Patents

Literature

393results about How to "Strong bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental-friendly waterproof polymer mortar

InactiveCN101560084AImprove adhesionStrong bondSolid waste managementSilicate CementConstruction aggregate

The invention relates to environmental-friendly waterproof polymer mortar, which comprises the following components in portion by weight: 50 to 230 portions of low-clinker silicate cement, 200 to 450 portions of quartz sand, 80 to 120 portions of fly ash, 1 to 18 portions of re-dispersible polyethylene vinyl acetate latex powder, 1 to 10 portions of dispersible polyvinyl acetate vinyl versatate latex powder, 0.2 to 0.6 portion of water reducing agent, 0.05 to 0.3 portion of antifoaming agent, and 0.25 to 2.25 portions of polypropylene fibers. A gel material prepared from steel slag, tailings and the fly ash replaces silicate cement and partial aggregate in the prior mortar; the modified waterproof polymer mortar has the advantages of excellent impermeability, good mechanical property and construction property, simple production technology, and easy manufacture, greatly consumes industrial and mining wastes, controls the ecological environment, and lowers the cost; and the product has reliable quality and wide market; and the environmental-friendly waterproof polymer mortar can be popularized and applied in large area.

Owner:黑龙江省学府环艺雕塑有限公司

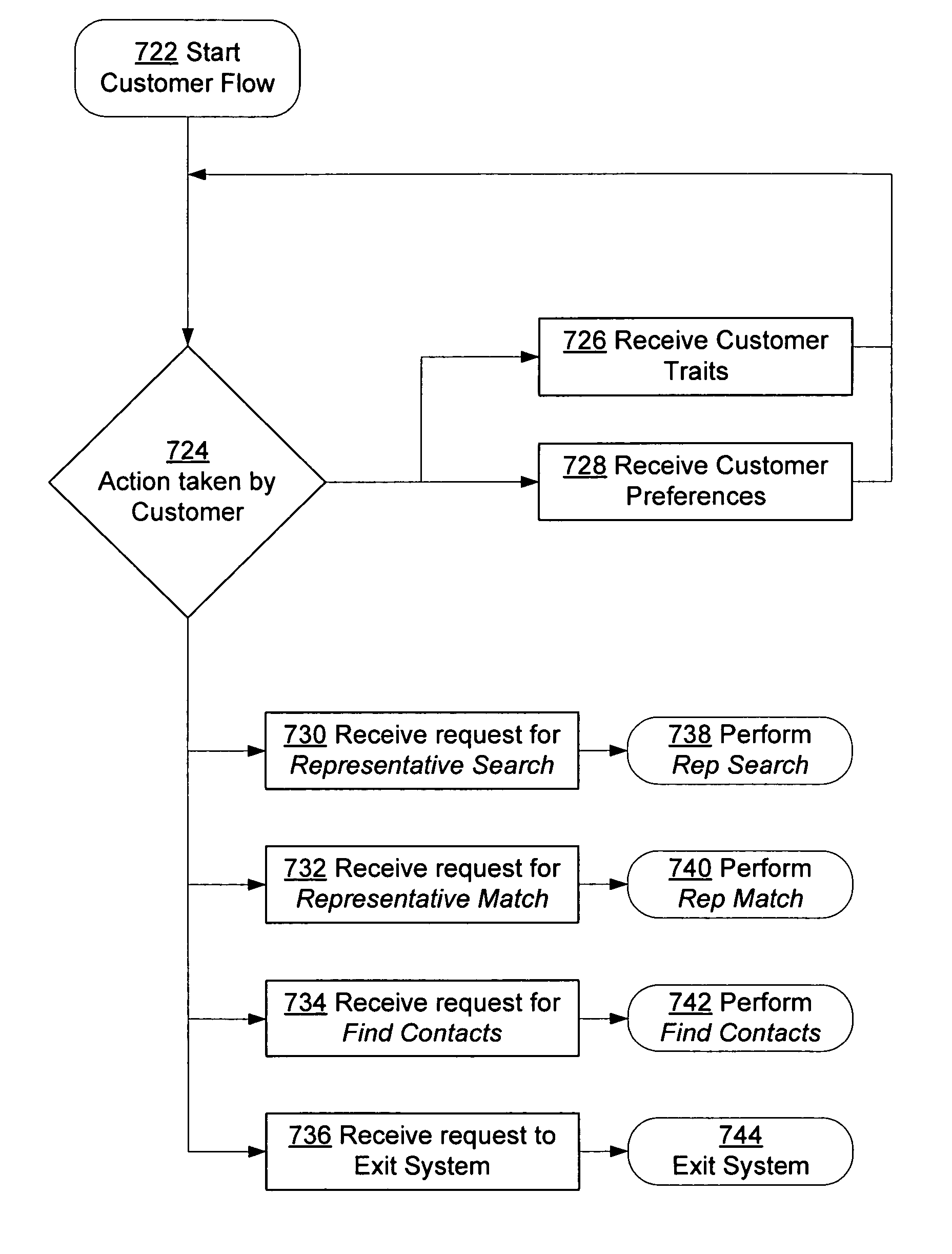

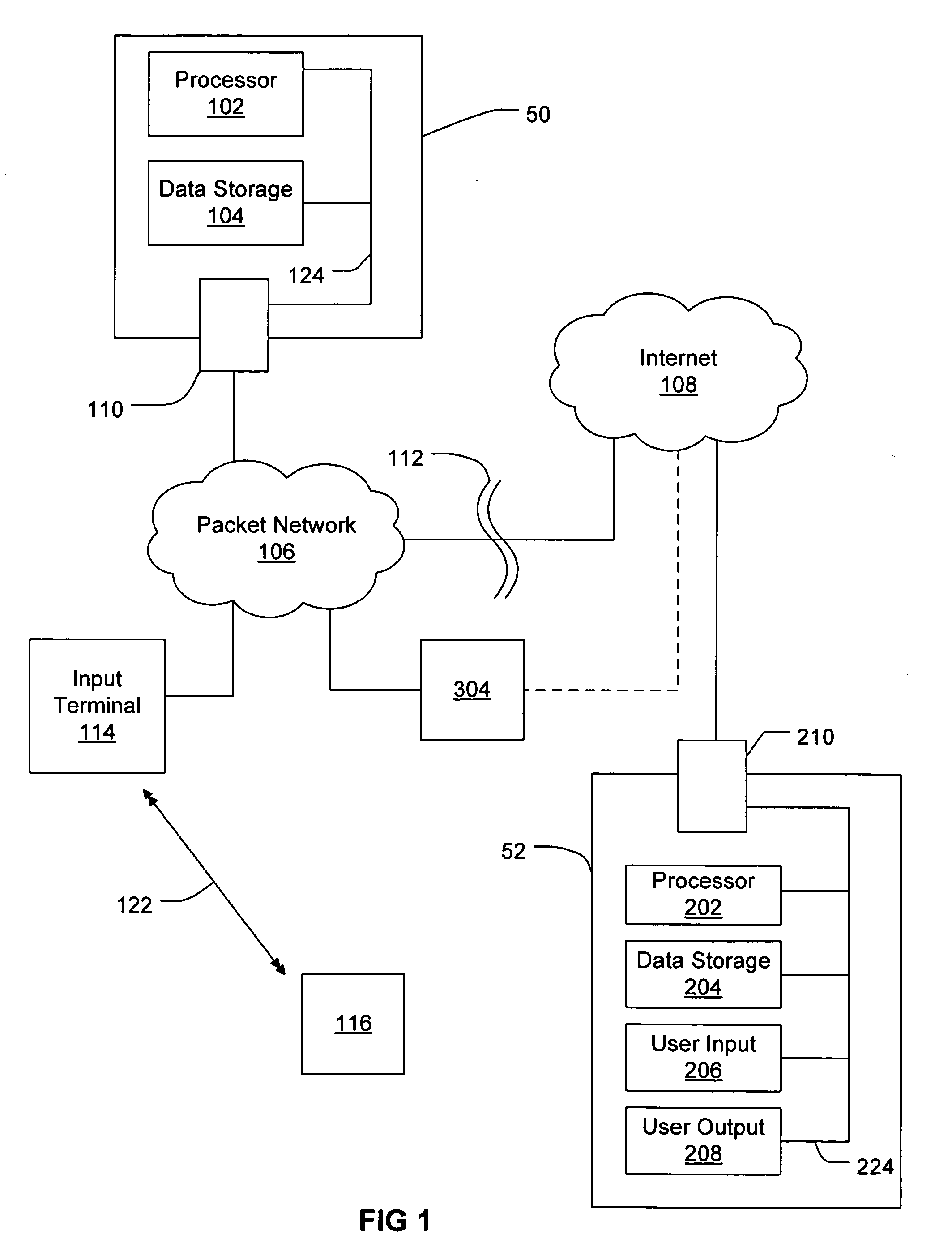

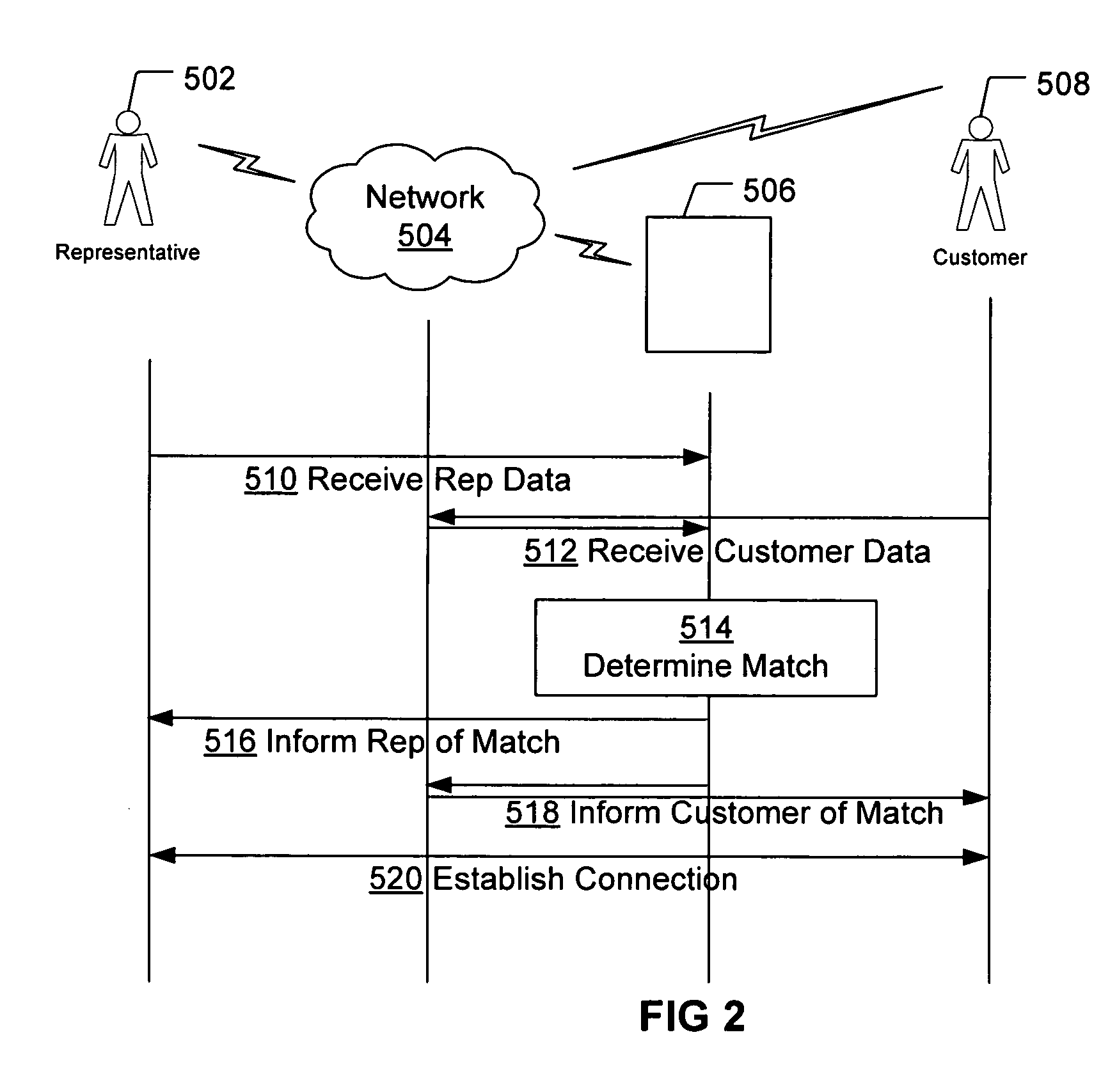

Method and system of allocating a sales representative

A method and system is disclosed for providing for customer input during sales representative allocation by a vendor. According to the embodiments, a customer can participate in the allocation through a representative search function, a representative match function, and a contact find function, for instance. The system is generally employed on a server that handles database and processing operations. The system may also provide for searching and navigating via an internet connection through available sales representatives based on one or more traits of the sales representative.

Owner:CERADO

Alcohol soluble polyacrylate resin and preparation method and application thereof

The invention discloses an alcohol soluble polyacrylate resin and a preparation method and an application thereof; the preparation method comprises the following steps: taking 260-800 parts of alcohols solvent, adding the solvent in a reaction kettle with a mixer, a reflux condenser, a heating jacket and a nitrogen covering layer, then heating the system to 70-150 DEG C, mixing the mixture for 10-30min; adding acrylic ester used as hard monomers, acrylic ester used as soft monomers, polar functional group monomers, organosilane monomers and initiator to react for 4-7h and obtain alcohol soluble polyacrylate resin. The alcohol soluble polyacrylate resin prepared by the method of the invention has no excitant odour, the number-average molar mass is 10,000-200,000, the molecular weight distribution is 1.1-4 and the Brookfield viscosity of the resin system is 100-5000cp. The coating which is prepared by mixing the resin with other pigments, fillers and assistants can be applied in glass, aluminium coil and polypropylene plastic for surface decoration and protective function.

Owner:SOUTH CHINA UNIV OF TECH

Ultrasonic bonding and embossing of an absorbent product

InactiveUS20050136224A1Easily and effectively makeStrong bondMechanical working/deformationSynthetic resin layered productsEngineeringPolymer

Ultrasonically bonded laminated absorbent products comprising a liquid permeable top sheet, a liquid impermeable back sheet, an absorbent core positioned between the liquid permeable top sheet and the liquid impermeable back sheet, and an adhesive composition are disclosed. The laminated structure further comprising an embossed pattern stamped onto the liquid permeable top sheet, the liquid impermeable back sheet, the absorbent core, or any combination thereof. The adhesive composition comprises a mixture of atactic and isotactic polymers such that it has melt and flow characteristics similar to those of the topsheet and backsheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Preparation method of novel cloudy-surface release paper

ActiveCN102350846AStrong bondImprove bindingPaper/cardboard layered productsPolyurea/polyurethane coatingsChemistryPolyester

The invention relates to a preparation method of novel cloudy-surface release paper, which comprises the following steps that: a film-coated layer is coated on one side surface of a base release paper, a cementing compound layer is coated on the other side surface of the base release paper after being cooled to obtain a substrate layer to standby use; a layer of cloudy-surface coating agent with the thickness of 0.2 micrometer to 2 micrometers is coated on the surface of a film layer; the cloudy-surface coating agent is radiated by ultraviolet rays to obtain a cloudy-surface coating, and then a layer of mold release agent is coated on the surface of the cloudy-surface coating to obtain a cloudy-surface release layer for standby use; and the cloudy-surface release layer is bonded with the substrate layer. Sine the polyester cloudy-surface coating is firstly coated on the surface of the film layer, a plurality of convex-concave structures are obtained on the surface of the film layer after being processed; and then the silicon release agent coating is coated on the surface of the cloudy-surface coating, the bottom surface of the silicon release agent coating at a liquid state penetrates into concaves on the surface of the polyester cloudy-surface coating and the silicon release agent coating is fixedly connected with the polyester cloudy-surface coating through the concaves after being solidified, so the bonding force is firmer and more reliable.

