Negative electrode material of lithium ion battery and preparation method of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high manufacturing cost and limited source of raw materials, and achieve the effects of low price, improved cycle performance, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: A lithium-ion battery negative electrode material and a preparation method of the lithium-ion battery, comprising the following steps:

[0041] a. Preparation of carbon material: Place polyacrylcyanide in a tube furnace at 600°C and calcinate for 4 hours under argon atmosphere to obtain carbon material;

[0042] b. Coated carbon material: mix the carbon material prepared in step (a) with polyvinylidene fluoride and conductive carbon in a mass ratio of 8:1:1, then add the solvent N,N dimethylacetamide for mixing, add the ingredients and The mass ratio of the solvent is 1:2, and the above four materials are mixed uniformly and then coated on the aluminum alloy foil with a coater on one side, as the negative electrode of the lithium-ion battery;

[0043] Among them, the mass fraction (content) of each component in the aluminum alloy foil is: 99.3% for Al, 0.3% for Fe, 0.3% for Si, 0.05% for copper, and 0.05% for Mn and other elements.

[0044] c. Prepare a...

Embodiment 2

[0046] Example 2: A lithium-ion battery negative electrode material and a preparation method of the lithium-ion battery, comprising the following steps:

[0047] a. Preparation of carbon material: mix polypropylene cyanide and elemental sulfur with a mass ratio of 1:2, place in a tube furnace at 600°C and calcinate for 4 hours under an argon atmosphere to obtain a carbon material;

[0048] b. Coated carbon material: mix the carbon material prepared in step (a) with polyvinylidene fluoride and conductive carbon in a mass ratio of 8:1:1, then add the solvent N,N dimethylacetamide, add the ingredients and solvent The mass ratio is 1:3, and the above four materials are mixed evenly and coated on one side of the aluminum foil with an applicator, as the negative electrode of the lithium-ion battery;

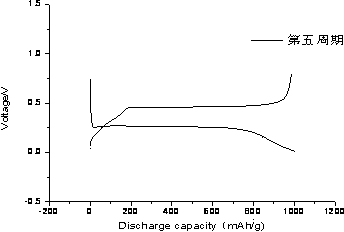

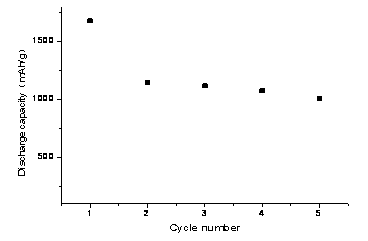

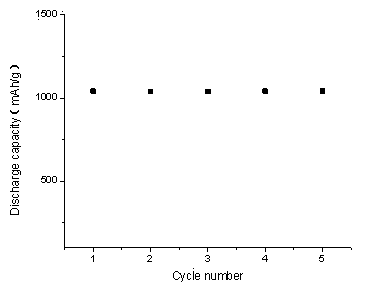

[0049] c. Prepare a simulated battery: use the coated carbon material obtained in step b as the cathode, metal lithium as the counter electrode, and a mixed solution of ethylene c...

Embodiment 3

[0051] Example 3: A lithium-ion battery negative electrode material and a preparation method of the lithium-ion battery, comprising the following steps:

[0052] a. Preparation of carbon materials: mix polypropylene cyanide and manganese dioxide in a mass ratio of 3:1, place them in a tube furnace at 600°C and calcinate for 4 hours under an argon atmosphere to obtain carbon materials;

[0053] b. Coated carbon material: mix the carbon material prepared in step (a) with polyvinylidene fluoride and conductive carbon in a mass ratio of 8:1:1, then add the solvent N,N dimethylacetamide, add the ingredients and solvent The mass ratio is 1:4, and the above four materials are mixed evenly and then coated on the aluminum foil with a spreader on both sides, as the negative electrode of the lithium-ion battery;

[0054] c. Prepare a simulated battery: use the coated carbon material obtained in step b as the cathode, metal lithium as the counter electrode, and a mixed solution of et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com