Patents

Literature

3835results about "Pump testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

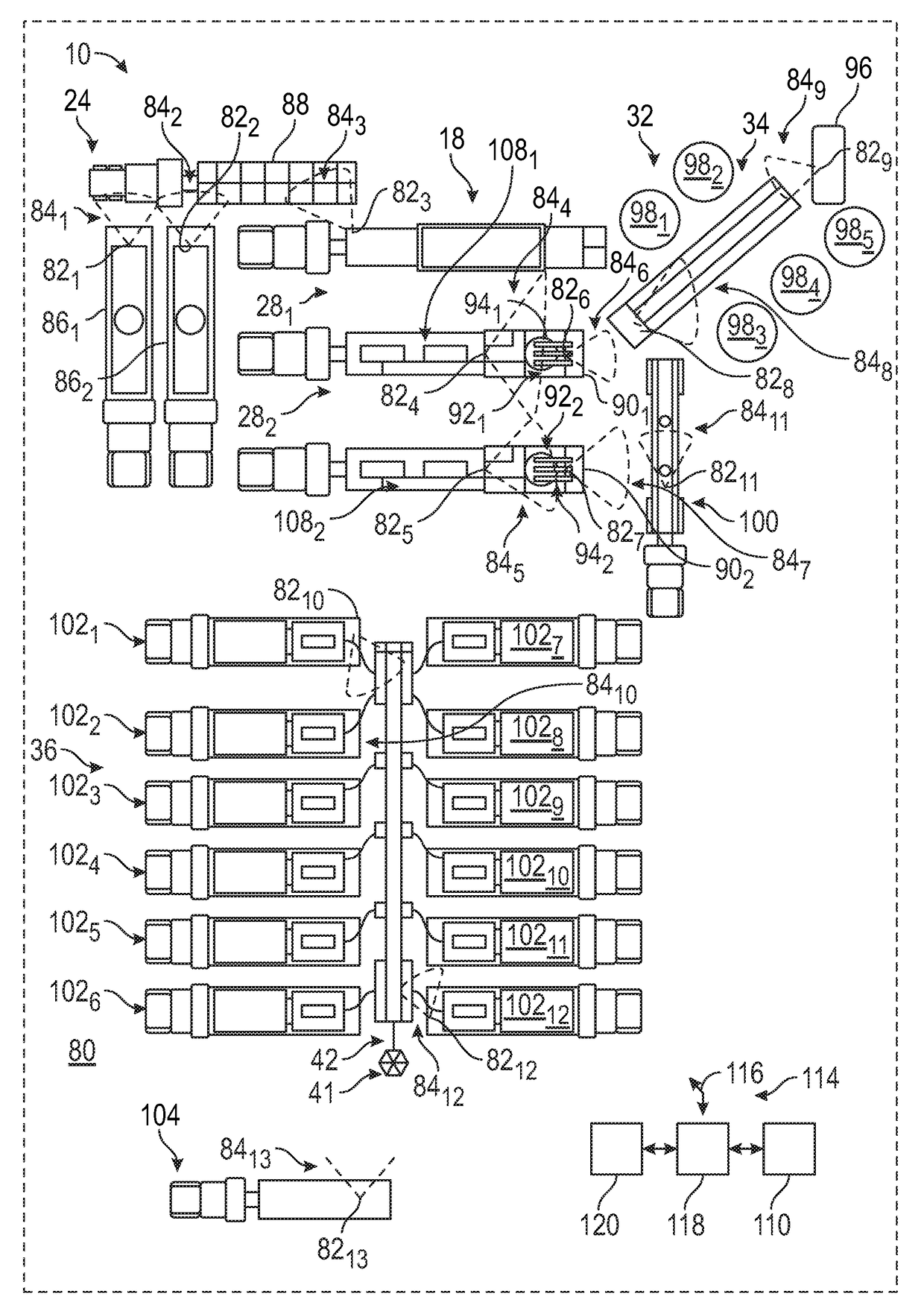

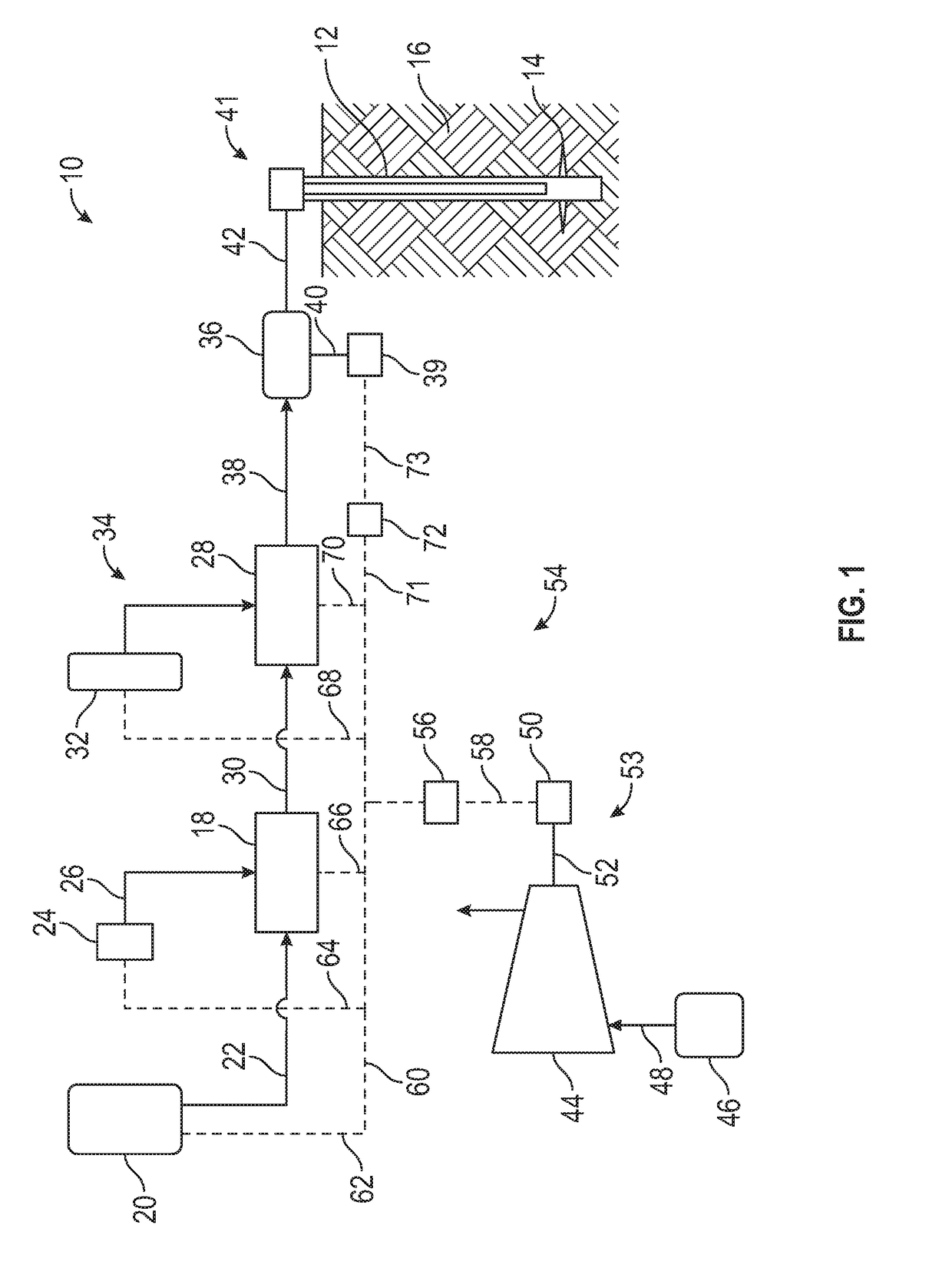

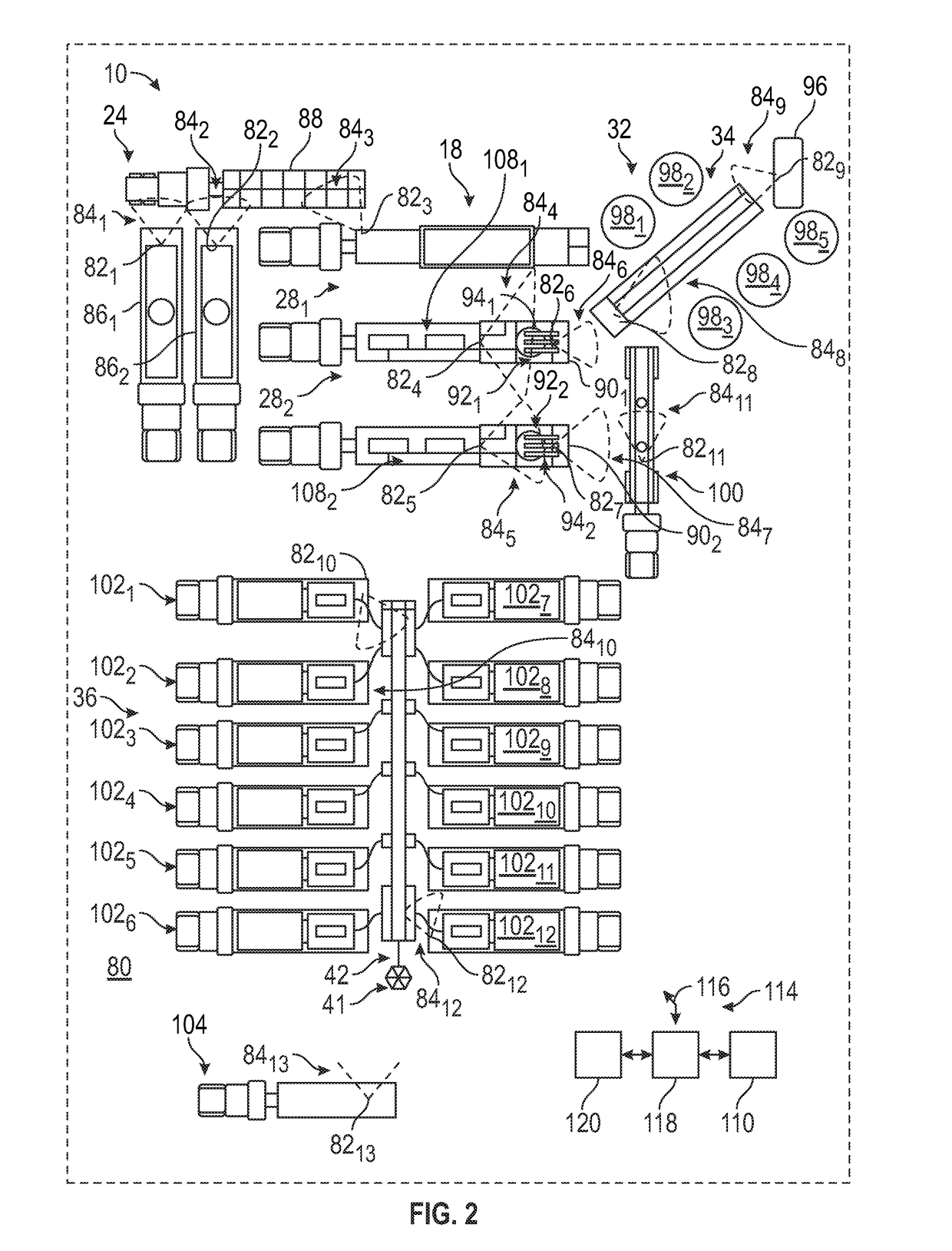

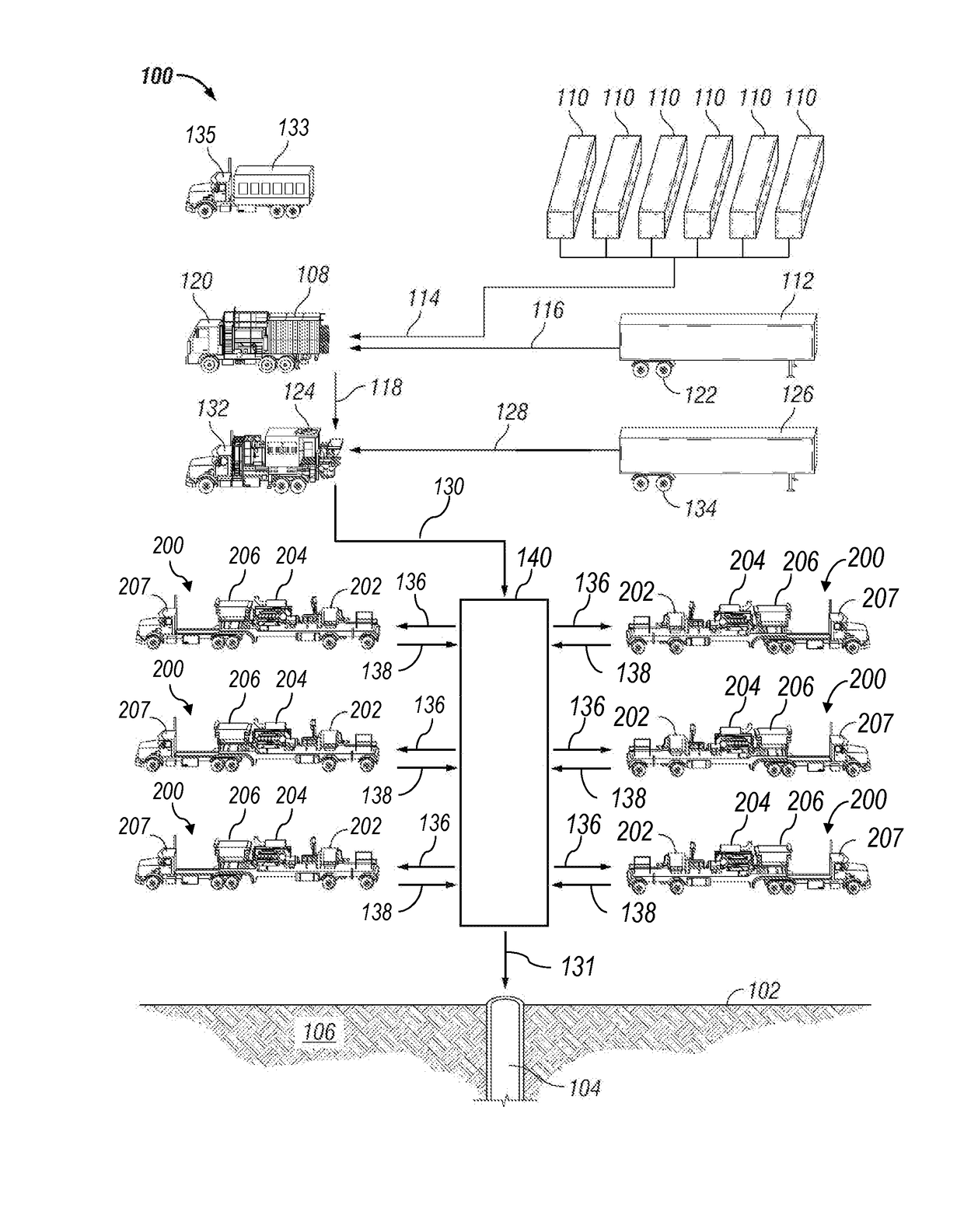

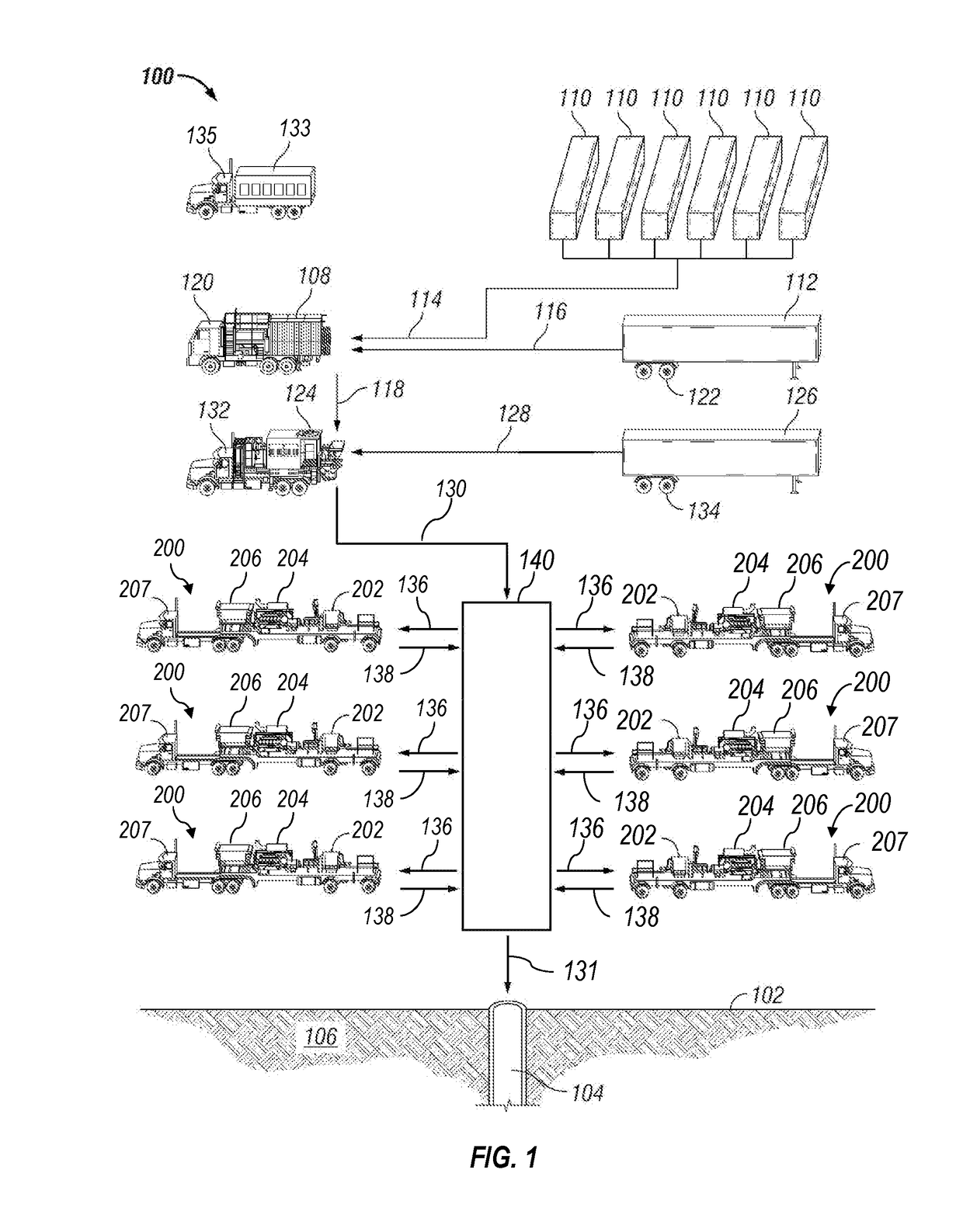

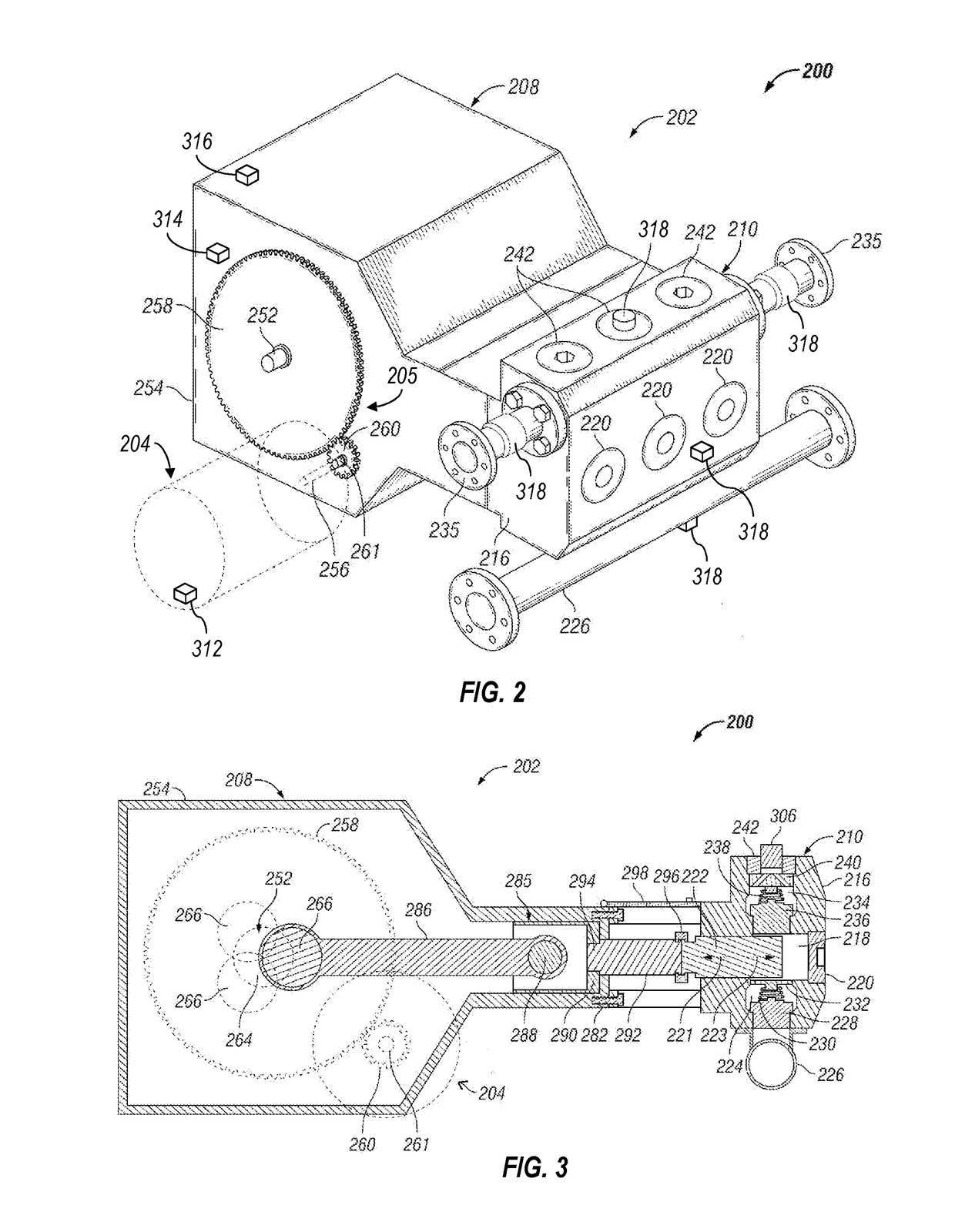

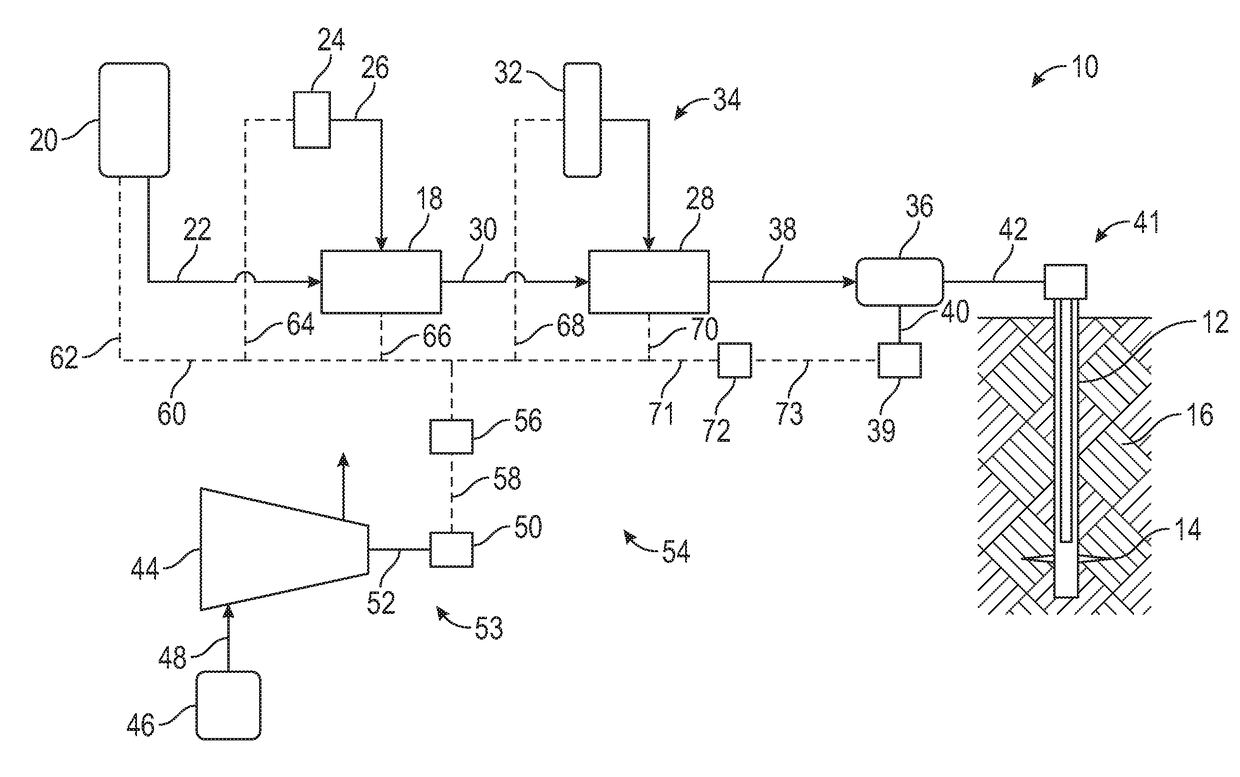

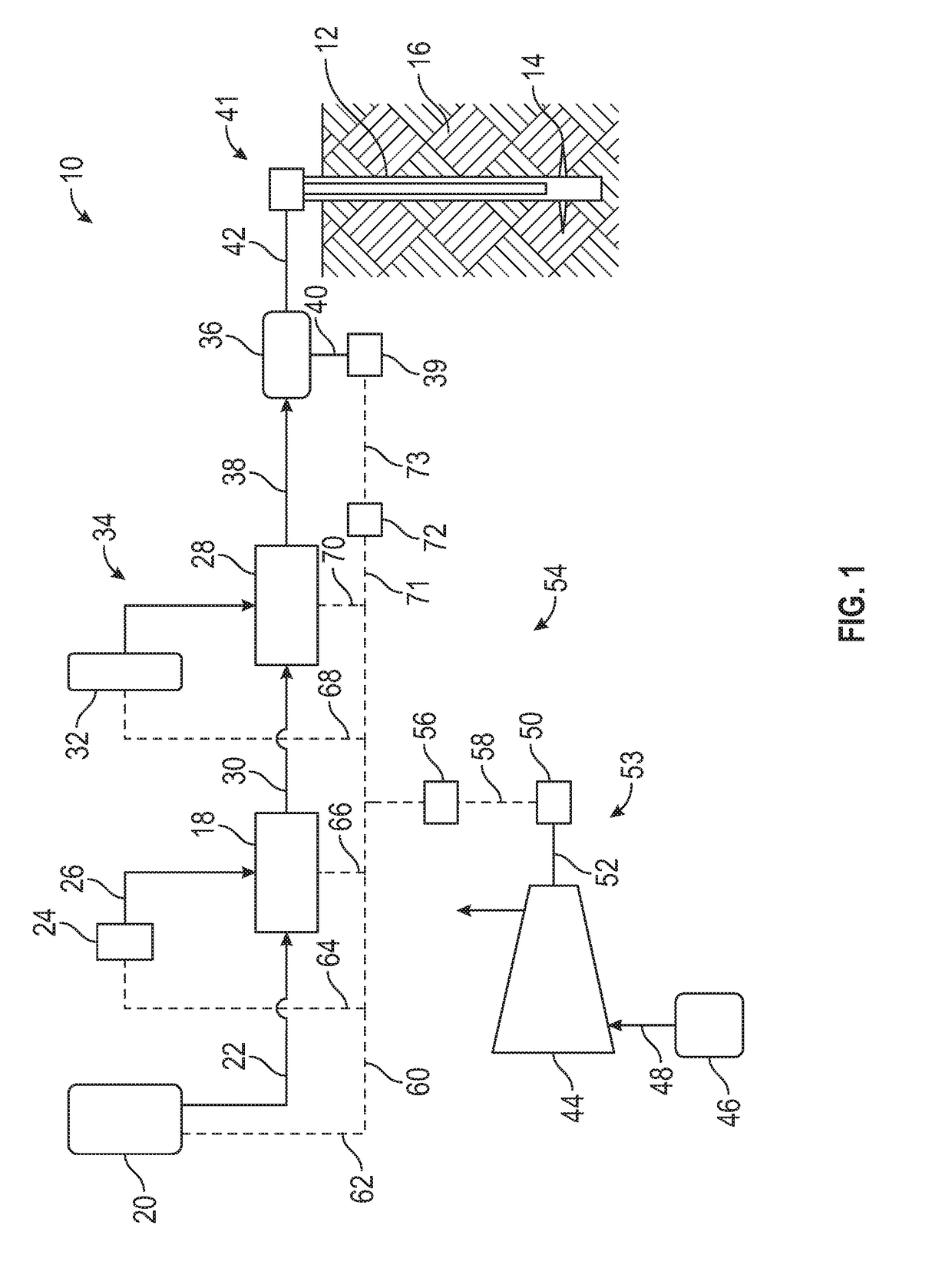

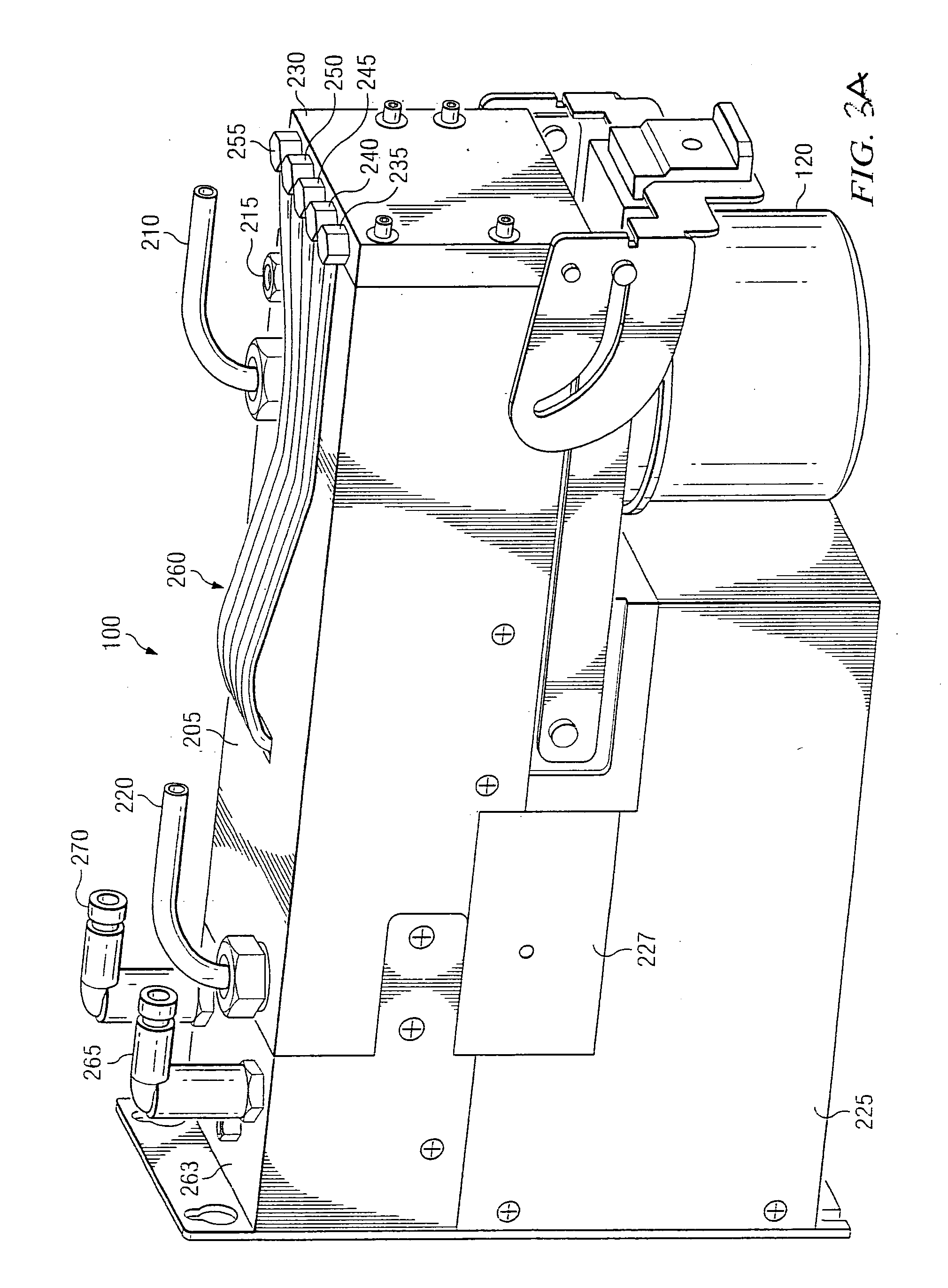

Remote monitoring for hydraulic fracturing equipment

A hydraulic fracturing system for fracturing a subterranean formation including a pump in communication via pump components with a wellbore that intersects the formation, and that pressurizes fluid in the wellbore, the fluid comprising a fracturing fluid slurry. The system further includes hydraulic fracturing system components for making the fracturing fluid slurry, and a monitoring system that selectively captures and transmits real