Patents

Literature

581 results about "Commutator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, the commutator gives an indication of the extent to which a certain binary operation fails to be commutative. There are different definitions used in group theory and ring theory.

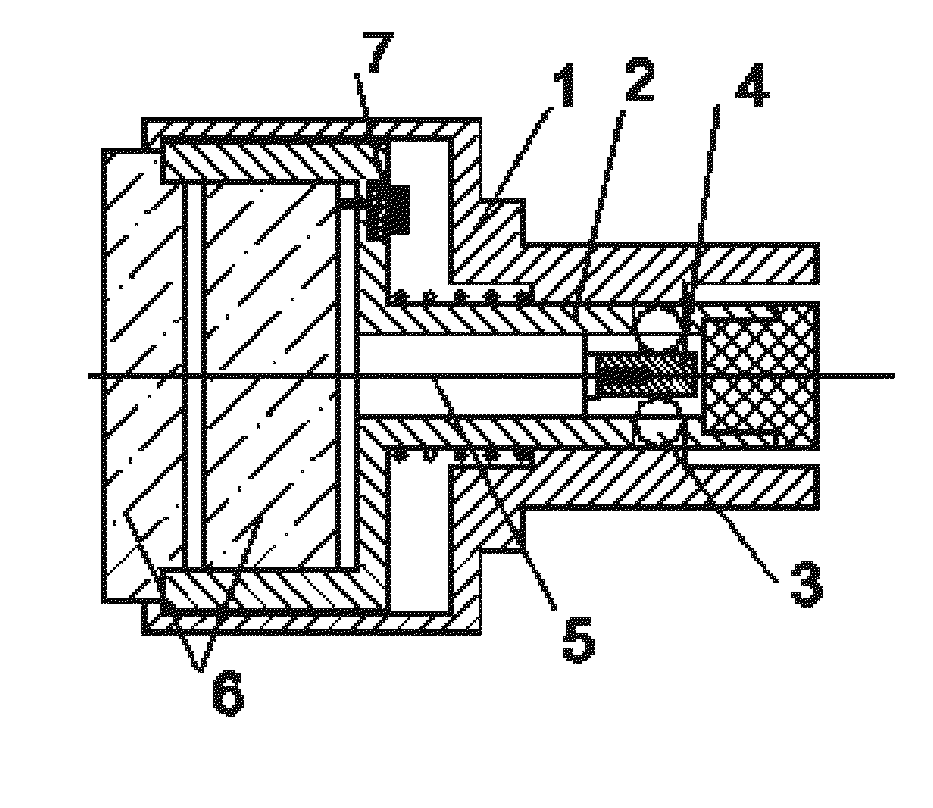

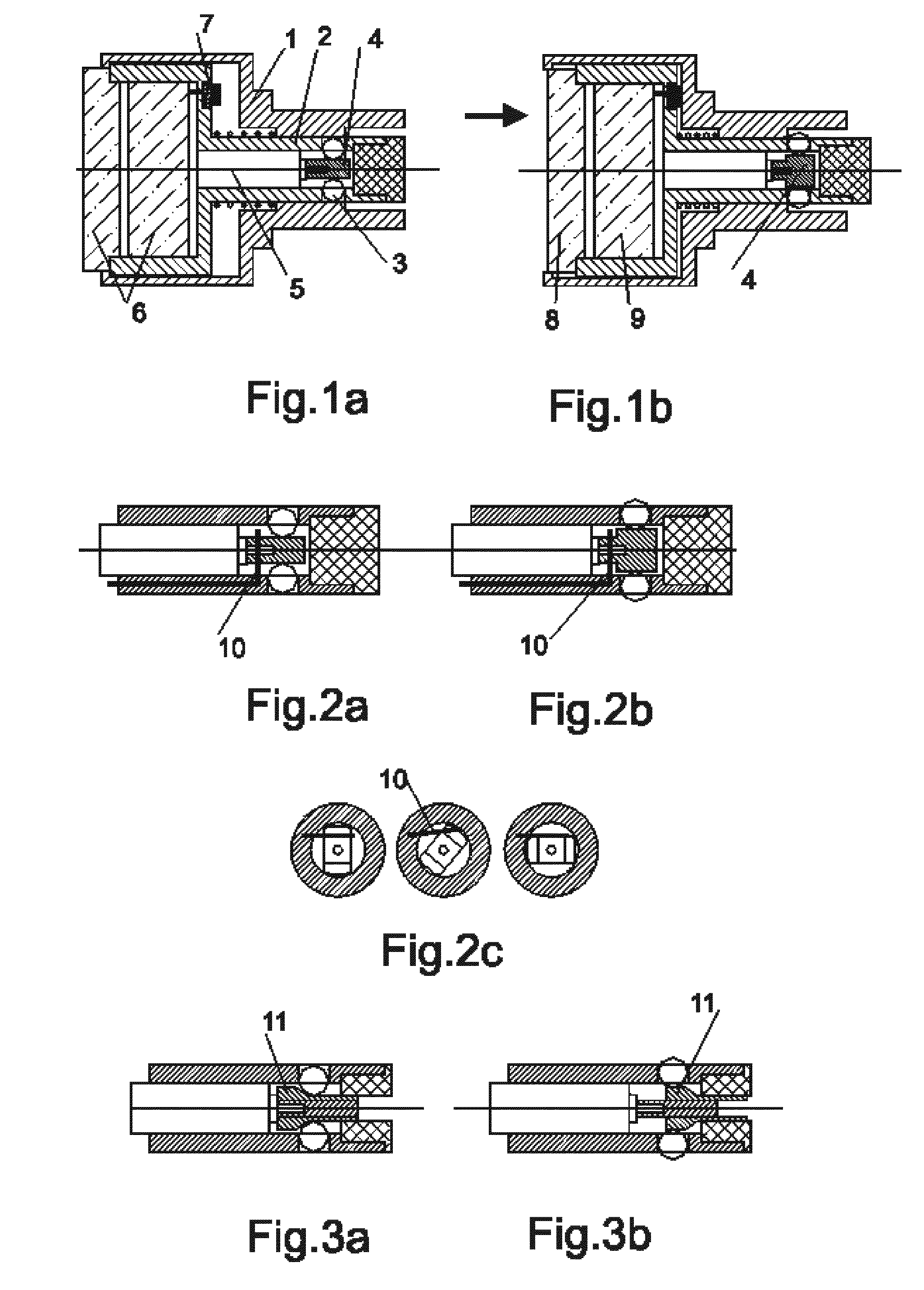

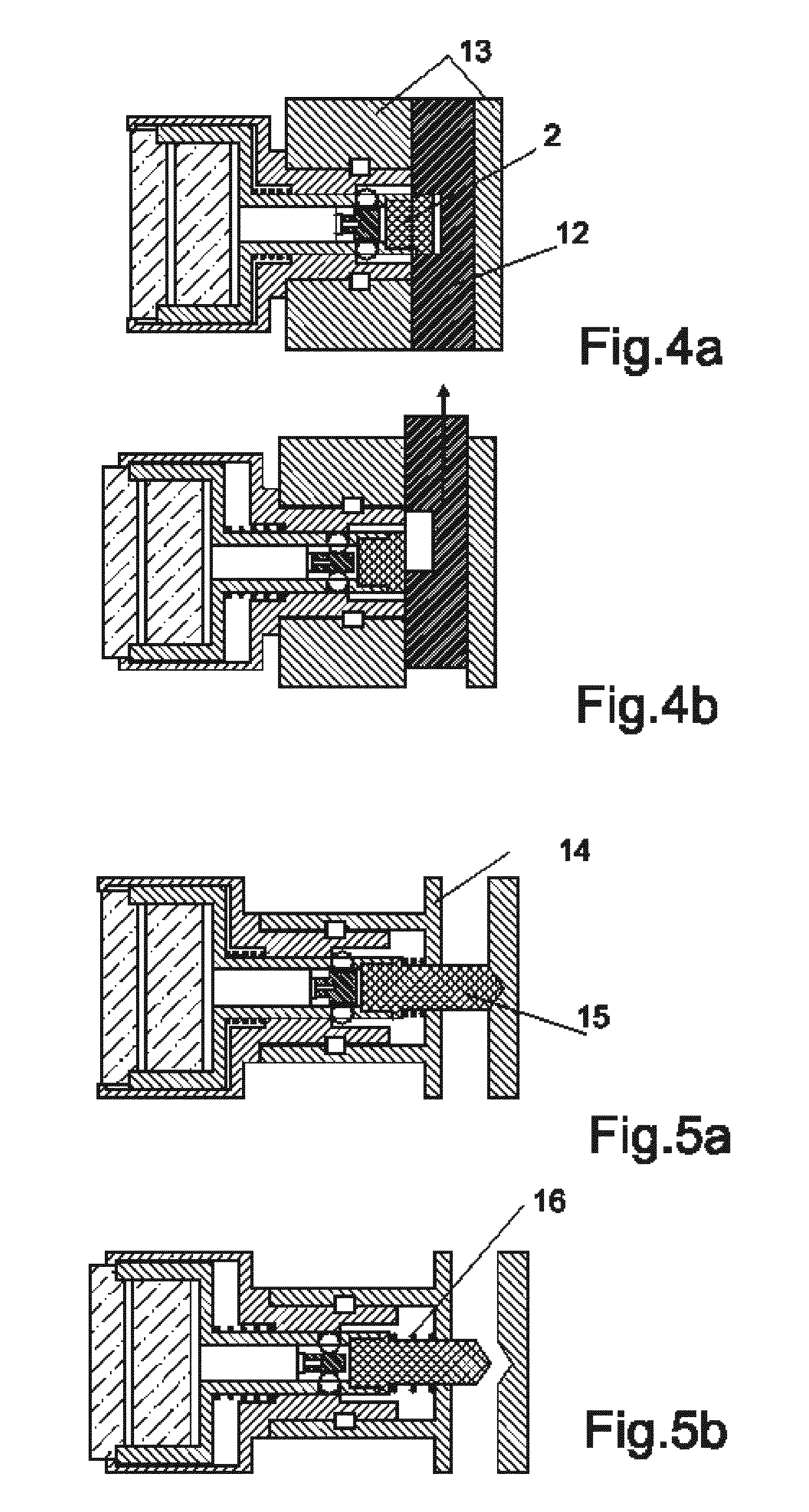

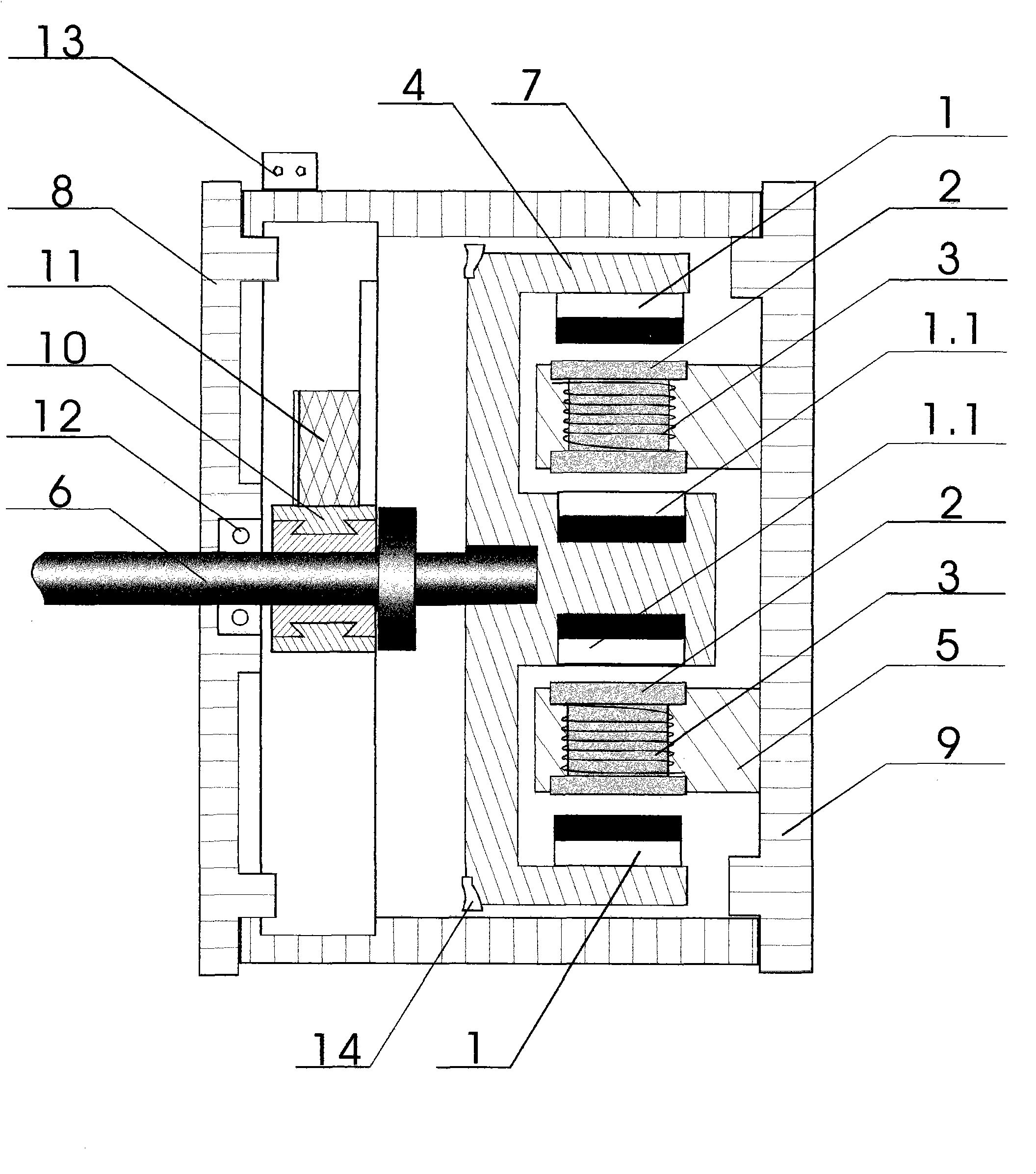

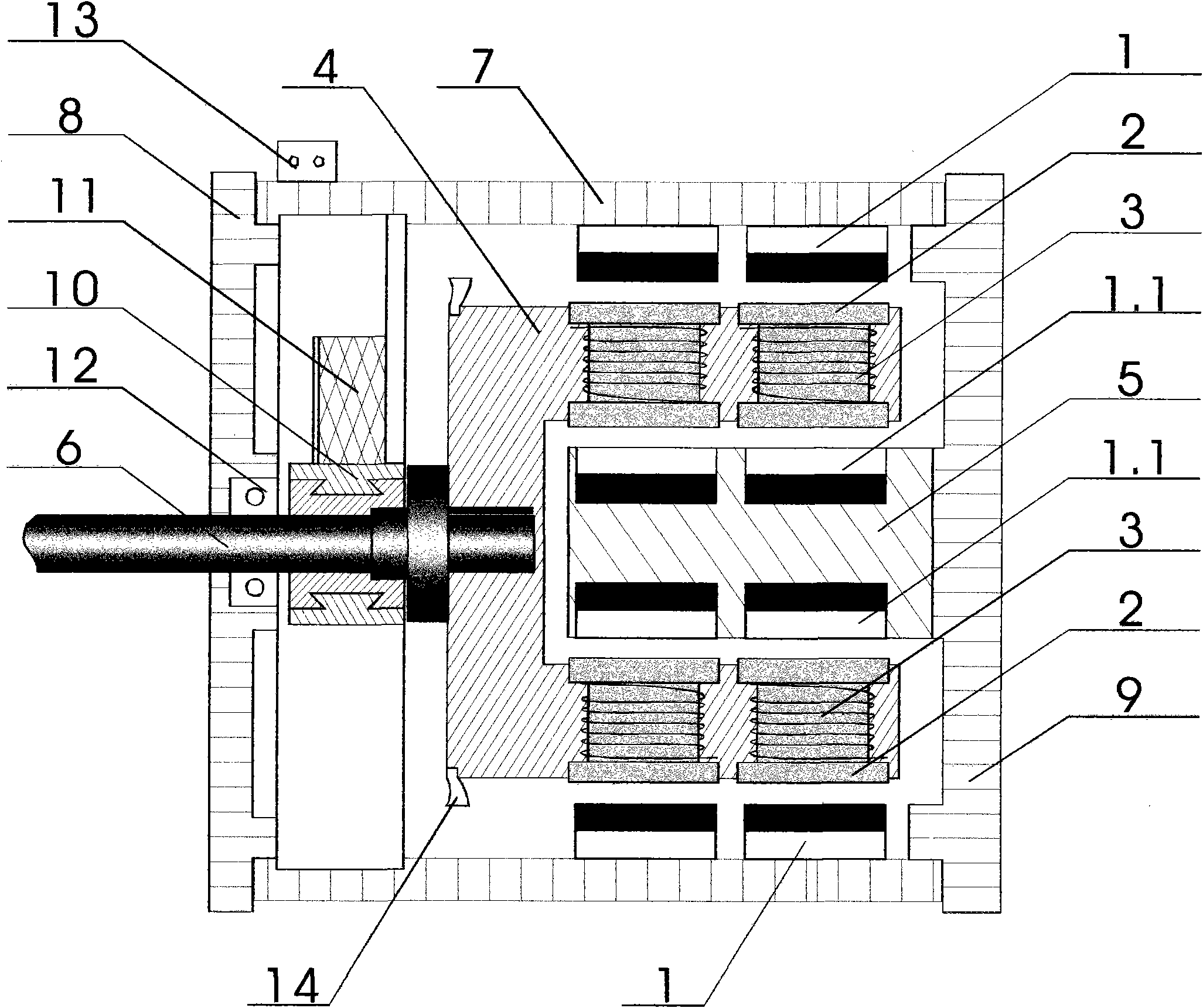

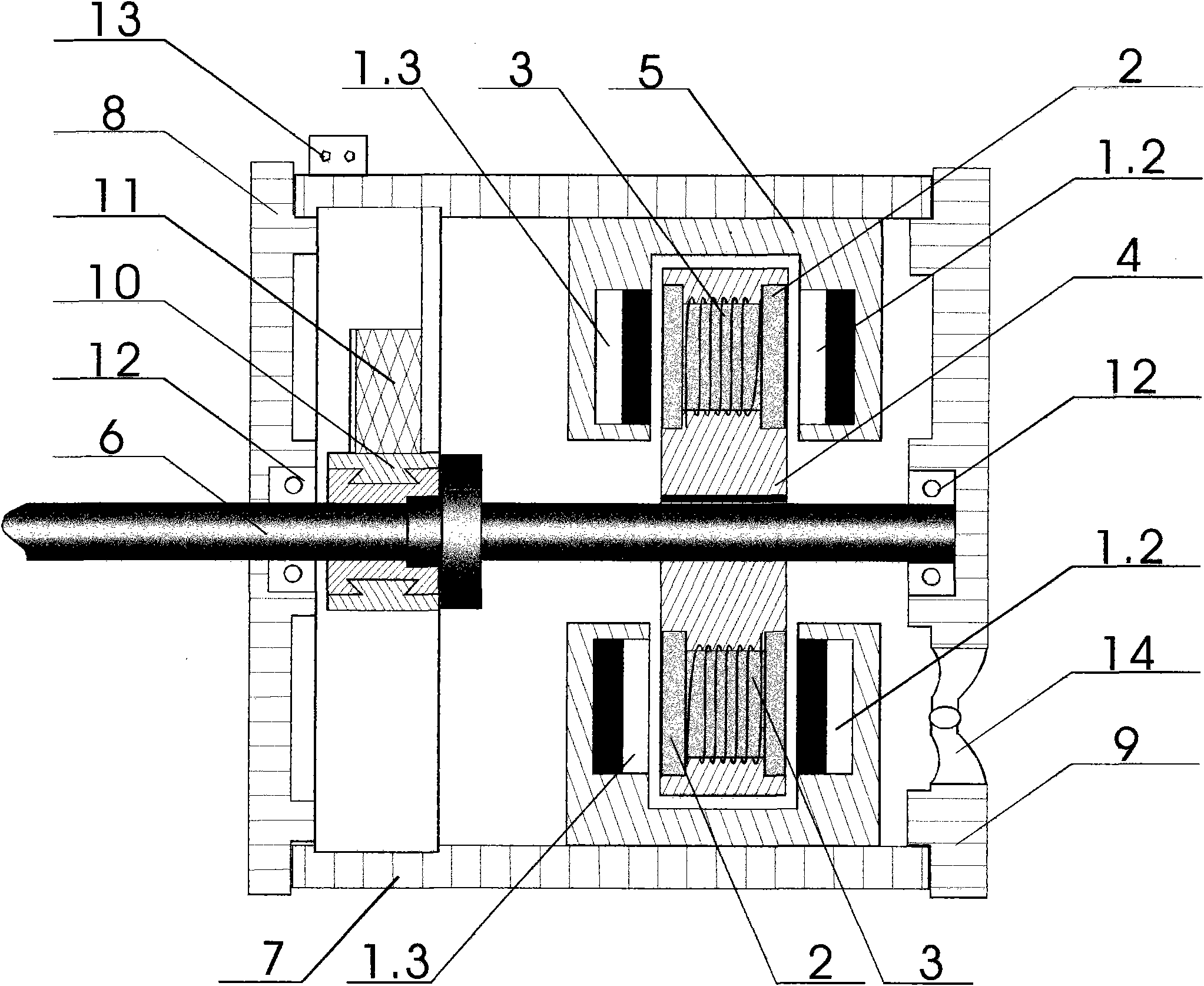

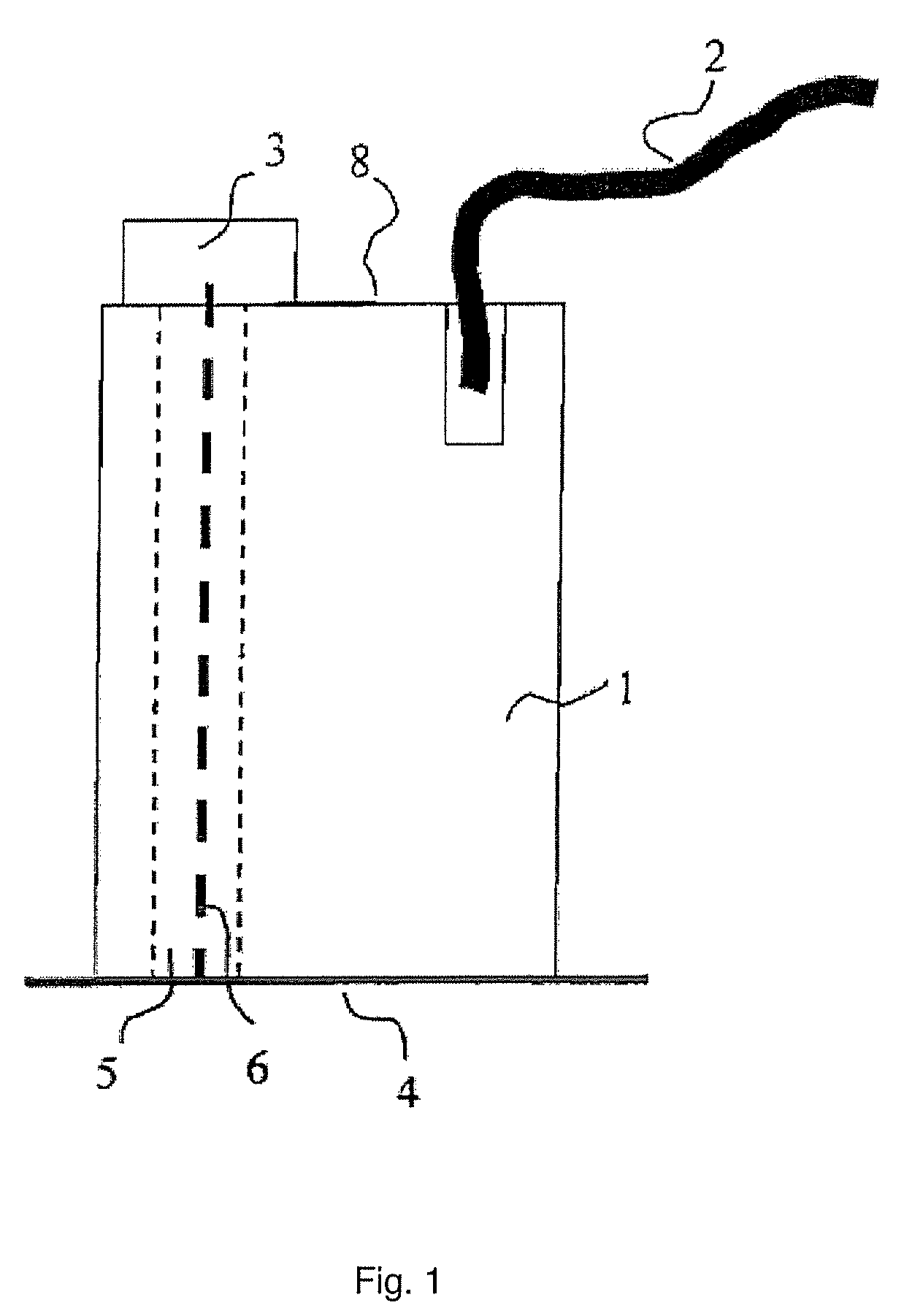

Electronic device for a mechanical blocking.

InactiveUS20110277520A1Reduce power consumptionSave energyNon-mechanical controlsControl powerElectrical battery

An electronic device for a mechanical blocking and power mechanisms on its basis, intended for use in electronic locks, hydraulic / pneumatic automation, electronically controlled valve(tap), electronically controlled power electrical switches and commutators, electro-mechanical clutches and couplings, etc. The devices based on invention are compact, have a simple design and are rather reliable in conditions of shocks and vibrations. Low electric power consumption and corresponding long battery life have been obtained at the prototypes of these devices. It will be effectively used in the systems of autonomous access control.

Owner:NUNUPAROV MARTYN SERGEEVICH

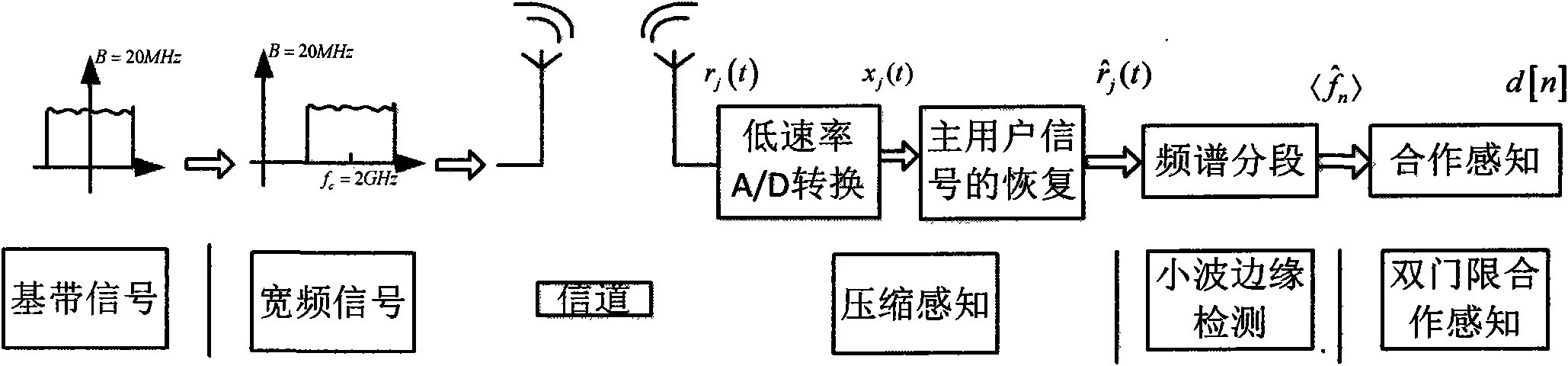

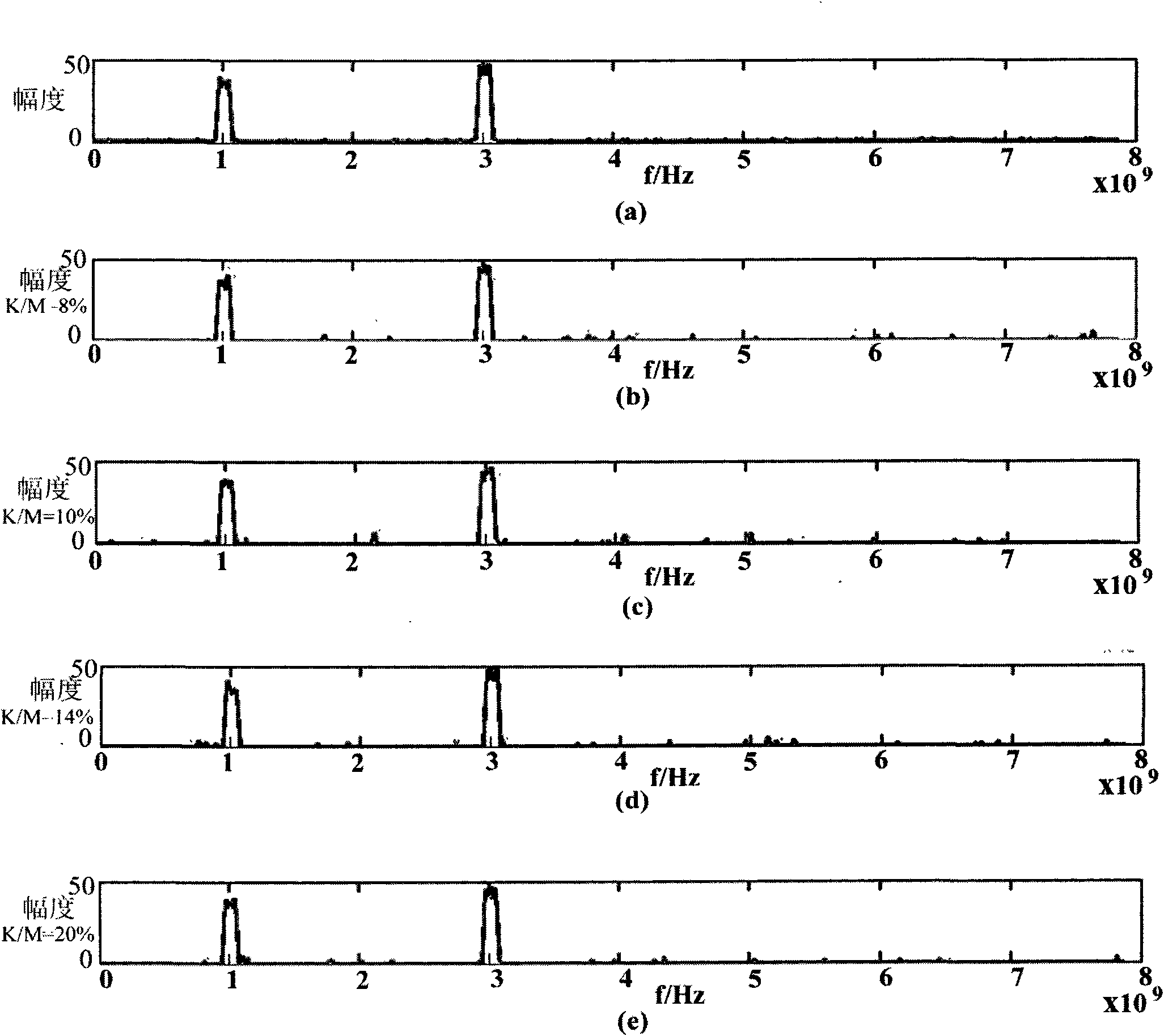

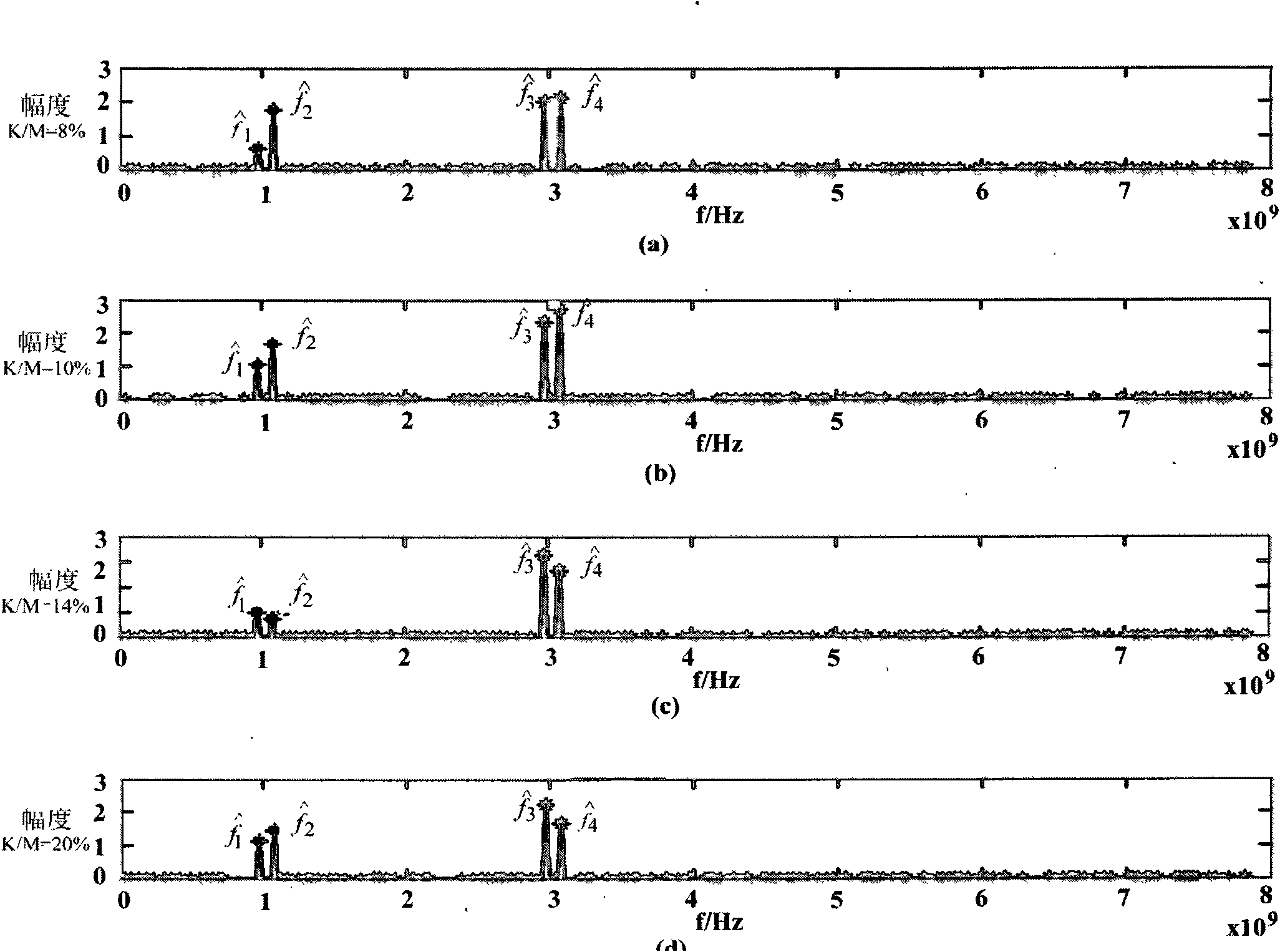

Double threshold cooperative sensing method in cognitive wireless network

The invention discloses a double threshold cooperative sensing method in a cognitive wireless network, comprising the following steps: 1. recovering a signal through local compressed sensing, and recovering the whole broadband frequency spectrum in the invention through the compressed sensing, thus a low-speed A / D commutator can be used, so as to lower the hardware requirement; 2. determining a sub frequency band, being capable of obtaining a frequency spectrum edge point of the recovered broadband frequency spectrum signal through the compressed sensing through a wavelet edge detection, and forming a plurality of sub frequency bands by segmenting the frequency spectrum; and 3. cooperative sensing: carrying out double threshold energy detection on all sub frequency bands by each cognitiveuser, transmitting the detection result to a fusion center for judgment to obtain the existing condition of the main user of the whole frequency spectrum, and self-adaptively determining the positionof the spectrum hole in the frequency band. Through the steps, the cognitive network can carry out sampling sensing on the main user signals under the condition of low nyquist frequency, and can self-adaptively determine the position of the spectrum hole in the frequency band.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

