Patents

Literature

46849results about How to "Quality assurance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

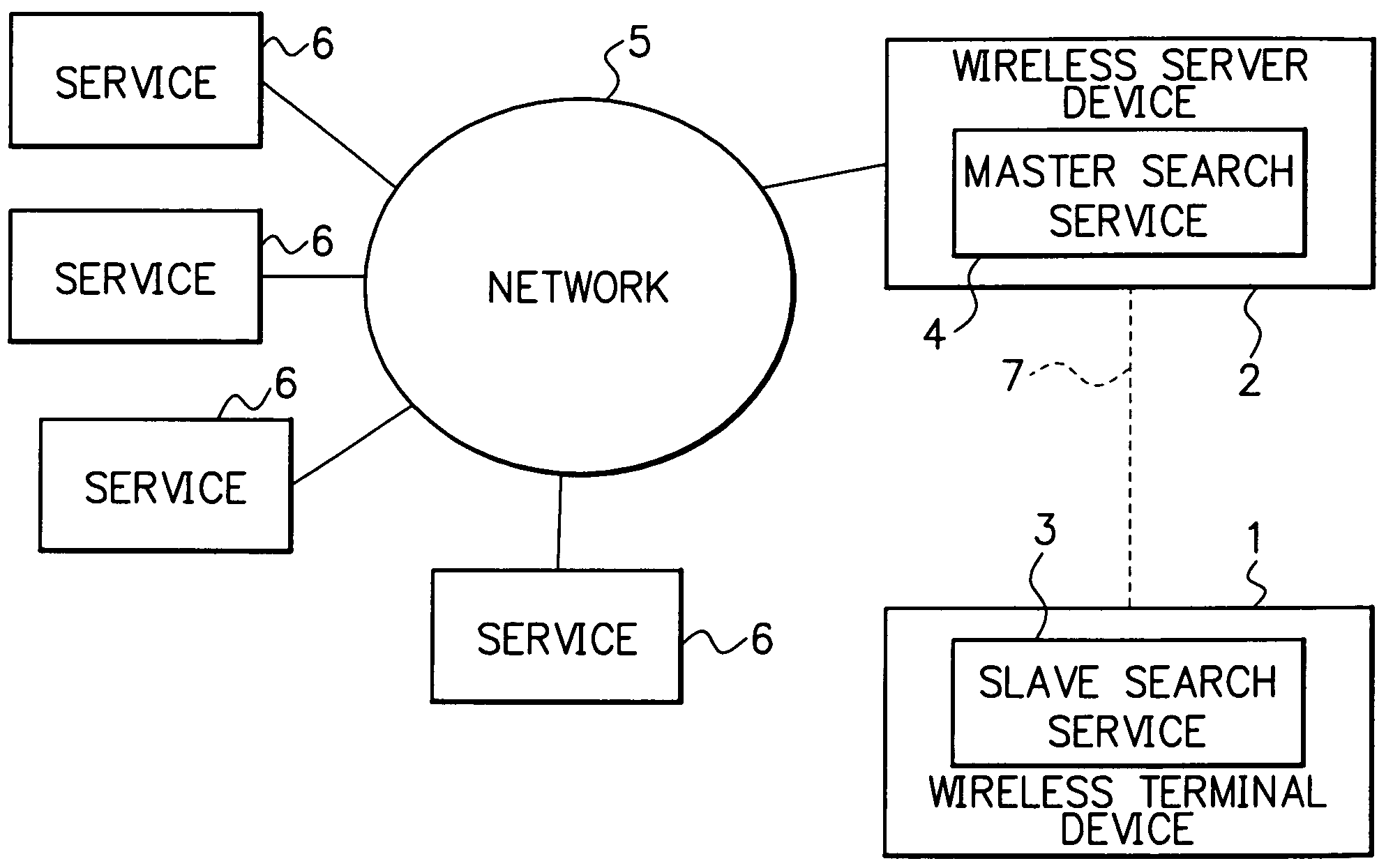

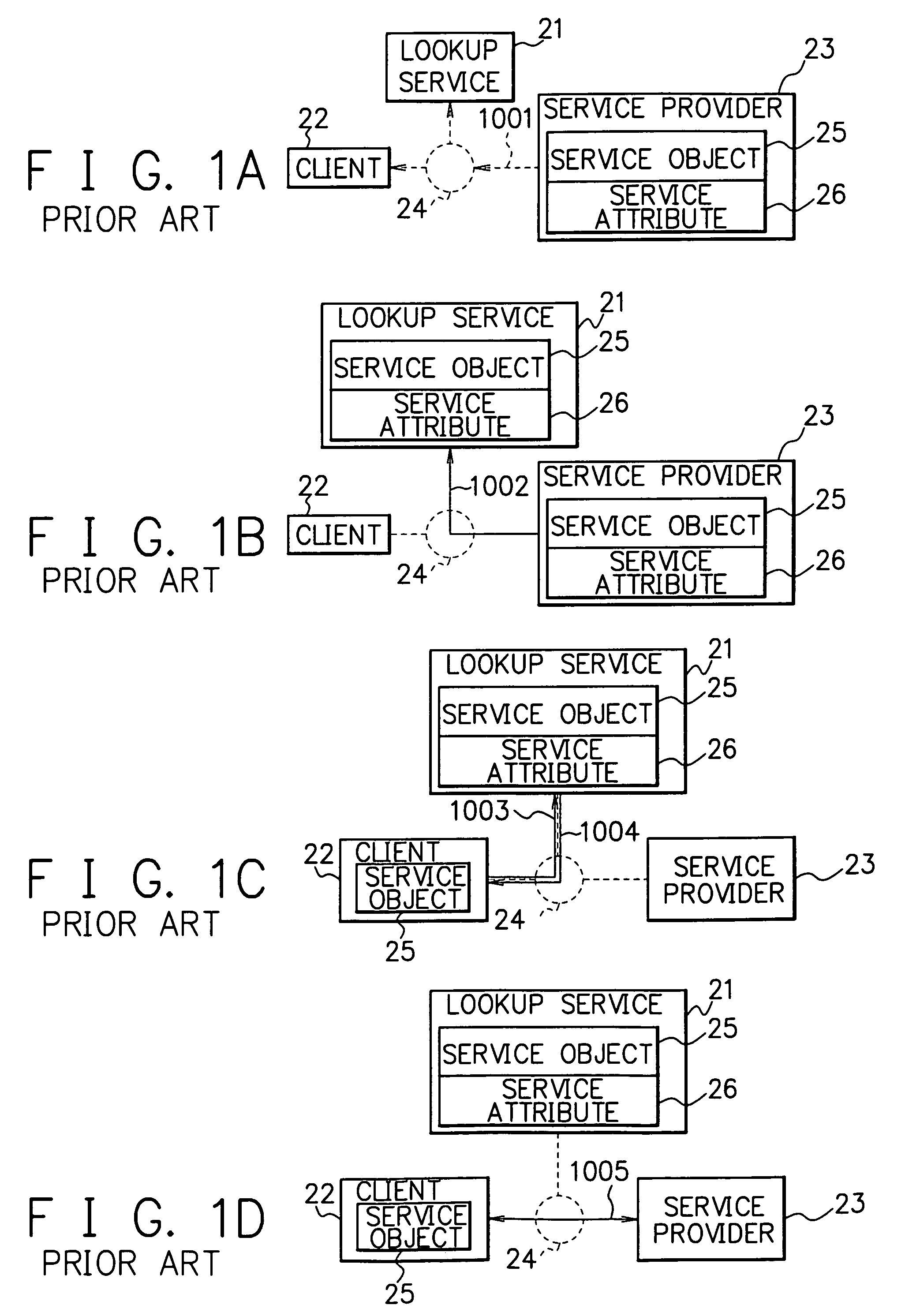

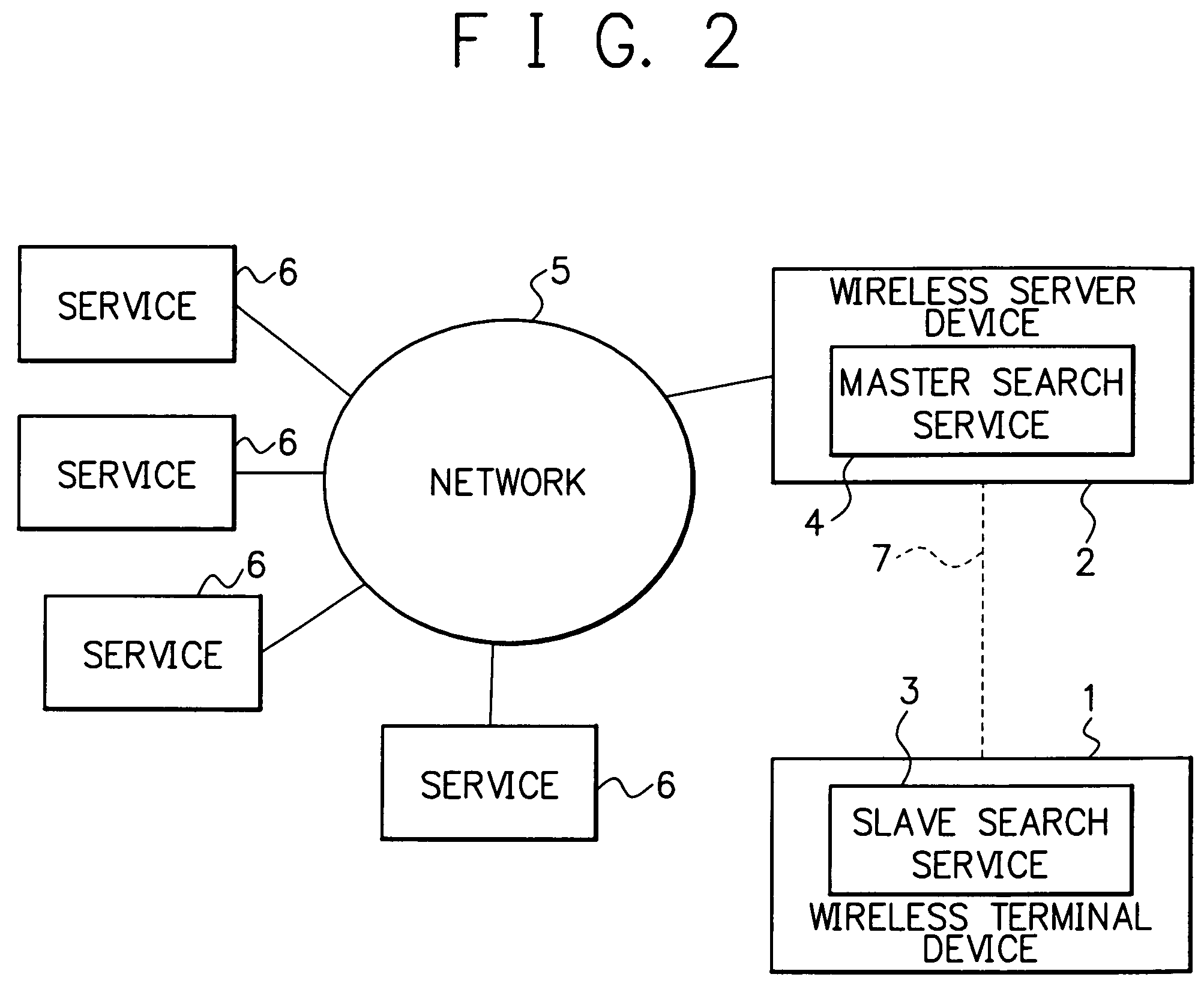

Service searching system

InactiveUS7139569B2Improve service rateReduce communication data volumeSpecial service for subscribersDigital computer detailsTerminal equipmentServer appliance

A service searching system for searching a service in a distributed system comprises a wireless server device and a wireless terminal device. The wireless server device is connected to a network and implements a master search service. On the other hand, the wireless terminal device implements a slave search service, and is capable of communicating with the server by wireless and utilizing the master search service. Besides, the wireless terminal device comprises a storage means that caches service objects obtained through the master search service. In addition, in searching the slave search service for a service, the wireless terminal device begins by searching the service objects cached in the storage means. In the case where the service is not detected, the wireless terminal device searches the master search service. The service objects are cached by being related to priority data. Thereby, there is provided a service searching system comprising a wireless terminal device, which is intended to search for a service in a distributed system in which a range of services are distributed in a network, wherein it is possible to cut down a service-searching time and costs, and further, it is possible to cut down communication interruptions by noise etc. in the wireless communication section compared to the conventional one.

Owner:NEC CORP

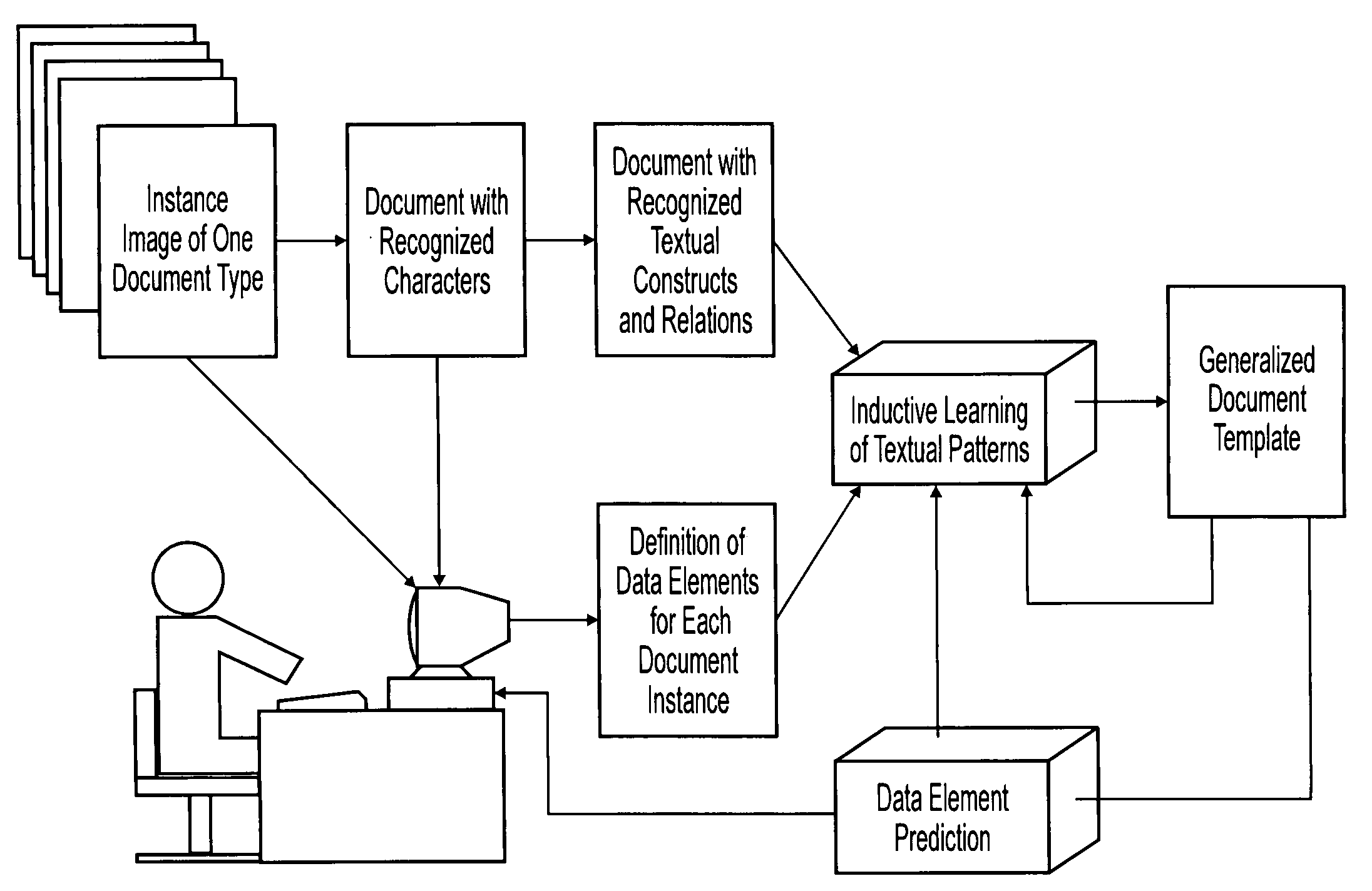

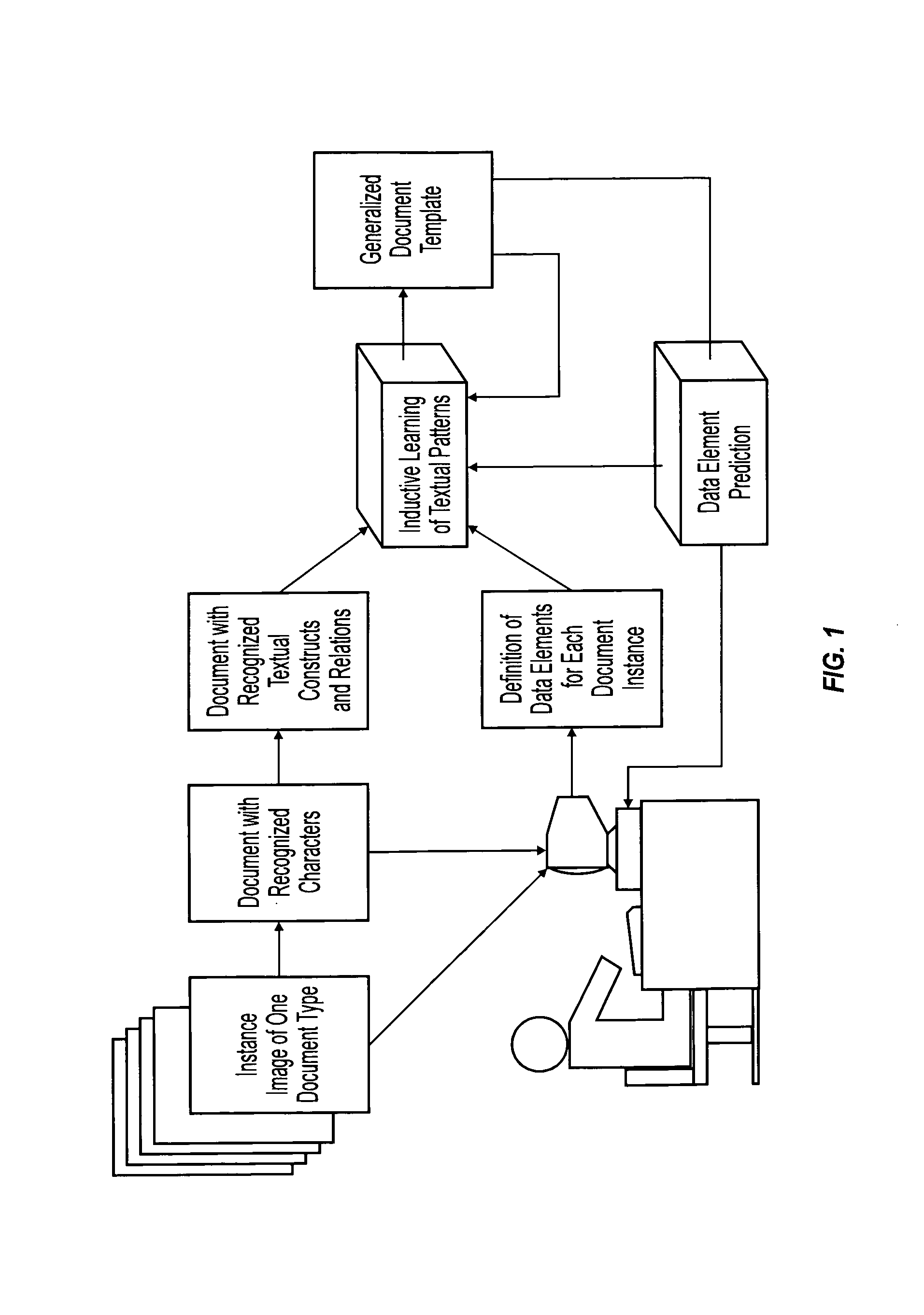

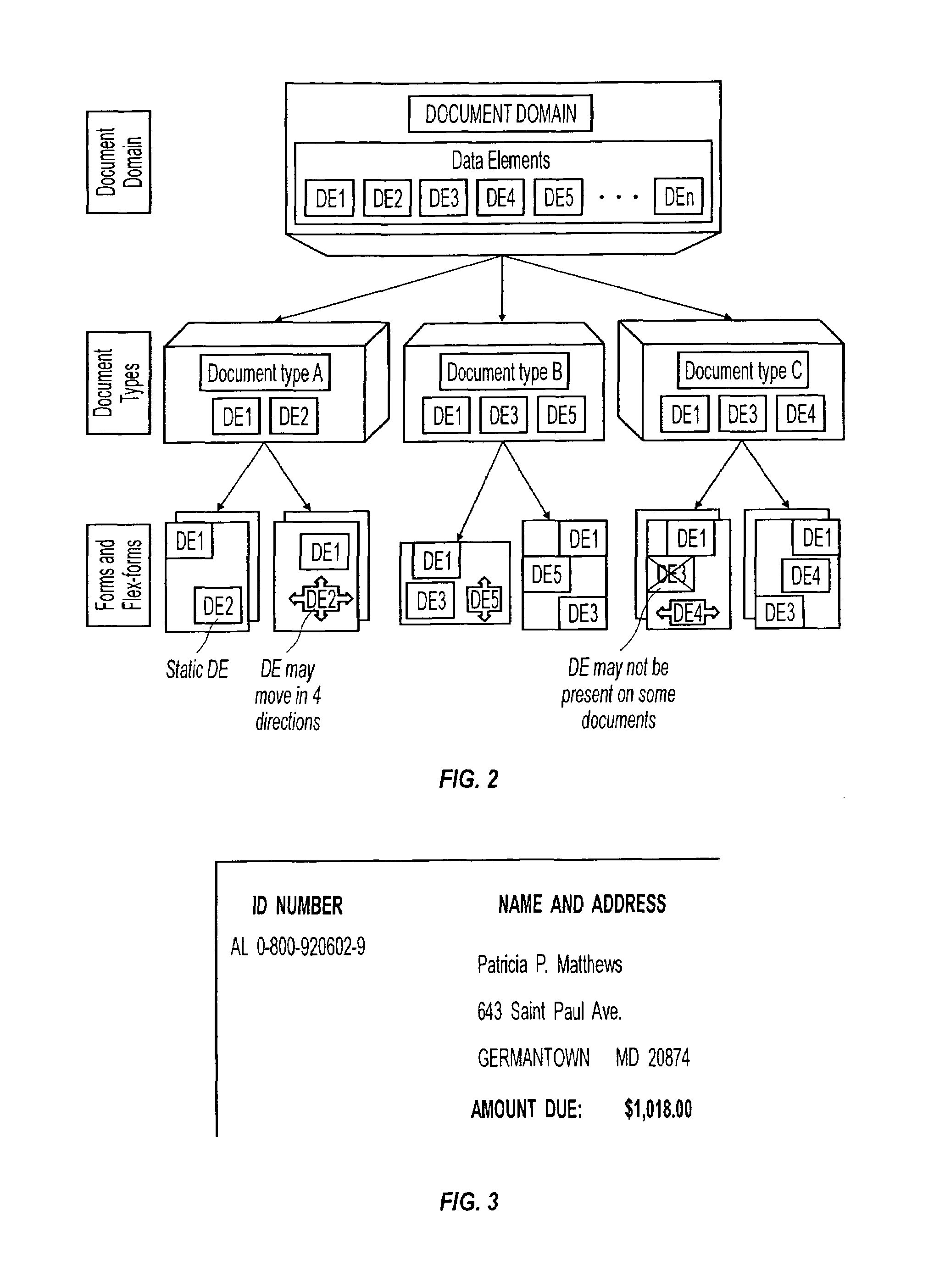

Machine learning of document templates for data extraction

InactiveUS7149347B1Quality assuranceMinimize effortCharacter recognitionData ingestionDocument preparation

The present system can perform machine learning of prototypical descriptions of data elements for extraction from machine-readable documents. Document templates are created from sets of training documents that can be used to extract data from form documents, such as: fill-in forms used for taxes; flex-form documents having many variants, such as bills of lading or insurance notifications; and some context-form documents having a description or graphic indicator in proximity to a data element. In response to training documents, the system performs an inductive reasoning process to generalize a document template so that the location of data elements can be predicted for the training examples. The automatically generated document template can then be used to extract data elements from a wide variety of form documents.

Owner:LEIDOS

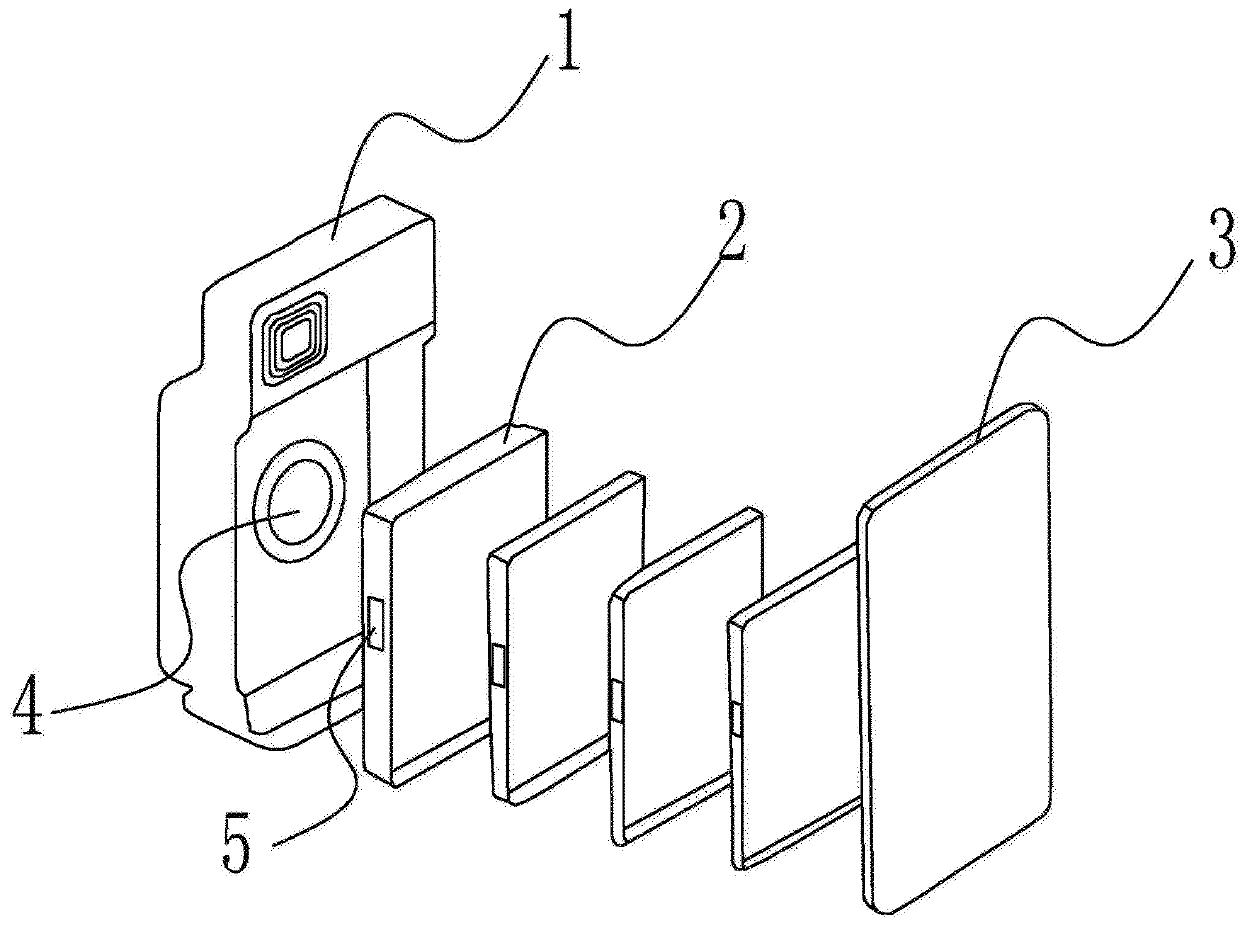

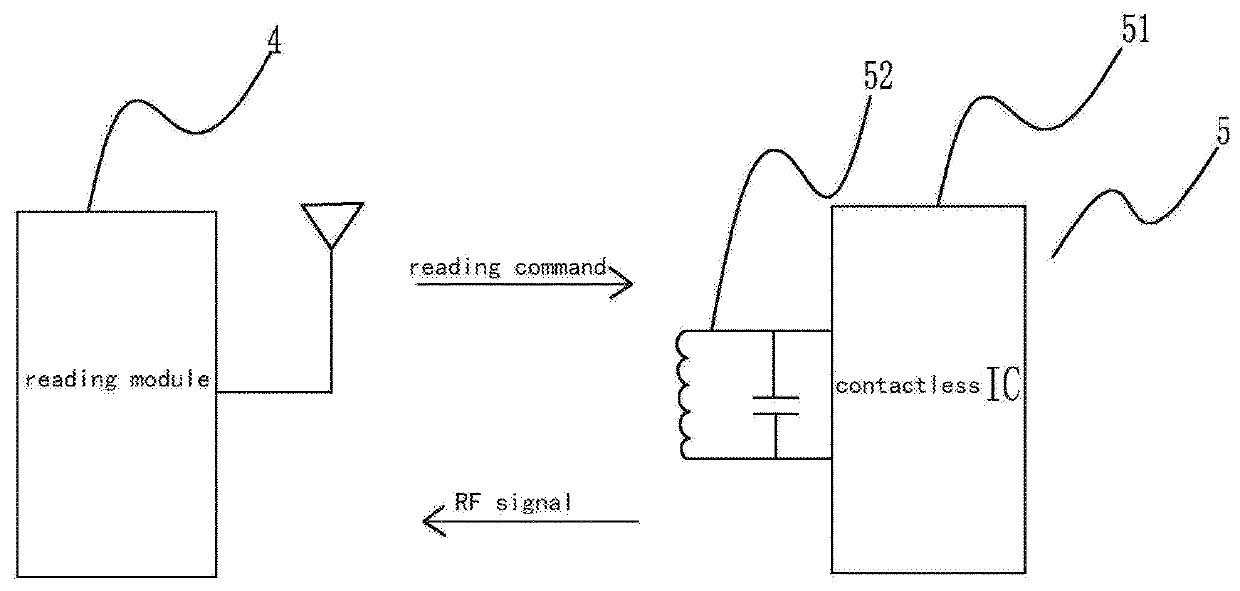

Air purifier based on filter Anti-counterfeiting identification

InactiveUS20180161716A1Guarantee product qualityPrevent counterfeitingDispersed particle filtrationTransportation and packagingAir purifiersPairing

Disclosed is an air purifier based on filter anti-counterfeiting identification, comprising a purifier body (1) in which control circuitry and a purifying chamber are provided; a filter (2) is arranged in the purifying chamber; the filters (2) are paired and coupled with the purifier body (1) via an identification unit; the identification unit comprises an identification chip configured on the filter (2) and an identifier configured on the purifier body (1); the identifier is connected with the control circuitry; the control circuitry is powered on and starts to operate until the pairing between the identification chip and the identifier succeeds. The identification process can identify multiple objects without manual intervention. Moreover, it responds quickly and no mechanical malfunction will happen. Thus, the air purifier can operate under harsh environment and serve for a long time. In this manner, counterfeits can be effectively prevented and quality of products can be guaranteed.

