Patents

Literature

1553results about How to "Improve discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

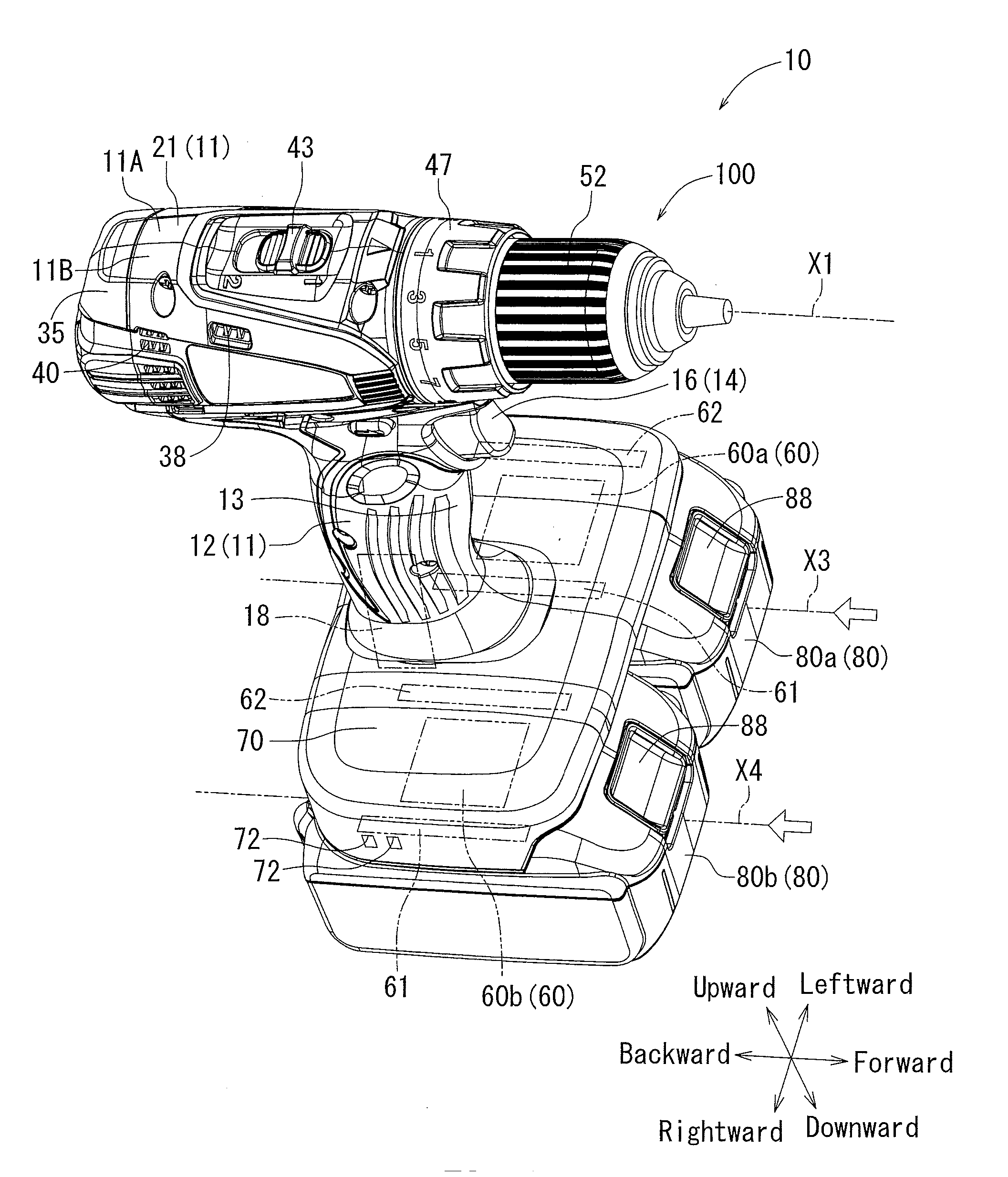

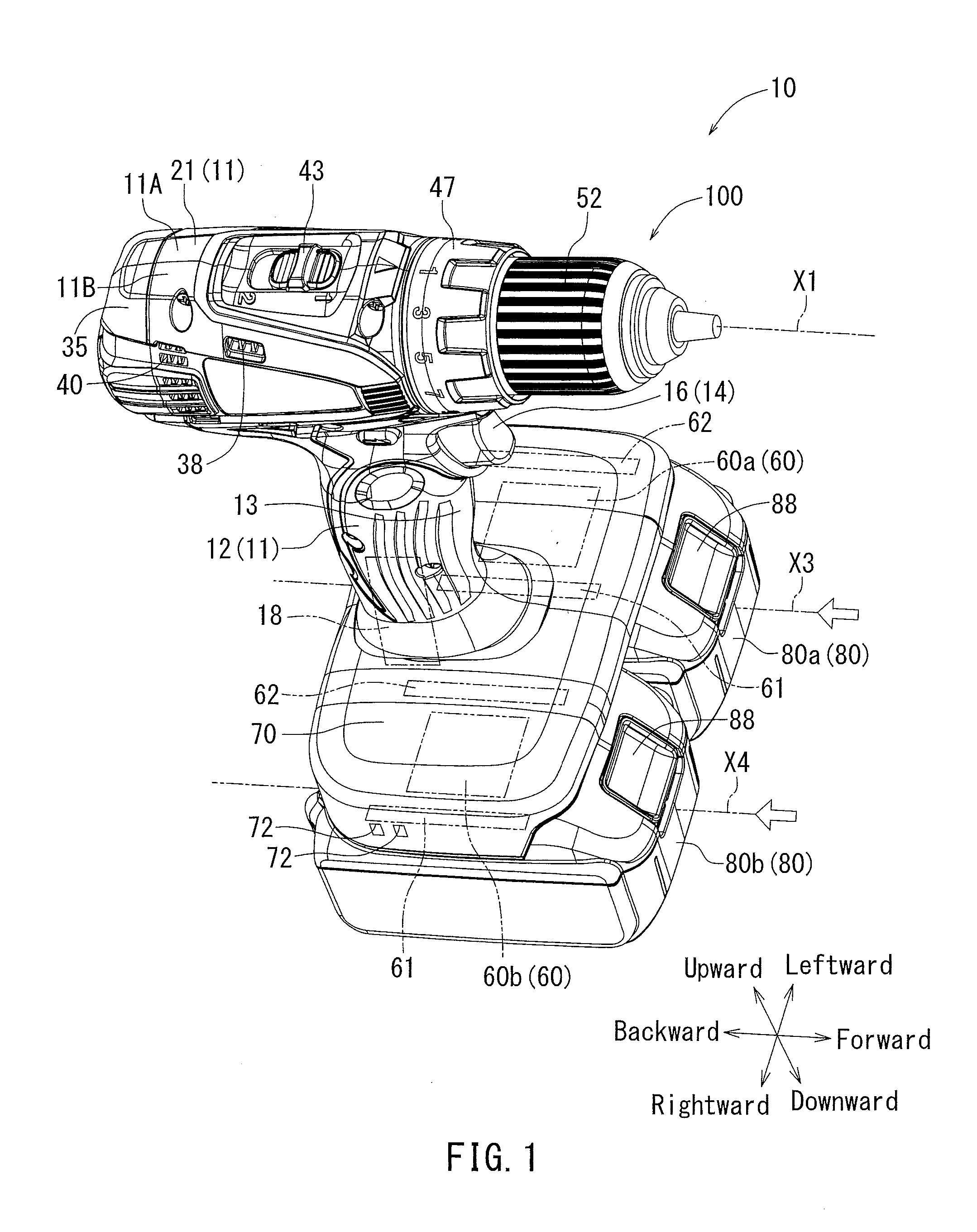

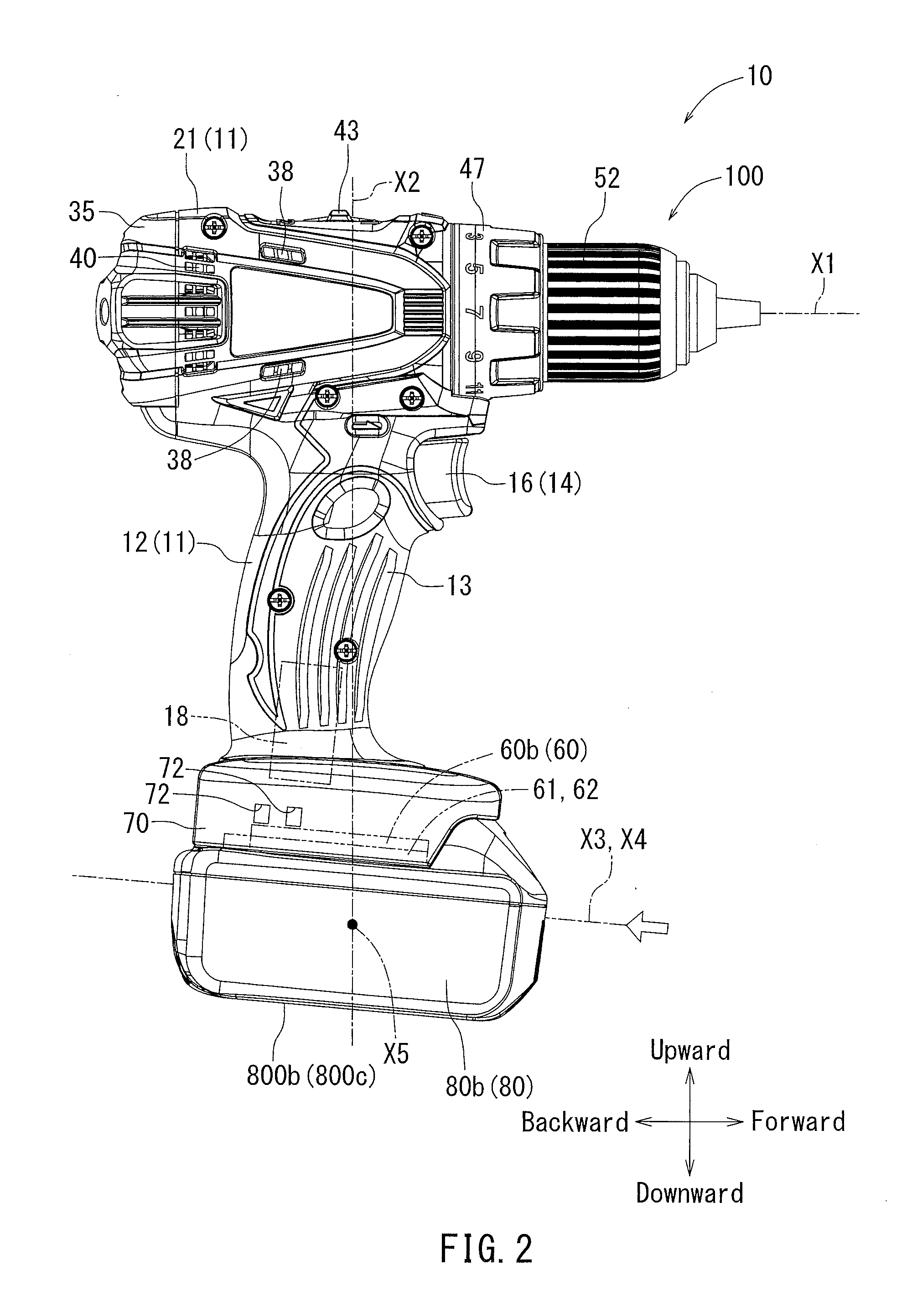

Electrical power tool

InactiveUS20150367497A1Low maneuverabilityHigh voltageDrilling rodsConstructionsElectrical batteryRechargeable cell

A driver drill may have two battery attachment portions to which two rechargeable batteries can be attached. Therefore, the driver drill can meet a need for an increased voltage or an increased discharge capacity. Further, the two battery attachment portions may be constructed as slide-fitting battery attachment portions. A combined gravity center of the rechargeable batteries attached to the first and second battery attachment portions may be positioned on a vertical line through a gravity center of a tool main body in a condition in which the two rechargeable batteries are detached therefrom.

