Patents

Literature

117032results about How to "Reduce labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

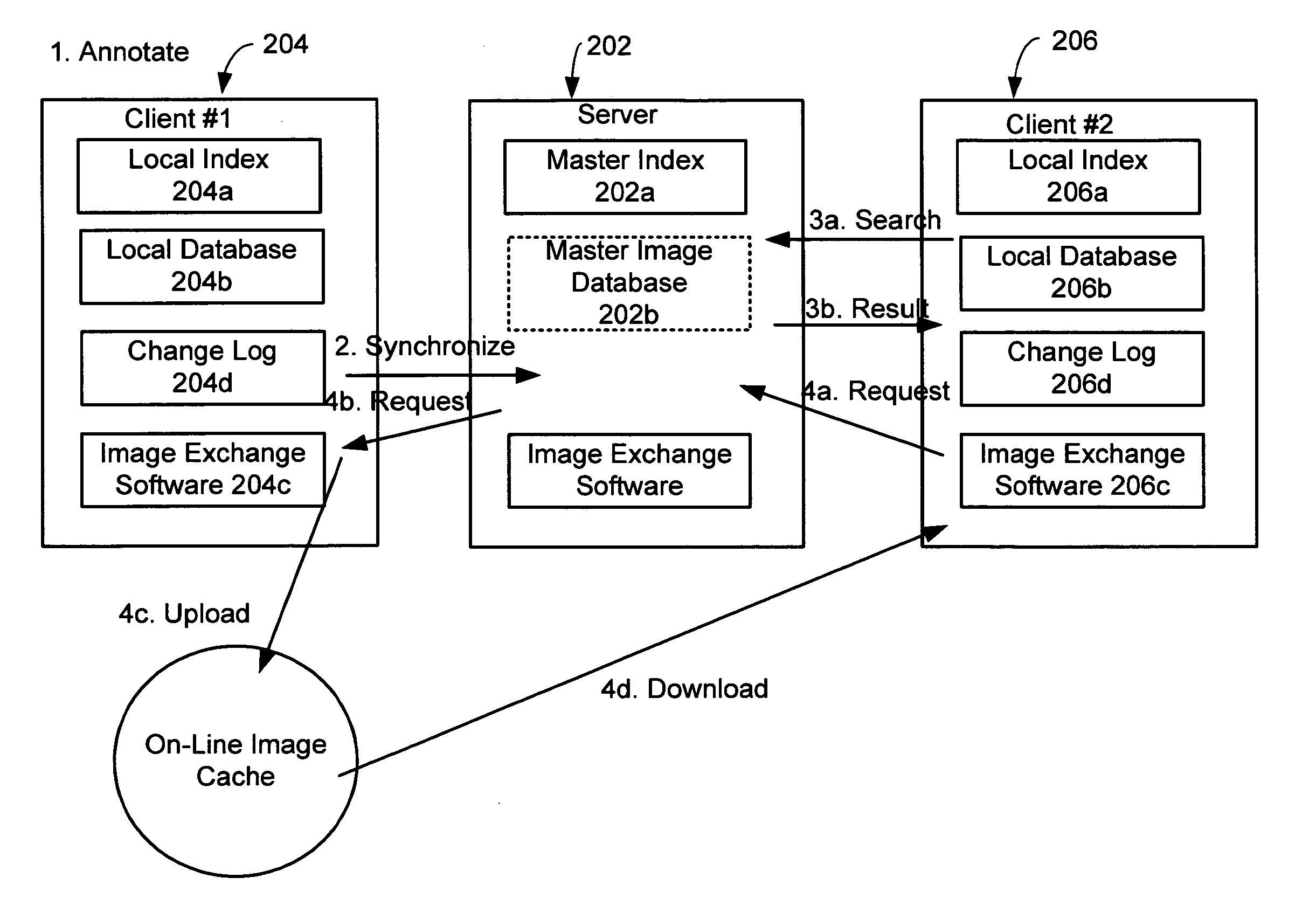

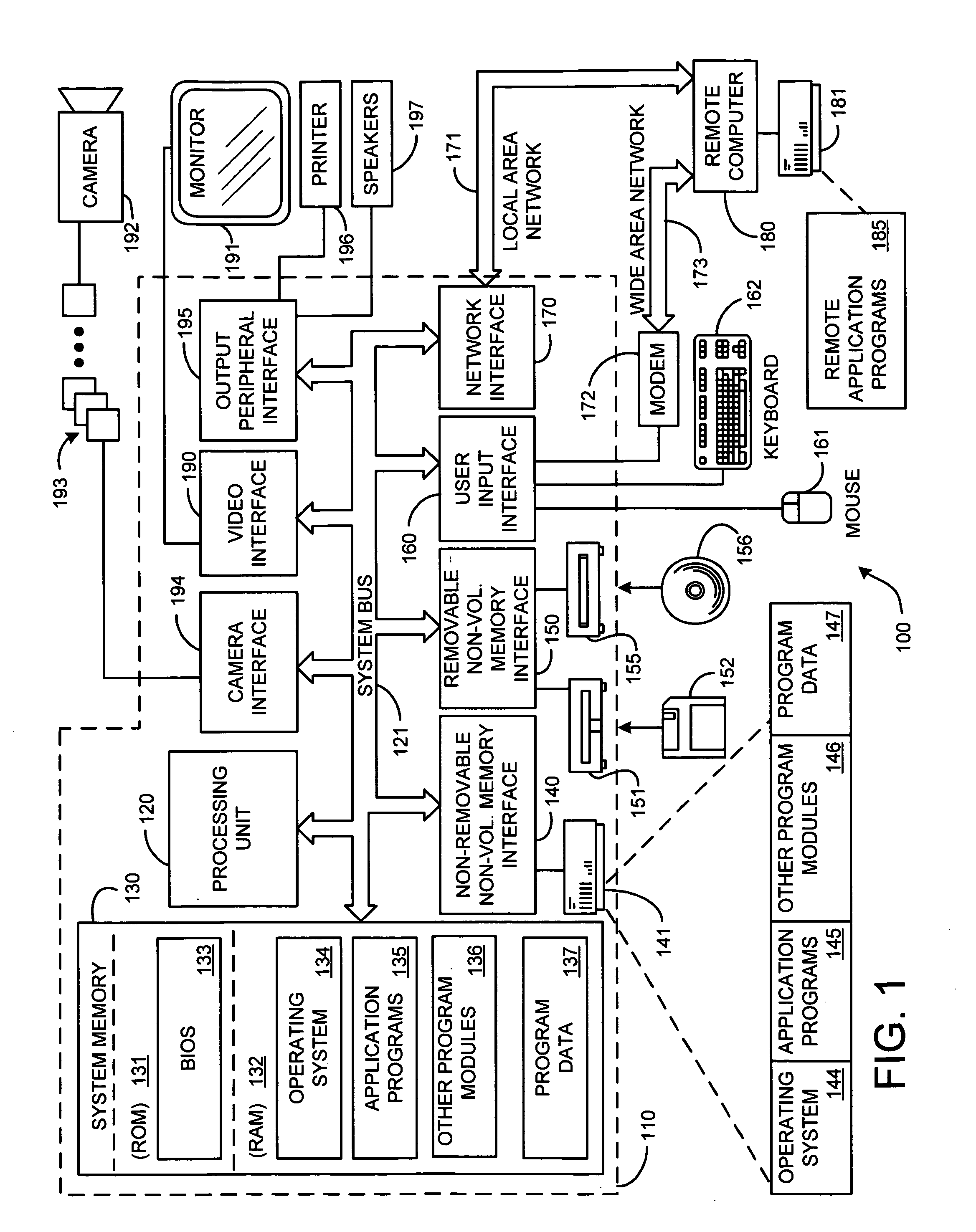

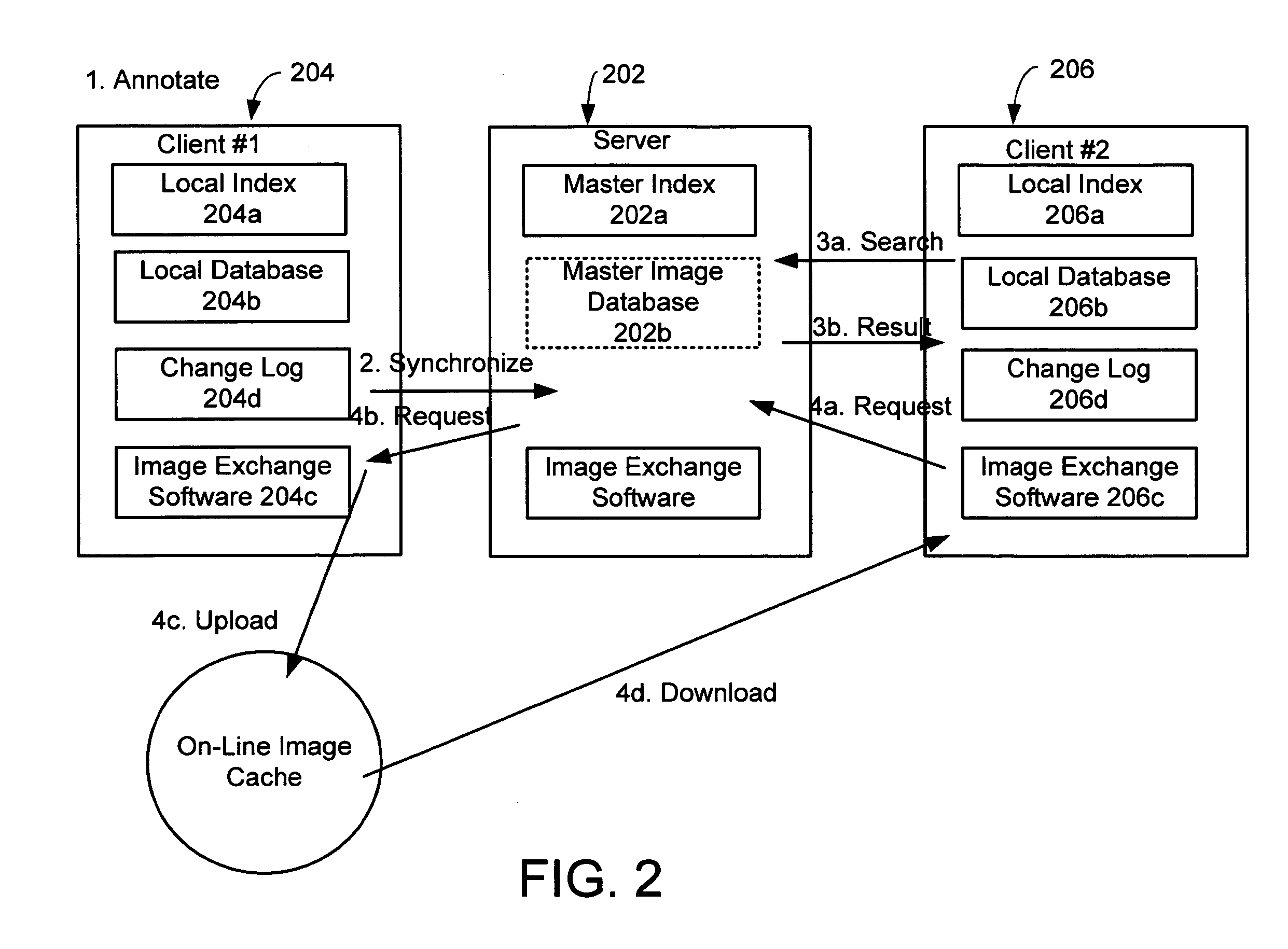

System and method for exchanging images

InactiveUS20060107297A1Easy to shareReduce labor intensityTelevision system detailsData processing applicationsShared environmentImage sharing

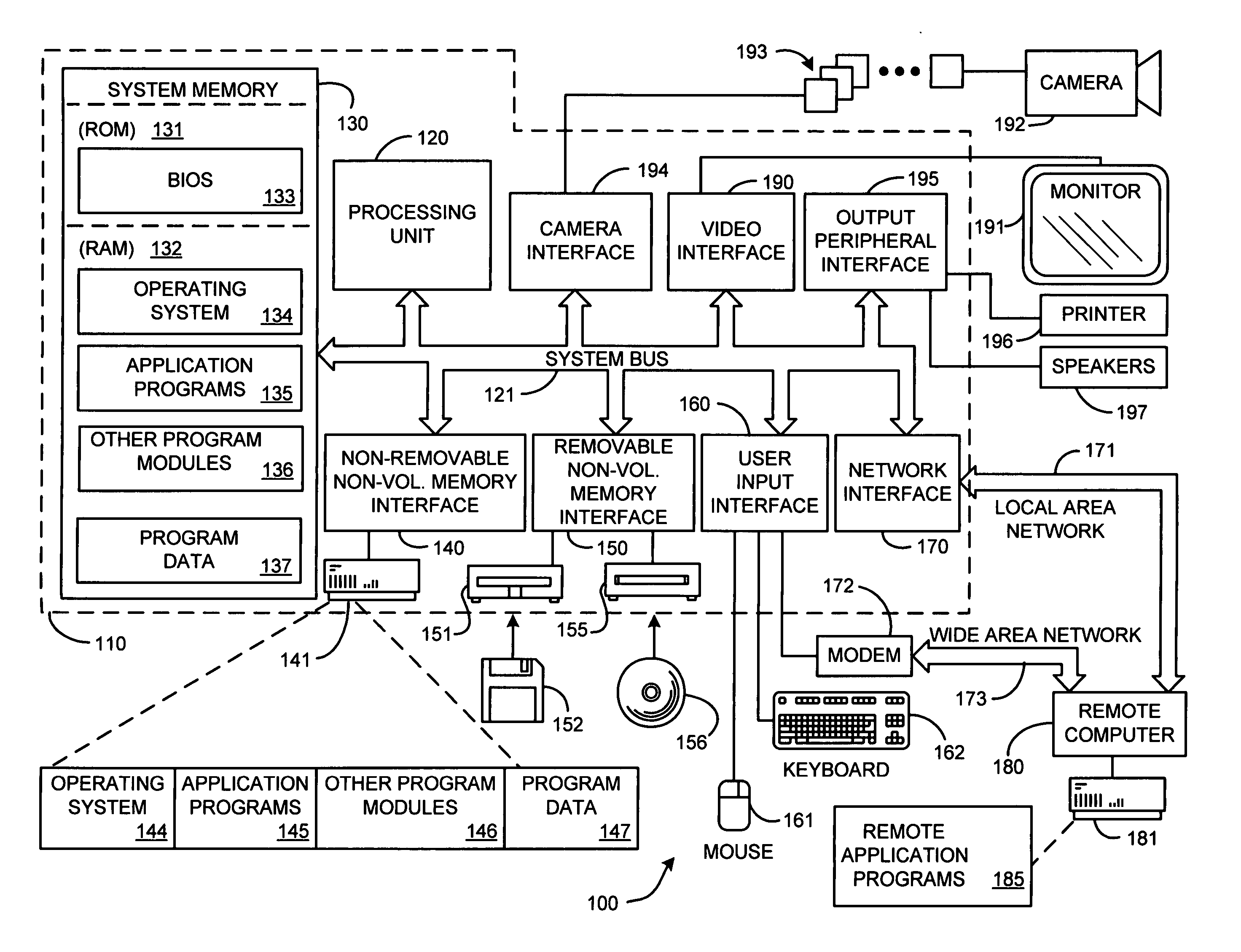

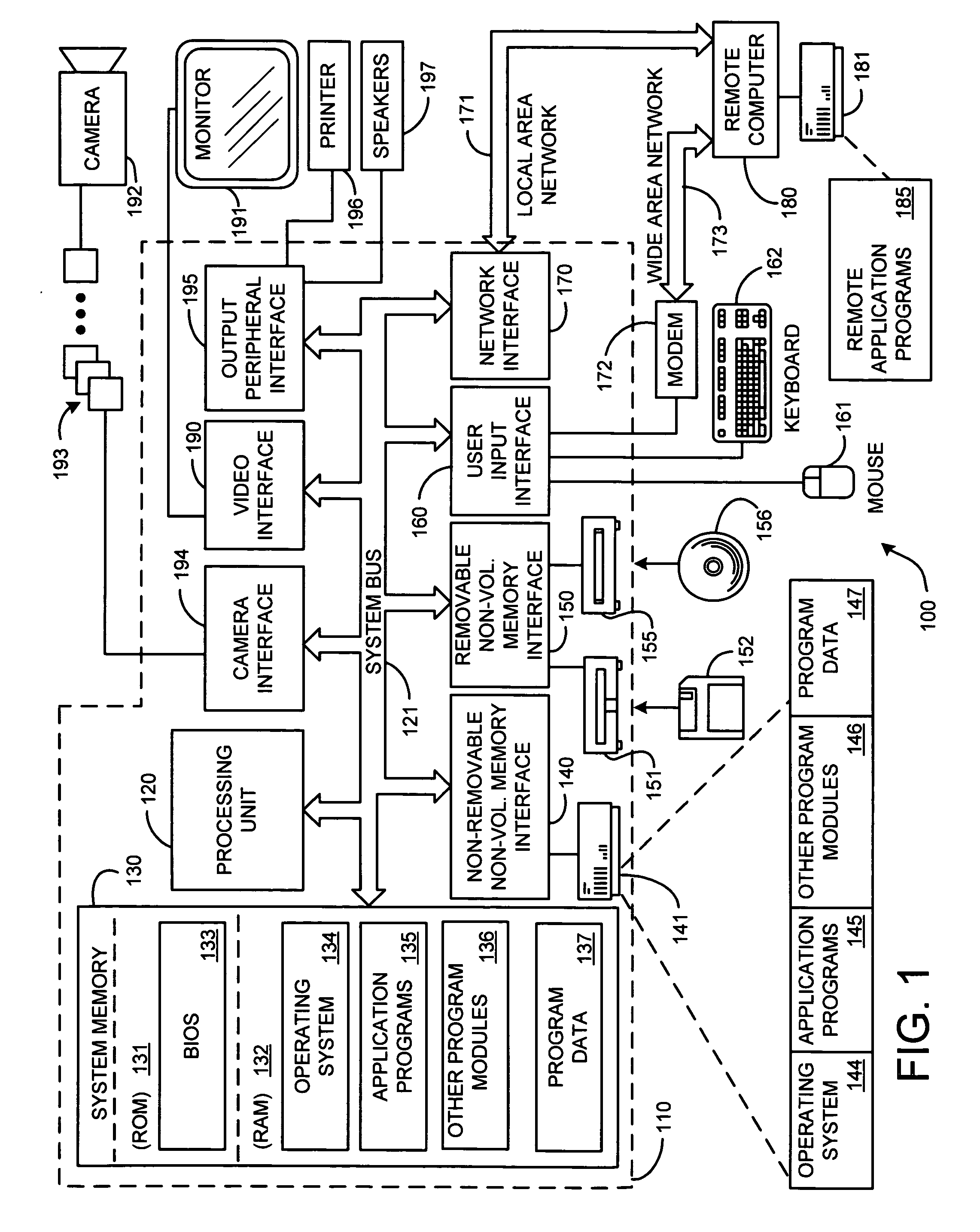

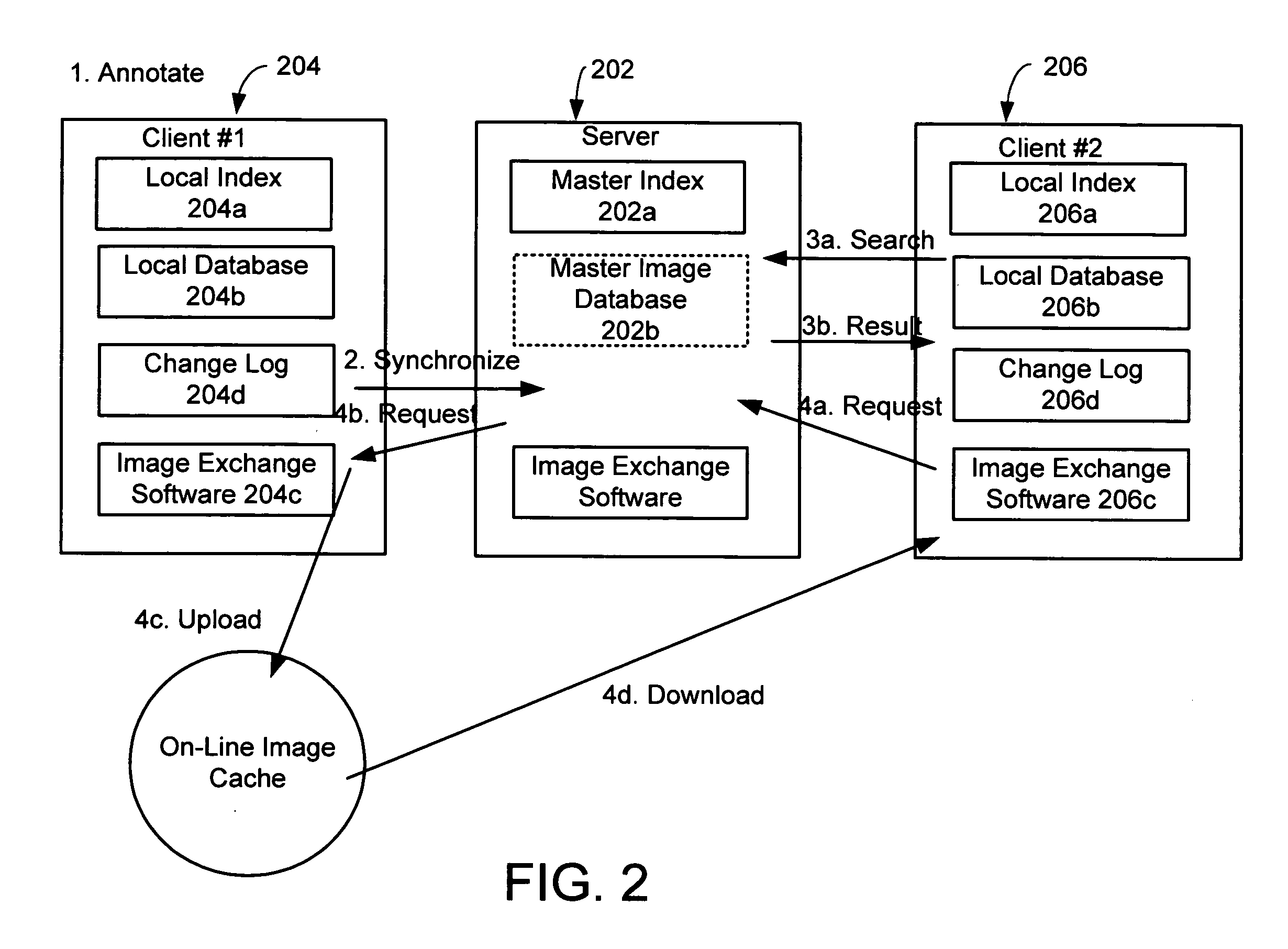

A system and method for providing a peer-to-peer photo-sharing environment. The system includes: manual and automatic photo annotation at the client; periodic client-server synchronization; an index of client photos on a central server or a photo database that is resident on the central server, which is updated by the client-server synchronization function; end-user search functionality to search the centralized index or photo database; and transmission of the relevant photos to the client via an on-line image cache. In one embodiment, one client's new photos are automatically displayed on another client's computer (e.g., via screen saver or another mechanism).

Owner:MICROSOFT TECH LICENSING LLC

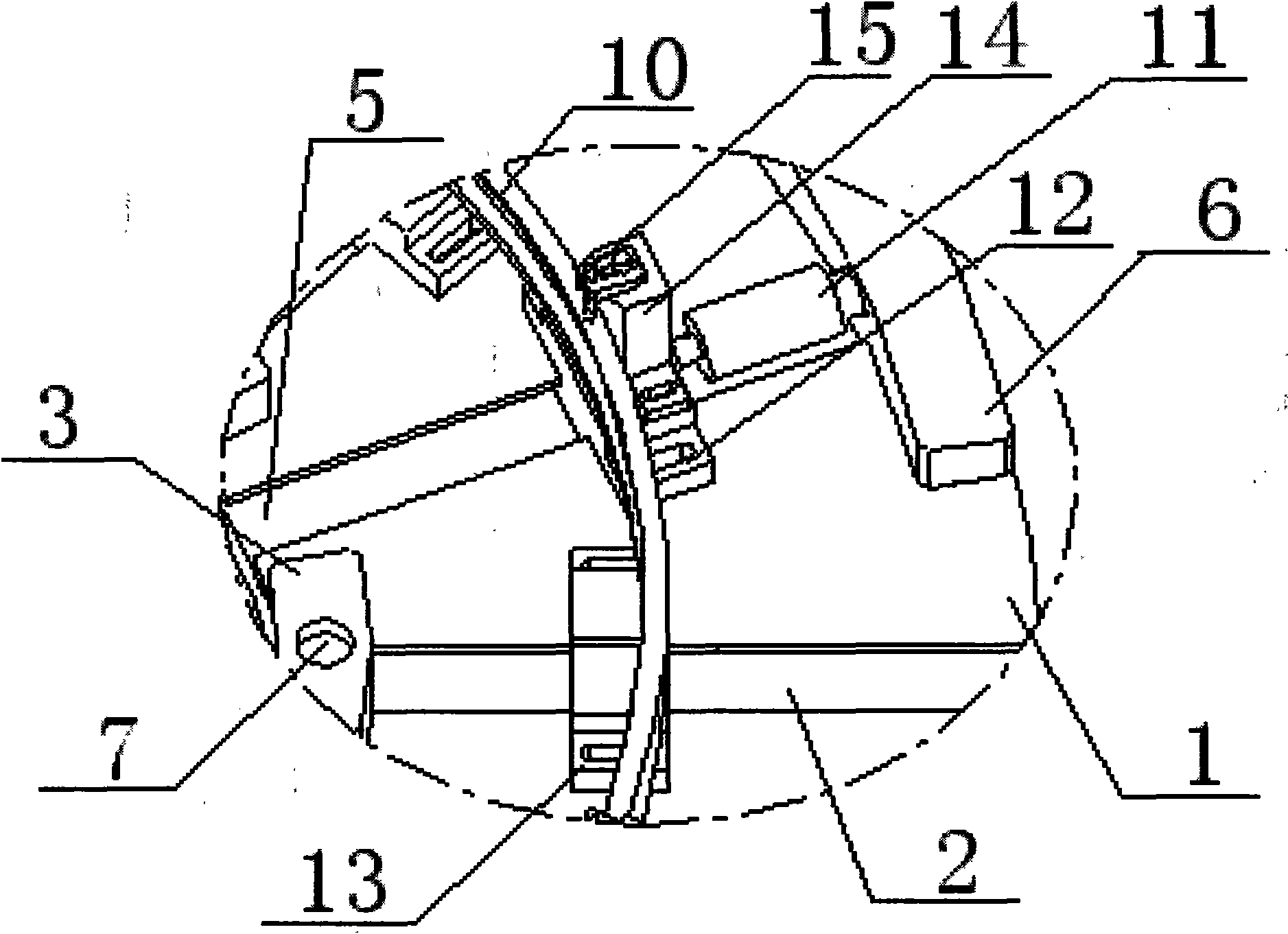

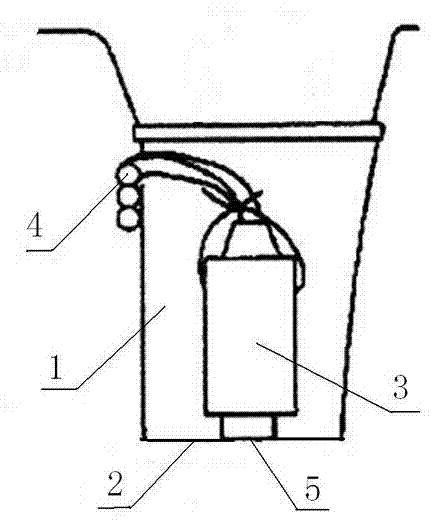

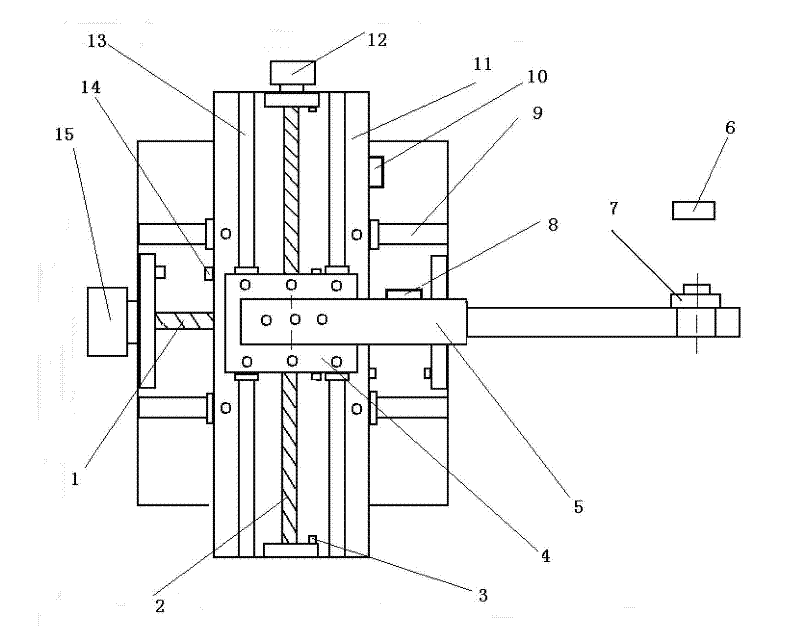

Thin-wall round pipe turning and clamping device

InactiveCN104607681AReasonable designCompact structureExpansion mandrelsEngineeringUltimate tensile strength

