Patents

Literature

400results about How to "Single structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid pump

InactiveUS6109889ASimple structural designLow costFlexible member pumpsPositive-displacement liquid enginesPump chamberEngineering

PCT No. PCT / EP96 / 05382 Sec. 371 Date Jun. 3, 1998 Sec. 102(e) Date Jun. 3, 1998 PCT Filed Dec. 3, 1996 PCT Pub. No. WO97 / 21924 PCT Pub. Date Jun. 19, 1997A fluid pump has a pump body and a displacer, the displacer and the pump body being implemented such that a pump chamber is defined therebetween, the pump chamber having an inlet opening and an outlet opening, neither the inlet opening nor the outlet opening being provided with a check valve. A drive means is provided which positions the displacer periodically at a first and at a second end position. The displacer closes the outlet opening when it occupies its first end position and leaves the outlet opening free when it occupies its second end position and leaves the inlet opening free at both end positions thereof. The displacer, when moving from the first to the second end position, defines a flow-through gap which opens between the displacer and the pump body in the area of the outlet opening in dependence upon the movement, the flow-through gap being defined such that the flow through the outlet opening depends on the pressure in the pump chamber as well as on the respective opening degree of the flow-through gap.

Owner:EPPENDORF AG +1

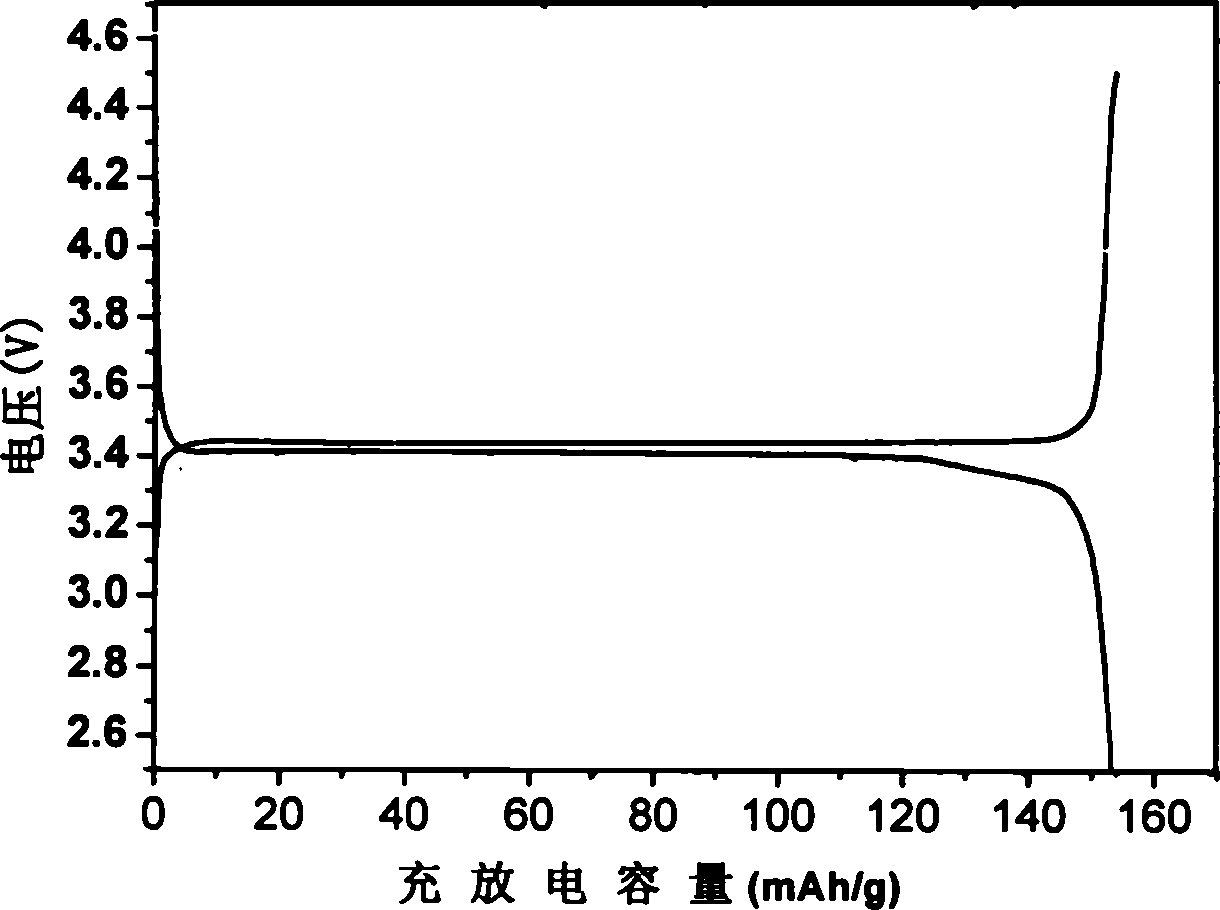

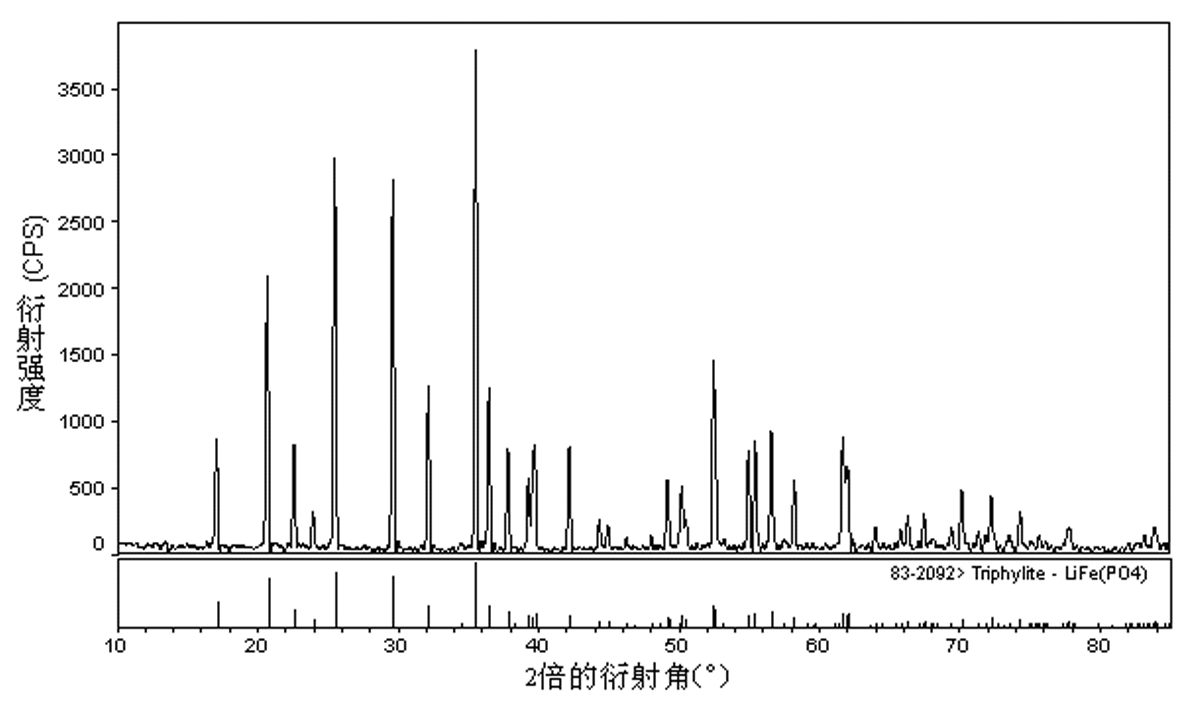

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

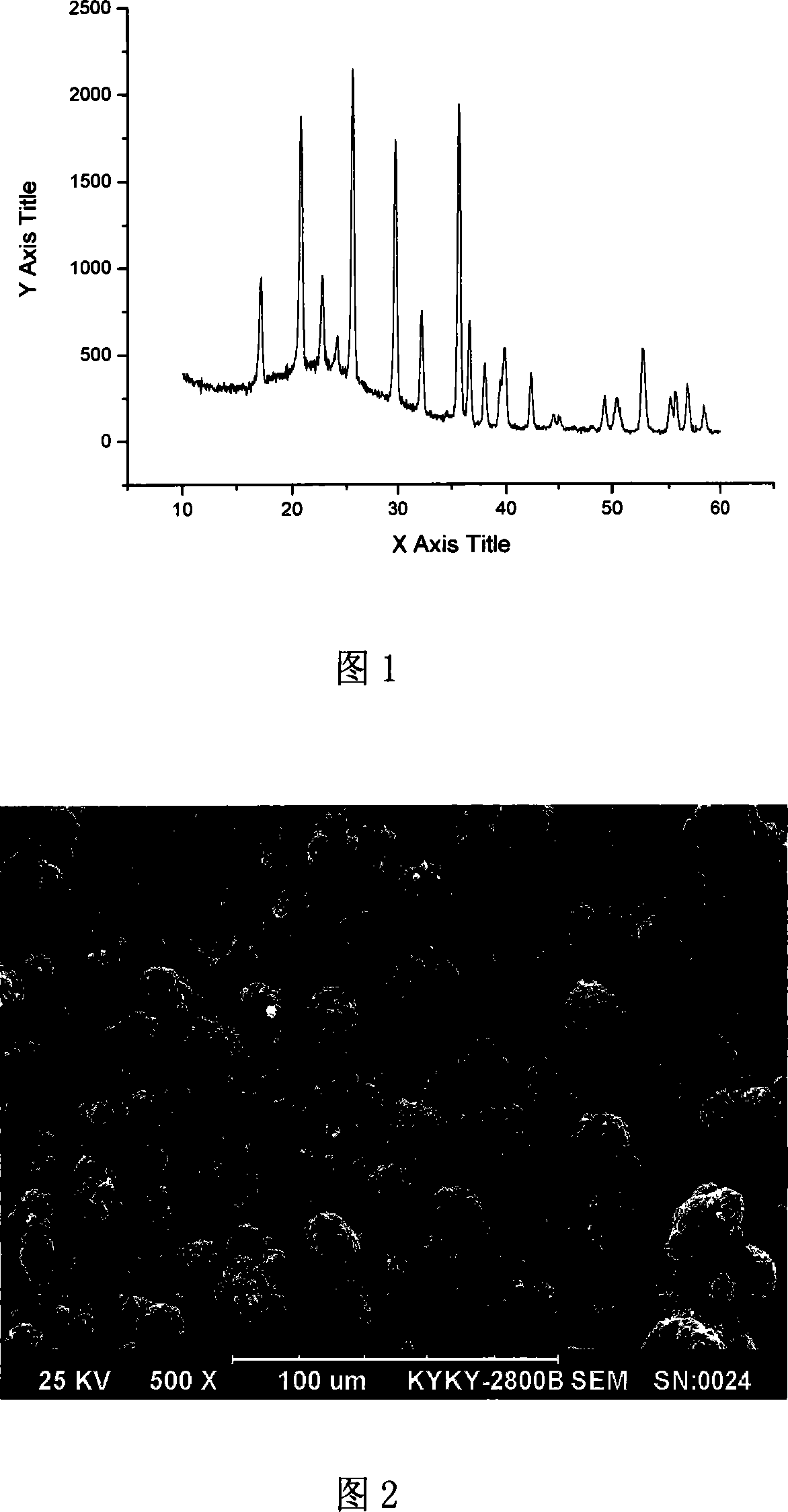

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

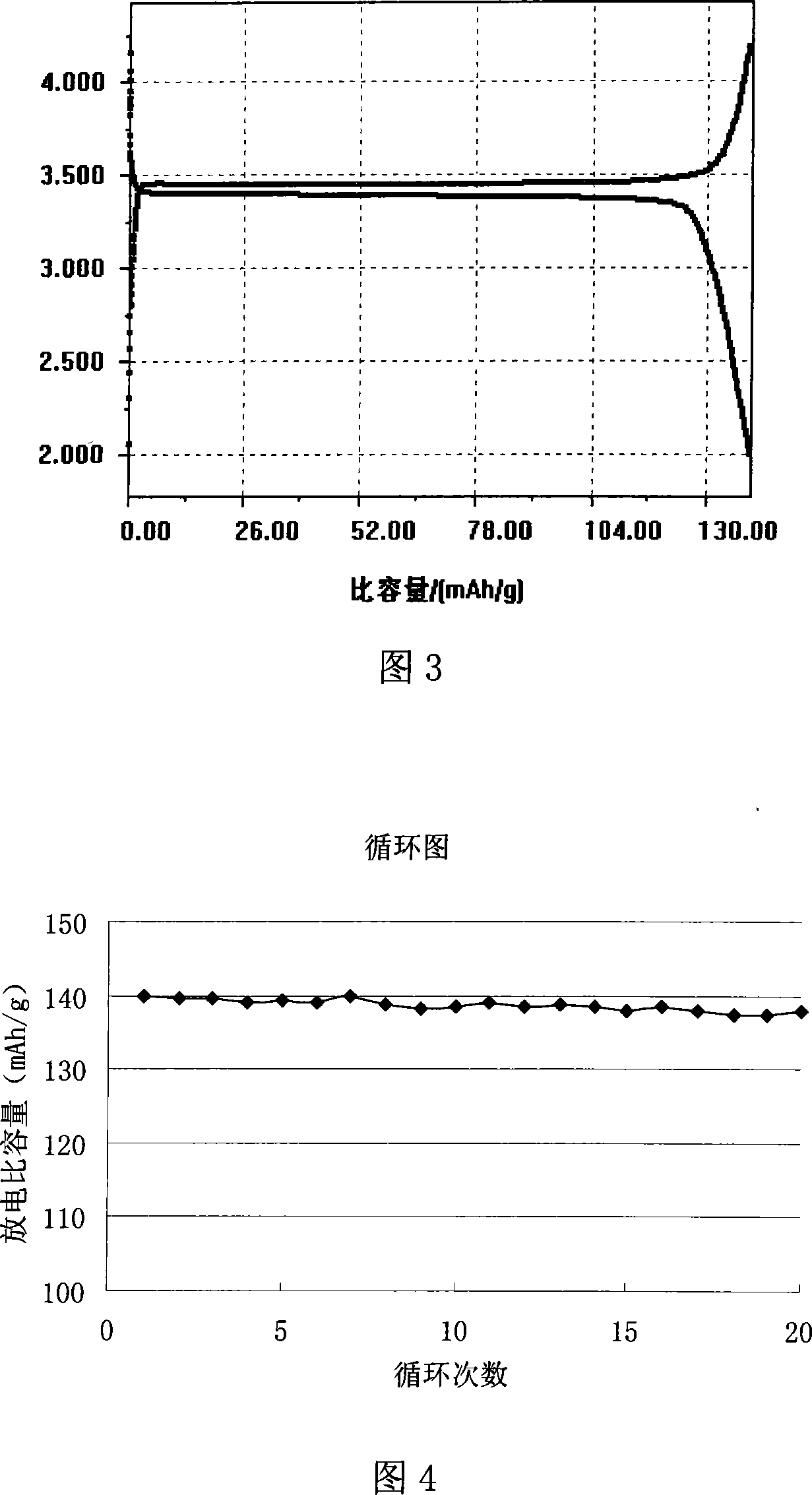

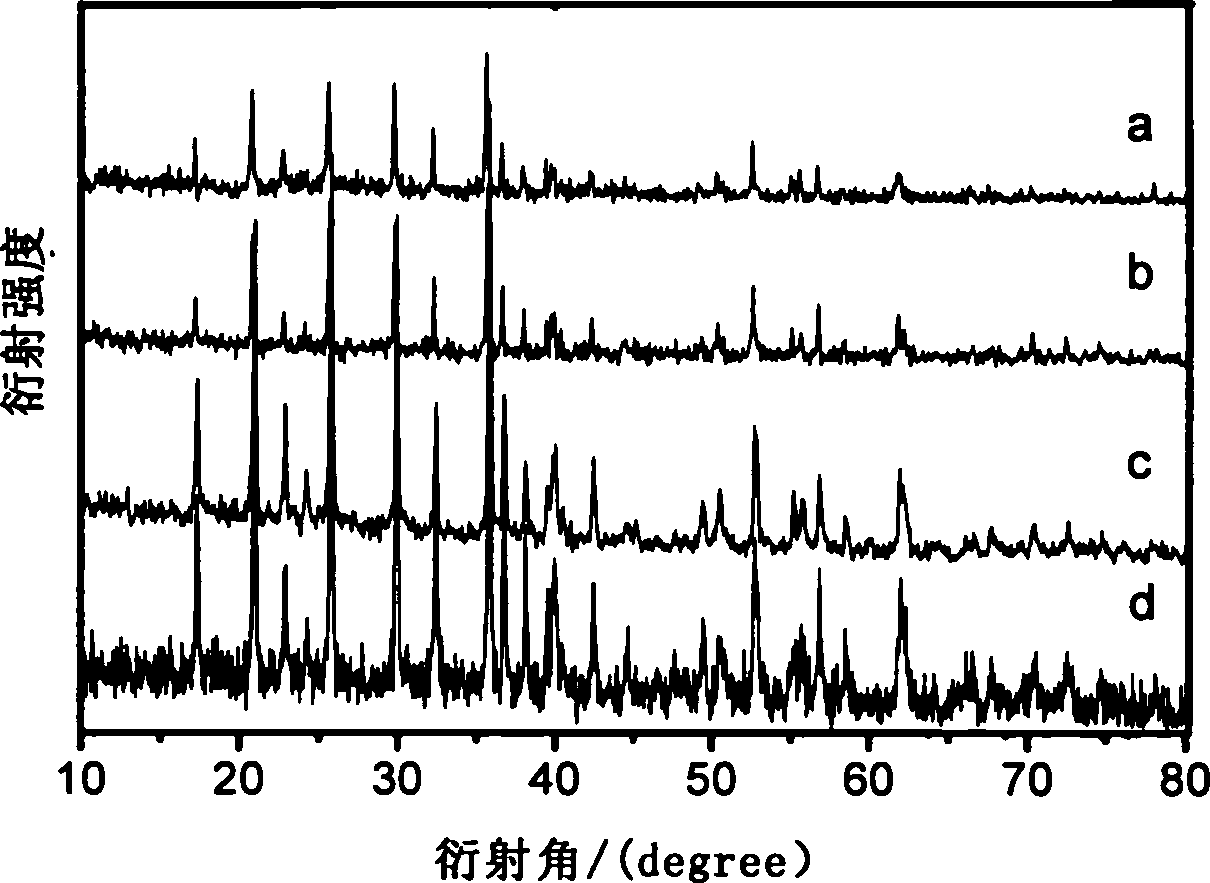

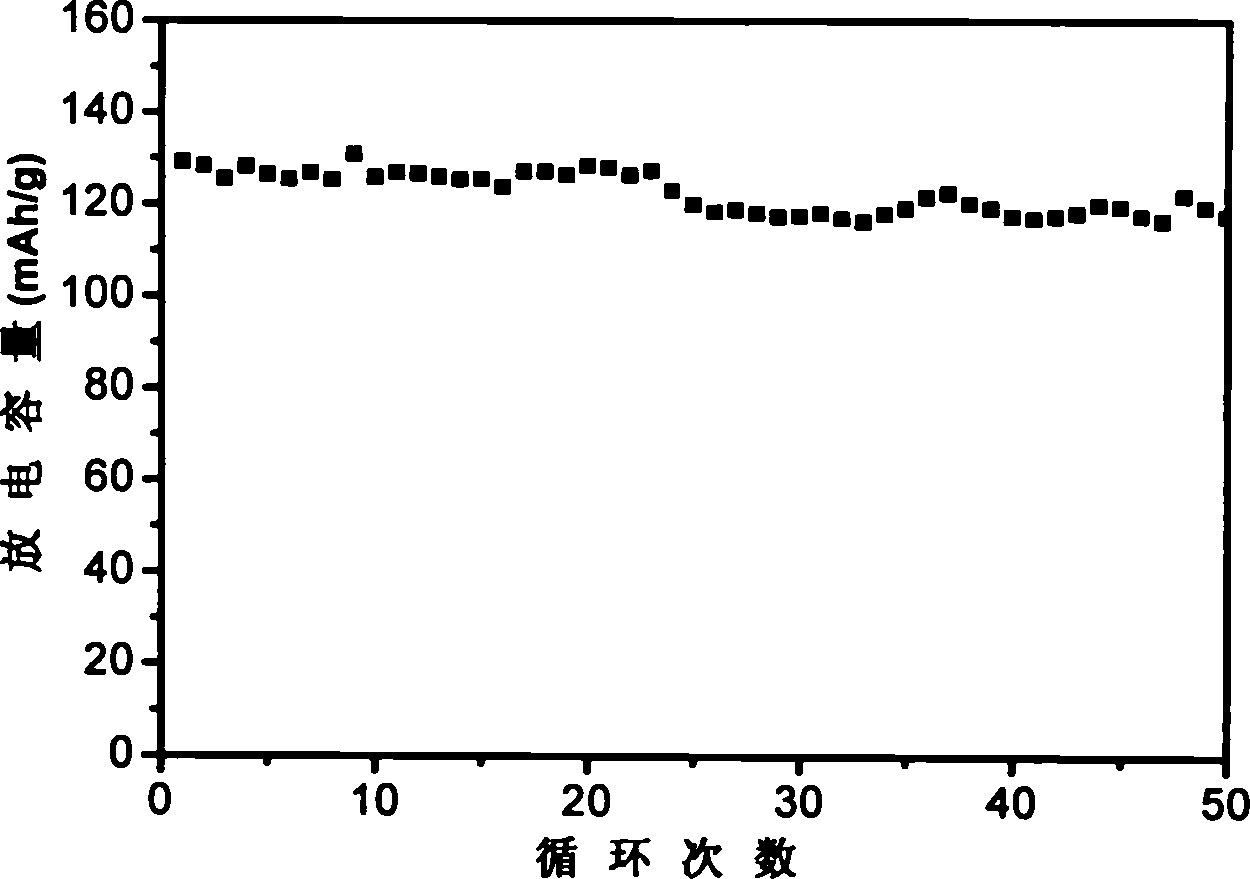

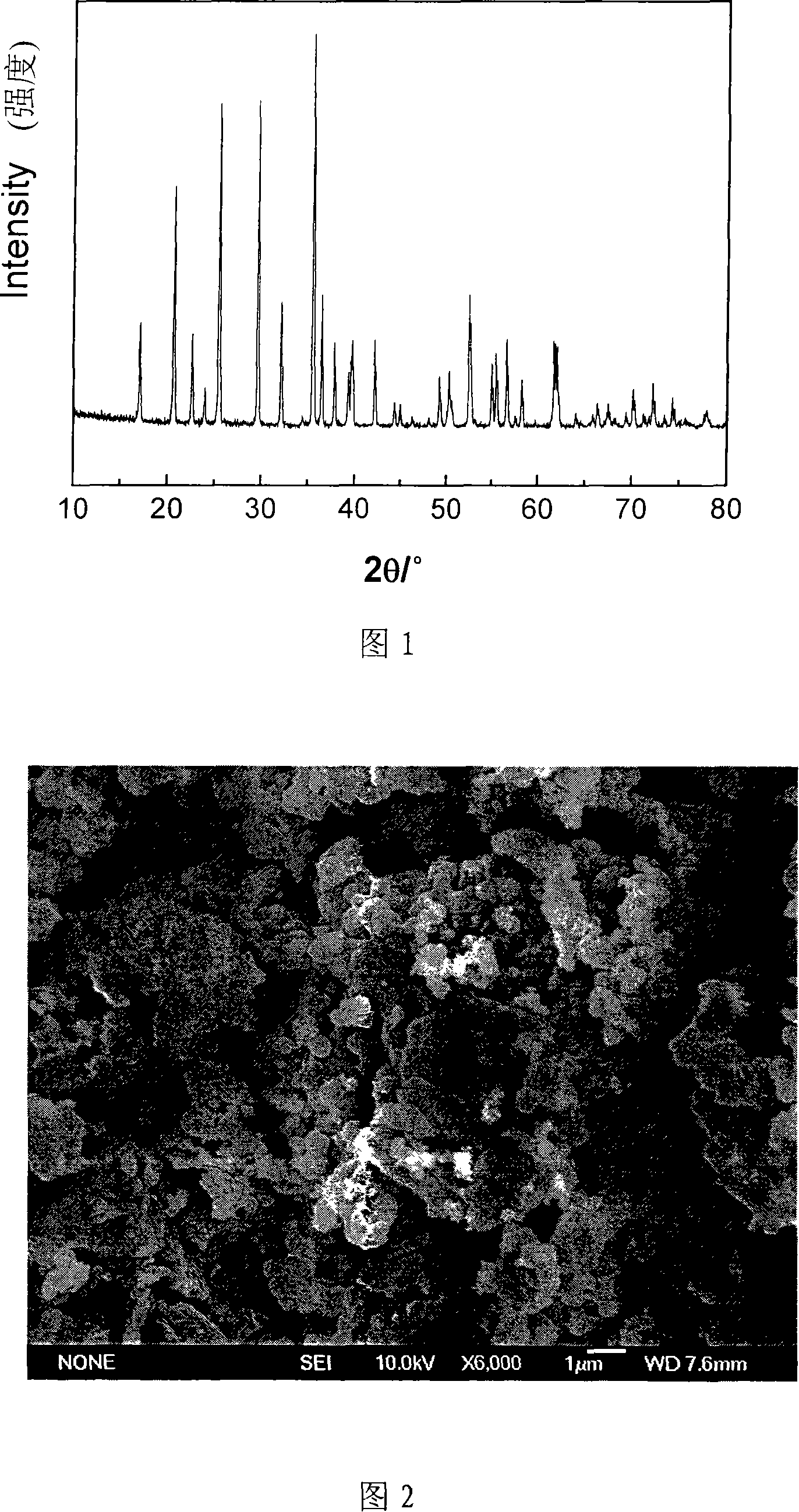

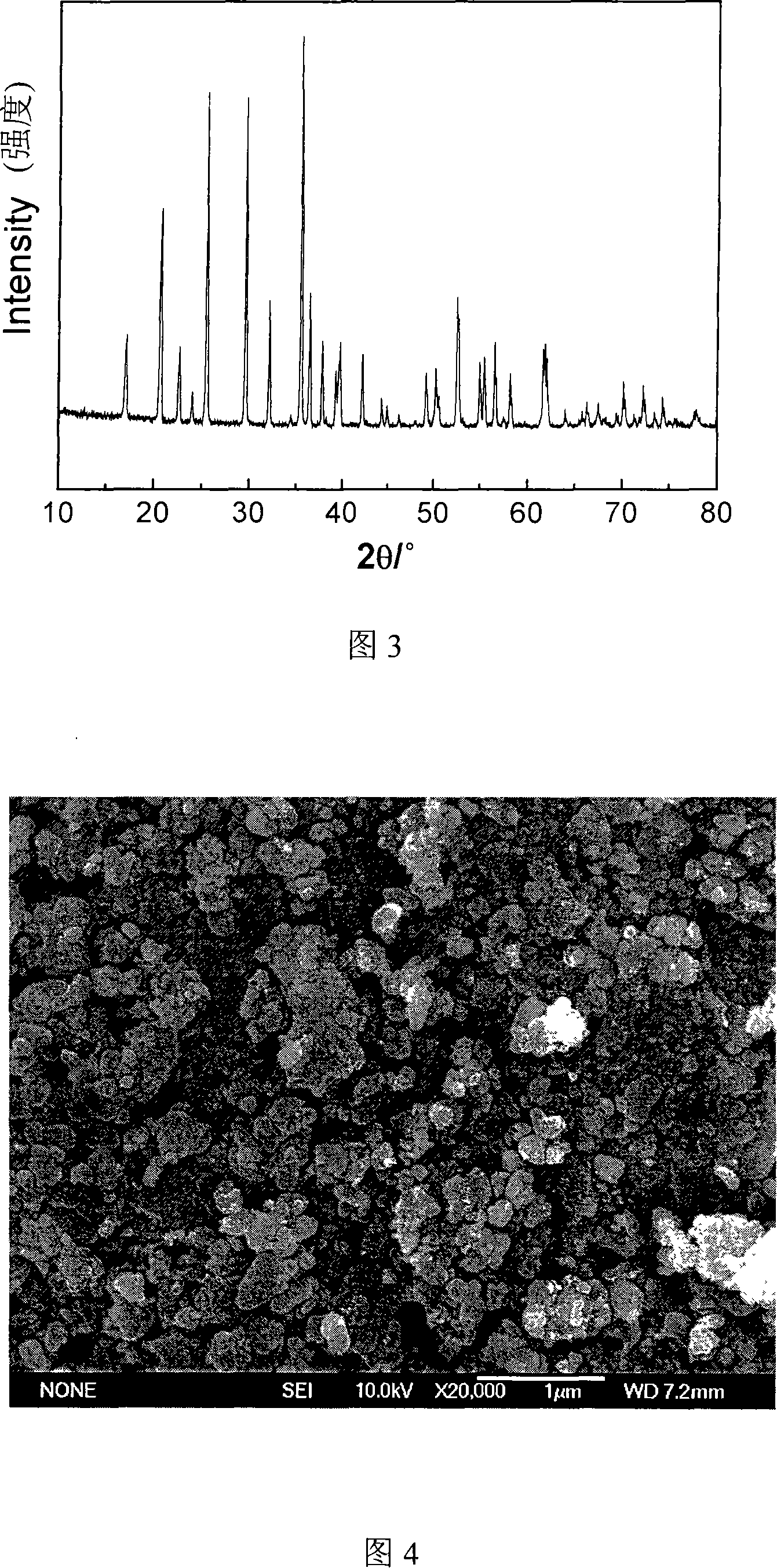

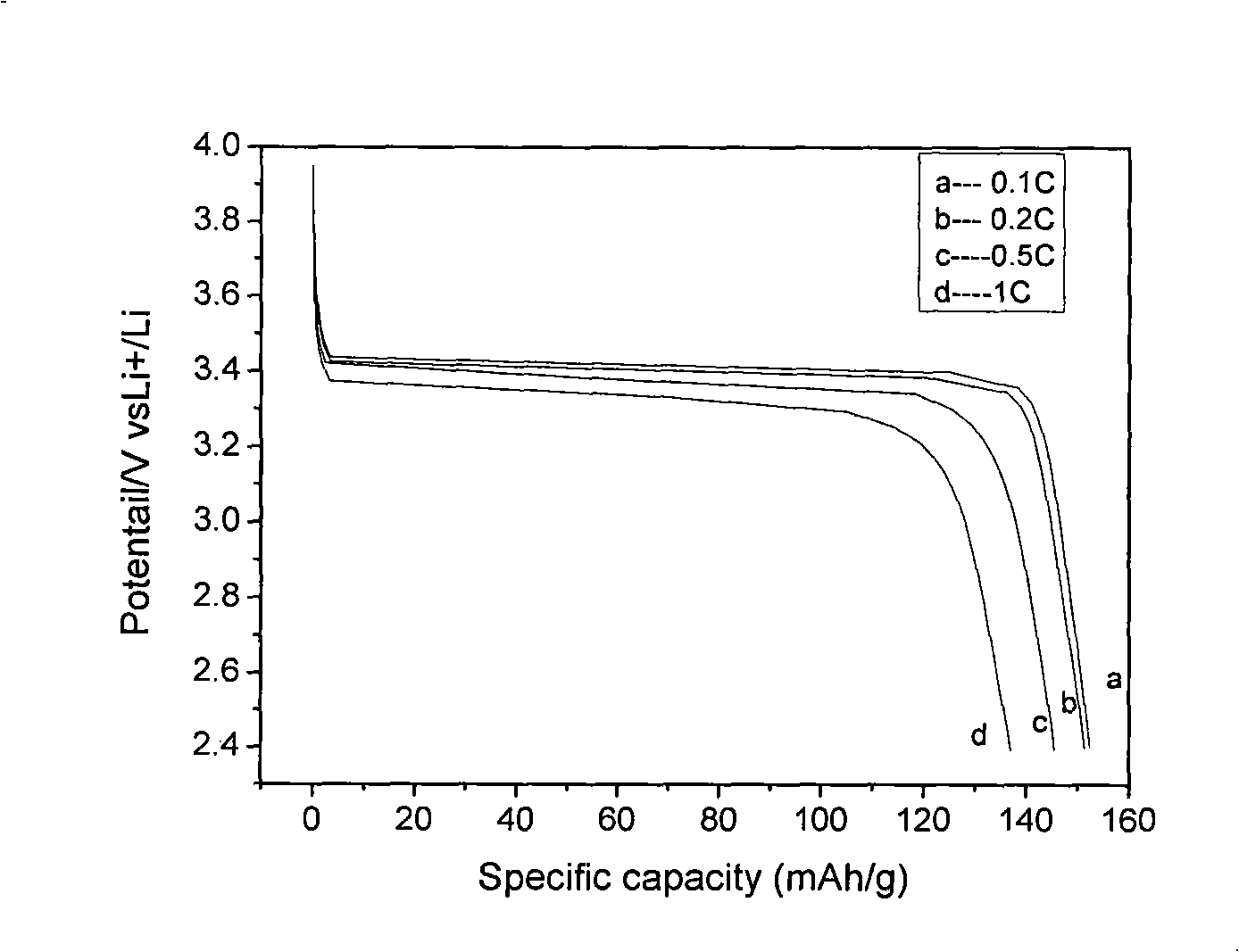

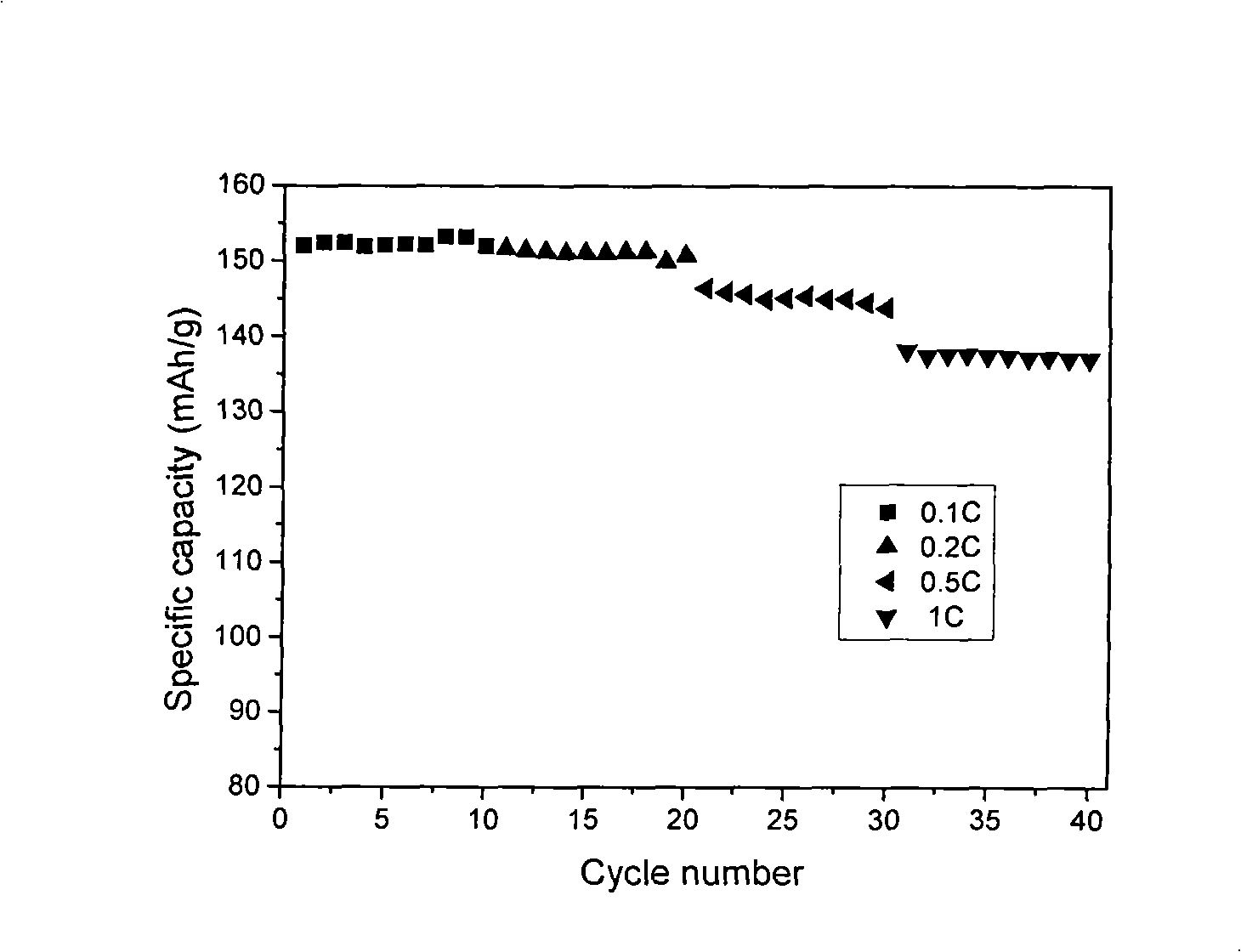