Owner:MAKITA CORP

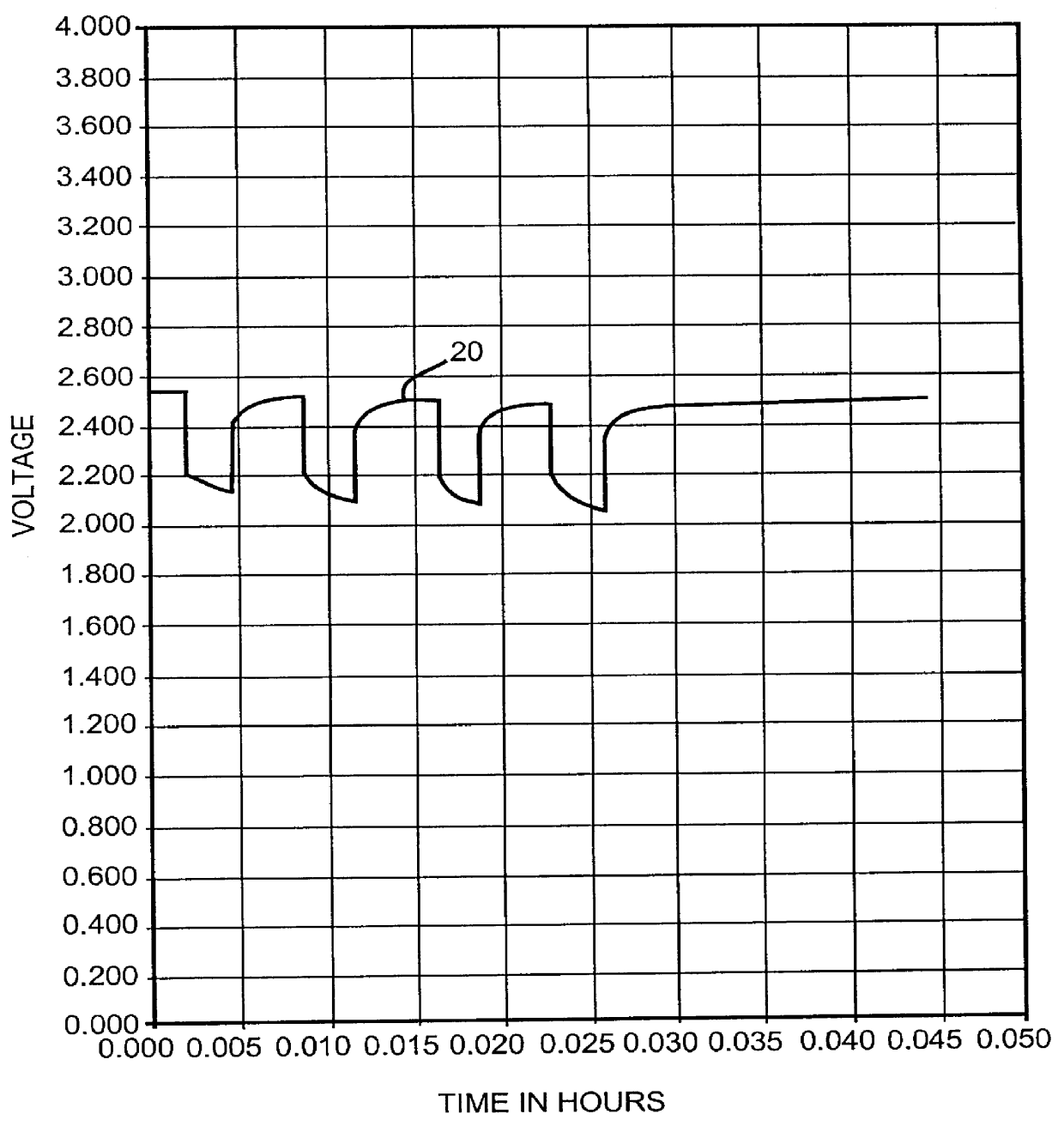

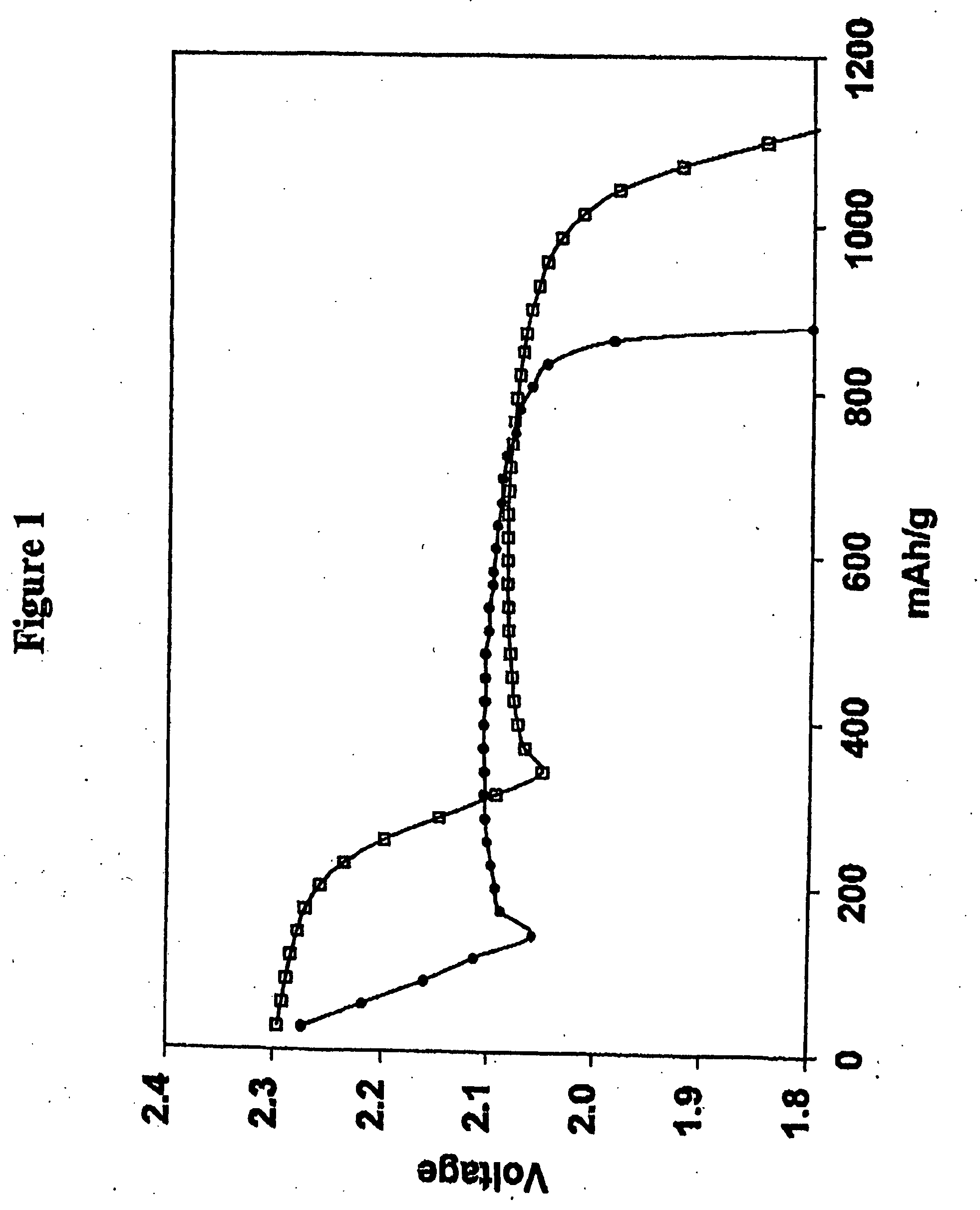

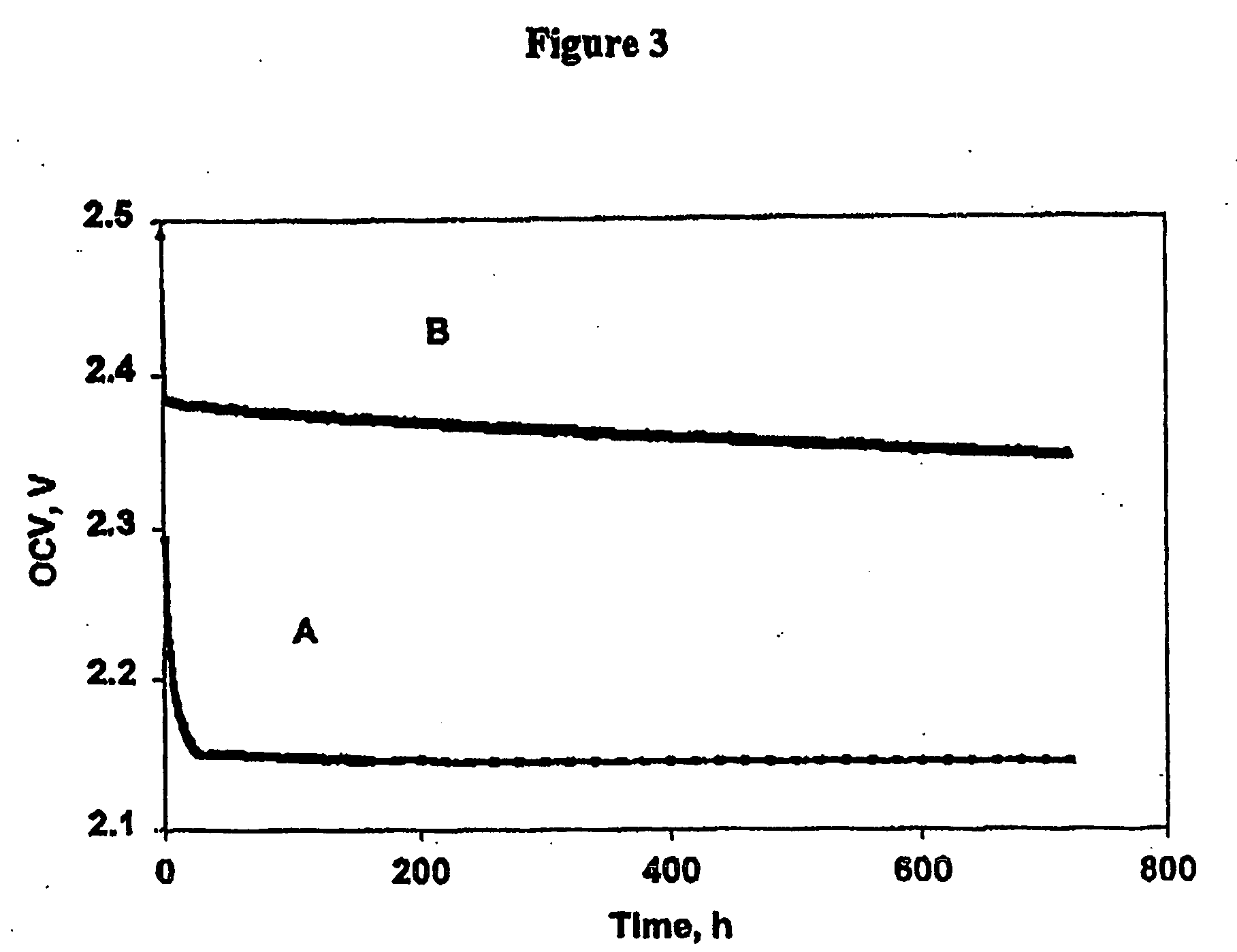

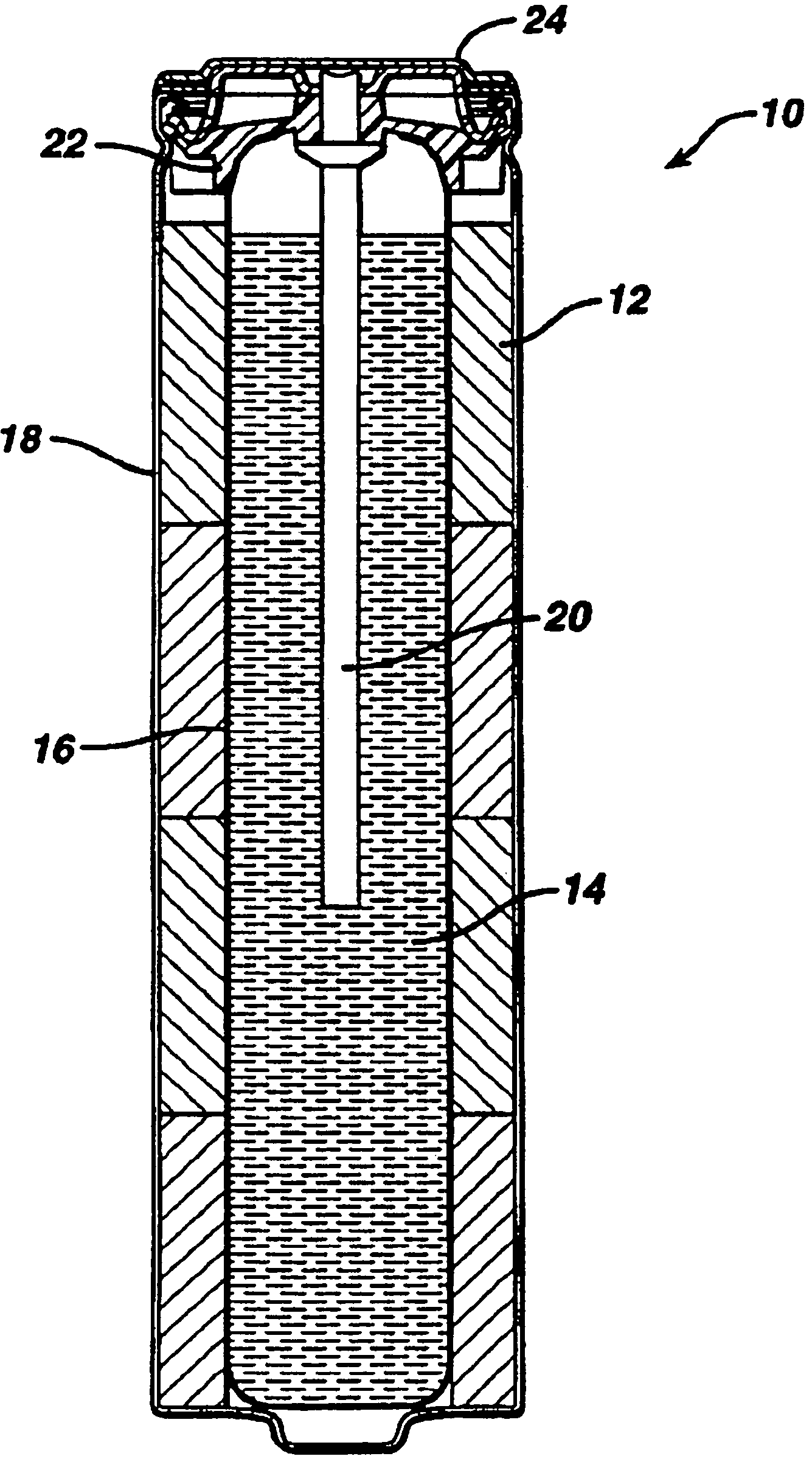

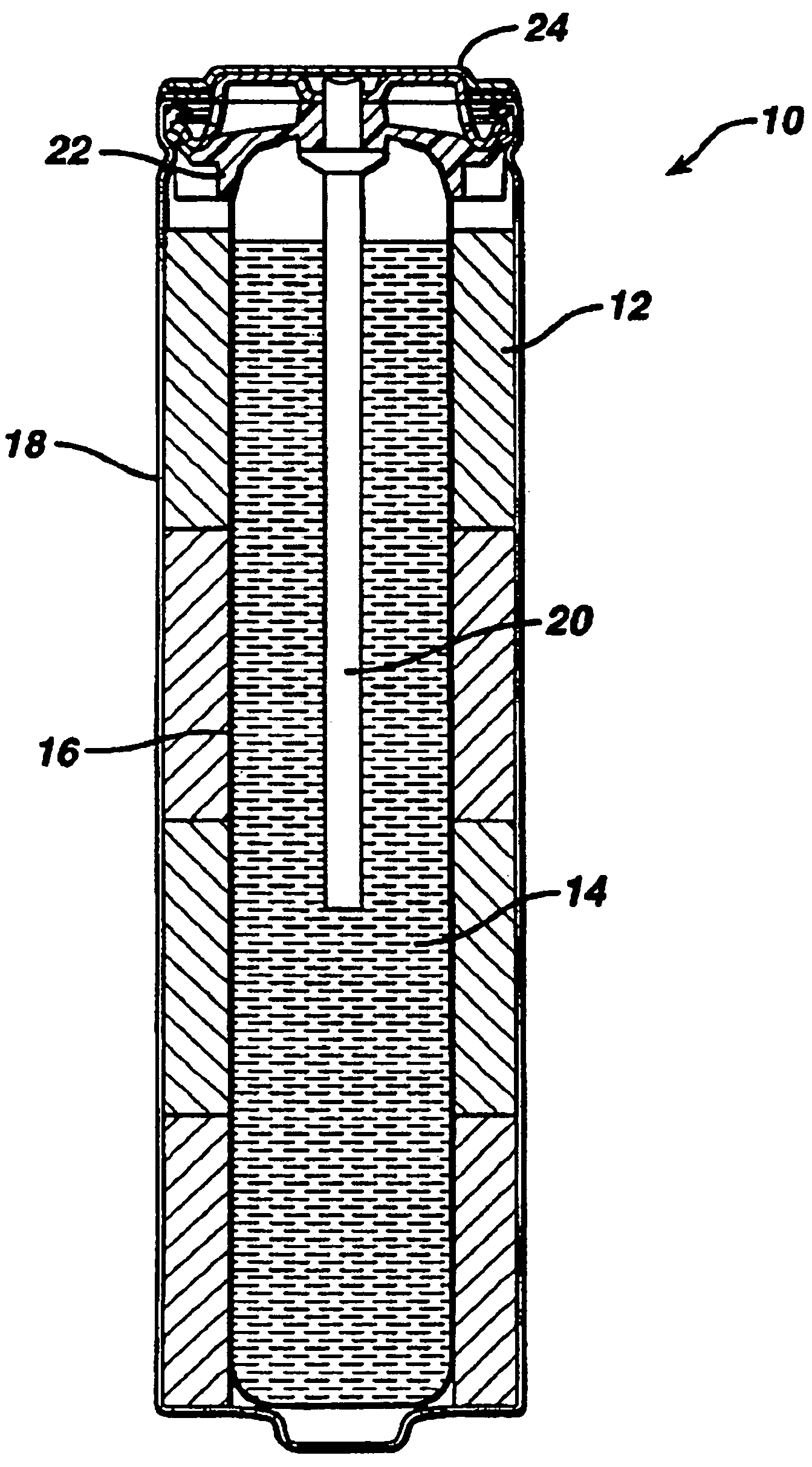

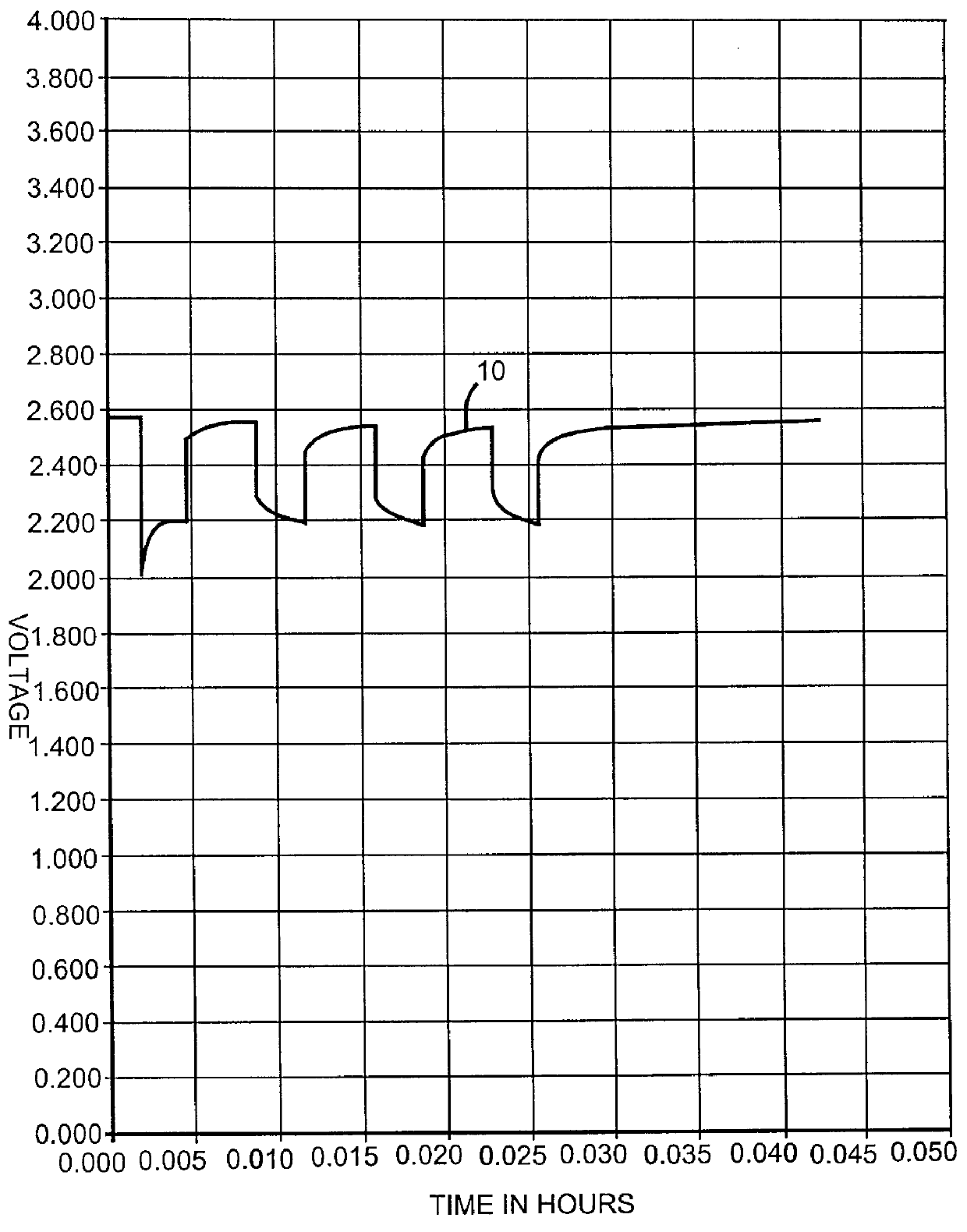

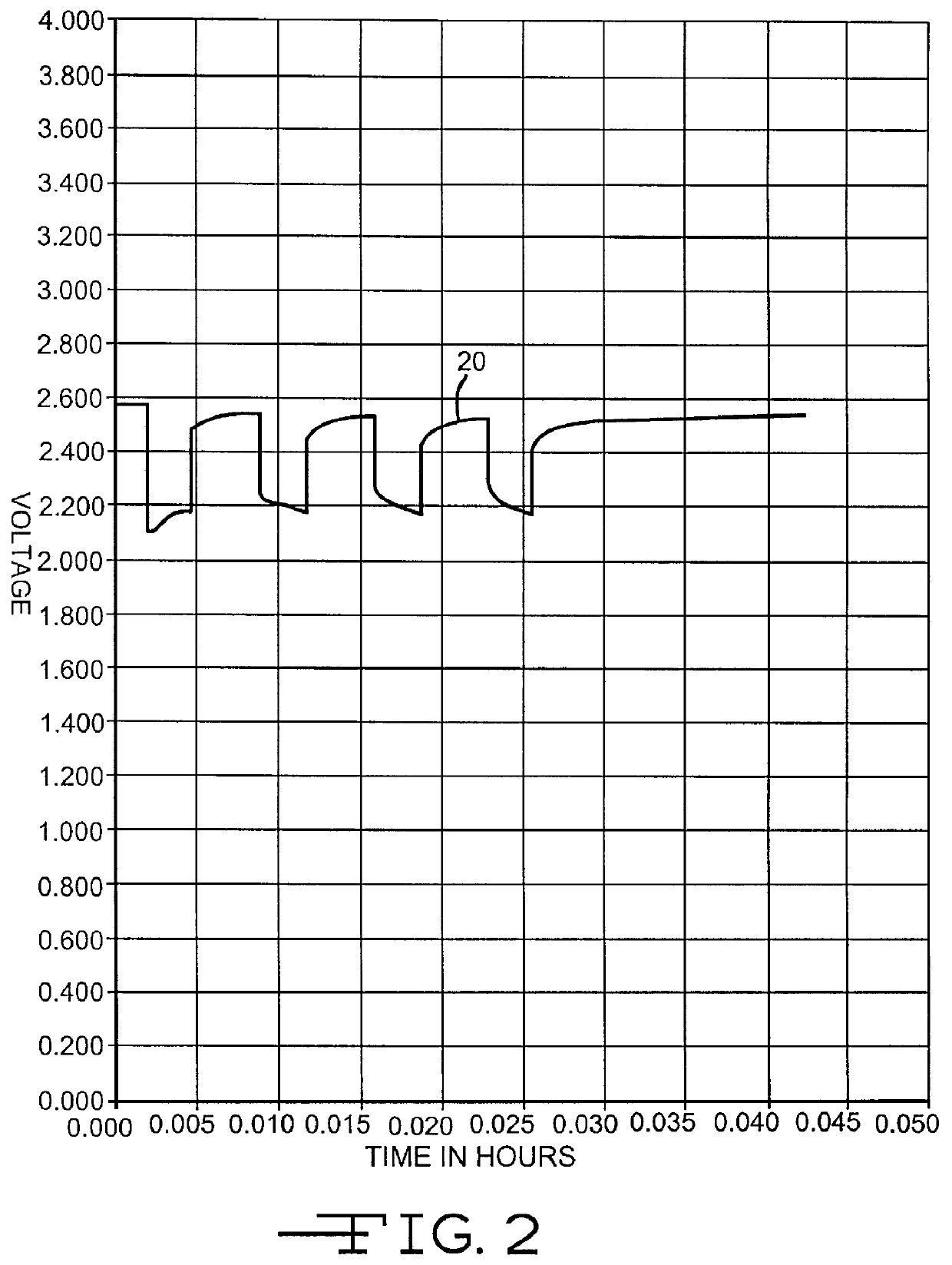

Inorganic and organic nitrate additives for nonaqueous electrolyte in alkali metal electrochemical cells

InactiveUS6060184AGood charge and discharge cycleImprove efficiencyOrganic electrolyte cellsSecondary cells charging/dischargingAlkaline earth metalOrganic nitrates

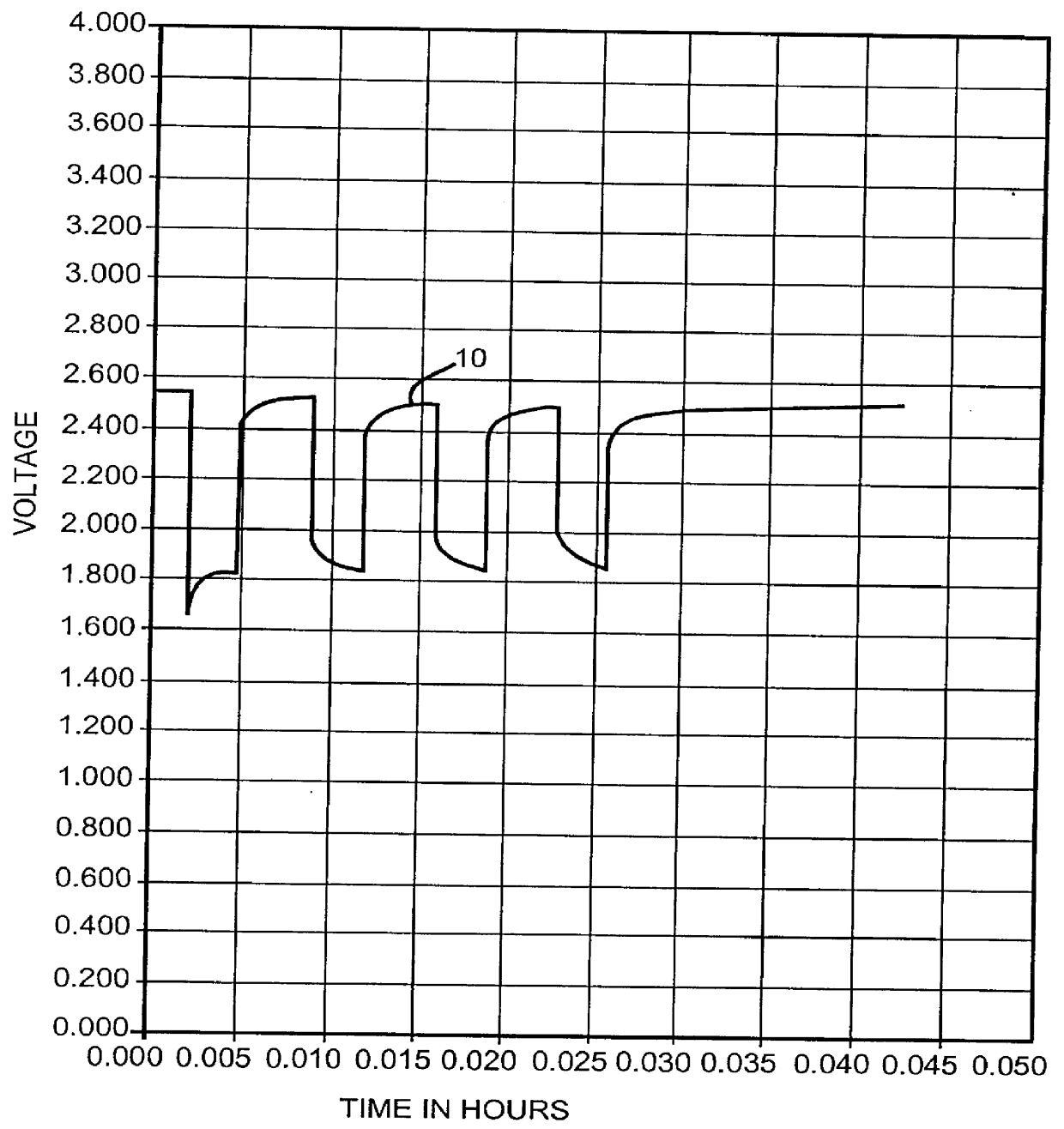

An alkali metal, solid cathode, nonaqueous electrochemical cell capable of delivering high current pulses, rapidly recovering its open circuit voltage and having high current capacity, is described. The stated benefits are realized by the addition of at least one nitrate additive to an electrolyte comprising an alkali metal salt dissolved in a mixture of a low viscosity solvent and a high permittivity solvent. A preferred solvent mixture includes propylene carbonate, dimethoxyethane and an alkali metal nitrate, alkaline earth metal nitrate and / or an organic alkyl nitrate additive.

Owner:WILSON GREATBATCH LTD

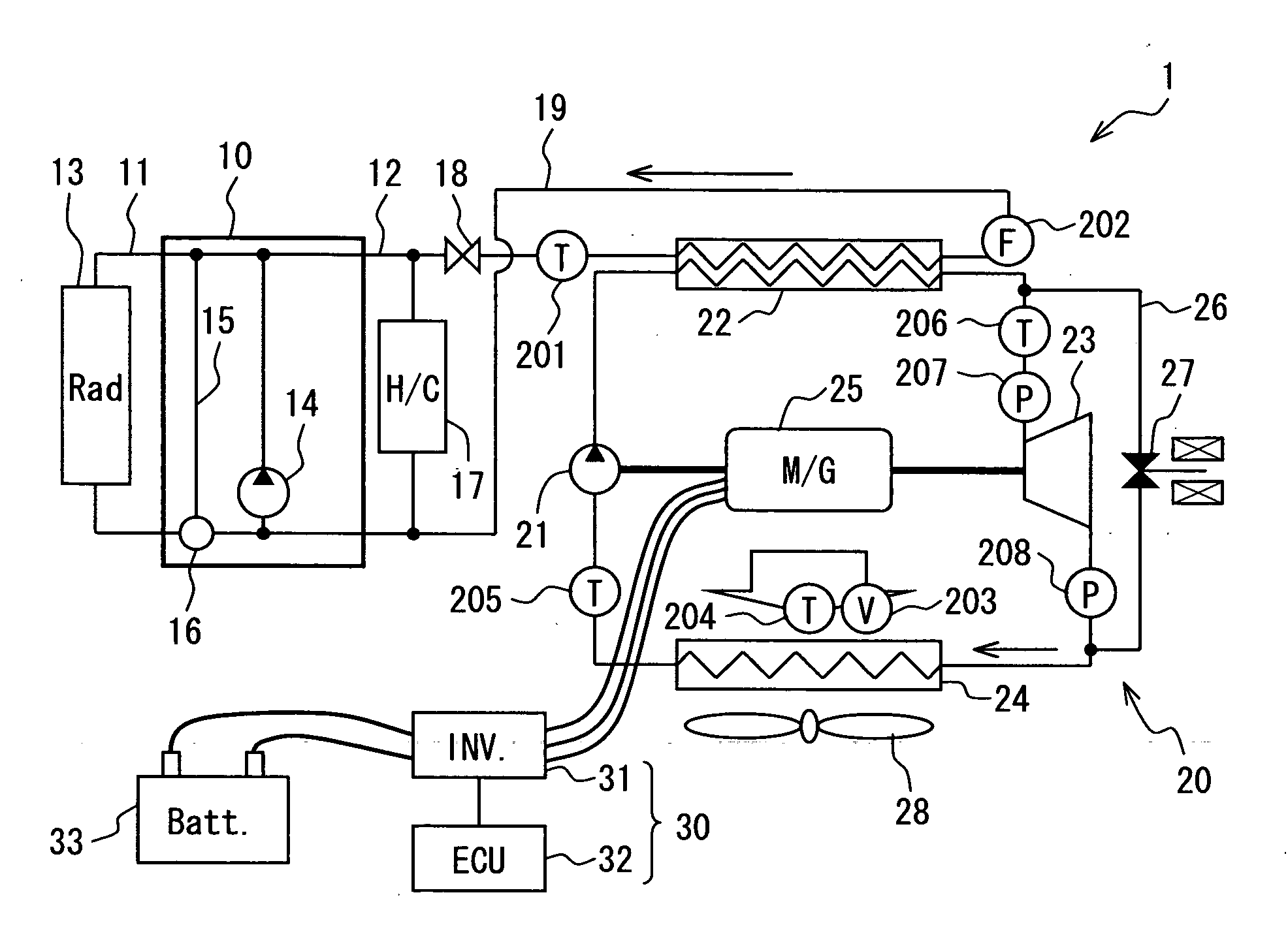

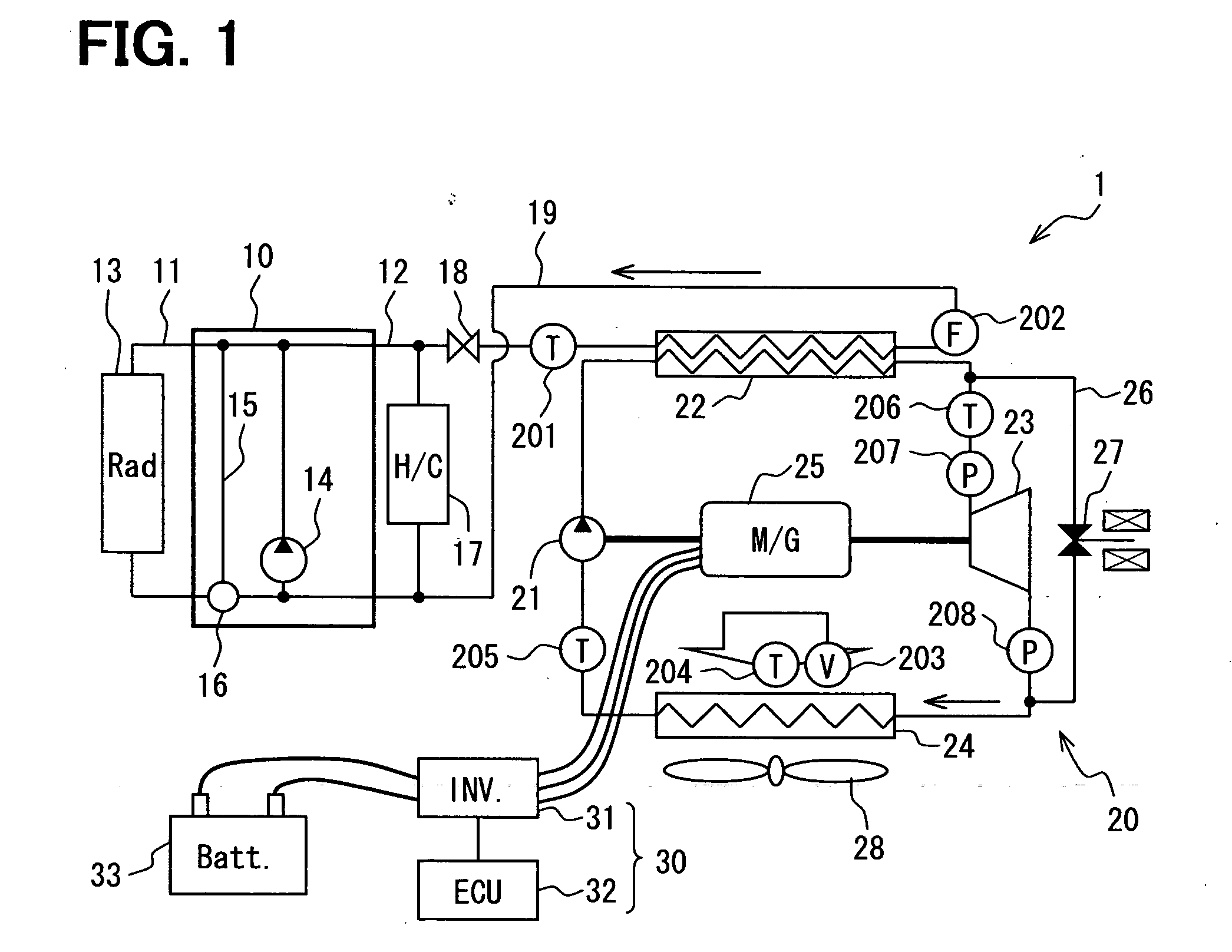

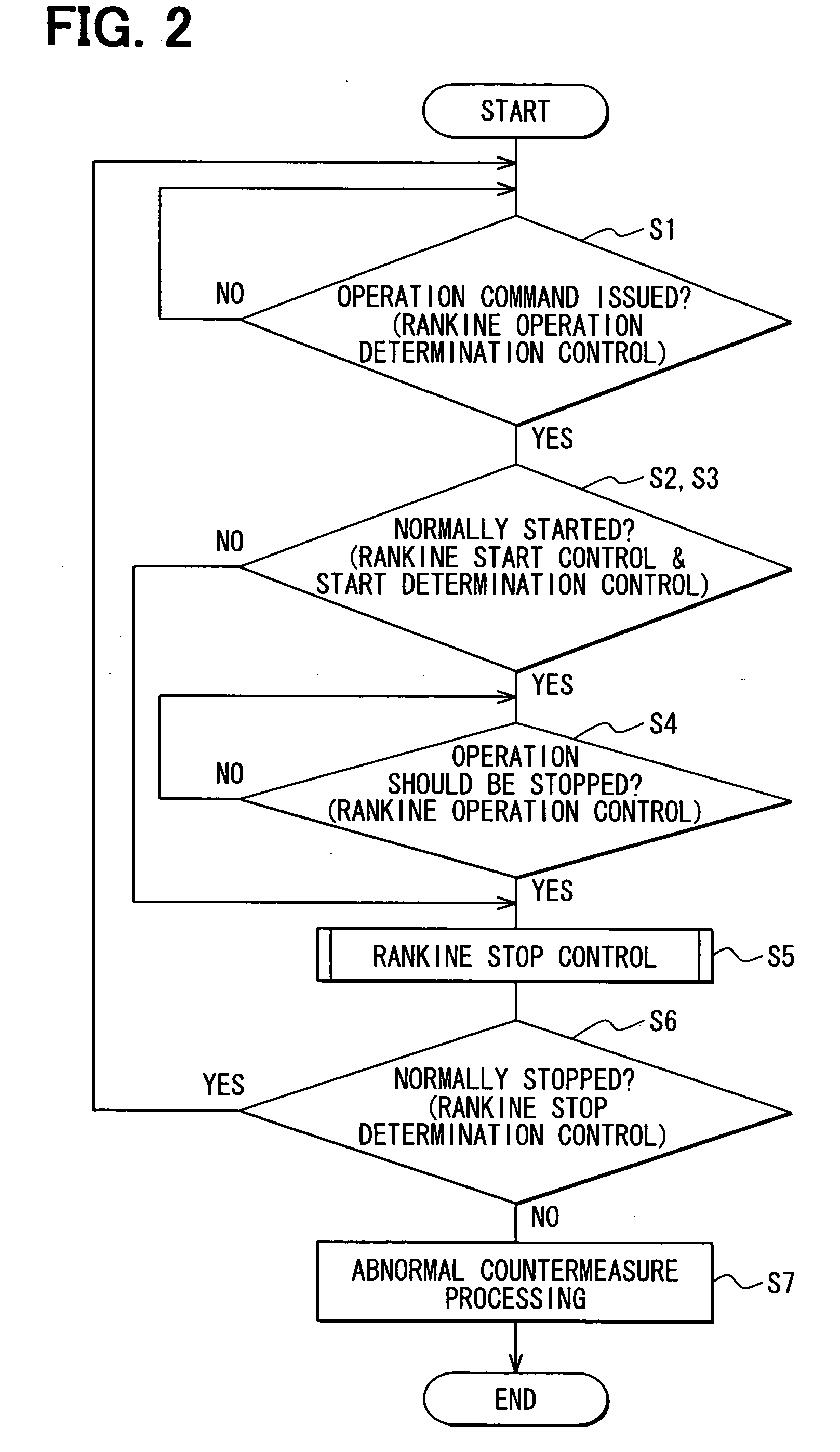

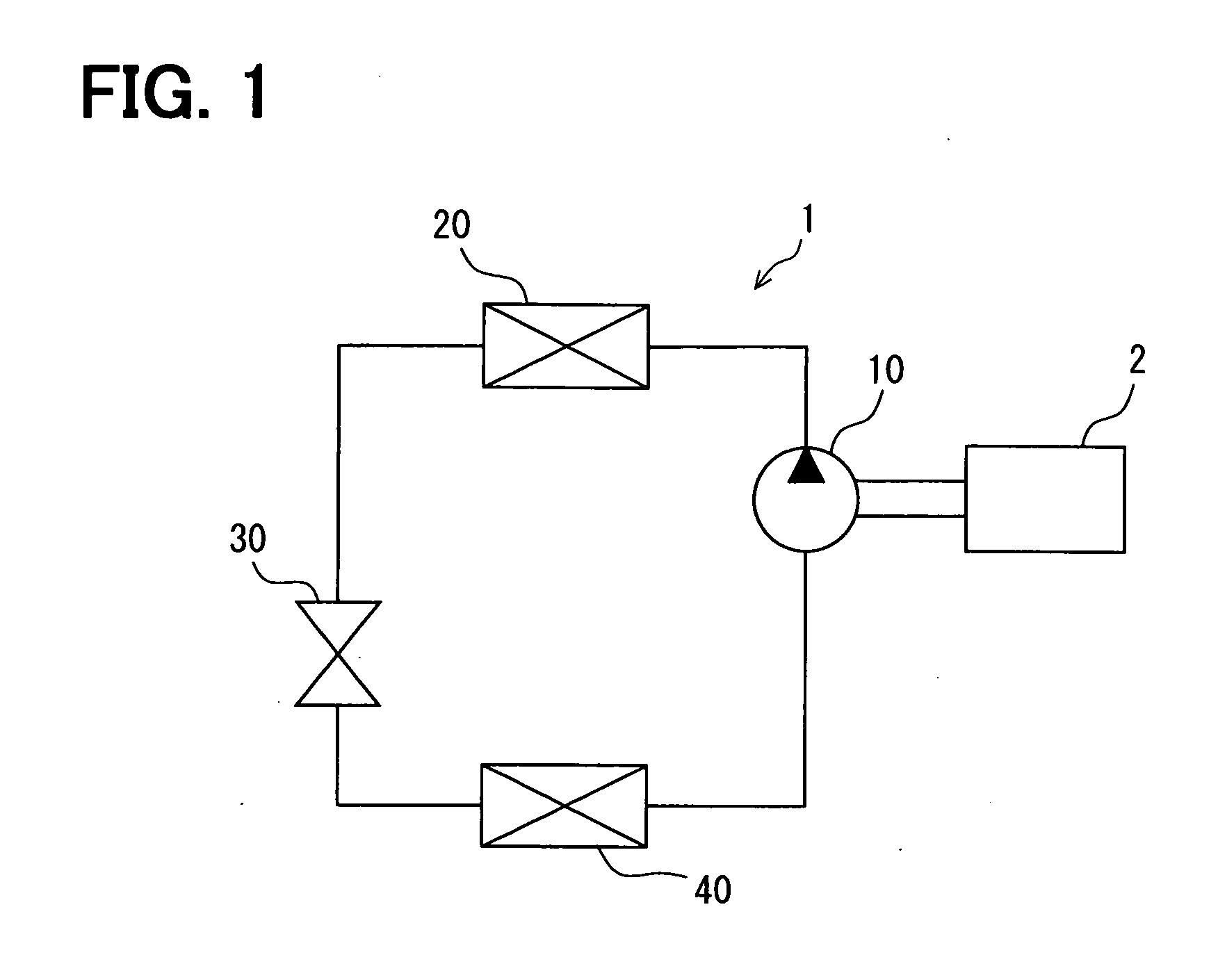

Waste heat recovery apparatus

InactiveUS20090071156A1High speedImprove discharge performanceInternal combustion piston enginesEngine componentsWorking fluidEngineering

A waste heat recovery apparatus including a Rankine cycle which includes a heater for heating an operation fluid by waste heat from a heat-generating device, an expansion unit for converting energy of expansion of the operation fluid flowing out from the heater into mechanical energy, and a condenser for condensing and liquefying the expanded operation fluid, a temperature detector for detecting the temperature of the operation fluid on the inlet side of the expansion unit, a pressure detector for detecting inlet-side pressure of the expansion unit, a pressure detector for detecting outlet-side pressure of the expansion unit, and a control unit. The control unit controls a command rotational speed of the expansion unit based on superheated degree information at the inlet of the expansion unit obtained from the operation fluid temperature and the inlet-side pressure, and pressure information in which the outlet-side pressure is considered.

Owner:DENSO CORP +1

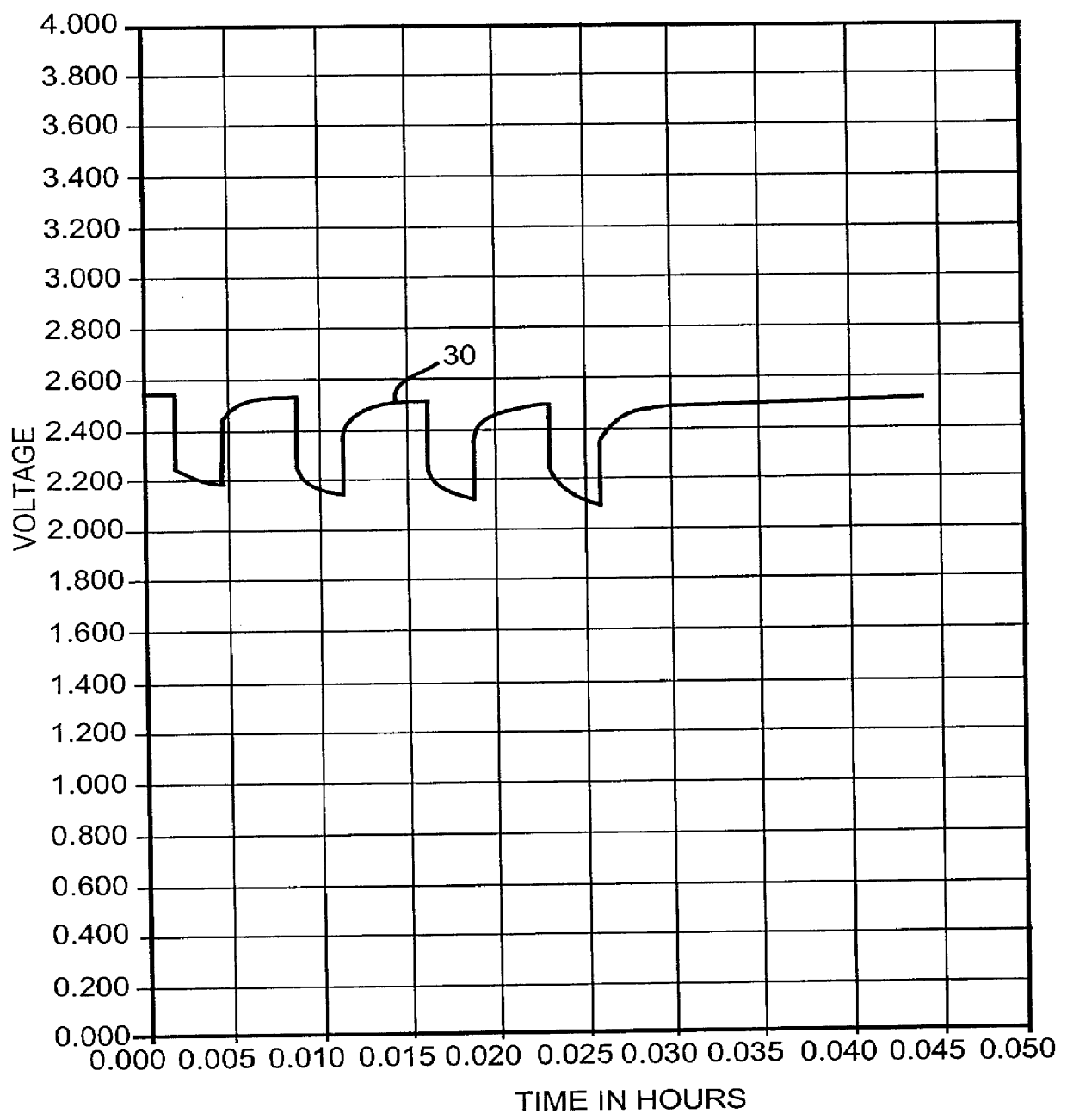

Phosphonate additives for nonaqueous electrolyte in alkali metal electrochemical cells

InactiveUS6096447AGood charge and discharge cycleImprove efficiencyOrganic electrolyte cellsHeart stimulatorsPermittivityPropylene carbonate

An alkali metal, solid cathode, nonaqueous electrochemical cell capable of delivering high current pulses, rapidly recovering its open circuit voltage and having high current capacity, is described. The stated benefits are realized by the addition of at least one phosphonate additive to an electrolyte comprising an alkali metal salt dissolved in a mixture of a low viscosity solvent and a high permittivity solvent. A preferred solvent mixture includes propylene carbonate, dimethoxyethane and an alkyl phosphonate additive.