time images of at least one of the hydraulic fracturing system components or pump components to enable remote monitoring of the at least one of the hydraulic fracturing system components or pump components.

Owner:US WELL SERVICS LLC

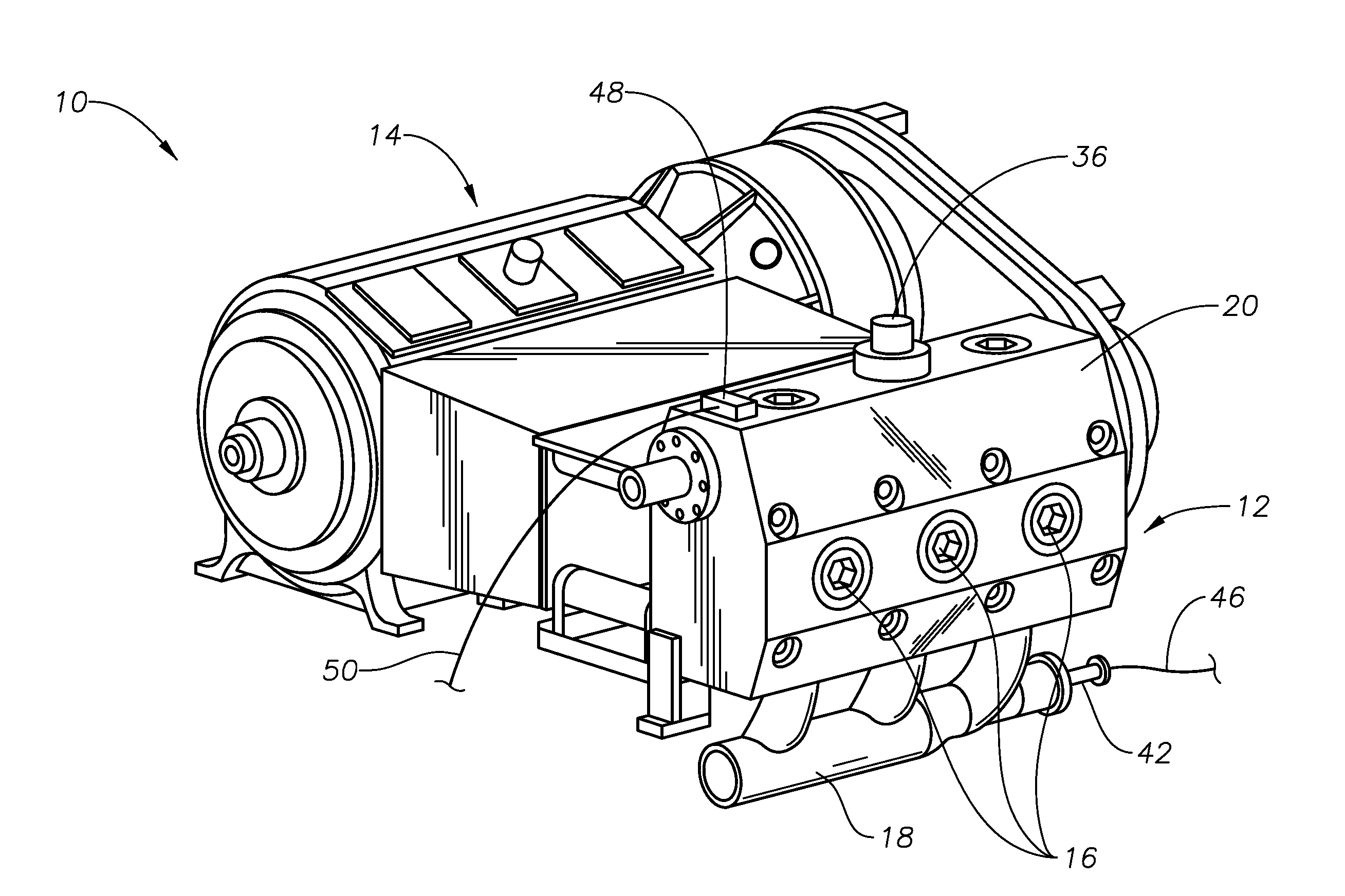

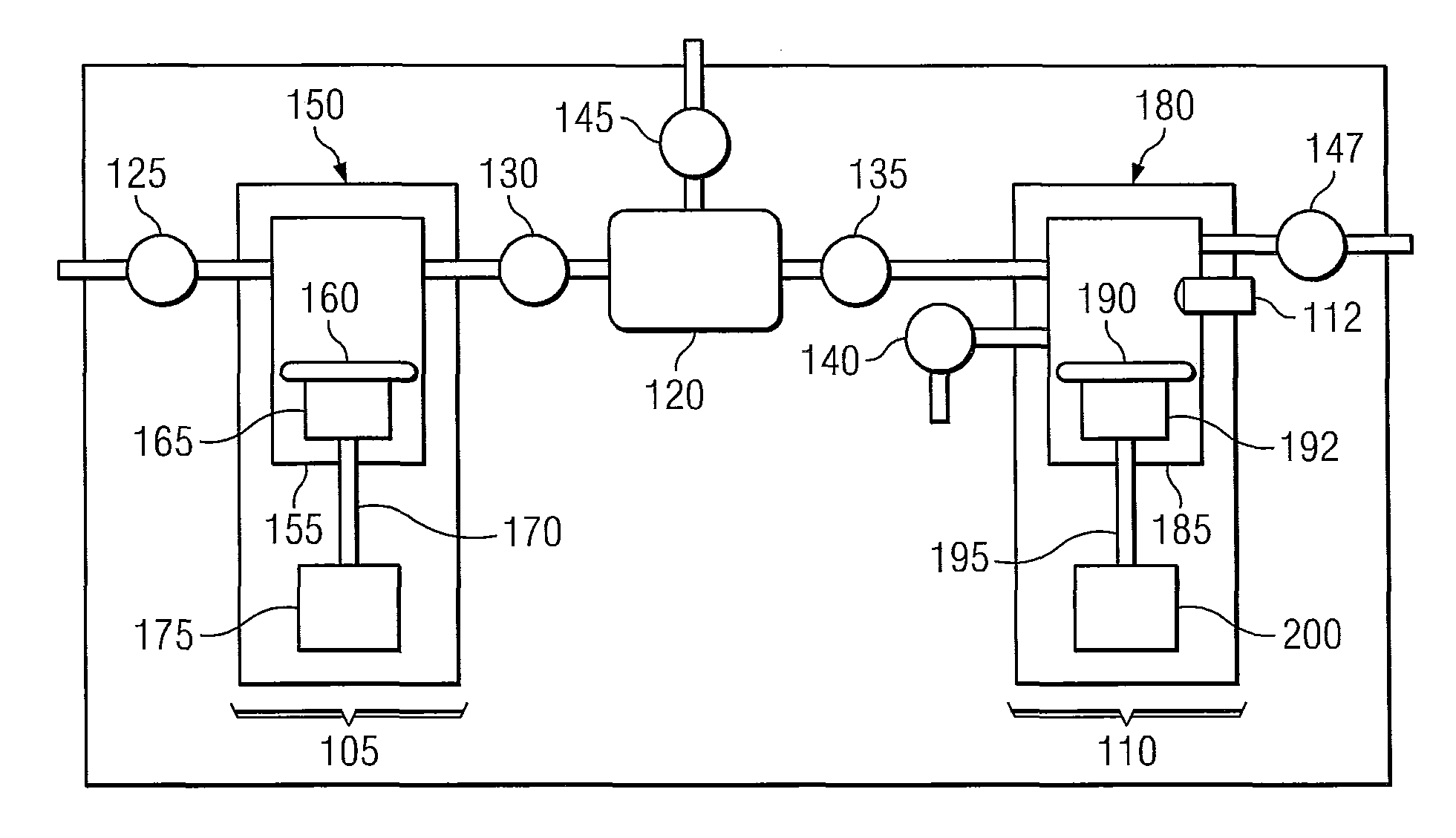

Reciprocating pump cavitation detection and avoidance

Systems and methods for detecting cavitation in a reciprocating positive displacement pump. Fluid pressure proximate the pump's suction manifold is compared to a predetermined pressure that would be conducive to cavitation. If the detected pressure approximates the predetermined pressure, the presence of cavitation is confirmed via correlation of increased vibration.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

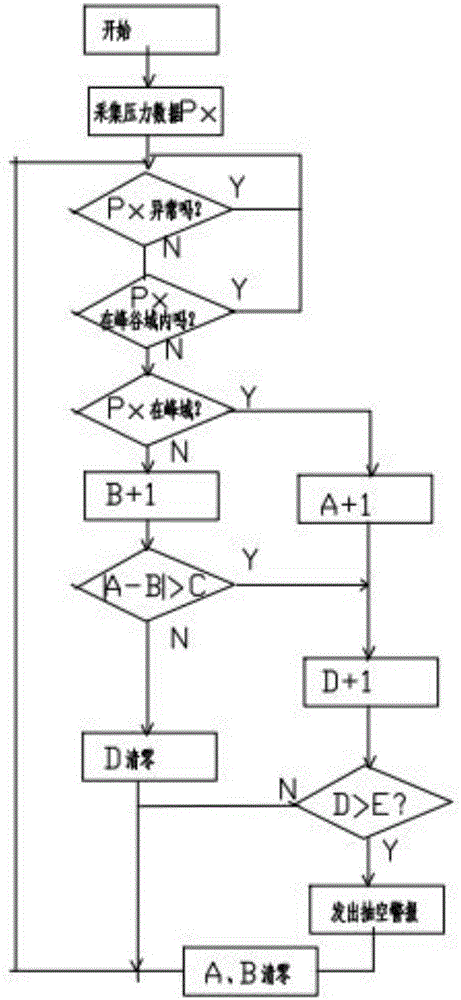

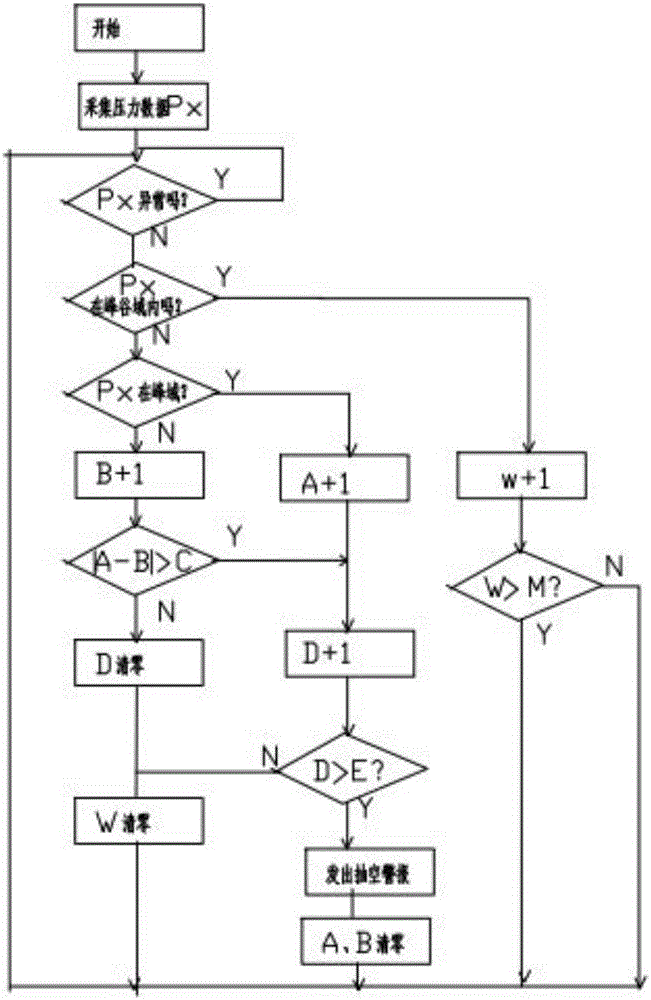

Method for preventing evacuation of plunger pump based on monitoring of output pressure

