Patents

Literature

2944 results about "Zinc alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc is alloyed with Lead and Tin to make solder, a metal with a relatively low melting point used to join electrical components, pipes, and other metallic items. Other Zinc Alloys include Nickel Silver, typewriter metal, and German Silver.

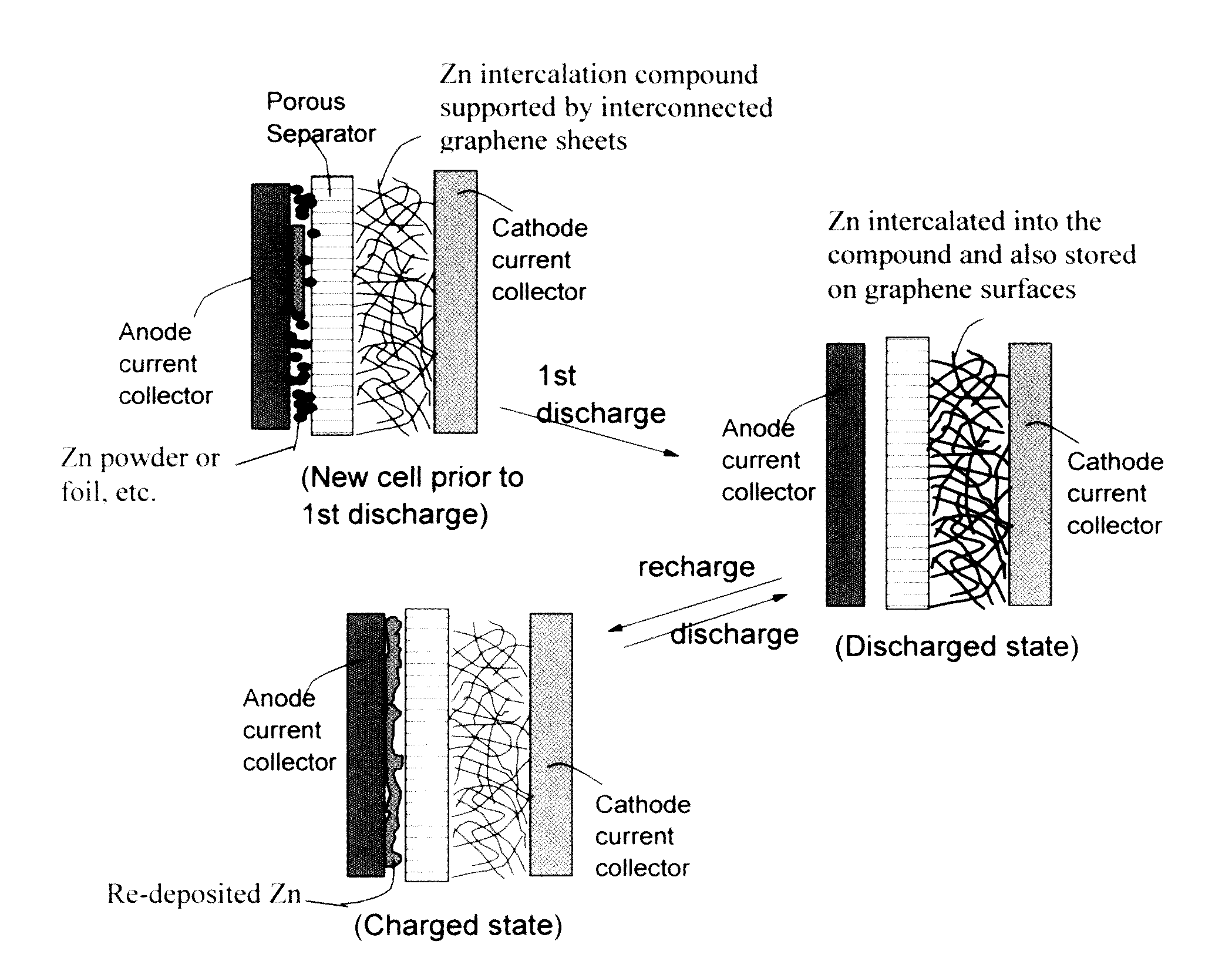

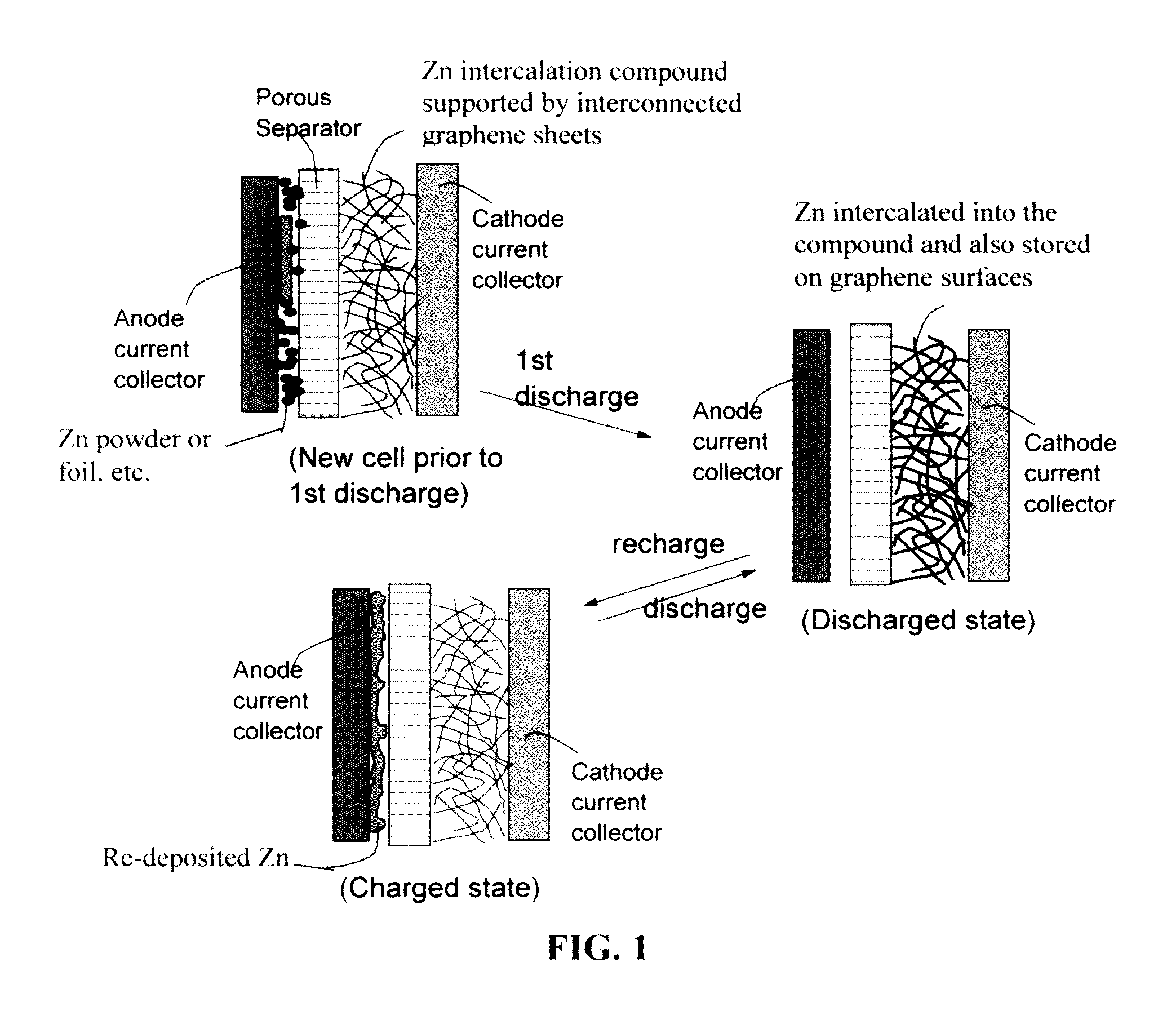

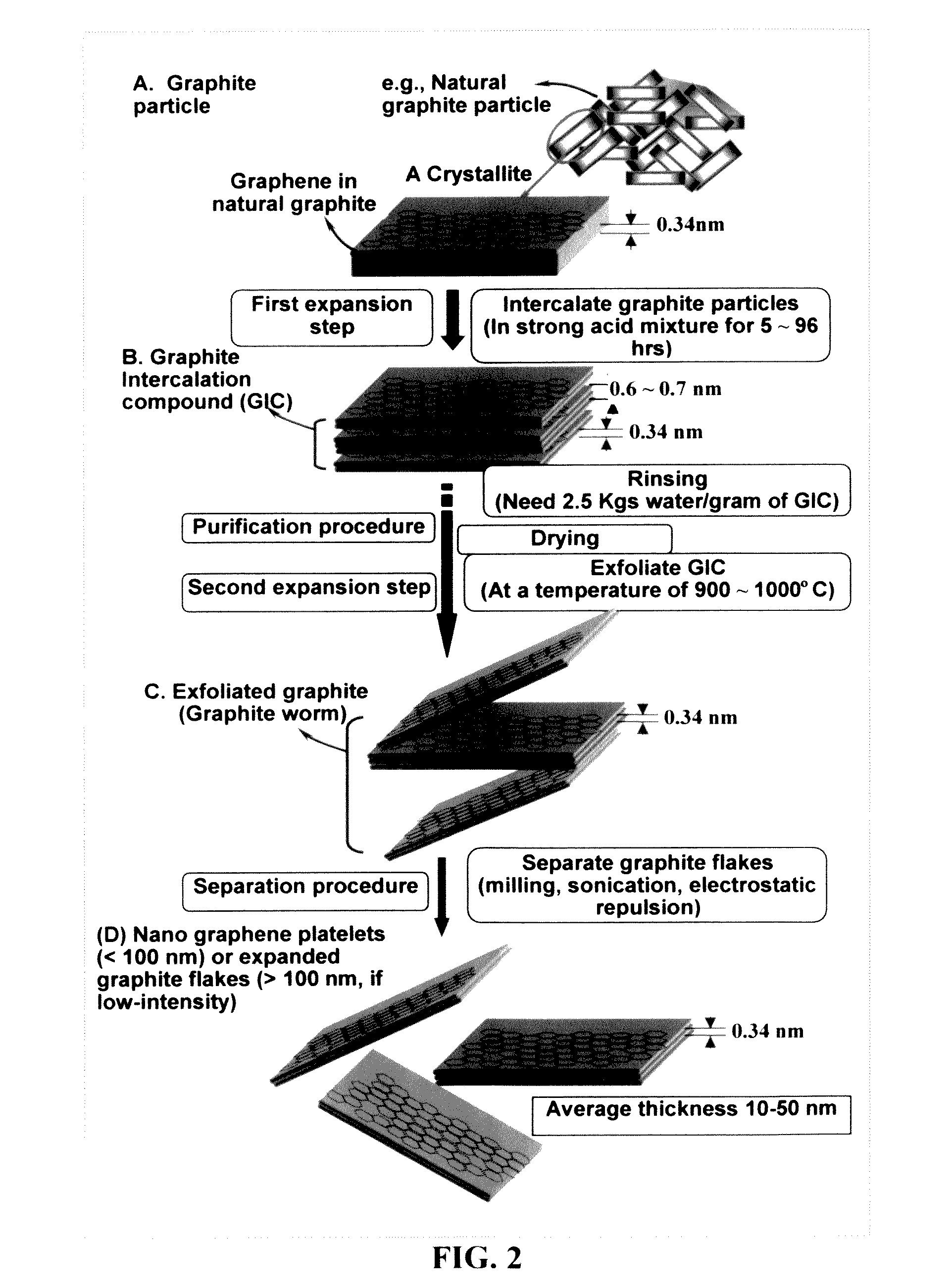

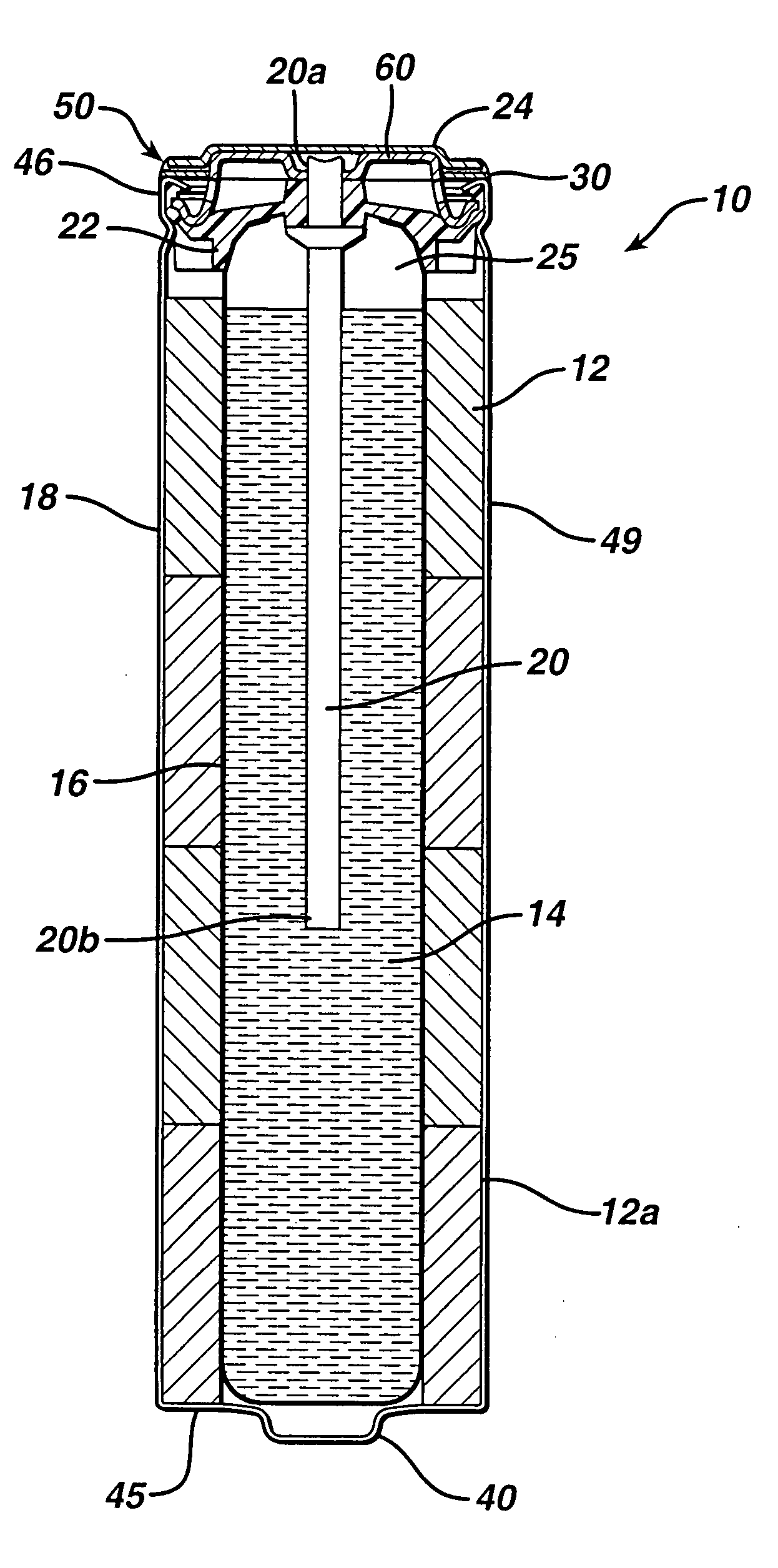

Zinc Ion-Exchanging Energy Storage Device

ActiveUS20160301096A1Quick releaseRapid depositionHybrid capacitor electrolytesAlkaline accumulatorsChemical treatmentZinc metal

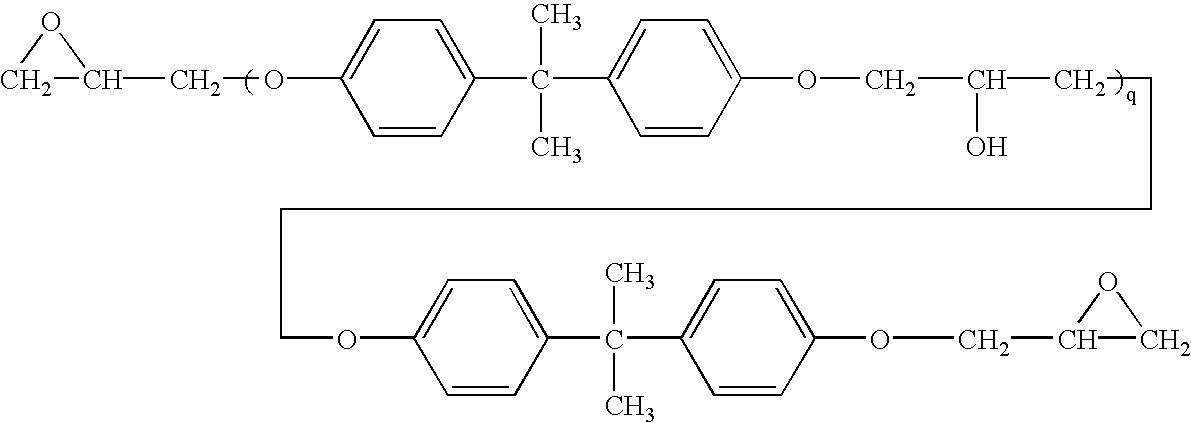

A zinc ion-exchanging battery device comprising: (A) a cathode comprising two cathode active materials (a zinc ion intercalation compound and a surface-mediating material); (B) an anode containing zinc metal or zinc alloy; (C) a porous separator disposed between the cathode and the anode; and (D) an electrolyte containing zinc ions that are exchanged between the cathode and the anode during battery charge / discharge. The zinc ion intercalation compound is selected from chemically treated carbon or graphite material having an expanded inter-graphene spacing d002 of at least 0.5 nm, or an oxide, carbide, dichalcogenide, trichalcogenide, sulfide, selenide, or telluride of niobium, zirconium, molybdenum, hafnium, tantalum, tungsten, titanium, vanadium, chromium, cobalt, manganese, iron, nickel, or a combination thereof. The surface-mediating material contains exfoliated graphite or multiple single-layer sheets or multi-layer platelets of a graphene material.

Owner:GLOBAL GRAPHENE GRP INC

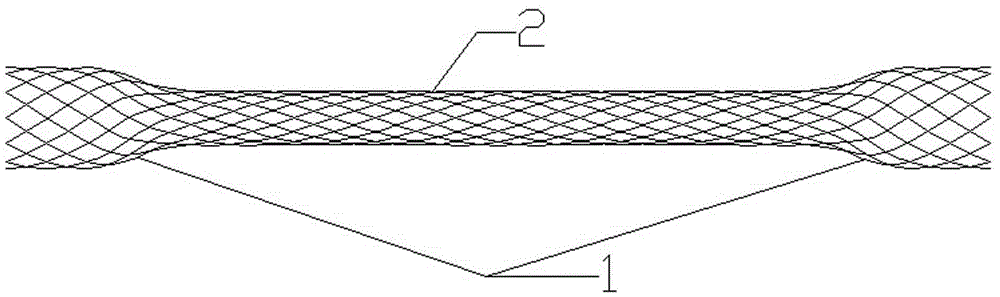

Process for producing bioresorbable implants

A process for producing implants made of a bioresorbable metal, particularly magnesium alloys or zinc alloys, in which the material properties of the magnesium or the zinc are changed and the processing and utilization properties are improved by combining process steps for adjusting the properties of the material and subsequent machining. In this way it is possible to produce thin-walled tubular implants, particularly blood vessel support stents, from bioresorbable magnesium or zinc alloys, which are readily deformable without the risk of fracture during implantation.

