Patents

Literature

32results about How to "Good charge and discharge cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

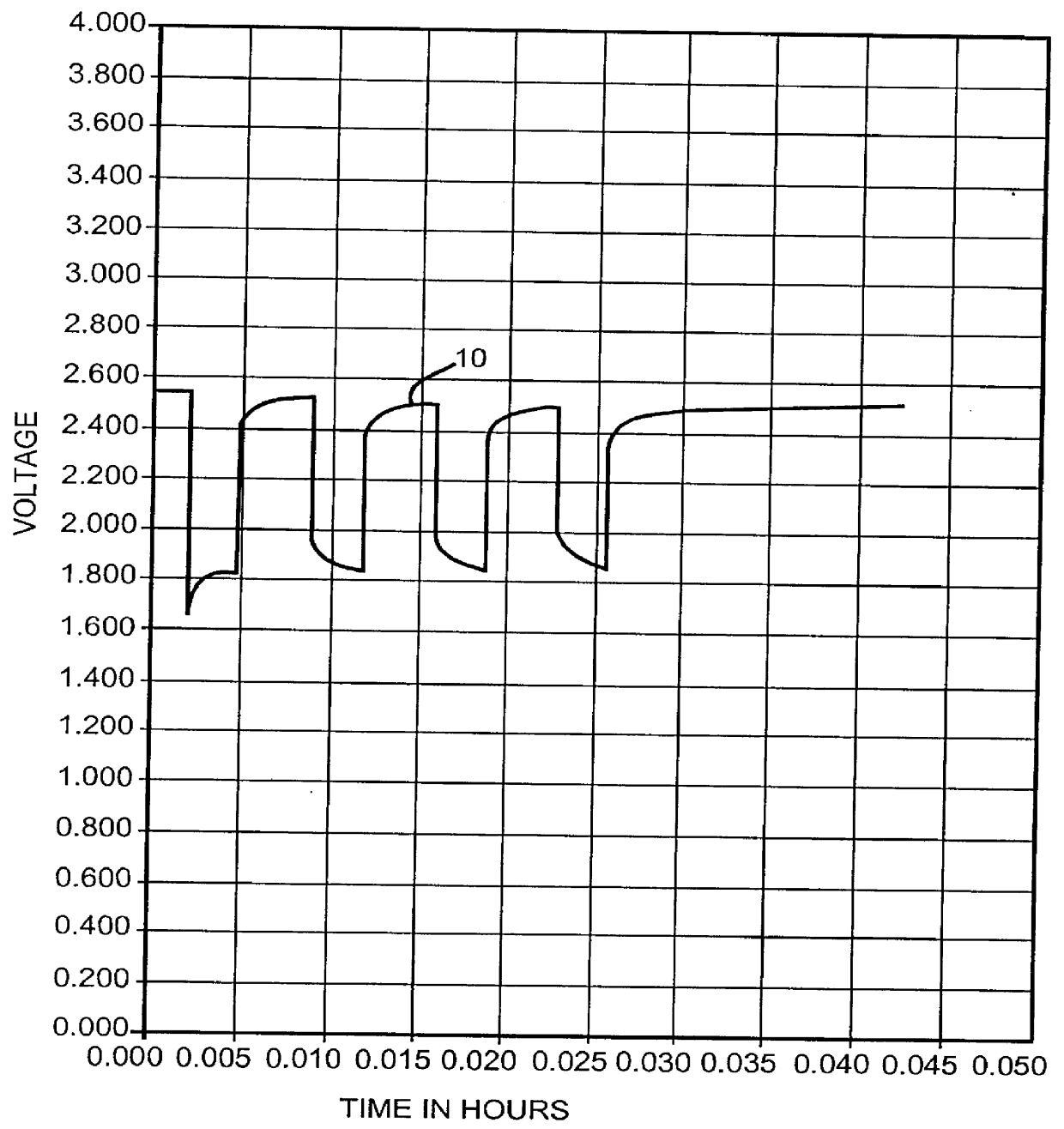

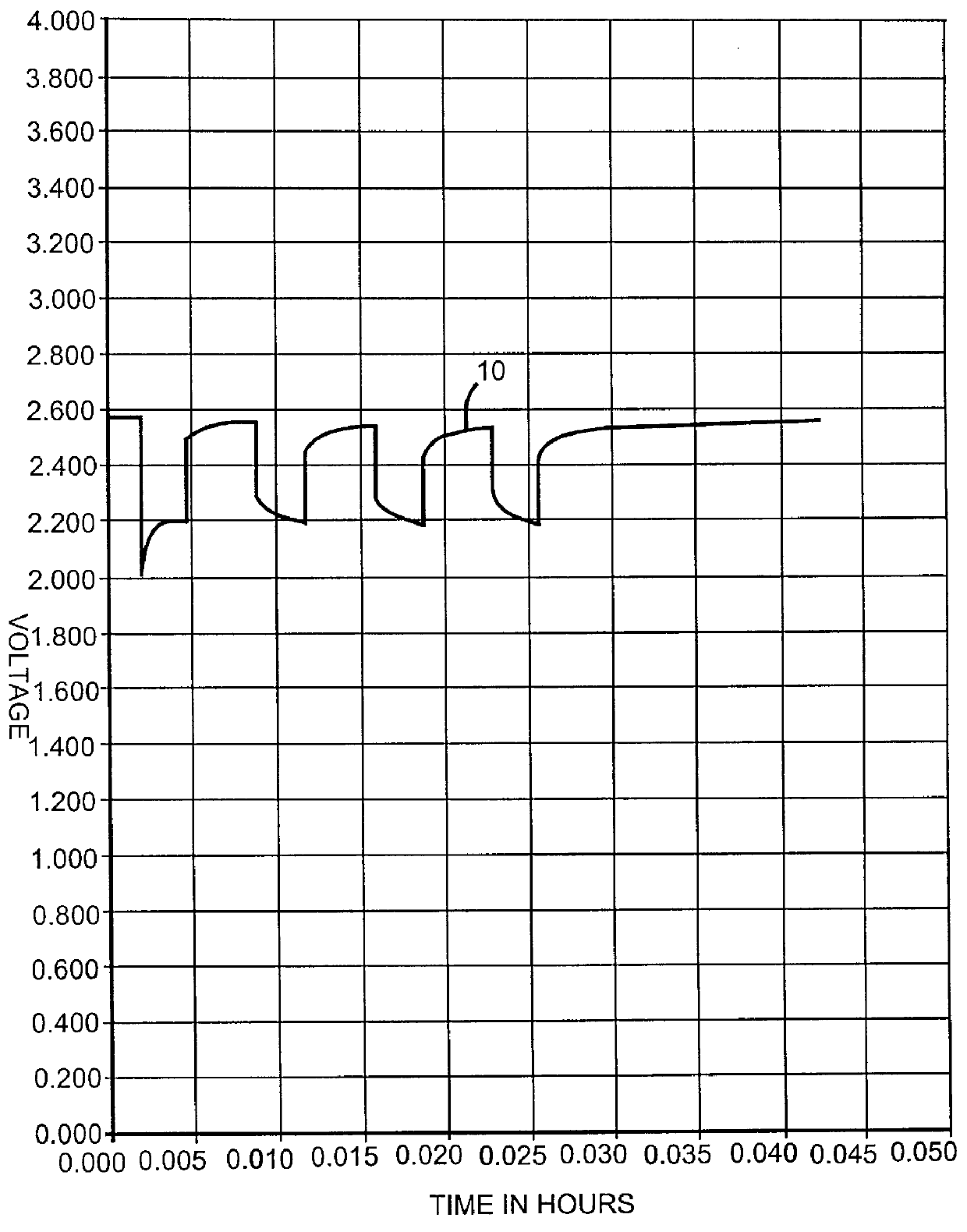

Inorganic and organic nitrate additives for nonaqueous electrolyte in alkali metal electrochemical cells

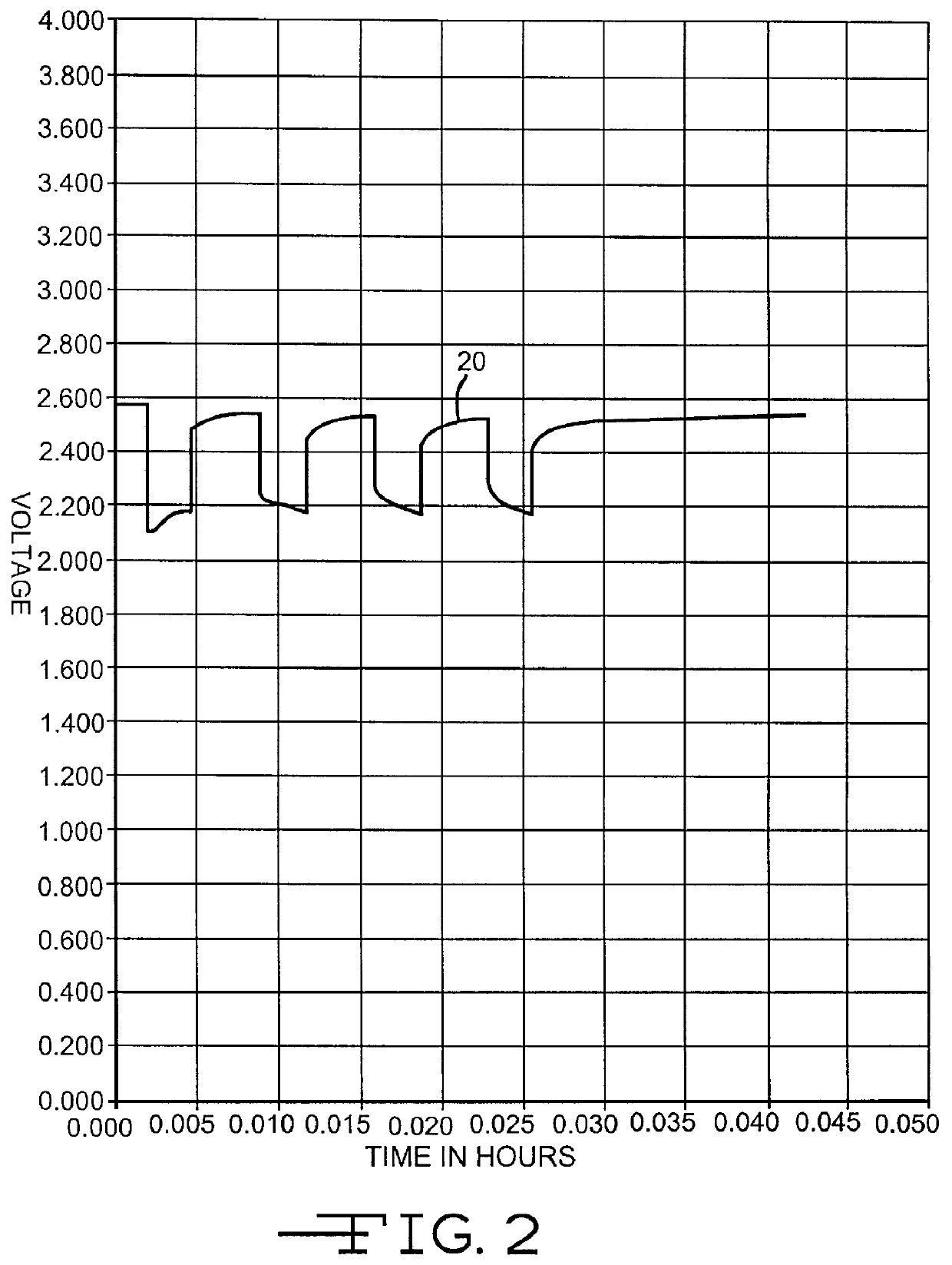

InactiveUS6060184AGood charge and discharge cycleImprove efficiencyOrganic electrolyte cellsSecondary cells charging/dischargingAlkaline earth metalOrganic nitrates

An alkali metal, solid cathode, nonaqueous electrochemical cell capable of delivering high current pulses, rapidly recovering its open circuit voltage and having high current capacity, is described. The stated benefits are realized by the addition of at least one nitrate additive to an electrolyte comprising an alkali metal salt dissolved in a mixture of a low viscosity solvent and a high permittivity solvent. A preferred solvent mixture includes propylene carbonate, dimethoxyethane and an alkali metal nitrate, alkaline earth metal nitrate and / or an organic alkyl nitrate additive.

Owner:WILSON GREATBATCH LTD

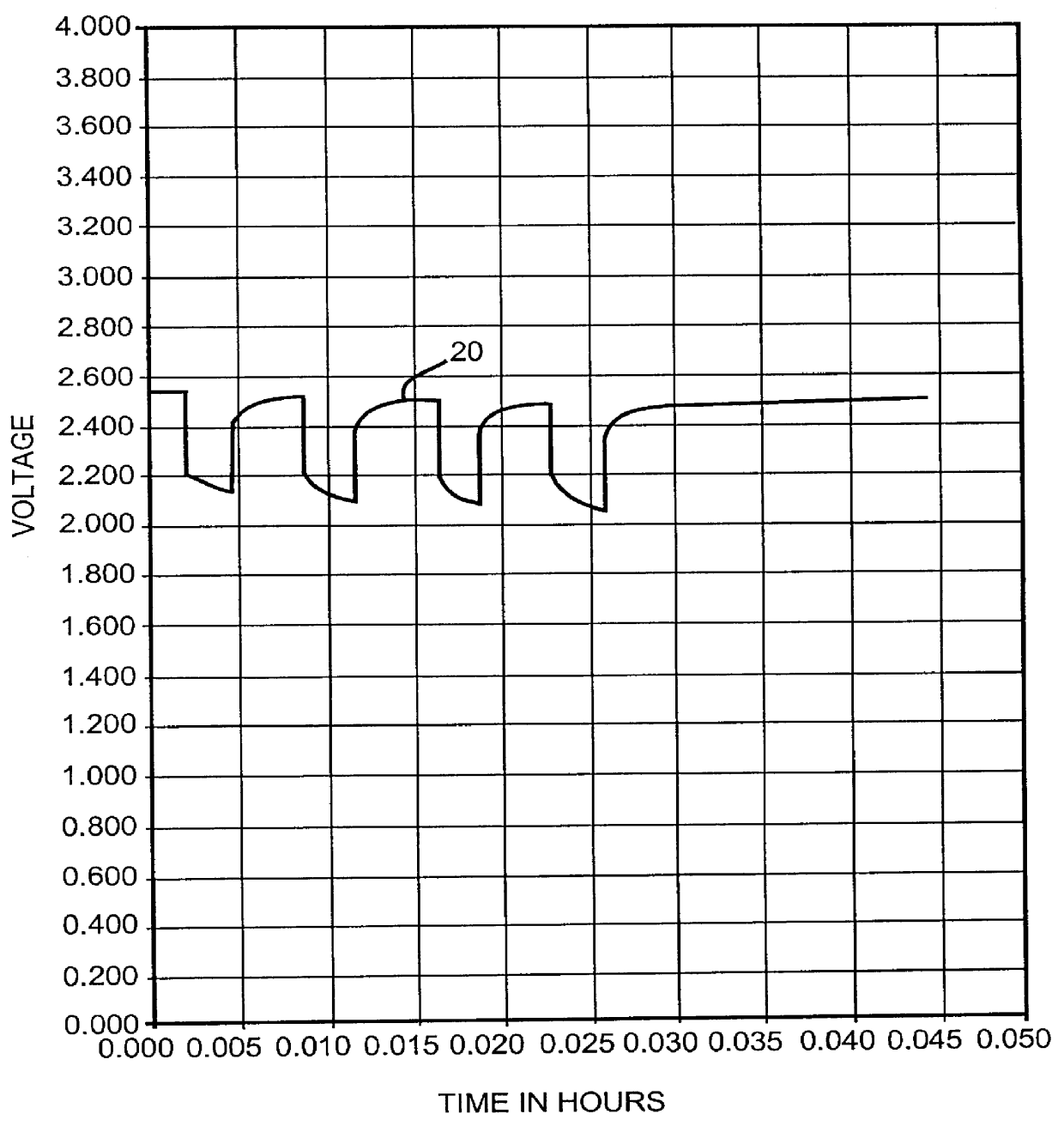

Phosphonate additives for nonaqueous electrolyte in alkali metal electrochemical cells

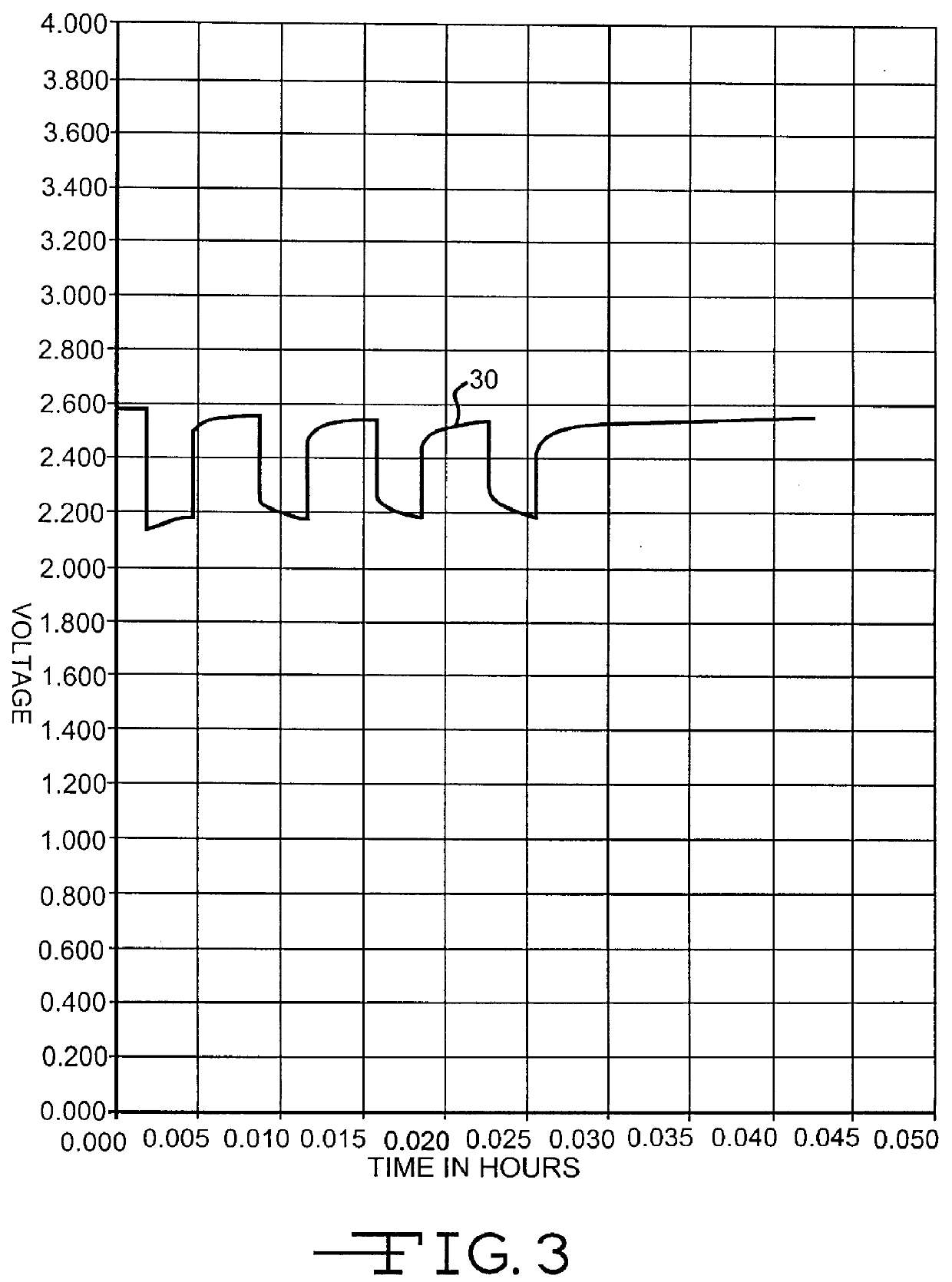

InactiveUS6096447AGood charge and discharge cycleImprove efficiencyOrganic electrolyte cellsHeart stimulatorsPermittivityPropylene carbonate

An alkali metal, solid cathode, nonaqueous electrochemical cell capable of delivering high current pulses, rapidly recovering its open circuit voltage and having high current capacity, is described. The stated benefits are realized by the addition of at least one phosphonate additive to an electrolyte comprising an alkali metal salt dissolved in a mixture of a low viscosity solvent and a high permittivity solvent. A preferred solvent mixture includes propylene carbonate, dimethoxyethane and an alkyl phosphonate additive.