Owner:太仓斯迪克新材料科技有限公司

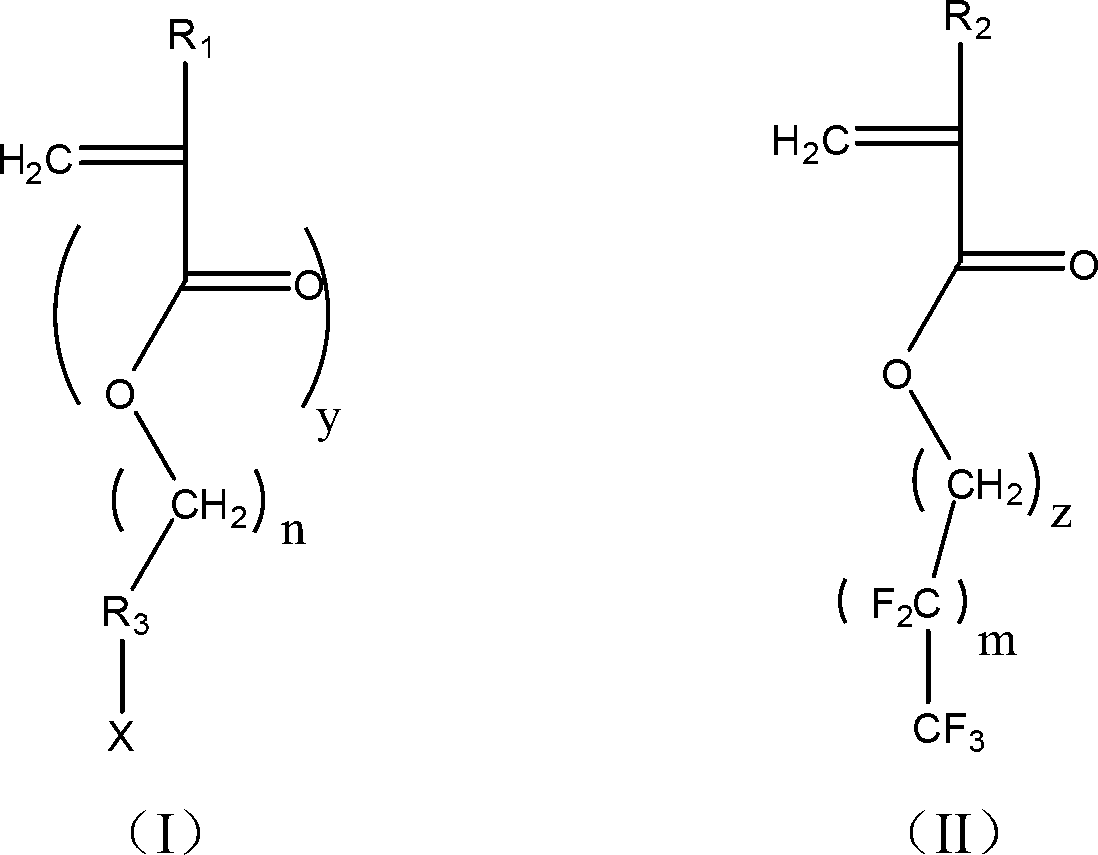

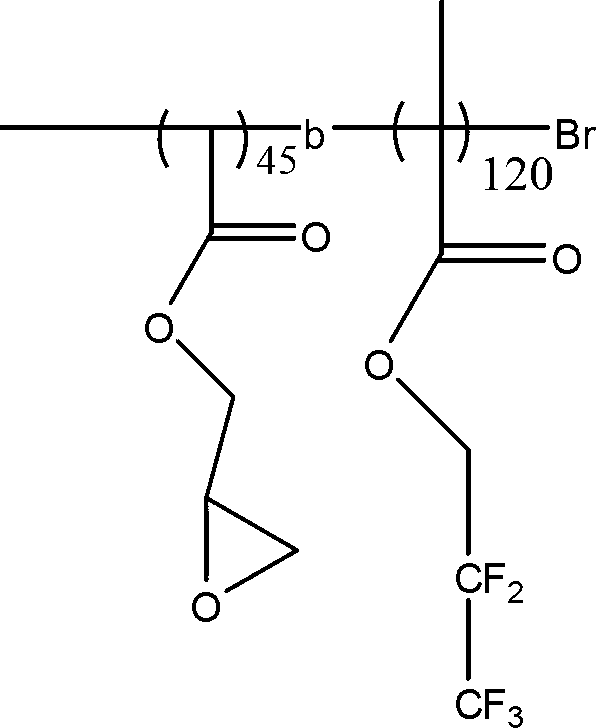

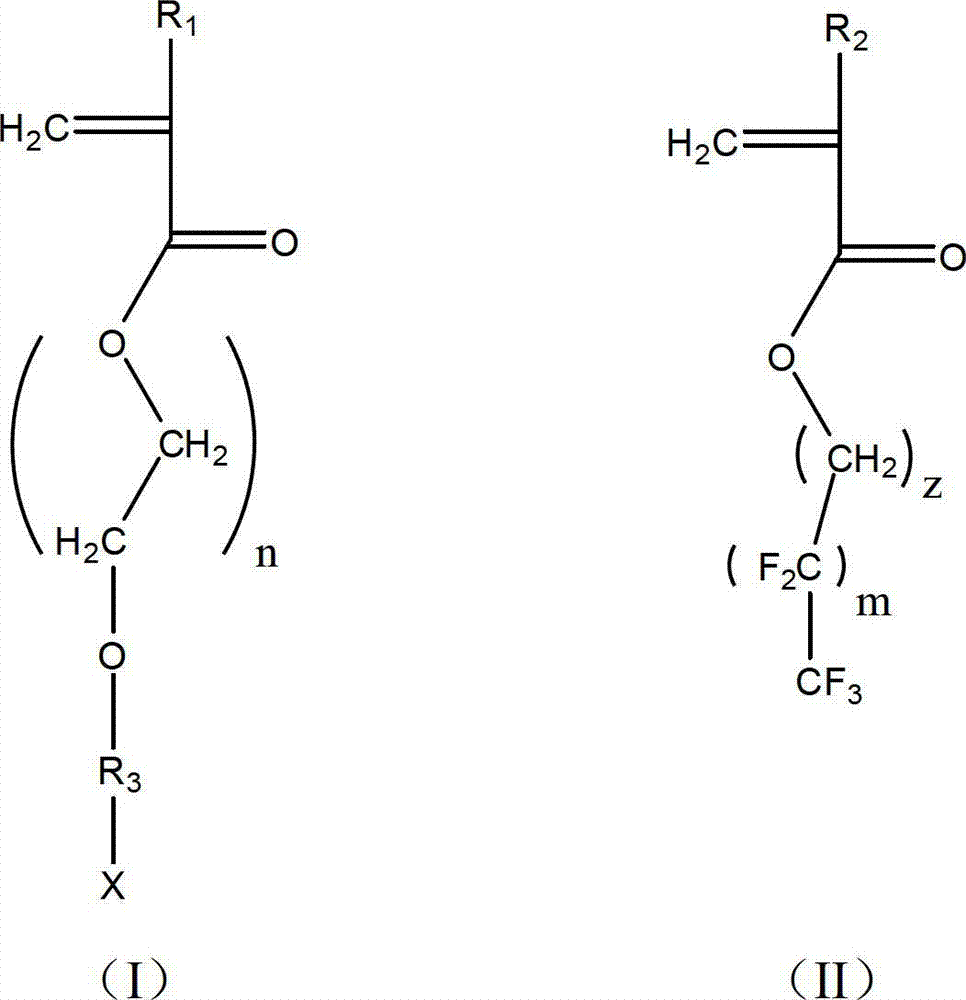

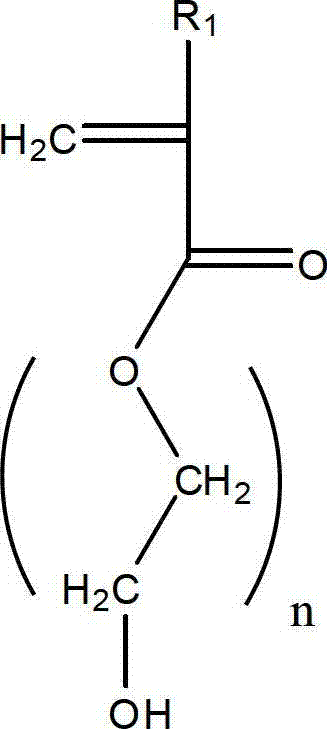

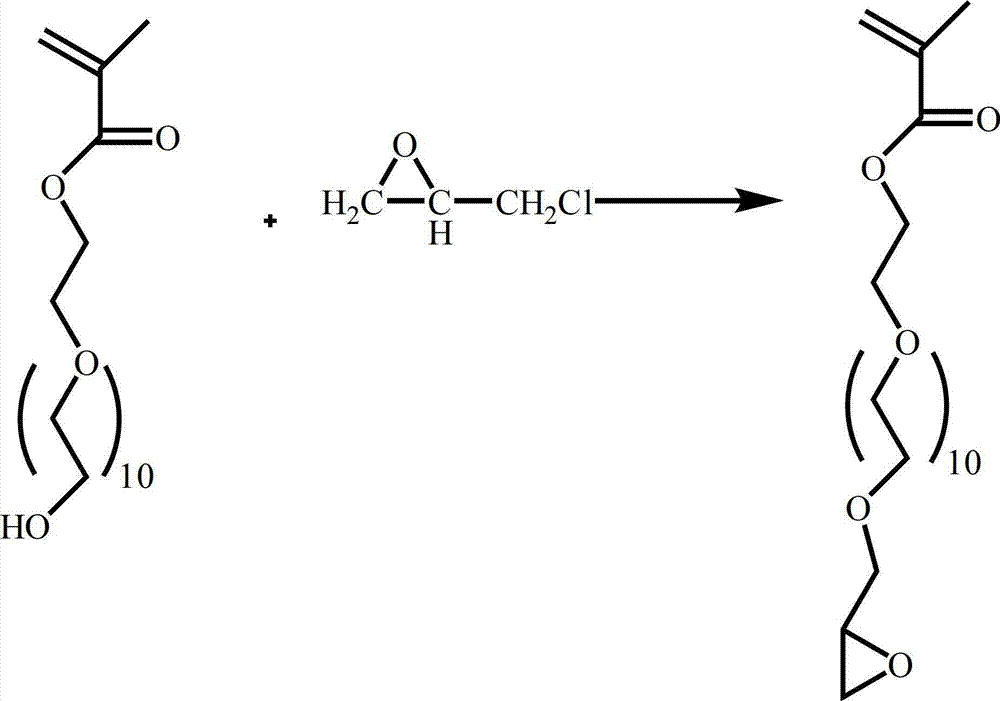

Cross-linkable fluorine-containing polymer, and its application in preparation of super-amphiphobic surfaces

The invention discloses a cross-linkable fluorine-containing polymer, and its application in the preparation of super-amphiphobic surfaces. The cross-linkable fluorine-containing polymer is obtained through polymerizing a monomer A and a monomer B, and has a molecular weight of 500-47000, wherein the molar ratio of the monomer A to the monomer B is 1:(0.2-10); the structures of the monomer A and the monomer B are represented by formula I and formula II respectively; and in the formula I and the formula II, R1 and R2 are H or CH3, R3 is CH2, O, COOCH2 or C6H6, n, m and z are integers between 0 and 10 respectively, y is 0 or 1, and X is an epoxy group. The cross-linkable fluorine-containing polymer prepared in the invention contain the epoxy group, so the advantage of the bonding of the epoxy group with most base material surfaces is utilized to construct the super-amphiphobic surfaces on the most base material surfaces. The super-amphiphobic surfaces prepared through utilizing the cross-linkable fluorine-containing polymer have the advantages of firm bonding with base materials, friction resistance and laundering durability.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

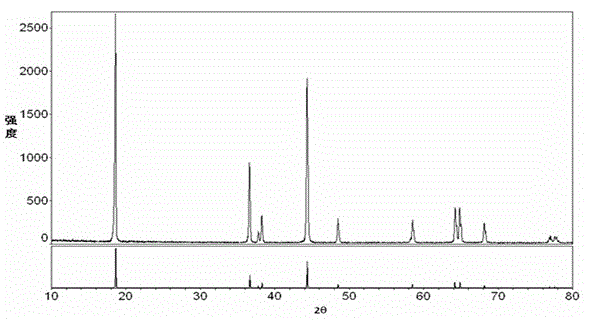

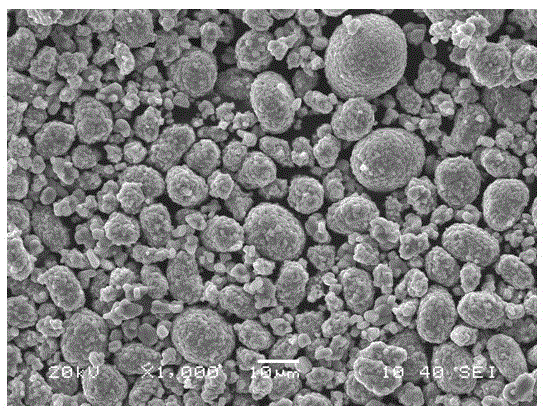

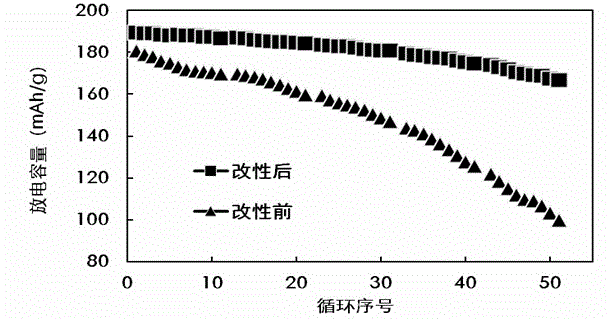

Positive electrode material of high-capacity dynamic-type nickel-rich lithium ion battery and preparation method thereof

ActiveCN103606671AStable structureImprove cycle performanceCell electrodesMaterials processingLithium-ion battery

The invention relates to a positive electrode material of a high-capacity dynamic-type nickel-rich lithium ion battery and a preparation method. The molecular formula of the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery is LiaNi1-x(MM')xO2.M''O, wherein a is equal to 0.9-1.2, x is more than or equal to 0 and less than or equal to 0.7, and M is at least one of Co, Mn and Al; M' is at least one of Co, Al, V, Mn, Zr, Mg, Ti, Cr, Zr, La, Ce, Pr, Nd, Nb, Mo, Y, Sr, Ba, B, Sr, Sn and Ta; M''O is a cladding layer, and M'' is Co and Al. The invention also relates to a preparation method for the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery. The material machining performance is excellent, the battery prepared by utilizing the material, the cycling performance and the high-voltage performance are excellent, the safety and stability in use can be realized, not only can the application performance requirement of a portable electronic device on the battery be met, but also the positive electrode material is applicable to the power battery.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

