Patents

Literature

1451 results about "Rolling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

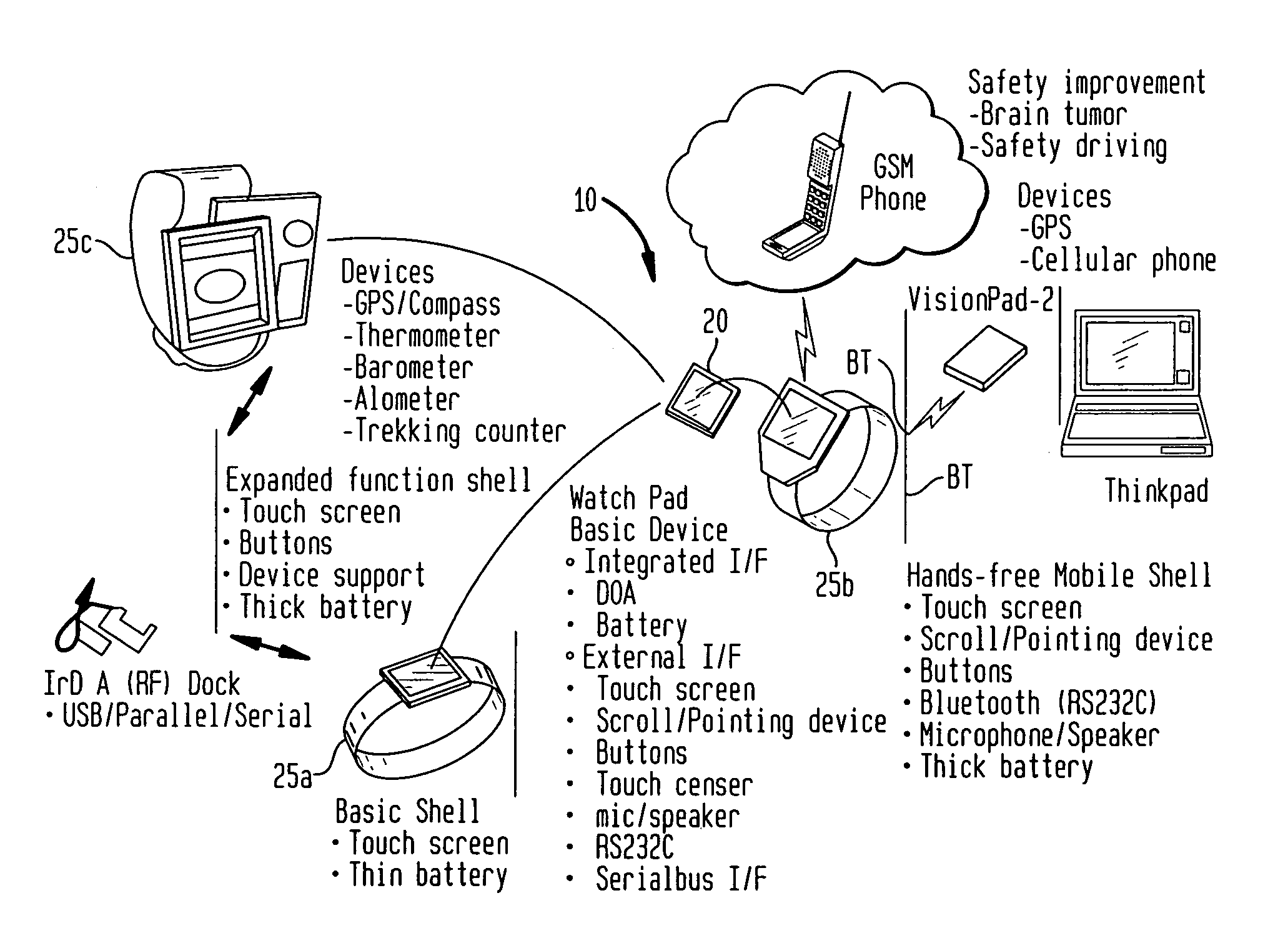

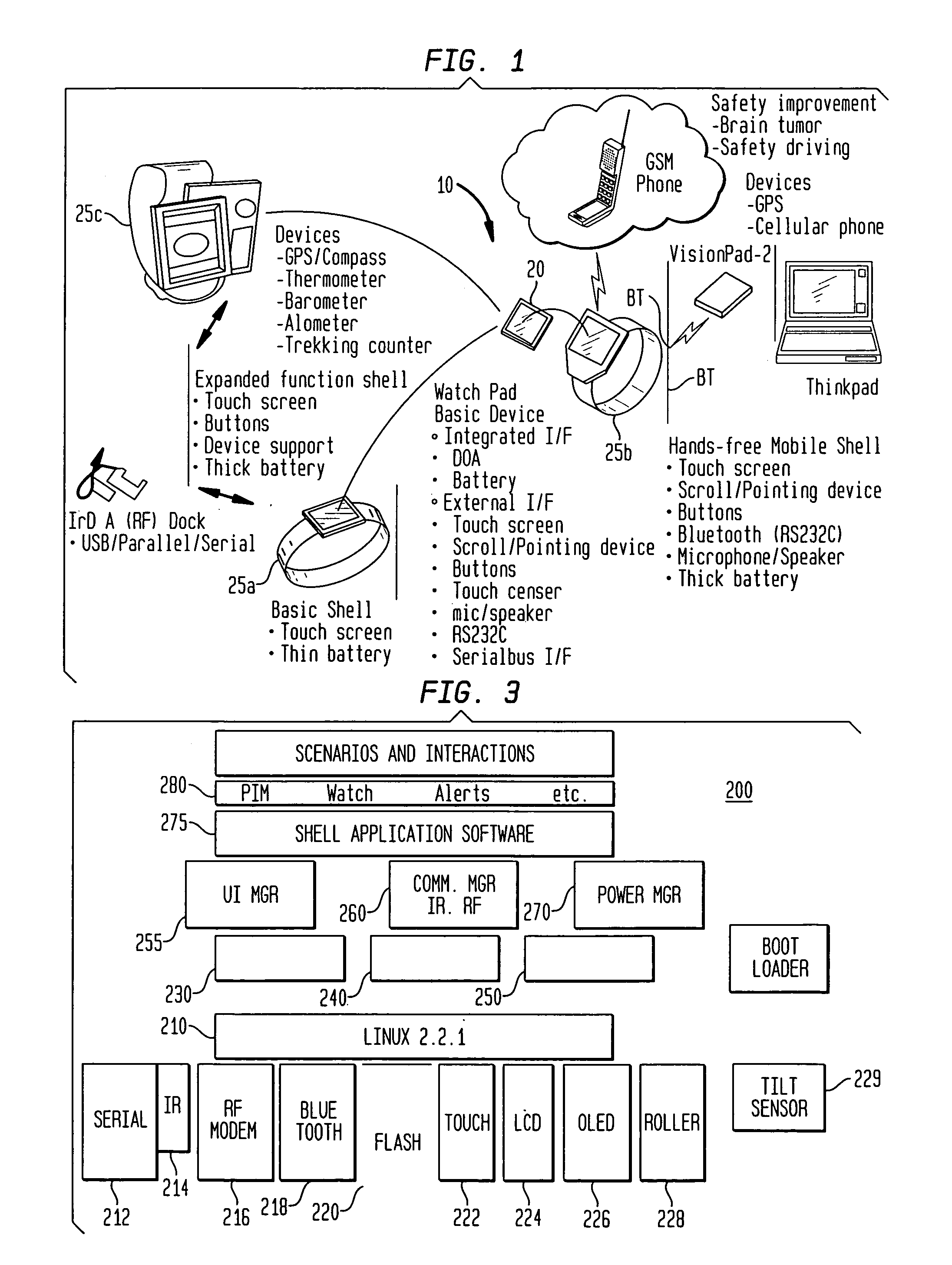

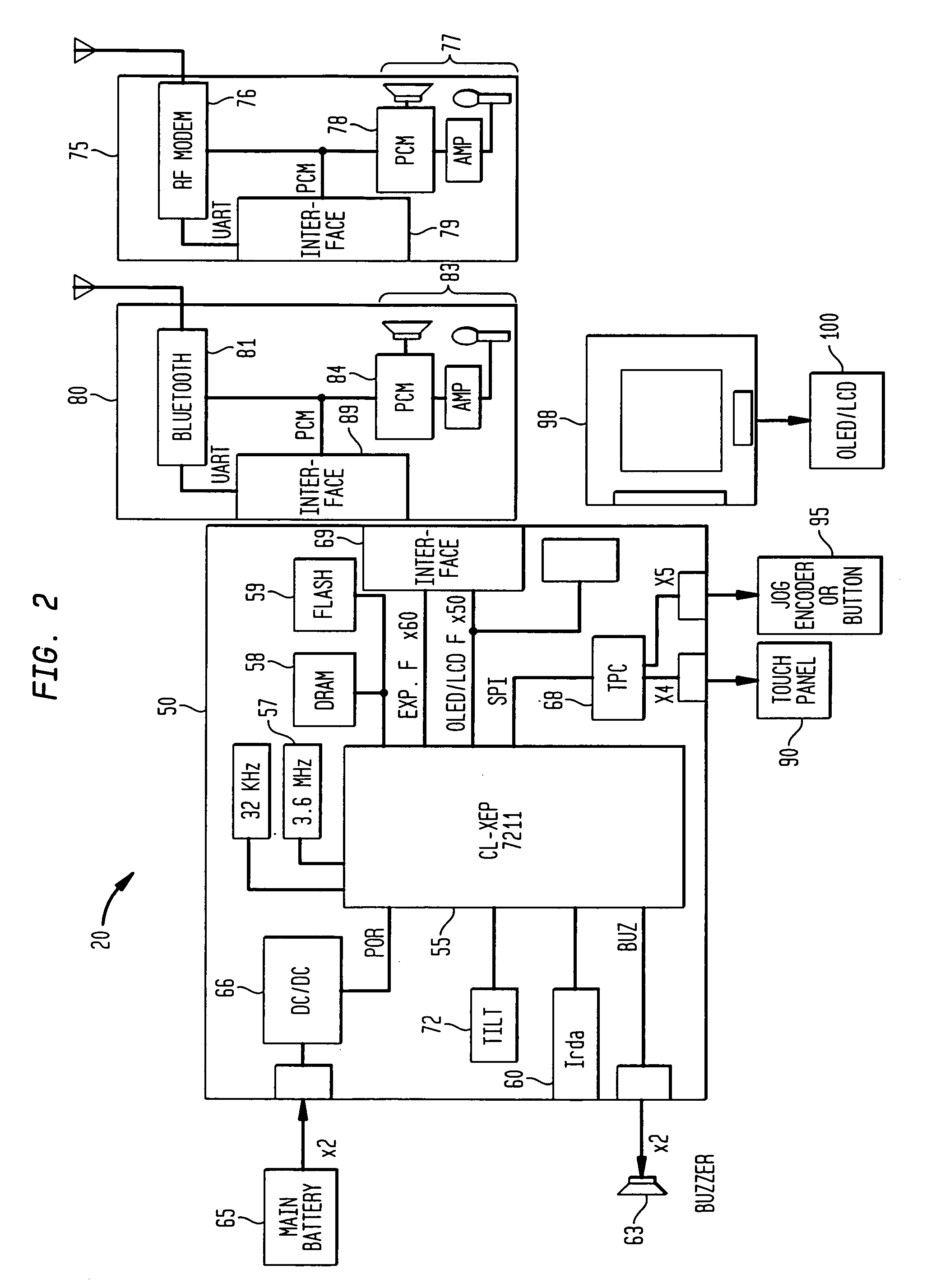

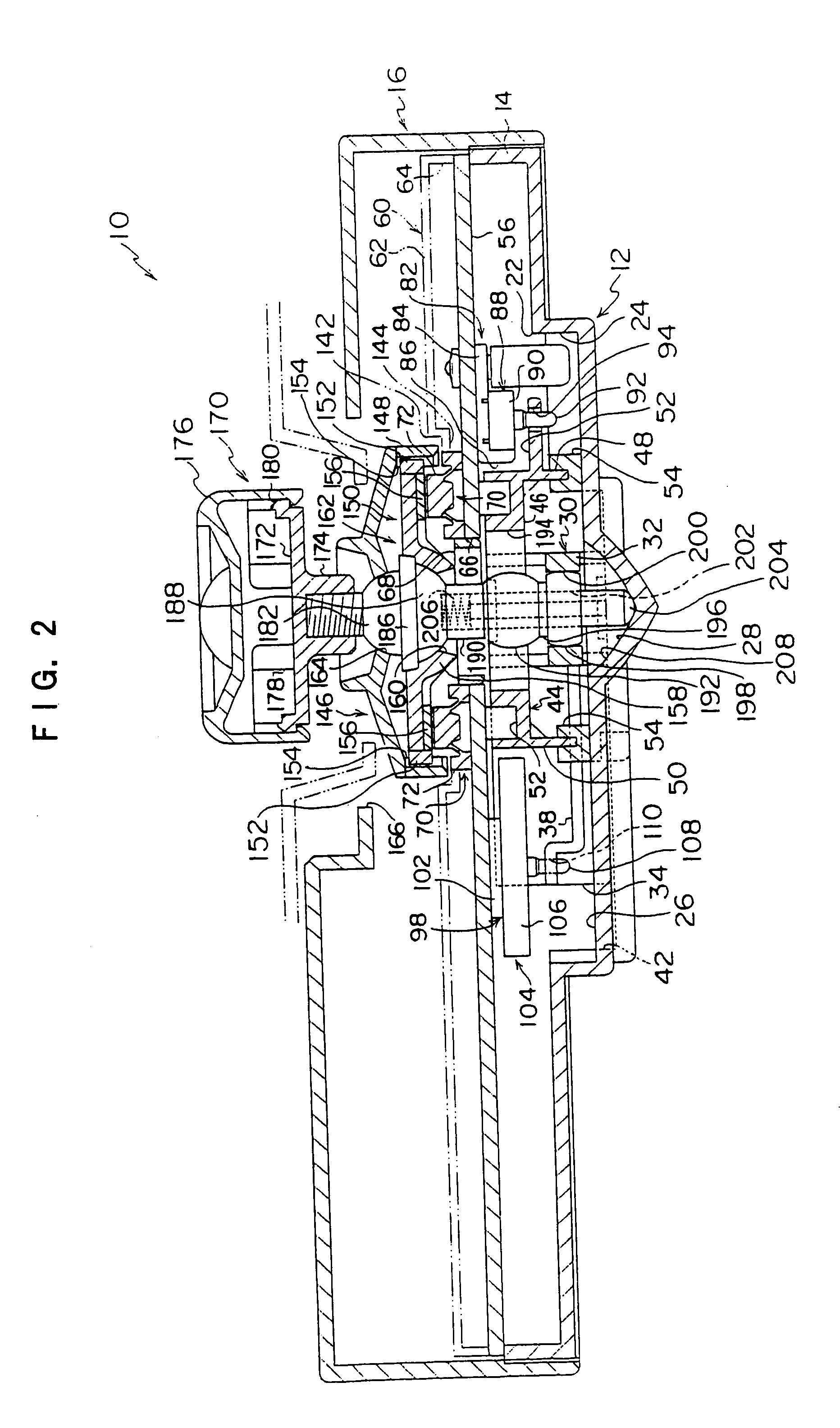

Method and apparatus for dynamically controlling scroller speed employed for a user interface of a wearable appliance

InactiveUS7081905B1Amount of user manipulation of the scroller to get to a particular positionElectric indicationFrequency stabilisation mechanismDisplay deviceHuman–computer interaction

A wearable mobile computing device / appliance (e.g., a wrist watch) with a high resolution display that is capable of wirelessly accessing information from the network and a variety of other devices. The Wrist Watch device / appliance includes a user interface that is used to efficiently interact with alarms, time keeping functions and notifications on the watch via use of a scroll device implementing dynamic scroll speed controller capability which enables seamless fine-grain and coarse-grain scroll and / or cursor movement through displayed content without notice to the user of the scroll device.