Owner:WILSON GREATBATCH LTD

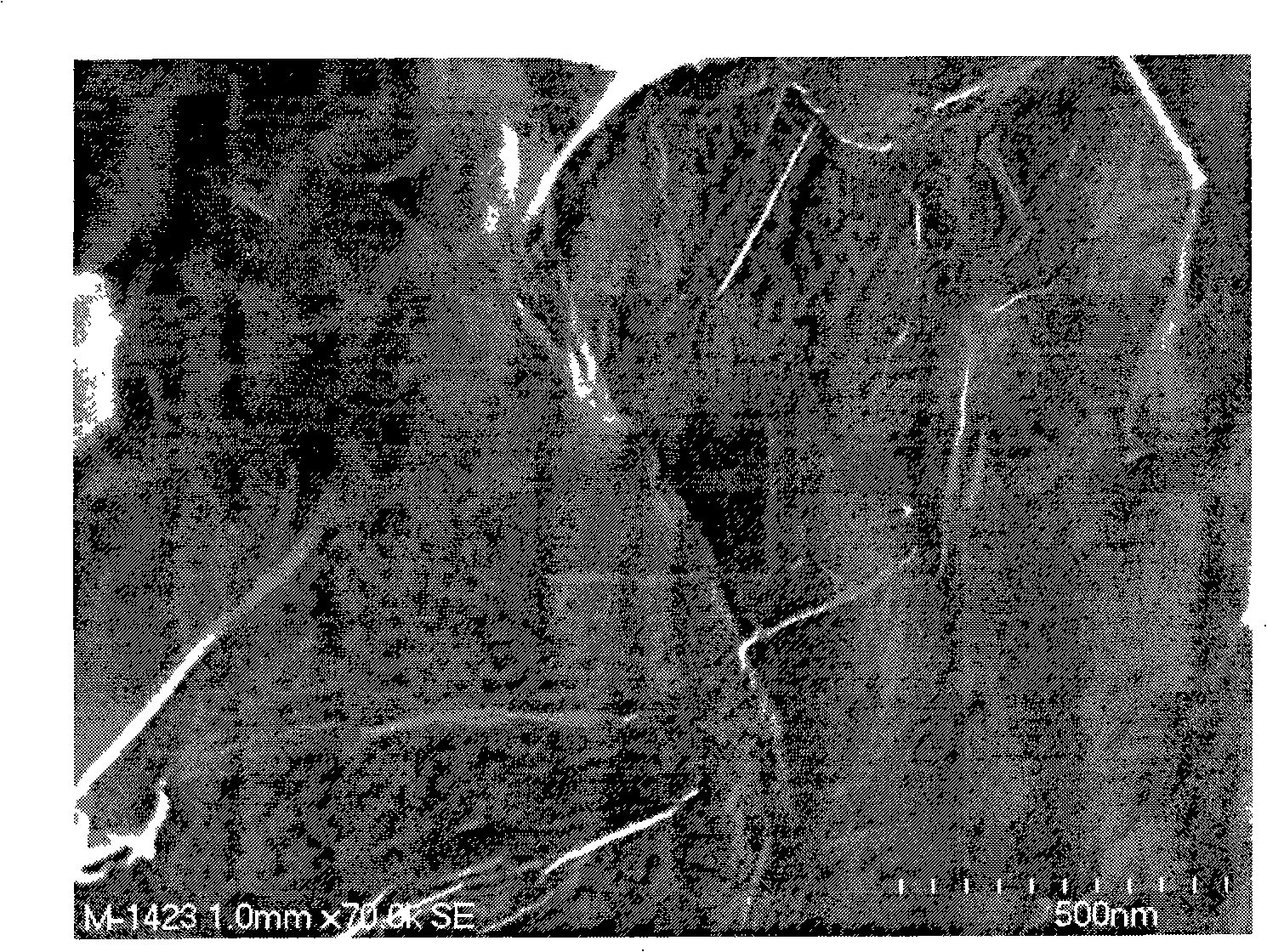

Graphite powder of lithium ionic cell cathode and preparation thereof

ActiveCN101323447AHigh purityImprove liquid absorption capacityCell electrodesSpherical shapedGraphite

The invention discloses a graphite powder of the cathode of a lithium ion battery, and a preparation method thereof; the technical problem to be solved is that the transmission speed of a lithium ion and an electrolyte to the inside of the electrode needs to be increased. The graphite powder of the cathode of the lithium ion battery of the invention has the microscopic feature of massive, spherical and near-spherical shapes and has the characteristics of nano-porous. The preparation method thereof comprises the following steps of: grinding, adding coating modifiers or / and catalysts, mixing, dissolving, and carrying out preheating treatment and heat treatment. Compared with the prior art, the invention carries out modifying treatment to graphite material and realizes the characteristic of nano-porous by adding pore-forming agents, thus being beneficial to the transmission of the lithium ion, improving the liquid-absorbing performance of a pole piece after compaction, reducing the content of impurity in the graphite, improving the liquid-absorbing performance and the magnification performance of the graphite material, meeting the requirements of the lithium ion dynamic battery for the compatibility and the charging and discharging performance with large magnification of the electrolyte of the graphite material and having the advantages of lower production cost, simple technique and easy industrialization.

Owner:BTR NEW MATERIAL GRP CO LTD

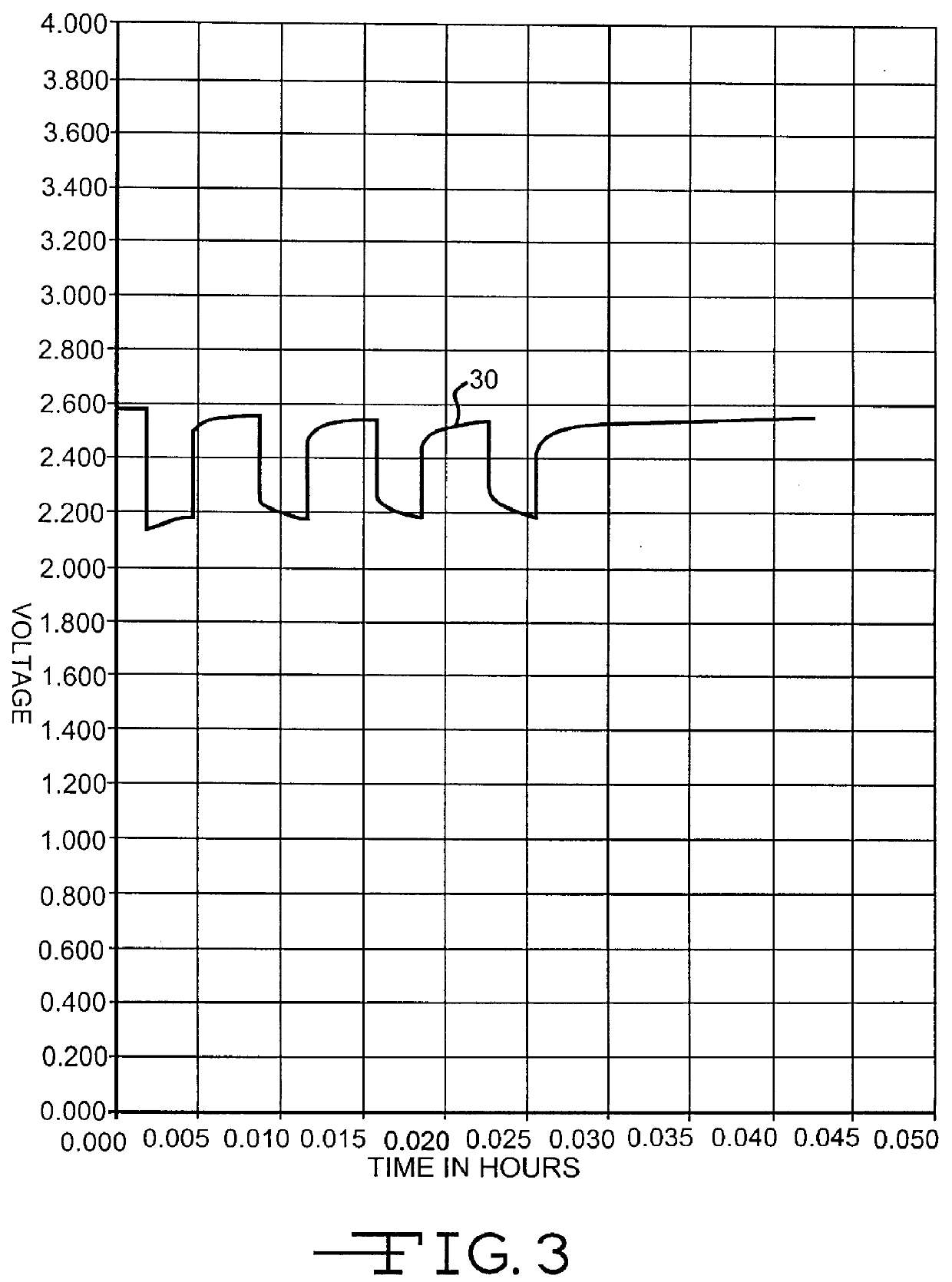

Methods of charging lithium sulfur cells

ActiveUS20050156575A1Reduce the probability of reactionLow self-discharge rateCell electrodesPrimary cellsLithium–sulfur batteryLithium sulfur

Owner:SION POWER CORP

Cathode active material powder for lithium secondary battery

ActiveUS20070099087A1Large volume capacity densityHigh safetyPositive electrodesCobalt compoundsComposite oxideCharge and discharge

It is to provide a cathode active material powder for a positive electrode for a lithium secondary battery, which has a large volume capacity density, high safety and excellent durability for charge and discharge cycles. A cathode active material powder for a lithium secondary battery characterized by comprising a first composite oxide powder represented by the formula (1) LipQxMyOzFa (wherein Q is Co or Mn, M is aluminum or an alkaline earth metal element or a transition metal element other than Q, provided that when Q is Co, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02, and when Q is Mn, 1≦p≦1.3, x=2−y, 0≦y≦0.05, z=4, and a=0), having an average particle size D50 of from 5 to 30 μm, and having a compression breaking strength of at least 40 MPa; and a second composite oxide powder represented by the formula (2) LipNixCoyMnzNqOrFa (wherein N is aluminum or an alkaline earth metal element or a transition metal element other than Ni, Co and Mn, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦y≦0.4, 0≦z≦0.5, 0≦q≦0.05, 1.9≦r≦2.1, x+y+z+q=1, and 0≦a≦0.02), having an average particle size D50 of from 2 to 30 μm, and having a compression breaking strength less than 40 MPa; in a ratio (weight ratio) of the first composite oxide powder / the second composite oxide powder being from 95 / 5 to 30 / 70.

Owner:SUMITOMO CHEM CO LTD

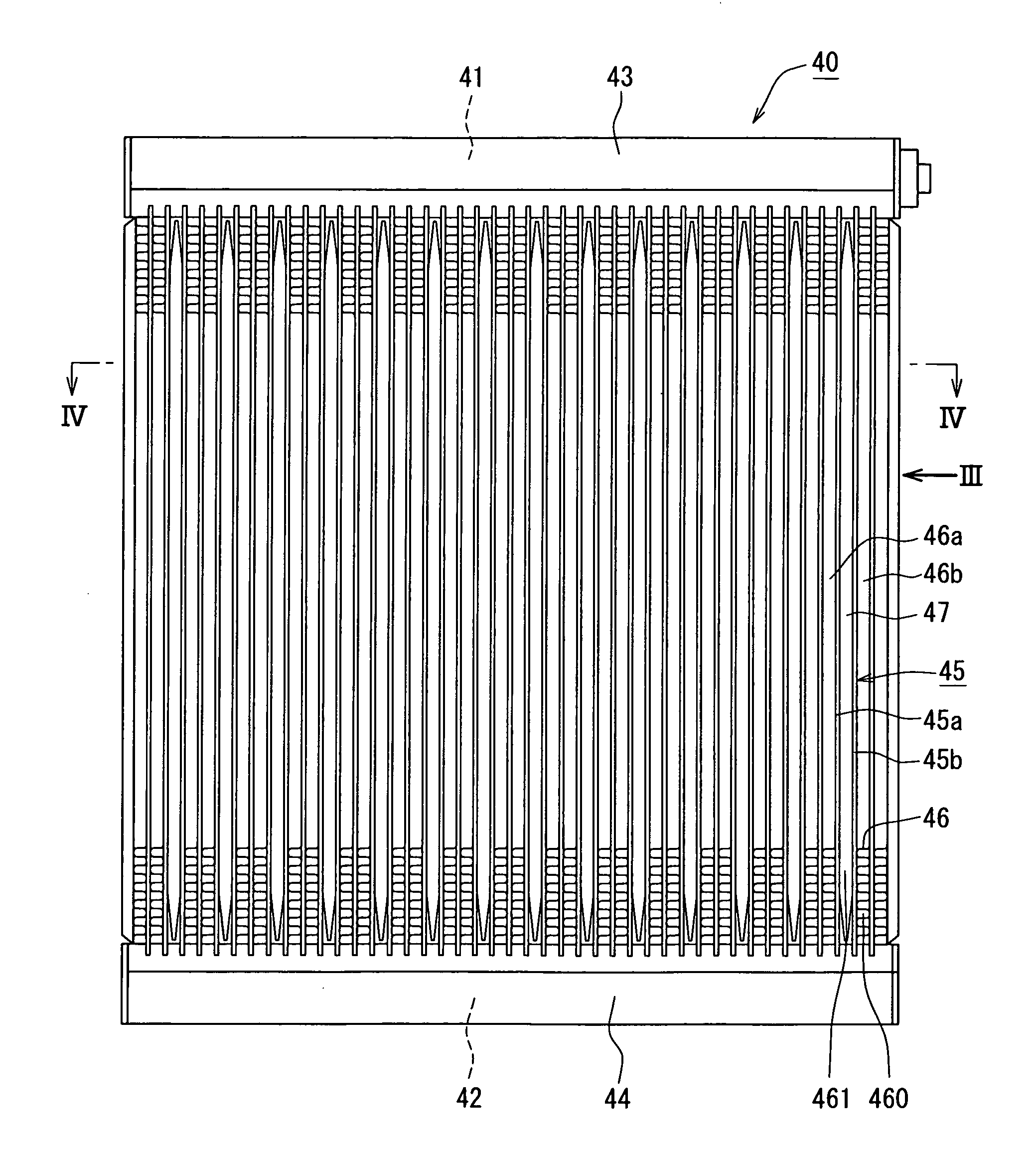

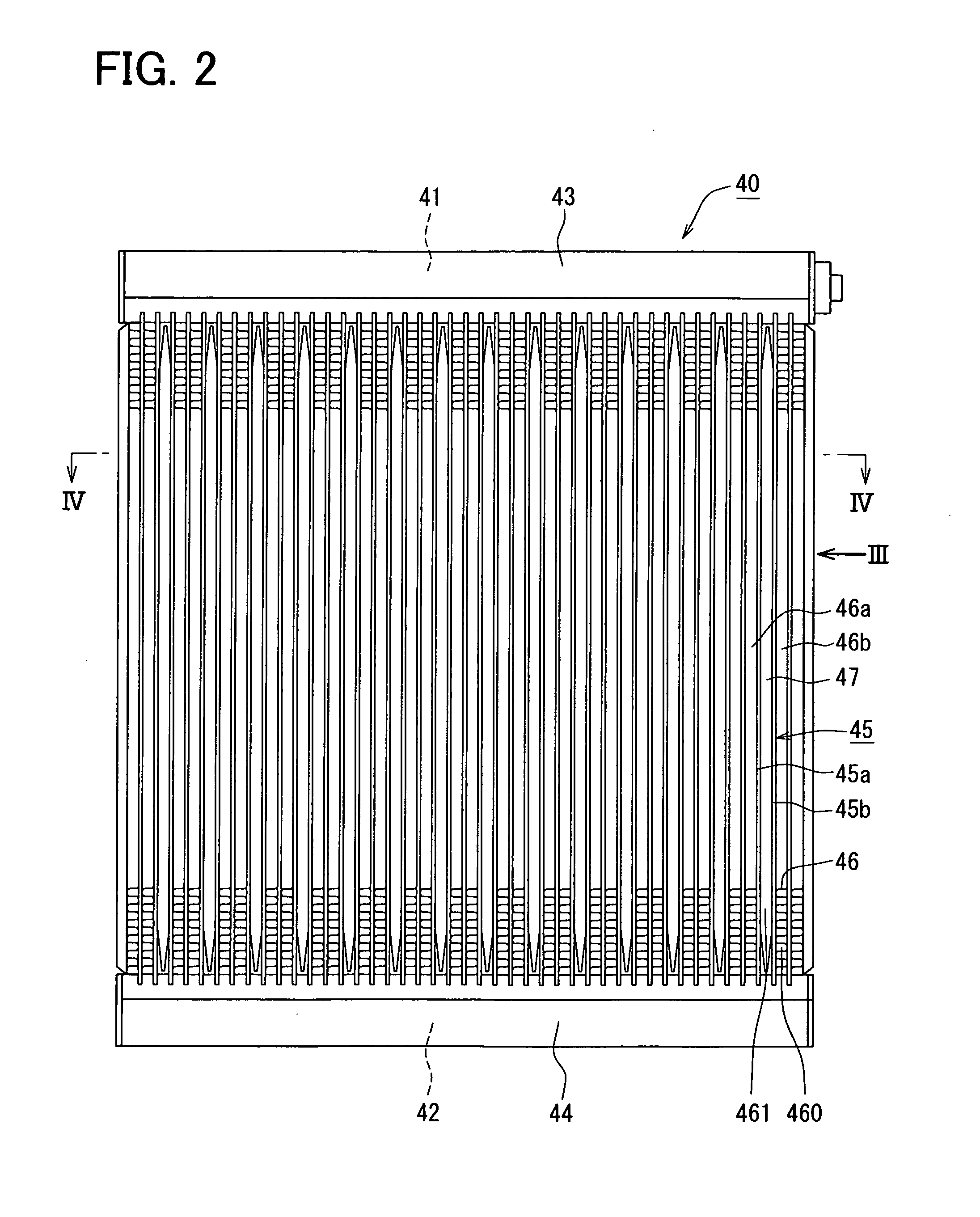

Cold-storage heat exchanger

ActiveUS20100307180A1Increase volumeReduce heat transferHeat storage plantsEvaporators/condensersPlate heat exchangerRelease time

An outer surface of a cold-storage container (or a refrigerant tube) is provided with a plurality of protrusion portions or recess portions. A cooling air passage, in which air flows to cool a space to be cooled in a cold storage time and in a cold release time of the cold storage material, is provided to contact a surface of the refrigerant tube on a side opposite to the cold storage container bonded to the refrigerant tube. The refrigerant tubes and the cold storage container form therebetween a cold-storage side air passage by the protrusion portions or the recess portions, such that air flows in the cold-storage side air passage separated from the cooling air passage. For example, the cold-storage side air passage is provided with a slanting space that causes condensed water or ice generated in the cold storage time to be drained along the cold-storage side air passage.

Owner:DENSO CORP

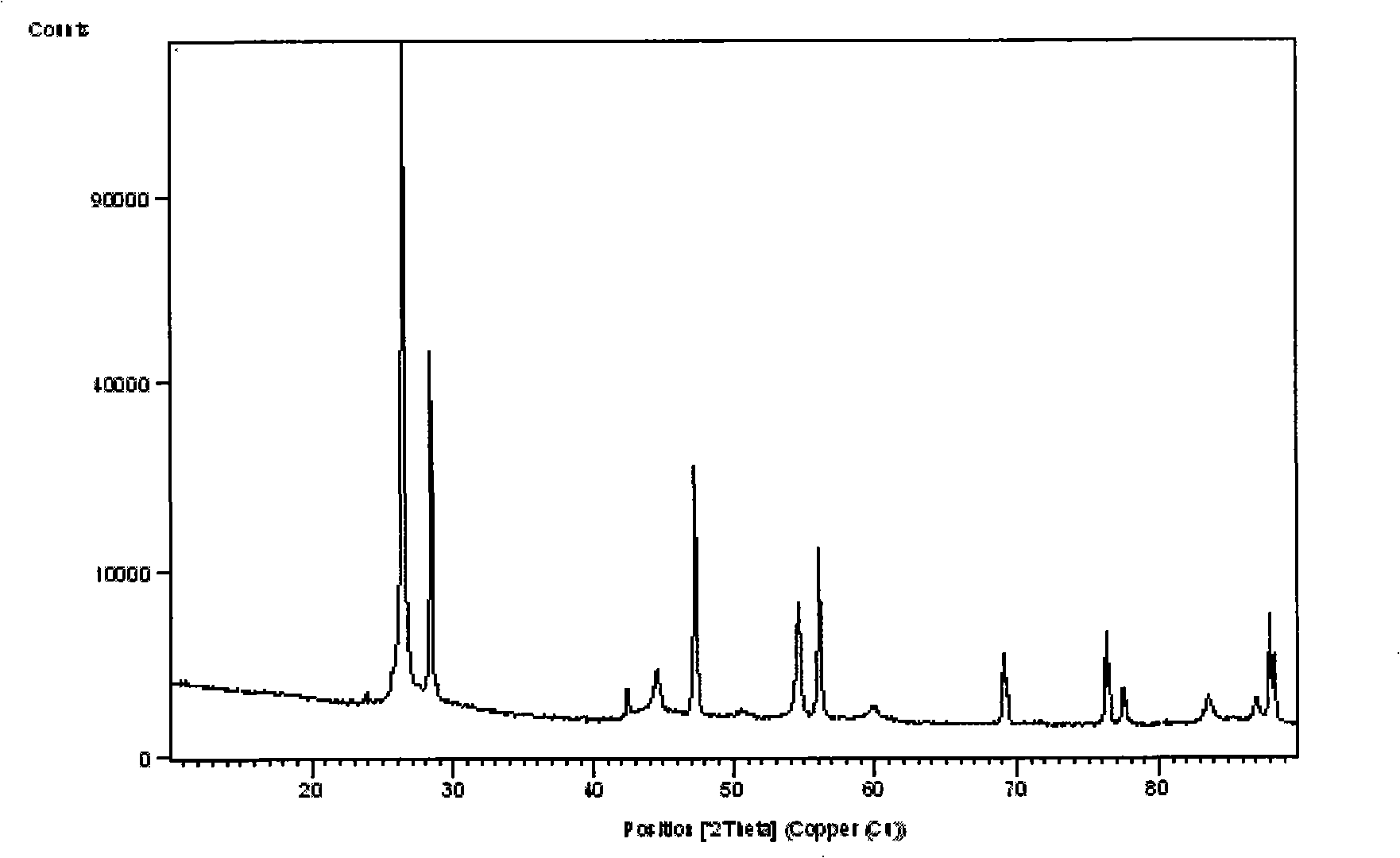

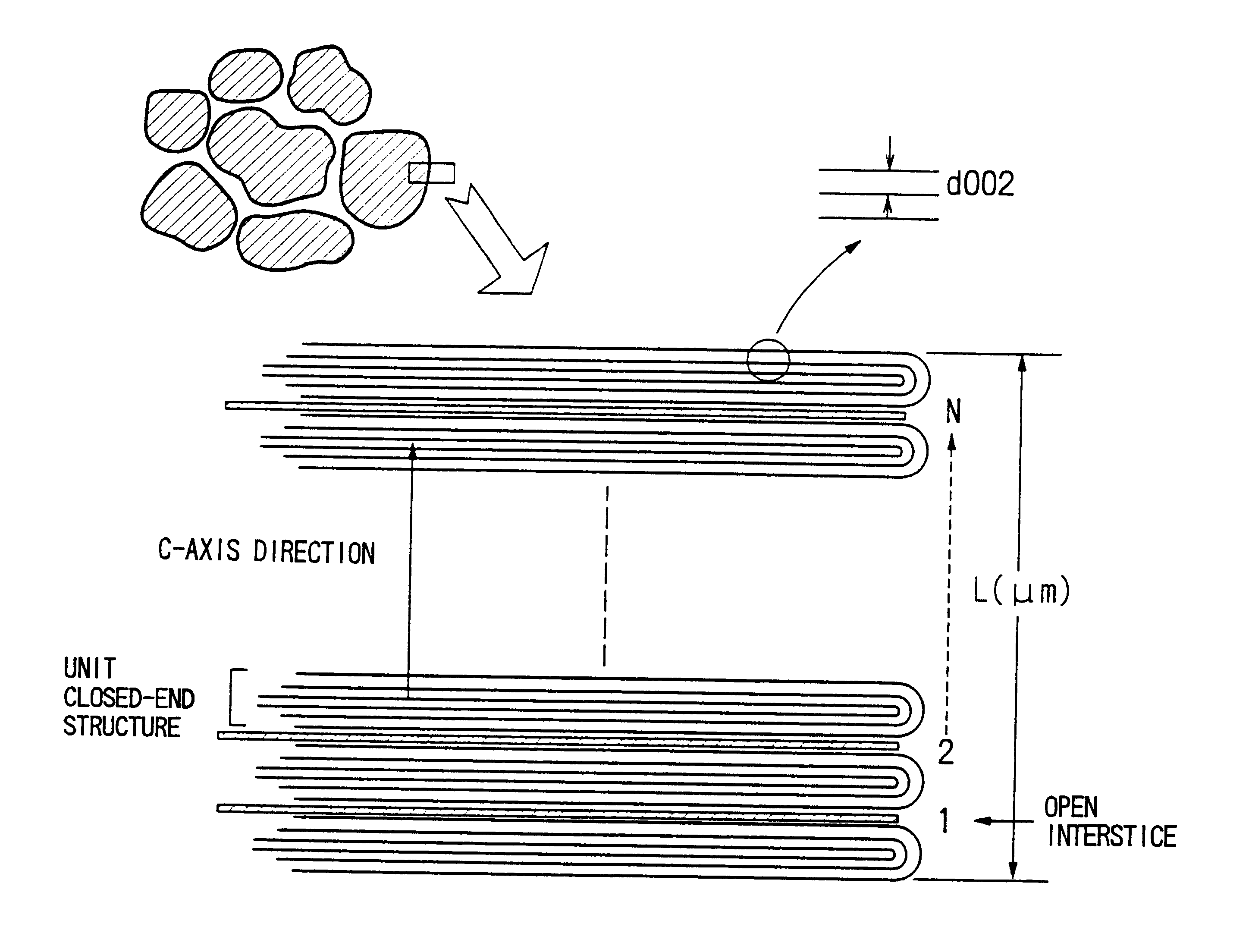

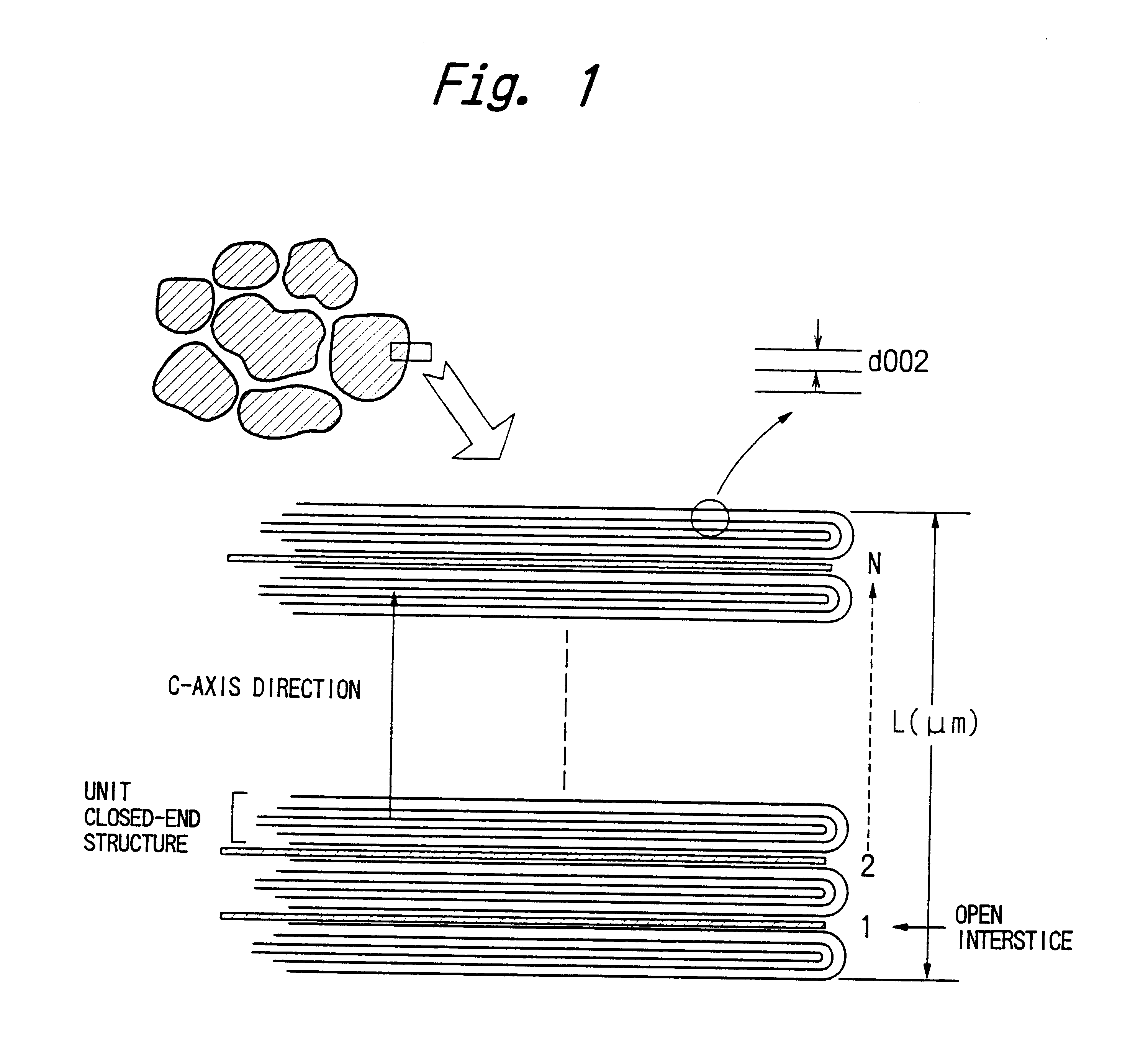

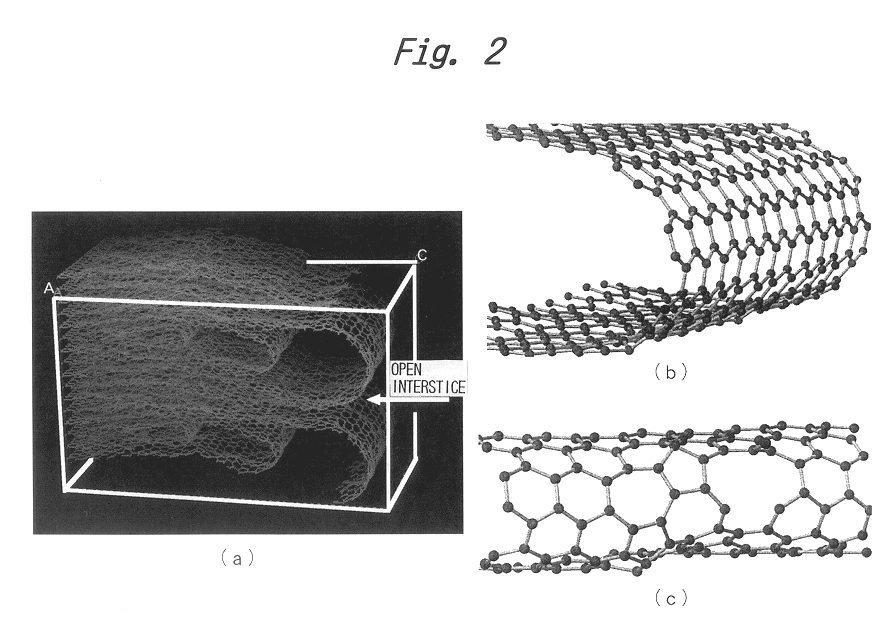

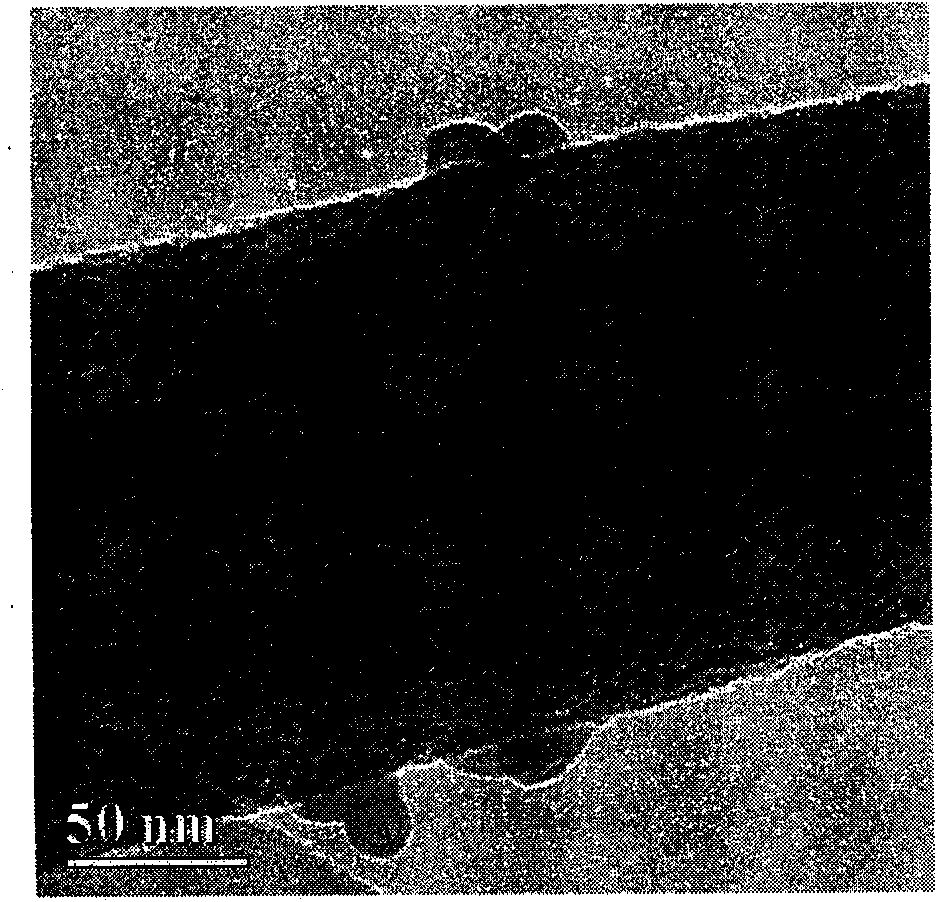

Graphite powder suitable for negative electrode material of lithium ion secondary batteries

InactiveUS6576369B1Improve discharge capacityImprove Coulombic efficiencyNon-aqueous electrolyte accumulatorsGraphiteLithiumMicrometer

A graphite powder has surface closed-end structures in which the graphite c-plane layers of the graphite layer crystal lattices have closed-ends on the surface of the graphite powder by linking the ends of one or more pairs of the c-plane layers, leaving interstices which are open on the surface of the graphite. The number of open interstices is at least 100 and at most 1500 per micrometer in a c-axis direction of the graphite. Preferably, the graphite powder has a specific surface area of 1.0 m2 / g or less. Such a graphite powder can be prepared either by graphitizing a carbon material, which has been pulverized at a high speed under well-controlled conditions before and / or after the carbonization, or by subjecting a carbon material, which has been pulverized under well-controlled conditions before and / or after the carbonization, to graphitization and then to oxidative heat treatment at a temperature of 600-800° C. and finally to heat treatment at a temperature of 800° C. or higher in an inert gas. The graphite powder can be used to produce negative electrodes of lithium ion secondary batteries having a high discharge capacity of at least 320 mAh / g and a high charge / discharge coulombic efficiency of at least 90%.

