Patents

Literature

984results about How to "Solve shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Positive electrode current collector and preparation method and application thereof

ActiveCN107123812AIncrease energy densityReduce thicknessFinal product manufactureElectrode carriers/collectorsEvaporationAluminum metal

The invention discloses a positive electrode current collector and a preparation method and an application thereof. The positive electrode current collector is of a multilayered structure and comprises a plastic thin film, wherein the upper and lower surfaces of the plastic thin film are coated with a bonding force enhancement layer, an aluminum metal coating layer and an anti-oxidization layer in sequence. The preparation method comprises the steps of coating the bonding force enhancement layer, the aluminum metal coating layer and the anti-oxidization layer through an evaporation film-coating process in sequence. The application of the positive electrode current collector mainly refers to an application in a lithium ion battery. By virtue of the positive electrode current collector, light weight of the battery can be realized, energy density can be improved, the aluminum coating layer does not fall off easily, and easy oxidization can be avoided.

Owner:CONTEMPORARY AMPEREX TECH CO +1

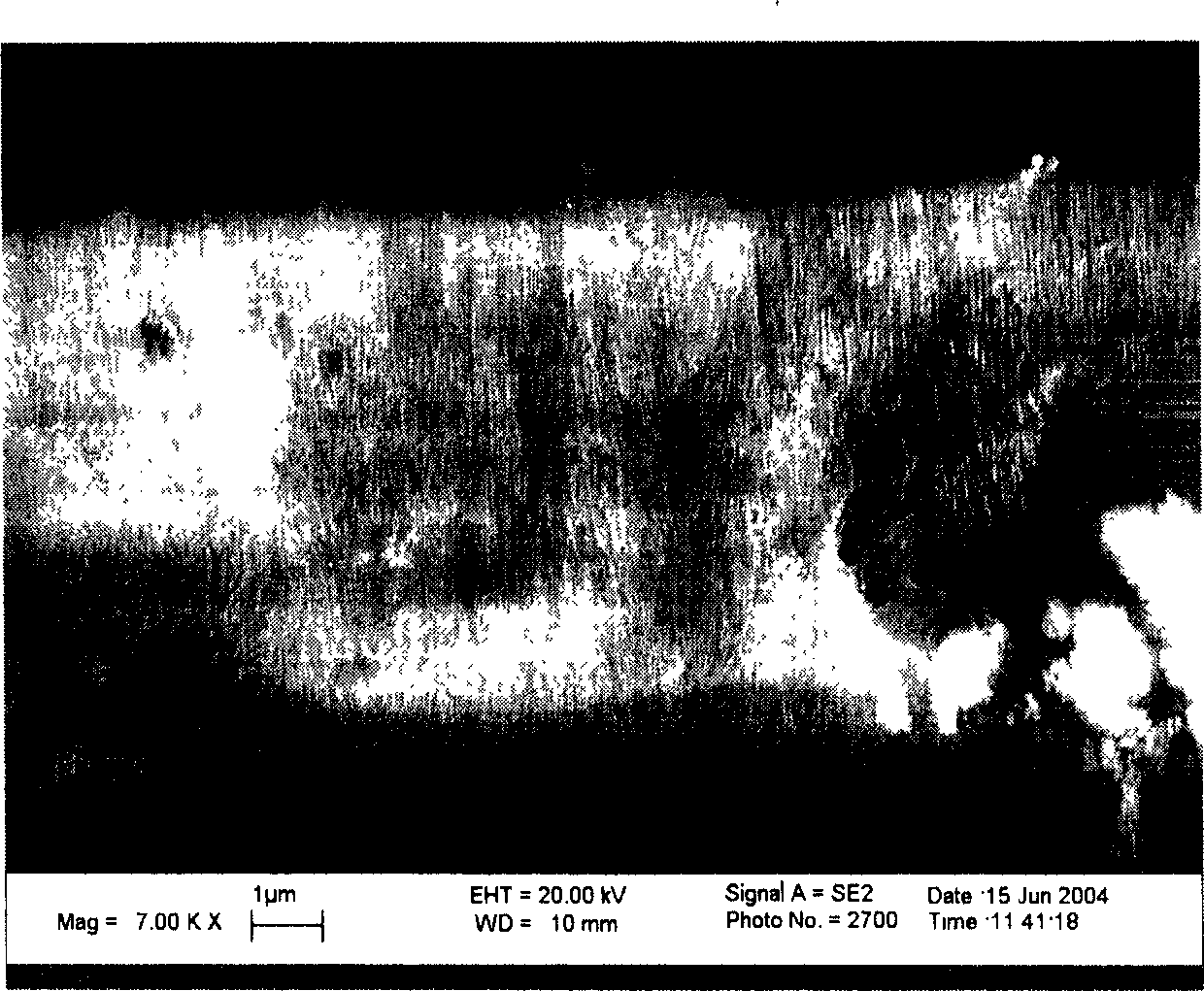

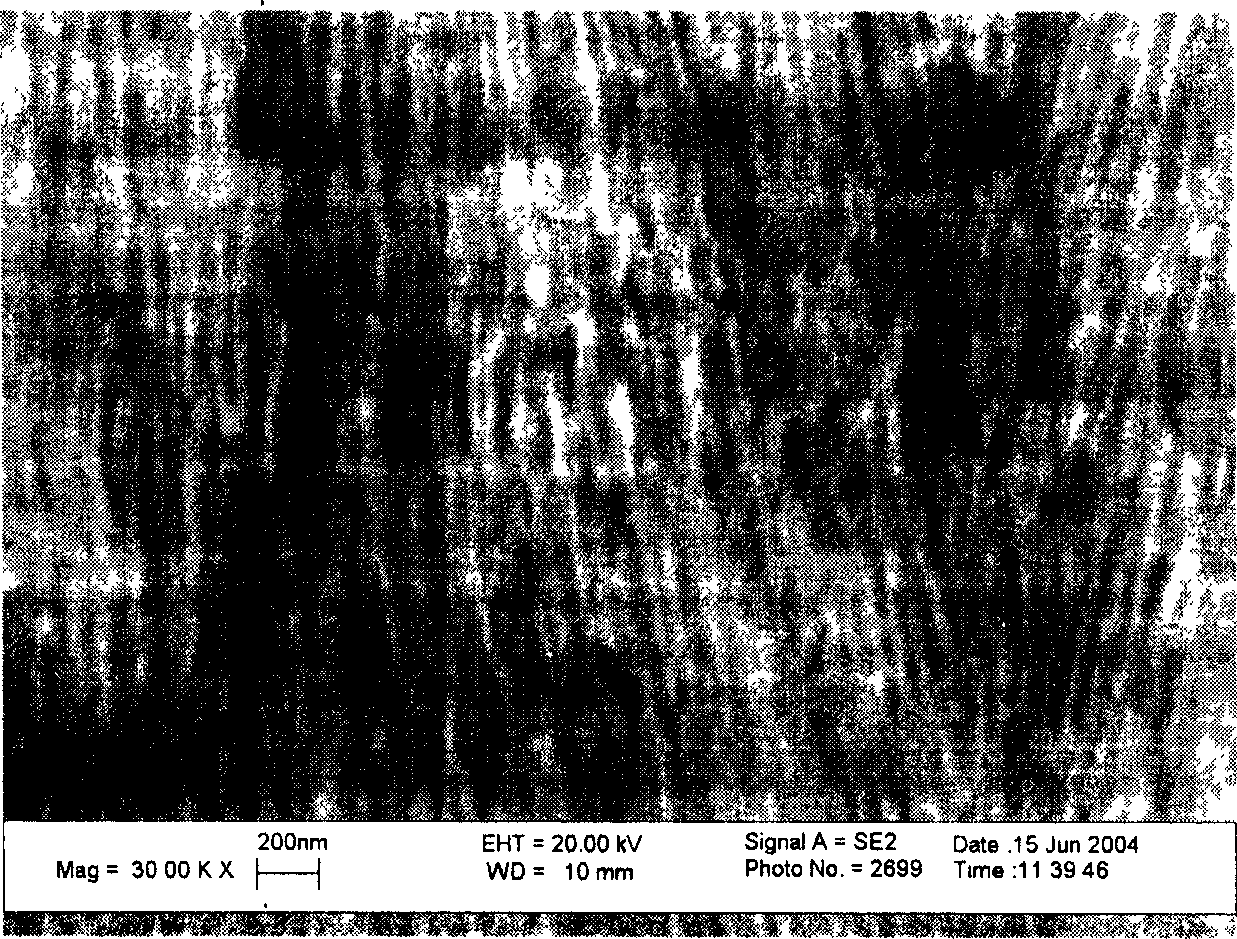

Aliminium base wave absorbing material and preparing method

InactiveCN1715458AAvoid Tangle ProblemsImprove the absorbing effectMagnetic/electric field screeningSurface reaction electrolytic coatingAnode oxidationAluminium

The present invention belongs to the field of aluminum-base material in metallurgical technology, and is especially aluminum-base wave absorbing material and its preparation process. The present invention features that aluminum or aluminum alloy plate is treated first through one-step or two-step DC or AC anode oxidation process to form aluminum-base porous alumina template, or AAO template, with porous alumina film in the surface; and the template is then DC or pulse current electrochemically deposited to assemble nanometer magnetic metal wire array in the AAO porous film, so as to make the aluminum-base wave absorbing material with in-situ assembled nanometer magnetic metal wire array in the surface. The present invention has close combination between the wave absorbing material and the substrate and high wave absorbing effect caused by the coupling effect and the size effect of the nanometer wire array. The present invention may be used widely in stealth and electromagnetic shield.

Owner:CENT SOUTH UNIV

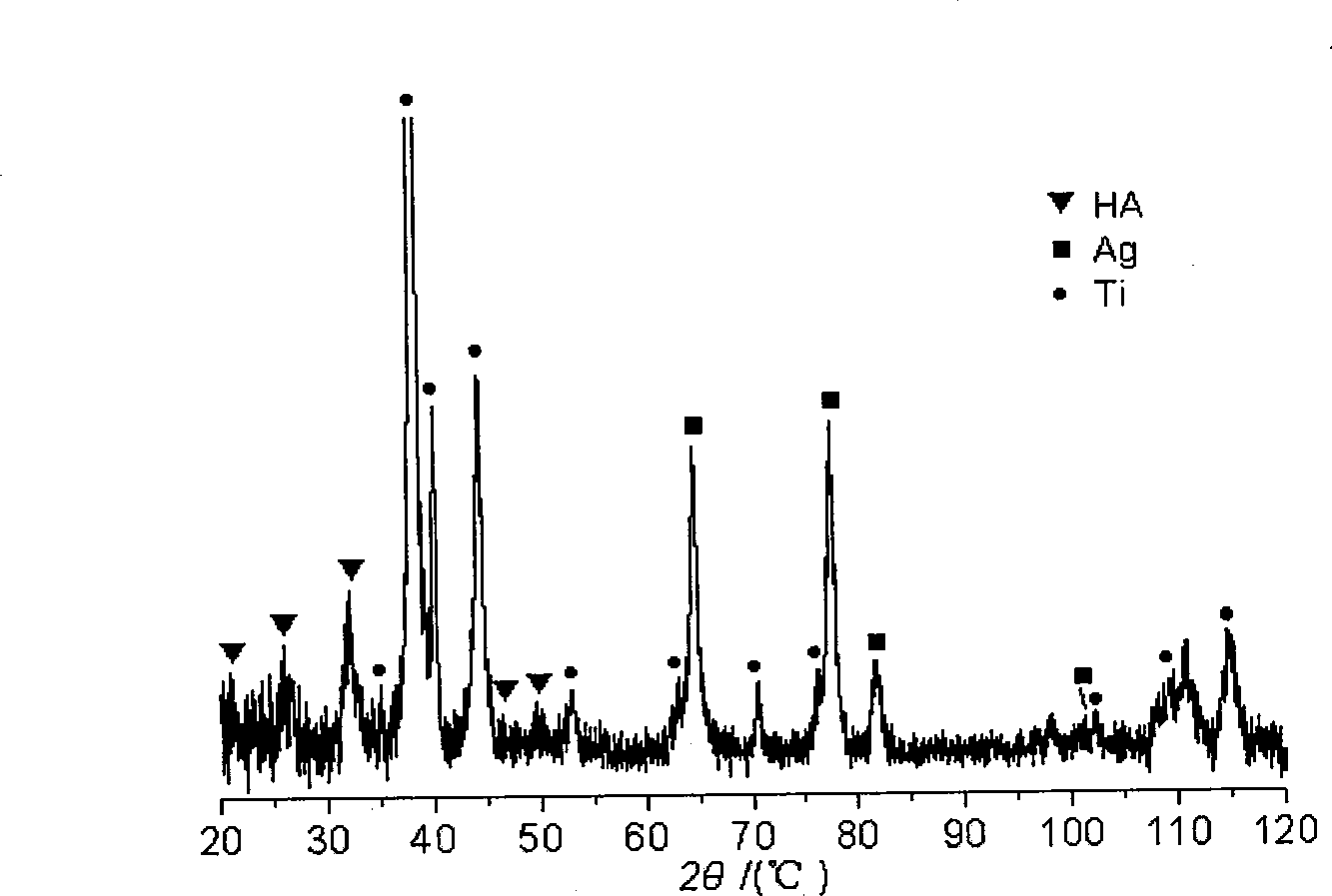

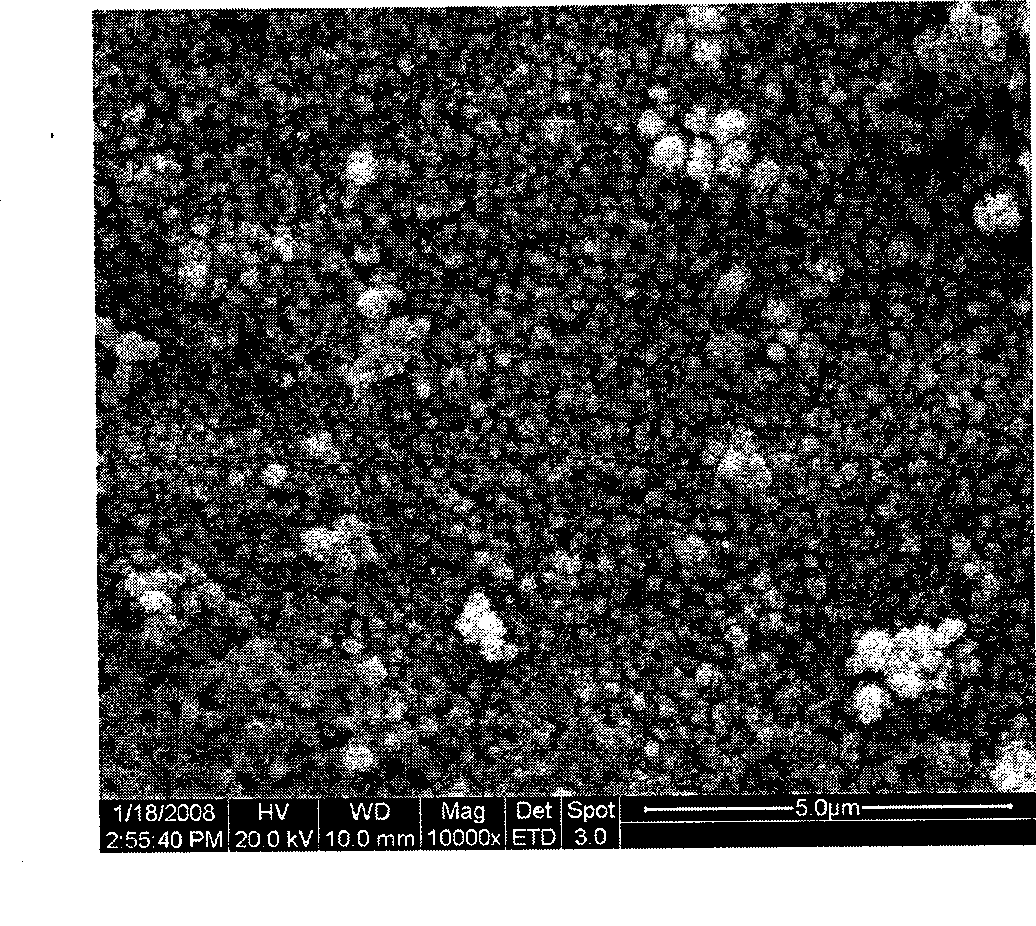

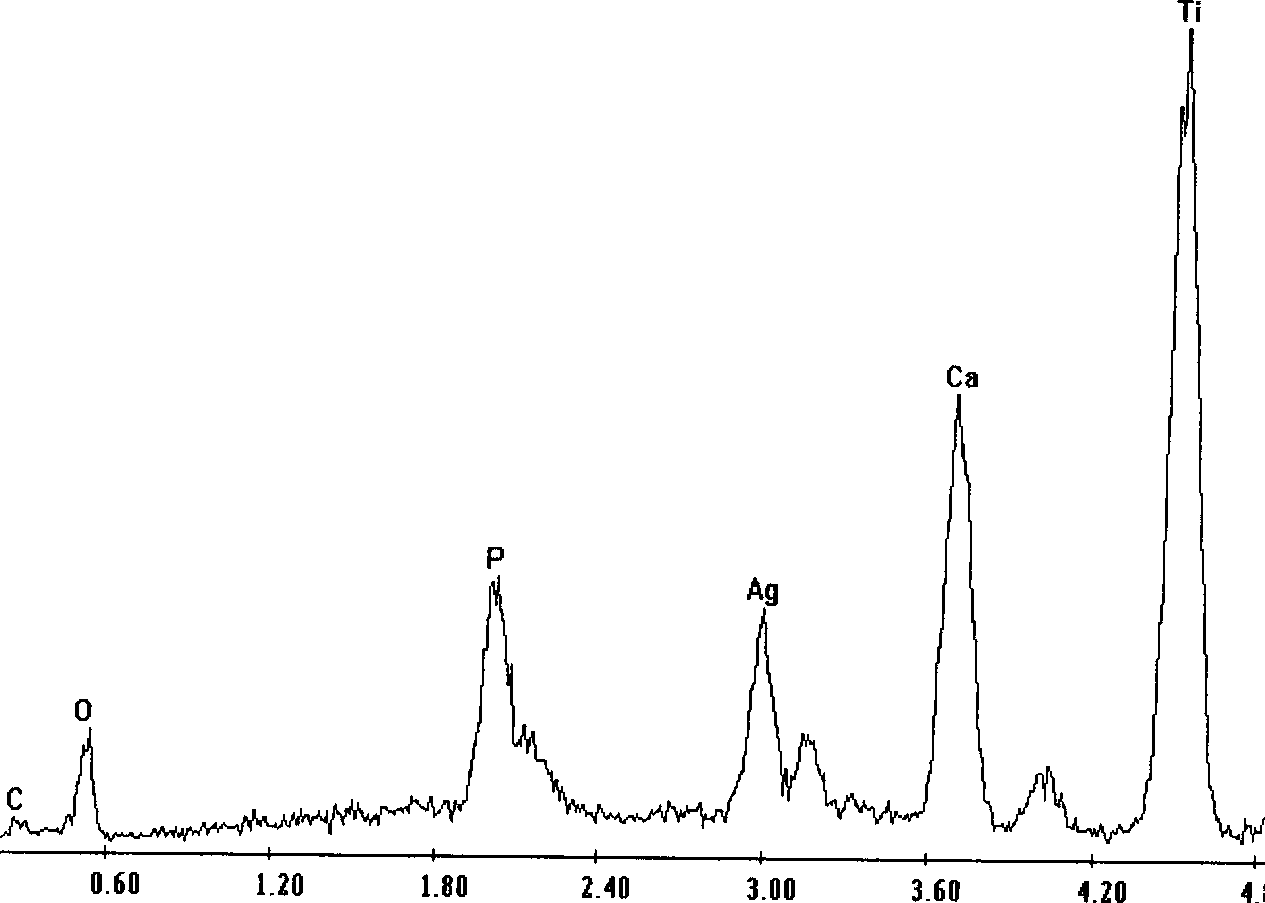

Method for preparing hydroxyapatite/nano silver antimicrobial composite coating by pulse electrochemical deposition

InactiveCN101485901AReduce concentration polarizationCrystal denseCoatingsProsthesisElectrolytic agentPhosphate

The invention discloses a method for preparing a hydroxyapatite / nano silver antibacterial composite coating through pulse electrochemical deposition, which comprises: using a calcium salt, phosphate, silver nitrate and a proper amount of coordination agent to prepare electrolyte with certain concentration and pH value, and performing electrodeposition in a electrolytic cell provided with a three-electrode system; taking a saturated calomel electrode as a reference electrode, a platinum sheet as a counter electrode and biological medical metal to be coated as a working electrode, wherein the pulse high electric potential is 0 volt, the pulse low electric potential is -2.0 volts, the pulse width is 100 seconds, and the deposition time is 2 hours; and depositing compositions in the coating on a base material in a mode of ions, uniformly dispersing nano silver generated during deposition in the composite coating, and finally preparing the hydroxyapatite / nano silver antibacterial compositecoating.

Owner:SOUTHWEST JIAOTONG UNIV

Cathode current collector, and preparation method and application of cathode current collector

ActiveCN107369810AIncrease energy densityHigh tensile strengthNitrogen-metal/silicon/boron binary compoundsElectrode carriers/collectorsCopper platingEvaporation

The invention discloses a cathode current collector, and a preparation method and an application of the cathode current collector. The cathode current collector is in a multilayer structure, and comprises a plastic film, wherein the upper and lower surfaces of the plastic film are sequentially coated with bonding force reinforcement layers, copper coating layers and antioxidation layers. The preparation method comprises the steps of coating the bonding force reinforcement layers on the plastic film by utilizing a magnetron sputtering coating technology, coating the copper coating layers by utilizing an evaporation coating technology, and coating the antioxidation layers by utilizing an electron beam evaporation coating technology or the magnetron sputtering coating technology. The application of the cathode current collector is mainly in a lithium ion battery. The cathode current collector can realize lightweighting of the battery, improves the energy density, lowers the cost, and can reduce the possibility of falling and oxidation of the copper coating layers.

