Patents

Literature

17509 results about "Ball mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

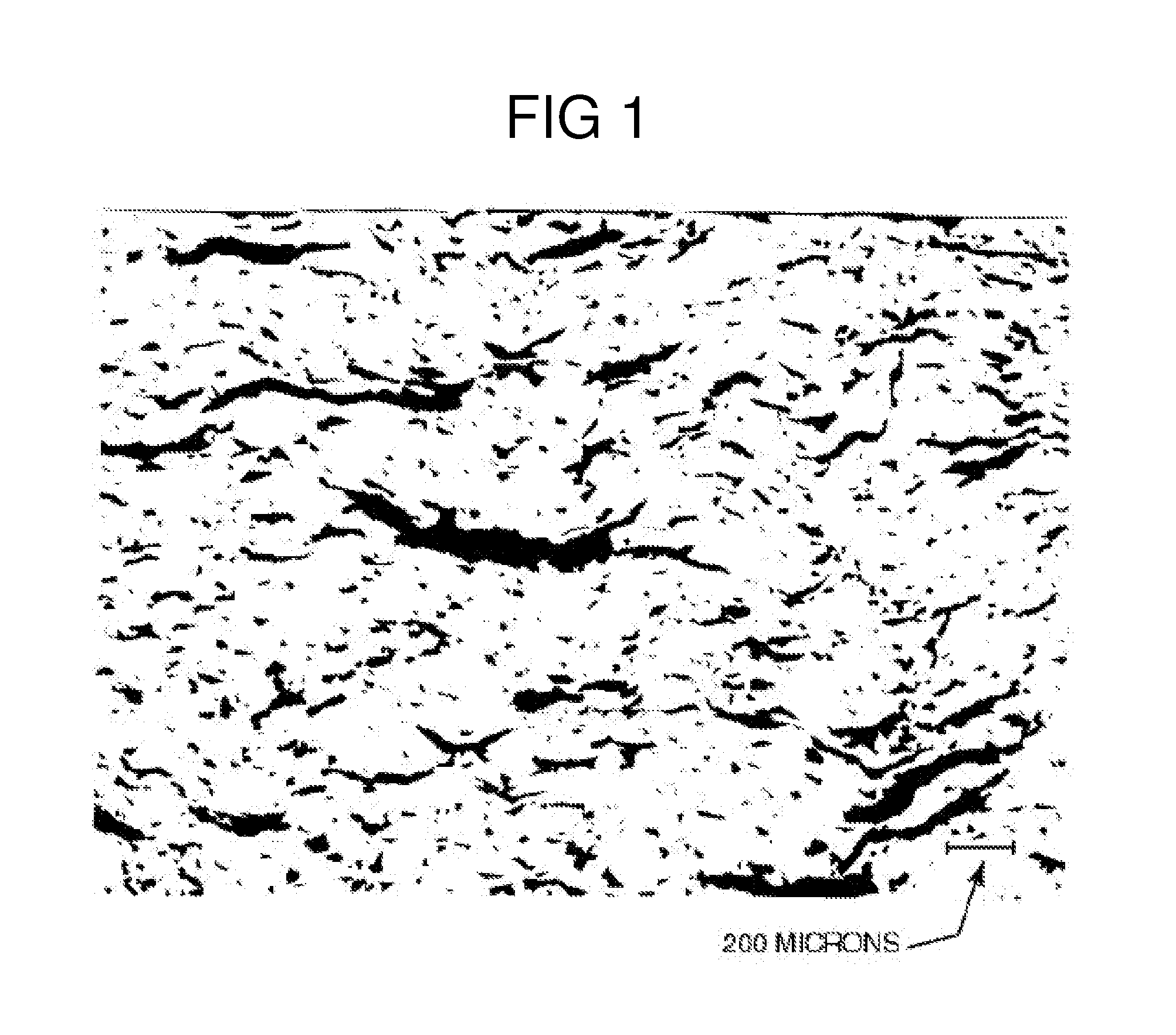

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

Ultra-dispersed nanocarbon and method for preparing the same

InactiveUS20050008560A1Avoid reorganizationMaterial nanotechnologyPigmenting treatmentDispersed mediaHigh energy

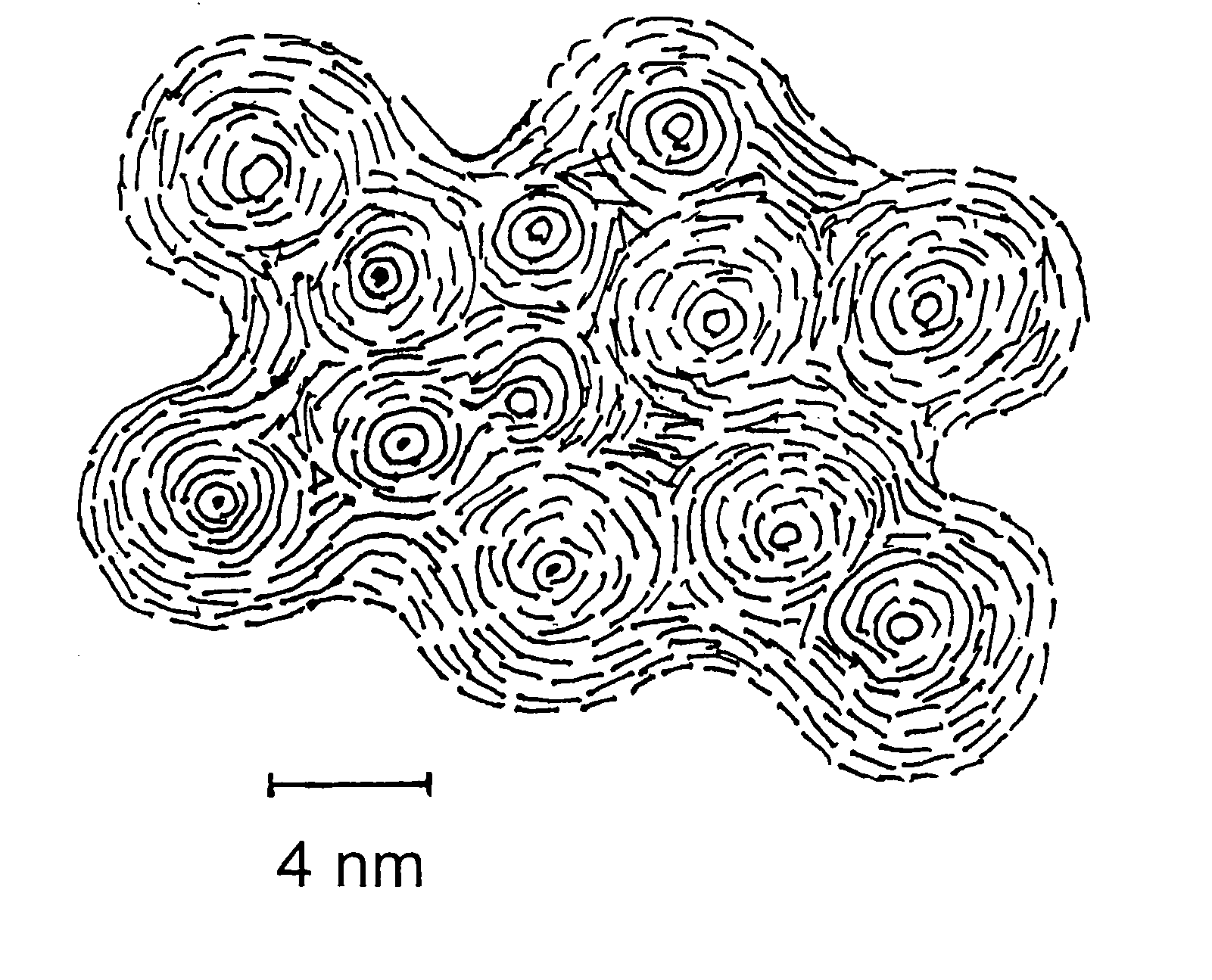

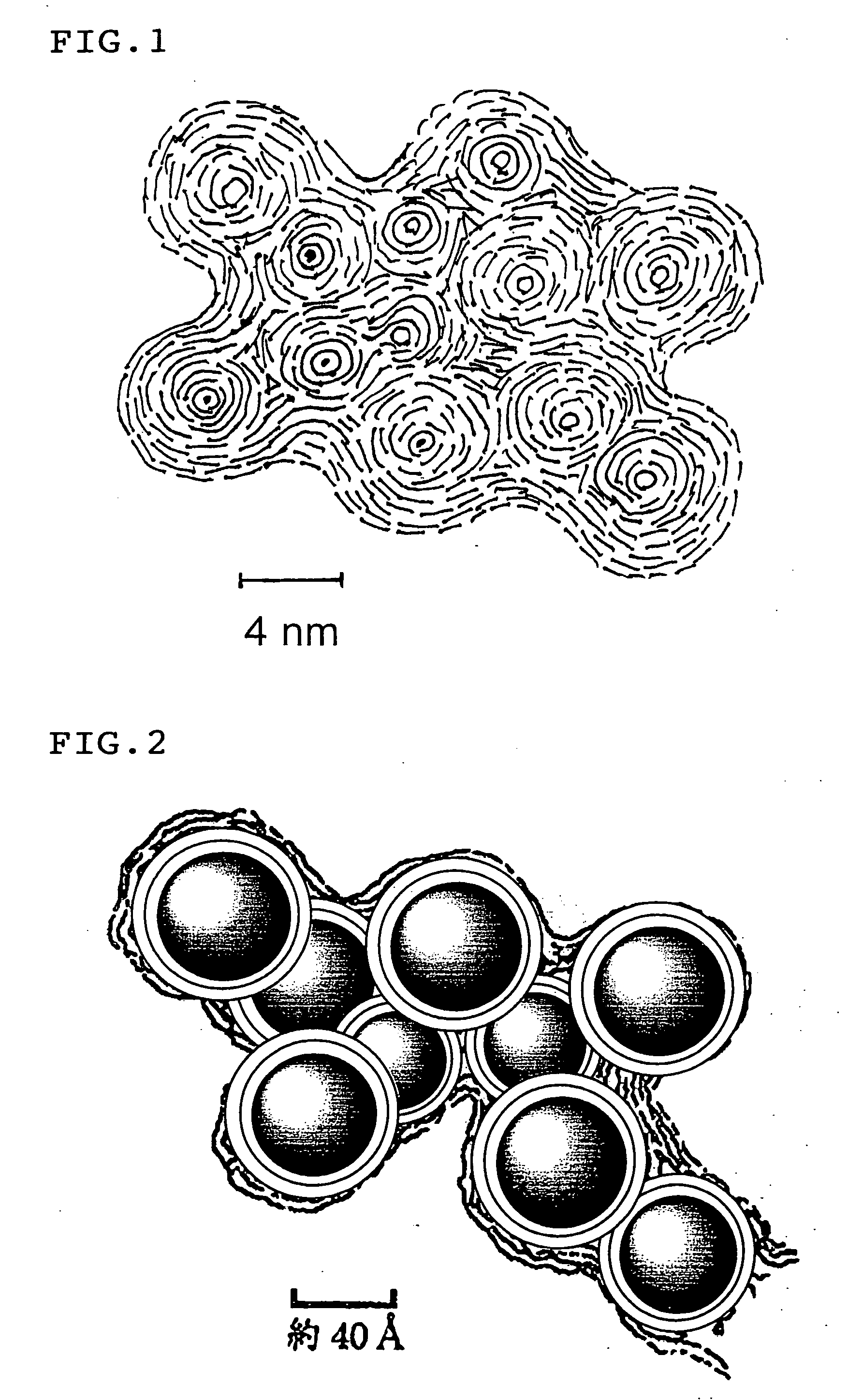

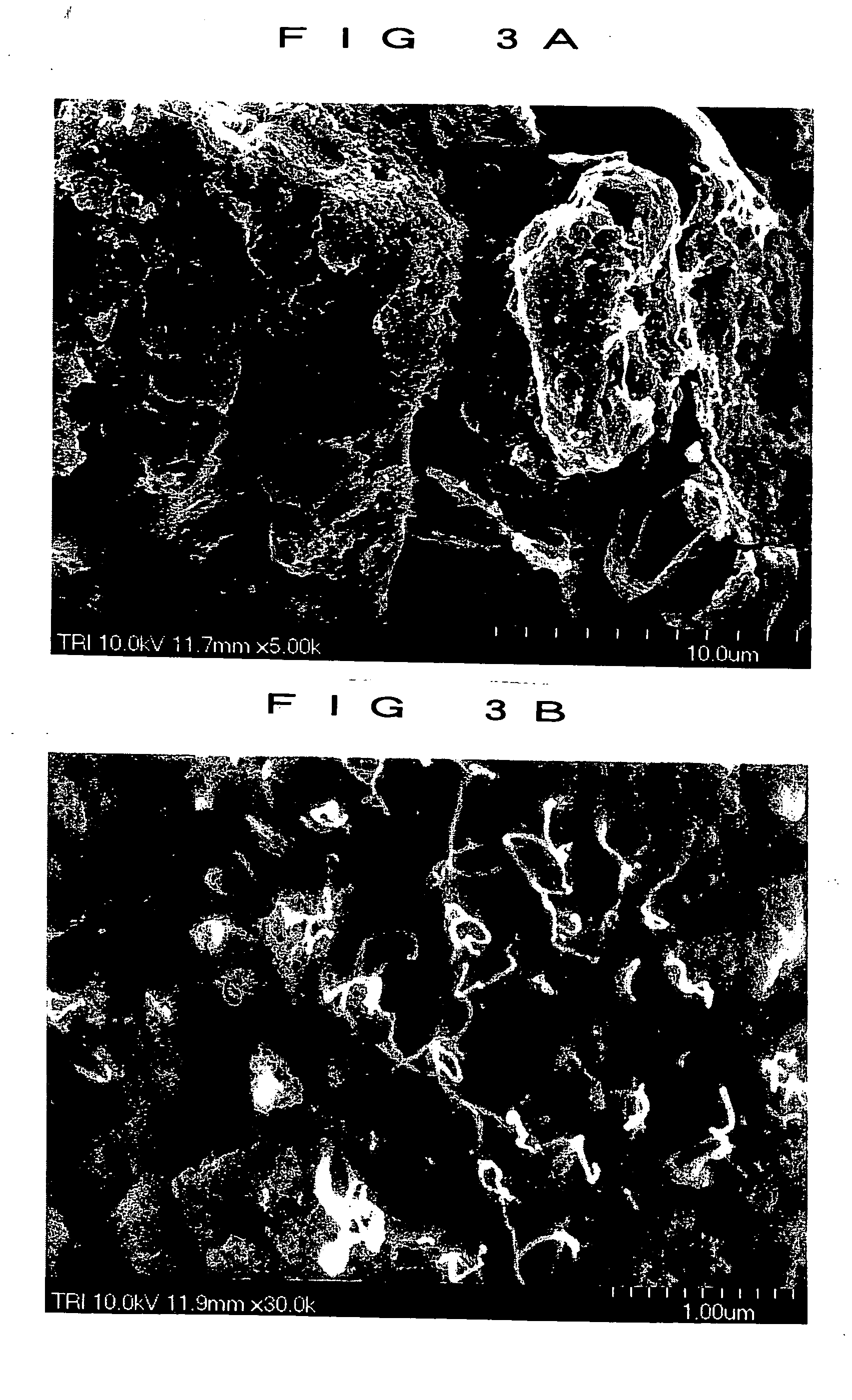

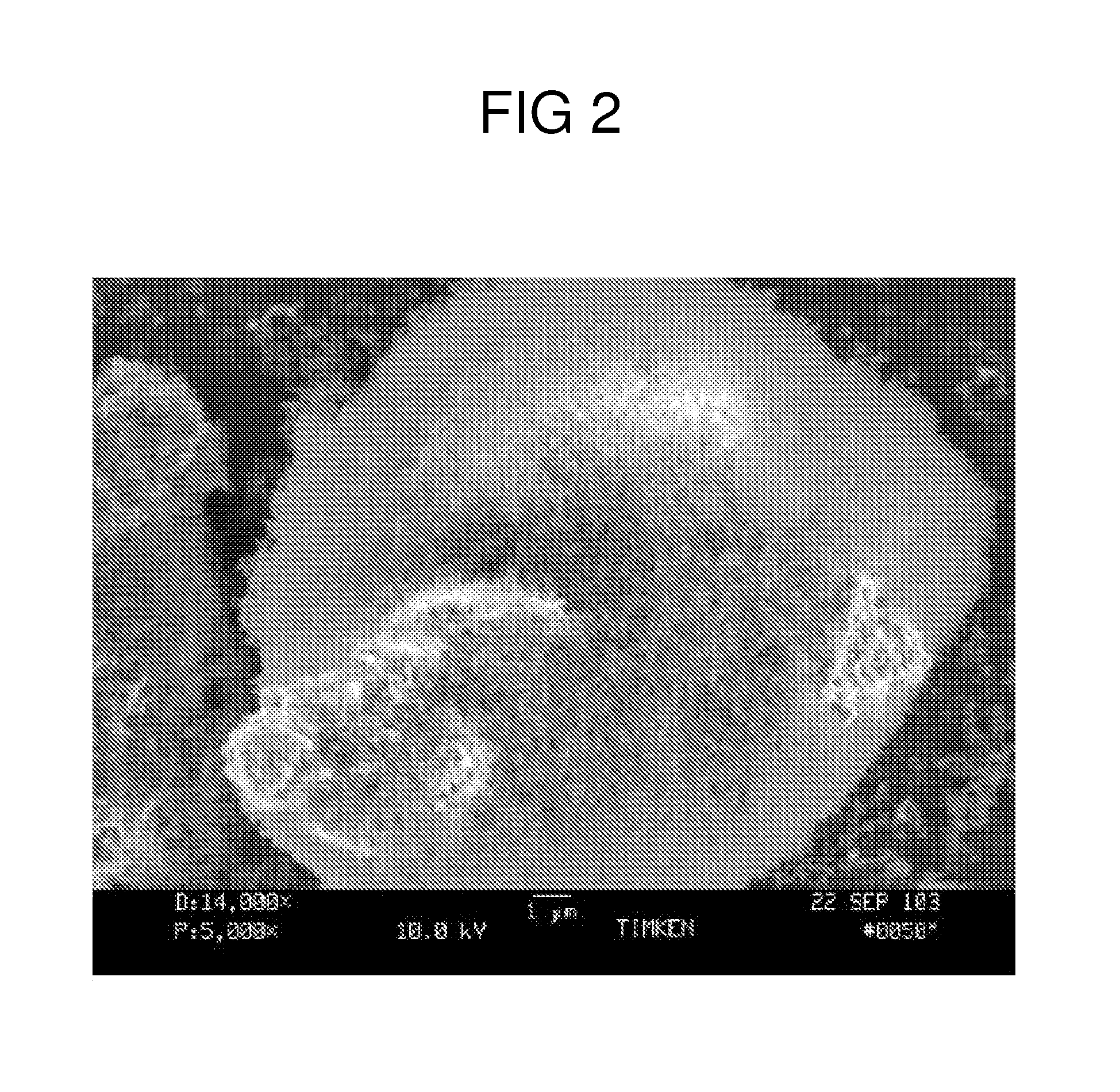

Ultradispersed ones of primary particles of nanometer-sized carbon are obtained by applying a wet-type milling method and / or a wet dispersion method to an aggregate structure of the primary particles to overcome van der Waals forces, by which forces the primary particles are held together to form the aggregate structure, whereby the ultradispersed primary particles are obtained in a colloidal dispersion on a large-scale basis at low cost without using any additive. In a method of manufacturing the ultradispersed primary particles, the wet-type milling method is carried out in a ball mill, preferably in combination with a high-energy ultrasonic-wave process carried out in a dispersing medium such as pure water, whereby a colloidal solution or slurry with a low-concentration of the primary particles ultradispersed in the dispersing medium is obtained.

Owner:FUTABA CORPORATION +2

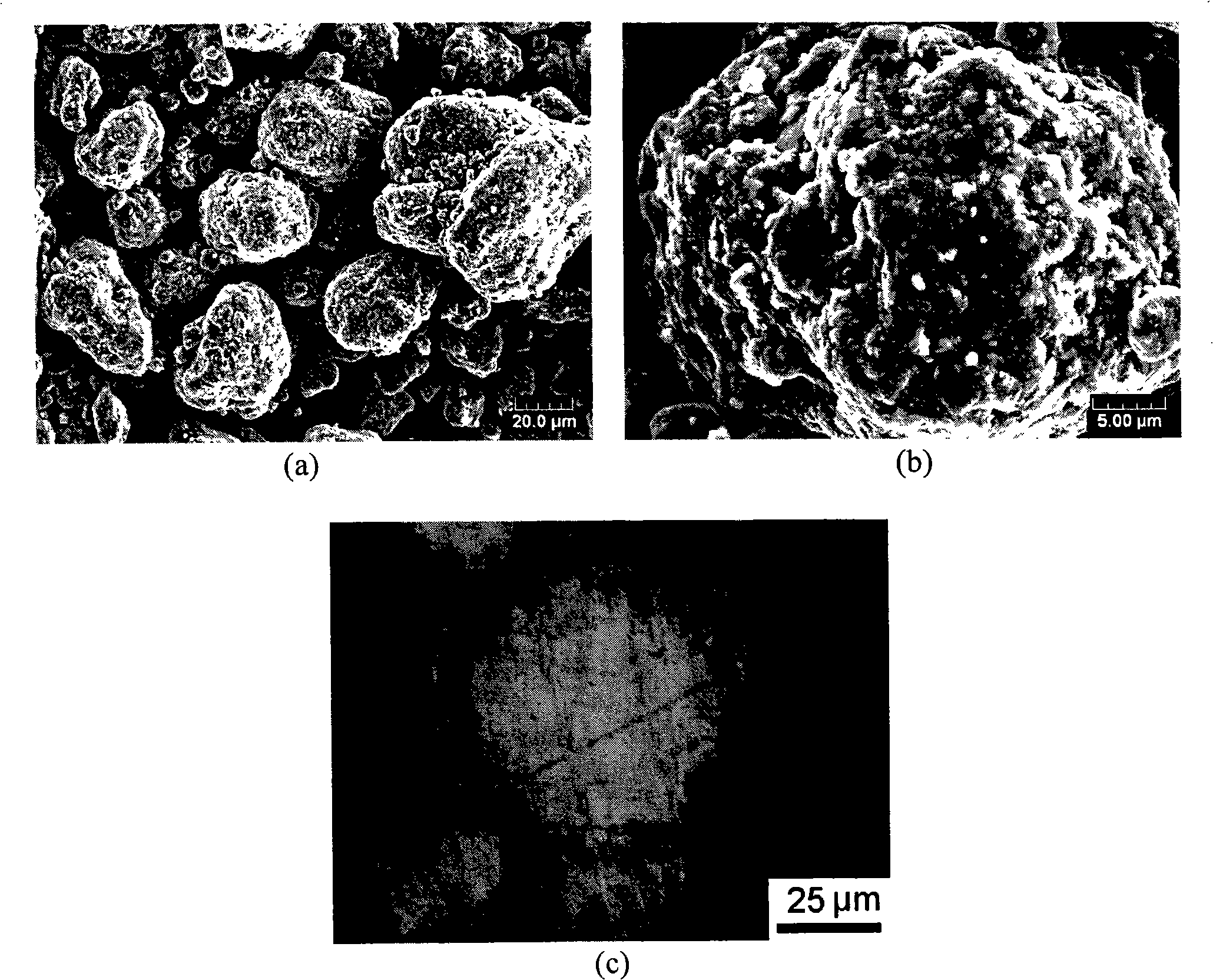

Recycling treatment method of waste and old lithium iron phosphate battery anode materials

InactiveCN102208706ANo pollution in the processEasy to operateSolid waste disposalWaste accumulators reclaimingLithium iron phosphateHigh energy

The invention discloses a recycling treatment method of waste and old lithium iron phosphate battery anode materials, which comprises the following steps of: firstly, scattering waste and old lithium iron phosphate batteries and stripping and collecting anode materials in the waste batteries; heating the collected anode materials at high temperature and removing carbon and an adhesion agent to obtain solid powder; adding a lithium source compound and a carbon source into the solid mixture; ball-milling the mixture through a high-energy wet method; and finally, charging the ball-milled powder into a non-oxide atmosphere and roasting at high temperature to obtain the qualified lithium iron phosphate anode materials. The recycling method disclosed by the invention has the advantages of simple process, convenience for operation and high recovery rate.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