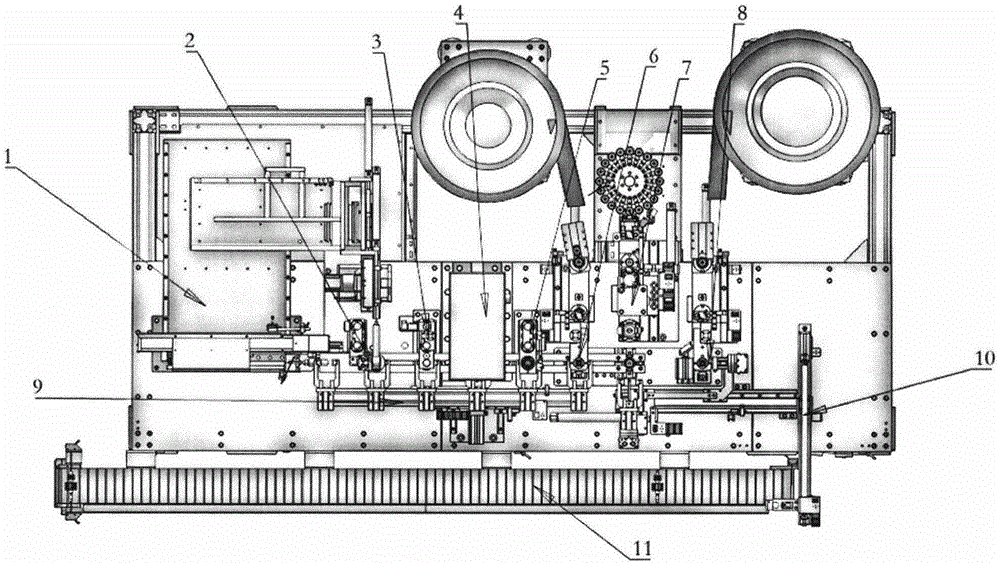

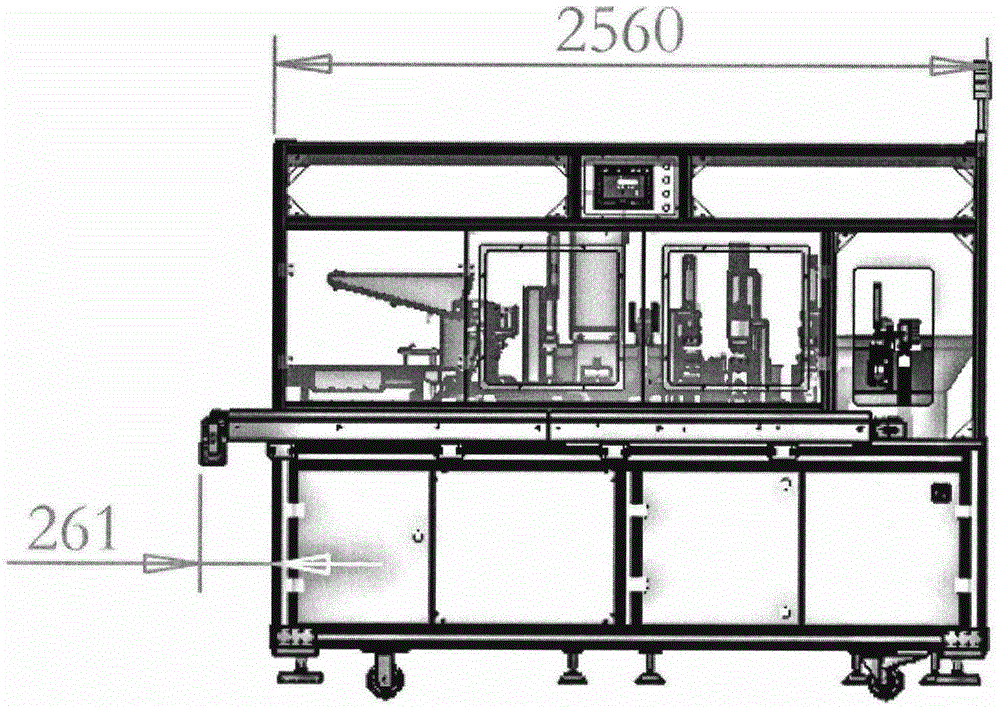

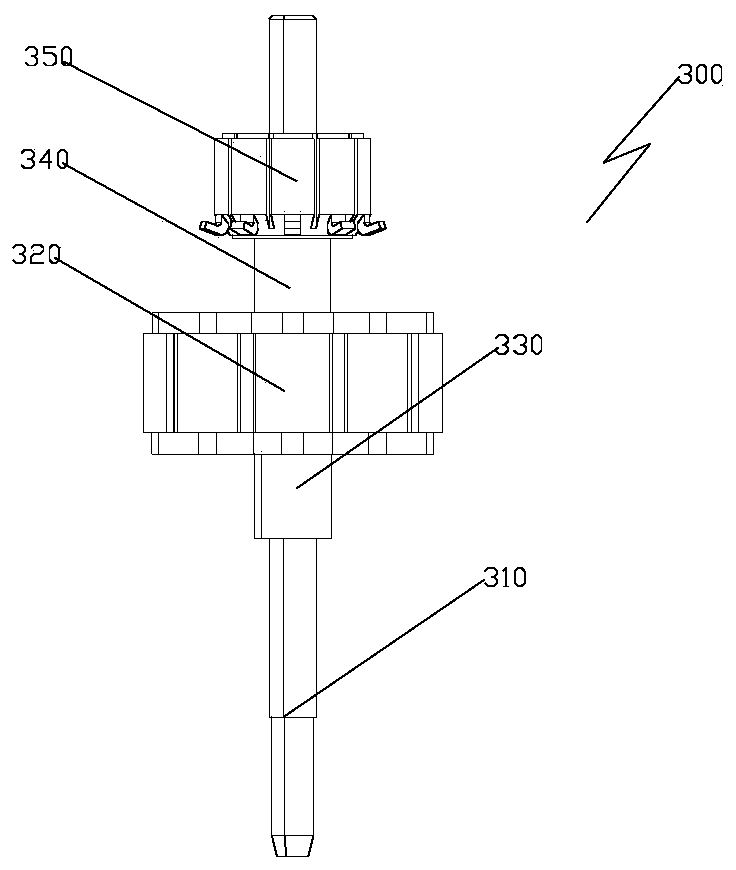

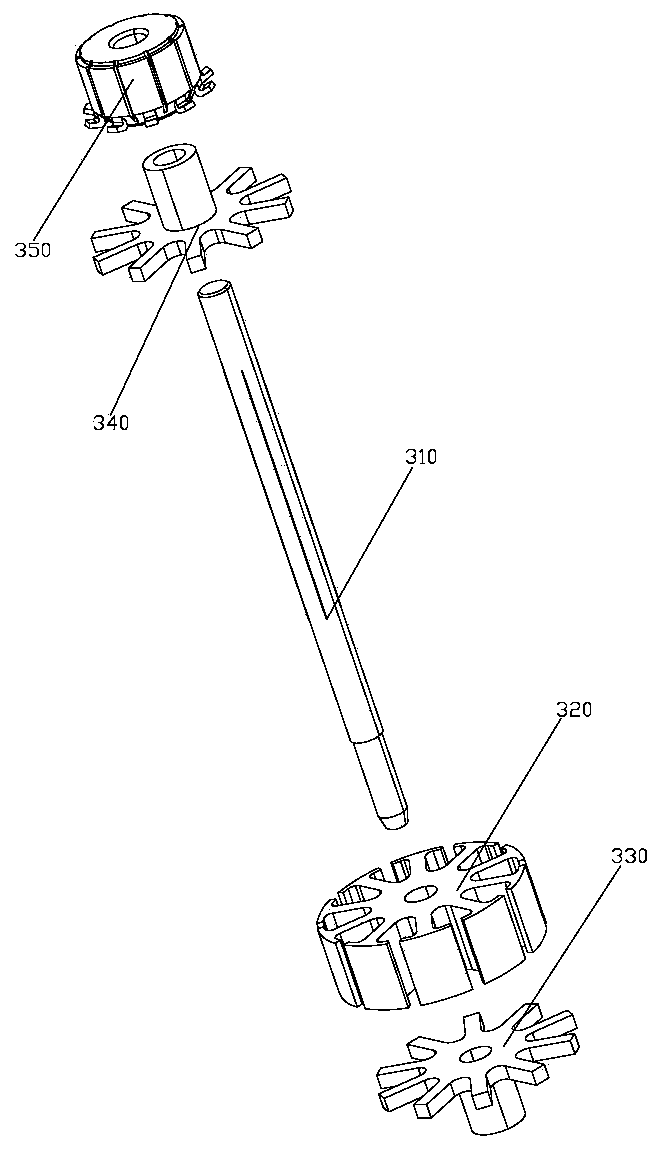

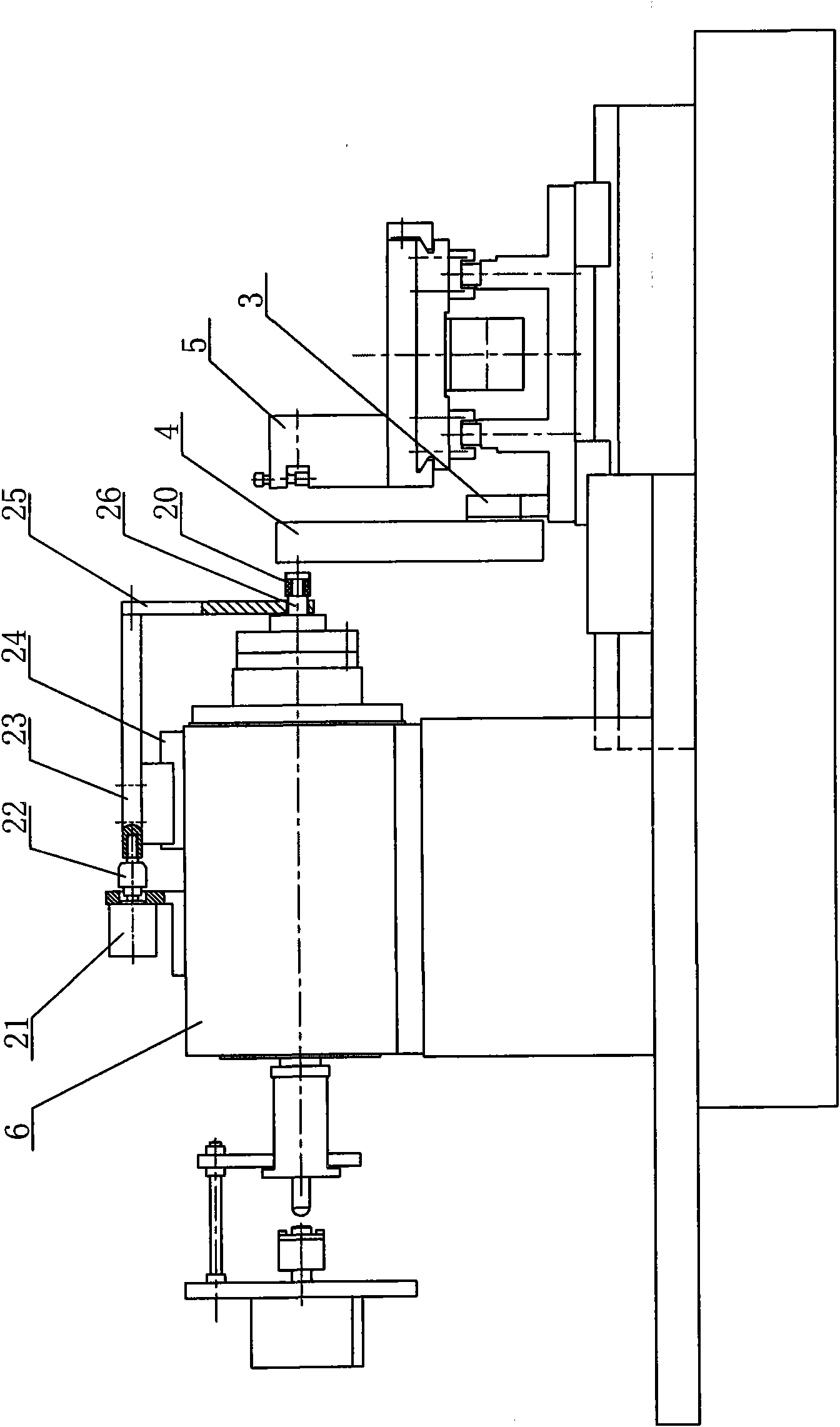

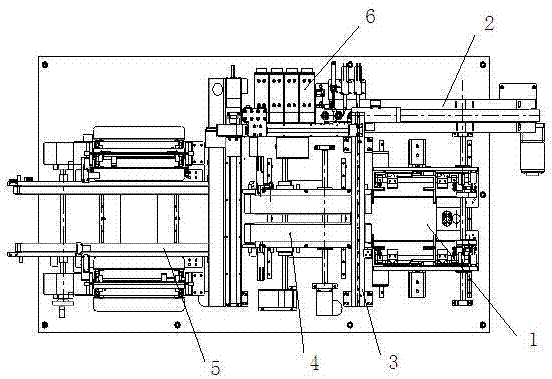

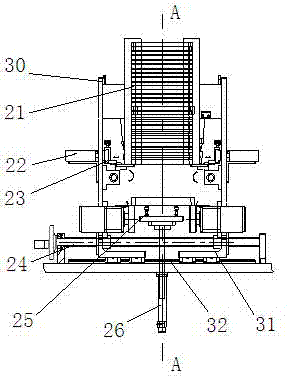

Integrated rotor assembly center

InactiveCN105345463AQuality assuranceCompact structureAssembly machinesManufacturing stator/rotor bodiesSmall footprintEngineering

The invention provides an integrated rotor assembly center. The integrated rotor assembly center aims to solve the problems of existing split type rotor assembly equipment. The integrated rotor assembly center comprises a rotor core storing and feeding mechanism, a rotor spindle storing, checking, feeding and assembling mechanism, a core thickness checking mechanism, a spindle pressing mechanism, a core wire duct mid-splitting mechanism, an end cover storing, feeding, positioning and pressing mechanism, a rotor commutator storing, feeding, positioning, pressing and assembling mechanism, a bottom cover storing, feeding, positioning and pressing mechanism, a station connection and material transfer manipulator, a station connection and finished product collection manipulator and a collection conveying belt, wherein all the units are sequentially installed on a machine table according to procedures and all located in a protective cover installed on the machine table. According to the assembly center, all the procedures of rotor assembly are integrated, the structure is compact, the occupied area is small, the production efficiency and quality are high, and the integrated rotor assembly center has great significance for creating first-class rotor production enterprises.

Owner:NINGBO HUIFENG AUTOMATION TECH CO LTD

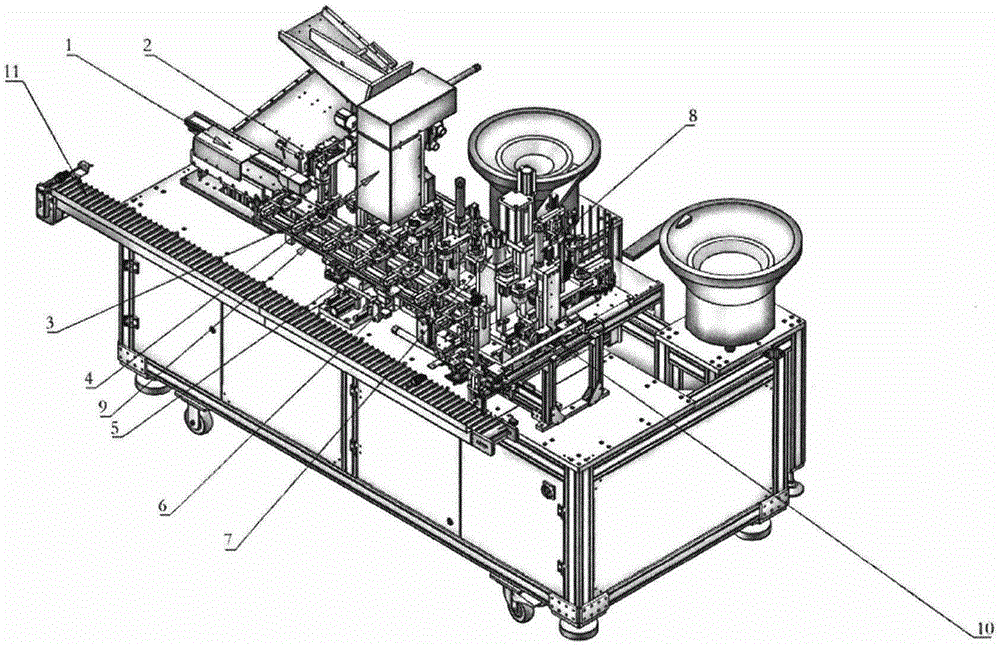

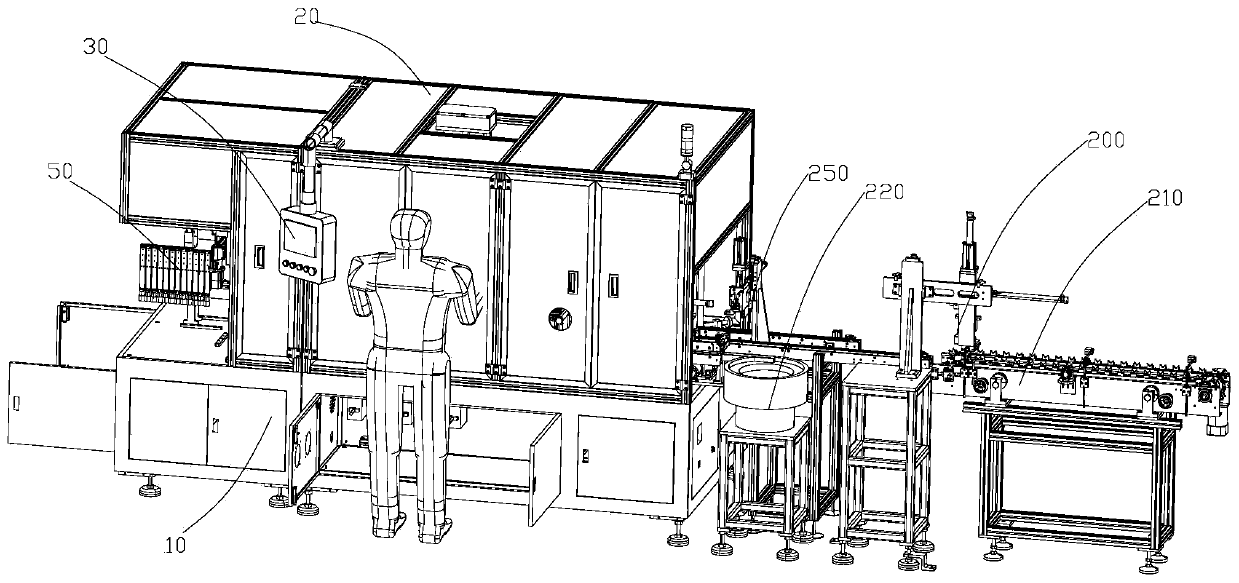

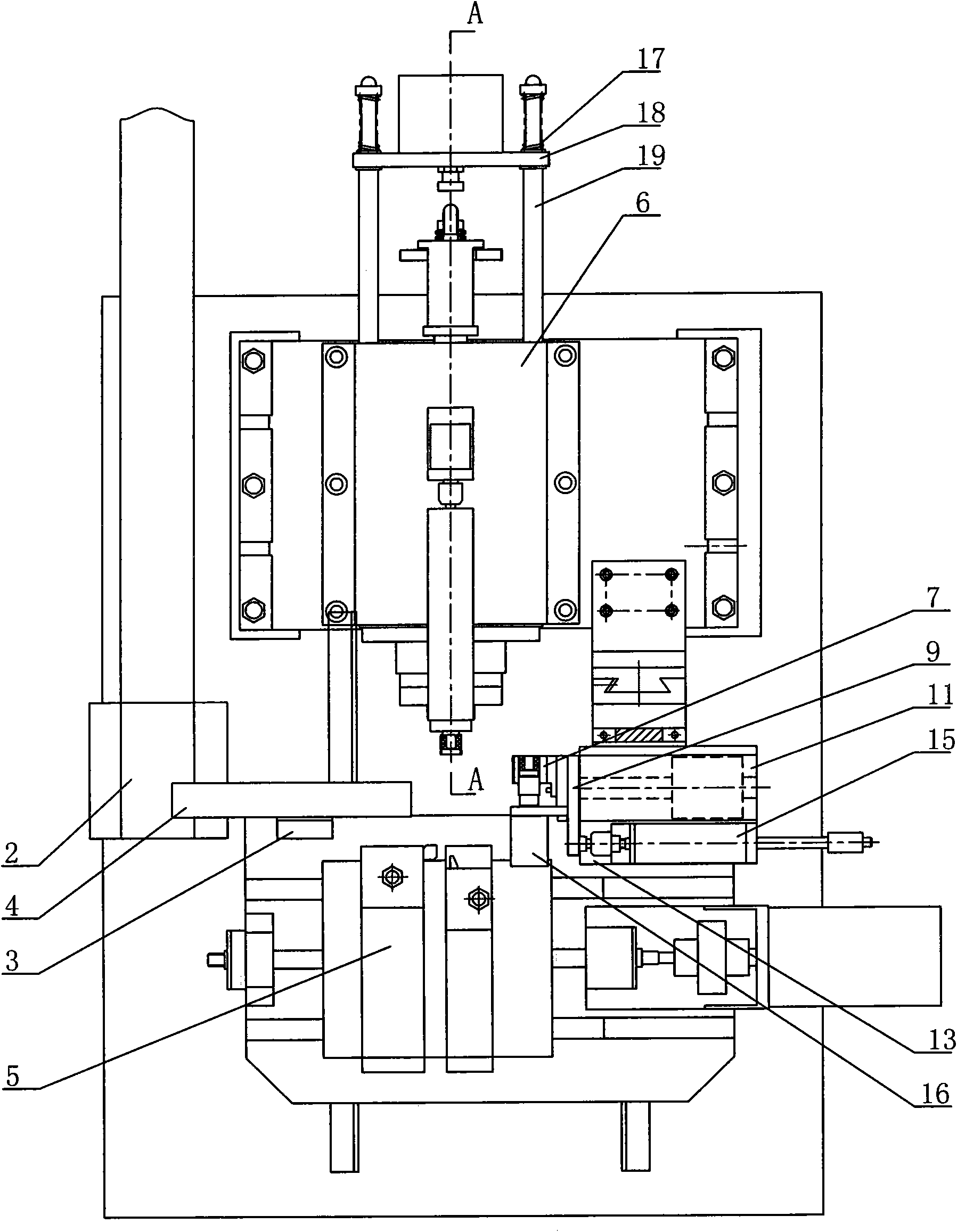

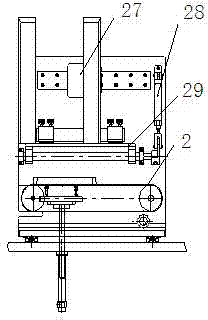

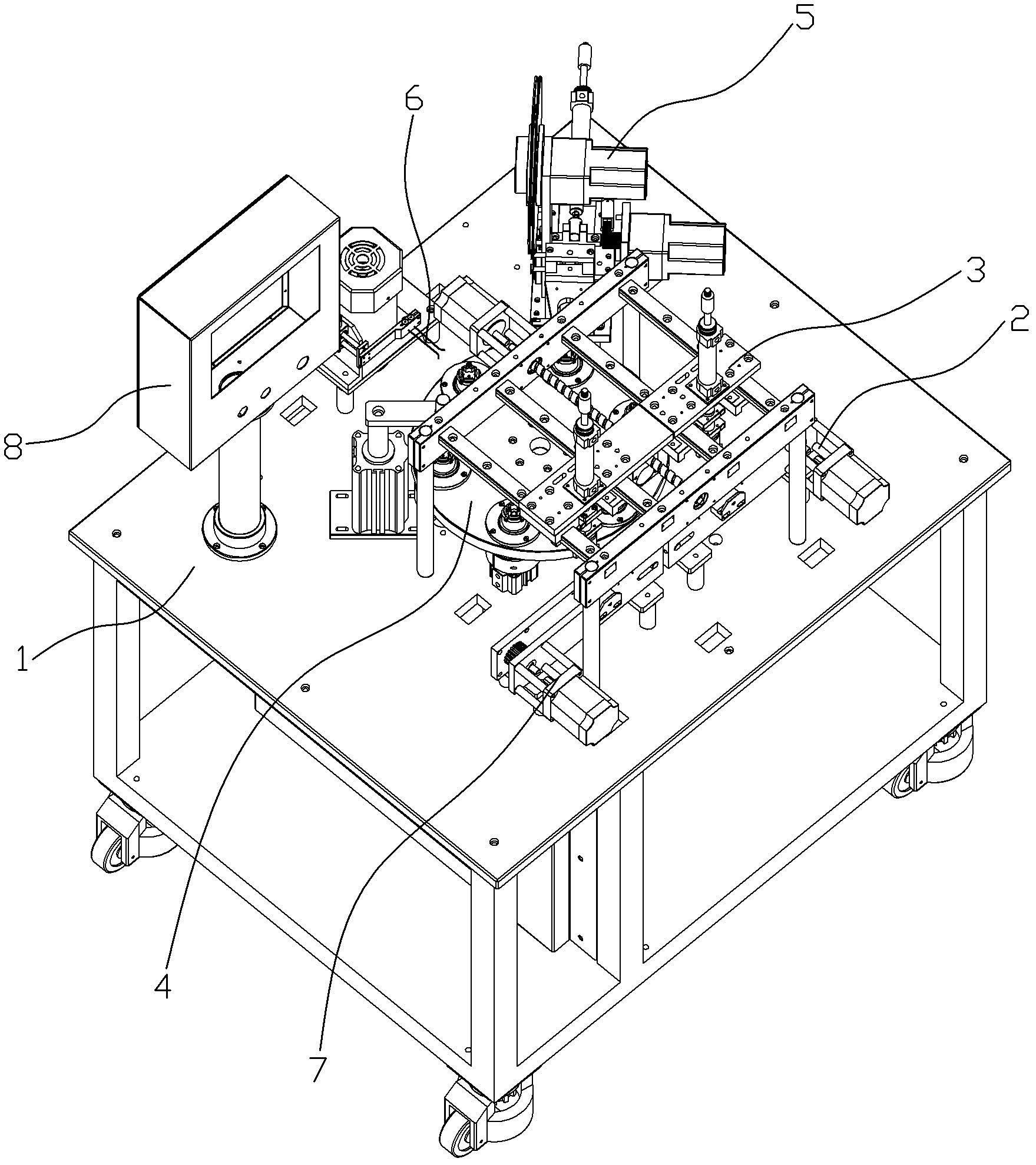

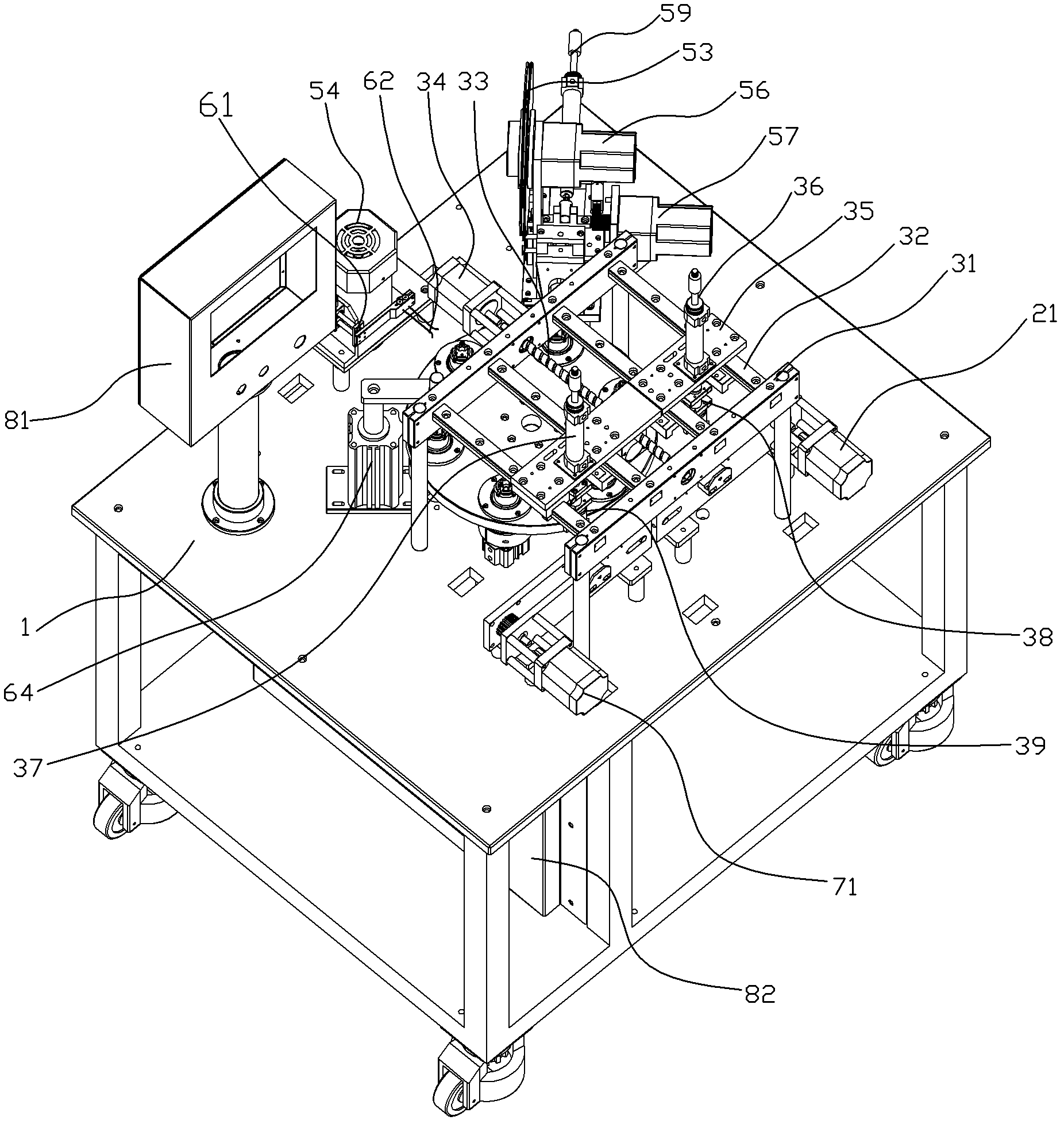

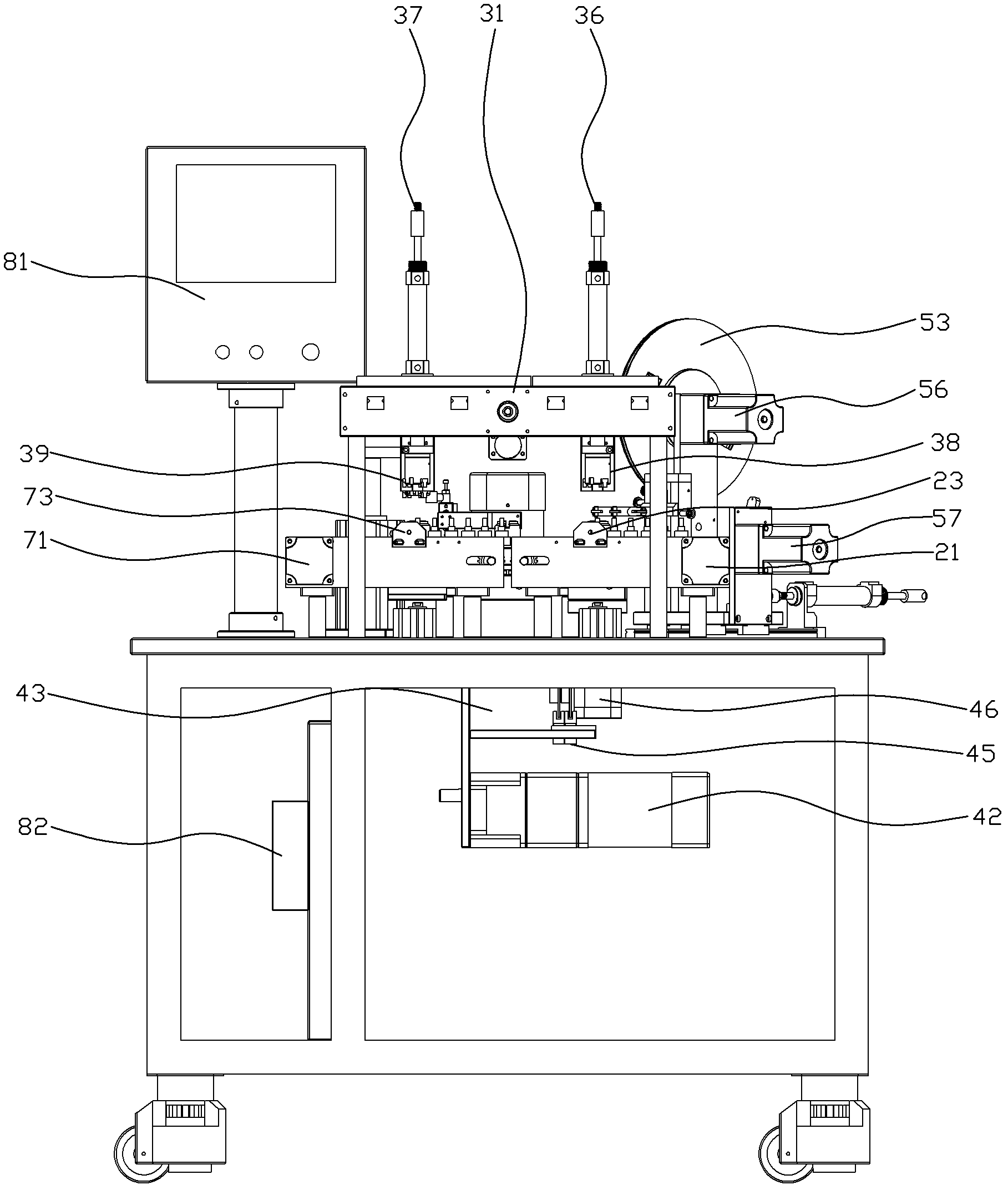

Electric machinery rotor automatic press-fitting machine

ActiveCN110142590ARealize automated assemblyIncrease productivityManufacturing stator/rotor bodiesMetal working apparatusElectric machineryCharging station

The invention discloses an electric machinery rotor automatic press-fitting machine. The electric machinery rotor automatic press-fitting machine comprises a machine frame, an iron core conveying device, a limiting transfer platform, a rotary workbench and a discharging conveying device; an iron core charging device is arranged on one side of the front end of the iron core conveying device; a mandrel charging device and a mandrel press-in device are arranged at the corresponding positions of the two sides of a mandrel insertion station at the front end of the limiting transfer platform; an automatic discharging device corresponding to a limiting transfer channel of the limiting transfer platform is arranged; the mandrel press-in device is arranged on one side of a mandrel press-in stationlimiting transfer channel at the rear end of the limiting transfer platform; a transition conveying device is arranged between the tail end of the limiting transfer platform and the rotary workbench;and a lower end plate charging station, a lower end plate insertion station, an upper end plate insertion station, a commutator insertion station, a commutator correction adjustment station, a commutator press-in station and a rotor discharging station are uniformly arranged on the rotary workbench. Automatic assembly of electronic rotors can be achieved, the production efficiency is high, and theassembly quality is stable.

