Patents

Literature

3390 results about "Sodium hypochlorite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium hypochlorite is a chemical compound with the formula NaOCl or NaClO, comprising a sodium cation (Na⁺) and a hypochlorite anion (OCl⁻or ClO⁻). It may also be viewed as the sodium salt of hypochlorous acid. The anhydrous compound is unstable and may decompose explosively. It can be crystallized as a pentahydrate NaOCl·5H₂O, a pale greenish-yellow solid which is not explosive and is stable if kept refrigerated.

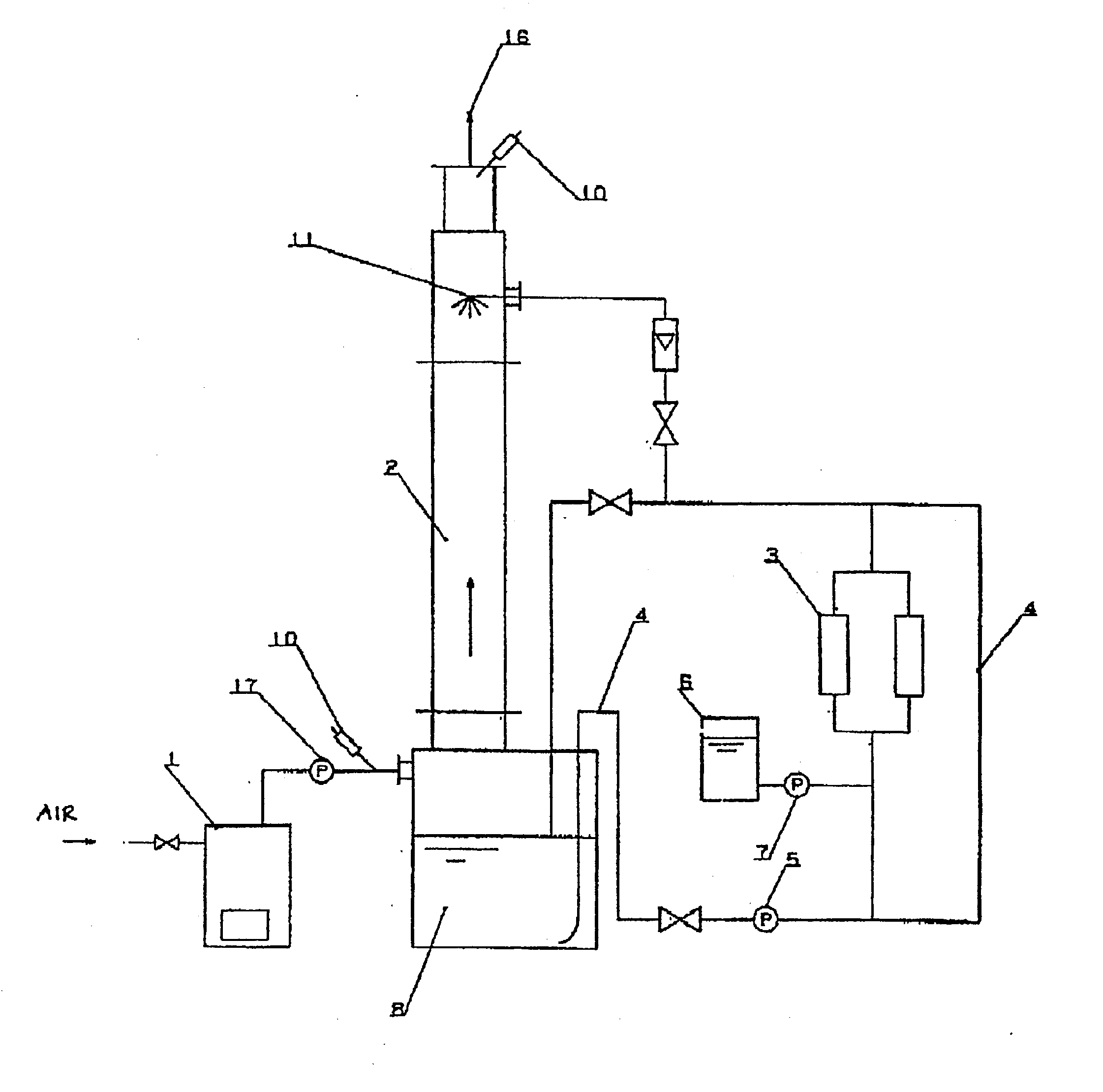

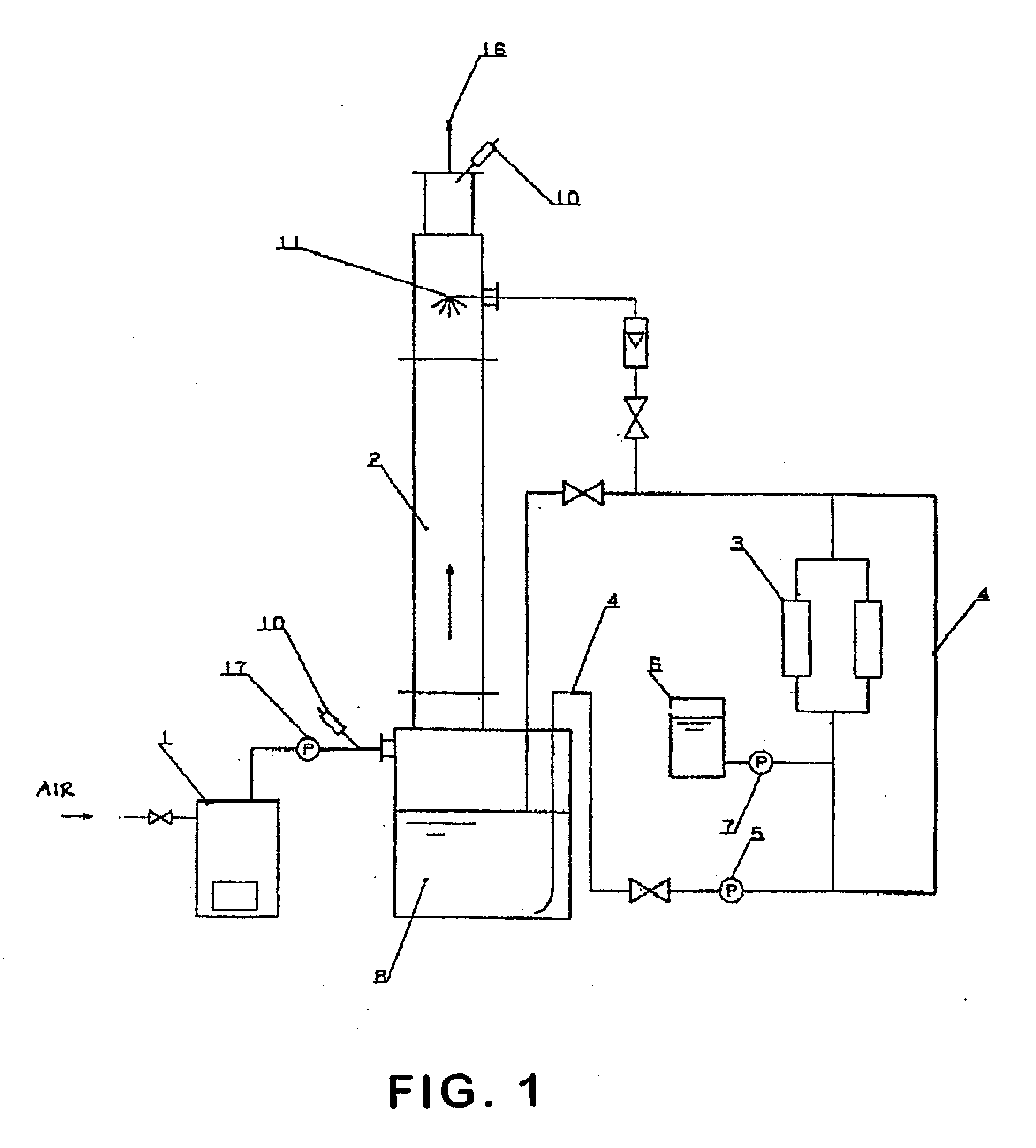

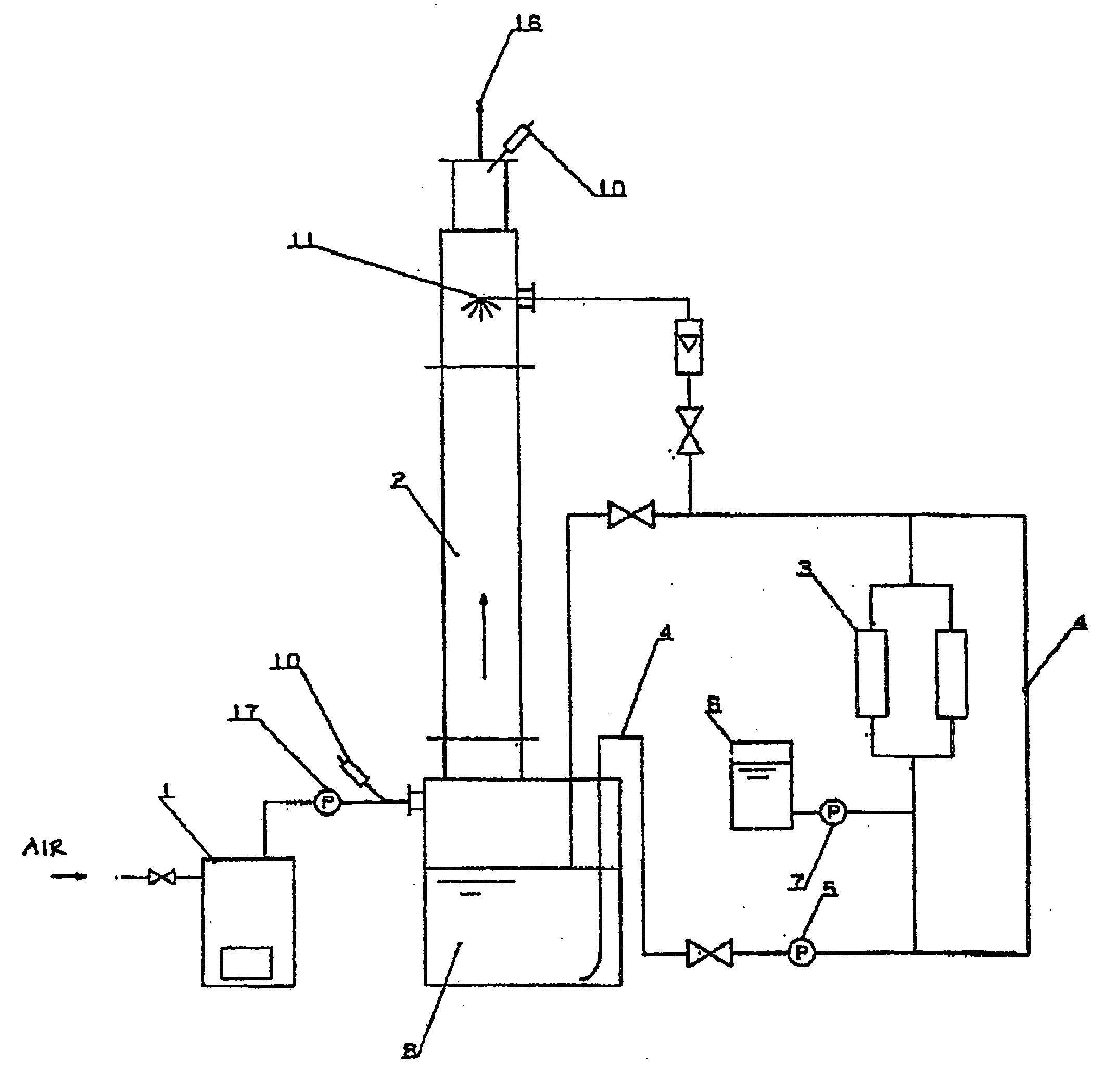

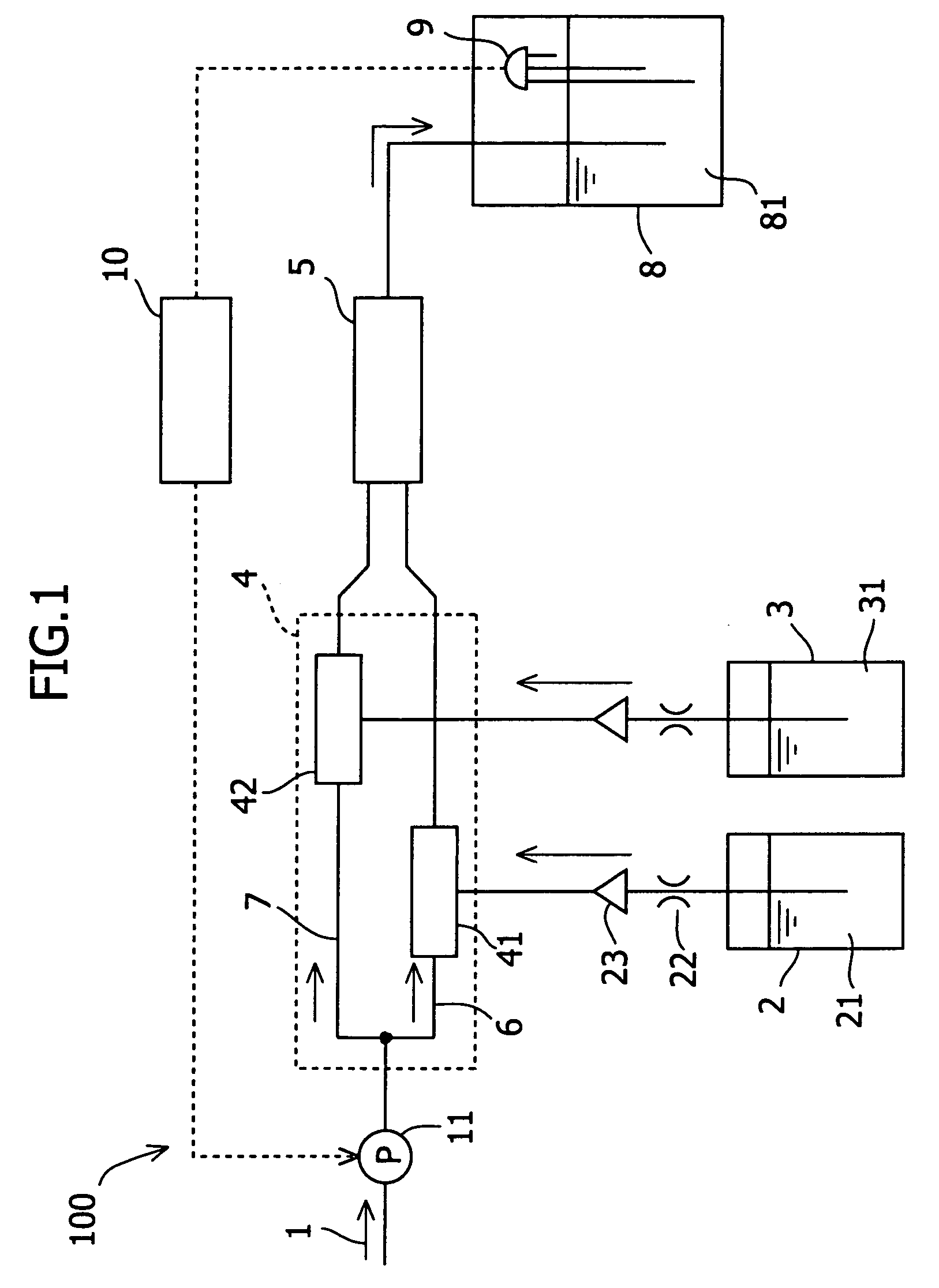

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20030164309A1Easy can be electrolyzedHigh densityCyanogen compoundsLighting and heating apparatusHazardous substancePotassium hydroxide

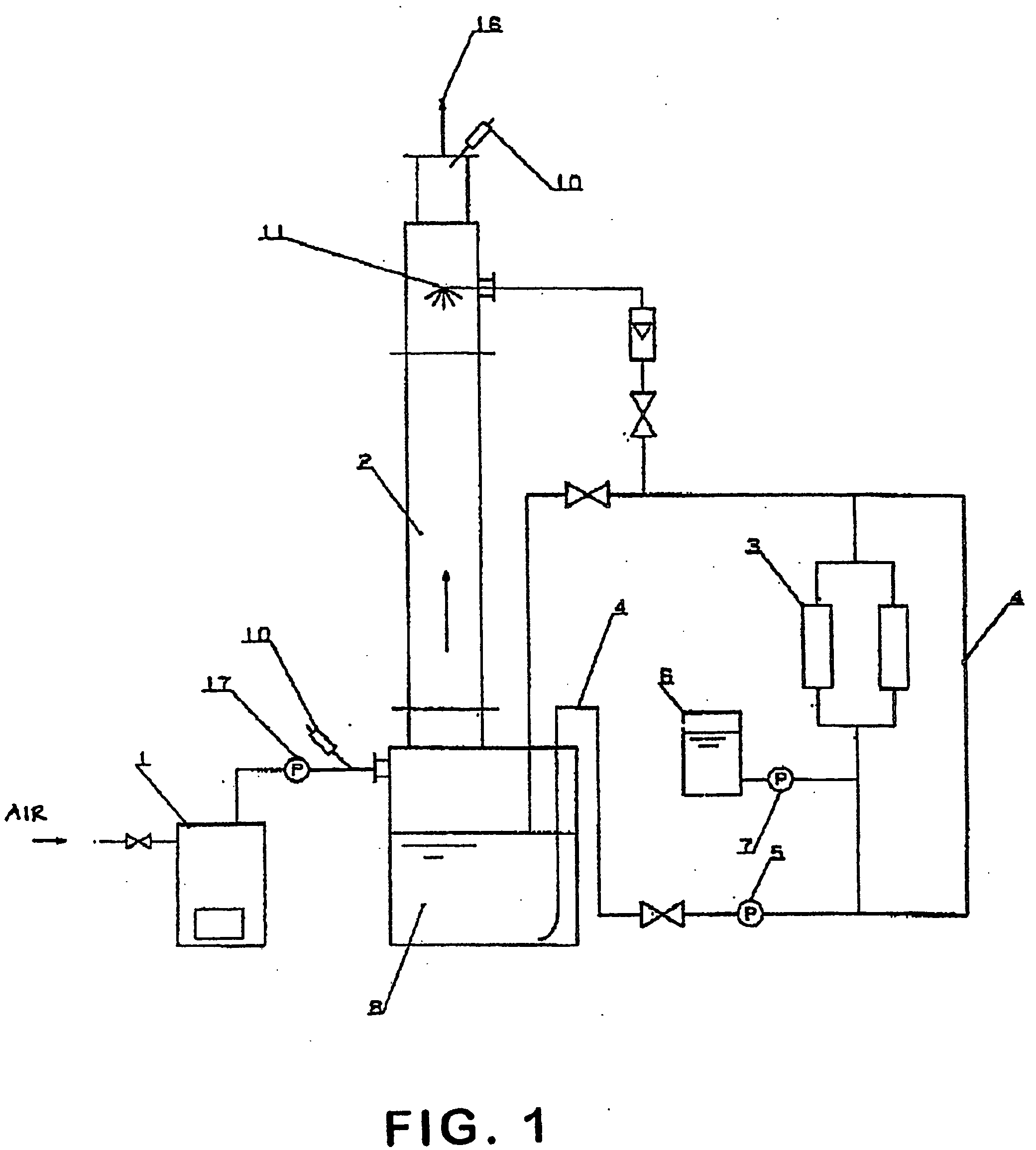

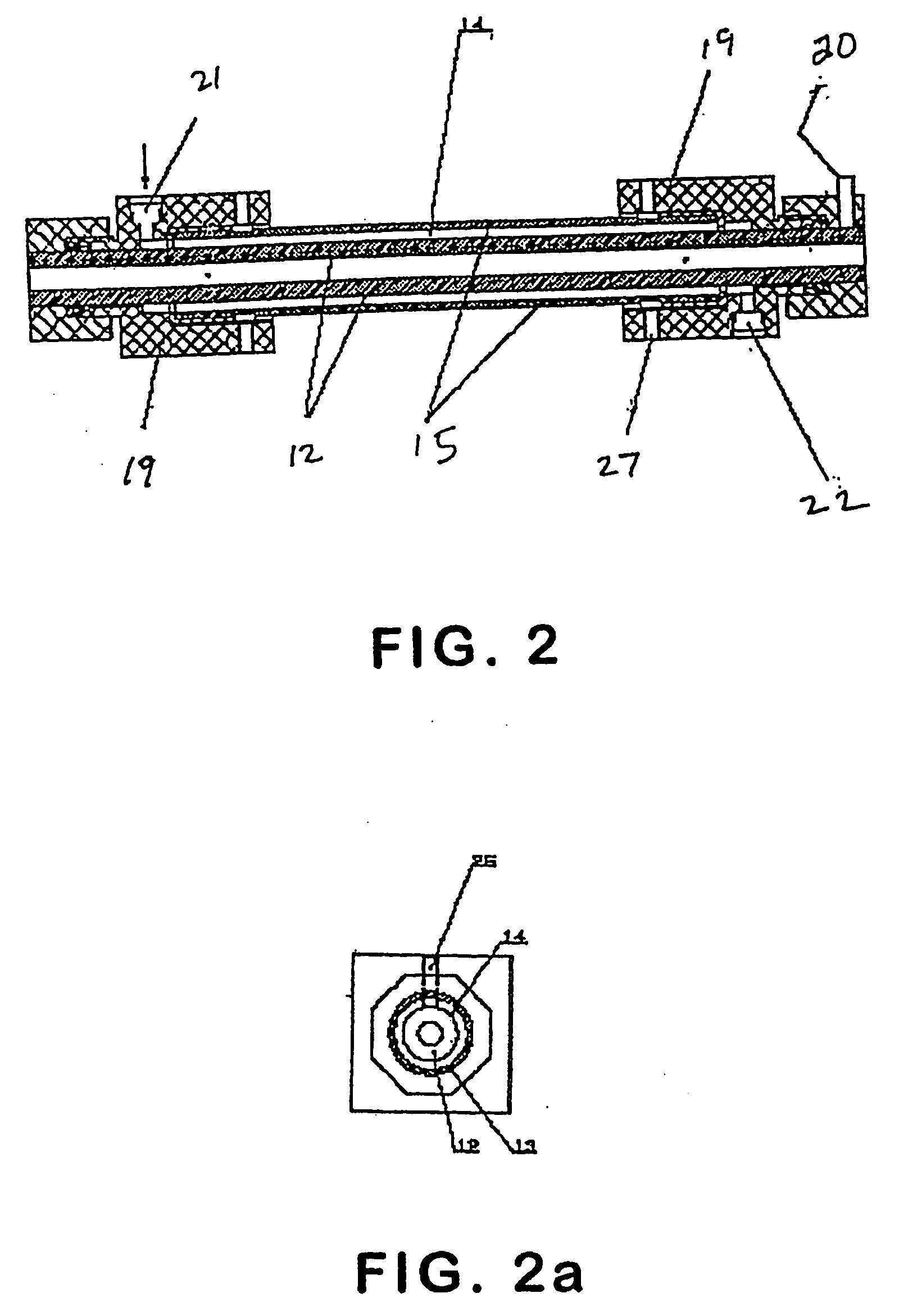

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogen acid such as hypochlorous acid soda, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:OMEGA CO LTD