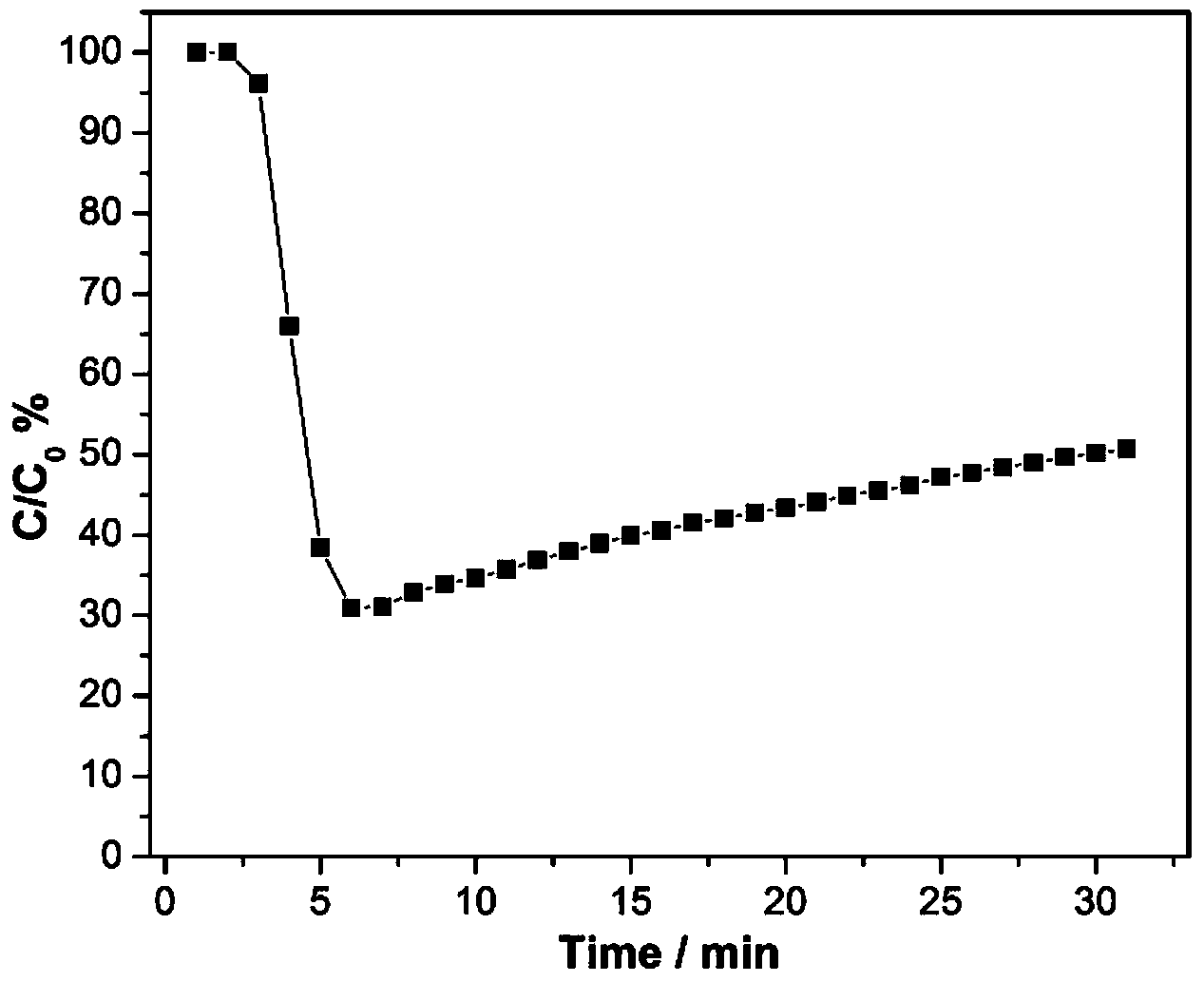

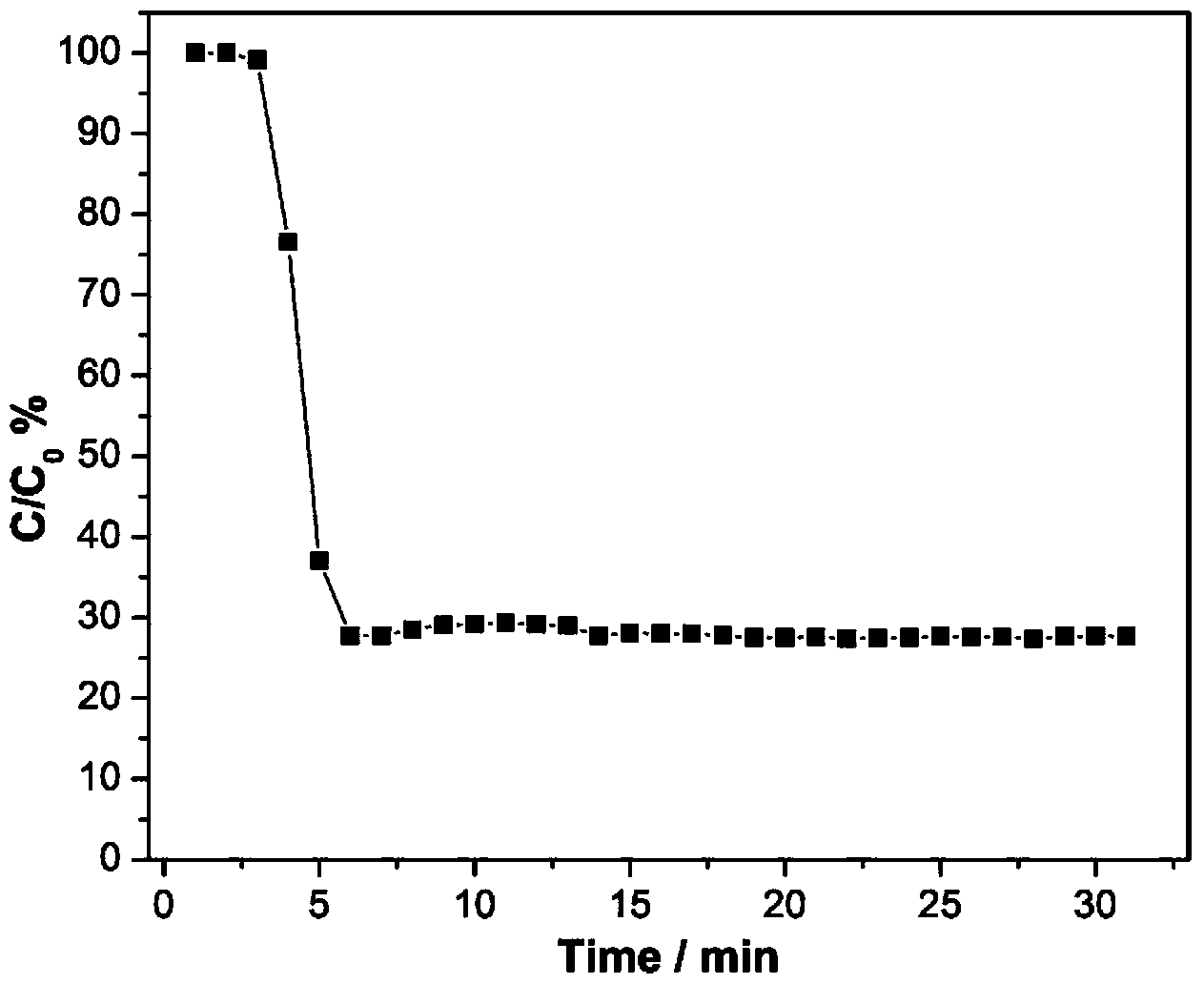

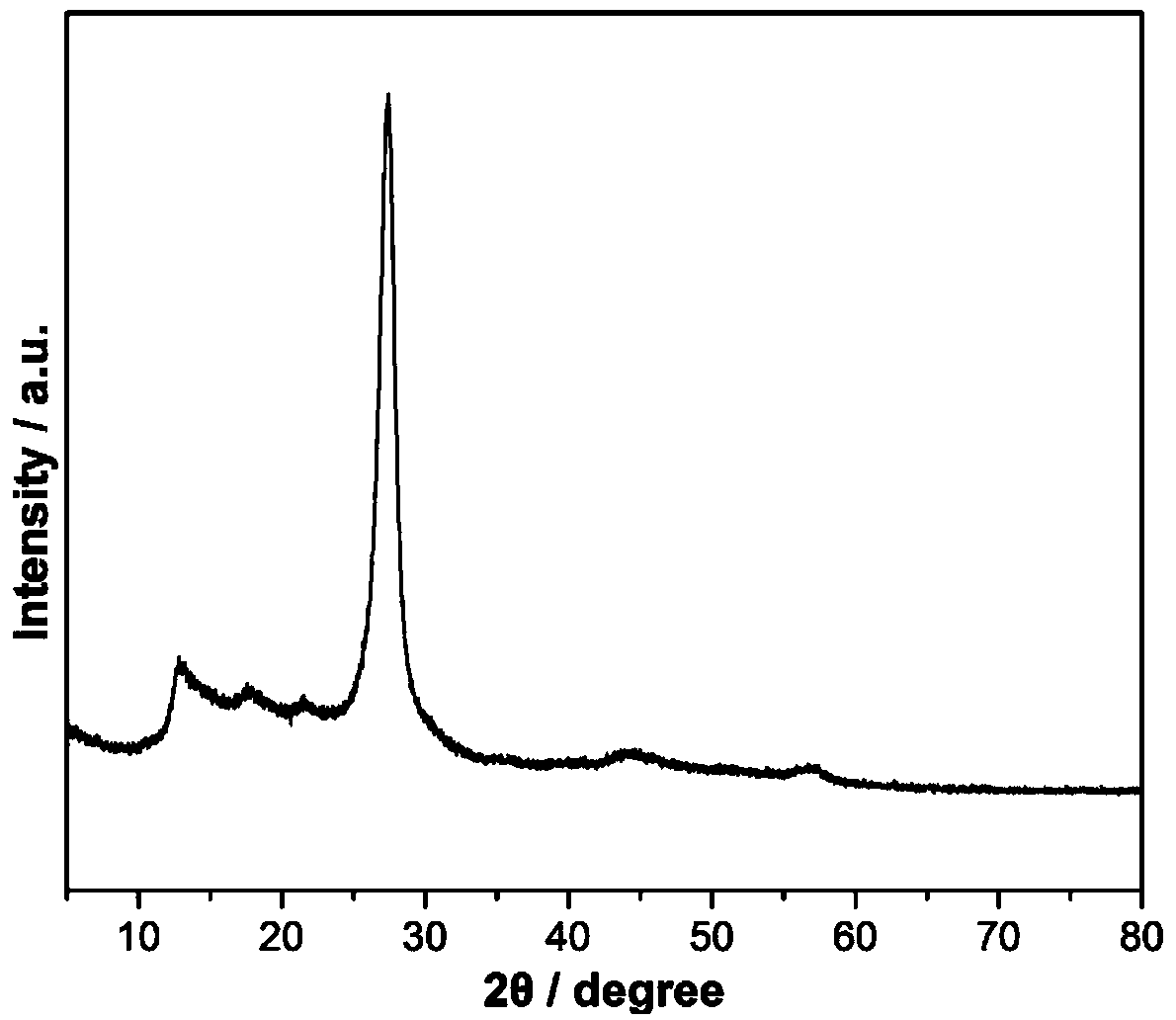

Preparation method of supported carbon nitride photo-catalyst

ActiveCN103638961AStrong bondIncrease loadPhysical/chemical process catalystsDispersed particle separationChemistryNitrogen source

The invention provides a preparation method of a supported carbon nitride photo-catalyst. The preparation method of the supported carbon nitride photo-catalyst comprises the following steps: mixing a carrier and a carbon and nitrogen source in water, and dipping to obtain a photo-catalyst precursor; recrystallizing the photo-catalyst precursor to obtain a recrystallization product; and calcinating the recrystallization product to obtain a supported carbon nitride photo-catalyst. Through the method, the carrier and the carbon and nitrogen source are mixed in the water to be dissolved, and recrystallizing and calcinating are carried out to obtain the supported carbon nitride photo-catalyst. The supported carbon nitride photo-catalyst prepared by the preparation method is in an in-situ supported type, so that a firm bonding force is formed between the carrier and a catalyst core component; meanwhile, a support amount and a supported evenness of the catalyst core component are improved; consequently, the supported carbon nitride photo-catalyst is efficient and stable in photo-catalytic activity and is beneficial to the actual application of the carbon nitride photo-catalyst.

Owner:CHONGQING TECH & BUSINESS UNIV

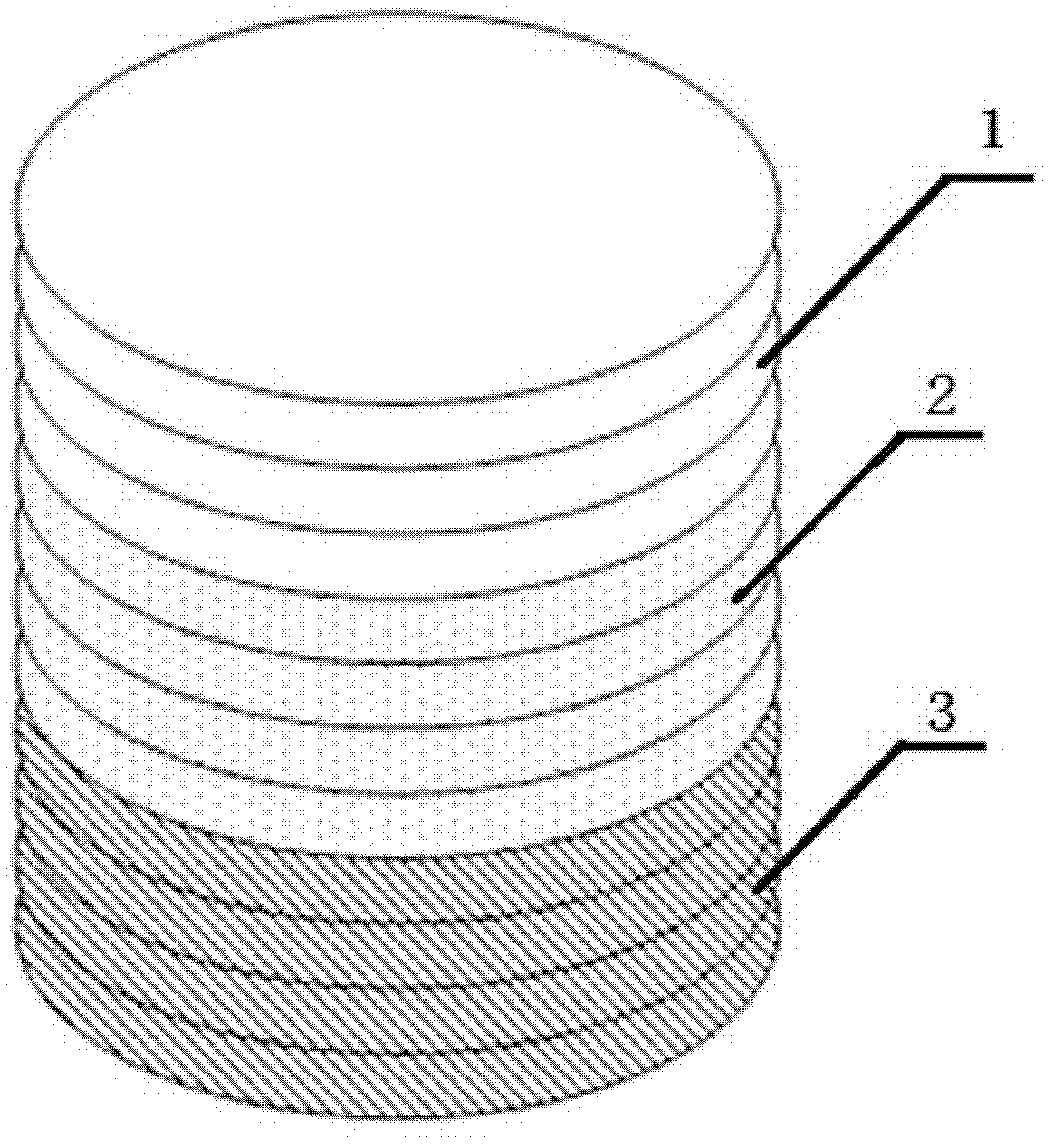

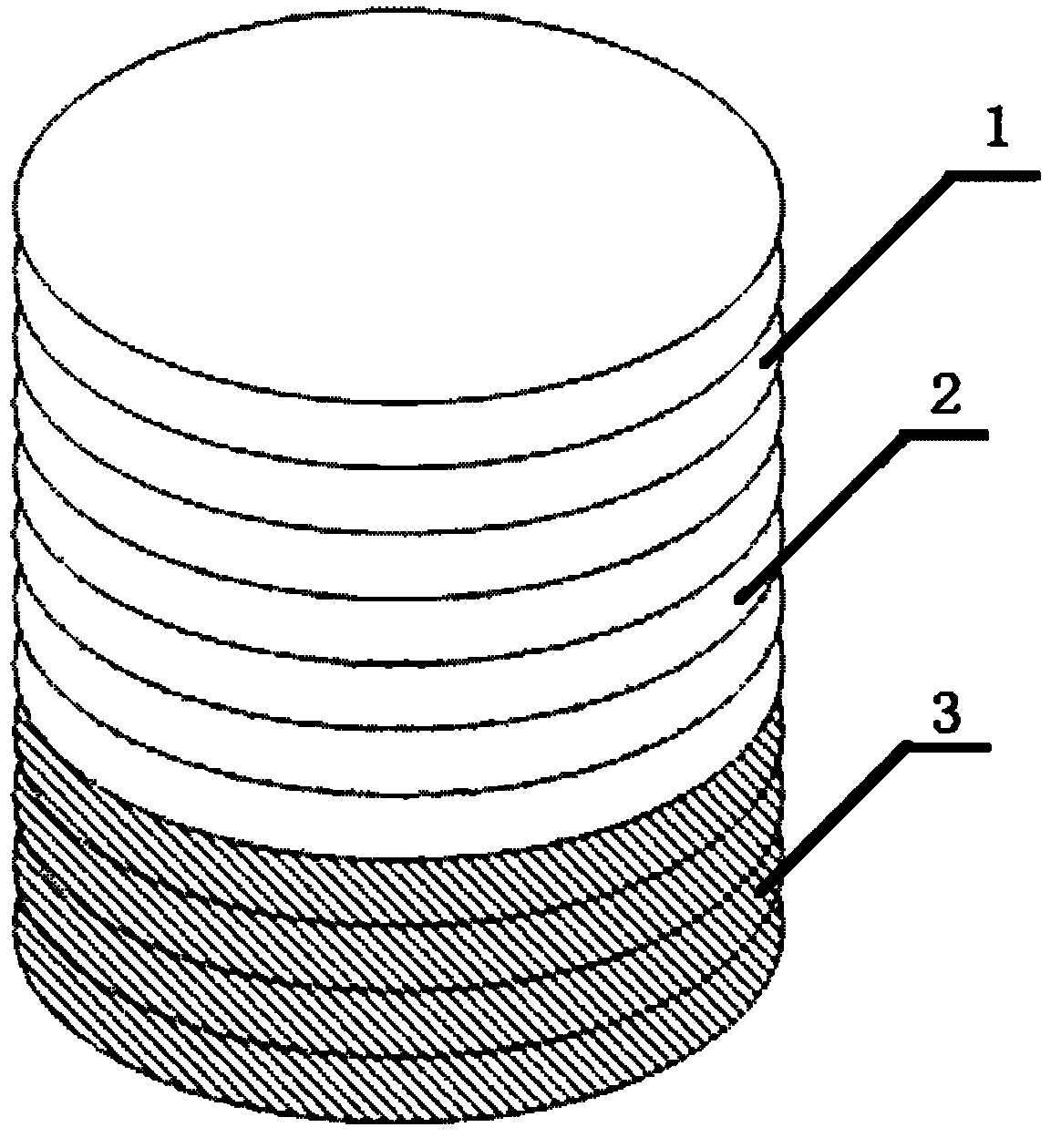

Gradient active scaffold material for osteochondral repair and its preparation method and application

The invention relates to a gradient active scaffold material for osteochondral repair and its preparation method and application. The active scaffold material is mainly composed of a cartilage layer, a calcified layer and a subchondral bone layer respectively loaded with biologically active substances, wherein the calcified layer is placed Between the cartilage layer and the subchondral bone layer, between the cartilage layer and the calcified layer, and between the calcified layer and the subchondral bone layer are organically connected by a biomedical degradable polymer; the cartilage layer, the calcified layer and the subchondral bone layer It has interpenetrating pores; its preparation method is: (1) preparation of HA / Col-I composite powder; (2) construction of bioactive substance controlled release system; (3) molding preparation of gradient active scaffold material for osteochondral repair The active scaffold material is used to prepare osteochondral complex; the active scaffold material can effectively promote the adhesion, proliferation and differentiation of cells, and is suitable for the repair and reconstruction of bone and cartilage and the delivery of nutrients.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