The invention discloses a thin-wall round pipe turning and clamping device. The thin-wall round pipe turning and clamping device comprises a slide block bracket for slidingly mounting inclined surface slide blocks, a screw rod for slidingly mounting and supporting taper sleeves, and a clamping base, wherein the slide block bracket and the screw rod are both fixedly mounted at one end of the clamping base; the taper sleeves are slidingly mounted on the screw rod; at least two inclined surface slide blocks fitting the taper sleeves to tightly eject workpieces from the inner sides are slidingly mounted on the slide block bracket; elastic cushion blocks are respectively arranged between all the inclined surface slide blocks and the workpieces; fastening nuts for tightly pressing the taper sleeves are arranged at the ends of the screw rod; and antiskid washers are arranged between the fastening nuts and the end surfaces of the taper sleeves. The thin-wall round pipe turning and clamping device has the characteristics of reasonable design, simple structure, good use effect, high machining precision, convenience for disassembly of the workpieces, low labor intensity, high production efficiency, low production cost and convenience for promotion and application.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

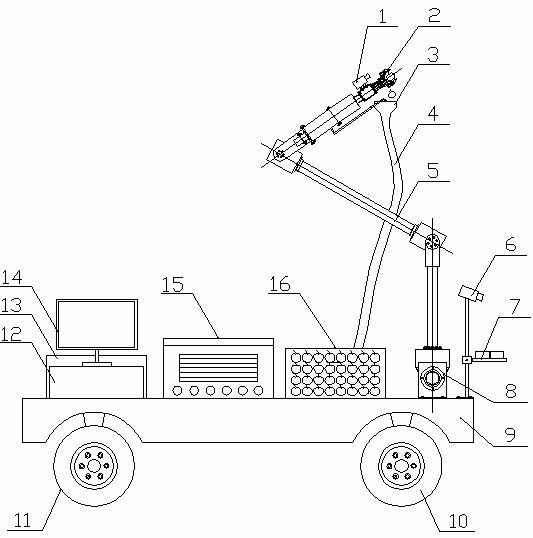

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

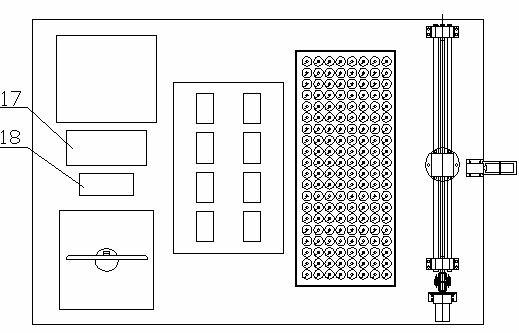

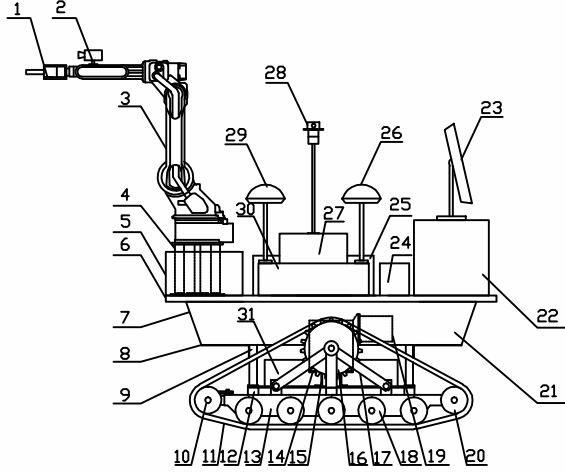

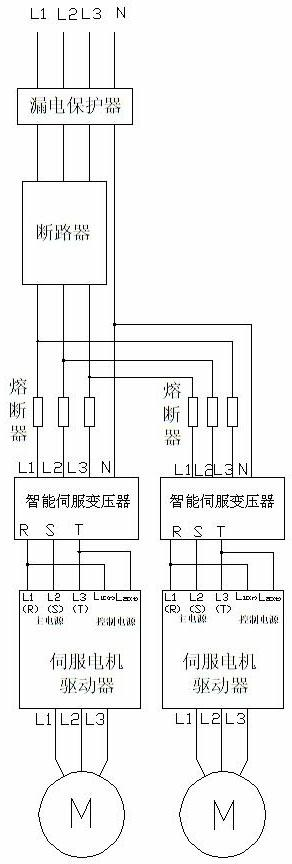

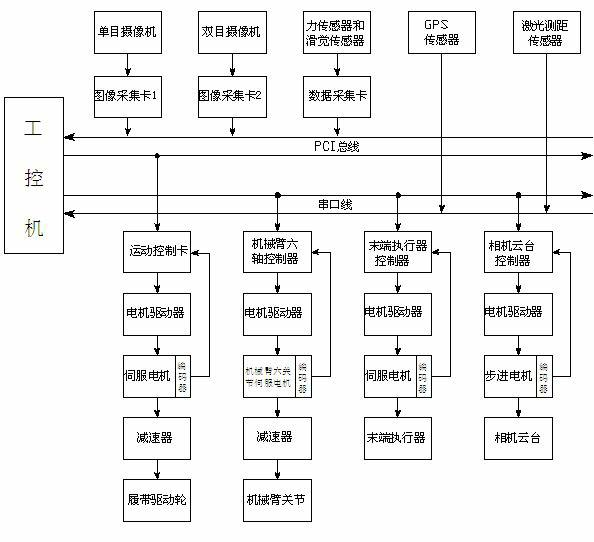

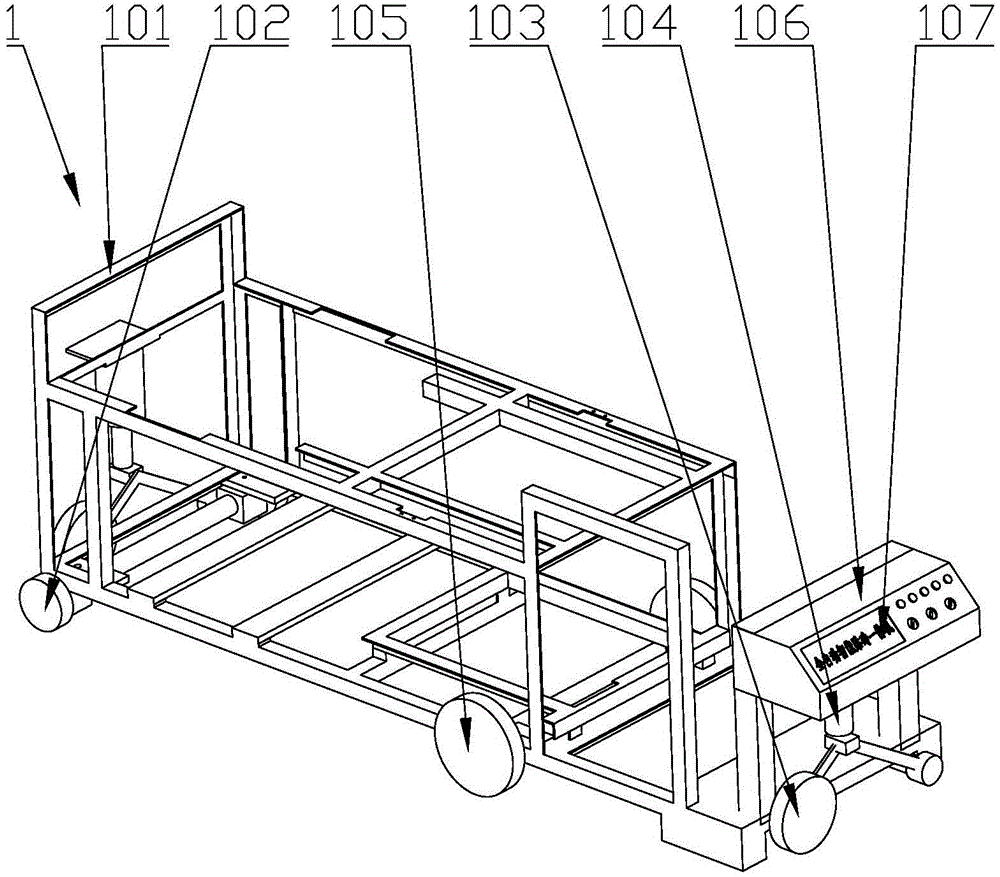

Automatic-navigation crawler-type mobile fruit picking robot and fruit picking method

InactiveCN102165880AFully automated pickingSimple structureProgramme-controlled manipulatorPicking devicesSimulationActuator

The invention discloses an automatic-navigation crawler-type mobile fruit picking robot which comprises a mechanical execution system and a control system and is characterized in that the mechanical execution system comprises an intelligent movable platform, a fruit picking mechanical arm and a two-finger type manipulator, wherein the intelligent movable platform comprises two crawler assemblies, an experimental facility fixing rack, a supporting stand column, a cross beam, a speed reducer and the like; and the control system comprises an industrial personal computer, a motion control card, a data collecting card, an image collecting card, an encoder, a GPS (global position system), a monocular zooming camera assembly, a binocular camera, a laser ranging sensor, a control circuit and the like. The automatic-navigation crawler-type mobile fruit picking robot integrates the fruit picking mechanical arm, the two-finger type manipulator, the intelligent movable platform and the sensor system, integrates multiple key technologies such as fruit identification, motion of the picking mechanical arm, grabbing of a tail-end executer, automatic navigation and obstacle avoidance of the movable platform, and the like, and really realizes automatic and humanized fruit picking.

Owner:NANJING AGRICULTURAL UNIVERSITY

System and method for exchanging images

InactiveUS20050190273A1Easy to shareReduce labor intensityTelevision system detailsData processing applicationsShared environmentImage sharing

A system and method for providing a peer-to-peer photo-sharing environment. The system includes: manual and automatic photo annotation at the client; periodic client-server synchronization; an index of client photos on a central server or a photo database that is resident on the central server, which is updated by the client-server synchronization function; end-user search functionality to search the centralized index or photo database; and transmission of the relevant photos to the client via an on-line image cache. In one embodiment, one client's new photos are automatically displayed on another client's computer (e.g., via screen saver or another mechanism).

Owner:MICROSOFT TECH LICENSING LLC

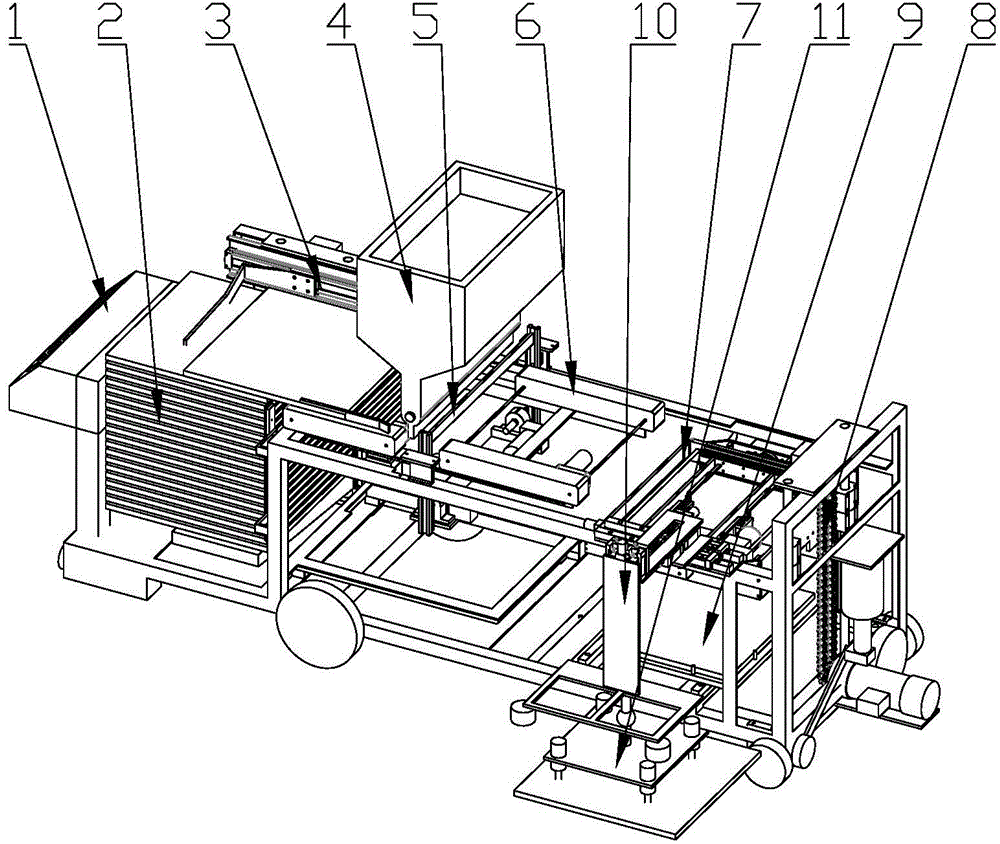

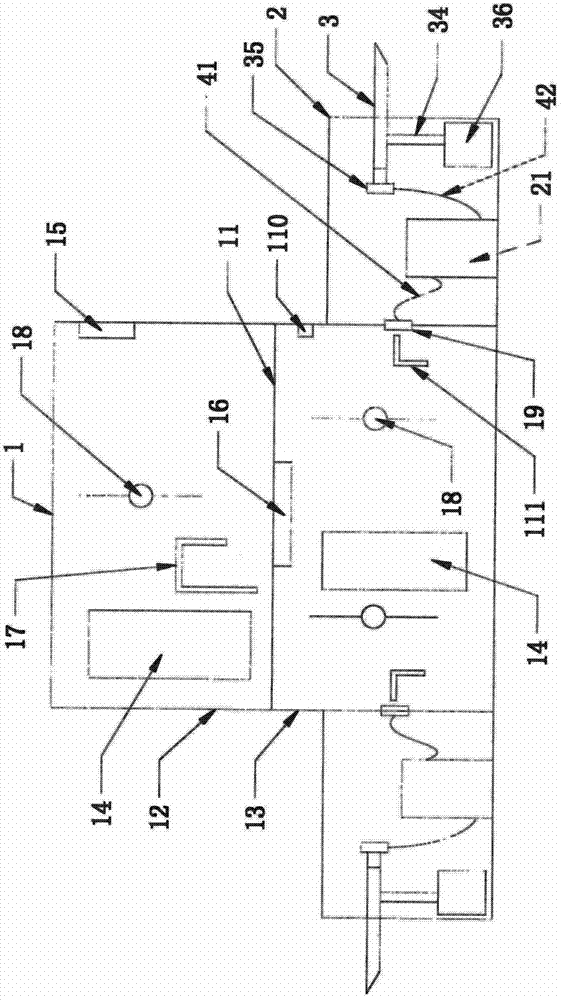

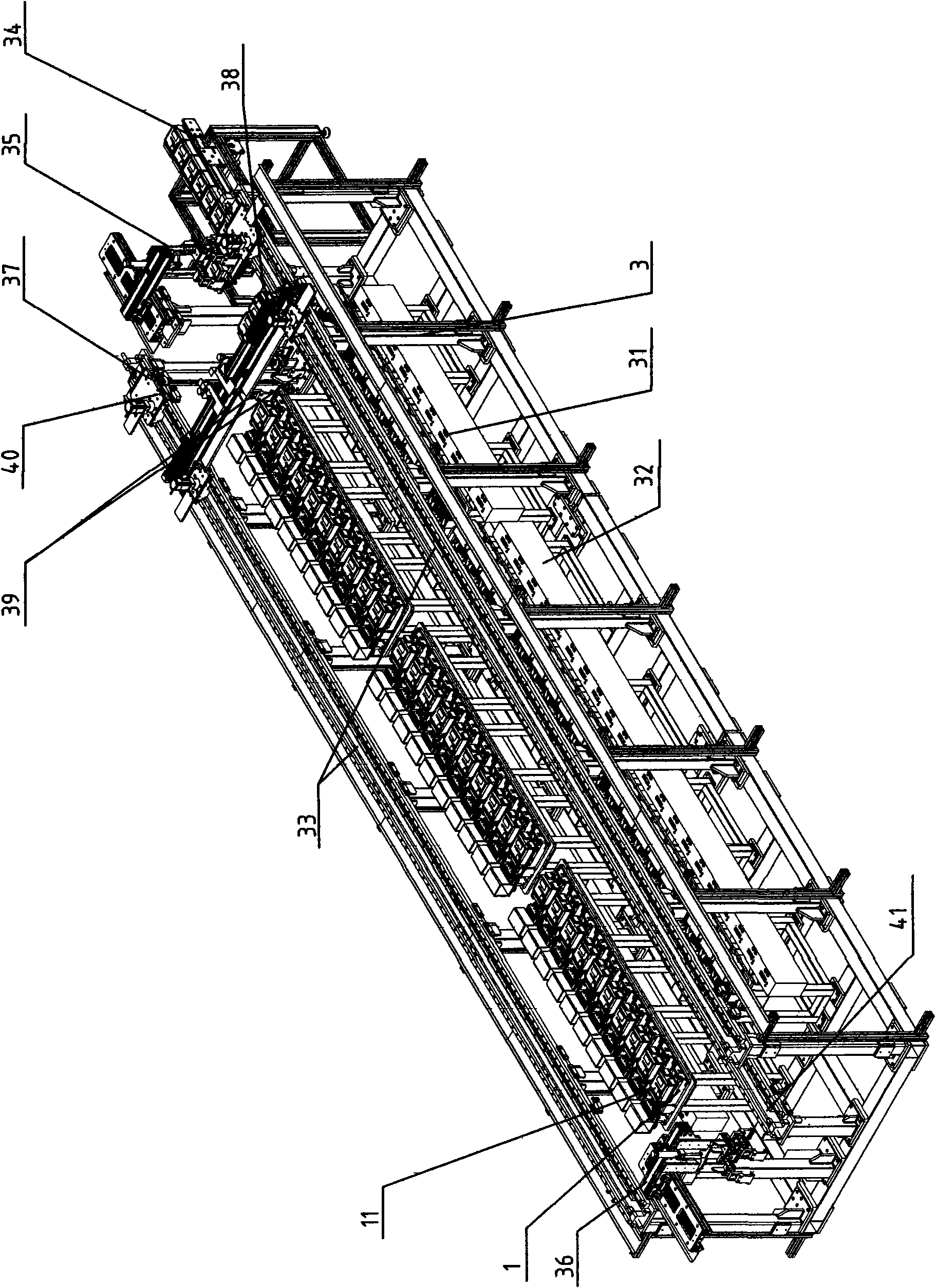

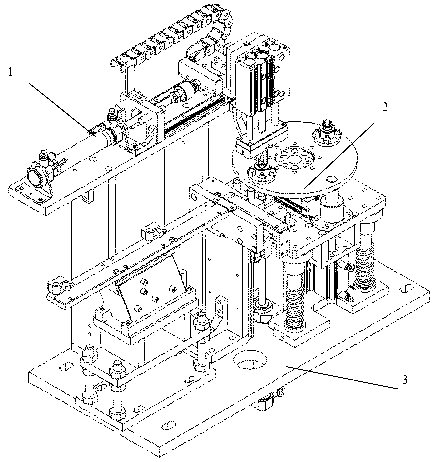

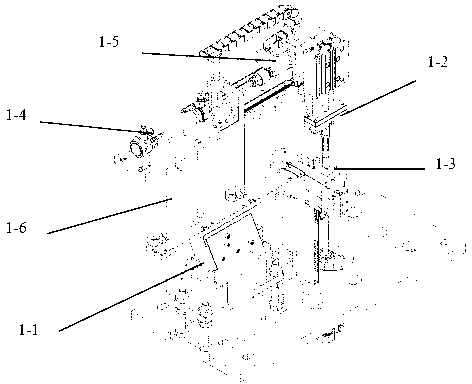

Full-automatic intelligent tiling machine

InactiveCN104060808ARealize fully automatic mechanized operationImprove work efficiencyBuilding constructionsEngineeringPositioning system

The invention discloses a full-automatic intelligent tiling machine, which comprises a rack, a feeding lifting system, an automatic pulling system, an automatic plastering hopper, an automatic mortar scraping mechanism, a material transportation mechanism, a feeding automatic turnover mechanism, a feeding automatic lifting platform, a second-time positioning system, a four-axis positioning system for floor tile tiling, and a measurement and vibration tiling mechanism. The tiling machine is also provided with a wall tiling system and a ground and wall tiling pouring system. The full-automatic intelligent tiling machine has the advantages that due to the adoption of the tiling machine which enables that ground tiles and wall tiles can be tiled simultaneously, manpower can be replaced completely and a full-automatic machinery operation in tiling is realized, so that working efficiency is greatly improved and labor intensity is reduced; besides, the wall tiles and the ground tiles tiled by the intelligent tiling machine are superior in quality in consideration of good tidiness, sound smoothness and aesthetic appearances, so that the intelligent tiling machine is particularly suitable for large-area ground or wall tiling; the craft of plastering first and then tile paving, and that of tile paving first and then mortar pouring can be adopted by the intelligent tiling machine simultaneously, and a suitable tiling craft can be chosen according to the smoothness degree of ground surfaces and wall surfaces, so that tiling efficiency is better improved.

Owner:王越

Catalyst used for synthesis of vinyl acetate and its prepn. method

ActiveCN1903435AHigh activityReduce consumptionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidActivated carbon

A catalyst for synthesizing vinyl acetate from acetylene and acetic acid is prepared from activated carbon, zinc acetate and alkaline bismuth carbonate in mass ratio of 100: (27-40): 0.026 by excessive solution dipping method.

