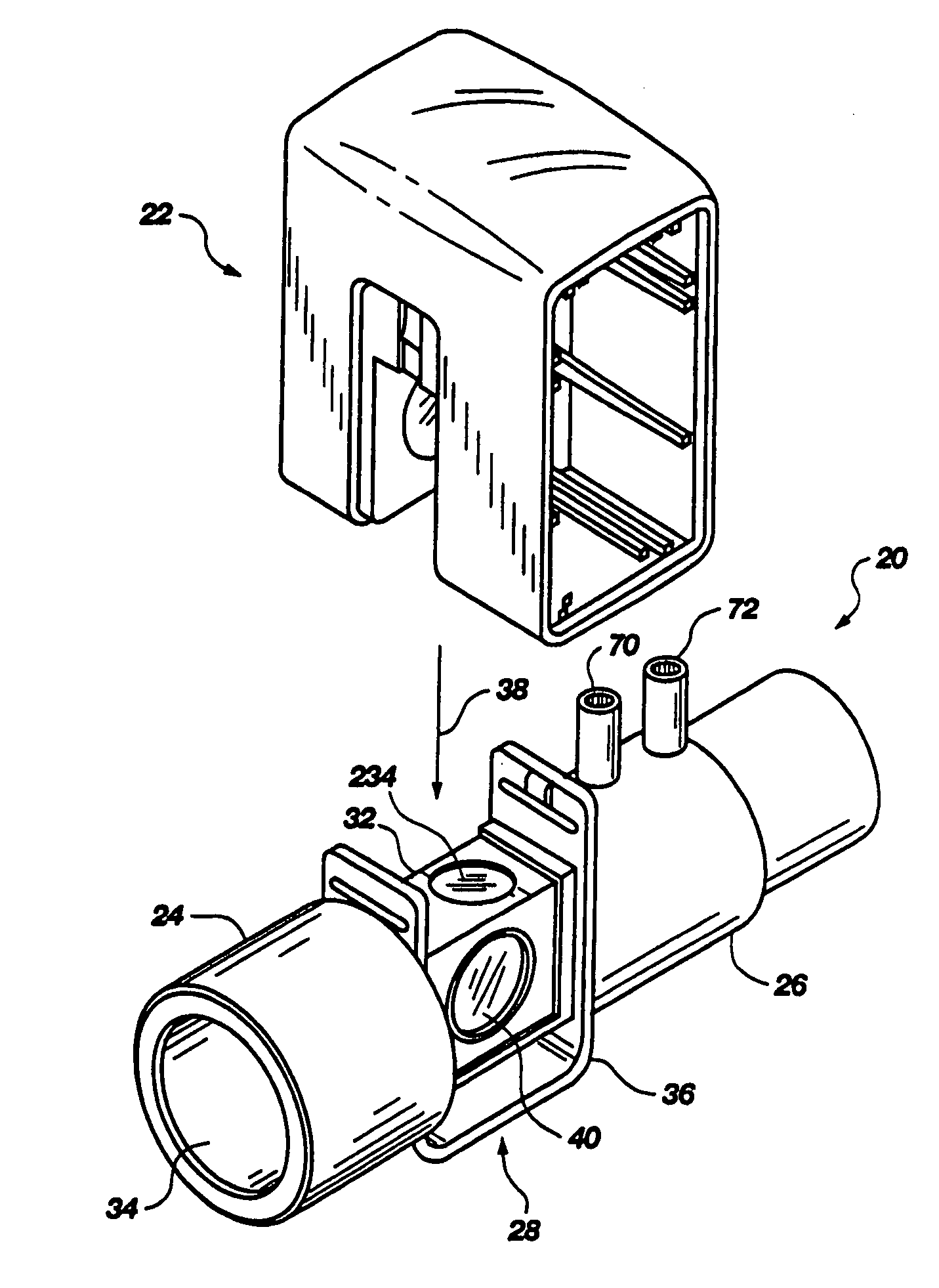

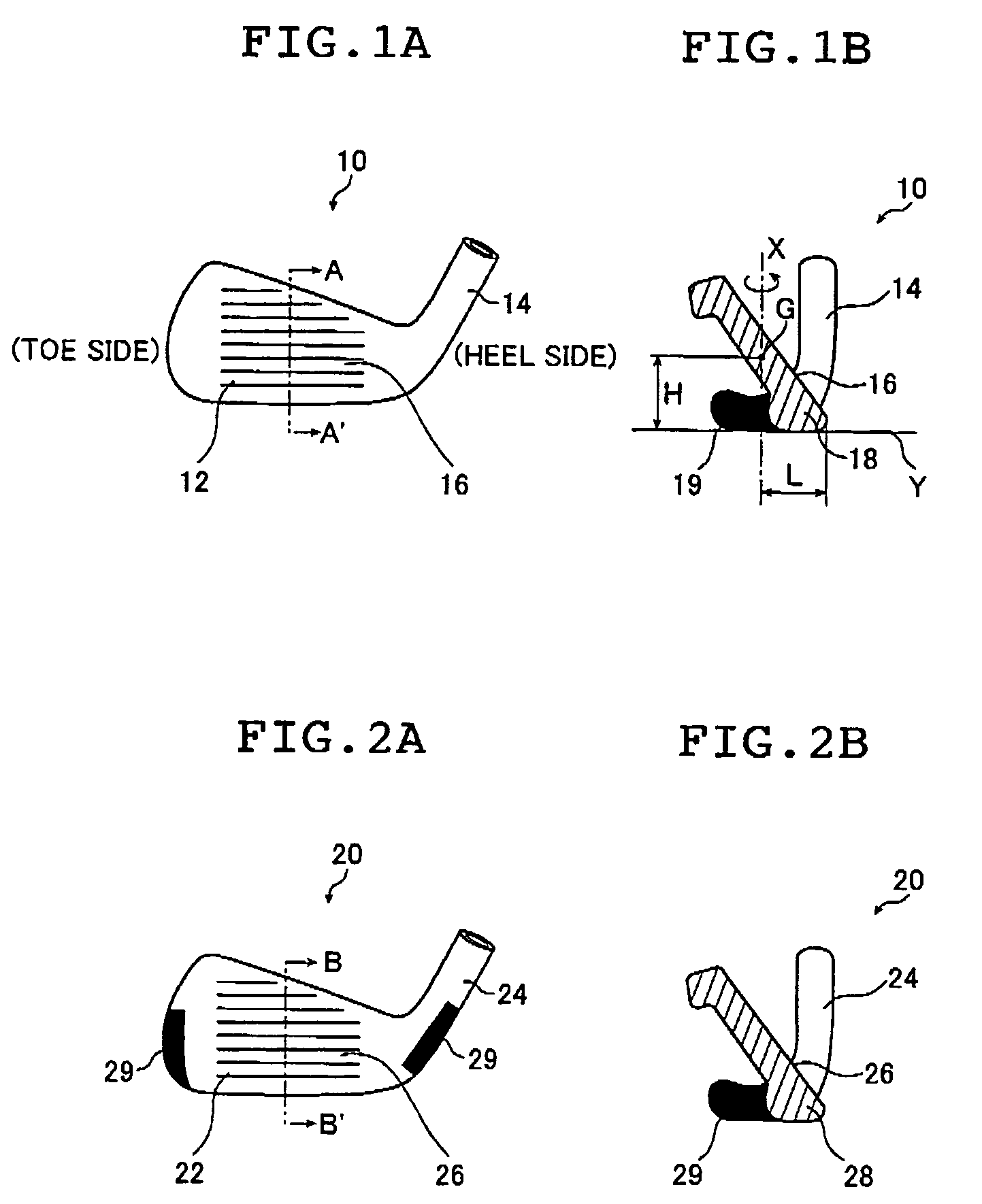

Method and apparatus for forming melt spun nonwoven webs

ActiveUS20070057414A1Easy to controlReduce widthLaminationFilament/thread formingEngineeringQuenching

A method and apparatus for forming nonwoven melt spun webs by spinning a curtain of filaments into a pressurized chamber where they are contacted with pressurized quenching fluid, then using the fluid to draw the filaments through a slot at the bottom of the chamber. The slot is a narrow two dimensional impingement point running the length of the filament curtain where the pressurized quench fluid passes through, escaping to atmosphere. The fluid pressure (potential) energy in the chamber is exchanged for velocity (kinetic) energy at the slot impingement point. The fast moving stream of fluid inside and exiting the slot acts to pull, or draw the filaments through the slot. The fluid and fiber stream is deposited onto a porous collection conveyor belt, forming a fleece web. The invention is more efficient, less complicated, easier to maintain and easier to control than prior systems for melt spinning nonwoven webs.

Owner:HARTGE HILLS DEV

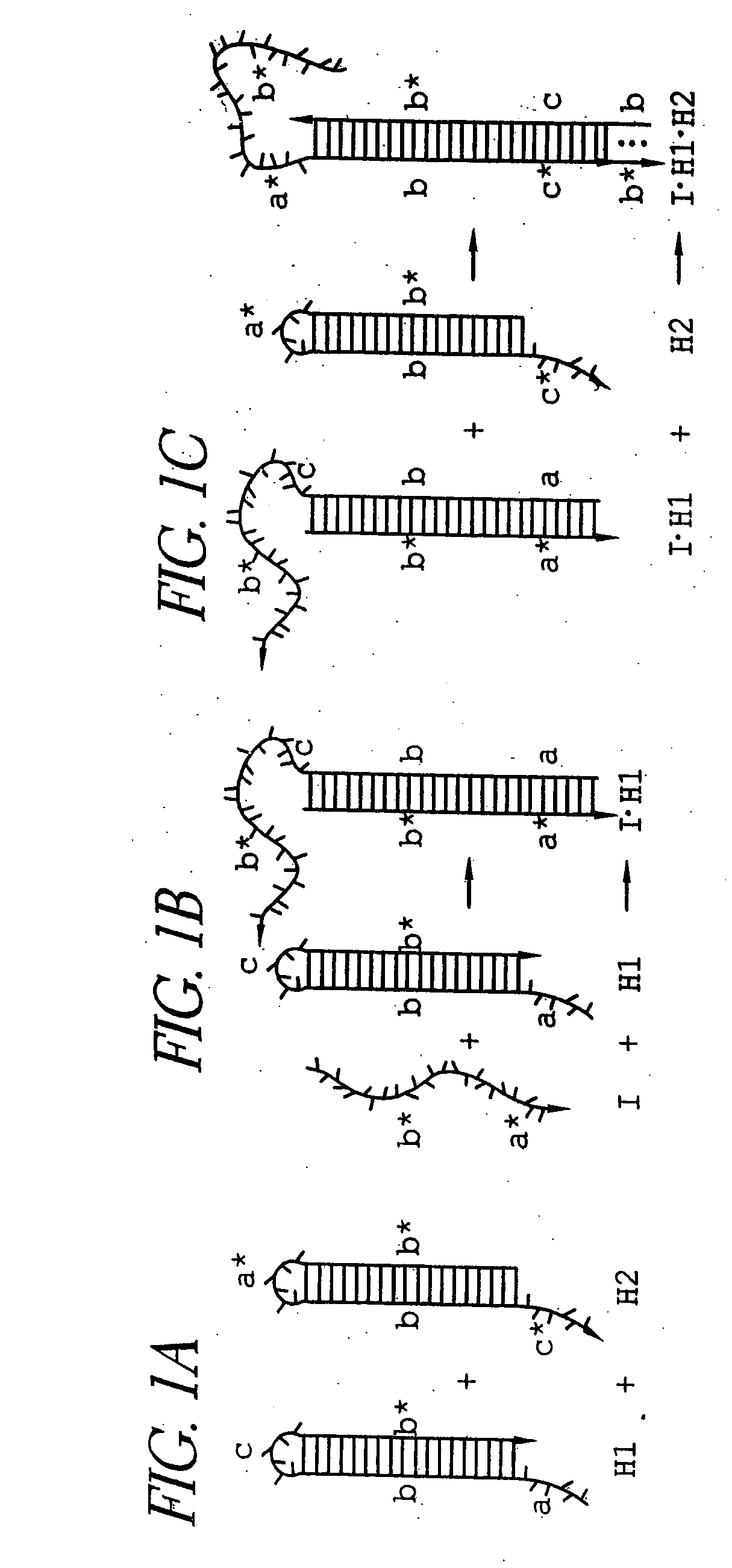

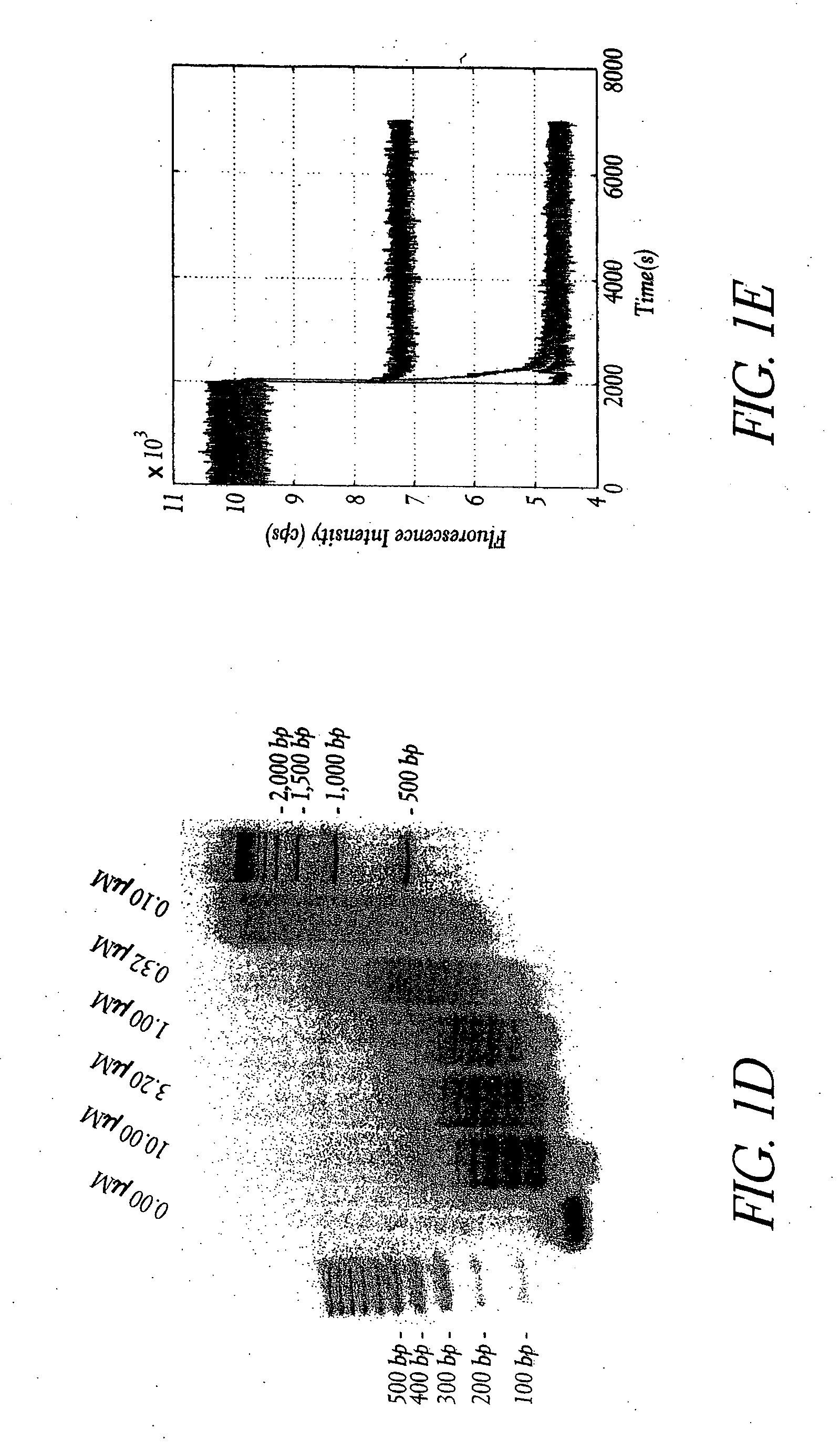

Hybridization chain reaction amplification for in situ imaging

ActiveUS20060228733A1Rapidly amplifyLow backgroundSugar derivativesMicrobiological testing/measurementAnalyteNucleic Acid Probes

The present invention relates to the use of fluorescently labeled nucleic acid probes to identify and image analytes in a biological sample. In the preferred embodiments, a probe is provided that comprises a target region able to specifically bind an analyte of interest and an initiator region that is able to initiate polymerization of nucleic acid monomers. After contacting a sample with the probe, labeled monomers are provided that form a tethered polymer. Triggered probes and self-quenching monomers can be used to provide active background suppression.

