Patents

Literature

3691 results about "Equipment requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen mixed grapheme hydrogel or aerogel and preparation method thereof

InactiveCN102874796AImprove adsorption capacityGood processing effectGrapheneApparent densityNitrogen

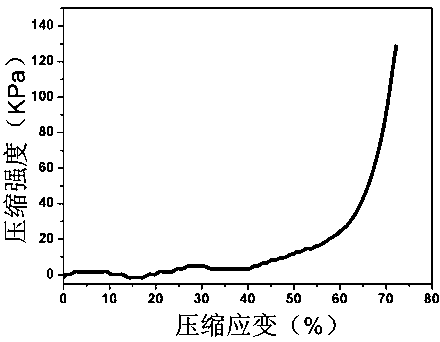

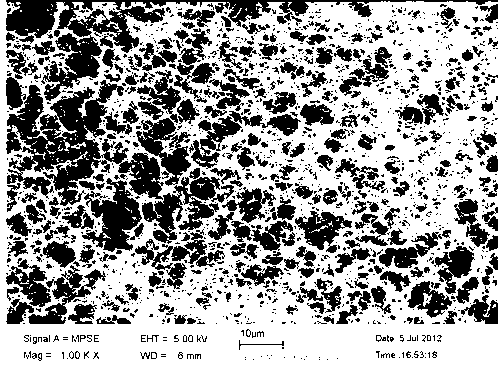

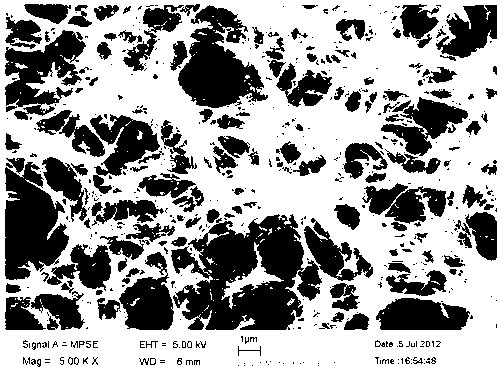

The invention provides nitrogen mixed grapheme hydrogel of which the water content is 90 to 99.5 percent, the electric conductivity is 10-3-100 S / m, and the molar ratio of N and C is 1 to 25 percent. The invention further provides nitrogen mixed aerogel of which the molar ratio of N and C is 2 to 20 percent, the molar ratio of C and O is 15 to 5, nitrogen atoms existing in the form of amidogen nitrogen accounts for 40 to 70 percent, pyridine type nitrogen accounts for 10 to 40 percent, graphite type nitrogen accounts for 10 to 30 percent, the specific area is 300 to 1500 m<2> / g, the apertures which are micropore account for 10 to 20 percent, the apertures which are mesoporous 20 to 50 percent, the apertures which are macropore 30 to 70 percent, the apparent density is 0.01 to 0.2 g / cm<3>, the pore volume is 5 to 20 cm<3> / g, and the electric conductivity is 1 to 1000 S / m. The nitrogen mixed grapheme hydrogel or aerogel and preparation method thereof provided by the invention has the characteristics that the operation is simple, the equipment requirement is low, the production efficiency is high, the scale-up of the technology is easy, the nitrogen mixed content is controllable and the compounding with other functional substances is simple.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

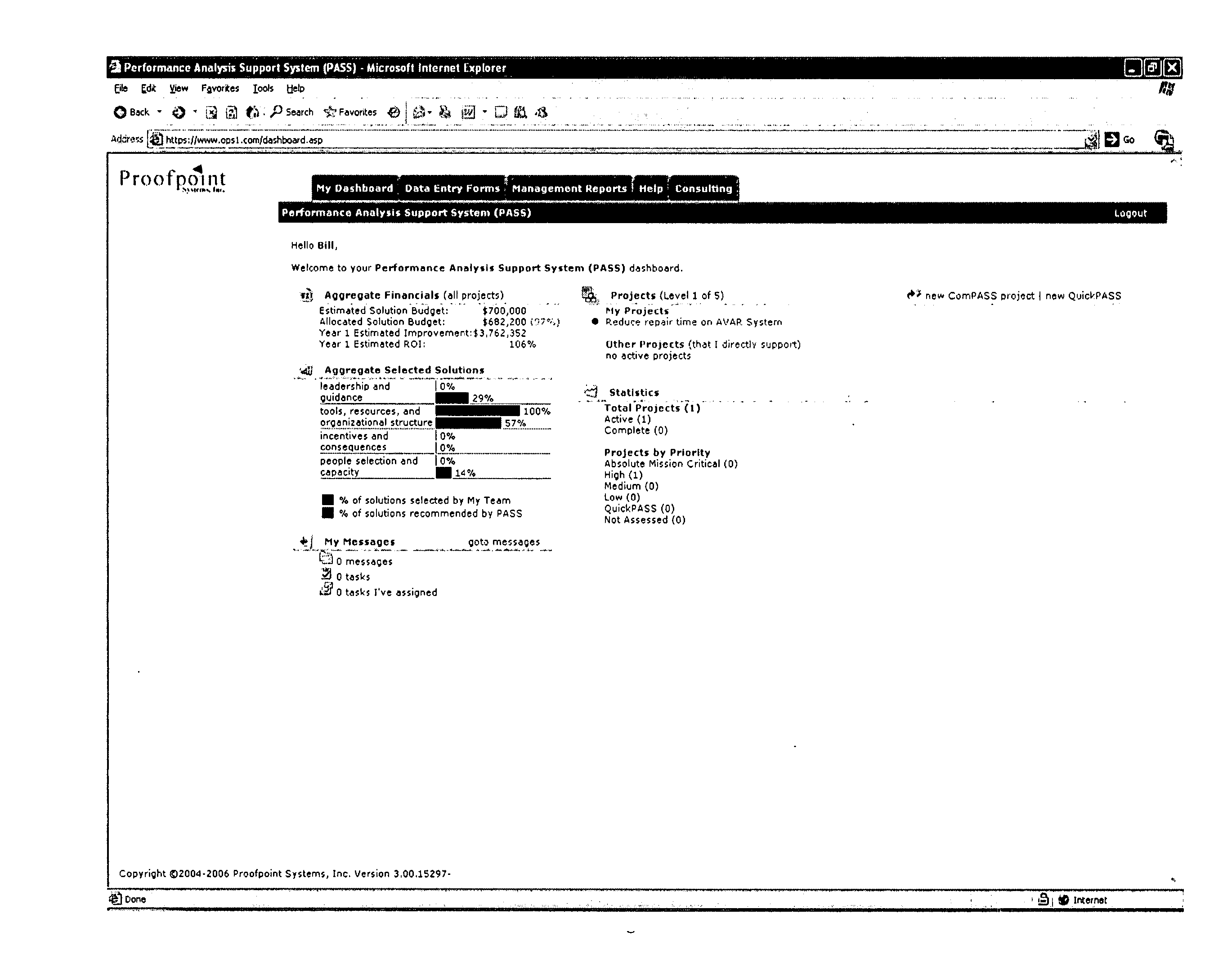

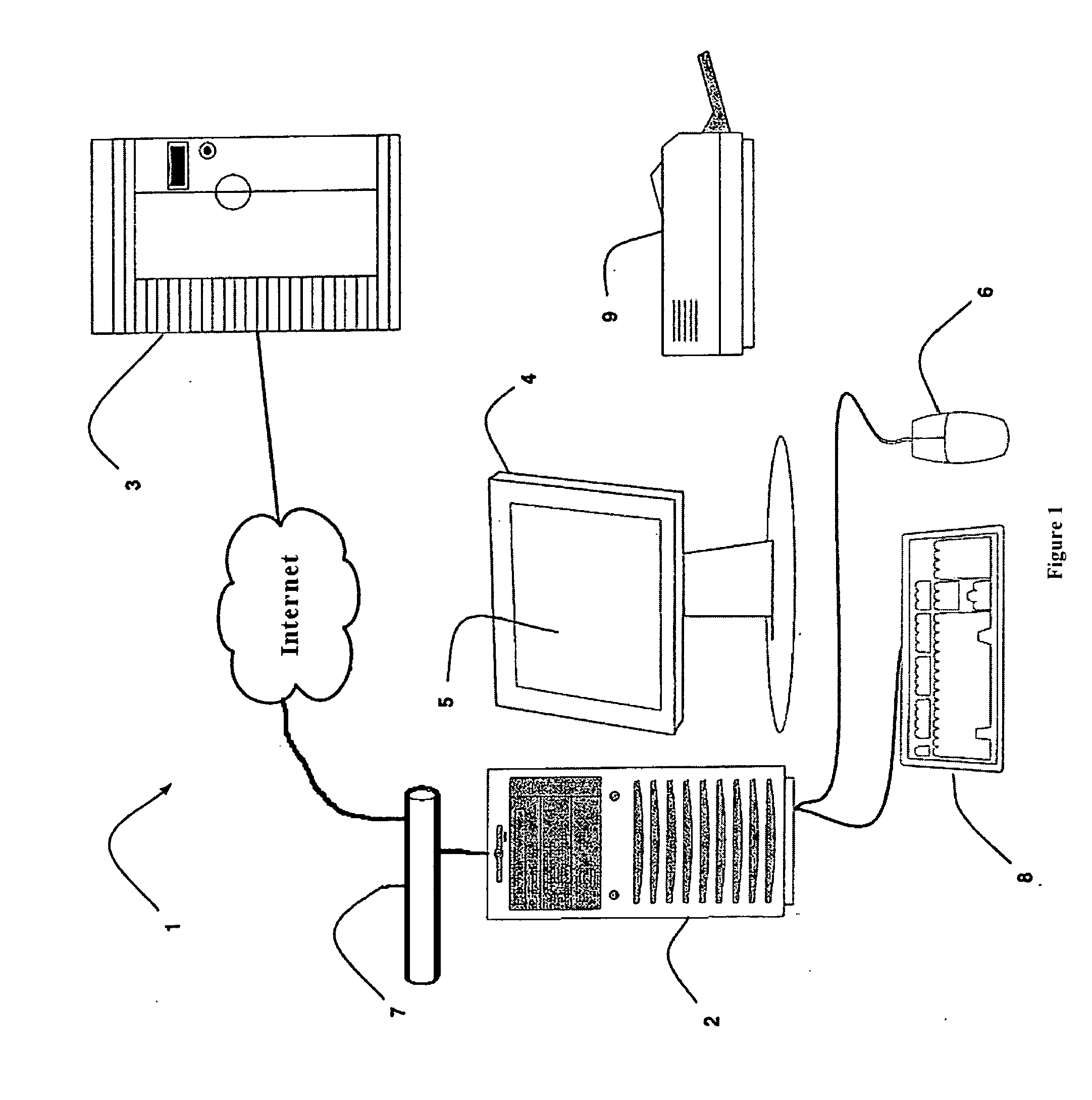

Performance analysis support system

A performance analysis support system is disclosed that provides one or more recommended solutions of a performance improvement project to management and the expected improvement benefit of each solution. The performance analysis support system guides a user through a detailed, consistent analysis process, helping organizational leaders accurately diagnose critical performance or productivity issues. Then, the performance analysis support system estimates the personnel and equipment requirements, time, costs, and return on investment associated with each solution generated based on the analysis results. In addition, the performance analysis support system provides management immediate access to ongoing and past analyses.

Owner:PROOFPOINT SYST INC

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

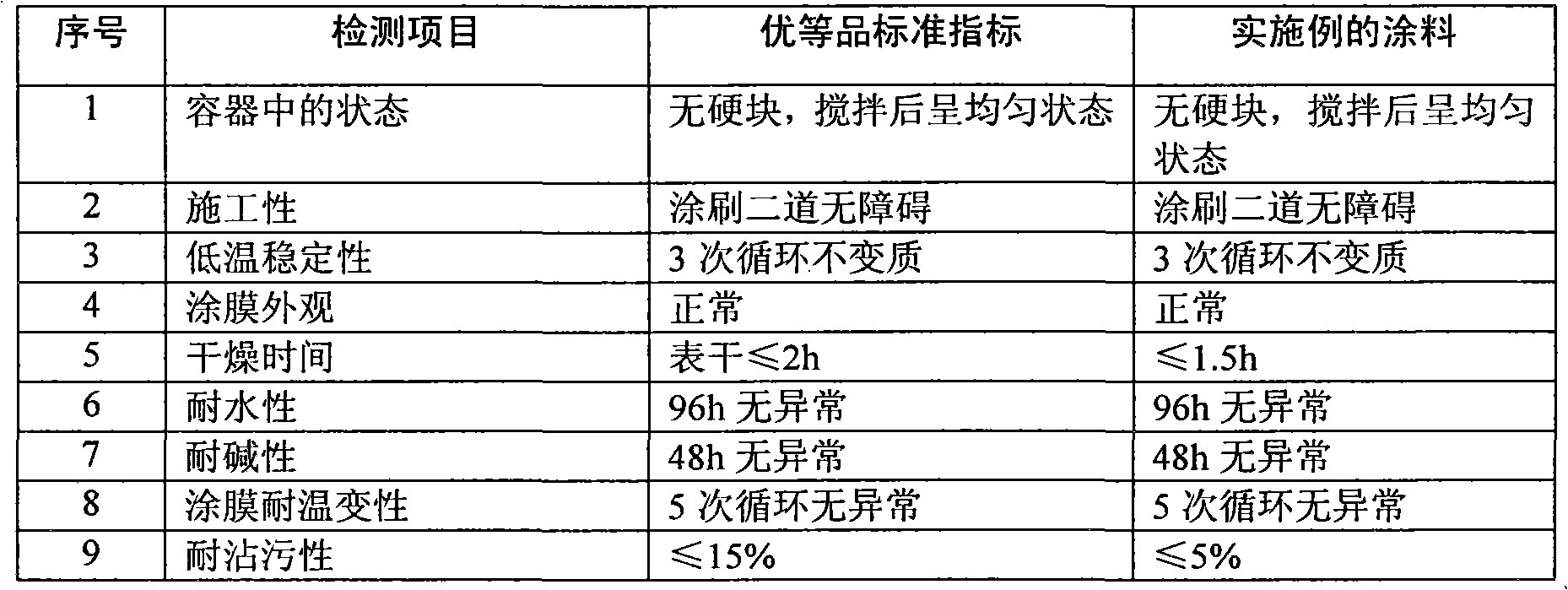

Exterior wall coating and preparation method thereof

InactiveCN101974273ASimple preparation processLow equipment requirementsAnti-corrosive paintsPolymer scienceDefoaming Agents

The invention discloses a multifunctional exterior wall coating with strong weather resistance, brushing resistance and high adhesion and a preparation method thereof. The exterior wall coating is prepared from the following raw materials in percentage by weight: 10-30% of silicone acrylic emulsion with a interpenetrating network structure, 10-40% of acrylic ester emulsion, 1-15% of hydrophobically modified inorganic nanoparticles, 10-40% of pigment and filler, 0.3-1% of a dispersing agent, 0.1-0.2% of a defoaming agent, 0.1-0.3% of a preservative, 0.3-0.6% of a flatting agent, 1-2% of a thickening agent, and the balance deionized water. The exterior wall coating of the invention has the advantages of strong weather resistance, brushing resistance, strong adhesion, long service life, simple and convenient preparation process and low equipment requirement, thus being easy for large-scale popularization and application. The exterior wall coating overcomes the defects of poor brushing resistance, poor ageing resistance and the like of the existing exterior wall coating.

Owner:广州市枫源化工有限公司

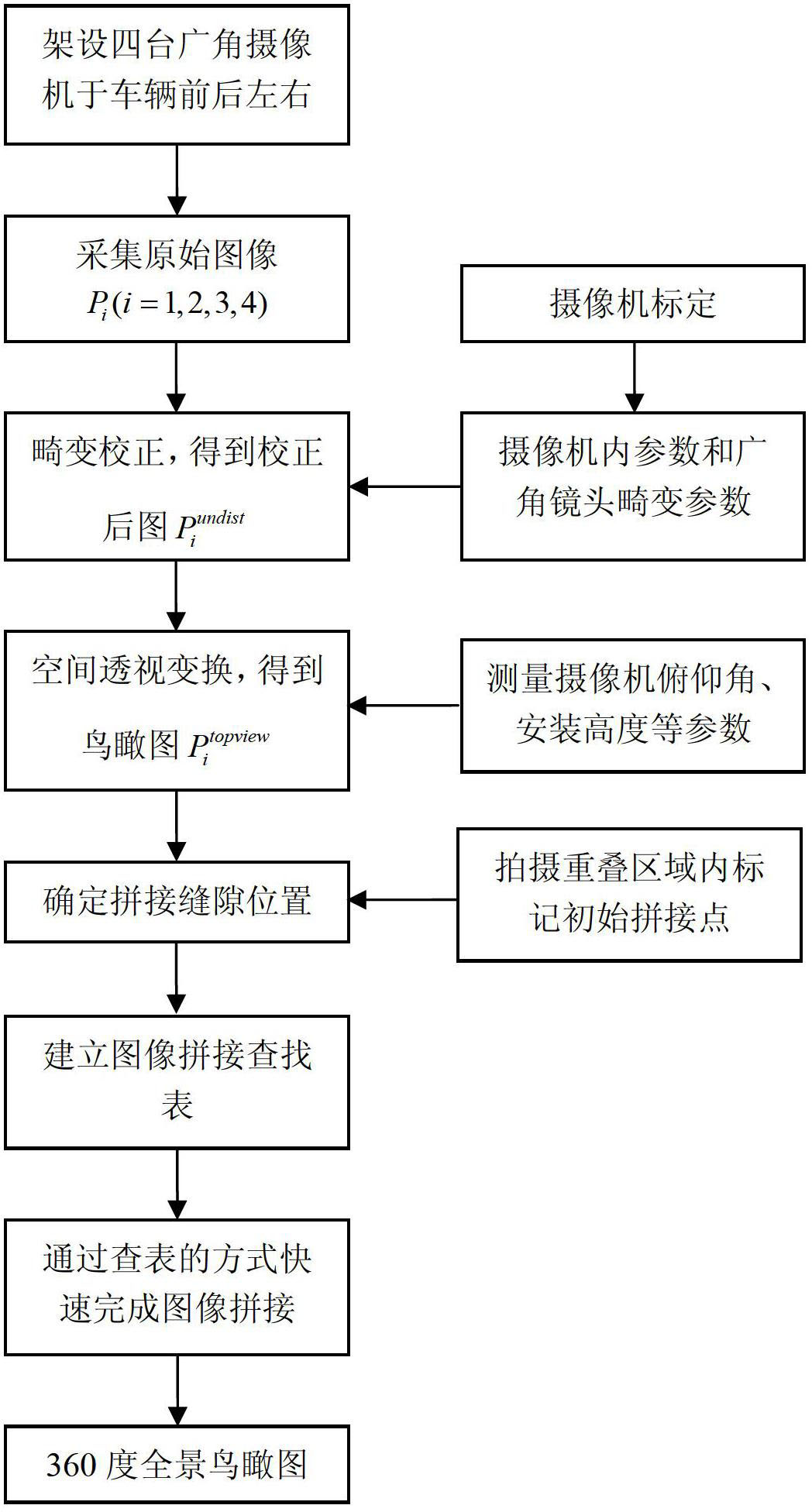

360 degree panoramic aerial view generation method used for assisting vehicle driving

InactiveCN102629372ALower requirementReduce computationImage enhancementRoad vehicles traffic controlVehicle drivingPerspective transformation

A 360 degree panoramic aerial view generation method used for assisting vehicle driving is disclosed. The method is characterized by: firstly, erecting four wide-angled cameras around a vehicle and guaranteeing that the cameras can cover all the field areas surrounding the vehicle; secondly, calibrating a camera parameter and carrying out distortion rectification on the collected image; then, carrying out areal perspective transformation on the rectified image so as to obtain the aerial view with a downward view effect; finally, establishing a image splicing lookup table so that a system can rapidly complete splicing of a panoramic picture through a lookup table method. The method is simple is easy to perform. A hardware equipment requirement is low. The system realizes the splicing of four pictures through the lookup table mode, which is rapid and has less amount of calculation. The operation parameter which is calibrated once by using the method can be served as a constant, be stored and be used in real time hardware system work so that system processing time can be substantially reduced and the real-time performance requirement of the system can be satisfied.