Owner:CONTEMPORARY AMPEREX TECH CO

Autoclaved aerated concrete block made of gold tailings and its production process

InactiveCN1631836AKeep healthyTake advantage ofSolid waste managementSlagAutoclaved aerated concrete

The invention relates to gold tail mine concrete block and its productive technique, which belongs to wall material for building and productive technical field. Its characteristics is that the main raw material for making concrete block includes slag, cement, burnt lime, aluminum powder and water, and their mess ratio is: slag 60~70%, cement-6~10%, burnt lime-20~30% aluminum powder -0.01~0.05% and the water content can be changed according to the requirement of gold tail slime density. The invention can reach the purposes of environmental protection, energy saving, using the waste, increasing the building's quality and assuring people's health, it can use waste slag completely, with good resistance to coldness and without radioactive harm, can be compound with mortar so that solve the problem of wall surface falling down.

Owner:QIXIA HONGJIAN NOVEL BUILDING MATERIAL

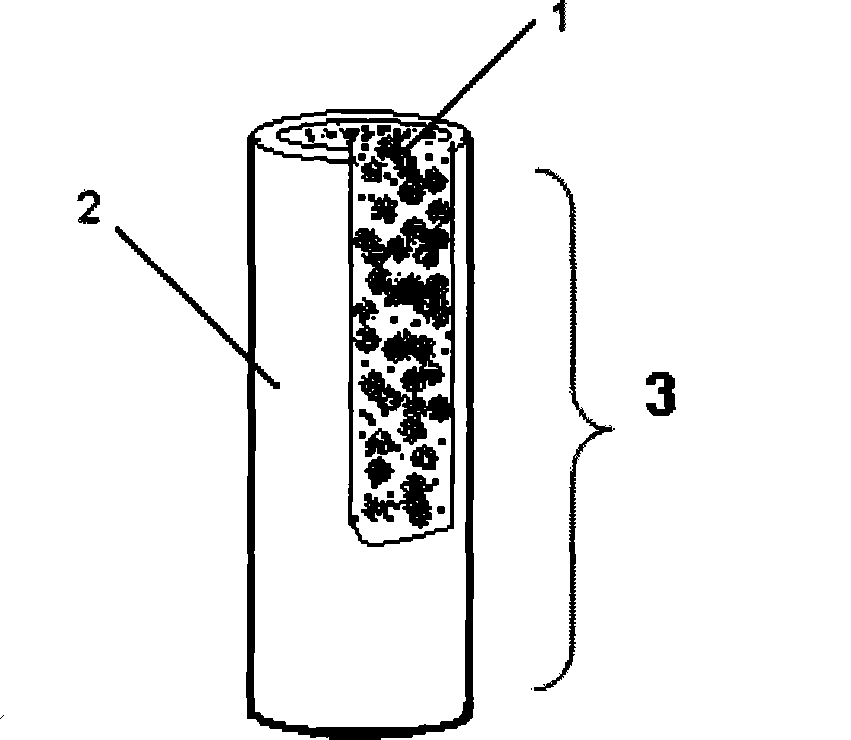

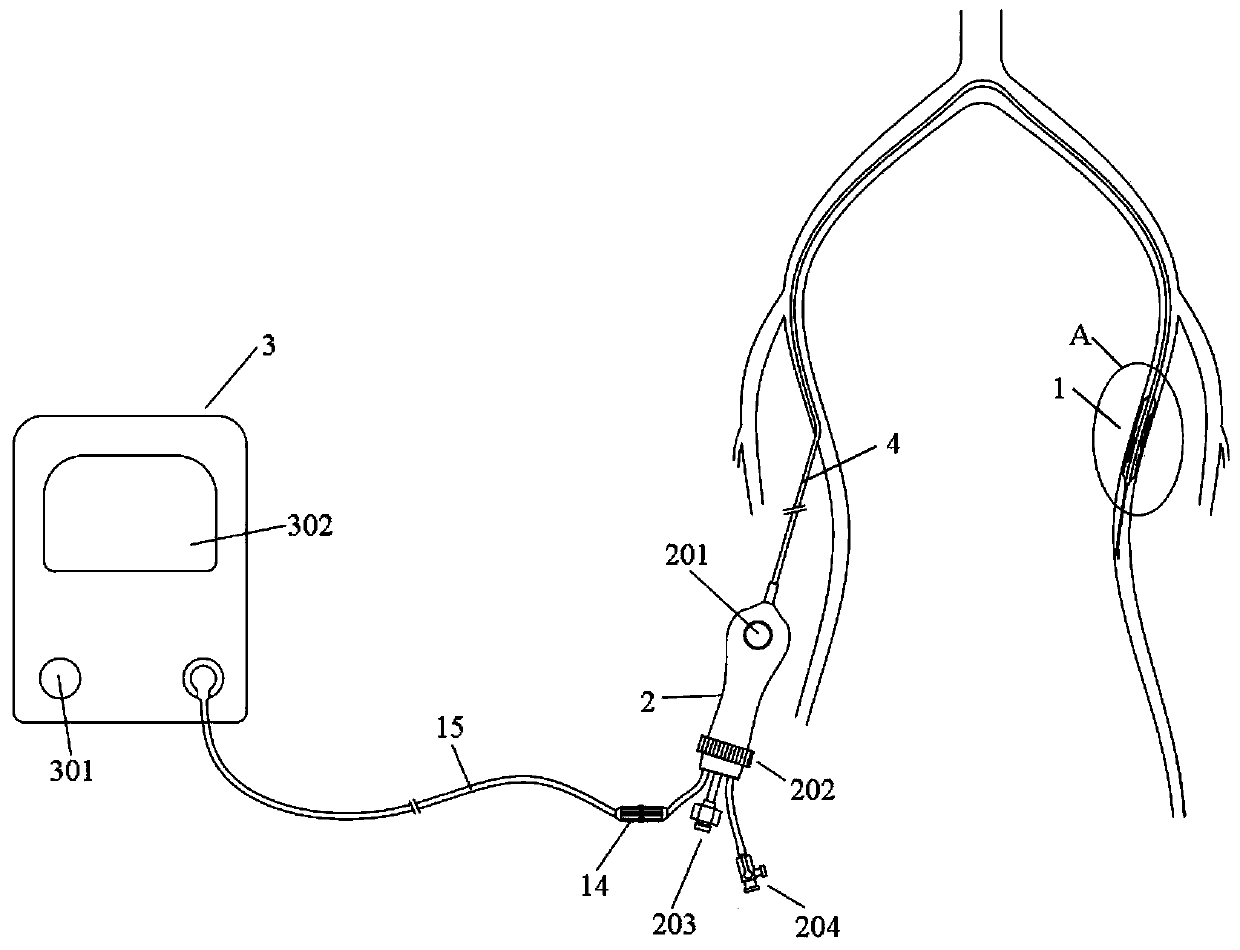

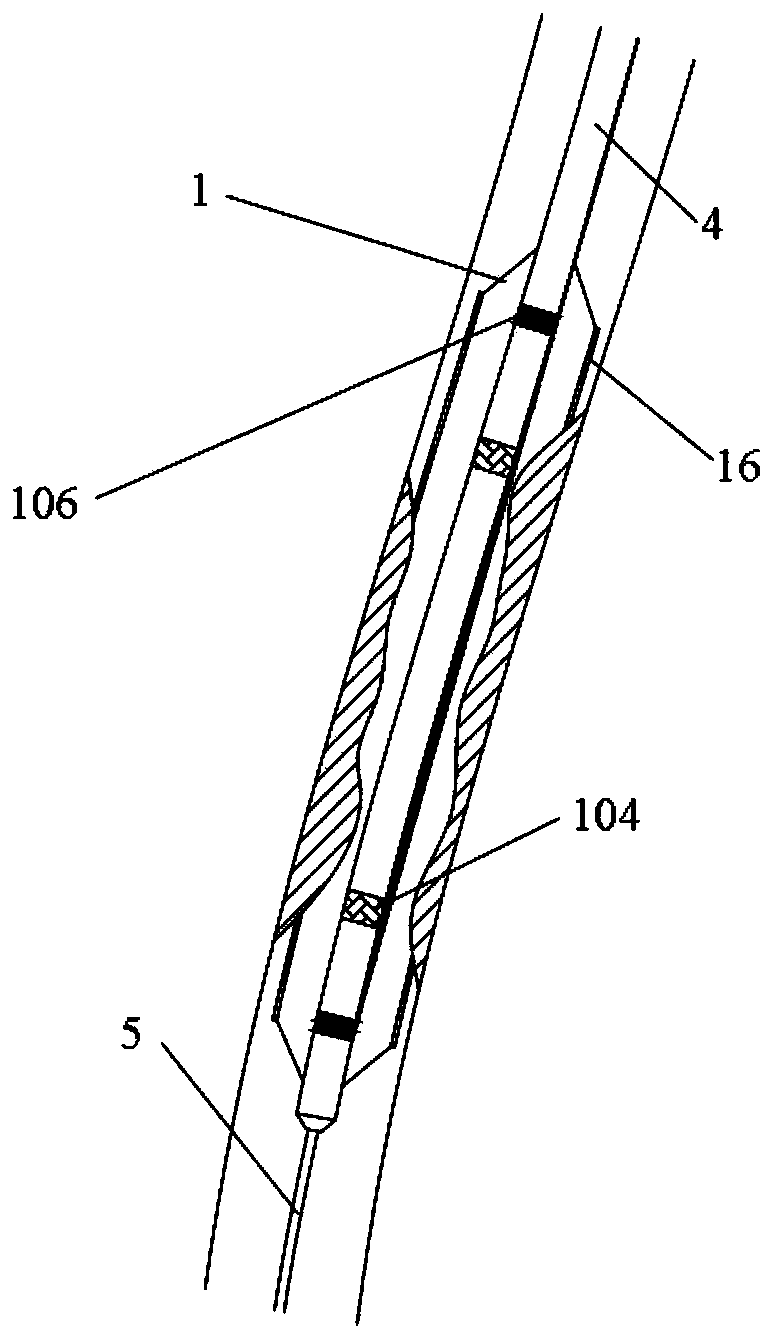

Vascular recanalization system for cardiovascular stenosis lesions

InactiveCN111568500AAchieve recanalizationAddressing injuries, such as dissectionsSurgeryMedical devicesStenotic lesionRestenosis

The invention relates to a vascular recanalization system for cardiovascular stenosis lesions. The vascular recanalization system comprises a balloon, an energy generation controller and a catheter. The catheter comprises a main body tube, one end of the catheter is connected with the energy generation controller, and the main body tube at the other end of the catheter is connected with one end ofthe balloon; wherein the balloon mainly comprises a balloon main body, an inner tube and an electrode pair, and the inner tube is arranged in the balloon main body; and the energy generation controller can send out and regulate a vibration signal with a specific frequency to enable the electrode pair to generate a vibration wave. The system further has a drug delivery function, can inhibit increase of endovascular membranes after recanalization and avoid restenosis after recanalization, thereby achieving the function of long-term treatment of stenotic lesions. For many vascular diseases needing to be implanted with stents, the purpose of achieving long-term patency rate without stent implantation is achieved, and therefore real intervention implantation-free is achieved.

Owner:苏州汇禾医疗科技有限公司

Collagen fiber solidified tannin adsorptive material and its preparation method and its adsorption and separation of metallic ion

InactiveCN1410157AEliminate solubilityEliminate strengthOther chemical processesWater/sewage treatment by sorptionFiberTannin

An adsorbing collagen fibre-solidified tannin material for adsorbing and separating metallic ions (Pb, Cd, Hg, Cr and Cu) is prepared from animal skin through preparing collagen fibre membrane or granules, adding the said collagen fibres along with the aqueous solution of tannin to a reactor, reacting at 10-45 deg.c for 6-24 hr, laying aside for 12-24 hr, filtering, washing to remove excessive tannin, adding cross-linking agent, reacting at 20-70 deg.c for 2-8 hr, filtering, washing and drying at 60 deg.c for 12-24 hr. It has very high adsorption selectivity.