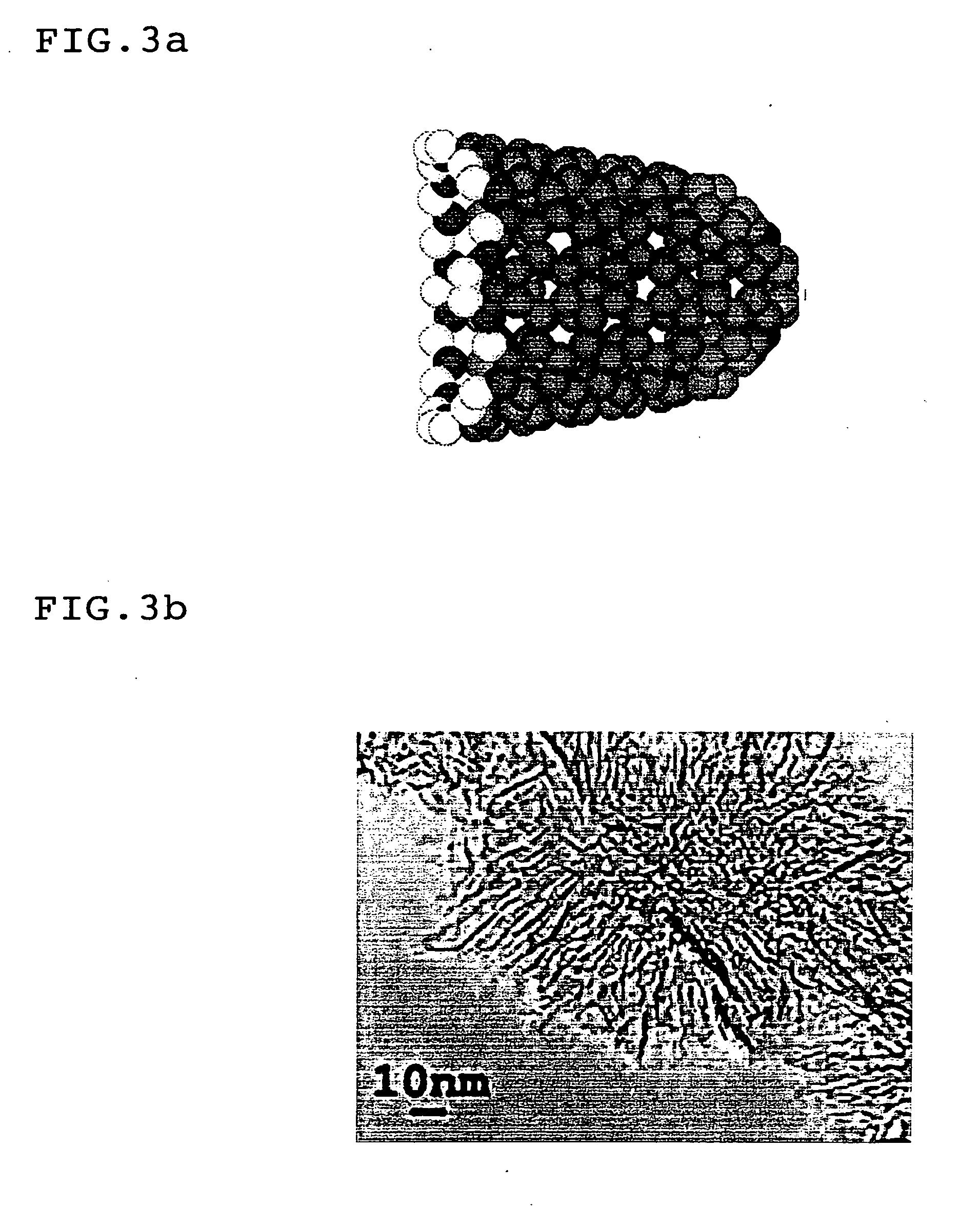

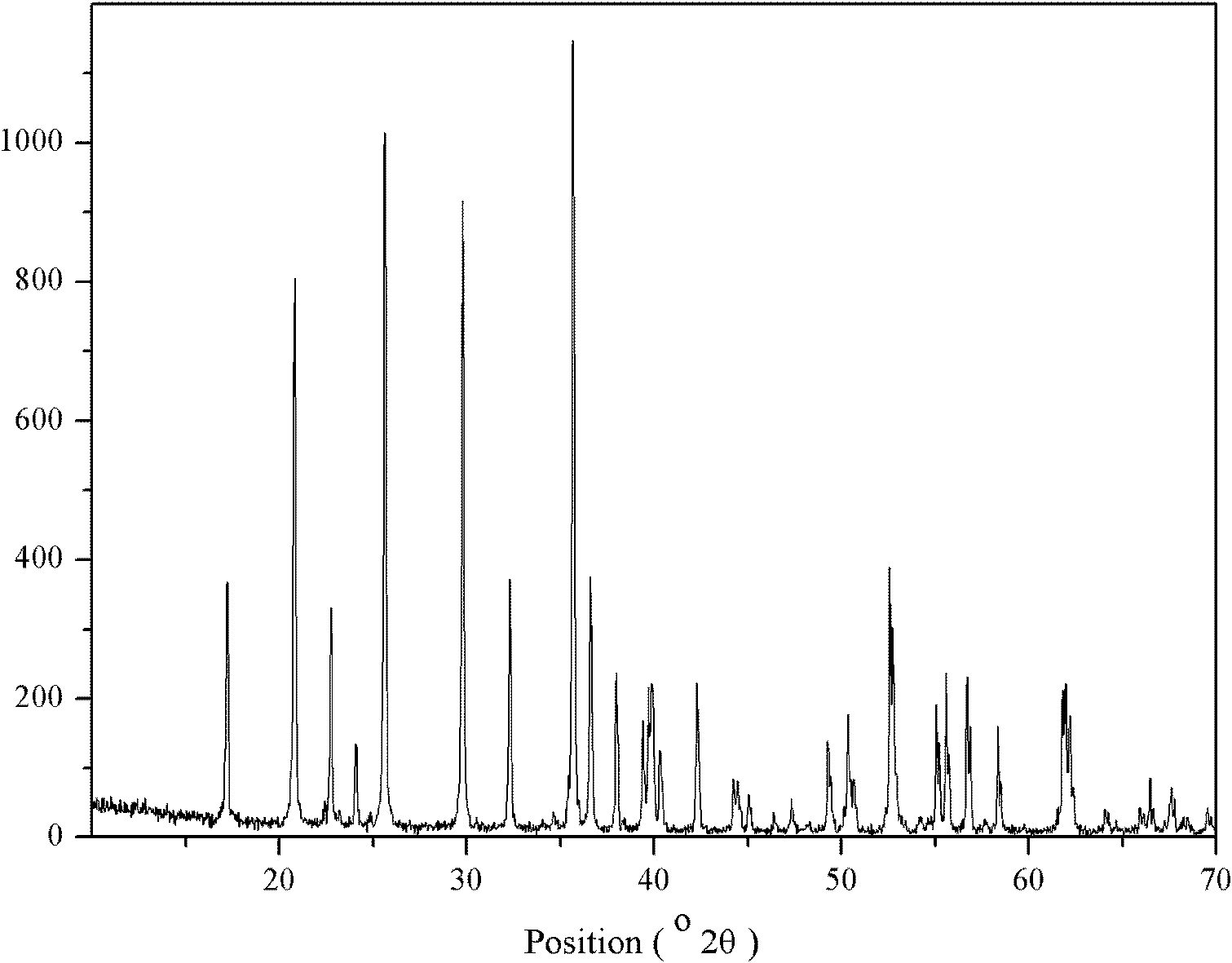

Method for producing carbon nanotube-dispersed composite material

InactiveUS20070057415A1Improve corrosion resistanceExcellent in heat releasabilityMaterial nanotechnologyCell electrodesHeat resistanceCarbon nanotube

The present invention has an object of providing a carbon nanotube dispersed composite material utilizing as much as possible excellent electric conductivity, heat conductive property and strength property owned by a carbon nanotube itself and taking advantage of features of ceramics having corrosion resistance and heat resistance such as zirconia and the like, and a method of producing the same; and long-chain carbon nanotubes (including also those obtained by previous discharge plasma treatment of only carbon nanotubes) are kneaded and dispersed by a ball mill, planet mill and the like together with calcinable ceramics and metal powder, further, the knead-dispersed material is treated by discharge plasma and this is integrated by sintering by discharge plasma, and carbon nanotubes can be thus dispersed in the form of network in the sintered body, and the electric conductivity property, heat conductive property and strength property of the carbon nanotube can be effectively used together with the properties of the ceramics and metal powder base material.

Owner:SUMITOMO PRECISION PROD CO LTD +1

Particulate material containing thermoplastics and methods for making and using the same

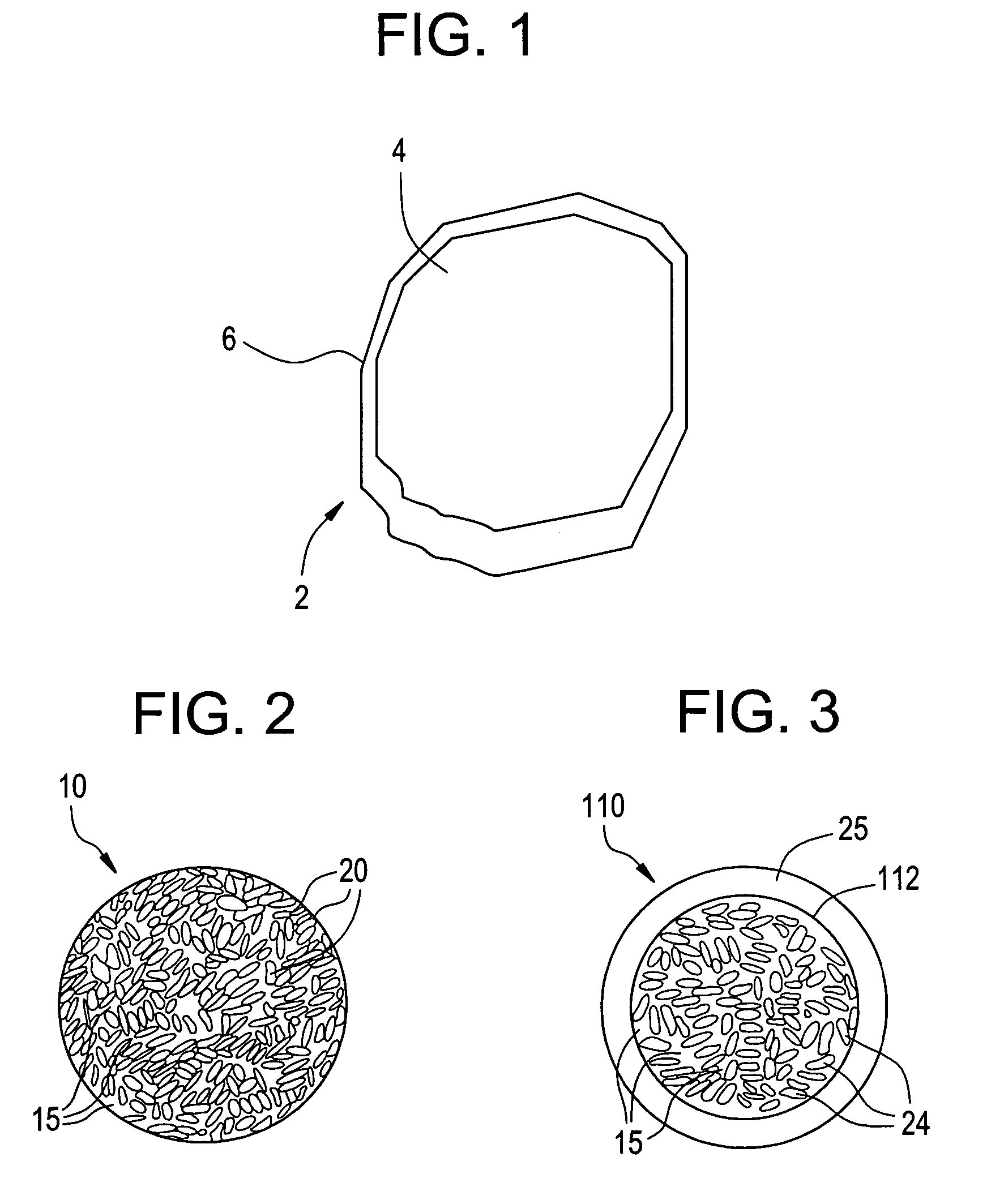

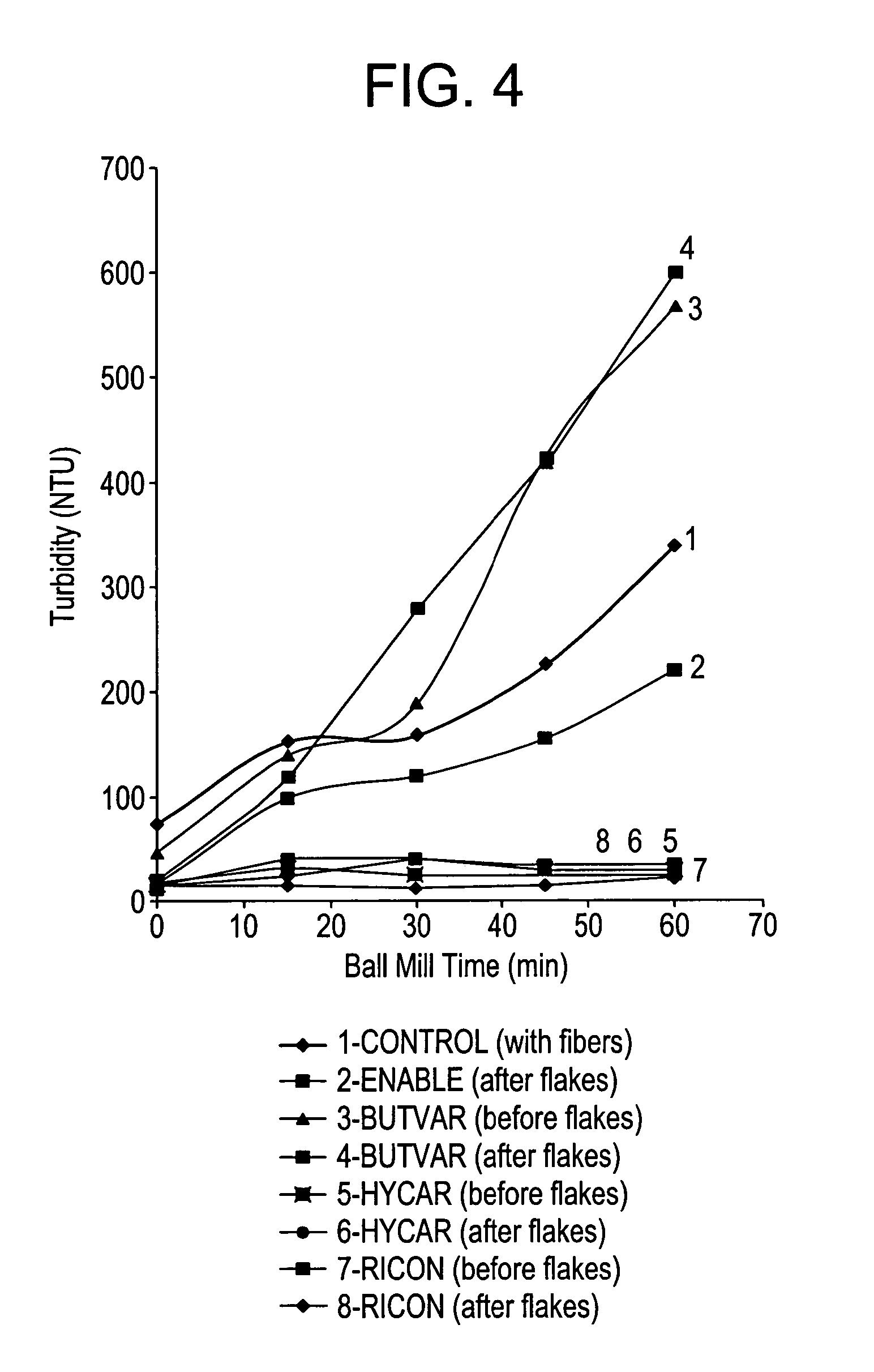

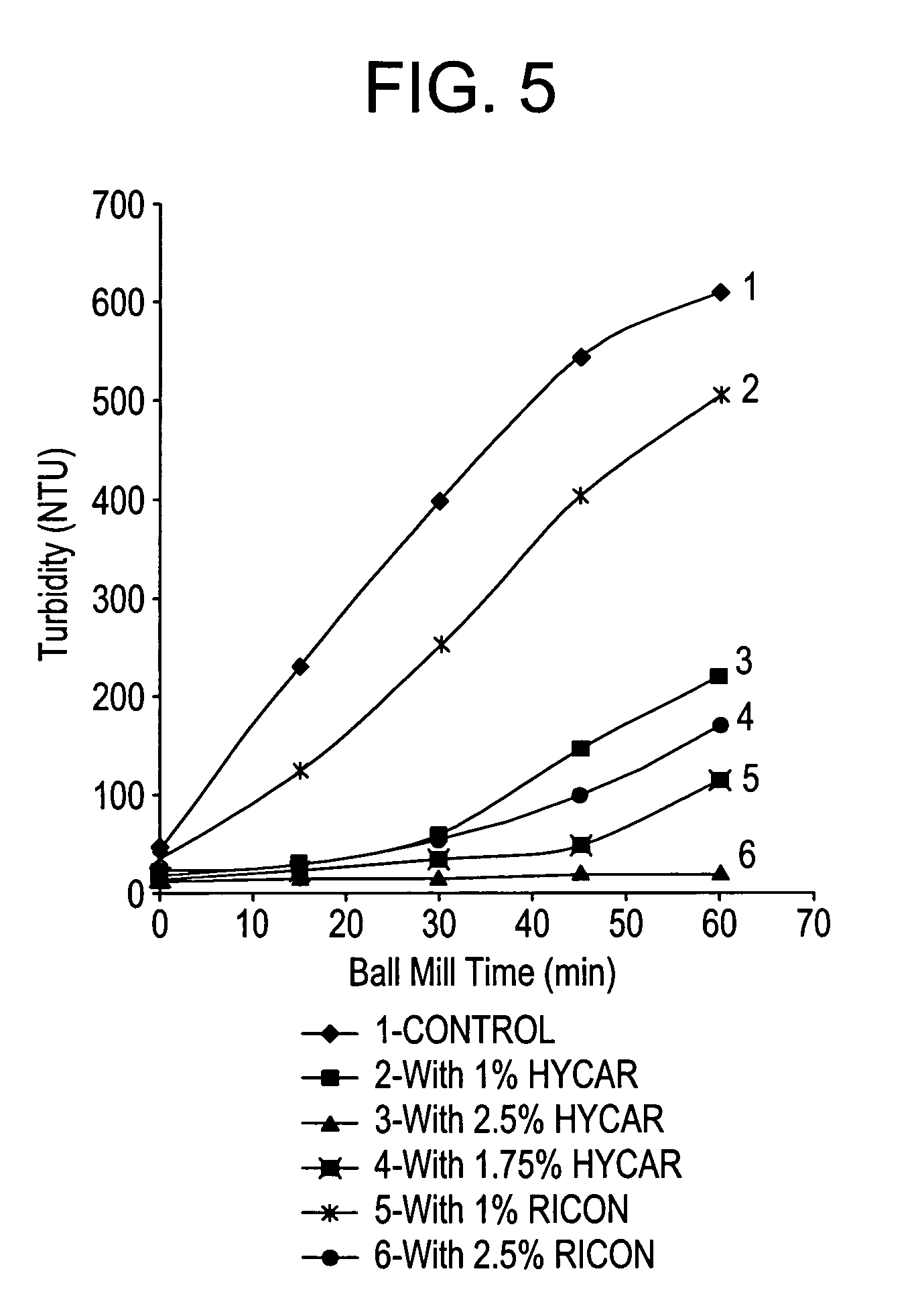

ActiveUS7270879B2Trend downImprove abilitiesPretreated surfacesGlass/slag layered productsParticulatesThermoplastic

Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer present on or in the substrate as an amount sufficient to improve the dust suppression of the particle above that which would occur if the thermoplastic elastomer was absent. Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer, wherein the particle has a compressive strength retention of greater than about 50% as measured by a UCS test and a turbidity of about 10 to 200 NTU after a one hour ball mill test.

Owner:HEXION INC

Method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate battery

ActiveCN102751548AEasy to separateImprove electrochemical performanceWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateHigh energy

The invention discloses a method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate batteries. The method comprises: 1) dismantling the recovered waste lithium iron phosphate batteries, stripping battery cases, immersing the batteries, separating the electrode plates from the powder material of positive and negative terminals through a method of alternation of ultrasonic and mechanical stirring, taking out the electrode plates and diaphragms, and obtaining mixed liquor; 2) performing a preliminary ball milling to the mixed liquor, and drying the uniformly mixed slurry obtained by the preliminary ball milling; 3) calcining the dried material in oxidizing atmosphere to obtain a recovered material, adding iron source, phosphorous source and optionally new lithium iron phosphate, then adding carbon source, high energy ball milling the obtained material, drying the material to obtain a pre-burning material of the recovered material; 4) microwave sintering or solid state sintering the pre-burning material of the recovered material in protective atmosphere to obtain the product of lithium iron phosphate. The preparation method has the advantages of environmental protection, no pollution, simpleness and practicality, high production utilization rate, simple