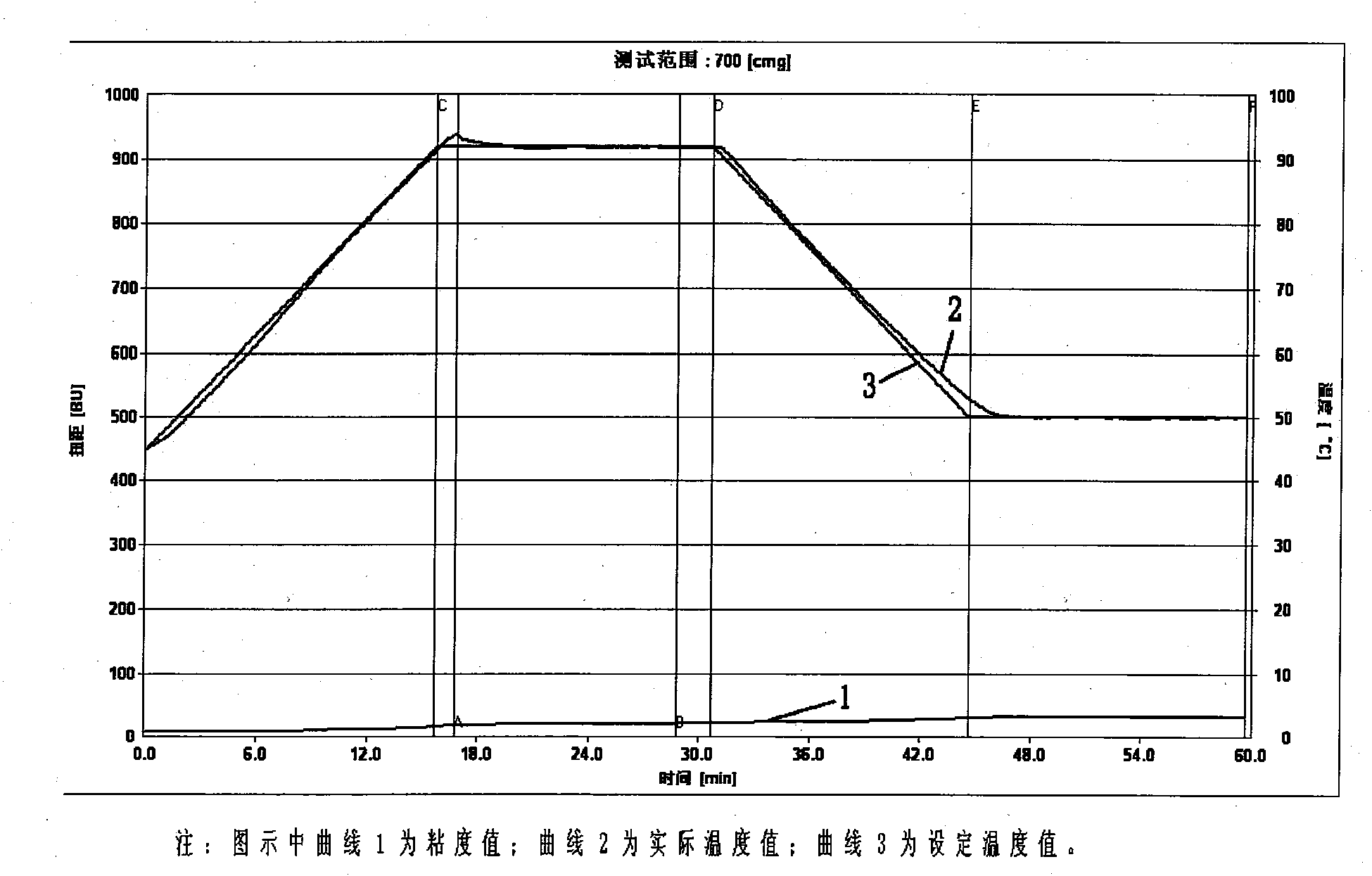

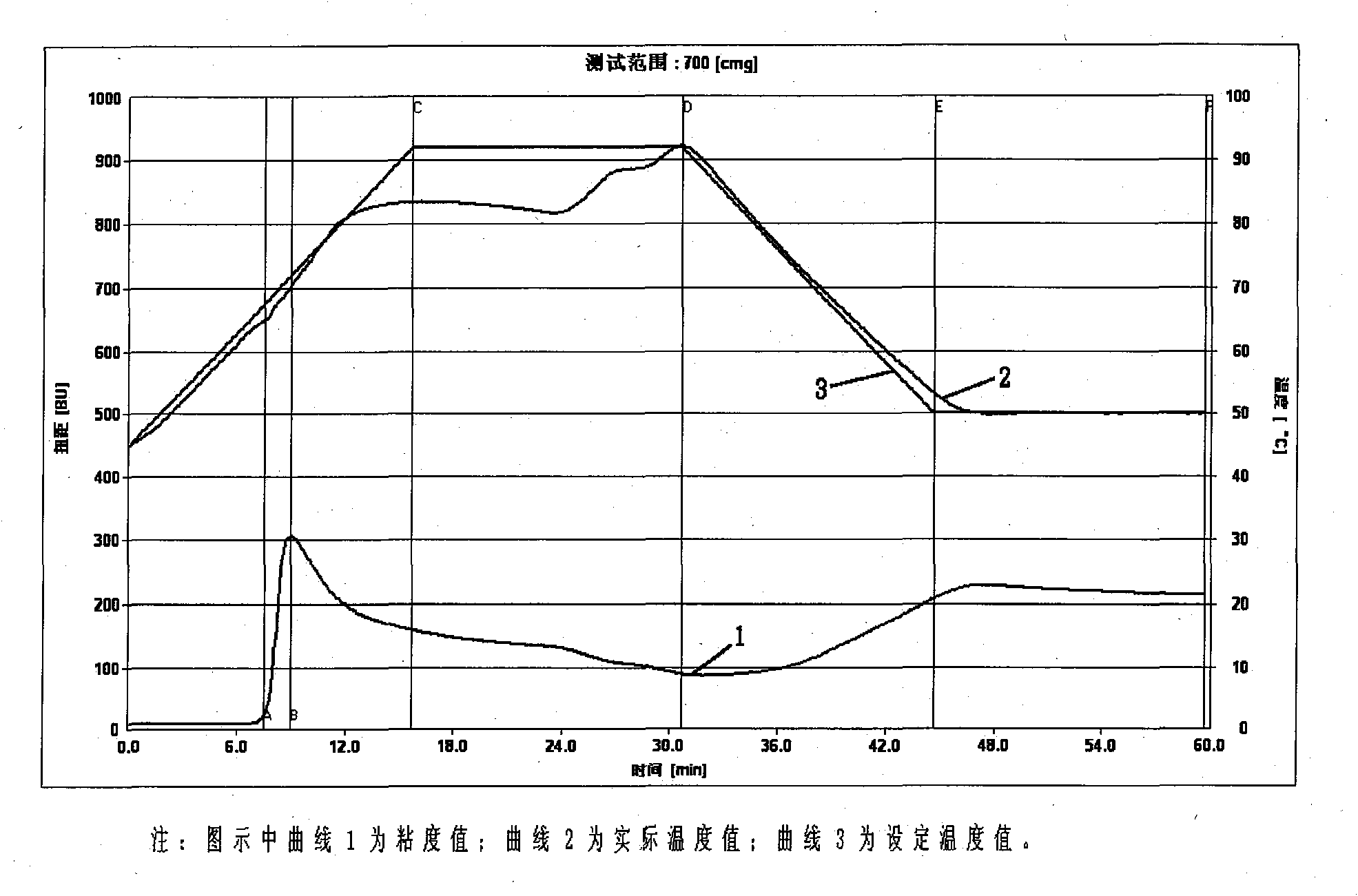

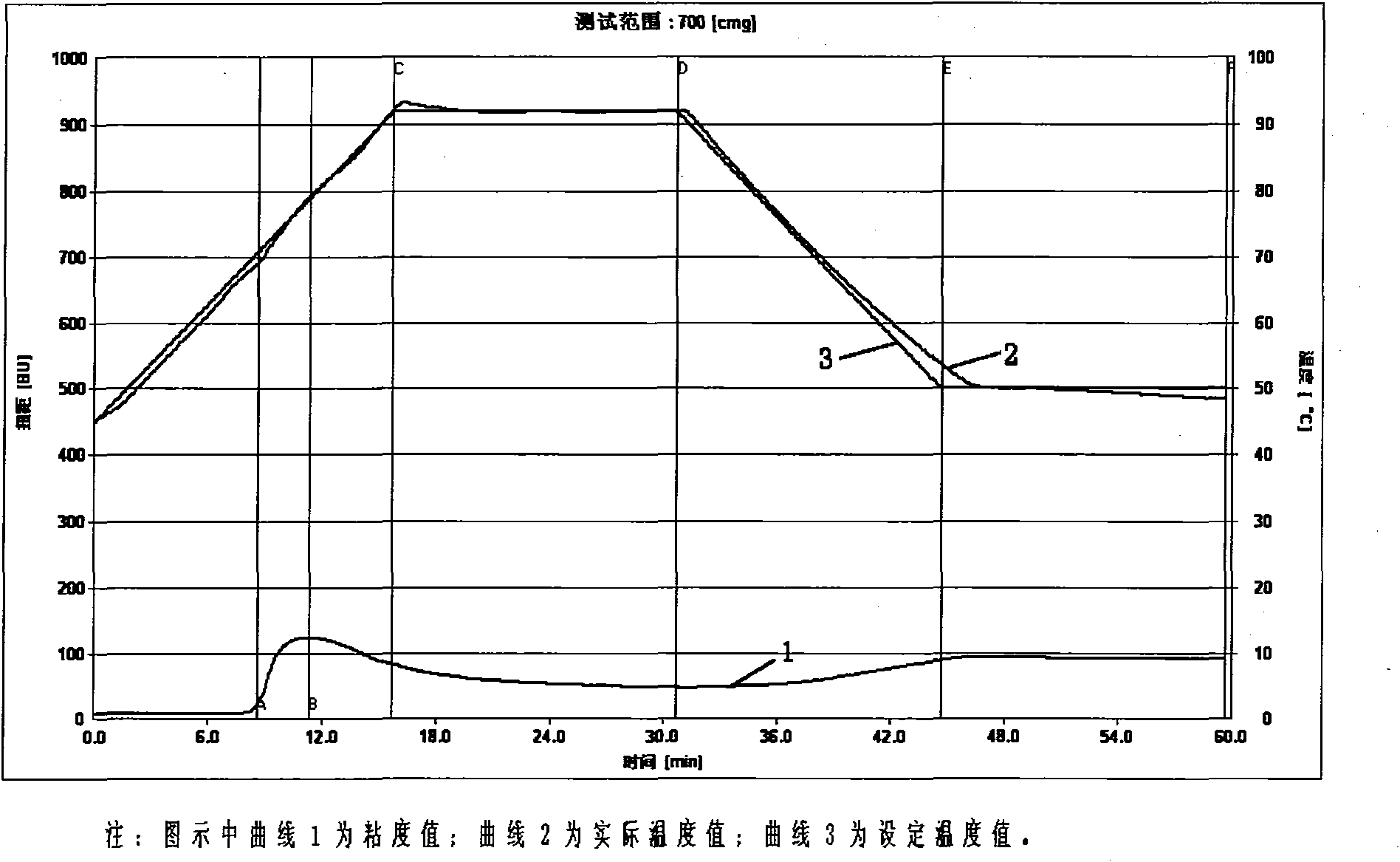

Starch bonding agent, and preparation method and use thereof

InactiveCN101962518AStrong adhesionStrong bondMechanical working/deformationStarch derivtive adhesivesHardnessSodium hypochlorite

The invention provides a preparation method for a starch bonding agent, which comprises the following steps of: performing crosslinking treatment on starch by adopting a crosslinker to form modified starch A, performing oxidation with sodium hypochlorite, esterification with butanedioic anhydride and treatment with a cationic etherifying agent on the starch to form modified starch B, and mixing the modified starch A and the modified starch B according to a certain proportion to form the modified starch bonding agent. The preparation method has the advantage of ensuring higher bonding power, firm bonding, high hardness of bonded paper products, high drying speed, low viscosity of paste, high flowability and wettability, convenience of coating, high storage stability and difficulty in gel production.

Owner:内蒙古奈伦农业科技股份有限公司

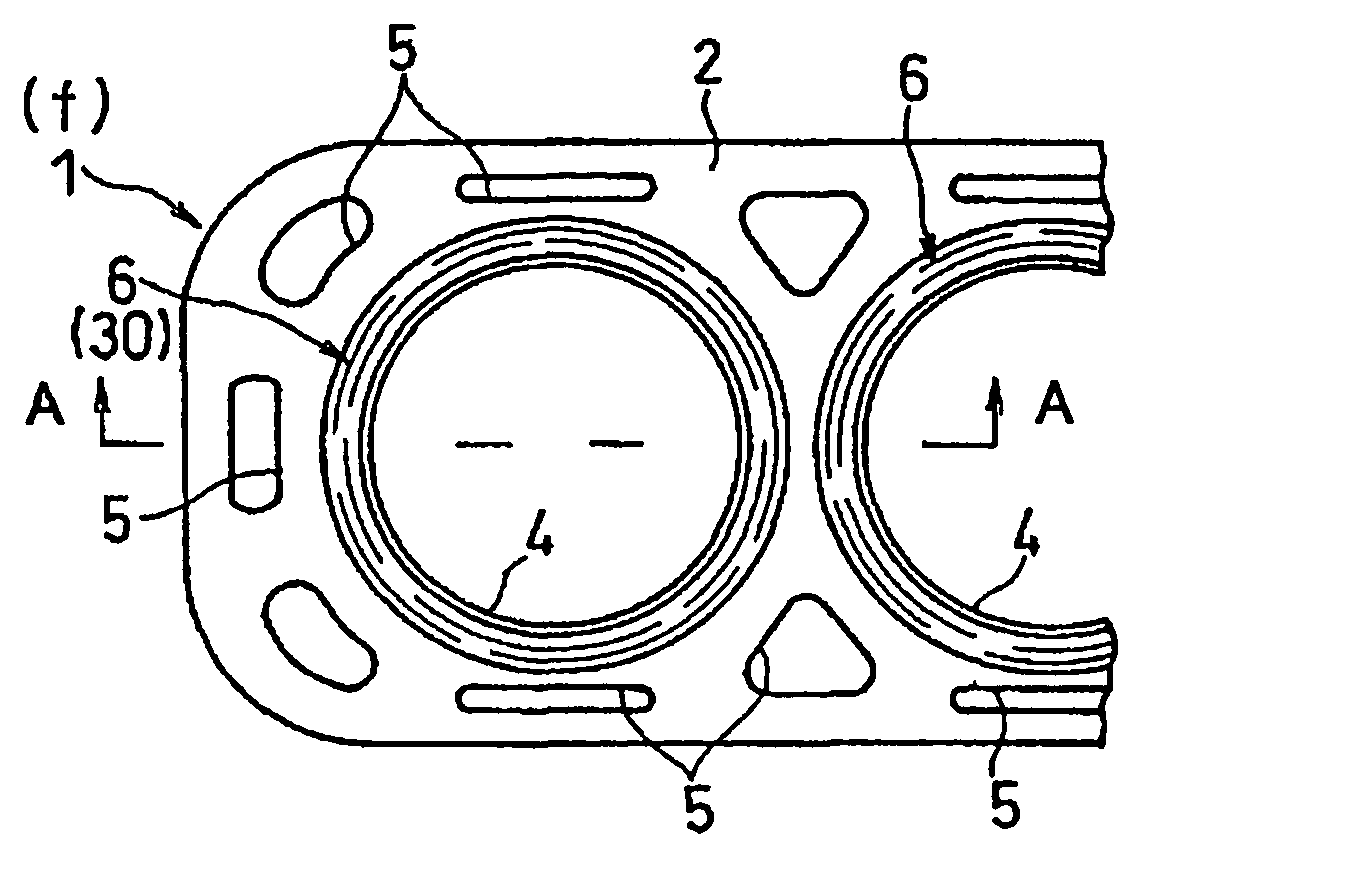

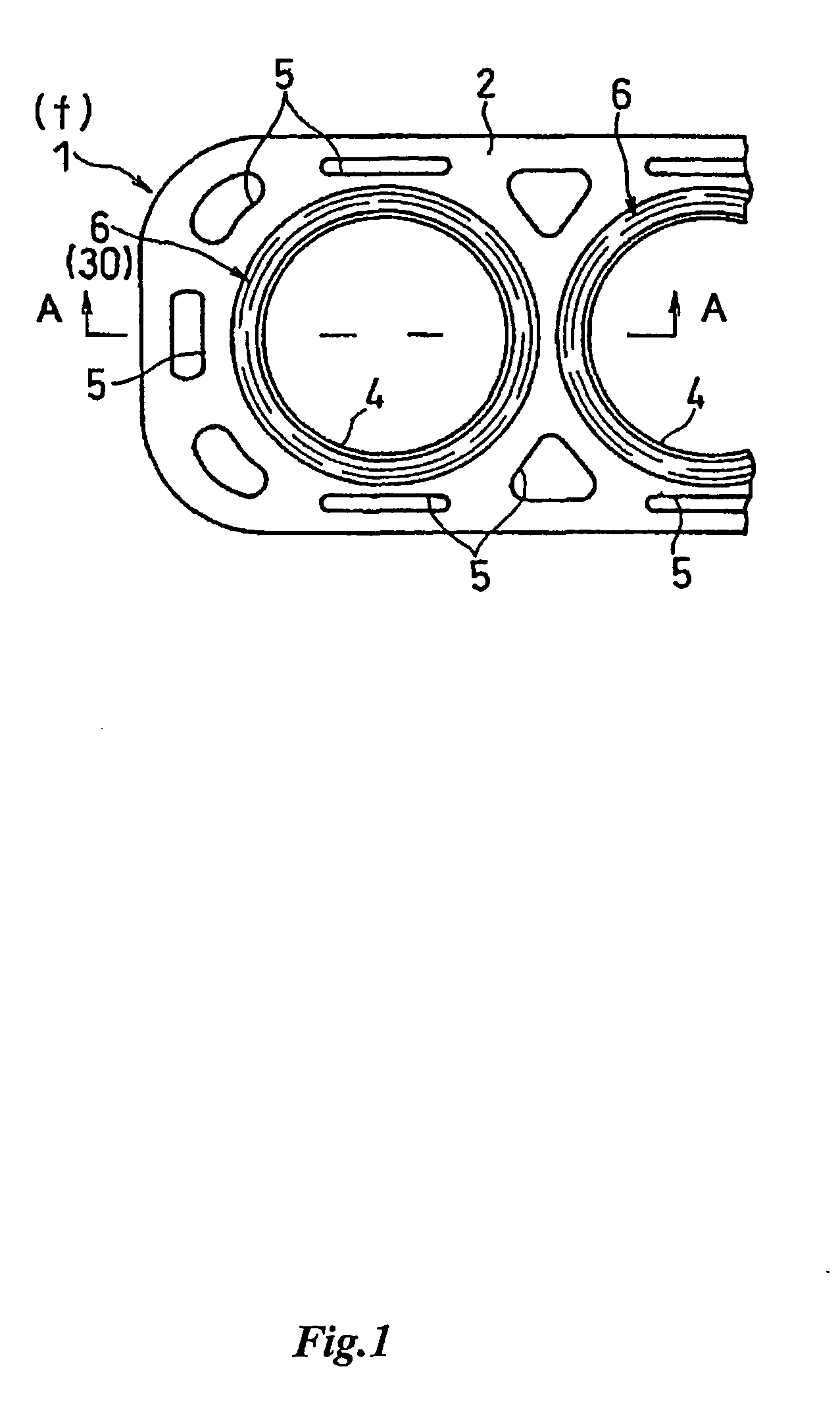

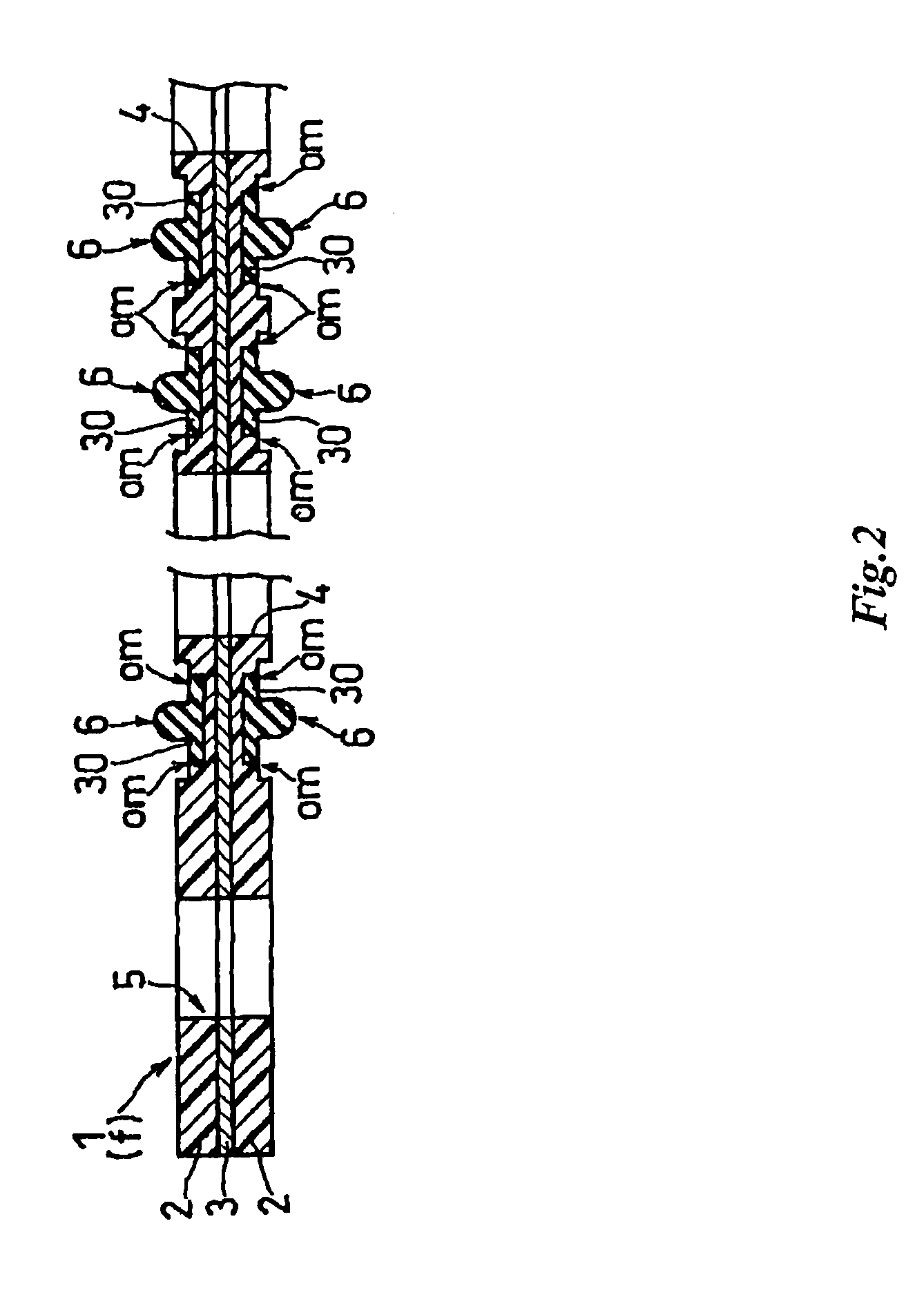

Cylinder head gasket

InactiveUS20050127615A1Facilitate productionSuperior processEngine sealsOther chemical processesEngineeringCylinder block

A cylinder head gasket for sealing between a cylinder block and a cylinder head, composed of a composite base plate, the composite base plate comprising a core material plate and a compound layer formed on the front and back surfaces of the core material plate, the compound layer being formed by coating compound materials which contain a rubber and a fiber material. The cylinder head gasket is comprised of an annular groove which is formed by pressing the corresponding region around the cylinder bore of the compound layer, and a bead projecting from the surface of the compound layer which is formed by inserting the rubber material into the annular groove.

Owner:UCHIYAMA MFG +2

Novel phosphorus and magnesium based cement grouting material and preparation method

The invention discloses a novel phosphorus and magnesium based cement grouting material and a preparation method and belongs to the field of technical application of grouting materials. The grouting material is prepared from the following raw materials in parts by weight: a component A: 30 to 90 parts of a compound magnesium compound, 0.5 to 5 parts of a compound retarder, 0.2 to 0.7 part of a water reducer, 0.2 to 1.5 parts of an acid-alkali buffering agent, 1 to 5 parts of a compound stabilizer and 0.5 to 1.5 parts of a compound surfactant; a component B: 20 to 50 parts of phosphate and 0.2to 2 parts of a de-foaming agent. The preparation method comprises the following steps: accurately weighing materials of the component A and the component B according to the ratio and uniformly stirring; mixing with water according to the weight ratio of 100 to (20 to 50) and stirring to form slurry; after uniformly mixing, pressing a mixture into gaps or cracks and curing. The novel phosphorus and magnesium based cement grouting material disclosed by the invention has the beneficial effects of controllable coagulation time, large adjustable range, high early age strength, high bonding strength, good permeability, simplicity and convenience for construction, greenness and environment protection and low cost, and meets the requirements on three properties including injectability, controllability and permeability resistance.