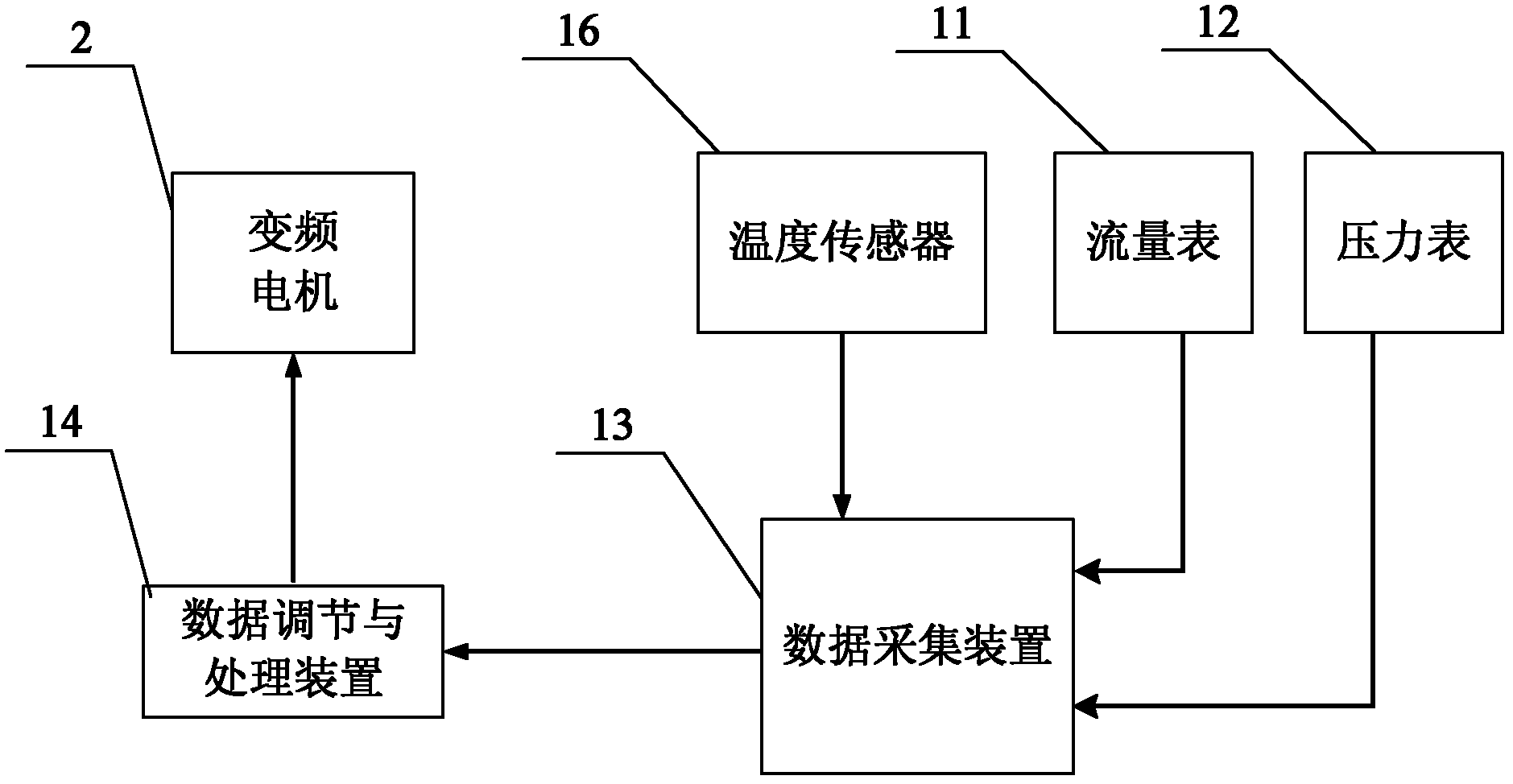

ActiveCN106438310AImprove protectionThe detection method is accuratePump testingPump controlData acquisitionEngineering

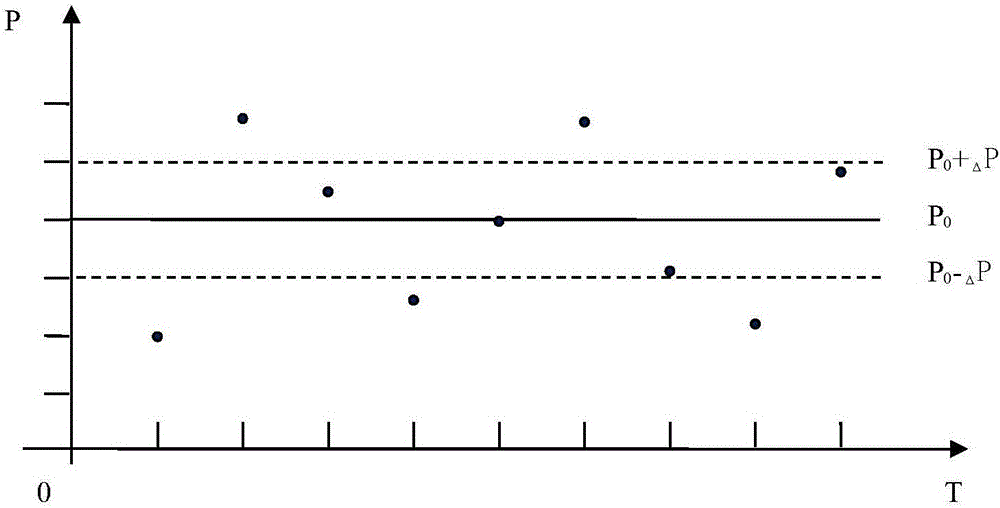

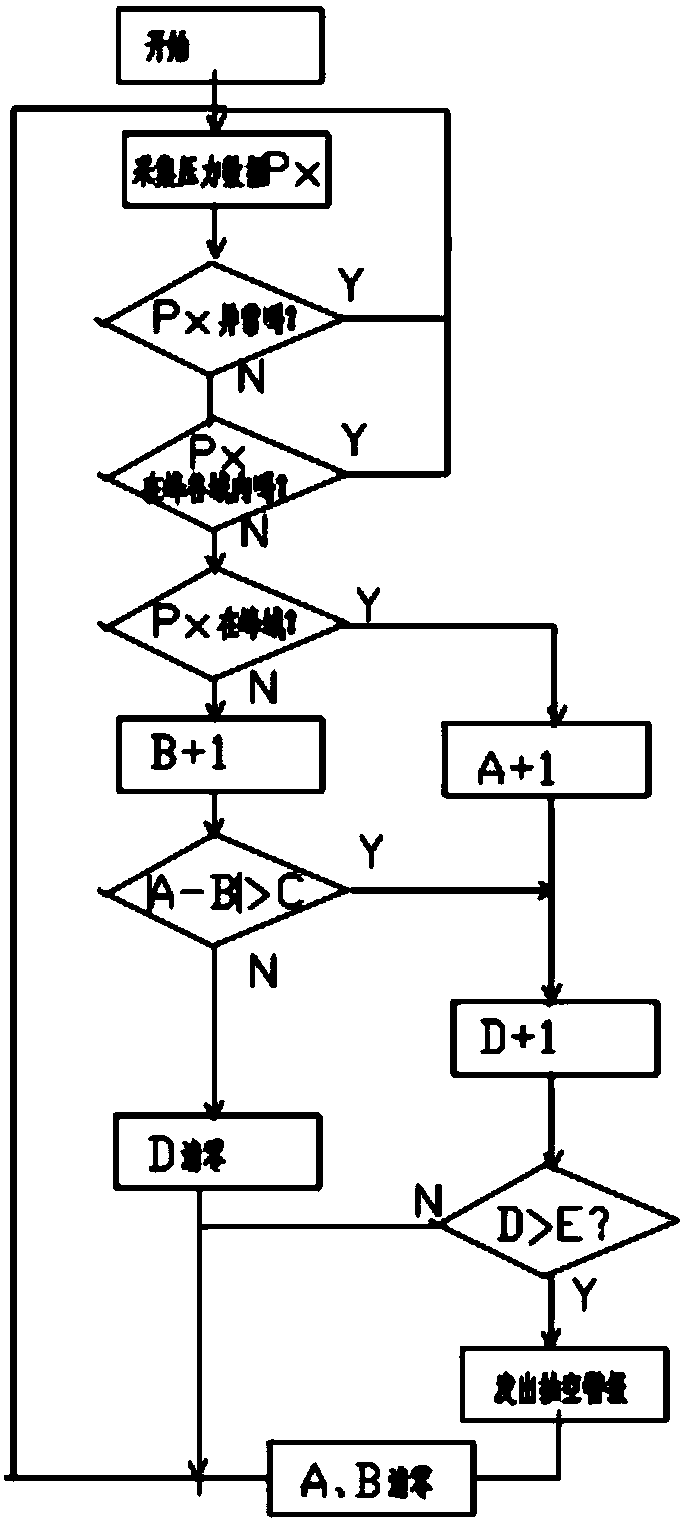

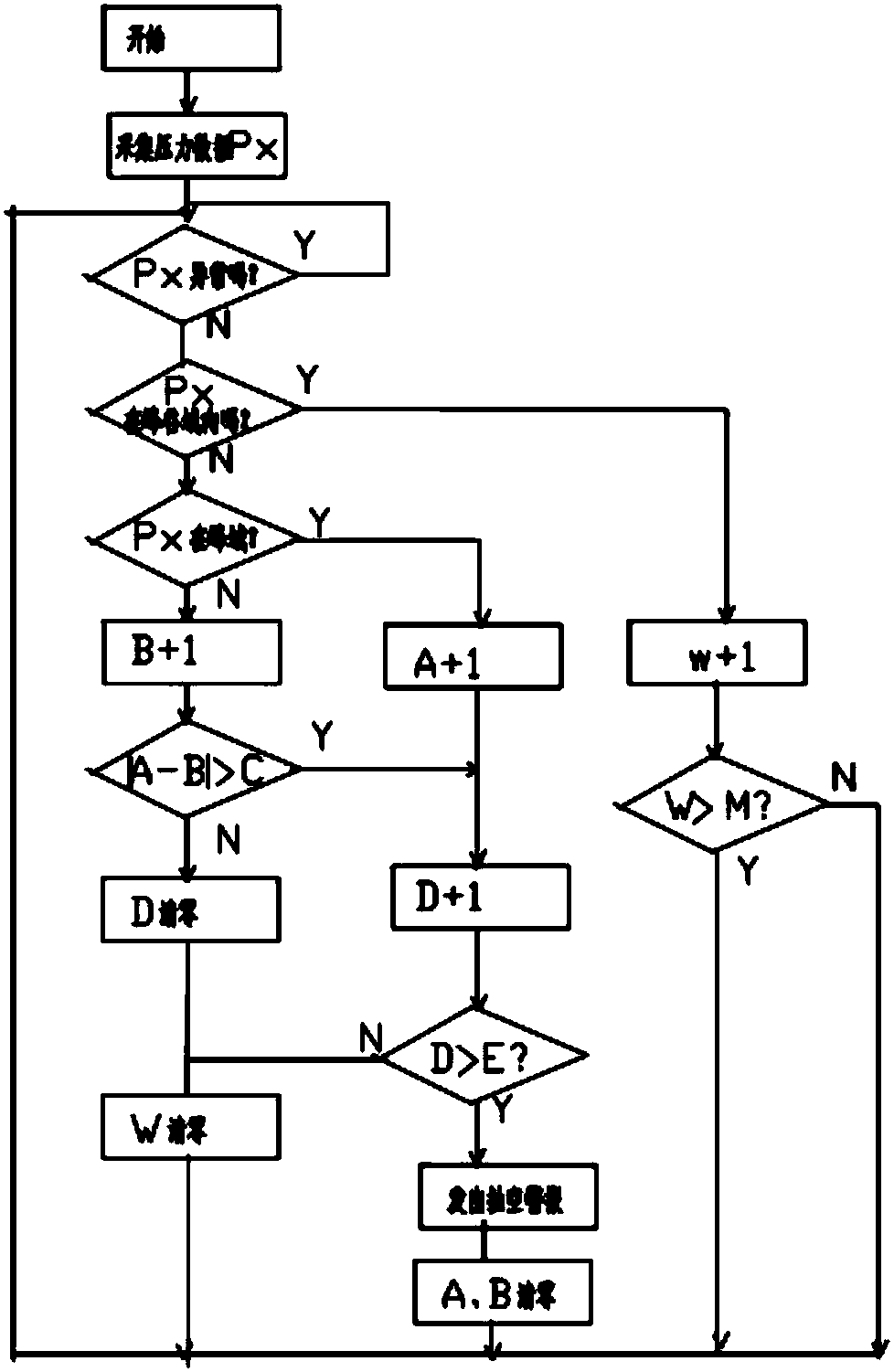

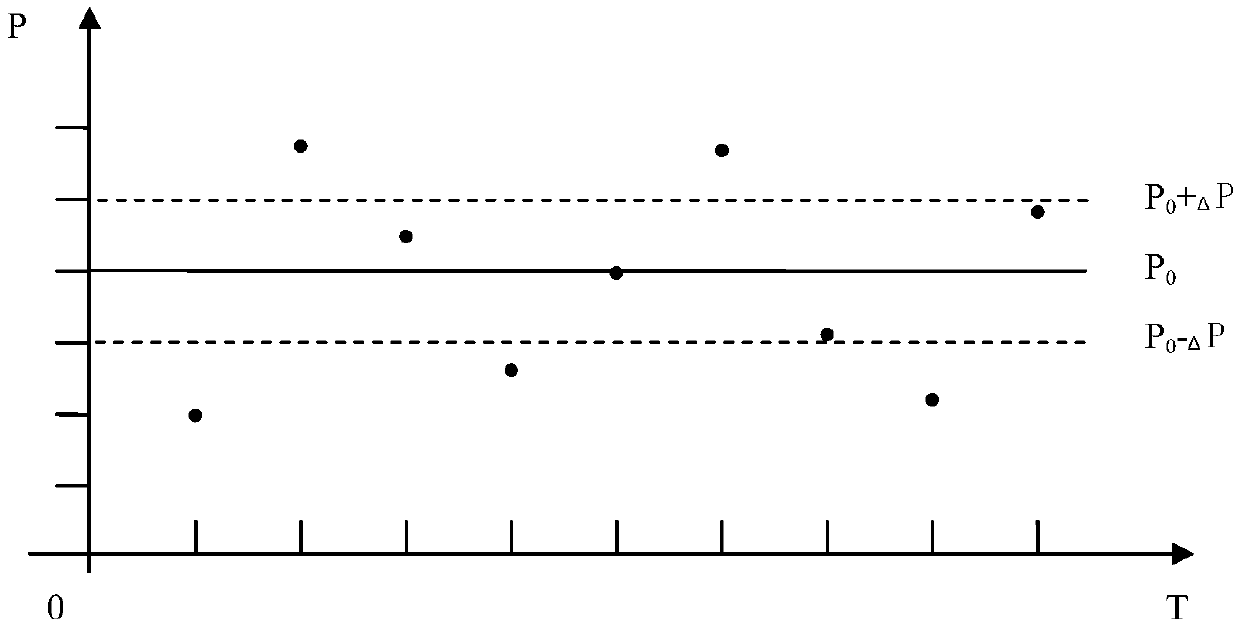

The invention relates to the technical field of monitoring of plunger pumps, in particular to a method for preventing evacuation of a plunger pump based on monitoring of the output pressure. The method relates to the plunger and an output pipeline, and is characterized in that a pressure data acquisition control device is arranged on the outlet pipeline; and a data processing method comprises the following steps that (1) the average value P0 of the output pressure is obtained, specifically, the output pressure setting tolerance delta P is set, the domain above a P0+delta P line is called a peak domain, and the domain below a P0-delta P line is called a valley domain; a peak domain counter A and a valley domain counter B are set correspondingly; the allowable difference value between the peak domain counter A and the valley domain counter B is the numerical value C; and an out-of-tolerance time counter D and an upper limit E are set; (2) pressure data Px is acquired; (3) abnormal data are removed; (4) the number of times of Px falling into the peak domain and the valley domain is calculated; and (5) whether the out-of-tolerance time D of the difference value between the peak domain counter A and the valley domain counter B exceeds a preset value E or not is judged, and if yes, an evacuation alarm is given out. Compared with a detection method in the prior art, the method is accurate and reliable, and false alarms are avoided.

Owner:JEREH OIL & GAS ENG

A method for preventing plunger pump from pumping out based on monitoring output pressure

ActiveCN106438310BImprove protectionThe detection method is accuratePump testingPump controlData acquisitionEngineering

