Patents

Literature

473 results about "Thin film sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Immersible thermal mass flow meter

ActiveUS6971274B2Quality improvementImprove measurement qualityVolume/mass flow by thermal effectsThin film sensorEngineering

Owner:SIERRA INSTR

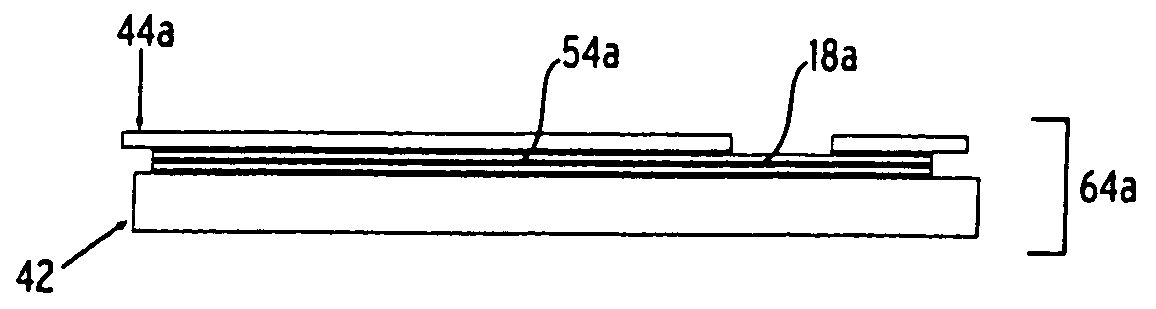

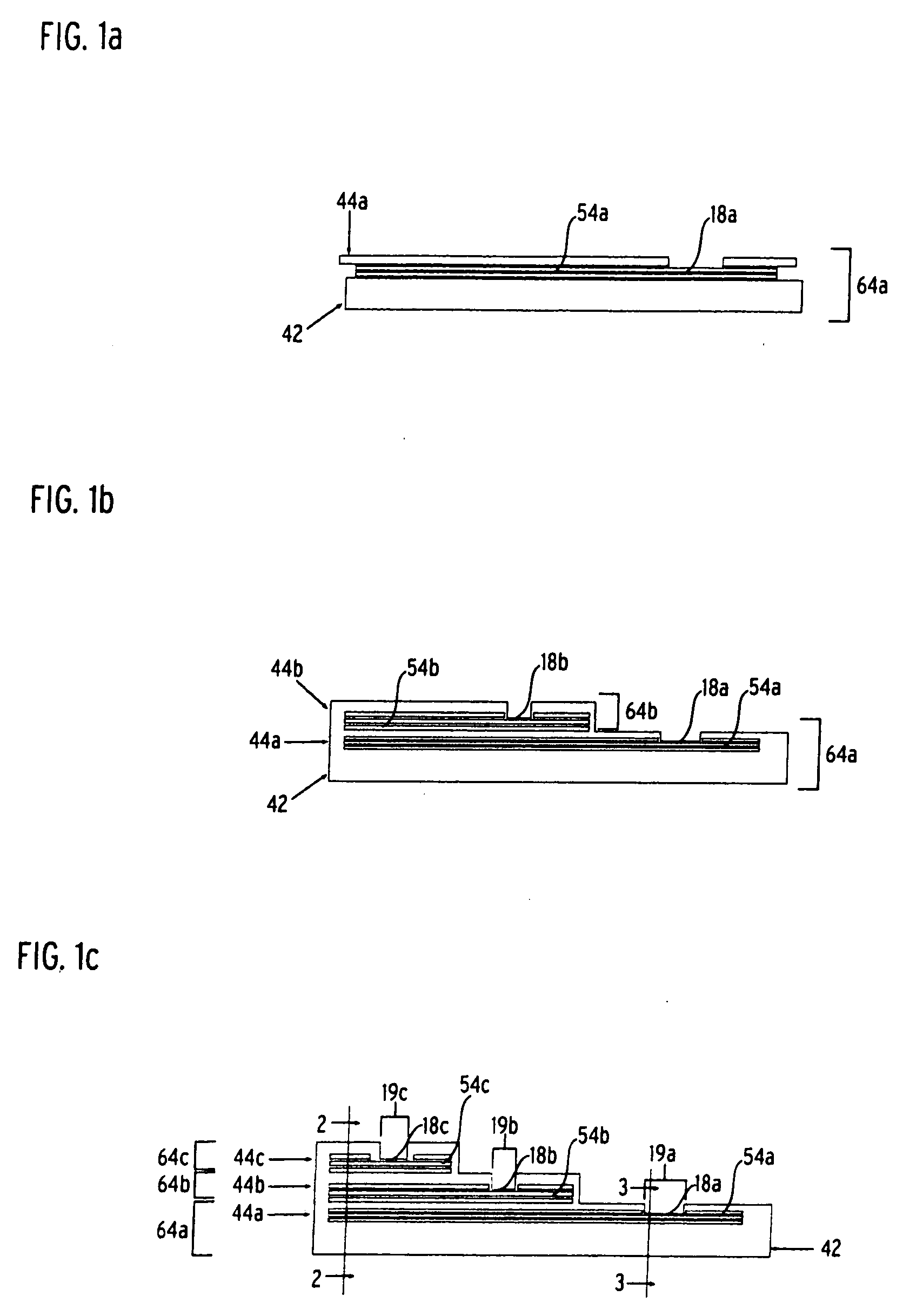

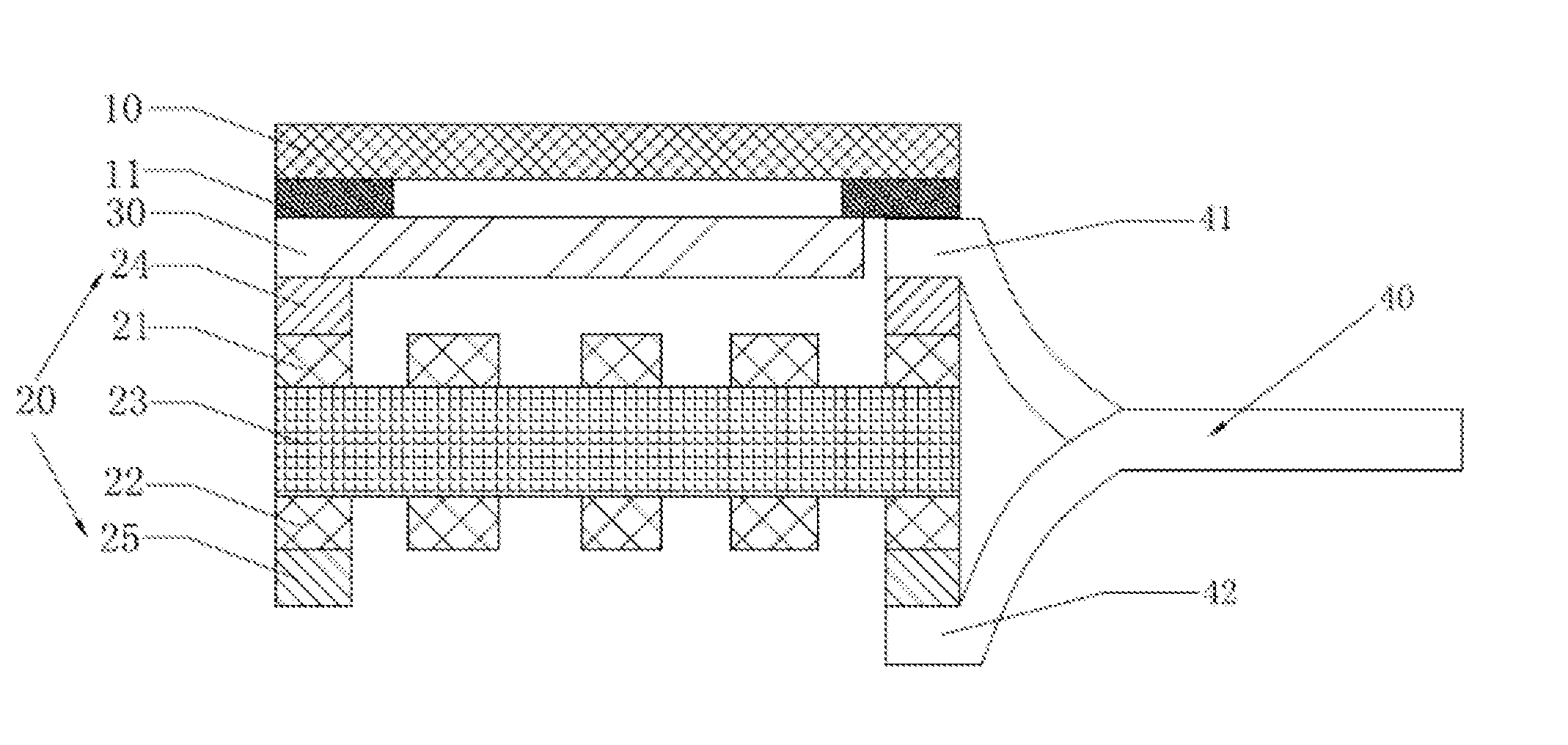

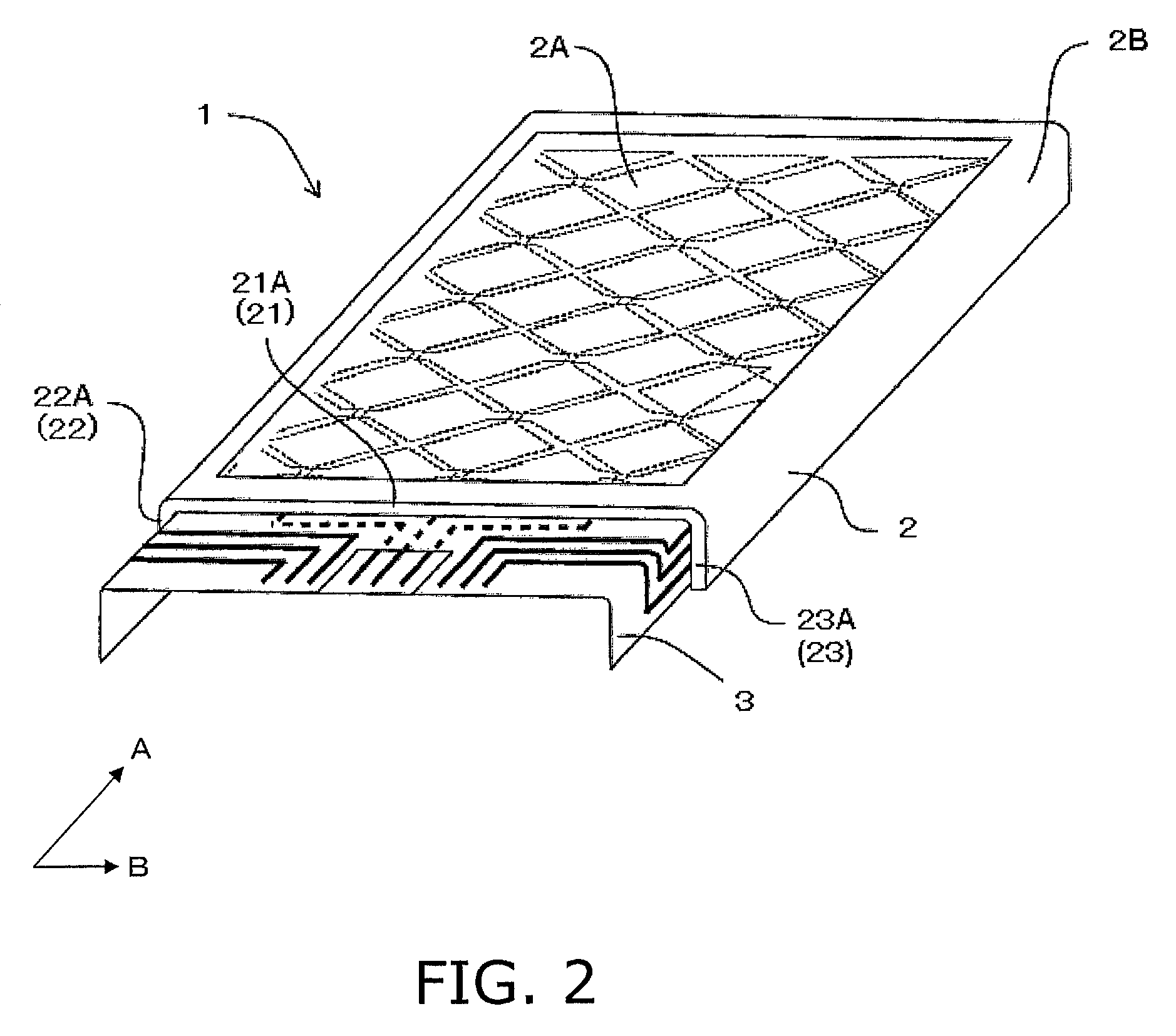

Sensor with layered electrodes

ActiveUS20070173711A1Easy and quick to placeImmobilised enzymesBioreactor/fermenter combinationsThin film sensorGlucose sensors

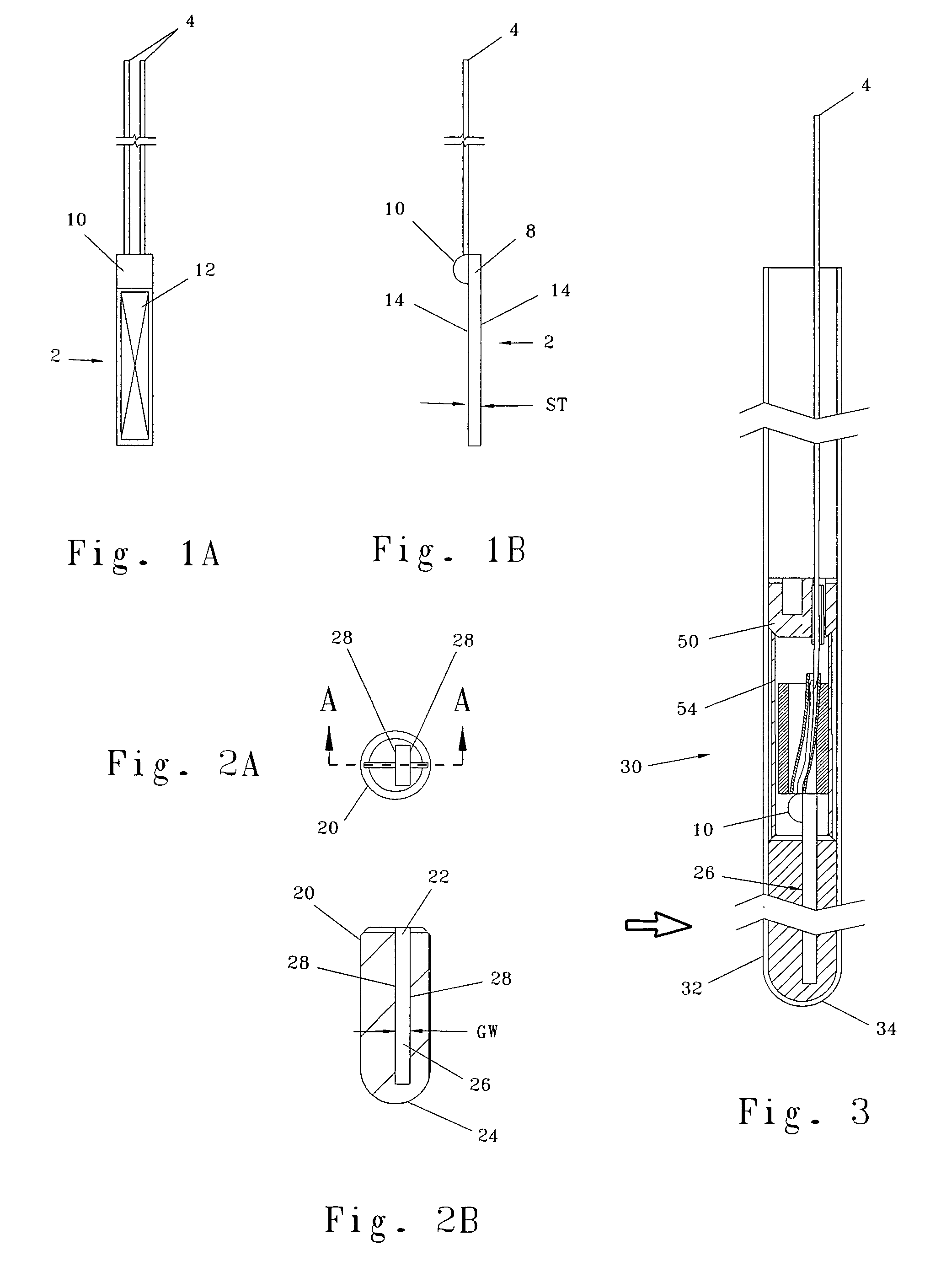

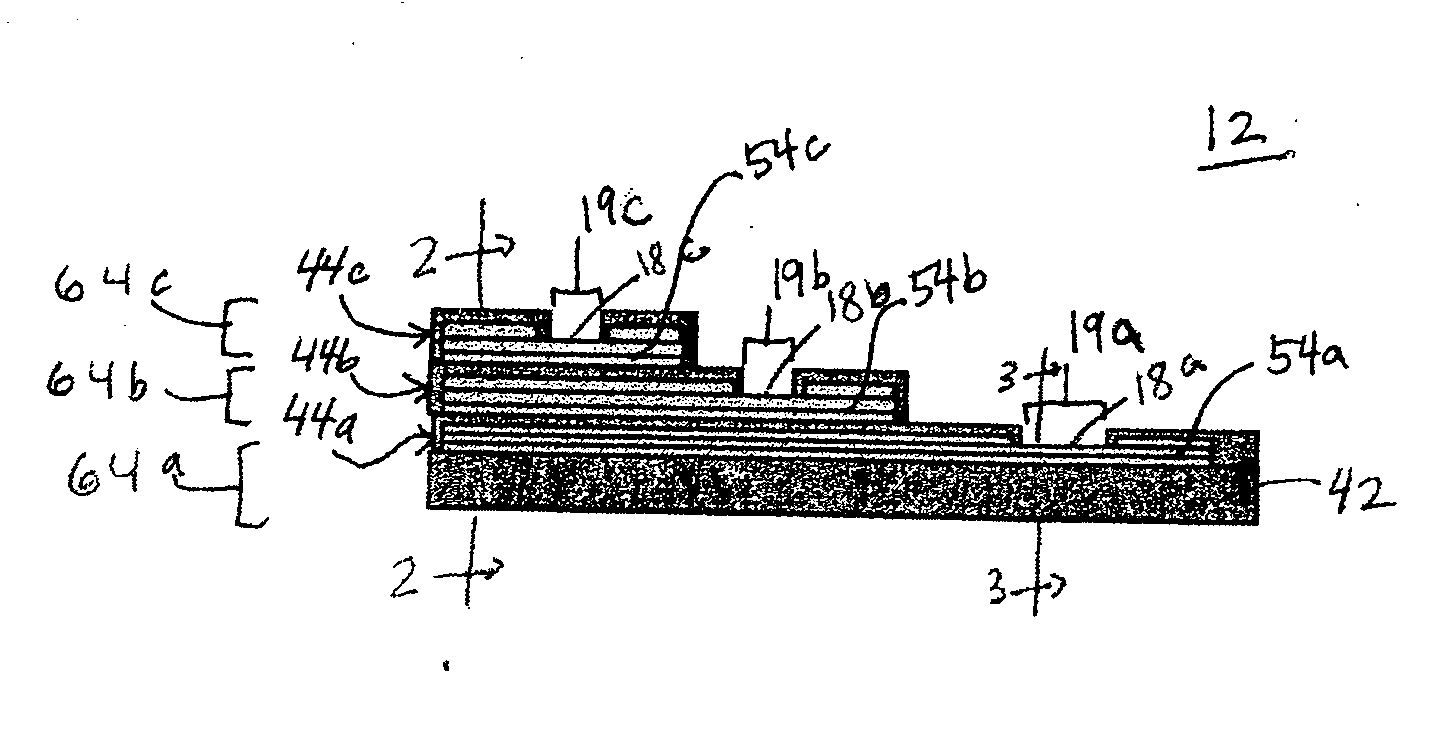

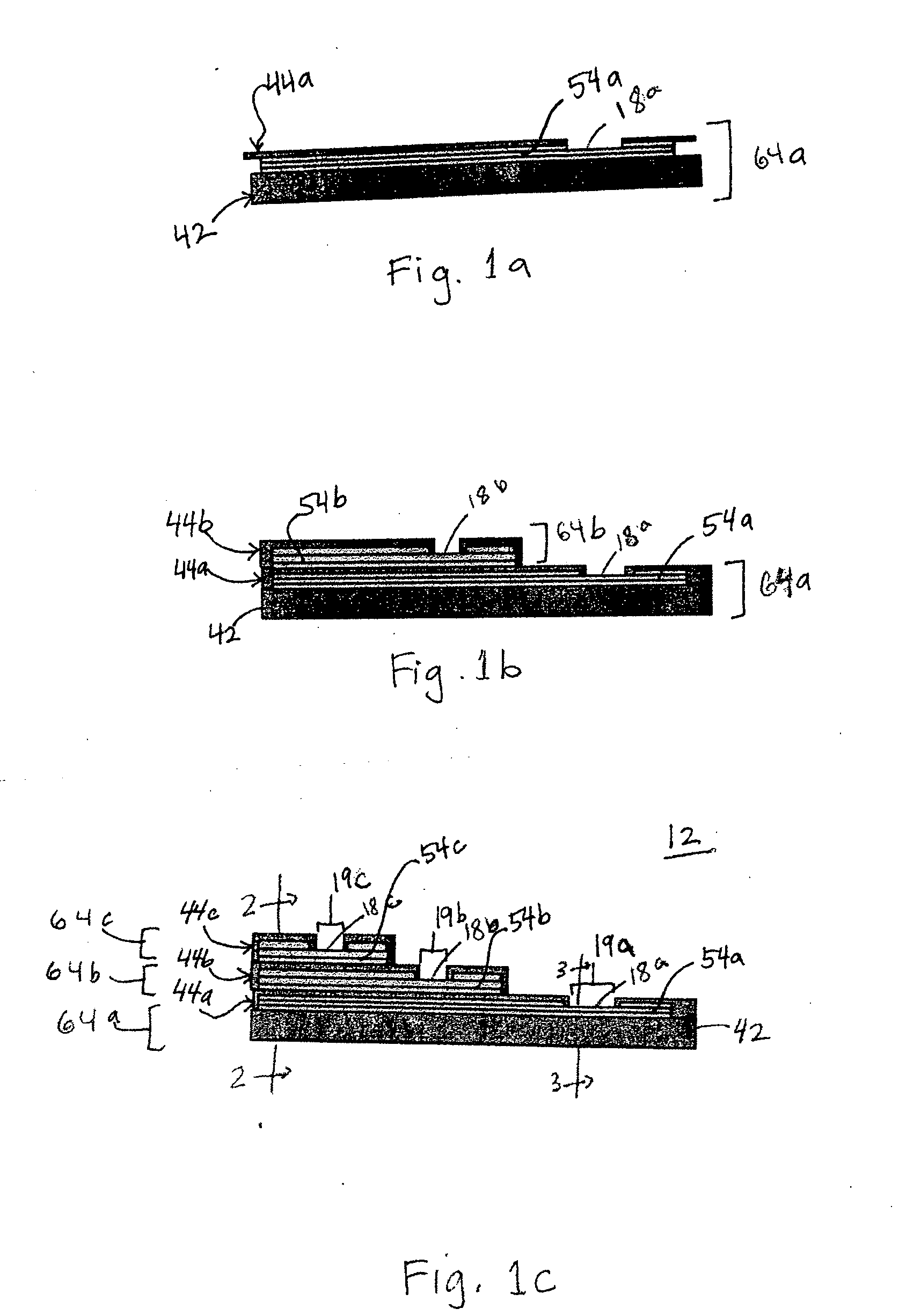

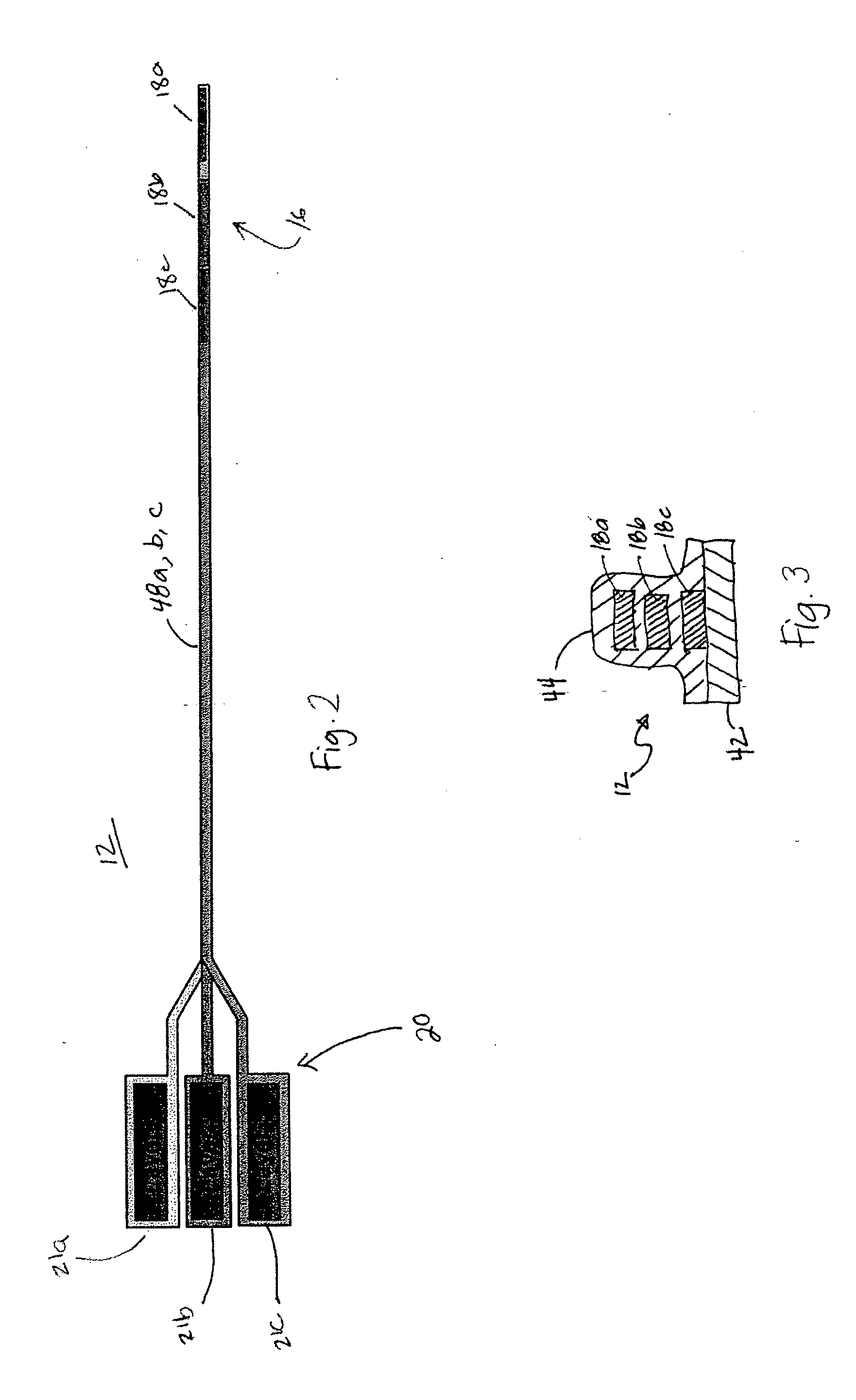

A thin film sensor, such as a glucose sensor, is provided for transcutaneous placement at a selected site within the body of a patient. The sensor includes several sensor layers that include conductive layers and includes a proximal segment defining conductive contacts adapted for electrical connection to a suitable monitor, and a distal segment with sensor electrodes for transcutaneous placement. The sensor electrode layers are disposed generally above each other, for example with the reference electrode above the working electrode and the working electrode above the counter electrode. The electrode layers are separated by dielectric layer.

