Preparation method of carborundum particle reinforced aluminum matrix composite material with high volume fraction

An aluminum-based silicon carbide, high volume fraction technology is applied in the field of forming metal matrix composite materials, which can solve the problems affecting the infiltration of aluminum liquid and the overall performance of composite materials, high equipment requirements, and high energy consumption, and achieves a small thermal expansion coefficient. The effect of eliminating SiO2 impurity phase and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

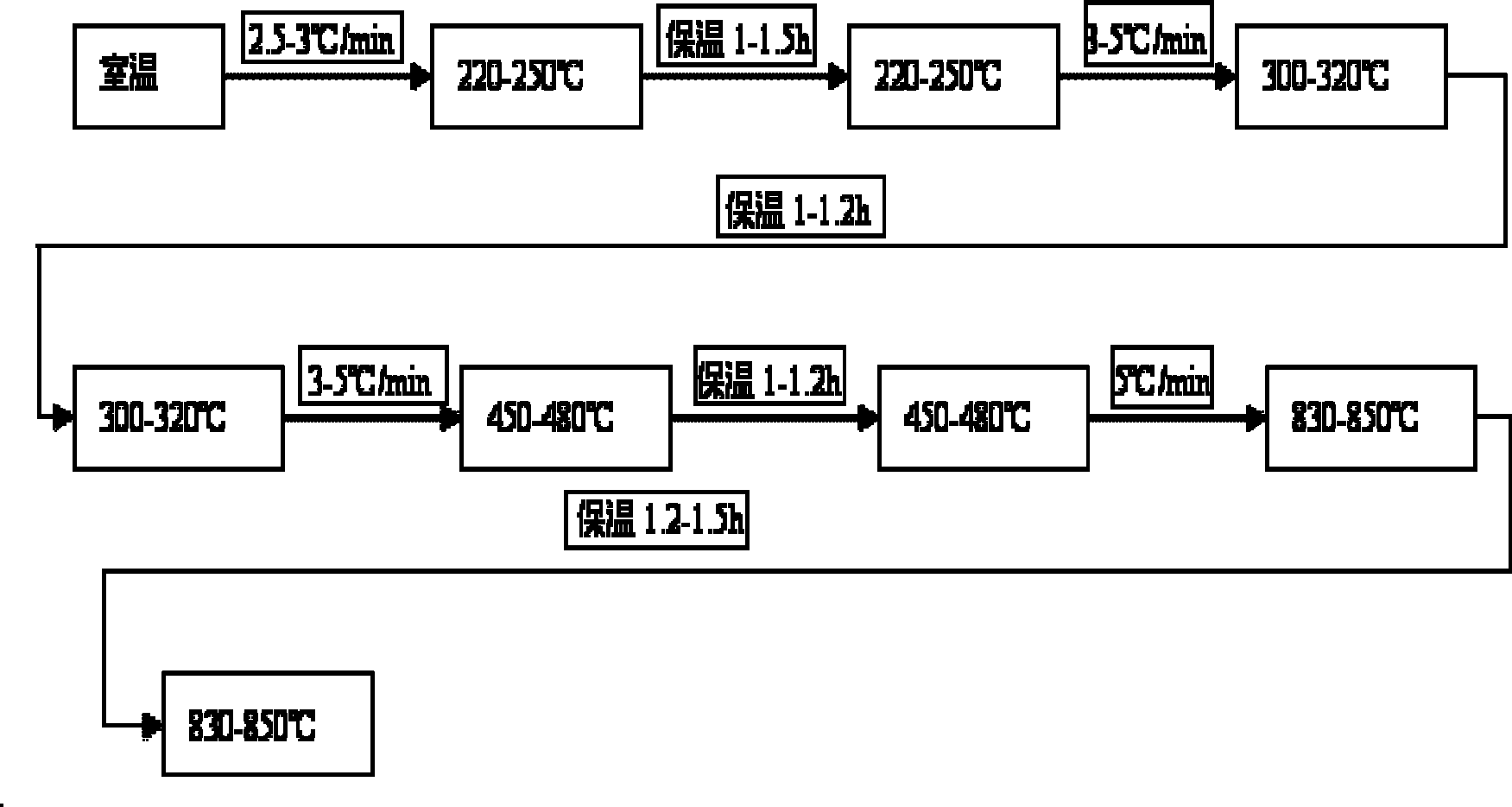

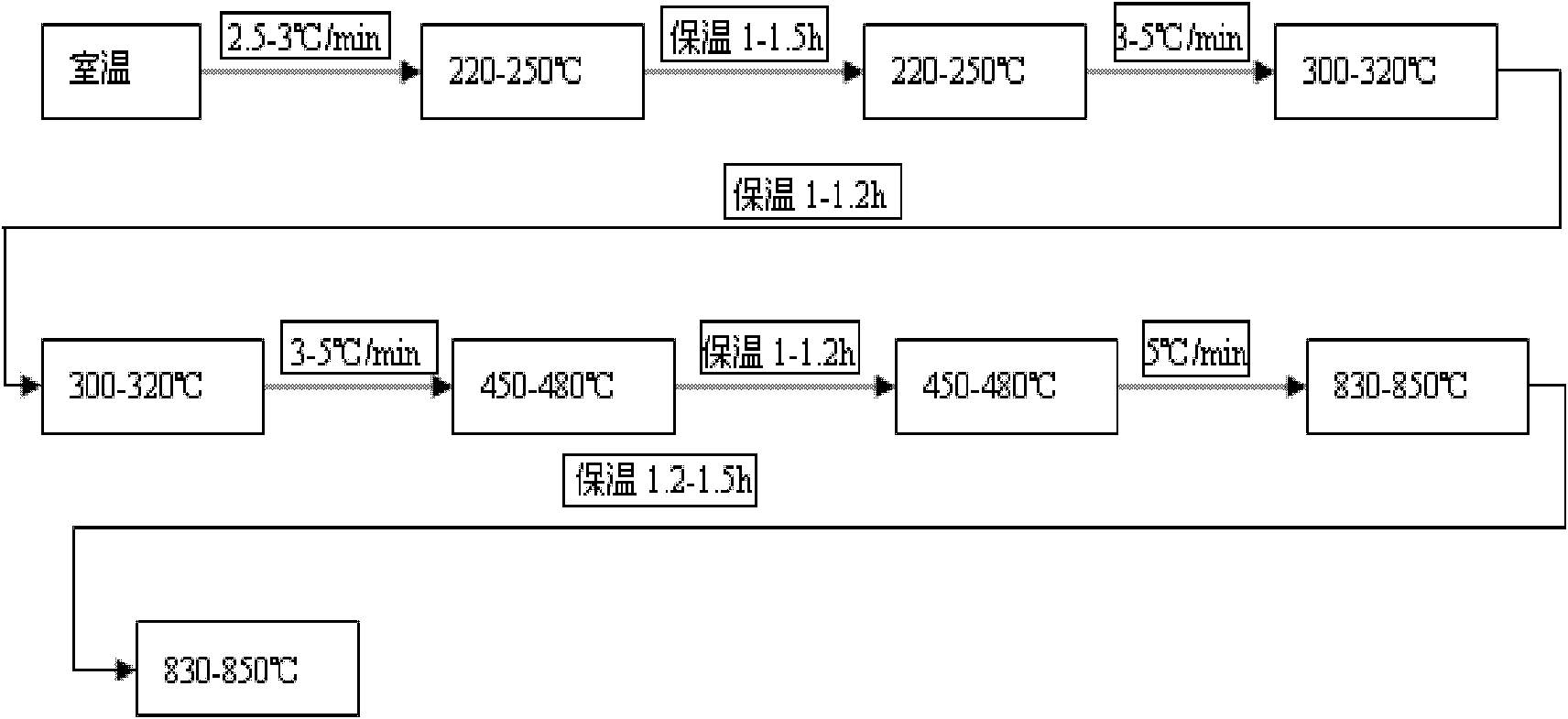

[0024] Embodiment 1: low temperature multistage sintering method

[0025] Put the pressed silicon carbide in the sintering equipment, raise the temperature from room temperature to 220-250°C at a rate of 2.5-3°C / min, and keep it warm for 1-1.5h; then raise the temperature at a rate of 3-5°C / min to 300-320°C, keep warm for 1-1.2h; then raise the temperature to 450-480°C at a heating rate of 3-5°C / min, keep warm for 1-1.2h; finally raise the temperature to 830-850 at a heating rate of 5°C / min ℃, heat preservation for 1.2-1.5h to obtain the silicon carbide preform.

Embodiment 2

[0026] Example 2: Preparation of SiCp / AI composite material with a silicon carbide volume fraction of 75%

[0027] (1) The volume percentage of silicon carbide powder is 75%, and the volume percentage of aluminum alloy is 25%;

[0028] (2) According to the gradation theory, select 70 parts of silicon carbide powder of W63, 20 parts of silicon carbide powder of W28, and 10 parts of silicon carbide powder of W7, pour into the mixer and mix for 3 hours;