Owner:深圳市兴特创自动化设备有限公司

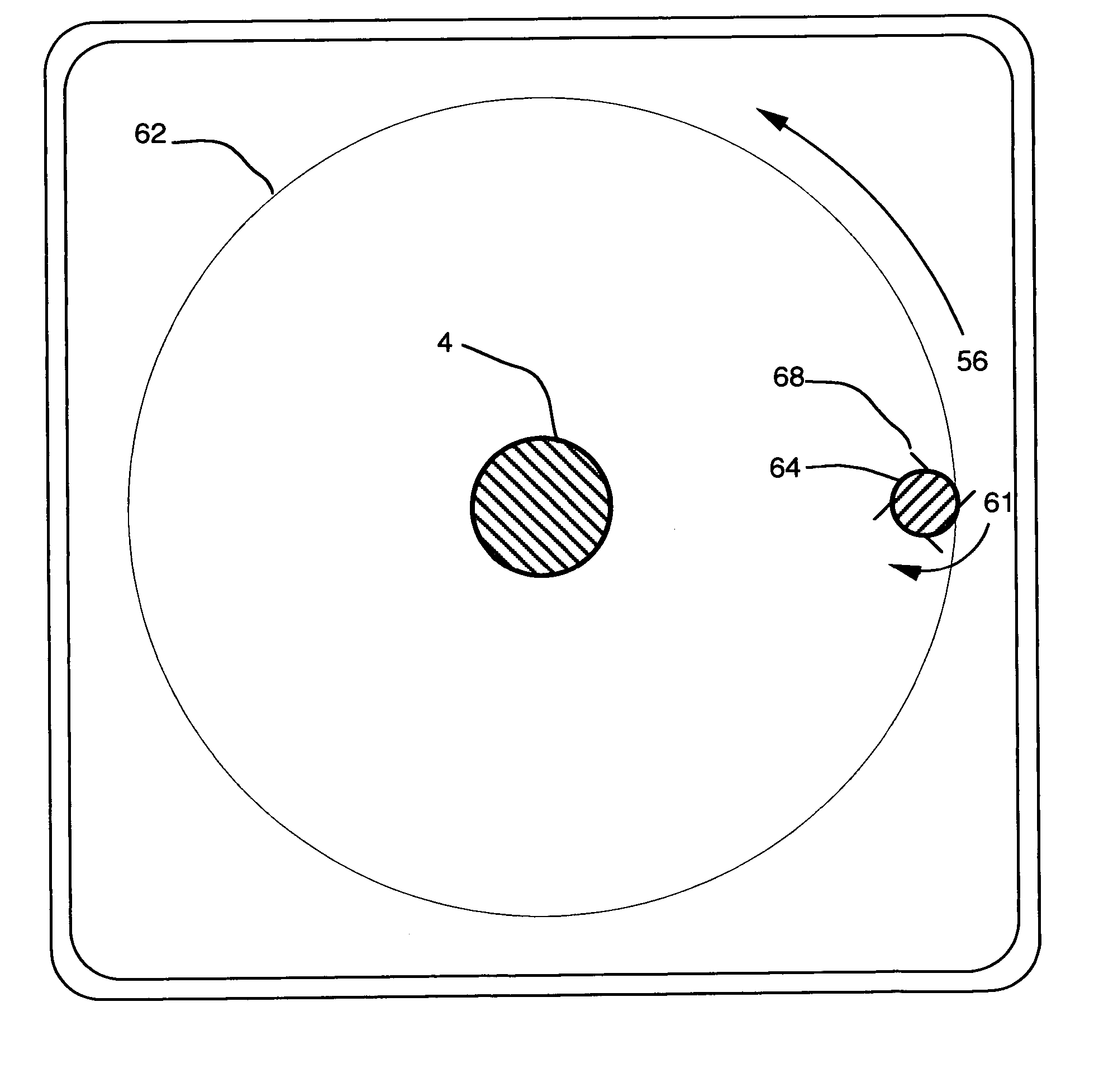

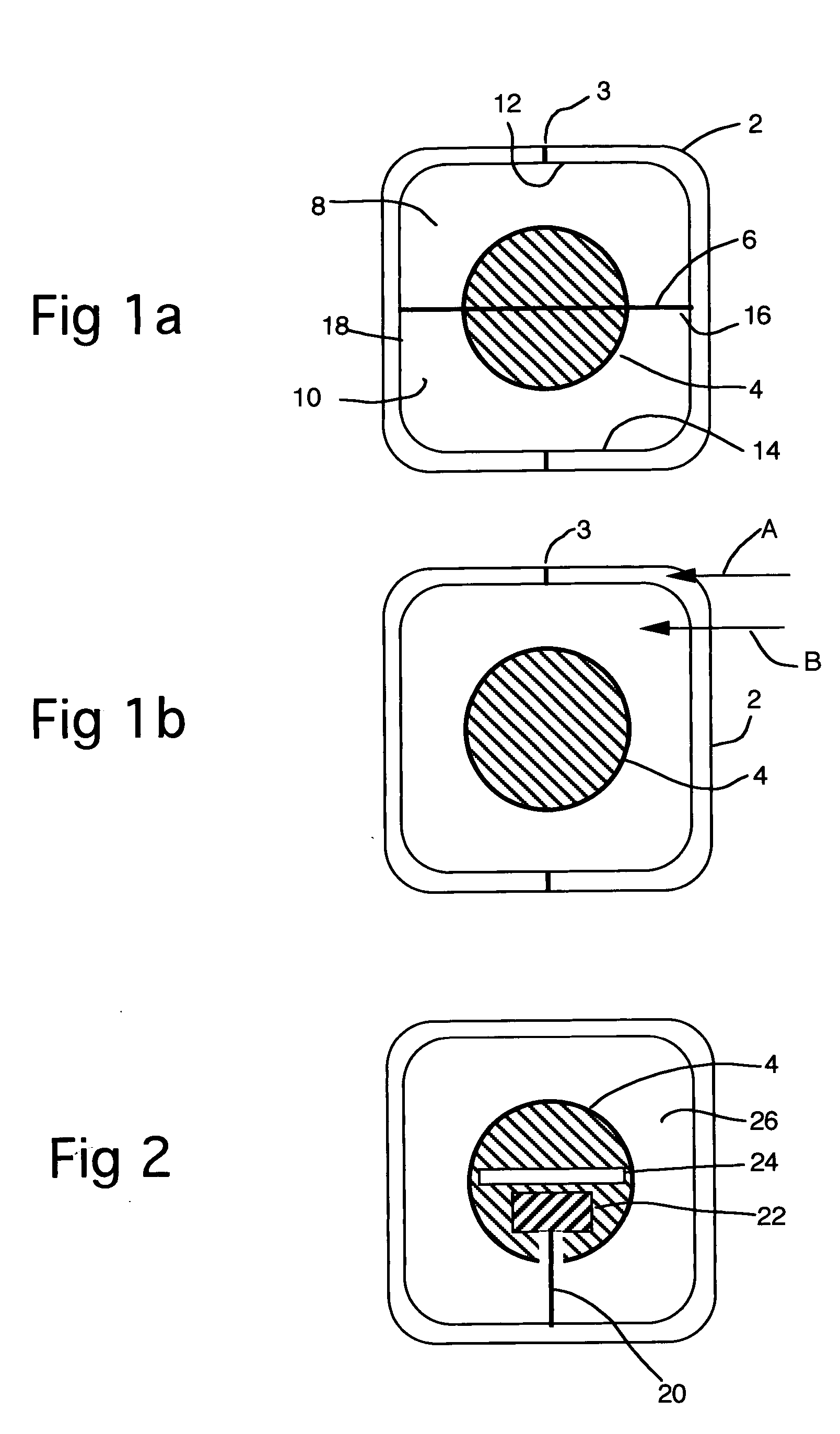

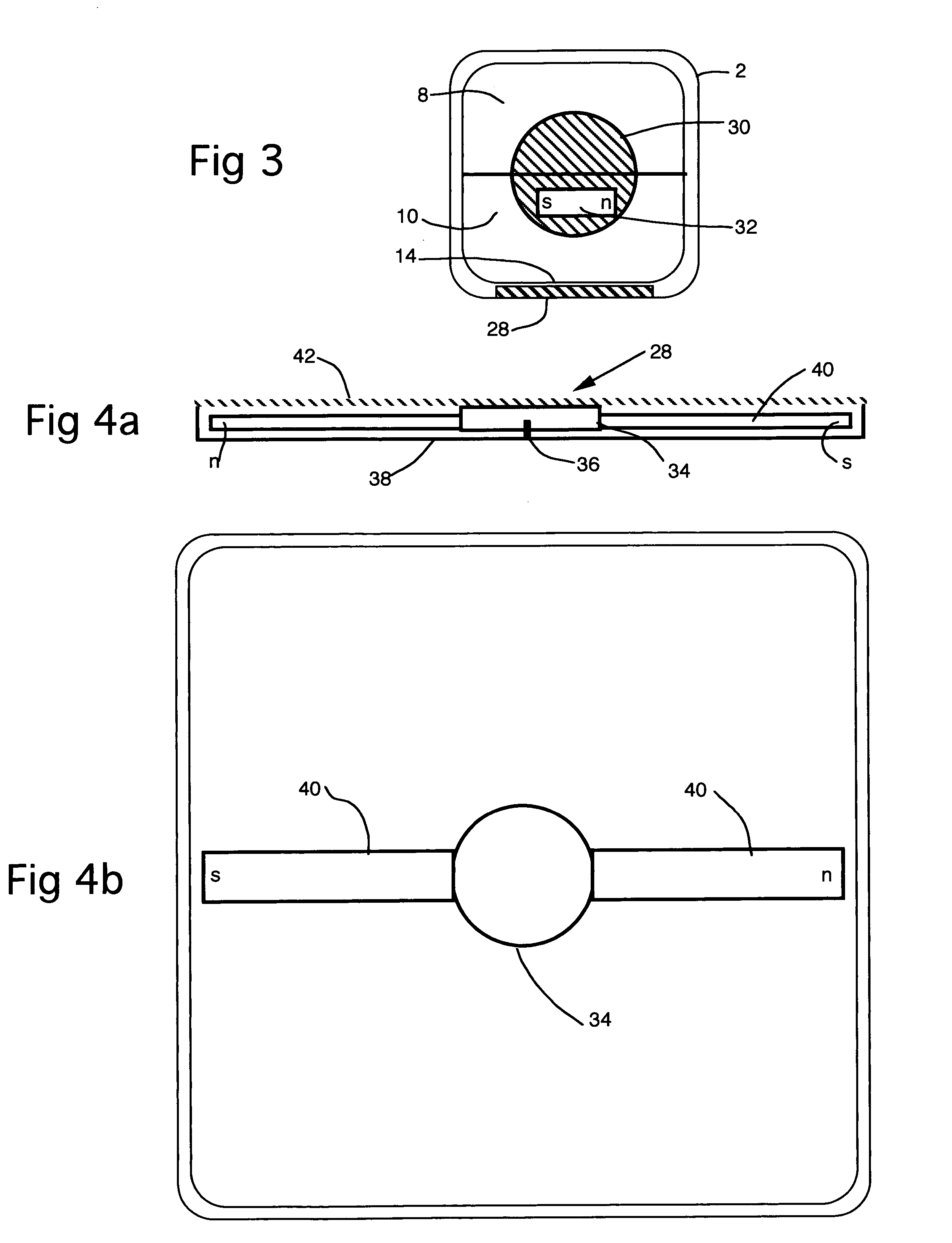

Fluid suspended self-rotating body and method

In a display device where a moving object is immersed in a fluid filling a transparent sealed, vesel (72) and is rotated by an internal electrical mechanism that derives it power from a photo cell (128) and its counter torque from an internal compass (140), the index of refraction of the fluid is adjusted by addition of water to match the index of refraction of the vesel material. The formula of the fluid is also tailored to minimize, absorption of ambient moisture into the vessel. In one embodiment of the electrical spinning mechanism, the magnet acts both as a biasing compass and as a magnetic field generator for the motor. In a second embodiment of the spinning mechanism, the stator is constituted by a multipole ring-shaped magnet (120) that does not interfere with the operation of the biasing compass magnet (140). Multiple windings in the electrical spinning mechanism are energized through a split-ring and brush commutator (92) that use the mechanism shaft (122) as conductor.

Owner:TURTLETECH DESIGN

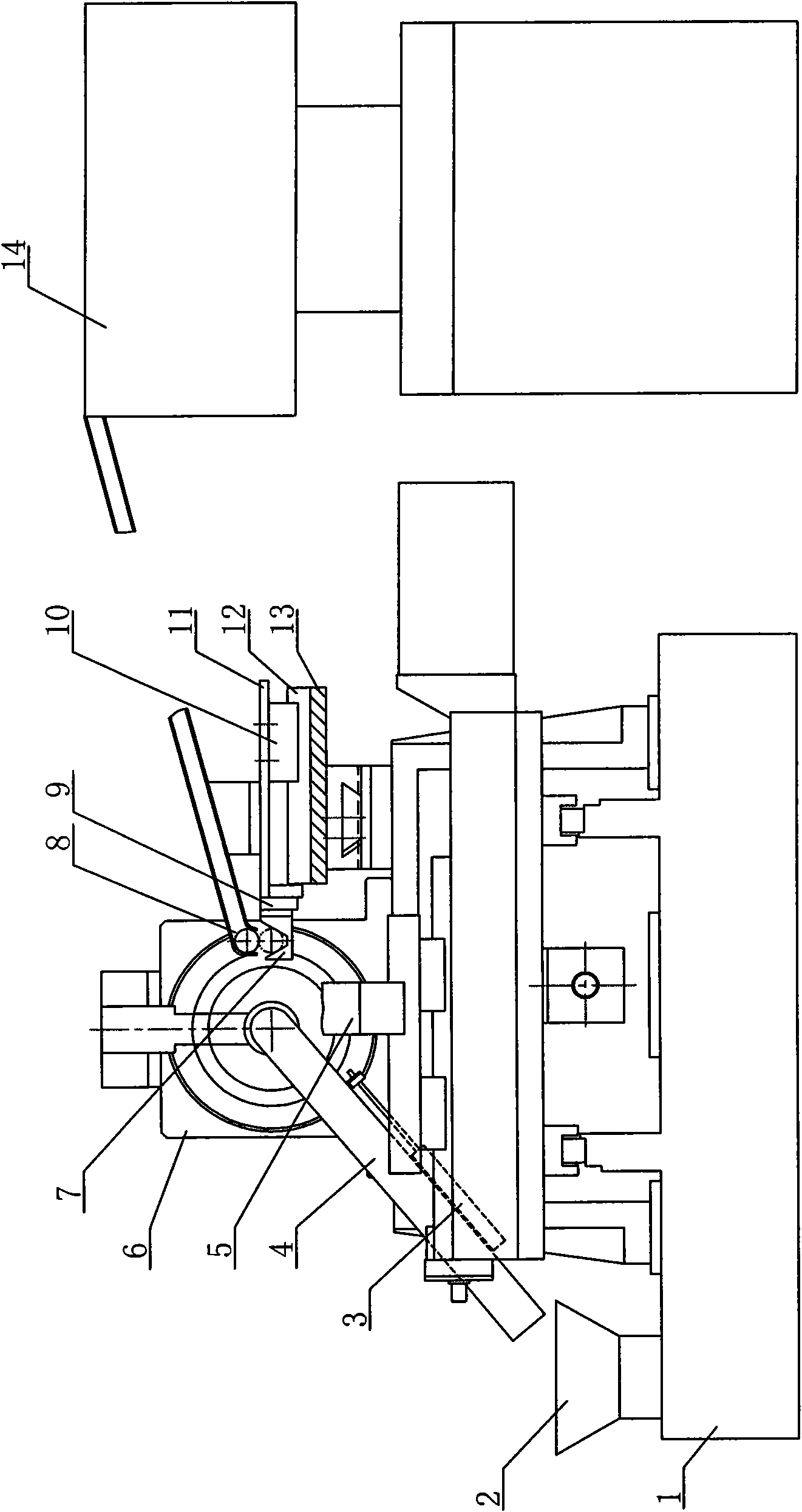

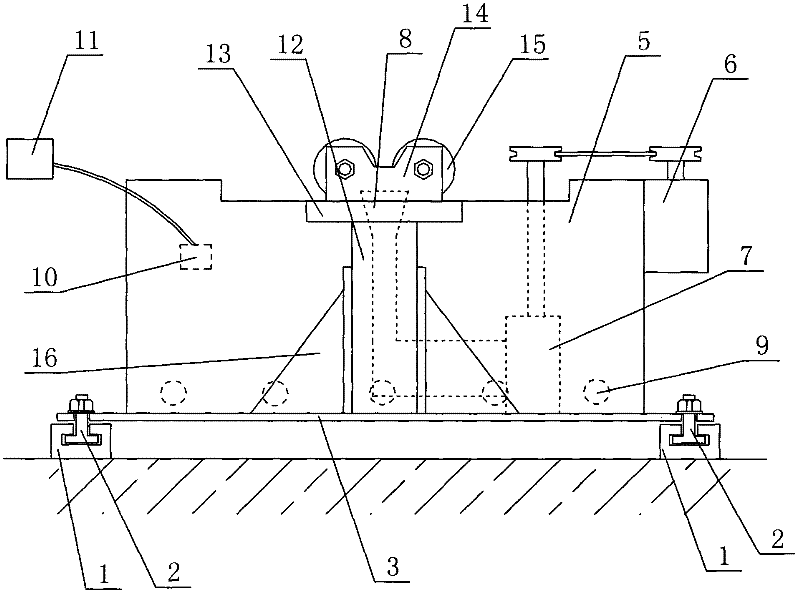

Full-automatic commutator excircle lathe

ActiveCN101972857ARealize fully automatic processingSimple structureTurning machinesEngineeringAutomatic testing

The invention discloses a full-automatic commutator excircle lathe which comprises a lathe bed, a main spindle box and a tool rest, wherein the main spindle box is fixedly arranged on the lathe body and is internally provided with an electrical main spindle; and the tool rest is slidably arranged on the lathe body and is driven by a motor. The invention is characterized in that the full-automatic commutator excircle lathe also comprises an automatic loading device, a rapid clamping device and an automatic unloading device. The lathe can realize full-automatic processing of the excircle of a commutator, has simple structure, greatly improves the processing efficiency and lightens the labor intensity.

Owner:ANGU GRP CO LTD

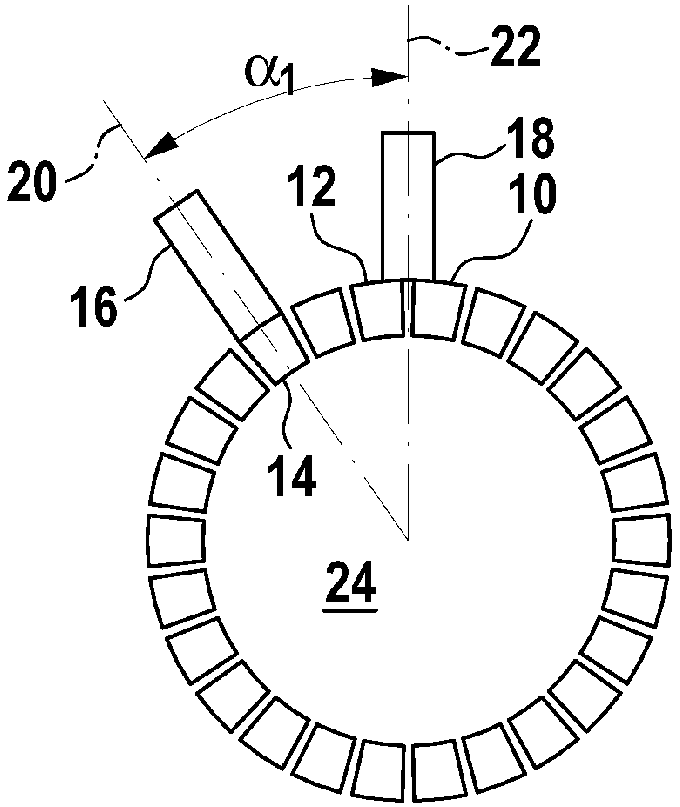

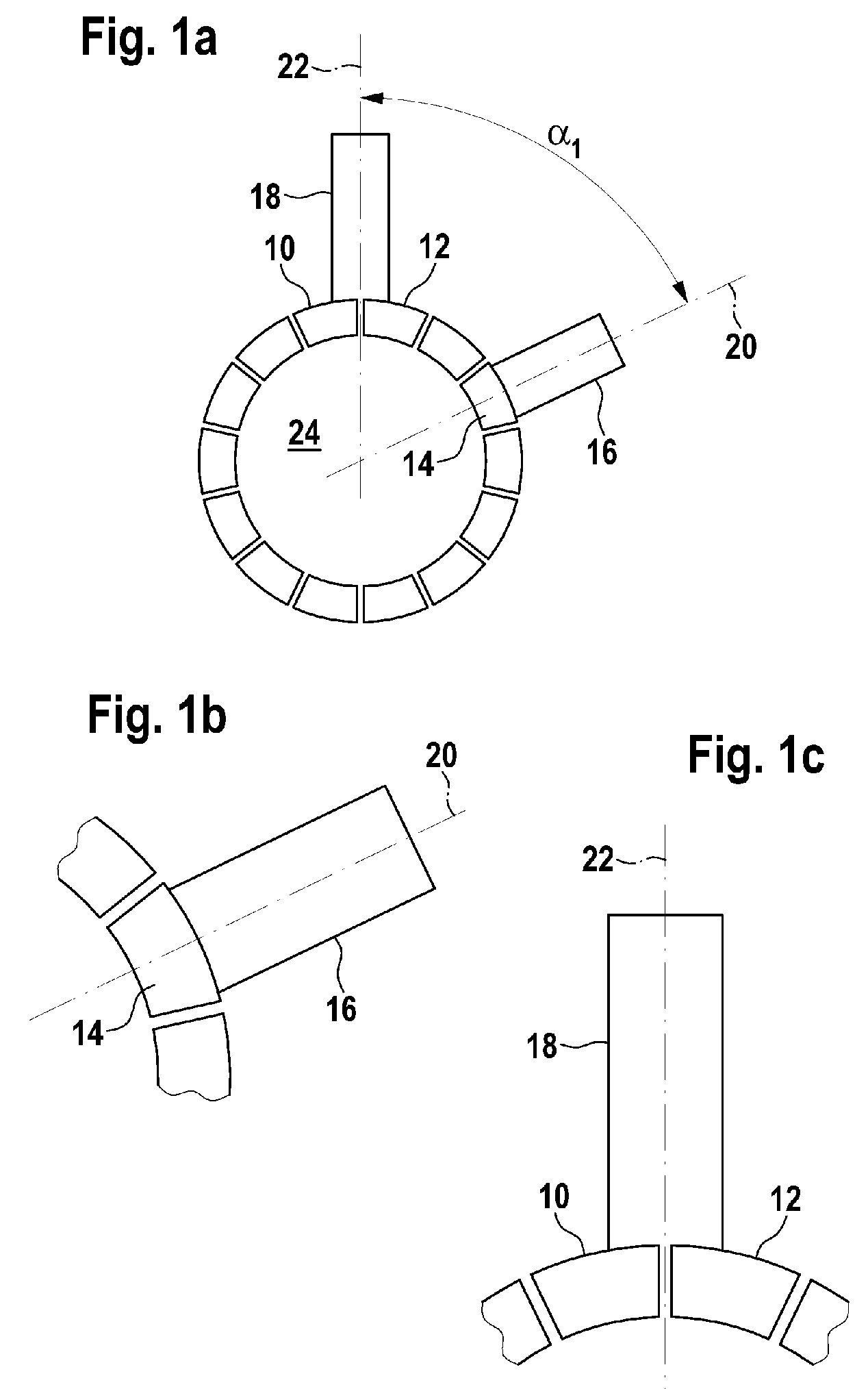

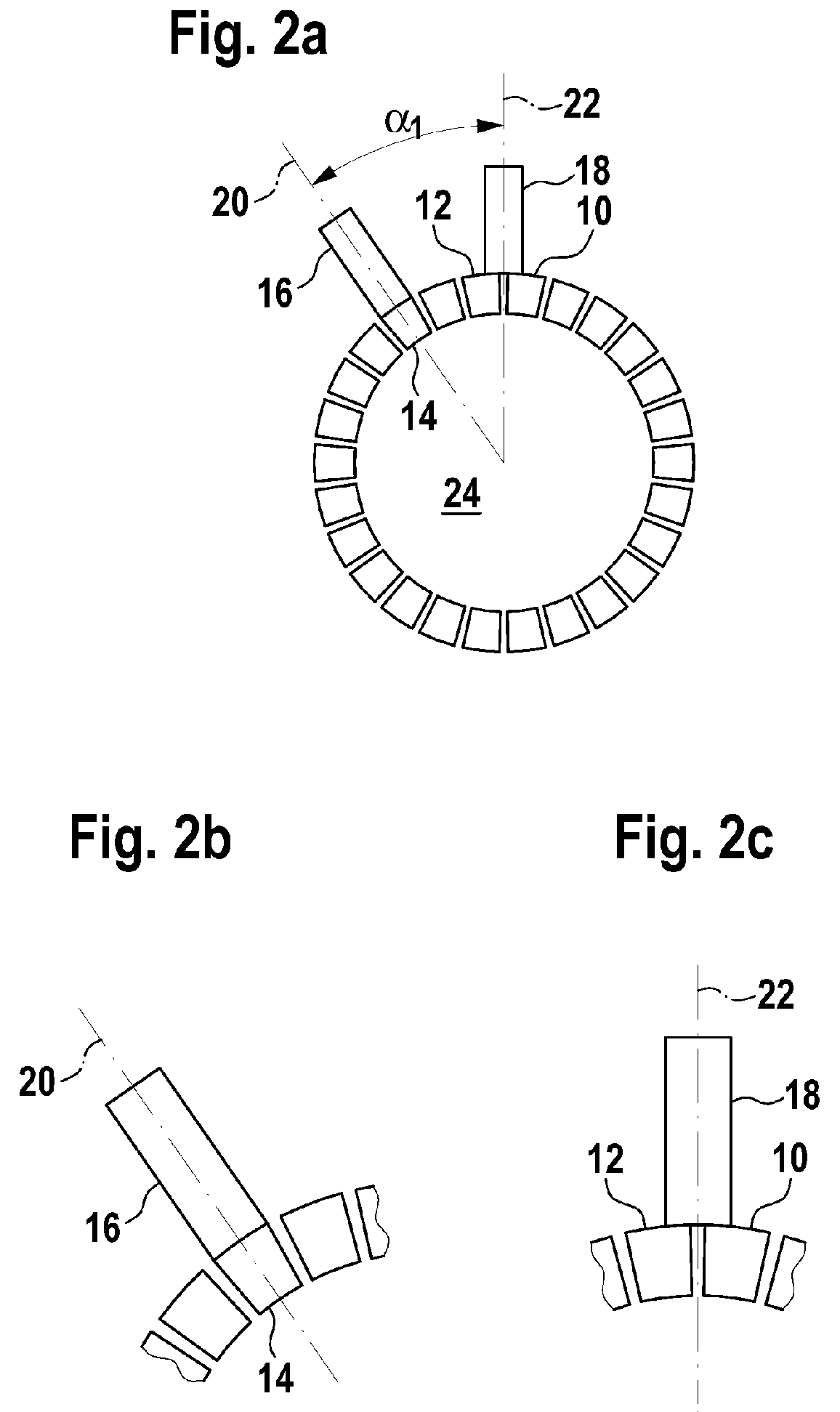

Brush arrangement for electrical machine

An electrical machine, in particular an electric motor, has a first number (k) of commutator laminates (10, 12, 14) and brushes (16, 18), wherein the commutator laminates (10, 12, 14) are arranged distributed uniformly in the circumferential direction of a circumference of a laminate support (24). The brushes (16, 18) are arranged such that commutation times are distributed as uniformly as possible in order to reduce current ripple when using a wave winding and a number of brushes (16, 18) which is less than a number of poles (2p) in the electrical machine.

Owner:ROBERT BOSCH GMBH

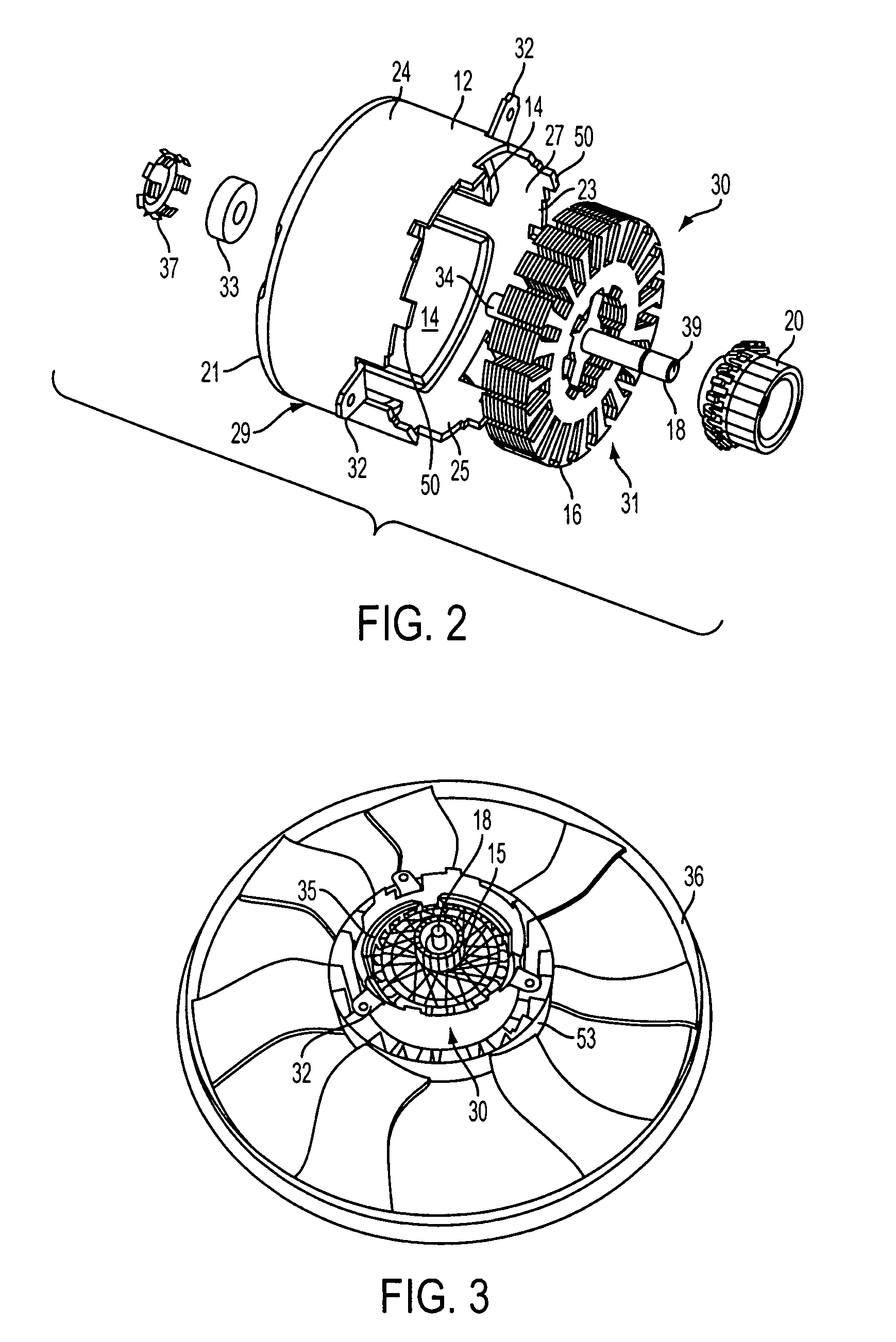

Electric motor cooling module having bearing structure nested directly in a brush and connector unit that is mounted directly to a cover of a shroud

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

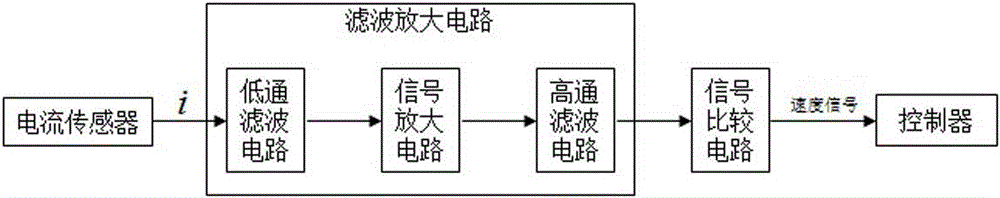

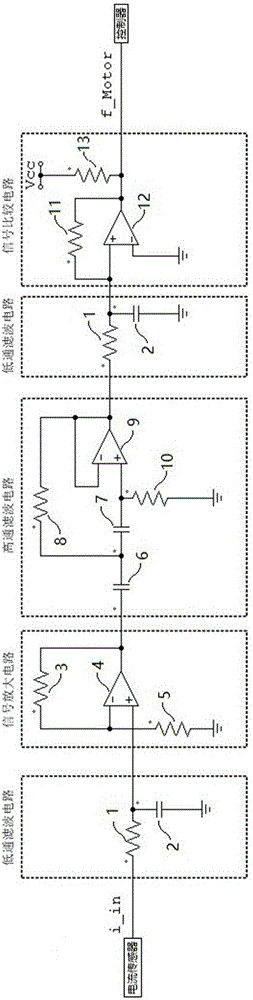

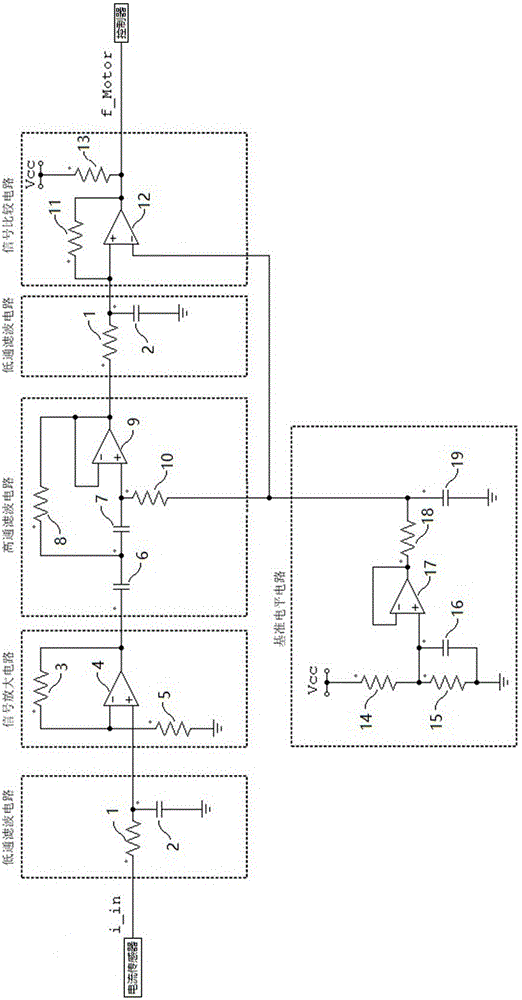

Direct current brushed motor speed measurement device and speed measurement method

InactiveCN105675906ARealize the speed measurement functionEasy to detectDevices using electric/magnetic meansMotor speedMeasurement device

The invention relates to a direct current brushed motor speed measurement device and speed measurement method. The speed measurement device is characterized by comprising a current sensor, a filter amplifying circuit, a signal comparison circuit, and a controller which are serially connected in turn. A logical operation unit is arranged in the controller. The speed measurement method is characterized by comprising the steps of: collecting a current signal of the direction current brushed motor through the current sensor; filtering and removing high frequency noise and direct current component in the current signal through the filter amplifying circuit; amplifying the signal; comparing a pulse component of the current signal with a reference voltage through the signal comparison circuit; generating a high-low alternating square wave speed signal to the controller; finally calculating the period or frequency of the speed signal through a logical operation unit built in the controller; and combining the number of mica sheets in a direct current brushed motor commutator and obtaining the corresponding motor speed through simple calculation. The speed measurement device and the speed measurement method can realize the speed measurement function of the direct current brushed motor through a simple circuit combination without increasing additional large devices on the motor, have low cost and no limitation of the use environment or a motor mechanical structure, and have a more accurate measurement result.