Owner:ZHEJIANG UNIV

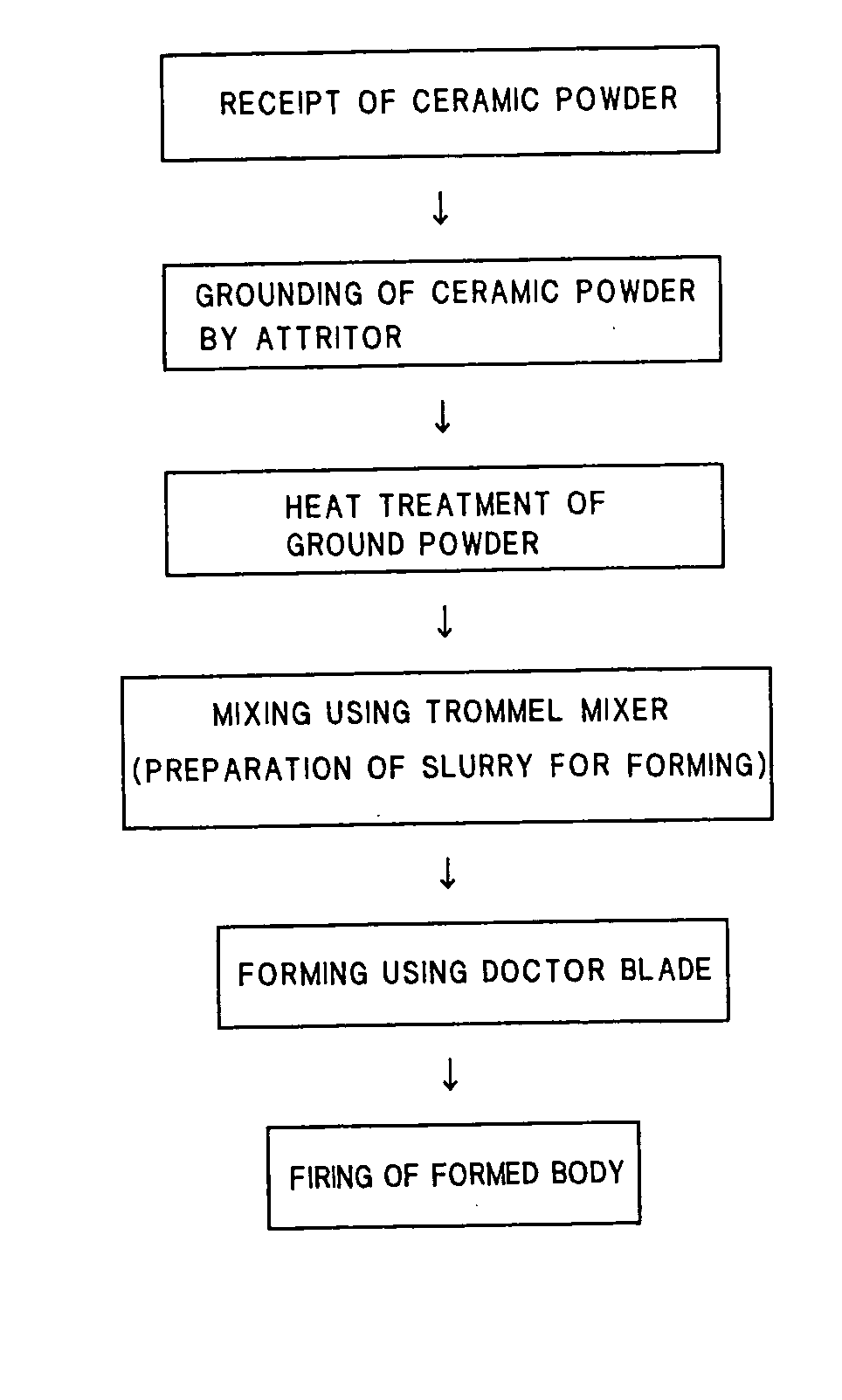

Method for controlling shrinkage of formed ceramic body

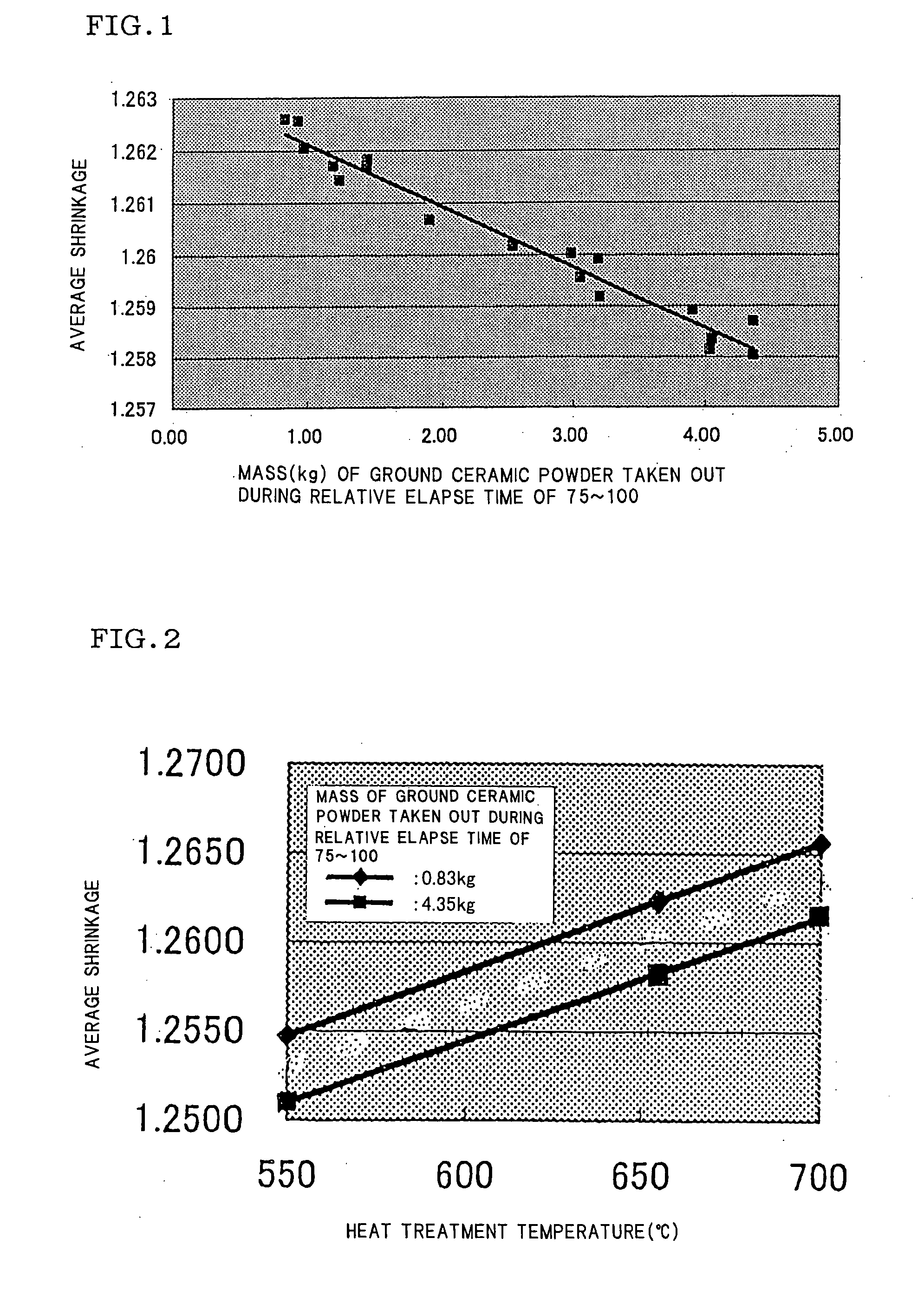

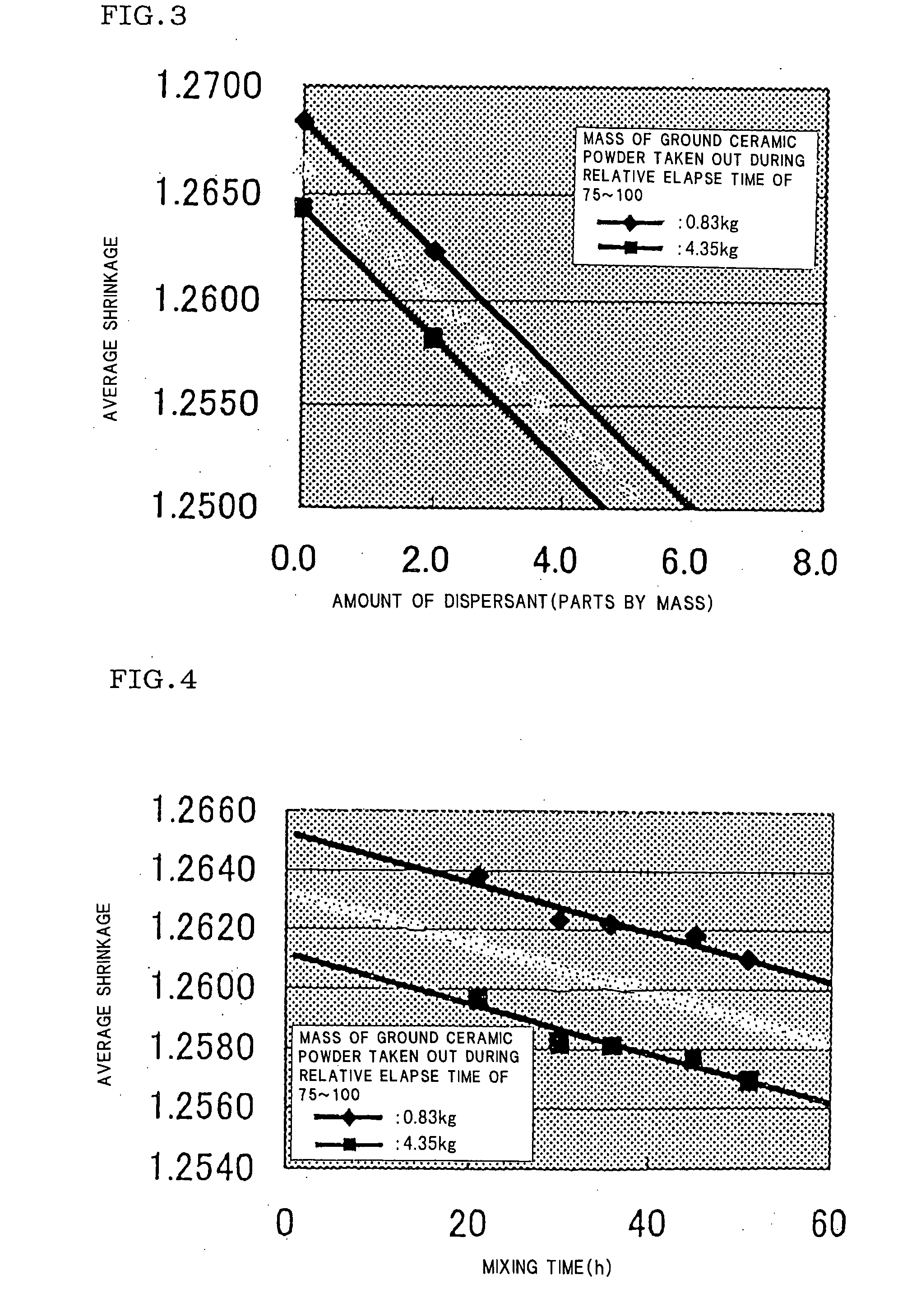

ActiveUS20060043648A1Easy to controlSuppress fluctuationsCeramic shaping apparatusClaywaresManufacturing technologyBall mill

The present invention provides a method for controlling the shrinkage of formed ceramic bodies, by which it is possible to suppress fluctuation of the shrinkage of formed ceramic bodies and to cause the shrinkage to approximate the target rate. The method comprises controlling the shrinkage of formed ceramic bodies in manufacturing ceramic products by a predetermined manufacturing process from ceramic powder ground by a dry-type ball mill. Such control can be achieved by determining a correlation between the change in the amount of the ground ceramic powder taken out from the dry-type ball mill with elapse time and the shrinkage during firing of the formed ceramic body, and thereafter adjusting the manufacturing conditions based on the previously-determined conditions for the above-mentioned manufacturing process and the correlation with respect to the shrinkage obtained.

Owner:NGK INSULATORS LTD

Aquosity bi-component polyurethane coloured paint and method of manufacturing the same

InactiveCN101108951AReduce pollutionPolyurea/polyurethane coatingsEmulsion paintsOrganic solventDisinfectant

The invention discloses a two-component waterborne polyurethane colored paint and the preparation method. The components of the paint are 5 to 15 water, 0.2 to 0.5 dispersant, 0.1 to 0.3 antifoamer, 0.1 to 0.3 wetting agent, 3 to 25 paints, 0 to 50 fillers, 10 to 80 film forming resins, 0 to 5 film forming additives, 0.1 to 0.3 disinfectant, 0.1 to 0.3 antiflash rust agent, 0.5 to 2 thickeners, 1 to 20 hydrophilically-modified polyisocyanate. The preparation method is that water, dispersant, antifoamer, wetting agent, paints and fillers are dispersed evenly by a sand mill, a ball mill or a high-speed stirrer after stirring, and are added with film forming resins, film forming additives, disinfectant, antiflash rust agent and thickeners to gain the product-component A. The hydrophilically-modified polyisocyanate is component B. The component A and component B are mixed uniformly when using. The invention is characterized in that the invention does not adopt organic solvents, does not contain toxic paints and has no harm on the human body and environment, and the properties can reach the solvent two-component polyurethane paint, which can be produced to the primer, intermediate coat and finishing coat, and can be applied in the surface of the wooden ware, cement and metals.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

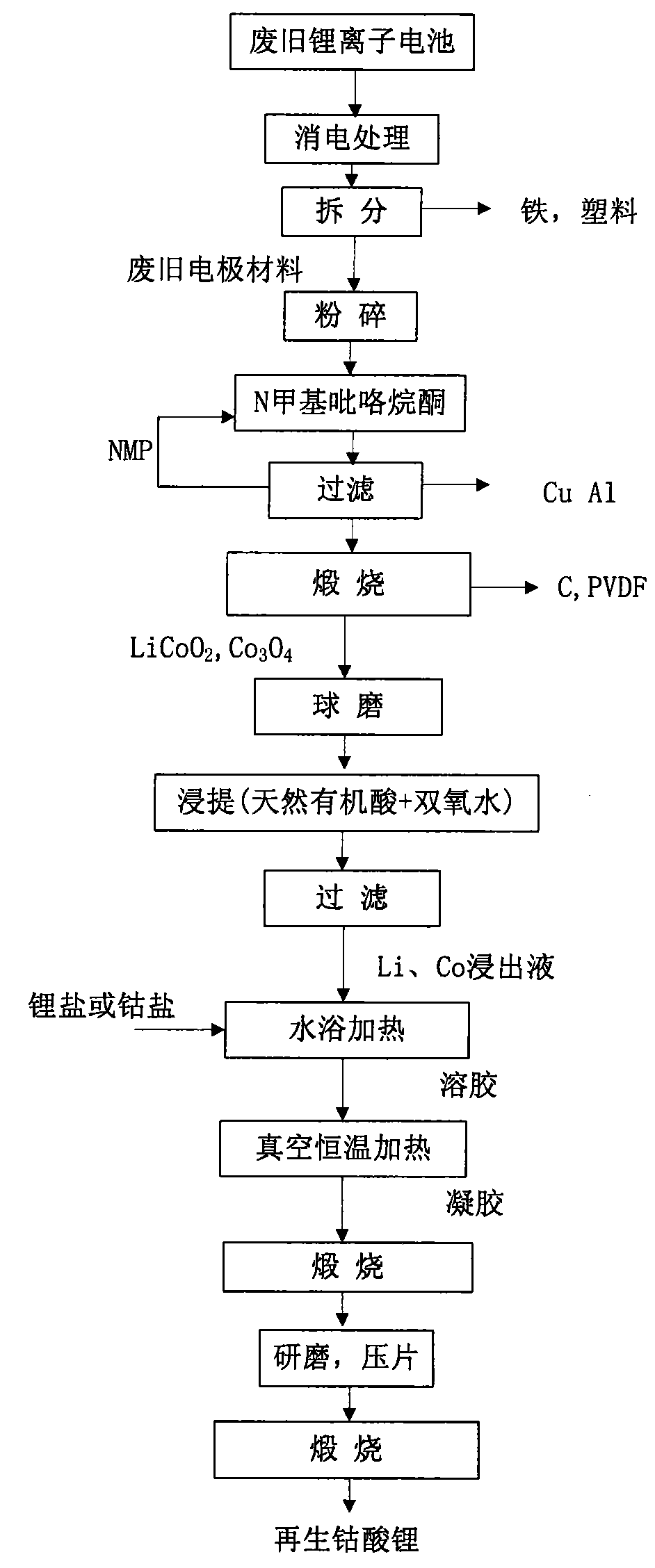

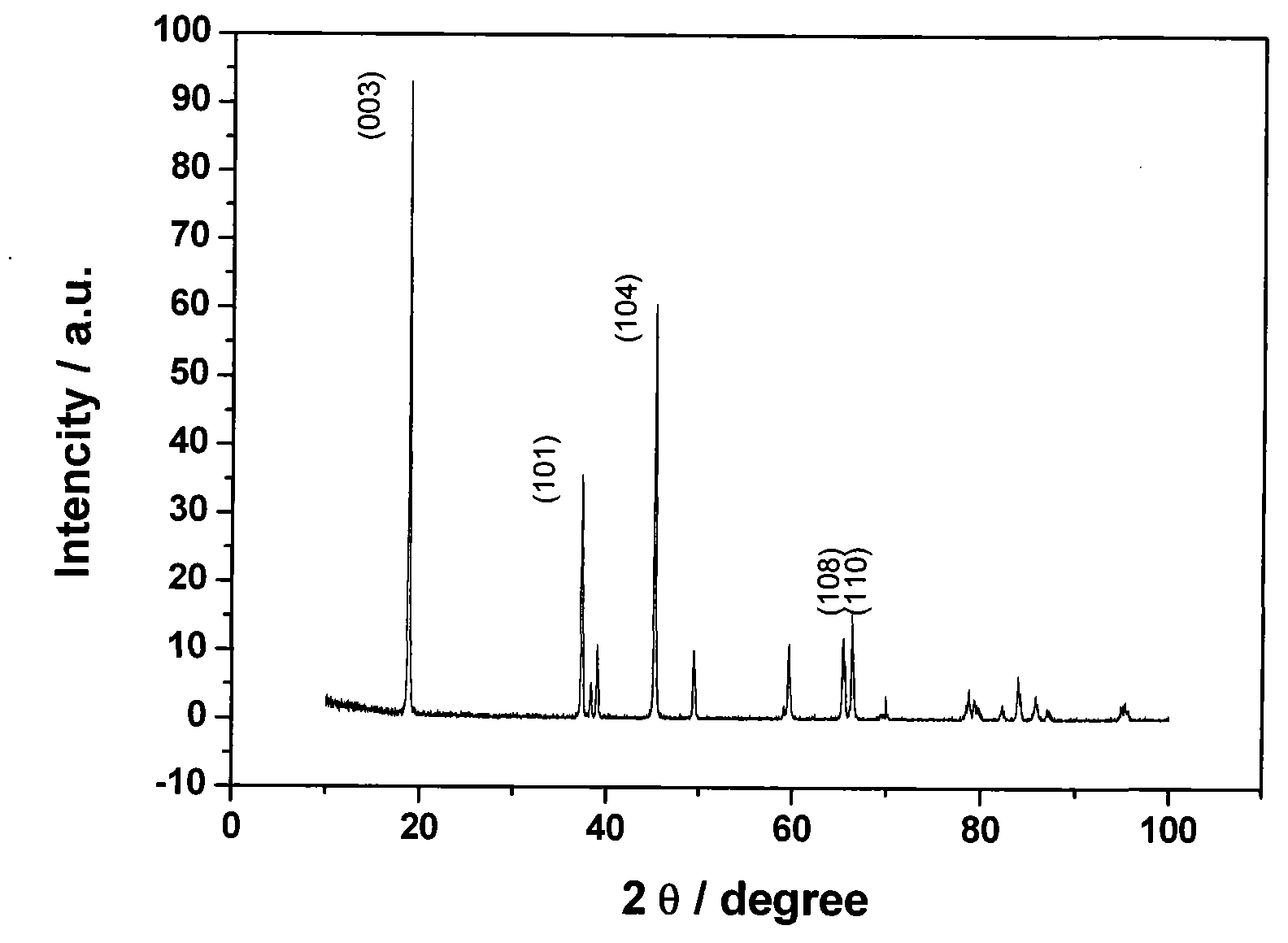

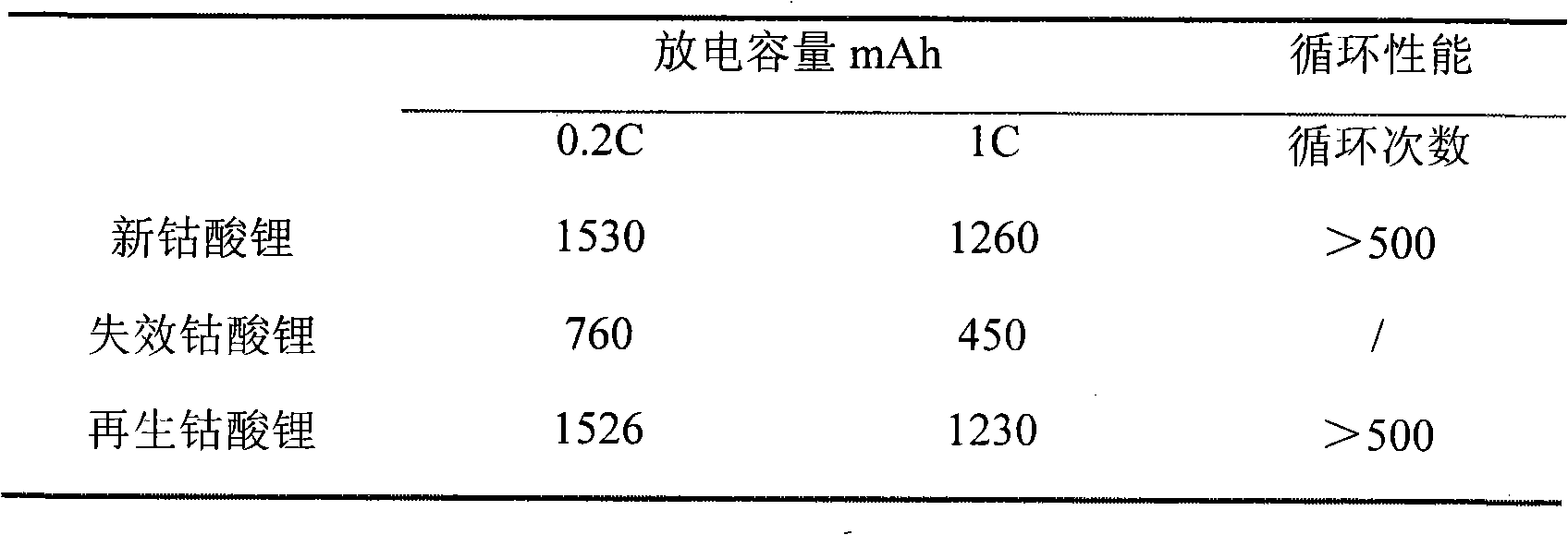

Method for recovering and preparing lithium cobalt oxide by using disused lithium battery

ActiveCN101673859ASolve the hazardSolve resource problemsLithium compoundsWaste accumulators reclaimingWater bathsOrganic acid

The invention relates to a method for recovering and preparing lithium cobalt oxide by using a disused lithium battery, belonging to the technical field of recovery and recycle of electrode materials.The method comprises the steps of: discharging, disassembling, smashing, NMP processing and burning a disused lithium battery sequentially, to obtain a disused LiCoO2 material; ball-milling the disused LiCoO2 material and adding natural organic acid and hydrogen peroxide to obtain a solution of Li<+> and Co<2+>; adding lithium salt or cobalt salt after filtering, and then heating by water bath; dropwise adding ammonia water in the solution to prepare a xerogel; and performing secondary burning to obtain an electrode material of lithium cobalt oxide. The method has the advantages that the electrochemical properties of the electrode material of the disused lithium battery can be recycled with obvious effect as well as simple and easy operation; the natural organic acid used in the process of acid dipping has small damage to apparatus; and the method is environment friendly and efficient, and has low cost, simple technique, high recovery rate and industrialized promotion.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

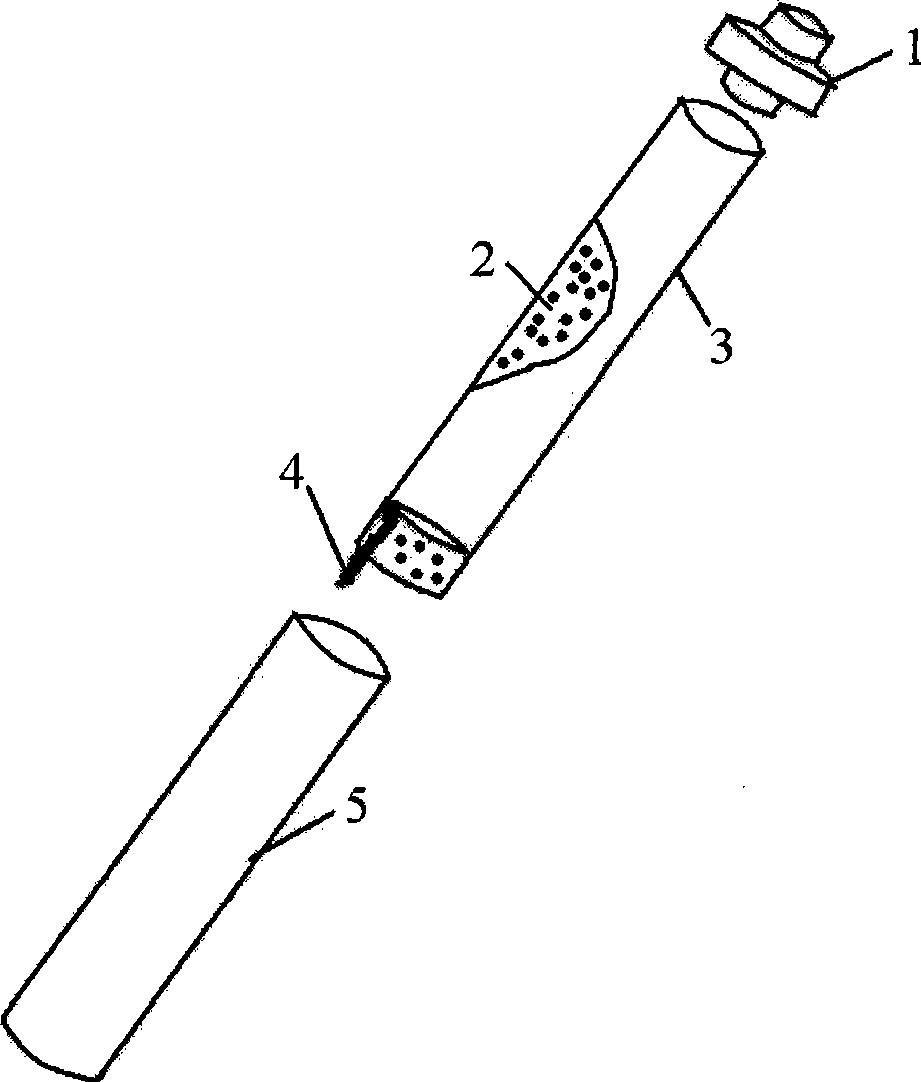

Manual thermit welding electrode and preparation and using methods thereof

ActiveCN101444876AFirmly connectedEasy to weldWelding/cutting media/materialsAlumino-thermic welding apparatusSlagEngineering

The invention discloses a manual thermit welding electrode and preparation and using method thereof which belong to the technical field of welding. A welding compound of the welding electrode comprises a thermit, a slag forming constituent and an alloying agent. Raw materials are weighed according to the proportion and arranged in a ball mill, a grinding ball and a milling medium are added, and the welding compound is obtained by drying after wet grinding; the welding compound is filled in a cylinder which is made of paper, a lead wire is arranged at one end of the cylinder, and the other end is sealed by a plastic plug, thereby forming the thermit welding electrode; the welding electrode is arranged in a sleeve which is made of paper and sealed for preservation. When in use, the sleeve is fixed on the plug at the back end of the welding electrode, the sleeve is held by a hand, and the lead wire at the front end of the welding electrode is ignited, and then the manual welding or cutting operation can be carried out. The welding electrode is small, lightweight and portable, the welding and the cutting operations are simple, rapid and safe, the welding and the cutting operations can be carried out anytime and anywhere, and the welding electrode can be applied in the welding and the cutting of steels, stainless steels or copper alloy materials.

Owner:TSINGHUA UNIV

Method for preparing particulate reinforced metal-based composite material

InactiveCN101285187AImprove performanceDense tissuePressure inorganic powder coatingParticulatesHigh energy

The invention relates to a method for preparing a particulate reinforced metallic matrix composite material. The method is characterized in that: metal powder and hard phase powder are mechanically mixed and the mixture is added into a high-energy globe mill container for ball milling; powder after ball milling is sieved; sandblasting coarsing pretreatment is performed on the matrix surface and the ball milling powder is sprayed on a matrix by adoption of the cold spraying method, and then the particulate reinforced metallic matrix composite material is obtained. The preparation method adopts the high-energy ball milling method to prepare and spray the powder, and can make distribution of hard phases more uniform on one hand and thin metallic matrix crystal grains through ball milling on the other hand, thereby the performance of the MMC material prepared is further improved. The particulate reinforced metallic matrix composite material prepared by the method has compact tissue and excellent performance, and not only can prepare a coating but also can realize near-net forming of parts. The method has simple technique, good controllability, low production cost and high production efficiency, and is favorable for realizing industrialized application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