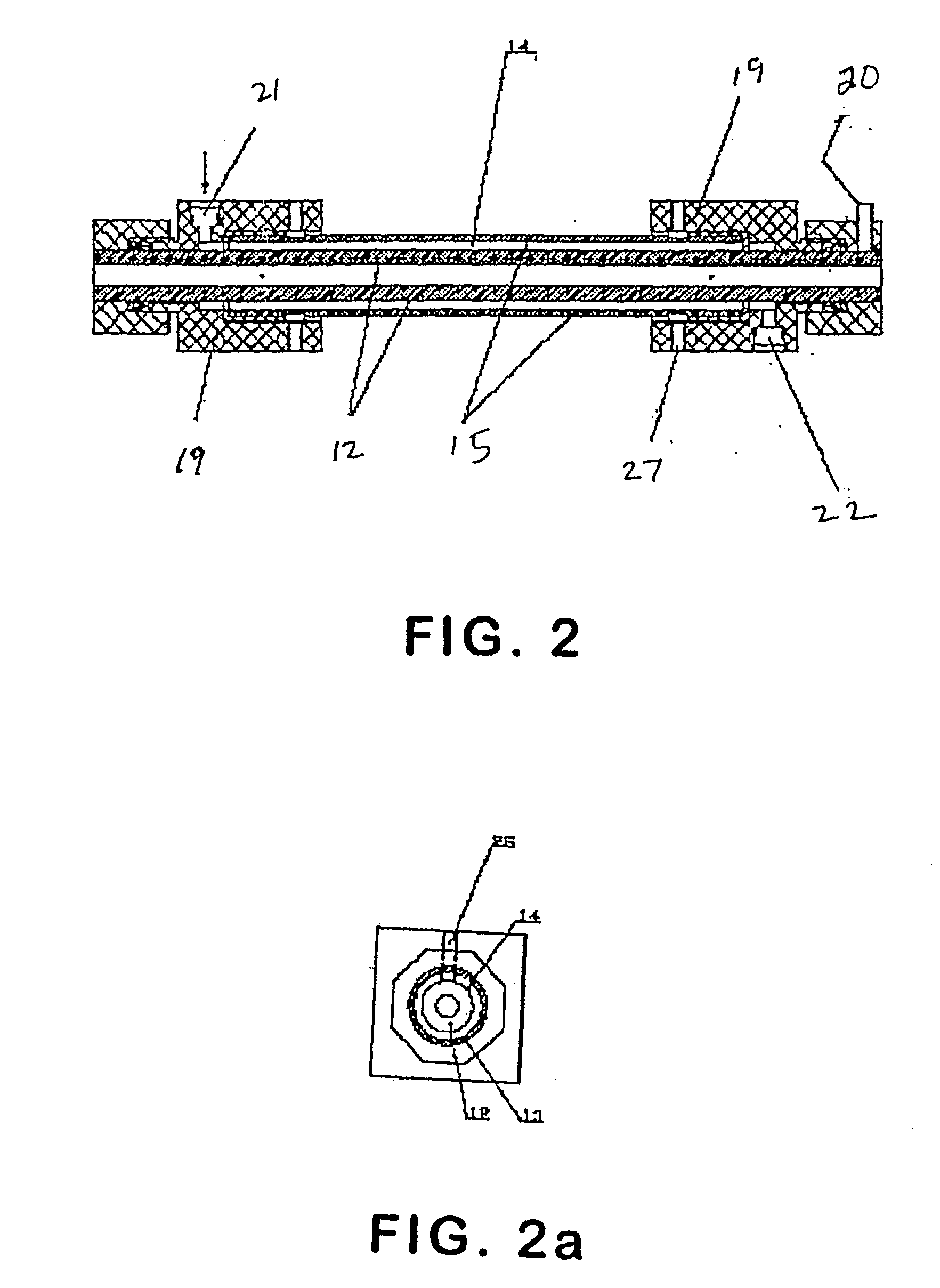

Preparation method of homogenized fine nano-cellulose fiber

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

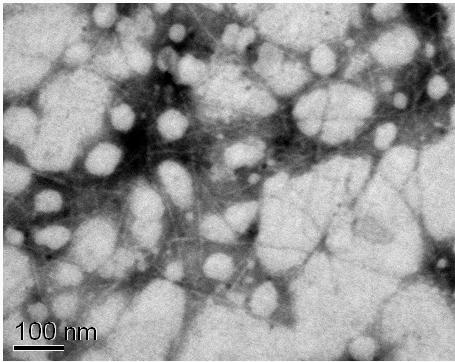

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

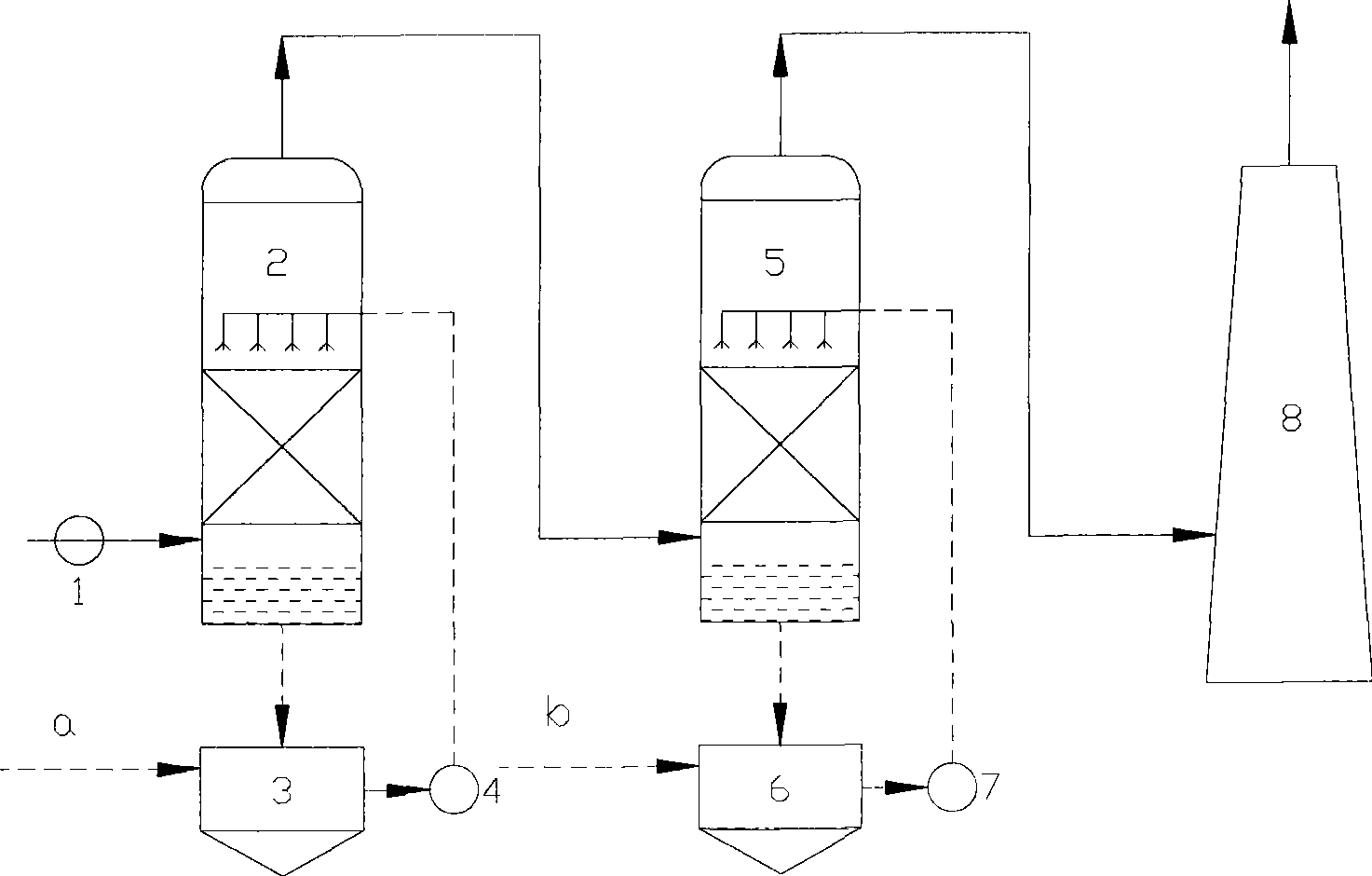

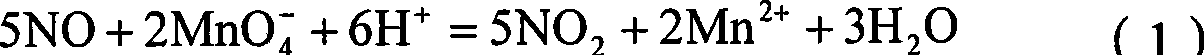

Liquid-phase oxidation-absorption two-stage wet method flue-gas denitration technique

ActiveCN101385942ALow investment costLow running costDispersed particle separationPartial oxidationGas phase

The invention discloses a wet method smoke gas denitration technology of two segments of liquid phase oxidation and absorption, which adopts solution or mixtures of one or more of potassium permanganate, sodium chlorite, sodium hypochlorite, calcium hypochlorite, oxyful and chlorine dioxide as oxidizing agents to ensure nitrogen oxide in smoke gas contact and react with the oxidizing agents. After the nitrogen oxide is partially oxidized into nitrogen dioxide, oxidized nitrogen oxide in the smoke gas is absorbed by alkali liquid to generate corresponding nitrite. The technology adopts liquid phase oxidation to replace gas phase oxidation so as to reduce the investment and the running cost, simplify the technical process and the system structure, and enhance the operability. Compared with a method that oxidation and absorption are simultaneously carried out in the liquid phase, the two-segment technology not only can increase the removal efficiency, avoid secondary pollution caused by incomplete absorption of NO2, but also can achieve the purposes of selectively generating and recovering the nitrite in the absorption stage by controlling the oxidation degree of the oxidation stage.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

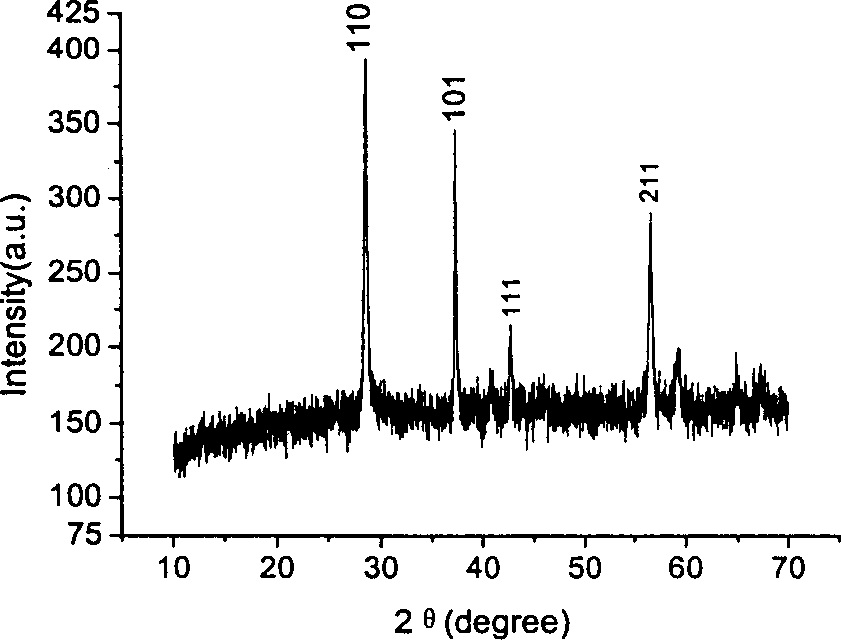

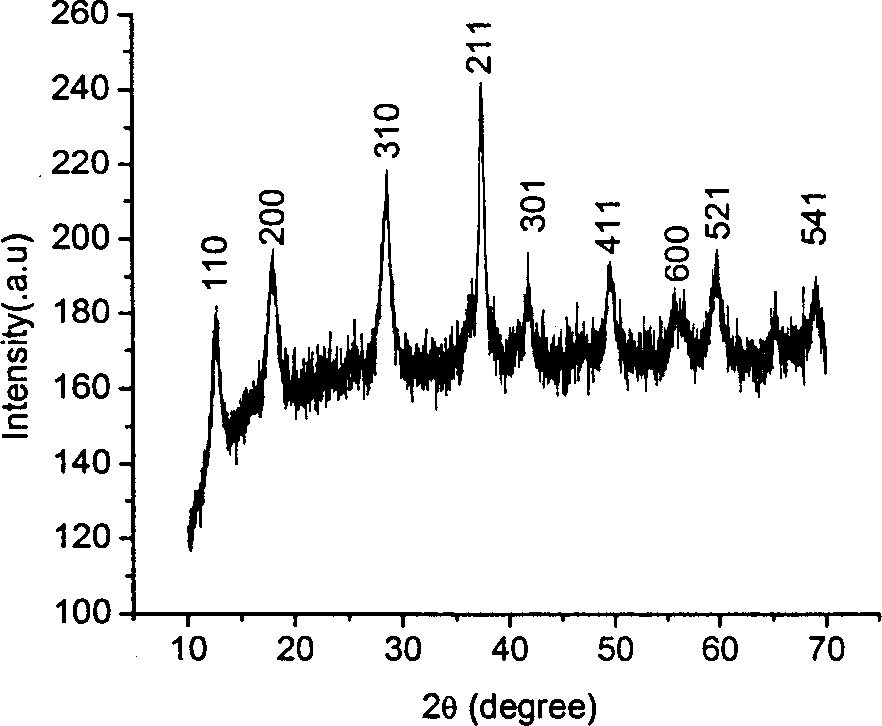

Process for synthesizing different crystal form one-dimensional single crystal mangnesium dioxide nano wire

InactiveCN1377832ALow costSimple processPolycrystalline material growthManganese oxides/hydroxidesNanowireManganese

The present invention relates to the preparation of nano material. One-dimensional monocrystalline nano manganese dioxide wire of different crystal form is synthesized selectively via controlling thetemperature, period and material control of the hydrothermal reaction of two-valent manganese salt and ammohnium persulfate as raw material and ammonium sulfate as additive at 100-220 deg.c inside one sealed reactor. The process may be widely used in basic theory research in lithium ion cell, molecular sieve and relevant fields.

Owner:TSINGHUA UNIV

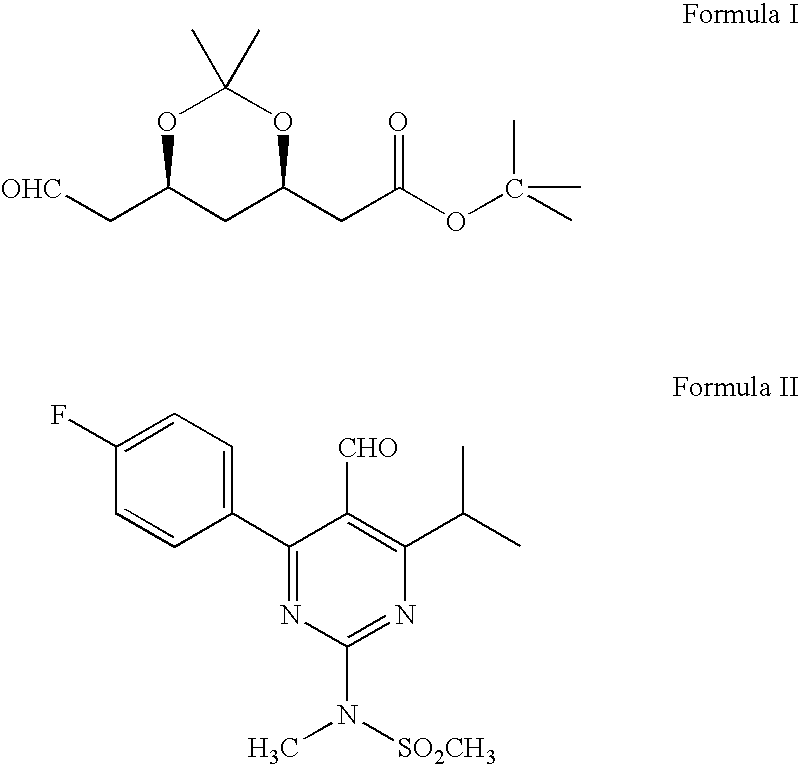

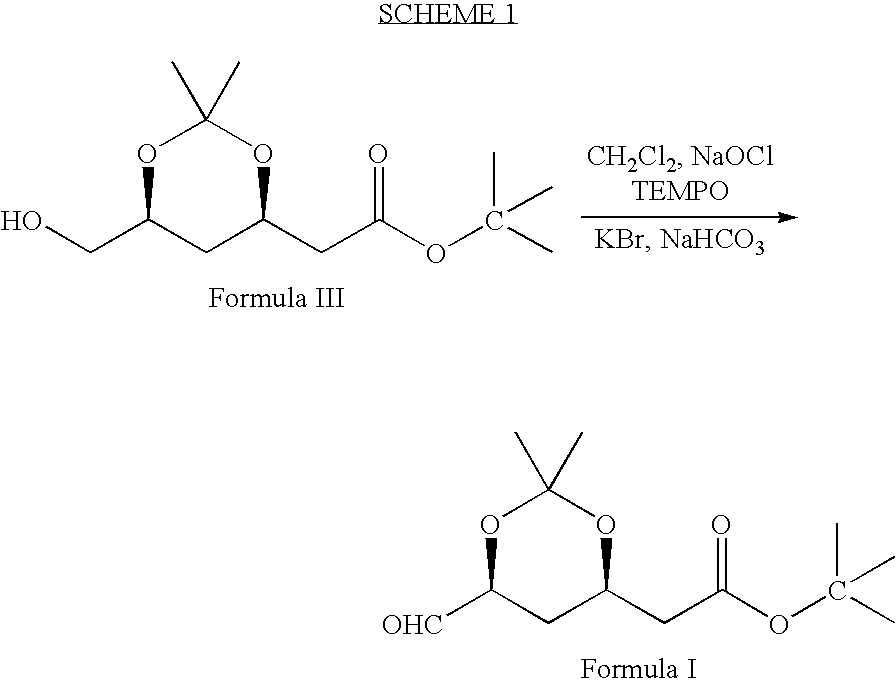

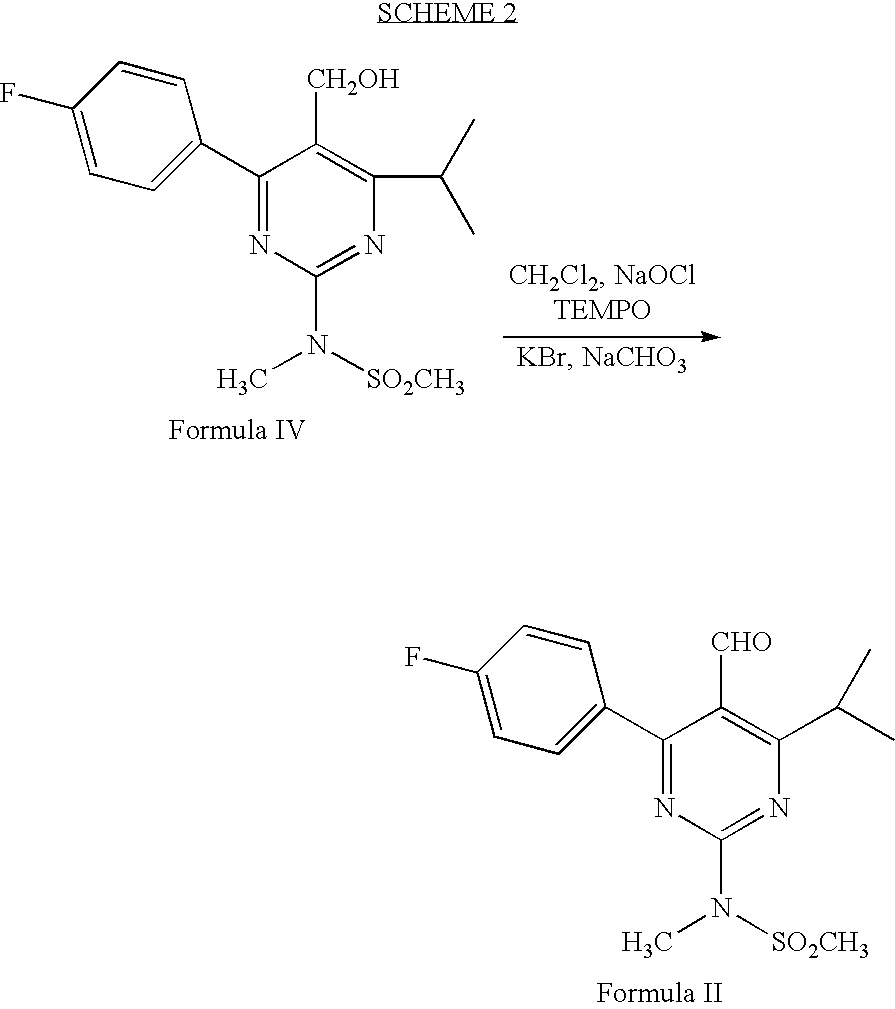

Processes to produce intermediates for rosuvastatin

Intermediate compounds for preparing rosuvastatin are prepared by a process comprising oxidizing hydroxy groups to aldehyde groups, using sodium hypochlorite and 2,2,6,6-tetramethyl piperidinyl oxy free radical (TEMPO) as a catalyst.