Owner:SHUNDE APOLLO AIR CLEANER

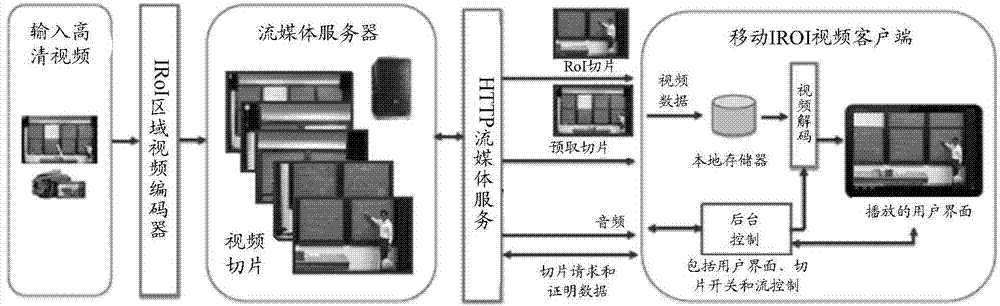

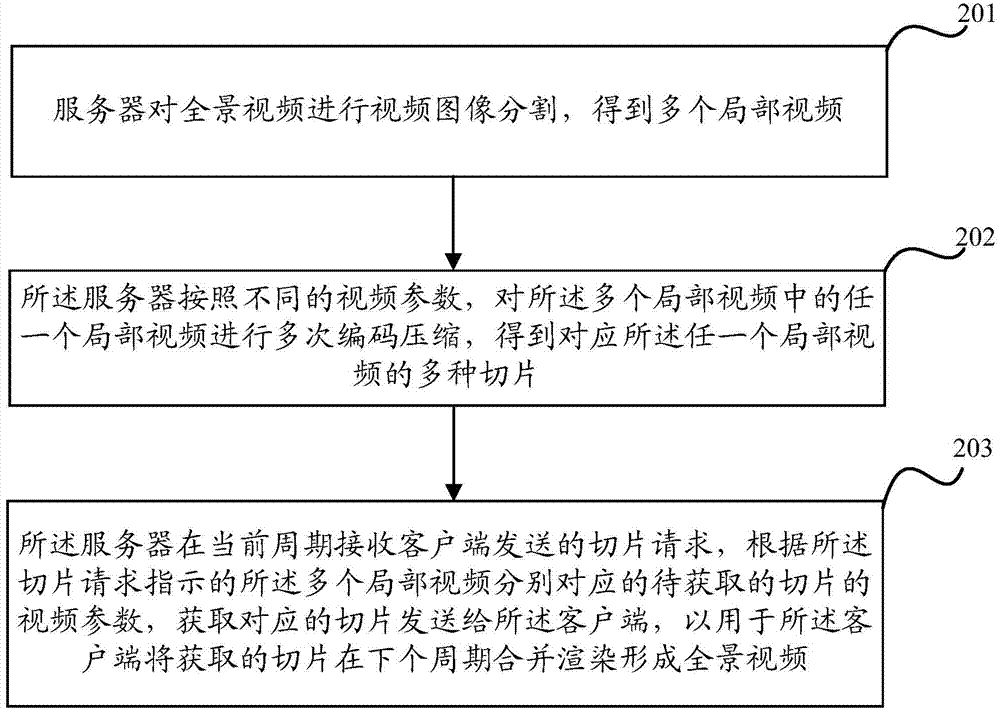

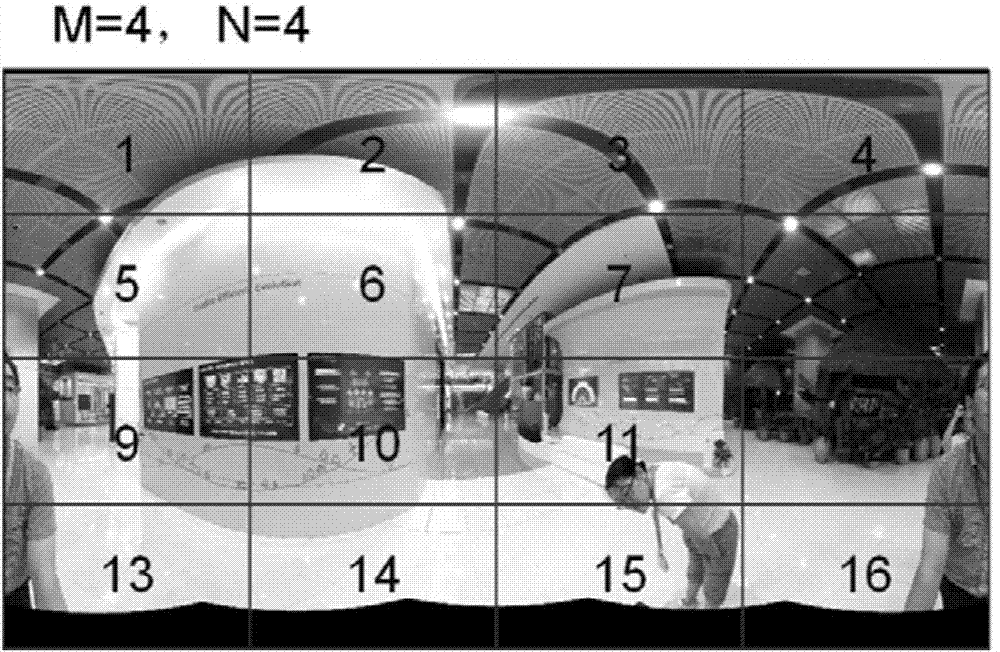

Panorama video interactive transmission method, server and client end

InactiveCN104735464AQuality assuranceSelective content distributionComputer graphics (images)Video quality

The invention discloses a panorama video interactive transmission method, server and client end, and is used for guaranteeing the panorama video quality in the interactive processes such as zoom or visual angle free transforming. The method of a client end side comprises the steps that an interest area in a previous period panorama video is confirmed by the client end, a working state of the client end is confirmed according to a touch-controlled action, an edge region, a general region and a non-interest region of the panorama video are confirmed according to the interest area and the working state, and then according to the interest area, the edge region, the general region and the non-interest region, video parameters of to-be-obtained slices corresponding to each partial video contained in the panorama video are confirmed, the confirmed video parameters of the to-be-obtained slices corresponding to each partial video are brought in a slice request and sent to the server, returned slices of the server is received according to the slice request, finally received slices are combined and rendered in the next period, and the panorama video is formed.

Owner:HUAWEI TECH CO LTD

Premixing mortar with high moisture retention and production method thereof

The invention discloses pre-stirring mortar with high moisture retention and a production method thereof. The premixing mortar comprises the following components by weight ratio: 100 parts of cement with the high moisture retention, 1 to 900 parts of fine aggregate and 30 to 200 parts of water, wherein the cement with the high moisture retention contains a cellulose ether component and has the moisture retention above 90 percent; and the fine aggregate is natural sand or artificial sand obtain through screen sizing or removing harmful components, and has the maximum grain diameter of 1.18 mm to 2.36 mm. The production method comprises the following steps: arranging a mortar stirring machine on a construction site or nearby; adopting the cement with the high moisture retention and the fine aggregate to automatically meter and stir, enable mortar to be usable while stirring, and the like to ensure the mortar quality; and adopting a closed stirring mode, a dust-collecting mode and the like to reduce dust raise. The pre-stirring mortar can effectively improve and ensure the qualities of the mortar buildings, obviously improves the construction environment, greatly decreases the production cost of the pre-stirring mortar and solves the difficult problems that the prior pre-stirring mortar has over-high cost and are difficult to popularize and apply.

Owner:SOUTH CHINA UNIV OF TECH

Heavy distillate oil hydrotreating method

ActiveCN101348732AQuality improvementQuality assuranceHydrocarbon oils refiningGasoline stabilisationWaxOil and grease

The invention relates to a method for hydrotreating heavy oil, in particular to the method for hydrotreating heavy oil, which improves the quality of diesel oil. Heavy distillate oil and animal and vegetable oil are used as raw material oil; under the hydrotreatment condition, the raw material oil and hydrogen gas are mixed and pass through a hydrotreatment reaction region; hydrogen-rich gas which is obtained by separating oil generated by hydrotreatment is circulated and utilized; and liquid obtained by separation is distillated to prepare a diesel oil product and hydrogenated wax oil. Compared with the prior art, the method can effectively improve the material source of a wax oil hydrotreatment device, ensure the quality of the hydrogenated wax oil, substantially increase the quality ofthe hydrotreated diesel oil and improve the storage stability of the animal and vegetable oil as fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

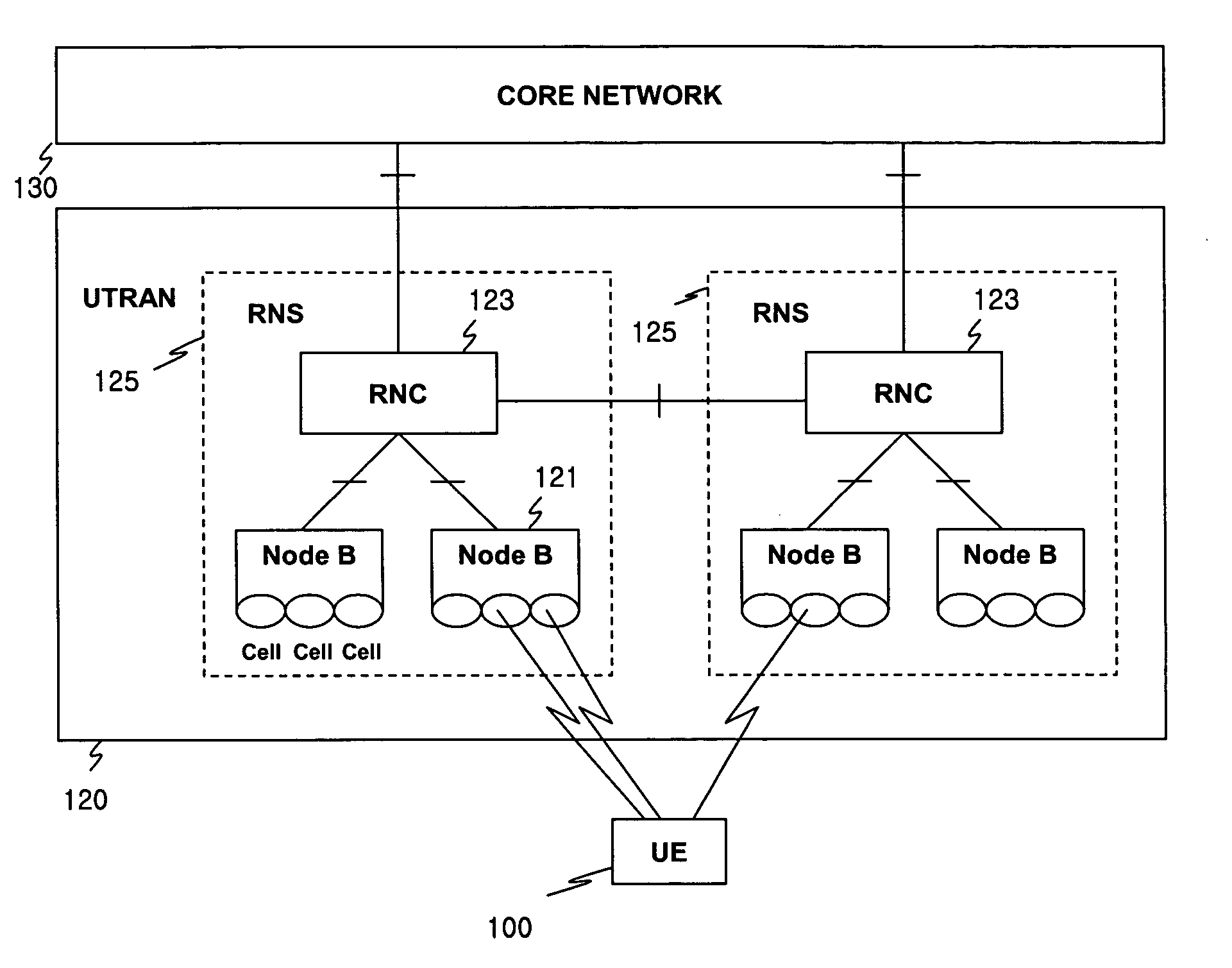

Apparatus and method for transmitting data blocks based on priority

InactiveUS20050238051A1Different quality of service requirementQuality assuranceError prevention/detection by using return channelFrequency-division multiplex detailsQuality of serviceDistributed computing

A particular protocol layer of the transmitting side (transmitter) initially receives service data units (SDUs) having the same priority through a single stream from an upper layer, processes these SDUs to generate protocol data units (PDUs) having different priorities, and uses respectively different transmission methods to transmit the generated PDUs over a radio interface in order to guarantee their respectively different quality of service (QoS) requirements.

Owner:LG ELECTRONICS INC

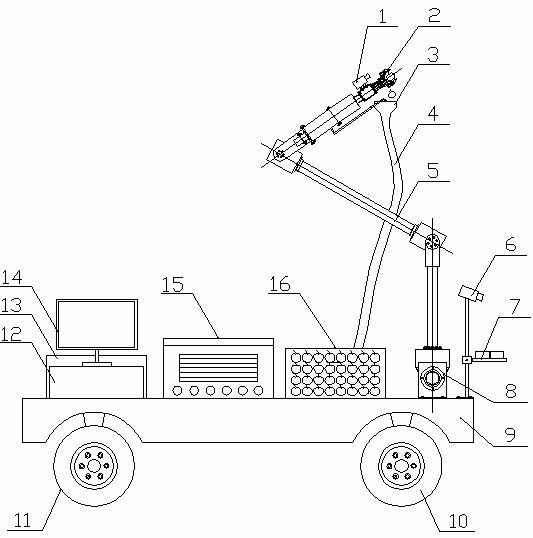

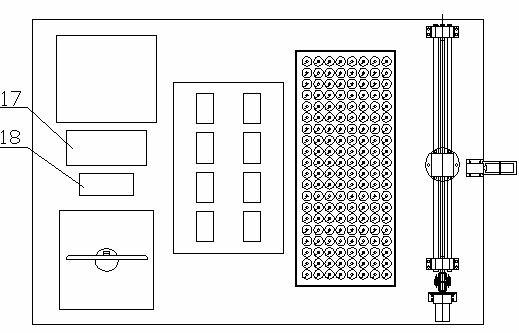

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

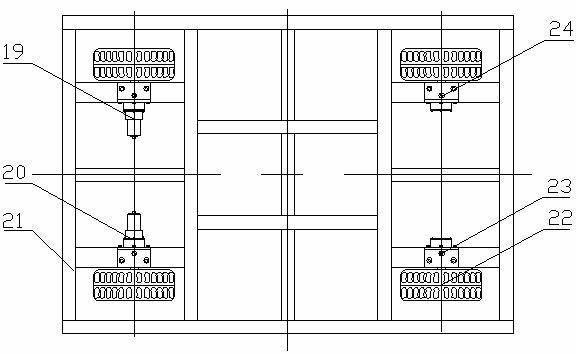

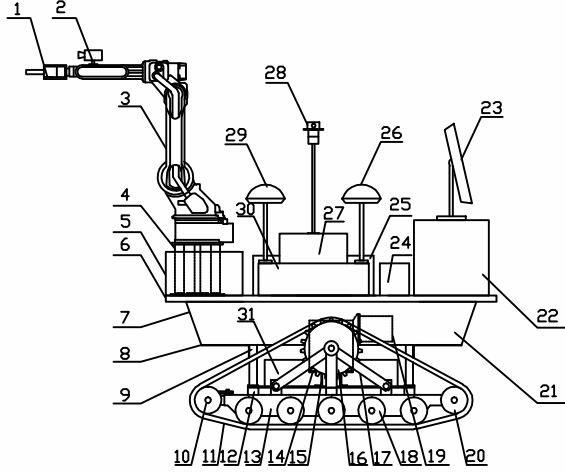

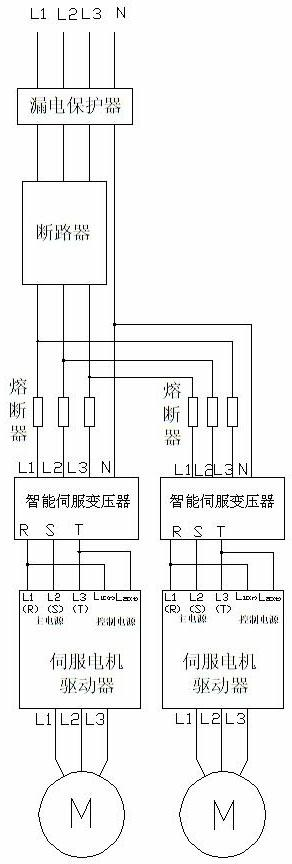

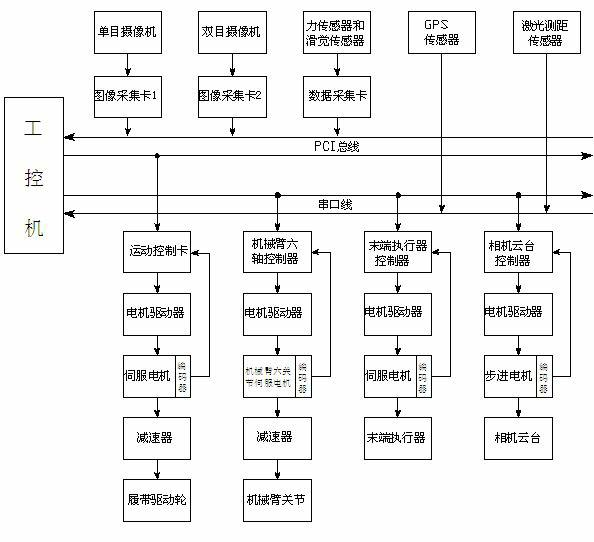

Automatic-navigation crawler-type mobile fruit picking robot and fruit picking method

InactiveCN102165880AFully automated pickingSimple structureProgramme-controlled manipulatorPicking devicesSimulationActuator

The invention discloses an automatic-navigation crawler-type mobile fruit picking robot which comprises a mechanical execution system and a control system and is characterized in that the mechanical execution system comprises an intelligent movable platform, a fruit picking mechanical arm and a two-finger type manipulator, wherein the intelligent movable platform comprises two crawler assemblies, an experimental facility fixing rack, a supporting stand column, a cross beam, a speed reducer and the like; and the control system comprises an industrial personal computer, a motion control card, a data collecting card, an image collecting card, an encoder, a GPS (global position system), a monocular zooming camera assembly, a binocular camera, a laser ranging sensor, a control circuit and the like. The automatic-navigation crawler-type mobile fruit picking robot integrates the fruit picking mechanical arm, the two-finger type manipulator, the intelligent movable platform and the sensor system, integrates multiple key technologies such as fruit identification, motion of the picking mechanical arm, grabbing of a tail-end executer, automatic navigation and obstacle avoidance of the movable platform, and the like, and really realizes automatic and humanized fruit picking.