Owner:SICHUAN UNIV

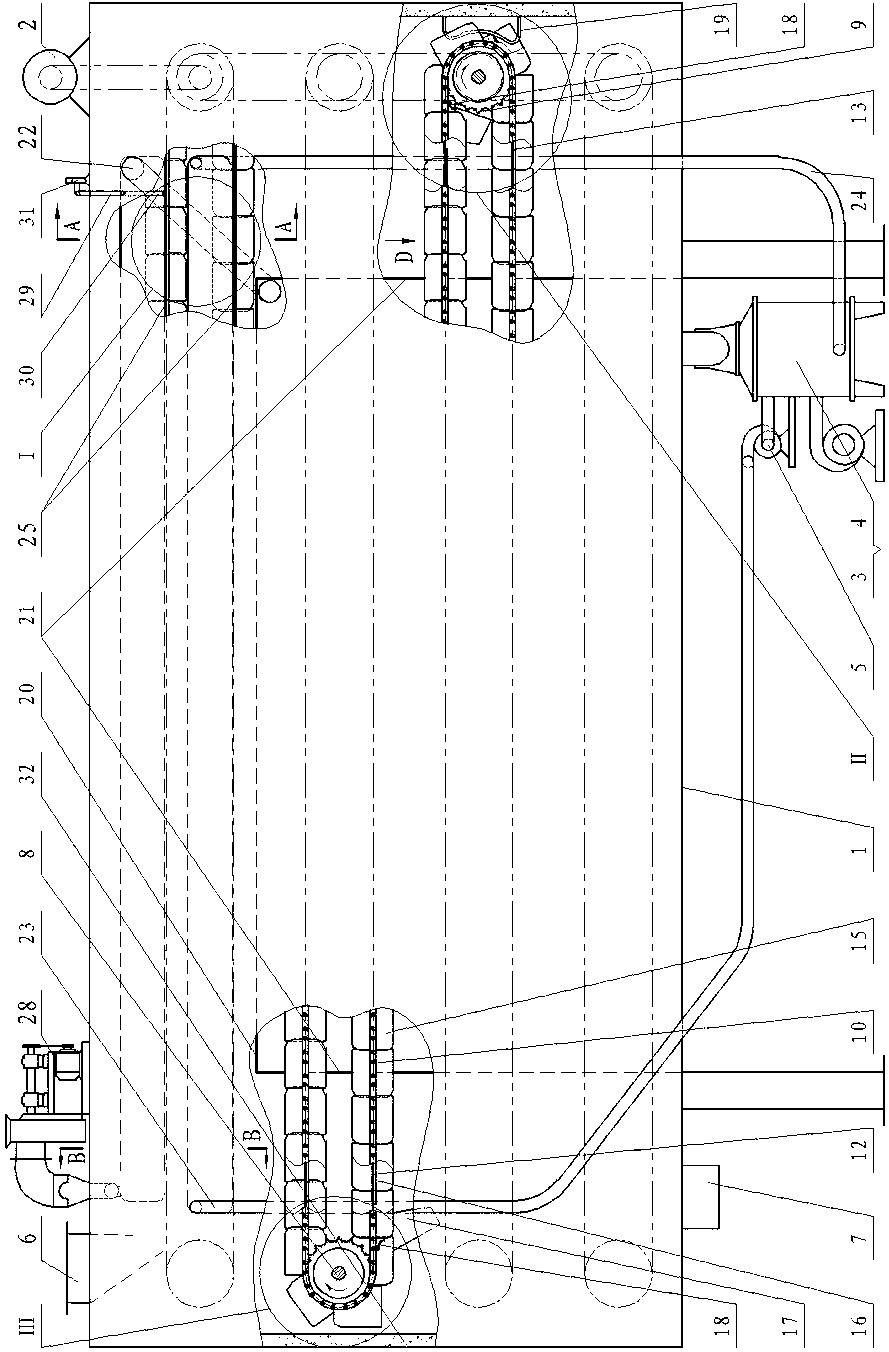

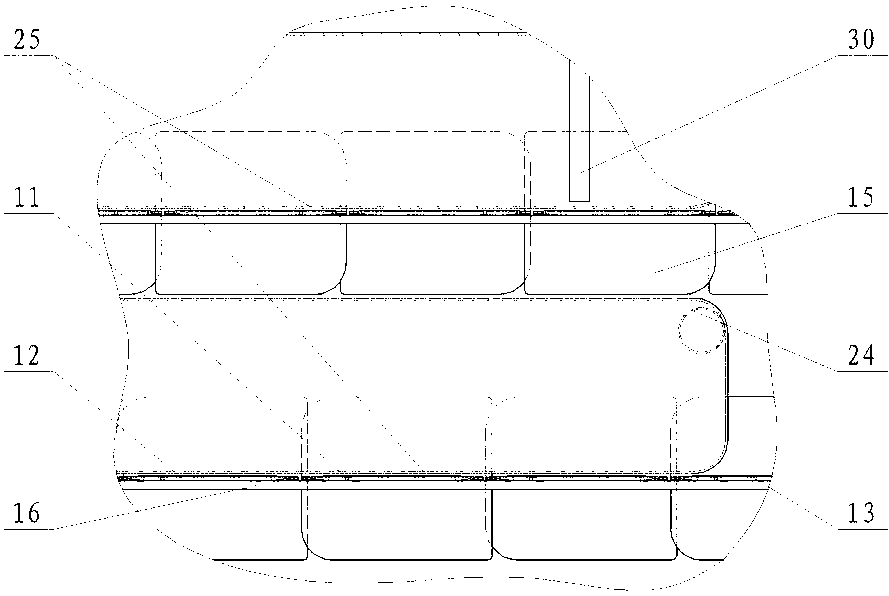

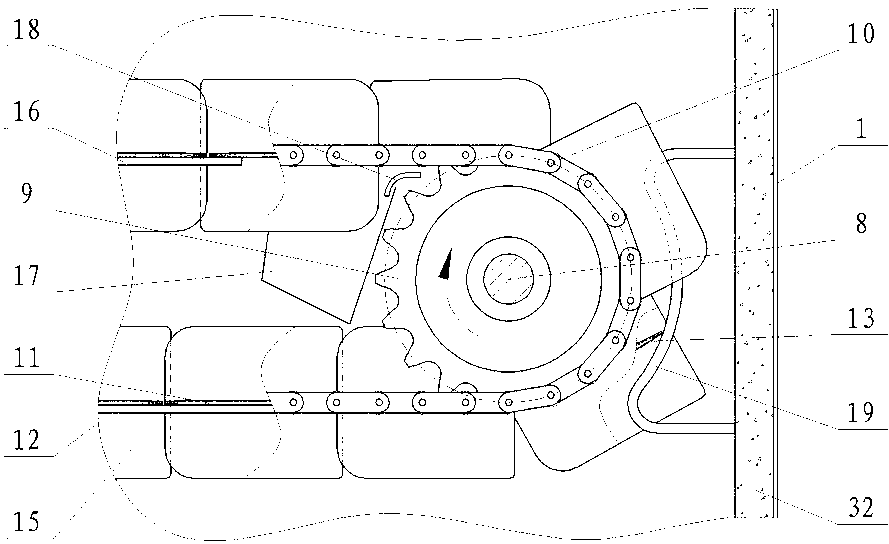

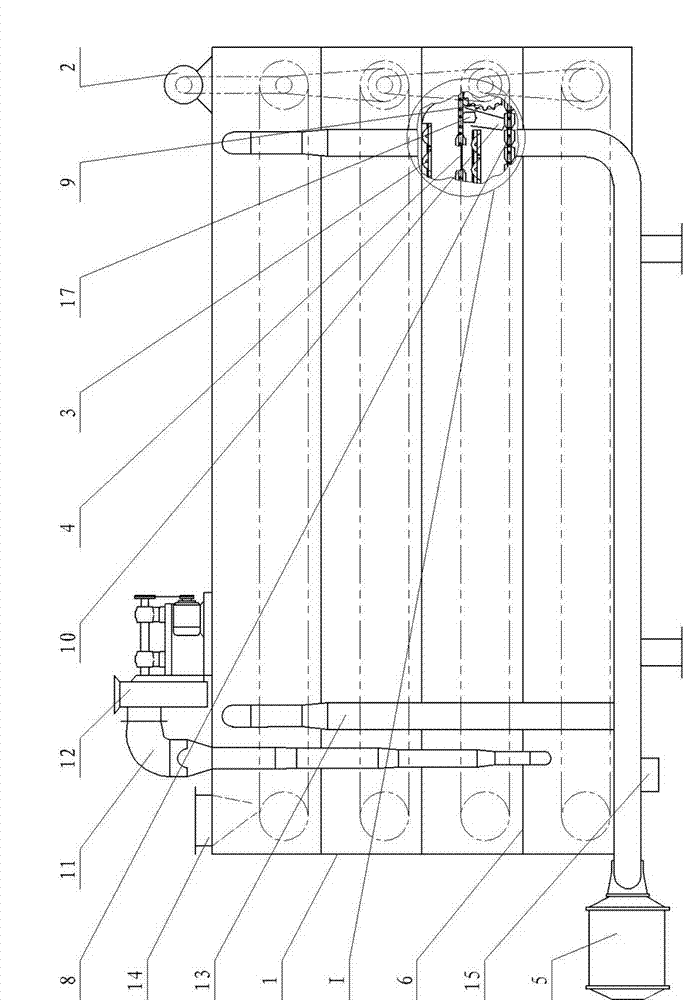

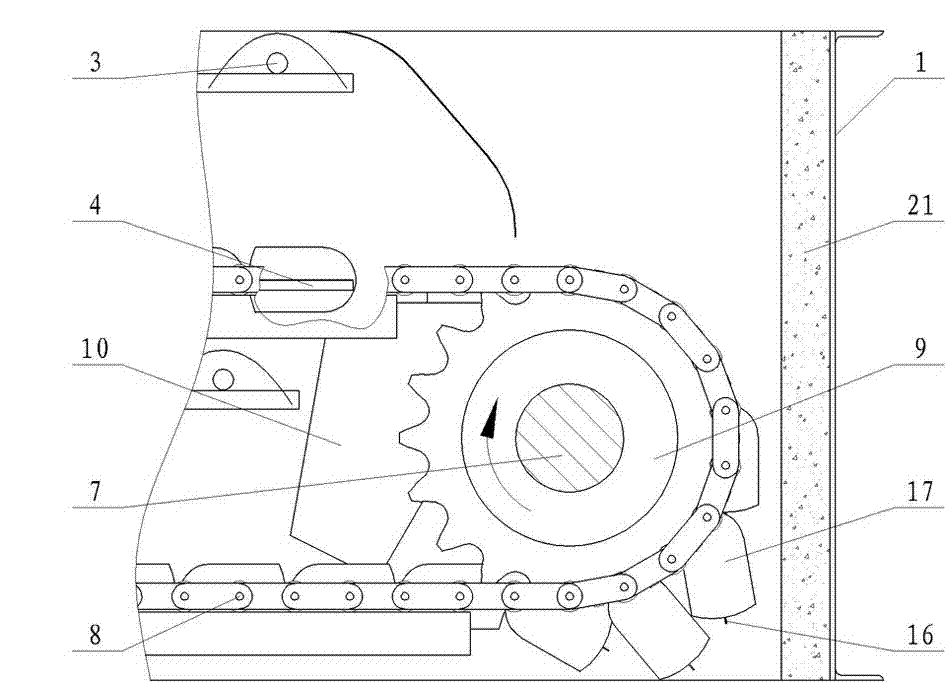

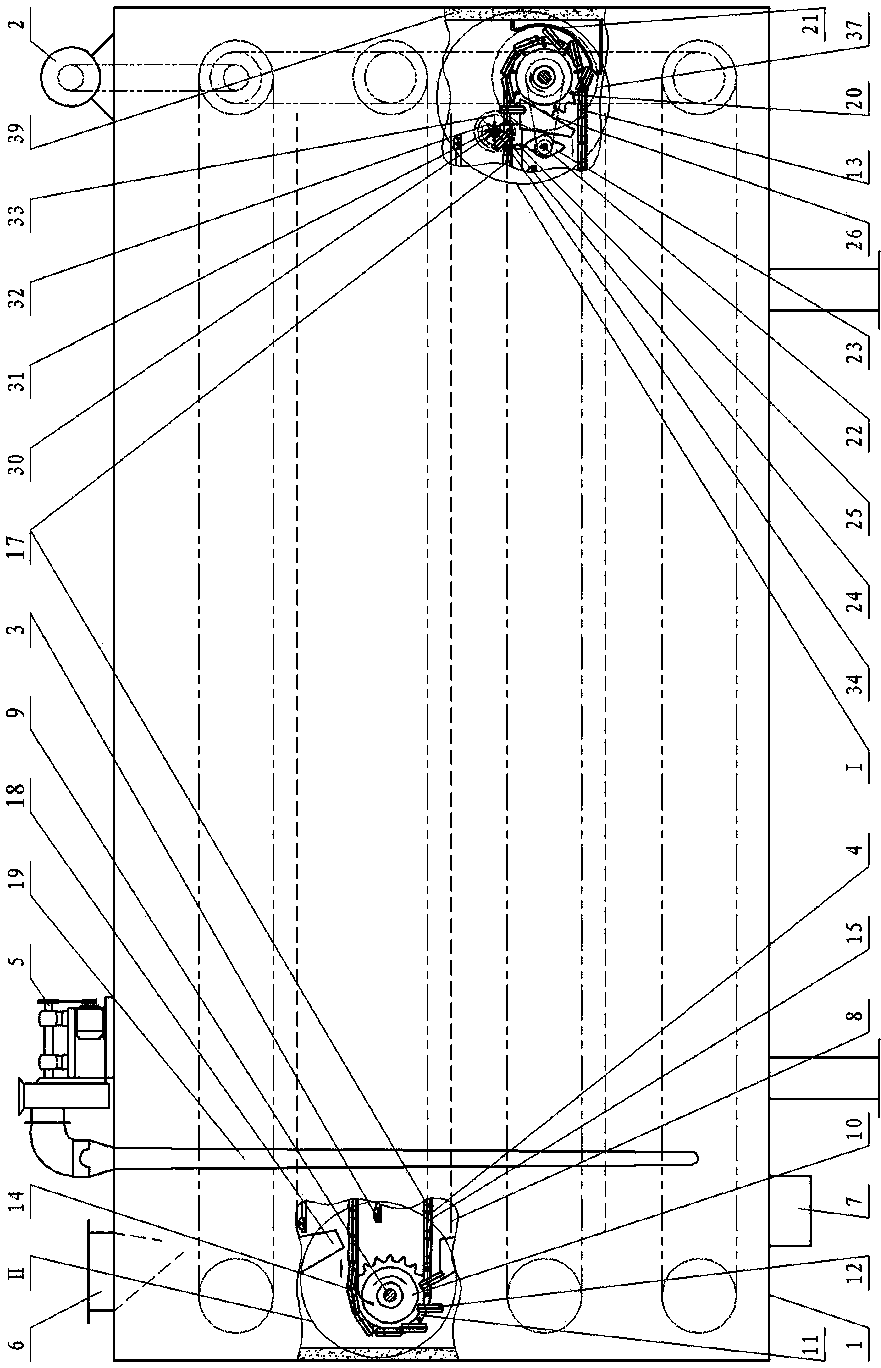

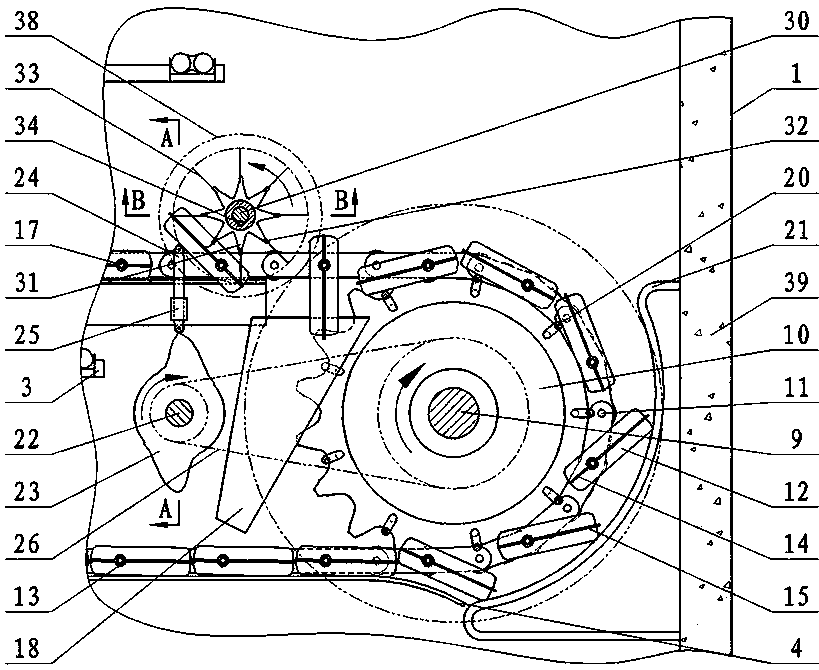

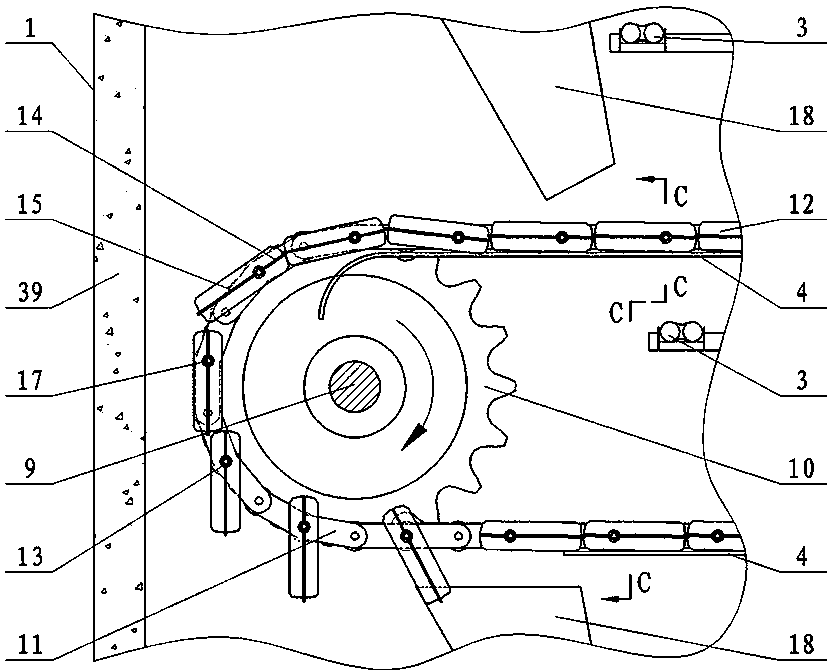

Waste heat recovering ear-corn drying machine

InactiveCN103070234AOptimized drying programKeep dryFood processingClimate change adaptationChinese charactersEngineering

The invention provides a waste heat recovering ear-corn drying machine, which is characterized in that the chamber of the drying machine is divided into an upper area and a lower area by a partition I; the lower area is divided into three parts by partitions II; the bottom of the middle chamber is provided with an air heater with a blower; a plurality of heat exchange boxes are arranged in the upper area and are communicated with one another by annular air pipes; the heat exchange boxes on the lower part are communicated with the middle of the lower area of the chamber; the heat exchange boxes on the upper part are connected with an induced draft fan mounted at the top of the chamber; a water pump at the top of the chamber is connected with a straight pipe inserted in each heat exchange box by a water pipe which is shaped like a Chinese character 'YUE'; a plurality of conveying devices running under the driving of a driving device are arranged in the chamber; molding link plates of I and II types are hung on a pin shaft extending out of the inner side of a conveying chain at intervals and are arrayed and supported on a guide rail to form a trough material channel; a guide chute is arranged below the tail end of the channel; and a feed inlet and a discharge port are formed at the top and the bottom of the chamber respectively. The waste heat recovering ear-corn drying machine is large in moisture reducing range, good in preheating effect and reliable in working.

Owner:SHANDONG UNIV OF TECH

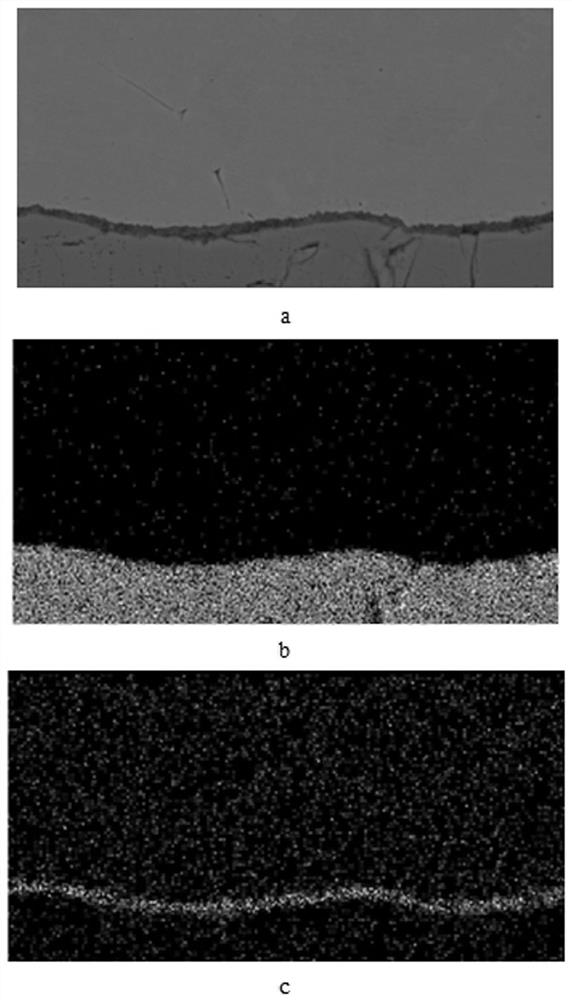

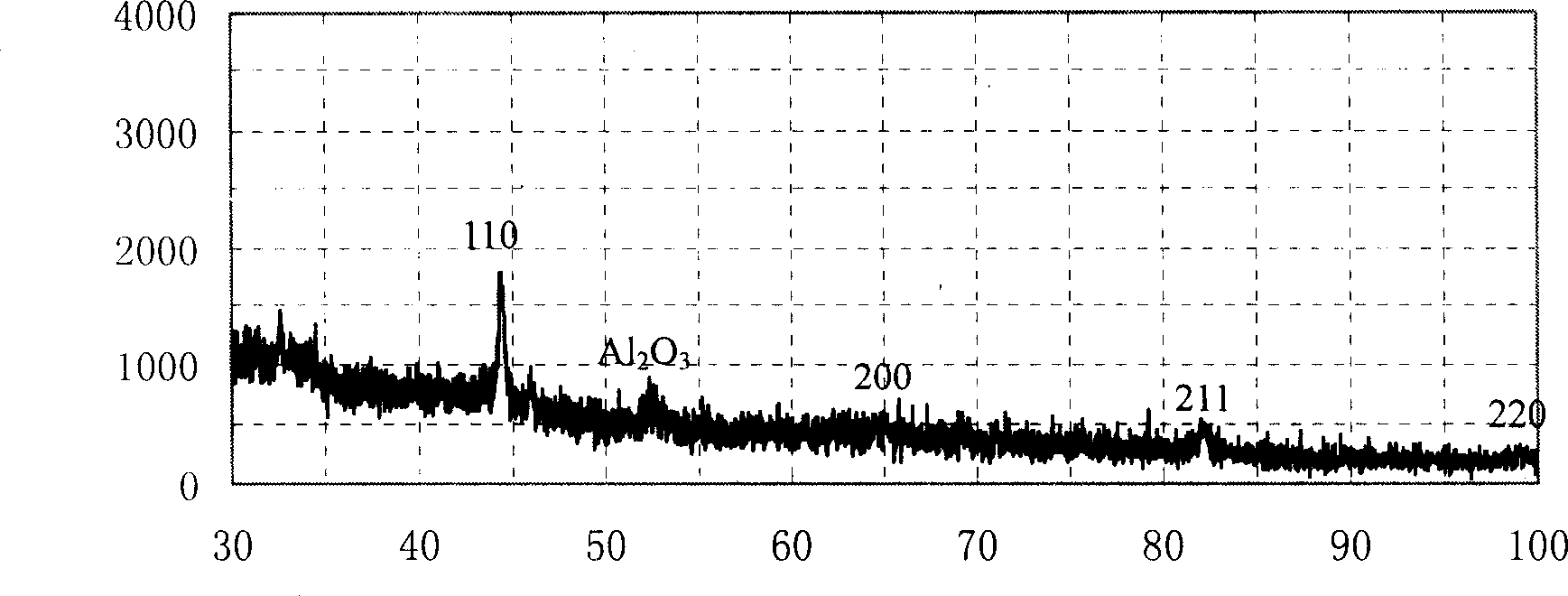

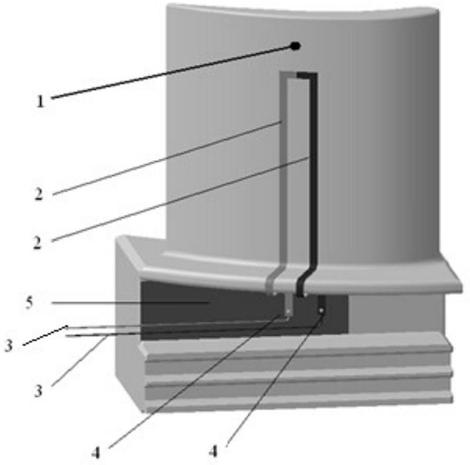

Film temperature sensor for turbine blades of aero-engine

ActiveCN109338290ASolve insulation problemsSolve sheddingMolten spray coatingThermometers using electric/magnetic elementsThin film sensorSputtering

The invention discloses a film temperature sensor for turbine blades of an aero-engine. The film temperature sensor comprises a transition layer, a thermal growing layer, an insulating layer and a thermocouple layer which are sequentially connected, wherein the thermocouple layer is formed by lapping a first thermocouple and a second thermocouple through one end part, and the lapping part forms athermal connecting point which is a measuring end; an outgoing conductor is a fine wire which has the same quality as the first thermocouple and the second thermocouple; and the outgoing conductor iscorrespondingly connected to the other end part of each of the first thermocouple and the second thermocouple through high-temperature conductive glue. According to the film temperature sensor for theturbine blades of the aero-engine, a film layer structure of the sensor is specially designed for the aero-engine in a high-temperature severe environment; the film sputtering, annealing and other preparation technologies are optimized; the ion deposition technology is carried out to directly deposit a plurality of layers of films on the surfaces of the turbine blades, and thus the function and structure integrated film sensor is obtained; the adhesion strength of the film layers is improved; the problems such as high-temperature insulating of the film layer, separating and signal exporting can be solved; and the total thickness of the film sensor is less than 25 microns, and the maximum measurement temperature is 1100 DEG C.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