Owner:MEDTRONIC MIMIMED INC

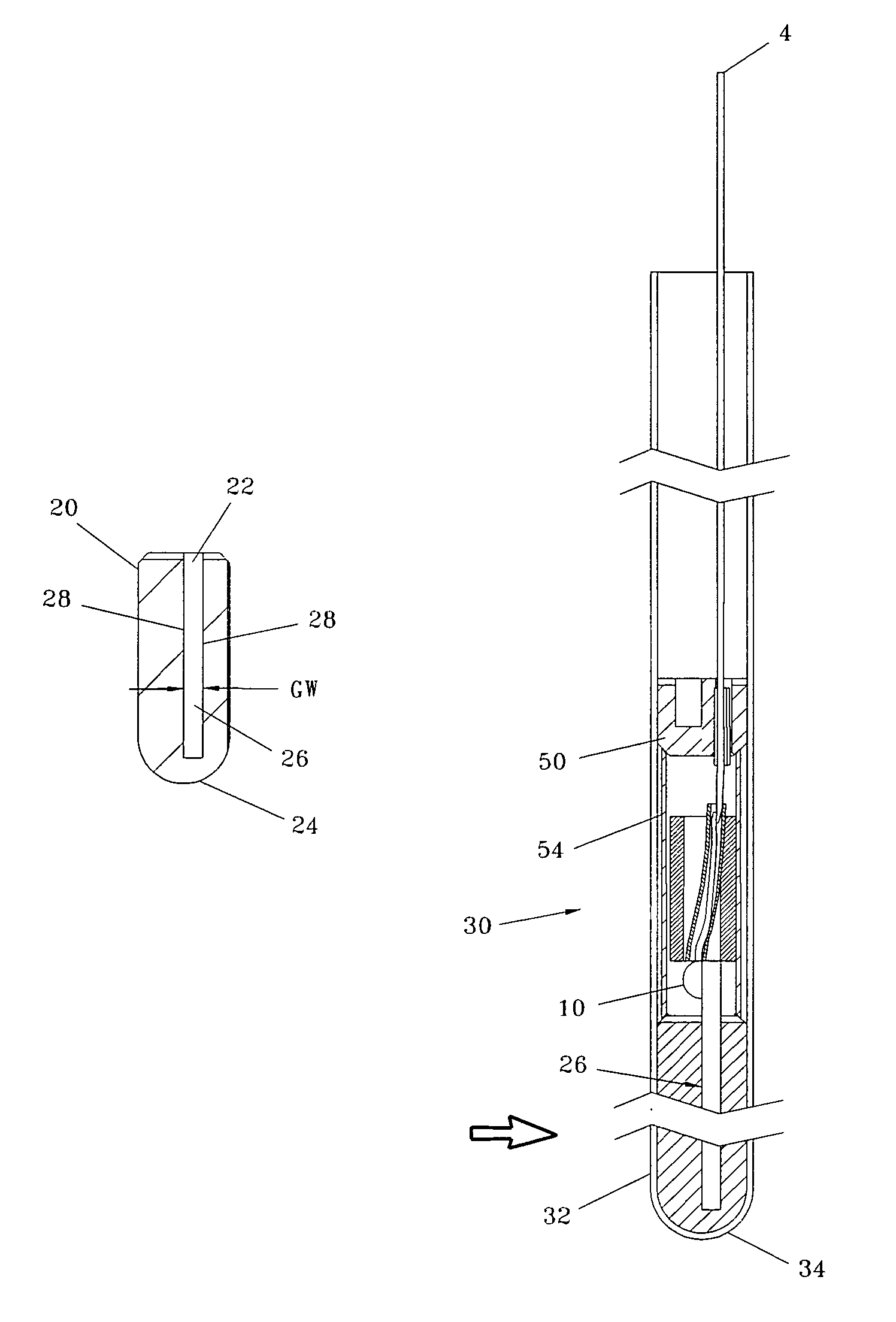

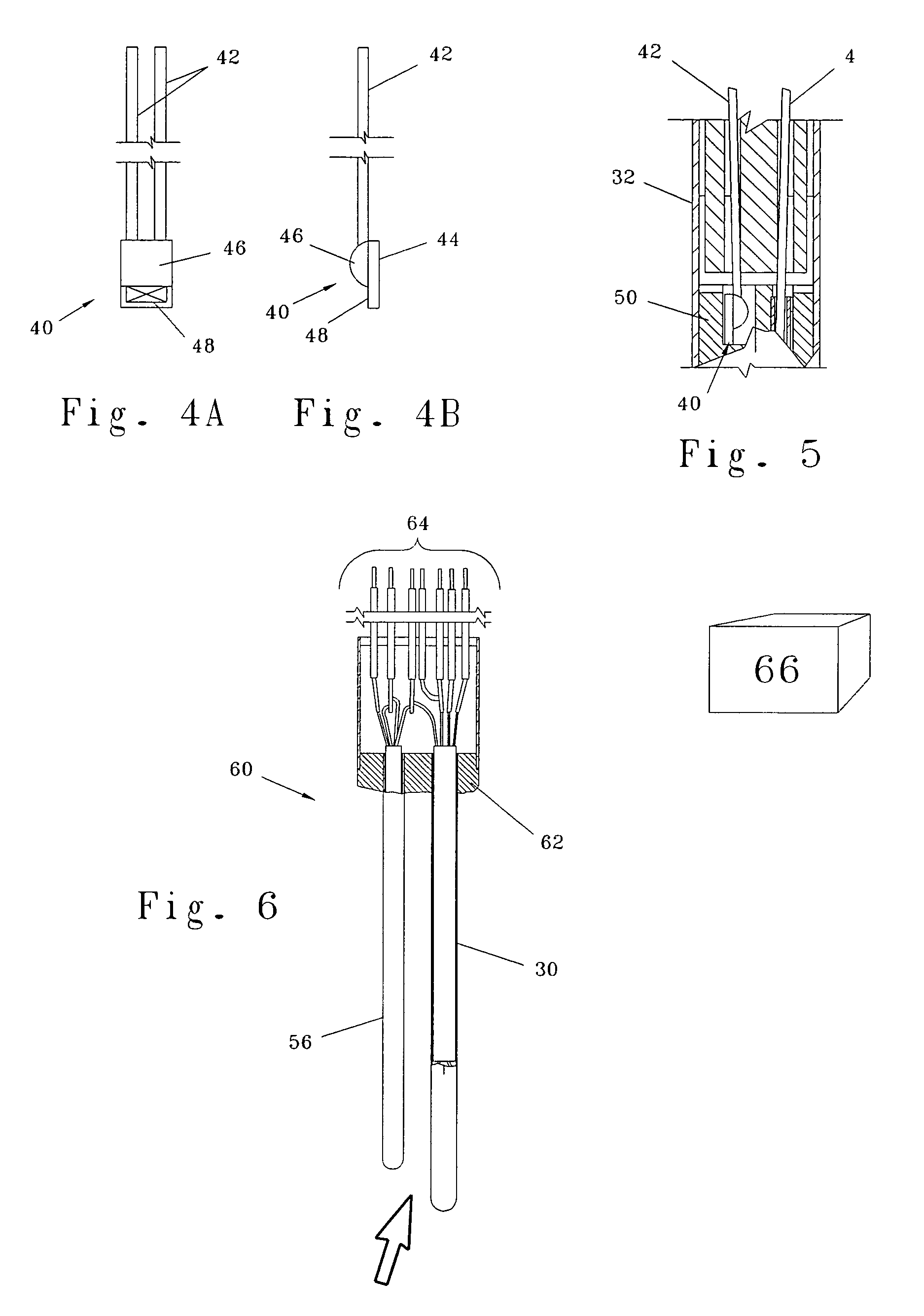

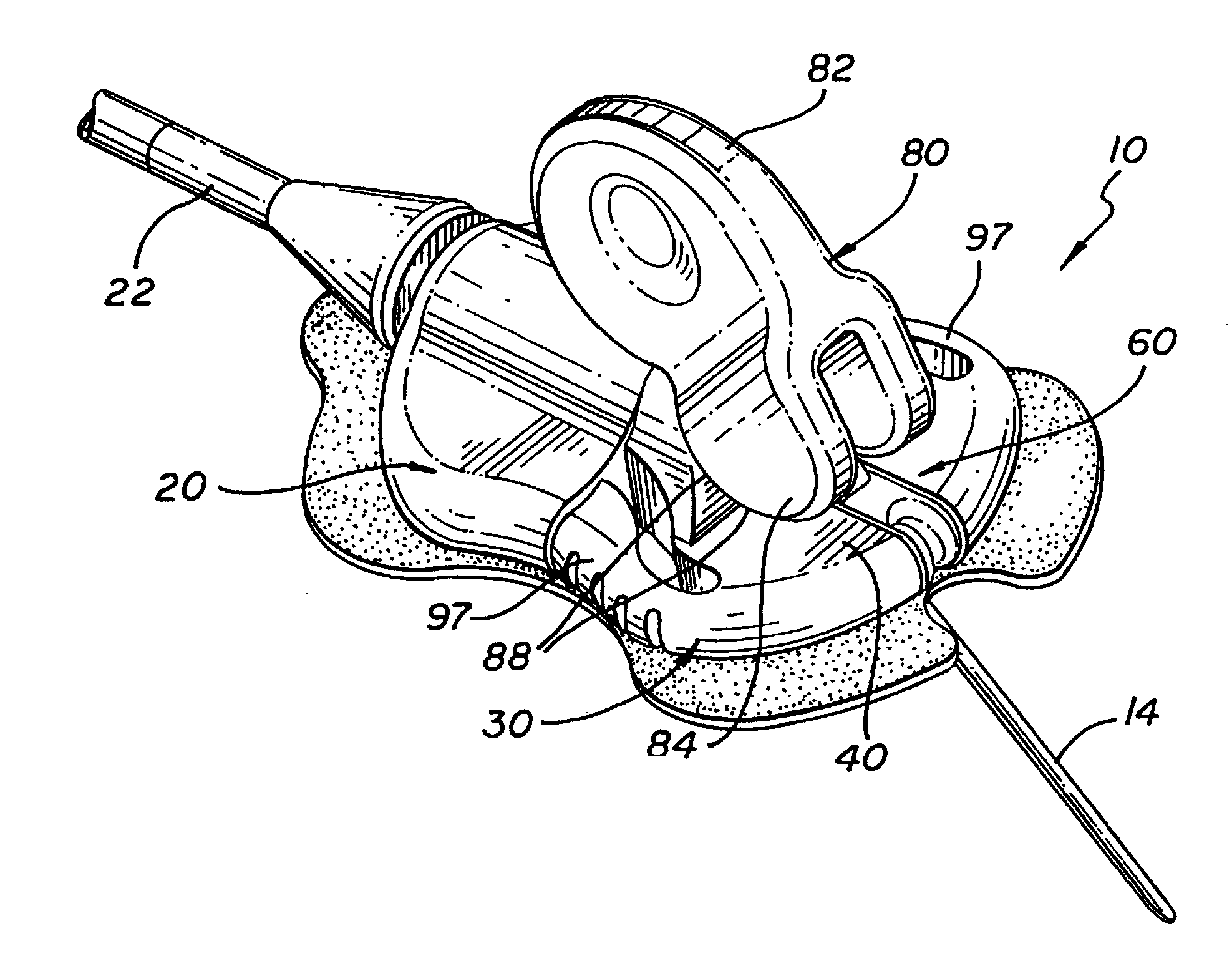

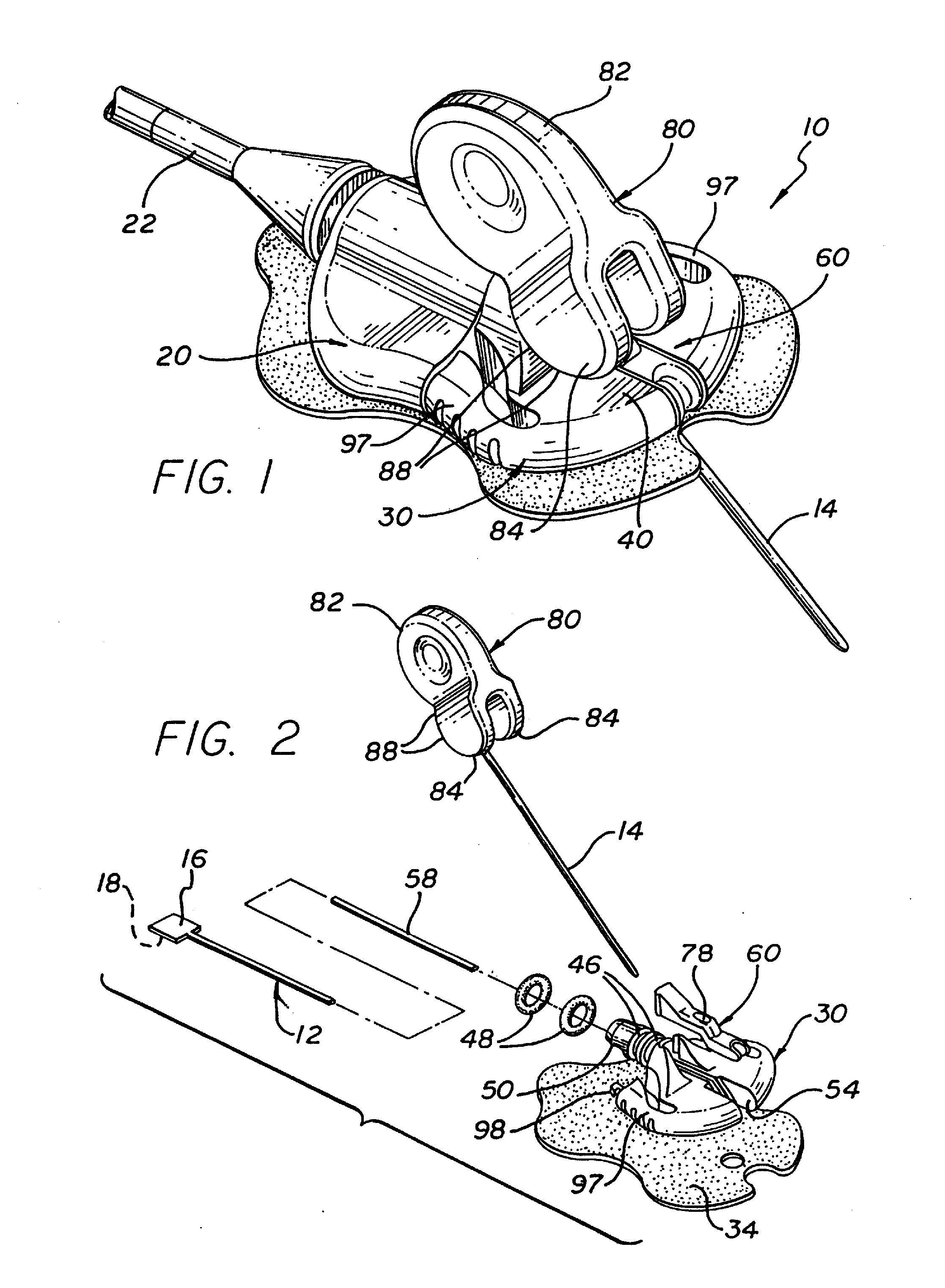

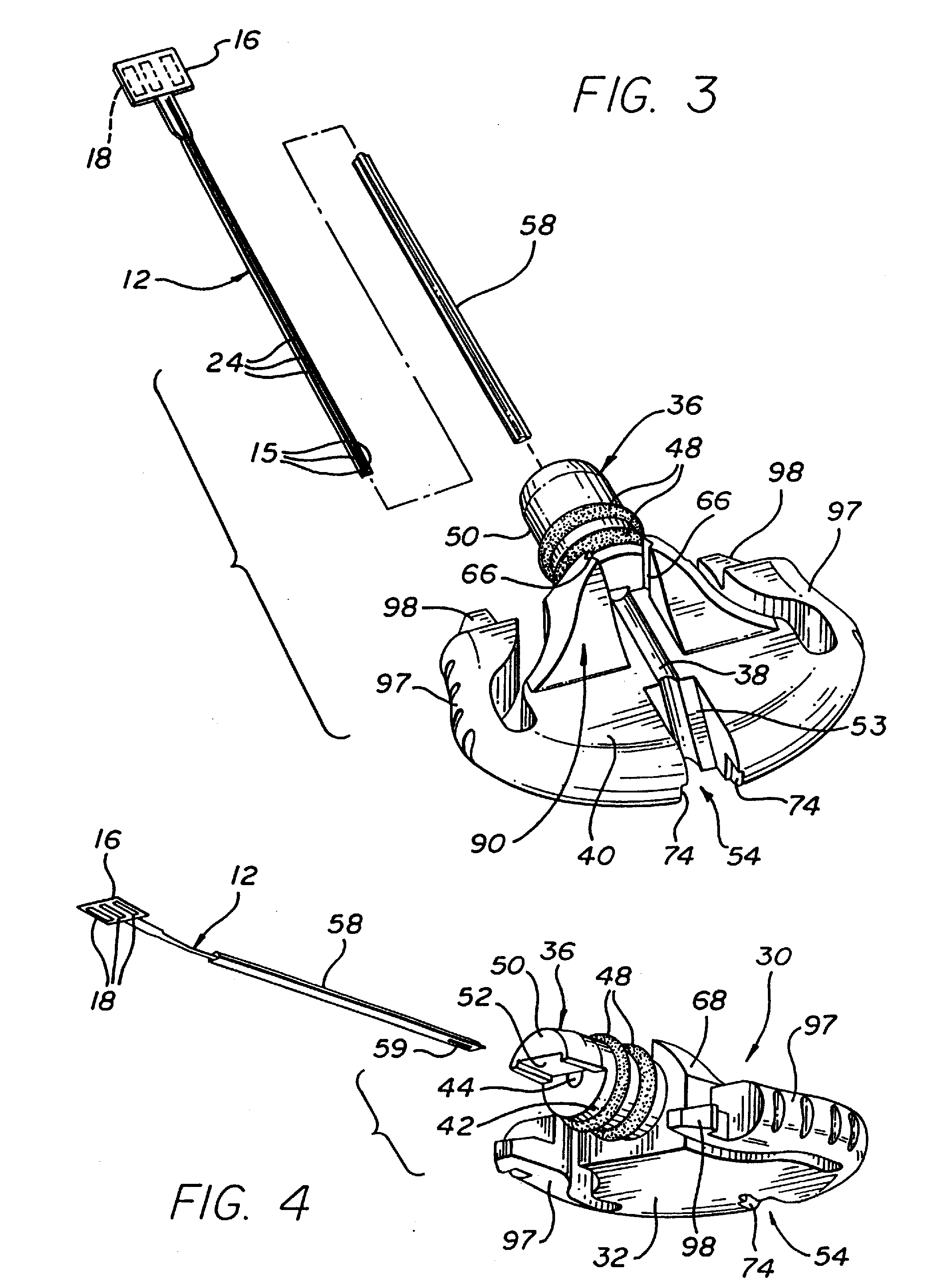

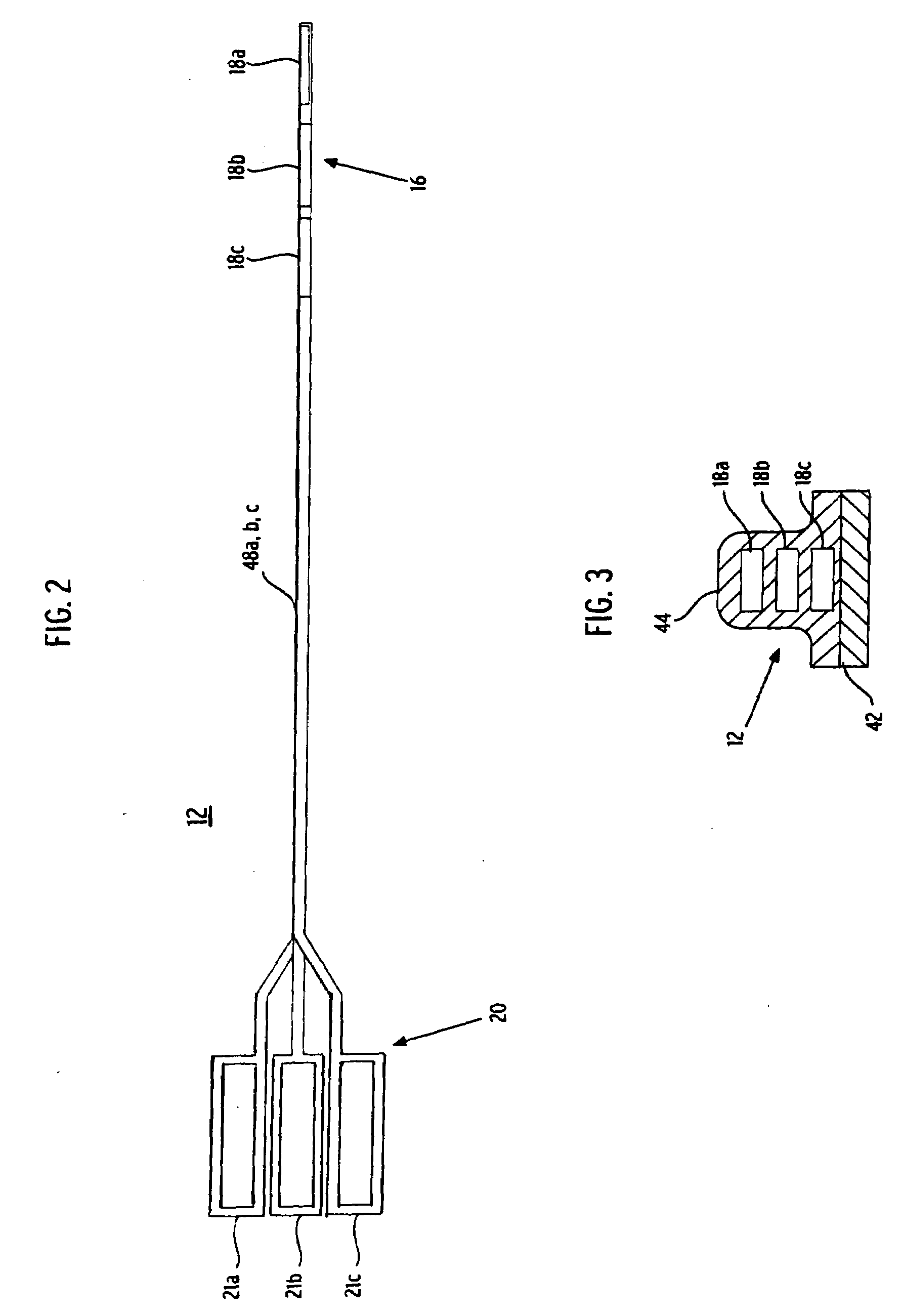

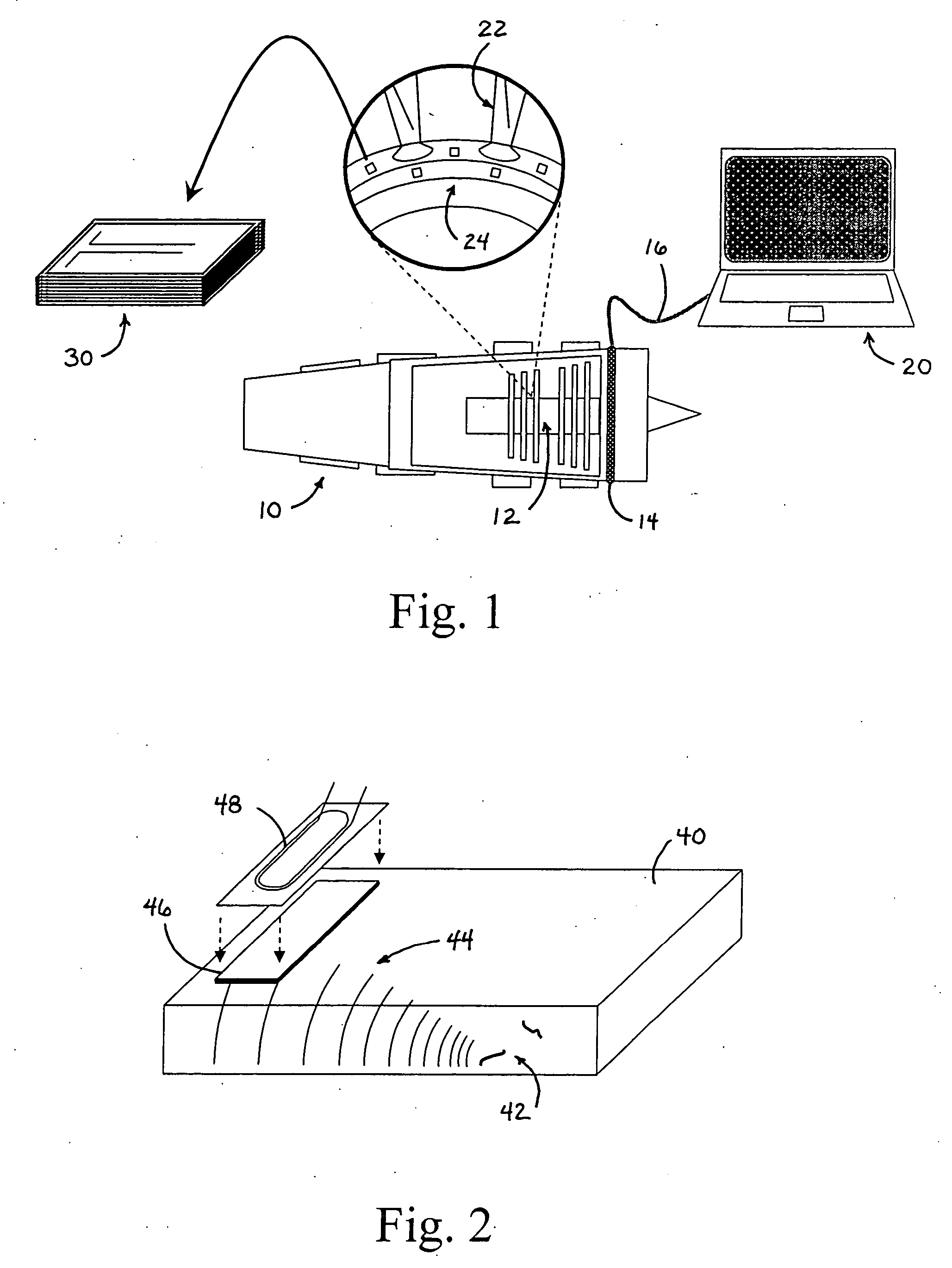

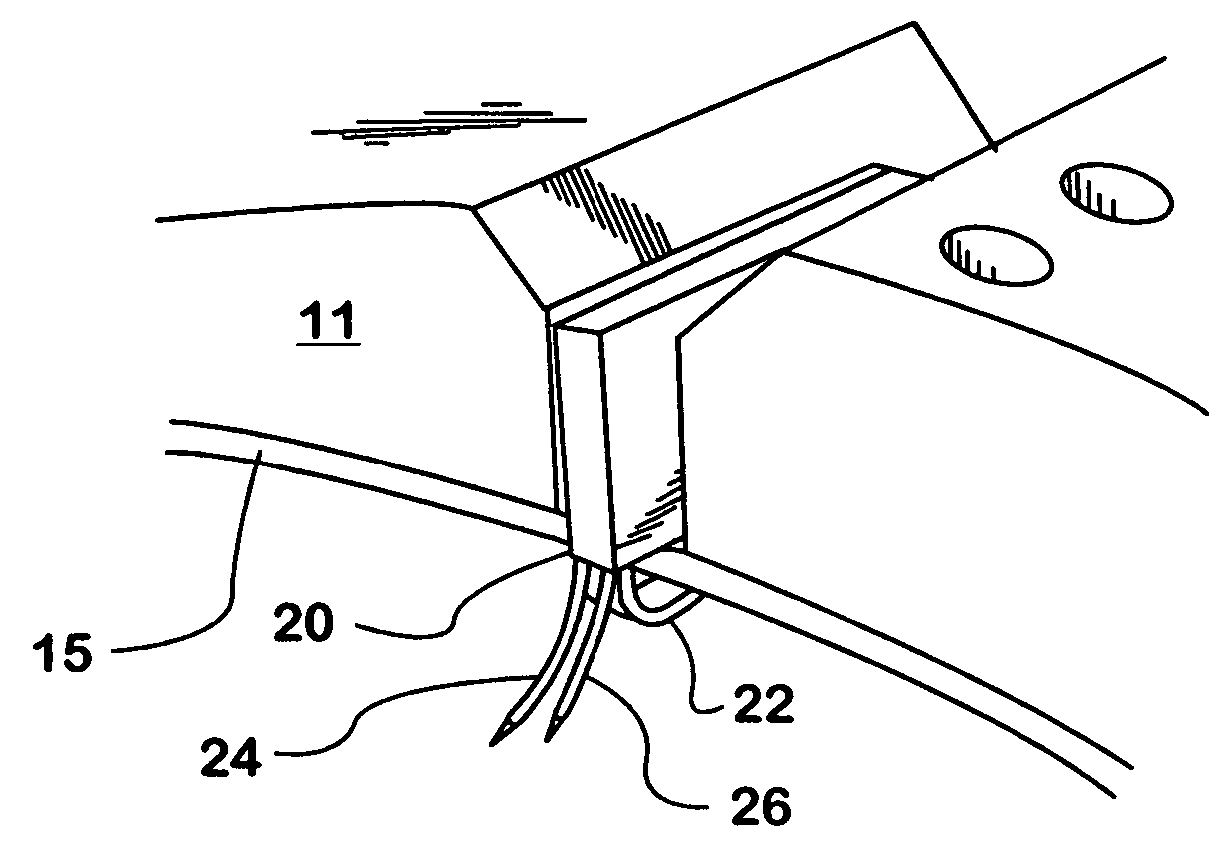

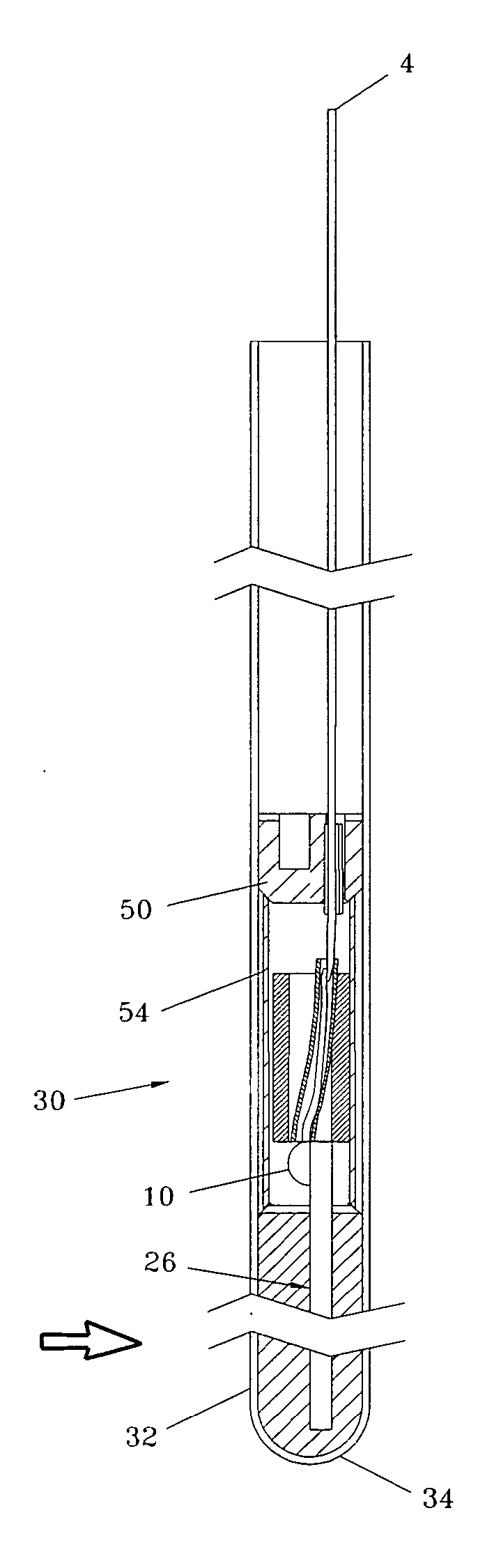

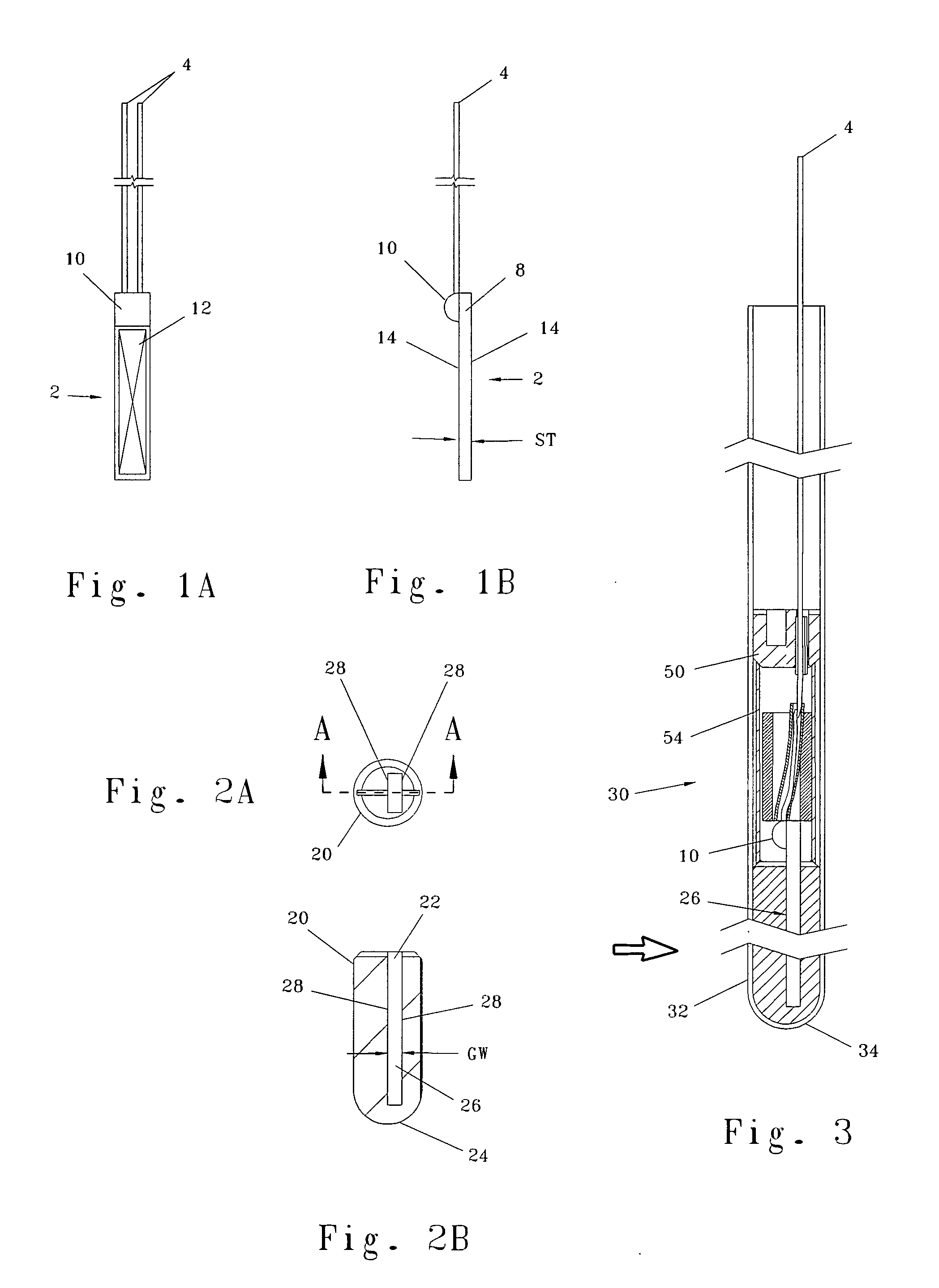

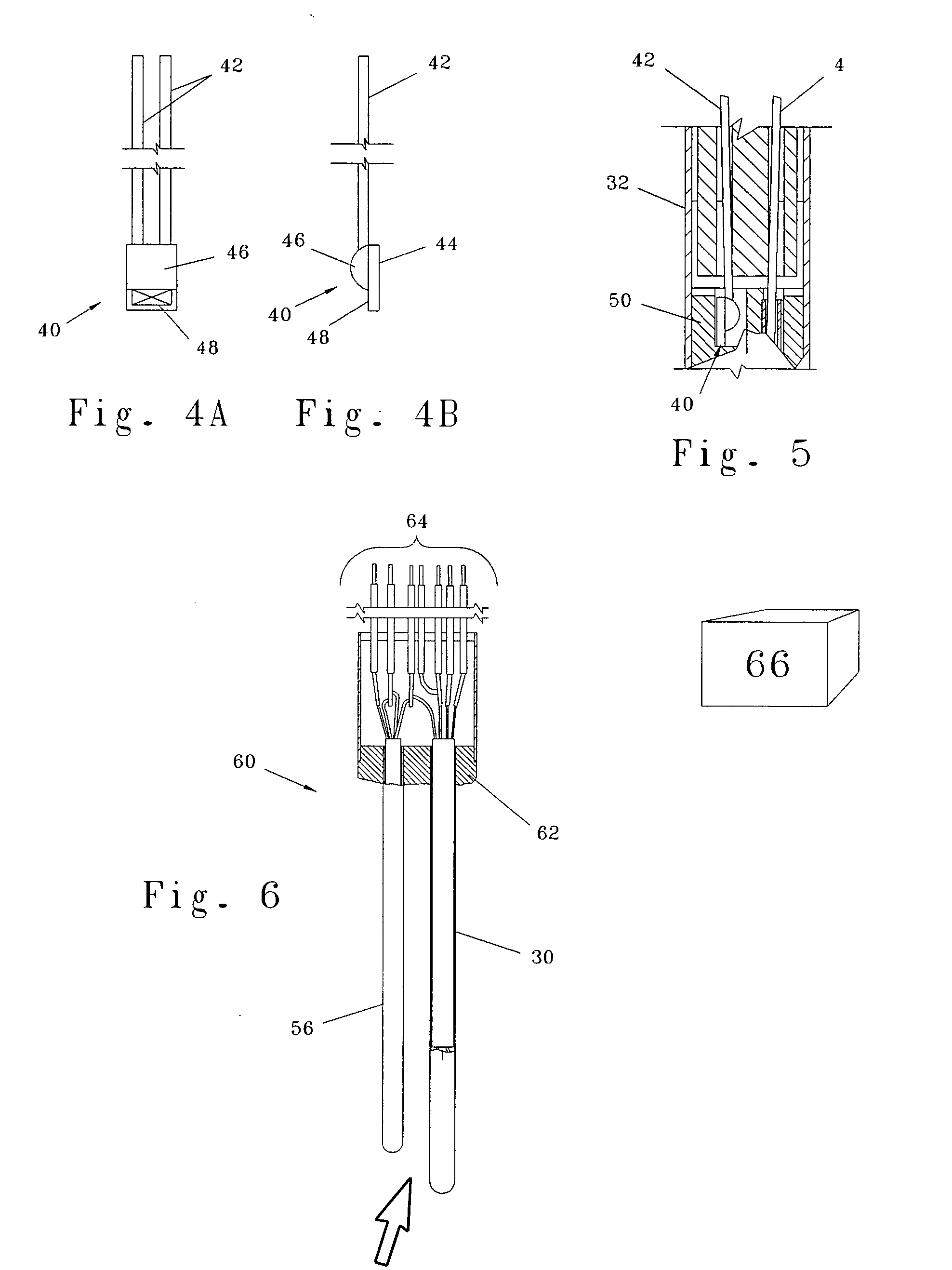

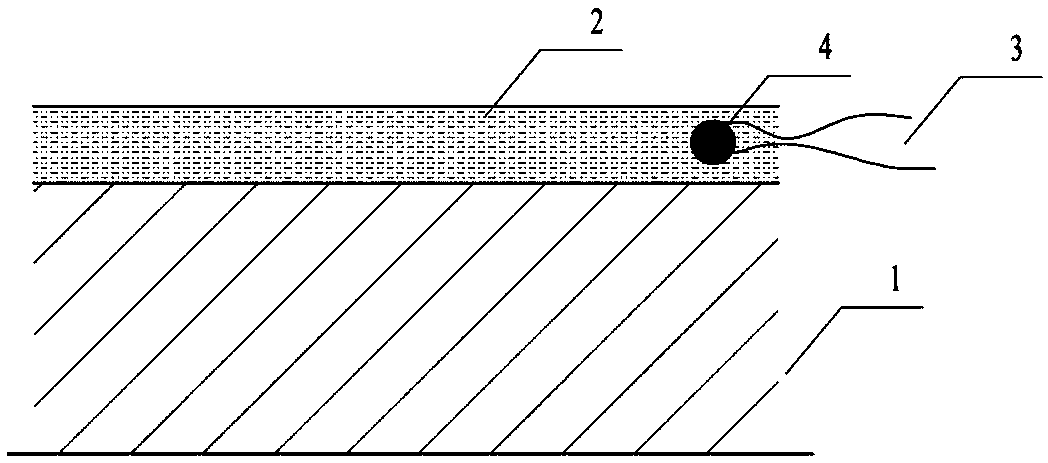

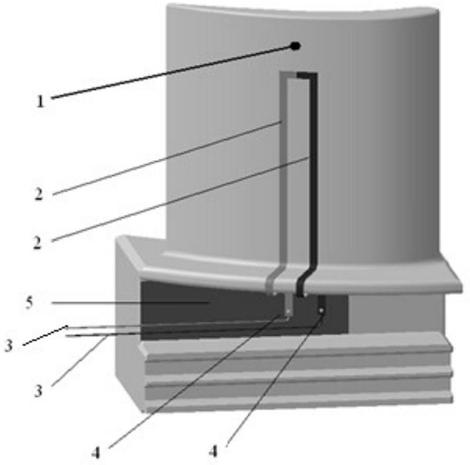

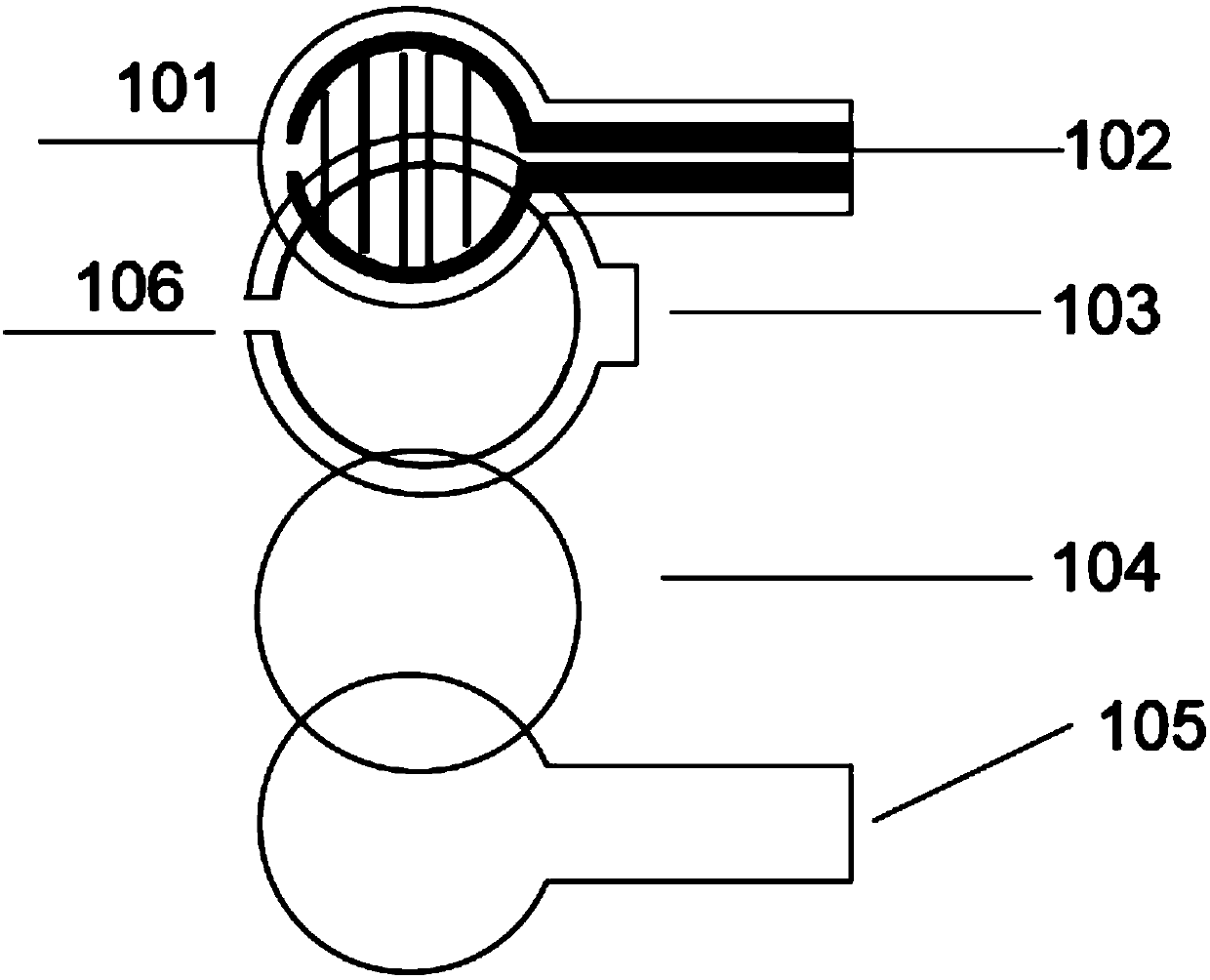

Insertion Set for a Transcutaneous Sensor

An improved insertion set is provided for transcutaneous placement of a sensor such as a glucose sensor at a selected site within the body of a patient. The insertion set comprises a mounting base defining an upwardly open channel for receiving and supporting a flexible thin film sensor, in combination with a cap assembled with said mounting base to capture and retain a proximal end of the sensor within said channel. The sensor further includes a distal segment with sensor electrodes thereon which protrudes from the mounting base for transcutaneous placement, wherein the sensor distal segment is slidably carried by a slotted insertion needle fitted through the assembled base and cap. Placement of the insertion set against the patient's skin causes the insertion needle to pierce the skin to carry the sensor electrodes to the desired subcutaneous site, after which the insertion needle can be slidably withdrawn from the insertion set. The mounting base further includes a fitting and related snap latch members for mated slide-fit releasable coupling of conductive contact pads on a proximal end of the sensor to a cable connector for transmitting sensor signals to a suitable monitoring device.