Owner:NANJING AGRICULTURAL UNIVERSITY

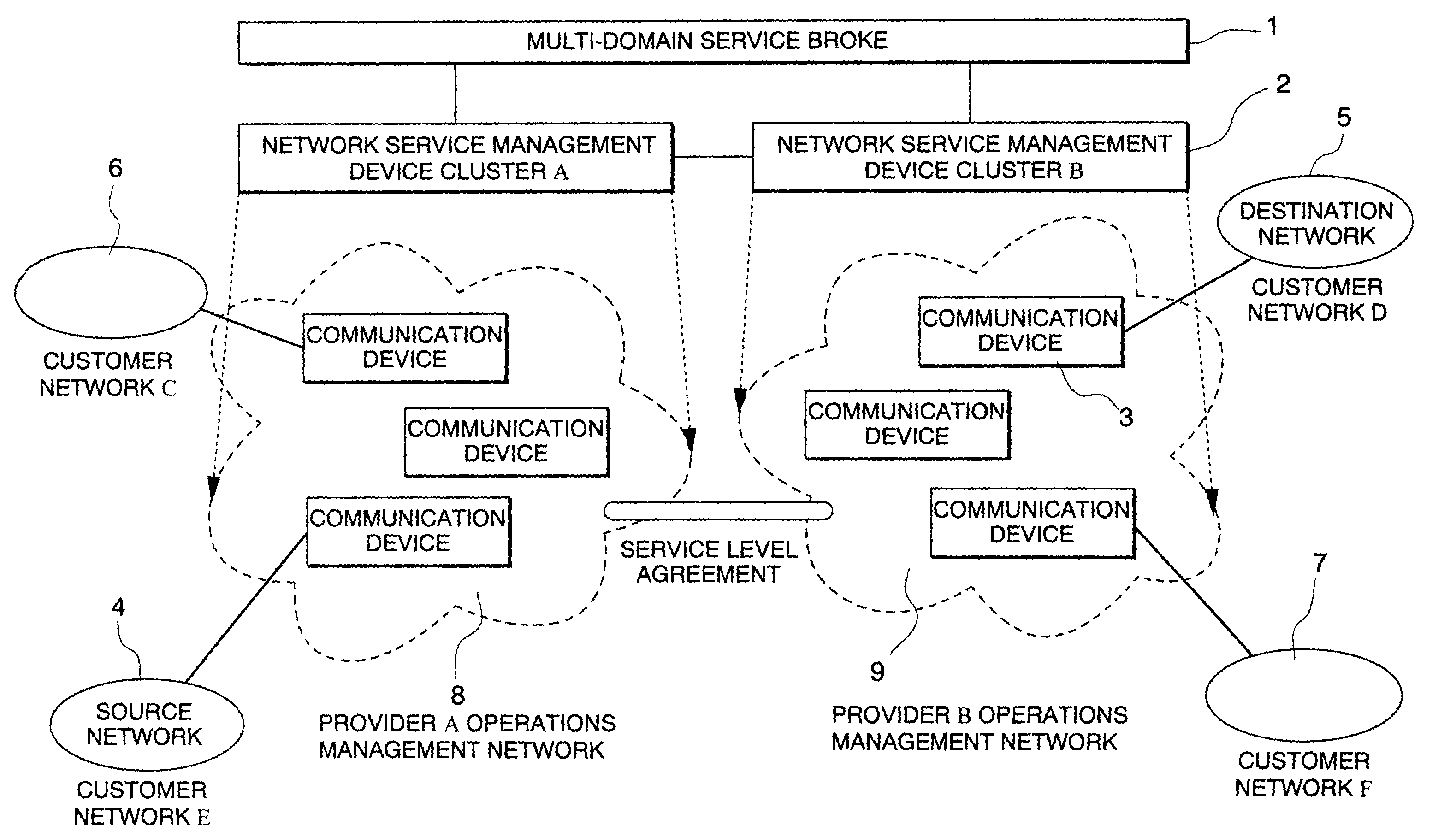

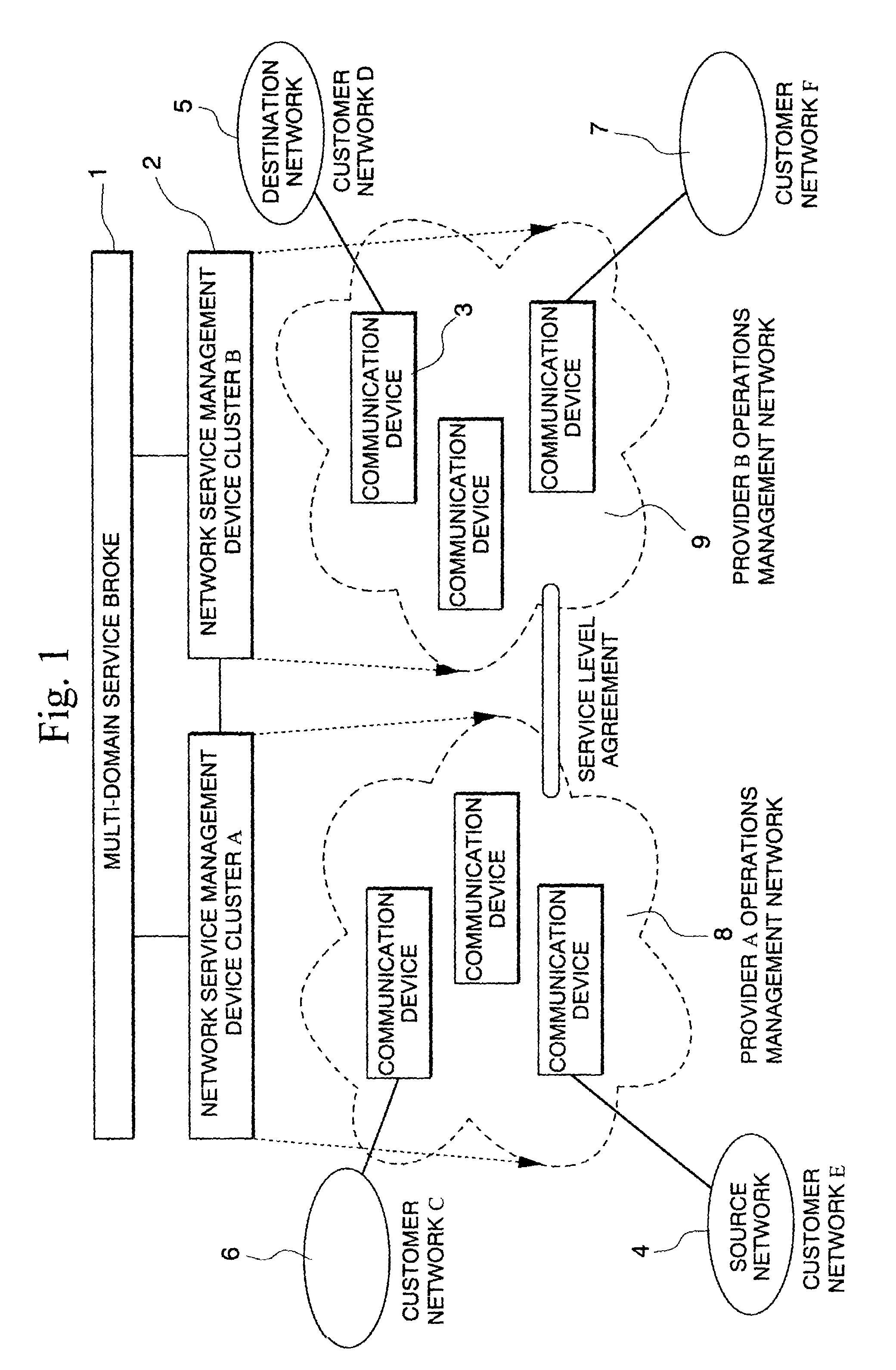

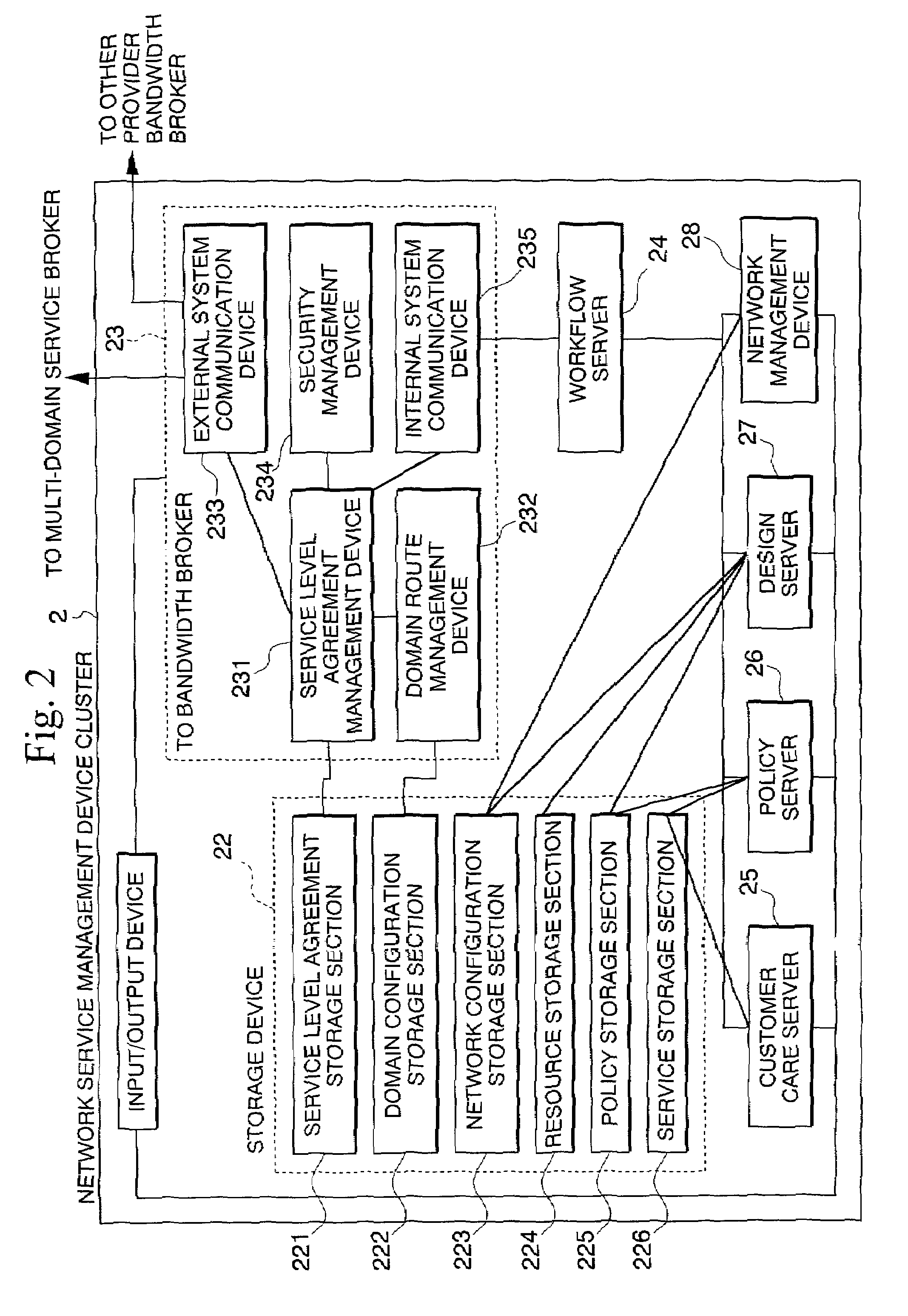

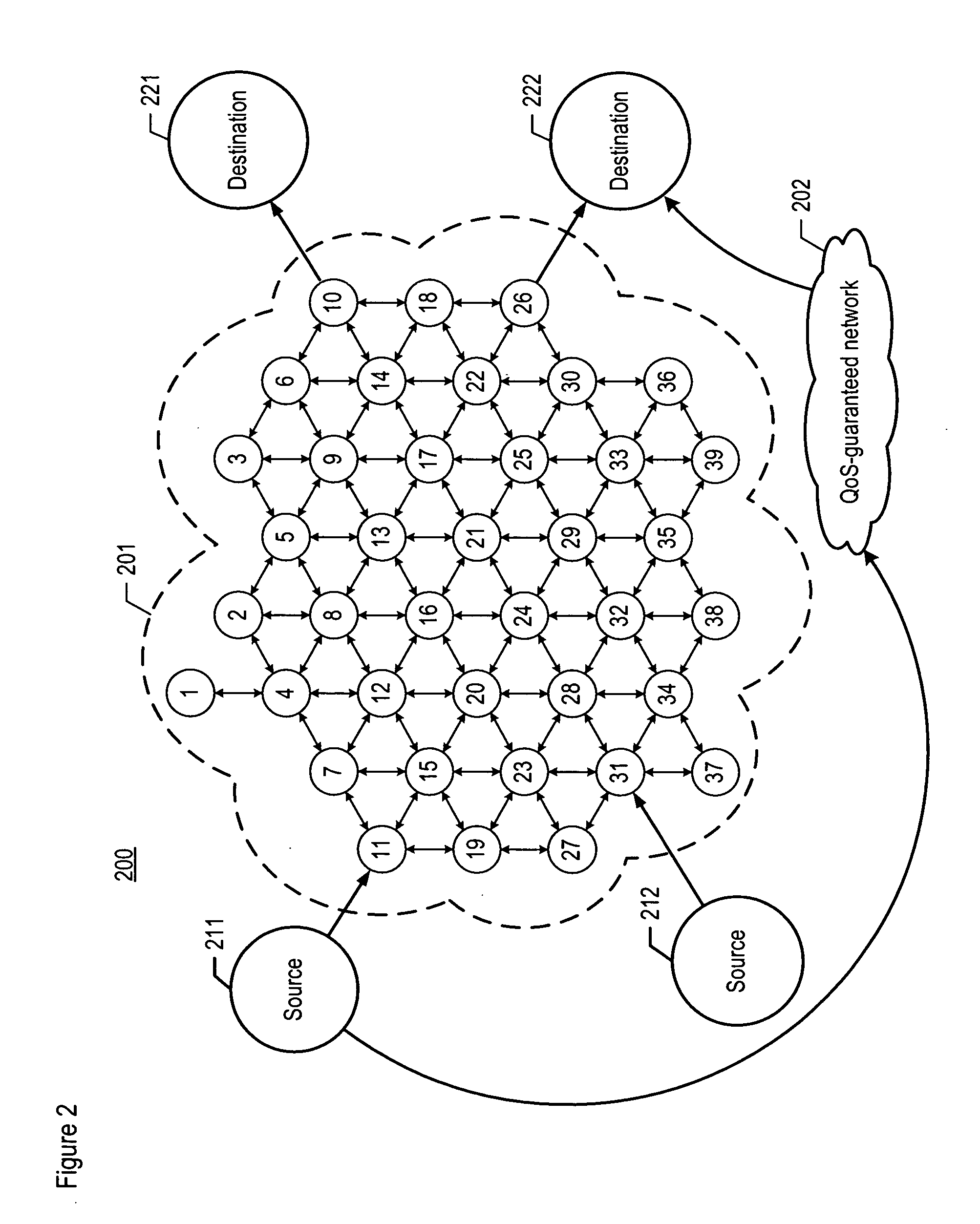

Quality assured network service provision system compatible with a multi-domain network and service provision method and service broker device

InactiveUS7254645B2Guaranteed communication qualityQuality assuranceResource allocationMultiple digital computer combinationsQuality levelService provision

The invention provides quality assured network services in a multi-domain network and comprises a network service management device for managing device clusters incorporated within the operations management network of each provider network and receiving service orders, and a multi-domain service broker for providing a broker function for achieving agreement between a plurality of providers, and the multi-domain service broker further comprises a device for collecting domain information and information relating to the services each provider is able to provide from the network service management devices, and a device which on receipt of a network service request from a customer, extracts the network service management device of the domain which is able to satisfy the required quality level, and then issues instructions for the setting of the required information within the extracted network service management device.

Owner:NEC CORP

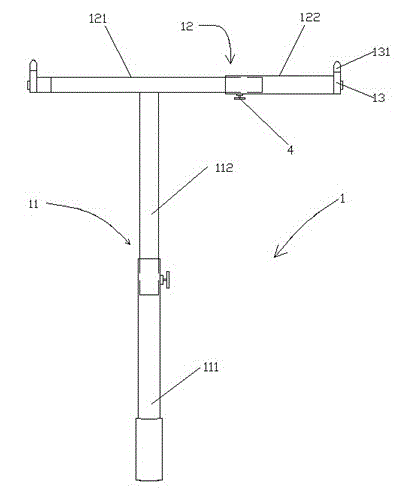

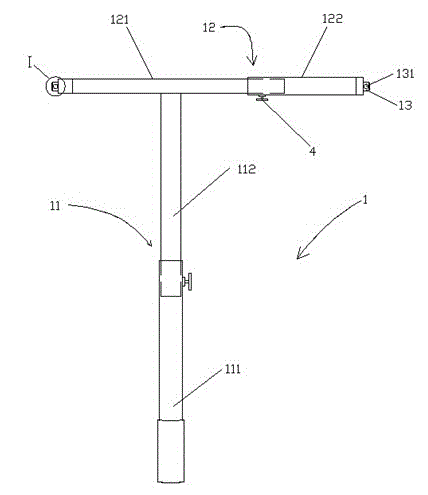

High-altitude drill positioning method of building

InactiveCN102979457AAvoid safety hazardsQuality assuranceDerricks/mastsDirectional drillingArchitectural engineeringDrill bit

The invention discloses a high-altitude drill positioning method of a building, which comprises a high-altitude marking device, a high-altitude drilling device and a high-altitude tightening device. The high-altitude drill positioning method comprises the following steps that when a plurality of fixing holes need to be drilled in the top surface of the building, the length of an adjustment rod of the high-altitude marking device is adjusted to be equal to the distance between any two fixing holes; a support rod of the high-altitude marking device is adjusted, so that the altitude from the top end of a marking rod to the ground is equal to the altitude from the fixing holes to the ground; the marking end head is pressed to the top surface, so as to draw marking points of the two fixing holes; the high-altitude drilling device is placed below the fixing holes, and a handle is pressed downward, so that a drill which is fixedly arranged on drilling equipment aligns with the marking points of the fixing holes; the drilling equipment is turned on to drill the holes which conform to a size; one end of an expansion bolt, which is provided with a nut, is inserted into the top end of the high-altitude tightening device; the expansion end of the bolt is inserted into a drilled fixing hole, and then a handle of the high-altitude tightening device is rotated to tighten the expansion bolt; and the steps are repeated, so as to complete the drill tightening operation of the remaining fixing holes. According to the high-altitude drill positioning method, the disadvantages of low construction quality and large difficulty because no reliable application point exists at high altitude are overcome, the construction quality is guaranteed, various potential safety hazards due to high-altitude construction of construction personnel are avoided, and the construction efficiency is greatly increased.

Owner:CHINA RAILWAY 19 BUREAU GRP ELECTRIC ENG

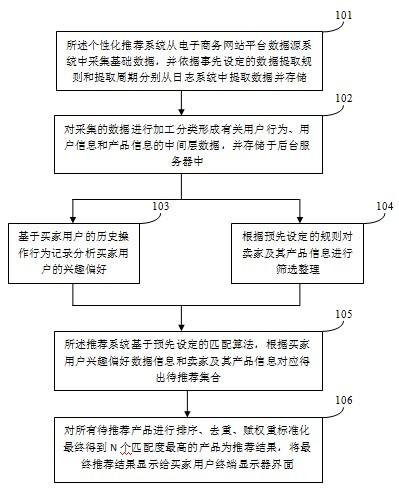

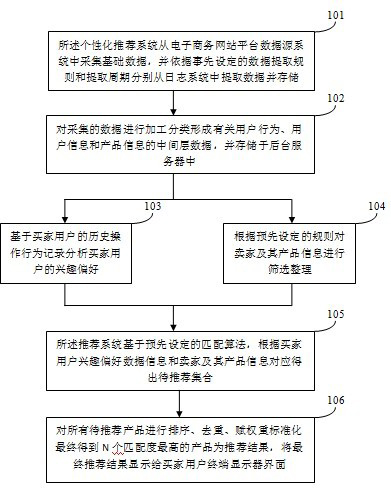

Personalized recommendation method

InactiveCN102663627AAchieve recommendationHigh degree of demand matchingMarketingPersonalizationData information

The invention discloses a personalized recommendation method. The method comprises the following steps of: acquiring basic data; processing and classifying the basic data, and analyzing the interest and preference of a purchaser on the basis of historic operation behavior records of the purchaser; filtering and collecting seller information and product information according to a preset rule; correspondingly acquiring a set of products to be recommended according to the interest and preference data information of the purchaser, the seller information and the product information on the basis of a preset matching algorithm; de-duplicating, sorting, weighting and standardizing all products to be recommended, and thus obtaining N optimally-matched products which serve as a recommendation result; and displaying the final recommendation result to the purchaser. By adoption of the personalized recommendation method, the product information which is in accordance with the interest and preference of a user can be accurately recommended to the user in the conventional electronic-commerce business-to-business (B2B) website.

Owner:FOCUS TECH +1

Adhesives for vehicle body manufacturing

InactiveUS20040079478A1Significant production advantageHigh strengthLamination ancillary operationsAdhesive processes with adhesive heatingCross-linkEngineering

Two-component systems are described which are suitable for underlining, adhesive bonding of the crimped fold and sealing of auto body sections, particularly for crimped fold sealing of add-on vehicle parts. The two-component systems attain the requisite grip strength for mounting the add-on parts on the body as well as the requisite strength and dimensional stability for the production process up to and with the CIP passage, within the predetermined cycle time, on the basis of cross-linking of the sealant composition twice. In one embodiment, the surface of the two-component system is pre-cross-linked by a UV-induced reaction and by the cross-linking of the two-component system to the extent of portability. In addition, two-component systems are described which cross-link intentionally only partially up to a consistency that permits a rugged course of the process through cleaning baths and which harden completely only by means of a further hardening process, for instance in the CIP forced circulation oven.

Owner:SIKA AG VORMALS KASPAR WINKLER

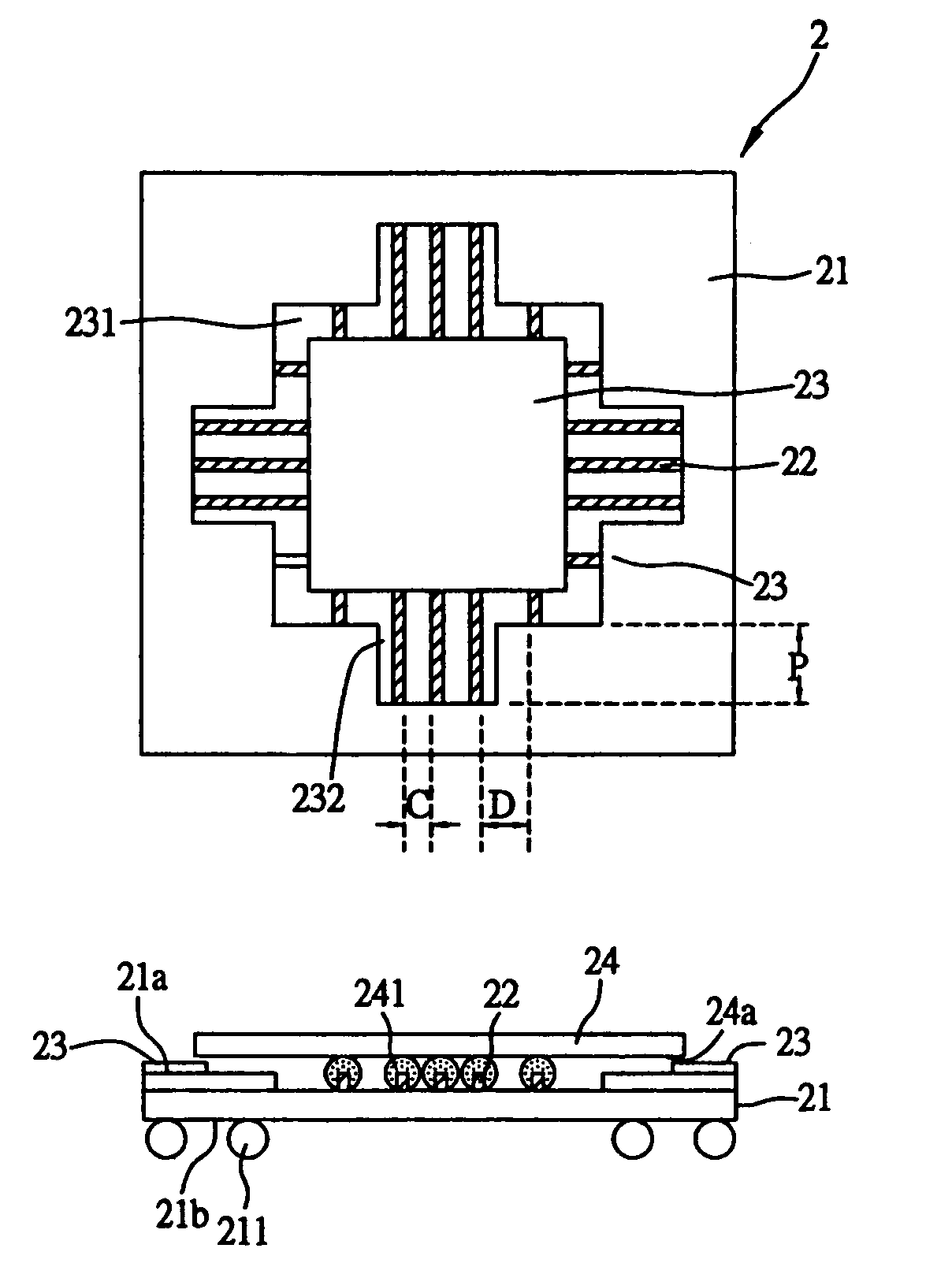

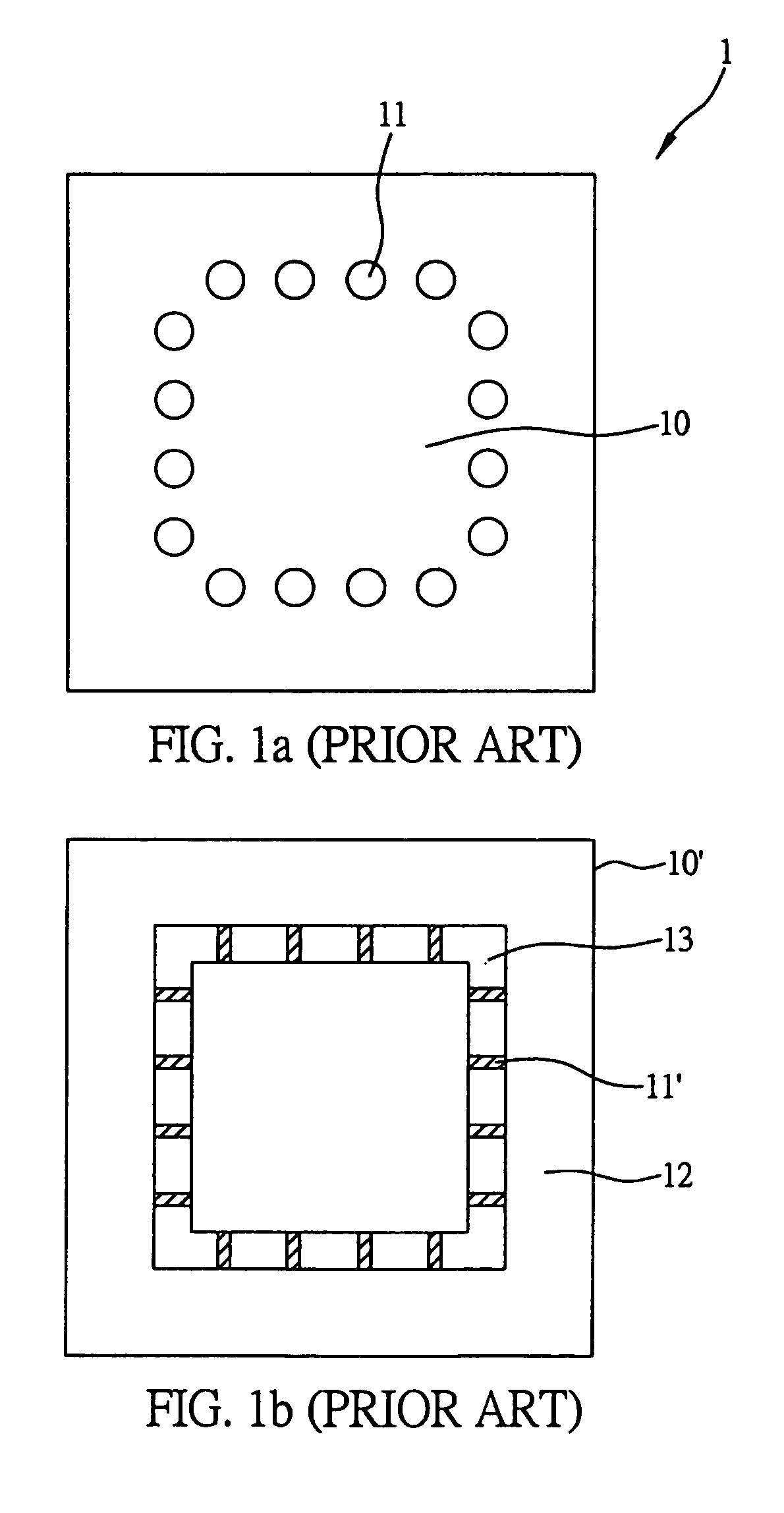

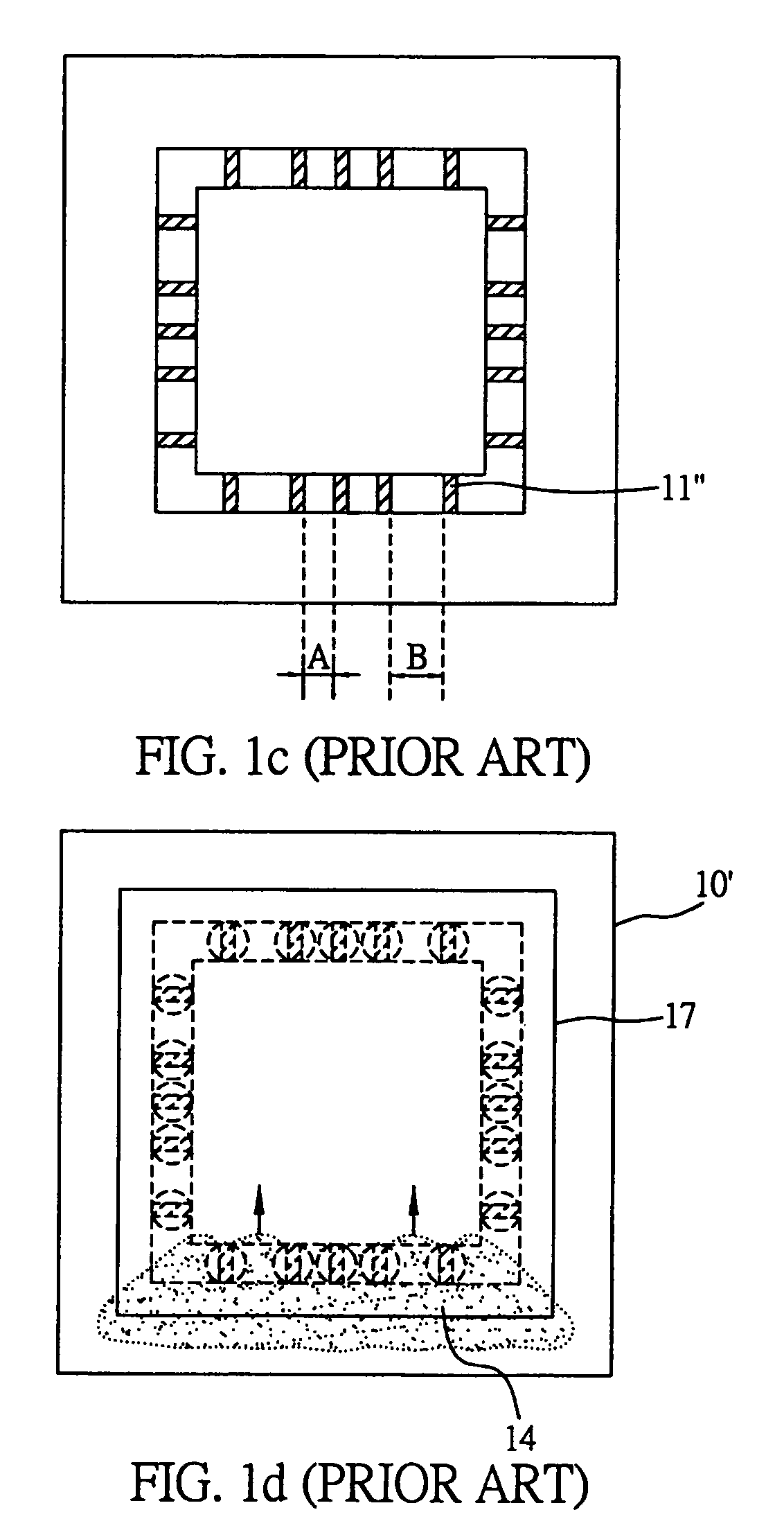

Chip carrier for semiconductor chip

ActiveUS7102239B2Reduce formationInhibition effectSemiconductor/solid-state device detailsSolid-state devicesSolder maskSemiconductor chip

A chip carrier for a semiconductor chip is provided. A plurality of solder pads for bump soldering are formed on a chip mounting surface of the chip carrier, to allow a flip chip to be mounted and electrically connected to the chip carrier. A solder mask layer is formed on the chip carrier, wherein a plurality of openings are provided in the solder mask layer to expose the solder pads, and an outwardly opening extended portion is formed respectively from the openings corresponding to the solder pads having a relatively narrower pitch therebetween, so as to prevent formation of voids during an underfill process for filing a gap between the flip chip and the chip carrier.