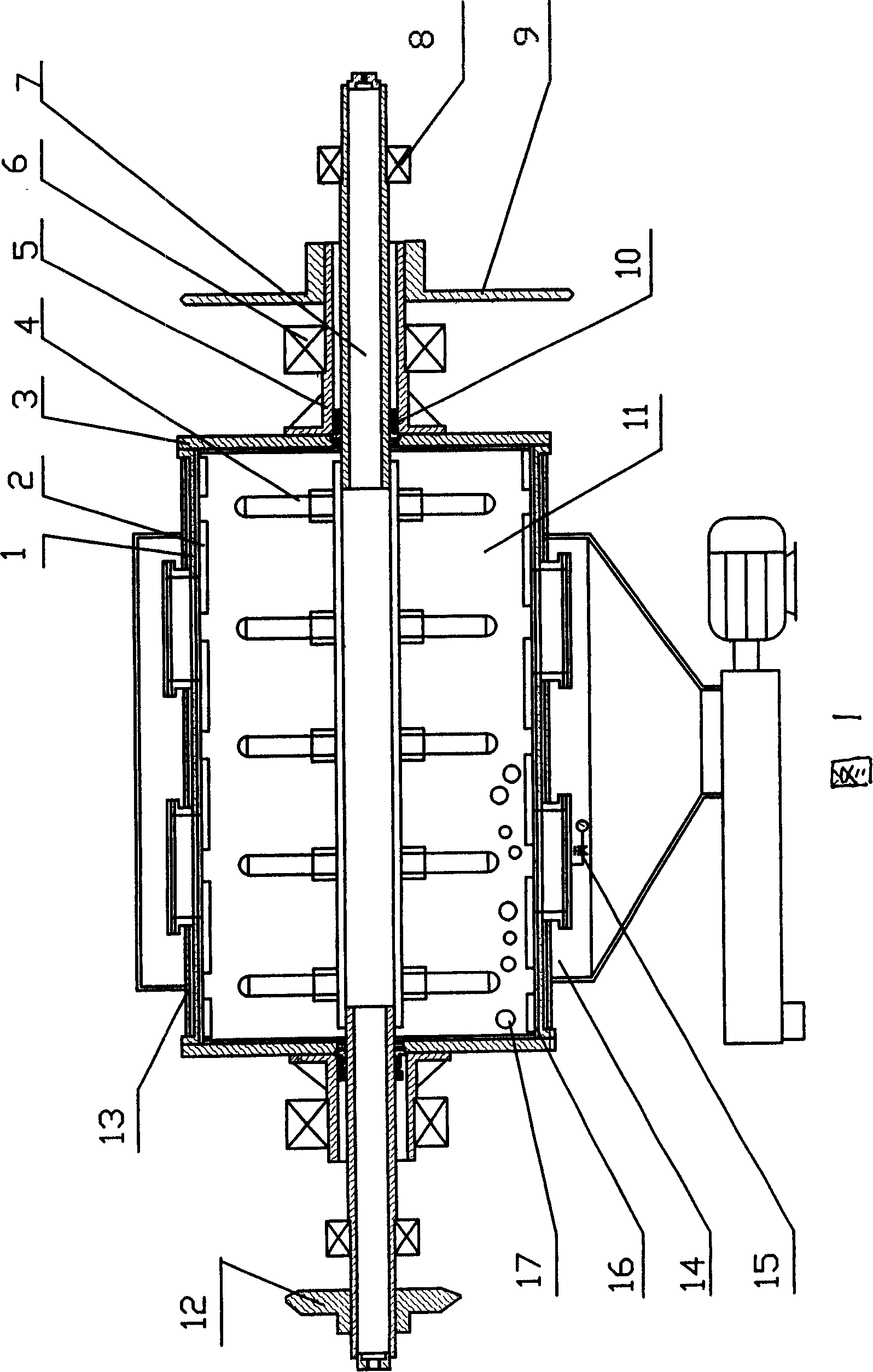

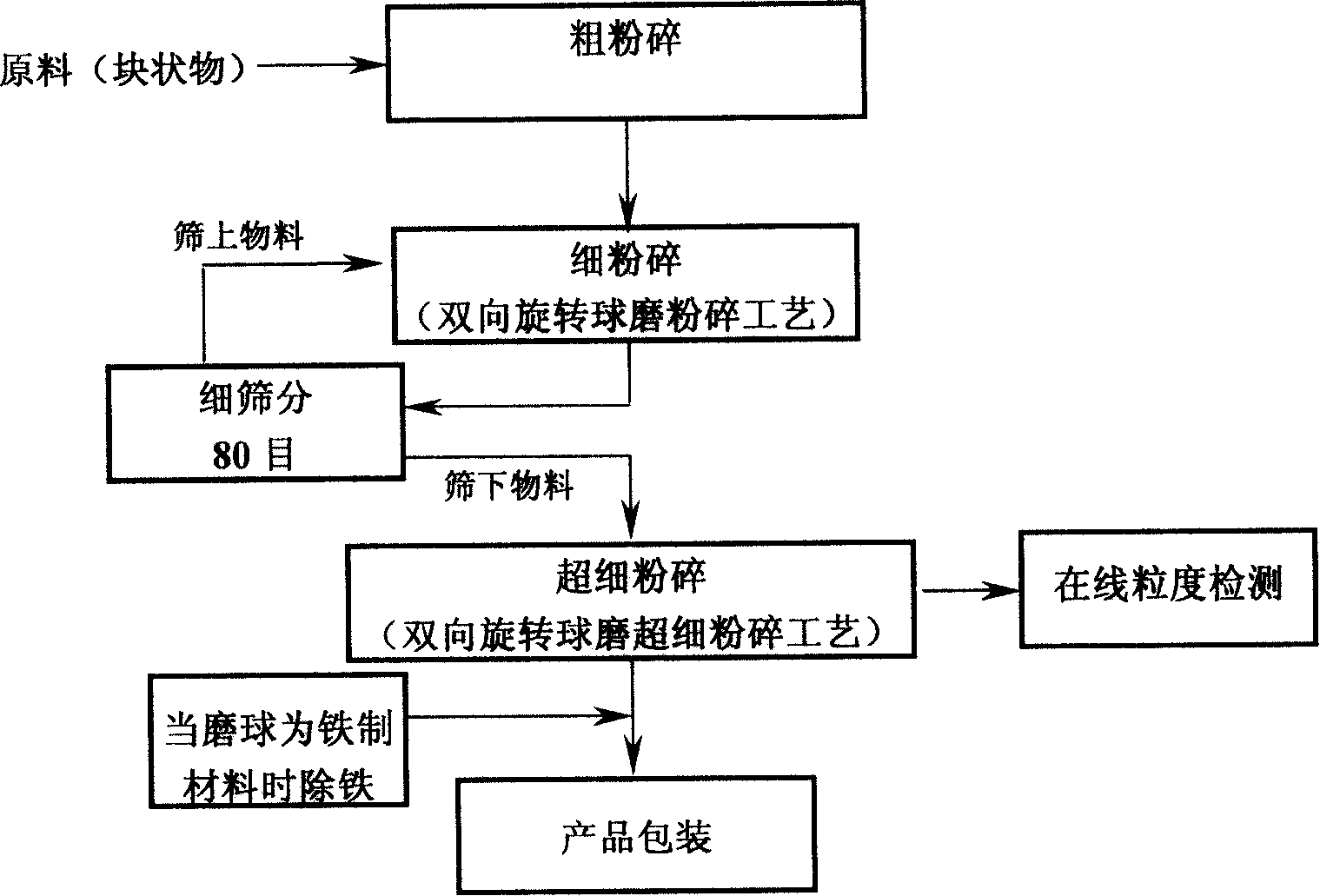

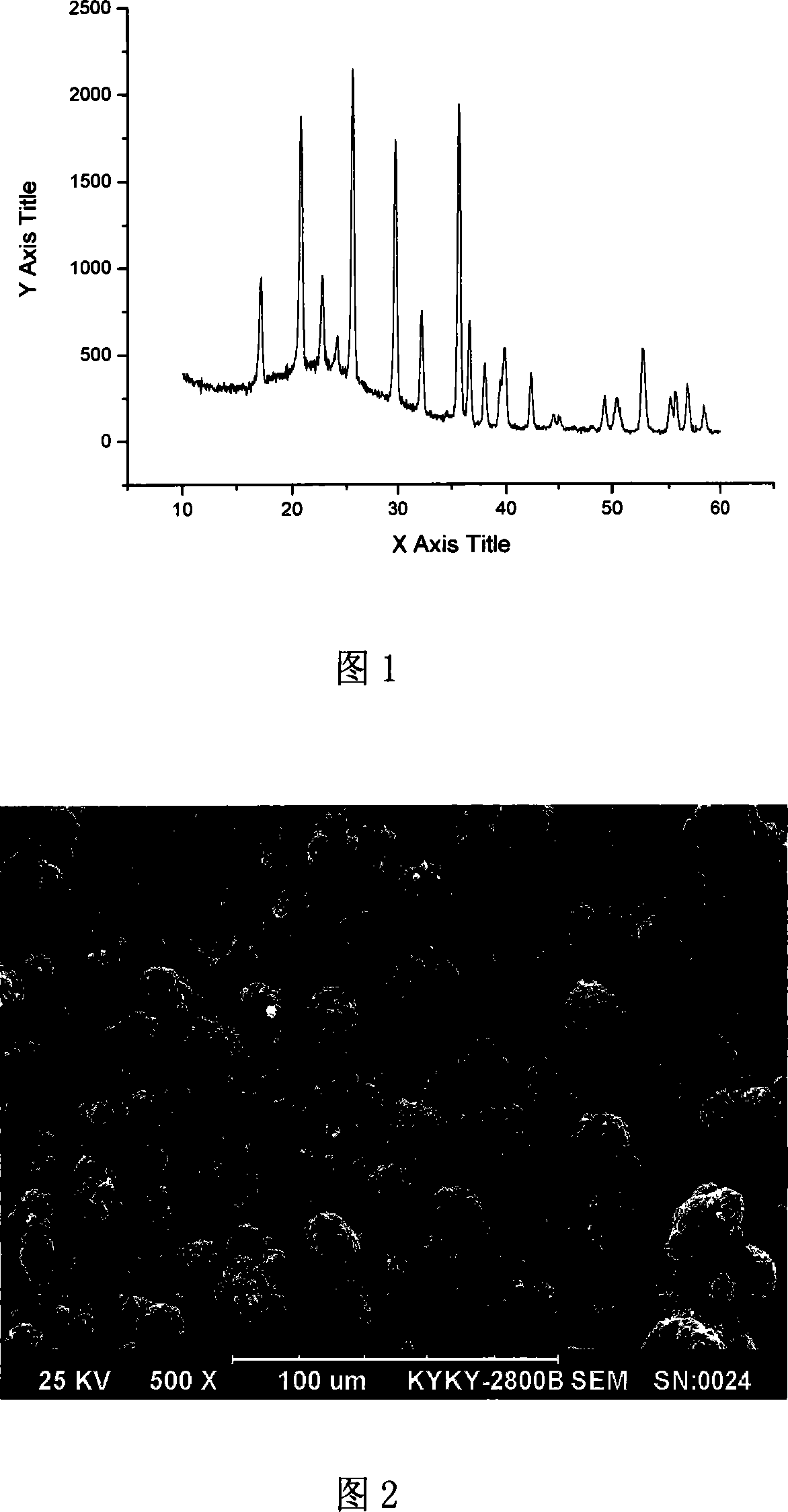

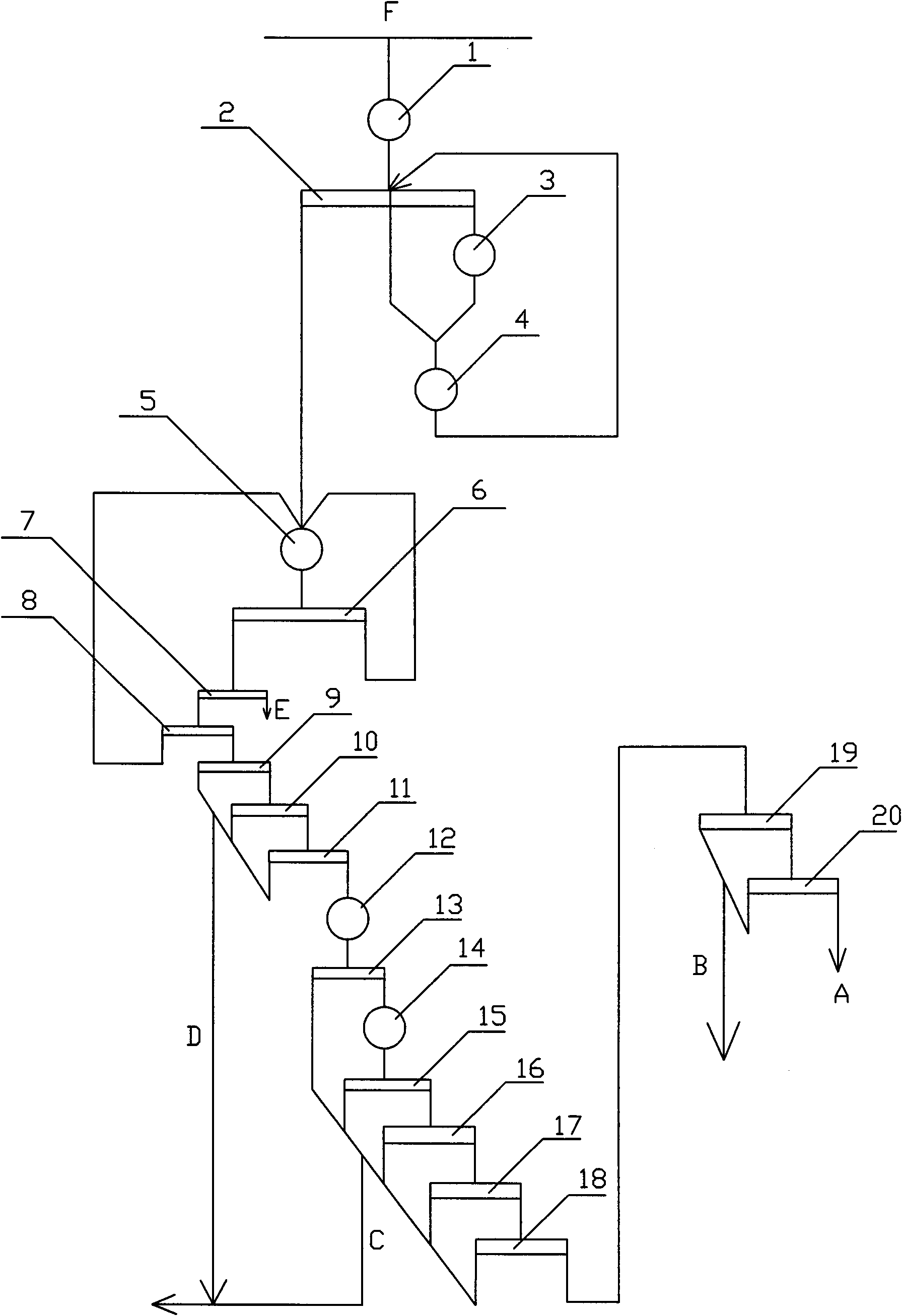

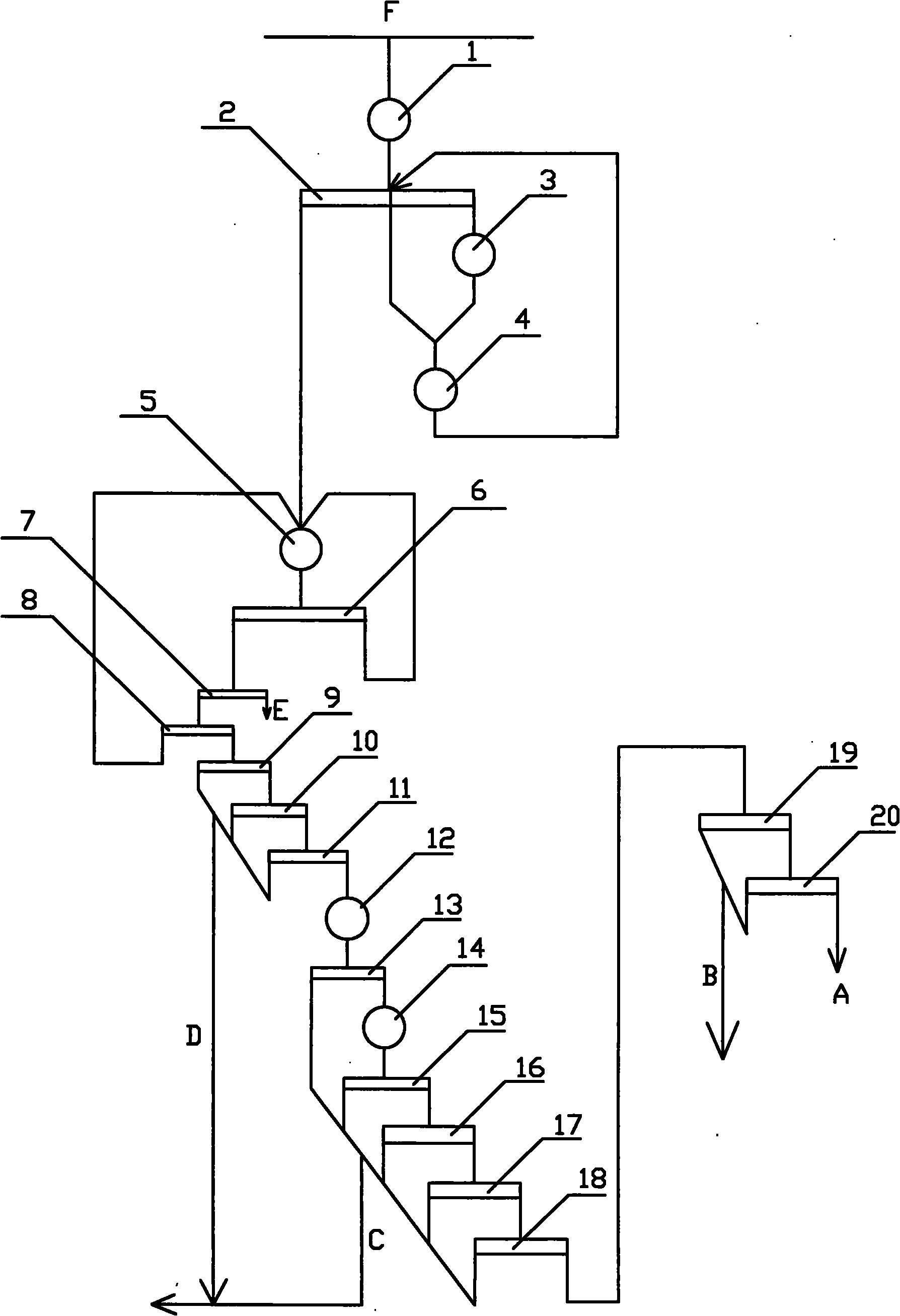

Bidirectional tosh grinding ultra-fine crashing objects and its method

InactiveCN101161347AReduce surface activityReduce the temperatureGrain treatmentsVacuum pumpingMass ratio

The present invention discloses a bidirectional-rotating ball-milling ultra-fine crushing device and the method thereof. The device is arranged with a jacket which is provided with cooling water; a closed material storing warehouse which closes the feeding / discharging material opening is arranged at the lower end of the barrel body; a vacuum pumping valve which is connected with the vacuum pumping device is arranged at random feeding / discharging cover plate on the barrel body; and an inner lining is arranged at the inner surface of the barrel body. The bidirectional-rotating ball-milling ultra-fine crushing method is doing vacuum pumping to the inner side of the barrel body and actuating the transmission device to do ultra-fine crushing when the raw material above 80 mu is added into the barrel body, wherein the rotary speed of the barrel is 40 to 70 rotation / minute and the rotary speed of the inner rotating axle is 20 to 40 rotation / minute; the mass of the grinding ball gradation phi between 5 to 10mm accounts for 35% to 55% of the total grinding ball mass, phi between 10 to 20mm accounts for 25% to 35% of the total grinding ball mass and the phi between 20 to 30mm accounts for 20% to 35% of the total grinding ball mass; and the mass ratio of the material ball is 1:4 to 1:15. The invention has the advantages of short producing time, low energy consumption and reduced producing cost, and the invention overcomes the fine particle problems of easy aggregation to block and fusing-aggregation, etc.