Owner:JEREH OIL & GAS ENG

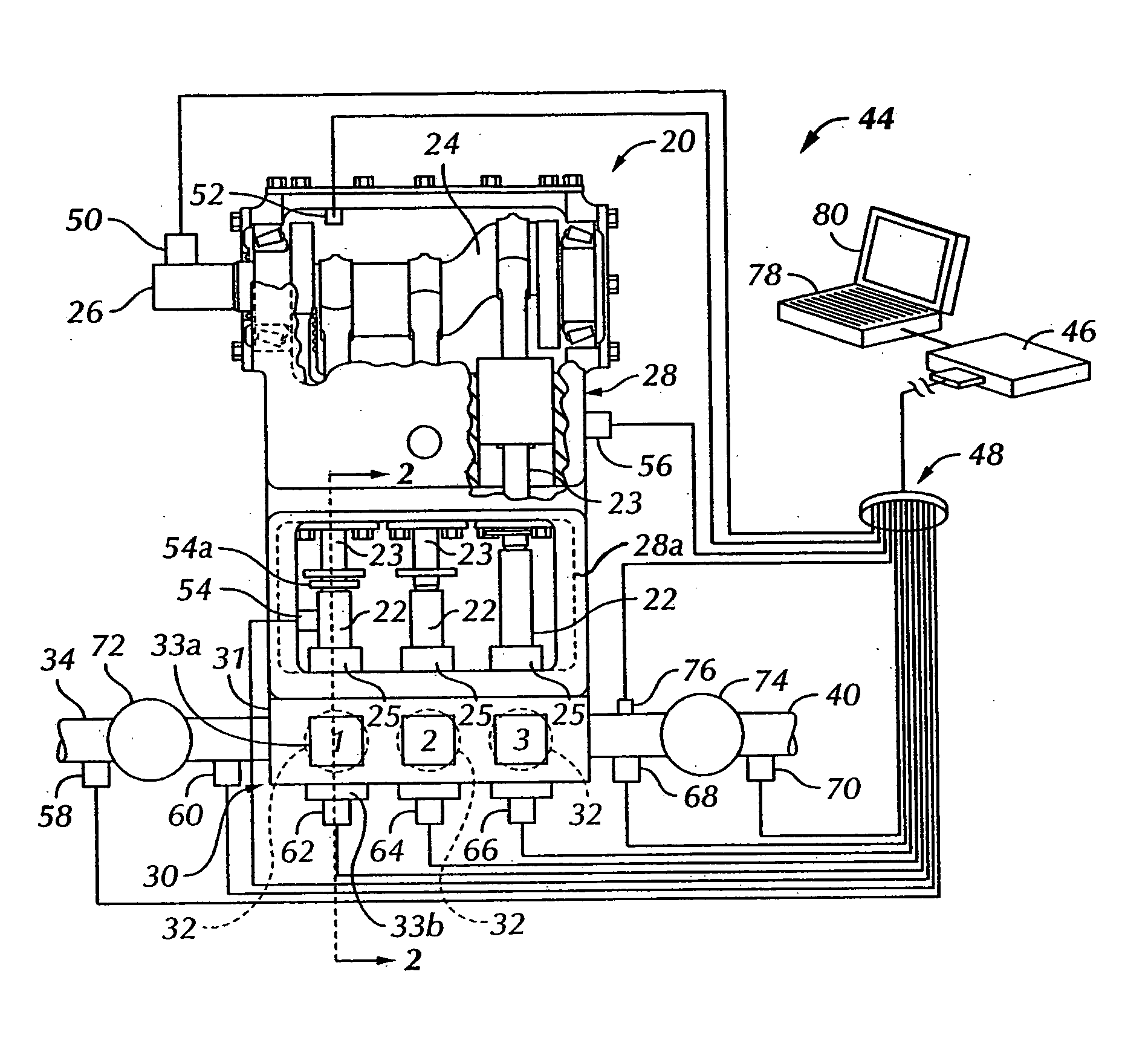

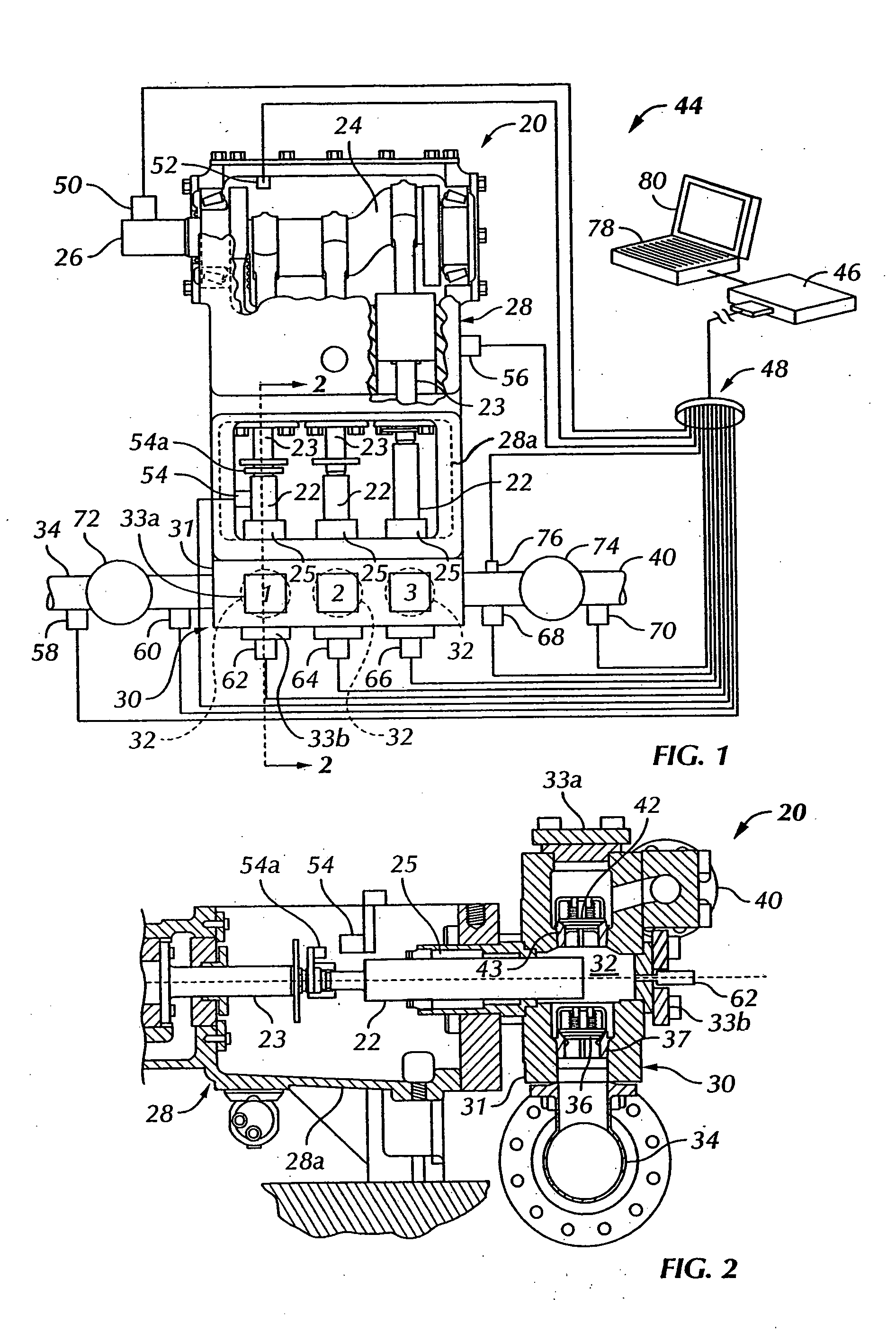

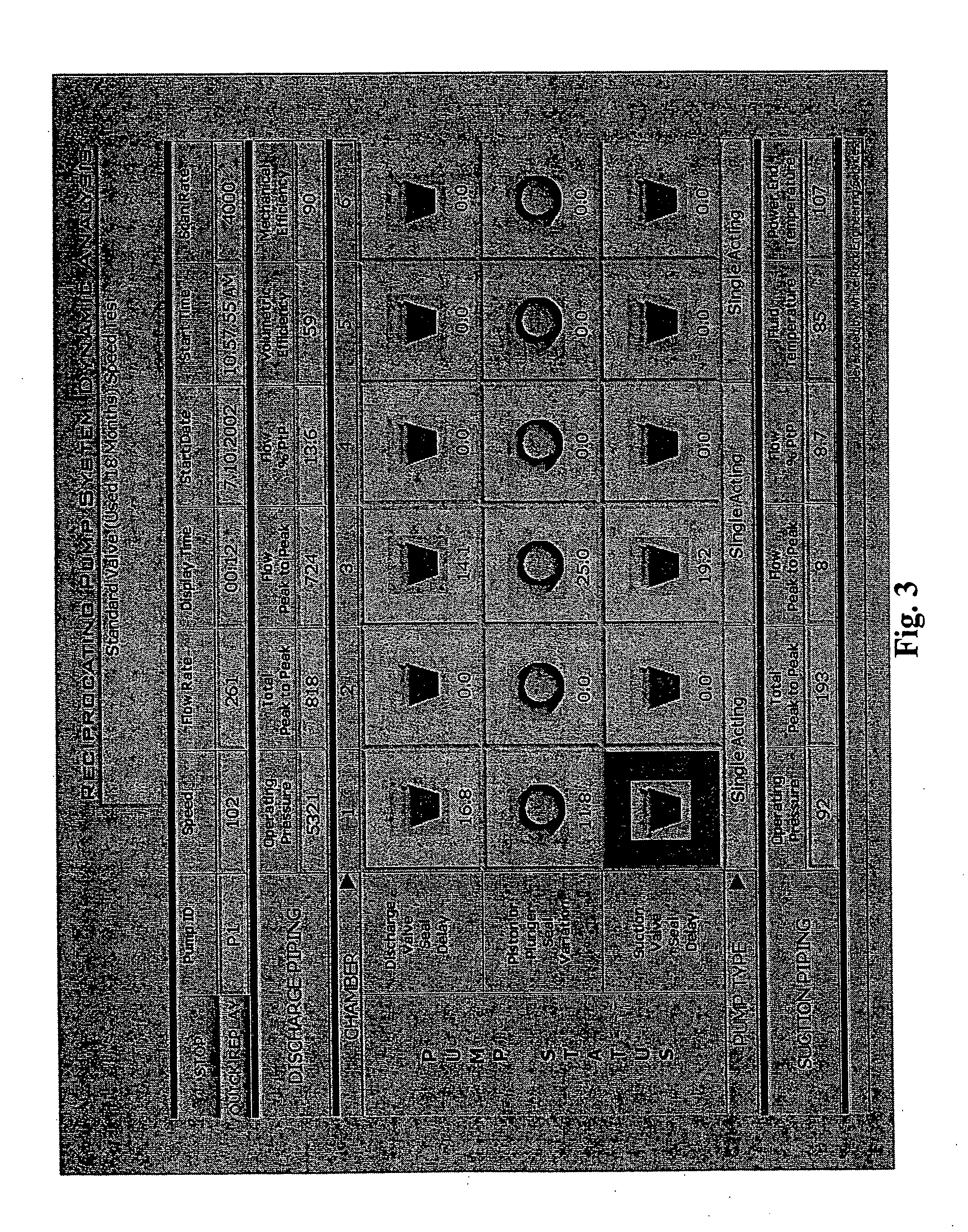

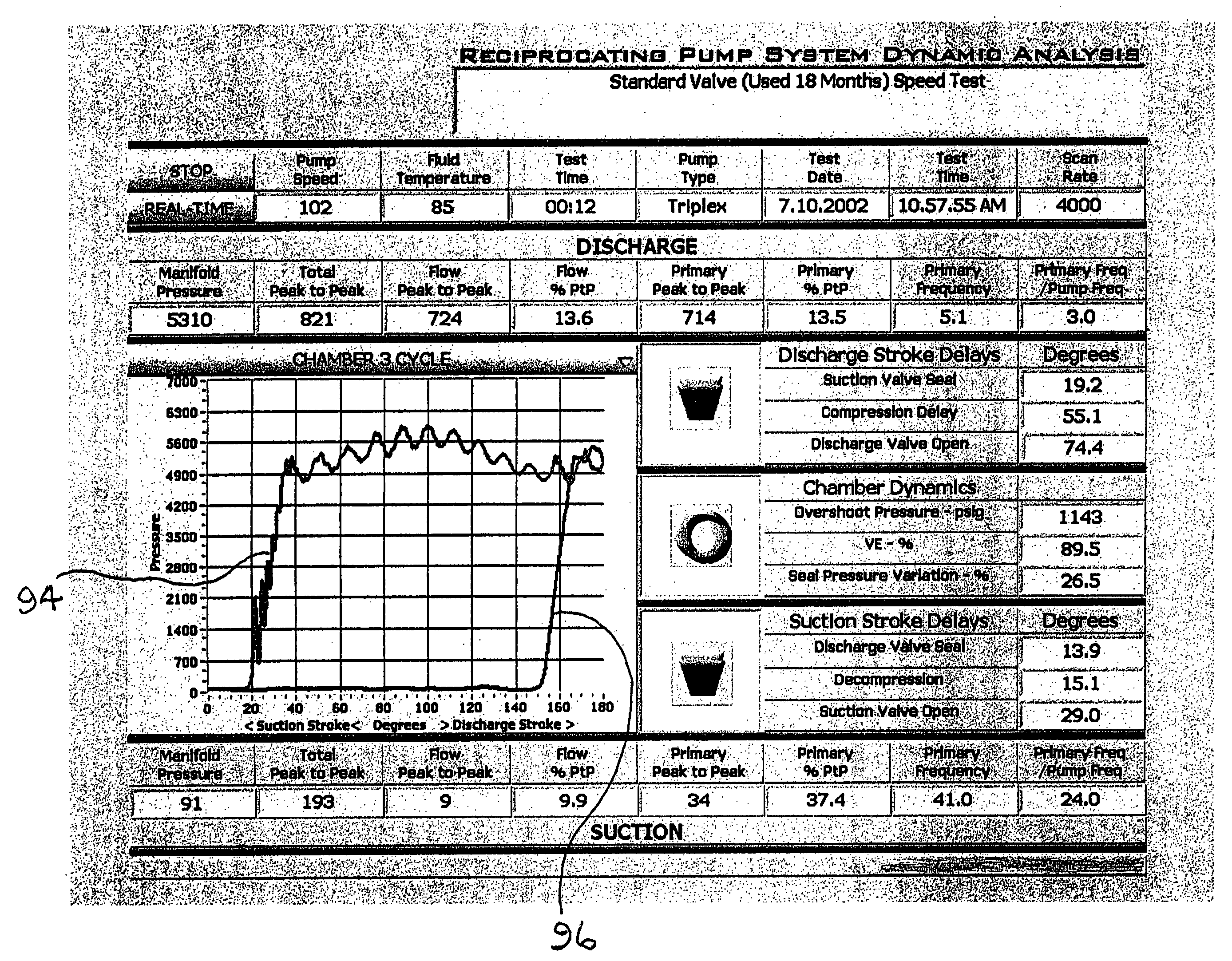

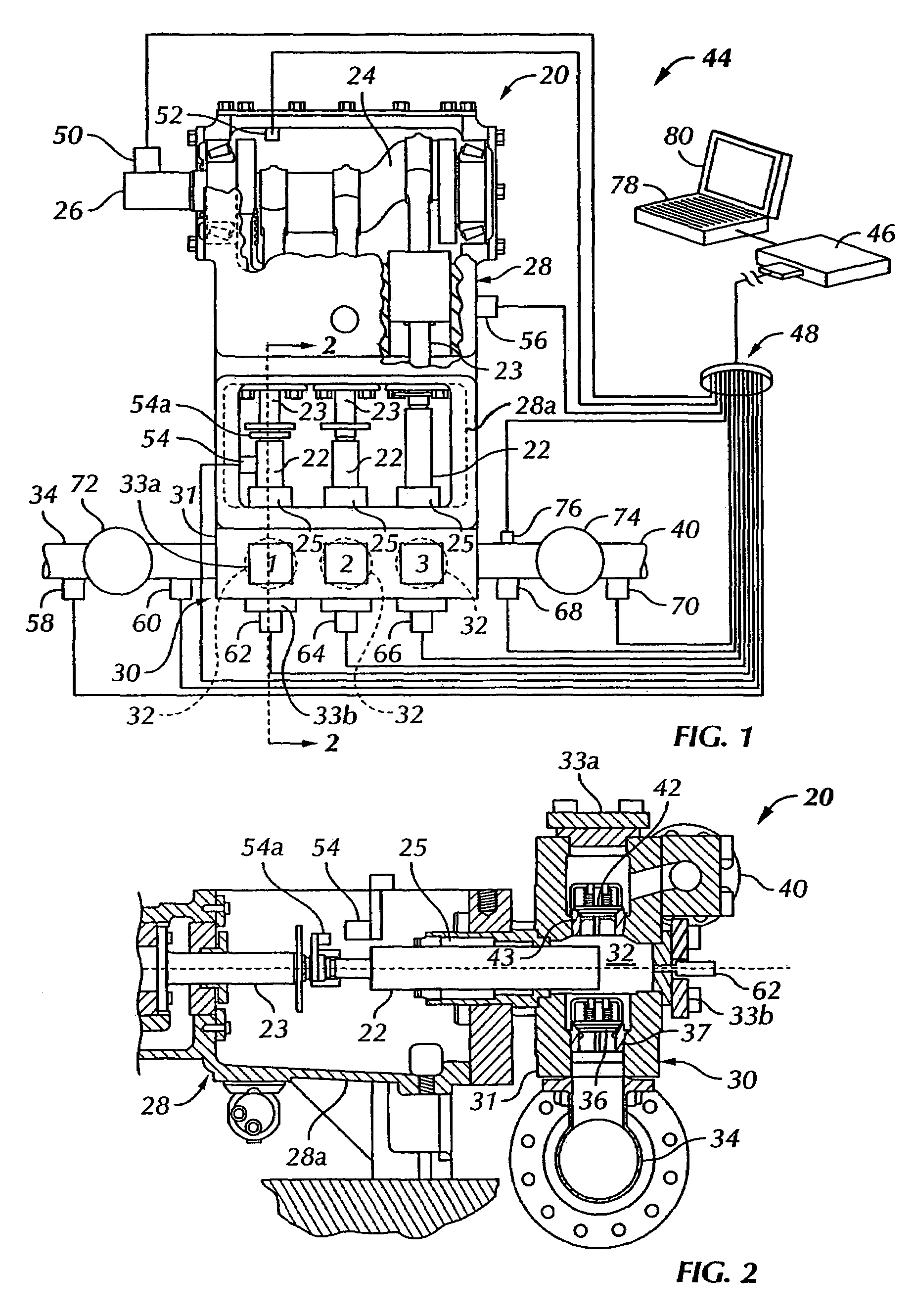

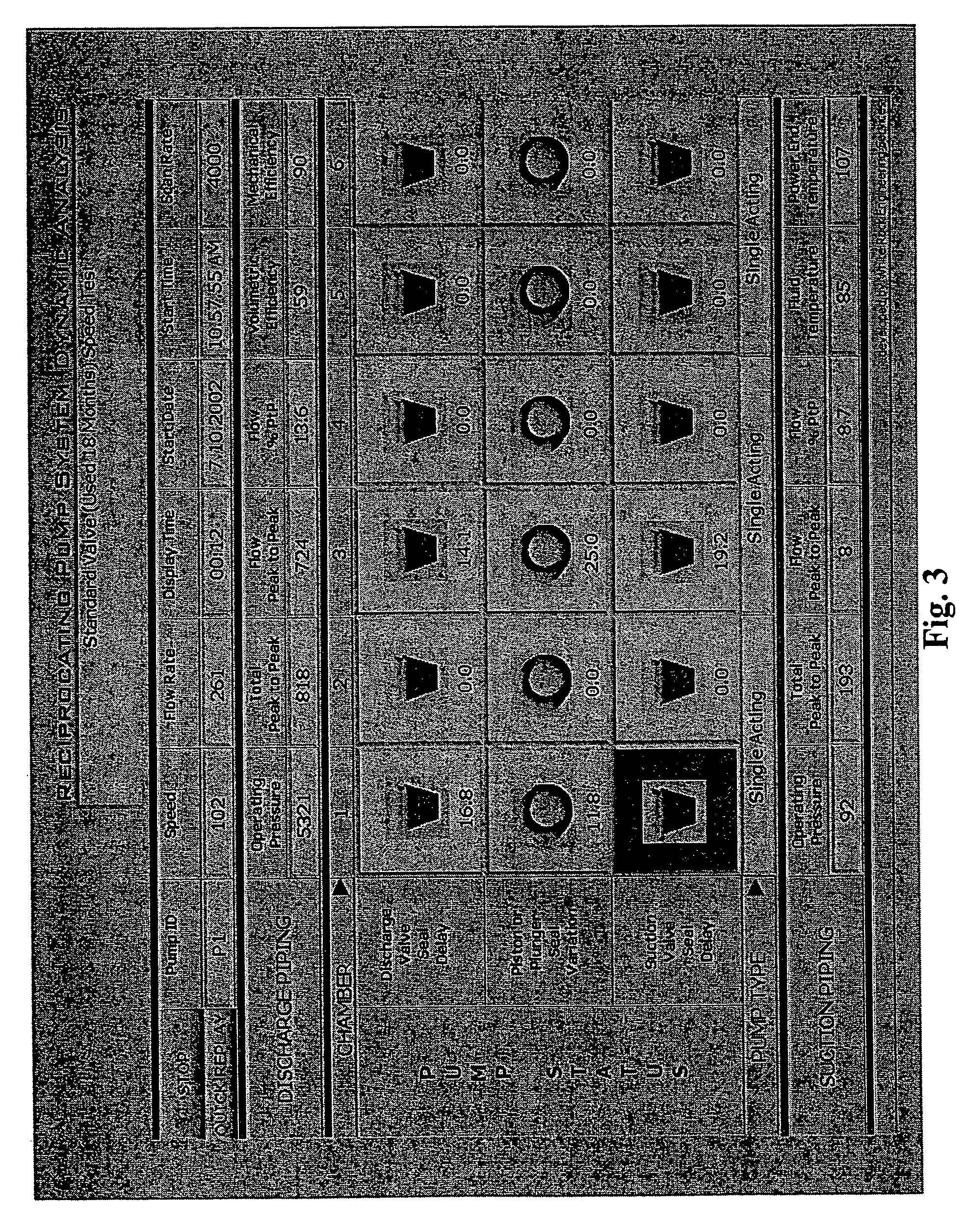

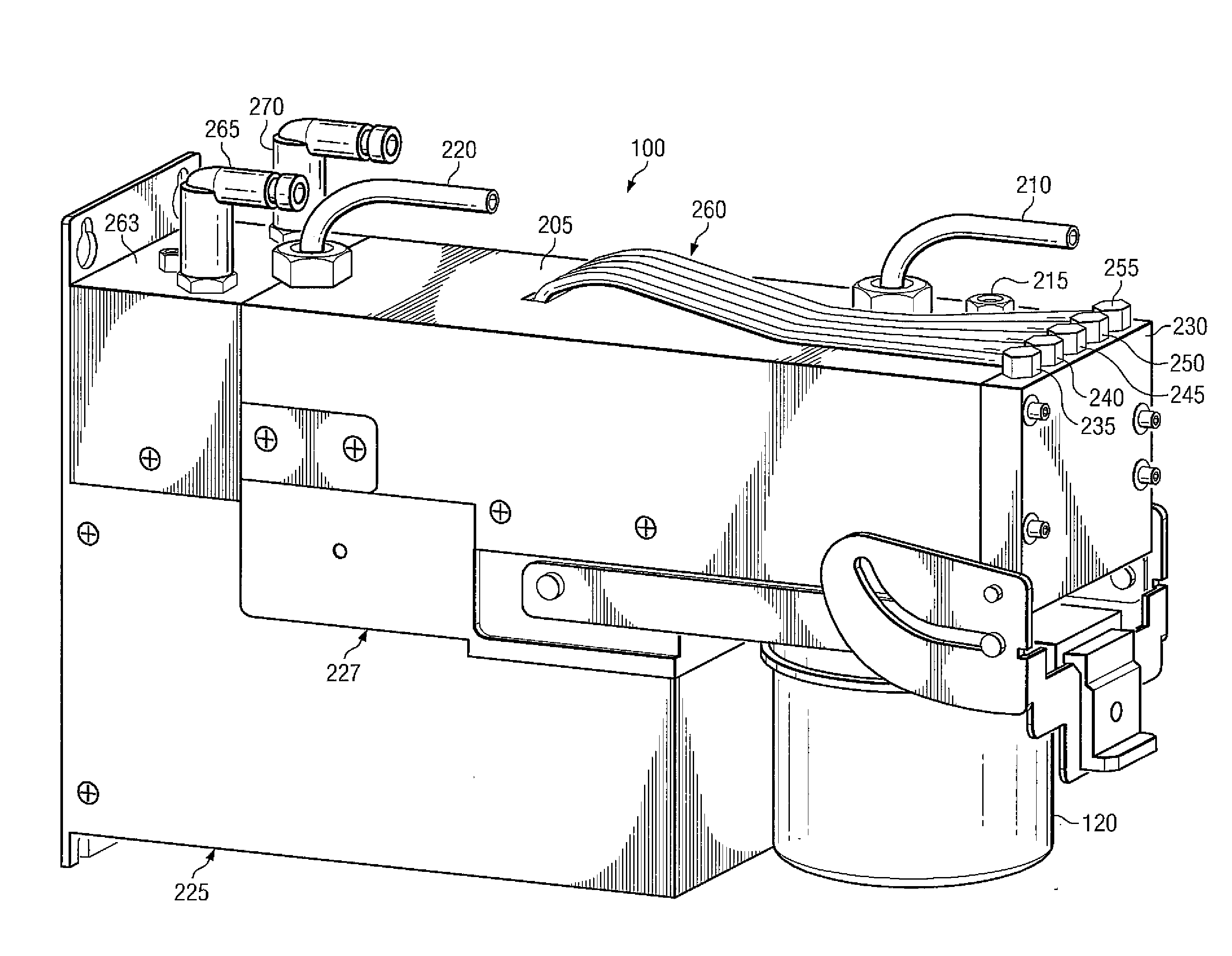

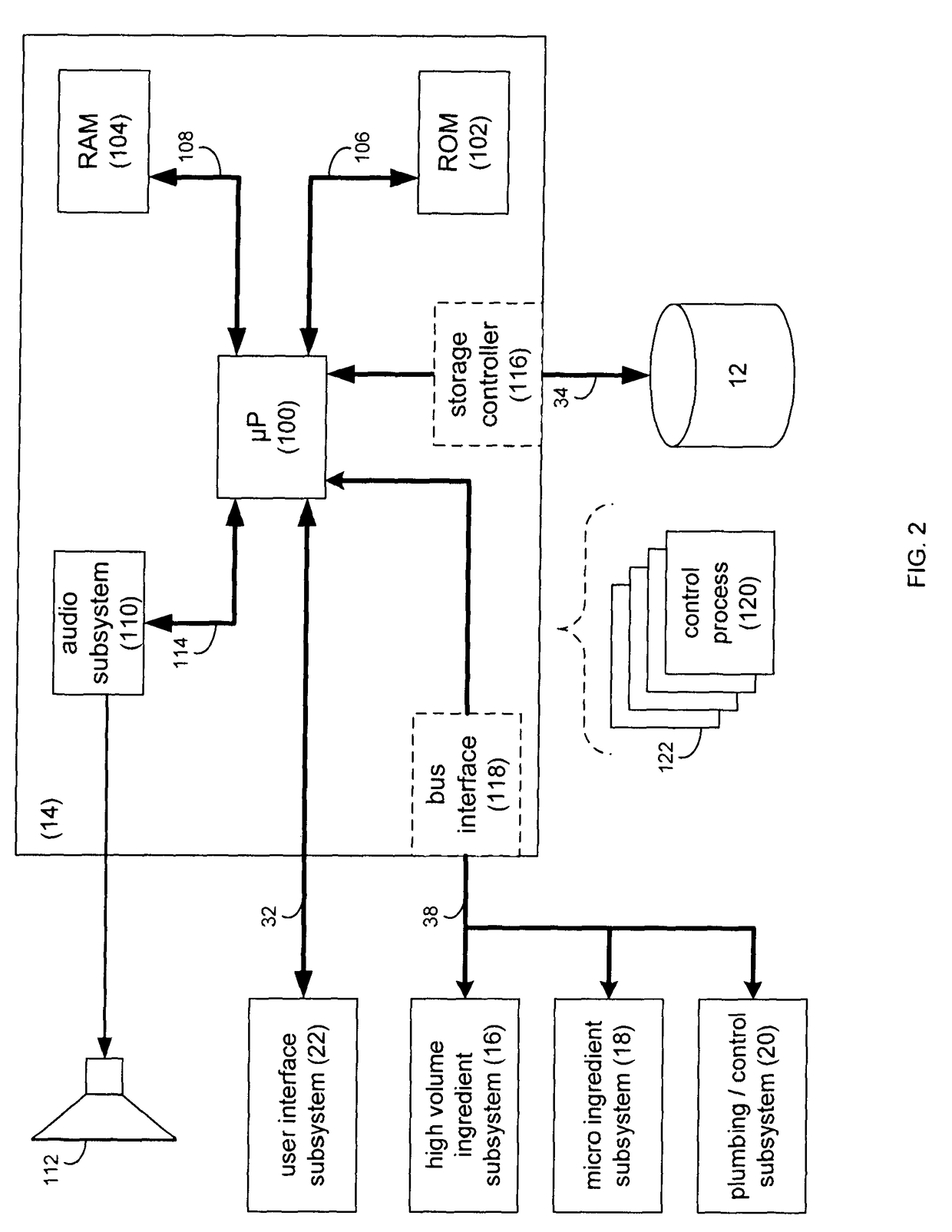

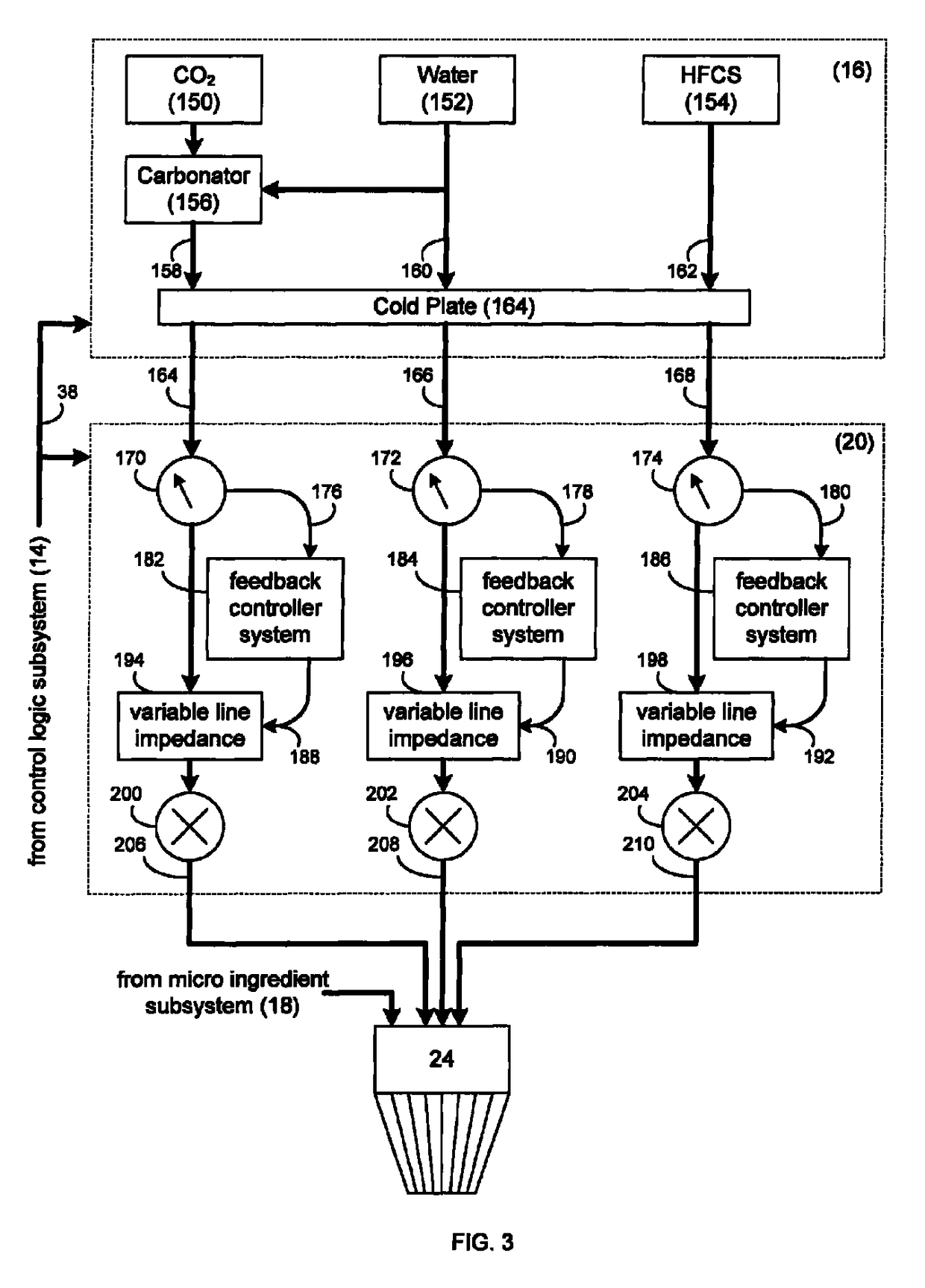

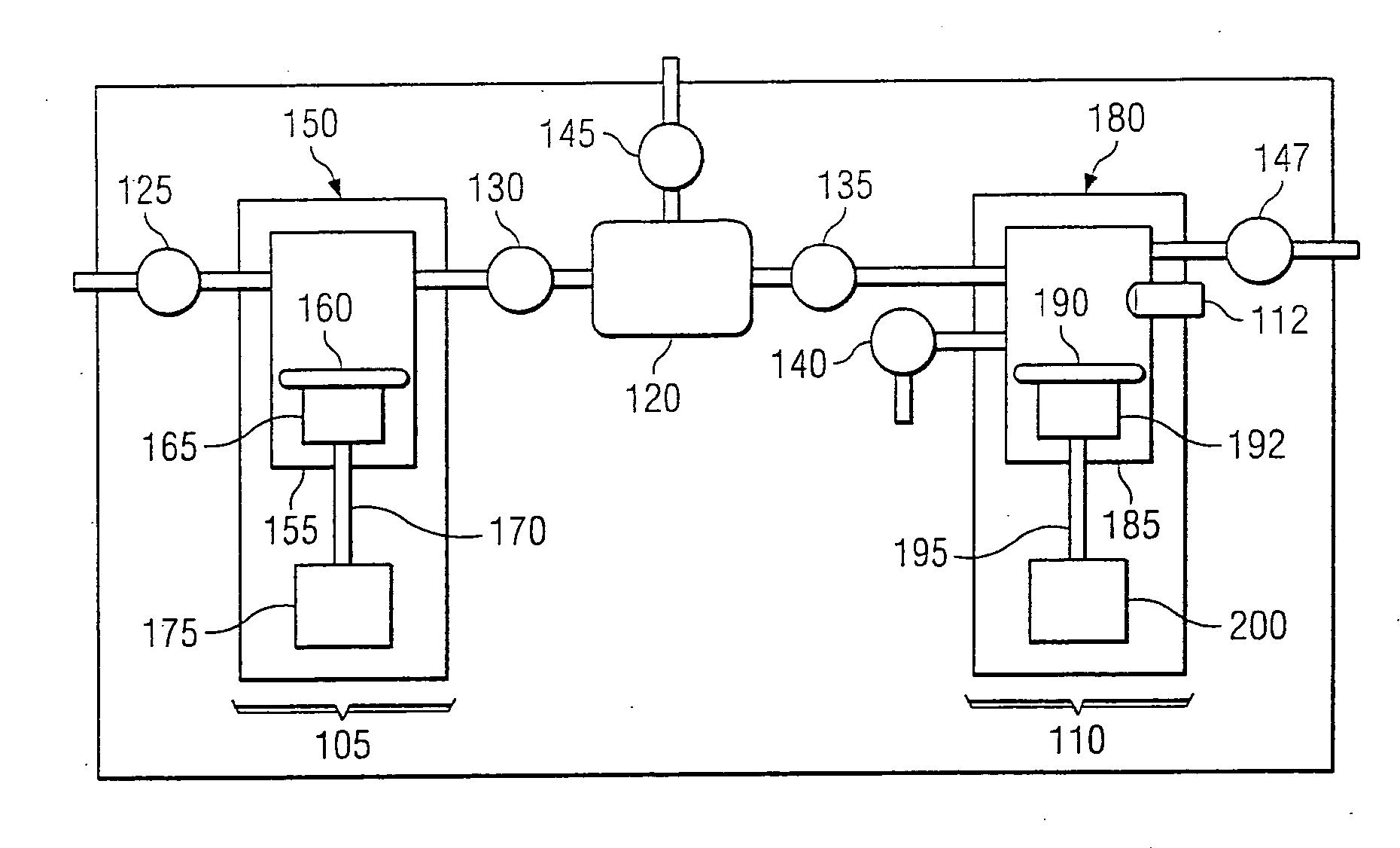

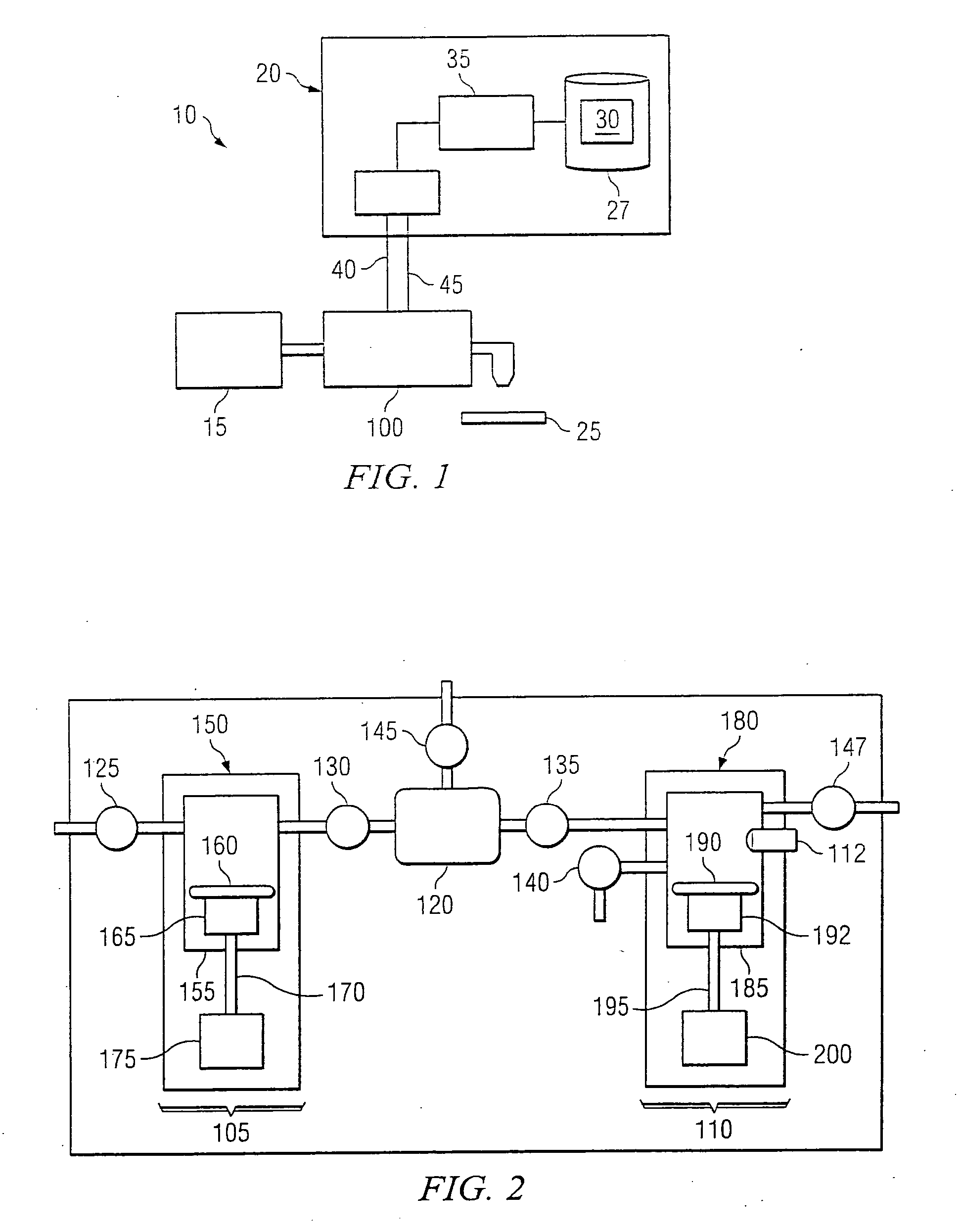