Owner:NIPPON DENKO CO LTD +1

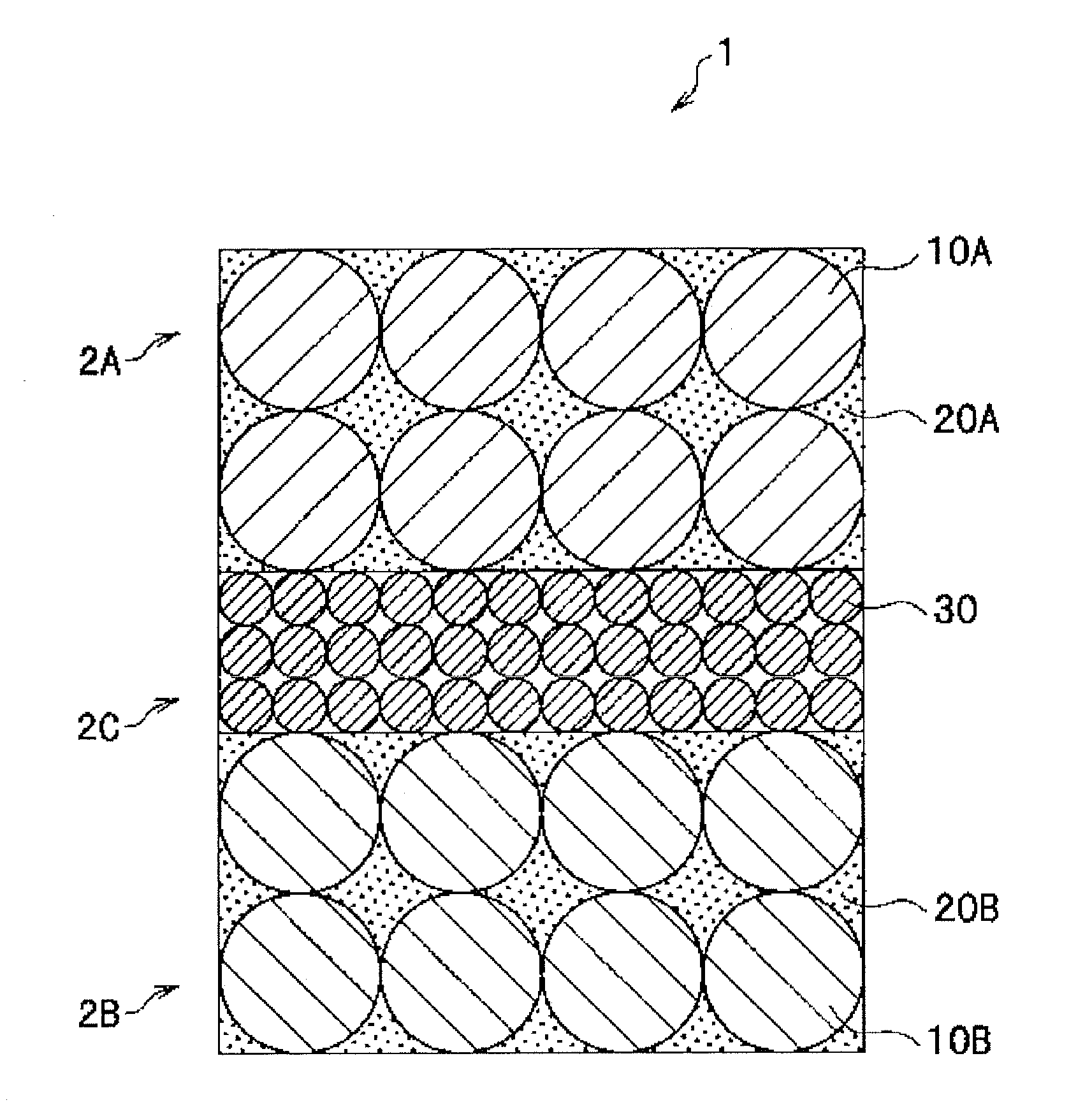

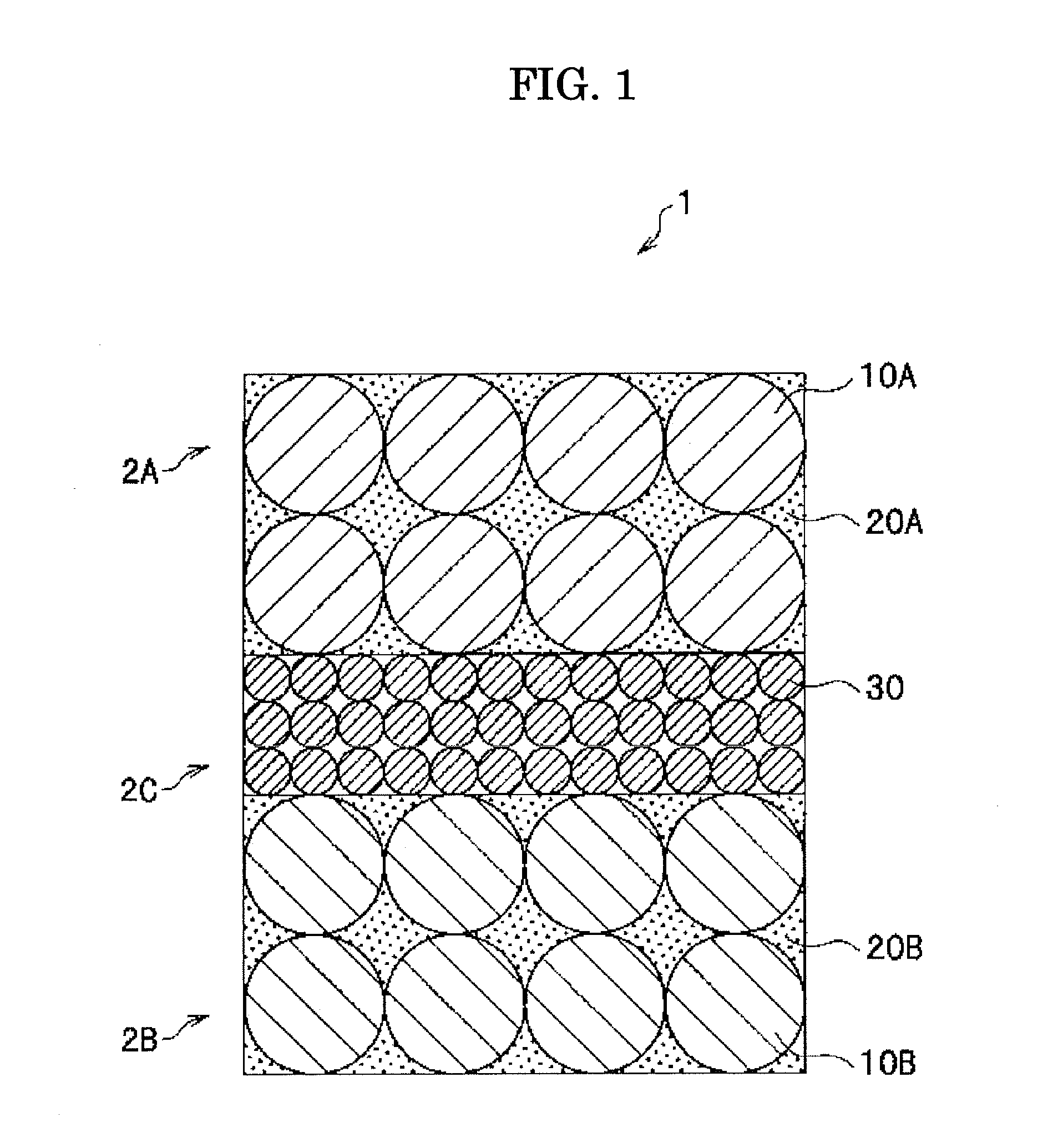

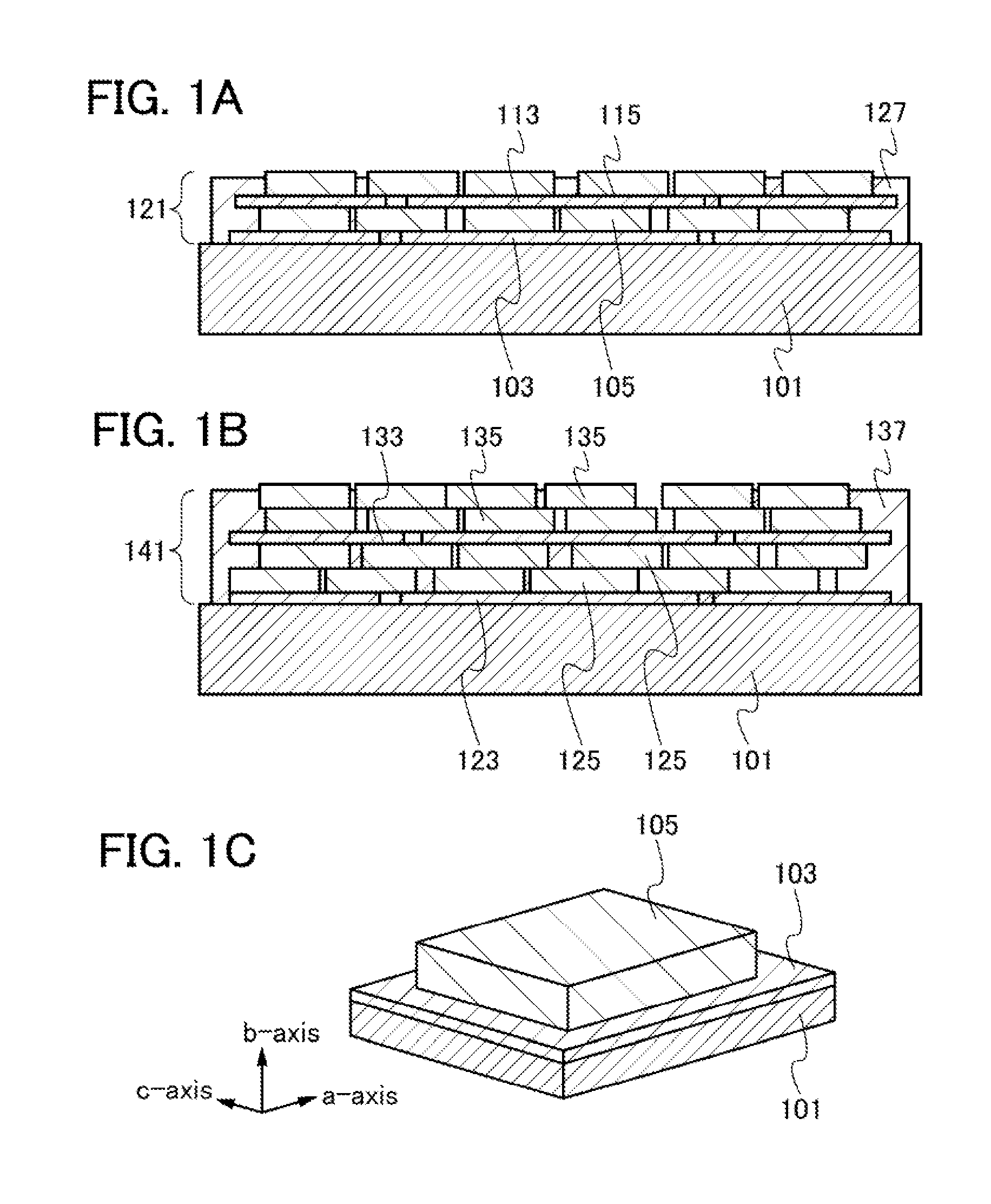

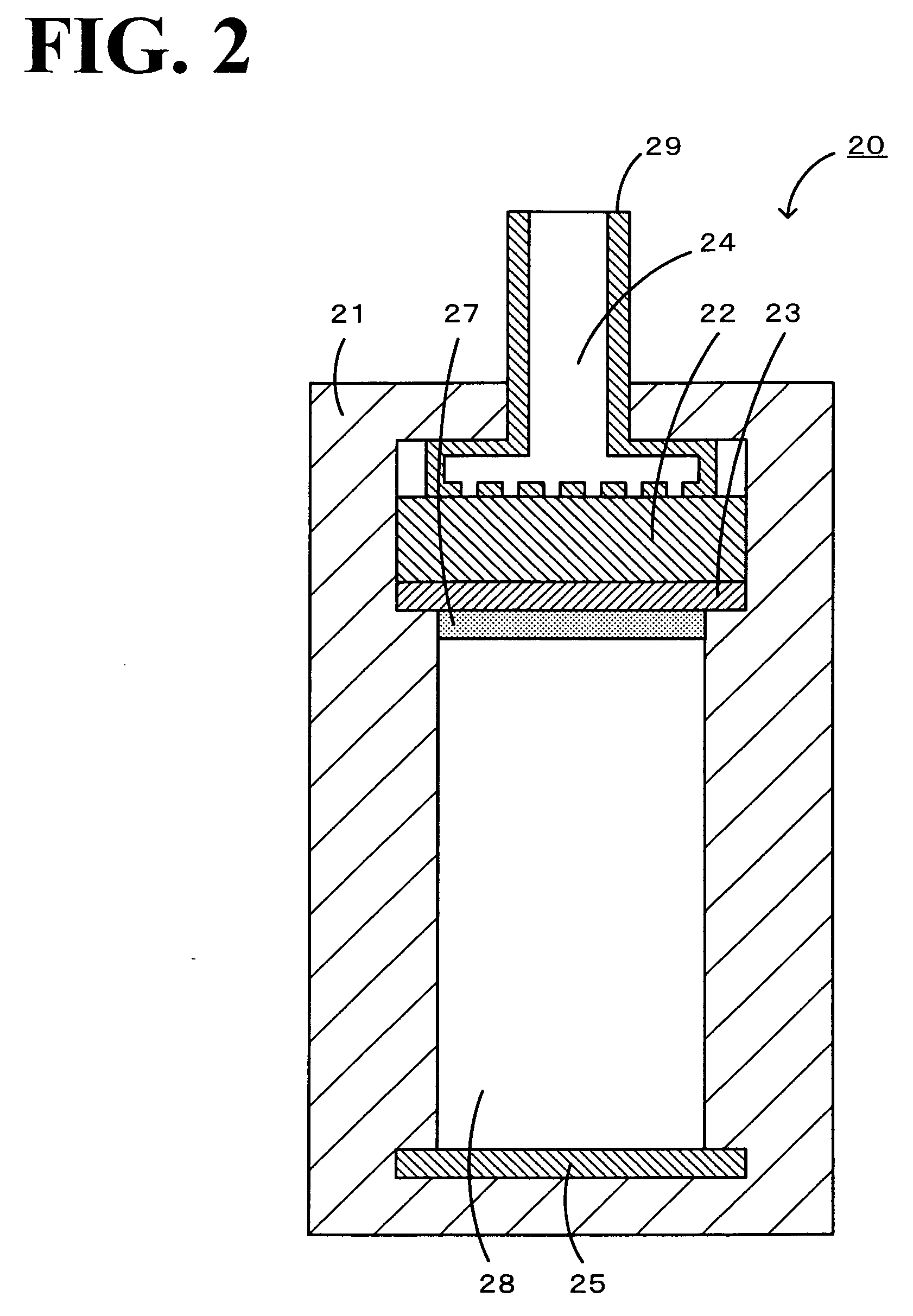

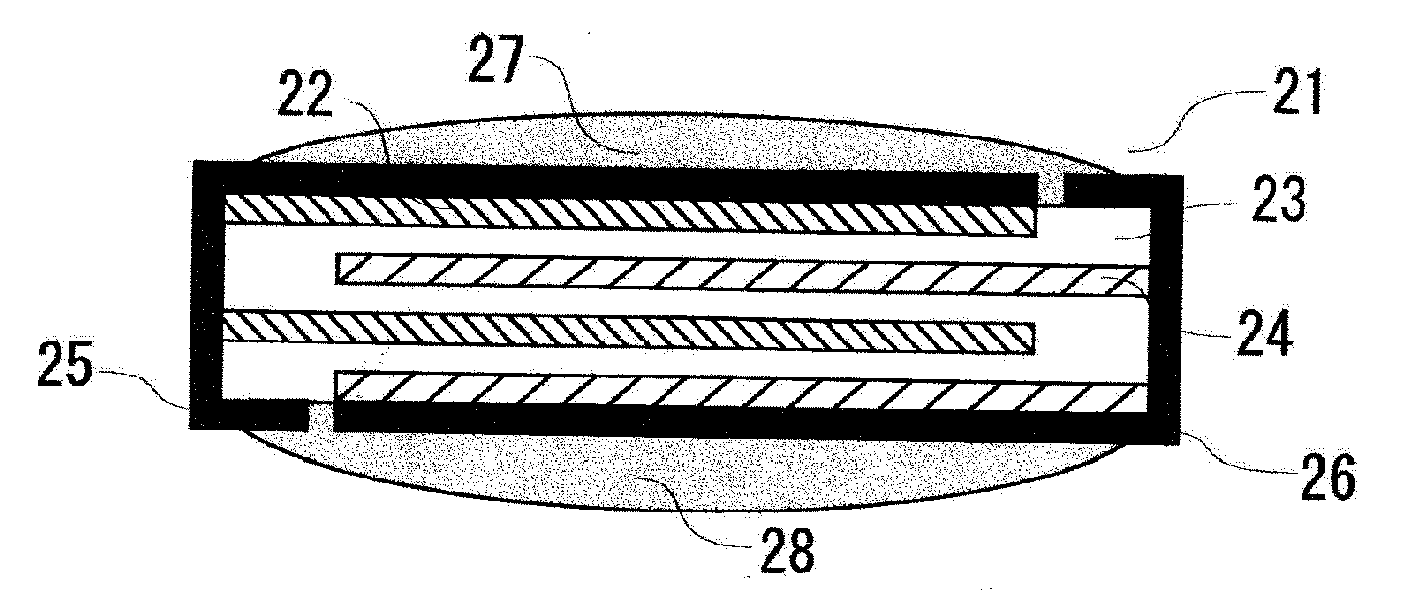

All-solid state battery, electrode for all-solid state battery, and method of manufacturing the same

InactiveUS20160233510A1Improve contact qualityImprove discharge performanceNon-aqueous electrolyte accumulatorsElectrode thermal treatmentAll solid stateEngineering

Provided are an all-solid state battery with a better quality of contact among particles of an active material and with an enhanced discharge capacity; an electrode for an all-solid state battery; and a method of manufacturing the same. The all-solid state battery is manufactured through the steps of: causing a deliquescent solid electrolyte to deliquesce, the deliquescent solid electrolyte having ionic conductivity, electronic conductivity and a deliquescent property; preparing an electrode mixture by mixing the deliquescent solid electrolyte having deliquesced and an active material together; heat-treating and shaping the electrode mixture to produce an electrode; and bonding the thus-produced electrode and a solid electrolyte layer with the solid electrolyte layer interposed between the electrode and another electrode which are paired to serve as a positive electrode and a negative electrode.

Owner:HITACHI LTD

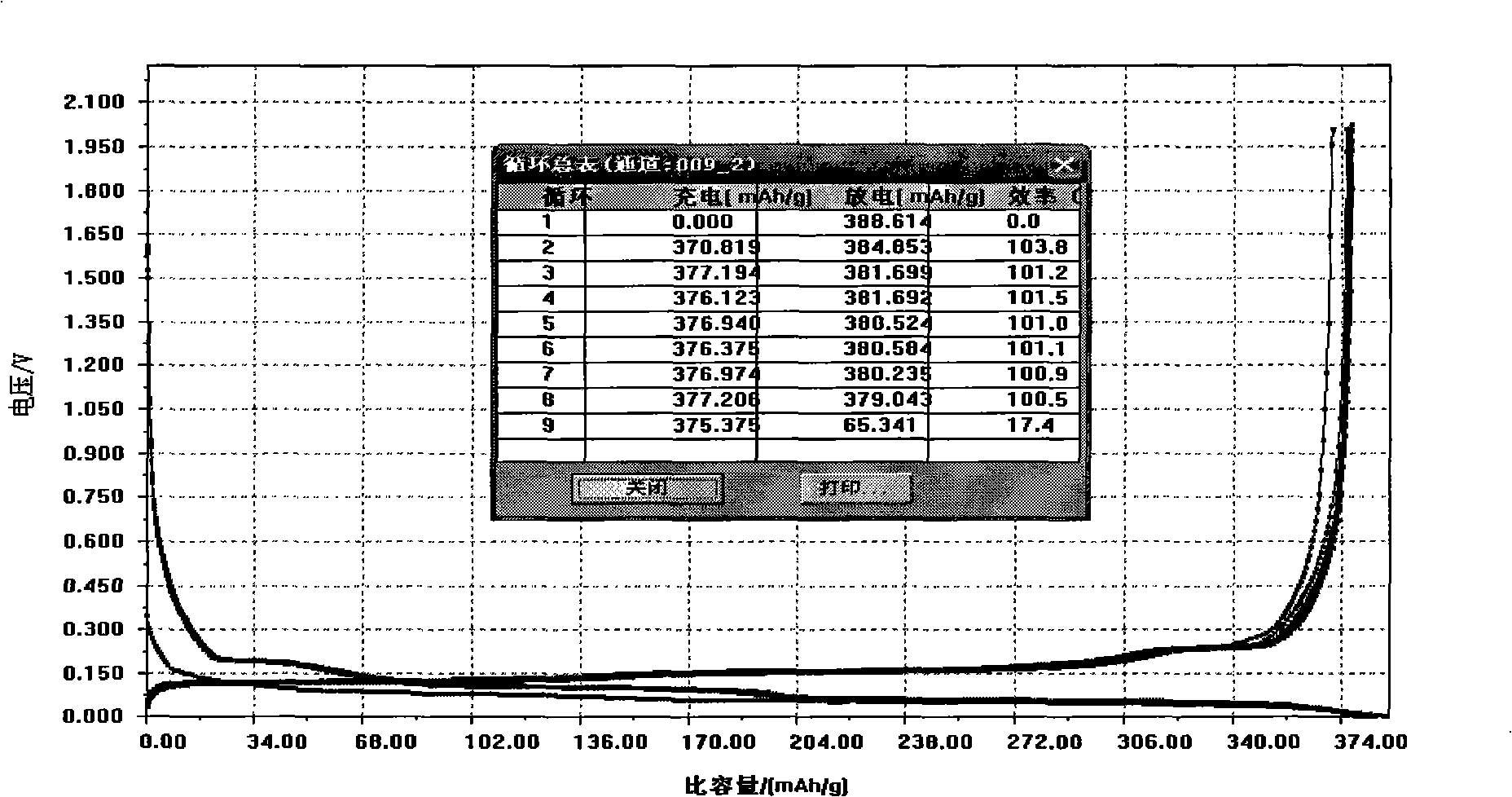

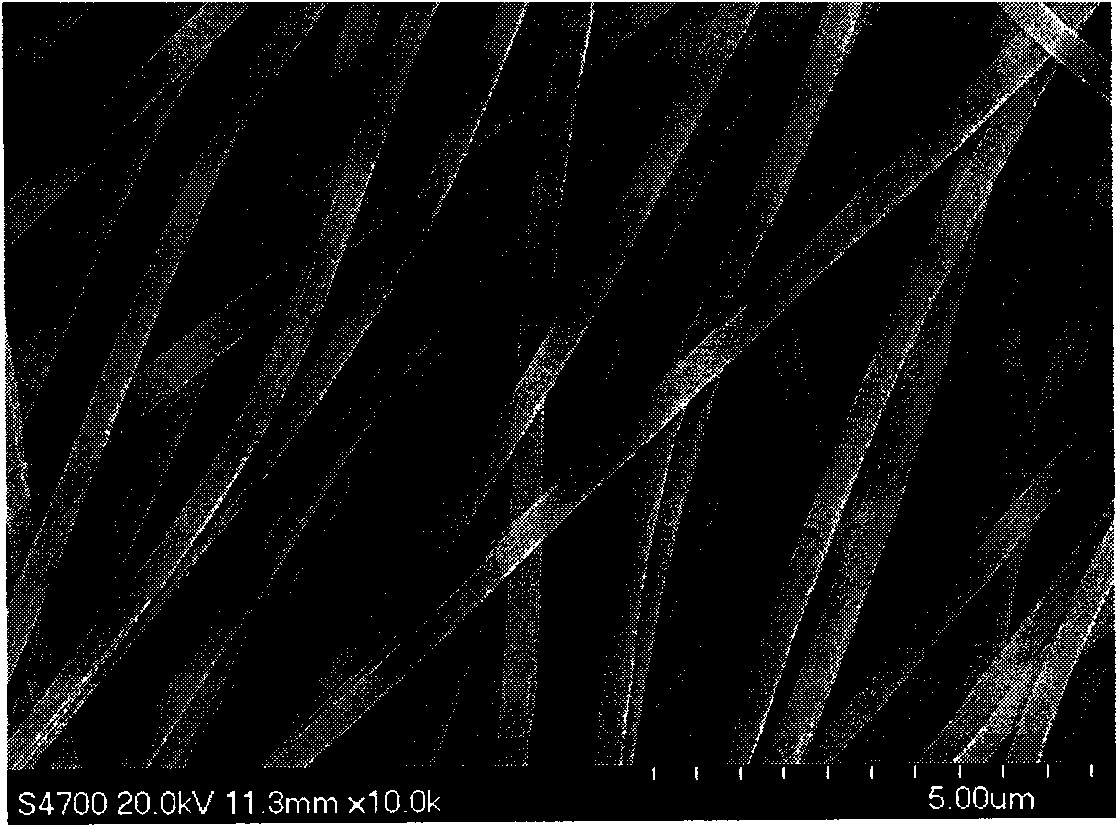

Stannum and carbon composite nano-fiber film negative-electrode material and preparation method thereof

ActiveCN101626075AExcellent discharge performance and charge-discharge cycle stabilitySimple configuration processElectrode manufacturing processesSolventCarbon composites

The invention relates to stannum / carbon nano-fiber composite film material used in the negative electrode of a lithium ion battery and a preparation method thereof and also provides an assembly method of the stannum / carbon nano-fiber composite film material generated according to the preparation method and used as the electrode of the lithium ion battery. The preparation method comprises the following steps: preparing an uniform spinning solution by mixing a stannum precursor compound, a solvent, a precursor polymer of carbon nano-fibers and an organic solvent together; obtaining a polymer nano-fiber film by electro spinning according to a suitable electrostatic spinning technology; and obtaining a stannum / carbon nano-fiber composite film used in the negative electrode of the lithium ion battery through final treatment technologies, such as preoxidation, carbonization, and the like, thereby effectively collaborating the electrochemical performance of stannum / carbon nano-fibers and improving the specific capacity, the first charge-discharge efficiency and the cycle performance of the lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Energy storage device with both capacitor and lithium ion battery characteristics and manufacturing method thereof

InactiveCN101320821AIncrease energy densityImprove power densityFinal product manufactureActive material electrodesCapacitanceHigh energy

An energy storage device having both characteristics of super capacitor and lithium ion battery and manufacturing method thereof are provided. The invention adopts the mixture of anode material of lithium ion battery and electrode material of super capacitor or composite material as anode active substance, and uses the mixture of cathode material of the lithium ion battery and electrode material of the super capacitor or composite material as cathode active substance. In the electrode active substance, the electrode material of the lithium ion battery has a content of 20% to 95%; the electrode material of the super capacitor has a content of 5% to 80%. The electrode active substance is mixed with the bonder, conducting agent, additive and solvent etc to prepare slurry, then experience steps of coating, drying, roll forming, parting, so that the anode sheet and cathode sheet of the super capacitance battery are produced. By adopting multi-core winding parallel connection and the assembling technology of the winded wore parallel to the narrow arrangement, the anode sheet, the cathode sheet and the membrane are loaded in the battery shell and then welded, dried, dehydrated, and injected with electrolyte, then activated by electricity to obtain super capacitance battery with high energy density and high power density.