Owner:山东塔罗斯智能装备有限公司

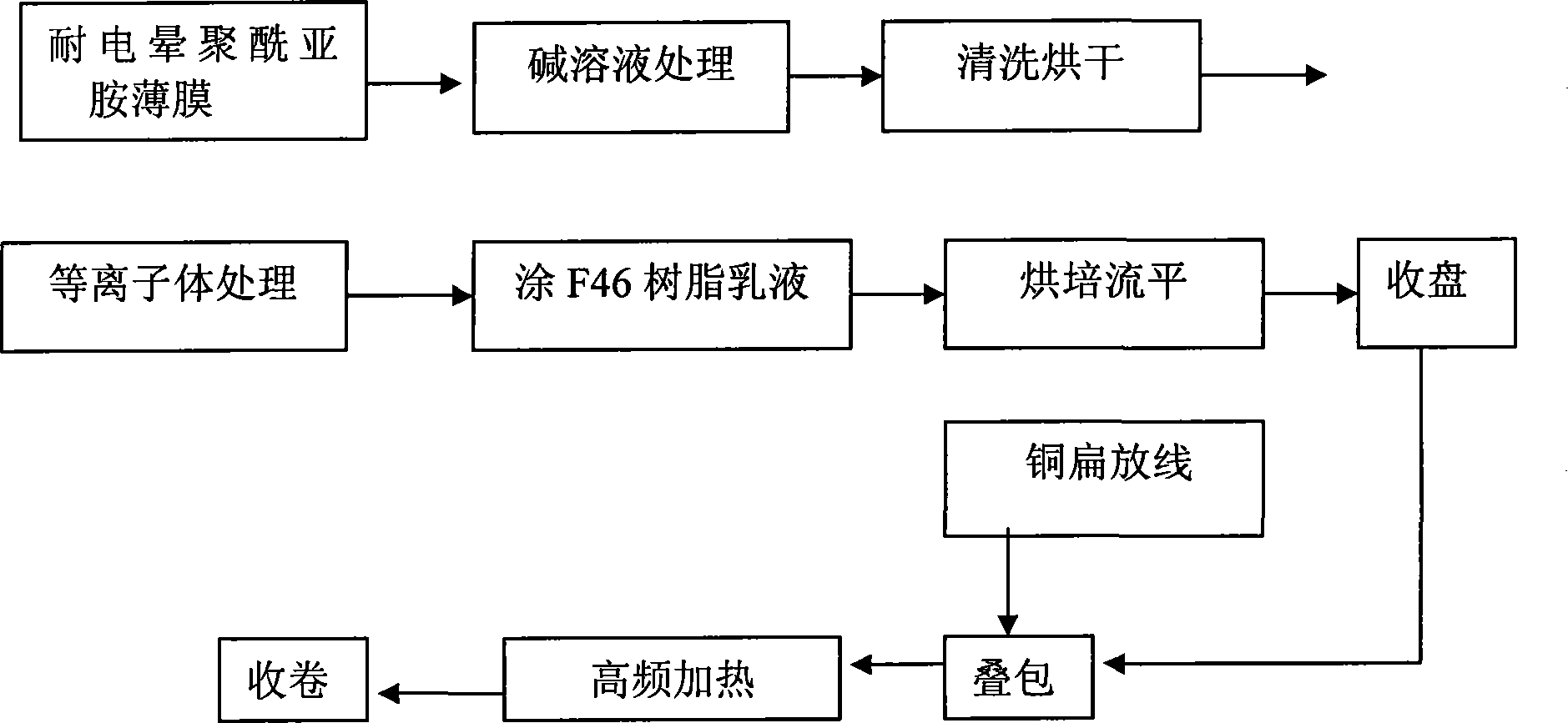

Production process for corona resistant polyimide film to produce winding wire

InactiveCN101252033AStrong bondHigh mechanical strengthWindingsFlat/ribbon cablesPlasma treatmentMoisture

The present invention discloses a method for manufacturing winding wires by corona resistant polyimide films, comprising the following steps: 1) alkaline solution processing; 2) cleaning and drying; 3) plasma processing at normal temperature; 4) coating resin latex; 5) baking and flowing and leveling; 6) withdrawing trays; 7) releasing copper flat wires; 8) folding packages; 9) high-frequency heating; 10) roll-up. With the present invention, after a surface chemical treatment and a normal temperature plasma treatment, the adhesion between the film and the copper conducting wires and between the films is firm, the mechanical strength is high. After being bent or stretched, the winding wire still has good adhesion performance and electric insulation performance, sealing and moisture resistant performance, heat resistant performance, and heat conduction performance. The thickness of the film is controlled between 0.03 and 0.038 mm. In the condition that the volume of a motor is not changed, the cross section of the conductor of the motor can be enlarged. The thermal resistance encountered during the period, when the heat generated during the running process of the motor is dissipated outward, is reduced. The insulation thermal aging speed is slowed and the service life of the motor is greatly prolonged.

Owner:JIANGSU ICE CITY INSULATION MATERIALS STOCK

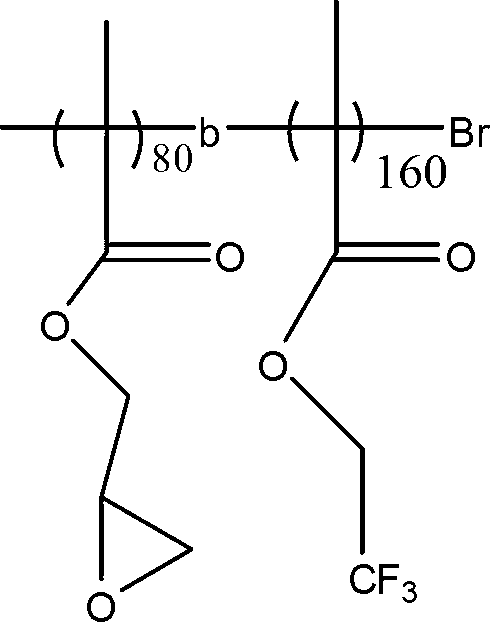

Water-dispersible crosslinking type fluoropolymer and application of fluoropolymer in preparation of super-amphiphobic surfaces

ActiveCN102964544ARealizing superhydrophobicity and superamphiphobiaImprove hydrophilicityFibre treatmentPaper coatingPolymer scienceWater dispersible

The invention discloses a water-dispersible crosslinking type fluoropolymer and application of the fluoropolymer in preparation of super-amphiphobic surfaces. The fluoropolymer is a block polymer polymerized by a monomer A and a monomer B and has a molecular weight of 500-47000, wherein the mole ratio of the monomer A to the monomer B is 1: (0.2-10); and the structures of the monomer A and the monomer B are respectively shown in formulas I and II. The fluoropolymer can be used for preparing the super-amphiphobic surfaces. As a crosslinking block part of the water-dispersible crosslinking type fluoropolymer has favorable hydrophilcity, the water-dispersible crosslinking type fluoropolymer can be prepared into an aqueous micelle which takes the fluoropolymer as a core and takes a hydrophilic chain segment as a shell in water, so as to realize the aim of constructing the super-amphiphobic surfaces in a green and environment-friendly water solution. The super-amphiphobic surfaces prepared by using the fluoropolymer are firm in bonding with base materials, rub-resistant and washing-endurable.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

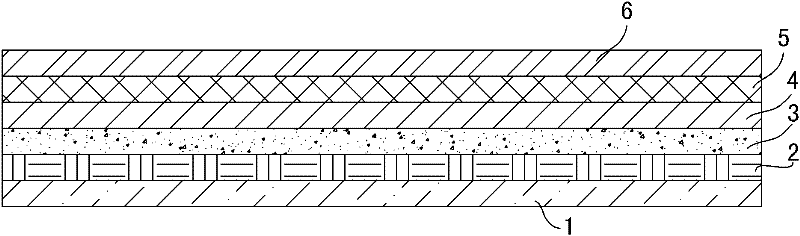

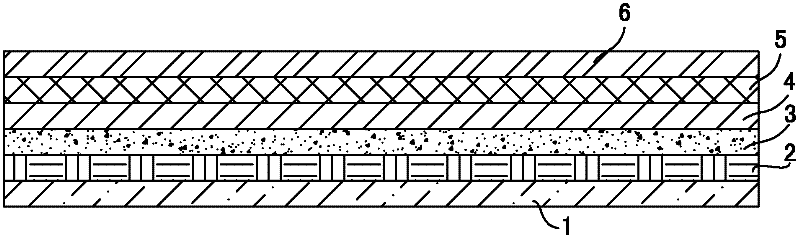

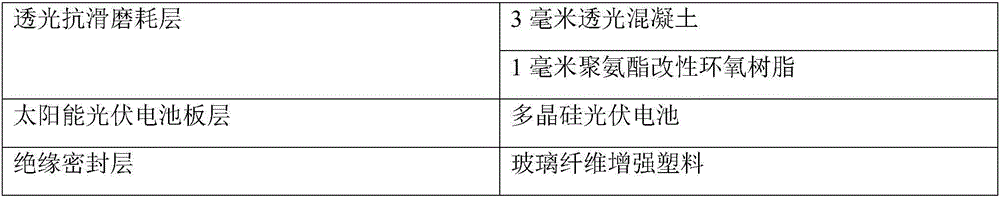

Assembly type solar photovoltaic power generation road surface module and application thereof

InactiveCN106549629AIncrease profitCapable of bearing pressurePhotovoltaic supportsPhotovoltaic energy generationComputer moduleRoad surface

The present invention provides an assembly type solar photovoltaic power generation road surface module and application thereof. The module comprises at least the following structures from bottom to top: an insulated sealing layer, a solar photovoltaic panel layer, and a transparent anti-slide wearing layer. The module is mainly used for solar photovoltaic power generation. The assembly type solar photovoltaic power generation road surface module can meet both the road bearing demand and the solar photovoltaic power generation demand, and has a broad market prospect.

Owner:张宏超 +1

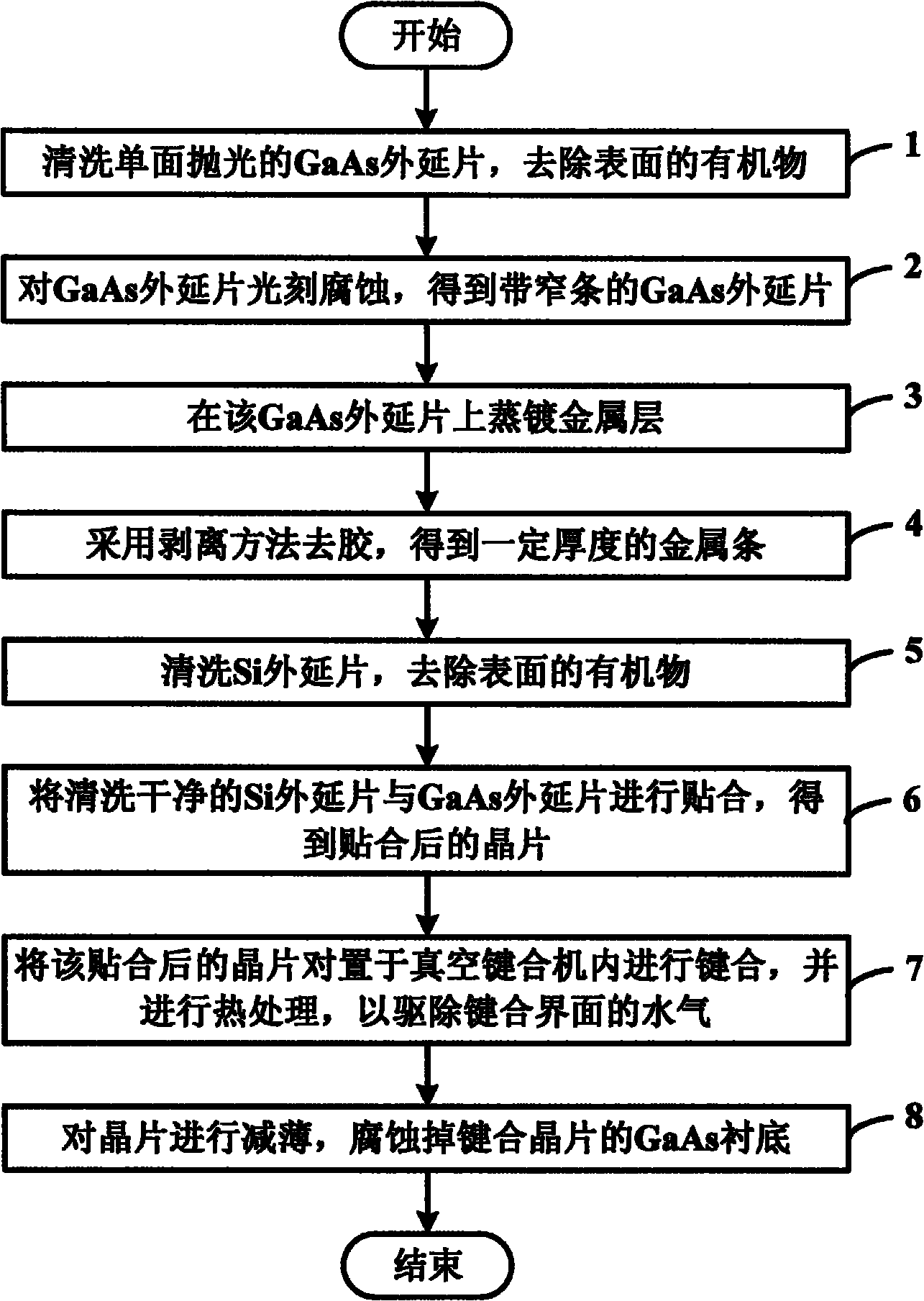

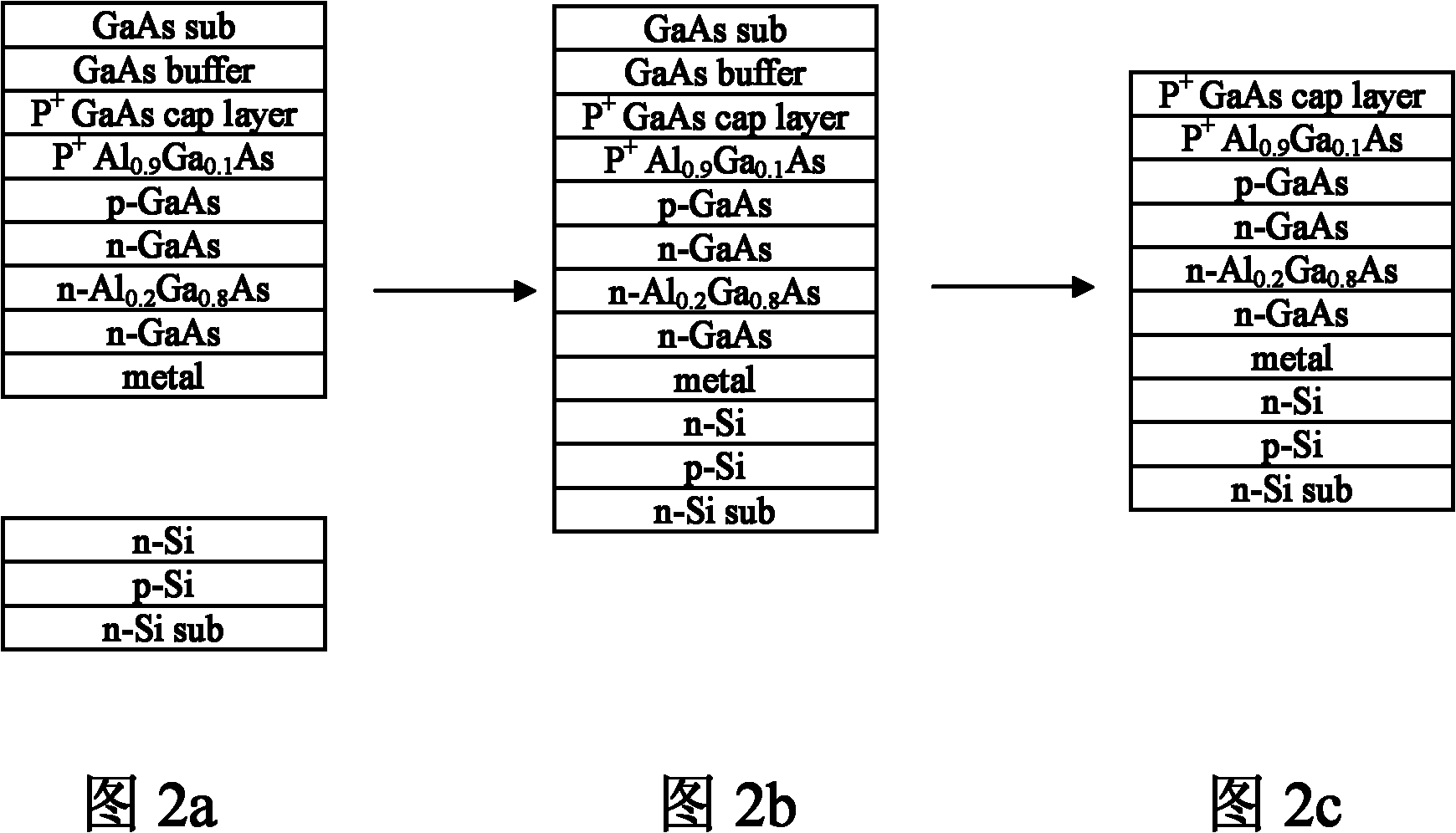

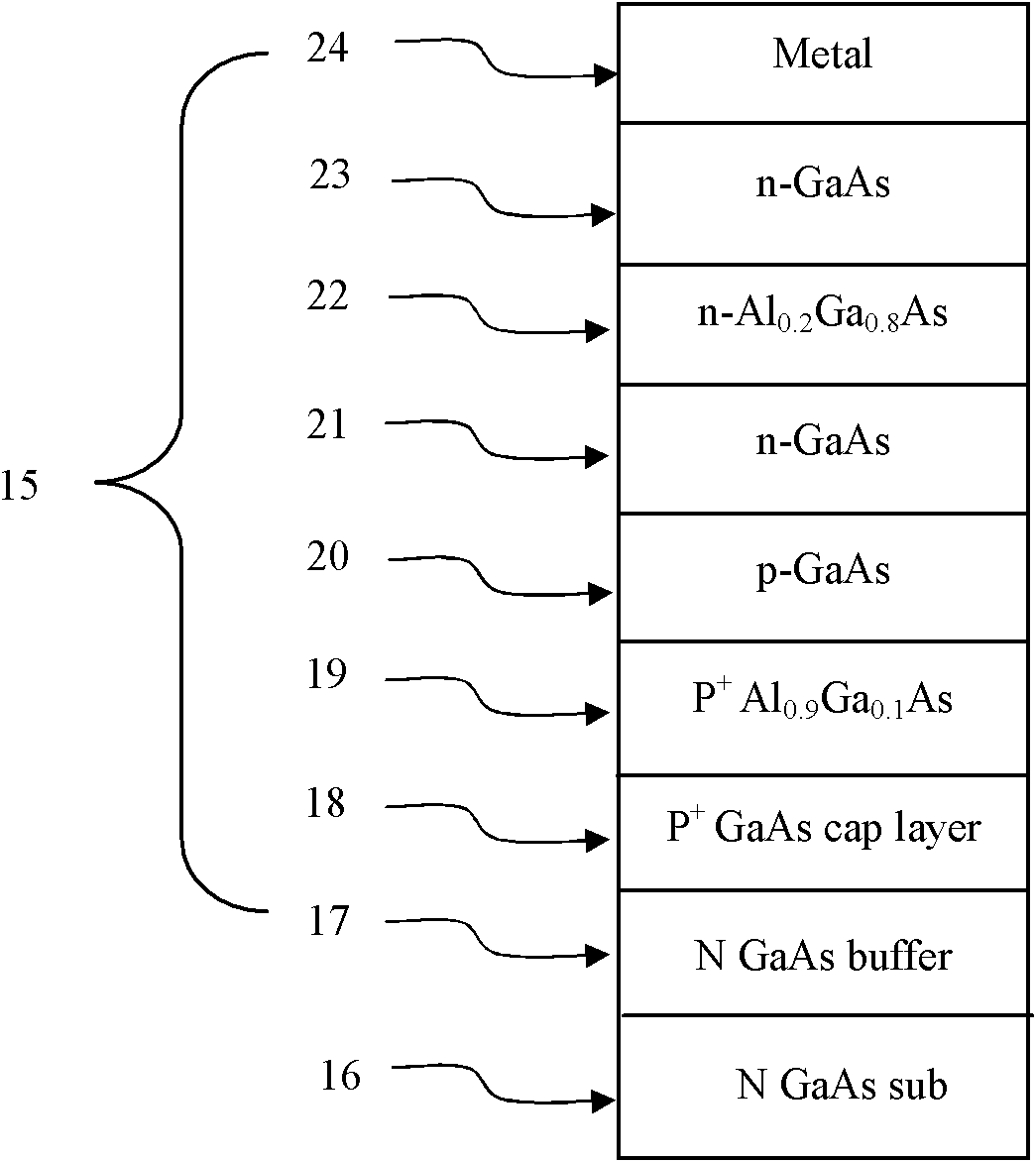

Method for performing low-temperature metal bonding on GaAs and Si

InactiveCN102110594ARealize the structureAchieve bondingFinal product manufactureSemiconductor/solid-state device manufacturingMetal stripsBond interface

The invention discloses a method for performing low-temperature metal bonding on GaAs and Si. The method comprises the following steps of: cleaning a single-side polished GaAs epitaxial wafer to remove organic substances on the surface of the wafer; performing photoresist etching on the GaAs epitaxial wafer to obtain the GaAs epitaxial wafer with a narrow strip; performing evaporation on the GaAs epitaxial wafer to form a metal layer; removing a photoresist by a stripping method to obtain a metal strip with a certain thickness; cleaning a Si epitaxial wafer to remove organic substances on the surface of the wafer; treating the surface of the Si epitaxial wafer by using H2SO4 solution and RCAl solution and attaching the cleaned Si epitaxial wafer to the GaAs epitaxial wafer so as to obtain an attached wafer; oppositely arranging the attached wafer in a vacuum bonding machine for bonding and performing thermal treatment to remove vapor of a bonding interface; and thinning the bound wafer and corroding off the GaAs substrate of the bound wafer. By the method, the low-temperature metal bonding of the GaAs and the Si is realized; and the method can be extended to the bonding between two III-V groups (or materials such as Si, Ge and the like of an IV group).