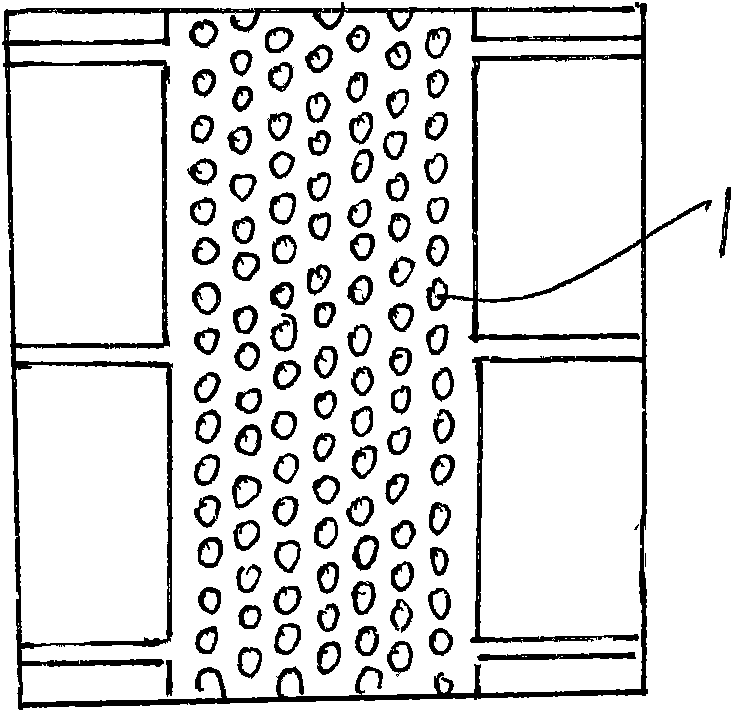

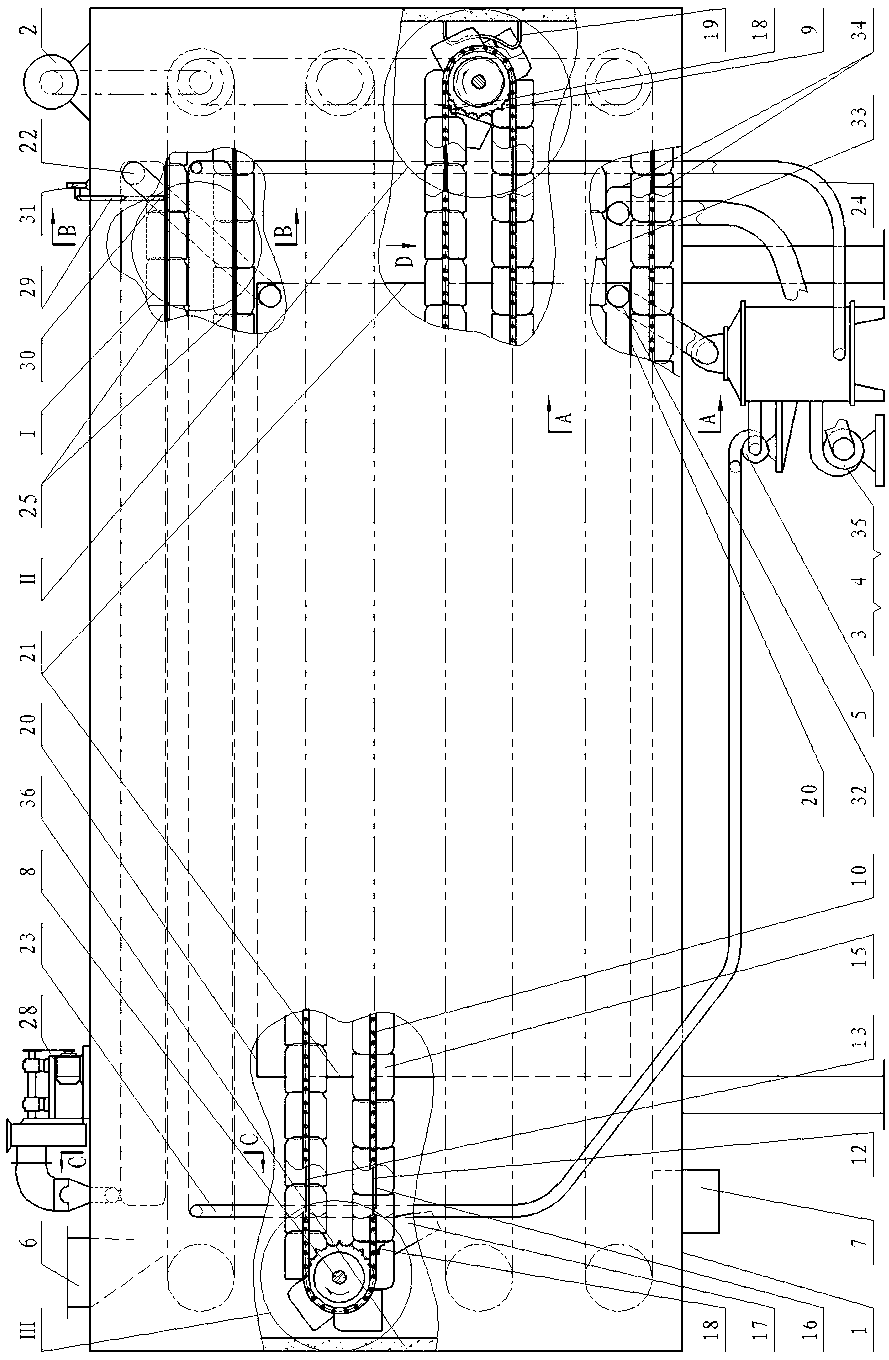

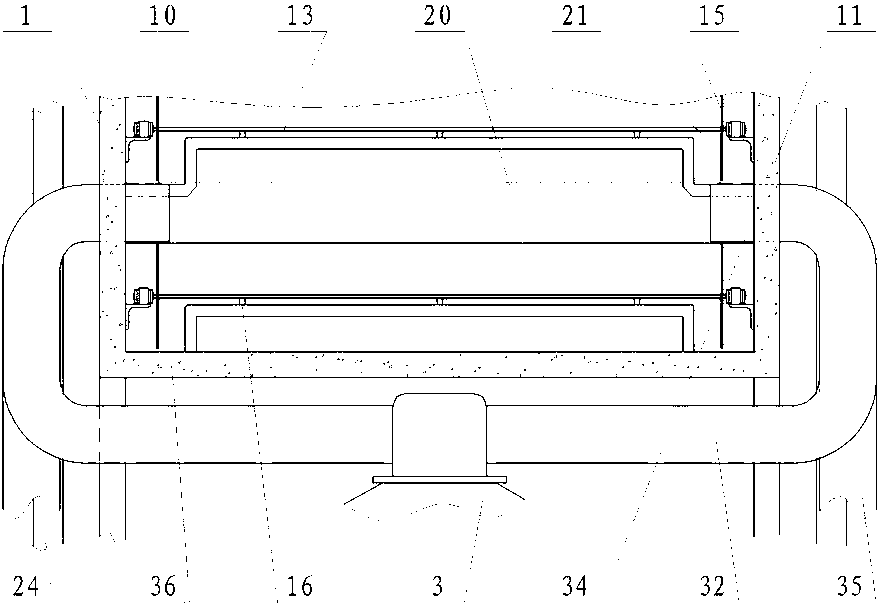

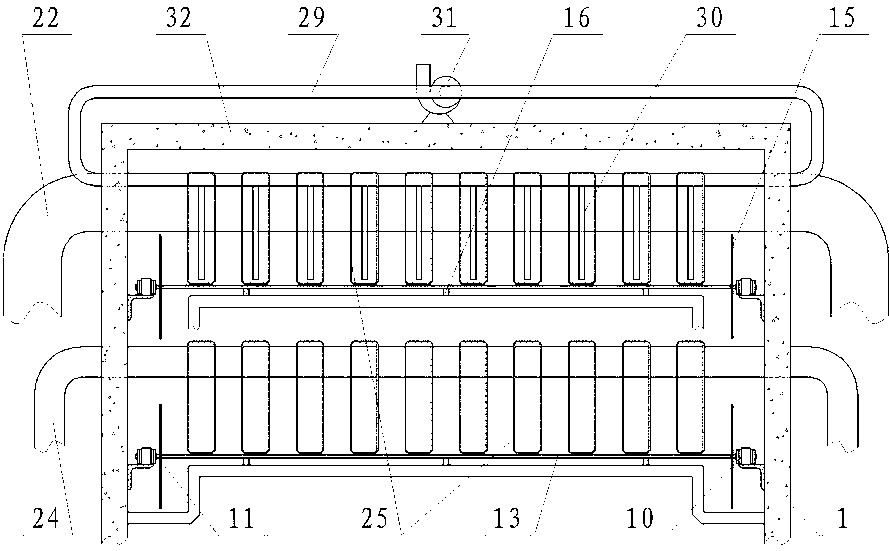

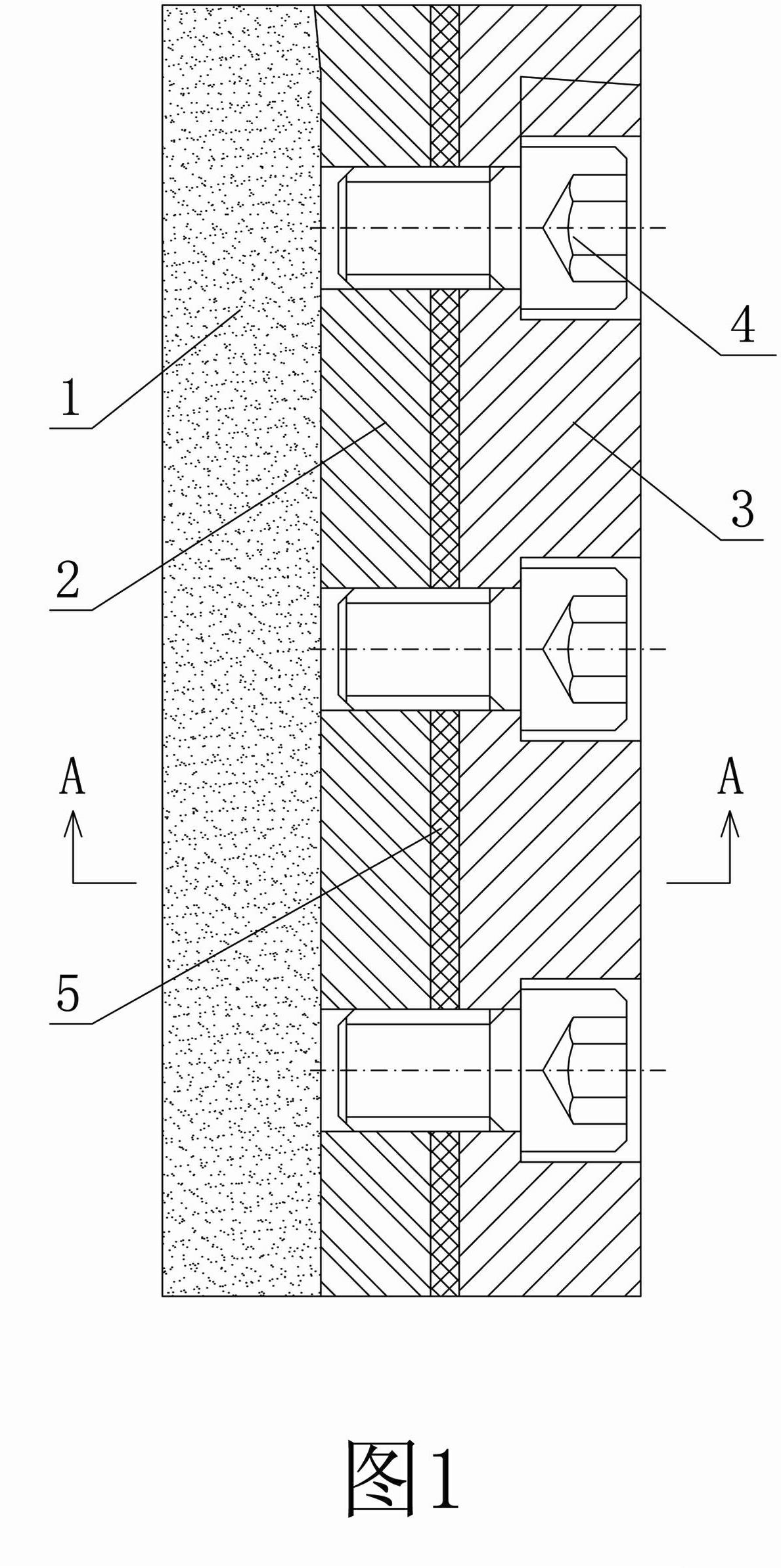

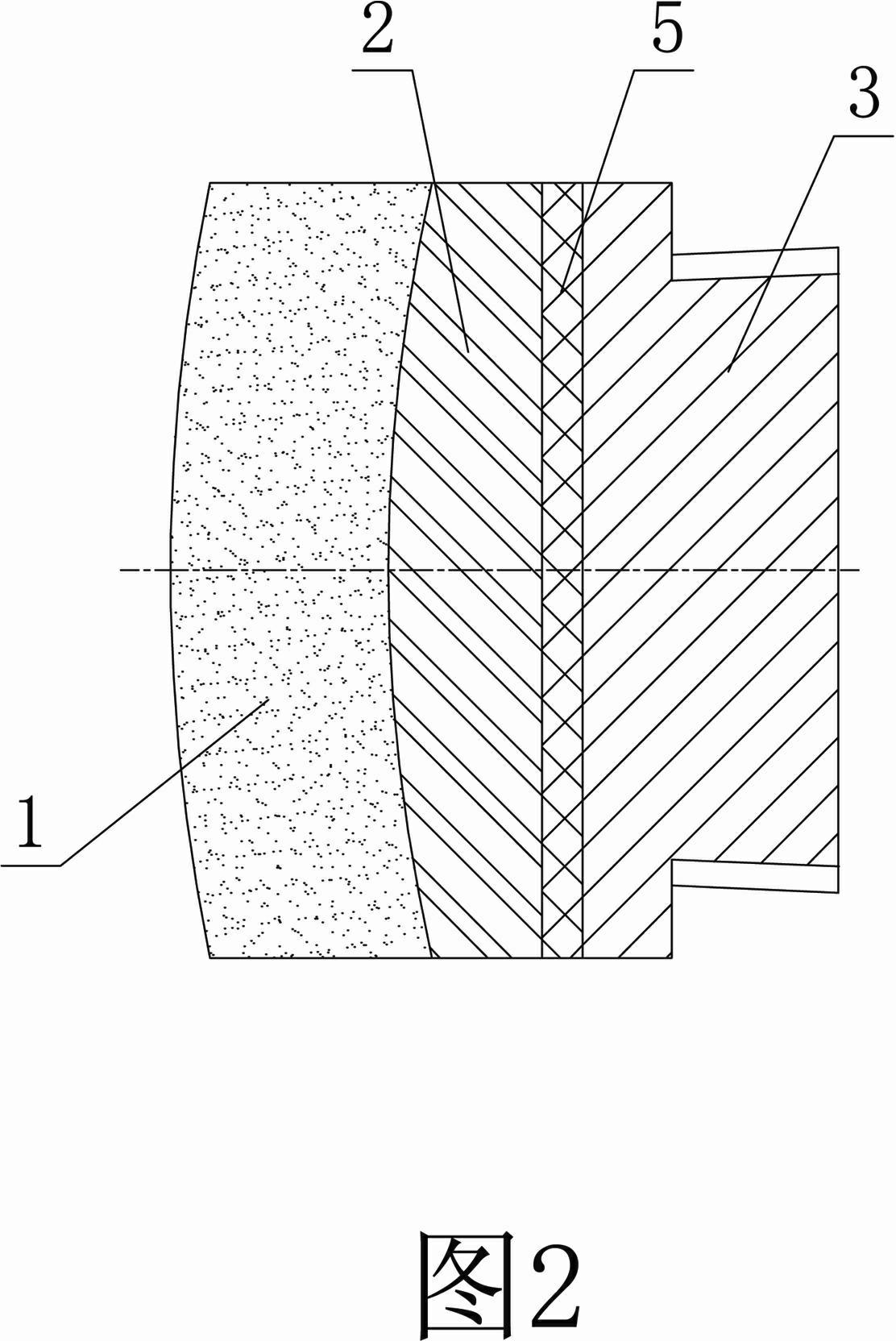

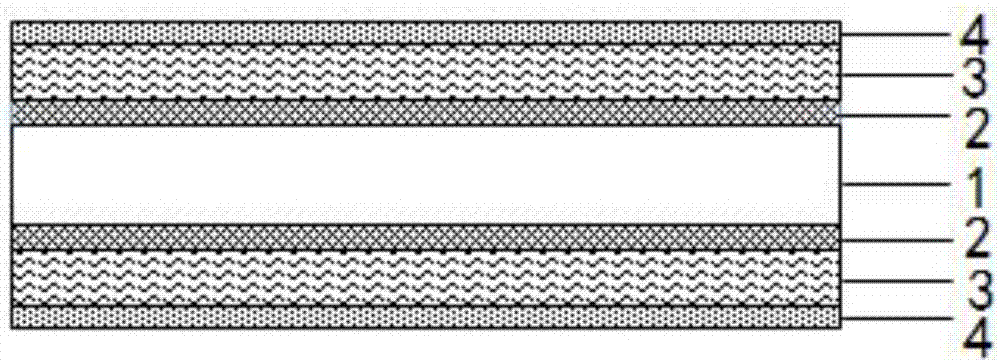

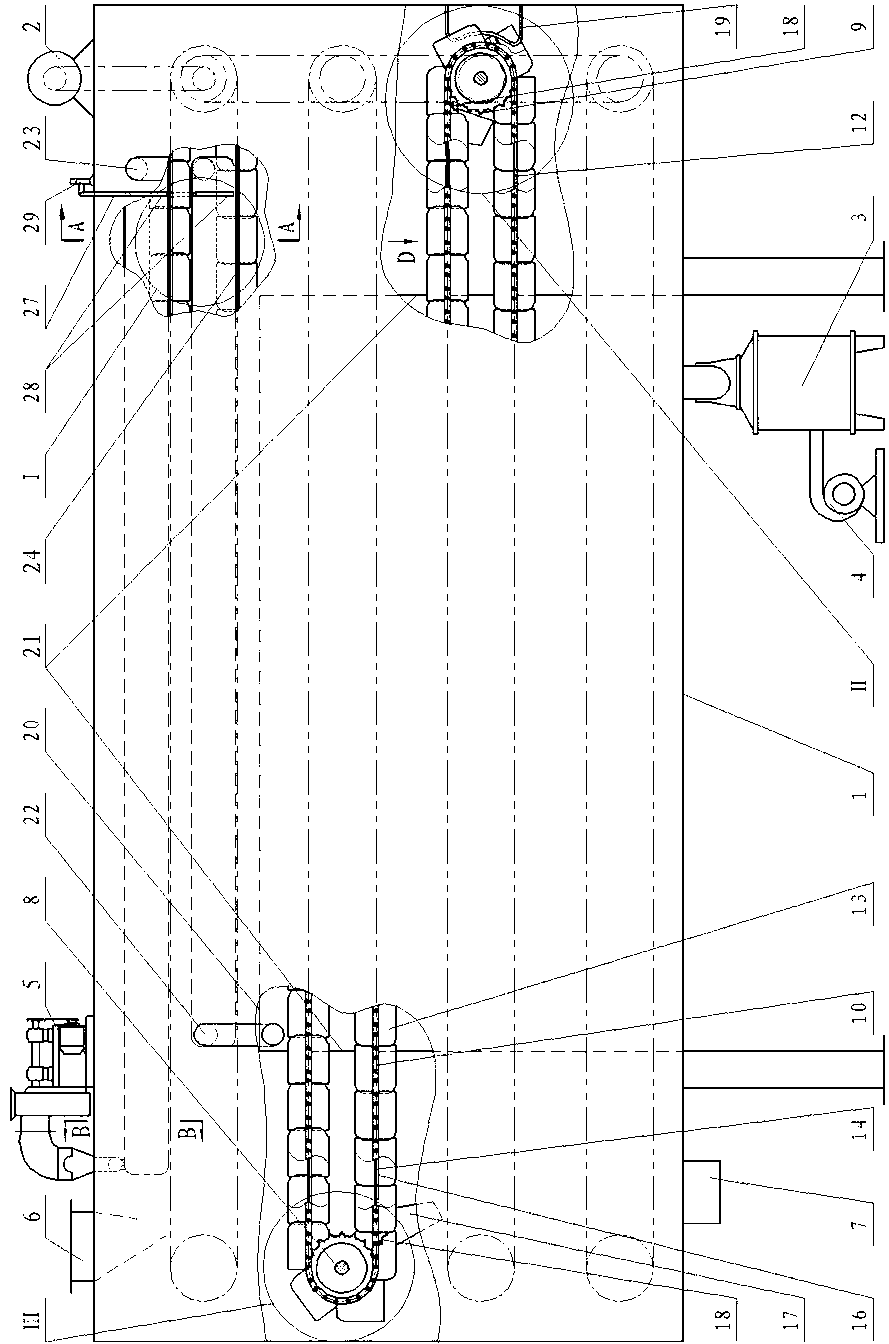

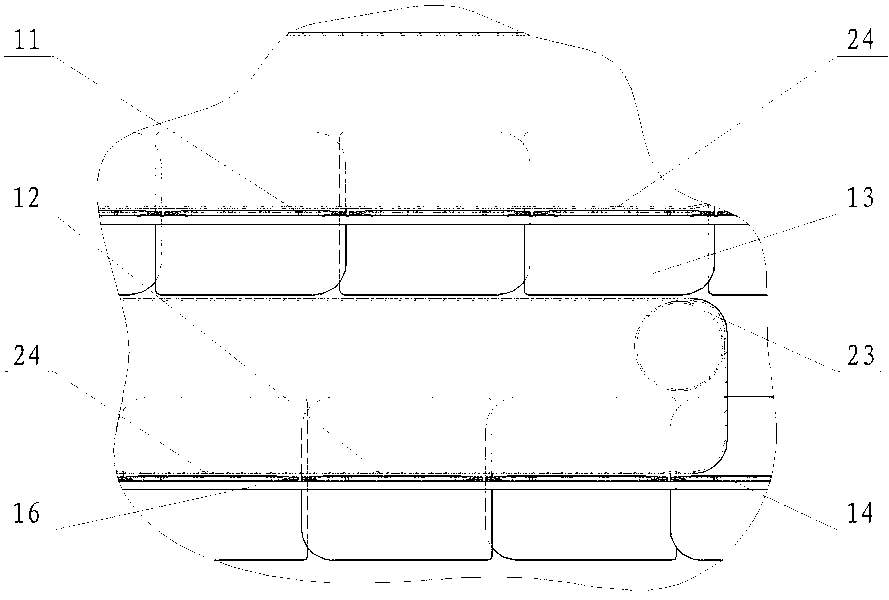

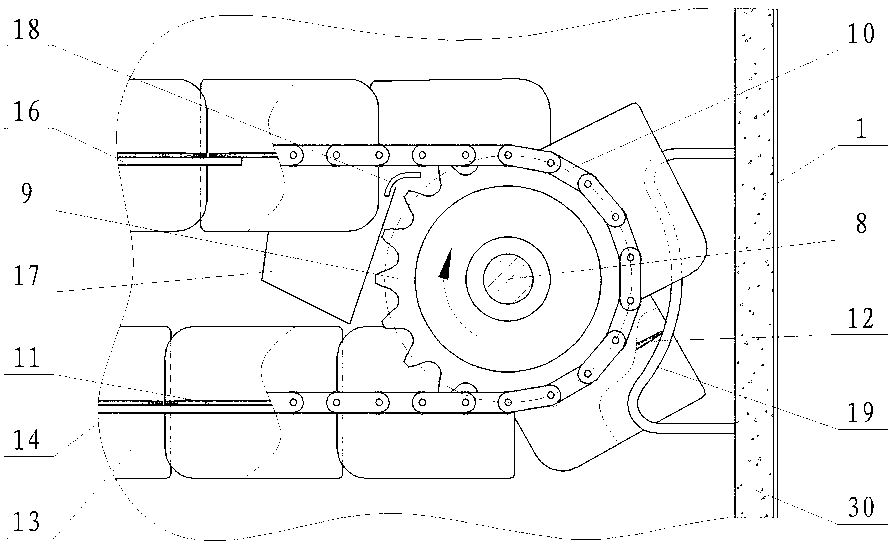

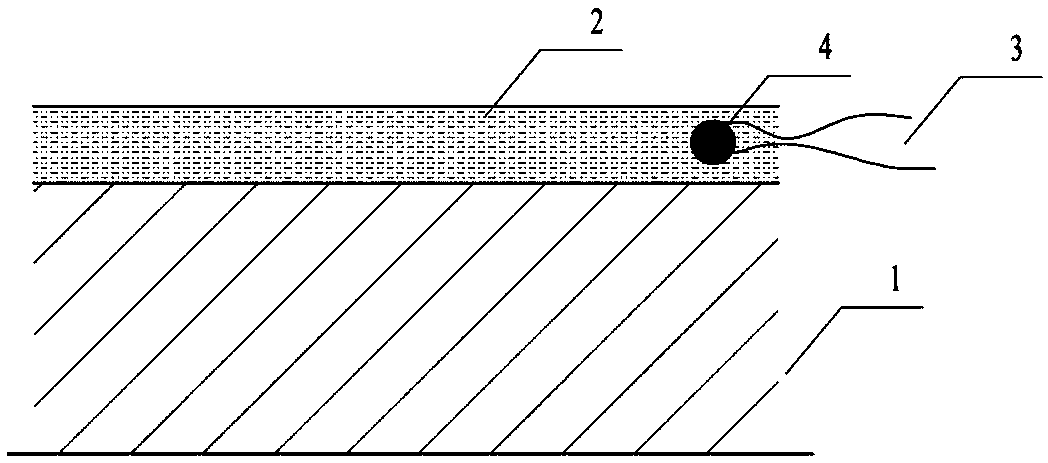

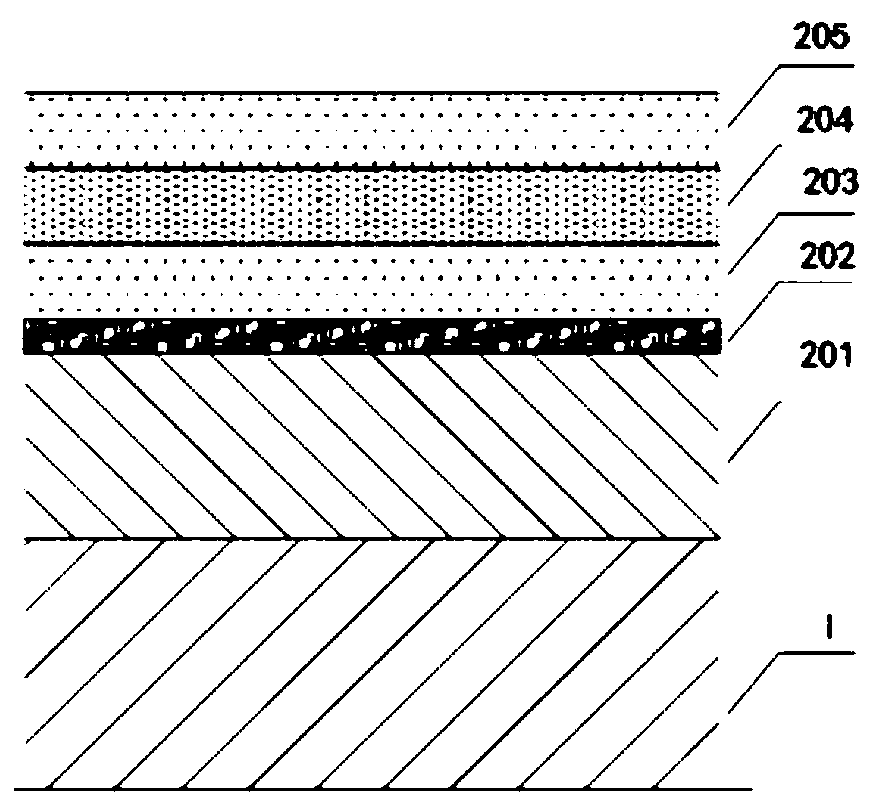

Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m

The present invention provides a film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m. The film system structure comprises a ZnS substrate and a color separation film system, and the color separation film system is made of three film materials; the number of the film layers is 51, wherein the first layer and the 51th layer are oxidation zirconium film layer, the even layers from the second layer to the 50th layer are ytterbium fluoride film layers and the odd layers from the second layer to the 50th layer are zinc sulfide film layers. The transmittance is smaller than 2% with the waveband from 0.5 to 0.8 [Mu]m; the transmittance is smaller than 1% with the laser waveband of 1.064 [Mu]m; and the transmittance is larger than 95% with the medium wave infrared band from 3.7 to 4.8 [Mu]m. The film system structure is small in the number of layers, small in thickness, low in plating difficulty, good in technology repeatability, high in obtained film firmness and good in spectral property, is able to satisfy the use requirement of multi-waveband co-window optoelectronic system and the work requirement in the condition of the inclination with 45 degrees, and stand against the environment tests such as high and low temperature storage, temperature impact and the like, the adhesion test and the moderate friction test.

Owner:西安应用光学研究所

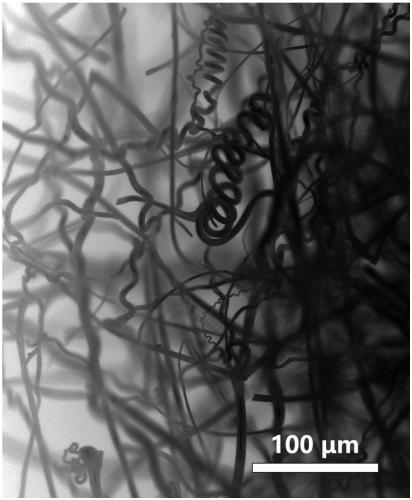

Ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application thereof

ActiveCN109161331AImprove the interface binding forceImprove erosion resistanceFireproof paintsPolymer scienceThermal insulation

The invention relates to a ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application of the ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating, the ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating is a double-layer composite coating systemand is compounded from a TI thermal insulation coating on the inner layer and a TA ablation resistance coating on the outer layer, the thickness ratio of the TI thermal insulation coating to the TA ablation resistance coating is (4-7):(2-5), a component B is added in a component A of the TI coating prepared according to the formula in the application, the mixture is blended by using a solvent inthe component A to the specified spraying viscosity and is blade-coated, roller-coated or sprayed to the thickness of 4-7 mm on the surface of a device; a component D is added in a component C of theTA coating prepared according to the formula, the mixture is blended by using a solvent in the component C to the specified spraying viscosity, is sprayed on the surface of a dried TI coating film, and is blade-coated or roller-coated to the thickness of 2-5 mm. Compared with the prior art, the bonding strength of a formed coating is high, and the coating can resist the instantaneous high temperature of more than 1500 DEG C, has an excellent heatproof effect, effectively protects a launcher against ablation damages, and is higher in strength.

Owner:SHANGHAI JIAO TONG UNIV +1

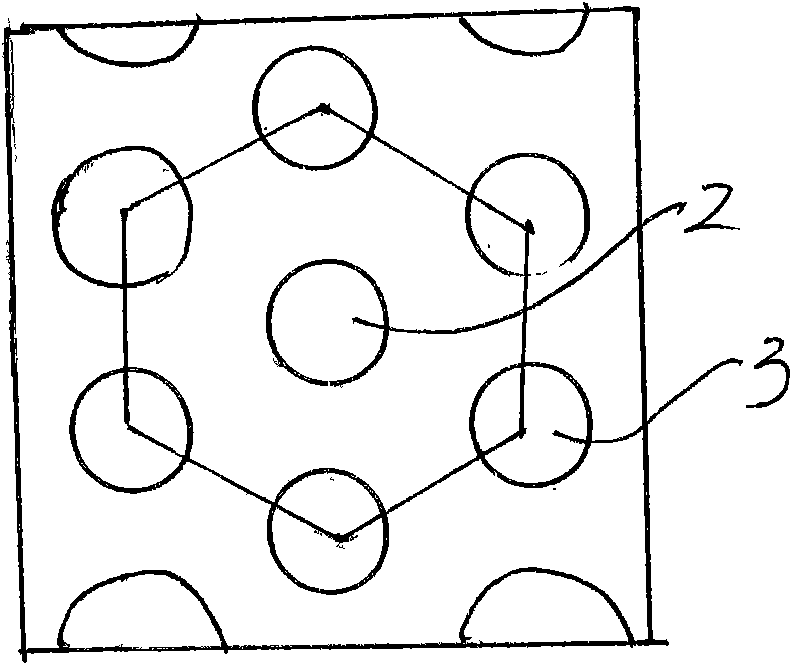

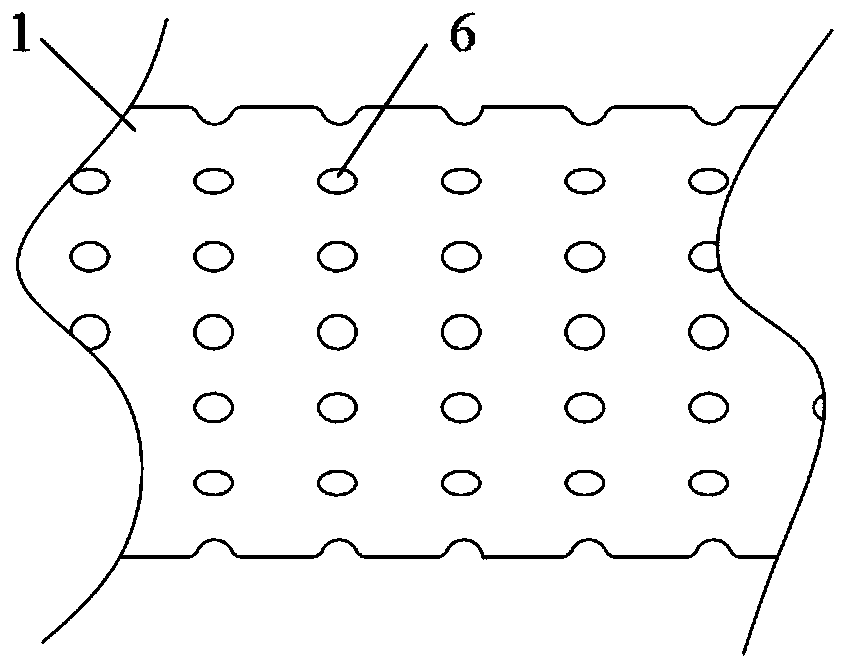

Front and back surface electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof

ActiveCN101609848AStress reliefLess bendingFinal product manufactureSemiconductor devicesScreen printingConductive paste

The invention discloses front and back surface electrodes of a screen printing crystalline silicon solar cell and a manufacturing method thereof; array points which are not printed into conductive paste are manufactured in an electrode main gate line; and the graphics of each array point is in a closed type. The manufacturing method comprises the step of arranging latex film array points on the screen printing plate electrode main gate line for blocking the conductive paste. The positive and back surface electrodes of the screen printing crystalline silicon solar cell and the manufacturing method thereof can effectively save the conductive paste on the positive and back surfaces of the crystalline silicon solar cell, and effectively eliminate the stress caused by different expansion coefficients of silver silicon alloy and silicon, thereby reducing the bending rate of a cell film and the welding debris rate of a component; the invention can enhance the adhesion firmness of the main gate line conductive paste on the silicon surface after being sintered and effectively solve the falling-off problem of a silver main gate line; and the invention reduces the surface contact area of the conductive paste and the silicon, and increases the open-circuit voltage and the short-circuit current.

Owner:HANWHA SOLARONE QIDONG

Water circulation pre-heating type corncob drier