Owner:DR REDDYS LAB LTD +1

Sodium hypochlorite based disinfectant and sterilizer for medical-surgical instruments

A first embodiment of the present invention is directed to an aqueous disinfectant solution comprising an alkali metal or alkaline earth metal hypochlorite, an amount of base sufficient to raise the pH of the solution to at least 12, and water. A second embodiment of the present invention is directed to a method for sterilizing medical and dental instruments and hard surfaces which comprises contacting the medical or dental instruments or hard surfaces with an aqueous disinfecting solution comprising an alkali metal or alkaline earth metal hypochlorite, an amount of a base sufficient to raise the pH of the solution to at least 12, and water, for a time sufficient to disinfect the medical or dental instruments or hard surface.

Owner:AMUCHINA INT

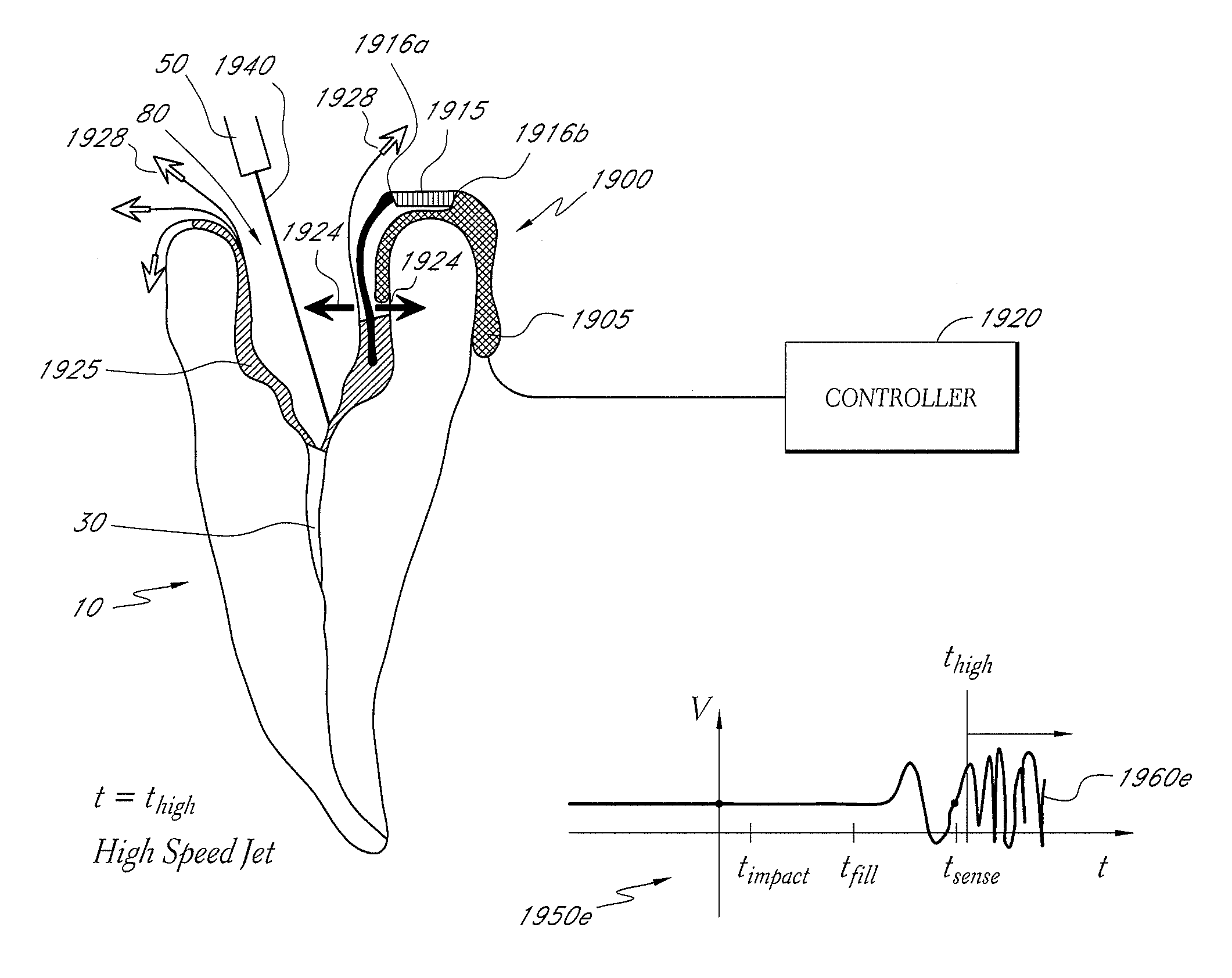

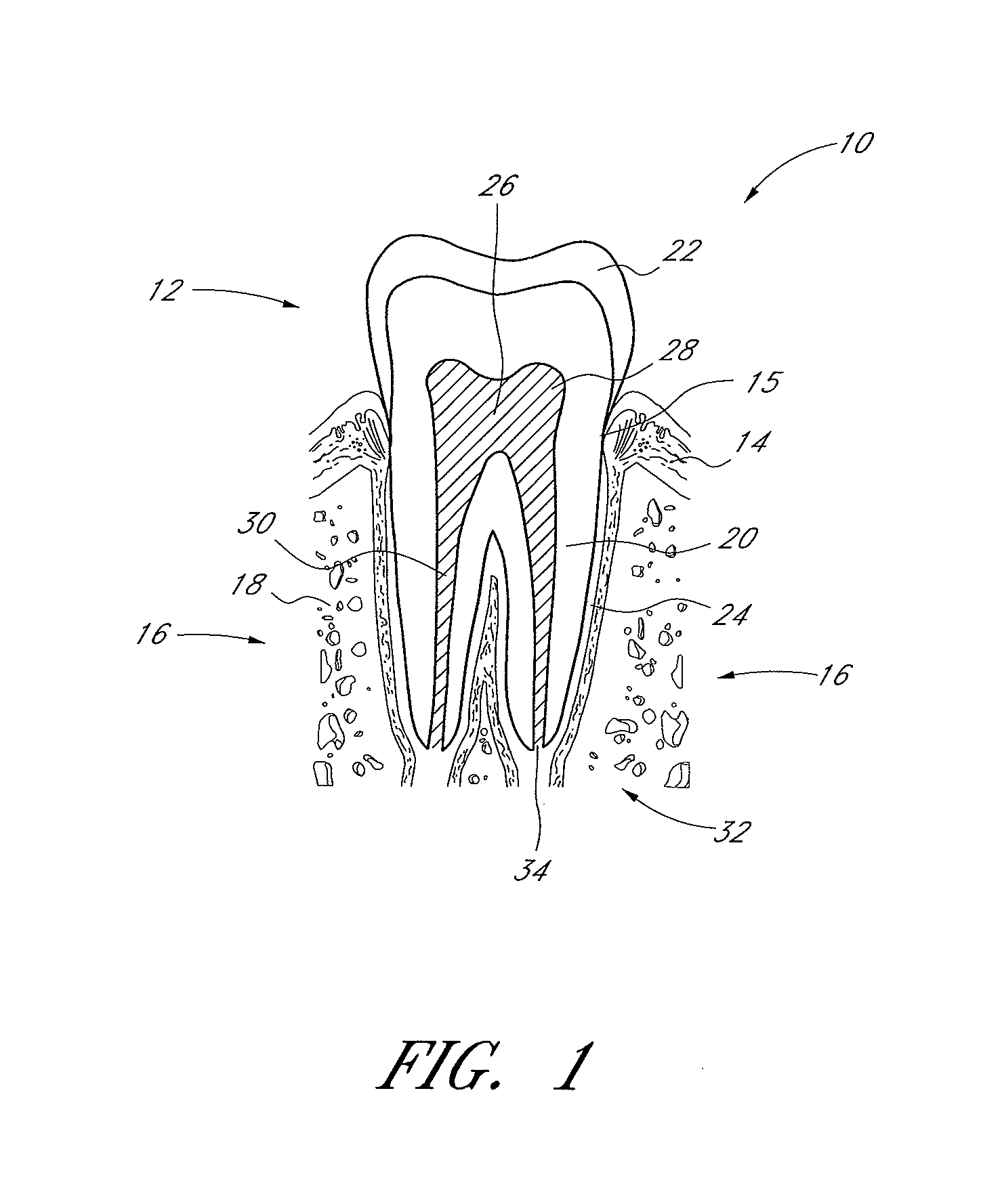

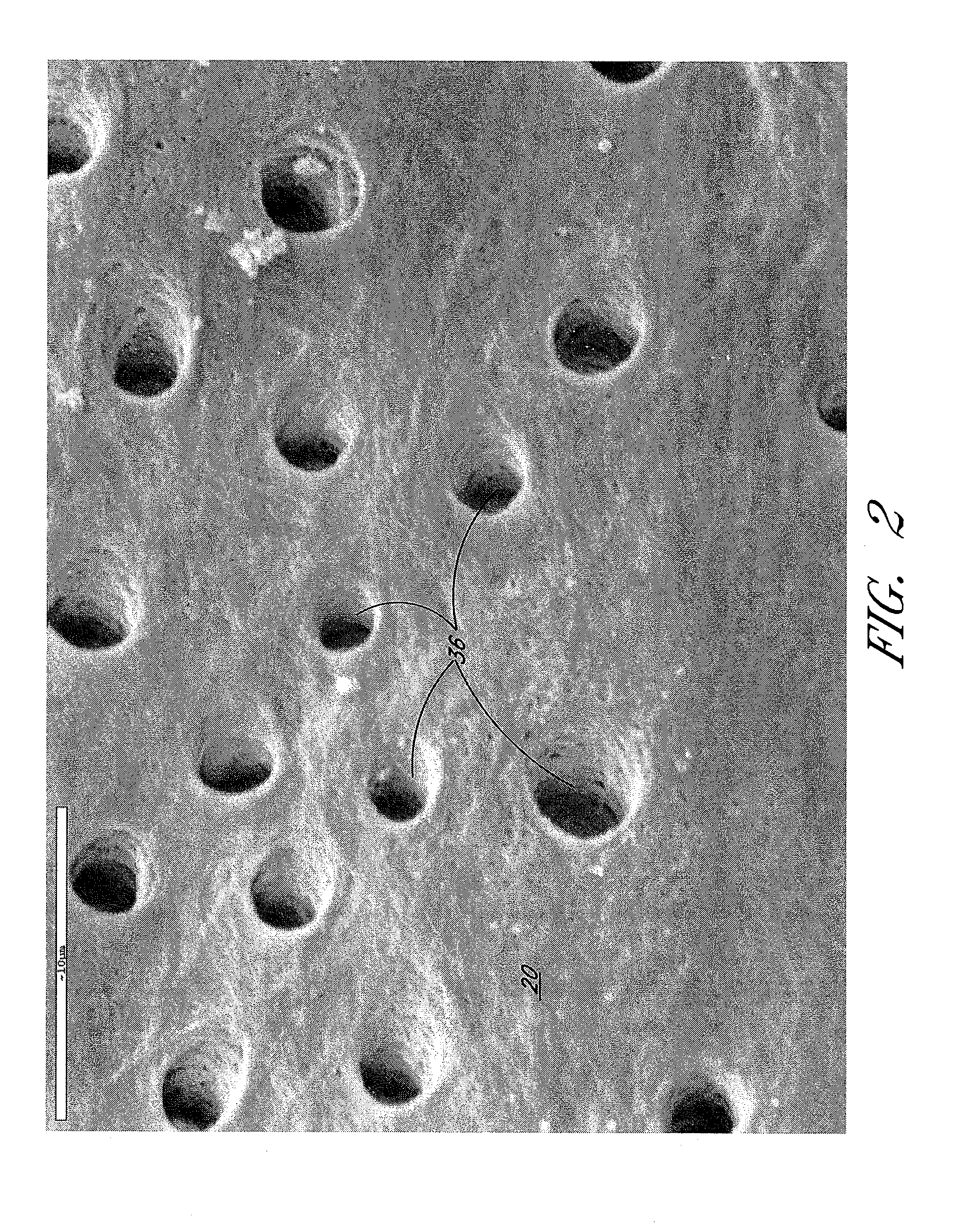

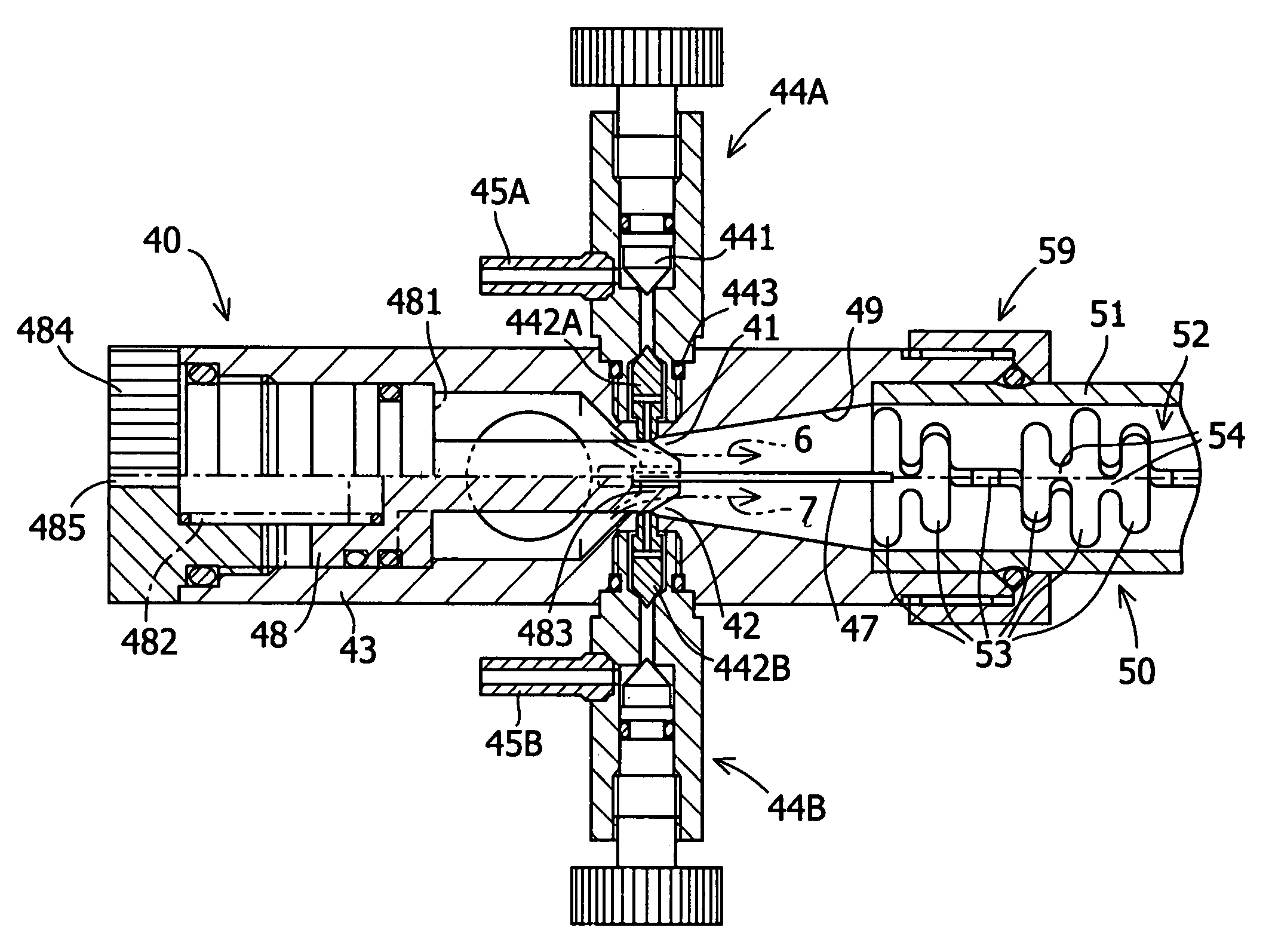

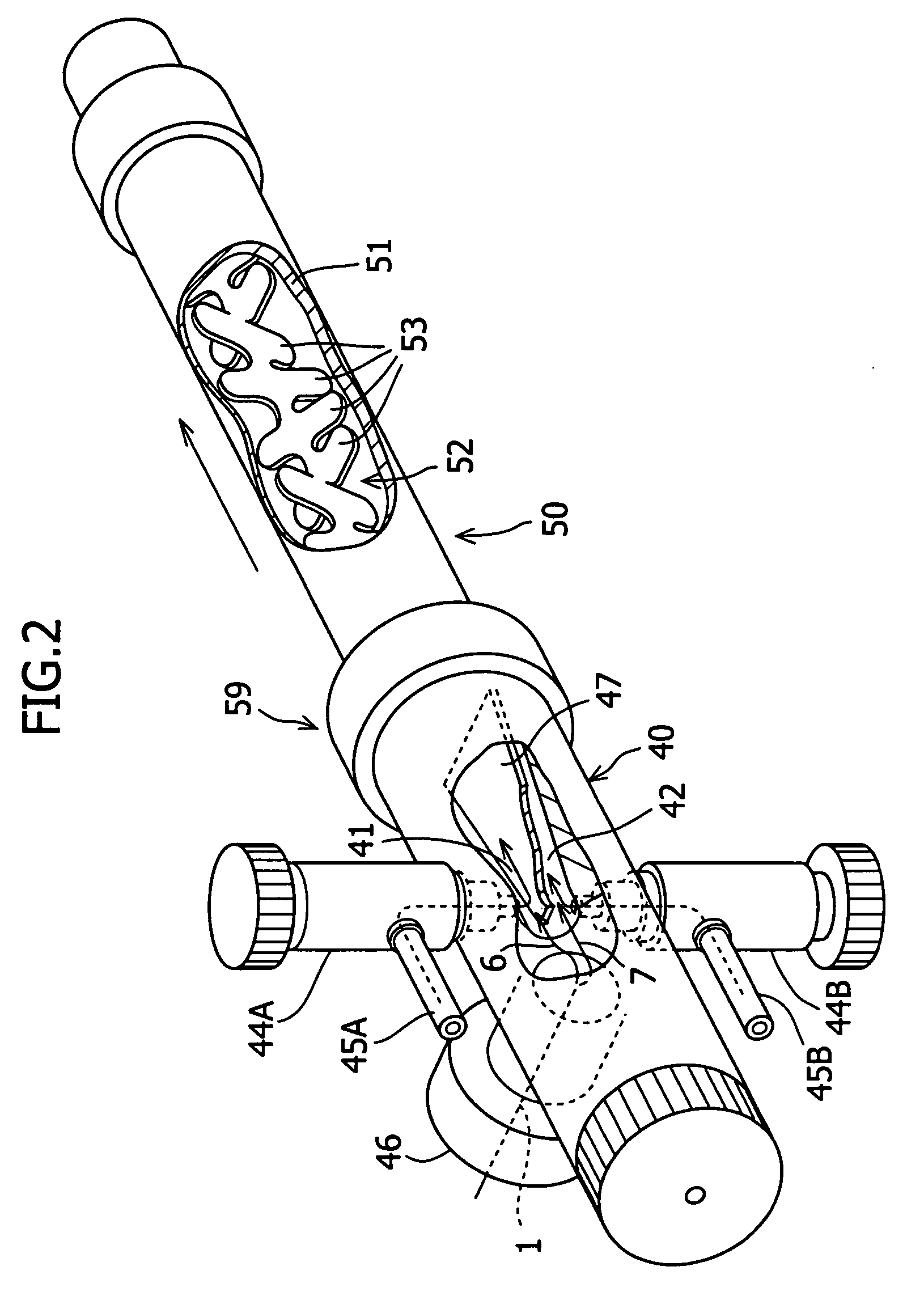

Apparatus and methods for root canal treatments

InactiveUS20120276497A1Preventing pressurizationEasy to cleanWheelchairs/patient conveyanceDental toolsLiquid jetDisinfectant

Apparatus and methods for root canal treatments are provided. In some embodiments, an aiming element may be used to position a high-velocity liquid jet near a desired location in the tooth. Embodiments of the aiming element may include an interrupter that deflects or impedes the liquid jet when it is not desirable for the jet to propagate from the aiming element. Embodiments of the aiming element may include an elongated member that permits passage of the liquid jet through a channel. The elongated member may include one or more openings, for example, on sides and / or ends of the member. Some root canal cleaning techniques include one or more applications of the liquid jet followed by application of a disinfectant such as, for example, an aqueous solution of sodium hypochlorite.