Owner:CENT SOUTH UNIV

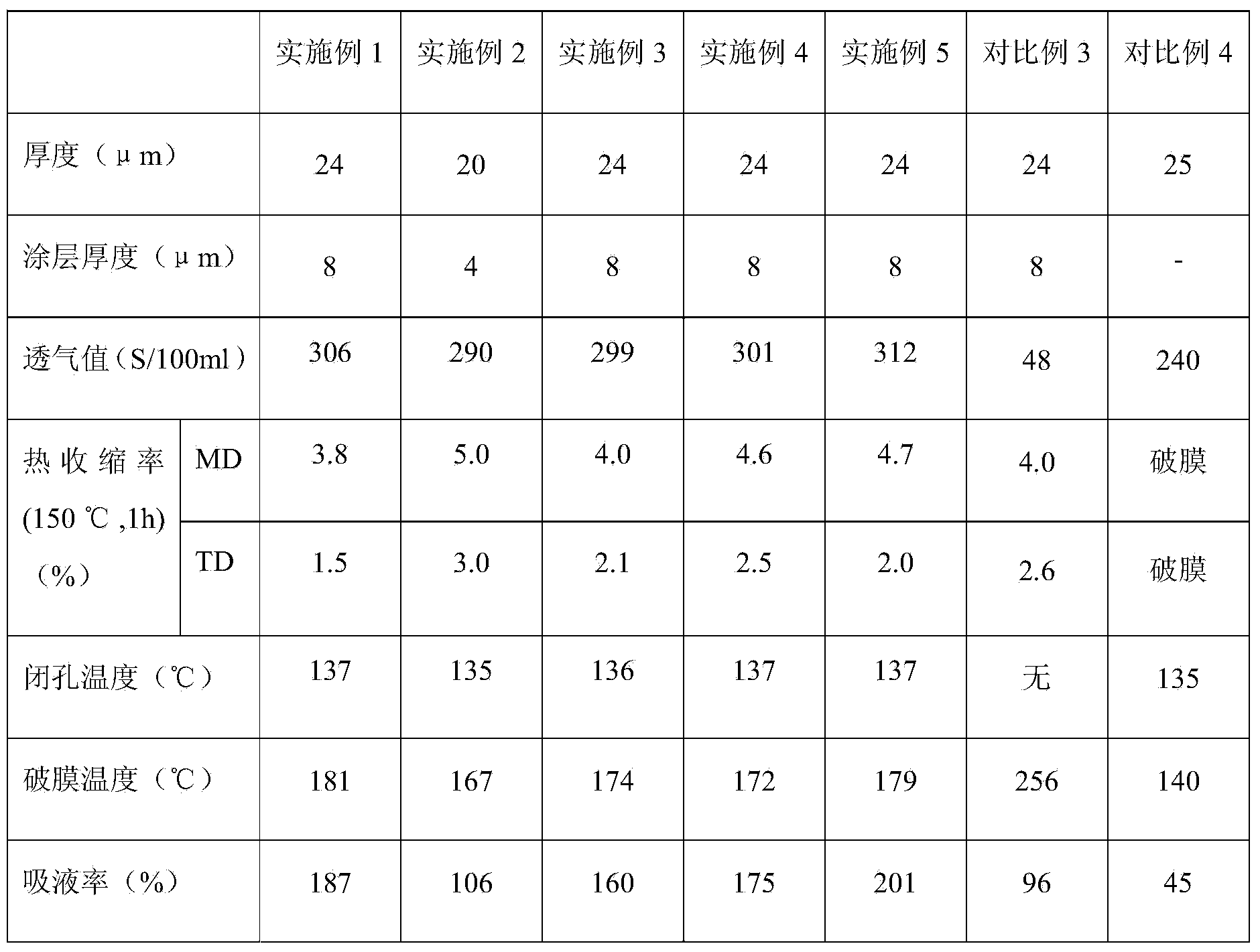

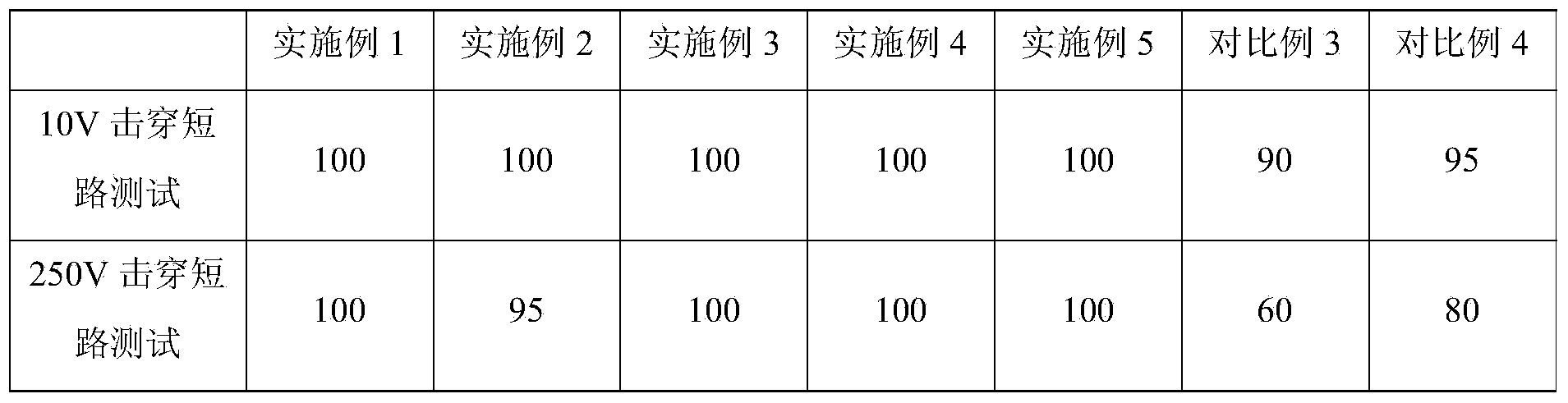

Novel ceramic coating polyolefin composite film and preparation method thereof

ActiveCN103811702AReduced service lifeExtended service lifeSecondary cellsCell component detailsSolventPolyolefin

The invention relates to a novel ceramic coating polyolefin composite film which comprises a polyolefin substrate with micro pores, wherein one side or both sides of the polyolefin substrate is / are compounded with ceramic coating(s); the ceramic coating comprises porous ceramic particles, an inorganic filler and an adhesive. The invention also relates to a method for preparing the novel ceramic coating polyolefin composite film. The method comprises the following steps: a, dissolving the adhesive in a solvent, thereby preparing an adhesive solution; b, adding the porous ceramic particles and the functional inorganic filler into the adhesion solution prepared in the step a, and performing dispersing treatment, thereby preparing coating slurry; and c, coating one or two surfaces of the polyolefin substrate with the coating slurry prepared in the step b, and drying and curing to prepare the product. The novel functional composite film has high liquid absorption and retention performance, has the functions of reducing harmful gases inside a battery, improving the performance of the battery and prolonging the service life of the battery, and has the safety characteristics of low closed pore temperature, high melting temperature and low hot-shrinkage rate.

Owner:河南惠强新能源材料科技股份有限公司

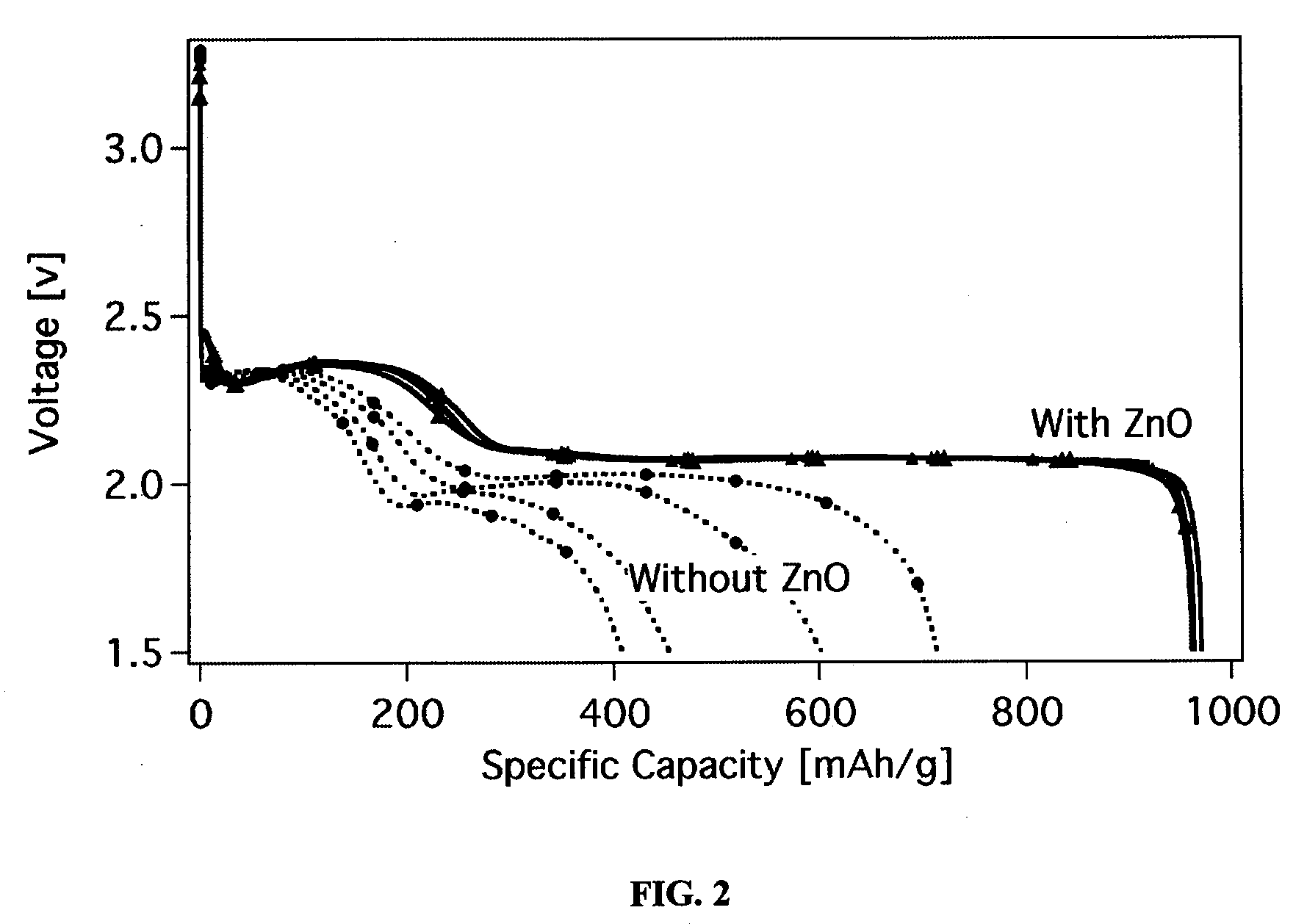

Lithium-sulfur battery and cathode therefore

ActiveUS20090226809A1Increase energy densityIncrease specific energyDeferred-action cellsCell seperators/membranes/diaphragms/spacersHigh energyLithium sulfur

An improved cathode suitable for lithium-sulfur batteries, a battery including the cathode, and a battery including a separator containing inorganic fillers are disclosed. The cathode includes sulfur and a metal oxide and optionally includes an additional polymeric material. The metal oxide reduces dissolution of sulfur at the cathode and reduces sulfur-containing deposits on the battery anode, thereby providing a battery with relatively high energy density and good partial discharge performance. The separator also reduces unwanted diffusion of sulfur species.

Owner:EAGLE PICHER TECH LLC

Nonaqueous-electrolyte batteries and nonaqueous electrolytic solutions

InactiveUS20120244425A1Low viscosityIncrease resistanceNegative electrodesPositive electrodesLithiumEther

The invention is to provide a nonaqueous-electrolyte battery which comprises a current collector, a positive electrode containing a lithium-containing phosphoric acid compound represented by LixMPO4 as a positive-electrode active material, a negative electrode containing a negative-electrode active material capable of occluding and releasing lithium ions, and a nonaqueous electrolytic solution containing a chain ether and a cyclic carbonate having an unsaturated bond.

Owner:MITSUBISHI CHEM CORP

Alkaline battery including nickel oxyhydroxide cathode and zinc anode

ActiveUS7273680B2Improve discharge performanceHigh capacity retentionActive material electrodesJackets/cases materialsZinc alloysNickel

Owner:DURACELL U S OPERATIONS

Organic nitrite additives for nonaqueous electrolyte in alkali metal electrochemical cells

InactiveUS6027827AGood charge and discharge cycleImprove efficiencyElectrotherapyPrimary cell maintainance/servicingPermittivitySolvent

Owner:WILSON GREATBATCH LTD

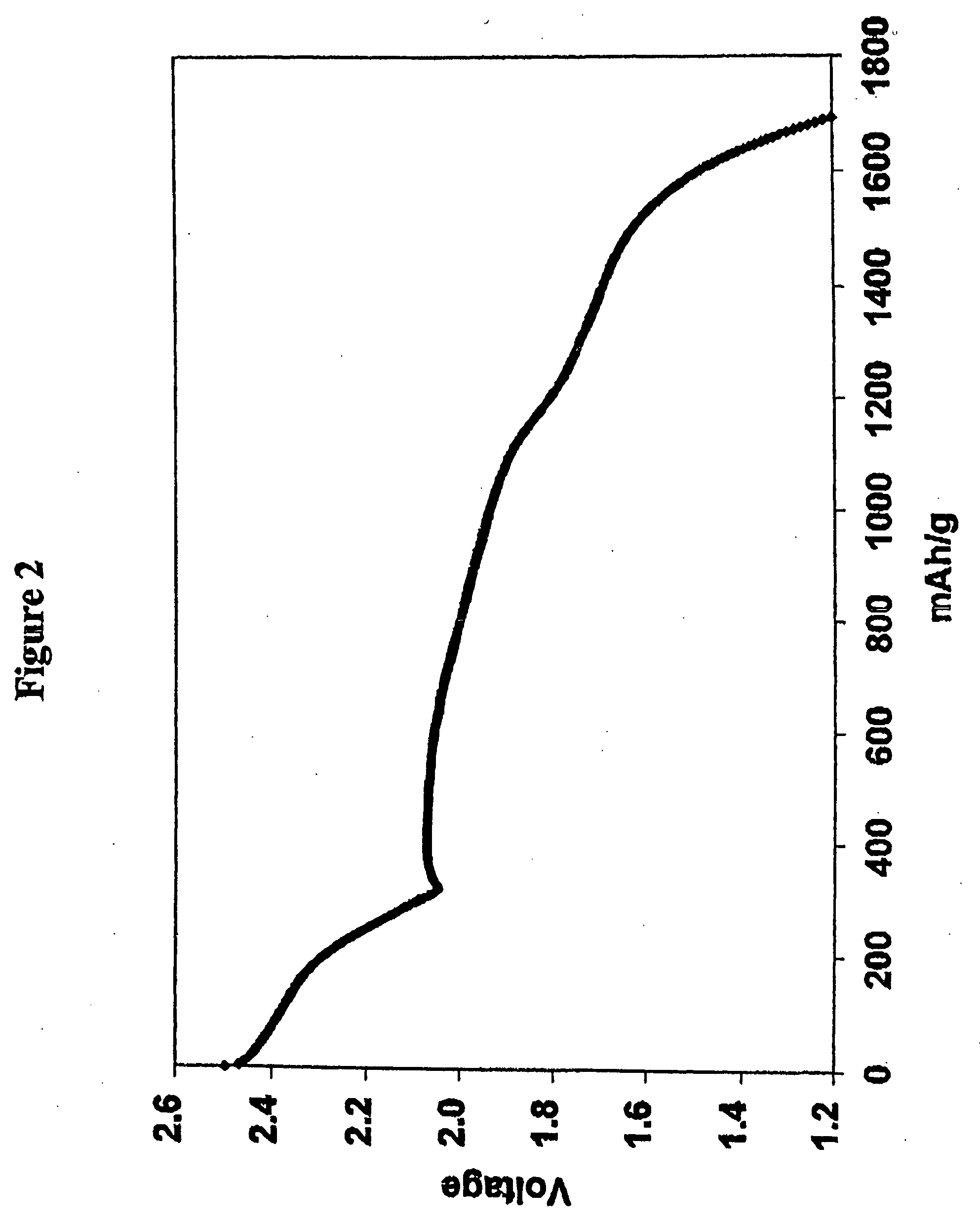

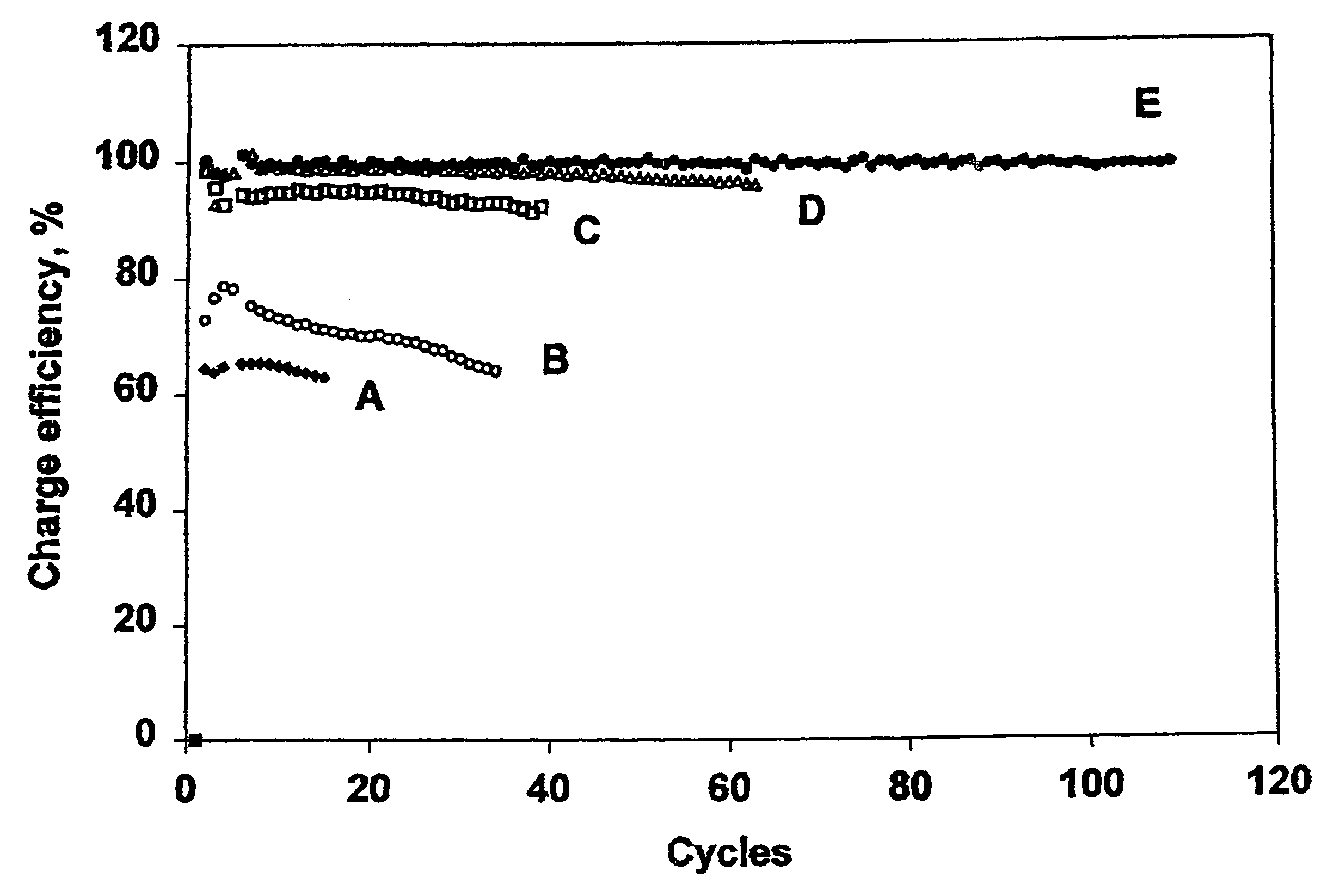

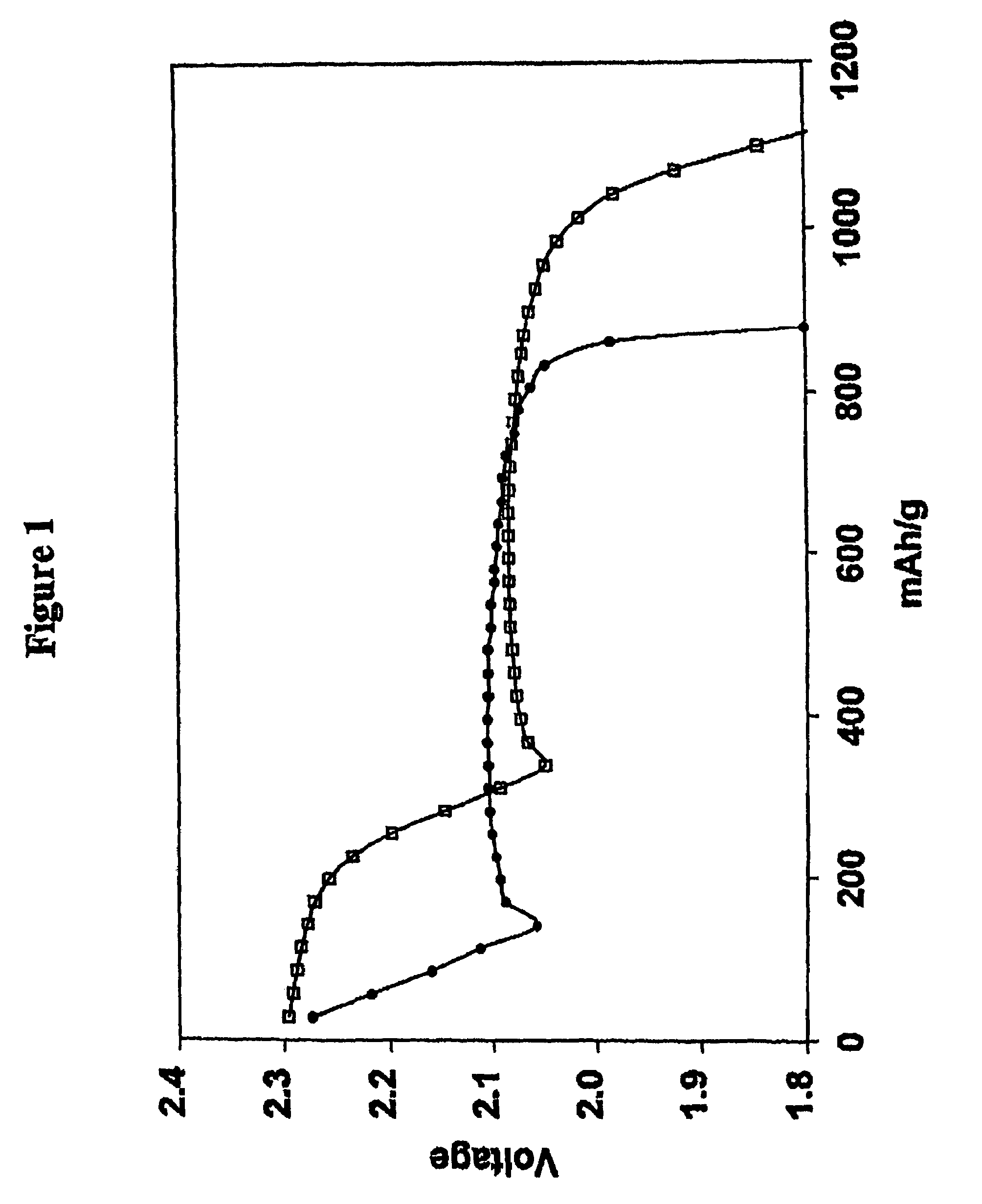

Electrolytes for lithium sulfur cells

ActiveUS7358012B2Reduce the probability of reactionLow self-discharge rateFinal product manufactureOrganic electrolyte cellsLithium sulfurCharge discharge

Disclosed is an electrochemical cell comprising a lithium anode and a sulfur-containing cathode and a non-aqueous electrolyte. The cell exhibits high utilization of the electroactive sulfur-containing material of the cathode and a high charge-discharge efficiency.