Owner:CALIFORNIA INST OF TECH

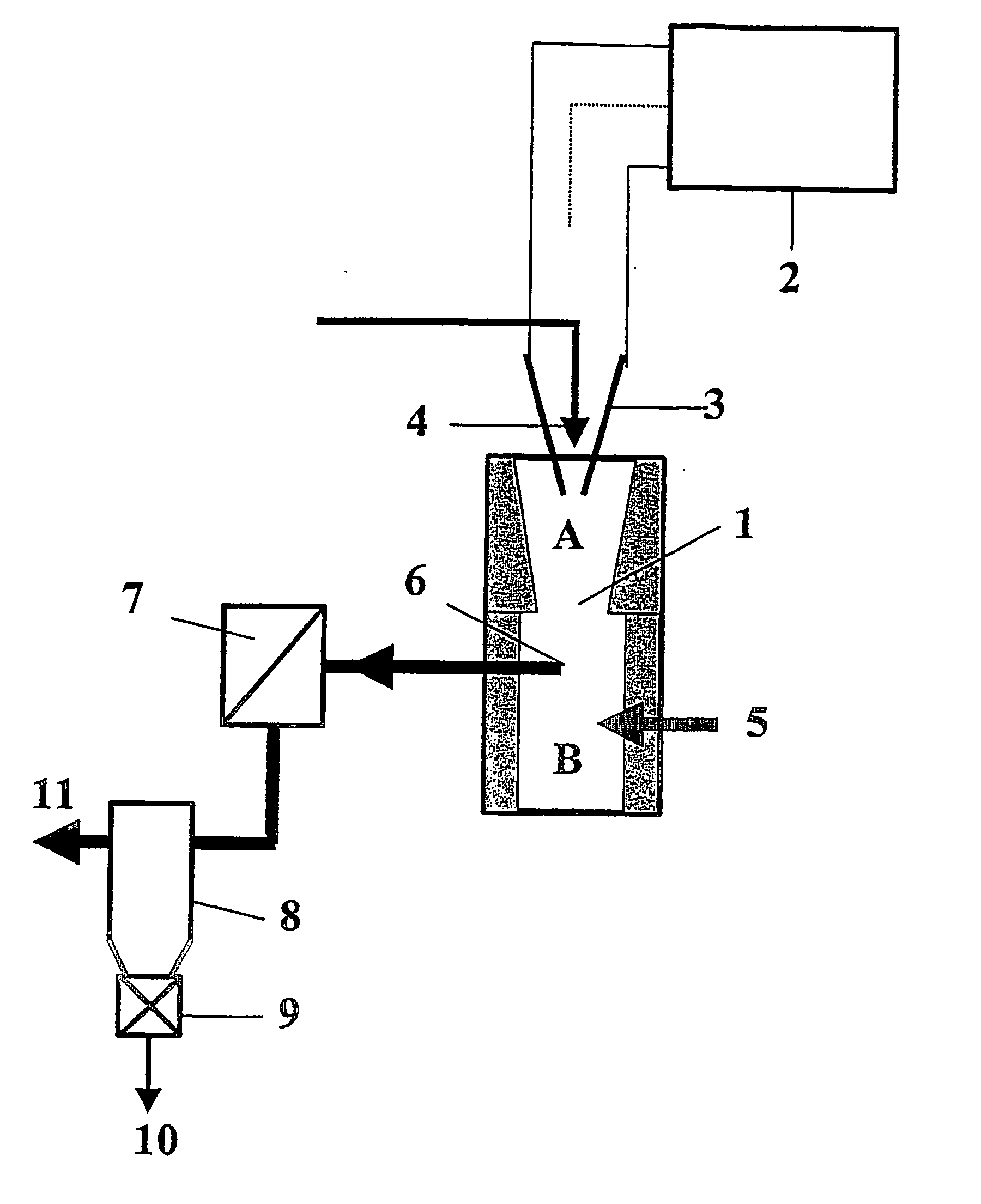

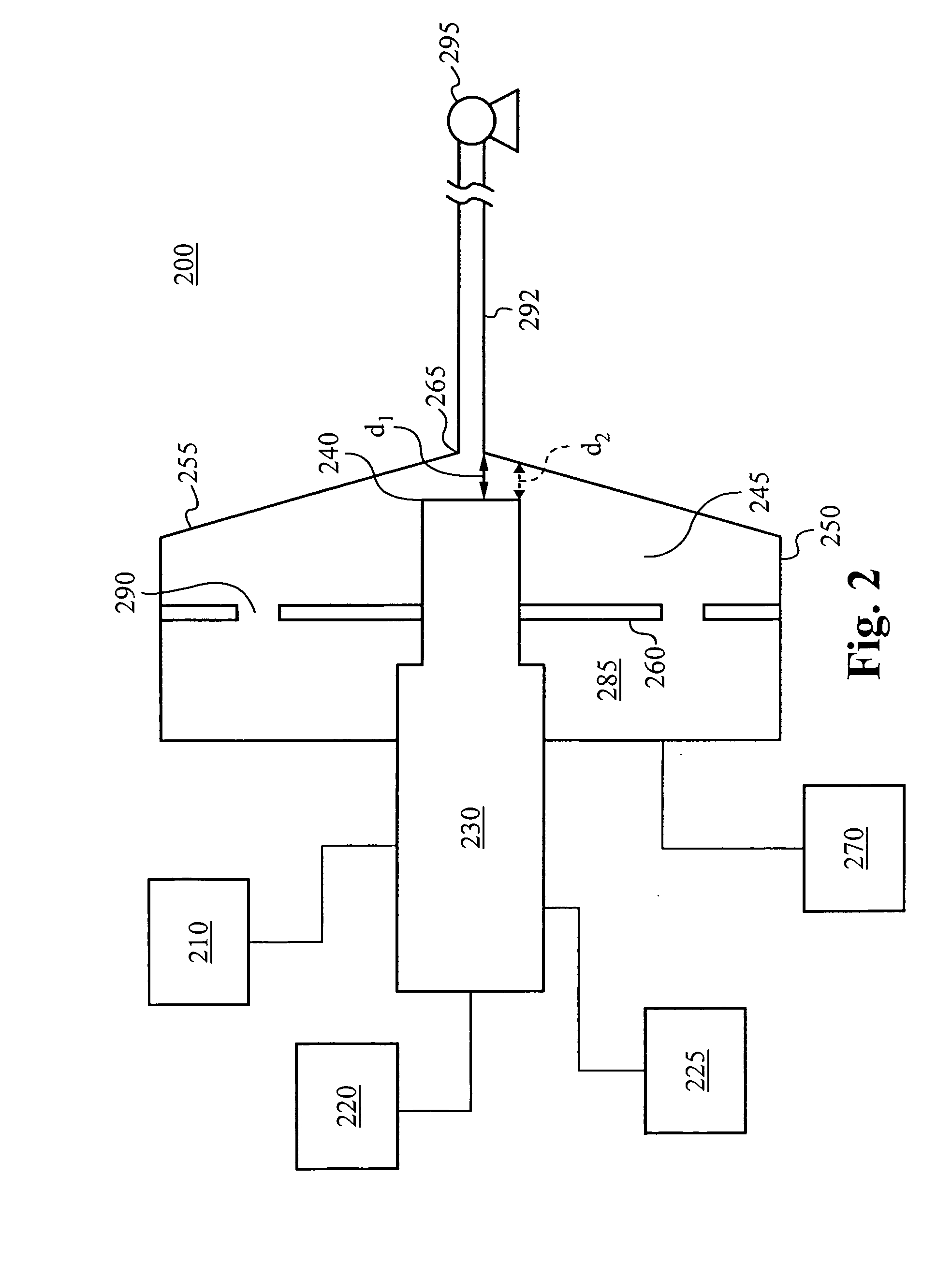

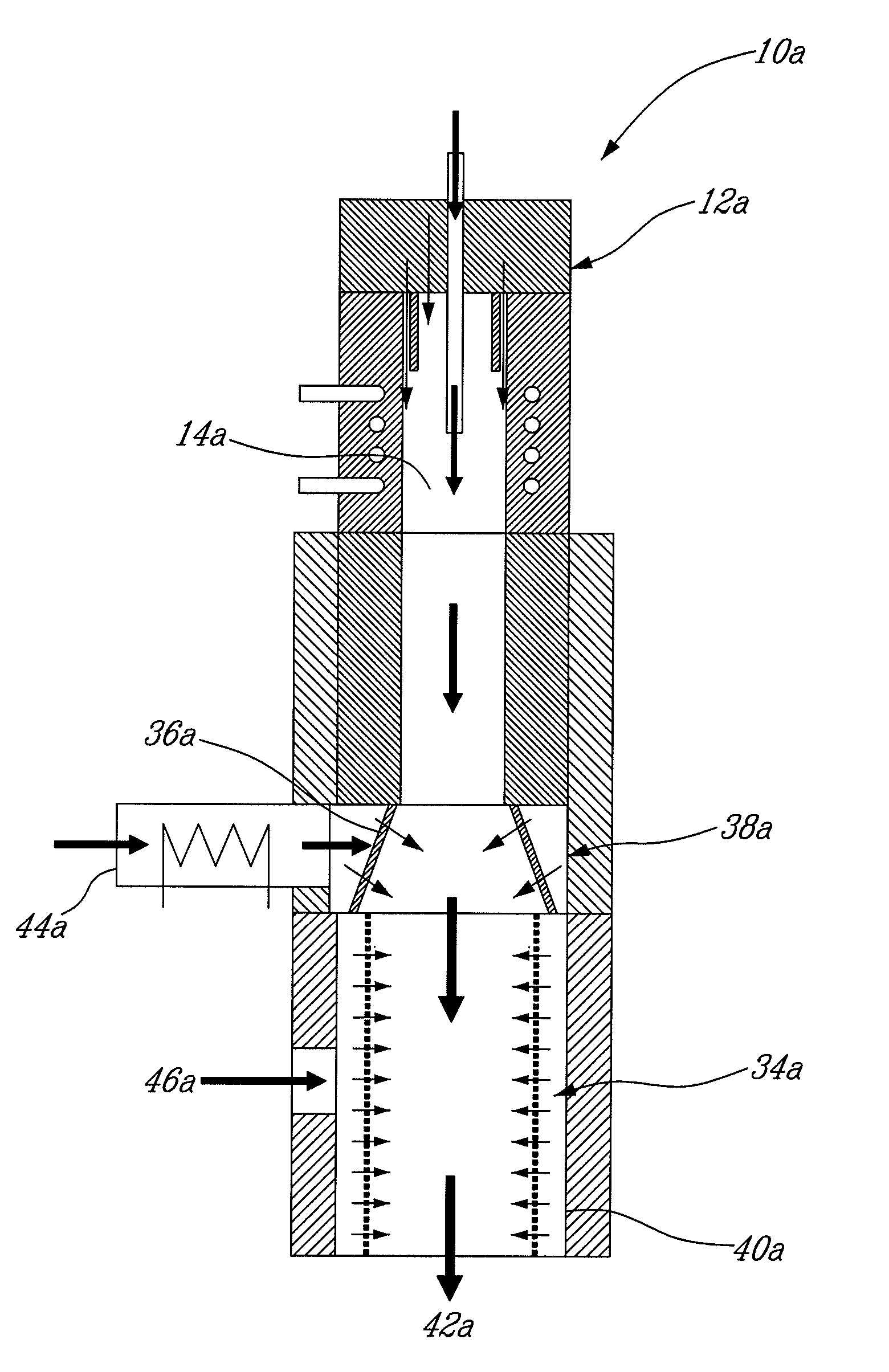

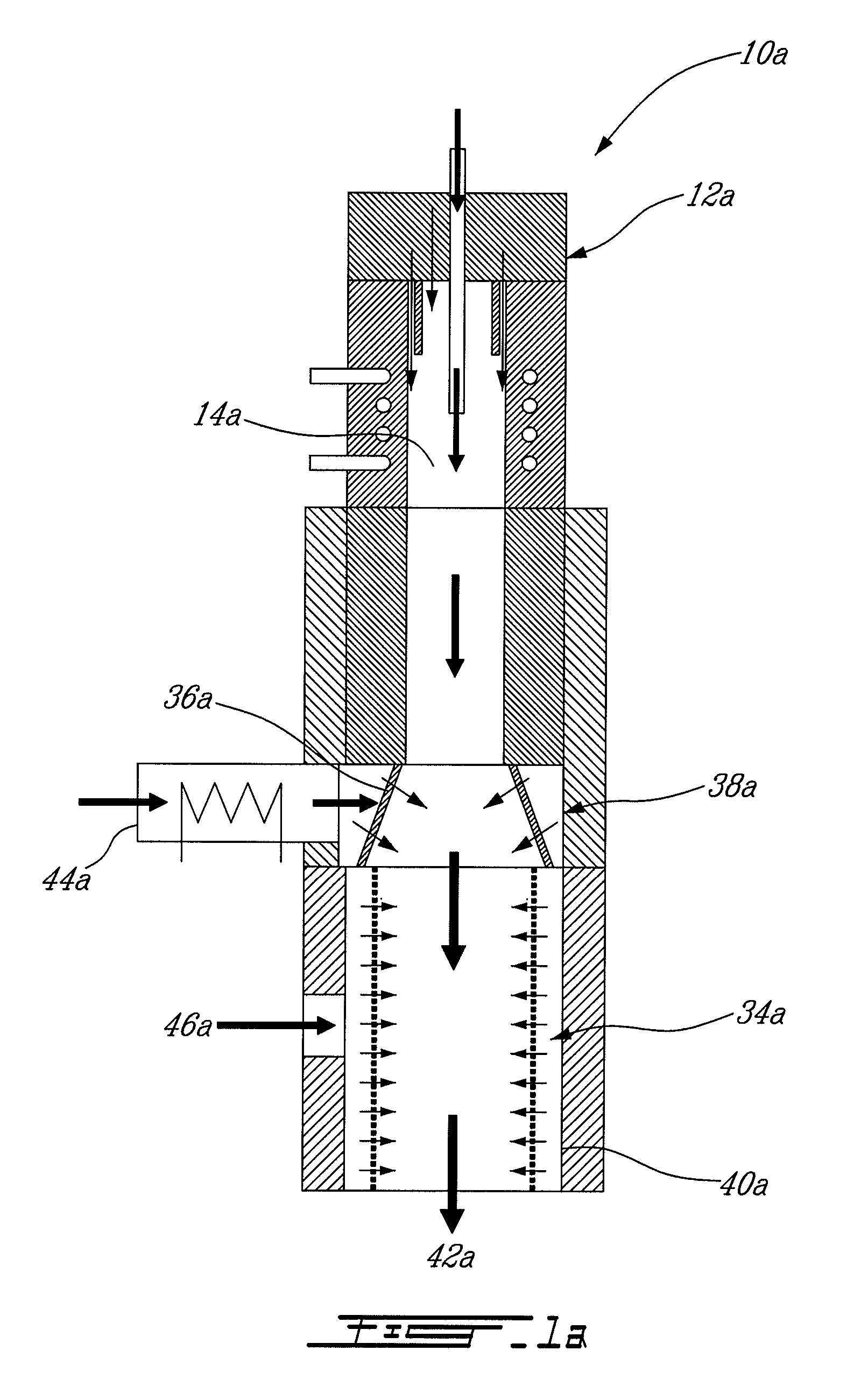

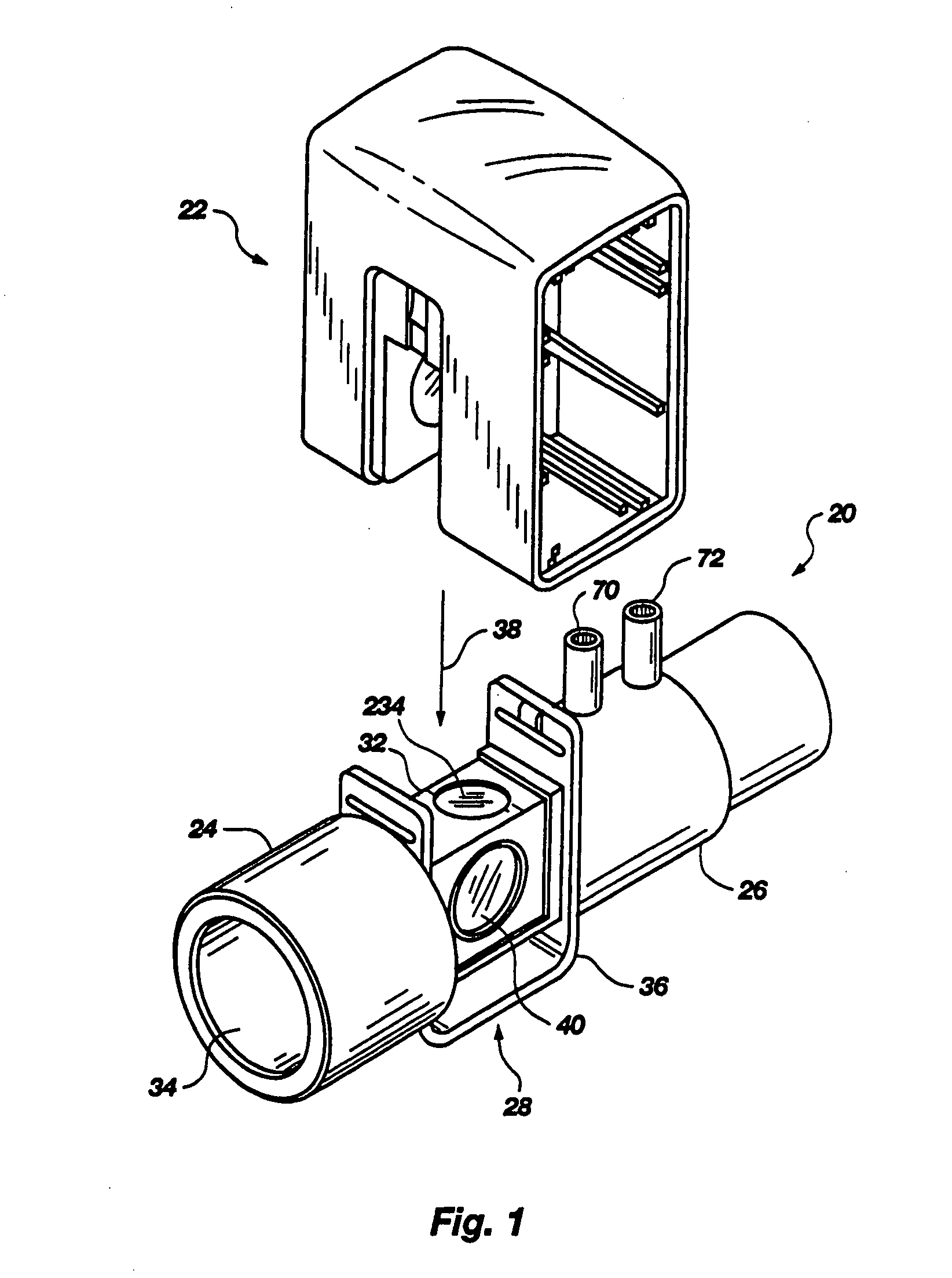

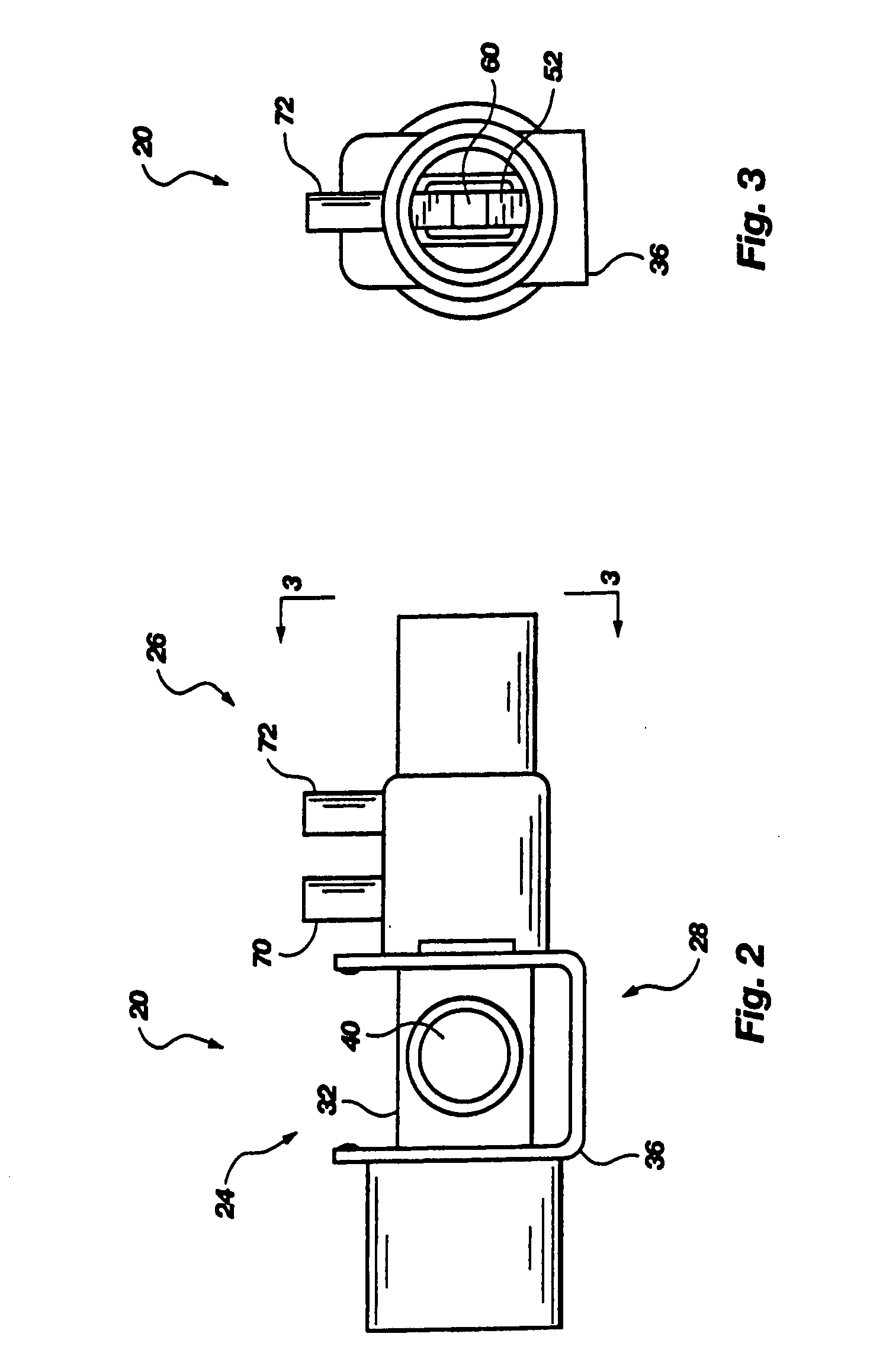

Highly turbulent quench chamber

ActiveUS20080277267A1Temperature controlDirect contact heat exchangersStationary tubular conduit assembliesEngineeringQuenching

An apparatus for cooling a reactive mixture, comprising: a reactor configured to form the reactive mixture; a quench chamber comprising a frusto-conical body having a wide end, a narrow end, and a quench region formed between the wide and narrow end, wherein the quench chamber is configured to receive the reactive mixture from the plasma reactor through a reactive mixture inlet into the quench region, to receive a conditioning fluid through at least one fluid inlet, and to flow the conditioning fluid into the quench region, wherein the frusto-conical body is configured to produce a turbulent flow within the quench region with the flow of the conditioning fluid into the quench region, thereby promoting the quenching of the reactive mixture to form a cooled gas-particle mixture; and a suction generator configured to force the cooled gas-particle mixture out of the quench chamber.