Owner:BEIJING UNIV OF TECH

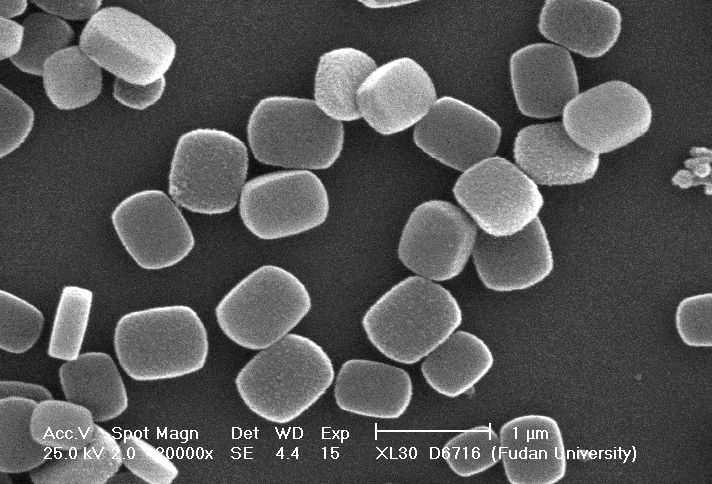

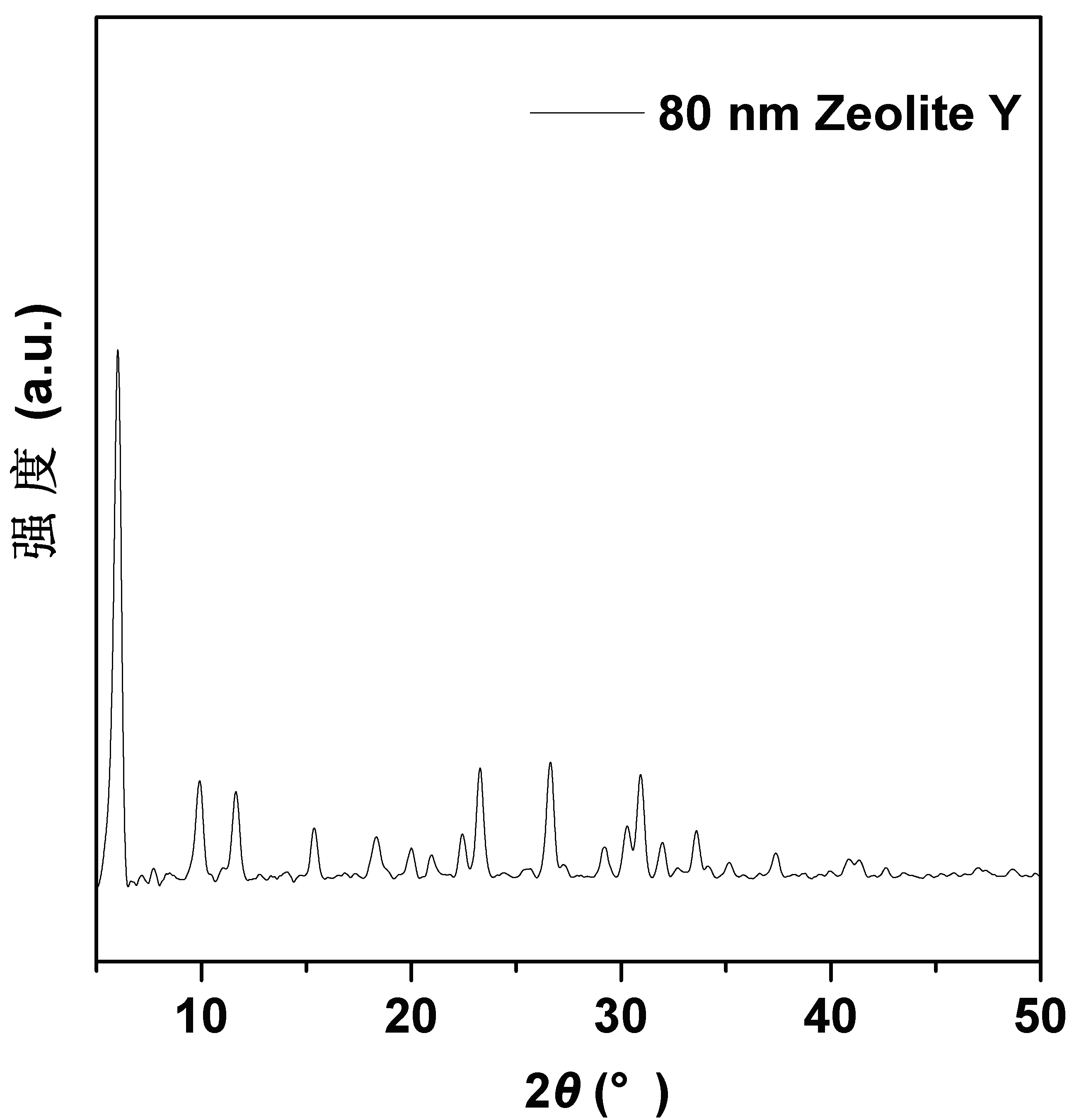

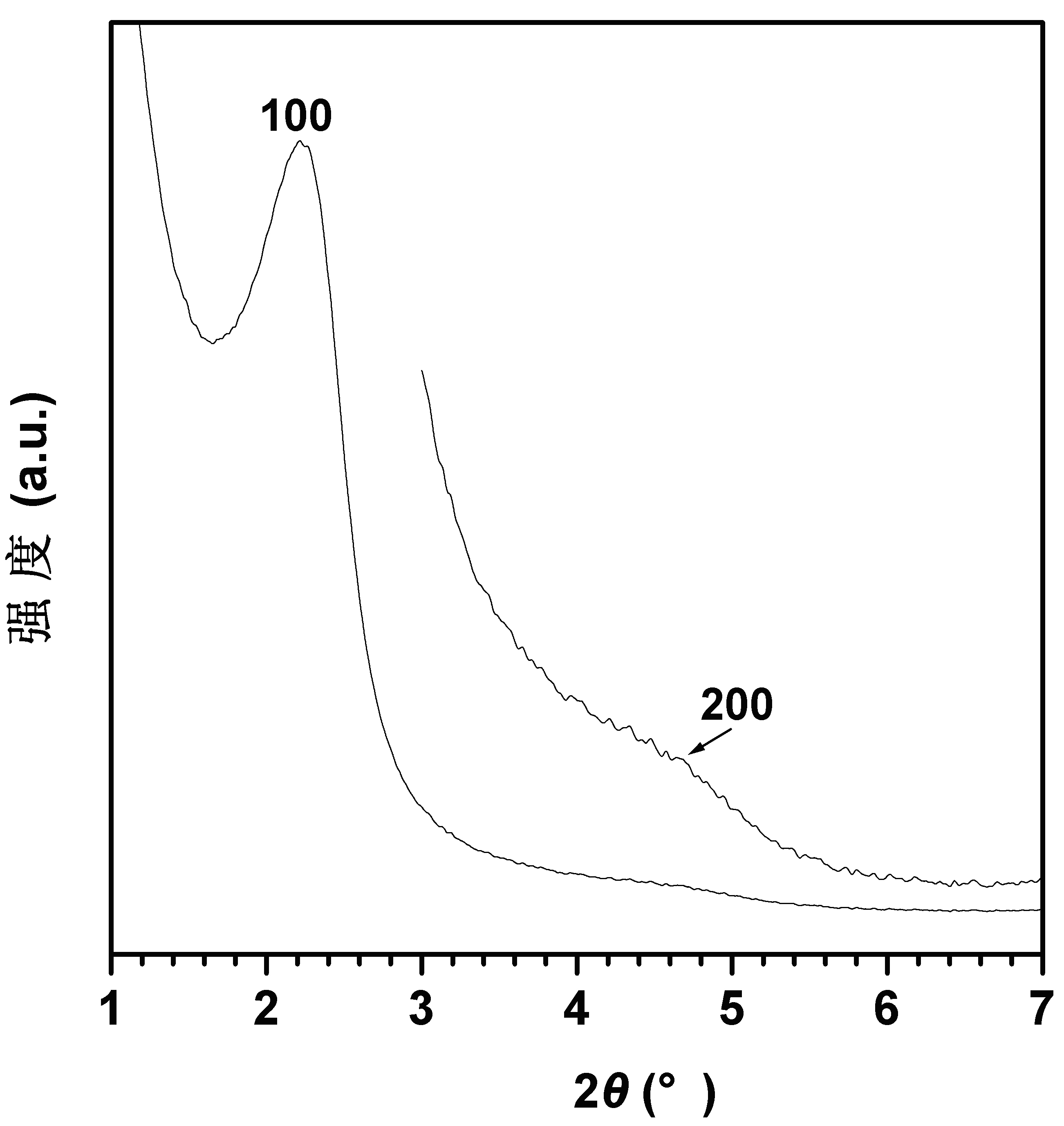

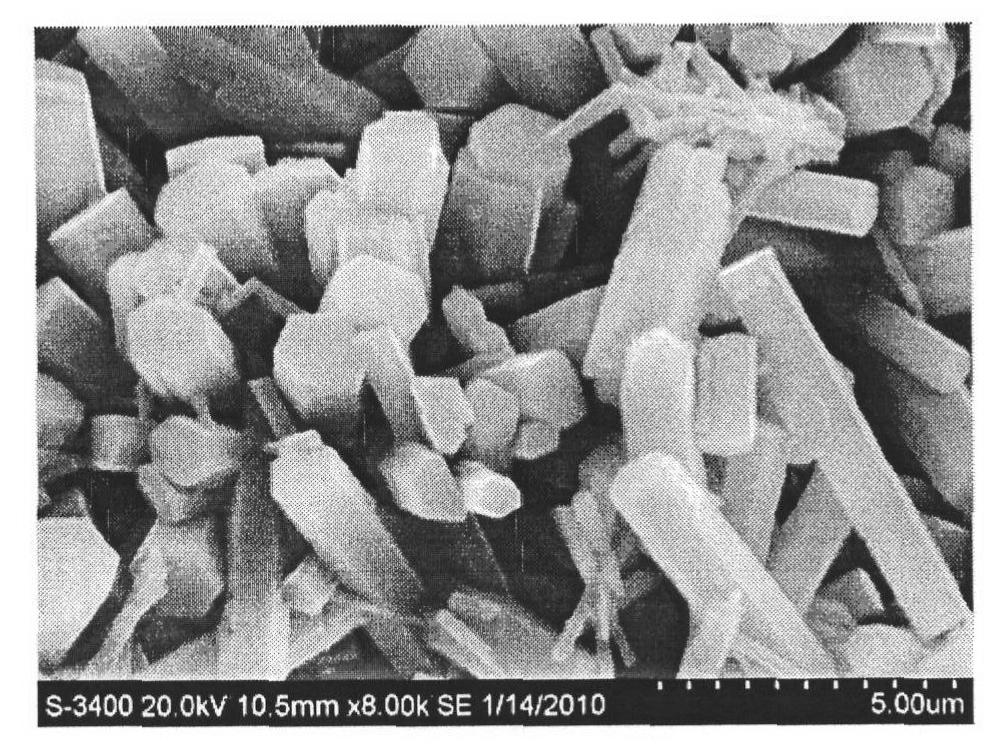

Preparation method for mesopore-micropore core-shell composite molecular sieve catalyst

ActiveCN101890363AMaintain microporosityHigh and adjustable microporosityMolecular sieve catalystsSilicon oxideSolution phase

The invention belongs to the technical field of material preparation and oil chemical engineering, and in particular discloses a preparation method for a mesopore-micropore core-shell composite molecular sieve catalyst. Zeolite particles are dispersed in organic solvent / water mixed solution which contains cationic surfactant and alkali under the action of ultrasound, and then silicon or silicon-aluminum species are introduced into the mixed solution to obtain a mesopore-micropore core-shell composite molecular sieve by solution phase self-assembly and a sol-gel process, wherein micropore zeolite serves as a core, and mesopore silicon oxide or aluminum-containing mesopore silicon oxide serves as a shell layer. The obtained composite molecular sieve has a retained zeolite micropore framework and an ordered two-dimensional hexagonal mesopore structure, a mesopore path is vertical with the surface of the zeolite particles, the path has high openness, the thickness of the mesopore shell layer is adjustable, and after the mesopore shell is packed, the mesopore-micropore can maintain high un-obstruction. The method has the advantages of simple operation, low raw material cost, low equipment requirement and the like.

Owner:上海介孔谷新材料发展有限公司

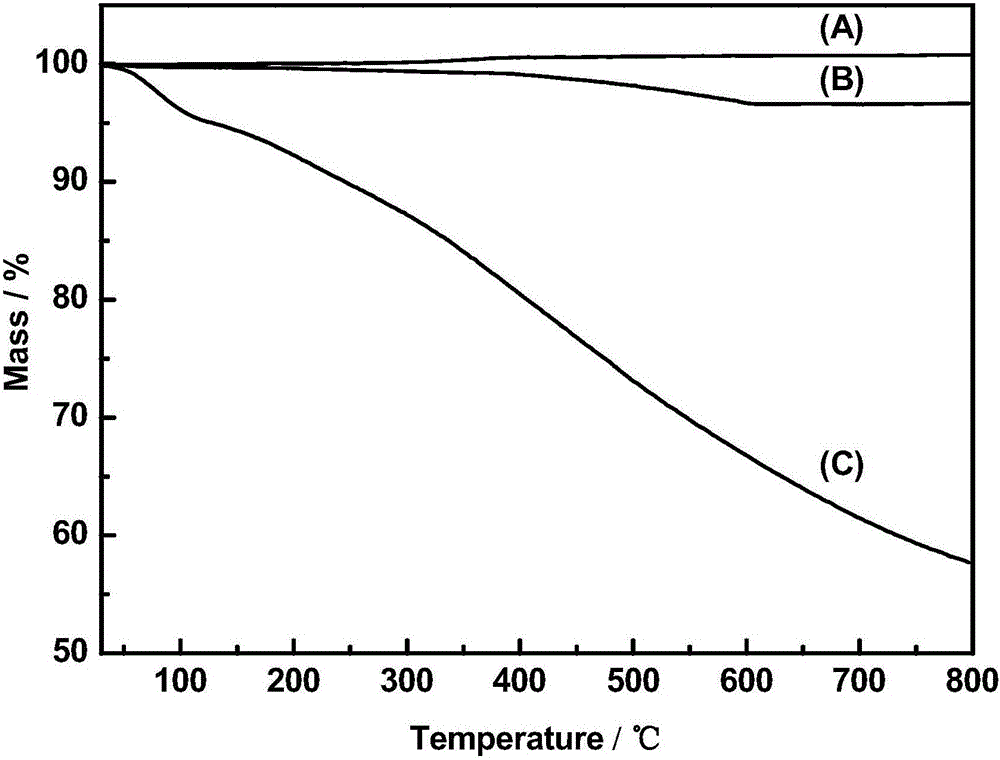

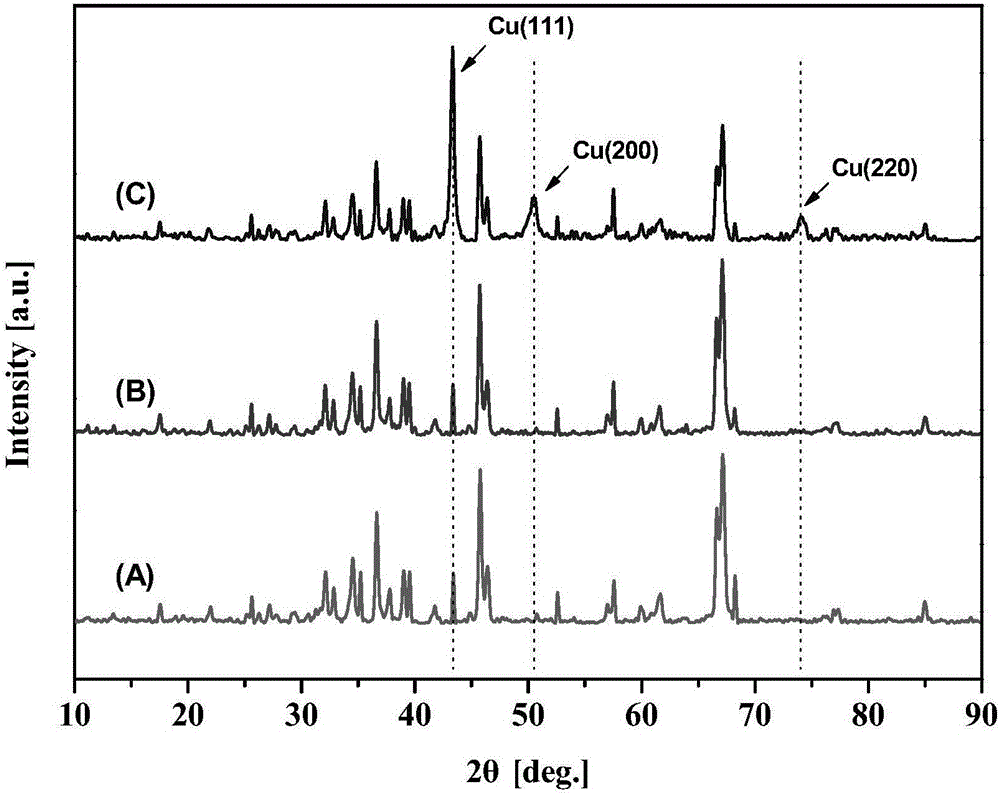

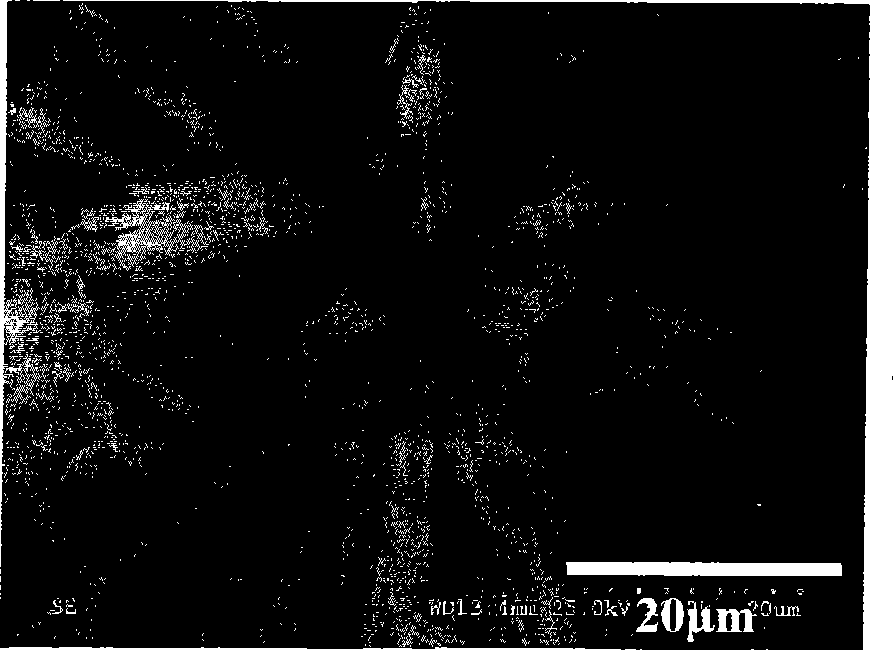

Method for conducting surface chemical copper plating on inorganic particles through dopamine