Owner:MEDTRONIC MIMIMED INC

Sensor with layered electrodes

ActiveUS20080313896A1Easy and quick to placeAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationThin film sensorGlucose sensors

A thin film sensor, such as a glucose sensor, is provided for transcutaneous placement at a selected site within the body of a patient. The sensor includes several sensor layers that include conductive layers and includes a proximal segment defining conductive contacts adapted for electrical connection to a suitable monitor, and a distal segment with sensor electrodes for transcutaneous placement. The sensor electrode layers are disposed generally above each other, for example with the reference electrode above the working electrode and the working electrode above the counter electrode. The electrode layers are separated by dielectric layer.

Owner:MEDTRONIC MIMIMED INC

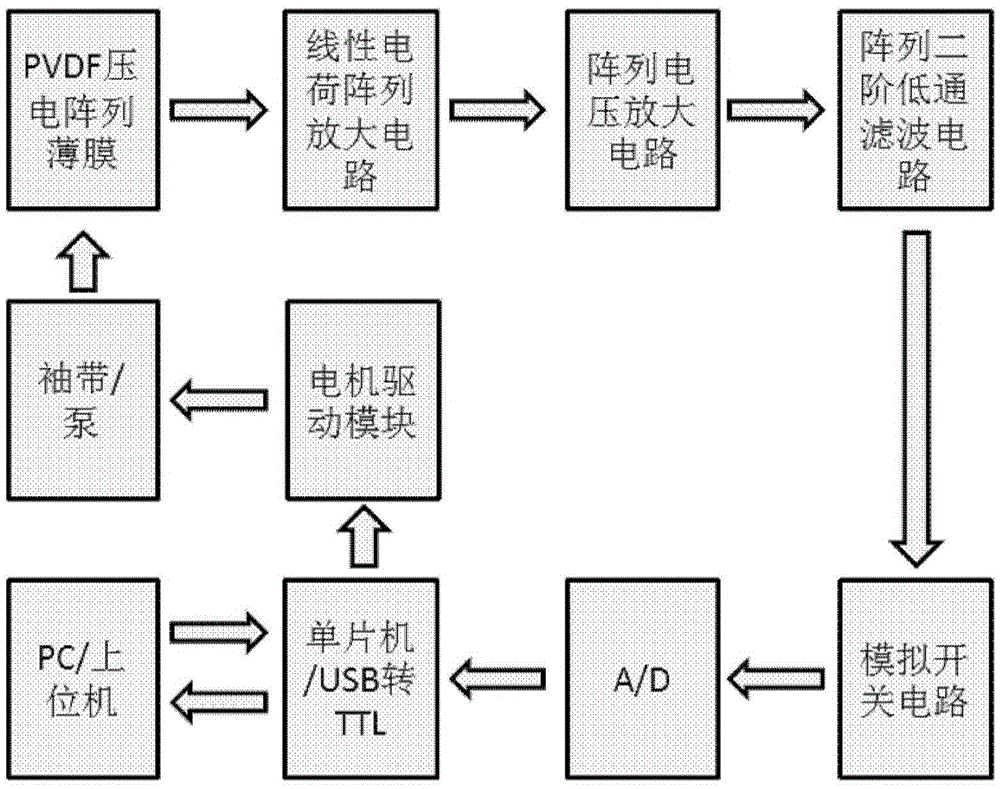

Pulse wave array sensor acquisition system and method

InactiveCN105640513AMeet the frequency characteristicsHigh piezoelectric constantCatheterDiagnostic recording/measuringResponse sensitivityWrist

The invention provides a pulse wave array sensor acquisition system and method. The acquisition system comprises multiple piezoelectric film sensors. The piezoelectric film sensors are PVDF film sensors arranged in an array mode and are used for converting pulse pressure signals into voltage signals. Array PVDF piezoelectric films are adopted in the acquisition system, the piezoelectric constant is large, variable force response sensitivity is high, the films are light and flexible, preparation is easy, impedance coupling with human tissue is good, mechanical quality factors are low, resistance is low, density is low, and the frequency characteristics of the pulse signals can be met. In addition, the acquisition system can guarantee that information of three positions of cun, guan and chi is completely acquired, more accurate positioning can be achieved, and artificial errors are eliminated. Gradual pressurized measurement can be conducted on wrist positions, and the problems that existing pulse sensors hardly conduct positioning and calibrate floating, centering and sinking are effectively solved. Circuits are simplified, and miniaturization of the circuits can be achieved.

Owner:北京中科芯健医疗科技有限公司

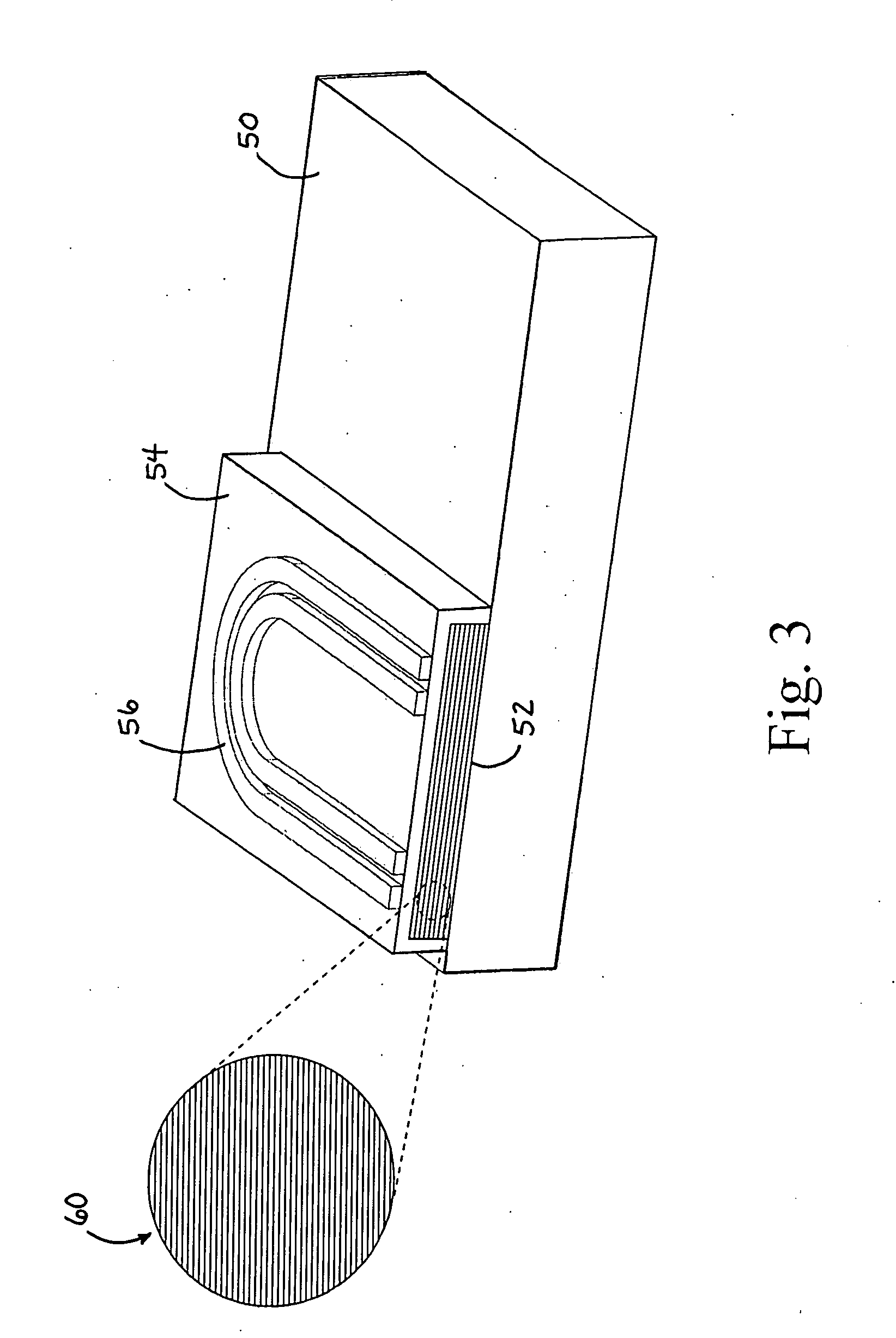

Systems & methods for flaw detection and monitoring at elevated temperatures with wireless communication using surface embedded, monolithically integrated, thin-film, magnetically actuated sensors, and methods for fabricating the sensors

ActiveUS20070108973A1Effective structural health managementEffective prognosisNanomagnetismVacuum evaporation coatingThin film sensorElectricity

Systems and methods for flaw detection and monitoring at elevated temperatures with wireless communication using surface embedded, monolithically integrated, thin-film, magnetically actuated sensors, and methods for fabricating the sensors. The sensor is a monolithically integrated, multi-layered (nano-composite), thin-film sensor structure that incorporates a thin-film, multi-layer magnetostrictive element, a thin-film electrically insulating or dielectric layer, and a thin-film activating layer such as a planar coil. The method for manufacturing the multi-layered, thin-film sensor structure as described above, utilizes a variety of factors that allow for optimization of sensor characteristics for application to specific structures and in specific environments. The system and method integrating the multi-layered, thin-film sensor structure as described above, further utilizes wireless connectivity to the sensor to allow the sensor to be mounted on moving components within the monitored assembly.

Owner:SOUTHWEST RES INST

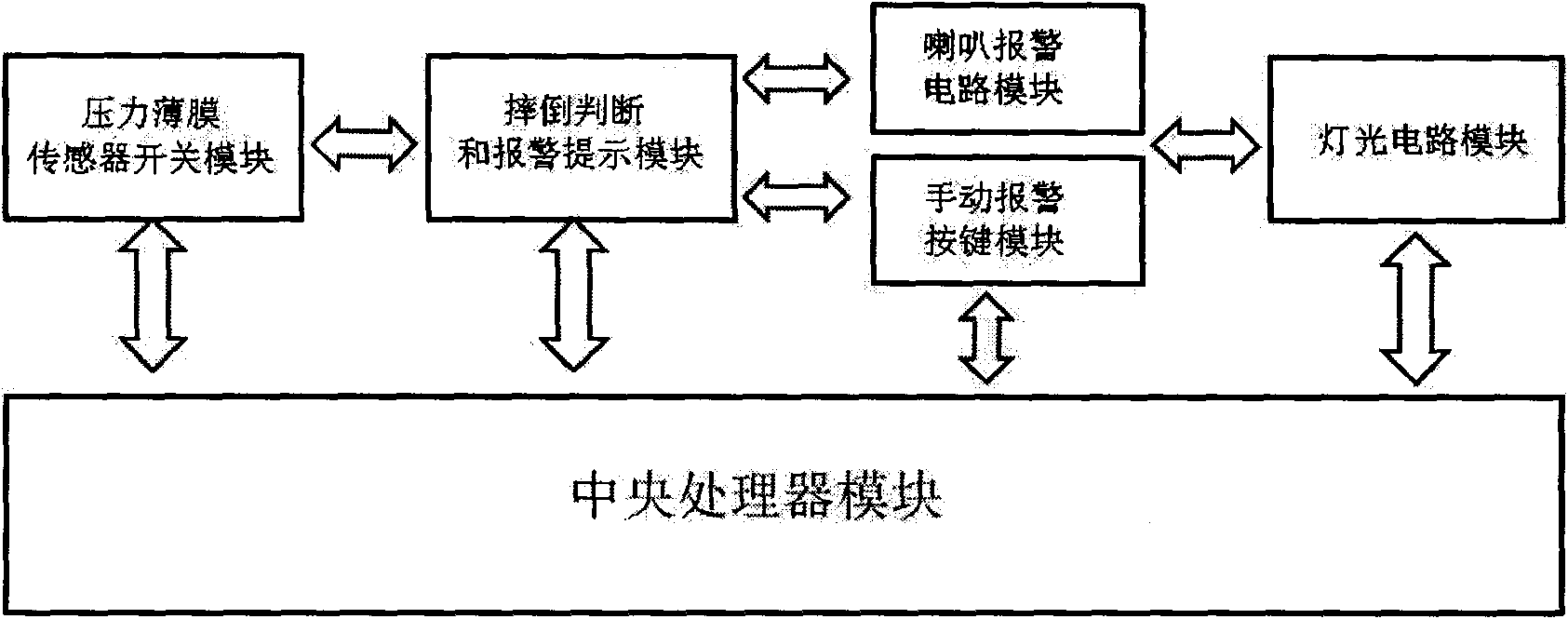

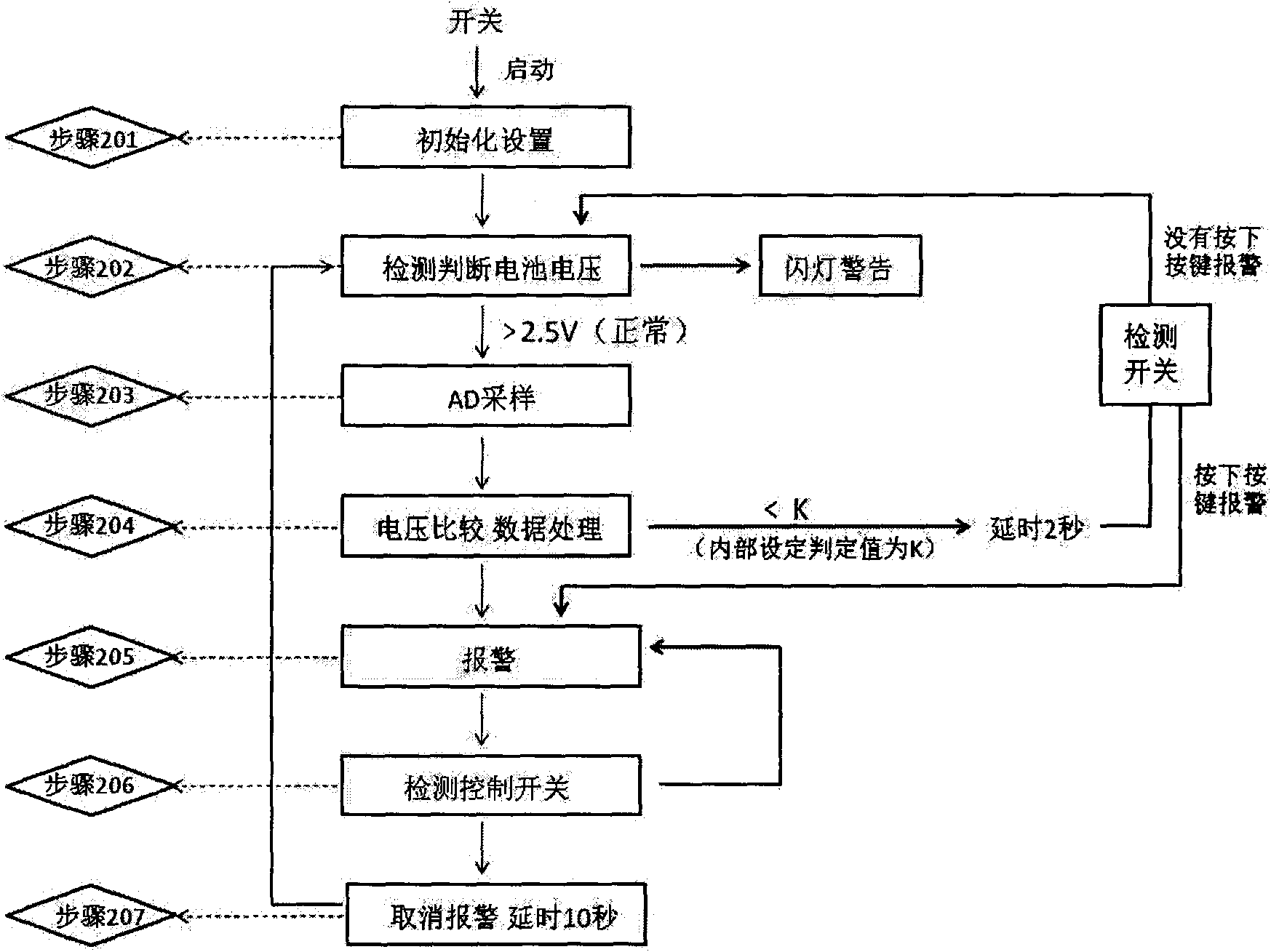

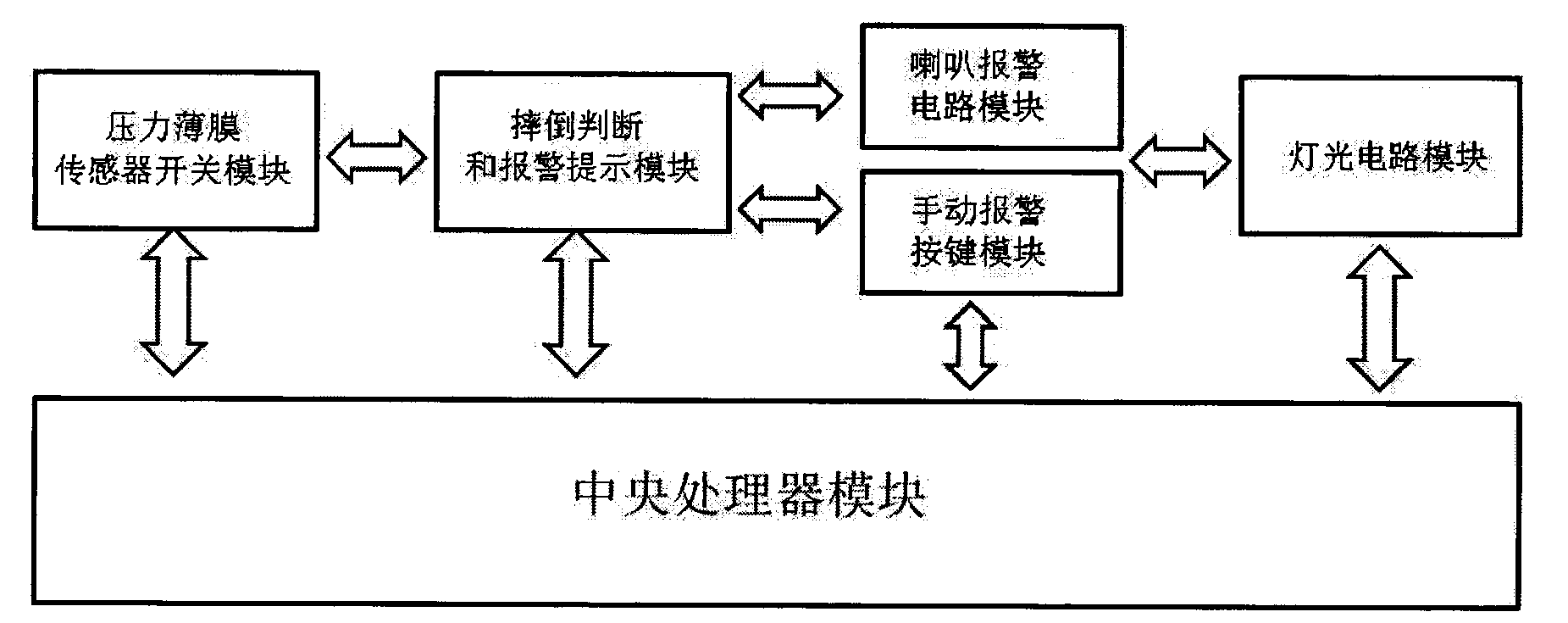

Bath mat with accidental fall alarm prompt function

InactiveCN101972102AAvoid bad consequencesCause serious consequencesAlarmsFloor carpetsThin film sensorComputer module

The invention relates to a bath mat with an accidental fall alarm prompt function, comprising a central processing unit, a pressure thin-film sensor switch module, a fall judgment and alarm prompt module, a horn alarm circuit module, a manual alarm key module and a lamplight circuit module. A limited resistance voltage value is tested through pressure sensing on the thin-film switch module, and the alarm is jointly given through the Internet; whether the behaviors of the disabled have the alarm prompt effect or not is comprehensively judged through calculating the number of thin-film switches and voltage values.

Owner:ZHEJIANG UNIV

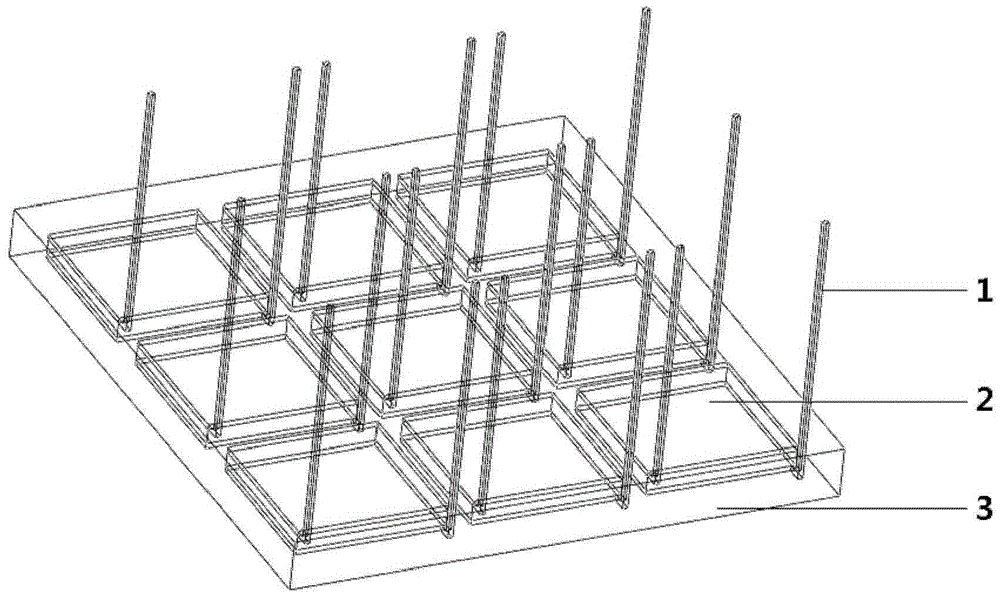

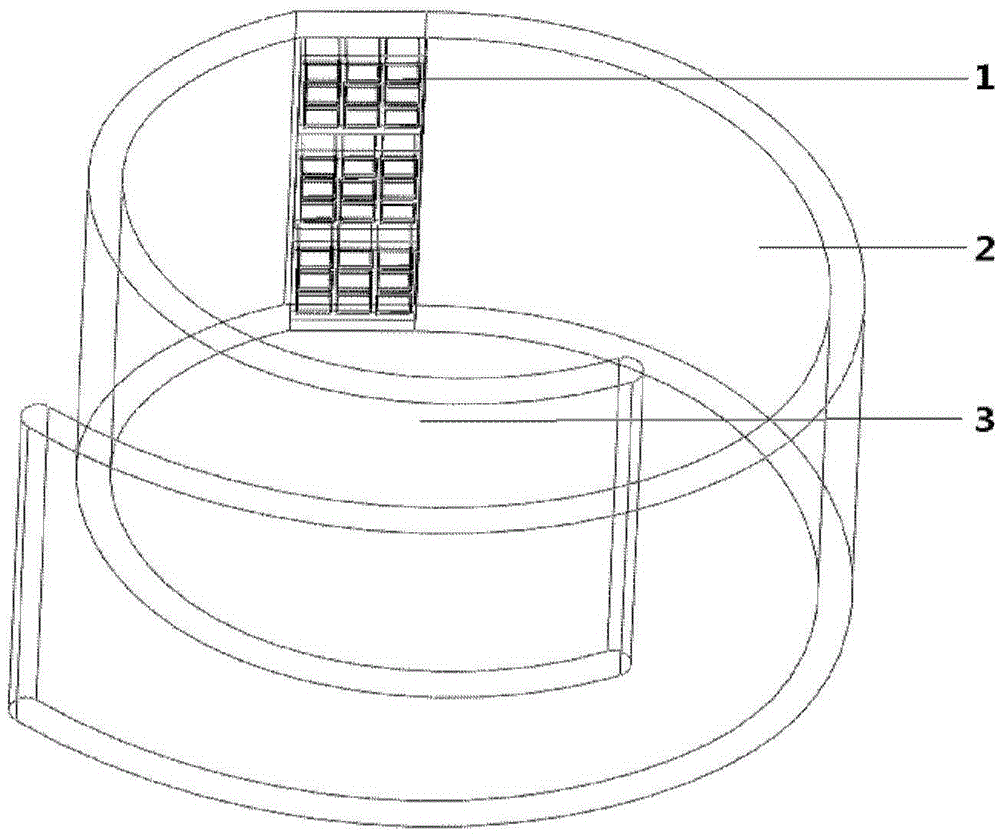

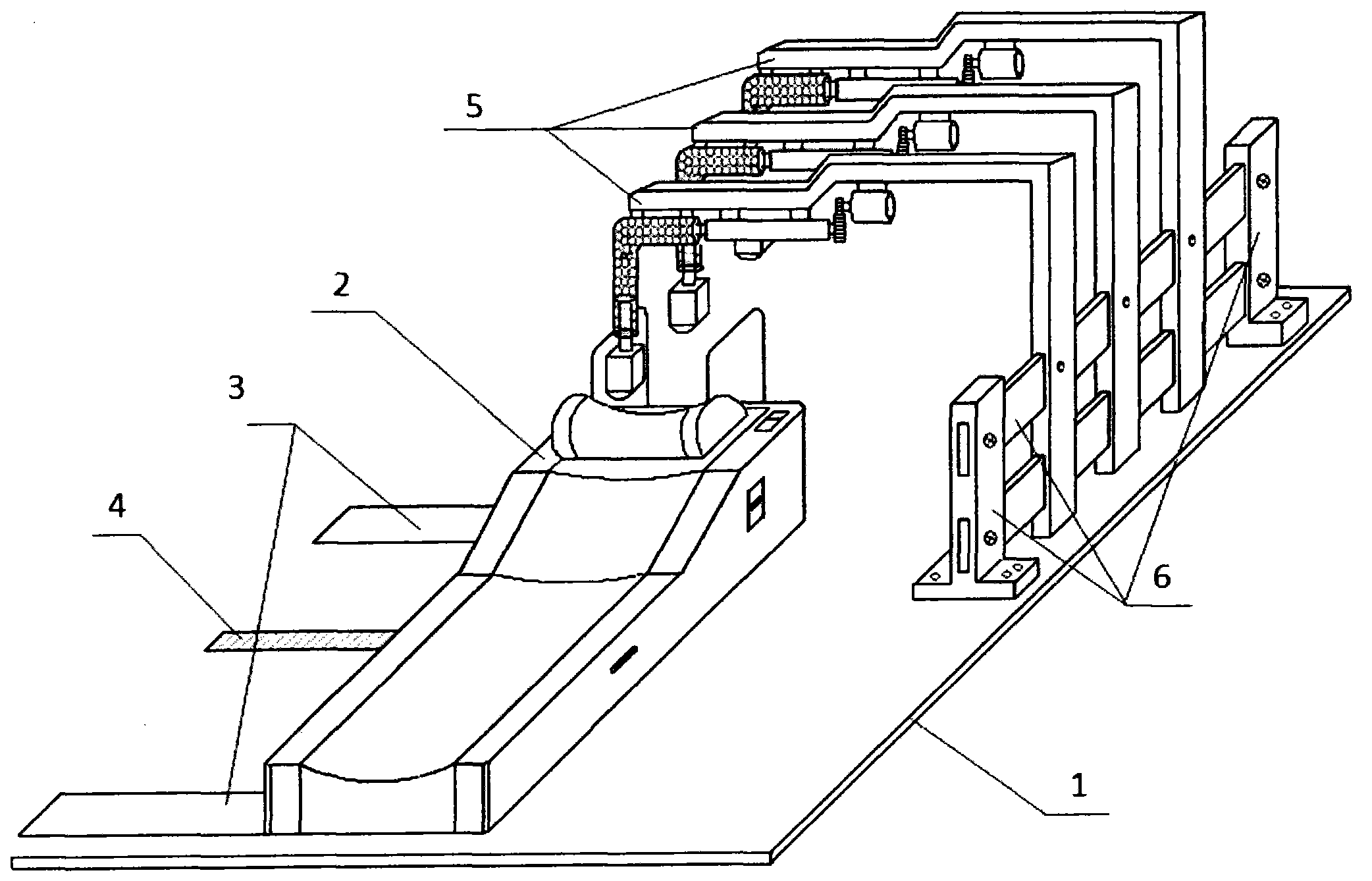

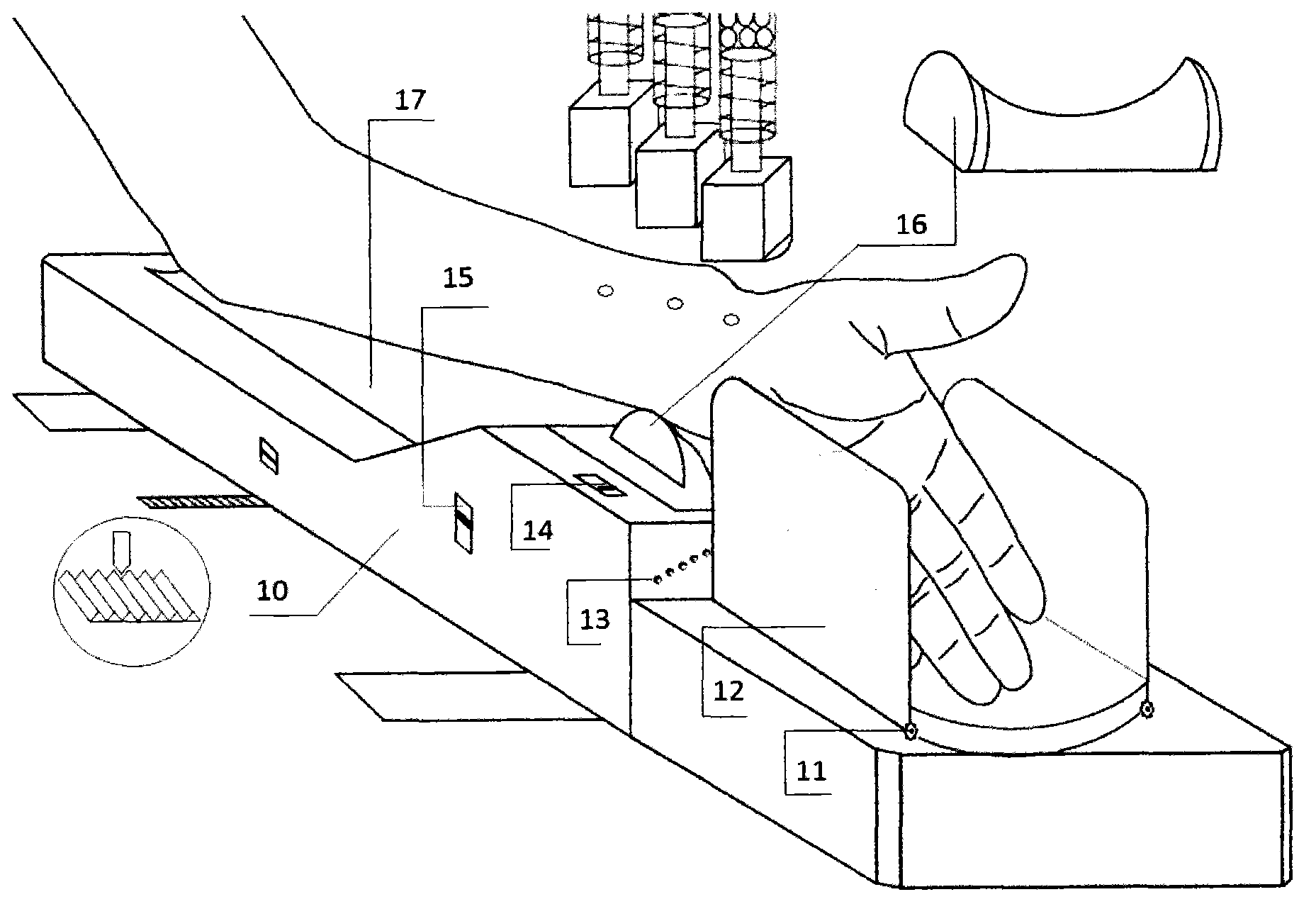

Flexible, micro-array and three-portion precision t pulse testing system

The invention belongs to the field of biomedical testing instruments, and mainly relates to a precision pulse testing system which comprises a forearm positioning device, three channels of signal acquiring devices, a power supplying module, a pressure monitoring and controlling module, a signal acquiring and converting module, a signal processing and displaying module and the like. The precision pulse testing system has the advantages that three-portion and nine-pulse taking procedures carried out by traditional Chinese physicians can be precisely simulated by the aid of a manipulator on the basis of a bionic principle; sensors are graphene capacitive micro-array flexible thin-film sensors, are effectively adaptive to individual tissue structure difference and accordingly can be effectively in contact with tissues of the skins of the wrist of a patient, 400 channels micro-array signals can be acquired by each sensor in real time, and transversal and longitudinal spatial resolution (of 0.4 millimeter) of the signals can be greatly improved; postures of the forearm elbow, the wrist and the palm of the patient can be adjusted and keep in optimal acquisition states by the aid of the precision pulse testing system, pulses can be simultaneously acquired from the forearm elbow, the wrist and the palm of the patient, and the forearm elbow, the wrist and the palm of the patient can be repeatedly and precisely positioned; by the aid of the precision pulse testing system, 28 pulses of the patient can be precisely judged and taken, a microscopic pulse condition of the patient can be analyzed, and four-dimensional image maps of pulse waves of the patient, time-domain pseudo-color topographical maps and the like can be outputted.