Owner:UNIVERSITY OF HANOVER

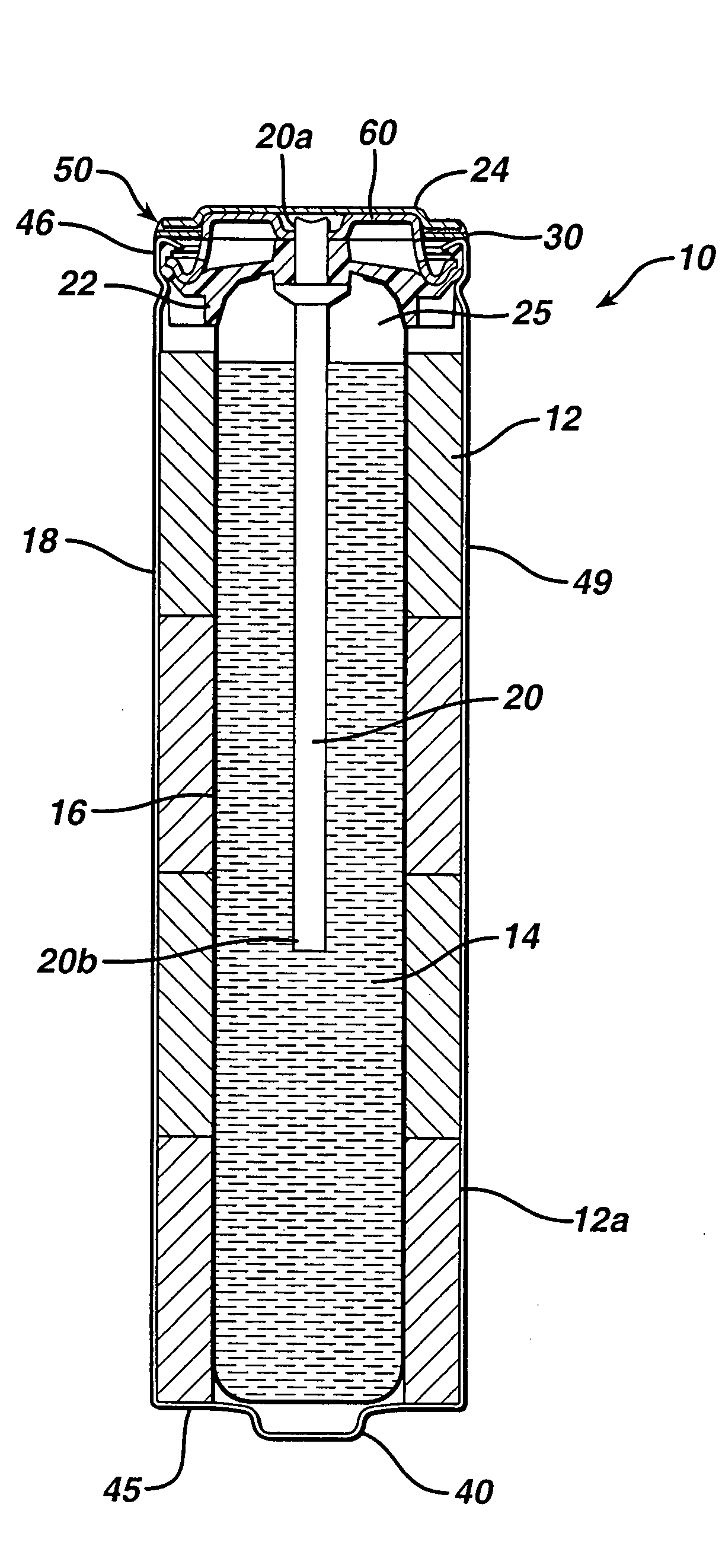

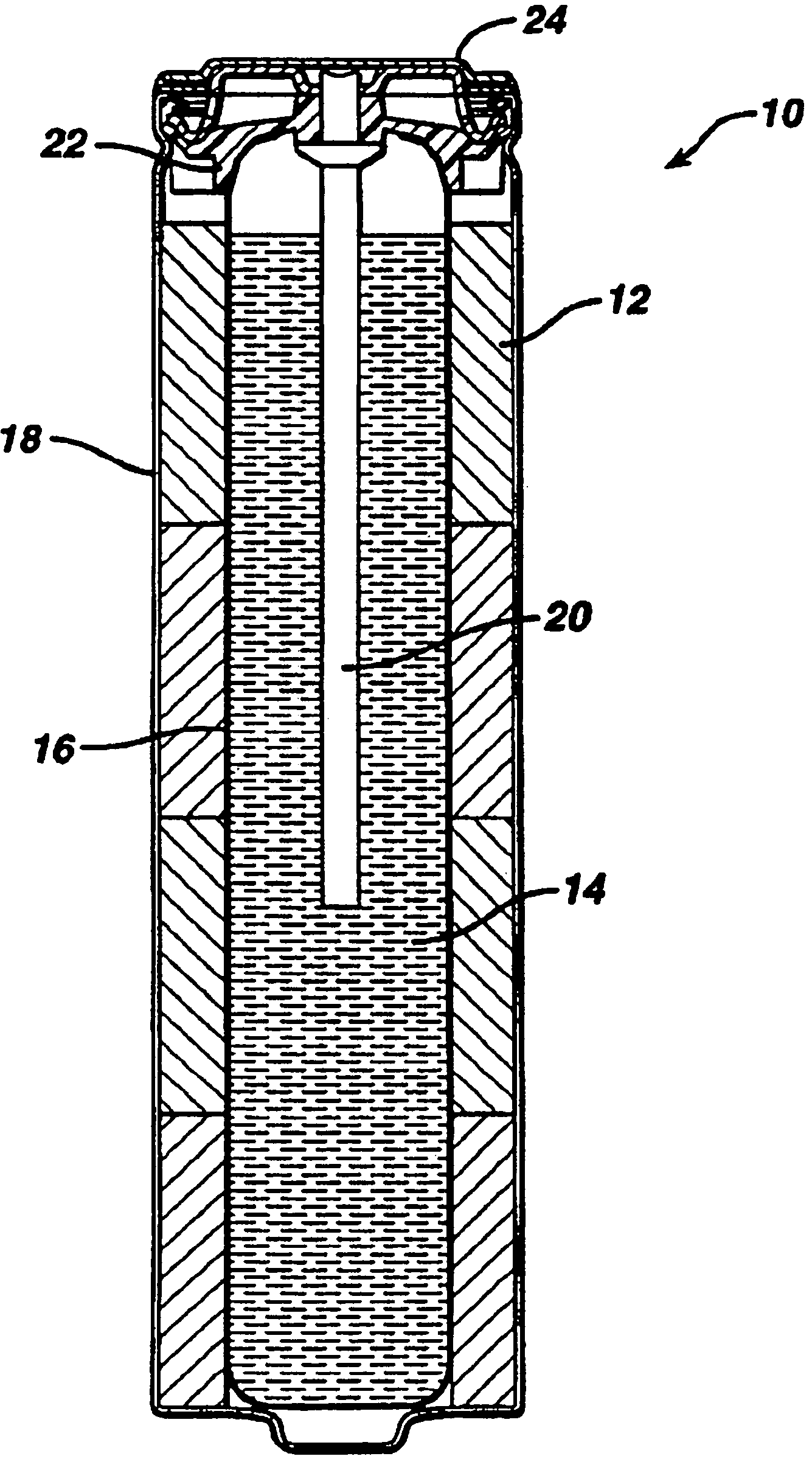

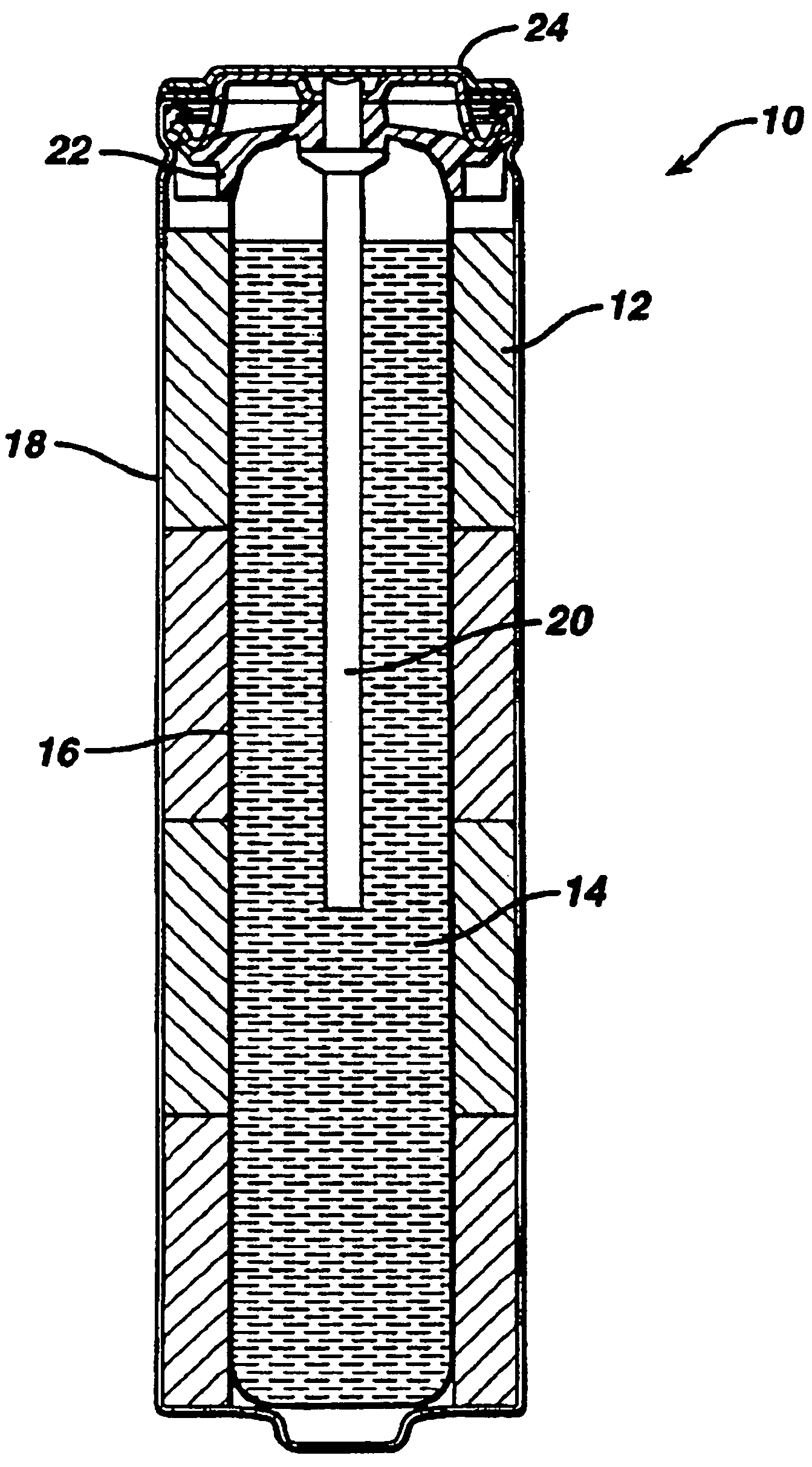

Alkaline battery including nickel oxyhydroxide cathode and zinc anode

InactiveUS20070248879A1Improve discharge performanceHigh capacity retentionActive material electrodesJackets/cases materialsConductive coatingZinc alloys

A primary alkaline battery includes a cathode including a nickel oxyhydroxide and an anode including zinc or zinc alloy particles. Performance of the nickel oxyhydroxide alkaline cell is improved by adding zinc fines to the anode and by including an oxidation resistant graphite in the cathode as well as in a conductive coating applied to the inside surface of the cell housing.

Owner:THE GILLETTE CO

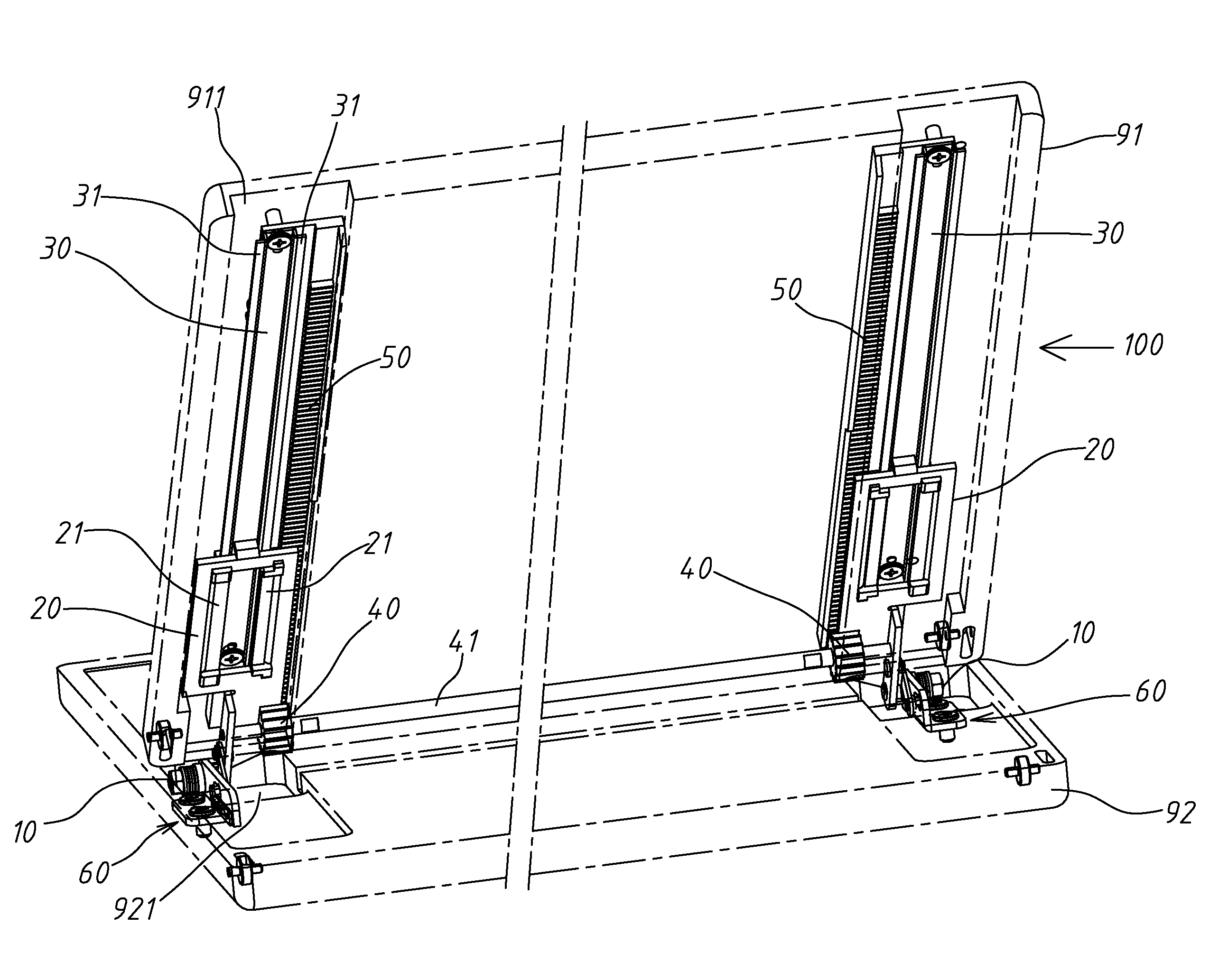

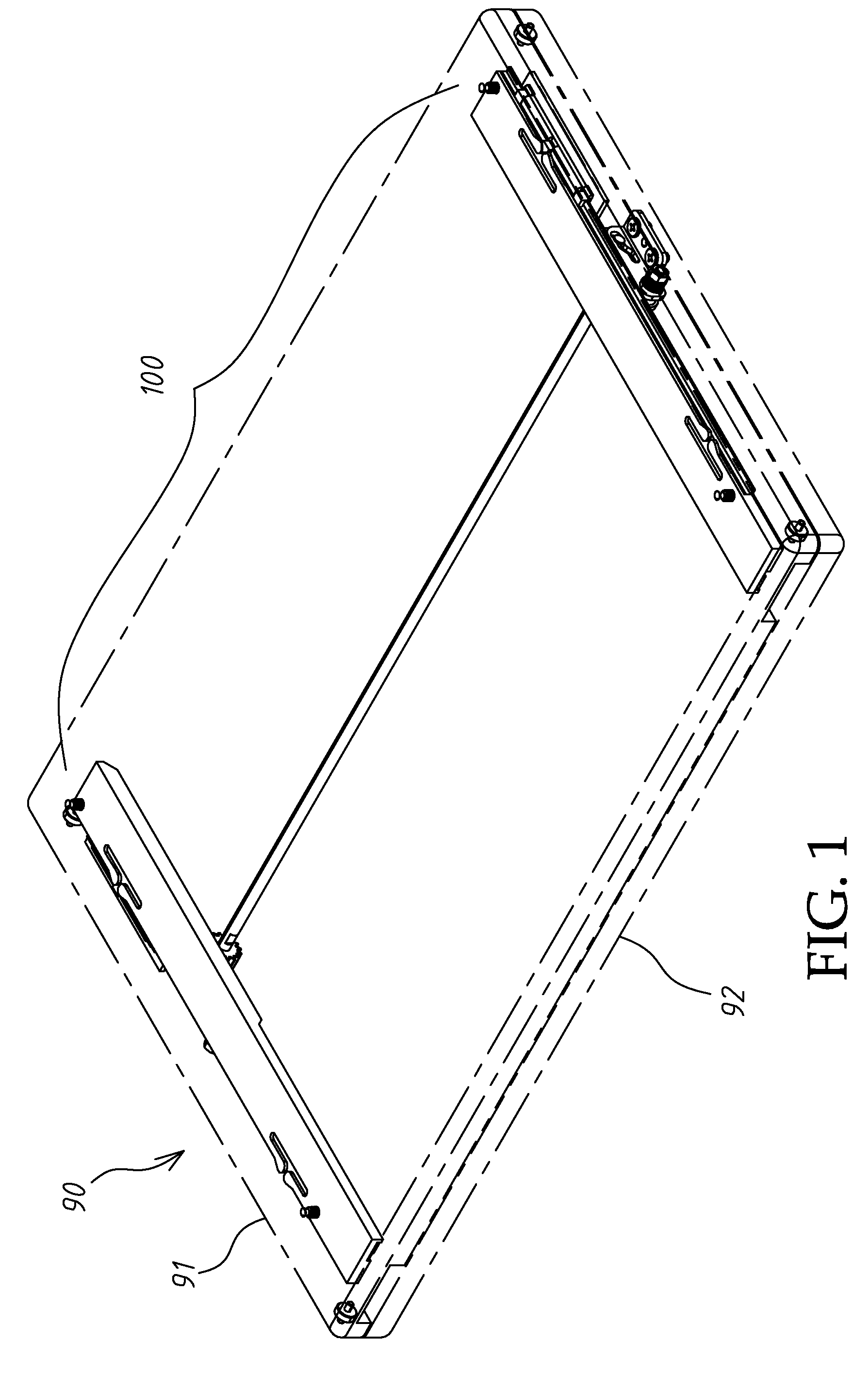

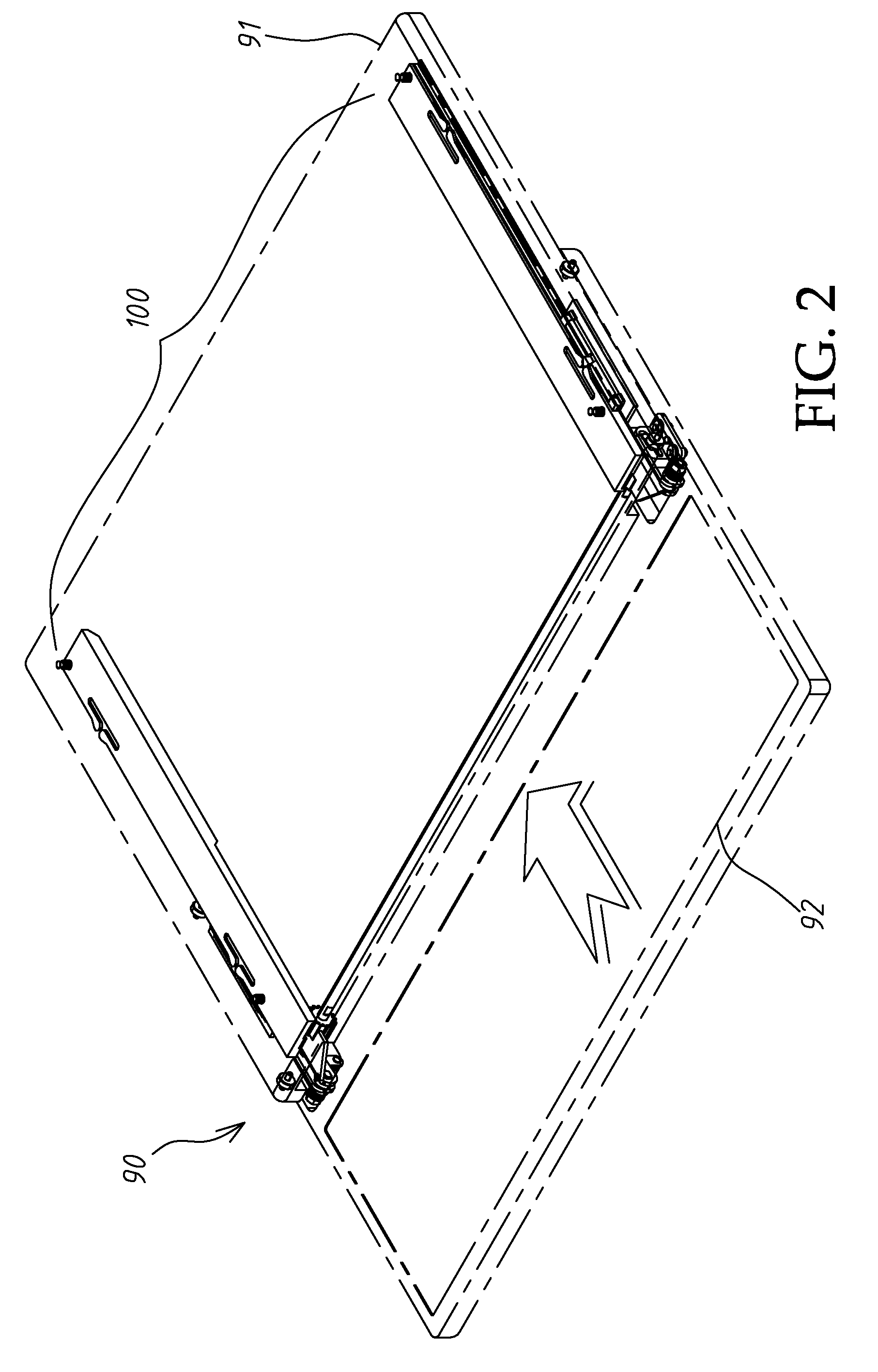

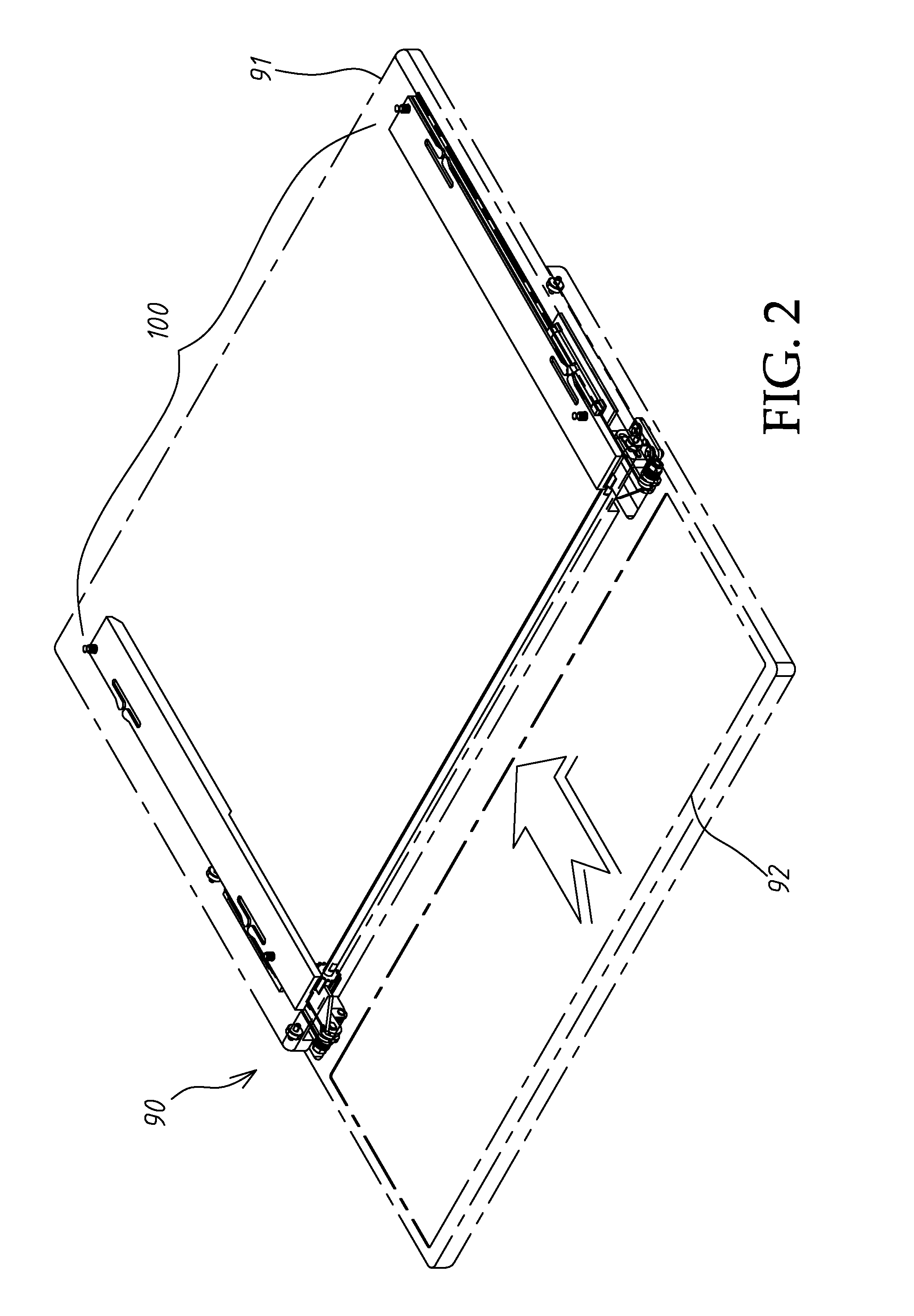

Hinge-slide cover mounting structure using a sheet metal bracket mechanism

ActiveUS8272104B2Reduce weightAvoid noiseDetails for portable computersPin hingesMetal sheetEngineering

A liftable slide cover mounting structure consisting of two hinges, two metal sheet bracket mechanism, two sliding rails, two gears, two gear racks and two supplementary support mechanisms. Subject to the use of the sheet plate bracket mechanisms to hold the sliding rails instead of zinc alloy sliding rail holders, the weight of the liftable slide cover mounting structure is minimized. Further, when the cover panel is opened from the base member, the sheet plate bracket mechanisms are forced into engagement with the supplementary support mechanisms to support the cover panel in position for enabling the user to operate the display screen of the cover panel positively.

Owner:LIANHONG TECH

Al-Zn-Mg-Si alloy for hot dipping steel

InactiveCN101457320AAvoid gatheringDeterioration of surface propertiesHot-dipping/immersion processesRare earthZinc alloys