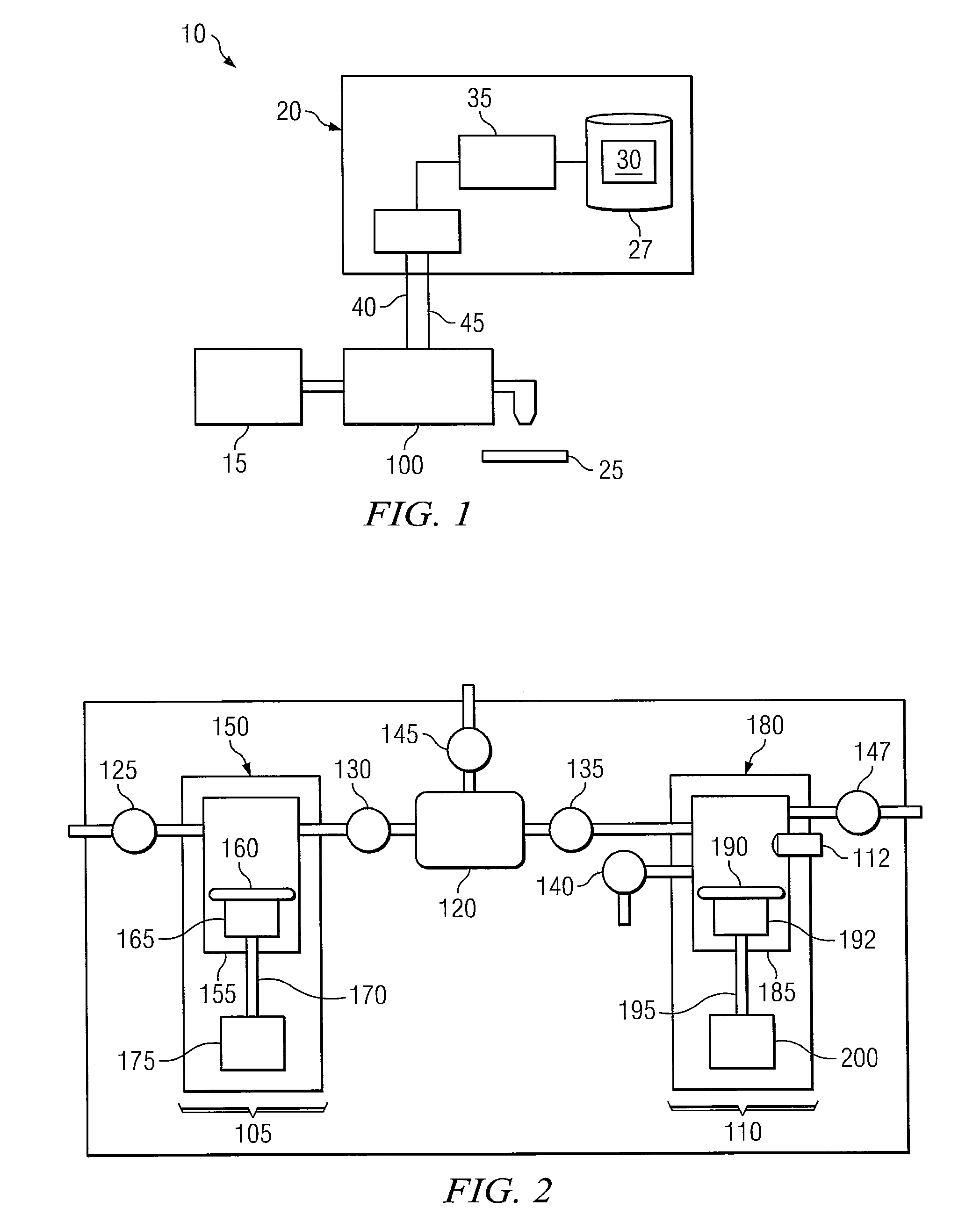

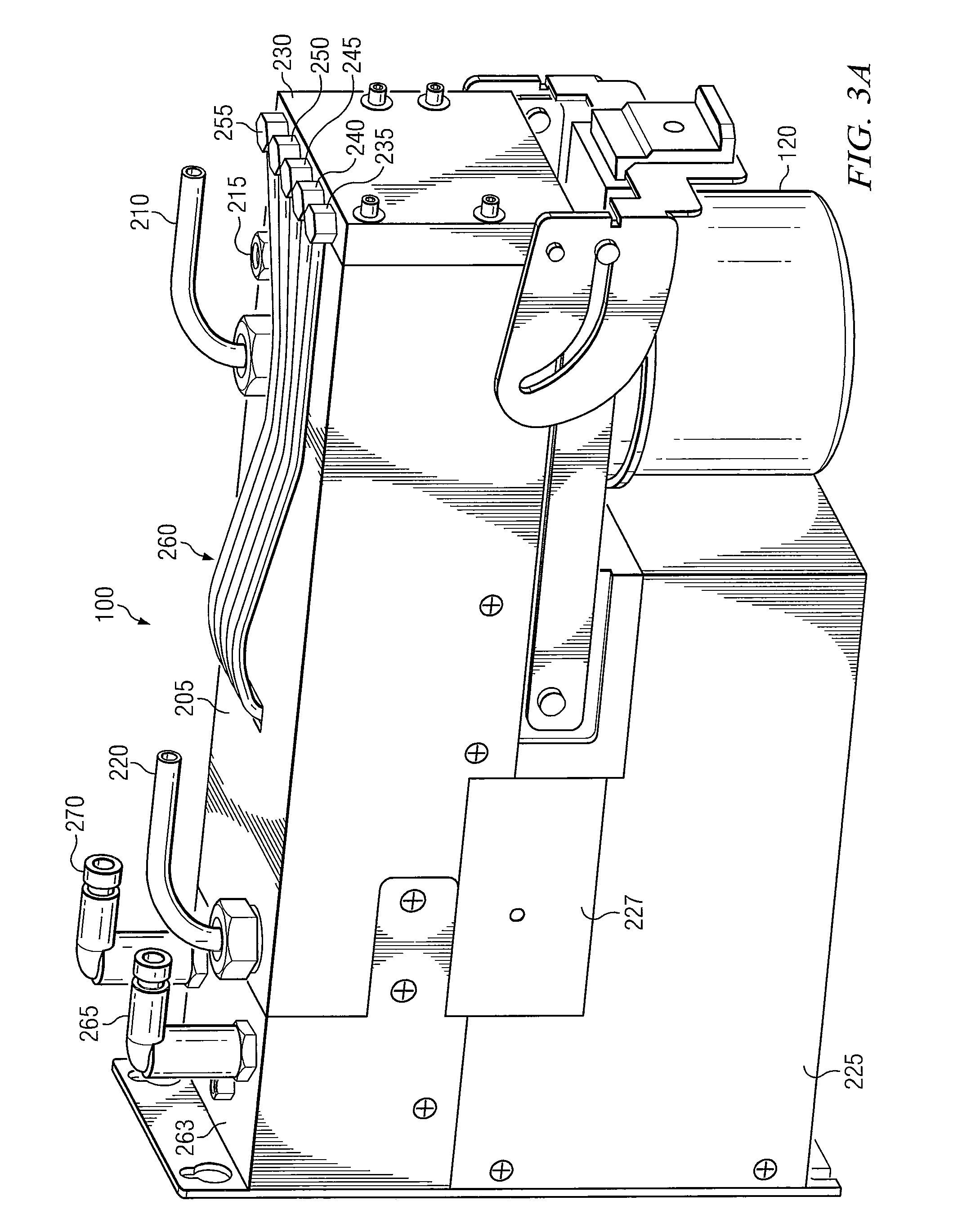

System and method for power pump performance monitoring and analysis

InactiveUS20050180868A1Easy to useEasy to provideTime indicationProgram control using stored programsDisplay deviceEngineering

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

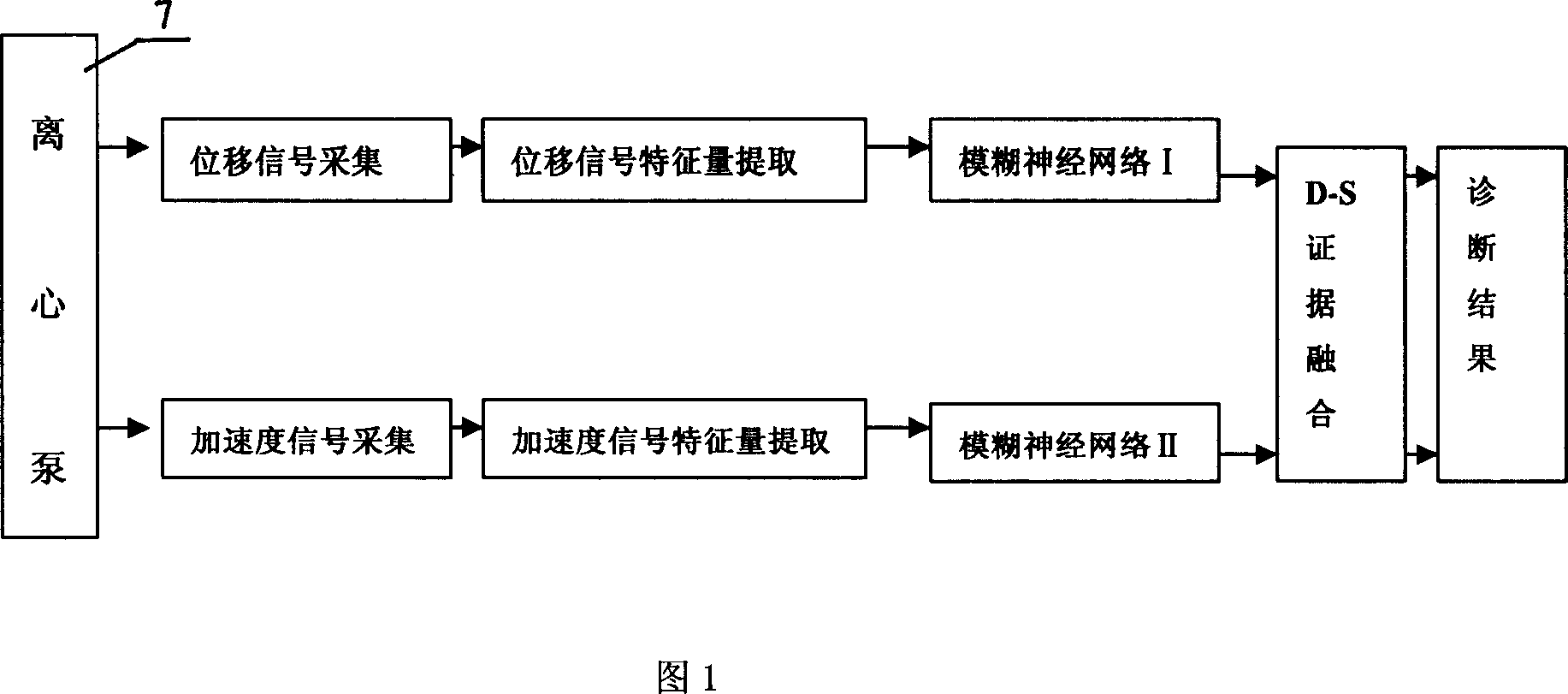

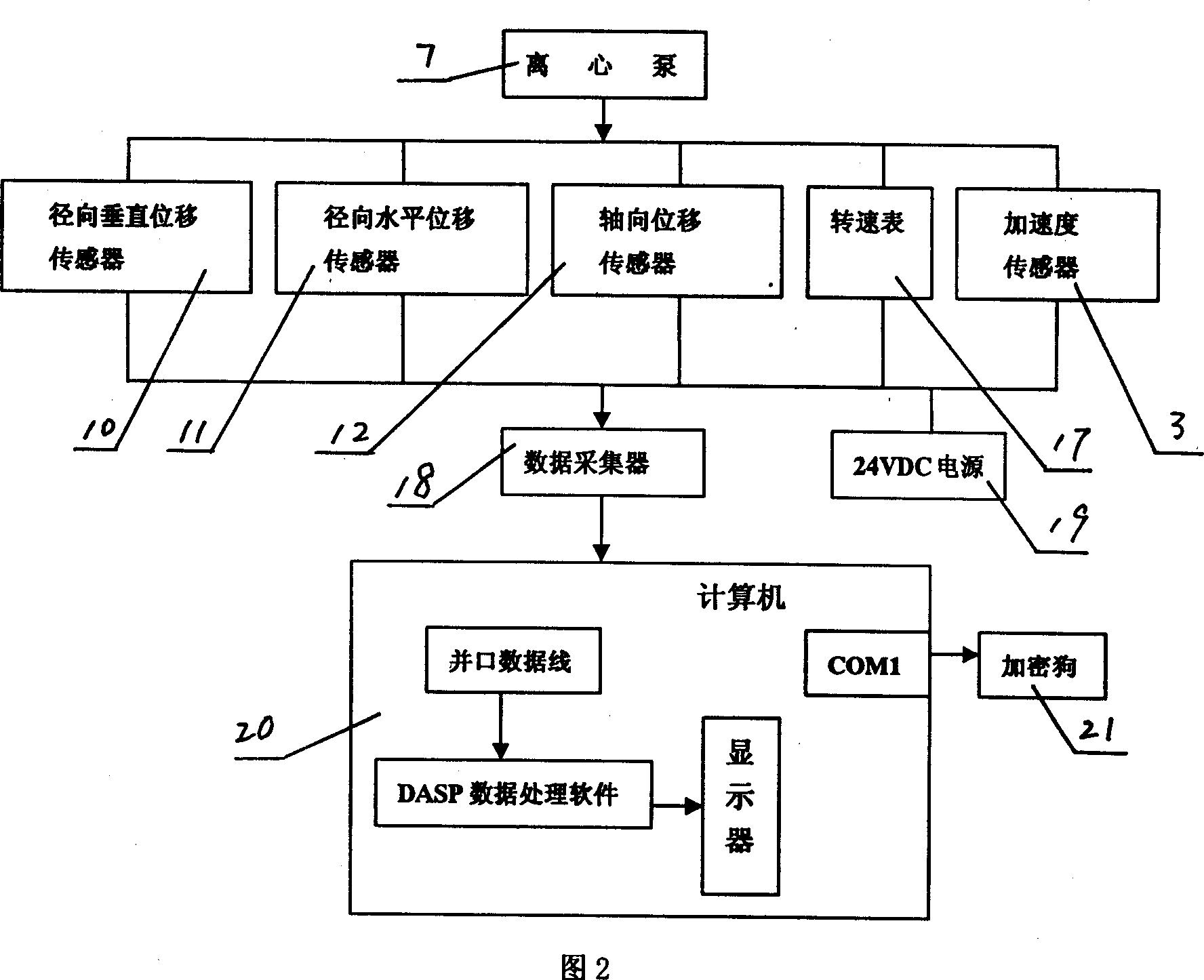

Fusion diagnosing method of centrifugal pump vibration accidents and vibration signals sampling device

