Composite phase-change energy storage material for microcapsule and preparation method thereof

A phase change energy storage material and a technology for energy storage materials, applied in the field of microcapsule composite phase change energy storage materials and their preparation, can solve the problems of low compressive strength, failure of automatic temperature control performance, leakage of phase change materials, etc. It is not easy to be corroded, improves the situation of power shortage, and has the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

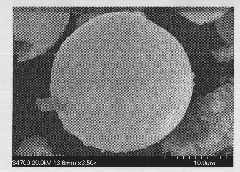

[0028]Add 3.0kg of n-octadecane and 3.0kg of tetraethyl orthosilicate into 10.0kg of aqueous solution containing 0.032kg of nonionic surfactant (PEO-PPO-PEO), in a 30-35°C water bath, at 8000rpm Stir and emulsify at a rotating speed for 3 hours to form a stable O / W emulsion. Add 3.0 kg of hydrochloric acid solution with a pH of about 2.80 into the O / W emulsion to initiate a polymerization reaction, the hydrochloric acid solution continuously diffuses into the micelles, gradually polymerize, react for 24 hours, stop stirring, and naturally cool the reaction solution to room temperature to obtain Precipitation solution, to ensure the stability of the reaction product, the precipitation was continuously washed several times with petroleum ether, and then cleaned with deionized water, suction filtered, and dried to obtain the product, and obtained the inorganic silica shell material coated micro The surface of the capsule composite phase change energy storage material is smooth an...

Embodiment 2

[0030] Add 5.0kg of n-octadecane and 3.0kg of tetraethyl orthosilicate into 10.0kg of aqueous solution containing 0.036kg of nonionic surfactant (PEO-PPO-PEO), in a water bath at 30-35°C, at 8000rpm Stir and emulsify at a rotating speed for 3 hours to form a stable O / W emulsion. Add 3.0 kg of hydrochloric acid solution with a pH of about 2.80 into the O / W emulsion to initiate a polymerization reaction, the hydrochloric acid solution continuously diffuses into the micelles, gradually polymerize, react for 24 hours, stop stirring, and naturally cool the reaction solution to room temperature to obtain Precipitation solution, to ensure the stability of the reaction product, the precipitation was continuously washed several times with petroleum ether, and then cleaned with deionized water, suction filtered, and dried to obtain the product, and obtained the inorganic silica shell material coated micro The surface of the capsule composite phase change energy storage material is smoot...

Embodiment 3

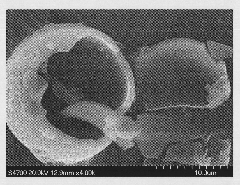

[0032] Add 6.0kg n-octadecane and 3.0kg tetraethyl orthosilicate to 10.0kg aqueous solution containing 0.095kg surfactant (PEO-PPO-PEO), stir and emulsify at a speed of 8000rpm in a water bath at 30-35°C 3h, forming a stable O / W emulsion. Add 3.0 kg of hydrochloric acid solution with a pH of about 2.80 into the O / W emulsion to initiate a polymerization reaction, the hydrochloric acid solution continuously diffuses into the micelles, gradually polymerize, react for 24 hours, stop stirring, and naturally cool the reaction solution to room temperature to obtain Precipitate solution, to ensure the stability of the reaction product, the precipitate was washed several times with petroleum ether, and then cleaned with deionized water, filtered, dried, and the product was obtained, and the inorganic silica shell material was obtained. The shell material of the microcapsule composite phase change energy storage material is relatively thin, with a typical "core-shell" structure, its pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com