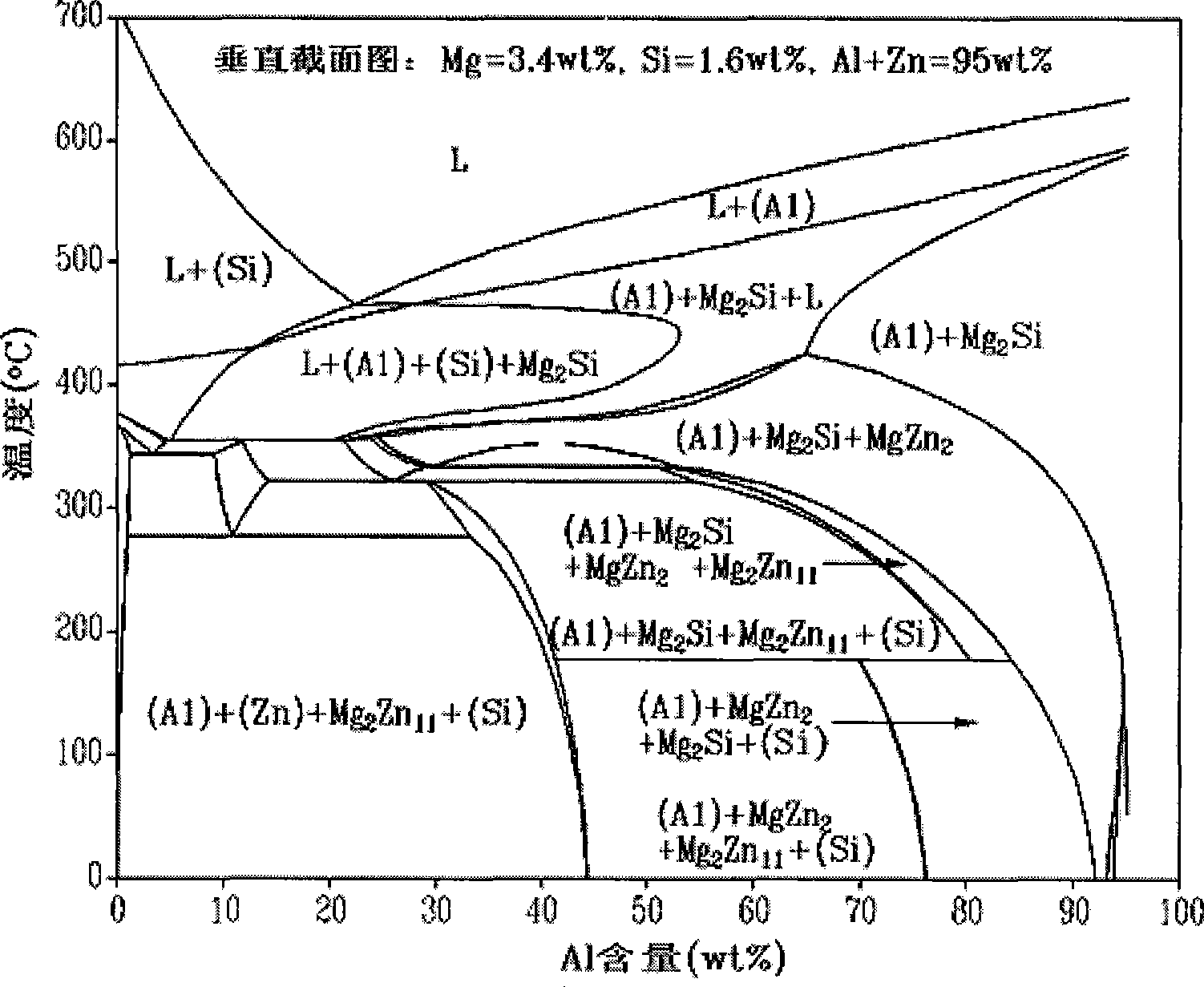

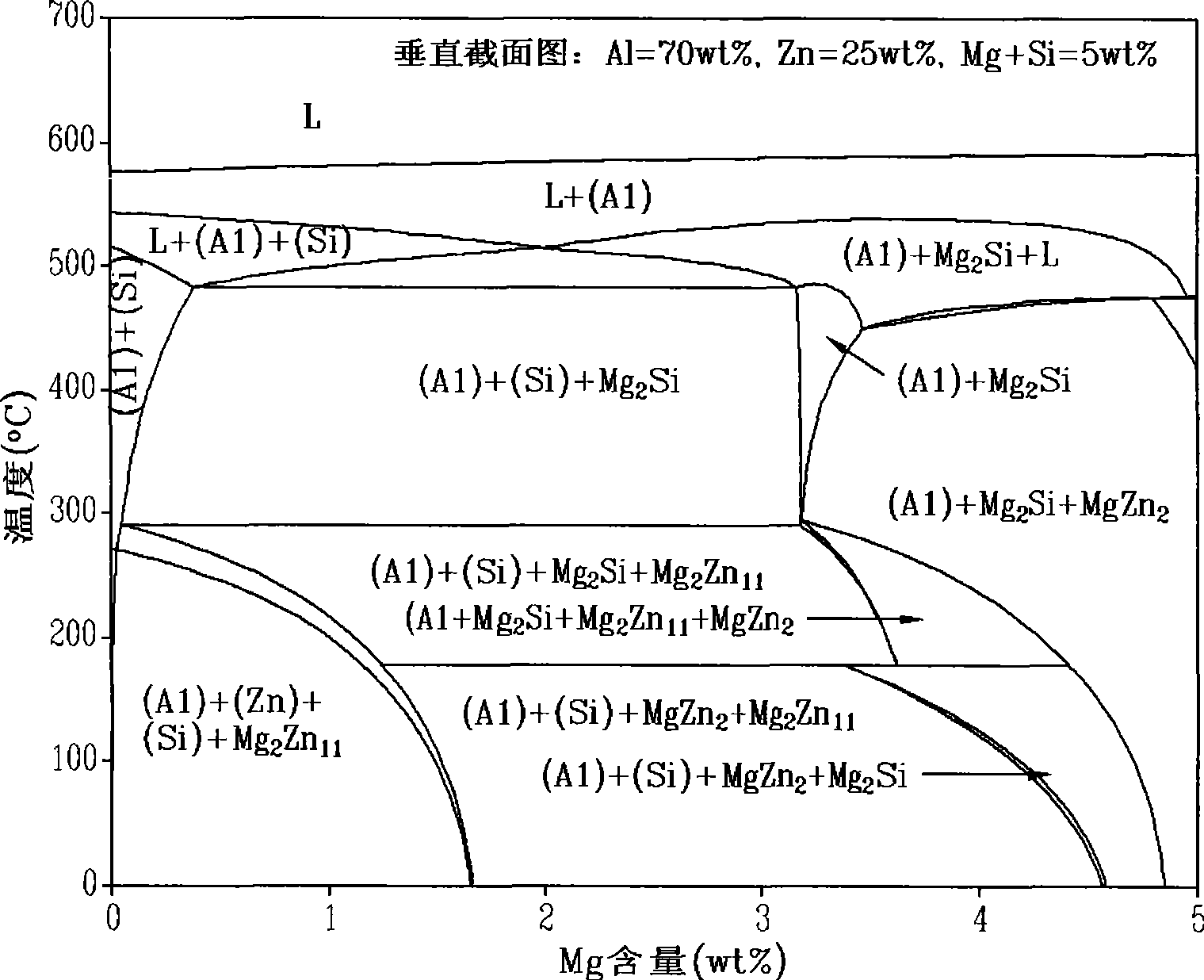

The invention provides a rare earth-containing Al-Zn-Mg-Si alloy with high aluminum content for hot-dipping steel products, comprising the following compositions by weight percent as follows; Al: 50-75%, Mg: 1-5%, Si: 0.5-2.5%, the addition of 0.002-0.1% of Ti, 0.001-0.045% of B and 0.05-1% of rare earth (La or Ce), and the balance of Zn and unavoidable impurities. The invention utilizes corrosion resistance of Mg2Si and grain-refining effect of the rare earth, the Ti and the Bi elements to improve quality of plating solution and obtain a high aluminum content aluminum-zinc alloy cladding with ,a bright and smooth surface and great corrosion resistance property. In addition, the content of aluminum in the alloy is up to 50-75%, thereby lowering production cost.