Owner:UMICORE AG & CO KG +1

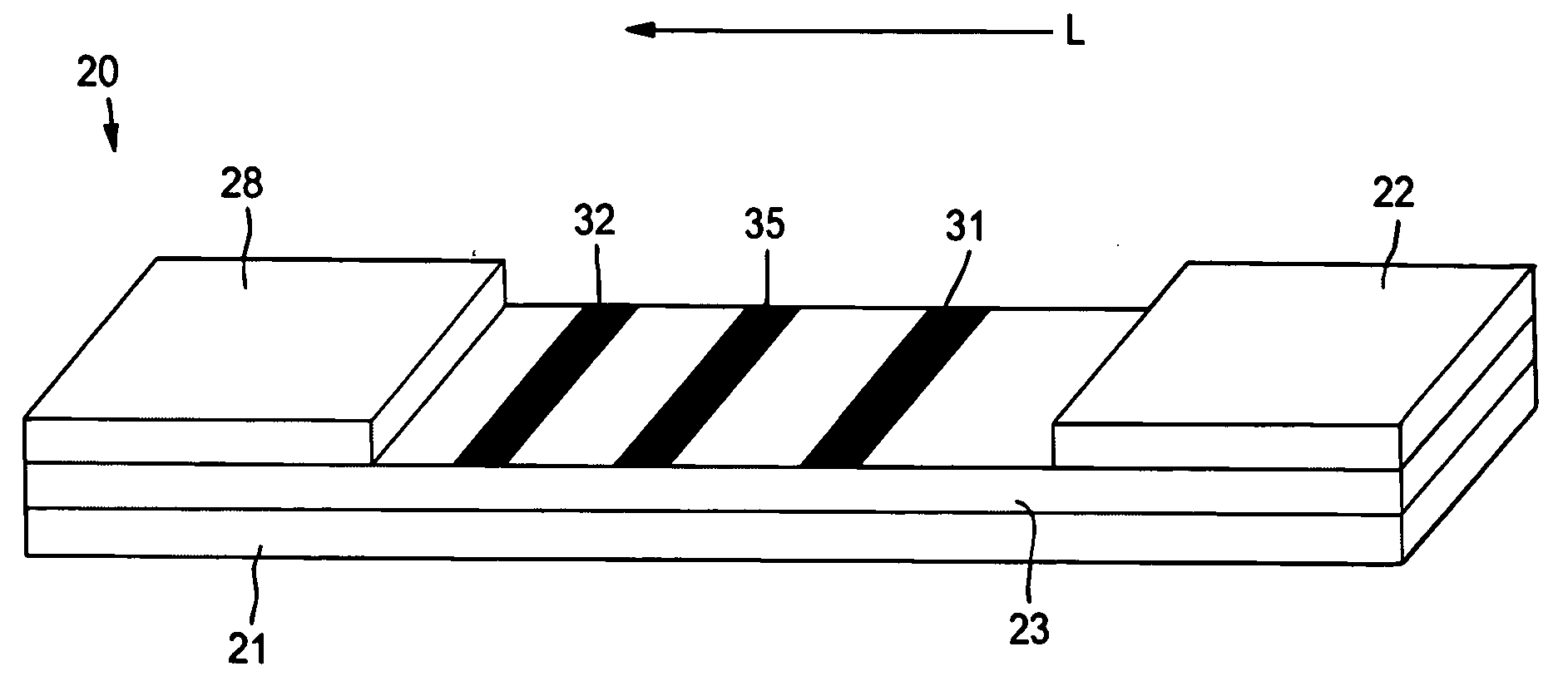

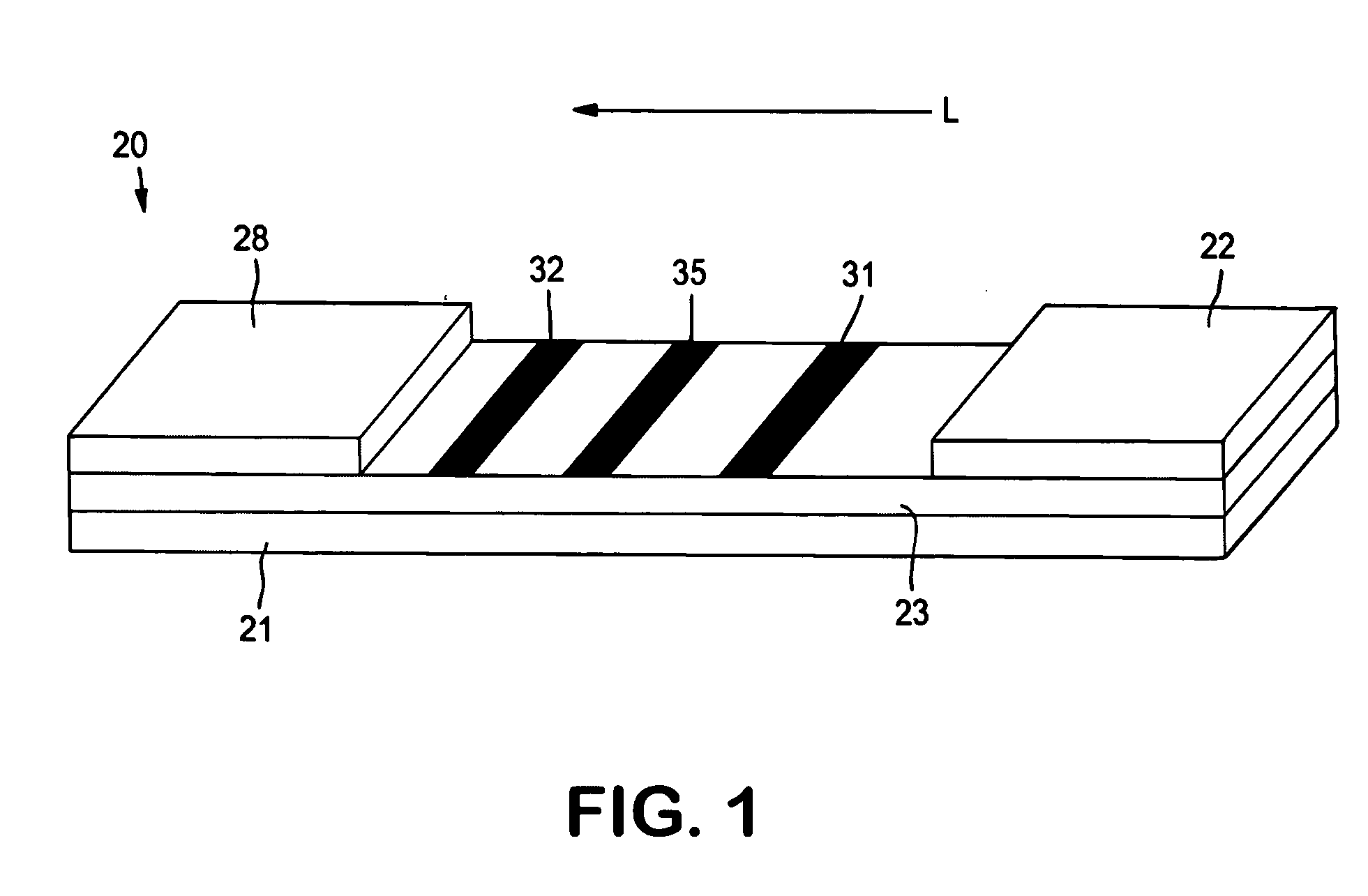

Method for extending the dynamic detection range of assay devices

InactiveUS20050112780A1Improve accuracyGood compensationBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteTest sample

A flow-through assay device for detecting the presence or quantity of an analyte residing in a test sample is provided. The device utilizes a detection zone and compensation zone within which are immobilized capture reagents. The present inventor has discovered that the presence of a compensation zone may enable the detection of an analyte over extended concentration ranges. In particular, the compensation zone facilitates the binding of probes that would otherwise bind within the interior of assay device or that would exhibit “self-quenching.”

Owner:KIMBERLY-CLARK WORLDWIDE INC

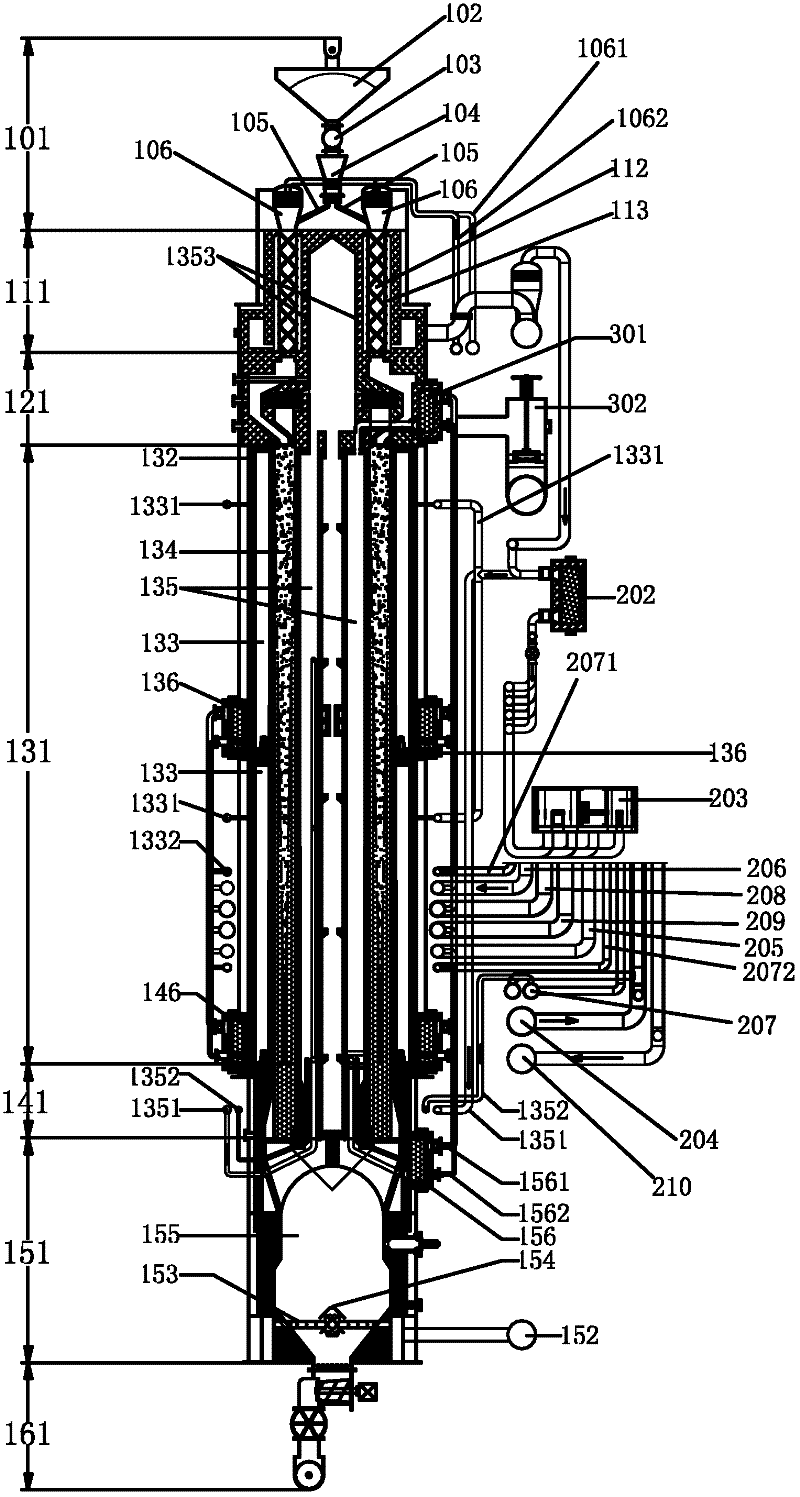

Coking furnace capable of recycling heat energy and coking method

InactiveCN102250629AExtend the industrial chainReduce pollutionCoke quenchingGas purification with selectively adsorptive solidsThermal energyCombustion

The invention discloses a coking furnace capable of recycling heat energy, and the coking furnace comprises a furnace body, an exhaust gas recycling system and a raw coal gas treatment system, wherein the furnace body sequentially comprises a coal feeding segment, a rapid coal heating segment, a raw coal gas leading-out segment, a coal carbonization coking segment, a coke quenching and tempering segment, a dry coke quenching segment and a coke discharging segment from top to bottom; the exhaust gas recycling system comprises an exhaust gas leading-out unit, an exhaust gas heat exchanger, a commutator and the like; and the raw coal gas treatment system comprises a raw coal gas leading-out unit. By using the coking furnace disclosed by the invention, continuous coal carbonization coking canbe achieved and the exhaust gas after combustion is used for dry coke quenching in the furnace; pre-dried coal can be quickly heated to 300 DEG C during entering the furnace, the coal is carbonized and coked in the furnace body, and the exhaust gas generated by self-combustion is used for dry coke quenching at the furnace bottom after the exhaust gas is cooled by heat exchange with air, thus continuously producing coke; the pollution is less in the production process; the coal industrial chain is extended, the coking cost is lowered, the coking coal types are broadened, and the product quality is improved; the profit margins are expanded in a large extent; and the maintenance cost is low.

Owner:山西华天新能源发展有限公司

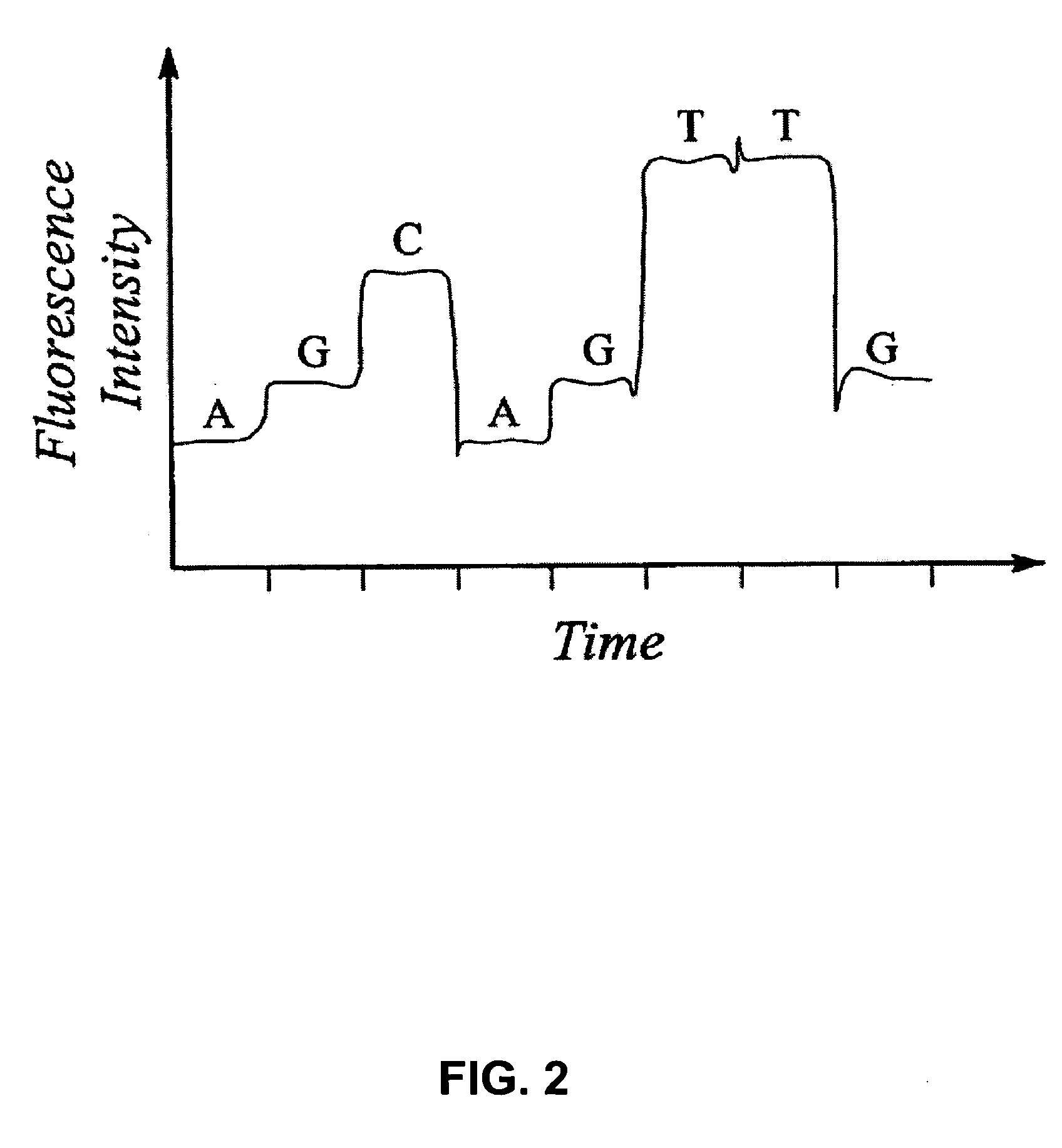

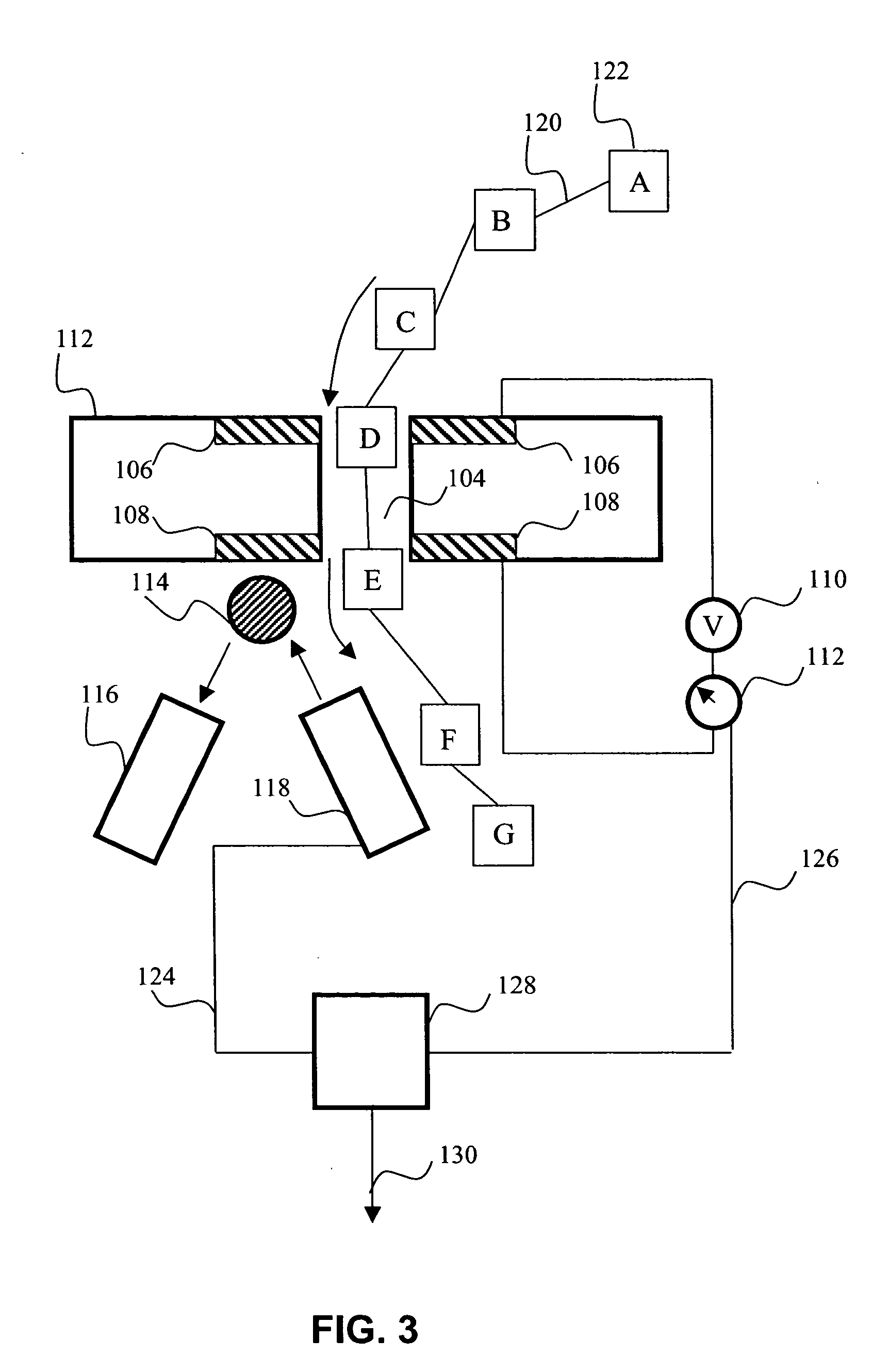

Detection and identification of biopolymers using fluorescence quenching

InactiveUS20050095599A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFluorescenceBiopolymer

The present invention provides an apparatus for detecting a nanoscale moiety and a method for sensing a nanoscale moiety. The apparatus includes a substrate having a nanopore, at least one excitable molecule attached to the substrate adjacent to the nanopore, and a light source for exciting the excitable molecule attached to the substrate adjacent to the nanopore wherein the excitable molecule is quenched by the quencher molecule on the nanoscale moiety as it passes by the excitable molecule. The invention also includes a method for detecting the presence or identity of the nanoscale moiety.