Owner:IBM CORP

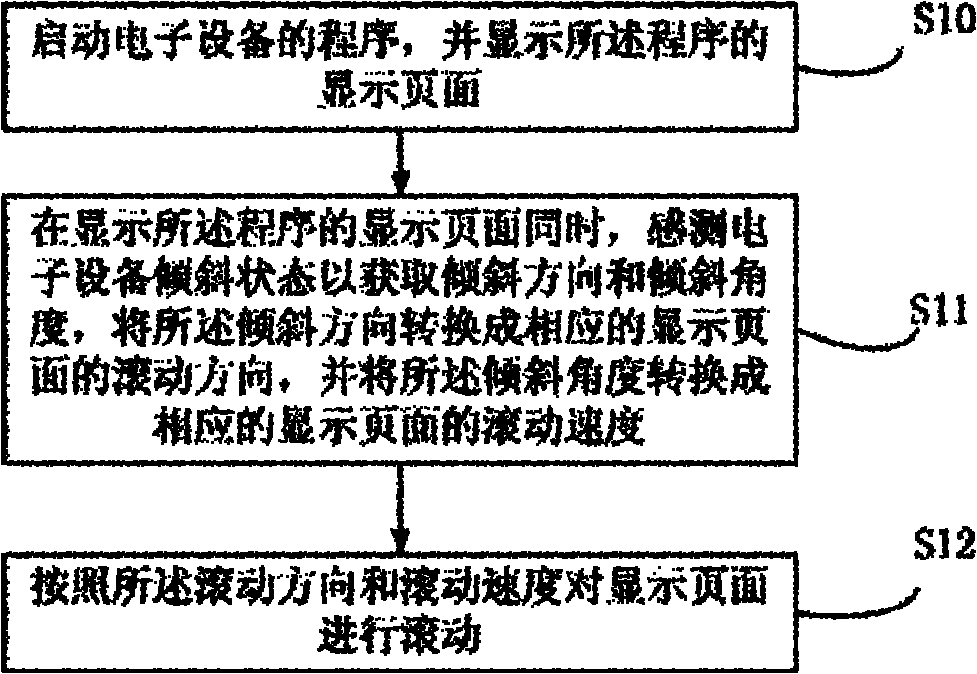

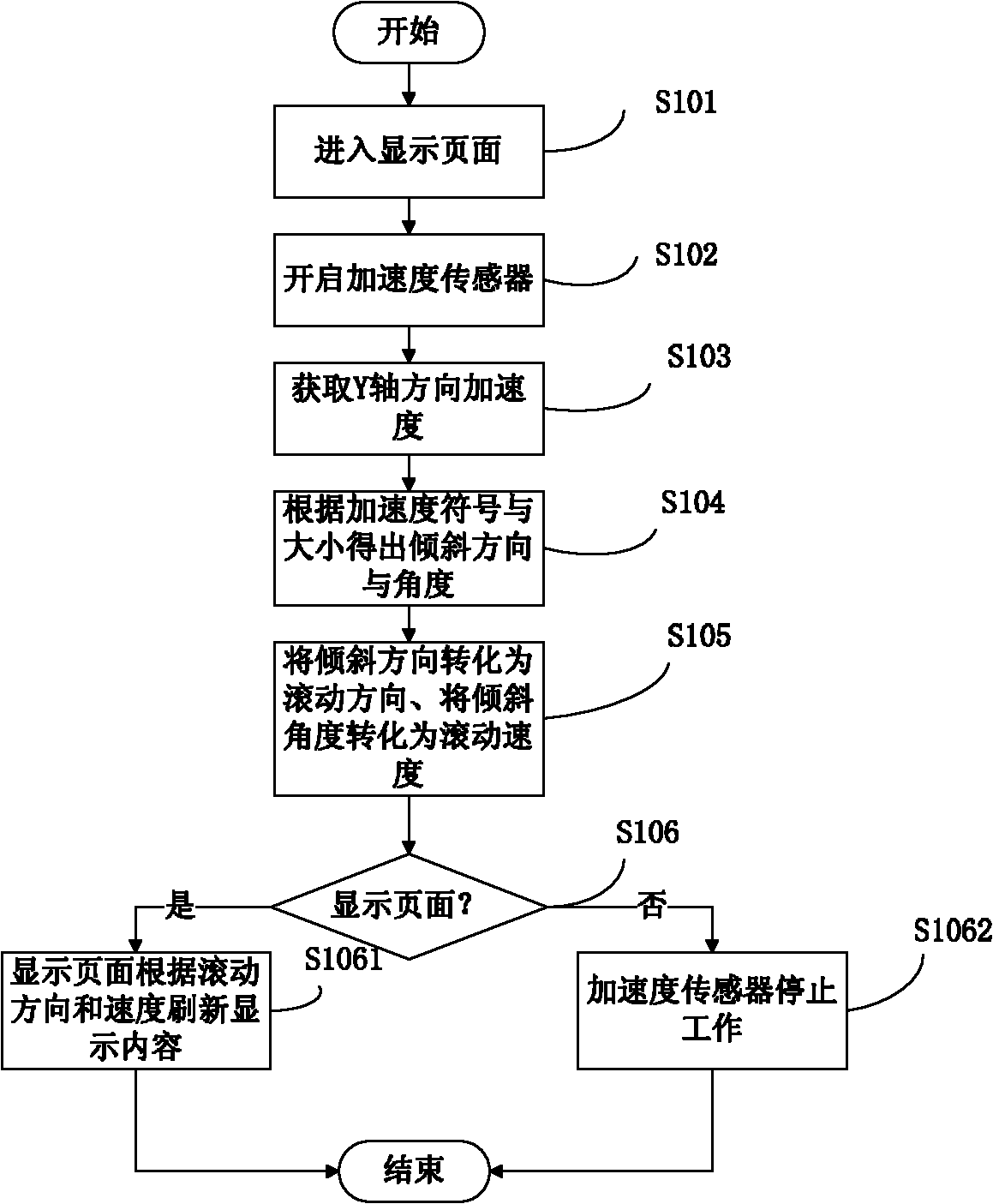

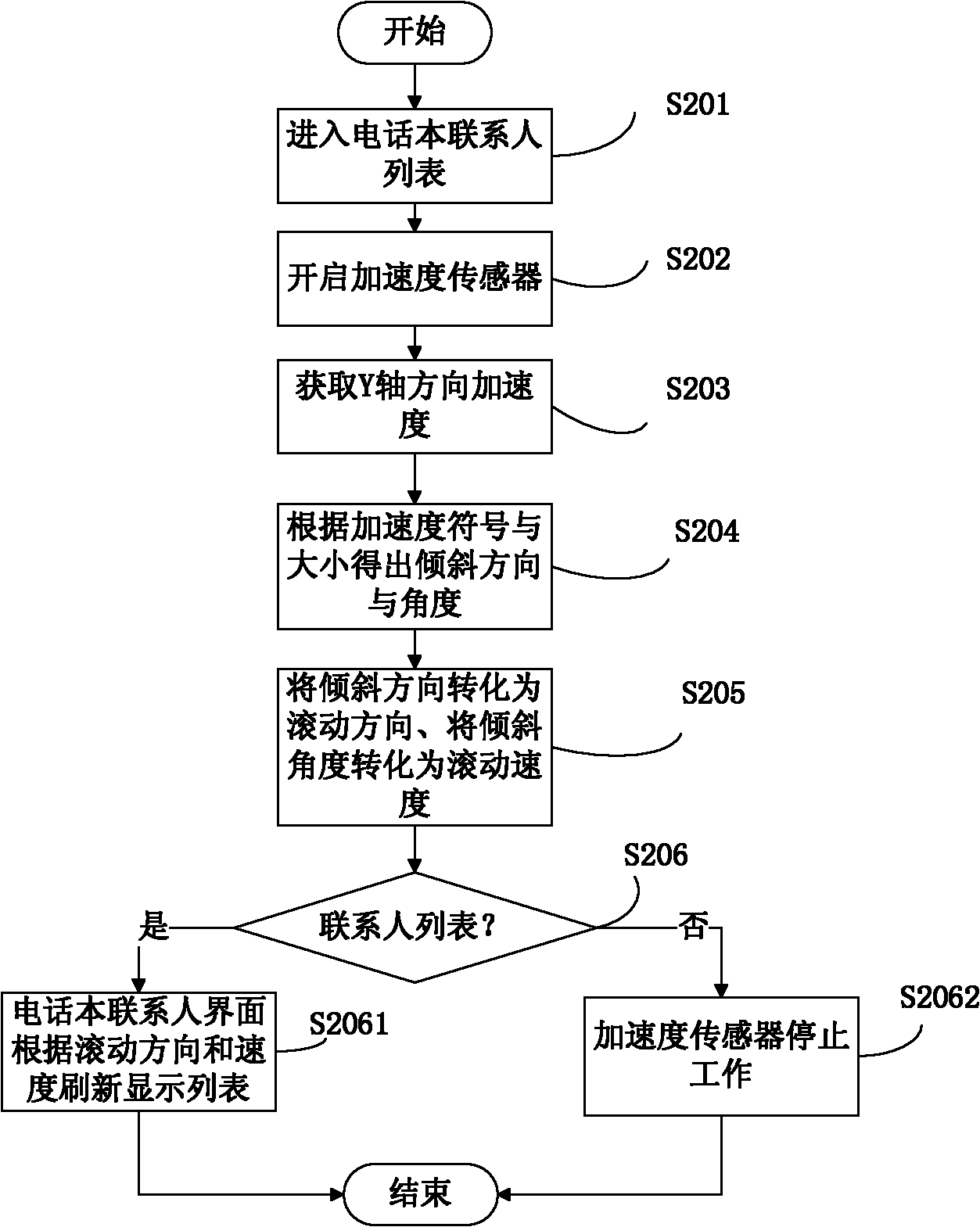

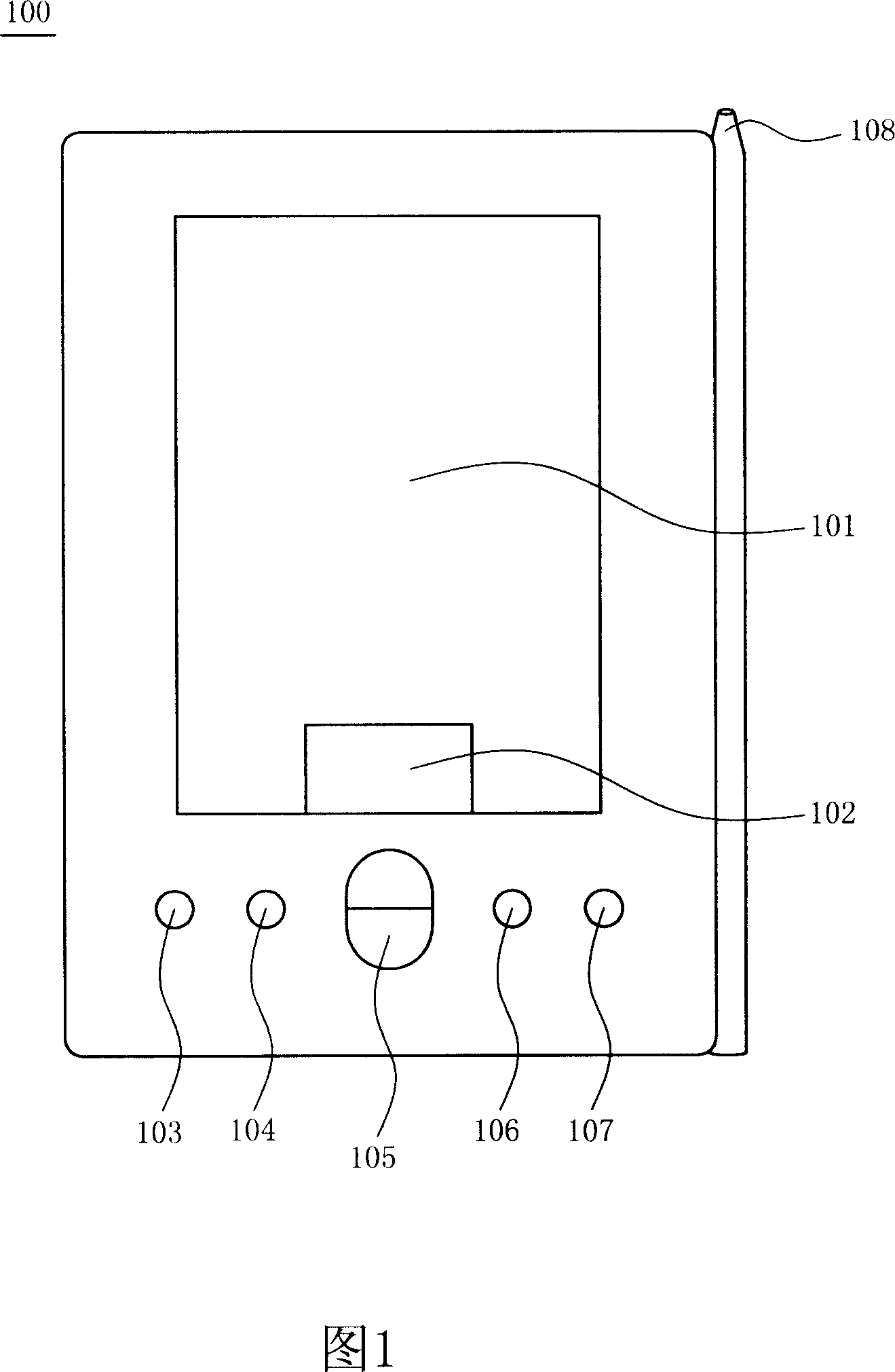

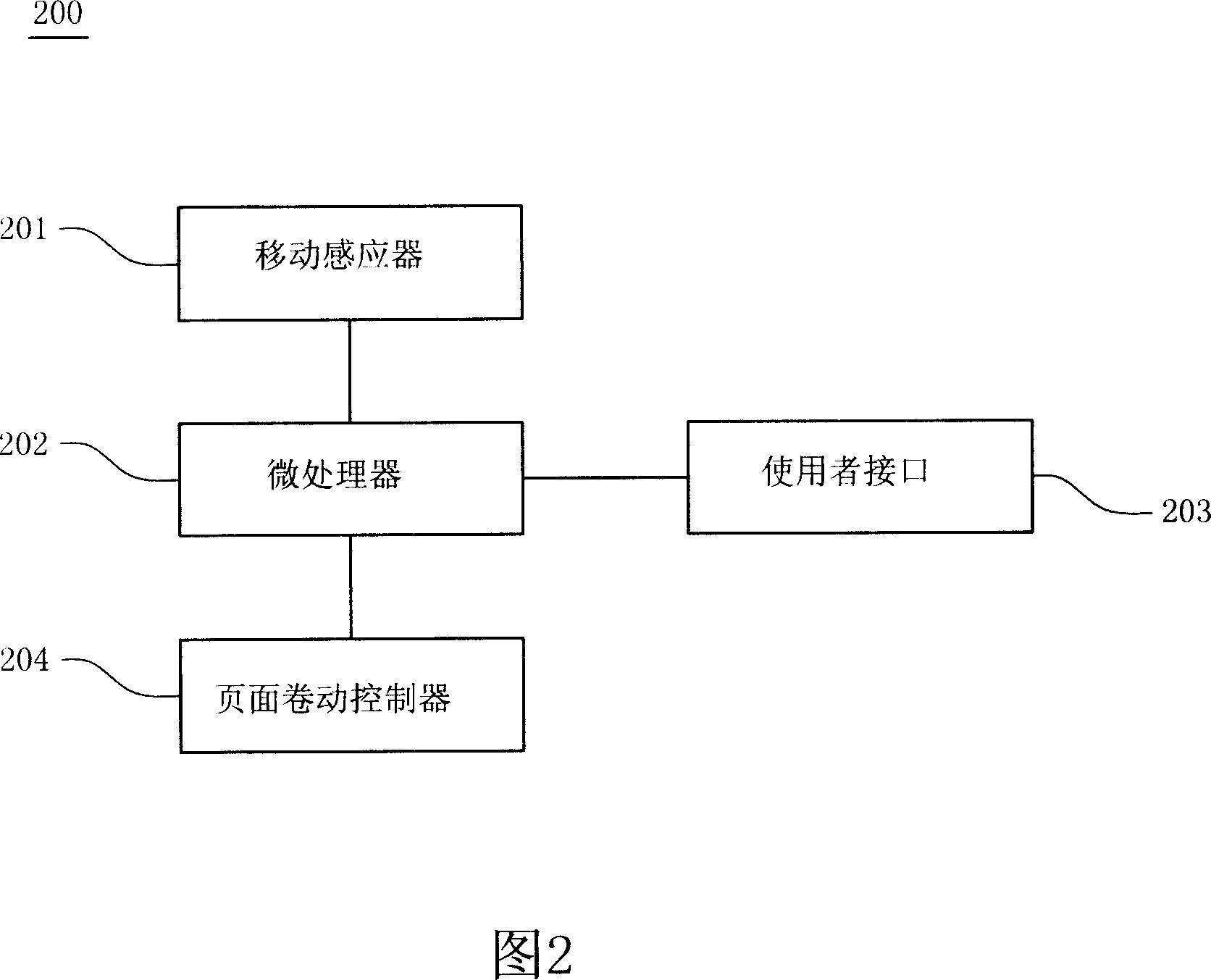

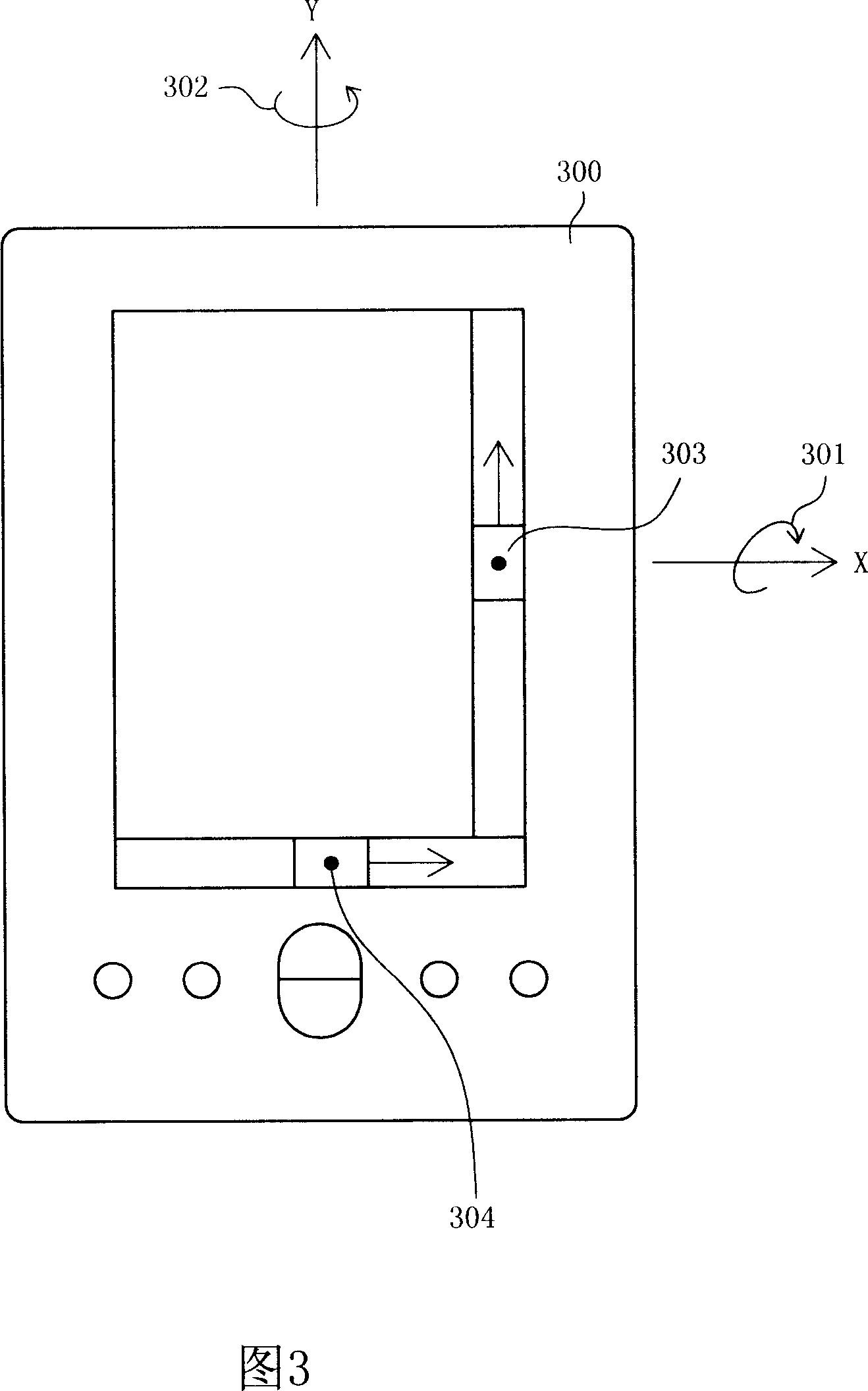

Page browsing method and electronic equipment using same

InactiveCN102156555AImprove convenienceReduce buttonDigital data processing detailsInput/output processes for data processingComputer graphics (images)Rolling speed

The invention discloses a page browsing method and electronic equipment using the same. The method comprises the following steps of starting the program of the electronic equipment; displaying the displaying page during the running process of the program; sensing the inclination state of the electronic equipment and obtaining the inclination direction and the inclination angle when simultaneously displaying the displaying page of the program; converting the inclination direction into the rolling direction of the corresponding displaying page; converting the inclination angle into the rolling speed of the corresponding displaying page; and rolling the displaying page according to the rolling direction and the rolling speed. By adopting the method, the convenience of browsing the page can be improved, and furthermore, the interest of a user on the operating of the electronic equipment can be increased.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

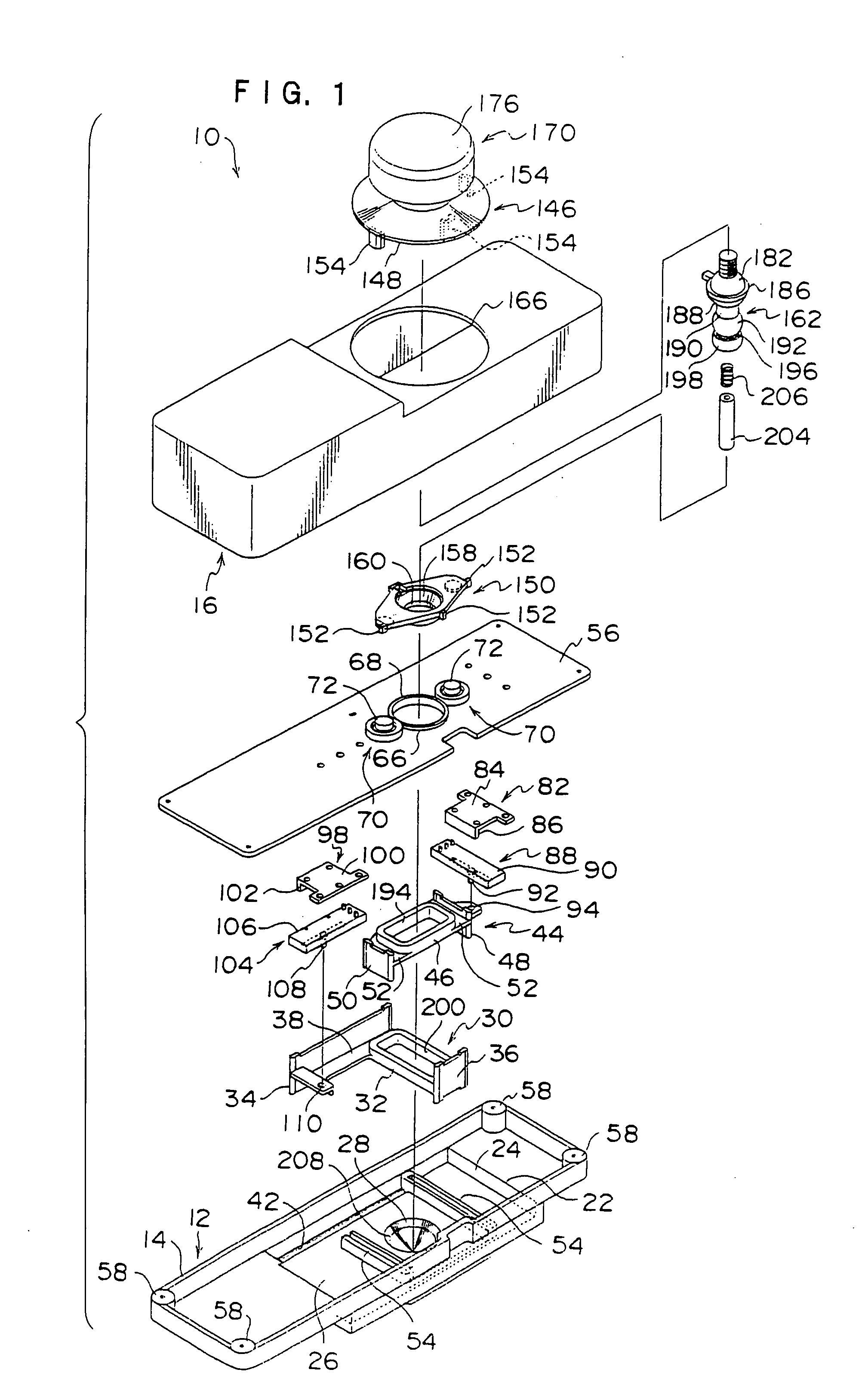

Monitor display control apparatus and monitor display control method

InactiveUS20050083299A1Easy to operateInstruments for road network navigationCathode-ray tube indicatorsRolling speedControl unit

The present invention is to provide a monitor display control apparatus and a monitor display control method, in which ease of operation of scrolling a map image can be improved with an intention of an operator being reflected at the time of scrolling the map image. A value RV corresponding to the square of a distance up to a current position centering on a reference position is operated on the basis of output voltages of potentiometers detecting a tilted position of an operating rod. In a control unit, a scrolling speed and a scale factor of the map image displayed on a display screen of a monitor television are varied in accordance with a signal UP including information on an amount of displacement of the operating rod from the reference position.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

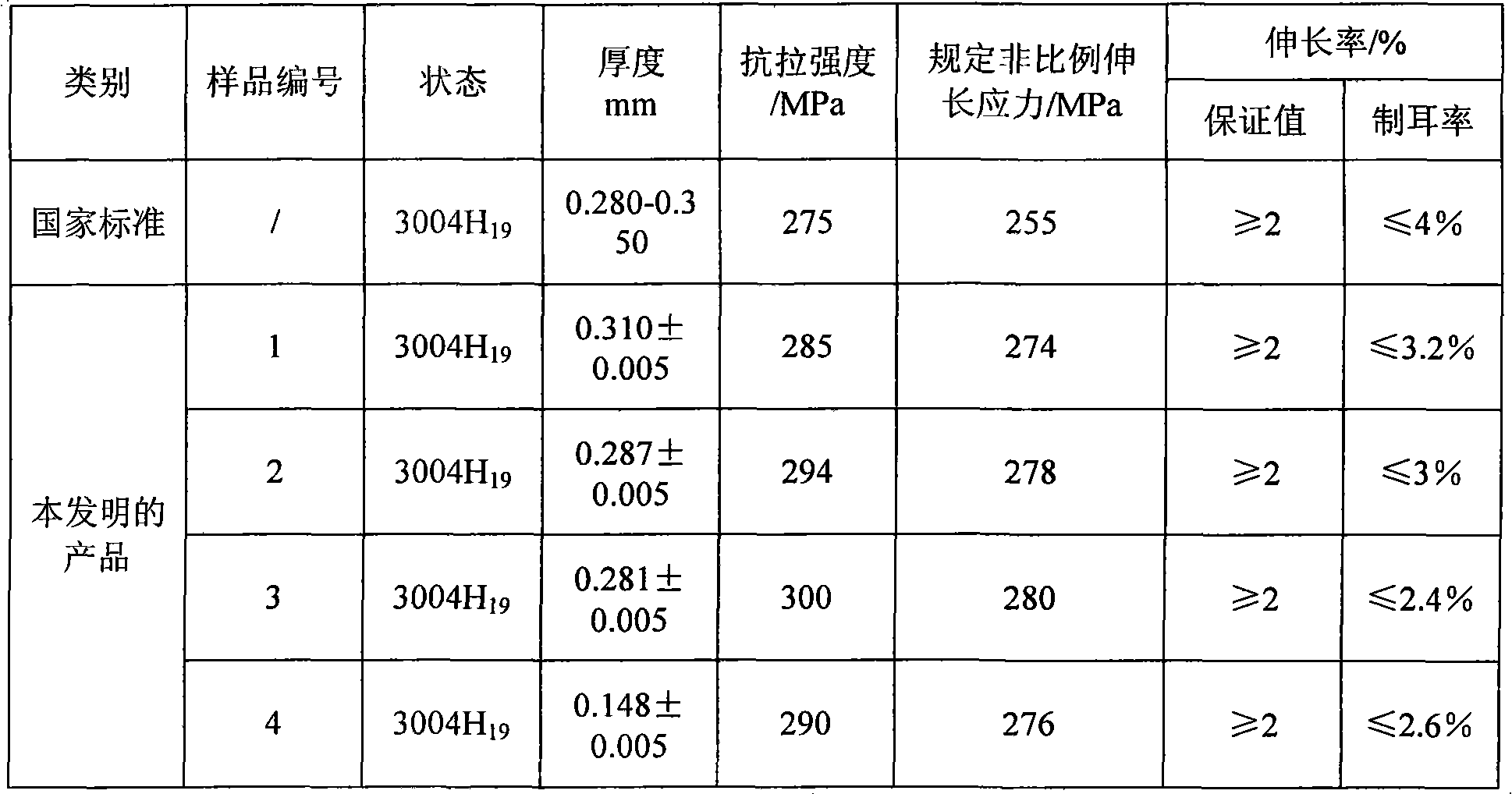

Engineering process for producing low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid

The invention relates to an engineering process for producing a low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid. The process comprises the procedures of alloy aluminium melting, ingredient adjusting, on-line refining for three times, standing, outgassing, grain refining, filtering, tilting cast-rolling, homogenizing, cold rolling, intermediate annealing, another cold rolling, full annealing, recoiling and packaging. The refining comprises powder spraying refining in a melting furnace and combined refining of on-line argon and carbon tetrachloride introducing. The annealing comprises high-temperature quick annealing, the intermediate annealing and the full annealing. During the cast-rolling, the temperature in a front box is 710-720 DEG C, and the cast-rolling speed is 600-900 mm / min. The product is the low-iron low-silicon 3004 alloy. The low-iron low-silicon 3004 alloy comprises 0.06-0.14 wt% of Si, 0.25-0.43 wt% of Fe, 0.012-0.14 wt% of Cu, 1.0-1.2 wt% of Mn, 0.8-1.0 wt% of Mg, at most 0.02 wt% of Zn, 0.015-0.03 wt% of Ti and the balance of Al. The invention has the characteristics of simple procedure, energy saving, emission reduction, goodalloy performance and low earring rate.