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

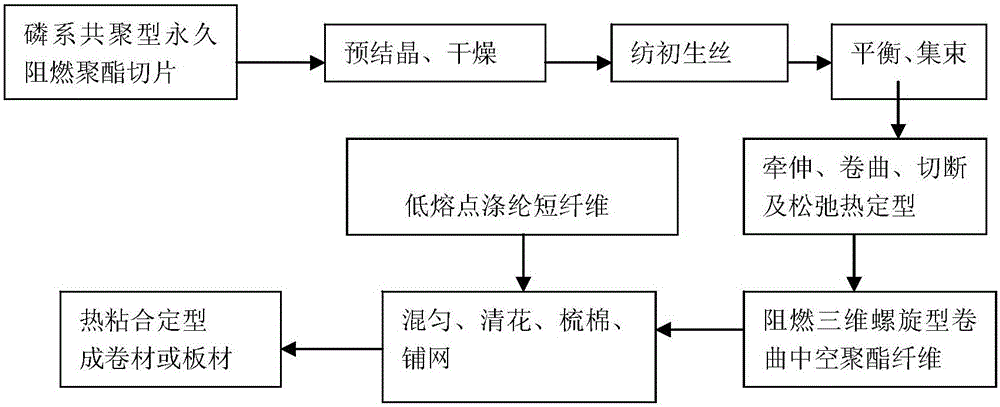

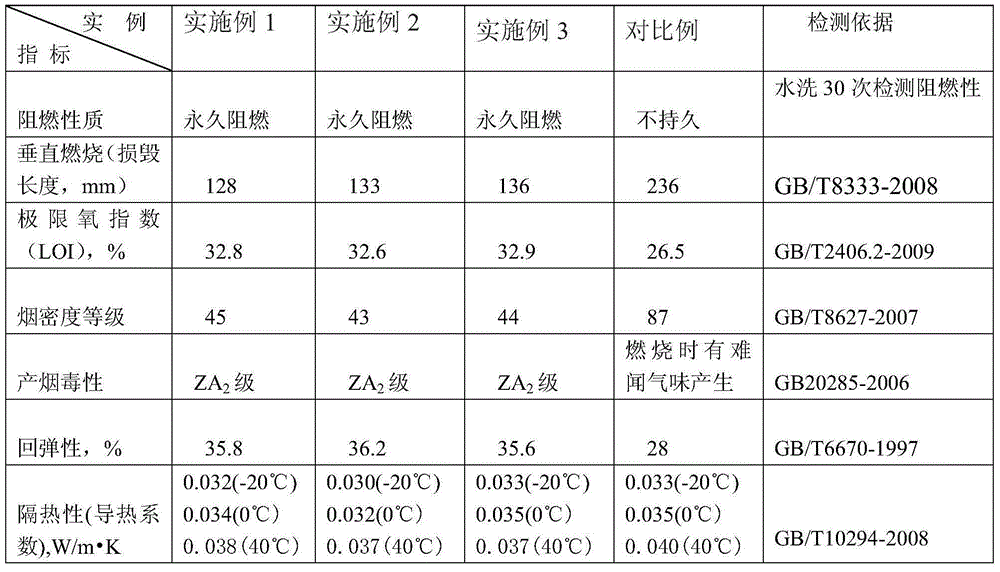

Novel flame-retardant heat-insulation elastic polyester material and preparing method and application thereof

ActiveCN105088535AStrong bondProduct environmental protectionFilament/thread formingMonocomponent copolyesters artificial filamentWater contentChemistry

The invention discloses a preparing method of a novel flame-retardant heat-insulation elastic polyester material. The preparing method includes the steps that phosphorus co-polymerized permanent flame-retardant polyester chips are pre-crystalized and dried, and then the water content is smaller than or equal to 30 ppm; spun filaments are obtained through spinning, and after the spun filaments are balanced and bundled, 2-10 D flame-retardant three-dimensional spiral crimped hollow polyester fibers are obtained through drafting, crimping, cutting-off and relaxation heat setting; 85-95wt% of flame-retardant three-dimensional spiral crimped hollow polyester fibers and 15-5wt% of low-melting-point polyester staple fibers are mixed evenly, treated in the mode of blowing, carding and lapping and then thermally bonded through a hot mill or a hot air dryer. The material is superior in performance and can replace polyurethane foaming plastic to be used as a furniture pad material, a vehicle seat pad material and various soft pad laminated composite materials.

Owner:HIGHTEX CO LTD ZHEJIANG

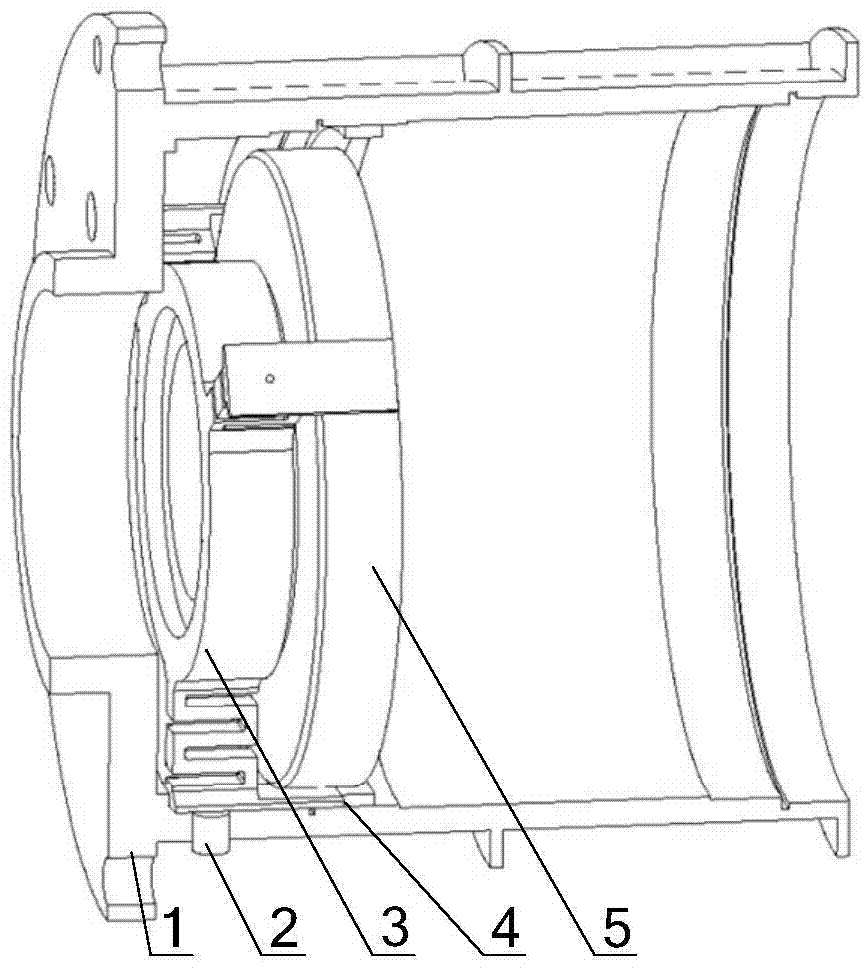

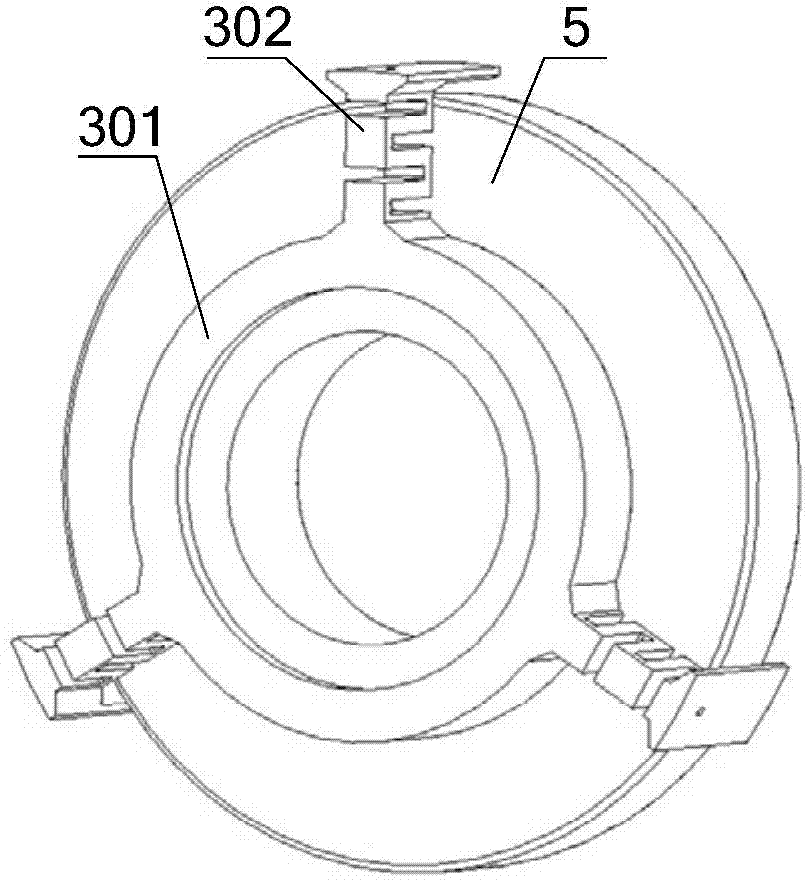

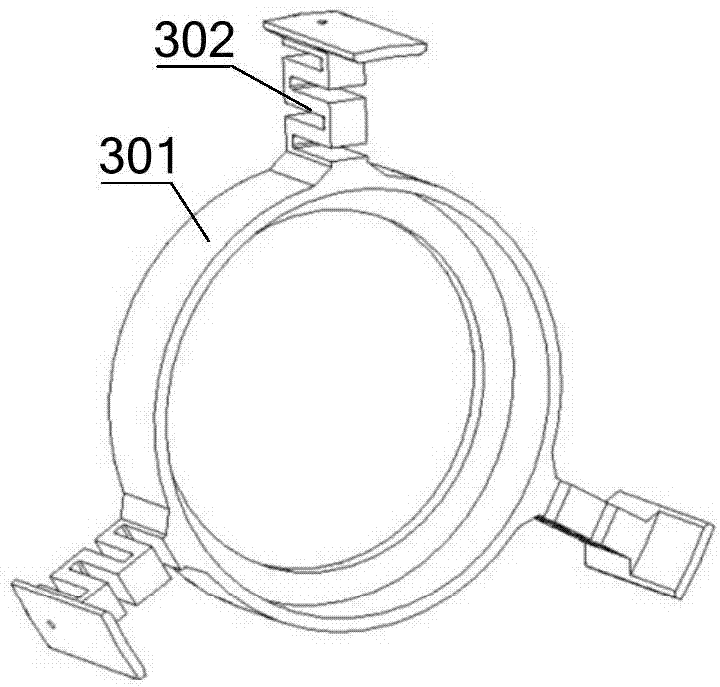

Small reflector ultrahigh power thermal stability supporting structure

The invention provides a small reflector ultrahigh power thermal stability supporting structure, and belongs to the technical field of the aerospace technology. The supporting structure solves the problems that in the prior art, a reflector is low in intrinsic frequency and poor in external disturbance resistance, a reflection mirror surface is large in shape change, the requirement for the assembly technique level is high, interchangeability is poor and mass production is difficult to achieve. The supporting structure comprises a mirror chamber and a flexible joint, the flexible joint and the reflector are in glue joint and fixed concentrically, the flexible joint is fixed in the mirror chamber and comprises a cylindrical barrel and multiple flexible single arms which are uniformly distributed on the outer side of the cylindrical barrel in the circumference direction and each flexible single arm is a double-layer flexible hinge. Under the action of temperature loads, in the process that thermal deformation stress deformation energy of the lens barrel is transmitted to the reflector, the thermal deformation stress deformation energy is absorbed when passing a flexible unload groove of the flexible joint, uniform deformation of the reflector is guaranteed, at the moment, surface precision slightly changes, the parts are fixedly connected, the requirement for the assembly technique is not high, and the supporting structure is good in interchangeability and high in external dynamic interference resistance.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Leadless ohmic electrode silver coating for PTC ceramic and its preparation method

InactiveCN1870179AReliable bondingExcellent aging resistanceNon-conductive material with dispersed conductive materialResistor manufactureCeramicOhm

A method for preparing silver size pole of lead free ohm electrode used on PTC ceramic includes mixing and grinding silver micro powder, zinc powder and organic carrier together to obtain silver size pole material then firing obtained material at temperature of 480-580deg.c to let electrode layer attached on surface of ceramic body tightly for forming excellent ohm contact property.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

Water plugging agent for carbonatite and preparation method and using method thereof

InactiveCN101712863AHigh densityLow densityDrilling compositionSealing/packingHigh densityVolumetric Mass Density

The invention provides a water plugging agent for carbonatite and a preparation method and a using method thereof. The water plugging agent consists of the following raw materials in part by weight: 5 to 14 parts of cement, 4 to 8 parts of quartz, 0.1 to 0.5 part of cement flocculating agent, 4 to 11 parts of density lightening admixture, 1 to 2 parts of grid structure agent and 72 to 74 parts of water. The water plugging agent has high bonding strength and low density, and is suitable for high-temperature and high-mineralization carbonatite oil wells so as to solve the problem that the water plugging agent in the prior art is not suitable for the high-temperature and high-mineralization environment, has poor bonding strength and high density, and cannot effectively control water or improve the oil recovery ratio.

Owner:北京德美高科科技股份有限公司

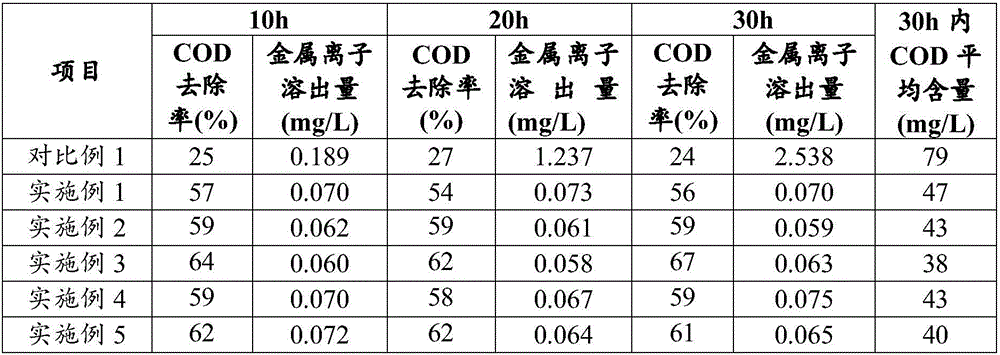

Preparation method of modified alumina carrier, catalytic ozone oxidation catalyst, and application of catalyst

ActiveCN106732509ANot easy to loseEasy to drainCatalyst carriersHeterogenous catalyst chemical elementsFree coolingRoom temperature

The invention relates to the technical field of water treatment, and especially relates to a preparation method of a modified alumina carrier, a catalytic ozone oxidation catalyst, and an application of the catalyst. The preparation method of the modified alumina carrier comprises the following steps: providing an alumina substrate; carrying out primary modifier spray immersion, primary drying and primary calcination on the alumina substrate, and naturally cooling the obtained calcined alumina substrate to room temperature; and carrying out secondary modifier spray immersion, secondary drying and secondary calcination on the alumina substrate, and naturally cooling the secondary calcined alumina substrate to obtain the modified alumina carrier. The catalytic ozone oxidation catalyst prepared from the modified alumina carrier greatly improves the COD removal rate, so the sewage treatment cost is reduced; the dissolution rate of metal ions is greatly reduced, so the service life of the catalyst is prolonged; and the catalyst has the advantages of low cost and simple preparation method, and is very suitable for industrial production.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