Owner:SILICONWARE PRECISION IND CO LTD

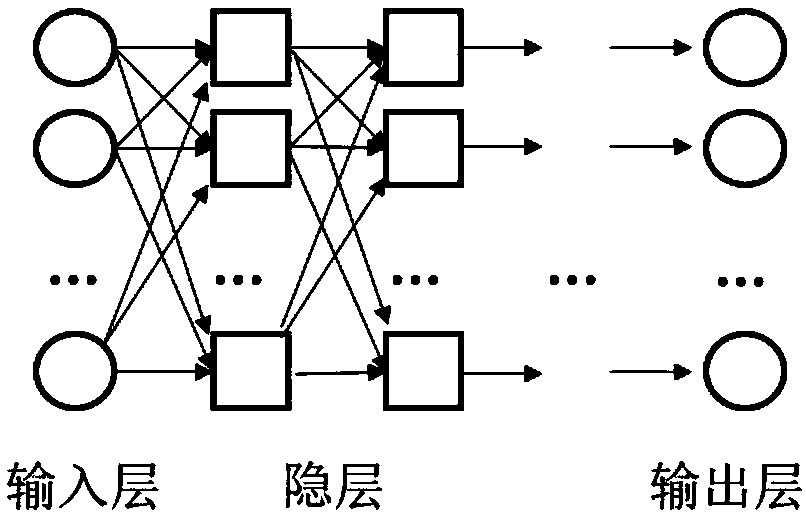

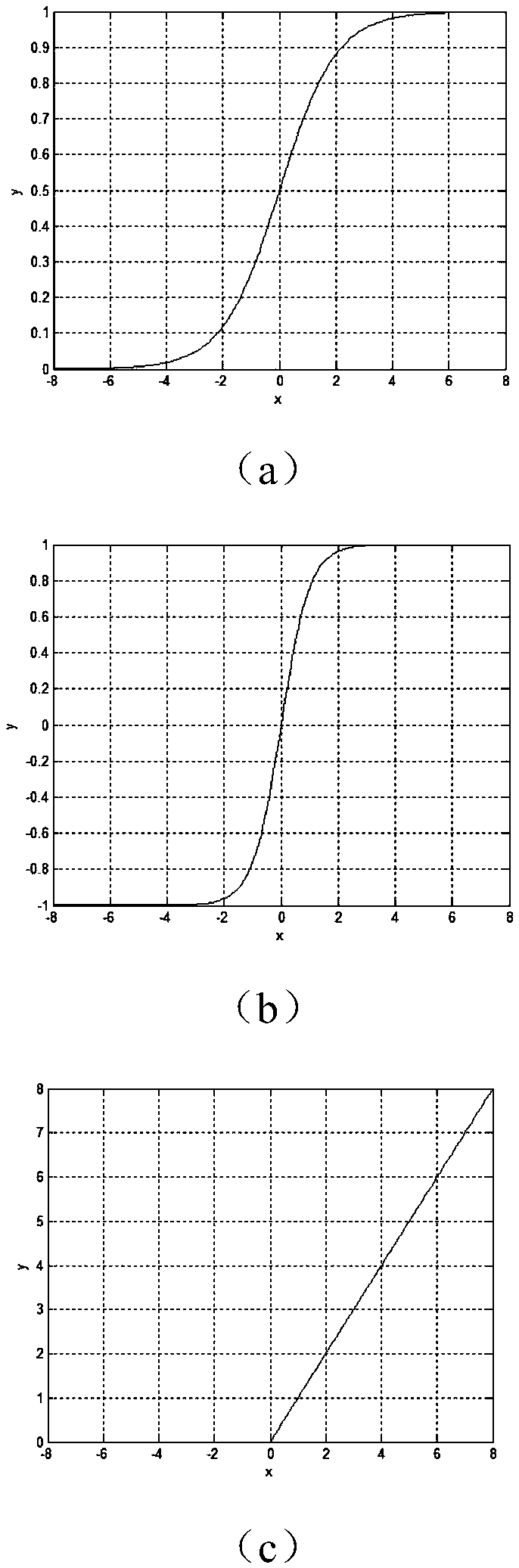

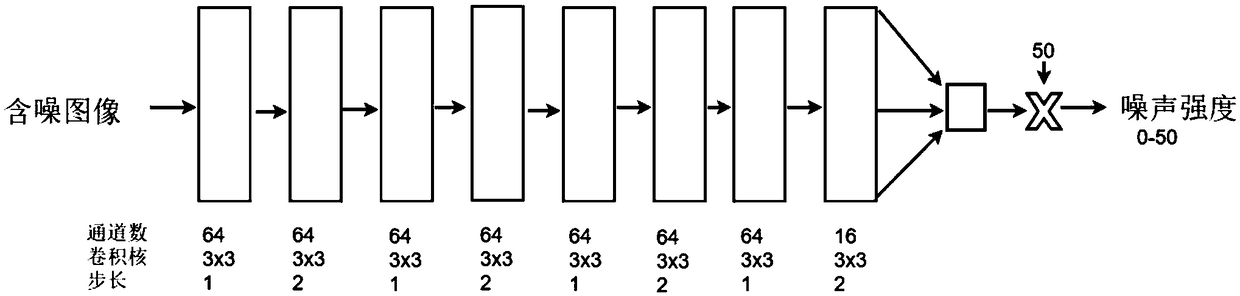

Image denoising method based on generative adversarial networks

InactiveCN108765319AEasy to trainEvenly distributedImage enhancementImage analysisGenerative adversarial networkImage denoising

The invention provides an image denoising method based on generative adversarial networks, and belongs to the technical field of computer vision. The method comprises the following steps: (1) designing a neural network for estimation for noise intensity of an image containing noises; (2) using image blocks in an image library to add noises of the intensity according to the estimated noise intensity to use the same as samples of training the networks; (3) in network training, designing a new generation network and discrimination network, and adopting a form of fixing the generation network to train the discrimination network and fixing discrimination network parameters to train the generation network to enable the networks to carry out adversarial training; and (4) using the trained generation network as a denoising network, and selecting a network parameter according to a result, which is obtained by the noise recognition network, to denoise the image containing the noises. The methodhas the effects and the advantages that a visual effect of the denoised image is improved without the need for manual intervention for adjusting the parameter, and texture details of the image can bebetter restored.

Owner:DALIAN UNIV OF TECH

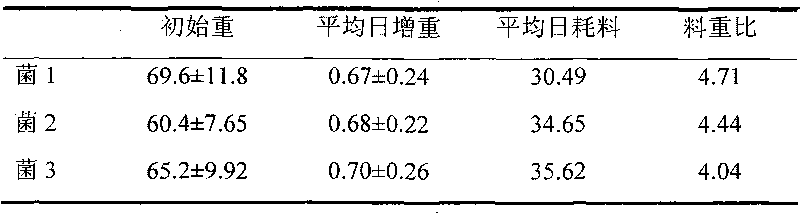

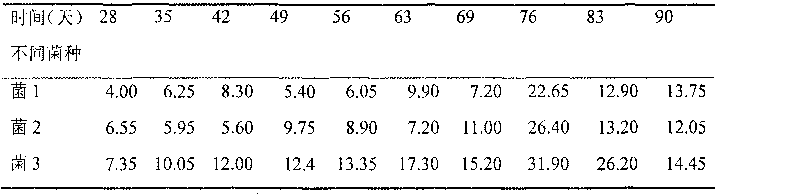

Compound microbial culture starter and application thereof

InactiveCN101760431AQuality assuranceReduce the cost of farmingFungiBacteriaLactobacillusMicrobiology

The invention discloses a compound microbial culture starter and application thereof, which belong to an application of a beneficial microbial preparation at low cost. The active microorganism of the compound microbial culture starter comprises saccharmyces cerevisiae, bacillus subtilis, bacillus natto and lactococcus lactis. The compound microbial culture starter can be used for livestock and poultry raising beds, feeds addictive and other aspects and is characterized by reducing the cost input of users on the culture starter and having stable effect.

Owner:河北瑞塞可环保科技有限责任公司

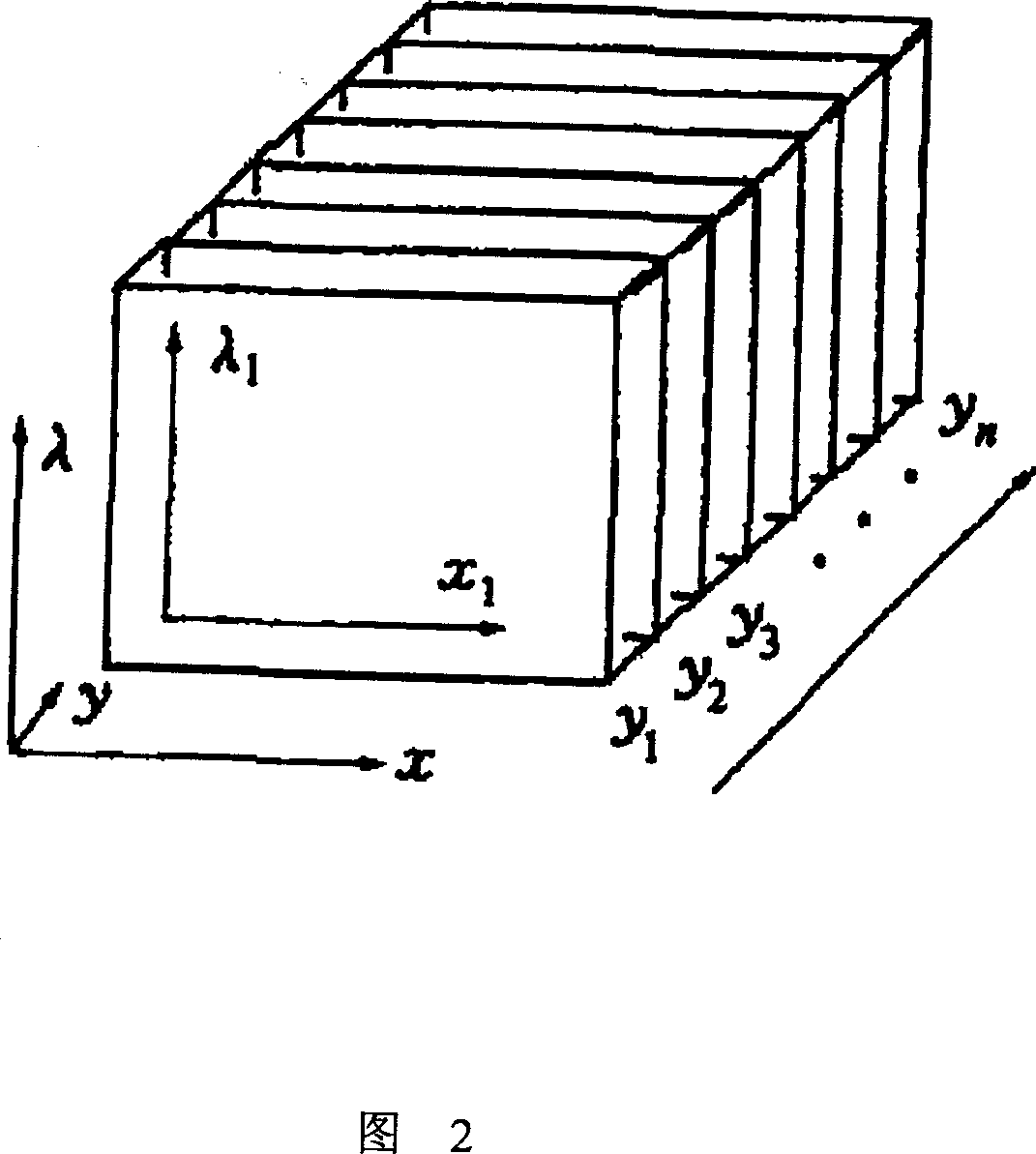

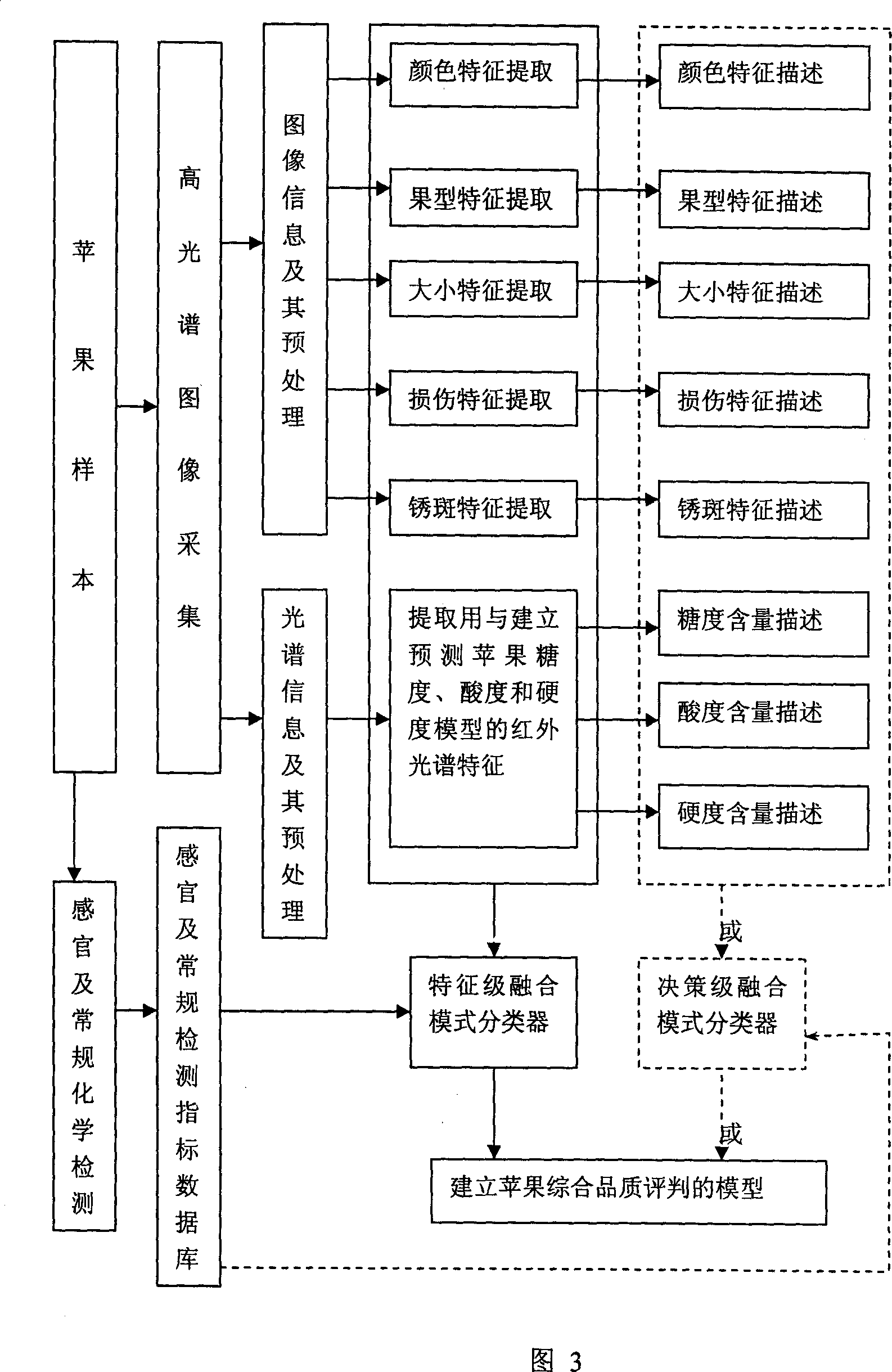

Non-destructive detection method and device for agricultural and animal products based on hyperspectral image technology

InactiveCN1995987AWith artificial intelligenceGuaranteed sampling qualityImage analysisMaterial analysis by optical meansNon destructiveAnimal product

The invention relates to high optical spectral image technique without harm to agricultural products. It can reflect the appearance of the agriculture products like color, shape, texture, dimension, scar and son on, and internal features like hardness, protein content and connected with knowledge base and experience of experts to make judgment. It can make quick, accurate, timely judgment of products, controlling the overall production with guarantee of the agriculture quality.

Owner:JIANGSU UNIV

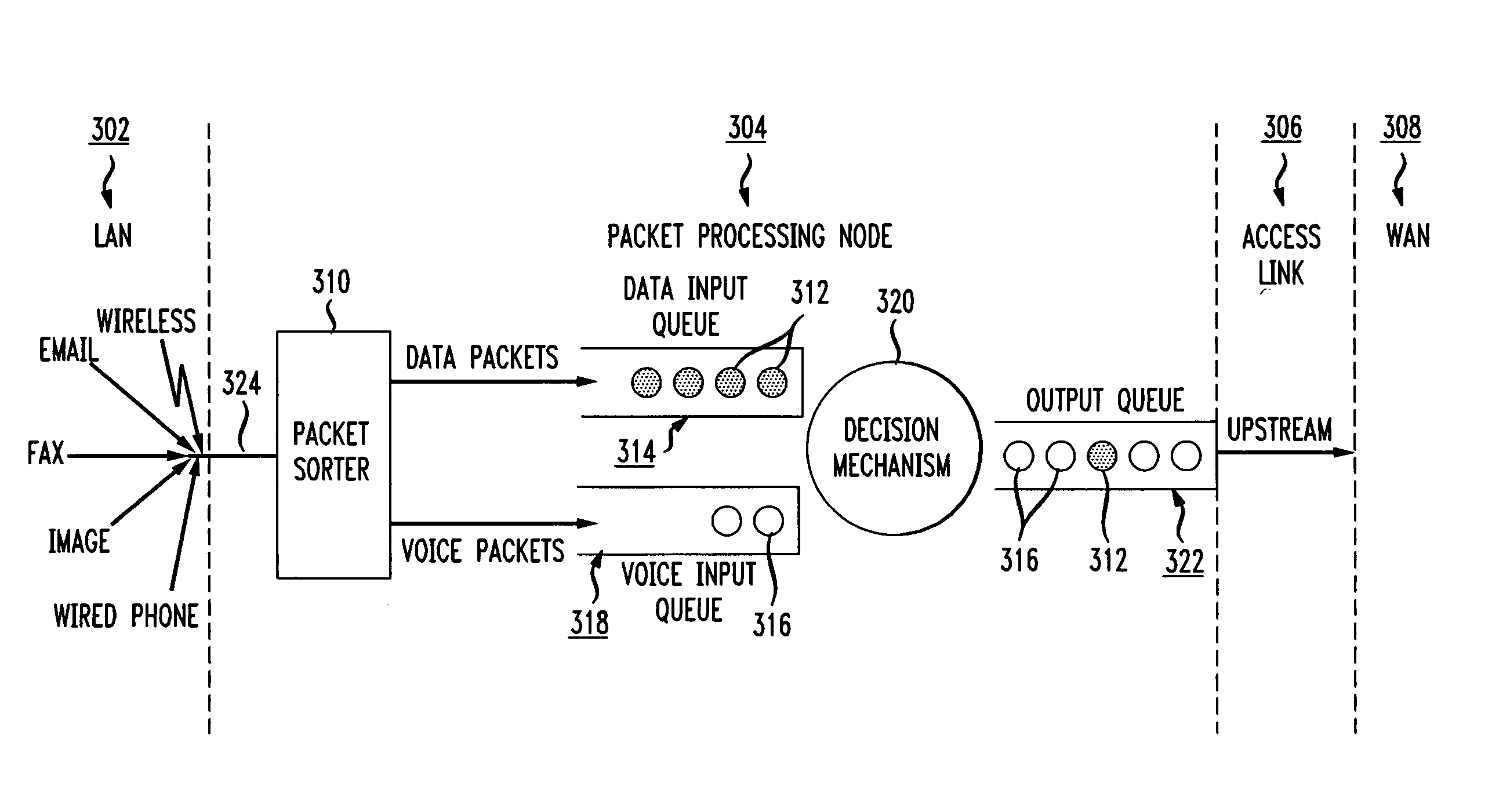

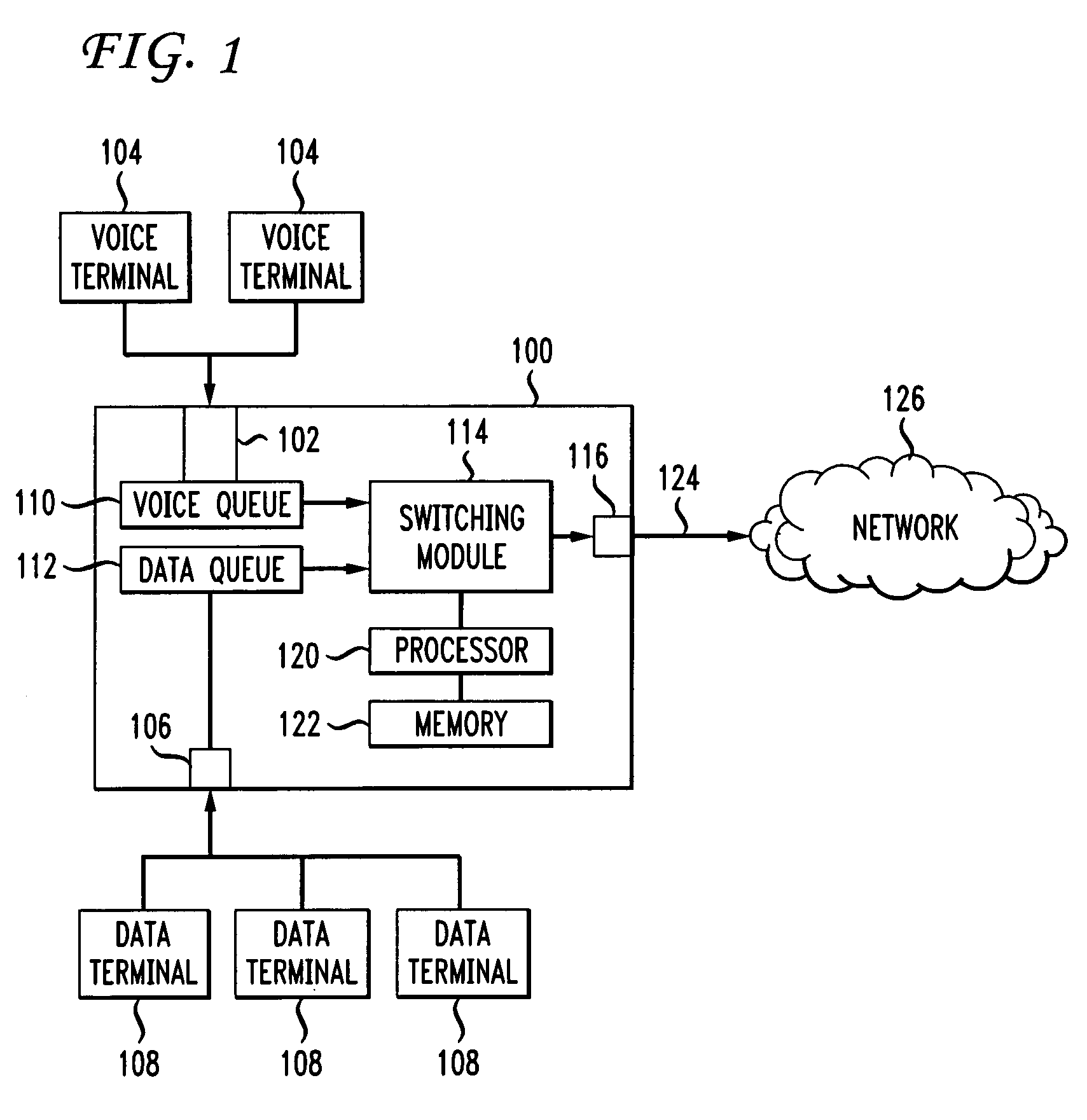

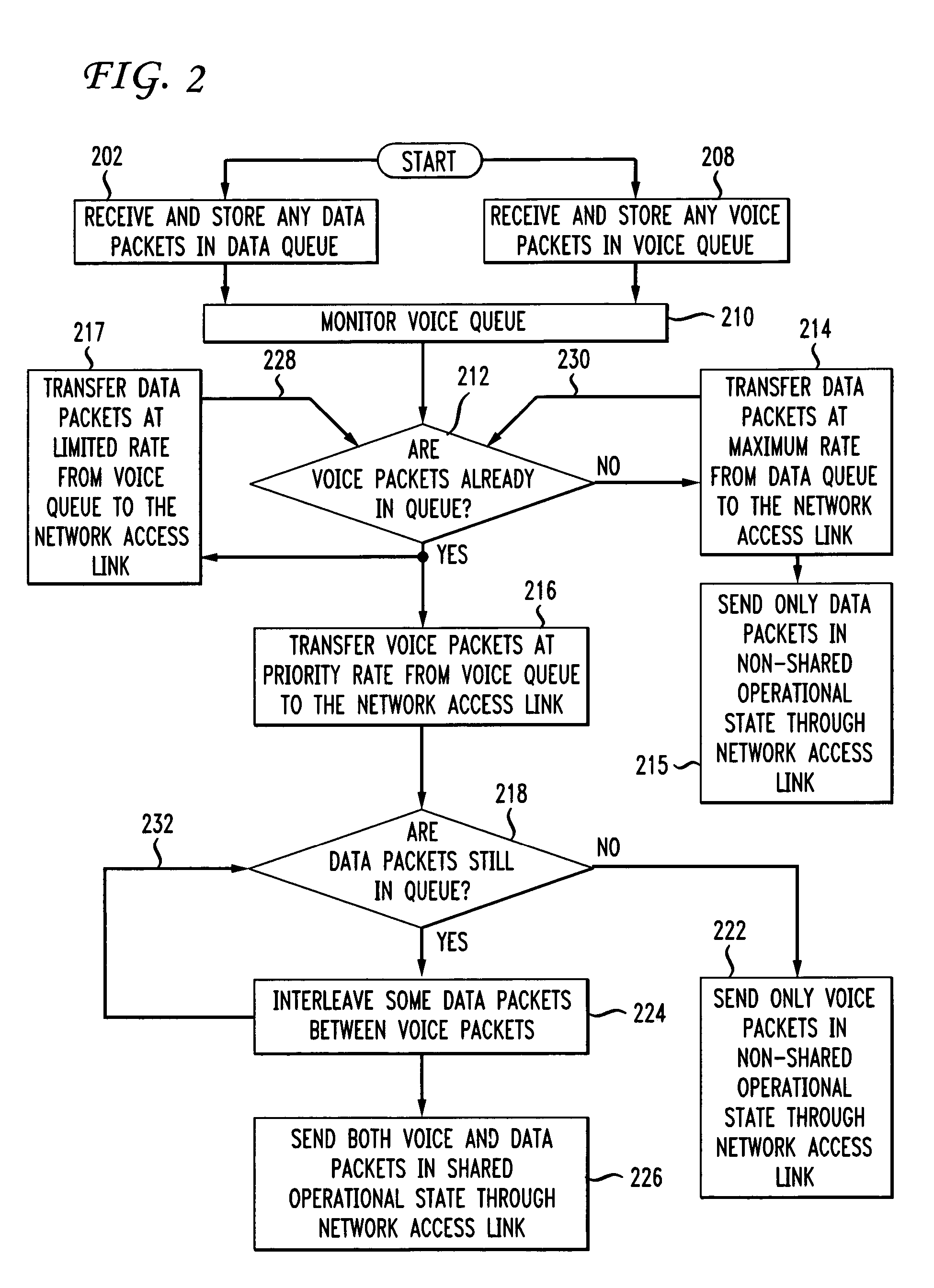

Establishing traffic priorities in a voice over IP network

InactiveUS20050281277A1Speed up upstream voice packetAlleviate packet congestionMultiplex system selection arrangementsData switching by path configurationTraffic capacityVoice over IP

A method and apparatus for establishing traffic priorities in an IP network connected with multiple communication sources is disclosed. Different types of packets such as voice packets and data packets are received for transmission over a single network access link. In order to assure quality voice transmissions, voice packets are given priority over data packets by limiting a transmission rate from a data input queue whenever voice packets are detected in a voice input queue. Different combinations of interleaved voice and data packets help to alleviate packet congestion while maintaining priority for voice packets. In one aspect of the invention, priority for voice packets is further accomplished by limiting the size of data packet frames. In some instances when no voice packets are awaiting transmission, data packets are transmitted at a maximum rate in order to make full use of the network access link bandwidth. The invention is particularly beneficial when implemented over cable and DSL network access links with slow upstream feed rates.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

