Patents

Literature

11496 results about "Oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidation Resistance. (resistance to sealing), the ability of metallic materials to resist chemical degradation of the surface caused by the action of air or other gaseous mediums at high temperatures.

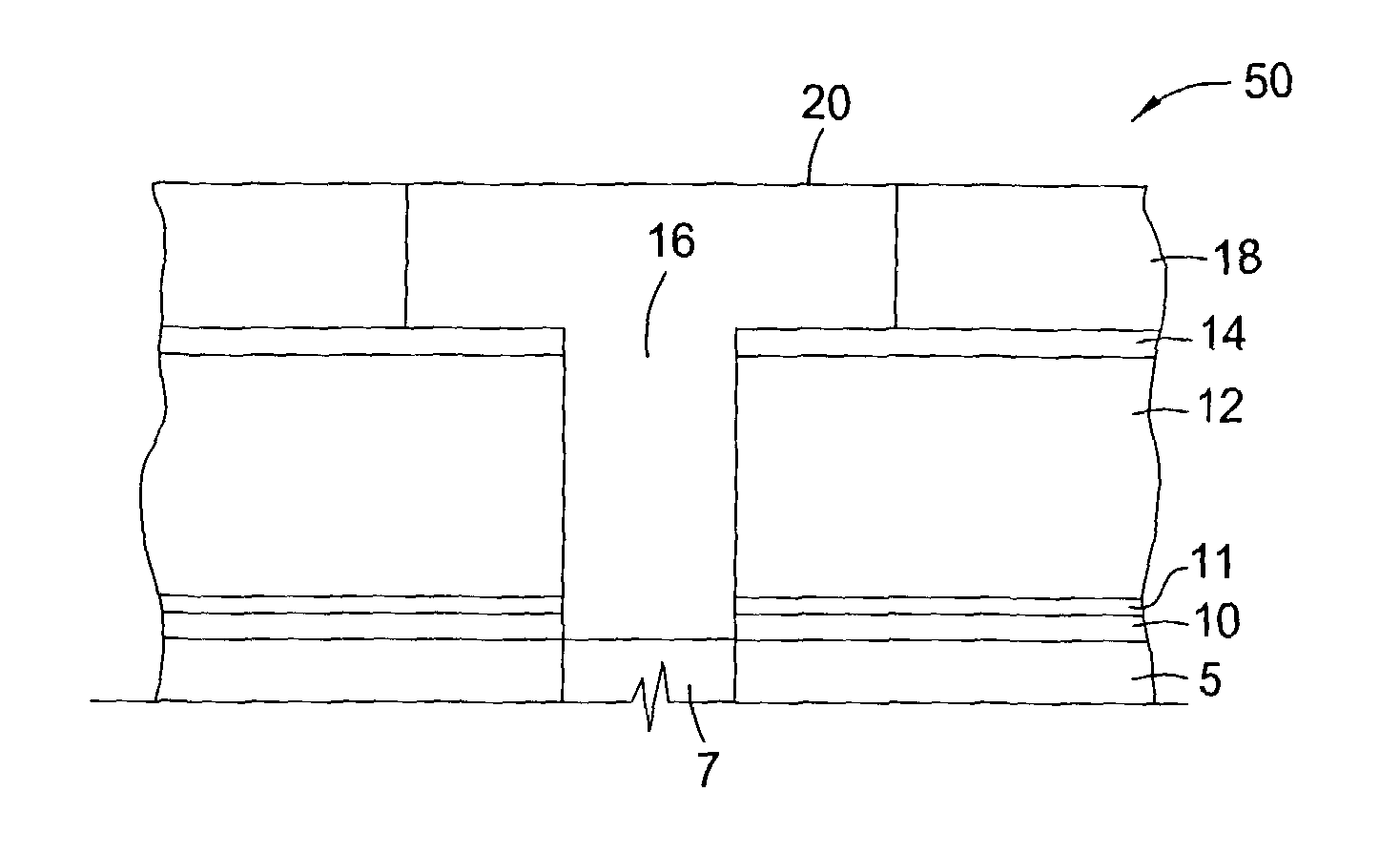

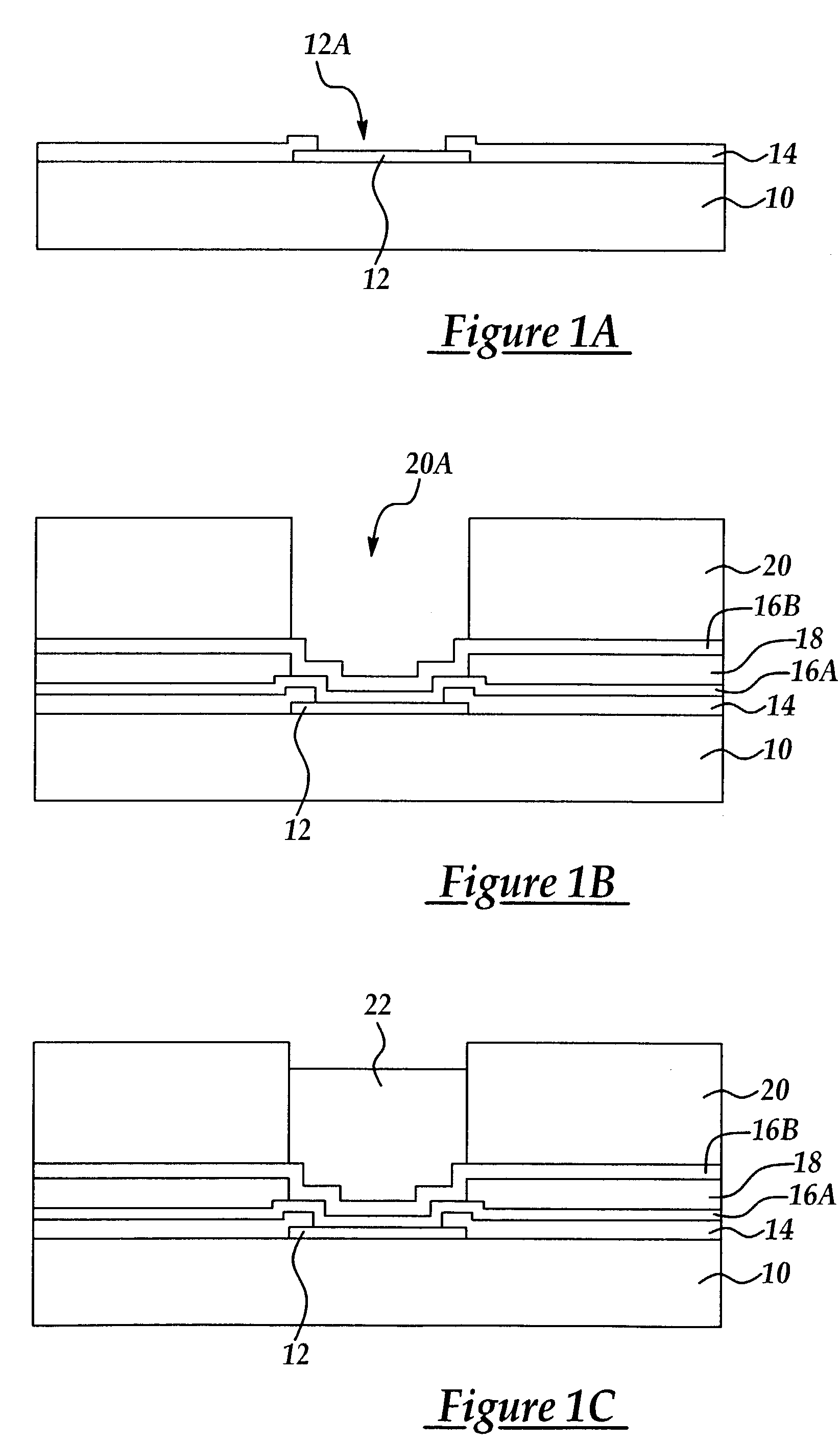

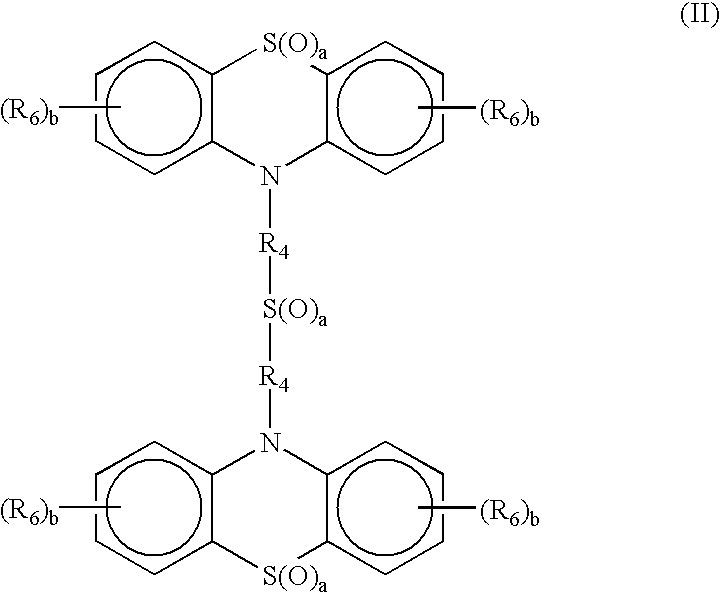

Two-layer film for next generation damascene barrier application with good oxidation resistance

InactiveUS7749563B2Low dielectric constantLiquid surface applicatorsSemiconductor/solid-state device manufacturingOxygenPhenyl group

A method is provided for processing a substrate including providing a processing gas comprising an organosilicon compound comprising a phenyl group to the processing chamber, and reacting the processing gas to deposit a low k silicon carbide barrier layer useful as a barrier layer in damascene or dual damascene applications with low k dielectric materials. A method is provided for depositing a silicon carbide cap layer that has substantially no phenyl groups attached to silicon atoms from a processing gas comprising an oxygen-free organosilicon compound on a low k silicon carbide barrier layer.

Owner:APPLIED MATERIALS INC

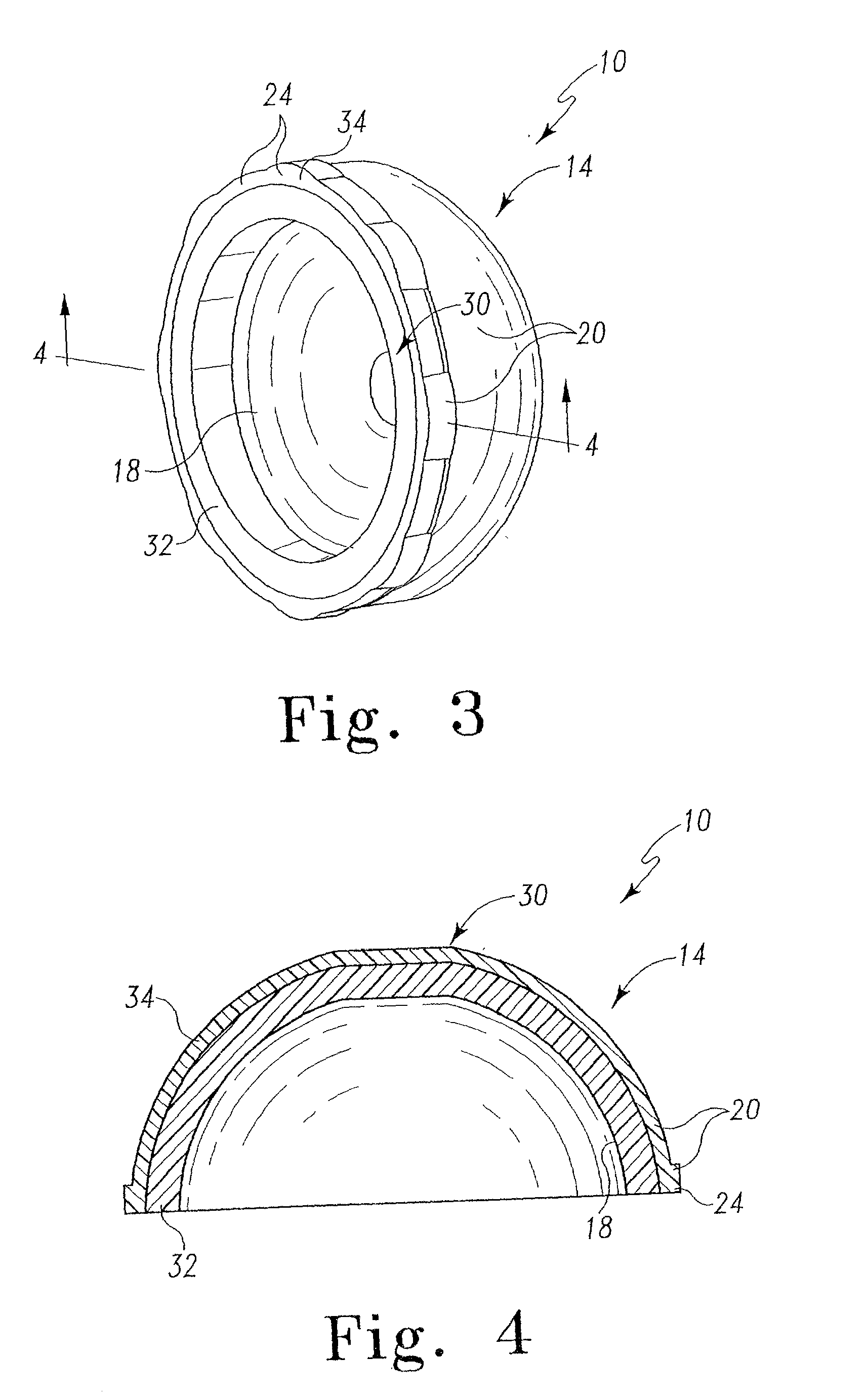

Process for medical implant of cross-linked ultrahigh molecular weight polyethylene having improved balance of wear properties and oxidation resistance

A medical implant of ultrahigh molecular weight polyethylene having an improved balance of wear properties and oxidation resistance is prepared by irradiating a preform of ultrahigh molecular weight polyethylene, annealing the irradiated preform in the absence of oxygen to a temperature at or above the onset of melting temperature, and forming an implant from the stabilized cross-linked polymer. Implants prepared according to the process of the present invention have comparable oxidation resistance and superior wear performance compared to unirradiated ultrahigh molecular weight polyethylene.

Owner:DEPUY ORTHOPAEDICS INC

Method for forming copper bump antioxidation surface

InactiveUS7008867B2Improve oxidation resistanceImprove thermal stabilitySemiconductor/solid-state device detailsSolid-state devicesTitaniumDeposition process

A method for forming a copper bump for flip chip bonding having improved oxidation resistance and thermal stability including providing a copper column having a thickness of at least about 40 microns overlying a metallurgy including an uppermost copper metal layer and a lowermost titanium layer the lowermost titanium layer in contact with an exposed copper bonding pad portion surrounded by a passivation layer; and, selectively depositing at least one protective metal layer over the copper column according to an electrolytic deposition process.

