Patents

Literature

4308results about How to "High thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

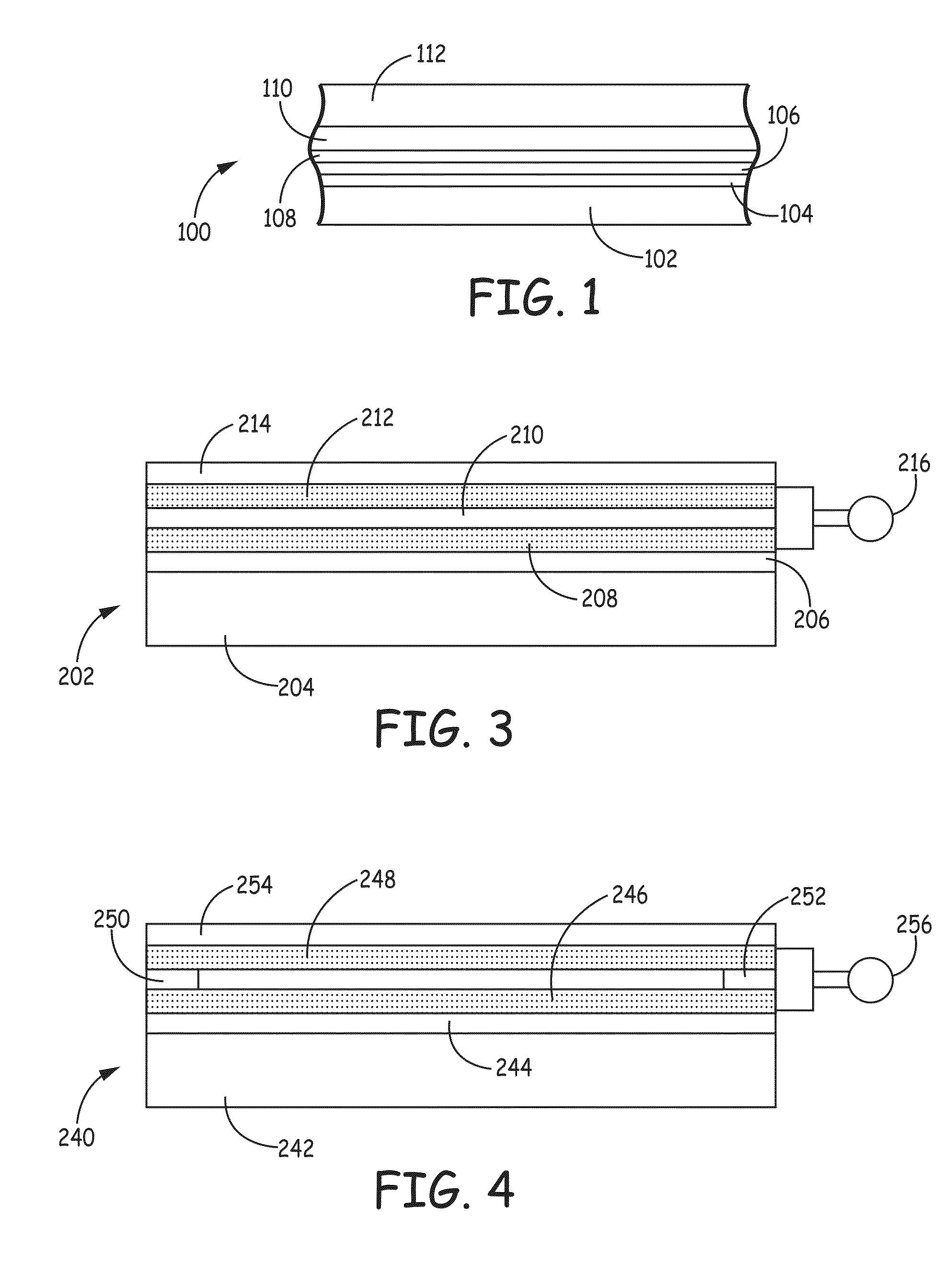

Package-integrated thin film LED

ActiveUS7256483B2Little absorption of lightHigh thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesThermal conductivityEngineering

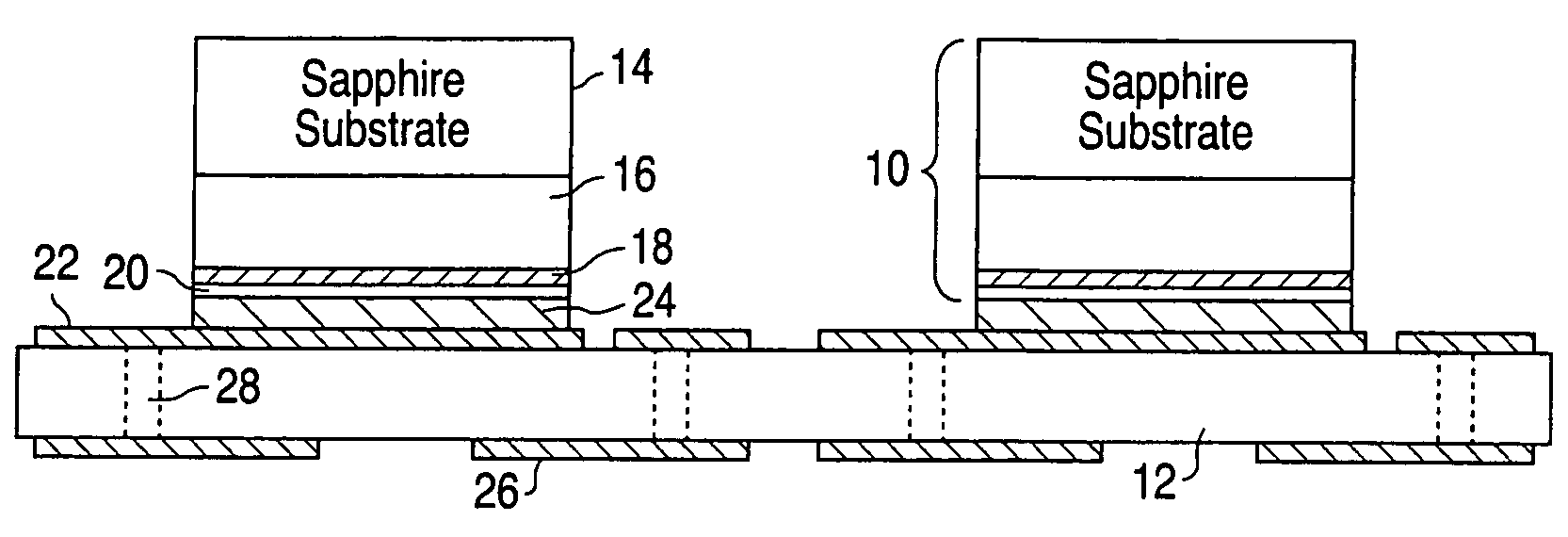

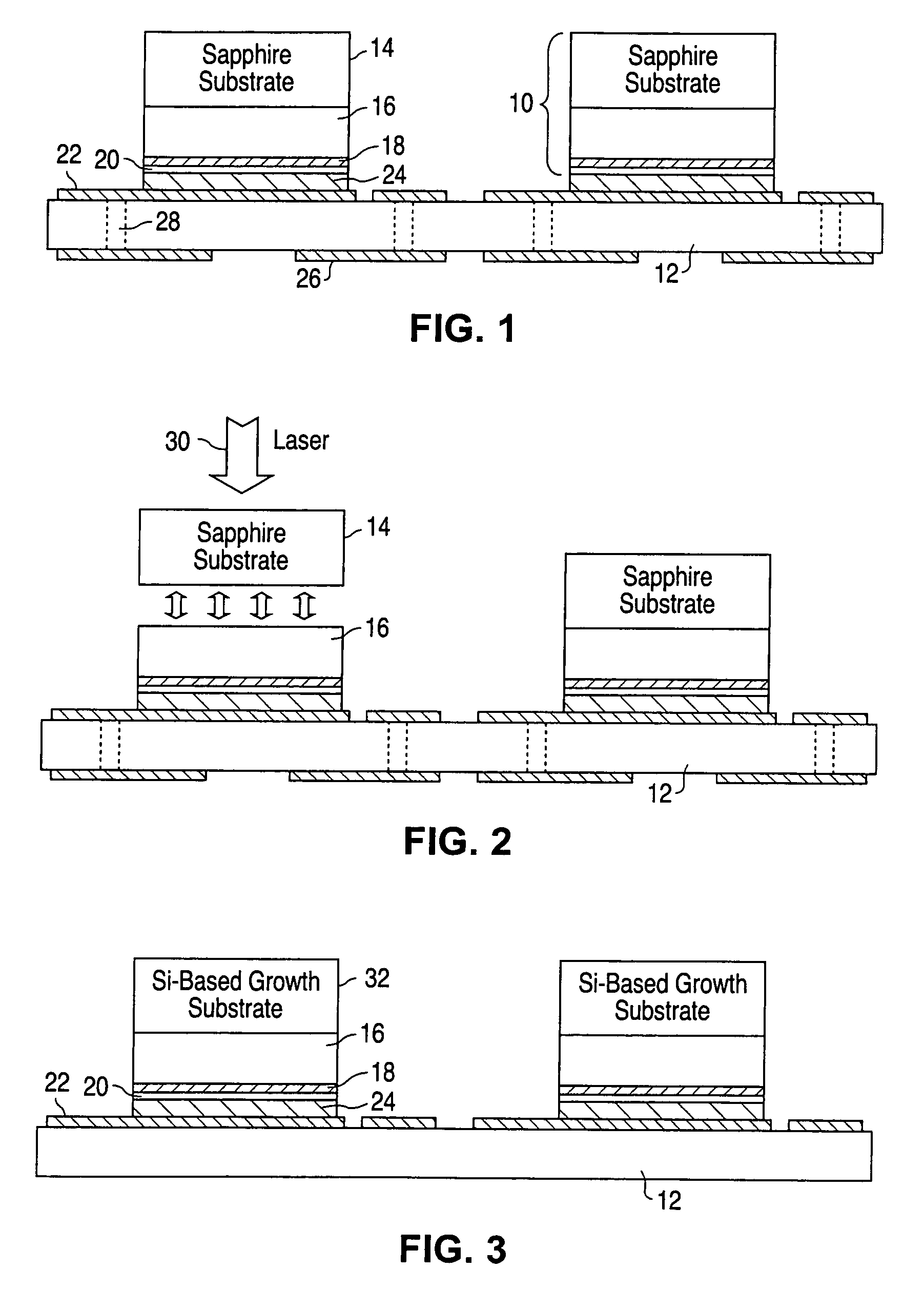

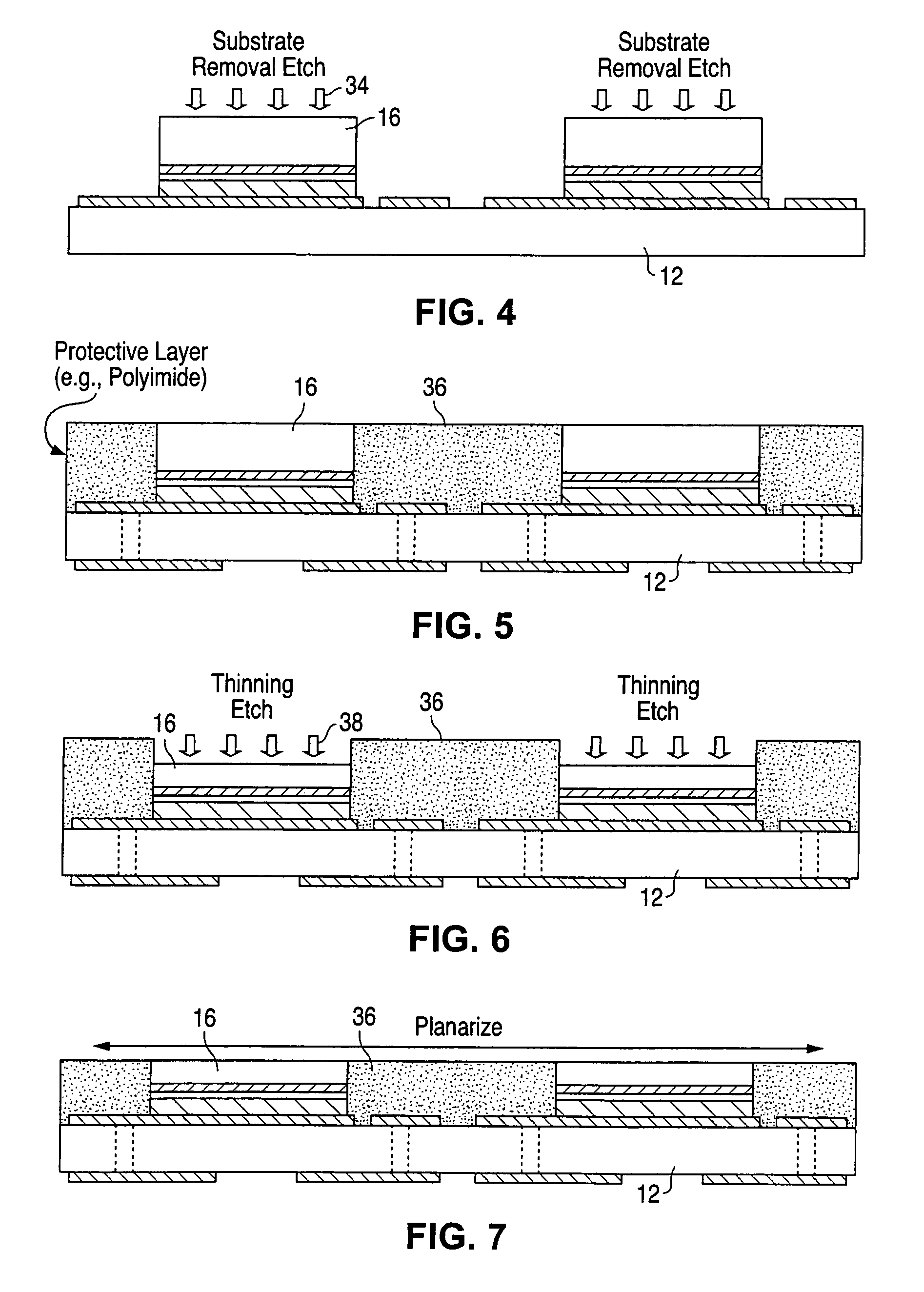

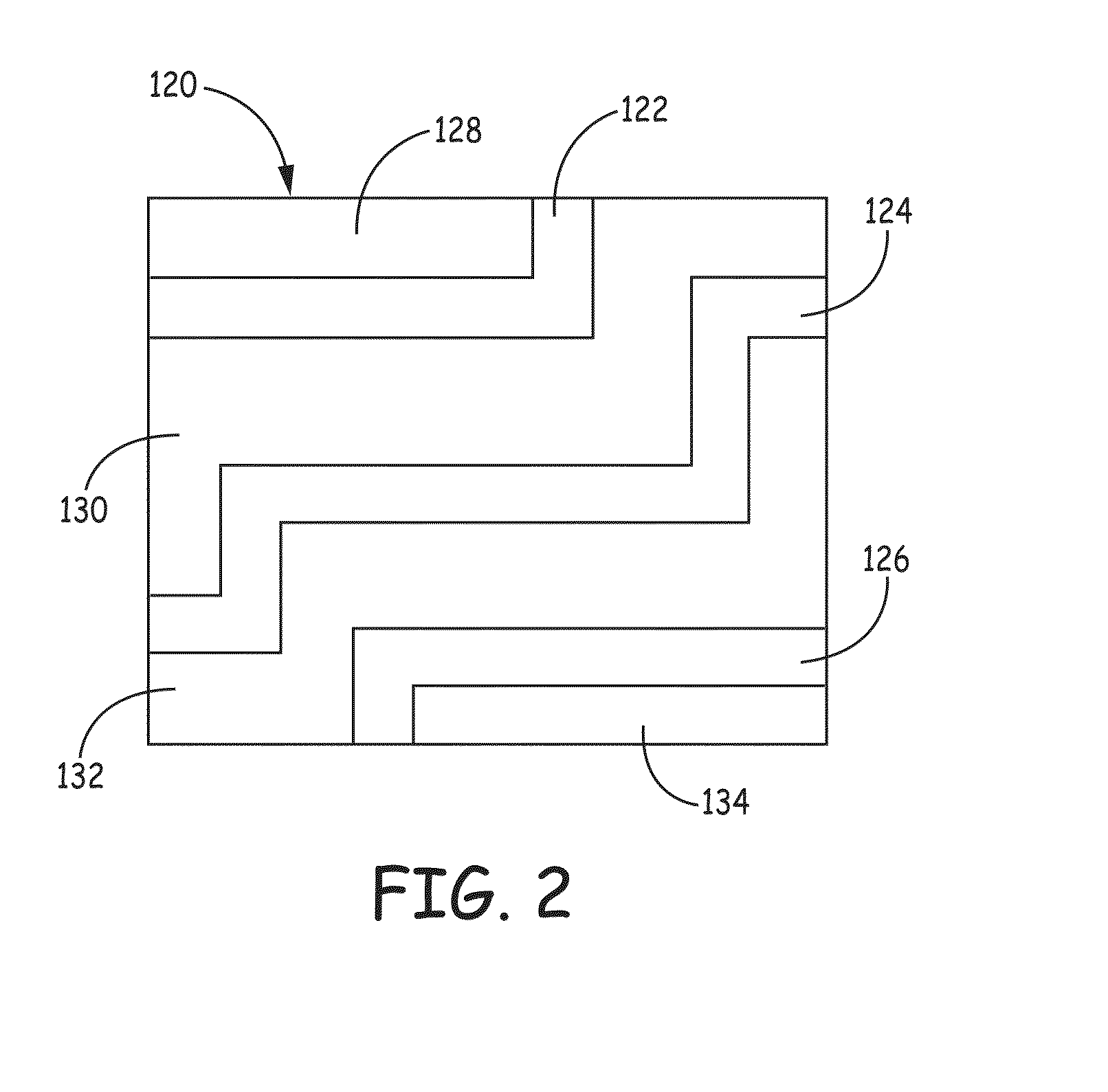

LED epitaxial layers (n-type, p-type, and active layers) are grown on a substrate. For each die, the n and p layers are electrically bonded to a package substrate that extends beyond the boundaries of the LED die such that the LED layers are between the package substrate and the growth substrate. The package substrate provides electrical contacts and conductors leading to solderable package connections. The growth substrate is then removed. Because the delicate LED layers were bonded to the package substrate while attached to the growth substrate, no intermediate support substrate for the LED layers is needed. The relatively thick LED epitaxial layer that was adjacent the removed growth substrate is then thinned and its top surface processed to incorporate light extraction features. There is very little absorption of light by the thinned epitaxial layer, there is high thermal conductivity to the package because the LED layers are directly bonded to the package substrate without any support substrate therebetween, and there is little electrical resistance between the package and the LED layers so efficiency (light output vs. power input) is high. The light extraction features of the LED layer further improves efficiency.