Owner:SHANGHAI UNIV

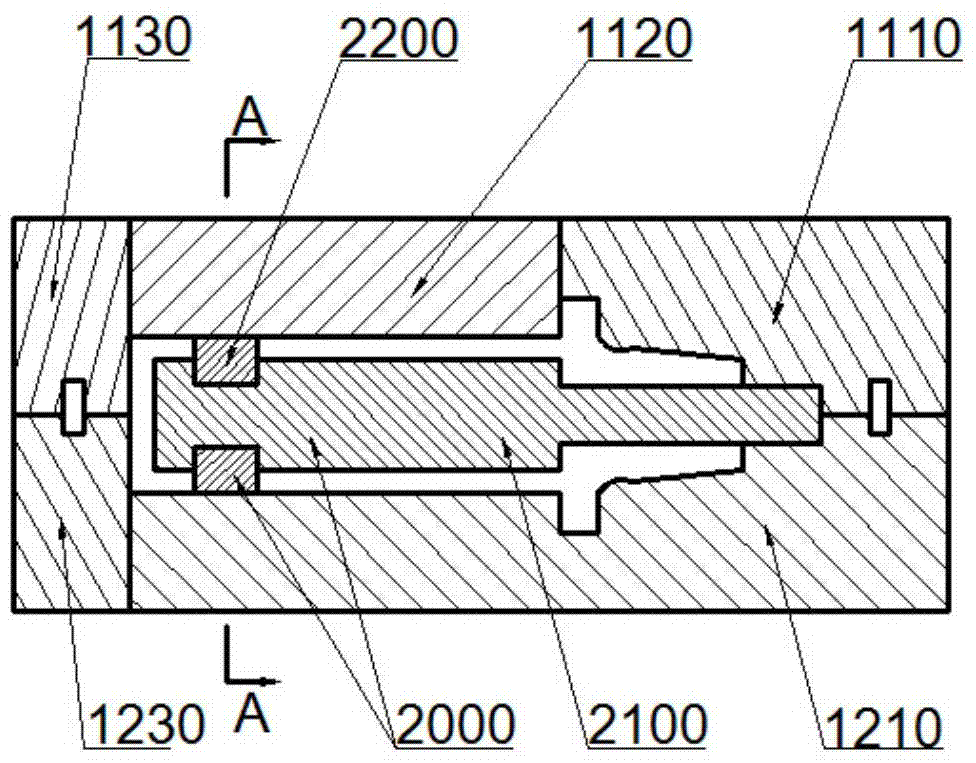

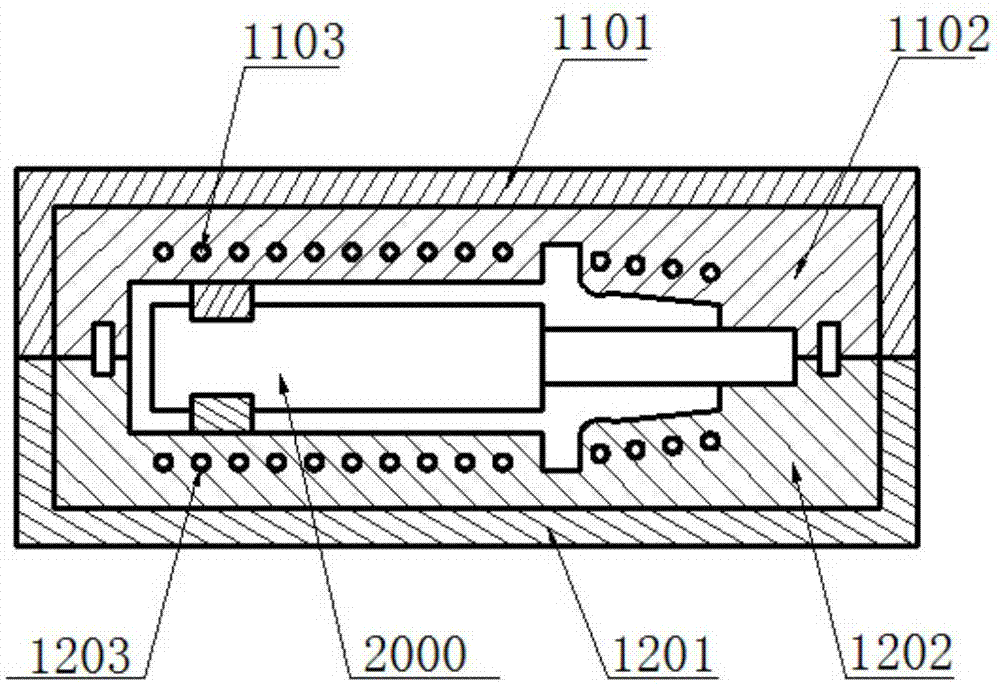

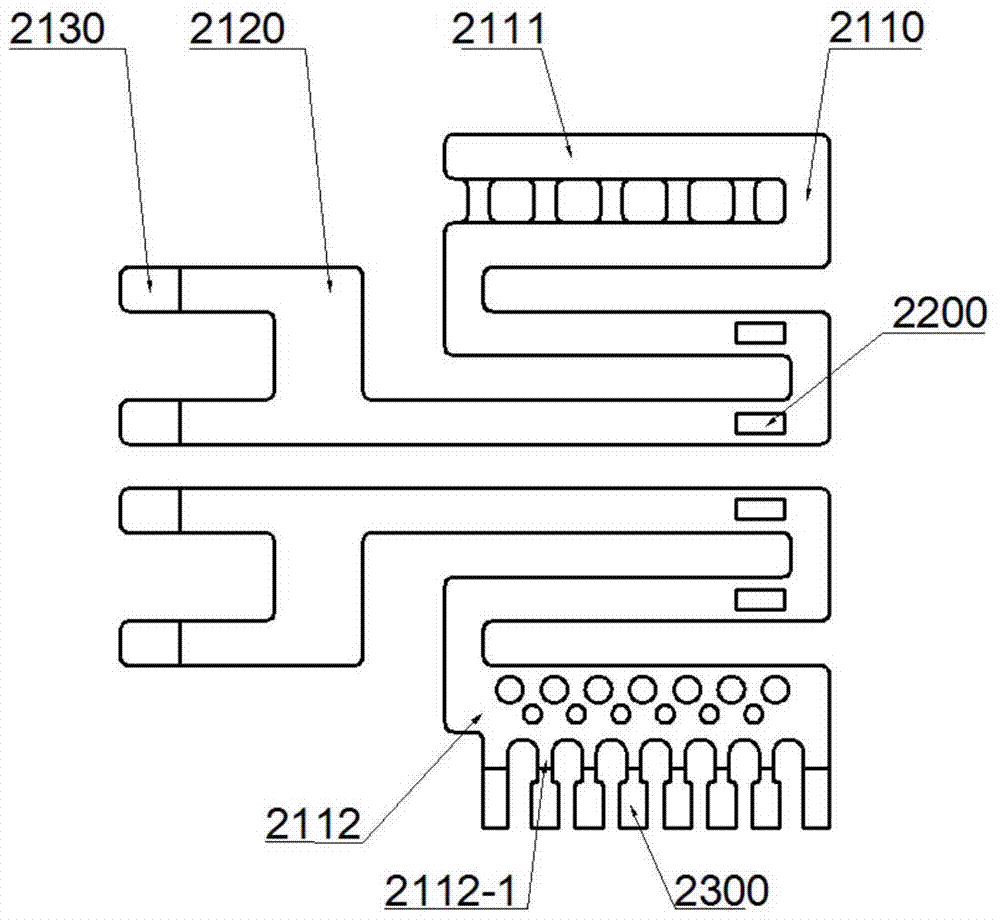

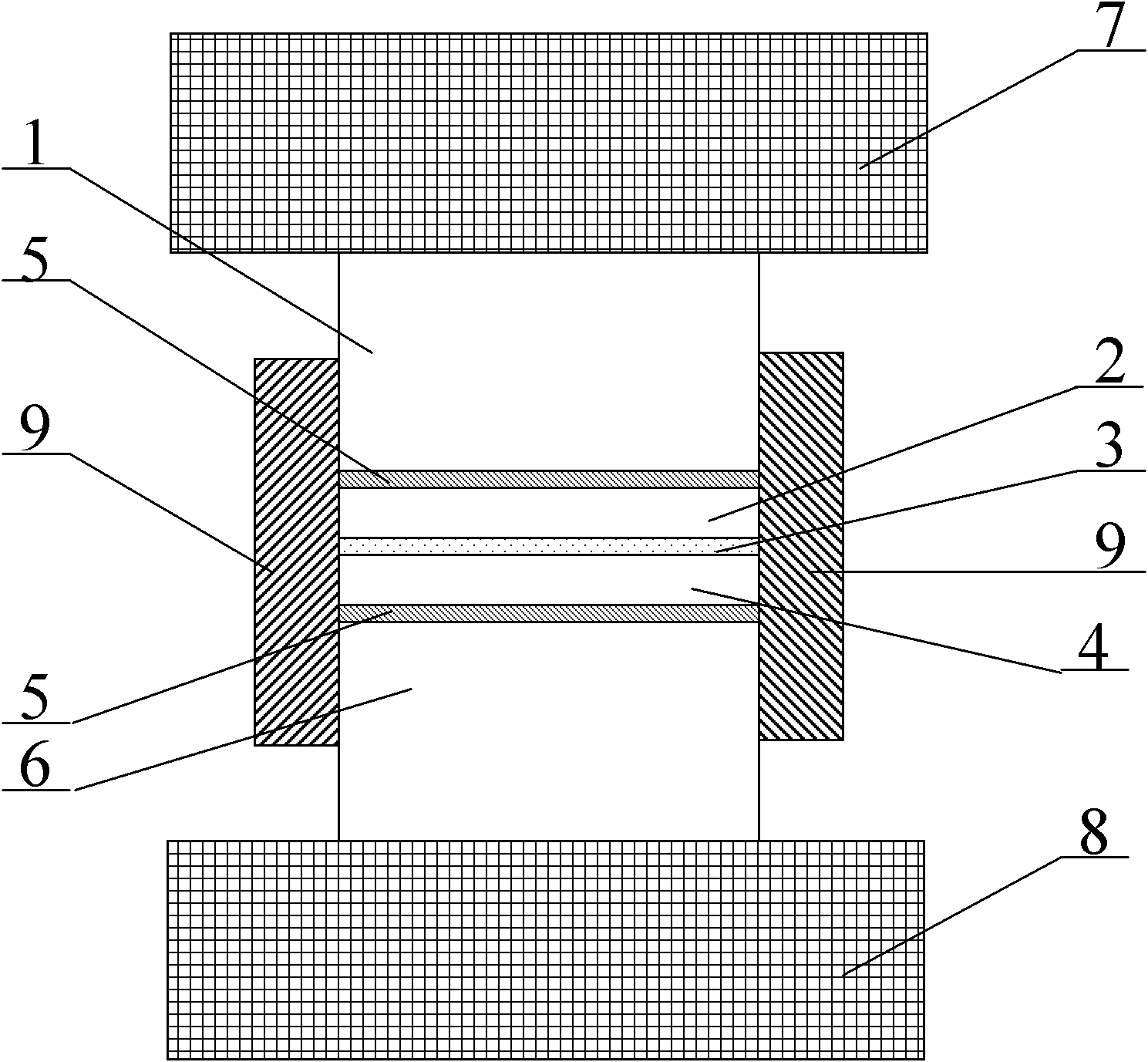

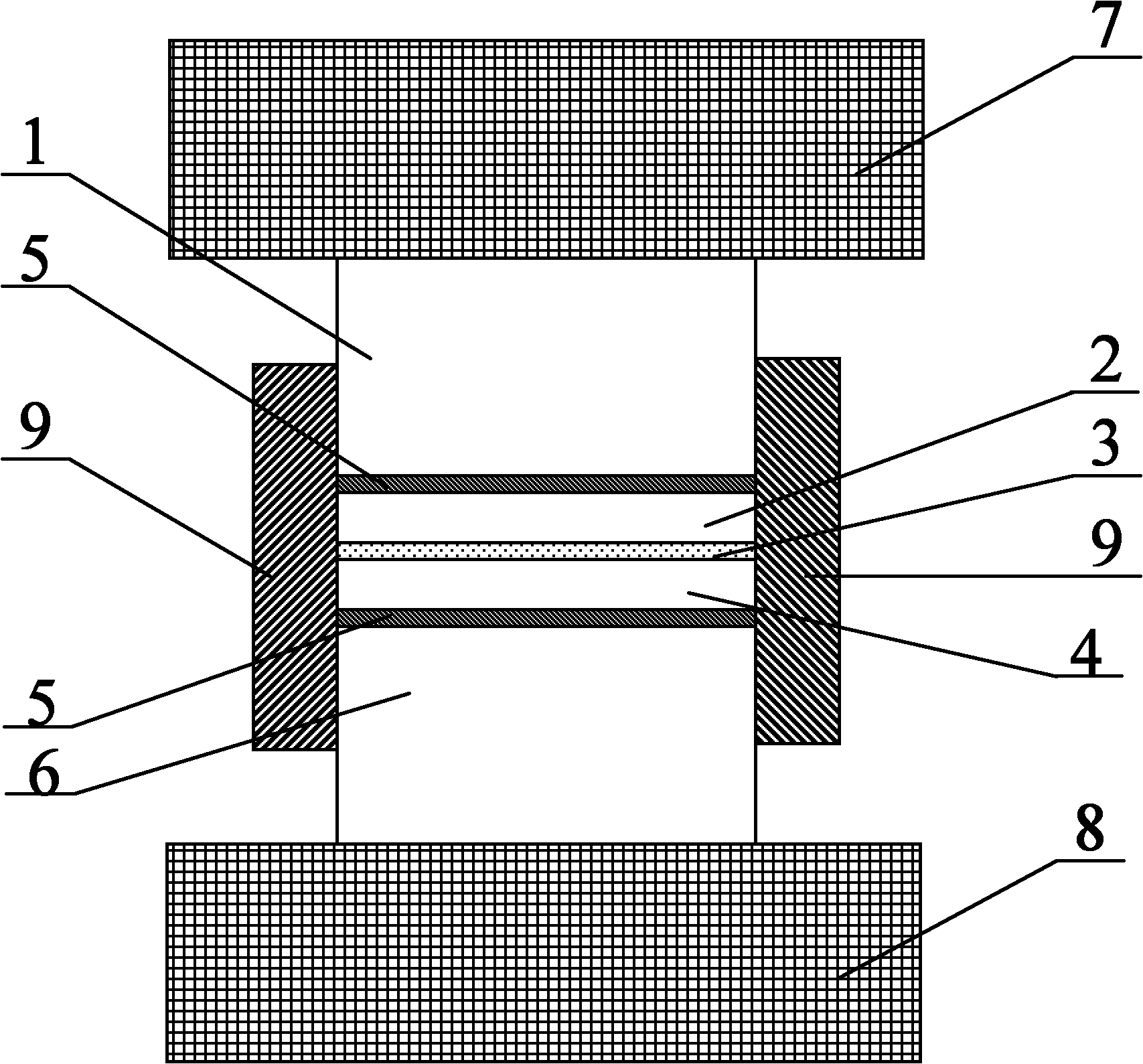

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

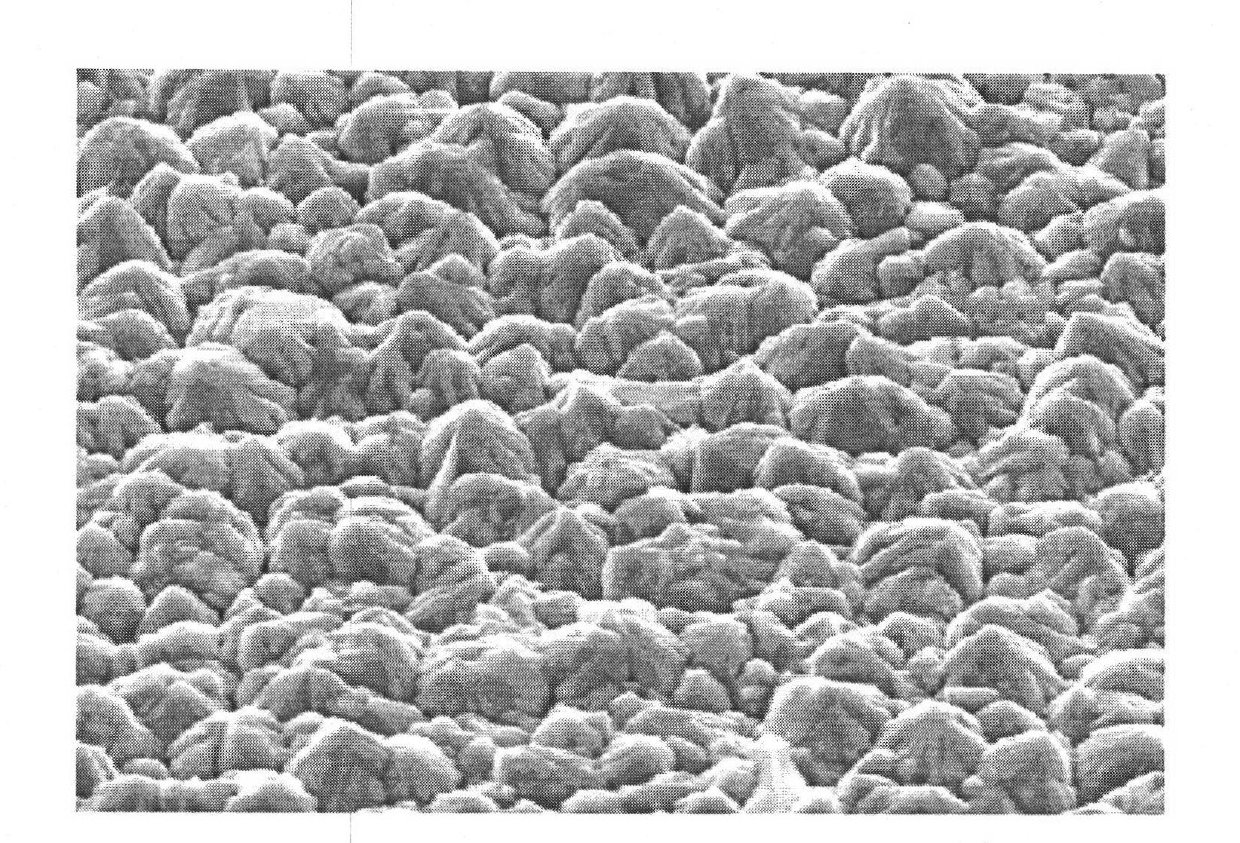

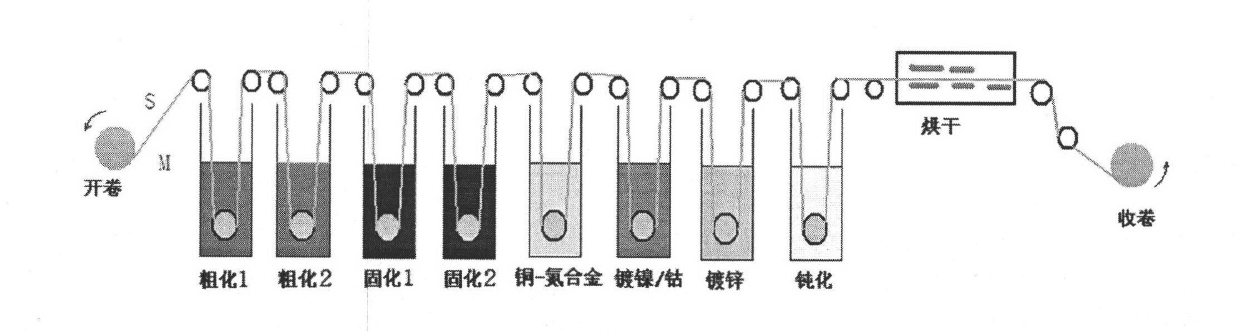

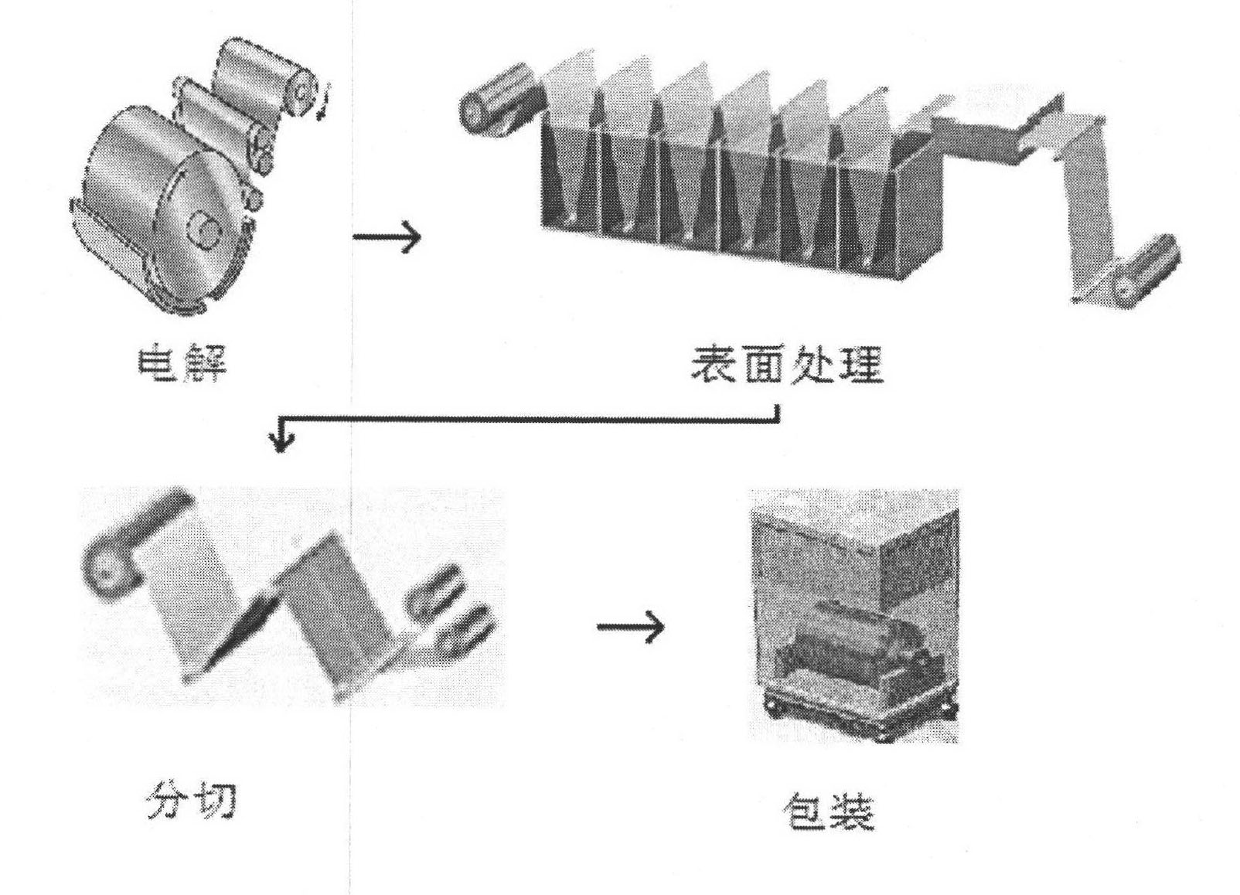

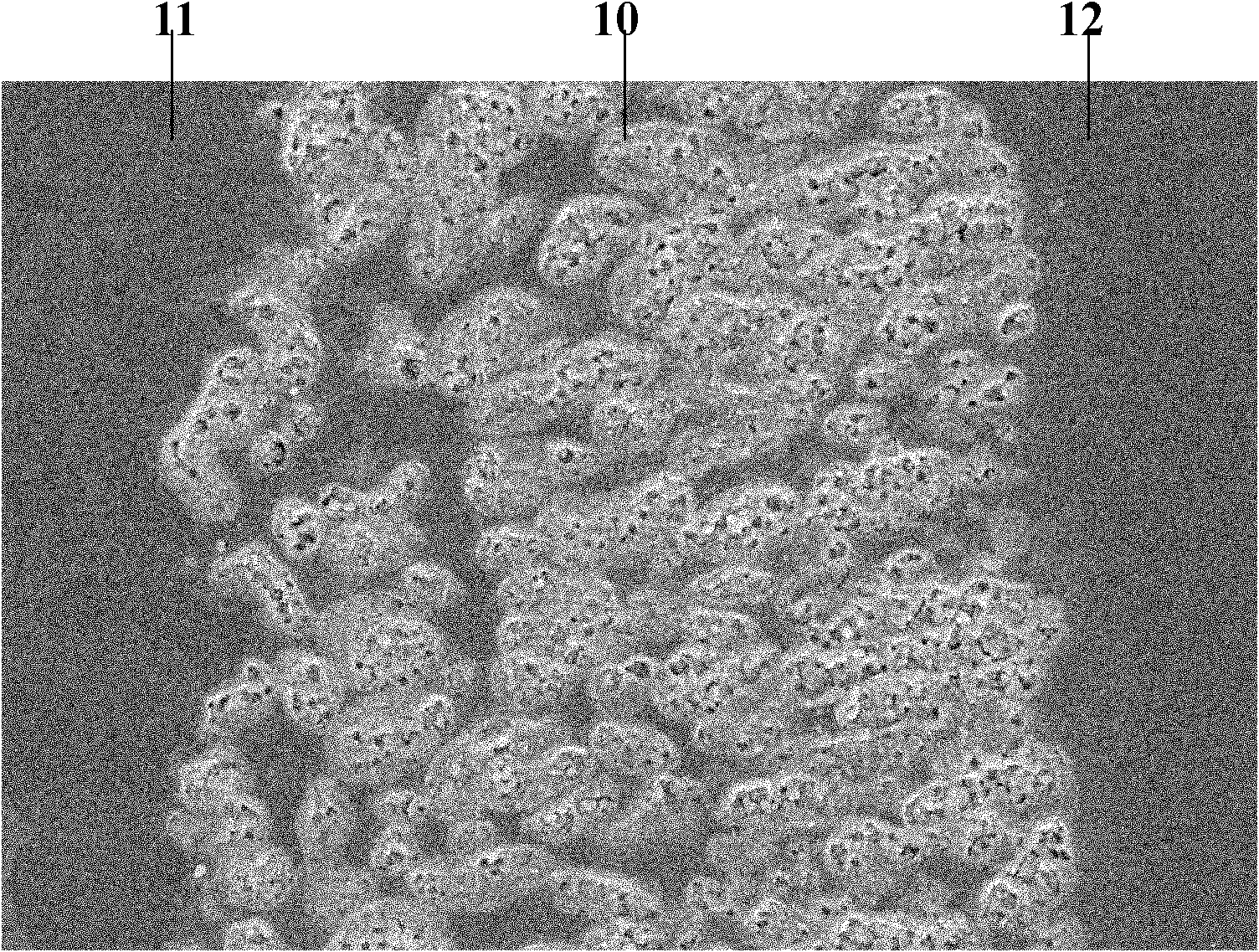

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

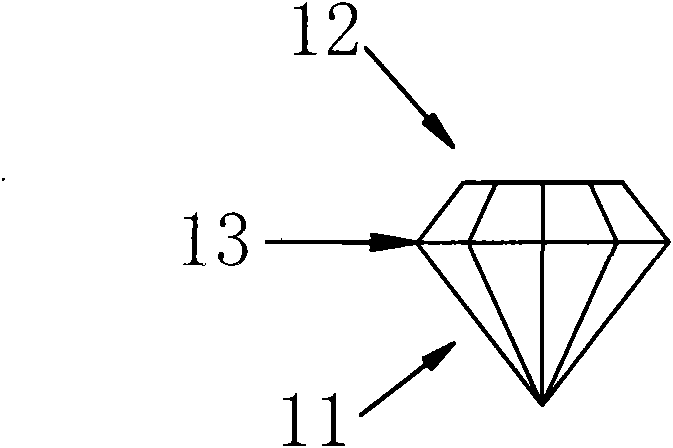

Method for plating surface of rhinestone and plastic-suction disk

ActiveCN101569447AEliminate the deplating processReduce management difficultyMetallic material coating processesJewelleryZinc alloysCopper

The invention discloses a method for plating the surface of a rhinestone. The method comprises the following steps: arranging a plurality of rhinestones in the same direction, and forming a plastic-suction disk by plastic suction, wherein, a plurality of absorption holes are formed on one surface of the plastic-suction disk, and the facial part of the rhinestone is embedded and fixed in the absorption hole; plating the surface of the plastic-suction disk with the embedded rhinestones with a reflection layer, wherein, the reflection layer is a silver, aluminum or chromium layer; coating the surface of the plastic-suction disk with the plated reflection layer with a protection layer, wherein, the protection layer is an anti-tarnishing paint, copper or copper-zinc alloy layer; and separating the rhinestones out from the plastic-suction disk. The invention further discloses a plastic-suction disk. By manufacturing the ground and polished rhinestones into a plastic-suction disk in a plastic-suction forming manner, the rhinestones can be fixed onto the plastic-suction disk, therefore, the plating treatment can be carried out on the entire disk of rhinestones, in this way, the invention can improve the processing efficiency, guarantee the processing quality, reduce the manual operation procedures and reduce the difficulties in plant management.

Owner:虞卫东

Steel sheet having organic coating and method for manufacturing the same

InactiveUS20030072962A1Hot-dipping/immersion processesLiquid surface applicatorsSheet steelZinc alloys

Steel sheet having organic coating comprises: a zinc or a zinc alloy plated steel sheet or an aluminum or an aluminum alloy plated steel sheet; a composite oxide coating formed on the surface of the plated steel sheet and containing at least one metal selected from the group consisting of Mn and Al; and an organic coating formed on the composite oxide coating and containing a rust-preventive additive component.

Owner:NIPPON KOKAN KK

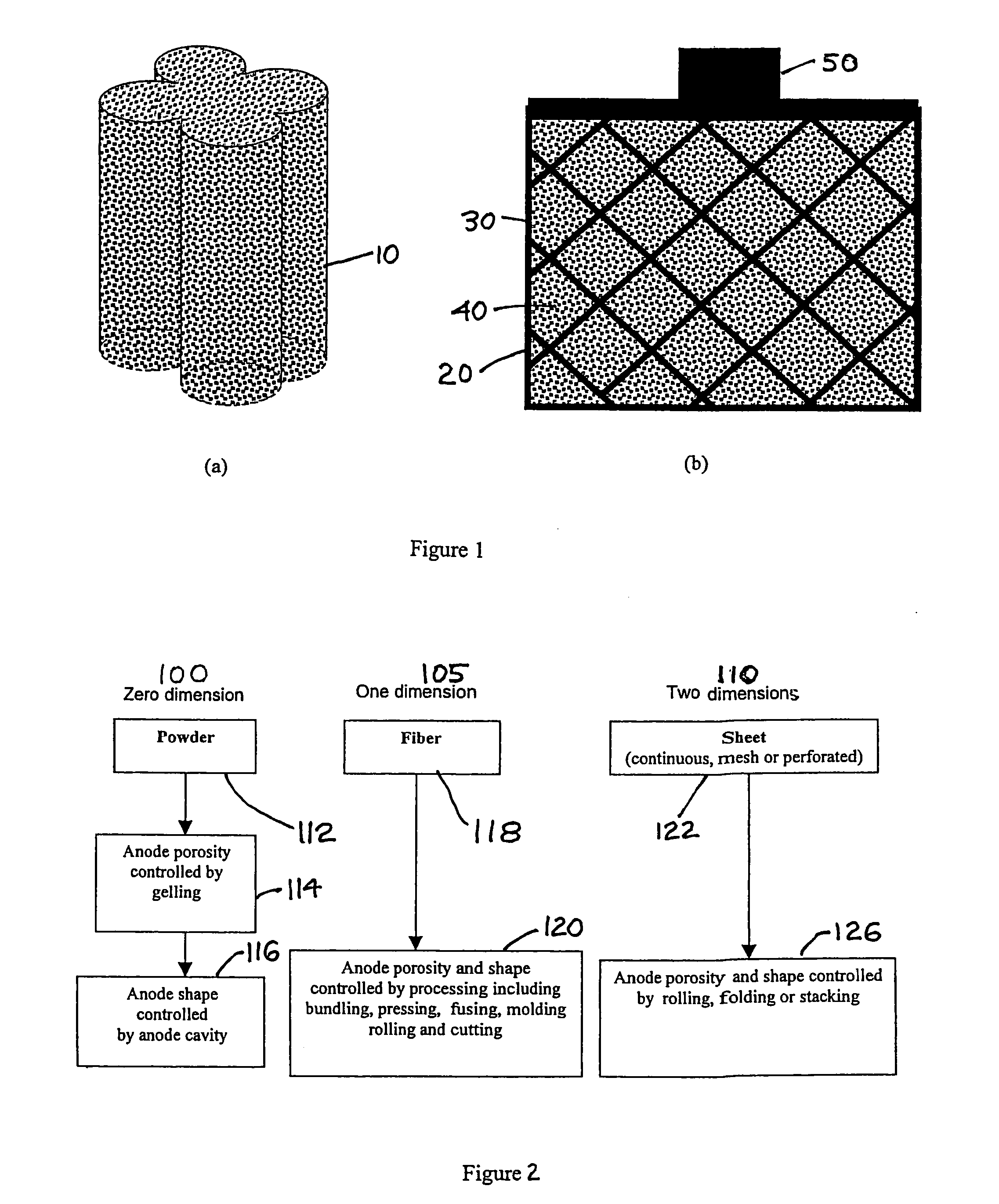

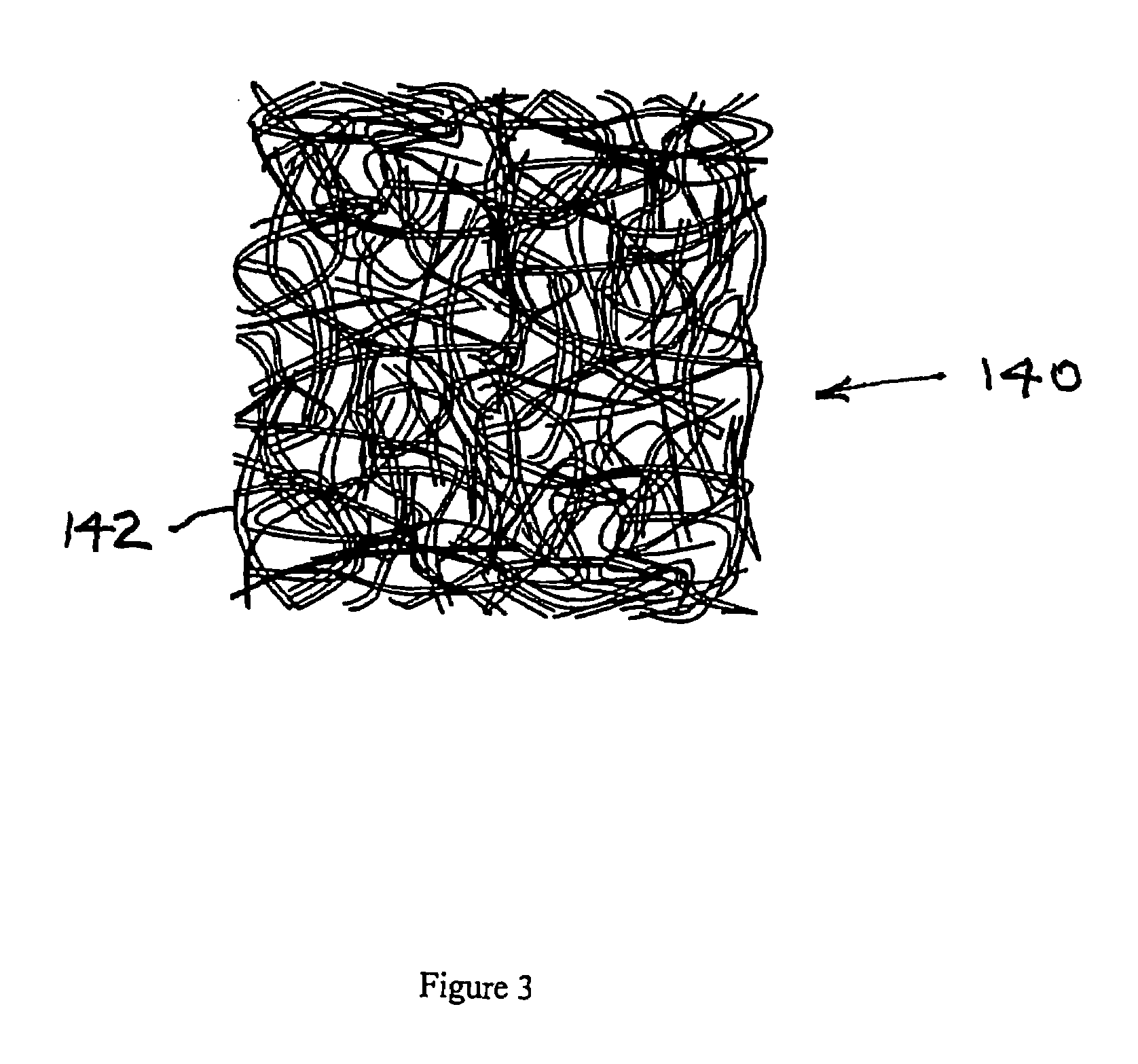

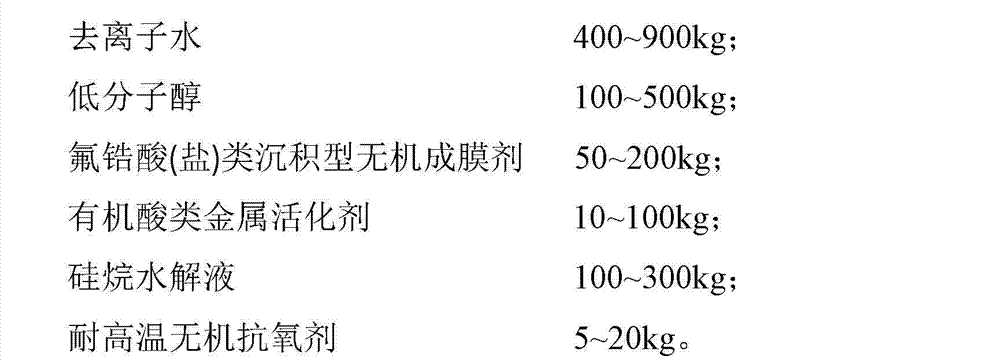

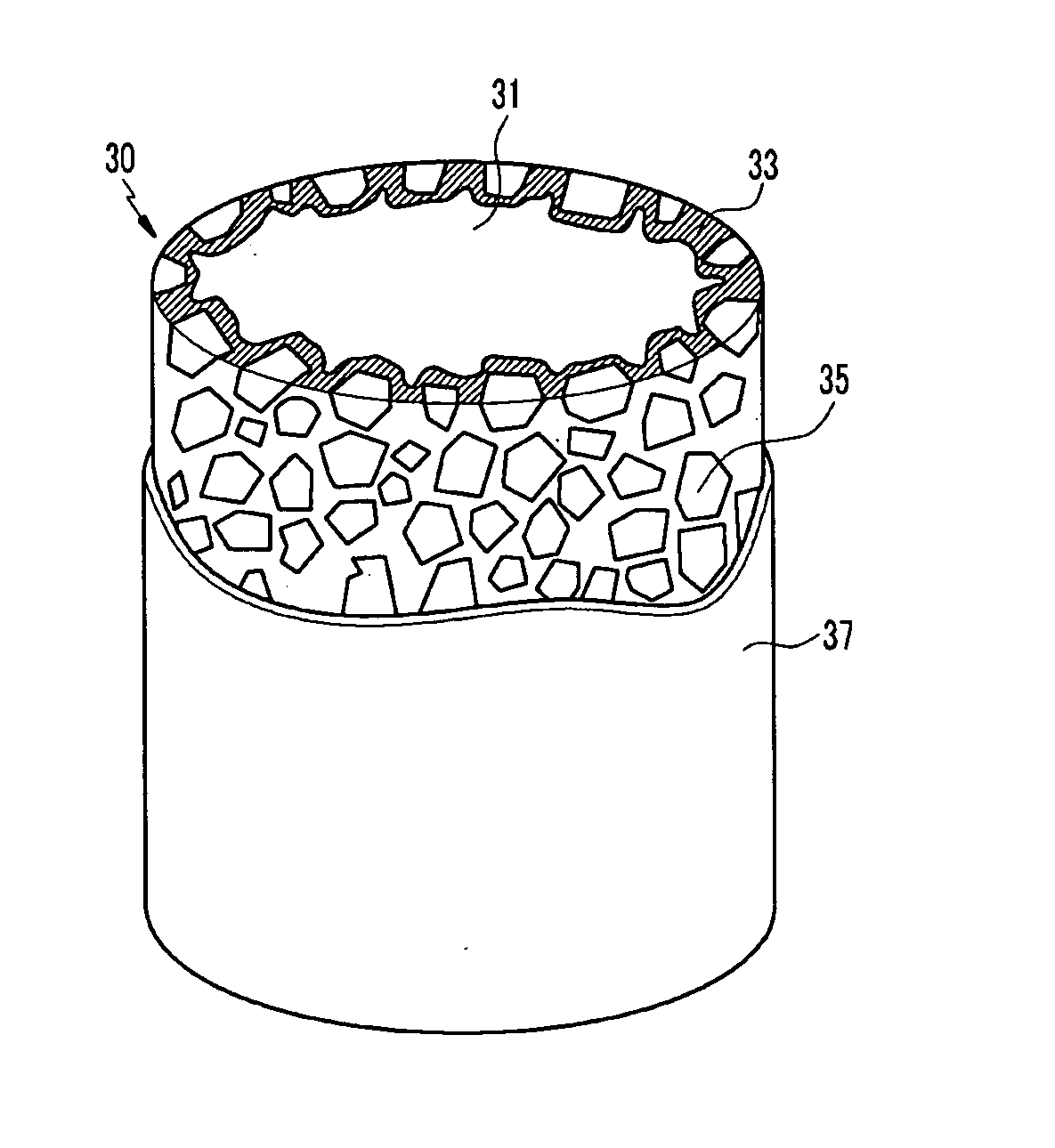

Solid porous zinc electrodes and methods of making same

InactiveUS7291186B2Improve conductivityImprove stabilityFuel and primary cellsAlkaline accumulatorsPorosityFiber

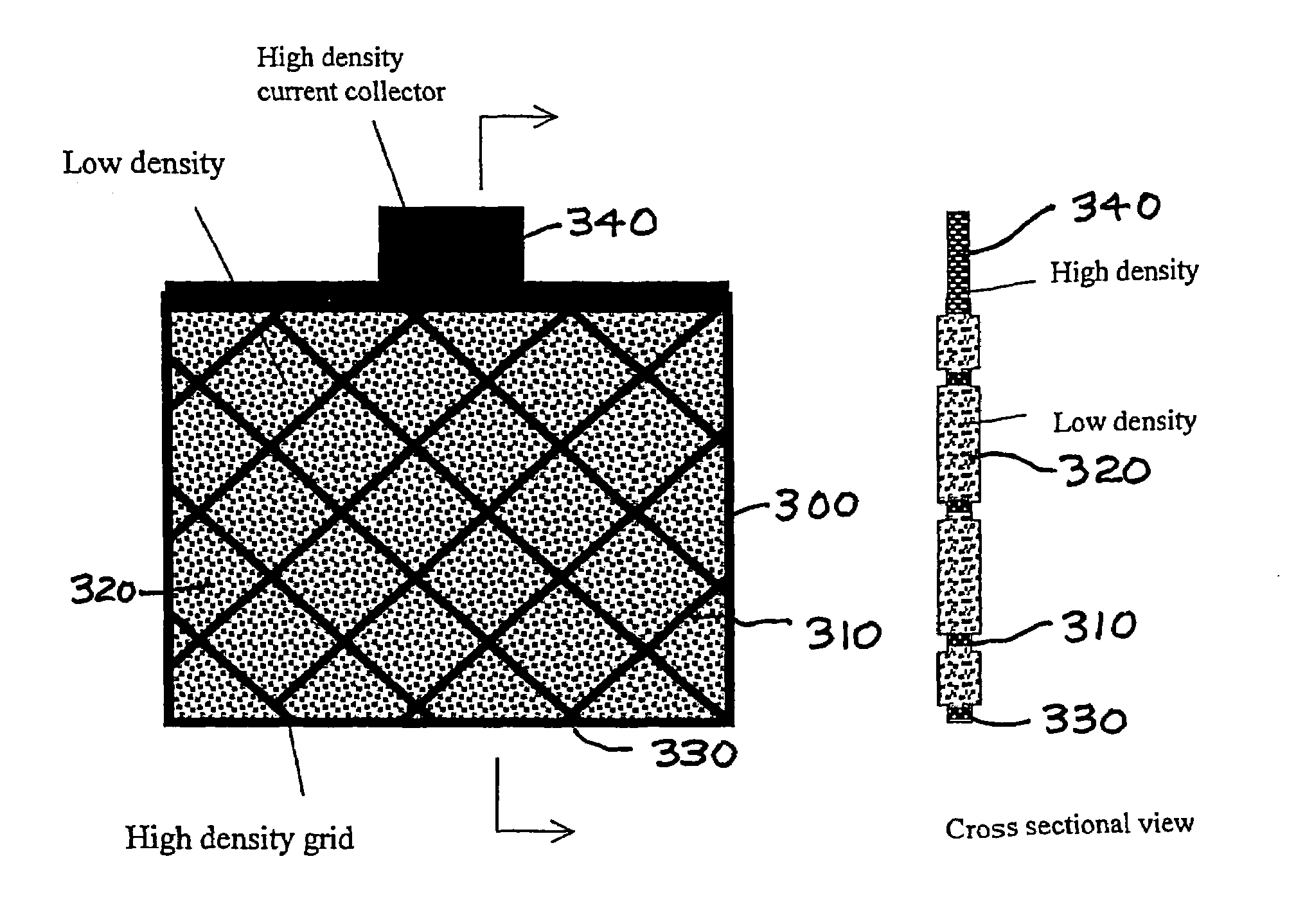

A solid porous zinc electrode for use in alkaline-zinc batteries, zinc-air batteries and fuel cells is provided which comprises specific zinc filaments, fibers, threads or strands compressed into a physically-stable wooly mass to form the electrode with a controlled geometrical shape and porosity distribution. Differential densification incorporates ribs, borders, grids or tabs for good structural integrity, mechanical strength, electrochemical behavior, and electrical conductivity. Pressing in a mold or rolling of a compressed sheet can also provide an anode with a large anode / cathode interface area and a complex geometry. The filaments of controlled dimension and composition are preferably made by spin forming from molten zinc alloys. Such anodes are not susceptible to breakage, have a long storage life and can be used in high rate discharge applications.