Owner:AGILENT TECH INC

Low-alloy super-strength multiphase steel and heat treatment method thereof

The invention discloses a low-alloy superhigh-intensity diphase steel and the heat treatment method, which is characterized in that: the components of the diphase steel (wt %) are C of 0.3 to 0.7, Si of 0.01 to 3.0, Al of 0.0 to 2.0, Nb of 0.0 to 0.25, V of 0.0 to 0.3, Mo of 0.0 to 2.0, Ni of 0.0 to 4.0, Mn of 0.05 to 3.0, Cr of 0.00 to 3.0, Co of 0.00 to 2.0, W of 0.0 to 2.0, S less than 0.04, P less than 0.04 and Fe of balance; the heat treatment method is that: a workpiece is first heated to 800 to 1000 degree centigrade to process the austenite treatment, and then the workpiece is quickly quenched into a liquid quenching medium of 50 to 250 degree centigrade, and then the workpiece is partitioned in a liquid quenching medium of 250 to 450 degree centigrade, and then the workpiece is quickly quenched into a liquid quenching medium of 100 to 250 degree centigrade for holding, finally the workpiece is quenched into water, and then the workpiece has a three-phase organization with martensite, nanometer ferrito martensite and remaining austenite with rich carbon. The low-alloy superhigh-intensity diphase steel and the heat treatment method has an advantage of increasing the intensity and plasticity of workpieces.

Owner:SHANGHAI JIAO TONG UNIV

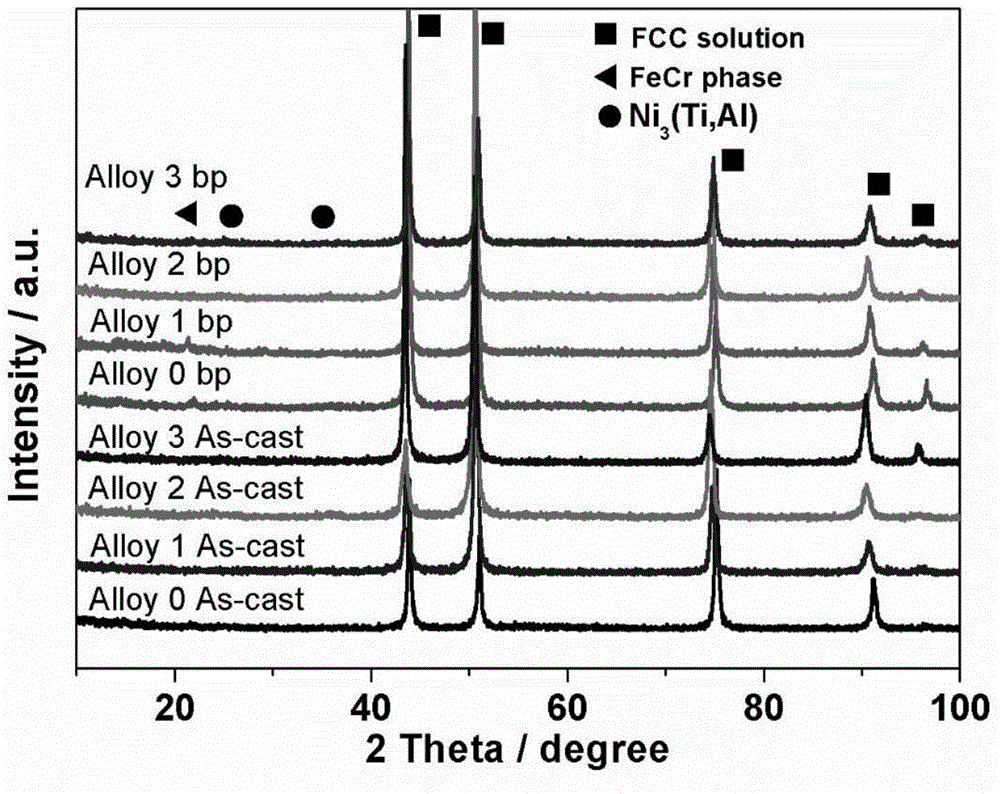

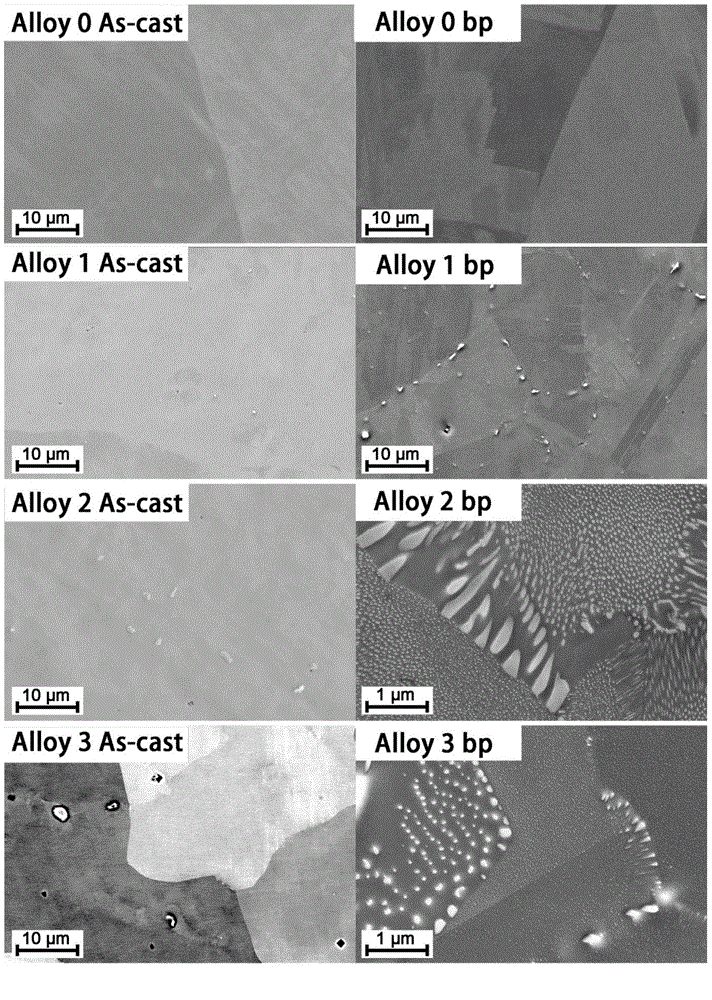

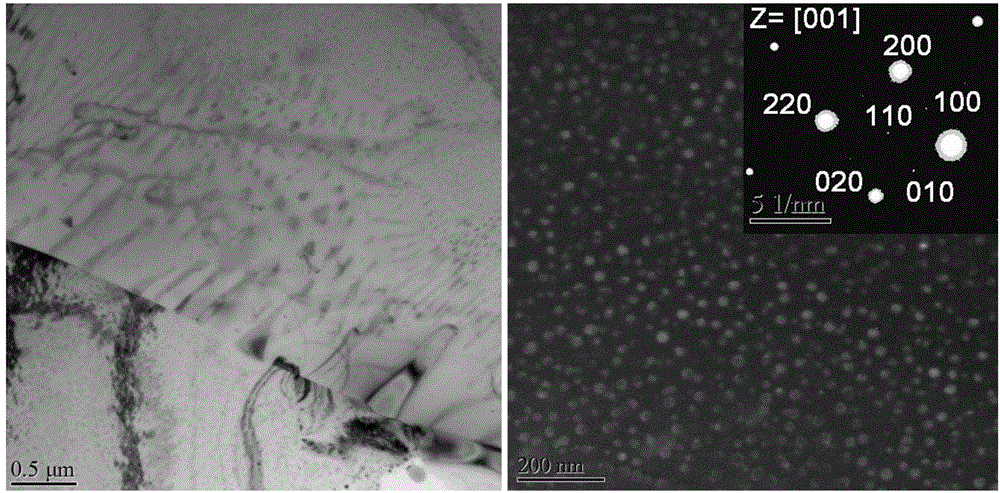

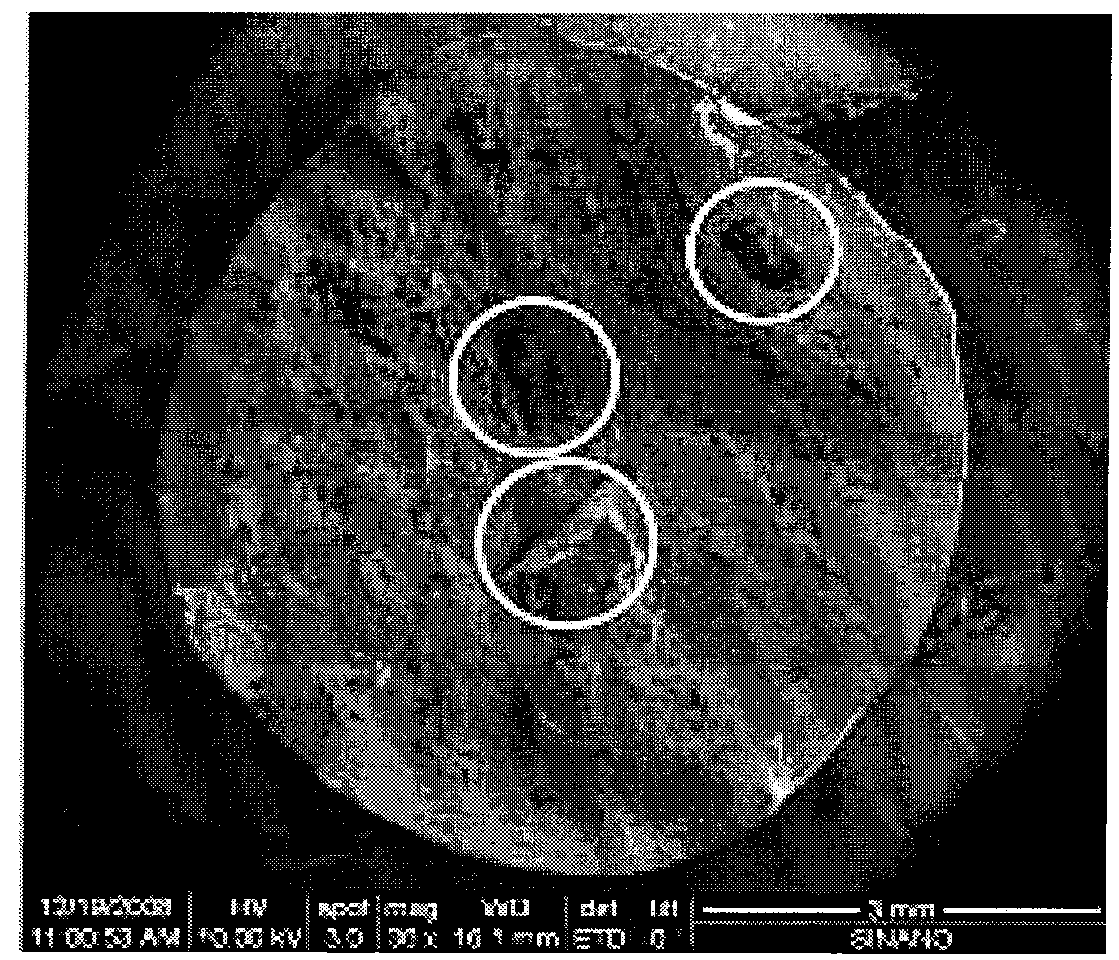

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

Processing method of high-toughness Al-Si system die-casting aluminum alloy

The invention provides a processing method of a high-toughness Al-Si system die-casting aluminum alloy. The method comprises the following steps: carrying out die-casting molding of an Al-Si system aluminum alloy melt, wherein the die casting die temperature is 350-400DEG C and the pressure maintaining time is 1-60s; carrying out die opening, rapidly taking out the obtained object, putting the object in circulating cooling water for quenching, taking out the object from the circulating cooling water after complete cooling, and burring, wherein the time for transferring the object to the circulating cooling water from the die is less than 5s, the quenching temperature is 350-550DEG C and the temperature of the cooling water is less than 30DEG C; and carrying out annealing heat-insulation at 50-250DEG C for 2-3h. The method enables Al-Si system alloy die castings to have the advantages of substantially improved strength and toughness, uniform workpiece structure, excellent mechanical performances, and good safety and reliability, and the application range of the Al-Si system alloy die castings to the enlarged.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

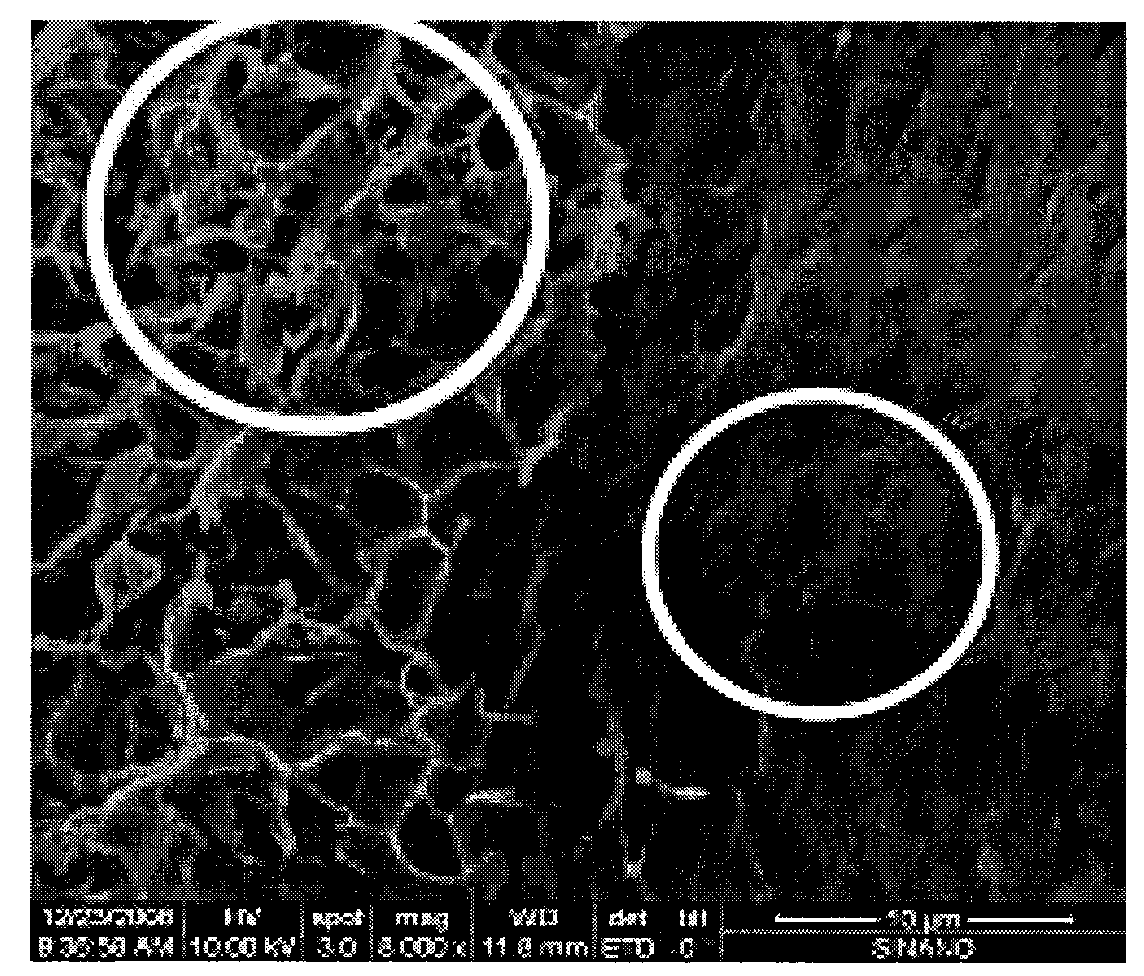

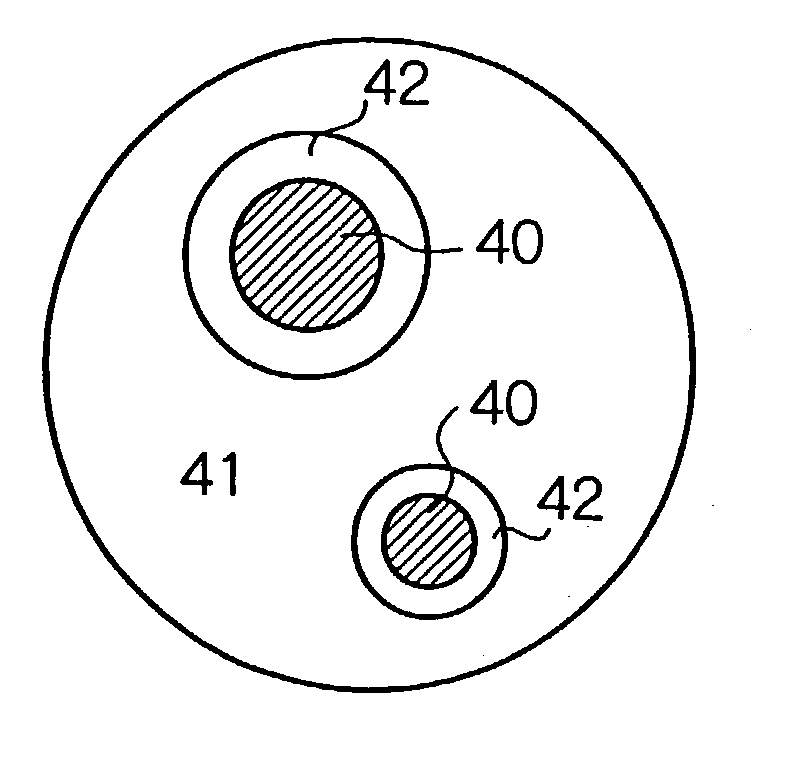

Process for manufacture of negative electrode material for a non-aqueous electrolyte secondary battery

InactiveUS20030175589A1Maintain good propertiesReduce battery sizeSolid electrolytesElectrode manufacturing processesAlloySolid solution

A negative electrode material for a nonaqueous electrolyte secondary battery having a high discharge capacity and a good cycle life is made from alloy particles having an average particle diameter of 0.1-50 mum and including Si phase grains 40 and a phase of a solid solution or an intermetallic compound of Si and other element selected from Group 2A elements, transition elements, Group 3B elements, and Group 4B elements from the long form periodic table (for example, an NiSi2 phase 42 and an [NiSi2+NiSi] phase 41) at least partially enveloping the Si phase grains. 5-99 wt % of this material is Si phase grains. The alloy particles can be manufactured by rapid solidification (such as atomization or roller quenching) of a melt including Si and the other element, or by adhering the other element to Si powder by electroless plating or mechanical alloying and then performing heat treatment. Even if rapid solidification is carried out, a negative electrode material having a good discharge capacity and cycle life is obtained without heat treatment.