Owner:HON HAI PRECISION IND CO LTD

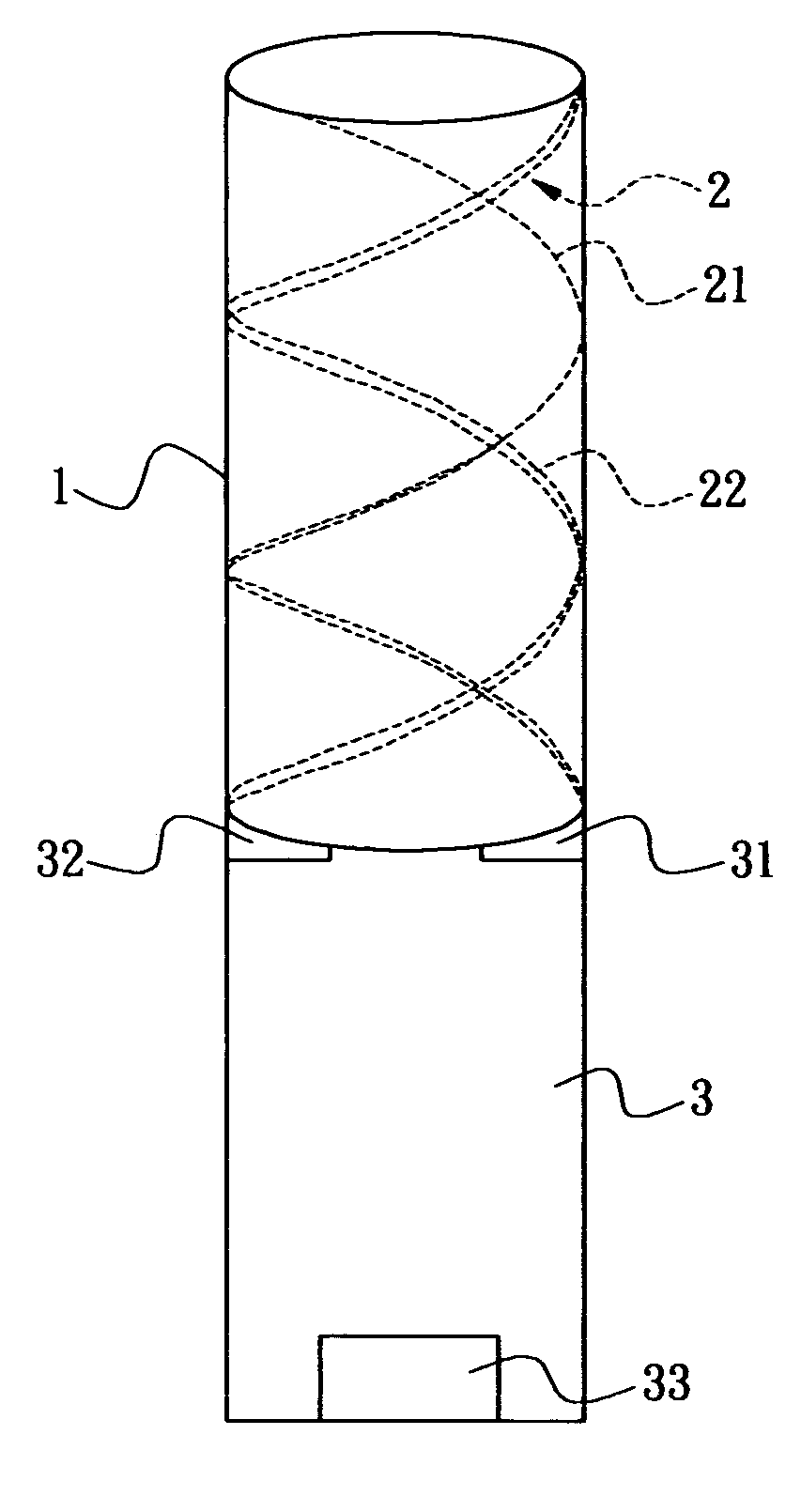

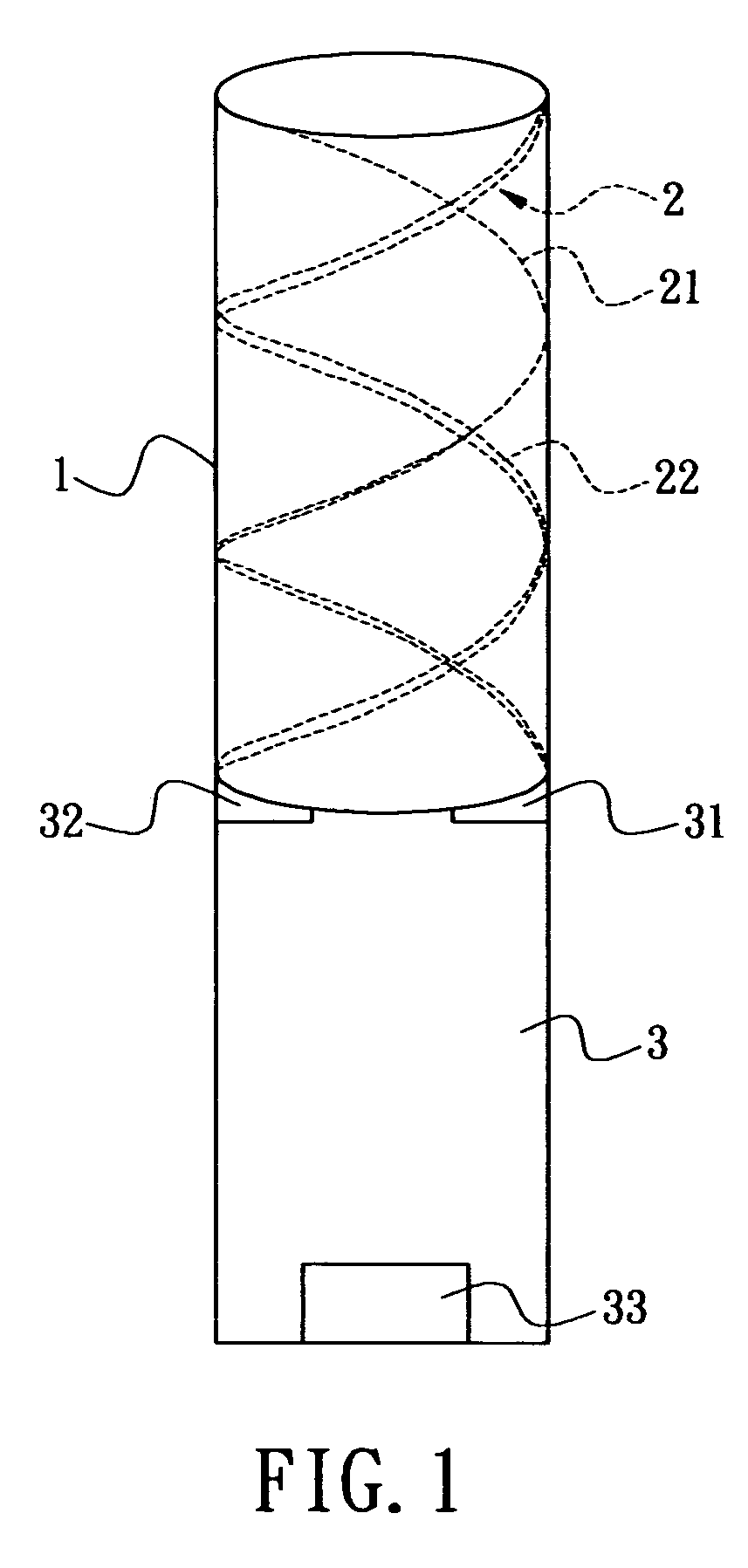

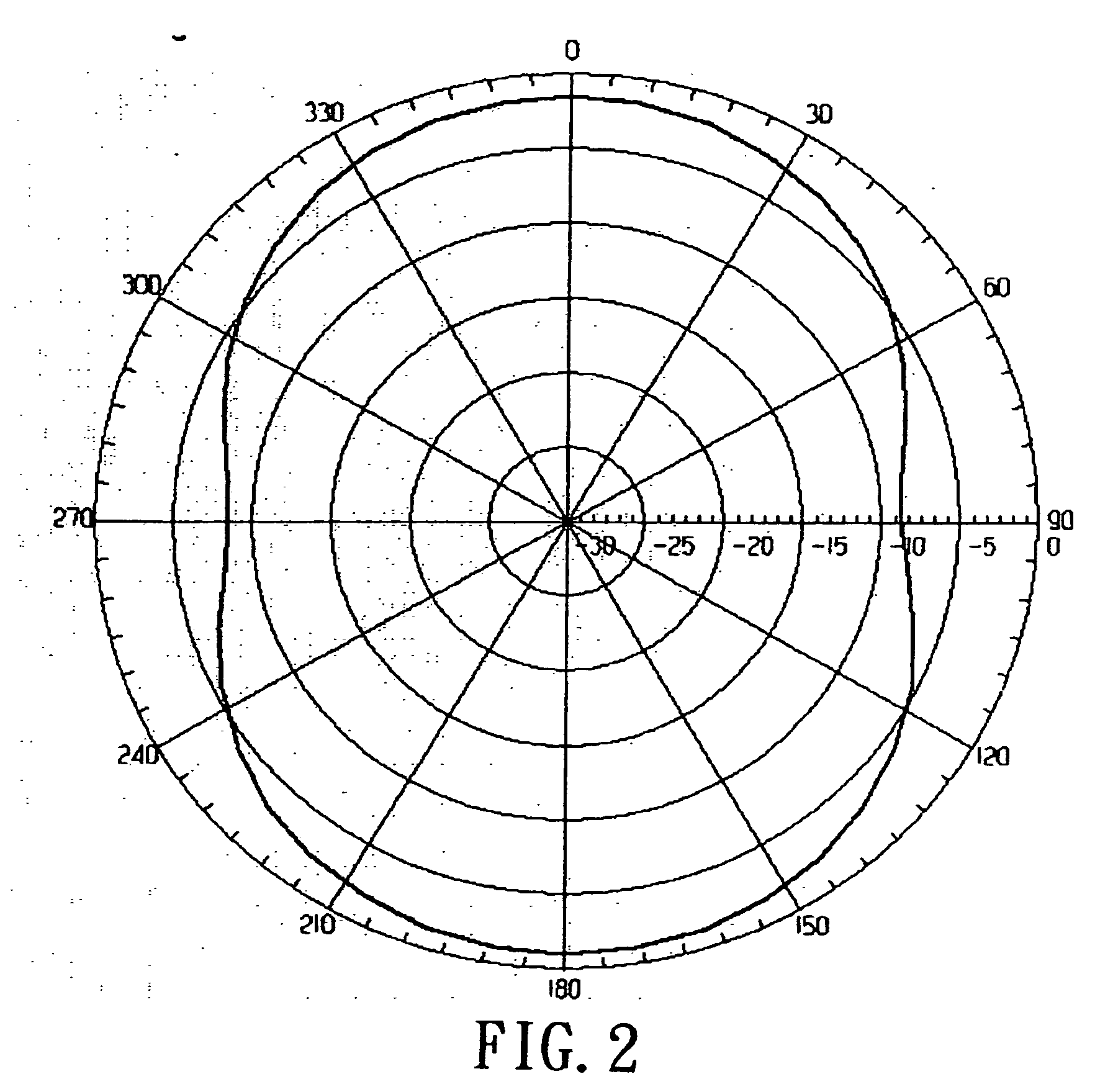

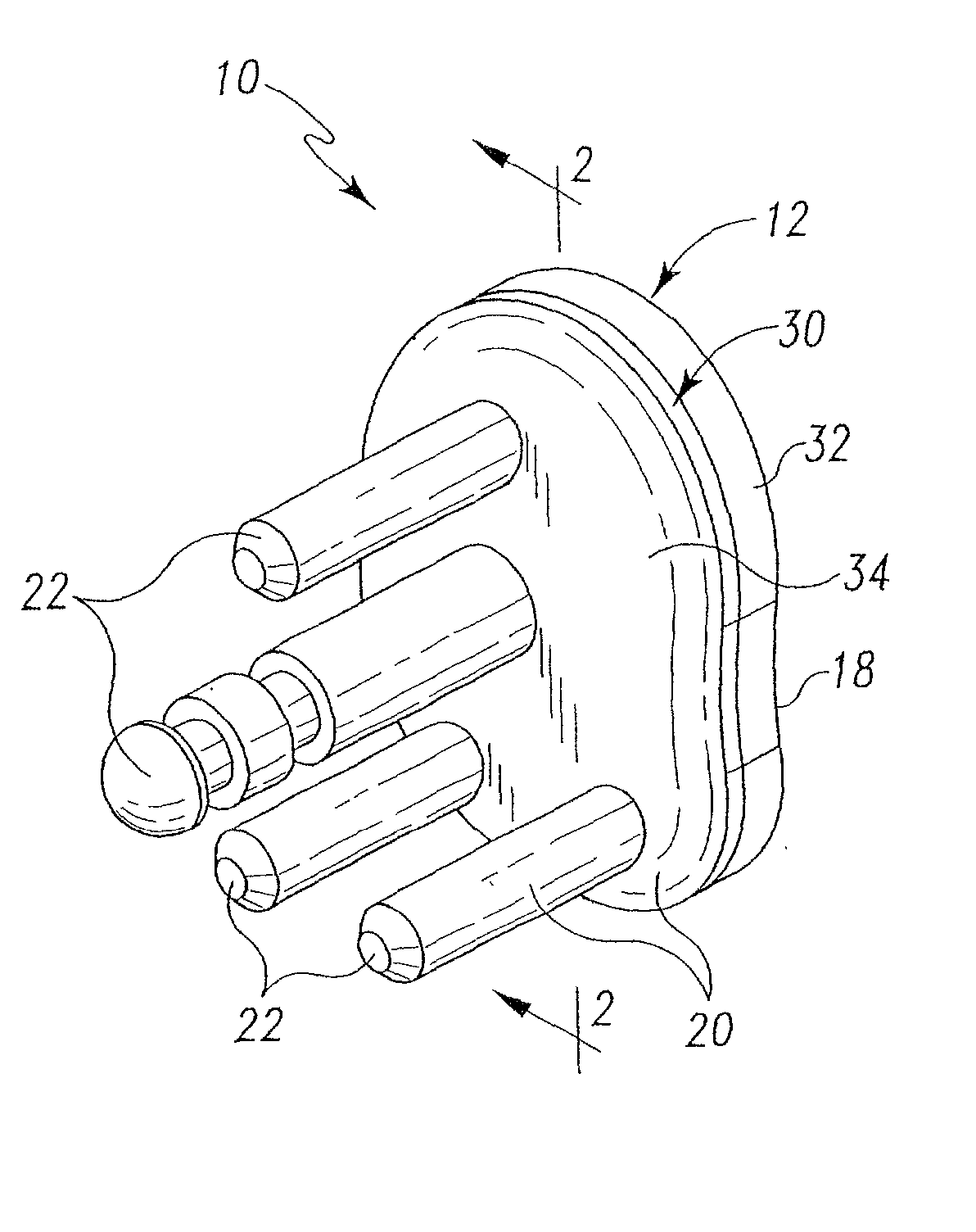

Circular-polarization dipole helical antenna

InactiveUS20060232493A1Quick fine-tuningReduce lossRadiating elements structural formsHelical antennasElectrical conductorPhase difference

A circular-polarization dipole helical antenna is used for electronic device and satellite terminal and includes a base, and an antenna conductor arranged on surface of the base. The antenna conductor includes a plurality of metal conductors with high Q value and anti-oxidation property and continuously and helically coated on surface of the base. The base is made of low loss and high dielectric constant material. An unbalance-to-balance circuit module connects two signal-feeding ends to the base with phase difference of 180 degree. The problems of narrow bandwidth, low efficiency, complicated structure and precise manufacture can be solved.