Owner:LUMILEDS

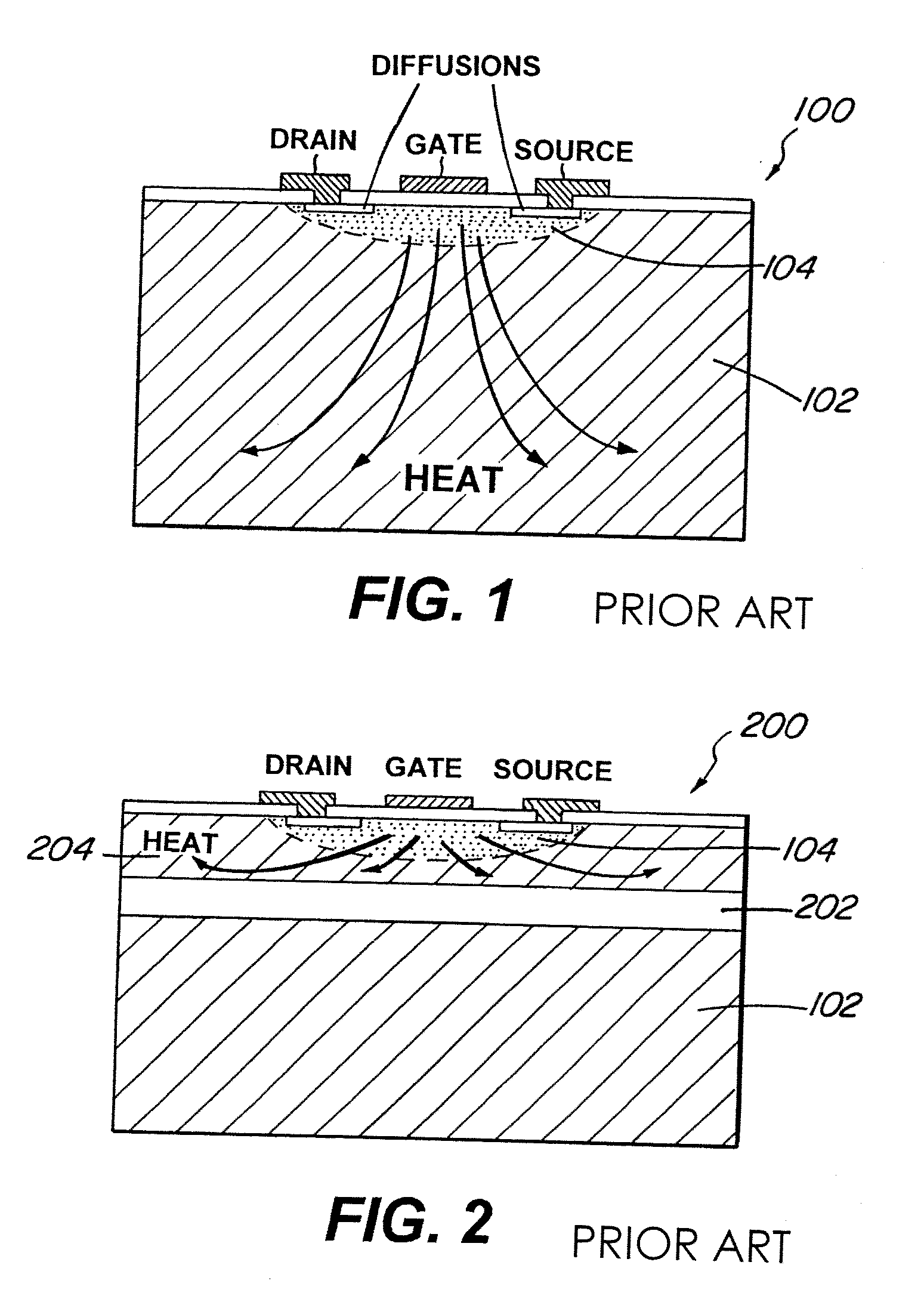

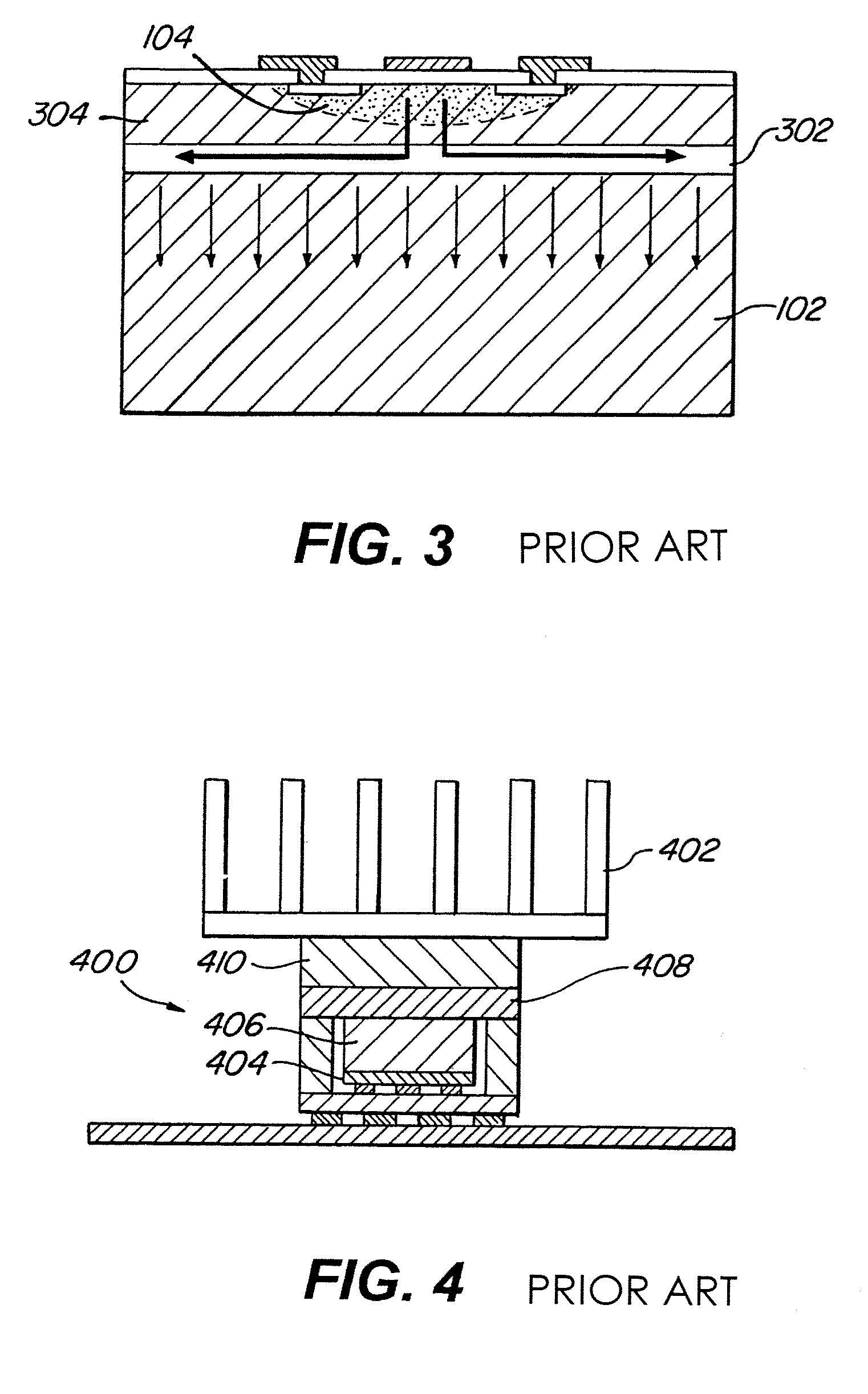

Lateral graphene heat spreaders for electronic and optoelectronic devices and circuits

InactiveUS20100085713A1High thermal conductivityWell thermal managementSemiconductor/solid-state device detailsPrinted circuit aspectsSingle layer grapheneBilayer graphene

Owner:RGT UNIV OF CALIFORNIA

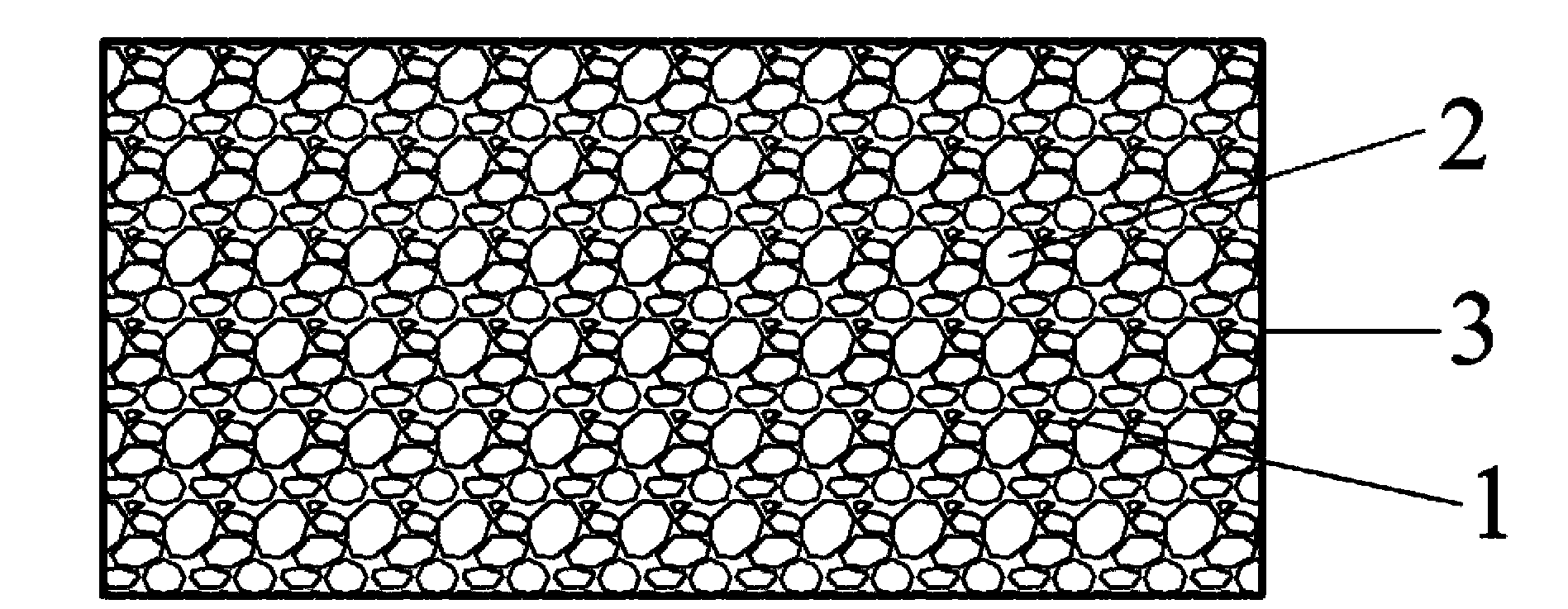

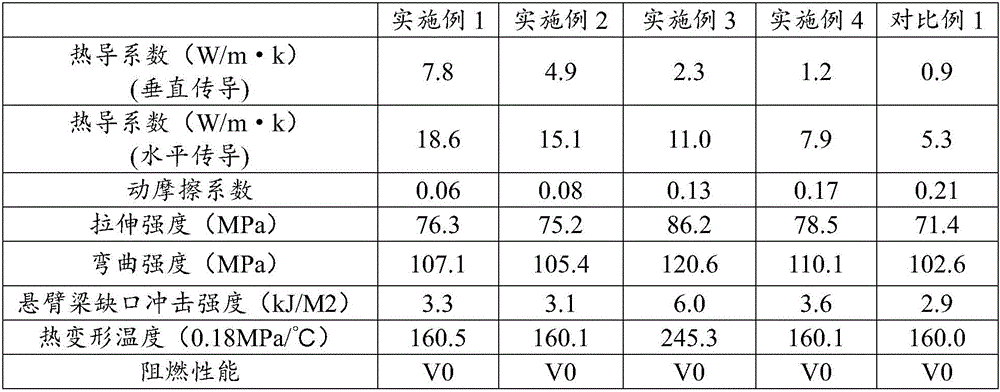

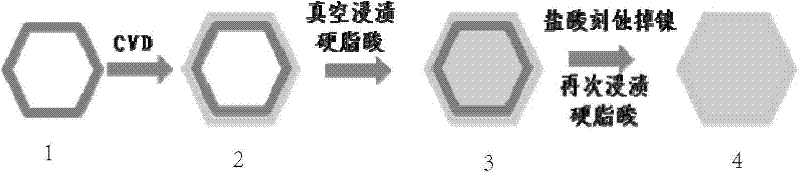

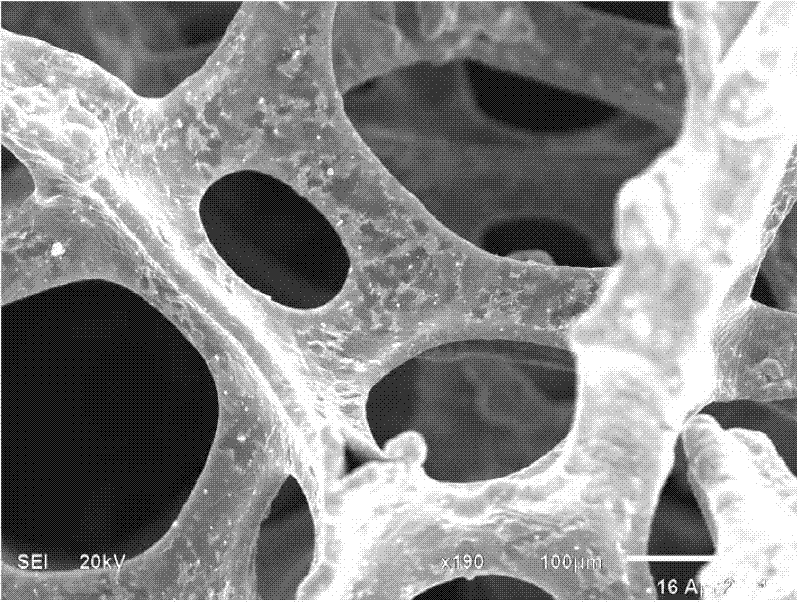

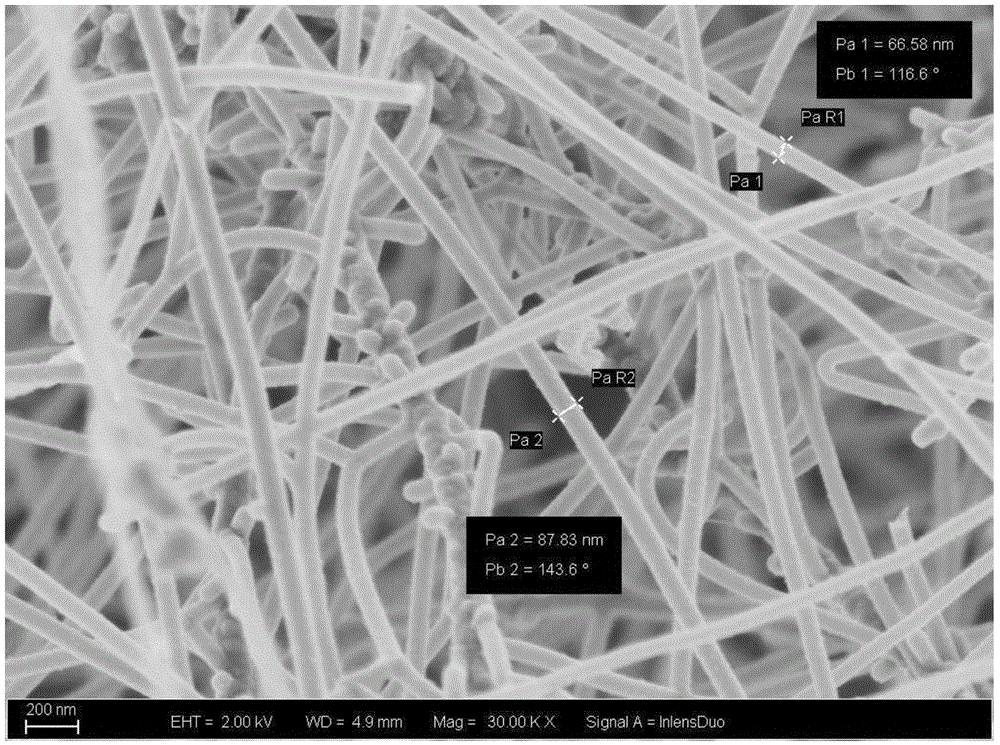

Surface-modification three-dimensional-network-carbon-fiber-reinforced composite material and preparing method

ActiveCN105818476AMitigating Galvanic CorrosionImprove resilienceLamination ancillary operationsLaminationCarbon nanotubeFiber-reinforced composite

The invention discloses a surface-modification three-dimensional-network-carbon-fiber-reinforced composite material and a preparing method.Three-dimensional carbon fiber frameworks with different bore diameters are prepared as required, and after surface pretreatment, diamond, carbon nanometer tubes and graphene are subjected to chemical vapor deposition; then the mixture and matrix materials are compounded, wherein the matrix materials are metal or polymers; the carbon-fiber-reinforced metal-based or polymer-based composite material with the three-dimensional net-shaped framework structure is obtained.A three-dimensional continuous heat conduction channel is formed in the composite material through the surface-modification three-dimensional net-shaped carbon fibers, and therefore the heat conduction performance of the composite material is greatly improved; meanwhile, according to space distribution of carbon fibers in the matrix material, the mechanical performance of the composite material can also be improved, and the density and the thermal expansion coefficient can be decreased; the thermal expansion coefficient, the mechanical performance and the thermal performance can be further regulated and controlled by adding zero-dimensional particle reinforcement.