Owner:TECK METALS

Anti-corrosion high-toughness zinc alloy implant material capable of being absorbed by human body

ActiveCN103736152AGood matching of mechanical propertiesImprove mechanical propertiesSurgeryTissue regenerationSide effectZinc alloys

The invention relates to an anti-corrosion high-toughness zinc alloy implant material capable of being absorbed by a human body. The anti-corrosion high-toughness zinc alloy implant material comprises the following elemental constituents by mass percent: 0.001-2% of Ce, 0.001-2% of Mg, 0.001-2% of Ca, 0.01-3% of Cu, and the balance of Zn. The zinc alloy material is prepared into a medical implant with absorbability by using a conventional method in the field, especially an intravascular stent, and orthopedic implants (a nail or bone lamella and the like). The zinc alloy material created by the invention has high corrosion resistance and high toughness, and the prepared medical implant can be absorbed by the human body, and is free of a side effect.

Owner:XIAN ADVANCED MEDICAL TECH

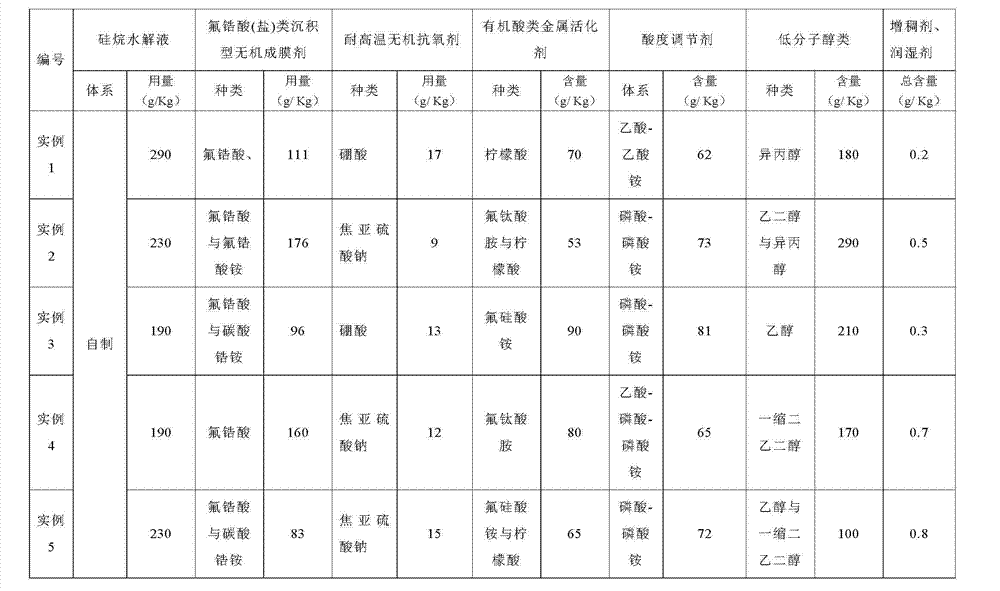

Non-chrome purified liquid

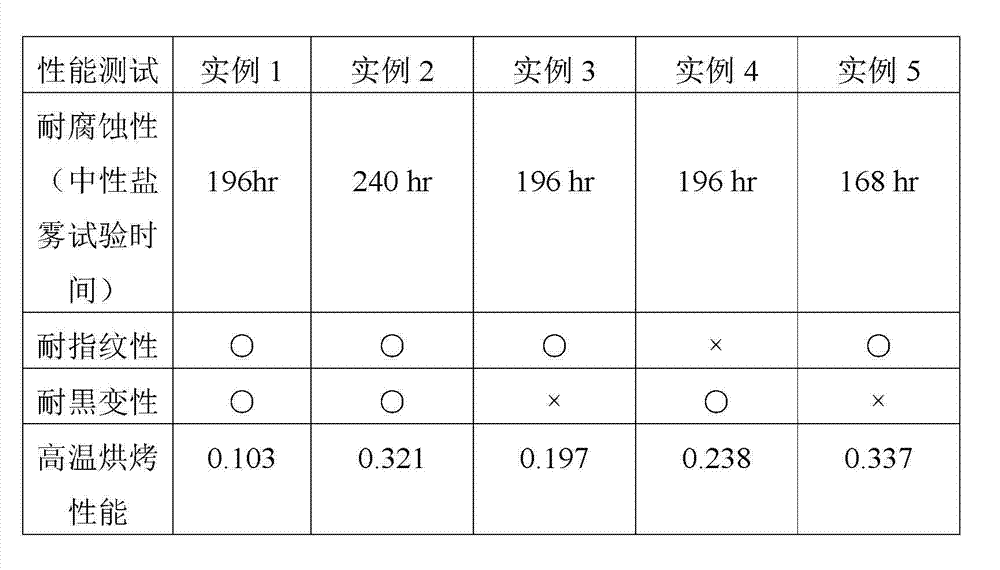

ActiveCN103205738AImprove corrosion resistanceGood resistance to high temperature yellowing propertiesMetallic material coating processesAntioxidantSilanes

The invention discloses a non-chrome purified liquid. Components of each 1000kg of the non-chrome purified liquid include: 400-900kg of deionized water, 100-500kg of low molecular weight alcohol, 50-200kg of zirconium-fluoride-acid (salt) type sedimentary inorganic film-forming agent, 10-100kg of organic-acid type metal activator, 100-300kg of silane hydrolyzate and 5-20kg of high-temperature-resistant inorganic antioxidant. The non-chrome purified liquid is good in corrosion resistance, has good high-temperature and xanthochroia resisting features since the high-temperature-resistant inorganic antioxidant is added in without organic aqueous resin, is adaptable to surface passivation processing of galvanized and aluminum-zinc alloy plated type metal products, and is further adaptable to surface passivation processing of galvanized plates (the galvanized plates for computer cases and the like) with special requirements for high-temperature and xanthochroia resisting features.

Owner:武汉钢实硅钢浩源润滑油有限公司

Alkaline battery including nickel oxyhydroxide cathode and zinc anode

ActiveUS7273680B2Improve discharge performanceHigh capacity retentionActive material electrodesJackets/cases materialsZinc alloysNickel

Owner:DURACELL U S OPERATIONS

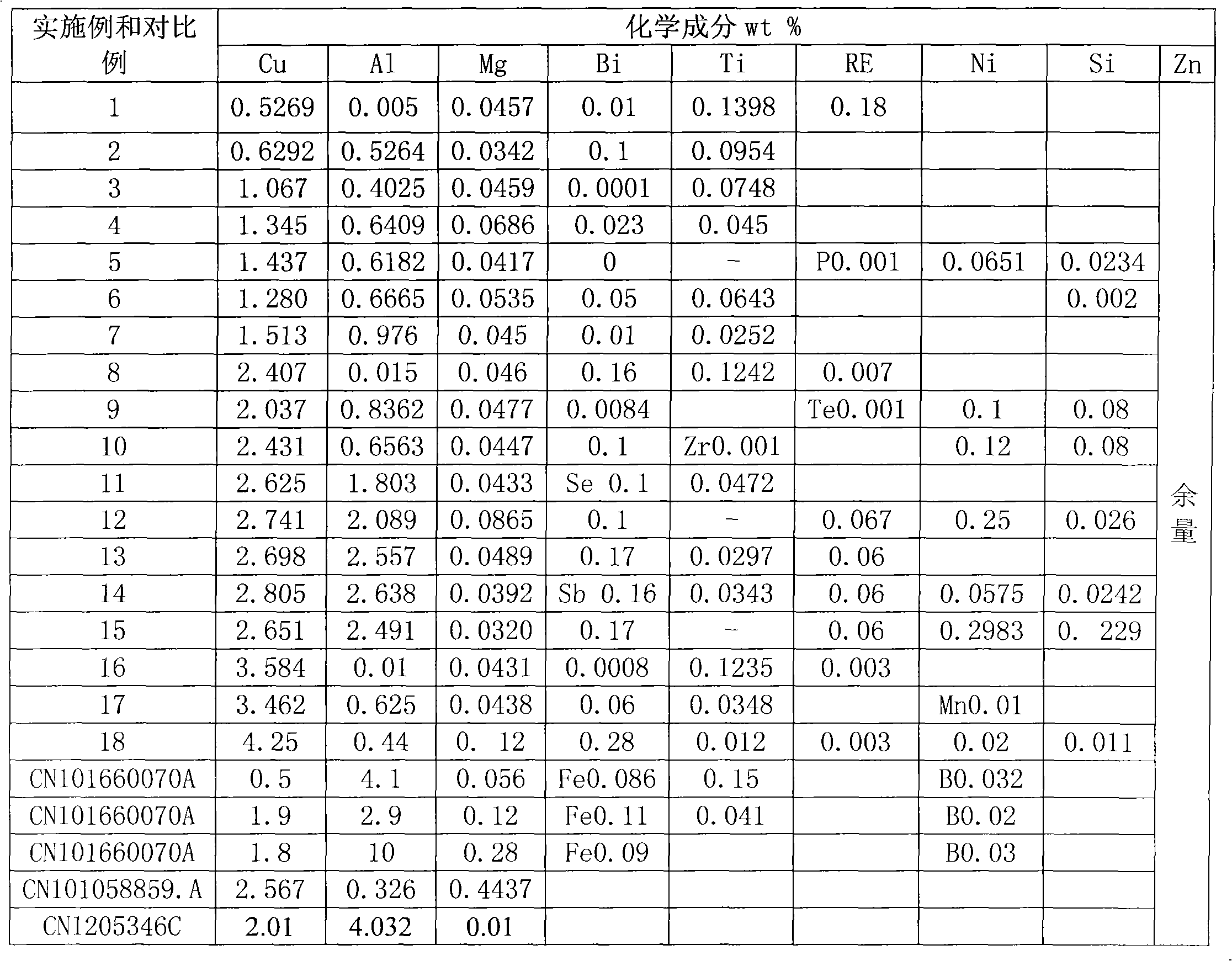

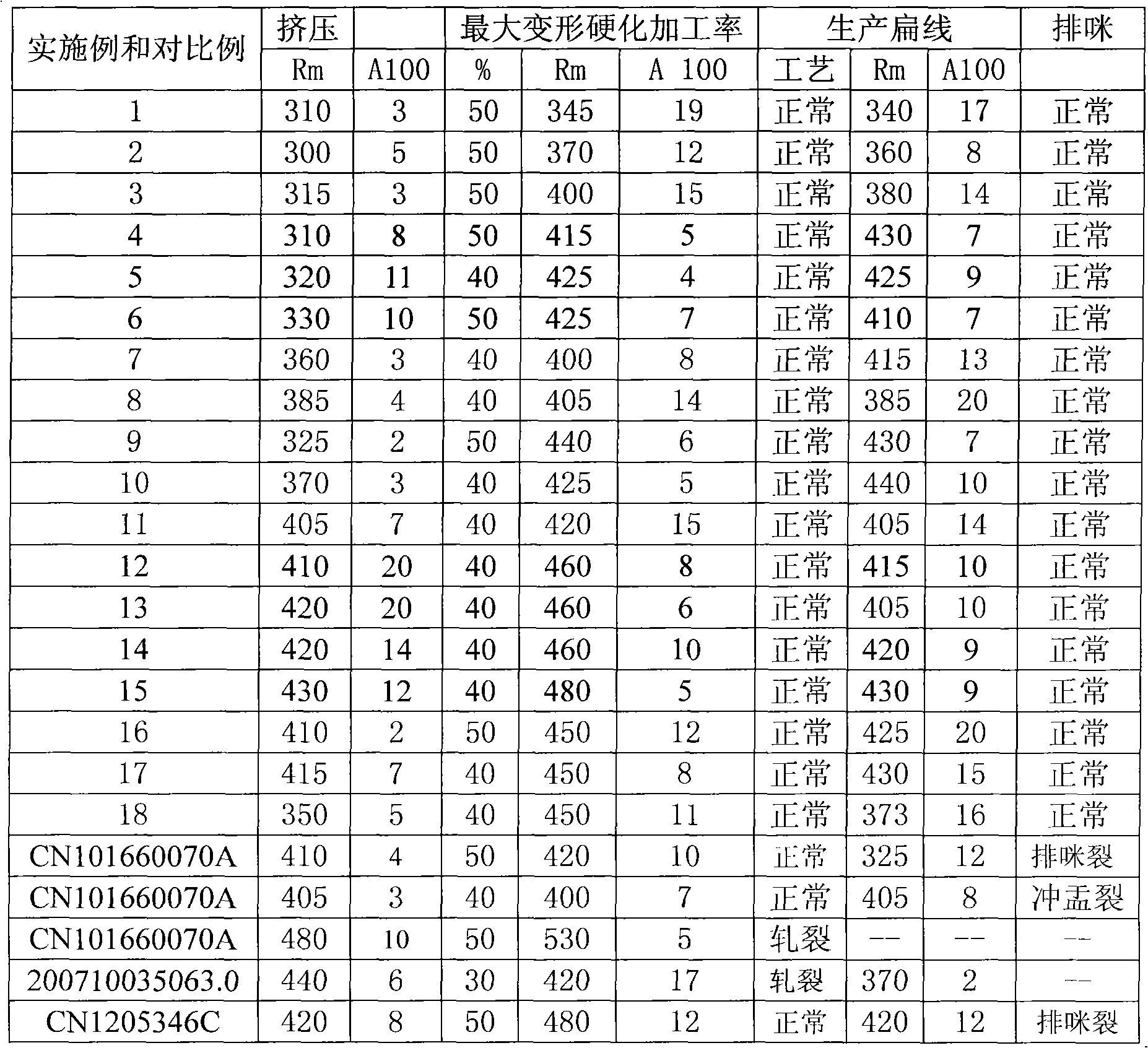

Zinc alloy for zipper tooth belt and preparation method of zipper tooth belt

ActiveCN102011029AOvercoming difficult deformationMeet the mechanical performance requirementsSlide fastenersZinc alloysImpurity

The invention discloses a zinc-alloy zipper tooth belt produced by a row microphone method, in particular to zinc alloy for a zipper tooth belt and a preparation method of the zipper tooth belt. The alloy comprises the following components by weight percent: 0.5-5% of Cu, 10-4.5% of Al, 0.01-0.2% of Mg and the balance of X, Y, Zn and unavoidable impurities, wherein the sum of the percentages of the components is 100%; the X is selected from at least one of 0.0001-0.5% of Bi, 0.01-0.19% of Ti, 0.001-0.3% of RE, 0.001-1% of Ni and 0.001-1% of Si; and Y is selected from at least one of Mn, Co, Nb, Zr, Cr, Ca, P, Sb, Te and Se. By adopting the deformed zinc alloy and the alloy producing method disclosed in the invention, the production of the zipper line can be met, and the zipper tooth belt can be produced smoothly by the row microphone method; and the produced zipper can be processed into different colors.

Owner:NINGBO POWERWAY ALLOY MATERIAL

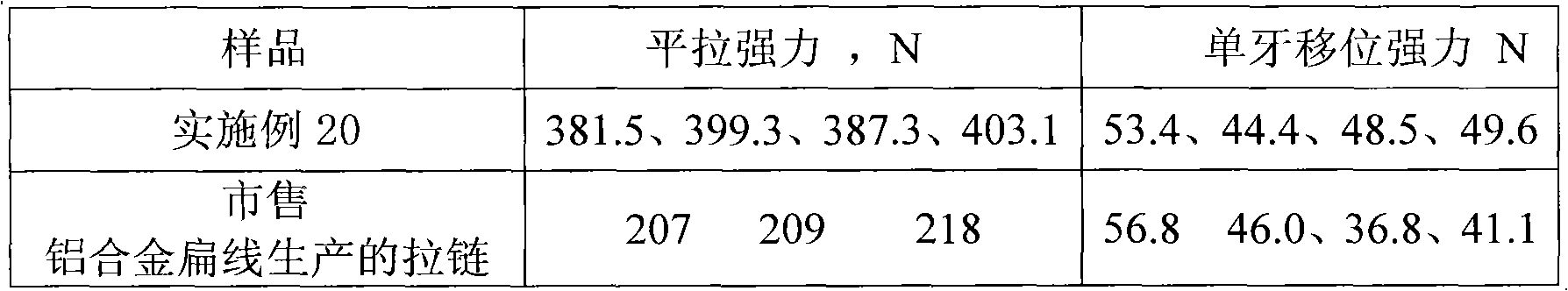

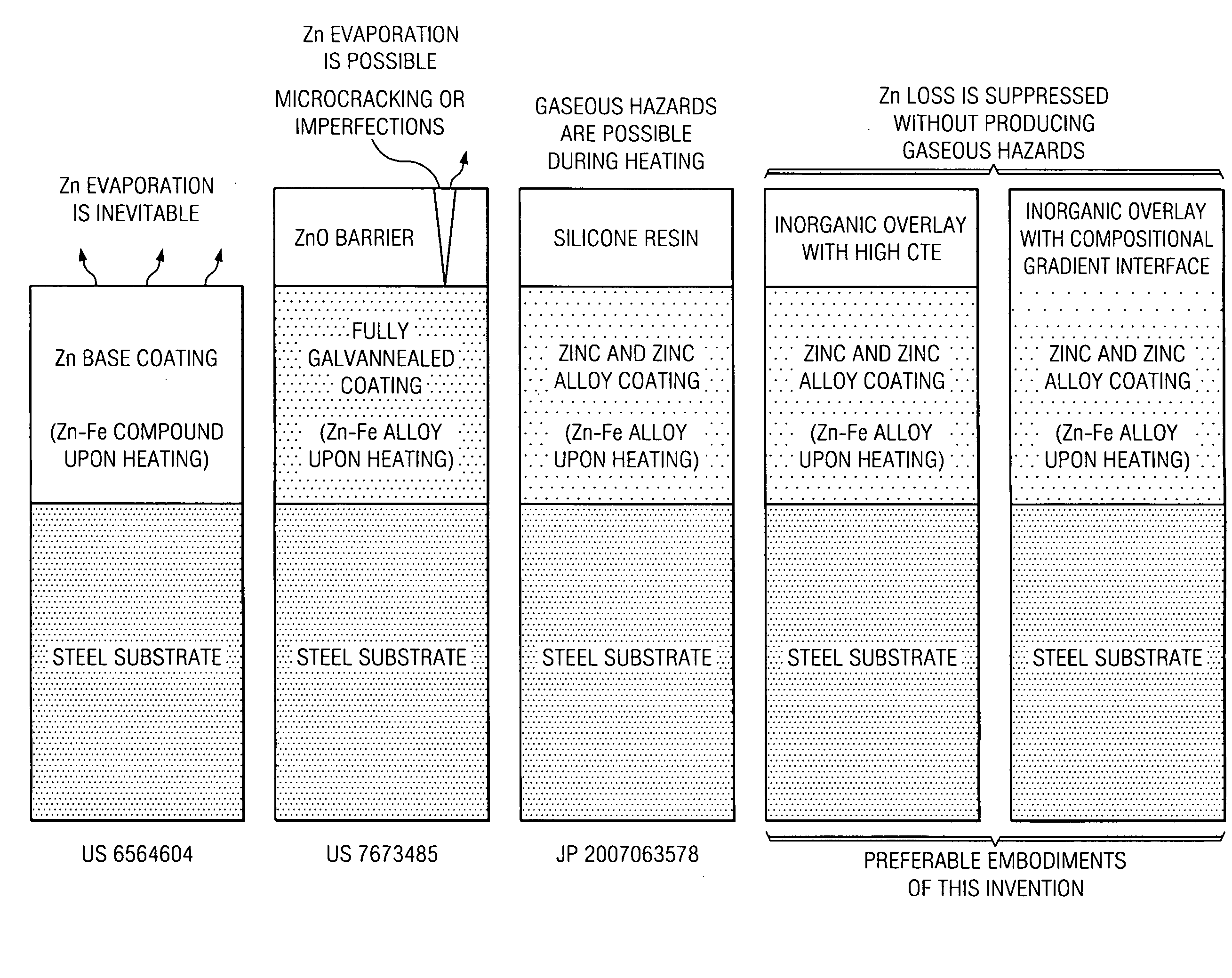

Zinc coated steel with inorganic overlay for hot forming

InactiveUS20120118437A1Retard and restrict lossReduce hardnessHot-dipping/immersion processesPretreated surfacesTungstatePhosphate

The present invention is of zinc or zinc alloy coated steel for hot forming having an inorganic overlay covering the zinc or zinc alloy coating to prevent loss of zinc during heating and hot forming. In one embodiment, the inorganic overlay has a coefficient of thermal expansion greater than the coefficient of thermal expansion of zinc oxide. In another embodiment, the inorganic overlay has a compositional gradient interface with the zinc or zinc alloy coating. Preferably the inorganic overlay may be comprised of material selected from phosphates, oxides, nitrates, carbonates, silicate, chromate, molybdate, tungstate, vanadate, titanate, borate, fluoride and mixtures thereof. A method of preparing the steel for hot forming and a method for hot forming the steel are provided.

Owner:WANG JIAN +1

Chemical polishing liquid and polishing method

InactiveCN101851470AIncrease brightnessFlat surfacePolishing compositionsAcetic acidSimple component

The invention provides chemical polishing liquid, comprising sulfuric acid, hydrogen peroxide, acetic acid, an auxiliary oxidant, a brightening agent and an adjusting agent, and the PH of the polishing liquid is 1-3. The polishing liquid has simple components and easy control, the obtained chemical polishing surface has high brightness and smooth surface, and can achieve the mirror polishing effect. The polishing liquid can be widely applied in polishing of the surface of copper-zinc alloy.

Owner:深圳市新合富力科技有限公司

Novel biodegradable zinc-based metal material and ureteral expandable stent obtained through material

ActiveCN105925847AGood biocompatibilityPromote degradationStentsSurgeryMetallic materialsBiocompatibility Testing

The invention belongs to the field of medical implant materials and particularly relates to a novel biodegradable zinc-based metal material and a ureteral expandable stent obtained through the material. The zinc-based metal material is composed of zinc and / or zinc alloy. The zinc alloy is composed of Zn and one or more elements of Mg, Al, Ti, Cu, Ag, Si, Ca, Sr, Y, Zr, Sc, Gd, Nd, Dy, Er, Li, Mn, La, Ce, Pr, Sm, Tb, Ho, Tm, Yb and Lu. The biodegradable zinc-based metal material has good biocompatibility, degradability and mechanical properties, and has wide market application prospects.

Owner:管仁国

Mn-containing creep-resisting rolled zinc alloy belt material and preparation method thereof

InactiveCN101906555AOutstanding advantagesHighlight positive effectsRoll mill control devicesMetal rolling arrangementsRare-earth elementManganese

The invention relates to a Mn-containing creep-resisting rolled zinc alloy belt material. The material comprises the following components in percentage by weight: 0.5 to 3.0 percent of copper, 0.01 to 2.0 percent of manganese, 0.05 to 0.3 percent of titanium and the balance of zinc and less than 0.05 percent of impurities. An alloy component can also contain the following component in percentage by mass: 0.01 to 0.5 percent of X, wherein the X is at least one of aluminum and rare earth elements (Ce+La). A method for preparing the material comprises the following steps of: smelting by a protective covering method and adding alloy elements in the forms of pure zinc, Zn-Cu, Zn-Ti, Cu-Mn, pure aluminum and Ce+La composite rare earth, wherein a smelting temperature is between 650 and 740 DEG C; pouring at the temperature of between 420 and 480 DEG C; uniformly annealing cast ingots at the temperature of between 350 and 380 DEG C for 6 to 10 hours; performing hot rolling for multiple times at the temperature of between 220 and 280 DEG C, wherein total deformation is between 60 and 95 percent; performing cold rolling, wherein the total deformation is between 50 and 80 percent; and after rolling, annealing at the temperature of between 180 and 200 DEG C for 2 to 3 hours. The alloy of the invention has high creep resistance, hot processing performance and mechanical property and is suitable for the fields of building decoration, transportation, instruments, meters and the like.