Owner:CHINA PETROCHEMICAL CORP +2

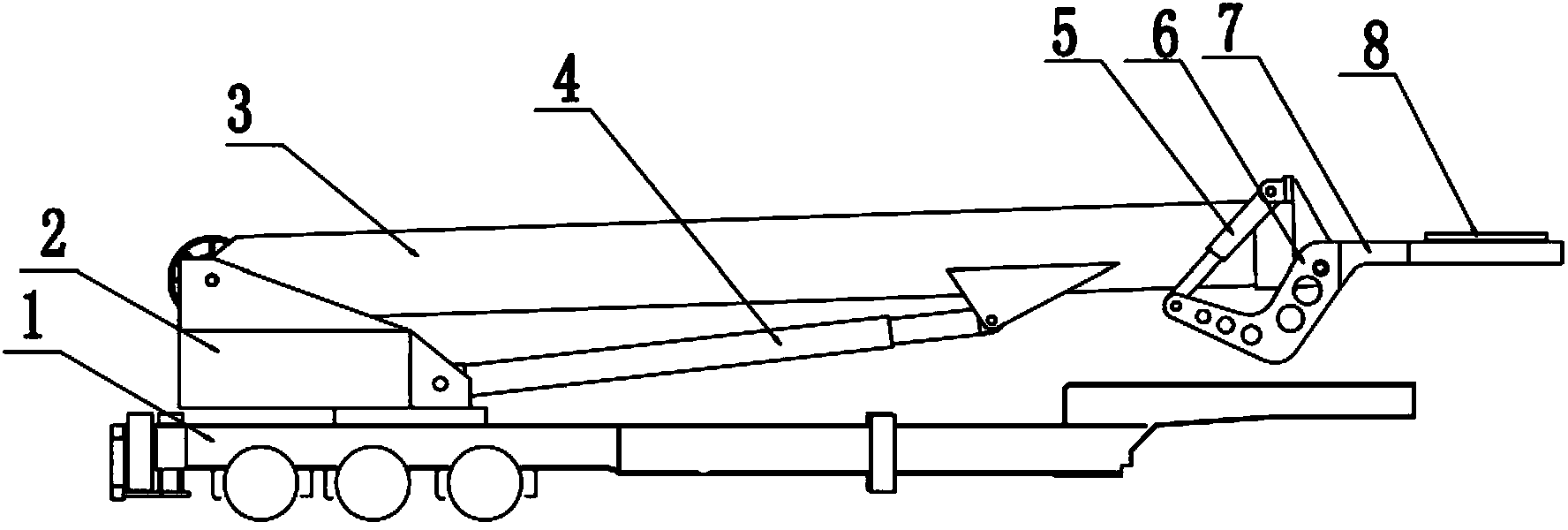

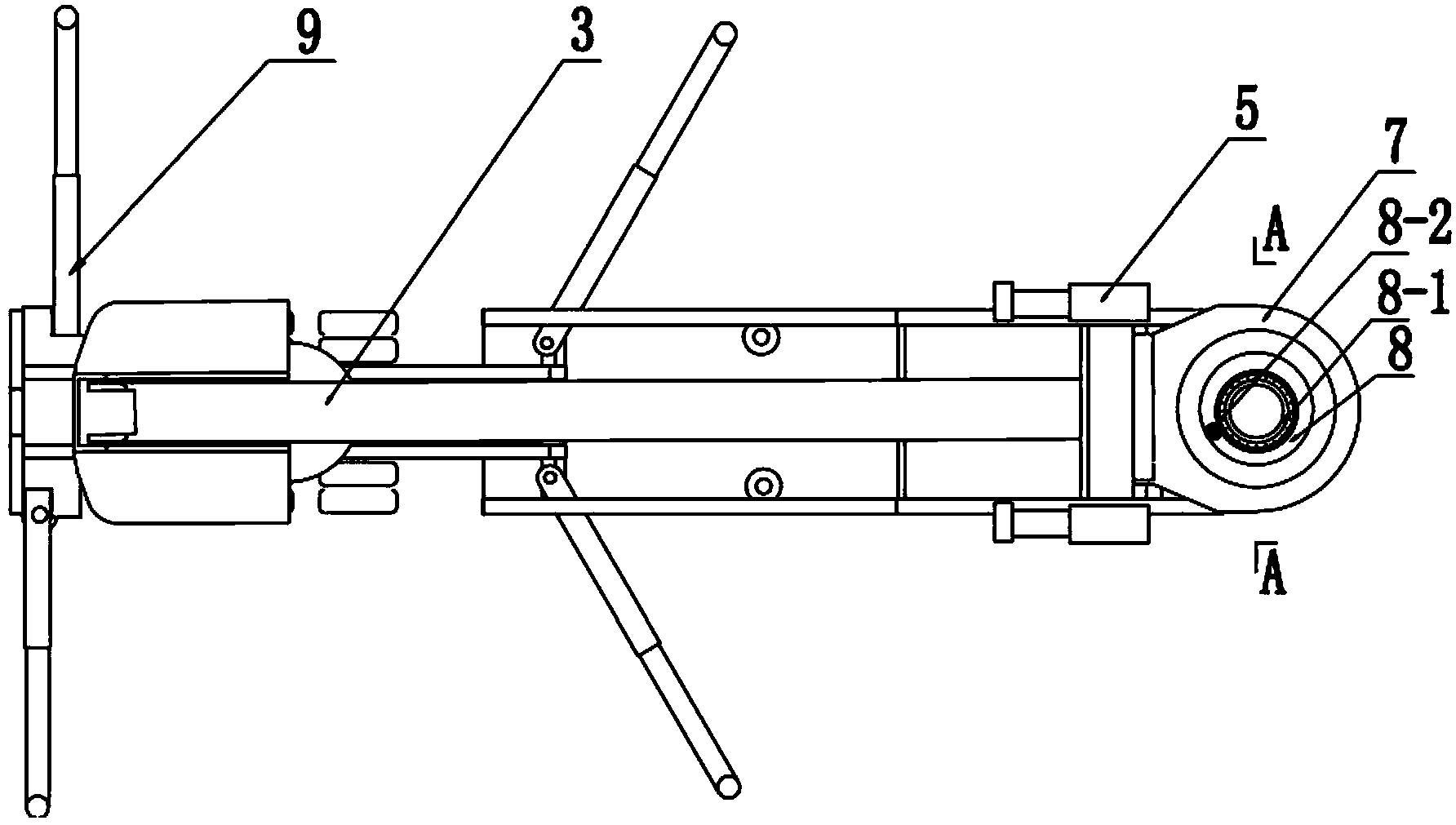

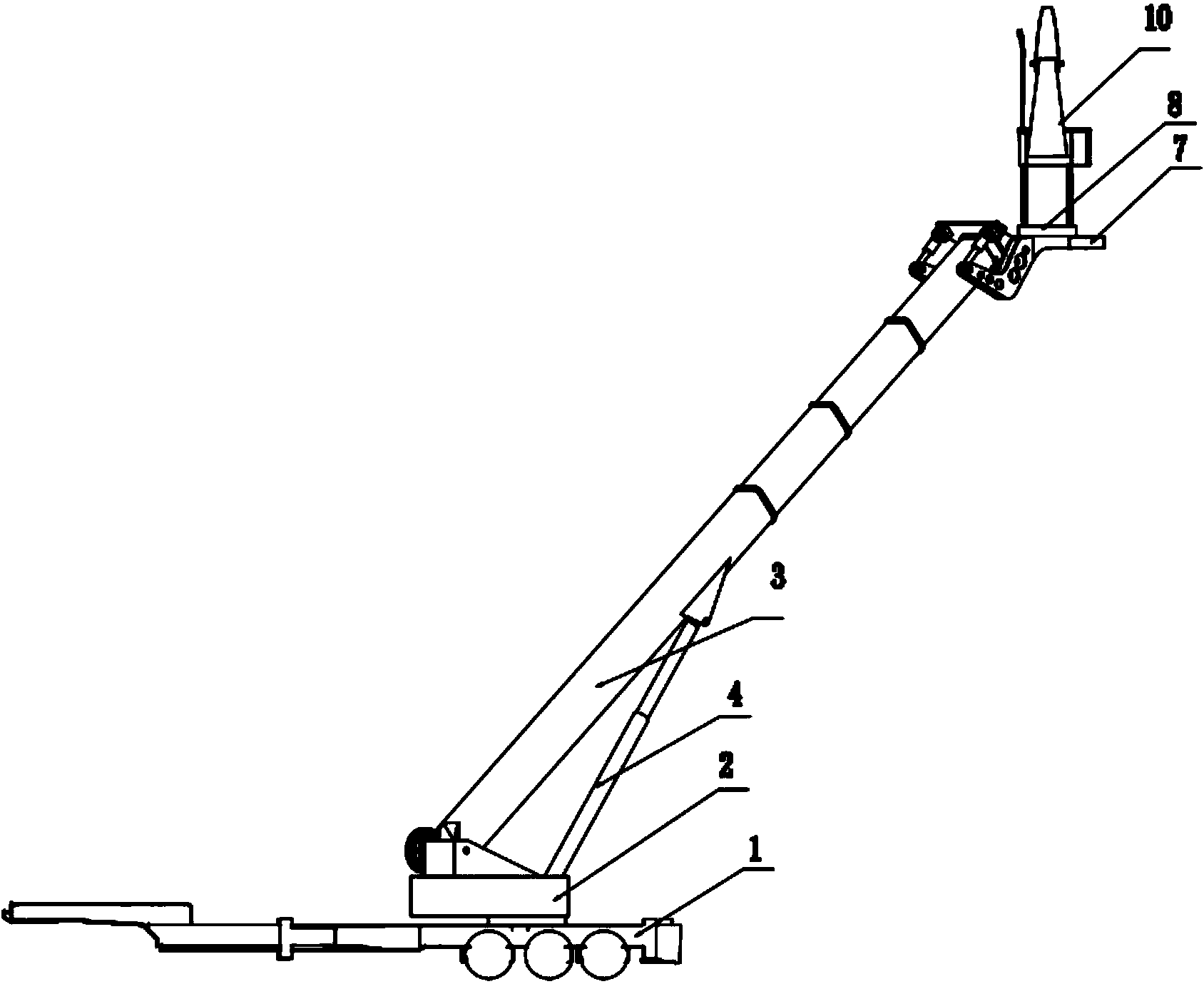

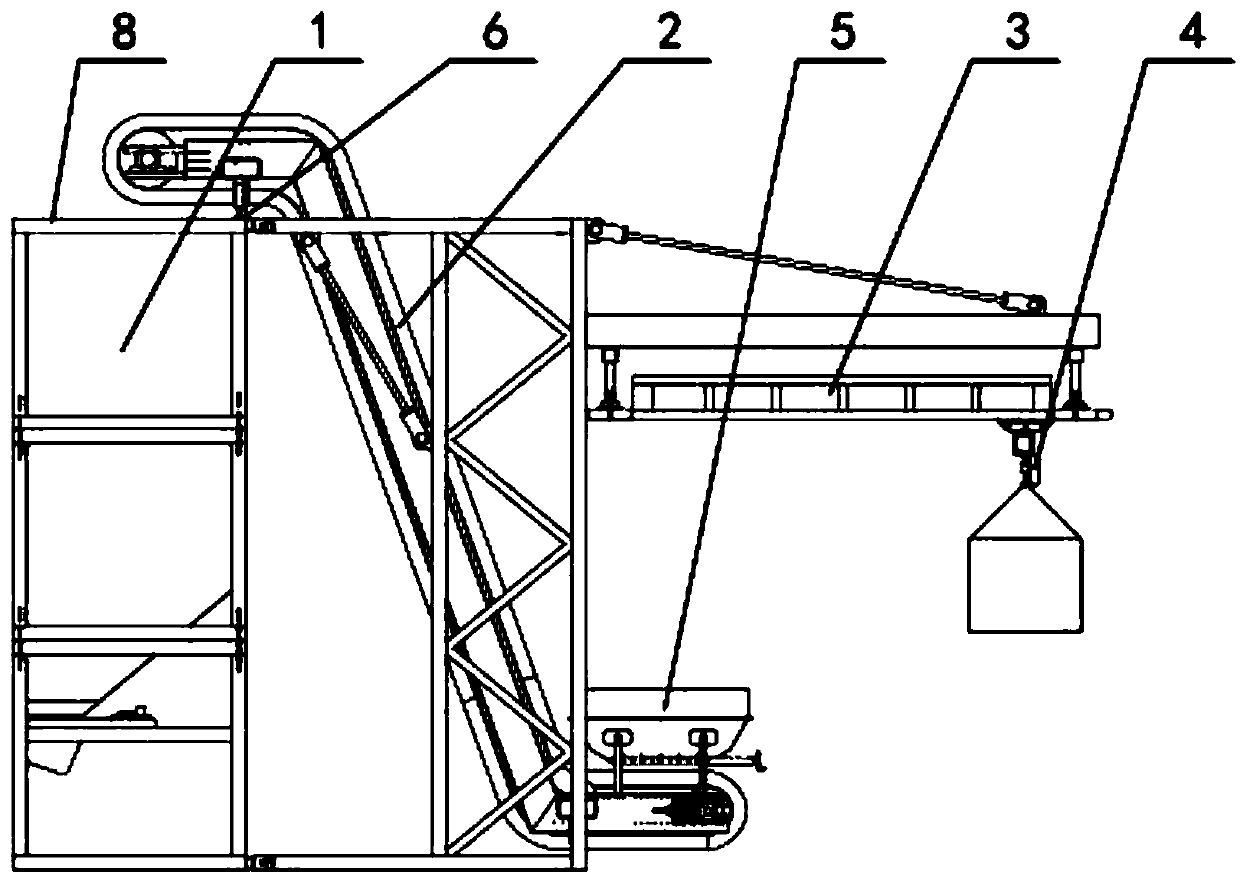

Hoisting derrick specially for coiled tubing equipment

The invention relates to a hoisting derrick specially for coiled tubing equipment. The hoisting derrick comprises a derrick transportation supporting platform, a derrick swinging base, a derrick telescopic boom, a first telescoping cylinder and second telescoping cylinders, which are connected with one another through rotation and articulation; the hoisting derrick is characterized by also comprising an injection head mounting platform, wherein lever arms are arranged on the injection head mounting platform, one ends of the level arms are fixedly connected with the injection head mounting platform, the other ends of the level arms are articulated with the plunger piston ends of the second telescoping cylinders, the cylinder body ends of the second telescoping cylinders are articulated with the derrick telescopic boom, and the level arms and the second telescoping cylinders are arranged in pairs and are arranged on two sides of the derrick telescopic boom respectively. The hoisting derrick has the beneficial effects that the injection head and an oil well can be centered rapidly, the labor intensity of workers is reduced and the mounting cost is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

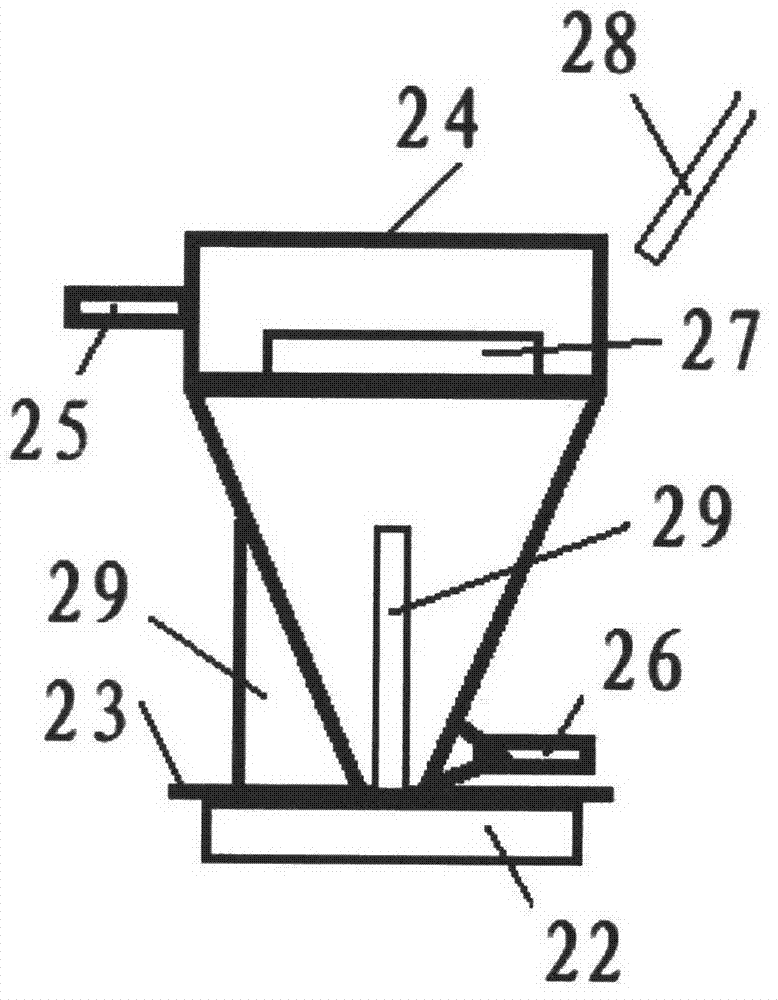

Down filling machine

ActiveCN102808245AStable outputHighly stable suedeUpholstery manufactureOakum treatmentEngineeringUltimate tensile strength

The invention discloses a down filling machine, which comprises a down storage box, weighing cabinets, down filling pipes and a programmable controller, wherein the down storage box is provided with at least two weighing cabinets; at least two weighing boxes are arranged in each weighing cabinet; the total number of the weighing boxes is equal to the total number of down outlets of the down storage box; each weighing cabinet is provided with at least one down filling pipe; the total number of the weighing boxes in each weighing cabinet is dual, and the number of the down filling pipes is a half of the total number of the weighing boxes. According to the down filling machine, the close full-automatic down filling can be carried out, the labor intensity is reduced, the production efficiency is improved, and the production cost is decreased. The down filling machine has the advantages of reasonable design, simple structure, low cost and good practicability. The down storage box of the down filling machine has stable down output, so that the down filling consistence and the down filling precision are ensured; a weighing process of the weighing boxes is independent, precise and effective; the down filling pipes cannot fill the down to airtight cutting pieces; working conditions of the multiple weighing boxes are alternatively changed and one down filling pipe is used for outputting, so that the down filling efficiency is further improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

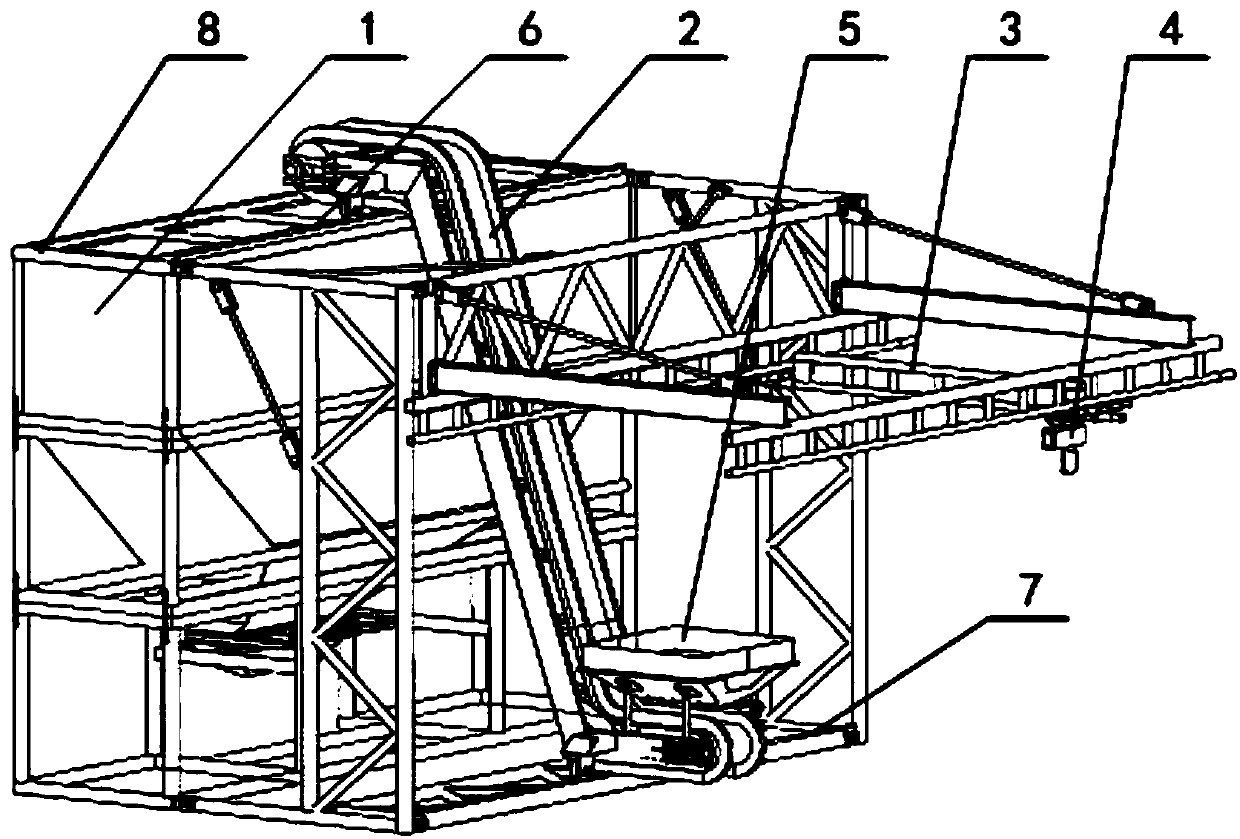

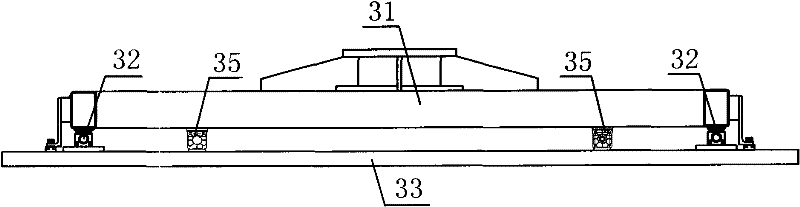

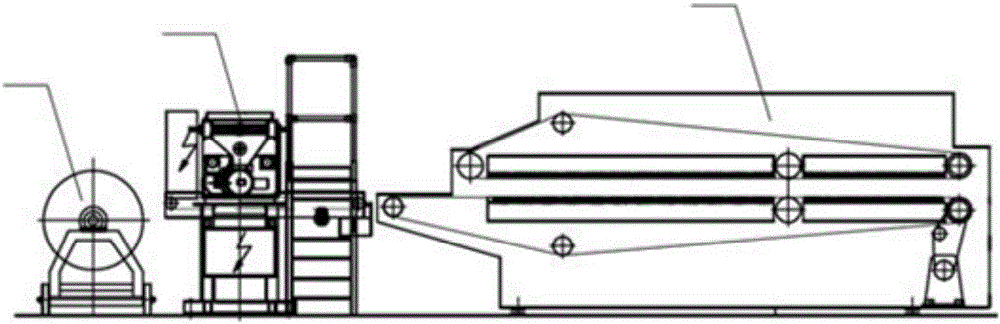

Material hoisting and transportation device

PendingCN107902427ASave on high costsEliminate potential safety hazardsStorage devicesEngineeringOrbit

The invention relates to the oil gas industry, particularly to a material hoisting and transportation device utilized in oil and gas field fracturing operation. The material hoisting and transportation device is characterized in that a material storage tank is mounted on the left of a frame body; an upper orbit is mounted at the upper part of the frame body; a lower orbit is mounted at the right end of the lower part of the frame body; a belt conveying device is mounted on the upper orbit and the lower orbit; a feeding hopper is mounted at the bottom of the belt conveying device; a hoisting device is mounted at the right end of the upper part of the frame body; the hoisting device is mounted in an operation orbit; a hook is mounted on the hoisting device; during operation, the belt conveying device can longitudinally move on the upper orbit and the lower orbit; and during operation, the hoisting device can longitudinally and transversely move in a horizontal plane. The material hoisting and transportation device has a one-key locating function, and automatic operation and locating of the belt conveying device and the hoisting device can be achieved through the function.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