Owner:CENT SOUTH UNIV

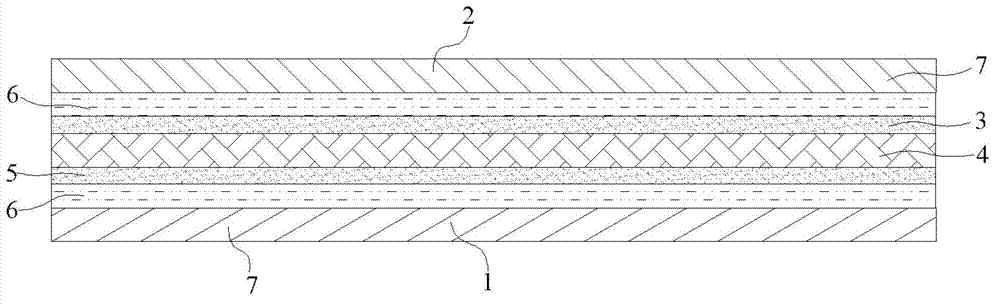

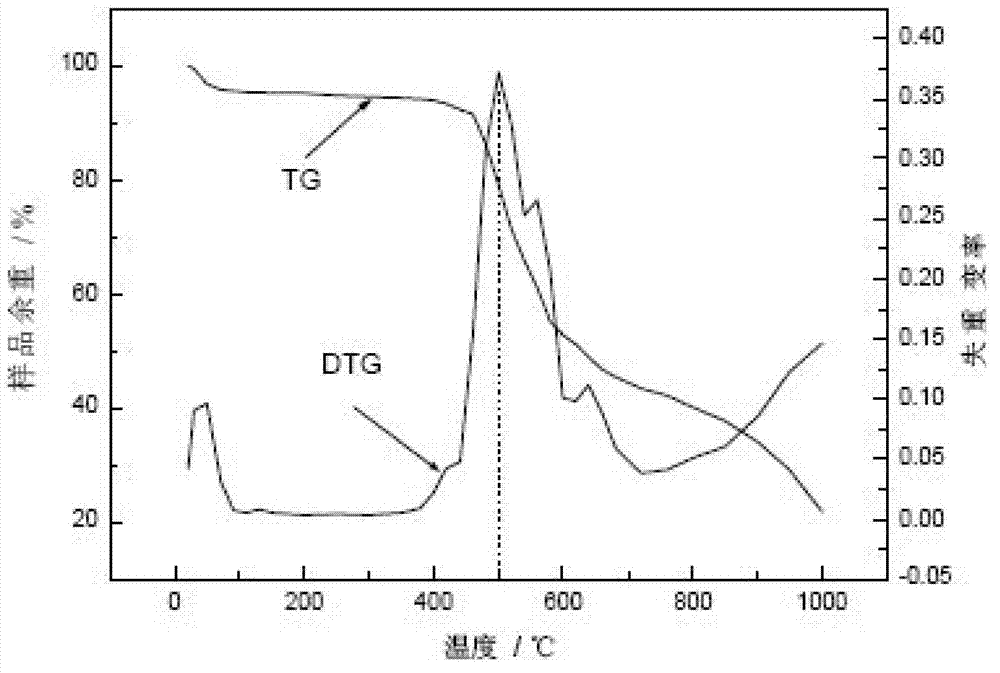

Heat-dissipating double-sided adhesive tape with ultrahigh heat conductivity coefficient

ActiveCN103045119AAvoid local overheatingAchieve uniformityCarbon compoundsFilm/foil adhesivesPolymer sciencePolyamide

The invention discloses a heat-dissipating double-sided adhesive tape with an ultrahigh heat conductivity coefficient. Ethylene glycol or triethylamine is added into a polyamic acid solution, the resulting mixture is put in an oven in a vacuum environment and maintained at 100 DEG C for 0.9-1.1 hours, the temperature is raised to 300 DEG C and maintained for 0.9-1.1 hours, followed by natural cooling, to produce a polyimide film; the polyimide film is heated up to 250 DEG C from room temperature and then heated up to 500 DEG C, and further heated up to 1200 DEG C at a rate of 9-11 DEG C / min, to produce a prefired carbonized film; the prefired carbonized film obtained in the step 4 is rolled by a calendar; the rolled product is heated up to 2400 DEG C at a rate of 19-21 DEG C / min and maintained for 0.9-1.1 hours and then heated up to 2900 DEG C at a rate of 19-21 DEG C / min and maintained for 1.8-2.2 hours, followed by cooling, to produce a fired graphite film; and subsequently the graphite film is rolled to obtain a graphite coating. The heat transfer performance of the double-sided adhesive tape in both the vertical and the horizontal directions are improved, so as to prevent local overheat of the adhesive tape and ensure uniformity of heat transfer performance of the adhesive tape.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

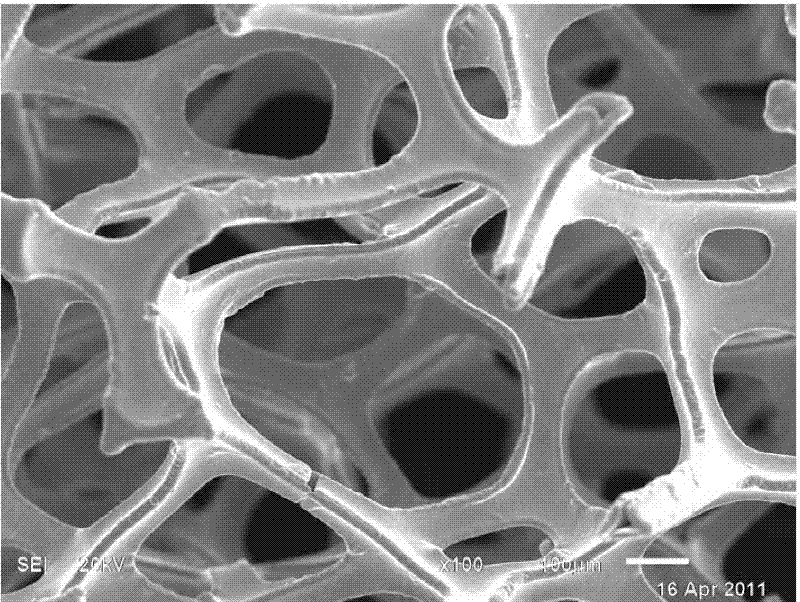

Nanometer cellulose/polyvinyl alcohol gel composite material

ActiveCN102786642ALarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

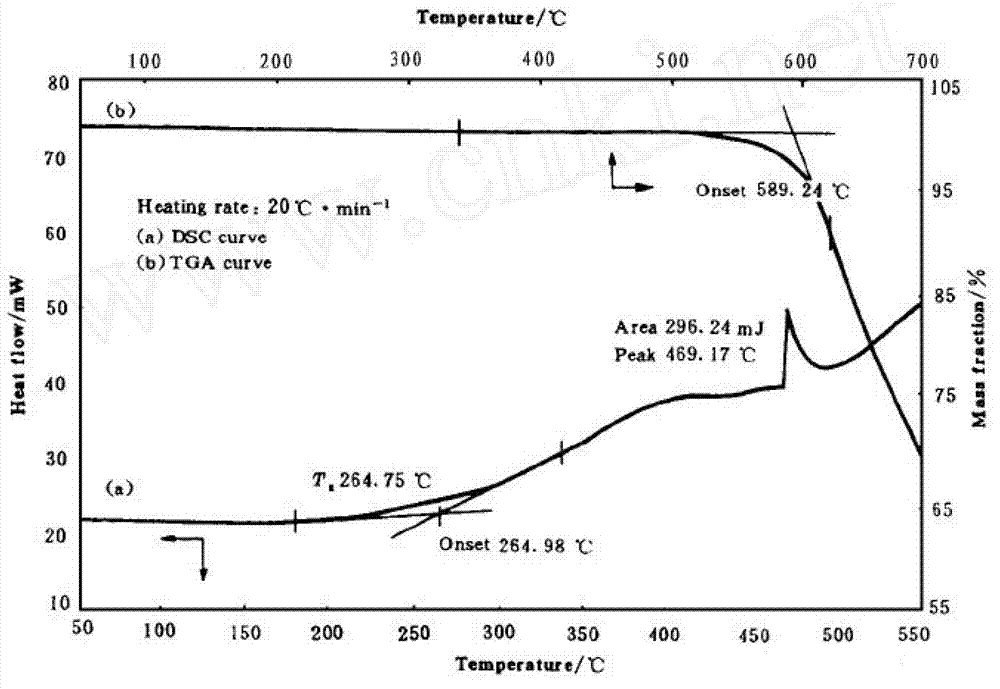

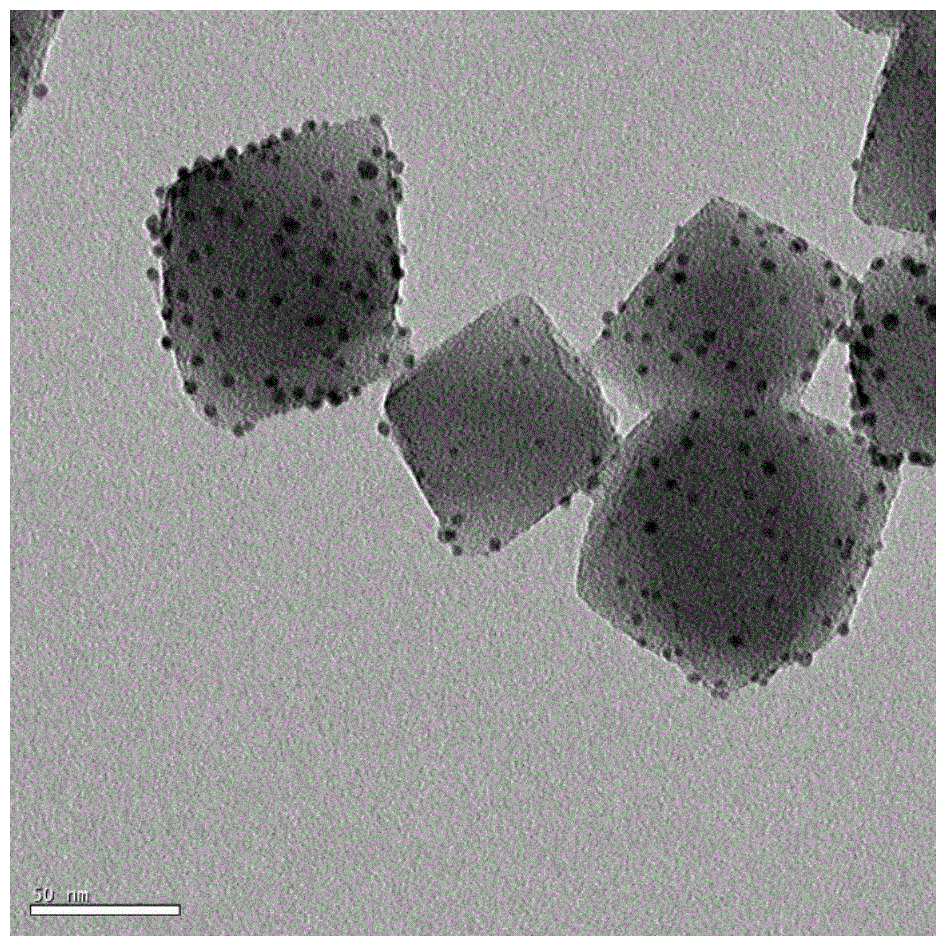

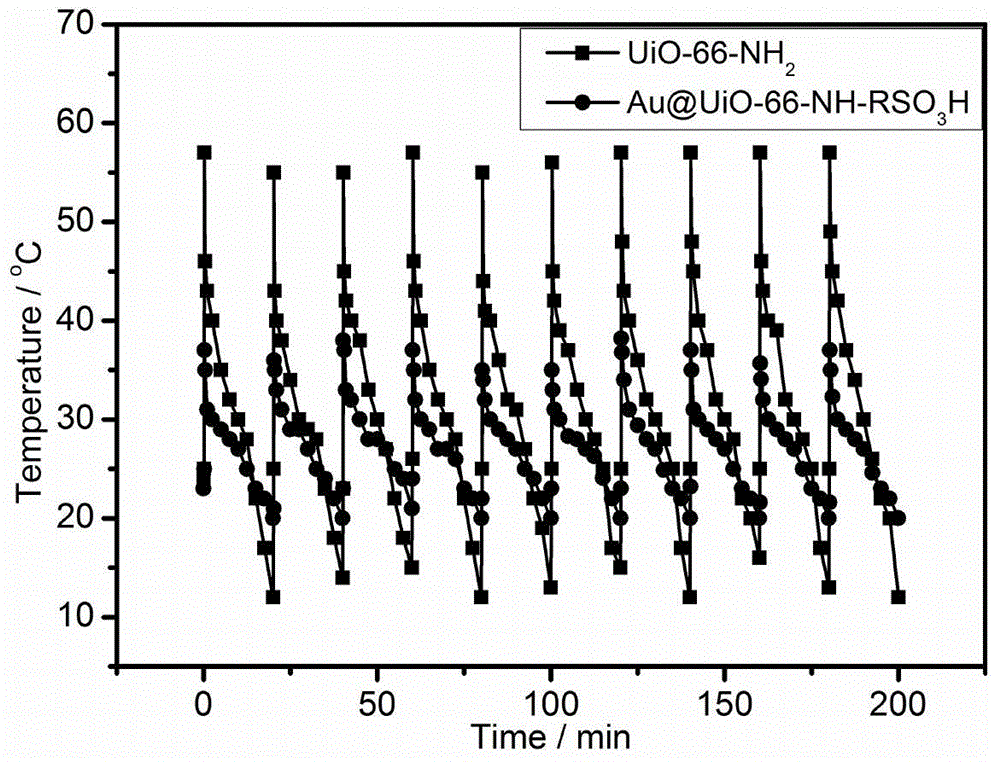

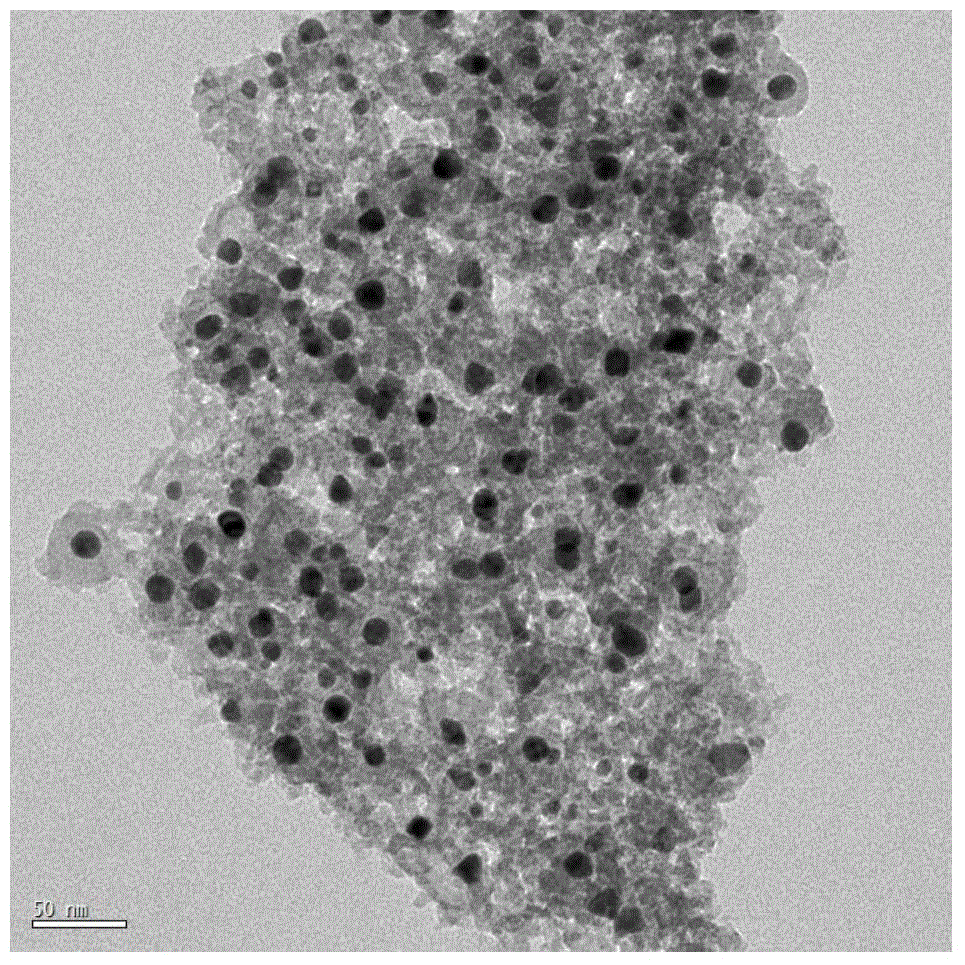

Preparation method of thermal conduction enhanced metal organic framework gas storage material