ActiveCN105112894AReduce pollutionShort processLiquid/solution decomposition chemical coatingCopper platingElectromagnetic shielding

The invention discloses a method for conducting surface chemical copper plating on inorganic particles through dopamine. The method comprises the steps that poly-dopamine layers are made to subside on the surfaces of the inorganic particles in an alkaline solution through the oxidative polymerization effect of the dopamine, then by utilizing functional groups of the poly-dopamine layers, and meanwhile under the effect of an additional auxiliary reducing agent of dimethylamine broane (DMAB), copper ions are reduced to pure copper on the surfaces of the inorganic particles, and a continuous and compact metal copper layer is formed. The method is simple to operate, low in equipment requirement and low in cost; the prepared copper-plated inorganic particles have the characteristics of being low in density, good in conductivity and the like; the method can be used for preparing electricity and thermal conductive coatings, electromagnetic shielding paint, wave-absorbing materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

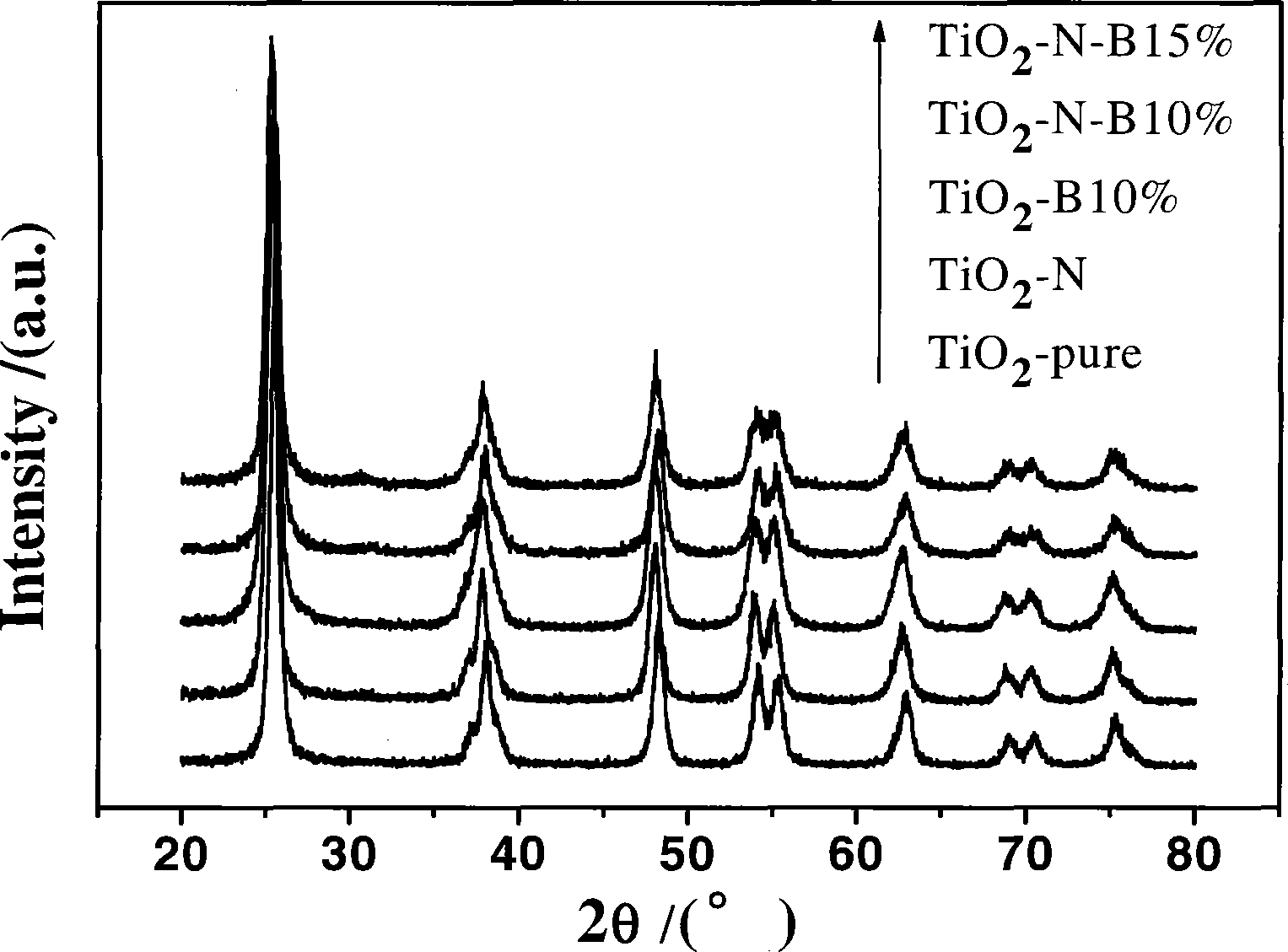

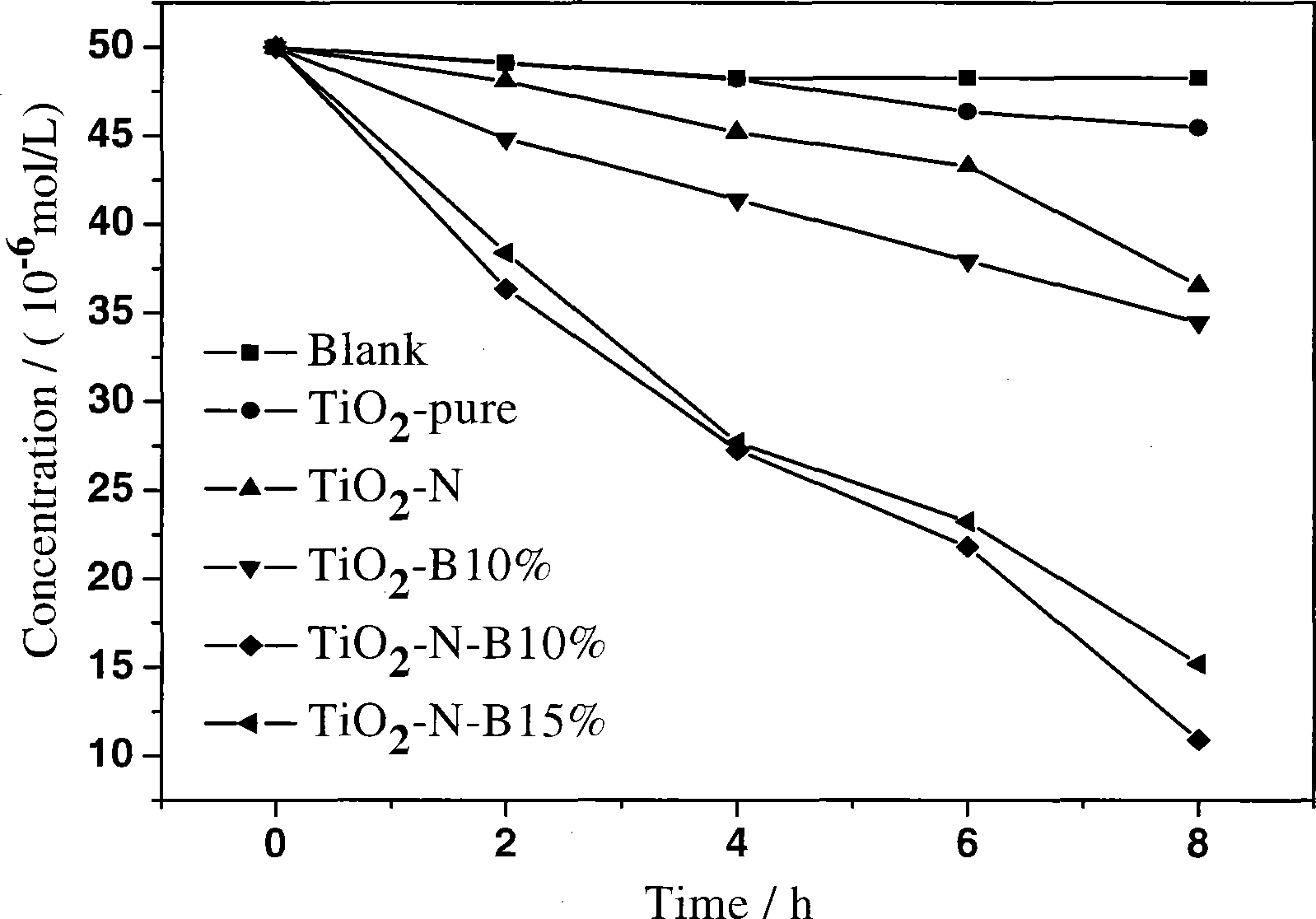

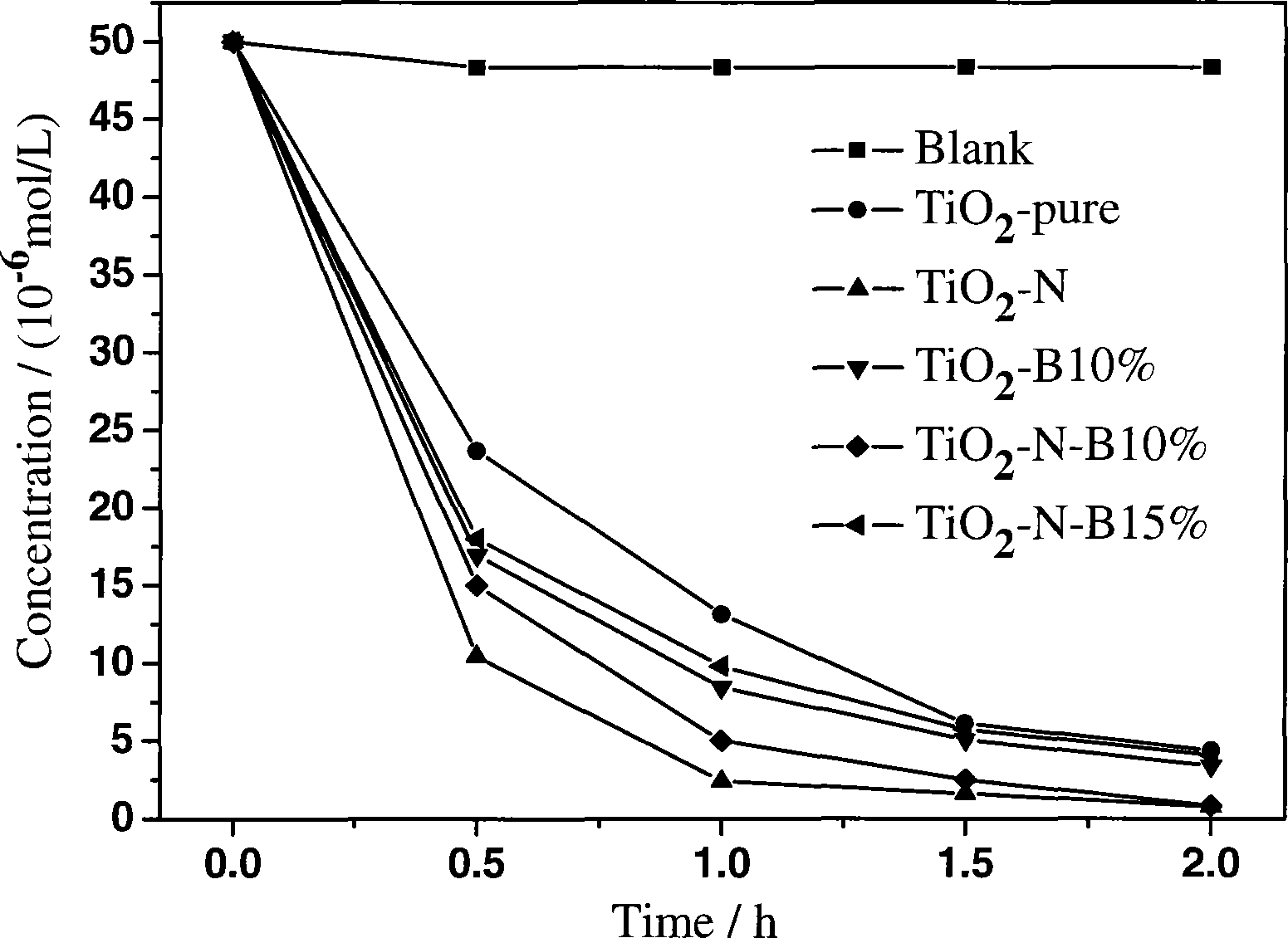

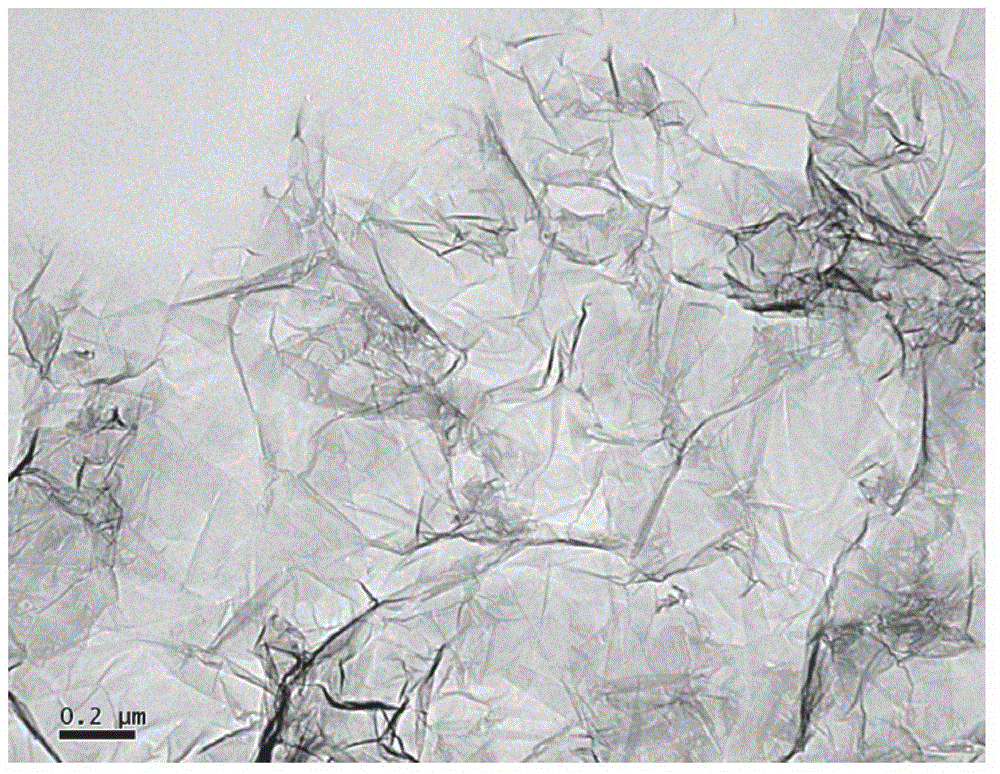

Method for preparing high activity non-metallic ion co-doped titanium dioxide photochemical catalyst

InactiveCN101444724ASimple processLow equipment requirementsPhysical/chemical process catalystsCatalyst degradationUltraviolet lights

In order to degrade the pollutants in water and atmosphere by the photocatalysis technology, the invention discloses a method for preparing a high activity non-metallic ion co-doped titanium dioxide photochemical catalyst. In the photochemical catalyst, titanium ester or titanate is used as a precursor, non-metallic compound comprising boron, carbon, nitrogen, fluorin, silicon, phosphor, sulfur, chlorine, bromine, iodine, and the like, are used as doping agents, the high activity non-metallic ion co-doped titanium dioxide photochemical catalyst is prepared by adopting the sol gel method. Compared with a titanium dioxide photochemical catalyst single-doped with pure titanium dioxide and the non-metallic irons, the visible light catalytic activity of the titanium dioxide photochemical catalyst on the degradation of parachlorophenol is greatly improved, and the ultraviolet light catalytic activity can also exceed the catalytic activity of the pure titanium dioxide catalyst. The method also has the advantages that the preparation technique is simple, the equipment requirement is low; the particle diameter of the product is small, the specific surface is relatively high, the dispersivity is good, thus having a wide application prospect in the environmental cleaning scientific field.

Owner:NANKAI UNIV

Method for reclaiming carbon fiber reinforced epoxy resin composite material

ActiveCN102181071ARelieve stressImprove degradation efficiencyPlastic recyclingBulk chemical productionEpoxyPhosphomolybdic acid

The invention relates to a method for reclaiming a carbon fiber reinforced epoxy resin composite material. The conventional method is high in equipment requirement and high in reclamation cost. The method comprises the following steps of: adding a catalyst into an organic reagent to prepare supercritical CO2 composite solution; putting the carbon fiber reinforced epoxy resin composite material tobe decomposed into a reaction kettle, and adding the supercritical CO2 composite solution; and reacting for 1 to 24 hours at the temperature of between 100 and 250 DEG C under the pressure of 7.5 to 25.0MPa, cooling the product to normal temperature, washing and drying the solid product in the product to obtain carbon fibers, and performing reduced pressure distillation on the liquid product in the product to obtain phenol and derivatives thereof. The catalyst is one or two of liquid super acid, solid super acid, phosphotungstic acid, phosphomolybdic acid, acetic acid, formic acid, hydrochloric acid, sulfuric acid and nitric acid. The method has the advantages of high degradation efficiency, environmental friendliness, low cost and the like, and is a green method for reclaiming the waste and old carbon fiber reinforced epoxy resin composite material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