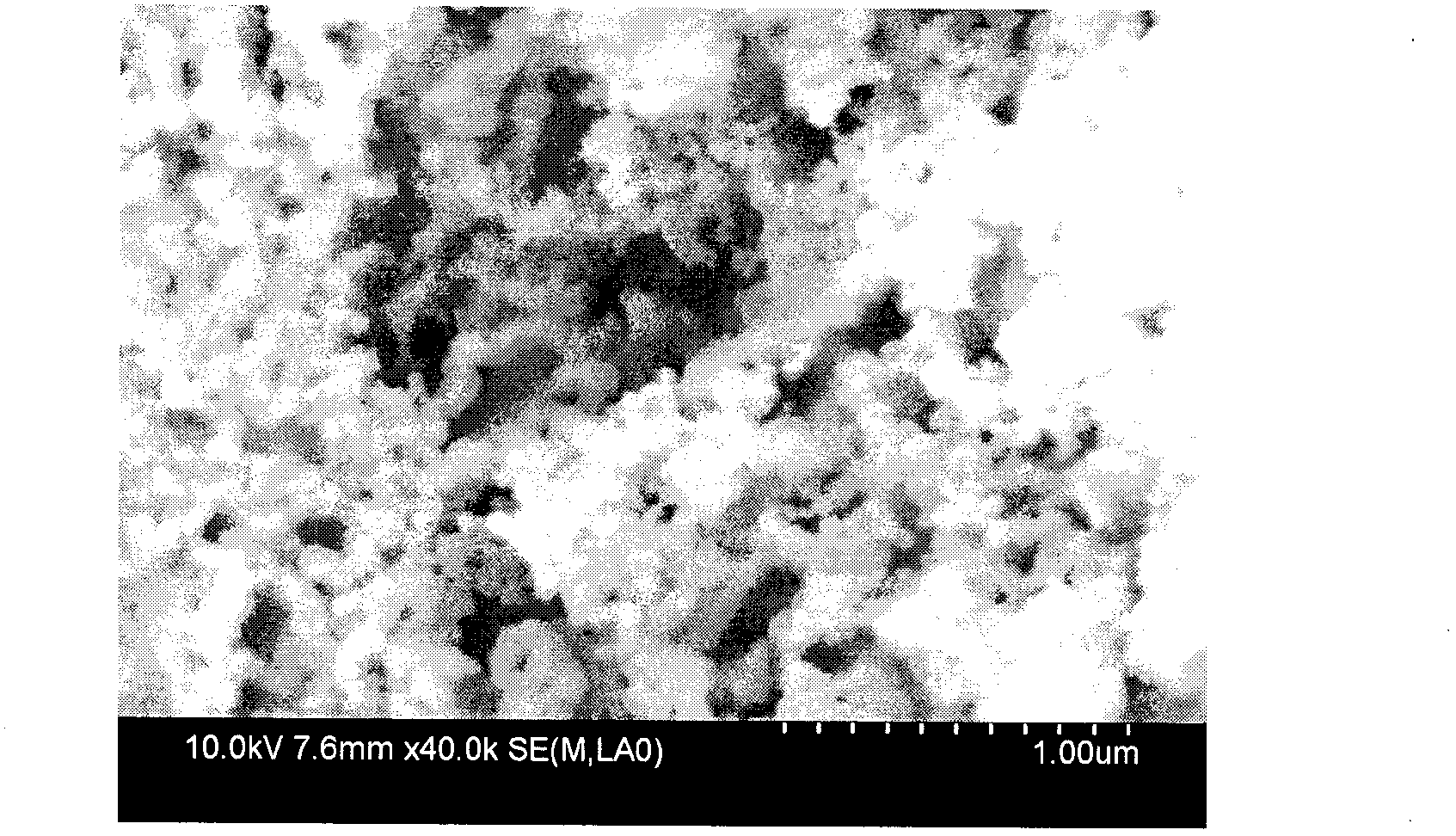

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

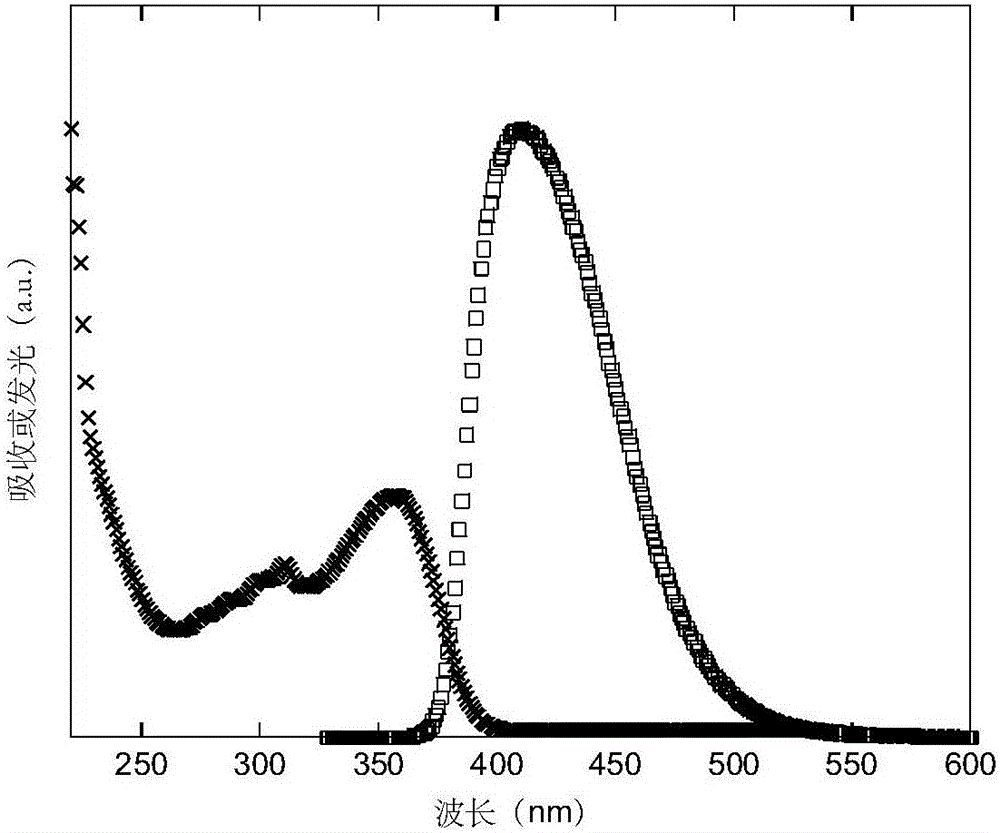

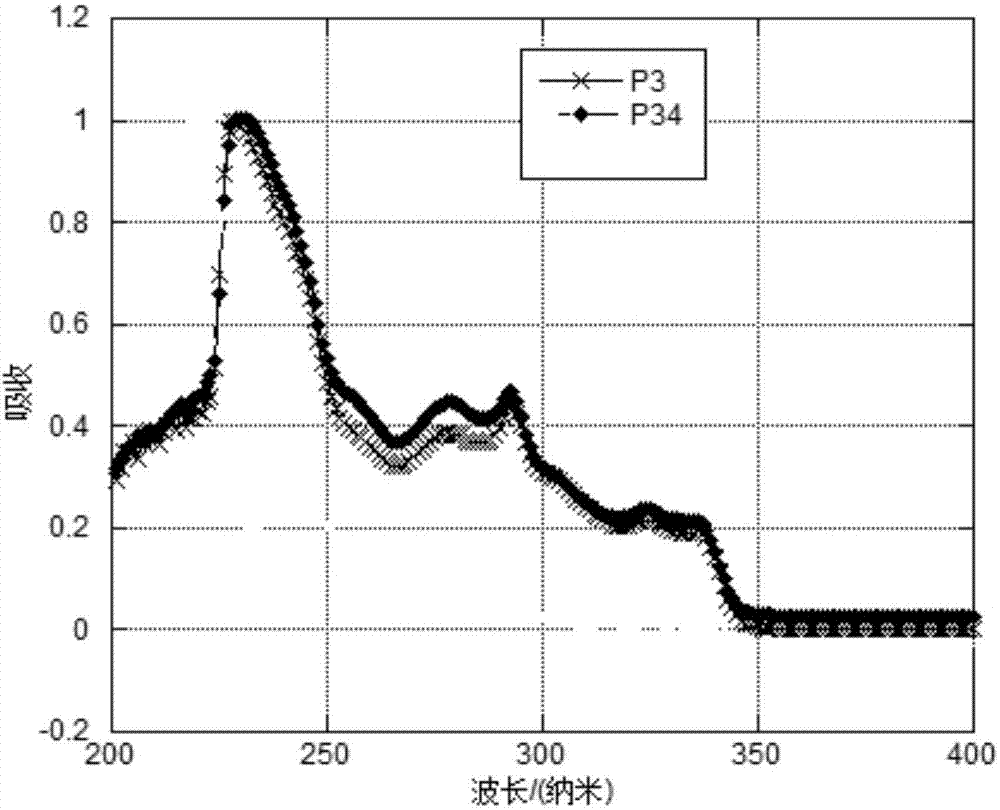

Spiro-di-thioxanthene-based small-molecule luminescent material and preparation and application thereof

InactiveCN105154067ASingle structureMolecular weight determinationOrganic chemistrySolid-state devicesSolubilitySolvent

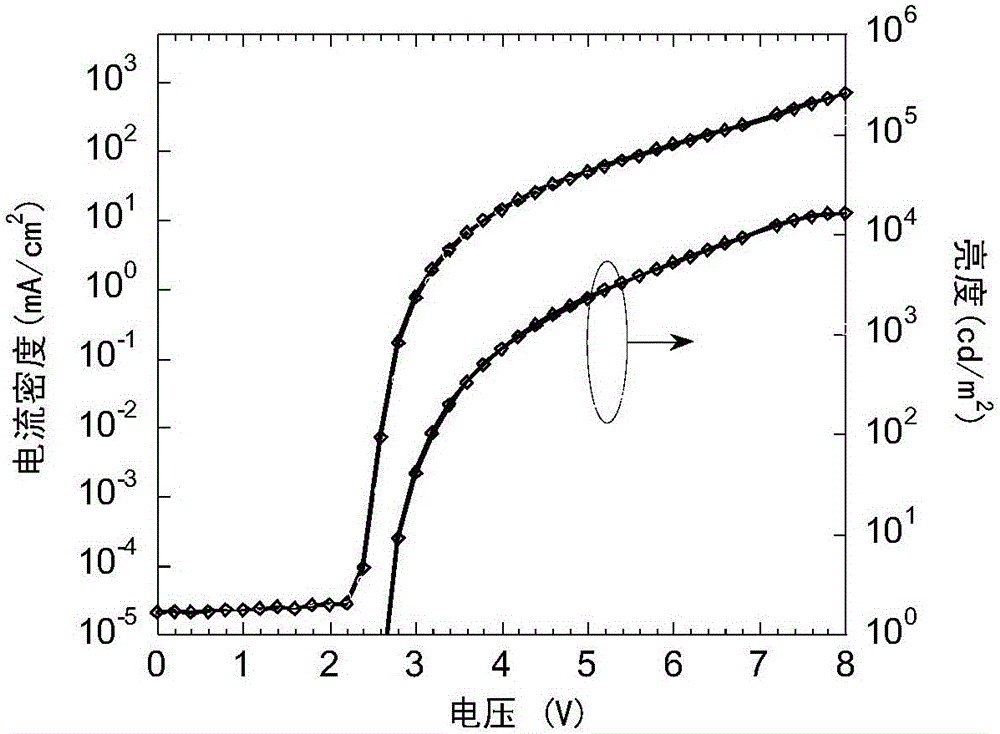

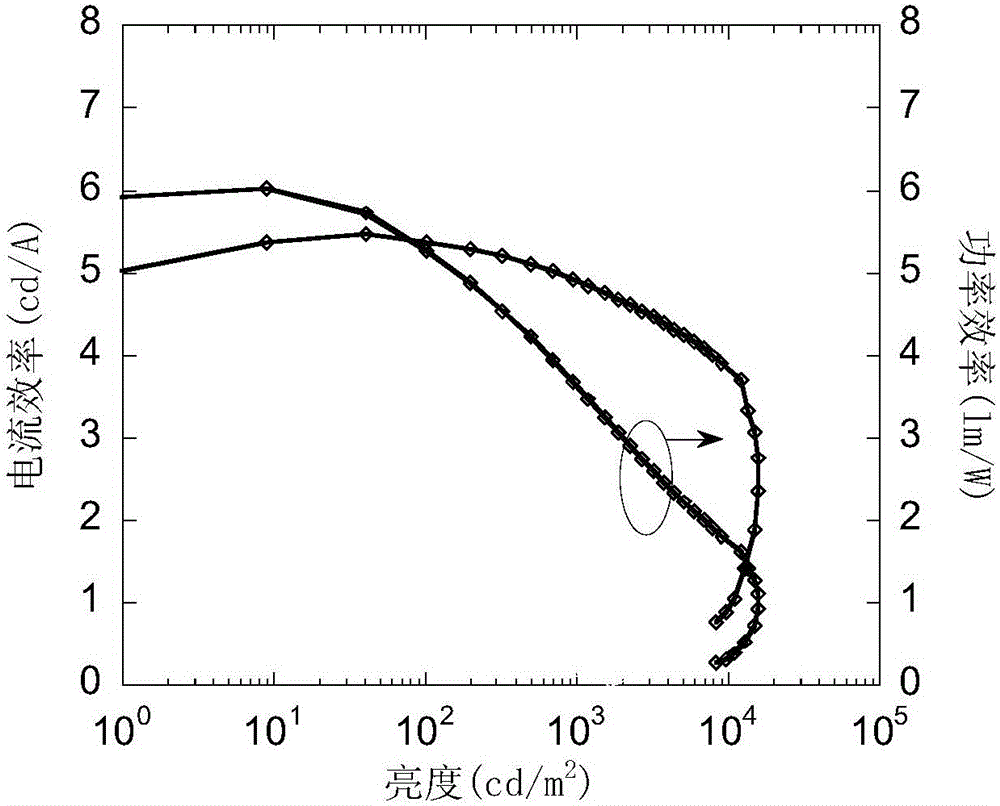

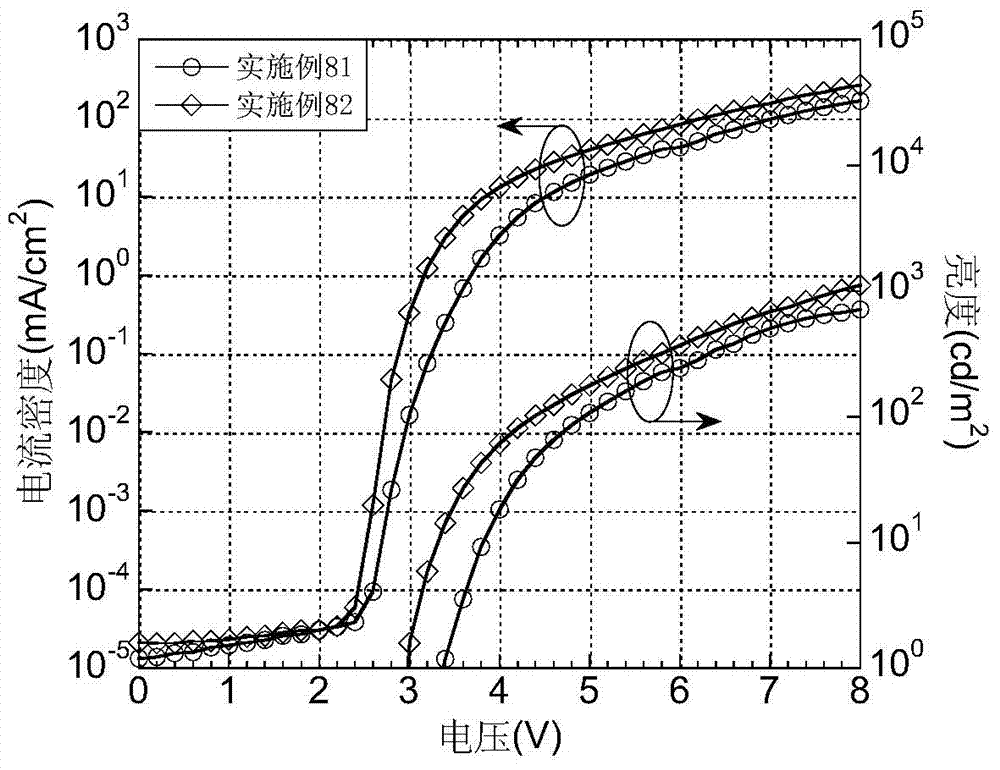

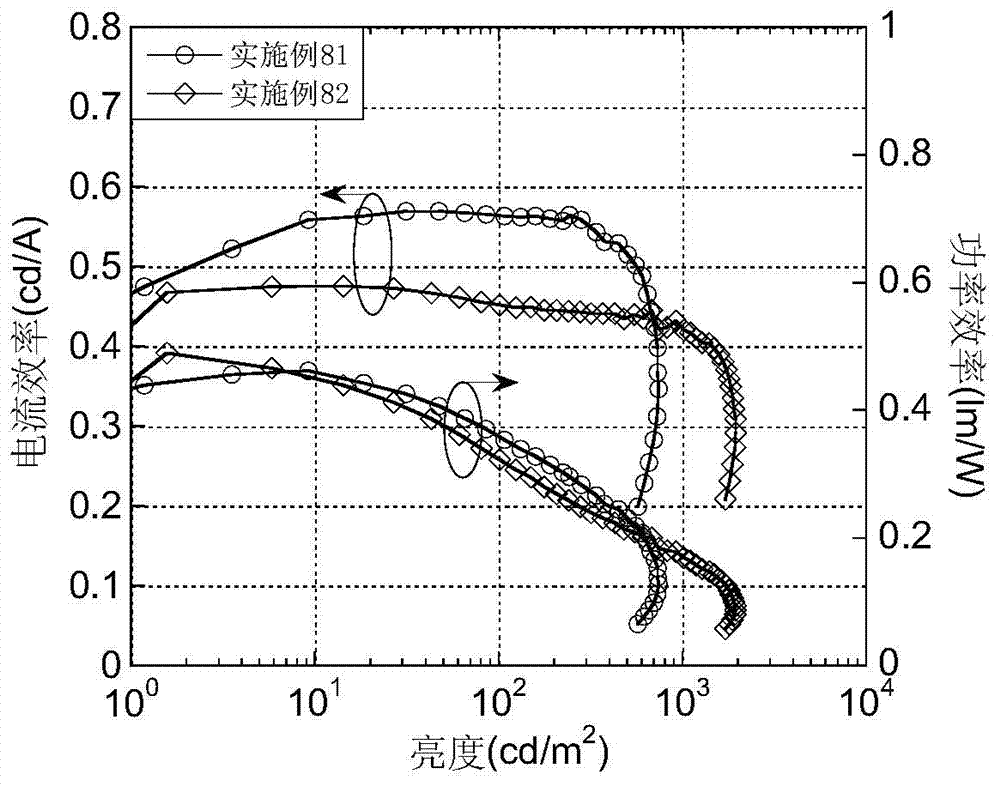

The invention belongs to the technical field of organic photoelectric materials, and discloses a spiro-di-thioxanthene-based small-molecule luminescent material and preparation and application thereof. With spiro-di-thioxanthene nucleuses as framework units, and by changing connecting units at both sides of each spiro-di-thioxanthene nucleus and the number of the spiro-di-thioxanthene nucleuses, the molecular weight, Pi conjugacy and intramolecular charge transfer properties of the small-molecule luminescent material disclosed by the invention can be regulated. A spiro-structure therein can adjust the packing method among molecules. The preparation method of the material disclosed by the invention obtains a target compound with diphenyl sulfide and thioxanthone as original reaction materials by a series of simple reactions. The material structure is uniform, and the molecular weight is determined, and the spiro-di-thioxanthene-based small-molecule luminescent material has good solubility and film-forming property in common solvents. The spiro-di-thioxanthene-based small-molecule luminescent material can be applied as a hole transport material, an electron transport material and a luminescent material in OLED (Organic Light Emitting Diode) devices to improve the performance of the devices, and has profound significance for the development of high-performance devices.