Owner:SION POWER CORP

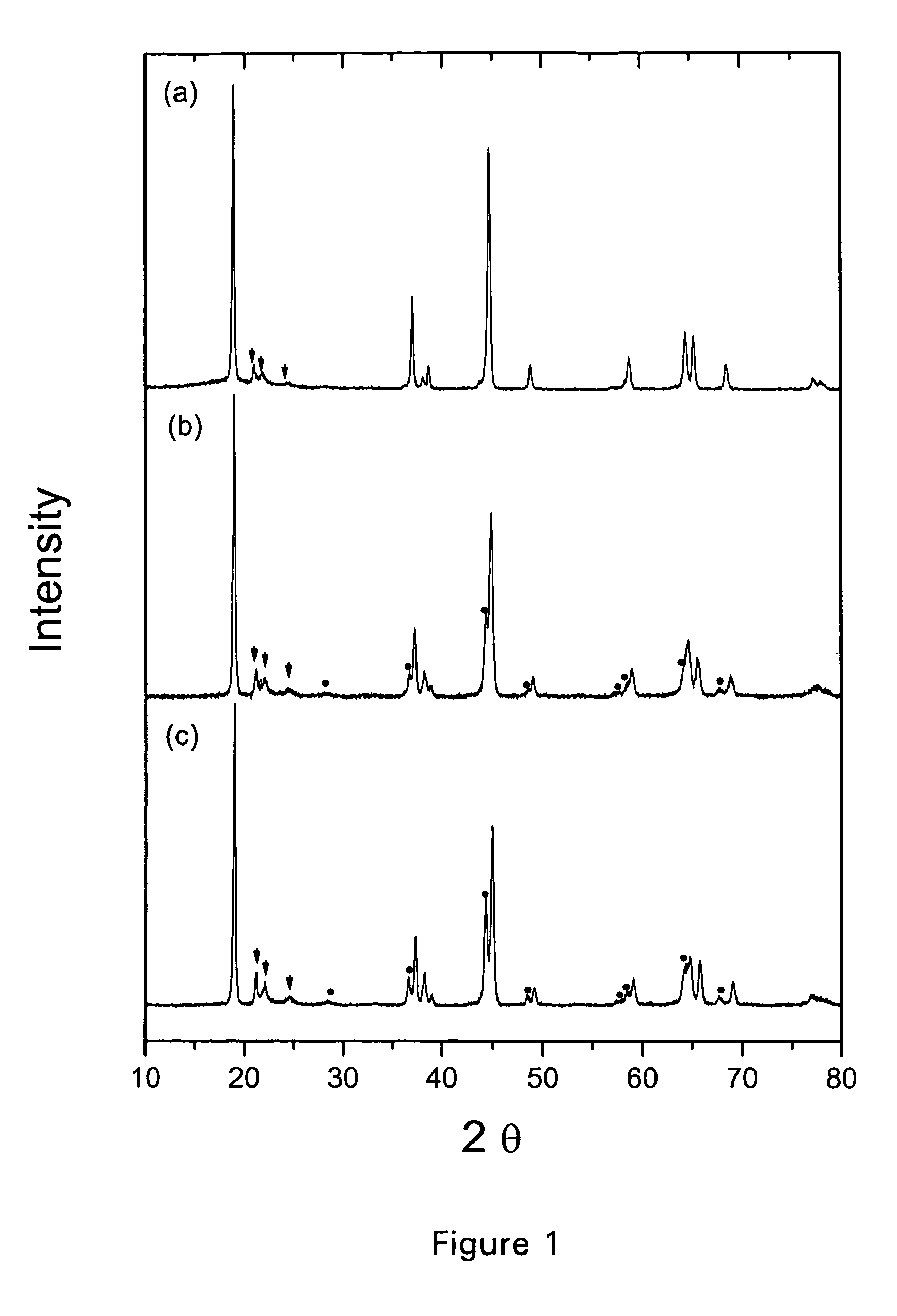

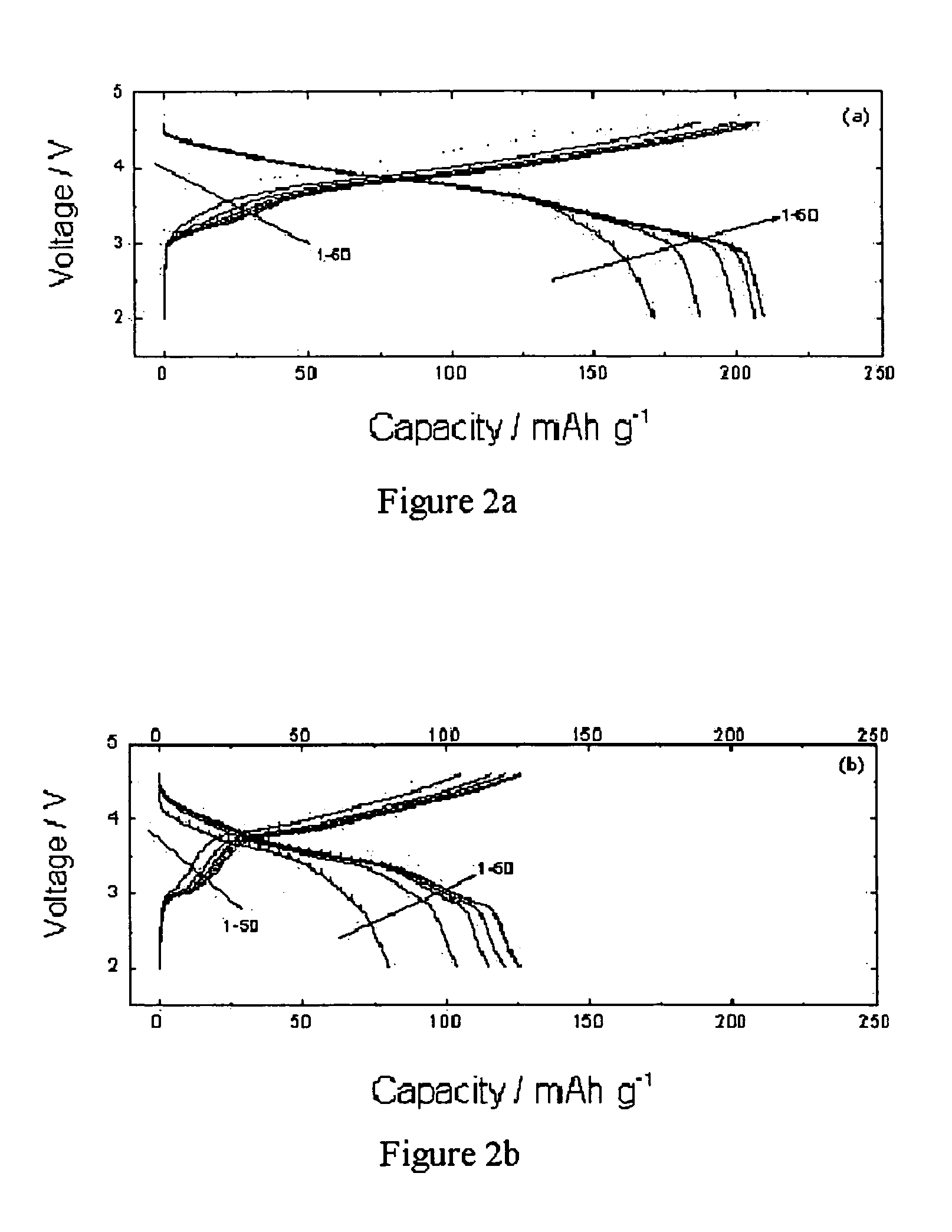

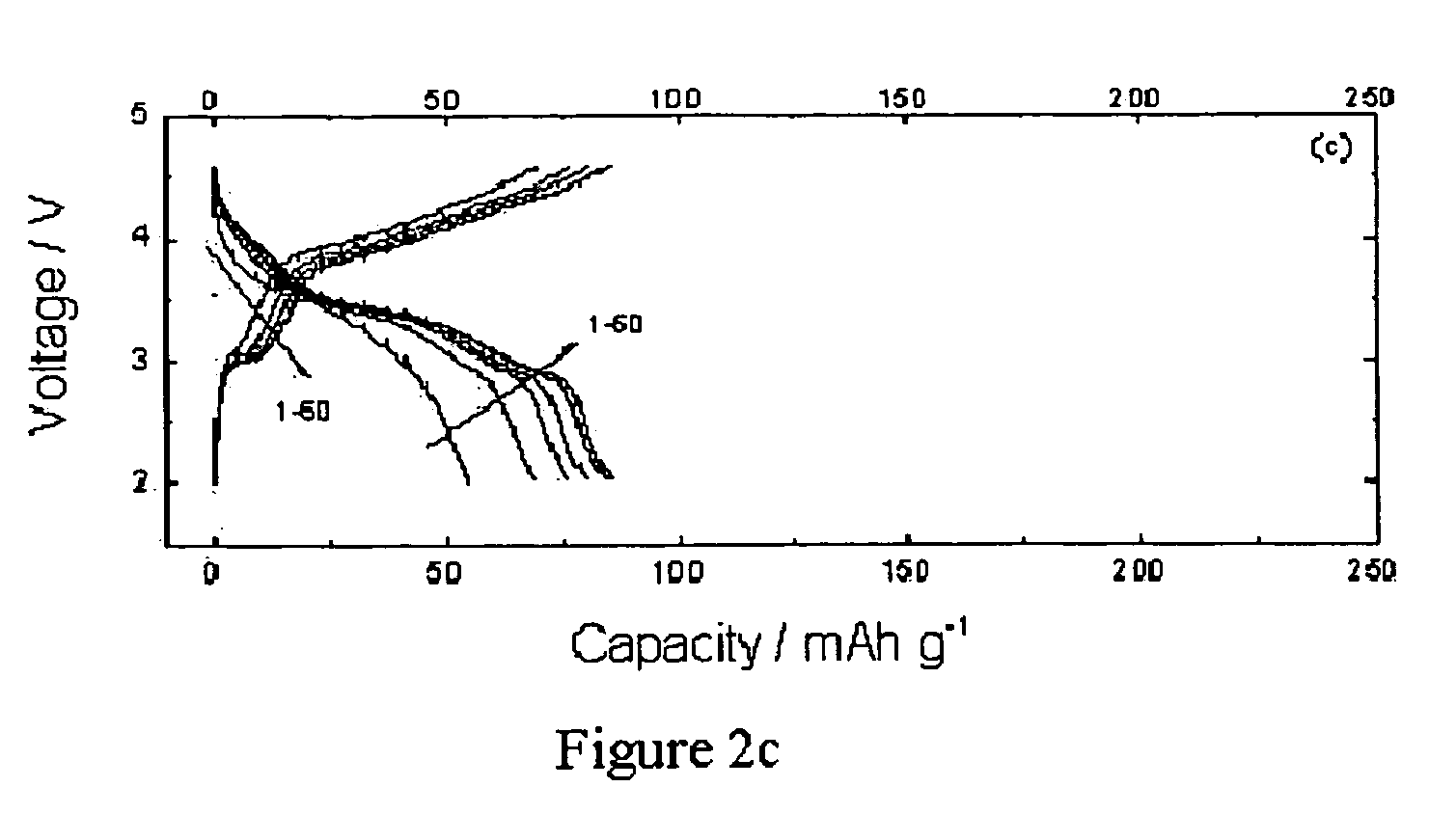

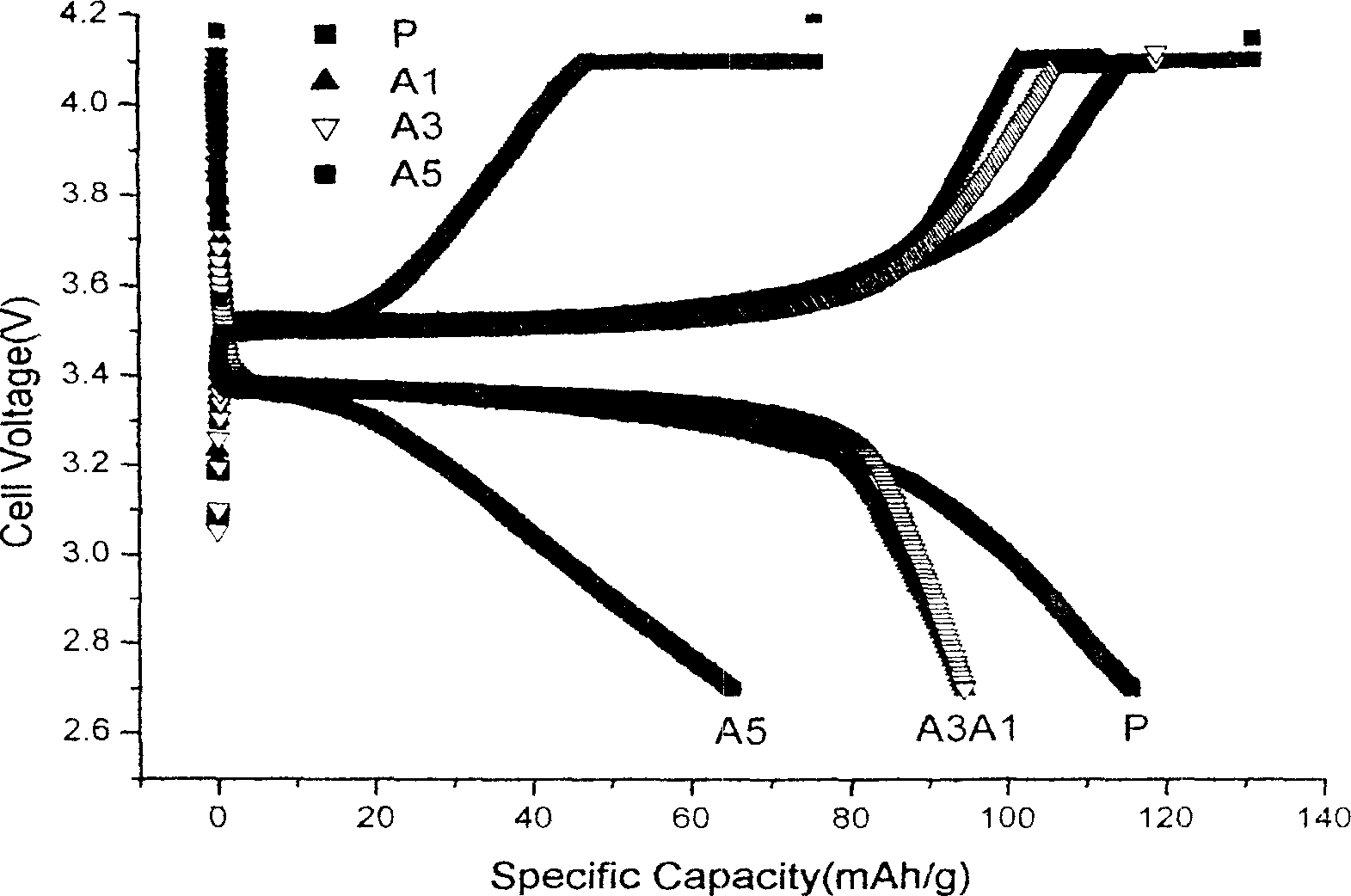

Layer cathode methods of manufacturing and materials for Li-ion rechargeable batteries

ActiveUS7314684B2Lower performance requirementsRapid coolingSecondary cellsAlkali metal oxidesLithiumSolid state reaction method

A positive electrode active material for lithium-ion rechargeable batteries of general formula Li1+xNiαMnβAγO2 and further wherein A is Mg, Zn, Al, Co, Ga, B, Zr, or Ti and 0<x<0.2, 0.1≦α≦0.5, 0.4≦β≦0.6, 0≦γ≦0.1 and a method of manufacturing the same. Such an active material is manufactured by employing either a solid state reaction method or an aqueous solution method or a sol-gel method which is followed by a rapid quenching from high temperatures into liquid nitrogen or liquid helium.

Owner:CHICAGO UNIV OF THE +1

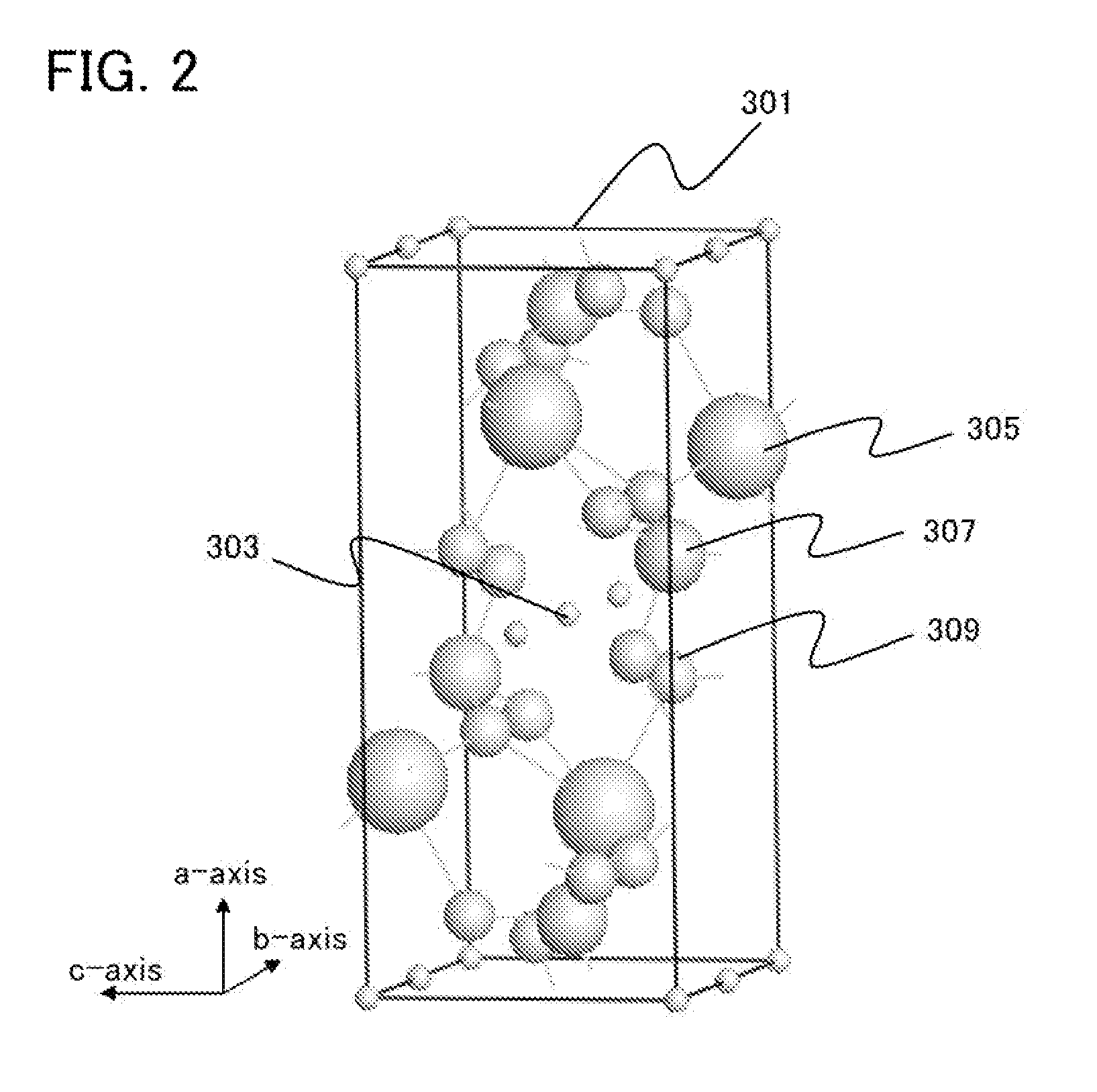

Lithium-ion secondary battery

InactiveUS20120244430A1Easy to spreadRaise the ratioFinal product manufactureElectrode carriers/collectorsHigh energyElectrical battery

To provide a lithium-ion secondary battery having higher discharge capacity and higher energy density and a manufacturing method thereof. The lithium-ion secondary battery includes a positive electrode, a negative electrode, and an electrolyte provided between the positive electrode and the negative electrode. The positive electrode includes a positive electrode current collector and a positive electrode active material layer provided over the positive electrode current collector. In the positive electrode active material layer, graphenes and lithium-containing composite oxides are alternately provided. The lithium-containing composite oxide is a flat single crystal particle in which the length in the b-axis direction is shorter than each of the lengths in the a-axis direction and the c-axis direction. Further, the lithium-containing composite oxide is provided over the positive electrode current collector so that the b-axis of the single crystal particle intersects with a surface of the positive electrode current collector.

Owner:SEMICON ENERGY LAB CO LTD

Methods of charging lithium sulfur cells

ActiveUS7019494B2Reduce the probability of reactionLow self-discharge rateCell electrodesPrimary cellsLithium–sulfur batteryLithium sulfur

Owner:SION POWER CORP

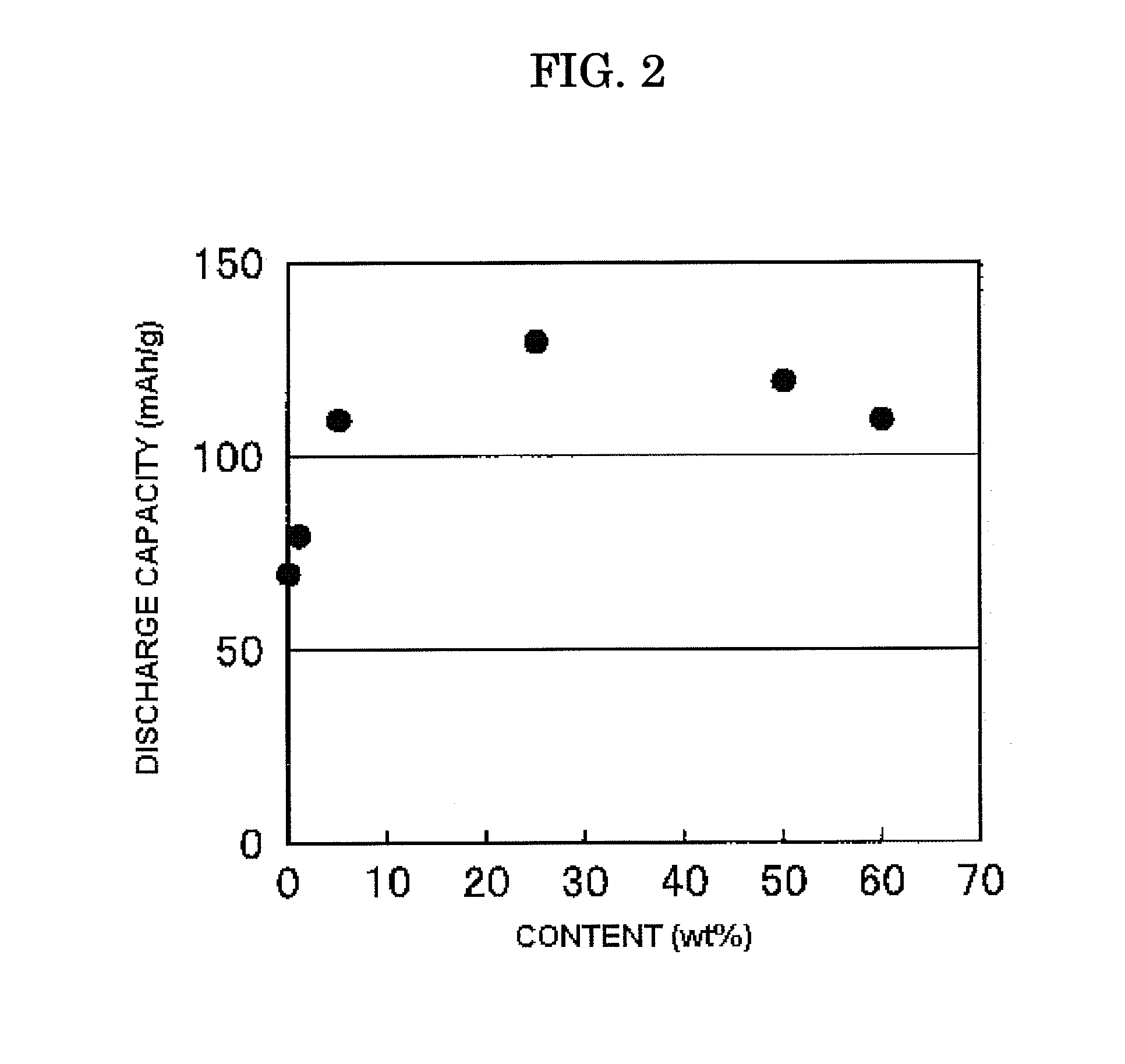

Positive electrode active material for lithium secondary battery, method of manufacturing the same, and lithium secondary battery using the same

InactiveUS20110200880A1Improve discharge capacityImprove discharge performanceNon-aqueous electrolyte accumulator electrodesSpecial surfacesLithiumBoron oxide

A positive electrode active material for lithium secondary batteries having a lithium-containing transition metal oxide having a layered structure and represented by the general formula Li1+xMn1-x-yMyO2, where 0<x<0.33, 0<y<0.66, and M is at least one transition metal other than Mn, the lithium-containing transition metal oxide having a boron oxide layer formed on the surface thereof.