Owner:NANJING UNIV OF SCI & TECH

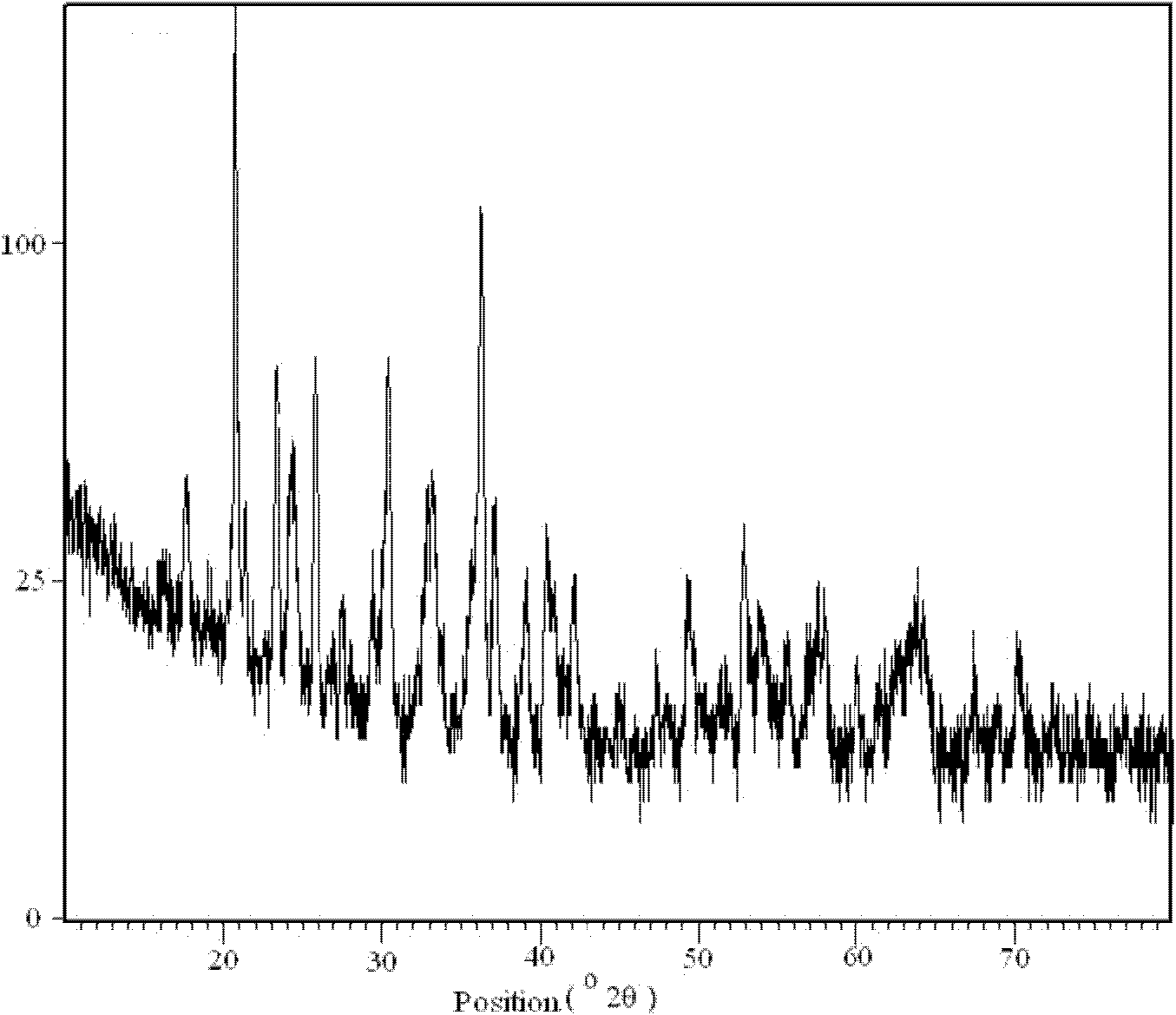

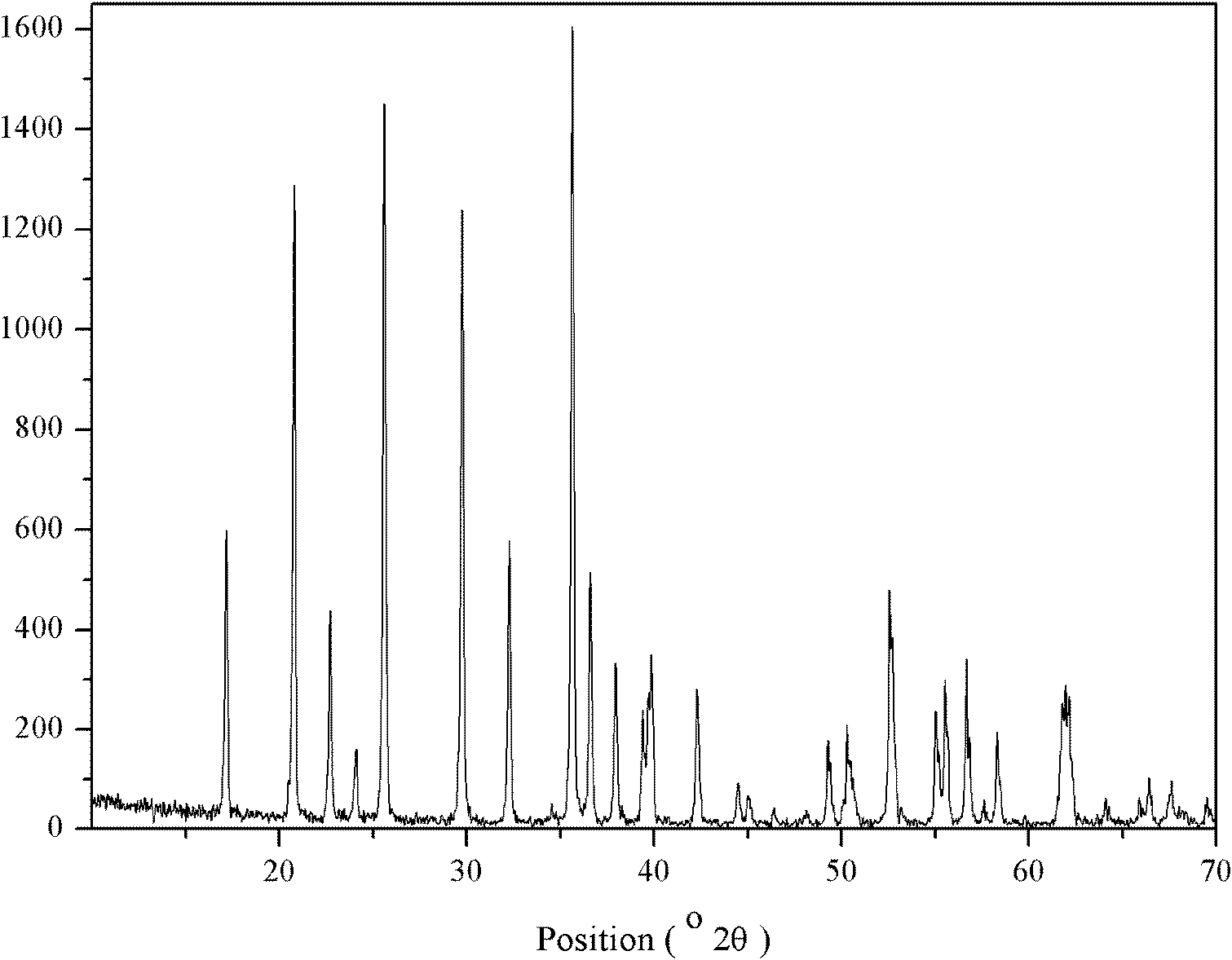

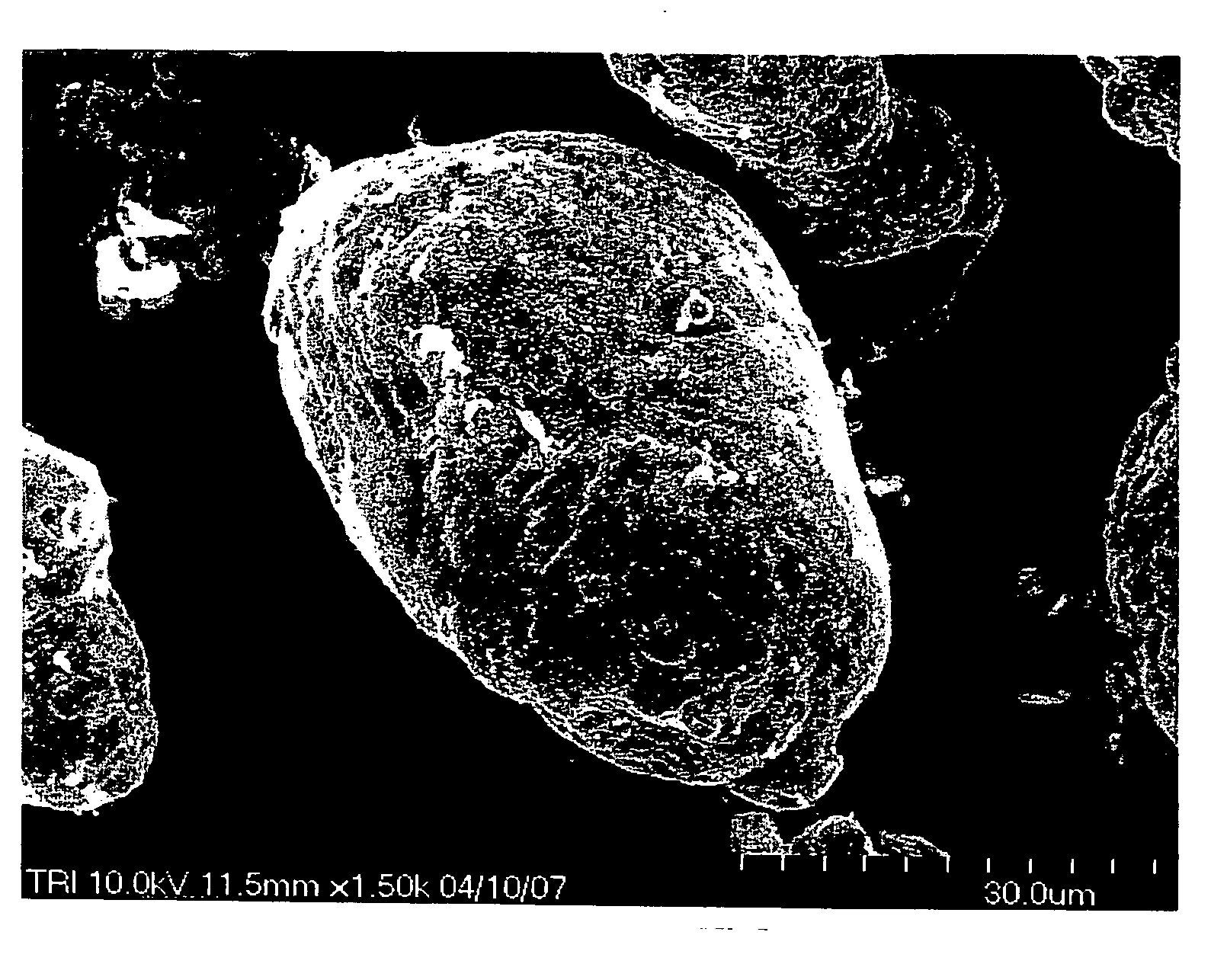

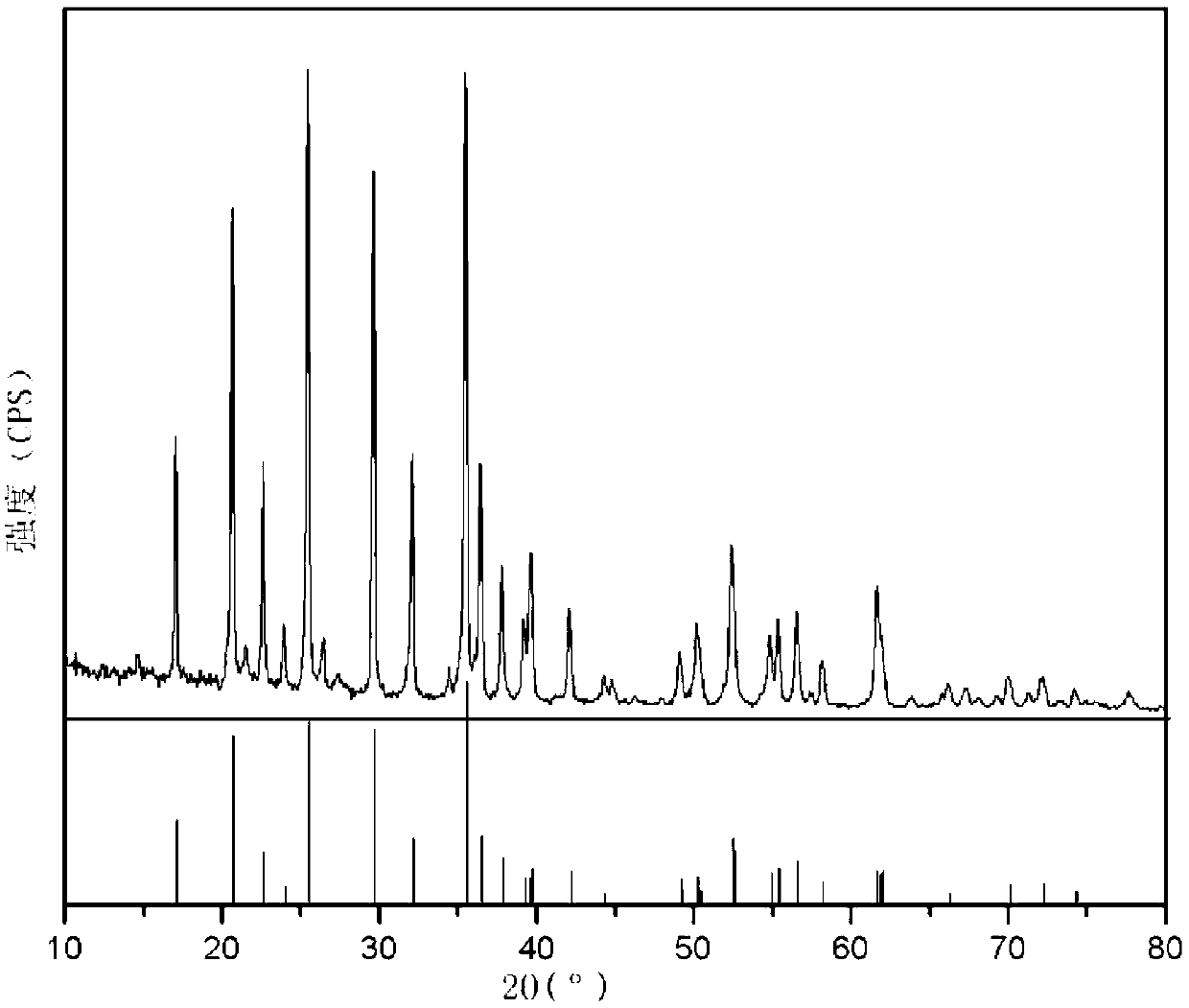

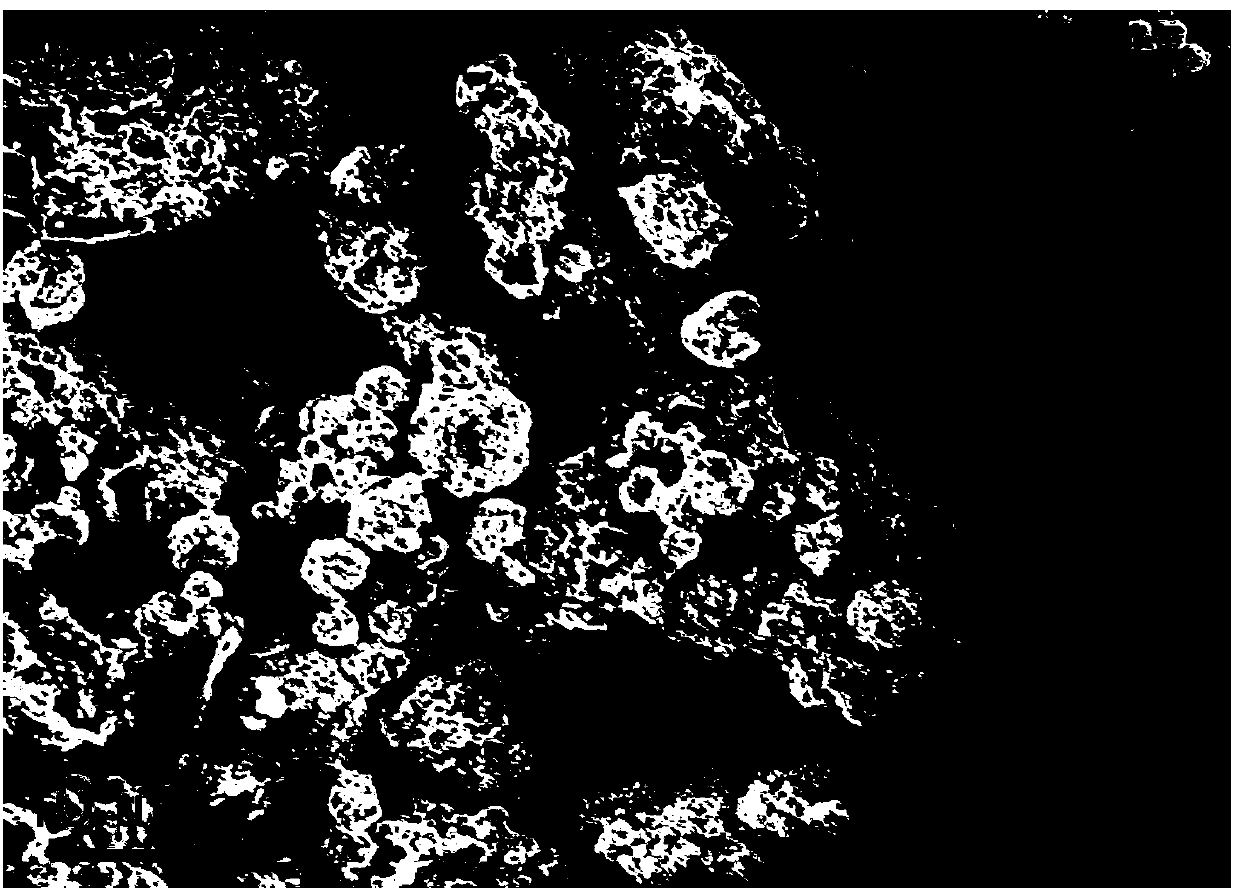

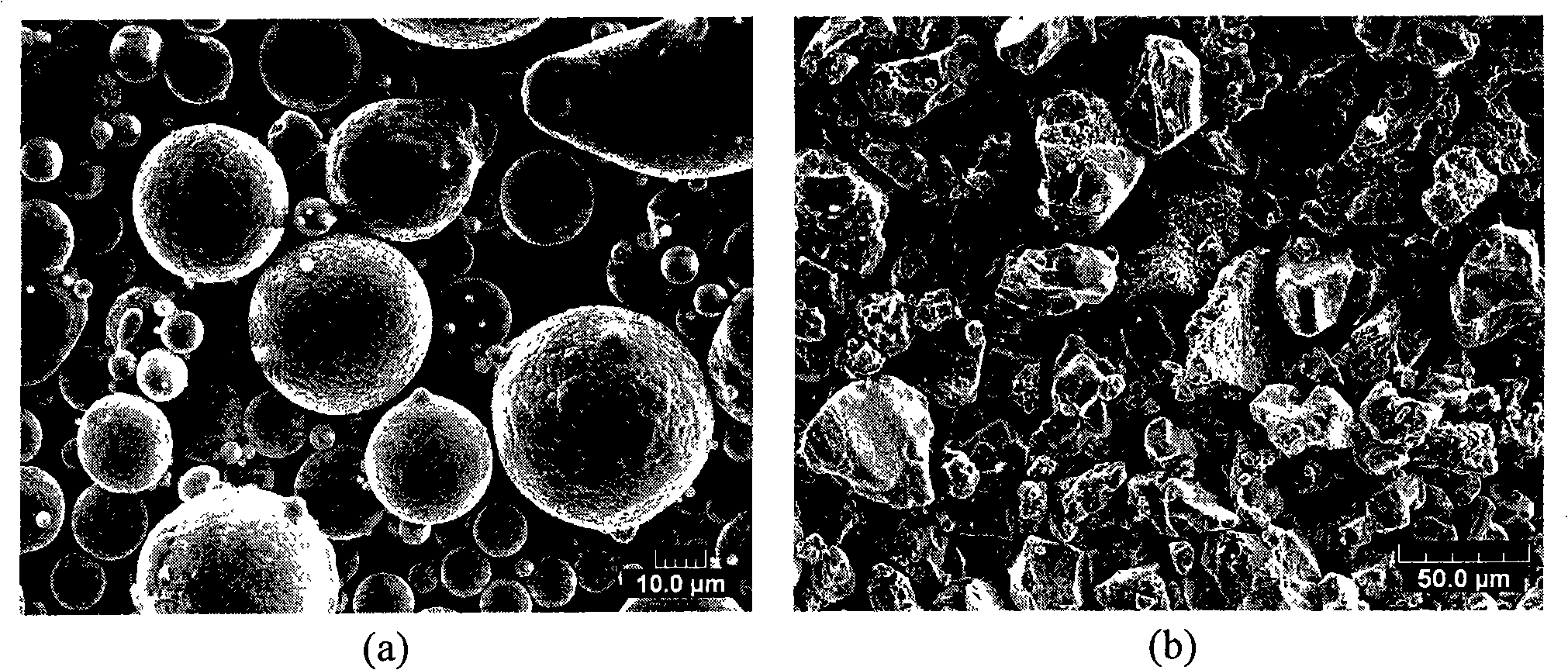

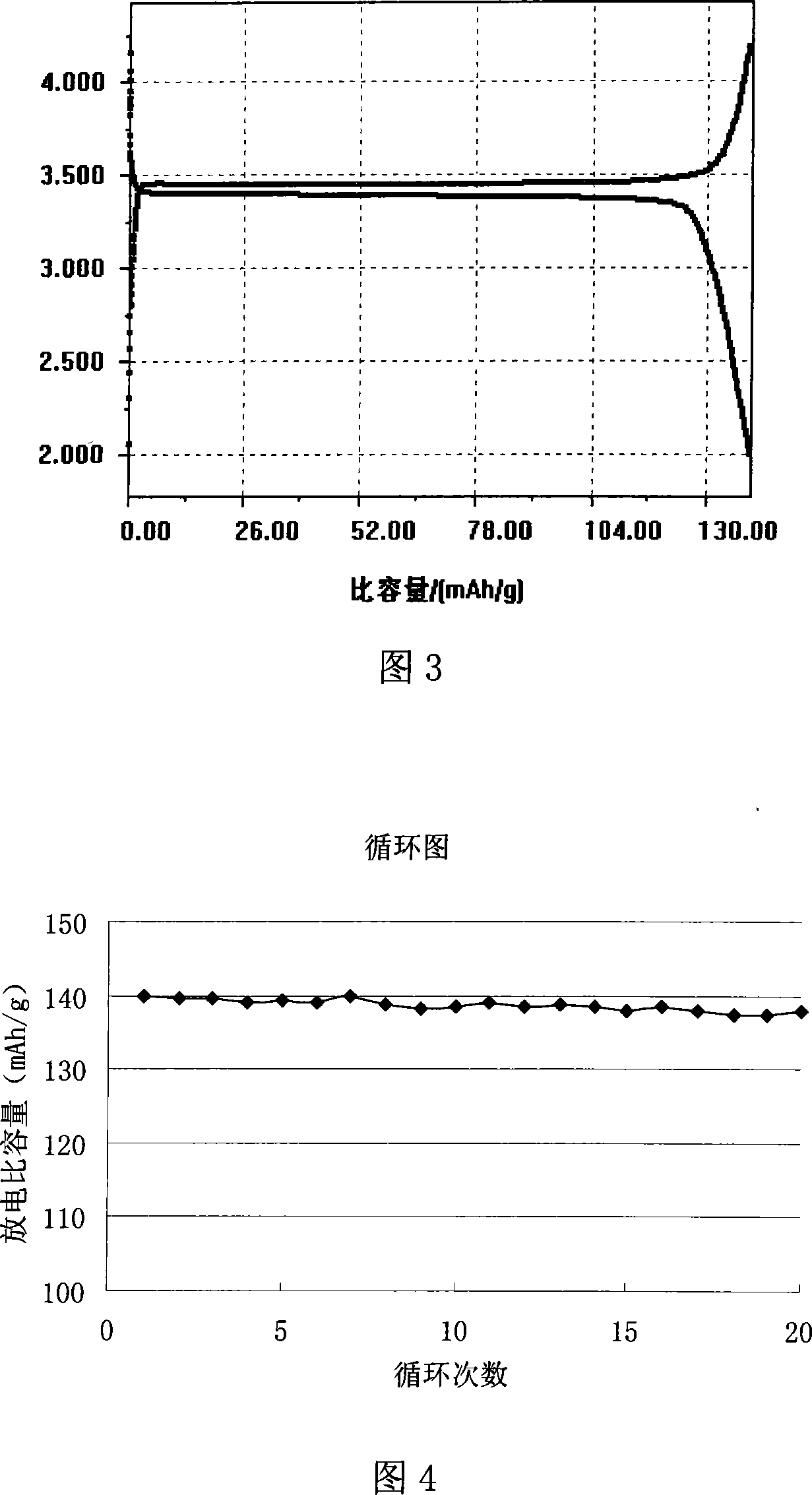

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

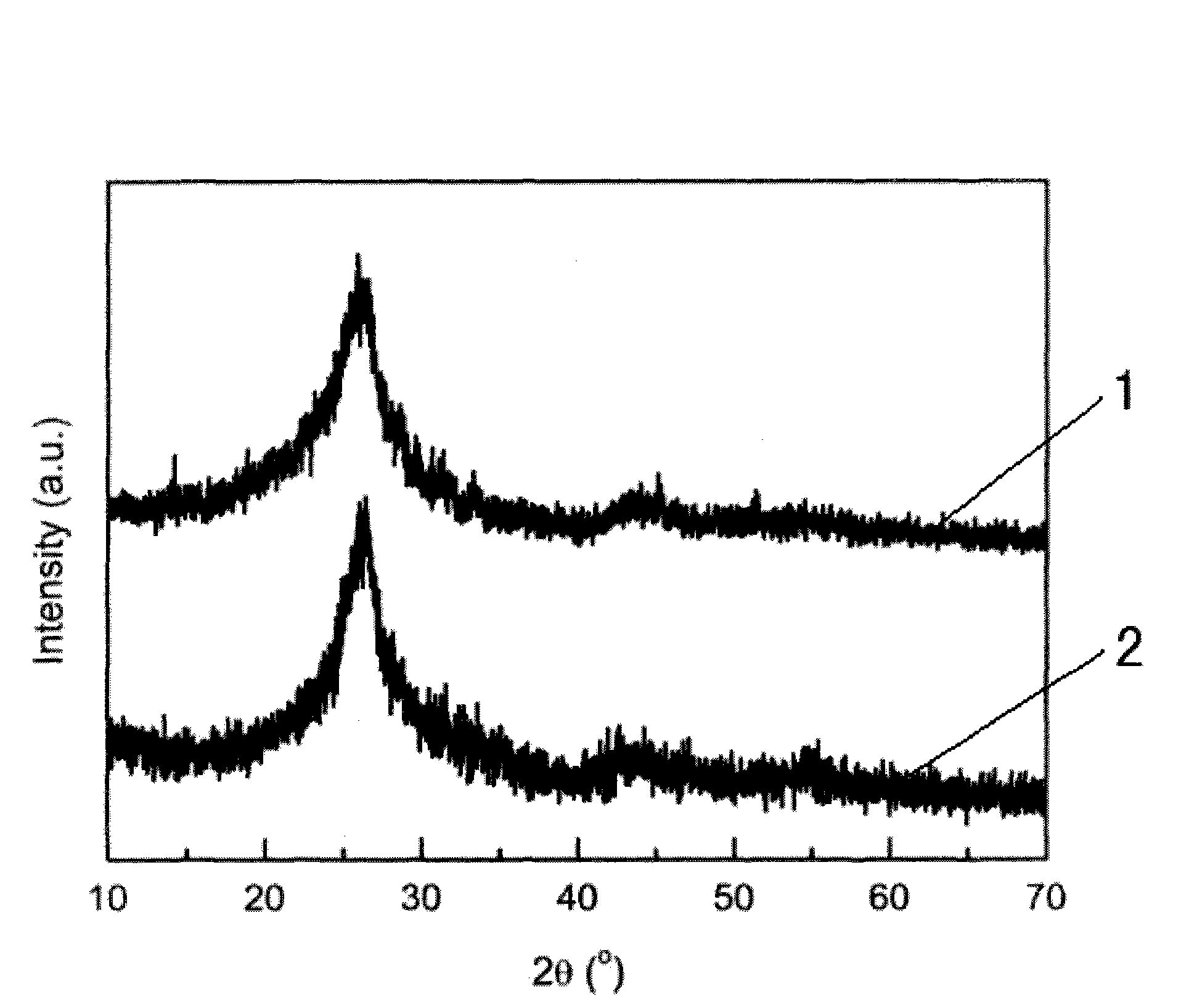

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

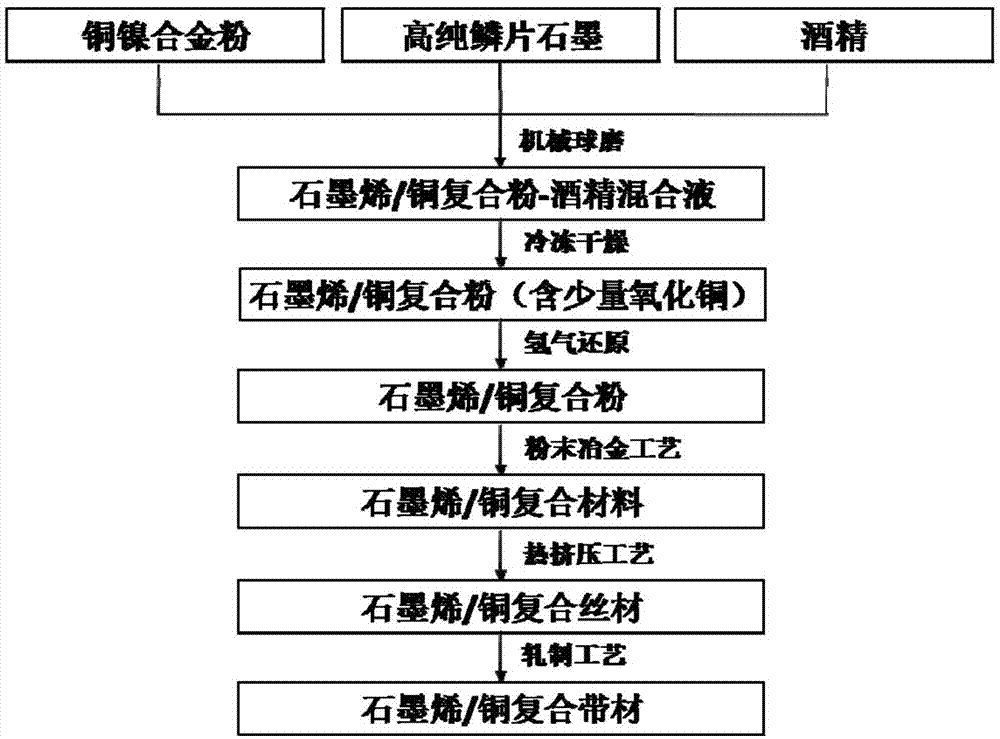

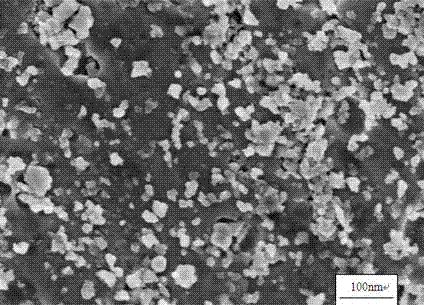

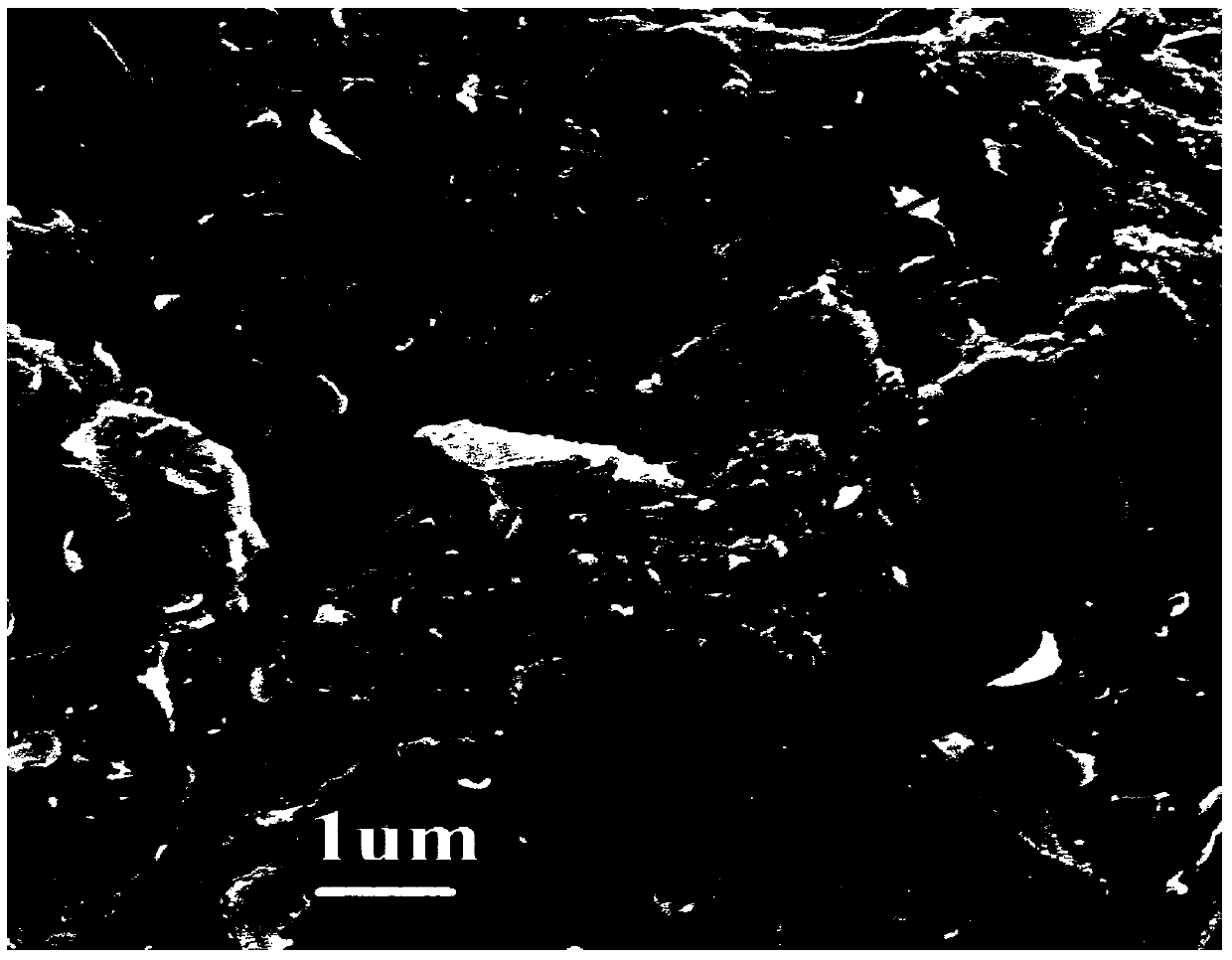

Graphene/copper composite and preparation method thereof

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

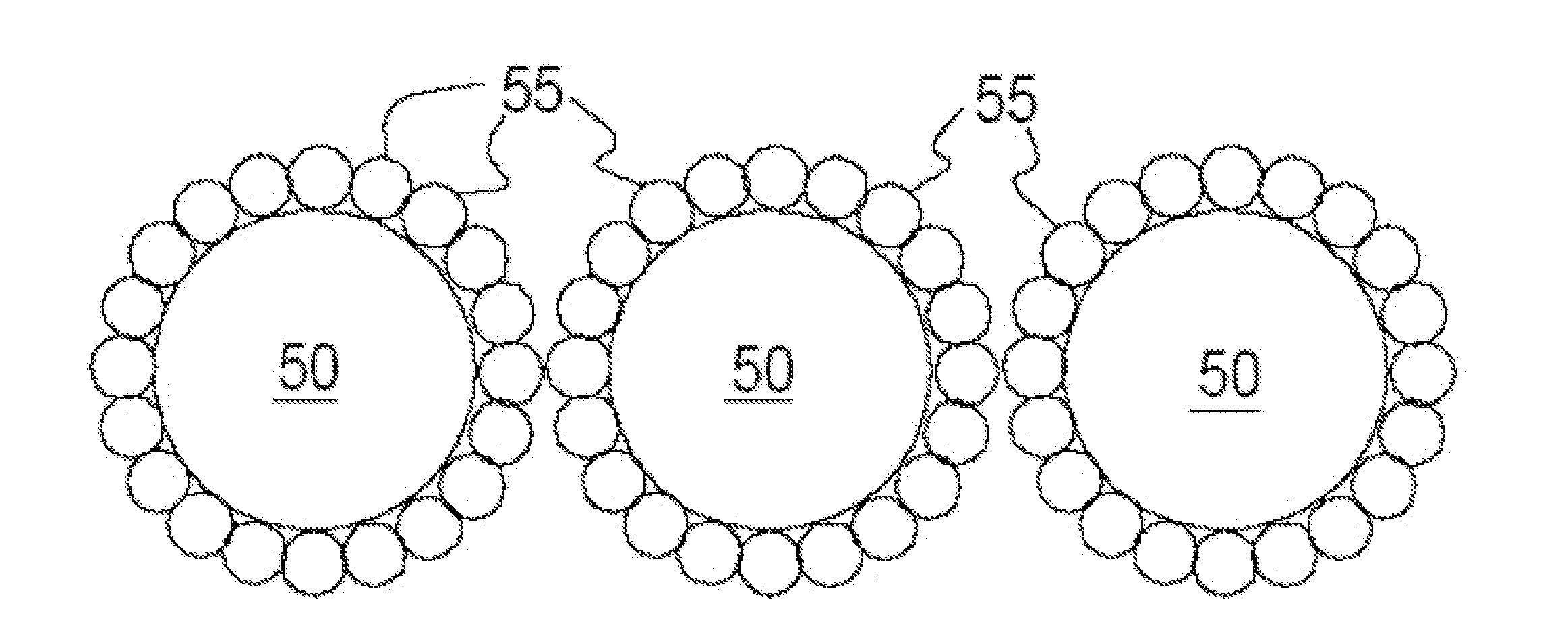

Composite particles and method for production thereof and use thereof

InactiveUS20060116279A1Improve photocatalytic activityImprove efficiencyPigmenting treatmentMaterial nanotechnologyFiberUltraviolet