Owner:SOUTH CHINA UNIV OF TECH

Process for solid phase synthesis of lithium iron phosphate anode materials under high pressure

InactiveCN1884053ALow reaction temperatureReduce manufacturing costCell electrodesPhosphorus compoundsAir atmosphereLithium iron phosphate

The invention discloses a synthesizing method of anode material of high-pressure solid-phase ferric-lithium phosphate, which comprises the following steps: blending lithium salt, ferric salt and phosphate according to 1:1:1 proportion evenly; grinding the material into ball for 6-24 h to obtain priority; disposing priority for 2-10 h at 200-350 deg.c in the air environment; cooling naturally; grinding to obtain powder material; adding carbon material in the powder material with weight percentage of carbon material at 1-20 percent; grinding again for 6-24 h; disposing for 4-24 h at 450-1000 deg.c in the 1-15 Mpa inert environment; cooling naturally to obtain the product.

Owner:SOUTH CHINA UNIV OF TECH

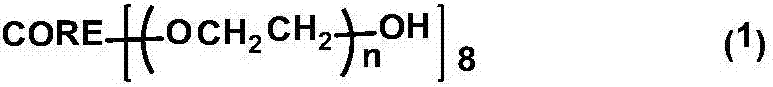

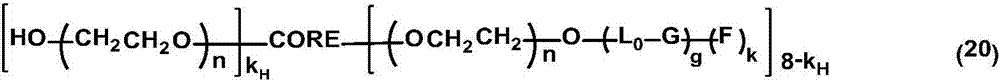

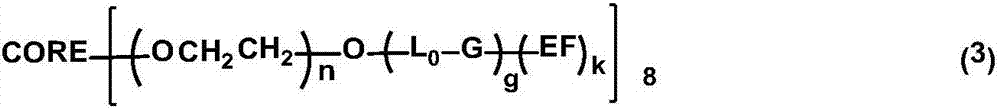

Eight-arm polyethylene glycol, preparation method and functionalized derivative thereof, and biologically relevant substance modified with functionalized derivative

ActiveCN106967213AReduce manufacturing costHigh purityPharmaceutical non-active ingredientsPolyethylene glycolDistribution control

The present invention discloses an eight-arm polyethylene glycol (formula 1), a preparation method and a functionalized derivative thereof, and a biologically relevant substance modified with the functionalized derivative, wherein the octavalent center structure CORE contains the residue obtained after the dehydroxylation of an octahydroxy disaccharide molecule, and n is the polymerization degree of a polyethylene glycol chain, and is selected from 1-2000. According to the present invention, the eight-arm polyethylene glycol has monodispersity or polydispersity; the molecular cost of the initiator is low and the purity of the initiator is low, such that the production cost is substantially reduced, the molecular weight and the distribution control of the polymerization product and the functionalized derivative are precise, and the purity and the performance of the product can be easily improved in the biologically relevant substance modified with the functionalized derivative; and the eight-arm polyethylene glycol and the derivative thereof can further have natural chiral centers. The formula 1 is defined in the specification.

Owner:XIAMEN SINOPEG BIOTECH

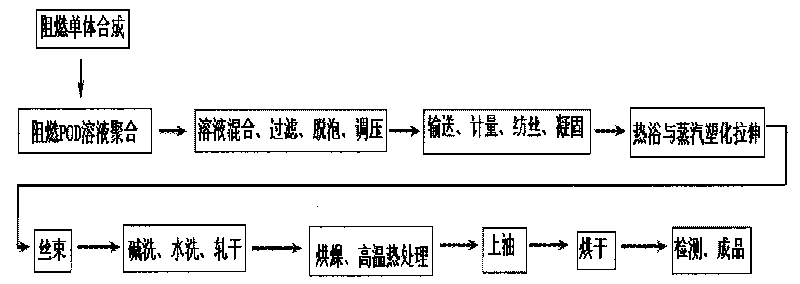

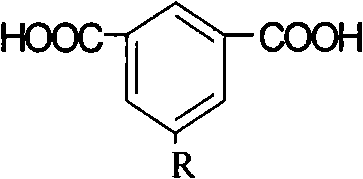

Method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof

ActiveCN101735455ASingle structureEasy to synthesizeWet spinning methodsMonocomponent synthetic polymer artificial filamentChemistryDecomposition

The invention discloses a method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof. The special aromatic polyoxadiazole is prepared by the following method that the special aromatic polyoxadiazole is prepared from terephthalic acid, compound of which the structural general formula is expressed as formula I and hydrazine salt serving as monomers through condensation polymerization reaction. The polyoxadiazole fiber with high flame retardancy and high temperature resistance is prepared by using the special aromatic polyoxadiazole as a raw material. The fiber number of the prepared polyoxadiazole fiber is 1 to 20 dtex, the breaking strength is 2.5 to 5 cN.dtex-1, the elongation at break is 10 to 40 percent, the initial modulus is 50 to 250 cN.dtex-1, the moisture regain is 5.0 to 12.0 percent, the limited oxygen index is 30 to 38 percent, and the initial decomposition temperature is above 480 DEG C. The fiber can be widely used in the fields of protective products, filter materials, electric insulating materials, frictional sealed materials, various industrial textiles, high-temperature resistant paper, aviation and aerospace materials and the like.

Owner:JIANGSU BAODE NEW MATERIAL

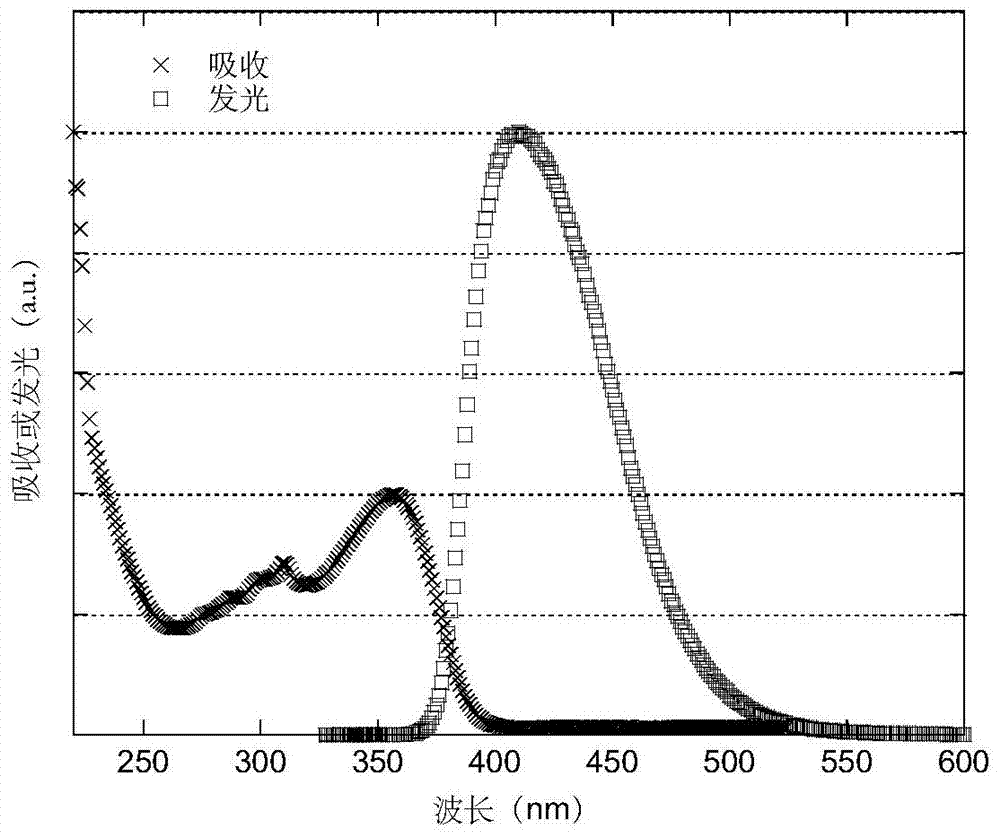

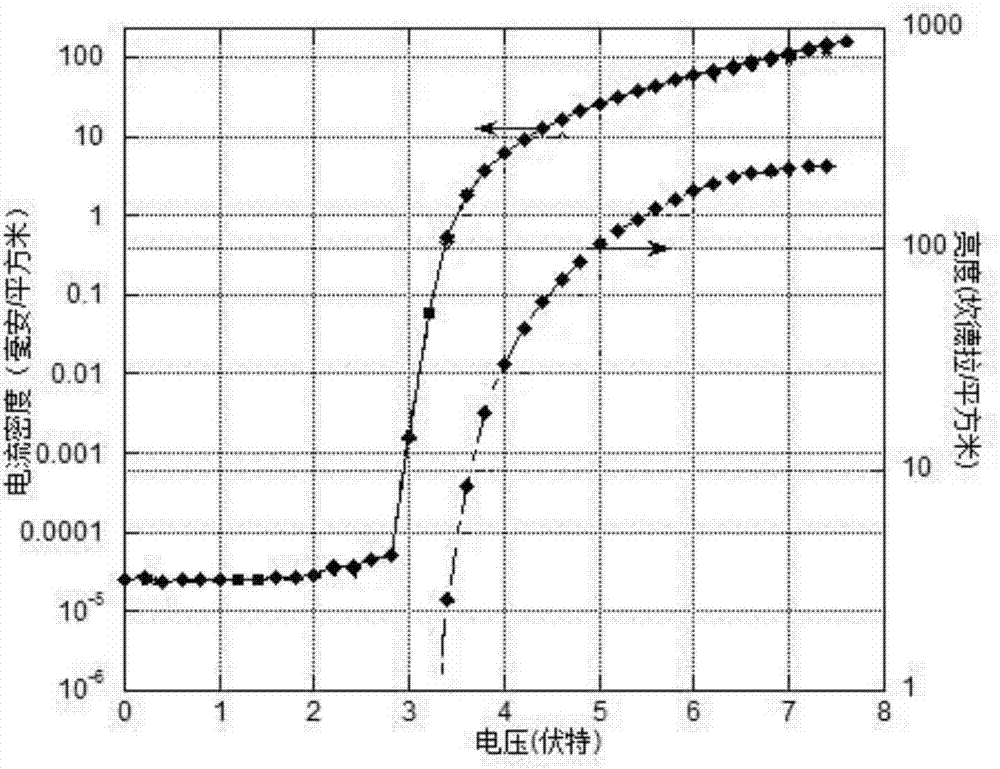

Luminescent materials based on thioxanthene-fluorene spiral structures and organic optoelectronic devices adopting the materials as luminescent layers

ActiveCN104263351ASingle structureMolecular weight determinationOrganic chemistrySolid-state devicesSuzuki reactionLight-emitting diode

The invention belongs to the technical field of photoelectric materials, and particularly relates to luminescent materials based on thioxanthene-fluorene spiral structures and organic photoelectric devices adopting the materials as luminescent layers. The luminescent materials adopts the thioxanthene-fluorene spiral structures as skeleton units. Intermediates are prepared through Ullmann reactions, and then the target compounds are obtained through Ullmann reactions or Suzuki reactions. The materials are single in structure and definite in molecular weight. The spiral structures of the materials can adjust an intermolecular accumulation manner, thus effectively inhibiting exciplex luminescence. The materials have deep meaning for development of high-effect devices. The organic photoelectric devices adopting the materials as the luminescent layers have good luminescent properties and can be used for small organic molecule light emitting diodes.

Owner:SOUTH CHINA UNIV OF TECH

Anode material lanthanum or Ac adulterated LiFePO4 of lithium ion secondary battery and its making method

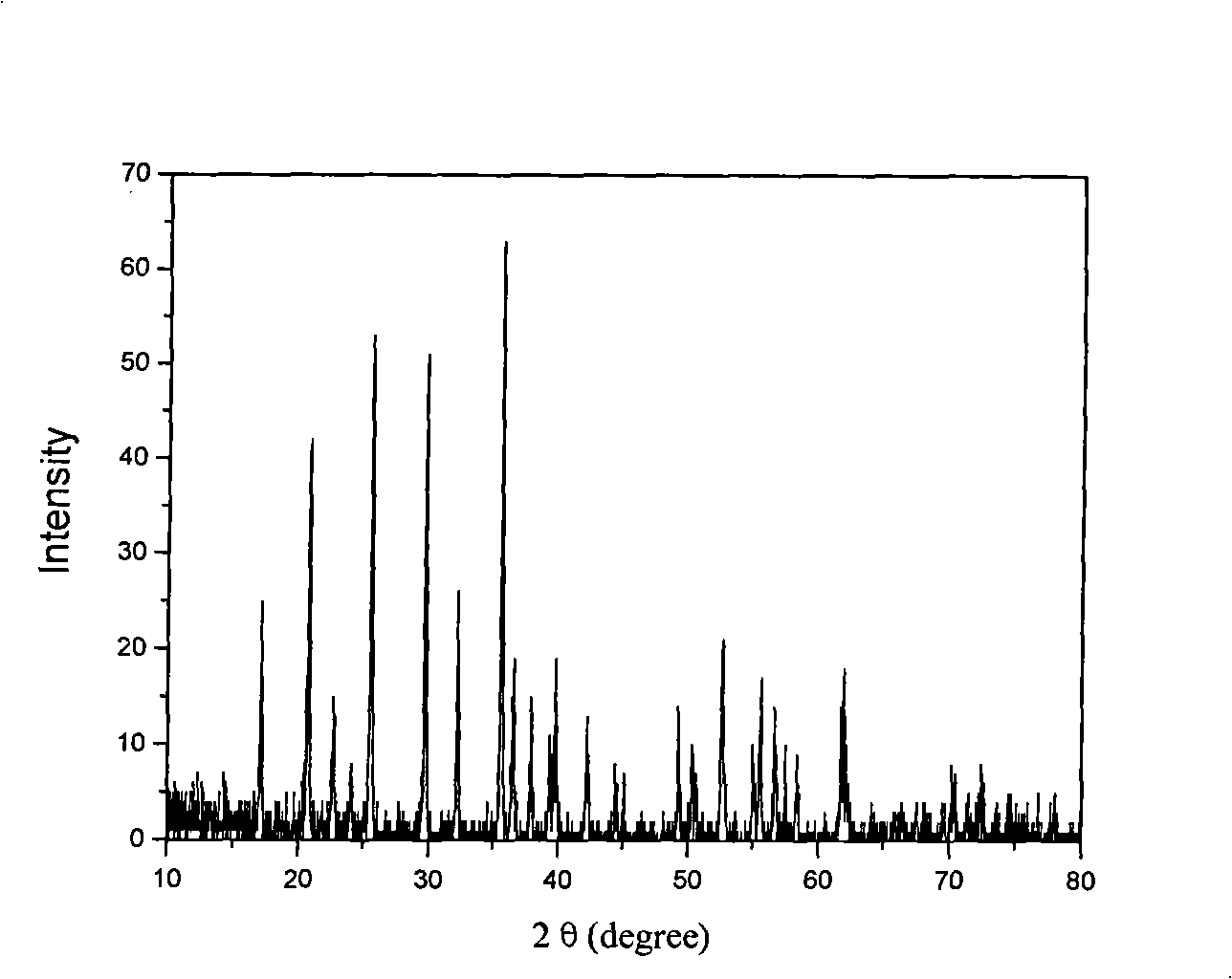

InactiveCN101150191AHigh charge and discharge capacityPromote crystallizationCell electrodesPhosphorus compoundsPhosphateVolumetric Mass Density

This invention relates to FeLiPO4 doped with La or Ac, positive material of Li ionic secondary cells and its preparation method characterizing that the formula is: LiMxFe1-xPO4 (M is La or Ac, 0.01<-x<-0.05) in the structure of olivine, the preparation includes the following steps: taking Li compound, Fe, phosphate, La or Ac as the raw materials to add them into a ball mill for wet mill then putting them into N2 and H2 mixed atmosphere for pre-calcining, then wet-grinding them and drying them and then ball-milling them, then putting them into N2 and H2 mixed atmosphere for secondary calcining to get the invented positive material. Advantages: fine crystalizatin, conduction performance of ions is good and discharge performance of heavy current is good, tap density is great and the problem of easy oxidation of Fe2+ is solved.