Owner:JIANGSU REYA ELECTRIC

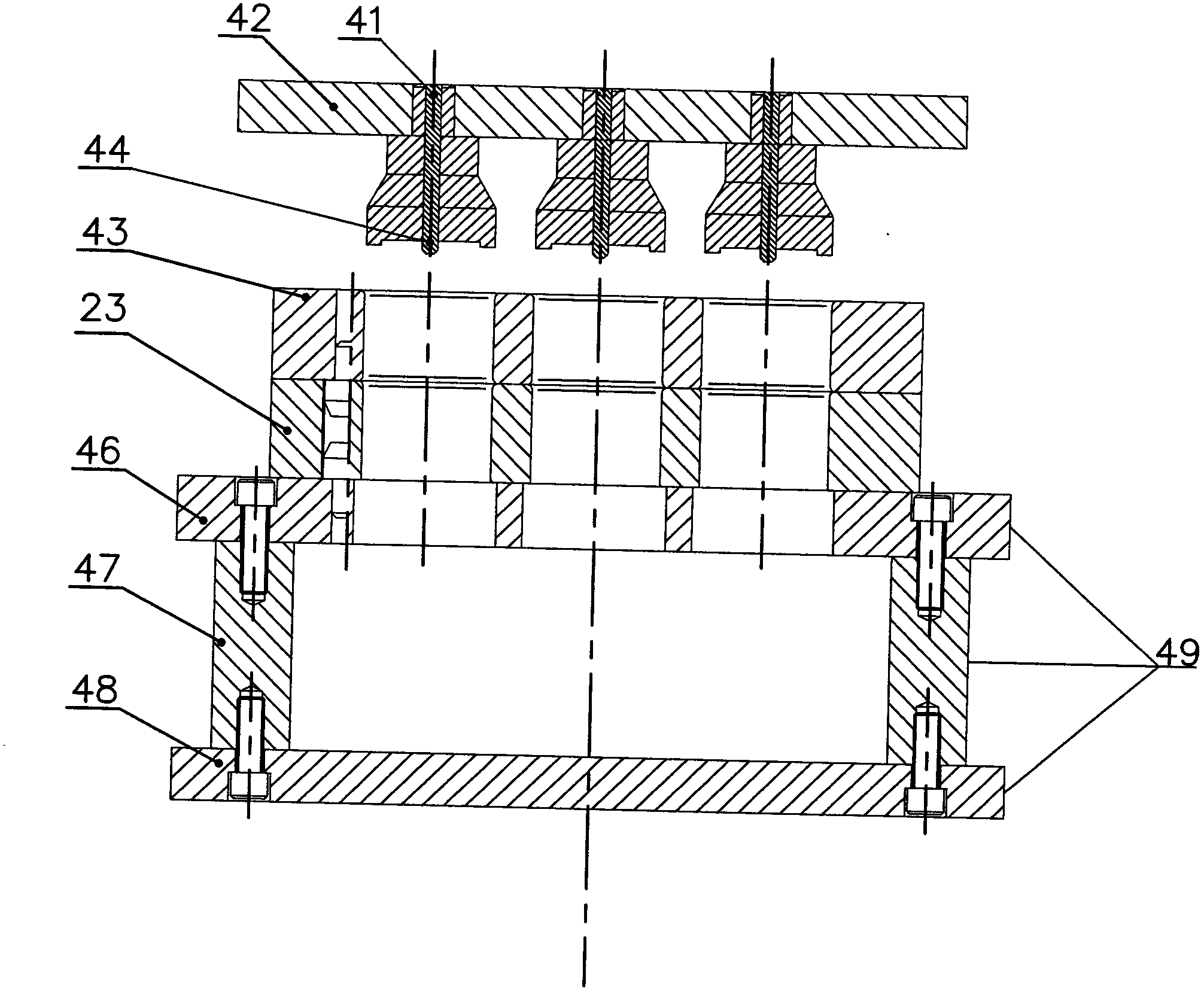

Automatic pallet filler of commutator

InactiveCN103569637AImprove general performanceEasy to installConveyor partsEngineeringAutomatic variable

Owner:SHANGHAI ZHAOCHENG COMMUTATOR TECH

Tin soldering device for commutator and armature wire

InactiveCN102389997AAdjustable installation positionImprove welding qualityMetal working apparatusSolder feeding devicesSpray nozzleEngineering

The invention discloses a tin soldering device for a commutator and an armature wire, which is used for welding the commutator and the armature wire of a motor, and comprises a base, a tin basin and supports, wherein the tin basin is arranged on the base; the supports are arranged at both sides of the tin basin; one side of the tin basin is provided with a drive motor; the drive motor is connected with a tin spraying pump arranged in the tin basin; the tin spraying pump is communicated with a spray nozzle arranged in the tin basin; heating pipes are arranged in the tin basin; the inner wall of the tin basin is provided with a temperature sensor; and the temperature sensor is electrically connected with a controller. In the tin soldering device for the commutator and the armature wire, a motor rotor is arranged above rollers of the supports, so that the connected faces of the armature wire and the commutator on the motor rotor are just located above the spray nozzle in the tin basin; the drive motor is started to drive the tin spraying pump to spray molten tin onto the connected faces of the armature wire with the commutator, and simultaneously, the motor rotor is rotated to implement welding, thereby, not only is the welding efficiency high, but also the welding quality is good.

Owner:无锡先锋电机有限公司

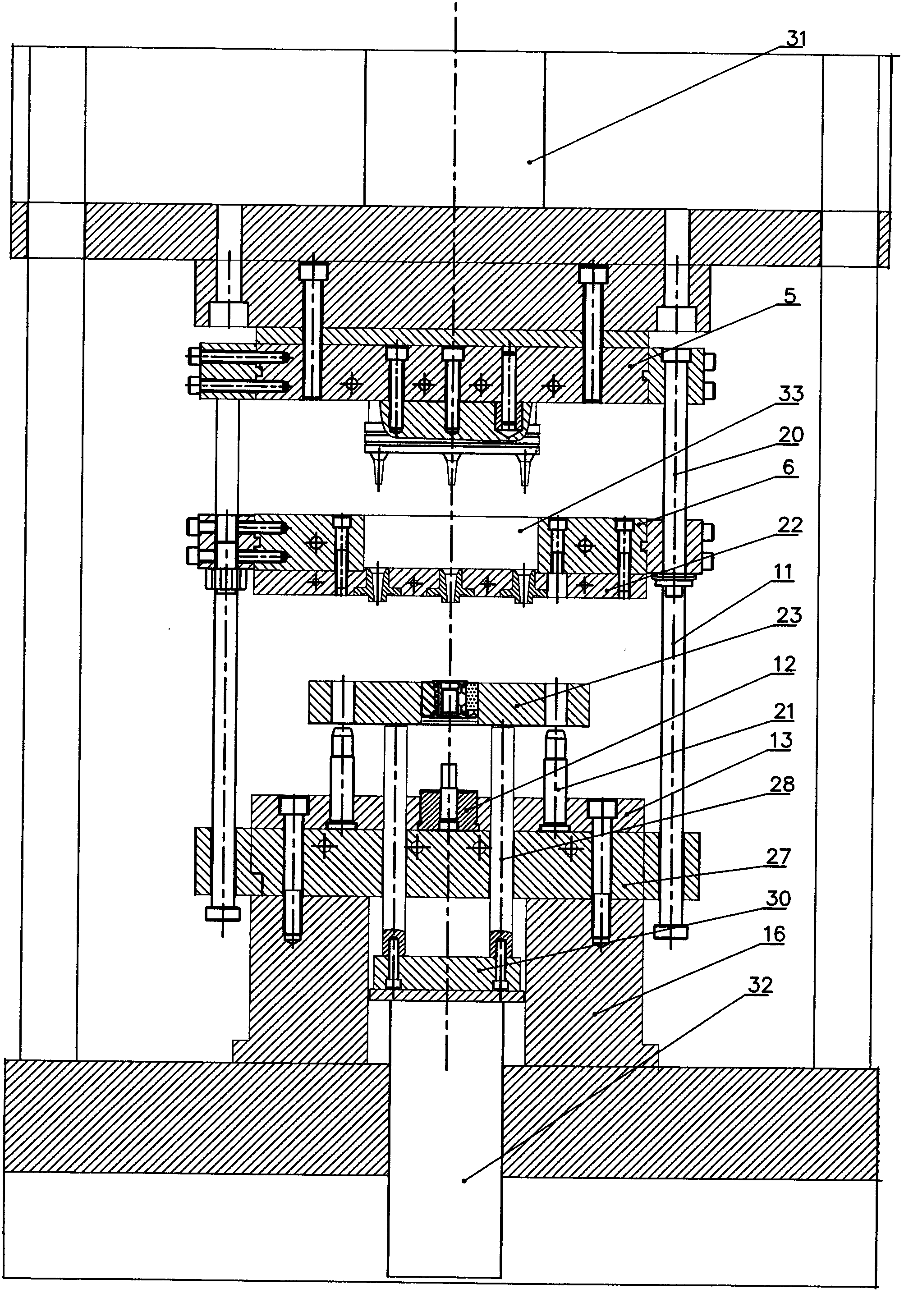

Method and device for automatically demolding commutator injection-compression mold

InactiveCN102709787AReduce labor intensityAutomate operationCommutators manufactureCompression moldingWork in process

The invention relates to a method for automatically demolding a commutator injection-compression mold, comprising the steps of: loading a molding material into a material compartment plate, arranging commutator segment components in a middle mold of a middle template, performing mold closing on a heating plate, the material compartment plate, an upper template, the middle template and a lower template, filling the molding material into the commutator segment components and performing injection-compression molding; and then, separating the heating plate and the upper template from an upper oil cylinder and supporting the separated heating plate and upper template by a suspender, separating the upper template and the lower template and supporting the separated upper template and lower template by a pull rod, jacking the middle template by ejector rods driven by a lower oil cylinder so as to separate the middle template and the lower template, taking out the middle template, and jacking out a semi-finished product of the commutator in the middle template by a delivery foot on an injection-compression demolding frame. A device for automatically demolding the commutator injection-compression mold is characterized in that the heating plate is connected with the upper oil cylinder, the lower template and a base plate are provided the ejector rods in contact with the middle template, and the ejector rods are connected with the lower oil cylinder; the suspender is arranged between the material compartment plate and the heating plate, and the pull rod is arranged between the base plate and the material compartment plate. The method and the device disclosed by the invention has the advantages of realizing automatic operation of demolding, reducing labor intensity and increasing working efficiency; and the specification or quantity of the commutator segment components on the middle template can be increased properly.

Owner:瑞安市博诺机电有限公司

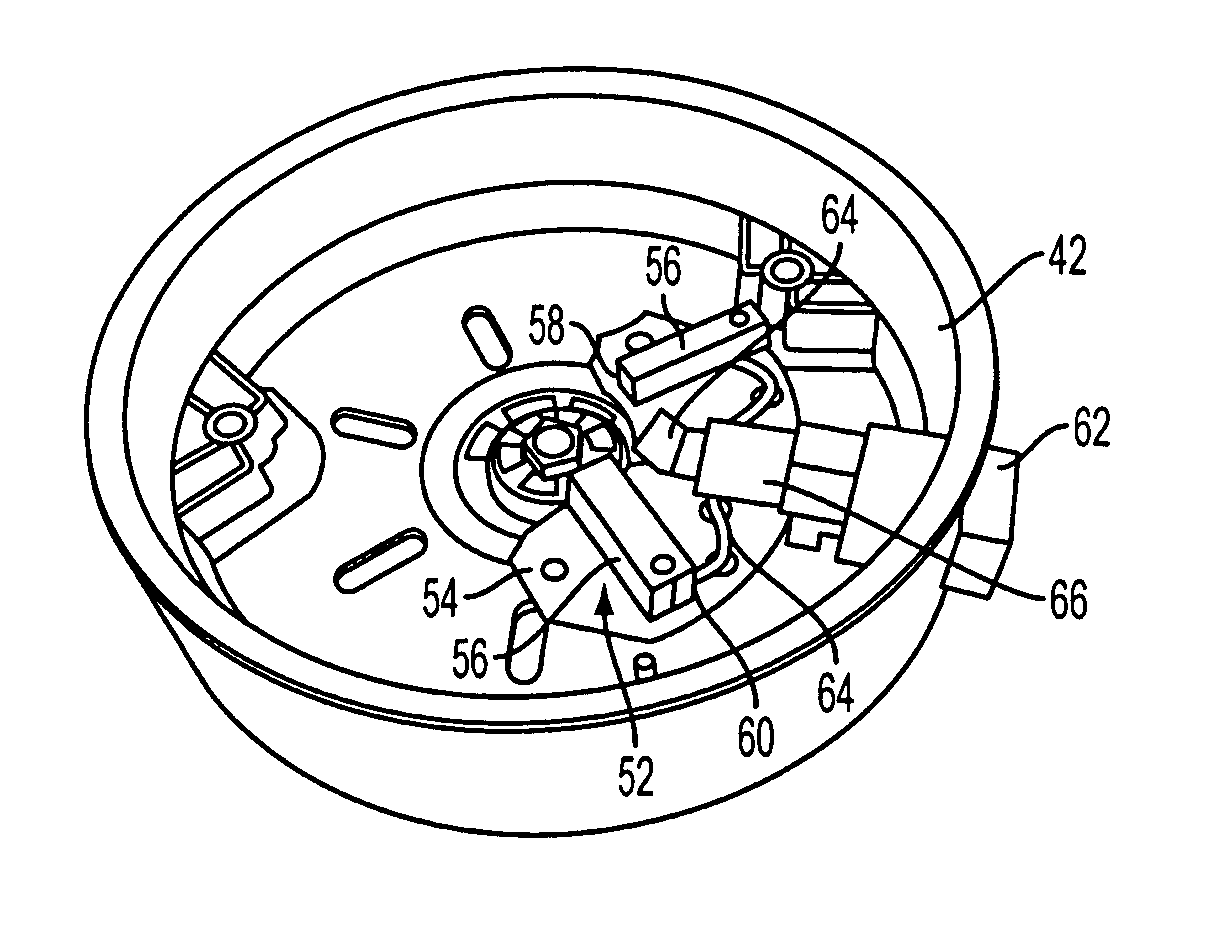

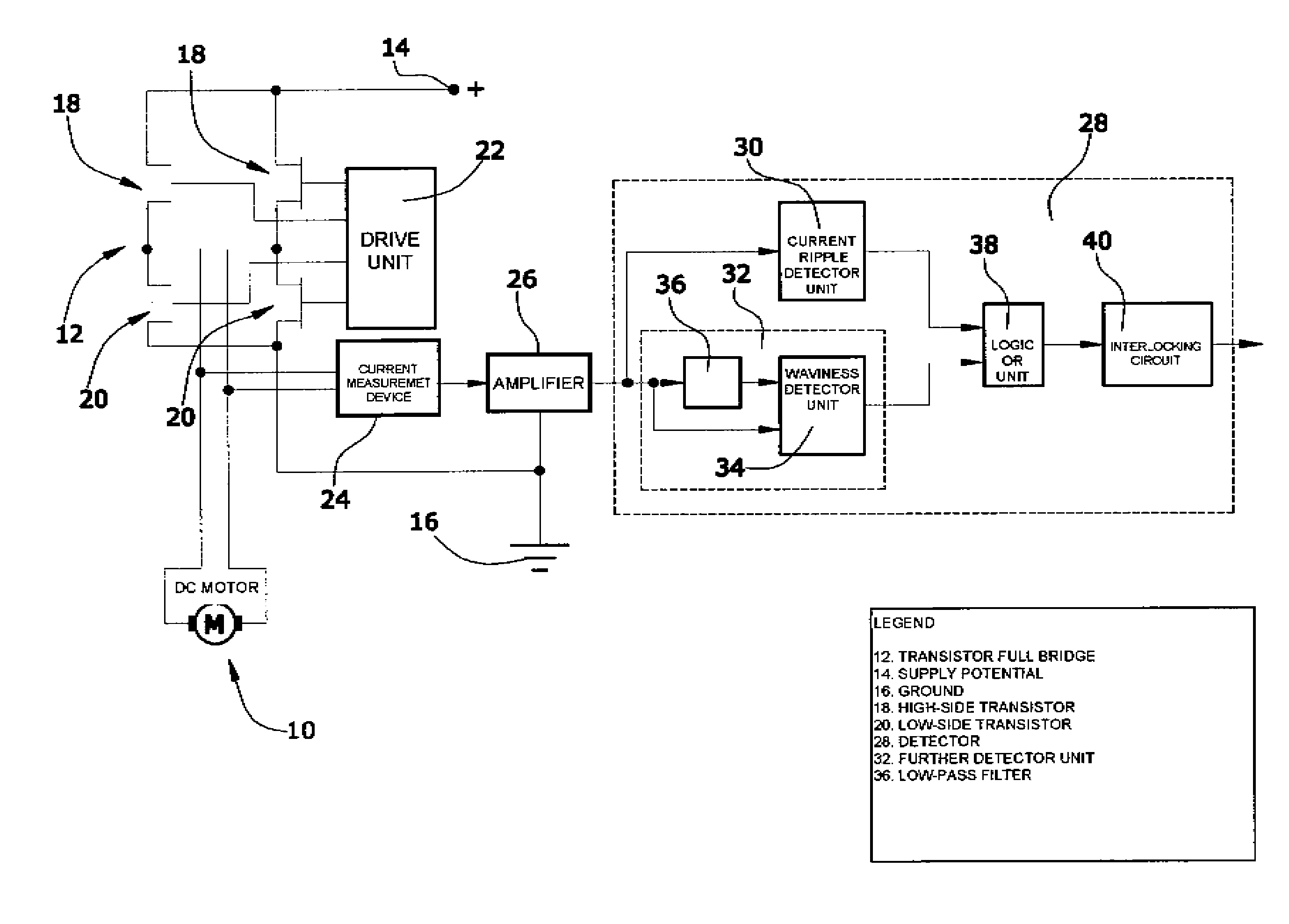

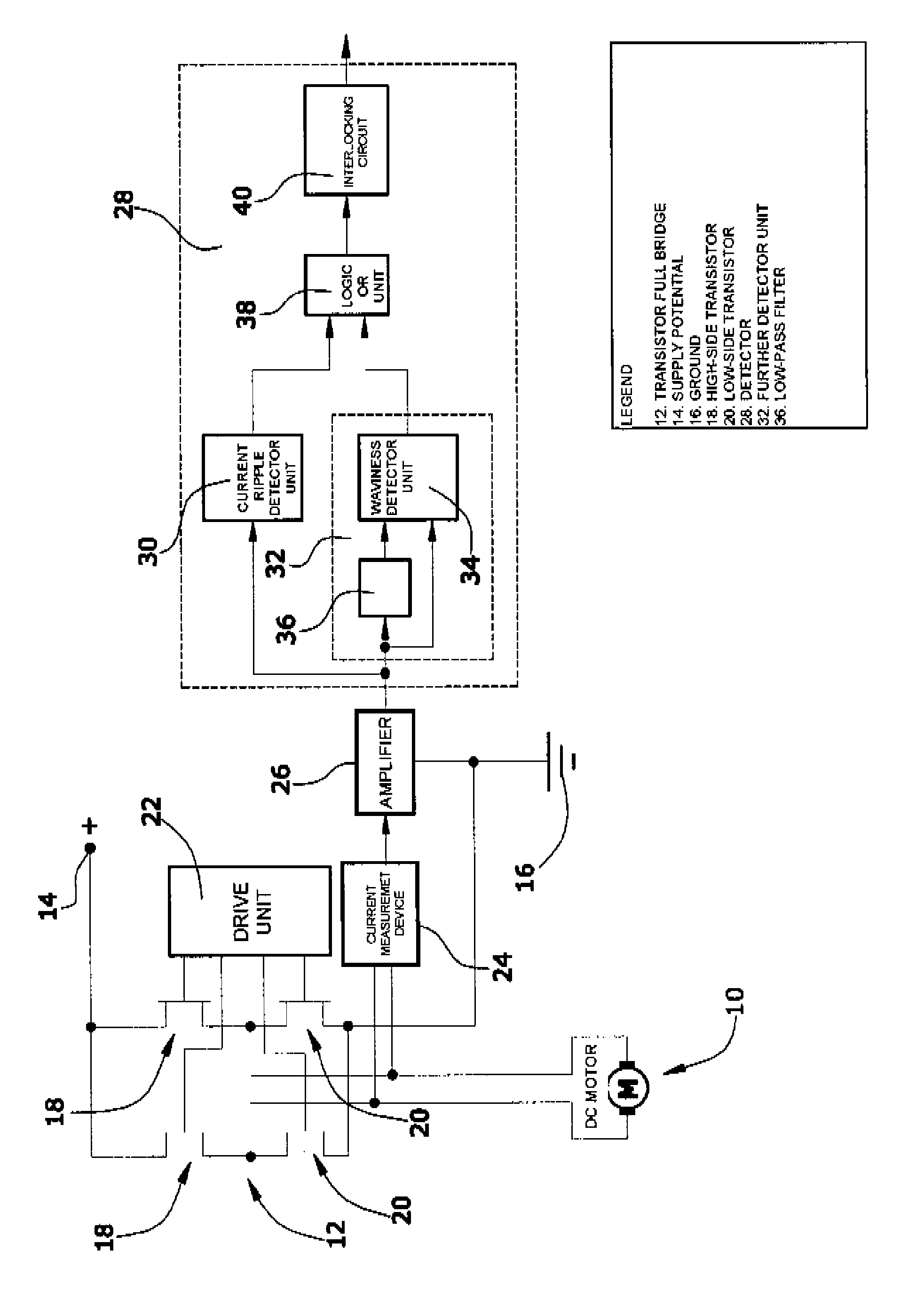

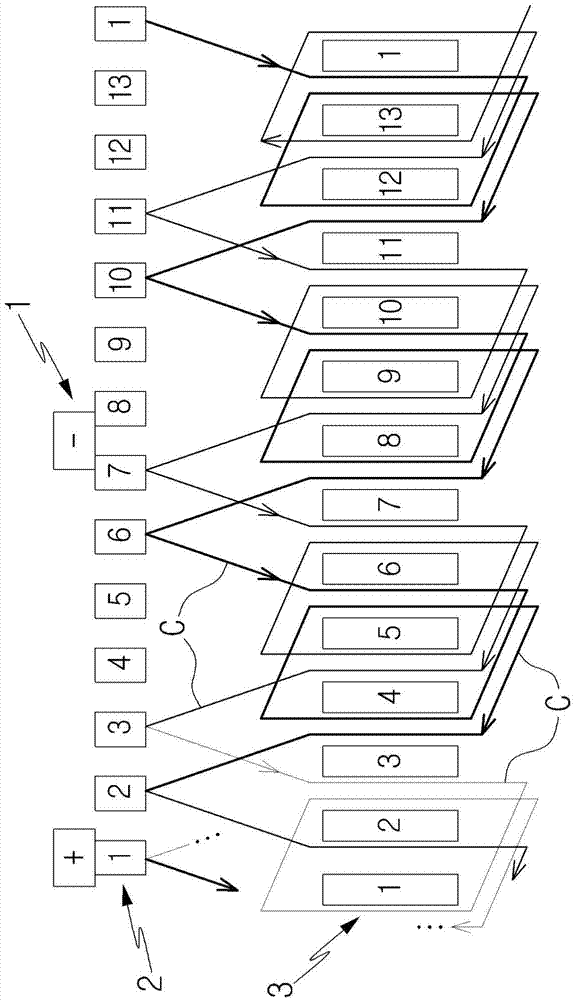

Method for the detection of the rotational position of the rotor of a DC motor with commutator

In a method for the detection of the rotational position of the rotor of a DC motor with commutator by evaluating the time development of a rotor current signal of the DC motor, said signal comprising a periodic waviness around an average value and comprising current ripples generated by commutation which are superimposed to said waviness, the rotor current signal of a current ripple detector unit (30) is supplied for detecting the current ripples of the rotor current signal. The rotor current signal is further supplied to a waviness detector unit (34) for detecting a half or full wave of the rotor current signal. The current ripple detector unit (30) is arranged to output a current ripple pulse for each detected current ripple. The waviness detector unit (34) is arranged to output a waviness pulse for each period of the waviness. The output signals of both detector units (30,34) are supplied to a logic OR unit (38) for generating a logic signal. Within a period of the rotor current signal, at least one of the detector units (30,34) will output a pulse. Thereby, the logic signal comprises a logic pulse for each period of the rotor current signal.

Owner:BEHR HELLA THERMOCONTROL

Mixed-excitation high-efficiency motor based on Halbach array

InactiveCN102315707AEasy to operateHigh torqueMagnetic circuit rotating partsWindings conductor shape/form/constructionMechanical energyMagnetic poles

The invention relates to a mixed-excitation high-efficiency motor based on a Halbach array, mainly comprising magnetic rings of the Halbach array, iron cores, windings, a rotor yoke, a stator frame, a rotating shaft, a case, a front end cover, a rear end cover, a commutator and an electric brush, wherein the two permanent magnetic rings of the Halbach array with S poles and N poles being arranged at interval are fixed on the rotor yoke; four or more than four iron cores and windings are arranged between the two magnetic rings and are fixed on the stator frame or the case; or the two magnetic rings are fixed on the stator frame or the case, and the iron cores and the windings arranged between the two magnetic rings are fixed on the rotor yoke; the quantity of magnetic poles of one magnetic ring is 1.5 times than the quantity of the magnetic poles of the iron cores and the windings; the rotating shaft is provided with the commutator and the electric brush; when a rotor rotates by certain angle for one time, the adjacent magnetic poles of the iron cores and the windings change the directions of the S poles and the N poles alternatively for one time; and the S poles and the N poles of the iron cores and the windings generate attractive force and repulsive force respectively with the two magnetic rings, so that the purpose of converting the electromagnetic energy into the mechanical energy is achieved.

Owner:李贵祥

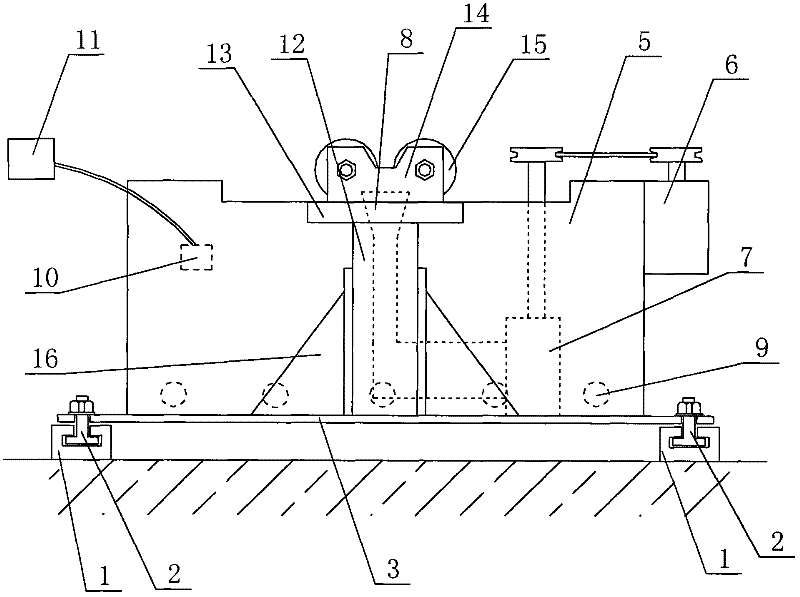

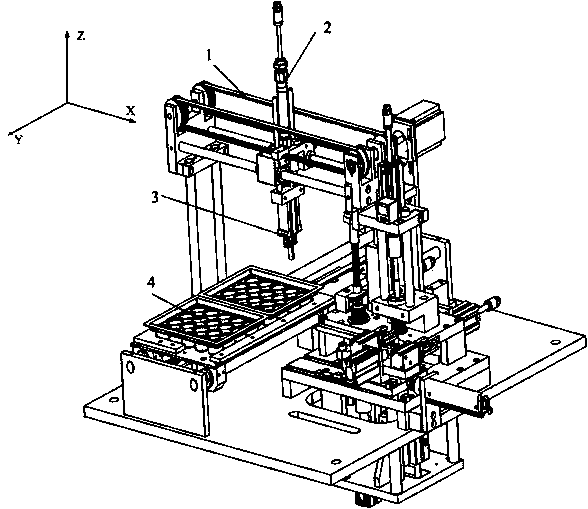

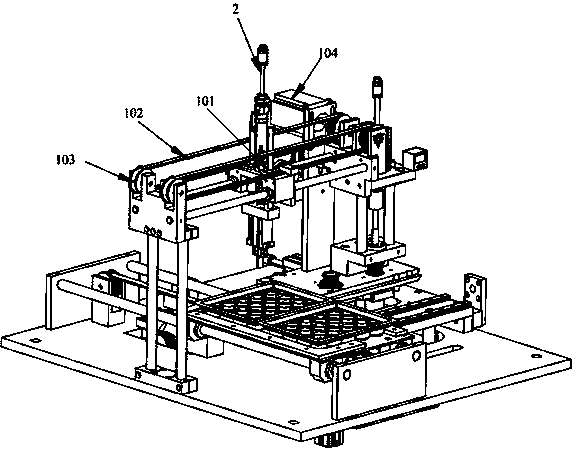

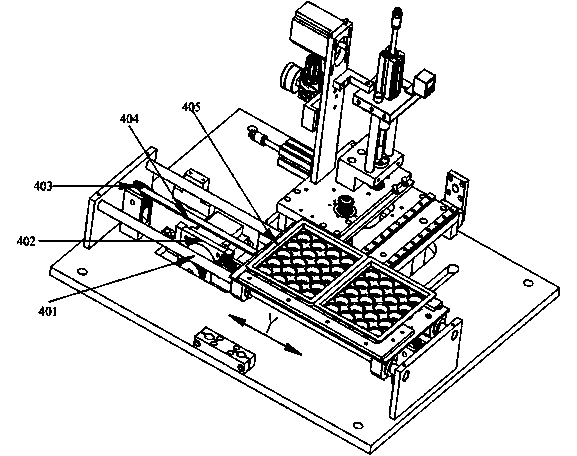

Manipulator conveying device used for automatic detection of commutator

InactiveCN103407786AMeet the needs of transportation and transmissionUnique designConveyor partsEngineeringManipulator

The invention relates to a manipulator conveying device used for automatic detection of a commutator. The manipulator conveying device comprises an X-axis conveying unit, a Y-axis conveying unit and a Z-axis conveying unit, wherein the Y-axis conveying unit comprises a Y-axis synchronous belt and a Y-axis motor for controlling the Y-axis synchronous belt to move, the X-axis conveying unit is positioned above the Y-axis conveying unit and comprises an X-axis synchronous belt and an X-axis motor for controlling the X-axis synchronous belt to move, the Z-axis conveying unit is installed on the X-axis synchronous belt of the X-axis conveying unit and comprises a Z-axis sliding rail and an air cylinder for controlling the Z-axis sliding rail to move, a clamping paw is installed on the Z-axis sliding rail, a Y-axis motion platform is arranged on the Y-axis synchronous belt of the Y-axis conveying unit, a supporting box is arranged on the Y-axis motion platform, and a three-dimensional motion trace is realized through the coordinative motion and mutual cooperation of the X-axis conveying unit, the Z-axis conveying unit and the Y-axis conveying unit. The manipulator conveying device is easy to control and high in stability.