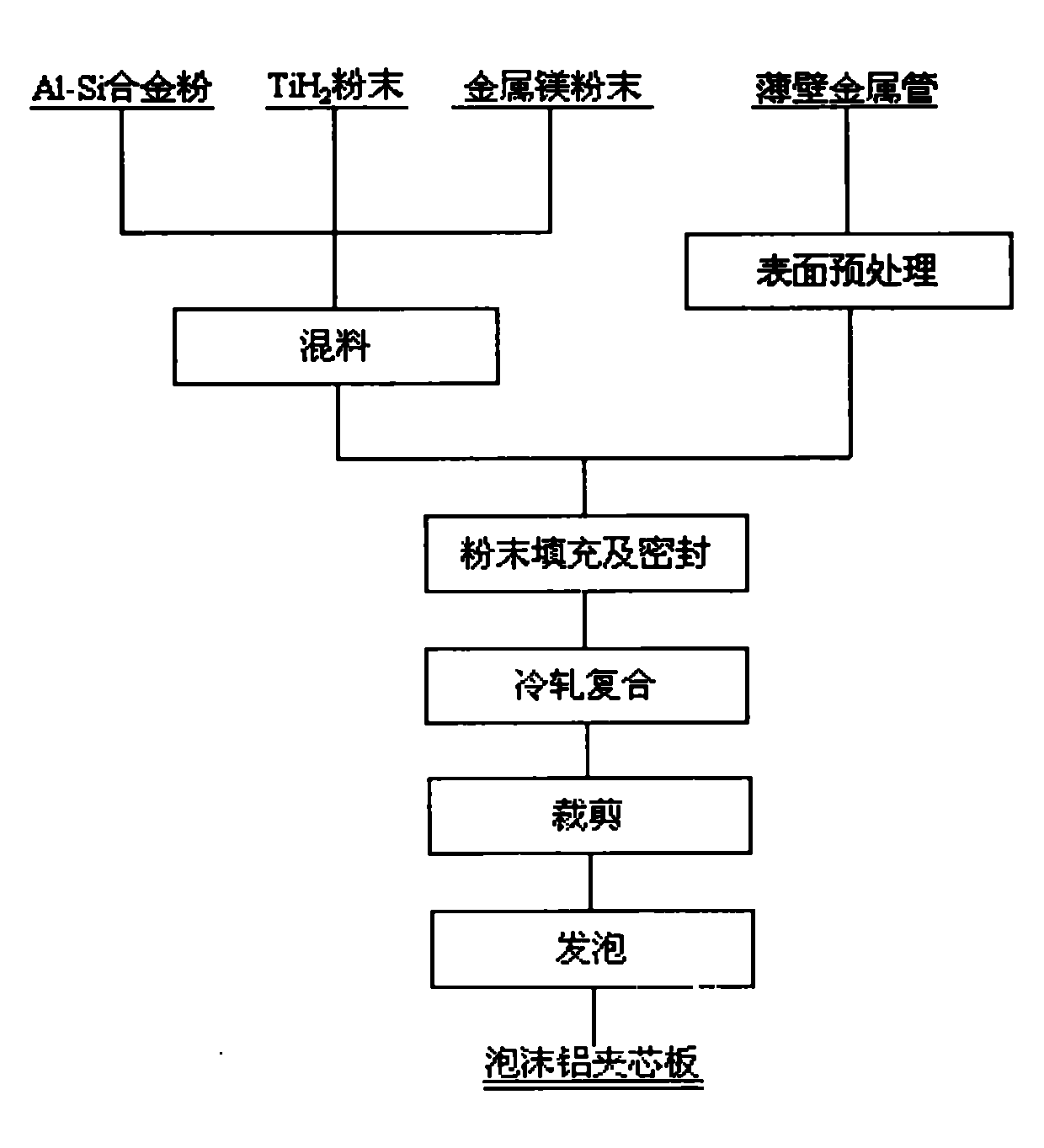

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

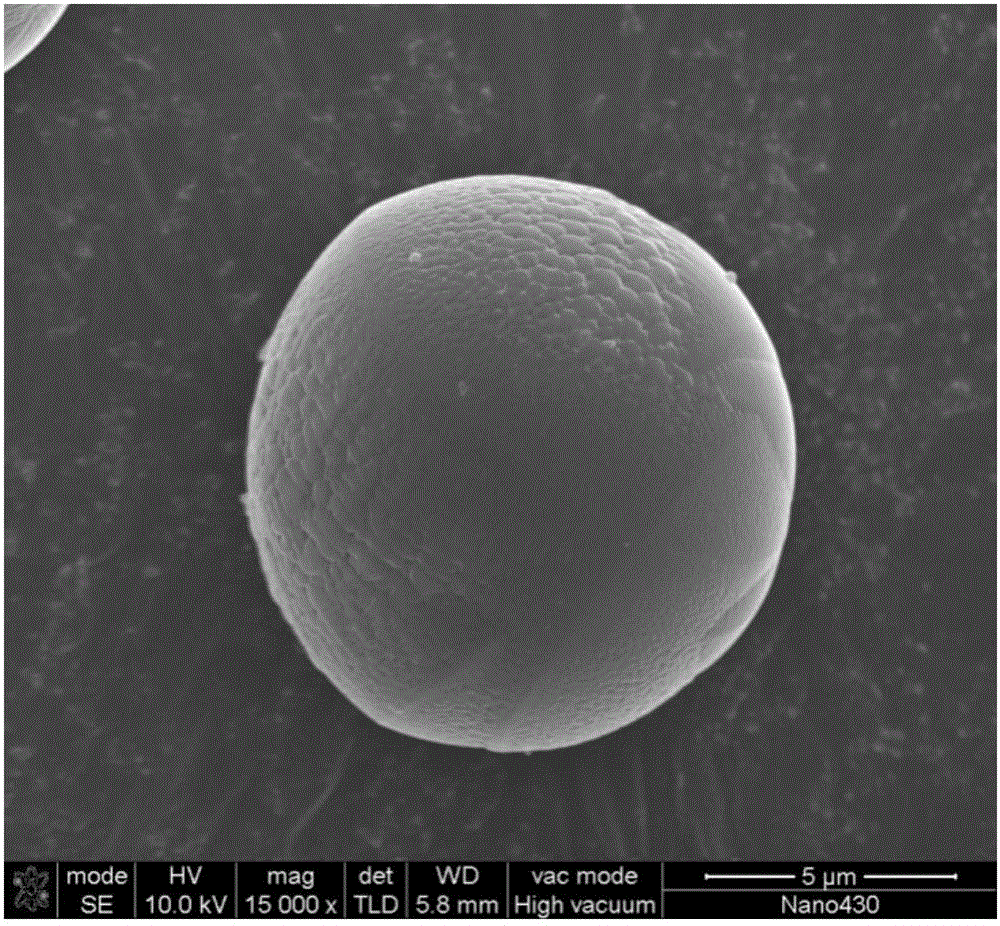

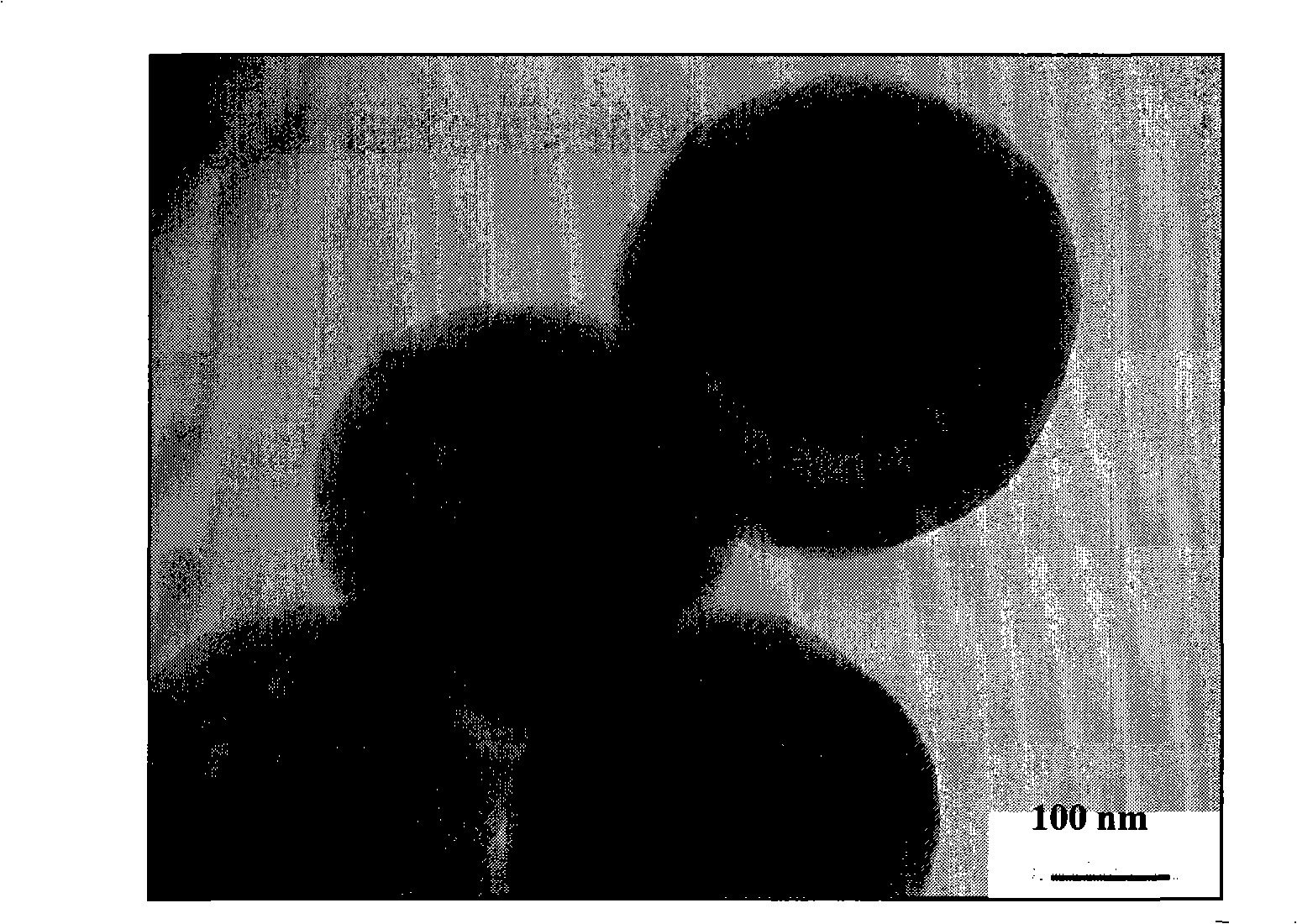

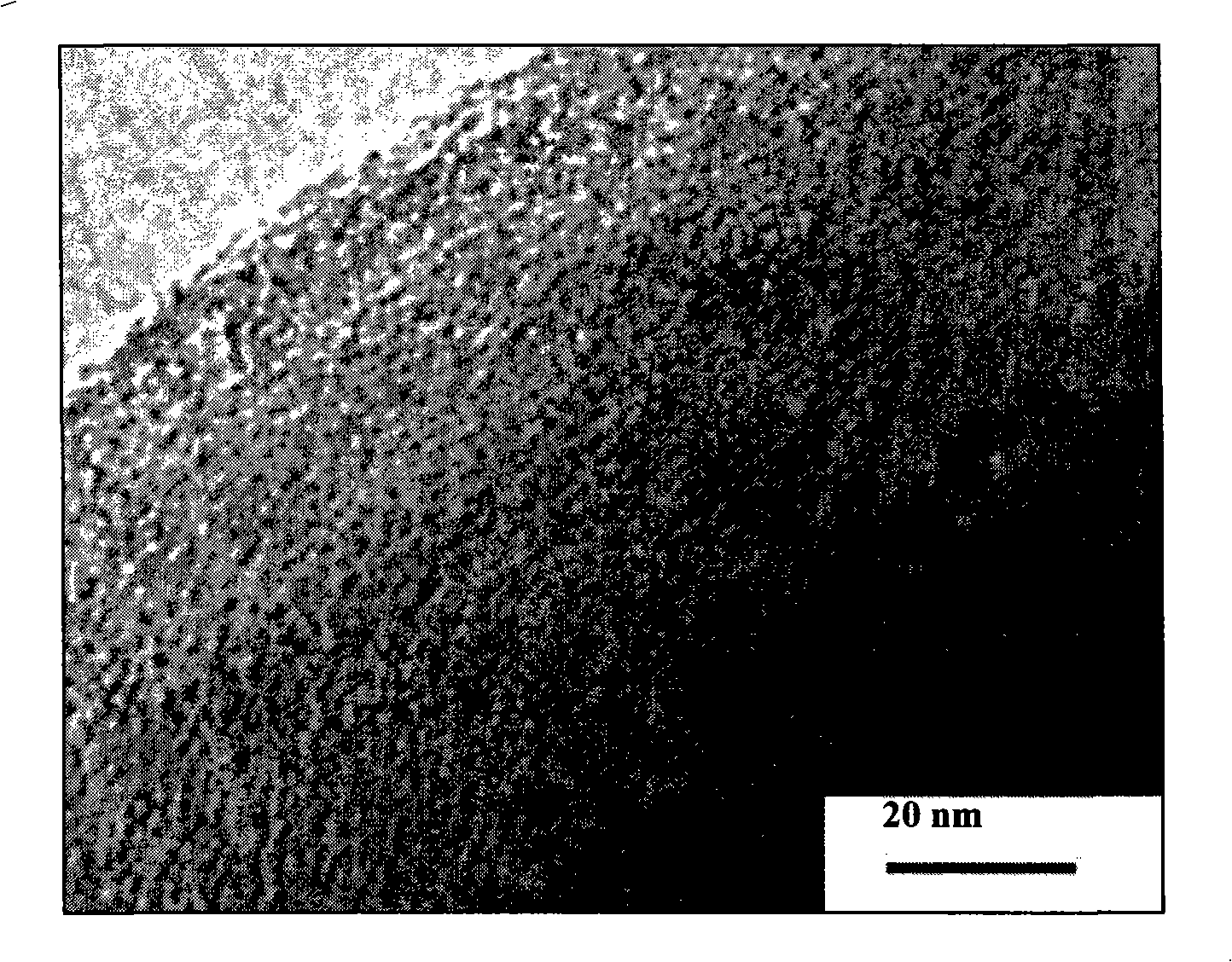

Superparamagnetism mesoporous silicon dioxide composite ball and preparing method thereof

InactiveCN101256864ALarge specific surface areaHigh content of magnetic substancesSilicaInorganic material magnetismParticulatesMesoporous silica

A superparamagnetism mesoporous silicon dioxide composite ball of the present invention and manufacture method thereof belong to nucleocapsid type technology field of magnetic nano particle. The shape of the composite ball is global; inner core being made of magnetic ferrite nano particle cluster, shell coating layer being made of mesoporous silicon dioxide; quality ratio of magnetic ferrite nano particle in particulate being 40-80%. Method of manufacturing has that producing magnetic ferrite nano particle is by using coprecipitation method; executing surface modification by adding oleic acid stirring; ultrasonic forming oil-in-water emulsion in the mix solution of ethyl orthosilicate and cyclohexane, cetyl trimethyl ammonium bromide as surfactant; ethyl orthosilicate hydrolytic condensation forming mesoporous silicon dioxide coating layer by adding ammonia spirit; finally taking off molding plate and getting products. Product of the invention has bigger specific surface area and stronger magnetic separation capacity, and has good dispersancy in water, and is further functionalization after being decorated at surface. The method of the present invention has simple process, and lower equipment requirement.

Owner:JILIN UNIV

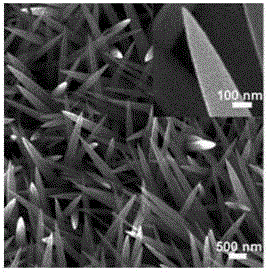

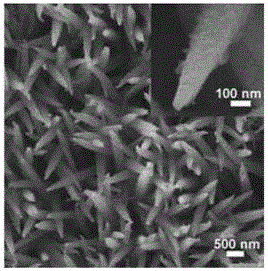

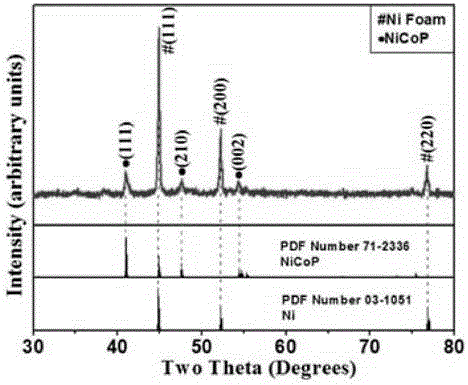

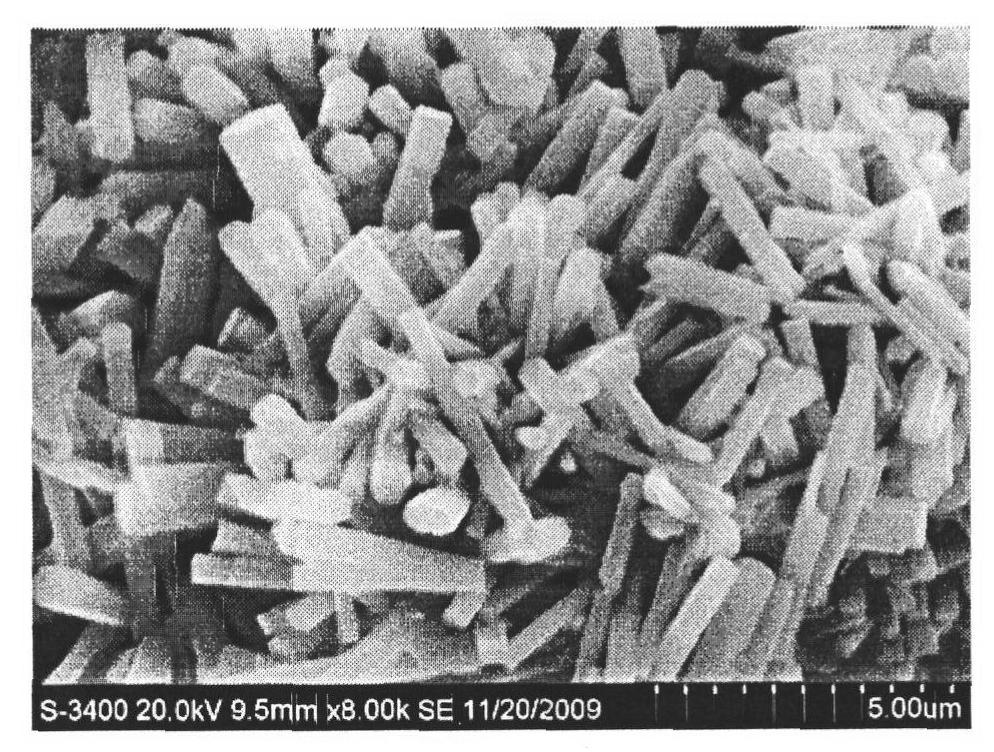

Preparation method for NiCoP nanowire electro-catalytic electrode

InactiveCN105951123AAvoid introducingSimple preparation processMaterial nanotechnologyElectrode shape/formsNanowireReactive material

The invention discloses a preparation method for a NiCoP nanowire electro-catalytic electrode. A NiCo salt nanowire is adopted as a phosphorization precursor, hypophosphite is used as a phosphorus source, and the phosphorization process of the NiCo salt nanowire is achieved by controlling the annealing technique in a stored program control tube type annealing furnace. The diameter of the NiCoP nanowire obtained through the method is 140 nanometers, the length of the obtained NiCoP nanowire is about 3.2 micrometers, and the surface of the nanowire is roughly and evenly grown on a 3D netty foamed nickel substrate, so that the specific surface area and the electric conductivity of an electro-catalytic material are effectively improved, and the electro-catalytic hydrogen evolution performance and stability of an electrode material are improved. The electro-catalytic hydrogen production performance of the electrode is tested in 1M of a KOH electrolyte, the overpotential under the electric current density of 10 mA / cm<2> is 109 mV, and the Tafel slope is 88.5 mV / dec, so that the material has the superior electro-catalytic hydrogen production performance compared with common electro-catalytic hydrogen evolution materials. Meanwhile, the preparation technique is simple, the equipment requirement is conventional, reactive materials are abundant, price is low, and the electrode is environmentally friendly.