Owner:TIANJIN B&M SCI & TECH

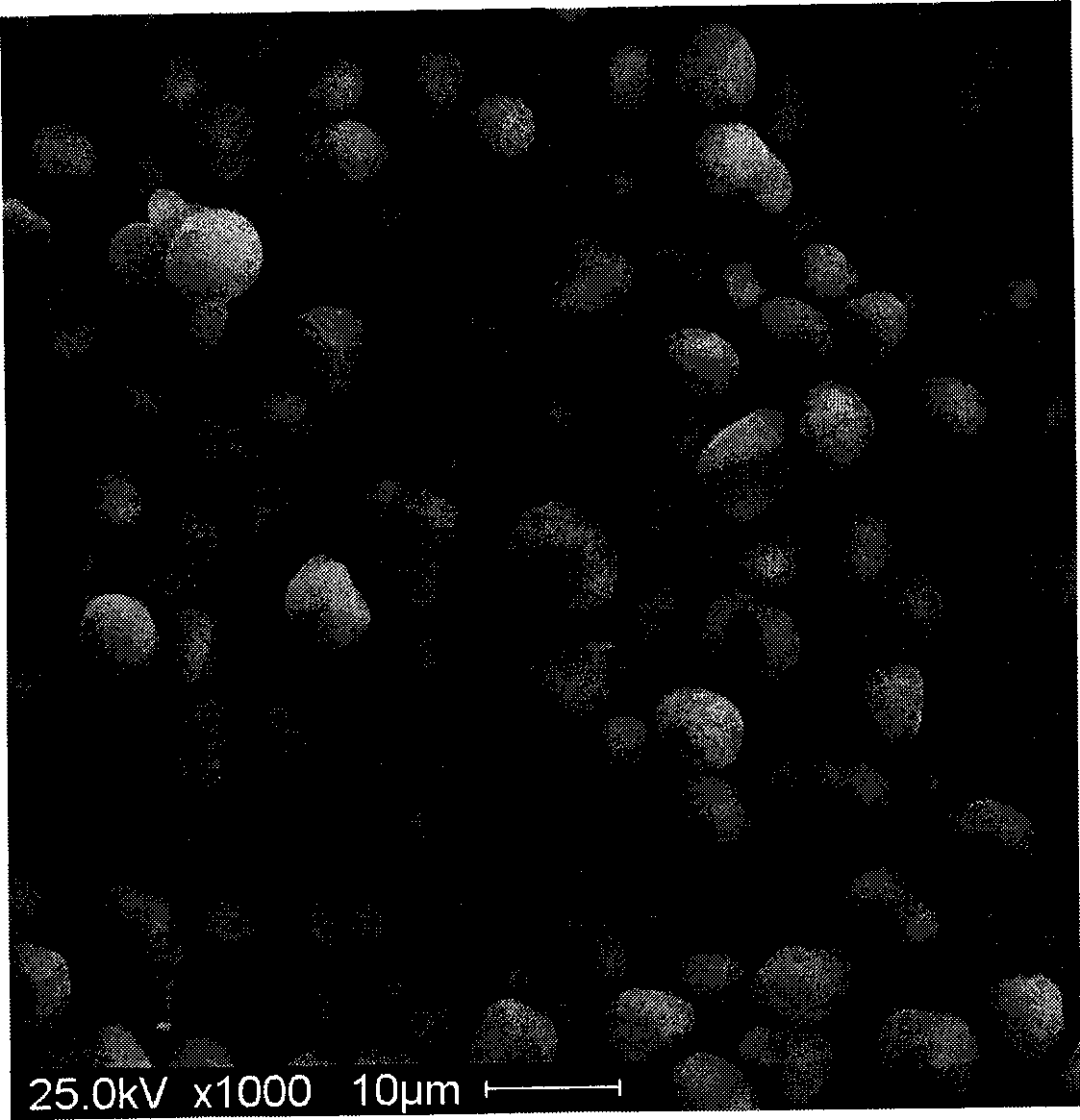

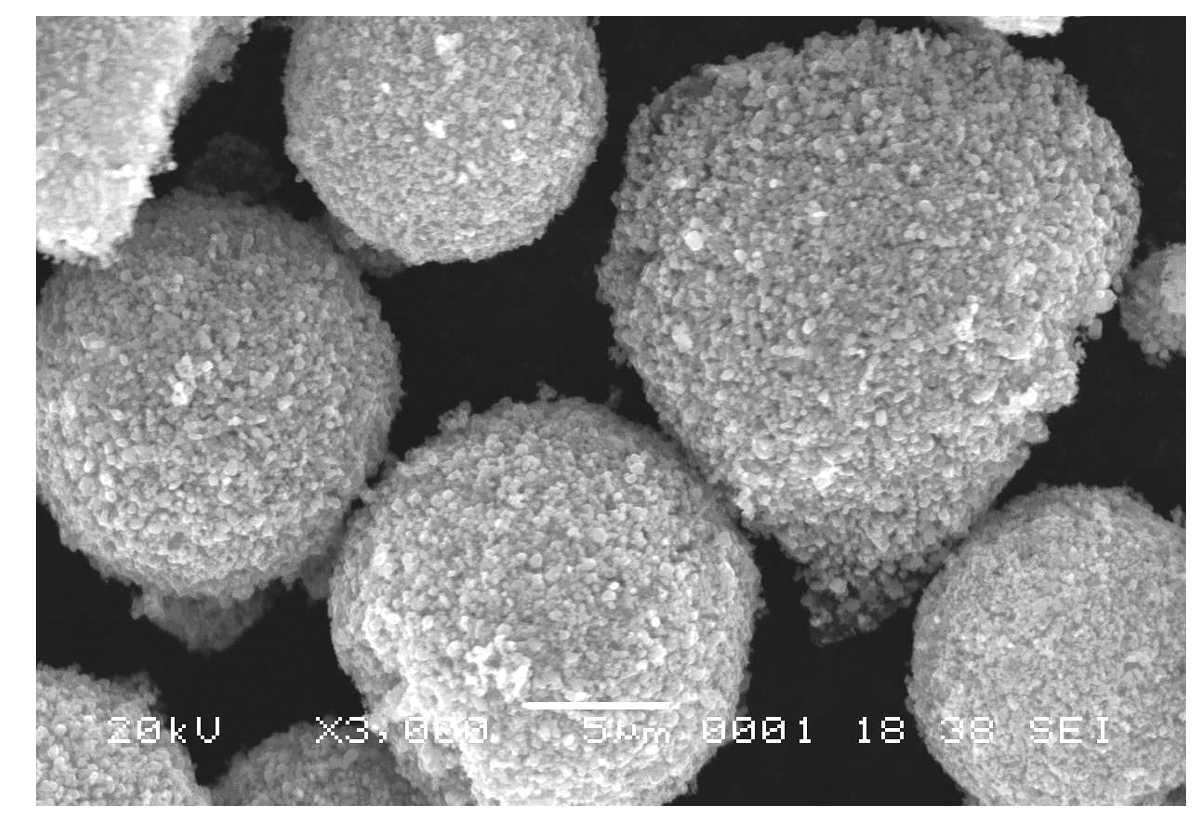

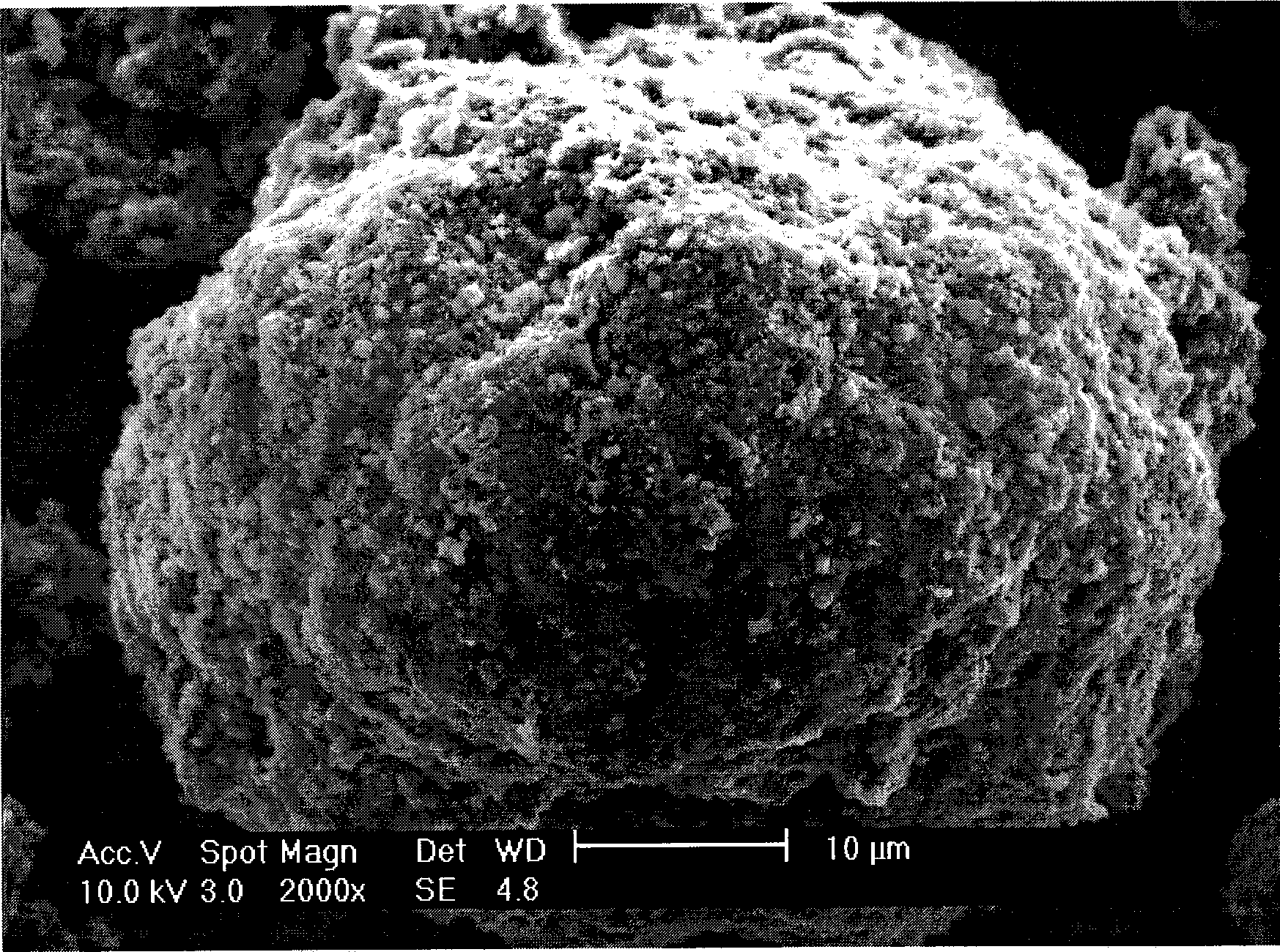

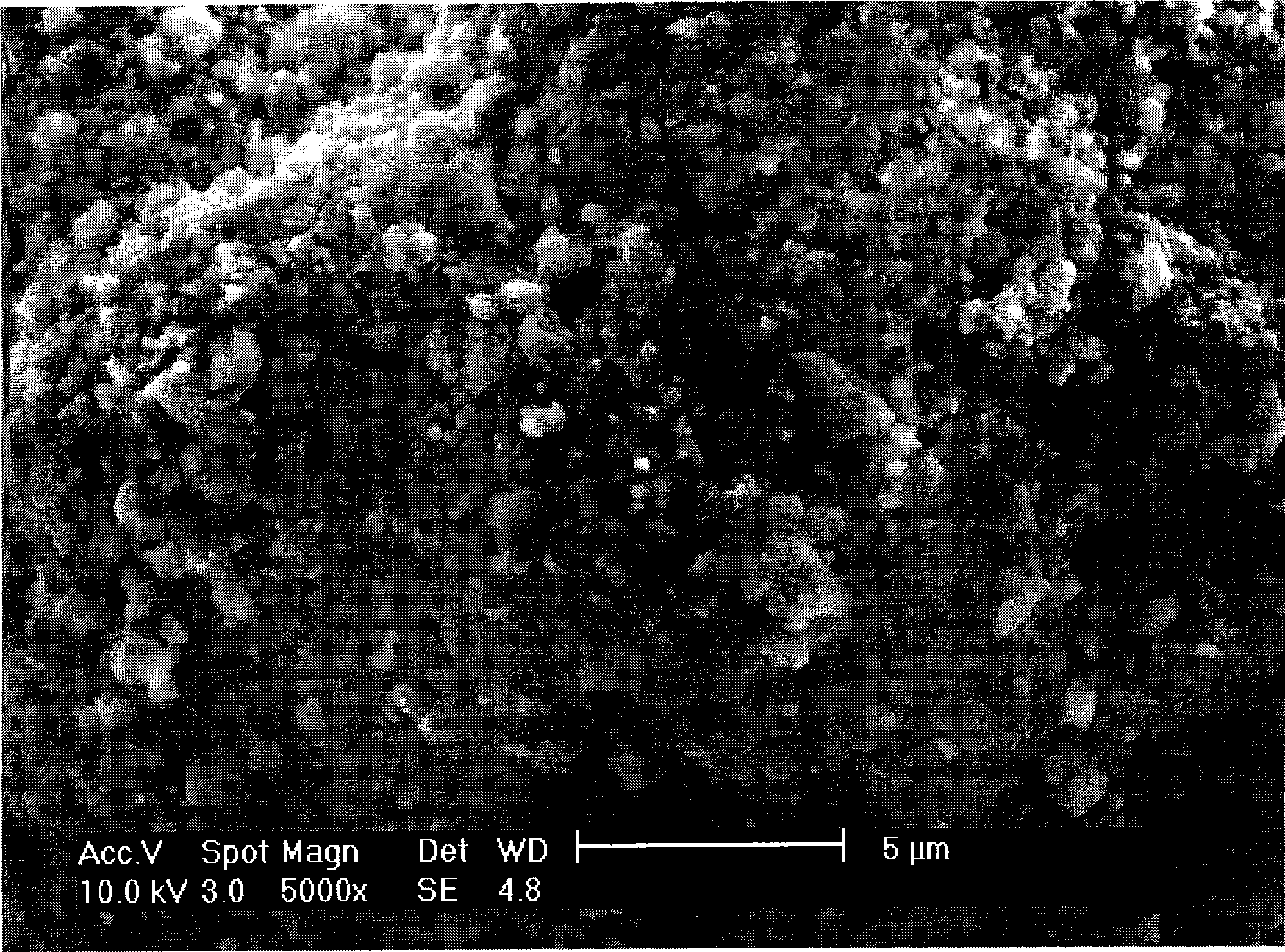

Method for preparing high-density spherical lithium iron phosphate for lithium ion power battery

InactiveCN101519199APromote crystallizationSingle structureElectrode manufacturing processesPhosphorus compoundsElectrical batteryVolumetric Mass Density

The invention relates to a method for preparing high-density spherical lithium iron phosphate for lithium ion power batteries, which is characterized by comprising the preparing processes: acid, a ferric iron resource and phosphor resource are mixed into mixed water solution; alkali is prepared into water solution; the mixed water solution and the alkali water solution are respectively and continuously introduced into a reaction kettle to carry out coprecipitation reaction, and a spherical iron phosphate precursor is synthesized; the precursor is used as a raw material and is evenly mixed with a lithium resource, a carbon resource and a doping metal compound, and then, the mixture is heated in a stove to obtain a spherical lithium iron phosphate powder material under a protective atmosphere. The spherical lithium iron phosphate powder material prepared by the method has freely controllable average grain diameter being from 4 microns to 15 microns, narrow distribution of the grain diameter tap density as higher as 1.4 g / cm<3> to 2.2 g / cm<3>, and has the characteristics of high specific capacity, rate discharge and good safety performance. The method has simple technical processes and is suitable for industrial mass production.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

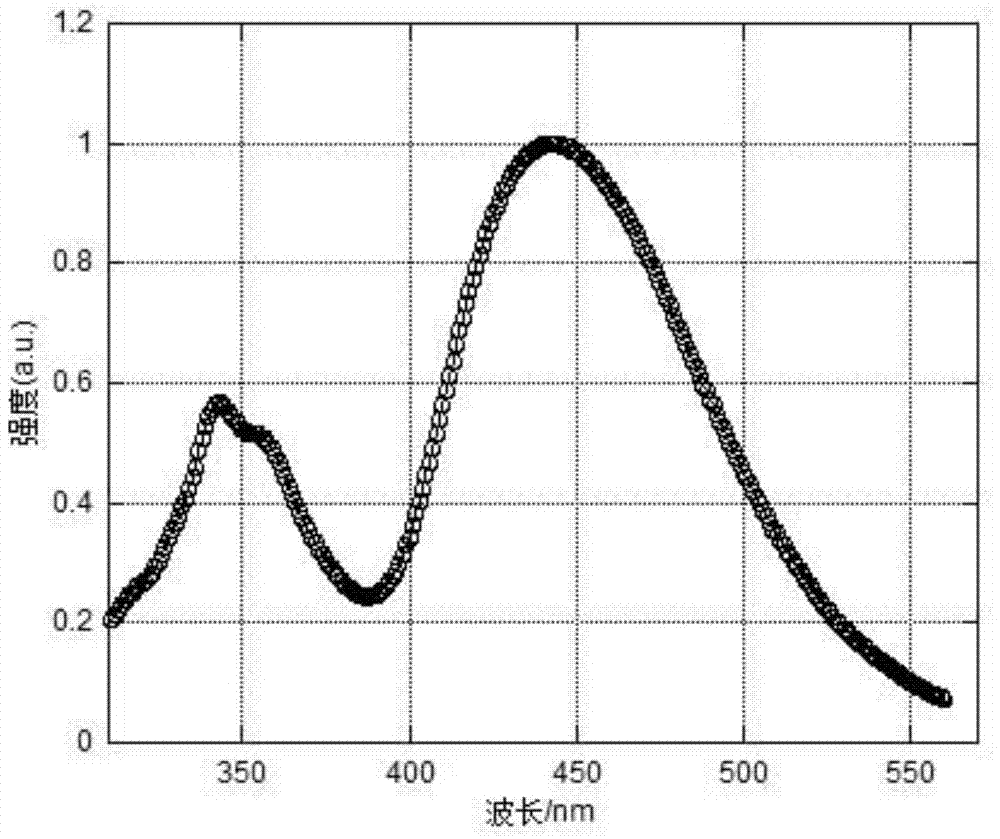

Glycosylated boron dipyrromethene fluorophore derivatives as well as preparation and application thereof

InactiveCN103755753AStrong penetrating powerLess likely to cause skin phototoxicitySugar derivativesEnergy modified materialsFluorophoreGlucoside

The invention discloses glycosylated boron dipyrromethene fluorophore derivatives as well as a preparation method and application of the glycosylated boron dipyrromethene fluorophore derivatives. The method comprises the following steps: by taking glucose and glucosides thereof as action targets, connecting covalent bonds of the action targets to boron dipyrromethene fluorophore derivatives for photodynamics therapy, so that a third generation photosensitizer against cancer which can be used for targeted therapy is obtained. The dipyrromethene fluorophore derivatives containing glucose and glucosides are taken as study researches, activity study of in-vitro breast cancer-resistant cells MBA-MD-231 is expanded, a prodrug suitable for molecular targeted therapy is screened, and a foundation is laid for applying the glycosylated boron dipyrromethene fluorophore derivatives to targeted therapy of cancers. Moreover, the compound synthesis method is simple, readily available in raw materials, low in cost, few in side reactions, high in yield and simple in purification, and industrial production is promoted.

Owner:FUZHOU UNIV

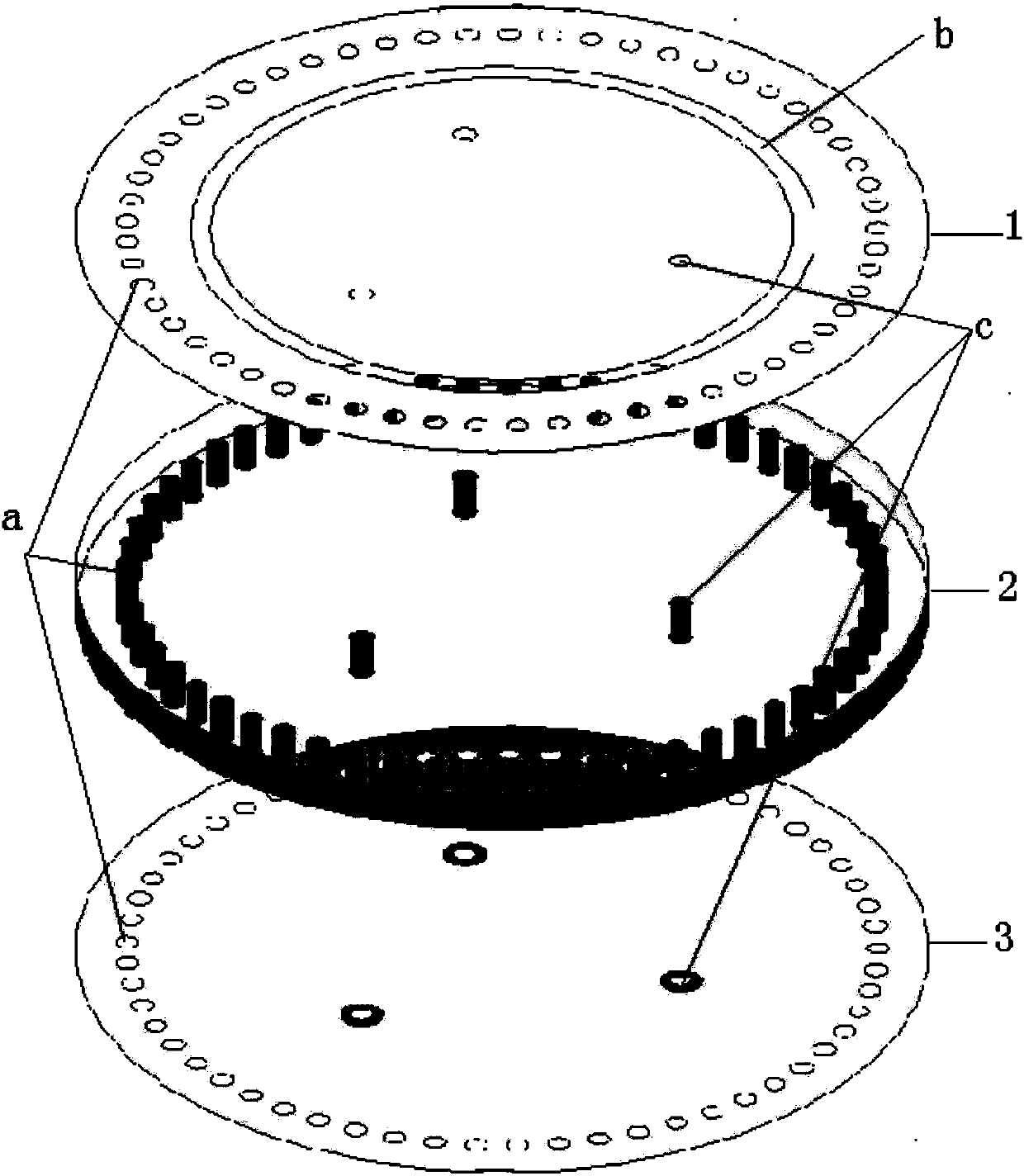

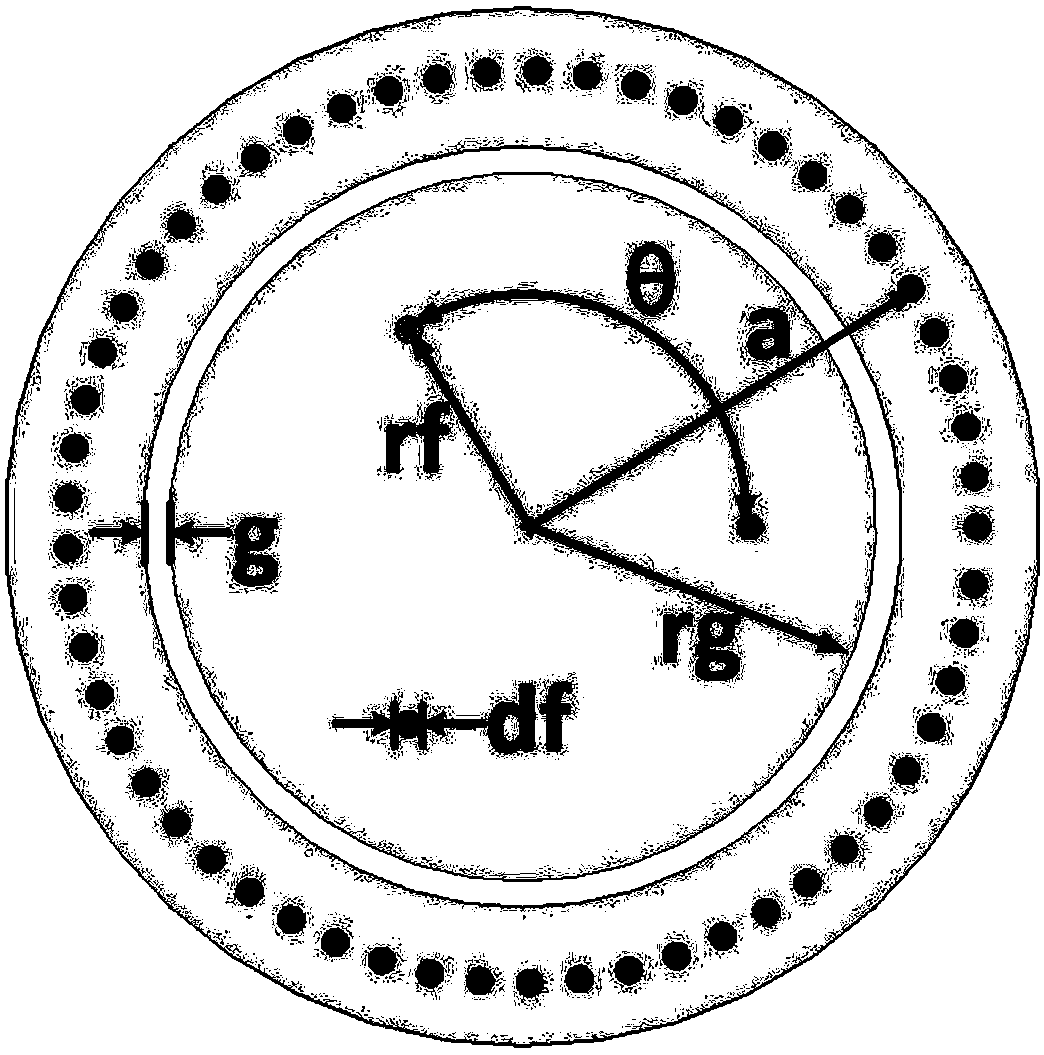

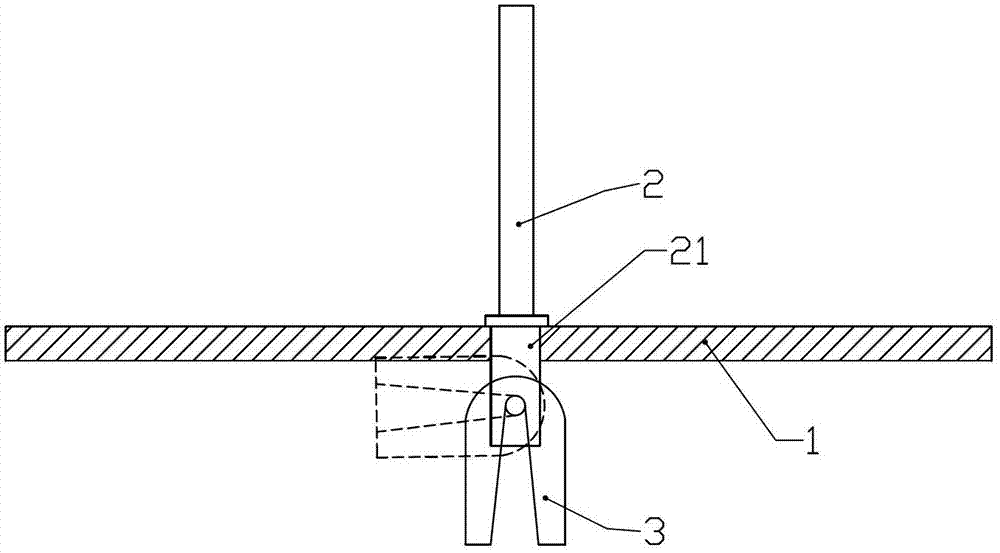

SIW ring slot antenna generating dual-mode OAM vortex electromagnetic waves

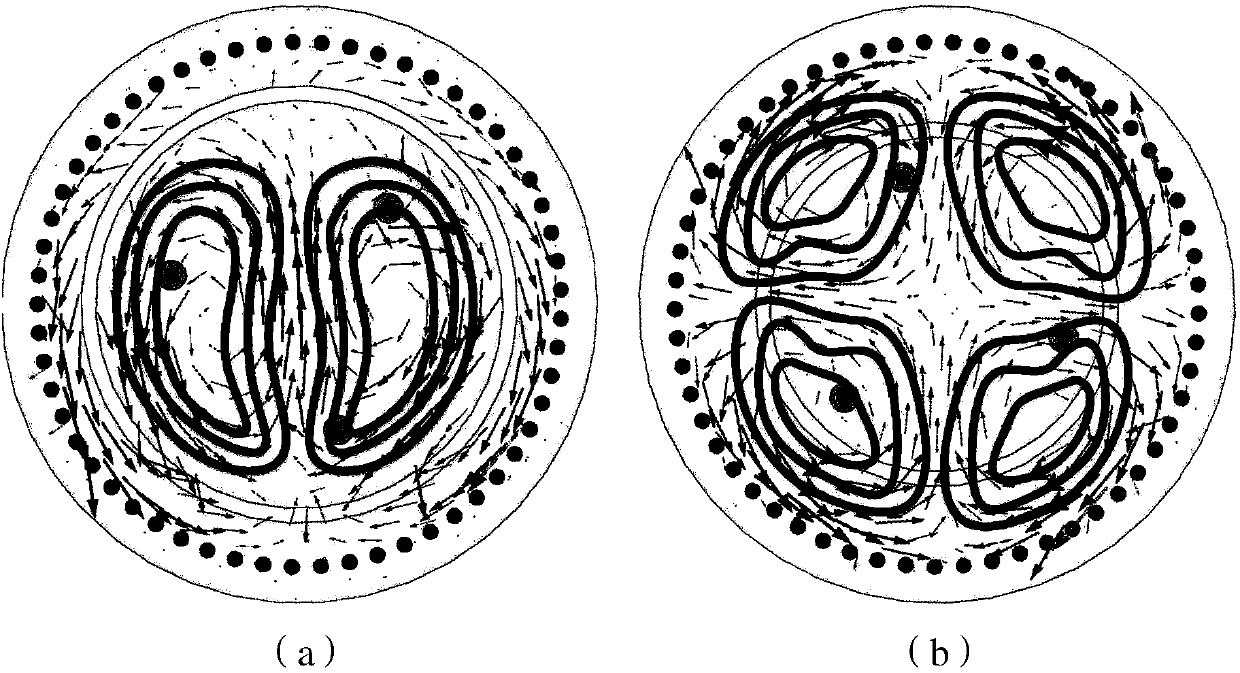

InactiveCN107611600AAvoid designSmall sizeRadiating elements structural formsAntennas earthing switches associationCoaxial probeDual mode

The invention belongs to the technical field of wireless communication, and discloses a SIW ring slot antenna generating dual-mode OAM vortex electromagnetic waves. The cross section of the SIW ring slot antenna is a circular cross section, and the center of circle is O. The SIW ring slot antenna is composed of an upper metal surface, an intermediate dielectric substrate and a lower metal surface.The SIW ring slot antenna is provided with multiple metalized through holes, a ring radiation slot and three feed coaxial probes which are arranged from outside to inside in turn. Multiple metalizedthrough holes are uniformly arranged along the circumference. The ring radiation slot is etched on the upper metal surface. The three feed coaxial probes are three solid metal columns which are uniformly distributed in the internal side of the ring radiation slot along the circumferential direction. According to the SIW ring slot antenna, the design of the complex feed network can be avoided, thesize of the antenna can be reduced and the compactness and the degree of integration of the antenna can be enhanced.