Owner:WILSON GREATBATCH LTD

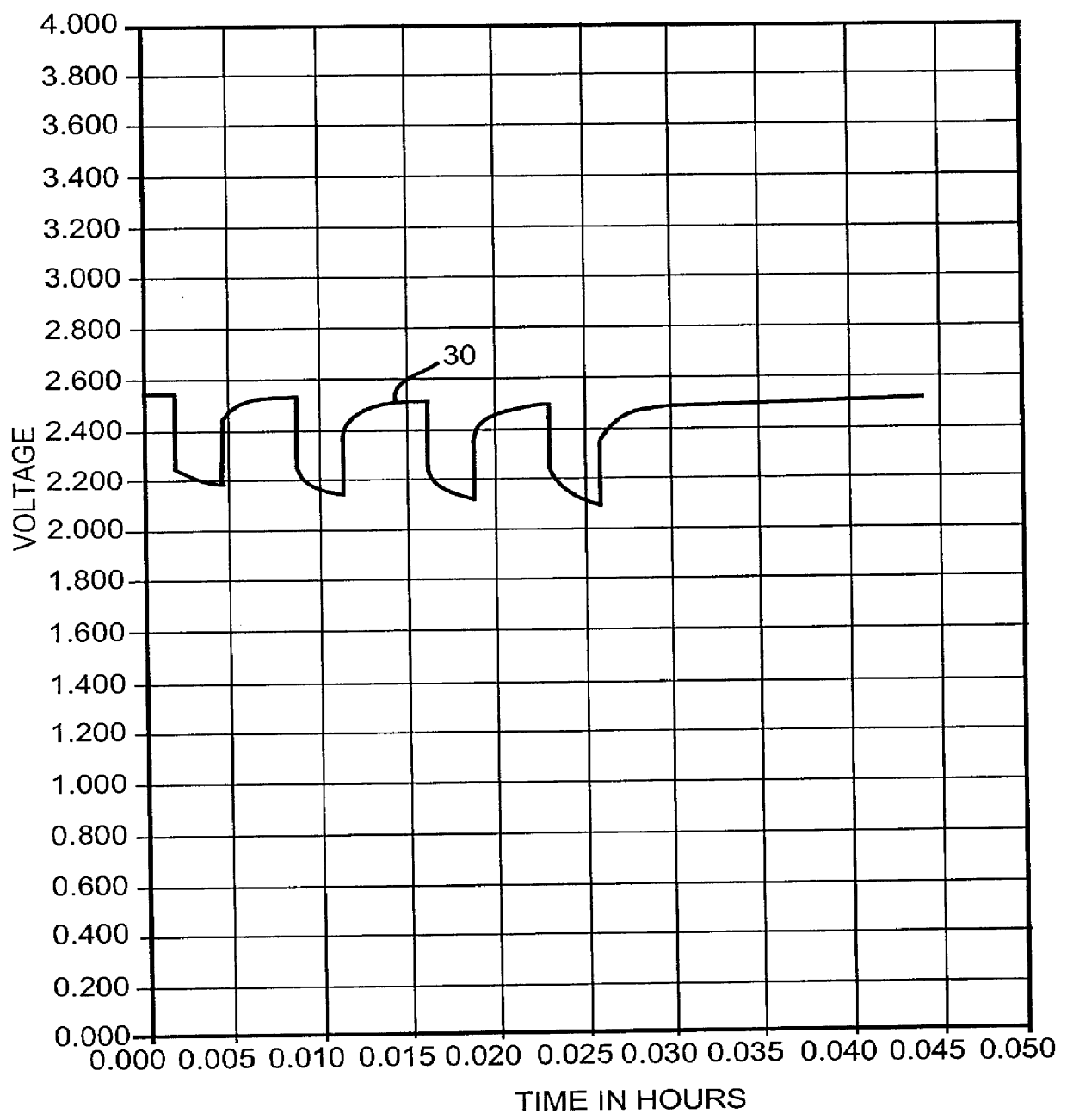

Organic nitrite additives for nonaqueous electrolyte in alkali metal electrochemical cells

InactiveUS6027827AGood charge and discharge cycleImprove efficiencyElectrotherapyPrimary cell maintainance/servicingPermittivitySolvent

Owner:WILSON GREATBATCH LTD

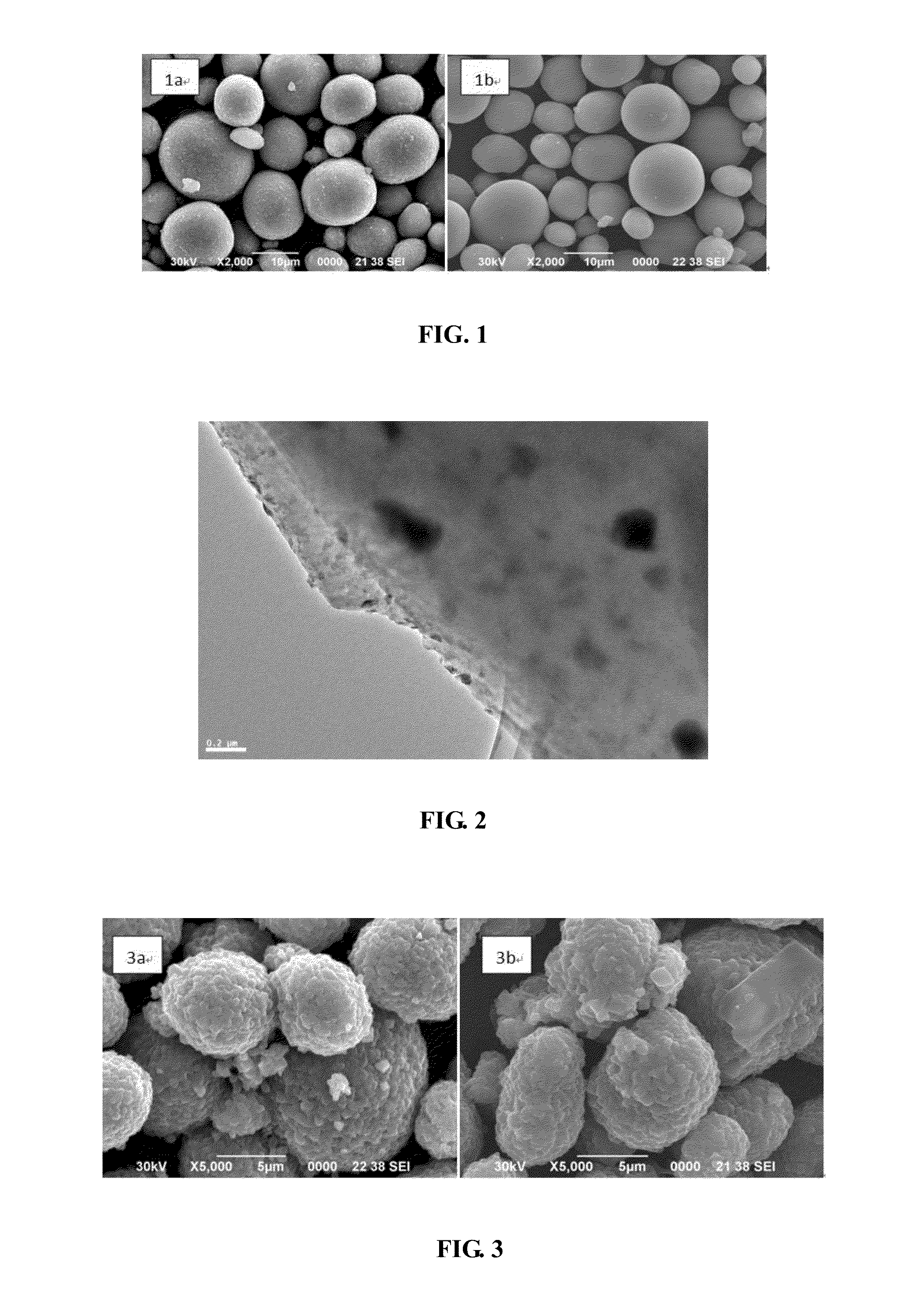

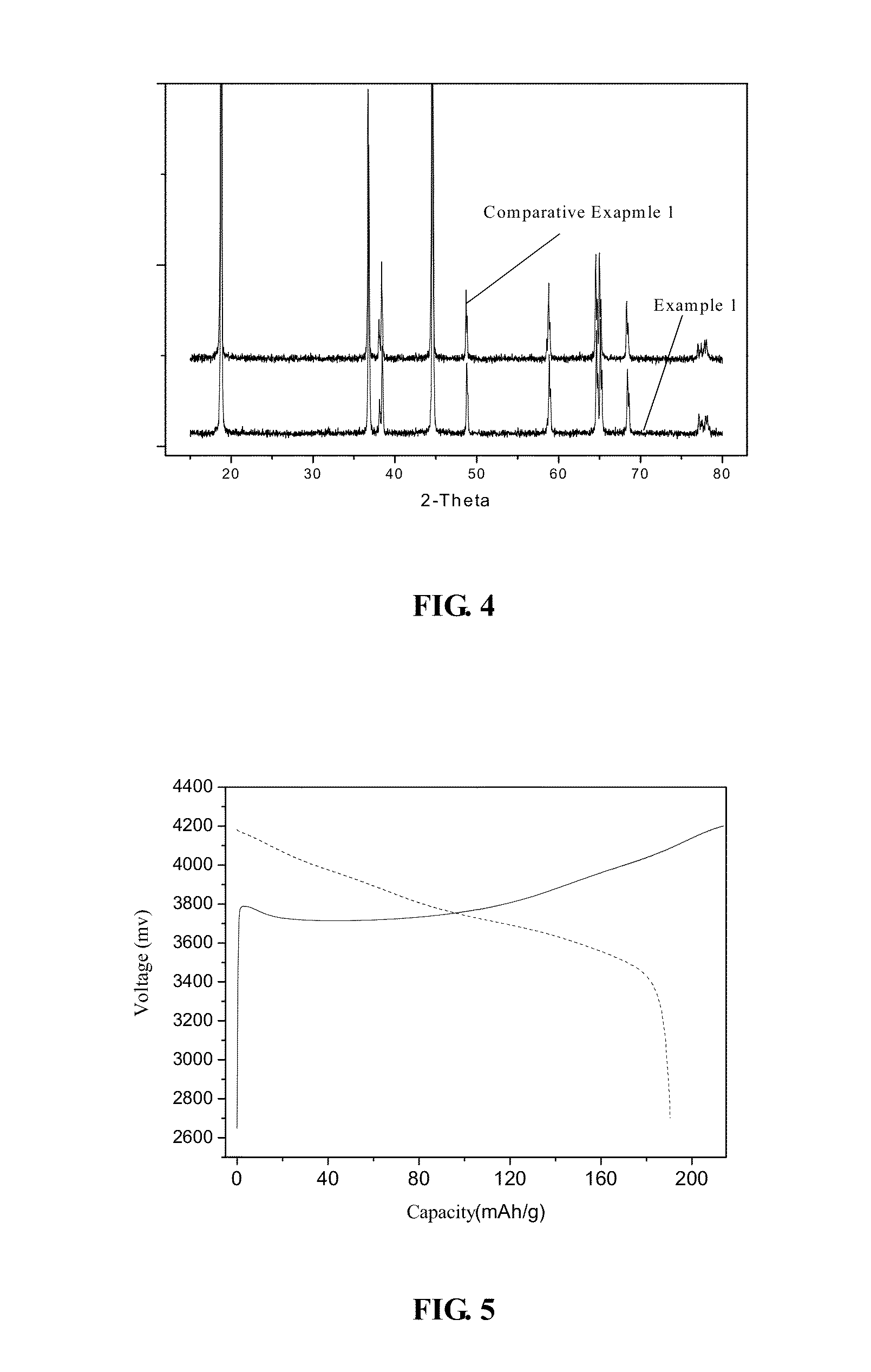

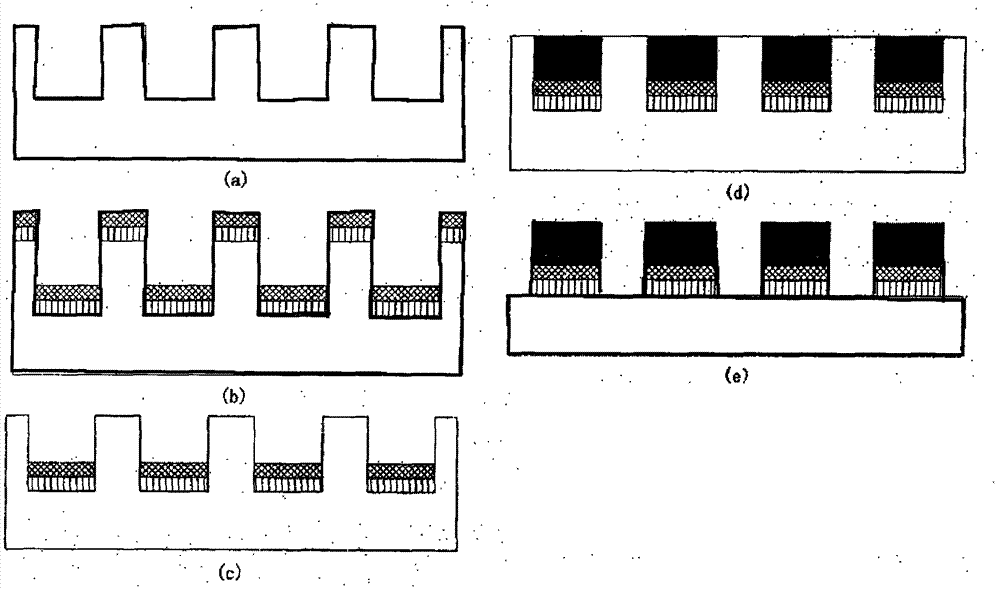

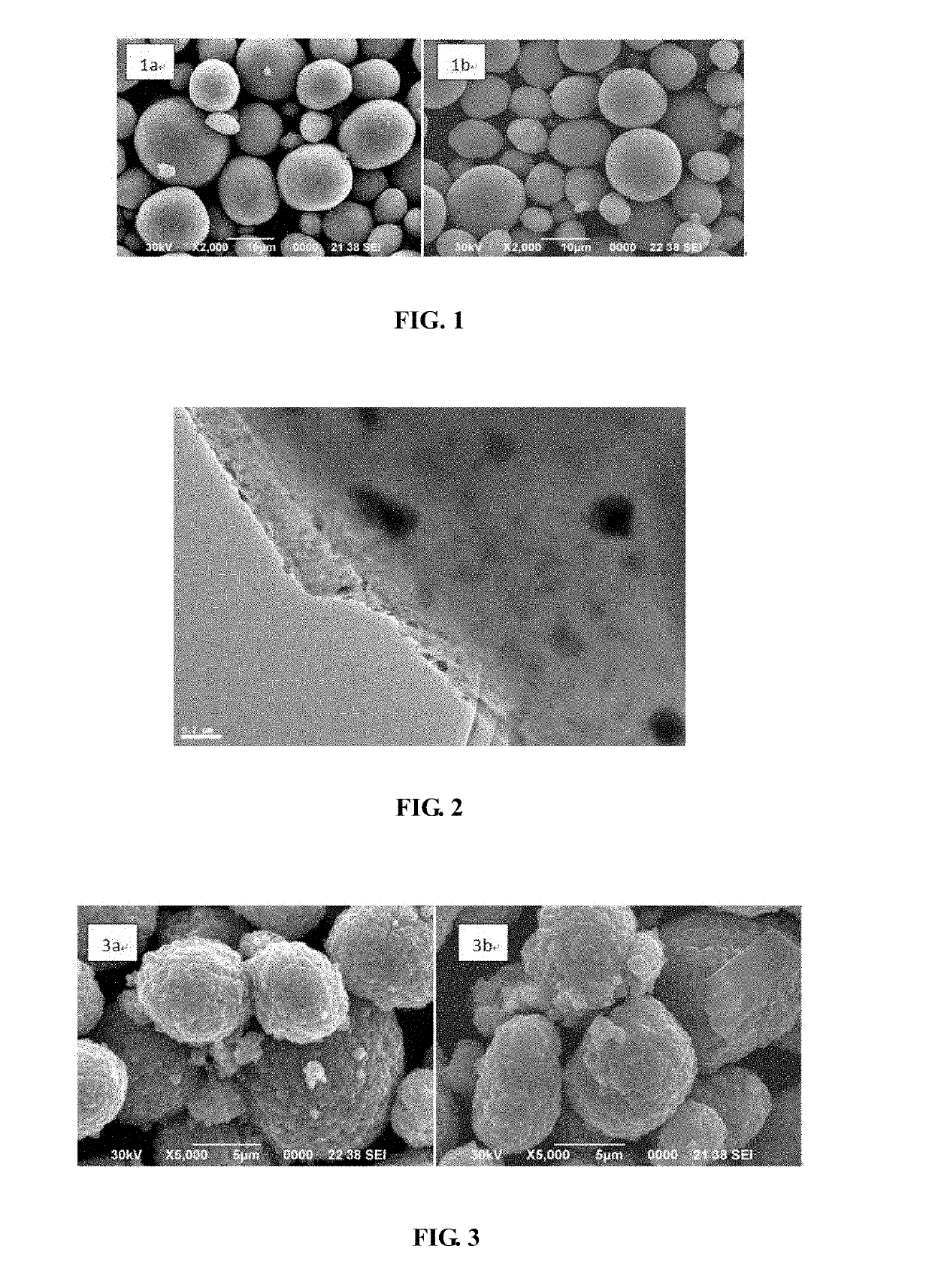

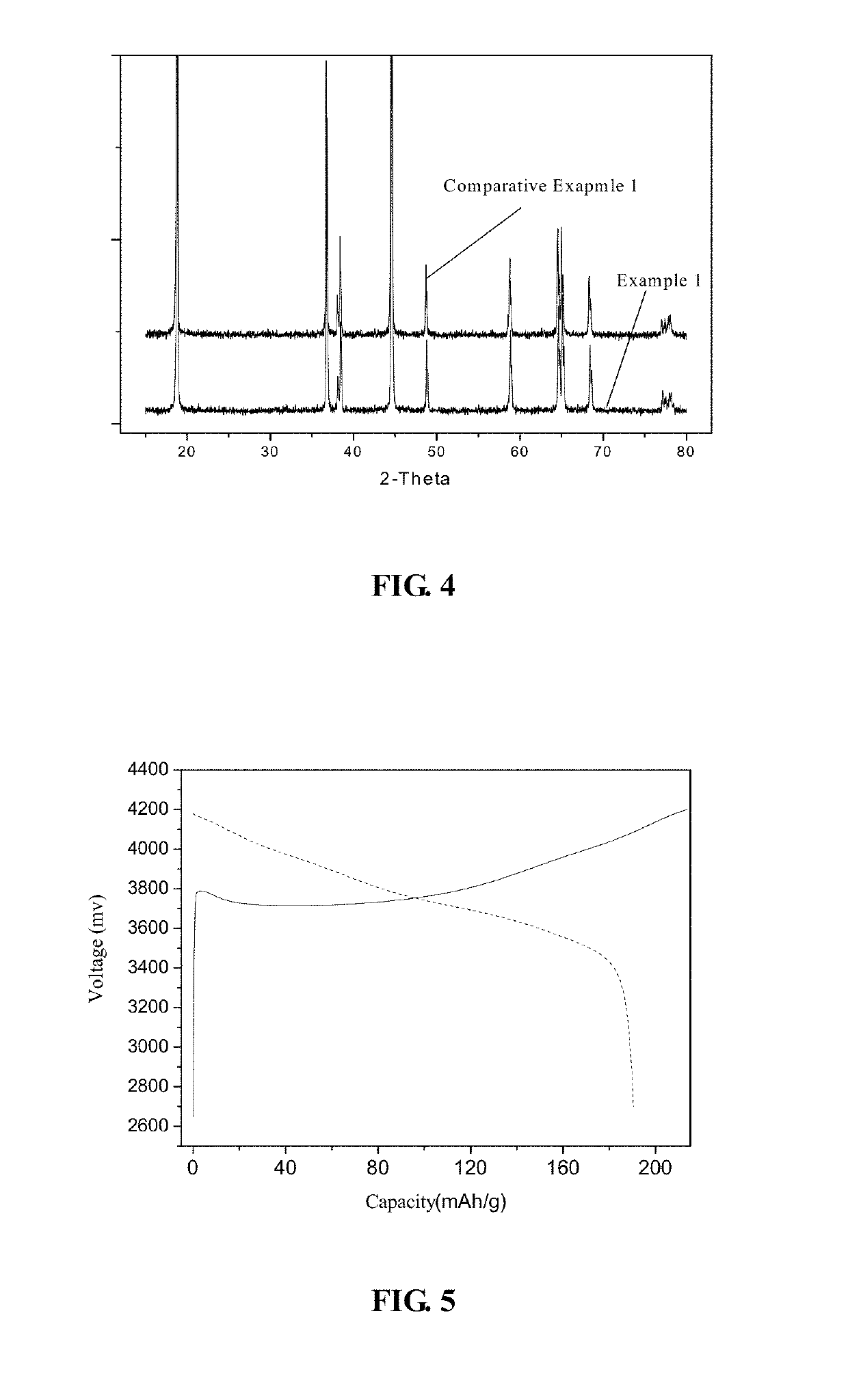

Cathode material for lithium ion secondary battery, method of producing the same, and lithium ion secondary battery

ActiveUS20160049645A1Improve thermal stabilityGood charge and discharge cyclePositive electrodesNon-aqueous electrolyte accumulator electrodesChemical activityComposite oxide

The present invention discloses a cathode material for lithium ion secondary battery. The cathode material is in the form of powder particles. The powder particle includes a bulk portion and a coating portion coated on the outer surface of the bulk portion. The bulk portion is formed of at least one first cathode material which is a lithium-nickel based composite oxide. The first cathode material has electrochemical activity and has high charging-discharging specific capacity at a charged voltage of 4.2V versus Li / Li+. The coating portion is formed of at least one second cathode material. The second cathode material has no electrochemical activity or has low charging-discharging specific capacity at a charged voltage of 4.2V versus Li / Li+. Lithium ion secondary battery using the cathode material has high energy density, cycling stability, security, and output power.