Owner:CHUO DENKI KOGYO CO LTD

Cherry and tomato composite beverage and preparation method thereof

InactiveCN104312859AComprehensive and balanced nutritionEvenly ruddy colorAlcoholic beverage preparationThirstNutrient solution

The invention discloses a cherry and tomato composite beverage and a preparation method thereof. The cherry and tomato composite beverage is prepared from the following raw materials, by weight, 30-45 parts of cherry, 15-20 parts of tomato, 10-15 parts of guava, 10-14 parts of pitaya peel, 10-15 parts of buckwheat, 14-18 parts of red glutinous rice, 1-3 parts of stevioside, 2-3 parts of very precious flower in Plateau Snow Mountain, 2-4 parts of ginseng fruit, 3-5 parts of grapefruit flower, 1-2 parts of flower of Intermediate peashrub, 1-2 parts of Japanese metaplexis, 12-18 parts of setose abelmoschus, a proper amount of rose wine, and 8-10 parts of a nutrient solution. The cherry and tomato composite beverage prepared in the invention maximally reserves nutritional components of cherry and tomato, has the characteristics of red and uniform color, aroma, sweet and delicious taste, smooth mouthfeel, abundant and balanced nutrition, and simple and feasible technology, has the efficacies of body fluid production promoting, thirst quenching, stomach strengthening, food digesting, pressure reducing, lipid lowering, heat clearing, detoxifying, toxin expelling and face nourishing through the synergistic effect with health care components of traditional Chinese medicines, and can promote digestion, enhance muscle power and improve the oxidation resistance of human bodies through long term drinking.

Owner:徐九山

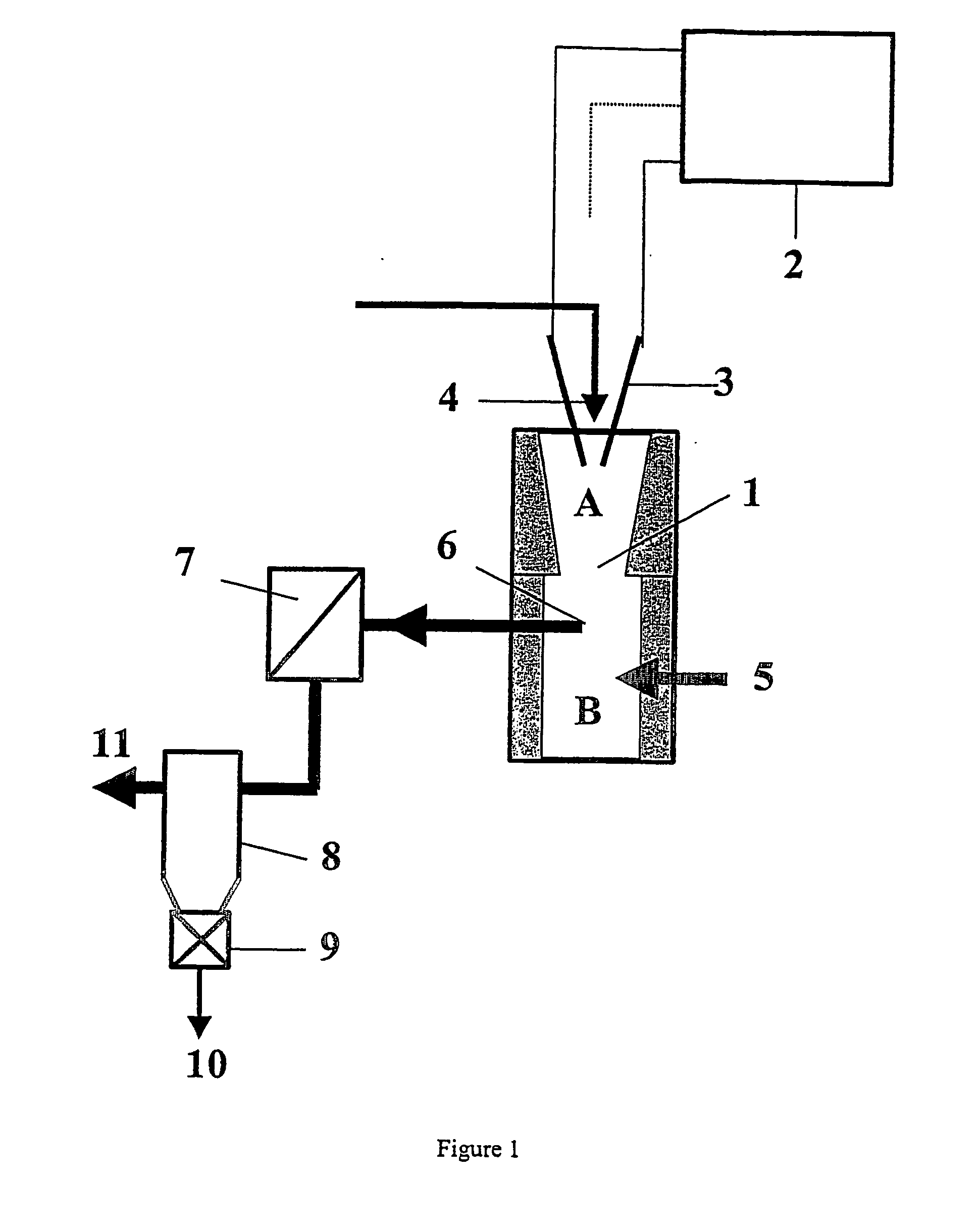

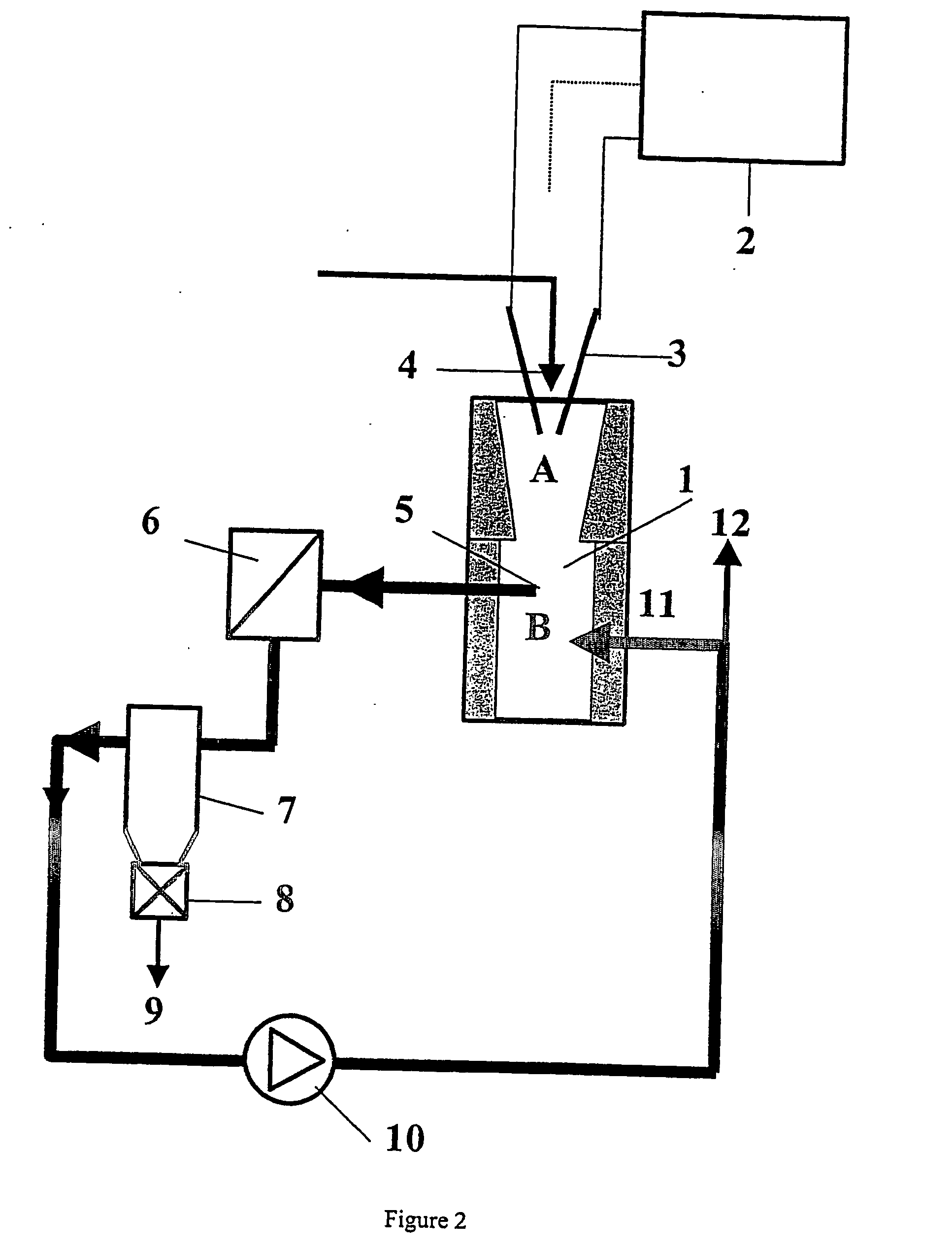

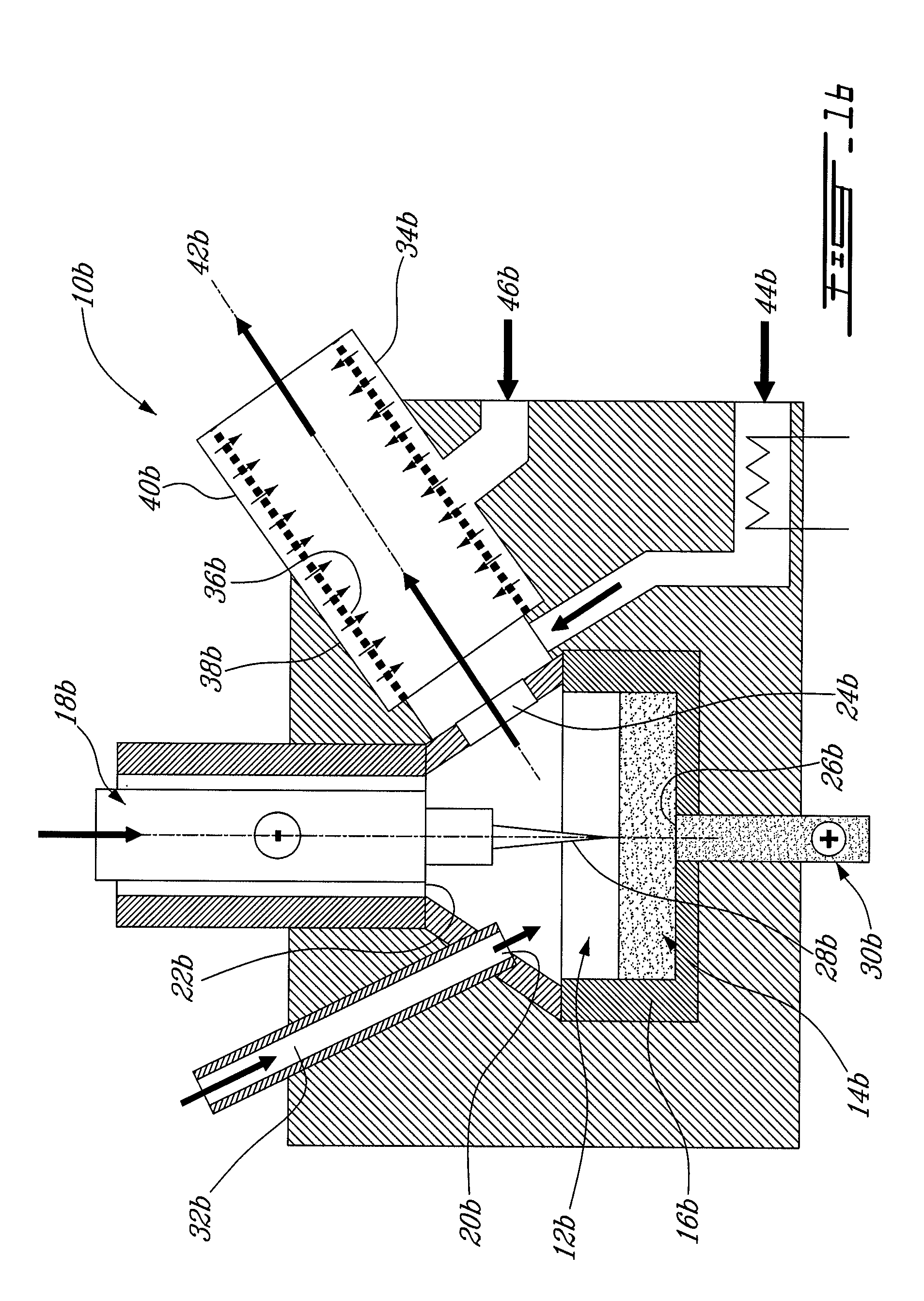

Plasma synthesis of nanopowders

ActiveUS20070221635A1Improve scalabilityReduce the possibilityArc welding apparatusPlasma techniquePlasma flowQuenching

A process and apparatus for preparing a nanopowder are presented. The process comprises feeding a reactant material into a plasma reactor in which is generated a plasma flow having a temperature sufficiently high to vaporize the material; transporting the vapour by means of the plasma flow into a quenching zone; injecting a preheated quench gas into the plasma flow in the quenching zone to form a renewable gaseous condensation front; and forming a nanopowder at the interface between the renewable controlled temperature gaseous condensation front and the plasma flow.

Owner:TEKNA PLASMA SYST INC

Metabolic measurements system including a multiple function airway adapter

InactiveUS20070225612A1Easy to reusePromote generationRespiratory organ evaluationSensorsAnesthetic AgentRespiratory flow

A system for measuring a metabolic parameter. The system includes an integrated airway adapter capable of monitoring any combination of respiratory flow, O2 concentration, and concentrations of one or more of CO2, N2O, and an anesthetic agent in real time, breath by breath. Respiratory flow may be monitored with differential pressure flow meters under diverse inlet conditions through improved sensor configurations which minimize phase lag and dead space within the airway. Molecular oxygen concentration may be monitored by way of luminescence quenching techniques. Infrared absorption techniques may be used to monitor one or more of CO2, N2O, and anesthetic agents.