Owner:郭福生

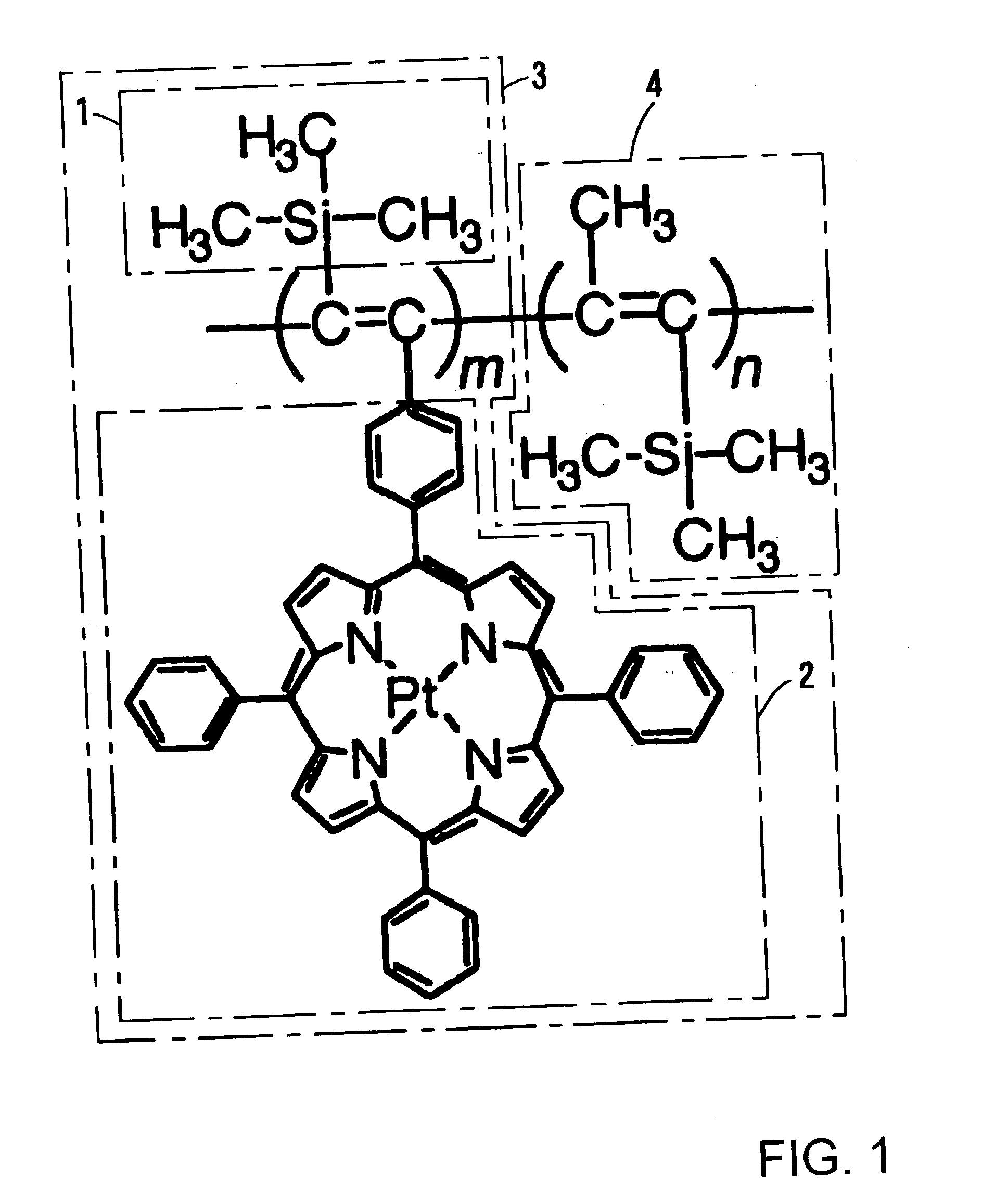

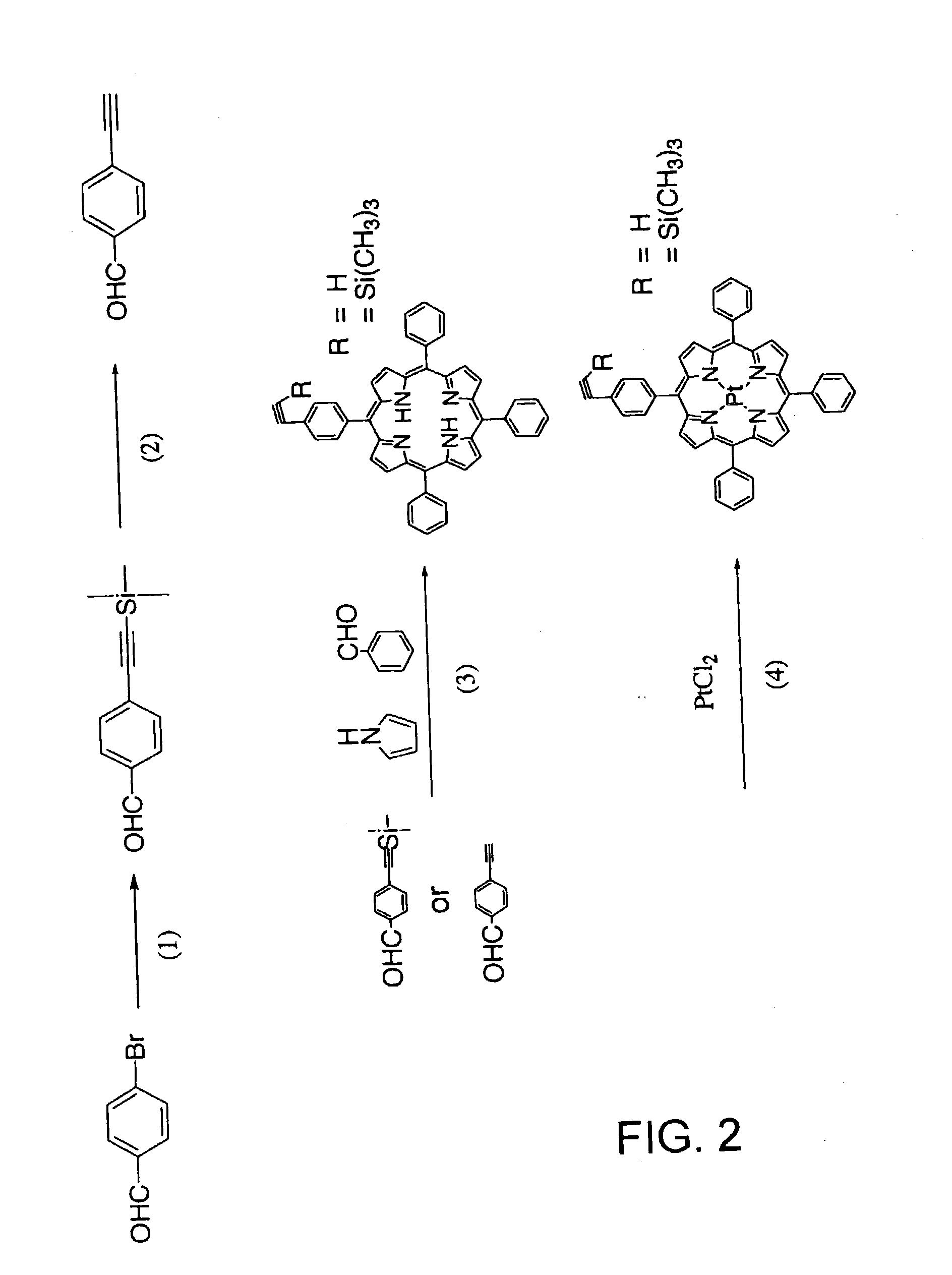

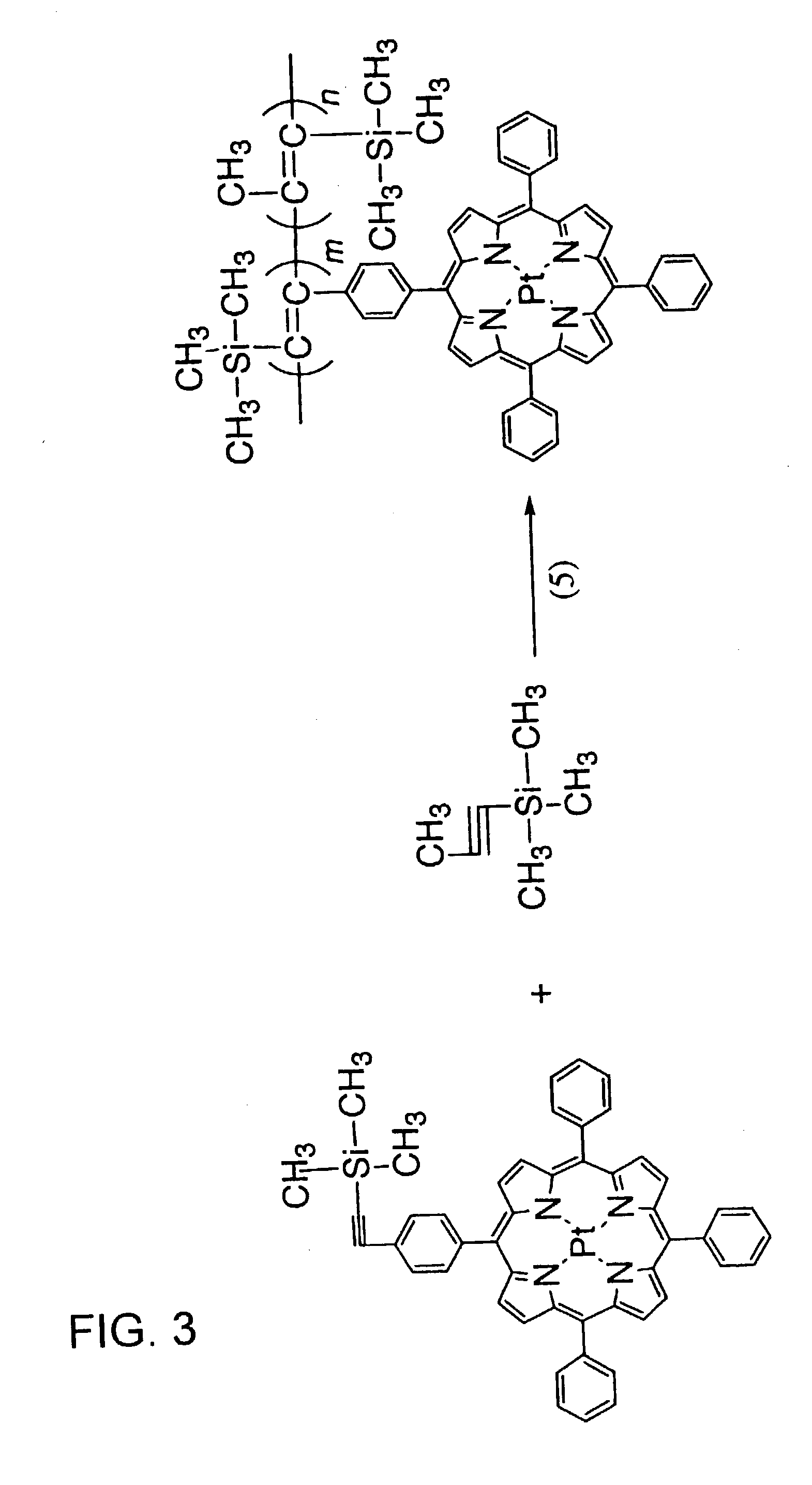

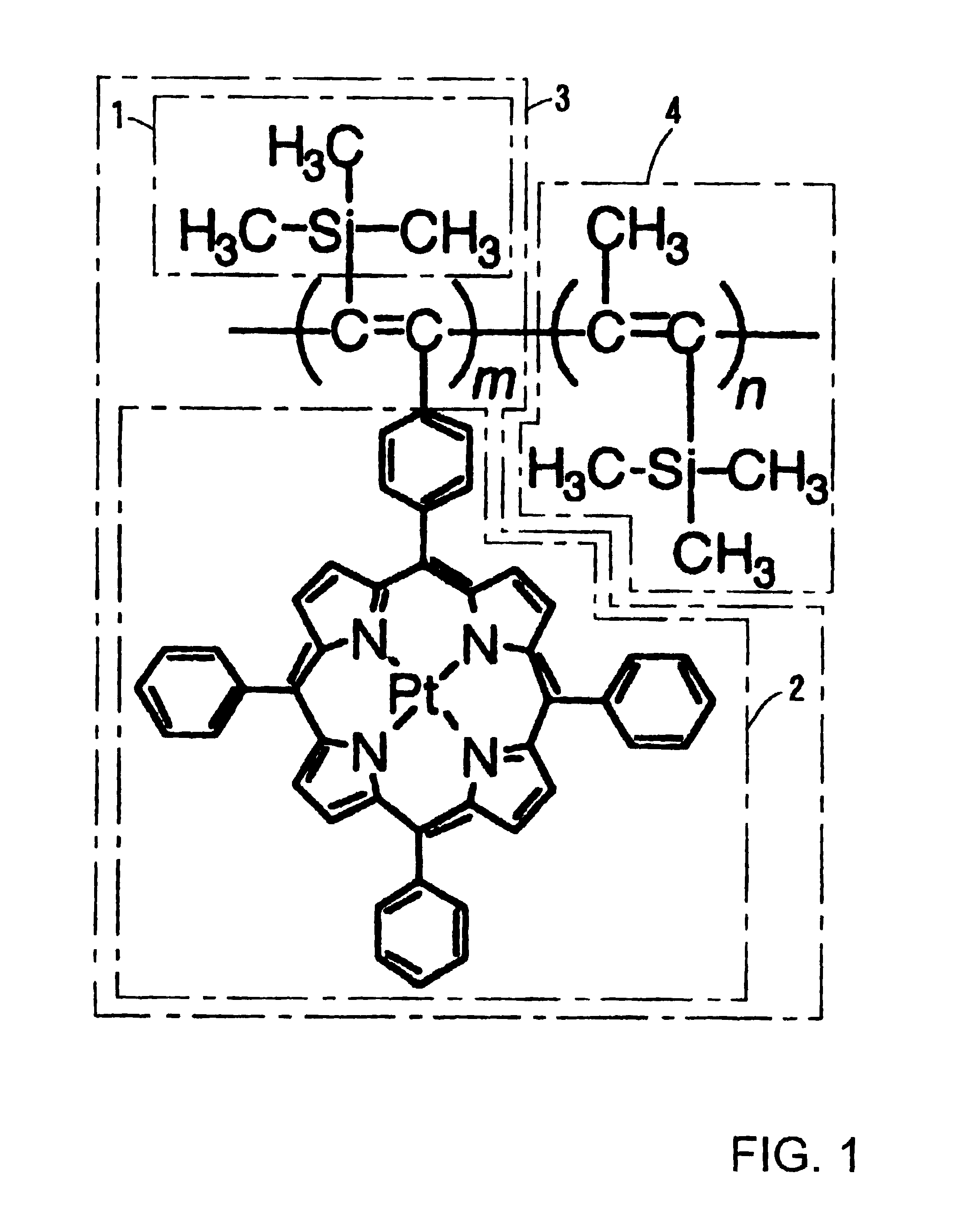

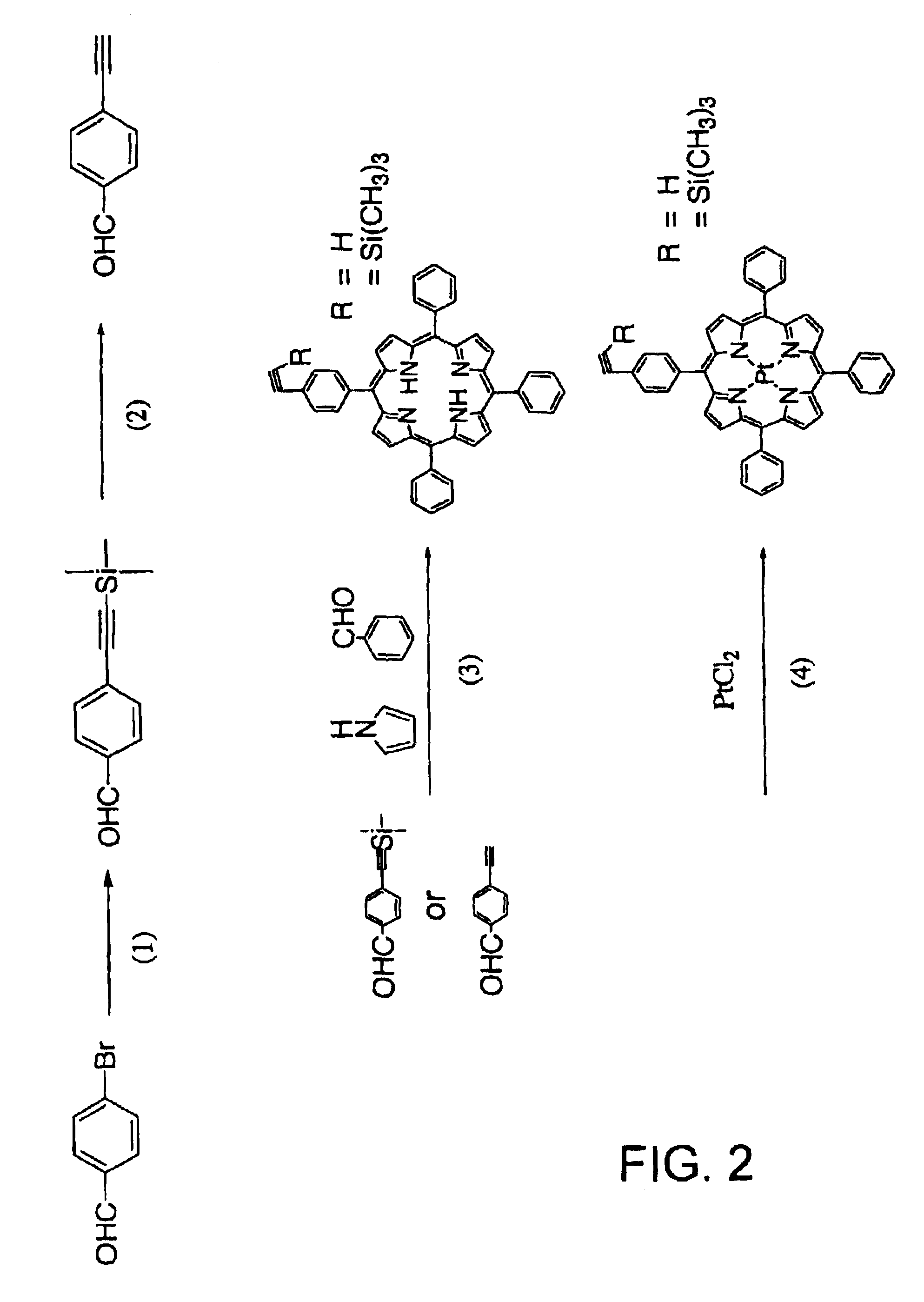

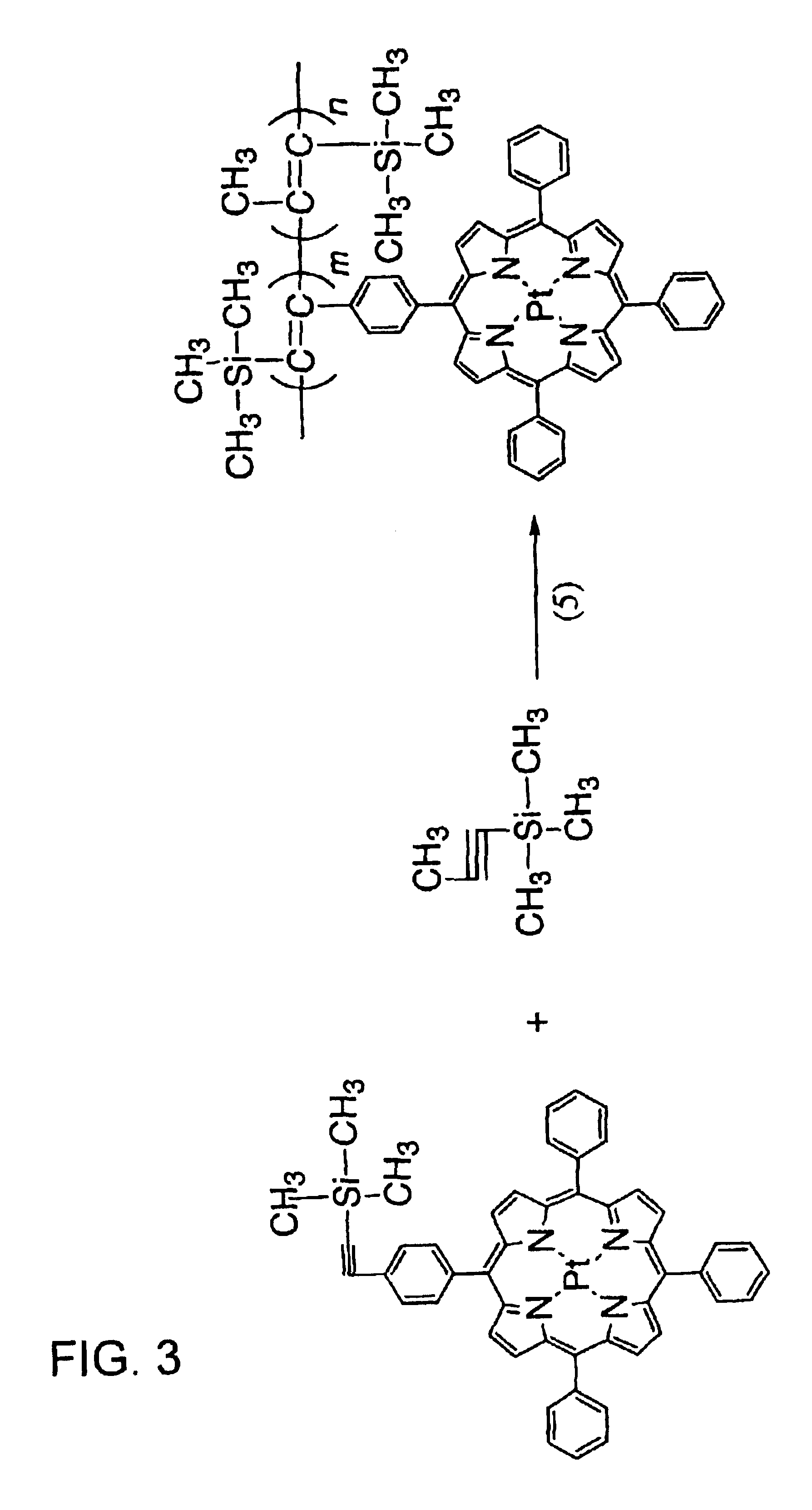

Functional polymer with supported pressure-sensitive luminophore, and pressure-sensitive paint and pressure-sensitive element using same

InactiveUS20030175511A1Inhibitory responsePreventing steric hindranceForce measurementBiological testingHybrid typeEvaporation

An oxygen-quenching luminophore constituting part of a pressure-sensitive luminophore is directly bonded by a covalent bond to an organic polymer compound having trimethylsilyl groups, so the luminophore molecules are retained in the polymer and free aggregation is inhibited when the organic solvent is evaporated. It is therefore possible to prevent light response from being reduced by the aggregation of the luminophore molecules during evaporation of the organic solvent, which is a drawback of forming films from conventional mixed-type pressure-sensitive paints. A thin-film sensor with uniform characteristics can be formed by spraying or application from a pressure-sensitive paint obtained by mixing a functional polymer with a solvent. In addition, a coating solution that has high reproducibility and is suitable for spraying or application can be obtained merely by dissolving the functional polymer as a single component in a suitable solvent. It is possible to obtain a functional polymer, a pressure-sensitive paint, and a pressure-sensitive element in which a reduction in light response due to luminophore aggregation can be prevented, and a thin sensor film having uniform characteristics can be formed, even when the organic solvent has evaporated.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