Owner:MICROVAST POWER SYST CO LTD

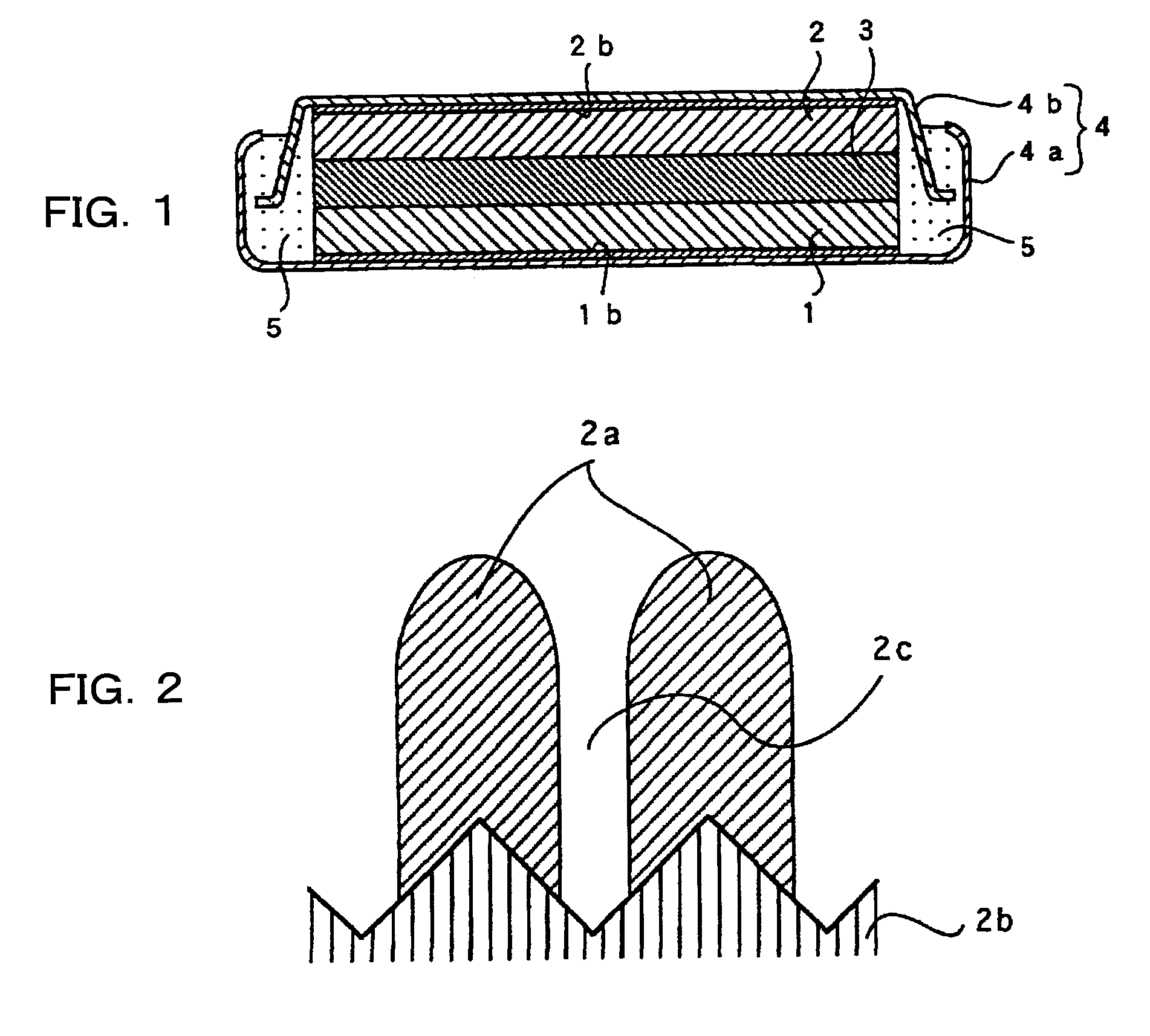

Manufacturing method of electrode for electrochemical element

InactiveUS20080248189A1Junction strength be increaseHigh capacityHybrid capacitor electrodesElectrode carriers/collectorsCurrent collectorEngineering

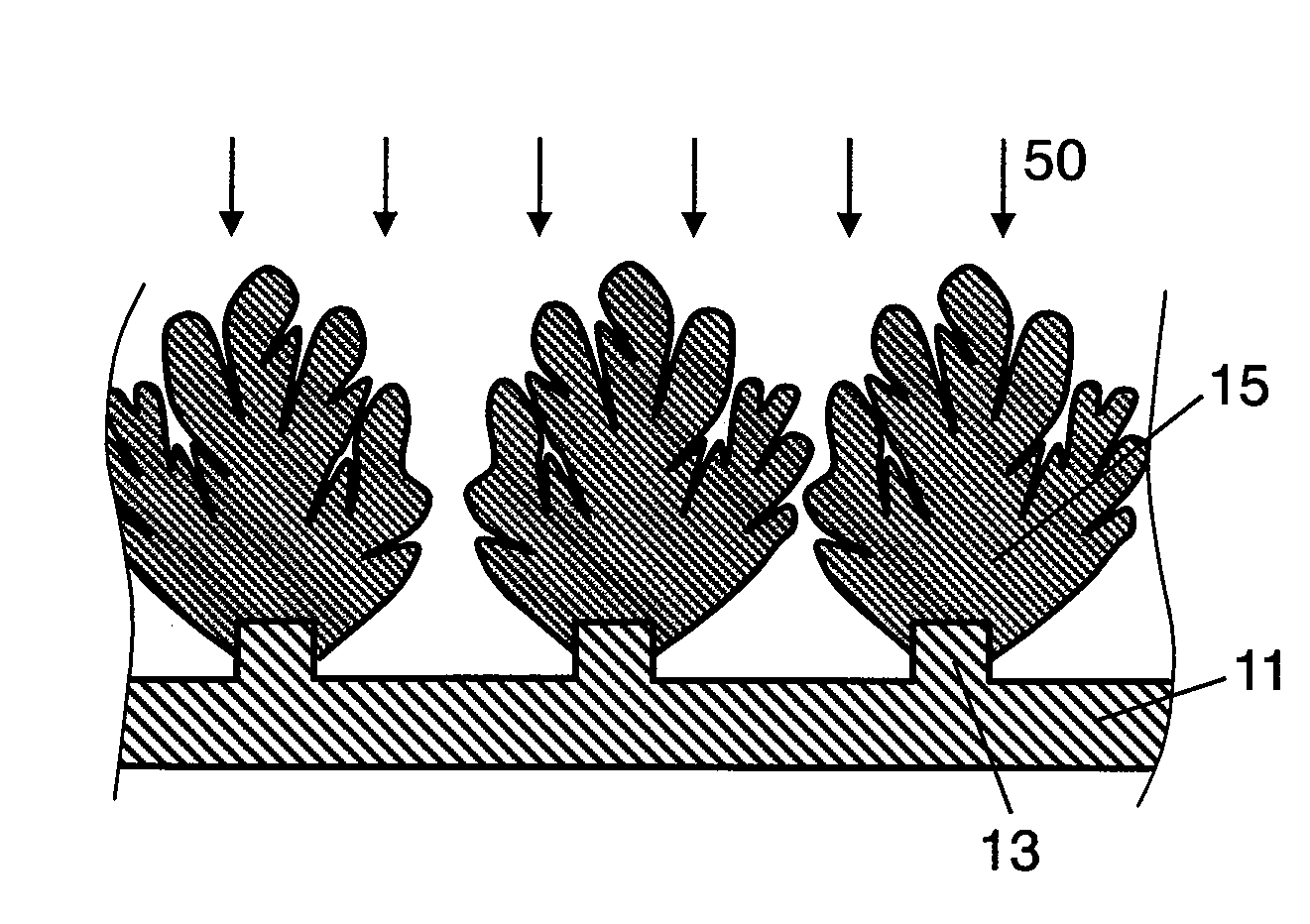

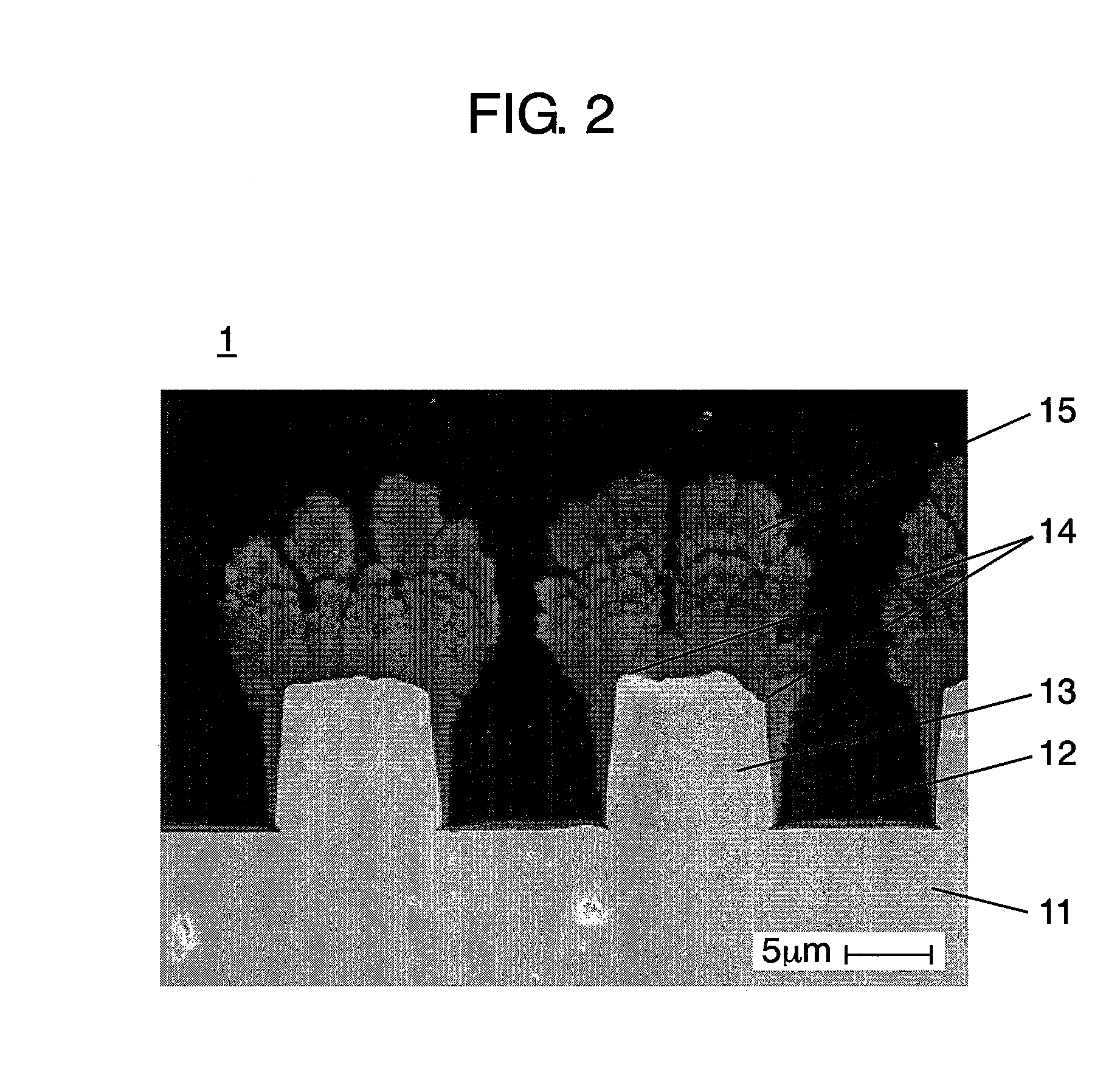

The invention presents a manufacturing method of an electrode for an electrochemical element for inserting and extracting a lithium ion reversibly, comprising; forming a concave portion and a convex portion at least on one side of a current collector, preparing a raw material containing a element for composing an active material, introducing a specified supply amount of the raw material and a carrier gas into a film forming device to form a plasma, and injecting the plasma of the raw material on the current collector, in which the active material is grown on the convex portion of the current collector, and a columnar body is formed by covering at least a part of respective sides of the convex portion.

Owner:PANASONIC CORP

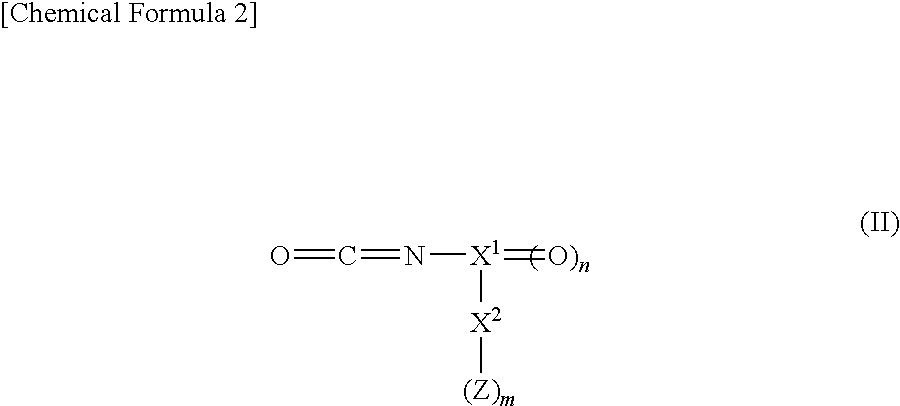

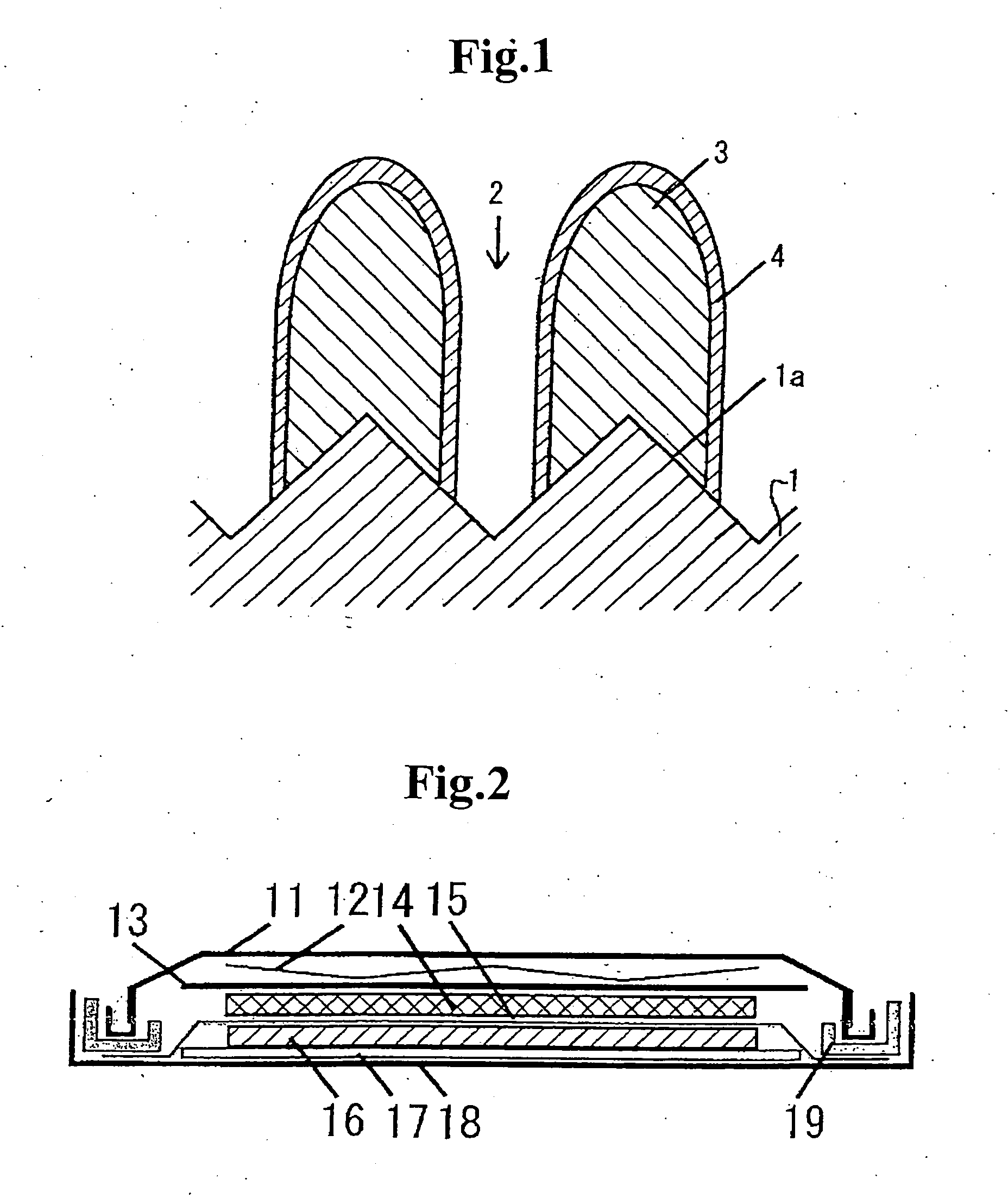

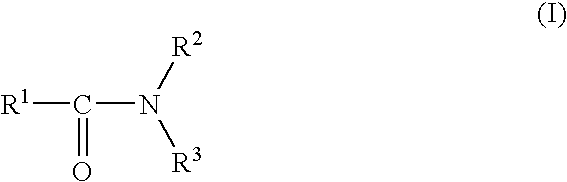

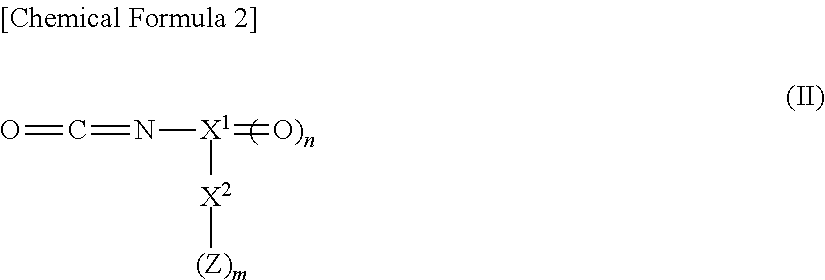

Nonaqueous electrolyte secondary battery and nonaqueous electrolyte solution

ActiveUS20090311609A1Avoid reactionGood charge and discharge cycleAlkaline accumulatorsElectrolytic capacitorsHydrogenThin layer

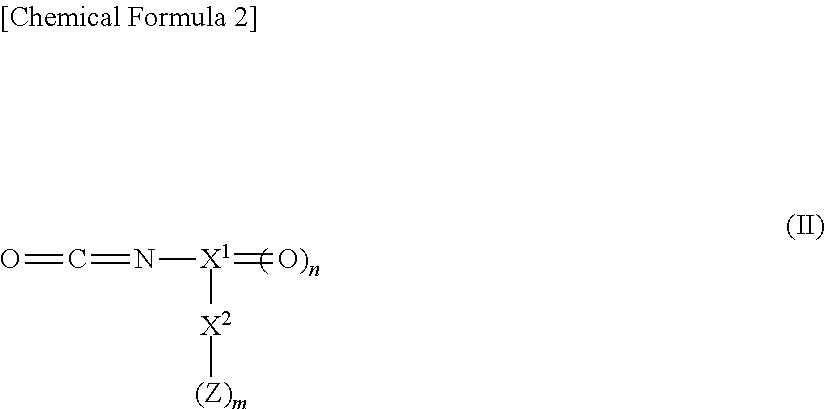

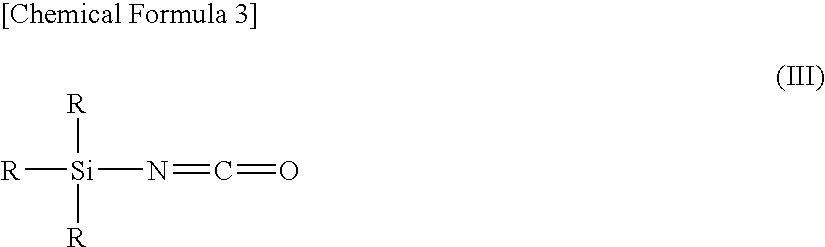

The objective of the present invention is to prevent deterioration and expanding of anode active material and to improve charge-discharge cycle characteristics in a non-aqueous electrolyte secondary battery comprising an anode of which current collector has thereon a thin layer of an anode active material containing a metal. To solve this problem, in a non-aqueous electrolyte secondary battery wherein a thin layer of anode active material containing a metal which absorbs and discharges lithium is formed on a current collector and the thin layer of the anode active material is divided into columns by a gap formed along the thickness thereof, a compound represented by the following formula is contained in the non-aqueous electrolyte.A-N═C═OIn the above formula, A represents an element or a group other than hydrogen.

Owner:PANASONIC ENERGY CO LTD +2

Nonaqueous electrolyte solution for secondary battery and nonaqueous electrolyte secondary battery

InactiveUS20060035155A1High charge and dischargeGood charge and discharge cycleElectrochemical processing of electrodesElectrode carriers/collectorsSolventDecomposition

Owner:SANYO ELECTRIC CO LTD +1

High-proportion zinc borate battery electrolyte and preparation method

ActiveCN104752777ATransfer of controlGood charge and discharge cycleFinal product manufactureAlkaline accumulators manufacturePotassium ionsBenzene

The invention relates to high-proportion zinc borate battery electrolyte and a preparation method. The molar ratio of potassium ions or / and sodium ions in the zinc battery electrolyte to boric acid ions is 0.28-2, and the total content of an additive in the electrolyte is less than or equal to 40 g / L. According to KOH or / and NaOH 2-6.2 mol / L, H3BO3 3.1-7 mol / L, LiOH.H2O 0.1-0.5 mol / L, a base solution is formed by blending with water as a solvent, then phytic acid, benzene-m-disulfonic acid, isophthalic acid-sulfonic acid, micro-nano SiO2 or micro-nano TiO2 are added, and after stirring, standing and naturally cooling, a 400-mesh screen is used for filtering to obtain the high-proportion zinc borate battery electrolyte. The high-proportion zinc borate battery electrolyte and the preparation method provided by the invention substantially solve the problems of dendrite growth, zinc element transfer, polar plate deformation and the like of a zinc cathode in charging and discharging processes, the cycle performance is significantly improved, and reliable technical guarantee is provided for enabling zinc series alkaline batteries to become a new generation of power batteries.