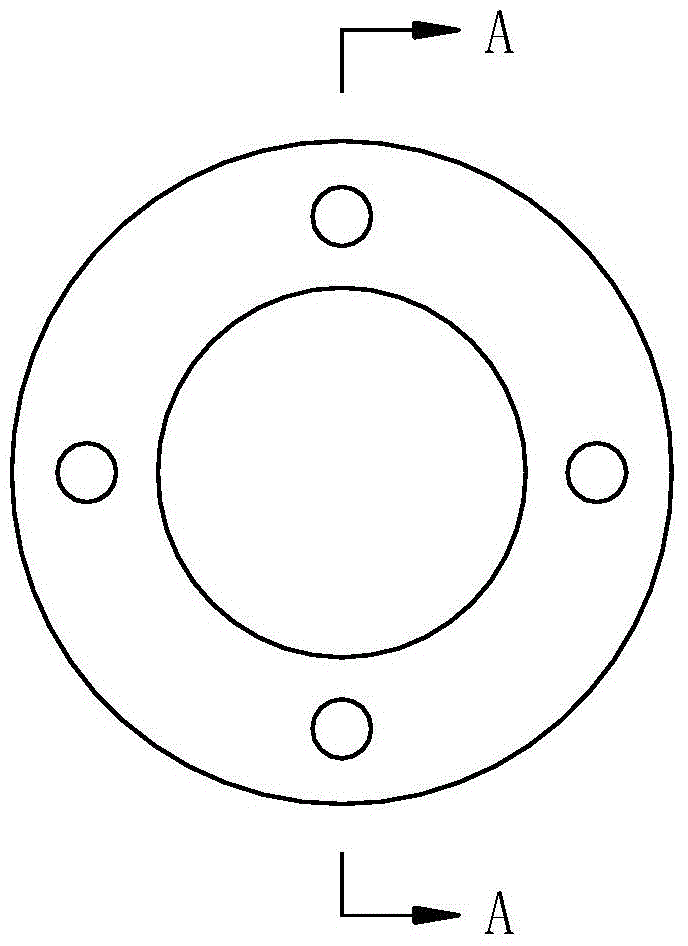

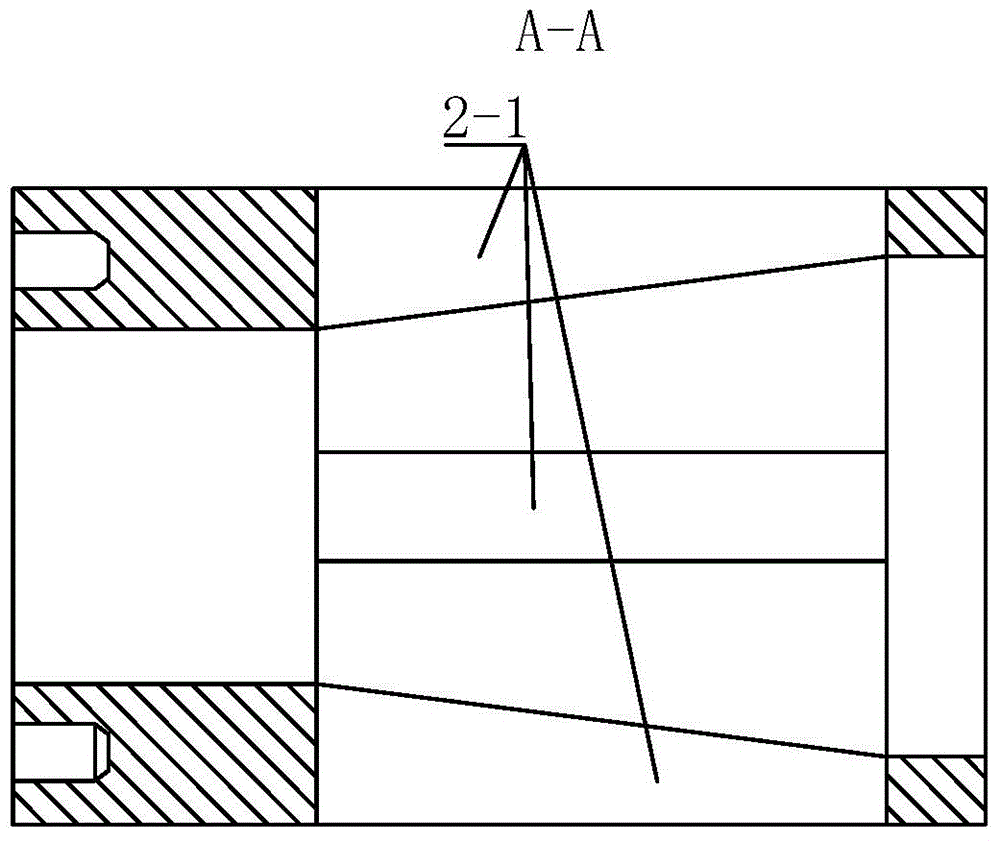

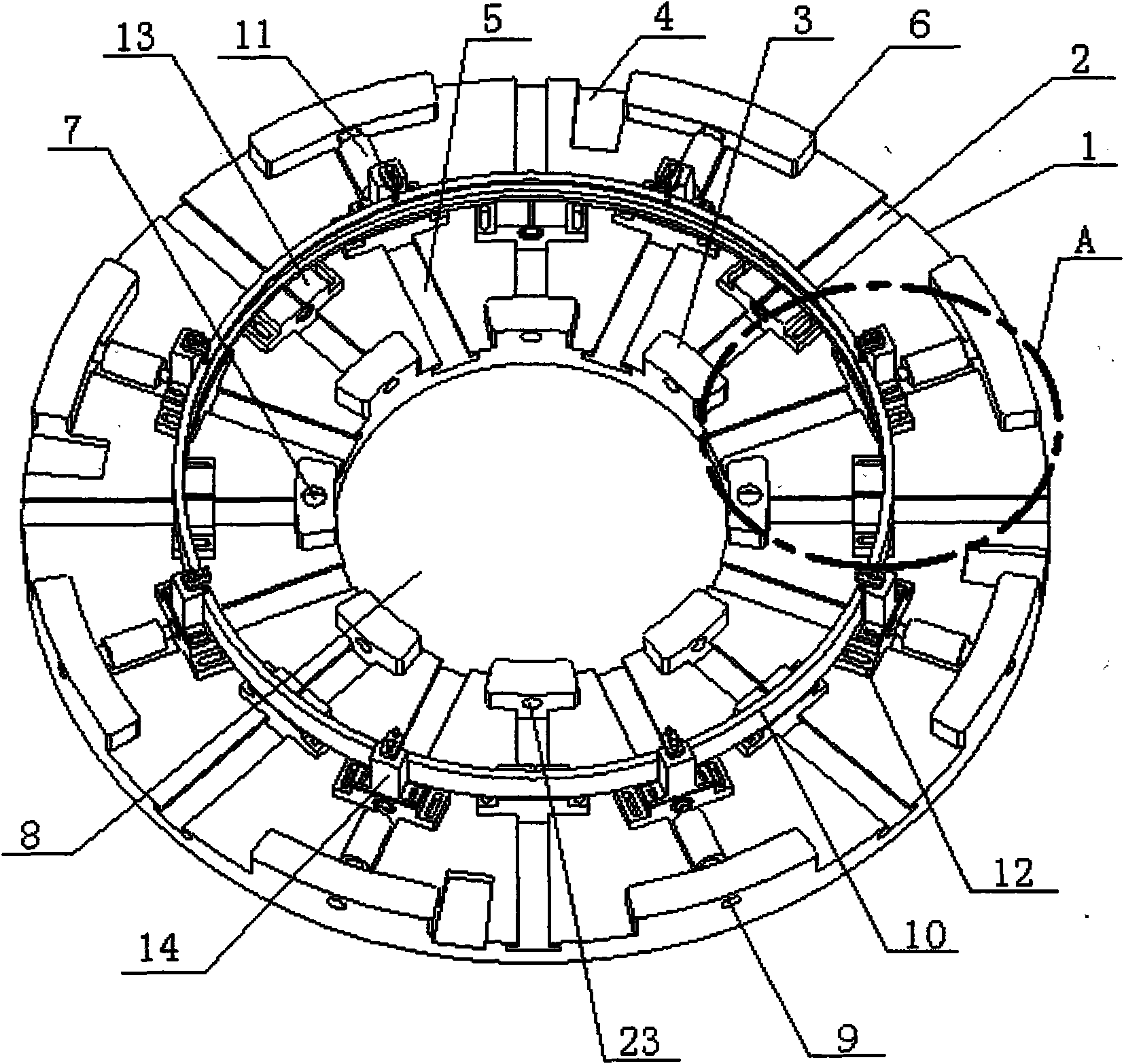

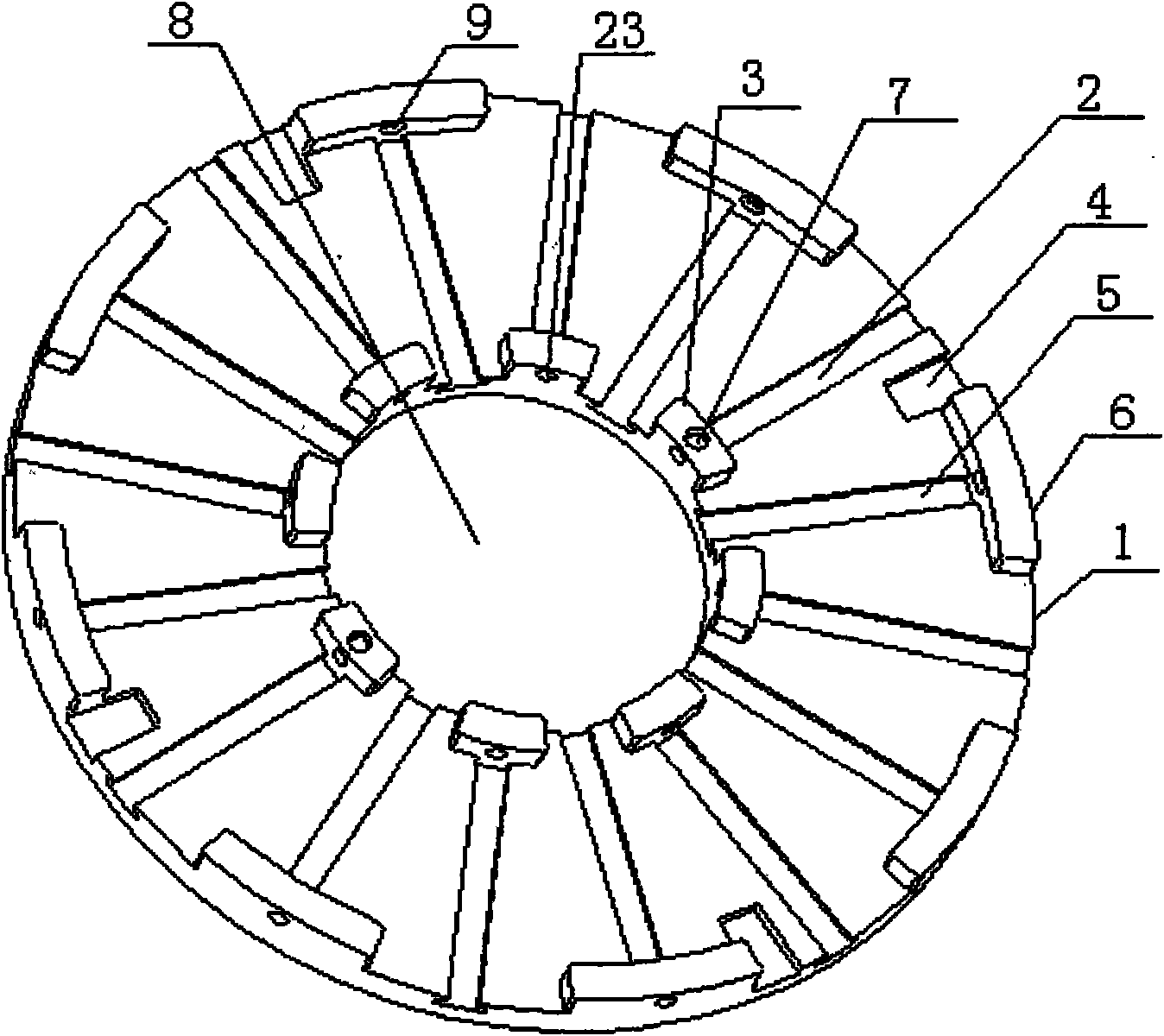

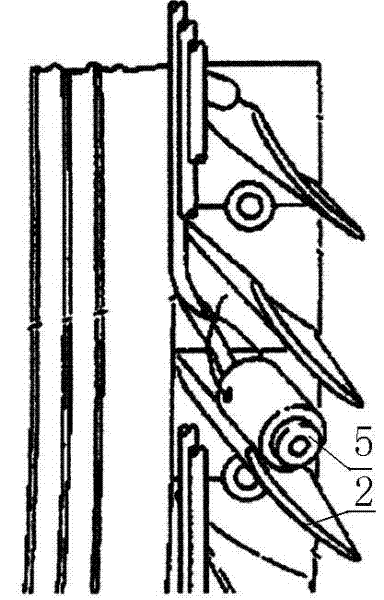

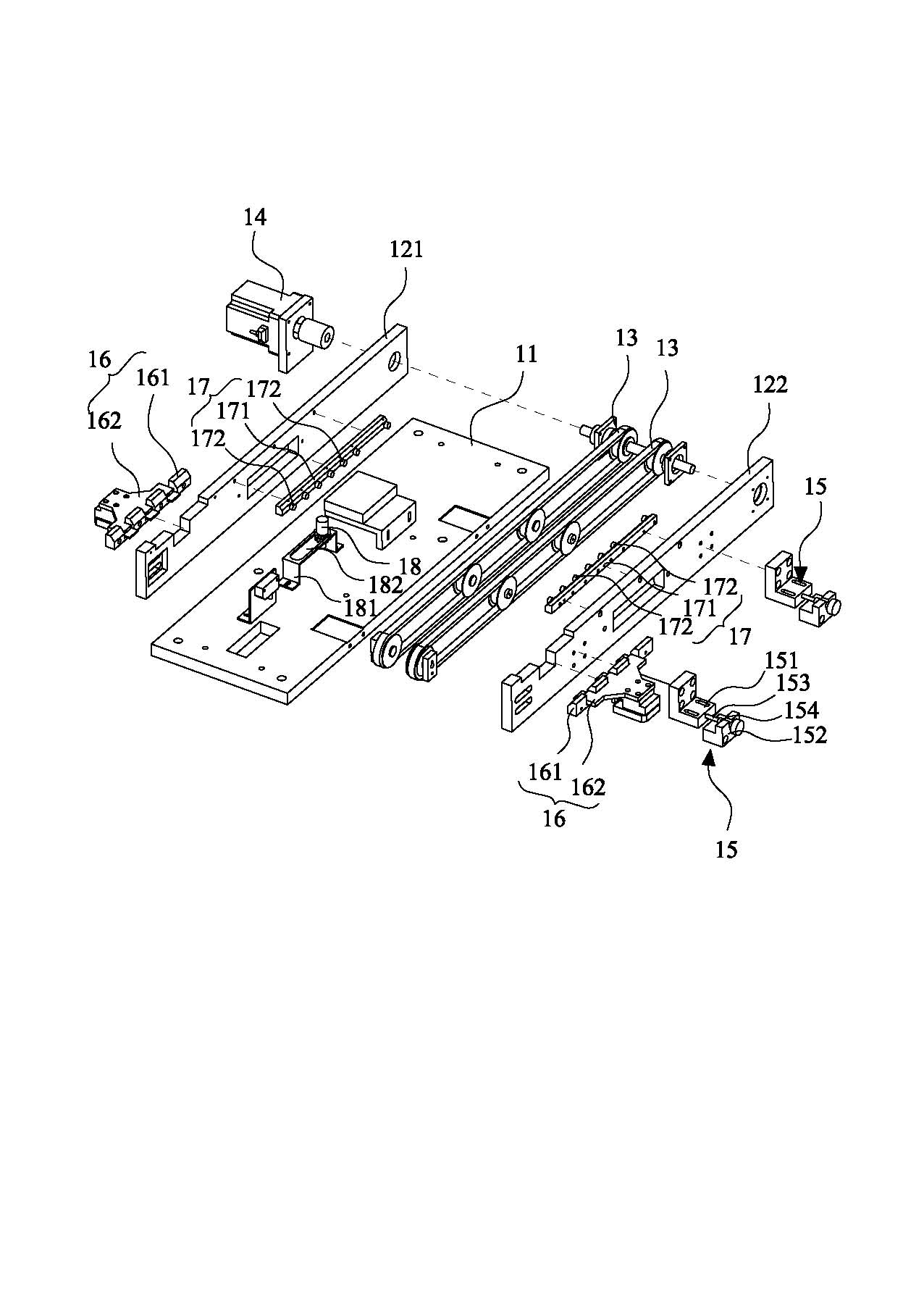

Annular thin-wall article clamping device and using method thereof

ActiveCN101954604AGuaranteed accuracyReduce labor intensityAutomatic conveying/guiding stockPositioning apparatusEngineeringThin walled

The invention provides an annular thin-wall article clamping device and a using method of the device. The clamping device comprises an annular chassis; the chassis is provided with a radial regulation mechanism of a locating workpiece; the radial regulation mechanism is divided into an inner radial regulation mechanism and an outer radial mechanism; two radial regulation mechanisms position workpiece respectively from the inner side or the outer side of the workpiece; the chassis is respectively provided with track-directed sliding grooves for the two radial adjustment mechanisms; the inner end of the sliding groove of the inner radial regulation mechanism is provided with a stopping block; the outer end of the sliding groove of the outer radial regulation mechanism is provided with the stopping block; the sliding grooves of the two groups of radial regulation mechanisms are disposed at intervals; one of the two groups of radial regulation mechanisms is provided with an axial compacting mechanism for fixing the workpiece; and the axial compacting mechanism is displaced alternatively between the two groups of radial regulation mechanisms when turning the workpiece. The clamping device can realize the processing of two side walls of the workpiece by clamping the workpiece once, and is fit for the clamping of the workpieces with different specifications. The device has the characteristics of high use rate, strong practical applicability, good generality, time saving and labor saving, light labor intensity, high production efficiency and the like.

Owner:DONGFANG TURBINE CO LTD

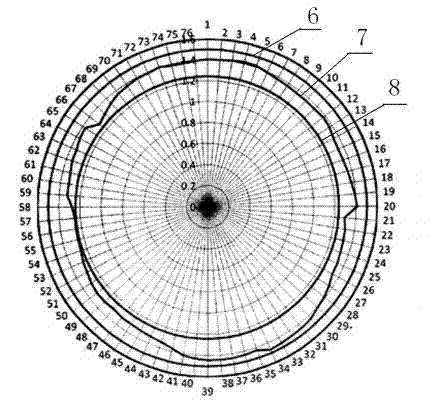

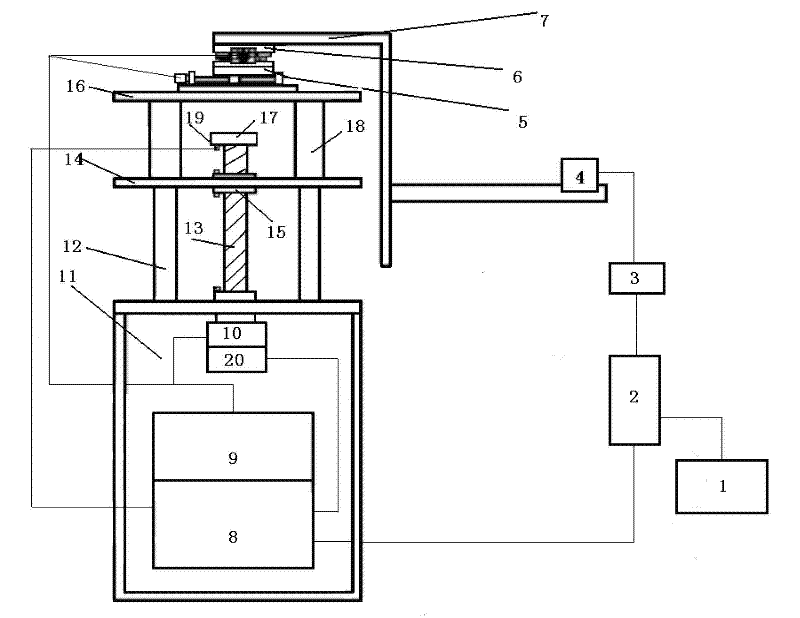

Non-contact measuring method for leaf apex radial clearance of engine rotor

InactiveCN102175135AImprove assembly qualityReduce disassemblyEngine testingUsing electrical meansCapacitanceFailure rate

The invention relates to a non-contact measuring method for a leaf apex radial clearance of an engine rotor, and the method comprises the following steps: 1) assembling a measuring system, calibrating a sensor and determining the relation between the radial clearance and voltage of a leaf apex; 2) preparing before measuring; and 3) measuring the leaf apex radial clearance of the engine rotor. In the measuring method provided by the invention, a measurement technique based on a capacitance method is adopted; the measuring course and the assembling are synchronously carried out; the once cartridge disassembly and assembly is reduced; the measuring time is shortened; the production efficiency is improved; and the measuring accuracy is improved, thereby improving the assembly quality of an engine and reducing the failure rate of the engine. The non-contact measuring method provided by the invention is mainly used for measuring the leaf apex radial clearance of the rotors of parts such as an engine, a high-pressure compressor, a low-pressure compressor, a high-pressure turbine, a low-pressure turbine and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

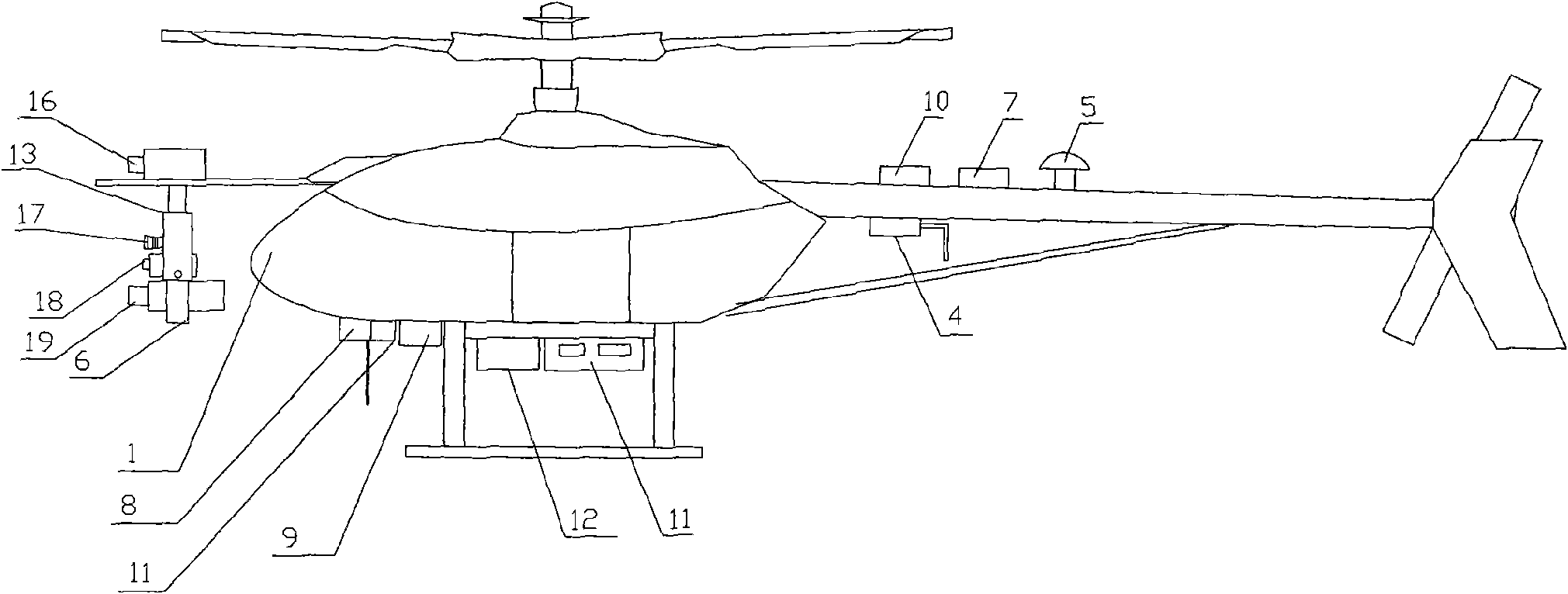

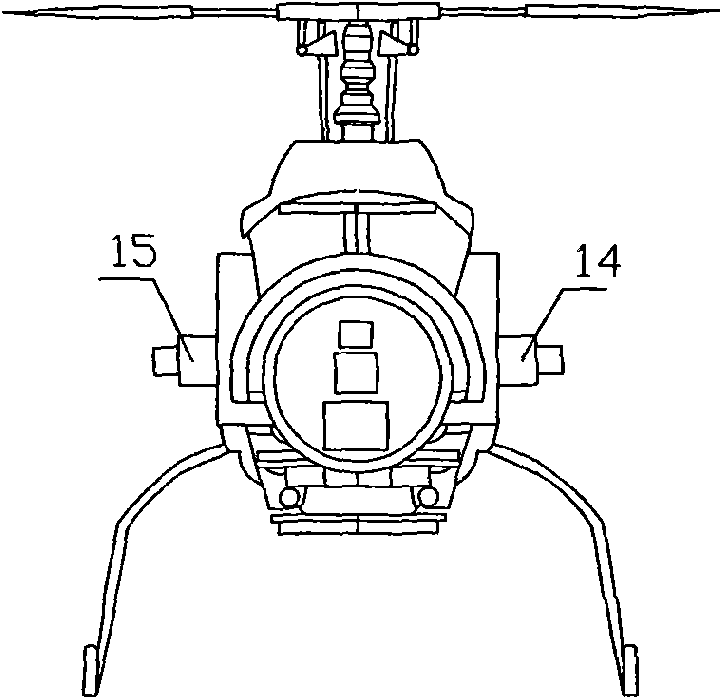

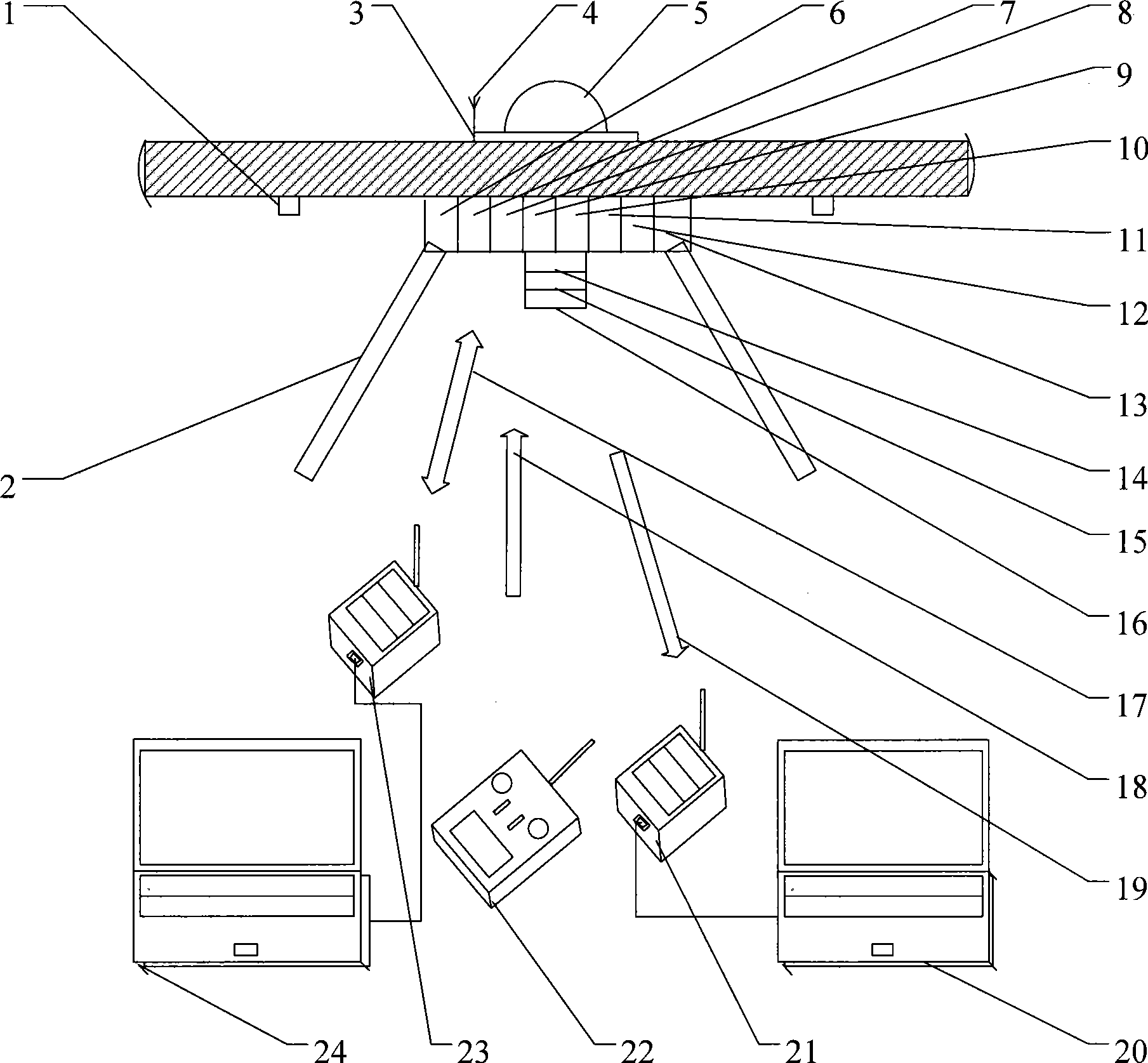

Unmanned helicopter system for patrolling trolly wire route and tower and method thereof

ActiveCN101604830AReduce labor intensityReduce riskTesting dielectric strengthRadiation pyrometryControl equipmentMarine engineering

The invention discloses an unmanned helicopter system for patrolling trolly wire routes and towers and a method thereof. The unmanned helicopter system adopts an unmanned helicopter carrying a detection device, a control device and a communication device, and patrols the trolly wire routes and the towers along a trolly wire route passage. The method can cope with complex and changeable surface features to finish detecting the defects of the devices of the trolly wire routes and the towers. The structure of the unmanned helicopter system comprises an unmanned helicopter, a remote controller and a ground control car, wherein, the unmanned helicopter is provided with a flight control system and a patrolling detection system; the two systems are both wirelessly communicated with the ground control car; the ground control car remotely carries out remote control for the unmanned helicopter and analyzes and processes patrolling detection results.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

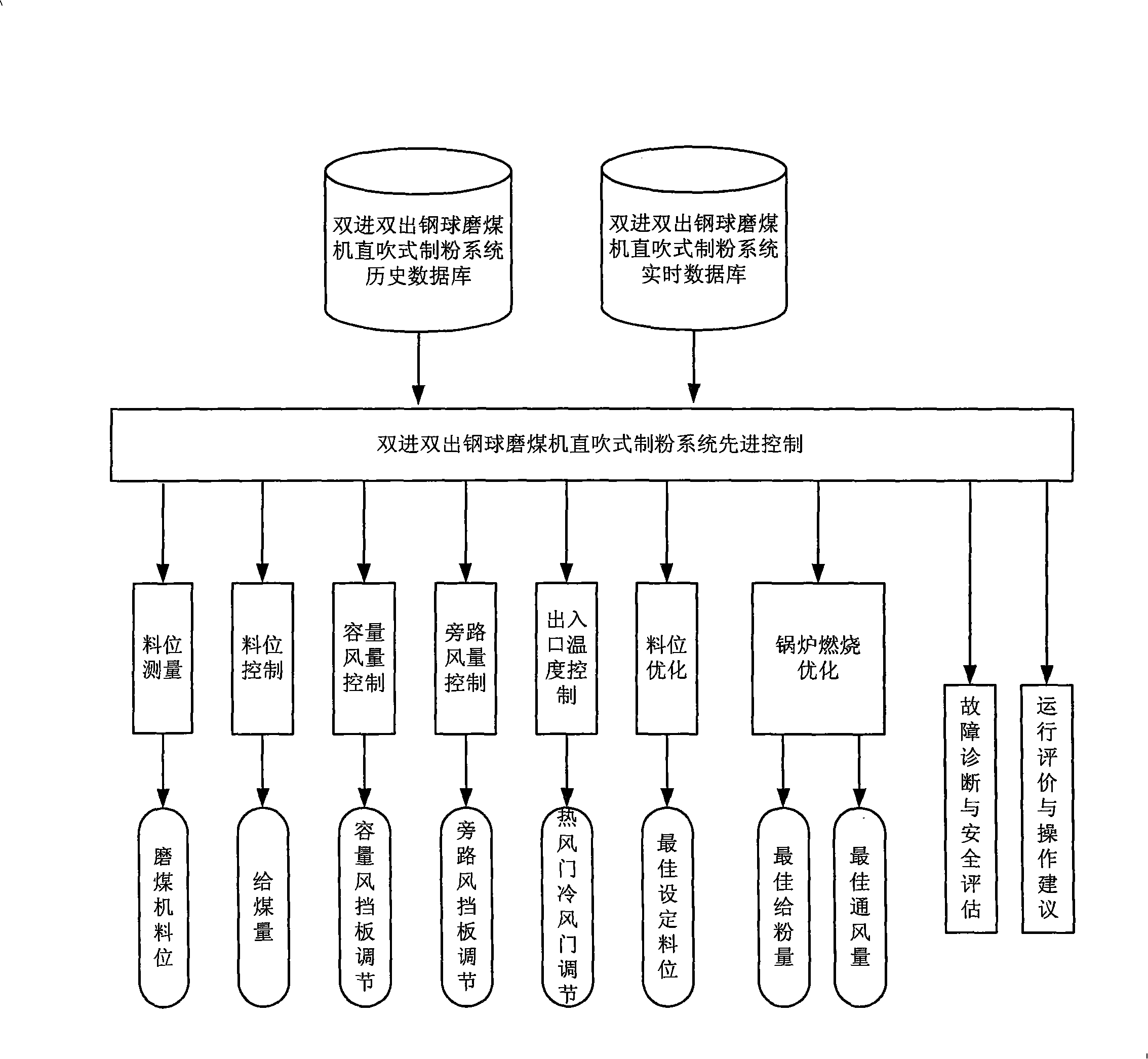

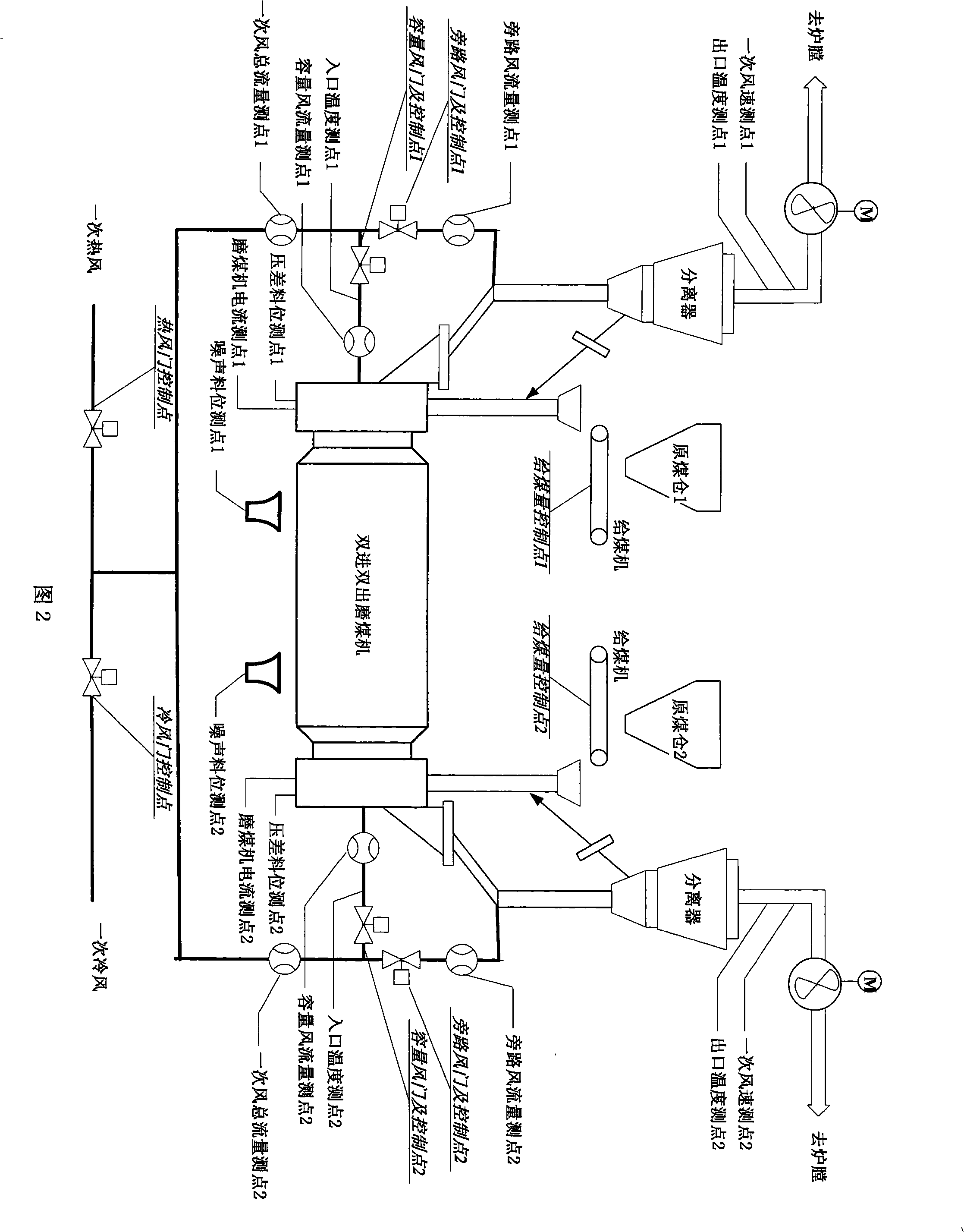

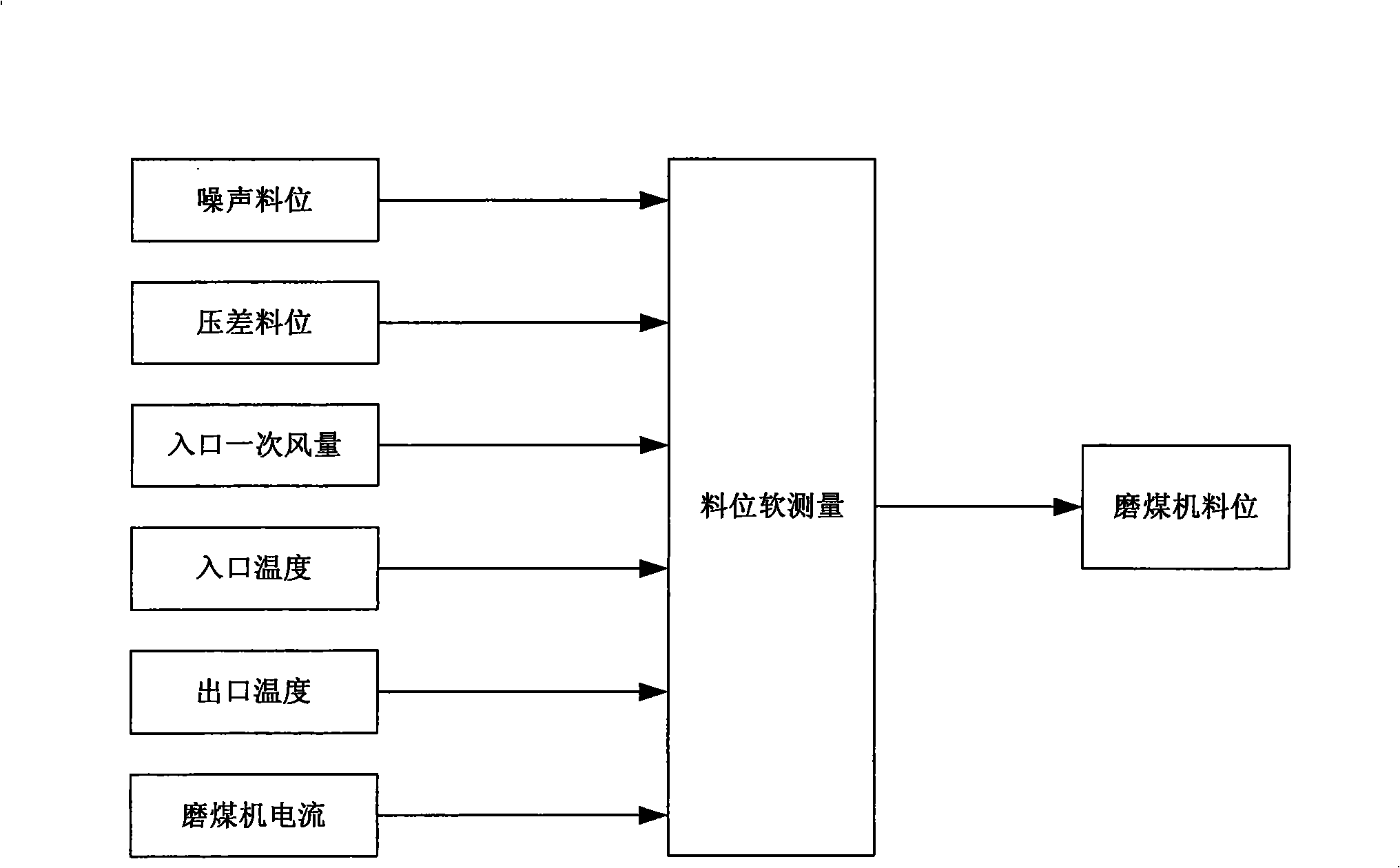

Double-inlet double-outlet steel ball coal mill straight blowing type milling system optimized control method

ActiveCN101334666AImprove combustion efficiencyGuaranteed uniformityGrain treatmentsProgramme total factory controlTemperature controlCombustion

The invention discloses an optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method. The method obtains the material position of the coal grinding machine after carrying out soft-measurement processing by collecting the noise material position of the coal grinding machine, the material position of pressure difference, the current of the coal grinding machine, one-time air quantity, one-time opening of the hot wind door and the cold wind door of an inlet, inlet temperature and outlet temperature; the control comprises material position control, air quantity capacity control, bypass air quantity control and the temperature control of the inlet and the outlet; the material position is optimized and the best material position of the coal grinding machine is searched online so as to ensure the combustion safety of the boiler and coal powder supply quantity when the load of the boiler is adjusted. The boiler combustion is optimized: according to the boiler technology, the load and the running working conditions, the powder supply quantity and the ventilation quantity of each coal grinding machine are optimized and the combustion efficiency of the boiler is improved. Malfunction diagnosis, running evaluation and analysis are carried out to the system and reasonable suggestions are provided so as to ensure the system to run continuously, stably, safely and economically; the optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method is widely applied to the dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation system or industrial similar systems in other industries.