ActiveCN104624160AImprove adsorption capacityHigh thermal conductivityOther chemical processesGroup 4/14 organic compounds without C-metal linkagesIndustrial gasSorbent

The invention relates to a preparation method of a thermal conduction enhanced metal organic framework gas storage material and belongs to the field of nanocomposites. The preparation method comprises the following steps: firstly selectively preparing a metal organic framework material with a large surface area and a high micropore proportion; performing synthesis post-modification on the metal organic framework material by a 'one-pot' method, regulating the polarity and contained functional groups of pores, immobilizing metal nanoparticles inside the pores to enhance the thermal conduction property of the metal organic framework material; adsorbing industrial gas by utilizing the ultra-large specific surface area and the nano duct structure of the metal organic framework material, wherein the thermal conduction enhanced adsorption material can be used for quickly transmitting the heat generated in the adsorption and desorption process of the industrial gas. The metal organic framework industrial gas adsorber prepared by the invention can be used for efficiently adsorbing and desorbing the industrial gas and effectively improving the thermal conduction property of the adsorber, and avoiding the influence of the heat effect on the adsorption quantity in the adsorption and desorption process. The preparation method provided by the invention has the advantages of use of readily available and inexpensive raw materials, simple process, and mild reaction conditions and is suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

Graphene-containing insulated radiating composition and preparation and application thereof

ActiveCN103804942AHigh thermal conductivityImprove mechanical propertiesCoatingsPigment treatment with organosilicon compoundsHeat conductingGraphene

The invention discloses a graphene-containing insulated radiating composition and preparation and application thereof. The composition comprises the components of silica-coating graphene, insulated heat-conducting filler, a surface treating agent, and a function additive. The preparation method comprises the following steps of: hydrolyzing ethyl silicate on the graphene surface by the sol-gel method to obtain graphene coated with a silica film on the surface; adding the surface treating agent to a mixture of the insulated heat-conducting filler and modified graphene; uniformly agitating; then adding the function additive; and uniformly dispersing to obtain the insulated radiating composition. The composition has the advantages that the graphene is processed by insulating and coating, and the insulated heat-conducting filler and additive of other forms are coordinately added, thus the composition shows high radiating improvement effect in the plastic cement and coating fields; and the composition can be widely applied to a heating element and a radiating facility of various electronic products and electrical equipment, and can greatly improve the radiating effect as well as prolong the service life of devices.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

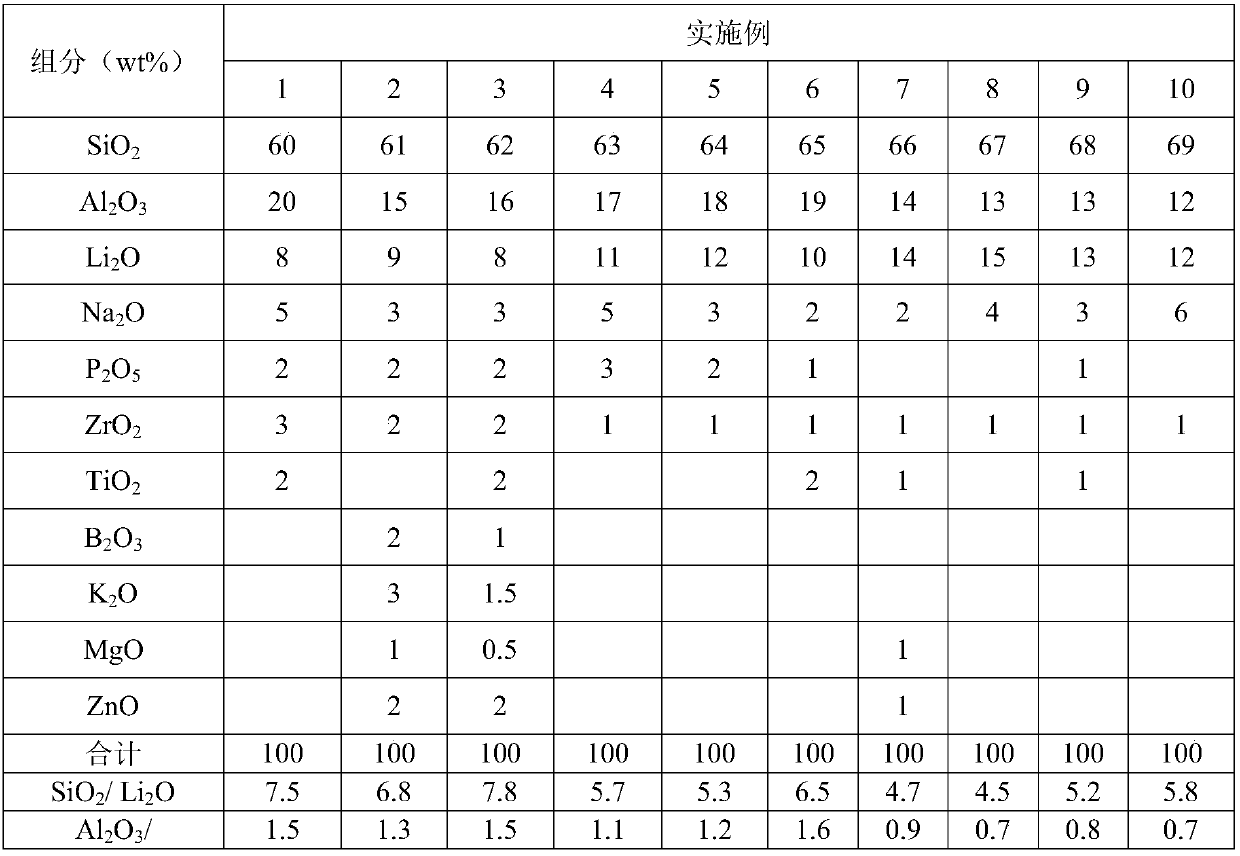

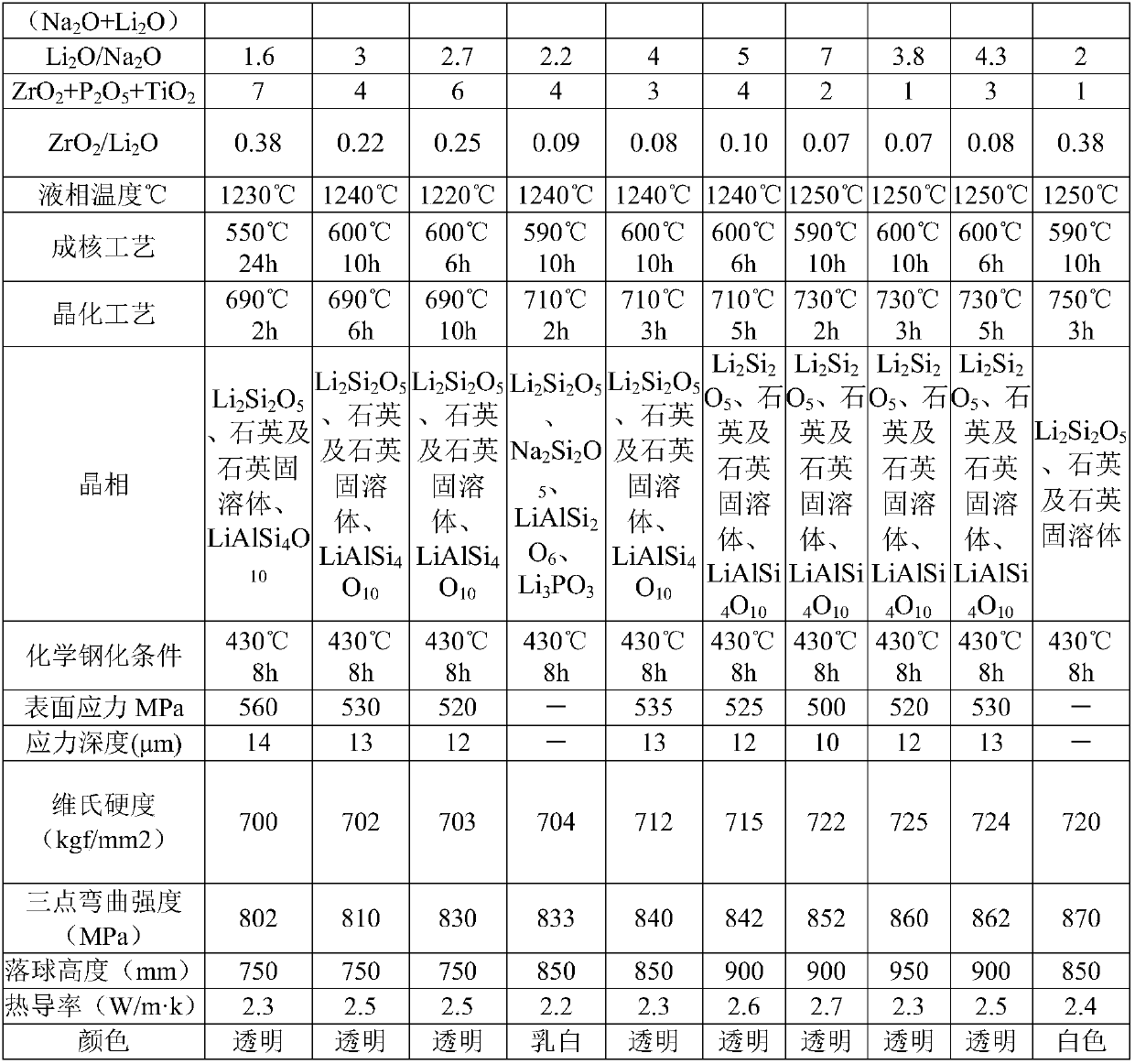

Microcrystalline glass and substrate thereof

The invention provides microcrystalline glass and a substrate thereof. The microcrystalline glass is low in liquidus temperature, and comprises the following components in percentage by weight: 60 to80 percent of SiO2; 4 to 20 percent of Al2O3; 0 to 15 percent of Li2O; greater than 0 and smaller or equal to 12 percent of Na2O; 0 to 5 percent of K2O; greater than 0 and smaller or equal to 5 percent of ZrO2; 0 to 5 percent of P2O5; 0 to 10 percent of TiO2. Crystalline phase contains one or more of R2SiO3, R2Si2O5, R2TiO3, R4Ti5O12, R3PO3, RAlSi2O6, RAlSiO4O10, R2Al2Si2O8, R4Al4Si5O18, quartz and quartz solid solution. The liquidus temperature of the microcrystalline glass is 1450 DEG C or less, the heat conductivity is 2w / m.k or more, the Vickers hardness is 600 kgf / mm<2> or more, and the microcrystalline glass is applicable to portable electronic equipment and optical equipment.

Owner:CDGM OPTICAL GLASS

Composite phase-change thermal storage material

ActiveCN104140786AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

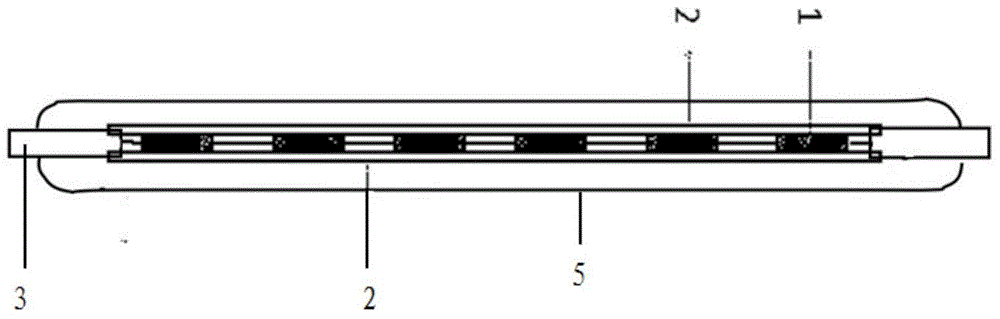

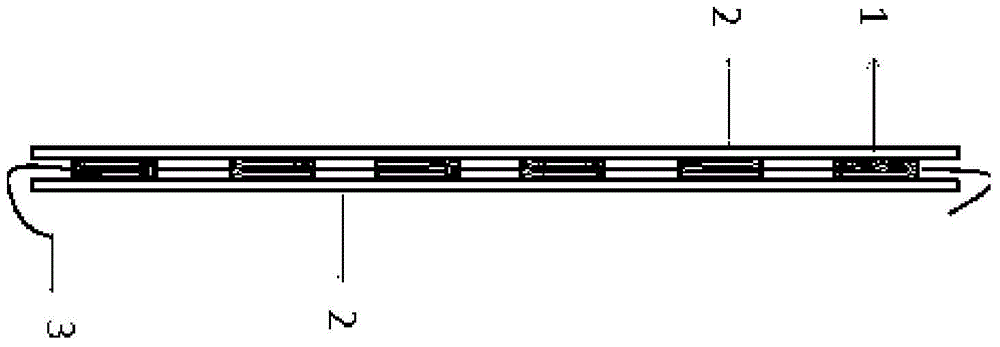

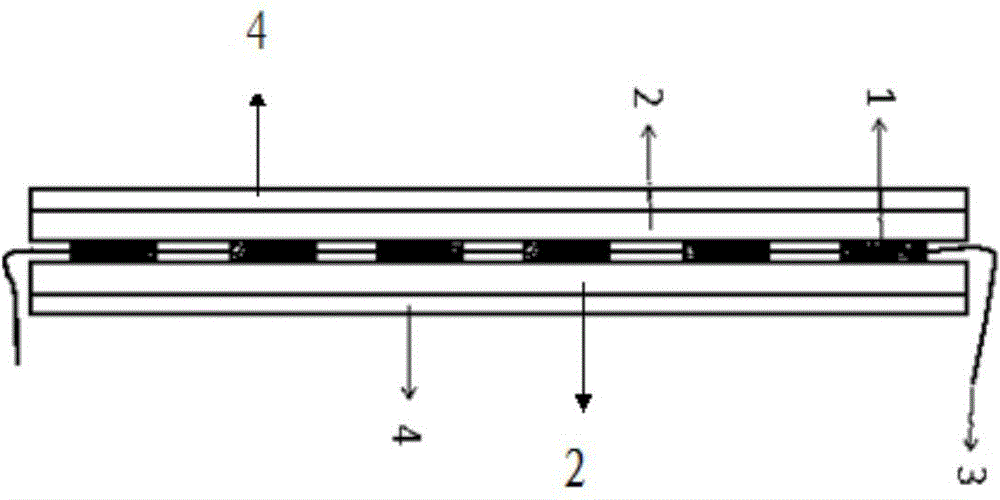

LED lamp based on transparent fluorescent ceramics

InactiveCN103956421AHigh thermal conductivityEfficient and stable light emissionPoint-like light sourceLighting heating/cooling arrangementsPhosphorFluorescence

Disclosed is an LED lamp based on transparent fluorescent ceramics. The LED lamp is composed of LED lamp filaments, electrode leads and a lampshade and is characterized in that the strip-shaped transparent fluorescent ceramics serve as the substrate of the LED lamp filaments, the width of the transparent fluorescent ceramics is equal to that of LED chips, then the blue LED chips (including leads) are sequentially fixed to the transparent fluorescent ceramic battens in an adhering mode, and identical transparent fluorescent ceramic strips adhere to the other sides of the LED chips or the other sides of the LED chips are coated with fluorescent optical cement. The transparent fluorescent ceramics can be Ce : YAG (including the situation when Ce ion concentration is zero), or Ce : Tb3Al5O12, or Ce, Cr : YAG, or Ce, Pr : YAG, or Ce : YAG+MgAl2O4, or Ce, Pr : YAG+MgAl2O4, or Ce, Cr : YAG +MgAl2O4. According to the LED lamp based on the transparent fluorescent ceramics, luminous decay of a fluorescent powder silica gel resin mixture phosphor can be effectively avoided, the performance of the LED lamp can be improved, and the service life of the LED lamp can be prolonged.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Heat-conducting nylon composite material, preparation method and application thereof

The invention provides a heat-conducting nylon composite material, a preparation method and application thereof. The formula comprises the components in parts by weight of 20.0-80.0 parts of PA66 and / or PA6, and 15.0-75.0 parts of thermal conductive filler, wherein the heat-conducting coefficient of the thermal conductive filler is 5W / m.k-900W / m.k. The preparation method comprises the steps of a) stirring and mixing the thermal conductive filler and carrying out surface modification; b) mixing and extruding the mixed material on an extruder, wherein the temperature is 220-265 DEG C; and c) obtaining the heat-conducting nylon composite material from the material by extruding, pelletizing and drying. The material is applied to the fields of a radiating material of a light-emitting diode (LED) lamp housing, or a low-voltage apparatus and an electronic radiating element.