Owner:SONENDO

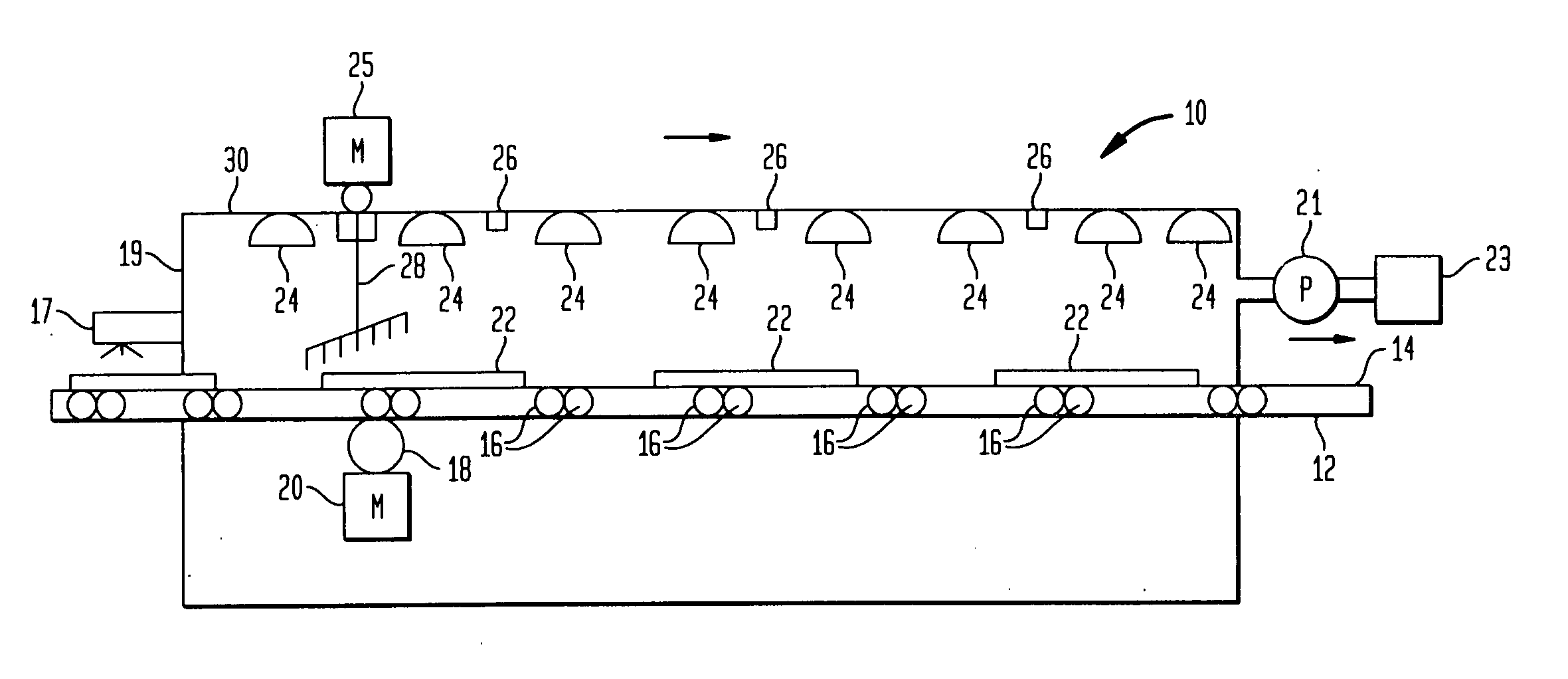

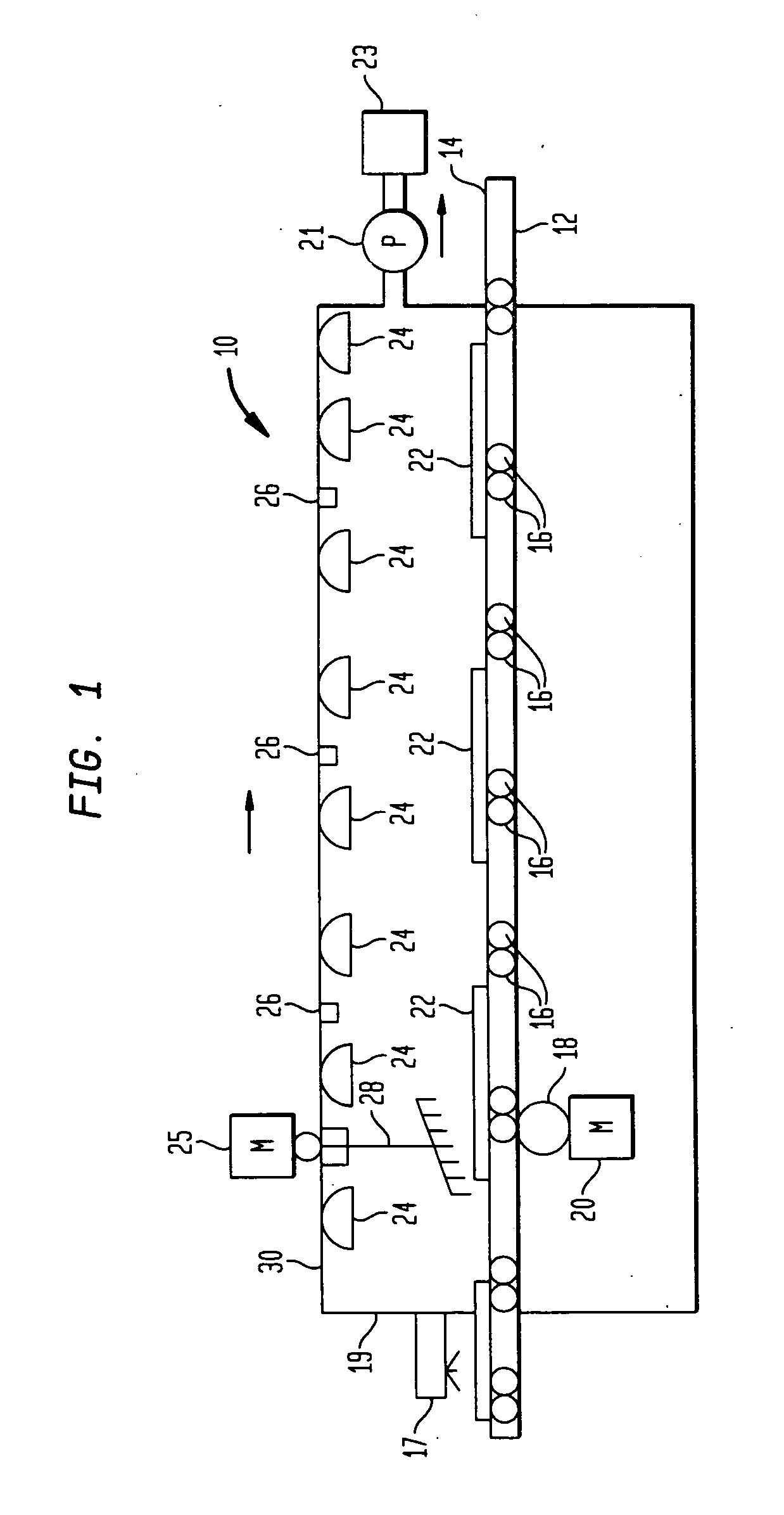

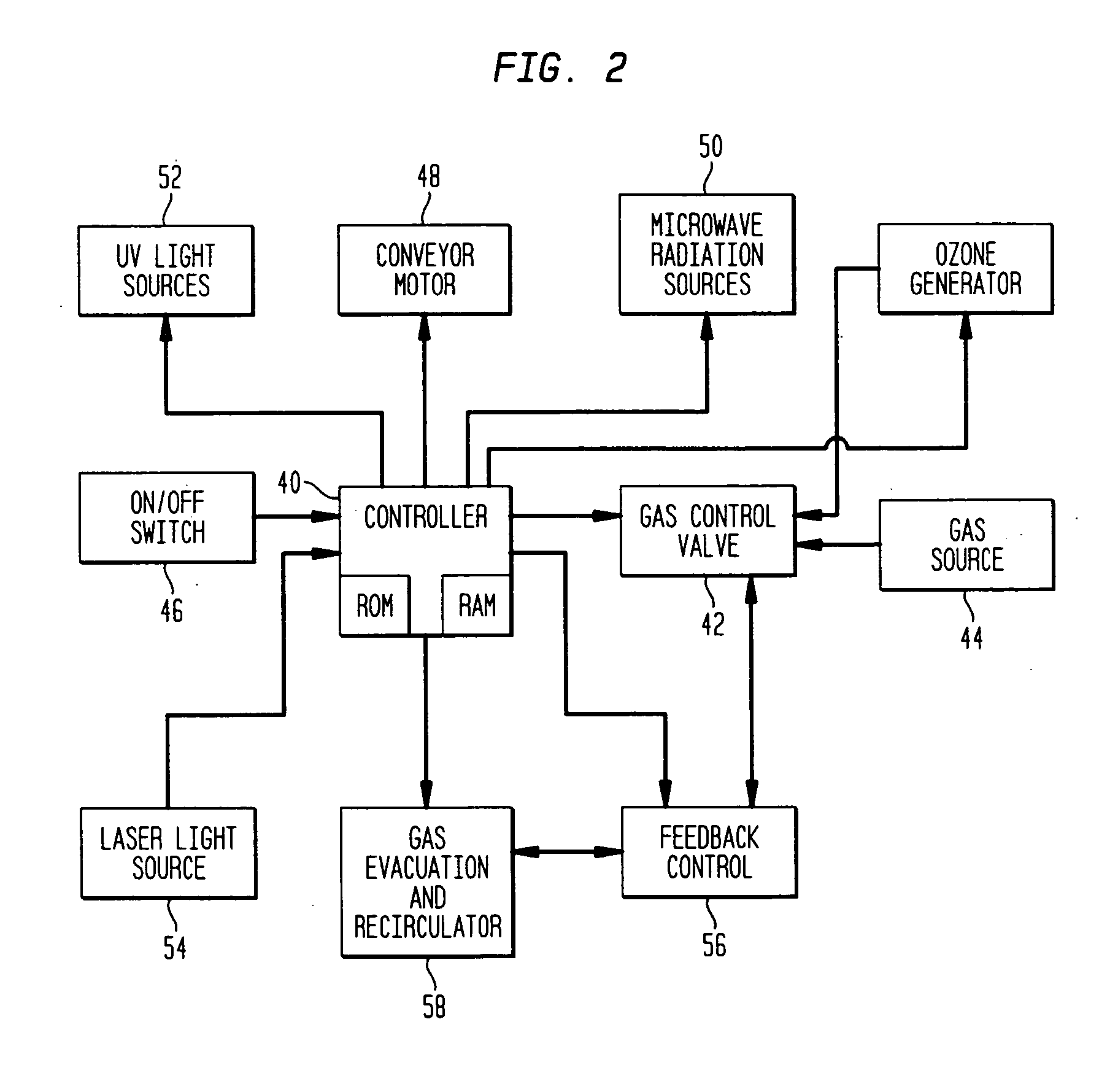

Sanitizing device and method for sanitizing articles

The invention provides an apparatus for sanitizing a plurality of articles, which comprises a housing enclosing a sanitizing zone, the housing having a seal for preventing leakage of gas or fluid from the sanitizing zone; a pump for introducing an antimicrobial fluid into the sanitizing zone; and a pump for withdrawing the fluid from the sanitizing zone. The device also includes at least one high power microwave source and at least one ultraviolet irradiating source, or a microwave source that also generates ultraviolet radiation. Preferably, the gas is a halogen, such as chlorine, bromine, or iodine, or a gas or fluid containing chlorine or bromine ions, but it can be ozone or another gas which kills bacteria, microbes, viruses, and other pathogens. The fluid can also be sprayed droplets or vaporized sodium hypochlorite, or similar antiseptic agent.

Owner:WEN SHEREE H

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20060124444A1Reduce needRemove films of protein oil and fatsLighting and heating apparatusExhaust apparatusElectrolysisHazardous substance

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogenous acid compounds such as sodium hypochlorite, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:NAKAMURA SHINICHI +2

Preparation method for tantalum-contained interlayer metallic oxide electrode

InactiveCN102174704AImprove stabilityImprove protectionLiquid/solution decomposition chemical coatingElectrodesElectrolysisElectrochemistry

The invention belongs to the electrochemical technical field, and relates to a preparation method for a tantalum-contained interlayer metallic oxide electrode. The electrode is suitable for occasions including steel plate high-speed electroplating, seawater electrolysis marine life pollution and damage prevention devices, sodium hypochlorite electrolysis production devices, sewage treatment, cathode protection and the like in the electrochemistry industrial field. The main process comprises three steps, namely substrate pretreatment, tantalum-contained interlayer preparation and oxide coatingpreparation: firstly, a tantalum-contained interlayer is prepared on a titanium substrate by adopting a thermal decomposition method, and then a mixed metallic oxide electro-catalysis coating is prepared on the tantalum-contained interlayer; the mass percent purity of the metallic titanium substrate is larger than 99%; and the process is simple and convenient to carry out, the metallic oxide electrode with larger size or more complicated structure can be prepared, and the tantalum-contained interlayer can better protect the titanium substrate, delay the titanium substrate inactivation, improve the stability of the oxide electrode and prolong the service life.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