A composite particle comprised of a larger particle and, supported thereon, smaller particles wherein the smaller particles are photocatalyst-containing fine particles with an average particle diameter of 0.005-0.5 μm as calculated from a BET specific surface area, and the larger particle has an average particle diameter of 2-200 μm as measured by the laser diffraction-scattering particle size measuring method. The smaller particle is preferably a composite particle of titanium dioxide with an inorganic compound exhibiting no catalytic activity, such as silica, or a particle containing a Brφonsted acid salt, especially on the surface thereof; and an advantageous method for producing the above composite particles wherein the above larger particles and smaller particles are dry mixed by a ball-mill or mixed by rotation of blades or by shaking, with an energy constant controlled within a specific range. A composition comprising an organic polymer and the above composite particles can give a shaped article, such as fiber, film or a molding, exhibiting ultraviolet ray-screening function.

Owner:SHOWA DENKO KK

Preparation method of nano silicon carbide reinforced aluminum-based composite material

InactiveCN103045914AAvoid reunionEvenly distributedIncreasing energy efficiencyNano siliconHigh energy

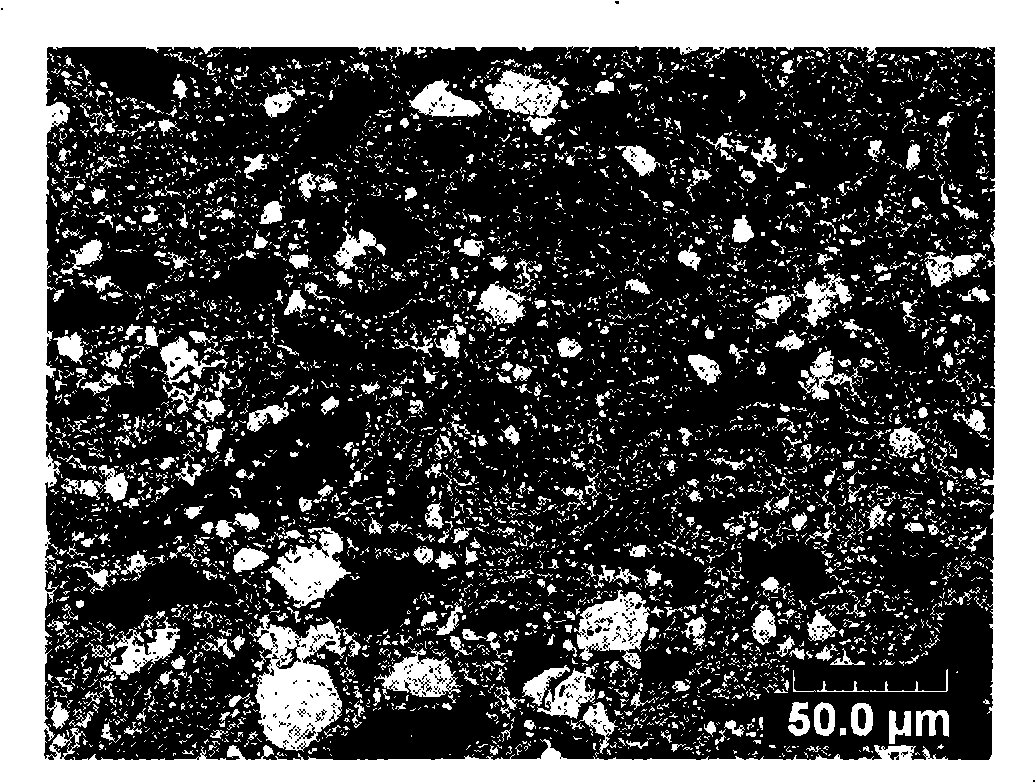

The invention discloses a preparation method of laser forming nano particle reinforced aluminum-based composite material, belonging to the technical field of particle reinforced aluminum-based composite materials. The method comprises the steps of: (1) selecting SiC powder with purity of more than 99.9% and granularity of 40-60 nanometers, and AlSi10Mg powder with purity of more than 99.9% and granularity of 15-30 micrometers; (2) mixing the powders, wherein the weight of the SiC powder is 3%-10% of the total weight of the mixed powder; (3) putting the mixed powder into a planetary high-energy ball mill for milling; (4) taking the milled powder for SLM forming; and (5) repeating the step (4) until a three-dimensional block sample is completed. According to the method provided by the invention, the aluminum-based composite material with uniform microscopic structures can be prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

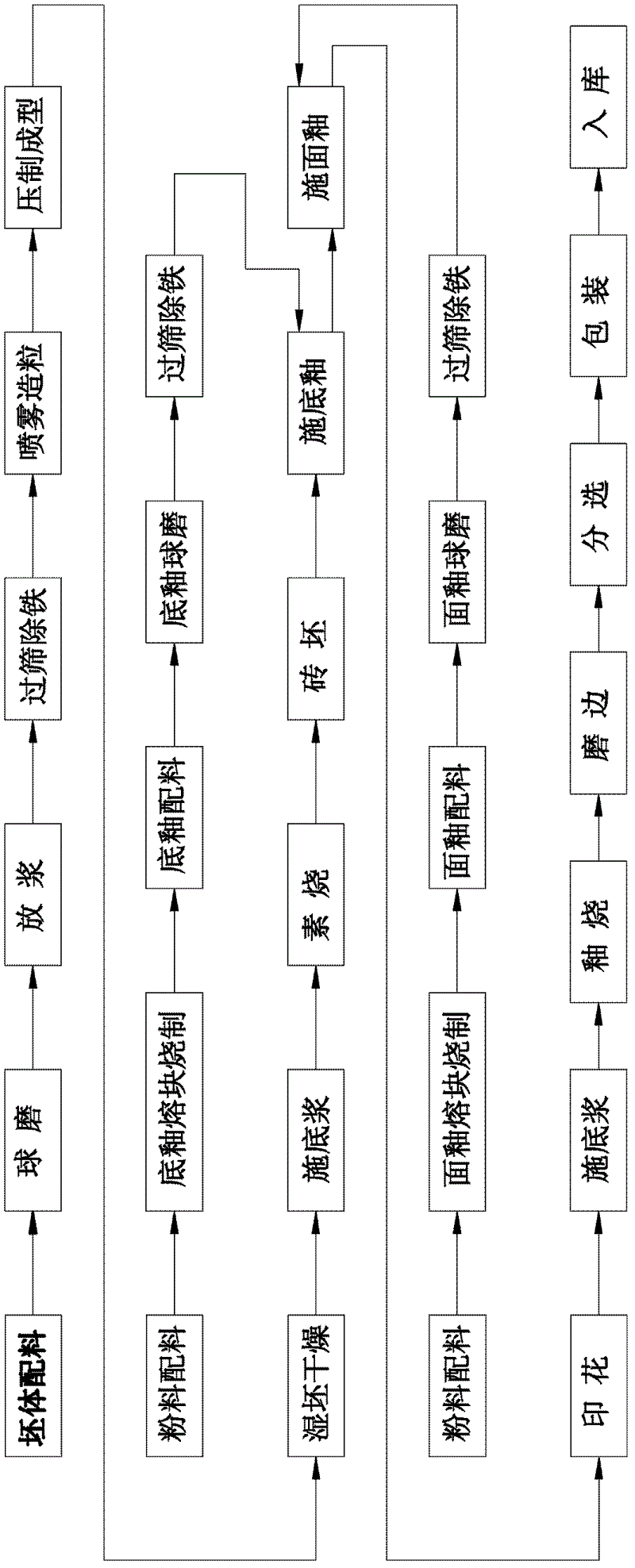

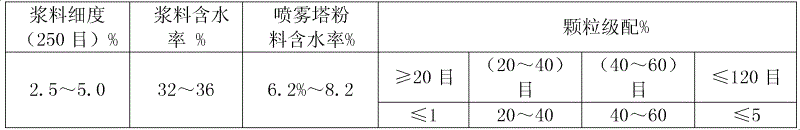

Formula and method for manufacturing ceramic tile blank bodies and glazed tiles by utilizing polished waste residues

The invention discloses a formula and a method for manufacturing ceramic tile blank bodies by utilizing polished waste residues. The formula adopts ingredients by weight portions: porcelain clays account for 18 to 40 parts, clays account for 20 to 30 parts, limestone grains account for 1 to 10 parts, wollastonite grains account for 3 to 15 parts, glazed tile sludge residues account for 3 to 10 parts, ceramic polished waste residues account for 15 to 45 parts, soluble glass accounts for 1 to 2 parts, thinners account for 0.15 to 0.4 parts, sodium tripolyphosphate accounts for 0.05 to 0.2 parts, and a proper amount of water is adopted. A manufacturing method of the ceramic tile blank bodies comprises the steps as follows: a. raw materials are put in a ball grinder for ball milling after being blended so as to form sizing agents with proper fineness and screen tailings through milling, and the sizing agents are processed through deferrization, sieving and spray drying so as to form powders; and b. the powders are put in a die cavity of a press forming machine to form waterish blanks through pressing, the waterish blanks are dried in a drying kiln, the dried waterish blanks are applied with base pulp and then enter a biscuit firing kiln, biscuit firing is carried out under the temperature ranging from 1080 to 1160 DEG C, heat preservation is carried out in an area with the temperature ranging from 1040 to 1060 DEG C, the sintering time of the area is prolonged, and the sintering process for oxidizing atmosphere can be enhanced at the same time so as to obtain the ceramic tile blank bodies.

Owner:GUANGDONG WINTO CERAMICS +1

Method for improving performance of sintered Nd-Fe-B permanent magnetic material

ActiveCN101615459AEvenly distributed and orderlySolve bad problems such as α-Fe segregationInorganic material magnetismHigh energyPositive pressure

The invention relates to a method for improving performance of sintered Nd-Fe-B permanent magnetic property by a rapid-hardening flake grain boundary diffusion heavy rare earth compound in rare earth material technical field, which comprises the following steps: 1) rapid-hardening technology is adopted to prepare an Nd-Fe-B alloy rapid-hardening flake; 2) a high-energy ball mill is used to prepare the heavy rare earth compound into powder particles with diameter being smaller than 1mu m; 3) the rapid-hardening flake is put into heavy rare earth compound turbid liquid to carry out ultrasonic coating; 4) the coated rapid-hardening flake is put into a sintered furnace filled with Ar2 to carry out positive pressure thermal diffusion; 5) ball milling, powder processing, orientation shaping, isostatic pressing and vacuum sintering are adopted to prepare the strip-casting flake after the heat treatment into a magnet. The chemical formula of the Nd-Fe-B permanent magnetic material is NdxFe(100-x-y-z-xl)ByCozCuxl, and the mass percent is as follows: x is 30-31.5, y is 0.95-1, z is 1-1.2, and xl is 0-0.06. The magnet prepared by the invention improves the intrinsic coercivity on the basis of keeping the current magnetic energy product.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

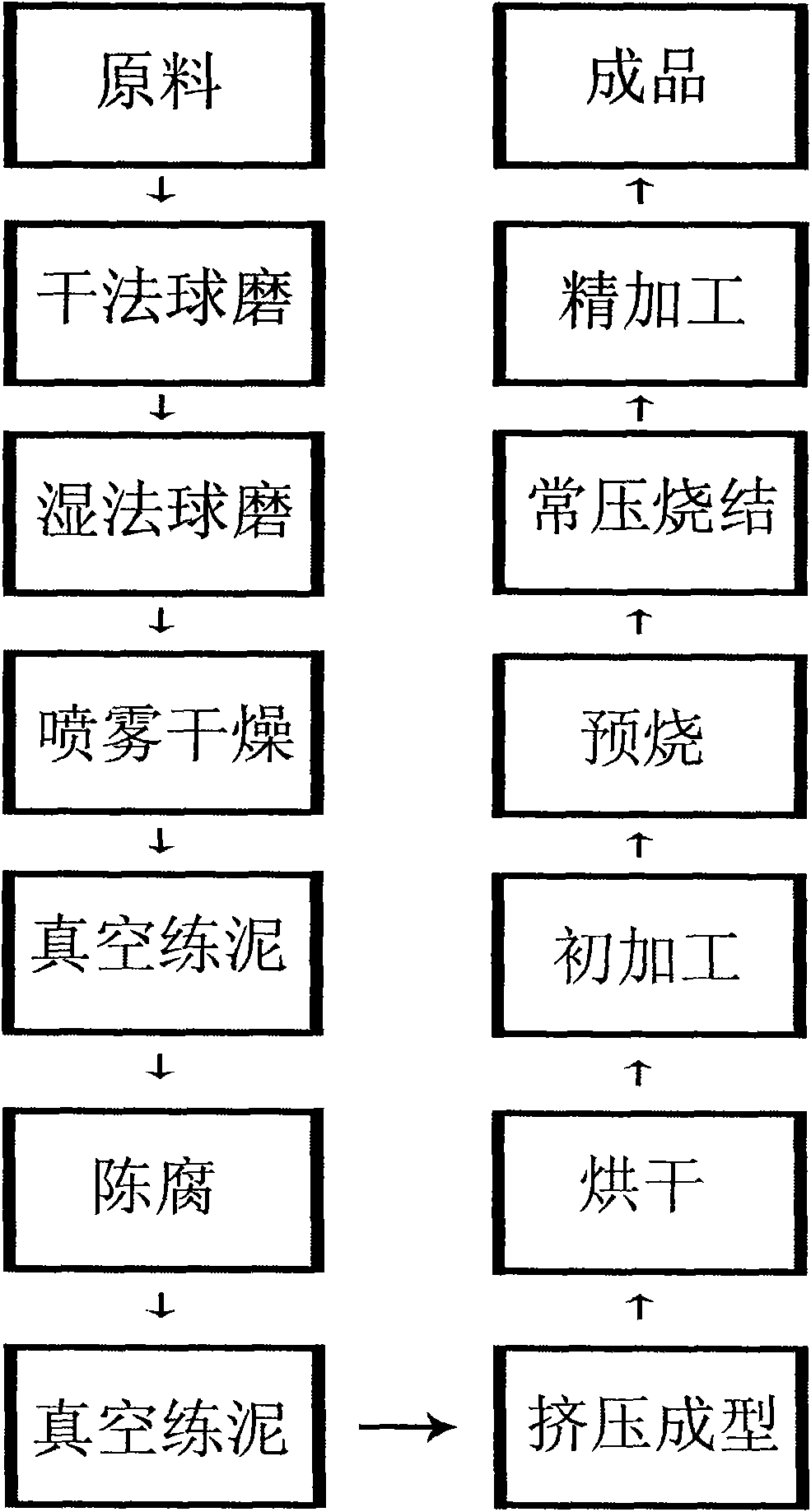

Preparation method for silicon carbide ceramic tube or rod

ActiveCN101560104AEvenly dispersedUniform moisture contentCeramic shaping apparatusClay processing apparatusShielding gasSlurry

The invention relates to a preparation method for a silicon carbide ceramic tube or rod. An extrusion moulding method is adopted to form a blank body; a normal pressure sintering method is adopted for sintering; and submicron level silicon carbide powder and additives are taken as main raw materials. The preparation method comprises the following steps: 1) carrying out ball milling on the main raw materials by a dry method, adding water, a dispersant, a plasticizer, a lubricant and a liquid state binder, and then carrying out ball milling by a wet method; 2) adopting a spray granulation process to granulate silicon carbide slurry; 3) extruding the blank body by a one-shot direct extrusion moulding method after vacuum pug, corrosion, and vacuum pug; 4) drying the molded blank body by a stage drying mechanism; and 5) placing the blank body of the silicon carbide ceramic tube or rod in a vacuum furnace and carrying out sintering for two times by taking argon gas as protective gas. The high temperature resisting strength and the corrosion resistance of the silicon carbide ceramic tube or rod prepared by the method are both better than those of a reactive sintered product. Compared with a hot press sintering method, the method has lower limit on the product shape and size, and lower cost. The method is suitable for the industrialized production.

Owner:宁波欧翔精细陶瓷技术有限公司

Method of producing uniform blends of NANO and micron powders

InactiveUS20100124514A1Reduces, or eliminates, the non homogeneity in distribution of the nano powderPromotes even distributionTransportation and packagingMetal-working apparatusRoom temperatureBall mill

A method of uniformly dispersing a nano powder throughout a micron powder. Ordinary mixing or agitation does not succeed in attaining uniform dispersal: the nano powder agglomerates into microscopic masses. In one form of the invention, a charge of a micron powder, with fifty weight percent of charge of nanopowder is loaded into a ball mill. The mixture is ball milled for less than two hours, at room temperature in a dry condition, and produces a highly uniform distribution of the nano powder throughout the micron powder.

Owner:IAP RES

Beneficiation method for removing long quarry impurities by adopting strong magnetic flotation

InactiveCN101898168AIncrease production capacityImprove grinding efficiencyFlotationMagnetic separationEngineeringBall mill

The invention relates to a beneficiation method for removing long quarry impurities by adopting strong magnetic flotation, comprising the steps of crushing, grinding, sieving, desliming, strong magnetically floating, floating, concentrating and dewatering. The concrete beneficiation method comprises the following steps of: breaking and grinding ore in a ball mill; grading ground minerals by a spiral grader and a hydraulic hydrocyclone twice; combining with the ball mill into a closed cycle; respectively mounting high-frequency linear vibration sieves in overflows graded twice; respectively removing impurities over 3 mm and 1 mm, such as mica, grass-roots bark, and the like; removing most of muddy substances from minerals through desliming equipment after the impurities are removed; removing mechanical iron, weakly magnetic iron ore, tourmaline and partial mica in a strong magnetic flotation machine; floating the minerals passing through the strong magnetic flotation machine again to remove residual iron minerals, mica and black minerals; and finally, concentrating and dewatering the minerals to form a product.

Owner:衡阳县湘雁矿业有限公司

Method of producing graphene

The invention relates to a method of producing grapheme, which is characterized by comprising the following steps: (1) mixing the raw material of graphite powder with organic solvent according to theconcentration of 1-100 mg / ml to form suspension, and adding grinding balls to the suspension; (2) grinding and dispensing the suspension by a ball-grinding machine for 0.5-6.0h, and taking out slurry;(3) carrying out ultrasonic processing to the slurry for 0.5-6.0h; (4) separating the slurry centrifugally at high speed to obtain the upper solution which is the mixed colloid of monolayer graphemeand multilayer grapheme; and (5) concentrating, separating and replacing the solvent of the mixed colloid of the monolayer grapheme and the multilayer grapheme to obtain grapheme powder and stable grapheme colloid. The invention can consecutively produce the high-conductivity high-thermal conductivity grapheme which is dispersive and stable on a large scale with lost cost by using noncorrosive poisonous flammable and combustible raw materials without discharging waste water and waste gas.

Owner:NANCHANG HANGKONG UNIVERSITY

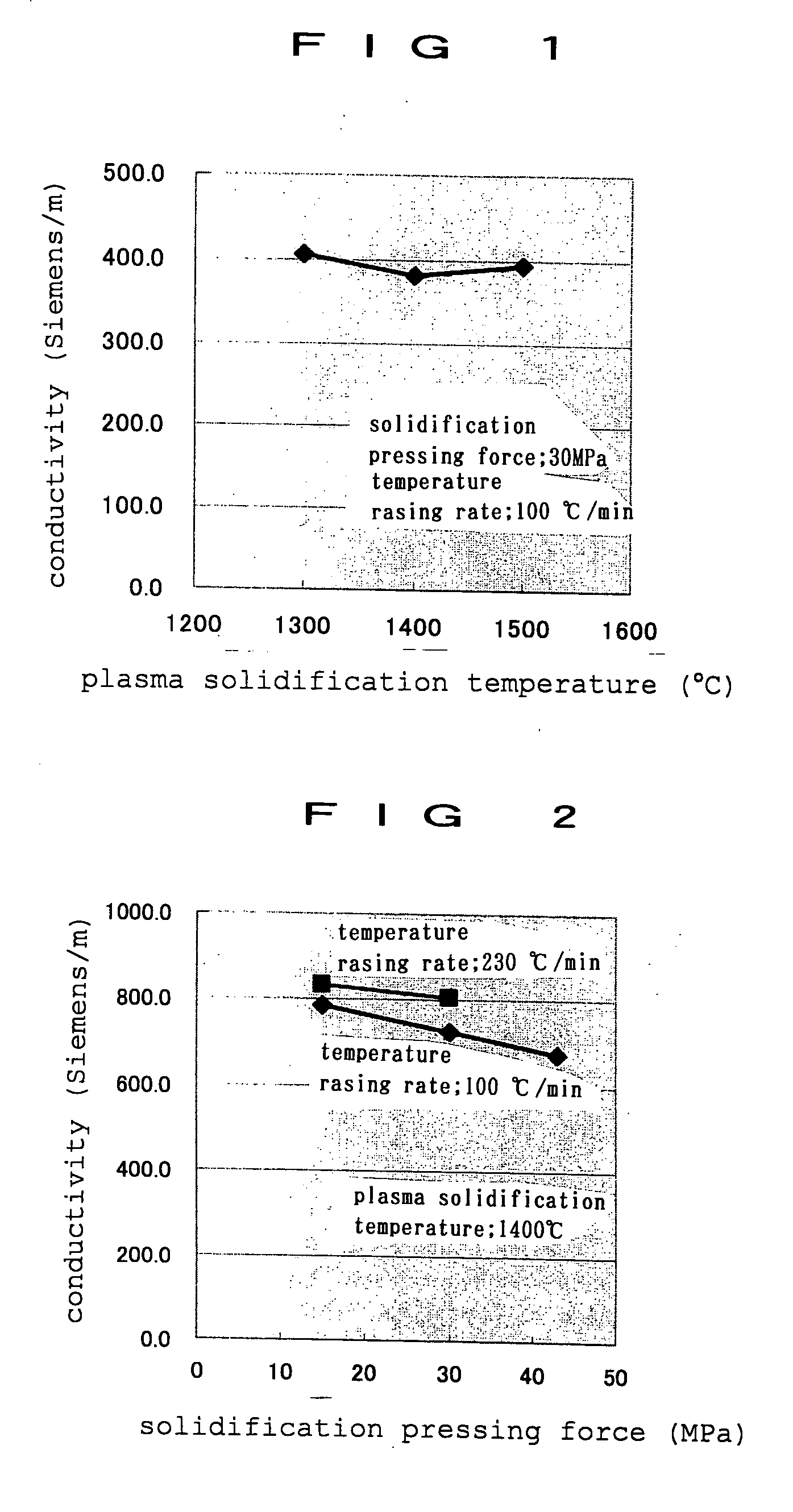

Process for preparing TiBw/Ti alloy-based composite material

Disclosed is a process for preparing a TiBw / Ti alloy-based composite material, which relates to a method for the preparation of a titanium alloy-based composite material. The invention provides the method for the preparation of the titanium alloy-based composite material, solving the problems of poor plasticity indexes, complex process and high cost when preparing the titanium alloy-based composite material in the prior art. The titanium alloy-based composite material is prepared according to the following steps of: firstly, mechanical mixing: namely mechanically mixing a TiB2 powder and a titanium alloy powder in weight percent by a ball mill, with the powder mixing time of 4 to 12 hours; and secondly, hot-pressing sintering: the mixed composite powders are put into a vacuumized closed vessel for hot-pressing sintering, the temperature directly rises to 1100 to 1500DEG C from the room temperature by heating, the pressure is maintained at between 15 and 30MPa, the holding time is 0.5 to 5 hours, and the titanium alloy-based composite material can be obtained after cooling the mixture to the room temperature. A matrix used by the method is 180 to 300mu m large particle size titanium alloy powder, and costs are effectively reduced.