Owner:XIDIAN UNIV

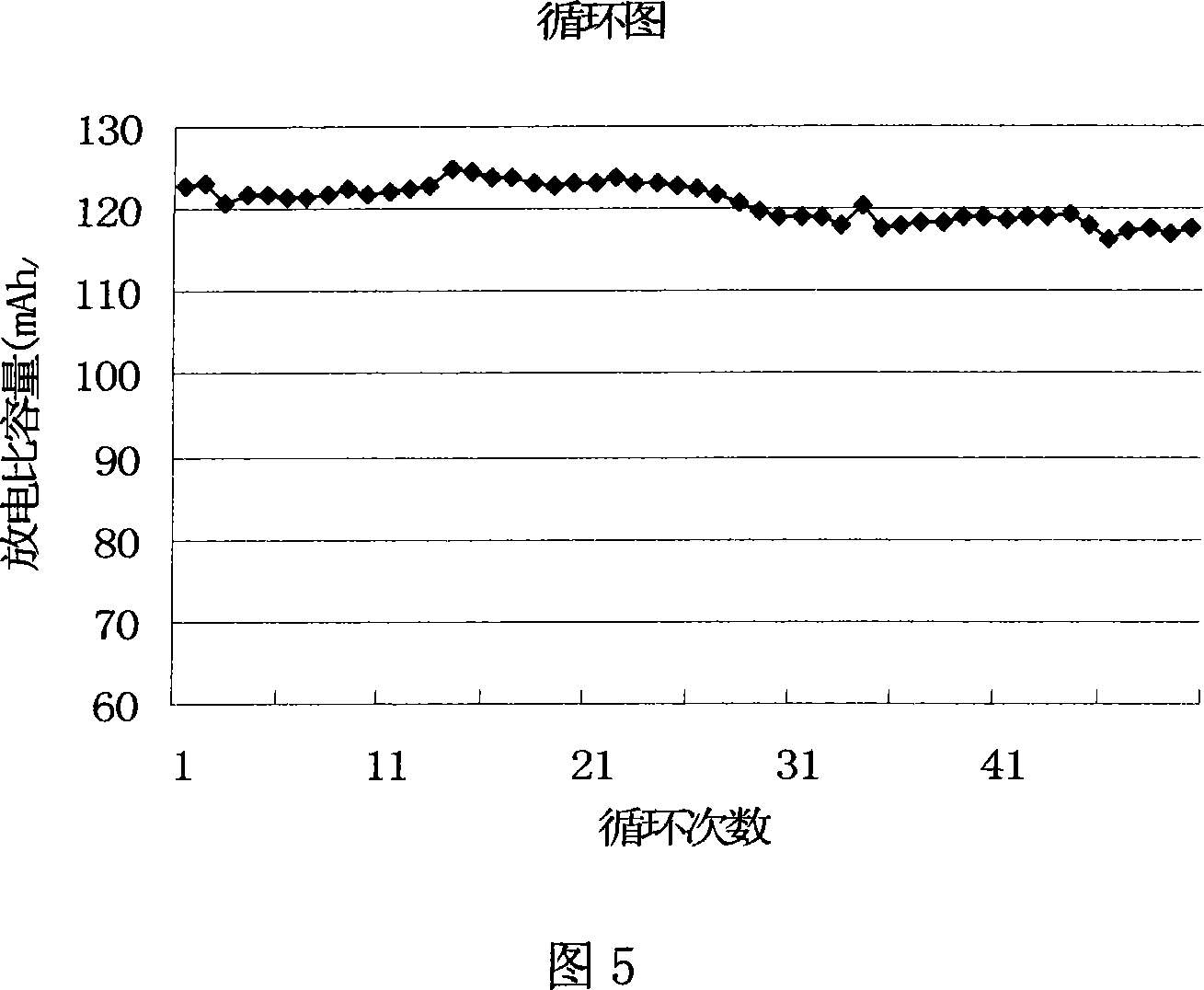

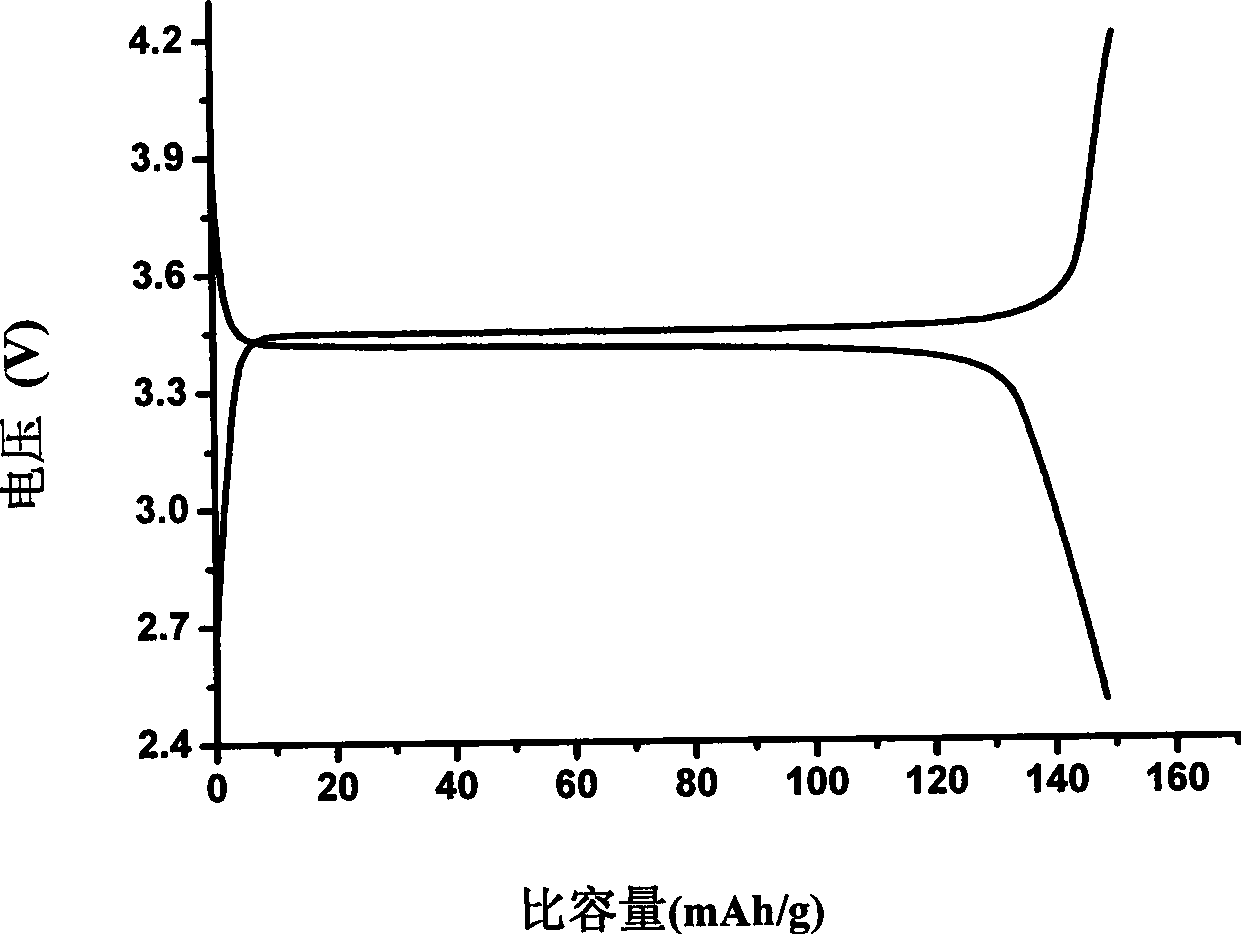

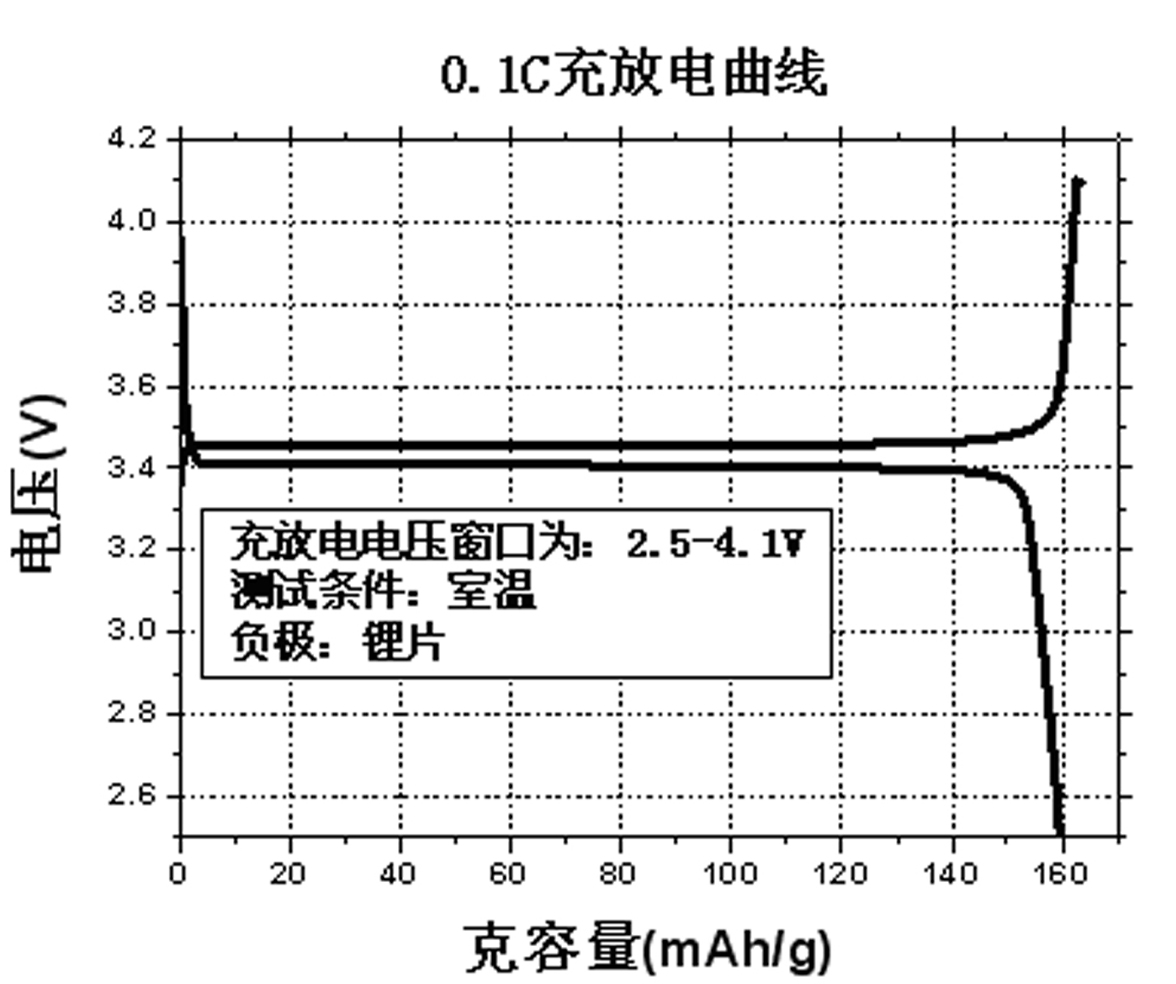

Method for preparing high-density lithium ferric phosphate

ActiveCN102009970AEvenly combinedImprove bindingCell electrodesPhosphorus compoundsPhosphatePotassium

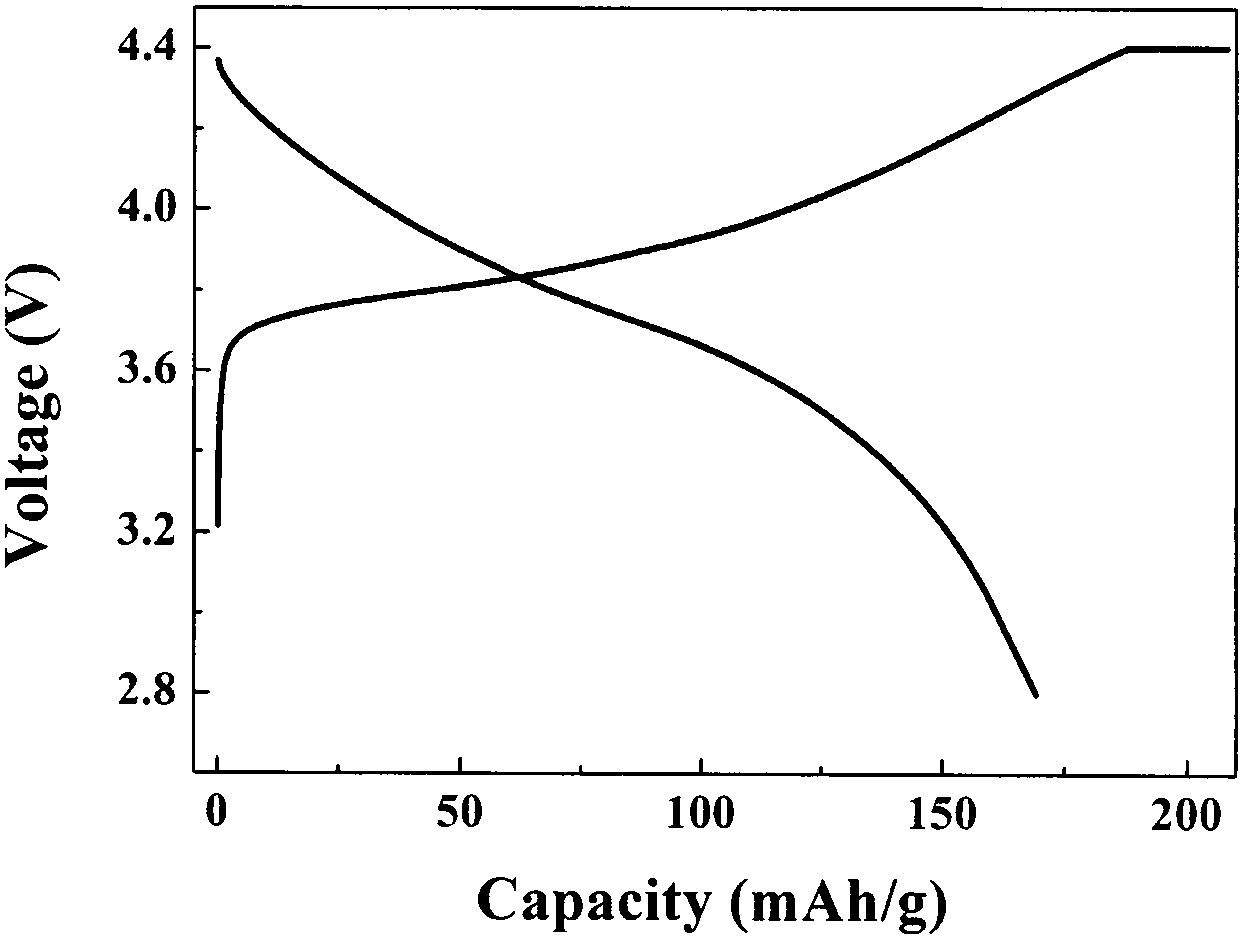

The invention relates to a method for preparing high-density lithium ferric phosphate, which comprises the following steps of: adding a lithium salt, a ferric salt, a phosphorus-containing compound and doping metal-containing elements into a dispersing agent by the conventional method, and performing ball mill twice; performing drying and predecomposition for 3 to 10 hours; crushing, adding at least one of lithium dihydrogen phosphate or potassium dihydrogen phosphate as a bonding agent in an amount which is 1 to 5 percent based on the weight of a predecomposition product, performing ball mill for 1 to 5 hours, and processing according to the prior art to obtain the high-density lithium ferric phosphate. In the method, the ball mill is performed twice in the first step, so that granules are fine; the grain size can be controlled within the range of between 300 and 2,000 nanometers, so that raw materials are mixed uniformly; more importantly, due to the addition of the bonding agent, the bonding among the granules is enhanced, the stacking density of products is improved, and contact conductivity among the granules is reduced; and the prepared products have good crystallization, simple structure and uniform grain fineness distribution and do not contain impure phases, the tap density is between 1.4 and 1.8 g / cm<3>, the specific surface area is between 5 and 11m<2> / g, the compaction density of pole pieces is between 2.4 and 2.8 g / cm<3>, and the specific capacity of first discharging at the room temperature is between 140 and 160 mAh / g.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Method for preparing cathode material of lithium iron phosphate

InactiveCN101519198ANo impuritiesSingle structureCell electrodesPhosphorus compoundsLithium iron phosphatePhosphate

The invention discloses a method for preparing a cathode material of lithium iron phosphate for a lithium ion battery. The method comprises the following steps: firstly, adding a certain amount of deionized water into a ball mill, and adding lithium dihydrogen phosphate and ionic compound with good conductivity into the ball mill for stirring and ball milling at a high speed; secondly, adding iron oxide for stirring and ball milling at a high speed, and adding a certain amount of anhydrous ethanol as a dispersing agent; and finally, adding superfine conductive carbon black for full mixing and stirring to obtain evenly mixed powder by spray drying at a high speed, adding the powder into a mixing roll for mixing and granule crushing, and pressing the mixed powder into a block to improve the density of materials once again. After being preserved and sintered for 2 to 6 hours at 600 to 800 DEG C in a non-oxidizing sintering furnace and cooled below 50 DEG C, the materials after tablet pressing and granulation are discharged, crushed, refined and sifted, and the powder is dried so as to obtain lithium iron phosphate powder with no impurities, single structure and small granule size distribution. In addition, the preparation process method through improvement significantly reduces the cost for preparing the lithium iron phosphate and has little pollution.

Owner:丁建民

Flexible nanofiber-based electronic skin as well as preparation method

ActiveCN105671962AGood biocompatibilityEasy to carryFibre treatmentSynthetic resin layered productsBiocompatibility TestingNanostructure

The invention relates to a flexible nanofiber-based electronic skin as well as a preparation method, and belongs to the field of flexible sensors. The flexible nanofiber-based electronic skin is characterized in that the electronic skin is prepared by attaching two layers of flexible nanofiber membranes which are treated by conductive treatment, and the thickness of the flexible nanofiber membrane is 30-500[mu]m, wherein at least one surface of the two surfaces which are attached is provided with micro groove or micro protrusion structures. The electronic skin solves the problems of high working voltage, large power consumption and low sensitivity in prior art; the electronic skin has the effects of sensitive layers and conductive electrodes with a single structure and a simple process, and the electronic skin can be used for industrial production; the electronic skin has good biocompatibility and can be well integrated with a human skin, and is convenient for constructing a wearable device; a unique nanostructure is applied to the electronic skin, so that the electronic skin has higher sensitivity and better stability; and the whole device is light, small, smart and is convenient for carrying.

Owner:WUHAN TEXTILE UNIV

Erlotinib modified 4-difluoro-4-borata-3a-azonia-4a-aza-s-indacene derivatives, and preparation method and application thereof

InactiveCN104387412AIncrease intakeEnhanced selective uptakeEnergy modified materialsGroup 3/13 element organic compoundsTumor targetErlotinib

The invention discloses erlotinib modified 4-difluoro-4-borata-3a-azonia-4a-aza-s-indacene derivatives, and a preparation method and application thereof. According to the invention, erlotinib which is a listed small-molecule inhibitor is used as a tumor target and is covalently connected to a 4-difluoro-4-borata-3a-azonia-4a-aza-s-indacene photosensitizer capable of being used for photodynamic therapy by the click reaction so as to obtain third-generation anti-tumor photosensitizers capable of being used for targeted therapy, namely, a double-erlotinib modified 4-difluoro-4-borata-3a-azonia-4a-aza-s-indacene derivative and a single-erlotinib modified 4-difluoro-4-borata-3a-azonia-4a-aza-s-indacene derivative. Meanwhile, by using the erlotinib modified 4-difluoro-4-borata-3a-azonia-4a-aza-s-indacene derivatives as research objects and respectively using human body hepatoma carcinoma cells HepG2 and HELF (Human Embryonic Lung Fibroblast) as tested cell strains, research on in vitro anti-tumor activity of the erlotinib modified 4-difluoro-4-borata-3a-azonia-4a-aza-s-indacene derivatives is developed, a prodrug suitable for molecular targeted therapy is screened out and the foundation is laid for application of the erlotinib modified 4-difluoro-4-borata-3a-azonia-4a-aza-s-indacene derivatives to targeted therapy of cancers. A synthetic method of the derivatives is simple; raw materials of the derivatives are easy to obtain and low in cost, have few side effects and high yield, are easy to purify and are beneficial to industrial production.

Owner:FUZHOU UNIV

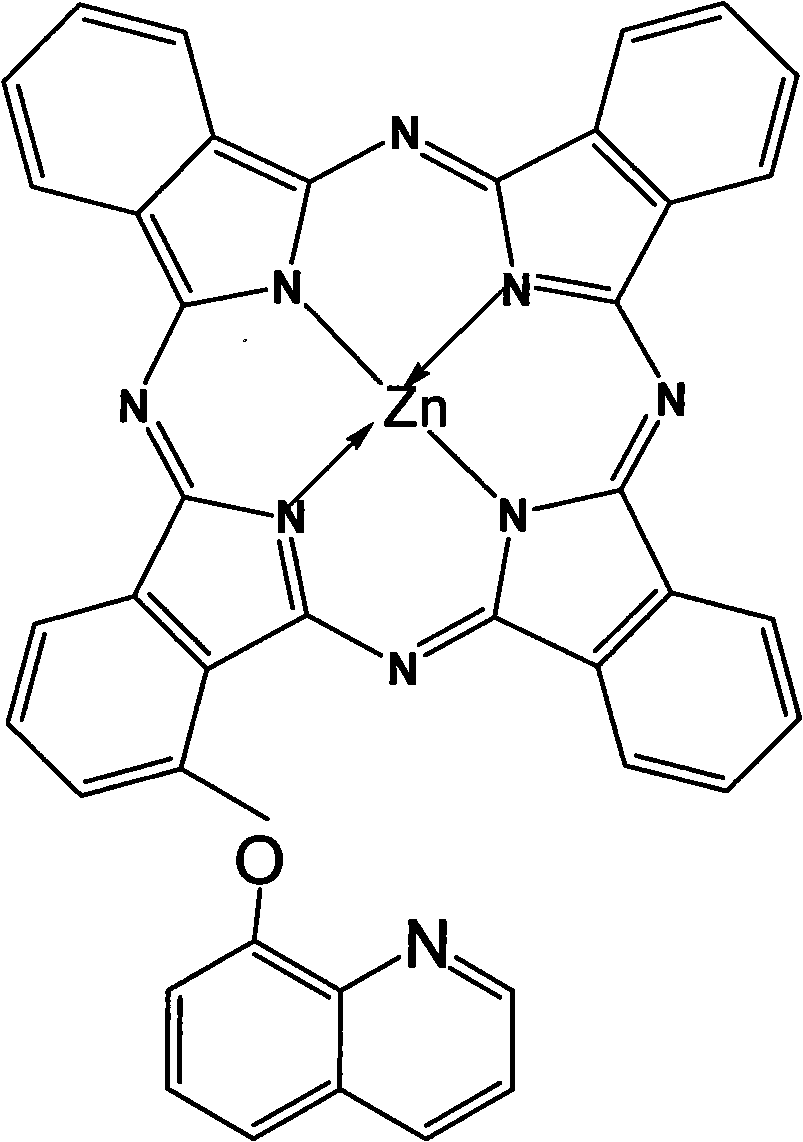

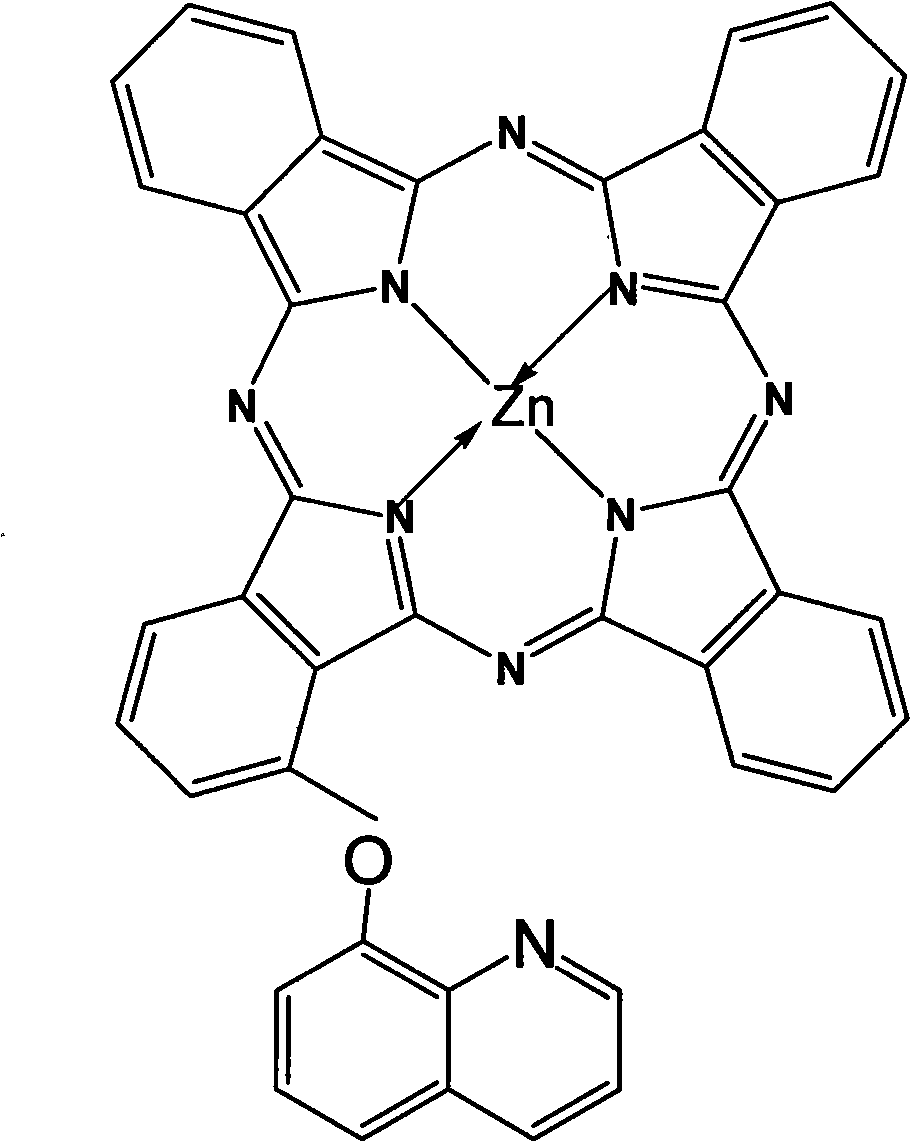

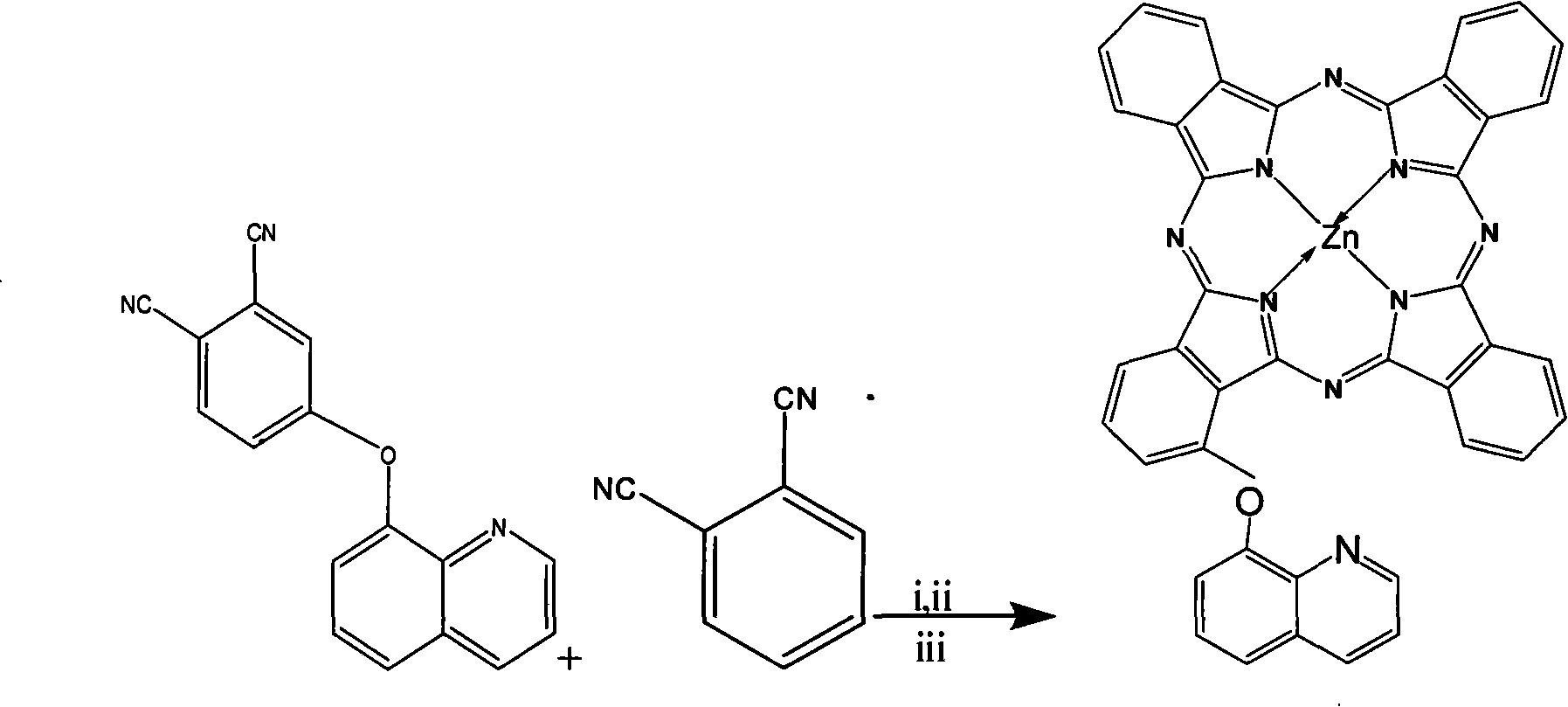

Alpha-(8-quinolineoxy)mono-substituted zinc phthalocyanine and preparation method thereof

ActiveCN101260110ASingle structureEasy to purifyZinc organic compoundsCoordination geometryZinc phthalocyanine

The invention provided an alpha-(8-quinoly) single substituted zinc phthalocyanine and a preparation method thereof, with the molecular formula of C41H21N9OZn; the preparation method is as follows: 8-hydroxyl quinoly and 3- nitrophthalonitrile are adopted as the original substances to synthesize 3-(8- quinoly) phthalonitrile; then 3-(8- quinoly) phthalonitrile, phthalonitrile, and the corresponding zinc salt are adopted as the original substances to synthesize a coordination compound of Phthalocyanine-zinc under the DBU catalysis, and then the coordination compound of Phthalocyanine-zinc is separated to obtain the final product. The coordination compound provided by the invention has a single structure without any isomer, and is characterized in defined structure and easy separation. The coordination compound can be applied in the high-tech fields such as the preparation of novel anti-cancer drugs.

Owner:FUZHOU UNIV

Method for preparing ferric phosphate lithium anode material combining solid and liquid

A method for preparing a lithium iron phosphate anode material through solid-liquid combination comprises the following steps that a lithium source compound, an iron source compound, a phosphoric acid and phosphorus source compound and a small amount of carbonic organic precursor are weighed in proportion and mixed evenly, and then dried at a temperature of between 80 and 120 DEG C; the dried mixture undergoes ball milling inside a star-type ball-milling tank for 10 to 60 minutes so as to obtain a precursor powder material; the precursor powder material undergoes sweeping in the inert atmosphere or the reducing atmosphere for 3 to 5 minutes and then is sealed; the precursor powder material is heated to 400 to 800 DEG C at a heating rate of between 1 and 30 DEG C / min, and the temperature is maintained for 3 to 8 hours; and finally, the material is cooled down to room temperature, and is crushed to prepare lithium iron phosphate powder. Due to adopting solid-liquid combined raw materials, the method not only ensures that the raw materials are mixed more evenly, but also provides effective reducing atmosphere to synthesize the anode material with excellent electrochemical property during later sintering; moreover, a high-temperature solid-liquid combination method is adopted to reduce reaction temperature, reaction time and production cost.