Owner:SANYO ELECTRIC CO LTD

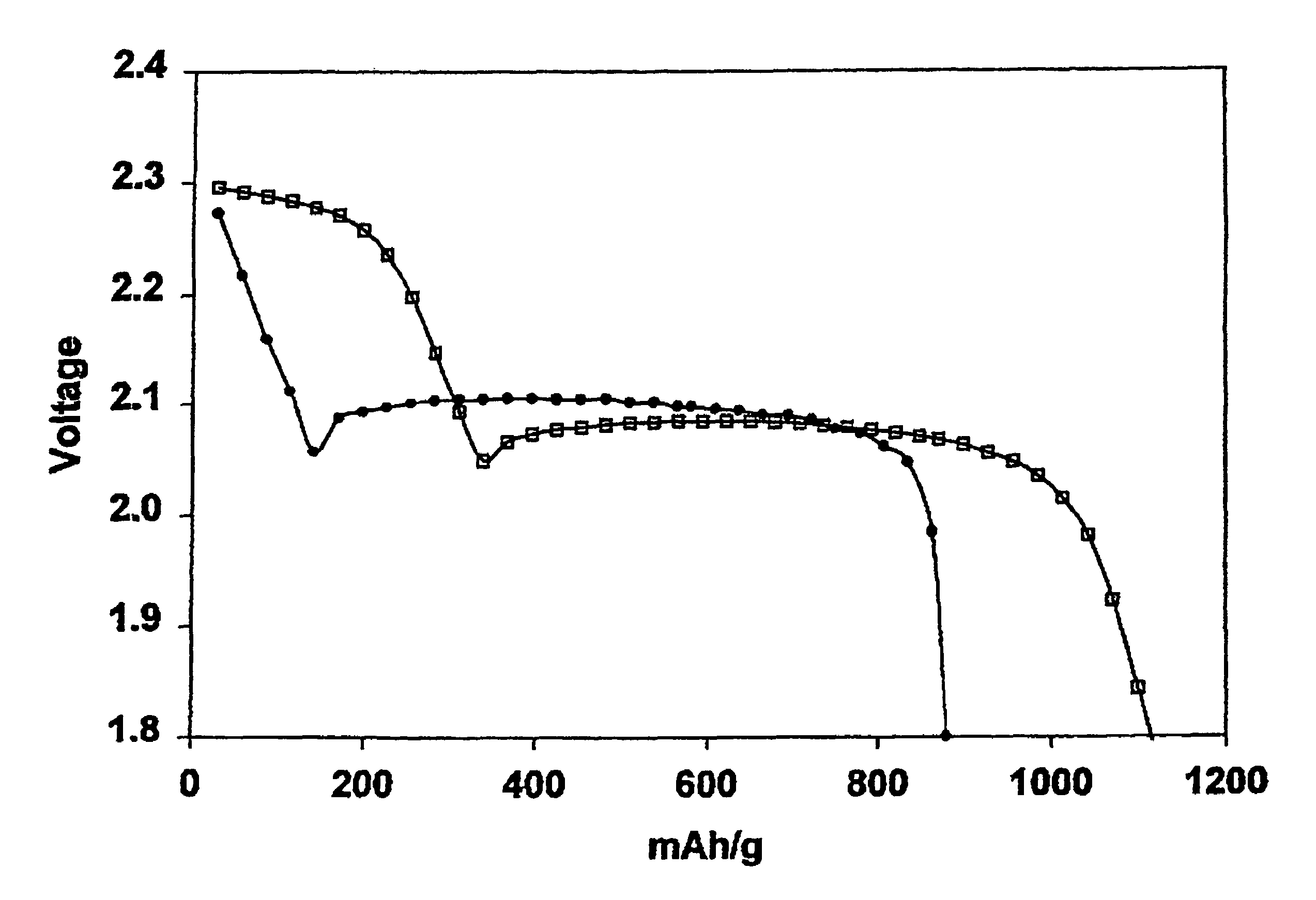

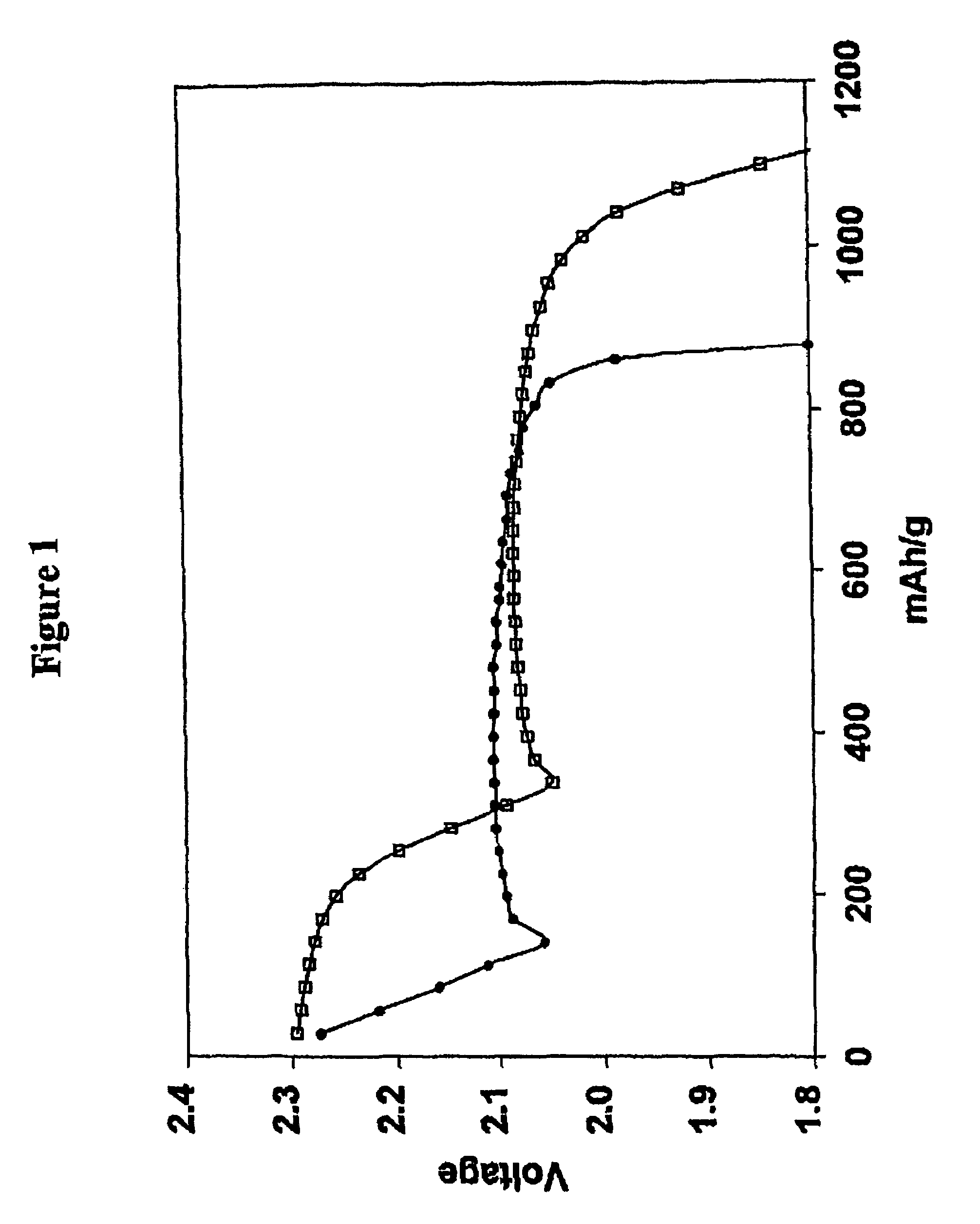

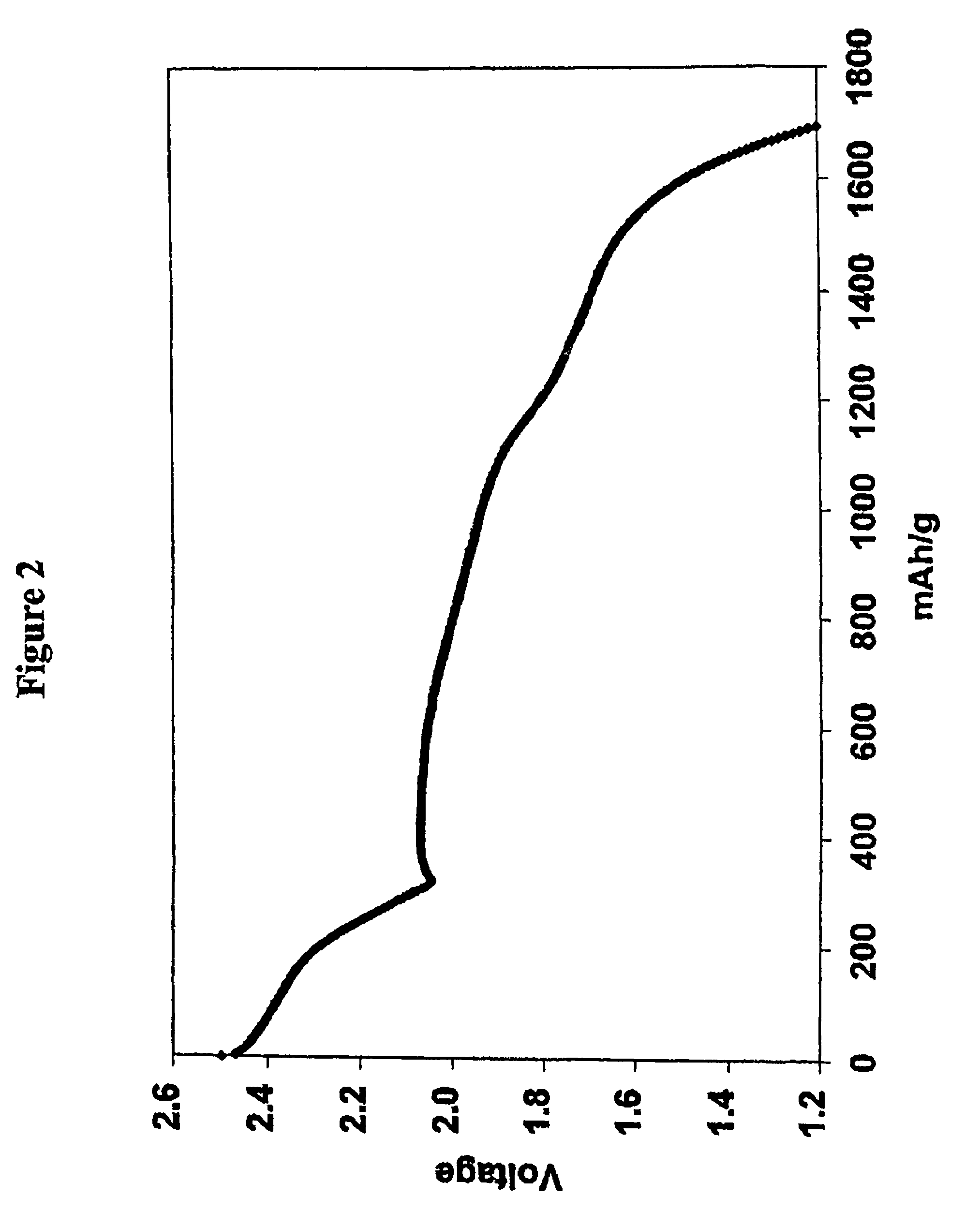

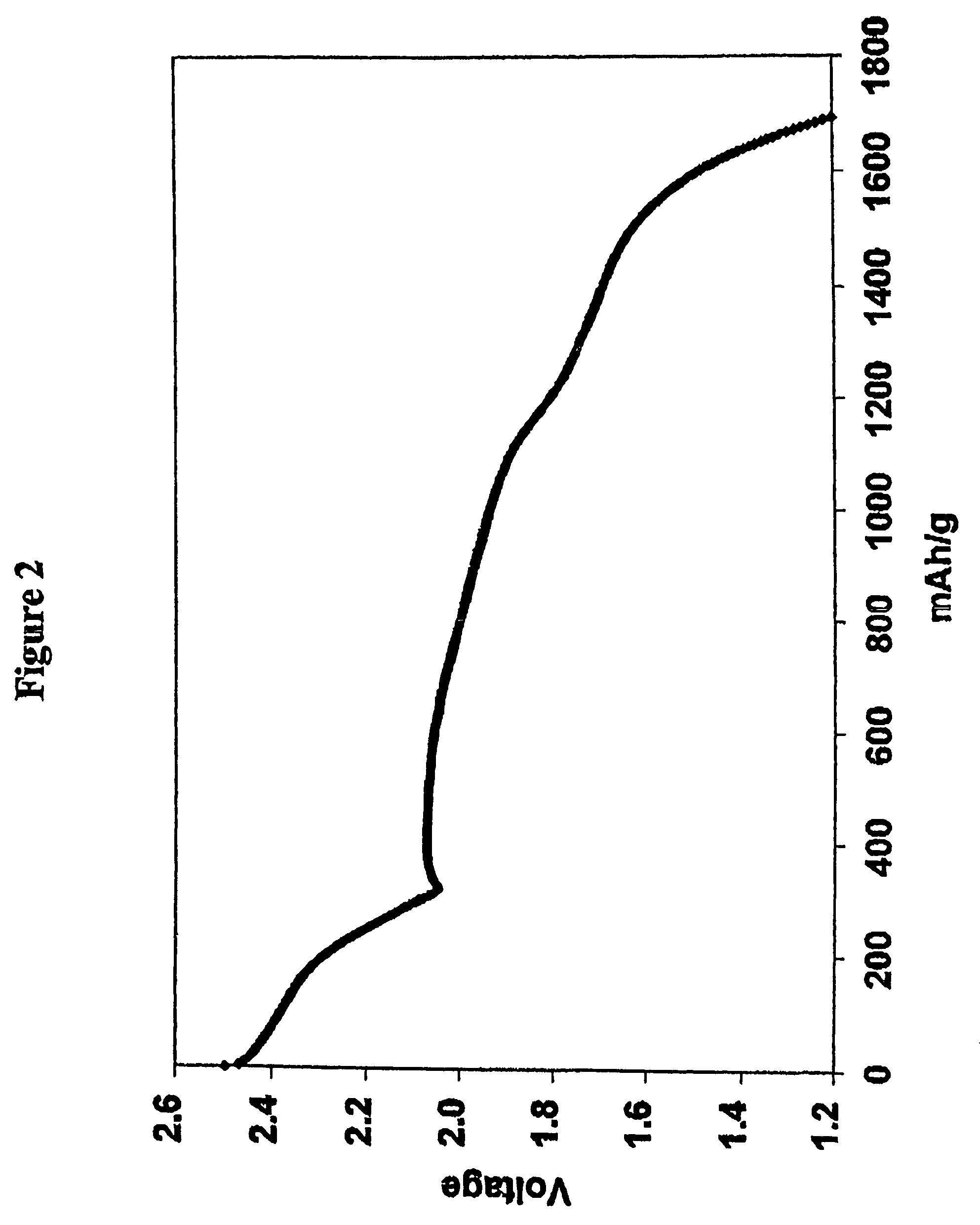

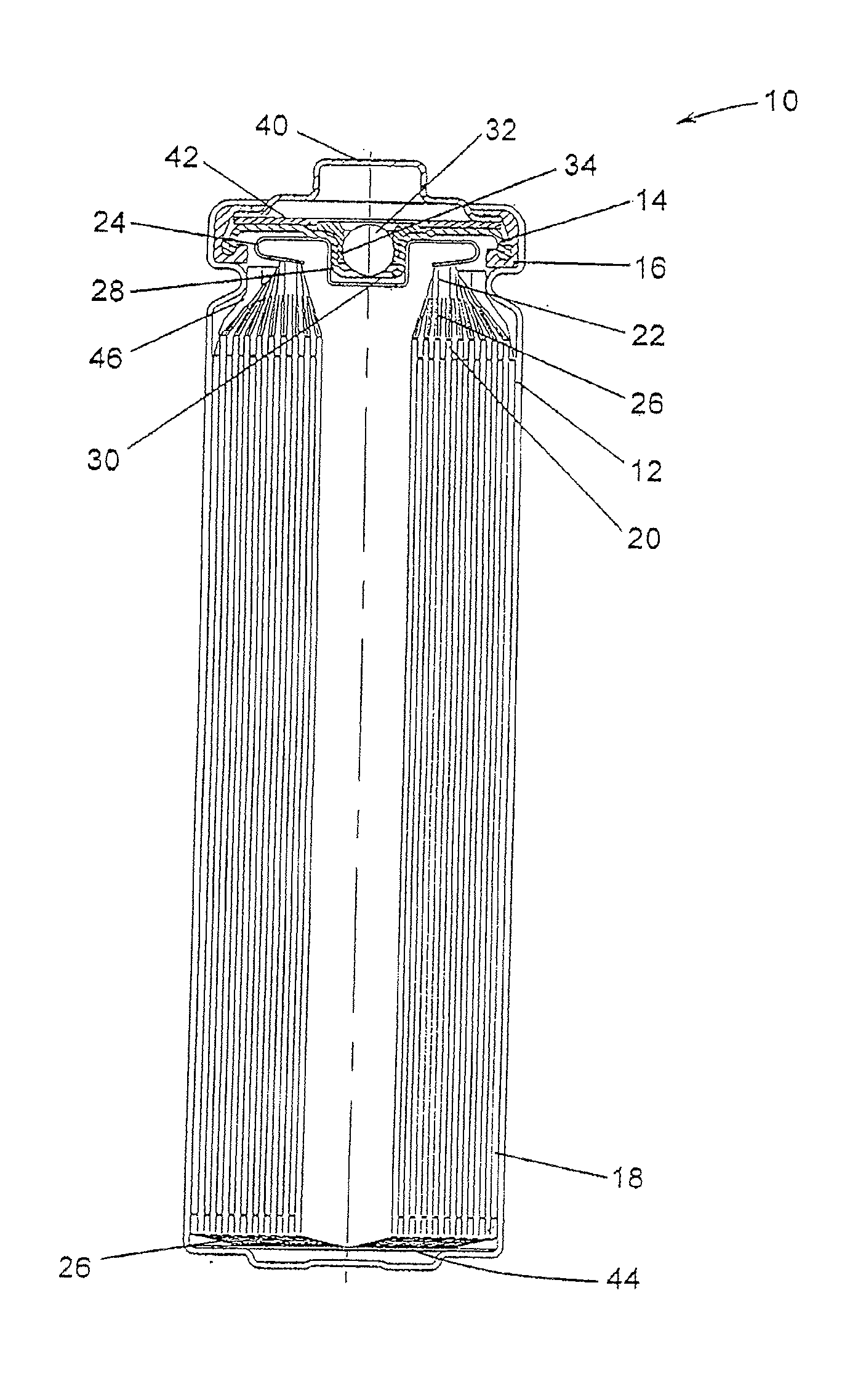

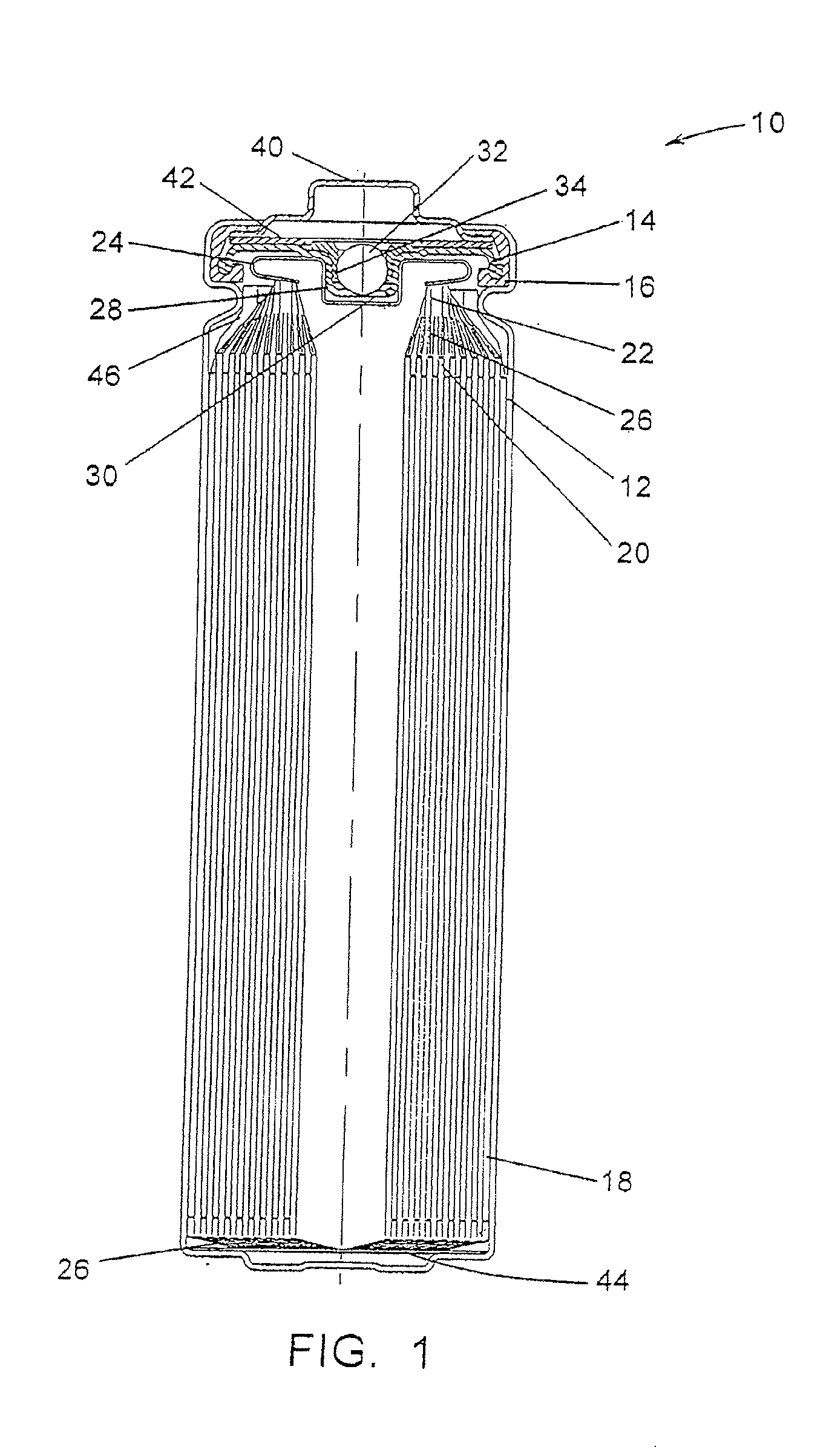

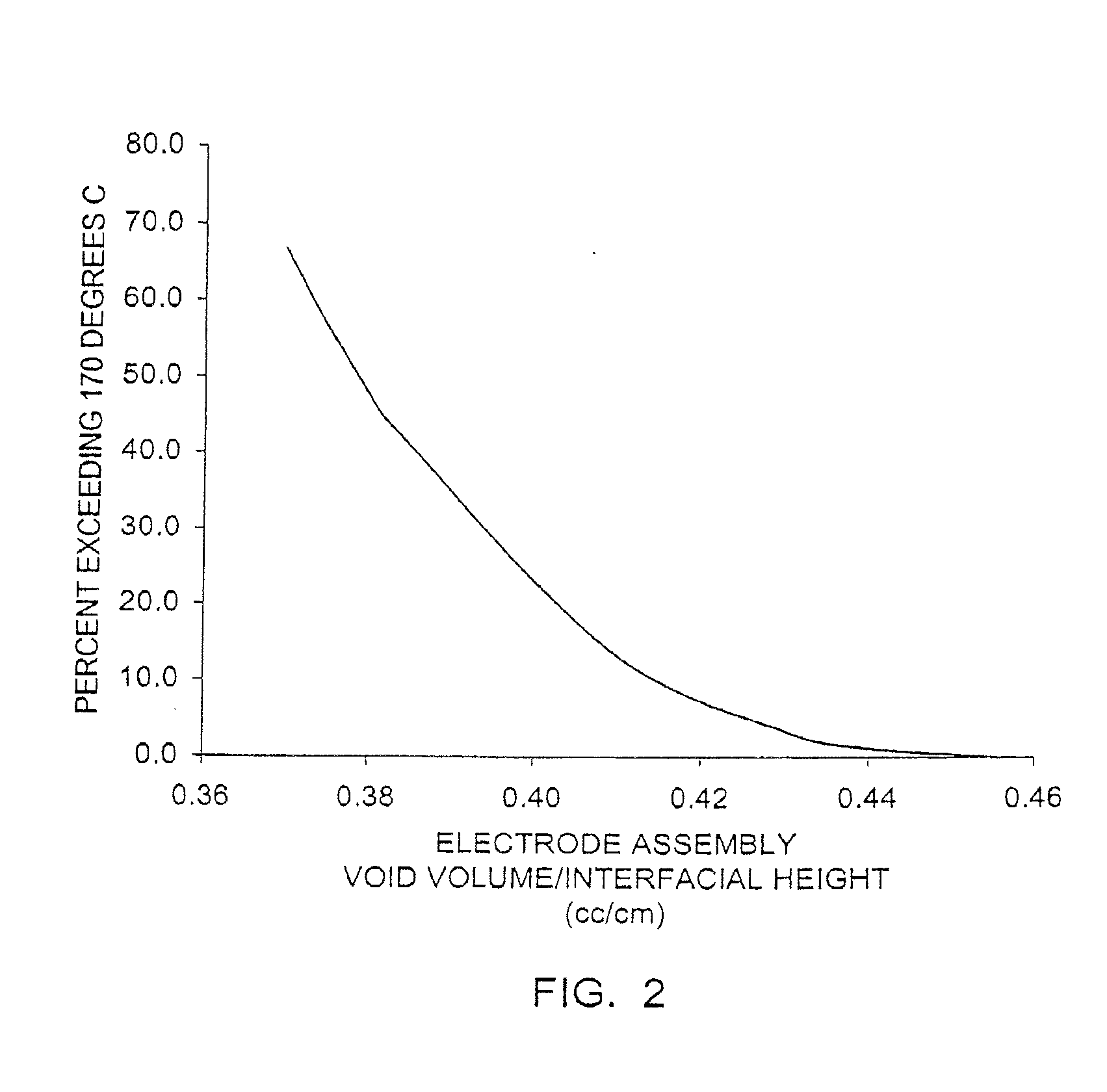

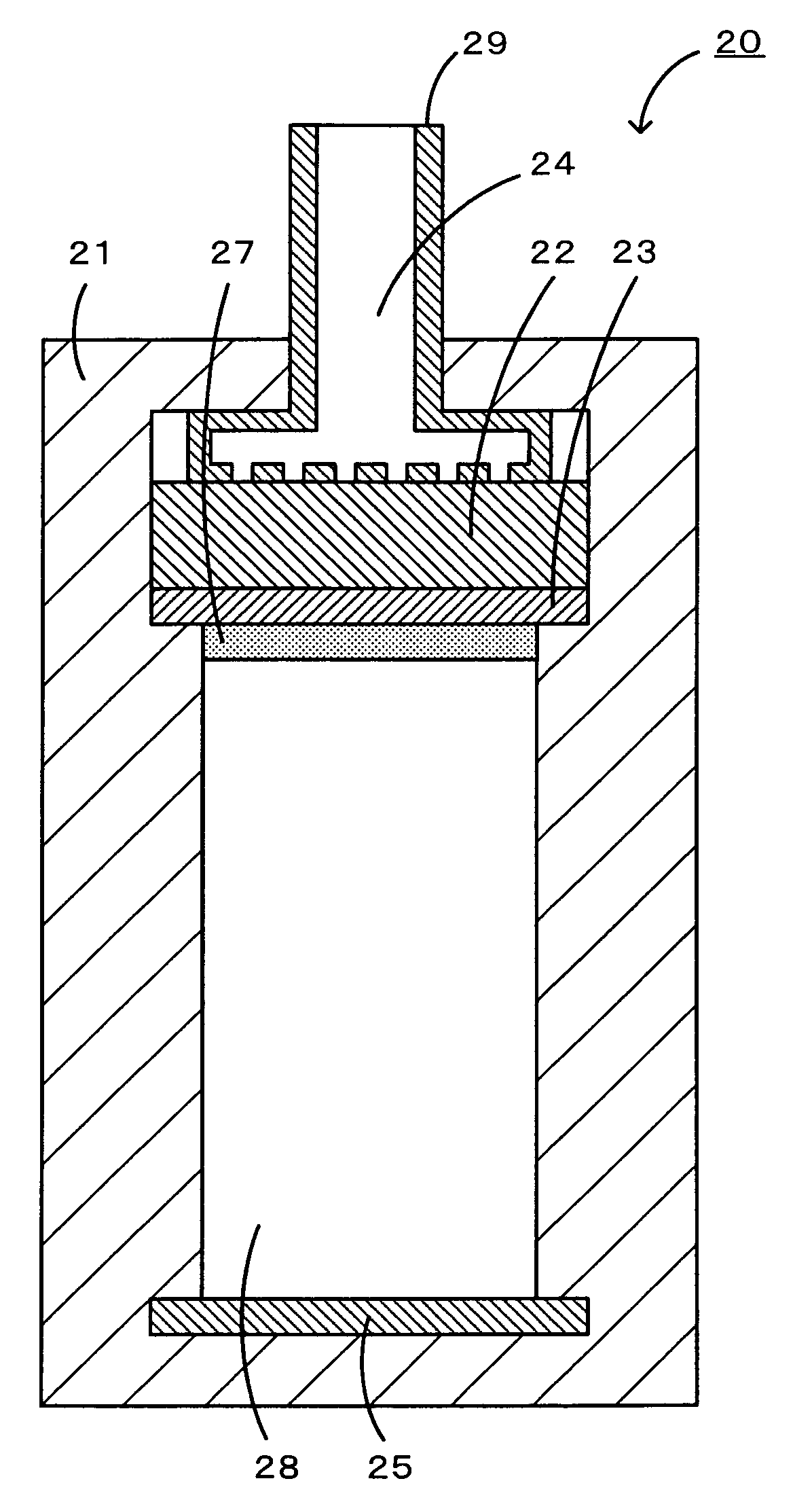

High Discharge Capacity Lithium Battery

ActiveUS20120021266A1Improve discharge performanceIncrease energy densityCell seperators/membranes/diaphragms/spacersCell electrodesHigh rateIron disulfide

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:ENERGIZER BRANDS

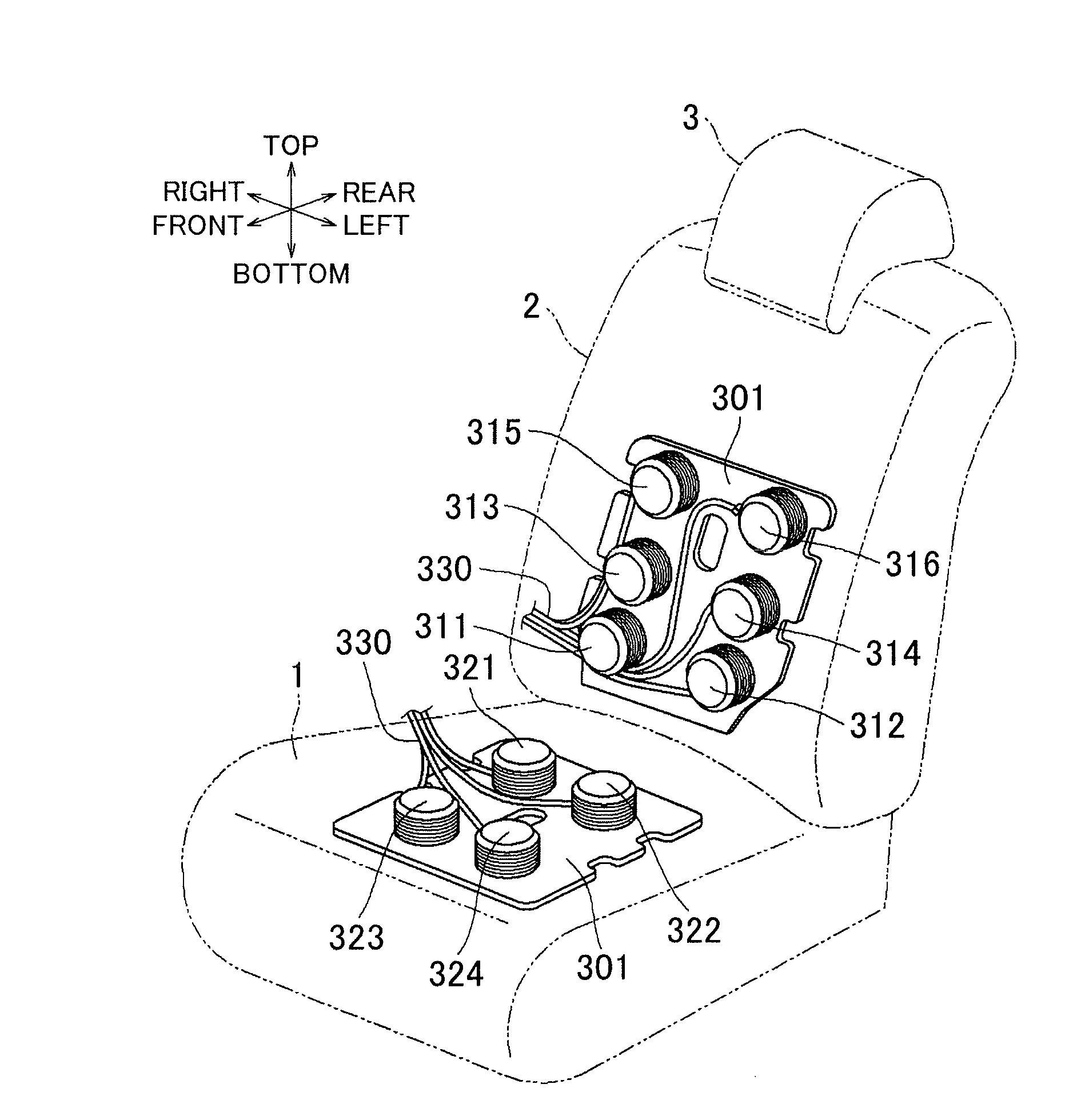

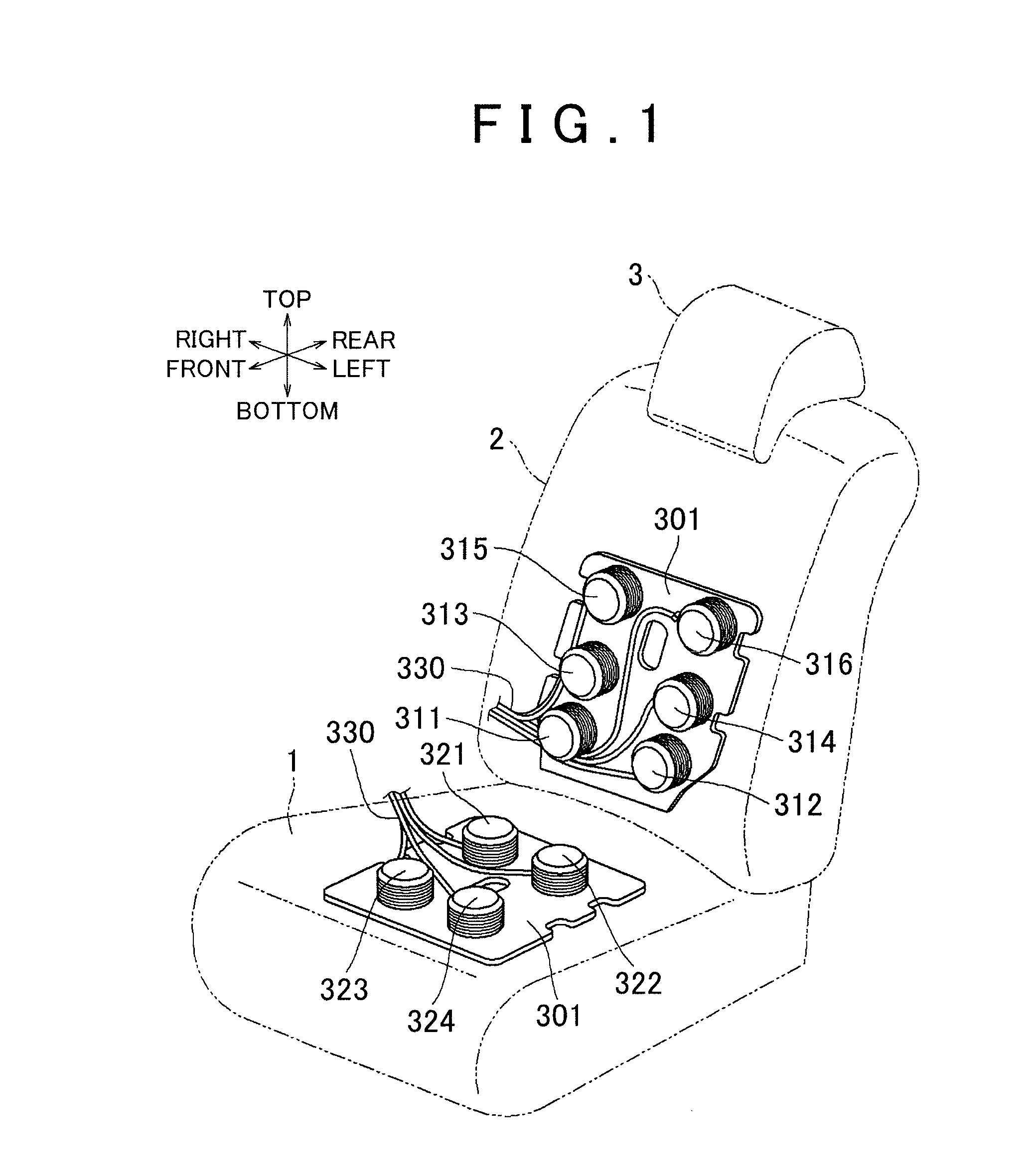

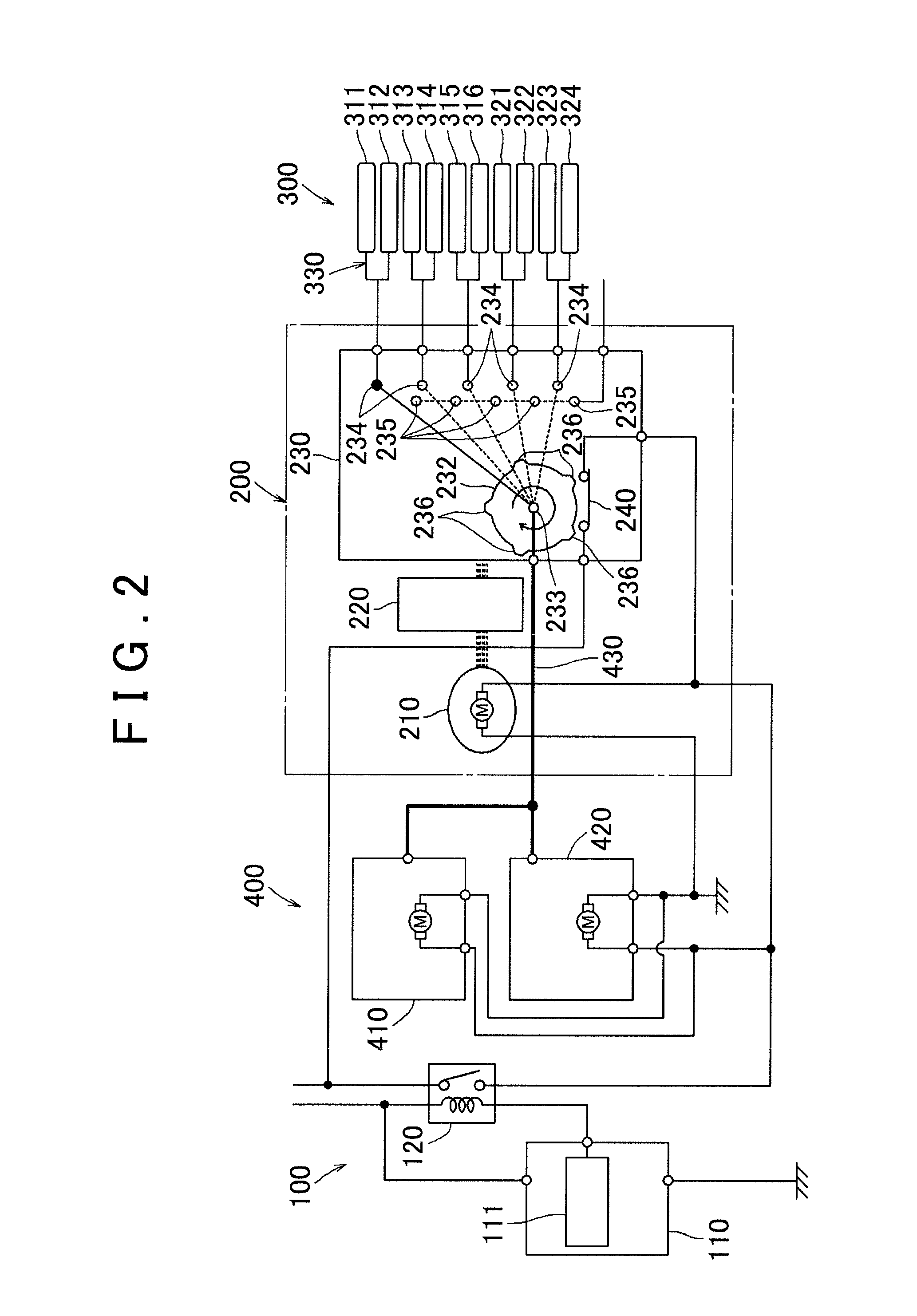

Massage apparatus

InactiveUS20160106620A1Increased durabilitySimple structureVehicle seatsPneumatic massageLimit switchCam

A massage apparatus includes: a pump that is an air supply source; a motor that actuates a distributor; a power switch that optionally supplies power to the pump and the motor to actuate the pump and the motor; and a limit switch that is connected in parallel with the power switch, and is operated by a cam working with the distributor so as to be turned ON when the distributor assumes a position to supply air to any of bladders, and so as to be turned OFF when the distributor assumes a position to discharge air from at least any of the bladders.

Owner:TOYOTA BOSHOKU KK

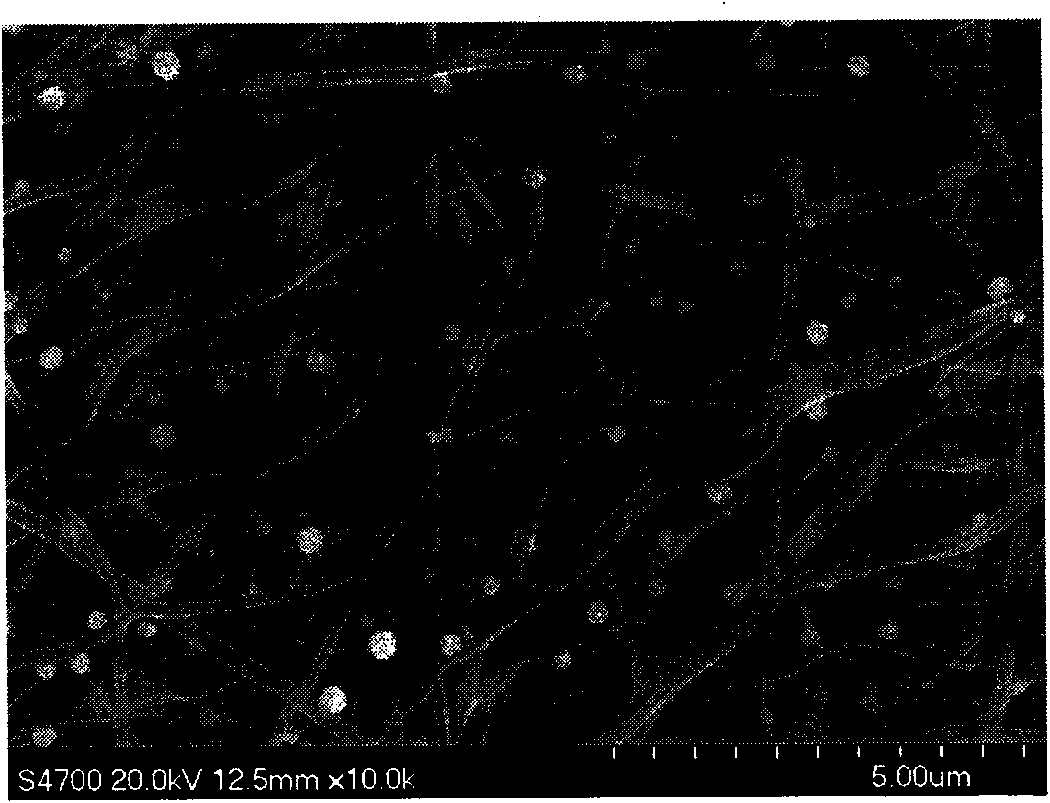

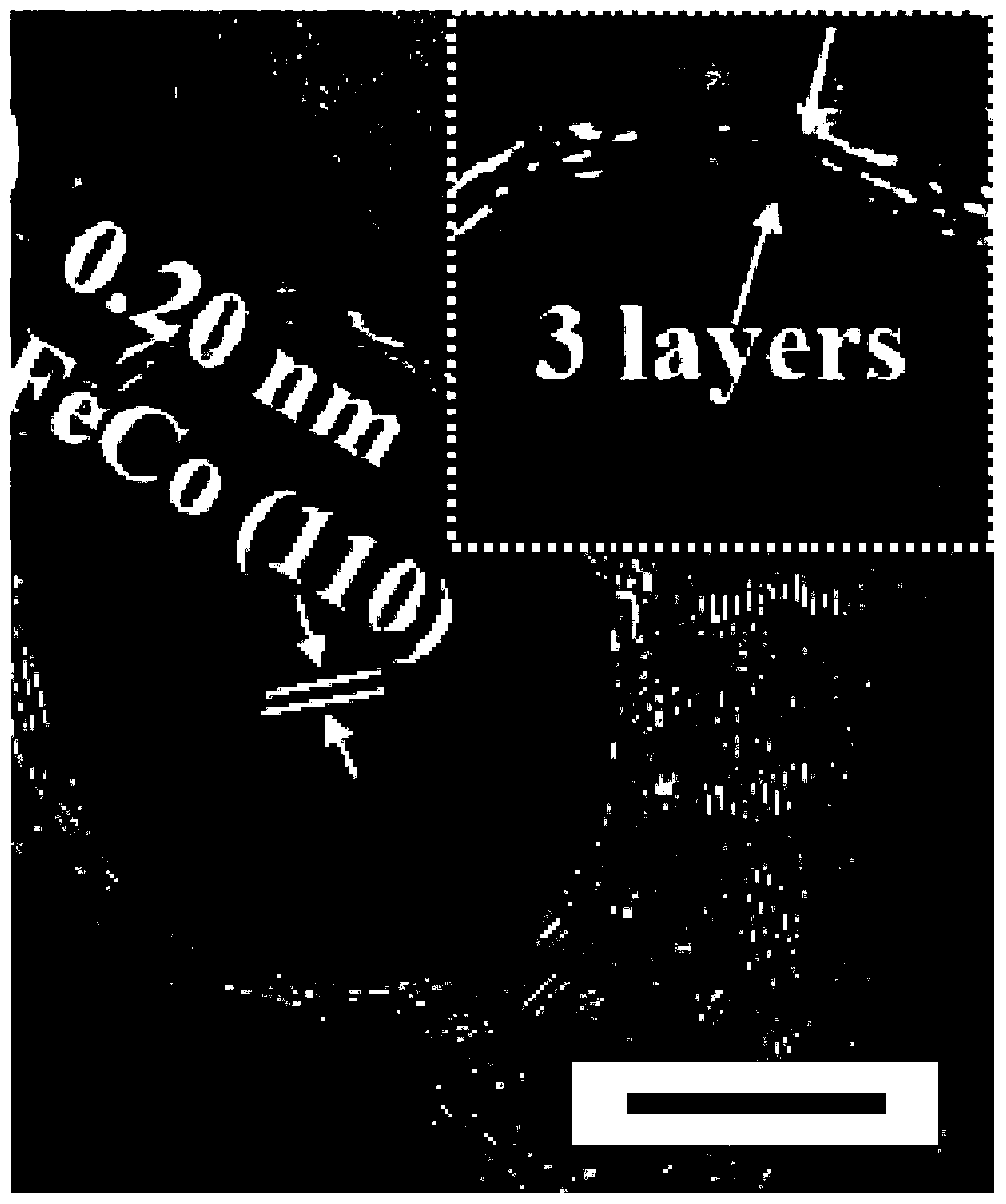

Nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and preparation method and application thereof

InactiveCN110783582ALarge specific surface areaMany active sitesMaterial nanotechnologyFuel and secondary cellsCarbon layerPtru catalyst

The invention discloses a nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and a preparation method and an application thereof. The catalyst is characterized in that for a structural unit, nitrogen-doped carbon nanotubes (NCNTs) are utilized as a conductive network, and iron-cobalt alloy nanoparticles wrapped by a nitrogen-doped ultrathin carbon layer are loaded on the nitrogen-doped ultrathin carbon layer. The preparation method comprises steps of pretreatment of carbon nanotubes, removing impurities on surfaces of the carbon nanotubesthrough cleaning, and generating a large number of defects and oxygen-containing surface functional groups on the surfaces of the carbon nanotubes through acid treatment; carrying out grafting reaction of an iron-cobalt organic ligand and melamine on the surfaces of the functionalized carbon nanotubes; calcining the iron-cobalt organic ligand and the melamine-grafted functionalized carbon nanotubes under a high-temperature condition to obtain the nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst.