Owner:SNTO TECH GRP

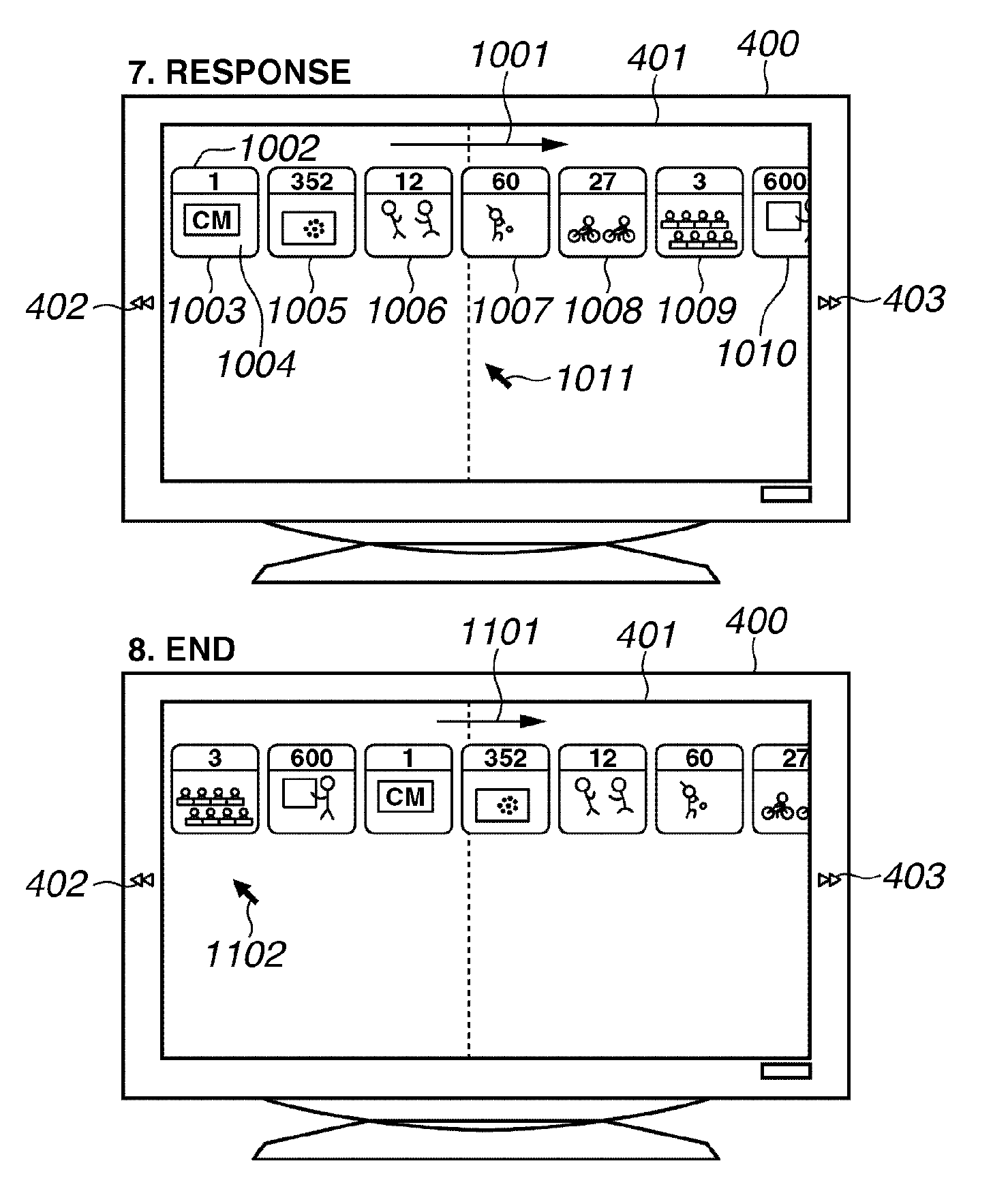

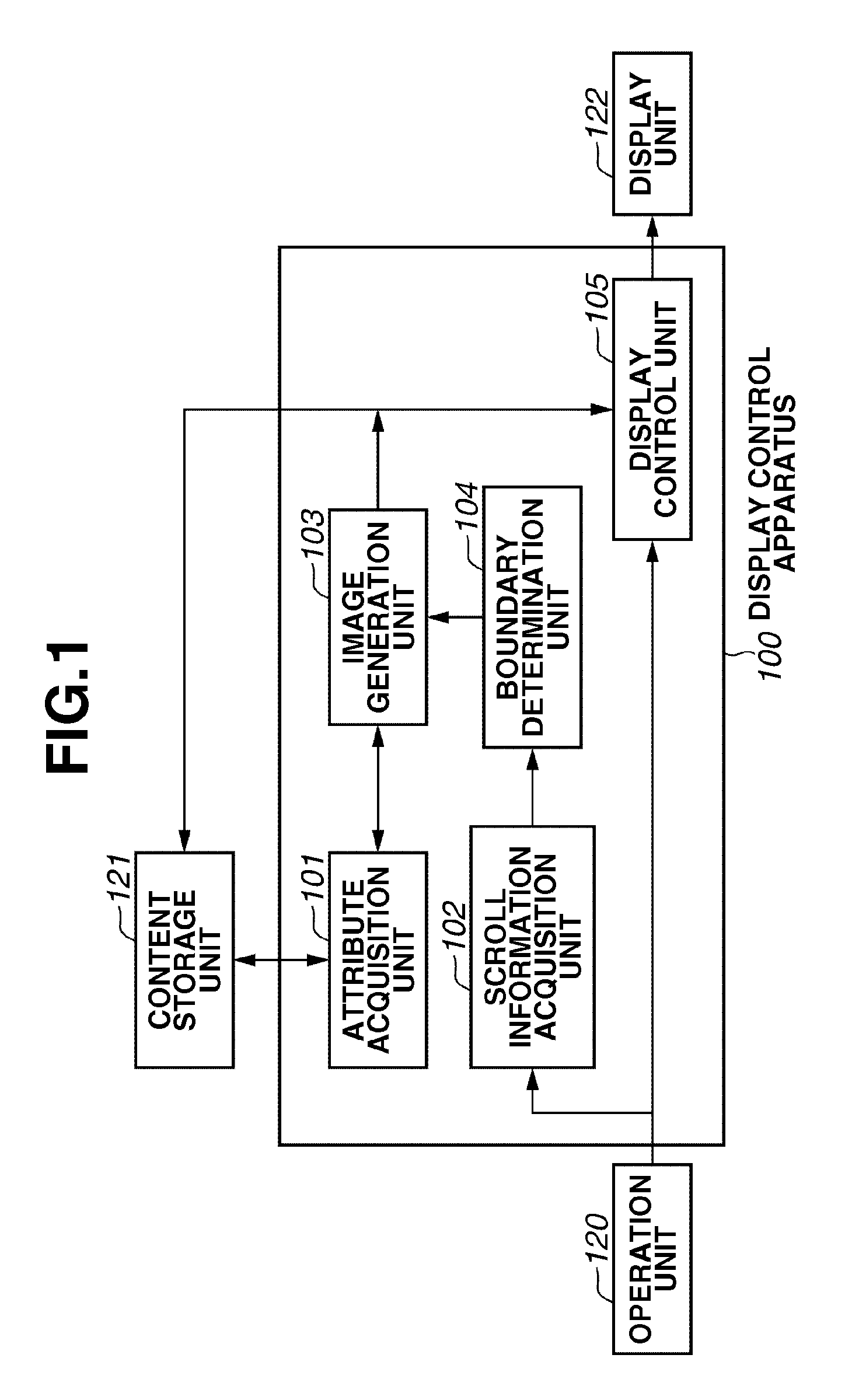

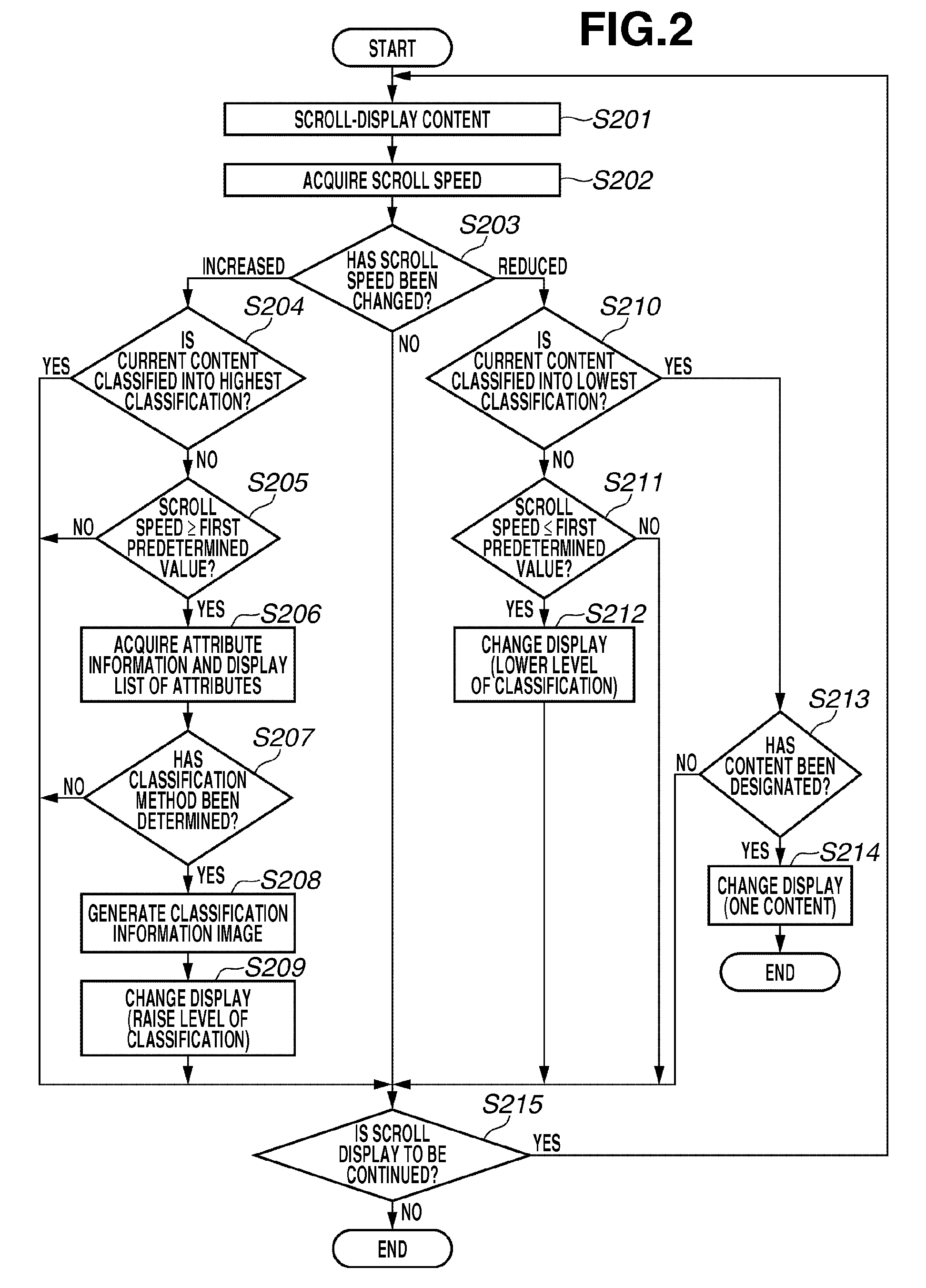

Display control apparatus and display control method

ActiveUS20100122214A1Valid choiceSelective content distributionInput/output processes for data processingArtificial intelligenceRolling speed

A display control apparatus includes a display control means. In the display control apparatus, the display control means is configured to scroll-display a plurality of contents. If it is determined that the speed of the scroll display has increased to reach a first predetermined value, then the display control means classifies and groups the plurality of contents by using group classification information corresponding to the plurality of contents and displays the grouped contents. On the other hand, if it is determined that the scroll speed has decreased to reach a second predetermined value, then the display control means sorts the plurality of contents in order according to a selected grouping method and displays group classification information images at a group classification level one stage lower than the current group classification level.

Owner:CANON KK

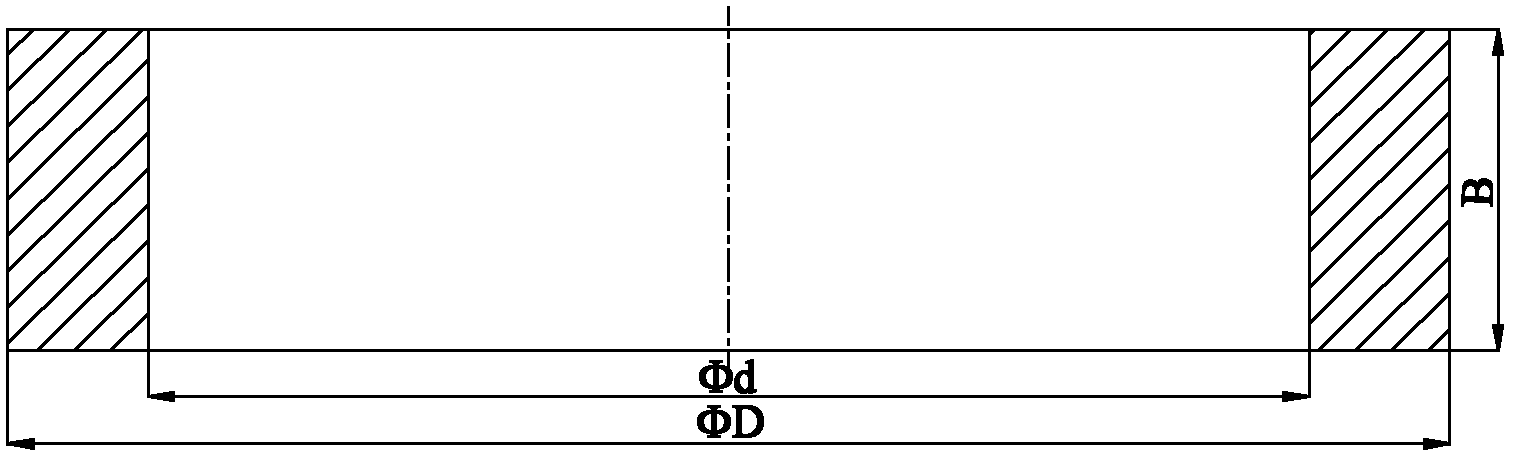

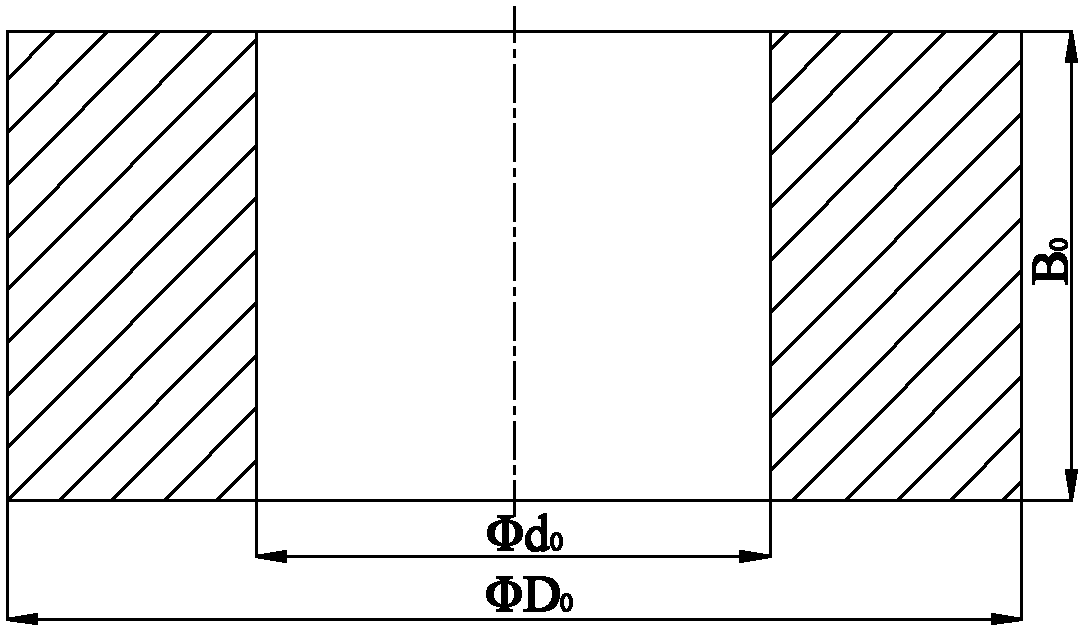

Fine-grain roll-forming method for large annular piece made of high alloy steel

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS +1

Device and method for detecting and controlling tilting buckle head of band steel in rough rolling process

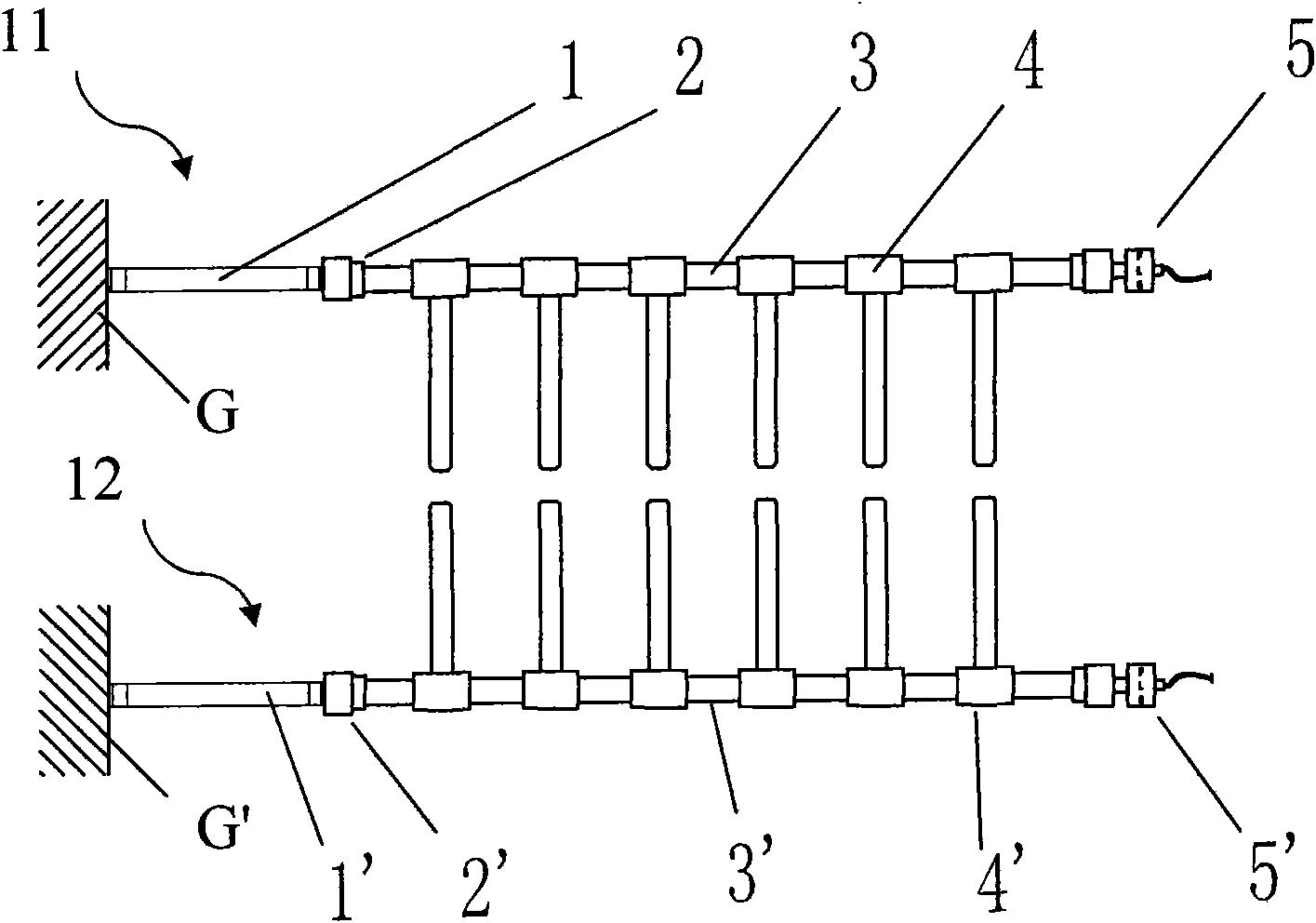

ActiveCN101920270AImprove rolling qualityImprove operational safetyMeasuring devicesMetal rolling arrangementsSheet steelHead tilting

The invention discloses a device and a method for detecting and controlling the tilting buckle head of band steel in the rough rolling process. The actual head tilting or buckle head condition of the rolled band steel can be detected by using head tilting and buckling detectors arranged above roller beds and between the roller beds and then the rolling speeds of an upper roller and a lower roller for biting the band steel can be automatically adjusted when the next band steel is rolled, so that upper surface band steel and the lower surface band steel consistently extend and the aim of controlling the tilting buckle head of the band steel can be achieved, wherein the control belongs to the feedback control. According to the invention, the rolling speeds of the upper roller and the lower roller can be adjusted by detecting the actual head tilting or buckle head condition of the band steel, and the detection process is not influenced by logged water, fog, the roughness of the rollers, the elevation of a rolling line, the amplitude of rolling reduction, the thickness of the band steel, the rolling speed and other factors, so that the invention has high accuracy of controlling the tilting buckle head, effectively improves the rolling quality of steel plates and the operation safety of operators and reduces the labor intensity.

Owner:BAOSHAN IRON & STEEL CO LTD

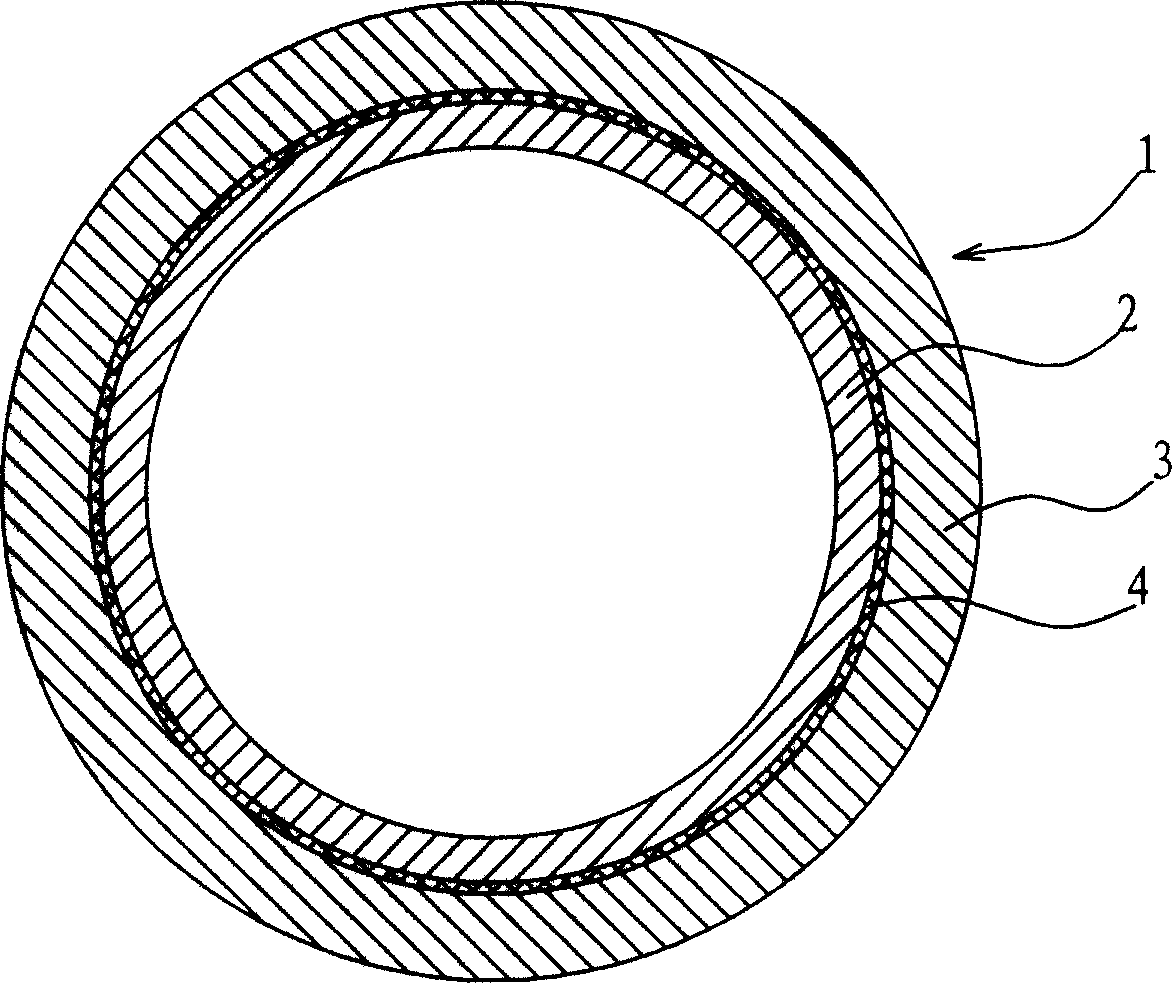

Method for manufacturing copper aluminium composite tubing and copper aluminium tubing produced thereby

The invention relates to a copper-aluminum compound tube material and relative producing method, belonging to the technique of metallic compound tube material production. Said invention comprises a copper inner layer and an aluminum outer layer. It is characterized in that: at the connection of copper and aluminum layers, said inner and outer layers are dispersed to each other to form a connecting layer to combine them. The producing method comprises; using planet rolling tube has single-rail sectional contraction rate on the compound tube is 50-95%; the outlet rolling speed is 5-30m / min; and the single-rail rolling is processed when the temperature of distortion section reaches 200-600Deg. C. The inventive method can combine two layers, with fewer processes, high efficiency, large batch and lower cost. And the product has better mechanical and thermal exchange properties, without defects in following process. It can be used to replace copper and alloy tube, to reduce producing cost.