InactiveCN1920511AImplementing a normal status signalComprehensive signal acquisitionMachine part testingPump testingEngineeringNormal state

The invention relates to an eccentric pump vibration accidence fusion diagnose method and relative vibration signal collector, wherein said invention is characterized in that: it uses the eccentric pump vibration signal collector to collect the normal state, the quantity imbalance, asymmetry rotate and loose base of eccentric pump; uses wavelet decomposition and reconstruction to extract the character of vibration signal; and inputs the character vectors into sub fuzzy neural networks I and II; to be treated and replace the relation factor matched with sensor signal function; the whole fuzzy neural network comprises data fuzzy layer, input layer, hidden layer and output layer; uses D-S theory to obtain the fused signal function distribution, realize the fusion diagnose on normal state, quantity imbalance, asymmetry rotate and loose base. The invention has simple structure and high effect.

Owner:NORTHEAST DIANLI UNIVERSITY

System and method for power pump performance monitoring and analysis

InactiveUS7623986B2Easy to useEasy to provideTime indicationProgram control using stored programsEngineeringStreamflow

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

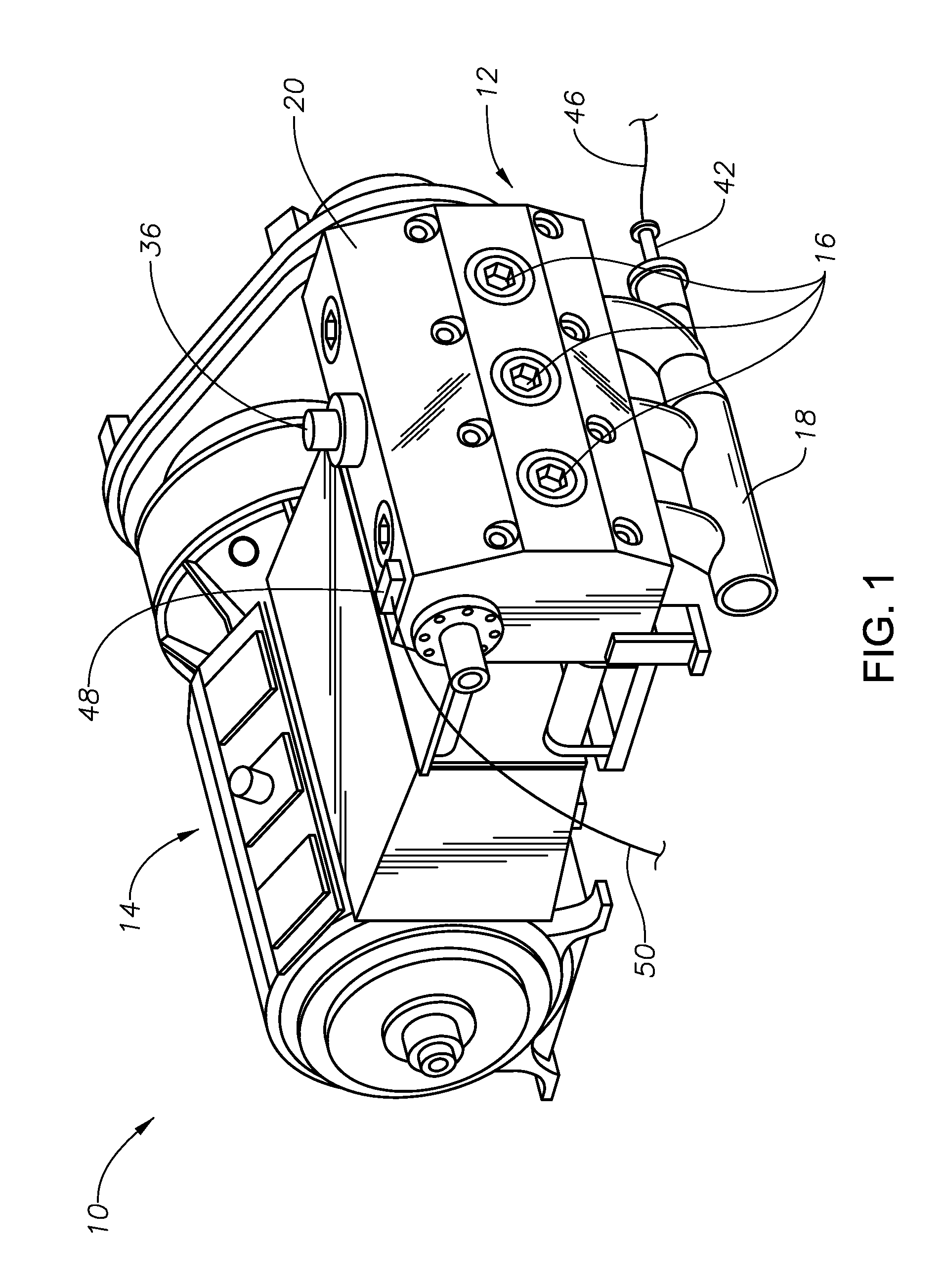

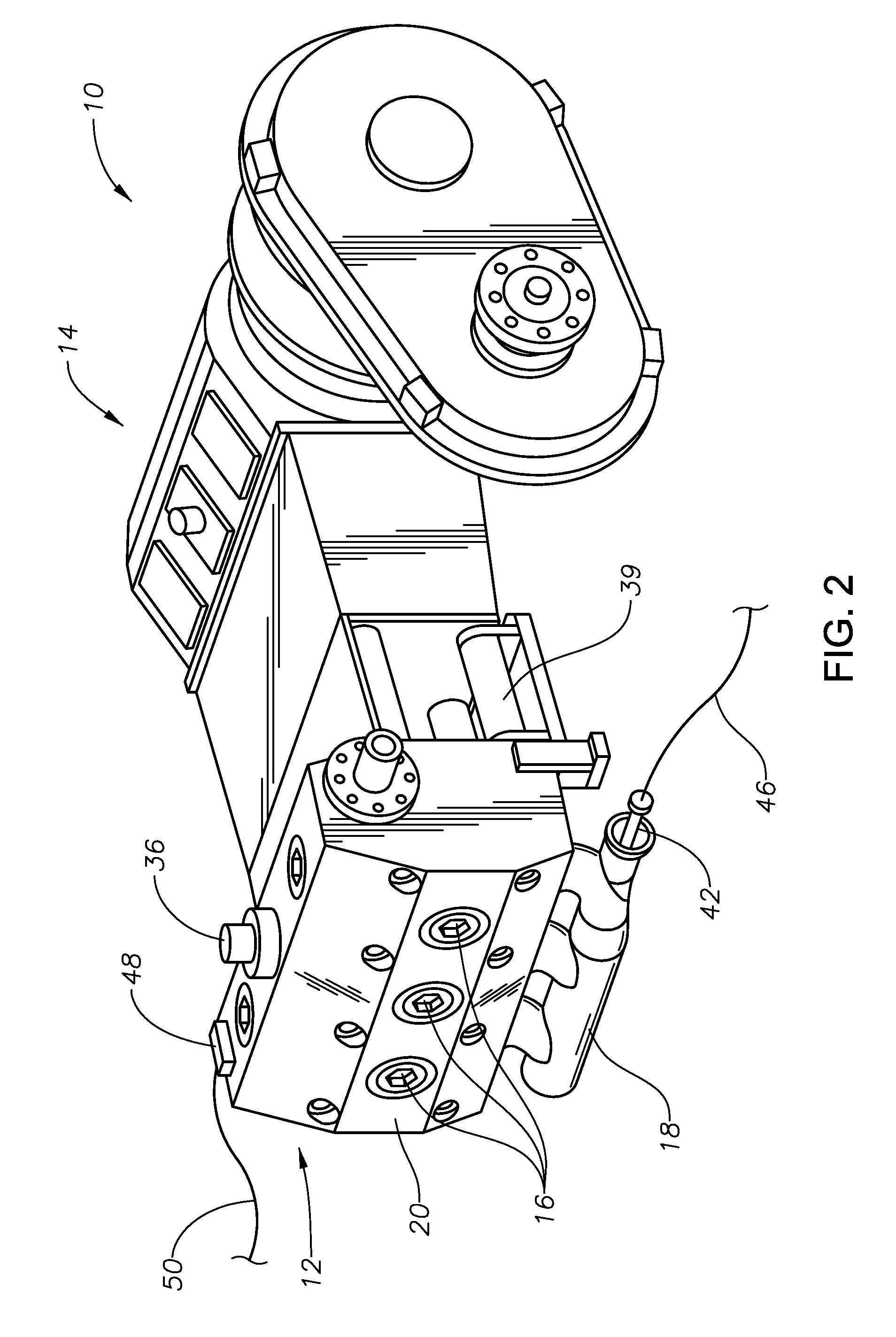

Pump Assembly Health Assessment

Method and apparatus for assessing health of fracturing fluid pump assemblies and other wellsite equipment. For example, predicted data indicative of a first operational parameter of a pump assembly is generated utilizing: a model relating the first operational parameter to each of a plurality of second operational parameters of the pump assembly; and real-time data indicative of each of the second operational parameters. Health of the pump assembly is then assessed based on: the predicted data indicative of the first operational parameter; and real-time data indicative of the first operational parameter.

Owner:SCHLUMBERGER TECH CORP

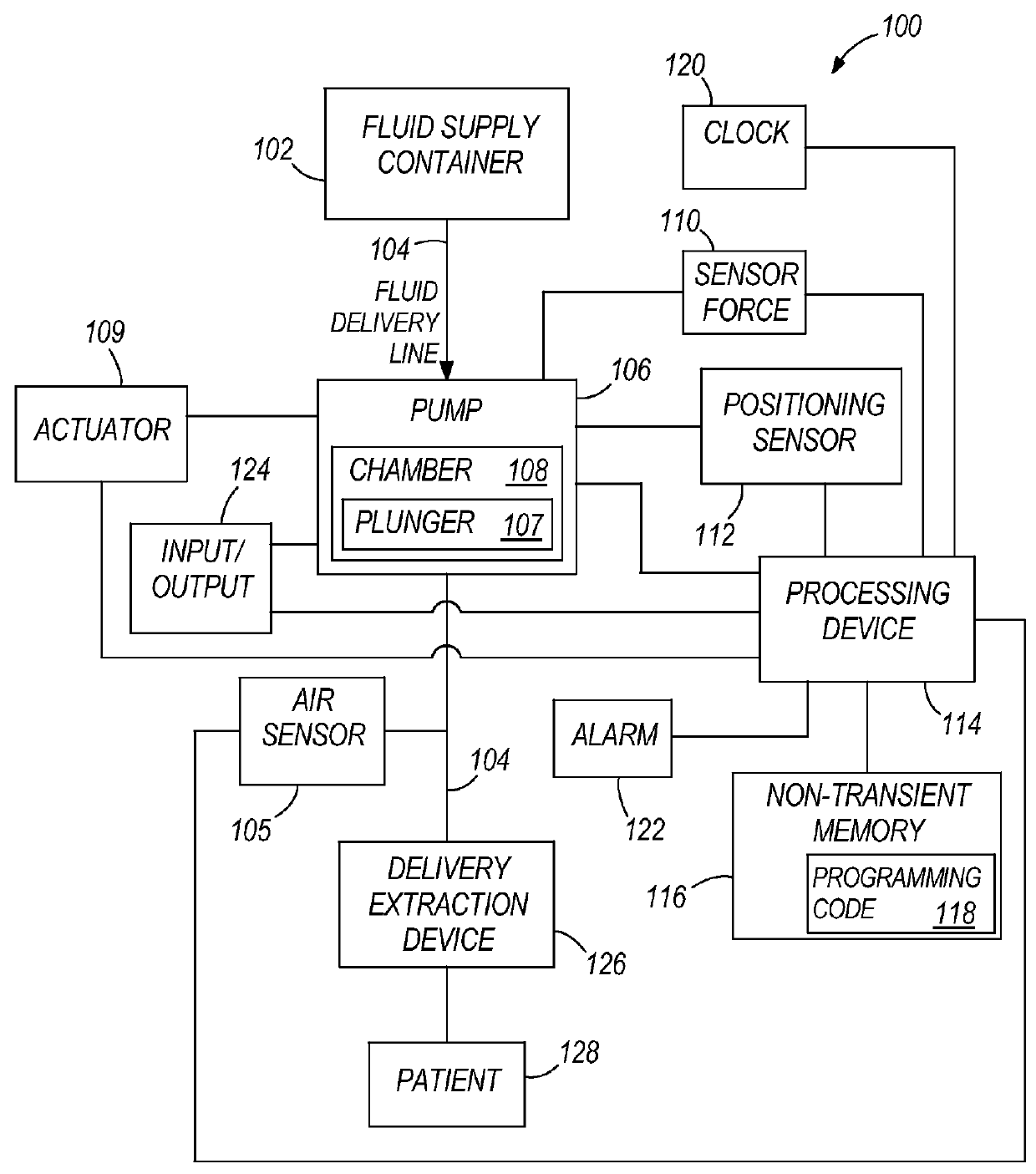

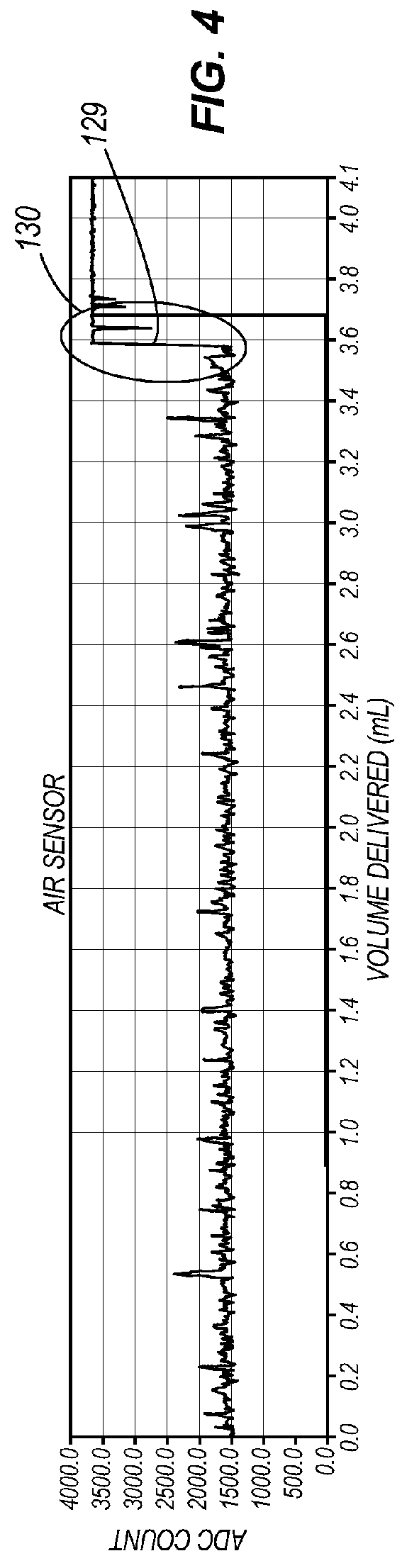

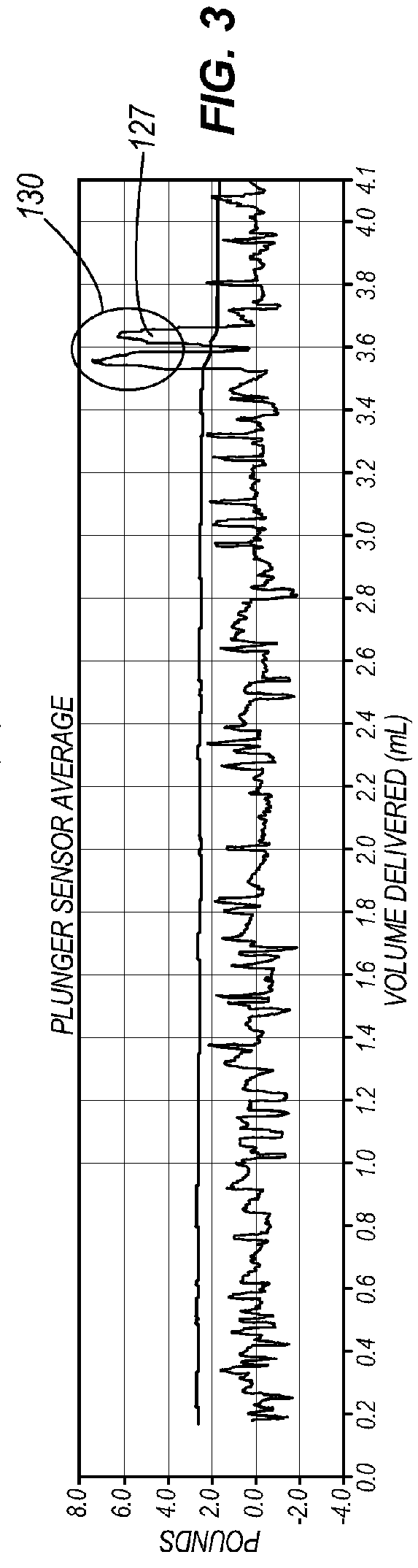

Air detection system and method for detecting air in a pump of an infusion system

Various systems and methods for detecting air in a chamber of an infusion system are disclosed. In one embodiment, a determination is made that air is contained in the chamber on the basis of a change in the average force exerted against the plunger utilizing a derivative spike for event detection and a systematic reduction in the average force to confirm the nature of the change. In another embodiment, a determination is made that the chamber contains air when a difference between the current force profile and a baseline force profile crosses a threshold. In an additional embodiment, a force profile is classified as being an air force profile or a liquid force profile based on extracted features of the force profile.