InactiveCN103070235AKeep dryImprove uniformitySeed preservation by dryingWater circulationEngineering

The invention provides a water circulation pre-heating type corncob drier. The water circulation pre-heating type corncob drier is characterized in that a box is partitioned into an upper region and a lower region by a partition plate I; the lower region is partitioned into three parts by partition plates II; a water gas heater is arranged at the bottom of the middle of the box; one end of a heat exchange box above a first conveying device is communicated with the middle of the box, and the other end of the heat exchange box is connected with an induced draft fan which is arranged on the top of the box; two ends of each heat exchange box between upper and lower groove-shaped material channels of the first conveying device are connected with the water gas heater through a circulating water pump; a condensing water pump which is arranged on the top of the box is connected with a straight water pipe which is inserted into each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device to rotate are arranged in the box; a first moulding chain plate and a second moulding chain plate are suspended on a pin shaft of a chain extending inwards at intervals and supported on a guide rail to form a groove-shaped material channel; a material guide groove is formed below the tail end of the channel; a charging hole is formed on the top of the box; and a discharging hole is formed at the bottom of the box. The water circulation pre-heating type corncob drier is good in preheating and drying effect, and reliable in operation.

Owner:SHANDONG UNIV OF TECH

Cooling discharge type corncob drying machine

InactiveCN103070236AReduce the temperatureGuaranteed temperatureSeed preservation by dryingWater pipeCondensate pump

The invention provides a cooling discharge type corncob drying machine. The cooling discharge type corncob drying machine is characterized in that the inner part of a box is divided into an upper region and a lower region by a separator plate I; the lower region is divided into three parts by a separator plate II; the separator plate I and separator plates III and IV located at the lower part of the box form a cooling region; a water heater is arranged at the bottom of the middle box; the cooling region is connected with the air inlet of the water heater by a blower; the air outlet of the water heater is connected with the middle part of the box; one end of each heat exchange box at the uppermost part in the box is communicated with the middle part of the box, and the other end of the heat exchange box is connected with an induced draft fan; two ends of each heat exchange box in the lower place are connected with the water heater by a circulating water pump; a condensate water pump is connected with straight water pipes in each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device are arranged in the box; each forming chain plate is supported on a guide rail to form a groove-shaped material channel; a guide chute is arranged under the tail end of the channel; a feed port is formed in the top part of the box; and a discharge port is formed in the bottom of the box. The cooling discharge type corncob drying machine is good in drying effect and low in energy consumption, and corncobs can be packaged directly after being dried by the drying machine.

Owner:SHANDONG UNIV OF TECH

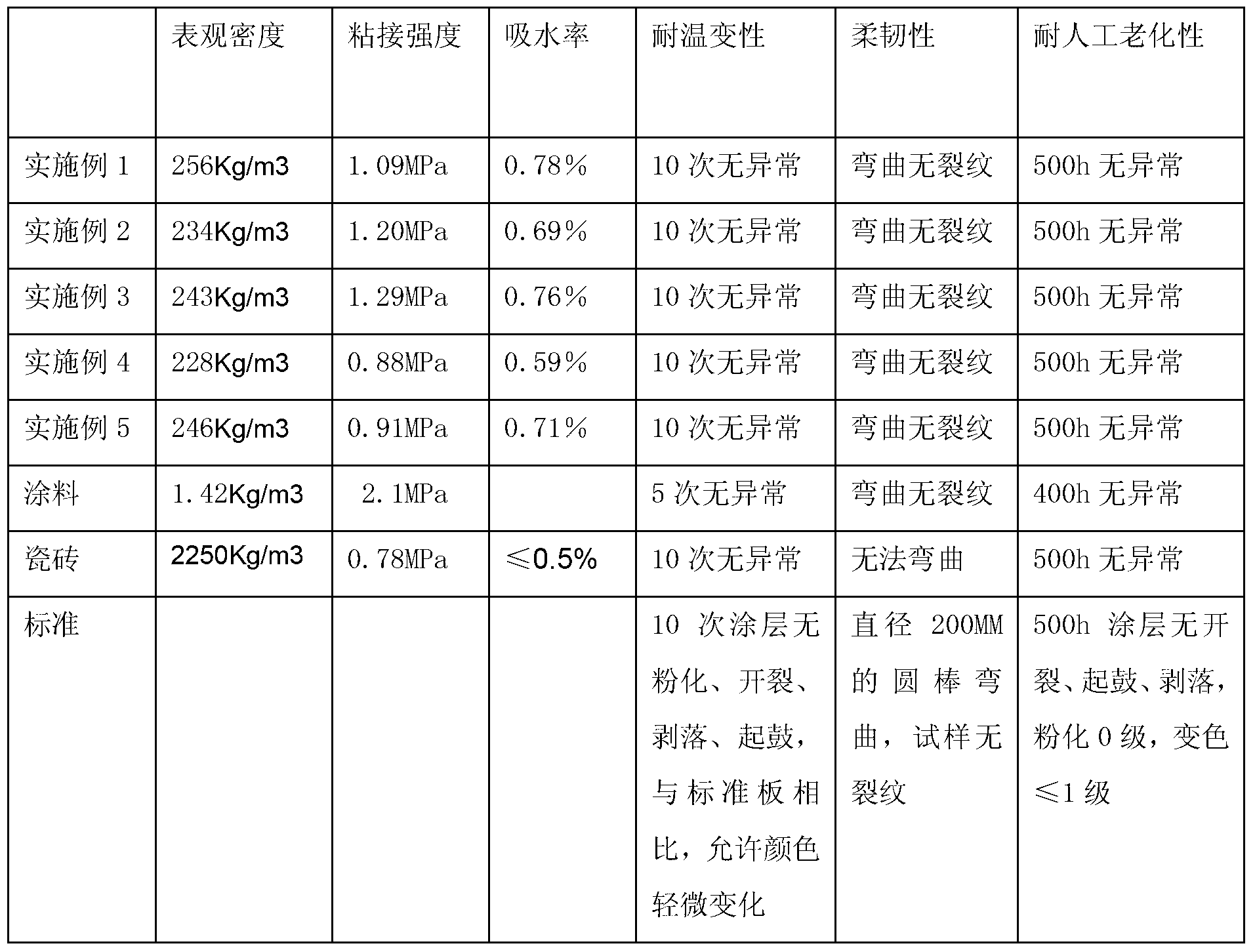

Inorganic composite flexible decorative coiled materials and producing method thereof

InactiveCN103266734ASolve empty drumSolve crackingCovering/liningsWater-setting substance layered productCelluloseGlass fiber

The invention belongs to the field of building, and discloses inorganic composite flexible decorative coiled materials. The thickness of the inorganic composite flexible decorative coiled materials is 2mm to 10mm, the inorganic composite flexible decorative coiled materials comprise an inorganic coiled material mortar layer, a decorative mortar layer is combined on the inorganic coiled material mortar layer, and reinforcing materials formed by alkali-resisting glass fiber gridding cloth or glass fiber roofing felts are arranged in the inorganic coiled material mortar layer or on the boundary of the inorganic coiled material mortar layer and the decorative mortar layer. The inorganic coiled material mortar layer is mainly formed by the following materials, by weight: 100 parts of portland cement with intensity no less than 42.5, 1.2 to 2.0 parts of cellulose, 350 to 450 parts of 50 to 100-mesh silica sand, 180 to 220 parts of coarse whiting, 1.8 to 2.2 parts of water reducing agent and 120 to 160 parts of 707 emulsion or cement-based elastic emulsion. The decorative mortar layer is mainly formed by the following materials, by weight: 150 parts of synthetic resin emulsion for maishi paint, 4 to 6 parts of coalescing agent, 8 to 12 parts of ethylene glycol, 1 to 2 parts of cellulose and 700 to 800 parts of natural color sand. The inorganic composite flexible decorative coiled materials are good in toughness, small in thickness, light in weight, good in application property, not prone to peeling off and good in weather fastness, and different decorative styles can be formed easily.