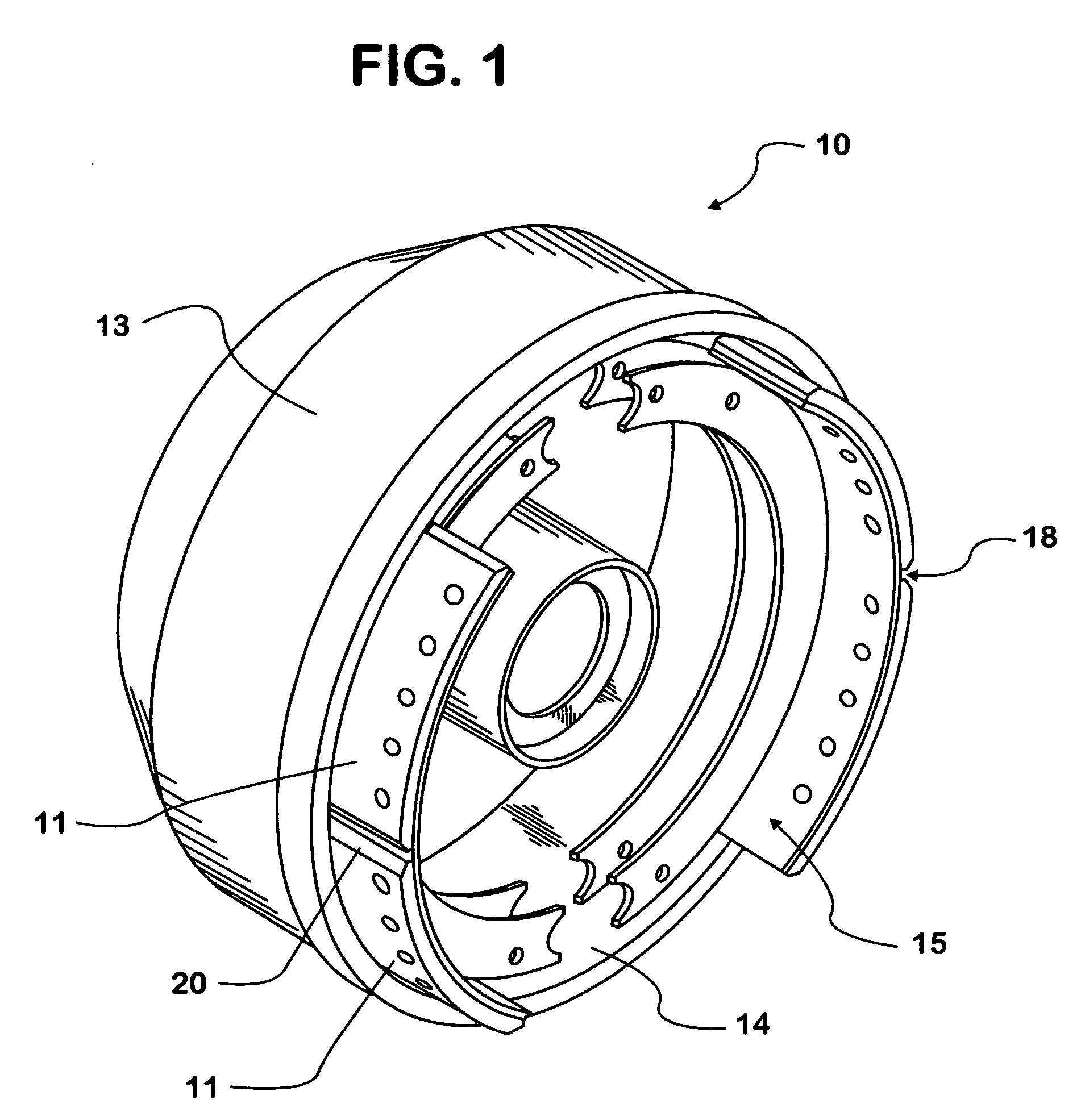

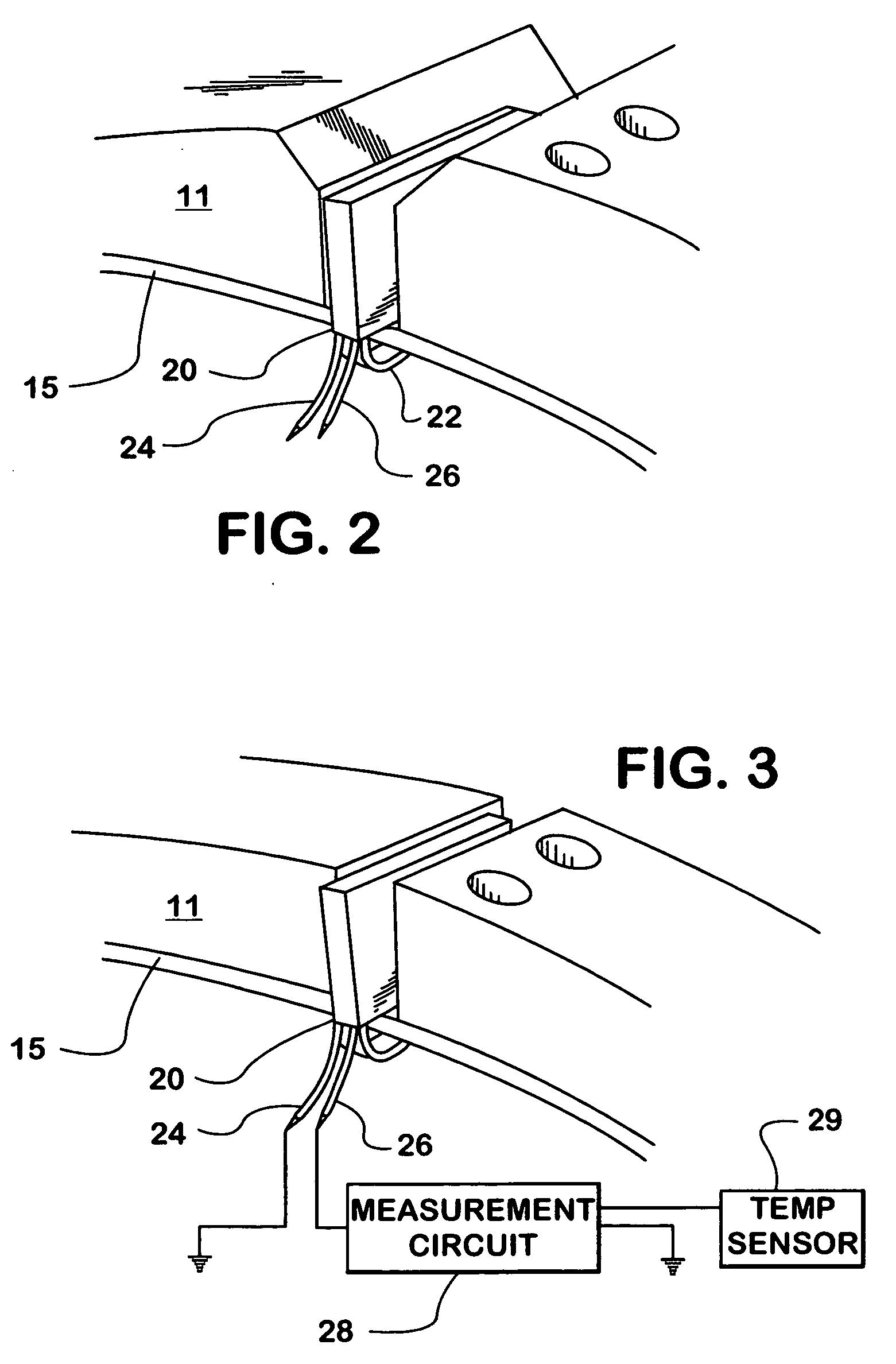

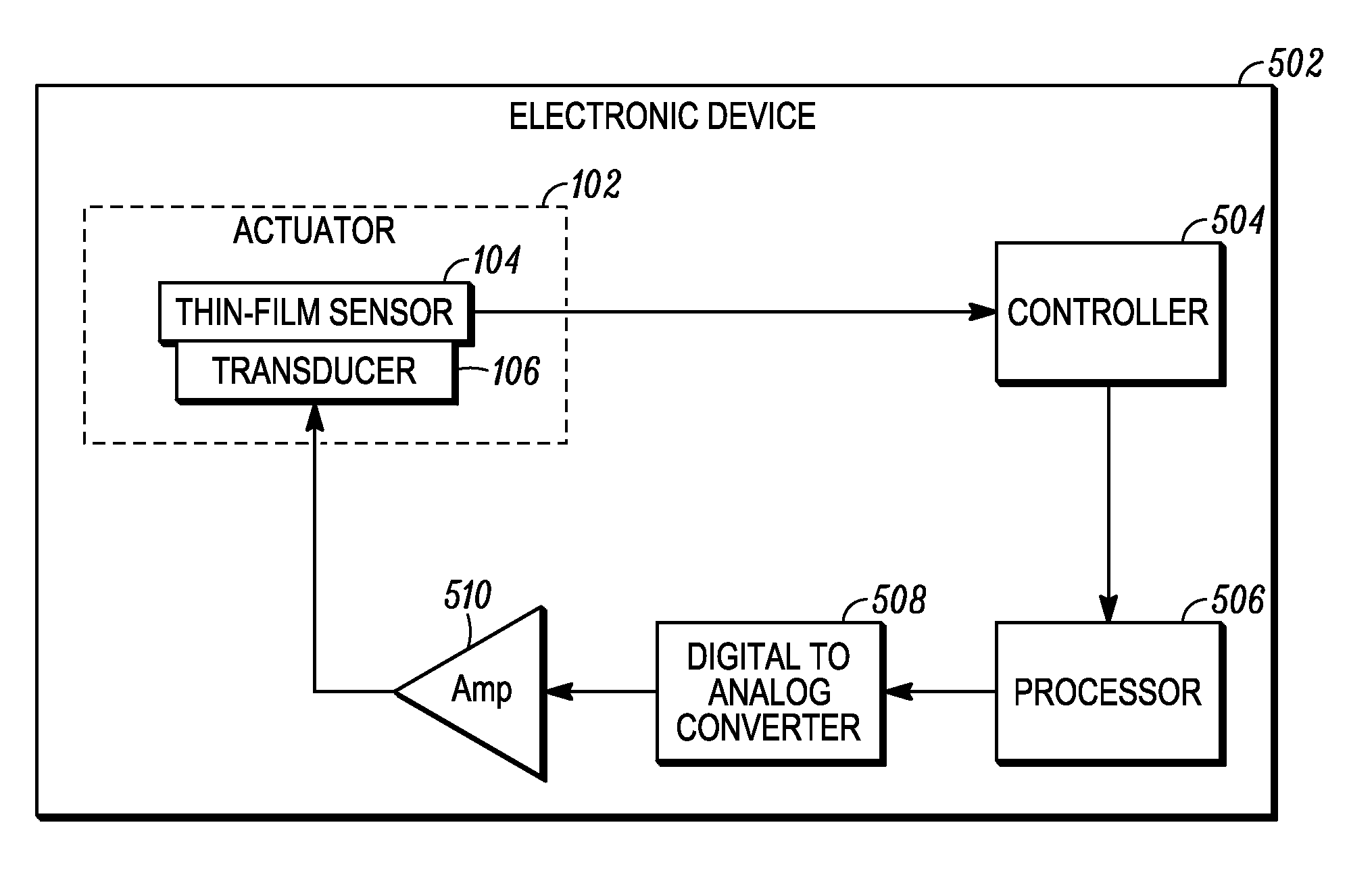

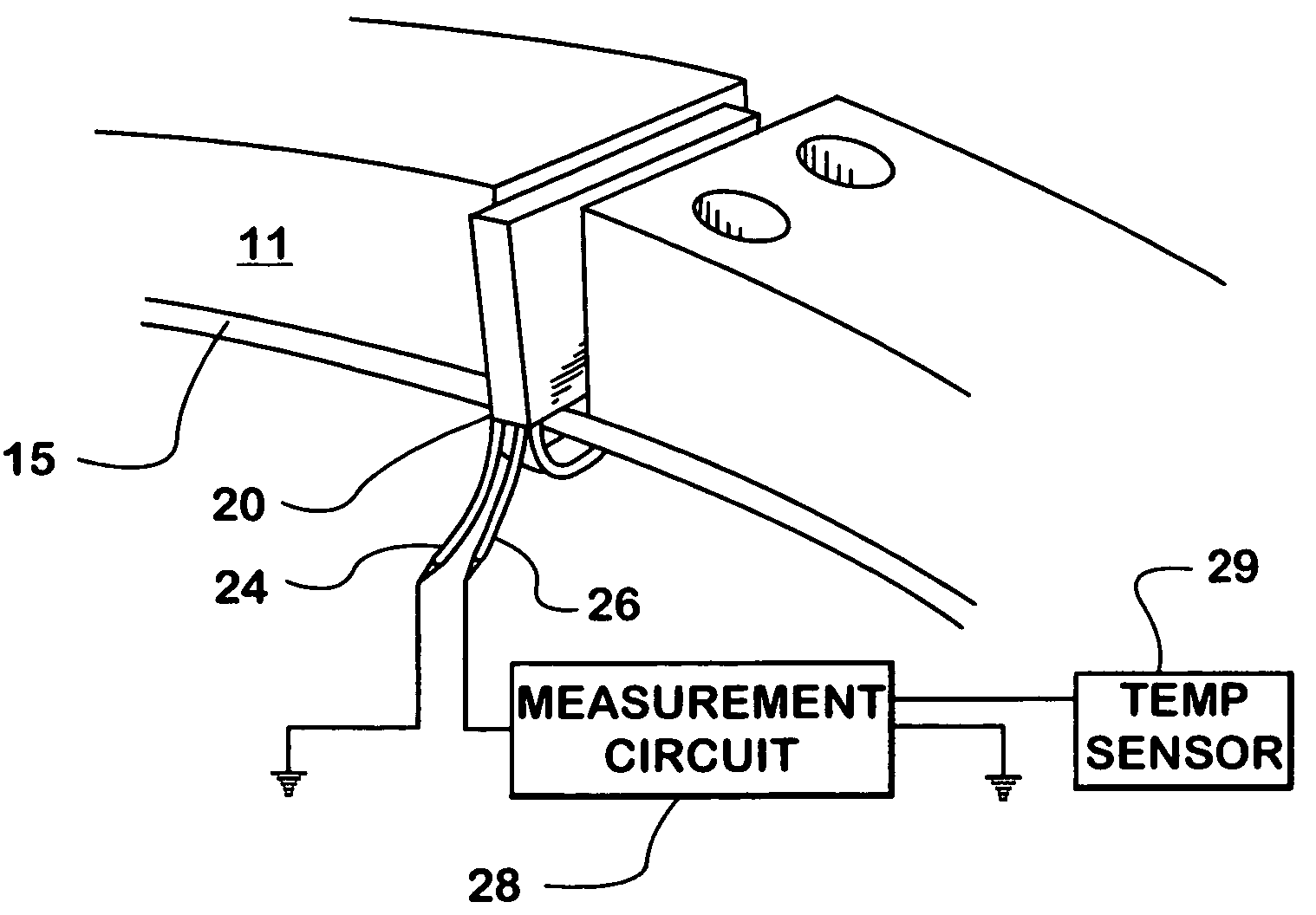

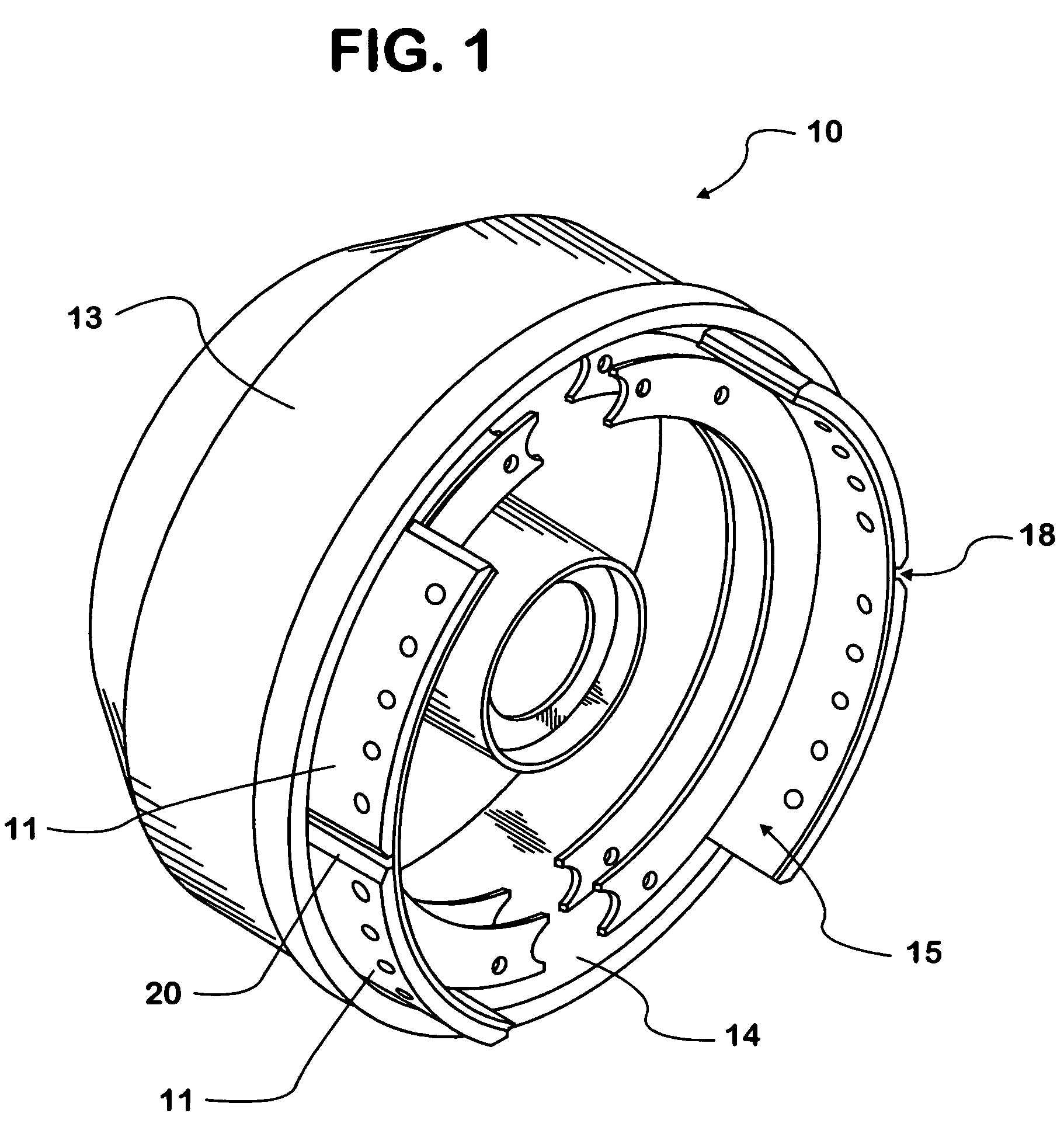

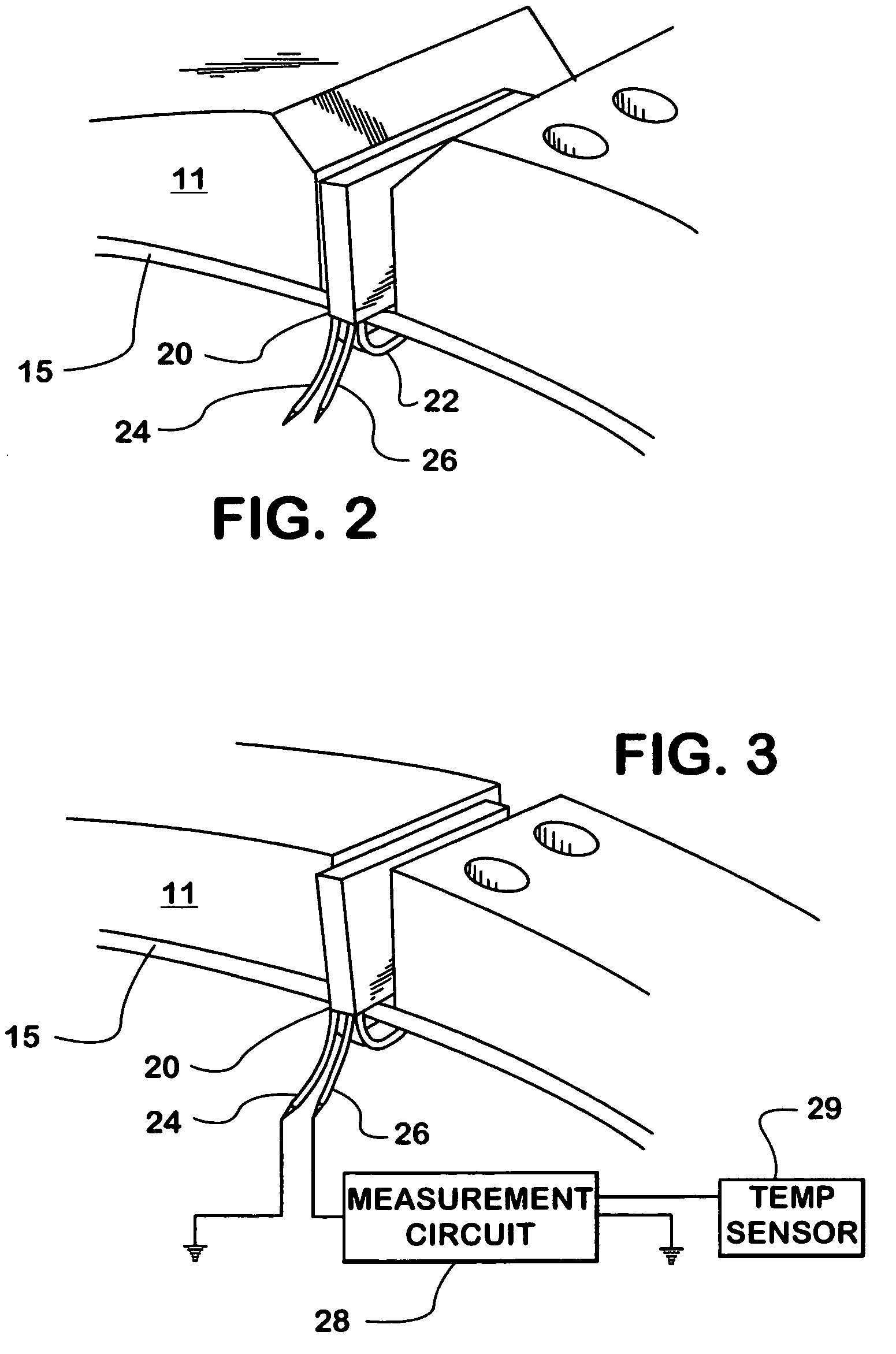

Thin film sensor for brake lining pad wear and brake temperature sensing

InactiveUS20060076196A1Improve electrical resistanceOptical signallingBrake typesThin film sensorElectrical resistance and conductance

A modular electrical resistance sensor is positionable in gaps between brake linings for a drum brake. The modular sensor is worn with the brake linings resulting in steadily increasing electrical resistance of the modular sensor. A measurement circuit associated with the modular sensor is programmed to equate electrical resistance to the degree of wear when the sensor has assumed a steady state temperature at or near the ambient temperature. Otherwise, particularly during periods of use of the brakes, resistance and the degree of wear last calculated become arguments into a function for determining brake lining temperature.

Owner:INT TRUCK INTPROP LLC

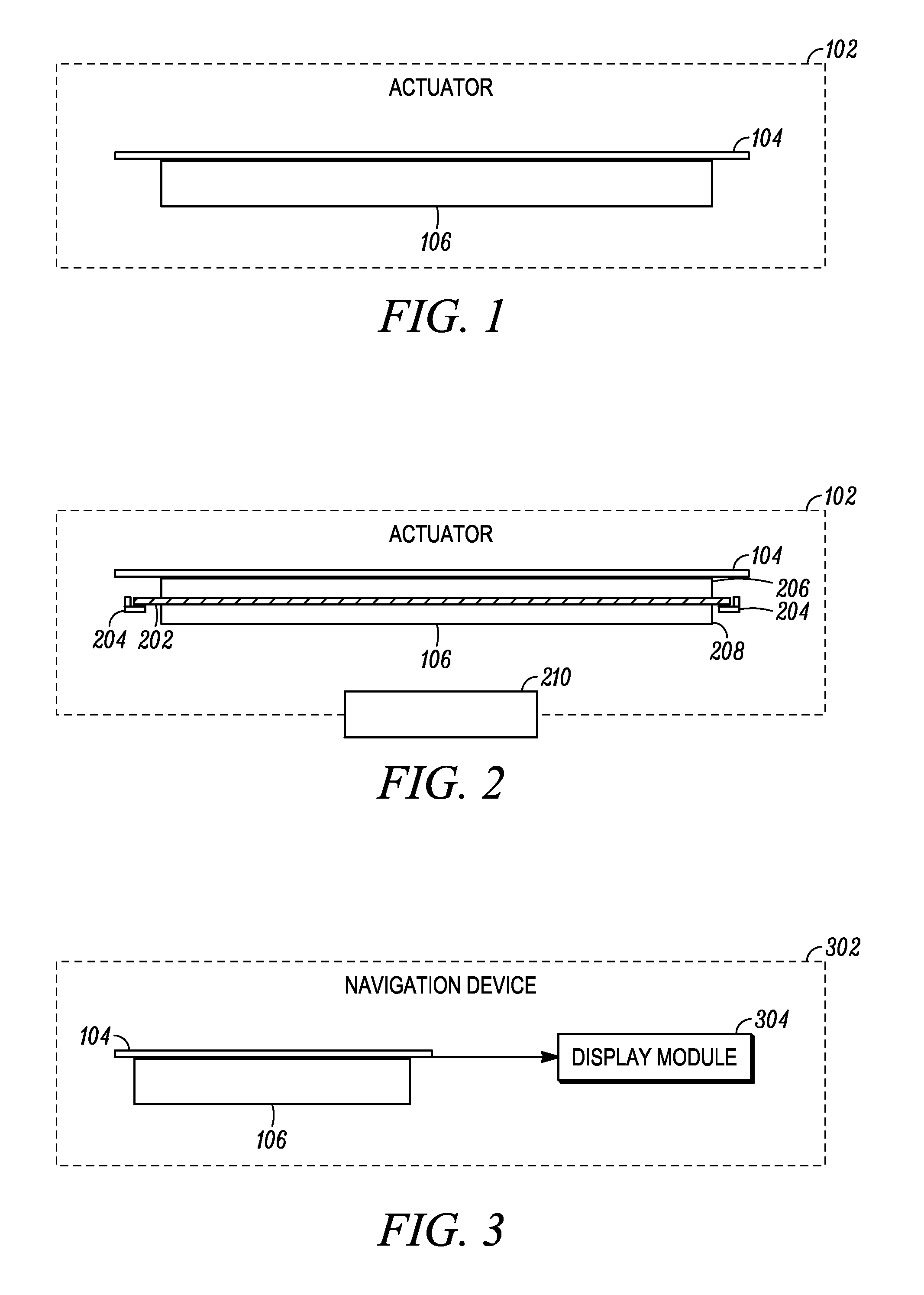

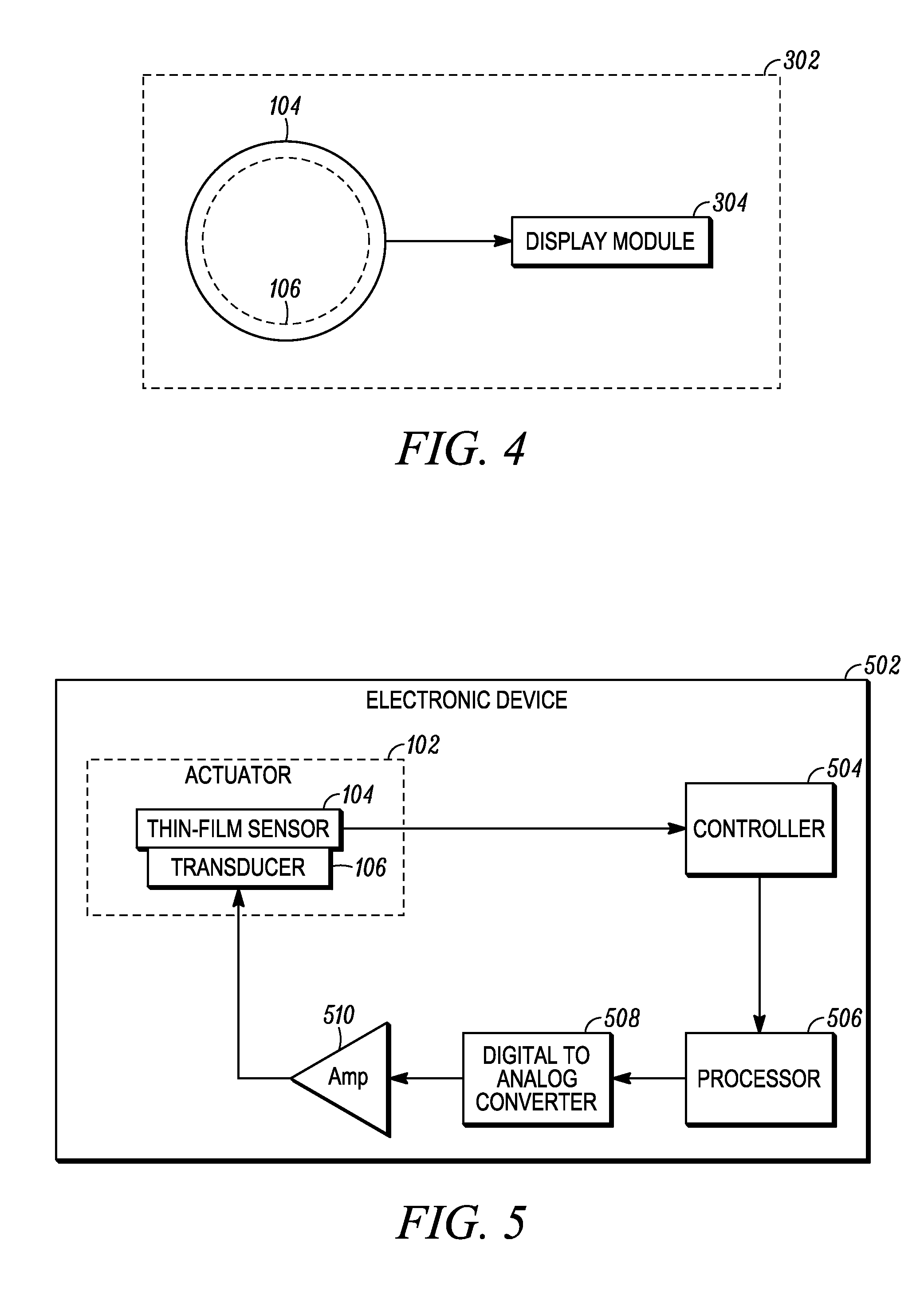

Electronic device with audio and haptic capability

InactiveUS20070145857A1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesThin film sensorTransducer

An actuator (102), suitable for use with an electronic device, is provided. The actuator includes a thin-film sensor (104) and a transducer (106). The transducer is bonded to the thin-film sensor. The thin-film sensor is capable of sensing an input, and the transducer is capable of providing a tactile output in response to the input.

Owner:MOTOROLA INC

Immersible thermal mass flow meter

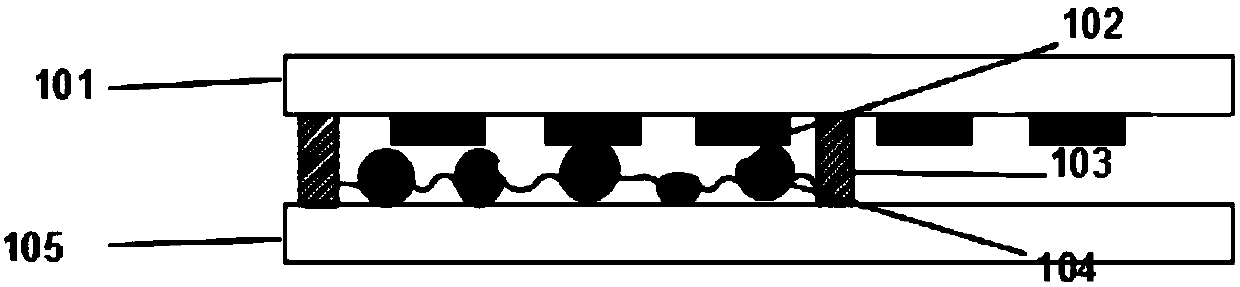

ActiveUS20050223828A1Improve device qualityImprove measurement qualityVolume/mass flow by thermal effectsThin film sensorThin membrane

A thermal anemometer or mass flow meter having temperature and flow velocity sensor elements is provided in which a thin film temperature sensor is provided in the heated sensor of the fluid velocity sensor element of the system. The thin-film sensor is captured at least partially within a spacer or interface member, the spacer being received within a housing. The thermal anemometer is constructed to offer sufficient precision and accuracy in its design to be suitable for sensitive scientific and industrial applications. This goal is achieved while using cost effective parts—as in the thin film temperature sensor(s)—in connection with a construction approach minimizing or eliminating gaps or other system configuration variability.

Owner:SIERRA INSTR

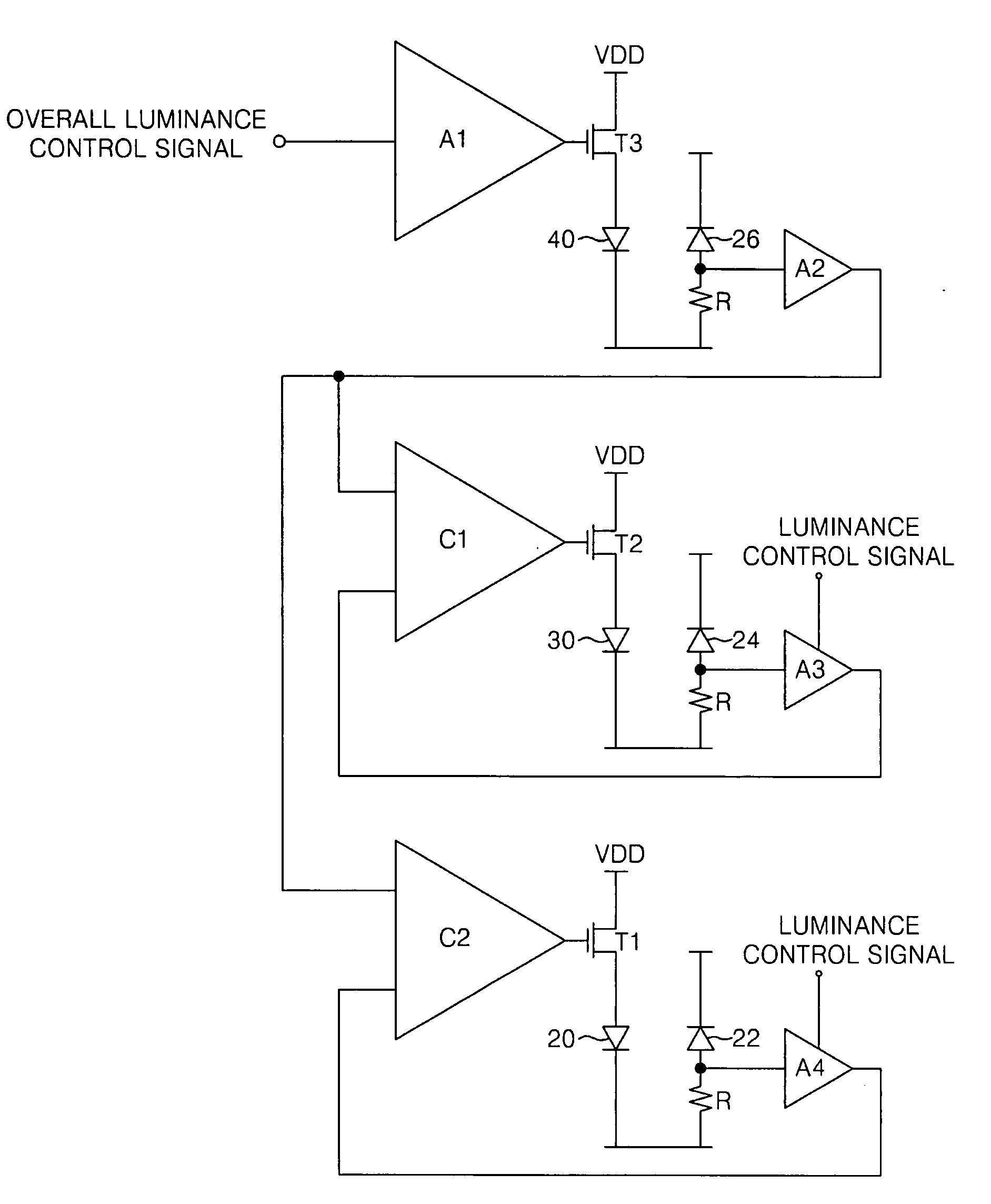

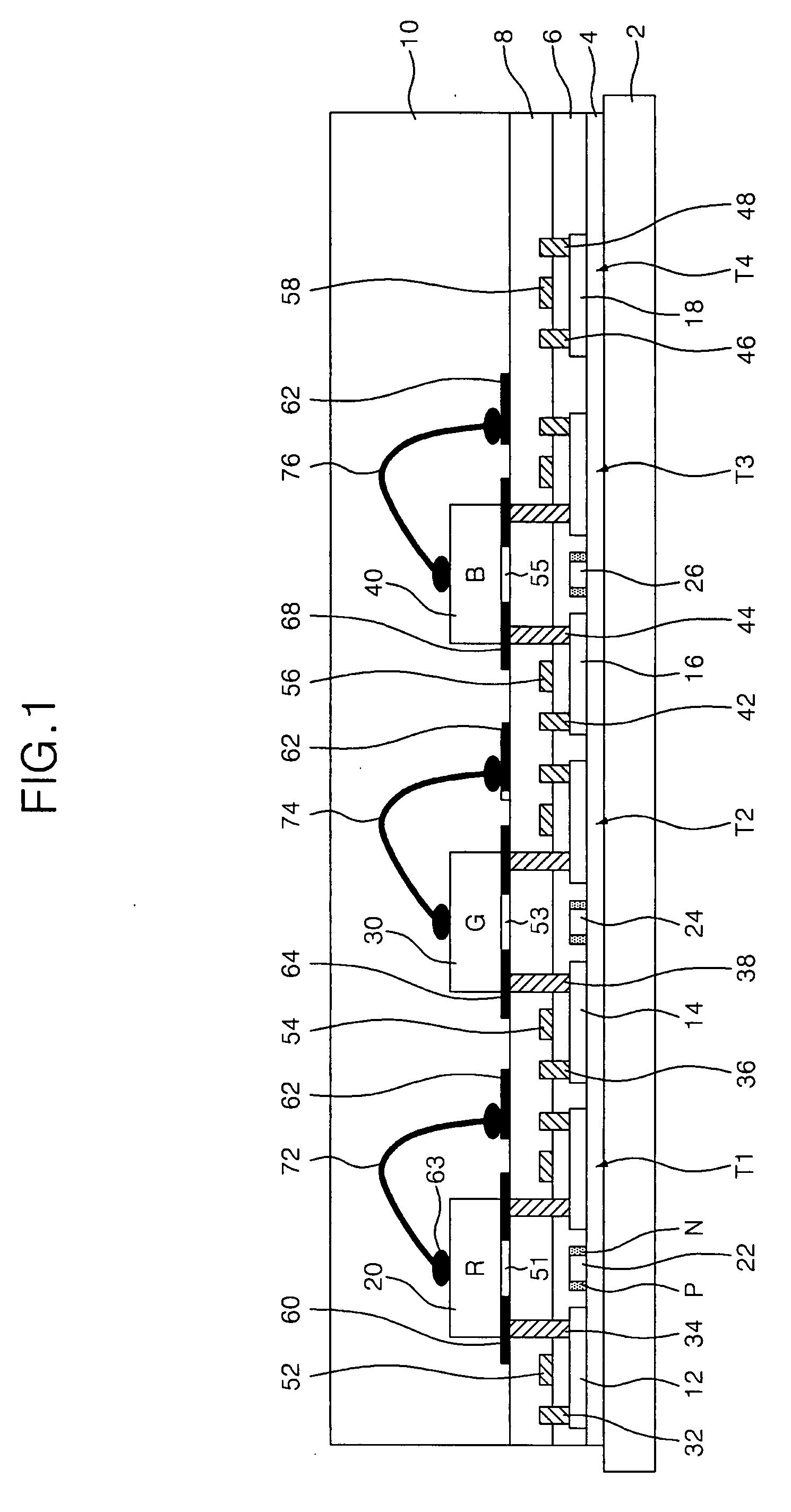

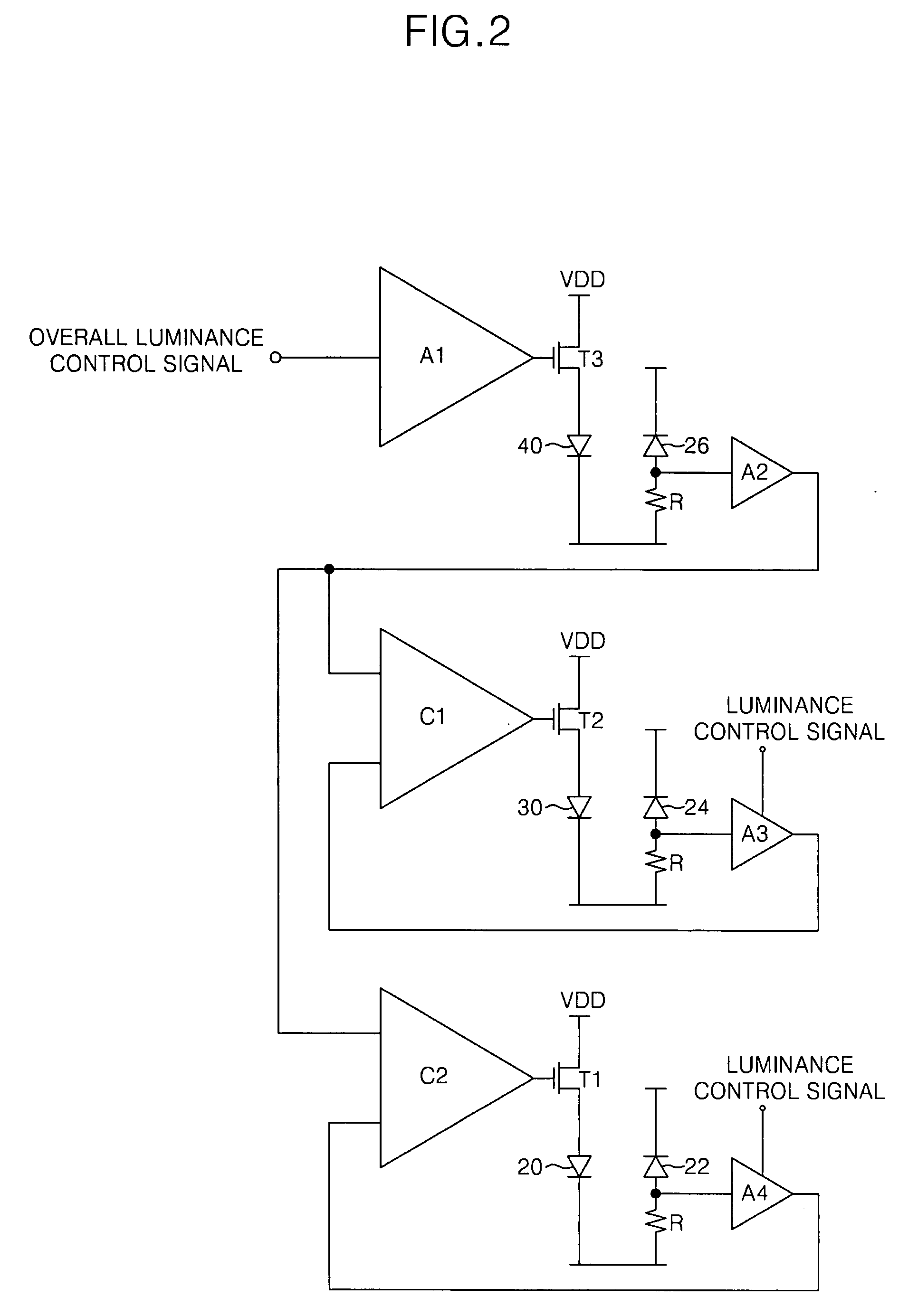

Light emitting diode substrate, method of manufacturing the same, and liquid crystal display device using the same

ActiveUS20070195044A1Reduce manufacturing costImprove color uniformityMechanical apparatusLighting support devicesLuminous intensityDisplay device

A luminance control circuit for controlling the luminance levels of different colored light sources that lends itself to easy incorporation into display devices is presented. A light emitting diode (LED) substrate includes a plurality of driving thin film transistors (TFTs) including a semiconductor layer deposited on a substrate. A plurality of LEDs for generating lights of different wavelengths is mounted respectively on the plurality of driving TFTs. A plurality of thin film sensors for sensing the luminous intensities of the plurality of LEDs is formed between the plurality of LEDs and the substrate. A luminance control circuit for controlling the driving TFTs has of a plurality of controlling TFTs including a semiconductor layer deposited on the substrate and is connected to the plurality of thin film sensors.