Owner:CIREX TECH CORP

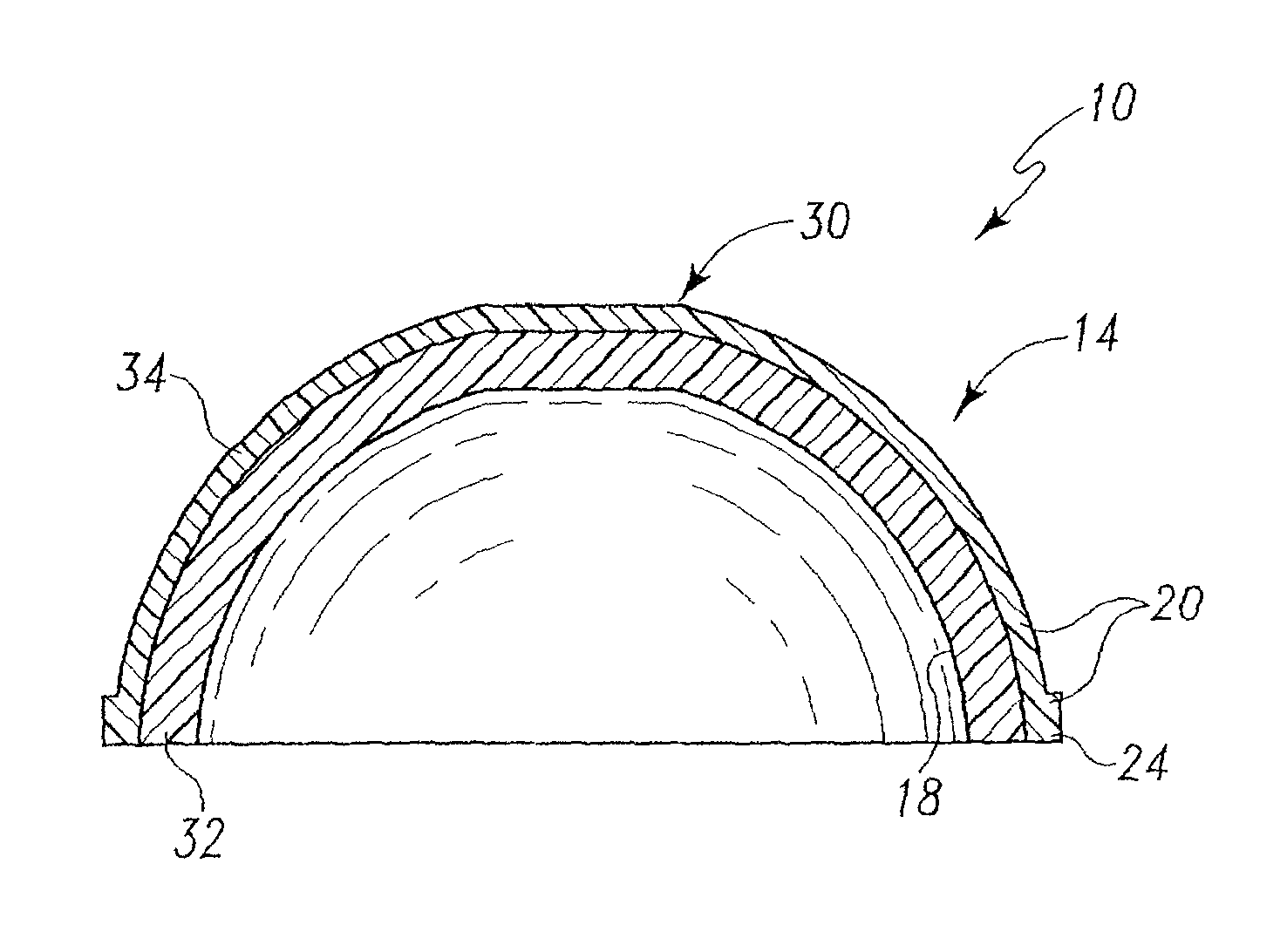

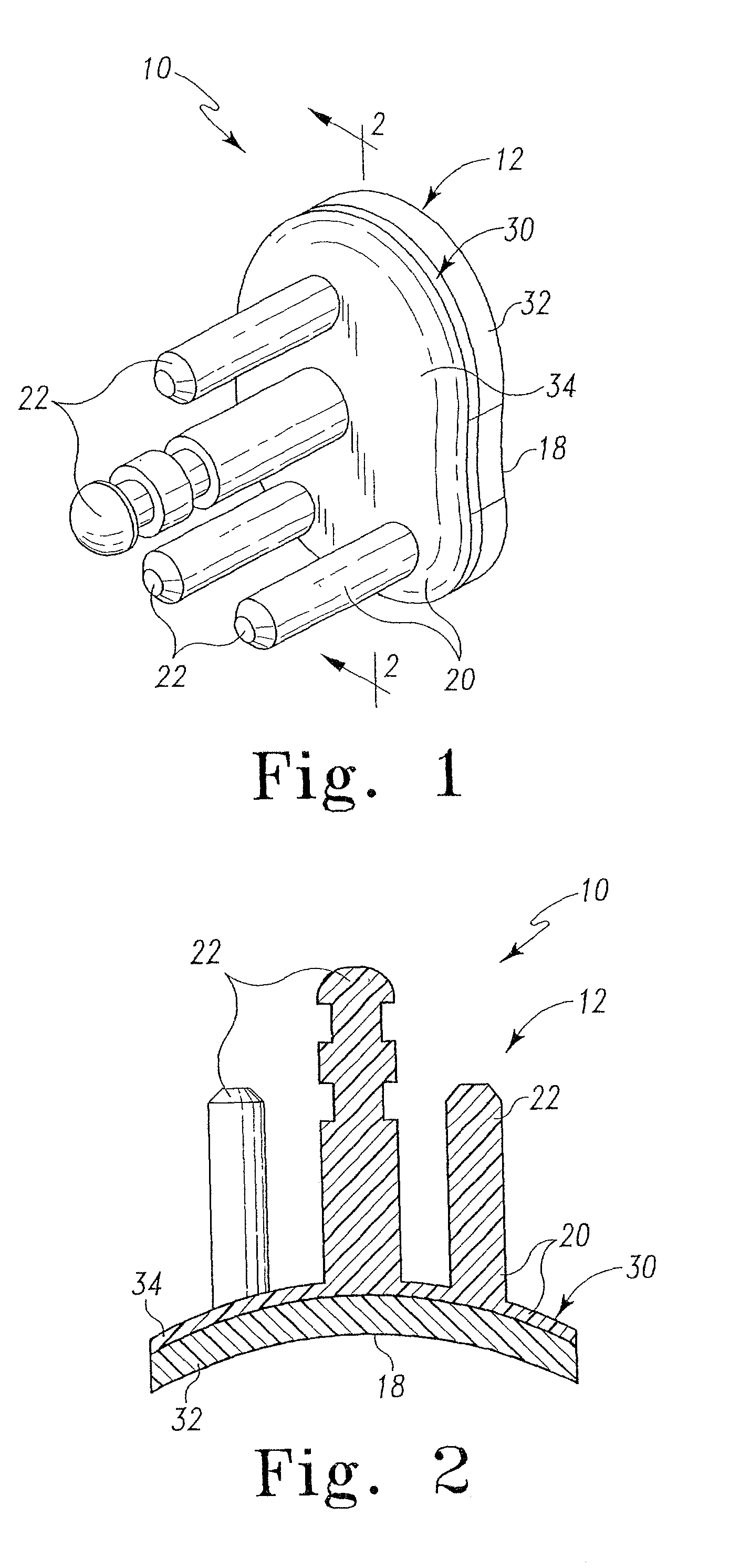

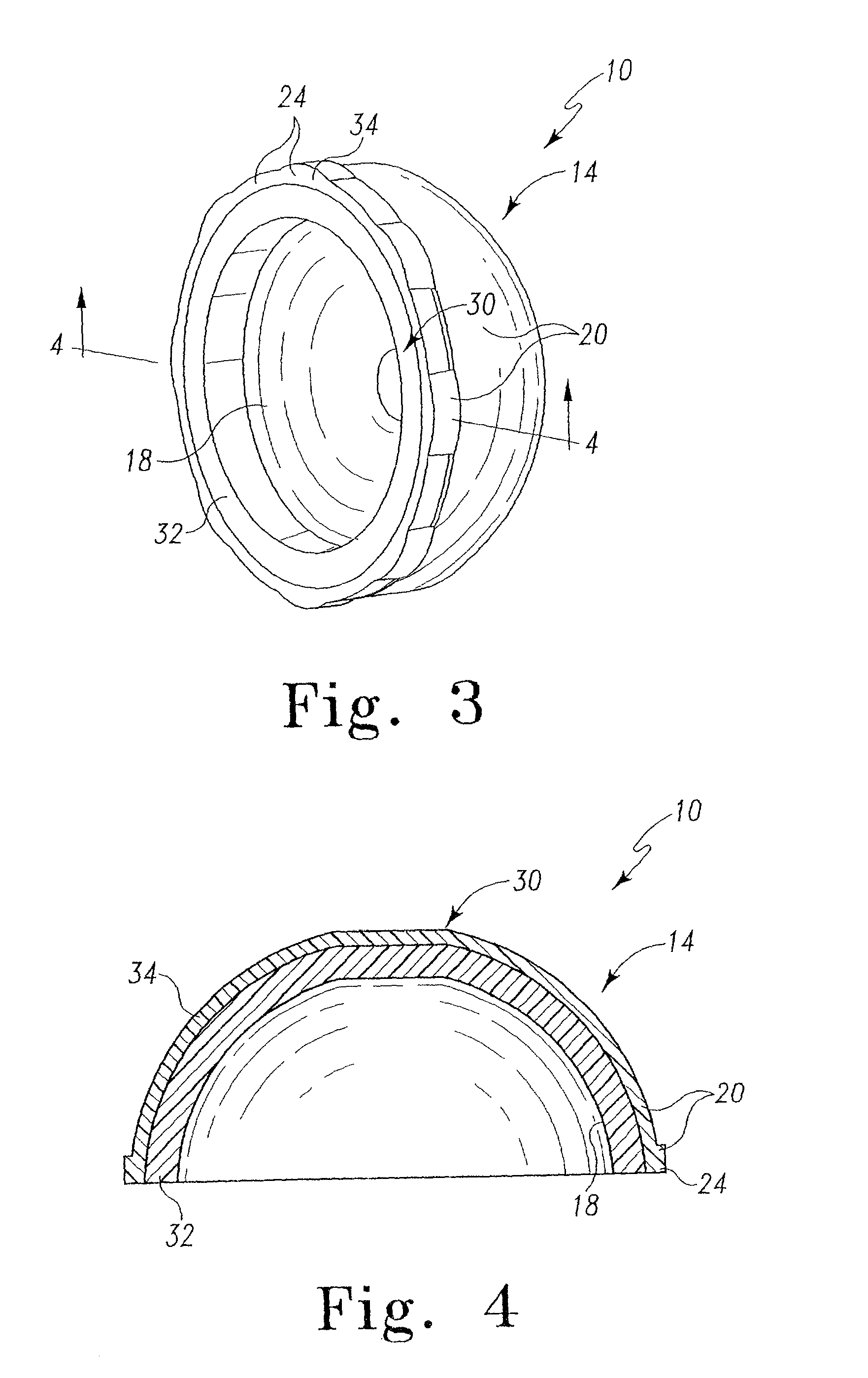

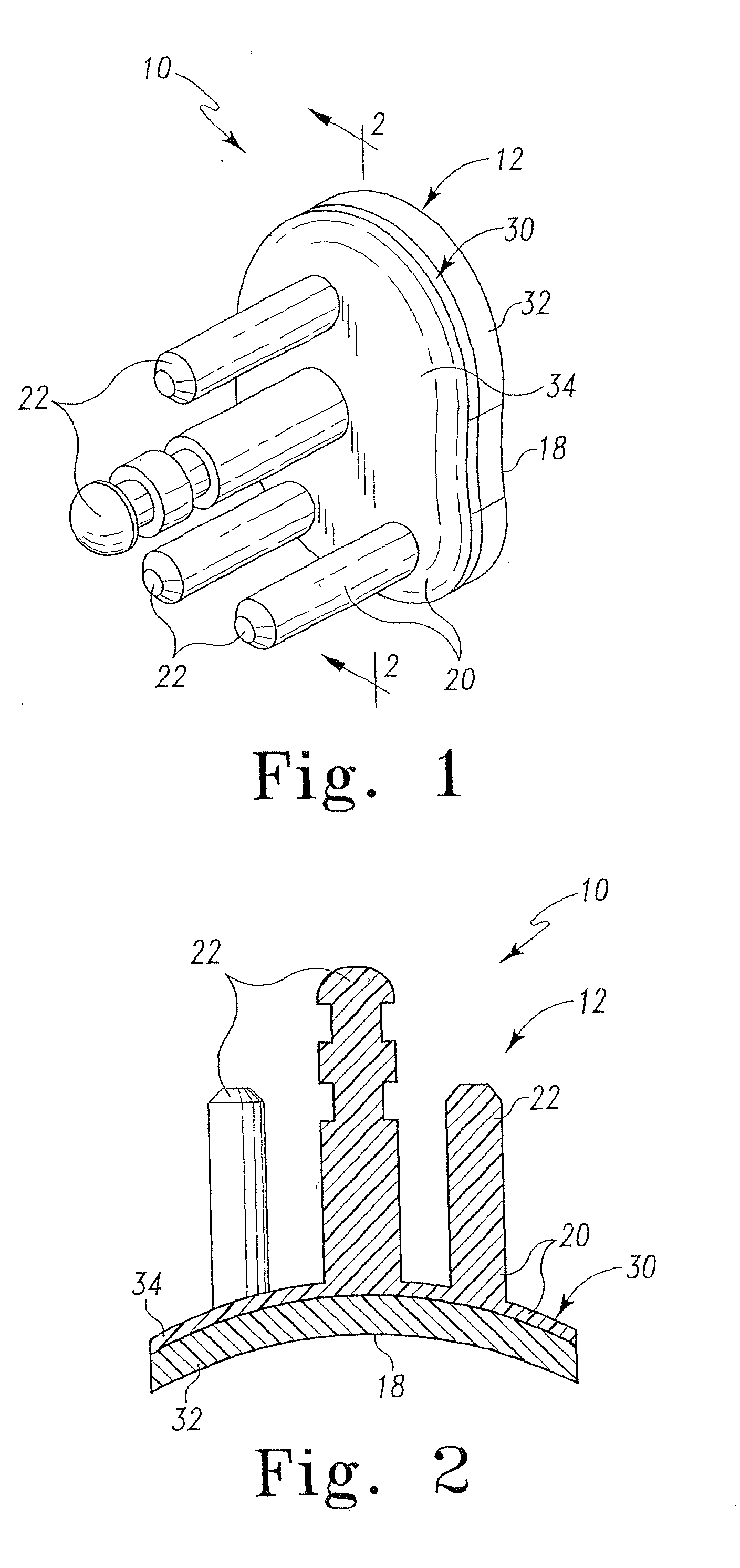

Composite prosthetic bearing having a crosslinked articulating surface and method for making the same

InactiveUS7819925B2Promote oxidationEasy to wearBone implantSynthetic resin layered productsProsthesisCrosslinked polymers

An implantable prosthetic bearing is constructed of a composite material having a first layer and second layer. The first layer has an articulating surface defined therein, whereas the second layer has a engaging surface defined therein for engaging either another prosthetic component or the bone itself The first layer of the implantable prosthetic bearing is constructed of crosslinked polymer such as Ultra-High Molecular Weight Polyethylene, whereas the second layer of the implantable prosthetic bearing is constructed of polymer such as Ultra-High Molecular Weight Polyethylene that is either non-crosslinked or crosslinked to a lesser degree than the first layer. In such a manner, the first layer possesses mechanical properties which are advantageous in regard to the articulating surface (e.g., enhanced wear and oxidation resistance), whereas the second layer possesses mechanical properties which are advantageous in regard to the engaging surface (e.g., high ductility, toughness, and creep resistance). A method of making a prosthetic bearing is also disclosed.

Owner:DEPUY SYNTHES PROD INC

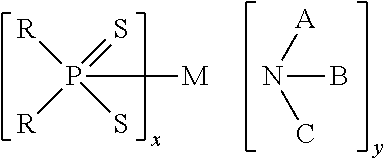

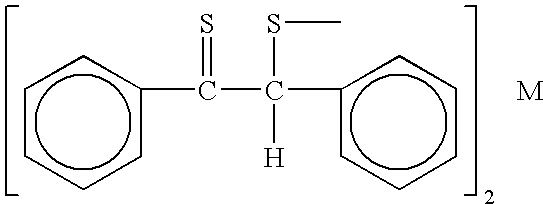

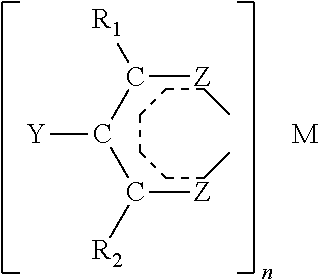

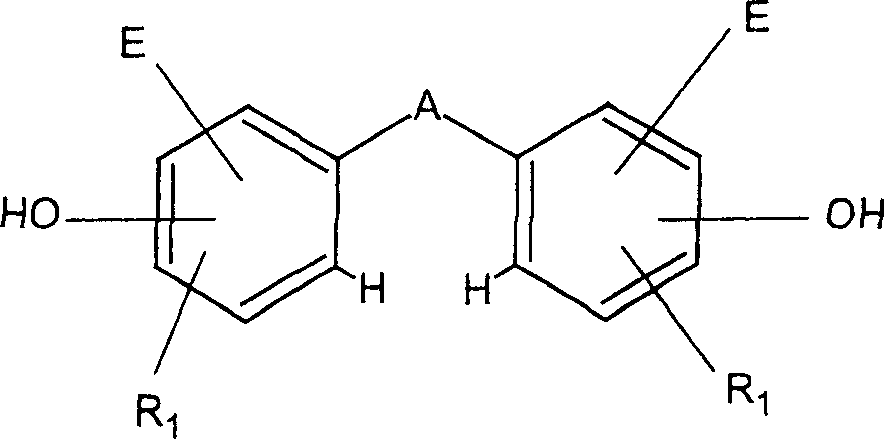

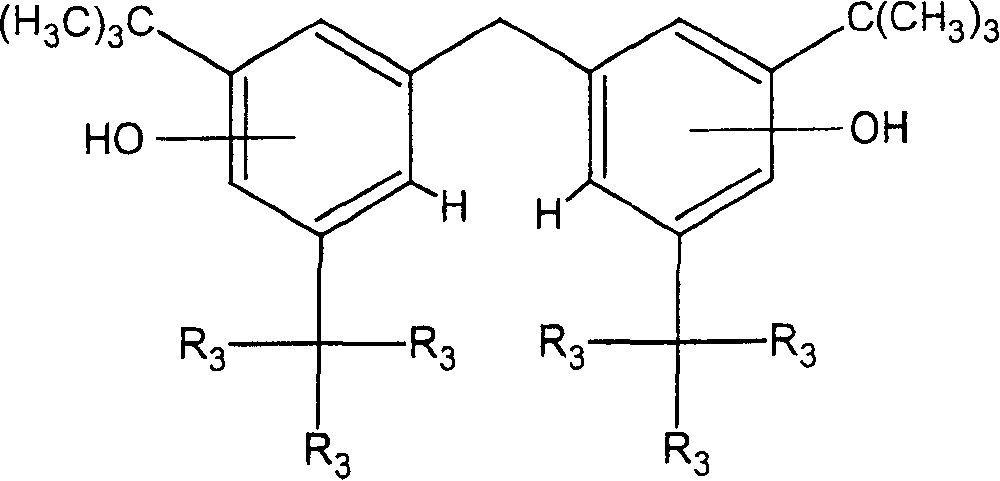

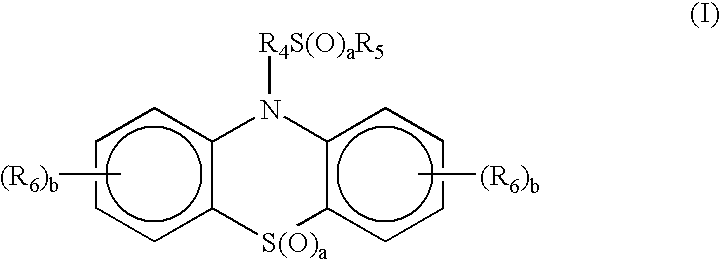

Catalytic antioxidants

The present invention is directed to lubricating oils exhibiting improved resistance to oxidation and deposit / sludge formation comprising a lubricant base oil and catalytic antioxidants comprising an effective amount of a) one or more polymetal organometallic compound; and, b) effective amounts of one or more substituted N,N′-diaryl-o-phenylenediamine compounds or c) one or more hindered phenol compounds or both, to a method for improving the antioxidancy and the resistance to deposit / sludge formation of formulated lubricating oil compositions by the addition thereto of an effective amount of the aforementioned catalytic antioxidants, and to an additive concentrate containing the aforementioned catalytic antioxidants.

Owner:EXXON RES & ENG CO

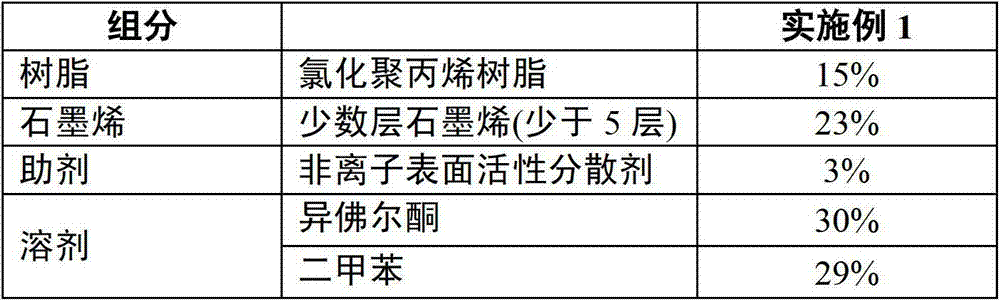

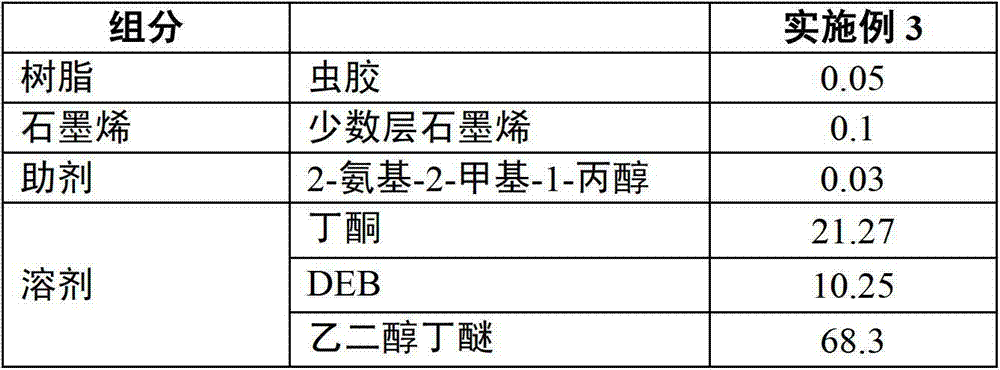

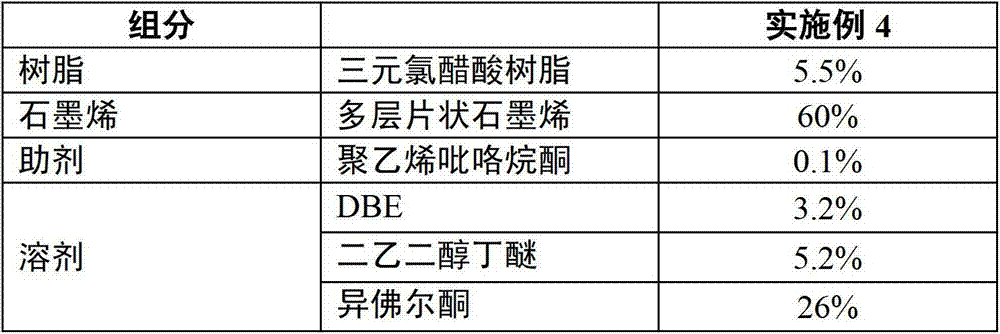

Graphene conductive ink and preparation method thereof

ActiveCN103113786AImprove thermal conductivityImprove mechanical propertiesInksConductive materialsSolvent

The invention relates to graphene conductive ink comprising the following components by weight percent: 0.01-25% of resin, 0.1-95% of graphene, 0.1-30.0% of assistant, and 5.0-99.79% of solvent. The two-dimensional conductive material graphene is used for the conductive ink; the graphene with special ratio is adopted as a conductive phase; the resin is taken as a binder; the assistant and the solvent are used for assisting; the prepared ink is good in anti-sedimentation property, and adjustable in viscosity and rheological behavior, and can be used for flexibly printing on the surfaces of a plurality of substrates; and the ink is stable in mechanical property, stable in electrical properties, oxidation resistance, acid resistance, alkali resistance and resistance to a chemical solvent after being cured.