Owner:王家祥

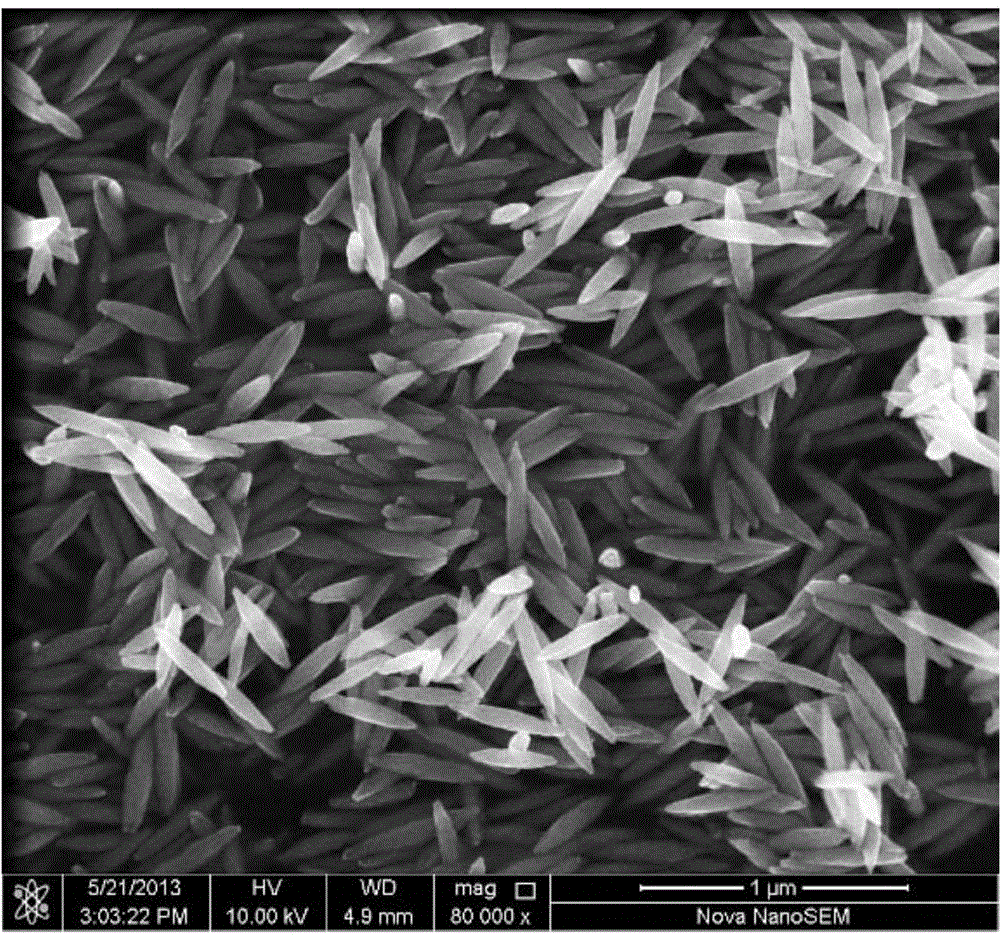

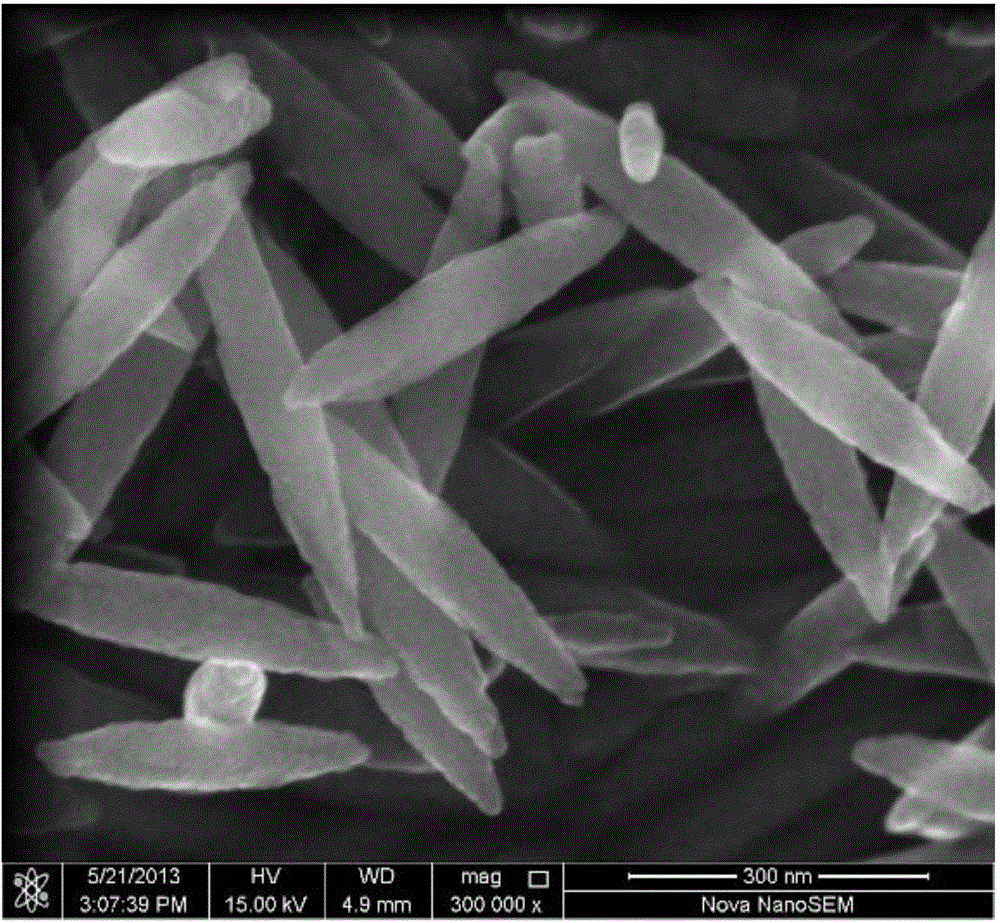

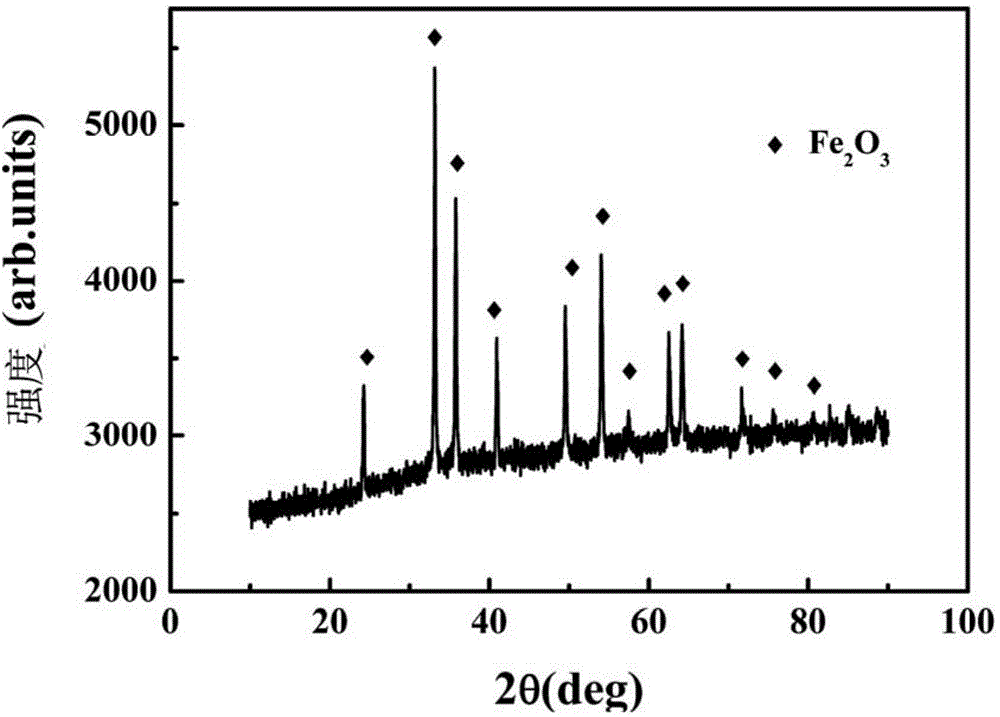

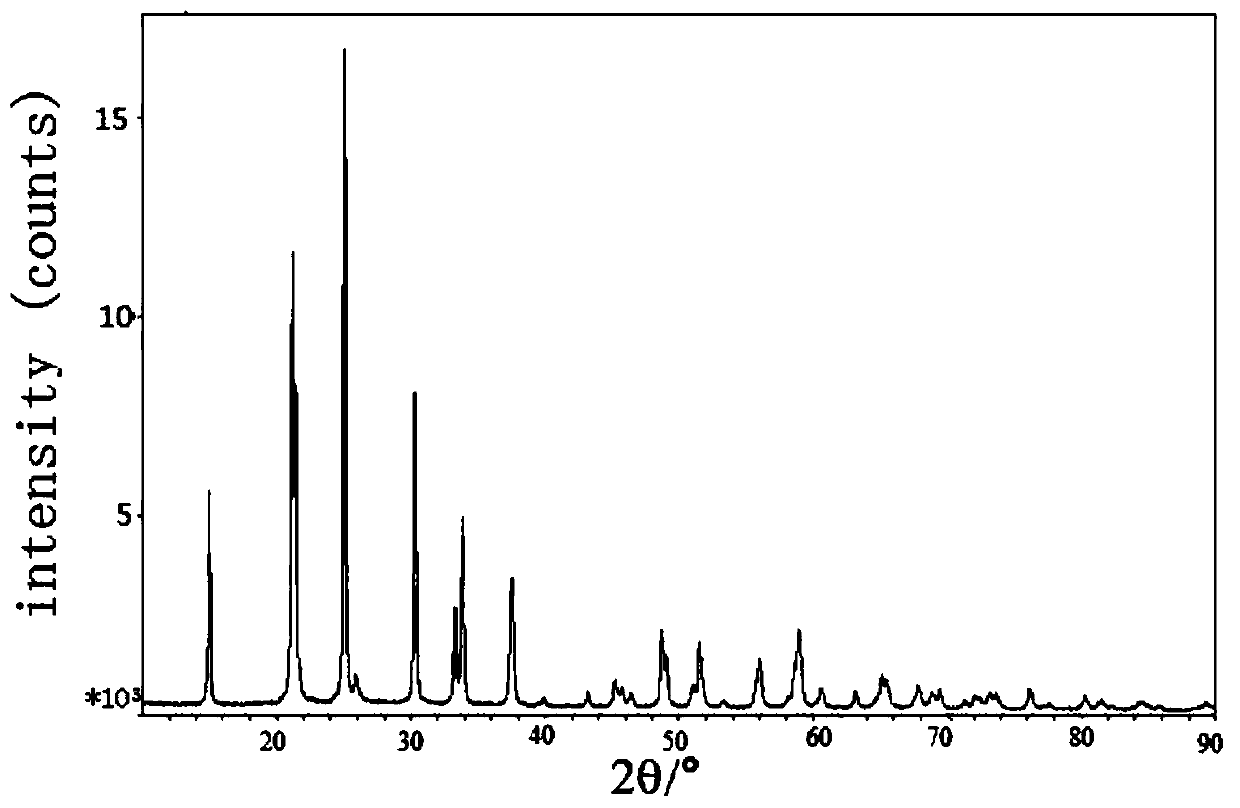

Rod-shaped nano iron oxide electrode material, and preparation method and application thereof

InactiveCN103606672AWide concentration rangeEasy to controlMaterial nanotechnologyCell electrodesLithium-ion batteryChemical stability

The invention discloses a rod-shaped nano iron oxide electrode material, and a preparation method thereof. The preparation method comprises the steps of carrying out a hydrothermal reaction by using FeCl3.6H2O, ammonium dihydrogen phosphate and water as raw materials; and washing produced precipitate to obtain the rod-shaped nano iron oxide. The nano iron oxide is in a rod shape, with an average diameter being 60-80 nm, length being 250-300 nanometers, purity higher than 99.9% and crystal phase being alpha-Fe2O3. The rod-shaped nano iron oxide electrode material can be used as both a positive electrode active material and a negative electrode active material for a lithium ion battery. Raw materials used in the preparation method are easily available, nontoxic and pollution-free to environment. A preparation process is simple; operation is convenient; and the preparation method is suitable for large-scale production. By using the rod-shaped nano iron oxide electrode material as the positive and negative electrode active materials for the lithium ion battery, cost is low; electrochemical performance is excellent; chemical stability of the electrode material is stable; specific capacity is high; and polarization of a charge and discharge platform is small.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Alloy negative electrode for lithium battery and process for production thereof, and lithium battery

InactiveCN102906906ANo vulnerabilitySuitable for industrial mass productionElectrode carriers/collectorsAlloyCopper

The present invention provides an alloy cathode for lithium battery, its manufacturing method and lithium battery. The alloy cathode for lithium battery is constituted by non-aqueous electrolyte. By filling metal lithium in a porous aluminum body, the skeleton of the porous aluminum body is further formed by using aluminum. Moreover, by forming an aluminum coating material with an aluminum layer on the surface of a core material constituted of any metal selected from the group consisting of copper, nickel and iron, the skeleton of the porous aluminum body is formed to increase the capacity and intensity and provide excellent charging and discharging cycles.

Owner:SUMITOMO ELECTRIC IND LTD

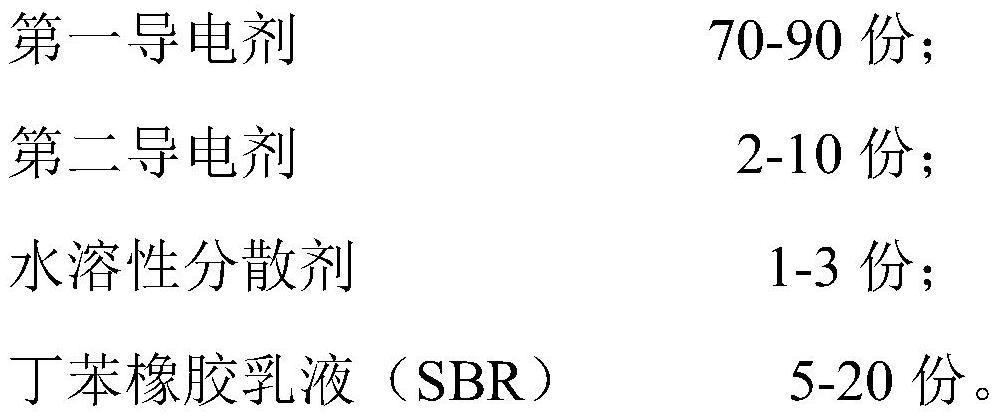

Method for preparing electrodes of capacitor in double electrode layer

InactiveCN1873867AExcellent adhesionHigh bonding strengthElectrolytic capacitorsCapacitor manufactureConductive materialsSolvent

The method for preparing electrode of double electric layer capacitor includes steps: solving bonding material in solvent, dispersing powder of charcoal material and conducting material so as to prepare pulp, where volume content of solid matter is 10-25%; coating the pulp on surface of collector; pressing dried pulp to 60-150 micro to integrate and glue polarization pole and collector firmly so as to form band electrode, which is cut into two pieces of band electrode in same size; riveting leading wire to each piece of band electrode; inserting membrane in 30-80 micro to insulate electrodes; winding electrodes and membrane into core, and vacuum drying it for 8-18h. In the invention, polarization pole is composed of charcoal material, conducting material and bonding material. Advantages are: large bond strength, withstanding high voltage, and good charging and discharging periodicity.

Owner:锦州凯美能源有限公司

Process for manufacturing lithium sulfur battery

ActiveCN103985913ALow purityPrevent oxidationElectrode thermal treatmentFinal product manufactureSolid state electrolyteHigh rate

The invention discloses a process for manufacturing a lithium sulfur battery. The process comprises the following steps: adding polyacrylonitrile resin micro powder and diatomite into a high-speed mixing stirrer according to a mass ratio of 36-39 to 64-61, adding an NMP solvent which accounts for 6-24 weight percent of the diatomite to serve as a raw material, performing pretreatment, and performing repeated dipping and high-temperature evaporation in an NMP solution of lithium salt (namely a 6-9 weight percent of NMP solution containing lithium polysulfide, lithium methylaminobutyrate, lithium perchlorate and lithium phosphate), thereby preparing a positive material; preparing all-solid-state electrolyte of the lithium sulfur battery from lithium methylaminobutyrate, lithium perchlorate and lithium phosphate; and adsorbing molten metal lithium through pores of carbon-containing diatomite at 630-660 DEG C when metal lithium and the formed carbon-containing diatomite electrode are in a vacuum electric heating furnace, thereby finishing preparation of a negative material. The all-solid-state electrolyte of the lithium sulfur battery prepared by the process has high sulfur containing capacity, high ion transport capacity and high conductive performance, and the high rate performance and high cycle performance of the lithium sulfur battery can be improved.

Owner:威海区域创新中心有限责任公司

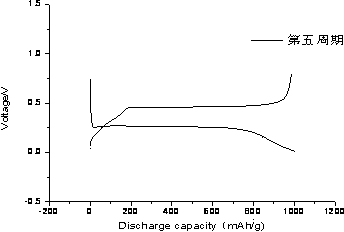

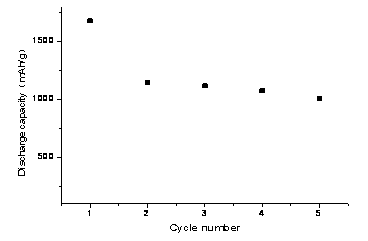

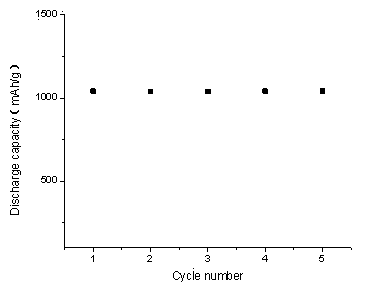

Negative electrode material of lithium ion battery and preparation method of lithium ion battery

ActiveCN103413923AHigh specific capacityPromote circulationCell electrodesGraphite carbonElectrical battery

The invention provides a negative electrode material consisting of a lithium ion battery formed by aluminum carbon and a preparation method of the lithium ion battery. The negative electrode material is provided with a 0.2-0.3 discharge potential platform for lithium, and the discharge capacity can reach 800-1,410mAh / g. Compared with the graphite preparation process, the preparation method of the negative electrode material of the lithium ion battery has the advantages that a super-high temperature calcination stage is omitted, so that the energy is obviously saved; the required various raw materials are wide in source and low in cost; the specific capacity of the negative electrode material prepared through the process method is obviously higher than that of the graphite carbon negative electrode material; the charge and discharge cycle performance of the material is good.