Owner:SAMSUNG DISPLAY CO LTD

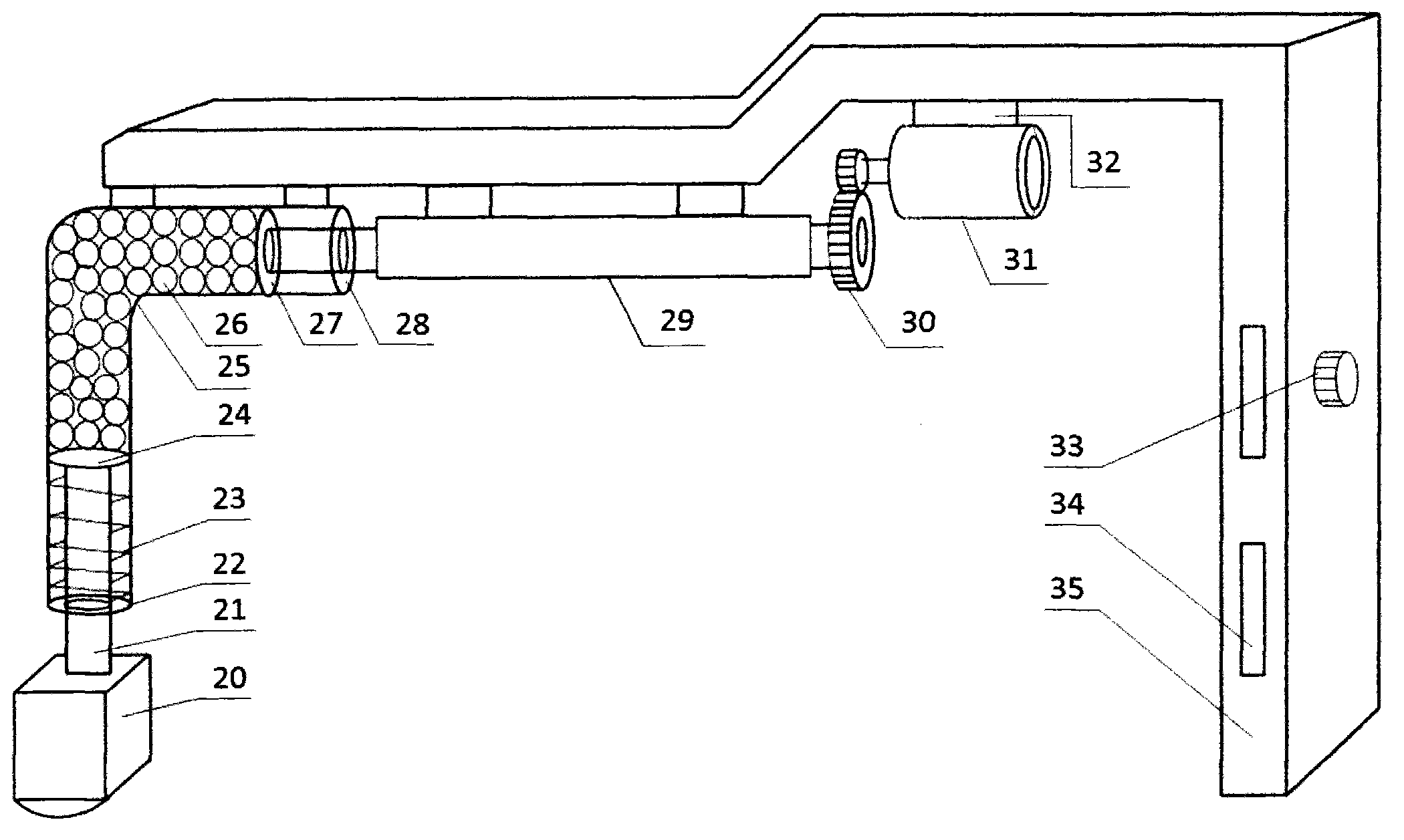

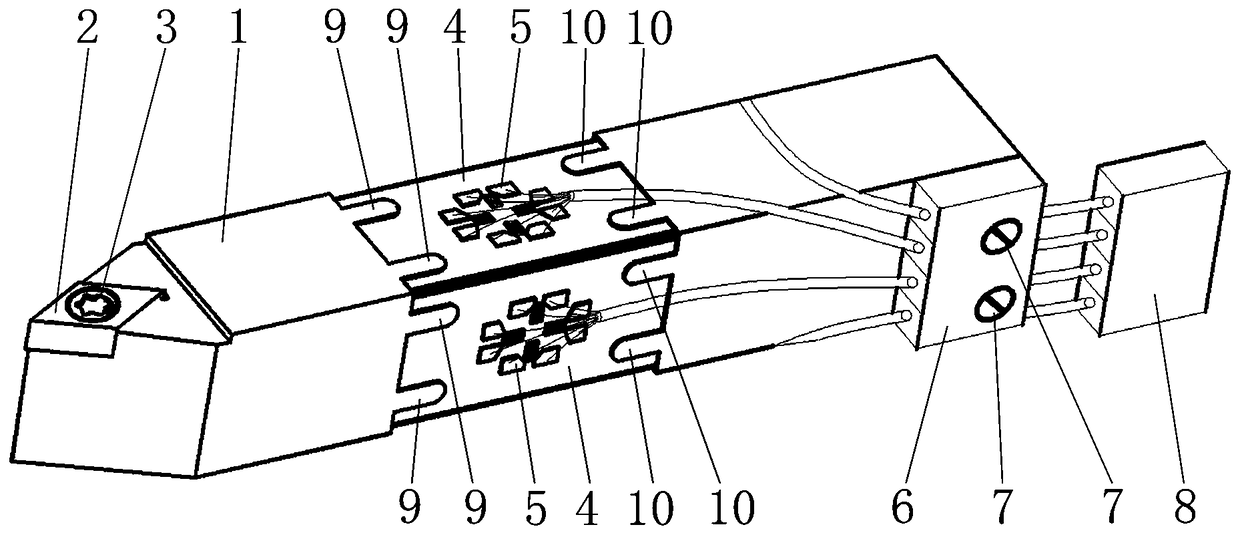

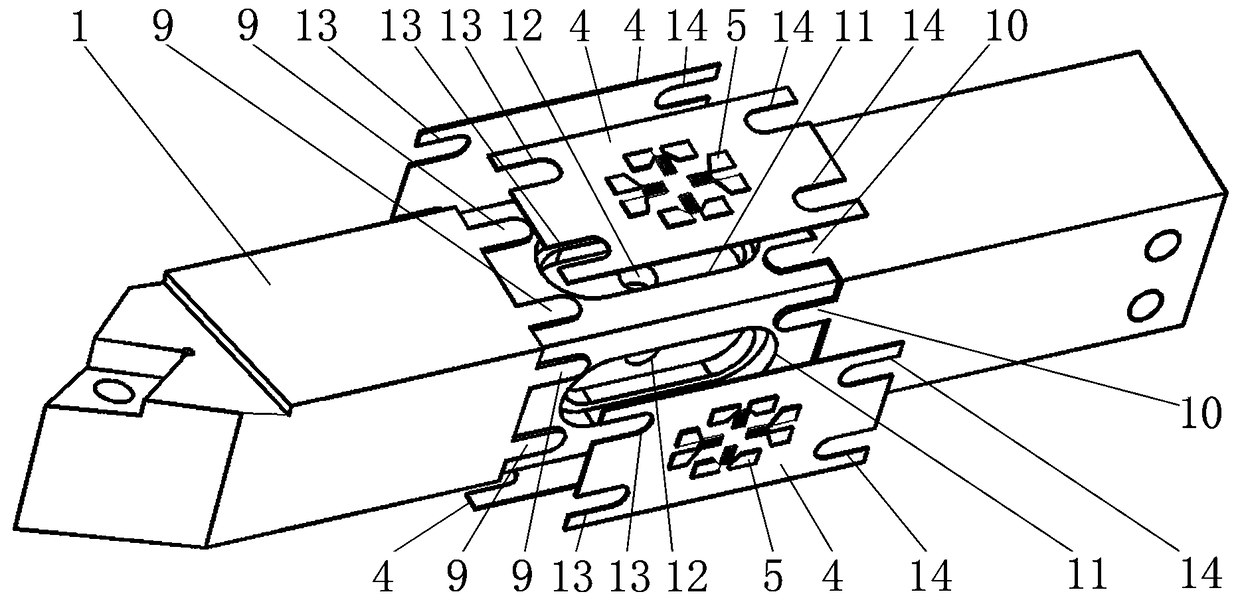

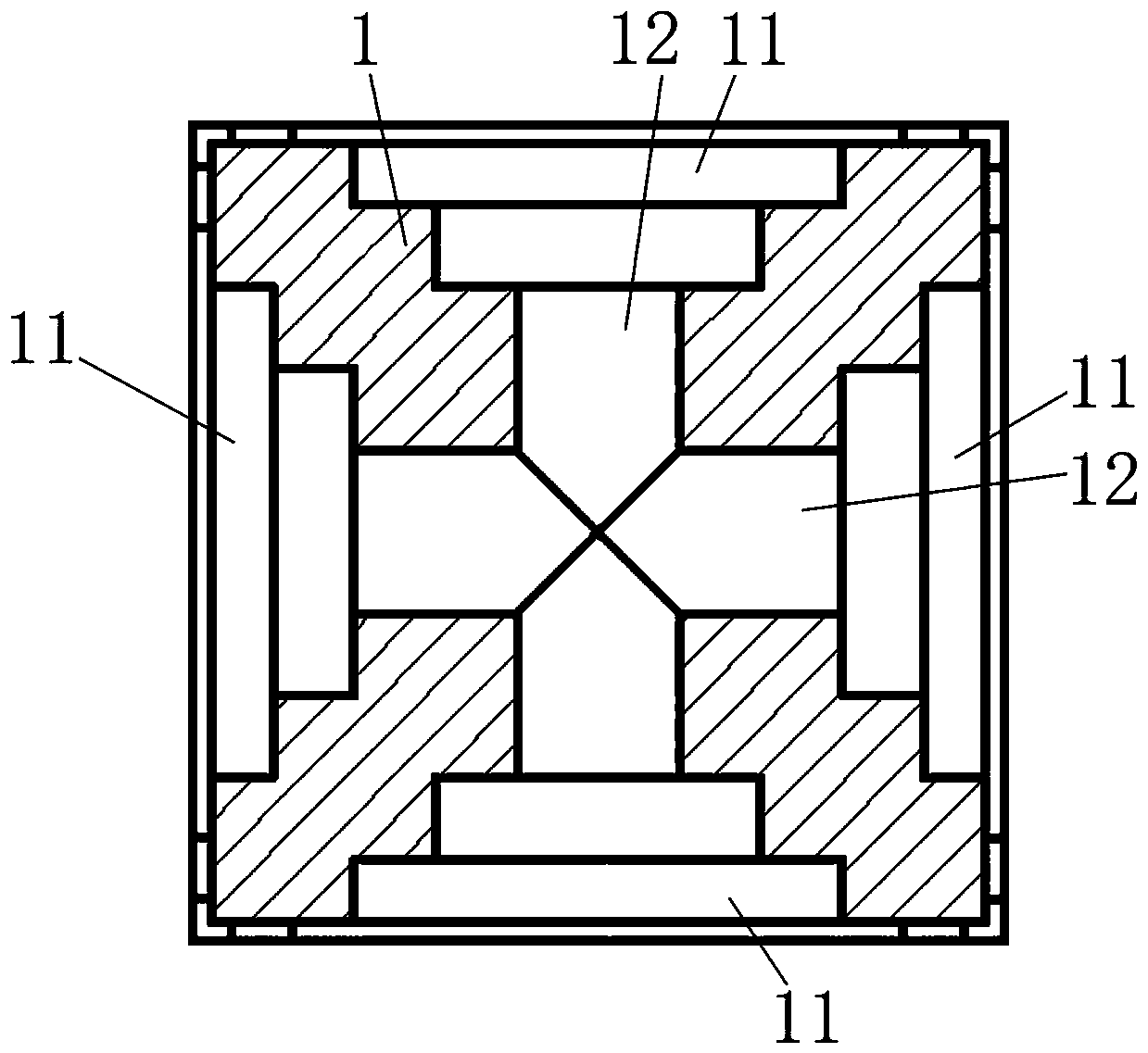

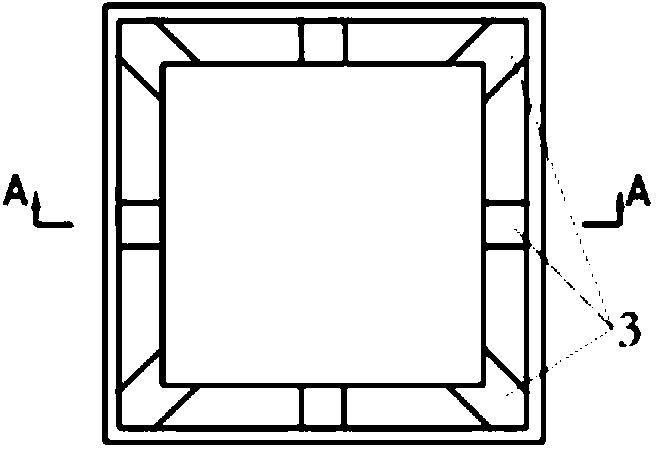

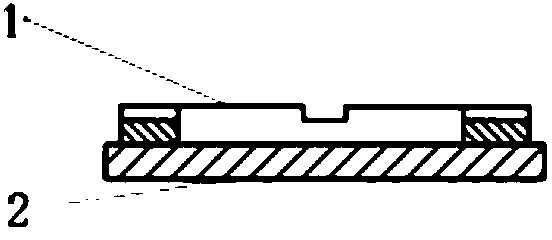

Integrated turning force measuring tool system with embedded film sensors

InactiveCN109175419AHigh measurement accuracyNo mutual interferenceAuxillary equipmentMeasurement/indication equipmentsThin film sensorElastic substrate

The invention relates to a turning force measuring technology in turning machining, in particular to an integrated turning force measuring tool system with embedded film sensors. The problems that anexisting turning force measuring technology is low in measuring precision and limited in application range are solved. The integrated turning force measuring tool system with the embedded film sensorscomprises a turning tool bar, a turning tool blade, a first sunk screw, square elastic substrates, the film sensors, a Wheatstone electrical bridge module, second sunk screws, a signal processing unit and a PC; the middles of the four side faces of the turning tool bar are each provided with a square positioning groove; a runway-shaped groove is formed in the center of the groove bottom of each square positioning groove; the four square elastic substrates are embedded into the four square positioning grooves respectively; and the four film sensors are arranged at the centers of the outer sidefaces of the four square elastic substrates in a magneto-sputtering deposition mode. The integrated turning force measuring tool system with the embedded film sensors is suitable for turning machining in various occasions (such as a laboratory and a production field).

Owner:ZHONGBEI UNIV

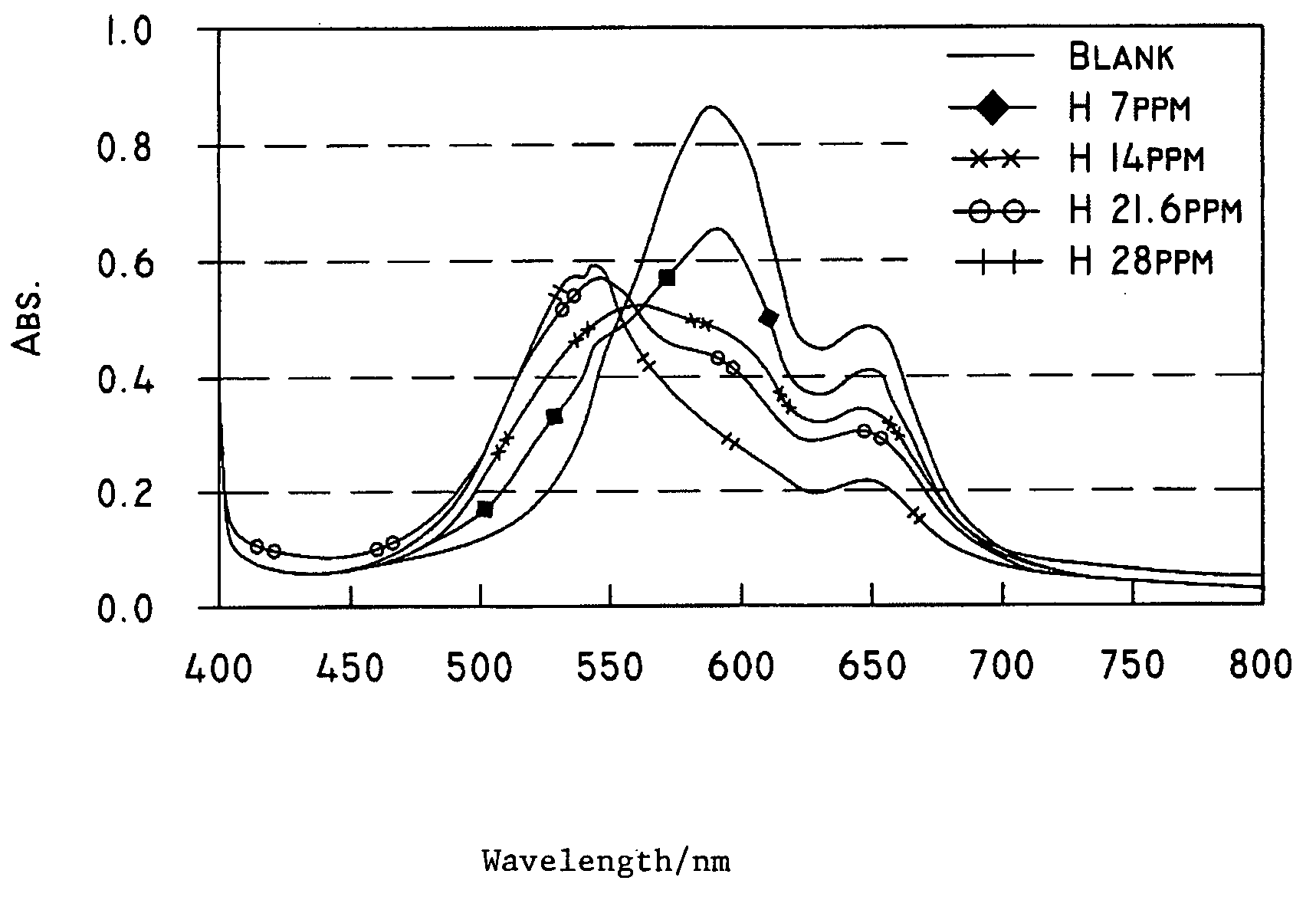

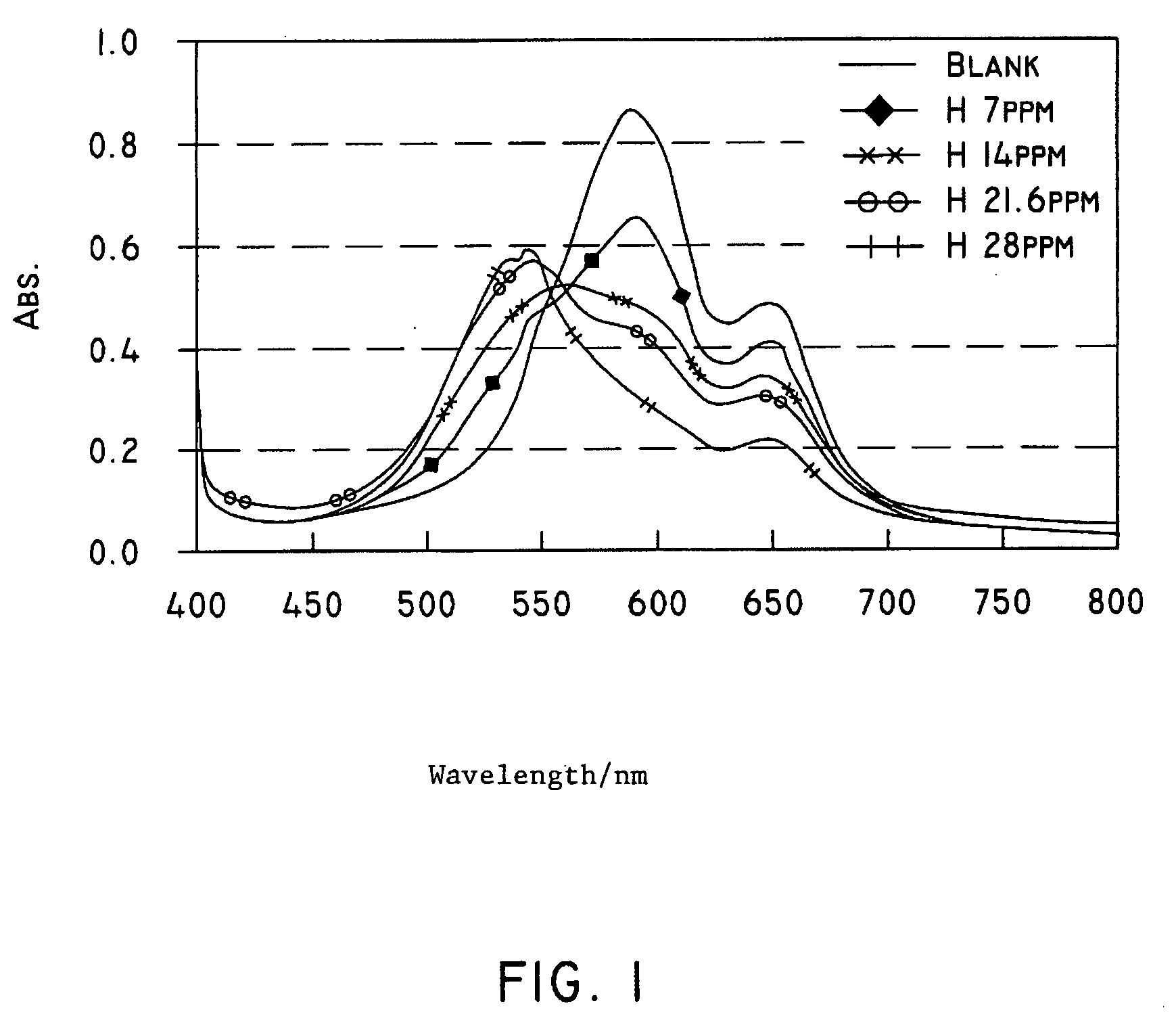

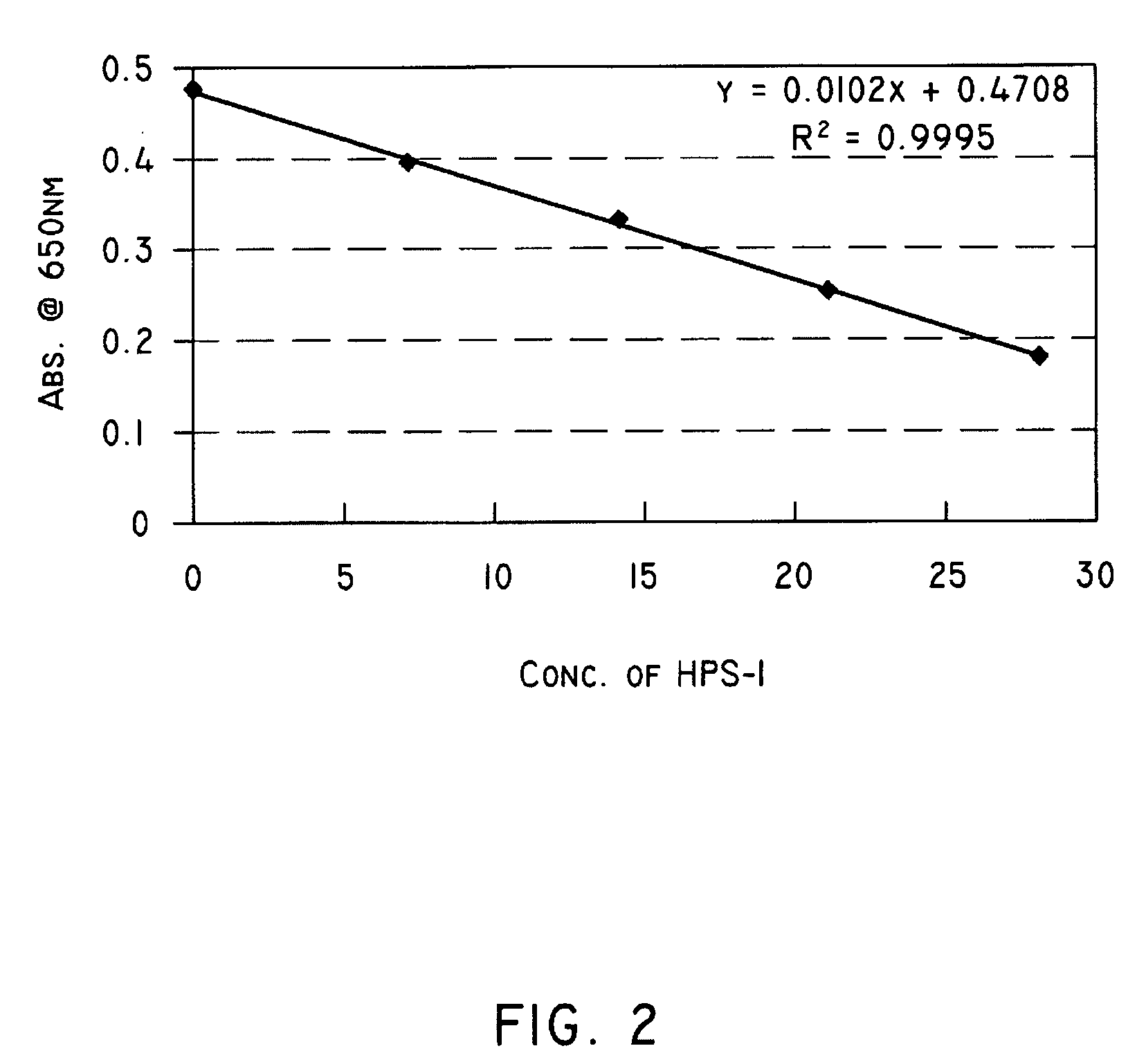

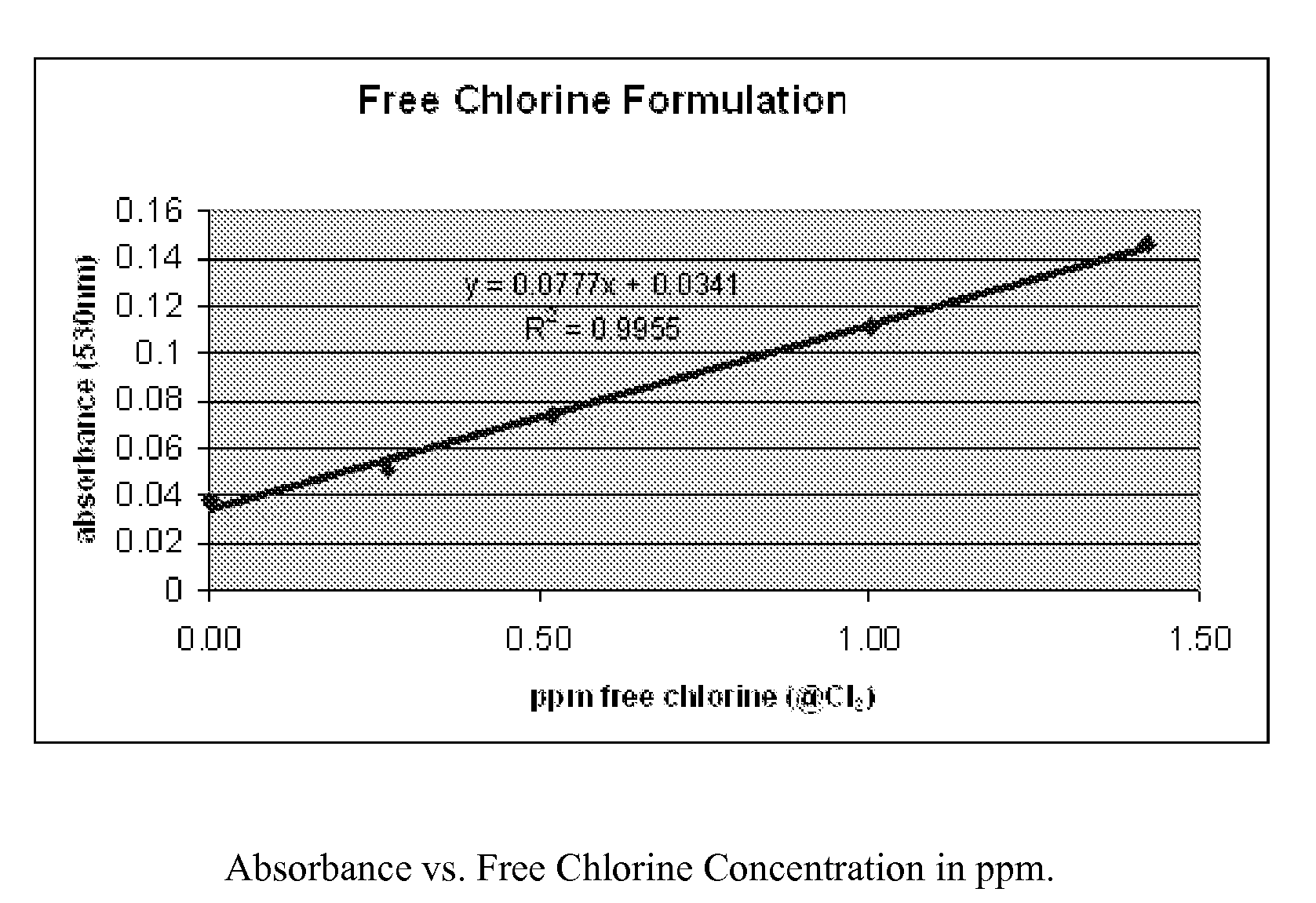

Method for the determination of aqueous polymer concentration in water systems

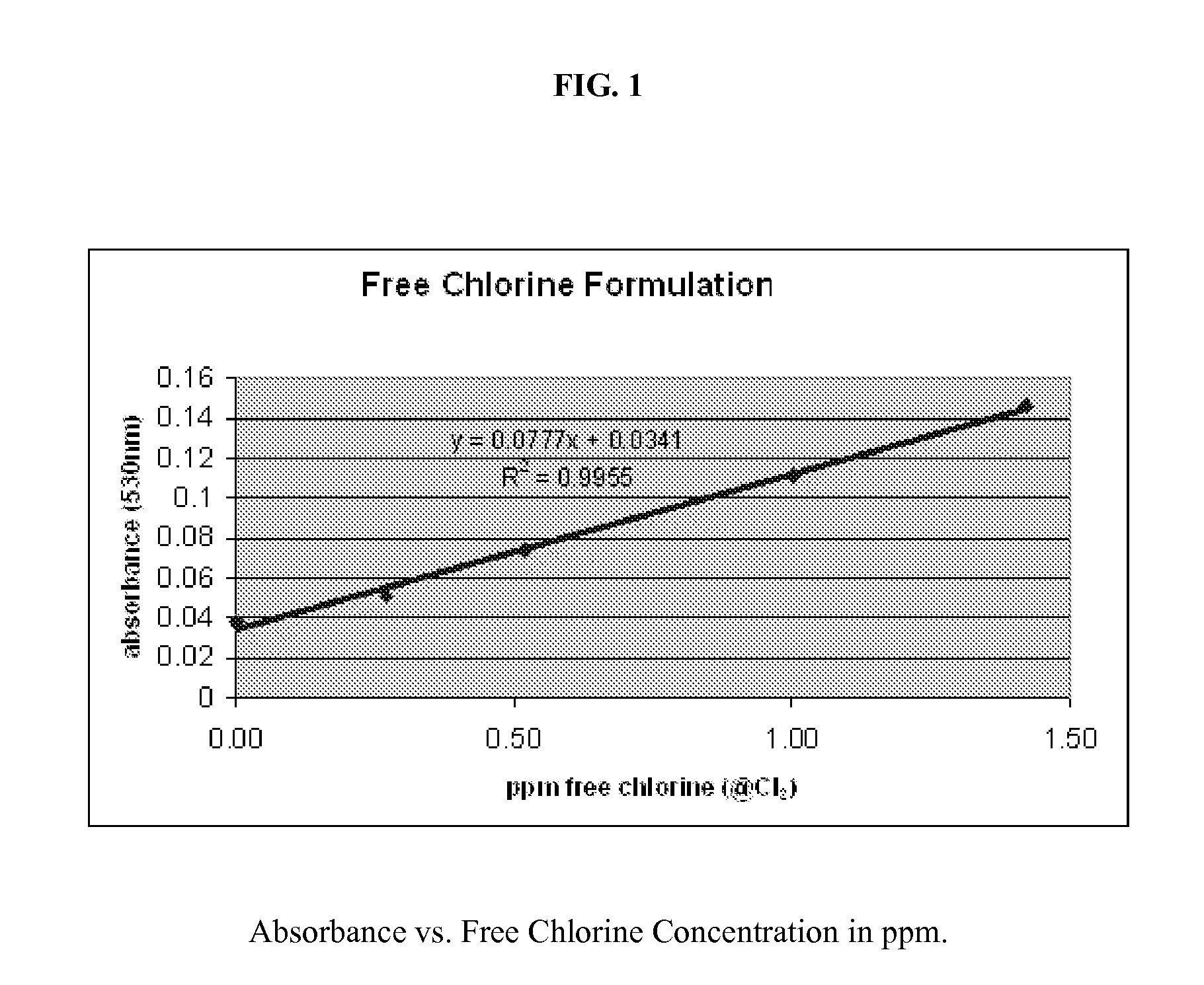

InactiveUS20080295581A1Analysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorThin film sensorAbsorbance

The concentration of an anionically charged polymer in an aqueous solution is determined with a thin solid film having a polymer matrix and a cationic dye. A sample of an aqueous solution containing at least one anionically charged polymer to be tested is applied to the film sensor. The absorbance of the film sensor is measured after the sample has been applied. The absorbance of the film sensor is then compared with a calibration curve of the absorbance of samples containing known concentrations of the anionically charged polymers to determine the concentration of anionically charged polymer in the sample.

Owner:GENERAL ELECTRIC CO

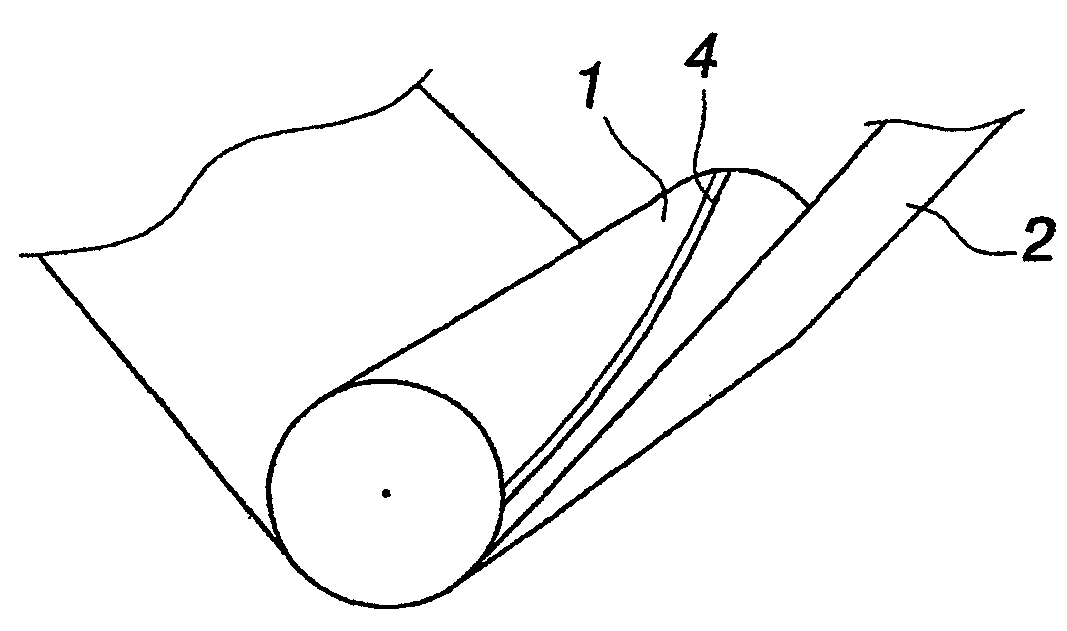

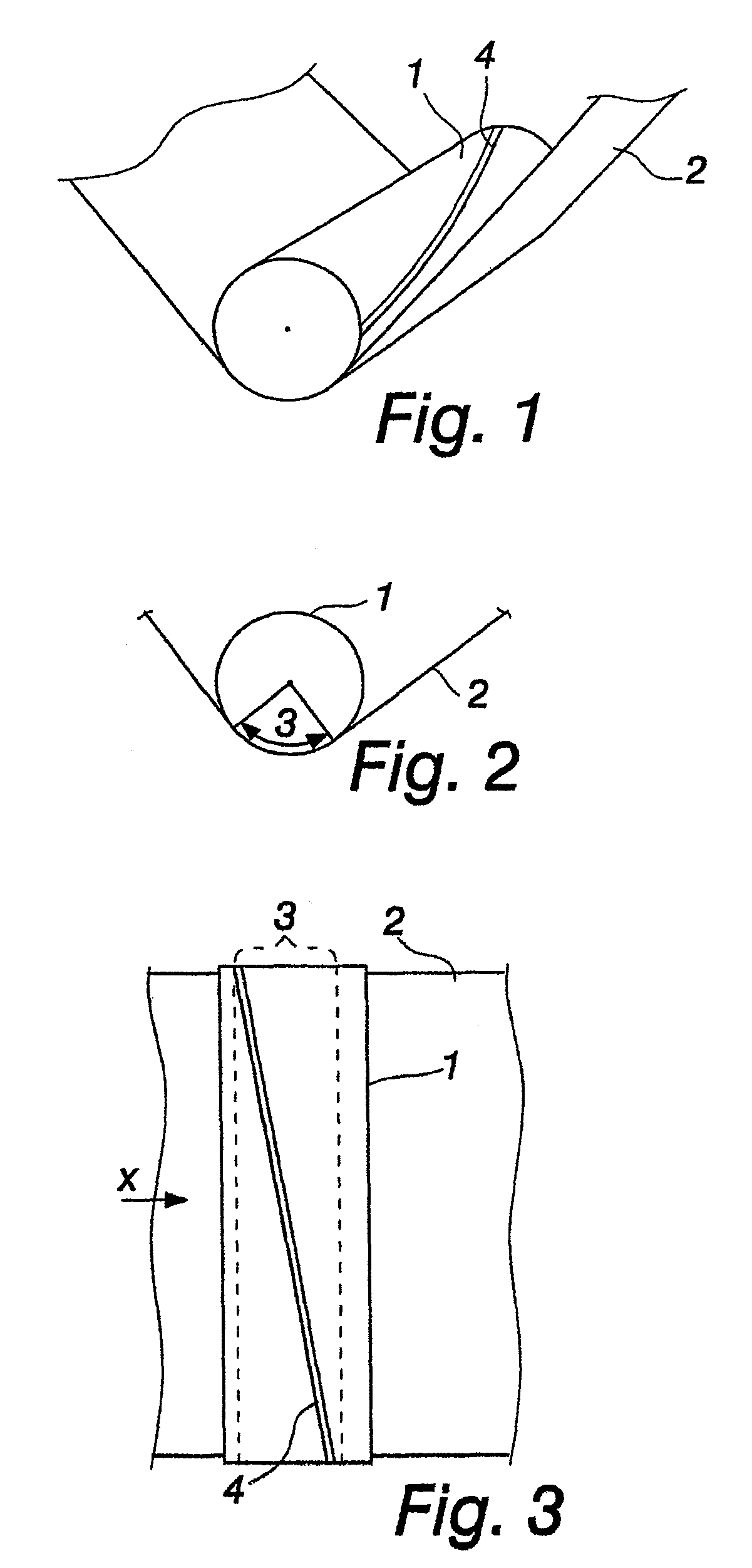

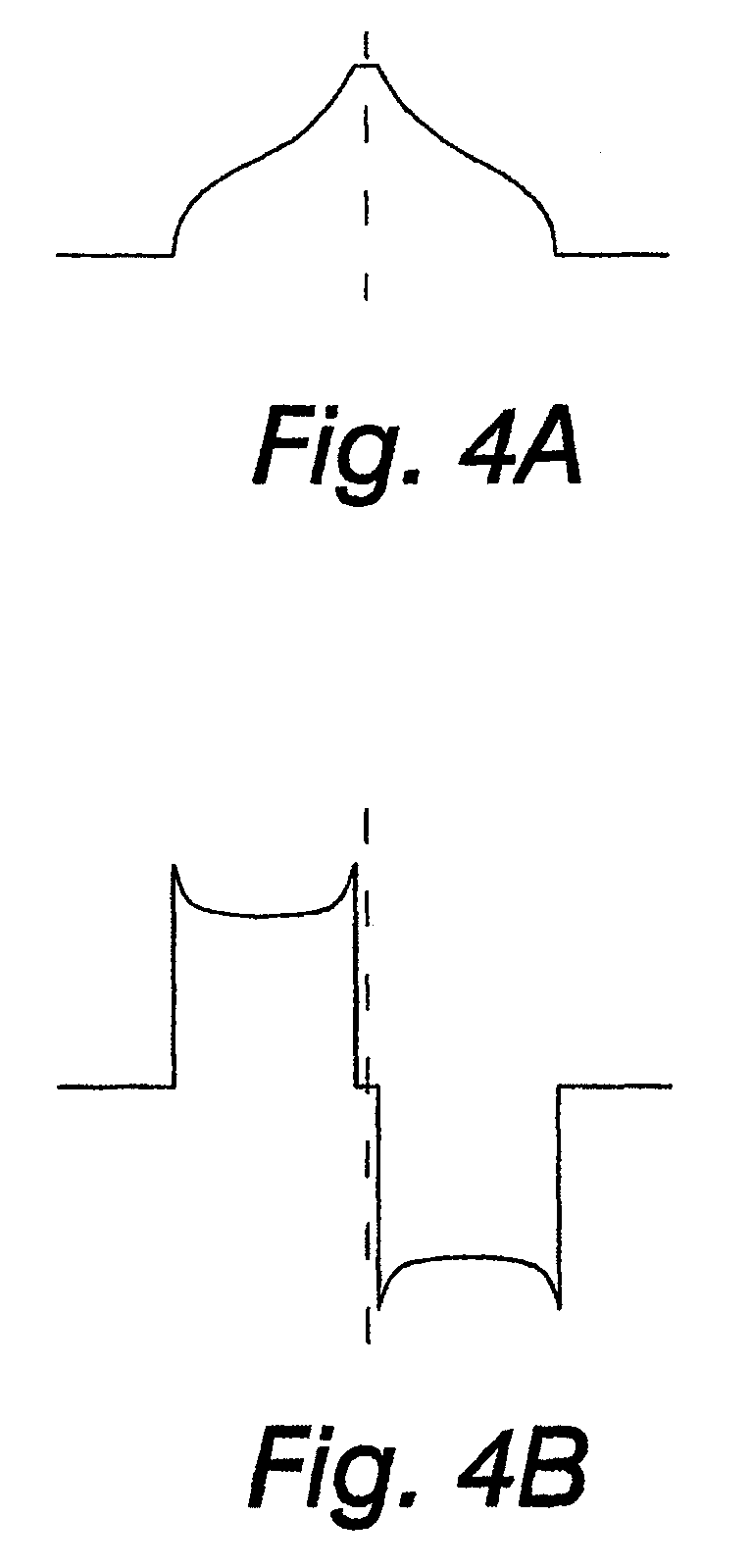

Web tension profile measuring method and roll applying the same

InactiveUS7444862B2Sufficiently precise measurementHigh measurement accuracyTesting/calibration apparatusForce measurementThin film sensorEngineering

A method and a roll for measuring a tension profile is provided. The roll has planted on its surface a spirally helical pressure-sensitive film sensor, such as an EMFi pressure-sensitive film sensor, which makes contact with a web obliquely and which, co-directionally with the web, has a measuring range which is substantially equal to or shorter than a web overlap angle when the roll is used for measuring a lateral tension profile of the web.