Owner:JIANGSU XINGRONG HI TECH

A copper adulterated aluminum complex flat line and its making method

ActiveCN101236798AImprove performanceEliminate processabilitySingle bars/rods/wires/strips conductorsCable/conductor manufactureCopperAluminum composites

The invention relates to a copper-clad aluminum composite flat wire and a preparation method thereof, relating to bimetal layered composite materials. The copper-clad aluminum composite flat wire is formed by composition of sandwich layer aluminum and clad copper, and the area ratio of the copper clad is 15 percent to 40 percent. The preparation steps are as follows: copper-clad aluminum composite blanks are directly compounded and formed by adoption of horizontal continuous casting; multi-pass groove rolling and / or multi-pass drawing is performed on the copper-clad aluminum blanks as required; the rolling speed of 3 to 60 meters per minute is adopted, and the single-pass relative percent reduction is 20 percent to 40 percent; or the drawing speed of 2 to 30 meters per minute is adopted, and the single-pass section scalage is 10 percent to 25 percent; under the condition of multi-pass processing and that the overall section scalage of the copper-clad aluminum composite materials reaches 75 percent to 95 percent, low-temperature intermediate annealing is performed on the copper-clad aluminum composite materials; the annealing temperature is 200 to 450 DEG C; the annealing time is 0.5 to 2 hours; the blanks after annealing are rolled or drawn further, and the copper-clad aluminum composite flat wire with required section shape and size is prepared. The invention not only can prepare the high performance copper-clad aluminum composite flat wire but also has high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

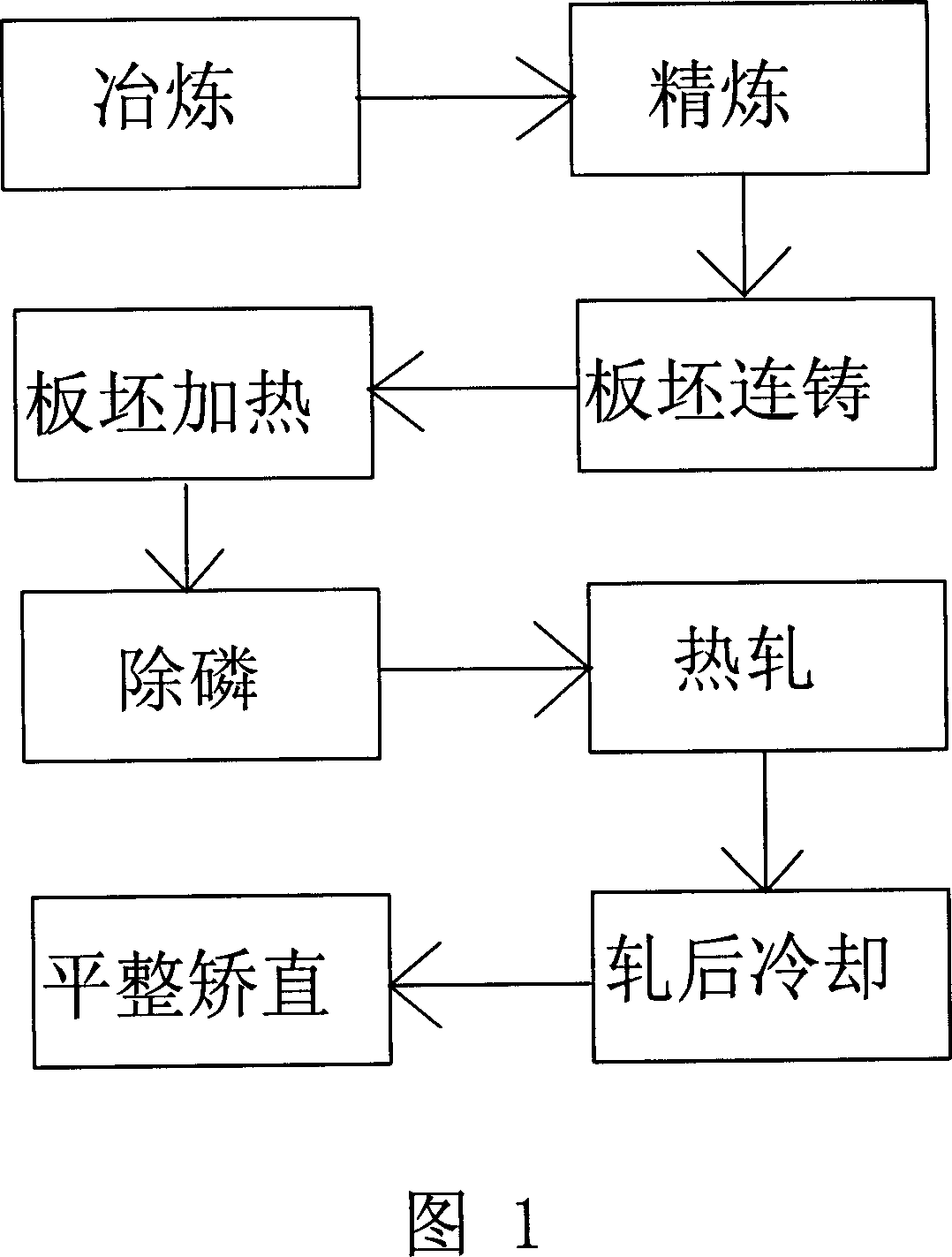

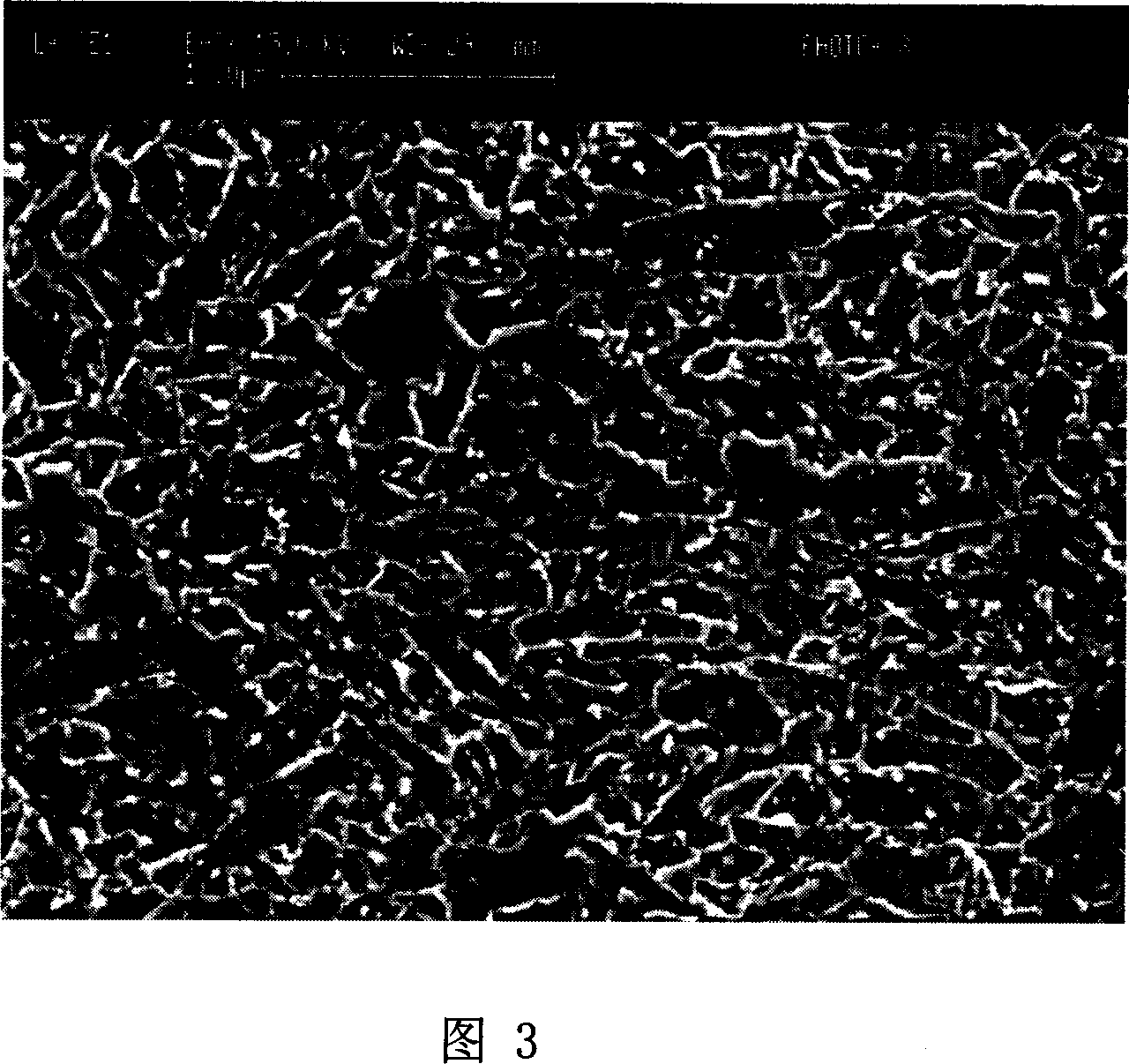

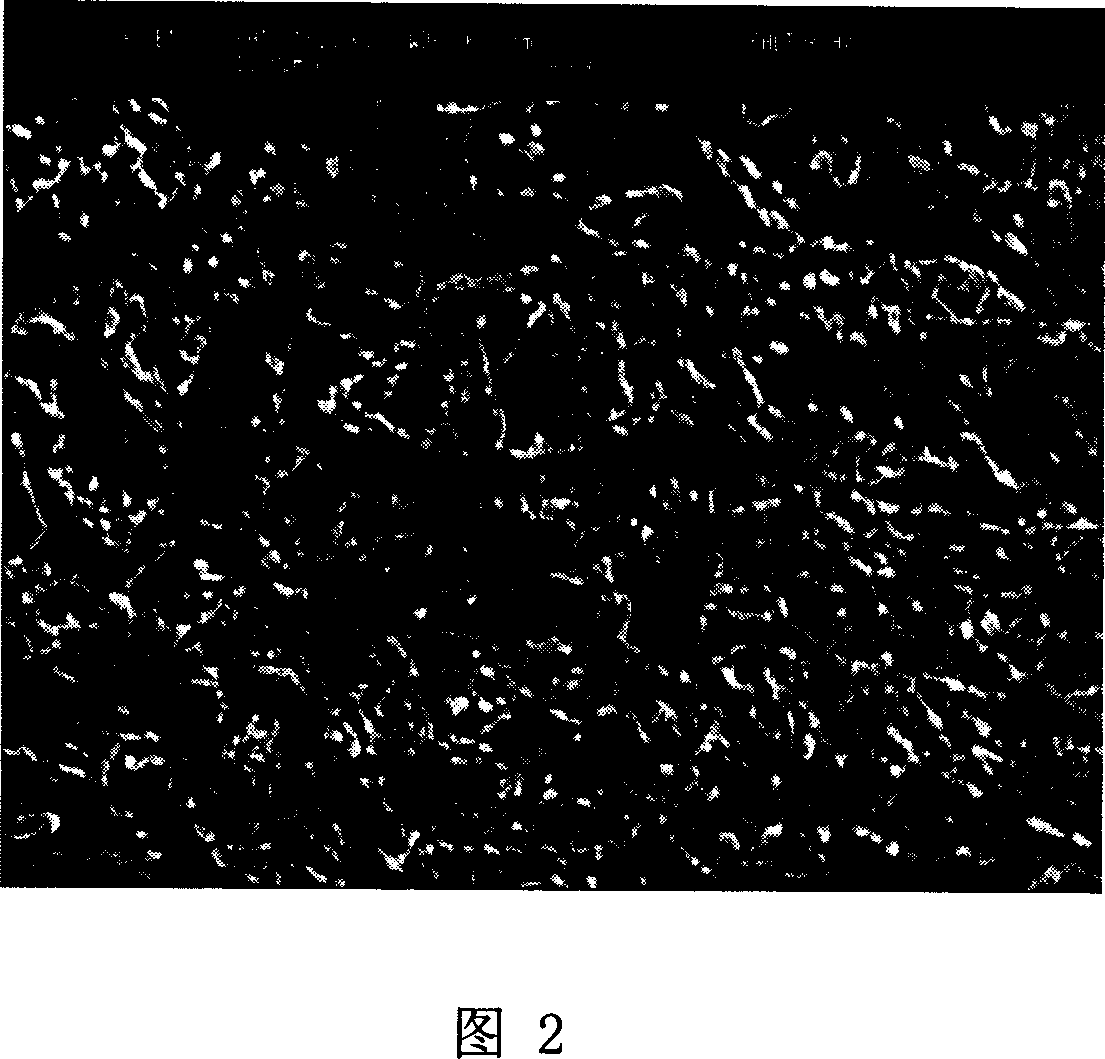

Manufacturing technique of low compression ratio high grade pipe line steel

InactiveCN1927486AImprove performanceRoll force/gap control deviceTemperature control deviceNiobiumHeating temperature

The invention relates to a method for producing high-strength low-alloy steel. Wherein, it comprises smelting, refining, casting sheet blank, heating blank, removing phosphor, cooling and flattening; the smelting step uses pure steel, low phosphor, and low sulfur; in the casting step, the loose of blank and the aliquation are lower than B0.5level; in the heating step, vanadium+niobium+ titanium0.15%, nickel+chromium+copper<=0.50%, and the heating temperature is 1180-1220Deg. C; in the thermal rolling step, in the crystallize process, the deformation temperature is 1070-1000Deg. C, the deformation amount is 40-60%, and the rolling speed is 1.5-2.5m / s, and in the second step that rolling the non-crystallized area, the pressure is 200-400MPa, the rolling speed is 5-1.5m / s, and the deformation amount is 60-75%; and the interlayer cooling speed in the cooling step is 15Deg. C / s-25Deg. C / s.

Owner:NANJING IRON & STEEL CO LTD +1

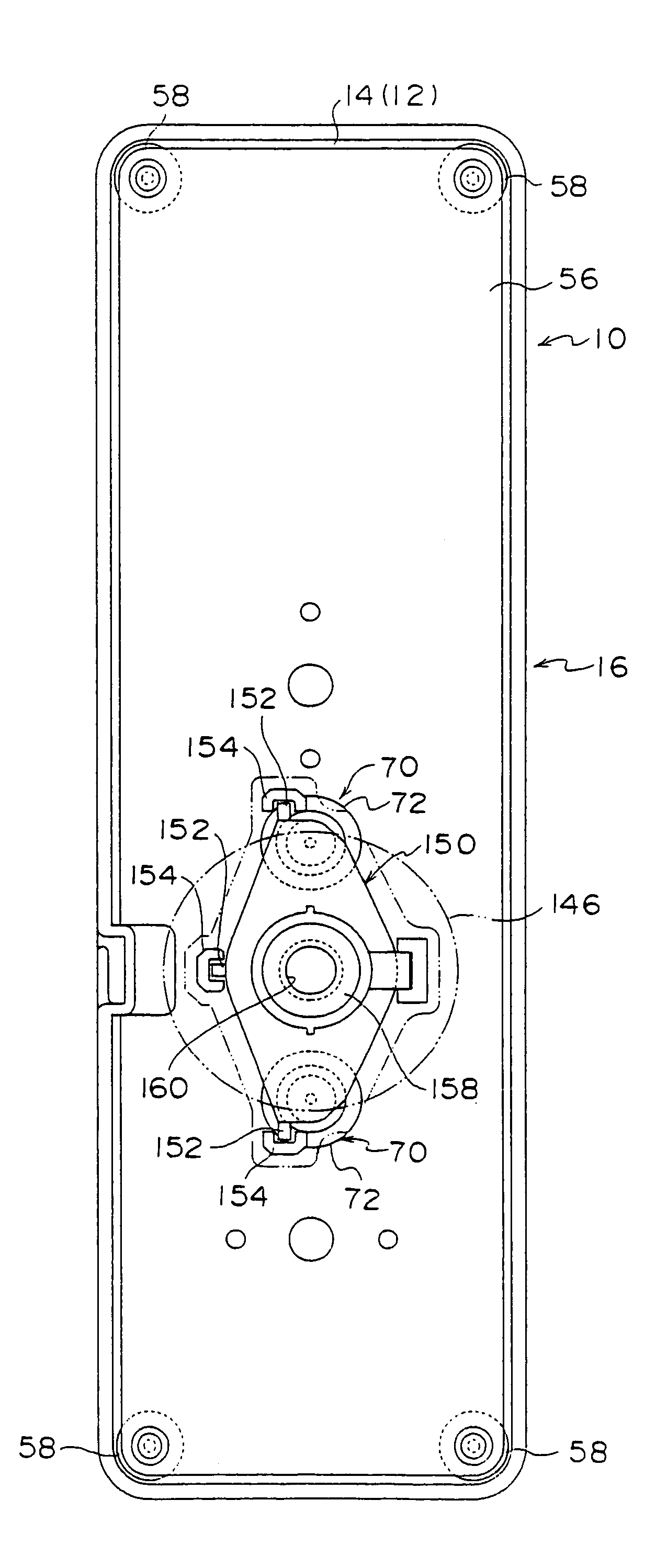

Screen display control device

InactiveCN101009089ADoes not affect the overall volumeEasy to useCathode-ray tube indicatorsDetails for portable computersOn-screen displayComputer science

Owner:HTC CORP

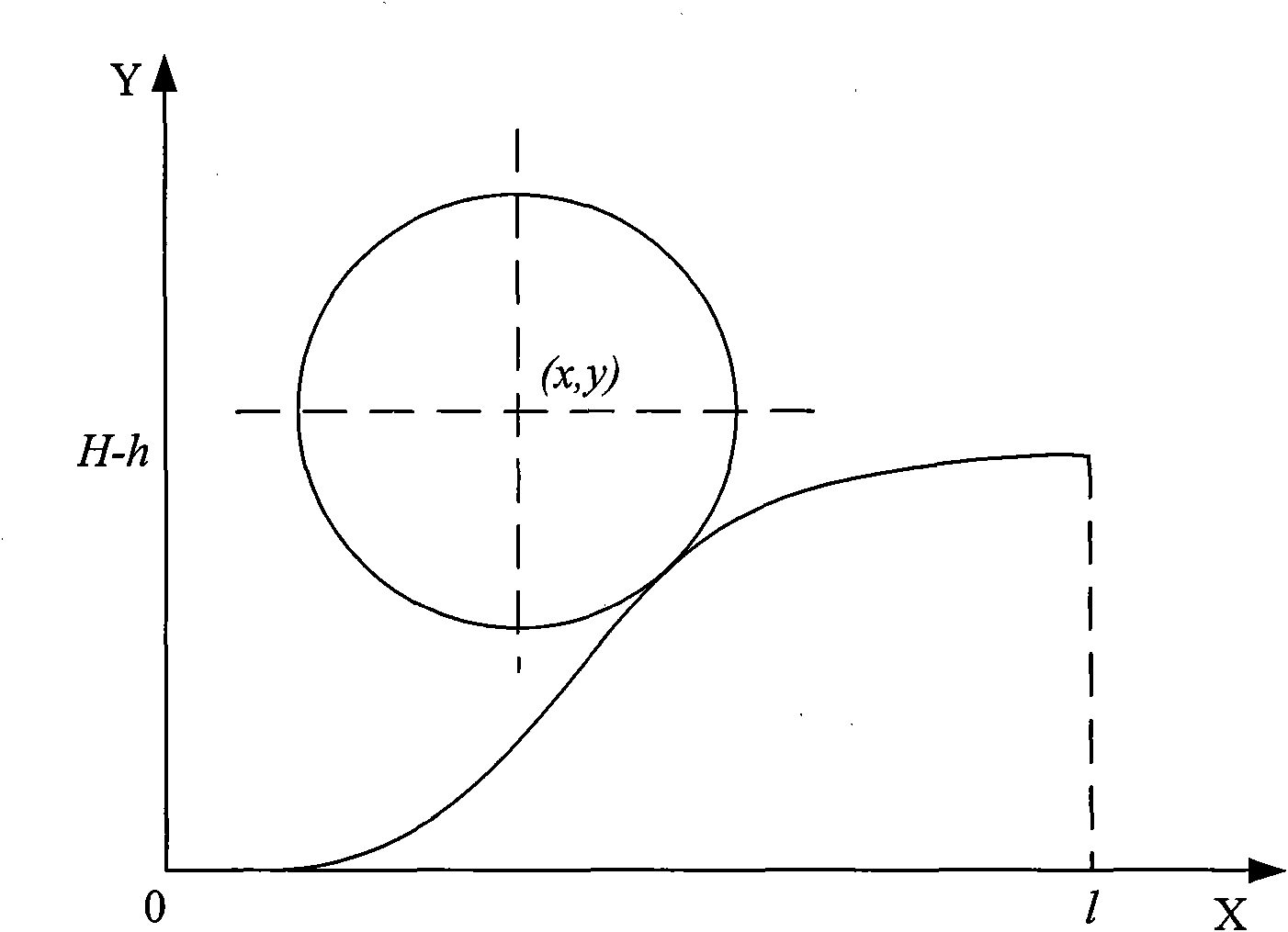

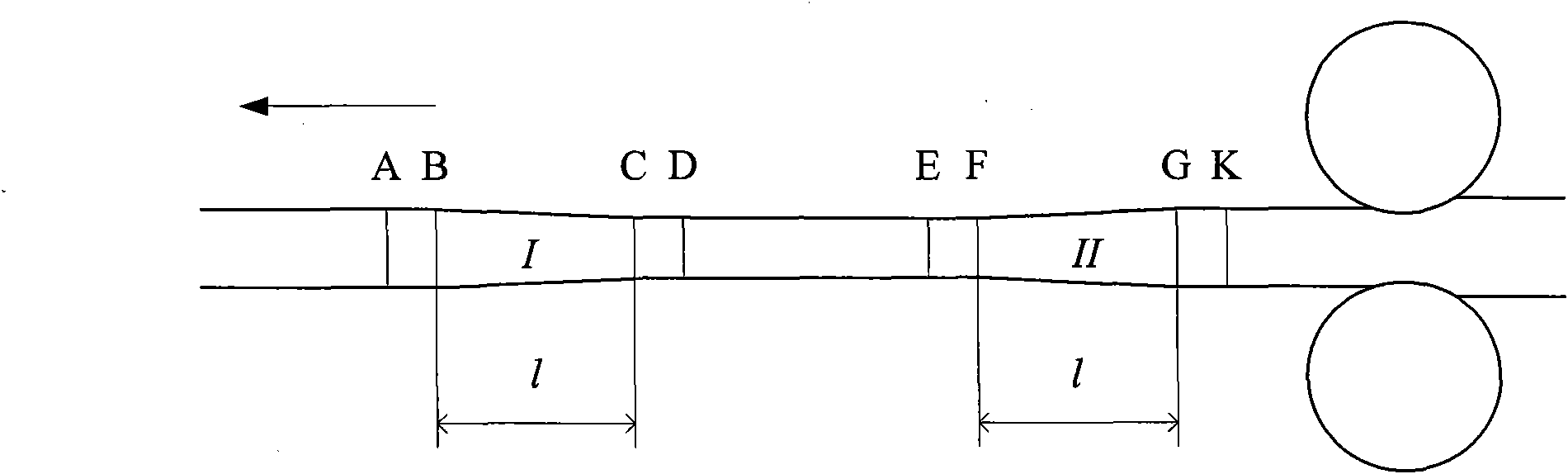

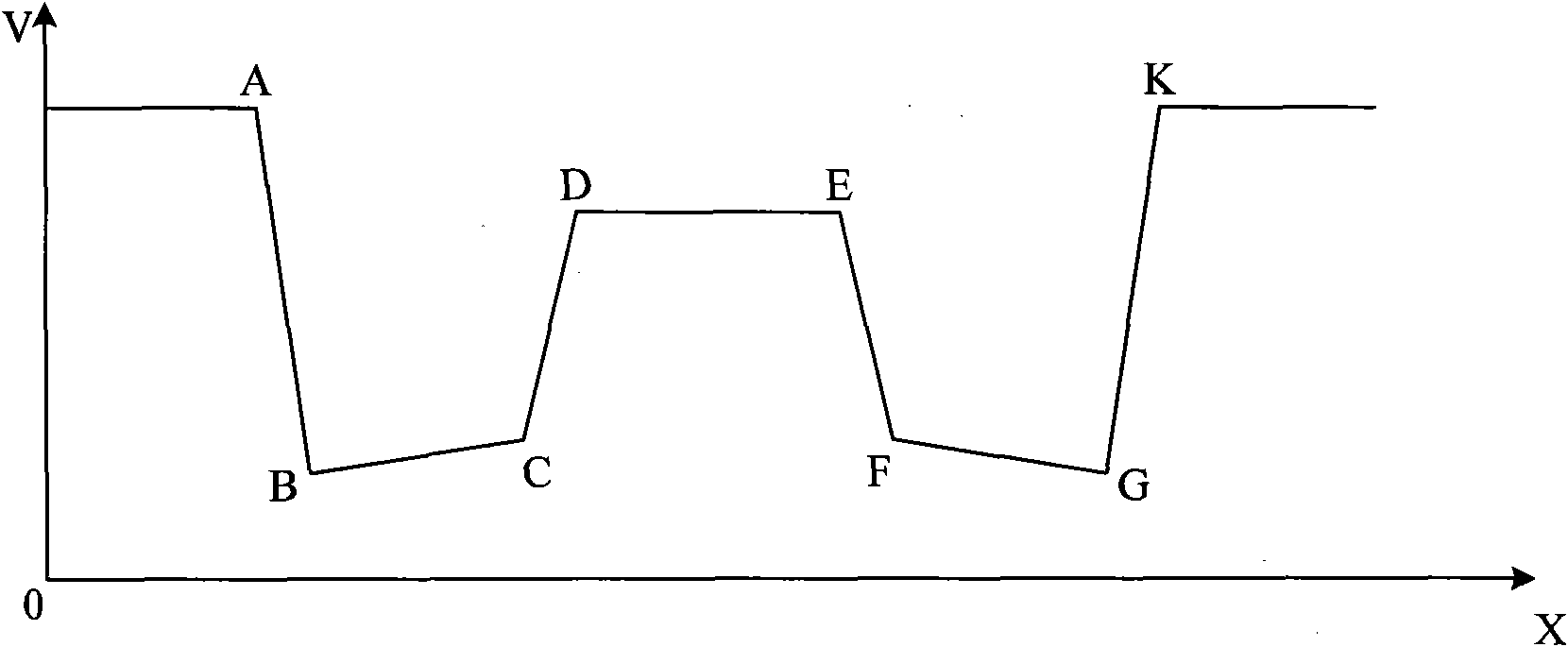

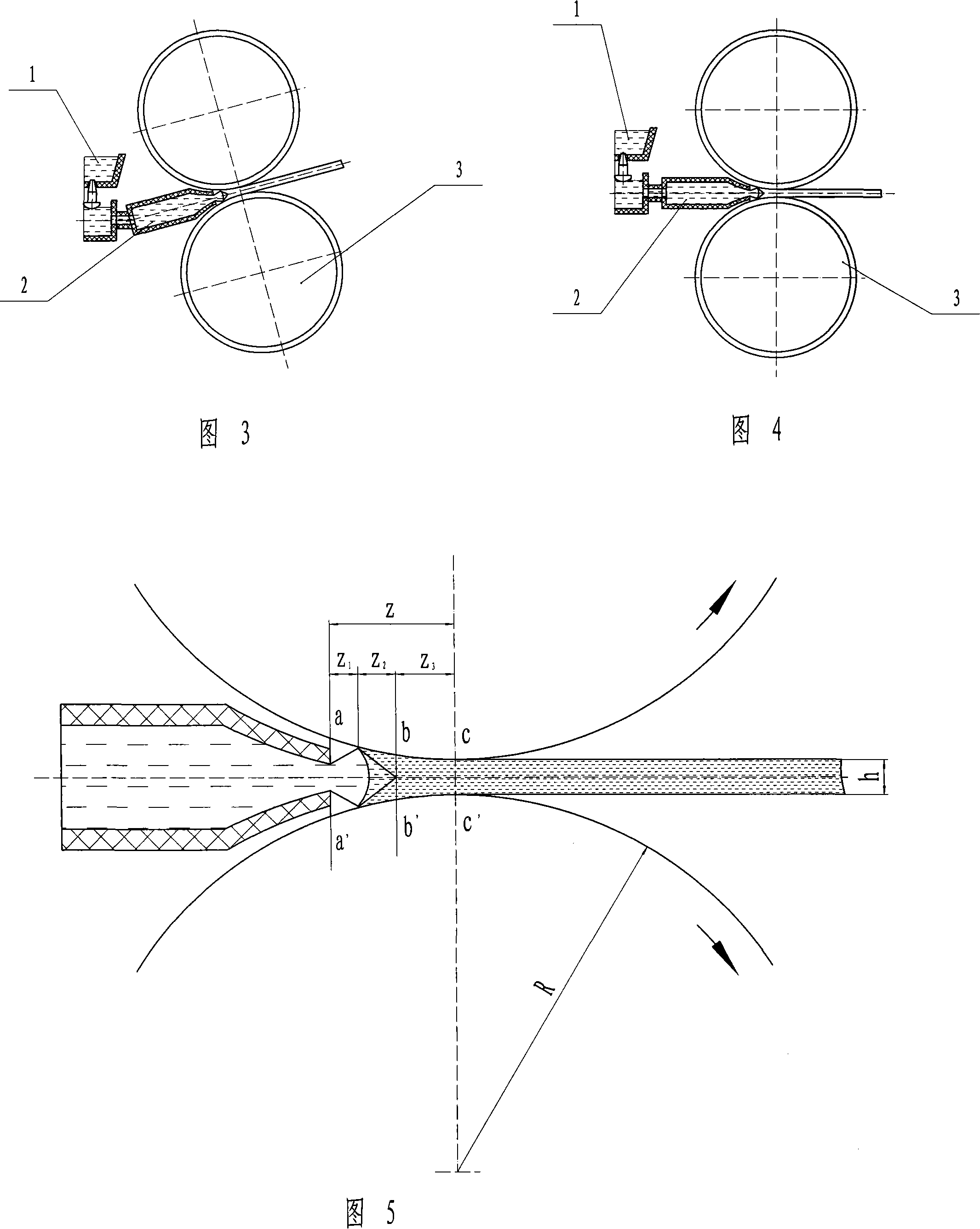

Control method for periodic variable-thickness strip rolling speed

ActiveCN101890434AGuaranteed shapeGuaranteed sizeMetal rolling arrangementsRoll speed control deviceVariable thicknessControl theory