Owner:西安蓝海机械仪表成套有限责任公司

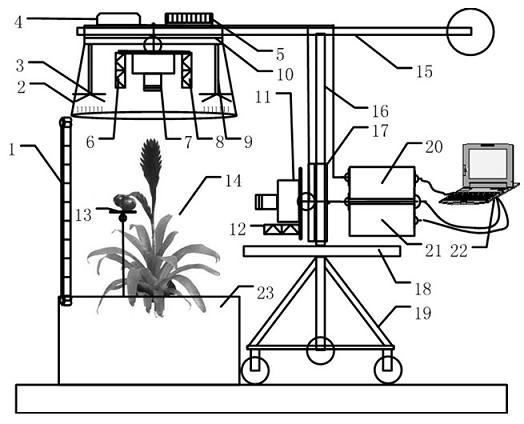

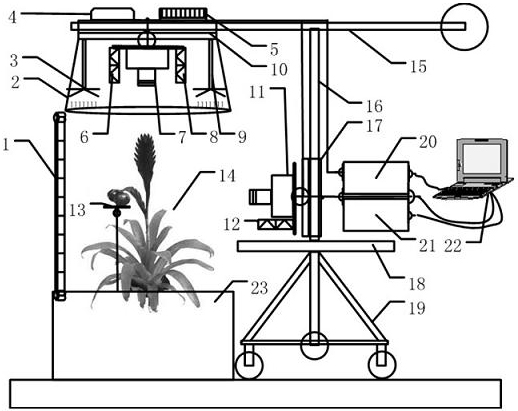

Nondestructive detection device and method for facility crop growth information

ActiveCN102384767AGrasp the state of growthImprove acquisitionMeasurement devicesPotassiumCharacteristic space

The invention discloses a nondestructive detection device and a nondestructive detection method for facility crop growth information, and belongs to the technical field of monitoring of facility crops. The device comprises a growth information sensing system, an electric control mechanical rocker arm and a control computer; the control computer drives the electric control mechanical rocker arm to be positioned at a detection position, and controls the growth information sensing system; reflection spectrums of nitrogen, phosphorus, potassium and moisture of crops, multispectral images, canopy temperature characteristic, multispectral morphological characteristics of canopies, stalks, plants and fruits, fruit quality information, and information of environmental illumination, temperature and humidity are acquired by using a multispectral imager and sensors of infrared temperature, irradiance, environmental temperature and humidity and load; nutrient and moisture characteristic spaces are acquired by optimizing and compensating the nutrient and moisture characteristics of the crops; and growth vigor information of canopy area, stalk thickness, fruit quality, plant height and the like is acquired by extracting the multispectral morphological characteristics of the crops, and comprehensive acquisition and nondestructive detection of the growth information of the crops are realized by combining nutrient, moisture and growth vigor characteristics.

Owner:JIANGSU UNIV

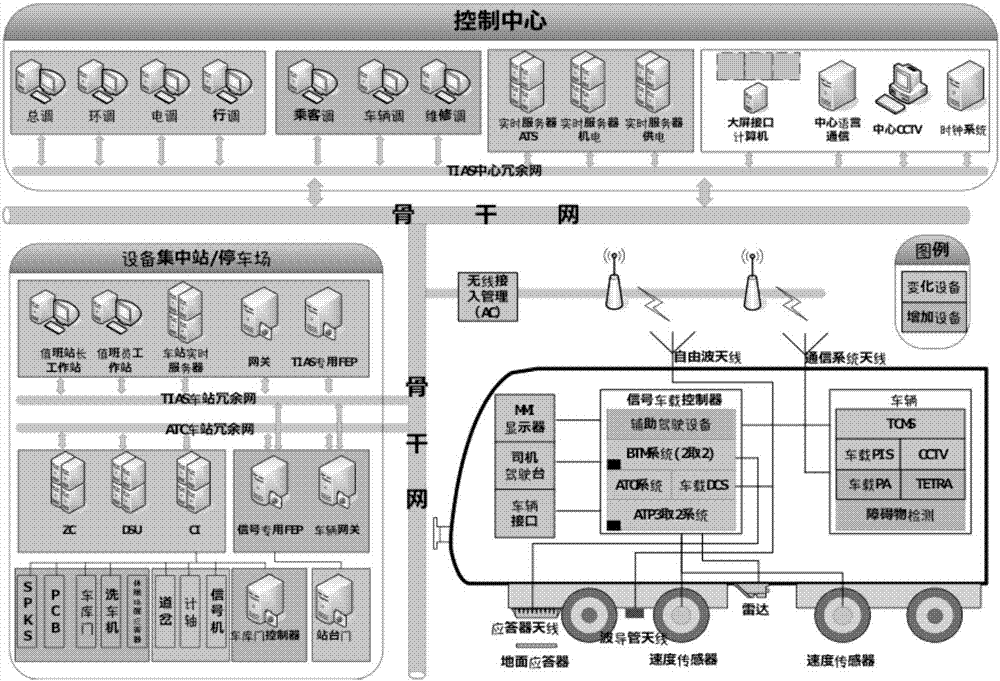

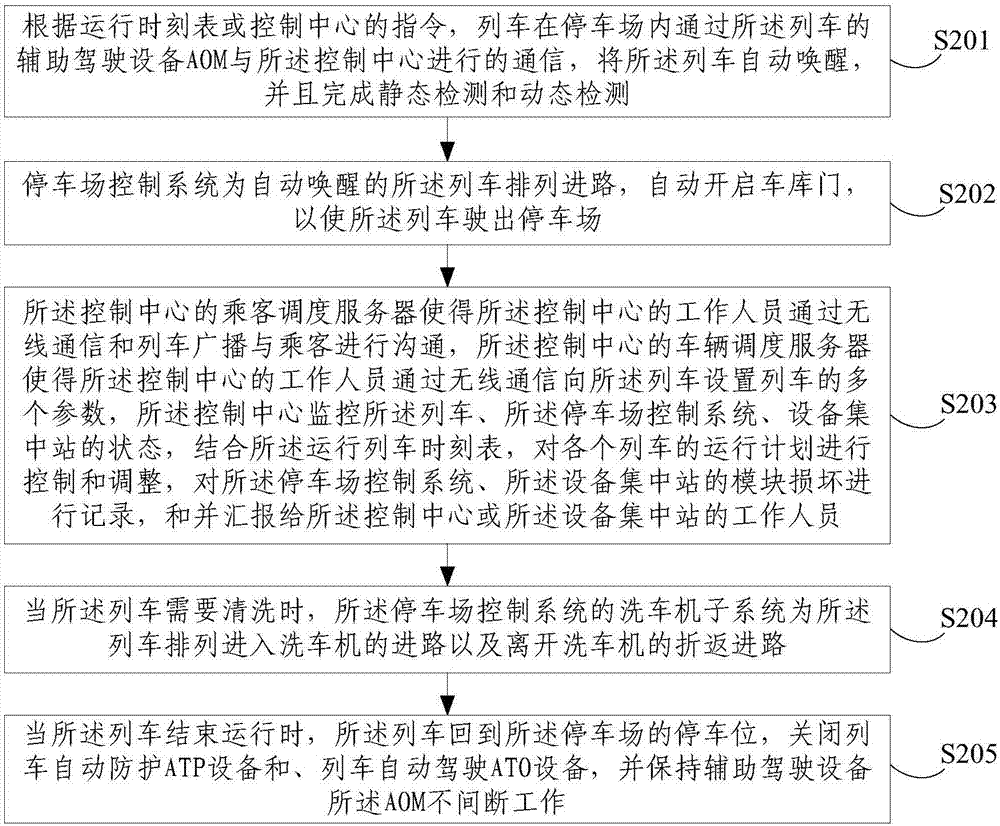

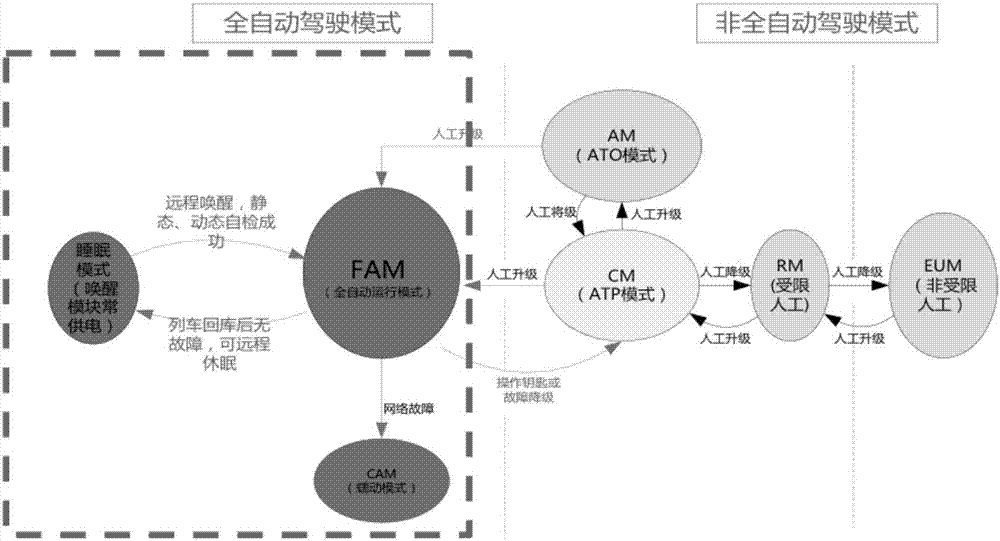

Train full-automatic running method and system

ActiveCN107226099ARealize fully automatic operationImprove reliabilityAutomatic systemsLocomotivesAutomatic train protectionProgram planning

The invention provides a train full-automatic running method and system. The train full-automatic running method comprises the following steps that according to a running schedule or a command of a control center, trains are automatically awakened, and static detection and dynamic detection are completed; a parking lot control system performs route arrangement on the trains which are automatically awakened; the control center monitors the condition of the trains, the condition of the parking lot control system and the condition of an equipment centralization station, and controls and adjusts the running plan of each train combining the running schedule; when the trains need cleaning, a train washing machine sub system of the parking lot control system arranges a route for the trains to enter the train washing machine and a reentrant route for the trains to leave from the train washing machine; and when the trains stop running, automatic train protection ATP equipment and automatic train operation ATO equipment are closed, and AOM is kept working continuously. Compared with a conventional CBTC system, the train full-automatic running method disclosed by the invention realizes full-automatic running, the reliability, the safety, the availability and the maintainability of the train full-automatic running system are further improved, the operating emergency handling level is improved, the automation level is improved, and the labor strength is reduced.

Owner:TRAFFIC CONTROL TECH CO LTD

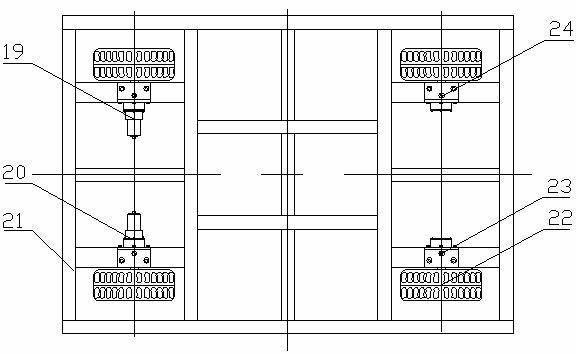

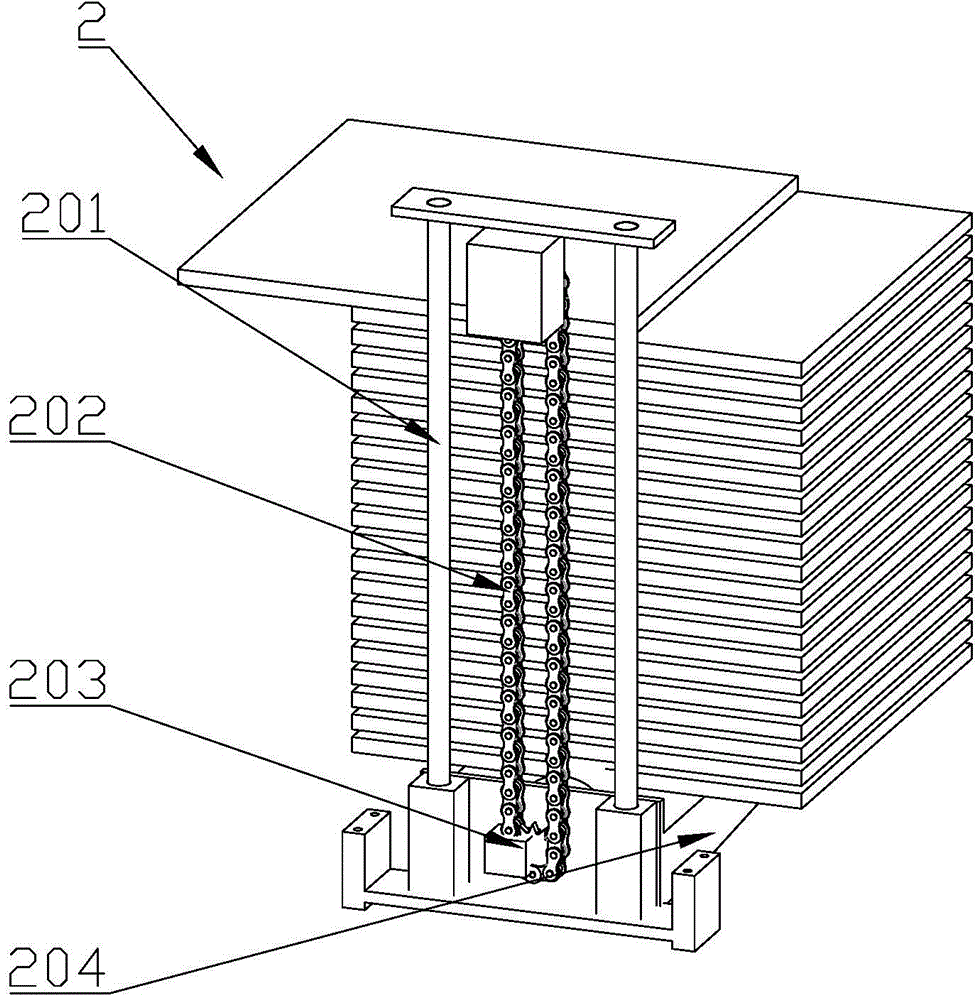

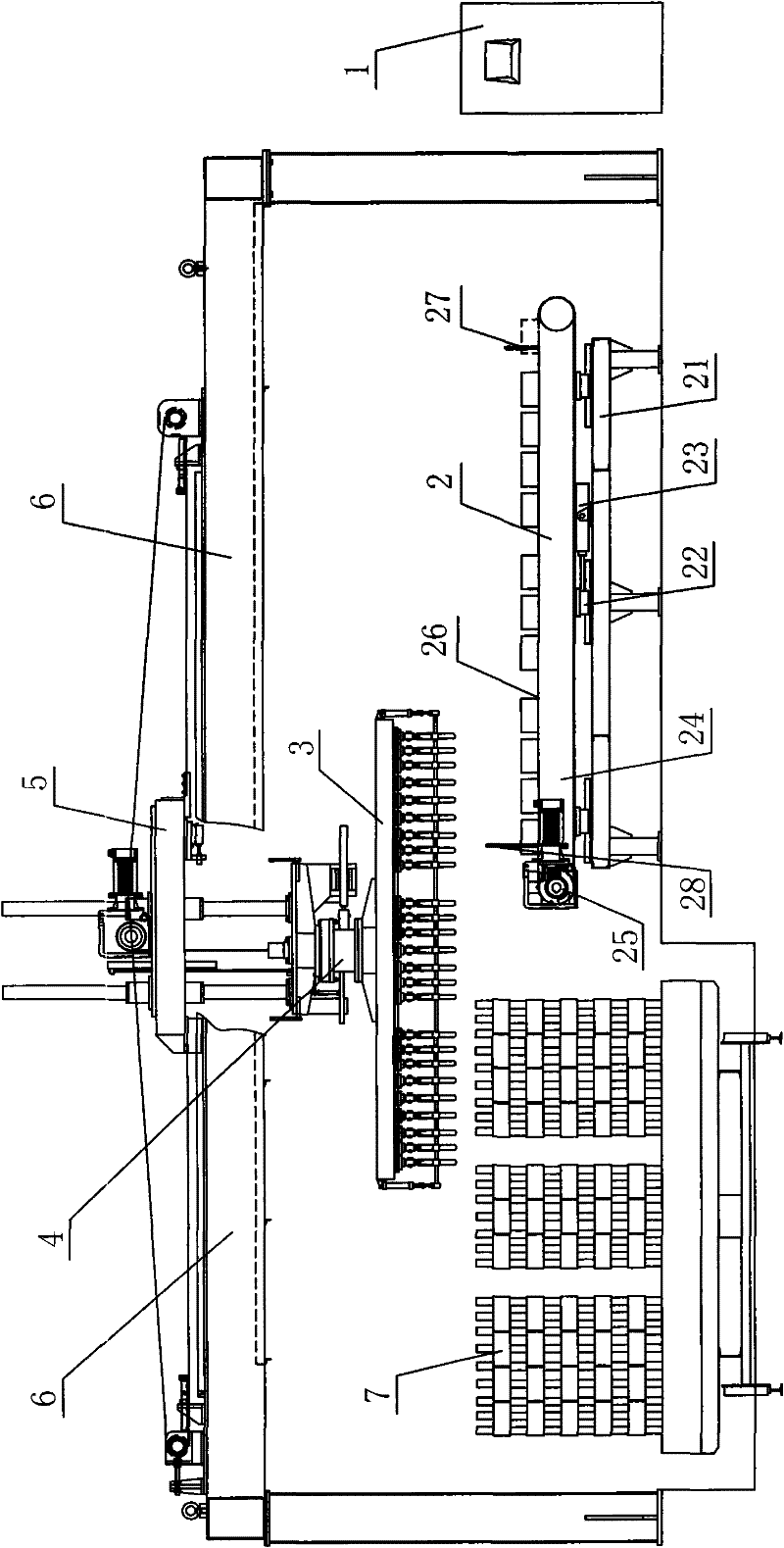

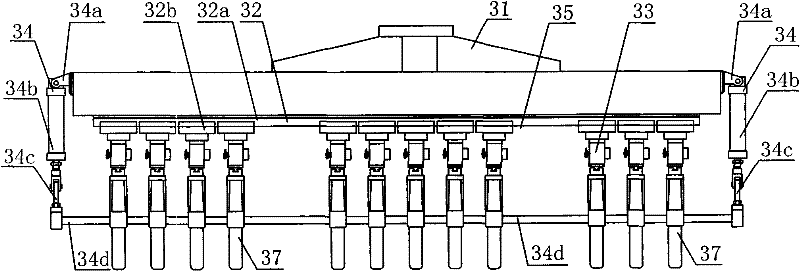

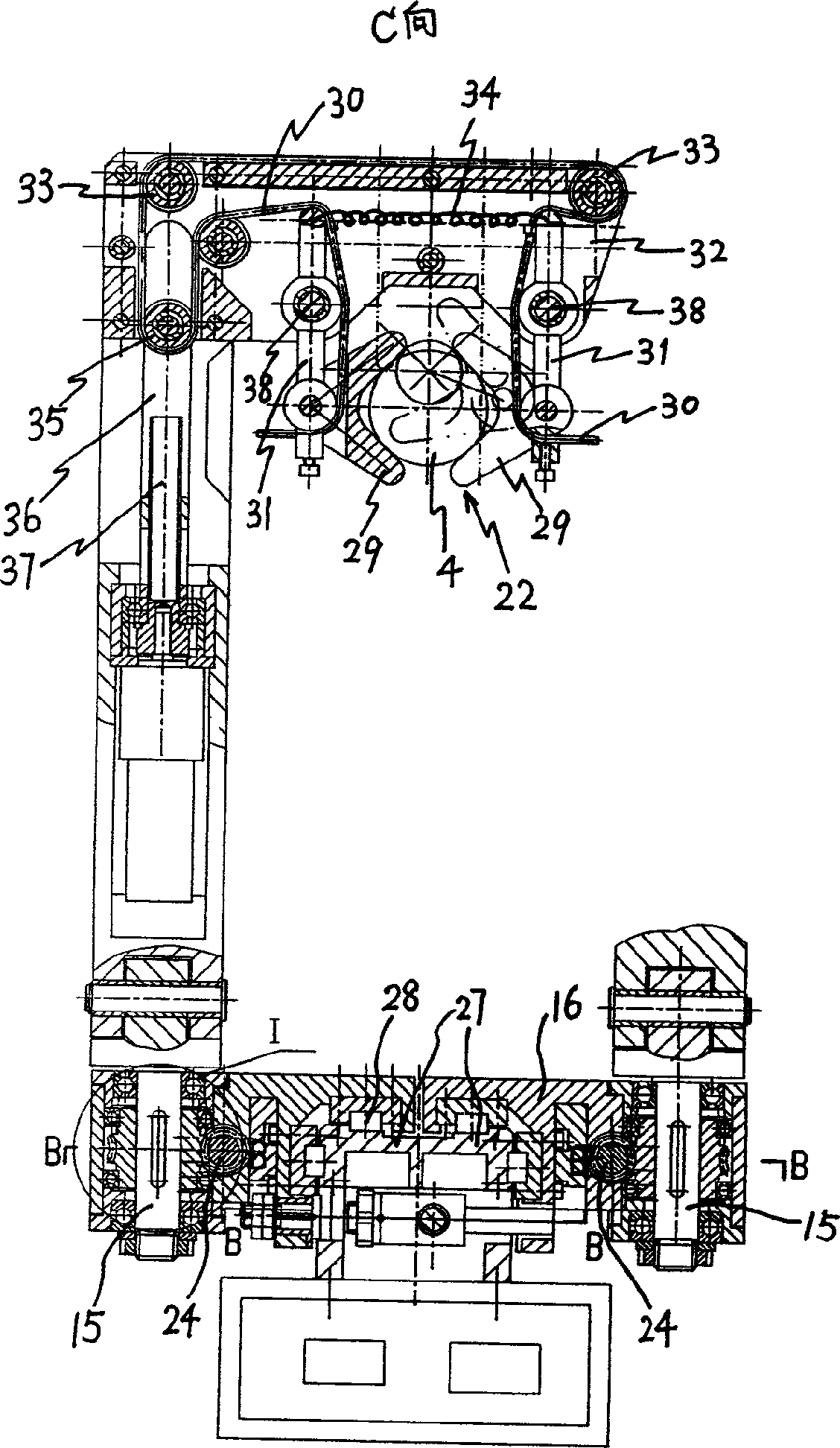

Automatic adobe stacking device

ActiveCN102225719AIncrease productivityImprove stack qualityDischarging arrangementStacking articlesAutomatic controlMechanical engineering

The invention provides an automatic adobe stacking device. The device comprises an automatic control device, an adobe group conveying mechanism, a horizontal travelling mechanism, a vertical lifting mechanism arranged on the horizontal travelling mechanism, a rotation mechanism fixed on the lower end of the vertical lifting mechanism and an adobe grabbing mechanism fixed on the lower end of the rotation mechanism, wherein the adobe group conveying mechanism is arranged below the adobe grabbing mechanism; and the automatic control device is respectively connected with the adobe group conveyingmechanism, the horizontal travelling mechanism, the vertical lifting mechanism, the rotation mechanism and the adobe grabbing mechanism so as to control the operation of the mechanisms. The adobe automatic stacking device has the advantages of accurate positioning, stable direction steering, neatly stacked adobes, firmly overlapped upper and lower adobes, simple structure, high automatic degree and easiness for operation, so that the labor intensity of workers is reduced, the production efficiency of stacking is greatly improved, and the stacking quality of adobe stacks is improved.