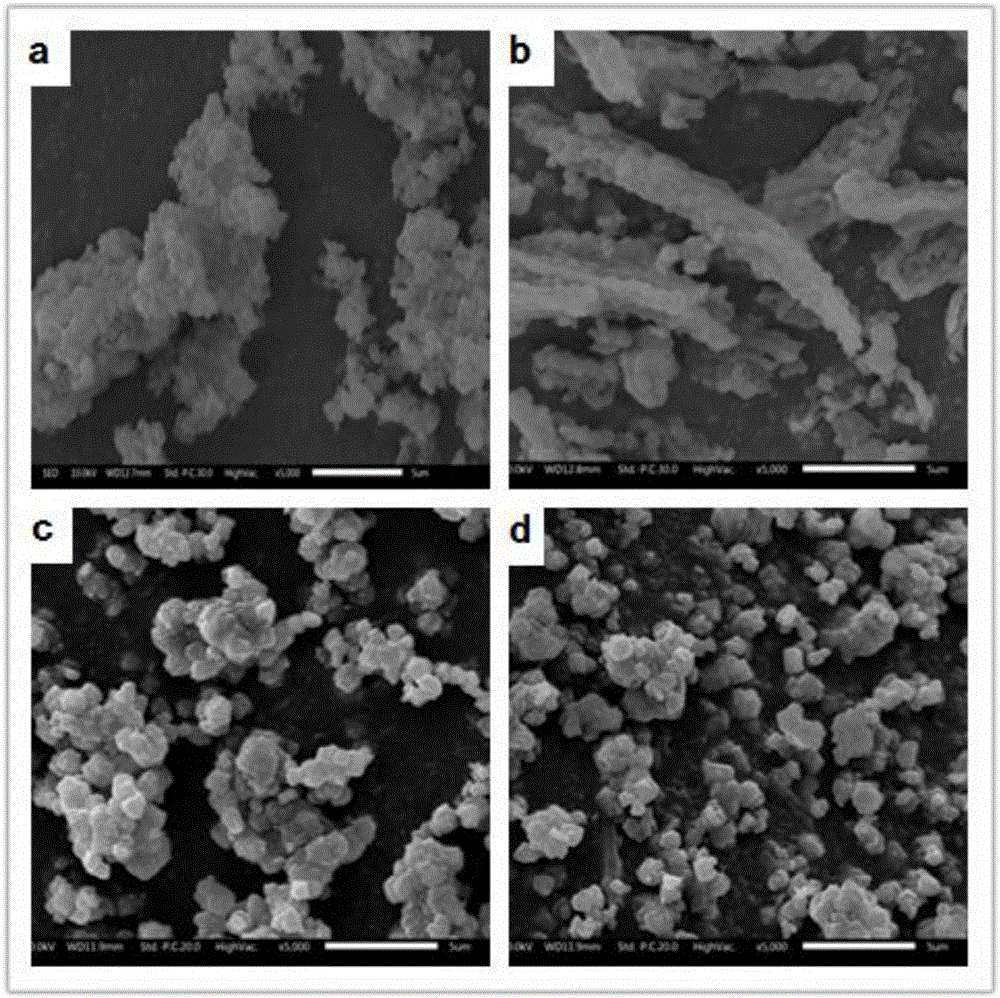

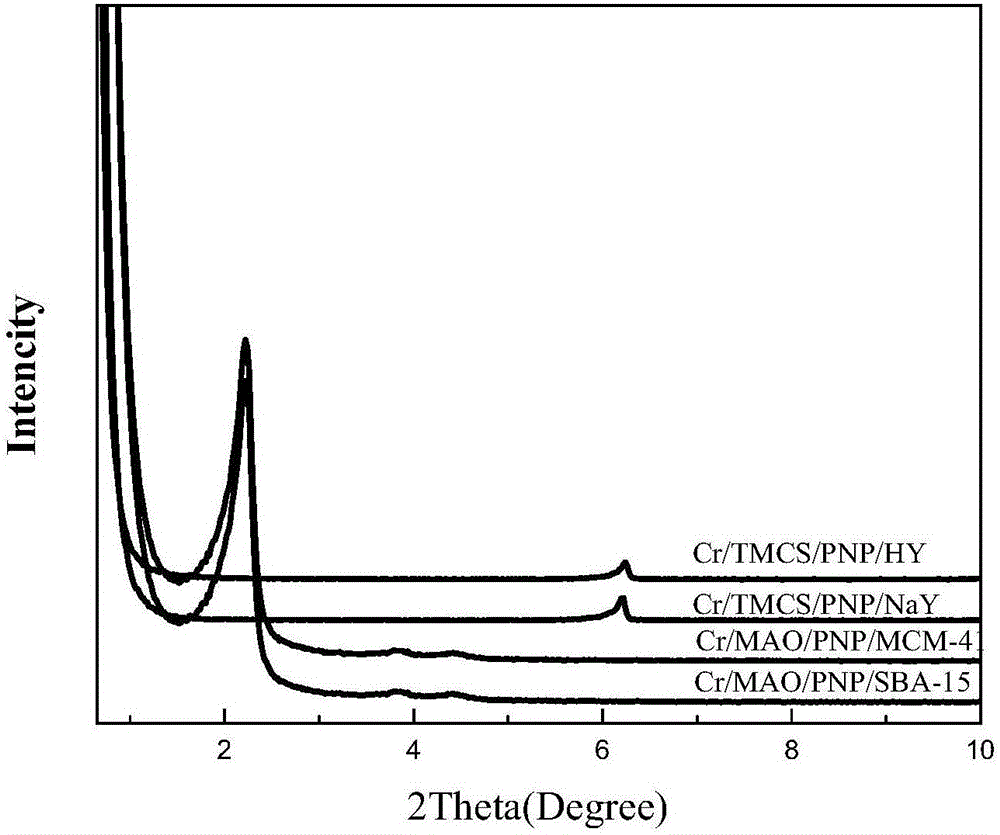

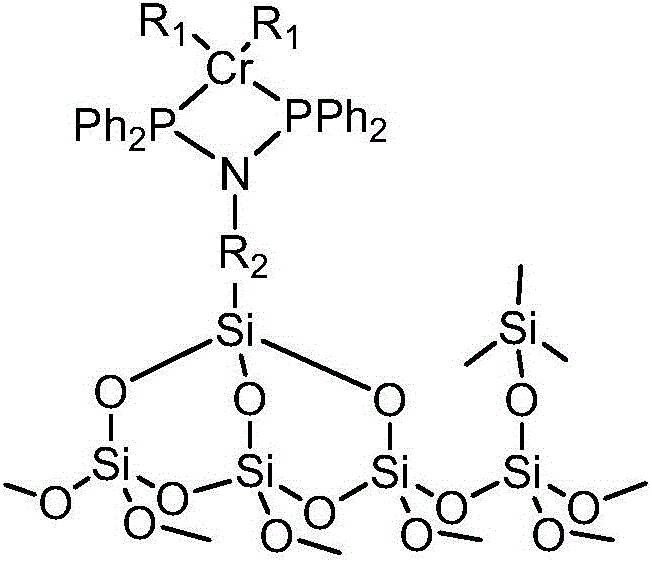

Catalyst for ethylene oligomerization and preparation method thereof

ActiveCN106492880ASingle structureStrong bondOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsMolecular sieveGrafting

The invention relates to a catalyst for ethylene oligomerization and a preparation method thereof. The catalyst comprises a main catalyst which is a catalyst obtained by the steps of taking molecular sieve as a carrier, carrying out chemical bond grafting of silicon hydroxyl on the molecular sieve surface and a bis(diphenylphosphino)ammonia ligand containing silicon ethoxy, and then complexing with a chromium active component. The invention also provides the preparation method of the catalyst. The catalyst has the advantages of high catalytic activity, easy separation from a product and high content of alpha-olefins in the oligomerization product when used for catalyzing ethylene oligomerization.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

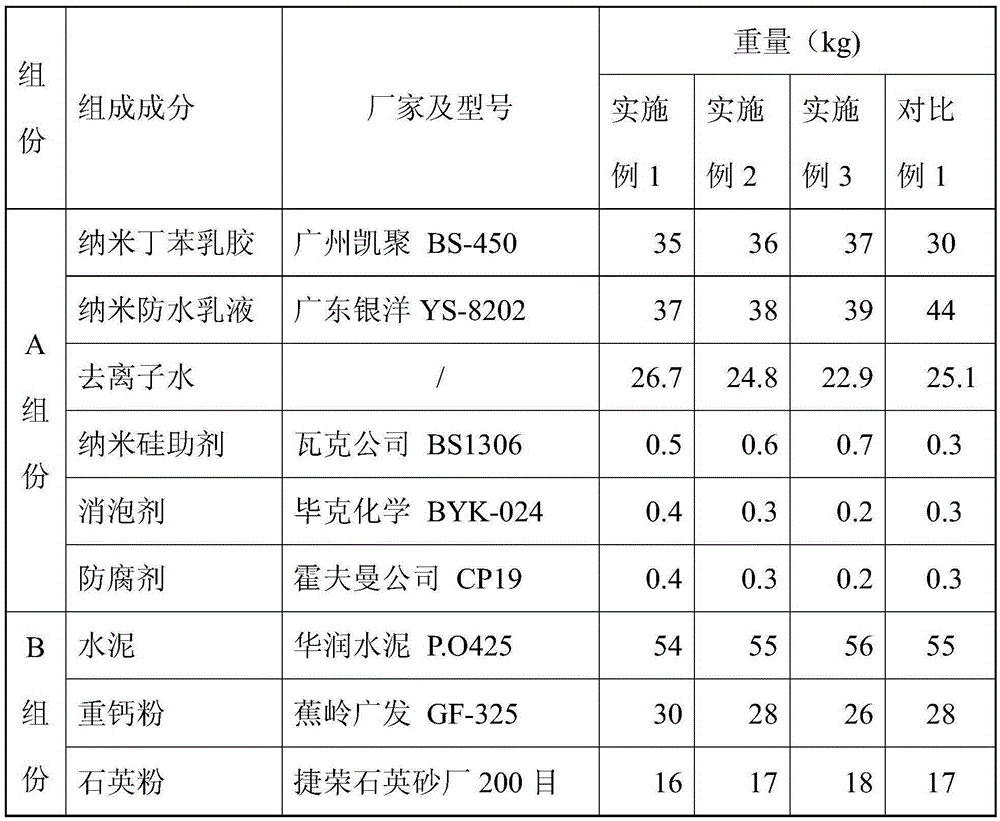

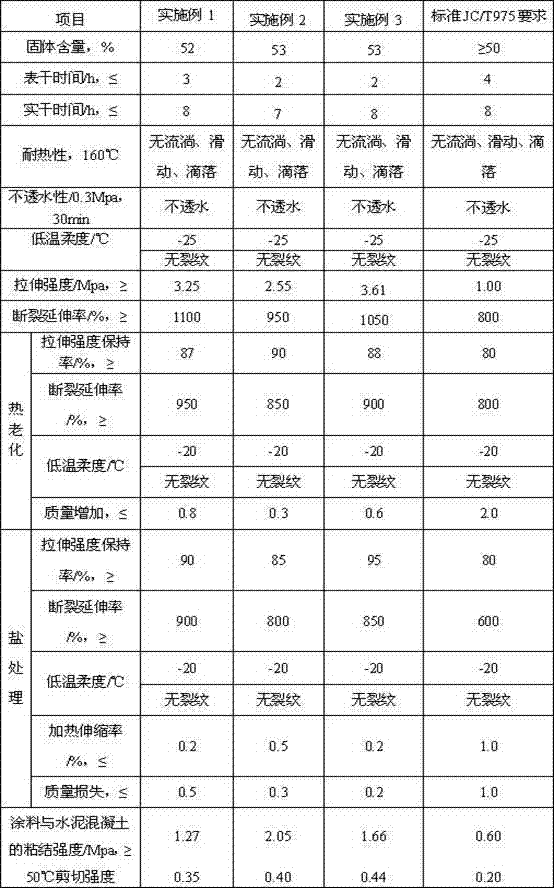

Bicomponent water-based nano waterproof coating and preparation method thereof

The invention discloses a bicomponent water-based nano waterproof coating and a preparation method thereof. The bicomponent water-based nano waterproof coating is prepared by mixing a component A and a component B, wherein the component A comprises the following ingredients in parts by weight: 35-37 parts of nano styrene-butadiene rubber, 37-39 parts of nano waterproof emulsion, 22.9-26.7 parts of deionized water, 0.5-0.7 part of a nano silicon auxiliary agent, 0.2-0.4 part of a defoaming agent and 0.2-0.4 part of a preservative; and the component B comprises the following ingredients in parts by weight: 54-56 parts of cement, 26-30 parts of ground calcium carbonate powder, and 16-18 parts of quartz powder. When the bicomponent water-based nano waterproof coating is used, the component A and the component B are mixed and stirred uniformly with each other according to a ratio of the component A to the component B of 1:(1.0-1.2). By using the bicomponent water-based nano waterproof coating, while the waterproof performance is implemented, the contraction stress of a waterproof coating layer during drying can also be reduced, thereby effectively improving or putting an end to the problem that a brick pasted on the waterproof coating layer generates bellowing and falling off. The construction method of the bicomponent water-based nano waterproof coating is consistent with that of a common polymer cement waterproof coating, and the product is environmentally friendly and nontoxic.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Method for preparing nano hydroxyapatite/collagen scaffold with directionally arranged particles

The invention discloses a method for preparing a nano hydroxyapatite / collagen scaffold with directionally arranged particles. The method takes polyvinylpyrrolidone as a template, a dispersant and a modifying agent simultaneously; the polyvinylpyrrolidone is fully mixed in an alkaline agent control system to form a sol system with the molar ratio of 1.6 to 1.7:1 between calcium and phosphorus and the content of 0.01 to 50 percent for the polyvinylpyrrolidone according to mass percent; the sol system is aged and washed, thus obtaining nano hydroxyapatite sol; then mixing and high-speed dispersion are conducted according to the proportion of 0.1 to 9:1 between the nano hydroxyapatite sol and a collagen solute according to mass ratio; and the mixture of the nano hydroxyapatite sol and the collagen solute is injected into a mould and refrigerated and dried, thus obtaining the nano hydroxyapatite / collagen scaffold. The hydroxyapatite particles in the scaffold are well dispersed in a collagenbasal body, form effective and stable linkage with collagens and are directionally arranged, thereby realizing a simulated structure of a natural bone from the view of the structure and the function.The method has simple technique, fast and convenient operation and easy promotion and application.

Owner:SOUTH CHINA UNIV OF TECH +1

Aluminum-plastic composite film for flexible packaging of lithium battery

ActiveCN107825773AStrong bondExtended service lifeSynthetic resin layered productsMacromolecular adhesive additivesComposite filmPolyolefin

The invention discloses an aluminum-plastic composite film for flexible packaging of a lithium battery. The aluminum-plastic composite film comprises a wear-resistant layer, a first bonding layer, analuminum foil layer, a passivation layer, a second bonding layer having corrosion resistance and a heat sealing layer which are sequentially arranged from the outside to the inside, and the passivation layer comprises, by weight, 100 parts of acrylic resin, 5-15 parts of a chromium-containing compound, 1-5 parts of a phenyltrimethylsilane coupling agent, 1-5 parts of a titanate coupling agent and30-50 parts of water; and the second bonding layer having corrosion resistance includes, by weight, 100 parts of acid-modified polyolefin resin, 1-5 parts of an epoxy system curing agent, 1-5 parts offluorine-containing micro-powder, 10-20 parts of a cyclohexane solvent and 20-40 parts of a butanone solvent. The aluminum-plastic composite film has the advantages of obviously improved electrolyteresistance, stability in bonding among the first bonding layer, the aluminum foil layer, the passivation layer, the second bonding layer having corrosion resistance and the heat sealing layer, high deep-drawing intensity and long service life.