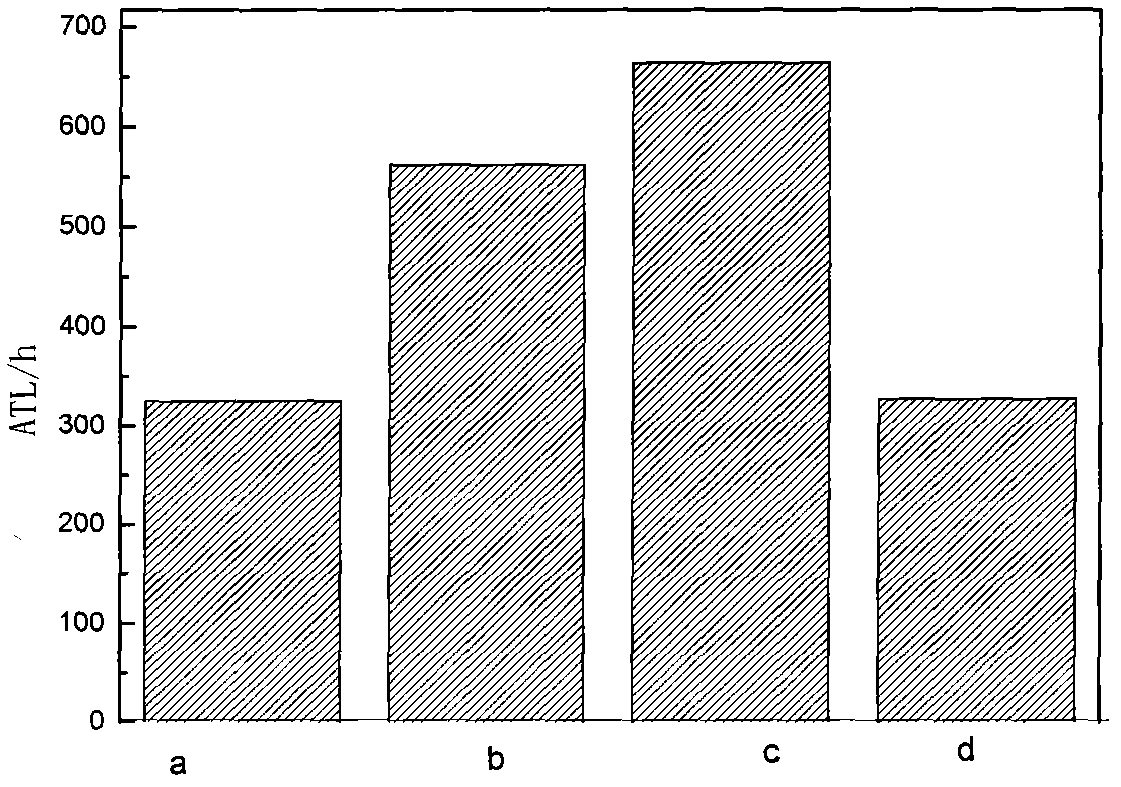

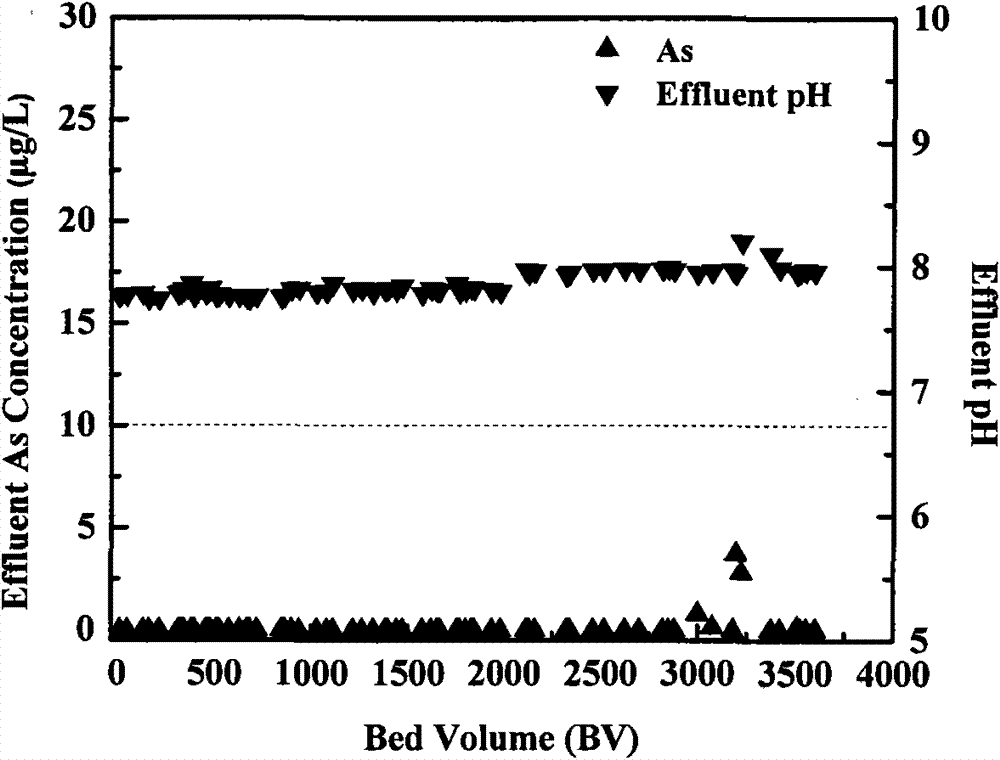

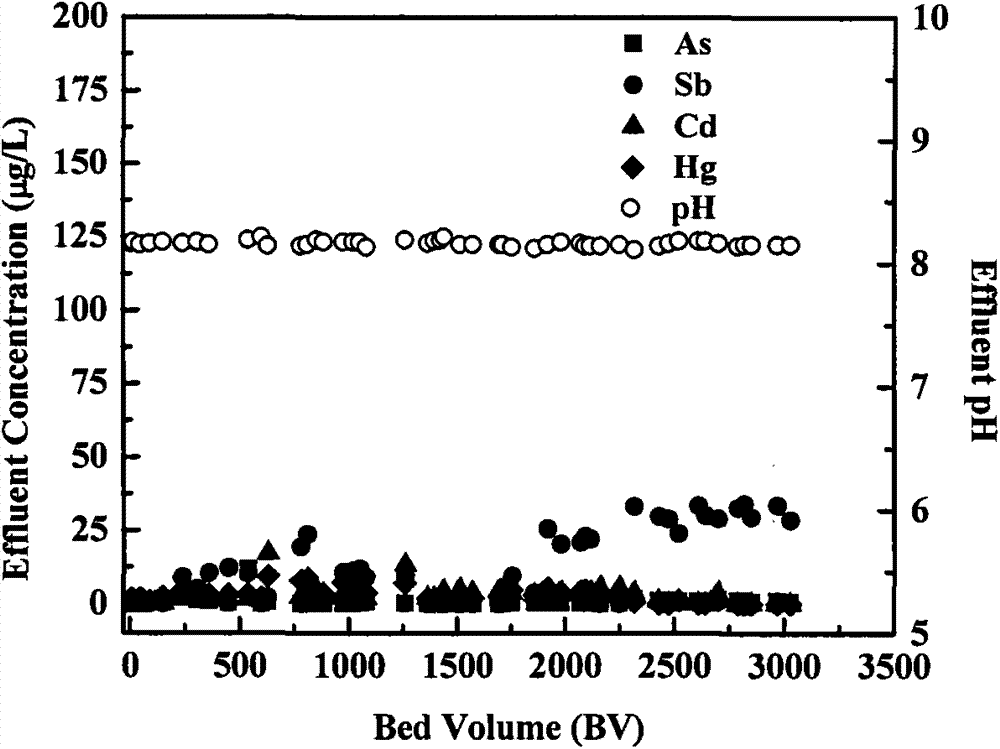

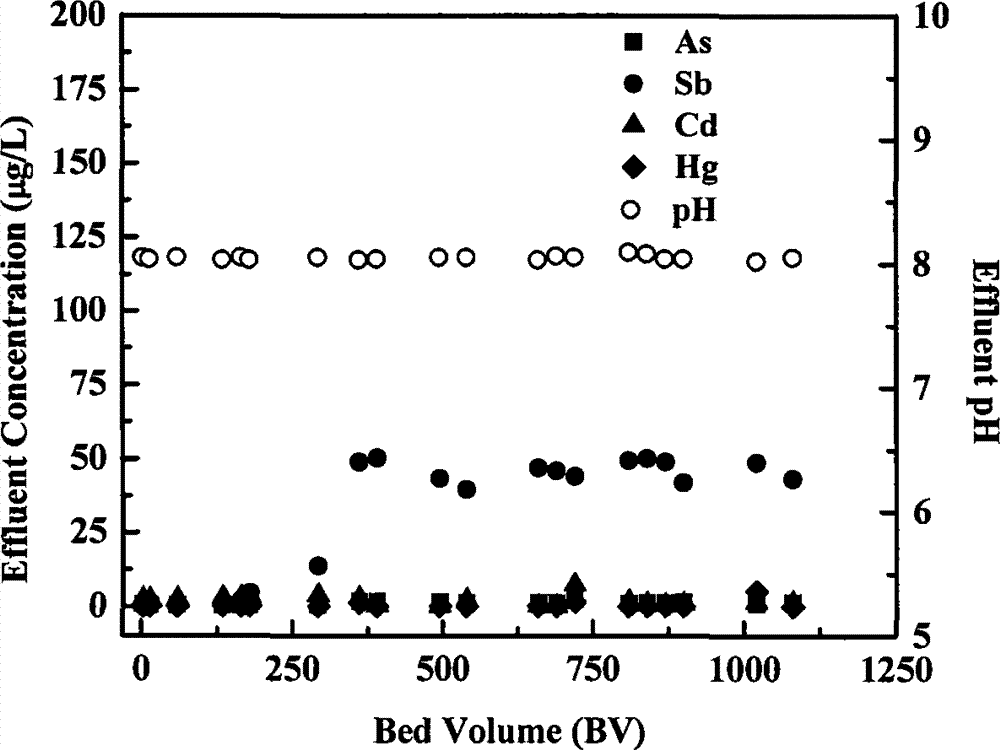

Method for quickly and efficiently removing heavy metals in water body

ActiveCN104276646AImprove cleanlinessGood chromaWater contaminantsMultistage water/sewage treatmentPotassium permanganatePrecipitation

The invention relates to a method for removing heavy metals in a water body, which is characterized in that common oxidizers for water treatment, such as hydrogen peroxide, sodium hypochlorite, potassium permanganate and the like, are utilized for oxidization to activate the zero-valent iron surface and continuously generate fresh iron (III) / (II) (hydro)oxide and other active components, thereby quickly and efficiently removing heavy metals in the water body, including As, Hg, Cd, Pb, Cr, Se, Sb, Cu, Zn and the like, in a mode of adsorption, precipitation, redox or the like.

Owner:BEIJING NORMAL UNIVERSITY

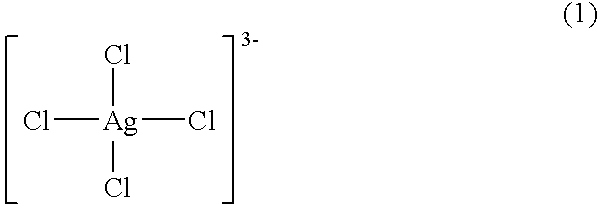

Antimicrobial agents

InactiveUS6726936B1Wide disinfecting spectrumAvoid problemsInorganic/elemental detergent compounding agentsBiocideMicrobial agentSolvent

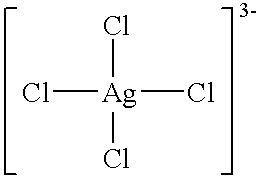

An antimicrobial agent includes silver-chloro complex salts and chloride, and further oxidizing agents such as sodium hypochlorite or sodium chlorite. As a result, it is possible to provide the antimicrobial agent having immediate and residual disinfecting and antimicrobial effects on bacteria and molds of a wide variety of species and capable of demonstrating instantaneous deodorizing effect. The antimicrobial agent includes the silver-chloro complex salts and chloride, and further a compound, for example, such as alcohols or surfactants, which has compatibility with a solvent such as water which dissolves the chloride. As a result, it is possible to provide the antimicrobial agent which can be used conveniently at the stored concentration, and which has immediate effect and cleansing ability without causing rust or deposition of salts in use. Further, the antimicrobial agent includes the silver-chloro complex salts, and chloride, for example, such as polyaluminium chloride or benzalkonium chloride, which has at least (I) a property capable of existing as a supersaturated aqueous solution in the presence of a crystal nucleus at least at room temperature for 24 hours or longer and (II) a property capable of being decomposed when dissolved in water.

Owner:YOKOSAWA METAL

Methods For Producing Sodium Hypochlorite With a Three-Compartment Apparatus Containing an Acidic Anolyte

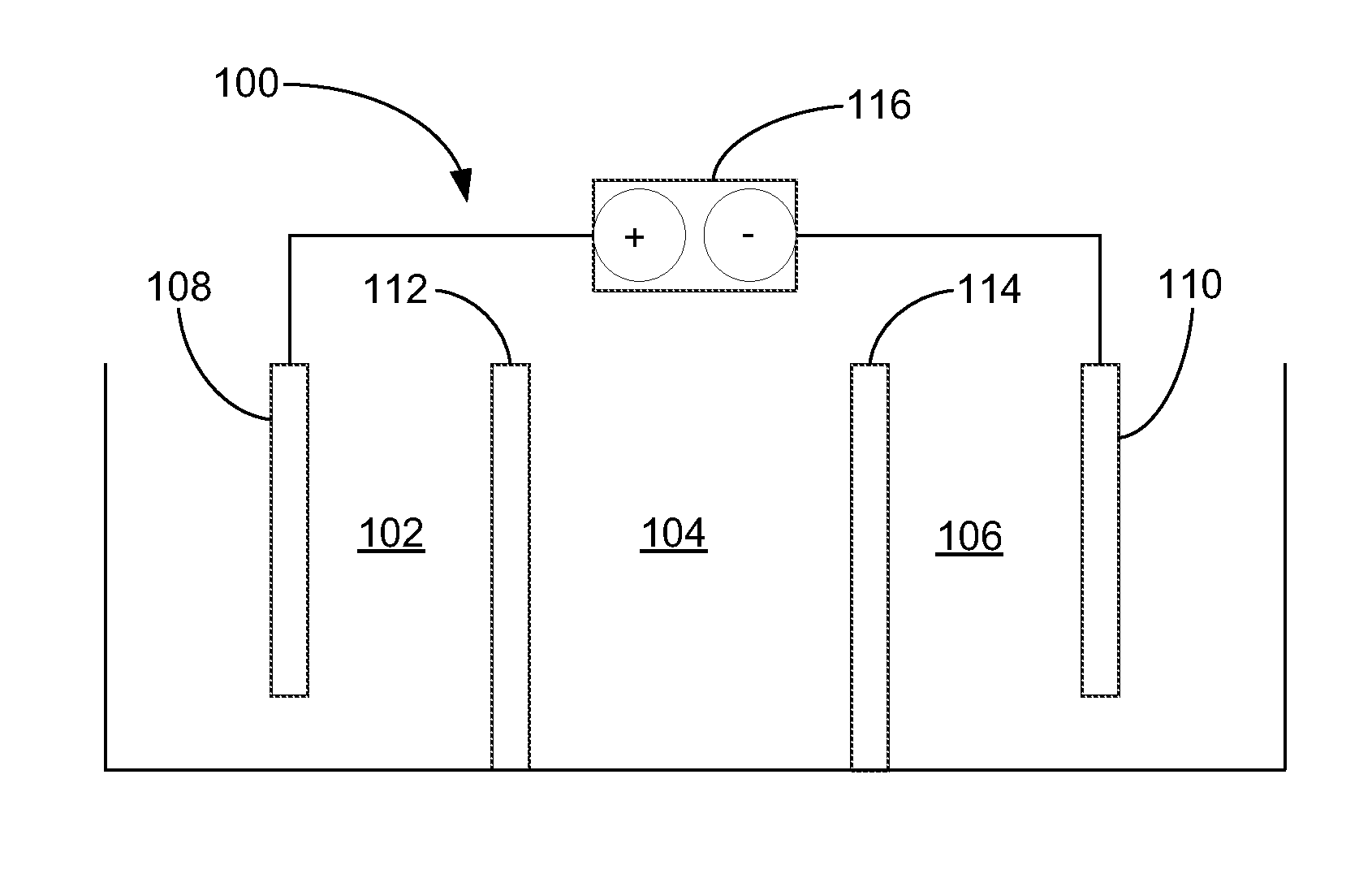

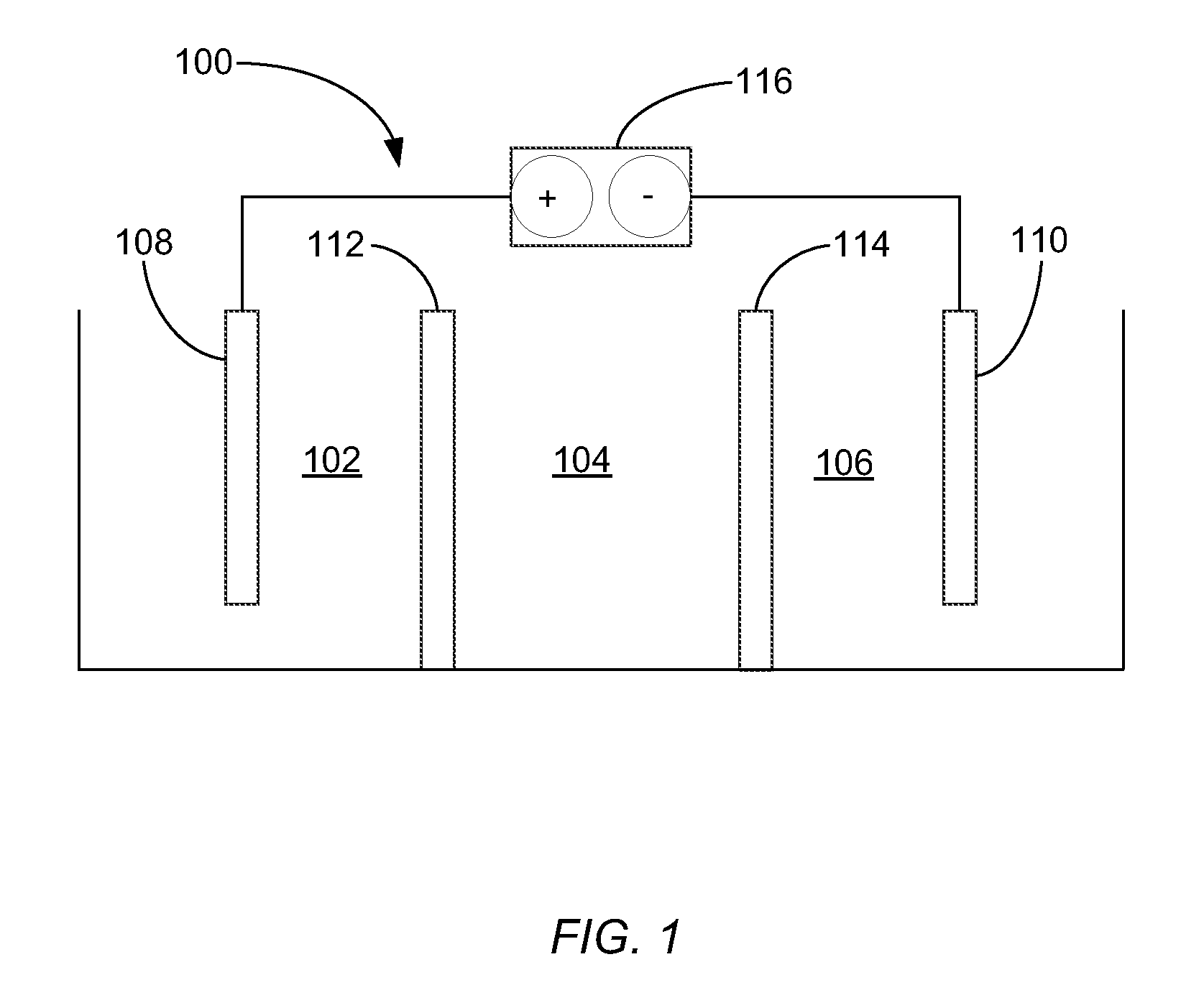

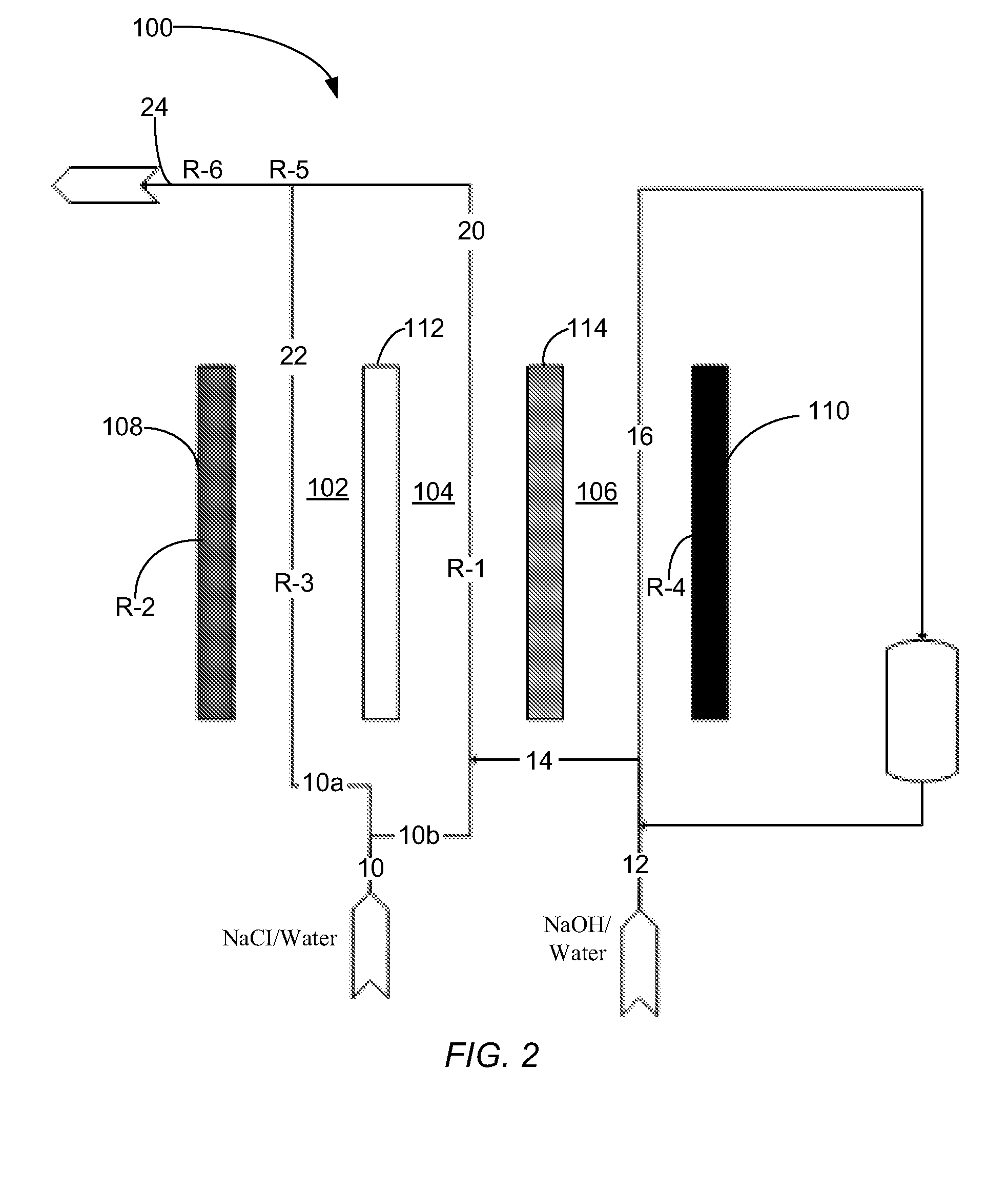

An electrochemical method for the production of a chlorine-based oxidant product, such as sodium hypochlorite, is disclosed. The method may potentially be used to produce sodium hypochlorite from sea water or low purity un-softened or NaCl-based salt solutions. The method utilizes alkali cation-conductive ceramic membranes, such as membranes based on NaSICON-type materials, and organic polymer membranes in electrochemical cells to produce sodium hypochlorite. Generally, the electrochemical cell includes three compartments and the first compartment contains an anolyte having an acidic pH.

Owner:CERAMTEC

Multi-enzyme and multi-steps type method for producing diet cellulose flour from wheat bran

ActiveCN1718107ACompletely hydrolyzedReduce lossesVegetable proteins working-upFood preparationPhytaseCELLULOSE FLOUR

A process for preparing the edible fibre powder from wheat bran by multi-enzyme step treating method includes such steps as treating wheat bran sequentially by endogenous phytase, amylase, proteinase and lipase to obtain high-purity edible fibres, decoloring by sodium hypochlorite and hydrogen peroxide, squeezing, laying aside and superfine pulverizing.