Owner:信阳雄狮装备科技股份有限公司

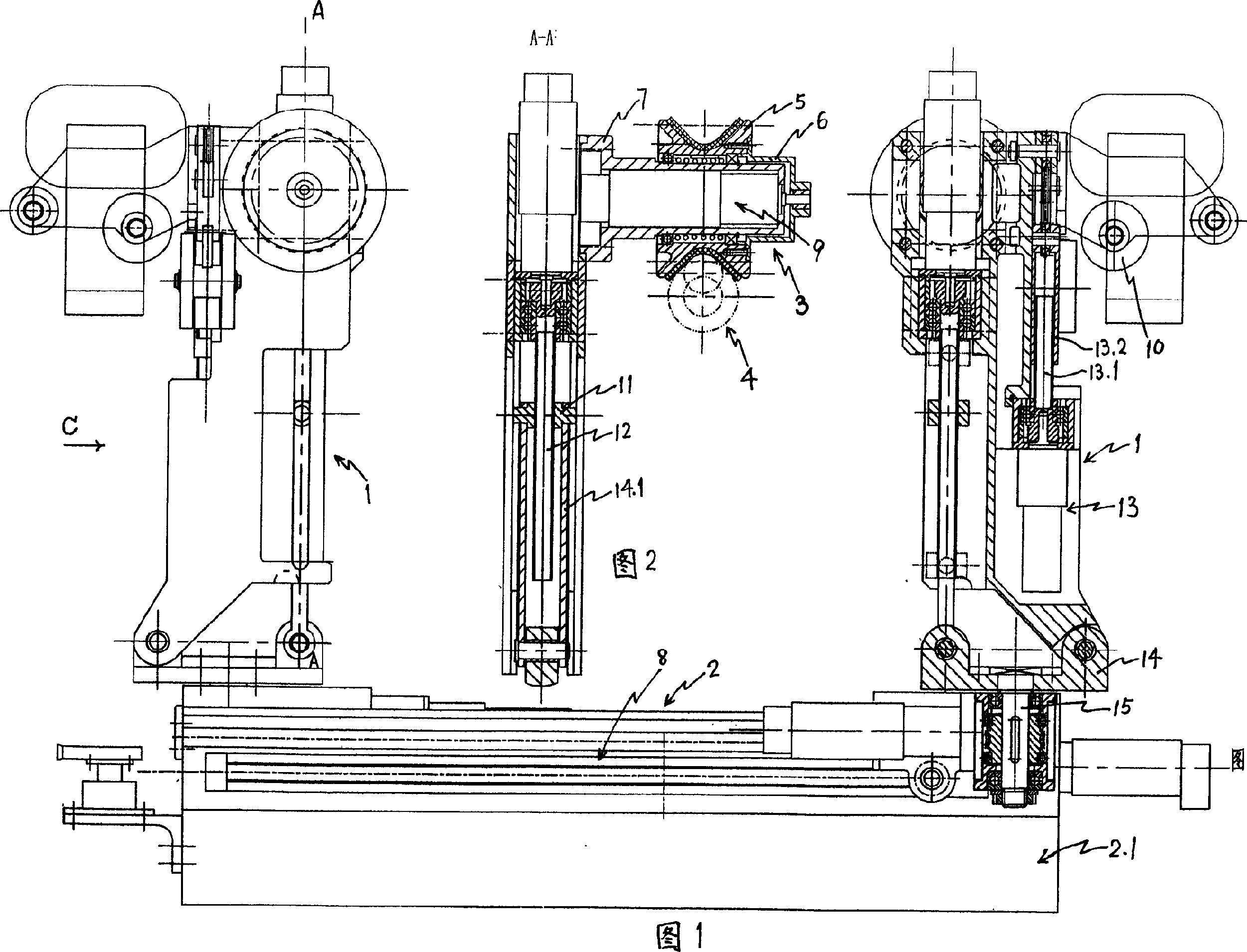

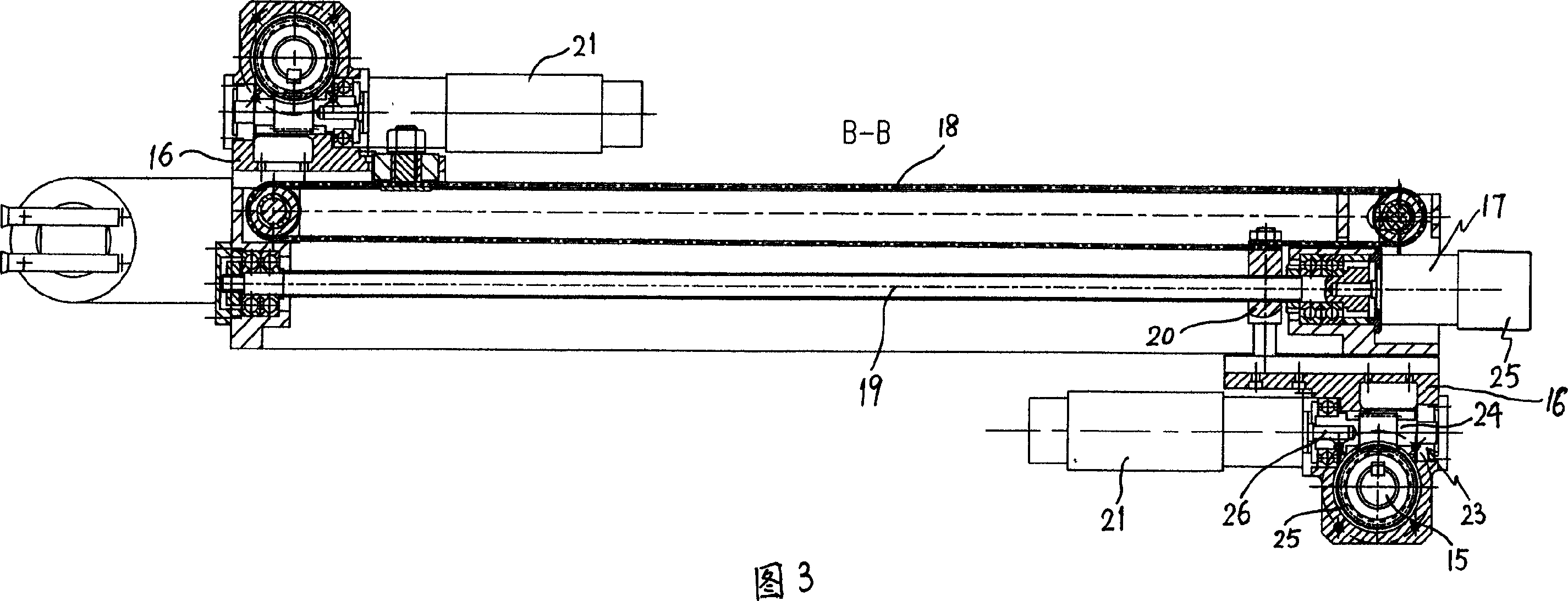

Robot travelling along overhead high voltage transmission line

InactiveCN1647898AImprove inspection accuracyReduce labor intensityManipulatorDrive wheelHigh pressure

The robot capable of traveling along overhead high voltage transmission line includes one pair of small arm manipulator mechanisms with four freedoms each, one large arm transmission mechanism connected to the lower ends of the small arm manipulators to change the interval between two small arms, and one terminal executing mechanism over the small arms and with one driving wheel hanging on the transmission line, one driving mechanism, one driven wheel and one transmission line grasping clamp mechanism. The present invention has the advantages of wide application range, high efficiency, high safety and high polling precision. The robot of the present invention can realize various motions for polling in the whole transmission line.

Owner:WUHAN UNIV +1

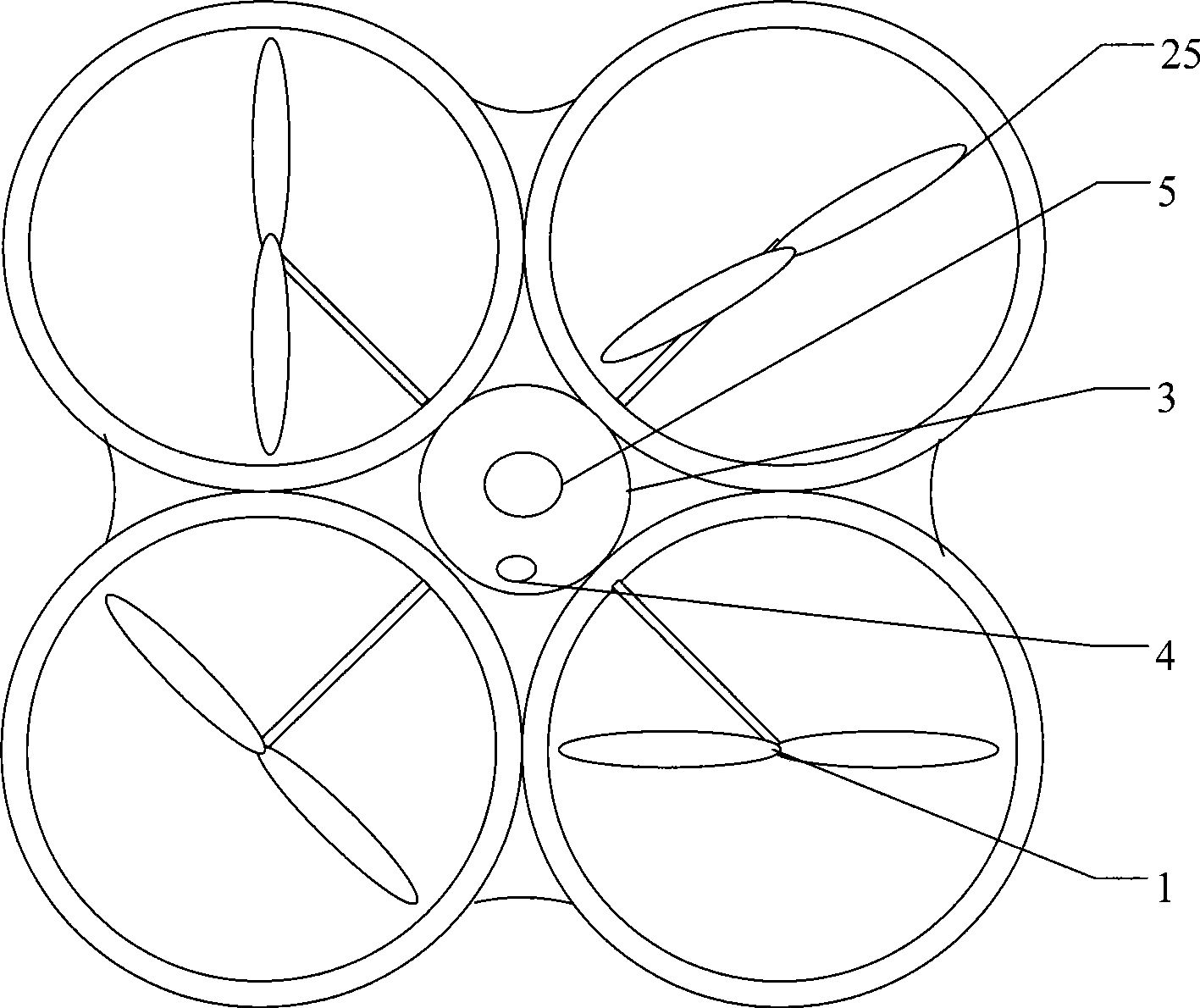

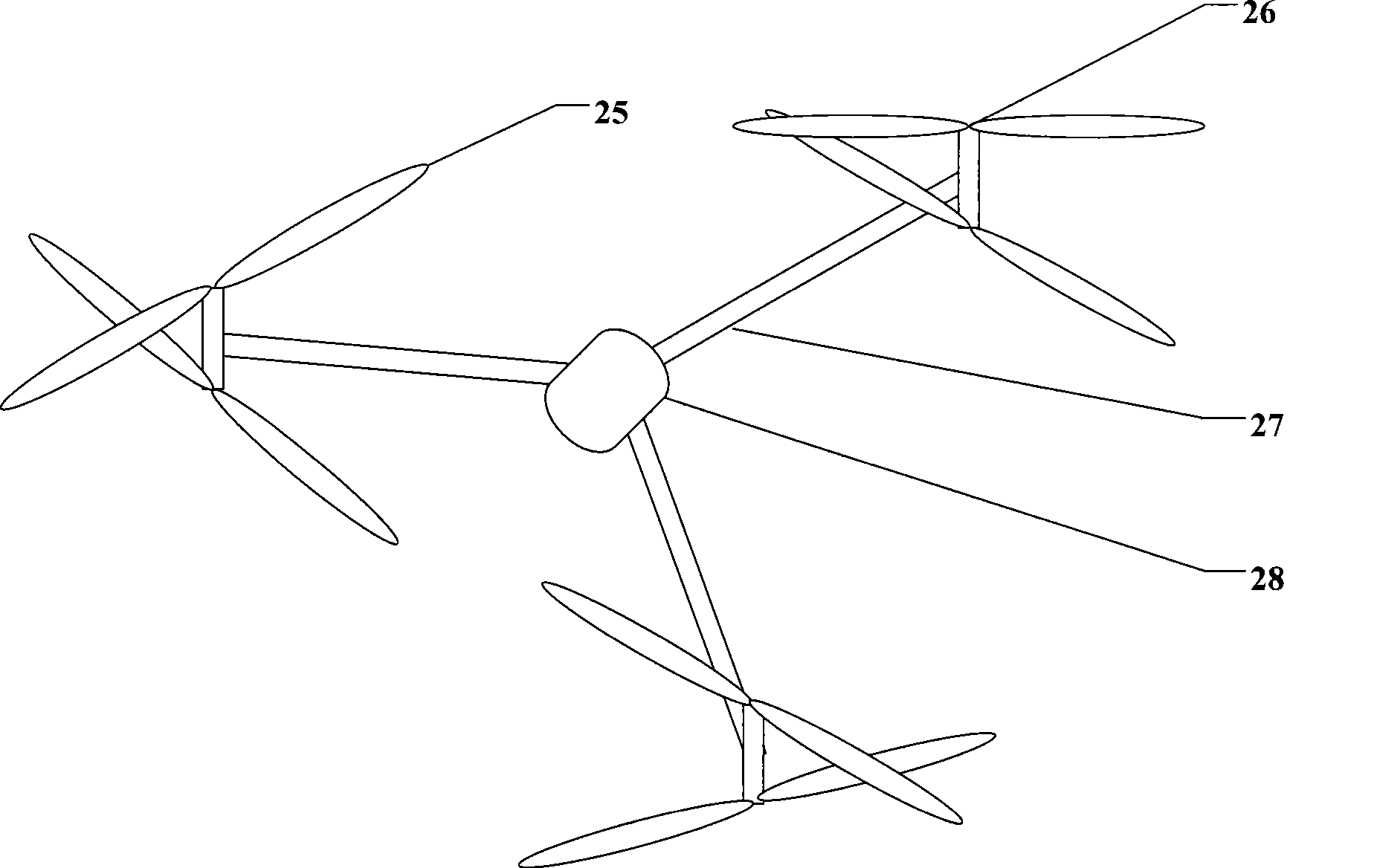

Flying robot for detecting transmission line insulator

InactiveCN101381002AImprove securityBest measurement distanceVehicle position/course/altitude controlPosition/direction controlFly controlBrushless motors

The invention discloses a flying robot used for detecting transmission line insulator in the field of aircraft control and image transmission technique. The technical proposal is that the flying robot used for detecting the transmission line insulator consists of a three-axis aircraft or four-axis aircraft, a flying control system and an objective recognition system; the power part of the three-axis aircraft consists of three pairs of airscrews, three coaxial motors and three supporting arms; the power part of the four-axis aircraft consists of 4 direct-drive brushless motors and four airscrews; the flying control system consists of an on-board self-control system and a ground station control system; the objective recognition system consists of on-board mission load and a ground image processing system. By installing a precise navigation system on the flying robot, the flying robot exactly flies in the space above the insulator to be detected; by adopting the image gaining and transmission system, the zero-value insulator is exactly detected, the labor intensity is lightened, and the safety of the detection personnel is improved during the detection process.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

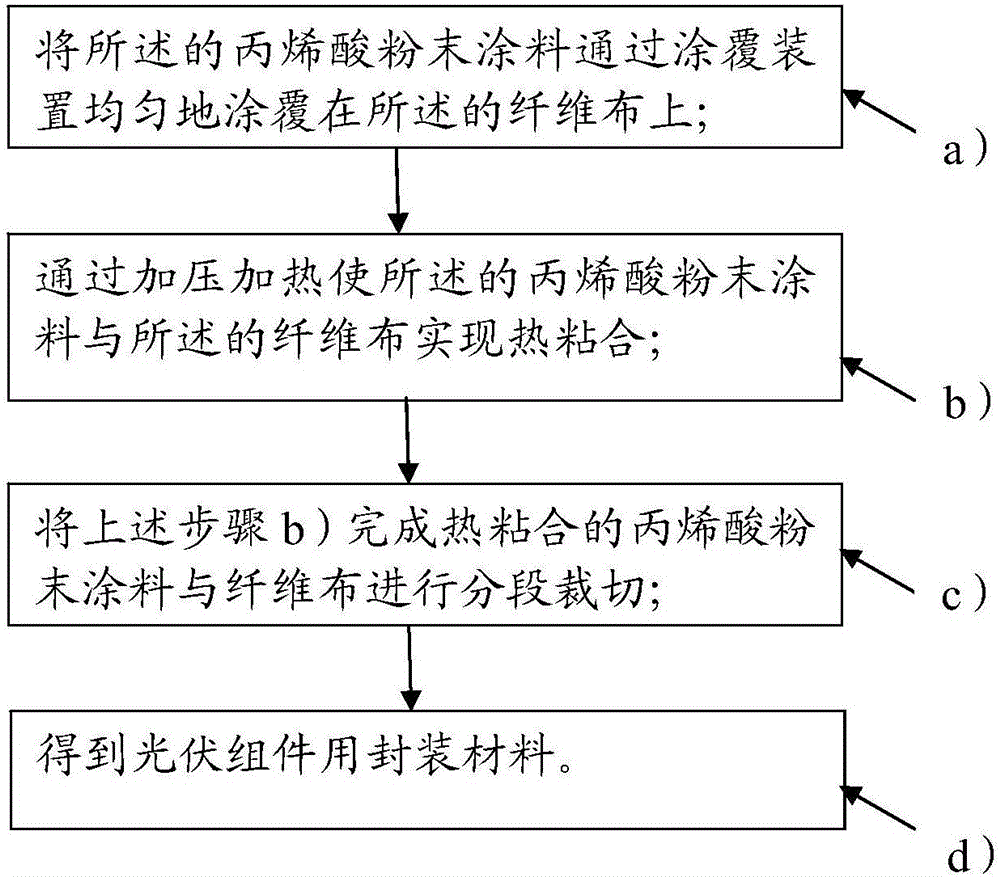

Packaging material for photovoltaic module and preparation method of the packaging material

ActiveCN106299000AReduce weightReduce installation costsFinal product manufactureFibre treatmentFiberPhotovoltaic industry

The invention discloses a packaging material for a photovoltaic module. The packaging material comprises the following raw materials in parts by weight: 30-50 parts of fiber cloth produced from fiber material through weaving; and 50-70 parts of acrylic powder coating including acrylic resins and a curing agent. The acrylic powder coating is evenly spread on the fiber cloth. The packaging material is low in manufacturing cost. While meeting the prerequisites of resistance to ultraviolet, aging, impact and fire which are standard requirements of the photovoltaic industry, the packaging material solves the problem of lightweight photovoltaic module packaging material, makes installation more convenient, reduces the installation cost, and thus is very suitable for large-scale promotion and application in the photovoltaic field. The invention also discloses a preparation method of the packaging material for a photovoltaic module. The method meets installation requirement for changing the packaging size of a photovoltaic module at will to adapt to different buildings and thus further facilitates installation and application of photovoltaic modules.

Owner:TIGER DRYLAC TAICANG +1

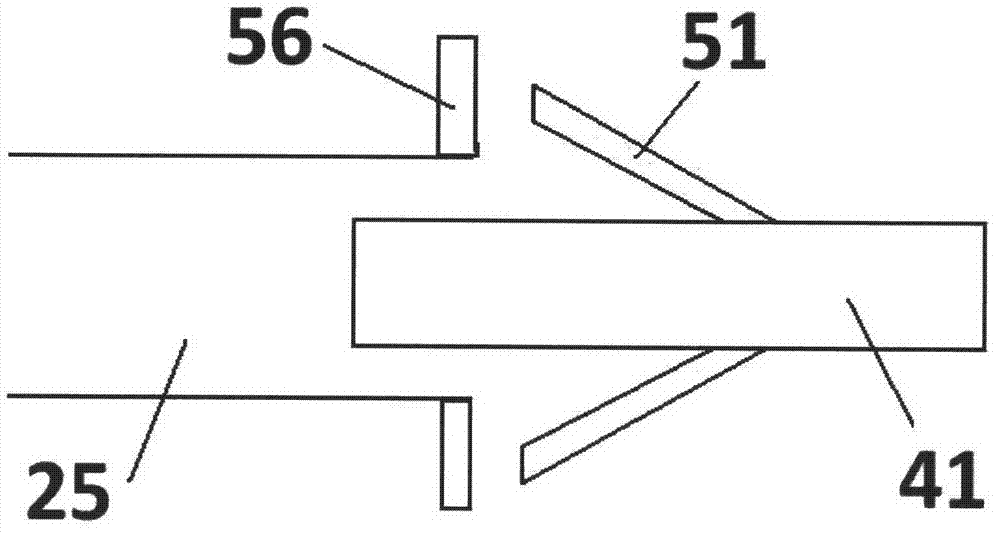

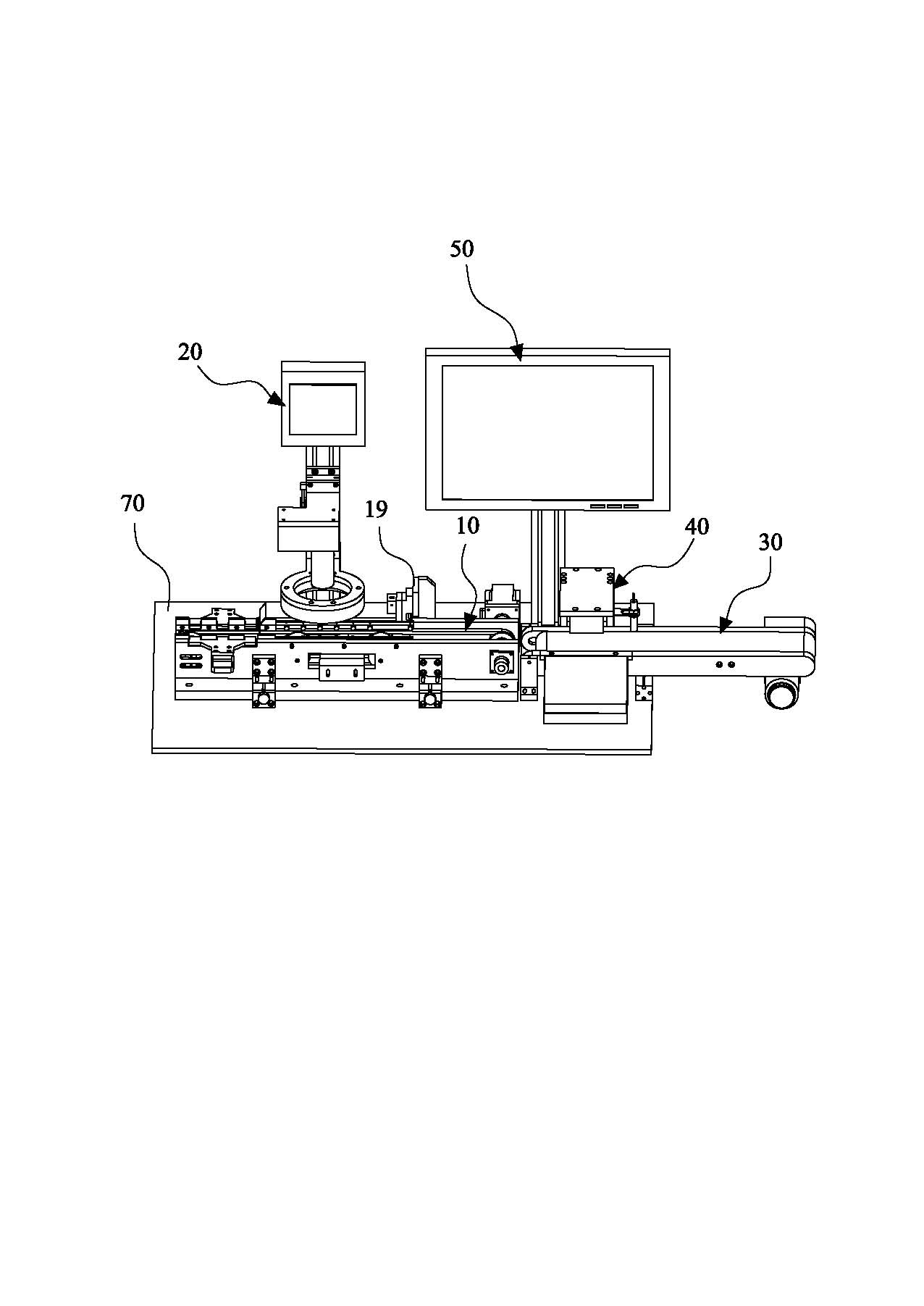

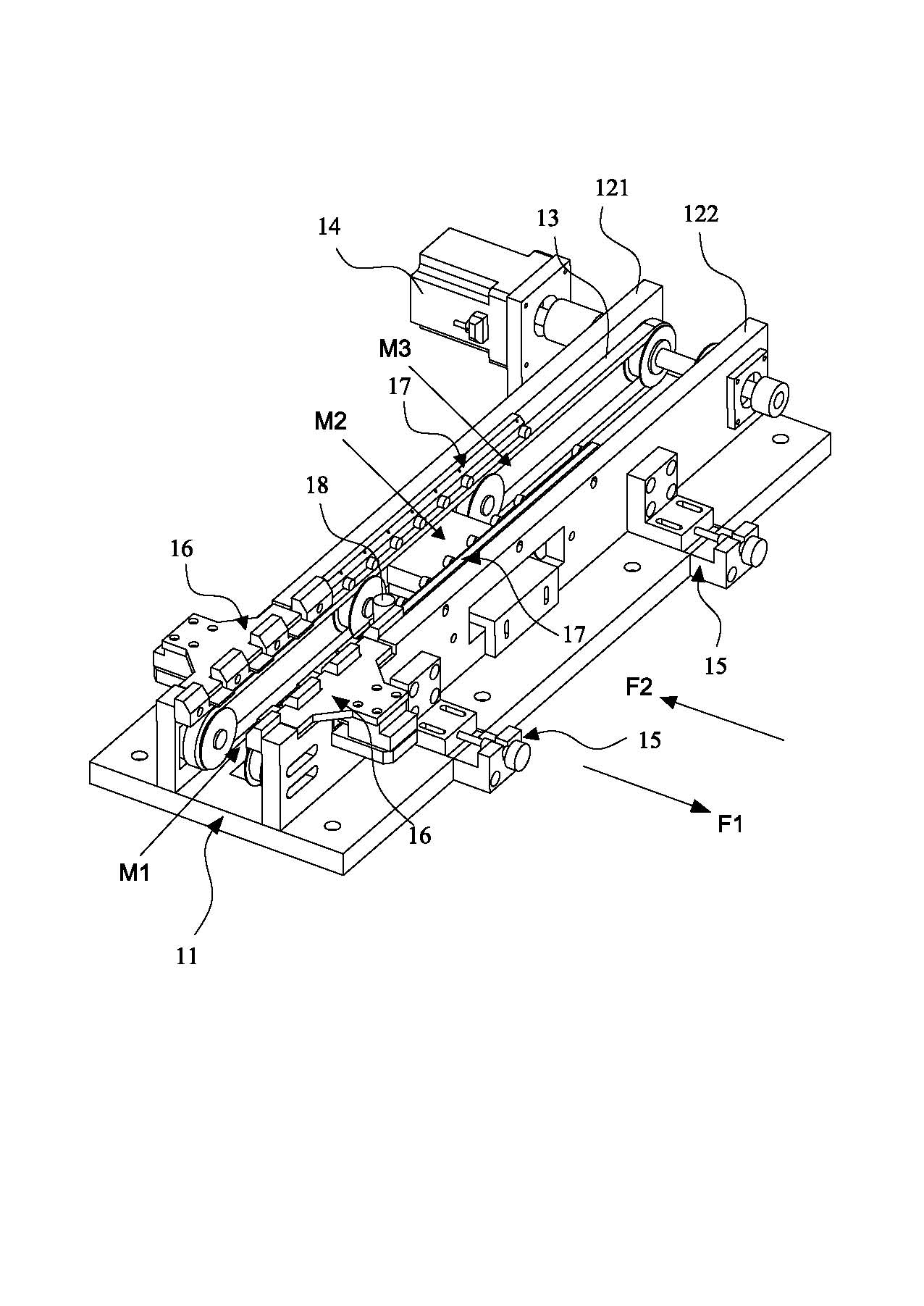

Device and method for automatically detecting and sorting light emitting diodes (LEDs)

The invention discloses a device and a method for automatically detecting and sorting light emitting diodes (LEDs). The system comprises a first conveying device which is used for loading materials onto LED material strips and conveying the LED material strips and is capable of dotting unqualified LED material strips, a detecting device which is used for detecting the surface appearance, the size, the color and defects of each LED bracket in the LED material strips, a second conveying device which is used for sending out the detected LED material strips, a sorting device which is used for storing out the unqualified LED material strips, a display device which is used for displaying detection data, and a control device which is used for comparing the detection data with standard data to determine whether the LED brackets are qualified or not, and controlling the whole process of material loading, detection, dotting, conveying and sorting of each device. The method comprises multiple steps of standard setting, control device startup, sampling, comparison and output. Products can be automatically classified, the automation degree is high and the labor force is effectively reduced.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