Owner:BEIJING SOLID BUILDING ENG

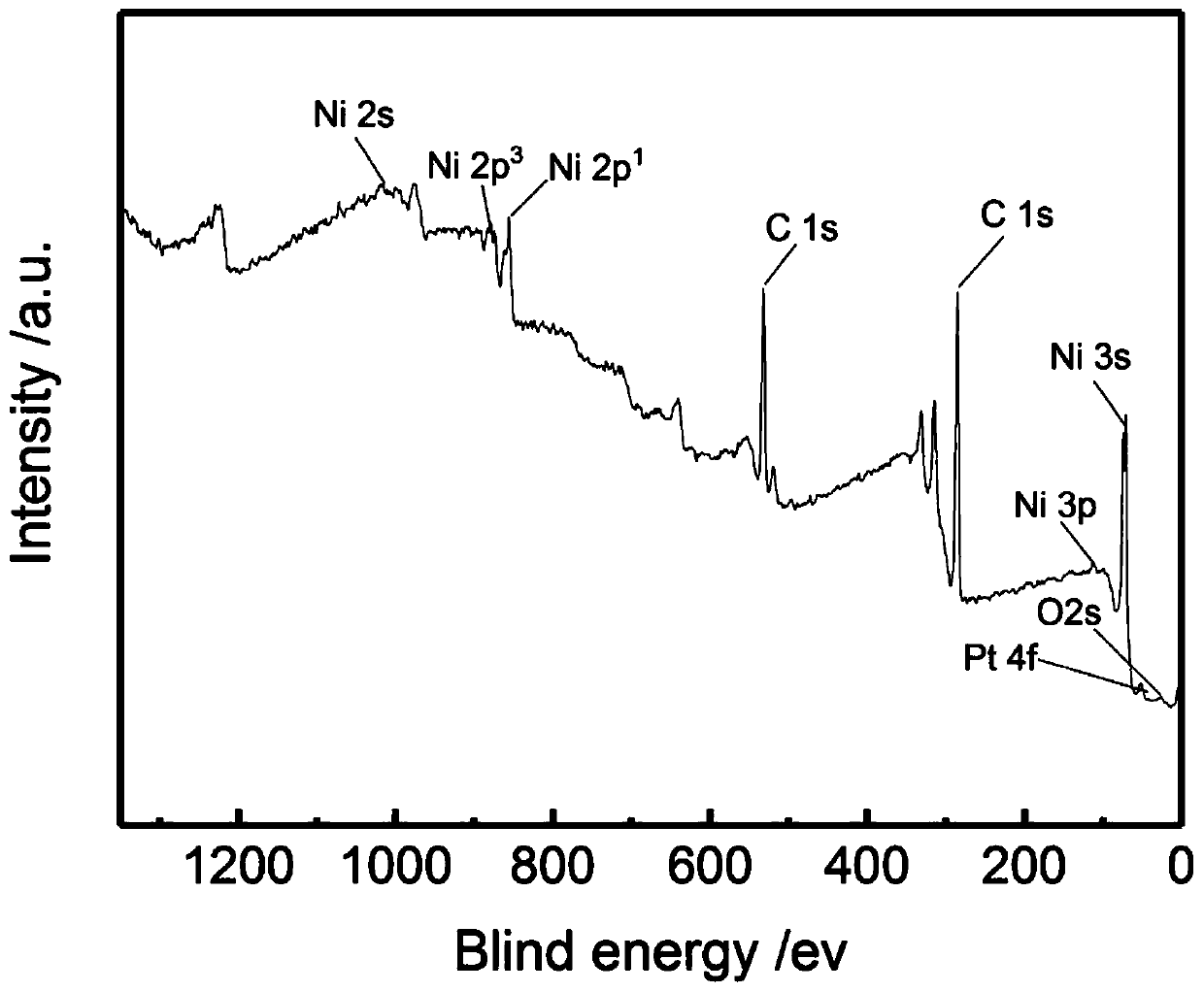

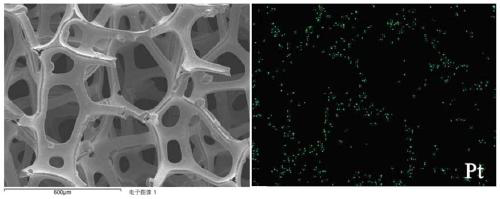

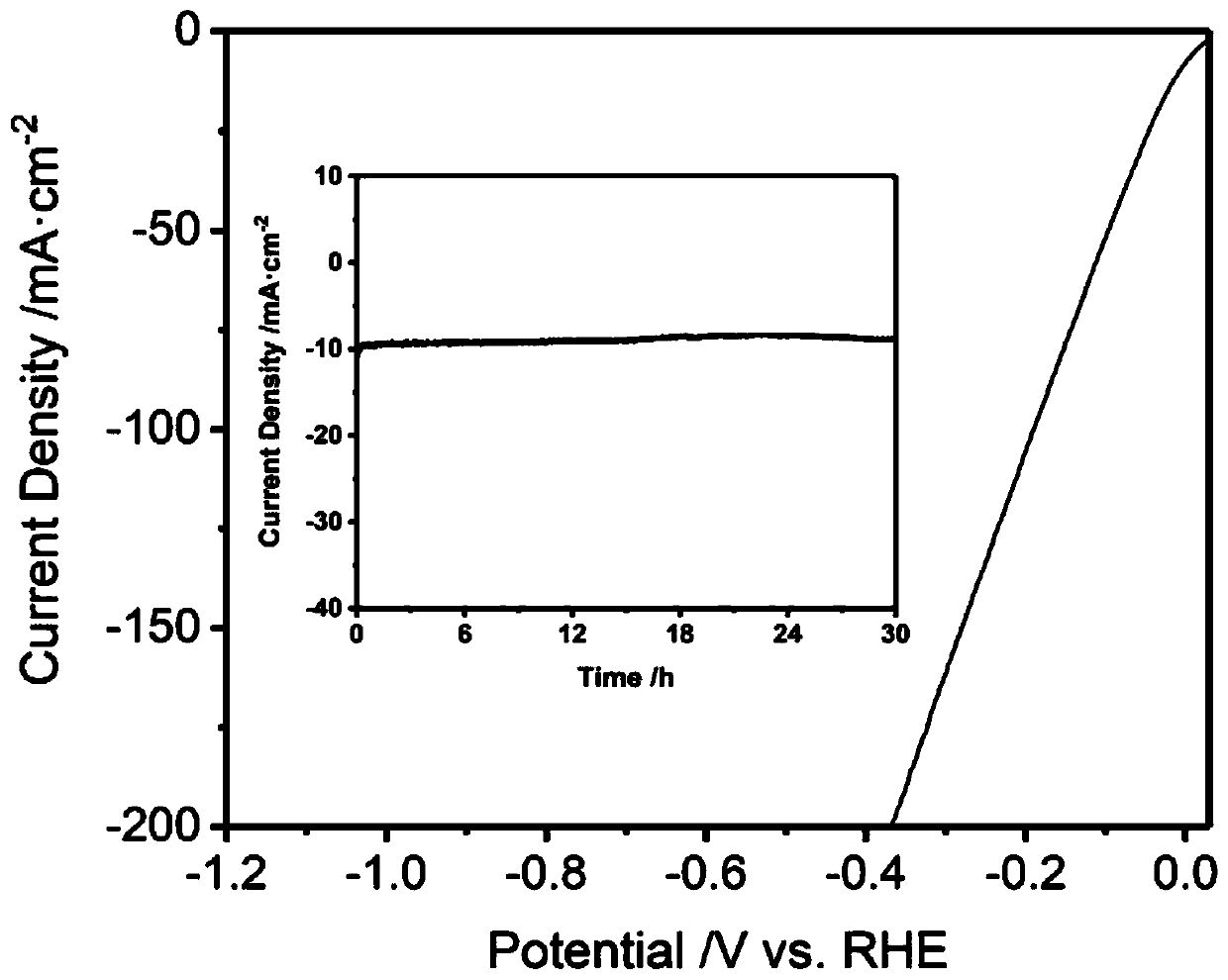

Modified foamed nickel supported noble metal catalyst hydrogen evolution electrode and preparation method thereof

ActiveCN110438528ARich sourcesSimple preparation processAnodisationMaterial nanotechnologyPlatinumNickel substrate

The invention relates to a modified foamed nickel supported noble metal catalyst hydrogen evolution electrode and a preparation method thereof. The preparation method comprises the following steps: (1) pretreating foamed nickel; (2) by taking the pretreated foamed nickel as an anode, a platinum sheet as a cathode, and an alcohol-water mixed solution of an ammonium salt as electrolyte, performing anode oxidation retreatment so as to obtain a modified foamed nickel substrate; and (3) putting the modified foamed nickel substrate into a precursor homogeneous solution with noble metal elements, performing heating treatment, and performing in-situ growth on the noble metal elements on the surface of the modified foamed nickel. The foamed nickel used in the electrode is rich in source, the electrode preparation process is simple and controllable, the equipment requirement is low, the prepared noble metal catalyst is small in granule size, uniform in dispersion and solid in combination with substrates, the loading amount of noble metal granules on the modified foamed nickel substrate is low, the raw material cost can be reduced, and t he prepared electrode has excellent electro-catalysis hydrogen evolution activity and stability in water decomposition and has significant application prospects.

Owner:阪吉化学(上海)有限公司

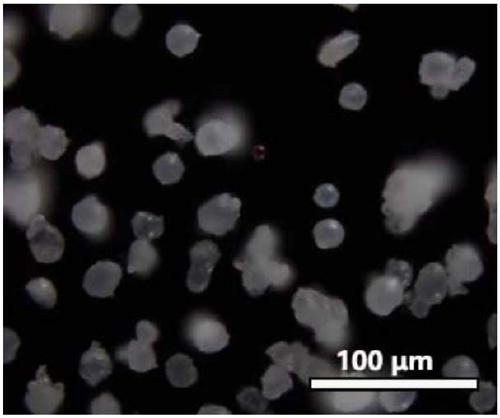

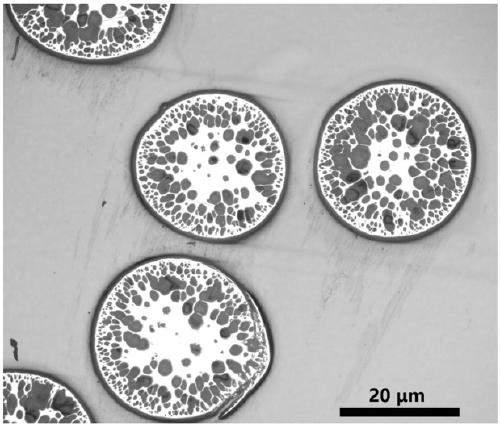

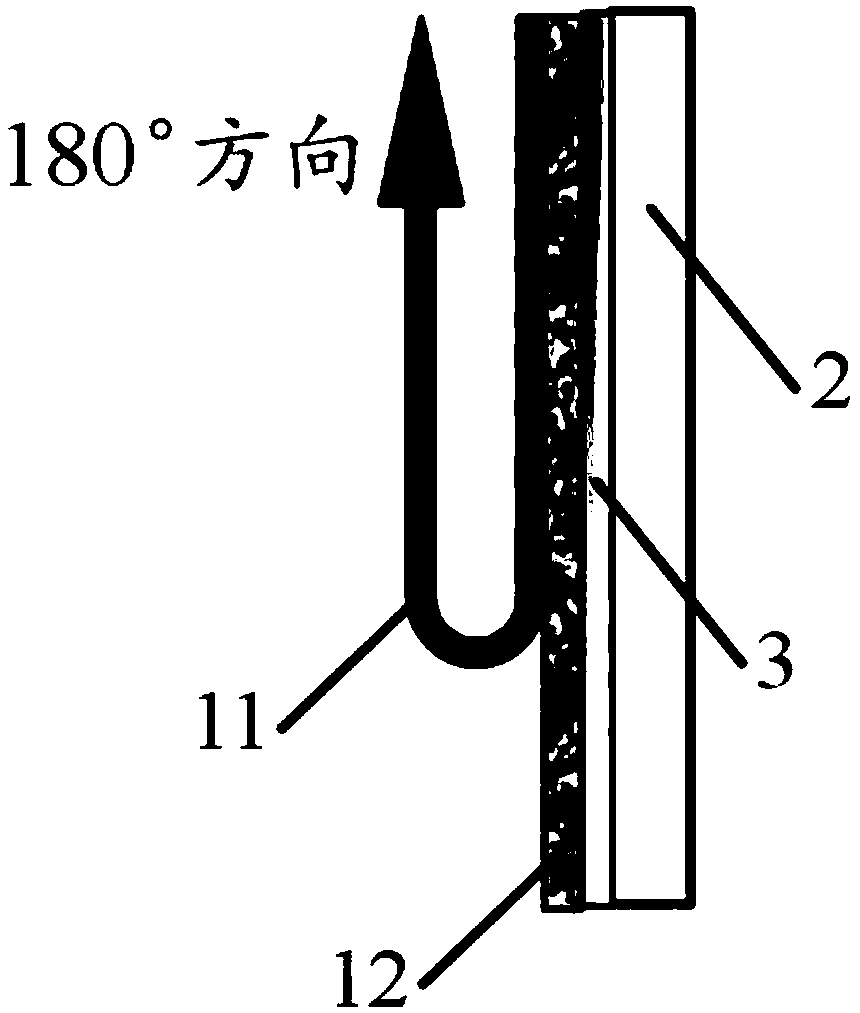

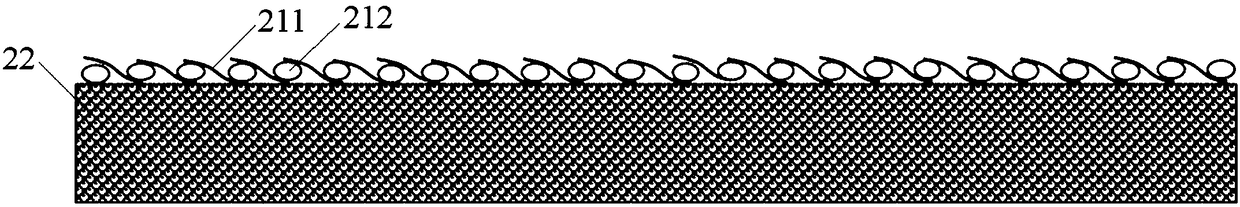

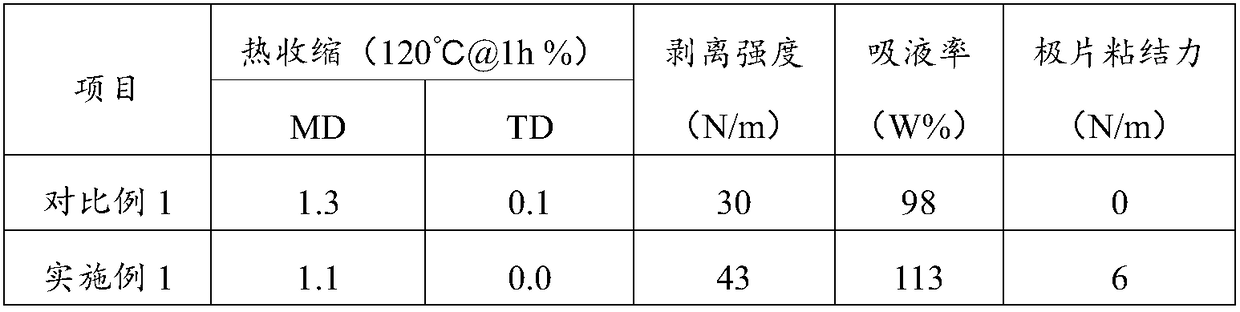

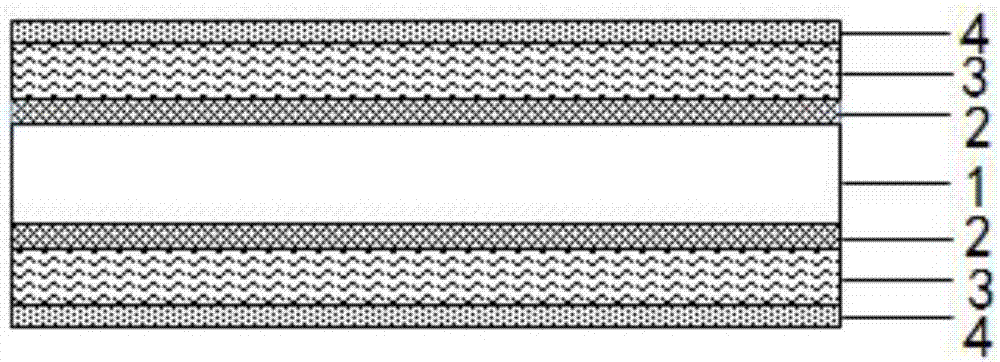

High-temperature resistant composite battery separator and preparation method thereof

ActiveCN108281592AGood thickening effectImprove hydrophilicityCell component detailsInorganic particleInorganic particles

The invention discloses a high-temperature resistant composite battery separator and a preparation method thereof. The high-temperature resistant composite battery separator comprises a base film anda high-temperature resistant coating layer, wherein the high-temperature resistant coating layer is coated on at least one surface of the base film and is formed by coating inorganic particles containing nanometer cellulose as a binding agent. In the composite battery separator, the nanometer cellulose is creatively used as the binding agent to prepare the high-temperature resistant coating layer,the interface bonding force of the coating layer and the base film is improved, the stripping strength of the composite battery separator is further improved, and the problems of falling and powder dropping of the coating layer are solved very well; with the addition of the nanometer cellulose, the inorganic particles are better in dispersion effect in water; moreover, the nanometer cellulose isused as the binding agent to form the coating layer, the high-temperature resistant composite battery separator is rapid in liquid conductivity and high in liquid absorption capability, gel is easilyformed after the electrolyte is absorbed, so that the composite battery separator can be attached onto a surface of an electrode very well, and the integral performance of the lithium ion battery is improved.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Novel expanded perlite insulation board and preparation method thereof

Provides are a novel expanded perlite insulation board and a preparation method thereof. The novel expanded perlite insulation board is mainly prepared by raw materials of 50%-80% of expanded perlite, 10%-40% of inorganic adhesive and organic adhesive, 0%-10% of fiber and 0%-10% of property-modifying additive. The novel expanded perlite insulation board uses a compression molding process and is high in production efficiency, good in size stability and low in production cost. The novel expanded perlite insulation board has excellent fireproofing safety to overcome shortcomings of poor fireproof performance, ageing resistant and environment pollution; and has excellent waterproofness and low thermal coefficients to overcome a shortcoming that a common inorganic insulation material is large in thermal coefficient and strong in water absorbability. The novel expanded perlite insulation board has excellent heat insulation performance, can achieve thermal insulation performance levels of the organic material, simultaneously has non-ignitable performance of the inorganic material, is good in durability and weather fastness, can achieve same service life of buildings, solves the problem that service life of an organic board is short, and is favorable for energy saving and environmental protection. The service life of the organic board can be asynchronous with the building.

Owner:SHENYANG JIANZHU UNIVERSITY

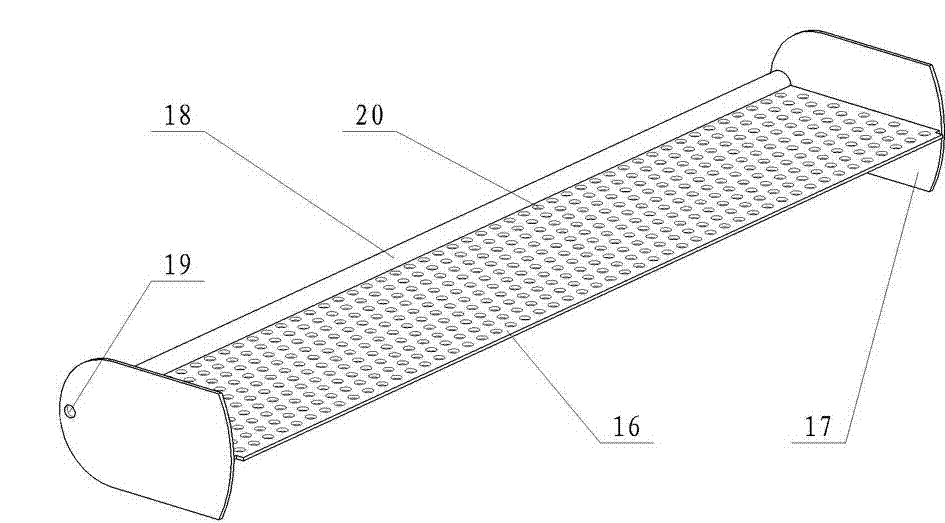

Vegetable dehydrator adopting stiffener chain plates

The invention provides a vegetable dehydrator adopting stiffener chain plates. The vegetable dehydrator is characterized in that the interior of a box body is horizontally divided into multiple layers by spacer plates; a group of transporters driven by a transmission device step by step to run are arranged in each layer; the stiffener chain plates are divided into two kinds, namely stiffener chain plates with a plurality of air vents on panels and stiffener chain plates without holes; one long side of each panel is along the bus of a stiffener; the two planes of the panel are maintained to be symmetrical relative to the stiffener and are fixedly connected with the stiffener; each stiffener chain plate is supported on a guide rail to form a groove-shaped material channel; a material guide groove is arranged below the tail end of each channel; an infrared radiation device is arranged above a channel in the box body at each layer with a larger layer number; a draught hole is arranged on the upper part of the side wall at one end of the box body at each layer and is connected with a fan by a draught pipe; air inlets are arranged at the two ends of the side wall of the box body at each layer with a smaller layer number and are connected with an air heater by an air supply pipe; a feeding hole is arranged at the top of the box body; and a discharge hole is arranged at the bottom of the box body. The vegetable dehydrator has the advantages of stable working performances, high reliability and good vegetable drying quality.

Owner:SHANDONG UNIV OF TECH

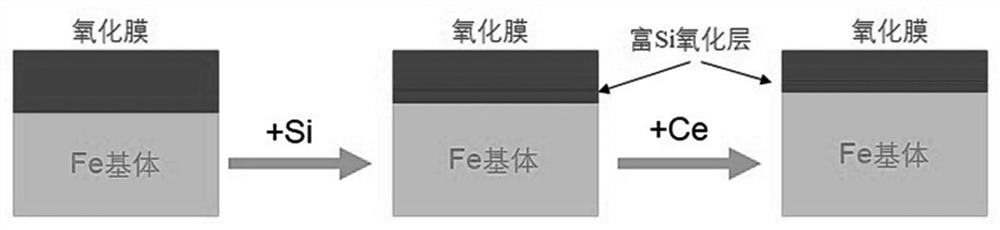

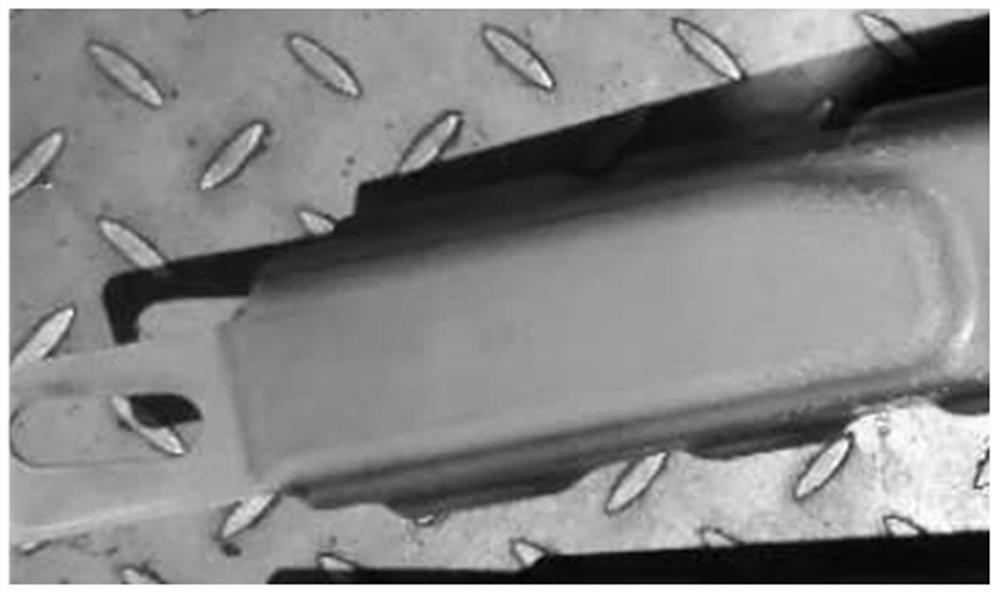

Hot stamping forming steel added with Ce alloy and hot stamping forming technology

The invention belongs to the technical field of steel preparation and particularly relates to hot stamping forming steel added with Ce alloy and a hot stamping forming technology. The hot stamping forming steel added with Ce alloy comprises the following chemical compositions in percentage by mass: 0.22-0.40% of C, 1.0-2.5% of Mn, 1.2-2.0% of Si, 0.05-0.5% of Al, 1.2-2.5% of Cr, less than 0.6% ofMo, less than 0.1% of Nb, less than 0.15% of V, 0-0.1% of Ti, 0-0.01% of B, 0.01-0.03% of P, less than 0.004% of O, less than 0.002% of S, 0.03-0.08% of Ce, less than 0.01% of Ca, less than 0.01% of Mg and the balance of Fe and unavoidable impurities. The hot stamping forming steel adopts brand new composition design and a conventional production process for production and hot stamping. Through changing the thickness and structure of oxidized scale during the heating and stamping process of hot forming steel, the problem about falling of the hot forming steel during the heating and stamping process is solved, and finally, a thin oxide layer with a stable and dense structure is formed on the surface of a stamping component, so that the problem that a die is worn because the oxide layer of the hot stamping steel falls off is solved, at the same time, shot blasting treatment is also avoided, and the hot stamping forming steel has the direct coating application condition and does not pollute the environment.