Owner:SUZHOU NIUJIAN NEW MATERIAL

Neuroceutical for improving memory and cognitive abilities

Owner:SUMMERS WILLIAM K

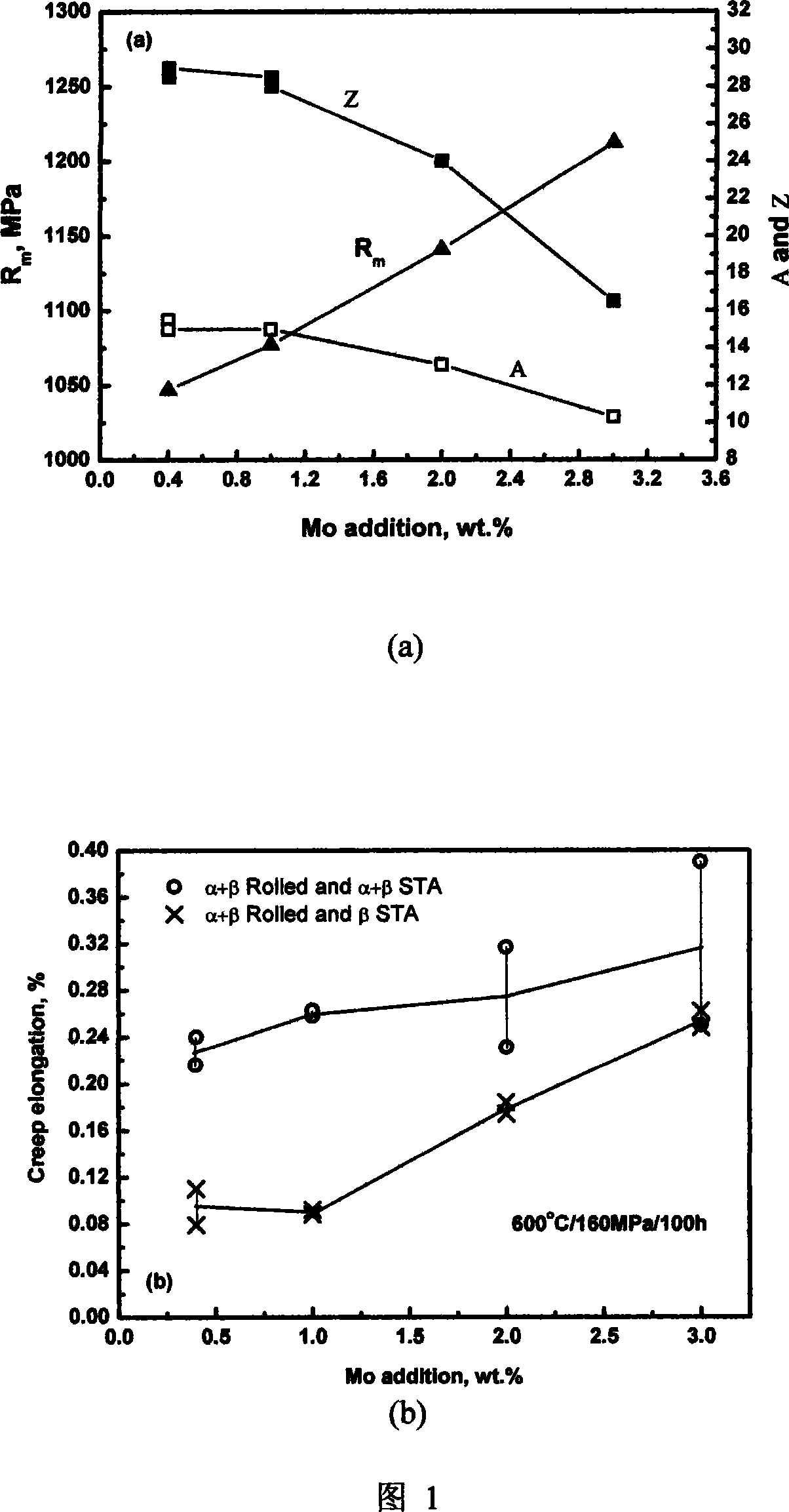

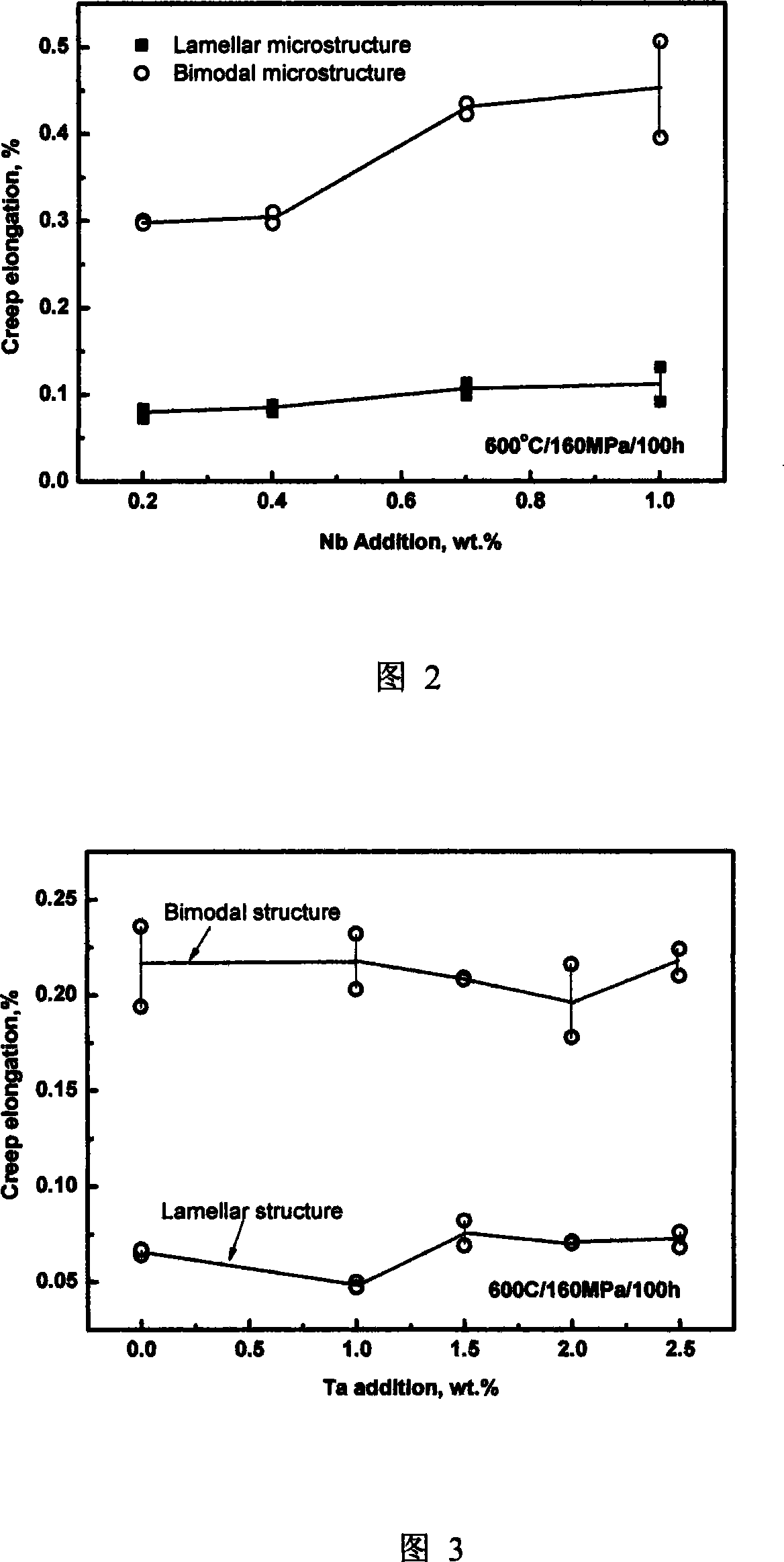

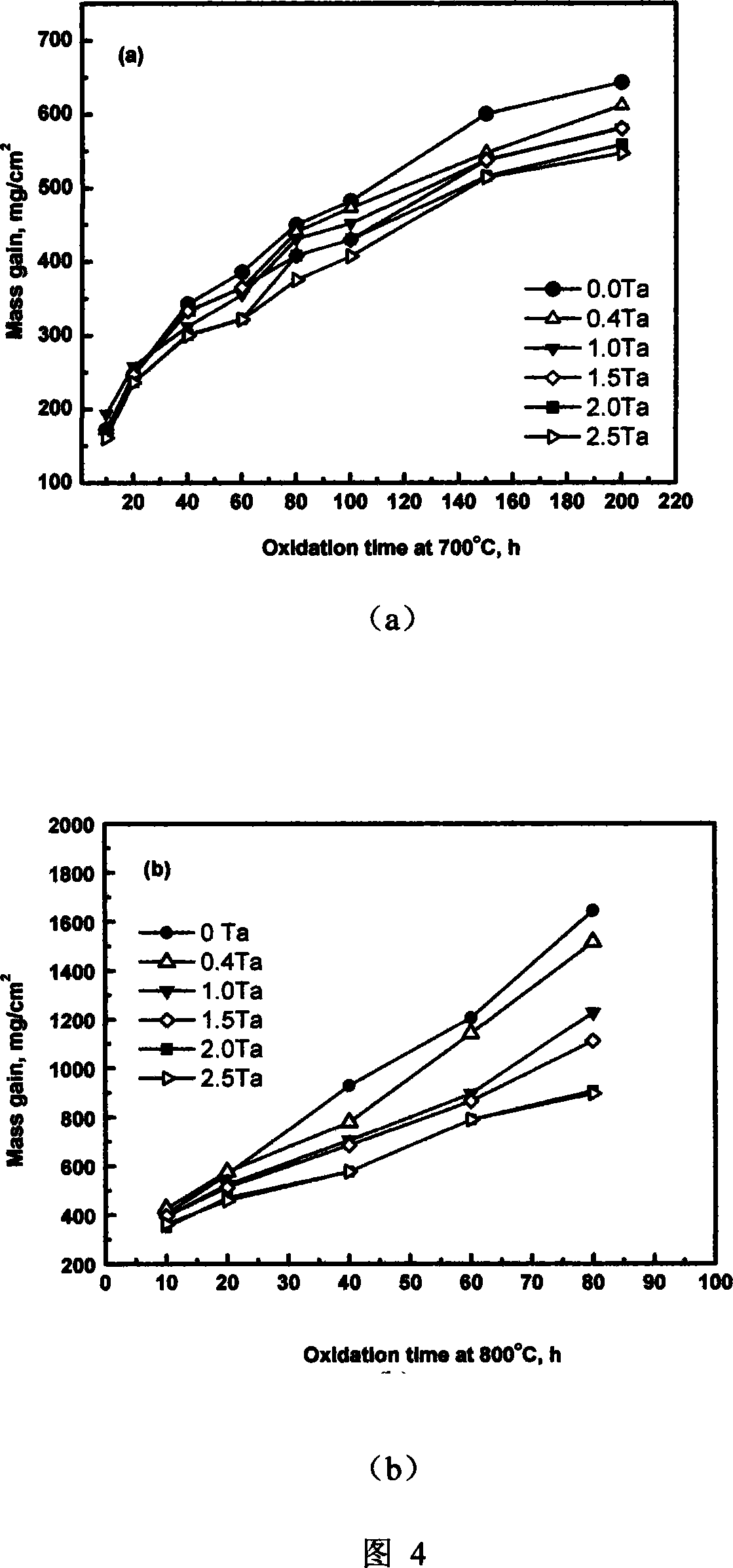

High-temperature titanium alloy with high heat resistance and high thermal stabilization

The invention provides a novel high-temperature Ti alloy with high heat resistance and high heat stability. The alloy contains eutectic Nb, Ta and Mo elements. Based on the appropriate proportion of these three elements, the alloy is superior in high resistance and stability to heat and good antioxidant effect. The alloy contains (by weight) Al 5.0-6.3 percent, Sn 3.0-5.0 percent, Zr 2.5-7.0 percent, Mo 0.2-1.5 percent, Si 0.20-0.55 percent, Nb 0.2-1.0 percent, Ta 0.2-3.0 percent, C 0.01-0.09 percent, and Ti and other inevitable impurities in balance. The alloy is an ideal alternative material for high-temperature parts of aircraft engine, such as wheel disk, drum barrel, barrel shaft and blade.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Synthesis of poly-alpha olefin and use thereof

InactiveUS7129197B2Improve oxidation stabilityImproved biodegradibilityOrganic chemistry methodsSolid fuelsHydrogenIsomerization

One or more oligomers of an olefin are prepared in the presence of a single-site catalyst. Preferably, the olefin is an α-olefin, and the oligomers are a poly-alpha-olefin (PAO). The PAO so prepared is completely or substantially free of tertiary hydrogen resulting from isomerization. Consequently, the PAO possesses improved biodegradability, improved oxidation resistance, and / or a relatively higher viscosity index. The PAO has many useful applications, such as a component of a lubricant.

Owner:SHELL OIL CO

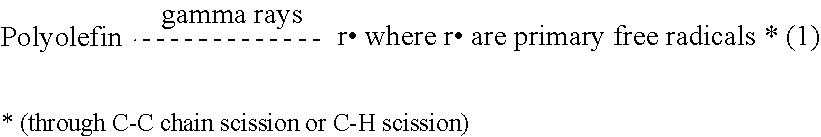

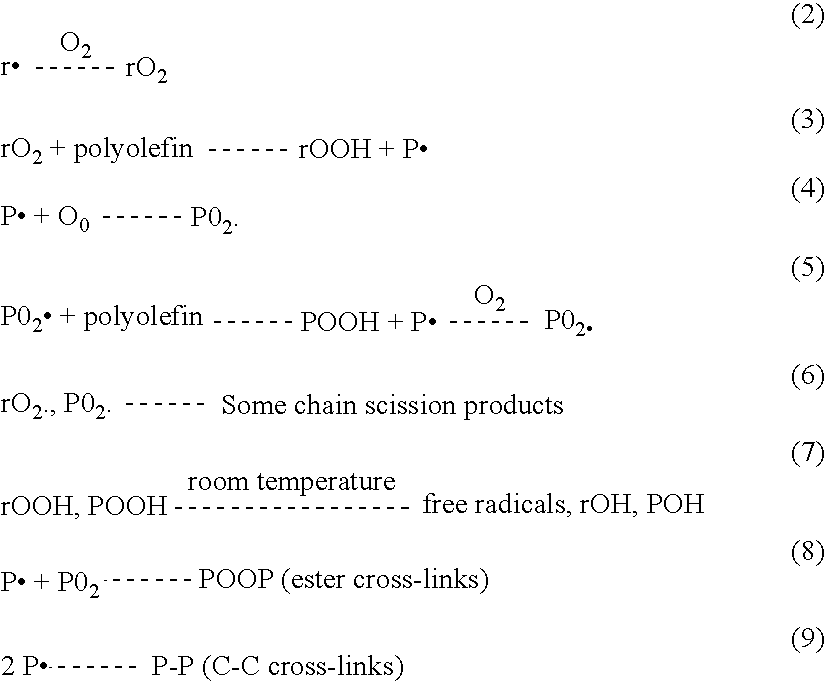

Non-oxidizing polymeric medical implant

InactiveUS20050059750A1Improve antioxidant capacityPrevent further oxidationSurgeryPharmaceutical containersCross-linkNitrogen gas

A medical implant made of polymeric material having an increased oxidation resistance is formed by a method including the steps of placing a resin powder in a sealed container. A substantial portion of the oxygen is removed from the sealed contained by either a vacuum, an oxygen absorbent or by flushing with inert gas. The container is then repressurized with a gas such as nitrogen, argon, helium or neon so that long term storage may be possible. On use, the resin in transferred to a forming device which both melts and forms the resin in an oxygen reduced atmosphere to produce a polymeric raw material such as a rod or bar stock. The medical implant is then formed from this raw material annealed and sealed in an airtight package in an oxygen reduced atmosphere. The implant is then radiation sterilized and thereafter annealed in the package for a predetermined time and temperature sufficient to form cross-links between any free radicals in neighboring polymeric chains.

Owner:HOWMEDICA OSTEONICS CORP

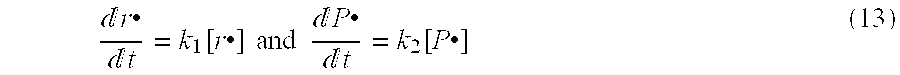

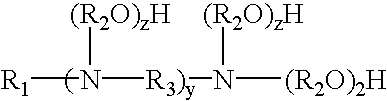

Polysilane-containing coating solution

InactiveUS20050279255A1Easy-to-clean propertyLow shrinkageFireproof paintsImpression capsBrickSolvent

A coating solution comprising 0.1 to 35% by weight of an inorganic or organic polysilazane having repeating units represented by the general formula below and soluble in a solvent and 0.1 to 10% by weight of catalyst such as 4,4′-trimethylenebis(1-methylpiperidine) based on a pure polysilazane content. By applying the coating solution onto the surface of base materials such as metals, plastics, glass, ceramic, wood, cement, mortar, bricks, etc., a silica coating strongly adhered to the base materials can be formed excellent in corrosion resistance and anti-scratch properties and simultaneously excellent in characteristics such as abrasion resistant, long-lasting anti-fouling properties, wetting properties to water, sealing properties, chemical resistance, oxidation resistance, physical barrier effect, heat resistance, fire resistance and antistatic properties.

Owner:CLARIANT INT LTD

Method for joining lead frames in a package assembly, method for forming a chip stack package, and a chip stack package

InactiveUS20040014257A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A method for joining lead frames in a chip stack package or a package stack, a chip stack package, and a method of forming a chip stack package. A joining mediator is formed on joining portions of at least one lead frame. The joining mediator has an anti-oxidation property and an inter-metallic diffusion property, and may be formed of gold wires, gold bumps, gold bars, solder bumps, solder, or solder bars. By clamping or compressing the lead frames under heat and pressure, the joining mediator forms an inter-metallic joint layer that reliably interconnects the lead frames at the joining portions.

Owner:SAMSUNG ELECTRONICS CO LTD

Cherry and tomato composite beverage and preparation method thereof

InactiveCN104312859AComprehensive and balanced nutritionEvenly ruddy colorAlcoholic beverage preparationThirstNutrient solution

The invention discloses a cherry and tomato composite beverage and a preparation method thereof. The cherry and tomato composite beverage is prepared from the following raw materials, by weight, 30-45 parts of cherry, 15-20 parts of tomato, 10-15 parts of guava, 10-14 parts of pitaya peel, 10-15 parts of buckwheat, 14-18 parts of red glutinous rice, 1-3 parts of stevioside, 2-3 parts of very precious flower in Plateau Snow Mountain, 2-4 parts of ginseng fruit, 3-5 parts of grapefruit flower, 1-2 parts of flower of Intermediate peashrub, 1-2 parts of Japanese metaplexis, 12-18 parts of setose abelmoschus, a proper amount of rose wine, and 8-10 parts of a nutrient solution. The cherry and tomato composite beverage prepared in the invention maximally reserves nutritional components of cherry and tomato, has the characteristics of red and uniform color, aroma, sweet and delicious taste, smooth mouthfeel, abundant and balanced nutrition, and simple and feasible technology, has the efficacies of body fluid production promoting, thirst quenching, stomach strengthening, food digesting, pressure reducing, lipid lowering, heat clearing, detoxifying, toxin expelling and face nourishing through the synergistic effect with health care components of traditional Chinese medicines, and can promote digestion, enhance muscle power and improve the oxidation resistance of human bodies through long term drinking.

Owner:徐九山

Composite prosthetic bearing having a crosslinked articulating surface and method for making the same

InactiveUS20030144741A1Easy to wearImprove oxidation resistanceBone implantSynthetic resin layered productsProsthesisCrosslinked polymers

An implantable prosthetic bearing is constructed of a composite material having a first layer and second layer. The first layer has an articulating surface defined therein, whereas the second layer has a engaging surface defined therein for engaging either another prosthetic component or the bone itself. The first layer of the implantable prosthetic bearing is constructed of crosslinked polymer such as UHMWPE, whereas the second layer of the implantable prosthetic bearing is constructed of polymer such as UHMWPE that is either non-crosslinked or crosslinked to a lesser degree than the first layer. In such a manner, the first layer possesses mechanical properties which are advantageous in regard to the articulating surface (e.g., enhanced wear and oxidation resistance), whereas the second layer possesses mechanical properties which are advantageous in regard to the engaging surface (e.g., high ductility, toughness, and creep resistance). A method of making a prosthetic bearing is also disclosed.