The invention discloses a control method for a periodic variable-thickness strip rolling speed, and belongs to the technical field of rolling. The control method comprises horizontal rolling speed control and the vertical rolling speed control of a roller, wherein the horizontal rolling speed control is performed in a way that: a thick region of a strip is rolled at a thick region rolling speed; the rolling speed starts to decrease at a near point A of a transition region and decreases to VB at a starting point B of the transition region; at the transition region, the horizontal rolling speed at the transition region is calculated according to a transition region curvilinear equation and a second flow equivalence principle; and the rolling speed starts to increase after an end point C of the transition region and increases to a thin region rolling speed at a far point D of the transition point to start to roll a thin region; the vertical rolling speed control of the roller is performed in the way that: the vertical rolling speed of the roller is 0 when the thick region of the strip is rolled; after the thick region is rolled and a rolled piece reaches the starting point B of the transition region, the roller starts downward pressing, and the vertical rolling speed of the transition region is Vdy(x); the Vdy(x) starts to decrease after reaching a maximum point Q1 and decreases to 0 at the end point C of the transition region; and the steps are repeated periodically.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

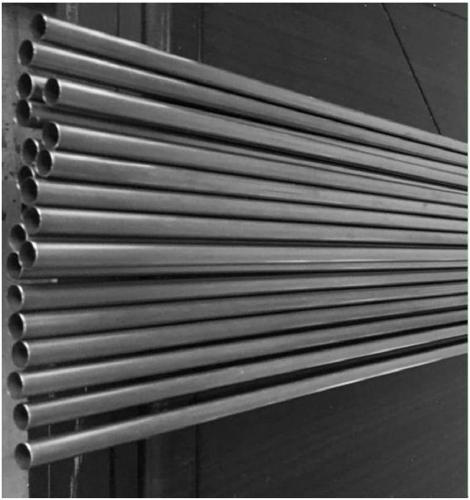

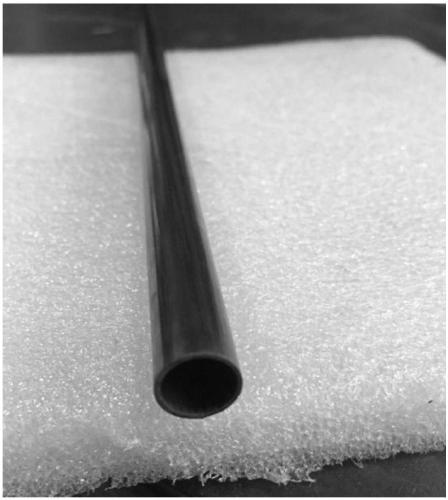

Titanium alloy TC4 hot-rolled tube and production method thereof

The invention relates to a titanium alloy, in particular to a titanium alloy TC4 hot-rolled tube and a production method thereof. By weight, the composition of the alloy is as follows: the balance of Ti, 5.5 percent to 6.75 percent of Al, 3.5 percent to 4.5 percent of V, less than or equal to 0.1 percent of Fe, less than or equal to 0.1 percent of C, less than or equal to 0.03 percent of N, less than or equal to 0.015 percent of H and less than or equal to 0.15 percent of O. A tube blank is heated and rolled on line, the on-line heating temperature is 600 DEG C to 1200 DEG C, and is kept for 1 to 45 minutes, the deformation at each pass is 15 percent to 85 percent, the rolling speed is 20 to 90 times / min, a finished product is produced after 1 to 10 times of rolling, the rolled finished product is annealed in oxygen or vacuum, the annealed finished product is washed by alkali and acid or acid and then by water, and thereby the product is obtained. The tensile strength of the titanium alloy tube is 895MPa to 1300MPa, the elongation of the titanium alloy tube is 8 percent to 25 percent, the metallographic structure is uniform, and a stress-relief annealed metallographic structure and a fully recrystalization annealed metallographic structure can be obtained.

Owner:忠世高新材料股份有限公司

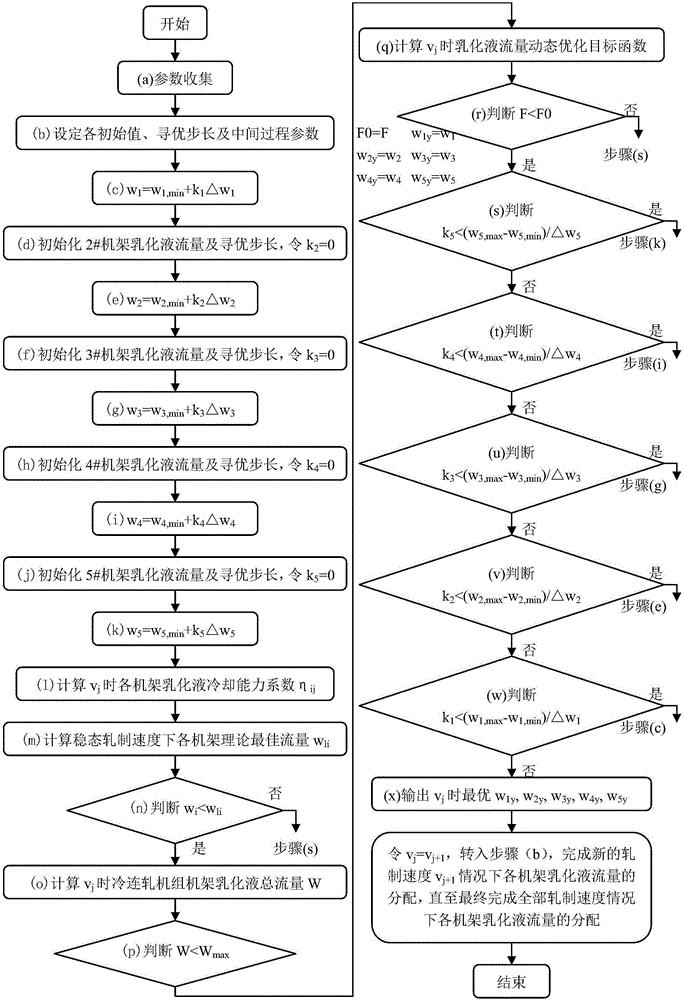

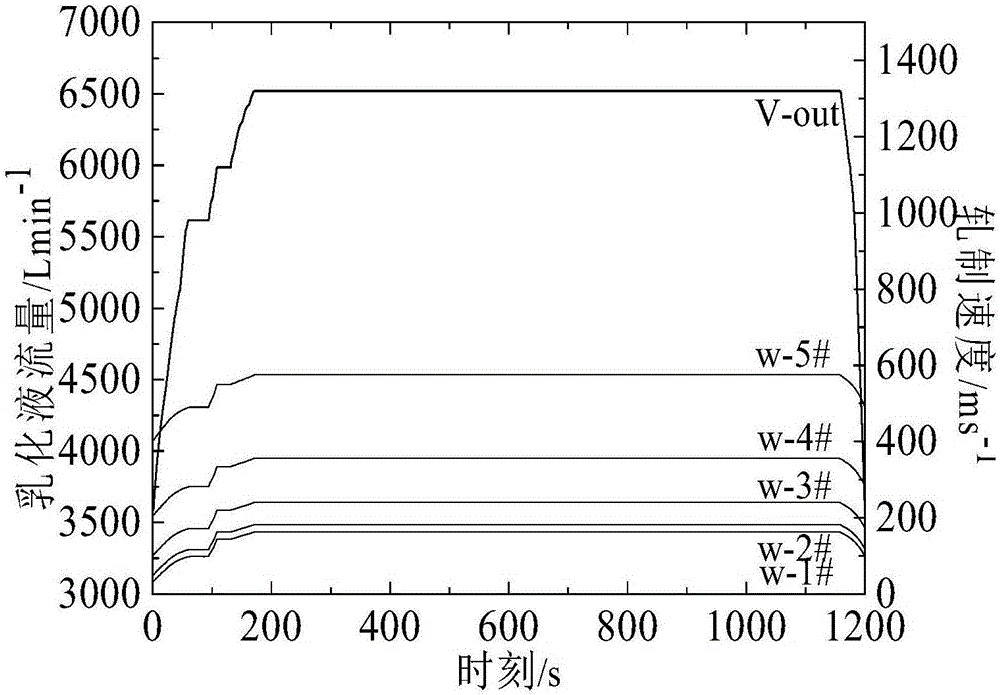

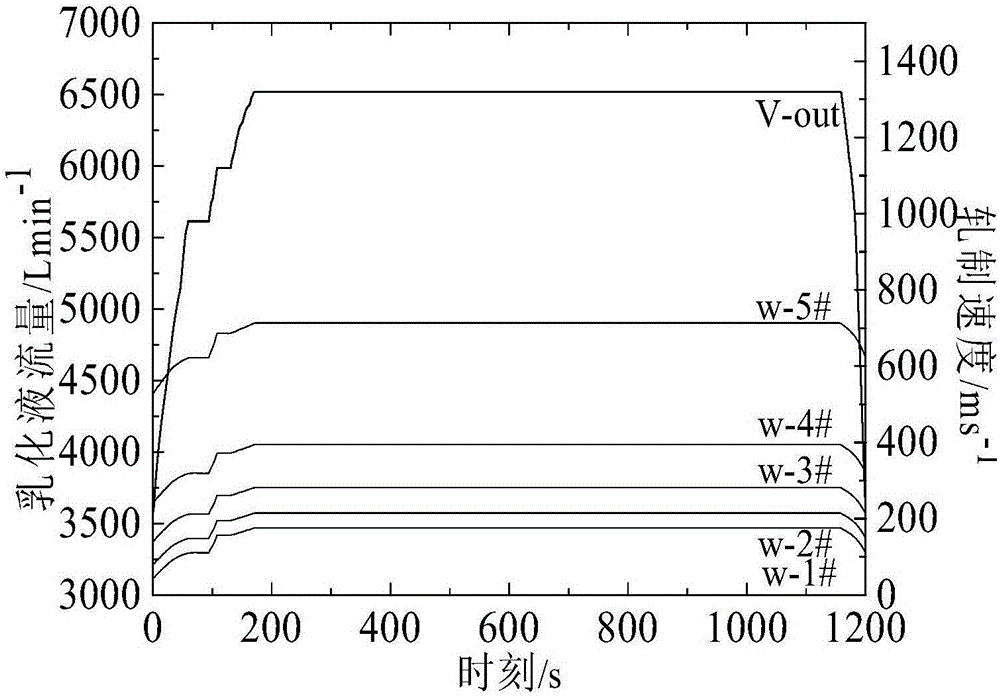

Emulsified liquid flow dynamic and comprehensive optimization setting method suitable for cold continuous rolling unit

ActiveCN106311754AFull cooling effectUniform cooling effectMass flow control deviceMetal rolling arrangementsEngineeringCooling capacity

The invention relates to an emulsified liquid flow dynamic and comprehensive optimization setting method suitable for a cold continuous rolling unit. The method mainly comprises the following steps that (1) parameters are collected; (2) initial values, optimizing step sizes and middle process parameters are set; (3) the flow and the optimizing step sizes of emulsified liquid of a No.2 rack, a No.3 rack, a No.4 rack and a No.5 rack are defined; (4) cooling capacity coefficients of the emulsified liquid of the racks are calculated; (5) the theoretical optimal flow of the racks at the steady rolling speed is calculated; (6) the total flow of the emulsified liquid of the racks is calculated; (7) an emulsified liquid flow dynamic and comprehensive optimization objective function is calculated; (8) the optimal flow of the emulsified liquid of the racks is output; and (9) distribution of the flow of the emulsified liquid of the racks at the new rolling speed is completed till distribution of all the flow is completed. According to the method, the problems that due to fixed distribution of the flow of the emulsified liquid between the racks, the rolling pressure is increased abnormally, and the rolling pressure is inverted are avoided; the cooling capacity of the emulsified liquid is given full play, and the cooling capacity of the emulsified liquid of the racks is more uniform; and the production stability is improved.

Owner:唐山市榕泽钢铁加工有限公司

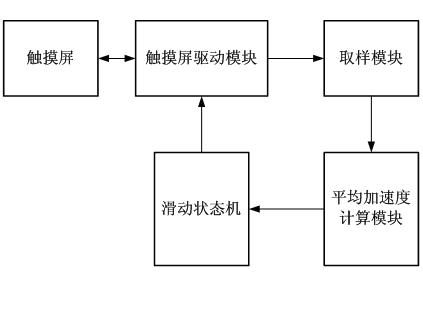

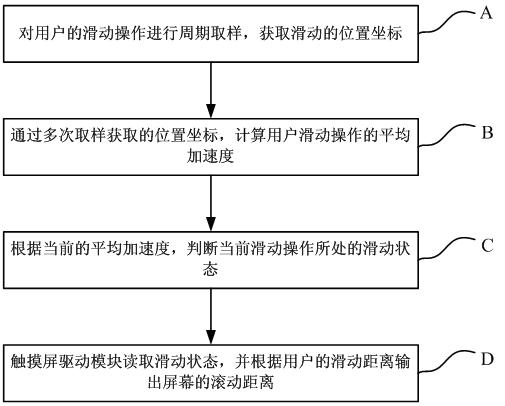

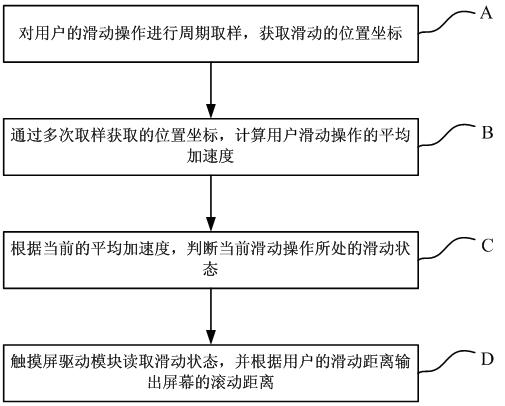

Solution for sliding of touch screen and electronic device using the same

The invention discloses a solution for sliding of a touch screen and an electronic device using the same, wherein the solution comprises the following steps of: A, periodically sampling the sliding operations of a user to obtain position coordinates of the sliding operations; B, calculating average acceleration of the sliding operations of the user according to the position coordinates obtained by multiple sampling; C, judging the sliding state of the current sliding operation according to the current average acceleration; D, reading the sliding state by a touch screen driving module, and outputting the rolled distance of the screen according to the sliding distance of the user. With the solution for sliding of the touch screen and the electronic device using the same provided by the invention, the operation mode of the user can be analyzed and matched, different rolling speeds are adopted under different states, and user can conveniently use the method and the electronic device.

Owner:盐城市盐南高新区西伏河数字智能产业发展有限公司

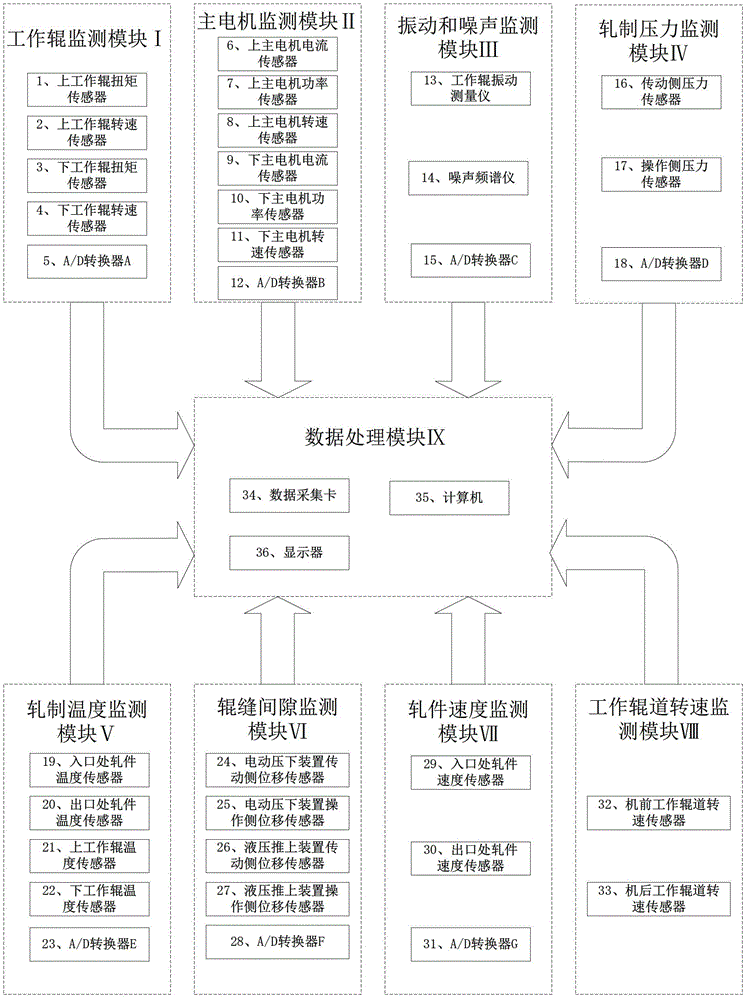

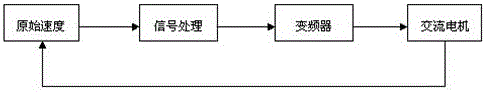

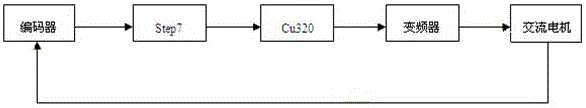

Magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method

InactiveCN103331310AGuaranteed operational reliabilityHigh industrial applicabilityMeasuring devicesMetal rolling arrangementsNoise monitoringWork roll

The invention discloses a magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method. The system is composed of a work roll monitoring module, a main motor monitoring module, a vibration and noise monitoring module, a rolling pressure monitoring module, a rolling temperature monitoring module, a roll gap interval monitoring module, a piece rolling speed monitoring module, a work roll way revolving speed monitoring module, a data processing module and a rolling mill, technological parameters such as rolling force and the rolling temperature and equipment parameters such as the motor current are monitored at the same time, the operating state of equipment is provided according to the parameters, and temperature prediction and fault diagnosis are conducted. Operating data of the equipment are recorded, a temperature monitoring model and a fault diagnosis model are completed, and an intelligent monitoring and diagnosing system with self-learning capacity is set up. A basis is provided for the design of the magnesium alloy rolling equipment, and the magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method has guiding significance for the design of rolling equipment. The magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method is strong in industrial applicability and has very good application prospects.