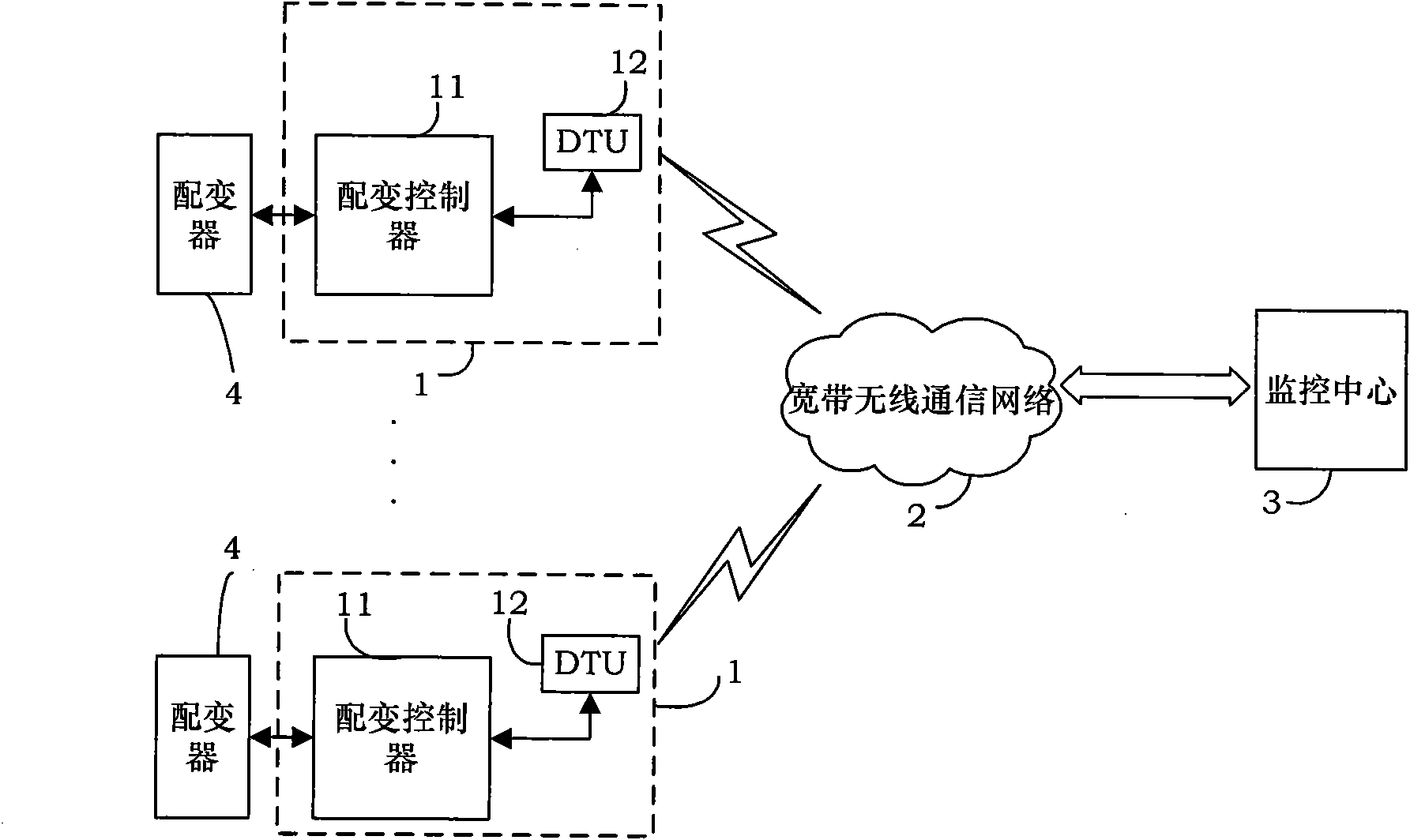

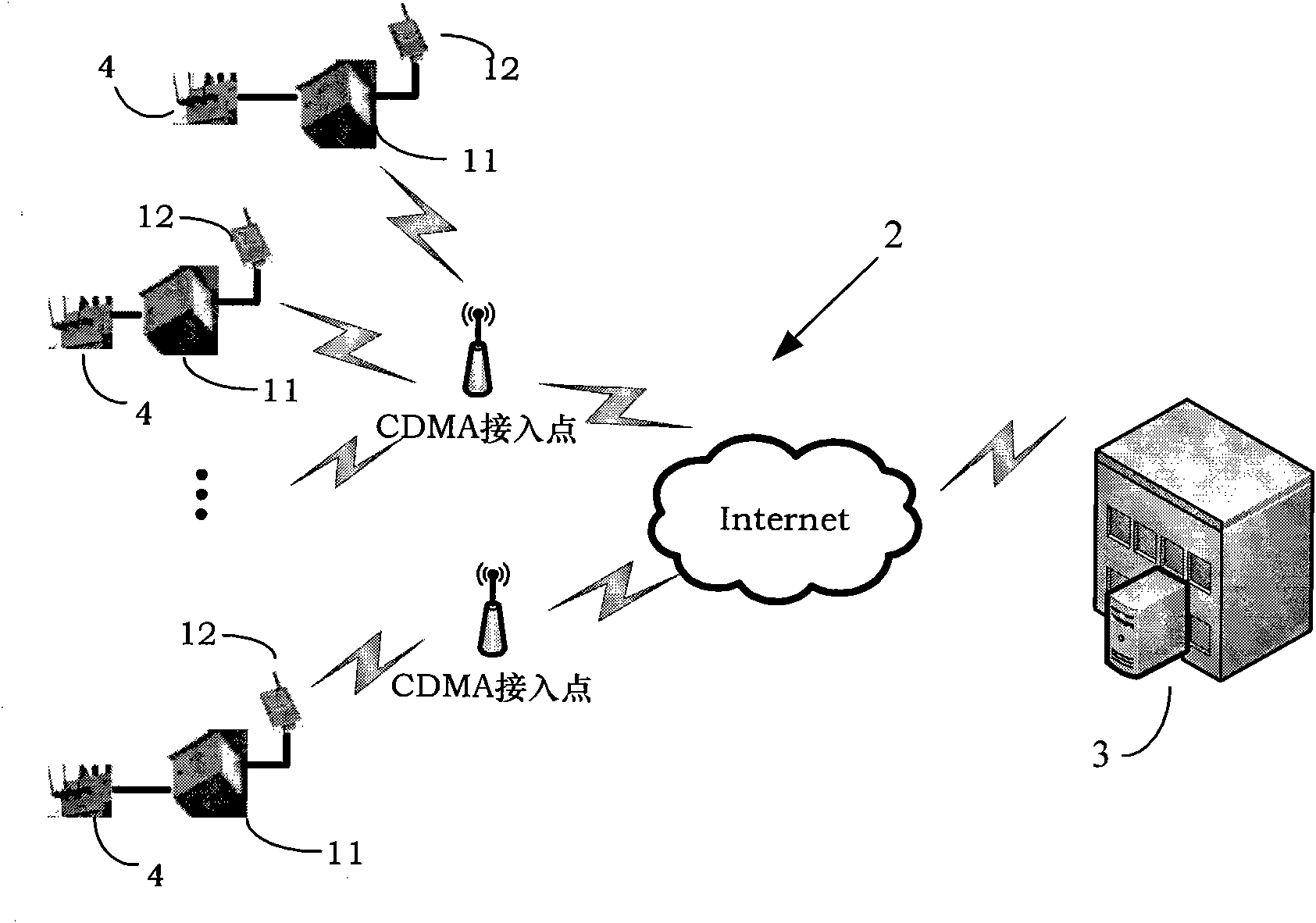

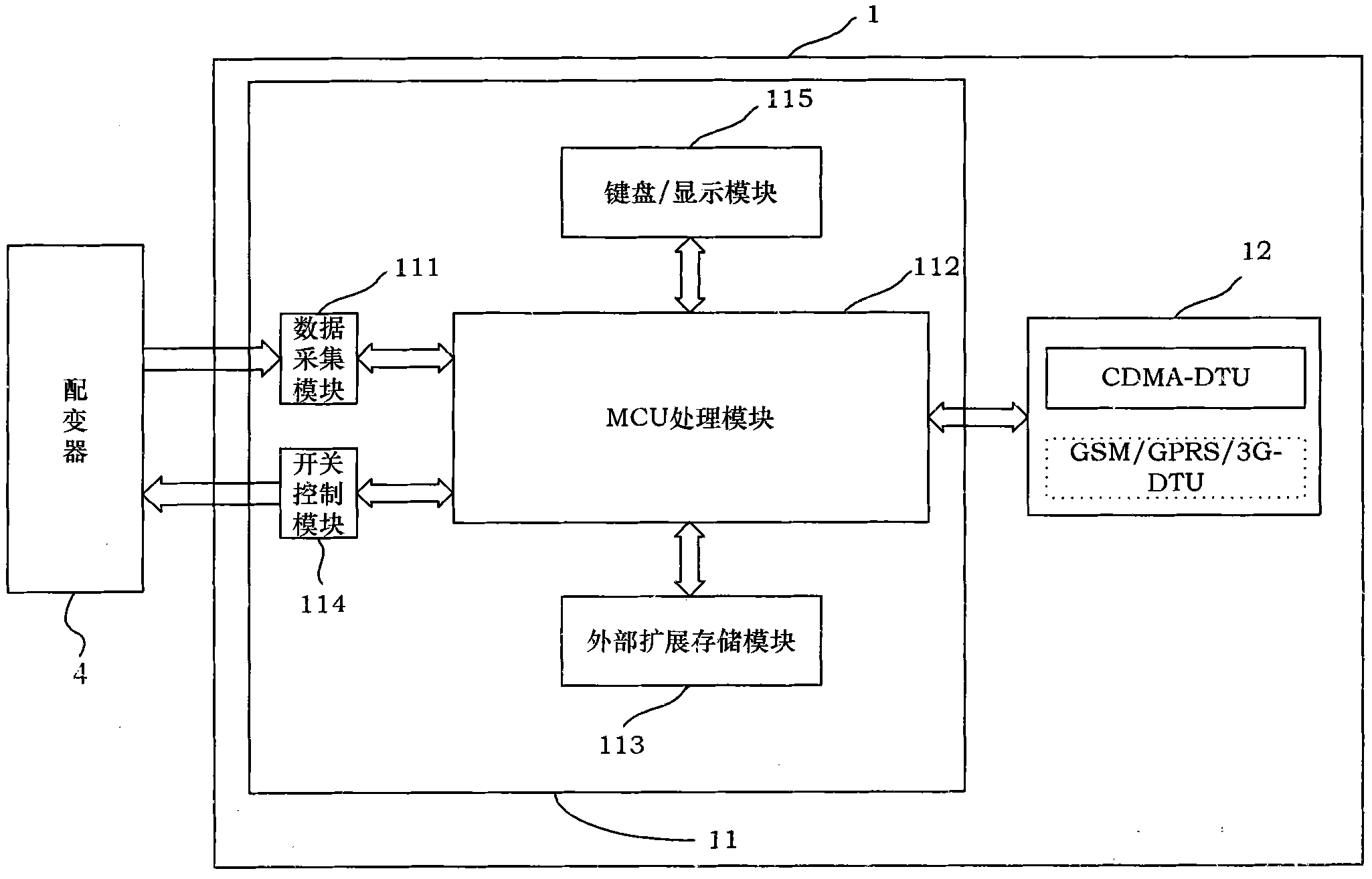

Distribution network automatic system based on broadband wireless communication and realization method thereof

InactiveCN101951031AReal-time power dataWide coverageCircuit arrangementsData switching networksDistribution transformerData acquisition

The invention provides a distribution network automatic system based on broadband wireless communication and a realization method thereof. The distribution network automatic system comprises a distribution transformer data collecting and monitoring device, a broadband wireless communication network and a monitoring center, wherein the distribution transformer data collecting and monitoring device is arranged in a transformer site for collecting and processing electric power parameters, transmitting data to the monitoring center by the broadband wireless communication network so as to responds to a control command sent by the monitoring center. In the realization method, the distribution transformer data collecting and monitoring device is connected with the monitoring center by the wireless communication network, a protocol in coincidence with electric power 101 protocol for the data transmission is set; and the distribution transform data collecting and monitoring device collects and processes the existing distribution transform parameters of the distribution transformer and responds to the control command from the monitoring center. The invention adopts a modular system architecture design, has upward and downward compatibility, and can realize various wireless broadband module communication services; in addition, the design of stipulations of an agreement of the monitoring center is based on the electric power 101 protocol and is compatible with protocols realizing different versions.

Owner:BEIHANG UNIV

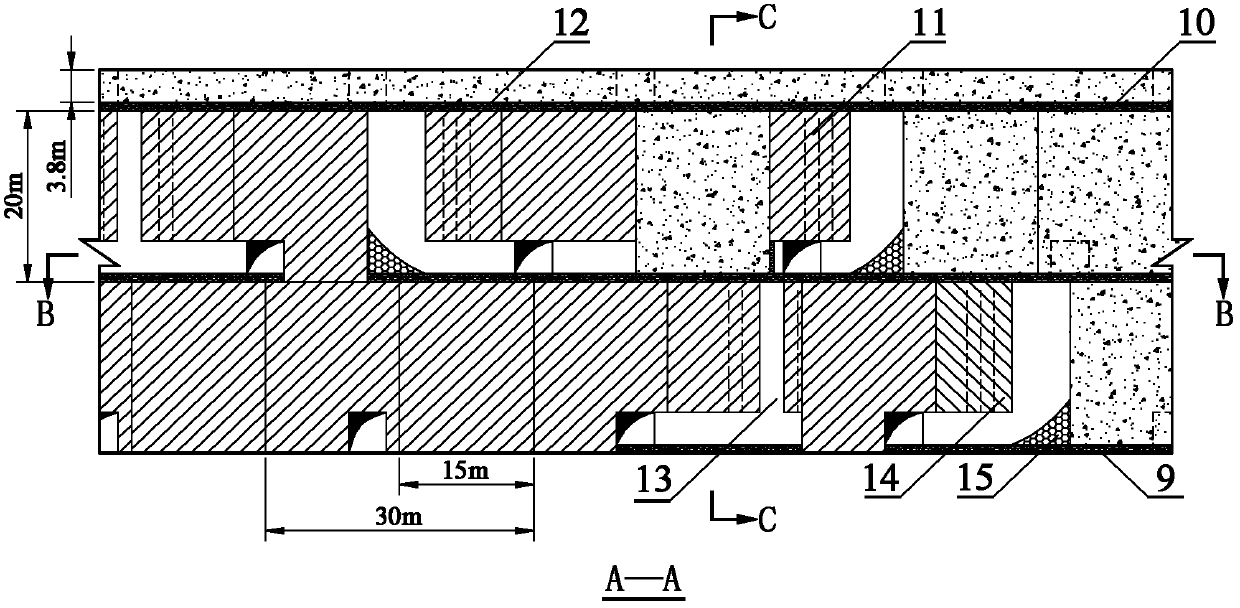

Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

ActiveCN106677780AImprove securityEnsure safetyUnderground miningTunnel/mines ventillationDetonationEngineering

The invention provides an upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method. The method includes the following steps that panels are divided in the ore direction, a stope preparation system is arranged, upward fan-shaped medium-depth blast holes are drilled from one side to the other side of a chamber, the blast holes are filled with explosives for detonation, and an undercut space is formed after detonation; cut grooves are formed through a VCR method, and as for ore above the undercut space, downward vertical deep holes are drilled in a drilling chamber at the top of the chamber, and the holes are filled with explosives for detonation with the cut grooves as a compensation space; the chamber in each panel is subjected to two-step backstoping, after ore removal of a first-step chamber is finished, the first-step chamber is filled with cementing materials, after the first-step chamber is filled and cured, a second-step chamber is subjected to backstoping, the backstoping steps of the second-step chamber are the same as those of the first-step chamber, and the second-step chamber is filled with cemented filling bodies and non-cemented filling bodies; and the steps are repeated in this way till backstoping of all chambers are completed. The upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method has the advantages that the rock drilling efficiency of the upward fan-shaped medium-depth blast holes is improved, the waste hole rate is lowered, efficient and safe bottom ore removal is achieved, and the mechanization level is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

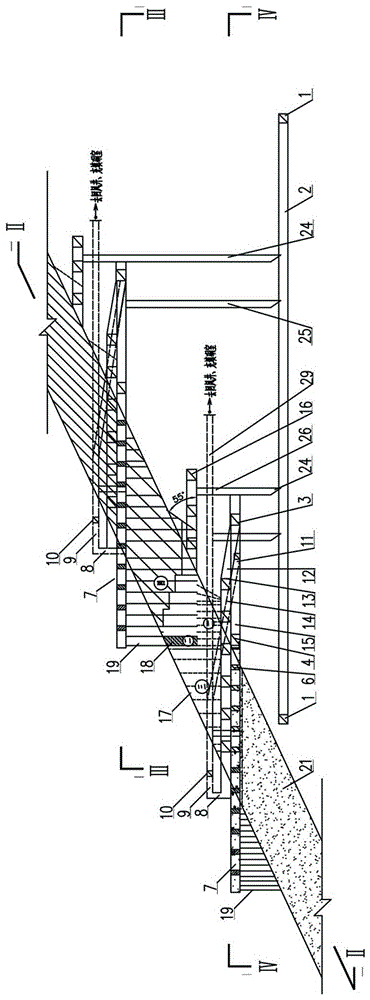

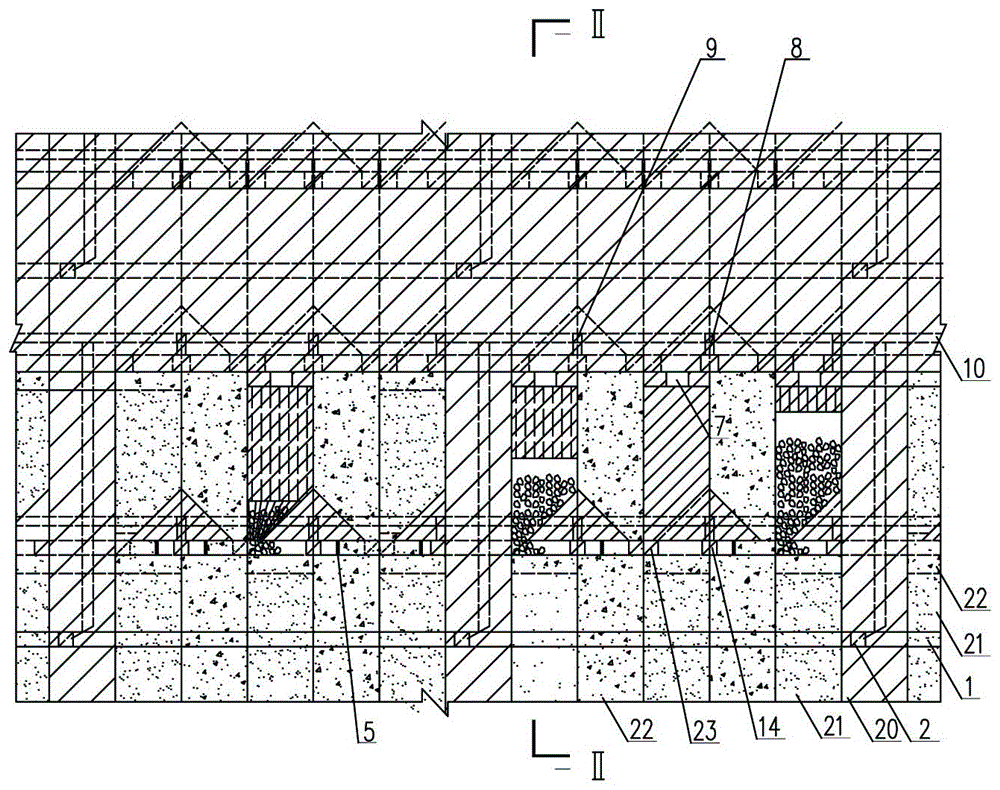

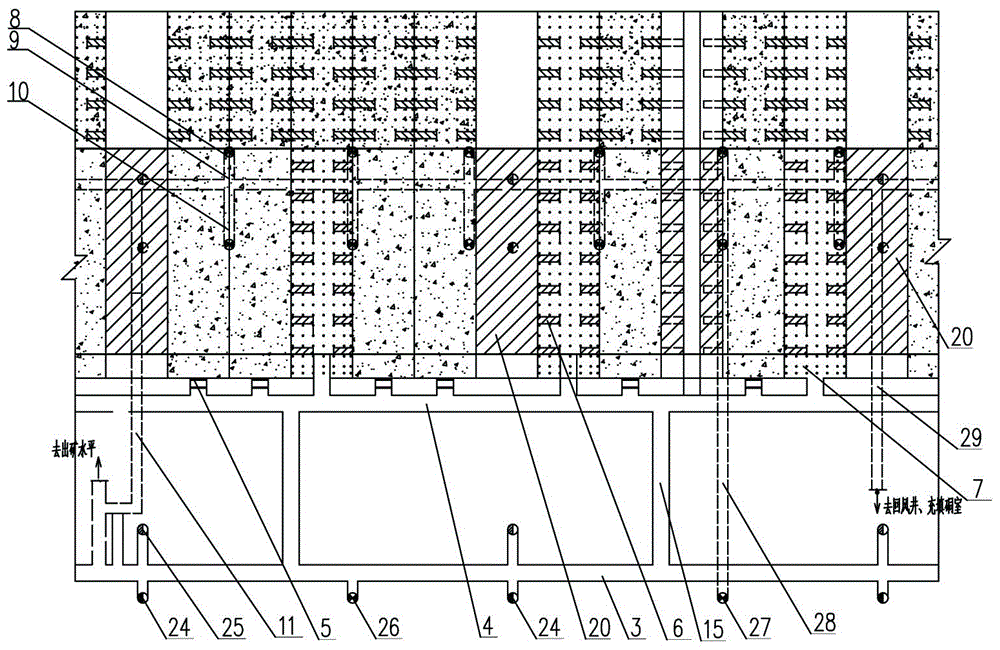

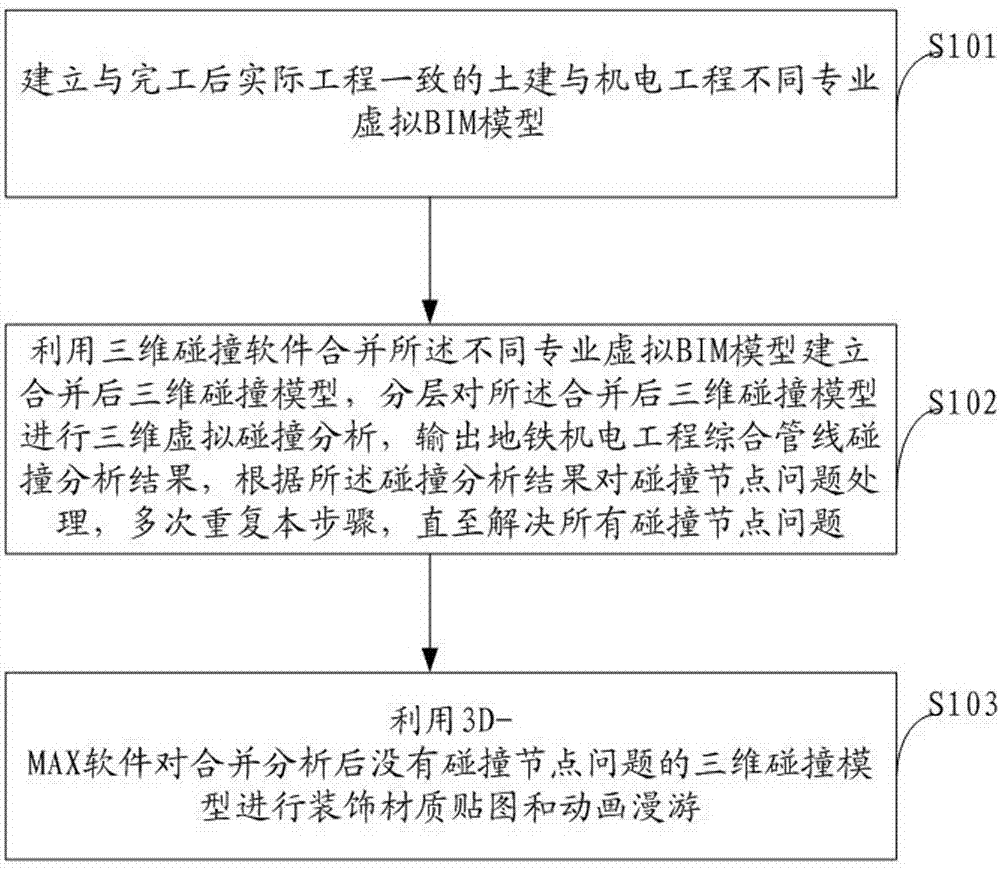

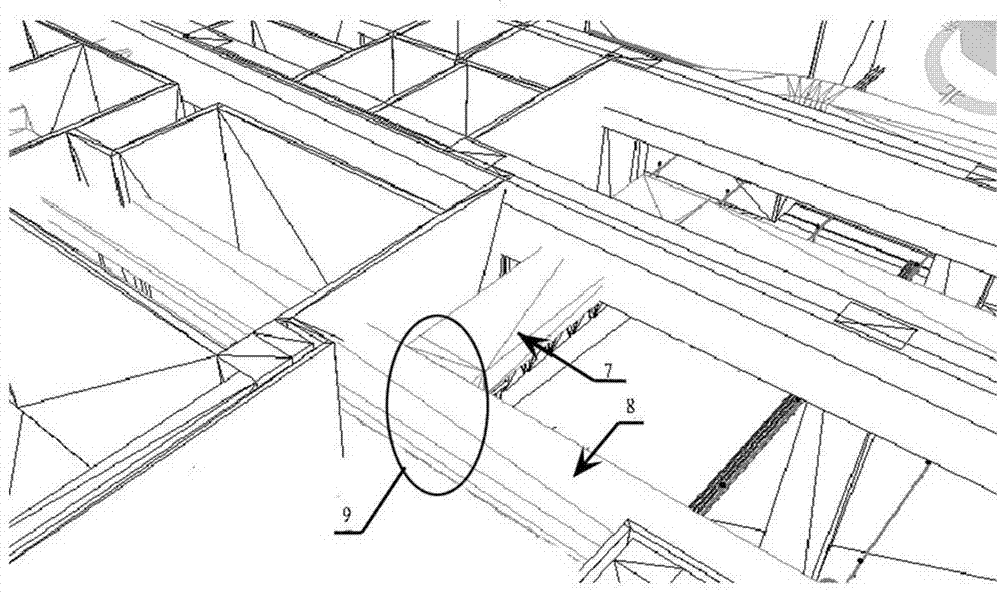

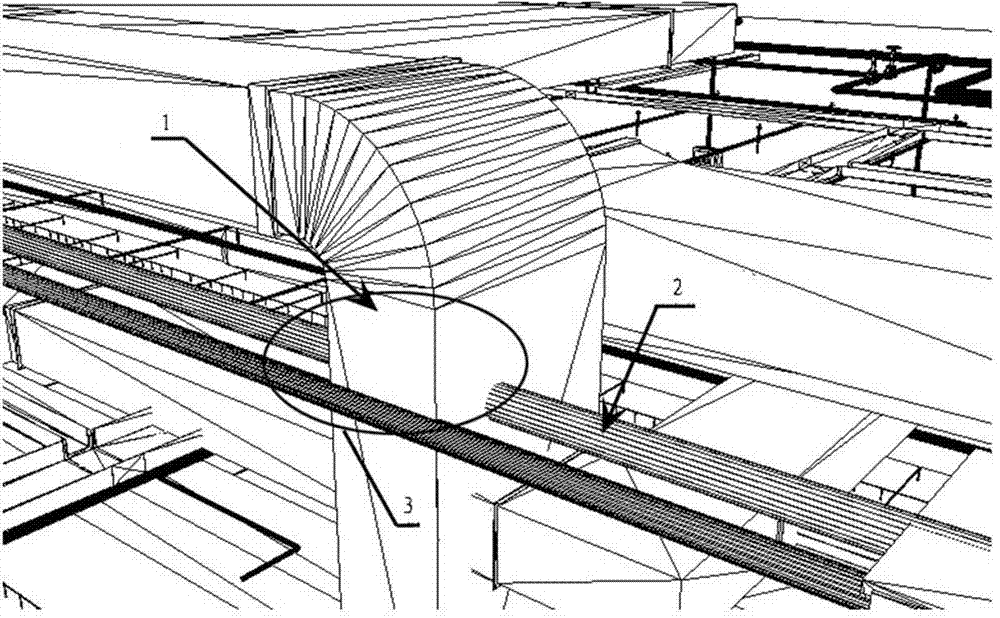

Complex pipeline collision optimization method of subway electromechanical engineering

ActiveCN103093061AOvercome the shortcomings of error-prone, omission and bump-to-missSolving technical issues with cross collisionsSpecial data processing applicationsNODALCollision analysis

The invention belongs to the technical field of electromechanical device installation and discloses a complex pipeline collision optimization method of subway electromechanical engineering. According to the method, three-dimensional bus interface module (BIM) software is used for establishing different professional virtual BIM models which are consistent with completed engineering and then output to three-dimensional collision software for establishment of a combined three-dimensional collision model for collision analysis, collision nodes are then processed and optimized, and then decorative texture mapping and animation roaming are carried out on the combined, analysed and processed three-dimensional collision model without the collision node problem through 3D - MAX software, and therefore collision optimization of complex pipelines of the subway electromechanical engineering is achieved. According to the complex pipeline collision optimization method of the subway electromechanical engineering, the BIM technology is utilized to solve the problem that collision of various complex pipelines causes construction ceasing during electromechanical installation, reasonable planning and utilization of electromechanical pipeline equipment and the like are achieved by means of the optimized design, construction waste is reduced, construction time is shortened, working efficiency at site is improved greatly, and initial investment of a proprietor is reduced.