Owner:CHONGQING TERUI BATTERY MATERIAL

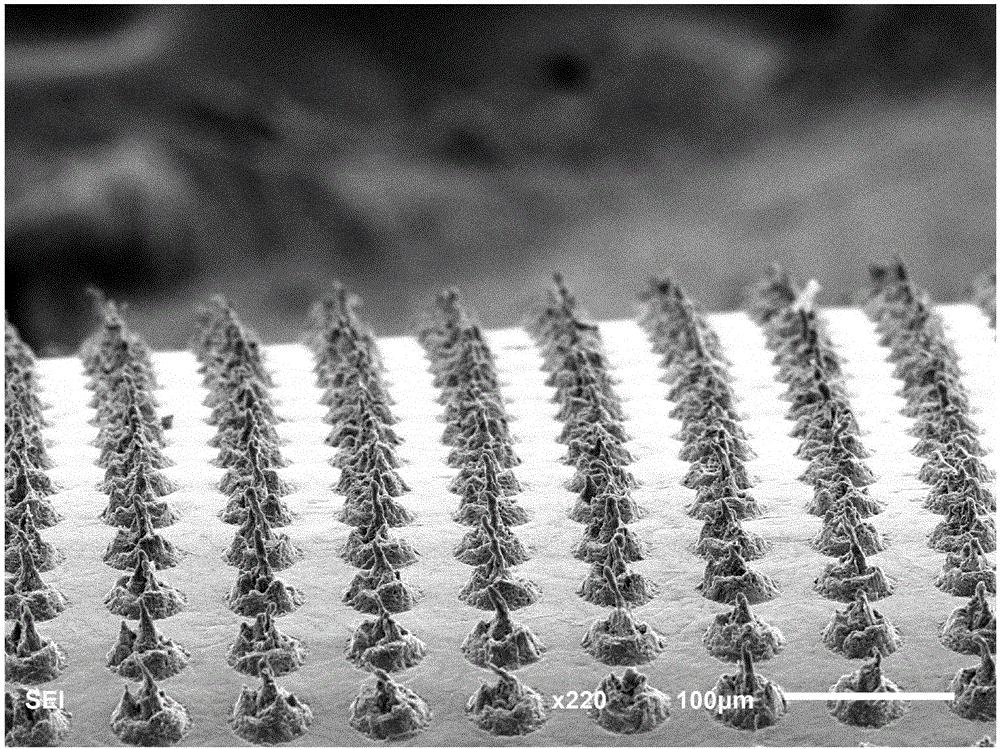

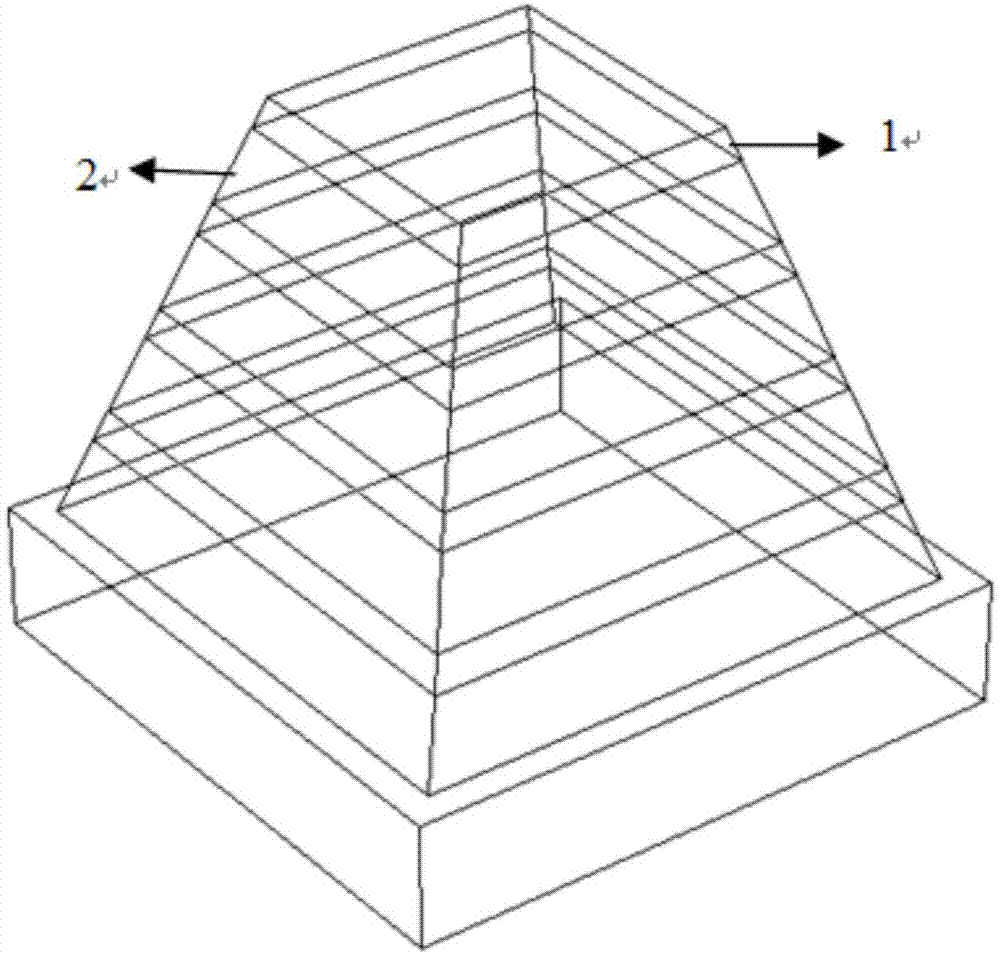

Structure of broadband wave absorber and preparation method

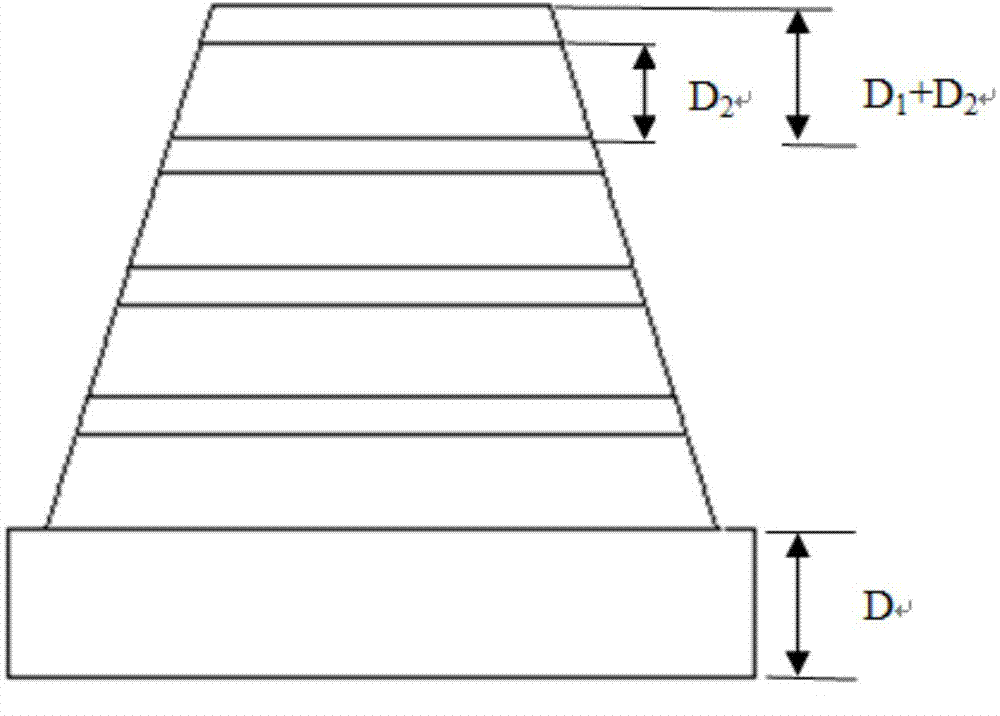

The invention provides a structure of a broadband wave absorber and a preparation method. The structure comprises a substrate layer and a half-pyramid structure arranged on the substrate layer, wherein the half-pyramid structure is formed by alternately stacking and combining multiple metal-medium layers, the size of the structure is decreased progressively from bottom to top in the Z direction, the structure is a symmetrical structure, and the axis of symmetrical is a connecting line of centers of the metal-medium layers. A substrate is coated with the metal-medium layers sequentially with a coating method, and then the half-pyramid structure is etched. The structure is simple: the structure of the wave absorber is single and convenient to prepare. The spectrum is easy to measure: at the measurement stage, the band ranging from 8 mu m to 14 mu m is a middle infrared band, and the transmission and reflection spectrum of the structure can be acquired easily by the aid of existing equipment, so that the absorption spectrum is acquired.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

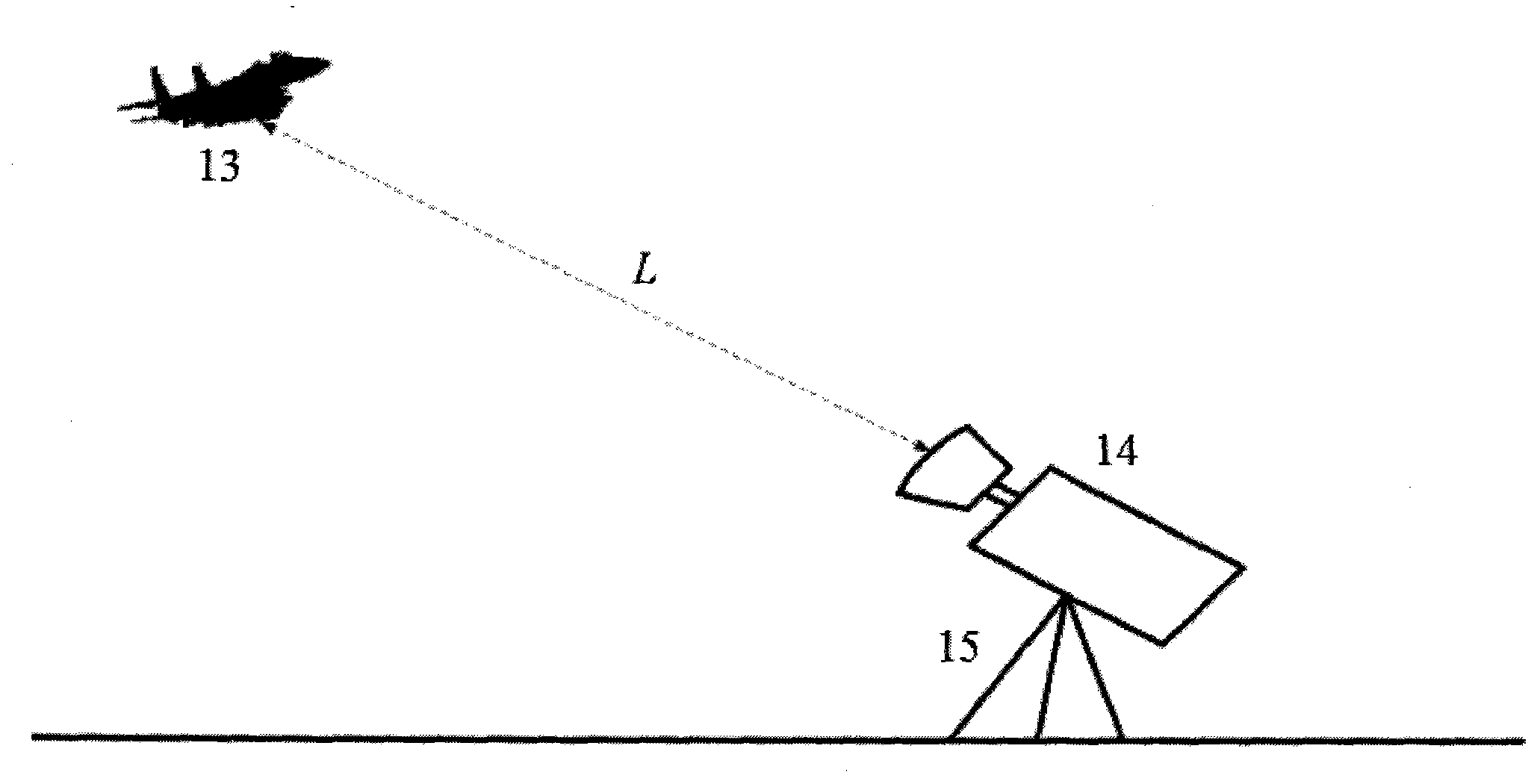

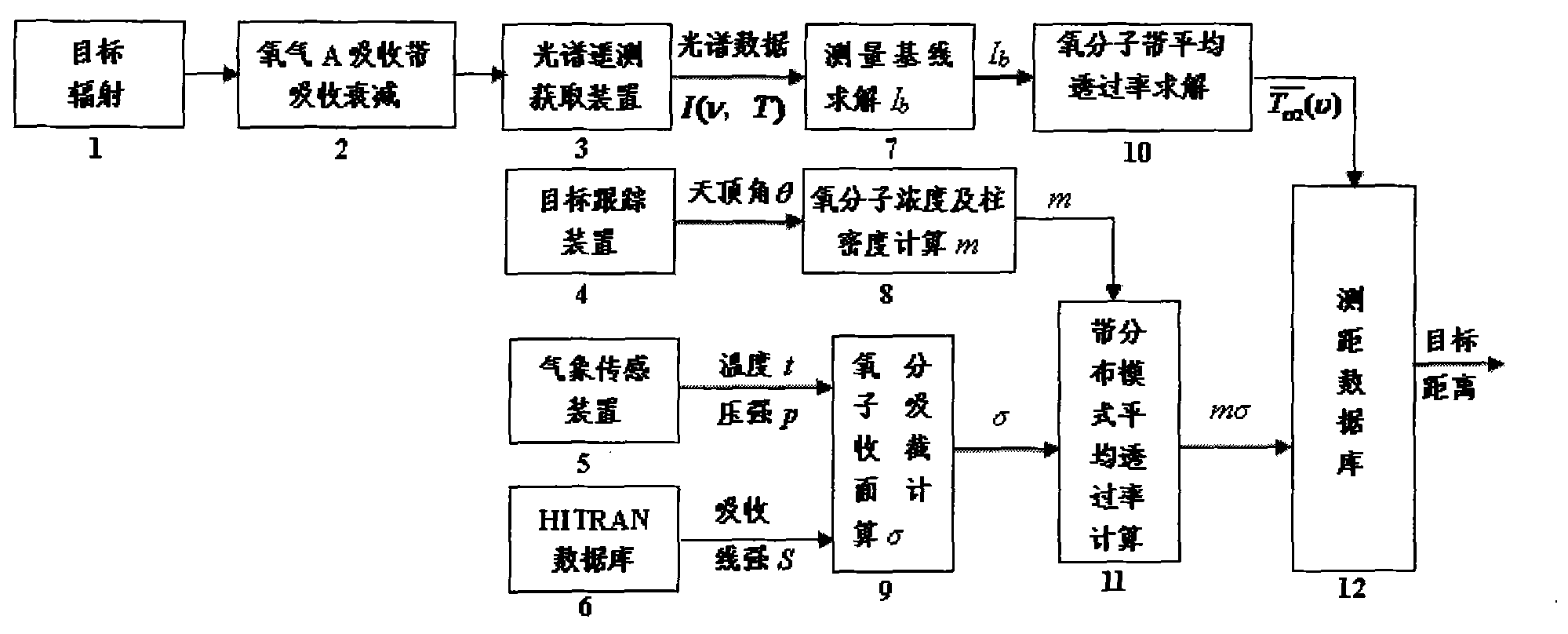

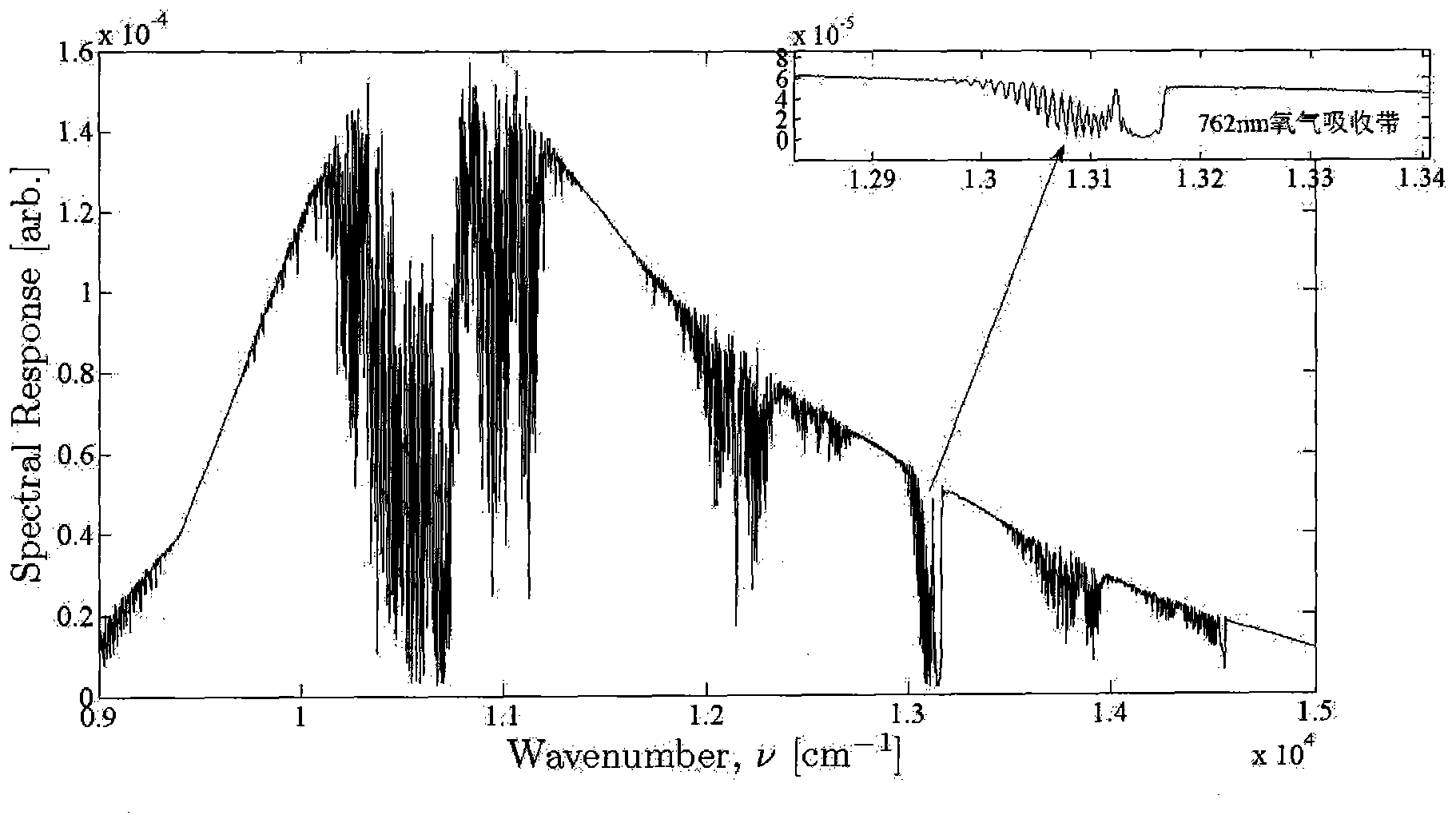

Passive distance measuring method based on target infrared radiation spectrum and band model

InactiveCN103728612ALong detection distanceImprove measurement reliabilityUsing reradiationAtmospheric sciencesCountermeasure

The invention discloses a passive distance measuring method based on a target infrared radiation spectrum and a band model. The method comprises the steps of (a) acquiring measurement data necessary for distance inversion through a corresponding sensing device, (b) establishing a distance measuring model based on the band model, and (c) establishing a passive distance measuring database and conducting object distance inversion. According to the method, the fact that the oxygen is evenly distributed in the atmosphere is utilized, a selected oxygen A absorption band is unitary in spectral line structure and has obvious features, an absorption cross section can be easily and accurately solved, interference of other gases in the atmosphere on measurement is avoided, oxygen concentration is stable, the influence of weather and districts is well avoided, and the established distance measuring model based on the band model solves the real-time problem during distance inversion. The technology not only can be used for fixing roadbed stations, but also can be applied to vehicle-mounted or airborne motion platforms, and has important application prospect in respect of infrared search and track systems and optoelectronic countermeasure.

Owner:ZHONGBEI UNIV

Benzene-substituted phenothiazine unit-based luminescent material, intermediate thereof and organic photoelectric device made by luminescent material

ActiveCN104293349ASingle structureGood reproducibility for multiple synthesisOrganic chemistrySolid-state devicesBenzeneSuzuki reaction

The invention belongs to the technical field of photoelectric material, and concretely relates to a benzene-substituted phenothiazine unit-based luminescent material, an intermediate thereof and an organic photoelectric device made by the luminescent material. The luminescent material takes phenothiazine as an initial reaction raw material, the intermediate is prepared through an Ullmann reaction, and a target compound is obtained through the Ullmann reaction or a Suzuki reaction. The material has the advantages of single structure and definite molecular weight; has high decomposition temperature and low sublimation temperature, and the luminescent material with high purity cab can be easily obtained through sublimation. The material has good luminescence performance as a luminescent layer of the organic photoelectric device and can be used for an organic micromolecule light emitting diode.