Owner:BENSONG ENG PLASTICS HANGZHOU

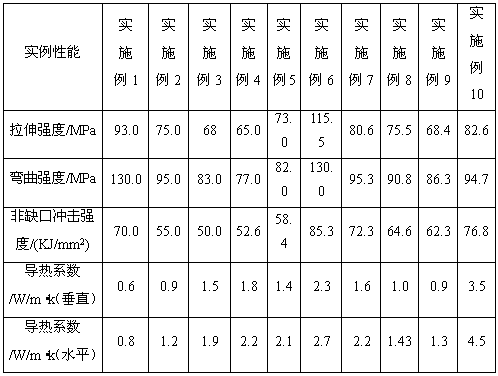

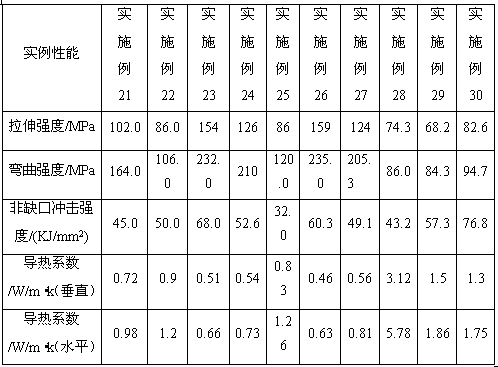

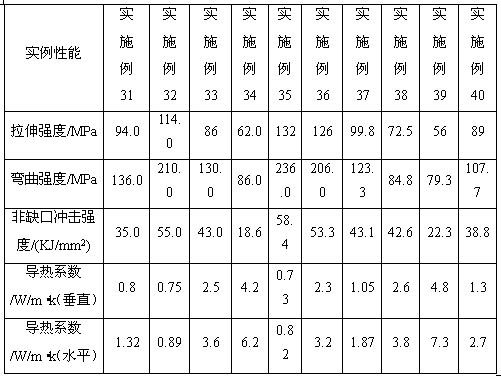

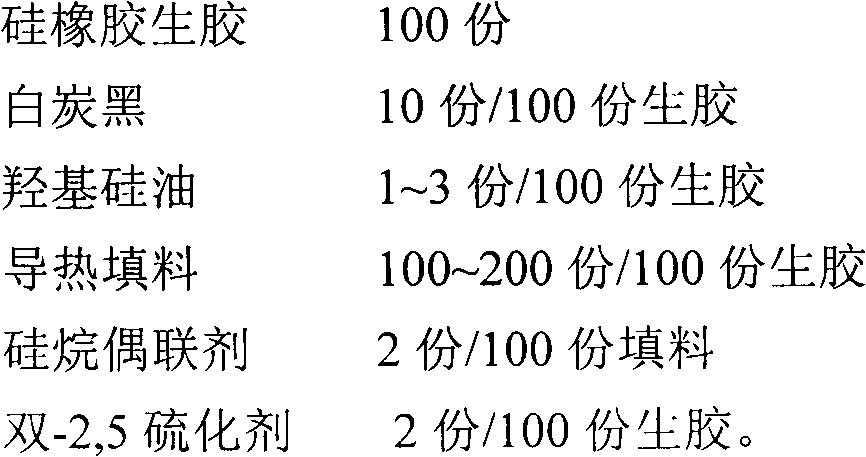

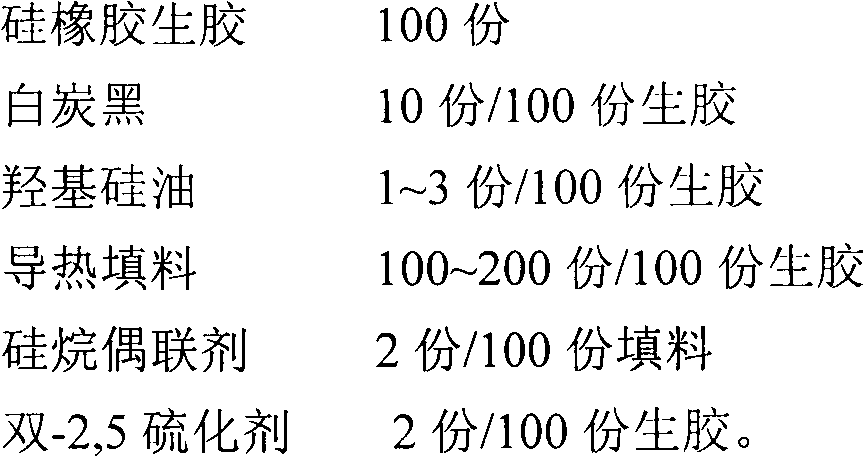

Mixed filling type thermal conductive silicone rubber composite and preparation method thereof

InactiveCN102220006APacked tightlyHigh thermal conductivityHeat-exchange elementsPolymer scienceVulcanization

The invention discloses a preparation method of a mixed filling type thermal conductive silicone rubber composite. Raw materials comprises the following components, by mass, 100 parts of raw silicone rubber, 10 parts of white carbon black, 1 to 3 parts of hydroxy silicone oil, 100 to 200 parts of a thermal conductive filler, 2 to 4 parts of a silane coupling agent and 2 parts of a di-2,5-vulanizator. The preparation method comprises the following steps: adding raw silicone rubber to a double roller mill; adding white carbon black, the thermal conductive filler, the silane coupling agent and hydroxy silicone oil according to a formula design after roller packaging; adding a peroxide vulcanizer after repeatedly and uniformly mixing; mixing uniformly to obtain mixed silicone rubber; putting in a die and carrying out first-stage vulcanization after cold pressing mold filling; and putting a molded sample in an air blasting drier and carrying out second-stage vulcanization to obtain a finished product. In the present invention, mixed particles of SiC and AlN are employed to fill high temperature vulcanized silicon rubber, effective thermal conductive net chains are formed in silicone rubber matrixes, so the obtained heat-conducting silicone rubber composite material has a good heat conducting performance.

Owner:TIANJIN UNIV

Graphene nylon composite material and preparation method thereof

The invention relates to a graphene nylon composite material and a preparation method thereof. The graphene nylon composite material comprises, by mass, 30%-85% of nylon, 1%-25% of graphene, 0.5%-4% of a wear-proof agent, 5%-45% of heat conduction filler, 1%-15% of a lubrication dispersing agent and additives including at least one of 15%-45% of a reinforcing agent, 2%-25% of a toughening agent, 5%-30% of a fire retardant and 0.02%-8% of auxiliaries. Due to addition of graphene, the graphene nylon composite material is excellent in abrasion resistance and heat conductivity.

Owner:NINGBO MORSH TECH

Three-dimensional graphene/phase change energy storage composite material and preparation method thereof

InactiveCN102585776AImprove thermal conductivityLow densityHeat-exchange elementsPorous grapheneLiquid state

The invention provides a three-dimensional graphene / phase change energy storage composite material and a preparation method thereof. The technical scheme is as follows: graphene and a phase change energy storage material are in situ compounded, wherein porous graphene with a three-dimensional structure is used as a heat conductor and a compound die, and a solid-liquid phase change organic material is used as the energy storage material and filler. The three-dimensional porous graphene is compounded with the phase change material, the phase change energy storage material is partitioned in a plurality of pore spaces and is in tight joint with the graphene wall so as to greatly increase the effective heat contact area, and the highly linked graphene three-dimensional heat conduction network channels can realize rapid system heat exchange. In addition, due to the capillary adsorption capacity of porous graphene, the liquid-state phase change energy storage material is localized, so as to effectively prevent seepage. Therefore, the three-dimensional graphene foam has good designability, and becomes a lighter and more effective heat dissipation material for electronic devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

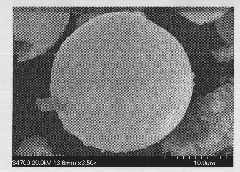

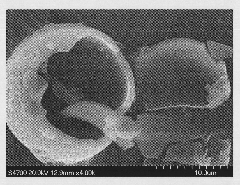

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

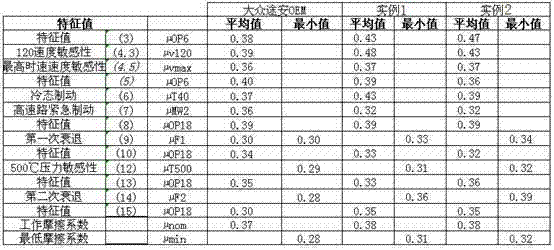

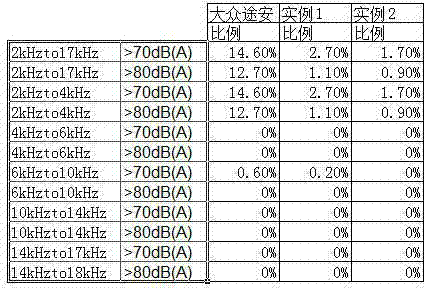

Environmental ceramic base friction material free of copper or metal and preparation method of material

InactiveCN103881657AGood mechanical skeleton performanceStable coefficient of frictionOther chemical processesFriction liningSulfurMetallic sulfide

The invention discloses an environmental ceramic base friction material free of copper or metal and a preparation method of the material. The environmental ceramic base friction material is characterized by comprising the following components by weight percent: 6-12% of phenolic resin, 2-10% of ceramic fiber, 2-8% of inorganic fiber, 2-10% of rubber, 4-12% of graphite, 10-25% of potassium titanate lamella, 3-15% of mineral fiber, 4-20% of metal sulfur compound, 6-20% of grinding aid and 5-20% of filler. The prepared friction material has excellent friction and wear properties, high heat-conducting property, excellent high-temperature decline property, stable friction coefficient, and excellent noise performance.

Owner:YANTAI SHENGRUI BRAKE SYST

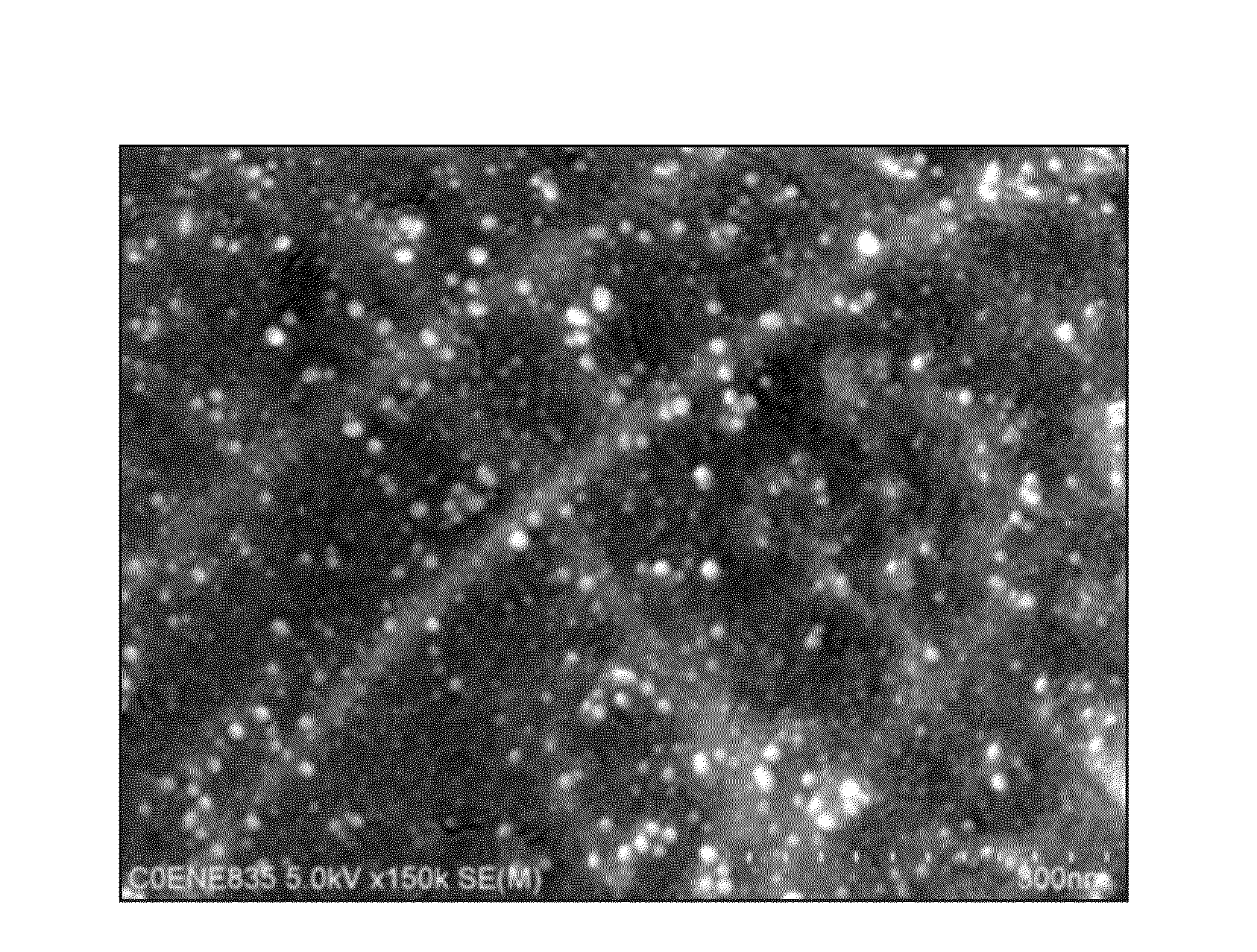

Property enhancing fillers for transparent coatings and transparent conductive films

PendingUS20160096967A1High thermal conductivityLowering of transmission of visible lightFilm/foil adhesivesCellulose coatingsElectrically conductiveThermal conductivity

Optically transparent films can comprise a coating of nanodiamonds to introduce desirable properties, such as hardness, good thermal conductivity and an increased dielectric constant. In general, transparent conductive films can be formed with desirable property enhancing nanoparticles included in a transparent conductive layer and / or in a coating layer. Property enhancing nanoparticles can be formed from materials having a large hardness parameter, a large thermal conductivity and / or a large dielectric constant. Suitable polymers are incorporated as a binder in the layers with the property enhancing nanoparticles. The coatings with property enhancing nanoparticles can be solution coated and corresponding solutions are described.

Owner:C3 NANO INC

Graphene radiating apparatus and preparation method therefor

ActiveCN105722375AHigh thermal conductivitySimple preparation processSynthetic resin layered productsGraphenePorous grapheneOptoelectronics

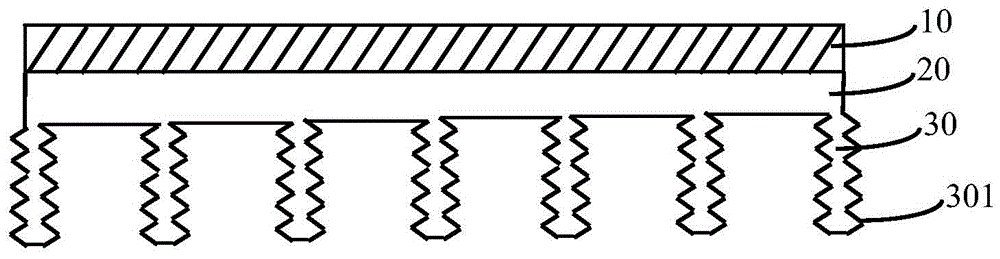

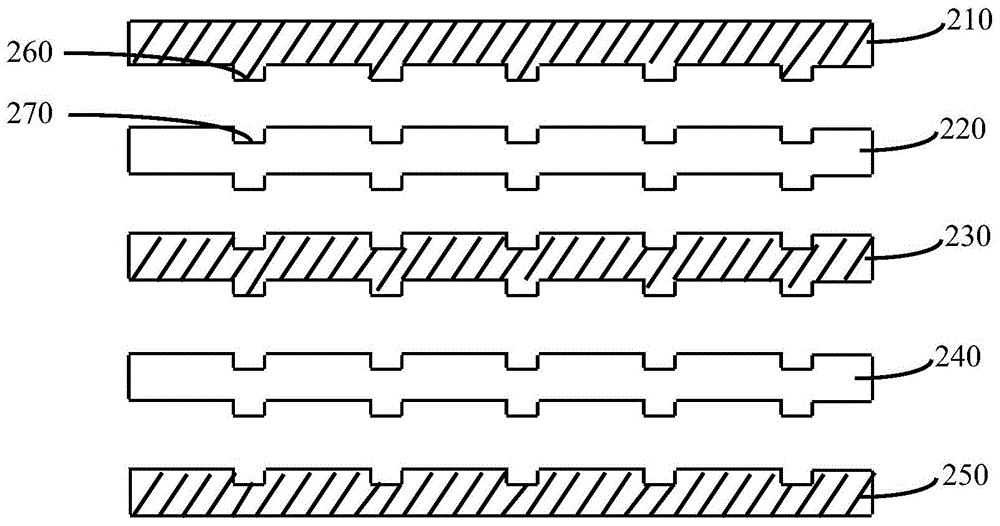

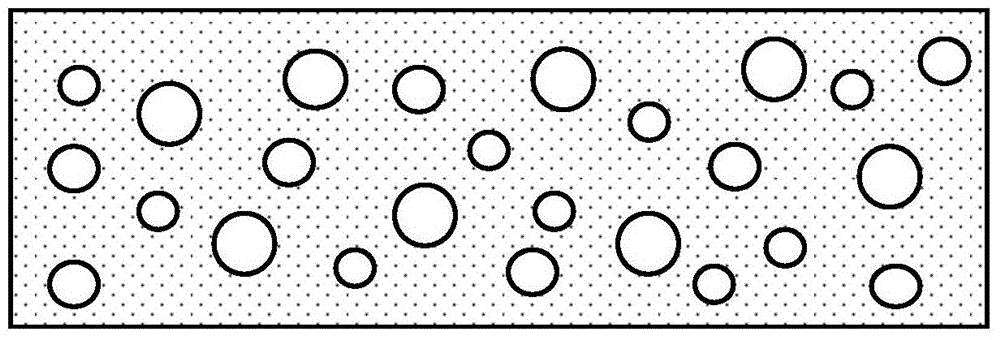

The invention relates to a graphene radiating apparatus. The radiating apparatus comprises a first radiating layer (10) and a substrate (20), wherein the substrate (20) adopts a two-dimensional or three-dimensional structure and is provided with a first surface and a second surface opposite to the first surface, wherein the radiating layer (10) arranged on the first surface is formed by porous graphene, at least one kind of polymer and / or a compound formed by polymer monomers; and a multi-layer structure at least including a first film layer (210), a second film layer (220), a third film layer (230), a fourth film layer (240) and a fifth film layer (250) is arranged on the second surface. The invention also relates to a preparation method for the graphene radiating apparatus. The graphene radiating apparatus provided by the invention has the advantages of simple structure, high thermal conductivity and thermal dissipation, and wide application range.