Owner:RIC INVESTMENTS LLC

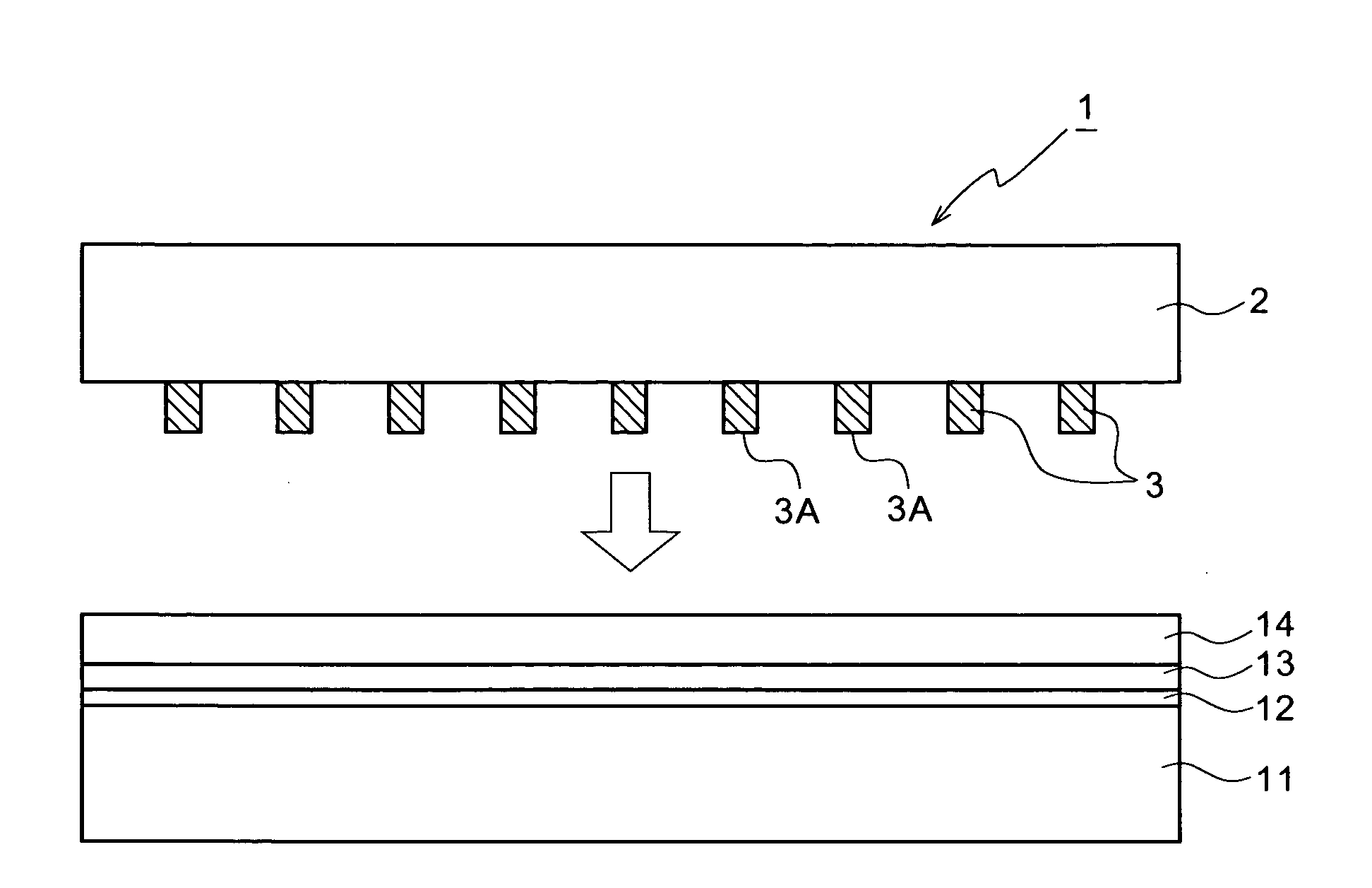

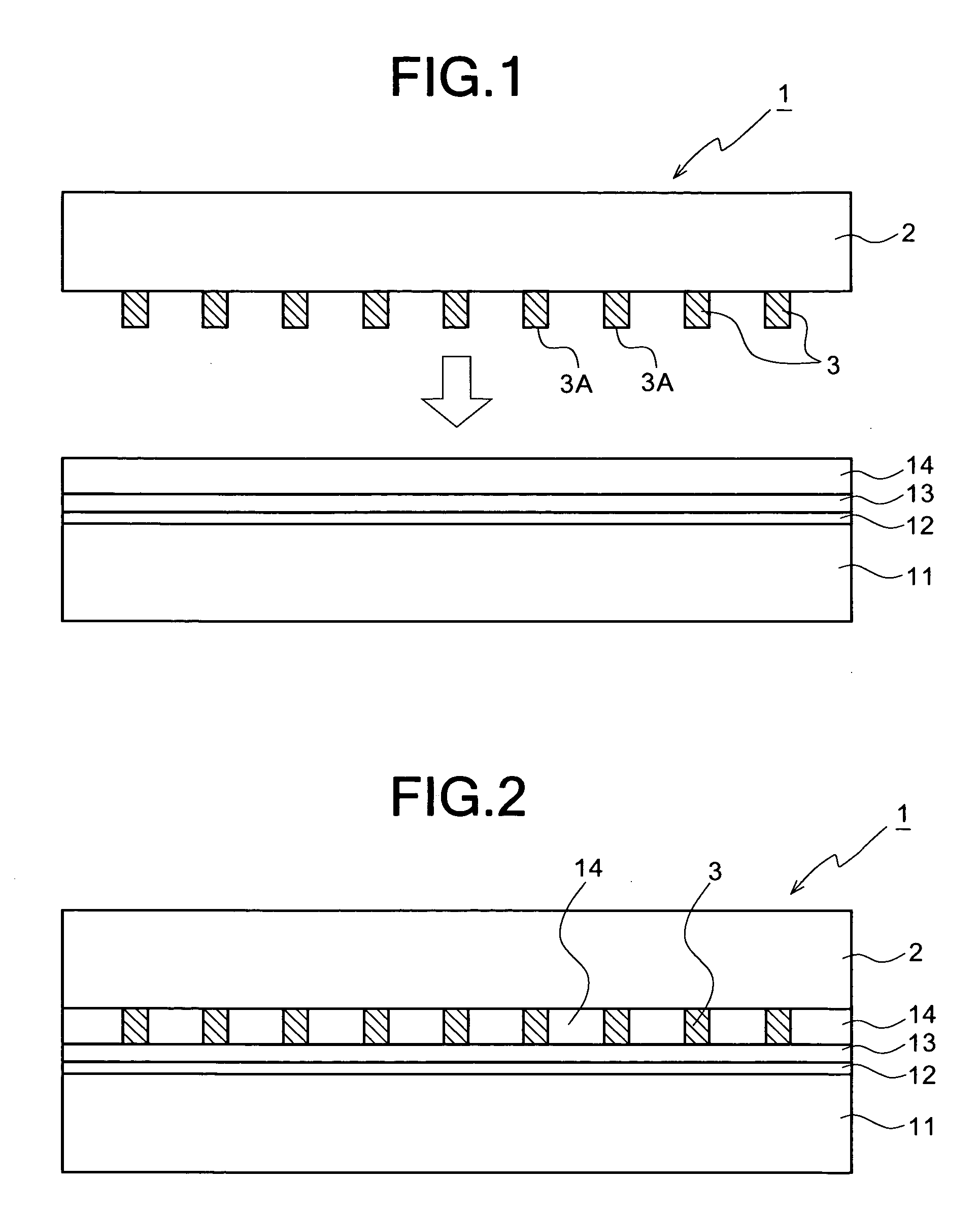

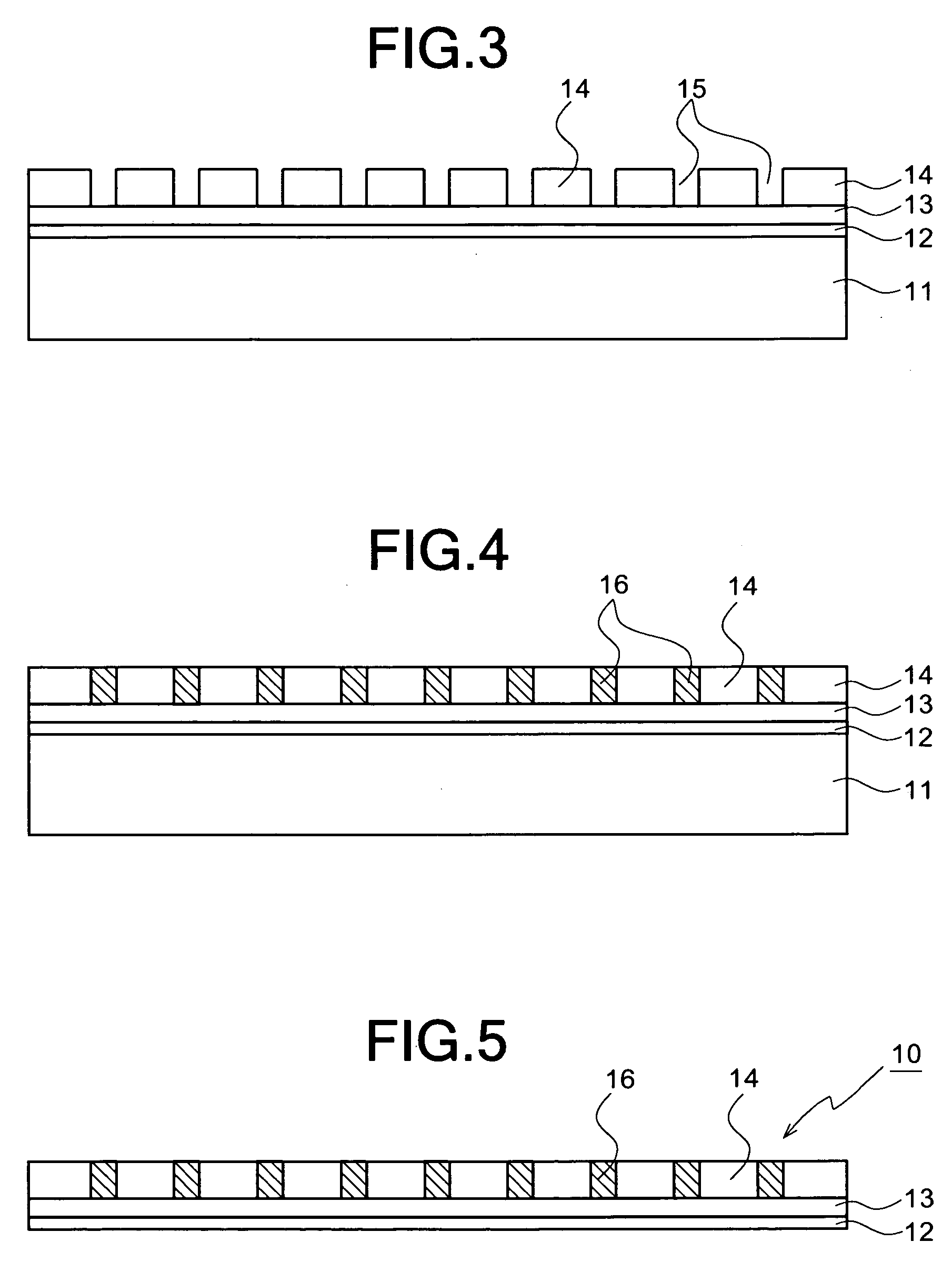

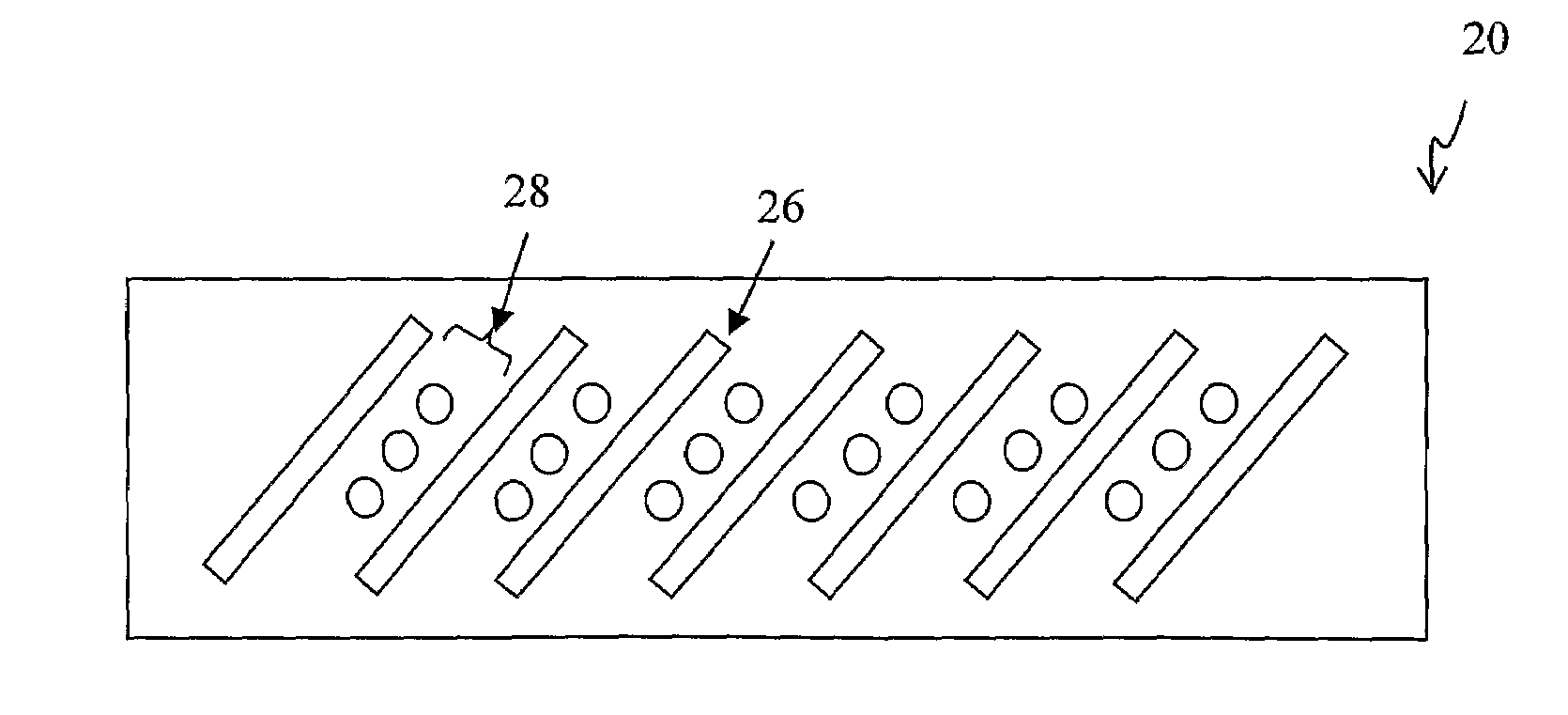

Wire grid polarizer and method for producing same

ActiveUS20050046943A1High light transmittanceLow costPolarising elementsOptical articlesWire gridLithographic artist

There are provided a thin wire grid polarizer having a high transmittance, a high quenching ratio and a high degree of polarization, and a method for producing the same at low costs. A fluoridated polyimide thin film 12, a hydrophilic thin film 13 and a hydrophobic thin film 14 are sequentially stacked on a glass substrate 11 to be pressed by a die 1 from the side of the hydrophobic thin film 14 to transfer the fine pattern of groove forming protrusions 3 of the die 1 to the hydrophobic thin film 14 and hydrophilic thin film 13 by the nano-imprinted lithography technique, and then, metal fine wires are caused to grow by plating.

Owner:ENPLAS CORP

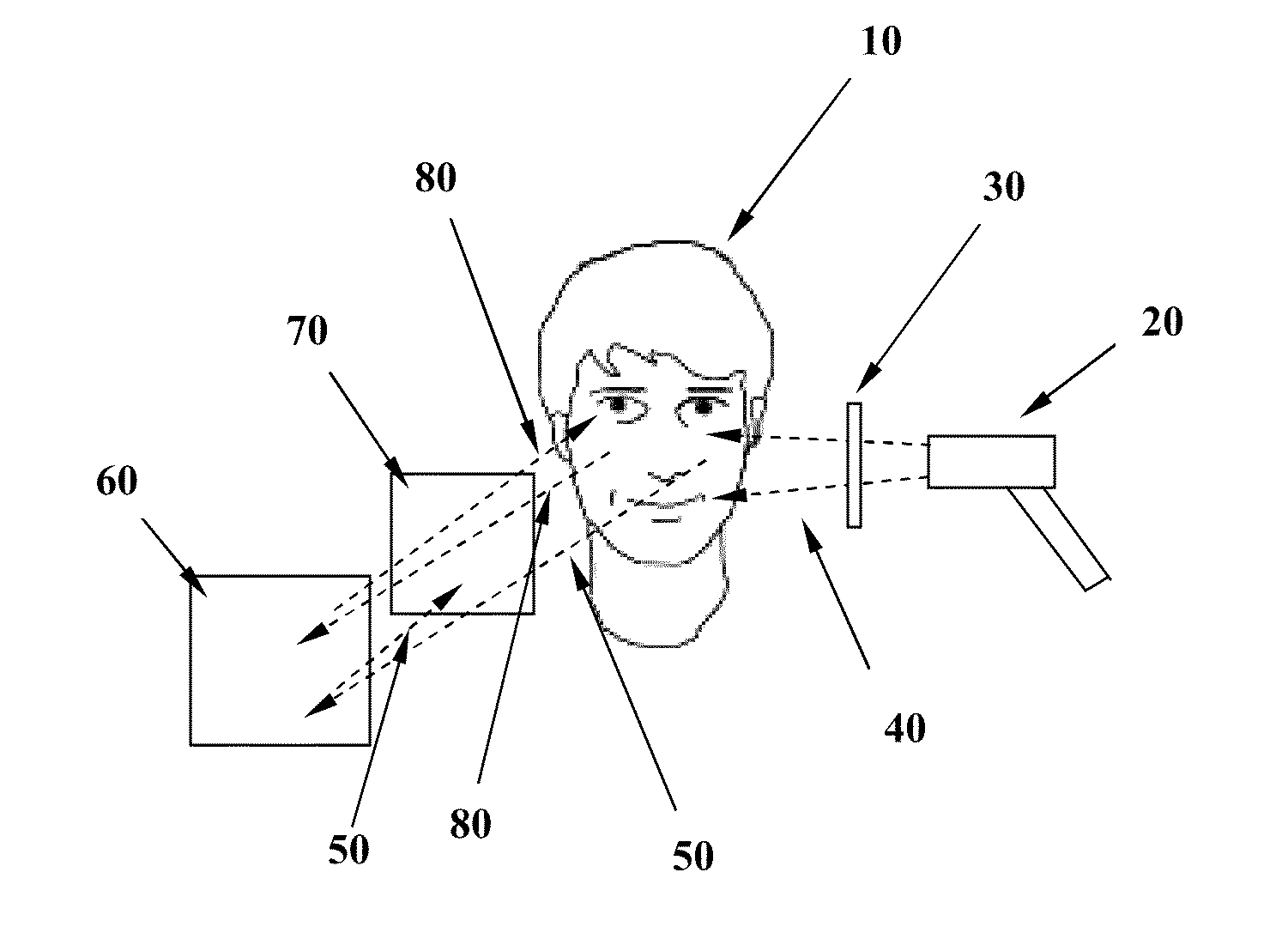

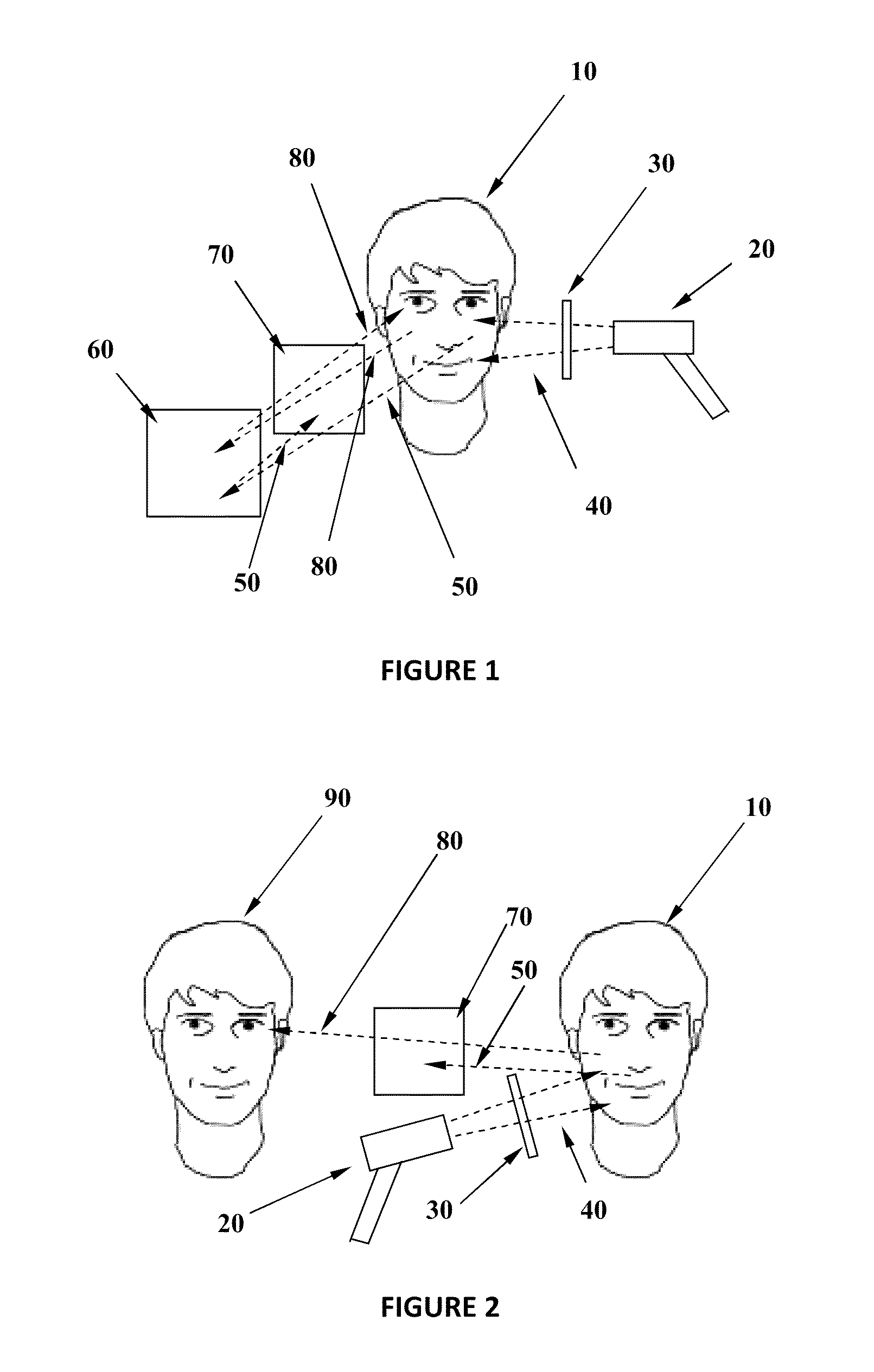

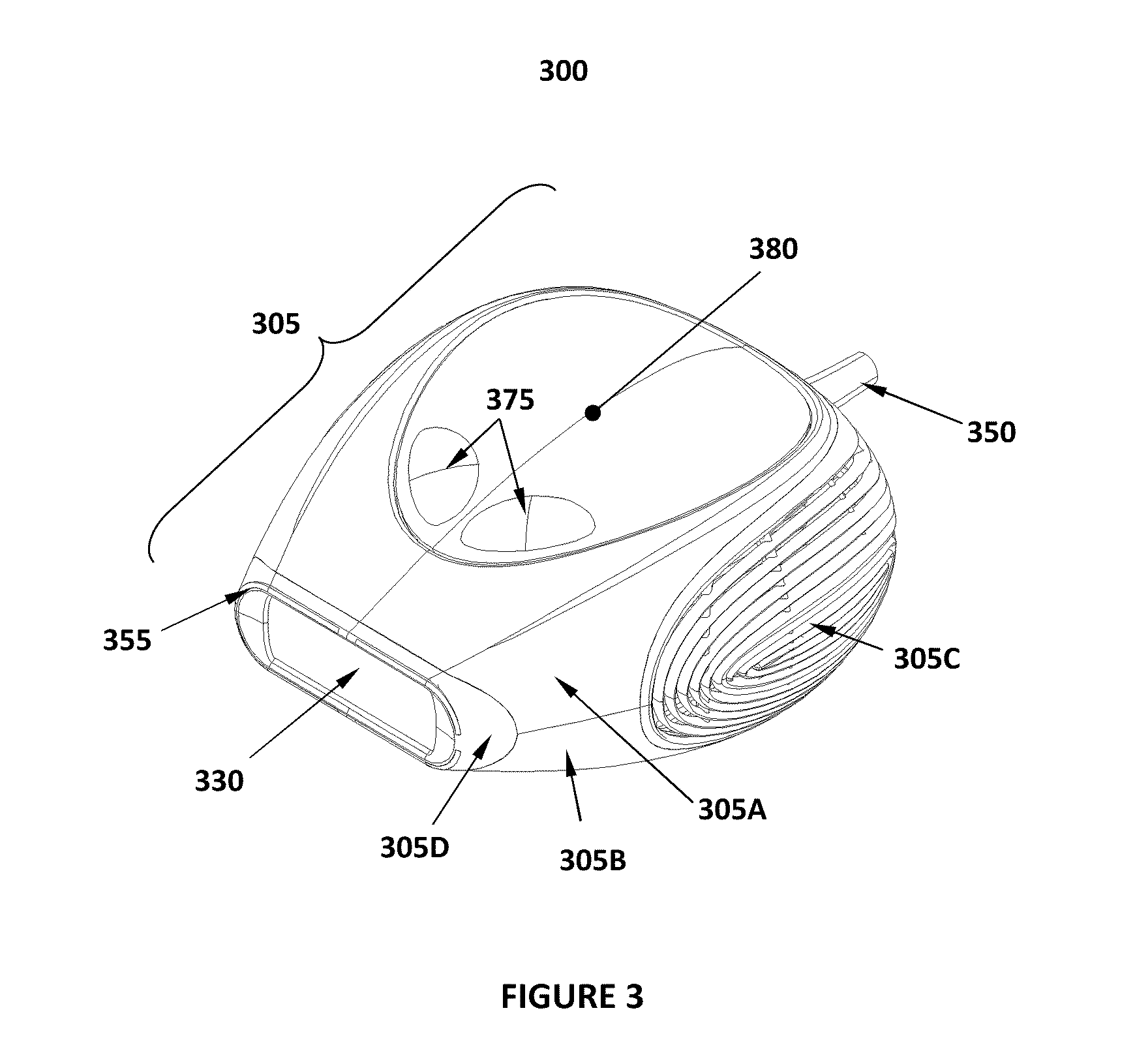

Acne Treatment Method, System and Device

InactiveUS20100069898A1Reduce developmentAvoiding hyperpigmentationDiagnosticsSurgical instrument detailsBacillus acnesPorphyrin

An acne treatment system, device and method includes optical visualization means for identifying areas of skin colonized by the P. acnes bacteria, and further comprises methods, techniques and apparatus for the reduction or elimination of such colonies through the use of light of a power density and wavelength configured to be absorbed by porphyrins produced by the bacteria, resulting in a quenching. Various alternative embodiments are disclosed, including eye safe embodiments, embodiments in which a treatment regimen is provided on a disposable cartridge, embodiments in which the authenticity of the cartridge is verified to ensure proper operation, as well as others.