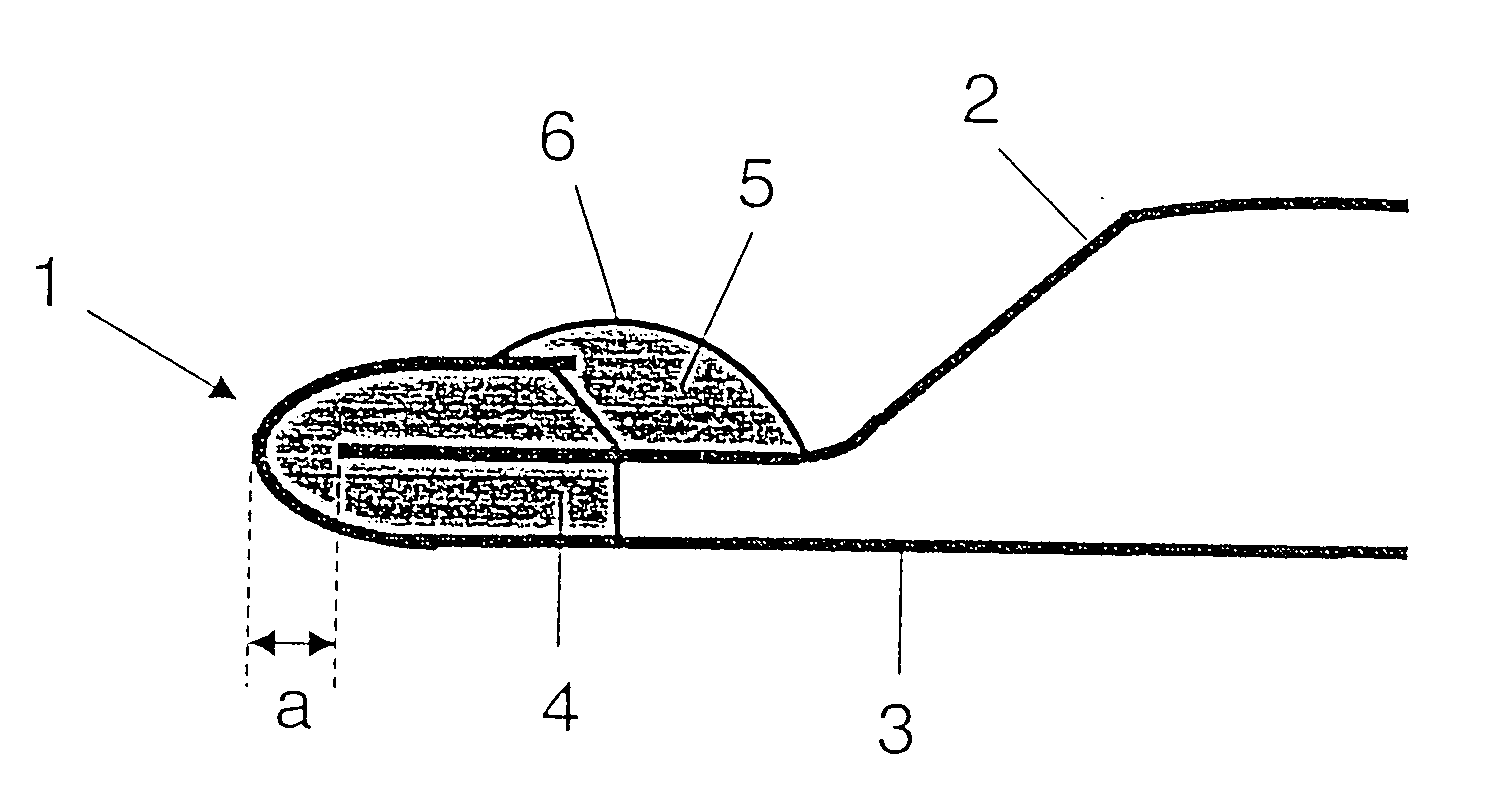

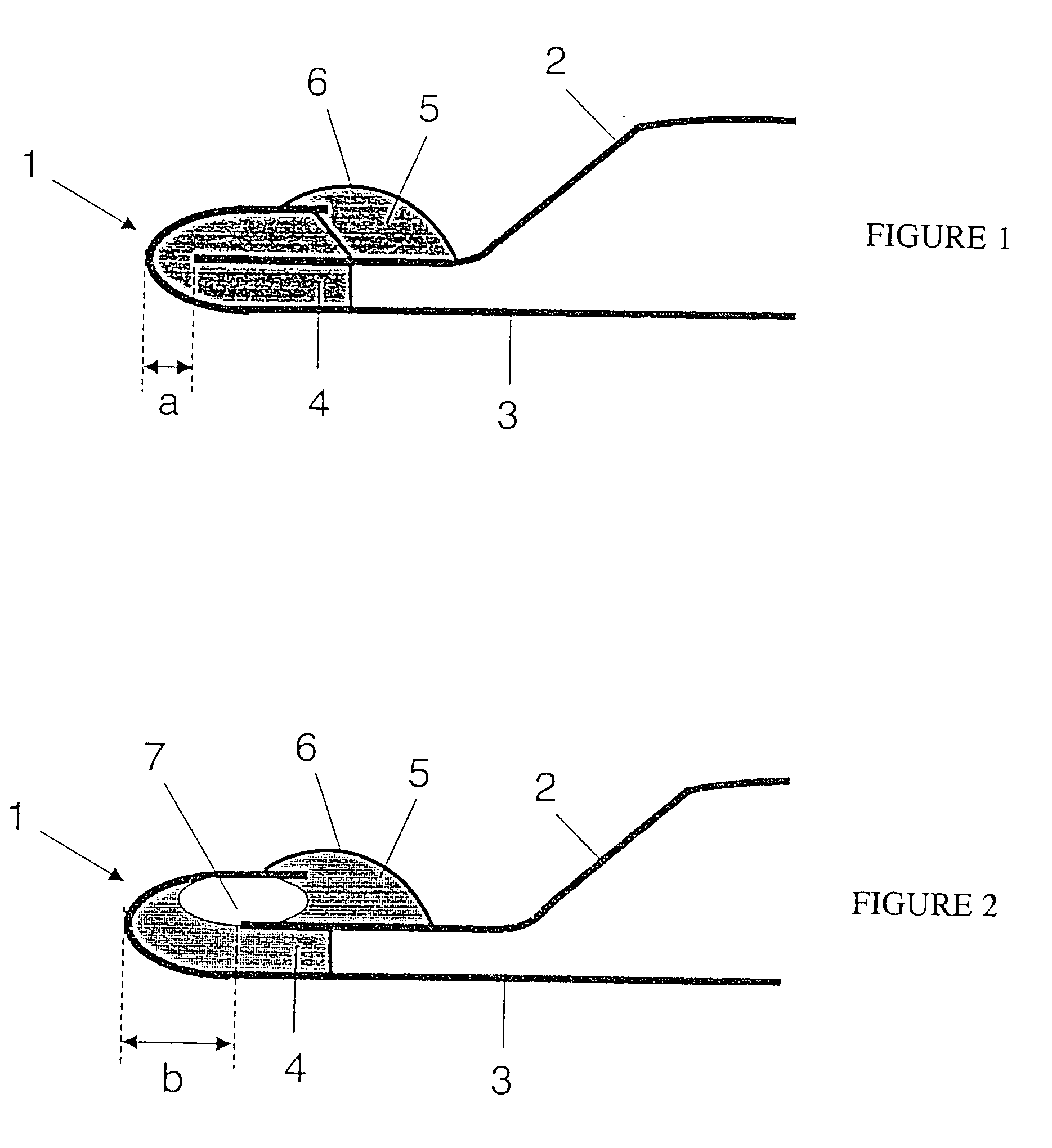

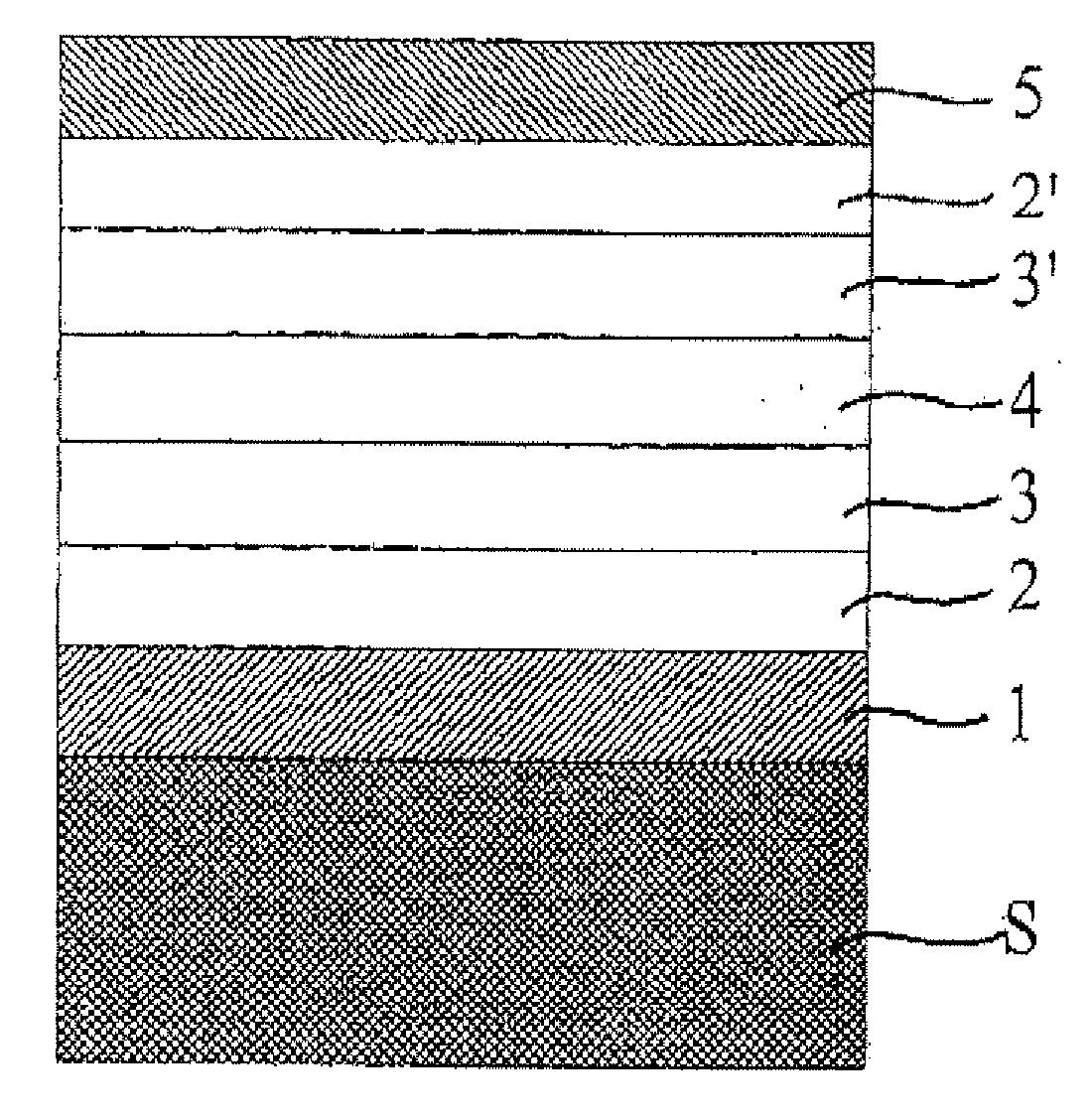

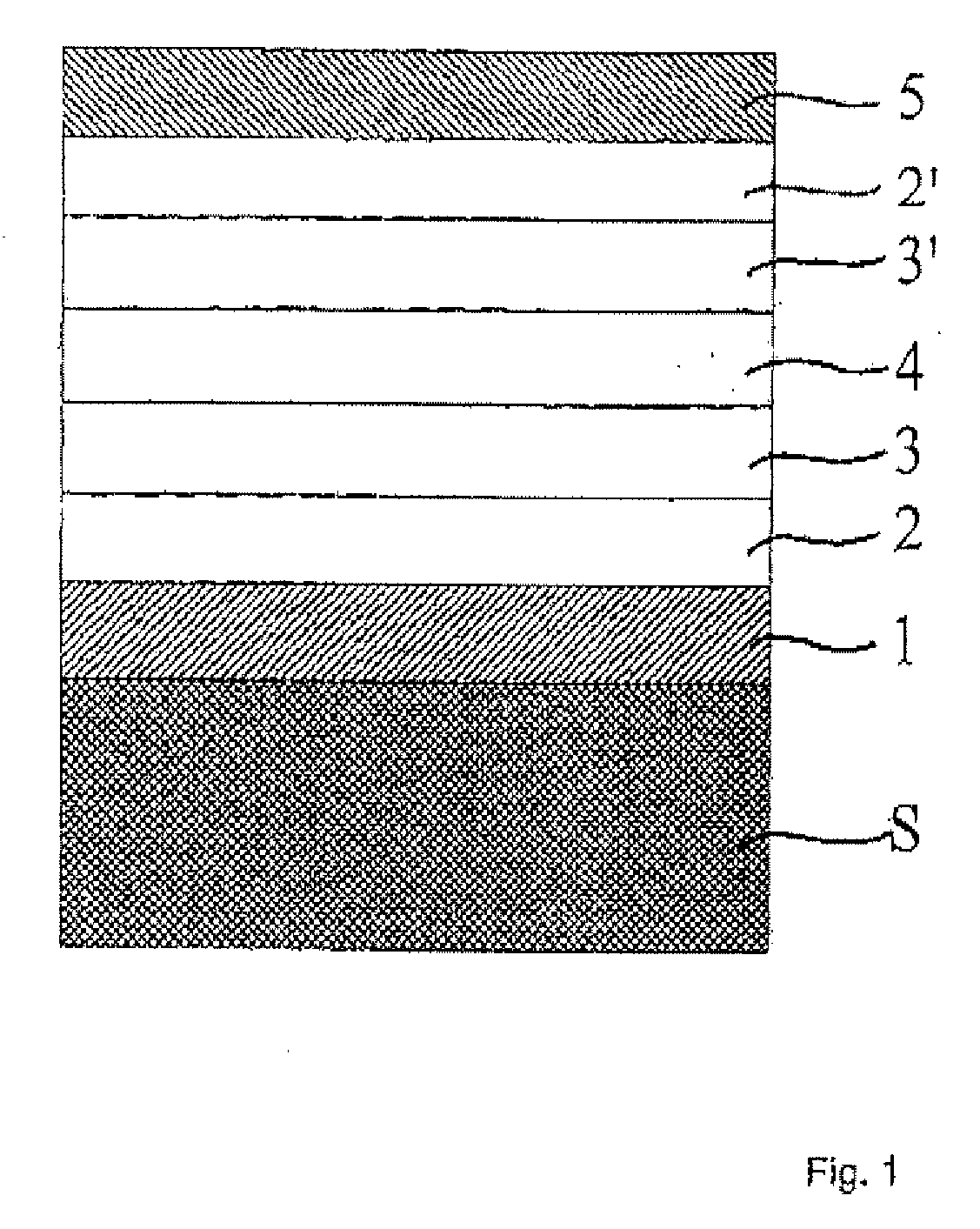

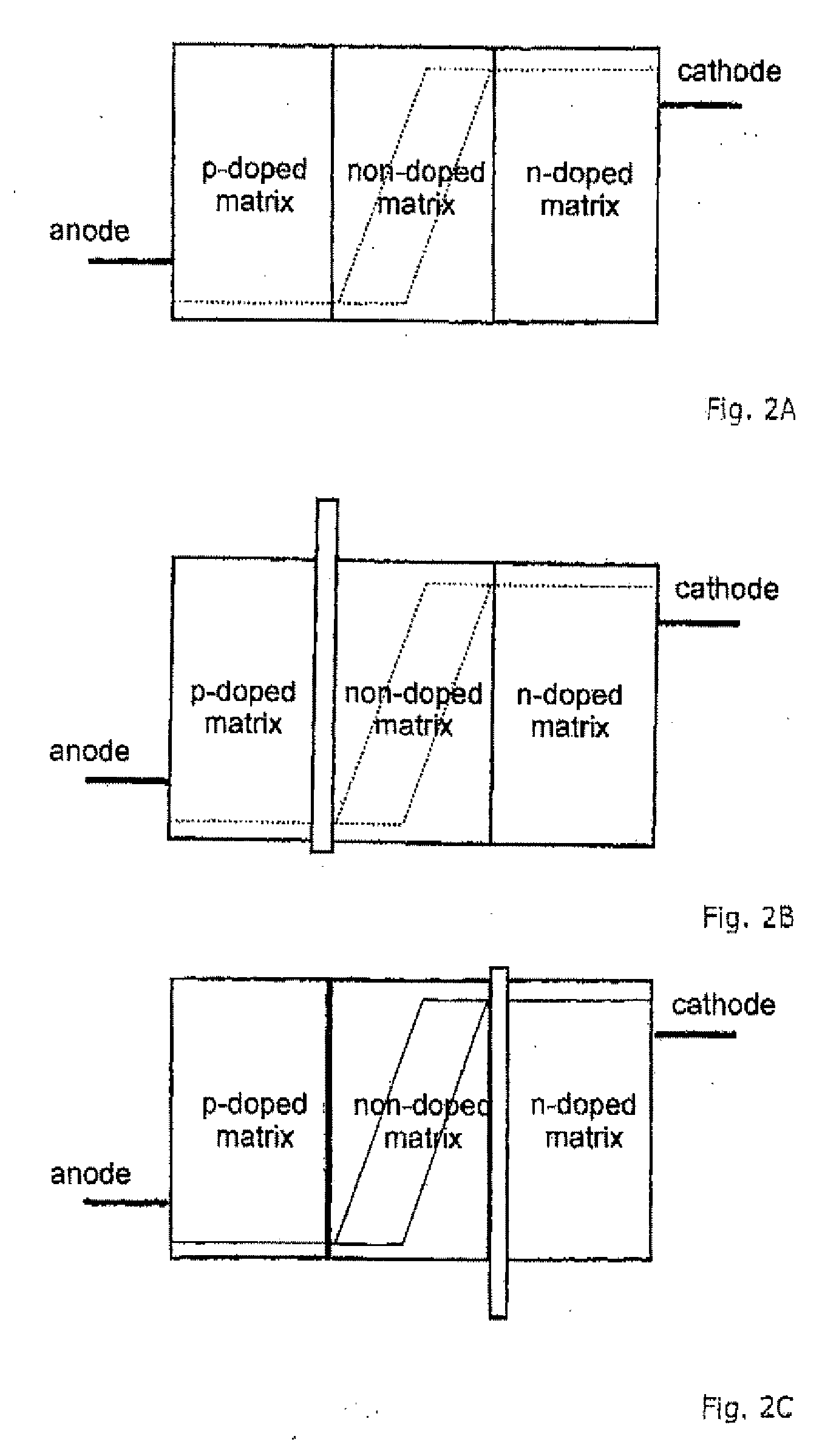

Arrangement for an Organic Pin-Type Light-Emitting Diode and Method for Manufacturing

ActiveUS20060250076A1Simple configurationReduce the number of layersDischarge tube luminescnet screensElectroluminescent light sourcesTransport layerCharge carrier

The invention relates to an arrangement for an organic pin-type light-emitting diode with an electrode and a counter-electrode and a stack with organic layers between the electrode and the counter-electrode, where the stack with the organic layers comprises an emission layer comprising a k (k=1, 2, 3, . . . ) organic matrix materials, a doped charge carrier transport layer, which is arranged between the electrode and the emission layer, a further doped charge carrier transport layer, which is arranged between the counter-electrode and the emission layer, and one block layer, which is arranged between one of the doped charge carrier transport layers and the emission layer. The organic layers of the stack are formed by means of n (n≦k+2) organic matrix materials, where the n organic matrix materials comprise the k organic matrix materials of the emission layer. The stack with the organic layers can also be executed in a block-layer-free manner, where then the emission layer and the doped charge carrier transport layer are formed from an organic matrix material. Furthermore, a method for manufacturing such arrangements is stated.

Owner:NOVALED GMBH

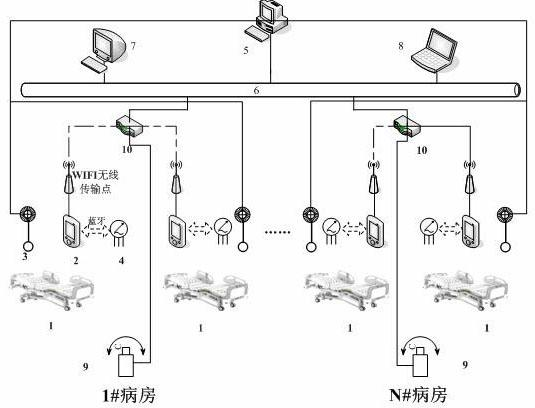

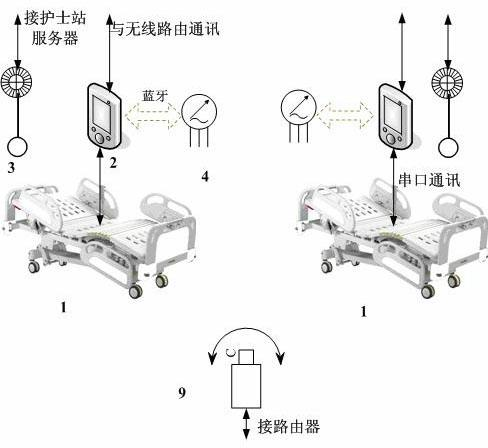

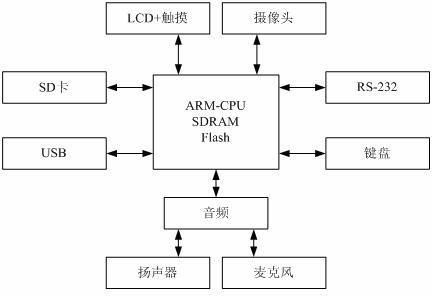

Digitalized information management system for nursing stations in hospitals and method for realizing same

InactiveCN102592063ASolve trivial mattersSolve hectic problemsFlow monitorsSpecial data processing applicationsPatient roomInformatization

The invention discloses a digitalized information management system and a method for realizing the same for nursing stations in hospitals. The digitalized information management system comprises nursing station monitoring management equipment, multiple ward field apparatuses and a communication network, and the communication network is used for connecting the ward field apparatuses with the nursing station monitoring management equipment. The digitalized information management system for nursing stations in hospitals integrates functions of general information processing, intelligent patient and bed combination, intelligent video tracking, calling information linkage and remote transfusion monitoring and alarming by the aid of the network communication, intelligent control and data processing and the like and realizes digitalization of general operation and informatization of ward management, and further, medical treatment technical level, medical treatment efficiency and safety in hospital of patients can be improved, meanwhile, resources are reasonably optimized and configured and resource waste is reduced.

Owner:HEBEI PUKANG MEDICAL INSTR

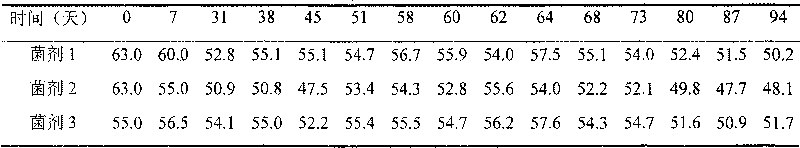

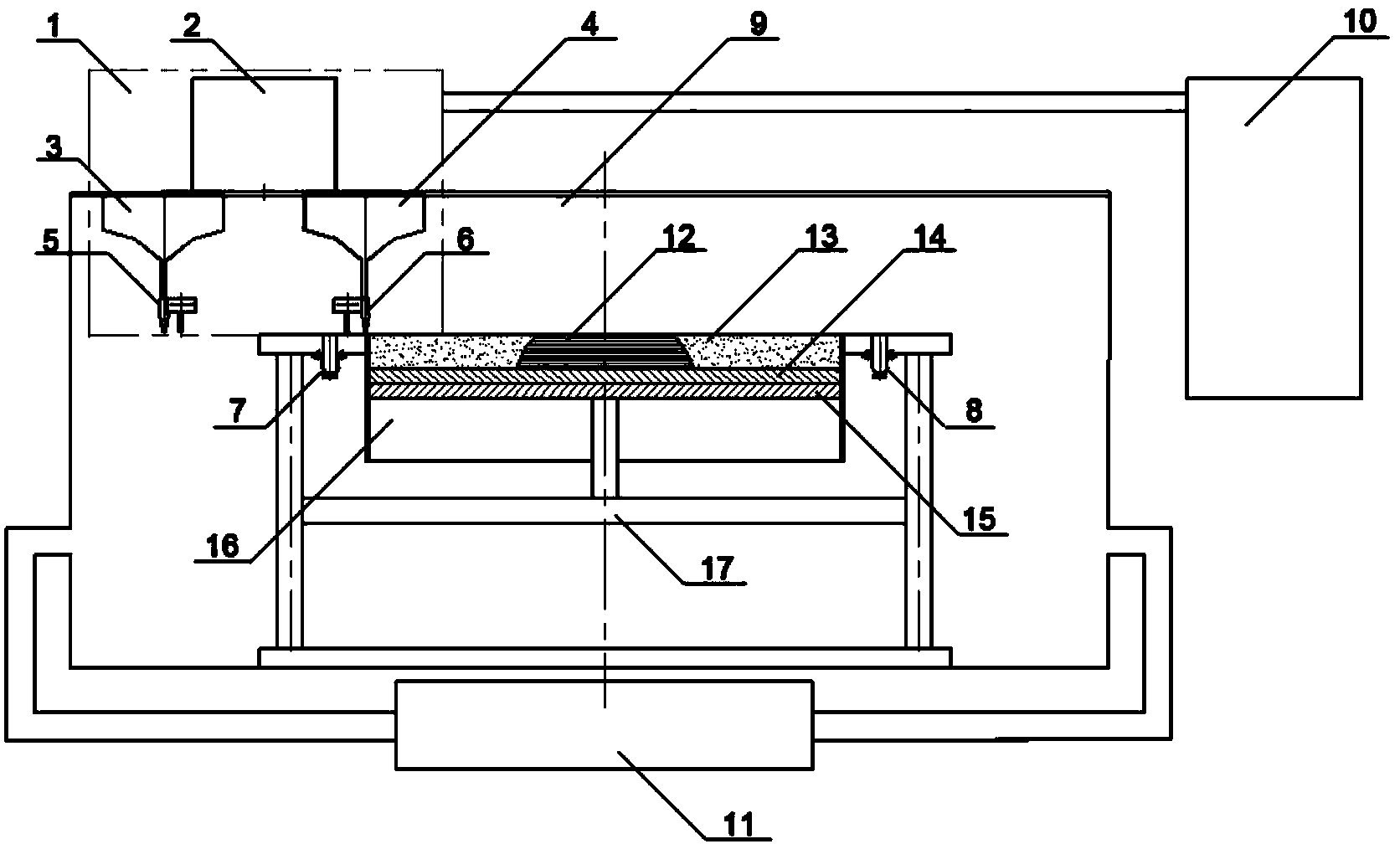

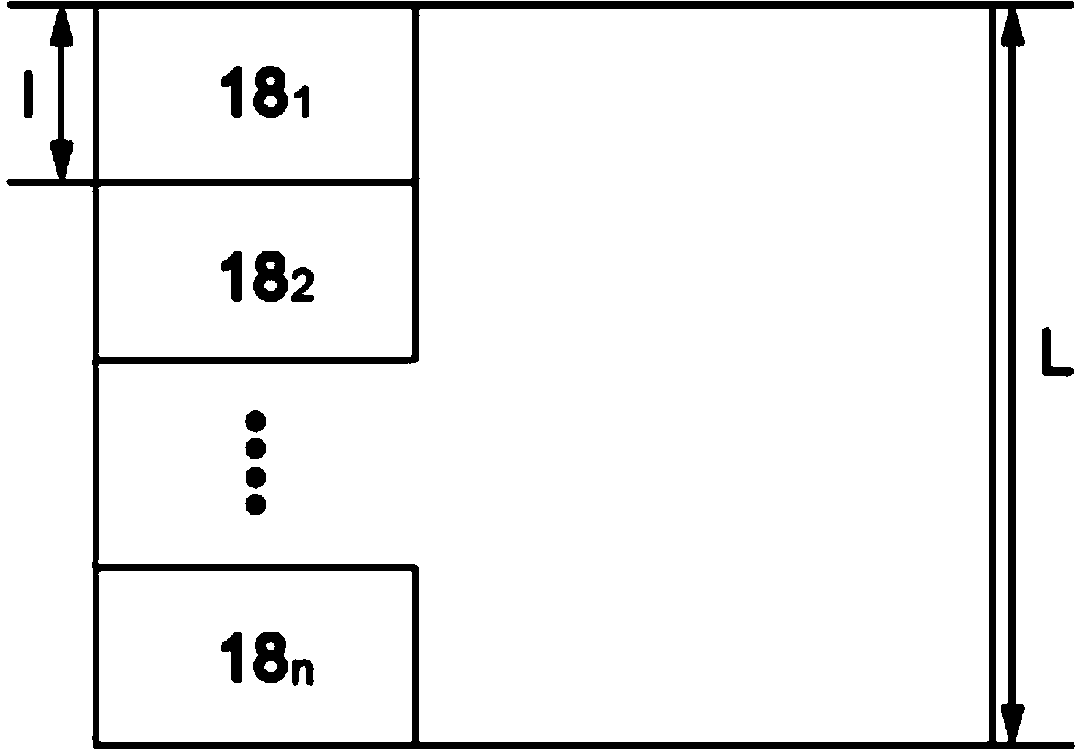

Equipment for manufacturing large-size metal part in high energy beam additive manufacturing mode and control method of equipment

ActiveCN104001915AImprove forming efficiencyShorten the "waiting time"Increasing energy efficiencyControl systemEngineering

The invention discloses equipment for manufacturing a large-size metal part in a high energy beam additive manufacturing mode and a control method of the equipment. The equipment comprises a work cavity, a worktable, a control system, a high energy beam scanning generator, a powder storage hopper, a powder laying device and a gas purification module, wherein the worktable is composed of a forming cylinder and a powder recycling cylinder, and the upper surface of the forming cylinder and the upper surface of the powder recycling cylinder are coplanar and form a work plane. The control system controls the high energy beam scanning generator and the powder laying device to move opposite to the worktable in the powder laying direction. The equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment largely shorten the waiting time caused by pre-installation of a powder bed when a common laser / electron beam selective melting technology is used for processing a part, thereby obviously improving the forming efficiency of high energy beam additive manufacturing. Through the application of the equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment, a metal part with a meter-grade size, high performance, high accuracy and a complex structure can be manufactured efficiently and rapidly.