Owner:ICU MEDICAL INC

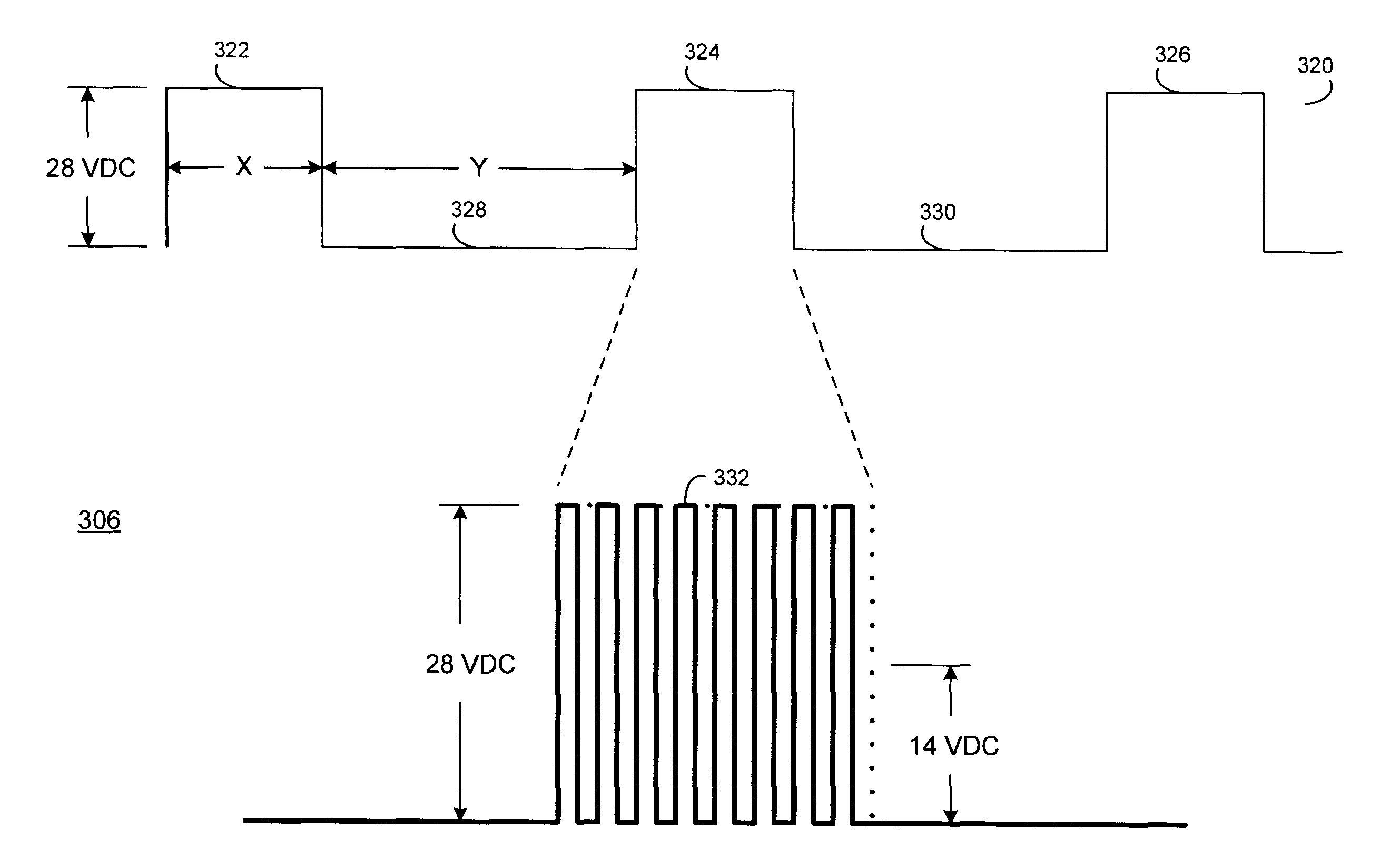

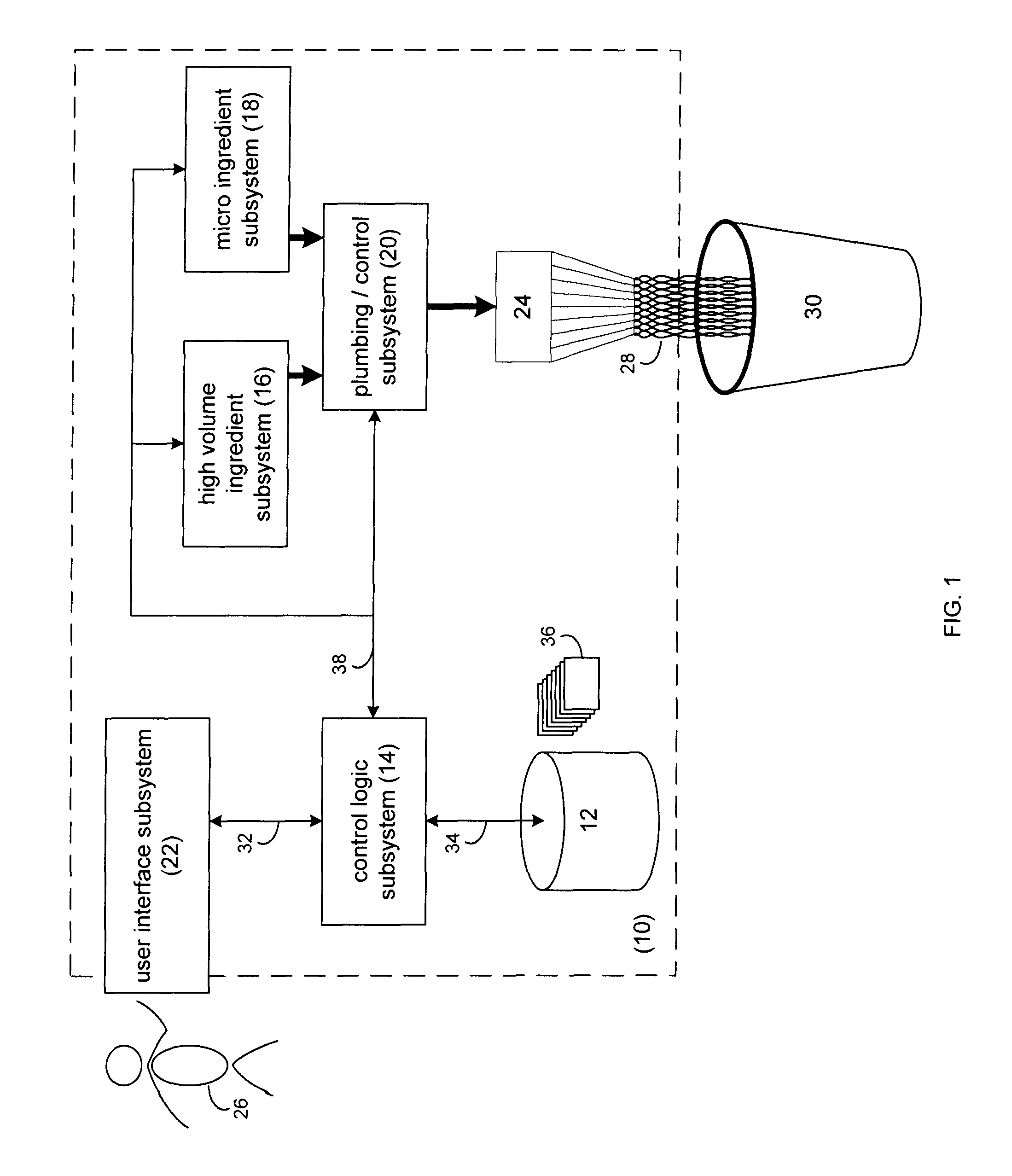

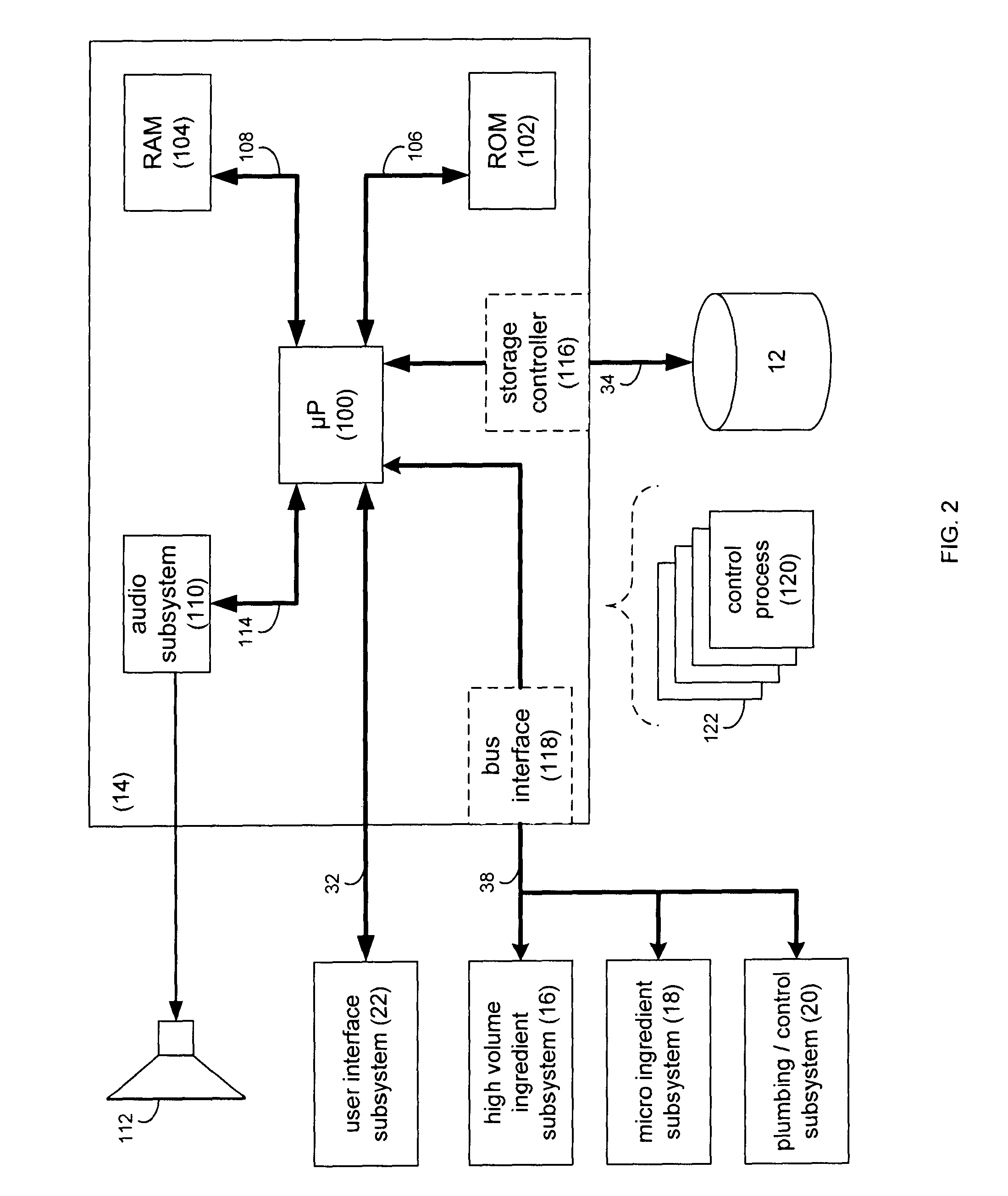

System and method for generating a drive signal

A method and computer program product for defining a PWM drive signal having a defined voltage potential. The PWM drive signal has a plurality of “on” portions and a plurality of “off” portions that define a first duty cycle for regulating, at least in part, a flow rate of a pump assembly. At least a portion of the “on” portions of the PWM drive signal are pulse width modulated to define a second duty cycle for the at least a portion of the “on” portions of the PWM drive signal. The second duty cycle regulates, at least in part, the percentage of the defined voltage potential applied to the pump assembly.