Owner:白德旭

Carbon composite high-thermal-conductivity plastic material and preparation method thereof

The invention discloses a carbon composite high-performance thermal-conductive plastic and a preparation method thereof; the thermal-conductive insulating plastic is prepared from a resin basic material, a carbon composite material, a thermal-conductive agent, a coupling agent, an antioxidant and other processing agents; by means of the special crystalline structure of the carbon composite material added in the formula of the thermal-conductive insulating plastic disclosed by the invention, the inter-particle bridging effect is realized; a thermal-conductive passage composed of the thermal-conductive agent is more and more perfect; therefore, the thermal conductivity of the composite material can be rapidly increased; a filling material gathering and thermal-conductive passage is more and more perfect; simultaneously, with the help of the processes, such as a pre-mixing process, an extrusion process, a cooling process, an air drying process and a granulating process, the problems of being degraded in high filling property and low in thermal-conductive property of the plastic are solved; the thermal-conductive composite material having excellent mechanical property and good thermal-conductive effect and insulating property can be prepared; and the thermal-conductive composite material can be widely applied in the fields, such as electrons, automobiles and LED (Light Emitting Diode) lamps.

Owner:HUIZHOU KINGBALI TECH

Vermicular graphite cast iron for producing brake drum of high-speed and heavy-load automobile

The invention discloses alloyed vermicular graphite cast iron produced by alloying the ordinary vermicular graphite cast iron. The cast iron comprises an alloy of two or more of elements such as Cu, Cr, Mo, Ni, Sn, Sb, B, Ti, Al, V and the like. The vermicular graphite cast iron comprises the following chemical ingredients in percentage by weight: 3.00-3.80 percent of C, 2.00-2.80 percent of Si, 0.45-0.95 percent of Mn, less than 0.06 percent of P, less than or equal to 0.02 percent of S, and 0.02-0.60 percent of alloy ingredient. The technical indexes of the vermicular graphite cast iron are that: VG is more than or equal to 80 percent, Rm is more than or equal to 380 MPa, hardness is between 180 HBW and 258 HBW, cast pearlite is more than or equal to 60 percent, and elongation rate is between 1 percent and 2 percent. The vermicular graphite cast iron has the advantages of high intensity, high heat conductivity, high wear resistance, high thermal fatigue resistance, small deformation, simple casting process and easiness in mechanical production. The service life of a produced brake drum for a high-speed and heavy-load automobile is remarkably prolonged, and safety is ensured.

Owner:罗云

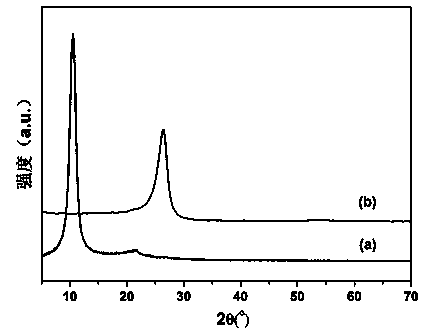

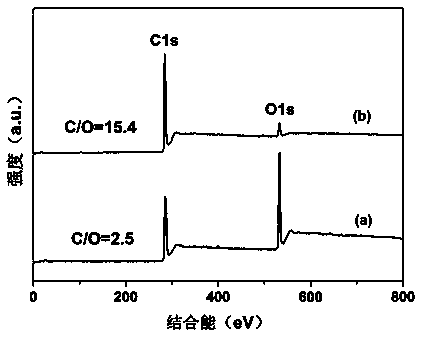

Preparation method of reduction graphene oxide heat-conducting film

InactiveCN104030275AHigh thermal conductivityOvercome fragileGraphenePhysical chemistryThin membrane

The invention relates to a preparation method of a reduction graphene oxide heat-conducting film. The preparation method comprises the following steps of: firstly weighing graphite oxide, adding the graphite oxide to deionized water, and carrying out ultrasonography, centrifugalizing at low speed for impurity removal, drying and grinding to obtain graphene oxide; dissolving the graphene oxide into a solvent, and carrying out the ultrasonography to prepare a graphene oxide dispersion solution; carrying out vacuum filtration on the graphene oxide dispersion solution by adopting a microporous filtering film, drying an obtained filter cake and the filtering film together, and then stripping the filter cake from the filtering film to obtain a graphene oxide film; acquiring the reduction graphene oxide heat-conducting film by adopting a high-temperature heat treatment or hydriodic acid reduction method in a restricted space. The preparation method disclosed by the invention effectively solves the technical problems of easiness for breakage and difficulty in large-area integrity keeping in preparing the reduction graphene oxide heat-conducting film from the graphene oxide film and is simple and higher in film heat conductivity; the prepared reduction graphene oxide heat-conducting film achieves potential practical application value in the field of heat radiation of a microelectronic device.

Owner:SHANGHAI INST OF TECH

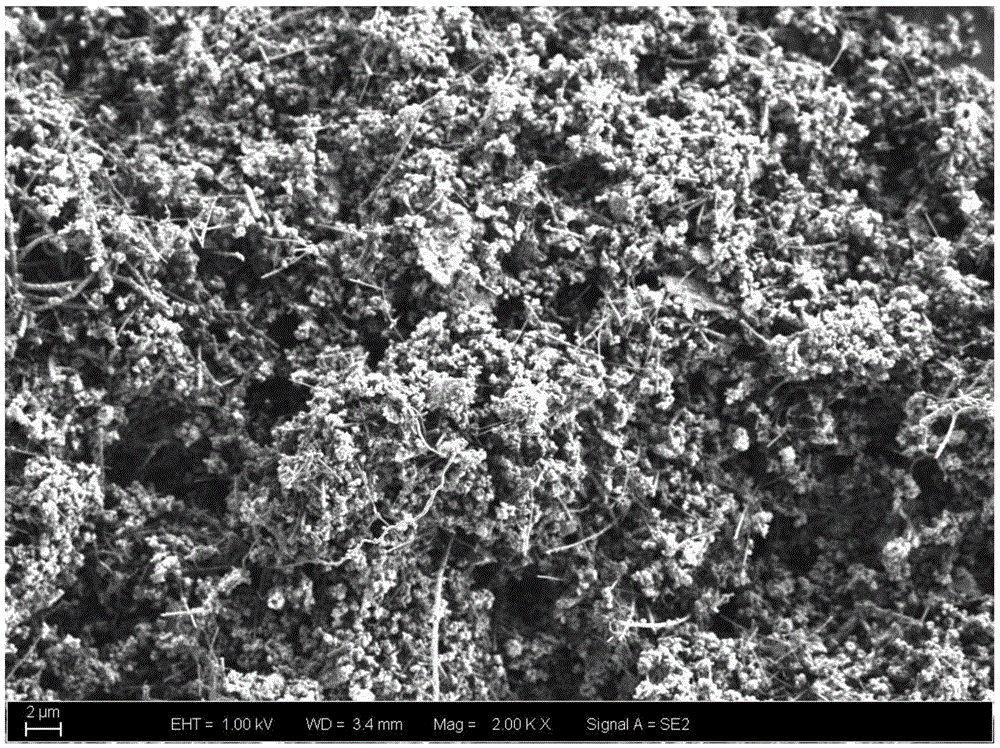

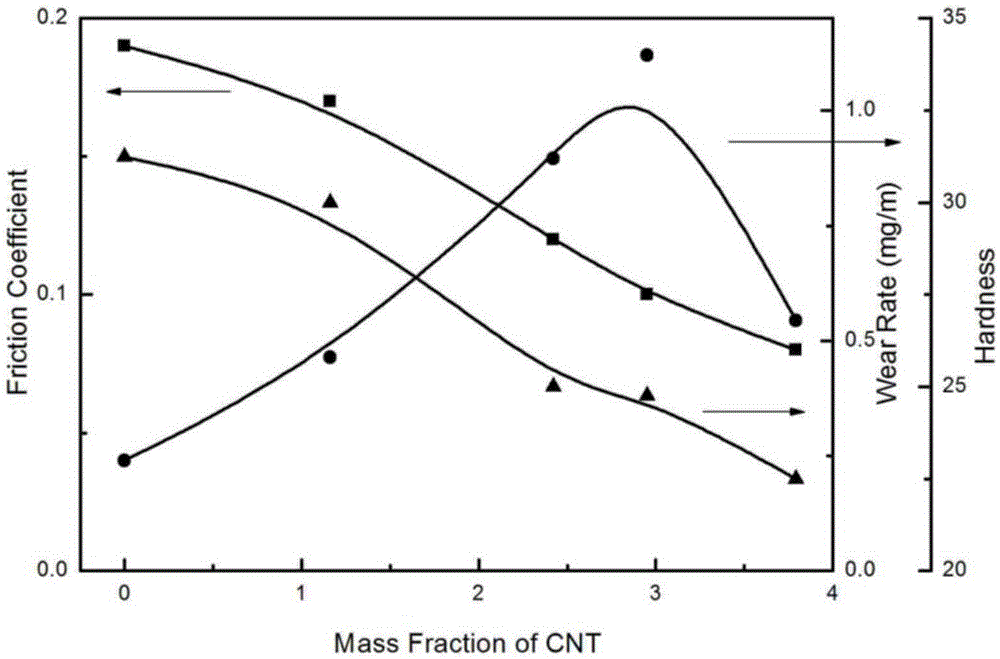

Nano-carbon-reinforced wear-resistant composite material

The invention belongs to the technical field of materials, and specifically relates to a nano-carbon-reinforced wear-resistant composite material. The nano-carbon-reinforced wear-resistant composite material comprises the following components in percentage by mass: 55-99% of metal powder, 0.1-35% of ceramic powder, and 0.01-15% of nano-carbon, wherein the metal powder is used as a composite material matrix; the ceramic powder is used as a wear-resistant filling material; and the nano-carbon comprises single-wall carbon nano-tubes, multi-wall carbon nano-tubes and other materials, and is mainly used for improving the heat-conducting performance, strength, toughness, wear resistance and other performances of the composite material. The wear-resistant composite material disclosed by the invention can keep a stable friction coefficient and a low wear rate under the conditions of a heavy load, a high speed, and long-time braking.

Owner:SUZHOU FIRST ELEMENT NANO TECH

Ethylene-vinyl acetate copolymer adhesive film for packaging solar energy battery and preparation method thereof

InactiveCN101240157AImproves UV resistanceImprove thermal conductivityOther chemical processesFilm/foil adhesivesAcetic acidPolymer science

The invention discloses an ethylene-acetic acid polymer rubber film for solar energy battery packaging and preparation method thereof. The rubber film is composed of ethylene-acetic acid polymer granular materials, solidifier, heat-conducting filler, antioxidant, UV stabilizer, and coupling agent according to certain mass parts; the preparation method is: 1, mixing heat-conducting filler and coupling agent, drying and dispersing the mixture by grinding, to obtain active heat-conducting filer; 2, mixing ethylene-acetic acid polymer granular materials and solidifier; 3, mixing antioxidant, UV stabilizer and said active heat-conducting filler; 4, adding mixture of said step 3 into mixture of step 2, mixing the mixture and extruding the mixture, casting, cooling, towing, coiling the extrusion, obtain rubber film of the invention. Compared with current products, the rubber film of the invention has a higher heat-conducting coefficient which is increased by more than 3 times, and properties of improved photo-electric conversion ratio of solar energy battery, and prolonged useful life.