Owner:JILIN UNIV

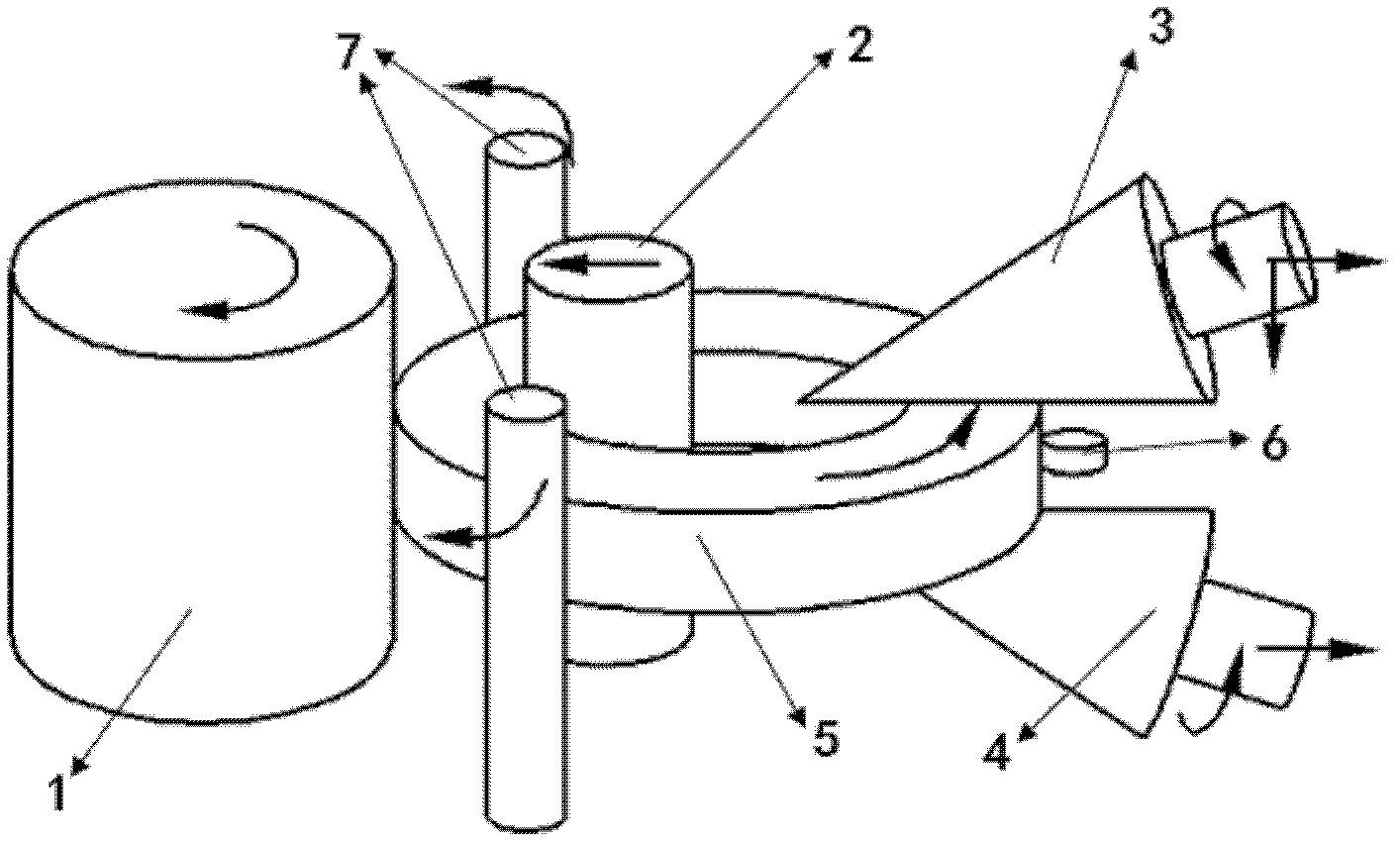

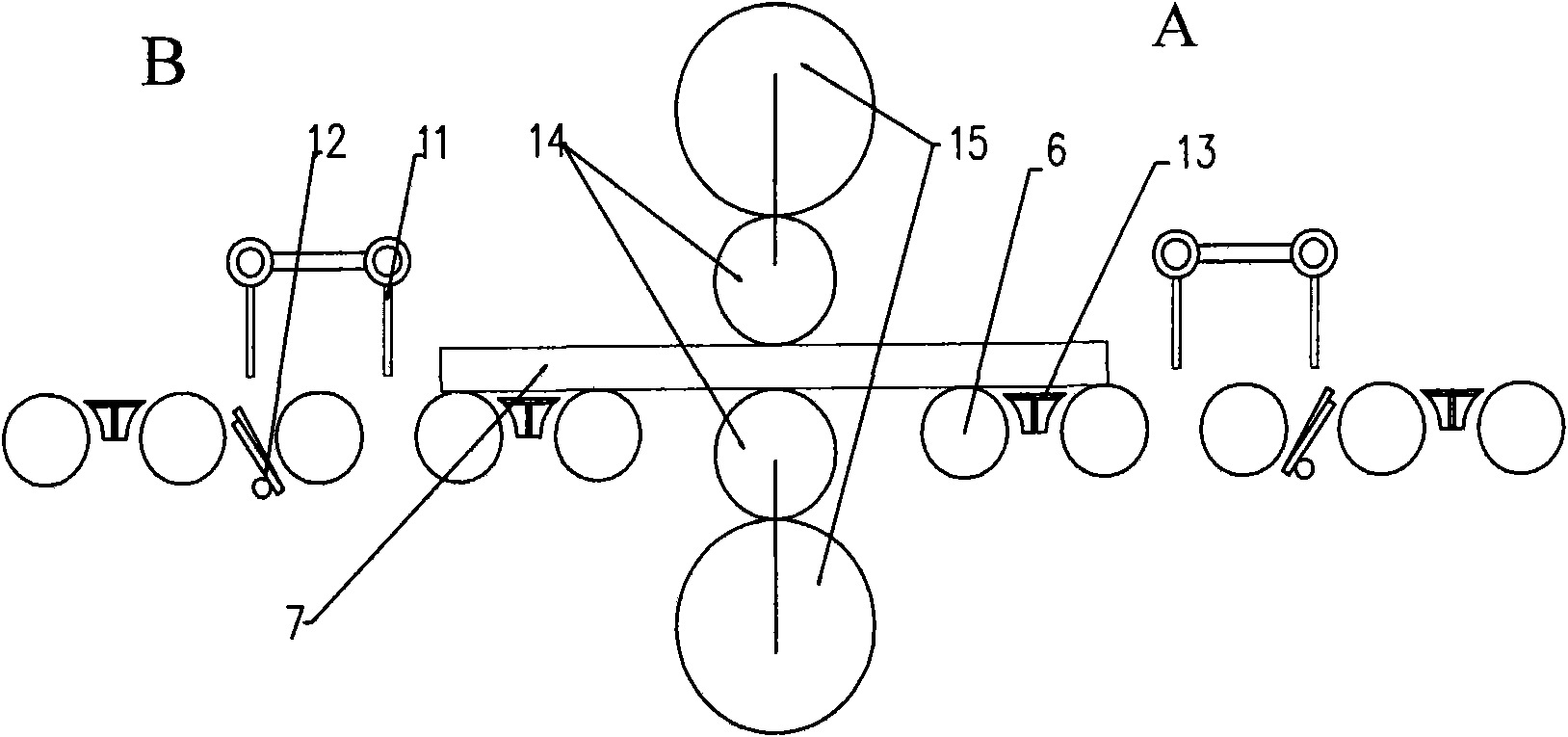

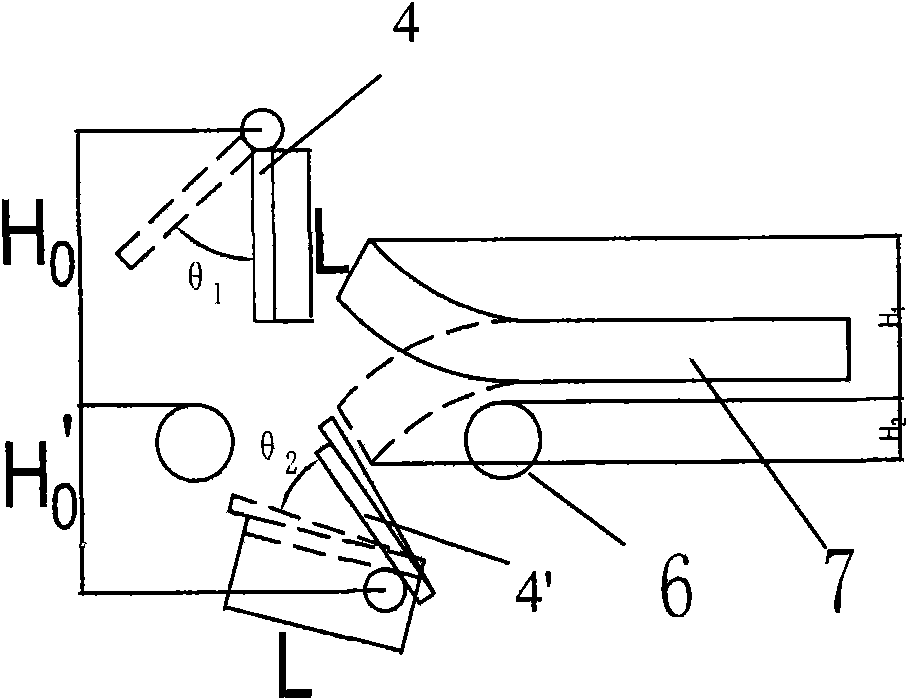

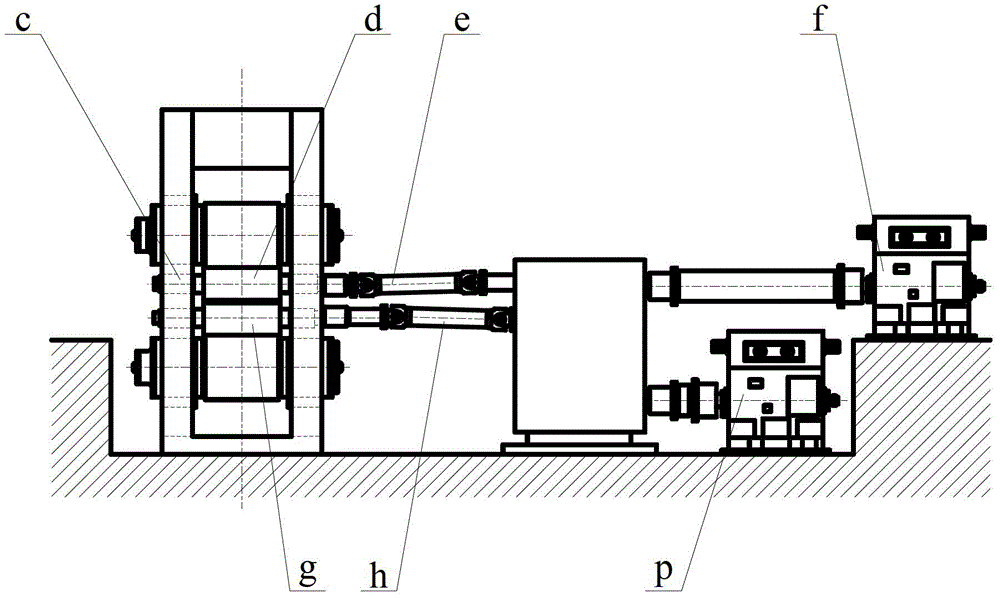

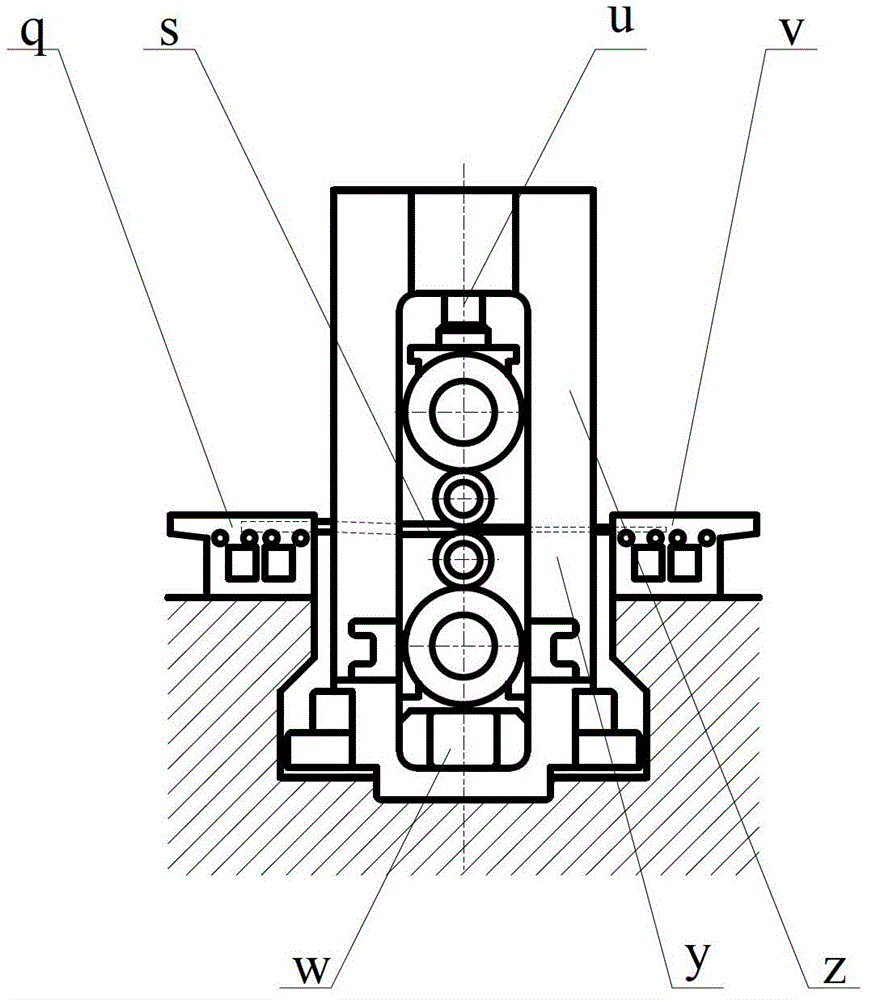

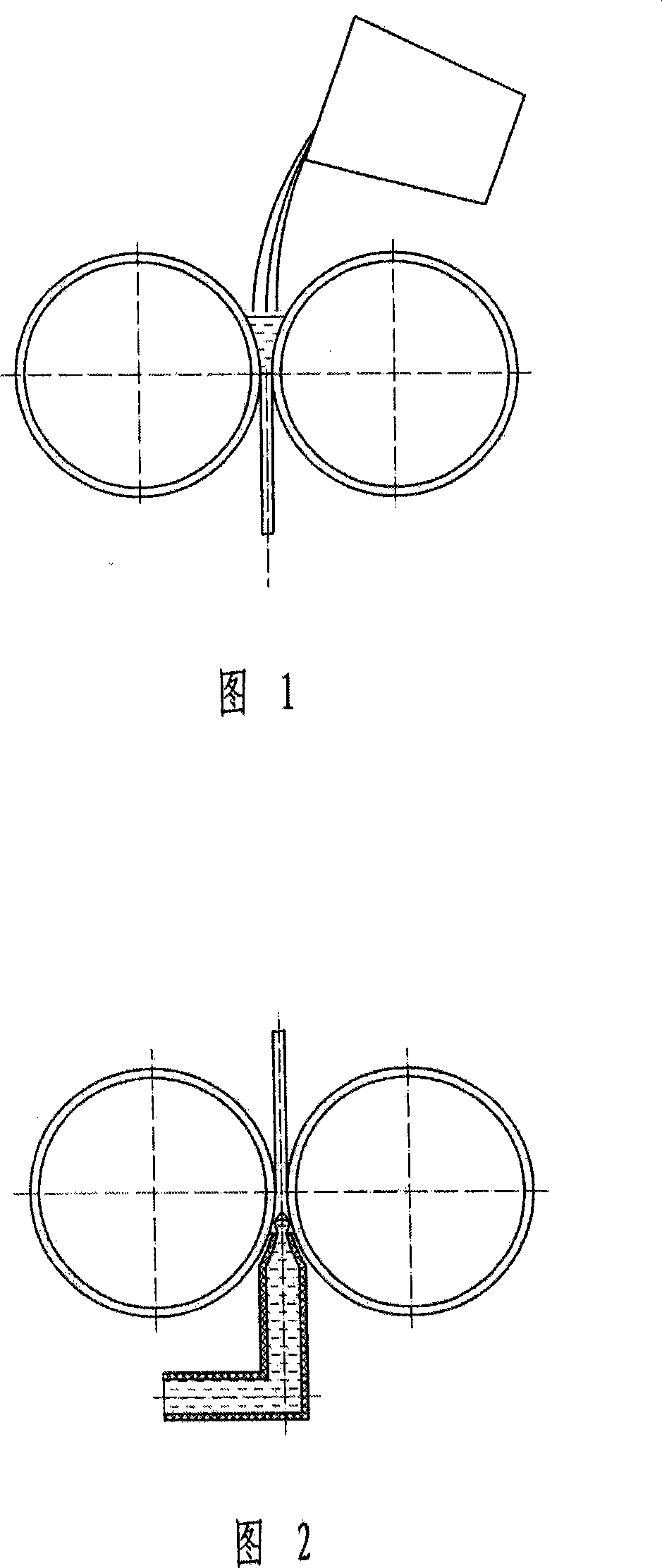

Double-roller casting rolling-hot continuous rolling method and equipment

ActiveCN101239358AIncrease productionHigh dimensional accuracyTemperature control deviceMetal rolling stand detailsProduction lineUltimate tensile strength

The invention provides a method and device for double-roller cast rolling-thermal tandem rolling, which are a method and device for producing aluminum and aluminum alloy plate blank. By using the method, thick cast rolling plate blank can be produced, and coiled material with quality corresponding to that of thermal rolling plate is produced by large rolling amount of thermal rolling, transmitting and coiling. The invention provides a method and device for producing aluminum and aluminum alloy coiled material with high efficiency and greatly improved property by modification aiming at shortcoming of limited cooling space and cooling intensity of the double-roller cast rolling mill in prior art. The invented device enlarges the cast rolling space of the cast rolling mill in prior art with 1.8-4.0 times, enlarges the roller gap thereof with 1.5-2.5 times, enhances the cast rolling speed thereof with 1.5-3.0 times, cast rolls the casting blank continuously with a temperature ranging from 310 DEC C to 510 DEG C, and the integral processing amount is controlled in the range of 40-85, thereby the yield, size accuracy and mechanical property are greatly improved, and the product range is enlarged. The invented device is: inclination angle adjustable off-centering reducing double-roller cast rolling-thermal tandem rolling- cutting-coiling production line.

Owner:张明

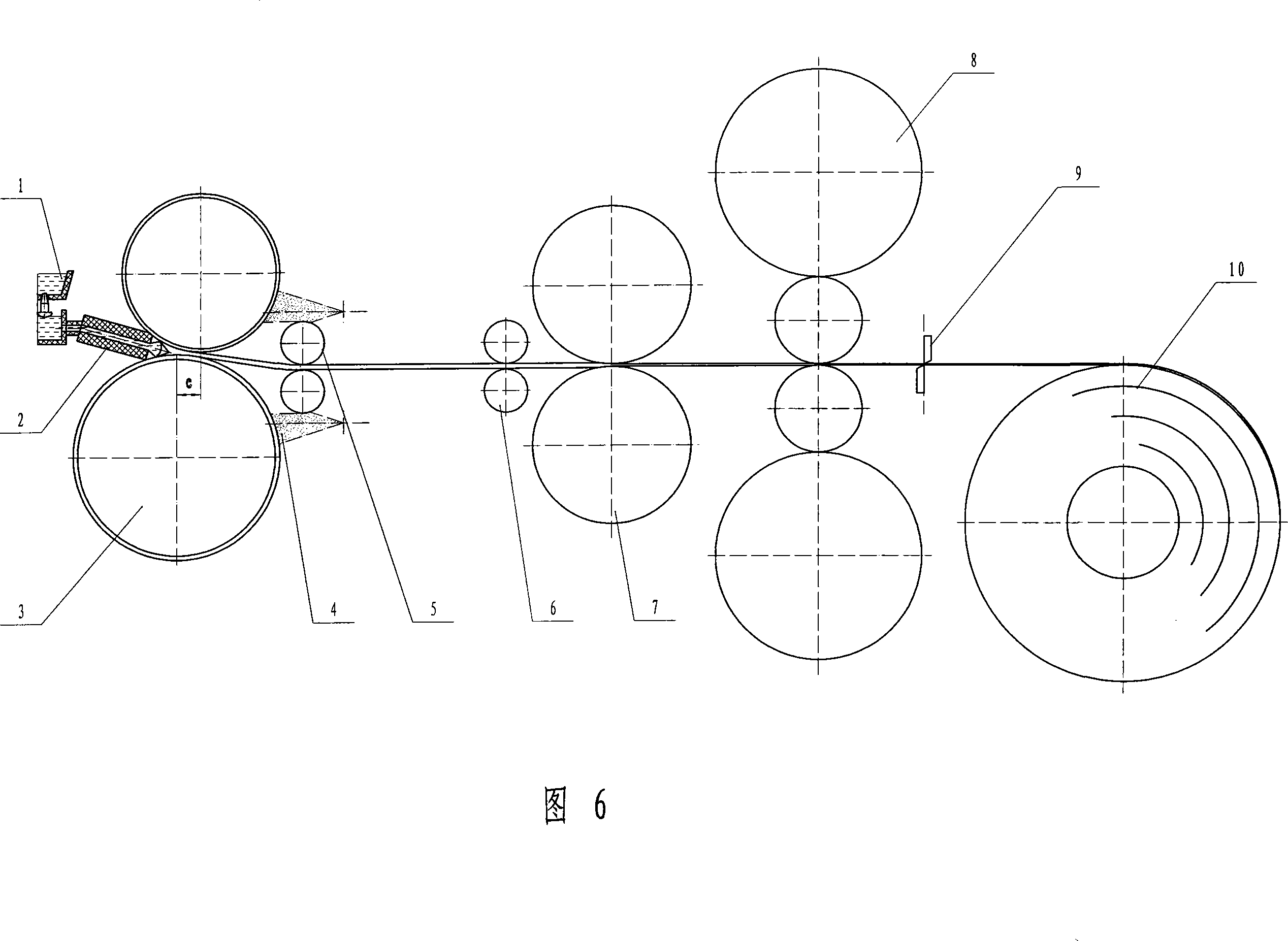

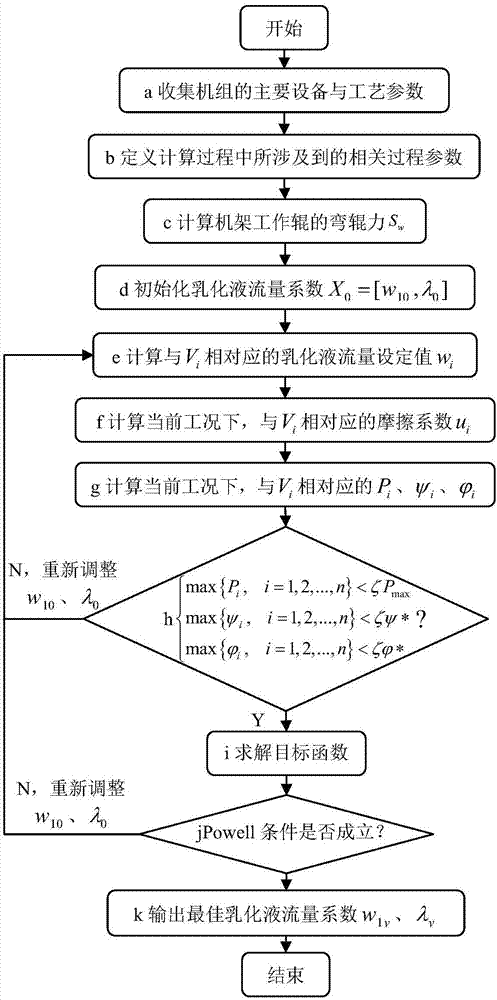

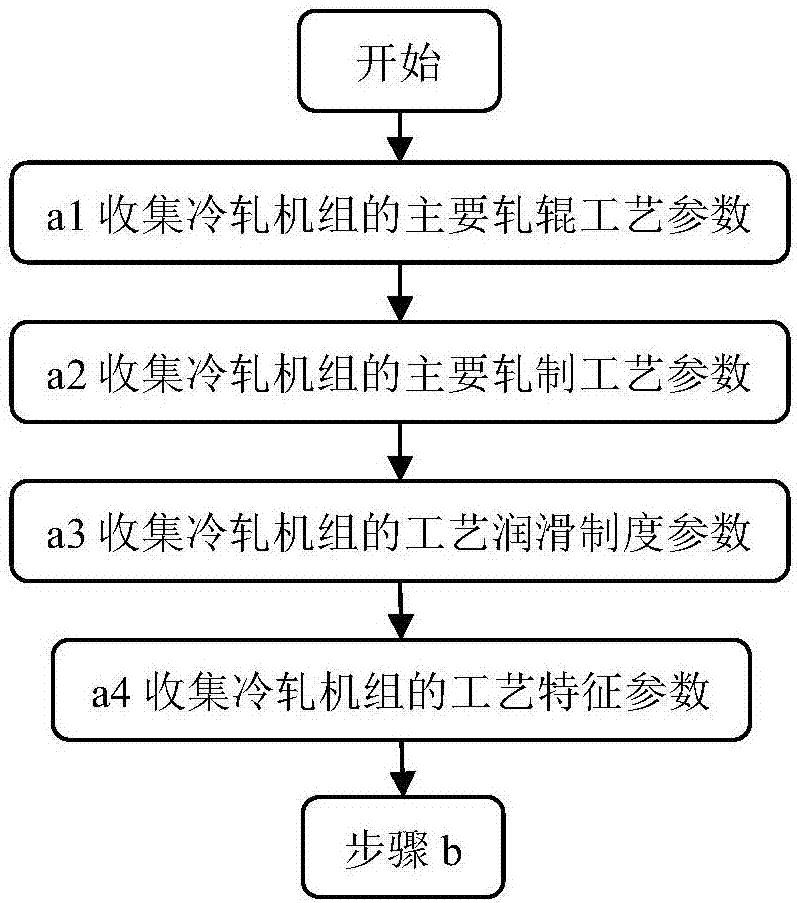

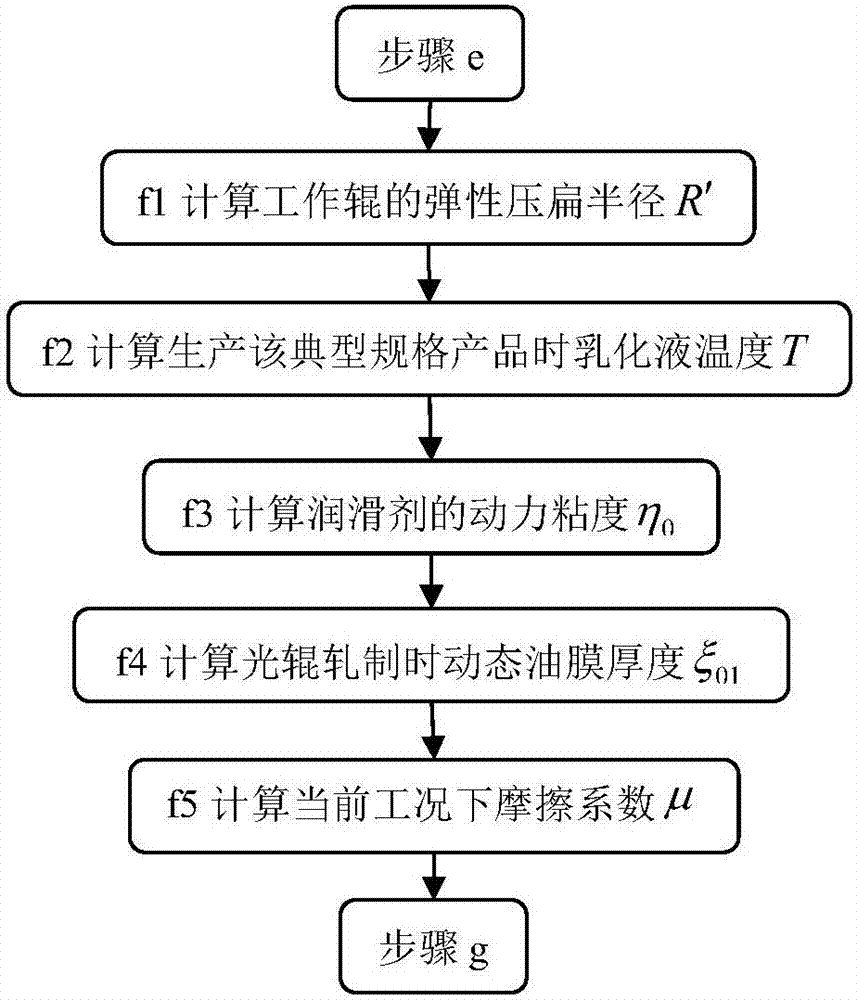

Optimal setting method for relationship curve of emulsion flow and rolling speed in cold rolling process

ActiveCN106909723ASmall fluctuationQuality assuranceForecastingDesign optimisation/simulationEmulsionStrip steel

Provided is an optimal setting method for the relationship curve of the emulsion flow and the rolling speed in the cold rolling process. The method mainly comprises the following steps: 1, collecting main equipment and process parameters of a cold rolling unit; 2, defining the process parameters involved in the optimization process of the emulsion flow; 3, calculating the roll bending force of a rack working roll; 4, initializing the emulsion flow coefficient; 5, calculating the set value of the emulsion flow corresponding to Vi; 6, calculating the friction coefficient mui corresponding to Vi; 7, calculating the rolling pressure, slipping factor and thermal slipping injury index corresponding to Vi; 8, solving the objective function; 9, outputting the best emulsion flow coefficient, and determining the relationship curve of the best emulsion flow and speed. The method has the advantages that the overall fluctuation rate and the maximum fluctuation rate of the rolling pressure can be kept smaller during the speed-up and speed-down process, and it is ensured that the slipping and thermal slipping defects are prevented from occurring in the rolling process, thus the surface quality and the strip shape control precision of strip steels are improved.