Owner:CHANNEL INVESTMENTS LLC

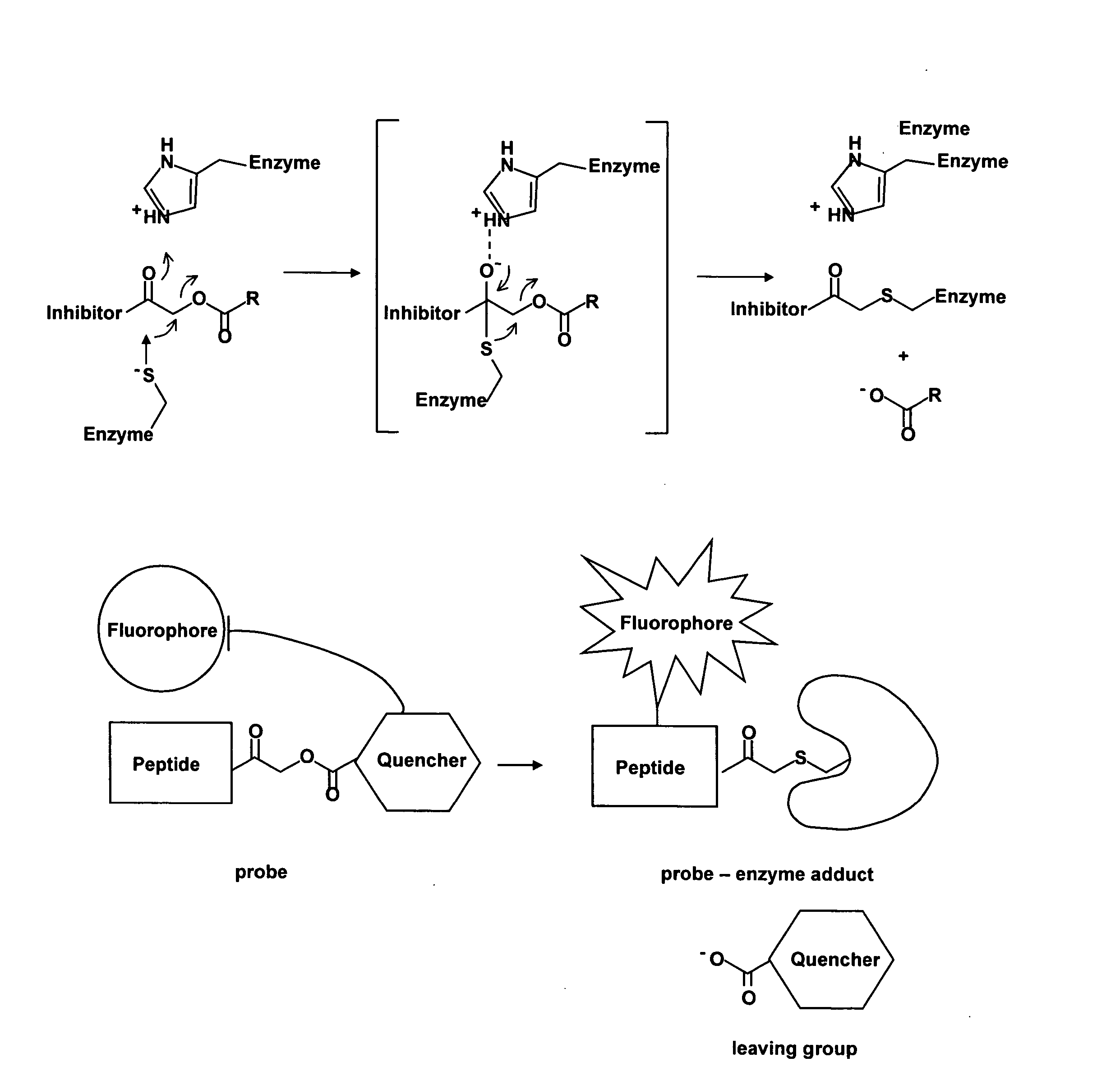

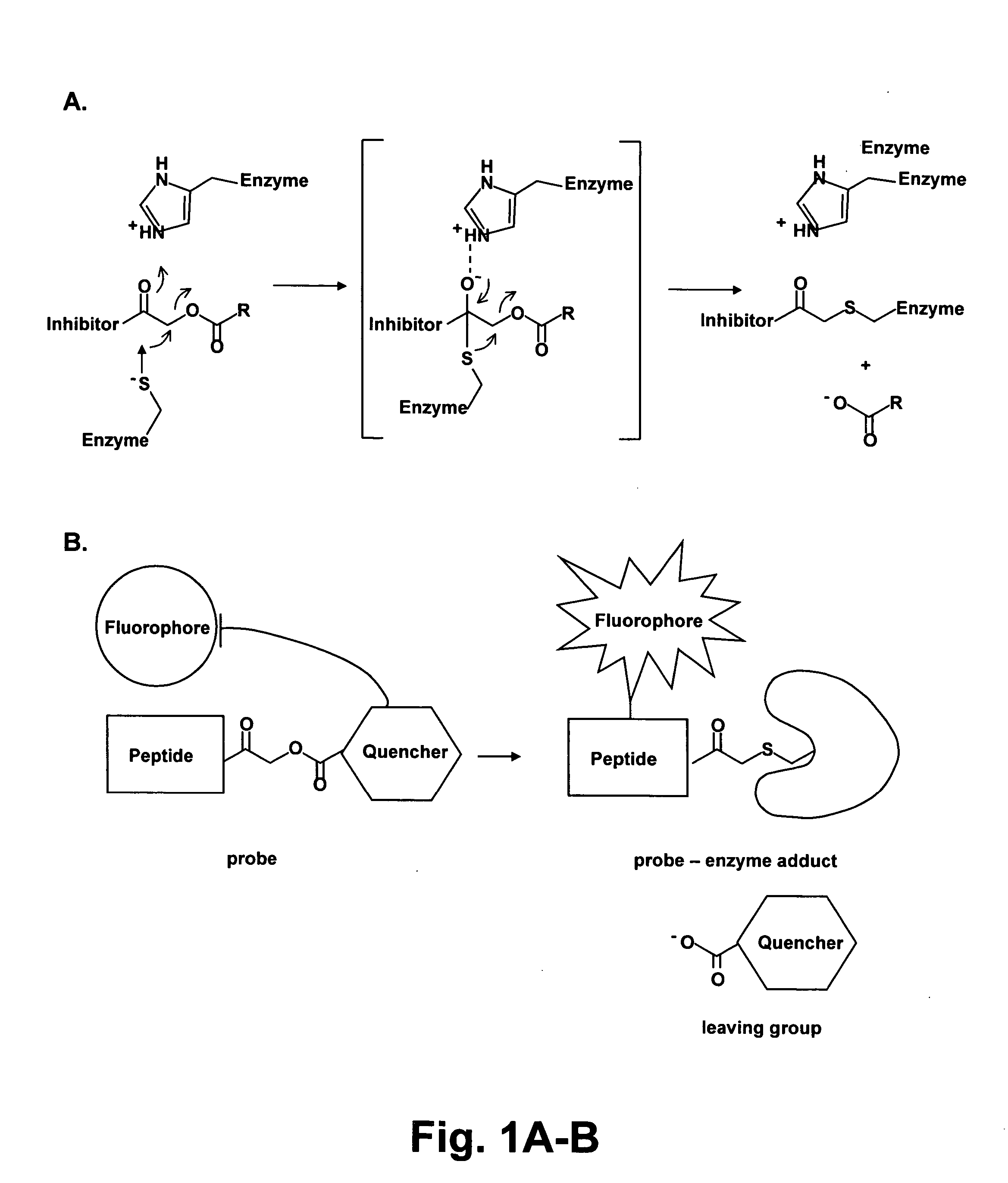

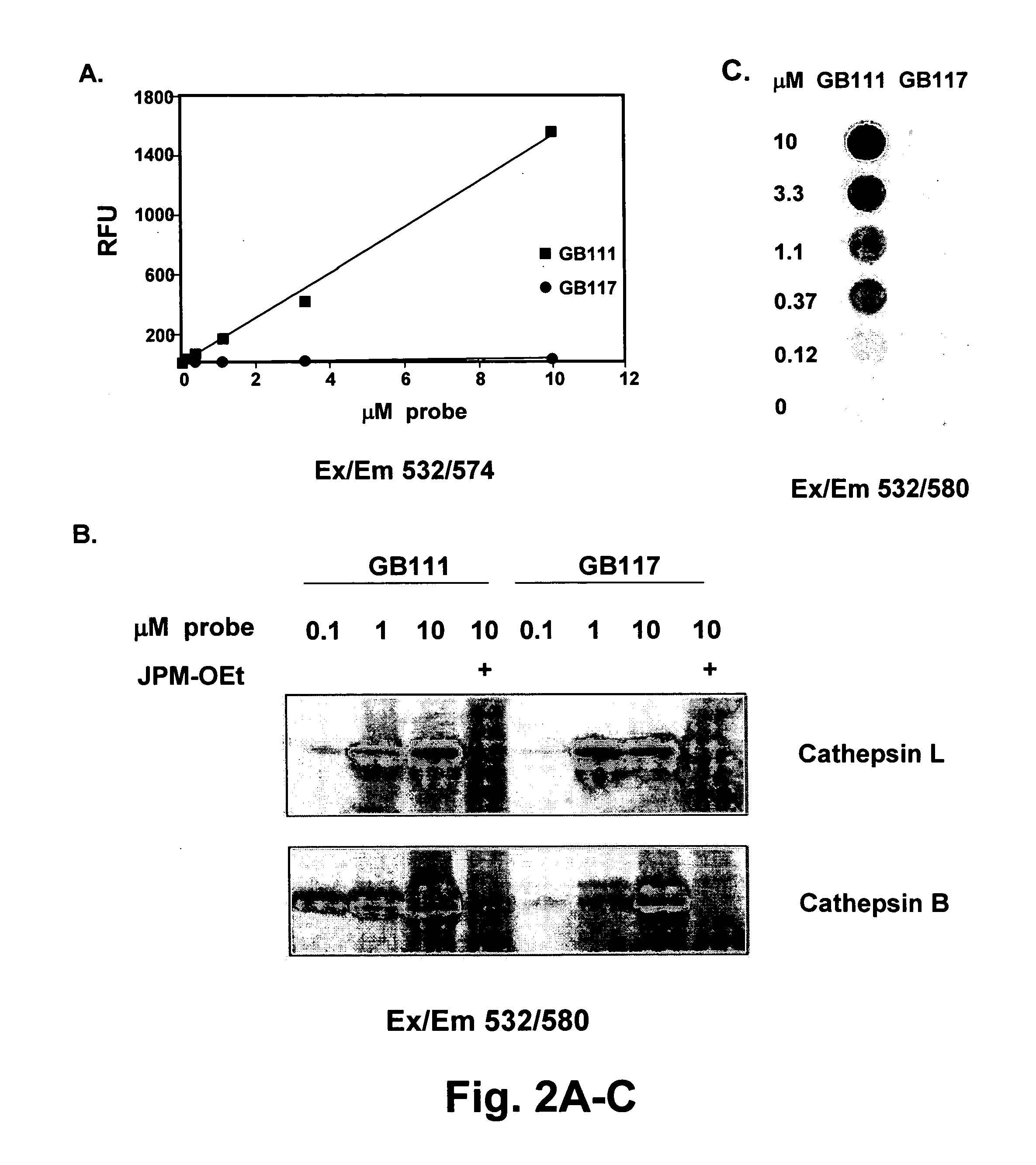

Imaging of protease activity in live cells using activity based probes

ActiveUS20070036725A1Improve resolutionHigh sensitivityUltrasonic/sonic/infrasonic diagnosticsSurgeryProteinase activityFluorophore

Methods and materials for the imaging of cells containing active proteases such as cathepsin are disclosed. The present materials include activity based probes that bind to an enzyme and are subsequently cleaved. Cleavage results in a fluorescent signal due to removal of a quenching group which, when present on the probe causes altered or no fluorescence. The probes employ an acyloxymethyl ketone reactive group, one or more amino acids for determining specificity, a fluorophore and a quencher. The probes are cell permeable and may use, for example, a QSY7 (diarylyrhodamine) quencher and a BODIPY (bora-diaza-indecene) dye.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