Owner:三笠电器技研(苏州)有限公司 +2

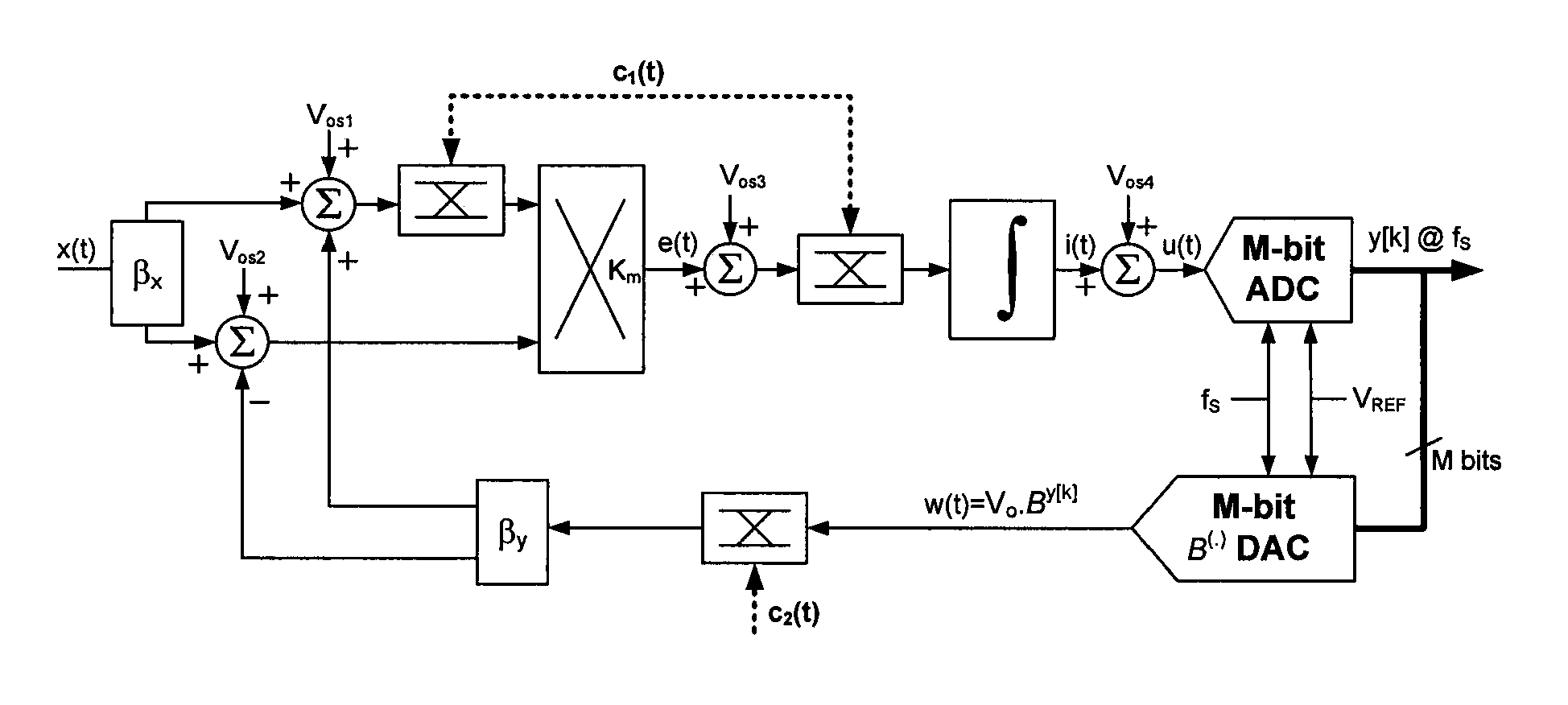

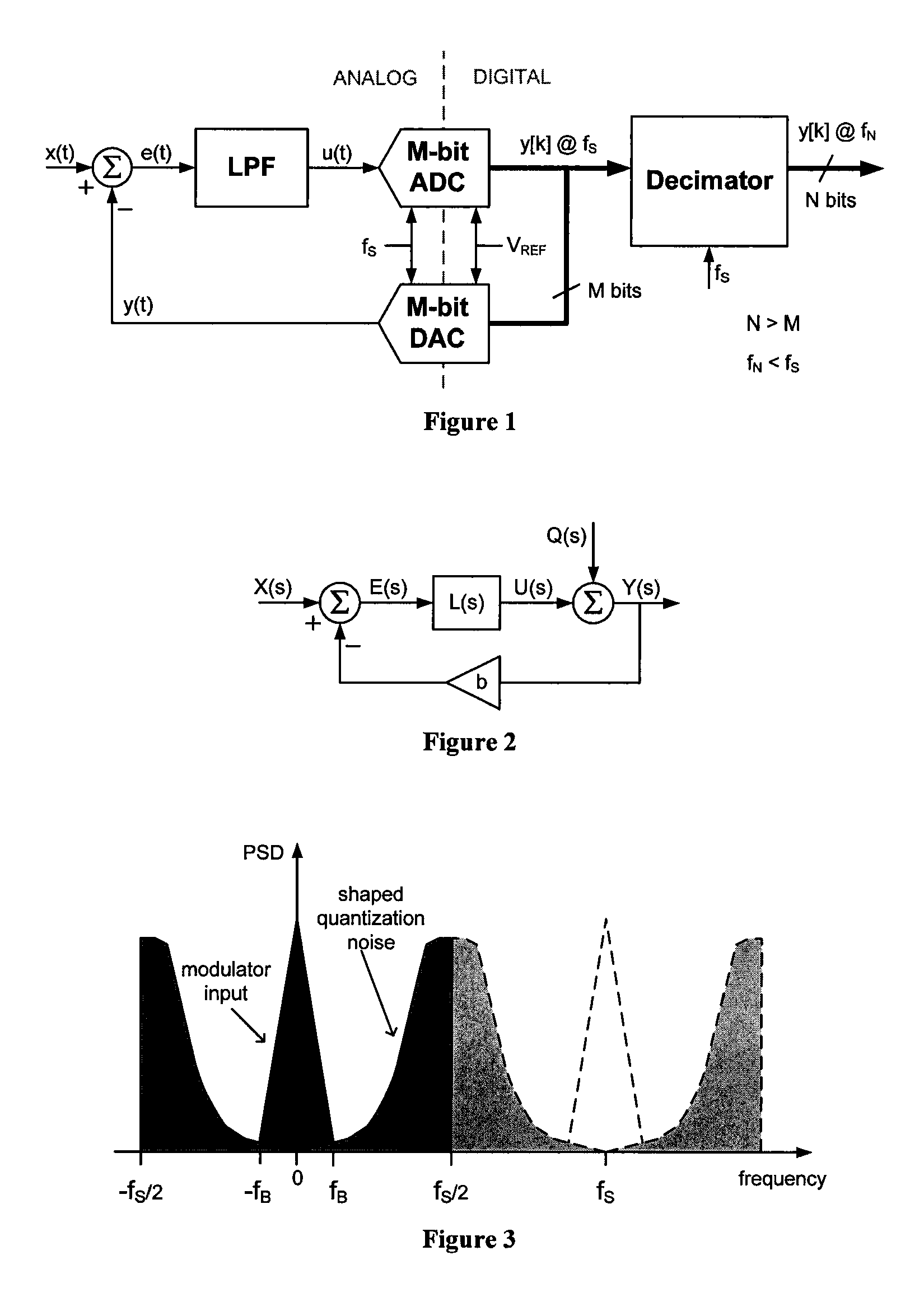

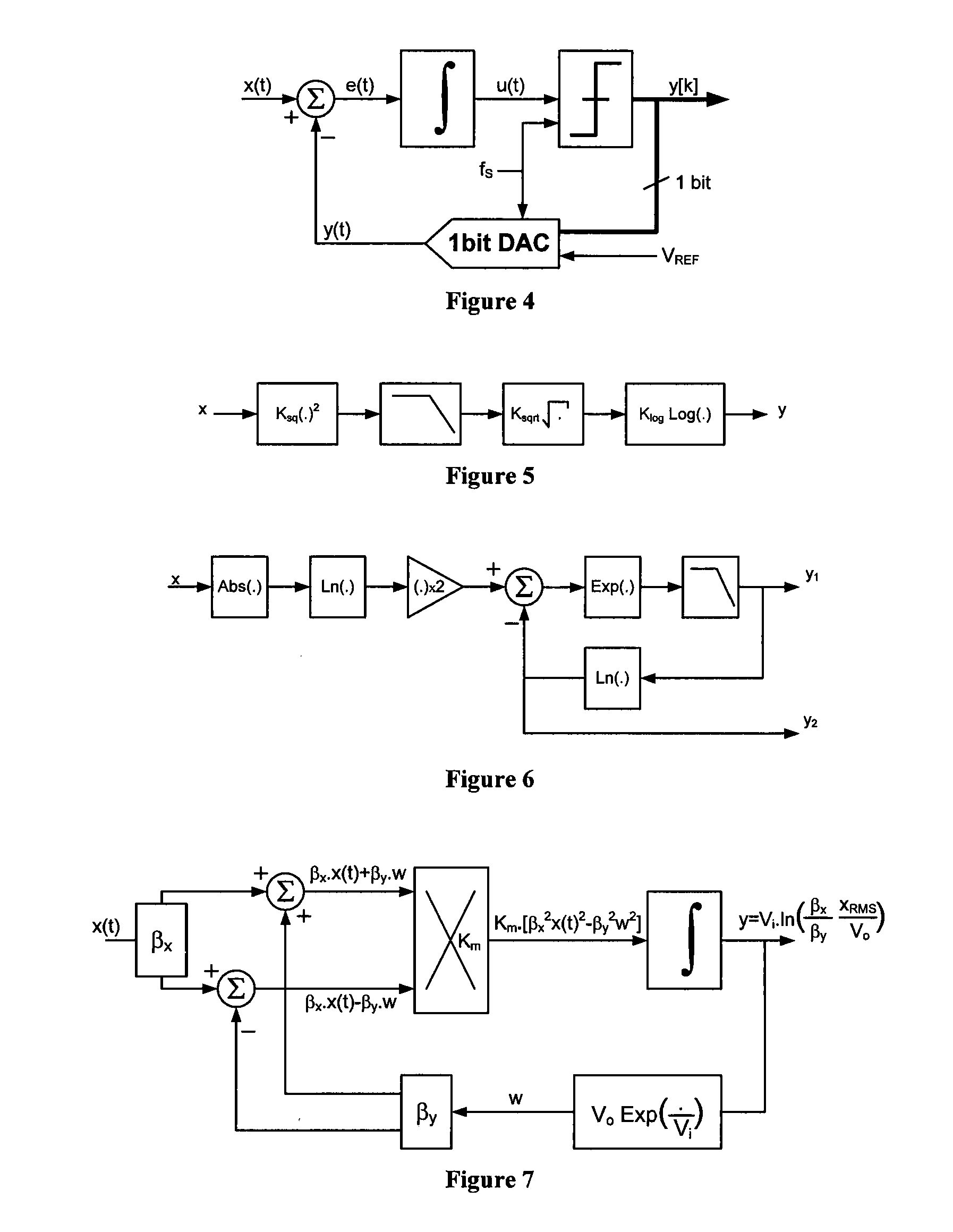

Sigma-delta difference-of-squares log-rms to DC converter with forward path multiplier and chopper stabilization

ActiveUS20120146819A1Reduce sensitivityExtension of useful input-referred dynamic rangeElectric signal transmission systemsAnalogue conversionLoop filterFrequency compensation

A sigma-delta (ΣΔ) difference-of-squares LOG-RMS to digital converter for true RMS detection by merging a ΣΔ modulator with an analog LOG-RMS to DC converter based on a difference-of-squares. Chopper-stabilization, implemented through commutators running at two different frequencies, can be employed to reduce sensitivity to DC offsets and low-frequency errors, resulting in an extension of the useful input-referred dynamic range. High-order ΣΔ LOG-RMS converters can be implemented with a loop filter containing multiple integrators and feedforward and / or feedback paths for frequency compensation. The resulting implementations are ΣΔ difference-of-squares LOG-RMS to DC converters with a natural digital output and a logarithmically compressed dynamic range.

Owner:NAT SEMICON CORP

Apparatus for monitoring of brushes, in particular slipring or commutator brushes, on electrical machines

InactiveUS8054190B2Association with control/drive circuitsMotor/generator/converter stoppersElectric machineEngineering

Owner:GENERAL ELECTRIC TECH GMBH

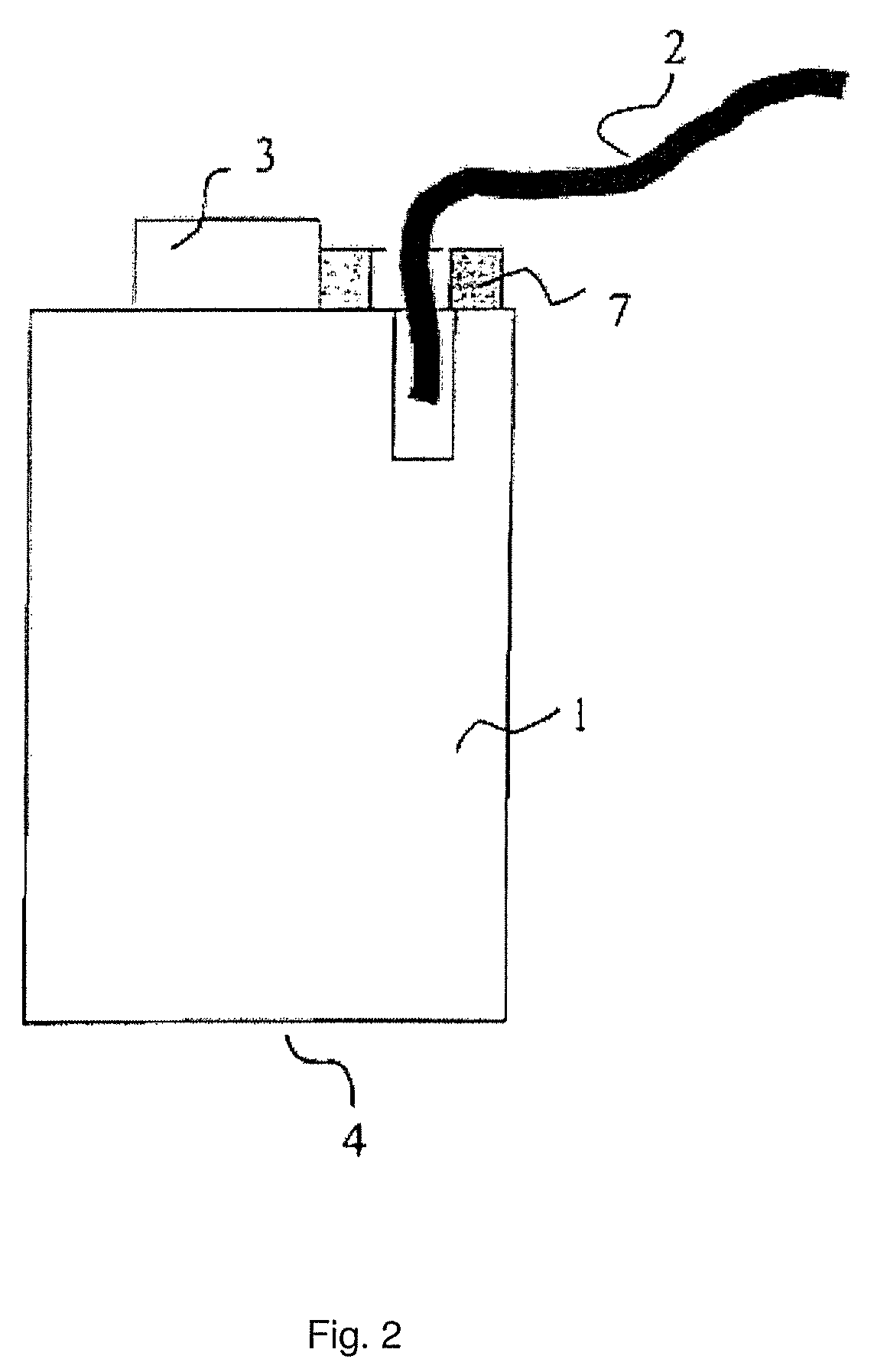

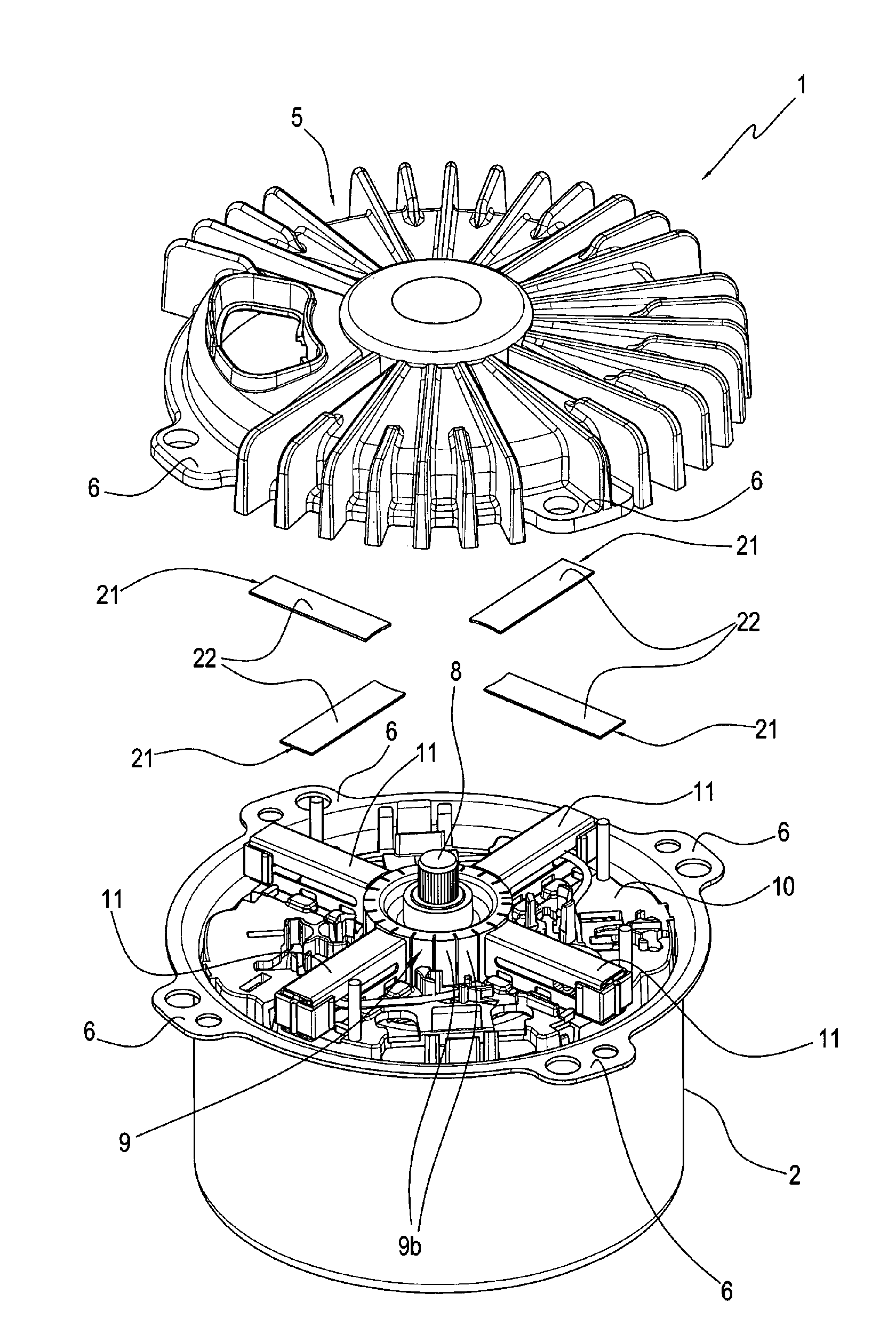

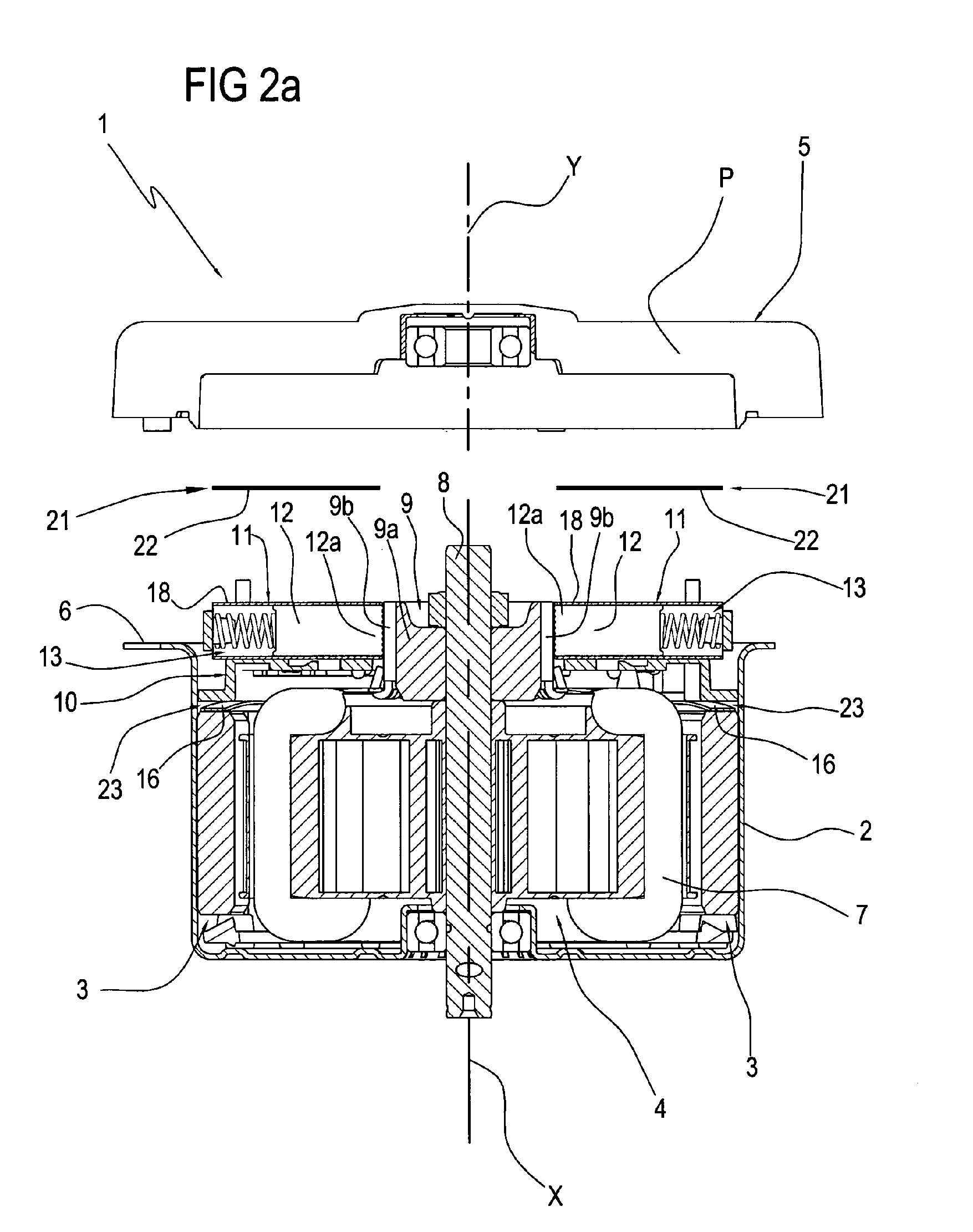

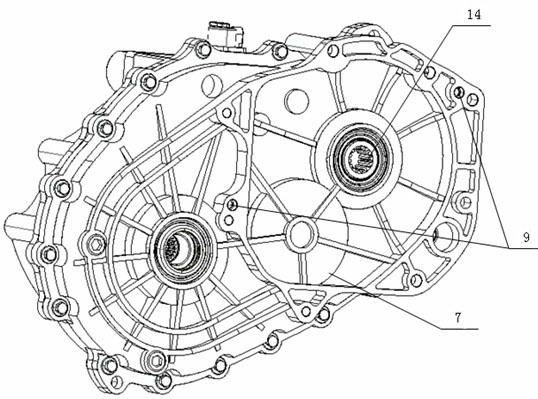

Electric machine

InactiveUS20100277032A1Improve reliabilityReduce manufacturing costRotary current collectorMagnetic circuit rotating partsElectric machineConductor Coil

An electric machine comprises: a casing (2); a stator (3) and a rotor (4) supported by the casing (2), the rotor (4) having at least one rotor winding (7); a commutator (9) connected permanently to the rotor (4) and electrically connected to the rotor winding (7); a pair of brushes (12), each having a first end (12a) maintained in a sliding position with the commutator (9) and electrically connected to respective terminals which may be connected to an electricity mains supply; a pair of brush holder elements (11) supported by the casing (2), each brush holder element (11) being associated with a respective brush (12) to keep it pressed on the commutator (9). Each brush holder element (11) has at least one lateral surface (18) to face a respective butting position (17) of the casing (2), and which may be joined to the butting portion (17) to transmit a thermal power to the butting portion. The lateral surface (18) of each brush holder element (11) is electrically isolated from the respective butting portion (17).

Owner:SPAL AUTOMOTIVE

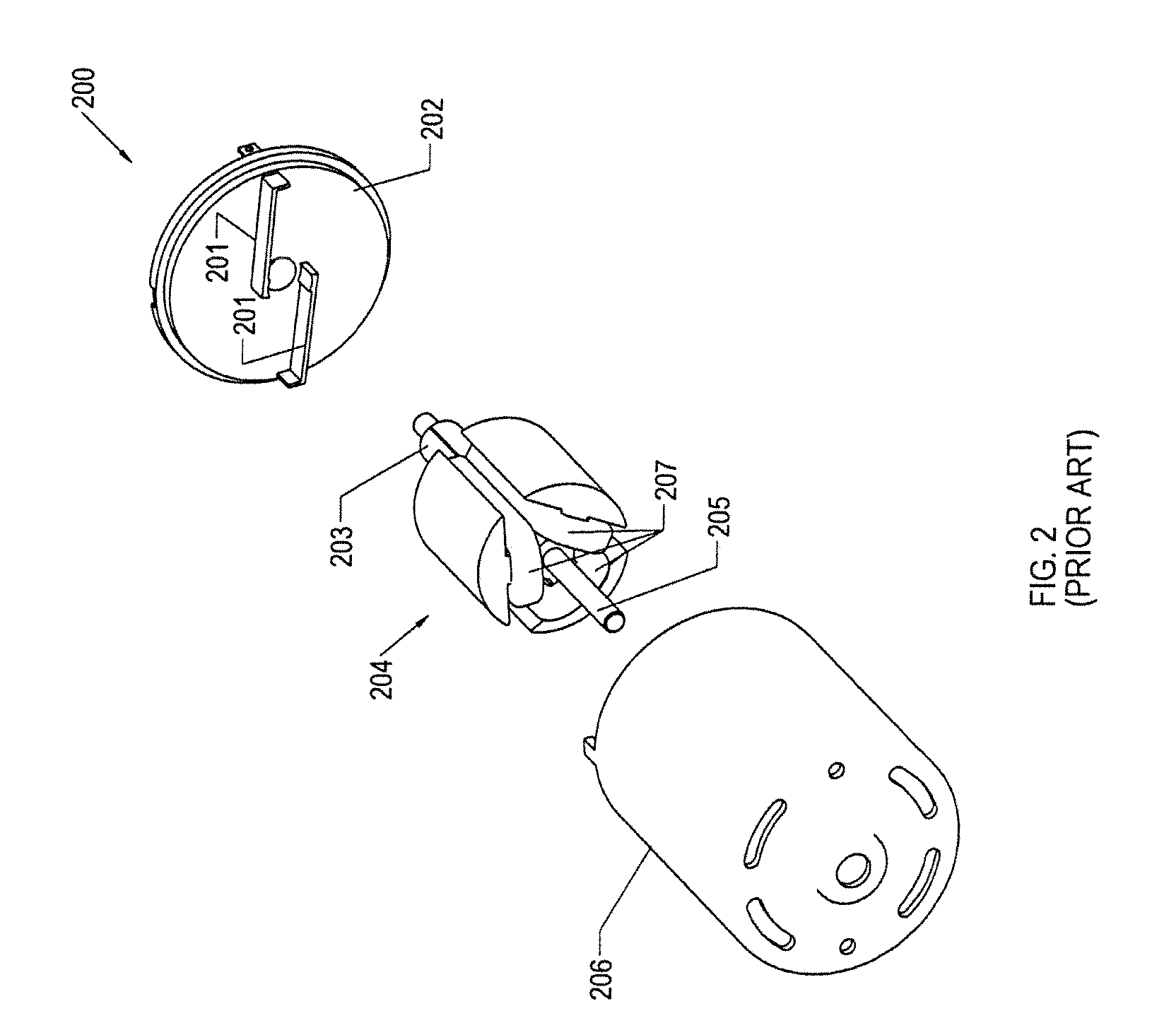

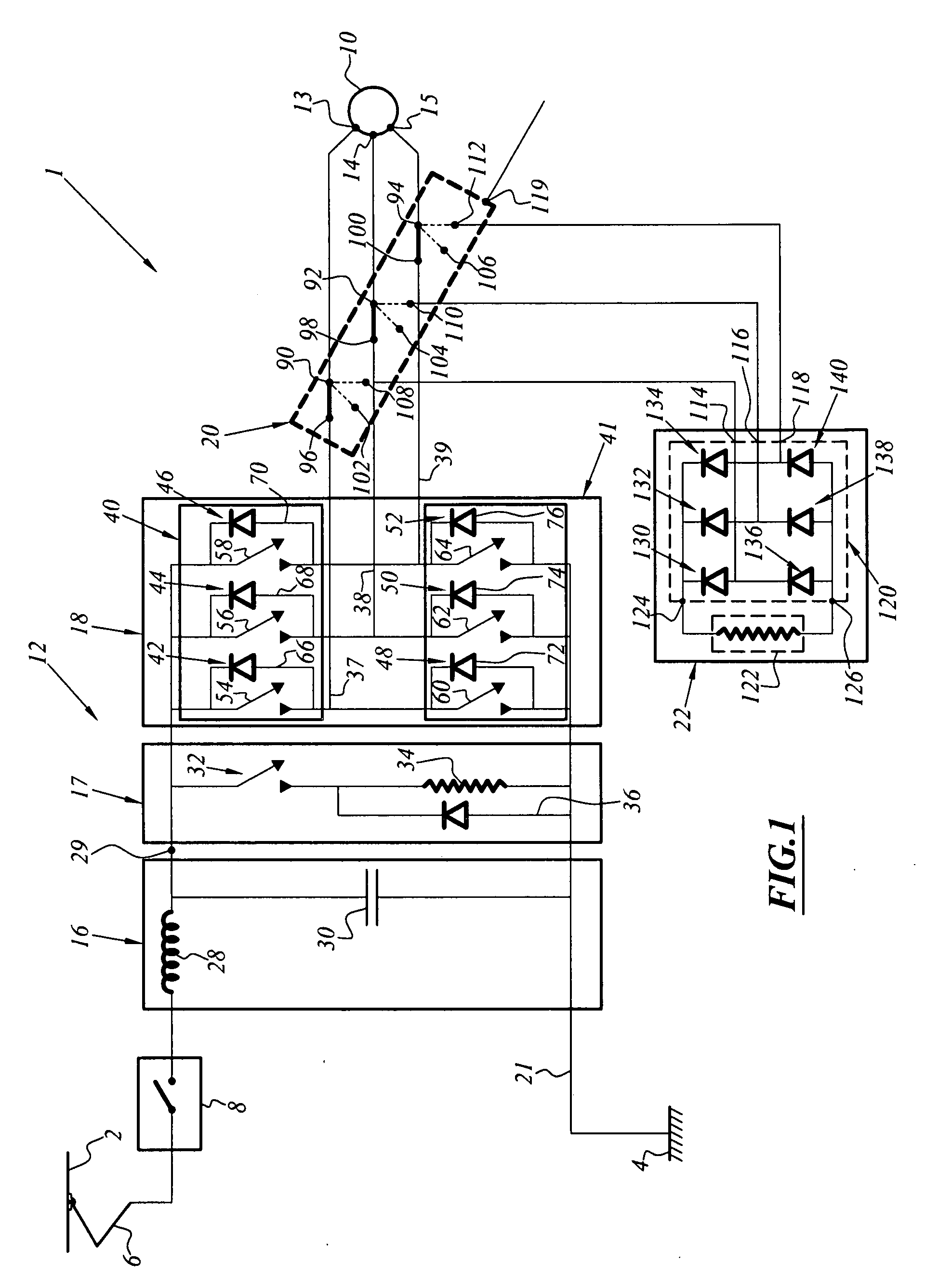

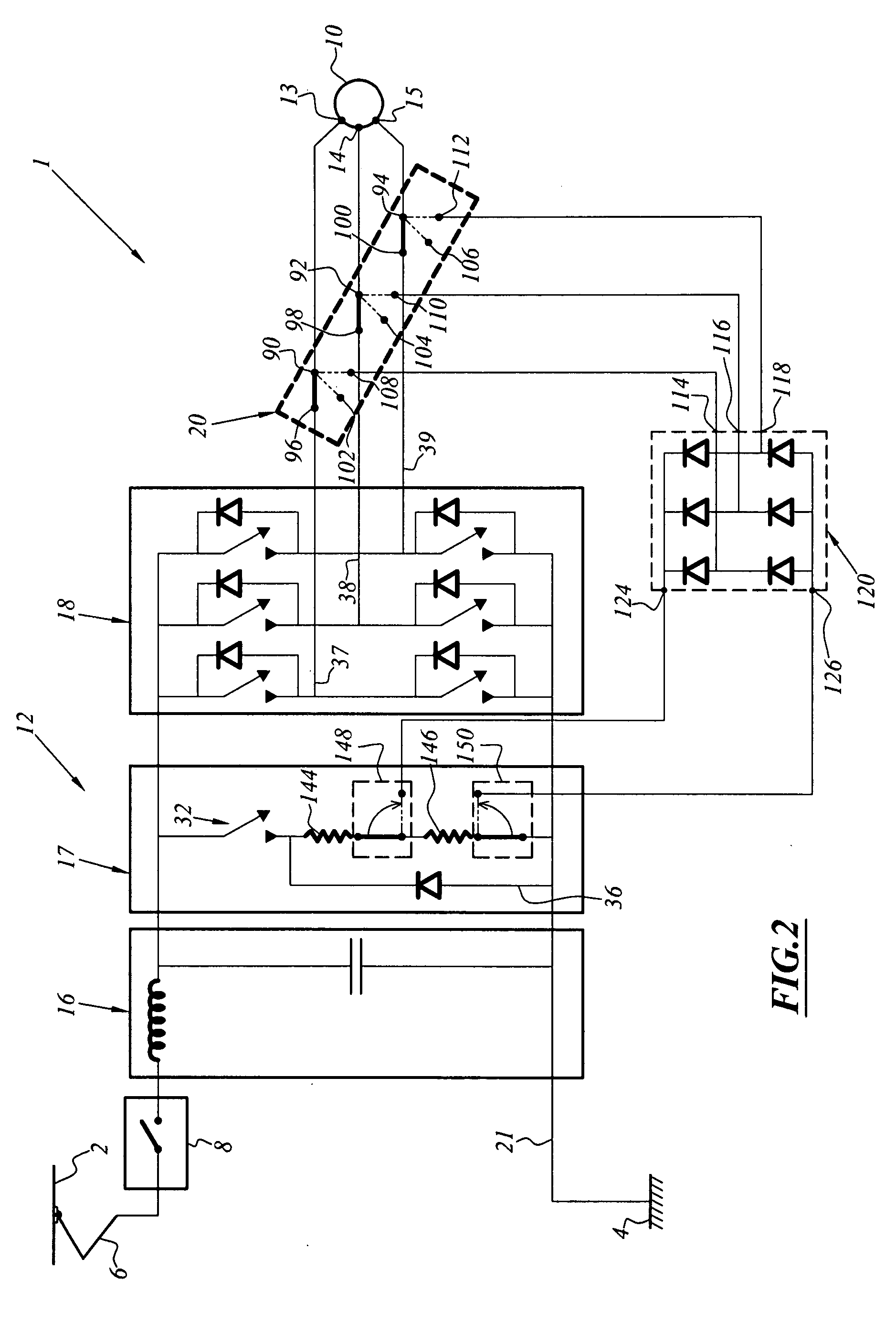

Commutation of Brushless Electrodynamic Machines

InactiveUS20070085442A1Rotary current collectorMagnetic circuit stationary partsElectric power transmissionDc current

A method, apparatus and system for selectably directing power signals to coils of active field pole members in brushless electrodynamic machinery are disclosed. In one embodiment, a field pole commutator includes a power transfer region configured to transfer at least a first power signal and second power signal to the coils. It also includes a first power region and a second power region configured to provide the first power signal and the second power signal, respectively, to the power transfer region. The first power region and the second power region each are configured to rotate together with the power transfer region about an axis of rotation. In one embodiment, the field pole commutator is implemented in a brushless direct current (“DC”) current motor, which includes a rotor having permanent magnets and a plurality of active field pole members. Each active field pole member has one or more coils wound about the periphery of field pole members to form said plurality of active field pole members. In a specific embodiment, permanent magnets of the rotor include either conical magnets or cylindrical magnets, or both.