Owner:ZHEJIANG SCI-TECH UNIV

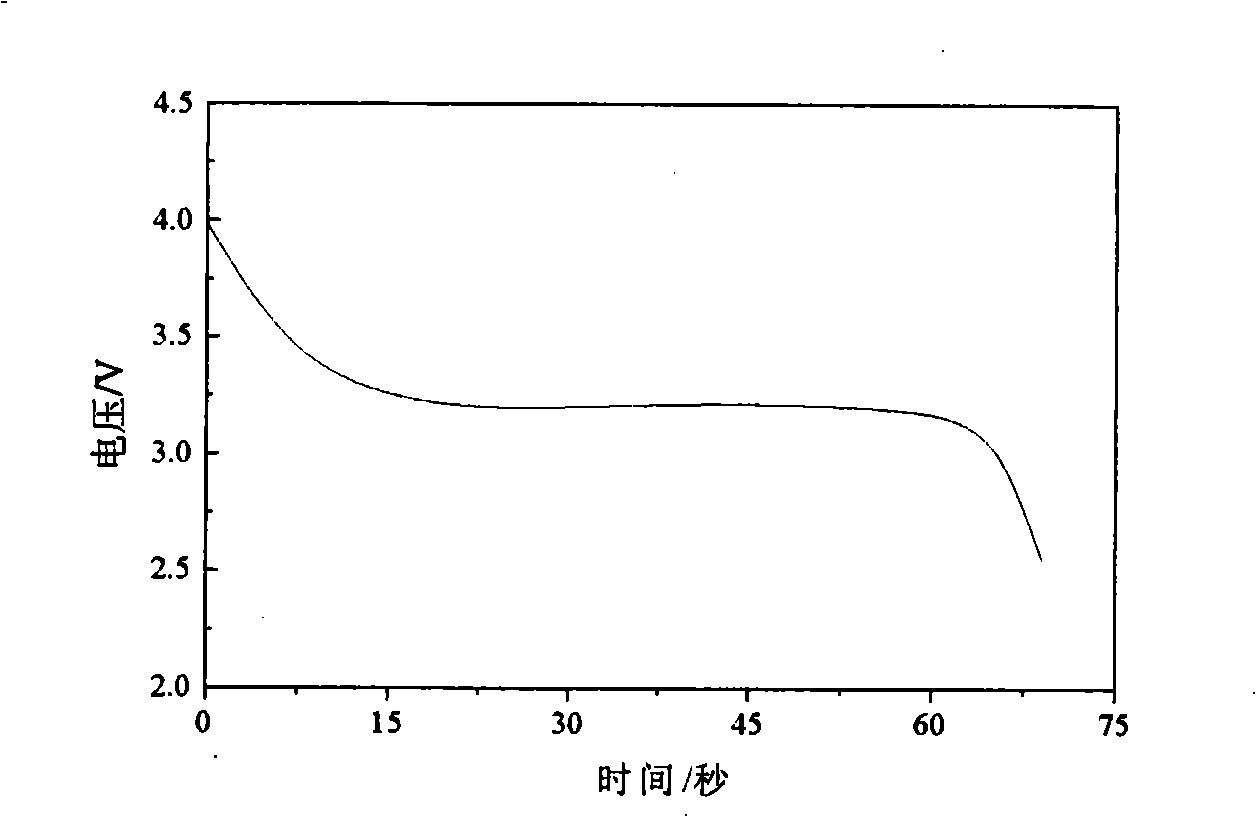

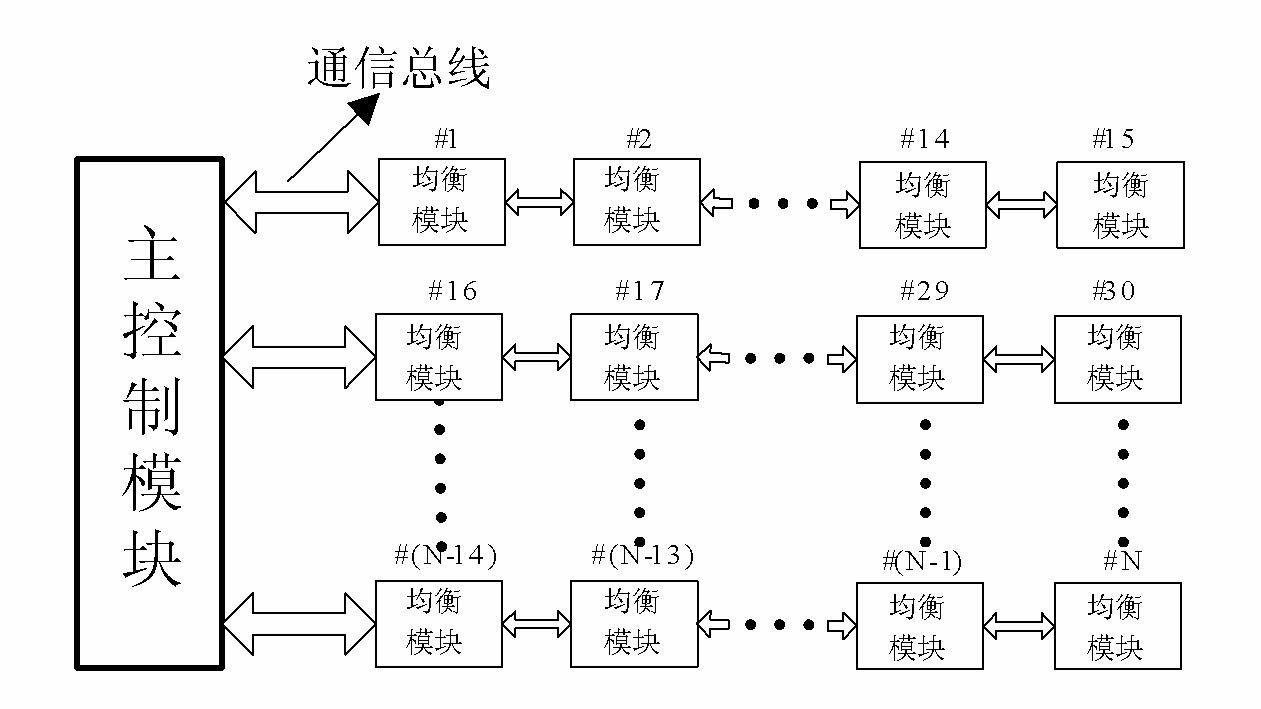

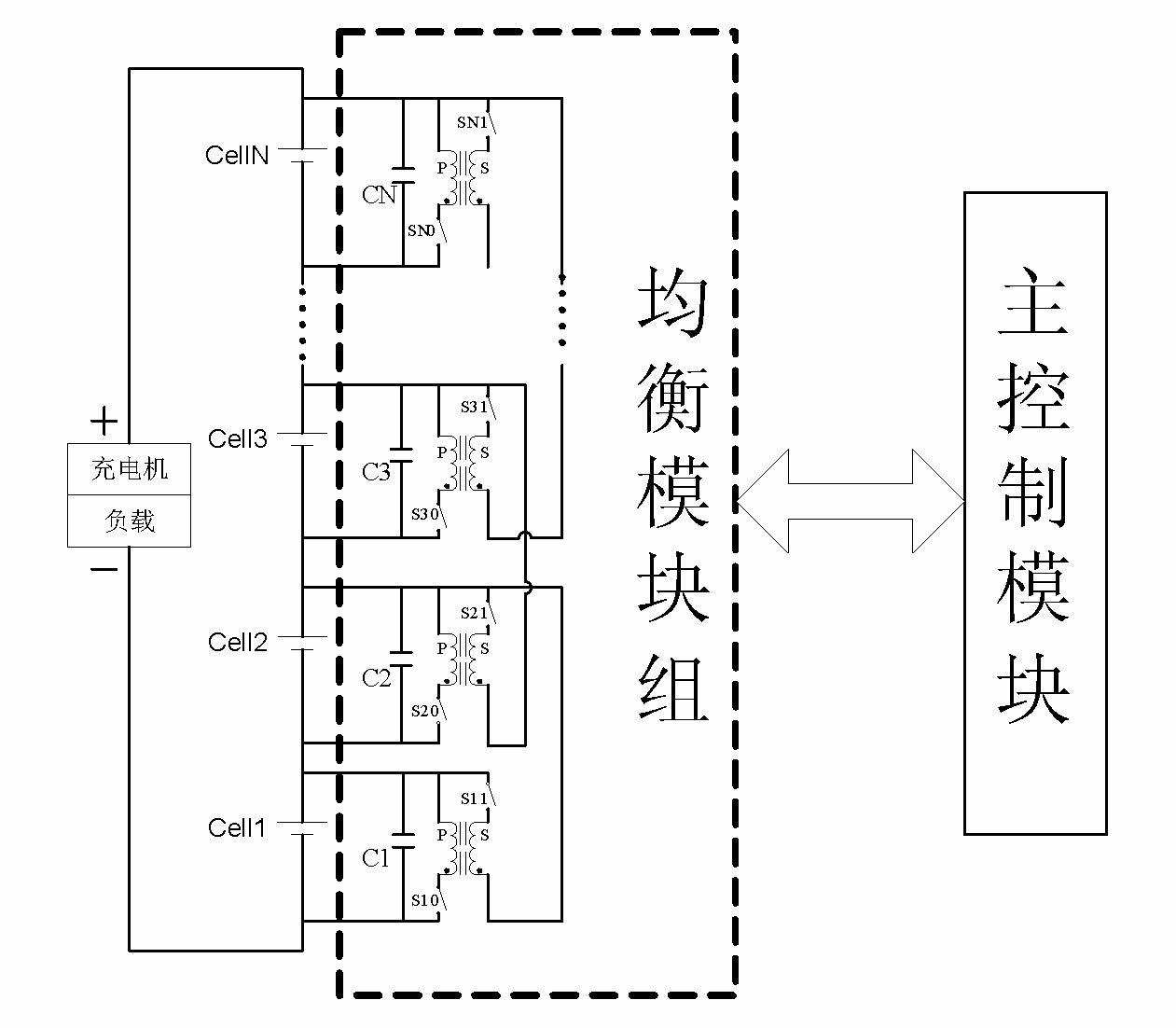

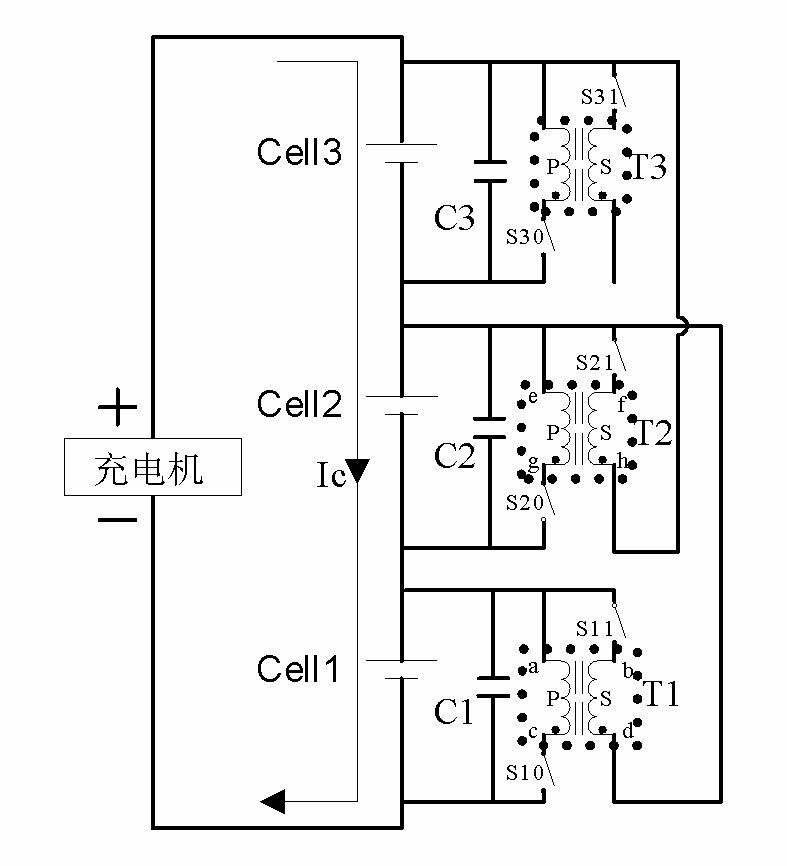

Charge-discharge equalizing circuit of multi-monomer tandem dynamic lithium battery

InactiveCN102163854AImprove securityImprove discharge performanceBatteries circuit arrangementsElectric powerElectrical batteryCapacitance

The invention relates to a charge-discharge equalizing circuit of a multi-monomer tandem dynamic lithium battery, comprising a master control module and a group of equalizing modules, wherein the group of equalizing modules are communicated with the master control module and correspondingly connected with a group of monomer batteries which are sequentially connected in series; each equalizing module comprises a flyback transformer, two switches and one or more than two parallel capacitor banks; one winding of the flyback transformer of each equalizing module is connected with the positive and negative poles of the corresponding monomer battery; the capacitor banks of each equalizing module are connected with the winding in parallel; the other winding is connected with the positive and negative poles of the monomer battery which is adjacent to and sequentially connected to the above monomer battery; and each winding return circuit is connected with one switch in series. The equalizing circuit realizes energy balance among all the monomer batteries, has the advantages that the equalization is lossless, the equalizing current is large, the equalizing efficiency is high, the expandability is good and the implementation is easy, and the purposes of quick large-current charging, enhancement of battery safety performance, improvement of discharging capacity and service life of the batteries and the like can be realized.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Lithium iron phosphate anode material and its preparing method

InactiveCN1767238AImprove conductivityHigh tap densityElectrode manufacturing processesCalcium/strontium/barium compoundsBorideAlcohol

The invention relates to ferric phosphate lithium anode material and its preparing method, which relates to a cell anode material, especially to a ferric phosphate lithium anode material used in lithium ion cell second time. It provides a cell anode material and ití»s preparing method which can elevate the LiFePO4 conductivity and tap density at the same time. It is formed by ferric phosphate lithium and calcium boride (by weight rate): ferric phosphate lithium: calcium boride=100í† (1.01- 5.26). It first syntheses pure ferric phosphate lithium: it balls the ferrous salt, microcosmic salt and lithium salt by alcohol grease, heats the mixed material and uses inactive gas as preserving gas. It balls the synthesis ferric phosphate lithium anode and calcium boride, burns the mixed material and adds inactive gas as preserving gas to obtain the object product.

Owner:河南天科科技有限公司

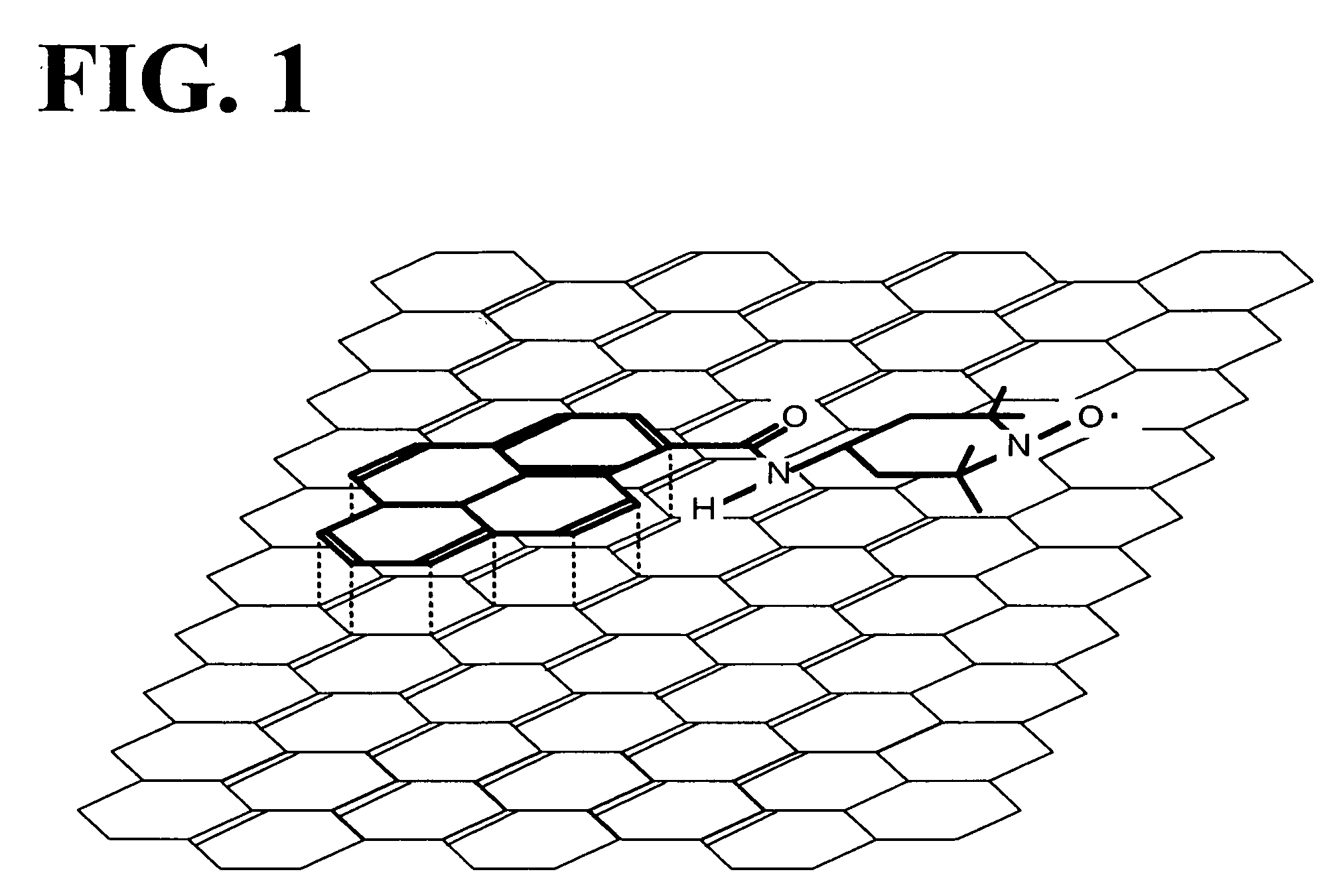

Alkali metal air battery

InactiveUS20090239113A1Raise the discharge potentialCharge capacityFuel and secondary cellsActive material electrodesMetallic lithiumLithium–air battery

A F-type electrochemical cell, which is a lithium air battery, includes a positive electrode facing a negative electrode composed of metallic lithium with a separator provided therebetween in a casing. Air is capable of flow to the positive electrode. A nonaqueous electrolytic solution is charged into a space between the positive electrode and the negative electrode. At least one of the positive electrode and the nonaqueous electrolytic solution of the lithium air battery contains a compound having a stable radical skeleton. The compound also serves as a redox catalyst for oxygen.

Owner:TOYOTA CENT RES & DEV LAB INC

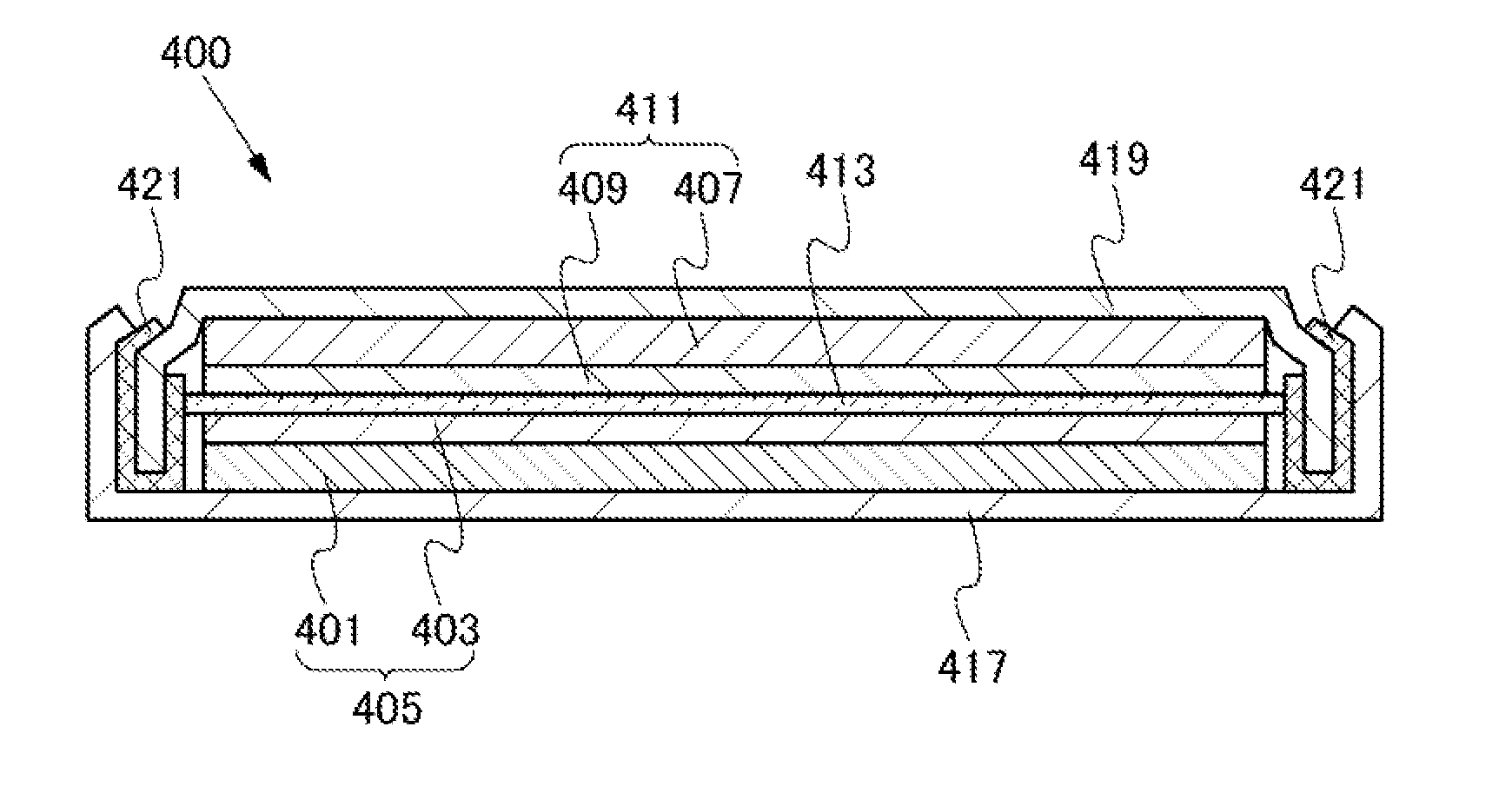

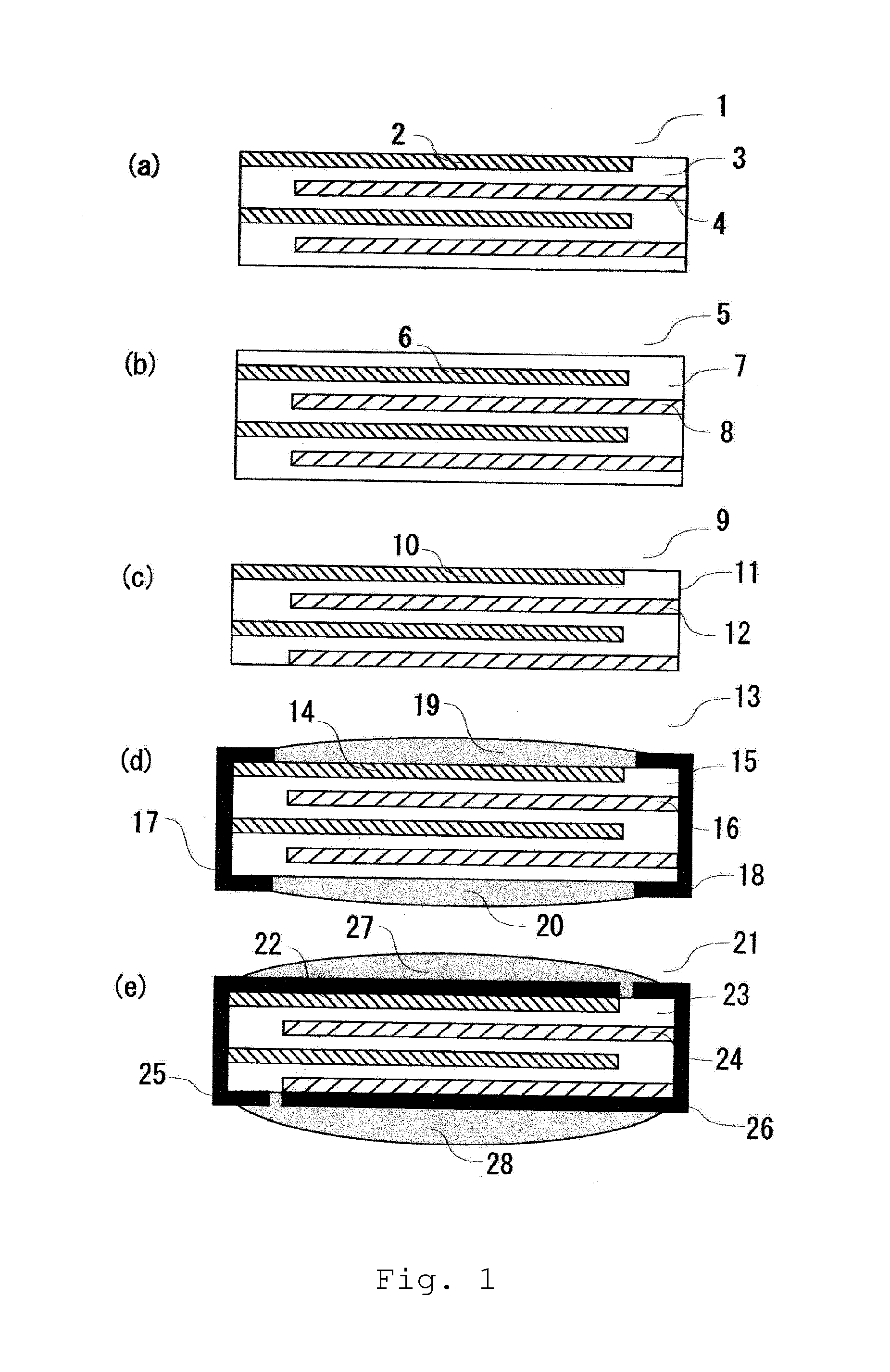

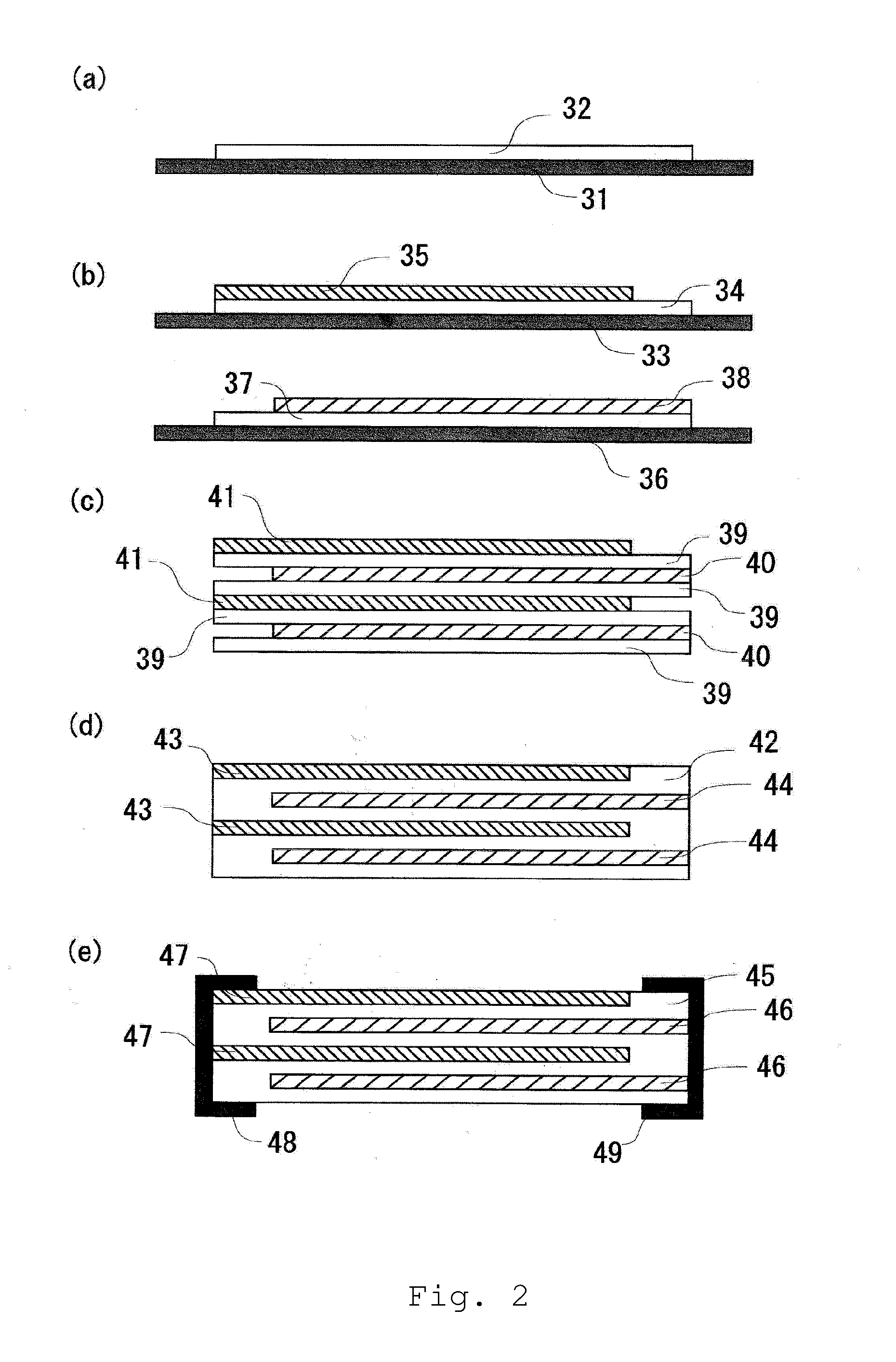

Lithium ion secondary battery and method for manufacturing same

ActiveUS20120015234A1Lower internal resistanceImprove discharge performanceSolid electrolytesFinal product manufactureAll solid stateElectrical battery

A conventional, multilayer, all-solid-state, lithium ion secondary battery where an electrode layer and an electrolyte layer are stacked has a problem that it has a high interface resistance between the electrode layer and the electrolyte layer and has a difficulty in increasing the capacity of the battery. A battery has been manufactured by applying pastes of a mixture of an active material and a solid electrolyte to form electrode layers and baking a laminate of electrode layers and electrolyte layers at a time. As a result, a matrix structure including the active material and the solid electrolyte has been formed in the electrode layers, so that a battery with a large capacity and a reduced interface resistance between the electrode layer and the electrolyte layer has been successfully achieved.

Owner:NAMICS CORPORATION

Electrolytes for lithium sulfur cells

ActiveUS20050147886A1Low self-discharge rateImprove overall utilizationFinal product manufactureOrganic electrolyte cellsLithium sulfurCharge discharge

Disclosed is an electrochemical cell comprising a lithium anode and a sulfur-containing cathode and a non-aqueous electrolyte. The cell exhibits high utilization of the electroactive sulfur-containing material of the cathode and a high charge-discharge efficiency.

Owner:SION POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com