Owner:ELECTRIFICATION ENG CO LTD OF CHINA RAILWAY 22TH BUREAU GRP +1

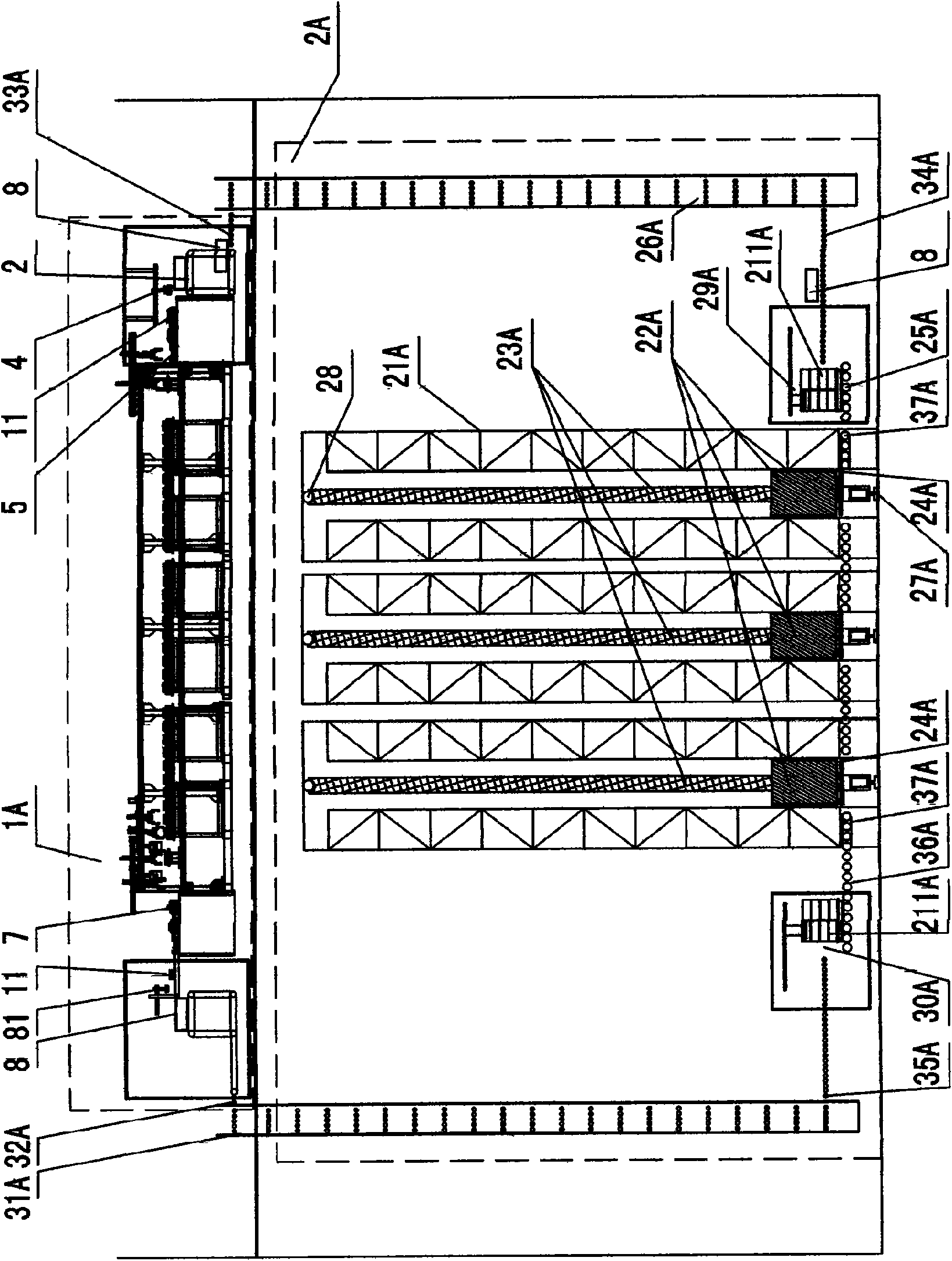

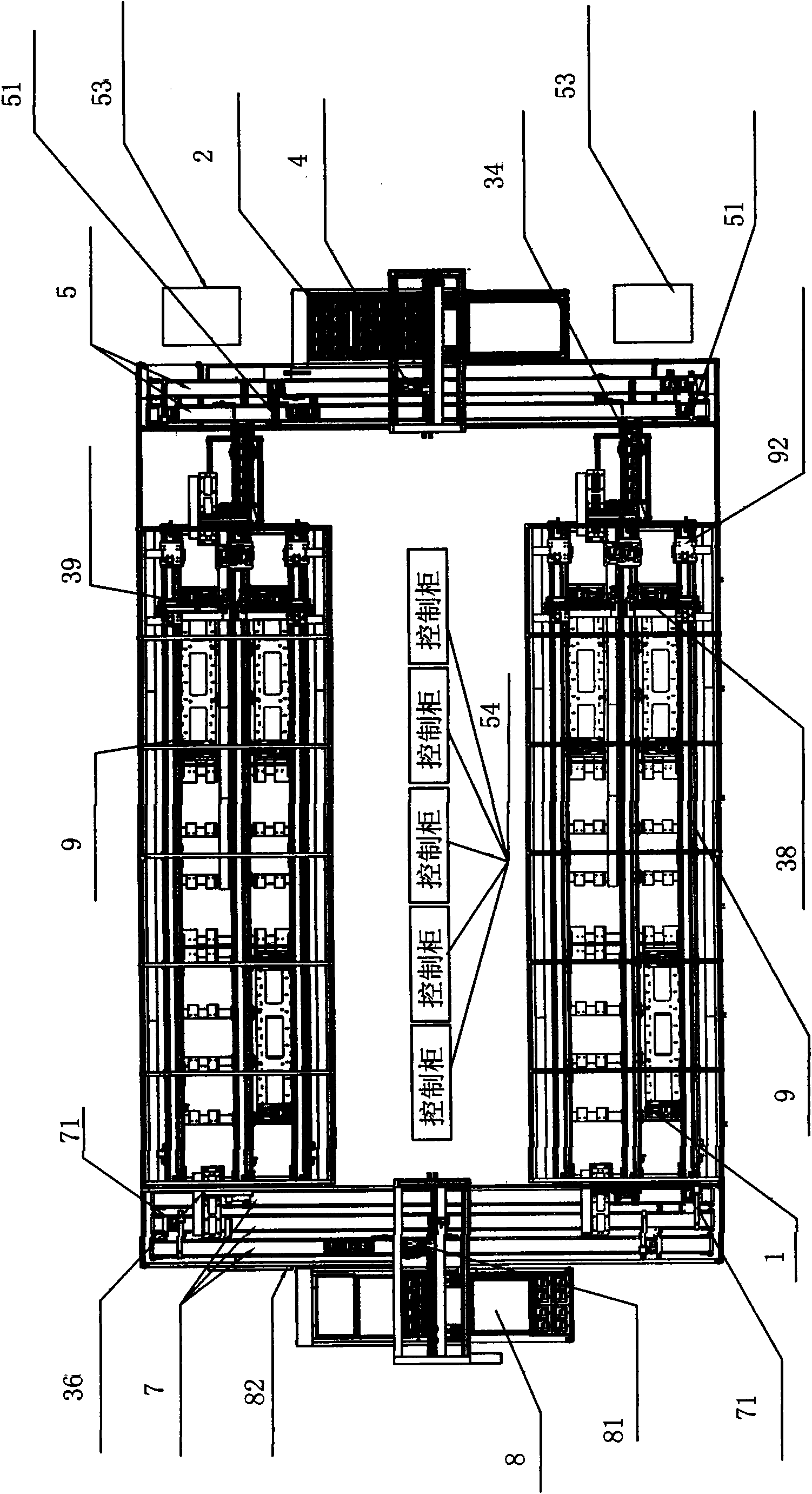

Automatic holographic management system integrating detection of electric energy meter and warehousing management

ActiveCN101539617ARealize automatic feeding processAchieve contactRadiation pyrometryElectrical measurementsTemperature monitoringEngineering

The invention discloses an automatic holographic management system integrating detection of an electric energy meter and warehousing management, comprising an automatic pipelining standard device for detection of the electric energy meter, an unboxing machine, a boxing machine and a three-dimensional table library; wherein the three-dimensional table library is respectively connected with the boxing machine and the unboxing machine; and the boxing machine and the unboxing machine are respectively connected with the automatic pipelining standard device for detection of the electric energy meter by a conveying belt. The system changes large amount of repeated and mechanical manual modes in the whole process of the operation of the electric energy meter, and has the automatic functions of automatic delivery from the warehouse, automatic distribution, automatic feeding, automatic positioning, automatic wire connection, automatic image recognition, automatic temperature monitoring, automatic wire disconnection, automatic discharging, automatic boxing, automatic disc packing and automatic warehouse entry.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

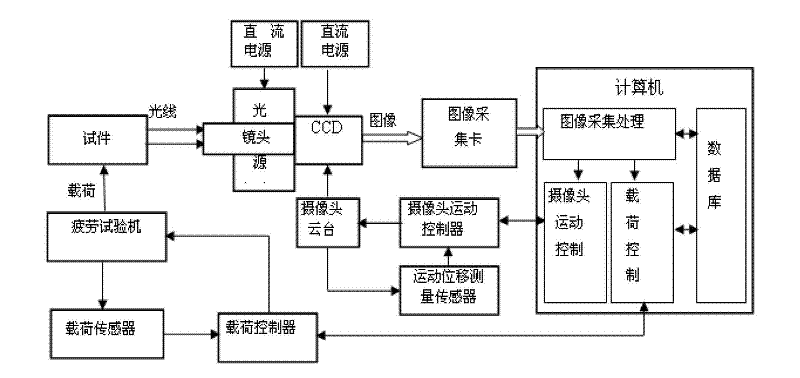

Camera automatic regulating image acquisition device and method for fatigue crack propagation test

InactiveCN102692347AAchieve regulationImprove work efficiencyTelevision system detailsColor television detailsControl systemComputer module

The invention relates to a camera automatic regulating crack image acquisition system for a fatigue crack propagation test, which comprises a crack image imaging and acquiring system, a camera position regulating system and a computer processing and analysis control system, wherein the crack image imaging and acquiring system comprises a CCD (Charge Coupled Device) camera, a lens, a light source illuminating device, a camera mounting bracket and an image acquiring card; the CCD camera, the lens and the light source illuminating device are arranged on the camera mounting bracket to form a crack image imaging unit; the image acquiring card is connected with a computer; a camera position regulating device comprises a stepping motor, a camera motion positioning cloud deck, a motion controller and a stepping motor driver; and the computer processing and analysis control system comprise the computer and a camera automatic regulating image acquisition module in an ARM motion controller. The invention also provides a camera automatic regulating crack image acquisition method for the fatigue crack propagation test. According to the camera automatic regulating image acquisition device and method for fatigue crack propagation test provided by the invention, the full-automatic operation is adopted; the control accuracy is high; and the real-time performance is excellent; and the labor intensity is reduced.

Owner:ZHEJIANG UNIV OF TECH

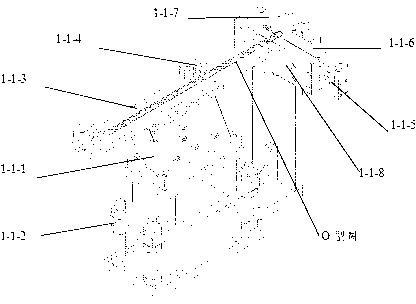

Automatic assembly device and method of O-type sealing ring

InactiveCN103317336ANo damageSmall support ringMetal working apparatusEngineeringUltimate tensile strength

The invention discloses an automatic assembly device of an O-type sealing ring. The automatic assembly device comprises a ring loading and supporting module and a ring moving and releasing module. The ring loading and supporting module forms a feeding station and a ring supporting station, and when a loading device of the O-type sealing ring is located at the feeding station, the O-type sealing ring is delivered to the loading device of the O-type sealing ring by a feeding device of the O-type sealing ring. A loading needle-shaped air cylinder drives the loading device of the O-type sealing ring to move to the ring supporting station, the ring supporting motion is carried out on the O-type sealing ring by a ring supporting device, the O-type sealing ring is delivered to the ring moving and releasing module by the ring supporting device, the ring moving and releasing module enables the supported O-type sealing ring to be delivered to a ring releasing station from the ring supporting station, the ring moving and releasing module breaks away from the supported O-type sealing ring, the supported O-type sealing ring is sleeved at the position of a groove of a workpiece to be assembled, and automatic assembly between the workpiece and the O-type sealing ring is achieved. According to the automatic assembly device, assembly automation of the O-type sealing ring can be achieved, the qualified rate and the assembly efficiency of products are greatly improved, the labor strength is relieved, and the production cost is reduced. The invention further discloses an automatic assembly method of the O-type sealing ring.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

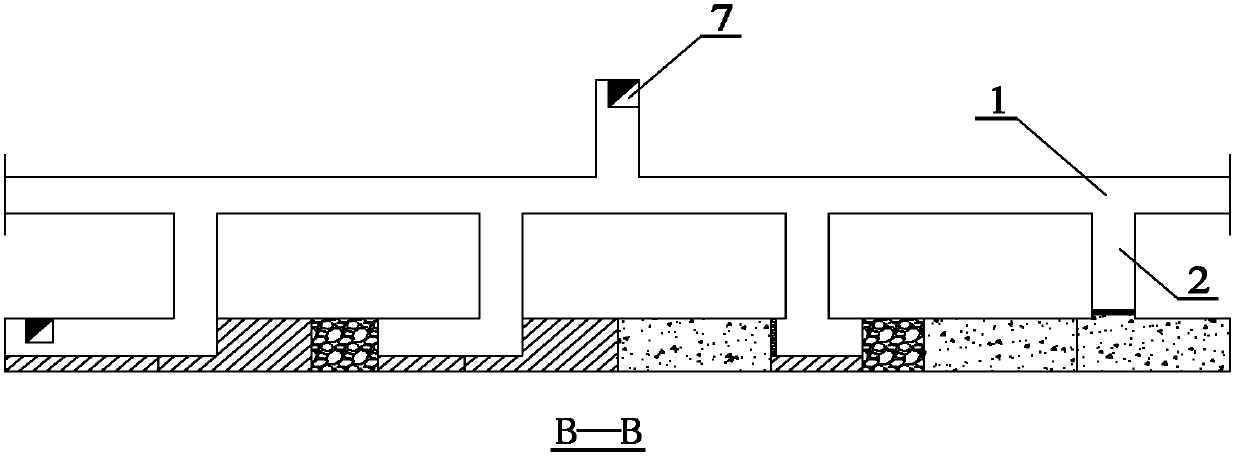

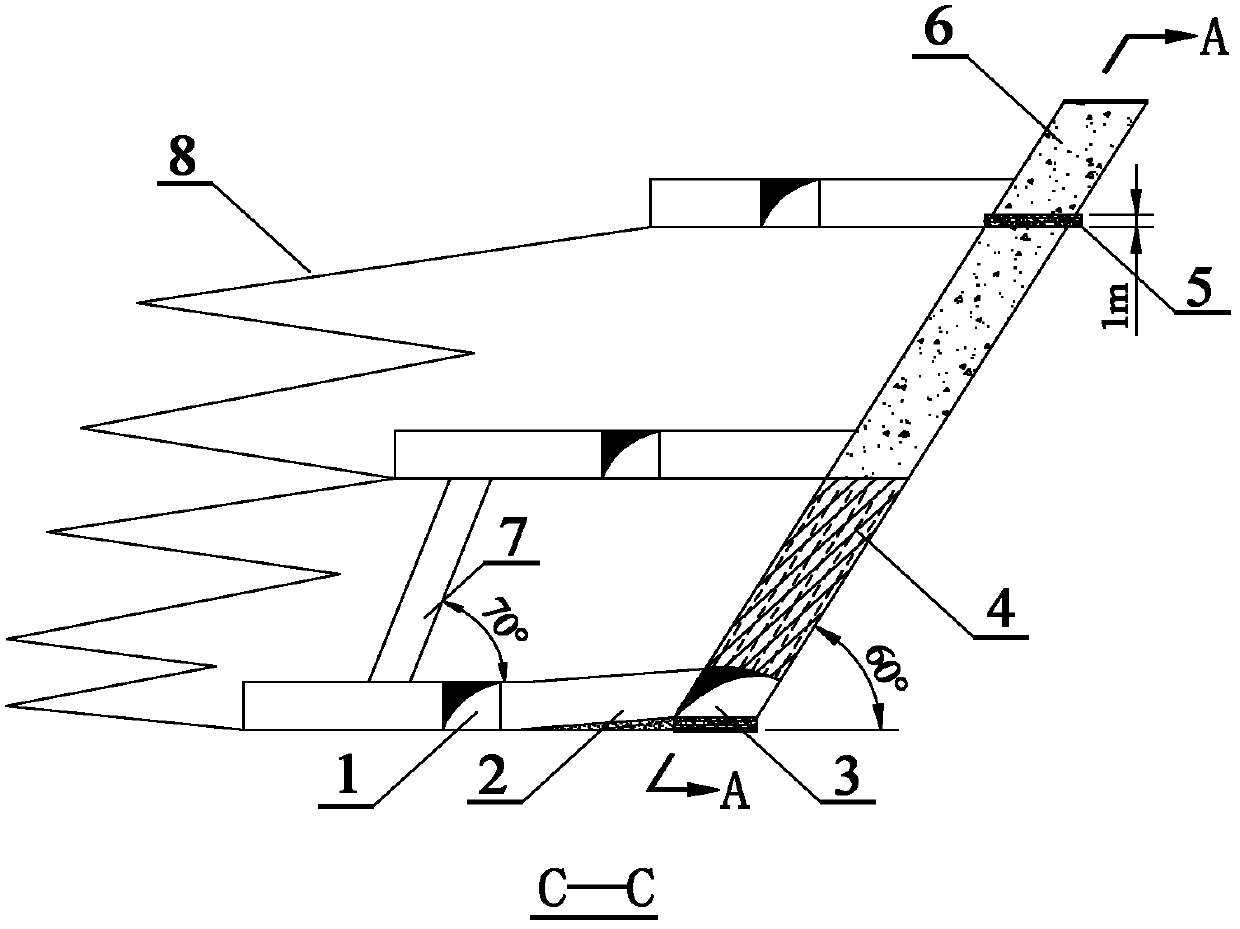

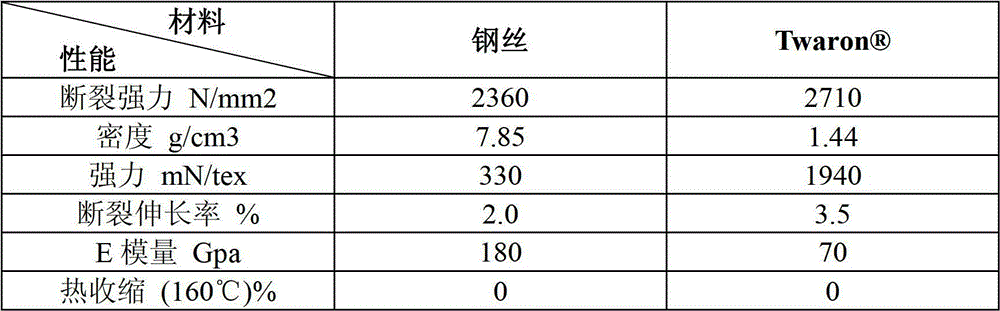

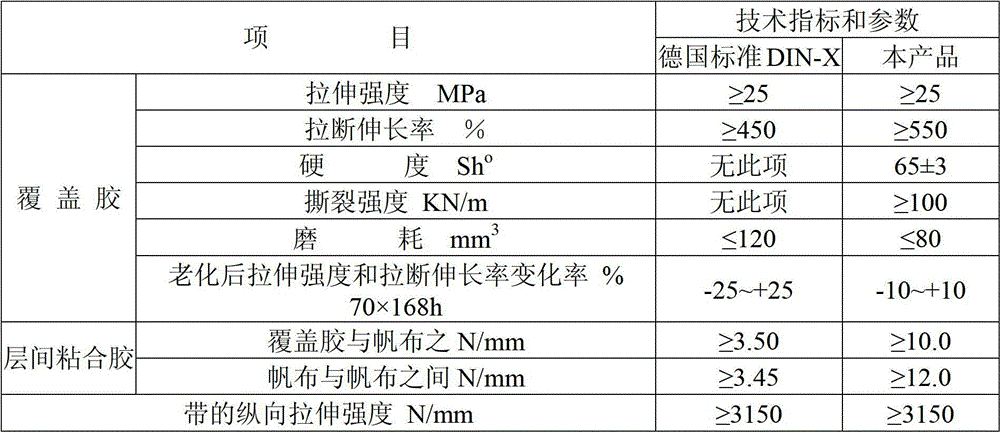

Energy-saving high strength aramid fiber conveyer belt and preparation method thereof

The invention relates to an energy-saving high strength aramid fiber conveyer belt and a preparation method thereof. The conveyer belt is composed of a skeleton layer, adhesive glue and an upper-lower cover adhesive laminated structure. Firstly, the skeleton layer employs aramid fiber canvas after dipping treatment to replace a conventional steel wire rope, so that the problems of large weight of the steel wire rope which brings much inconvenience for processes of shaping, installing, maintaining and the like is solved. Secondly, the aramid fiber canvas has structure in broadwise direction, has excellent anti-tear and anti-impact performances, so that phenomena of longitudinal tear and the like of the steel wire rope conveyer belt cab be prevented. Compared with a conventional steel wire rope high strength conveyer belt, the energy-saving high strength aramid fiber conveyer belt has high strength, good corrosion resistance, wear resistance and impact and fatigue resistance, and greatly reduce the weight and thickness of the conveyor belt, so that conveying power energy consumption is saved. The energy-saving high strength aramid fiber conveyer belt is expected to have longer service life and better energy-saving and environment-friendly properties, and is particularly suitable for long-distance material conveyance in industries such as coal mine, metallurgy, mine, etc.

Owner:WUXI BOTON TECH CO LTD +1

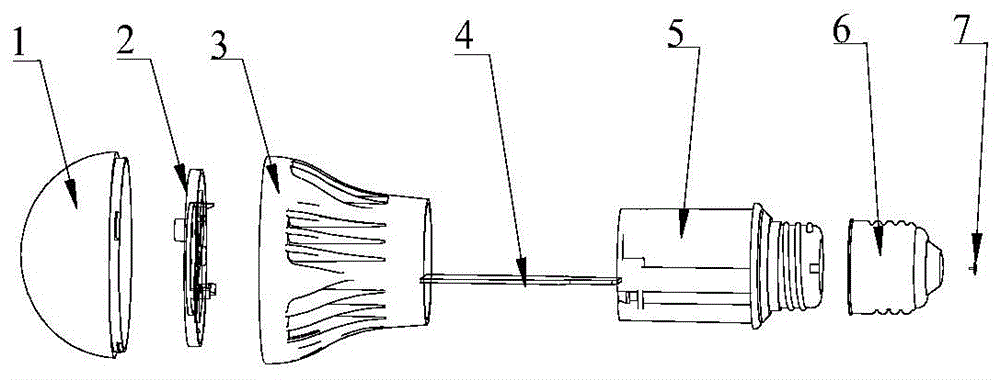

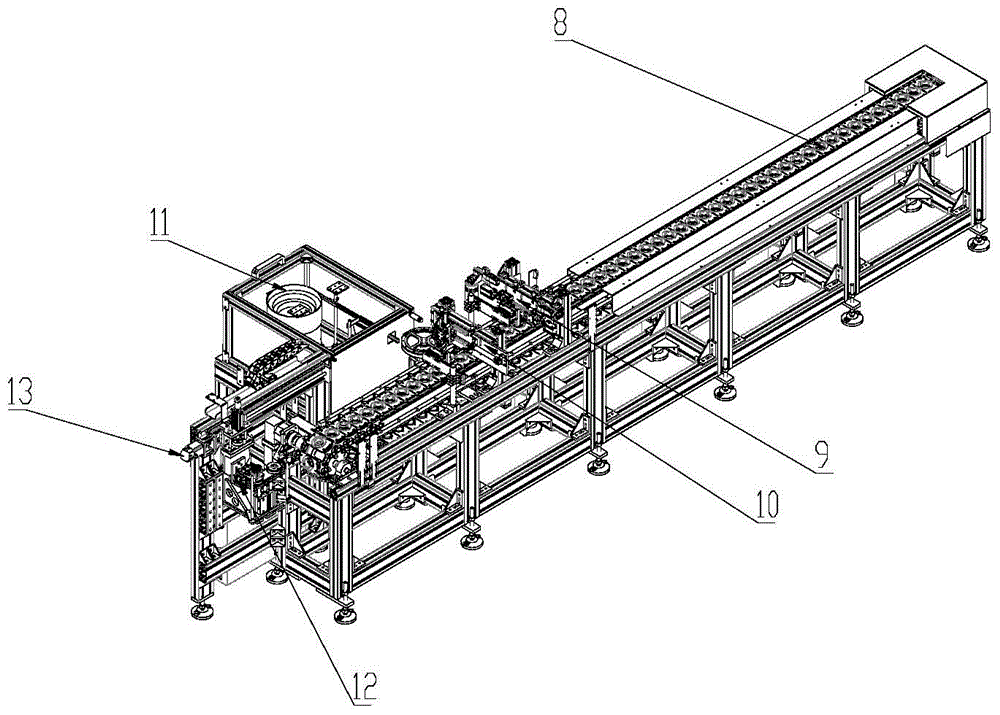

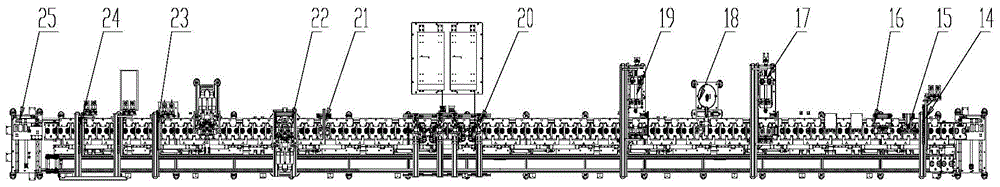

Automatic assembling and testing device for LED (Light-Emitting Diode) bulb lamp

ActiveCN103331607AQuality improvementReduce labor intensityAssembly machinesLamps testingElectricityProduction line

The invention discloses an automatic device, in particular to a specific production line method which is used for assembling parts of an LED (Light-Emitting Diode) bulb lamp, also implements online inspection and testing of the LED bulb lamp, obtains the LED bulb lamp qualified by inspection and improves production efficiency. The automatic device comprises a rivet assembly line, a light source plate assembly line, a lampshade assembly line, an LED lamp aging testing line and an LED lamp high voltage testing and light color electricity detecting line; and the parts of the LED bulb lamp are assembled and tested by the five workshop sections. The automatic device has the advantages that production efficiency can be effectively improved; quality of a produced product is stable; and labor intensity of workers is reduced. The automatic device can be widely applied to LED lamp production enterprises.

Owner:HANGZHOU ZHONGWEI PHOTOELECTRICITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com