Owner:LIAONING INST OF SCI & TECH

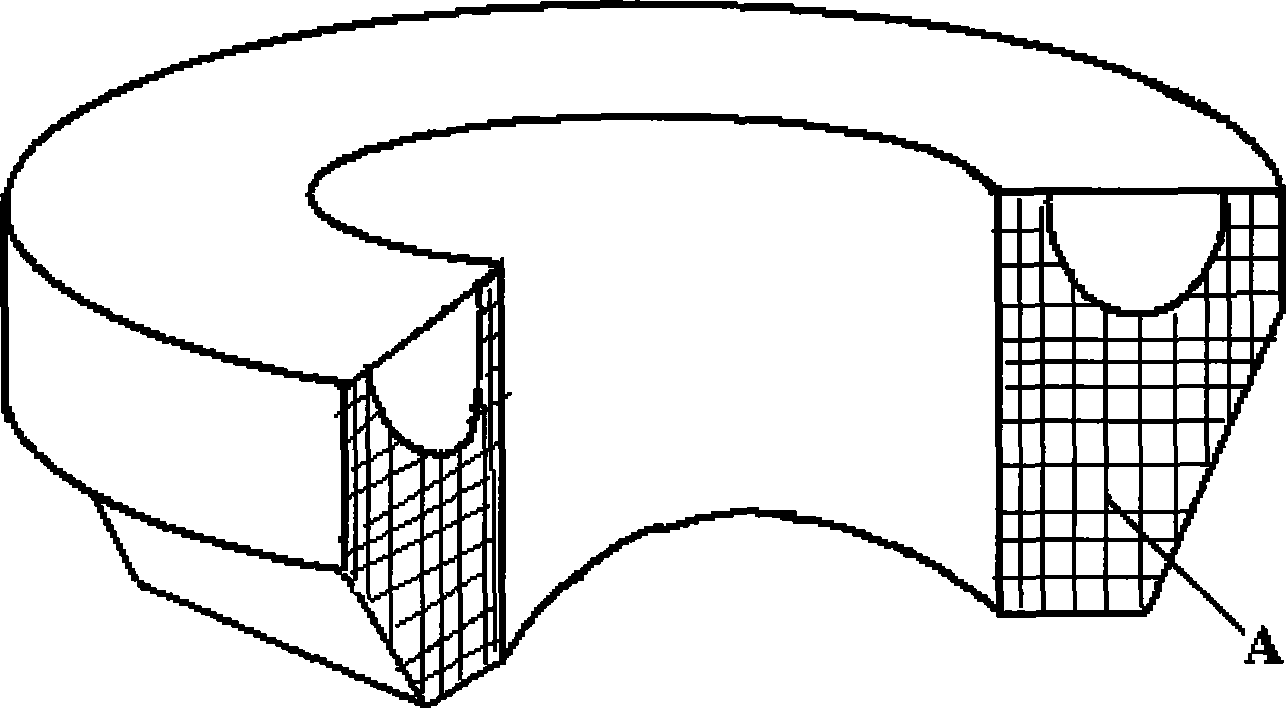

Method for preparing primary column shaped horniness phase composite wear-resistant grinder dish

The invention discloses a method for preparing a composite wear resistant abrasive disk with a protogenous columnar hard phase. The wear resistant abrasive disk prepared by the method is formed by pouring and compounding a high hardness columnar alloy hard phase and a high tenacity base metal. The method comprises the following steps: weaving an alloy powder core wire material into a framework similar to the shape of the abrasive disk, and pouring smelted high temperature base material molten steel into a die cavity of an abrasive disk casting mould; putting the woven framework similar to the shape of the abrasive disk into the casting die cavity filled with the high temperature base metal molten steel quickly, performing cast-infiltration, sintering or melting on the woven alloy powder core wire material framework by using the heat of the high temperature base metal molten steel so as to generate a highly-dispersed high hardness columnar alloy hard phase in situ; and cooling the phase at room temperature to produce the composite wear resistant abrasive disk using high-tenacity and high-strength metal as a base and containing the metallurgically-combined protogenous columnar hard phase. The composite wear resistant abrasive disk with the protogenous columnar hard phase has ultra wear resistance and good impact resistant toughness, and the service life of the abrasive disk is close to or exceeds the imported products of the same type.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Infrared radiation coating and preparation method thereof

The invention discloses an infrared radiation coating. The infrared radiation coating is formed by mixing a solid material with a liquid material based on a weight ratio of 1:1, wherein grain sizes of the components of the coating are from 100 nanometers to 2 microns; the liquid material is an adhesion agent; and the solid material comprises the following components in percentage by weight: 45-75percent of blackening agent, 20-45 percent of zircon sand and 0-15 percent of aluminum oxide. The grains sizes of the principal components of the coating are from 100 nanometers to 2 microns, so thatthe radiation property of the coating is improved and the service life of the coating is prolonged. The radiance (Epsilon) of the coating is higher at a high temperature of 1,000-1,400 DEG C and can reach more than 0.9; and even at the temperature of 1500 DEG C, the stable radiation still can be maintained and the normal total emissivity of the coating still can reach 0.87; meanwhile, the infrared radiation coating can be applied to different heating types of kilns.

Owner:唐山晟科陶瓷制品有限公司

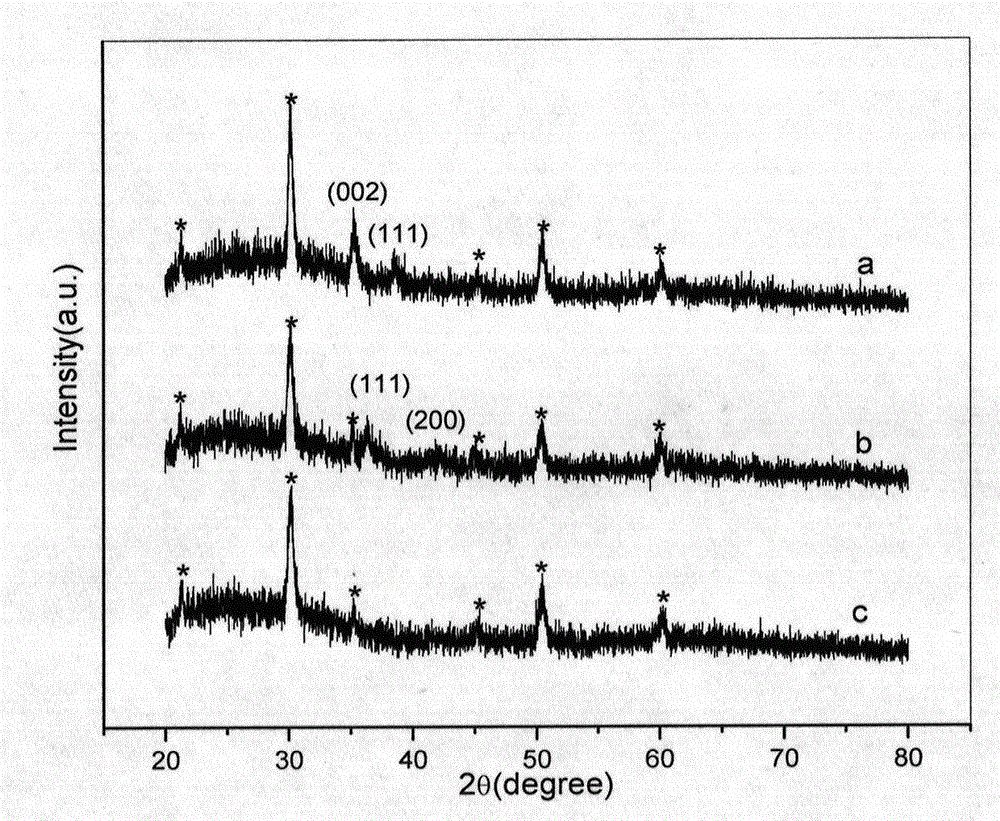

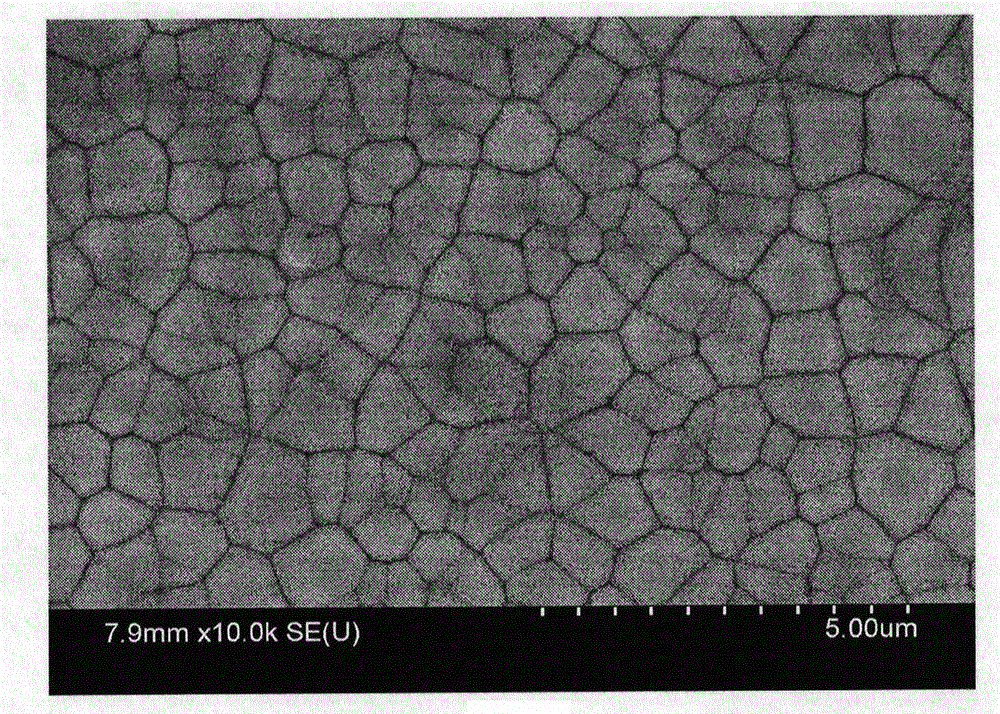

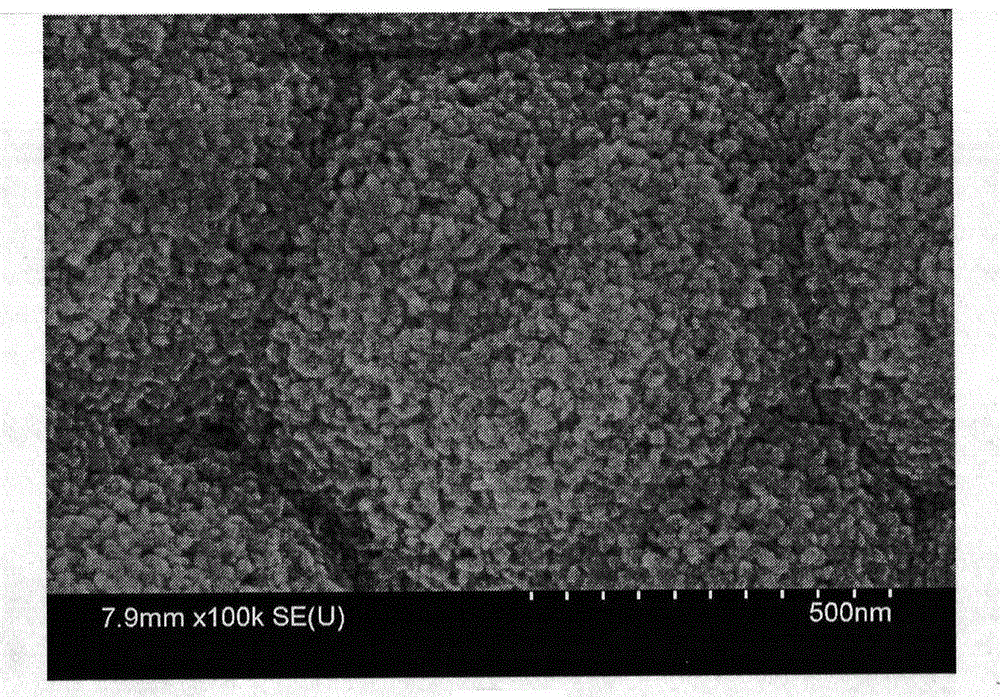

Preparation method of non-enzyme glucose sensor electrode material based on CuO film

InactiveCN105040060AEasy to prepareEasy to operateElectrolytic inorganic material coatingMaterial electrochemical variablesAir atmosphereGlucose sensors

The invention discloses a preparation method of a non-enzyme glucose sensor electrode material based on a CuO film. The preparation method mainly comprises the steps that 1, a conductive substrate is pretreated; 2, an electrochemical deposition method is adopted for preparing a Cu2O film of a special structure on the conductive glass substrate; and 3, heat treatment is performed on the Cu2O film obtained through electrochemical deposition under the air atmosphere so as to oxidize the Cu2O film into the CuO film of a similar structure, the CuO film can be directly used as the non-enzyme glucose sensor electrode material, and the electrode manufacturing process is simplified. The CuO film is composed of a plurality of spherical cluster units formed by self-assembly of spherical particles, has the uniform appearance, is large in specific surface area and can achieve the purpose of improving glucose detection sensitivity. In addition, the CuO film is stable in structure and can be well combined with substrate materials, the problem that powder materials are disengaged when the substrate is coated with the powder materials due to poor combination performance and then the number of active centers is reduced is avoided, and therefore electro-catalysis glucose activity is good.

Owner:MUDANJIANG NORMAL UNIV

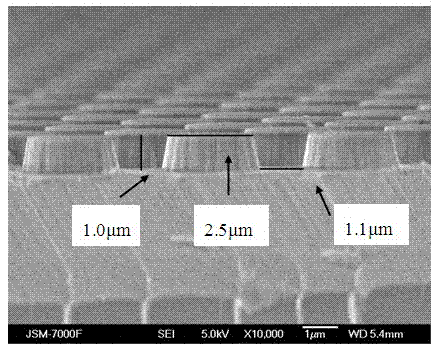

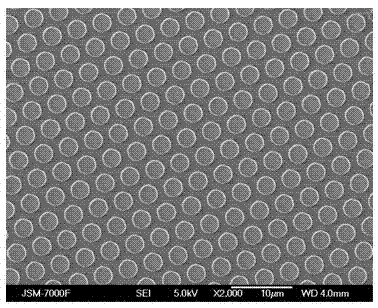

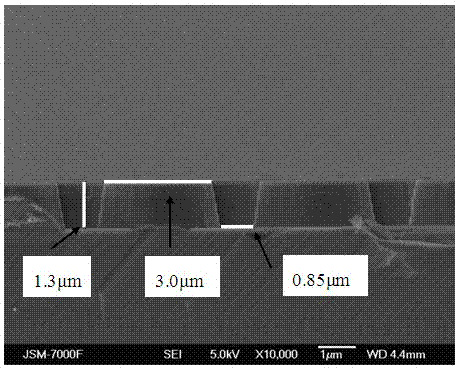

Preparation method of submicron-grade graph on sapphire substrate

InactiveCN102522467AStrong process controllabilityGood repeatabilitySemiconductor devicesDislocationIon

The invention relates to a preparation method of a submicron-grade graph on a sapphire substrate, which belongs to the technical field of semiconductors and comprises the following steps of: firstly depositing a photoresist-adhering layer on the sapphire substrate, then carrying out the ultrasonic processing of the sapphire substrate in acetone through photoetching and vapor deposition, and cleanly flushing by adopting deionized water; then placing the sapphire substrate into a hydrochloric-acid aqueous solution for heating to ultrasonically remove a metallic mask layer after being etched by adopting an inductively-coupled plasma dry method, flushing with the deionized water, and then placing the sapphire substrate into dilute hydrofluoric acid or a heated phosphoric-acid solution to remove the photoresist-adhering layer; and finally placing the substrate into the acetone and alcohol for ultrasonic processing, and then cleanly flushing with the deionized water. The preparation method of the submicron-grade graph on the sapphire substrate has the advantages of low manufacturing cost, easiness in operation and high finished-product rate, can be used for the epitaxial growth of low-dislocation-density high-crystal-quality nitrides and can be used for producing the substrate material of a nitride-semiconductor light-emitting diode with higher light-emitting efficiency.

Owner:南京大学扬州光电研究院

Anti-drop diamond brad and manufacturing process thereof

The invention discloses an anti-drop diamond brad, which comprises a cutter bit, a matrix and a base, and is characterized in that: the cutter bit is prepared from uniform powder prepared by mixing a soft matrix material and a superfine diamond in an irregular shape through hot-pressing sinter molding, wherein the soft matrix material consists of the following components in percentage by weight: 15 to 25 percent of copper, cobalt and iron alloy, 45 to 85 percent of bronze powder, 2 to 5 percent of tin powder, 5 to 10 percent of nickel powder, 2 to 5 percent of titanium powder, 2 to 6 percent of zinc powder and a proper amount of filler; the superfine diamond has the concentration of 12 to 25 percent; and a dovetail groove connecting mechanism is arranged on opposite surfaces of the cutterbit and the matrix. The diamond cutter bit is reasonable in components and proportion, the cutter bit has high bending strength and good self-sharpening property, and a holding force of diamond particles is improved; moreover, the dovetail groove connecting mechanism is arranged between the cutter bit and the matrix, so that the diamond cutter bit is firmly connected with the matrix, the phenomenon that the diamond cutter bit drops is avoided, potential safety hazards are eliminated, and the service life of the diamond brad is prolonged.