Owner:CENT SOUTH UNIV

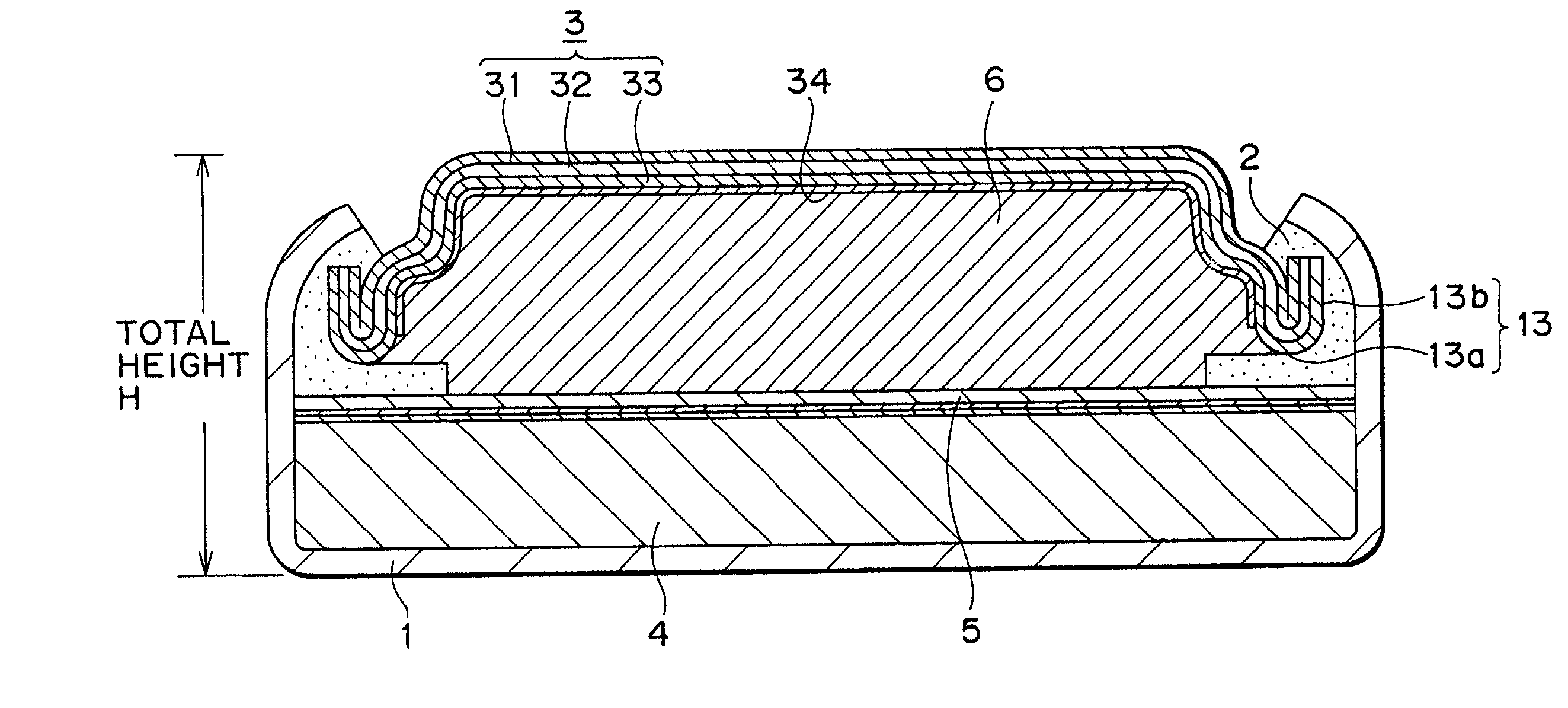

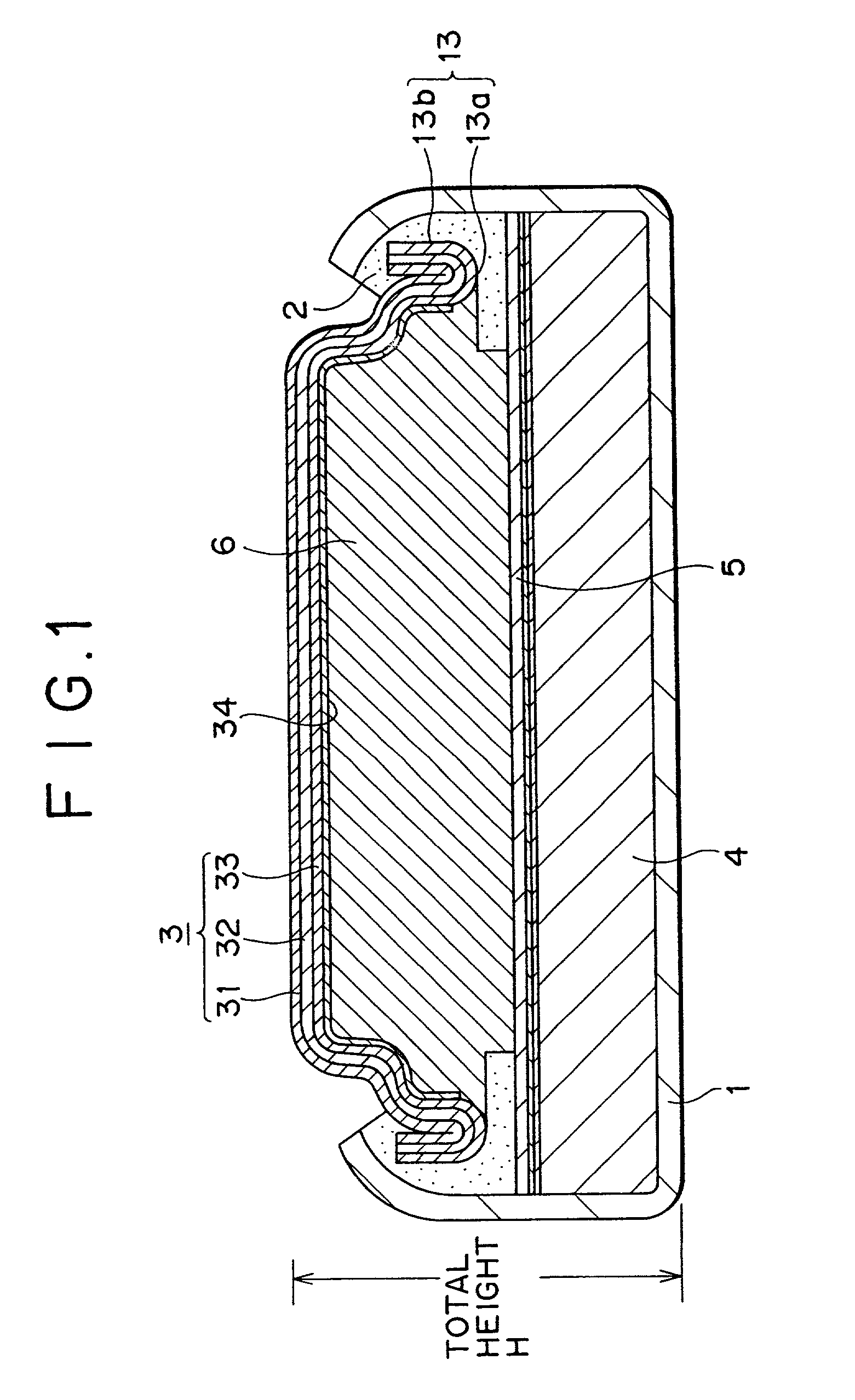

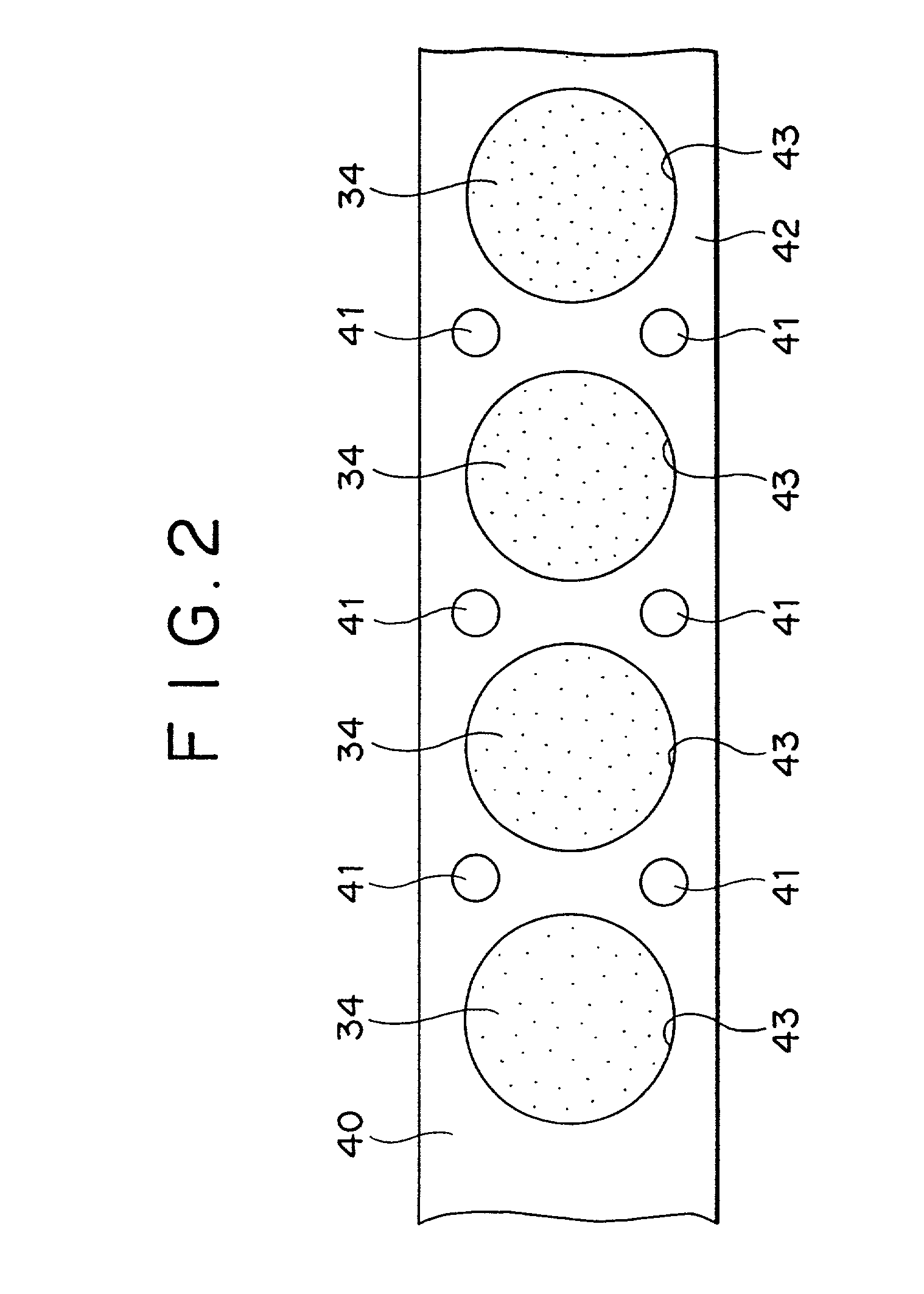

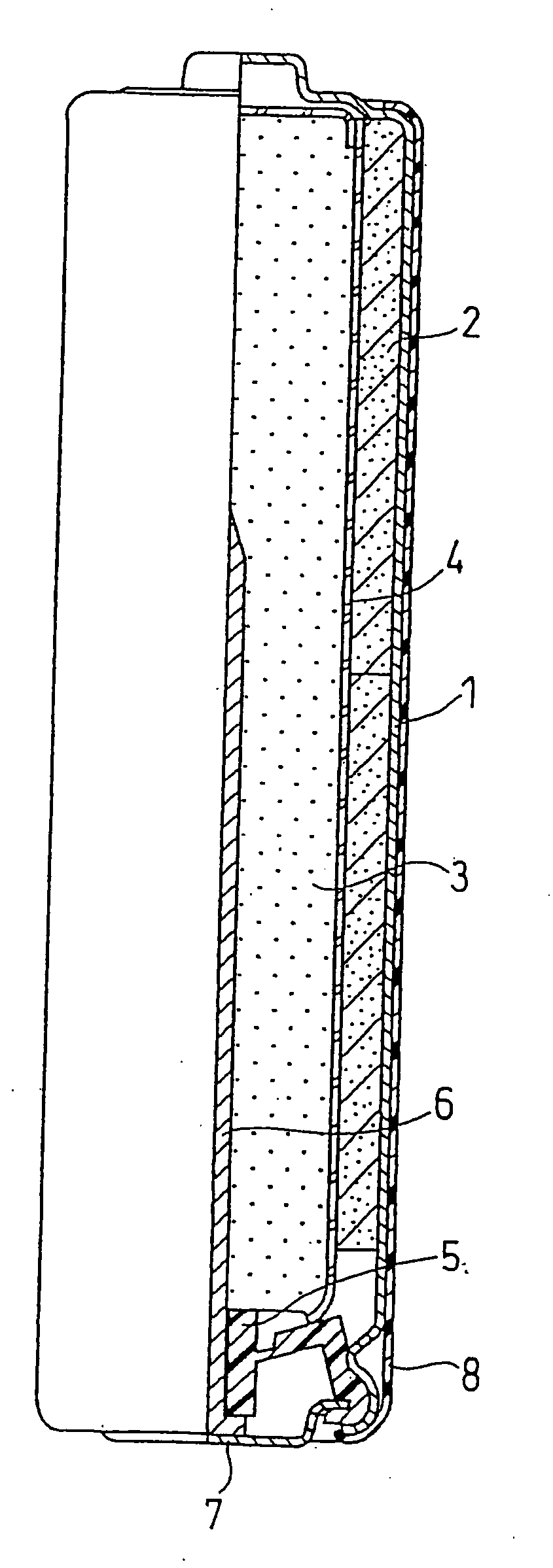

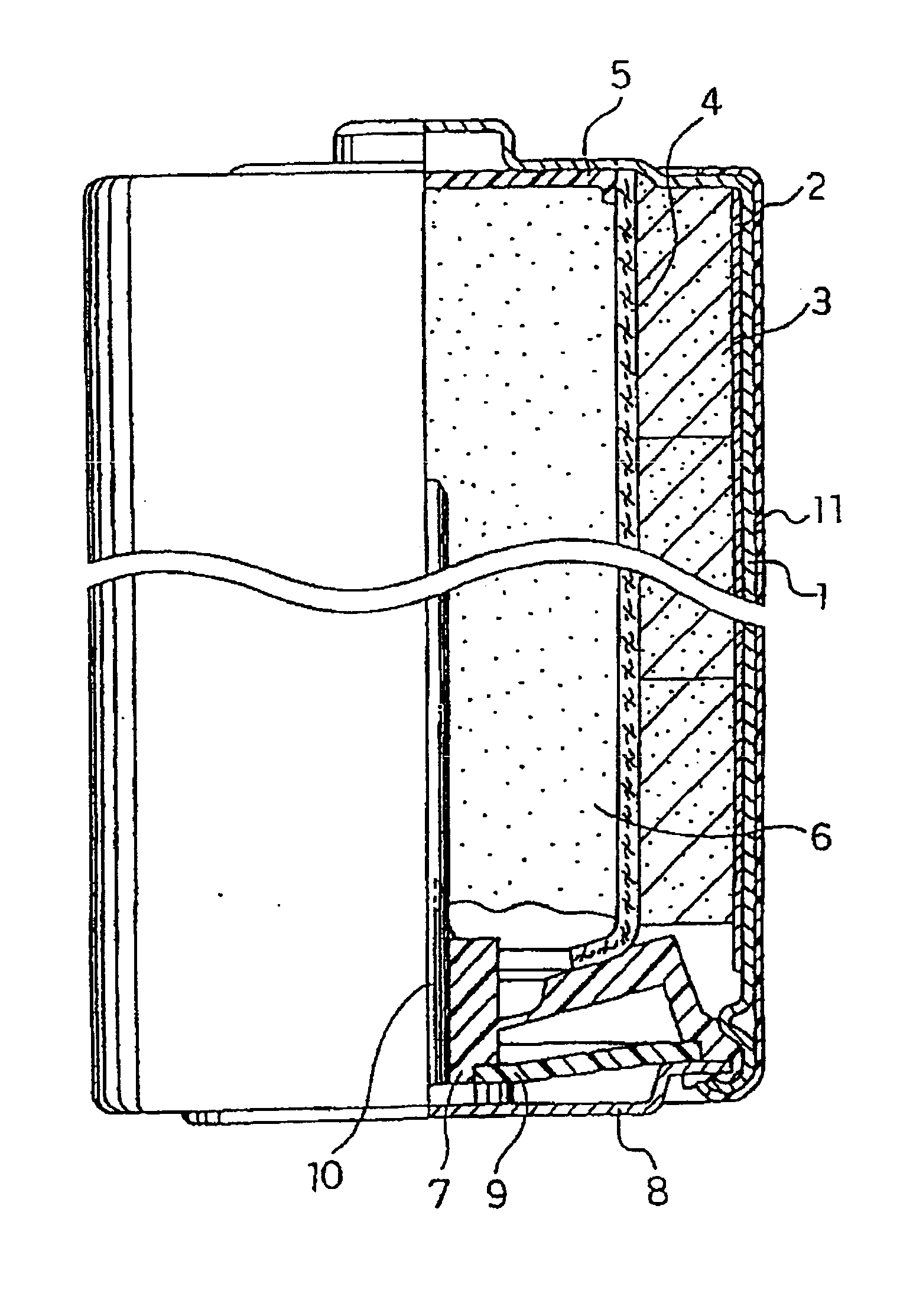

Alkaline battery

InactiveUS20020127469A1Improve reliabilityImprove the problemSilver accumulatorsPositive electrodesHydrogenOver potential

An alkaline battery constructed of a cathode can and an anode cup in such a way that an open end of the cathode can is sealed by the anode cup, with a gasket interposed between them, characterized in that the open end of the anode cup is folded back in U-shape along its periphery and the fold is tightened for hermetic sealing by the internal periphery of the open end of the cathode can, with the gasket interposed between them, the anode cup has a higher hydrogen over potential material coating layer formed in a limited region on the inside thereof excluding the bottom of the U-shaped fold and the outer periphery of the fold, the cathode can contains the cathode active material and silver-nickelite (AgNiO.sub.2), the anode cup contains the anode mix which is mercury-free zinc or zinc alloy powder as the anode active material.

Owner:MURATA MFG CO LTD

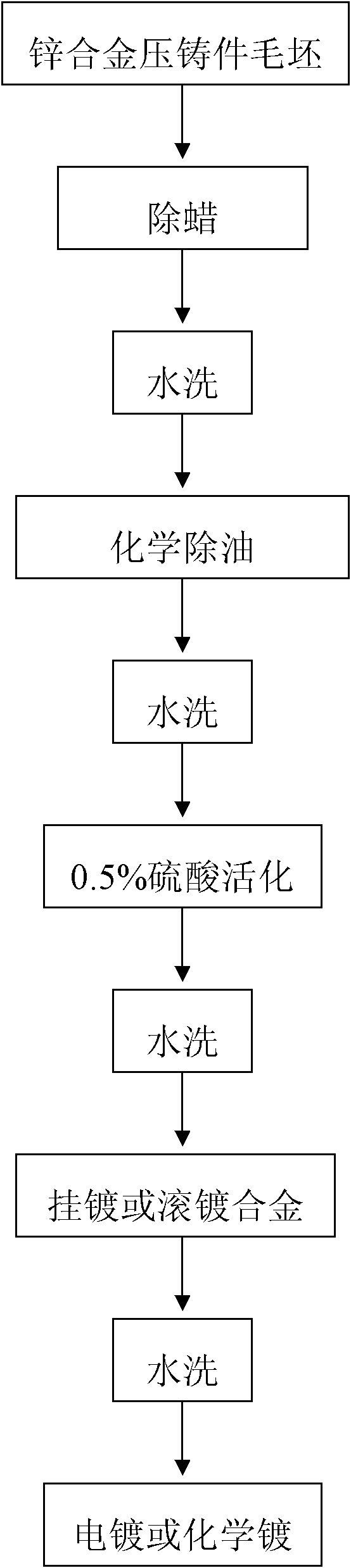

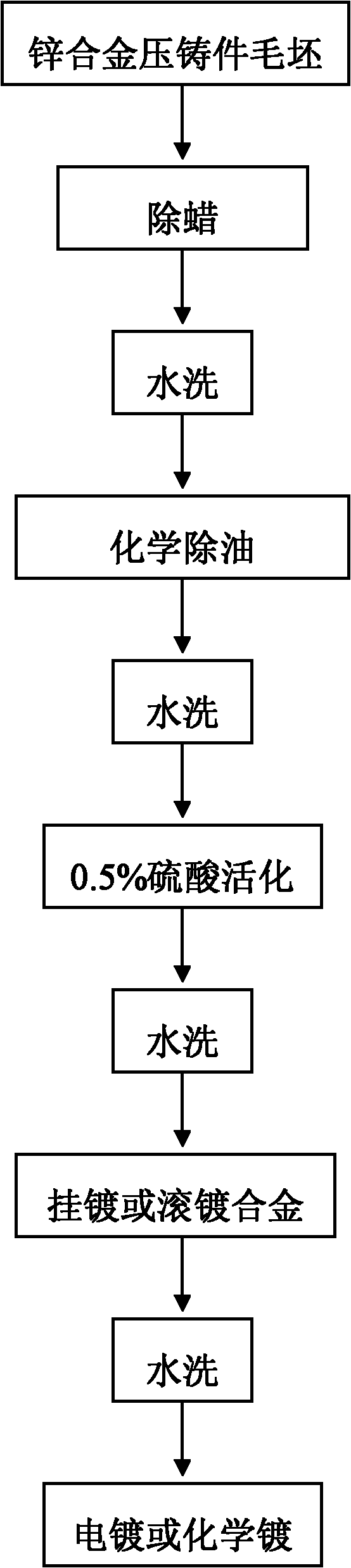

Cyanogen-free plating method of zinc alloy die casting

The invention discloses a cyanogen-free plating method of a zinc alloy die casting. The method is a plating method in which cyanogen-free copper-zinc alloy, copper-stannum alloy or ormolu is subjected to barrel plating or rack plating in a cyanogen-free copper-zinc alloy solution, copper-stannum alloy solution or ormolu solution as grounding layers so as to provide a pre-plating layer with good bonding force for subsequent plating or chemical plating. The method comprises the following steps: (1) carrying out ultrasonic wax removal or tumbling wax removal on a zinc alloy die casting blank; (2) washing; (3) chemically removing oil; (4) washing; (5) activating with 0.5% sulfuric acid; (6) washing; (7) carrying out barrel plating or rack plating on the alloys in the cyanogen-free copper-zinc alloy solution, copper-stannum alloy solution or ormolu solution; (8) washing; and (9) carrying out the subsequent plating or chemical plating. By using the method provided by the invention, cyanogen-free barrel plating or rack plating alloy is carried out on the zinc alloy die casting so that the obtained plating layer is semi-bright and has good bonding force.

Owner:广州市二轻研究所股份有限公司

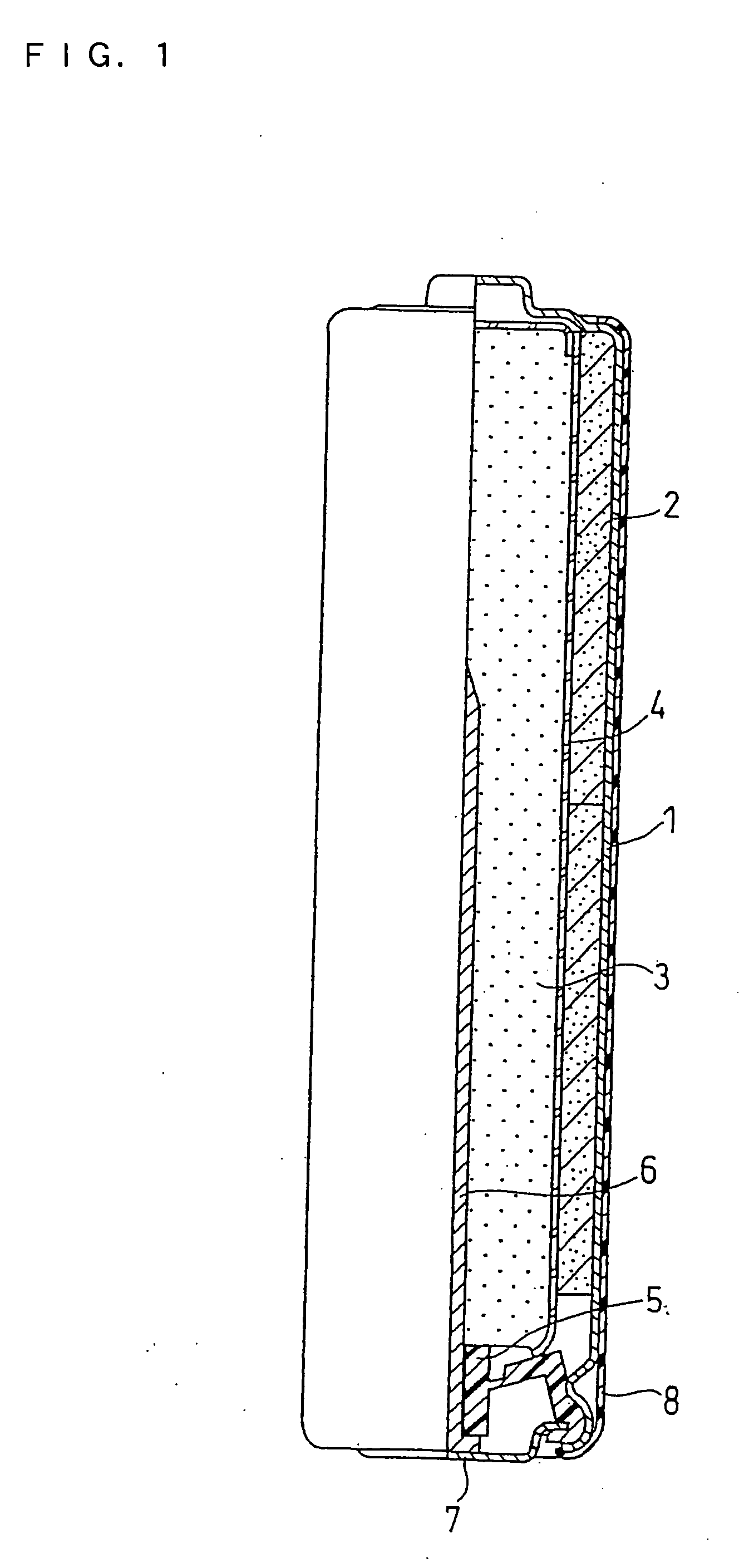

Alkaline battery

InactiveUS20080096108A1Improve leak-proof effectAlkaline accumulatorsNegative electrodesMethacrylatePolymer science

An alkaline battery of this invention includes: a positive electrode including at least one selected from the group consisting of a manganese dioxide powder and a nickel oxyhydroxide powder; a gelled negative electrode including a zinc alloy powder, a gelling agent, and an alkaline electrolyte; and a separator interposed between the positive electrode and the gelled negative electrode. The gelling agent comprises a polymer that is obtained by polymerizing a polymerizable monomer including at least an acrylic monomer, and part of the acrylic monomer remains in the gelling agent without being polymerized. The acrylic monomer includes at least one selected from the group consisting of acrylic acid, methacrylic acid, an acrylate, and a methacrylate. The weight ratio of the remaining acrylic monomer to the total weight of the polymer and the remaining acrylic monomer is 5000 ppm or less.