Owner:HARBIN INST OF TECH

Sand consolidation and water plugging profile control agent made by oil sand

InactiveCN101451061ATo achieve the goal of emission reductionEnhanced overall recoveryDrilling compositionSealing/packingSlagGranularity

The invention relates to a sand-consolidating and water-blocking profile modifying agent for oil sludge sand. The profile modifying agent is prepared by mixing the following raw materials: oil sludge sand, 10 to 90 portions of consolidation agent or adding modifier, a consolidation accelerant or a consolidation retardant; the oil sludge sand is subjected to ball milling through a ball mill; part of large crude oil is separated off so as to reach the requirement of granularity of the profile control agent; therefore, the oil sludge sand with granularity of less than 200 meshes is less than 70 percent of the total mass of the oil sludge sand; and the consolidation agent is selected from one or a mixture of one or more of cement or cement clinker, steel slag, slag, pulverized coal ash, gypsum, lime and magnesia. In application, the profile control agent is prepared to a 1 to 20 percent suspension solution; and the suspension solution is injected into a deep part of stratum of an oilfield through profile modification equipment. The profile modifying agent fully utilizes mass oil sludge sand produced in the production process of various oilfields, realizes the aim of emission reduction; and the oil sludge sand is recycled and is used as the sand-consolidating and water-blocking profile modifying agent, thereby achieving the aim of consolidating sand, blocking water and improving extraction yield.

Owner:SHANDONG UNIV

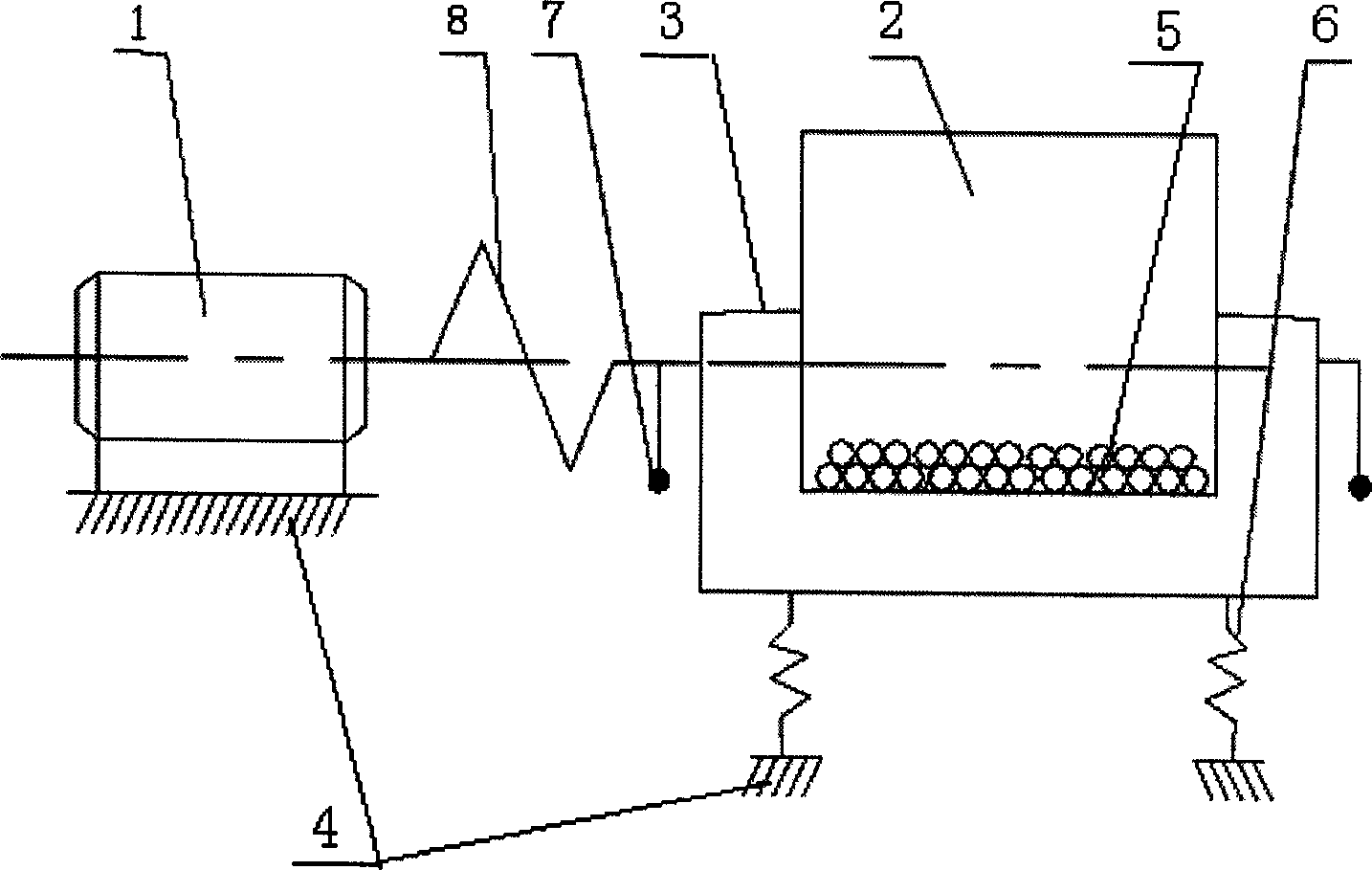

High energy ball mill method with plasma aid

A plasma aided high-energy ball grinding method includes such steps as installing the front cover plate and rod electrode of ball grinder, respectively connecting the ball grinder and rod electrode to the poles of plasma power supply, loading the powder to be ground in the ball grinder, pumping negative pressure, filling discharging gas medium, turning on the plasma power supply, regulating discharge parameters for corona discharge or glow discharge, and turning on the motor to drive the vibration exciting block for ball grinding.

Owner:SOUTH CHINA UNIV OF TECH

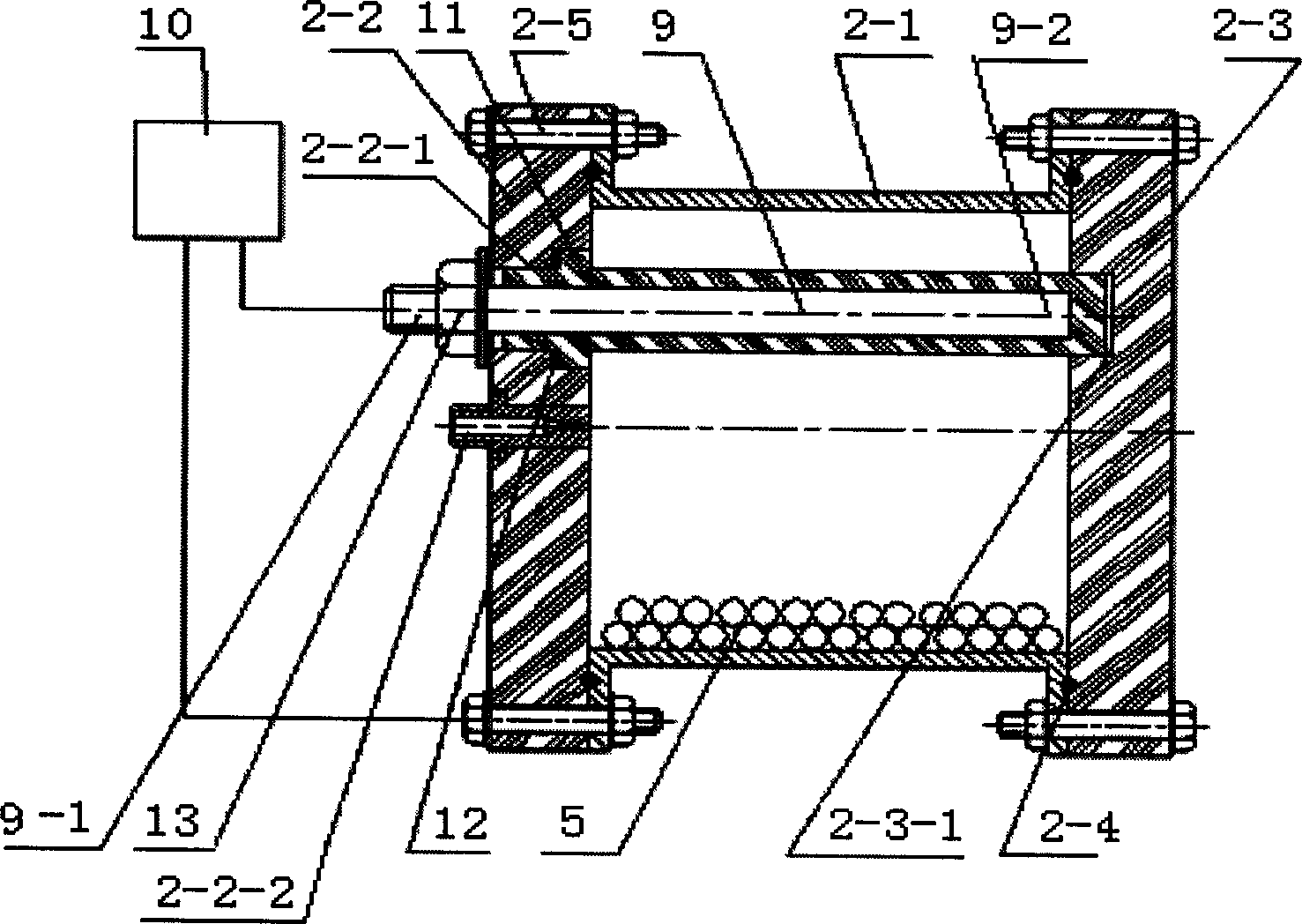

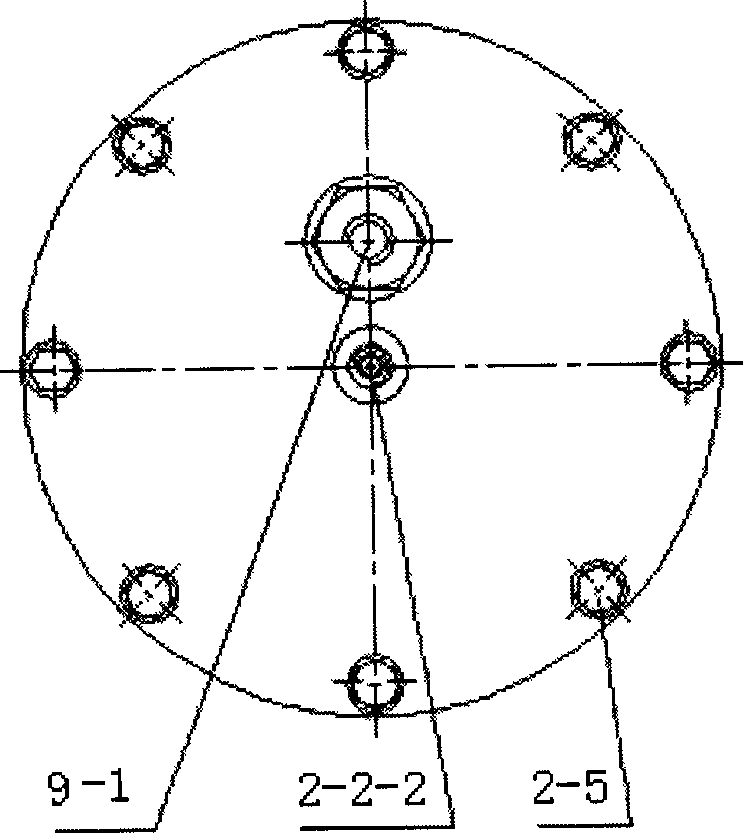

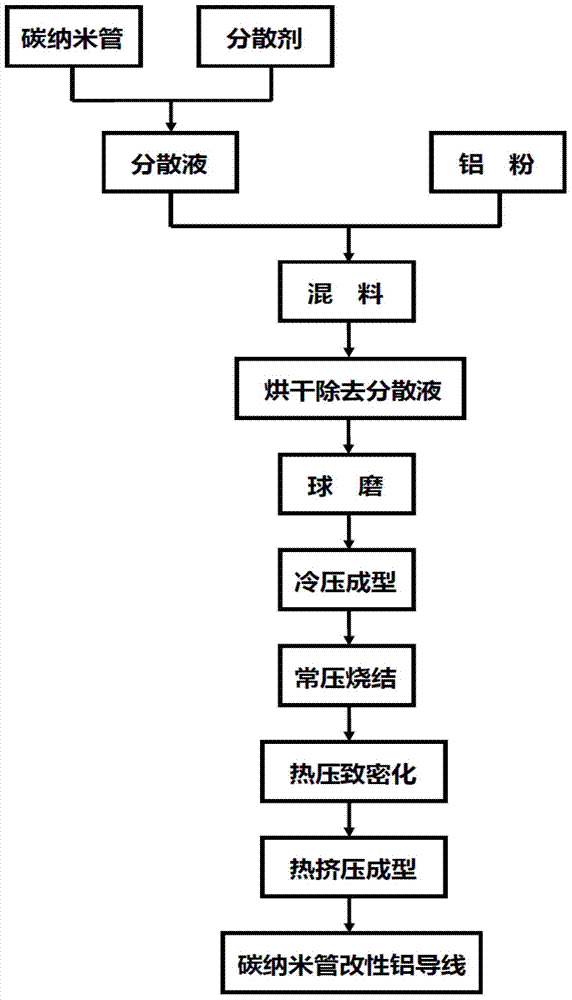

Preparation method of carbon nano tube-reinforced aluminum base composite material

ActiveCN103614672AAvoid the disadvantages of difficult sinteringWell mixedCarbon nanotubeWear resistance

The invention discloses a preparation method of a carbon nano tube-reinforced aluminum base composite material. The preparation method comprises the following steps: (1), uniformly dispersing carbon nano tubes into a dispersant which has chemical inertness on pure aluminum powder or aluminum alloy powder to obtain carbon nano tube dispersion liquid; (2), uniformly mixing the carbon nano tube dispersion liquid with the pure aluminum powder or the aluminum alloy powder, and drying to remove the dispersant to obtain a material mixture; (3), carrying out ball-milling onto the material mixture under protection of inert gases; and (4), carrying out cold pressing, normal-pressure sintering, hot-pressing and densifying under an atmospheric environment and hot-extrusion forming onto the ball-milled material mixture in sequence to obtain the carbon nano tube-reinforced aluminum base composite material. The preparation method disclosed by the invention further can reinforce the aluminum base body by utilizing co-action of base body processing and hardening, crystalline grain fining and reinforcing while bringing the excellent mechanical performances of the carbon nano tubes into play to reinforce the aluminum base body, so that tensile strength and wear resistance of the composite material are greatly improved; moreover, the carbon nano tube-reinforced aluminum base composite material with excellent performances can be industrially produced on a large scale.

Owner:STATE GRID CORP OF CHINA +3

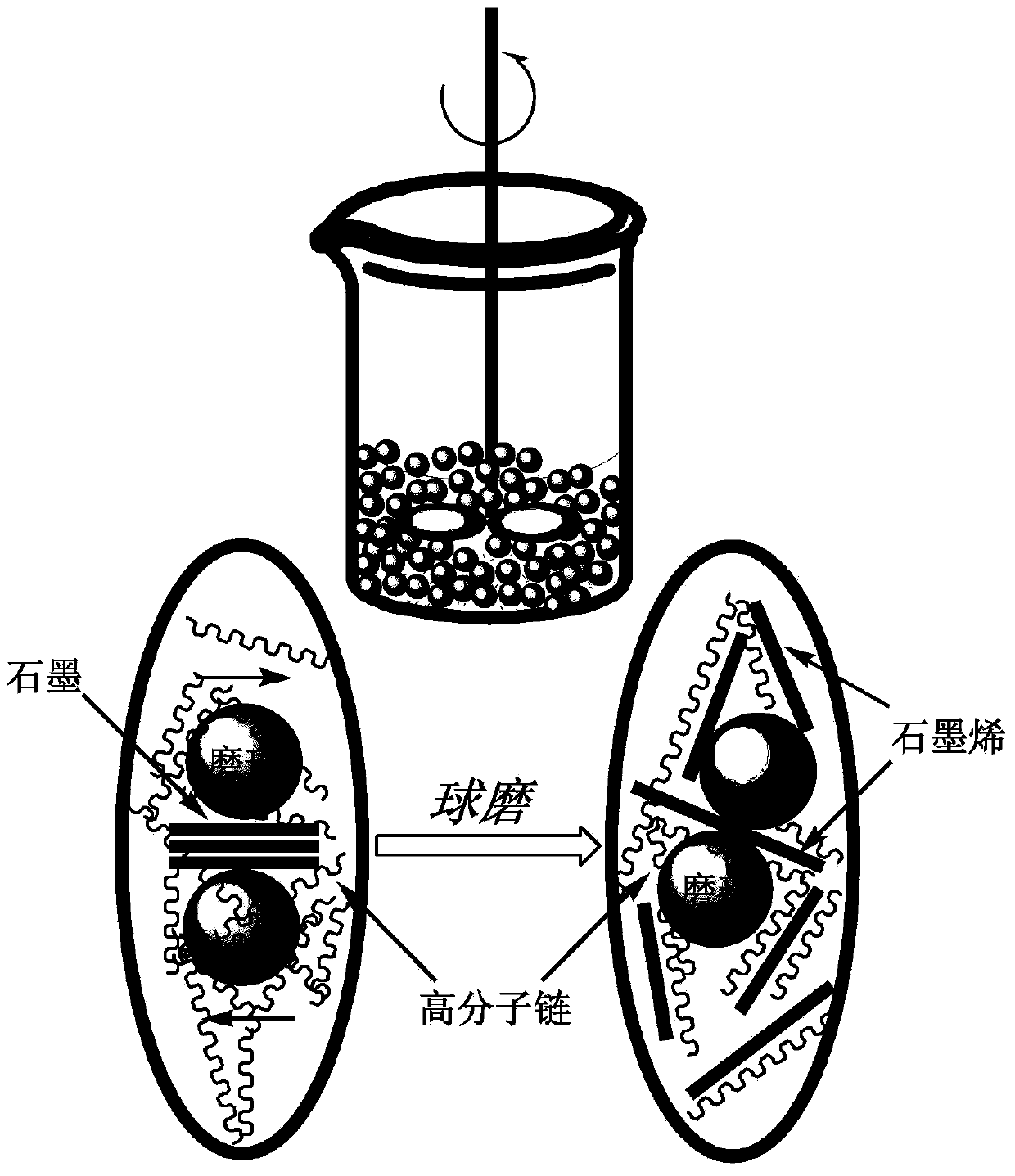

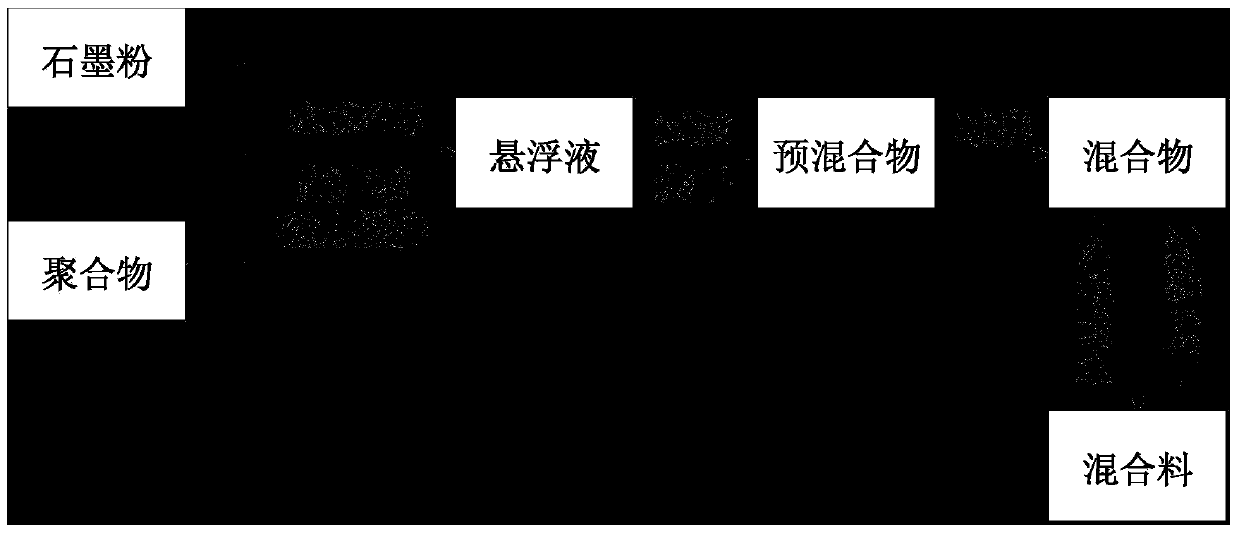

Preparation method for mixture of polymer and graphene

The invention discloses a preparation method for a mixture of a polymer and graphene. The advantage that graphite powder and the polymer are both granular powder is utilized, a graphite layer is stripped in situ according to a dry ball milling method, and the mixture of polymer and grapheme is prepared. The preparation method particularly comprises the following steps: (1) premixing the graphite powder and the polymer; (2) conducting ball milling and stripping on the pre-mixture fully in a ball mill to prepare the mixture of the graphite powder and the polymer. The preparation method adopts the dry ball milling method, so problems in solvent recovery and pollution caused by methods of solution mixing, in situ polymerization, wet ball milling, and the like are avoided; meanwhile, the defect of uneven dispersion of the graphene during fusing and dispersing process is overcome, the technological operation is simplified, and promotion and use are facilitated; the mixture of the polymer and the graphene is suitable for polymer processing methods of extrusion, injection molding, mould pressing, blow molding, curtain coating, and the like.

Owner:HUAQIAO UNIVERSITY +1

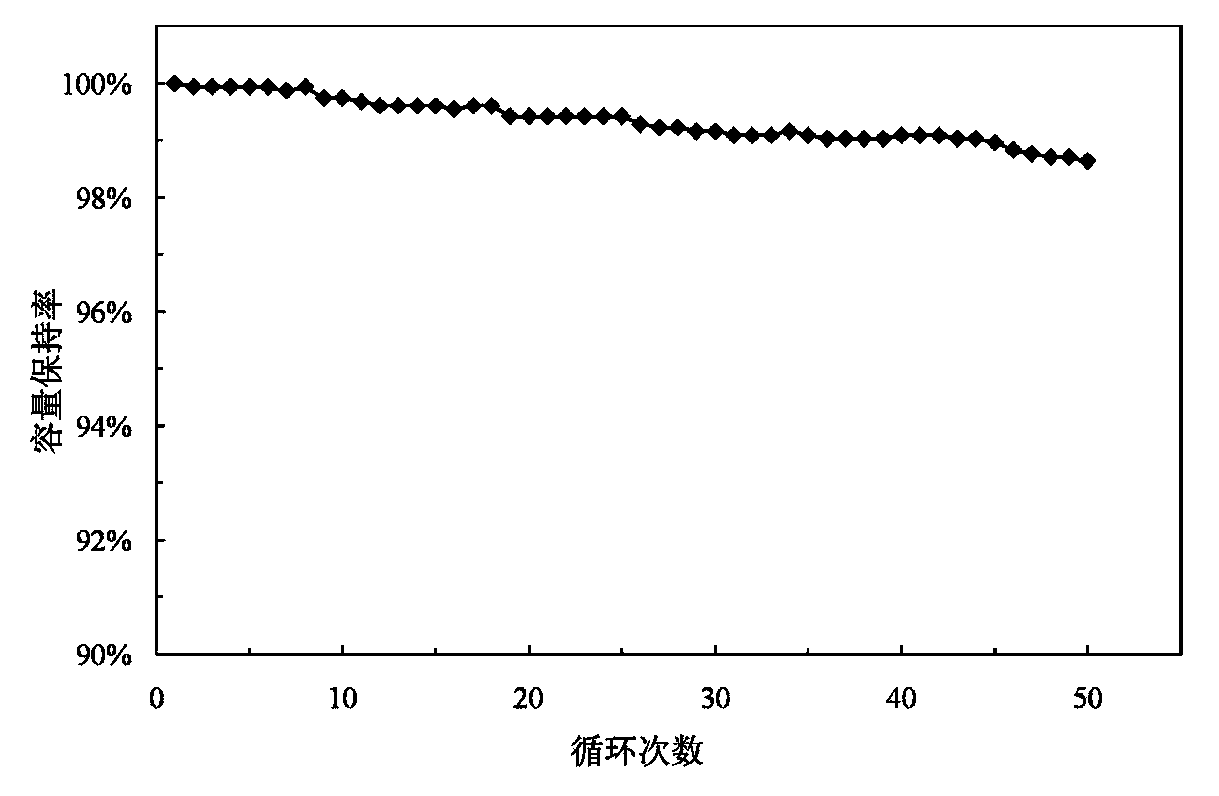

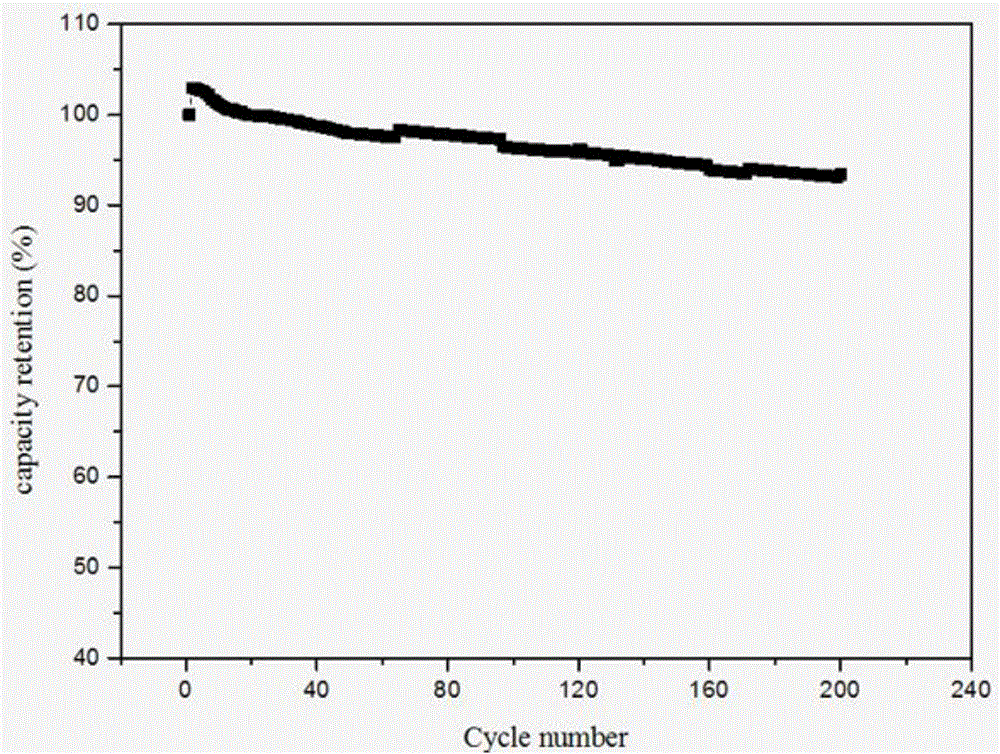

Rare-earth doping modified lithium ion battery ternary positive electrode material and preparation method thereof