Owner:江苏江南上一道科技股份有限公司

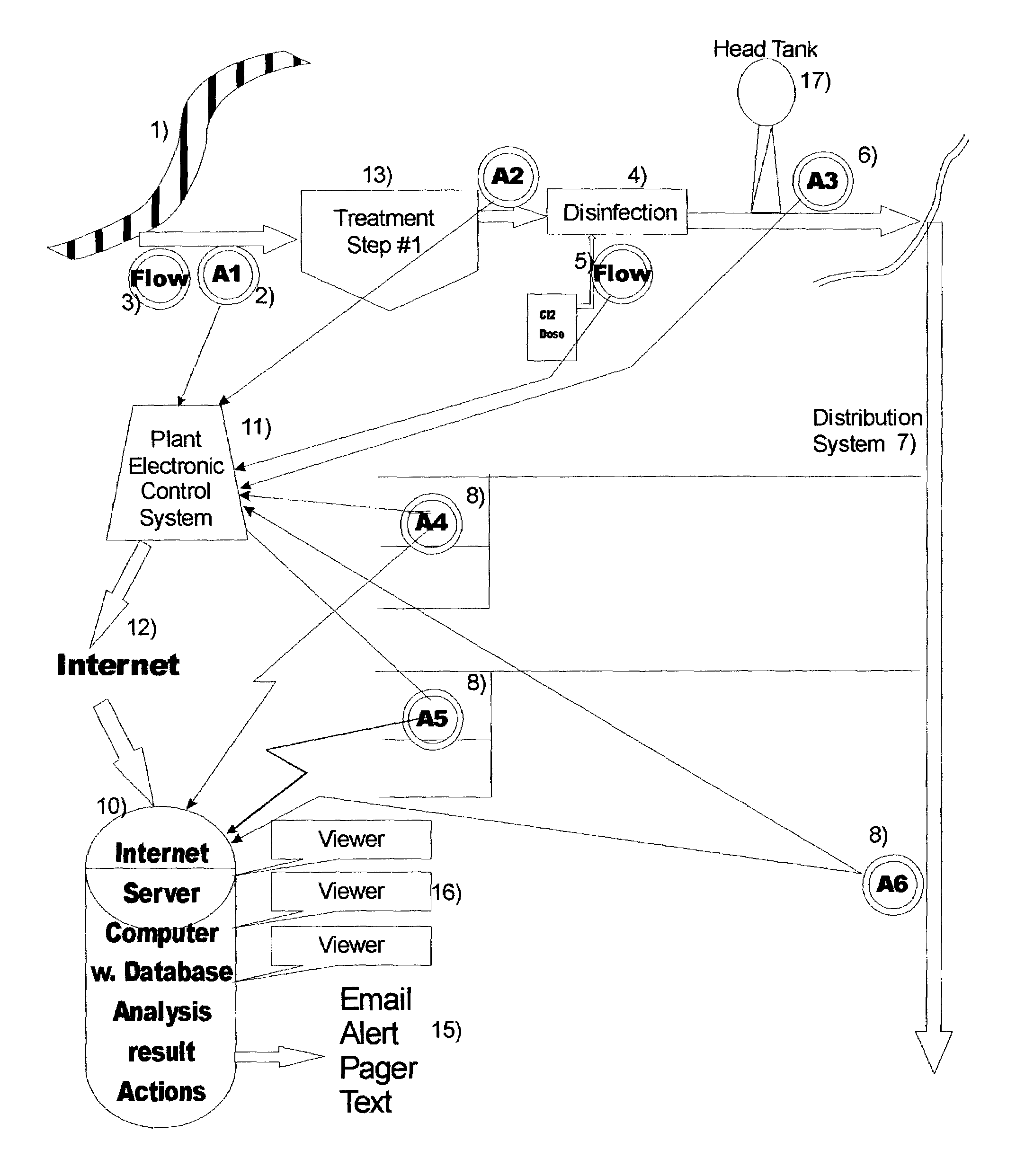

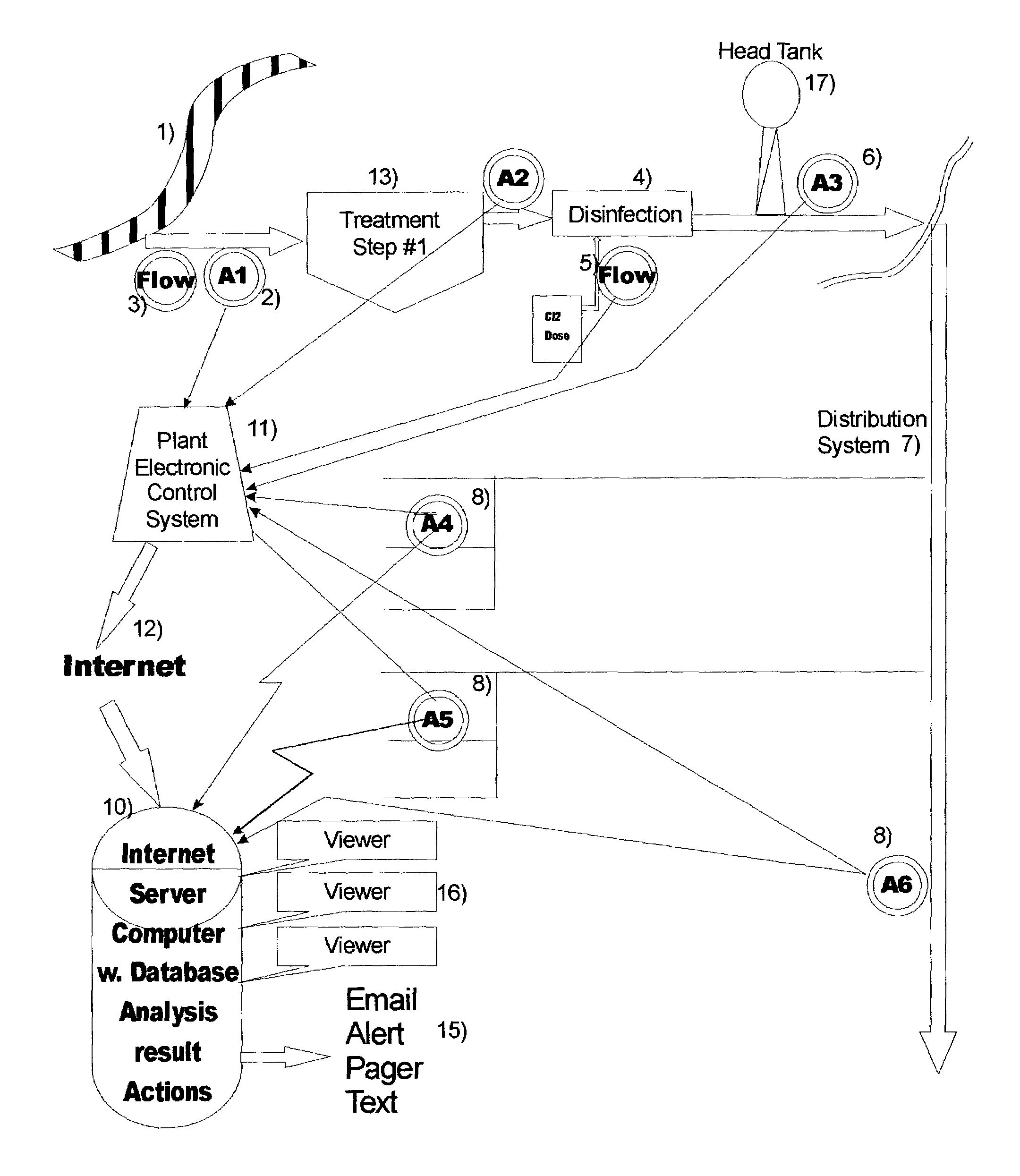

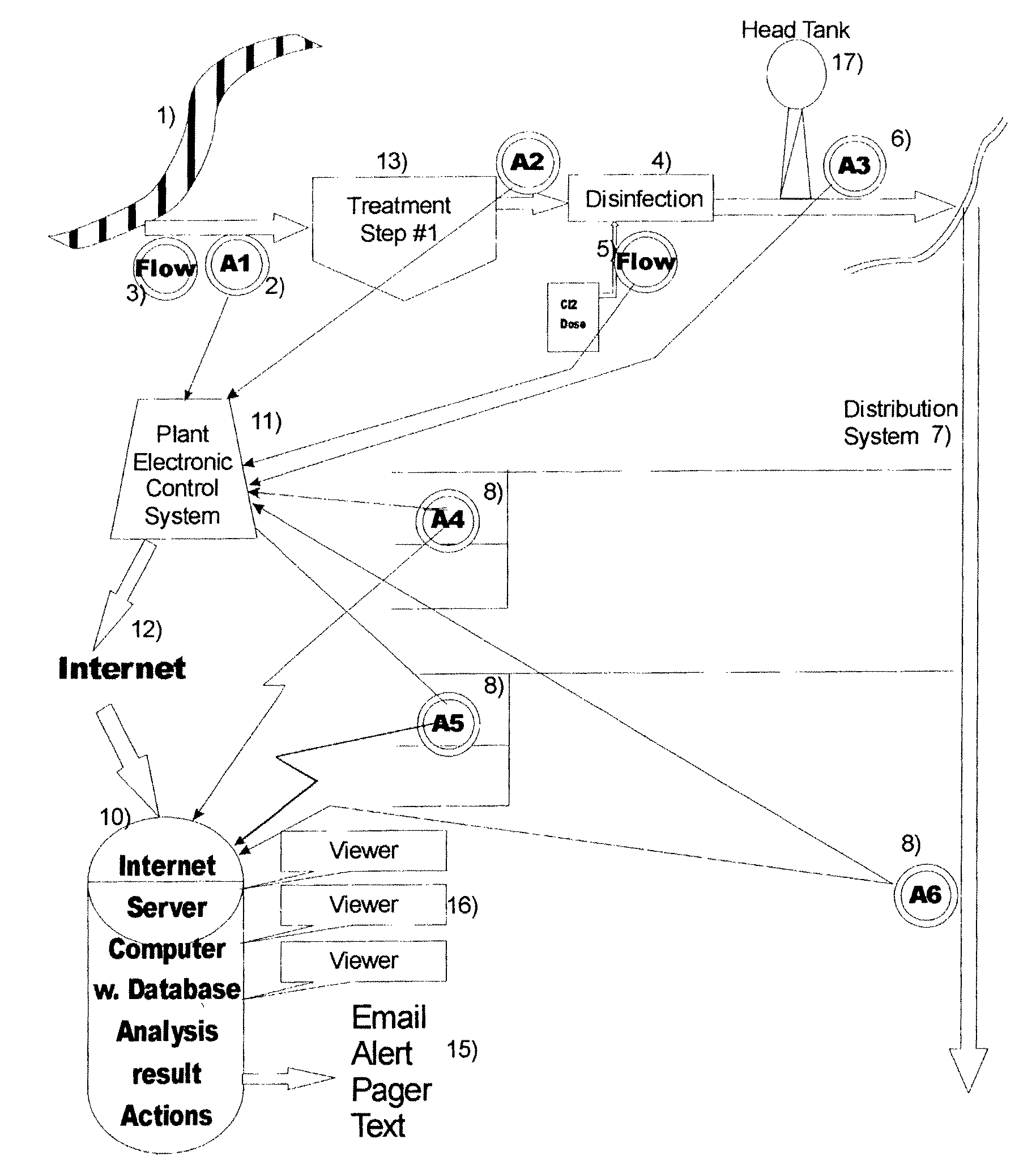

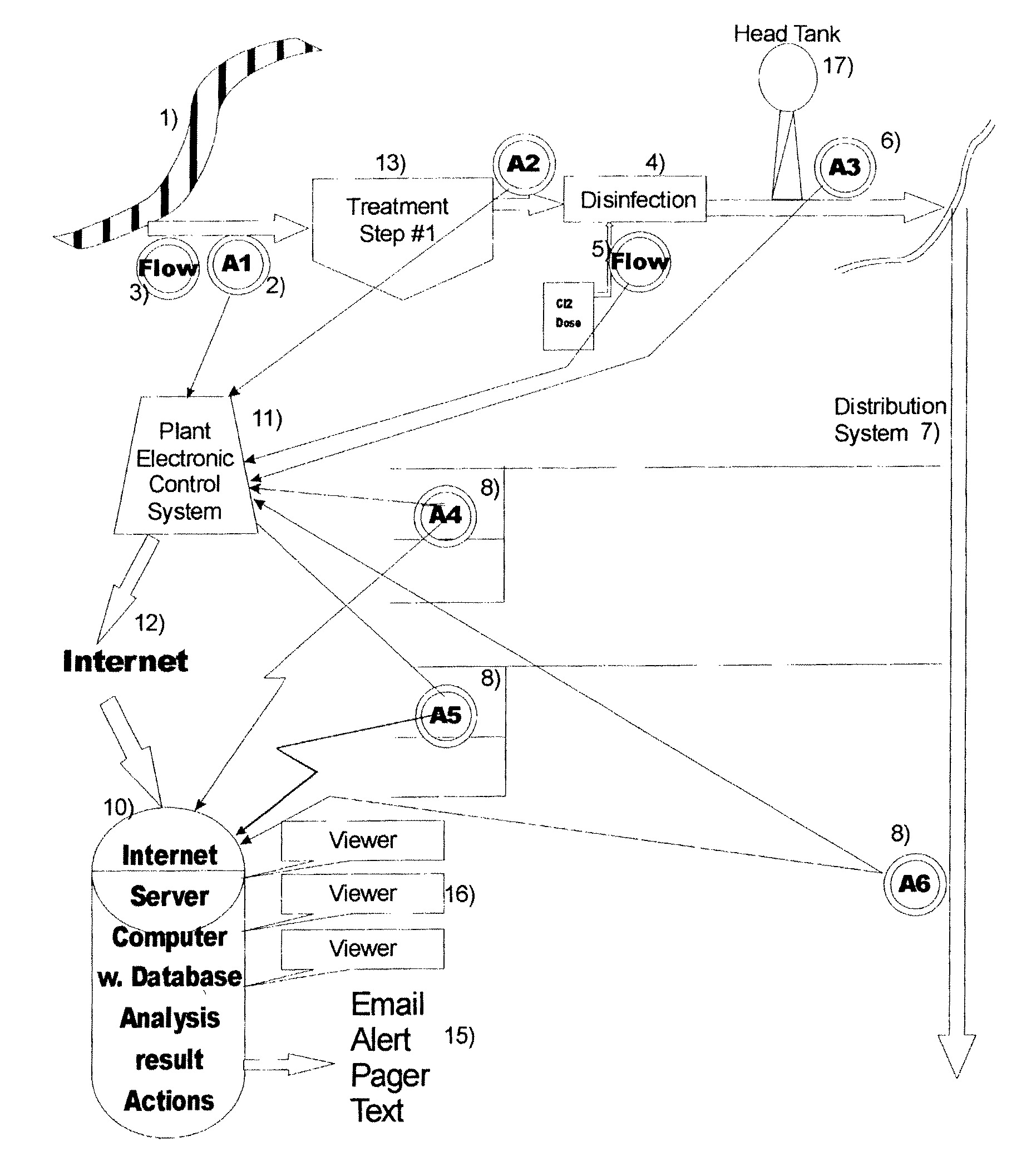

Anti-terrorism water quality monitoring system

InactiveUS7454295B2Prevent hackingRule out the possibilityGeneral water supply conservation2D-image generationChloramine BChlorine dioxide

An Anti-Terrorism water quality monitoring system for continuously monitoring a potable water treatment system and related potable water distribution network that provides potable water to a municipality, city, housing development or other potable water consumer. The system includes the collection of data from the water distribution system and from the water treatment facility and from advanced separation processes which are integrated into analytical instruments. The data collected are stored in a remote database on a remote server computer or bank of computers and accessible by Homeland Security or its designated agency. Preferred parameters of monitoring include the turbidity and disinfectant such as chlorine, hypochlorous acid, sodium hypochlorite, calcium hypochlorite, ozone, chlorine dioxide, chloramines, hydrogen peroxide, peracetic acid.

Owner:HACH CO

Apparatus for producing sterilized water

InactiveUS7416326B2Easy constructionRestrains fluctuation of pressure affecting feedingFlow mixersMixing methodsChlorine dioxideSterile water

Owner:FAMILY LIFE

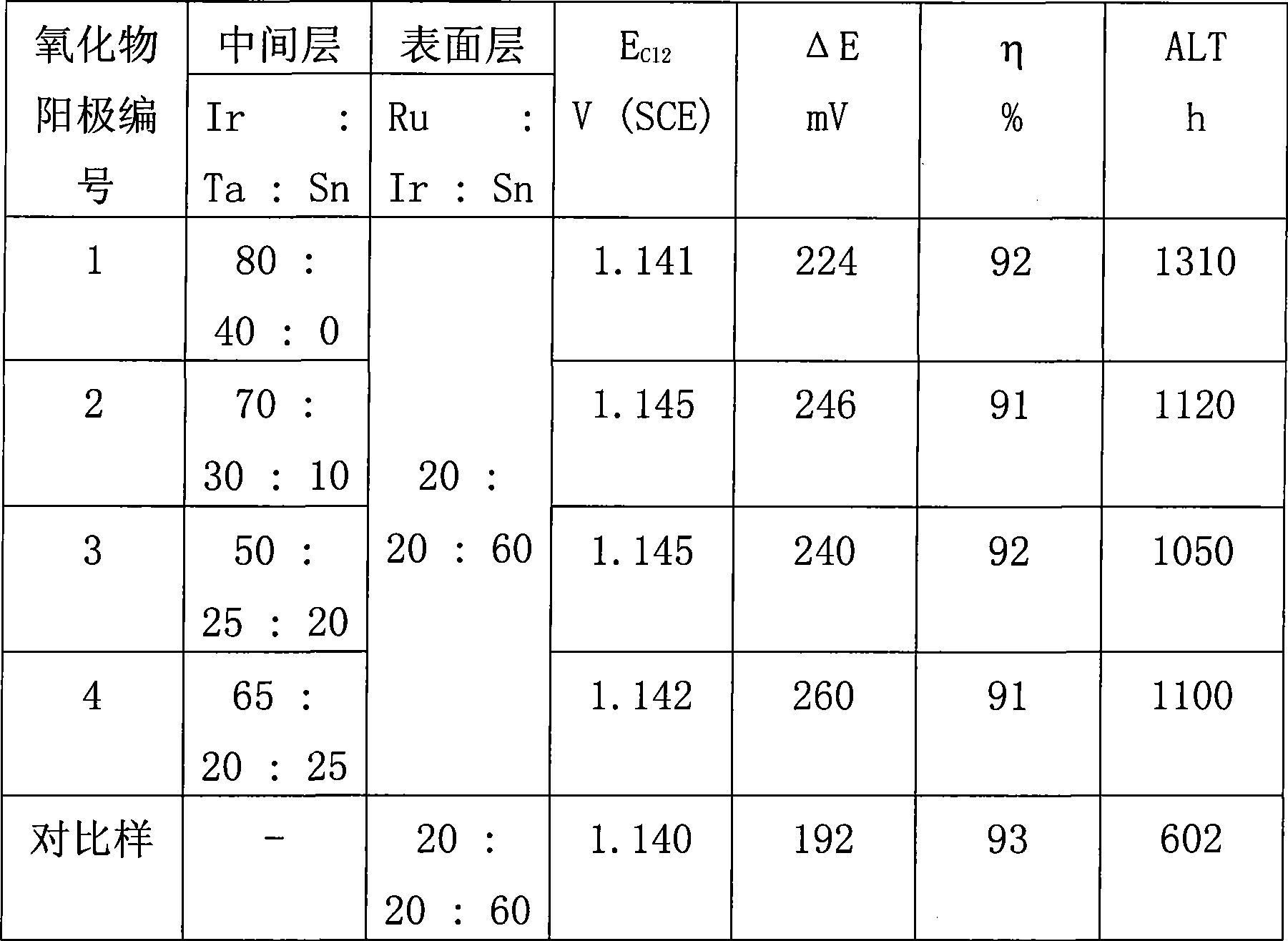

Nanocrystal metal oxide composite electrode and method for preparing same

The invention relates to a nanocrystal metal oxide composite electrode and a method for preparing the same. The electrode is suitable for a seawater electrolysis device for preventing the contamination of sea creature and used for electrolytic production of sodium hypochlorite, cathode protection and other electrochemical engineering; a main structure of the electrode comprises a substrate, an anticorrosive antipassivated middle layer and a surface activity layer, wherein the substrate is metal titanium; the purity of the metal titanium is over 99 percent; the middle layer is iridium-tantalum or iridium-tantalum-tin oxide; the surface activity layer is ruthenium-iridium-tin metal oxide; a process for preparing the electrode adopts a sol-gel method and comprises three process steps of the pretreatment of the substrate, the preparation of the anticorrosive antipassivated middle layer and the preparation of the surface activity layer; and the electrode has the characteristics of even compositions, difficulty for burning loss, fine crystal grains, simple preparation process, controllable process and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Calcium hypochlorite blended tablets

A non-Division 5.1 Oxidizer tablet consisting essentially of a blend of hydrated calcium hypochlorite with magnesium sulfate heptahydrate, wherein the blend contains at least about 17% by weight of water based on the total weight of the blend; contains from about 0.1% to about 10% of lime based on the total weight of the hydrated calcium hypochlorate and magnesium sulfate heptahydrate and the average dissolving rate of the tablet is less than 150 grams per day.