Owner:福建省泉州万龙石业有限公司

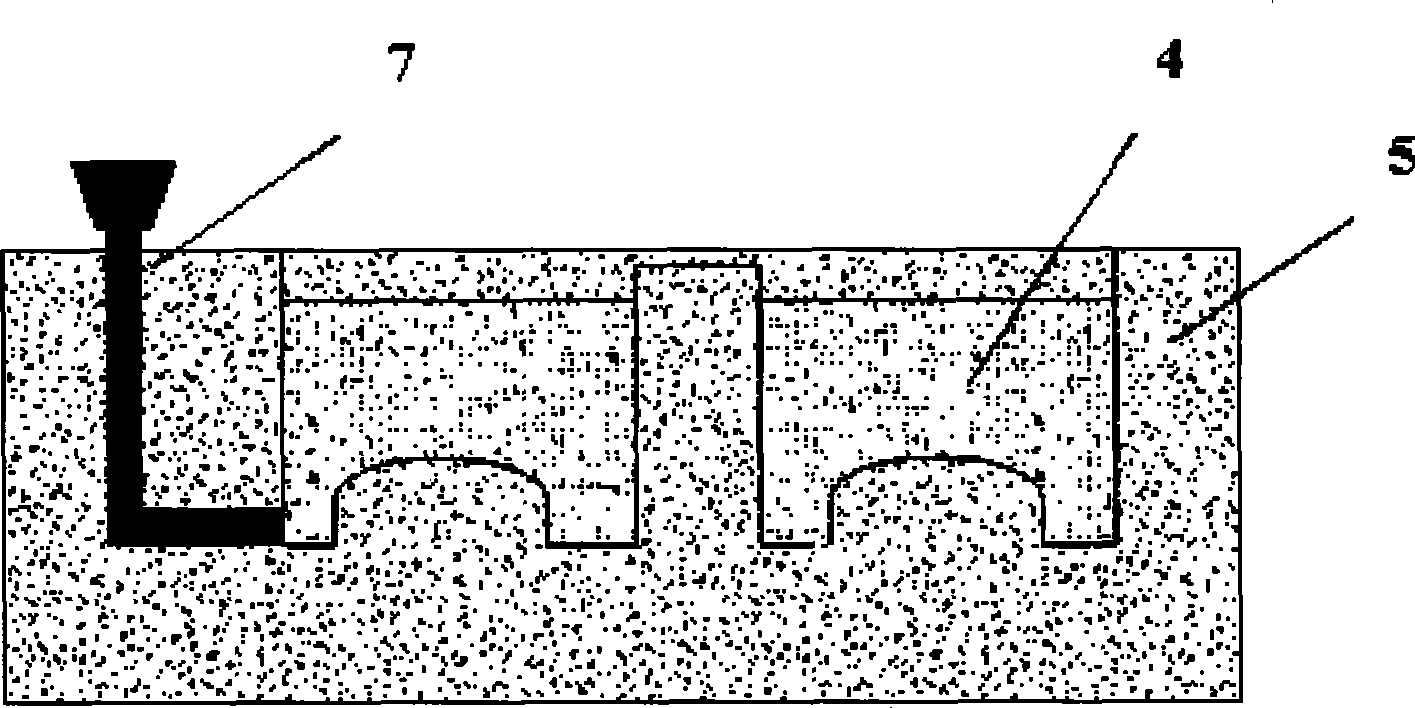

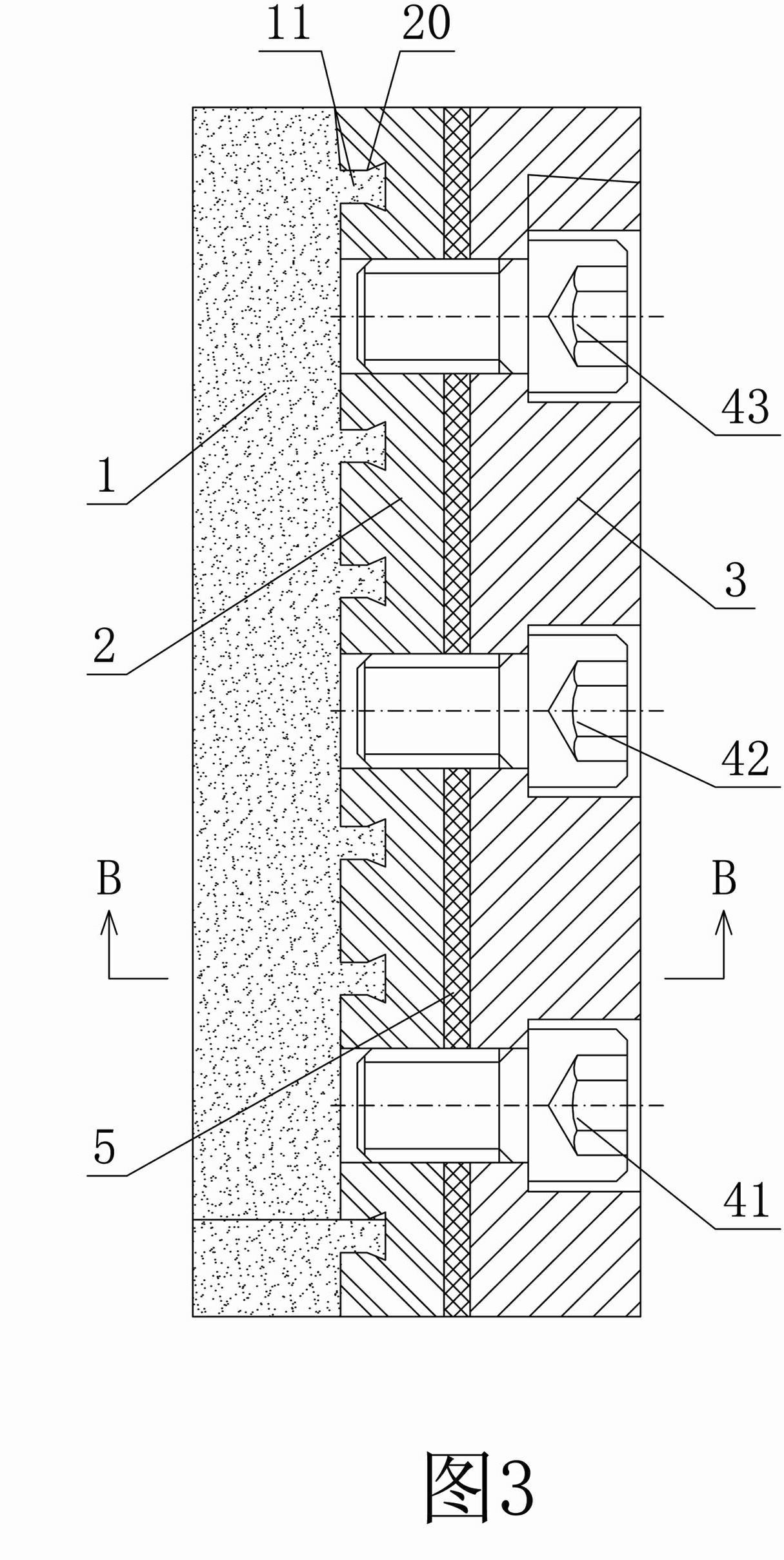

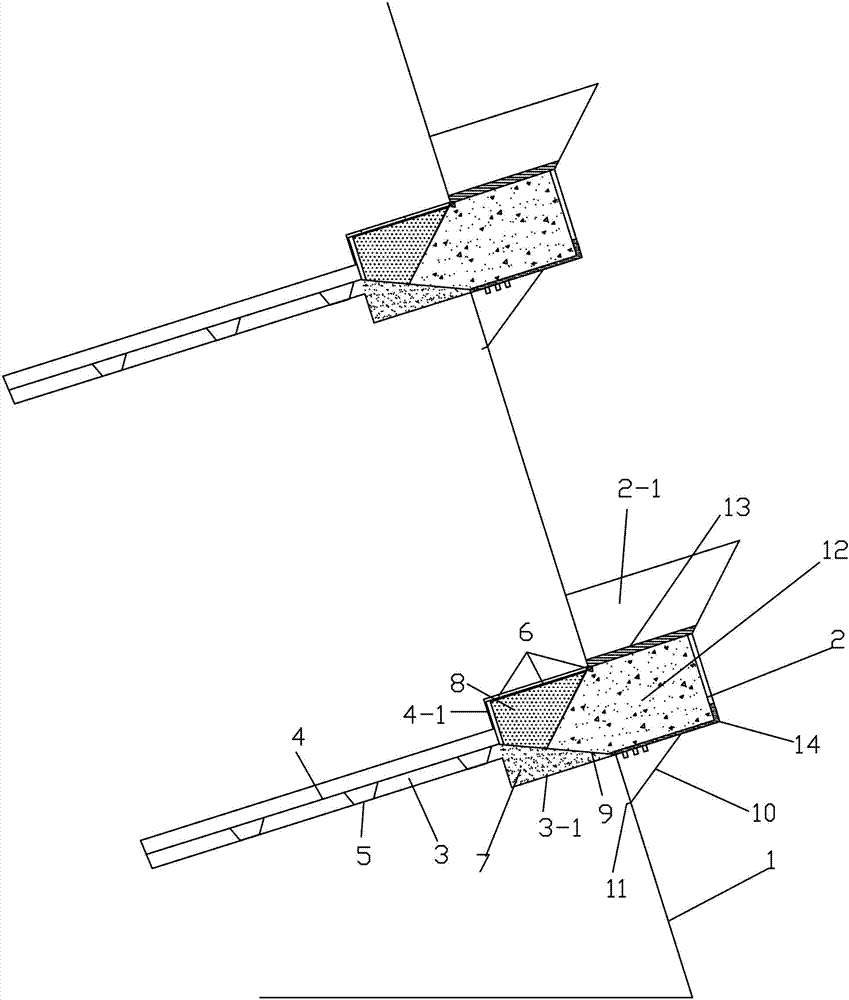

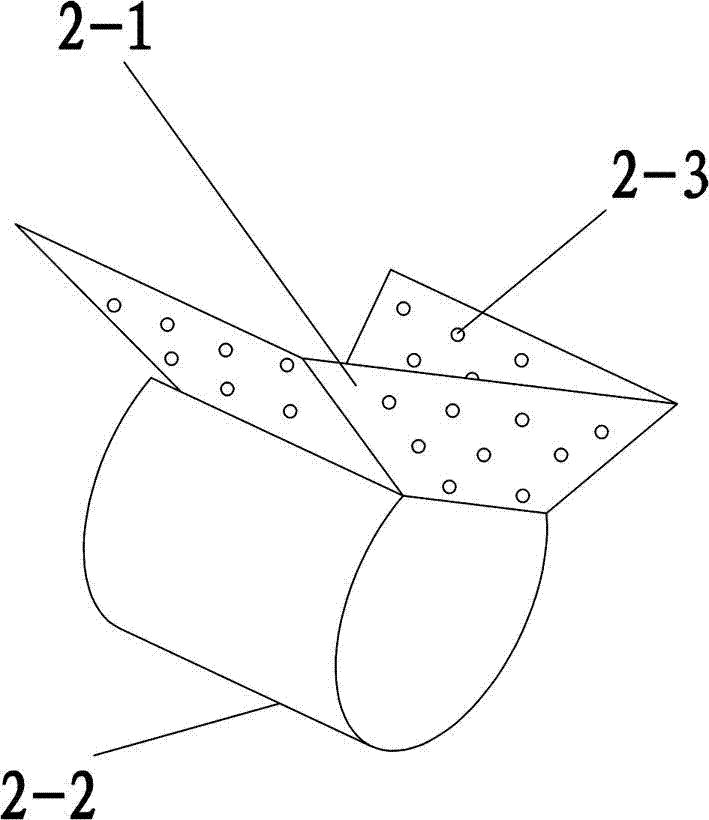

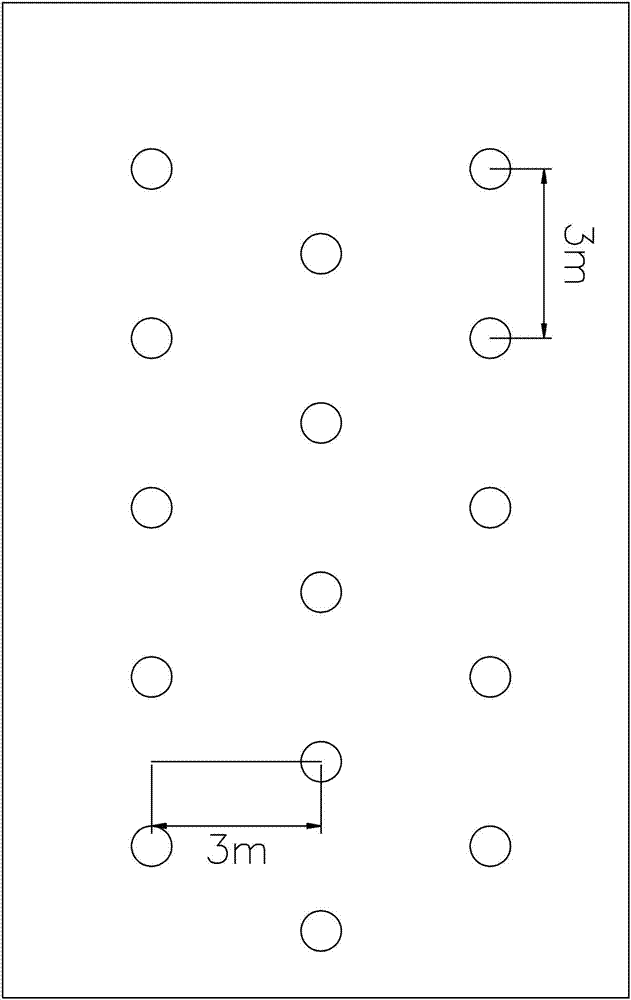

Anchor hole based slope afforesting method and system

InactiveCN104727330AAvoid weathering and slumpingSolve sheddingExcavationsBulkheads/pilesEngineeringFertilizer

Provided is an anchor hole based slope afforesting method. The method comprises the following steps that firstly, reconstructing is carried out on an anchor hole; secondly, an inner space of a water and fertilizer storing cavity is divided into a water storing area and a fertilizer storing area; thirdly, a prefabricated PVC pipe is embedded into the hole opening portion of the water and fertilizer storing cavity; fourthly, parthenocissus tricuspidata and kudzu seeds are planted into the prefabricated PVC pipe, and slope afforesting is achieved. According to an anchor hole based slope afforesting system, the water and fertilizer storing cavity is formed by hole broadening of the hole opening of the anchor hole, and an anchor rod is bended at the bottom of the water and fertilizer storing cavity to form a step shape to be matched with the water and fertilizer storing cavity; the inner space of the water and fertilizer storing cavity is divided into the water storing area and the fertilizer storing area, and the parthenocissus tricuspidata and the kudzu seeds are planted into the prefabricated PVC pipe. According to the anchor hole based slope afforesting method and the system, water preserving and fertilizer preserving can be effectively achieved, the manufacturing cost is low, the afforesting effect is good, the long-acting afforesting effect is good, and the afforesting can be achieved in a short time.

Owner:广东森维园林股份有限公司

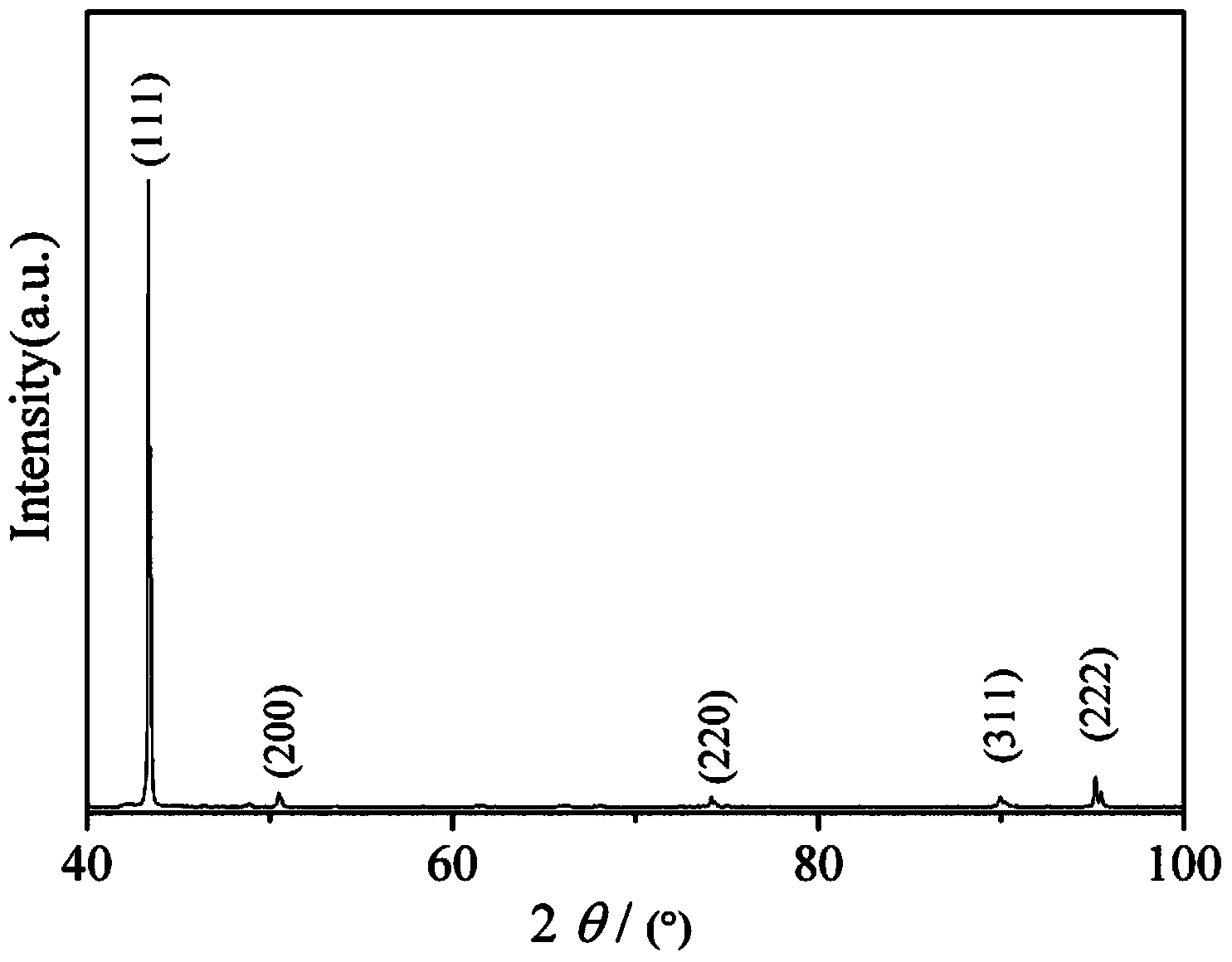

Glucose detection Cu-based CuO membrane electrode and reparation method thereof

ActiveCN103454328AReduced assembly stepsSolve sheddingMaterial analysis by electric/magnetic meansFlower likeSelf assemble

The invention discloses a glucose detection Cu-based CuO membrane electrode which comprises a Cu substrate and a CuO membrane attached on the surface of the Cu substrate, wherein the CuO membrane comprises a plurality of flower-like structure units, each flower-like structure unit is formed by self-assembling a CuO nano sheet vertical to the Cu substrate. In addition, the invention also discloses a preparation method of the Cu-based CuO membrane electrode. According to the Cu-based CuO membrane electrode, the preparation of a CuO active material and the combination with a conductive base body are synchronously completed, and assembling steps of a glucose non-enzyme biosensor are reduced. The CuO membrane of the glucose detection Cu-based CuO membrane electrode grows in situ on the surface of a metal Cu base body, the combining property of the CuO membrane and a base body material is good, and the stability is enhanced; the CuO membrane shows a well-aligned micro / nano hierarchical structure, and the problem of active center reduction caused by agglomeration when a powder body material is coated on the base body is not caused, therefore the electrocatalytic activity is high.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Slurry bed carbon dioxide methanation bimetallic catalyst and preparation method and application thereof

ActiveCN105618061AHigh activityImprove stabilityGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMethanation

The invention relates to a bimetallic catalyst applied to slurry bed carbon dioxide methanation, a preparation method of the bimetallic catalyst and application of the bimetallic catalyst in slurry bed carbon dioxide methanation. A regular-mesoporous nickel-cobalt bimetallic alumina catalyst is prepared in one step through an evaporation induced self-assembly method. The bimetallic catalyst is composed of, by mass, 20-60 wt.% of active component Ni, 0.1-8 wt.% of active component Co and 39-78 wt.% of alumina carrier, specific surface area of the prepared catalyst is 100-500 m<2> / g, pore volume is 0.2-1.0 cm<3> / g, and pore diameter is 5-15 nm. The bimetallic catalyst is simple in preparation process, the active components nickel and cobalt in the catalyst are dispersed on the carrier surface and in pores more uniformly, and interaction between the active components and the carrier is enhanced; when the catalyst is applied under reaction conditions of slurry bed carbon dioxide methanation, CO2 conversion rate can be up to 81.5%, CH4 selectivity can be up to 99.7% or above.

Owner:TAIYUAN UNIV OF TECH

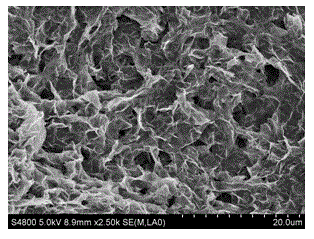

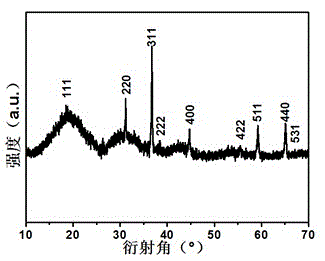

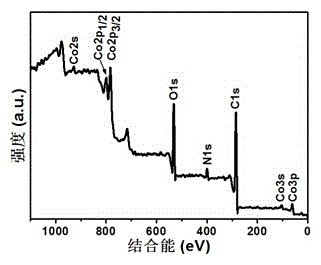

Three-dimensional graphene, polyaniline and cobaltosic oxide composite material and preparation method and application

InactiveCN104987715ASolve sheddingSolution to short lifeHybrid capacitor electrodesCobalt oxides/hydroxidesPolyaniline nanofibersGraphite oxide

The invention discloses a three-dimensional graphene, polyaniline and cobaltosic oxide composite material and preparation method. The graphene, polyaniline and cobaltosic oxide composite material is of a three-dimensional micron or nano porous structure and is composed of the graphene, polyaniline nano fibers and the cobaltosic oxide, wherein the cobaltosic oxide grows on the polyaniline nano fibers to form polyaniline and cobaltosic oxide nanoparticles with the particle size 10-50 nm, and the polyaniline and cobaltosic oxide nanoparticles are evenly distributed on the graphene surface; the preparation method of the three-dimensional graphene, polyaniline and cobaltosic oxide composite material comprises the steps that in-suit polymerization is conducted on graphene oxide and aniline to obtain a graphene oxide and polyaniline crude product, bivalent cobalt salt and the graphene oxide are added, and washing and freeze-drying are sequentially conducted on the obtained product under the hydrothermal condition to obtain the three-dimensional graphene, polyaniline and cobaltosic oxide composite material which has the specific capacity capable of reaching 1021 F / g to the maximum and excellent circulation and rate performance and serves as a supercapacitor. The preparation method is simple, low in cost and environmentally friendly.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Board-overturning material-clearing type vegetable water extractor

The invention provides a board-overturning material-clearing type vegetable water extractor, which is characterized in that a group of conveying devices driven by a transmission gear is arranged in each layer of a box body; pin shafts alternately stretch inwards from chains of the conveying devices; the two ends of each chain board are hung on the pin shafts stretching inwards from the chains via hanging holes in baffles, and chain boards are supported on a guide rail, so that a slot type material passage is formed; an infrared radiation device is arranged above each passage, and a guide chute is formed below the tail end of the passage; an induced draft port is formed in the upper part of a side wall of each layer of the box body; each layer of the box body is connected with a draft fan via an induced draft tube; deflector rods are uniformly fixed on the end surface of each chain wheel, positioned below the transmission gear, of each conveying device, and limit rods are arranged between the chain wheels and the inner wall of the box body; a cam board-overturning device is arranged on each conveying device and at the position between two sections of slot type material passages below the transmission gear, and correspondingly a material clearing device is arranged on the slot type material passage above the cam board-overturning device; a feed inlet is formed in the top of the box body, and a feed outlet is formed in the bottom of the box body. The board-overturning material-clearing type vegetable water extractor is quick in material clearing and reliable in working.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka.patsnap.com/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000011.PNG)

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka.patsnap.com/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000012.PNG)

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka.patsnap.com/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000021.PNG)