Owner:DEPUY SYNTHES PROD INC

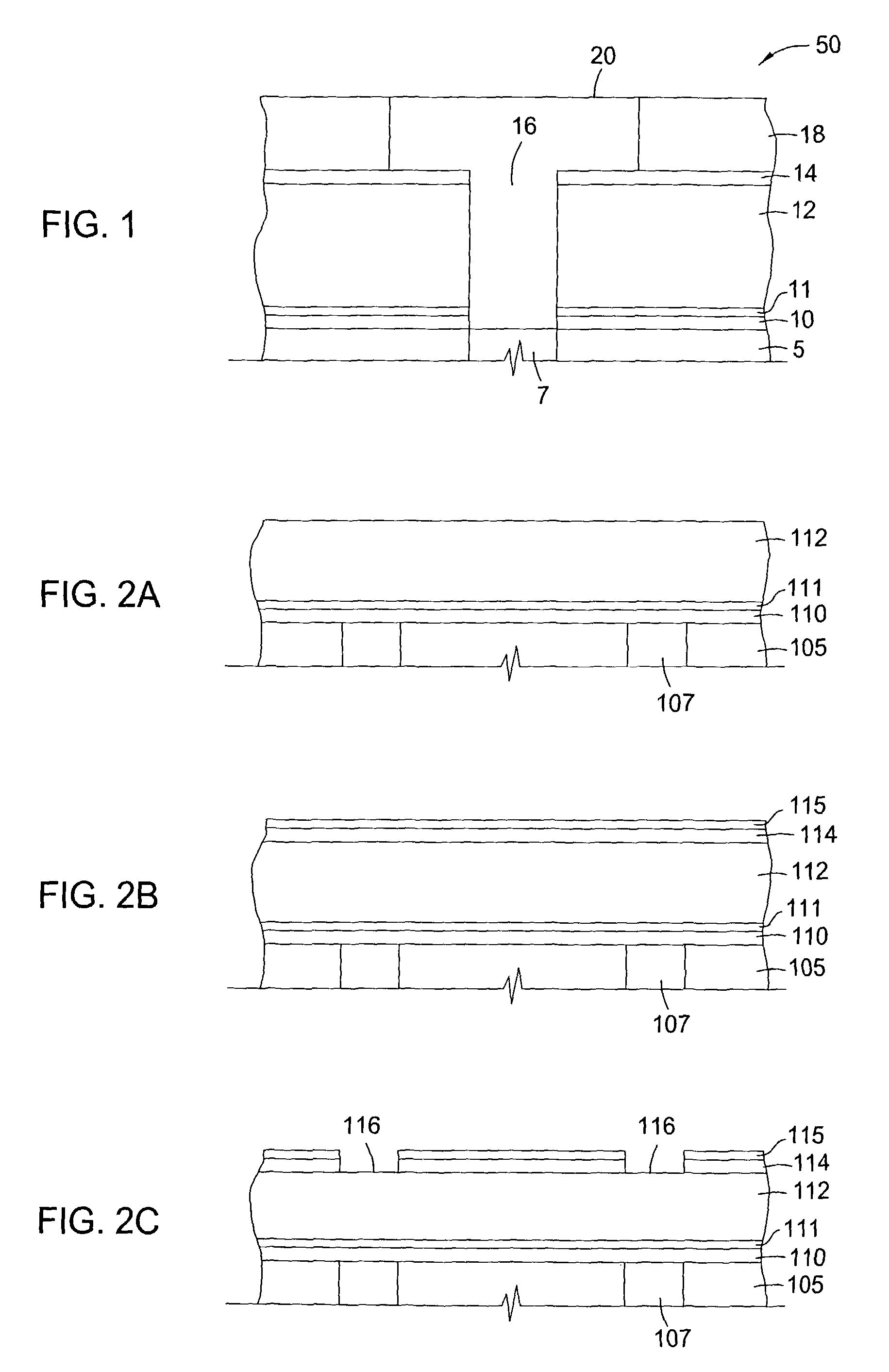

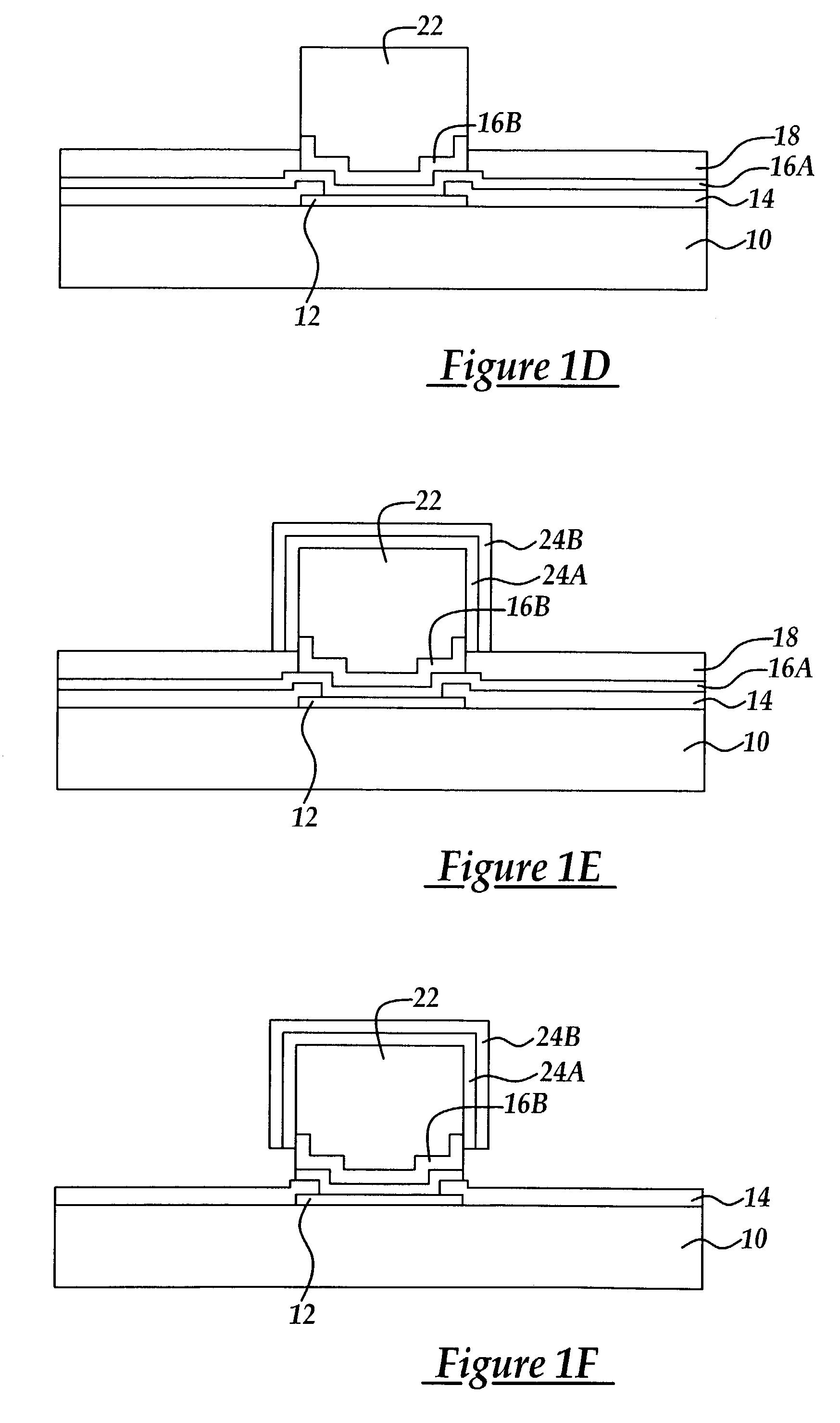

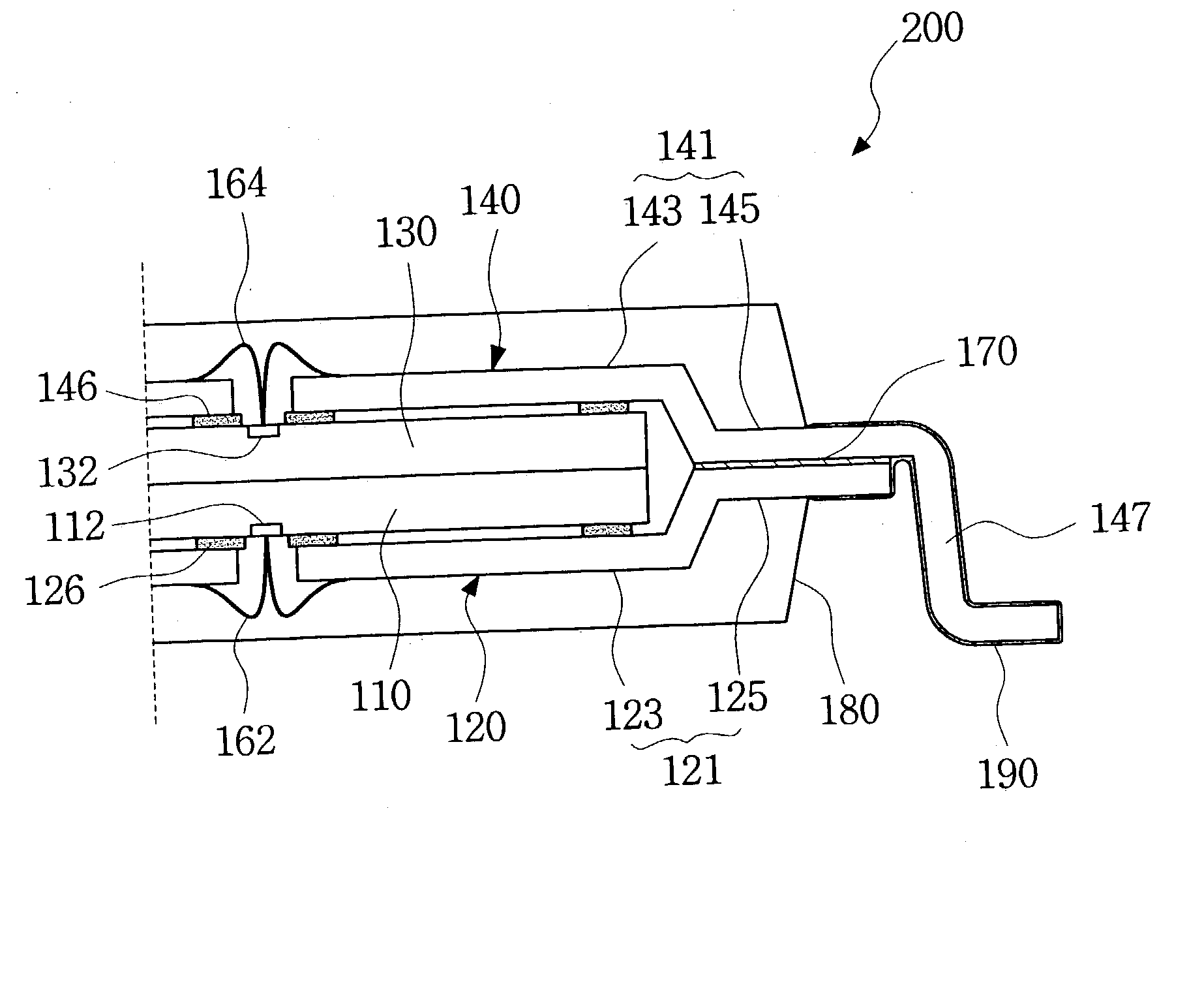

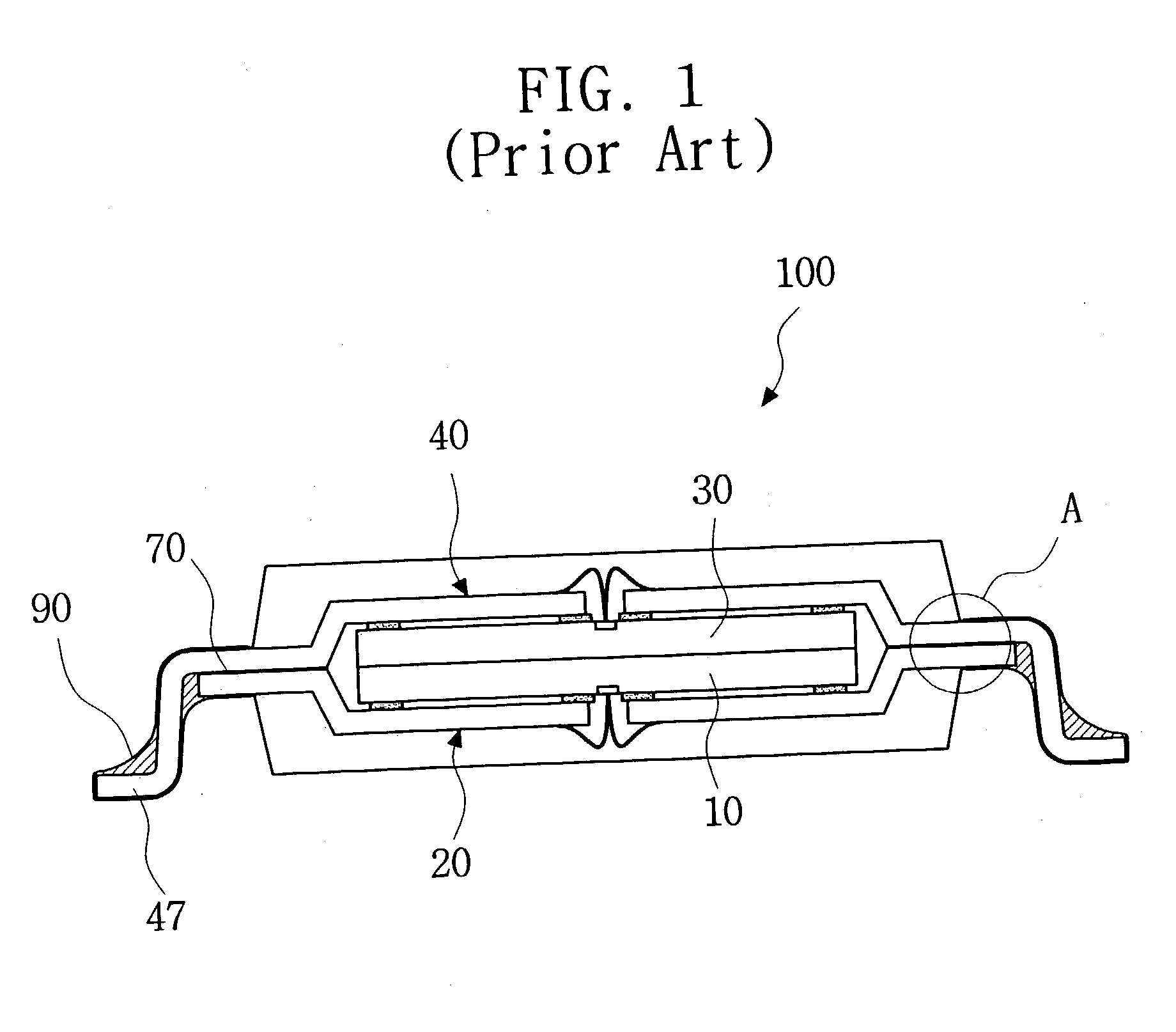

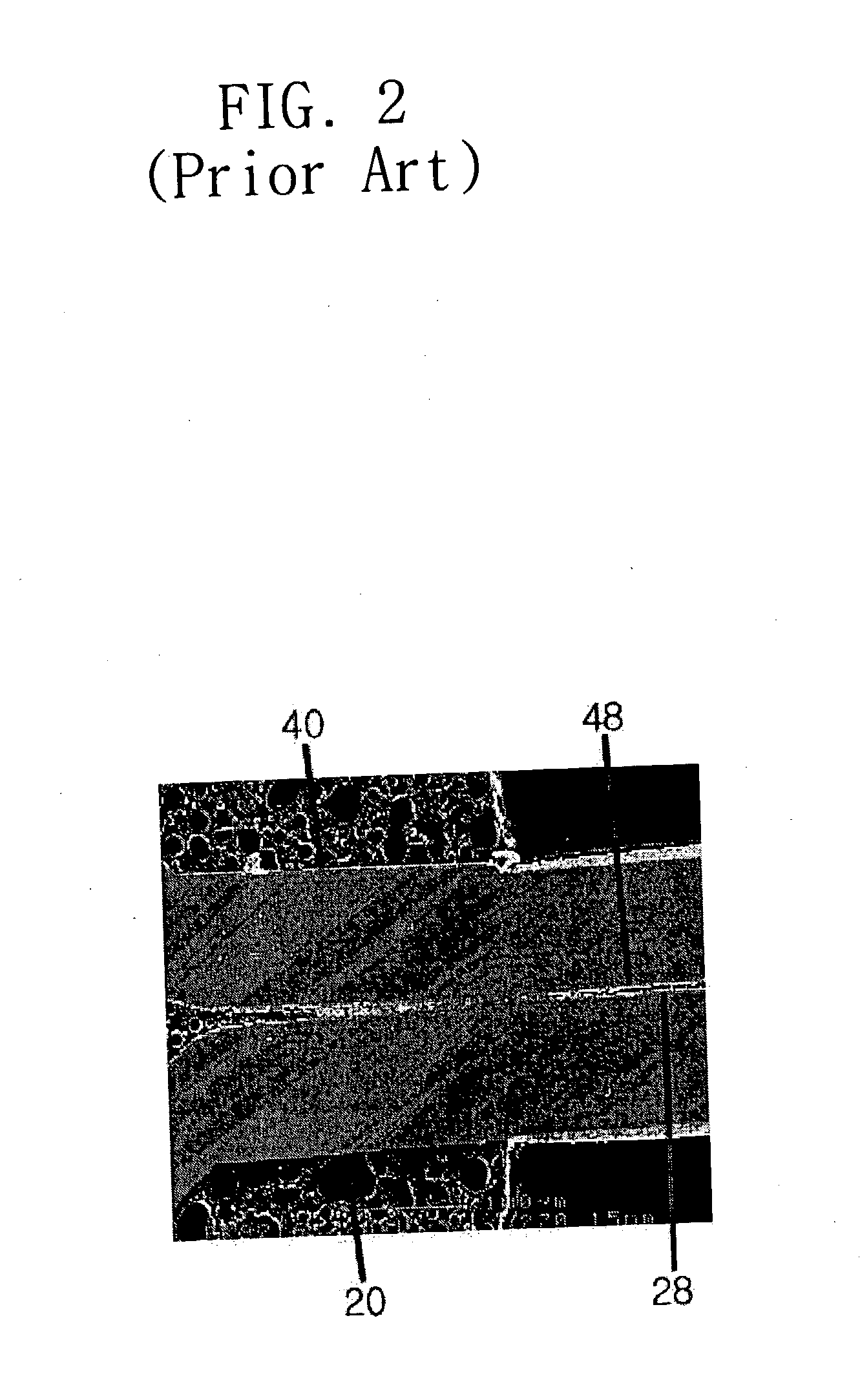

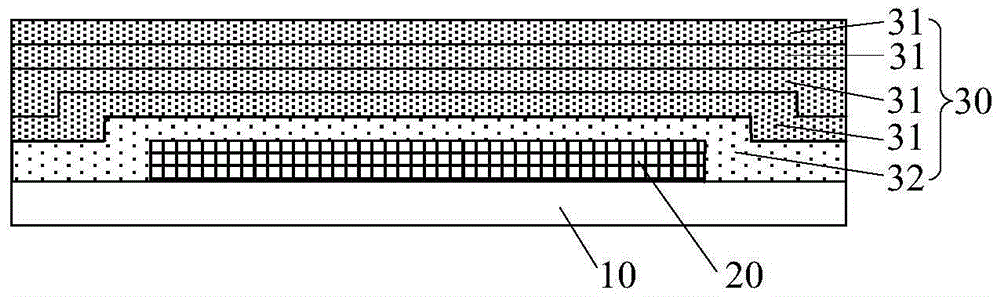

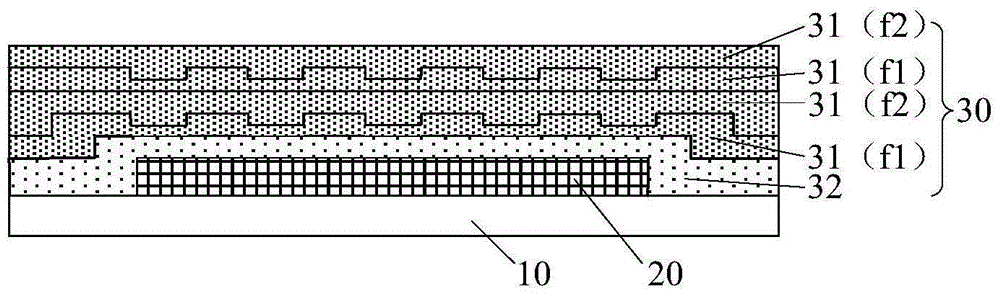

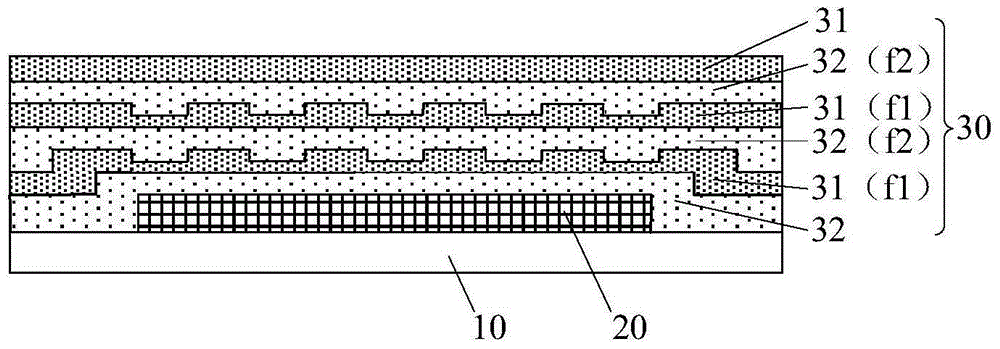

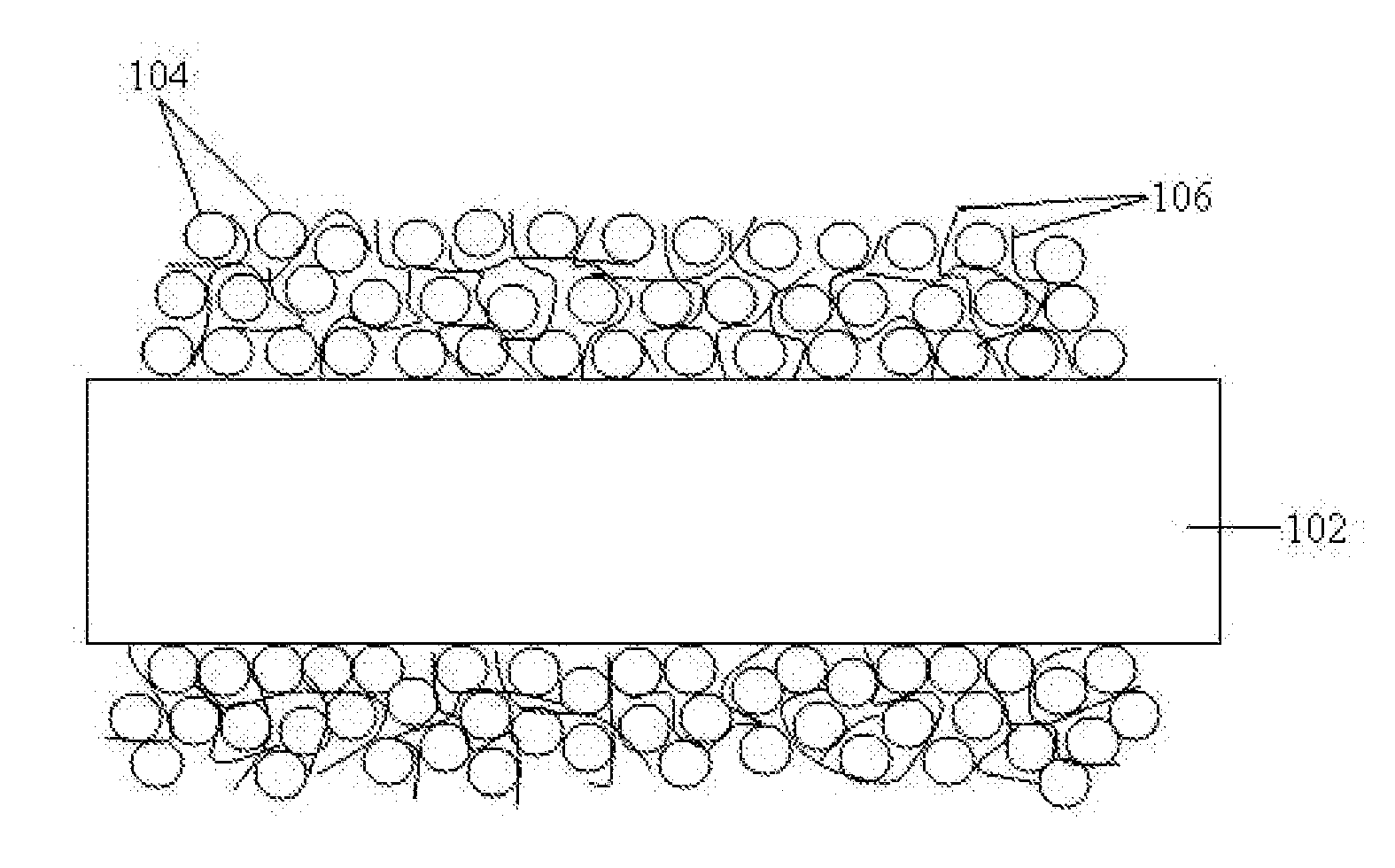

Flexible displayer and production method thereof

ActiveCN105206763AImprove antioxidant capacityImprove flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingConvex structureDisplay device

The invention provides a flexible displayer and a production method thereof, and relates to the technical field of displayers. A packaging structure of the flexible displayer can meet not only the requirement of oxidation resistance, but also the requirement of flexibility. The flexible displayer comprises the packaging structure; the packaging structure comprises a plurality of overlapped packaging films; the packaging films comprise a plurality of inorganic films; matched concave-convex structures are formed in two contact surfaces of at least one pair of adjacent packaging films; at least one of two adjacent packaging films is an inorganic film. The flexible displayer is used for picture displaying.

Owner:BOE TECH GRP CO LTD +1

Method of increasing the oxidation stability of biodiesel

Owner:DEGUSSA AG

Lubricant oil compositions

InactiveUS20070161522A1Extended shelf lifeImprove performanceLiquid carbonaceous fuelsAdditivesAntioxidantLubricant

Compositions comprise first antioxidants and first additives, such as, a surface additives, performance enhancing additives and lubricant protective additives and optionally second additives and / or second antioxidants. The compositions are useful to improve lubricants, lubricant oils and other lubricant materials. The compositions and methods generally provide longer shelf lives, increased oxidative resistance, improved quality and / or enhanced performance to lubricants or lubricant oils.

Owner:POLNOX CORP

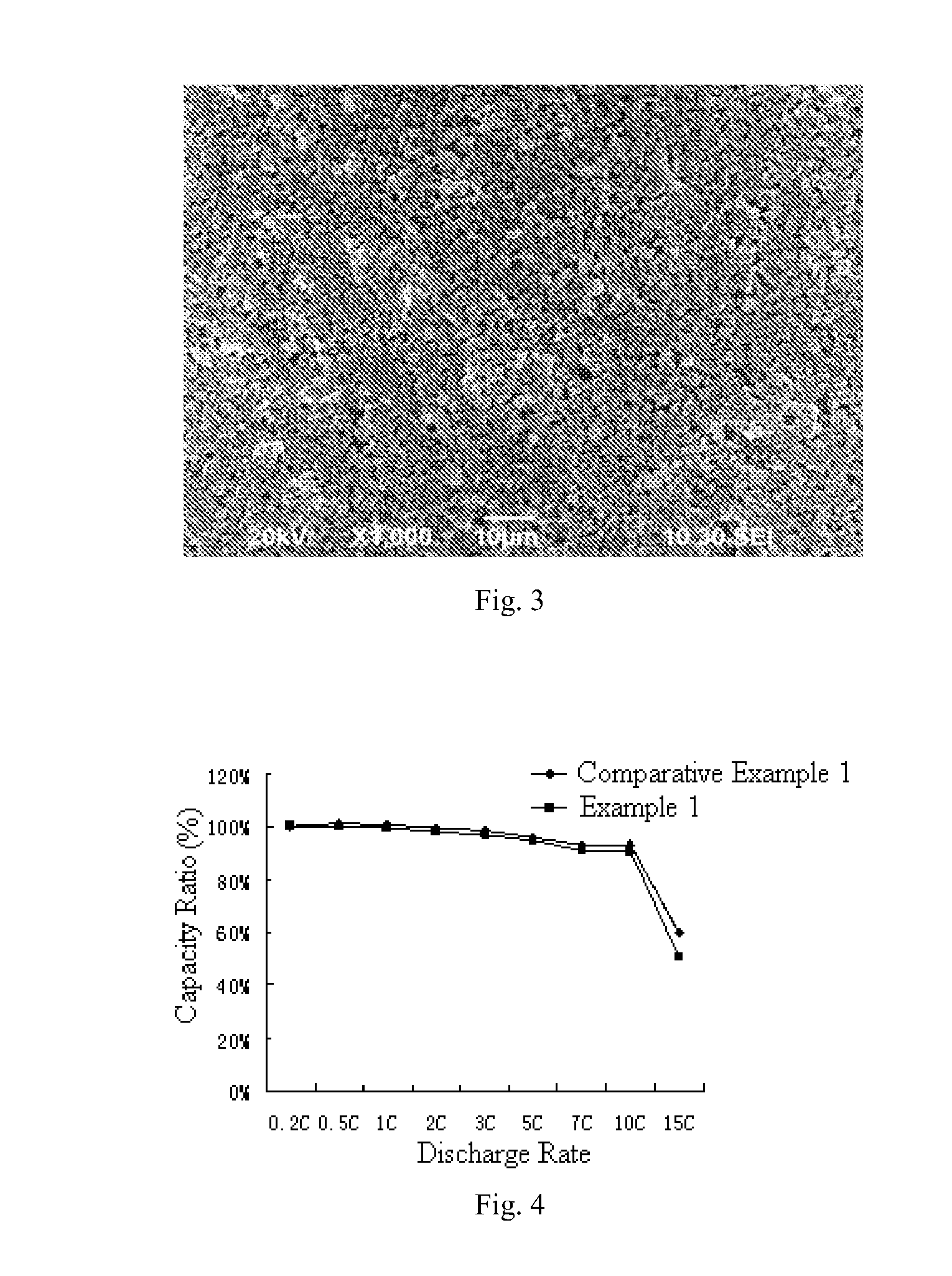

Graphene coating as well as preparation method and coating method thereof

The invention belongs to the technical field of materials and in particular relates to a graphene coating as well as a preparation method and a coating method thereof. The graphene coating is prepared from the components by weight: 5-95wt percent of less layer of grapheme, 5-95wt percent of adhesive, 0.01-50wt percent of dispersant and surfactant, 0.01-10wt percent of defoamer and the balance of solvent. With the adoption of the graphene coating, the thickness