Anode material made of doped lithium-iron phosphate active material and carbon and method for producing the same

A technology of active material and positive electrode material, applied in the field of positive electrode material and preparation of doped lithium iron phosphate active material and carbon, can solve the problems of limiting lithium ion extraction and intercalation, instability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

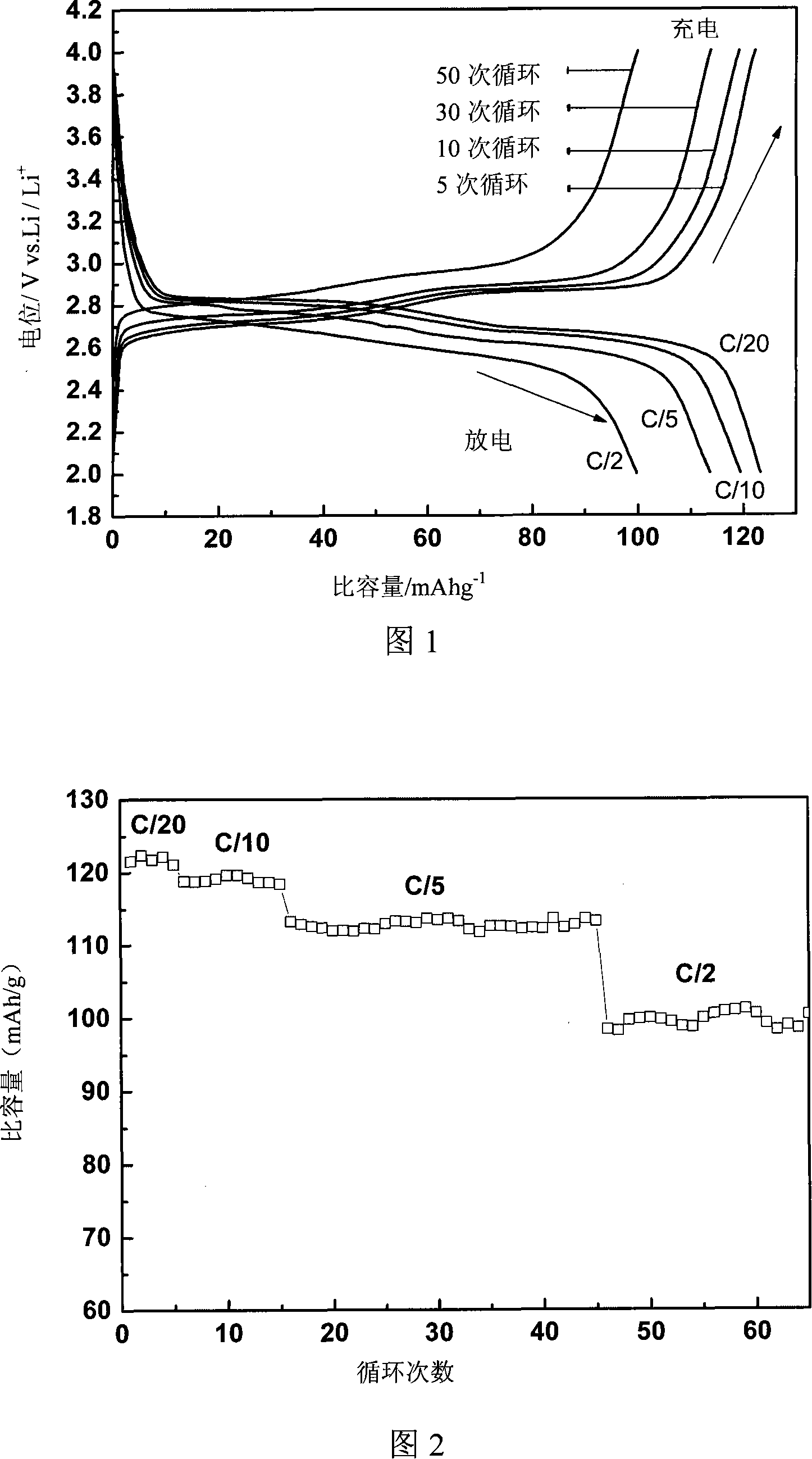

Examples

Embodiment approach 1

[0029] Choose Li 2 CO 3 、FePO 4 2H 2 O, NH 4 h 2 PO 4 and P25-TiO 2 powder (purity respectively 99.5%, 99%, 99%, 99%) was weighed, ground and mixed according to the molar ratio of 3:3.6:2.4:0.4, and the powder was loaded into an alumina crucible, at 400°C to 450°C Carry out solid-phase reaction, the reaction time is 4 hours, then grind the powder obtained after heating and pre-decomposition into an alumina crucible, carry out the second solid-phase reaction, and then carry out solid-phase reaction at 850 ° C, the reaction The time was 20 hours, and finally cooled naturally to room temperature to obtain Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 Powder. The prepared Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 Mixed with acetylene black through planetary ball mill to obtain Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 / C cathode material (mass ratio of active material to acetylene black is 95:5). Use Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 The process of assembling the / C cathode material into a battery is...

Embodiment approach 2

[0032] Choose LiOH·H 2 O, Fe(NO 3 ) 3· 9H 2 O, NH 4 h 2 PO 4 and P25-TiO 2 (the purity is respectively 99%, 98%, 99%, 99%) weighing and dissolving raw materials in deionized water according to the molar ratio of 6: 3.6: 2.4: 0.4, and stirring evenly with a magnetic stirrer; Put it into a high-pressure reactor and react at 170°C for 20 hours to obtain Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 Cathode material. Then the prepared Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 Mixed with acetylene black through planetary ball mill to obtain Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 / C (the mass ratio of active material and acetylene black is 95:5).

[0033] The performance test results are basically the same as those of Embodiment 1, and the specific capacity achieved by charging and discharging at the same rate is slightly lower than that of Embodiment 1.

Embodiment approach 3

[0035] Choose LiOH·H 2 O, Fe(NO 3 ) 3 9H 2 O, NH 4 h 2 PO 4 and Ti(OCH 3 ) 4 (the purity is 99%, 98%, 99%, 99.5% respectively) according to the molar ratio of 6: 3.6: 2.4: 0.4 weighing carries out batching. Dissolve the raw materials prepared according to the chemical composition ratio in deionized water, then add citric acid into the solution, then stir continuously under the magnetic stirrer, and finally use NH 3 ·H 2 O to adjust the pH to 3 and stir for about 6 hours to form a sol. Then heat the aqueous solution forming the sol at 120°C for 10h, evaporate the solvent until the gel is formed, and then pretreat the formed gel at 450°C for 5h, then grind the obtained powder, and then heat it at 750°C Heating for 15h, and finally cooling naturally to room temperature to obtain the positive electrode material Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 Powder. Then the prepared Li 3 Fe 1.8 Ti 0.2 (PO 4 ) 3 Mixed with acetylene black through planetary ball mill to obtain Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com