Owner:上海鑫忆丹新材料有限公司

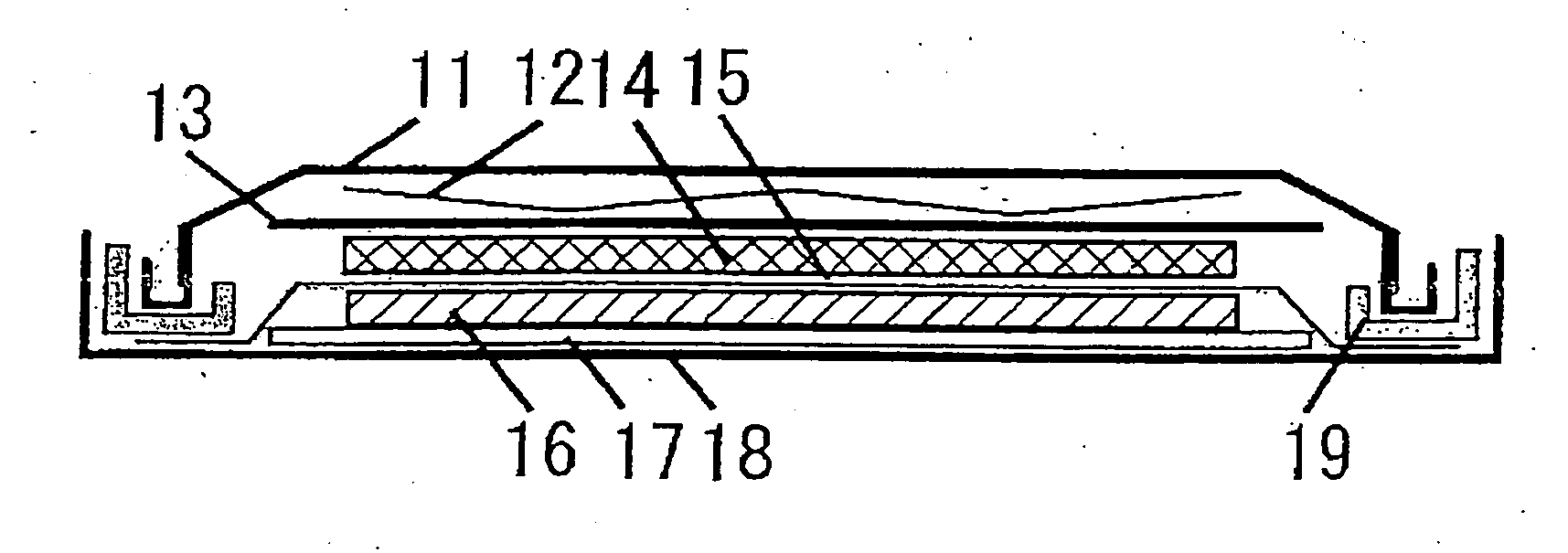

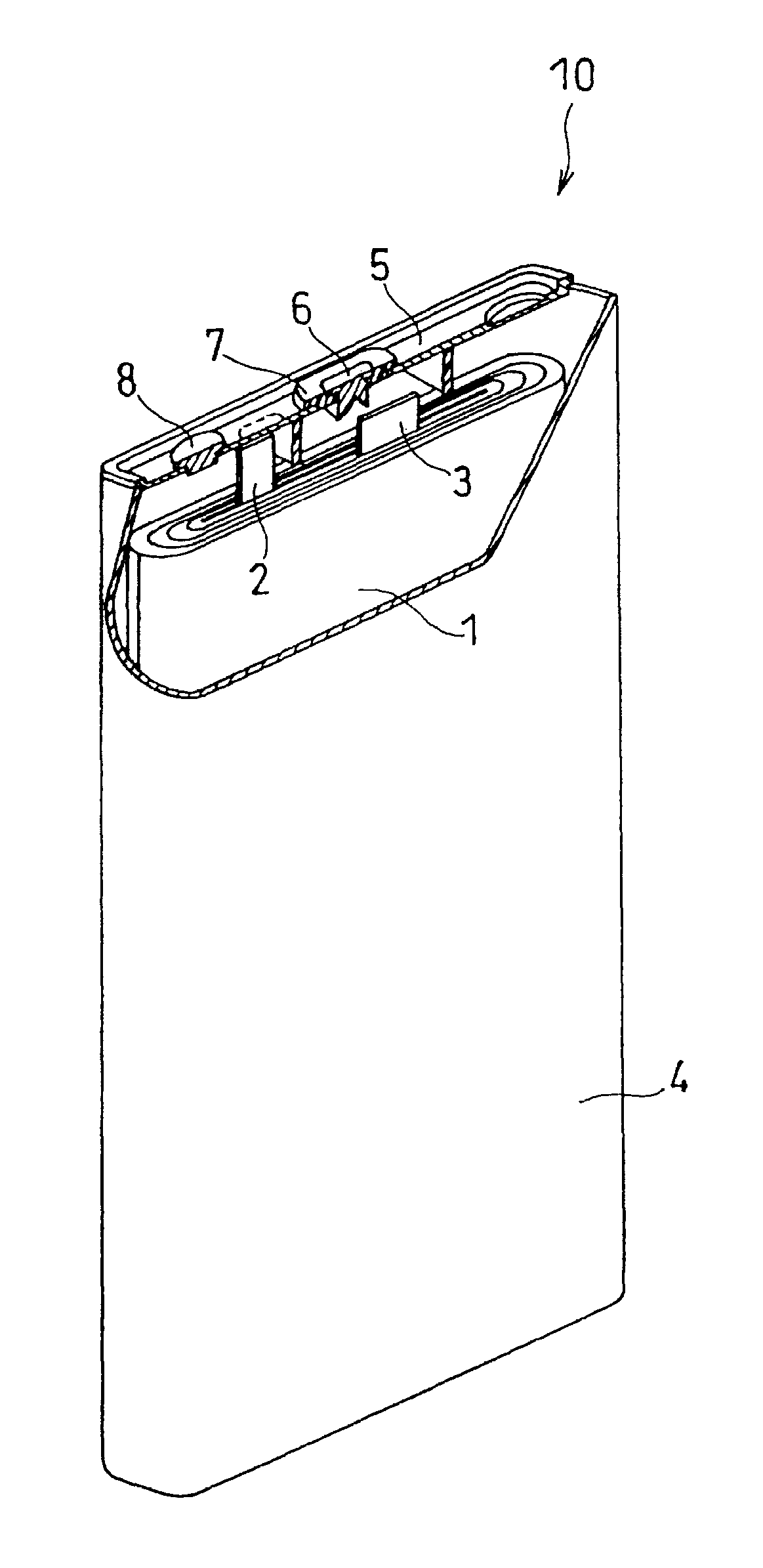

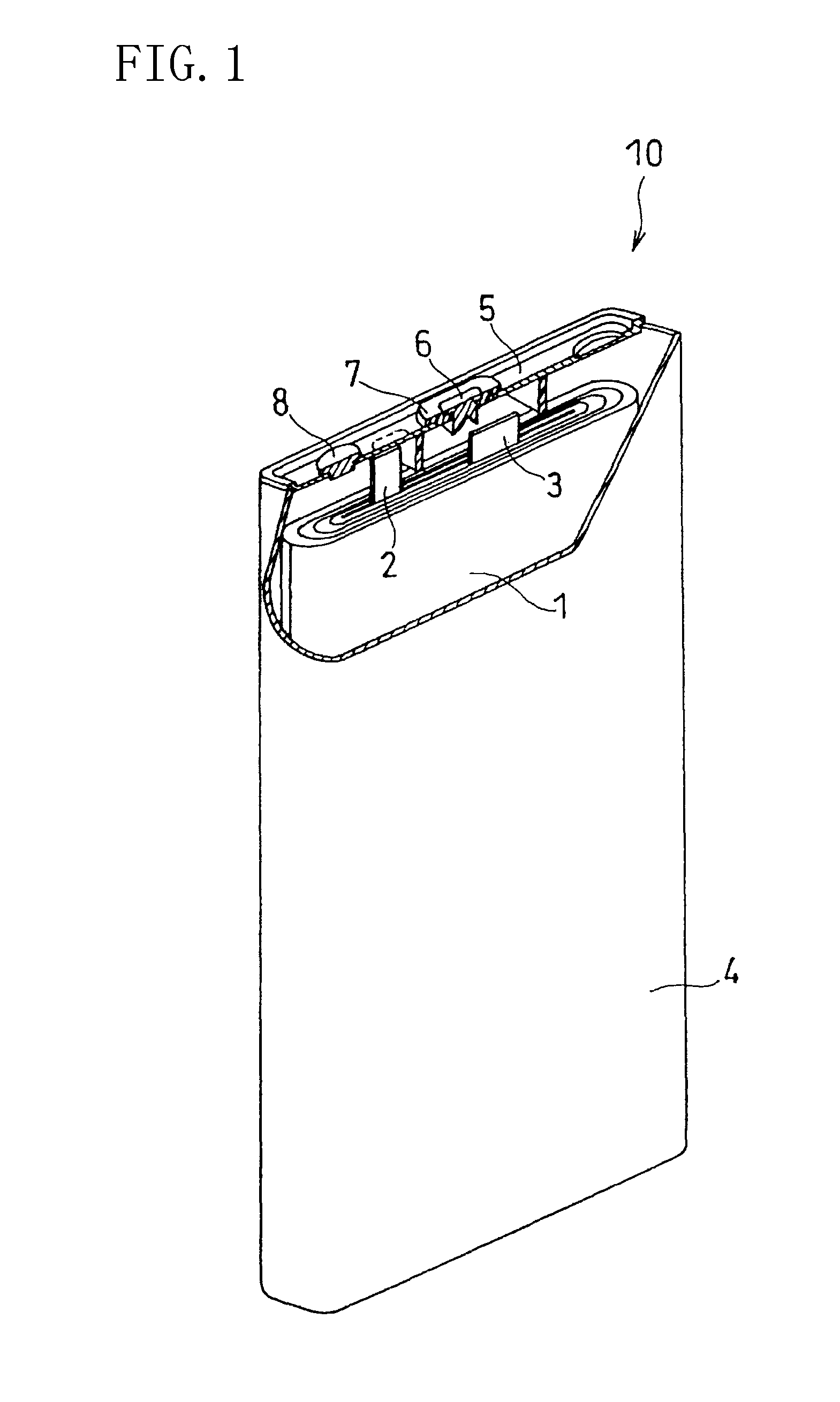

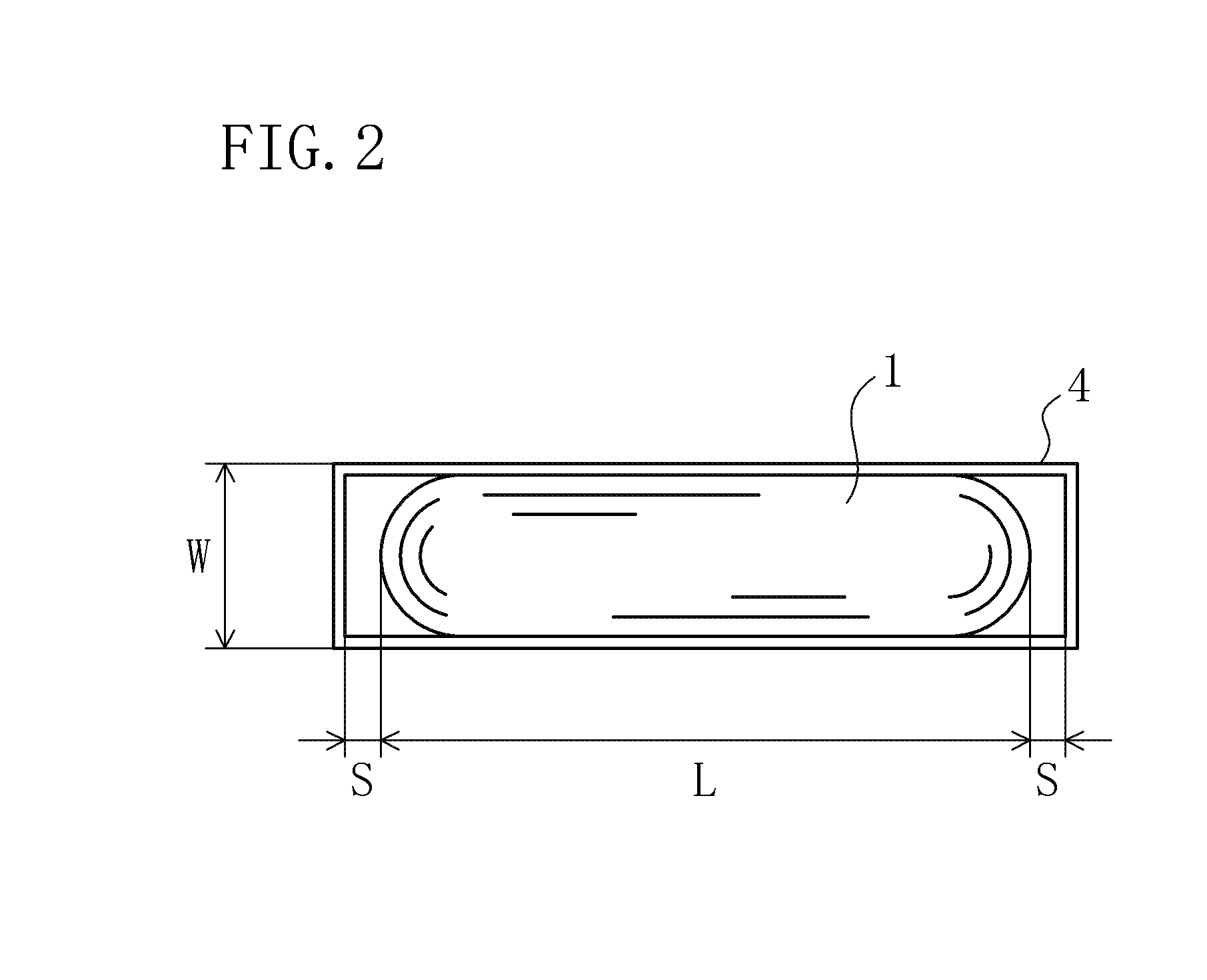

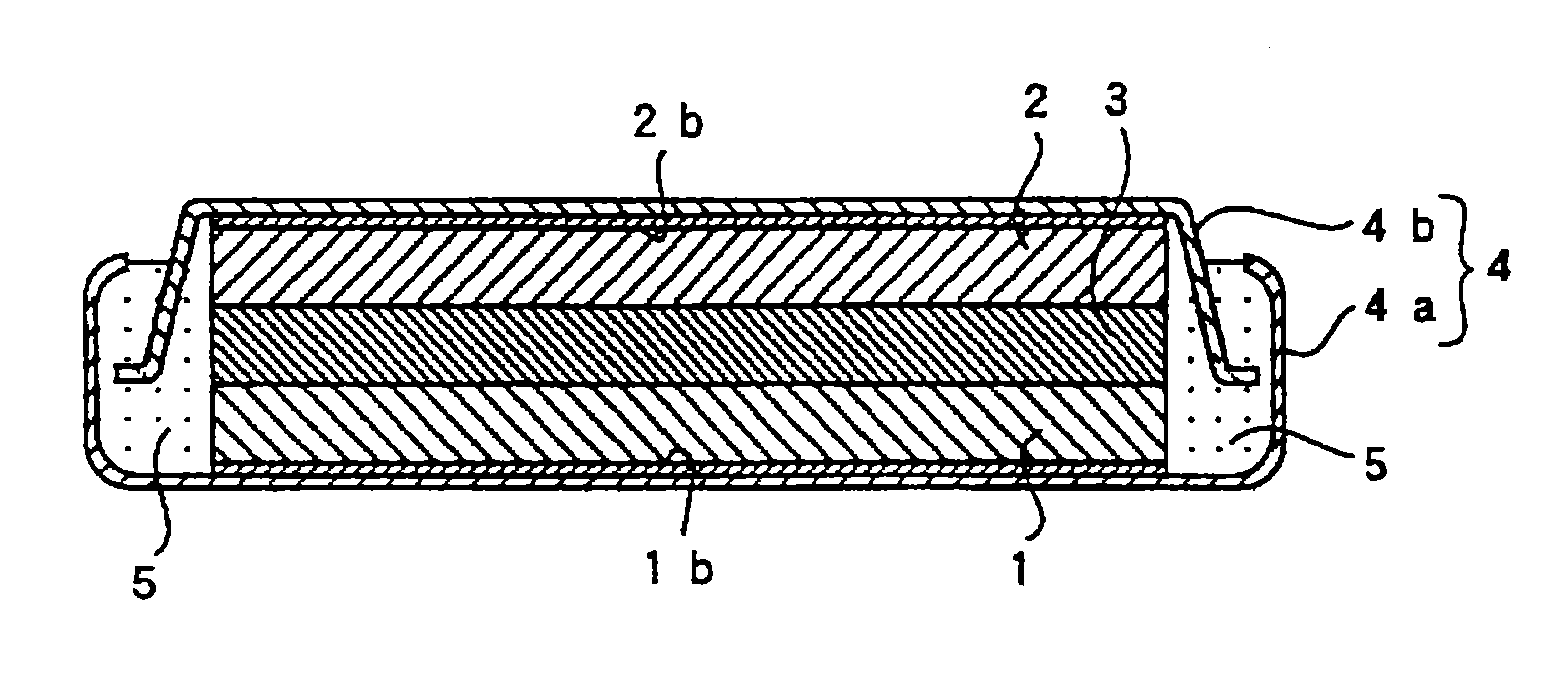

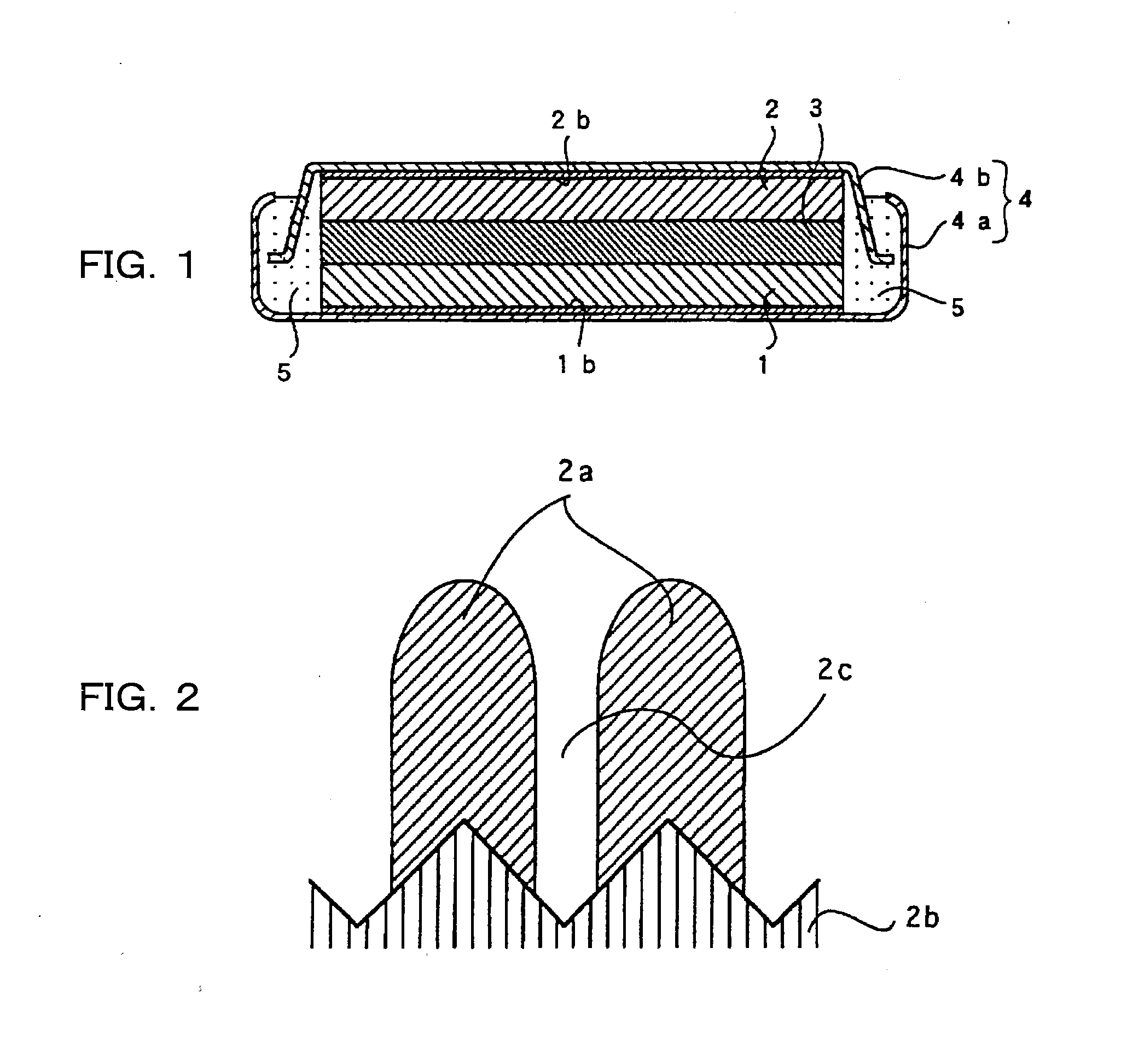

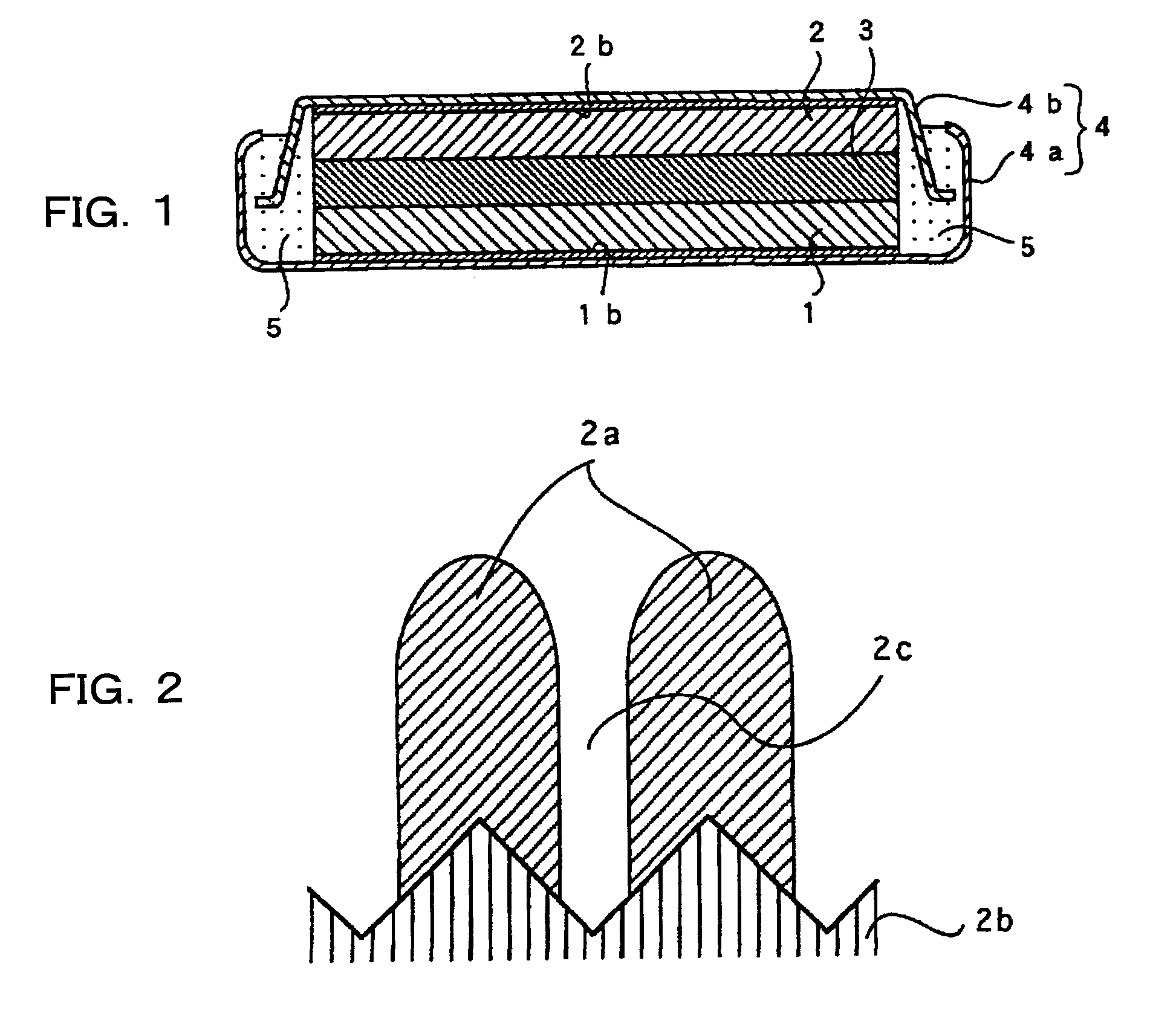

Nonaqueous electrolyte secondary battery and method for fabricating the same

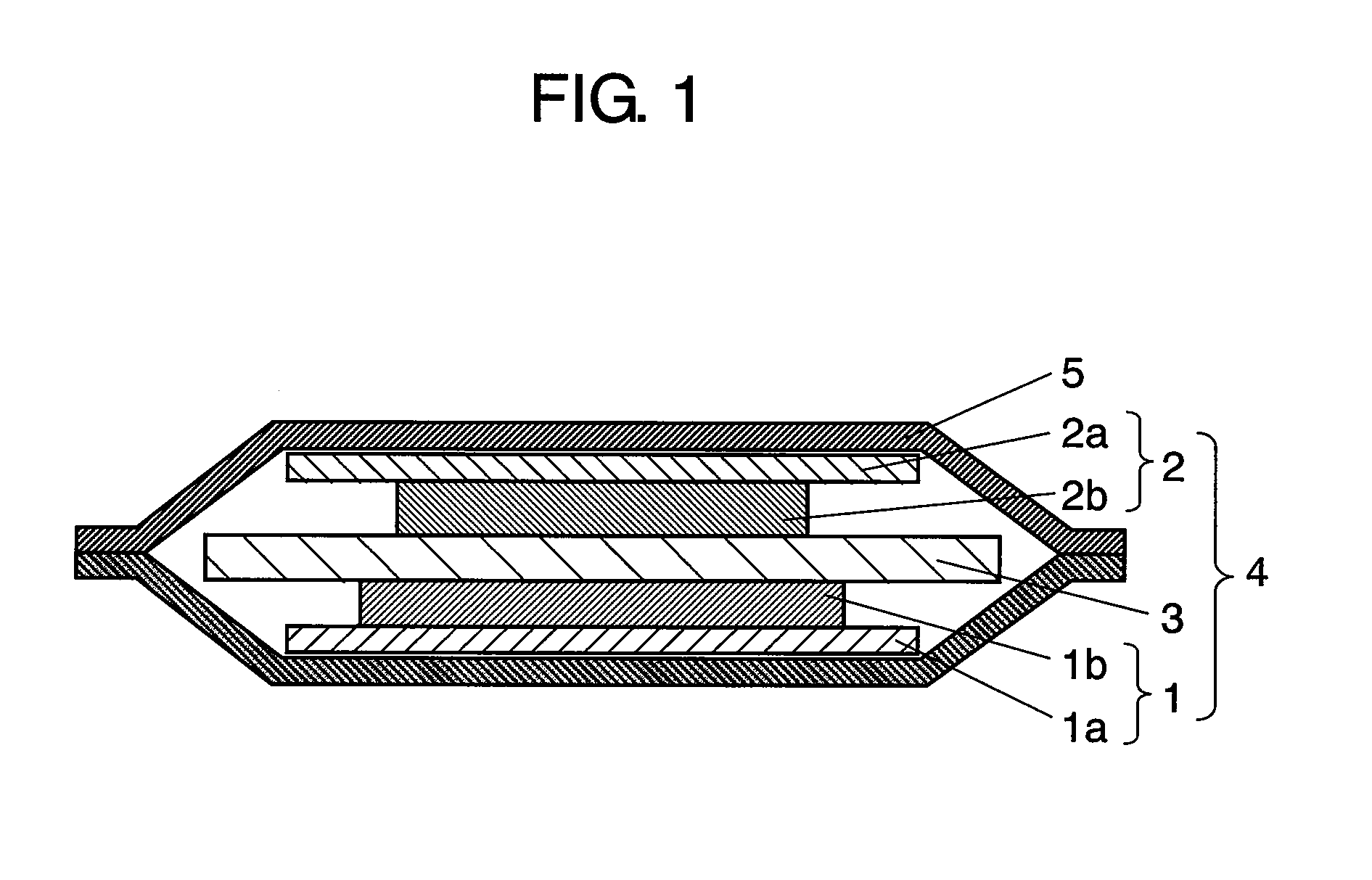

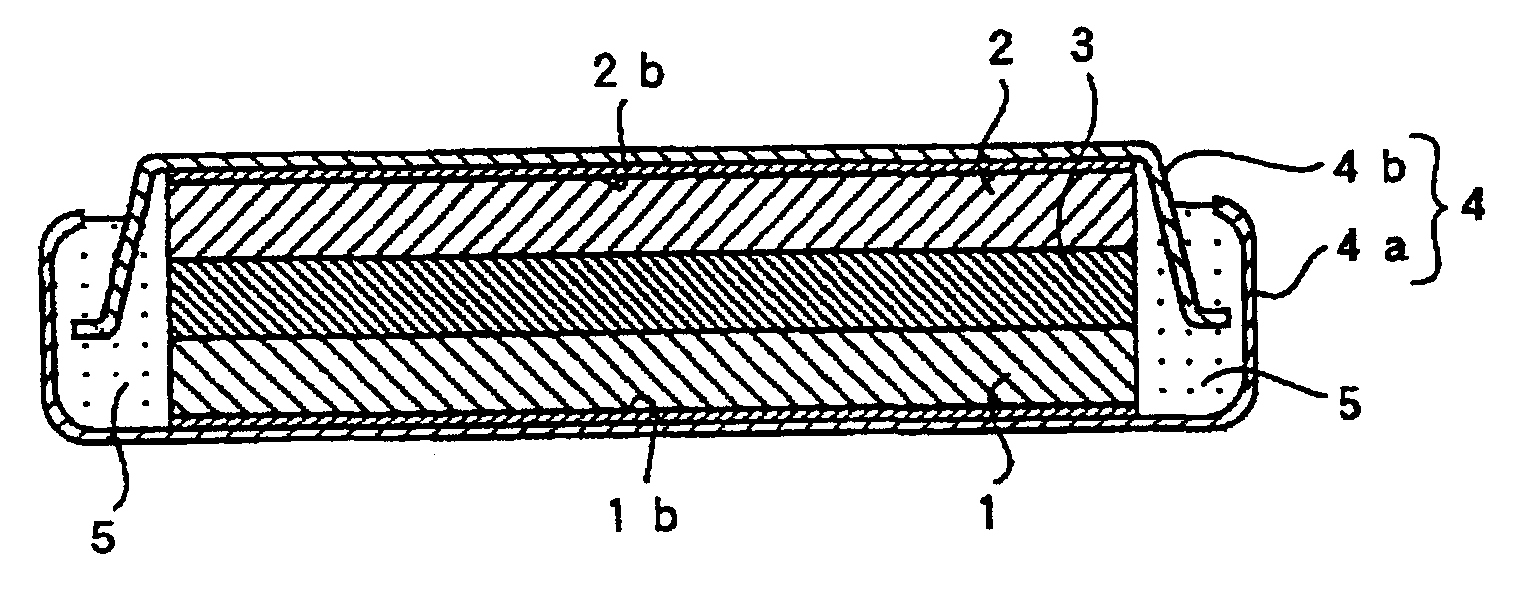

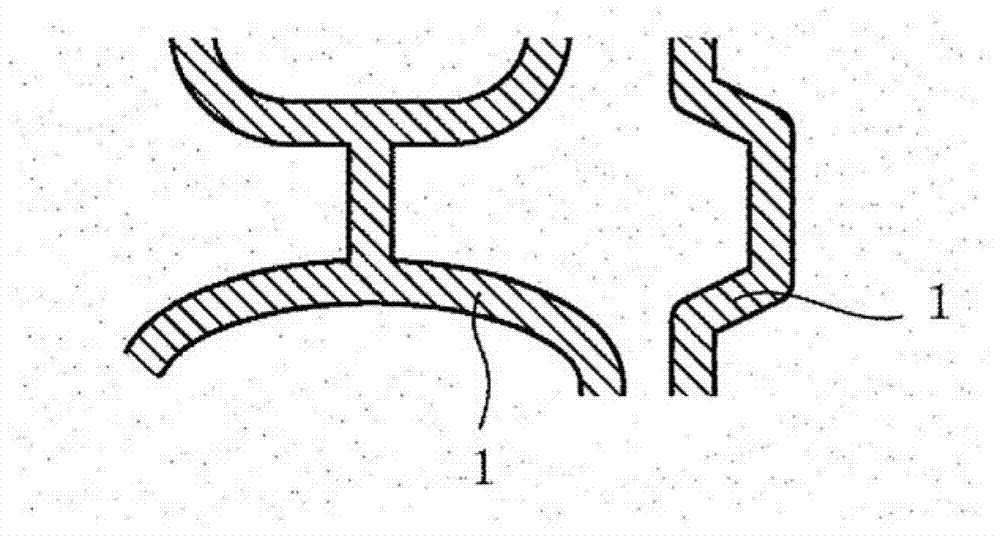

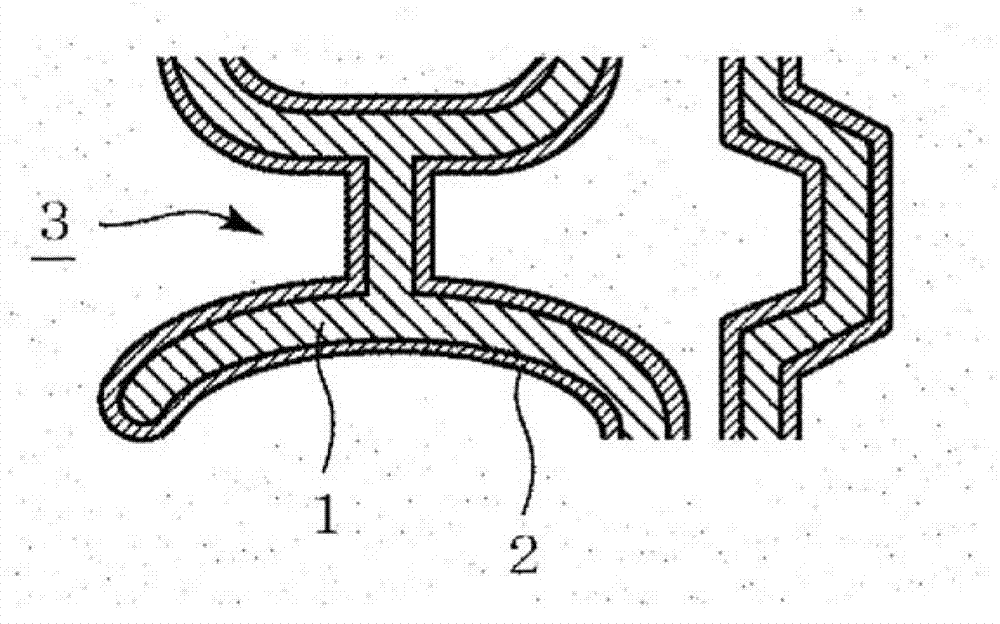

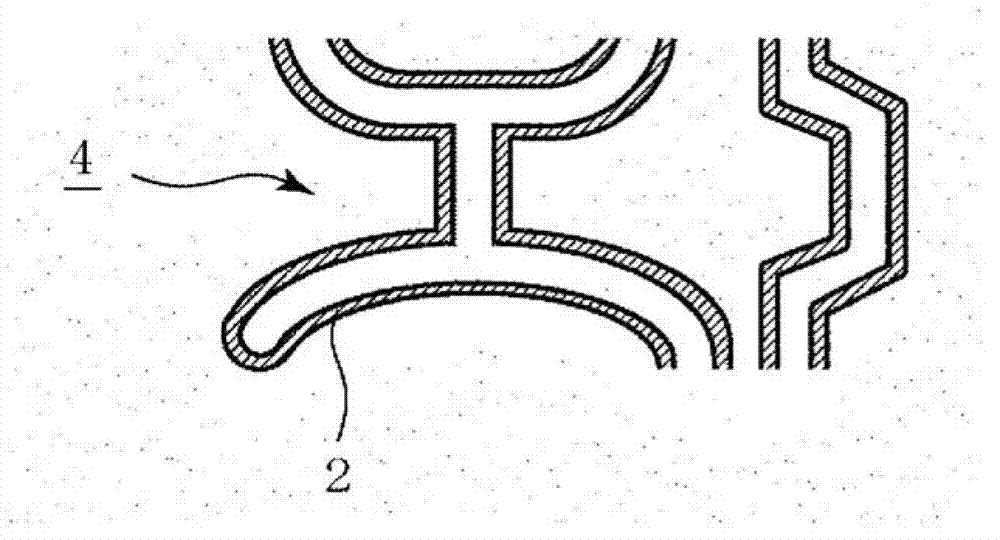

InactiveUS20110165445A1Improve featuresReduce generationElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsEngineeringUltimate tensile strength

An electrode group 1 which is formed by winding a positive electrode and a negative electrode into a flat shape with a separator interposed therebetween is contained in a rectangular battery case 4. The positive electrode has a tensile strength of 15 N / cm or lower when the positive electrode has a tensile extension of 1%, and the positive electrode has a tensile extension of 3% or higher when the positive electrode breaks. A gap S between a longitudinal end of the electrode group 1 and an inner surface of a short side of the rectangular battery case 4 meets the expression: S≧⅛(L×α) where L is a longitudinal length of the electrode group, and α is a tensile extension of the positive electrode when the positive electrode breaks.