Owner:TECH LASER TECH SHANGHAI CO LTD

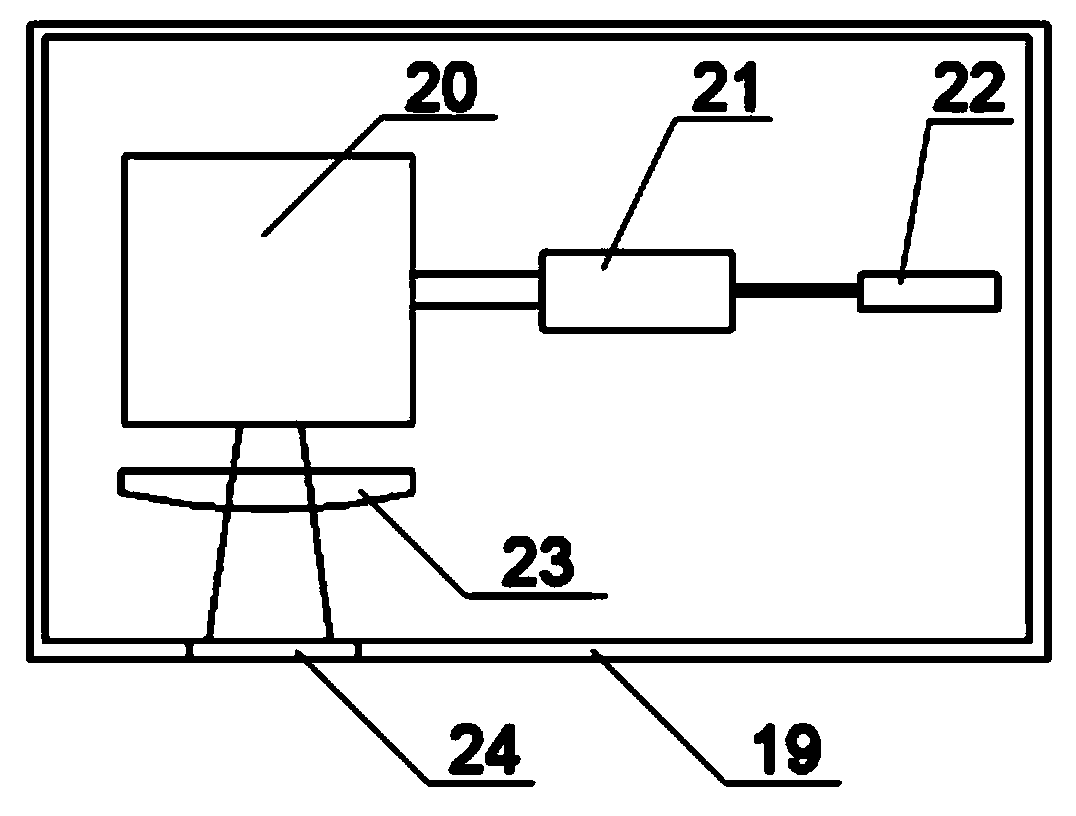

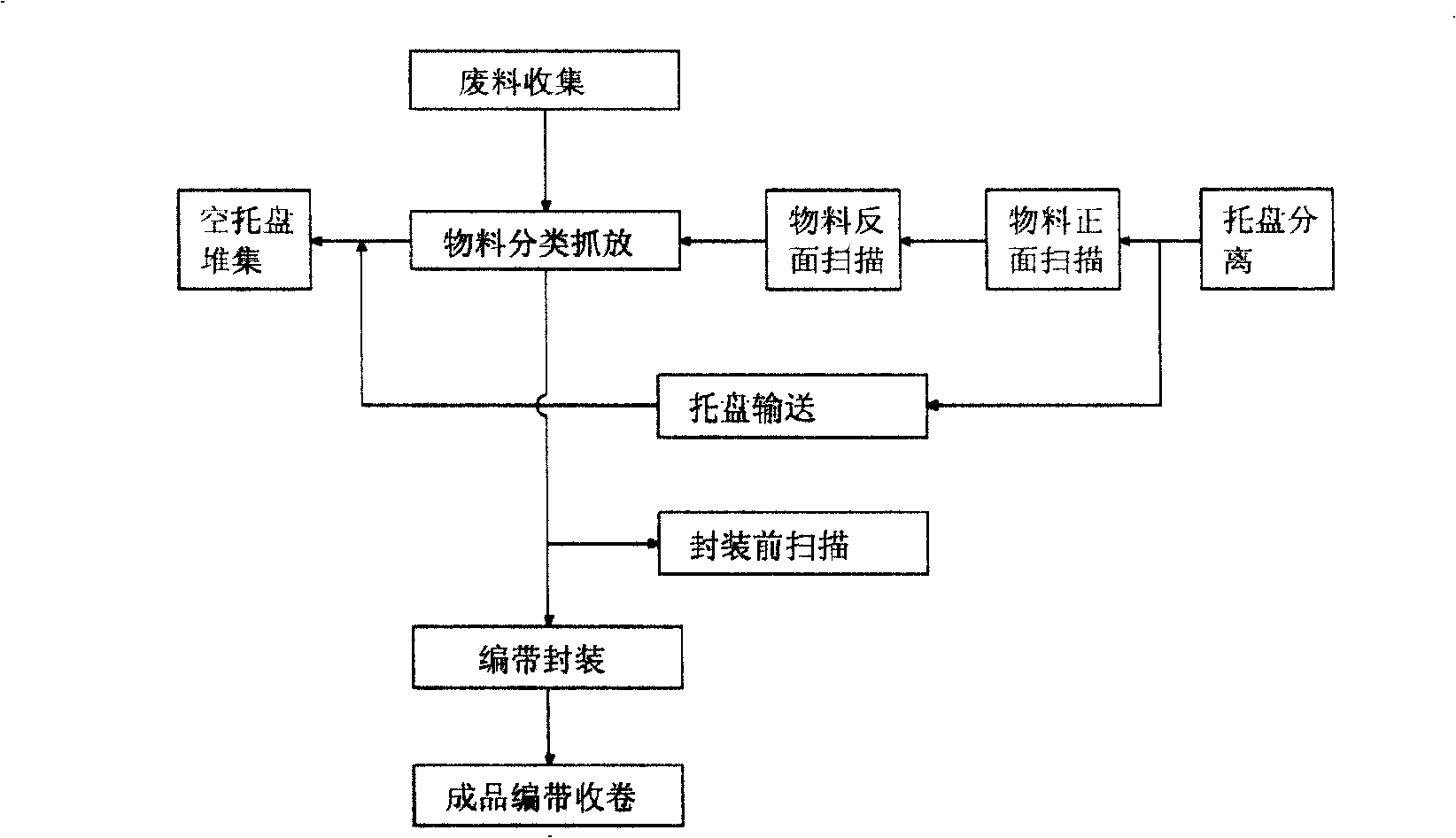

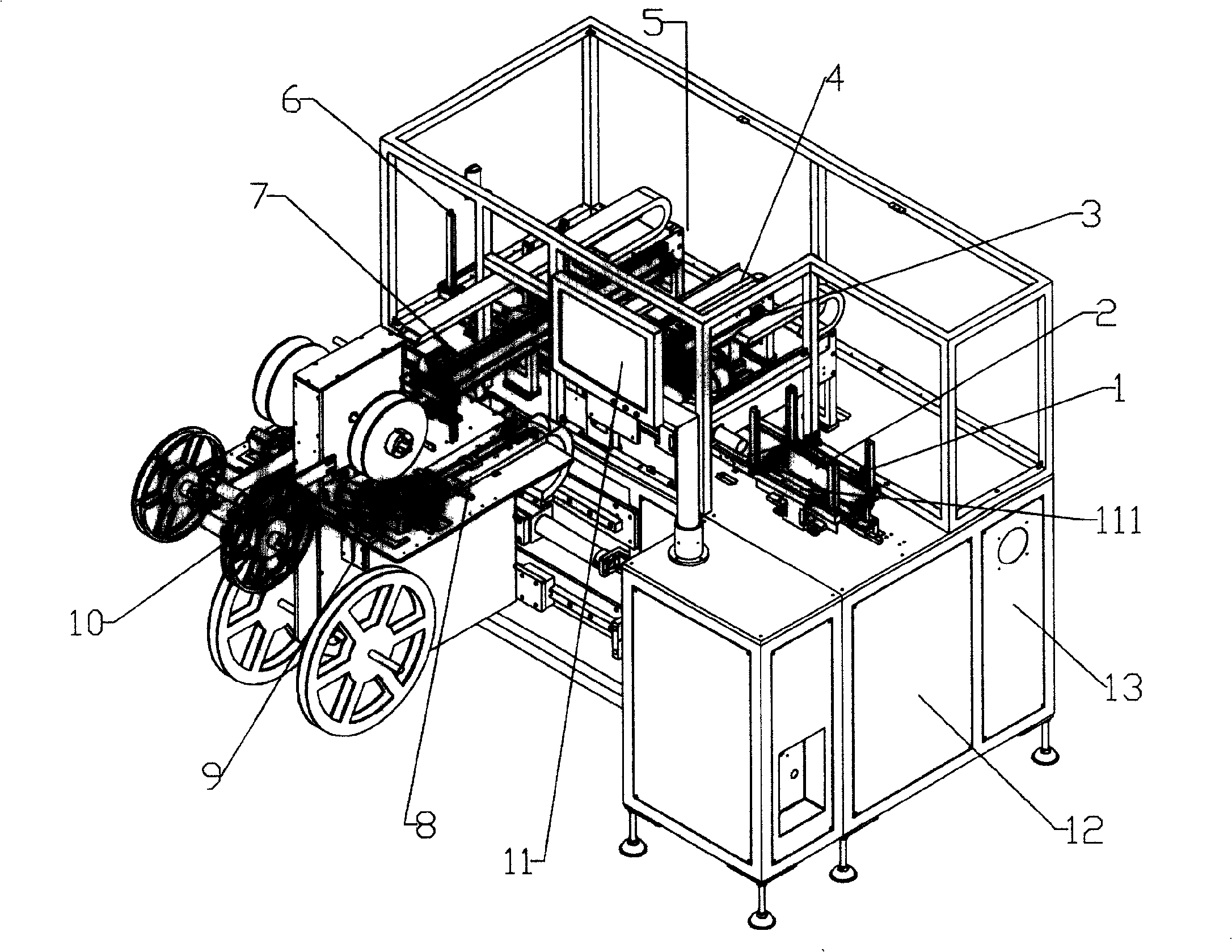

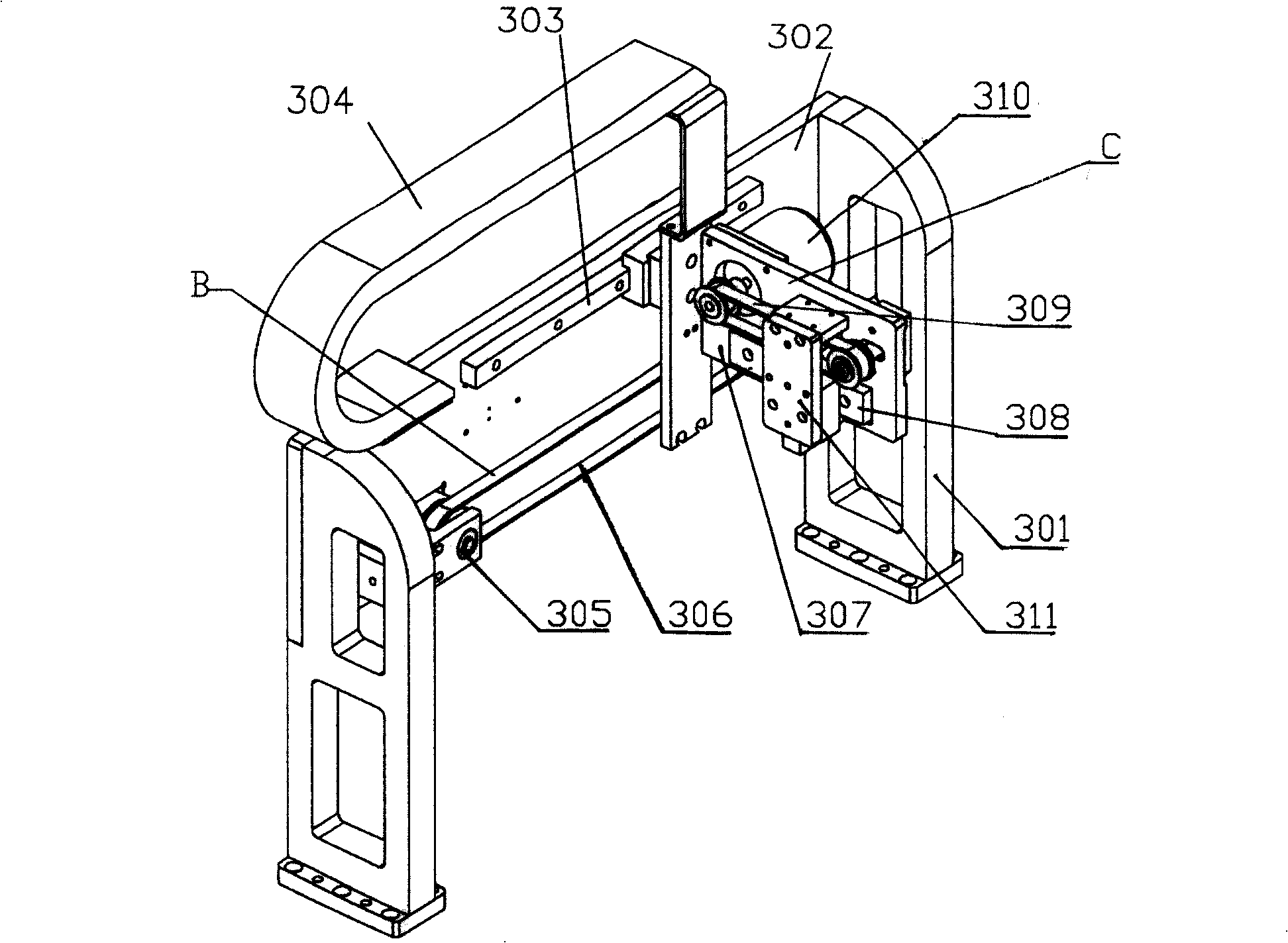

IC full-automatic method for testing brede and full-automatic holding tray type machine for testing brede

InactiveCN101244767AQuality assuranceAvoid lostSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationElectricityControl system

The invention discloses an IC automatic detecting braiding method and an automatic pallet type detecting braiding machine, comprising a pallet-transport device, a braiding packing device, a waste materials collecting device. A PC control system and an electrical control system as well as a pallet-separate device are arranged on the front end of the pallet transport device and an empty pallet-collect device is arranged on the back end. The braiding lead direction of the braiding packing device is vertical to the pallet-transport direction of the pallet-transport device. A face side scan device and a back side device for detecting IC as well as a catch-and-put device for catching IC from the pallet are orderly arranged in the transportation range of the pallet-transport device. The catch-and-put device is electrically connected with the PC control system and the electrical control system and is a classification catch-and-put device which can classify the ICs according to the detecting results of the face side scan device and the back side device and then send the eligible ICs to the braiding packing device and the unqualified ICs to the waste materials collecting device. The braiding machine has the advantages of good accuracy and reliability for scanning and detecting, rapid speed for braiding and packing, low composite cost and high production efficiency.

Owner:GRAND TECH SHENZHEN

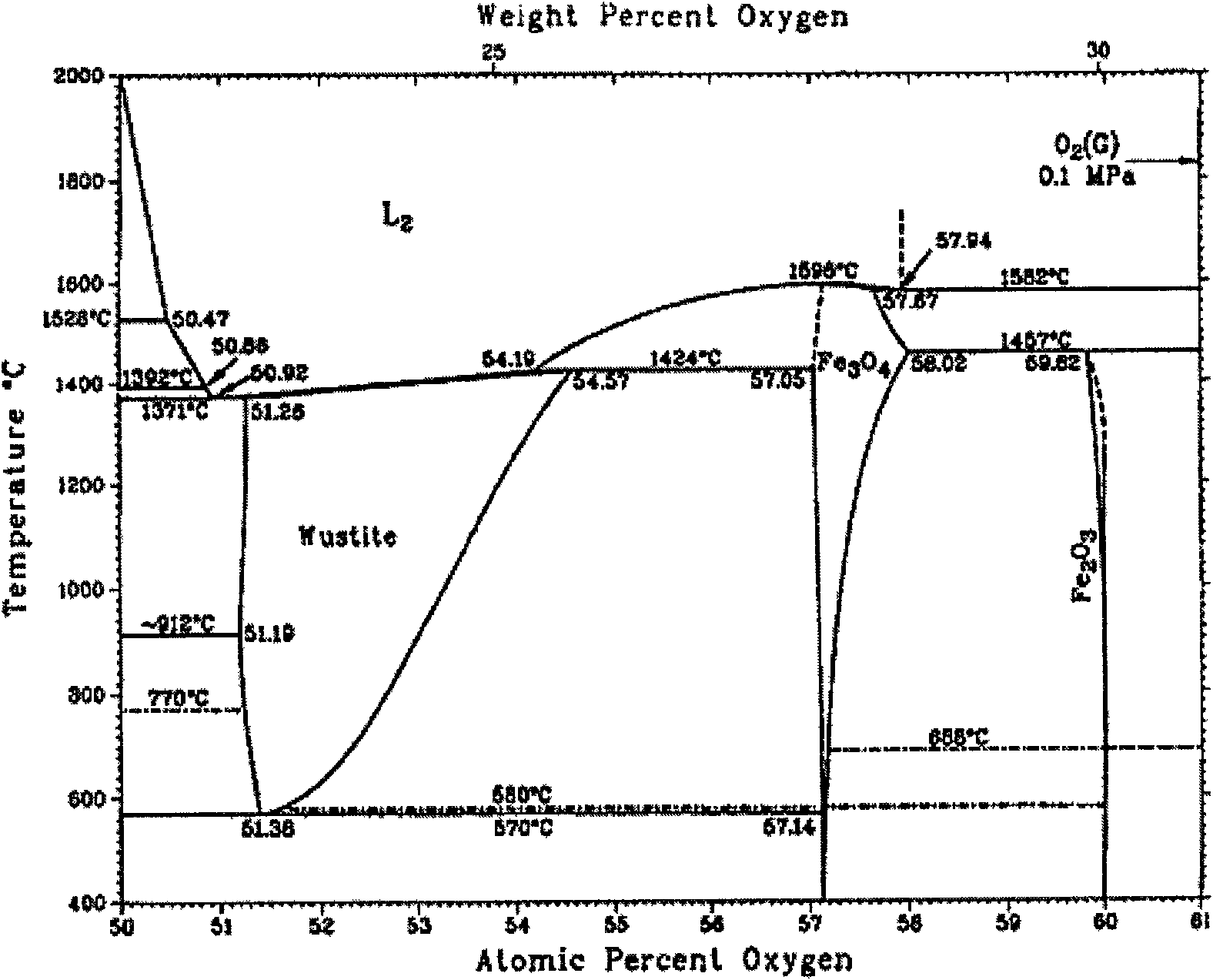

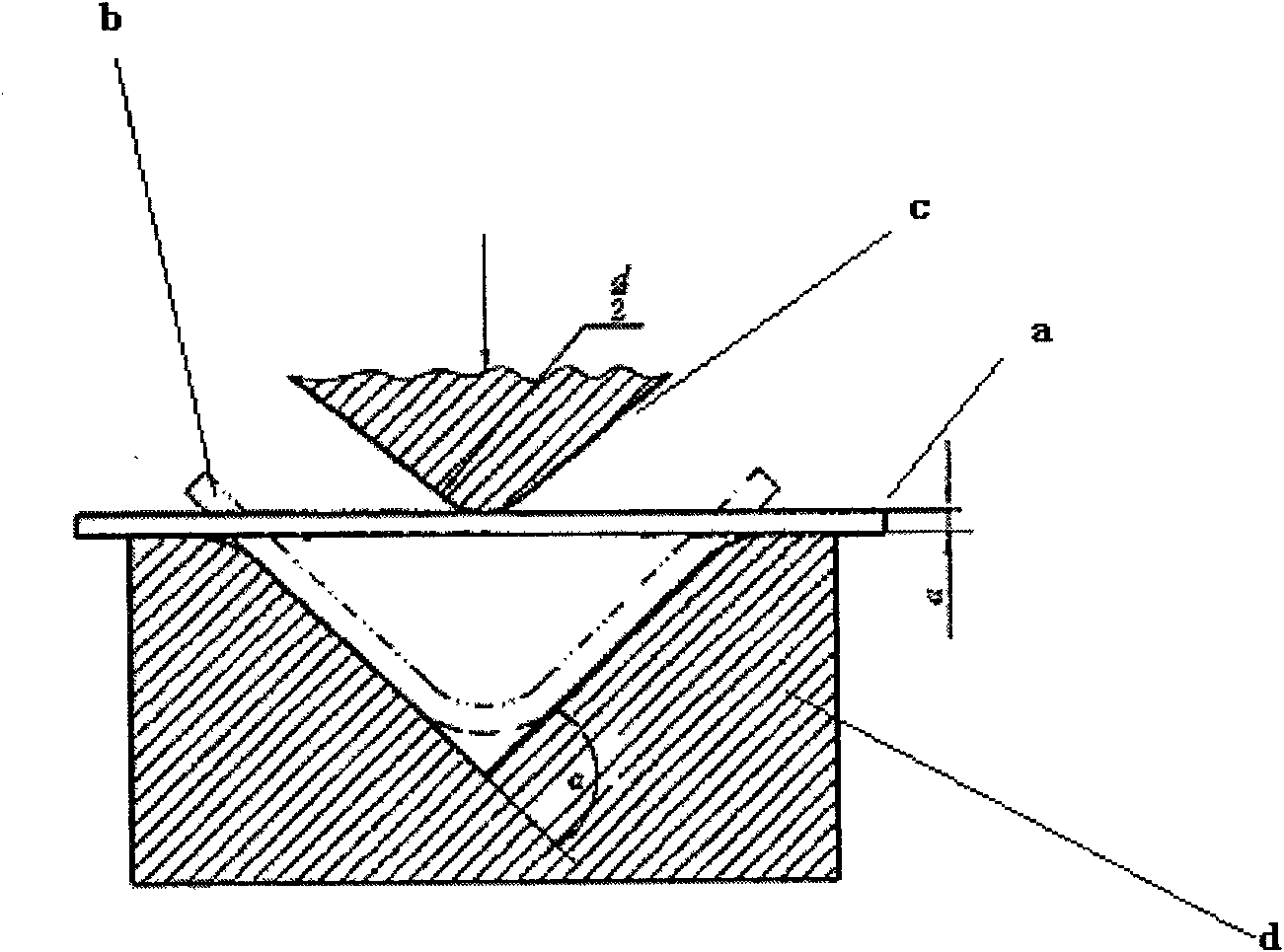

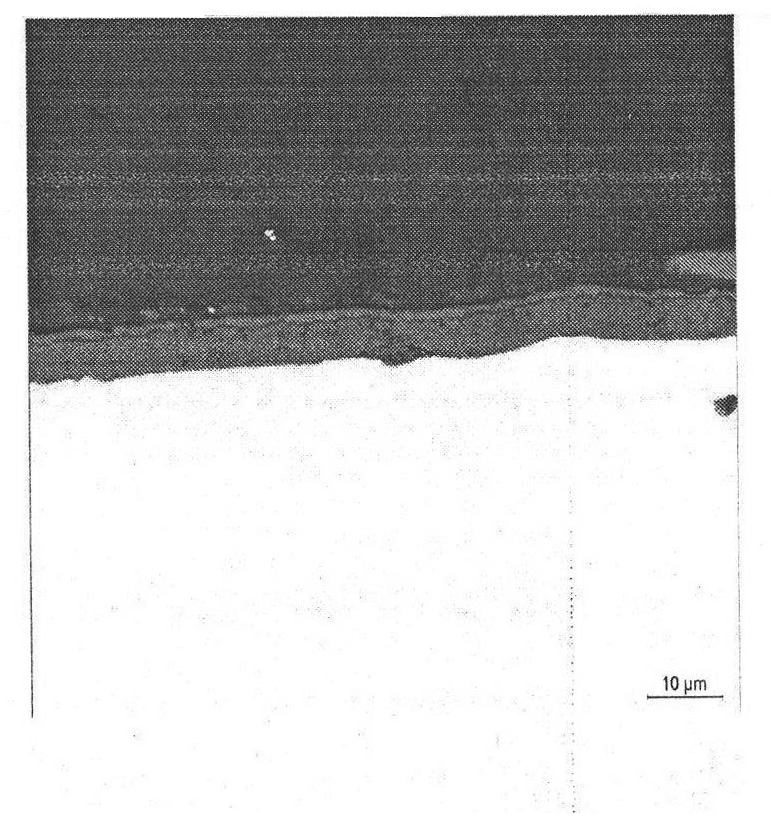

Control method of softness of oxide scales on surface of hot-rolling strip steel

ActiveCN101856669AImprove adhesionReduce FeO fragmentationTemperature control deviceWork treatment devicesOxideRolling speed

The invention provides a control method of softness of oxide scales on the surface of hot-rolling strip steel, belonging to the technical field of metallurgy. The method comprises the following steps: smelting liquid steel and continuously casting into plate blanks, heating and conducting thermal insulation on the plate blanks, then descaling, and rough rolling; and descaling again, and then finish rolling, wherein the initial rolling temperature is 1020-1070 DEG C, the finish rolling temperature is 870-920 DEG C, the rolling reduction is 75-95%, and the rolling speed is 3.5-12 m / s; cooling to 500-650 DEG C at the speed of 8-25 DEG C / s; and coiling. Aiming to different oxide scales structures, a hot-rolling process regulation scheme is provided in the method. In the hot-rolling process regulation scheme, by controlling the cooling speed and coiling temperature and the degree of a eutectoid reaction of FeO, reasonable control of the structure of the oxide scales is achieved, and loss of mechanical properties of products, which is caused by high temperature rolling, is compensated. The production efficiency is improved by using the existing devices and process conditions in a steel plant, surface quality is improved on the premise of ensuring mechanical properties of the steel plate and flexible production of oxide scale control.