Owner:REGAL BELOIT AMERICA

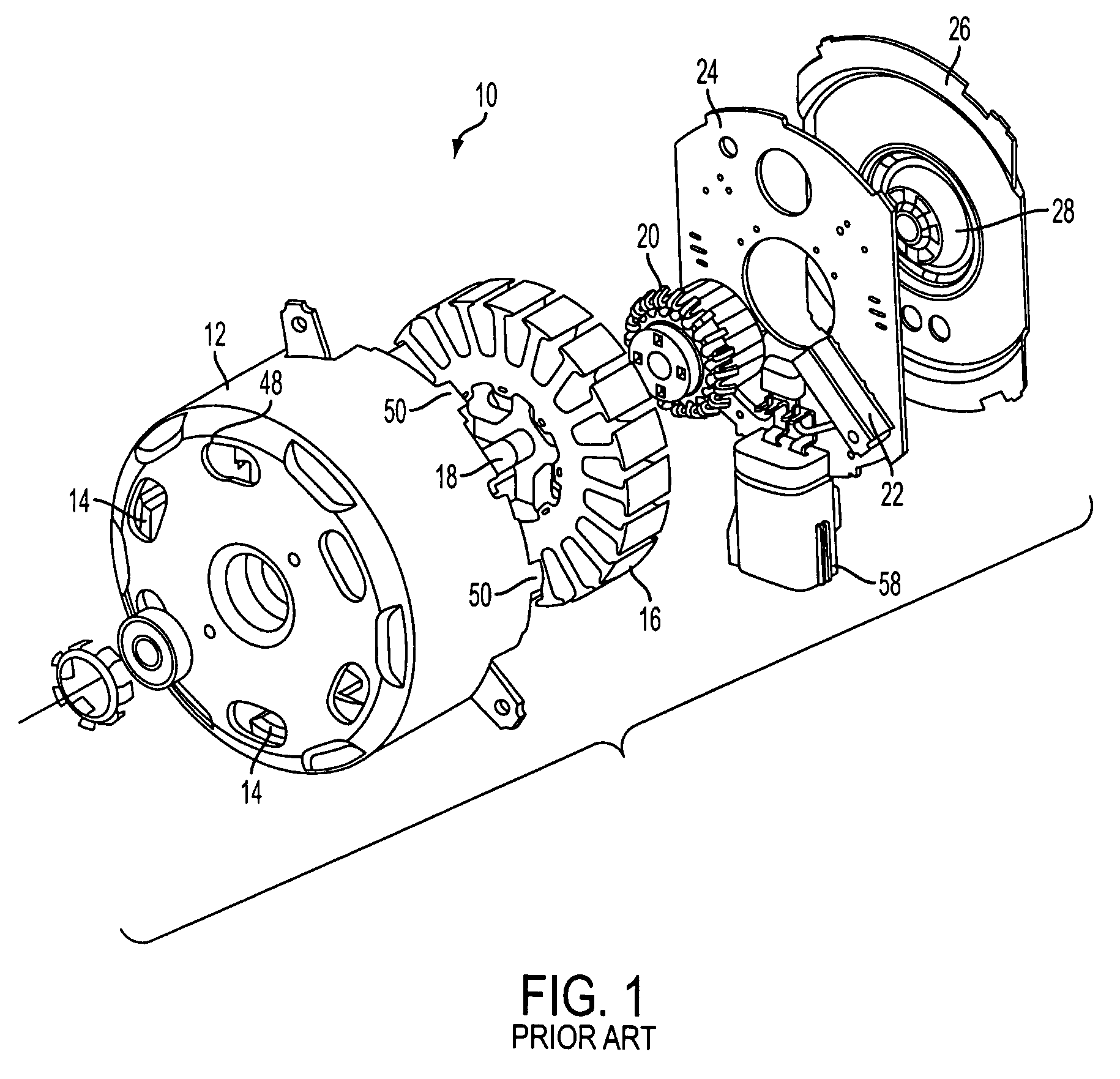

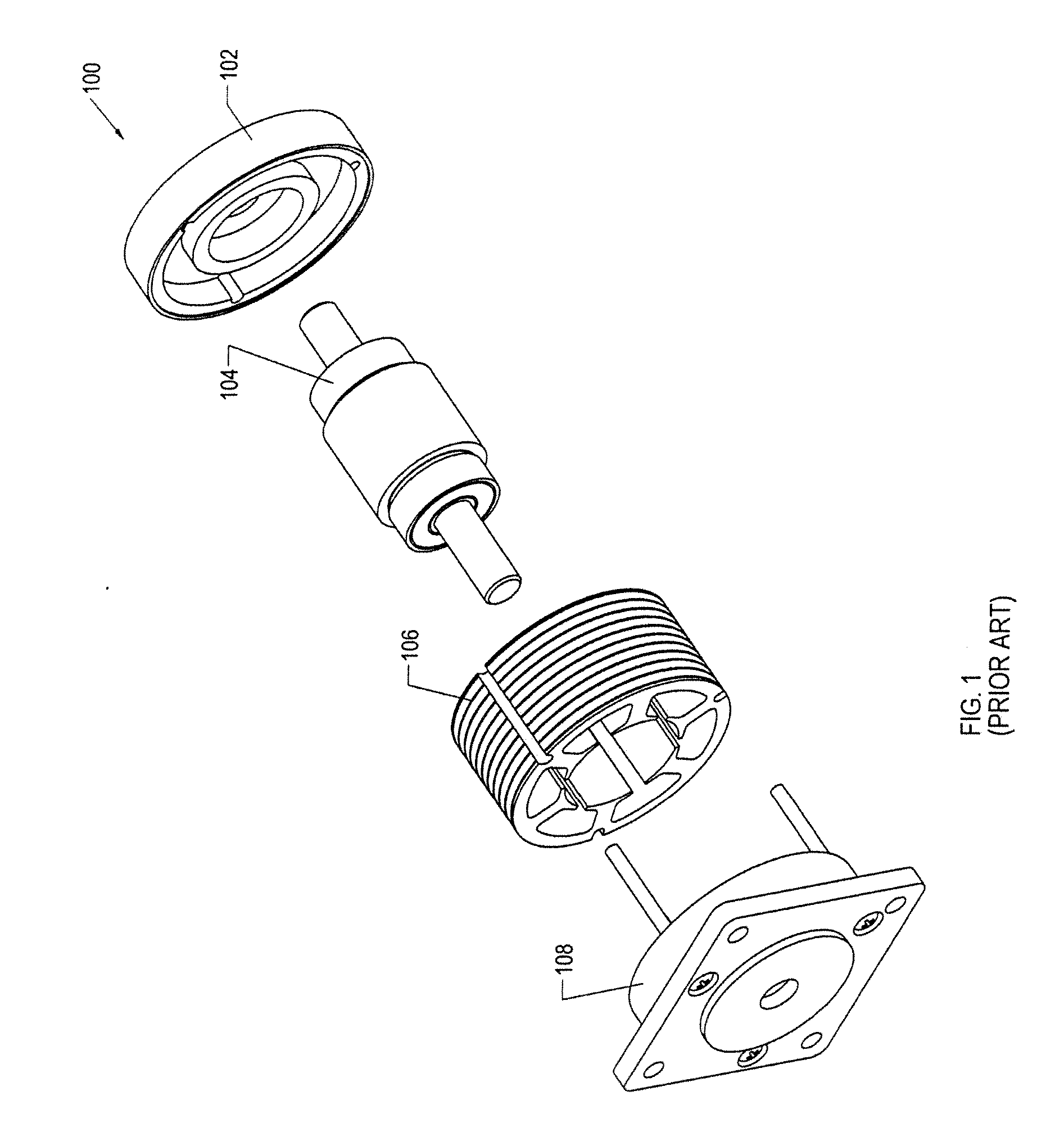

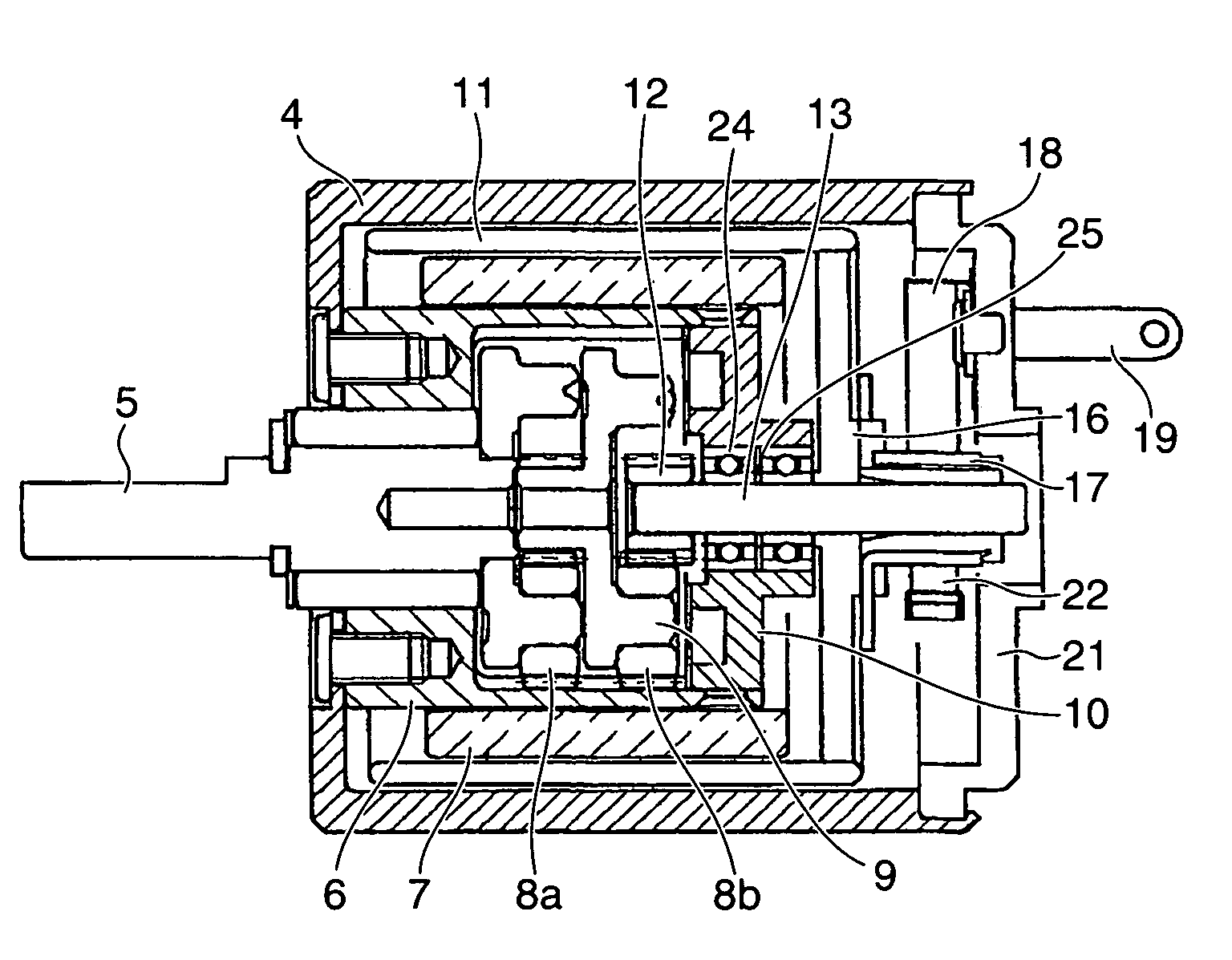

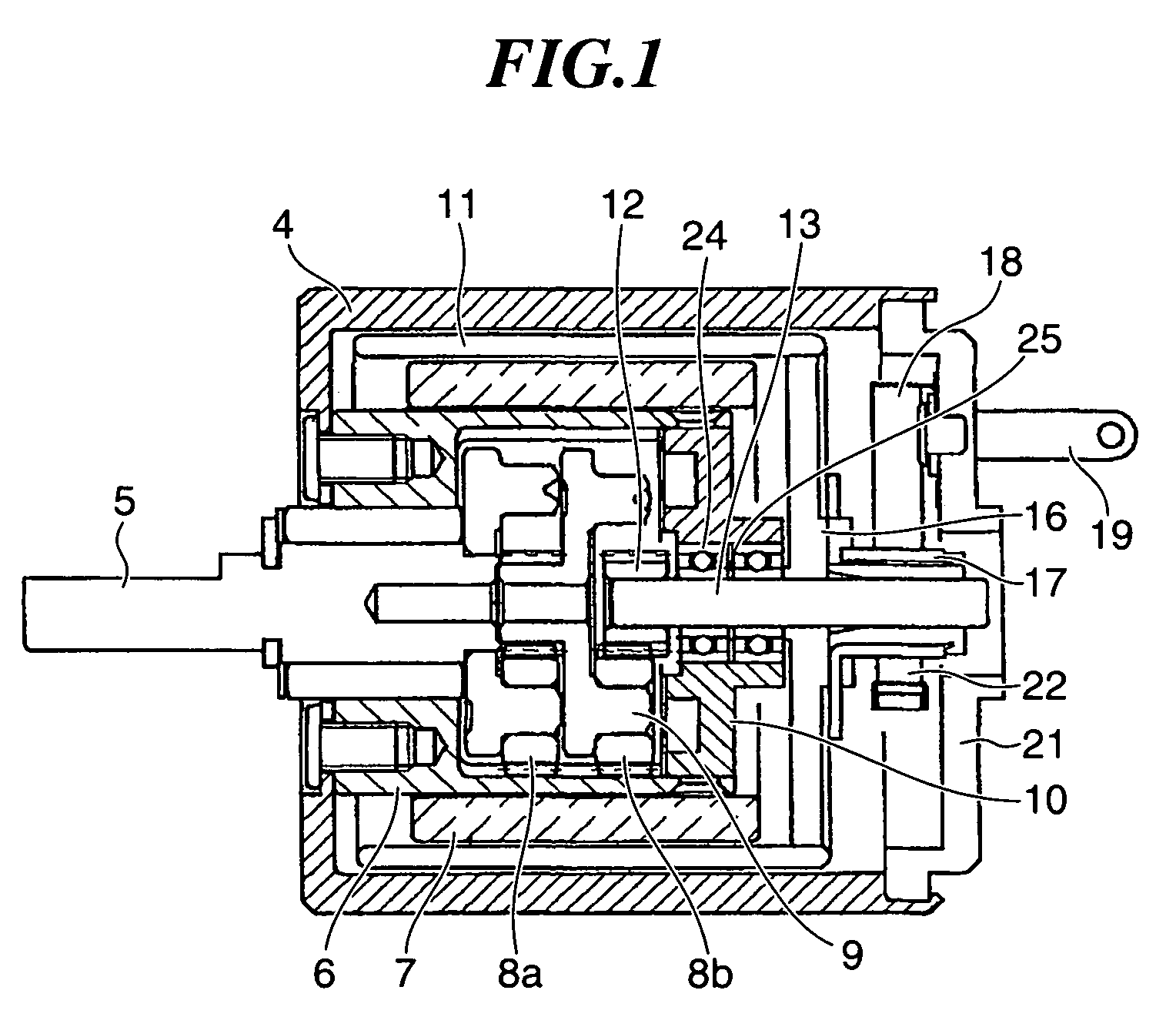

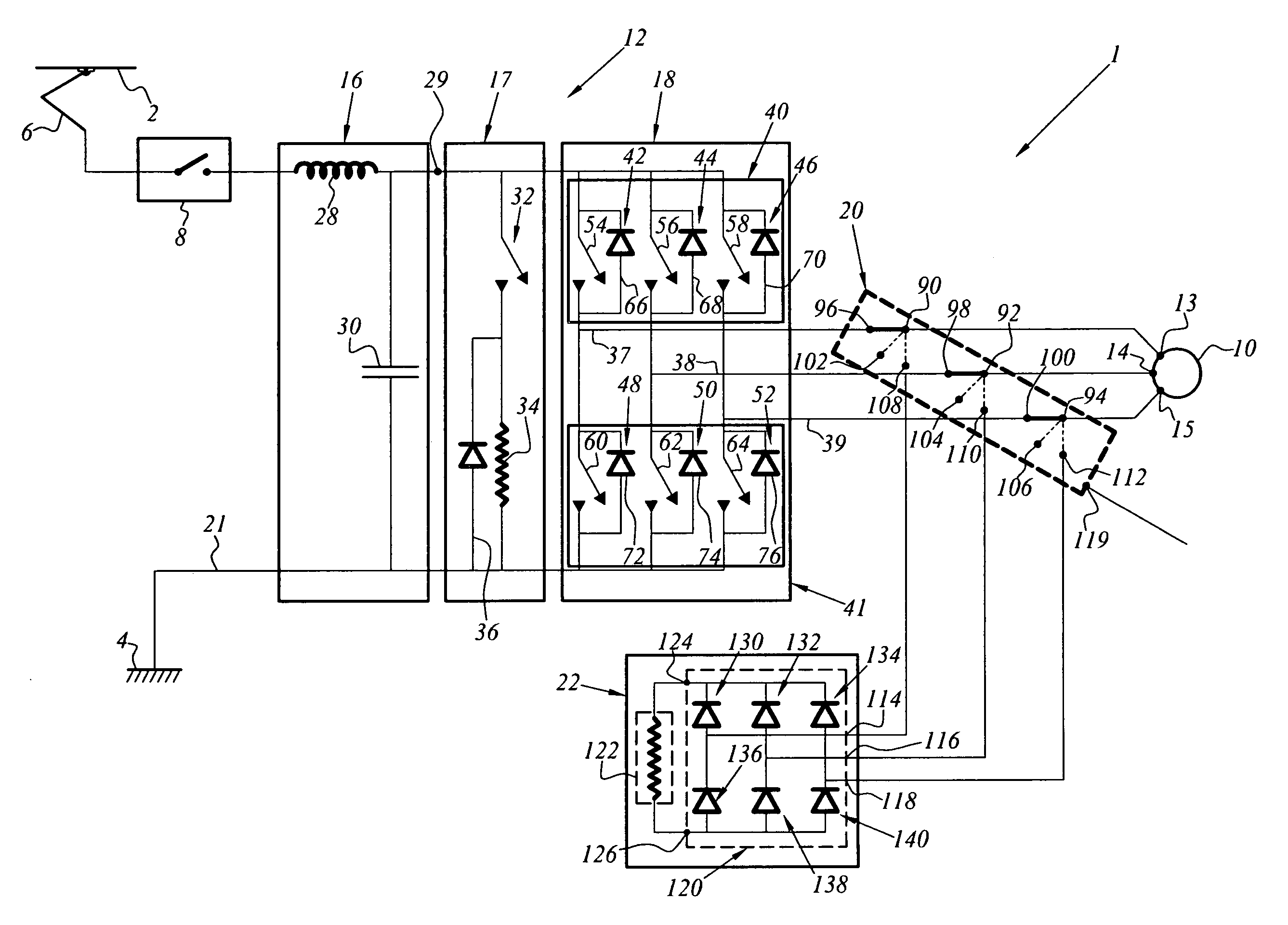

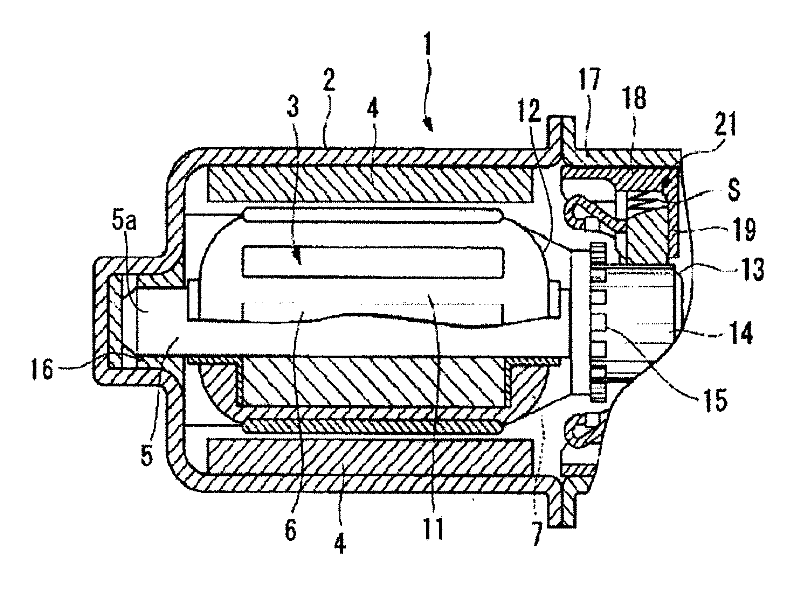

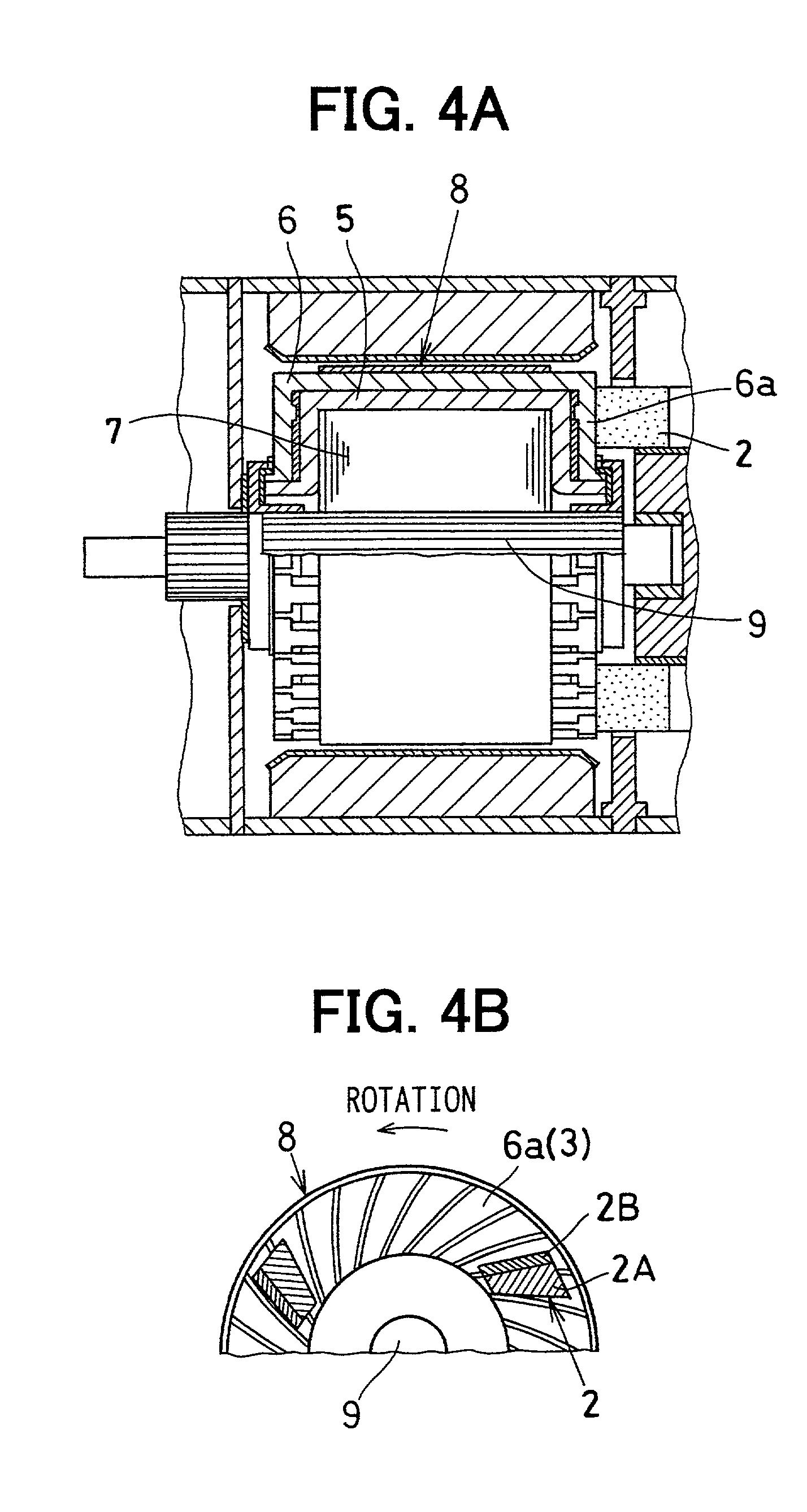

Coreless motor

ActiveUS8004132B2Easy to assembleEasy to guaranteeDC commutatorMechanical energy handlingBall bearingReducer

A coreless motor able to be downsized and easy to be assembled and to ensure the concentricity between a motor shaft, a magnet, and an outer cylinder. The coreless motor includes an outer cylinder gear unit having an output shaft and a speed-reducer mechanism incorporated into a field assembly having a magnet fitted on an inner yoke and an outer cylinder fitted on an outer periphery of the magnet, a motor shaft unit having an inner lid rotatably supporting a motor shaft via ball bearings, a rotor unit having a circular plate attached with a commutator electrically connected to a coil, an outer lid unit having an outer lid mounted with brushes. The inner lid is incorporated in the inner yoke, the coil is incorporated in between the outer cylinder and the magnet, and the outer lid unit is attached to the rotor unit and the outer cylinder.

Owner:CANON KK +1

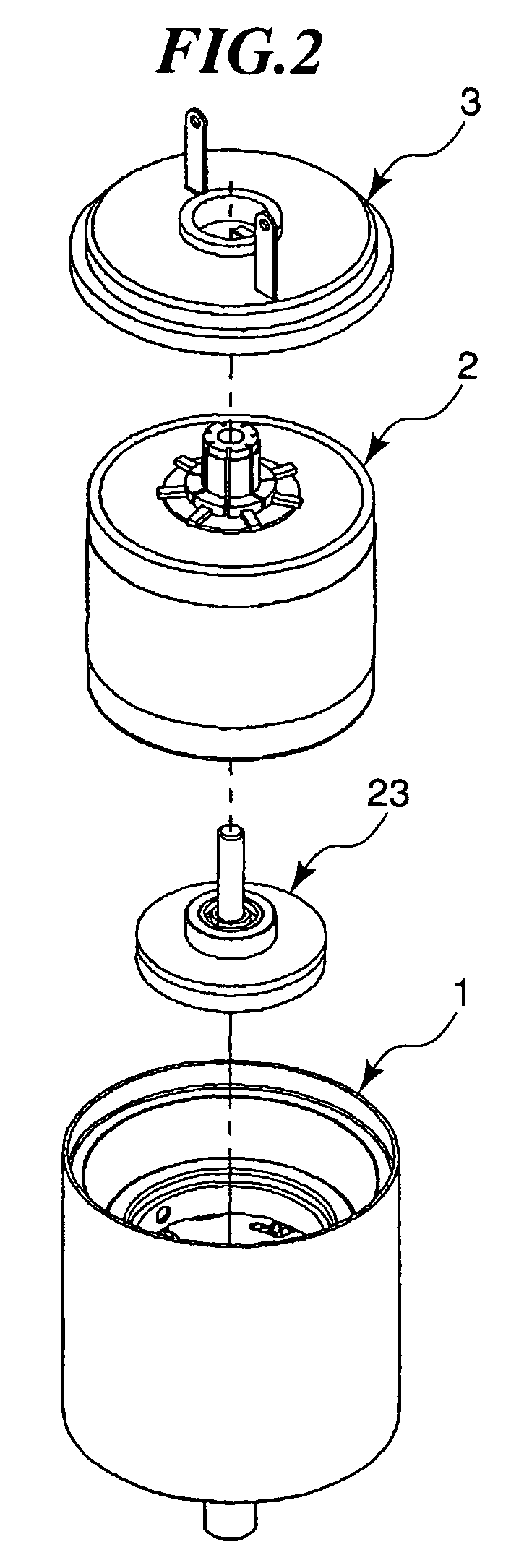

Rheostatic safety braking device having a bipolar resistive assembly with permanent magnet motor

This device is an electric safety brake which is intended for an electric traction vehicle, in particular a rail vehicle comprising: a rotating electromechanical machine (10) having permanent magnets having at least one coil with electric terminals (13, 14, 15), a resistive braking torque production device (22), an electromechanical commutator (20) which is capable of reliably connecting the electric terminals (13, 14, 15) of the machine (10) to the braking torque production device (22).It is characterised in that the braking torque production device (22) comprises, on the one hand, a bipolar assembly (122) of at least one dissipative resistor, the assembly having two single connection terminals and forming a common terminal bipolar electric output load for all the terminals (13, 14, 15) of the mechanism and, on the other hand, means (120) for converting the currents from all the terminals (13, 14, 15) into a single current which is supplied to the two single terminals of the assembly of at least one dissipative resistor, the conversion means (120) having no active power switches.

Owner:ALSTOM TRANSPORT TECH SAS

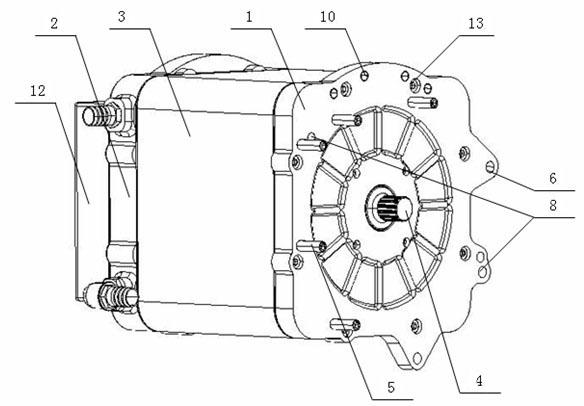

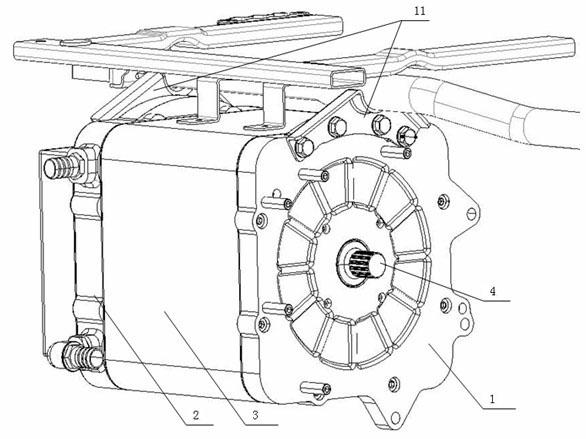

A pure electric vehicle drive motor

ActiveCN102280963ASolve space problemsSolve the installationElectric machinesSupports/enclosures/casingsElectric machineSpatial structure

The invention discloses a driving motor of a pure electric automobile. The driving motor comprises: a motor body, a drive end baring bracket and a commutator end bearing bracket. The drive end baring bracket is in an irregular shape and is arranged on a mounting surface of a reducer. Taking a motor shaft as a center, five studs, which are connected with a flange face of the reducer, are arranged on a half side, and through holes, which are connected with the flange face of the reducer, are respectively arranged on radial outward convex positions of the other half side so as to connect the flange face of the reducer. An upper edge of the drive end baring bracket is wider than the upper edge of the flange face of the reducer, and suspending installing holes are arranged on a part which exceeds the upper edge of the flange face so as to install a suspending support. By using the invention, a space structure in a front cabin can be reasonably used. The structure is compact, reasonable, practical and reliable.