Owner:PANASONIC CORP

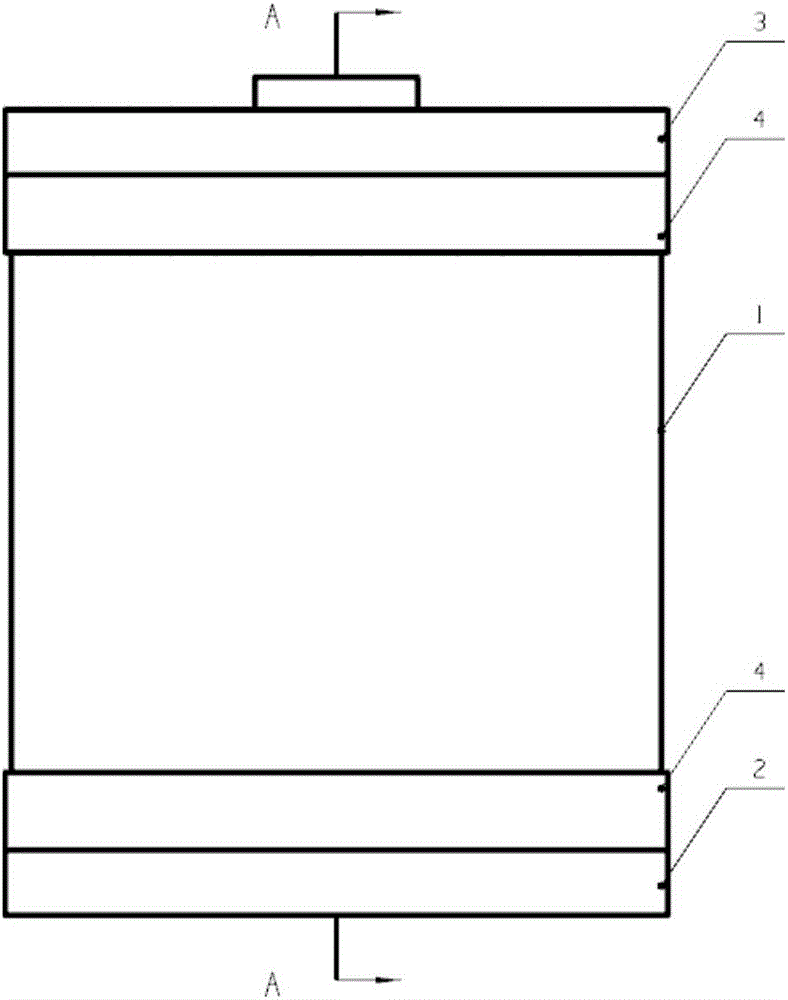

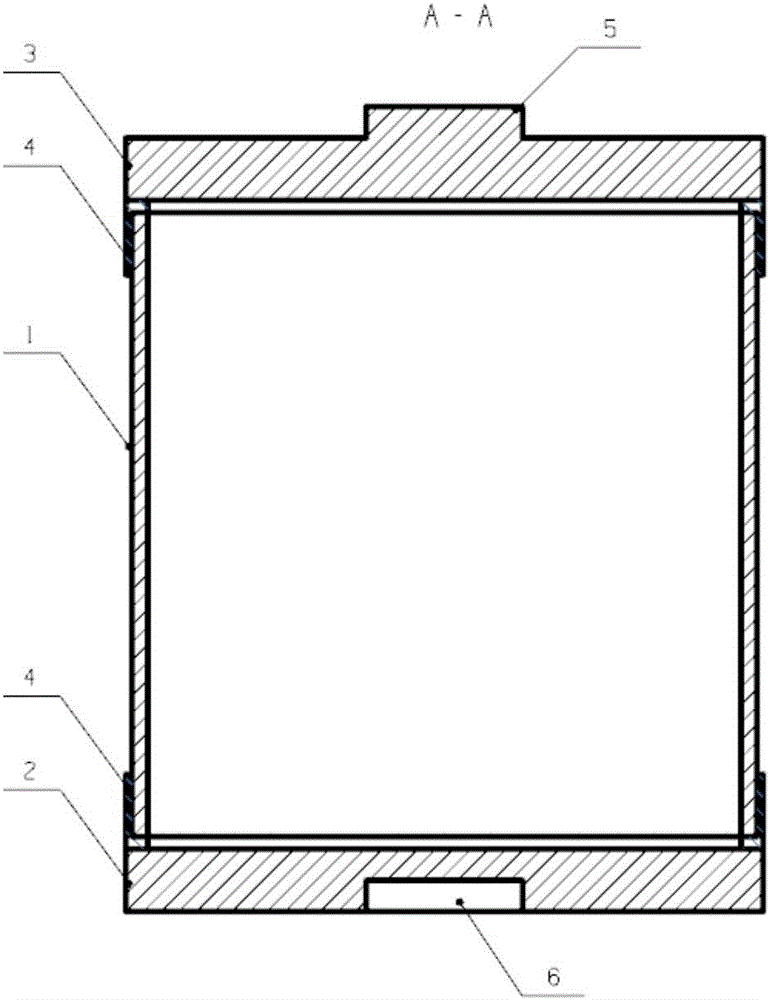

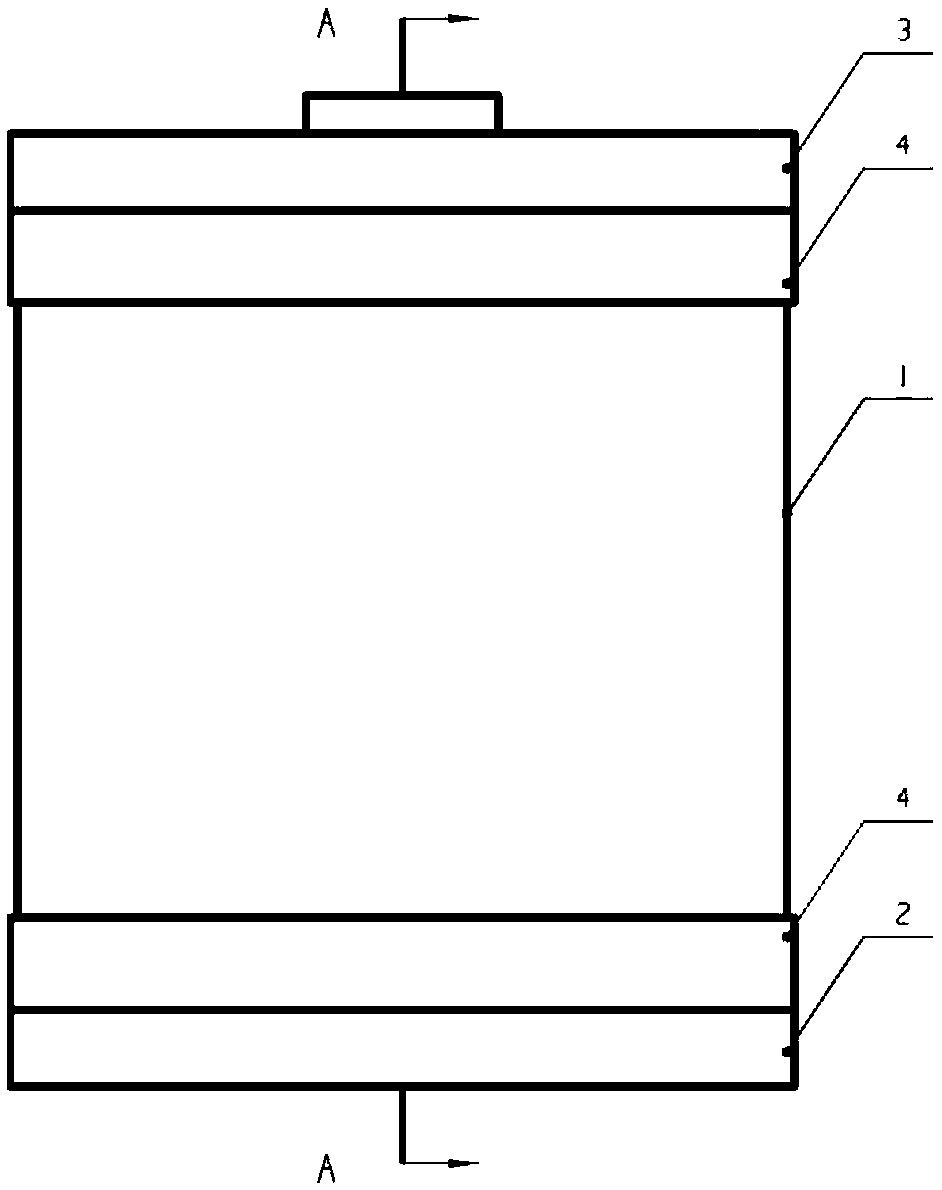

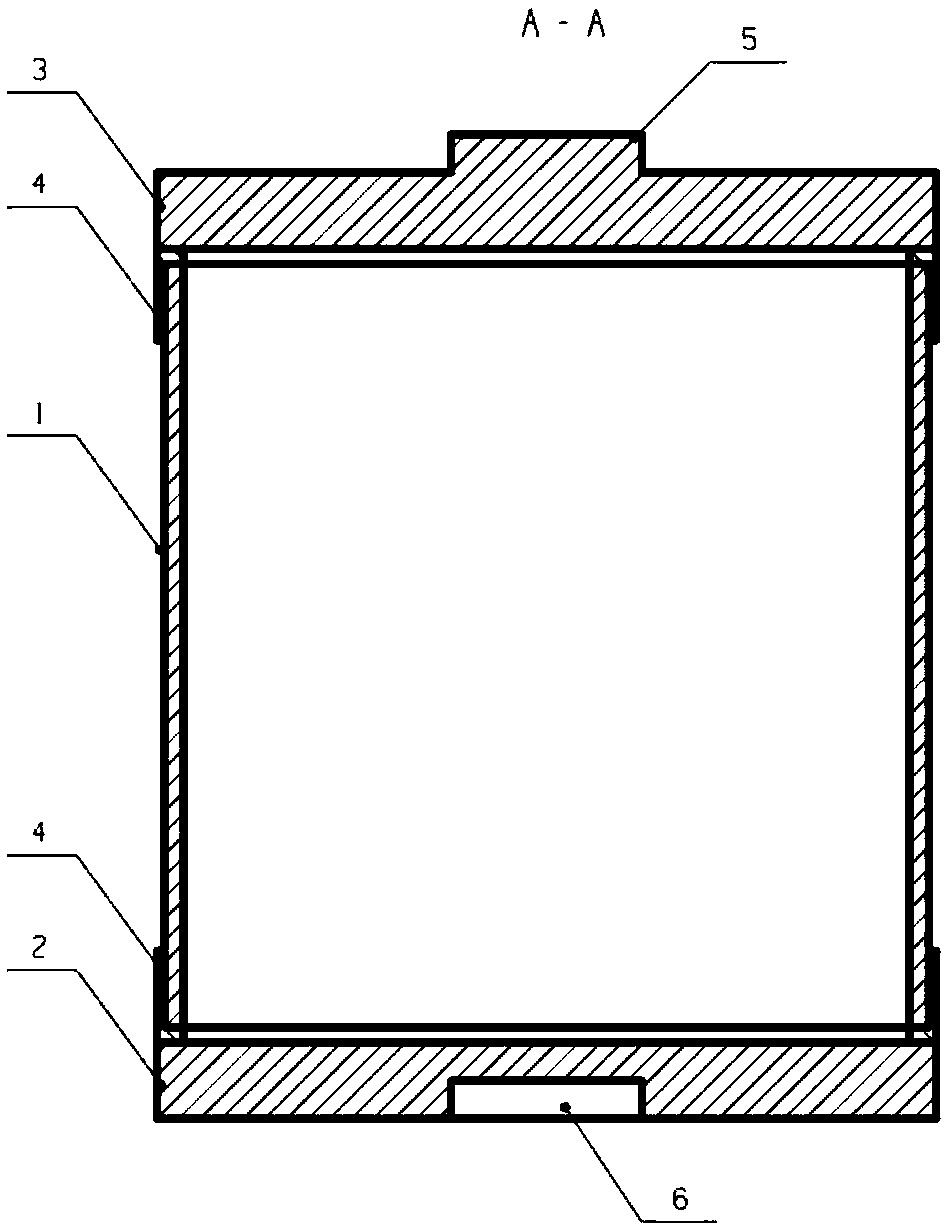

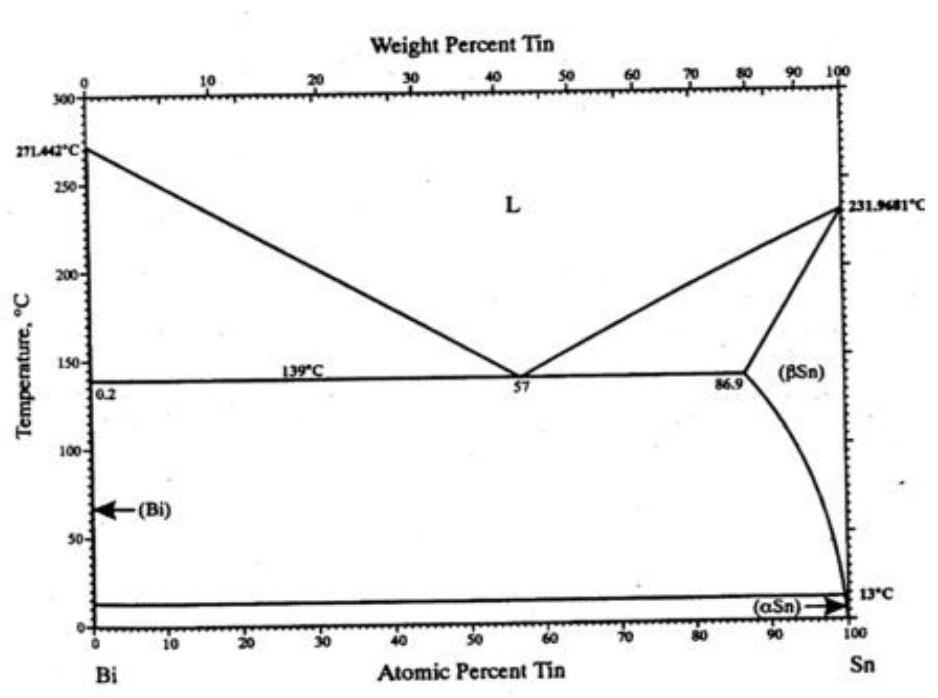

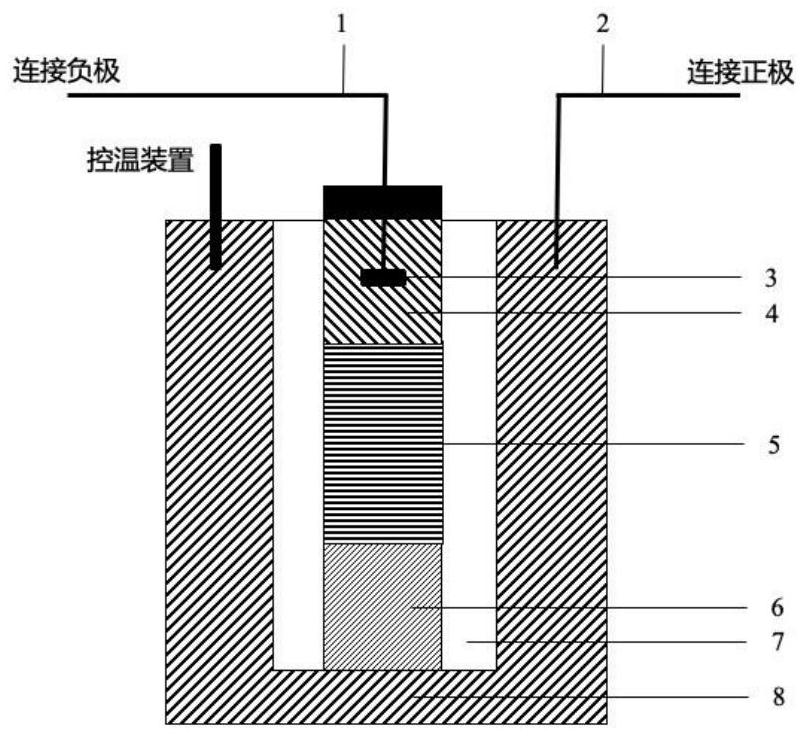

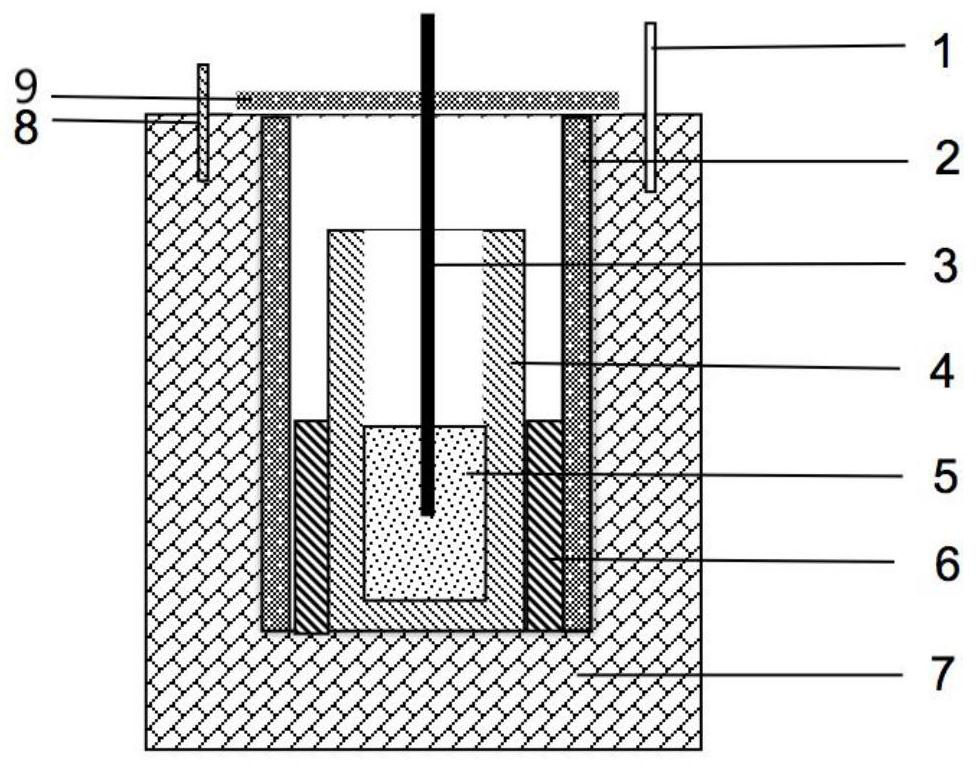

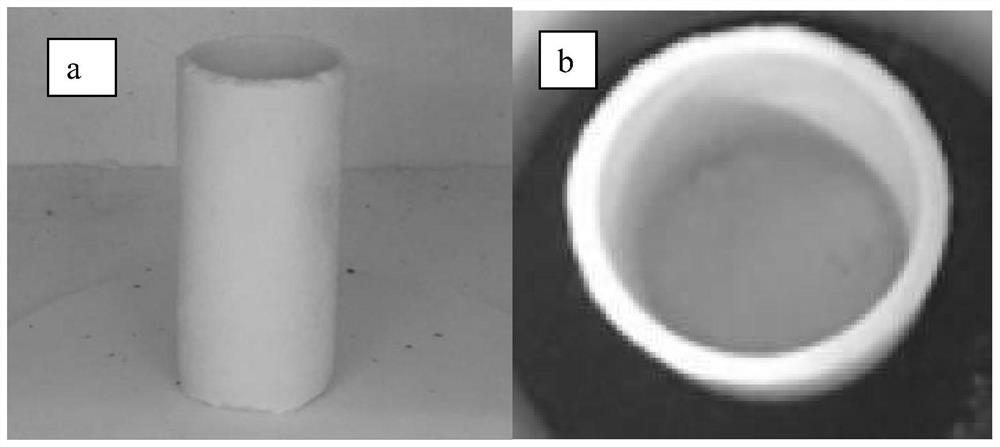

Shell structure for liquid metal battery and preparation method thereof

ActiveCN106252747ASimple manufacturing processImprove high temperature resistanceSecondary cellsElectrical batteryChemical compatibility

The invention discloses a shell structure for a liquid metal battery and a preparation method thereof. The shell structure comprises a ceramic tube, a metal base used as a positive pole and a metal top cover used as a negative pole, wherein two ends of the ceramic tube are respectively connected with the metal base and the metal top cover to form a sealed battery housing structure. The technical problems of sealing f a liquid metal battery housing, insulation between the positive pole and the negative pole, chemical compatibility between the housing and the active material of the housing and physical and chemical stability within battery storage and operating temperature range are solved.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

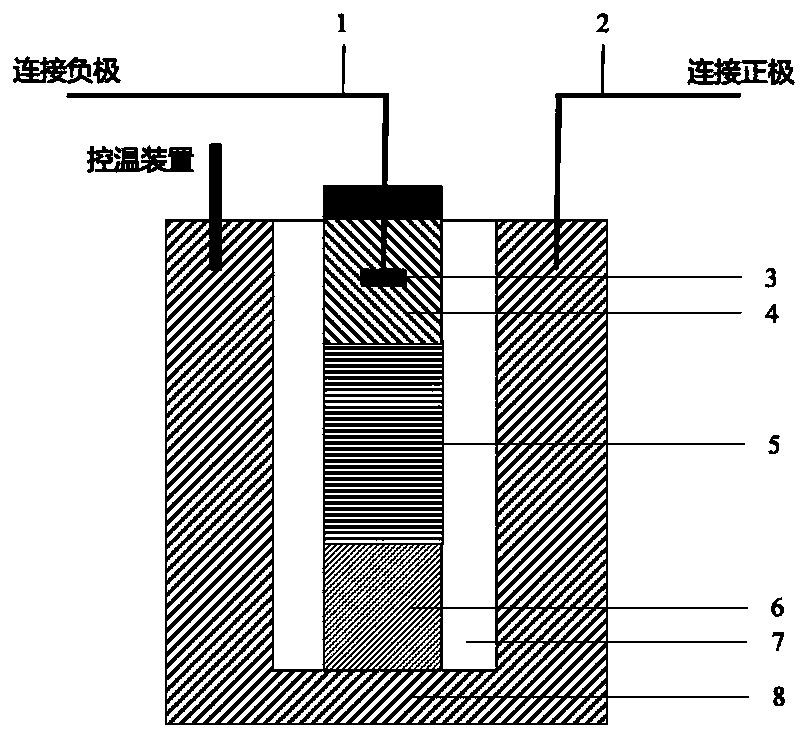

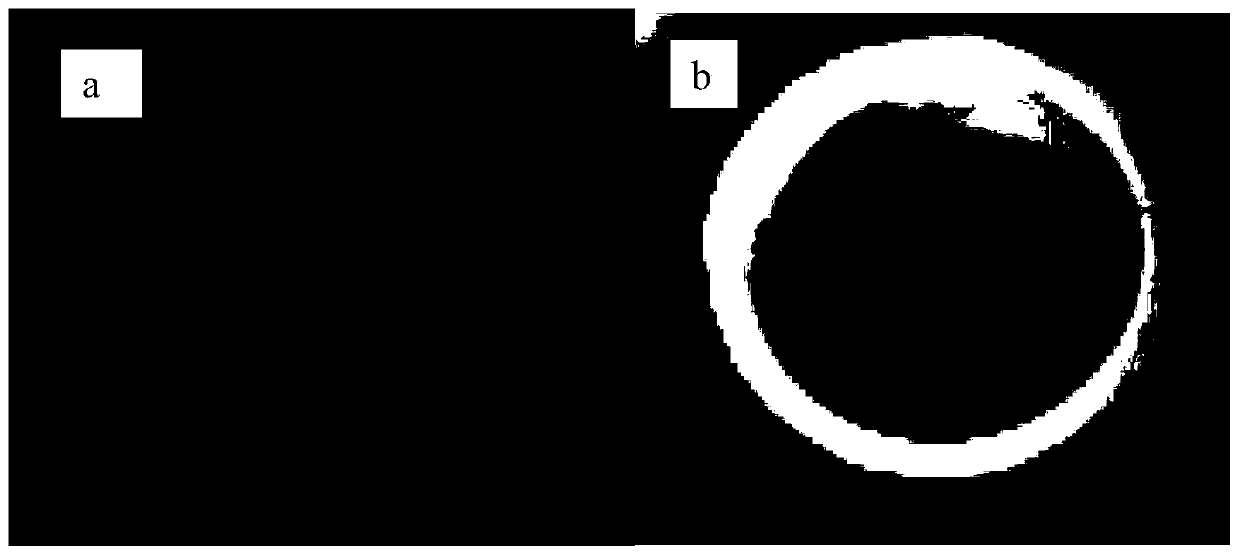

Application of LiI-KI eutectic salt in low-temperature liquid state molten salt lithium battery, and low-temperature liquid state molten salt lithium battery and preparation method thereof

ActiveCN110148779AGood charge and discharge cycleCoulombic efficiency is stableFinal product manufactureLi-accumulatorsElectrolyteMolten salt

The invention provides application of a LiI-KI eutectic salt in a low-temperature liquid state molten salt lithium battery, and a low-temperature liquid state molten salt lithium battery and a preparation method thereof, belonging to the field of lithium batteries. The present invention provides the application of the LiI-KI eutectic salt in the low-temperature liquid state molten salt lithium battery. The eutectic temperature of the LiI-KI eutectic salt taken as an electrolyte is 260-265 DEG C so that it is achieved that the whole liquid state molten salt lithium battery can work at an operation temperature below 300 DEG C. The experiment result shows that: The low-temperature liquid state molten salt lithium battery has good charge-discharge cycles, the open-circuit voltage is 0.76V, thedischarge platform voltage is stabilized at 0.5-0.6V, the discharge platform voltage is 0.8-0.9V, and the coulombic efficiency is basically stabilized at about 97%.

Owner:BEIHANG UNIV

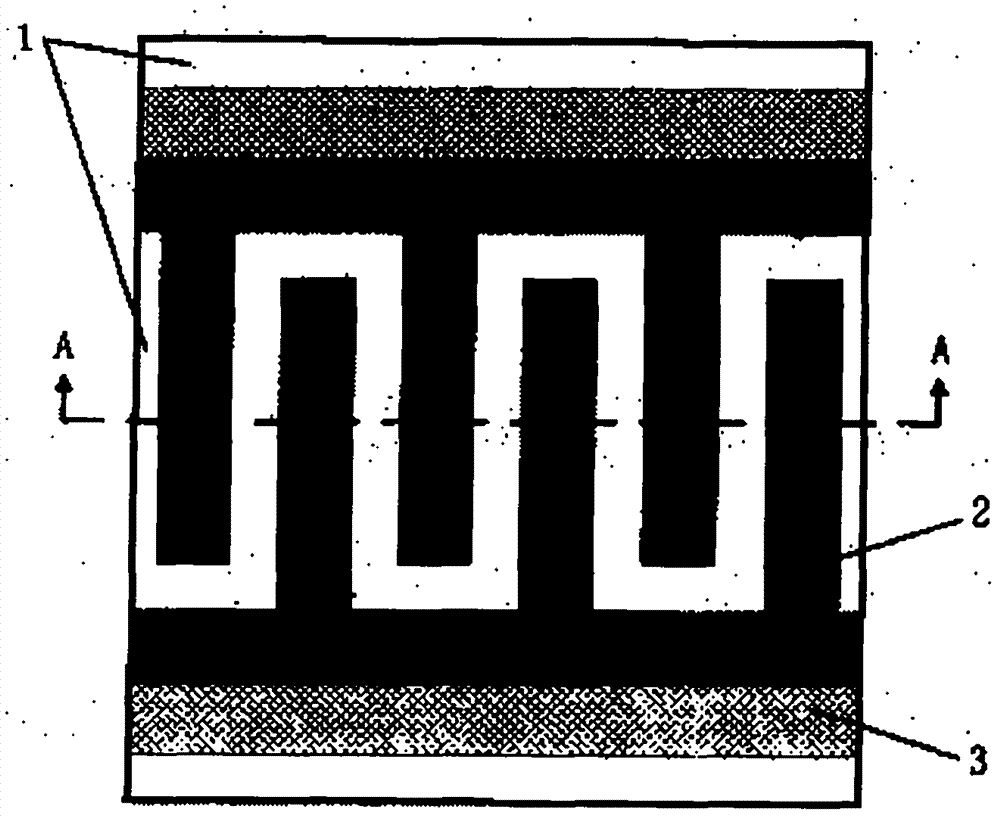

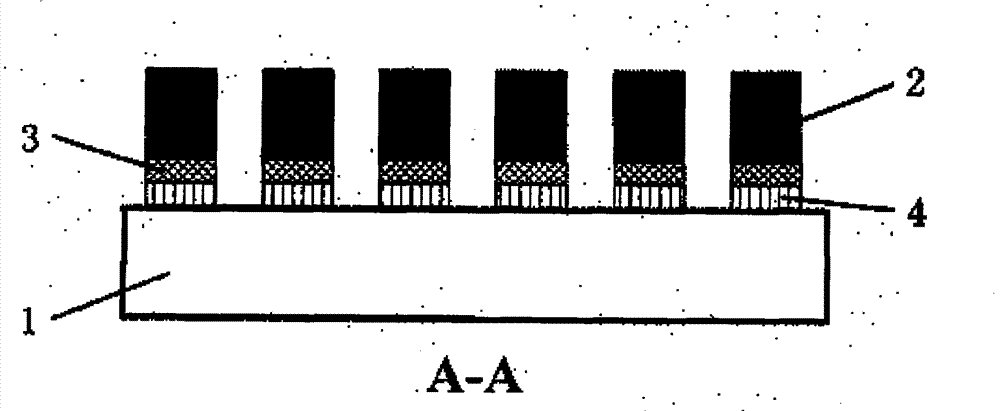

Three-dimensional miniature super capacitor electrode manufactured from nano porous composite material and manufacturing method thereof

ActiveCN102074371BHigh power outputImprove charge and discharge efficiencyCapacitor electrodesCapacitanceAdhesive

The invention relates to a three-dimensional miniature super capacitor electrode manufactured from a nano porous composite material and a manufacturing method thereof, which belong to the technical field of miniature energy-storing appliances and microelectronic mechanical processing. In the three-dimensional miniature super capacitor electrode, a silicon dioxide insulating layer, a metal currentcollecting and extracting layer and an electrode active material layer are sequentially formed on a silicon substrate to form the super capacitor electrode with a three-dimensional structure. The manufacturing method comprises the following steps of: forming a groove with a certain length, width and depth ratio on the silicon substrate through the micro-electromechanical systems (MEMS) etching technique; adhering an electrode active material and a conducting reinforcing agent through an organic adhesive; piling in the groove to form a self-supporting electrode; and etching the side wall of the self-supporting electrode to form the oppositely inserted three-dimensional electrode. The three-dimensional miniature super capacitor electrode adopts a three-dimensional electrode structure vertical to a chip area and extended in the third dimensional direction and has high microminiaturization degree and integration degree, so that the formed super capacitor can provide higher power output when compared with a battery and has better charge and discharge recyclability and higher charge and discharge efficiency.

Owner:TSINGHUA UNIV

Electrolyte solution and preparation method of high-proportion borate zinc battery

ActiveCN104752777BTo meet the actual application needsTransfer of controlFinal product manufactureAlkaline accumulators manufactureElectrolytic agentElectrical battery

Owner:王家祥

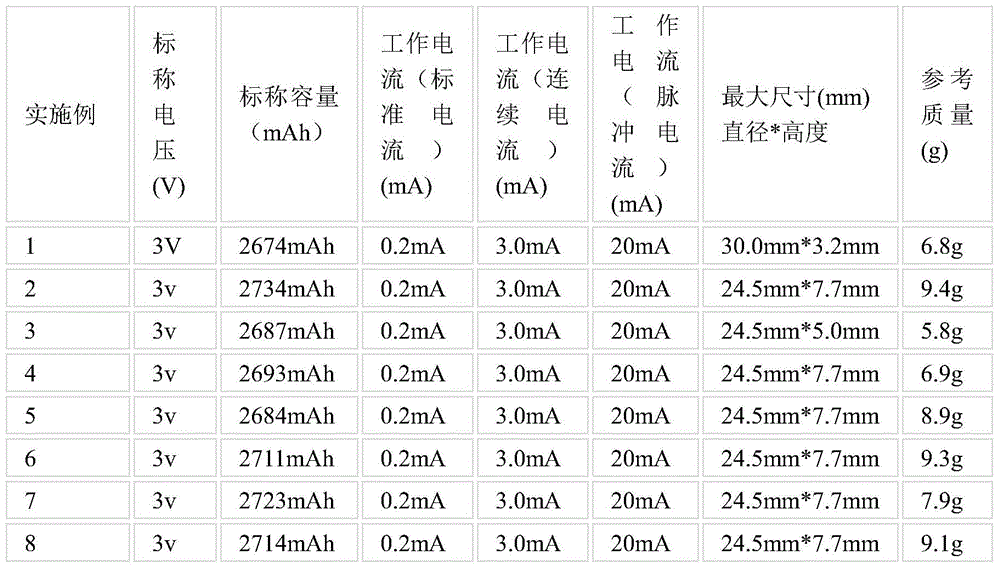

Cathode material for lithium ion secondary battery, method of producing the same, and lithium ion secondary battery

ActiveUS10319996B2Improve thermal stabilityGood charge and discharge cycleCell electrodesHigh energyCharge discharge

The present invention discloses a cathode material for lithium ion secondary battery. The cathode material is in the form of powder particles. The powder particle includes a bulk portion and a coating portion coated on the outer surface of the bulk portion. The bulk portion is formed of at least one first cathode material which is a lithium-nickel based composite oxide. The first cathode material has electrochemical activity and has high charging-discharging specific capacity at a charged voltage of 4.2V versus Li / Li+. The coating portion is formed of at least one second cathode material. The second cathode material has no electrochemical activity or has low charging-discharging specific capacity at a charged voltage of 4.2V versus Li / Li+. Lithium ion secondary battery using the cathode material has high energy density, cycling stability, security, and output power.