Owner:HUBEI UNIV

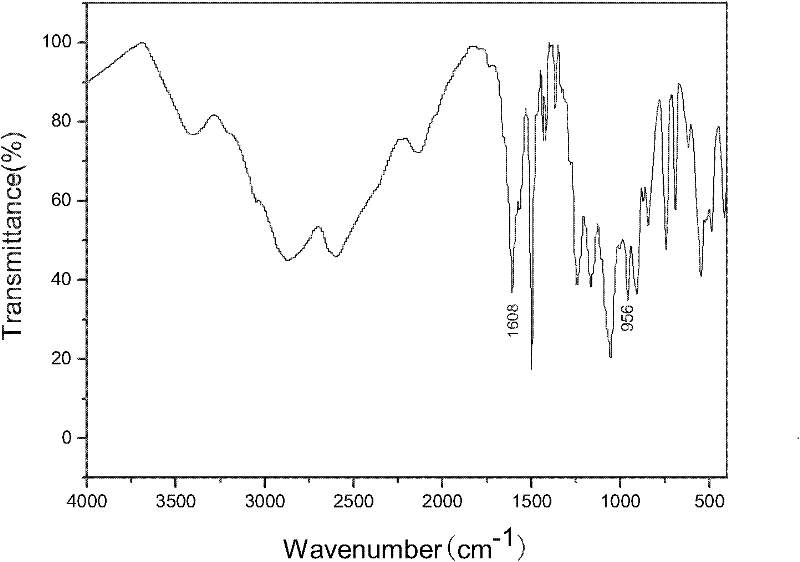

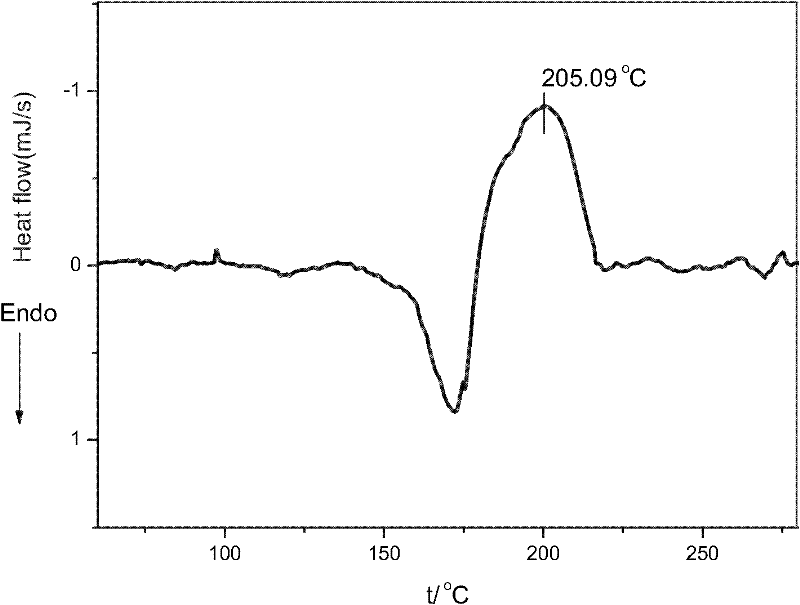

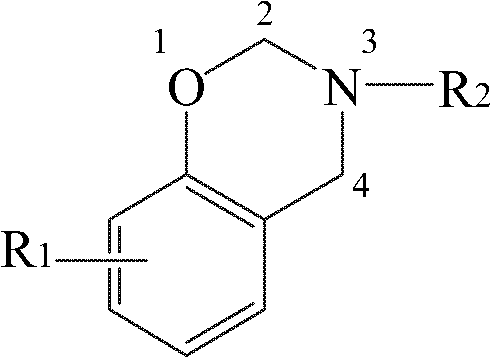

Dibenzoxazine containing oxazole ring and preparation method thereof

InactiveCN102250117ASimple preparation processLow equipment requirementsLiquid crystal compositionsOrganic chemistrySolventOrtho-aminophenol

The invention relates to a dibenzoxazine containing an oxazole ring and a preparation method thereof. The preparation method comprises the following two steps of: 1: mixing ortho-aminophenol hydrochloride and para-hydroxybenzoic acid, adding polyphosphoric acid as a solvent, reacting at 60-180 DEG C for 24-60 hours, and washing by using deionized water, filtering and drying to obtain diphenol containing an oxazole ring structure; and 2: mixing the diphenol containing the oxazole ring structure, phenylamine and paraformaldehyde, reacting at 80-110 DEG C for 40-80 minutes, then filtering and precipitating, washing 4-8 times by using alkali liquor, and then washing, filtering and drying to obtain the product. The dibenzoxazine disclosed by the invention has the advantages of very good mechanical property because the high temperature resistant oxazole ring structure is introduced to a benzoxazine molecule structure, dielectric constant of only 1.6-2.3, simple process, lower equipment requirement and suitability for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing high-purity molybdenum titanium sputtering target

InactiveCN101956159AHigh purityHigh densityVacuum evaporation coatingSputtering coatingImpurityElectron

The invention discloses a method for preparing high-purity molybdenum titanium sputtering targets, and relates to a method for preparing molybdenum titanium sputtering targets used in the electronic and photovoltaic field, which is characterized in that the preparation process comprises the following steps: taking ammonium dodecamolybdate as a raw material, preparing high-purity molybdenum powder through two sections of a hydrogen reductive method; carrying out cold isostatic pressing on the high-purity molybdenum powder to press into a molybdenum plate green body; presintering in vacuum; sintering into a molybdenum plate at high temperature at the atmosphere of hydrogen; processing the sintered molybdenum plate into a molybdenum target body by adopting a pressure processing manner of firstly forging and then rolling; vacuum annealing to process into the finished product of molybdenum titanium sputtering target according to a specific specification machine. The preparation method of the invention has low cost, simple operation and low equipment requirements; the prepared molybdenum titanium sputtering target has high purity, low impurity content, high density, uniform particle size and specific crystallization orientation.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Expandable polypropylene beading, preparation method thereof, and its foaming beading and foaming molding products

The invention provides an expandable polypropylene bead and a preparation method of the expandable polypropylene beads, and also provides foaming beads and foaming molding products of the expandable polypropylene beads, which relates to the resin expandable beads technical field. Random copolymerized polypropylene is used as basic resin, so that melting intensity can reach to an ideal range when in foaming with high melting intensity polypropylene and low density polyethylene resin being added. Expandable beads are prepared in a closed reactor without external pressure with pentane being used as foaming agent. The expandable beads contain 1 to 15 parts by weight of the high melting intensity polypropylene, 1 to 10 parts by weight of the low density polyethylene, 1.0 to 3.8 parts by weight of the foaming agent and 0.1 to 10 parts by weight of nucleating agent on the basis of 100 parts by weight of the random copolymerized polypropylene. The expandable polypropylene beads are easy to foam, whose foaming rate can reach to 16 times with uniform cells and whose foam volume weight is about 0.05 to 0.12g / cm3. The invention adopts a low-pressure method to produce the polypropylene foaming products in different shapes according to the requirement with low equipment requirement and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

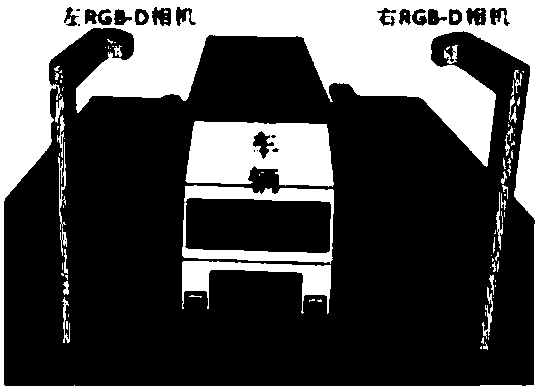

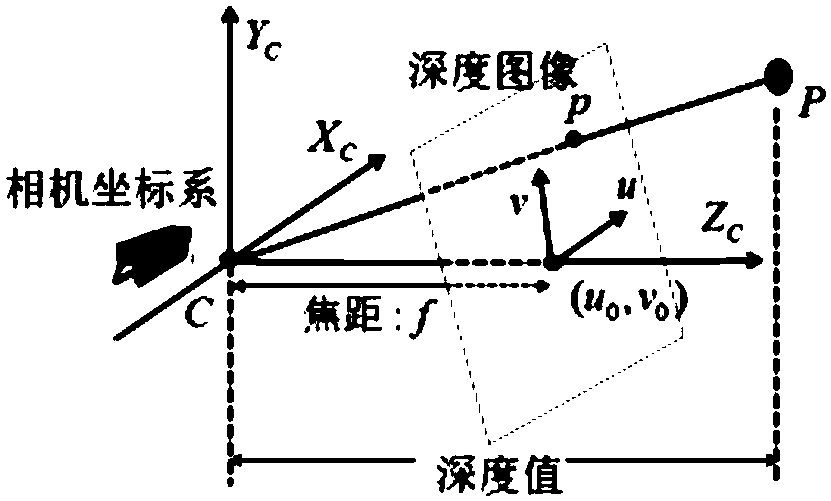

Measuring method for length, width and height of vehicle based on RGB-D camera

InactiveCN108550143ARealize 3D measurementRealize the solutionImage enhancementImage analysisGraphicsPoint cloud

The invention discloses a measuring method for length, width and height of a vehicle based on an RGB-D camera. The method comprises the steps of acquiring a clear vehicle image in a camera short-distance mounting manner, calibrating the camera according to a calibrating method based on a disappearing point, obtaining an internal parameter and an external parameter of the camera, realizing three-dimensional point cloud conversion of a vehicle target in a world coordinate system through a camera depth image solution, and acquiring three-dimensional coordinate information of the external surfaceof the vehicle; acquiring the three-dimensional coordinate of the external surface of the vehicle by means of prior knowledge and an image processing method, splicing a vehicle image according to sequence patterns in a vehicle motion process through a registering method, and realizing three-dimensional measurement to the profile of the vehicle. The measuring method overcomes defects of high equipment requirement and tedious operation in a traditional method and realizes high calibration precision. The actual displacement of the vehicle is comprehensively analyzed through a matching relation ofpoints which correspond with the same position of the vehicle in the image sequence, thereby realizing relatively high registering precision. The measuring method further has advantages of realizingaccurate splicing of the vehicle side surfaces, reducing vehicle length measurement error and improving accuracy in splicing the vehicle side surfaces.

Owner:CHANGAN UNIV

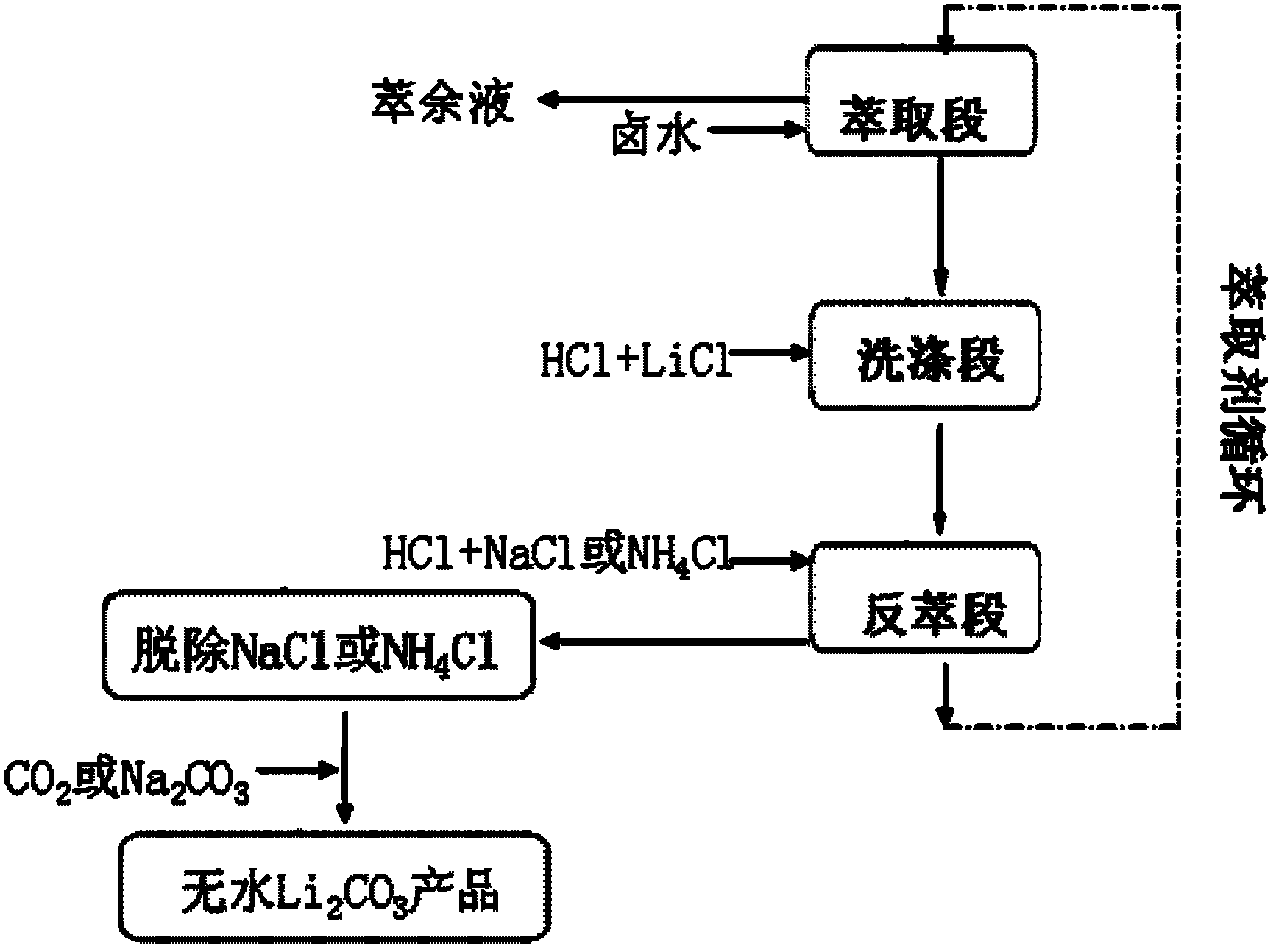

A method for extracting lithium carbonate from high magnesium-lithium ratio salt lake brine

InactiveCN102275956AReduce lossesNo decrease in recycling efficiencyNanotechnologyLithium carbonates/bicarbonatesHigh magnesiumInorganic salts

The invention discloses a method for extracting lithium carbonate from salt lake brine with high magnesium / lithium ratio, belonging to the technical filed of inorganic salt extraction. The method comprises the following steps of: carrying out extraction, washing and stripping steps to obtain a stripping solution composed of NaCl and LiCl or NH4Cl and LiCl, then introducing CO2 or adding Na2CO3, and controlling the pH value and dynamic conditions to obtain a nanoscale or microscale Li2CO3 product. The method disclosed by the invention has the advantages of simple steps, low equipment requirement and wide sources of raw materials, and is suitable for industrial production.

Owner:TSINGHUA UNIV

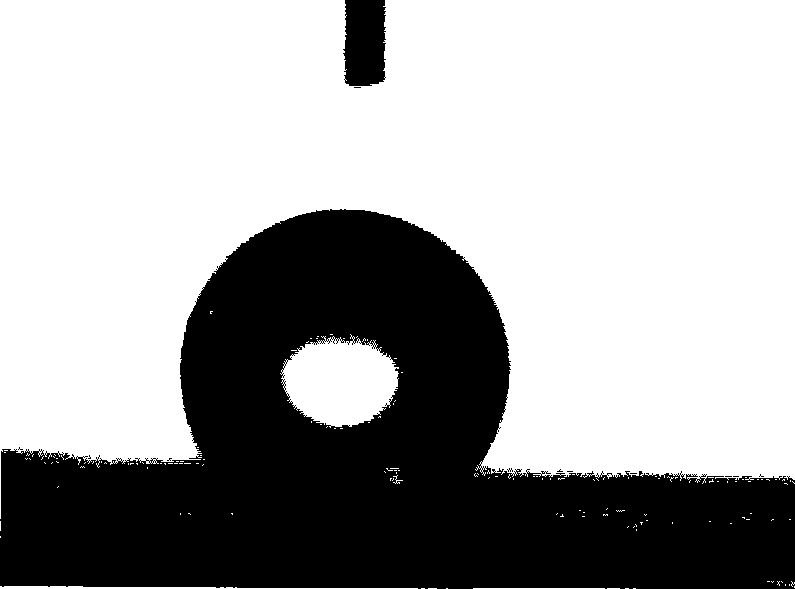

Preparation of super-hydrophobic surface for metal anti-corrosive and self-cleaning effects

InactiveCN101440510AGood environmental stabilityEasy to operateElectrolytic organic material coatingElectrochemical responseAlloy substrate

The invention relates to a method for preparing a super-hydrophobic surface with metal corrosion protection and self-cleaning functions, which comprises the following steps: 1) washing a metal or an alloy substrate clean by using acetone, deionized water and ethanol sequentially; 2) using the cleaned metal or the alloy substrate as an anode and a cathode respectively and putting the anode and the cathode into a fatty acid CH3(CH2)n-2COOH electrolyte solution with the concentration of between 0.001 and 0.5 mol per liter, wherein n is equal to between 10 and 14; and applying voltage of between 0.5 and 25 volts between the cathode and anode to perform an electrochemical reaction for 0.5 to 6 hours so as to deposit a layer of a fatty acid salt super-hydrophobic surface with the metal corrosion protection and self-cleaning functions on the surface of the metal or the alloy substrate serving as the cathode. The method has simple operation and low equipment requirement, is not limited by the shape of a substrate, is easy to achieve industrialization, and has comparatively wide practical value.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