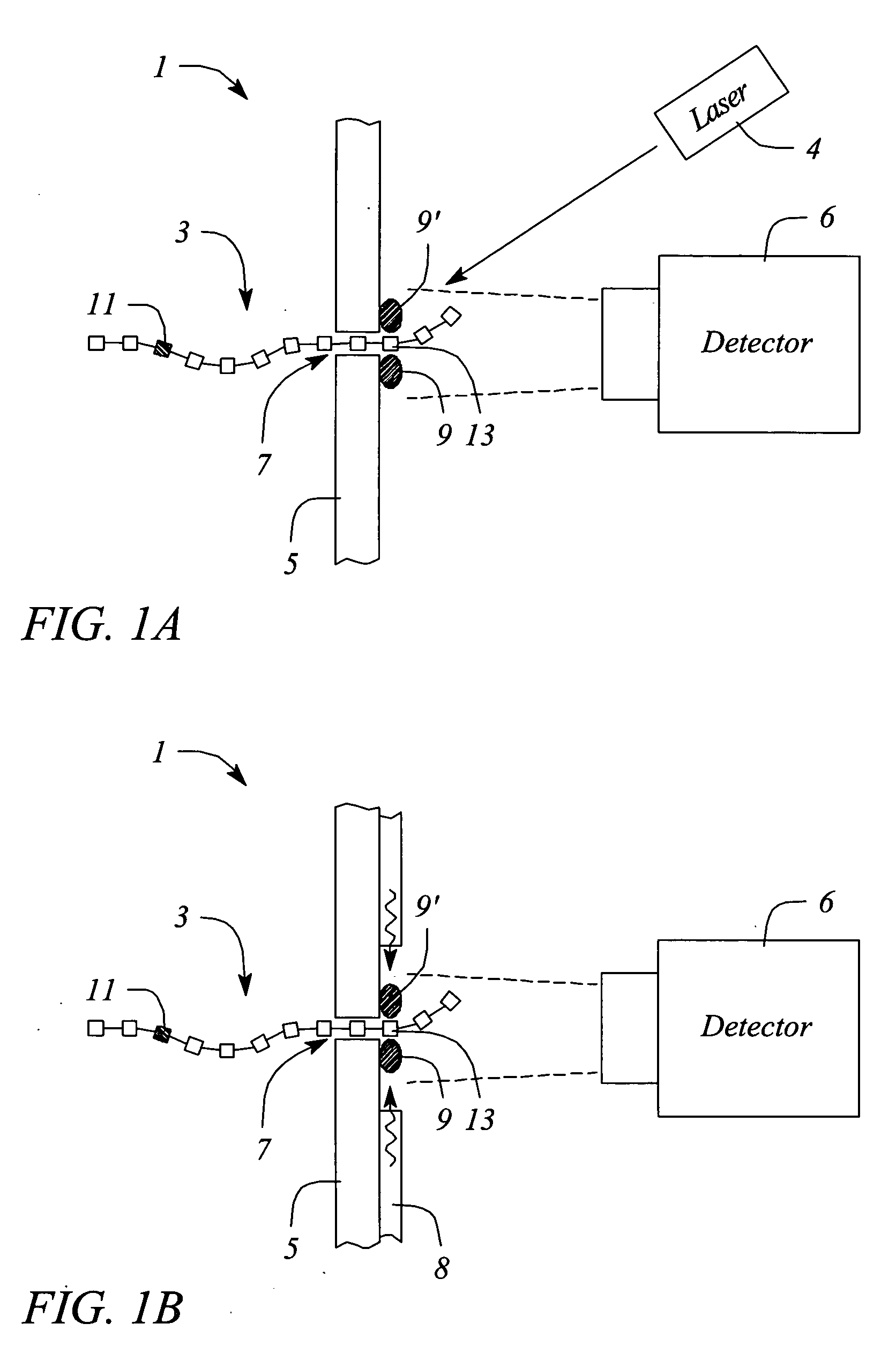

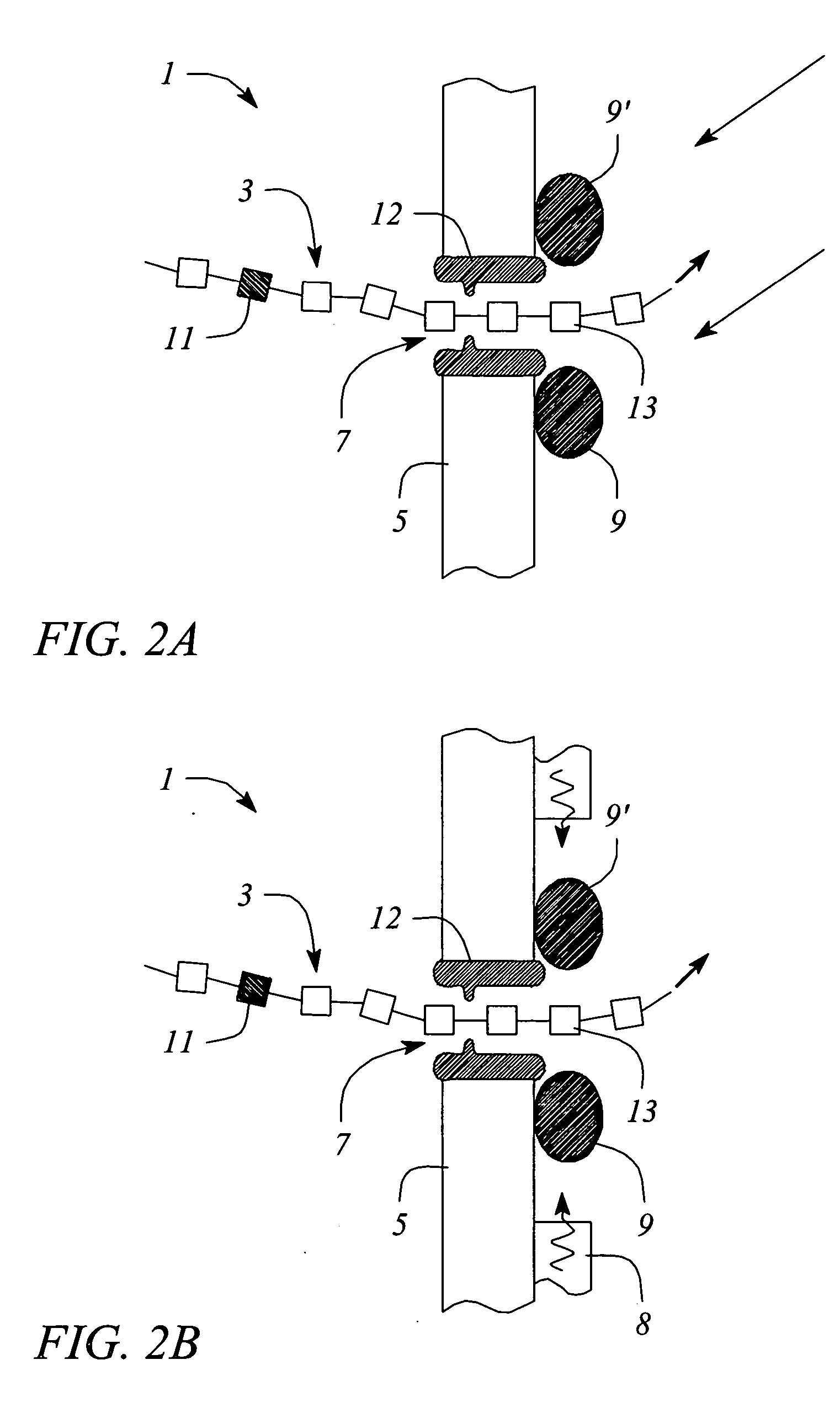

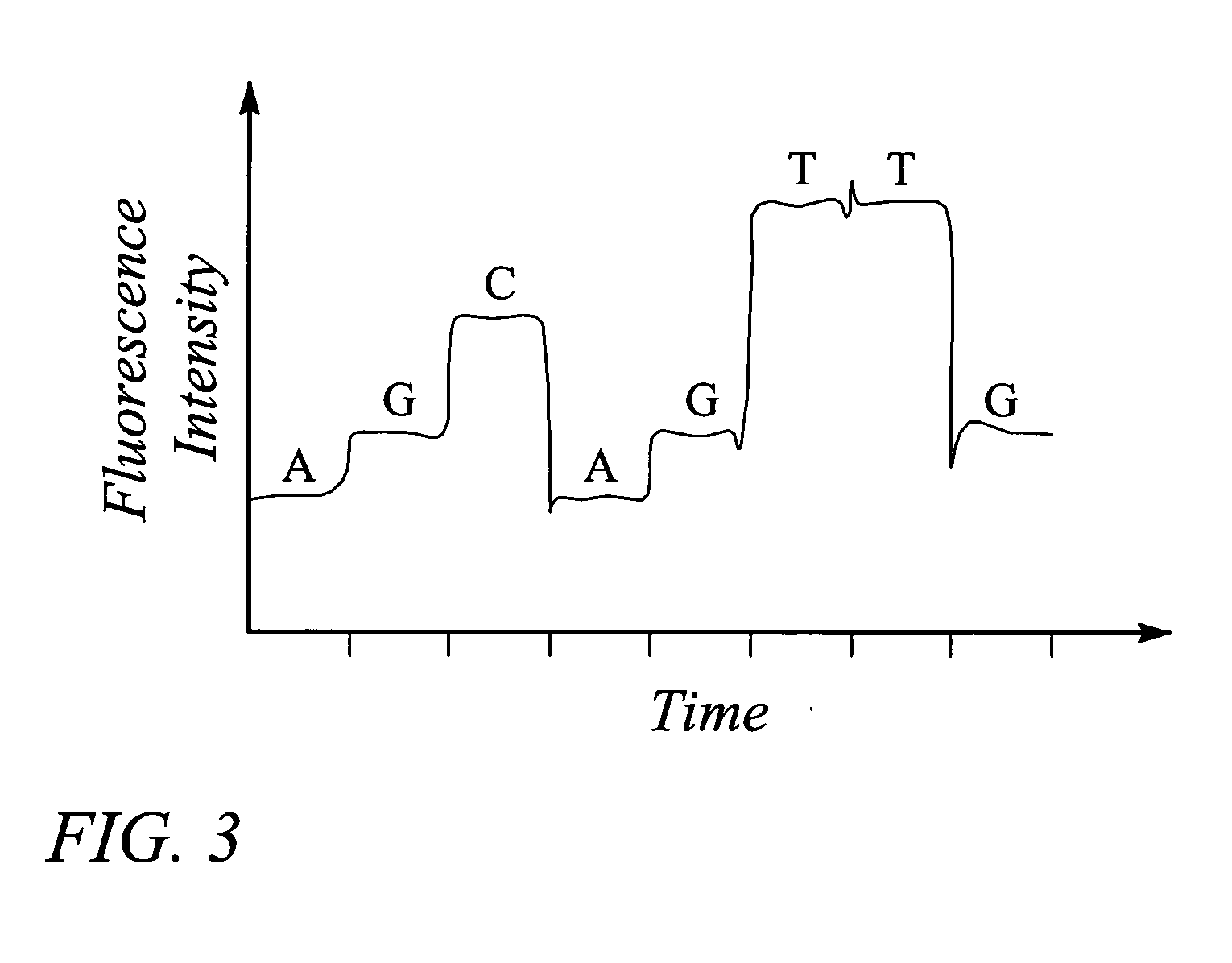

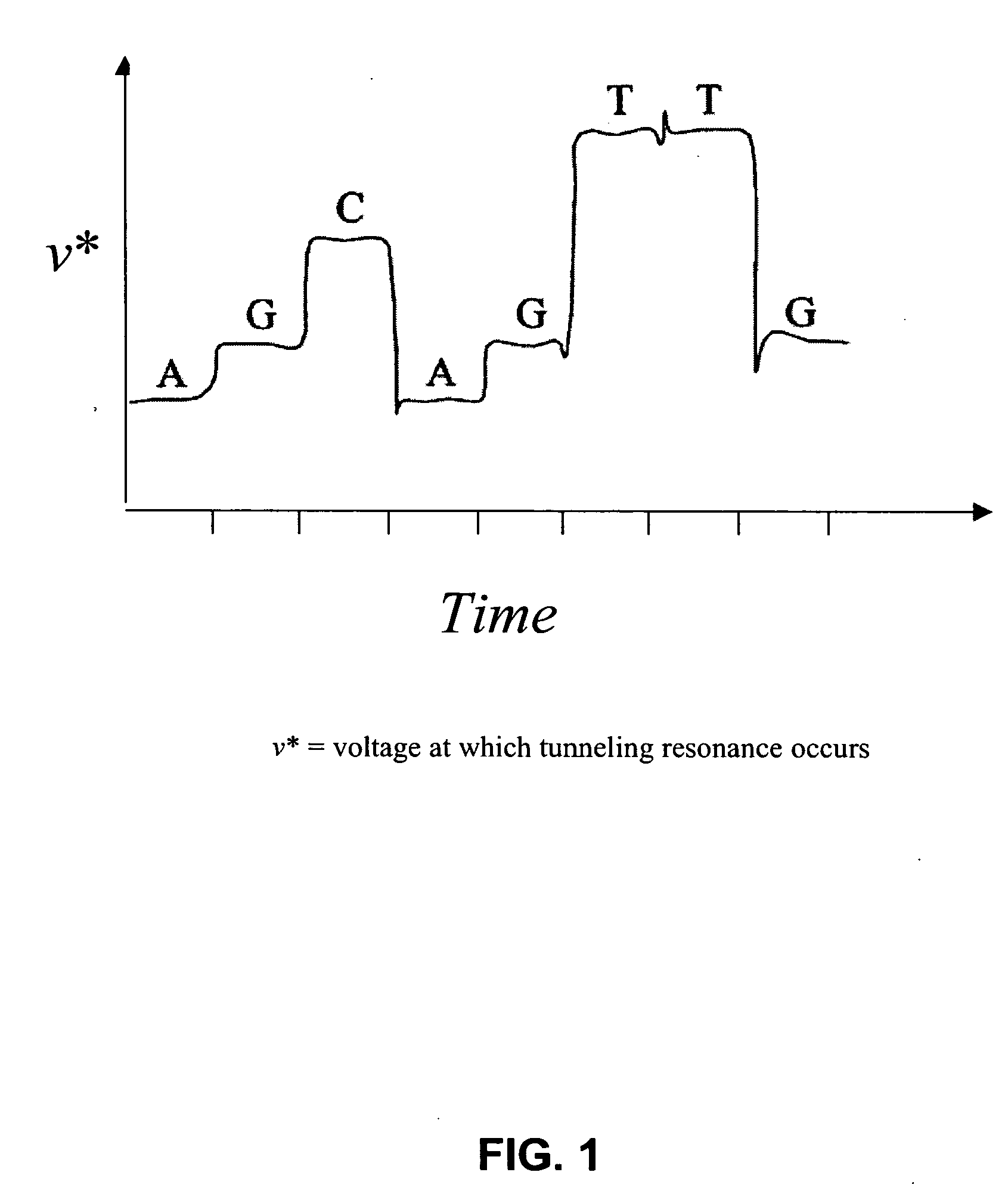

Characterization of biopolymers by resonance tunneling and fluorescence quenching

InactiveUS20060019259A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFluorescenceBiopolymer

The present invention provides a method and apparatus for determining the identity of a monomeric residue of a biopolymer. The apparatus comprises a substrate having a nanopore, a potential-producing element for producing a ramped potential across electrodes adjacent to the nanopore, and a quenchable excitable moiety adjacent to the nanopore. As a biopolymer passes through the nanopore, the identity of monomeric residues of a biopolymer may be determined by detecting changes in (a) current across the electrodes and (b) a signal of the quenchable excitable molecule. The subject method and apparatus find use in determining the identity of a plurality of monomeric residues of a biopolymer, and, as such, may be employed in a variety of diagnostic and research applications.

Owner:AGILENT TECH INC

Process and apparatus for forming uniform nanofiber substrates

ActiveUS7628941B2Reduce distanceDiminish interaction and cominglingConfectioneryFilament/thread formingFiberNanofiber

The present invention is directed to a method and apparatus for making nanofiber webs, wherein a source of process air is utilized to affect the spray pattern and quality of fibrillated material expressed from a die assembly including a multi-fluid opening. Appropriately, the aforementioned process air is defined herein as an alternate or ancillary air source apart from primary process air, which primary air is simultaneously supplied with the molten polymeric material to the fiber forming multi-fluid opening. The ancillary air source of the invention is further distinct from secondary air, which is also known in the art as quenching air. The ancillary air can be described as a continuous fluid curtain of shielding or shaping air.

Owner:AVINTIV SPECIALTY MATERIALS INC

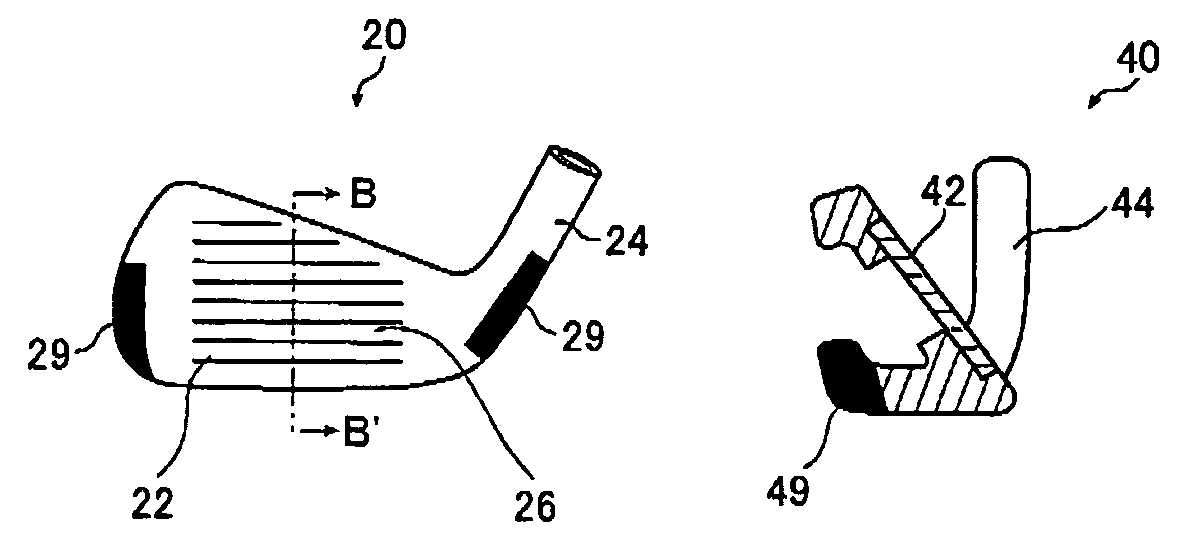

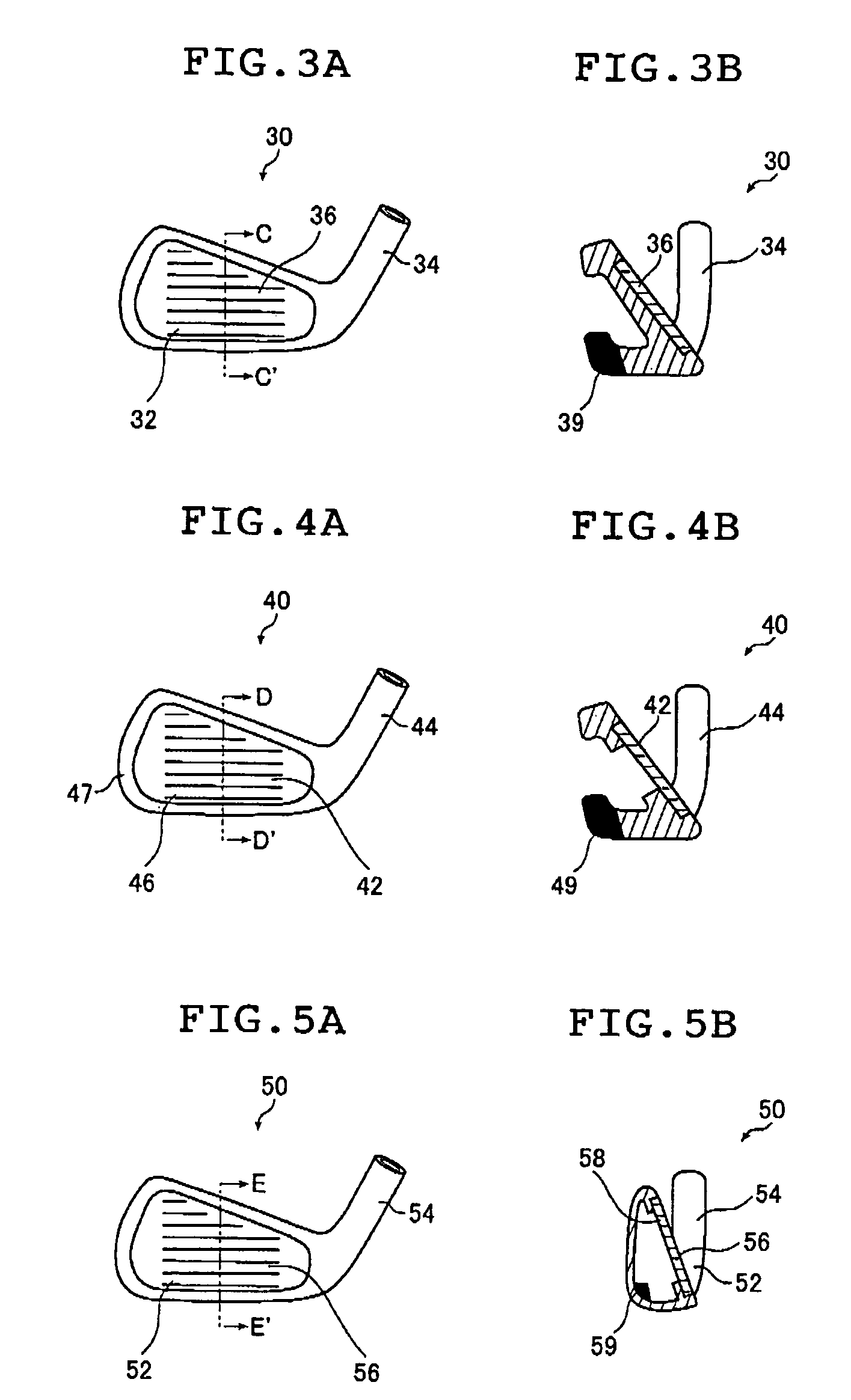

Golf club head

InactiveUS7232380B2Increase distanceImprove directionGolf clubsRacket sportsFlight directionThird generation

Owner:THE YOKOHAMA RUBBER CO LTD

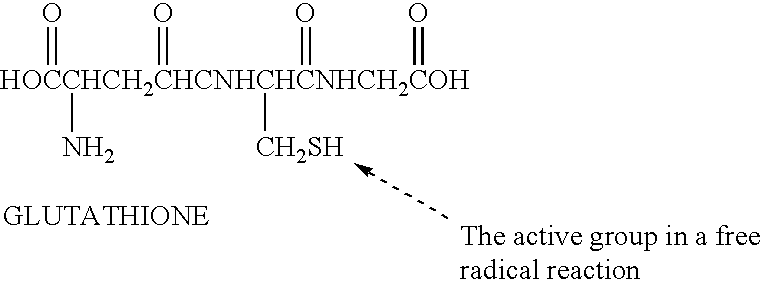

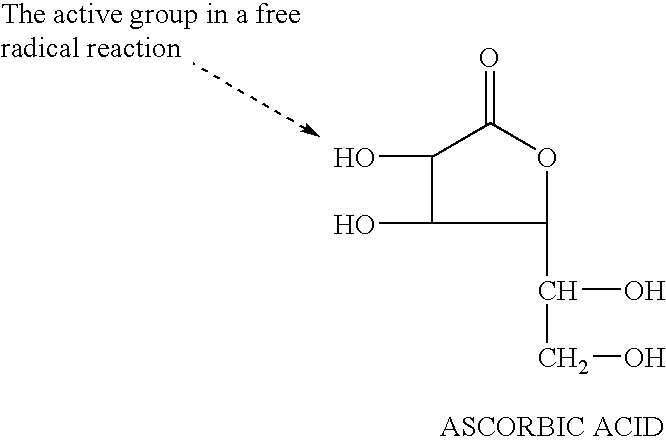

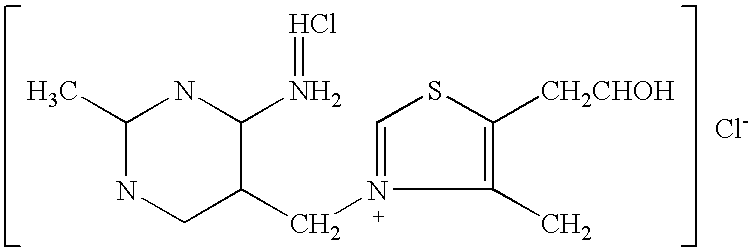

Free radical quenching composition and a method to increase intracellular and/or extracellular antioxidants

A free radical quenching composition is disclosed comprising a liposome containing at least two antioxidants selected from the following group: beta-carotene, vitamin E, vitamin C, glutathione, niacin, and optionally at least one trace metal (Zn, Se, Cr, Cu, Mn). Also disclosed is a method for reducing the undesirable side effects of free radicals in a mammal by administering to a mammal in need of such antioxidants an effective amount of liposomes containing at least two antioxidants.

Owner:AMAOX

Flat push coke wet quenching apparatus and process

InactiveUS7998316B2Reduce the amount requiredImprove efficiencyCoke quenchingDirect heating destructive distillationCoke ovenWater level

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of incandescent coke onto a substantially planar receiving surface of an enclosed quenching car so that substantially all of the coke from the coking oven is pushed as a unitary slab onto the receiving surface of the quenching car. The slab of incandescent coke is quenched in an enclosed environment within the quenching car with a plurality of water quench nozzles while submerging at least a portion of the slab of incandescent coke by raising a water level in the quenching car. Subsequent to quenching the coke, the planar receiving surface is tilted to an angle sufficient to slide the quenched coke off of the planar receiving surface and onto a product collection conveyer and sufficient to drain water from the quenched coke.

Owner:SUNCOKE TECH & DEV LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com