of an electricity and heat conductive coating can be controlled to be 100nm-20 microns; when the graphene coating is used on a plastic matrix, the volume resistivity can reach a range from 10<-2>ohm.cm to 10<-4>ohm.cm; while the graphene coating is used on a metal matrix, the volume resistivity can reach 10<-6>ohm.cm. The graphene coating can be applied to the metal surface so as to improve the cohesiveness, the electricity / heat conduction performance and the corrosion and oxidation resistance. When the graphene coating is coated on the plastic surface, the frictional resistance, the electricity and heat conduction performances and the static resistance can be lowered, and the graphene coating can be applied to the fields of printed circuits, electronic devices, radio frequency devices, touch screens, thin film solar energy, LEDs, magnetic shielding, radio frequency shielding and the like.

Owner:SUPERCDONGGUAN TECH

Solar selective coating having higher thermal stability useful for harnessing solar energy and a process for the preparation thereof

InactiveUS20070196670A1Easy to optimizeImprove thermal stabilitySolar heat devicesVacuum evaporation coatingAbsorptanceEngineering

The present invention provides an improved solar selective multilayer coating having higher thermal stability and a process for the preparation thereof. Solar selective coatings having higher thermal stability are useful in solar steam generation, solar steam turbines to produce electricity and also on automobile engine components. In the present invention, a tandem stack of three layers of TiAlN, TiAlON and Si3N4 is deposited on metal and non-metal substrates at room temperature using a planar reactive direct current magnetron sputtering process. The first two layers function as the absorber and the third antireflection layer further enhances the coating's absorptance. The solar selective coatings were annealed in air and vacuum to test the thermal stability at different temperatures and durations. The coatings of the present invention deposited on copper substrates are stable in air up to a temperature of 625° C. for a duration of 2 hours and exhibit higher solar selectivity in the order of 9-10 and these coating also show no change in the absorptance and the emittance values even after vacuum annealing at 600° C. for 3 hours. Coatings deposited on copper substrates showed no significant degradation in the optical properties even after continuous heating in air at 525° C. for 50 hours. The solar selective coatings of the present invention exhibit high hardness, high oxidation resistance, chemical inertness and stable microstructure.