Owner:INNOVATIVE WATER CARE LLC

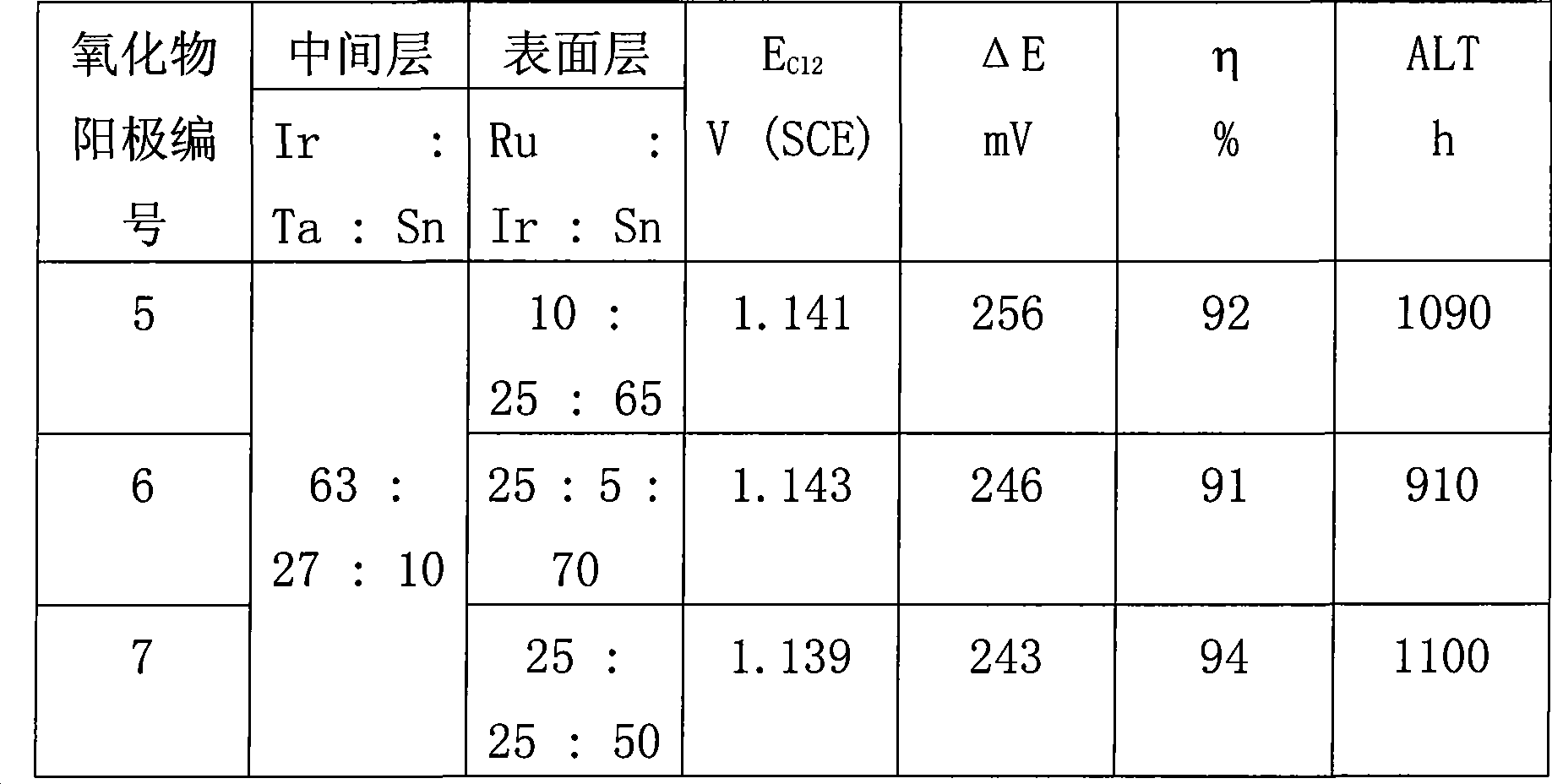

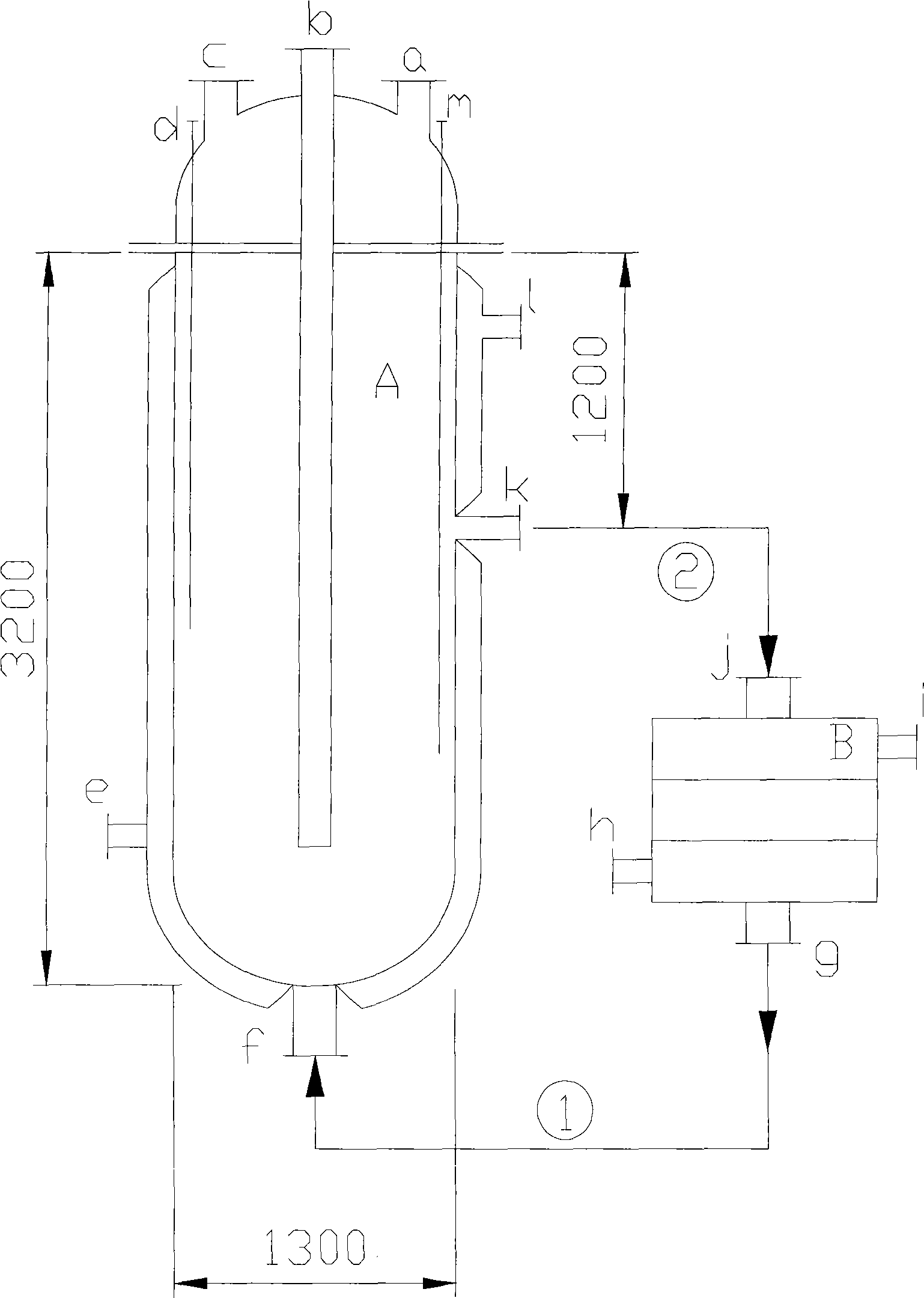

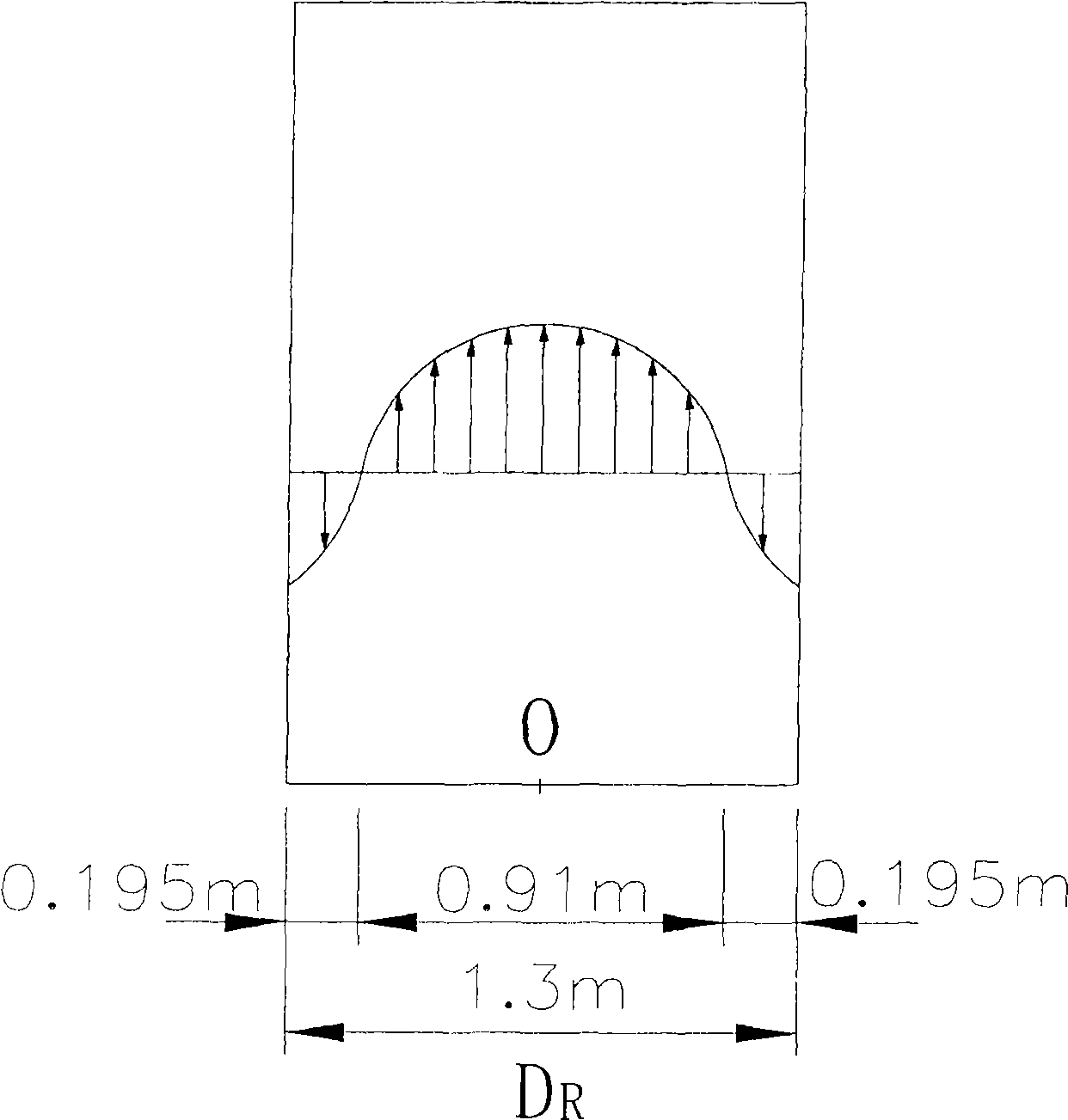

Self circulation heat exchange method for materials in production of chlorinating paraffin-52 and chlorination reaction device therefor

InactiveCN101544911AOrderly escapeNo reduction in mass transfer efficiencyPetroleum chemical modificationComing outParaffin wax

The invention provides a self circulation heat exchange method for materials in production of chlorinating paraffin-52 and a chlorination reaction device therefor. The method comprises the steps that: a, liquid paraffin is added into an automatic circulation main and auxiliary chlorination reaction kettle provided with a catalytic light source and a heat exchanger outside the kettle, and a catalytic light source lamp is turned on; b, liquid chlorine is introduced into a gasification kettle, stabilized by an accumulator still, and is introduced into a main kettle of the chlorination reaction kettle at a chlorine flowrate of between 200 and 230Kg / h, the chlorination temperature is controlled to be between 100 and 110 DEG C, the reaction is stopped when the chlorine content analyzed in a taken sample is between 50 and 54 percent to obtain a crude product of the chlorinating paraffin-52, dissolved chlorine and chlorine hydride in the crude product of the chlorinating paraffin-52 are removed by a degasification kettle, and then a stabilizing agent is added to obtain a finished product of the chlorinating paraffin-52; and c, gas coming out of the main kettle of the chlorination reaction kettle enters an auxiliary kettle of the chlorination reaction kettle, gas coming out of the auxiliary kettle of the chlorination reaction kettle passes through a graphitic absorber, a water falling film is used for absorbing the chlorine hydride in the gas to prepare hydrochloric acid, micro chlorine and chlorine hydride contained in tail gas which is discharged by the graphic absorber pass through a waste gas processor and are absorbed by water solution of sodium hydroxide to generate sodium hypochlorite and sodium chloride.

Owner:HENAN CHEM IND RES INST

Method for recovering ruthenium catalyst carried by active carbon

InactiveCN1872418AReduce manufacturing costReduce consumptionRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsCatalyst regeneration/reactivationRecovery methodActivated carbon

A recovering process for the activated carbon carried Ru catalyst not containing the compound of alkali metal or alkali-earth metal includes such steps as calcining at 600-1000 deg.C for 2-20 hr to obtain gray mixture, mixing it with KOH and KNO3, holding the temp at 300-950 deg.C for 105 hr, cooling, dissolving in hot water at 50-90 deg.C to obtain K2RuO4 solution, adding sodium hypochlorite and concentrated sulfuric acid, distilling to generate RuO4 gas, absorbing it by strong acid solution, and distilling to obtain Ru salt.

Owner:ZHEJIANG UNIV OF TECH +1

Oxidation nanocellulose adsorbing material and preparation method thereof

ActiveCN105498733AMicroscale reductionImprove accessibilityOther chemical processesSorbentCatalytic effect

The invention provides a preparation method of an oxidation nanocellulose adsorbing material. The preparation method comprises the following steps of conducting pretreatment and then cleaning cellulose; and under the catalytic action of 2, 2, 6, 6-tetramethyl piperidine-nitrogen-oxide and sodium bromide, conducting an oxidation reaction on obtain cellulose under the action of an oxidizing agent, so that oxidation nanocellulose is obtained, wherein sodium hypochlorite serves as the oxidizing agent; mixing the nanocellulose with an organic solution containing amino high molecules, then conducting centrifugation, then mixing the mixture with a cross-linking agent, and conducting a reaction, so that the oxidation nanocellulose adsorbing material is obtained. By means of the preparation method, the specific surface area of the cellulose is increased, the contactable performance of heavy metal pollutants and adsorbent is improved, the surface of the material can have a large number of adsorption functional groups, and heavy metal ions can be aggregated to the surface of the adsorbent from a sewage system through the complexation effect and the electrostatic effect. The invention further provides the oxidation nanocellulose adsorbing material.

Owner:UNIV OF SCI & TECH OF CHINA

Tuberculocidal synergistic disinfectant compositions and methods of disinfecting

InactiveUS6245361B1Remain stable and effectiveMore tolerableBiocideDead animal preservationAmmonium compoundsSodium chlorate

An aqueous cleaning and disinfecting composition is disclosed that is a synergistic combination of (a) a sufficient amount of a chlorine-containing bleach compound such as sodium hypochlorite or sodium dichloroisocyanurate to provide from about 1,100 parts per million by weight of available chlorine level with (b) from about 600 to 800 parts per million by weight of bactericidal quaternary ammonium compounds such as mixtures of didecyldimethylammonium chloride and (C12-C16 alkyl)dimethylbenzylammonium chlorides. Such compositions are tuberculocidal at unexpectedly low concentrations. Also disclosed are two component compositions and methods of disinfecting surfaces containing tubercule bacilli and other pathogenic micro-organisms such as bacteria and viruses.

Owner:JOHNSONDIVERSEY INC

Calcium hypochlorite blended tablets

A non-Division 5.1 Oxidizer tablet consisting essentially of a blend of hydrated calcium hypochlorite with magnesium sulfate heptahydrate, wherein the blend contains at least about 17% by weight of water based on the total weight of the blend and the dissolving rate of the tablet is less than 150 grams per day.

Owner:INNOVATIVE WATER CARE LLC

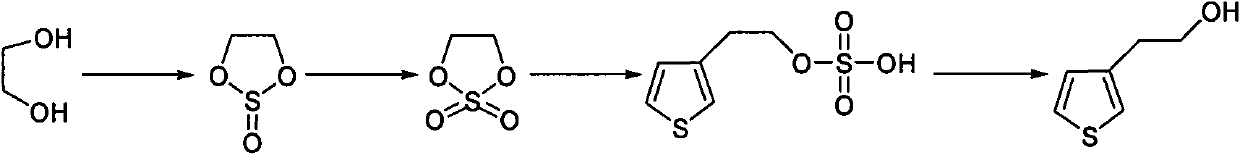

Synthetic method of thiophene-3-ethanol

The invention discloses a synthetic method of thiophene-3-ethanol. The method comprises the following steps of: adding a halogenated hydrocarbon solvent and ethylene glycol into a reaction kettle, dropwise adding thionyl chloride and preserving heat for reacting; separating liquid and extracting to obtain an organic phase containing a substance shown in the specifications; adding a ruthenium trichloride aqueous solution and a sodium bicarbonate aqueous solution in the presence of the halogenated hydrocarbon solvent and dropwise adding a sodium hypochlorite aqueous solution; after detecting that a system does not have oxidizing property, performing liquid separation, concentration, devitrification and drying to obtain a substance shown in the specifications, adding an ester solvent and butyl lithium into a reaction kettle, adding a prepared ester solution of tribromothiofuran and a prepared ester solution of the substance, separating the liquid and extracting to obtain a system containing a substance shown in the specifications; and adding a dilute sulfuric acid into the system containing the substance shown in the specifications, concentrating, neutralizing, extracting and concentrating to obtain an end product. The method has the advantages of high reaction purity and yield, stable process condition, easiness for operation and mass production capability; and the thiophene-3-ethanol is prepared from tribromothiofuran by performing low-temperature lithiation, so that the use of epoxy ethane serving as an explosive hazard is avoided, and mass production becomes possible.

Owner:ASYMCHEM LAB TIANJIN +4

Method for recovering noble-metal from waste catalyst

ActiveCN101074458AEasy to recycleHigh recovery rateProcess efficiency improvementPhysical chemistrySodium hypochlorite

A method for recovering noble metal from waste catalysts containing noble metal is carried out by pre-treating for waste catalysts containing noble metal, stage roasting, leaching noble metal into solution, purifying and recovering noble metal from solution. The immersion liquid adopts mixed solution with sodium hypochlorite, hydrion and chlorine ion. It's cheap, safe, clean and complete. It has less pollution and higher recovery rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemical cleaning method of ultrafiltration membrane

The invention discloses an ultrafiltration membrane chemical cleaning method and aims at an ultrafiltration membrane that is used for processing purified PTA waste water. The invention uses an acid lotion prepared by citric acid and sodium bisulfite for dissolving and eluting inorganic pollutants that are formed by cobalt and manganese ion hydroxide, deposited and absorbed on the surface of the ultrafiltration membrane, and uses an alkaline oxidative lotion that contains sodium hypochlorite for dissolving and eluting organic colloid pollutants that are deposited and absorbed on the surface of the ultrafiltration membrane. The ultrafiltration membrane chemical cleaning method can effectively elute the pollutants, recover the running flux and running pressure of the ultrafiltration membrane, and ensure stable running of the purified PTA waste water in an ultrafiltration process.