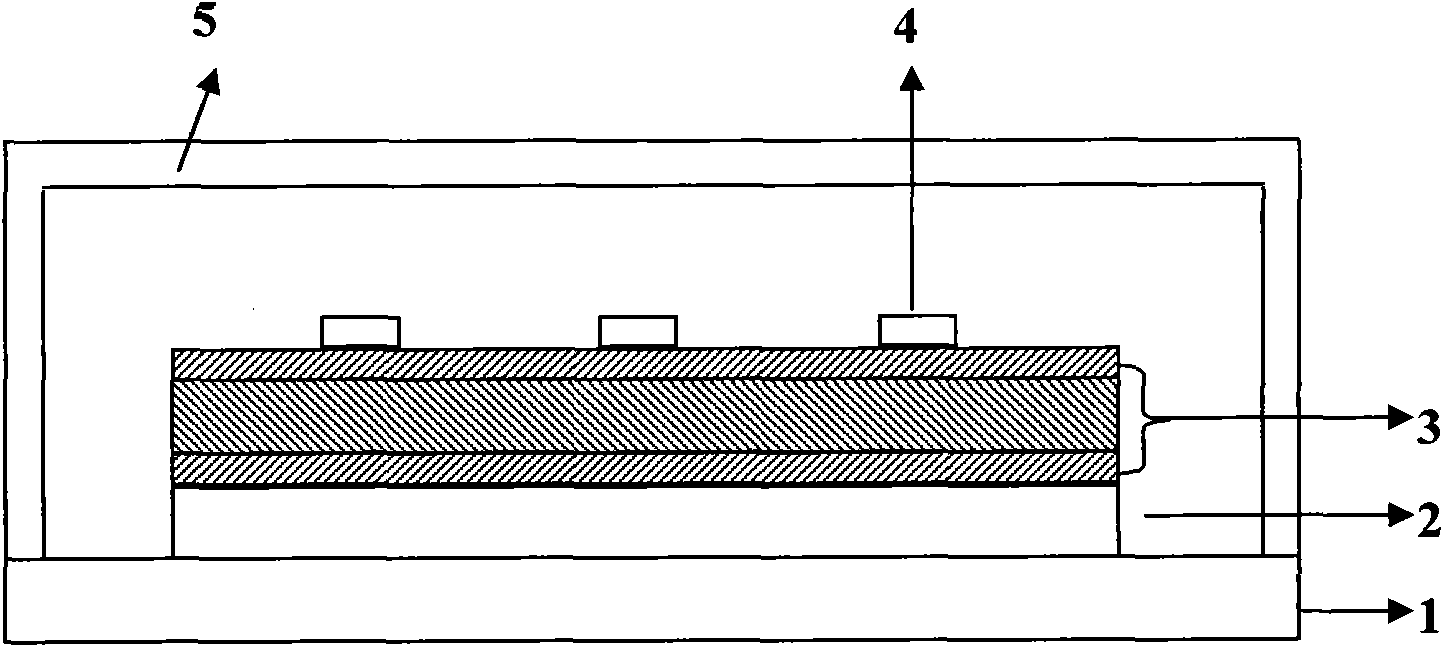

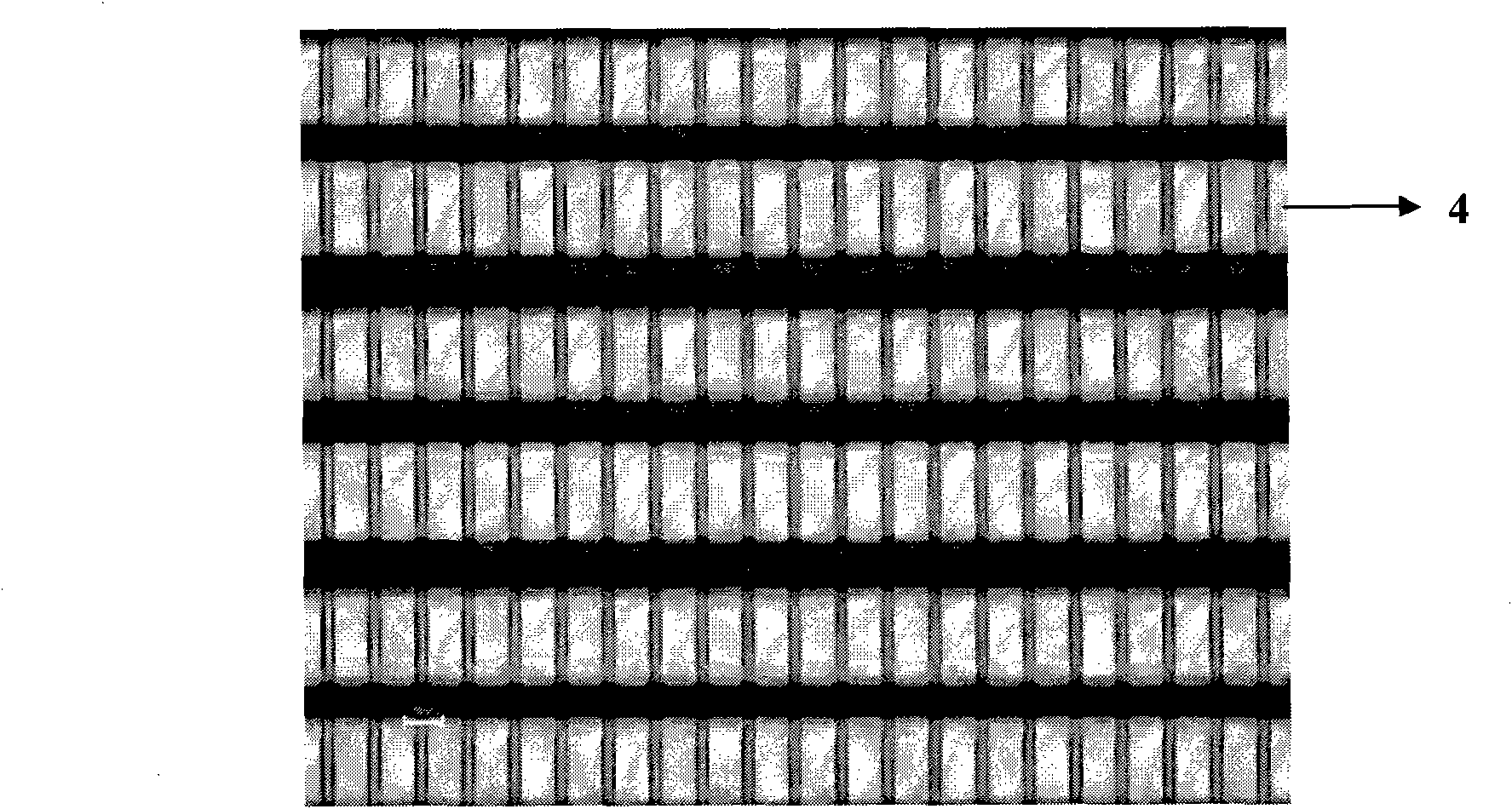

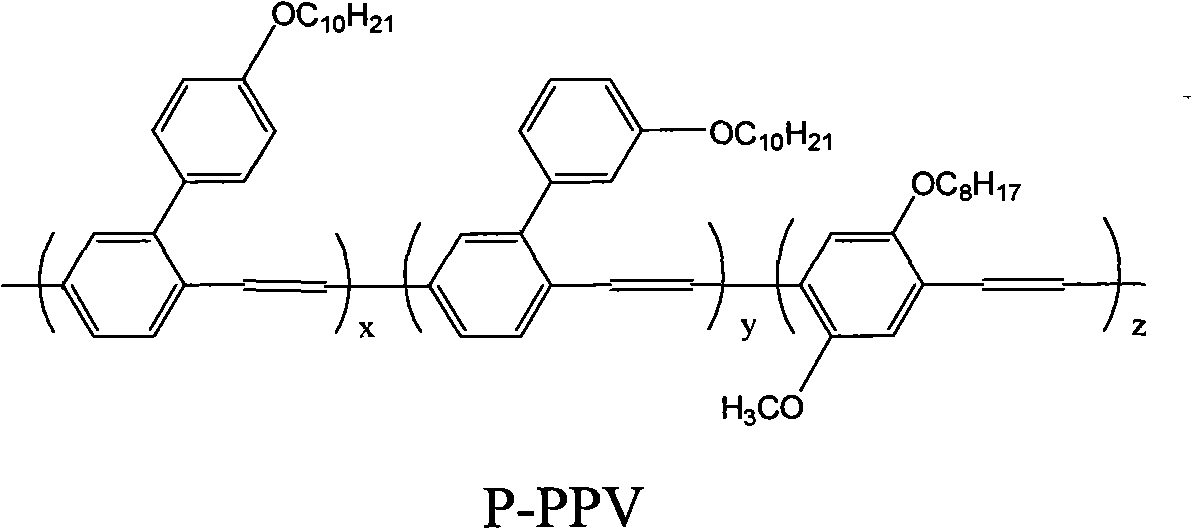

Method for preparing organic light-emitting diode (OLED) display screen by full printing process

ActiveCN101916831ALow affinityHigh affinitySolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodePolymer

The invention relates to a method for preparing an OLED display screen by a full printing process. The OLED display screen is formed by sequentially laminating a substrate, a substrate electrode, organic functional layers and a back electrode, wherein the substrate is made of a hard substrate or a soft substrate; the substrate electrode is a transparent or semi-transparent anode; the organic functional layers at least comprise light-emitting layers; the back electrode is prepared into a cathode by a printing process; the organic functional layers are prepared by performing rotary coating, ink-jet printing, screen printing, pulling and spraying on non-polar organic light-emitting polymers, small molecules or tree-like compounds on the substrate electrode. The method can completely simply the manufacturing process of full-color OLED display screens, further reduce the equipment requirement and manufacturing cost, greatly promote the solution for the high cost problem of the conventional OLEDs, and especially provide a brand-new technical scheme for manufacturing large-area OLED display screens without using an expensive and time-wasting vacuum vapor deposition system.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of soluble mesophase pitch

InactiveCN102942945AImprove solubilityFacilitate subsequent processingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

The invention belongs to the technical field of a preparation method of spinning raw materials of high-performance pitch-based carbon fibers, and particularly relates to a preparation method of soluble mesophase pitch, which mainly solves the problems of the existing mesophase pitch preparation method that the process is complicated, requirements on the equipment are high, the cost is high, the industrialization process is difficult and the like. The invention adopts the technical scheme that the preparation method of the soluble mesophase pitch comprises the following steps of (1) thermally treating raw material pitch or ethylene bottom oil with a low softening point in an inert atmosphere, then distilling the material in a short distance or flashing the material, removing light ends, and collecting heavy fraction, i.e. heavy end pitch; (2) preparing the heavy enbd pitch into mesophase pitch; and (3) cooling the mesophase pitch to 320DEG C to 400DEG C, removing internal light ends, and collecting the heavy fraction, i.e. the mesophase pitch. The preparation method has the advantages of simplicity in process, moderate in reaction condition, low equipment requirement, low cost and adaptability to industrialized production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

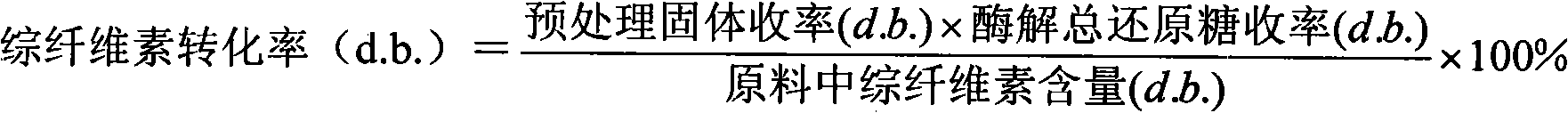

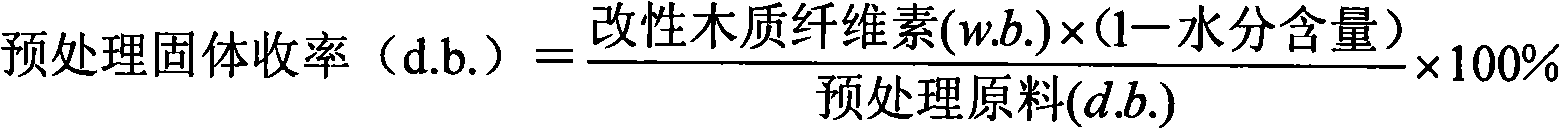

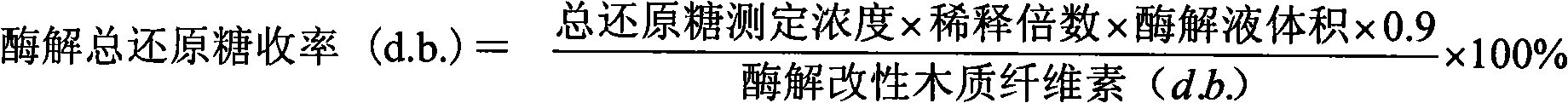

Pre-treatment method for highly-effective saccharification of lignocellulose

InactiveCN101255479AReduce the cost of trainingImprove securitySugar derivativesSugar derivatives preparationCelluloseLiquid glucose

The invention discloses a pretreatment method for effectively saccharifying lignocellulose, particularly discloses a pretreatment method of lignocellulose with room-temperature light-concentration lye, characterized in the method comprises the steps of coarse grinding, lye wetmilling, alkali recovery and enzymolysizing. The ground lignocellulose is mixed with univalent metal lye having a concentration of 0.1% to 3%, solid and liquid are separated under room temperature after wet grinding, wherein the liquid is used for recovering univalent metal lye, and the solid, namely the modified lignocellulose, is used for further enzymolysizing for preparing liquid glucose. According to the invention, lignocellulose is used as the raw material, room temperature condition without external heating can be selected, low-concentration lye is pretreated, the lye can be effectively recovered, the enzymolysis efficiency is improved, the glucose yield is increased, the cost is lowered, the economical efficiency is enhanced, and drawbacks of high energy consumption, low glucose recovery rate, and high equipment requirements in current lignocellulose pretreatment method are made up.

Owner:NANJING TECH UNIV

Preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers

The invention relates to a preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers, which comprises the following concrete steps of: a. washing and oil removal; b. coarsening: increasing the surface roughness and the surface wettability of fibers; c. sensitizing: soaking the fibers by adopting an aqueous solution formed by stannous chloride and hydrochloric acid; d. activation: soaking the fibers by adopting an aqueous solution formed by palladium chloride and hydrochloric acid; e. chemical nickel plating; f. sensitizing; g. activation; h. chemical silver plating; and i. coating protection. The prepared high performance nickel-plated and silver-plated aromatic polyamide conductive fibers have good electric conductivity, characteristics of heat resistance, flame retardance, light weight and high strength and functions of eliminating static electricity, conducting electricity and transmitting electrical signals. Therefore, the prepared nickel-plated and silver-plated aromatic polyamide conductive fibers can be widely applied to special departments of aviation, space flight, war industry, communication and the like and can also satisfy the clothing and equipment requirements of staffs engaging radars, television relaying and the like.

Owner:SHANGHAI UNIV

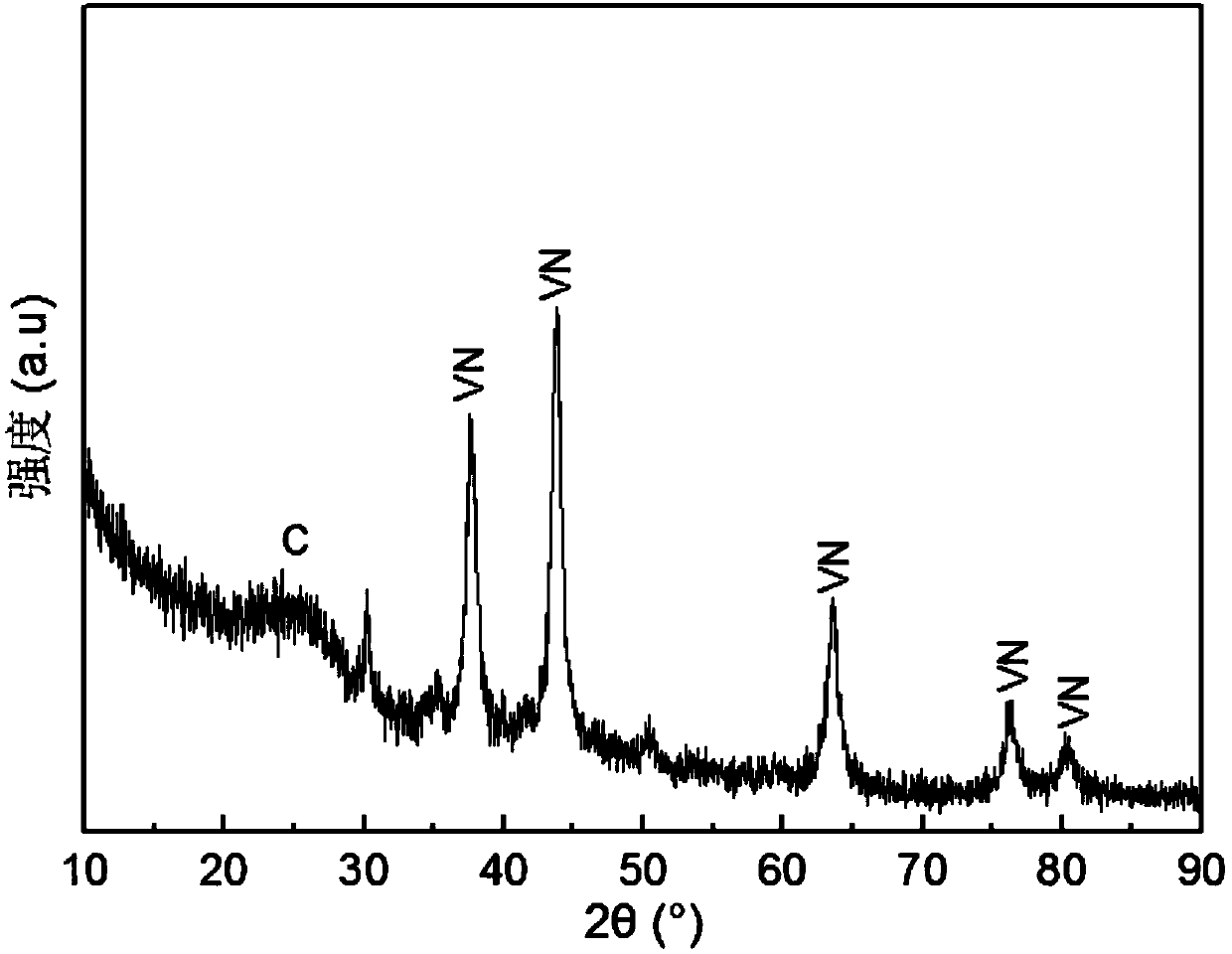

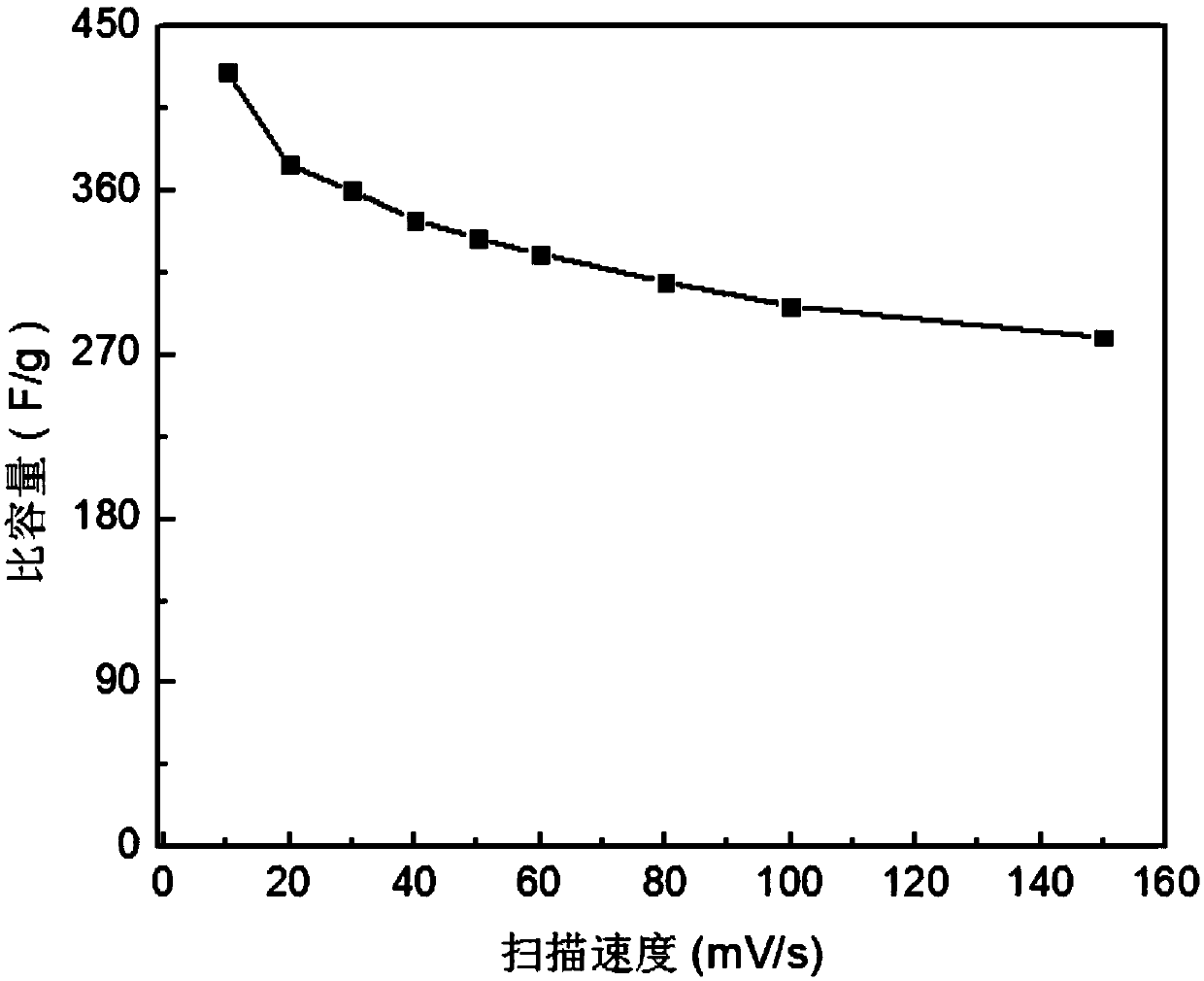

Transition metal nitride/nitrogen-doped graphene nanometer composite material and preparation method and application thereof