Owner:深蓝汽车科技有限公司

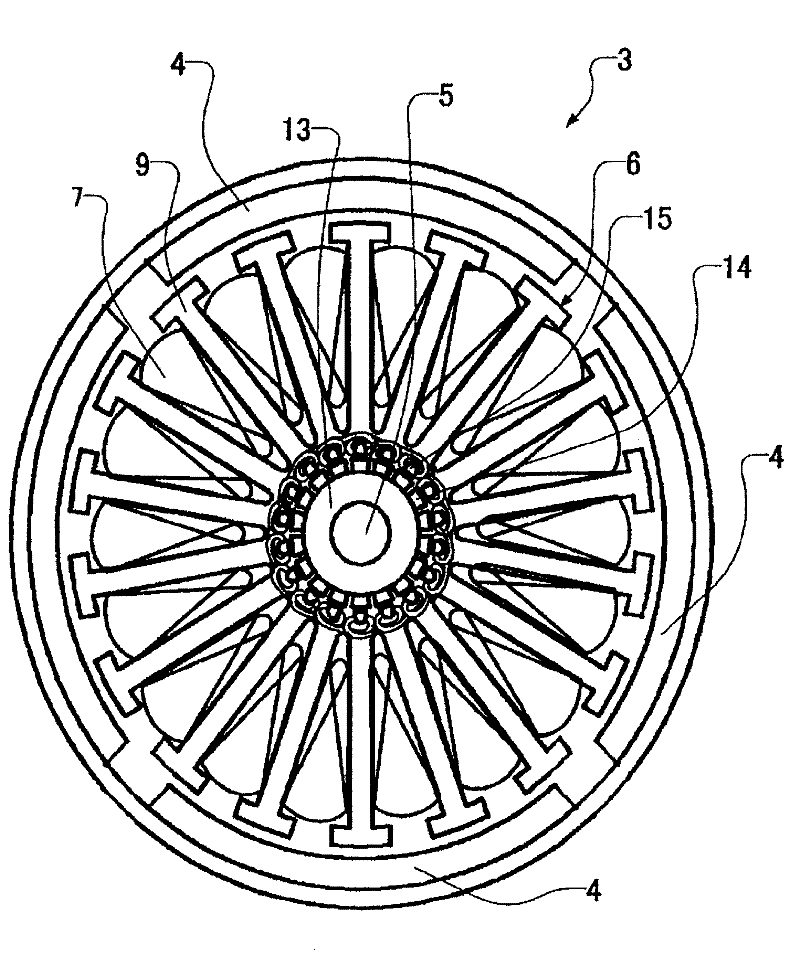

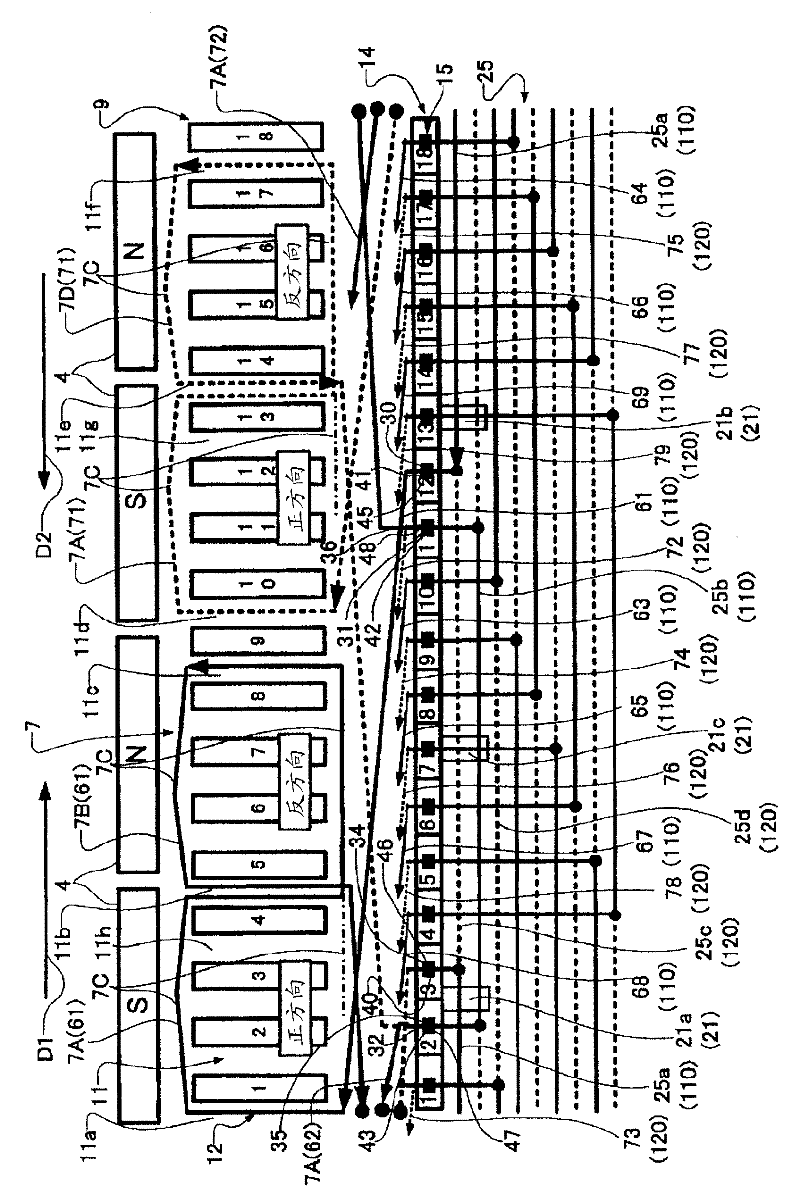

Electric motor

ActiveCN102132475AImprove workabilityReduce torque rippleElectric machinesDC commutatorElectricityEngineering

The present invention relates to an electric motor, wherein magnets (4) have two pairs of poles, the number of teeth (9) is 18, and the commutator has 18 segments (14). Winding wires (12, 25) for forming armature coils (7) are formed by first conductive wires (110) or second conductive wires (120). The winding wire (25) has first coil winding wires (7A) and second coil winding wires (7B). The coil winding wires are each wound around four teeth (9) adjacent to each other. An end section (31) of a second coil winding wire is connected to a segment (14) adjacent to a segment mounted at a position which is point symmetric about a segment to which an end section (30) of a first coil winding wire is connected. The rotational speed of an armature can be changed by switching the conduction of electricity among three brushes. This configuration reduces vibration and operating noise of the electric motor and facilitates mounting of connecting wires and the winding wires.

Owner:MITSUBA CORP

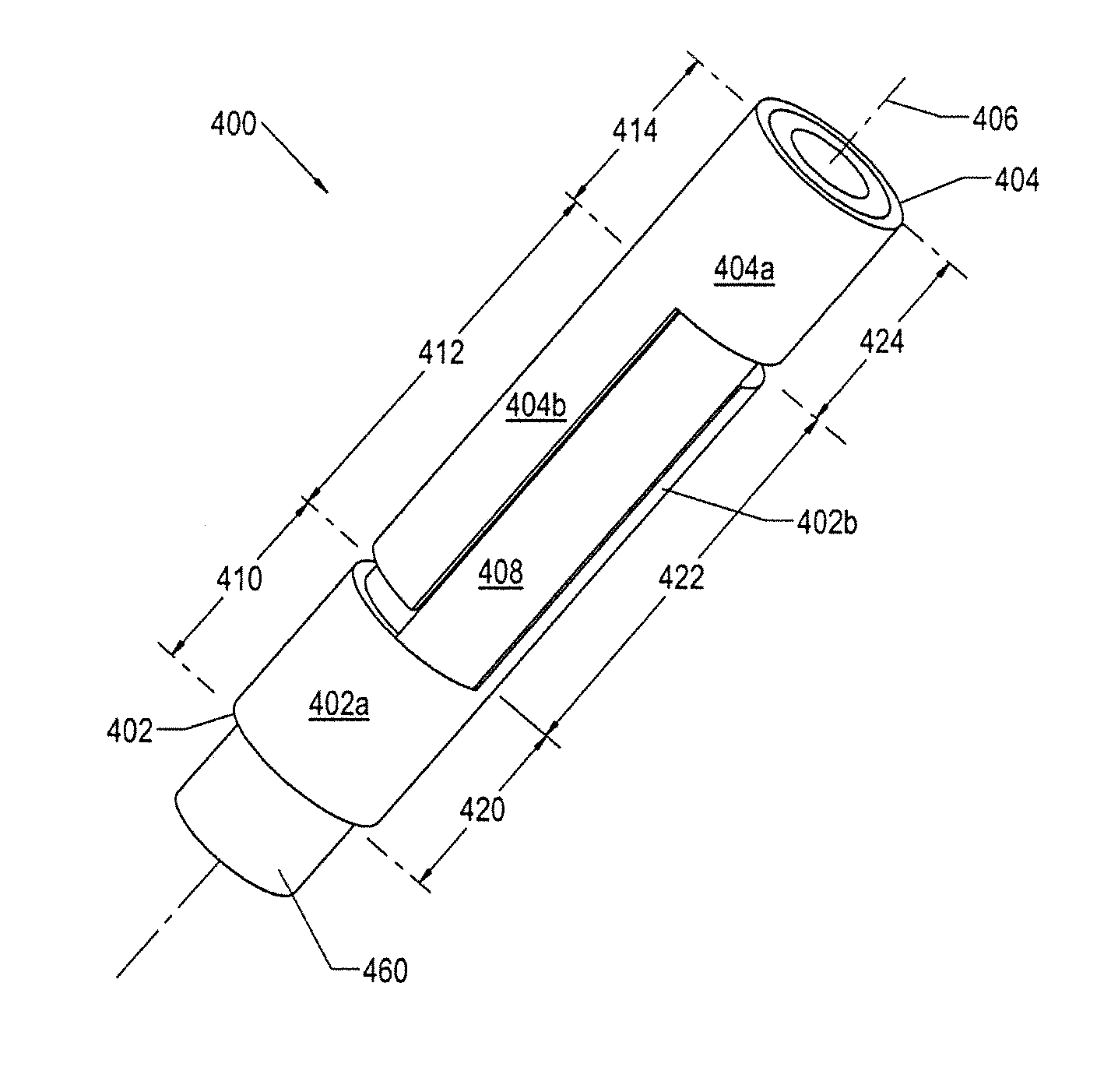

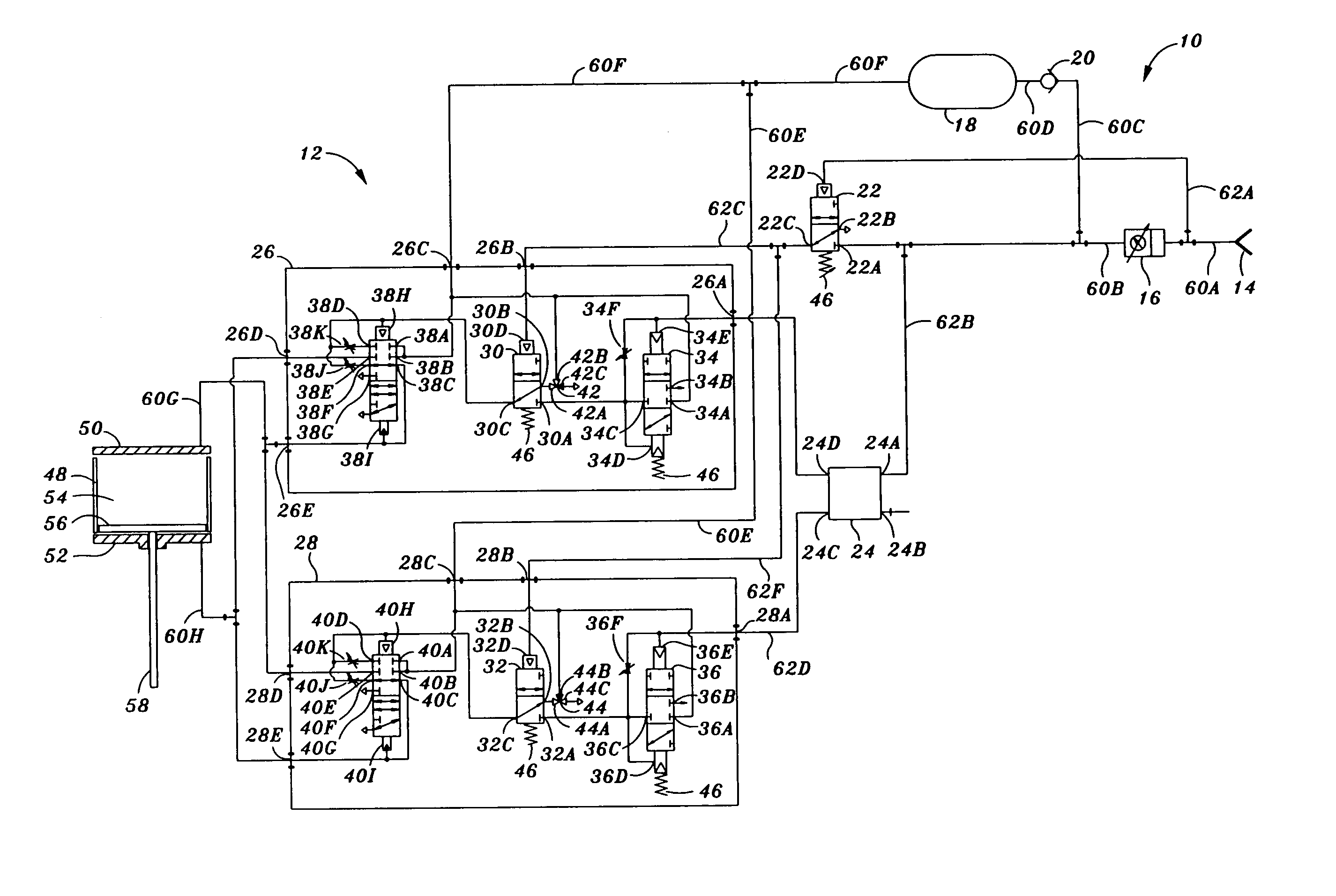

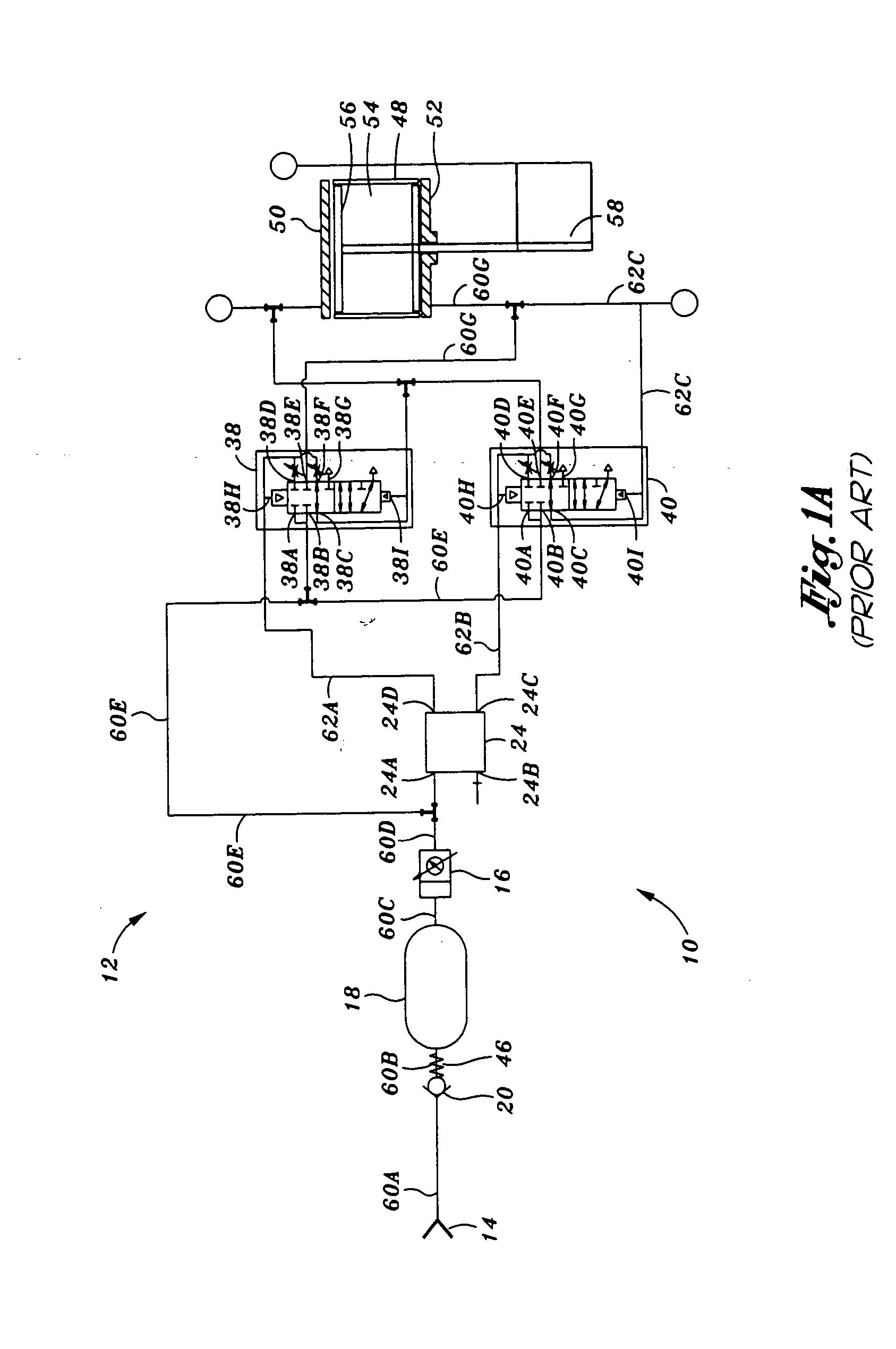

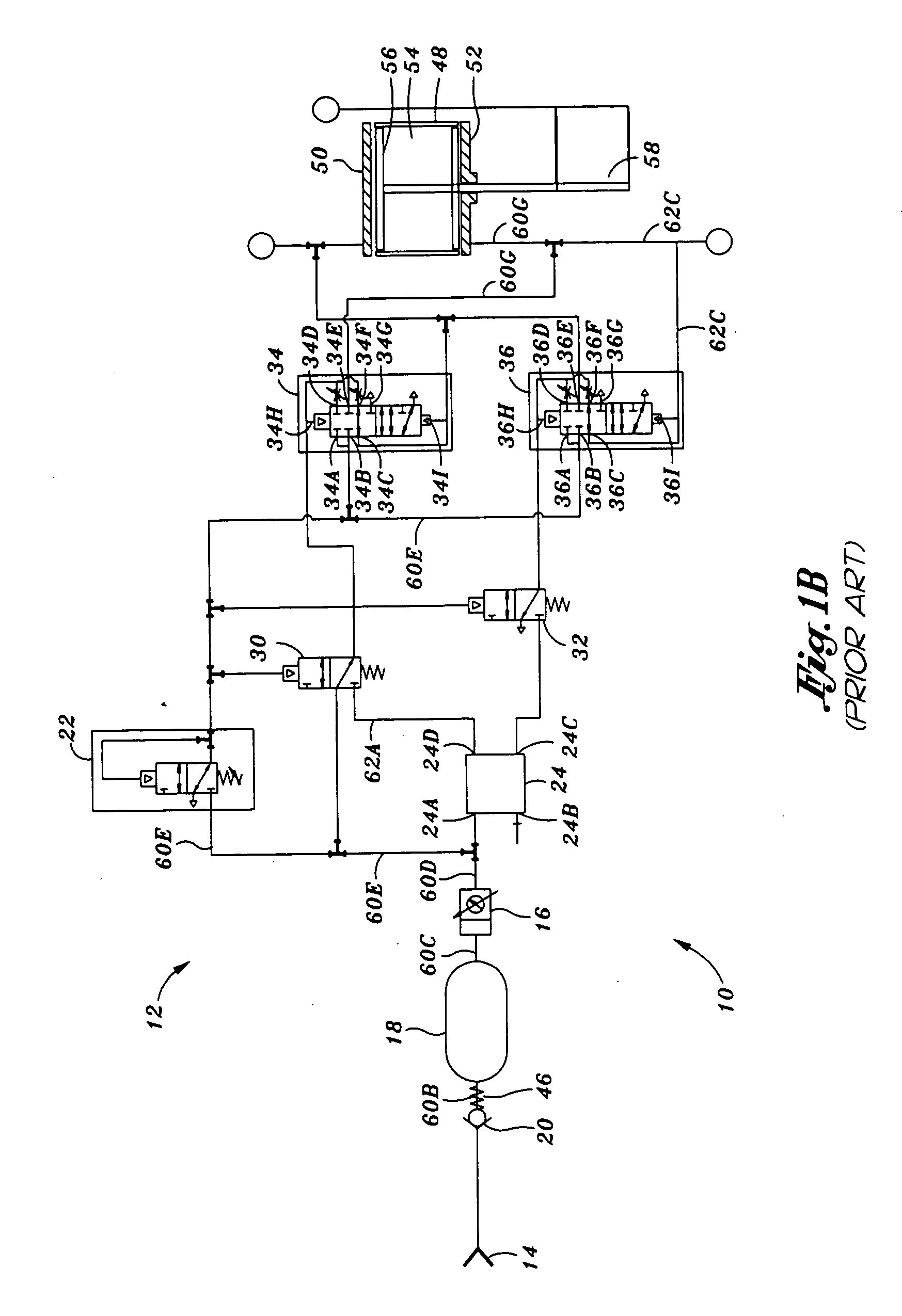

Three-way pneumatic commutator and volume booster

ActiveUS20050115232A1Shorten the lengthLower requirementFluid couplingsServomotor componentsActuatorSafety valve

Disclosed is an actuator system for positioning a piston within a cylinder and comprising a compressed air source, a positioner, and first and second pneumatic valving modules. The first and second pneumatic valving modules respectively comprise first and second volume boosters to amplify the flow of compressed air, first and second derivative boosters to alternately supply and exhaust compressed air into and out of the first and second ends at high flow rates, and first and second commutators to selectively allow the compressed air to flow respectively between the volume boosters and the derivative boosters. A safety valve opens at a predetermined pressurization level such that the first and second commutators may be energized. A volume tank provides compressed air to each one of the first and second pneumatic valving modules upon energization of the first and second commutators.

Owner:CONTROL COMPONENTS INC

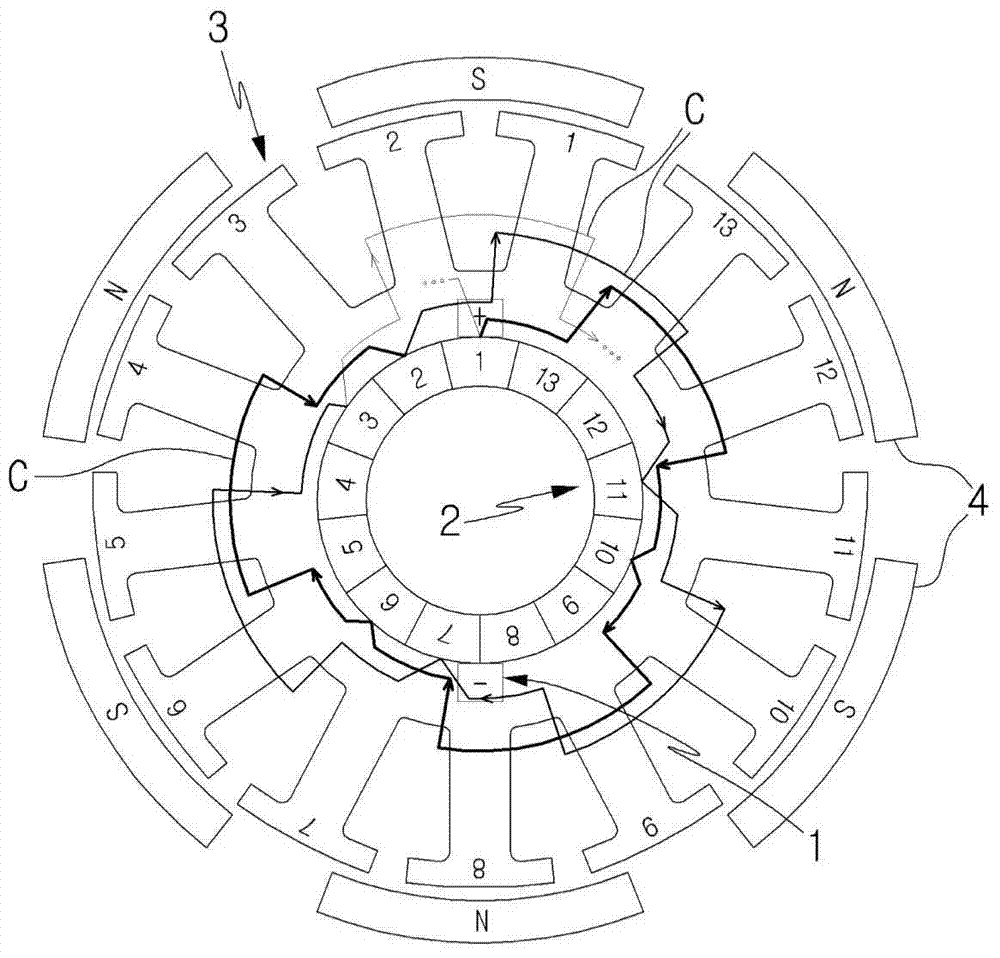

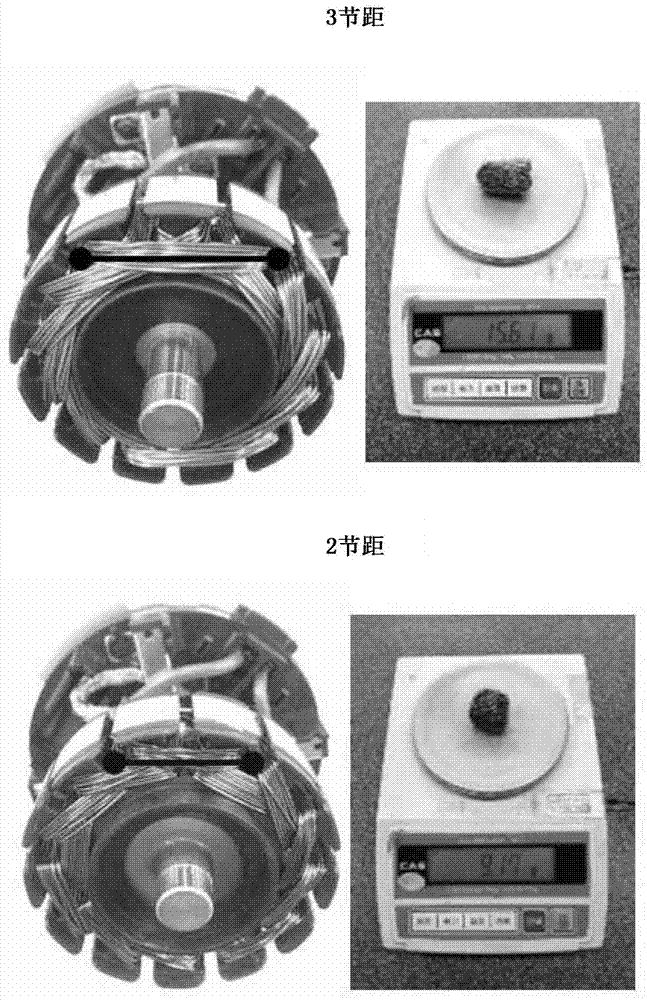

A motor coil winding structure

ActiveCN104518595AMaximize efficiencyReduce copper lossWindings conductor shape/form/constructionPower flowEngineering

The invention aims to provide a motor coil winding structure. After being led in a slot, a coil (C) from each segment of a commutator (2) to an iron core (3) side is led out to a slot with a 2-pitch interval from the slot and is wound on two teeth; in a motor, the coil is wound on the segments of the commutator (2) and the teeth and the slots of the iron core (3), the number of the segments of the commutator (2) of the motor is 13, the number of the teeth and the number of the slots of the iron core are 13, and the number of poles of a magnet (4) which is counterpoised to the outside of the iron core (3) is six; and thus, compared with a winding structure in the prior art which is wound with an interval of more than 3 pitches, the overall winding length and winding amount can be reduced, copper loss generated when a current flows through the coil (C) can be remarkably reduced, even if a coil (C) is wound with the amount less than that of a coil (C) of a motor in the prior art which is wound with an interval of more than 3 pitches set in the iron core (3), efficiency or more than the identity can be achieved, manufacturing cost is remarkably saved while motor efficiency is improved, and the size and the weight of the motor can be miniaturized.

Owner:HYO SEONG ELECTRIC

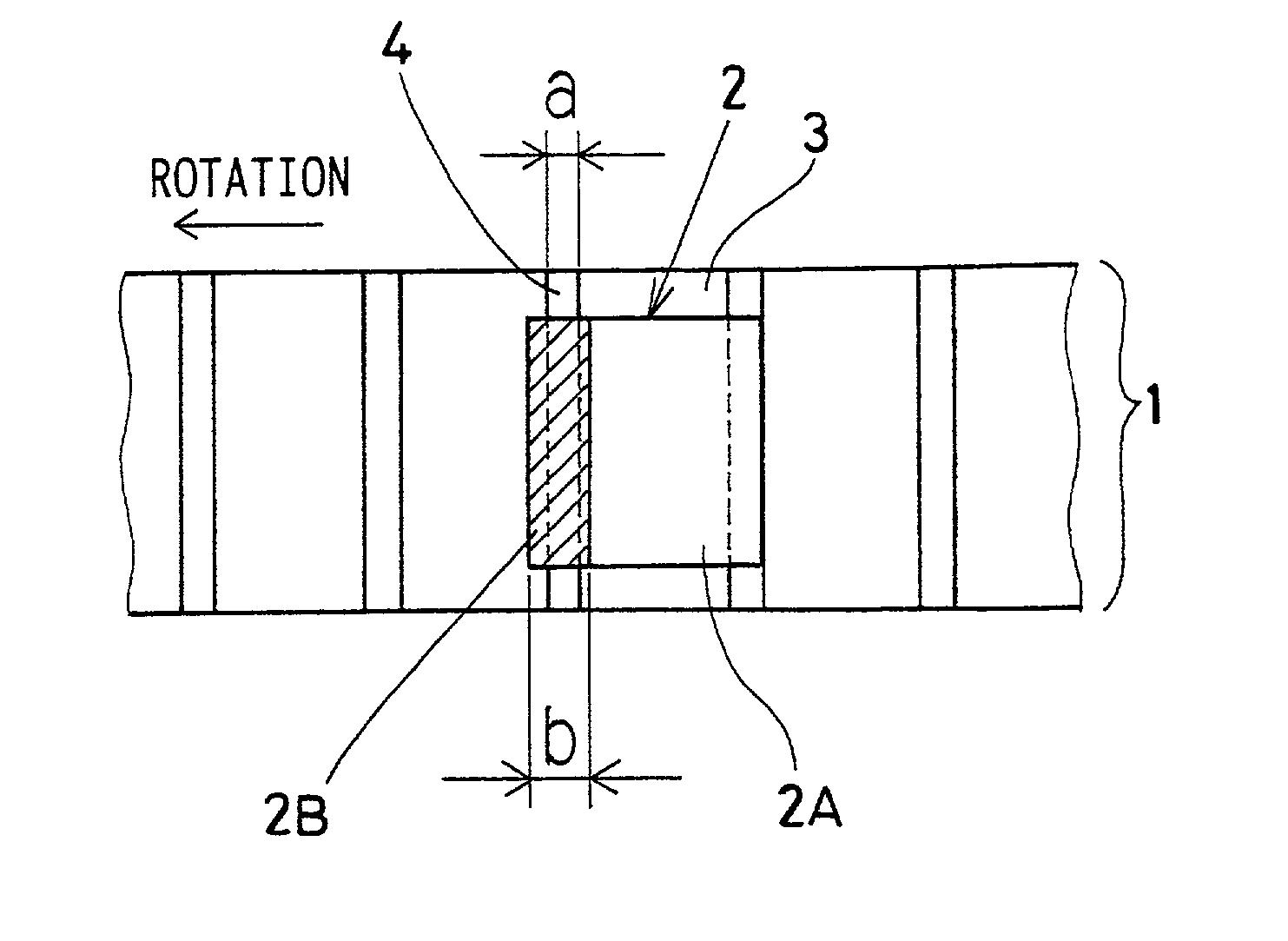

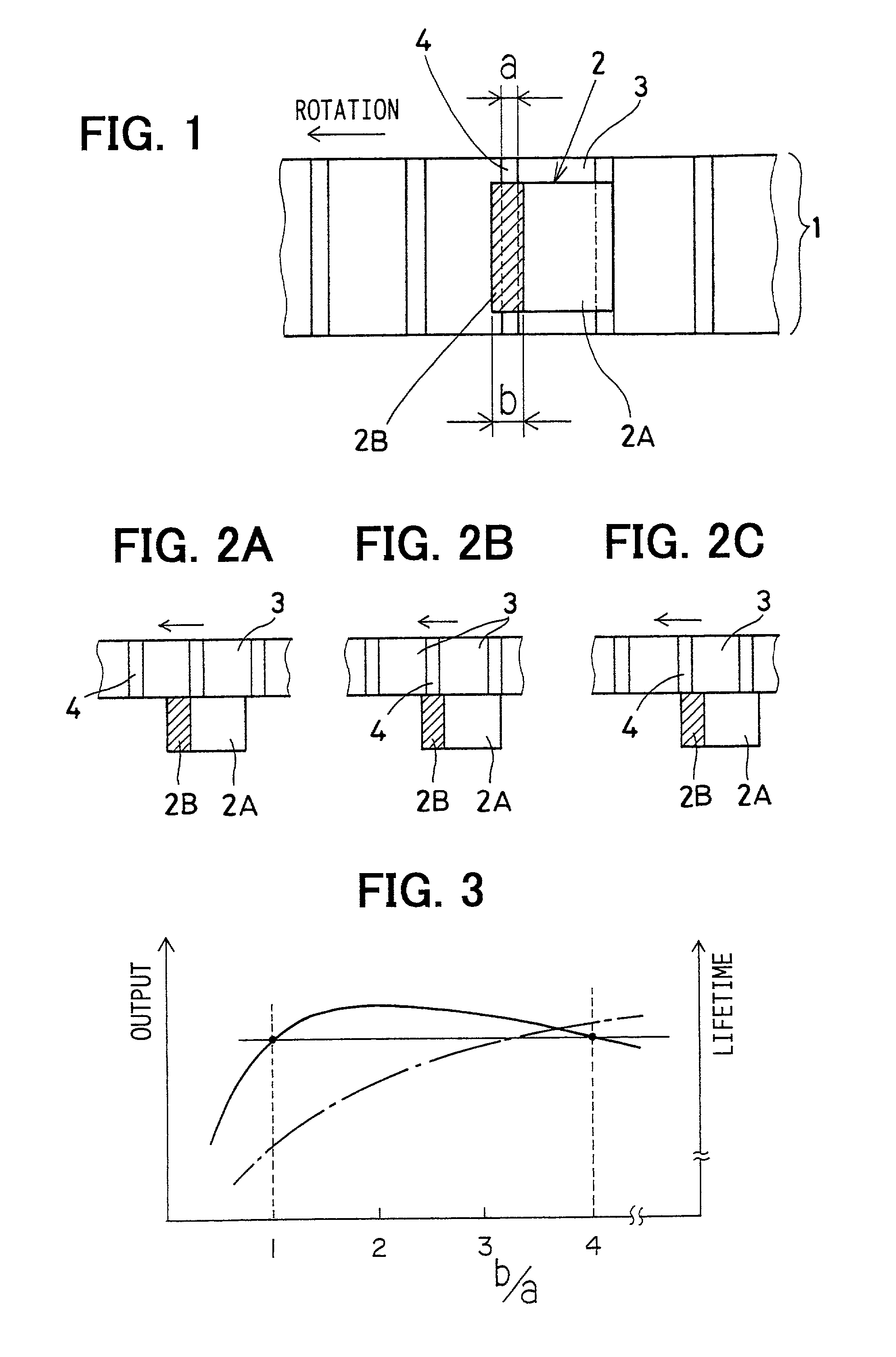

Rotary electric machine with stacked brush

A rotary electric machine includes a stacked brush, where low-resistance and high-resistance brush layers are disposed at the front and rear end sides in the rotational direction of a commutator, respectively. When the insulation gap between the neighboring segments of a commutator is "a" and the width of the high-resistance brush layer is "b", "a" and "b" are determined to satisfy a<b and b / a<4 to reduce sparks and improve commutation property. In order to reduce spark generation at the brush front end, especially, when the circumferential width of the segment is "c" and the width of the low-resistance brush layer is "d", "a" to "d" are determined to satisfy b+d>2xa+c, d>b, a<b and d<a+c.