Owner:PANASONIC CORP

Chromium(VI)-free, aqueous acidic chromium(III) conversion solutions

InactiveUS20070243397A1Improve protectionSolid state diffusion coatingMetal layered productsAlloy substrateZinc alloys

An essentially chromium(VI)-free, chromium(III)-containing corrosion resistant conversion solution, or layer thereof for treating metals such as zinc, zinc alloy, aluminum, or aluminum alloy substrates. The conversion solution, is substantially free of chromium(III)-chelates, is capable of producing thick conversion films even at low temperatures, has good corrosion resistance, and is self healing with regard to scratches and the like.

Owner:COLUMBIA CHEM , A CORP OF OH

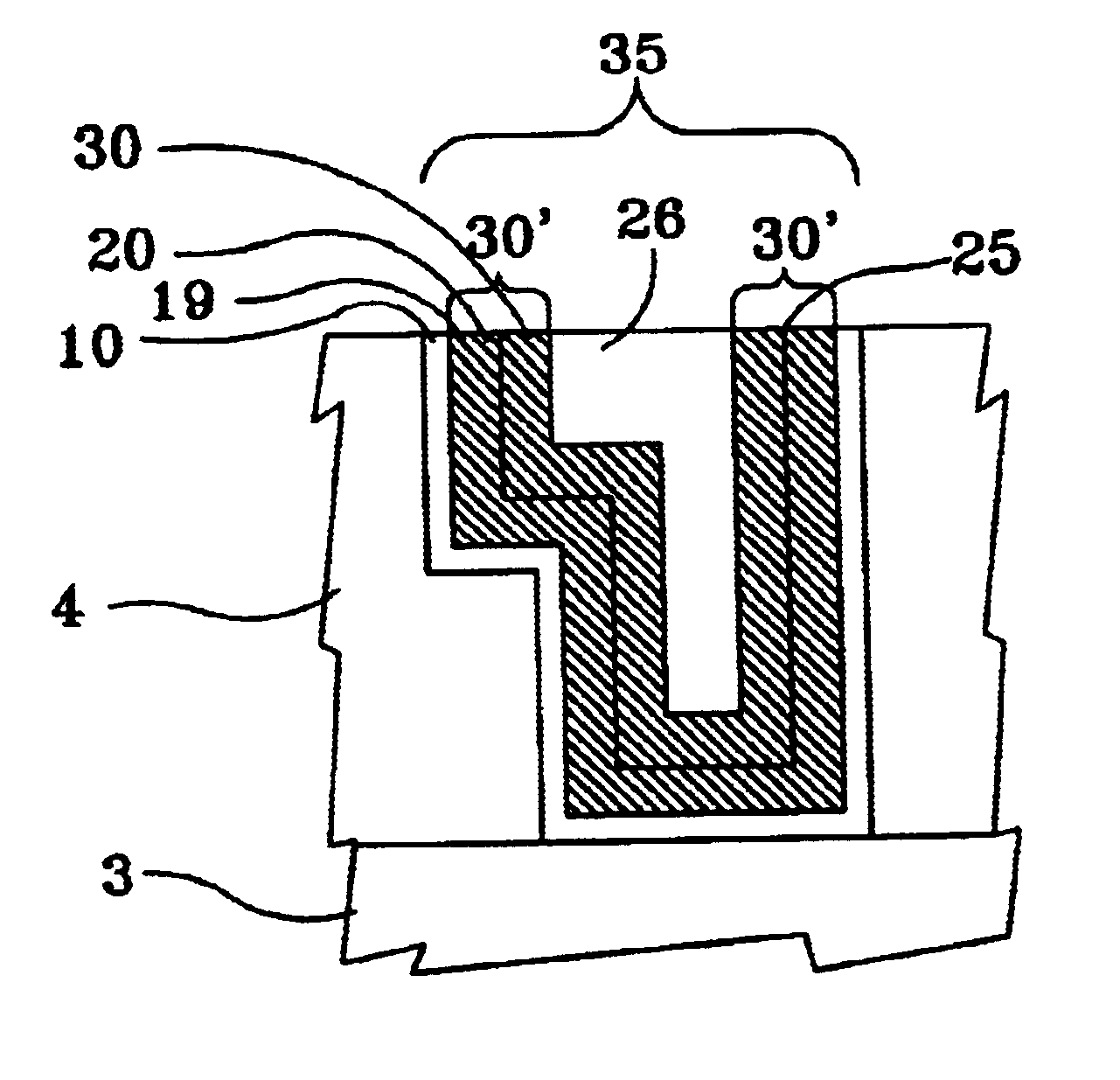

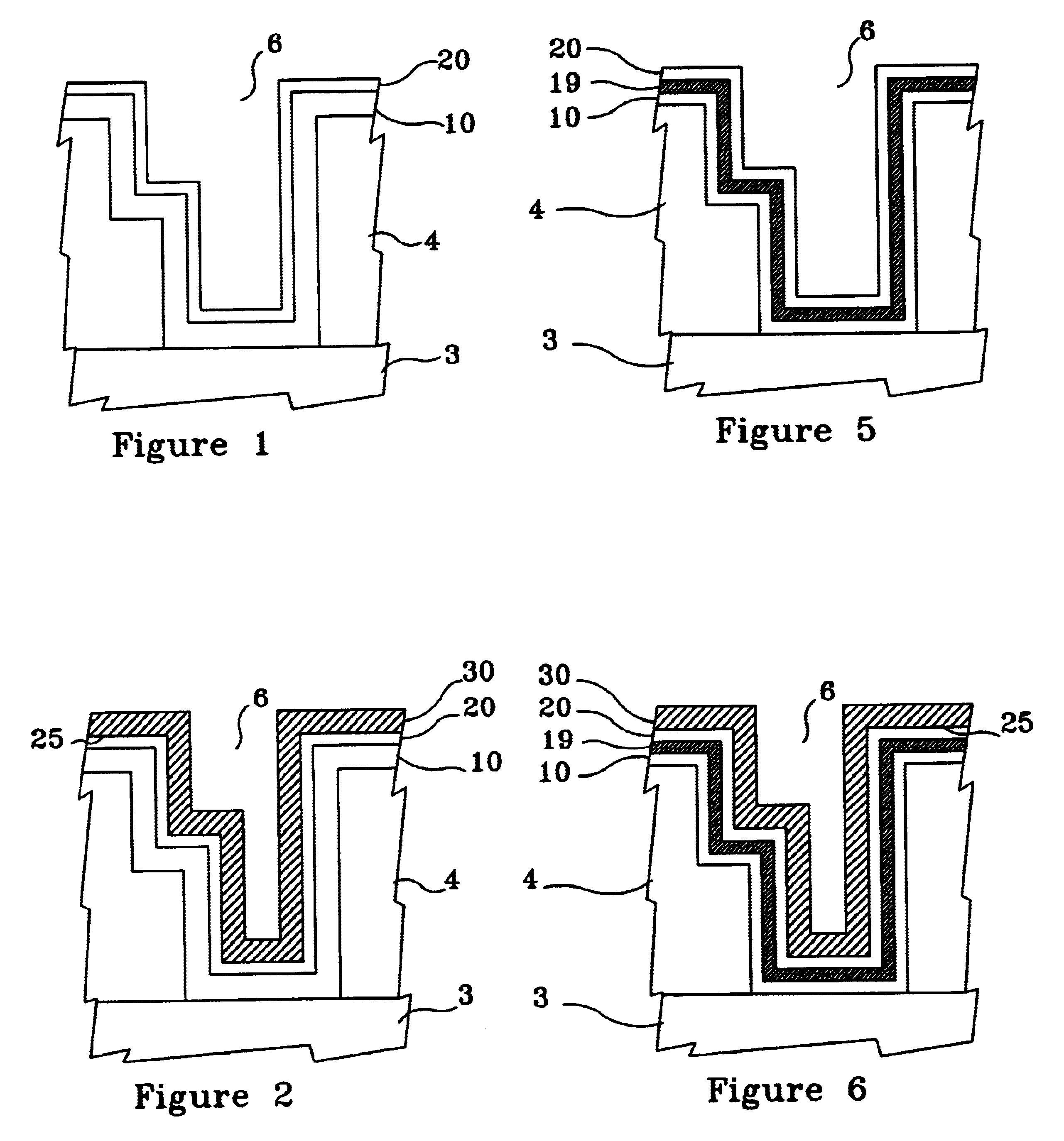

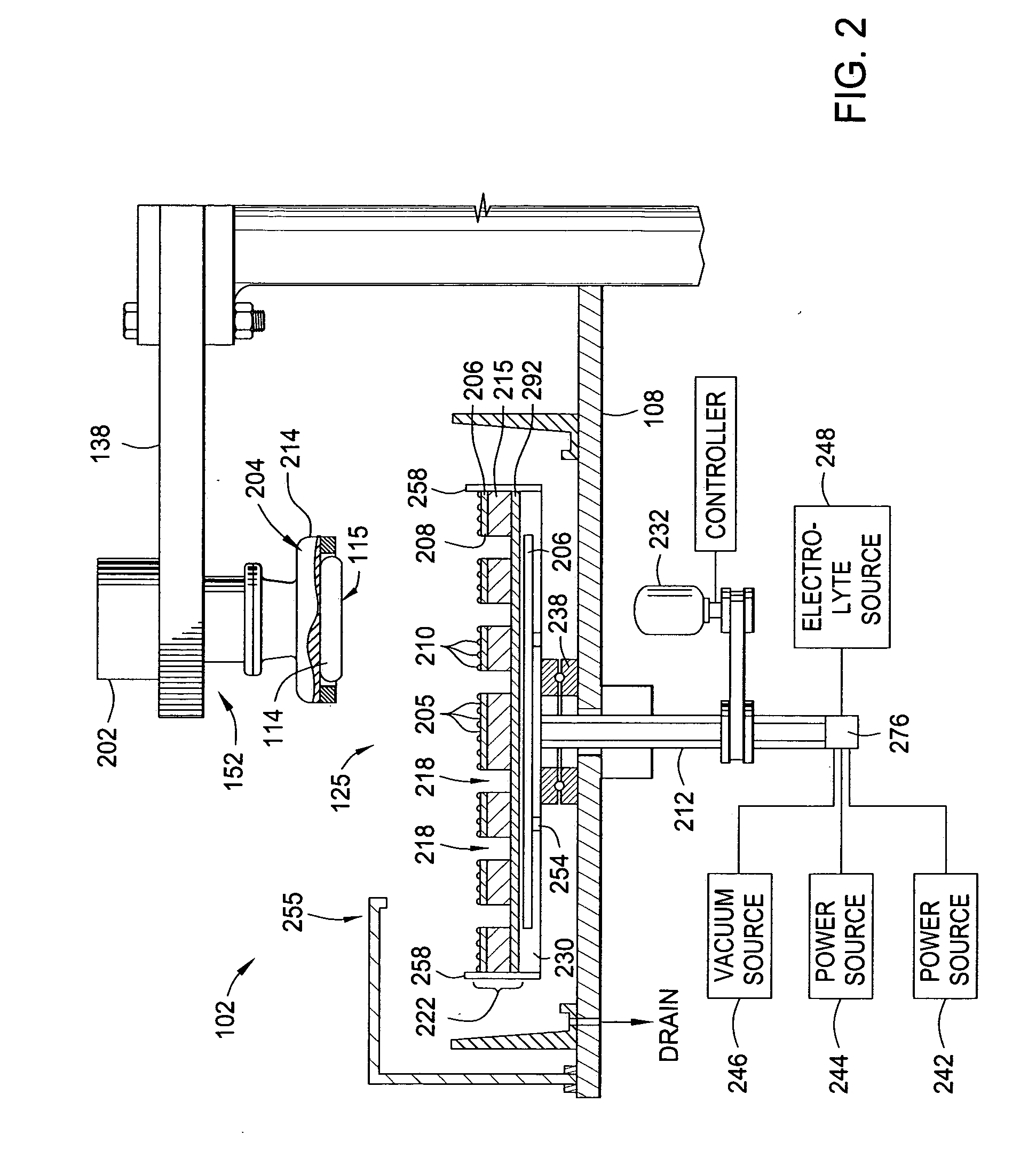

Method of reducing electromigration in a copper line by electroplating an interim copper-zinc alloy thin film on a copper surface and a semiconductor device thereby formed

InactiveUS6660633B1Improves Cu interconnect reliabilityReduce manufacturing costElectrolysis componentsSolid-state devicesCopper interconnectChemical solution

A method of fabricating a semiconductor device, having an interim reduced-oxygen Cu-Zn alloy thin film (30) electroplated on a blanket Cu surface (20) disposed in a via (6) by electroplating, using an electroplating apparatus, the Cu surface (20) in a unique chemical solution containing salts of Zn and Cu, their complexing agents, a pH adjuster, and surfactants; and annealing the interim electroplated Cu-Zn alloy thin film (30); filling the via (6) with further Cu (26); annealing and planarizing the interconnect structure (35); and a semiconductor device thereby formed. The reduction of electromigration in copper interconnect lines (35) is achieved by decreasing the drift velocity in the copper line (35) / via (6), thereby decreasing the copper migration rate as well as the void formation rate, by using an interim conformal Cu-rich Cu-Zn alloy thin film (30) electroplated on a Cu surface (20) from a stable chemical solution, and by controlling the Zn-doping thereof, which improves also interconnect reliability and corrosion resistance.

Owner:GLOBALFOUNDRIES US INC

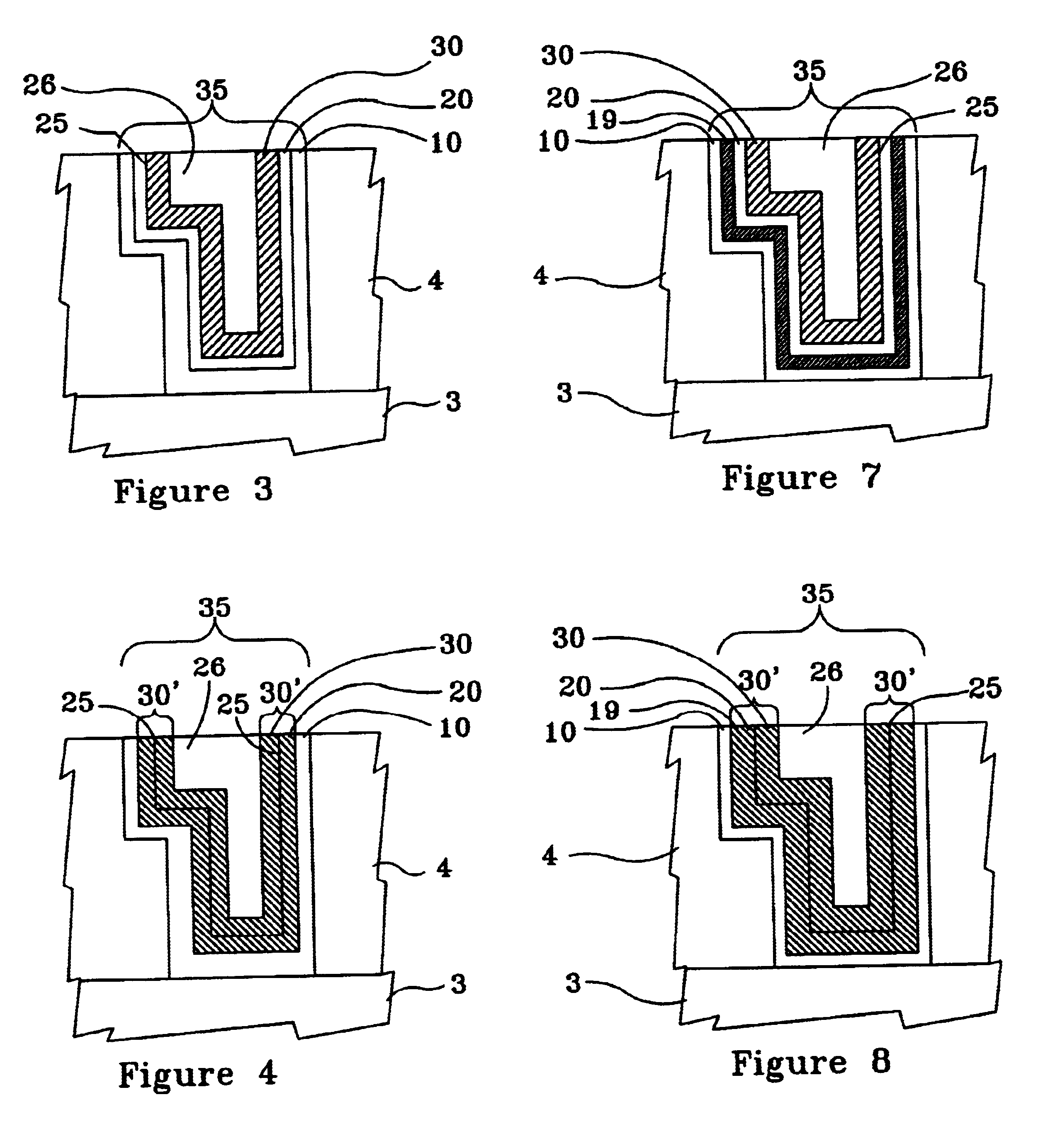

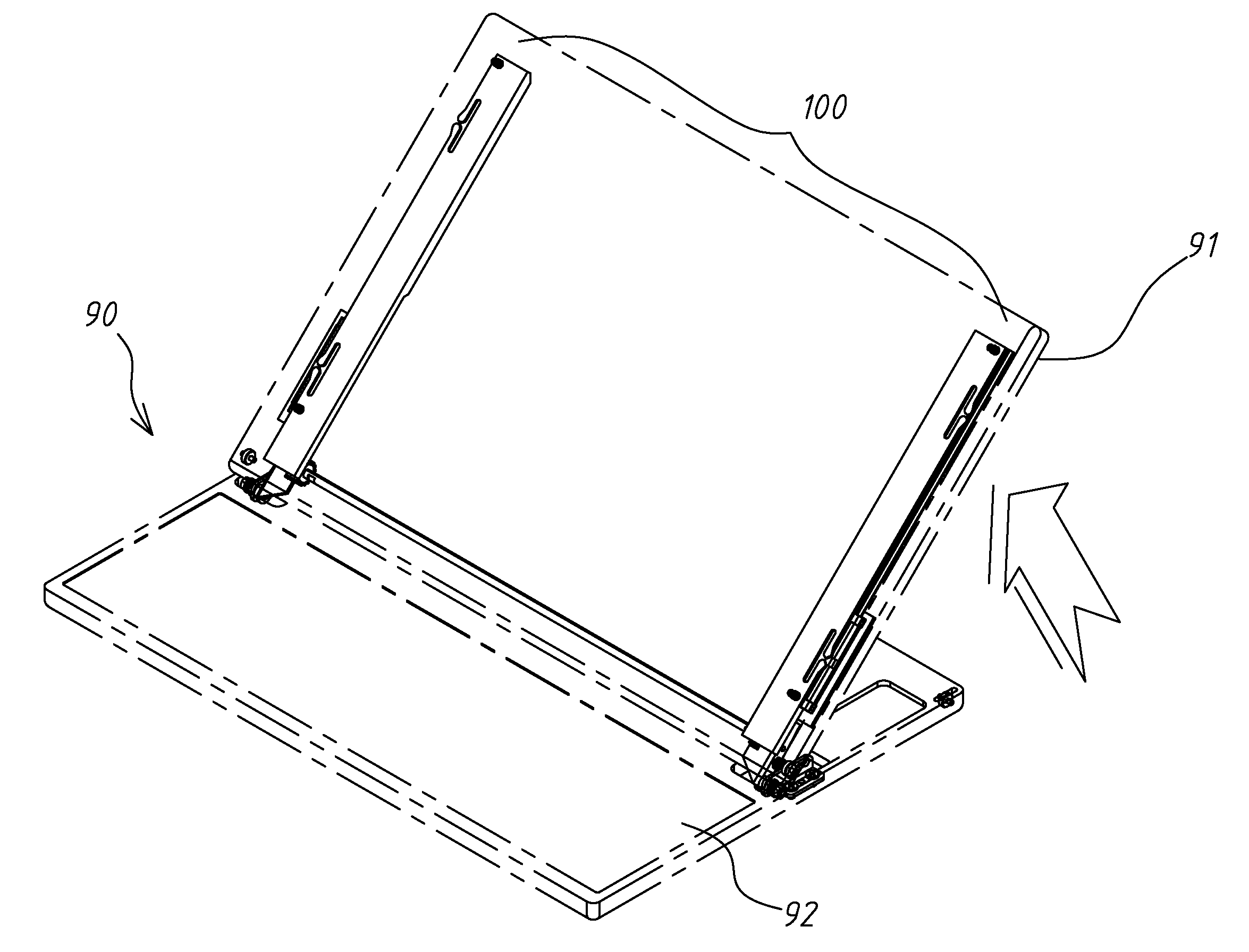

Liftable slide cover mounting structure using a sheet metal bracket mechanism

ActiveUS20120217855A1Reduce weightAvoid noiseCasings/cabinets/drawers detailsDetails for portable computersMetal sheetEngineering

A liftable slide cover mounting structure consisting of two hinges, two metal sheet bracket mechanism, two sliding rails, two gears, two gear racks and two supplementary support mechanisms. Subject to the use of the sheet plate bracket mechanisms to hold the sliding rails instead of zinc alloy sliding rail holders, the weight of the liftable slide cover mounting structure is minimized. Further, when the cover panel is opened from the base member, the sheet plate bracket mechanisms are forced into engagement with the supplementary support mechanisms to support the cover panel in position for enabling the user to operate the display screen of the cover panel positively.