Owner:MICROVAST ADVANCED MATERIALS INC

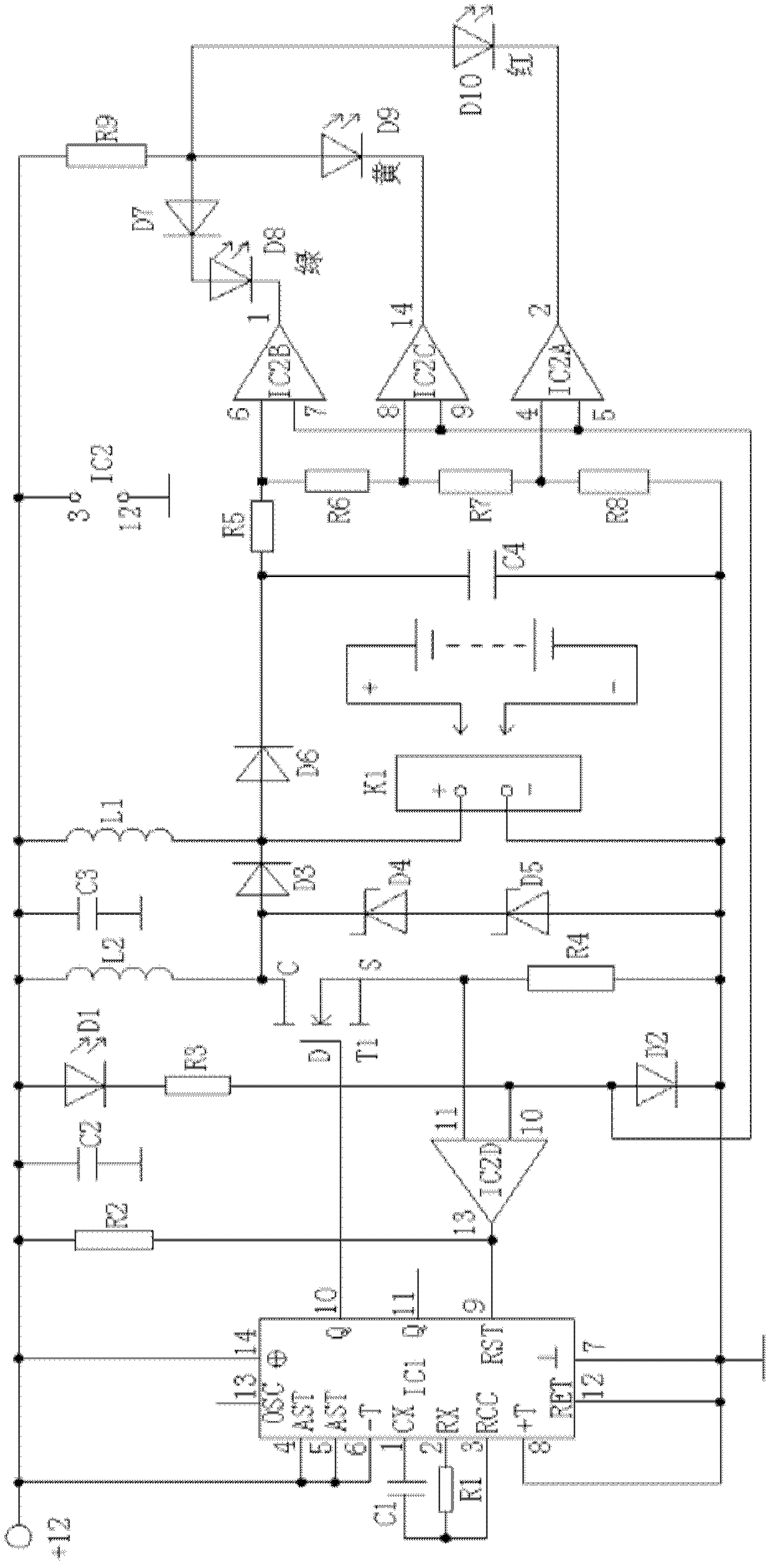

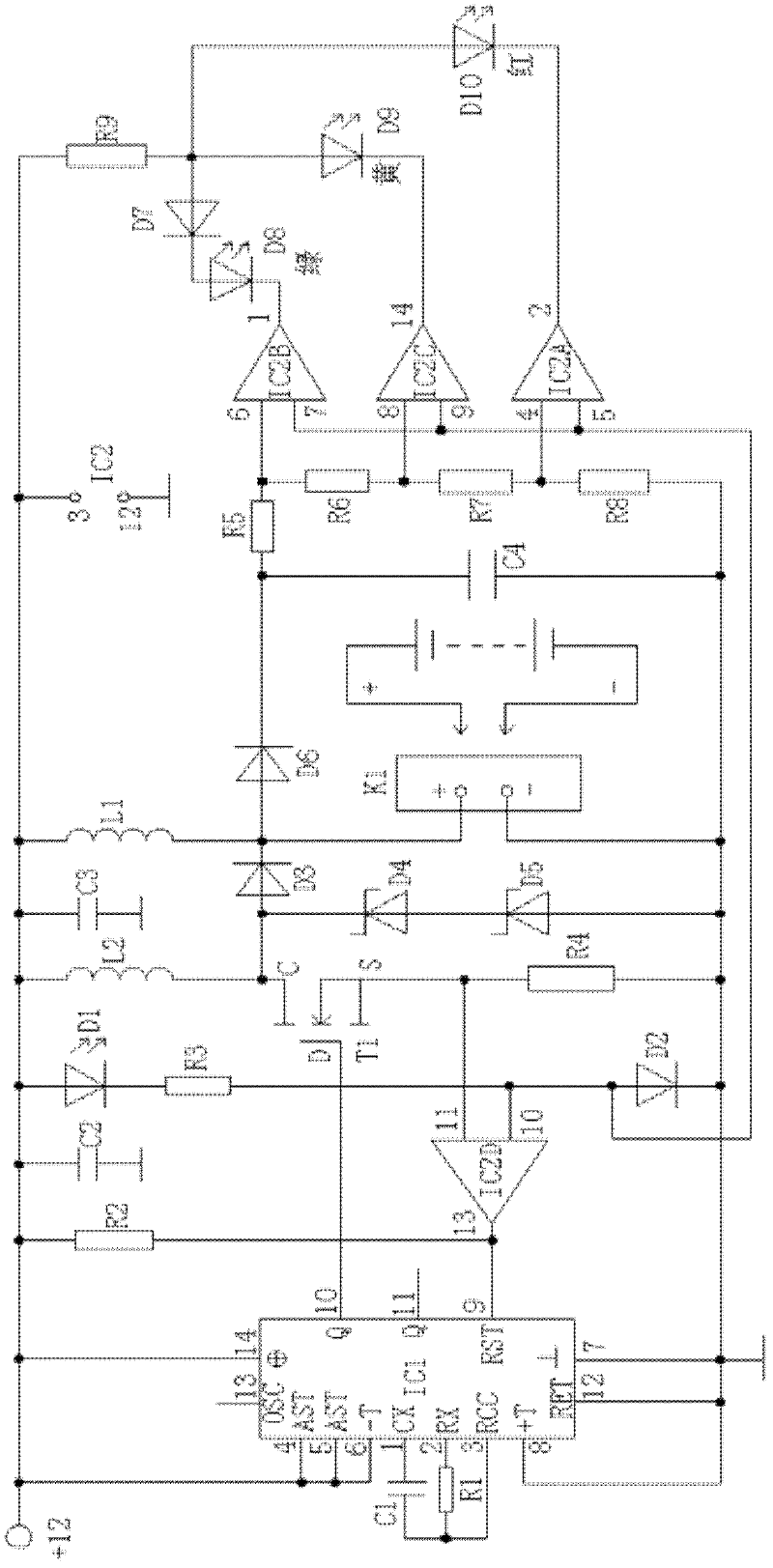

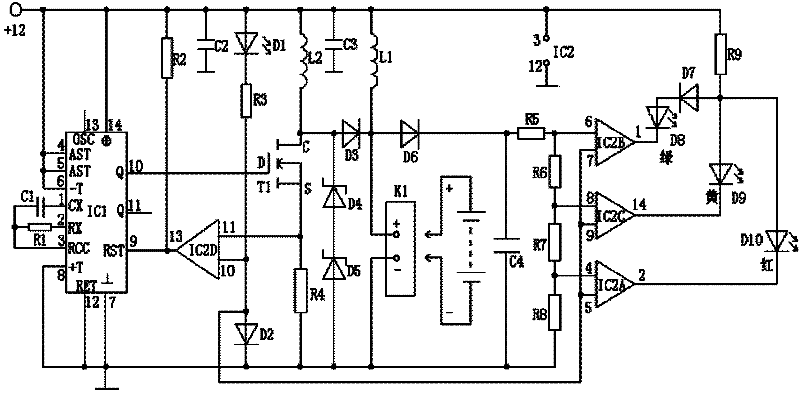

Lead-acid battery capacity restorer

InactiveCN102403549BIncrease capacityEfficient power storage functionSecondary cells charging/dischargingField-effect transistorComputer science

Owner:河北赵拓新能源科技有限公司

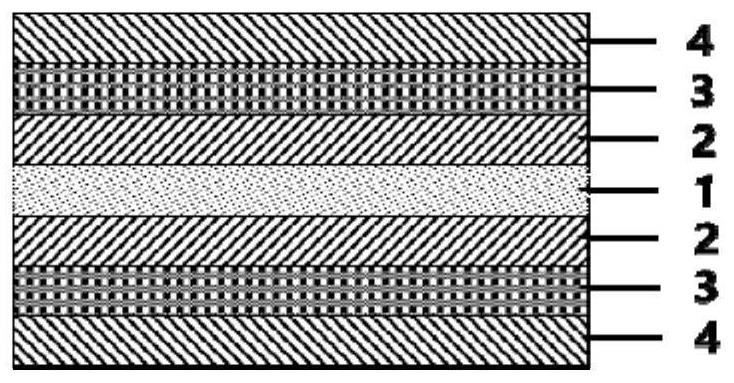

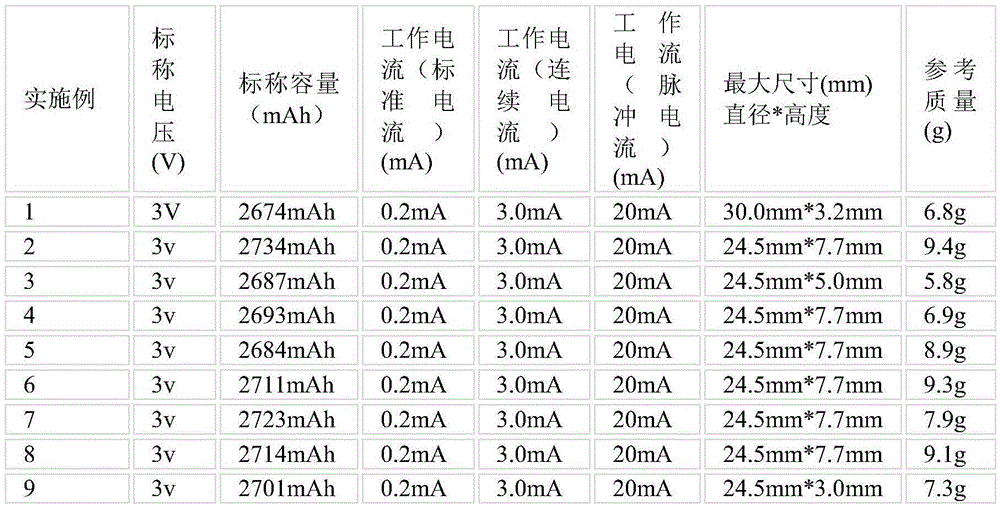

Lithium battery positive pole piece and preparation method thereof

PendingCN114883566AImprove conductivityIncreased tensile strength and flexibilityMicroscopic fiber electrodesFinal product manufactureElectrically conductiveCurrent collector

The positive pole piece comprises a current collector located on the inner layer of the positive pole piece, and a first coating, a conductive carbon cloth layer and a second coating which are sequentially and symmetrically arranged outwards from the two sides of the current collector, the first coating and the second coating comprise lithium ion active substances; the conductive carbon cloth is modified by composite slurry. The invention also provides a preparation method of the lithium battery positive pole piece and a lithium ion battery comprising the lithium battery positive pole piece. By using the conductive carbon cloth, different types of coatings can be better combined; the conductivity of the positive pole piece is improved; the tensile strength and the flexibility of the positive plate are improved; due to the constraint of the carbon cloth fibers, the active substances are not easy to fall off, more active substances and electrolyte can be accommodated, the electrolyte wettability of the active substances is better, and the capacity, the rate capability and the cycle performance of the battery are finally improved; and the safety of the battery is improved. The preparation method is simple and suitable for large-scale production.

Owner:南通赛得能源有限公司 +1

A kind of manufacturing method of all-solid-state electrolyte of lithium-sulfur battery

ActiveCN103985910BLow purityPrevent oxidationFinal product manufactureLi-accumulatorsSolid state electrolyteAdhesive

The invention discloses a method for manufacturing an all-solid-state electrolyte for a lithium-sulfur battery. Polyacrylonitrile resin micropowder and diatomite are added to a high-speed mixing agitator at a mass ratio of 46-56:54-66, and NMP solvent is added to make the diatomite The quality of the soil is 18-24%wt, uniformly mixed into viscose clay and made into block materials of corresponding shapes as required, and the block viscose clay becomes a block containing only carbon in a high-temperature furnace replaced by nitrogen Diatomaceous earth, then put it in 18-33%wt NMP solution containing lithium polysulfide, lithium methaminobutyrate, lithium perchlorate, lithium phosphate for 13-18min, take it out and put it in a high-temperature furnace for several All-solid-state electrolytes for lithium-sulfur batteries were obtained after several times of impregnation and high-temperature evaporation. The preparation method of the invention is simple and the cost is low, and the prepared all-solid-state electrolyte for the lithium-sulfur battery has high sulfur-accommodating capacity, relatively high ion transmission capacity and electrical conductivity, and can improve the high-rate performance and high-cycle performance of the lithium-sulfur battery.

Owner:高能时代(珠海)新能源科技有限公司

Shell structure for liquid metal battery and preparation method thereof

ActiveCN106252747BSimple manufacturing processImprove high temperature resistanceSecondary cellsElectrical batteryChemical compatibility

The invention discloses a shell structure for a liquid metal battery and a preparation method thereof. The shell structure comprises a ceramic tube, a metal base used as a positive pole and a metal top cover used as a negative pole, wherein two ends of the ceramic tube are respectively connected with the metal base and the metal top cover to form a sealed battery housing structure. The technical problems of sealing f a liquid metal battery housing, insulation between the positive pole and the negative pole, chemical compatibility between the housing and the active material of the housing and physical and chemical stability within battery storage and operating temperature range are solved.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

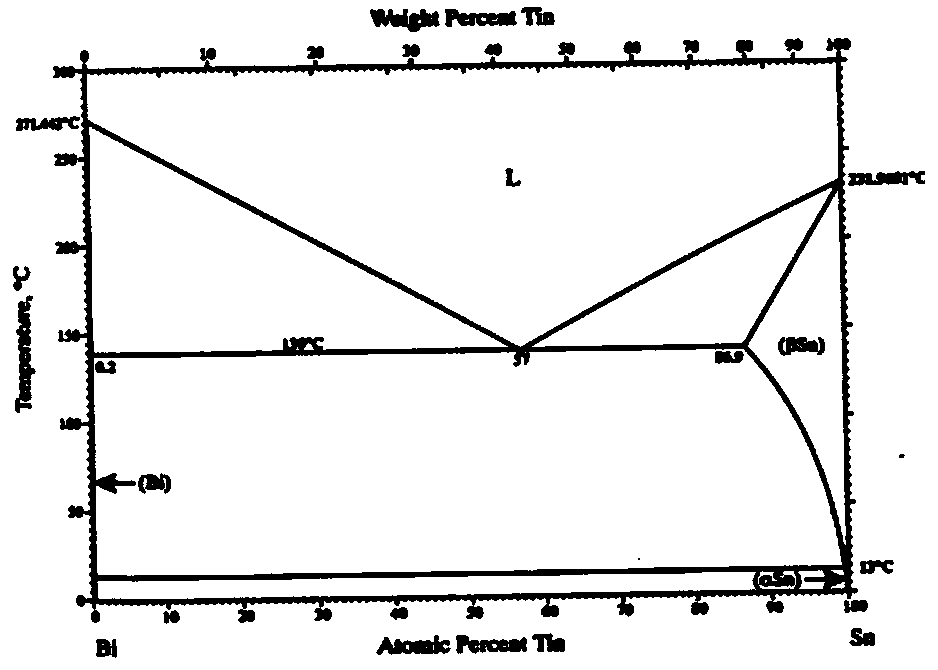

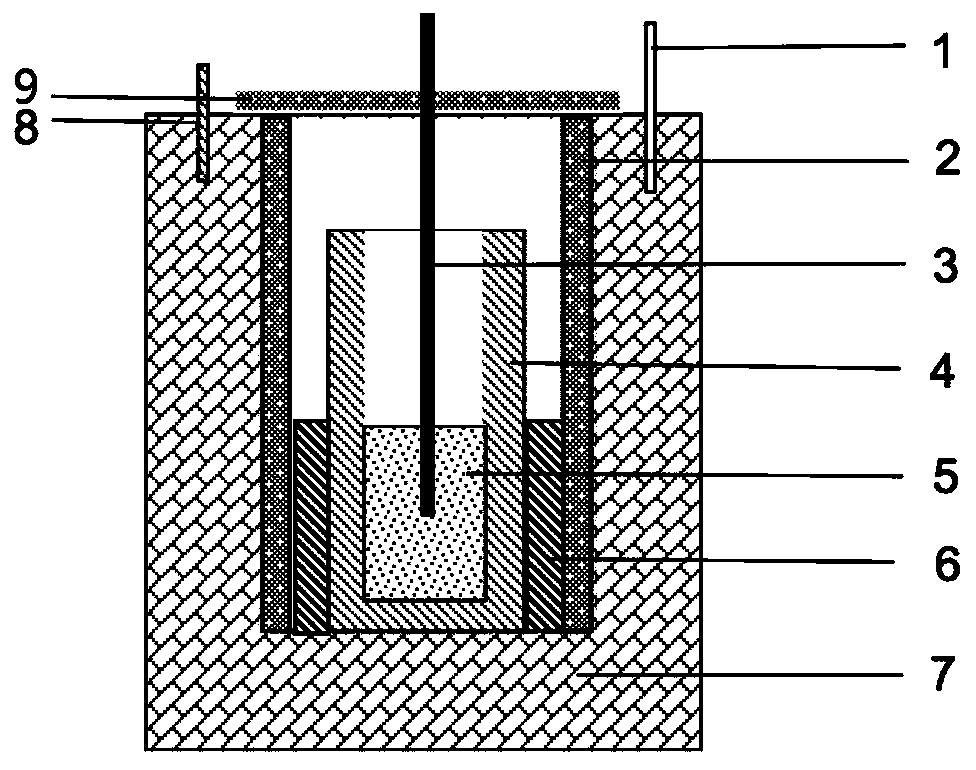

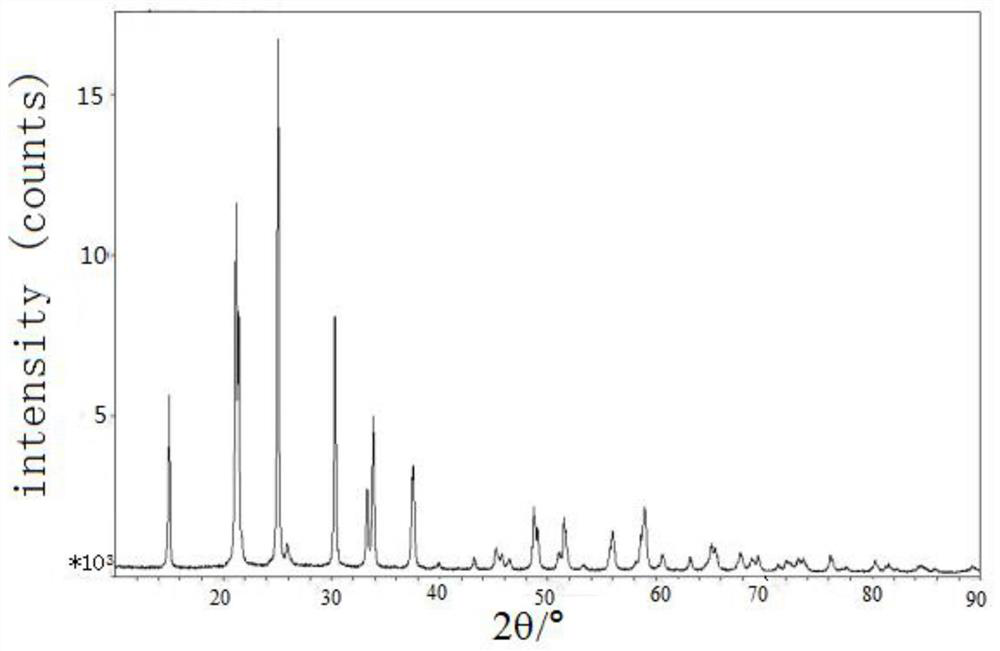

High-temperature liquid metal lithium battery and preparation method thereof

ActiveCN110429271ALower working temperatureGood charge and discharge cycleFinal product manufactureCell electrodesMolten stateSolid state electrolyte

The invention provides a high-temperature liquid metal lithium battery and a preparation method thereof and belongs to the field of a lithium ion battery. By precisely defining the mole fraction of components of an LAGP-type solid electrolyte shell, the LAGP-type solid electrolyte shell is provided; a larger energy storage battery can be prepared instead of a button battery; and only by ensuring that anode and cathode materials are in a molten state, operating temperature of the battery can be greatly reduced, wherein the operating temperature of the battery can be controlled at 240 DEG C, which is the lowest operating temperature reported so far in the field of an all-liquid lithium battery.

Owner:易航时代(北京)科技有限公司

Lead-acid battery capacity restorer

InactiveCN102403549AIncrease capacityEfficient power storage functionSecondary cells charging/dischargingAgricultural scienceElectrical battery

The invention discloses a lead-acid battery capacity restorer, comprising an integrated chip IC1, a field-effect tube T1, comparers IC2A, IC2B, IC2C, and IC2D, a wiring terminal K1 and a parallel access terminal IC2 of the lead-acid battery capacity restorer. According to the invention, a lead-acid battery needing capacity restoring is accessed into the wiring terminal K1 for charging through a pulse current, and the lead-acid battery is subjected to discharge during a pulse interval. The lead-acid battery capacity restorer of the invention can effectively stabilize the capacity of a lead-acid battery, inhibit sulfuration reaction, and make the battery always maintain an efficient electricity storing function, as well as carry out desulphurization treatment automatically to a vulcanized battery so as to enable the formation of a good charge-discharge circulation inside the battery and restore the capacity to an original nominal value.

Owner:河北赵拓新能源科技有限公司

Application of lii-ki eutectic salt in low temperature liquid molten salt lithium battery, low temperature liquid molten salt lithium battery and preparation method

ActiveCN110148779BGood charge and discharge cycleCoulombic efficiency is stableFinal product manufactureLi-accumulatorsPhysical chemistryMolten salt

Owner:BEIHANG UNIV

A kind of high-temperature liquid metal lithium battery and preparation method thereof

ActiveCN110429271BLower working temperatureGood charge and discharge cycleFinal product manufactureCell electrodesSolid state electrolyteElectrical battery

The invention provides a high-temperature liquid metal lithium battery and a preparation method thereof, belonging to the field of lithium ion batteries. The present invention provides a LAGP type solid electrolyte shell through the precise limitation of the mole fraction of the components of the LAGP type solid electrolyte shell, which can make a relatively large energy storage battery, not a button battery, as long as the positive and negative electrode materials are in a molten state. Yes, the operating temperature of the battery can be greatly reduced, and the operating temperature of the battery can be controlled at 240°C, which is the lowest operating temperature in the field of all-liquid lithium batteries reported so far.

Owner:易航时代(北京)科技有限公司

Non-aqueous electrolyte secondary battery and non-aqueous electrolyte

ActiveUS20120219868A1Avoid reactionGood charge and discharge cycleOrganic electrolyte cellsSecondary cellsHydrogenCharge discharge

Owner:PANASONIC ENERGY CO LTD

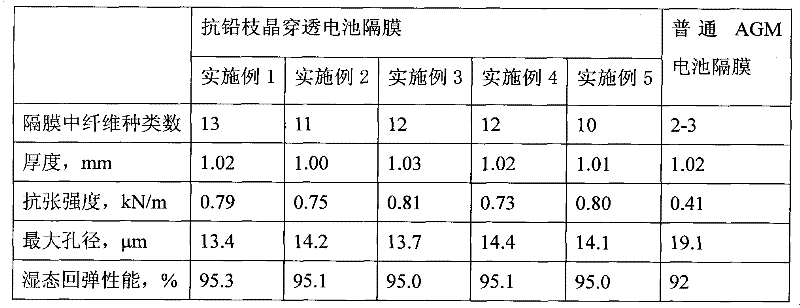

Preparation method of battery diaphragm resisting penetration of lead dendritic crystal

ActiveCN101702427BImprove acid resistanceImprove liquid absorption capacityCell component detailsGlass fiberPolyester

The invention provides a preparation method of a battery diaphragm resisting the penetration of a lead dendritic crystal. Uniform felty products are formed by processing high alkali glass microfibers, medium-alkali glass microfibers, medium-alkali glass fibers chopped strands and organic fibers according to the weight ratio of 18-24:9-15:1-1.5:1-1.5 by using a wet process, wherein the high alkaliglass microfibers comprise 39-degree SR and / or 44-degree SR high alkali glass microfibers; the medium-alkali glass microfibers comprise 39-degree SR, 44-degree SR, 49-degree SR, 54-degree SR and 59-degree SR medium-alkali glass microfibers; the medium-alkali glass fiber chopped strands comprise 6 micrometers / 6 mm and 9 micrometers / 9 mm medium-alkali glass fiber chopped strands; and the organic fibers comprise 6 mm / 2.5D of polyester fibers with skin-core structure, 6 mm / 2D of polypropylene fibers, 6 mm / 3.5D of polytetrafluoroethylene fibers and 6 mm / 2D of polyacrylonitrile fibers. The preparedbattery diaphragm resisting the penetration of a lead dendritic crystal can obviously improve the dendritic crystal penetration resistance of a battery.

Owner:中材科技膜材料(山东)有限公司

Non-aqueous electrolyte secondary battery and non-aqueous electrolyte

ActiveUS8206853B2Avoid reactionGood charge and discharge cycleAlkaline accumulatorsElectrolytic capacitorsHydrogenCharge discharge

The objective of the present invention is to prevent deterioration and expanding of anode active material and to improve charge-discharge cycle characteristics in a non-aqueous electrolyte secondary battery comprising an anode of which current collector has thereon a thin layer of an anode active material containing a metal. To solve this problem, in a non-aqueous electrolyte secondary battery wherein a thin layer of anode active material containing a metal which absorbs and discharges lithium is formed on a current collector and the thin layer of the anode active material is divided into columns by a gap formed along the thickness thereof, a compound represented by the following formula is contained in the non-aqueous electrolyte.A-N═C═OIn the above formula, A represents an element or a group other than hydrogen.

Owner:PANASONIC ENERGY CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com