Owner:YANSHAN UNIV

A high-performance cooper-coated aluminum rectangle section compound conductive bus bar and its making technology

ActiveCN101241778AMeet the requirements of multiple specificationsGreat widthSingle bars/rods/wires/strips conductorsMeasuring devicesCopperAluminum composites

The present invention provides a high-performance copper-clad aluminum cross section composite conductive bus-bar and the preparing technique thereof, and the invention relates to a rectangle-cross section bimetal composite material and the preparation thereof. The copper-clad aluminum rectangular cross section composite conductive bus-bar is compounded by the core-part aluminum and the coating layer copper. The area proportion of the coating copper layer is 15to 50 The technique comprises the following procedures: Adopting horizontal continuous casting for directly compounding and forming the copper-clad aluminum composite blank. Commonly flat-roller rolling and finish drawing-pulling the copper-clad aluminum blank according to requirement or rolling with the flat roller provided with a vertical roller, the range of the rolling speed is 3-50m / min, and the single-pass relative reduction is between 15and 40 The speed range of finish drawing-pulling is 1-20m / min and the single-pass cross section scalage is 10%. When the multiple-pass relative reduction is up to 70%, the low-temperature intermediate annealing is executed to the copper-clad aluminum composite conductive bus-bar. The annealing temperature is between 250 and 450 DEG C and the annealing time is between 0.5 and 3h. The annealed composite conductive bus-bar is executed with hole-form rolling or drawing. The invention not only can produce the high-performance copper-clad aluminum cross section composite conductive bus-bar, but also has the advantages of short process flow and high efficiency of the producing method.

Owner:UNIV OF SCI & TECH BEIJING

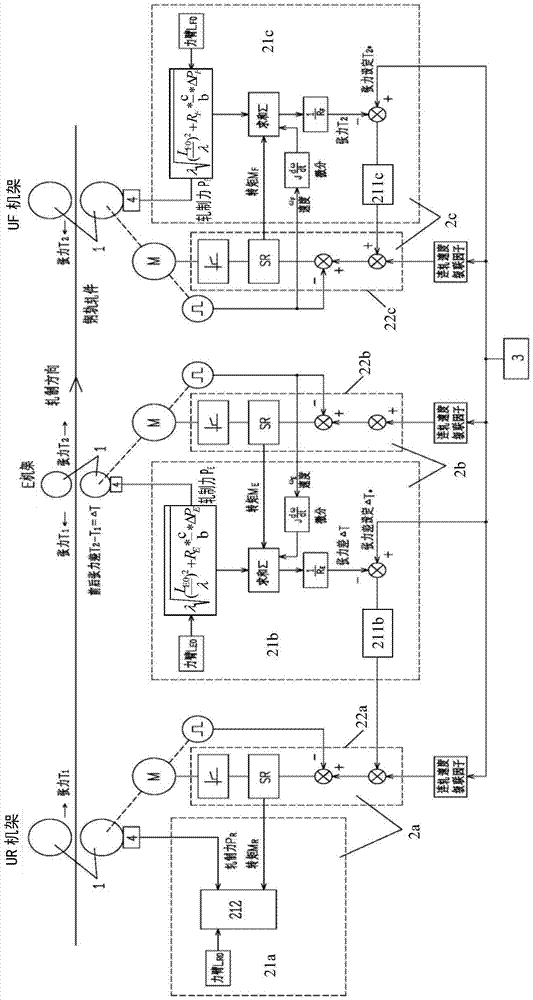

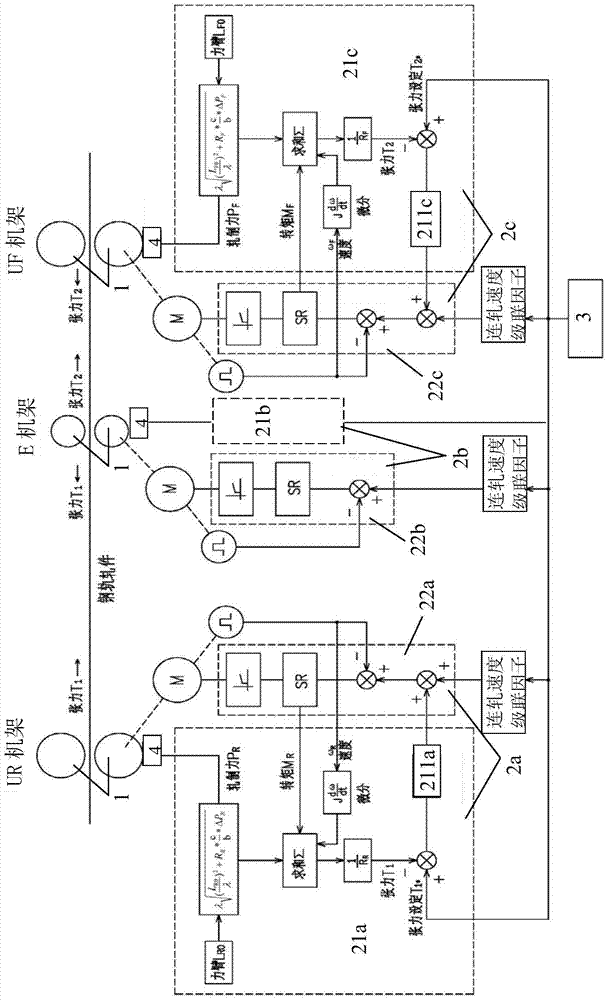

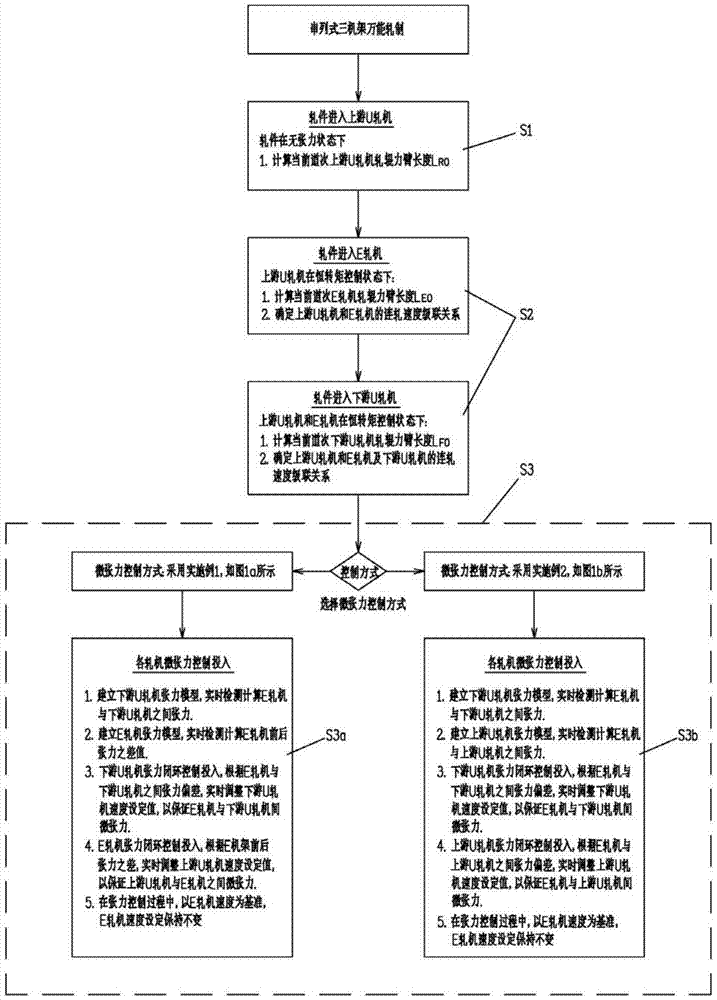

Micro-tension control system and method

ActiveCN103567230AGuaranteed tension control accuracyGeometry out-of-tolerance reductionMeasuring devicesTension/compression control deviceLoop controlClosed loop

The invention discloses a micro-tension control system and method. In the hot continuous rolling process, when a rolled piece enters a current machine frame and is stably bitten, the current machine frame is kept under speed control, speed control of main motors of machine frames on the upstream of the current machine frame is switched to constant torque control, on the basis, the torque and the rolling force of a main motor of the current machine frame are sampled to calculate the initial length of a rolling force arm, and the tension measurement calculating accuracy is improved. Each machine frame is provided with a pressure measuring head device to directly detect the rolling force, and consideration is given to the situation that the length of the rolling force arm is changed along with changes of the rolling force. Tension between the machine frames is obtained in real time through tension calculating models to form micro-tension closed-loop control to adjust the speeds of the machine frames so as to correct the tension deviations between the machine frames. As for a serial type universal rolling mill, the speed of the E machine frame serves as a standard, the rolling speed of the E machine frame is kept unchanged while speed set values of the other machine frames are adjusted, and real-time control is carried out on dynamic instantaneous values of the tension difference of the E machine frame before and after the adjustment process to guarantee micro-tension rolling of series universal rolling.

Owner:BERIS ENG & RES CORP

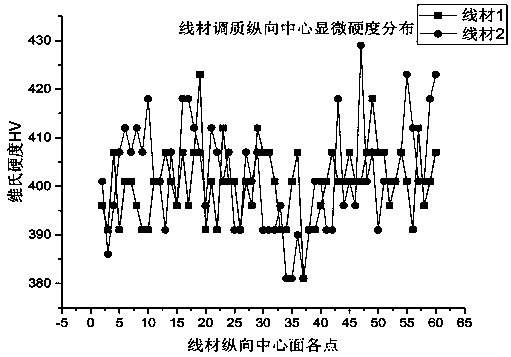

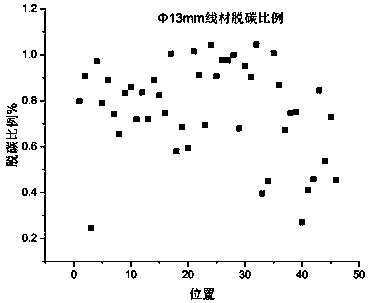

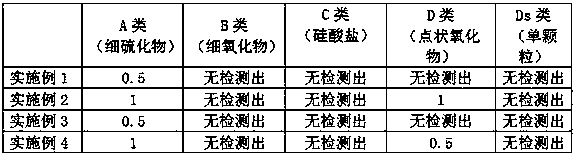

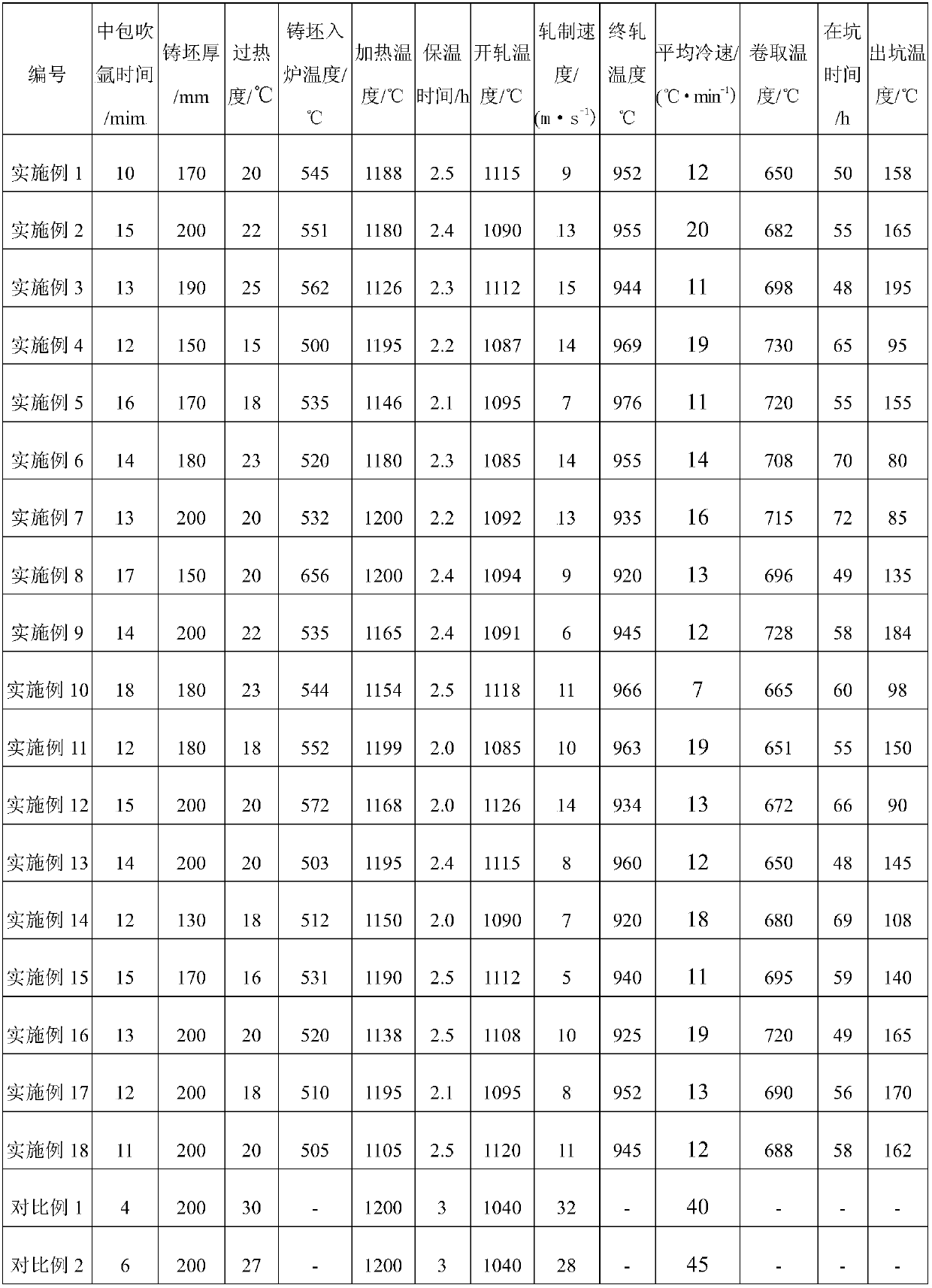

Production technology of spring steel 60Si2Mn hot-rolled wire rod for automotive suspension

ActiveCN109023059AGuarantee organizationGuaranteed performanceProcess efficiency improvementSlagDeoxygenation

The invention discloses a production technology of a spring steel 60Si2Mn hot-rolled wire rod for an automotive suspension. The production technology comprises the steps of a hot metal pretreatment working procedure, a converter smelting working procedure, an LF refining working procedure, an RH vacuum treatment working procedure, a continuous casting working procedure, a cogging working procedure, an ingot blank polishing working procedure and a wire rod rolling working procedure. According to the production technology, the generation of AL2O3 inclusion is controlled from the source by meansof hot metal pretreatment desulfurization, silicon iron deoxygenation, silicon carbide diffusion deoxygenation and wollastonite and active lime slag formation; by the adoption of special carburant andspecial silicon iron, the content of nitrogen and the content of titanium in steel are controlled, argon protection in the whole process and the sufficient standing time are adopted, the situation that the inclusion fully and upwards floats is guaranteed, and D and Ds inclusion in the molten steel is controlled; by means of large ladle slag detection and special covering slag, the phenomenon thatthe molten steel is subjected to secondary pollution can be completely eradicated, and a good effect of thermal-insulating adsorption of the inclusion can be achieved; by means of the stir and soft press operation of a large rectangular blank crystallizer, the internal quality of an ingot blank is ensured; and in the rolling process, due to the optimization of the rolling speed and the control over the rolling temperature, the structure and the performance of a finished product are guaranteed.

Owner:HANDAN IRON & STEEL GROUP +1

Method for producing metallic titanium plate using medium-wide strip hot rolling machine set

ActiveCN101412038ALow investment costRoll force/gap control deviceTemperature control deviceSocial benefitsProduction line

The invention discloses a method for producing a metallic titanium plate by adopting a medium-wide band heat rolling set. The method comprises the following steps: heating a titanium plate blank with a thickness of between 50 and 90 millimeters in a roller-hearth type soaking furnace to between 800 and 1,000 DEG C, controlling inlet temperature of the titanium plate blank entering the medium-wide band heat rolling set at a temperature of between 800 and 950 DEG C, controlling process temperature to between 700 and 950 DEG C, and keeping final rolling temperature at a temperature of between 700 and 800 DEG C after fine rolling for seven times; and well controlling roll gap width, depressing rate, roll force and roll (rolling) speed of each stander of the heat rolling set, controlling the rolling speed of the titanium plate rolled by the tail stander of the heat rolling set at between 4.0 and 8.0 meters per second, and coiling the titanium plate by a coiling machine after cooling the titanium plate by water, wherein the coiling temperature is between 550 and 680 DEG C. The method uses a CSP production line to produce the non-ferrous metallic titanium plate (coil) for domestic initiation, and has extremely great economic and social benefits.

Owner:湖南湘投金天钛金属股份有限公司 +1

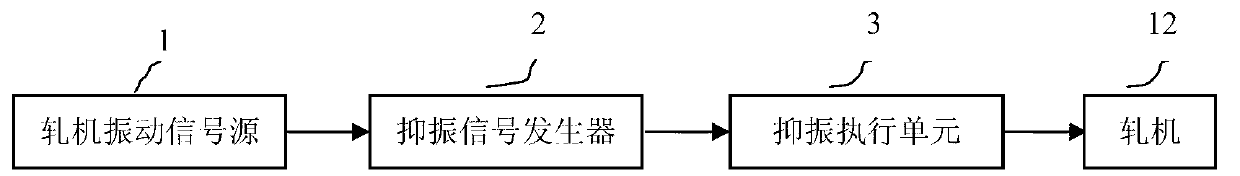

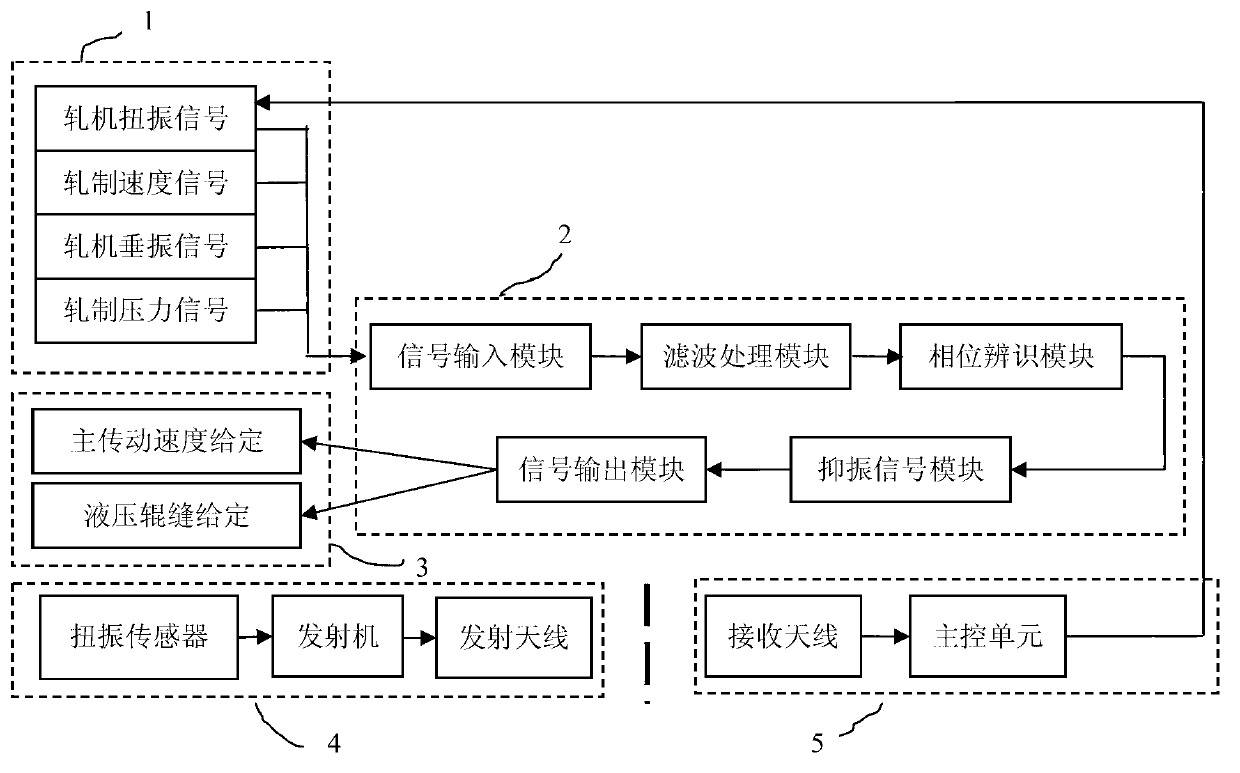

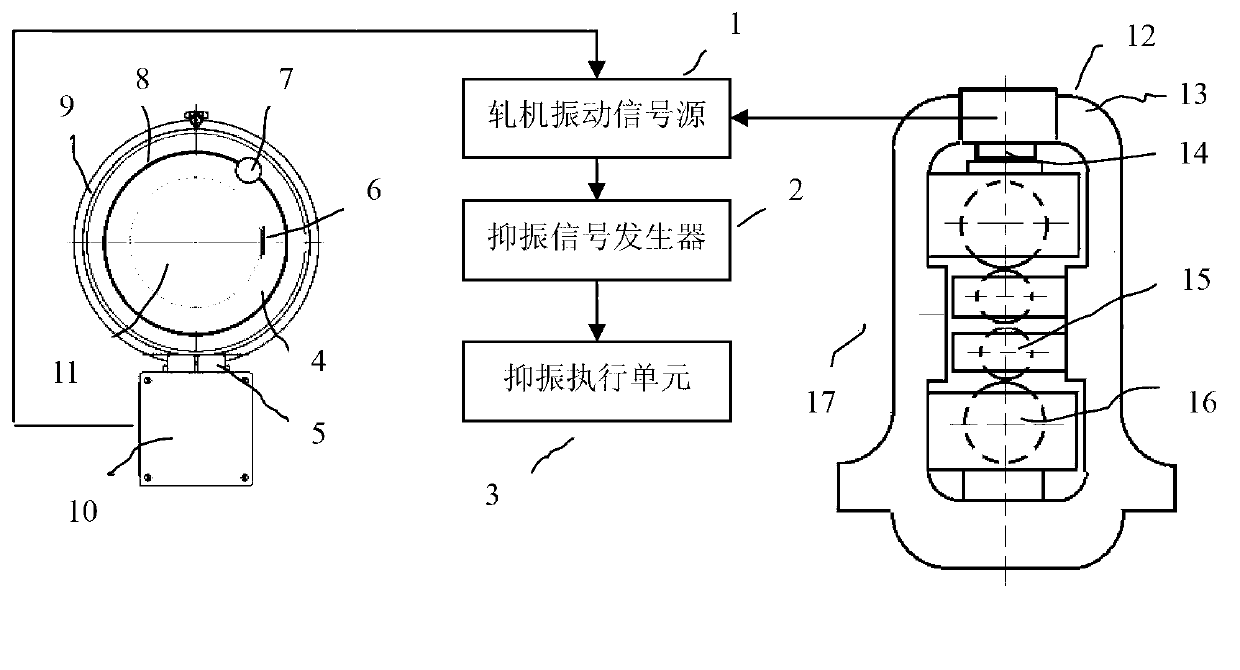

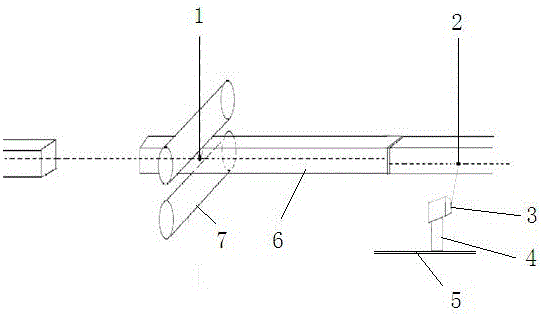

Device for suppressing vibration of rolling mill

InactiveCN103121037AReduce vibrationReduce vibrational energyRolling equipment maintainenceMetal rolling arrangementsVertical vibrationSetter

The invention belongs to the field of signal detection and automation control of rolling mills, and relates to a device for suppressing vibration of a rolling mill. The device for suppressing the vibration of the rolling mill is characterized by comprising a rolling mill vibration signal source, a vibration suppression signal generator, a vibration suppression actuating unit and the rolling mill, wherein the rolling mill vibration signal source is composed of rolling mill torsion vibration signals, rolling speed signals, rolling mill vertical vibration signals and rolling pressure signals, the vibration suppression signal generator is composed of a signal input module, a filter processing module, a phase recognition module, a vibration suppression signal module and a signal output module, and the vibration suppression actuating unit is composed of a main drive speed setter and a hydraulic roll gap setter. The device for suppressing the vibration of the rolling mill has the advantages that vibration suppression damping signals are generated by the vibration suppression signal generator according to the rolling mill vibration signal source and sent to the main drive speed setter and the hydraulic roll gap setter of the vibration suppression actuating unit so as to participate in control of the rolling mill to reduce the vibration energy of the rolling mill, so that the rolling mill can be prevented from vibrating severely, chatter marks on a roller and the surfaces of strips are eliminated, and therefore the surface quality of products is improved, and the on-line service life of the roller is prolonged.