Owner:NORTHEASTERN UNIV

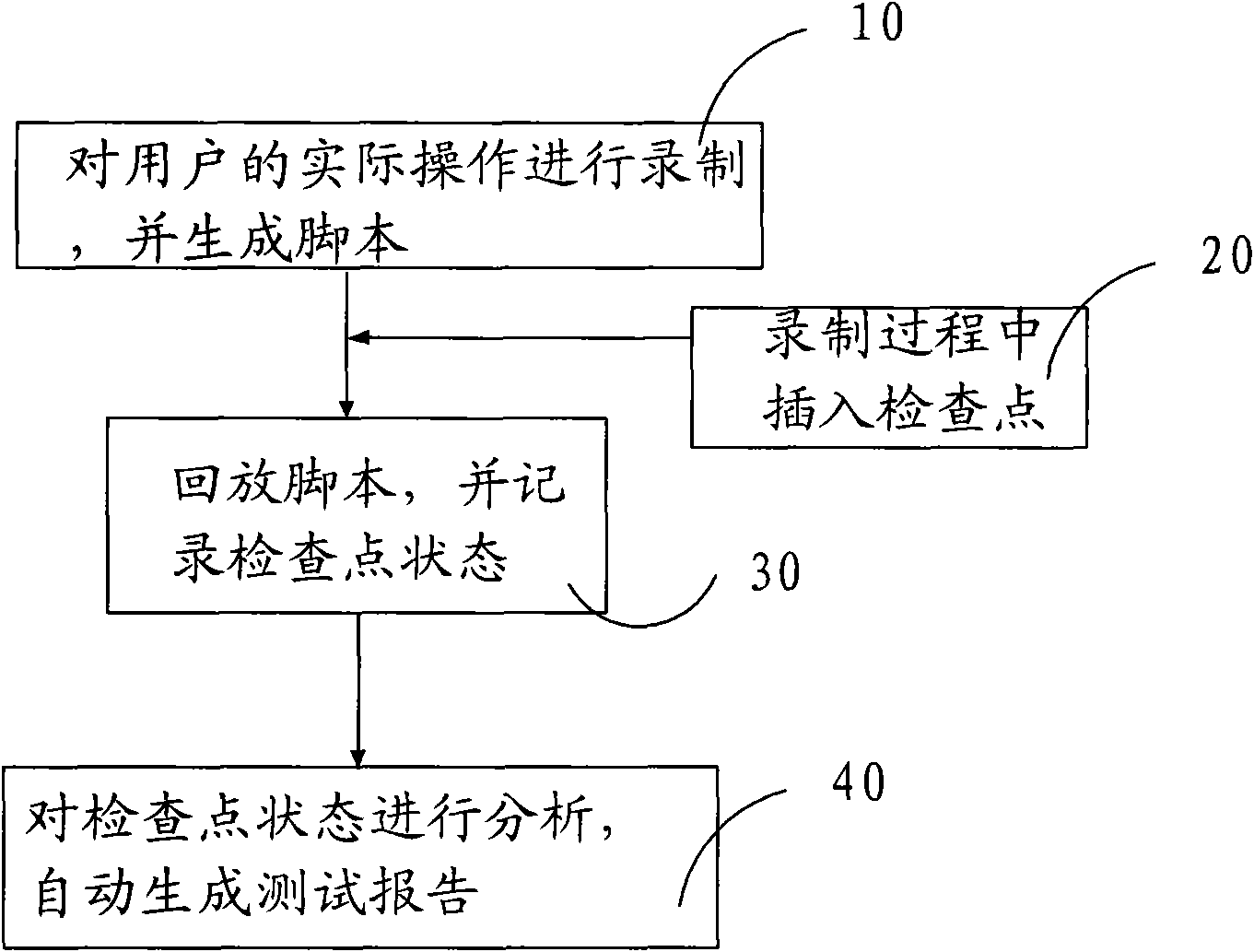

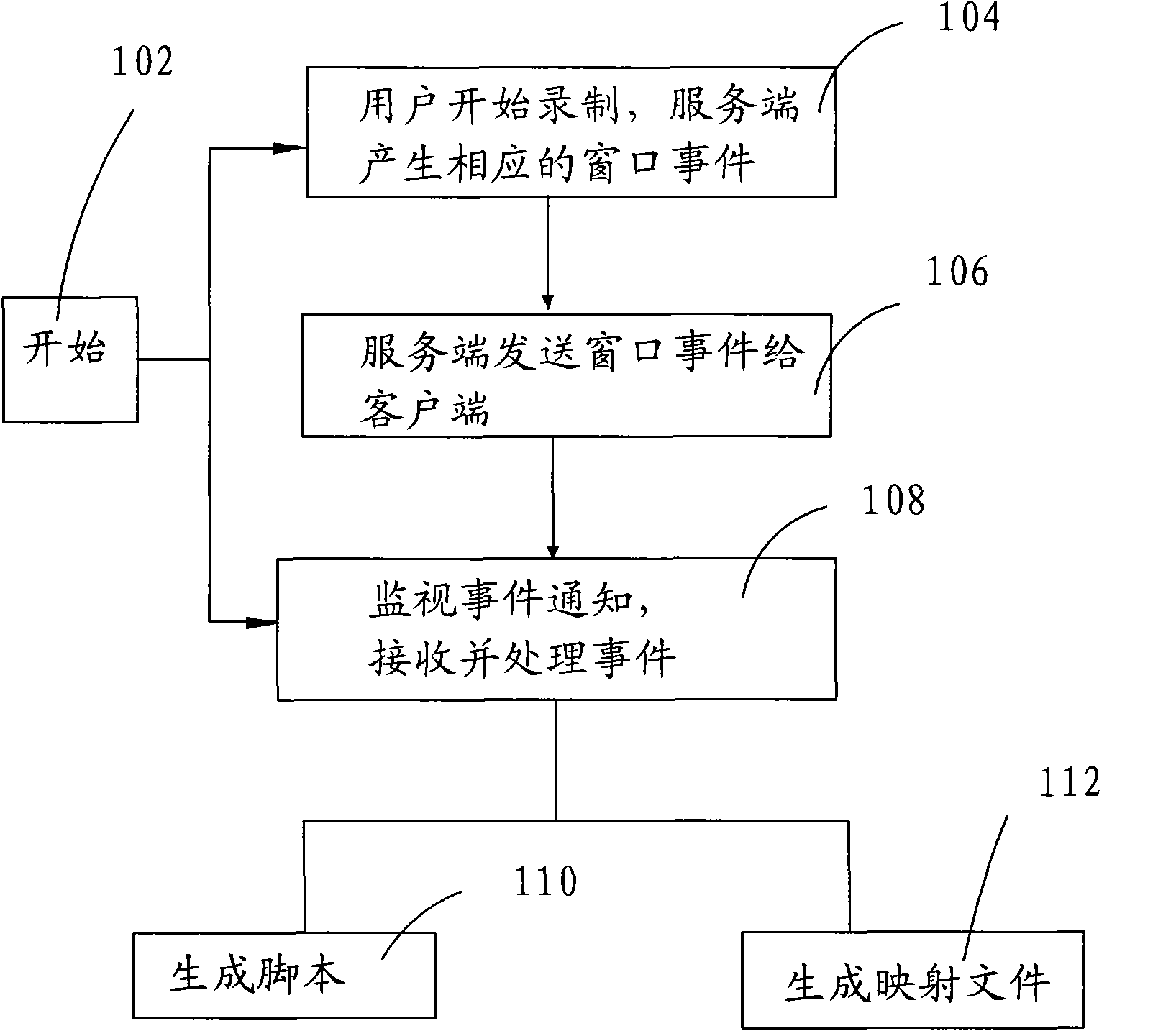

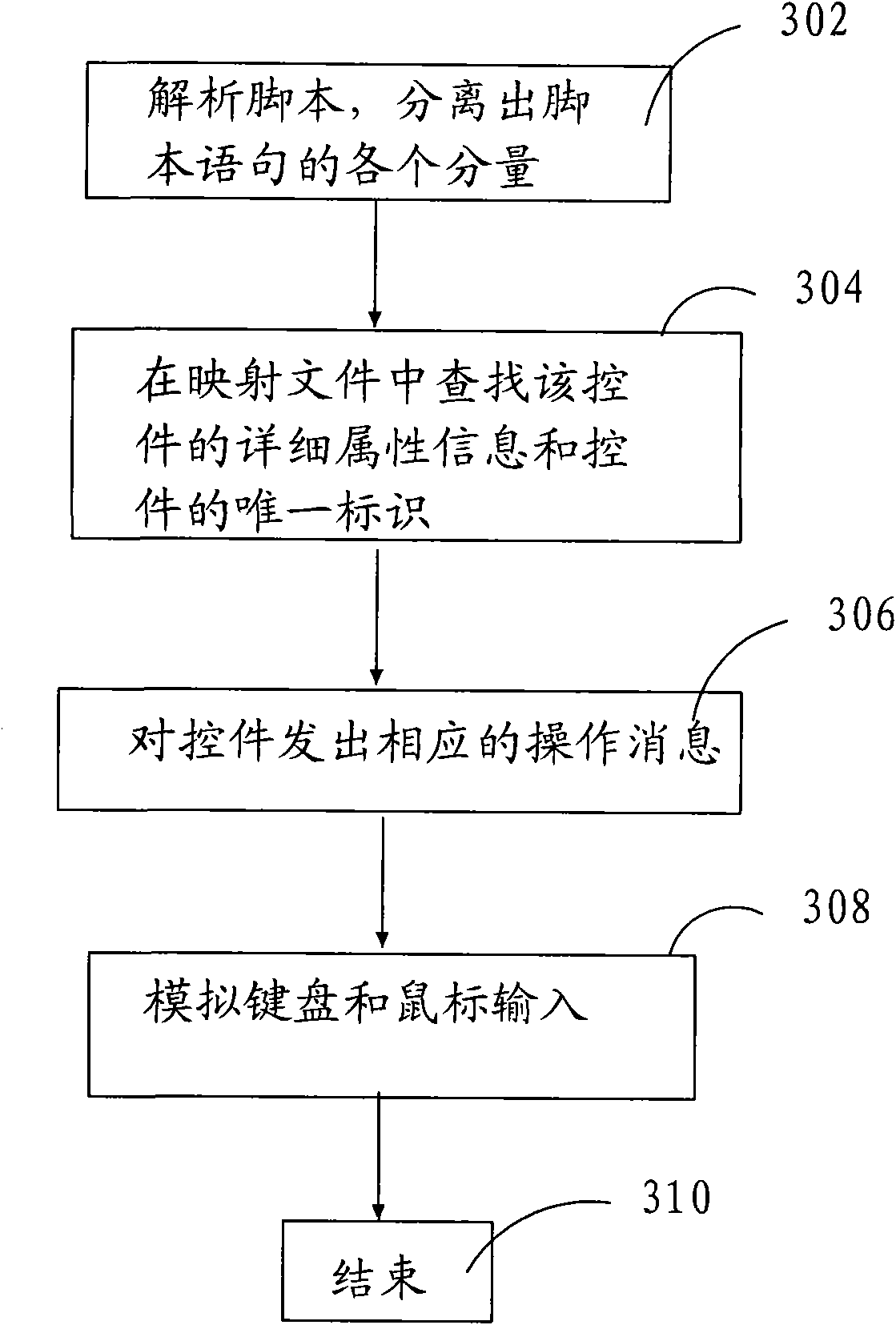

Method for automatically testing recording playback mode of terminal system

InactiveCN101620564ACheckpoints are reliableShorten test timeSoftware testing/debuggingCheck pointTerminal system

The invention relates to a method for automatically testing a recording playback mode of a terminal system, which comprises the following steps: 10, recording actual operation of a user, which comprises mouse operation and keyboard operation, and automatically generating a script which is easily understood by the user and can be edited manually; 20, in the recording process in the step 10, inserting a check point of which the state is required to be checked in an automatic test; 30, playing the script generated in the step 10 back, automatically executing the test, and recording the state of the check point; and 40, finishing the playback of the script, analyzing the recorded state of the check point, summarizing test results, and automatically generating a test report. The method has the advantages of being suitable for automatic functional tests of terminal embedded systems and non-embedded systems, supporting tests for functions of protocols such as ICA, RDP and the like, providing reliable check points for testing GUI functions, and saving testing time.

Owner:FUJIAN CENTM INFORMATION

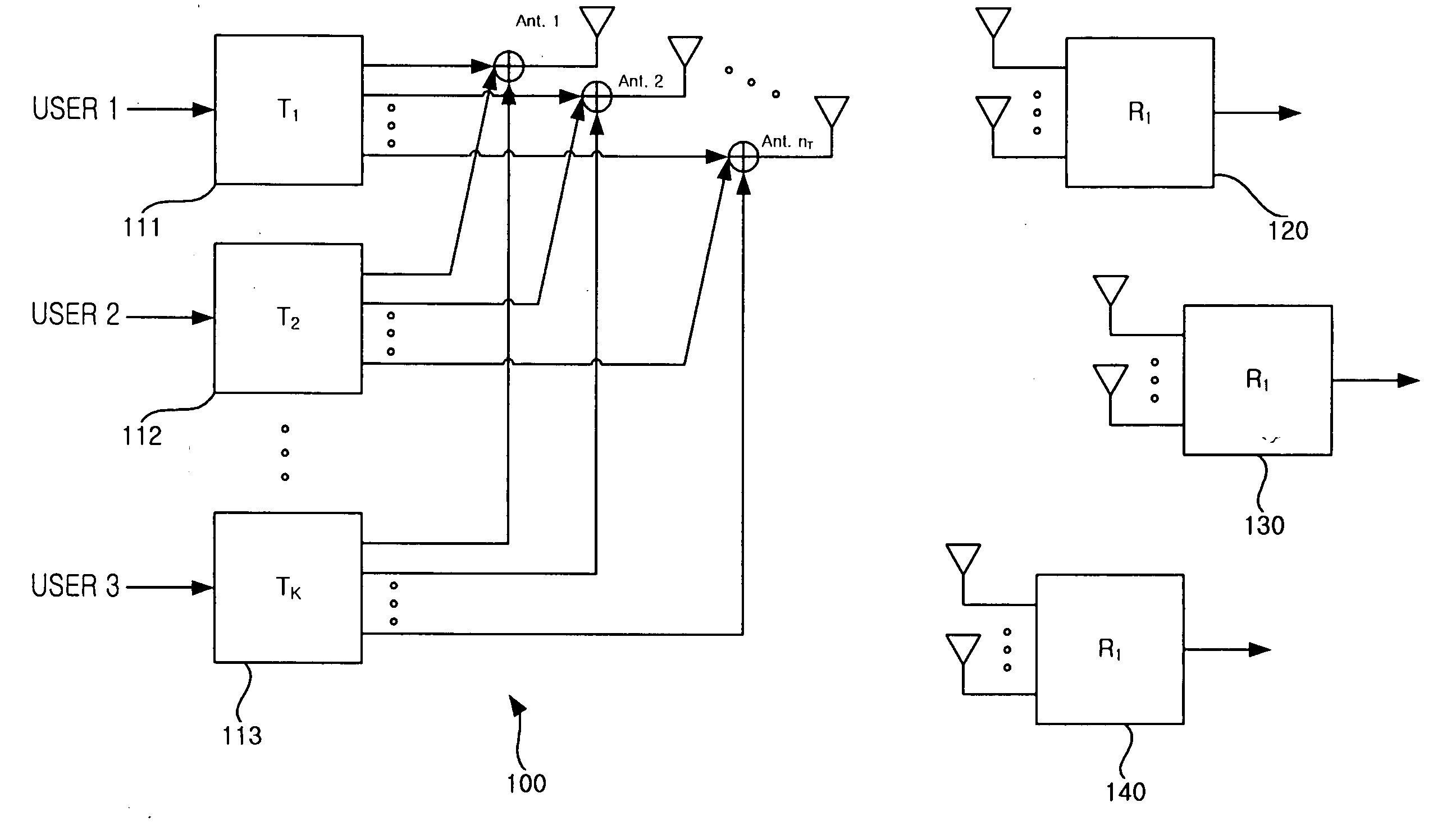

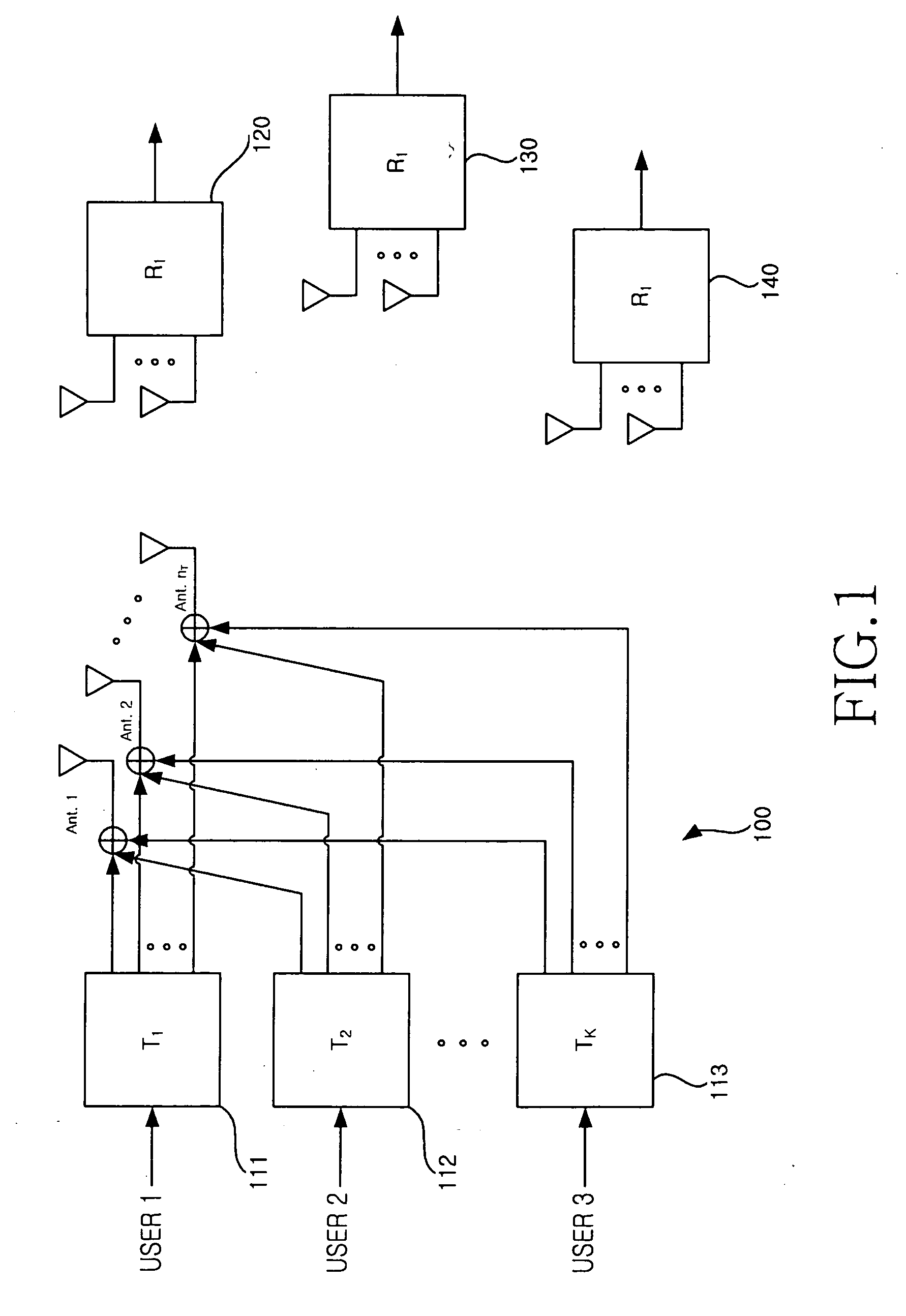

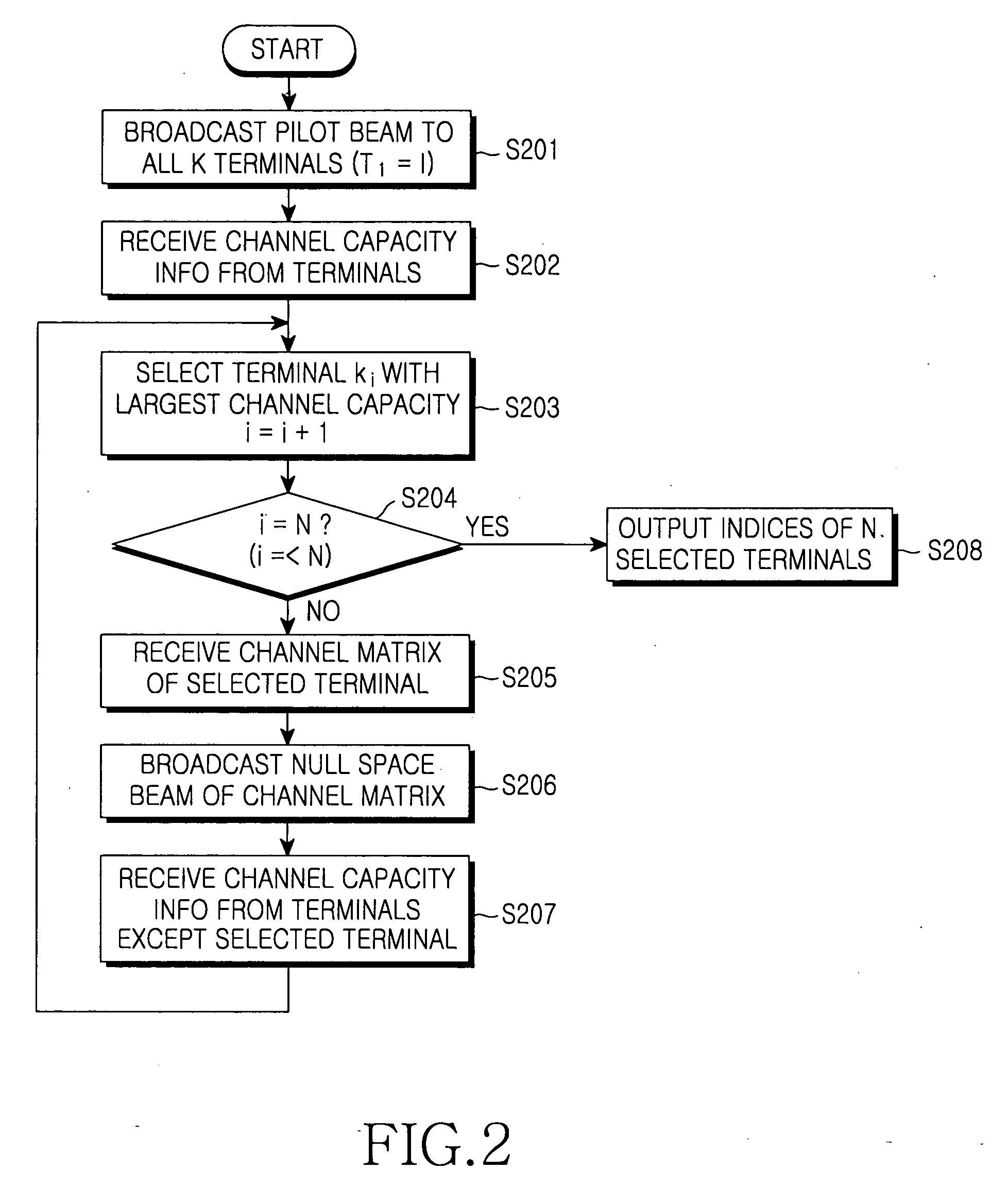

User selection method in a zero-forcing beamforming algorithm

InactiveUS20070058590A1Improve performanceIncrease throughputDiversity/multi-antenna systemsSubstation equipmentChannel capacityEngineering

In a method for selecting a transmission target terminal in a zero-forcing beamforming algorithm, information about a channel capacity of each terminal is received from all K terminals. A terminal with a largest channel capacity is selected as an initial transmission target terminal. A determination is made as to whether the number of currently selected terminals, i, is equal to the predefined number N. If the number of currently selected terminals, i, is different from the predefined number N, information about channel capacities of remaining terminals except previously selected transmission target terminals is received until i is equal to N and a terminal with a largest channel capacity is selected as a transmission target terminal.