Owner:SOUTH CHINA UNIV OF TECH

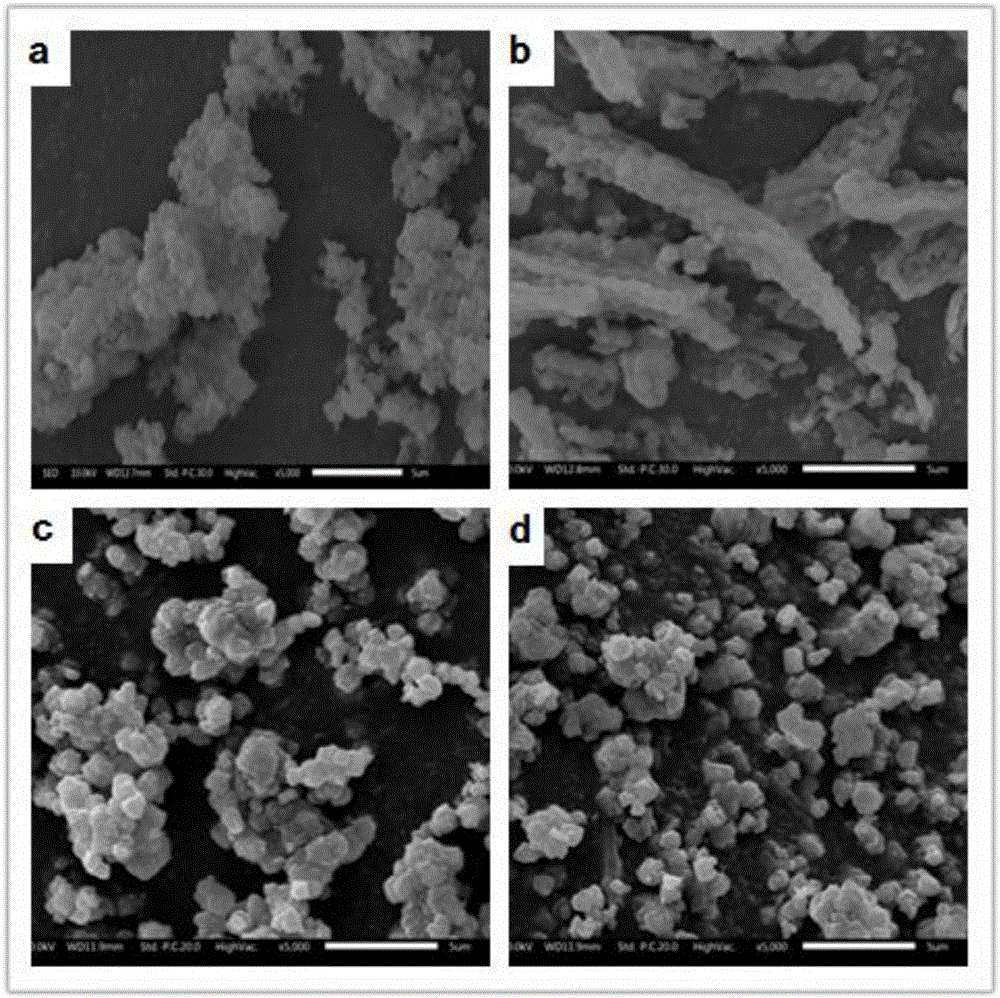

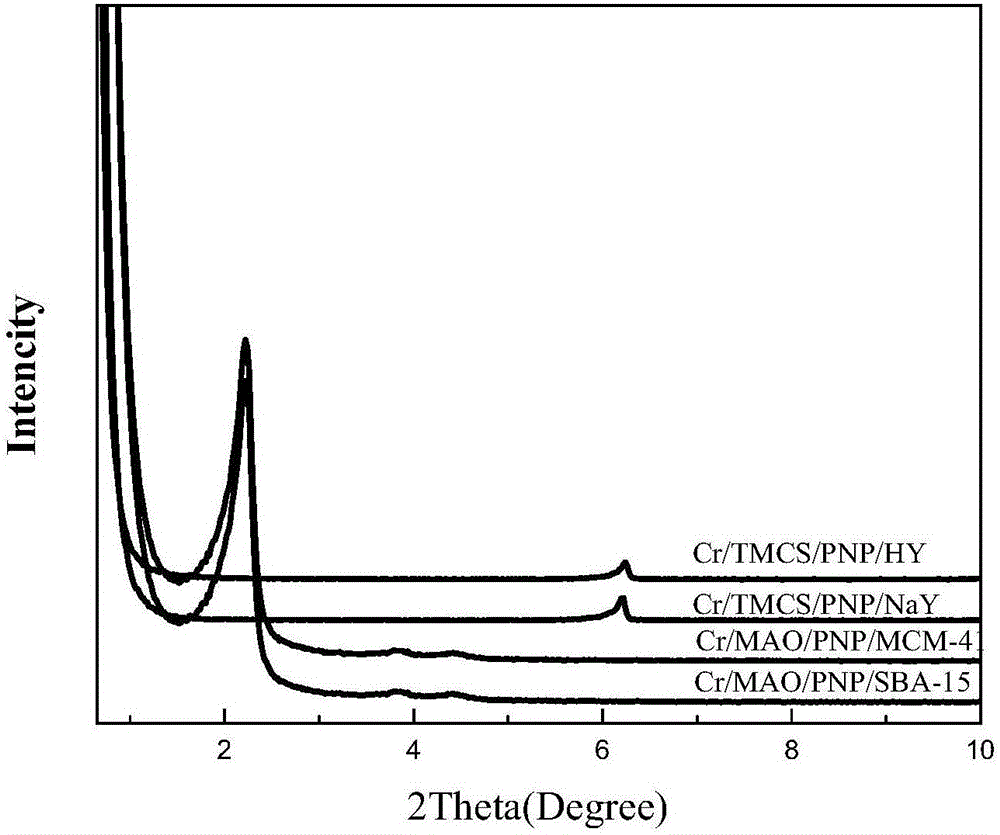

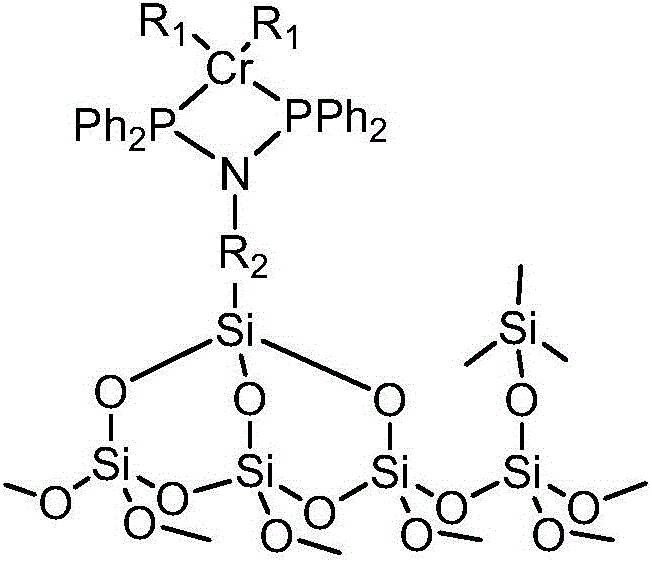

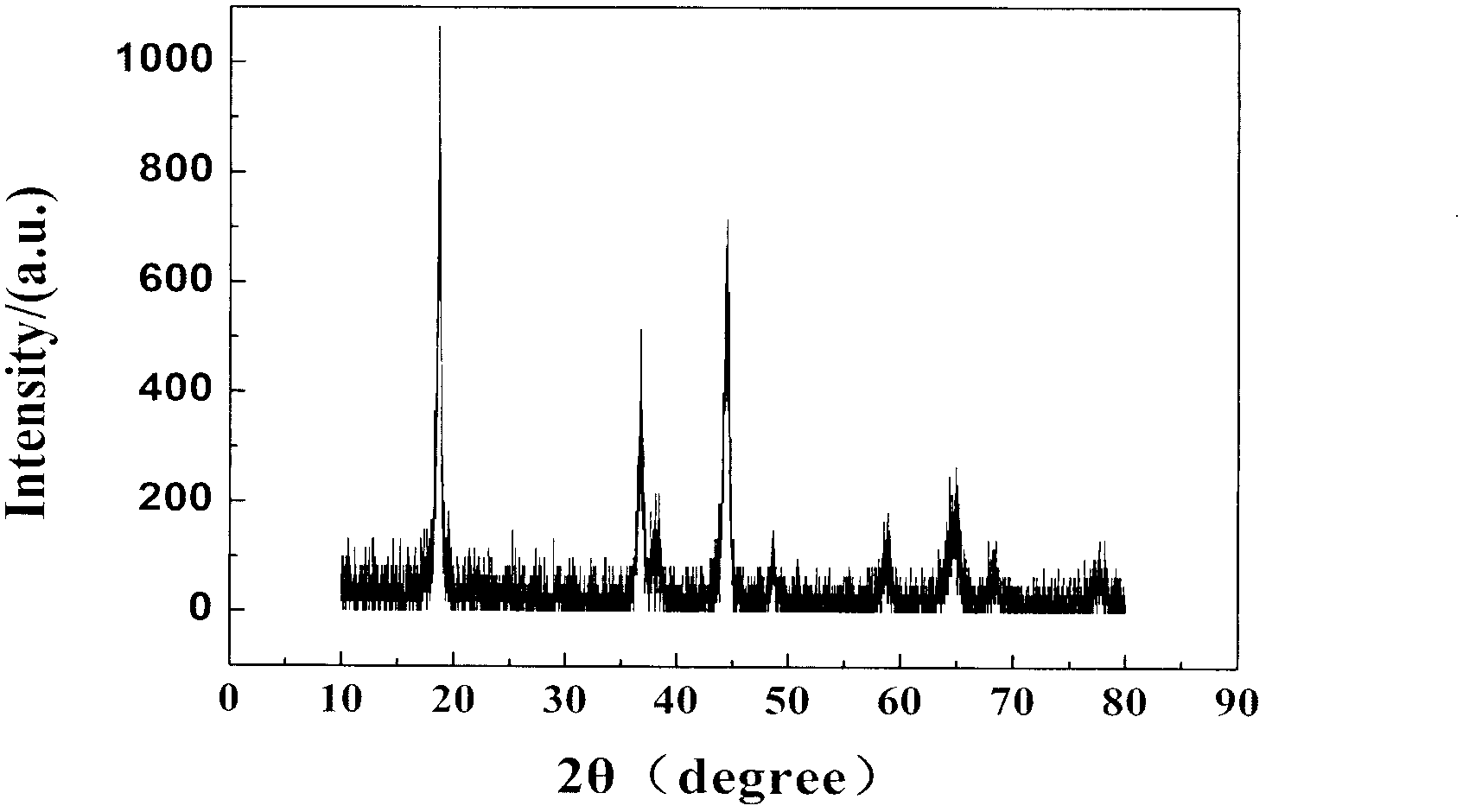

Catalyst for ethylene oligomerization and preparation method thereof

ActiveCN106492880ASingle structureStrong bondOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsMolecular sieveGrafting

The invention relates to a catalyst for ethylene oligomerization and a preparation method thereof. The catalyst comprises a main catalyst which is a catalyst obtained by the steps of taking molecular sieve as a carrier, carrying out chemical bond grafting of silicon hydroxyl on the molecular sieve surface and a bis(diphenylphosphino)ammonia ligand containing silicon ethoxy, and then complexing with a chromium active component. The invention also provides the preparation method of the catalyst. The catalyst has the advantages of high catalytic activity, easy separation from a product and high content of alpha-olefins in the oligomerization product when used for catalyzing ethylene oligomerization.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method for nickel cobalt lithium manganate LiNixConMn1-x-yO2 of anode material of lithium ion battery

InactiveCN102709568ASimple processOvercome ion segregationCell electrodesElectrical batteryManganate

The invention discloses a preparation method for nickel cobalt lithium manganate LiNixConMn1-x-yO2 of an anode material of a lithium ion battery, which belongs to the technical field of a novel material for energy source. The preparation method comprises the following steps of: 1, dissolving lithium source compound, nickel source compound, cobalt source compound and manganese source compound in deion water, adding complexant polyacrylic acid (PAA), and heating and stirring to obtain transparent red collosol; 2, heating and concentrating, evaporating unnecessary water to obtain red wet gel, and drying in a bake oven to obtain dried gel; and 3, carrying out calcination and heat treatment for ground dried gel in a muffle furnace to obtain powders of nickel cobalt lithium manganate LiNixConMn1-x-yO2. The method provided by the invention has the advantages of simple process, environment-protection, low energy consumption high efficiency and the like.

Owner:TIANJIN POLYTECHNIC UNIV

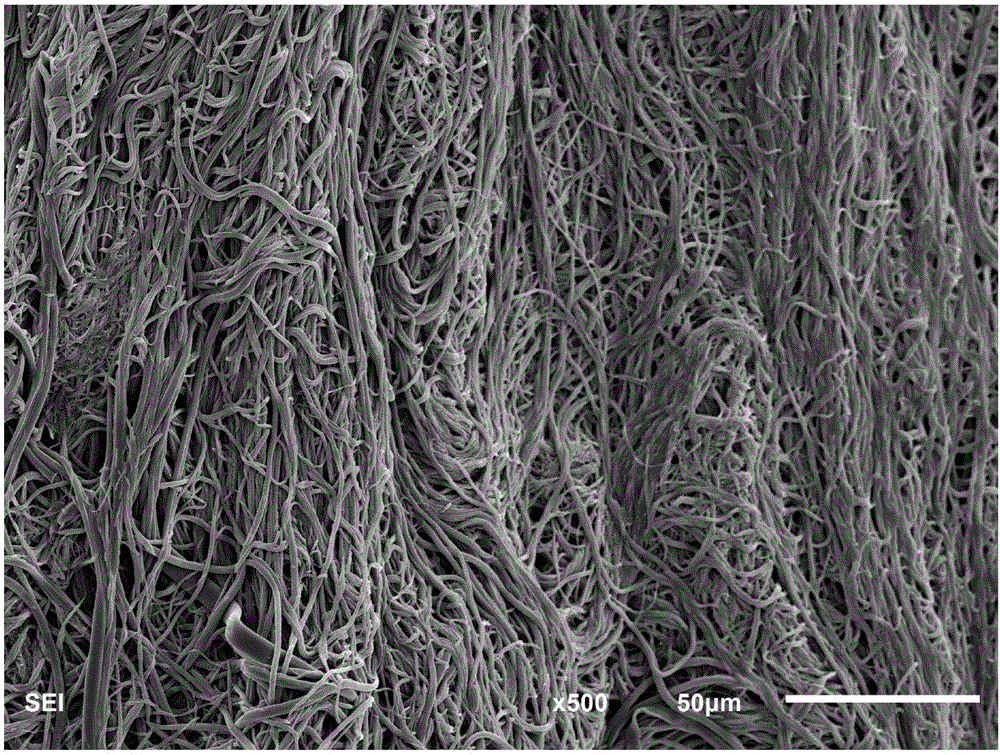

Method for preparing g-C3N4 hollow fiber film on large scale

The invention discloses a method for preparing a g-C3N4 hollow fiber film on a large scale. The method includes the following steps of putting melamine or urea or a mixture of melamine and urea in a muffle furnace, firing the material at a temperature of 450-600 DEG C for 1-4 hours to obtain yellow g-C3N4 blocks, evenly grinding the yellow g-C3N4 blocks to form g-C3N4 powder, putting the g-C3N4 powder in the muffle furnace, firing the g-C3N4 powder at a temperature of 400-700 DEG C for 1-4 hours to obtain g-C3N4 nanometer sheets, dispersing the g-C3N4 nanometer sheets and polymers in organic solvent to prepare a casting membrane solution, and spinning the casting membrane solution (as a shell solution) and water (as a core solution) in a coagulating bath at the same time through a spinning head of a spinning machine to obtain the g-C3N4 hollow fiber film, wherein the mass ratio of g-C3N4 nanometer sheets to polymer to organic solvent is 1:(0.2-1):(4-10) and the ratio of shell solution flow speed to core solution flow speed is (0.5-5):1.

Owner:DALIAN OCEAN UNIV

Functional peptide segment of epididymis protease inhibitors and uses thereof

InactiveCN101402674AImproving immunogenicityStimulationImmunoglobulins against animals/humansAntibody medical ingredientsEpididymal protease inhibitorBlood plasma

The invention discloses an epididymis protease inhibitor which is a functional peptide segment of Eppin. The inhibitor is any one selected from amino acid sequences shown from SEQ ID No.1 to SEQ ID No.7 and has advantages of single component, simple structure and strong pertinence of immunoreaction inspired; polypeptide with at least 80 percent of sequences the same as the functional peptide segment of Eppin can be used for constructing immunogen which can improve the immunogenicity of the functional peptide segment of Eppin, stimulate an organism to generate a specific antibody, reduce Eppin level in blood plasma and induce high-efficient, safe and reversible antifertility effect. The immunogen of the epididymis protease inhibitor can form a medicament composite with medically acceptable carriers, and the composite can be used for preparing male contraception vaccines, therefore, the epididymis protease inhibitor has broad application prospect.

Owner:ARMY MEDICAL UNIV

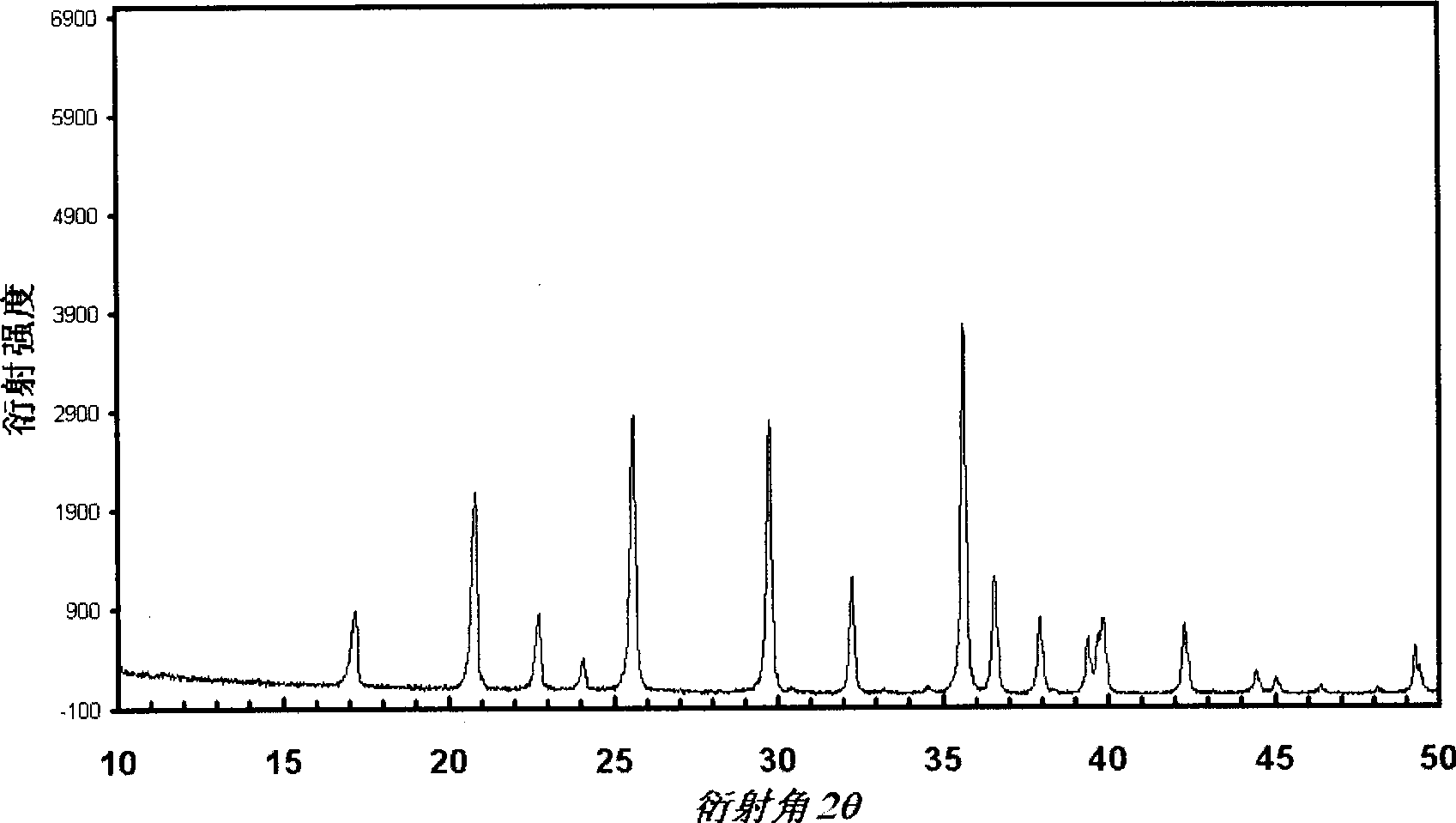

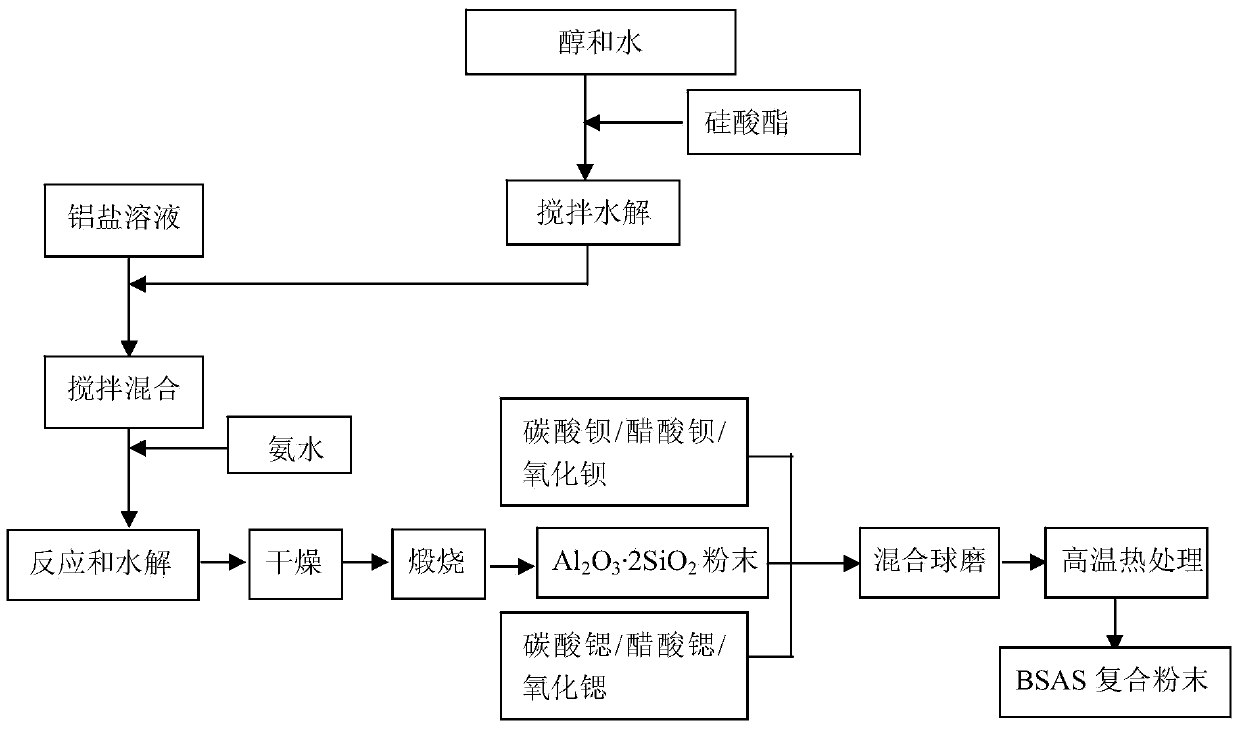

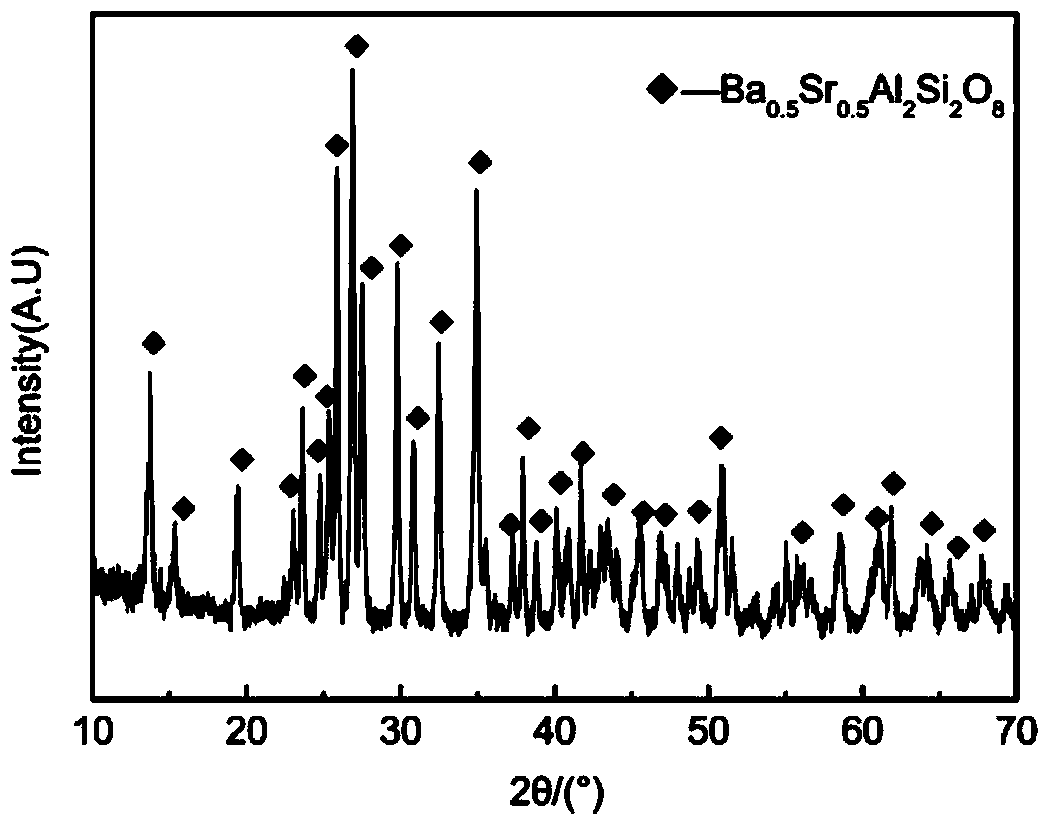

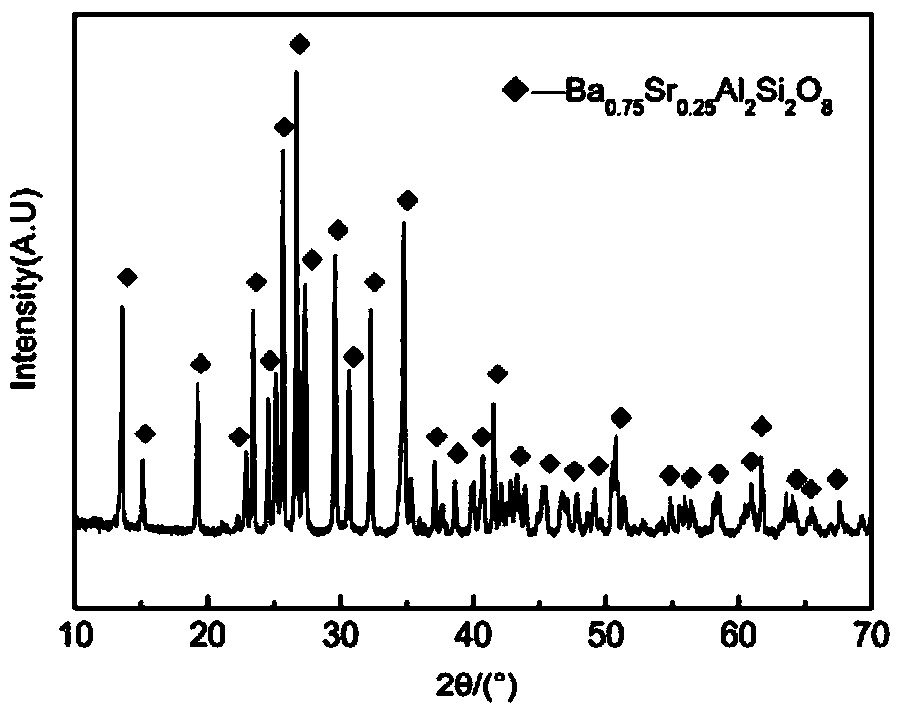

Preparation method of BSAS composite ceramic powder

ActiveCN104003697AProcess raw materials are cheapThe process is simple and easy to controlComposite ceramicCrystallinity

The invention discloses a preparation method of a composite ceramic powder material used for an environmental barrier coating. The composite ceramic powder is composed of single phase BSAS (1-xBaO-xSrO-Al2O3-2SiO2, x is more than 0 and less than 1). The obtained BSAS composite ceramic powder has the advantages of easiness for ingredient control, high purity, high crystallinity and low synthesis temperature. The composite ceramic powder can be used for plasma spraying after being subjected to ball milling, agglomeration, pelletizing and high-temperature heat treatment, so that the environmental barrier coating is prepared on the surface of a C / C-SiC composite material, the coating can be used for effectively improving high-temperature water oxygen corrosion resistance performance of a C / C-SiC matrix, is applicable to surface high-temperature protection of other silicon substrate materials, can be used for solving the problem of high-temperature water oxygen corrosion of a silicon substrate composite material and has an important application value.

Owner:CENT SOUTH UNIV

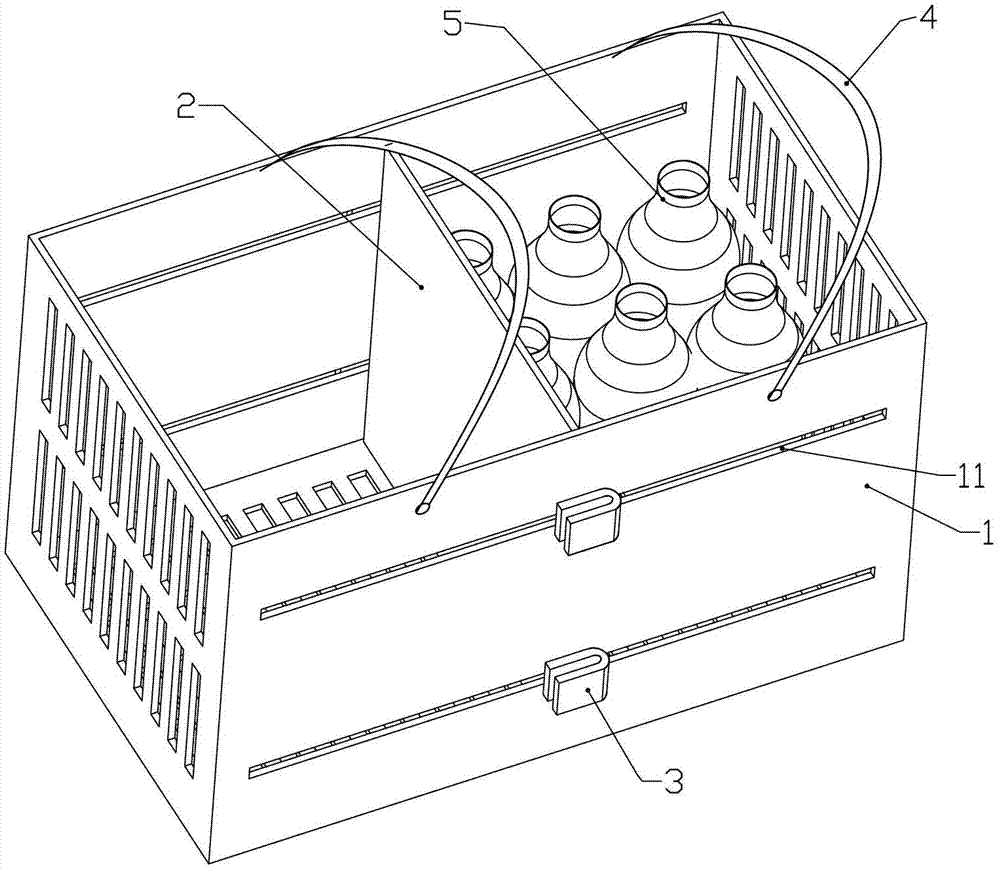

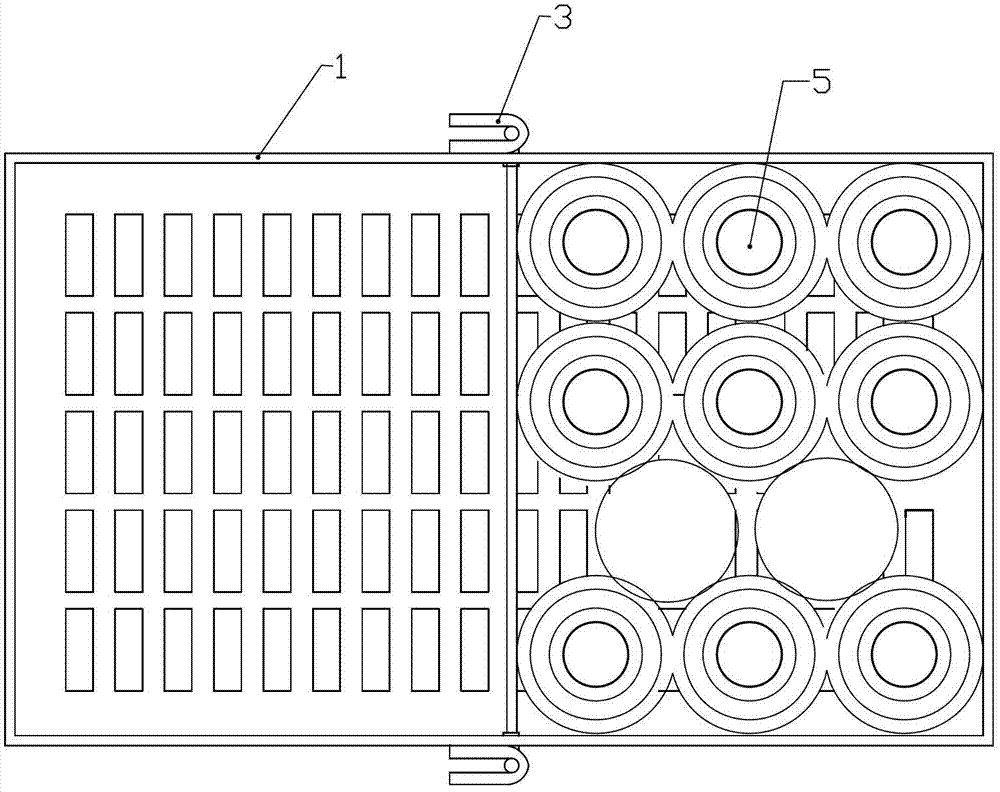

Sewage sample containing basket

The invention discloses a sewage sample containing basket with storage area adjustable. The sewage sample containing basket can fix sample containers and segregate sewage samples. The sewage sample containing basket comprises a rectangular basket body and is characterized in that at least one pair of sliding grooves which are symmetrically arranged on two opposite sides of the basket body and a partition board. Two sides of the partition board are arranged in the sliding grooves through match of sliding blocks in a sliding mode. Locking devices are arranged between the sliding blocks and the sliding grooves. The partition board can be used for adjusting the internal space of the basket so that sample bottles are pressed and fixed in the basket body and locked by buckles on two sides. Stability, convenience and safety of samples are ensured. The sewage sample containing basket is simple and single in structure and easy to manufacture.