Owner:VALMET TECH INC

Thin film sensor for brake lining pad wear and brake temperature sensing

InactiveUS7165657B2Optical signallingBrake typesThin film sensorElectrical resistance and conductance

A modular electrical resistance sensor is positionable in gaps between brake linings for a drum brake. The modular sensor is worn with the brake linings resulting in steadily increasing electrical resistance of the modular sensor. A measurement circuit associated with the modular sensor is programmed to equate electrical resistance to the degree of wear when the sensor has assumed a steady state temperature at or near the ambient temperature. Otherwise, particularly during periods of use of the brakes, resistance and the degree of wear last calculated become arguments into a function for determining brake lining temperature.

Owner:INT TRUCK INTPROP LLC

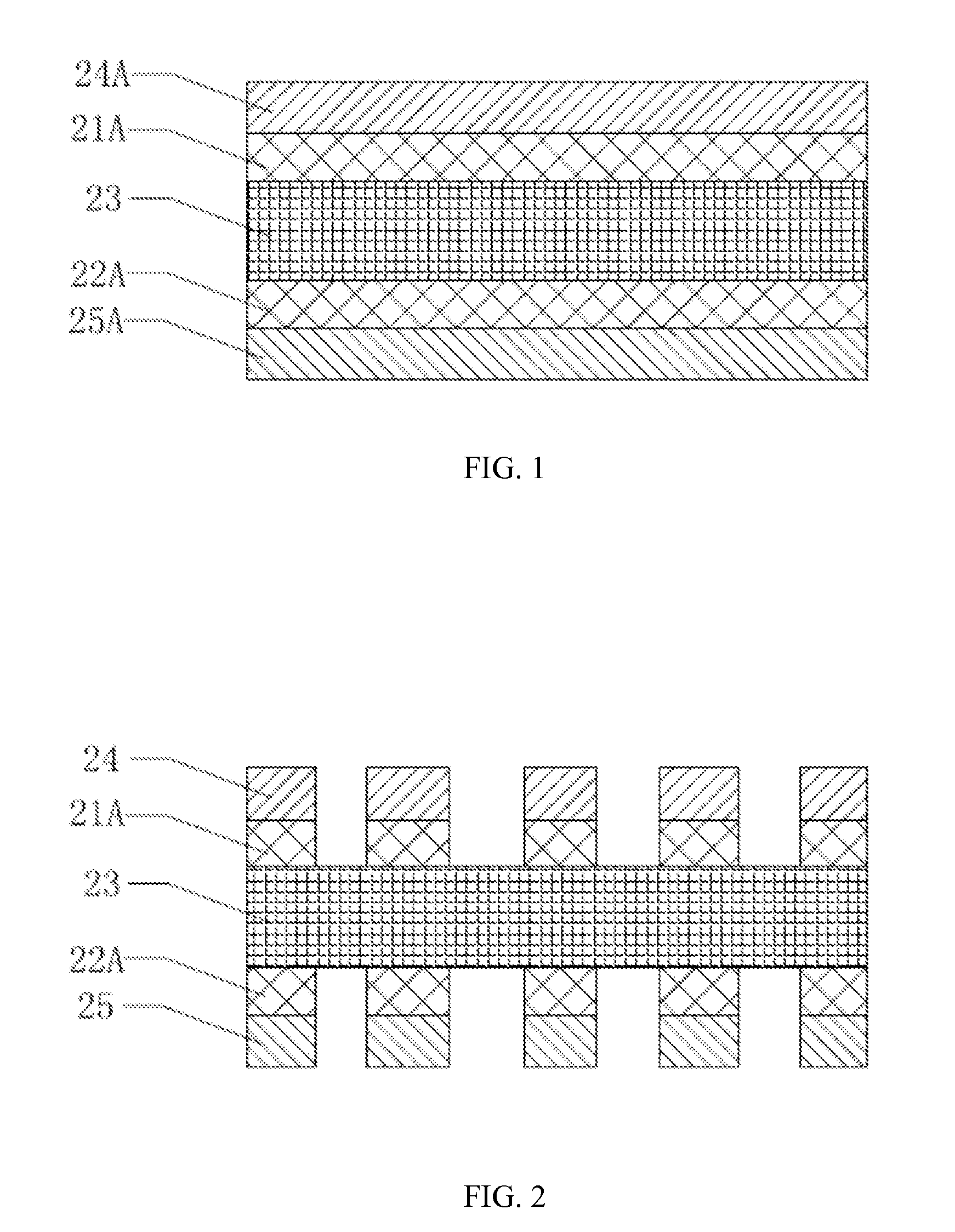

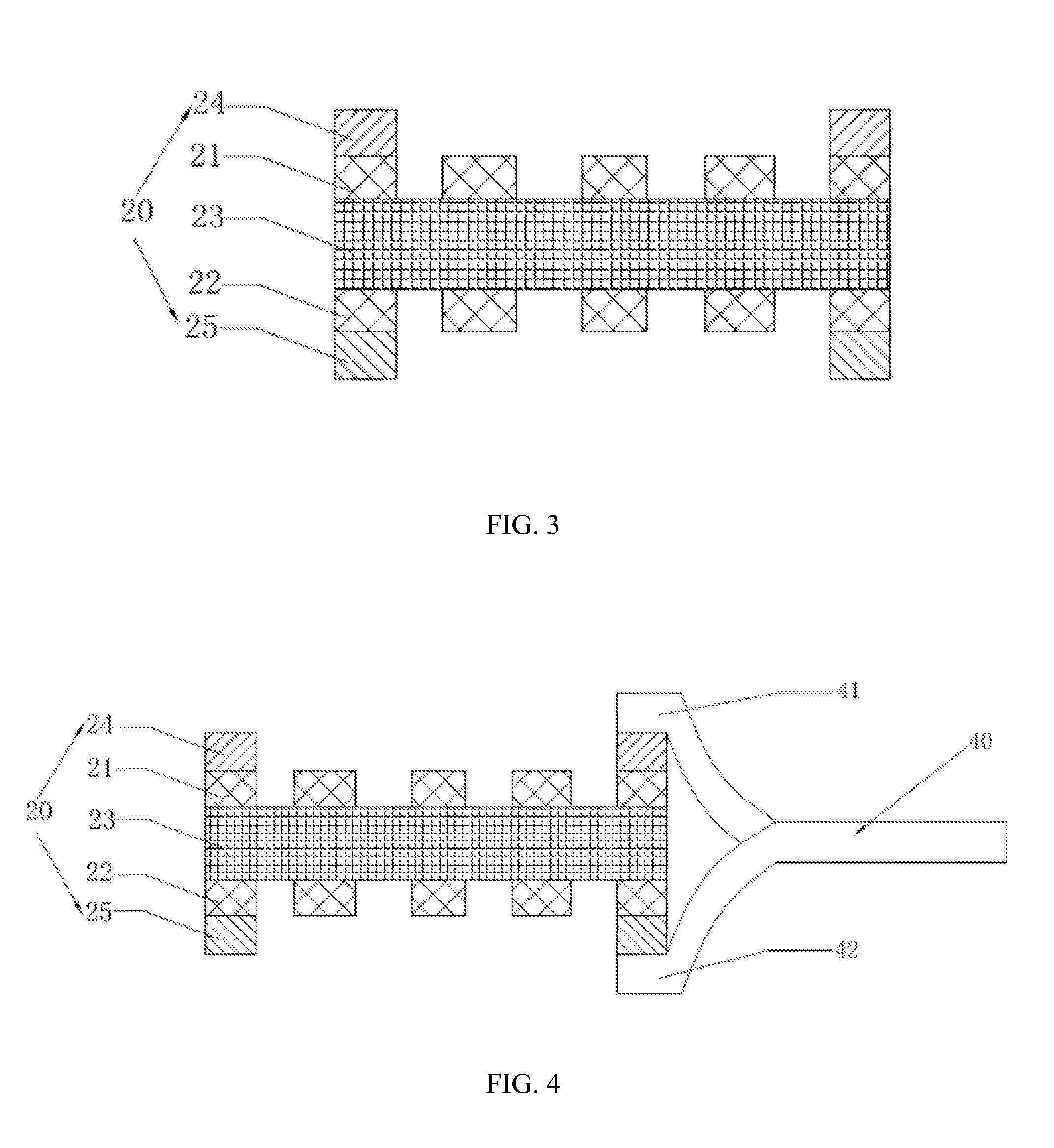

Thin film sensor, capacitive touch panel having the same and preparation method thereof and terminal product

ActiveUS20140111708A1Thinner thin filmReduce thicknessCapacitance measurementsDigital data processing detailsThin film sensorOptoelectronics

The present invention relates to a thin film sensor, capacitive touch panel having the sensor and preparation method thereof and terminal product. The thin film sensor of the present invention has only one optically conductive substrate. Specifically, only one optically transparent substrate is used, a sensing electrode layer and a driving electrode layer are coated on the upper and lower surfaces of the substrate, respectively, which helps to reduce the thickness of the thin film sensor on one hand, thus contributes to the development of light and thin of a touch panel and touch electronics; on the other hand, the material selection and the preparation process are simple, the selection of two substrates is not necessary to prepare two optically conductive thin film.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

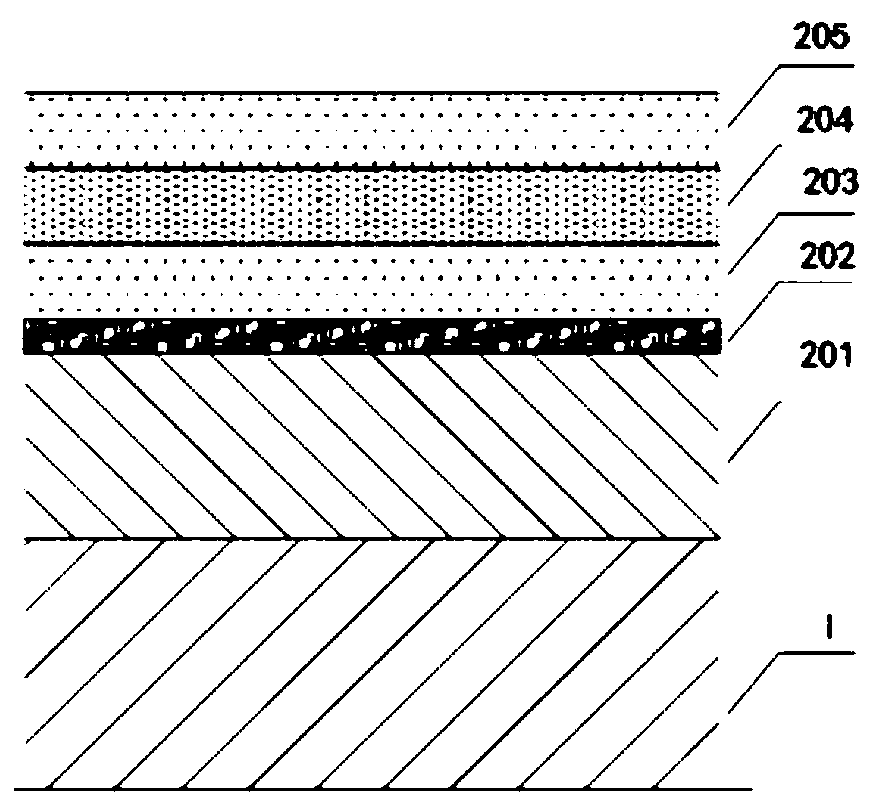

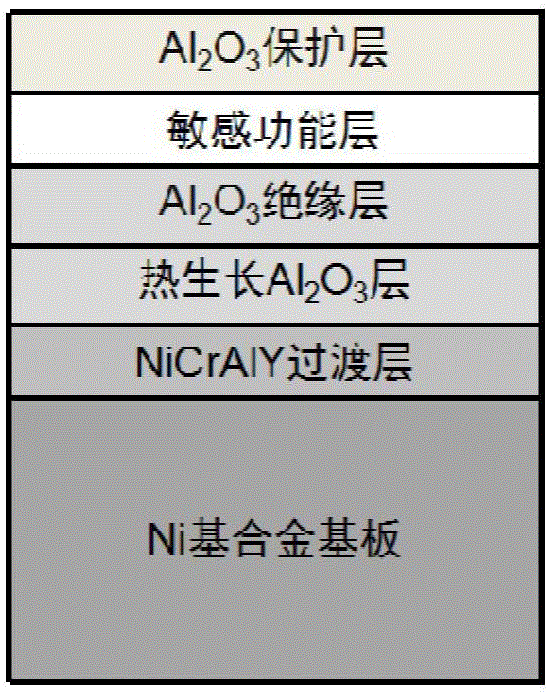

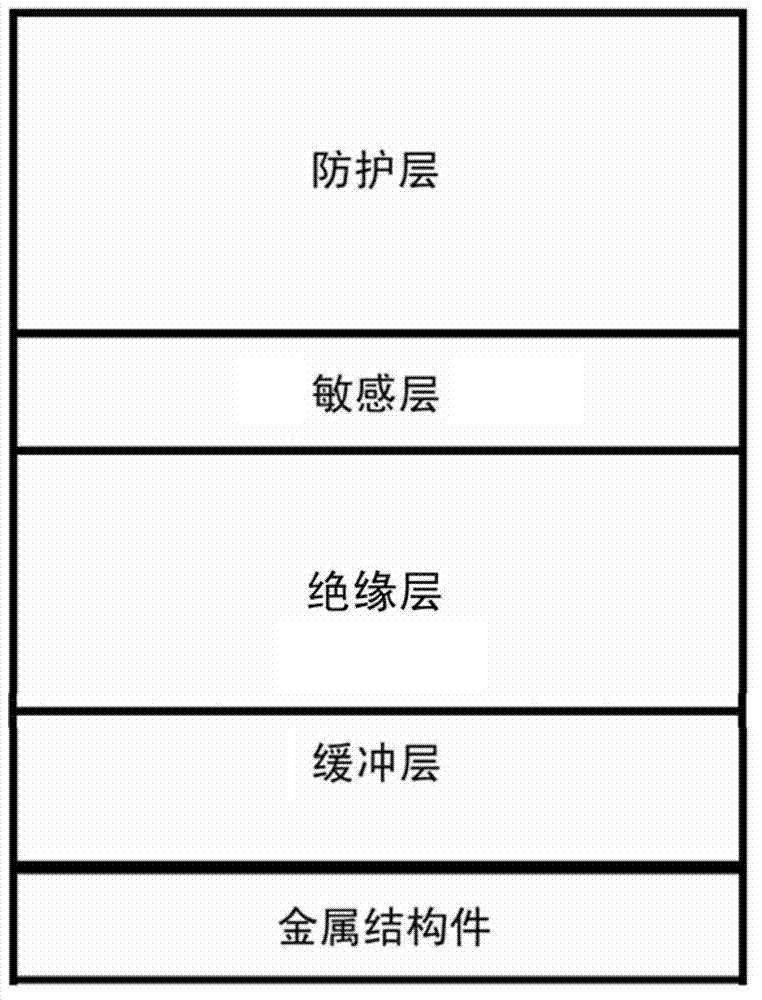

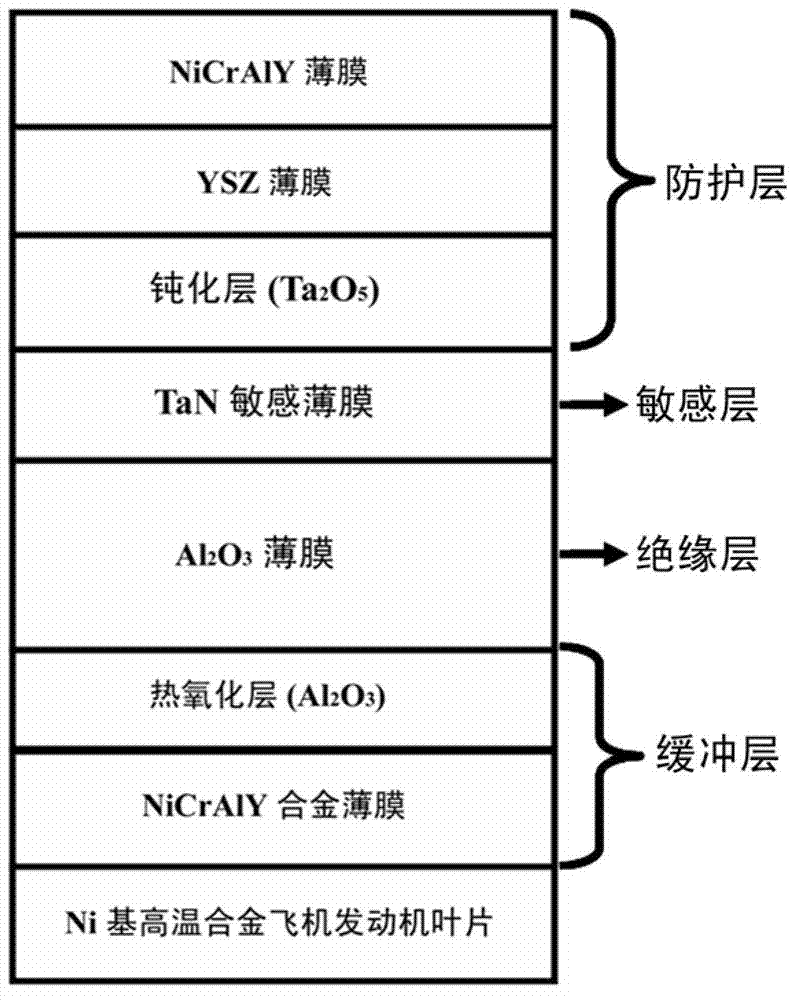

Film temperature sensor for turbine blades of aero-engine

ActiveCN109338290ASolve insulation problemsSolve sheddingMolten spray coatingThermometers using electric/magnetic elementsThin film sensorSputtering

The invention discloses a film temperature sensor for turbine blades of an aero-engine. The film temperature sensor comprises a transition layer, a thermal growing layer, an insulating layer and a thermocouple layer which are sequentially connected, wherein the thermocouple layer is formed by lapping a first thermocouple and a second thermocouple through one end part, and the lapping part forms athermal connecting point which is a measuring end; an outgoing conductor is a fine wire which has the same quality as the first thermocouple and the second thermocouple; and the outgoing conductor iscorrespondingly connected to the other end part of each of the first thermocouple and the second thermocouple through high-temperature conductive glue. According to the film temperature sensor for theturbine blades of the aero-engine, a film layer structure of the sensor is specially designed for the aero-engine in a high-temperature severe environment; the film sputtering, annealing and other preparation technologies are optimized; the ion deposition technology is carried out to directly deposit a plurality of layers of films on the surfaces of the turbine blades, and thus the function and structure integrated film sensor is obtained; the adhesion strength of the film layers is improved; the problems such as high-temperature insulating of the film layer, separating and signal exporting can be solved; and the total thickness of the film sensor is less than 25 microns, and the maximum measurement temperature is 1100 DEG C.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

Functional polymer with supported pressure-sensitive luminophore, and pressure-sensitive paint and pressure-sensitive element using same

InactiveUS6797390B2Inhibitory responsePreventing steric hindranceForce measurementBiological testingHybrid typeEvaporation

An oxygen-quenching luminophore constituting part of a pressure-sensitive luminophore is directly bonded by a covalent bond to an organic polymer compound having trimethylsilyl groups, so the luminophore molecules are retained in the polymer and free aggregation is inhibited when the organic solvent is evaporated. It is therefore possible to prevent light response from being reduced by the aggregation of the luminophore molecules during evaporation of the organic solvent, which is a drawback of forming films from conventional mixed-type pressure-sensitive paints. A thin-film sensor with uniform characteristics can be formed by spraying or application from a pressure-sensitive paint obtained by mixing a functional polymer with a solvent. In addition, a coating solution that has high reproducibility and is suitable for spraying or application can be obtained merely by dissolving the functional polymer as a single component in a suitable solvent. It is possible to obtain a functional polymer, a pressure-sensitive paint, and a pressure-sensitive element in which a reduction in light response due to luminophore aggregation can be prevented, and a thin sensor film having uniform characteristics can be formed, even when the organic solvent has evaporated.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

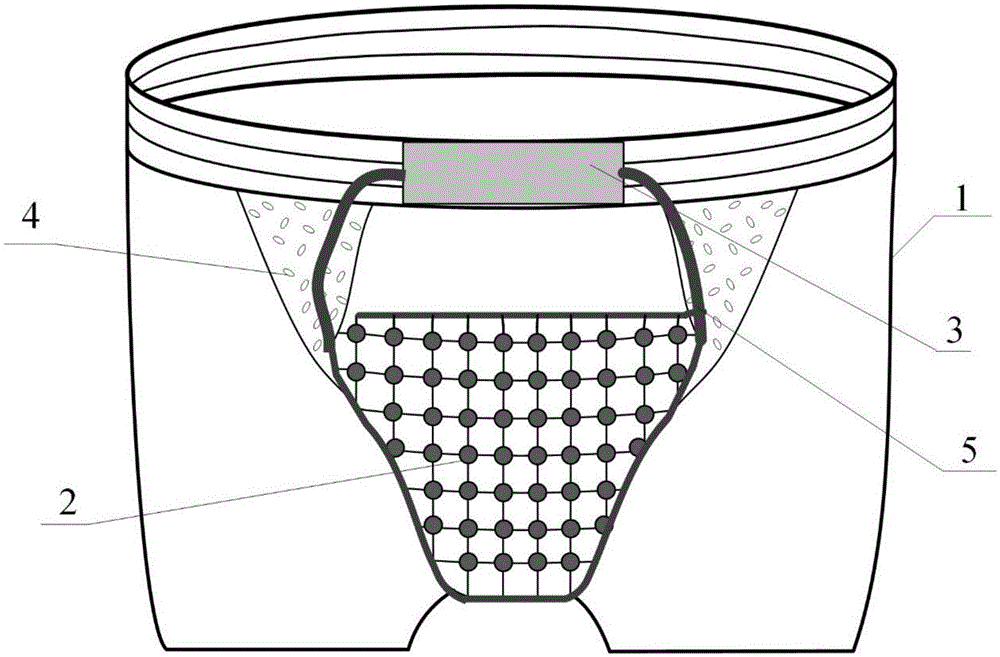

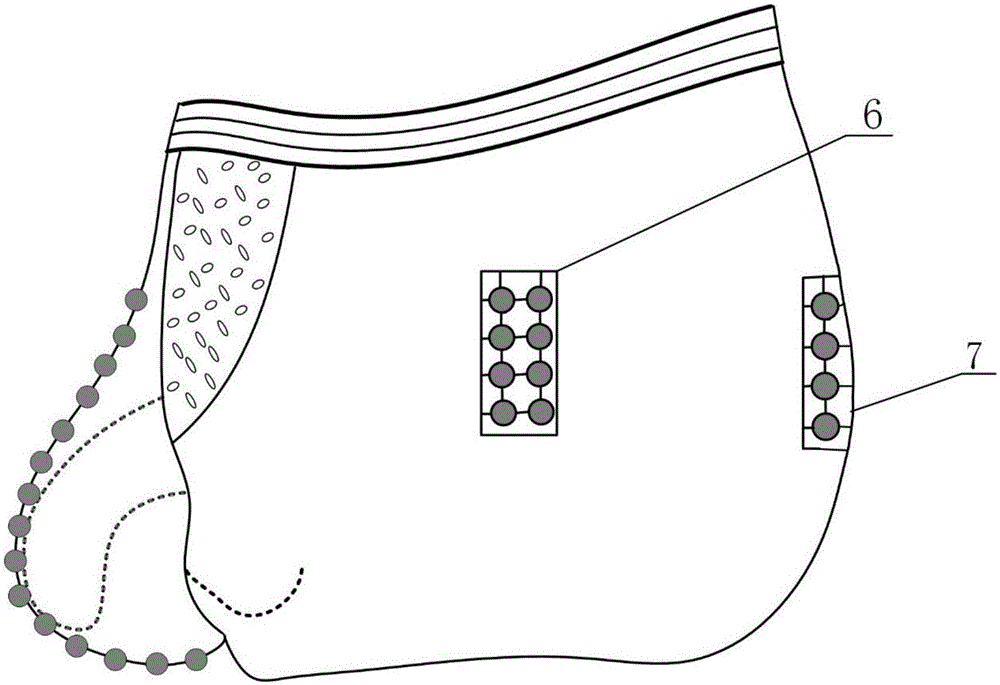

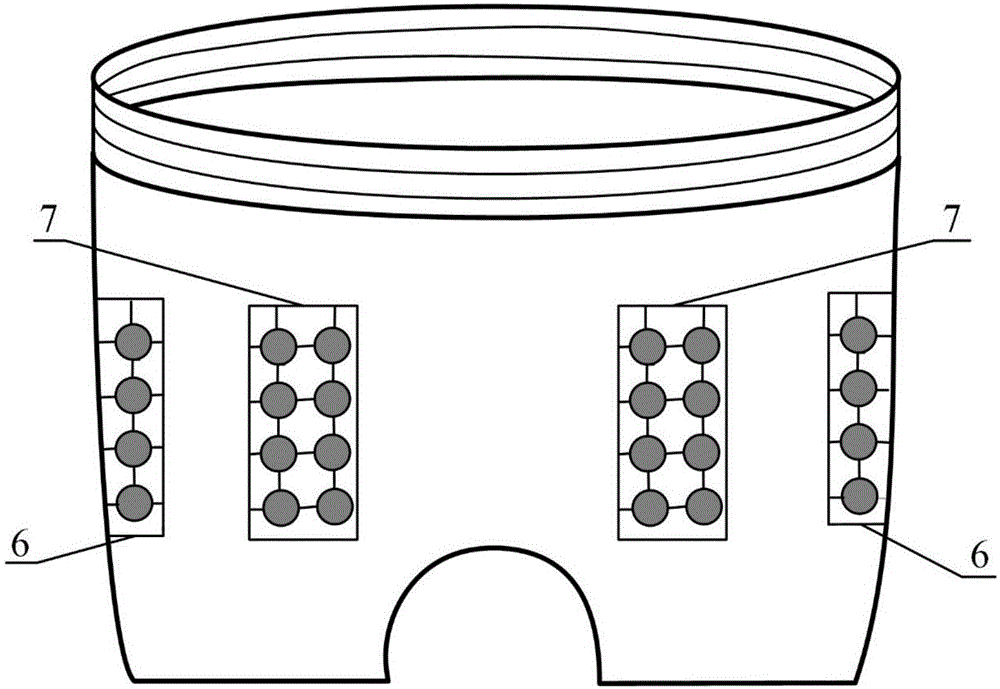

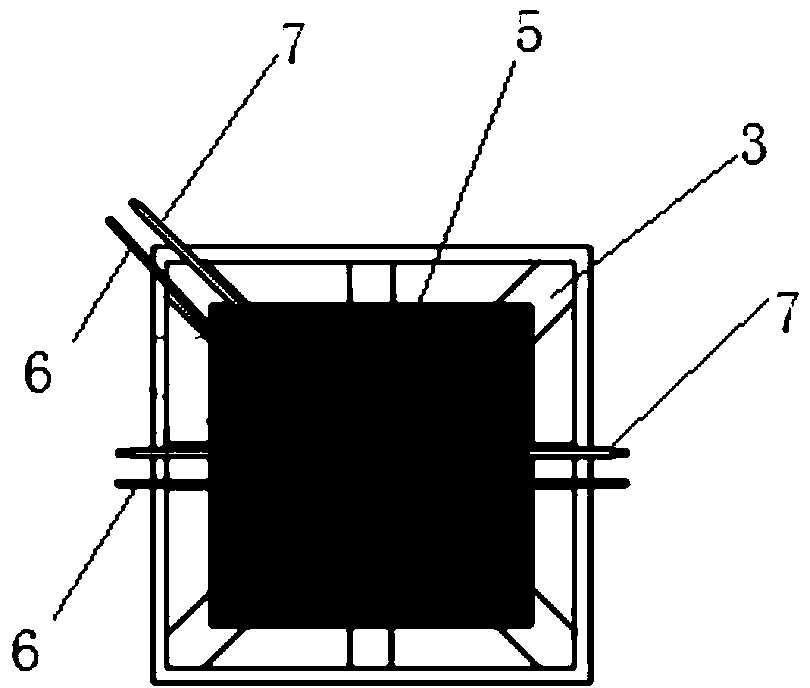

Intelligent monitoring underpants capable of evaluating male sexual function

ActiveCN105054942AImprove accuracyHelp preserveTransmission systemsDiagnostic recording/measuringThin film sensorPenis

The invention discloses a piece of intelligent monitoring underpants capable of evaluating the male sexual function. The pressing and changing conditions of an underpants contact region and particularly the night erection state can be continuously and dynamically monitored and recorded in the male pennies erection process through arranging a multi-point flexible grid sensing system with a distributive pressure sensing function between two legs at the front side of boxer shorts or triangle pants, so that the monitored male sexual function is truly and objectively evaluated, wherein the grid sensing system is of a row and line crossed array structure, each intersection is provided with a piezoresistive flexible film sensor, and an electronic switch is controlled by a signal recording and storing box arranged on the underpants, so that one-to-one scanning is realized, and the pressure values on all points in the whole sensing region can be rapidly detected and recorded. The intelligent monitoring underpants capable of evaluating the male sexual function is natural and convenient to wear, little in psychological effects of monitored persons, capable of continuously monitoring for a long term as well as reliable and accurate in result.

Owner:成都瑞迪康医疗科技有限公司

Testing device for resin matrix composite material heat mold pressing curing deformation and manufacturing and using method thereof

ActiveCN104315990AReduce difficultyAvoid damageUsing optical meansSpecial purpose recording/indication apparatusTemperature resistanceStrain sensor

The invention relates to a testing device for resin matrix composite material hot mold pressing curing deformation and a manufacturing and using method thereof. The testing device comprises resin matrix composite material prepreg and FBG sensors arranged in the prepreg. The method comprises the steps that the FBG sensors are laid on the nth layer in the fiber axial direction to be used as strain sensors, reference sensors for temperature compensation are laid on the nth layer or the (n+1)th layer or the (n-1)th layer, lead grooves are formed in a mold side wall frame board, the mold side wall frame board is coated with a high temperature resistance polymer film, leads of the sensors are led out of the lead grooves and connected with a signal receiver, a mold is closed, hot press molding is carried out, and curing forming on-line real-time monitoring is achieved. The problems that during composite material heat mold pressing curing deformation monitoring, grid regions are fragile and prone to breakage, and monitoring signals cannot be effectively transmitted if leading is inappropriate in a closed full-rigid hot mold pressing mold are solved, and meanwhile the problem that a composite material structure part with built-in FBG sensors is hard to break away from the full-rigid mold is solved.