Owner:CHINA PETROLEUM & CHEM CORP +1

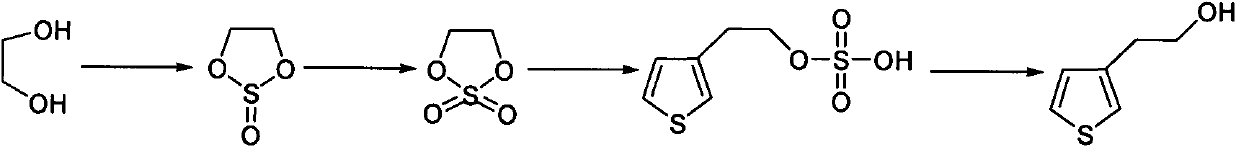

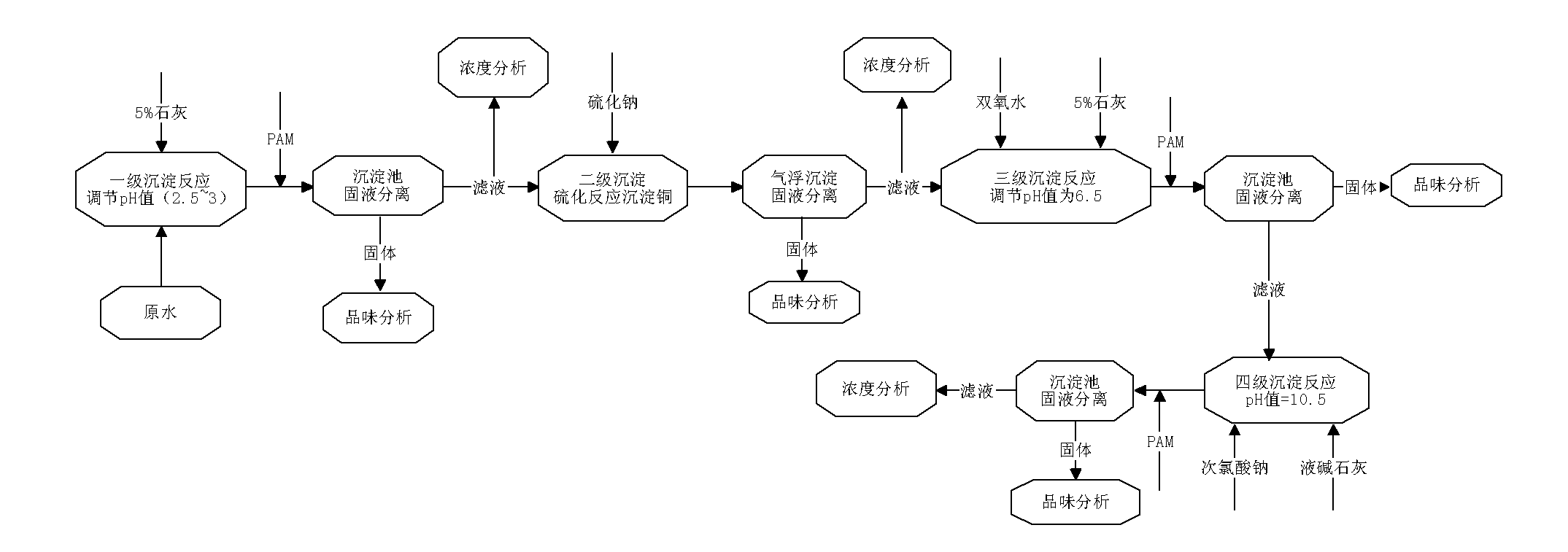

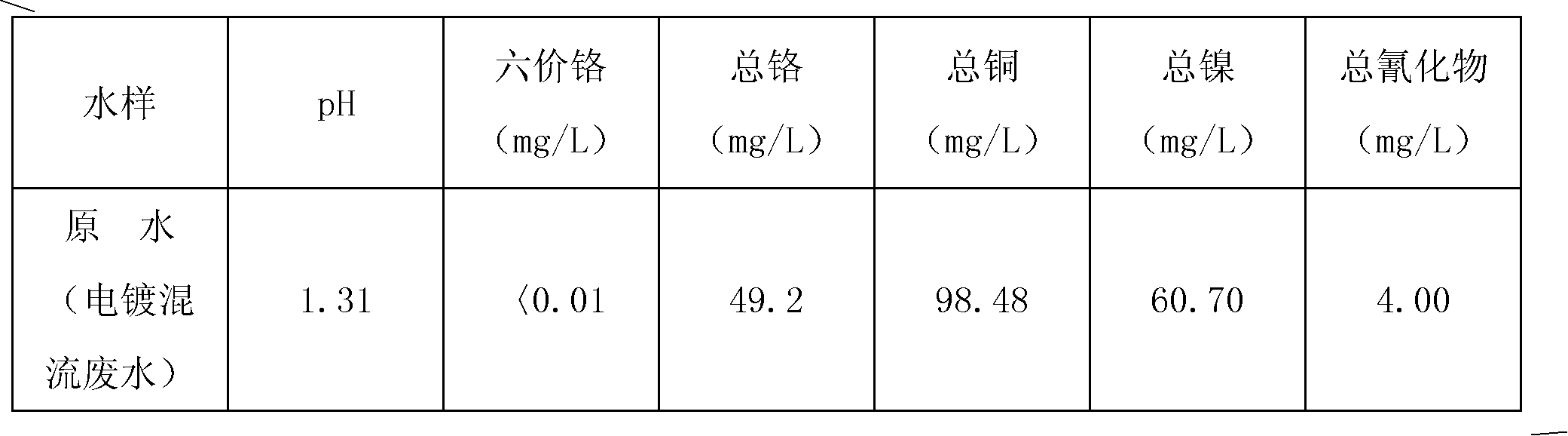

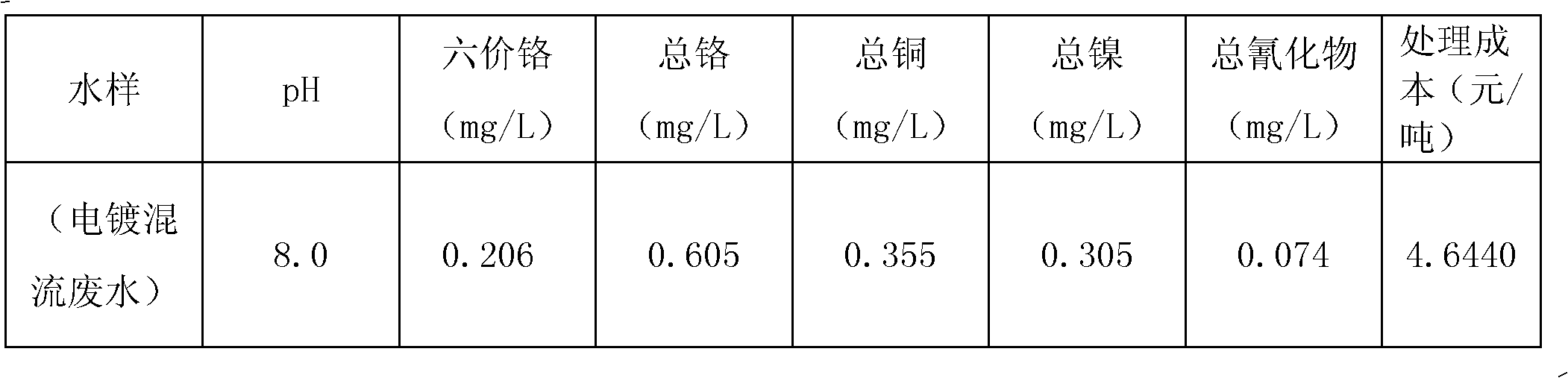

Recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water

ActiveCN102557299AReduce lossesReduce loss rateWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodCopper sulfide

The invention relates to a recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water. The recovery method comprises the following steps of: using lime to adjusting the pH value to be 2.5-3 in the electroplated mixed-flow waste water containing copper and nickel, adding a flocculating agent PAM (polyacrylamide), generating precipitate, and carrying out solid-liquid separation; then adding sodium sulfide, generating copper sulfide precipitate, and carrying out solid-liquid separation; then adding hydrogen peroxide for preventing complexation, using the lime to adjusting the pH value to be 6.5, simultaneously precipitating copper and chromium ions, adding the flocculating agent PAM, and carrying out solid-liquid separation; then using the lime to adjusting the pH value to be 10.5, simultaneously adding sodium hypochlorite for preventing complexation, generating precipitate containing nickel hydroxide, adding the flocculating agent PAM, carrying out solid-liquid separation, and recovering nickel mud; and finally, adjusting the pH value of the discharged water to be 8 by adding sulfuric acid, and realizing standard discharging. The recovery method has the advantages that the process is simple and convenient, the operation is easy, the recovery cost is low and the recovery rate is higher.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

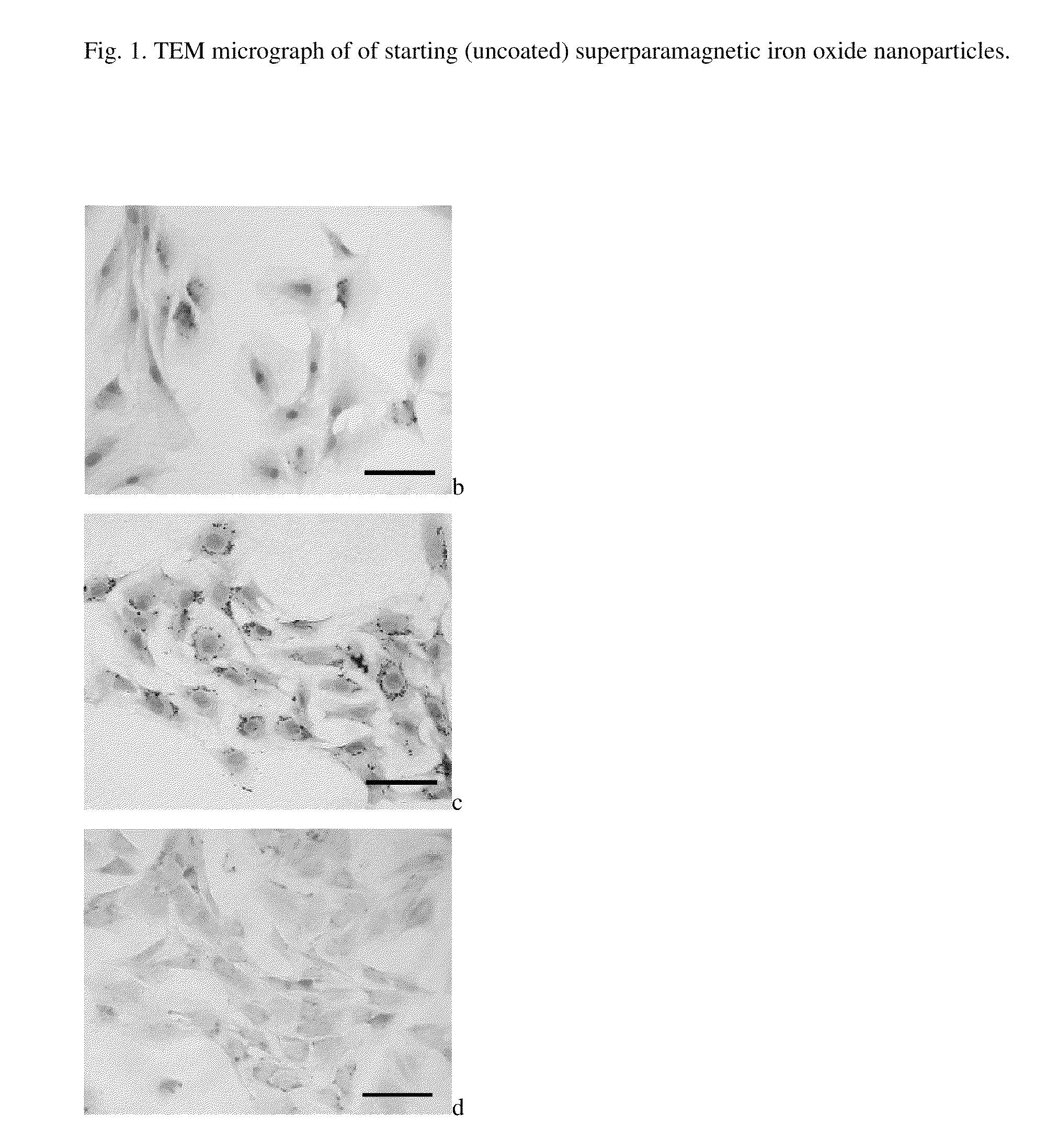

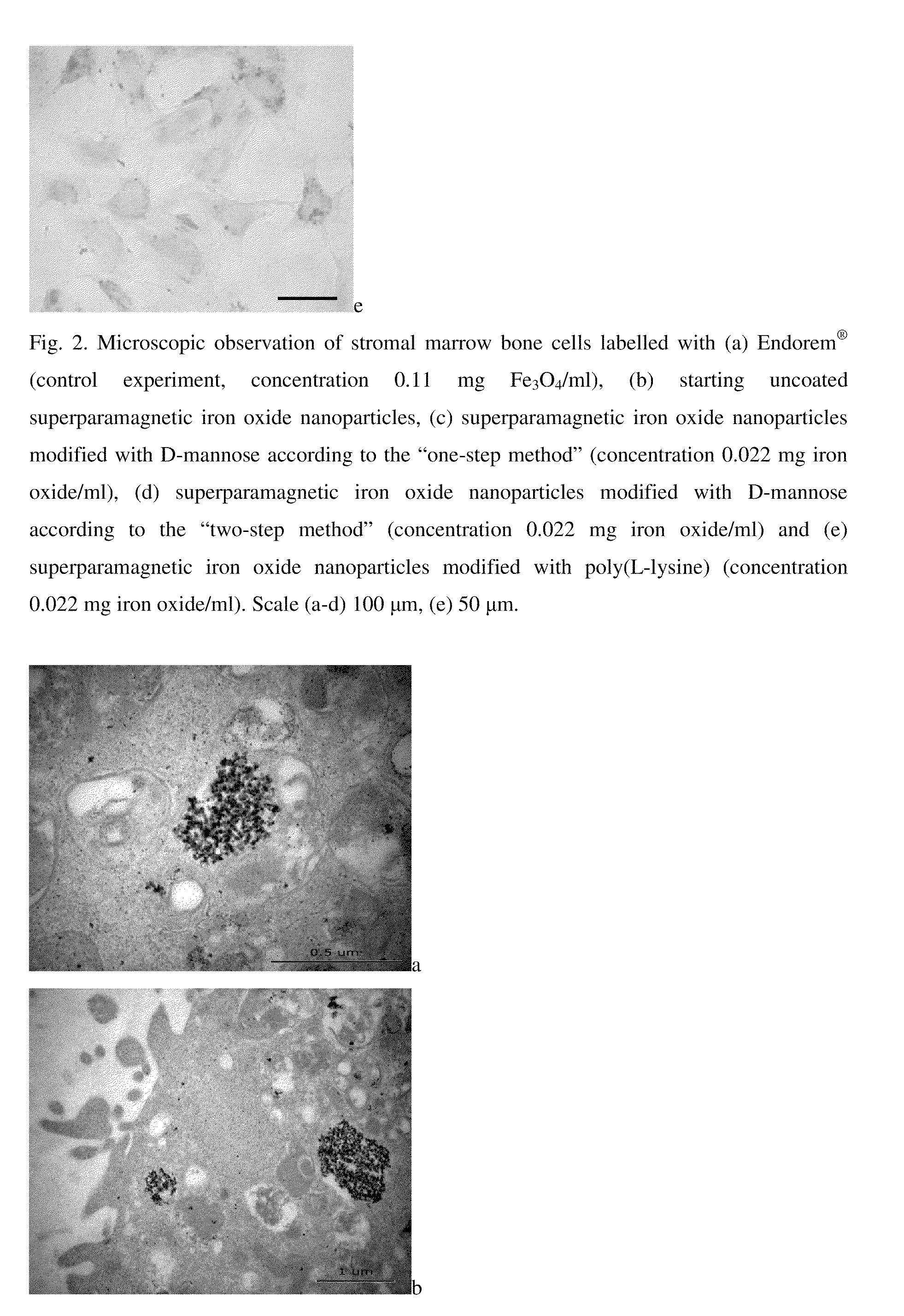

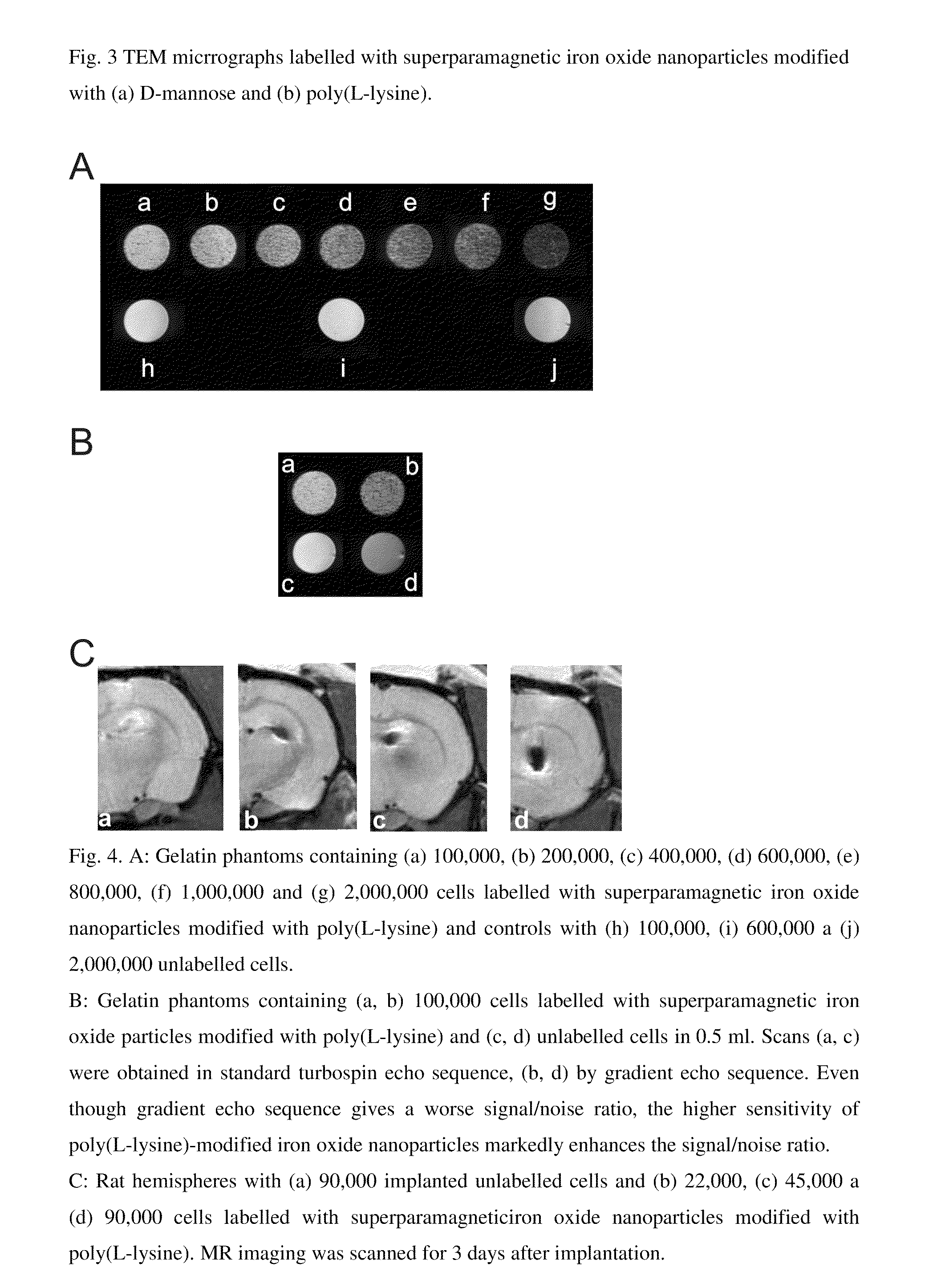

Superparamagnetic Nanoparticles Based on Iron Oxides with Modified Surface, Method of Their Preparation and Application

InactiveUS20090309597A1Less loadImprove abilitiesPigmenting treatmentMaterial nanotechnologyArginineDextran

The subject of the invention is superparamagnetic nanoparticle probes based on iron oxides, to advantage magnetite or maghemite, with modified surface, coated with mono-, di- or polysaccharides from the group including D-arabinose, D-glucose, D-galactose, D-mannose, lactose, maltose, dextrans and dextrins, or with amino acids or poly(amino acid)s from the group including alanine, glycine, glutamine, asparagine, histidine, arginine, L-lysine, aspartic and glutamic acid or with synthetic polymers based on (meth)acrylic acid and their derivatives selected from the group containing poly(N,N-dimethylacrylamide), poly(N,N-dimethylmethacrylamide), poly(N,N-diethylacrylamide), poly(N,N-diethylmethacrylamide), poly(N-isopropylacrylamide), poly(N-isopropylmethacrylamide), which form a colloid consisting of particles with narrow distribution with polydispersity index smaller than 1.3, the average size of which amounts to 0.5-30 nm, to advantage 1-10 nm, the iron content is 70-99.9 wt. %, to advantage 90 wt. %, the modification agent content 0.1-30 wt. %, to advantage 10 wt. %.The particles of size smaller than 2 nm with polydispersity index smaller than 1.1 can be obtained by a modified method of preparation.Superparamagnetic nanoparticle probes according to the invention are prepared by pre-precipitation of colloidal Fe(OH)3 by the treatment of aqueous 0.1-0.2M solution of Fe(III) salt, to advantage FeCl3, with less than an equimolar amount of NH4OH, at 21° C., under sonication, to which a solution of a Fe(II) salt, to advantage FeCl2, is added in the mole ratio Fe(III) / Fe(II)=2 under sonication and the mixture is poured into five- to tenfold, to advantage eightfold, molar excess of 0.5M NH4OH. The mixture is left aging for 0-30 min, to advantage 15 min, and then the precipitate is repeatedly, to advantage 7-10 times, magnetically separated and washed with deionized water. Then 1-3 fold amount, to advantage 1.5 fold amount, relative to the amount of magnetite, of 0.1 M aqueous solution of sodium citrate is added and then, dropwise, 1-3 fold amount, to advantage 1.5 fold amount, relative to the amount of magnetite, of 0.7 M aqueous solution of sodium hypochlorite. The precipitate is repeatedly, to advantage 7-10 times, washed with deionized water under the formation of colloidal maghemite to which, after dilution, is added dropwise, to advantage under 5-min sonication, an aqueous solution of a modification agent, in the weight ratio modification agent / iron oxide=0.1-10, to advantage 0.2 for amino acids and poly(amino acid)s and 5 for saccharides.The particles smaller than 2 nm with polydispersity index smaller than 1.1 are prepared by mixing at 21° C. 1 volume part of 10-60 wt. %, to advantage 50 wt. %, of an aqueous solution of a saccharide, disaccharide or polysaccharide, such as D-arabinose, D-glucose, D-galactose, D-mannose, lactose, maltose, dextran and dextrins, and 1 volume part of aqueous solution of a Fe(II) and Fe(III) salt, to advantage FeCl2 and FeCl3, where the molar ratio Fe(III) / Fe(II)=2. A 5-15%, to advantage 7.5%, solution of NH4OH is added until pH 12 is attained and the mixture is heated at 60° C. for 15 min. The mixture is then sonicated at 350 W for 5 min and then washed for 24 h by dialysis in water using a membrane with molecular weight cut-off 14,000 until pH 7 is reached. The volume of solution is reduced by evaporation so that the final dry matter content is 50-100 mg / ml, to advantage 80 mg per 1 ml.Superparamagnetic nanoparticle probes according to the invention can be used for labelling cells used in magnetic resonance imaging for monitoring their movement, localization, survival and differentiation especially in detection of pathologies with cell dysfunction and of tissue regeneration and also for labelling and monitoring cells administered for cell therapy purposes, in particular embryonal stem cells, fetal stem cells, stem cells of an adult human including bone marrow stem cells, olfactory glial cells, fat tissue cells, in the recipient organism by magnetic resonance.The preparation of labelled cells proceeds by adding to the complete culture medium 5-20 μl, to advantage 10 μl, of a colloid containing 0.05-45 mg iron oxide per ml, to advantage 1-5 mg iron oxide per ml of the medium, and culturing the cells for a period of 1-7 days, to advantage for 1-3 days, at 37° C. and 5% of CO2.

Owner:INST OF MACROMOLECULAR CHEM ASCR V V I +1

Anti-terrorism water quality monitoring system

InactiveUS7698073B2Rule out the possibilityGeneral water supply conservationUltrafiltrationChloramine BChlorine dioxide

An Anti-Terrorism water quality monitoring system for continuously monitoring a potable water treatment system and related potable water distribution network that provides potable water to a municipality, city, housing development or other potable water consumer. The system includes the collection of data from the water distribution system and from the water treatment facility and from advanced separation processes which are integrated into analytical instruments. The data collected are stored in a remote database on a remote server computer or bank of computers and accessible by Homeland Security or its designated agency. Preferred parameters of monitoring include the turbidity and disinfectant such as chlorine, hypochlorous acid, sodium hypochlorite, calcium hypochlorite, ozone, chlorine dioxide, chloramines, hydrogen peroxide, peracetic acid.

Owner:HACH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com