ActiveCN103855384AEase of industrial productionImprove charge and discharge efficiencyCell electrodesSecondary cellsCarbon compositesNickel salt

The invention relates to a rare-earth doping modified lithium ion battery ternary positive electrode material and a preparation method of the rare-earth doping modified lithium ion battery ternary positive electrode material. The chemical general formula of the material is as follows: LiNiaCo<1-a-b>MnbRxO2 / M, wherein a is more than 0 and less than 1, b is more than 0 and less than 1, (1-a-b) is more than 0 and less than 1, x is more than 0.005 and less than 0.1, R is one or more of rare-earth lanthanum, cerium, praseodymium and samarium, and M is a composite cladding layer of oxide of aluminum, titanium or magnesium and carbon. The soluble metal nickel salt, cobalt salt, manganese salt and rare-earth compound are mixed to prepare a mixed salt solution, the mixed salt solution is reacted with a mixed alkaline solution prepared by mixing NaOH and ammonium hydroxide, after the reaction solution is filtered, washed and dried, the obtained product is uniformly mixed with lithium salt powder to be ball milled, then the mixture is calcined at the high temperature and coated with the composite cladding layer of the aluminum, titanium or magnesium oxide and carbon, and finally the calcined mixture is calcined at a constant temperature to obtain the rare-earth doping modified lithium ion battery ternary positive electrode material. After doping the rare earth, the metal oxide and carbon composite cladding layer, which are cheap and easy to obtain, are adopted, so that the cycling performance and the rate performance can be improved, and the charging-discharging efficiency of the material also can be improved.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

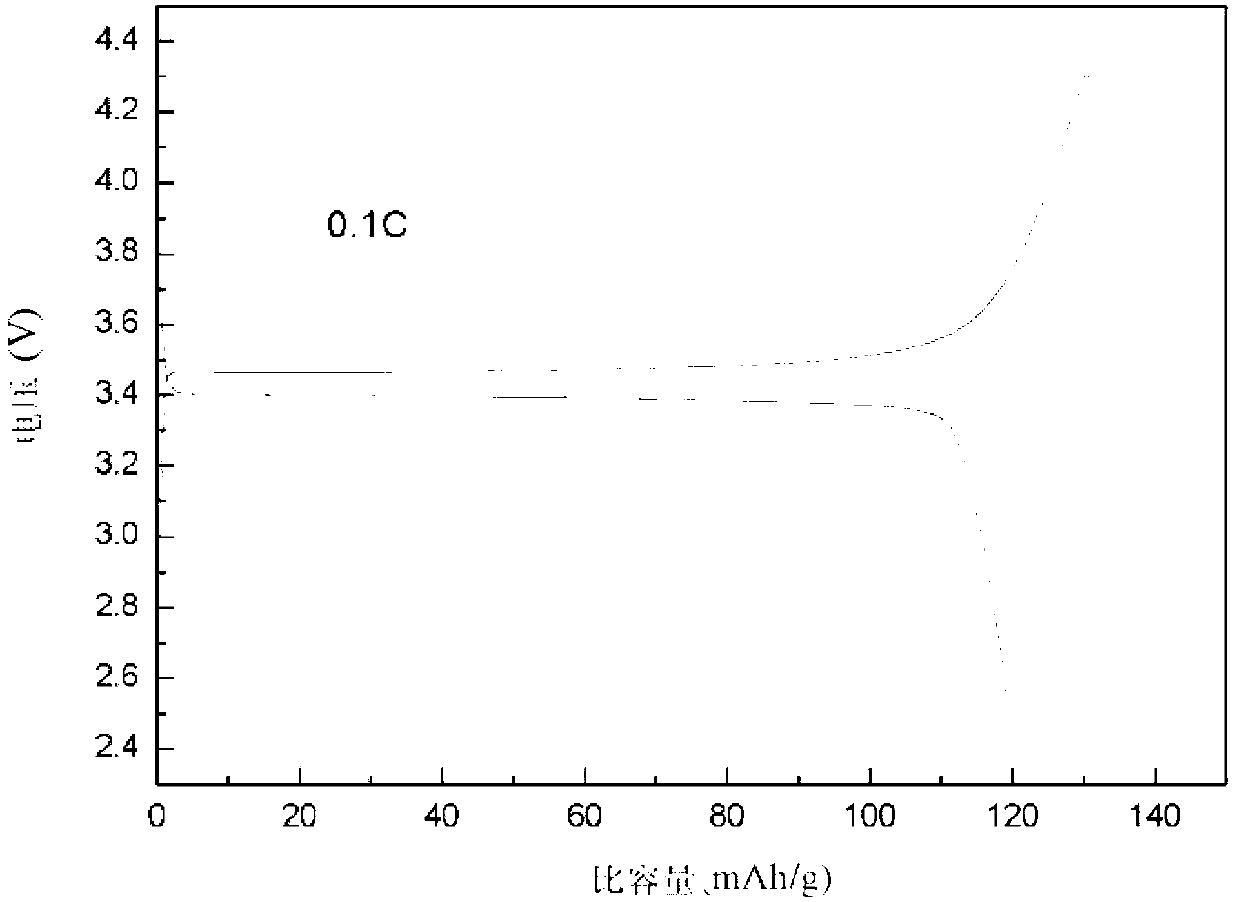

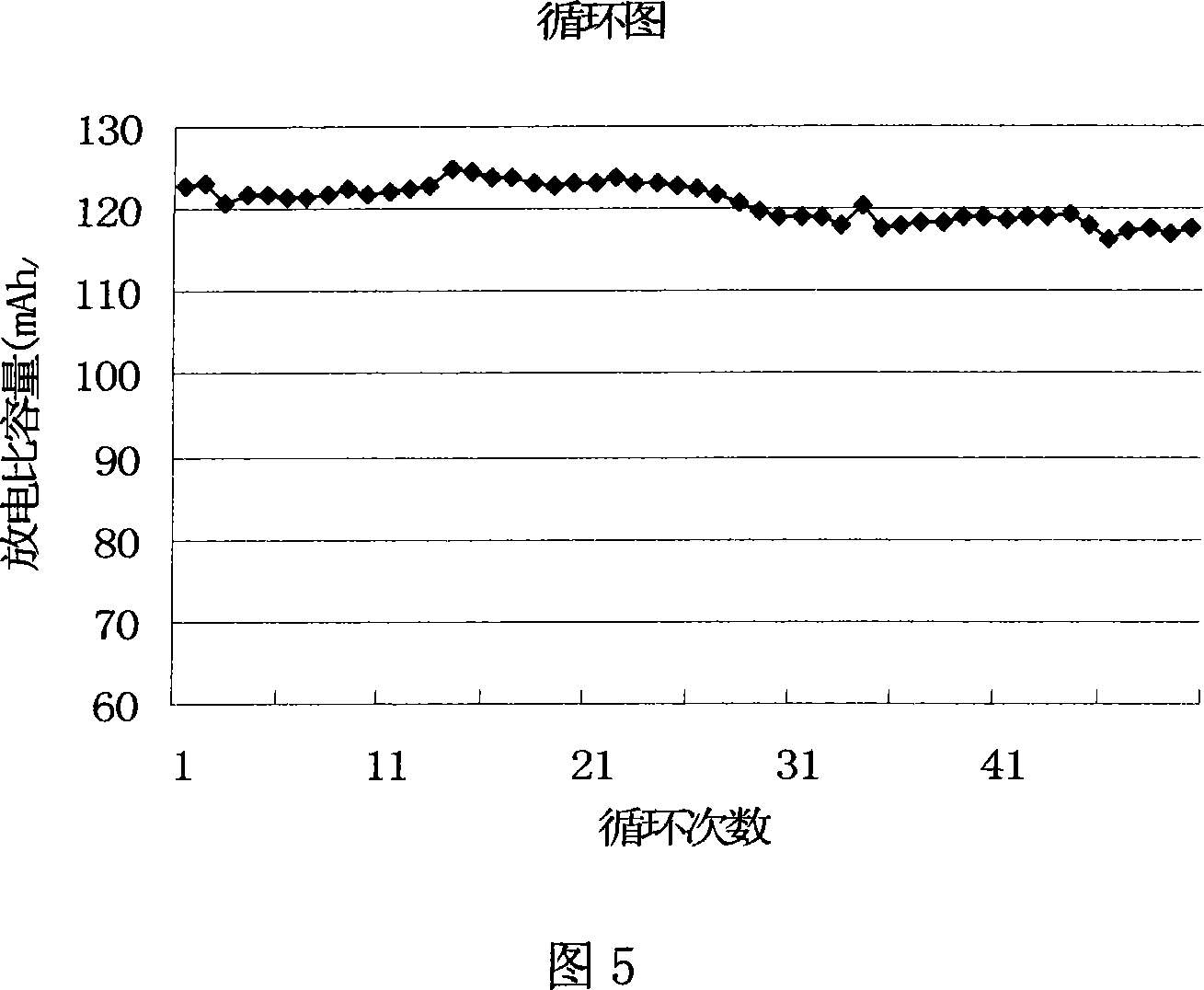

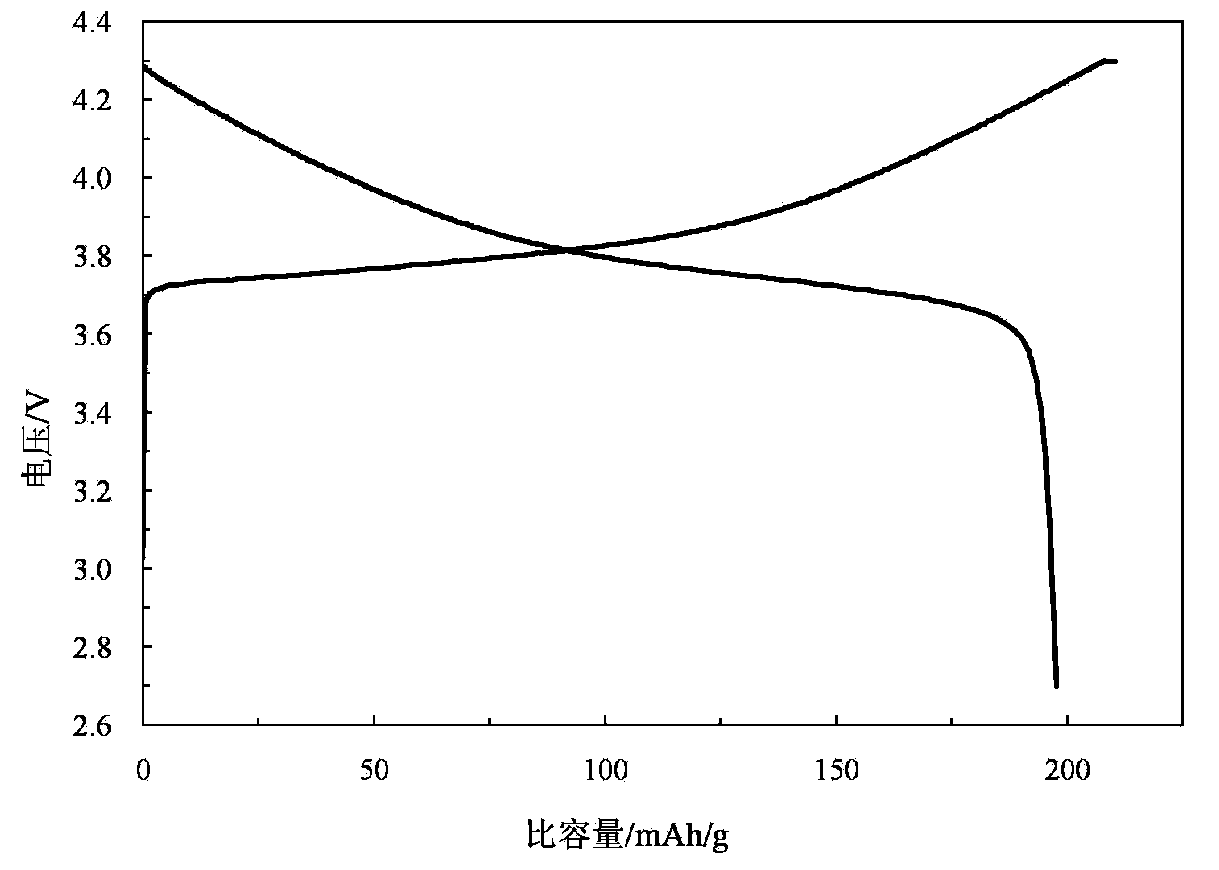

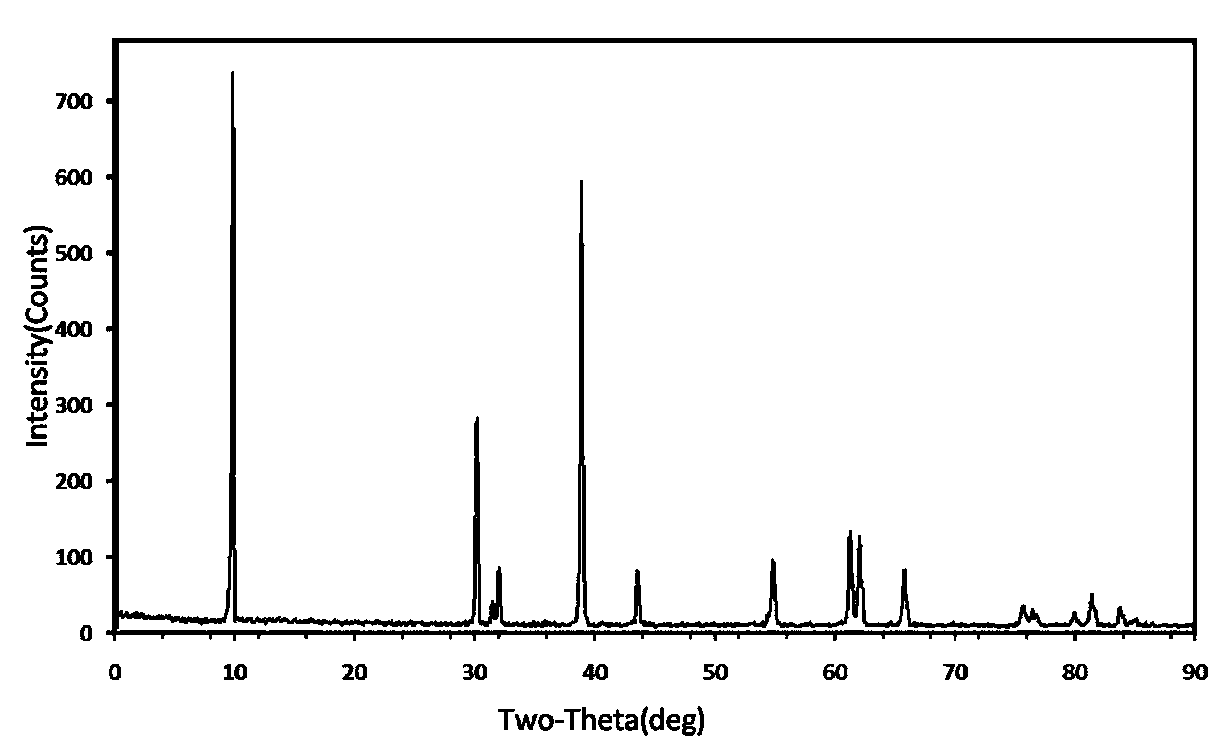

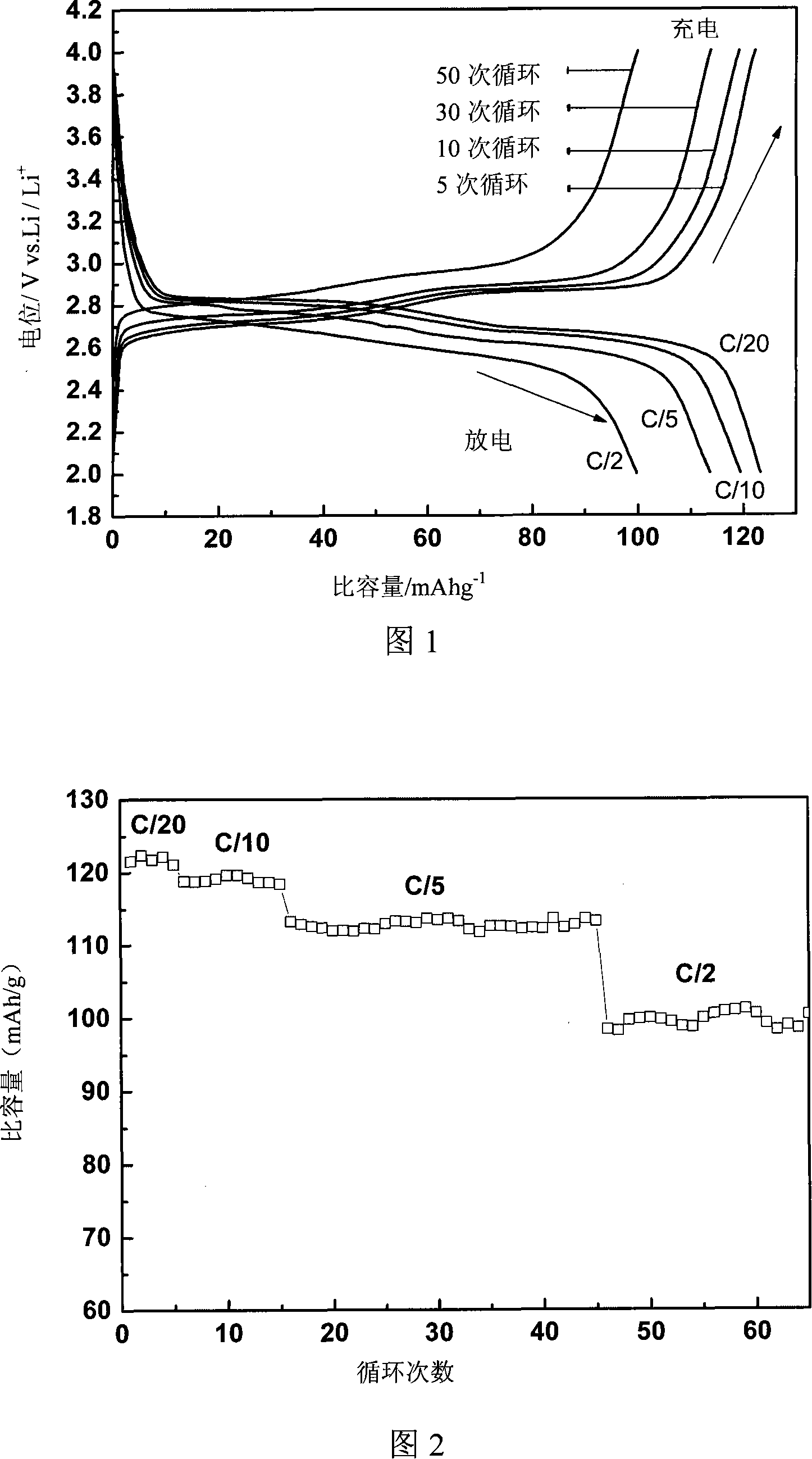

Anode material made of doped lithium-iron phosphate active material and carbon and method for producing the same

ActiveCN101212049ALow priceImprove securityElectrode manufacturing processesPhosphorus compoundsLithium iron phosphateSolid reaction

The invention relates to an anode material composed by doping phosphate iron and lithium active substance and carbon and used for the secondary lithium battery and a manufacturing method thereof. The invention is characterized in that the general expression of the active substance is Li<3+Y>Fe<2-X>Mex(PO4)3(Me = Ti, Sc, Ge, Al, Zr, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, and Pb, etc.); the characteristic in preparation is that the raw material is synthesized into the crystal state of Li<3+Y>Fe<2-X>Mex(PO4)3 through a solid reaction, an hydrothermal method and a sol-gel method in a proper proportion. Then the prepared powder and the carbon is grinded and mixed through a planetary ball mill to obtain the anode material Li<3+Y>Fe<2-X>Mex(PO4)3 / C The specific capacity of the anode material can be up to 122mAhg<-1> (charging and discharging at the rate of C / 20) and 100mAhg<-1> (charging and discharging at the rate of C / 2); furthermore, the material has a good circulation performance and retentivity of specific capacity, thus providing a favorable anode material for the practicality of the secondary lithium ion battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

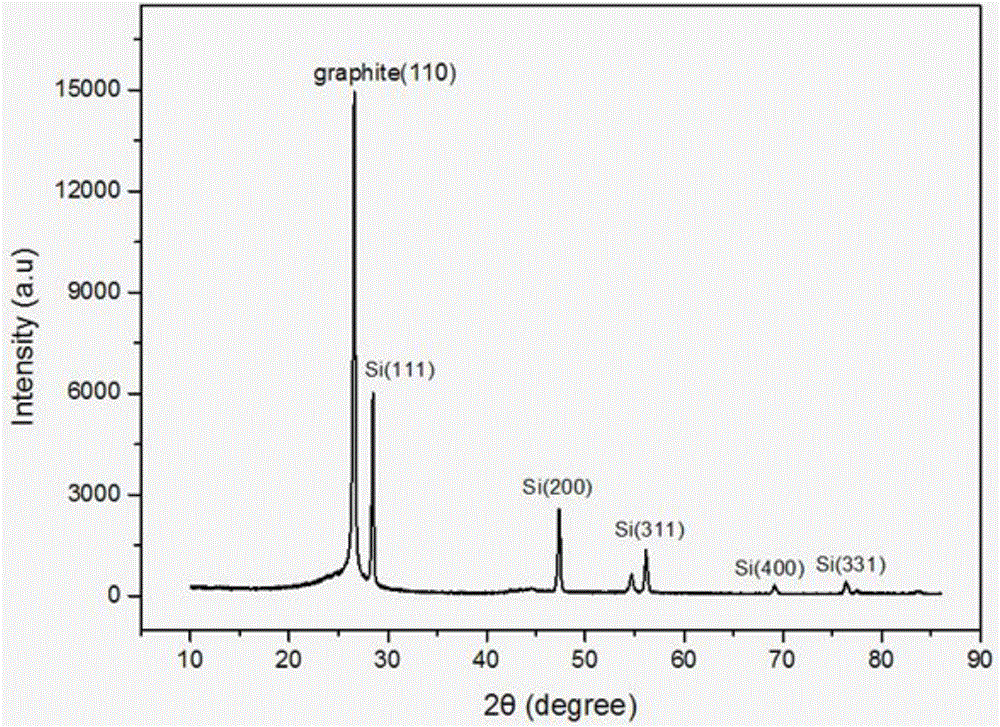

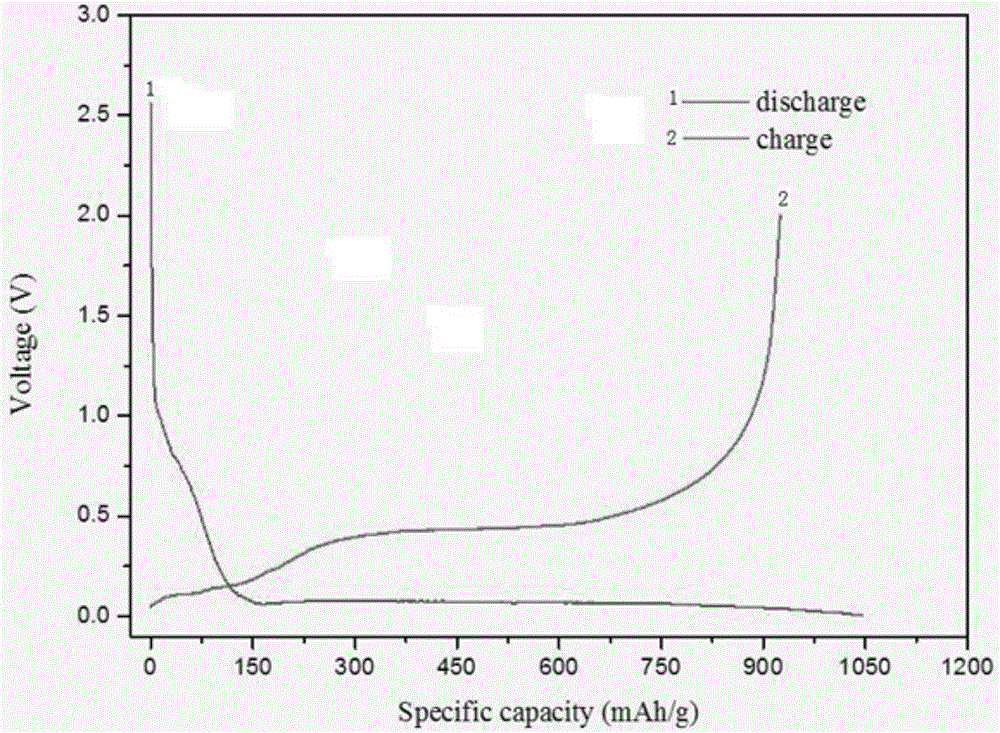

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com