Owner:SHANDONG UNIV

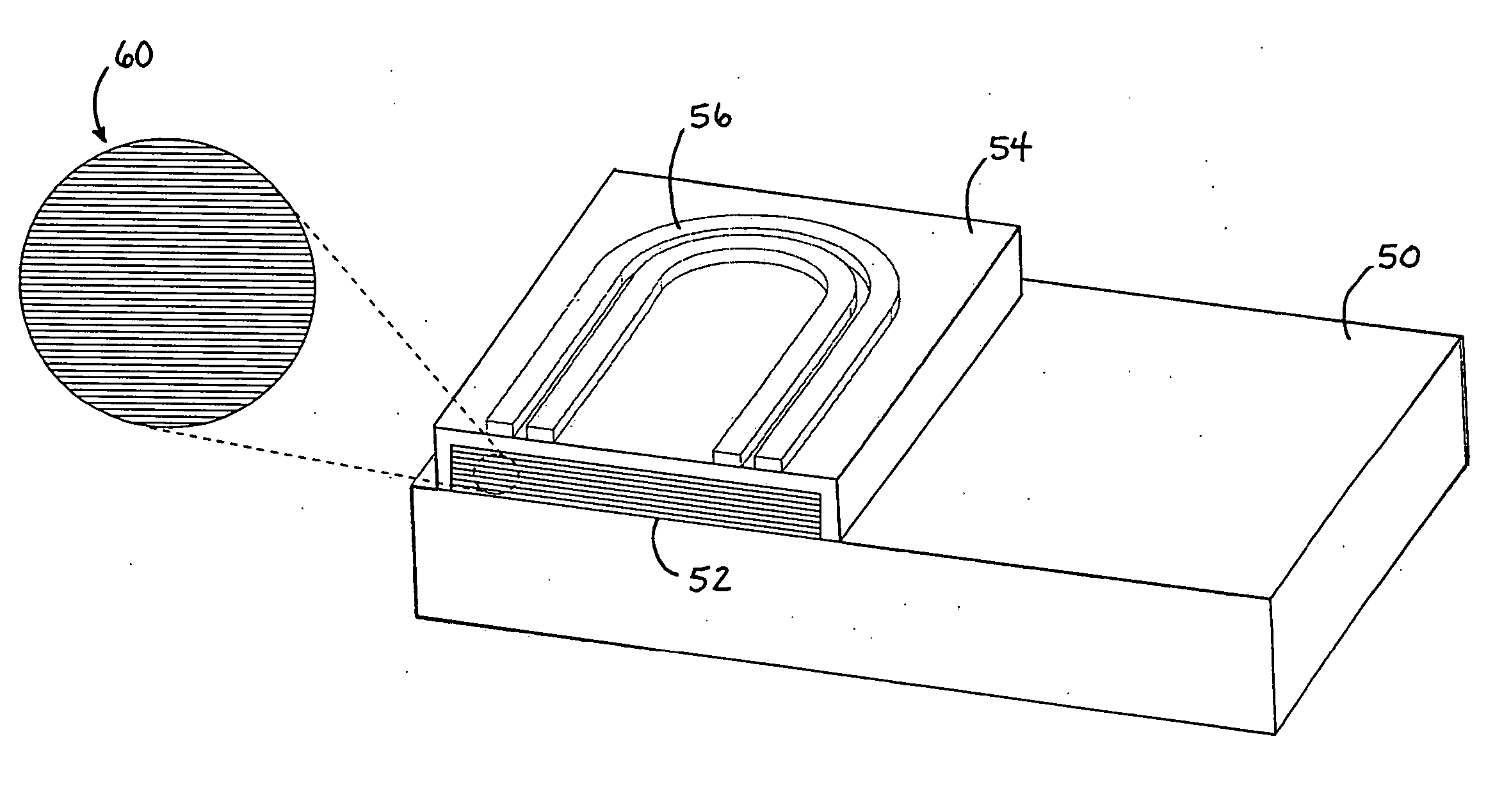

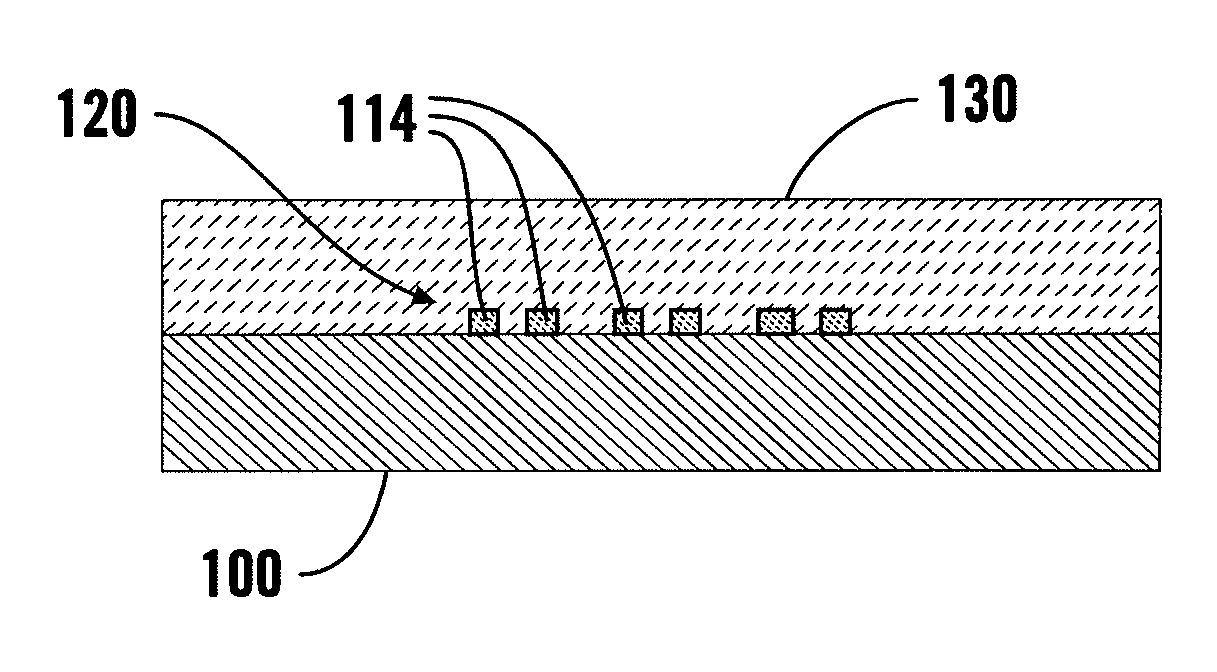

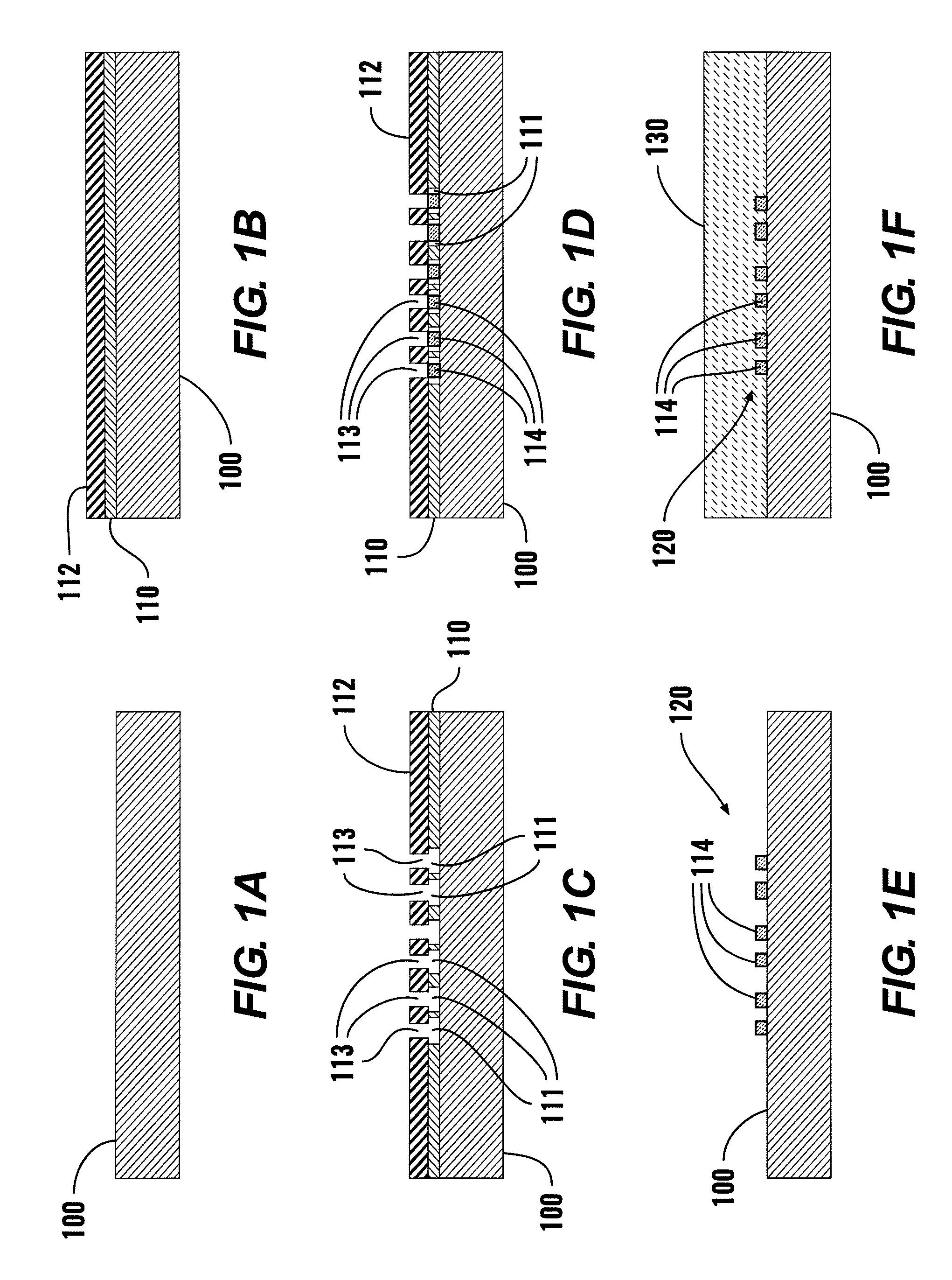

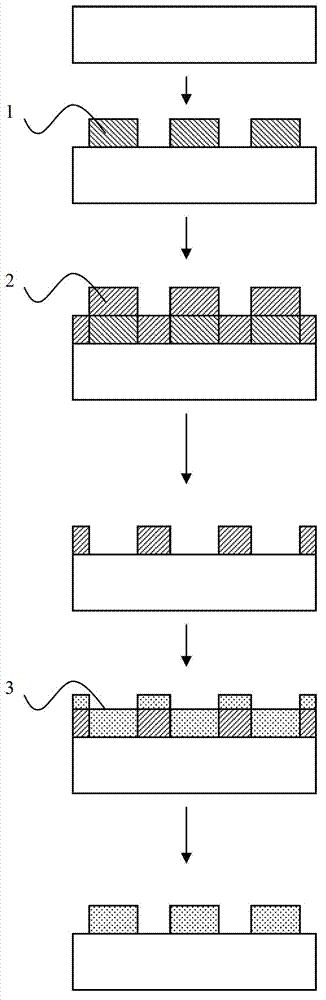

Embedded thin film sensors and methods of embedding thin film sensors

An embedded sensor or other desired device is provided within a completed structure through a solid-state bonding process (e.g., by diffusion bonding) and / or through a dynamic bonding process (e.g., by brazing). The embedded sensor or other desired device is provided on a substrate through any know or later-developed method (e.g., a photolithography or conductive ink printing process). A cover is then bonded to the substrate using a solid-state bonding process and / or a dynamic bonding process. The solid-state bonding process and / or dynamic bonding process may include providing heat and / or pressure to the substrate, the cover and / or a bonding agent (e.g., a filler metal or alloy) to bond the substrate and the cover together.

Owner:WISCONSIN ALUMNI RES FOUND

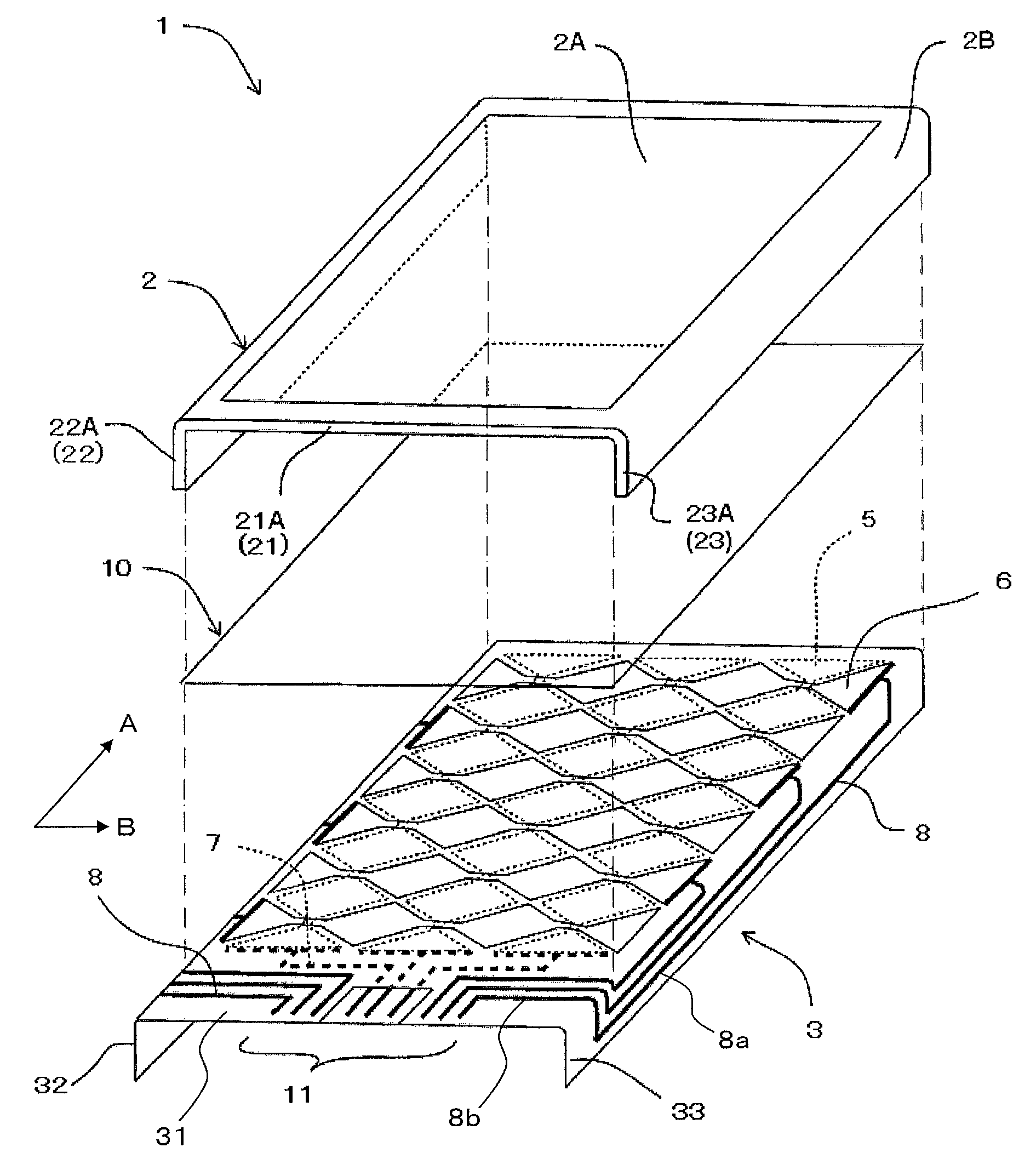

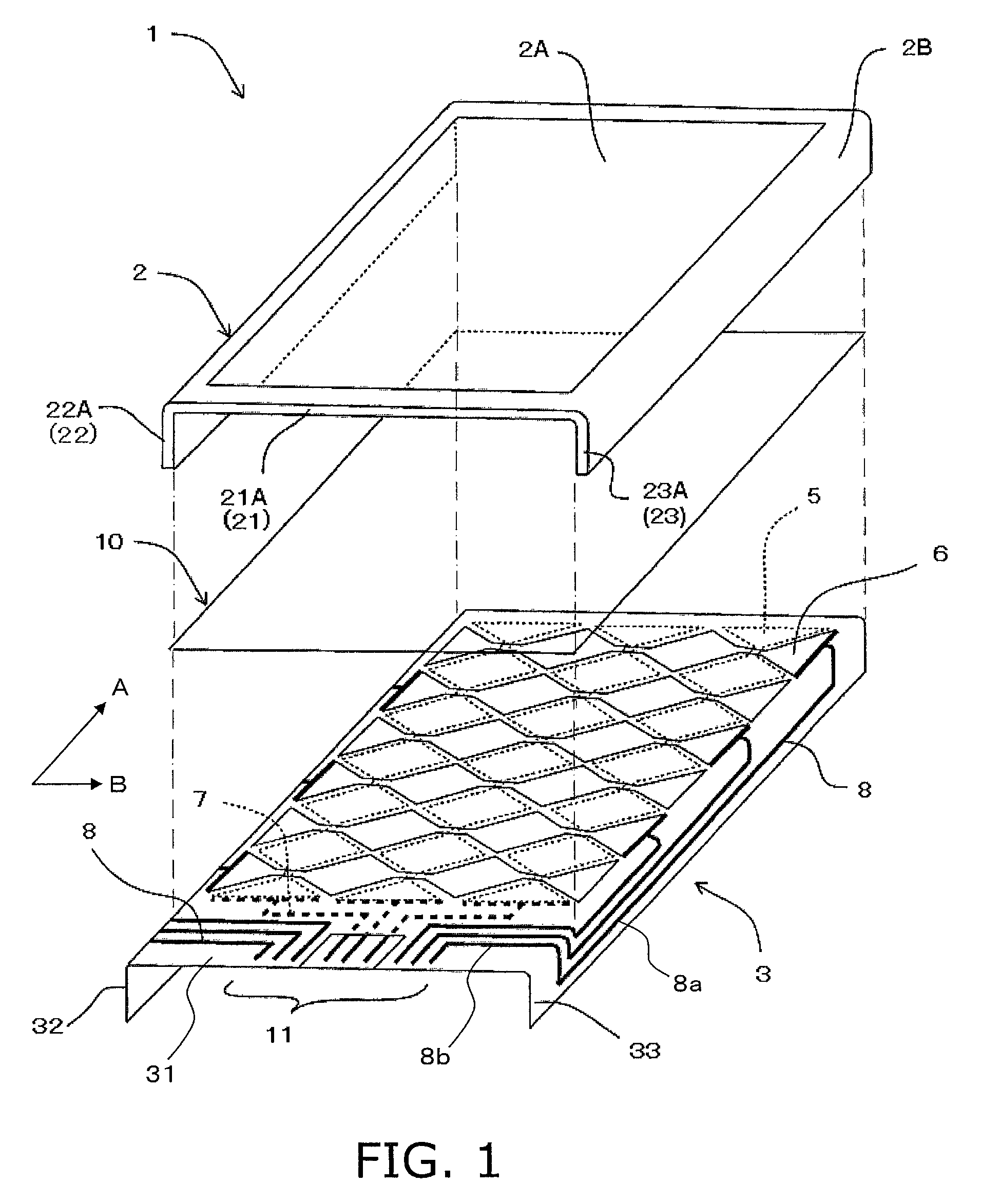

Capacitance type touch screen

ActiveUS9122088B2Non-conventional frame narrowing of the touch screenPossible to achieveDigital data processing detailsNon-linear opticsThin film sensorCapacitance

A capacitance type touch screen includes a cover lens and a film sensor. The film sensor includes a base film, first transparent electrodes arranged side by side extending in an A direction, second transparent electrodes insulated from the first electrodes and arranged side by side extending in B direction while crossing the first electrodes, a plurality of first lead wirings connected to the first electrodes and drawn to connection terminals, and a plurality of second lead wirings connected to the second electrodes and drawn to connection terminals. The first and second wirings are hidden by the cover lens decorated area. The film sensor includes a top-plate-corresponding-portion facing the cover lens top plate rear surface, and rising portions facing a rear surface of at least one of the first and second side plates. All or most of the second wirings is positioned in the rising portions.

Owner:NISSHA PRINTING COMPANY

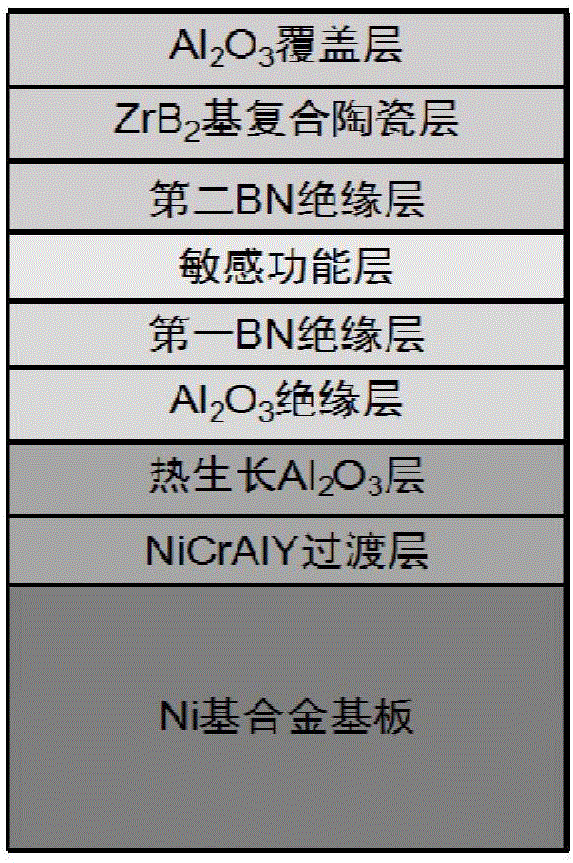

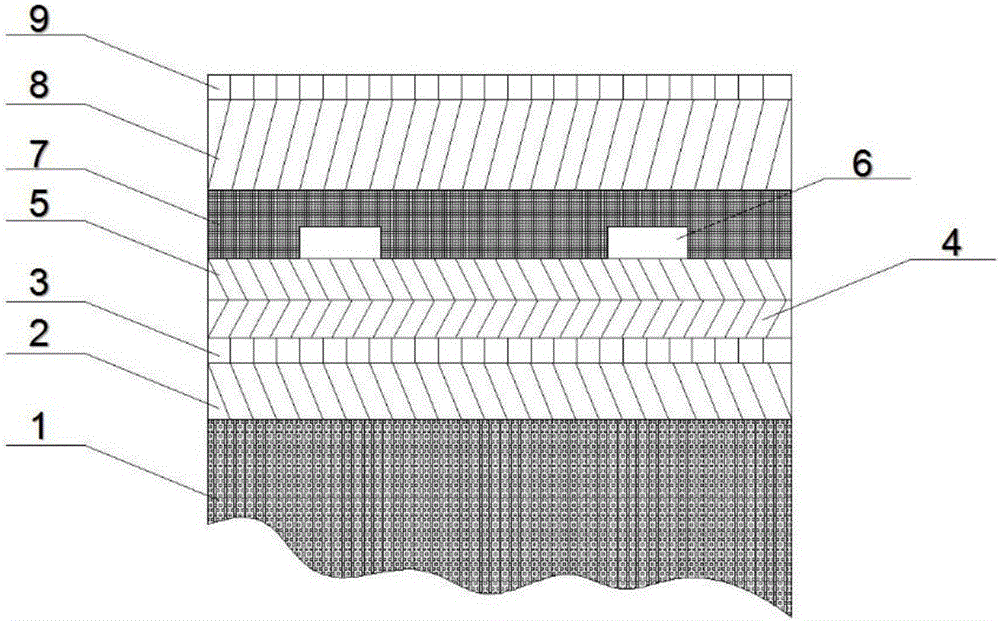

Antioxidant composite protective layer for high-temperature film sensor and manufacturing method of antioxidant composite protective layer

InactiveCN106498355AStrong covalent bond propertiesExcellent high temperature insulation performanceVacuum evaporation coatingSputtering coatingThin film sensorSputtering

The invention discloses an antioxidant composite protective layer for a high-temperature film sensor and a manufacturing method of the antioxidant composite protective layer, and belongs to the technical field of film sensors. The antioxidant composite protective layer sequentially comprises a BN insulation layer, a ZrB2-based composite ceramic layer and a Al2O3 covering layer from bottom to top, wherein the BN insulation layer, the ZrB2-based composite ceramic layer and the Al2O3 covering layer are sequentially deposited on a sensitive function layer of the film sensor in the way of evaporation or sputtering or the like. By means of the antioxidant composite protective layer for the high-temperature film sensor, the antioxidant protective requirements of the aero-engine high-temperature film sensor at the high temperature of 1000-1700 DEG C can be met, the stability and reliability of the film sensor in high-temperature high-pressure severe environment are effectively improved, and the service life of the film sensor in high-temperature high-pressure severe environment is effectively prolonged.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Film sensors for detecting free chlorine

InactiveUS20090004747A1Biological testingInvestigating presence of gasesThin film sensorCompound (substance)

The present invention discloses a thin reagent containing film sensor for detecting and measuring free chlorine in water, where components of the film sensor are a polymeric substrate that contains reactive material, an organic polyhydroxy compound, a reagent that creates an associated polymeric matrix, and an indicator; and a method for making the same. The film sensor can be formed to fit a specific dimension or shape. The film sensor swells or dissolves when exposed to aqueous solutions so that said reagent is released so that it can react with free chlorine, or the film sensor swells when exposed to aqueous solutions so that the aqueous solution diffuses into the film sensor and reacts with said reagent contained within the swollen film sensor.

Owner:GENERAL ELECTRIC CO

Member with thin film sensor and manufacturing method of member

InactiveCN103486961AImprove job stabilityImprove the protective effectForce measurementElectrical/magnetic solid deformation measurementThin film sensorEngineering

The invention provides a member with a thin film sensor, and belongs to the field of material and sensing technology. The thin film sensor is arranged on the surface of the member in a deposited or coated mode. The member with the thin film sensor has the advantages that manufacturing of the thin film sensor on the surface of the members with various curve surfaces can be adapted to, the sensor has good adhesive force, the sensor is protected reliably, and long-time work stability of the thin film sensor is good.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

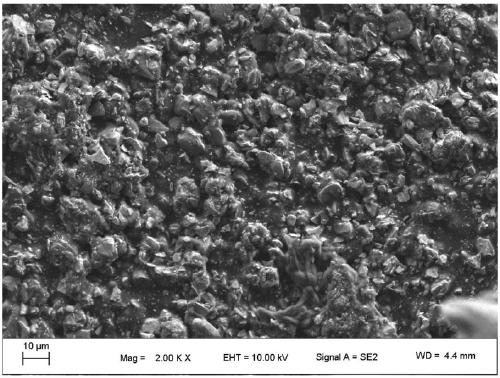

Sensitive printing ink material, flexible pressure film sensor and preparation method of flexible pressure film sensor

InactiveCN109682508AImproved Variation Curve RelationshipSimple structureInksForce measurement using piezo-resistive materialsElectrical resistance and conductanceMan machine

The invention provides a sensitive printing ink material, a flexible pressure film sensor and a preparation method of the flexible pressure film sensor. The flexible pressure film sensor comprises a first insulating protective layer, a conductive electrode layer, a supporting adhering layer, a sensitive printing ink layer and a second insulating protective layer; the conductive electrode layer andthe sensitive printing ink layer are arranged between the first insulating protective layer and the second insulating protective layer; the sensitive printing ink layer is composed of conductive sensitive printing ink materials with concave-convex surface micro structures; the supporting adhering layer is located between the first insulating protective layer and the second insulating protective layer, and bonds the first insulating protective layer and the second insulating protective layer. The flexible pressure film sensor has the advantages that a force-resistance change curve relation isimproved, the intensity of external stimulating force can be recognized to a certain degree, and the flexible pressure film sensor is well applied to the fields of human body pressure distribution detection, an automatic safety seat system and man-machine touch control.

Owner:BEIGU NEW MATERIAL TECH SHANGHAI

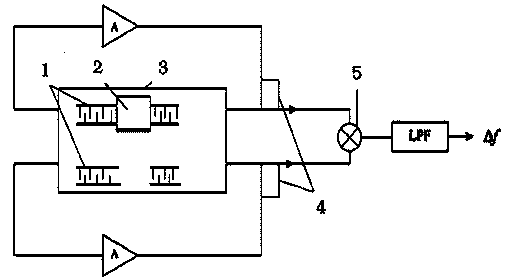

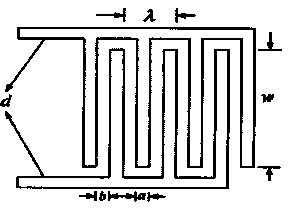

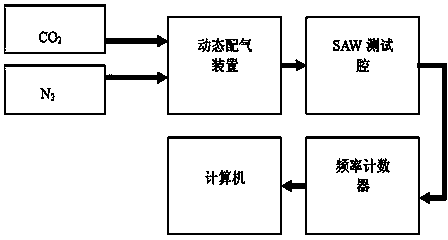

Manufacturing method of all-printed electronic carbon dioxide thin-film SAW (Surface Acoustic Wave) sensor

InactiveCN103994939ASimple processLow costWeighing by absorbing componentThin film sensorMechanical engineering

The invention relates to a manufacturing method of an all-printed electronic carbon dioxide thin-film SAW (Surface Acoustic Wave) sensor. The manufacturing method disclosed by the invention specifically comprises the following steps: selecting a piezoelectric substrate; designing and printing an electrode; preparing and printing a sensitive material; and designing and printing a driving circuit. Compared with the traditional microelectronic process, the carbon dioxide thin-film SAW sensor prepared based on printed electronics has the obvious advantages of being low in cost, simple and rapid in manufacturing process, environmentally friendly and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

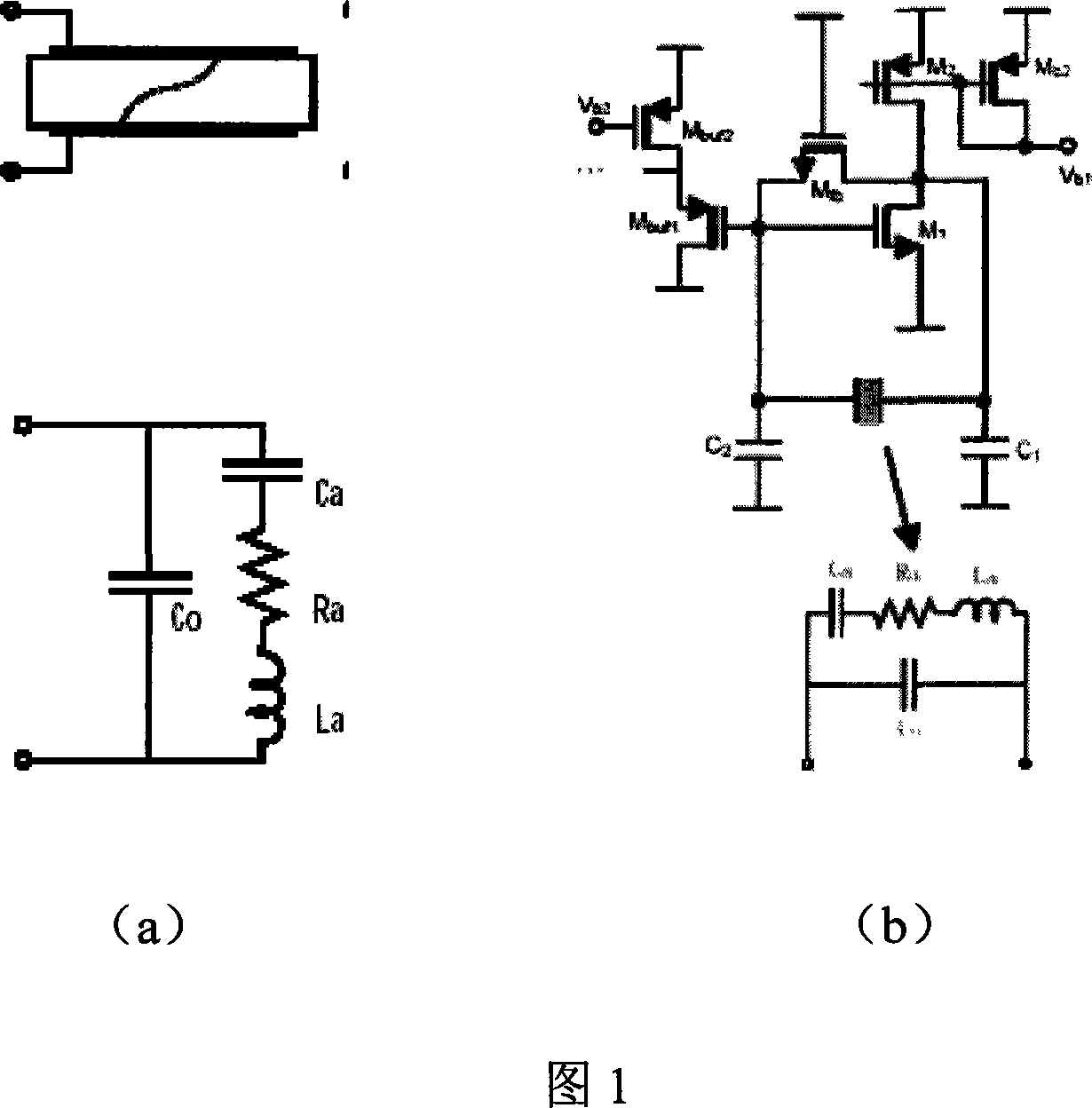

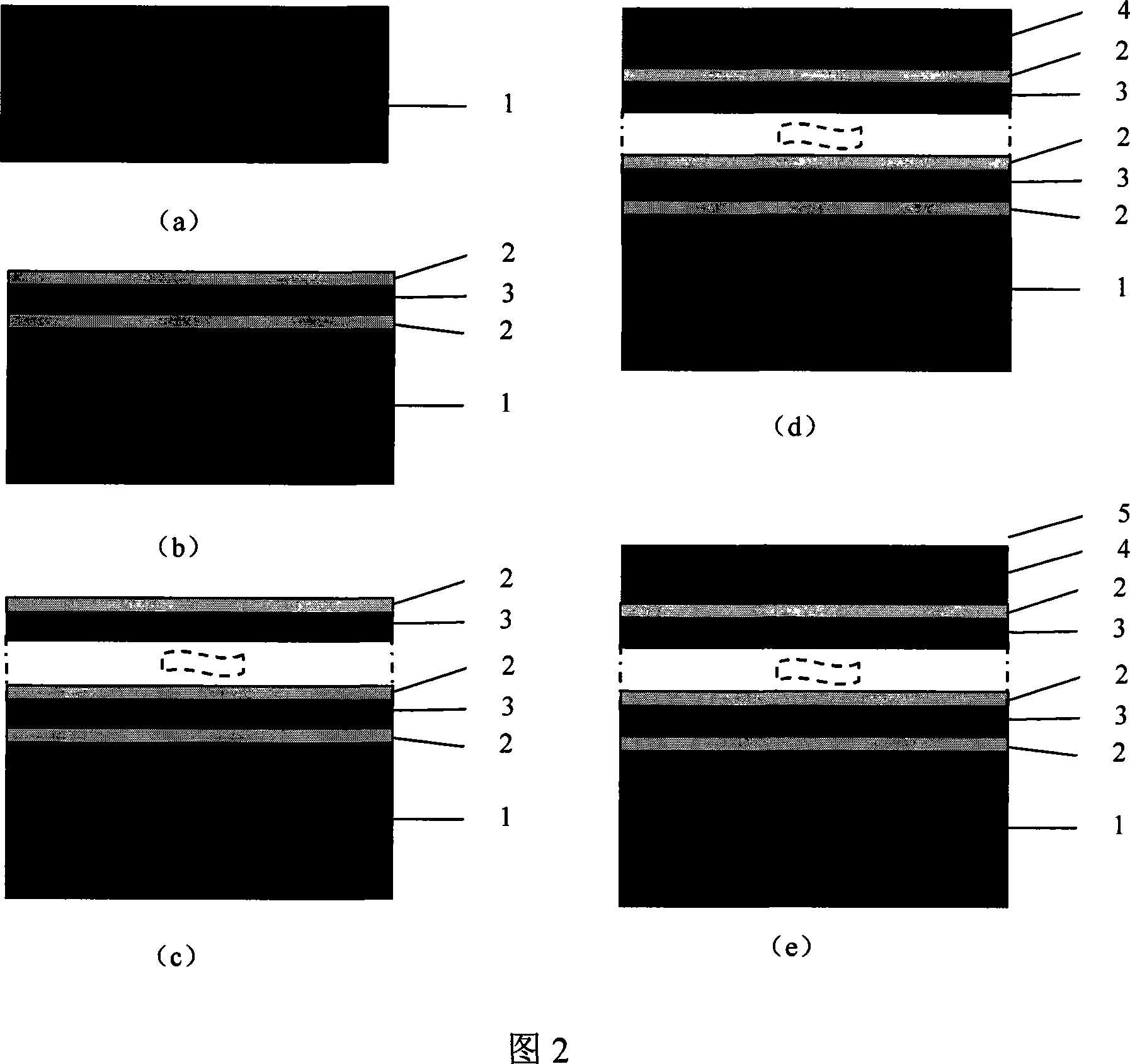

Silicon-base piezoelectric film sensor for biological micromass detection and its making process

ActiveCN101046457ARaise the resonant frequencyHigh detection sensitivityMaterial analysis using acoustic emission techniquesMaterial analysis by electric/magnetic meansThin film sensorMicrowave

The present invention is silicon-base piezoelectric film sensor for biological micro mass detection and its making process. The silicon-base piezoelectric film sensor is made through the following steps: depositing Bragg reflection layer of one quarter wavelength thickness on a (100) orientation silicon chip, depositing one piezoelectric film layer and one gold electrode layer, forming electrode structure matching standard microwave measurement, and annealing. During detection, serial biological probes are coated on the silicon-base piezoelectric film sensor and the sampled biological micro mass is combined so as to measure the changing sensor resonance frequency and to obtain the biological micro mass. The present invention has combination between multifunctional integral sensing technology and modern biotechnology to complete biological micro mass measurement in high flux, high specificity and high sensitivity.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com