Owner:COUNCIL OF SCI & IND RES

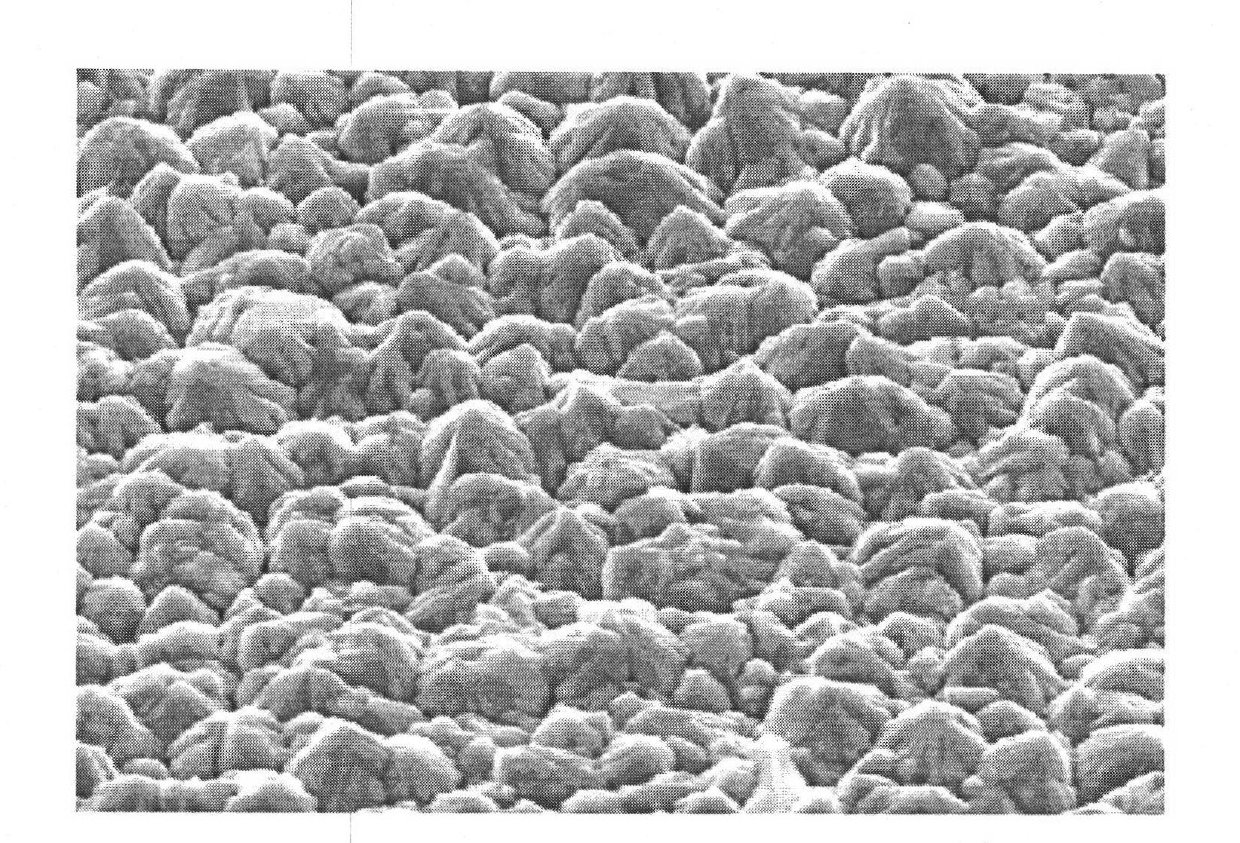

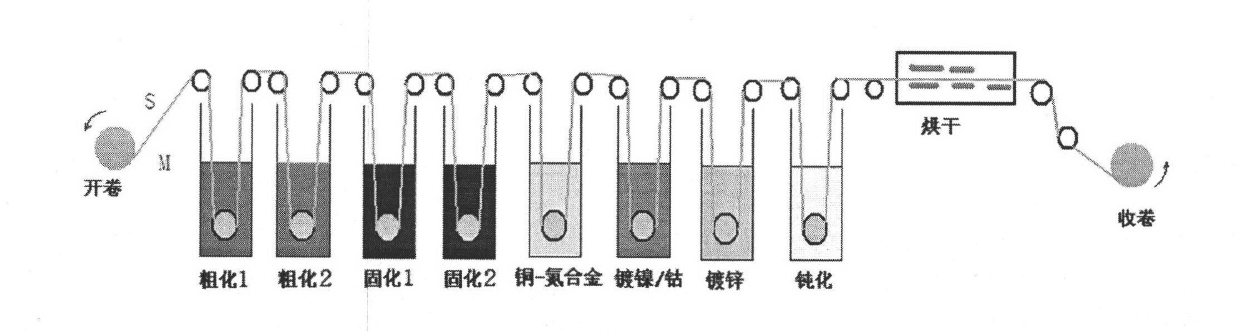

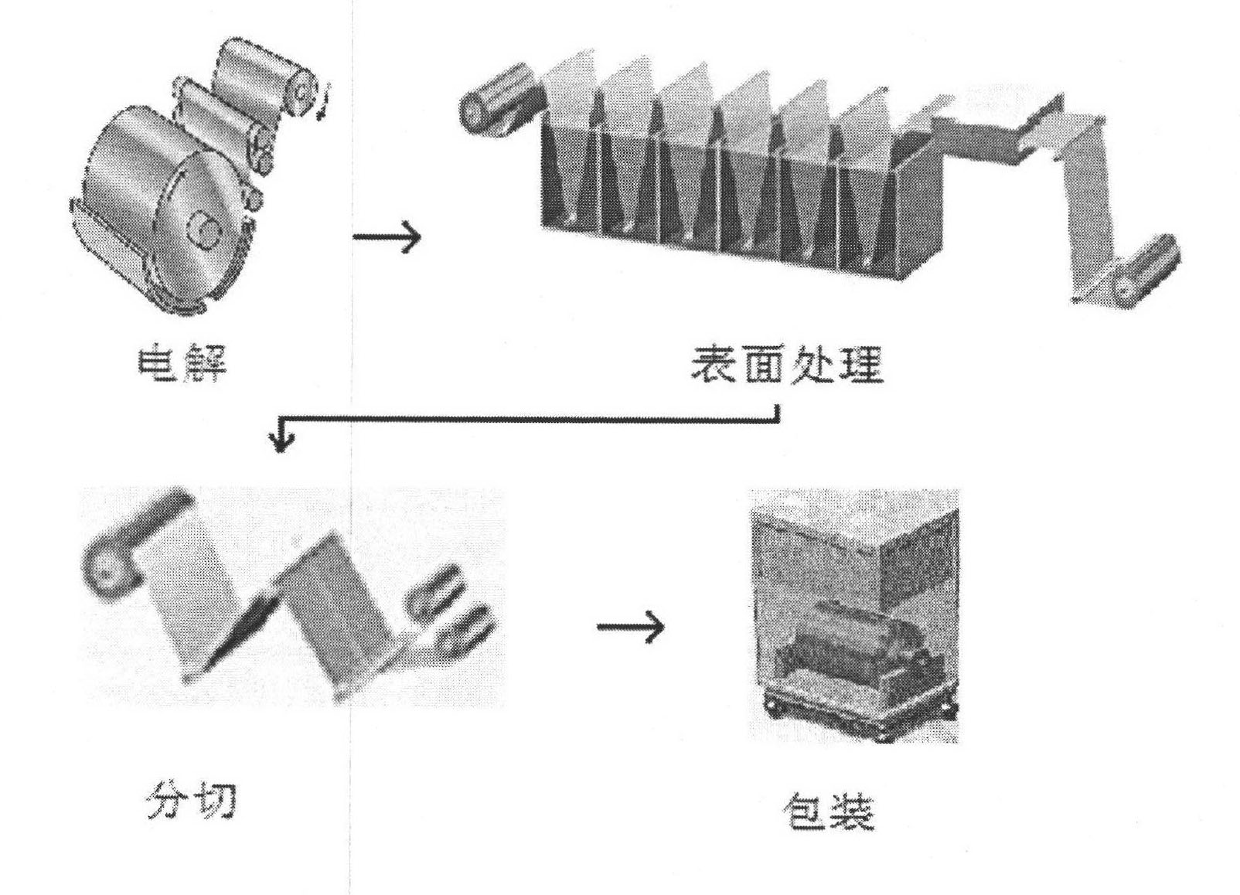

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

Activation-free electroless solution for deposition of cobalt and method for deposition of cobalt capping/passivation layer on copper

InactiveUS6902605B2Increase resistanceImprove barrier propertiesLiquid surface applicatorsSemiconductor/solid-state device manufacturingHigh resistanceElectroless deposition

The present invention relates to compositions and a method for electroless formation of alkaline-metal-free coatings on the basis of cobalt and composition of cobalt with tungsten and phosphorus, which have high resistance to oxidation and stability of electrical characteristics, when the Co—Cu system layer is used in IC chips. The composition of the electroless solution contains more than one reducing agents, one of which can catalyze the initial electroless deposition layer of cobalt on copper (called initiator), while the other maintains deposition of cobalt on the aforementioned initial layer as the process is continued. Small amount (100-5000 ppm) of elements from the initiator also builds into the electroless film, which is expected to further improve the barrier properties of the resultant film compared to the deposition bath without initiator. Such coating may find application in semiconductor manufacturing where properties of deposited films and controllability of the composition and physical and chemical characteristics of the deposited films may be critically important.

Owner:LAM RES CORP

Lubricating compositions

InactiveUS6962895B2Low and propertyImprove the immunityLiquid carbonaceous fuelsAdditivesAlpha-olefinViscosity

This invention relates to a lubricating composition comprising at least about 30% by weight at least one mineral oil, having a kinematic viscosity of less than about 8 cSt at 100° C., (A) from about 15% to about 40% by weight of at least one polymer, and (B) up to about 30% by weight of at least one fluidizing agent, provided that when the fluidizing agent is a polyα-olefin having a kinematic viscosity from about 2 to about 30 cSt at 100° C., then the polyα-olefin is present in an amount up to about 12% by weight, wherein the lubricating composition has a shear loss of less than about 15% in the 20 hour taper bearing shear test. The invention also relates to concentrates used in preparing lubricating compositions. The present combination of components provides good low and high temperature properties especially when used in combination with one or more mineral oils. In one aspect, the compositions provide improved oxidation resistance.

Owner:THE LUBRIZOL CORP

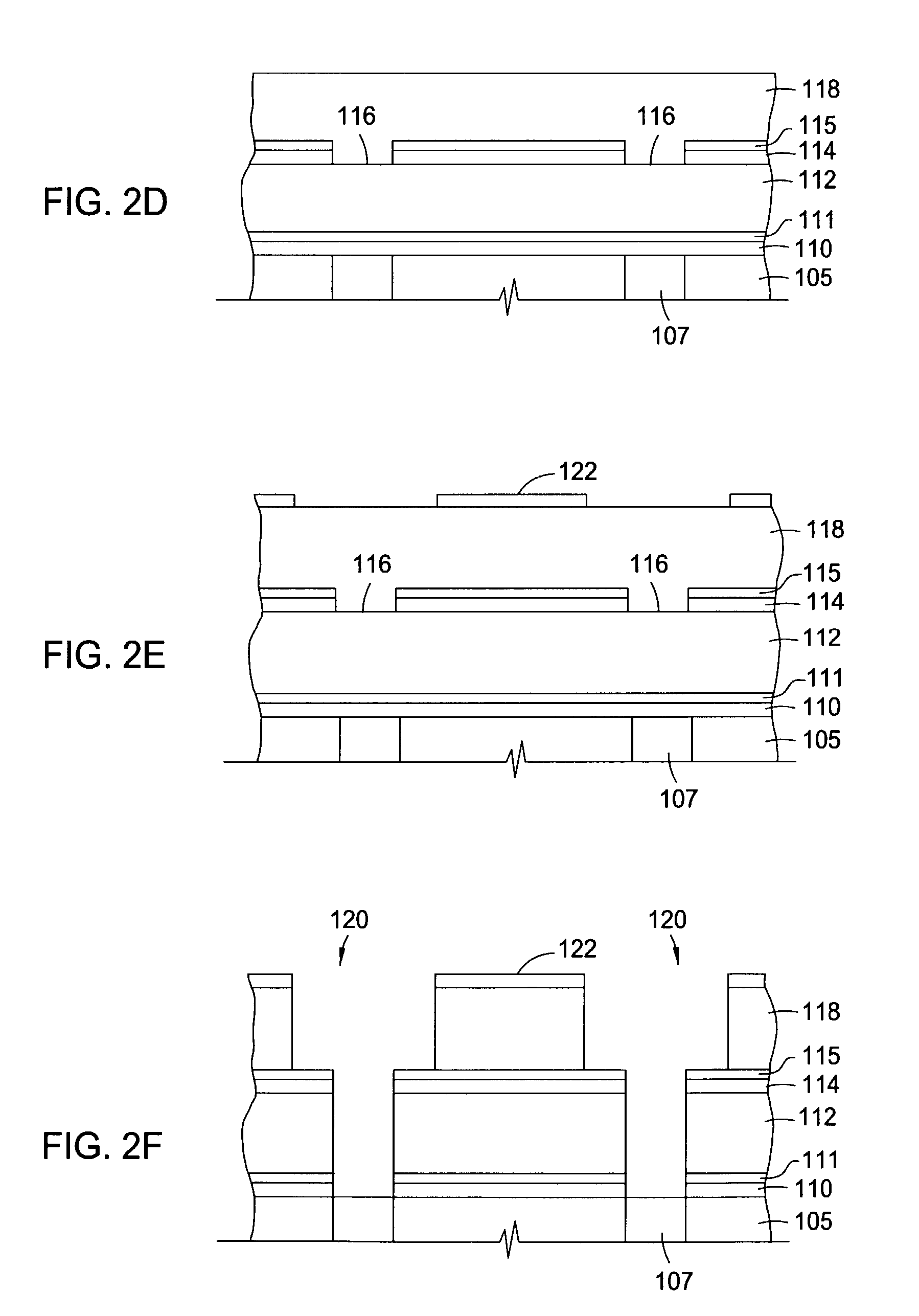

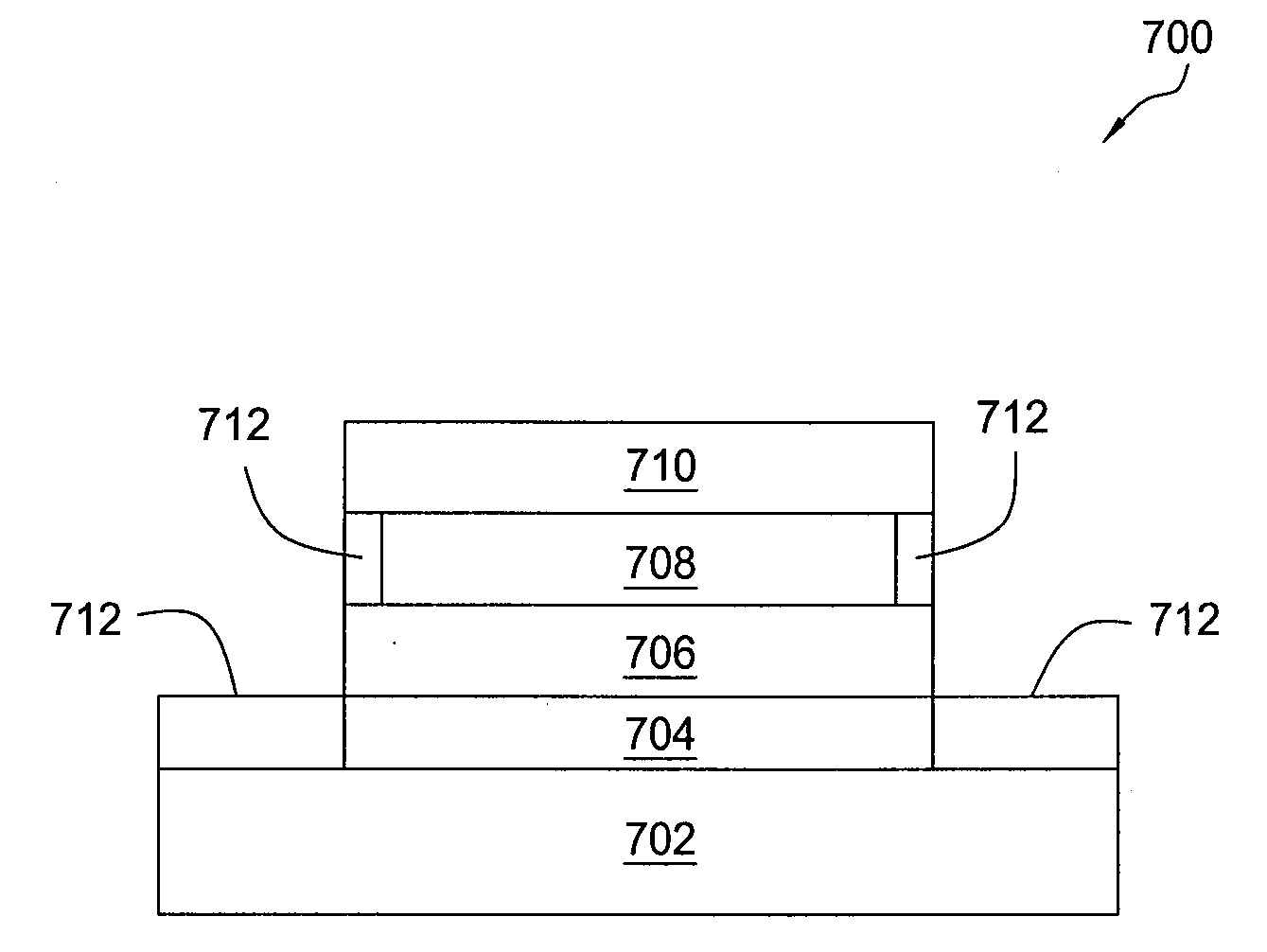

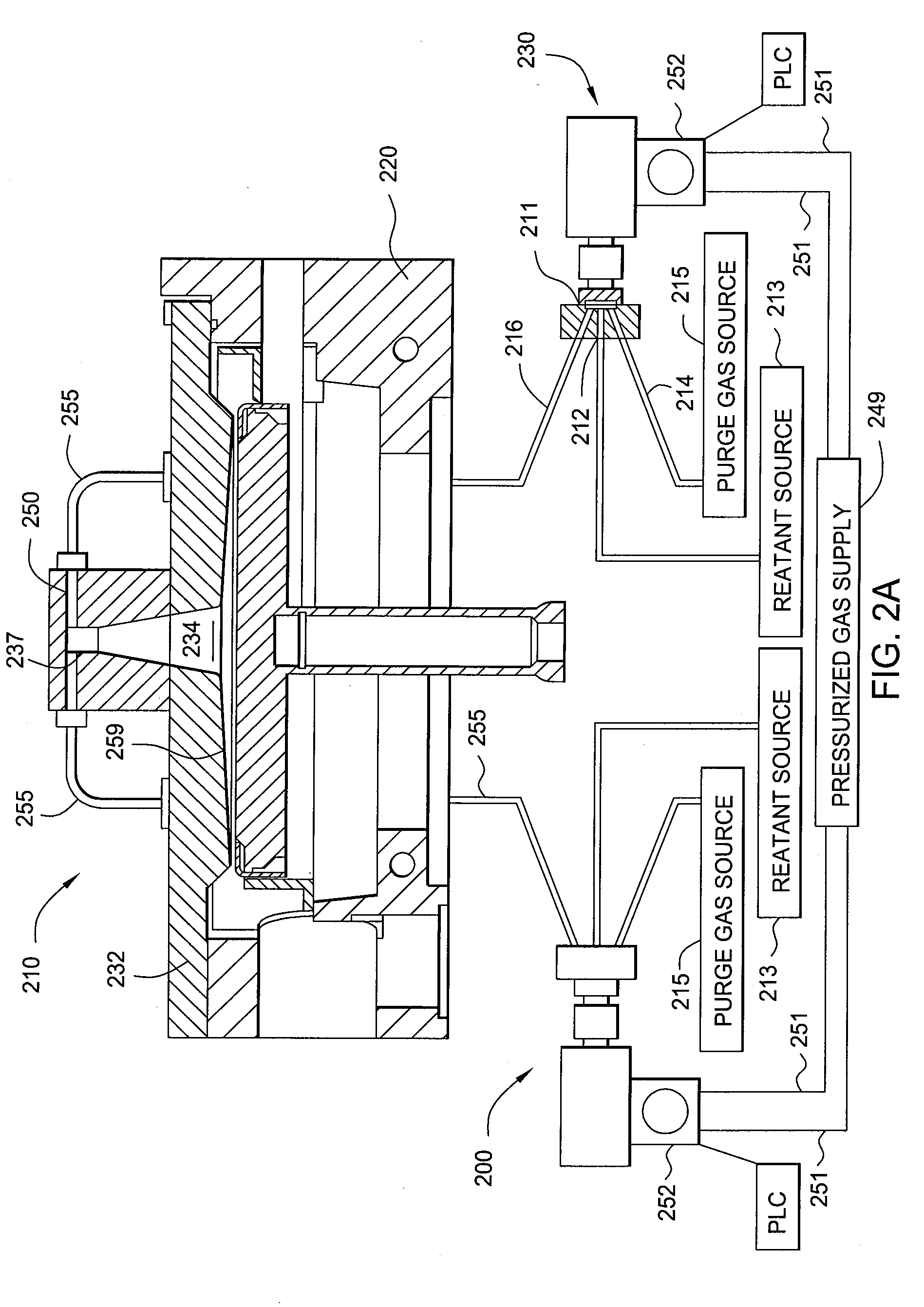

Plasma and thermal anneal treatment to improve oxidation resistance of metal-containing films

InactiveUS20100120245A1Lamination ancillary operationsLayered product treatmentAtomic layer depositionMaterials science

Method and apparatus are provided for treatment of a deposited material layer. In one embodiment, a method is provided for processing a substrate including depositing a metal-containing layer using an atomic layer deposition technique, exposing the metal-containing layer to a plasma treatment process at a temperature of less than about 200° C., and exposing the metal-containing layer to a thermal anneal process at a temperature of about 600° C. or greater. The plasma treatment process and / or the thermal anneal process may use a nitrating gas, which may form a passivating surface or layer with the metal-containing layer.

