Preparation method for tantalum-contained interlayer metallic oxide electrode

An intermediate layer and oxide technology, applied in the field of electrochemistry, can solve the problems of high cost, complicated process, unsuitable for preparing large-sized electrodes, etc., and achieve the effects of prolonging service life, simple process and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

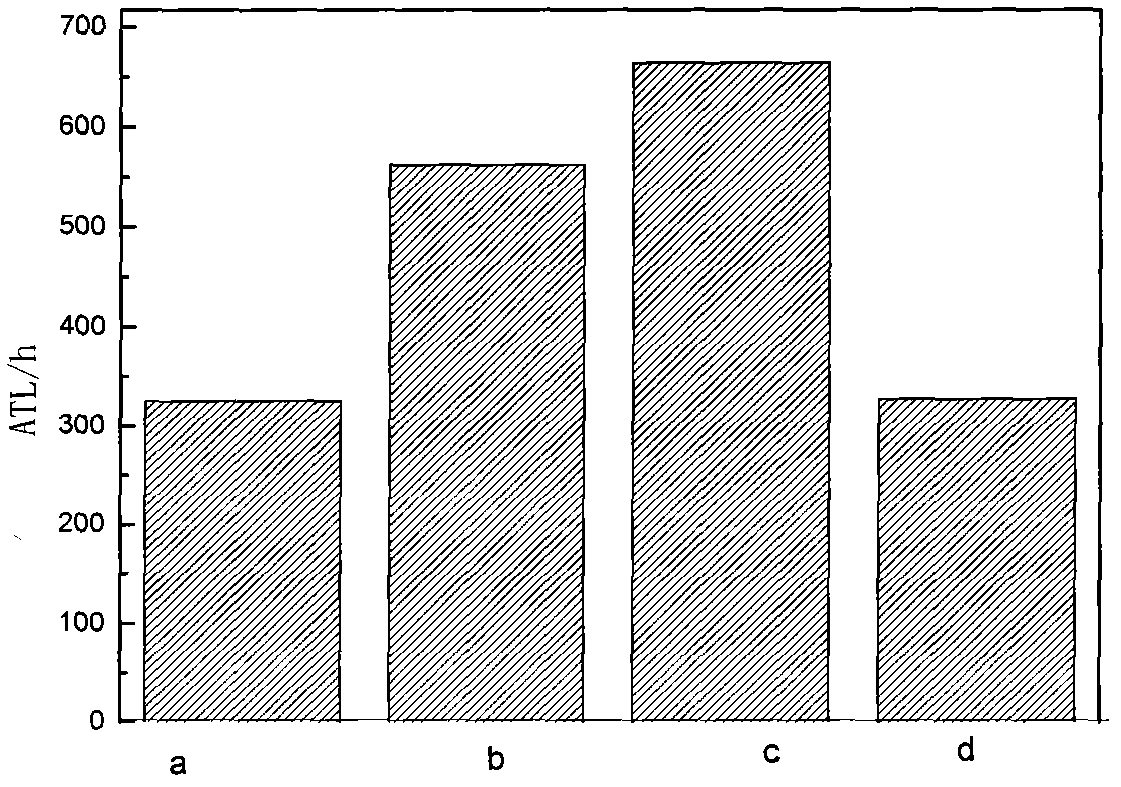

Image

Examples

Embodiment

[0009] This example includes three steps: substrate pretreatment, tantalum intermediate layer preparation, and oxide coating preparation. First, a tantalum-containing intermediate layer is prepared on a titanium substrate by a thermal decomposition method, and then a mixed metal oxide is prepared on a tantalum-containing intermediate layer. Electrocatalytic coating; the mass percentage purity of the metal titanium substrate is greater than 99%; the specific implementation process is:

[0010] Substrate pretreatment: use TA2 industrial pure titanium plate as the electrode substrate, put the titanium plate into the boiling degreasing solution for 1 hour, take it out and clean it with ultrasonic wave in deionized water for 10 minutes; Etching in 10% oxalic acid solution for 2 hours to obtain a uniform rough surface and put it in absolute ethanol for later use;

[0011] Preparation of the tantalum intermediate layer: thermally decompose the tantalum-containing layer in a vacuum at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com