Material hoisting and transportation device

A technology of conveying device and hoisting device, which is applied in the field of oil and gas industry, can solve the problems of uneconomical, low efficiency, high labor cost, etc., achieve the effect of reducing labor intensity, improving work efficiency and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

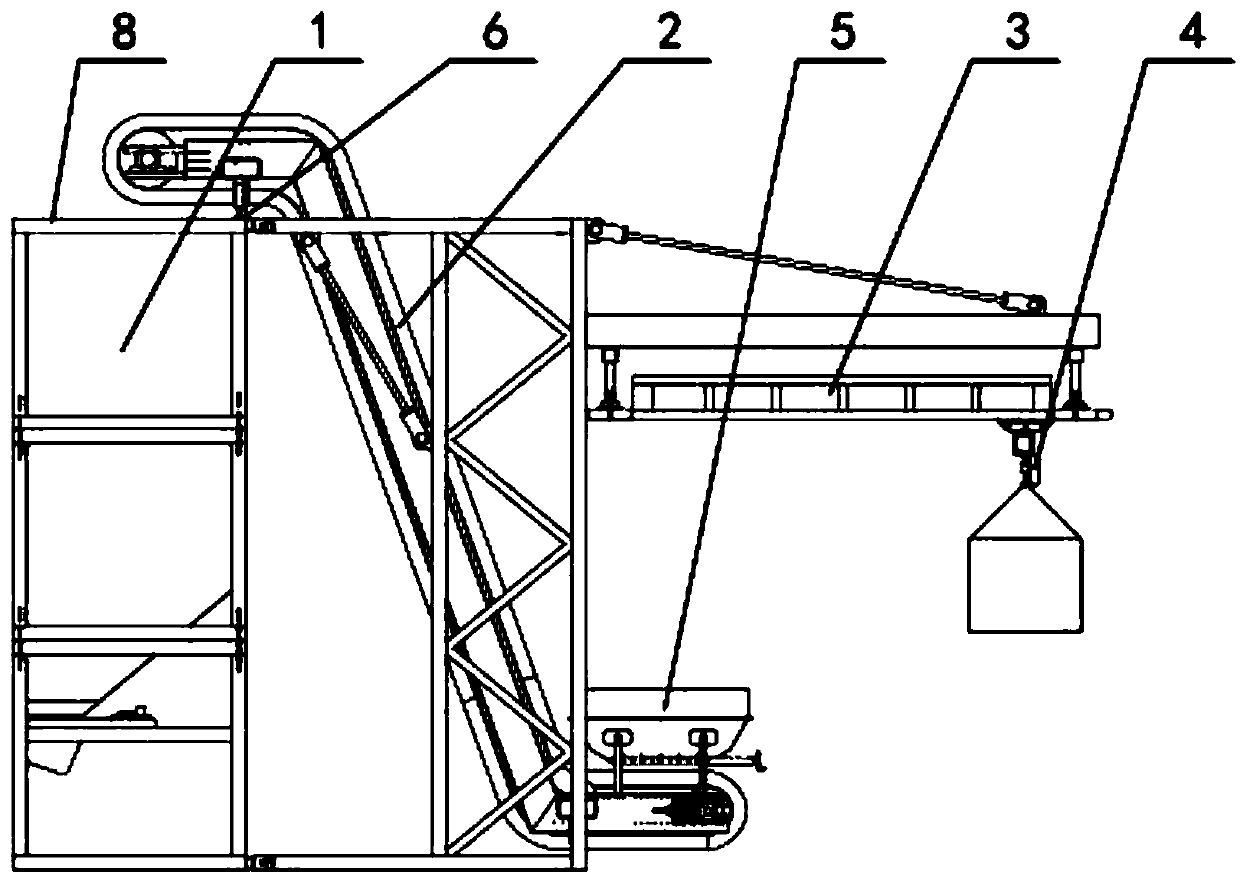

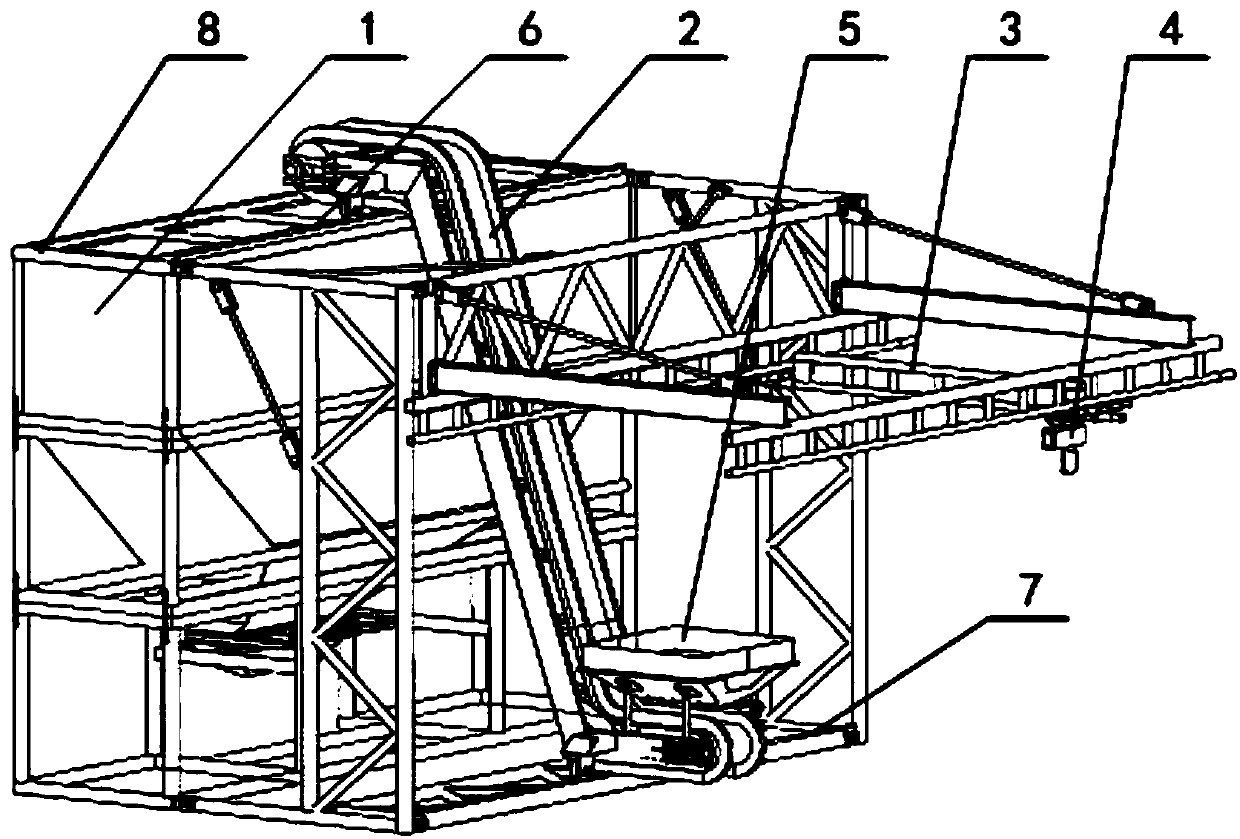

[0013] The frame body 8 of the present invention is welded with square pipes, and its effect is to fix and support the present invention. The stock tank 1 is made of a steel plate with a thickness of 4 mm, and its effect is to store sand. The belt conveyor 2 is made of a motor or Composed of a hydraulic motor and a conveyor belt, its function is to transfer the sand in the feeding hopper 5 to the storage tank 1. The installation frame of the hoisting device 3 is assembled from "I" steel and square pipe welding parts. The hoisting device 3 Both the horizontal track and the vertical track are made by plate bending, and the lifting device can make the hook 4 move vertically and horizontally to ensure that the hook 4 is within the set operating range, and the sandbags are hoisted into the feeding hopper 5 for feeding. The hopper 5 is made of a steel plate with a thickness of 4 mm. Its function is to transfer the sand in the feeding hopper 5 to the storage tank 1 through the belt co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com