Owner:APPLIED MATERIALS INC

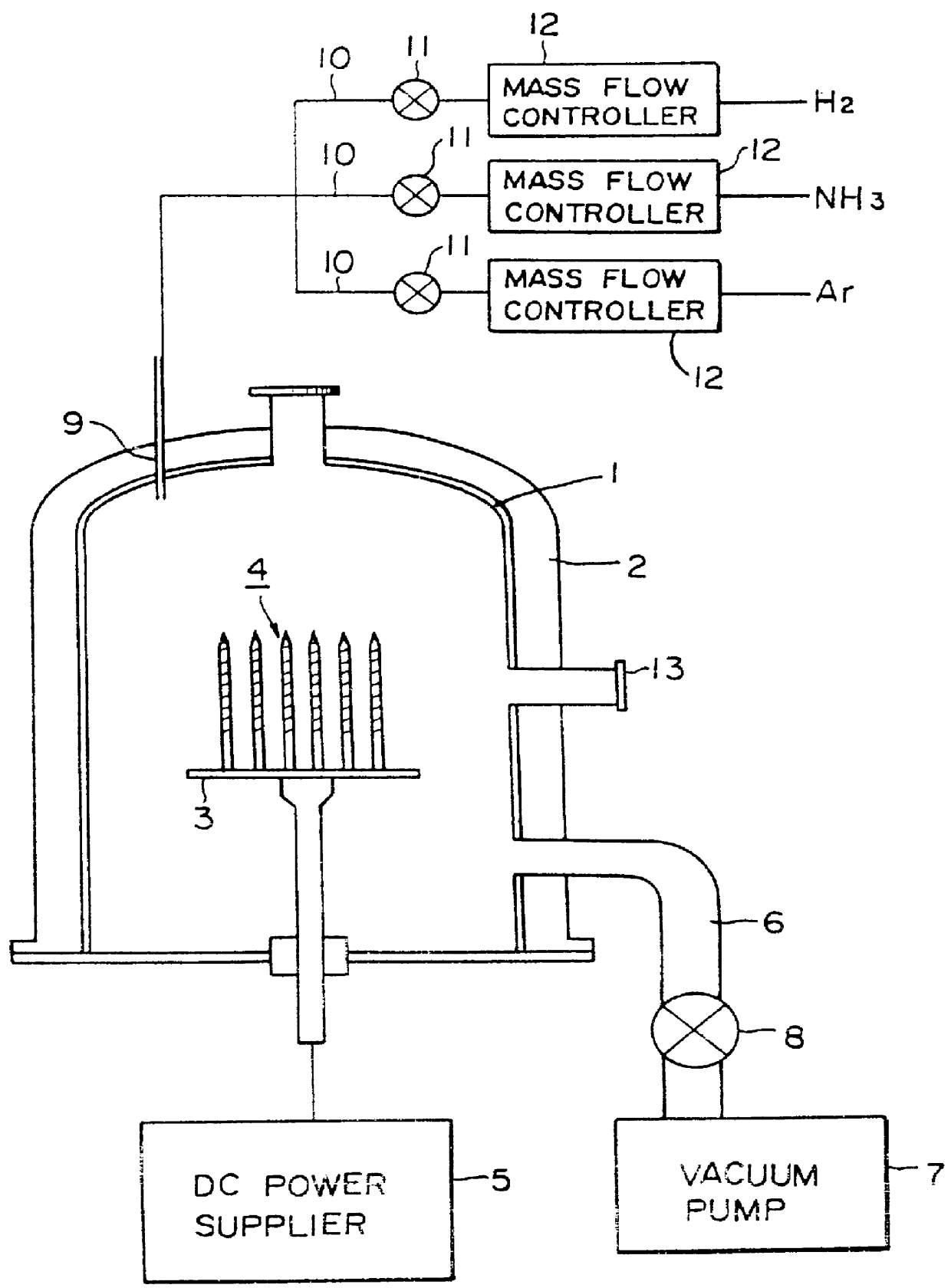

Duplex coated steel composite products and method of manufacturing them

InactiveUS6110571AEasy to useElevation is easyVacuum evaporation coatingSputtering coatingCarbidePlasma nitridation

Duplex coated steel composite products comprising a first layer of a nitrided layer formed by applying glow discharge at a current density from 0.001 to 2.0 mA / cm2 to the surface of metal parts by using gaseous ammonia and gaseous hydrogen while maintaining the temperature of the metal parts at 300 to 650 DEG C., thereby applying plasma nitriding and a second layer comprising a hard film comprising a nitride, carbide and / or carbonitride of one or more of elements selected from Ti, Zr, Hf, V, Nb, Ta and Cr coated on the first layer by the PVD method of a laminate film or a gradient laminate film of such hard film. The treated products are excellent in adhesion with the substrate and durability and have both oxidation resistance and wear resistance.

Owner:SUMITOMO METAL MINING CO LTD

Inorganic/organic composite porous separator and electrochemical device using the same

InactiveUS20120301774A1Desirable performanceDesirable safetyCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous substrateLithium

Provided is an inorganic / organic composite porous separator including a porous substrate having pores and an active layer formed on the porous substrate. The active layer contains mixture of binder and inorganic particles. The inorganic / organic composite porous separator of the present invention has desirable anti-oxidation performance, and can prevent the separator from being oxidized in the lithium secondary battery using high voltage anode material. Also provided is a method for manufacturing the inorganic / organic composite porous separator and an electrochemical device using the same.

Owner:DONGGUAN AMPEREX TECH

Polymerized thylene carbonate urethane elastomer and its preparation method

ActiveCN1865311AMolecular chain softRoom temperature and good flexibilityCross-linkMedical equipment

The invention discloses a polyethylene carbonate polyurethane elastomer and making method, which produces polycarbonate polyhydric alcohol through carbon dioxide and oxirane with 20-60 percent diisocyanate, 0.05-2 percent polymerization inhibitor, 2.4-17 percent chain-extending agent and or cross linking agent and 0-0.4 percent catalyst. The method possesses better mechanic property, plasticity, anti-oxidizing property and water weakened-durability, which can be applied in the liner, screen, sealing ring and medical equipments.

Owner:JIANGSU ZHONGKE JINLONG CHEM

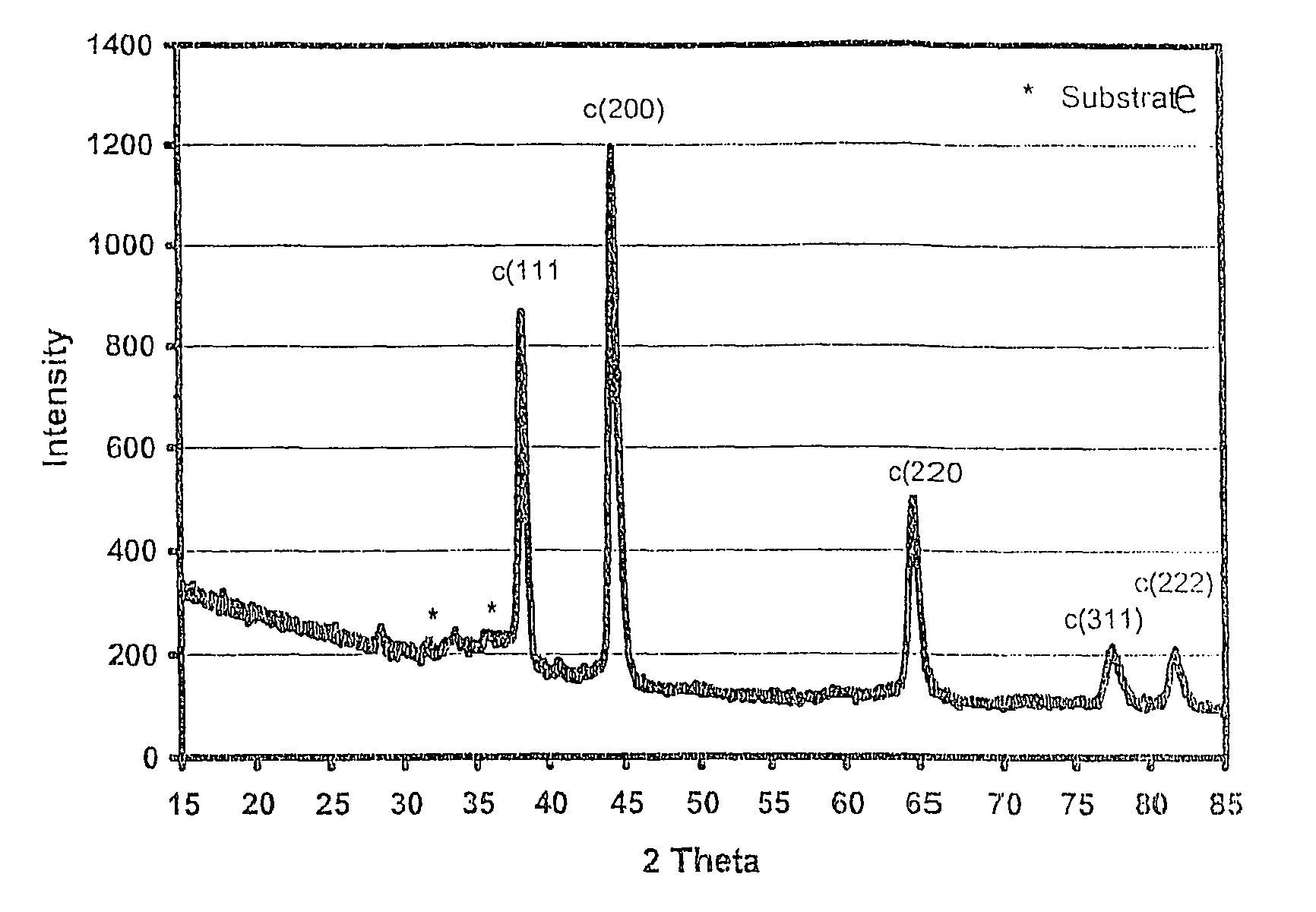

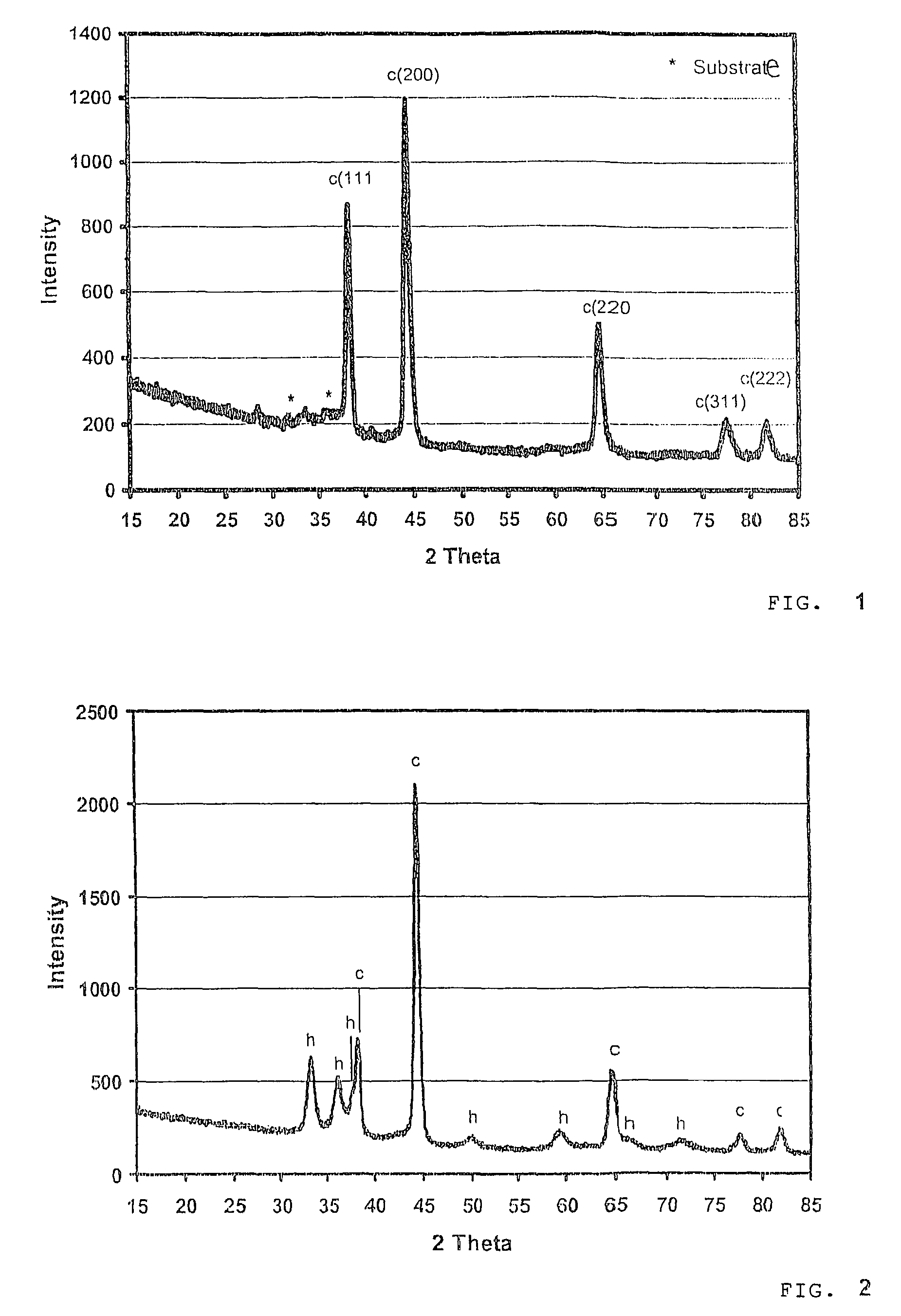

Hard-material-coated bodies and method for their production

ActiveUS7767320B2Improve the immunityExcellent friction and wear resistanceNatural mineral layered productsChemical vapor deposition coatingLattice constantChemical measurement

The invention relates to hard-coated bodies with a single- or multi-layer system containing at least one Ti1-xAlxN hard layer and a method for production thereof. The aim of the invention is to achieve a significantly improved wear resistance and oxidation resistance for such hard-coated bodies. Said hard-coated bodies are characterised in that the bodies are coated with at least one Ti1-xAlxN hard layer, generated by CVD without plasma stimulation present as a single-phase layer with cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, or as a multi-phase layer, the main phase being Ti1-xAlxN with a cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, with Ti1-xAlxN with a wurtzite structure and / or as TiNx with NaCl structure as further phase. Another feature of said hard layer is that the chlorine content is in the range of only 0.05 to 0.9 atom %. The invention further relates to a method for production of the body, characterised in that the body is coated in a reactor at temperatures from 700° C. to 900° C. by means of CVD without plasma stimulation with titanium halides, aluminium halides and reactive nitrogen compounds as precursors, mixed at elevated temperatures. Said coating can be applied to tools made from steel, hard metals, cermets and ceramics, such as drills, millers and indexable inserts.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

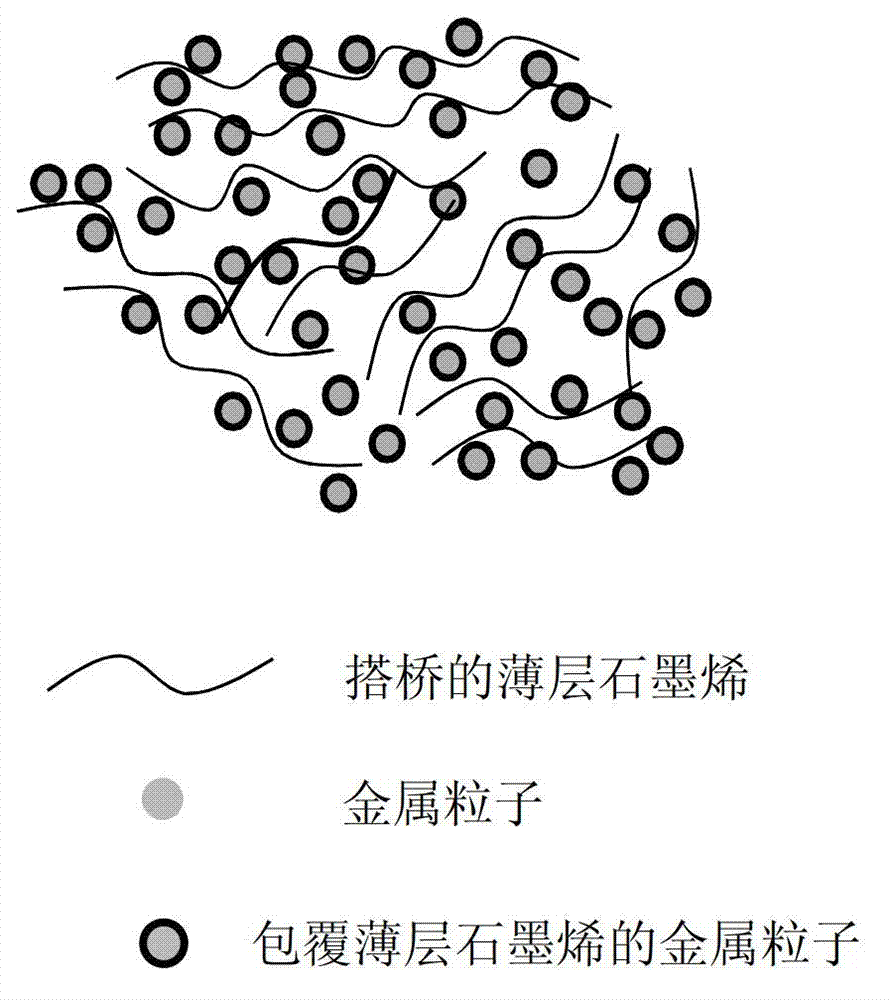

Material adopting thin graphene and metal powder composite structure, preparation method and application thereof

ActiveCN103192072AImprove antioxidant capacityImprove corrosion resistanceCarbon compoundsGas phaseSlurry

The invention discloses a material adopting a thin graphene and metal powder composite structure, a preparation method and an application thereof. The material adopting the composite structure comprises metal powder bridged by and coated with thin graphene. The preparation technology of the material comprises the steps as follows: mixing transition metal powder or reduced transition metal powder with the thin graphene, and growing the thin graphene on the surface of the transition metal powder through CVD (chemical vapor deposition) and coating the surface of the transition metal powder with the thin graphene, so as to obtain the metal powder bridged by and coated with the thin graphene; or growing the thin graphene on the surface of the transition metal powder through the CVD, and then compositing the metal powder with the thin graphene to obtain a target product. The invention has the advantages that the technology is simple; the oxidation resistance and the corrosion prevention of the metal powder can be enhanced, meanwhile, the metal powder has good heat conduction, antistatic and electromagnetic shielding properties, the service life of the metal powder can be prolonged, and the cost can be reduced; and besides, the material has a wide application prospect in antistatic performance, thermal management, heat conduction and radiation, electromagnetic shielding, catalysts, sintering activators, electro-conduction slurry, batteries, cemented carbide and the like.

Owner:苏州格瑞丰纳米科技有限公司

Austenitic stainless steel tube excellent in steam oxidation resistance and a manufacturing method thereof

InactiveUS7014720B2Excellent in steam oxidation resistanceHigh-temperature bendingFurnace typesHeat treatment furnacesAustenite grainOxygen

The present invention provides an austenitic stainless steel tube with a uniform fine grained structure of regular grains, which is not changed to a coarse structure and the steam oxidation resistance is maintained even if the tube is subjected to a high temperature reheating during welding and high temperature bending working. The austenitic stainless steel tube consists of, by mass %, C: 0.03–0.12%, Si: 0.1–0.9%, Mn: 0.1–2%, Cr: 15–22%, Ni: 8–15%, Ti: 0.002–0.05%, Nb: 0.3–1.5%, sol. Al: 0.0005–0.03%, N: 0.005–0.2% and O (oxygen): 0.001–0.008%, and the balance Fe and impurities, the austenitic stainless steel tube having austenitic grain size number of 7 or more and a mixed grain ratio of preferably 10% or less.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com