Owner:LIANHONG TECH

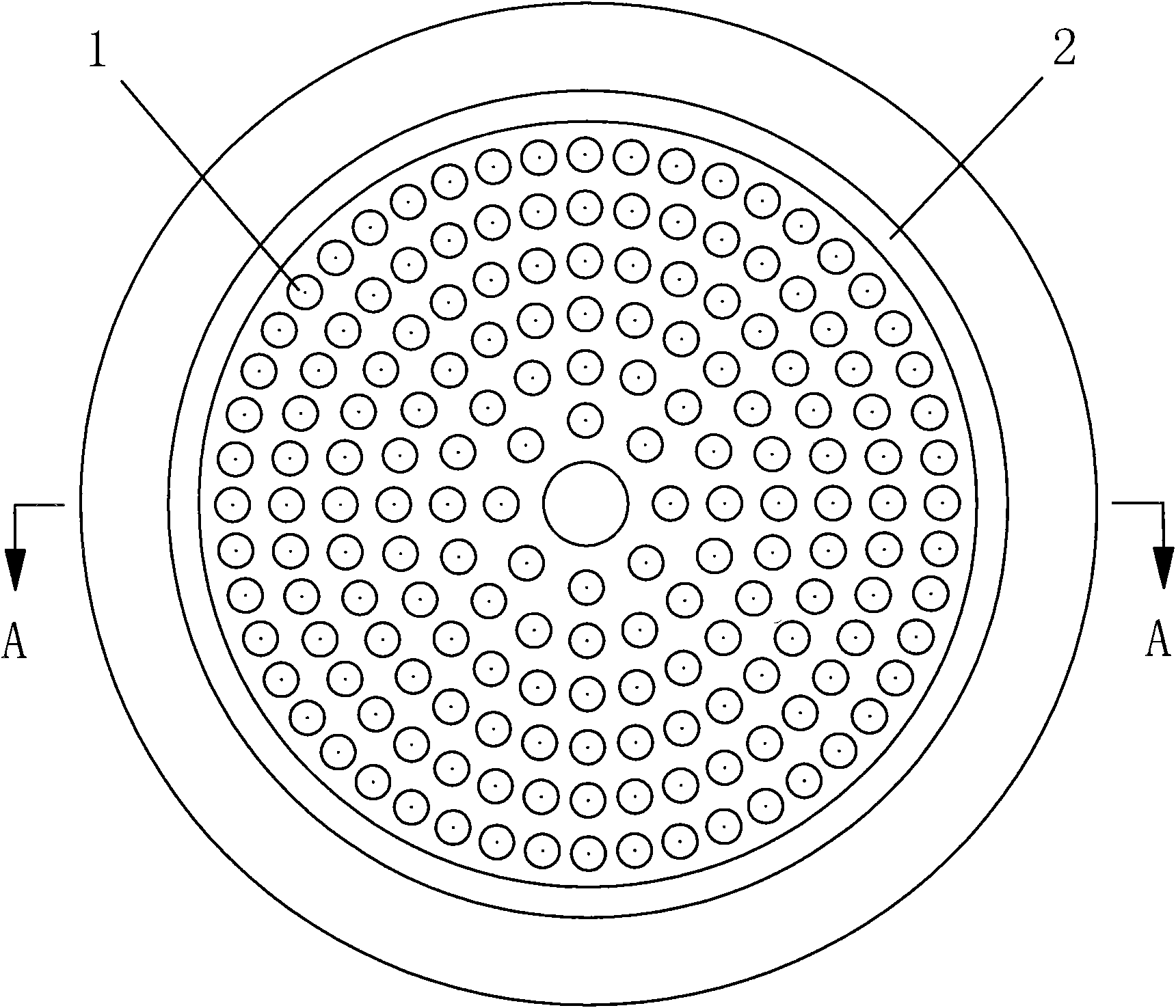

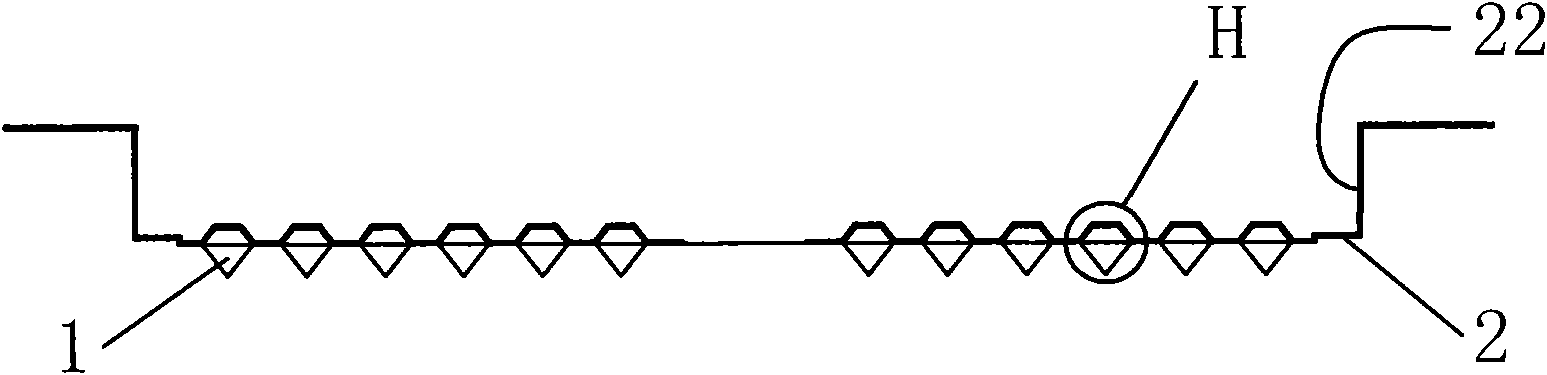

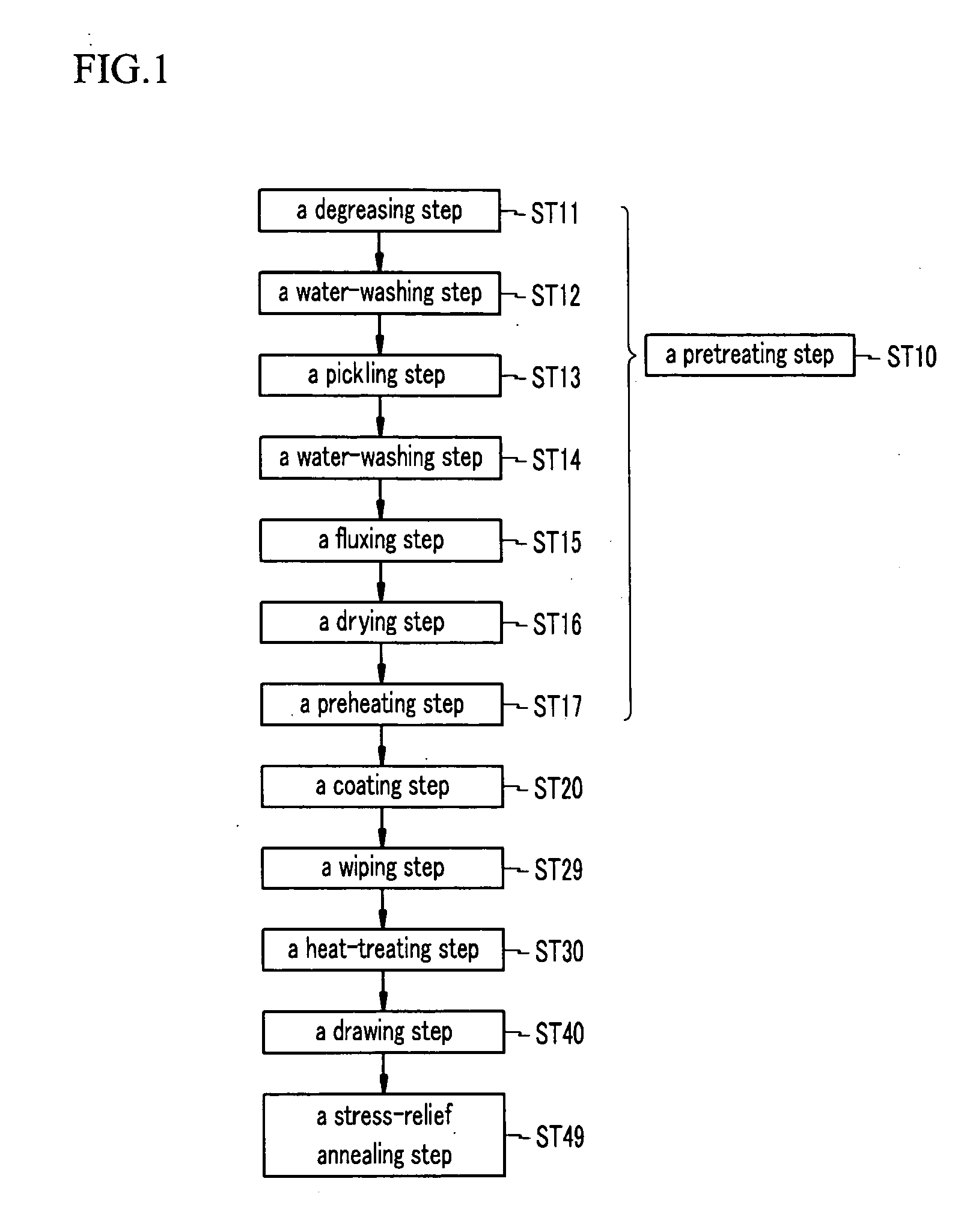

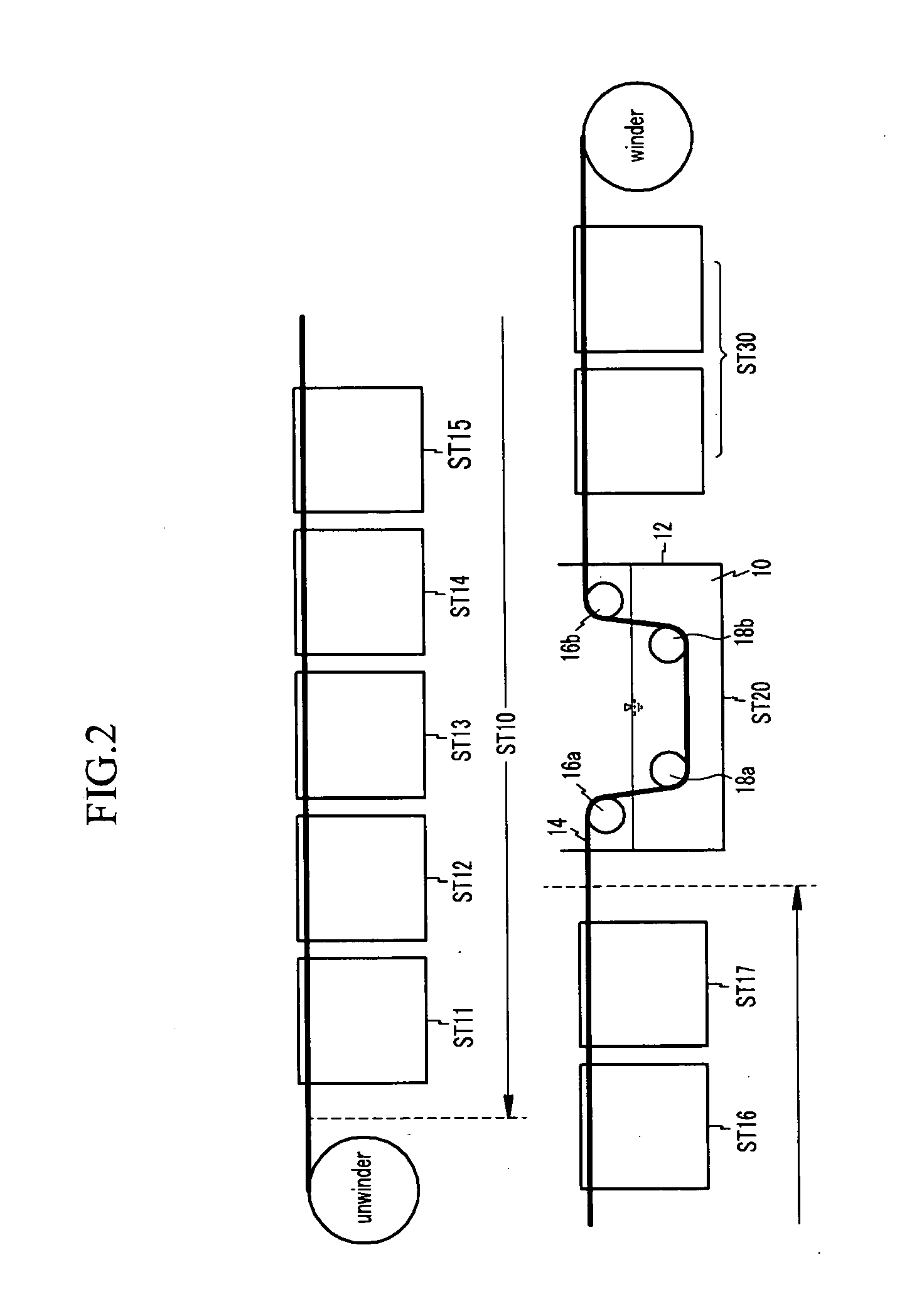

Electrode wire for electric discharge machining and manufacturing method of the same

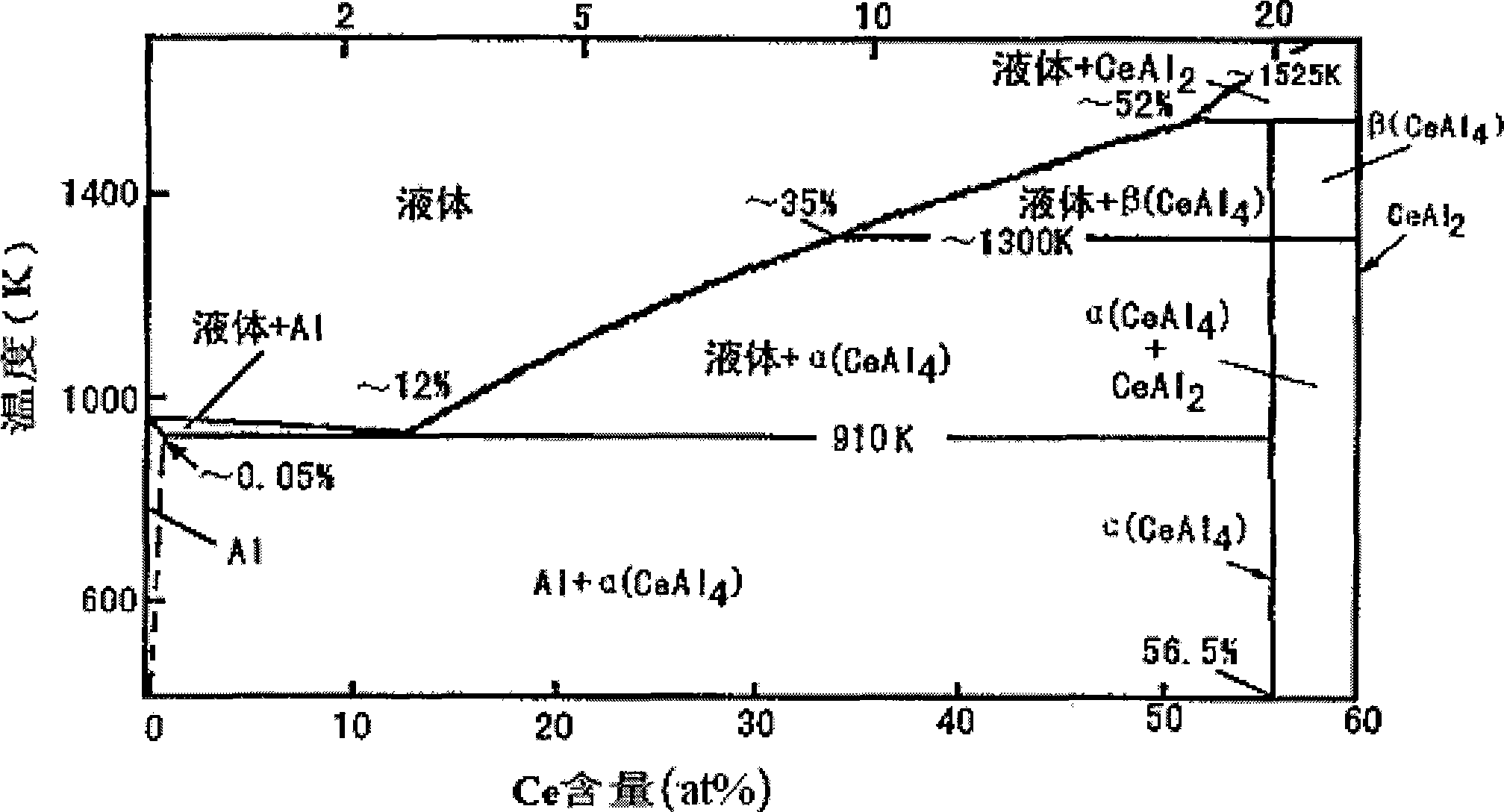

ActiveUS20060219666A1Enhancing property of electric discharge machiningImprove conductivityArc welding apparatusElectrical-based machining electrodesElectric dischargeCerium

Enhanced electrode discharge machining properties of an electrode wire are achieved when the electrode wire comprises a coil, a covering layer formed on a periphery of the coil, and grains formed on the covering layer. The grains comprise a copper-zinc alloy including about 0.01 to 0.5 weight % of at least one additive element selected from the group consisting of aluminum, tin, magnesium, lanthanum, cerium, nickel, manganese, titanium, and zirconium.

Owner:OPEC ENG CO LTD +1

Biodegradable medical Zn-Li-X series alloy material and preparation method and application

InactiveCN106319287AHigh strengthImprove plasticitySuture equipmentsTissue regenerationInsertion stentBiocompatibility Testing

The invention discloses a biodegradable medical Zn-Li-X series alloy material and a preparation method and application. The alloy material comprises 0.1-10 wt.% of Li, 0.01-4 wt.% of X and the balance Zn. X refers to at least one element of Cu, Ag, Mn, Mg, Si, Ca and Sr. Thermoplastic deformation processing is further required before smelted alloy is used, the alloy structure is refined, and thus alloy performance is improved. The zinc alloy has the advantages of excellent comprehensive mechanical property, good biocompatibility, regulatory degradation rate and the like and thus can be used as a material for preparing biodegradable medical implantation instruments to be applied to preparation of intravascular stents, bone implants, maxillofacial surgery and craniocerebral surgery implantation instruments, surgical sutures, various sorts of surgical patches, anastomats, vascular clamps or neural restoration catheters and the like.

Owner:SHANGHAI JIAO TONG UNIV

Low-temperature diffusion welding method for magnesium alloy and aluminum alloy

InactiveCN101920393AAvoid generatingHigh bonding strengthNon-electric welding apparatusSolder maskAxial pressure

The invention discloses a low-temperature diffusion welding method for magnesium alloy and aluminum alloy. The method comprises the following steps of: (1) workpiece surface cleaning: processing a magnesium alloy plate and an aluminum alloy plate to a specified size, and removing oxide layers from to-be-welded surfaces thereof; (2) workpiece assembly: placing a tin-zinc alloy foil serving as a middle layer between the aluminum alloy plate and the magnesium alloy plate, and placing a solder mask on and below the plates respectively to form a welded workpiece; and (3) charging the workpiece into a furnace and welding: putting the welded workpiece into a vacuum diffusion welding furnace, performing heating and heat preservation, applying an axial pressure to the welded workpiece when the heat preservation begins, and releasing the pressure when the heat preservation is finished. The method can effectively overcome the defect that the prior art cannot realize high-quality welding between the Mg alloy and the Al alloy, is suitable for reliable welding between the Mg alloy and the Al alloy of different categories, is particularly suitable for welding the thin magnesium alloy plate and the thin aluminum alloy plate, and has good welding planarity, high parallel precision and integral compactness.

Owner:WUHAN UNIV OF TECH

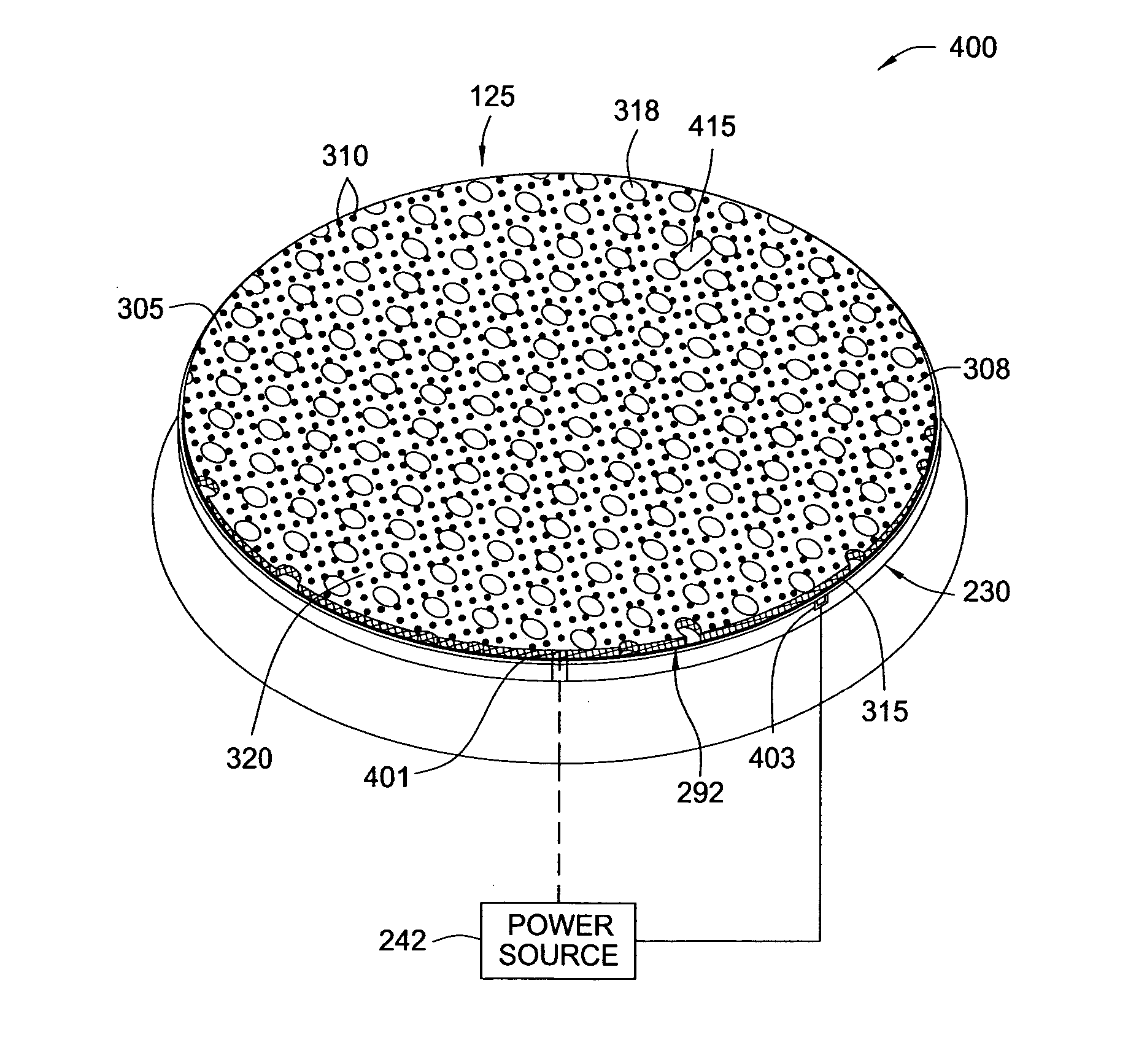

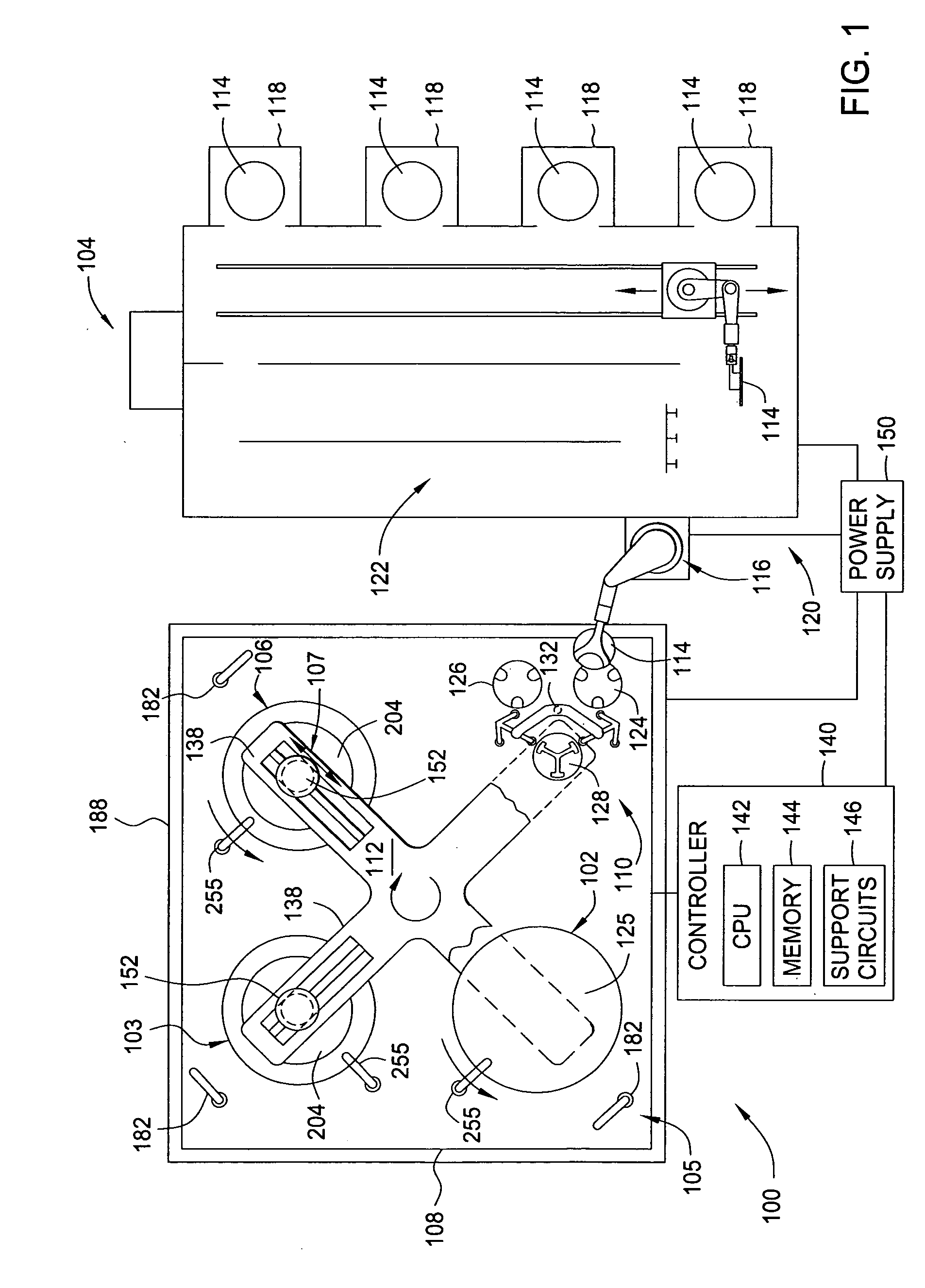

Conductive pad design modification for better wafer-pad contact

An apparatus and method for manufacturing and refurbishing a conductive polishing pad assembly for performing an electrochemical process on a substrate is disclosed. The conductive polishing pad assembly is formed using a contact surface as a foundation that is coated with a metallic coating to create a conductive contact surface. In one embodiment, the metallic coating is a high purity tin / zinc alloy that is sprayed on the contact surface. The contact surface contains abrasive particles while the metallic coating provides at least conductive qualities to the contact surface.

Owner:APPLIED MATERIALS INC

Alkaline dry battery

InactiveUS20080171266A1Ensures anticorrosion characteristicHigh aluminum contentCell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte cellsCross-linkIndium

An alkaline dry battery including a zinc negative electrode prepared by dispersing zinc alloy powder containing 0.015 wt % or less of indium and 0.008 wt % to 0.02 wt % both inclusive of aluminum into a gelled alkaline electrolyte containing 0.5 wt % to 3 wt % both inclusive of a cross-linked water-absorbing polyacrylate polymer, a separator made of a single nonwoven fabric sheet or a stack of multiple nonwoven fabric sheets and has a thickness of 360 μm to 880 μm both inclusive and a positive electrode containing manganese dioxide.

Owner:PANASONIC CORP

Hot press forming method, and a plated steel material therefor and its manufacturing method

InactiveUS20050252262A1Solve the lack of corrosion resistanceSolve the lack of resistanceHot-dipping/immersion processesAnodisationElectrolysisSurface oxidation

Hot press forming of a steel material is made possible by coating the surface of the steel material with a plated layer of zinc or a zinc alloy and forming thereon a barrier layer which prevents the vaporization of zinc even when heated to 700-1000° C. Corrosion resistance can also be guaranteed without requiring post treatment, and hot press forming of high tensile steel sheet and stainless steel sheet is made possible. The barrier layer is formed by forming an upper plated layer, by surface oxidation, by contact with an oxidizing agent, by contact with Zn and an oxidizing agent, by anodic electrolysis, by cathodic electrolysis, or by coating with a ZnO sol.

Owner:NIPPON STEEL CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com