Owner:JIGANG GRP

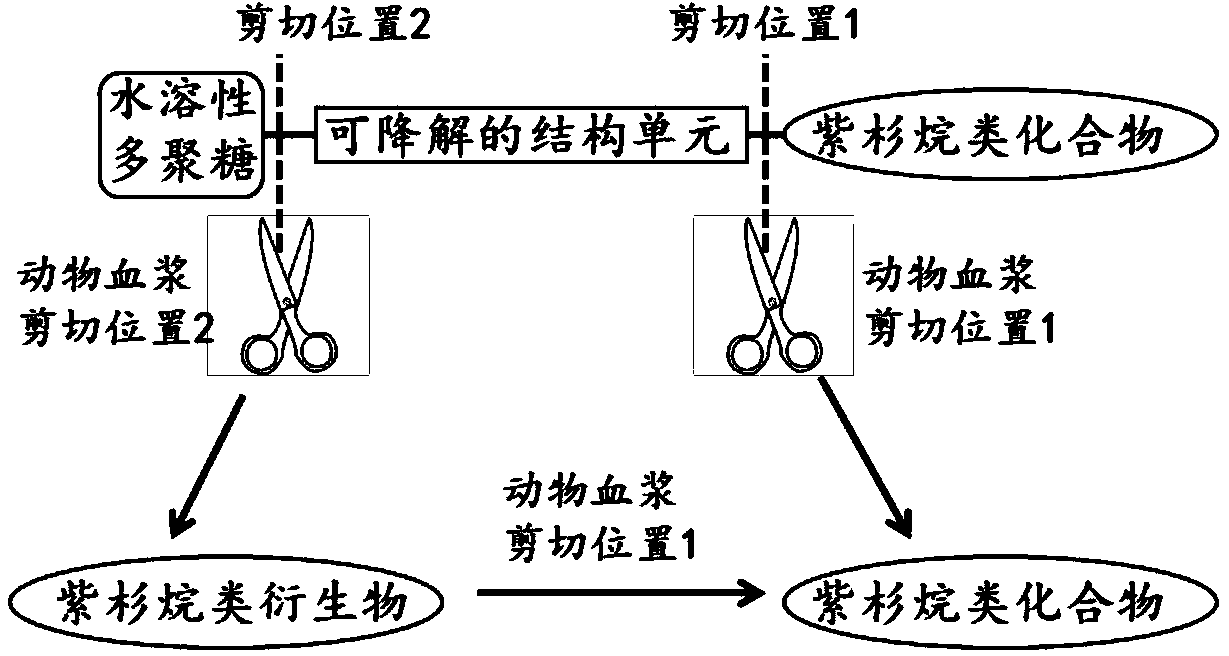

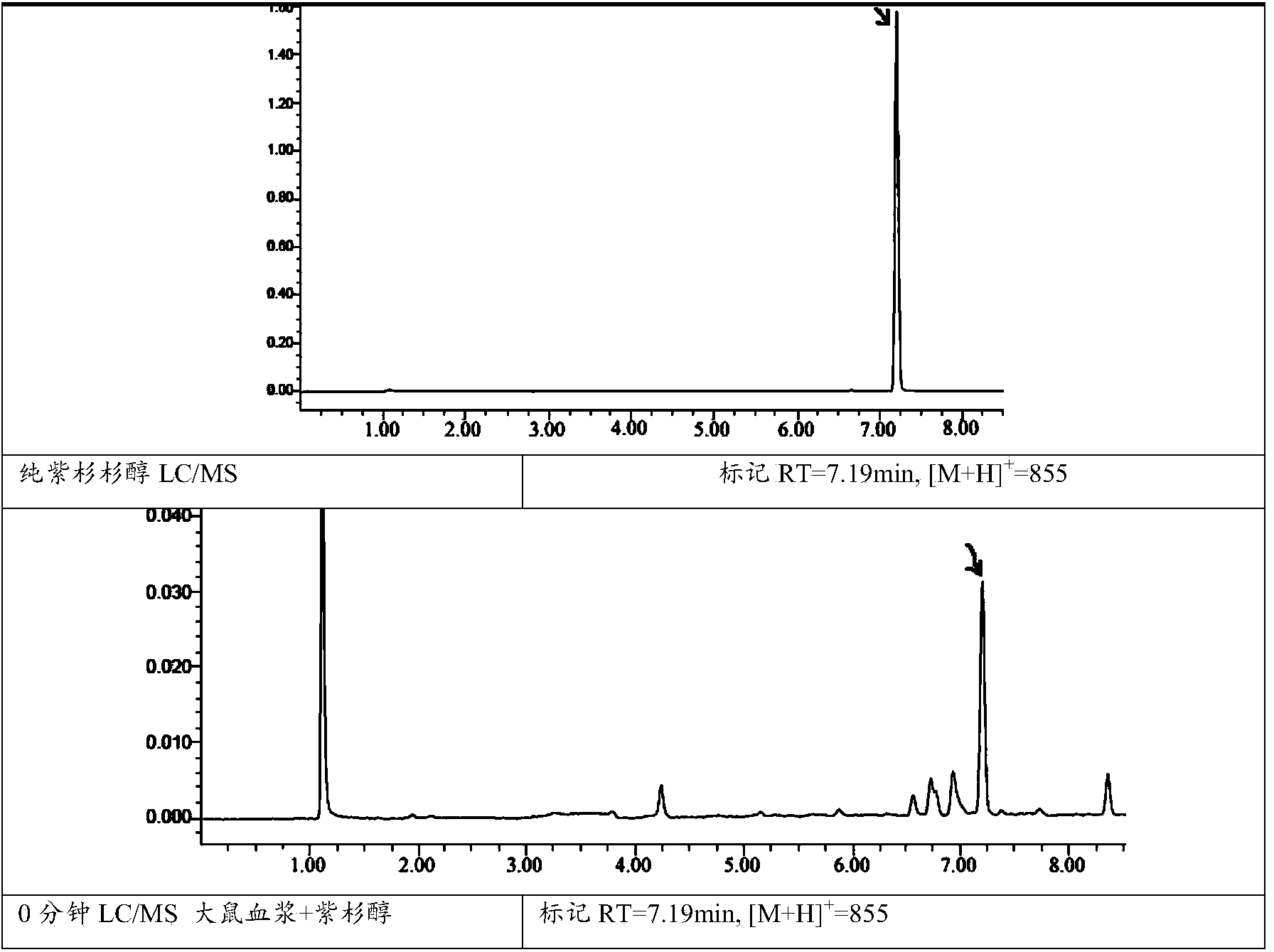

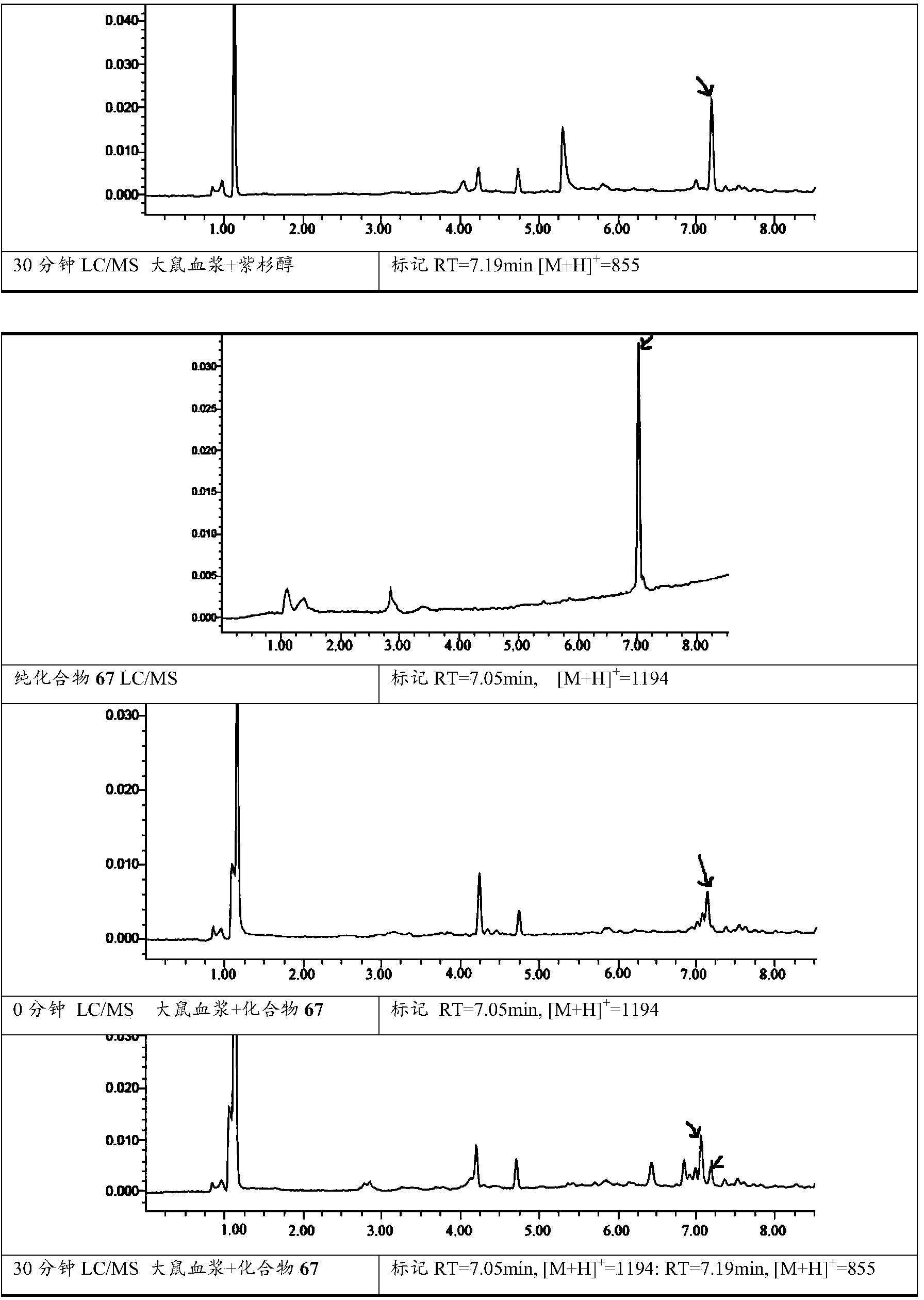

Covalent polycompound of water-soluble polysaccharide and taxane compound, and preparation method and medical application of covalent polycompound

ActiveCN103641925ASingle structureGood water solubilityGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsWater solubleSolubility

The invention relates to a covalent polycompound of water-soluble polysaccharide and taxane, and a preparation method and medical application of the covalent polycompound. The method disclosed by the invention comprises the following step: connecting the taxane compound to the water-soluble polysaccharide through a covalent bond by adopting selective protection and selective deprotection methods and a plurality of degradable structure units, so as to obtain the covalent polycompound which can retain the biological activity of the taxane compound and is relatively simplex in structure. The novel covalent polycompound is good in water solubility, and can replace an existing clinical taxane preparation free of a cosolvent with toxic and side effects.

Owner:王晖

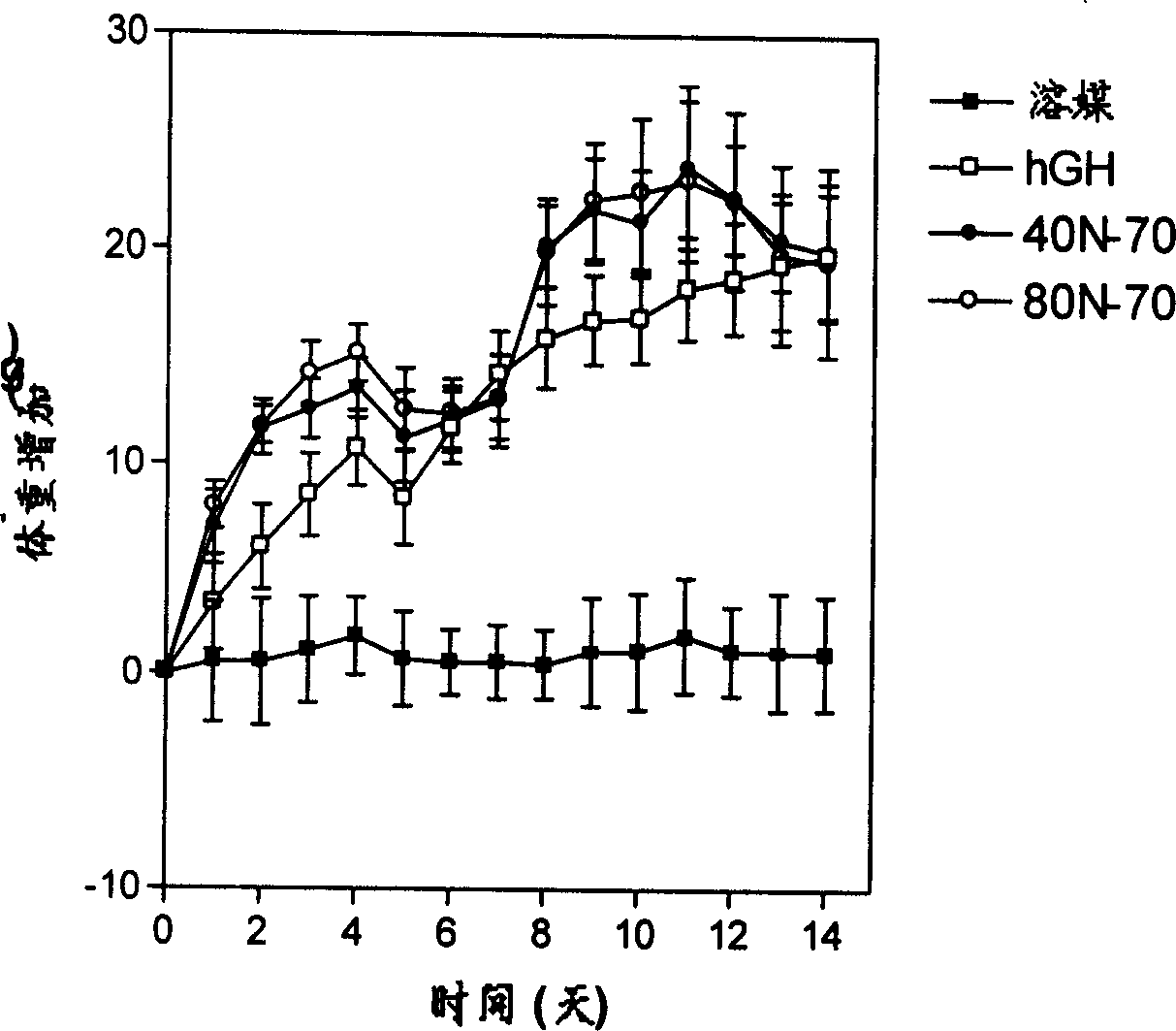

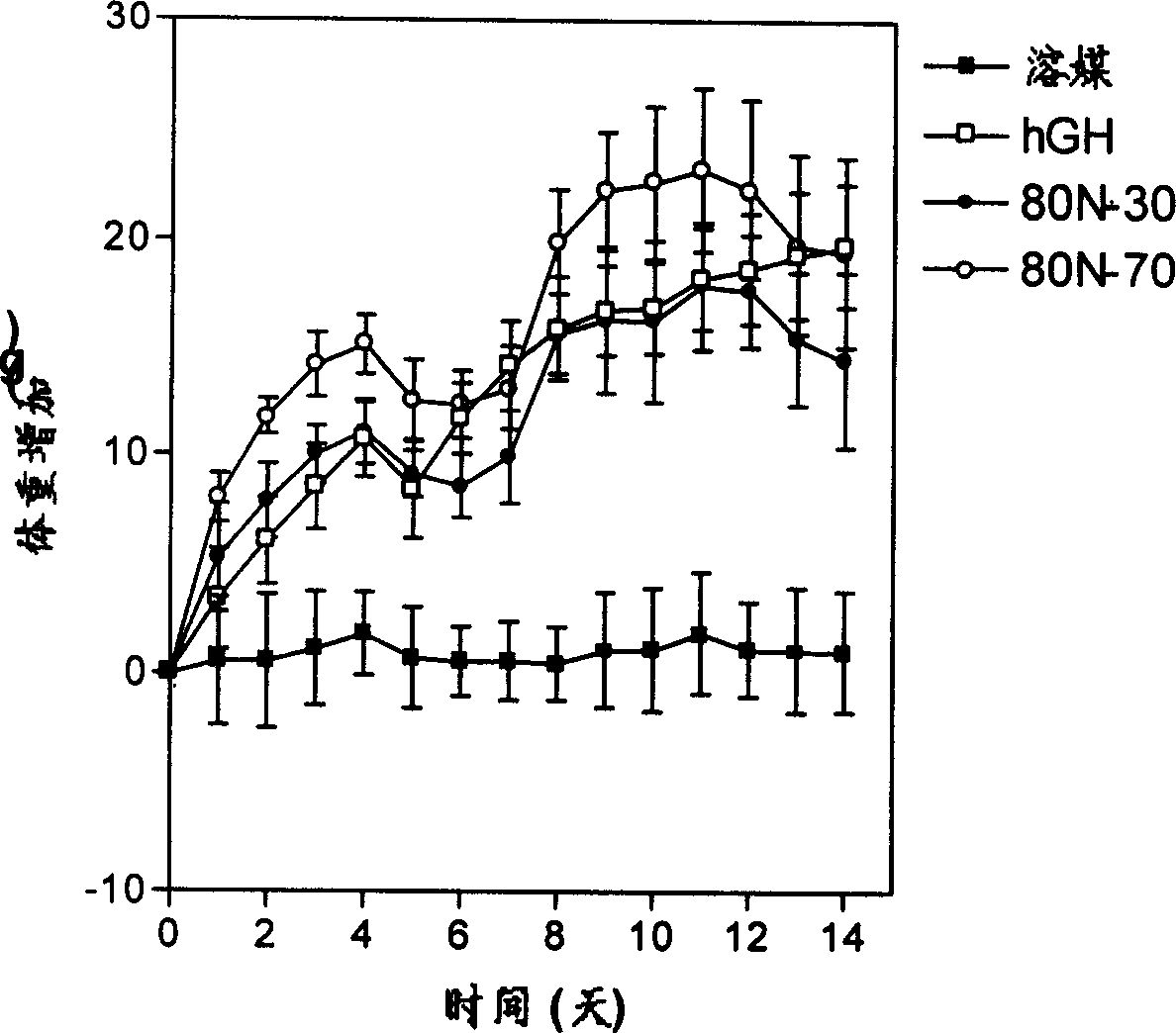

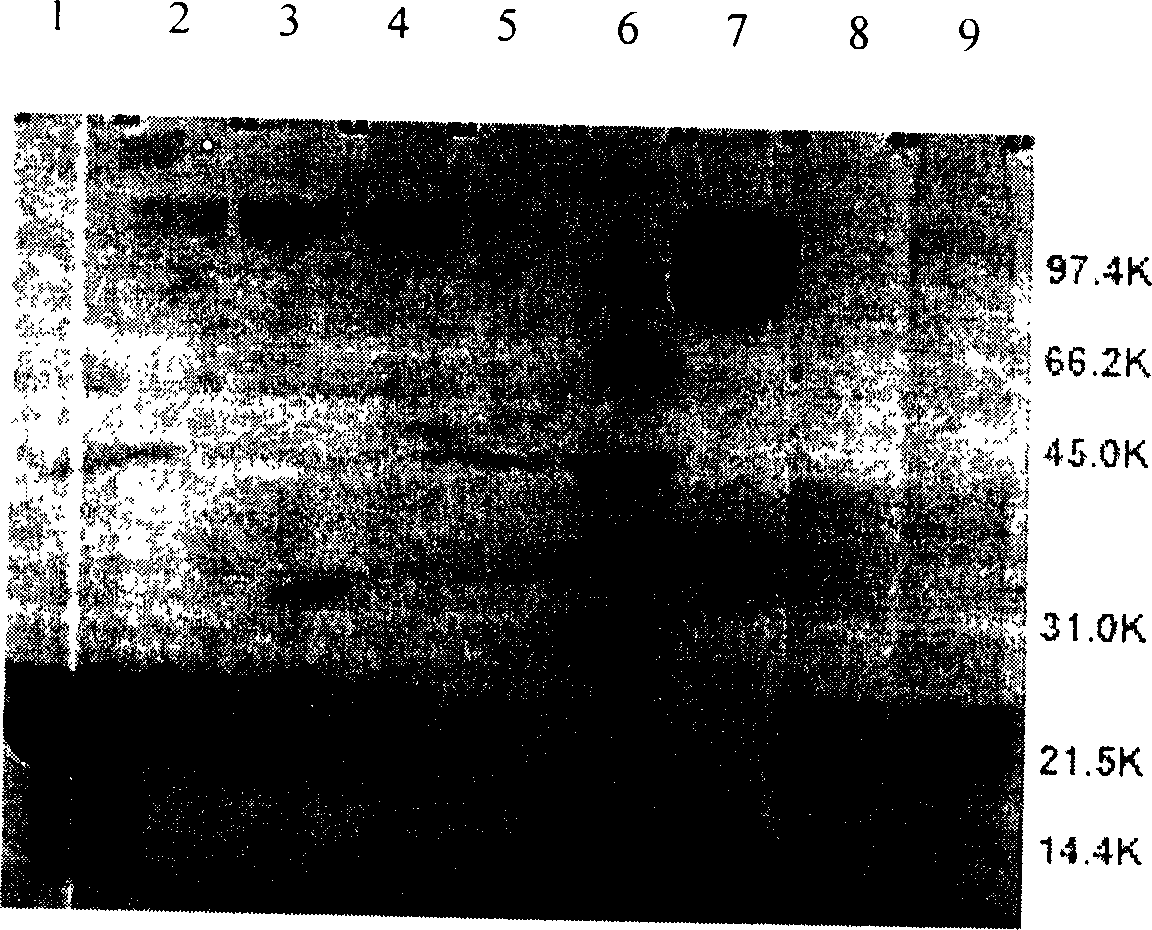

Long-acting growth hormone and medicine composition

InactiveCN1477126AGood curative effectSingle structurePeptide/protein ingredientsCarrier-bound/immobilised peptidesHalf-lifeGrowth hormone

The present invention discloses a method for adopting macromolecular weight polyglycol to modify growth hormone so as to obtain the modified product capable of obviously prolonging half-life period of the growth hormone.

Owner:CHANGCHUN GENESCIENCE PHARM CO LTD +3

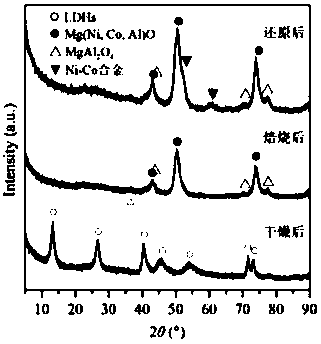

Supported uniform nickel-cobalt (Ni-Co) alloy catalyst and preparation method thereof

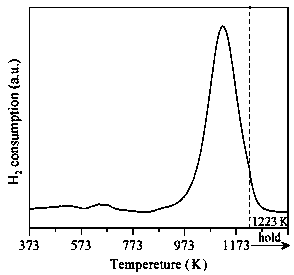

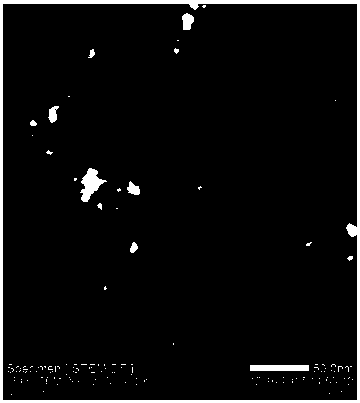

InactiveCN108380218AGood dispersionEvenly dispersedHydrogenHydrogen/synthetic gas productionActive phaseCobalt

The invention belongs to the field of catalysts for the preparation of synthesis gas by reforming hydrocarbons, and particularly relates to a supported uniform nickel-cobalt (Ni-Co) alloy catalyst anda preparation method thereof. The catalyst provided by the invention is prepared from the active phase of a Ni-Co alloy nano particle and a high-specific-surface-area Mg(Al)O composite oxide support.The preparation method comprises the following steps of firstly, synthesizing a Ni-Co-Mg-Al LDHs (Layered Double Hydroxides) lamellar composite hydroxide as a precursor by adopting a coprecipitationmethod, afterwards, obtaining a Mg(Ni,Co,Al)O oxide solid solution through roasting treatment, next, reducing through high-temperature hydrogen to in situ generate the Ni-Co alloy nano particle. The Ni-Co alloy nano particle of the supported uniform Ni-Co alloy catalyst is highly dispersed on the surface of the support, and the supported uniform Ni-Co alloy catalyst has the characteristics of being single in structure, uniform in composition, small in particle size which is approximately 8nm and high in metal-support interaction, and the like, and shows favorable catalytic activity, stabilityand anti-carbon performance to the reforming reaction of methane and carbon dioxide.

Owner:FUZHOU UNIV

Erlotinib-phthalocyanine conjugate as molecule-targeting anticancer photosensitizer

ActiveCN103341166AImprove targetingEnhance photodynamic activityEnergy modified materialsAntineoplastic agentsPhotosensErlotinib

The invention discloses an erlotinib-phthalocyanine conjugate as a molecule-targeting anticancer photosensitizer and its preparation method and use. Erlotinib structure units with alcoxyl long-chains are introduced to the periphery of a metal phthalocyanine large-ring so that amphipathy, biocompatibility and photosensitizer targeting are improved. The erlotinib-phthalocyanine conjugate is not aggregated easily, is conducive to cell uptake ratio improvement, has a single structure, has no isomers and can be purified easily. The erlotinib-phthalocyanine conjugate can improve photosensitizer targeting in photodynamic therapy and improve photosensitizer activity in photodynamic therapy. The preparation method has simple processes, less side reactions and a high yield, adopts easily available raw materials, has a low cost and is conducive to industrial production.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com