Owner:UNIV OF SCI & TECH BEIJING

Four-pass aluminum foil rolling process

The invention relates to a four-pass aluminum foil rolling process, and belongs to the technical field of aluminum foil rolling process. The process comprises the following steps: 1, selecting materials; 2, performing first-pass rolling; 3, performing second-pass rolling; 4, performing third-pass rolling; 5, folding; and 6, performing fourth-pass rolling. The four-pass aluminum foil rolling process has a simple process flow, reduces the loss of defective products caused by one-pass acceleration and deceleration by increasing the rolling reduction of each rolling pass, and simultaneously guarantees that the finished product has no defect such as twill, herringbone, hot blast and the like; the loss of defective products caused by each-pass acceleration and deceleration is about 1 percent, the loss of one-pass lap changing time is also saved, and the lost time of each lap changing is about 10 minutes; therefore, the rolling speed is improved, and the overall improved speed is about 13 percent.

Owner:SHANDONG NANSHAN ALUMINUM

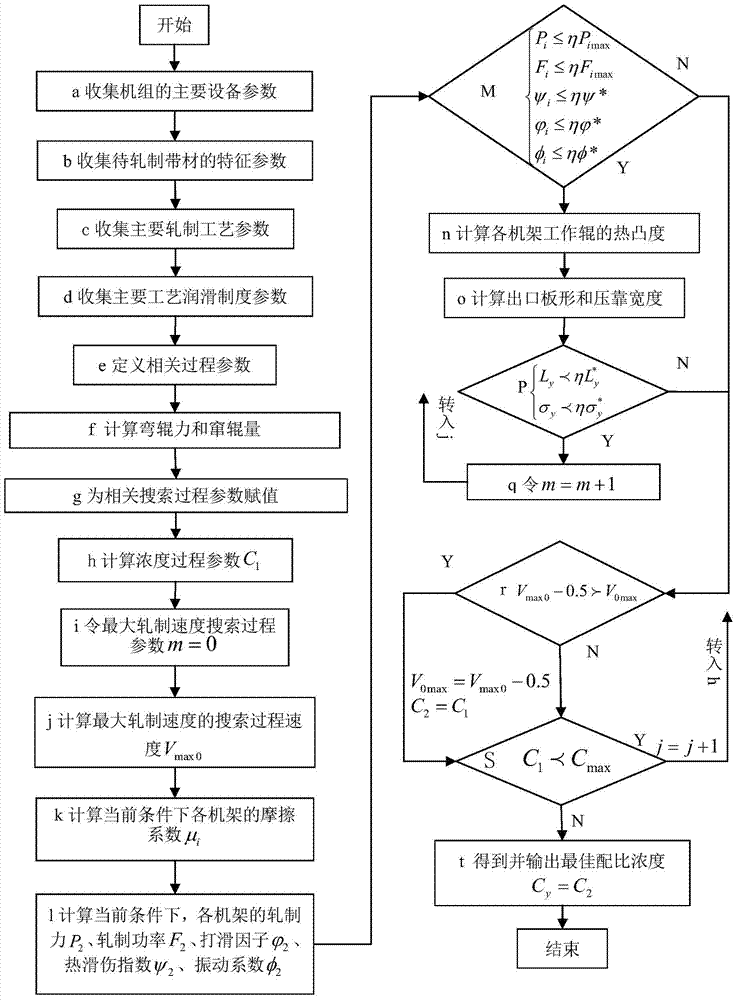

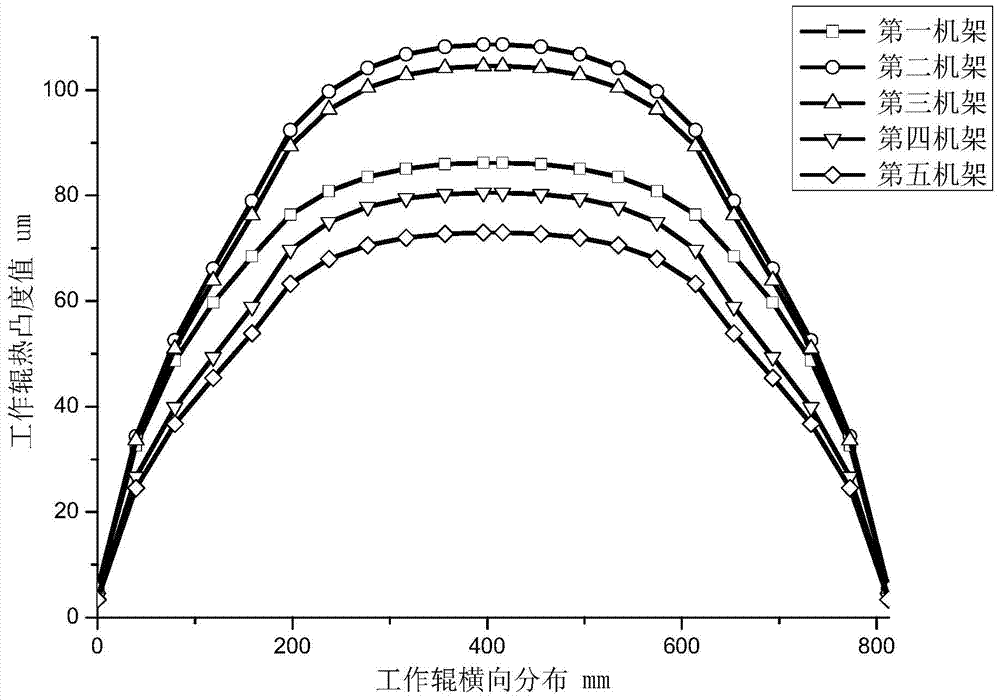

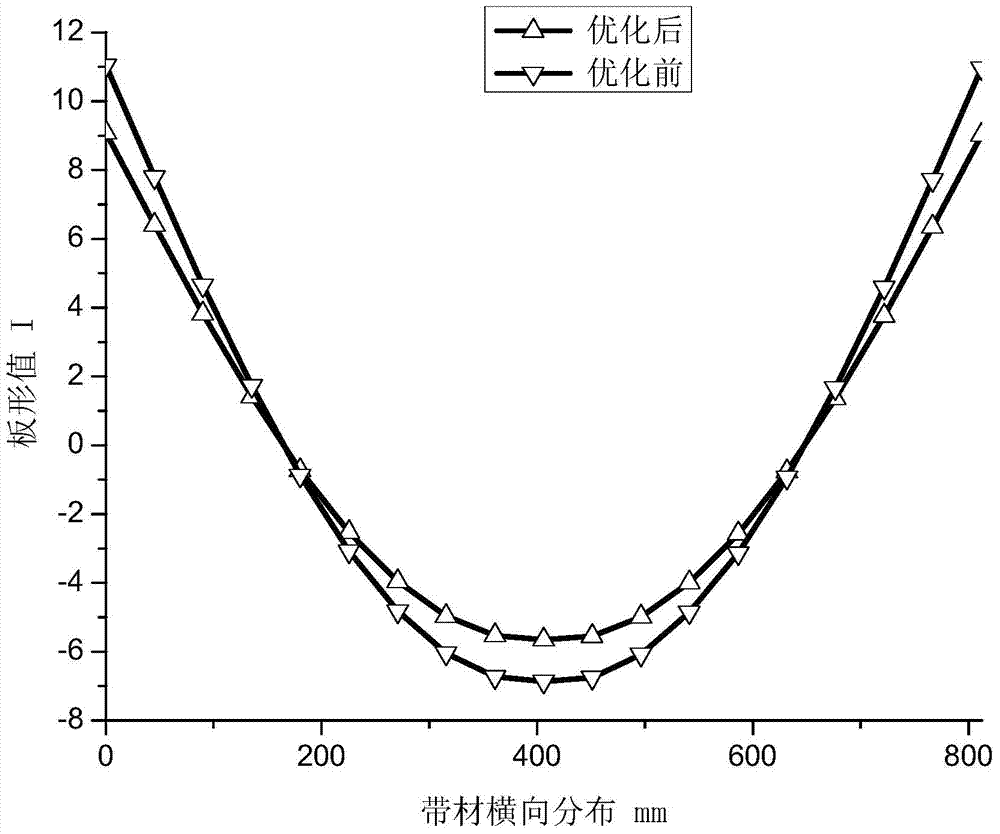

Method for setting concentration of emulsion in rolling of five-rack cold continuous rolling unit extremely thin band

InactiveCN103544340AIncrease rolling speedGuaranteed rolling efficiencyVibration control deviceSpecial data processing applicationsEmulsionBending force

The invention discloses a method for setting concentration of emulsion in rolling of a five-rack cold continuous rolling unit extremely thin band. The method includes the following steps: (1) collecting characteristic parameters of main devices of a unit and to-be-rolled bands, main rolling process parameters and process lubricating system parameters, (2) defining related process parameters, (3) computing roll bending force and the roll channeling amount, (4) assigning related search process parameters, (6) computing concentration process parameters, (6) computing the search process speed of the highest rolling speed, (7) computing friction coefficients of various racks under the current condition, (8) computing rolling force, rolling power, slip factors, heat slip damage indexes and vibration coefficients of the various racks under the current condition, (9) computing heat convexity degrees of working rollers of the various racks, (10) computing an exit plate shape and the pressing width, and (11) obtaining and outputting the optimum proportion concentration. The steps are executed by a computer. According to the method, the rolling speed can be quickened, the rolling efficiency can be guaranteed, slip, heat slip damage and vibration are avoided, and it is guaranteed that the exit plate shape of the final rack and the pressing width of the roller ends of the working rollers are the smallest.

Owner:唐山扬邦钢铁技术研究院有限公司

Method for rolling precise stainless-steel ultrathin steel belt

ActiveCN102699025AThickness tolerance fluctuations are smallGood Thickness ToleranceMetal rolling arrangementsSurface roughnessOil temperature

The invention relates to a method for rolling a precise stainless-steel ultrathin steel belt, comprising the following steps: 1, carrying out an initial rolling procedure by stainless-steel cold-rolling raw material of 0.3-05mm in thickness and carrying out cold rolling for many times so as to obtain 0.1-0.2 mm of a finished product thickness, wherein in the initial rolling procedure, a rolling oil temperature is 35-45 degrees centigrade; rolling machine working roller surface roughness Ra is 0.15-0.25 microns; 2, carrying out solid dissolving treatment to a steel roll after the first cold rolling at a speed of 35-45m / min; and 3, carrying out the second cold rolling to a cold-rolling steel belt after the solid dissolving treatment; rolling 0.1-0.2mm of the steel belt for many rolling procedures so as to obtain 0.05-0.1mm of the finished product thickness; wherein a rolling oil temperature is 28-40 degrees centigrade, working roller roughness Ra is 0.15-0.25 microns; a rolling speed in a first rolling procedure is 80-100m / min; the rolling speed in other rolling procedures is 150-200m / min; and tension is controlled within 500-600N / mm<2>.

Owner:SHANXI TAIGANG STAINLESS STEEL PRECISION STRIP CO LTD

Steel with excellent processing performance for gardening tool and production method thereof

The invention discloses steel with excellent processing performances for a gardening tool and a production method thereof. The steel comprises the following components of, by weight, 0.45%-0.65% of C,0.1%-0.40% of Si, 0.5%-1.5% of Mn, 0.1%-0.5% of Cr, 0.02%-0.05% of Al, less than or equal to 0.4% of Ni, less than or equal to 0.5% of Cu, less than or equal to 0.020% of P, less than or equal to 0.010% of S and the balance Fe and inevitable impurities. The production method comprises the following steps that deoxidation is carried out by adopting Al, and time of argon blowing in tundish is larger than or equal to 10 minutes, the casting superheat degree is less than or equal to 25 DEG C, the thickness of a casting blank is 130-200 mm; charing temperature of the casting blank is larger than or equal to 500 DEG C; heating temperature is 1100-1200 DEG C, the temperature is kept for 2-5 hours, the rolling speed is 5-15 m per second, rolling start temperature is larger than or equal to 1080 DEG C, and rolling finish temperature is larger than or equal to 920 DEG C; and the cold speed is less than or equal to 20 DEG C per second, the casting blank is coiled at the temperature of 650-730 DEG C, then is put into a slow cooling pit for heat preservation and slow cooling for more than or equal to 48 hours, is cooled to below 200 DEG C, and then is air-cooled to the room temperature. According to steel with the excellent processing performances for the gardening tool and the production method thereof, the steel plate has excellent formability and wear resistance.

Owner:ANGANG STEEL CO LTD

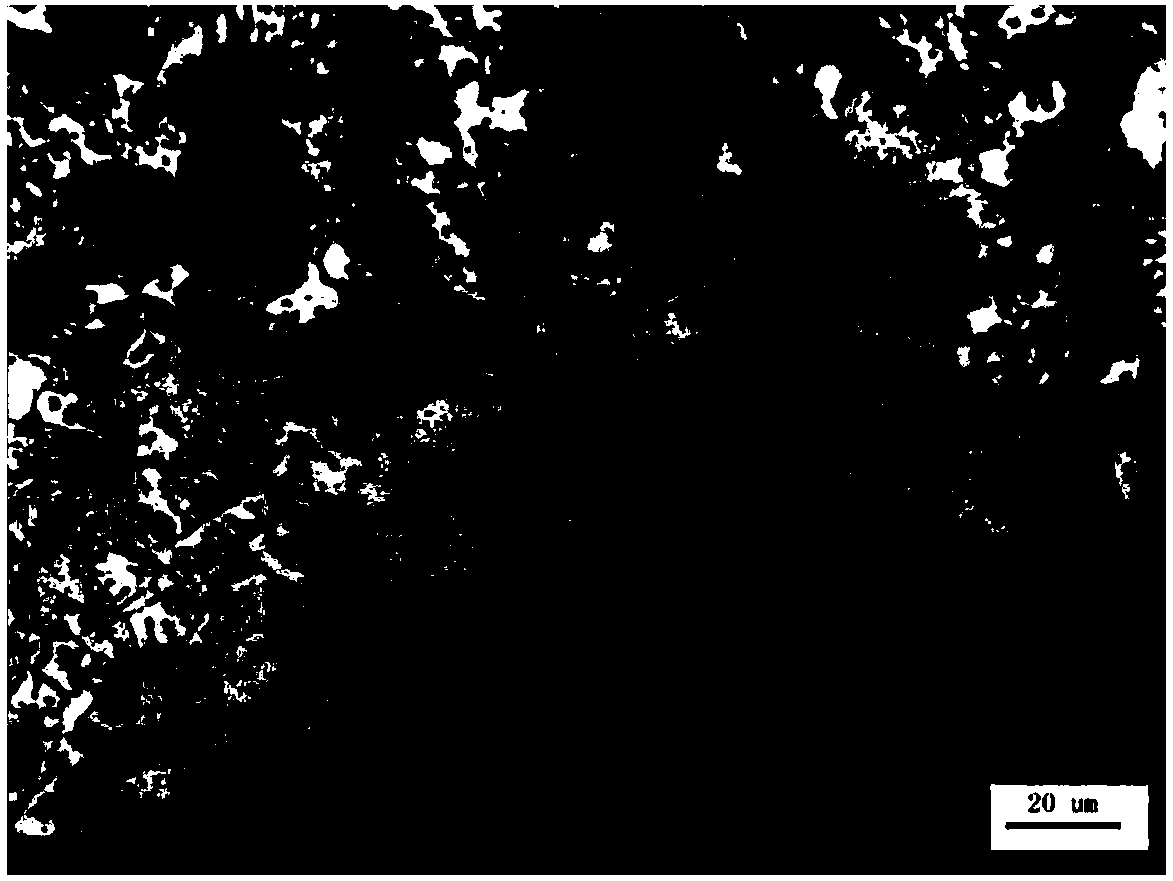

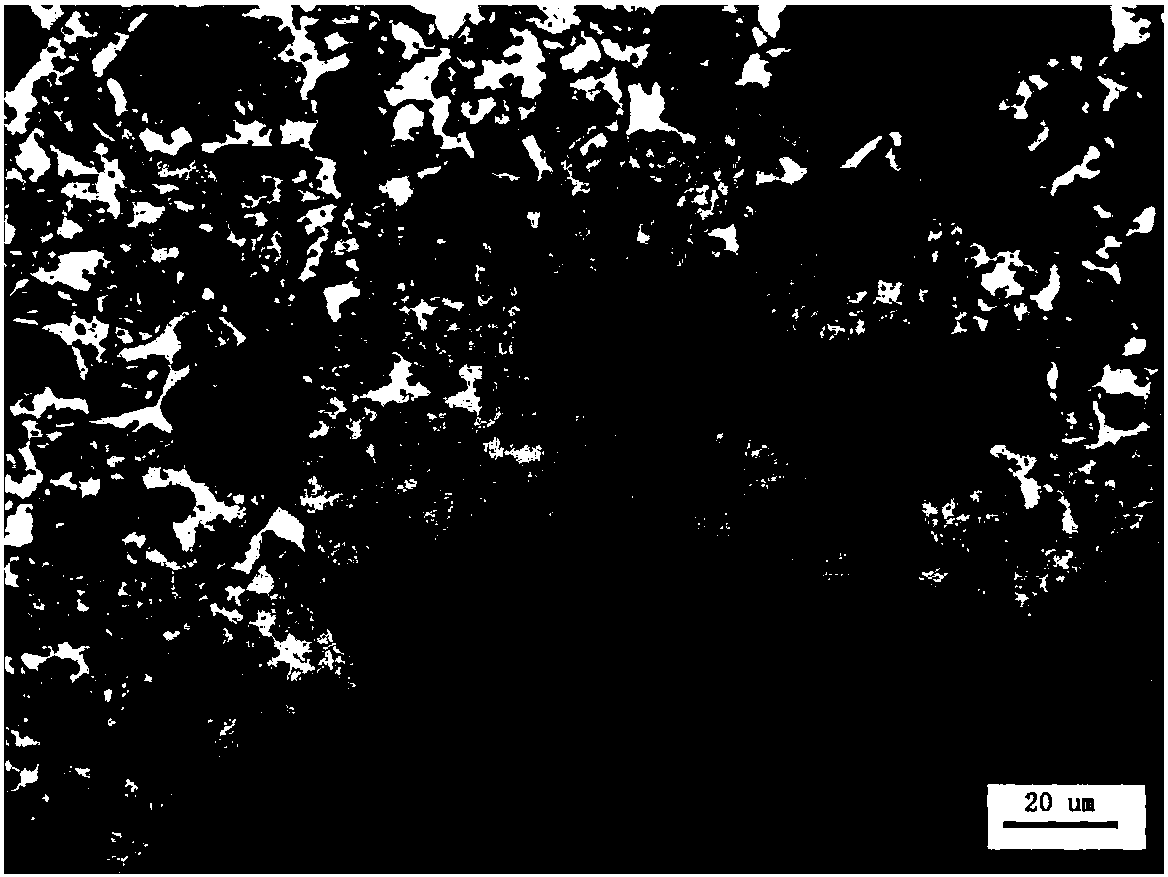

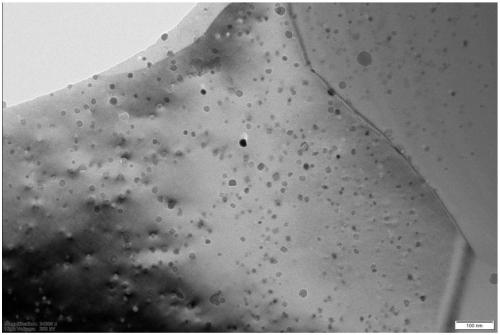

Preparation method of oxide dispersion strengthened FeCrAl alloy pipe

The invention provides a preparation method of an oxide dispersion strengthened FeCrAl alloy pipe, belongs to the technical field of nuclear power pipe preparation, particularly discloses a preparation method of an ODS (oxide dispersion strengthened) FeCrAl alloy pipe for a nuclear fuel canning material, and aims to realize localization of a high-strength ODS-FeCrAl alloy thin-walled pipe. The preparation method of the ODS FeCrAl alloy pipe adopts a cold rolling and pass thermal treatment process, and is characterized in that the rolling speed is controlled to 100-600 r / min, and the pipe deformation is controlled to 0%-50%. Each pass of thermal treatment mode adopts a vacuum annealing mode, the annealing temperature is 700-1150 DEG C, and the heat insulation time is 30-90 minutes. The preparation method does not influence the granular size and the dispersion state of a Y-Al-O oxide strengthening phase in the ODS FeCrAl alloy, the prepared pipe is of fine-crystalline-grain and uniform-texture crystal structure, and the ODS pipe has excellent strength and creep resistance and high oxidation resistance and irradiation swelling performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +3

Fine cashmere single-yarn textile and its production process

The invention relates to a high counts pure cashmere single yarn fabric and the manufacture method. It is spinning from pure cashmere high counts single yarn fabric and aqueous fusion. The mightiness could reach 200CN, weaving density 160 / 10cm-200 / 10cm. Using dying machine taking the place of washing dolly while washing, the rolling speed is 30-35round / minutes, fabric softening agent 0.1-0.5G / L, washing for 20-30 minutes in 50-80 degree centigrade water to form high counts pure cashmere single yarn fabric. The invention exerts the advantages of the fiber to extreme.

Owner:INNER MONGOLIA KINGDEER CASHMERE

Device and method for shortening continuous tapping time interval of rolled steel production line

ActiveCN106670241ANo false signalAvoid sensor placement challengesRoll mill control devicesMetal rolling arrangementsProduction lineLow speed

The invention discloses a device and a method for shortening a continuous tapping time interval of a rolled steel production line, belongs to the technical field of rolled steel production line equipment and processes, and is used for shortening the continuous tapping time interval of the rolled steel production line. A heat metal detector is placed in front of a first rolling mill from the center line of a roller of the first rolling mill by a length of a whole section of steel blank; and steel tail signals monitored by the heat metal detector are used for replacing steel containing signals when engaging in the rolling mill. When the head part of the latter steel blank is rightly engaged in the first rolling mill, an alternating-current main motor of the first rolling mill starts to decelerate. The reasonable steel separation distance is guaranteed by dint of the continuously quickened rolling speed of a downstream frame, the low-speed continuous time and the low-speed rate setting. The safe steel separation is realized by using the first rolling mill as a steel separation point, so that the normal operation of subsequent key equipment is guaranteed, and the effects of shortening the steel blank rolling interval time, improving the production efficiency and largely reducing the energy consumption are achieved under the precondition of not influencing the production process.

Owner:张家口宣钢机电工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com