ActiveCN107610938ALarge specific surface areaImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesMixed materialsNitrogen doped graphene

The invention provides a transition metal nitride / nitrogen-doped graphene nanometer composite material and a preparation method and application thereof. In the composite material, transition metal nitride nanoparticles with sizes being 5-20 nanometers are embedded into a nitrogen-doped graphene framework, and the composite material is relatively large in specific area, contains mesopores uniformlydistributed and has favorable electrical conductivity. The preparation method of the composite material comprises the steps of (1) mixing a template precursor, a carbon source and a metal source to obtain a mixed material; and (2) placing the mixed material of the step (1) in an atmosphere furnace, and performing calcination in a non-oxidization atmosphere to obtain the transition metal nitride / nitrogen-doped graphene nanometer composite material. The composite material is used for the supercapacitor, a fuel cell or a lithium ion battery and has excellent application prospect. Compared with the prior art, the preparation method of the composite material is simple in process, low in equipment requirement and low in energy consumption, the raw material is low in cost, and mass production iseasy.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

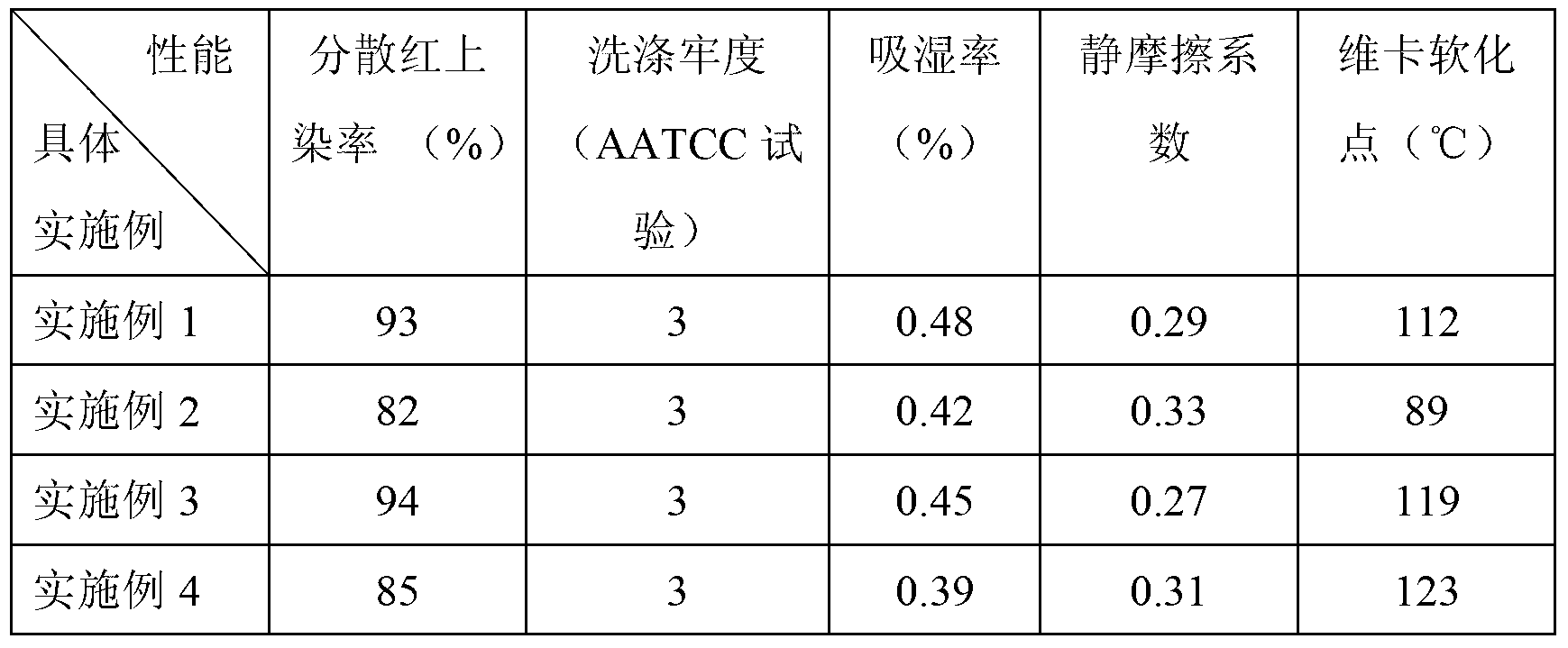

Modified polylactic acid fiber and preparation method thereof

ActiveCN103225125ASave raw materialsRich sourcesMelt spinning methodsMonocomponent polyesters artificial filamentEnvironmental resistanceCellulose diacetate

The invention discloses a modified polylactic acid fiber and a preparation method thereof. The modified polylactic acid fiber is prepared through blending polylactic acid, a cellulose derivative, a cellulose diacetate grafted polylactic acid copolymer, a lubricant, inorganic nanoparticles, a nucleating agent and an antioxidant. The preparation method comprises the following steps: adding partial polylactic acid slices and all other raw materials to a high speed mixer according to a mass component ratio, carrying out high speed dispersion, and carrying out melt blending and extrusion through a double screw extruder to obtain modified polylactic acid master batch slices; and carrying out dry mixing of the modified polylactic acid master batch slices and residual polylactic acid slices in the high speed mixer, carrying out melt spinning through a melt spinning machine, and stretching to obtain the modified polylactic acid fiber. The prepared polylactic acid fiber has the advantages of low cost, complete biodegradation, environmental protection, good spinning performance, stable filament bundle quality, excellent flexibility, excellent antifriction, excellent dyeing property and excellent comfortableness, and is a very good high-performance environmentally-friendly fiber material. The preparation method has the advantages of simplicity, low equipment requirement, and environmental protection in the production process, and is in favor of the industrialized production.

Owner:长沙乐远化工科技有限公司

High-adhesive property watersoluble polyurethane adhesion agent and method of producing the same

InactiveCN101429417AHigh solid contentFast dryingPolyureas/polyurethane adhesivesWater basedPolyurethane adhesive

The invention relates to water-based polyurethane adhesive with high adhesive property and a preparation method thereof, and belongs to the field of polyurethane adhesive. The preparation method comprises the following steps: (1) drying a polylol polymer for 1 to 3 hours in vacuum at a temperature of between 100 and 120 DEG C, reducing the temperature to between 80 and 90 DEG C, dripping diisocyanate into the polylol polymer, polymerizing the mixture for 1 to 1.5 hours, adding small molecular polylol and hydrophilic polylol into the mixture to carry out chain extension and polymerization reaction for 1 to 1.5 hours, then adding the diisocyanate into the mixture, and making the mixture subjected to end capping reaction for 0.5 to 1 hour; (2) dripping neutralizing agent into cross linking polyurethane pre-polymer, and adding acetone into the pre-polymer at the same time to reduce viscosity, wherein the neutralization degree is 95 to 100 percent after the mixture is reacted for 0.5 to 1 hour at a temperature of between 35 and 45 DEG C; (3) dripping the obtained hydrophilic cross linking polyurethane pre-polymer into a mixture of a polyamine compound and water, and dispersing the mixture evenly under high-speed shearing function of an emulsifying machine to obtain water-based polyurethane dispersant; and (4) removing organic solvent in the water-based polyurethane dispersant obtained in step (3) by a vacuum decompressing method. The preparation method effectively solves the problem of difficult emulsifying dispersion caused by cross linking, has simple emulsifying process, and reduces equipment requirement remarkably, has high solid content, reduces cost for production, storage and transportation, improves drying time, and is convenient for gluing operating process.

Owner:GUANGZHOU KELIN WAER BORNE MATERIAL

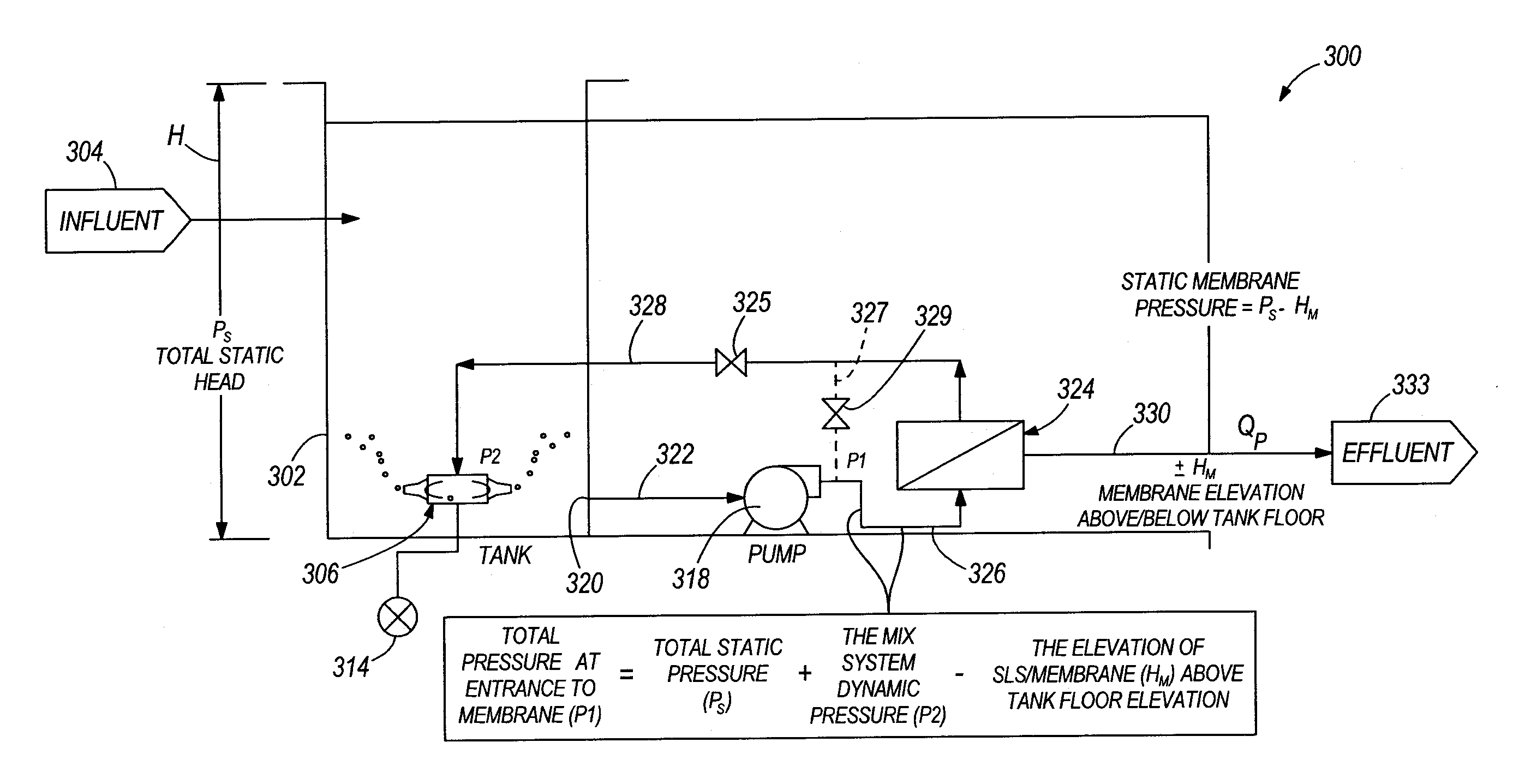

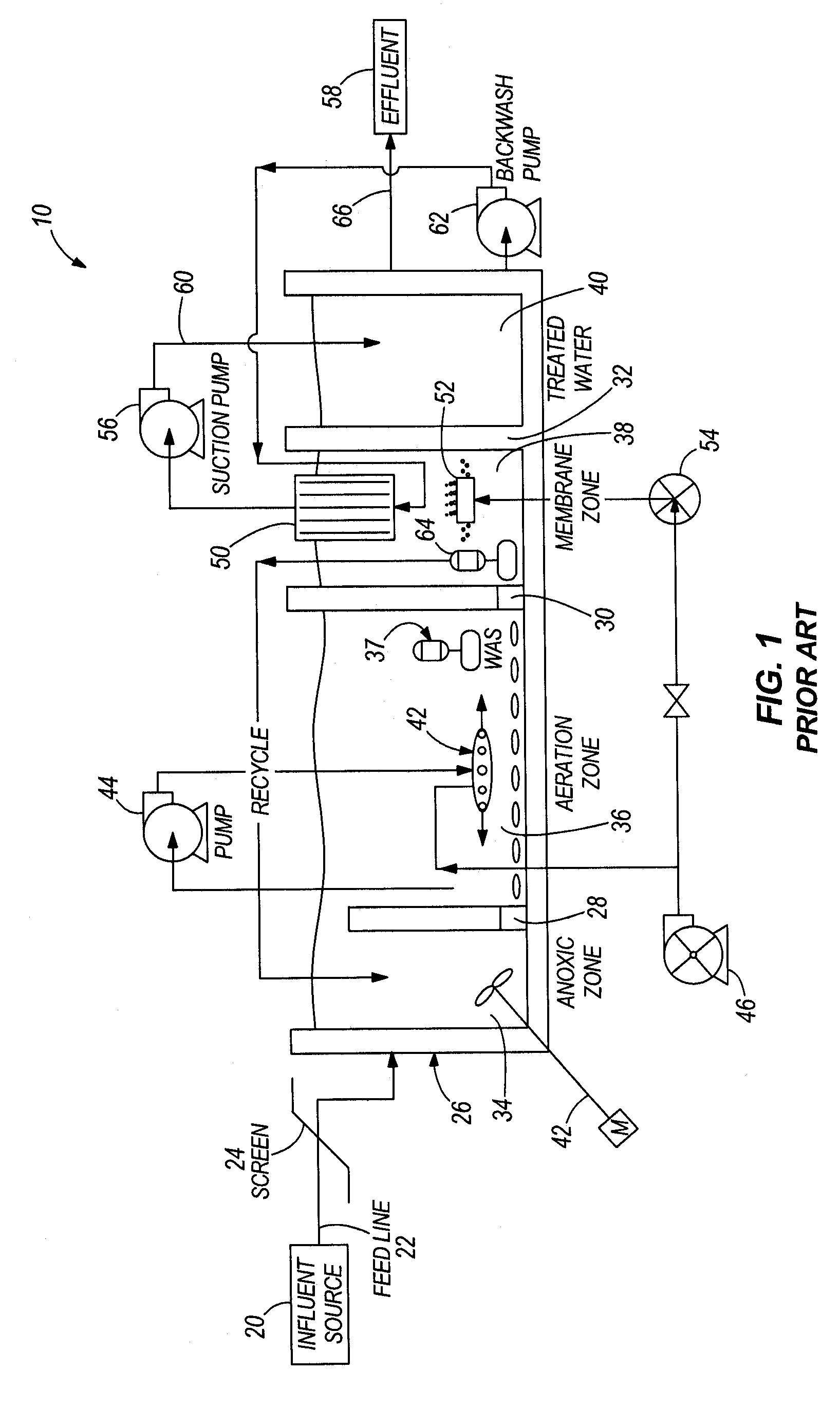

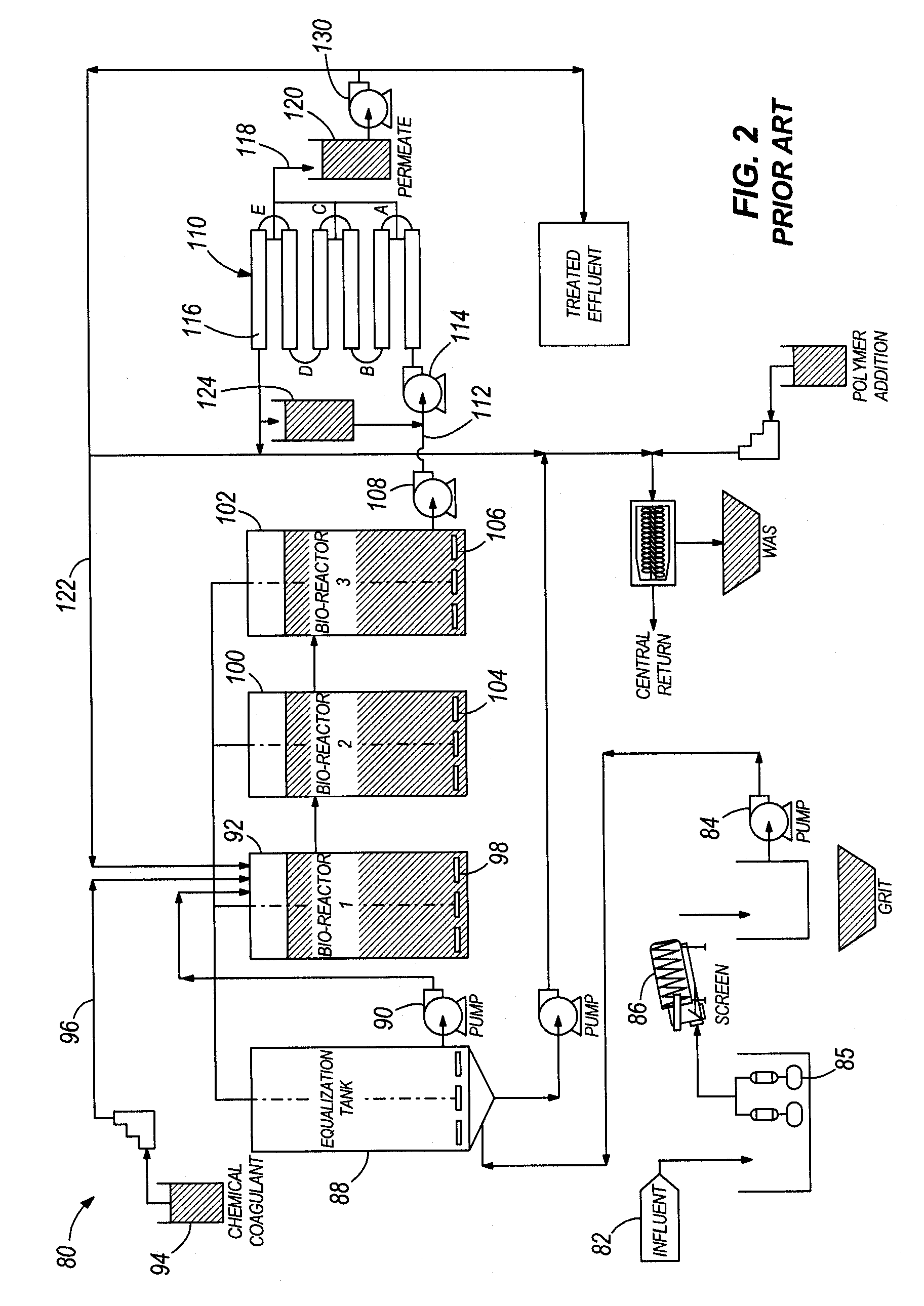

Hydraulically integrated solids/liquid separation system and method for wastewater treatment

InactiveUS20090014387A1Eliminate redundancyLess energySemi-permeable membranesMembranesAeration systemClosed loop