[0029] (3) Accurately weigh the high-temperature binder and the low-temperature binder according to the proportioning ratio, wherein the mass fraction of the low-temperature binder paraffin is 3 parts, and the mass fraction of the high-temperature binder silicone resin is 2.5 parts, which are dissolved in a solvent respectively , then add the mixed silicon carbide powder and mix evenly;

[0030] (4) The mixture is dried, granulated and sieved, and pressed into shape with a pressing pressure of 180MPa;

[0031] (5) Put the comp...

Embodiment 3

[0035] Example 3: Preparation of SiCp / Al composite material with a volume fraction of silicon carbide of 50%

[0036] (1) The volume percentage of silicon carbide powder is 50%, and the volume percentage of aluminum alloy is 50%;

[0037] (2) According to the gradation theory, select 90 parts of W63 silicon carbide powder and 10 parts of W10 silicon carbide powder, pour them into the mixer and mix for 2 hours.

[0038] (3) Accurately weigh the high-temperature binder and the low-temperature binder according to the proportioning ratio, wherein the mass fraction of the low-temperature binder paraffin is 4 parts, and the mass fraction of the high-temperature binder silicone resin is 4 parts, which are respectively dissolved with a solvent , then add the mixed silicon carbide powder and mix evenly;

[0039] (4) The mixture is dried, granulated and sieved, and pressed into shape by regulating and controlling the molding pressure, wherein the pressing pressure is 120MPa;

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com