Owner:HOHAI UNIV

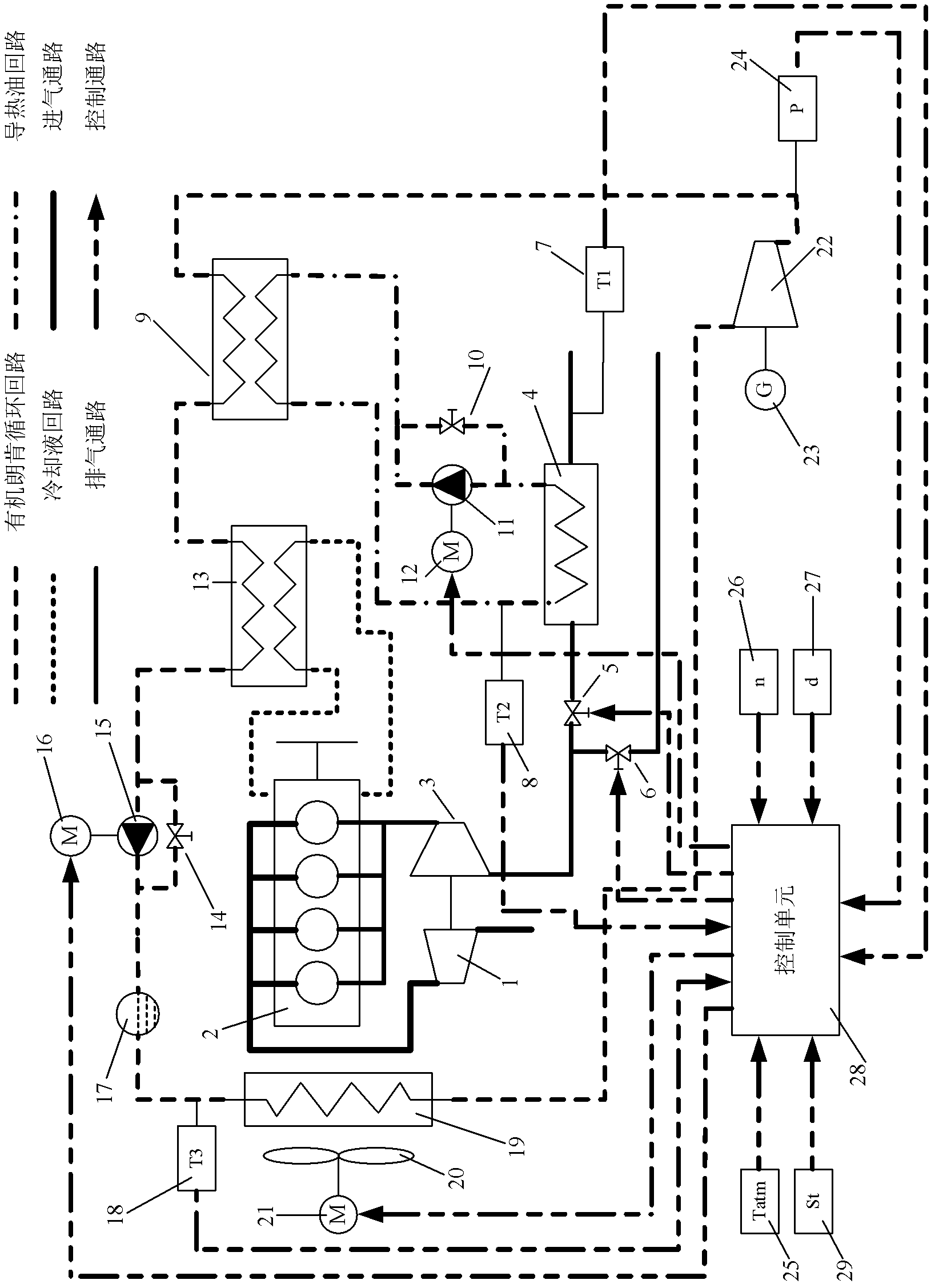

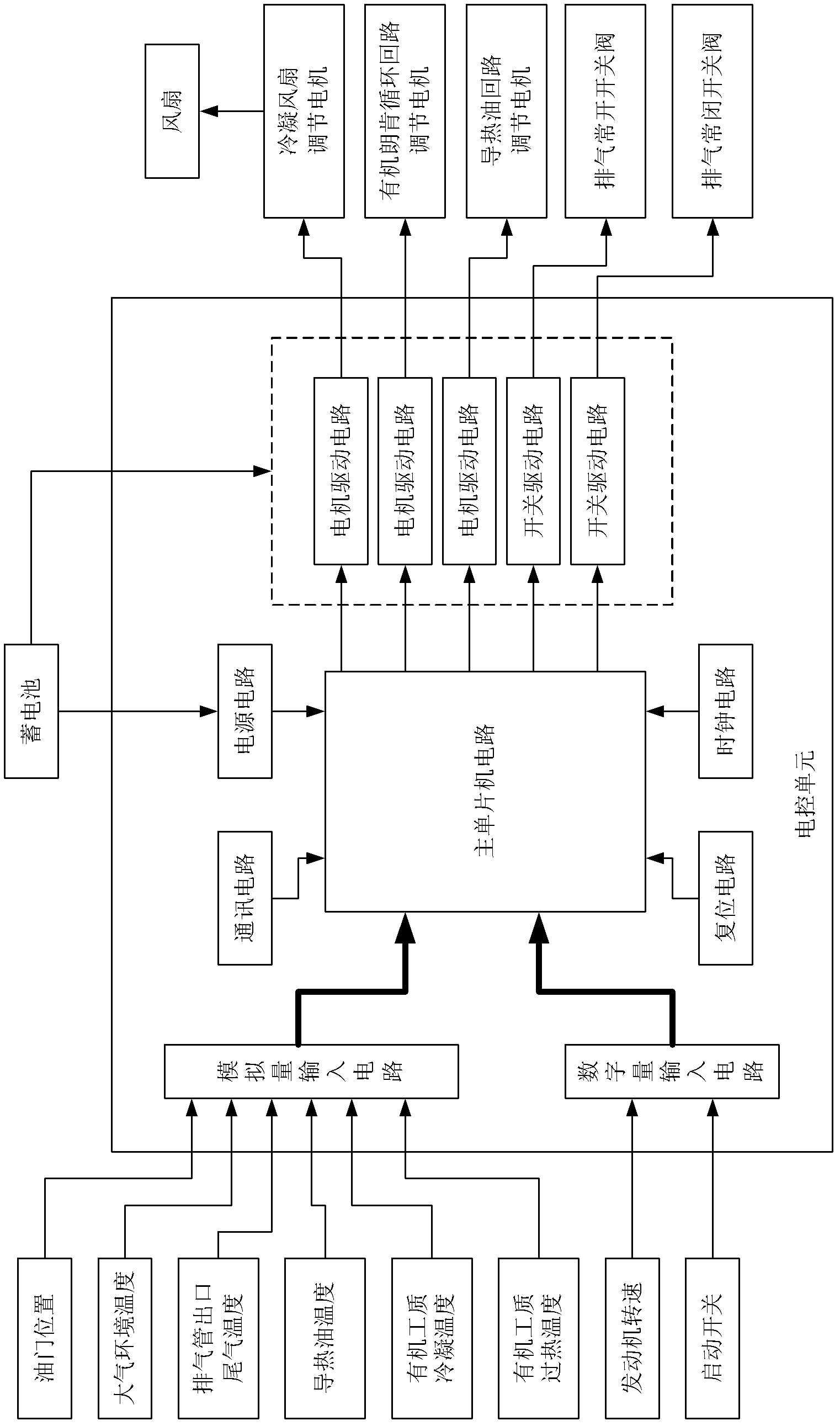

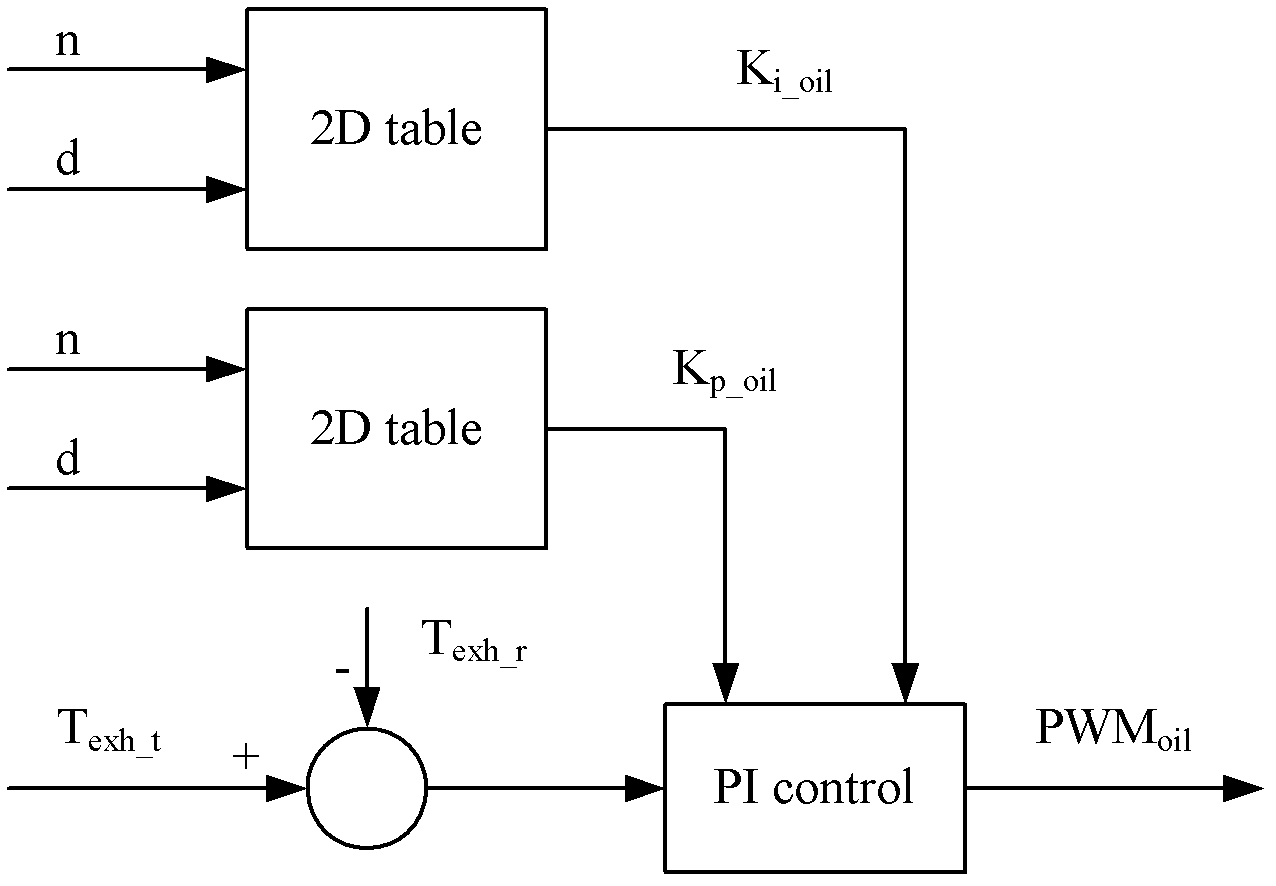

Power generation system using exhausting and cooling waste heat in internal combustion engine at the same time and control method therefor

InactiveCN102619641AHigh thermal conductivityReduce heat transfer area and volumeCoolant flow controlInternal combustion piston enginesDynamoHeating efficiency

The invention discloses a power generation system using exhausting and cooling waste heat in an internal combustion engine at the same time and a control method therefor. The control method comprises the steps as follows: transferring waste heat in the cooling liquid of the internal combustion engine to an organic working medium by using a preheater in an organic Rankine cycle loop; transferring waste heat taken away by the exhaust gas of the internal combustion engine to the working medium of the organic Rankine cycle loop by using a heat-conducting oil loop; evaporating and gasifying the working medium; transforming enthalpy change in a high-enthalpy expansion process into useful work for outputting by using a single-screw expansion machine; driving a power generator to generate power; taking the tail gas temperature of an exhaust pipe outlet as feedback quantity for realizing the flow closed-loop control of the heat-conducting oil; taking the inlet working medium temperature of the single-screw expansion machine as feedback quantity for realizing the flow closed-loop control of the organic working medium; and taking the outlet working medium temperature of a condenser as feedback quantity for realizing the closed-loop control of the fan motor of the condenser. According to the invention, the flow quantities of the working mediums of the organic Rankine cycle loop and the heat-conducting oil loop are adjusted by using the segmented PI (Proportion Integration) control, so that the waste heat in the internal combustion engine is made the best of, the heat efficiency of the internal combustion engine is improved, and the hazard of the exhaust gas on the environment is reduced.

Owner:BEIJING UNIV OF TECH

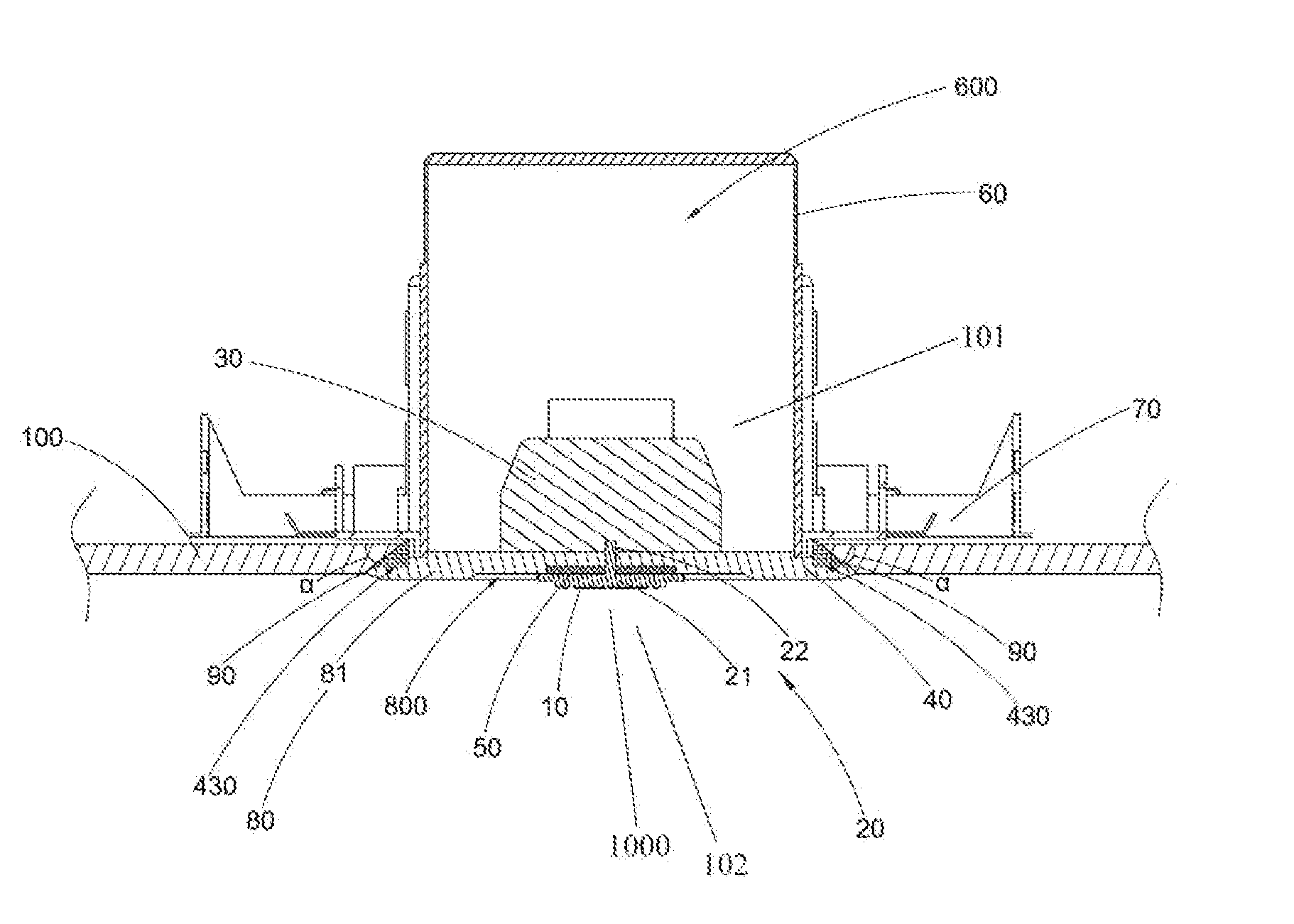

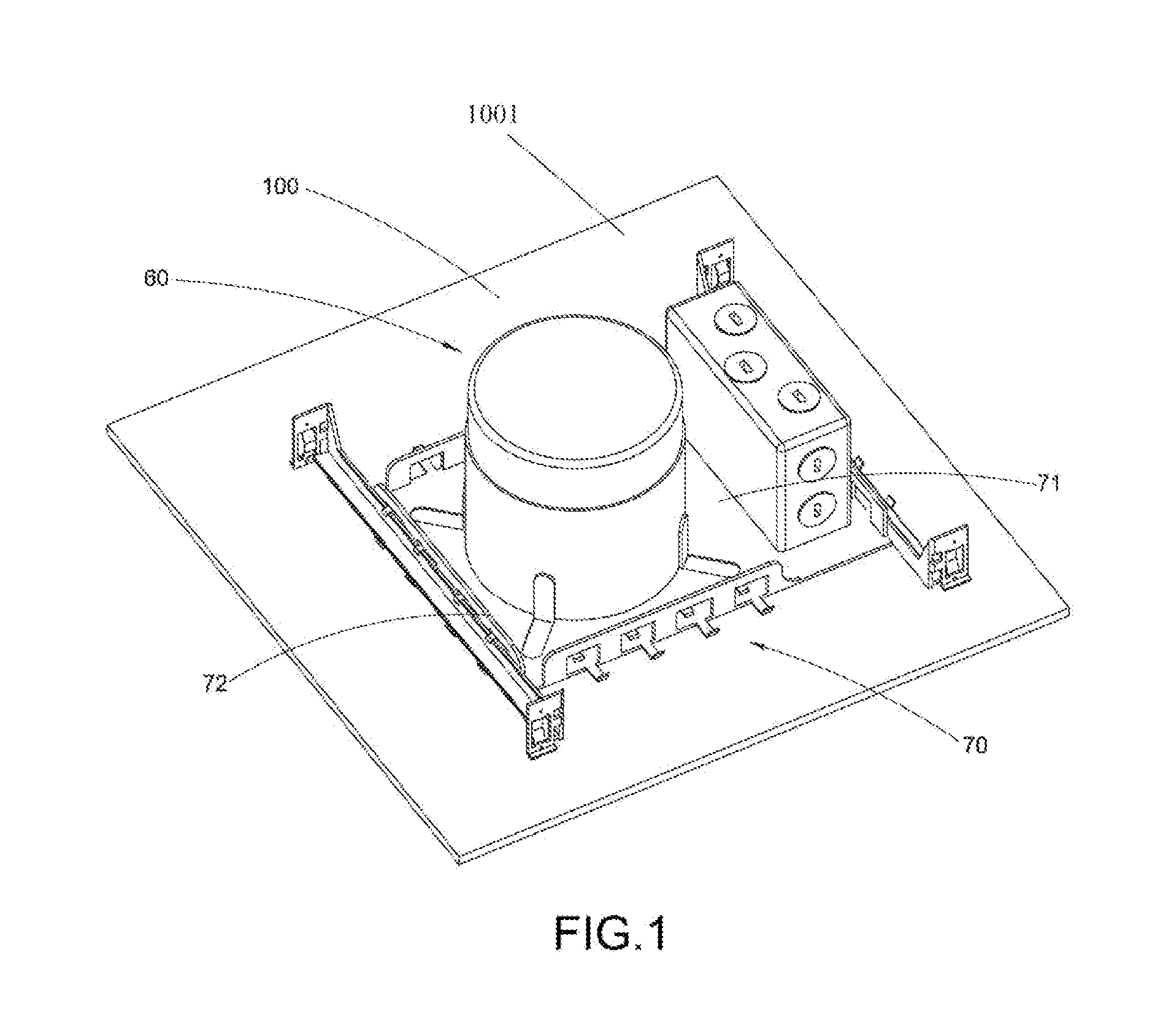

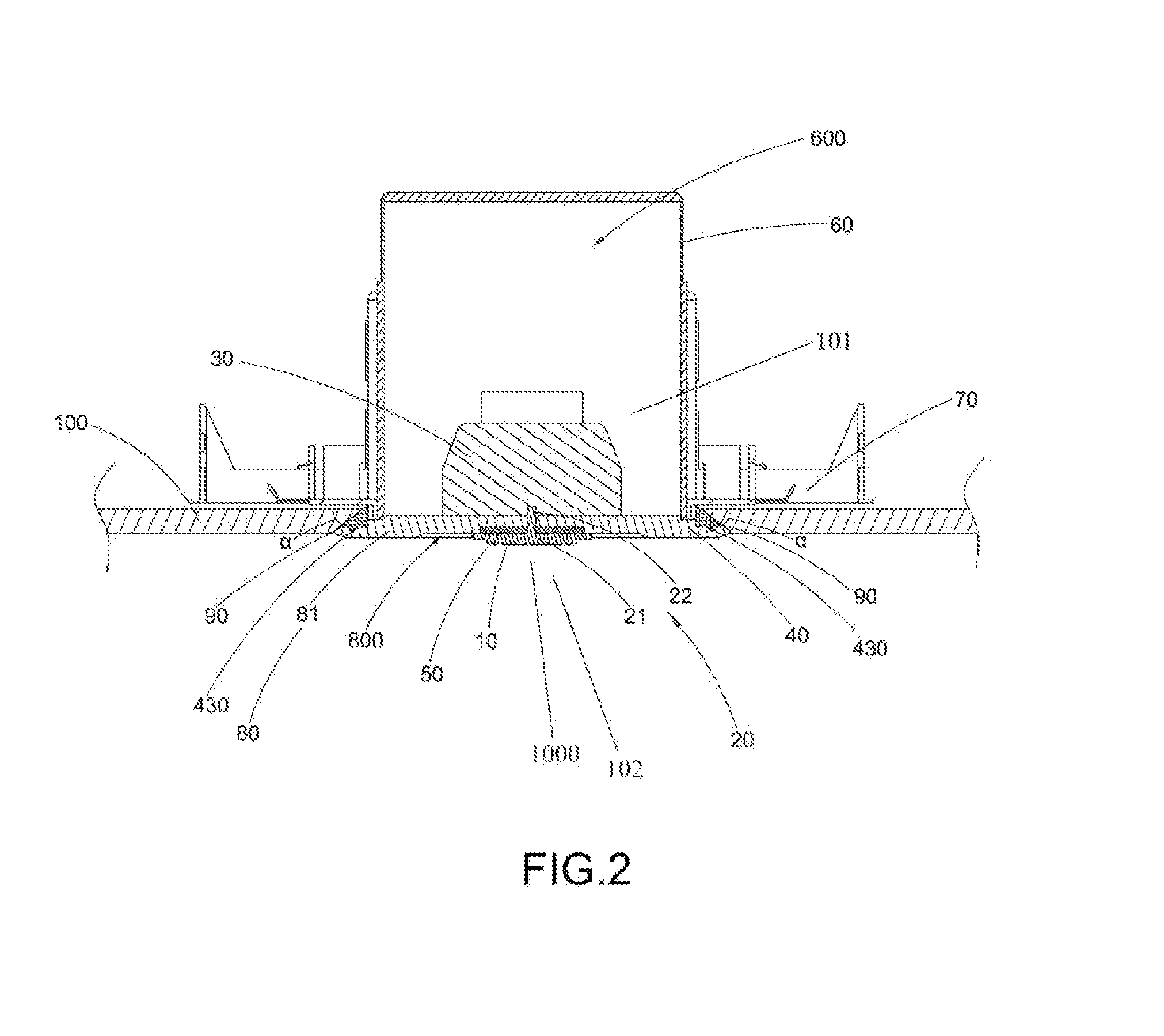

Recessed Light Apparatus

ActiveUS20160084488A1Effectively transmitHigh thermal conductivityPlanar light sourcesLighting support devicesEngineeringLight source

A recessed light apparatus for being installed at a ceiling includes a light source unit, a heat sink for dissipating heat generated from the light source unit, and a thermal insulating member coupled between the heat sink and the light source unit to define an upper space above the heat insulating member and a bottom space below the thermal insulating member. In case of fire, the heat insulating member prevents flame or fire spreading from the bottom space to the upper space.