Owner:PROCORP ENTERPRISES

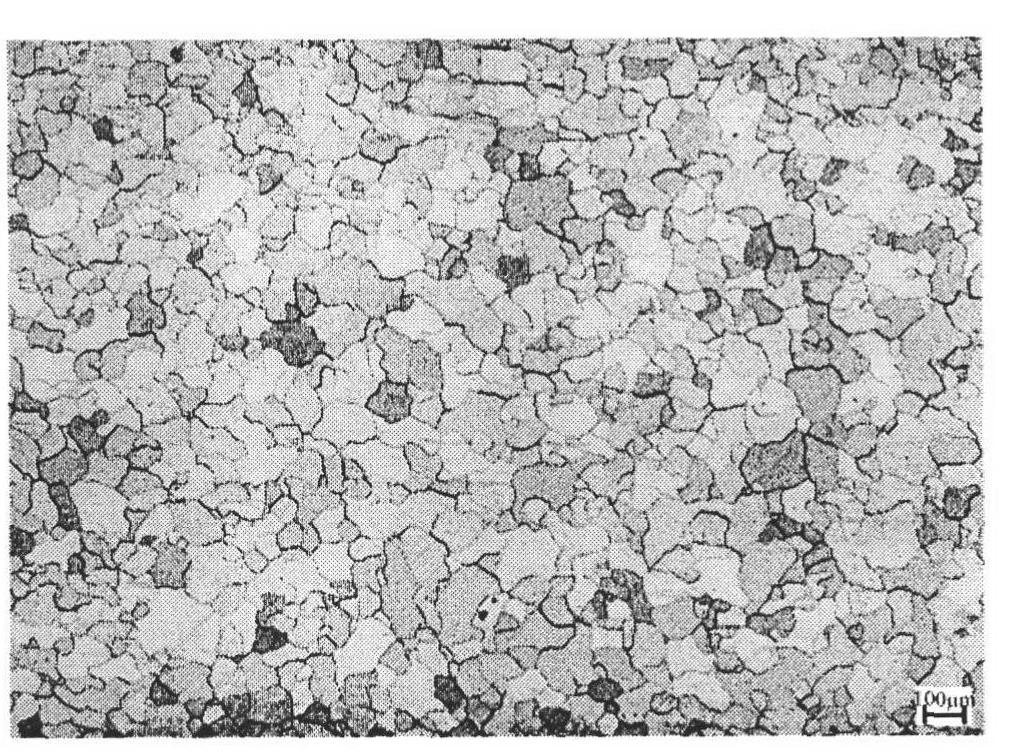

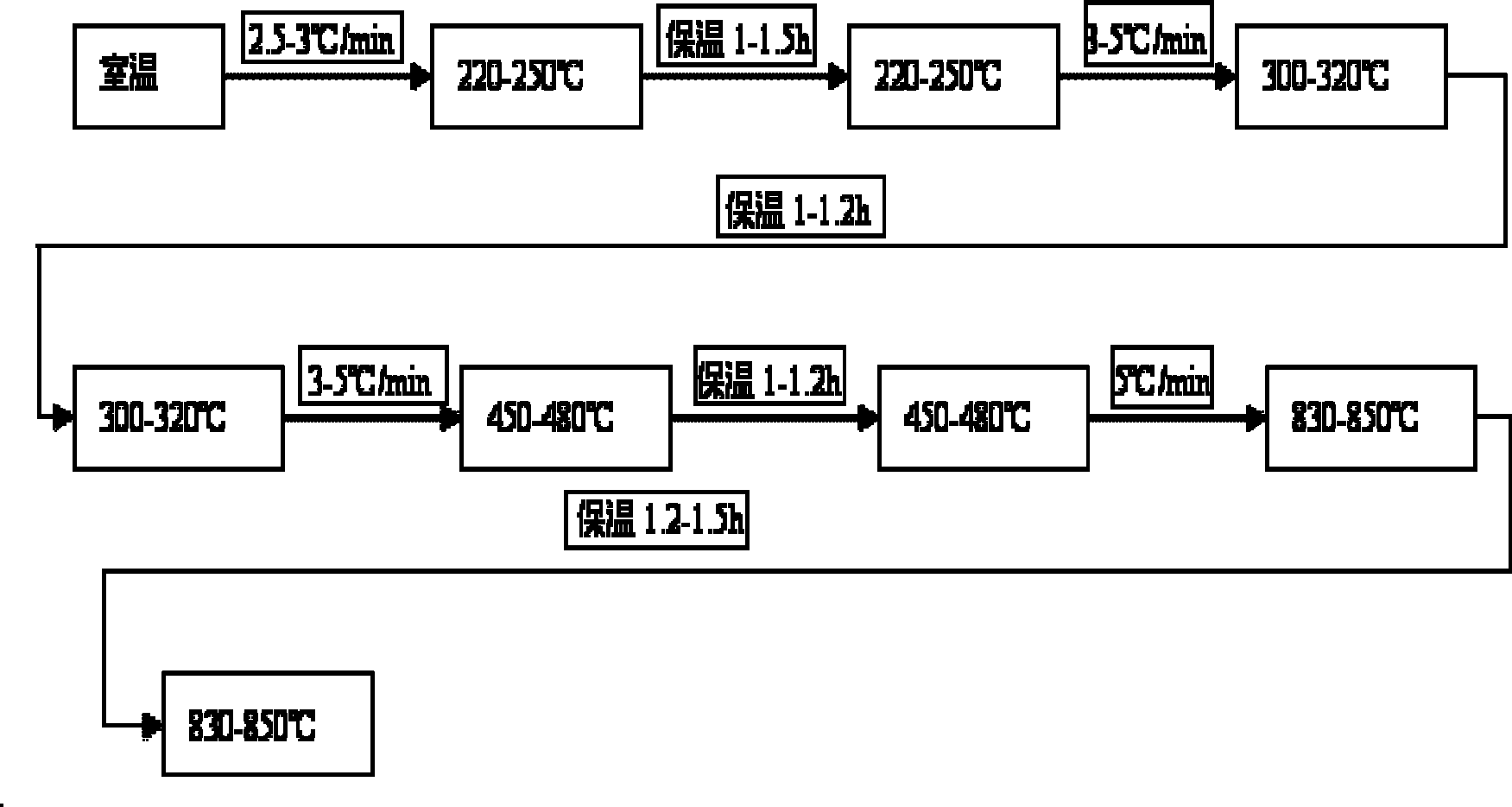

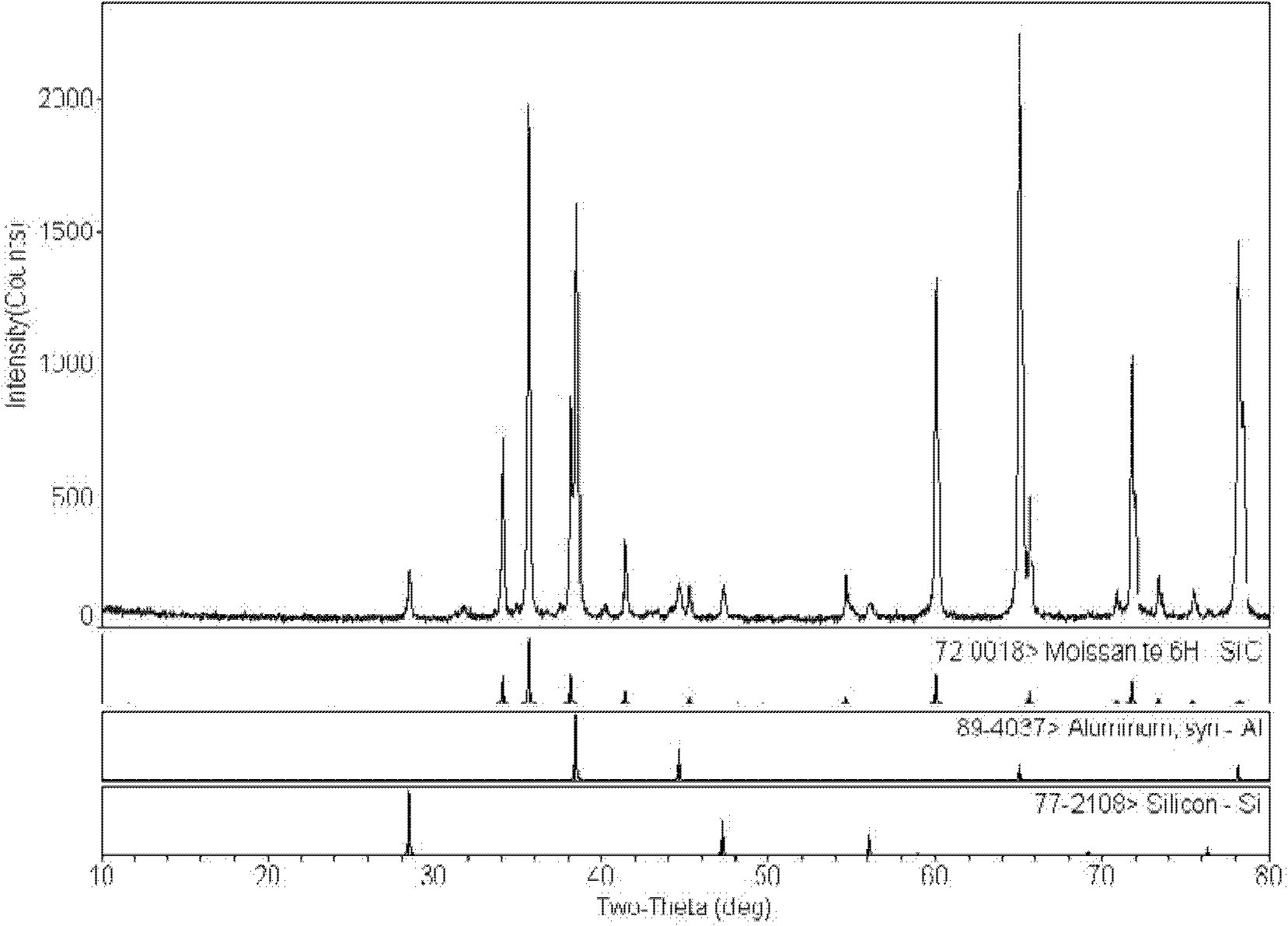

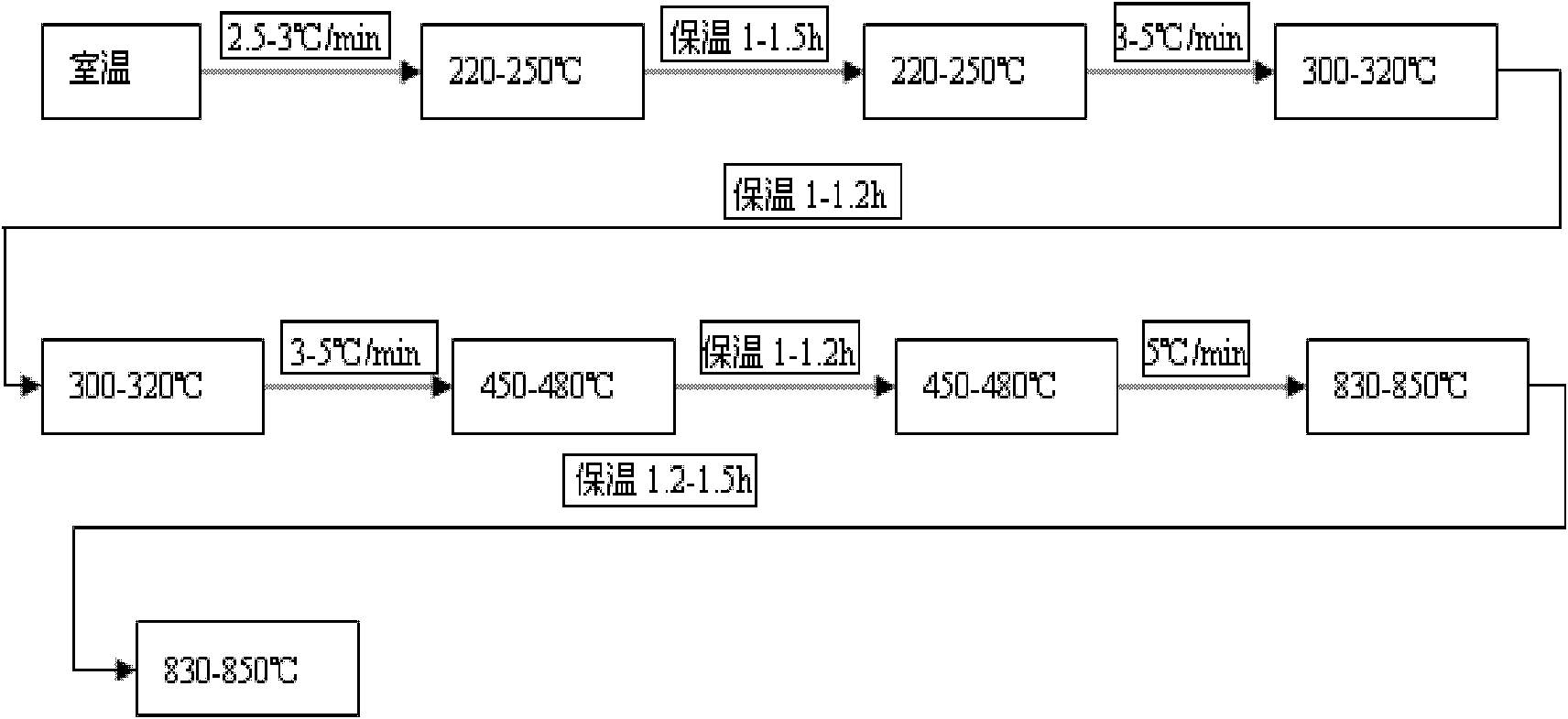

Preparation method of carborundum particle reinforced aluminum matrix composite material with high volume fraction

The invention discloses a preparation method of a carborundum particle reinforced aluminum matrix composite material with high volume fraction. The method adopts a low temperature multi-stage sintering technology, wherein a sintering temperature needed by the low temperature multi-stage sintering technology is obviously lower than a sintering temperature (over 1000 DEG C) needed by the prior arts at home and abroad. In the invention, carborundum powder and aluminium alloy are utilized as raw materials to prepare the carborundum particle reinforced aluminum matrix composite material, wherein volume fraction of the carborundum powder can be adjusted in a range of 50 to 75%. Through utilizing the method provided by the invention, the problems which are in the prior arts and comprise a high sintering temperature, easy generation of impurity phases and a harmful interface phase Al4C3, high equipment requirements, high energy consumption, poor overall performances of composite material products, etc. are solved. The method provided by the invention has the advantages of simple processes and low cost.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

Low temperature crystallized nano titanium dioxide powder and sol synthesizing method

InactiveCN1935669AImprove photocatalytic activityStable storageTitanium dioxideNanocrystalTitanic acid

The invention belongs to an organic metal oxide-TiO2 photocatalyst preparing process, especially relating a synthesizing method of low temperature-crystallizing nanometer TiO powder and sol with high catalytic activity. And it obtains n-titanic acid deposit by making alkali neutralization and dilution hydrolyzation or heating hydrolyzation on titanic solution, and implements synthesizing related system nano crystal materials with normal-pressure and low-temperature liquid phases by such a processing process of re-dispersing the deposit by oxydol. And it largely reduces the cost of raw materials and avoids using titanium tetrachloride with strong corrosivity, reducing equipment requirements.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

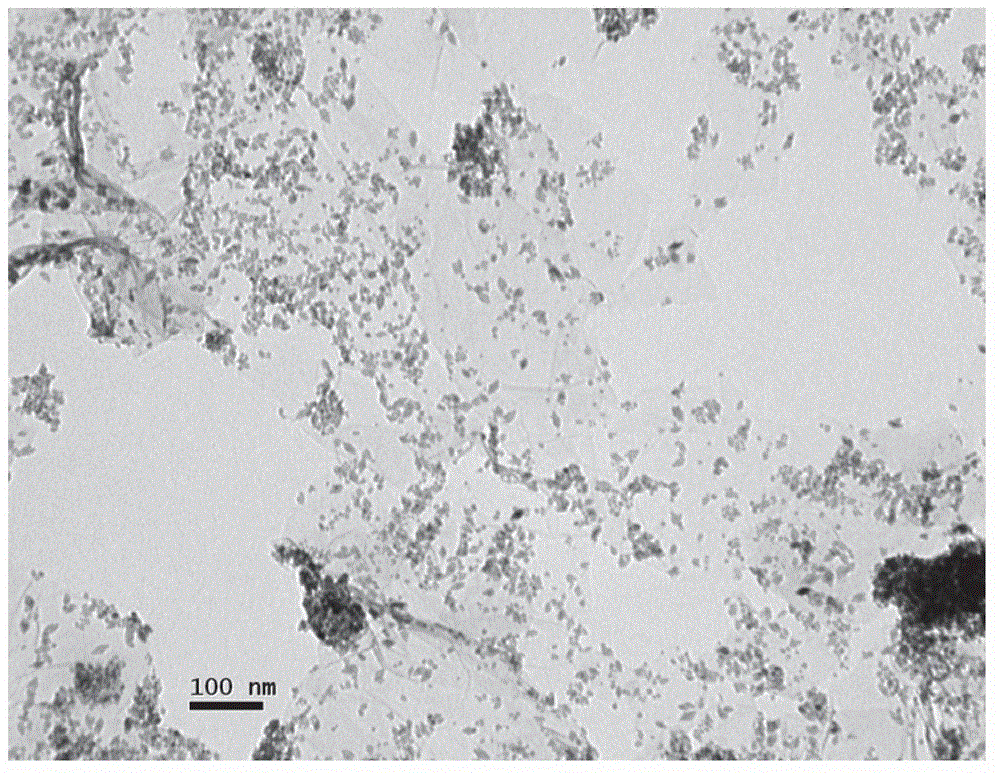

Preparation methods of graphene and graphene-oxide compound

ActiveCN103332678AFull reduction reactionHigh transparencySilicaGrapheneOxide compositeLithium-ion battery

The invention relates to the technical field of carbon material preparation and provides a preparation method of graphene. The preparation method comprises the following step that graphene oxide is dispersed in a solution of catechol or its derivatives and the mixed solution undergoes a hydrothermal reaction to produce the graphene having particle length and width of 10-200 microns. The invention also discloses a preparation method of a graphene-oxide compound comprising uniform-size and uniformly-dispersed oxide particles. The preparation method comprises that the graphene and an oxide precursor solution are dispersed in an aqueous solution and the mixed solution undergoes a hydrothermal reaction to produce the graphene-oxide compound. The preparation methods adopt a hydrothermal method and a water system, do not produce toxins and are environmentally friendly. The graphene has good transparency and small thickness. The graphene-oxide compound comprises the uniform-size oxide particles uniformly dispersed in the graphene, solves the problems of easy aggregation of the graphene and the oxide particles, uneven dispersion of the graphene and the oxide particles, complex preparation processes and high equipment requirements, and can be widely used in fields of supercapacitors, lithium ion batteries and electrochemical sensing.

Owner:SHANGHAI UNIV

Preparation method of silica aerogel

ActiveCN102674374AWide variety of sourcesEasy to controlSilicon compoundsOrganic solventDesalination

The invention discloses a preparation method of silica aerogel, and belongs to the field of preparation of inorganic porous materials. The preparation method includes: allowing alkaline silica sol to form aerogel directly under the action of acid catalyst and base catalyst; performing solvent displacement and surface silylanizing; and supercritical or atmospheric drying to obtain SiO2 aerogel. Organic solvents are not used in sol formation, and accordingly dangers in sol formation are eliminated. The complex process of sol preparation by organosilicone and desalination by sodium silicate is omitted from the aerogel preparation, the alkaline silica sol low in cost and stable in performance is used as raw material, process is simple, production cycle is short, reaction process is controllable, equipment requirements and investment are low, and industrial production of SiO2 aerogel is achieved.

Owner:纳诺科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com