Owner:SAMSUNG ELECTRONICS CO LTD +1

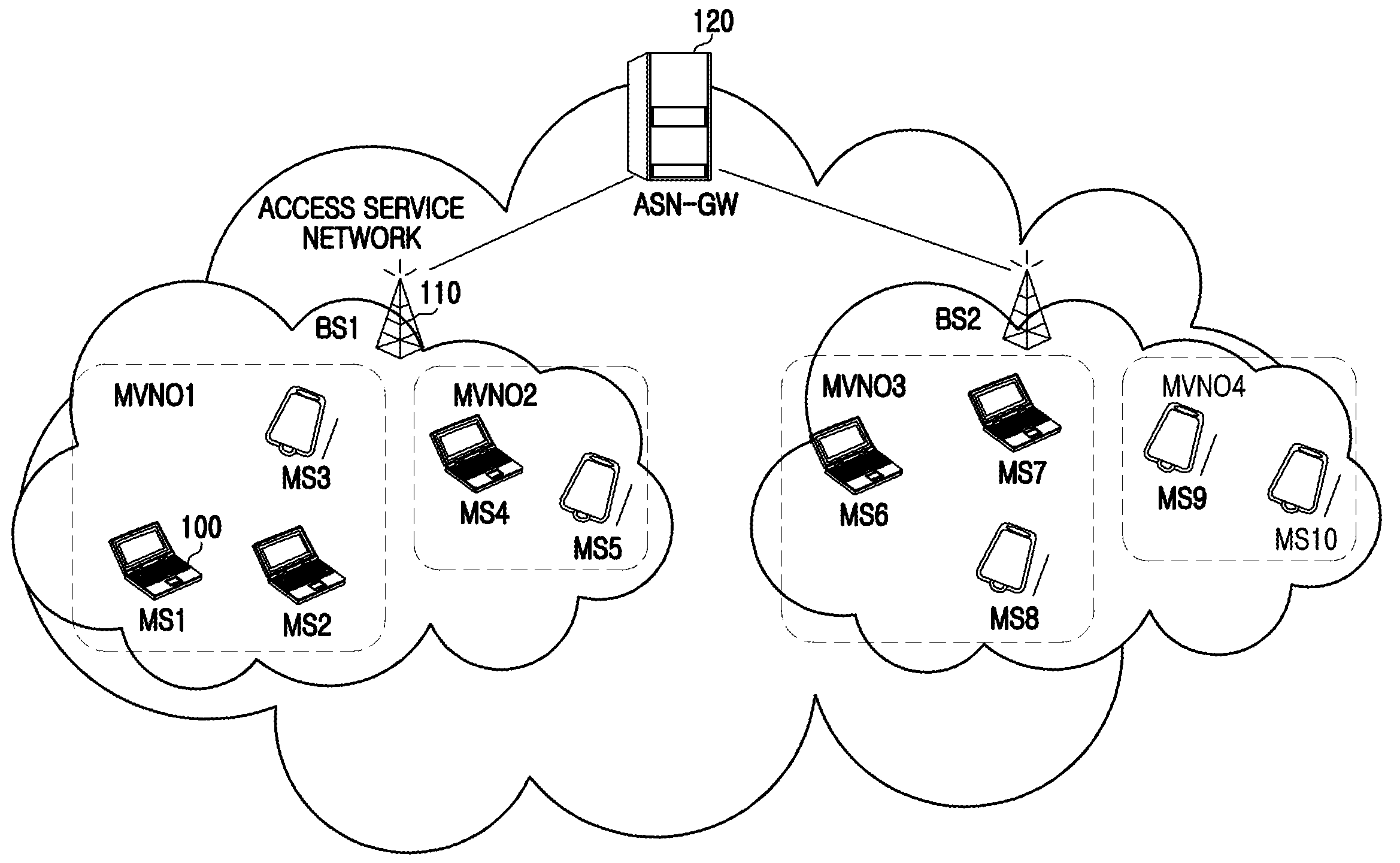

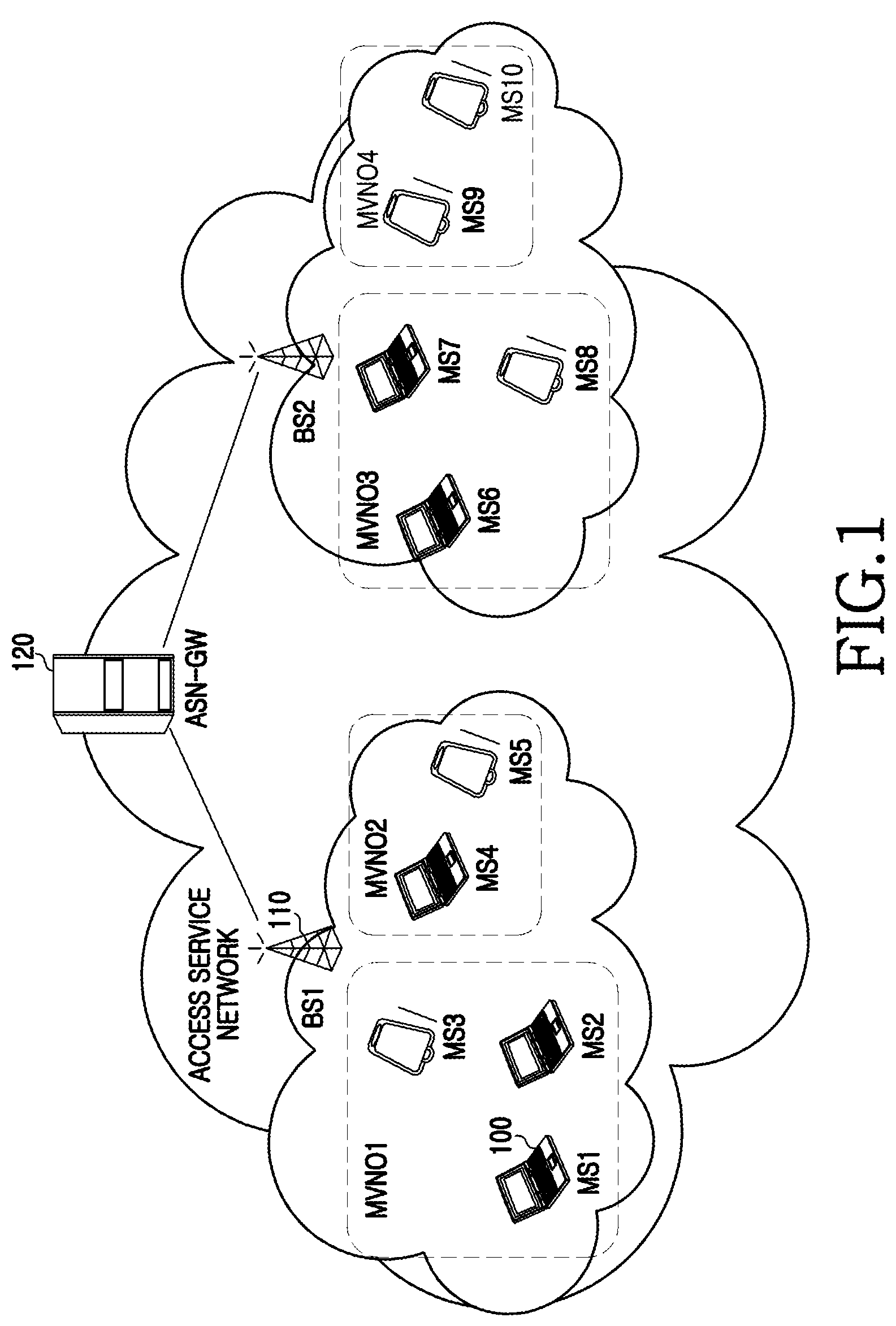

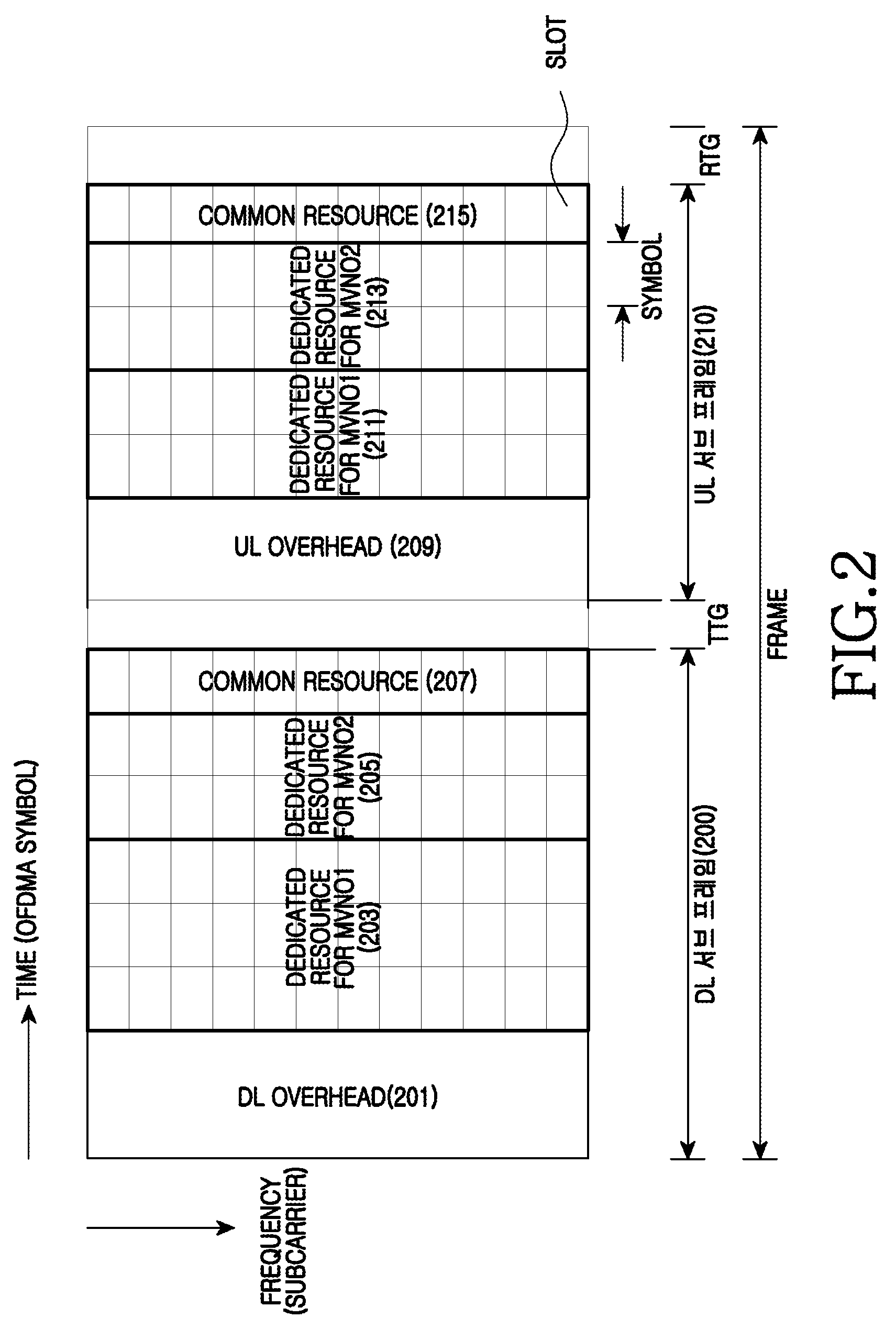

Scheduling apparatus and method for proportional resource allocation among mobile virtual network operators

InactiveUS20090154415A1Improve resource utilization efficiencyQuality assuranceNetwork traffic/resource managementTime-division multiplexQuality of serviceResource allocation

A scheduling apparatus and method for proportional resource allocation among Mobile Virtual Network Operators (MVNOs) are provided. The method includes, for each MVNO, allocating a dedicated resource of each MVNO to Quality of Service (QoS) traffic in consideration of priorities, for each MVNO, determining a presence or absence of unscheduled QoS traffic, and for MVNOs each of which has the unscheduled QoS traffic, allocating a common resource shared by all MVNOs to the unscheduled QoS traffic in consideration of priorities without distinguishing each MVNO. Accordingly, proportional resource allocation depending on a pre-set ratio can be guaranteed, efficiency of resource use can be improved, and QoS can be guaranteed.

Owner:SAMSUNG ELECTRONICS CO LTD

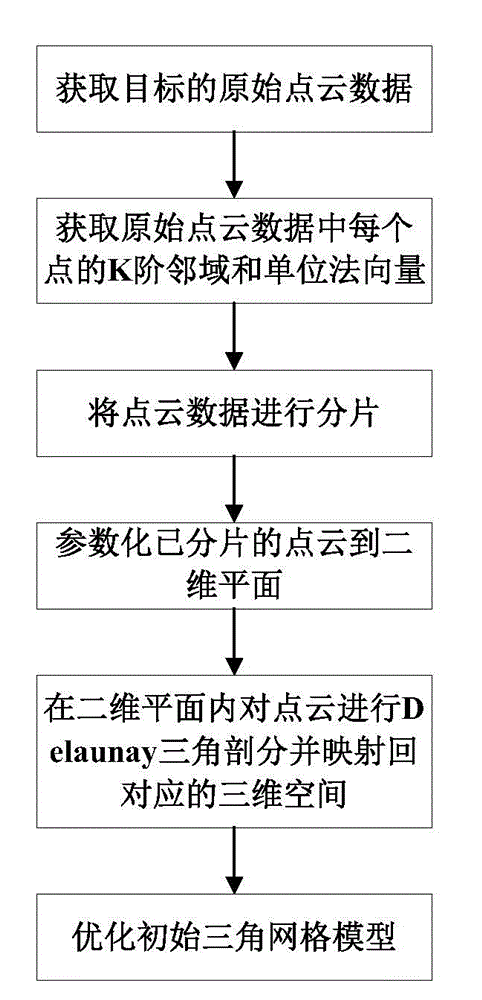

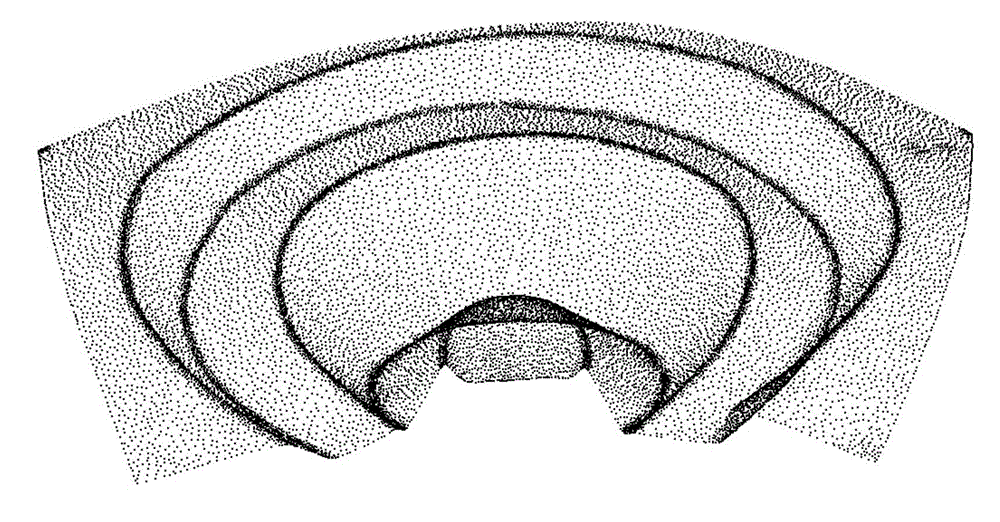

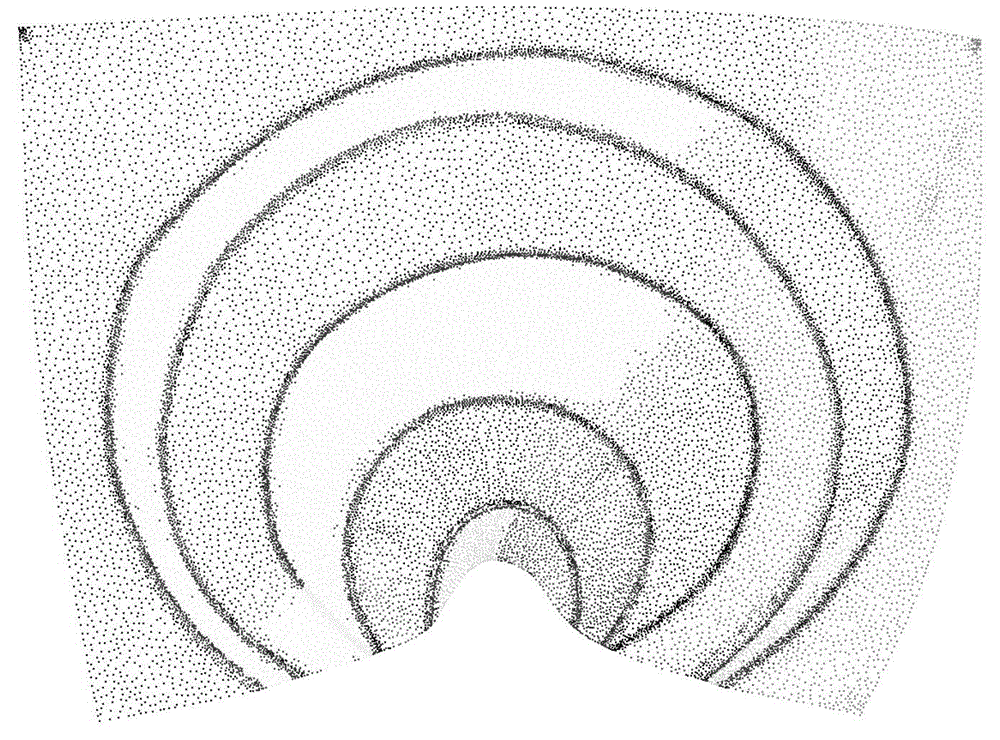

Scattered point cloud Delaunay triangulation curved surface reconstruction method based on mapping method

The invention relates to a scattered point cloud Delaunay triangulation curved surface reconstruction method based on a mapping method and belongs to the field of a computer graphics and virtual reality technology. The method specifically includes the first step of obtaining original point cloud data of a target, the second step of obtaining K-level neighborhoods and unit normal vectors of all points in the original point cloud data, the third step of fragmenting the point cloud data, the fourth step of parameterizing fragmented point clouds to a two-dimensional plane, the fifth step of conducting Delaunay triangulation on the point clouds in the two-dimensional plane and mapping the point clouds back to corresponding three-dimensional space, and the sixth step of optimizing an initial triangle mesh model. Compared with the prior art, the scattered point cloud Delaunay triangulation curved surface reconstruction method based on the mapping method has the advantages that the quality of a triangle mesh can be ensured and triangle meshing on the scattered point clouds can be quickly realized when mesh modeling is carried out on large-scale point cloud data, and the method has a better effect on large-scale point clouds.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

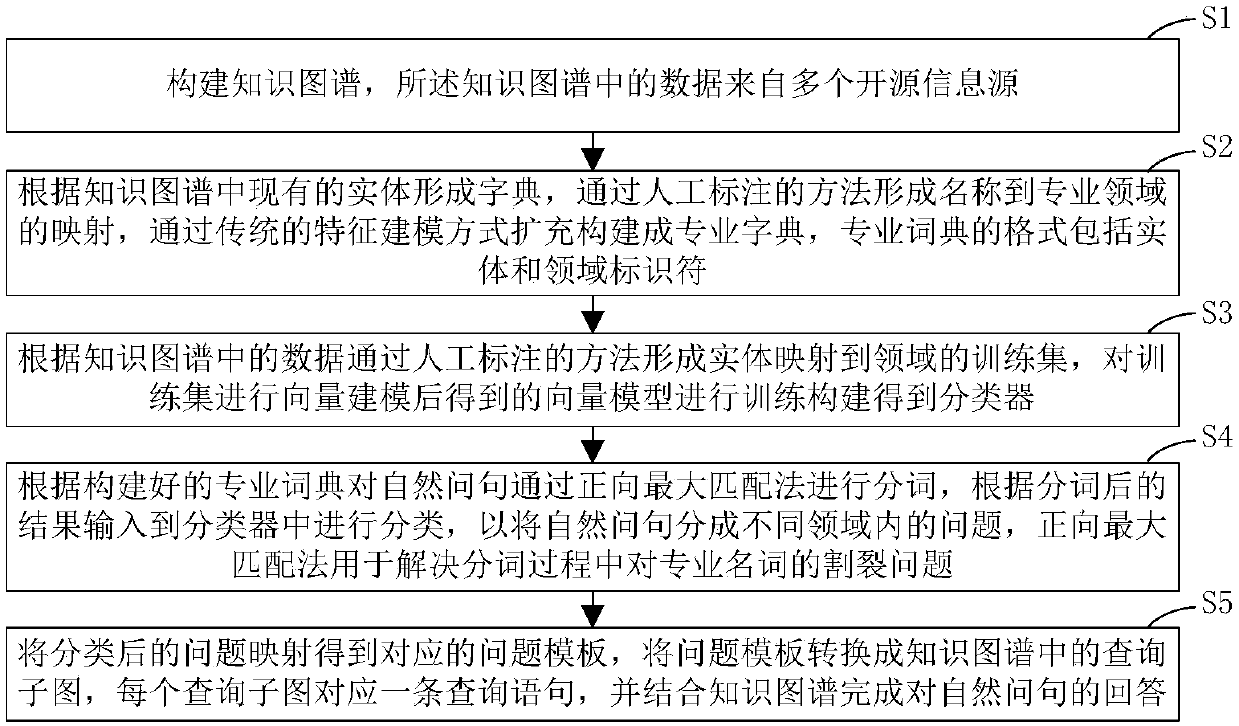

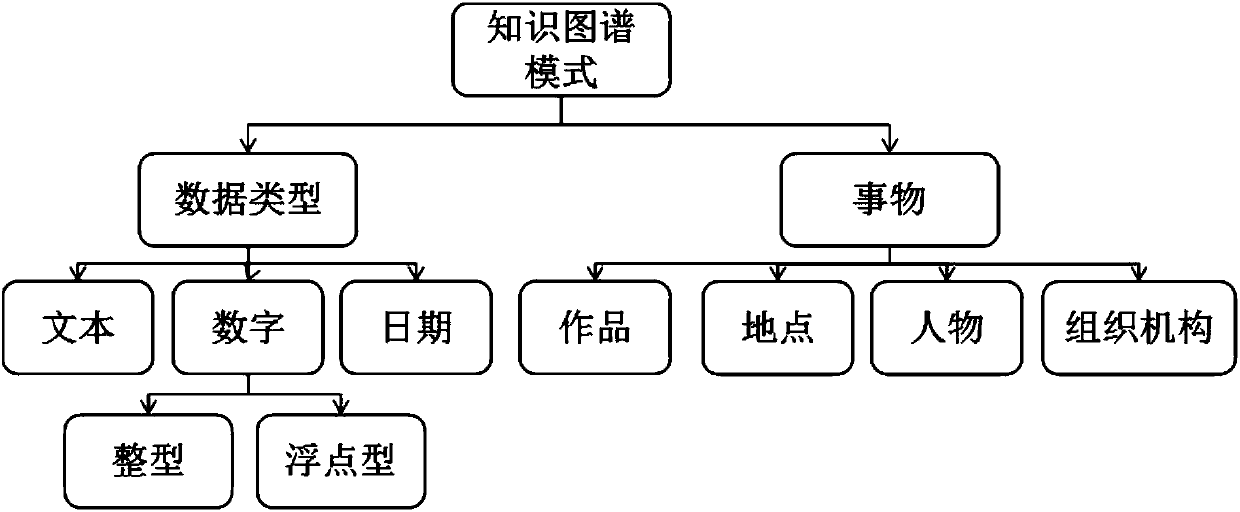

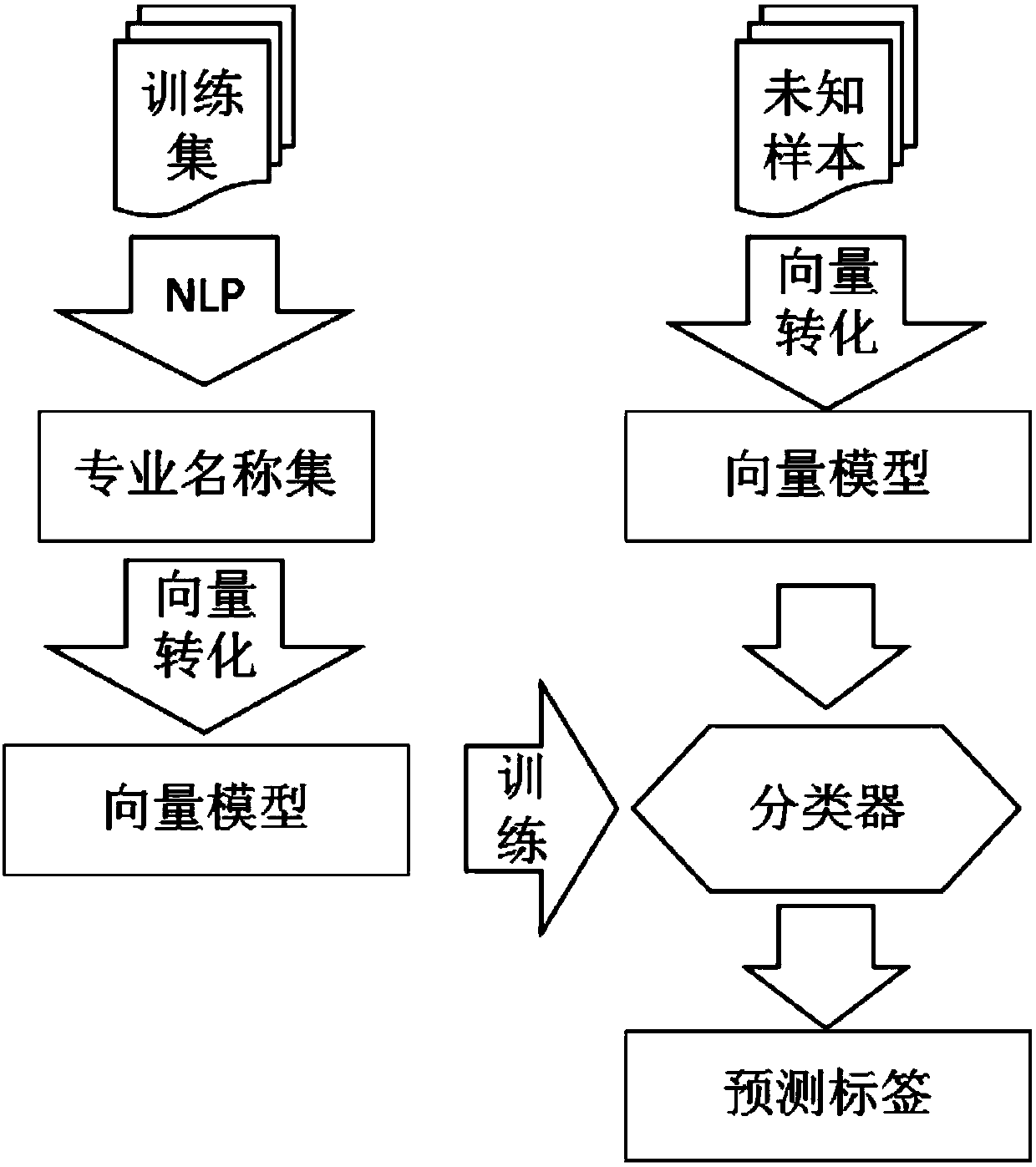

Knowledge graph-based interactive question and answer method and system

InactiveCN107766483AQuality assuranceReduce manual interventionRelational databasesNatural language data processingOpen sourceQuestions and answers

The invention discloses a knowledge graph-based interactive question and answer method and system. The method comprises the steps of constructing a knowledge graph, wherein data in the knowledge graphis from multiple open-source information sources; according to existing entities in the knowledge graph, forming a dictionary, forming mapping from a name to a professional field through a manual tagging method, and performing expansion in a conventional feature modeling mode to form a professional dictionary; according to the data in the knowledge graph, forming mapping from the entities to a training set of the field through the manual tagging method to establish a classifier; according to the professional dictionary, performing word segmentation on a natural question sentence through a forward maximum matching method, and according to results after word segmentation, inputting the results to the classifier for performing classification, thereby classifying the natural question sentenceinto questions in different fields; and mapping the classified questions to obtain corresponding question templates, and converting the question templates into query sub-graphs in the knowledge graph. Answer can be performed for sentences of more complex questions, so that the answer quality can be ensured and the manual intervention is effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

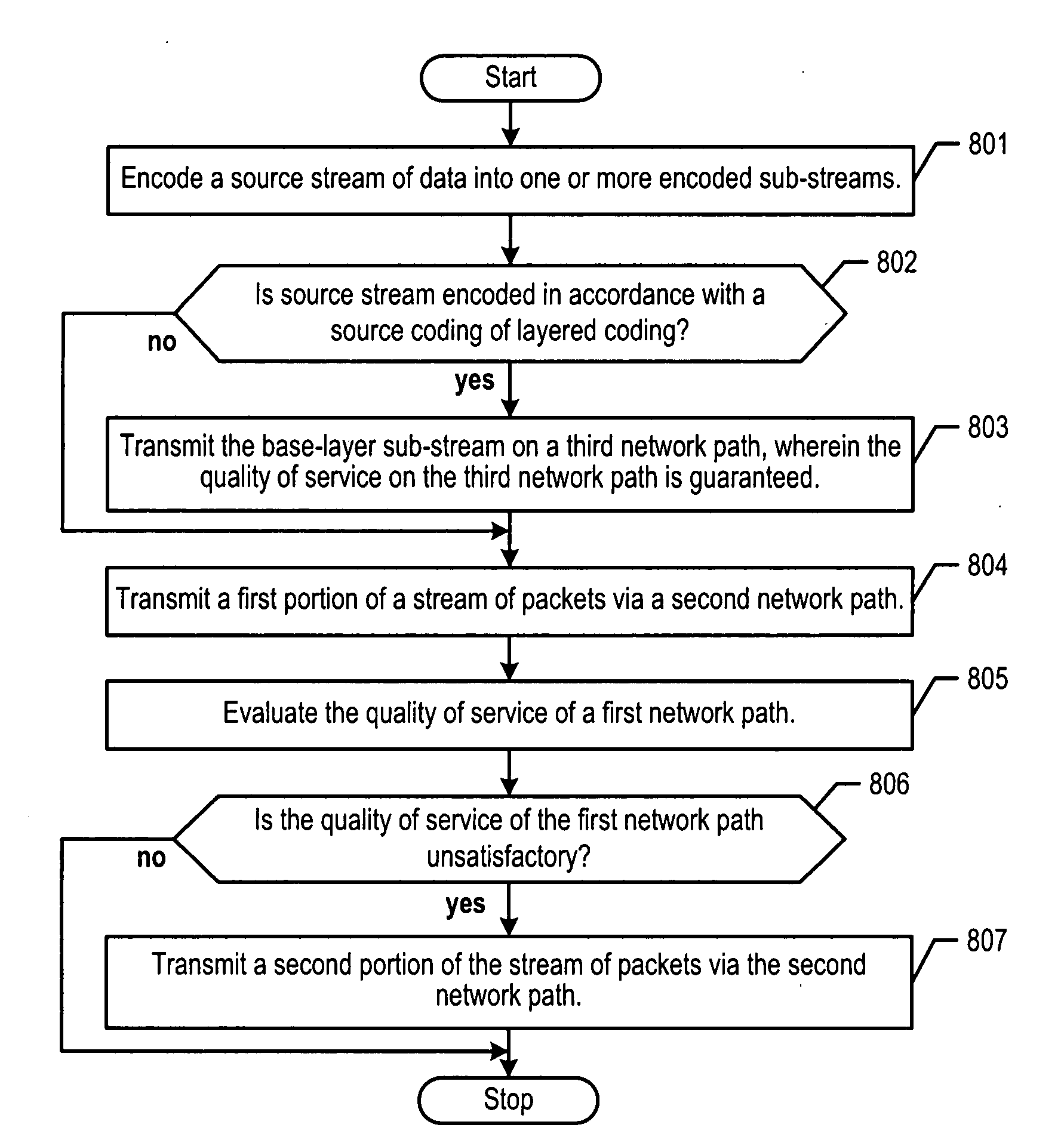

Coding and packet distribution for alternative network paths in telecommunications networks

ActiveUS20070177579A1Improve service qualityReduce and even eliminate glitchNetwork connectionsQuality of serviceTelecommunications network

A method and apparatus are disclosed that seek to improve the quality of service that is experienced during the transmission of a stream of packets across one or more paths. In particular, a transmitting node encodes a source stream of data (e.g., audio, video, etc.) into one or more sub-streams, and distributes those sub-streams onto multiple network transmission paths. In accordance with the illustrative embodiment of the present invention, the transmitting node evaluates the quality of service of a first network path that fails to provide a quality-of-service guarantee. When the quality of service of the first network path becomes unsatisfactory, the coding of one or more sub-streams that are being transmitted on a second network path is adjusted. In other words, the coding on a second channel is adjusted in response to the changing conditions on a first channel.

Owner:AVAYA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com