Owner:DENSO CORP

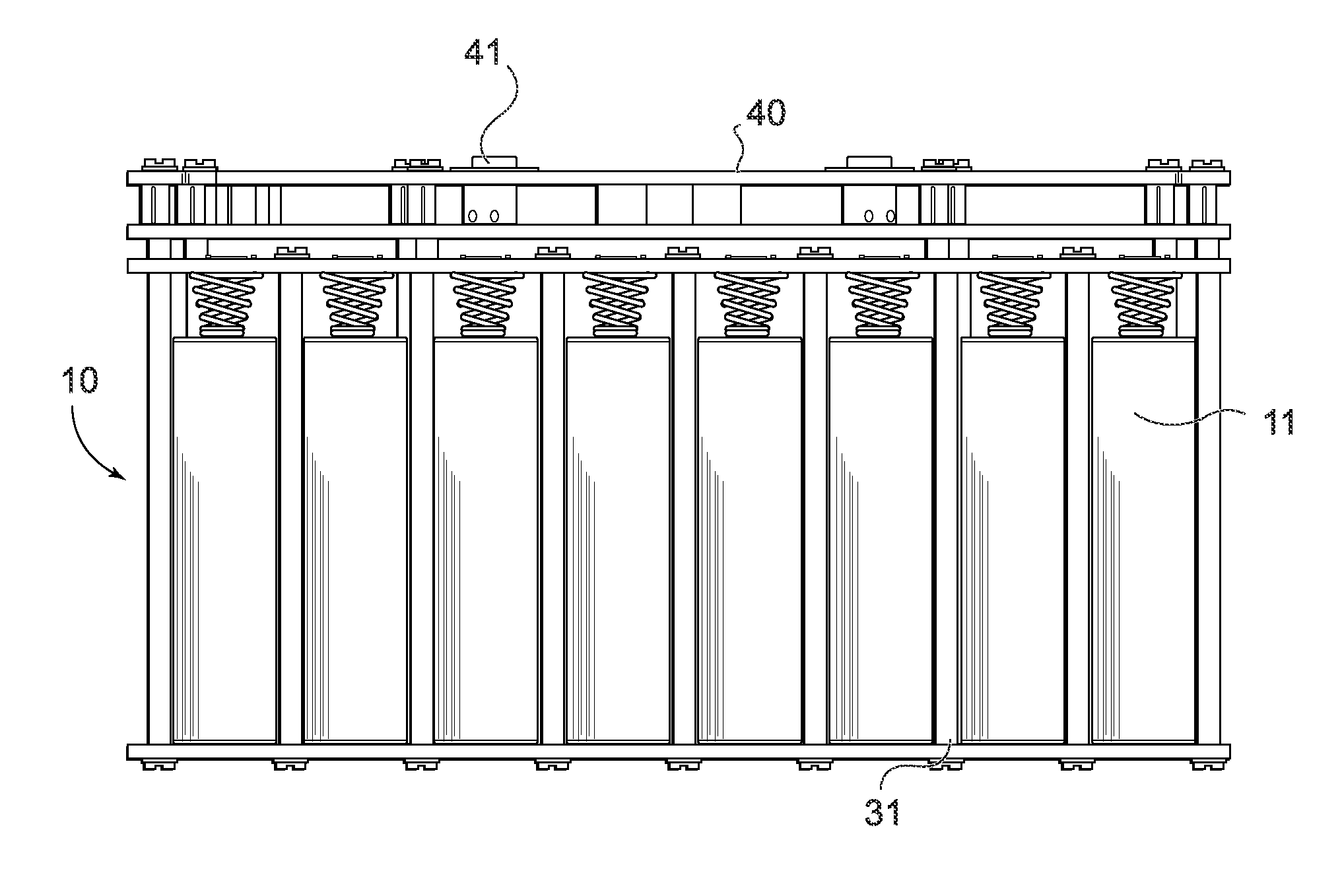

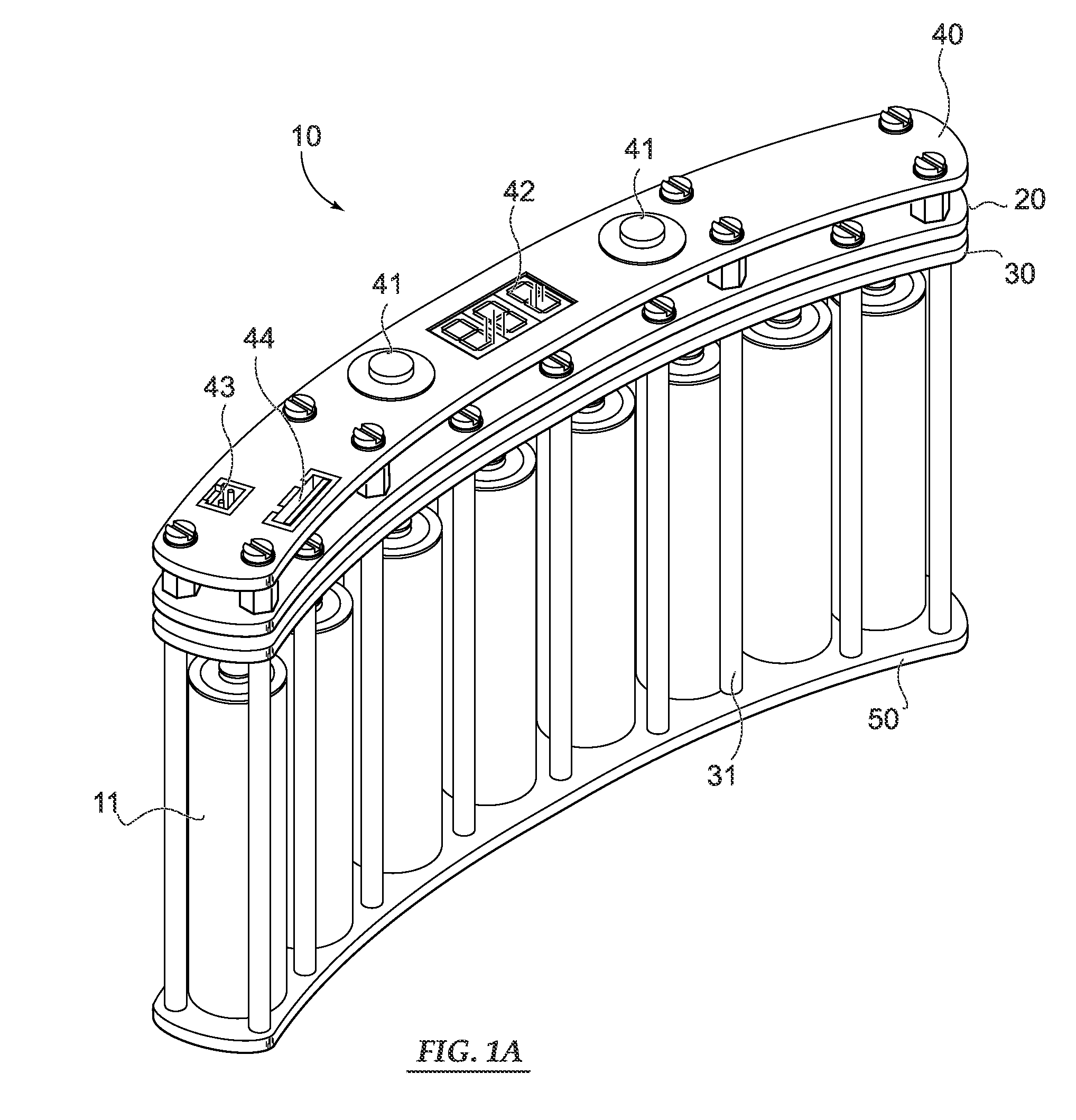

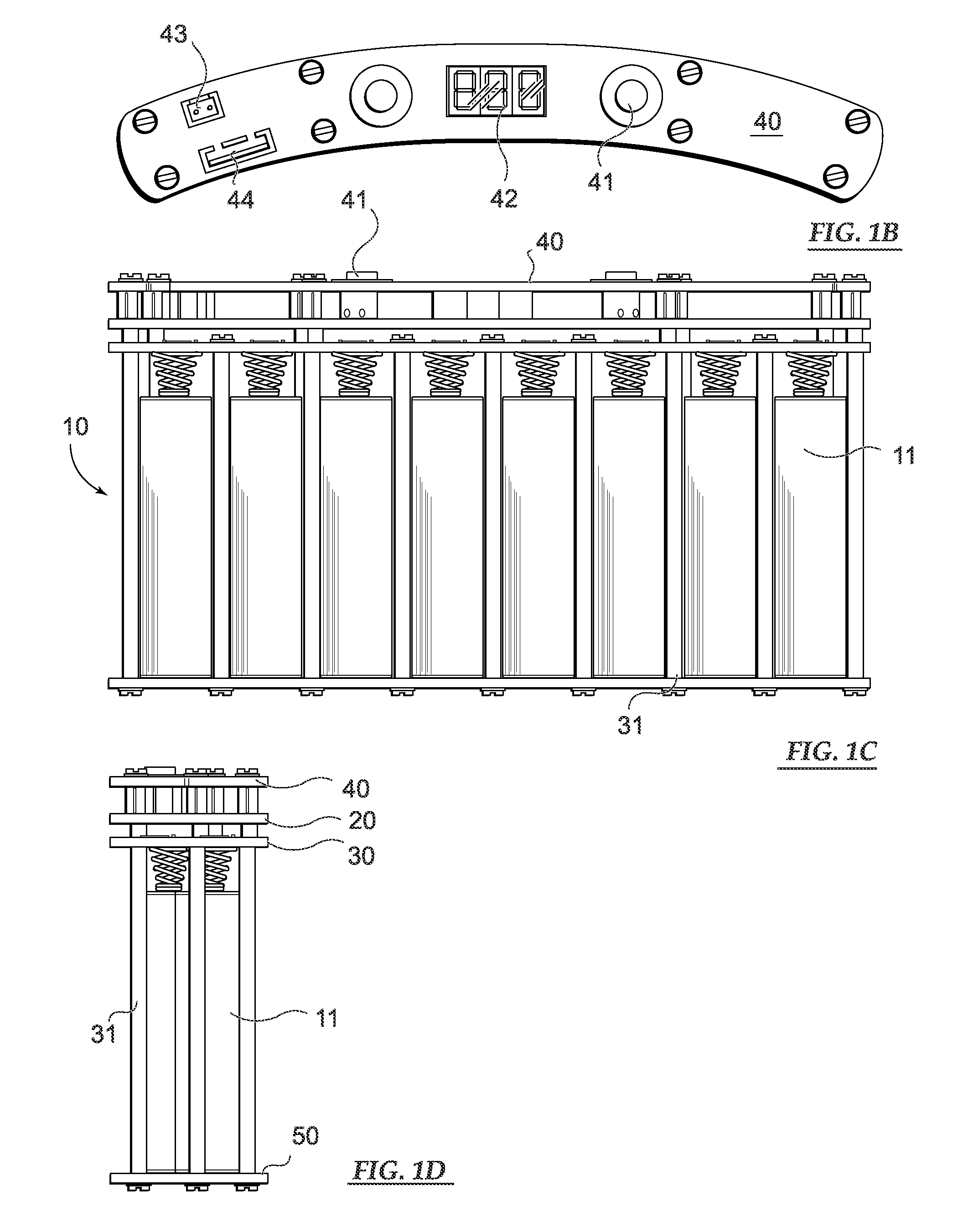

Ultra power supply

InactiveUS20120091115A1Increase supplyCharge equalisation circuitCircuit monitoring/indicationMicrocontrollerElectrical battery

An improved portable battery system having a plurality of accumulator batteries designed with circuit features to prolong life through cell balancing is disclosed. Further, the portable battery system is designed to be a lighter-weight alternative by use of individual field operators, for example, in colder climates configured to a heated garment. Additionally, the power supply includes a microcontroller that provides control and monitoring of accumulator properties. A power supply commutator is provided to aid efficient discharge of accumulators.

Owner:INNOVATIVE WIRELESS TECH

Hollow cup motor commutator polishing and coil resistance measurement all-in-one machine

ActiveCN102324808AReduce labor intensityImprove work efficiencyResistance/reactance/impedenceControl devices for conveyorsAutomatic controlEngineering

The invention provides a hollow cup motor commutator polishing and coil resistance measurement all-in-one machine. A commutator and a coil are fixedly provided on a transport mold together. The all-in-one machine comprises a base, and a charging mechanism, a clamping mechanism, a rotary mechanism, a commutator polishing mechanism, a coil resistance measurement mechanism, a discharging mechanism, and a PLC control mechanism which are installed on the base. The charging mechanism conveys the commutator, the coil and the transport mold to the clamping mechanism. The clamping mechanism picks up the commutator, the coil and the transport mold and places them on the rotary mechanism. The rotary mechanism conveys the commutator, the coil and the transport mold to the commutator polishing mechanism and the coil resistance measurement mechanism in succession. The commutator polishing mechanism carries out polishing processing on the commutator. The coil resistance measurement mechanism detectsresistance of the coil, and picks out a defective product. The discharging mechanism outputs the commutator, the coil, and the transport mold. The PLC control mechanism carries out automatic control on the above mechanism. Accordingly, work efficiency and a product qualified rate are greatly raised.

Owner:SHENZHEN SHUANGHUAN QX MOTOR

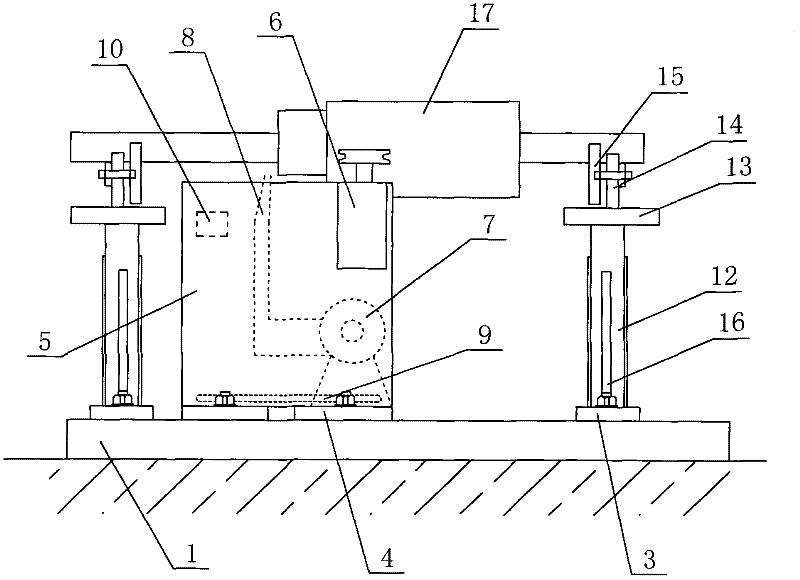

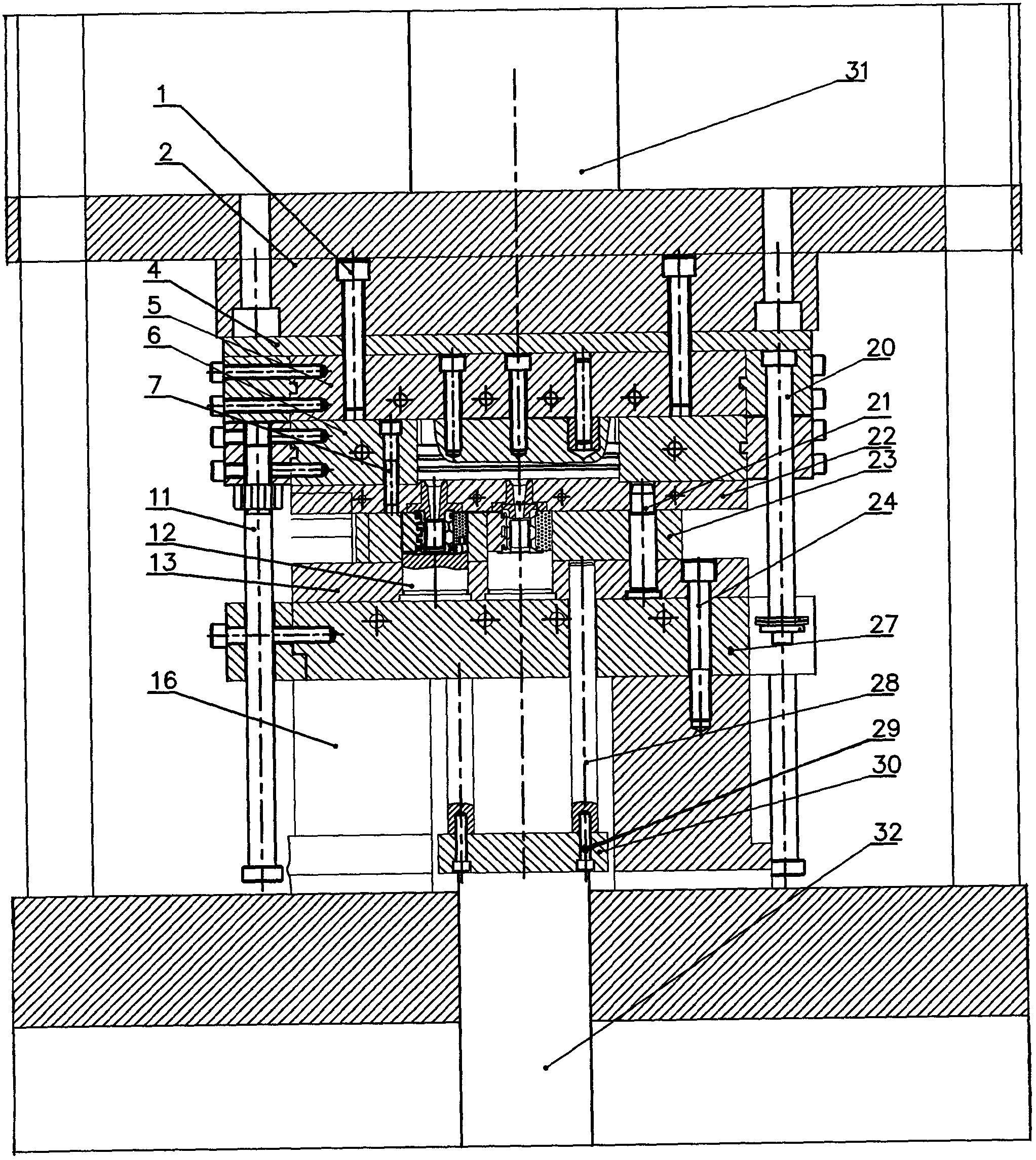

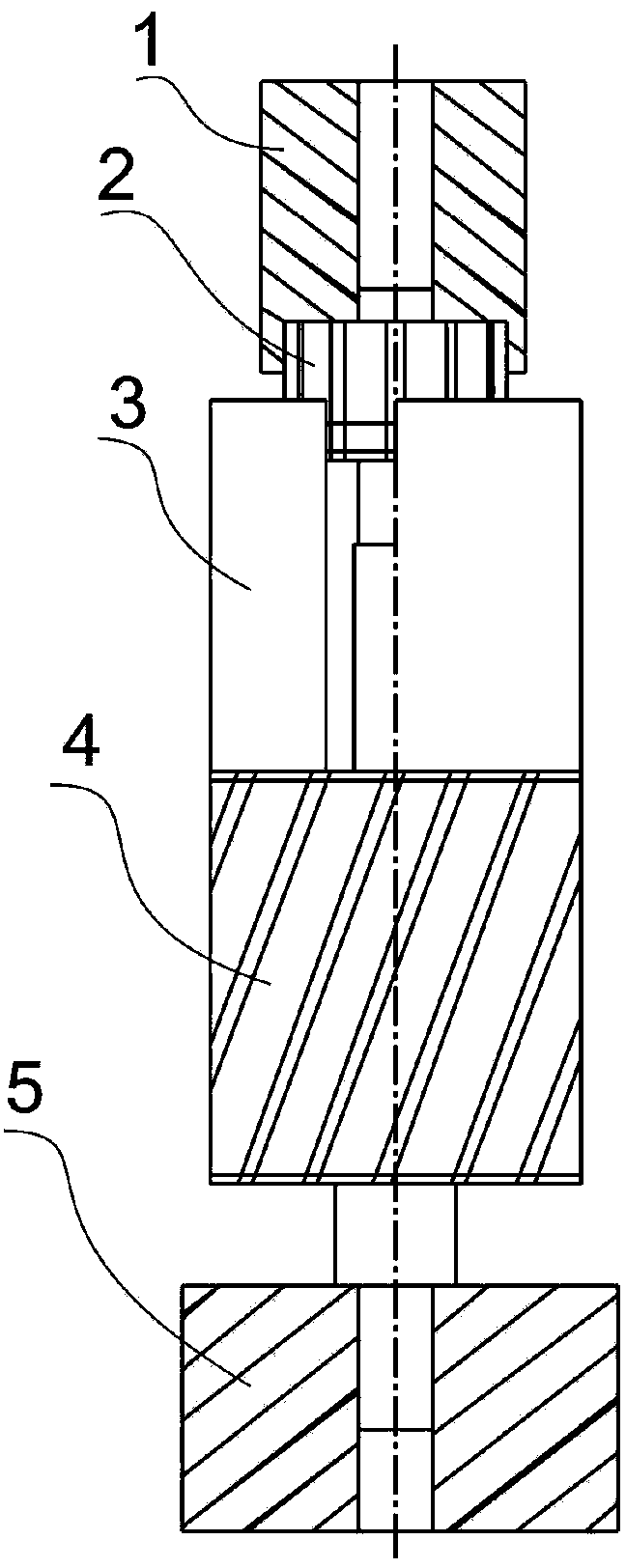

Commutator pressing assembling device of skewed slot iron core rotor and pressing assembling method thereof

ActiveCN103414289AStable slipReduce reworkManufacturing dynamo-electric machinesEngineeringMechanical engineering

The invention discloses a commutator pressing assembling device of a skewed slot iron core rotor and a pressing assembling method thereof. The pressing assembling device comprises a pressing assembling base, a positioning column, a guide column, a positioning ring, a spring and a pressing head. The pressing head is positioned above the positioning column. The positioning column and the guide column are arranged on the pressing assembling base respectively. The guide column is provided with a positioning sleeve which is provided with a cylindrical pin for fixing a skewed slot iron core rotor. The positioning ring is fixed on the pressing assembling base through a positioning button B. The spring is sleeved on the guide column and is placed between the positioning sleeve and the pressing assembling base. The pressing assembling method comprises the steps of the combination of the pressing assembling device and a pressing assembling operation, and the commutator pressing assembling operation is carried out combined with the pressing assembling device and a pneumatic press with adjustable pressure. According to the device and the method, through adopting a high precision mechanical conversion link, the accurate alignment of a commutator lower notch groove center with a skewed slot iron core groove center or tooth center is realized, and the production efficiency and product qualification rate are greatly improved.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

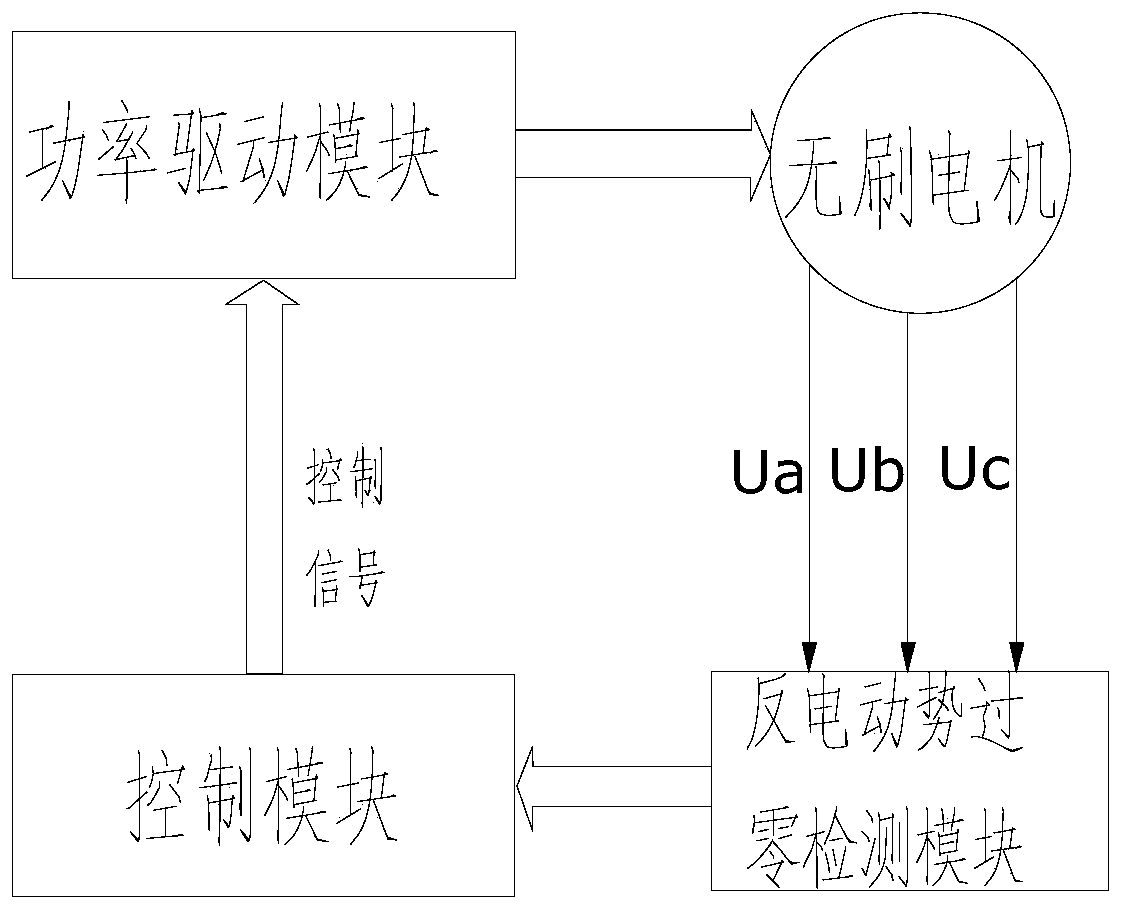

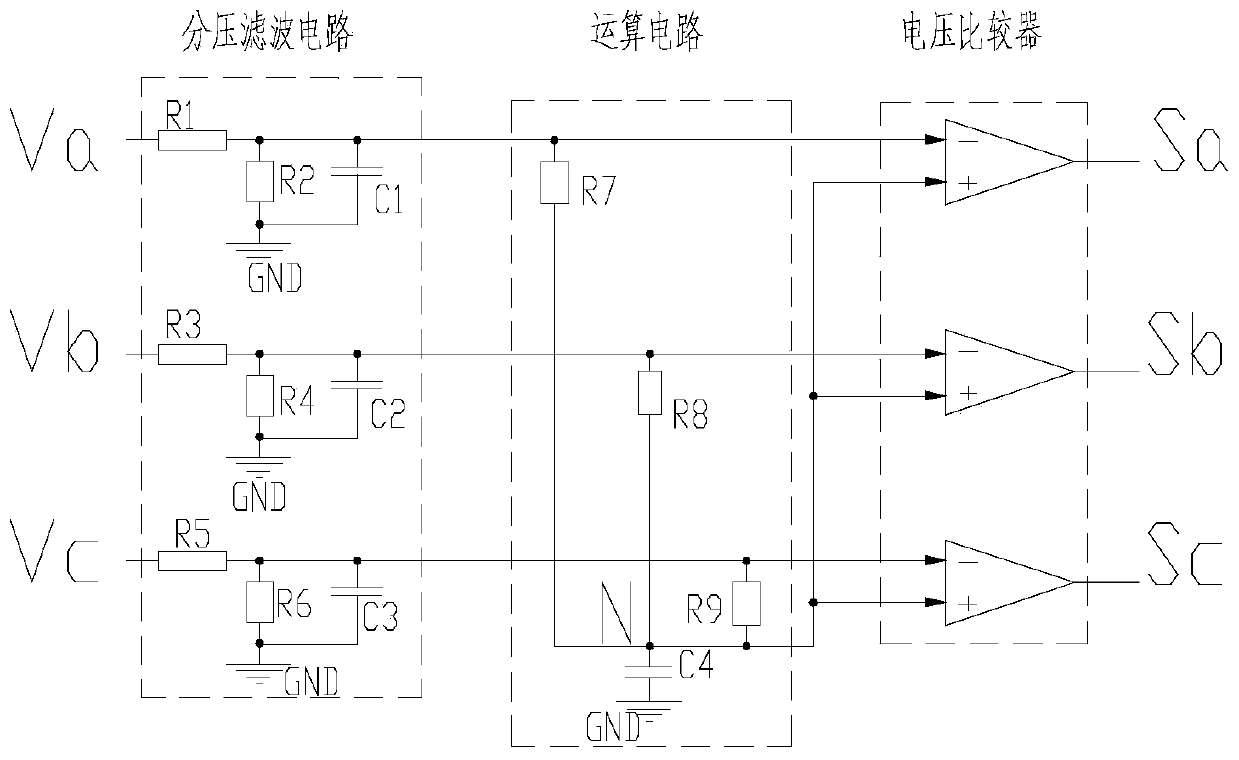

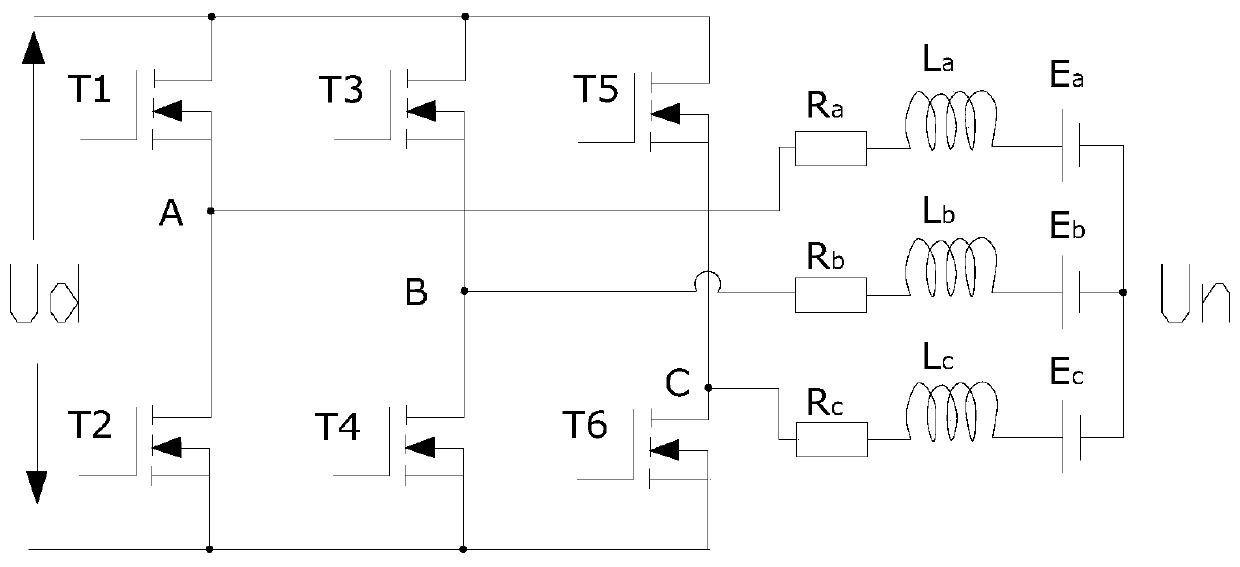

Zero-crossing point commutator and zero-crossing point commutation control method for permanent magnet brushless DC motor

InactiveCN109921696AImprove energy conversion efficiencyImprove environmental adaptabilityCommutation monitoringHigh energyControl signal

The invention discloses a zero-crossing point commutator for a permanent magnet brushless DC motor. The zero-crossing point commutator for the permanent magnet brushless DC motor comprises a counter electromotive force detection module, a control module and a power drive module which are electrically connected in sequence, wherein the counter electromotive force detection module is used to acquirestator voltage information of the permanent magnet brushless DC motor, so as to detect a counter electromotive force zero-crossing signal; the control module is used to determine the optimum commutation point according to the counter electromotive force zero-crossing signal, and output a PWM control signal to the power drive module; and the power drive module is used to control the commutation ofthe permanent magnet brushless DC motor according to the PWM control signal. The zero-crossing point commutator for the permanent magnet brushless DC motor disclosed by the invention has the advantages that a modular design is adopted, so that the zero-crossing point commutator achieves a simple structure, and can be independently packaged and directly installed and applied for motor control; andthrough a sensorless control mode, the motor can achieve high energy conversion efficiency, high environmental adaptability, higher reliability and lower cost.

Owner:湖南长高思瑞自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com