Owner:WU LIANGJU

Super-high thermal conductivity and low thermal expansivity diamond composite material and preparation method thereof

The invention discloses a super-high thermal conductivity and low thermal expansivity diamond composite material and a preparation method thereof, and belongs to the field of high-performance functional materials. The composite material consists of at least two phases of high thermal conductivity diamond grains and high thermal conductivity metals or alloy materials. The preparation method for the composite material comprises the following steps of: putting high thermal conductivity sheet or block metals or alloy materials on the high thermal conductivity diamond powder grains, loading, sealing, performing vacuum heat treatment, and performing melt infiltration sintering at certain high temperature under high pressure to make high thermal conductivity metals melted and infiltrated in the diamond grains so as to form the super-high thermal conductivity and low thermal expansivity composite material. The method makes high thermal conductivity nonmetal materials and high thermal conductivity metal materials firmly combined, so the composite material has the compactness of over 99 percent, and the thermal conductivity of 600 to 800W / (m.K); the thermal expansivity (less than 5ppm / K) matched with an electronic device can ensure that a workpiece works stably for a long time under the condition of high heating density; and the composite material has wide industrial application prospect.

Owner:UNIV OF SCI & TECH BEIJING +1

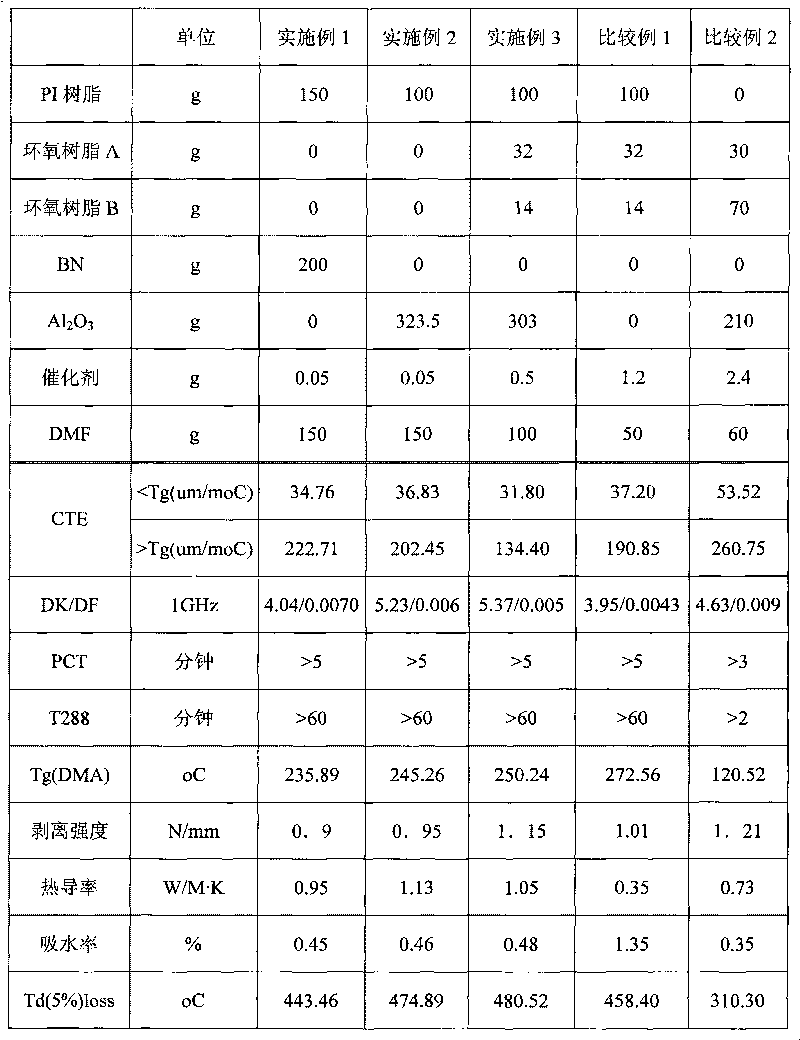

Thermosetting resin composition with high heat conductivity, prepreg manufactured by adopting same and copper-clad laminate

InactiveCN101735611AImprove thermal conductivityHigh glass transition temperatureFibre treatmentPaper coatingPolymer scienceDecomposition

The invention relates to a thermosetting resin composition with high heat conductivity, a prepreg manufactured by adopting the same and a copper-clad laminate. The thermosetting resin composition with high heat conductivity comprises the following components in parts by mass: 5 parts of allyl phenolic compound, 5-40 parts of bismaleimide compound, 0-30 parts of modified resin, 25-85 parts of filler and 1-8 parts of catalyst. The thermosetting resin composition with high heat conductivity, which is provided by the invention, has the superior properties of high heat conductivity, high glass transition temperature, low CTE, high heat decomposition temperature, favorable process deformability and the like; the prepreg is simple to manufacture and has better heat resisting effect and high heat conductivity; and the copper-clad laminate can be applied to the manufacture of a high multi-layer circuit with high-temperature resistance and has simple manufacture process and lower cost.

Owner:GUANGDONG SHENGYI SCI TECH

Graphene-containing silicone rubber composite material with high thermal conductivity and preparation method thereof

InactiveCN103627179AImprove thermal conductivityUnique two-dimensional sheet structureHeat-exchange elementsRubber materialVulcanization

The invention belongs to the field of a heat conducting polymer-based composite, and particularly relates to a graphene-containing silicone rubber composite material with the high thermal conductivity and a preparation method thereof. The composite material comprises a matrix, a heat conducting filler and a vulcanizing agent. The preparation method comprises the following steps: mixing at a room temperature so as to obtain a mixed rubber material; and carrying out hot press molding and one-stage vulcanization on the mixed rubber material by using a flat vulcanizing machine, and putting in a drying oven, carrying out two-stage vulcanization, thus obtaining the silicone rubber composite material with the high thermal conductivity. As graphene is high in thermal conductivity and has a unique two-dimensional lamellar structure, an interconnected heat conducting network is easy to form in the composite material, and the thermal conductivity of the silicon rubber composite material is obviously increased; and the thermal conductivity of the graphene-containing silicone rubber composite material is 0.3W / m.K-1.5W / m.K, and the hardness of the silicone rubber composite material can be reduced. The graphene-containing silicone rubber composite material with the high thermal conductivity is simple in preparation technology, high in production efficiency and easy for the realization of industrialization mass production, and meanwhile, a direction is pointed out for the batch application of graphene.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

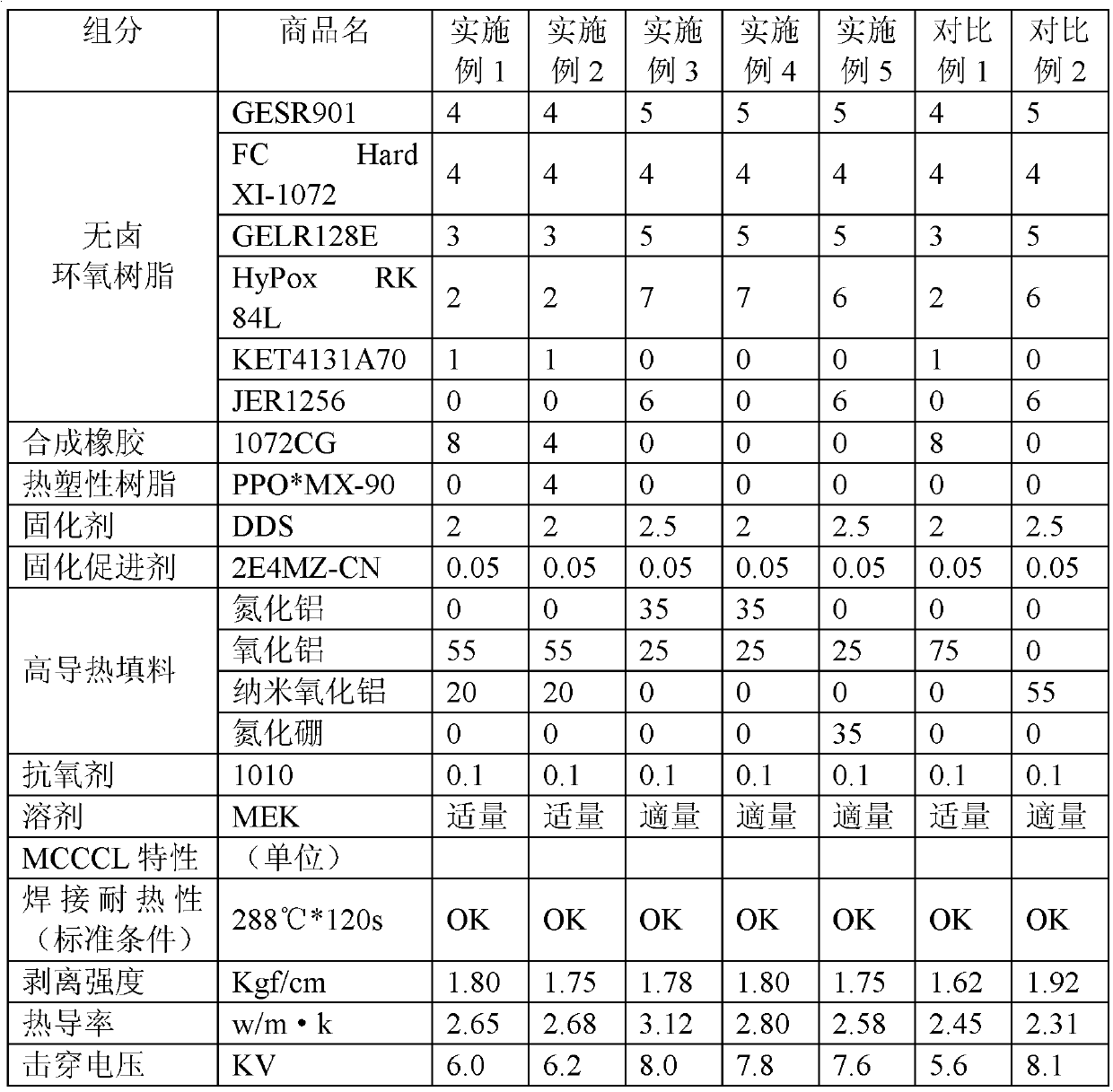

Halogen-free fire-retardant high heat conducting insulating resin composition and heat dissipation metal-base copper clad plate

ActiveCN102558765AImprove heat resistanceHigh peel strengthSynthetic resin layered productsEpoxy resin adhesivesEpoxyHeat conducting

The invention discloses a halogen-free fire-retardant high heat conducting insulating resin composition and a heat dissipation metal-base copper clad plate (CCL). The composition comprises the following components in parts by weight: 10-45 parts of halogen-free epoxy resin, 0-15 parts of thermoplastic resin and / or synthetic rubber, 0.1-5 parts of curing agent, 0.02-1 parts of accelerator, 0.5-1 parts of antioxidant and 25-80 parts of heat conducting filler. The halogen-free fire-retardant high heat conducting insulating resin composition of the invention adopts high heat conducting filler, and the cured composition shows good thermal conductivity, electric insulativity and welding heat resistance as well as high adhesive force. The invention also discloses a heat dissipation metal-base CCL prepared by using the above halogen-free fire-retardant high heat conducting insulating resin composition, which has high thermal conductivity and high peel strength, does not have the problems of peel-off and deterioration even being subjected to thermal cycle of quick heating and quick cooling, and also has high electrical breakdown resistance, good heat resistance and soldering resistance and the like, and the flame retardant rating of the heat dissipation metal-base CCL reaches UL-94V0.

Owner:ALLSTAE TECH ZHONGSHAN

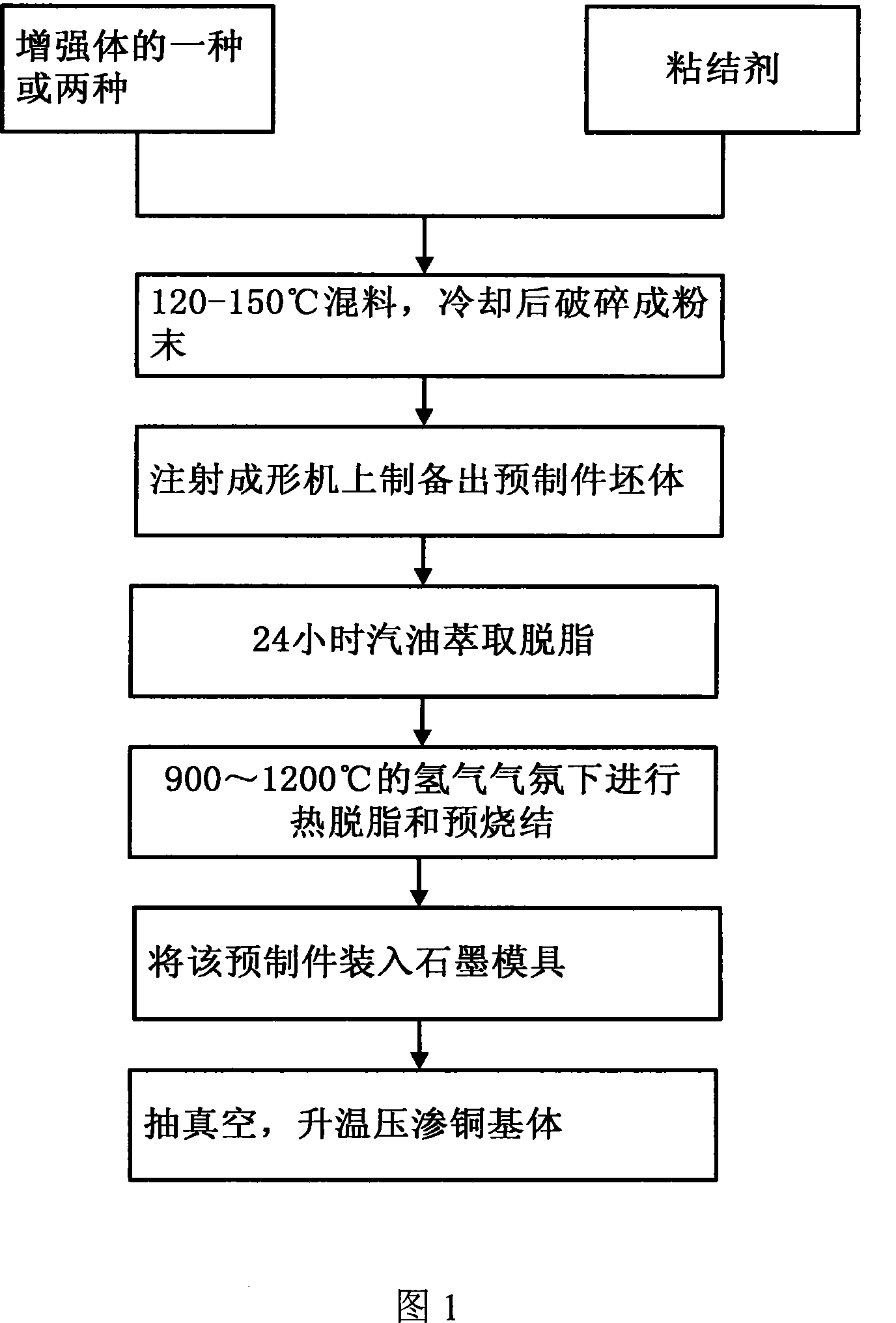

High heat conductivity copper-base composite material and preparation method thereof

The invention belongs to the technical field of preparation of electronic packaging materials, and particularly designs a copper-based composite material with high thermal conductivity and a preparation method thereof. The copper-based composite material is made of a reinforcement and a binder through a prefabricated injection molding process to make a reinforcement prefabricated part, wherein the size of the reinforcement particle is 7-60 μm, and it is composed of silicon carbide particles, diamond particles or aluminum nitride particles. One or two of them; the copper matrix is directly placed on the reinforcement preform, wherein the copper matrix is electrolytic copper or oxygen-free copper, and the volume ratio of the reinforcement to the copper matrix is 50-75%: 25-50 %, made by pressure infiltration process. The preparation method adopts the injection molding process of the prefabricated part and the pressure impregnation process to prepare the high thermal conductivity copper matrix composite material. The thermal conductivity of the copper-based composite material in the present invention is higher than that of the aluminum-based composite material with the same reinforcement system, the material itself has low density and small thermal expansion coefficient, which meets the requirement of light weight of the packaging material.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com