Owner:ZHEJIANG GREEN NEW MATERIALS

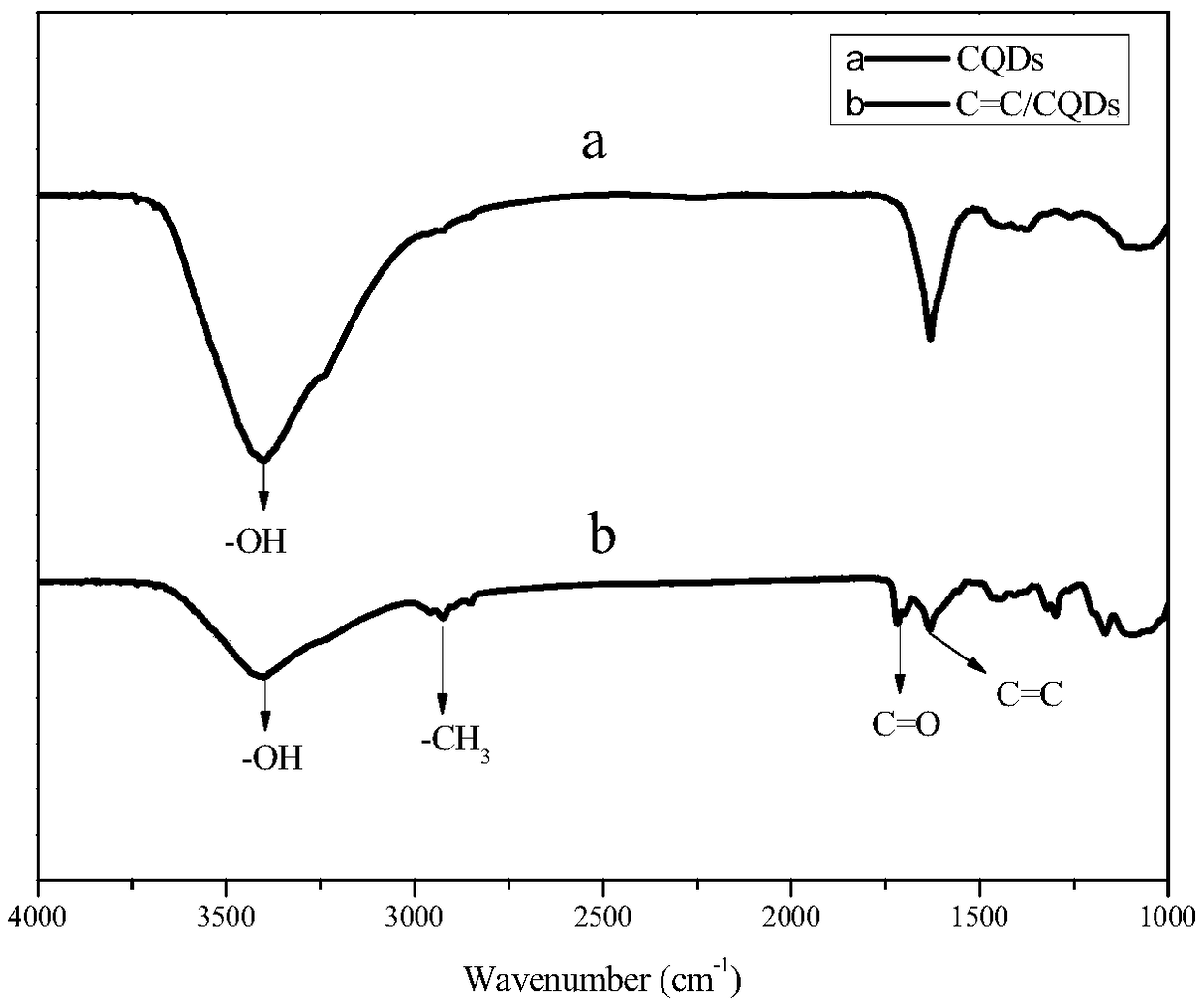

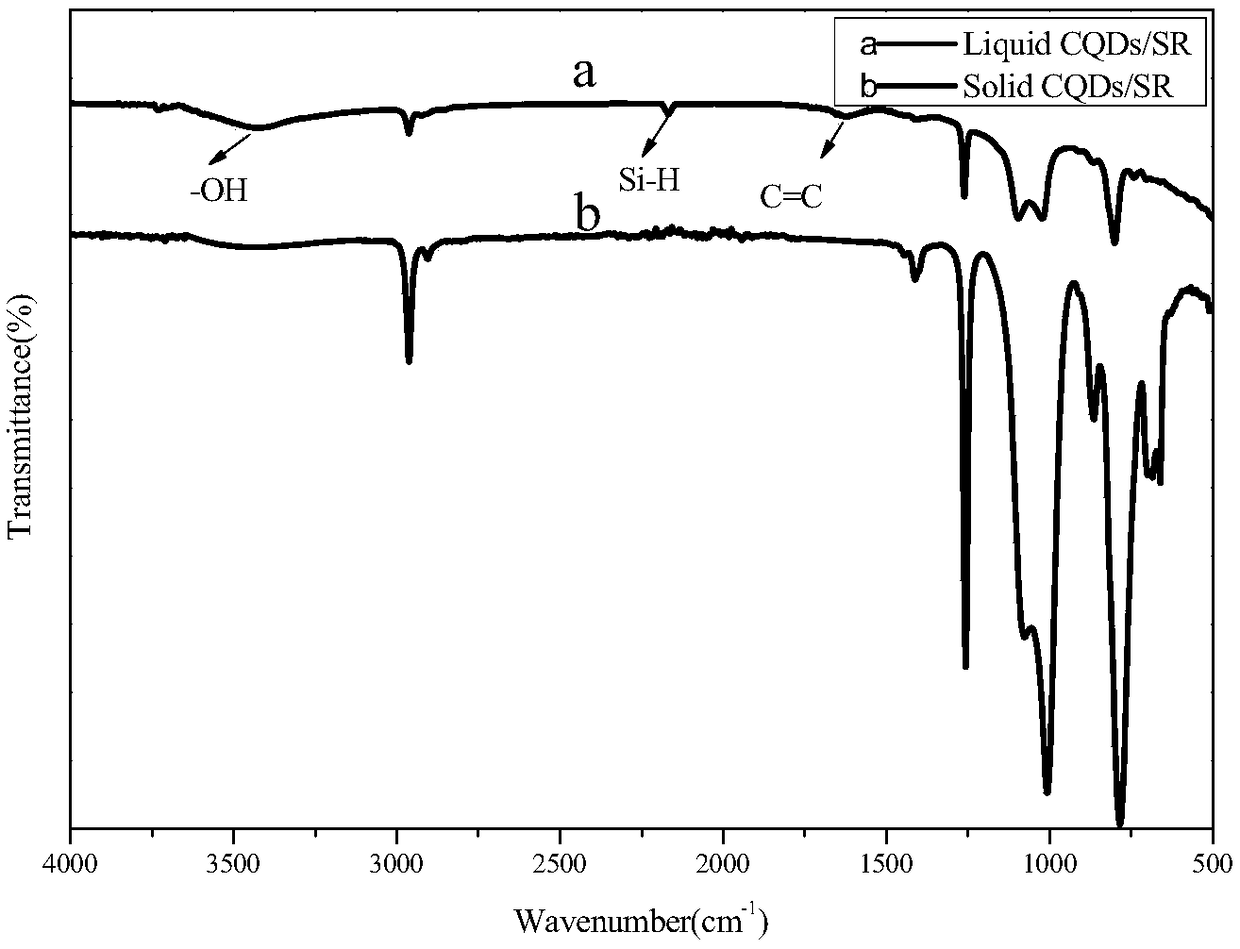

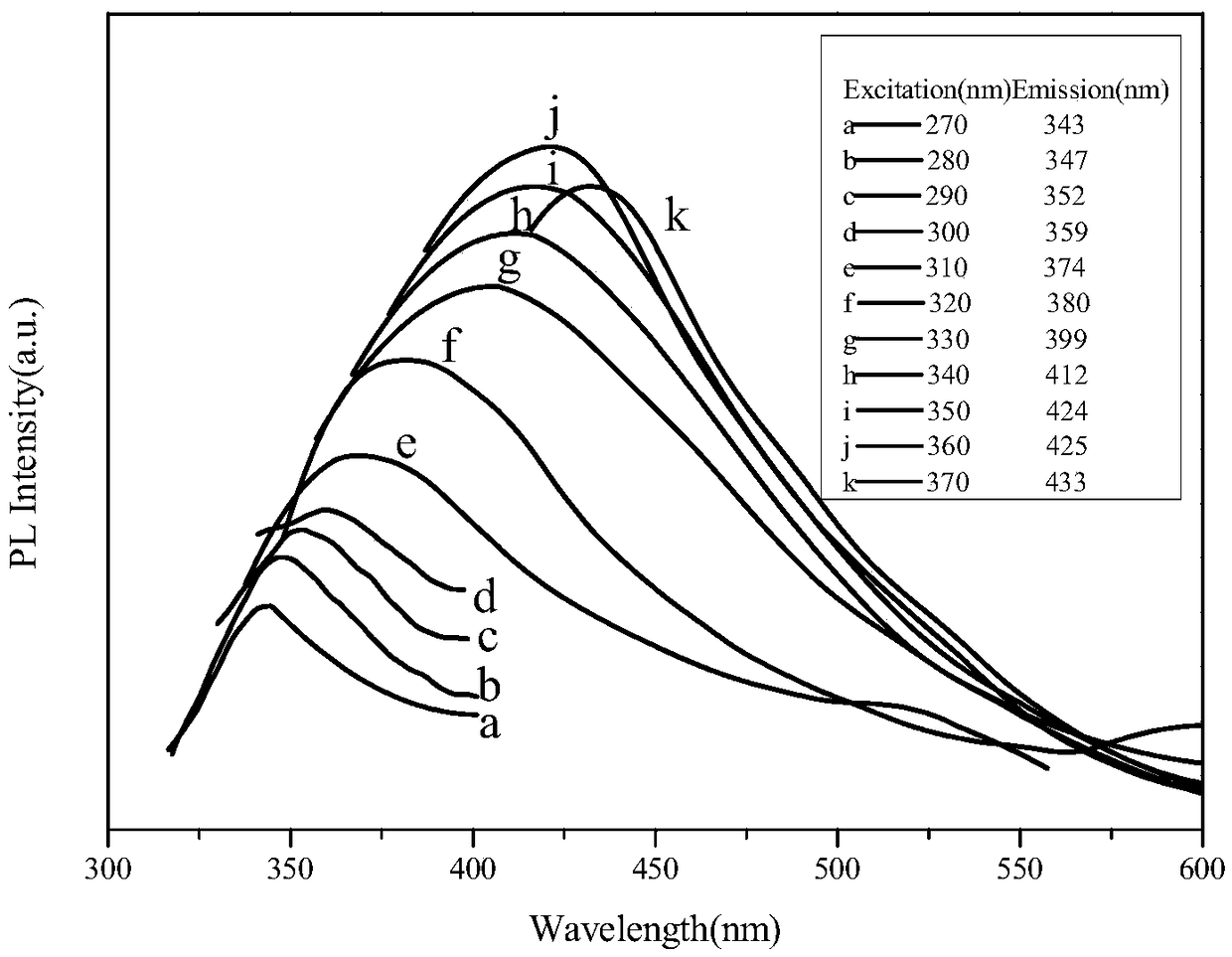

Preparation method for modified carbon quantum dot/silicone rubber fluorescent composite material

The invention belongs to the field of nano composite materials, and in particular relates to a preparation method for a modified carbon quantum dot / silicone rubber fluorescent composite material. Thepreparation method comprises the following steps: (1) preparation of carbon quantum dots: preparing a carbon quantum dot ethanol solution by taking a water soluble starch solution as a carbon source;(2) preparation of modified carbon quantum dots: modifying the carbon quantum dots with a silane coupling agent KH570; and (3) preparation of the modified carbon quantum dot / silicone rubber fluorescent composite material: preparing the modified carbon quantum dot / silicone rubber fluorescent composite material from base rubber I, base rubber II, hydrogen-containing silicone oil, a solvent and the modified carbon quantum dot ethanol solution as raw materials. By modifying the carbon quantum dots with the silane coupling agent KH570 and introducing the silane coupling agent to the surfaces of thecarbon quantum dots, the carbon quantum dots take part in a vulcanization reaction of silicone rubber, so that the carbon quantum dots are uniformly dispersed in the silicone rubber to obtain the carbon quantum dot / silicone rubber fluorescent composite material with a good fluorescent effect, and therefore, the application of the silicone rubber in the fields with fluorescent demands is expanded.

Owner:CHANGZHOU UNIV

Waterproof material for cement concrete bridge floor and preparation method of waterproof material

ActiveCN103045067AStrong bondStrong high and low temperature resistancePolyurea/polyurethane coatingsBituminous coatingsEthyl acetateIsocyanate compound

The invention relates to a waterproof material for a cement concrete bridge floor and a preparation method of the waterproof material. The waterproof material is obtained by the following steps of: generating amino methyl acid ester by using isocyanate and compound polyalcohol, then adding ordinary heavy-traffic paving asphalt, and compounding and modifying by a tertiary amine catalyst, a compound antifoaming agent and ethyl acetate. The waterproof material can be firmly bonded with the cement concrete bridge floor, the resistance to high temperature and low temperature is good, the waterproof material can undergo comprehensive function requirements of temperature transforming and long-term loading, the destruction of the bridge structure caused by water seepage is alleviated, the service life of the road bridge is prolonged, the construction operation is safe and simple, the construction speed is high, the film forming time is short, the requirement on bridge floor construction is not high, and the construction can be carried out fast. The preparation method of the waterproof material is simple and easy to operate, the isocyanate, the compound polyalcohol and the ethyl acetate in a dehydrated state are not decomposed or oxidized in vacuum, so that the stability of each component is guaranteed and the prepared waterproof material has high solid content and good material performance.

Owner:重庆市智翔铺道技术工程有限公司

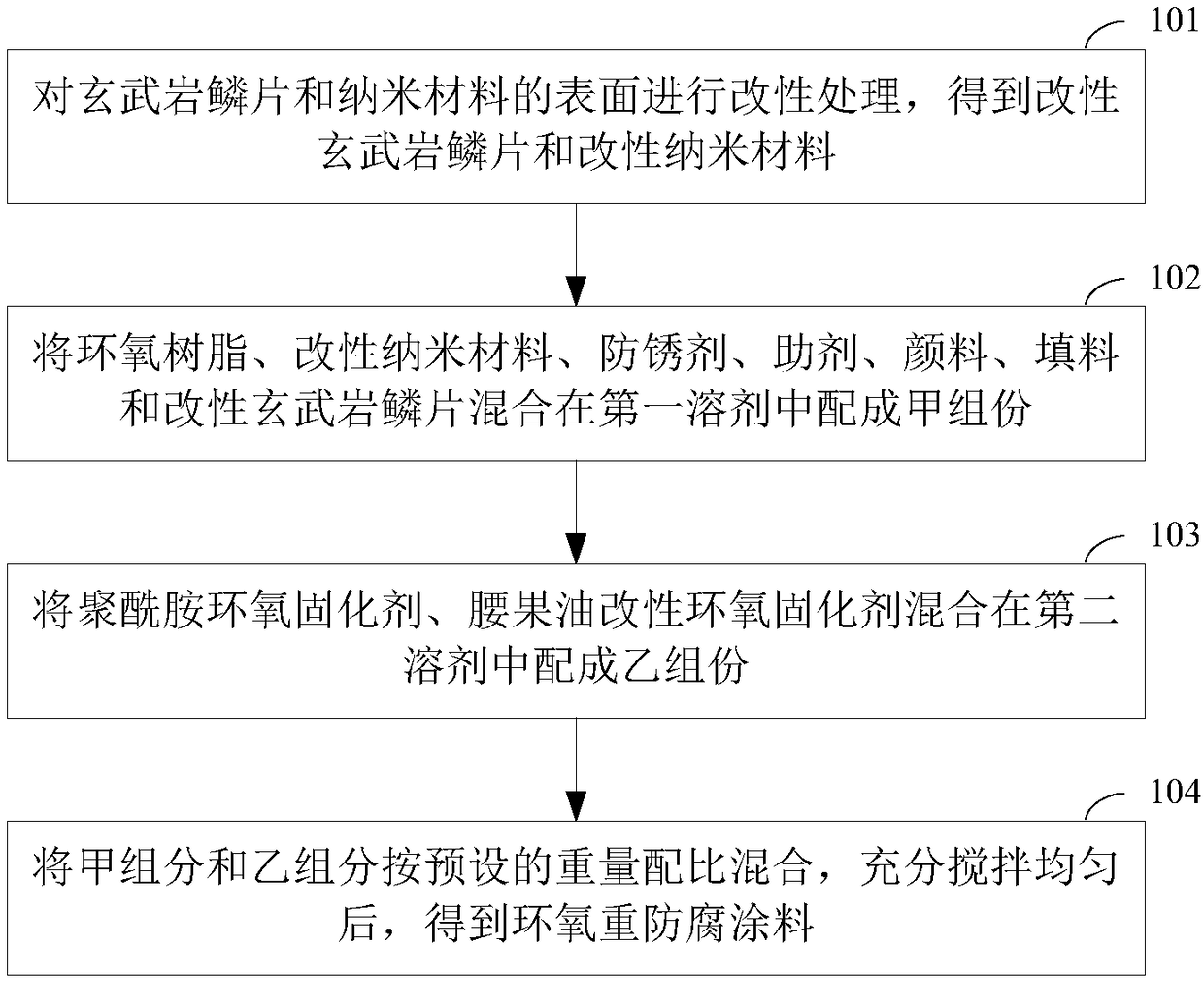

Preparation method of epoxy heavy duty anticorrosion coating

InactiveCN108129949AImprove penetration resistanceImprove shielding effectAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention provides a preparation method of an epoxy heavy duty anticorrosion coating. The preparation method comprises following steps: basalt scale and a nanometer material are subjected to surface modification treatment so as to obtain modified basalt scale and a modified nanometer material; epoxy resin, the modified nanometer material, an antirust agent, an auxiliary agent, a pigment, a filling material, and modified basalt scale are mixed in a first solvent so as to obtain a component A; a polyamide epoxy hardener, and a cashew oil modified epoxy hardener are mixed in a second solventso as to obtain a component B; the component A and the component B are mixed at a preset weight ratio, full stirring is carried out so as to obtain the epoxy heavy duty anticorrosion coating. The preparation method is capable of improving the compactibility, the corrosion resistance, and the durability of the epoxy heavy duty anticorrosion coating.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

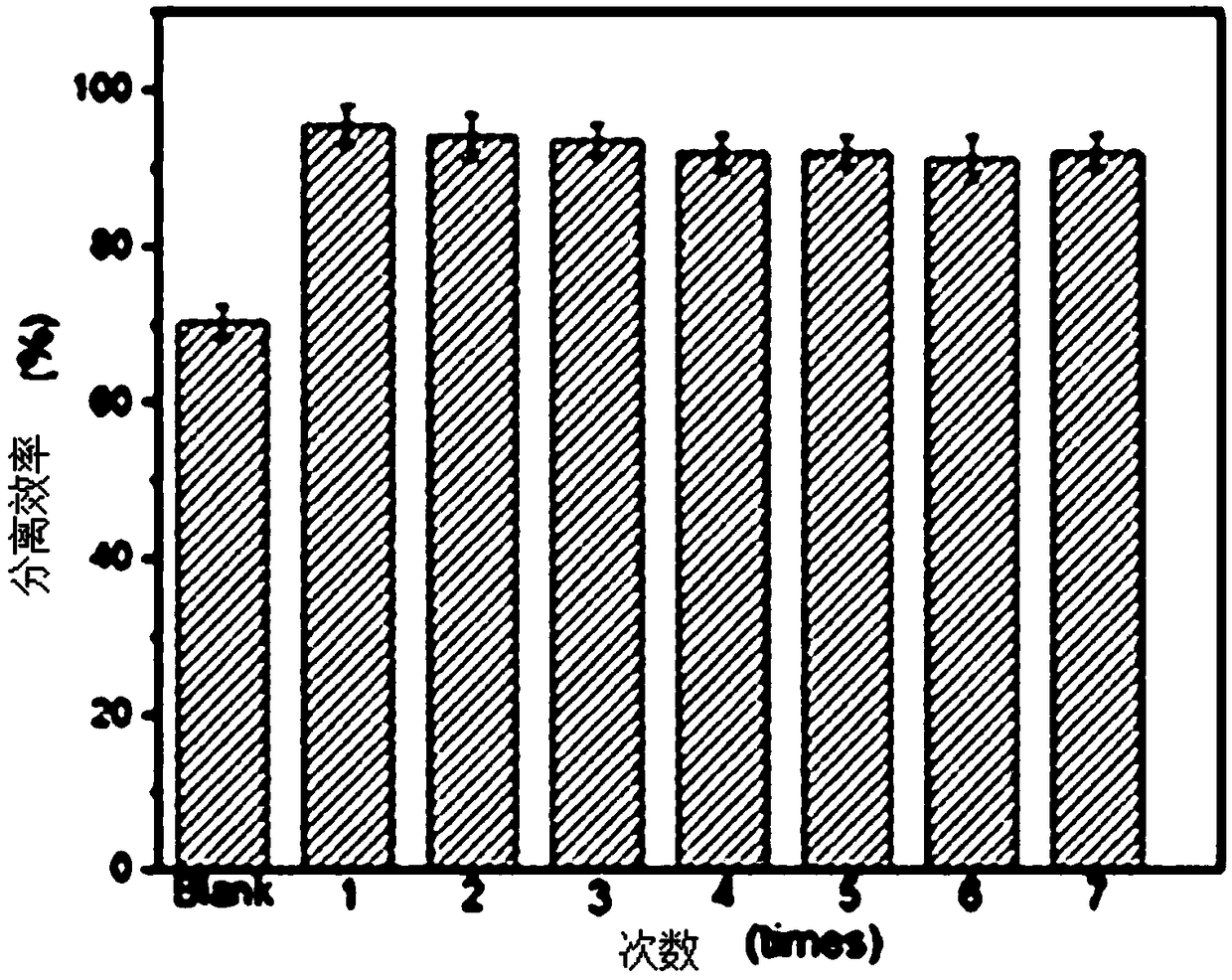

Metal organic skeleton/graphene oxide oil-water separation membrane and preparation method thereof

InactiveCN108176254AEasy to separateImprove separation efficiencyUltrafiltrationNon-miscible liquid separationMetal-organic frameworkOil water

The invention relates to a metal organic skeleton / graphene oxide oil-water separation membrane and a preparation method thereof. The metal organic skeleton / graphene oxide oil-water separation membranecomprises a PVDF bottom membrane and a ZIF-8 / GO composite material, wherein the ZIF-8 / GO composite material is firmly loaded on the PVDF bottom membrane through the bonding between the ZIF-8 / GO composite material and trimesoyl chloride, the bonding between trimesoyl chloride and dopamine, and the combination between dopamine and the PVDF bottom membrane. According to the present invention, GO isintegrally compounded through the multi-level pore channels and the regular hexagonal window of ZIF-8, and the oil-water separation effect is substantially improved by matching the pores of ZIF-8 andthe channels in the GO lamella, wherein the oil-water separation efficiency is up to more than 99.5%; and the bonding between trimesoyl chloride and dopamine is firm and is not easily disconnected, and the reusability of the oil-water separation membrane is strong, wherein the oil-water separation efficiency is not basically changed after repeated use seven times, and is still above 96%.

Owner:SHANDONG UNIV

Glass fibre reinforcement and surface modification method

ActiveCN104947410AImprove interface performanceIncreased flexural modulusPhysical treatmentPolyesterSilanes

The present invention discloses a glass fibre reinforcement and surface modification method in the material manufacturing field of the automotive upholstery. According to the method, firstly, a modified polyurethane waterborne emulsion is prepared. Secondly, a water-soluble polyester, the modified polyurethane waterborne emulsion, the gamma-propyl-trimethoxy-silane, the gamma-propyl tri-methoxy silane, the deionized water, an ammonium salt and a fatty acid amide are adopted as raw materials and are mixed up to prepare a dipping solution. After that, a continuous glass fiber mat is immersed in the dipping solution and is taken out of the dipping solution after being subjected to supersonic vibration and impregnation. The obtained continuous glass fiber mat is dried while being kept out of the sun, and then a reinforced and surface-modified continuous glass fiber mat. According to the invention, the gamma-propyl-trimethoxy-silane and the gamma-propyl tri-methoxy silane are adopted as coupling agents to react with polyurethane to generate a copolymer. In this way, the interface performance of the fiber mat with a resin matrix is improved. Products obtained through the above method can be used for manufacturing the automotive upholstery and automotive structural parts, which have the advantages of light weight, small thickness and low cost under the same intensity.

Owner:扬州市邗江扬子汽车内饰件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com