Owner:DEKA PROD LLP

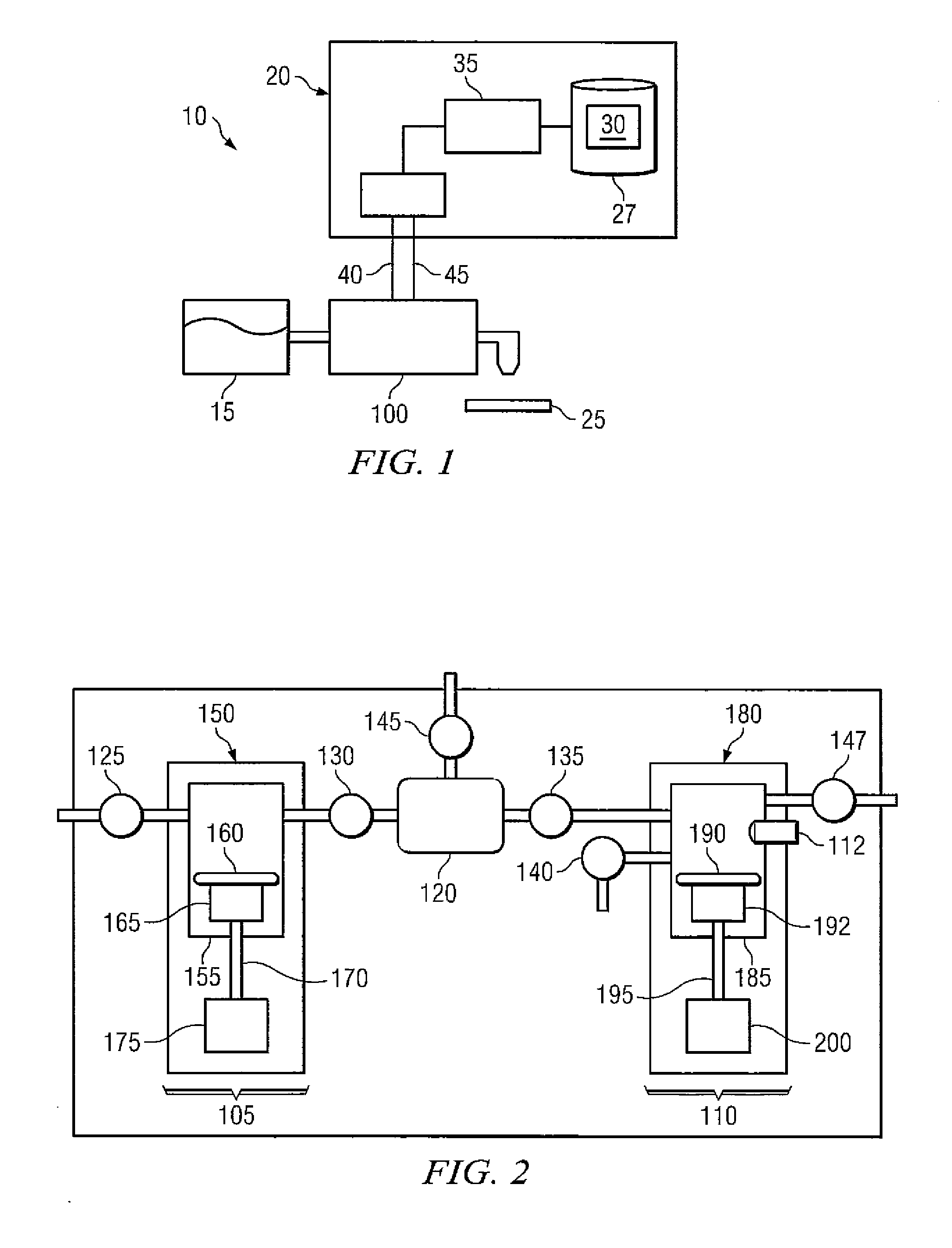

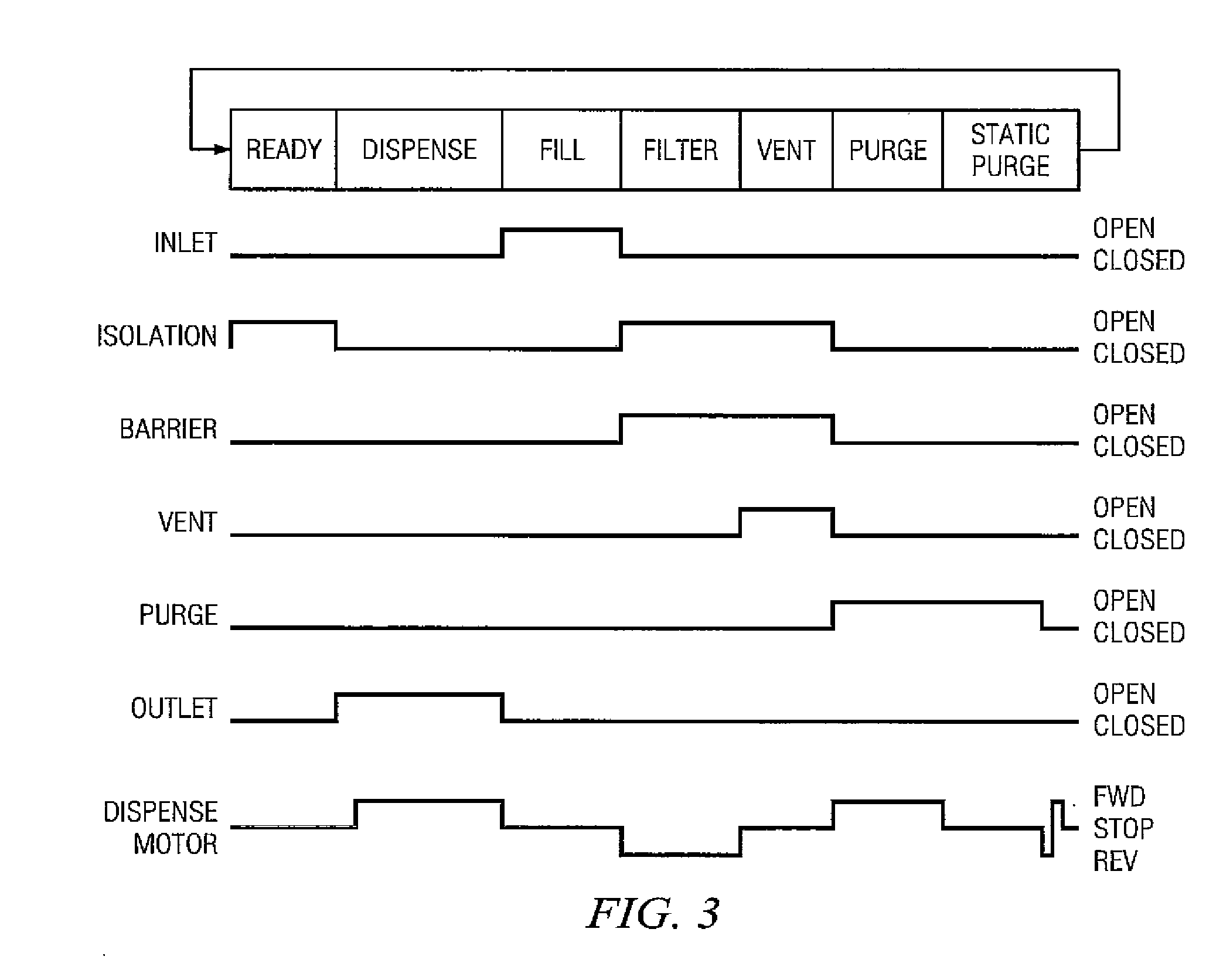

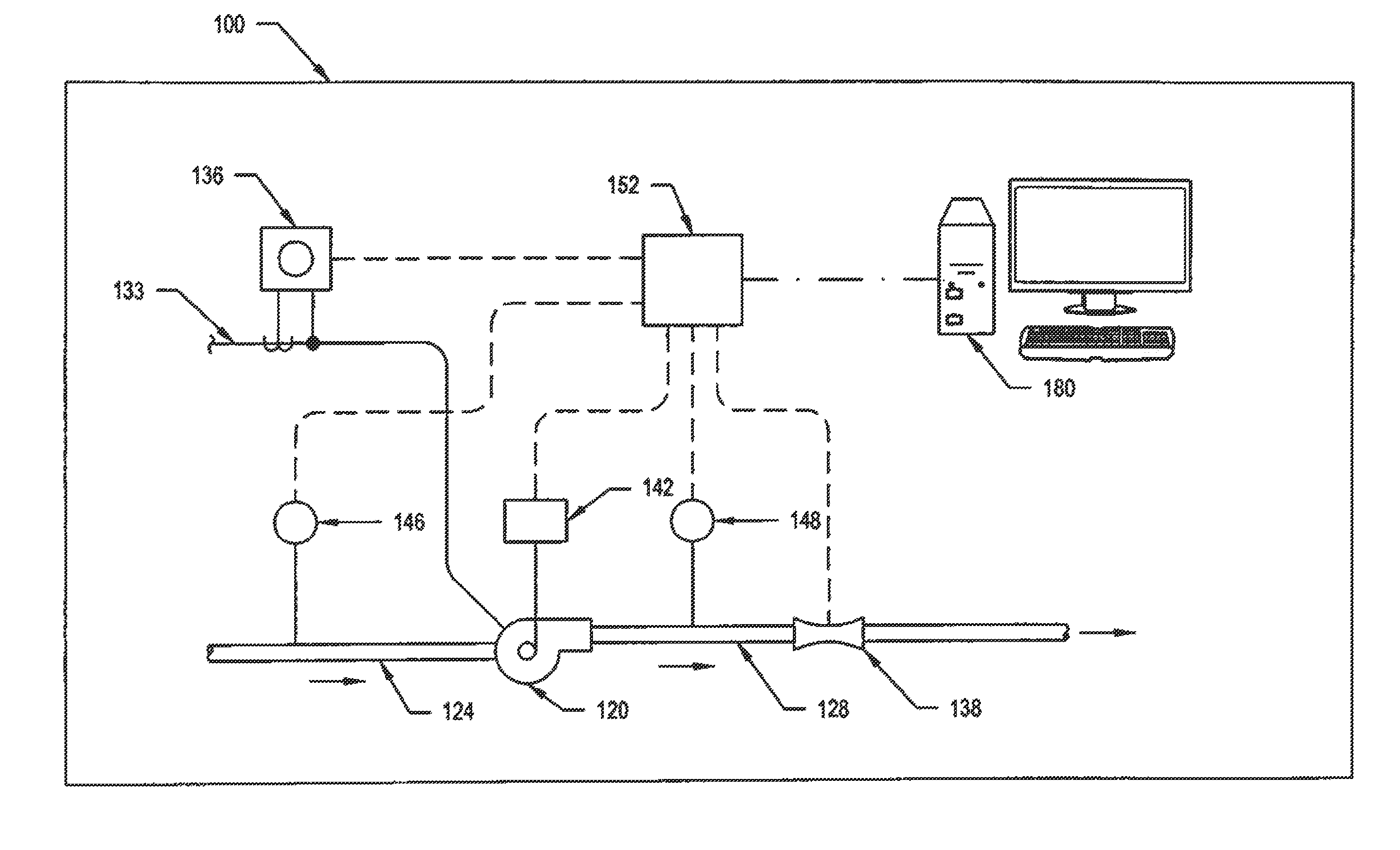

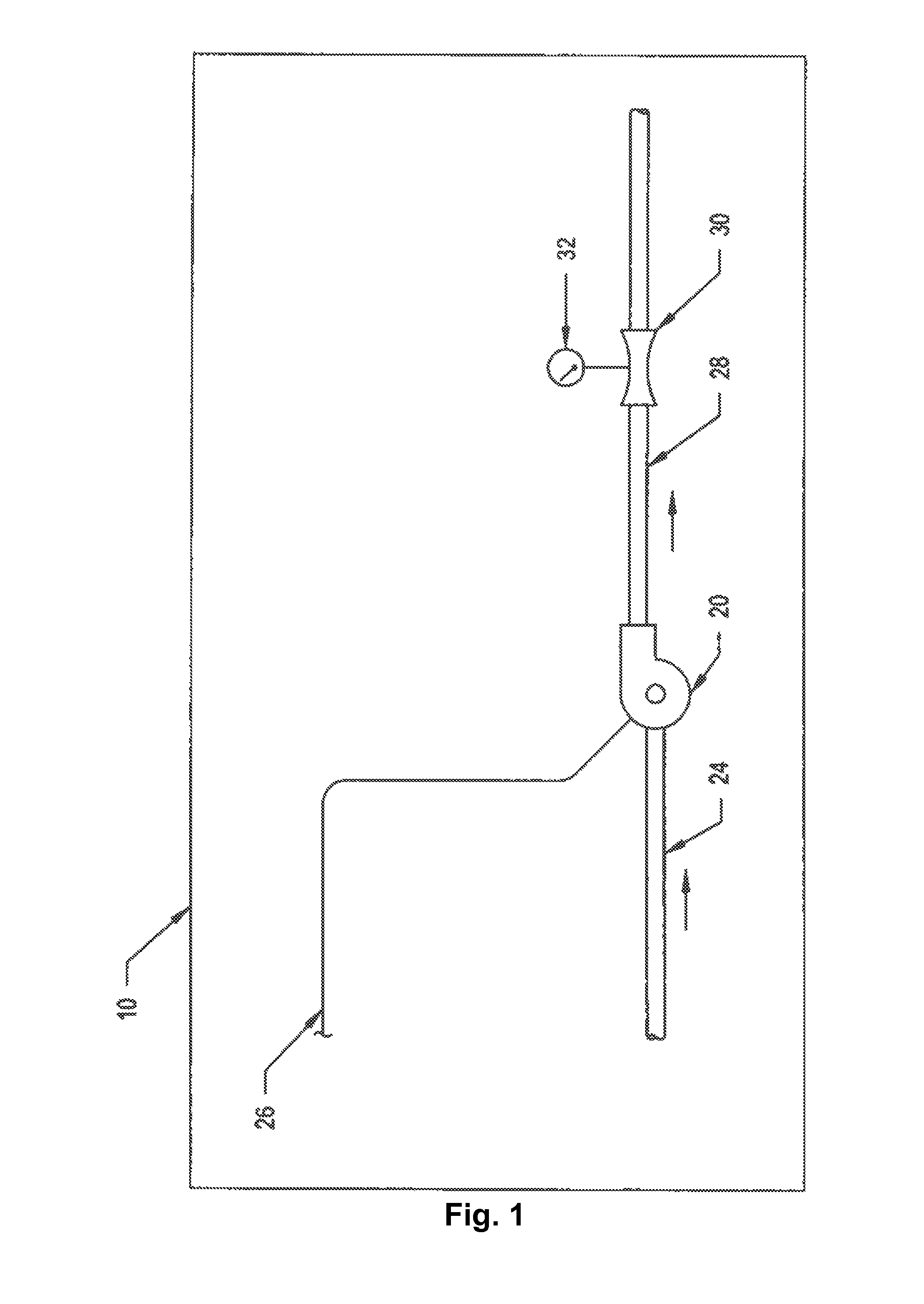

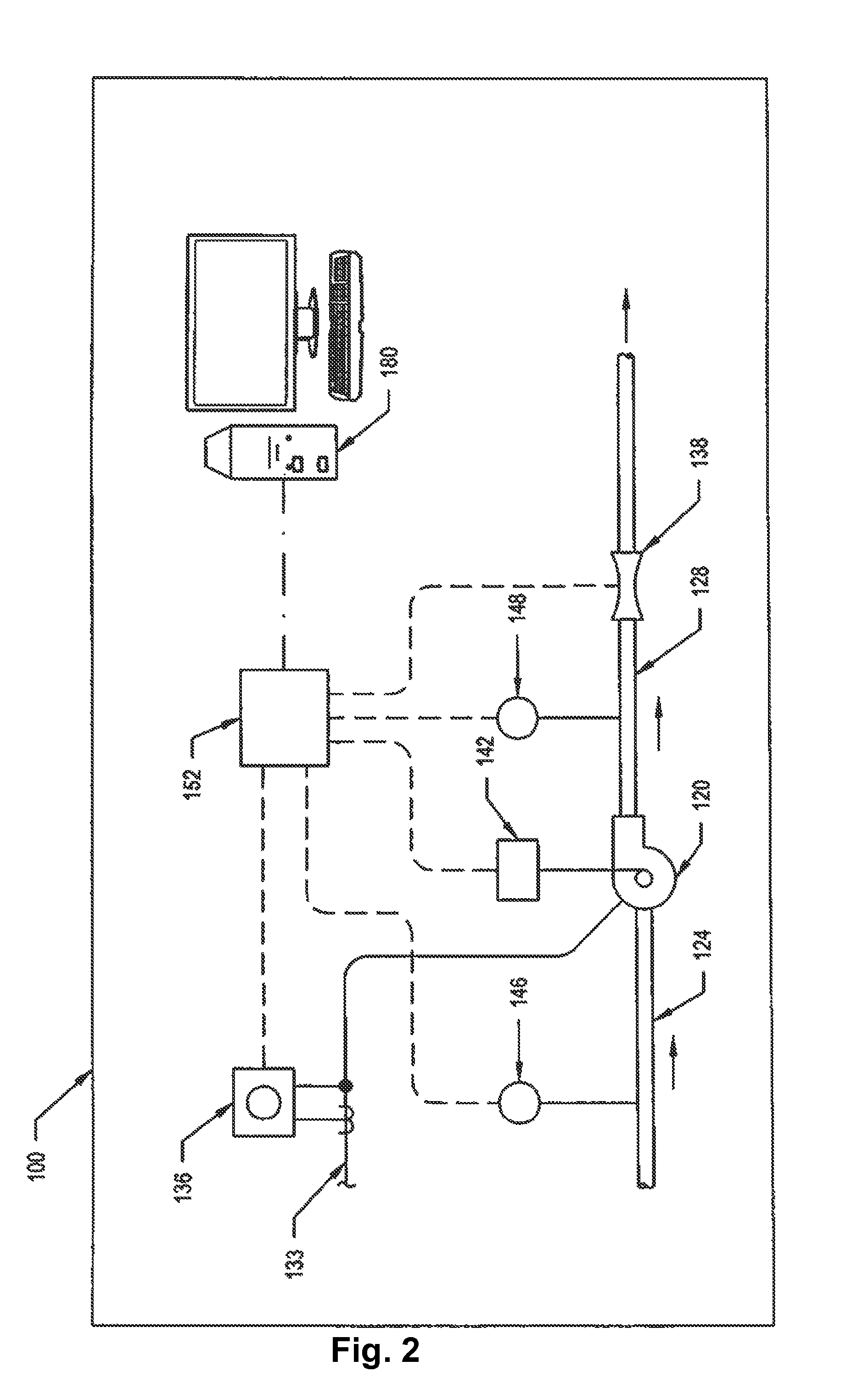

System and method for operation of a pump

ActiveUS20080131290A1Reduce in quantityEasy to detectPump testingStructural/machines measurementGoodness of fitEngineering

Systems and methods for monitoring operation of a pump, including verifying operation or actions of a pump, are disclosed. A baseline profile for one or more parameters of a pump may be established. An operating profile may then be created by recording one or more values for the same set of parameters during subsequent operation of the pump. A value for a goodness of fit measure comparing the operating profile and baseline profile can be established. If the goodness of fit measure is insufficient, an alarm may be sent or another action taken, for example the pumping system may shut down, etc. An example goodness of fit measure is an R-squared measure.

Owner:ENTEGRIS INC

Pump efficiency determining system and related method for determining pump efficiency

InactiveUS20140379300A1Increase opportunitiesEasy to modifyPump testingDigital computer detailsEngineeringPower usage

A system for measuring real time efficiency / performance of at least one pump in a plant or other facility includes a plurality of monitoring devices disposed in relation to said at least one pump to measure power usage, pump speed and flow characteristics of the at least one pump. A processing system is configured to receive input signals from the sensors in which the efficiency of the at least one pump can be calculated based on the sensor inputs in real-time. The processing system can also compare the calculated pump efficiency values with a user defined set point or threshold or compare to the expected pump performance.

Owner:GHD PTY LTD

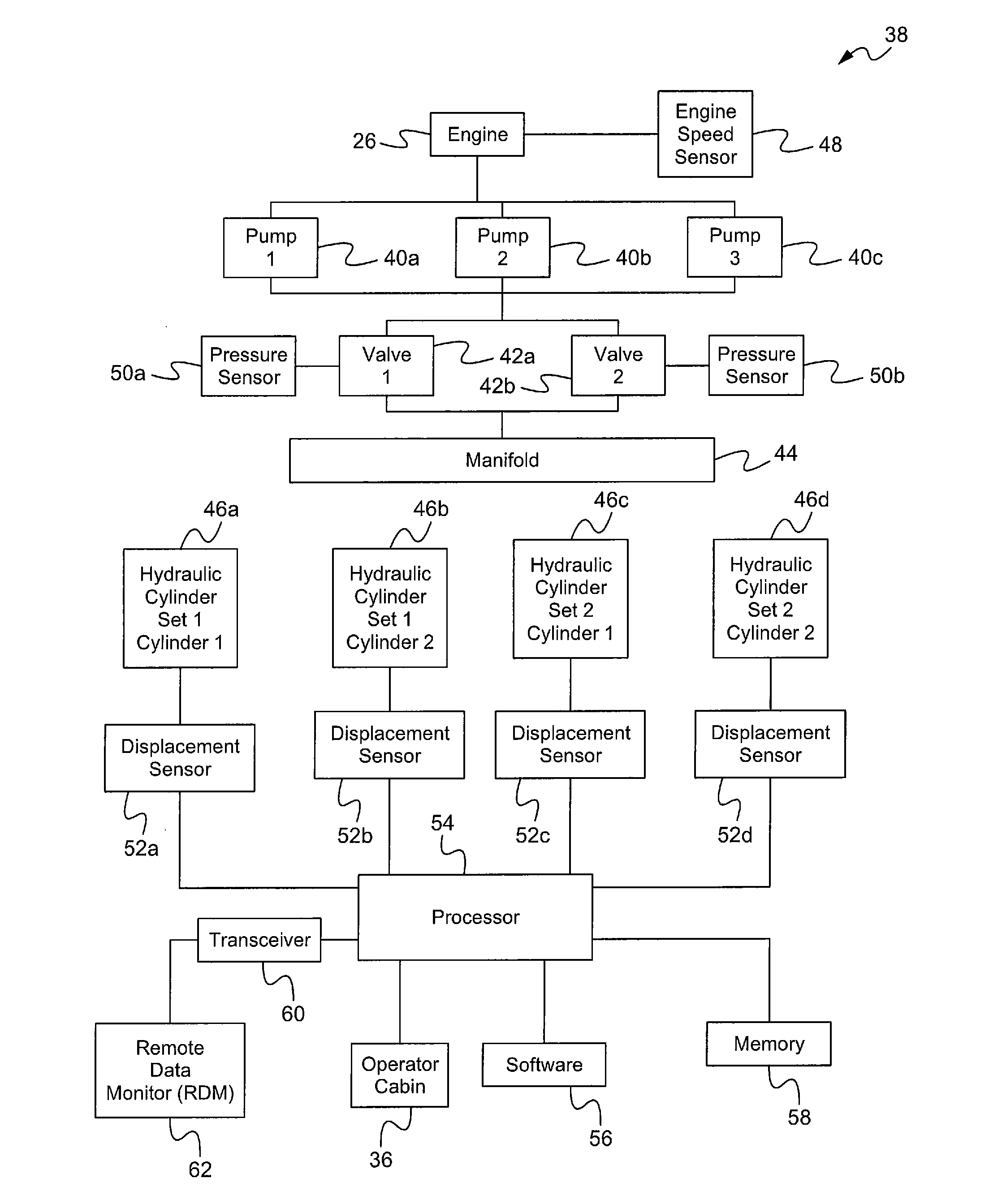

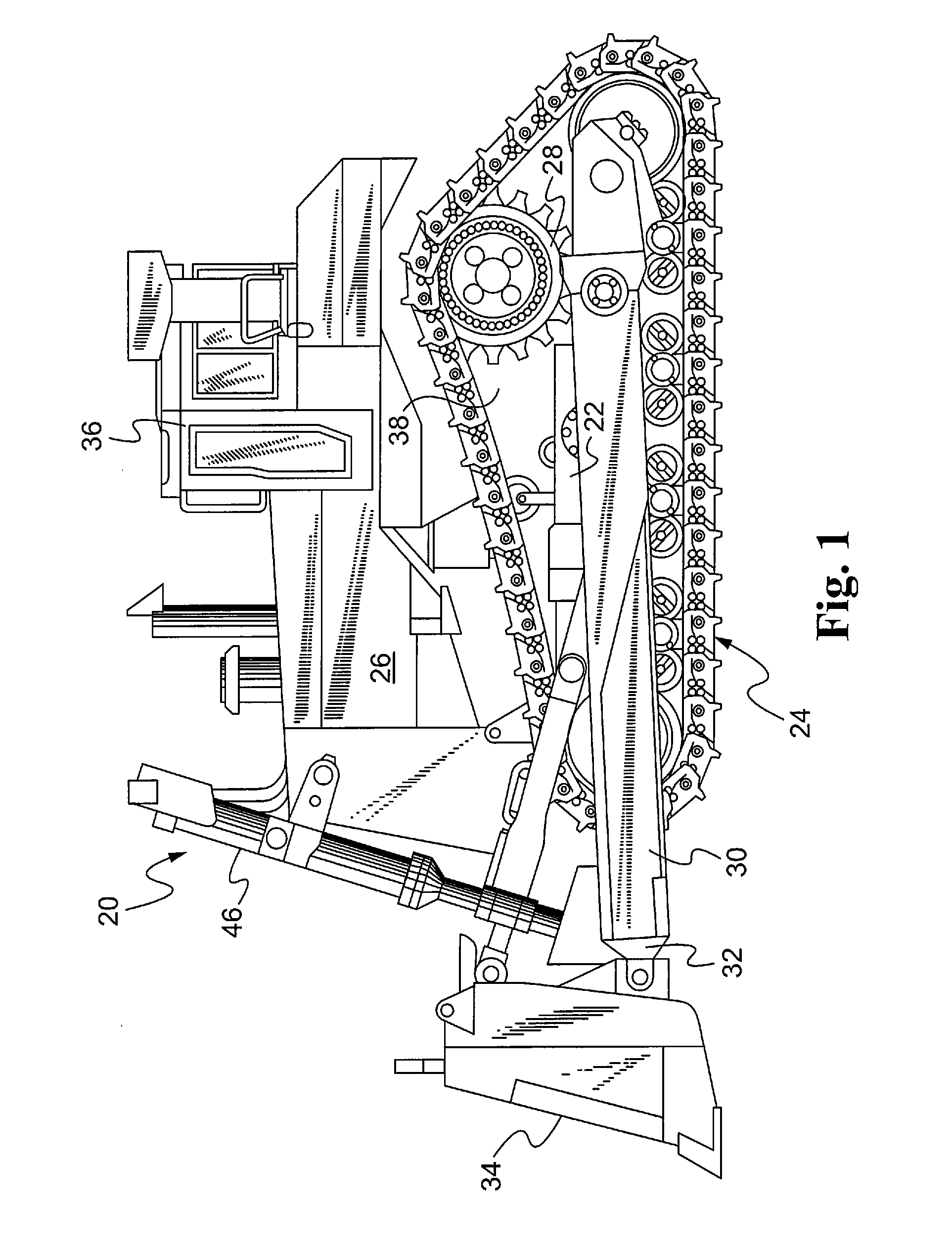

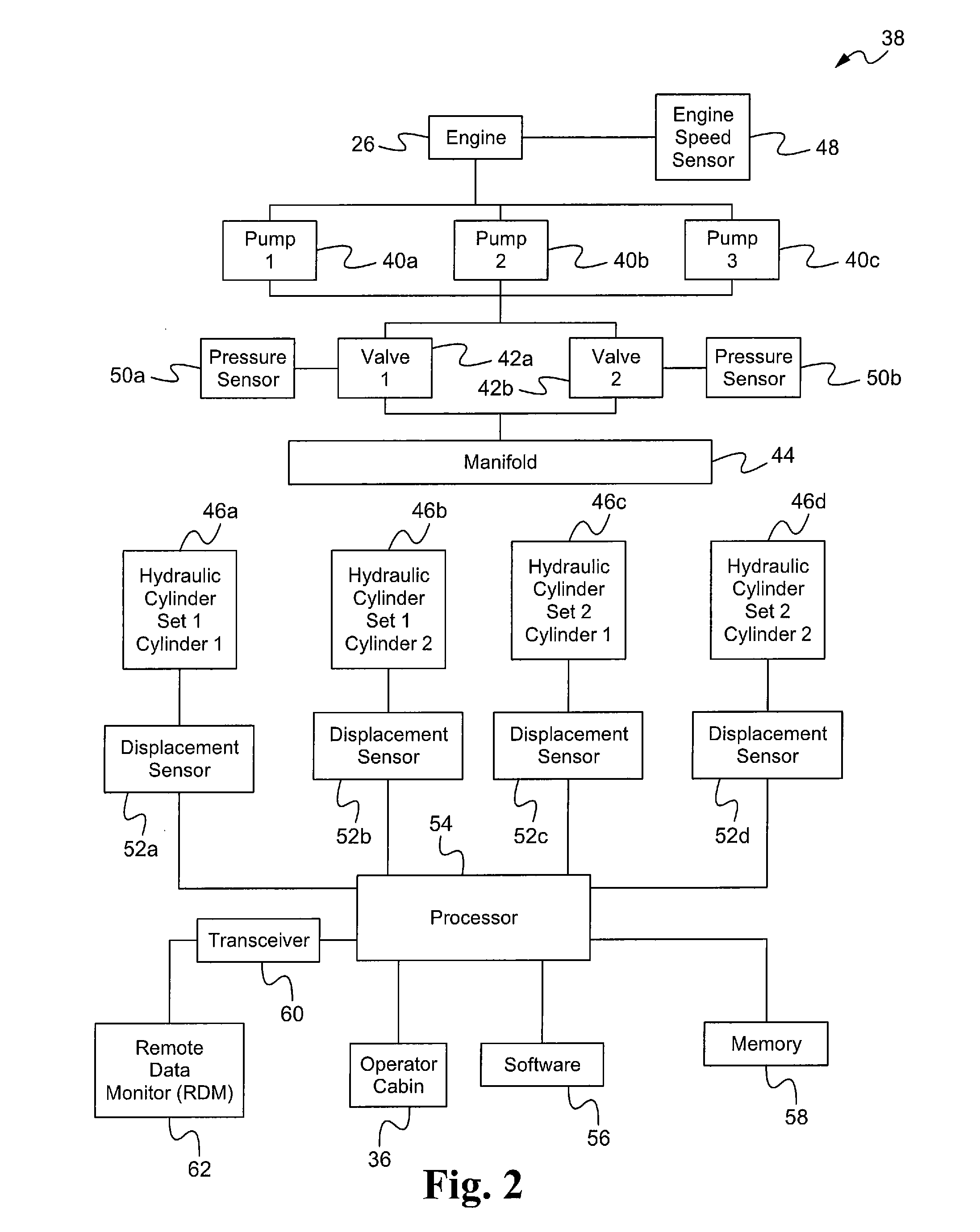

System and Method for Identifying Impending Hydraulic Pump Failure

ActiveUS20130283773A1Pump testingFluid-pressure actuator testingHydraulic pumpReliability engineering

A system and method for predicting impending pump failure in a hydraulic system is disclosed. The system measures and compares the running and moving volumetric deficiencies of the hydraulic system as a whole and if they are not within range of each other by a predetermined threshold, the system determines that at least one of the pumps in the system is about to fail. If such a determination is made by the system, the pump displacement is at standby of each pump is then calculated and the pump with the greatest displacement at standby is determined to be the pump approaching failure. Once the pump approaching failure is identified, a signal is generated to apprise the operator or other entity to enable corrective action to be taken.

Owner:CATERPILLAR INC

System and method for generating a drive signal

A method and computer program product for defining a PWM drive signal having a defined voltage potential. The PWM drive signal has a plurality of “on” portions and a plurality of “off” portions that define a first duty cycle for regulating, at least in part, a flow rate of a pump assembly. At least a portion of the “on” portions of the PWM drive signal are pulse width modulated to define a second duty cycle for the at least a portion of the “on” portions of the PWM drive signal. The second duty cycle regulates, at least in part, the percentage of the defined voltage potential applied to the pump assembly.

Owner:DEKA PROD LLP

Remote monitoring for hydraulic fracturing equipment

A hydraulic fracturing system for fracturing a subterranean formation including a pump in communication via pump components with a wellbore that intersects the formation, and that pressurizes fluid in the wellbore, the fluid comprising a fracturing fluid slurry. The system further includes hydraulic fracturing system components for making the fracturing fluid slurry, and a monitoring system that selectively captures and transmits real time images of at least one of the hydraulic fracturing system components or pump components to enable remote monitoring of the at least one of the hydraulic fracturing system components or pump components.

Owner:US WELL SERVICS LLC

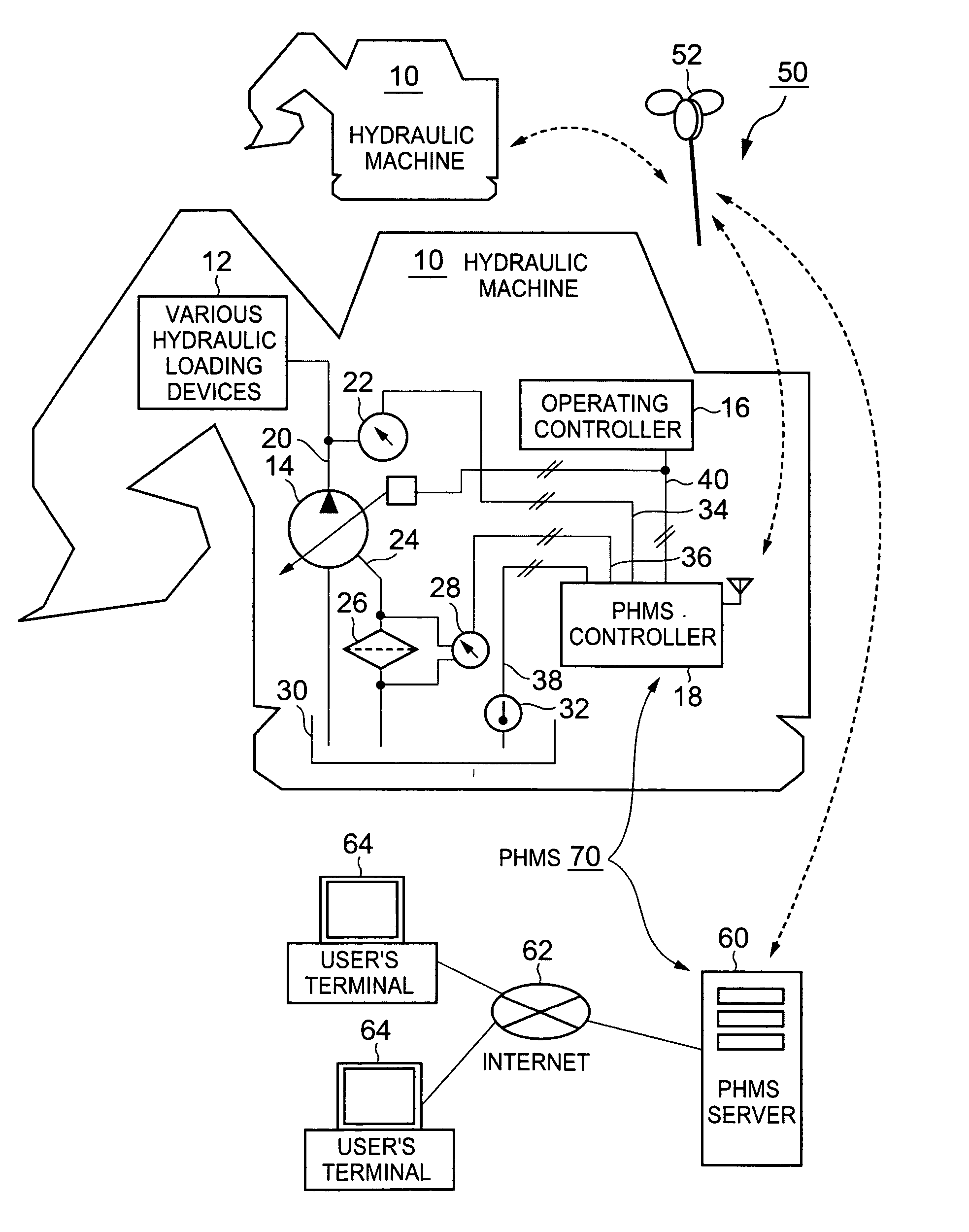

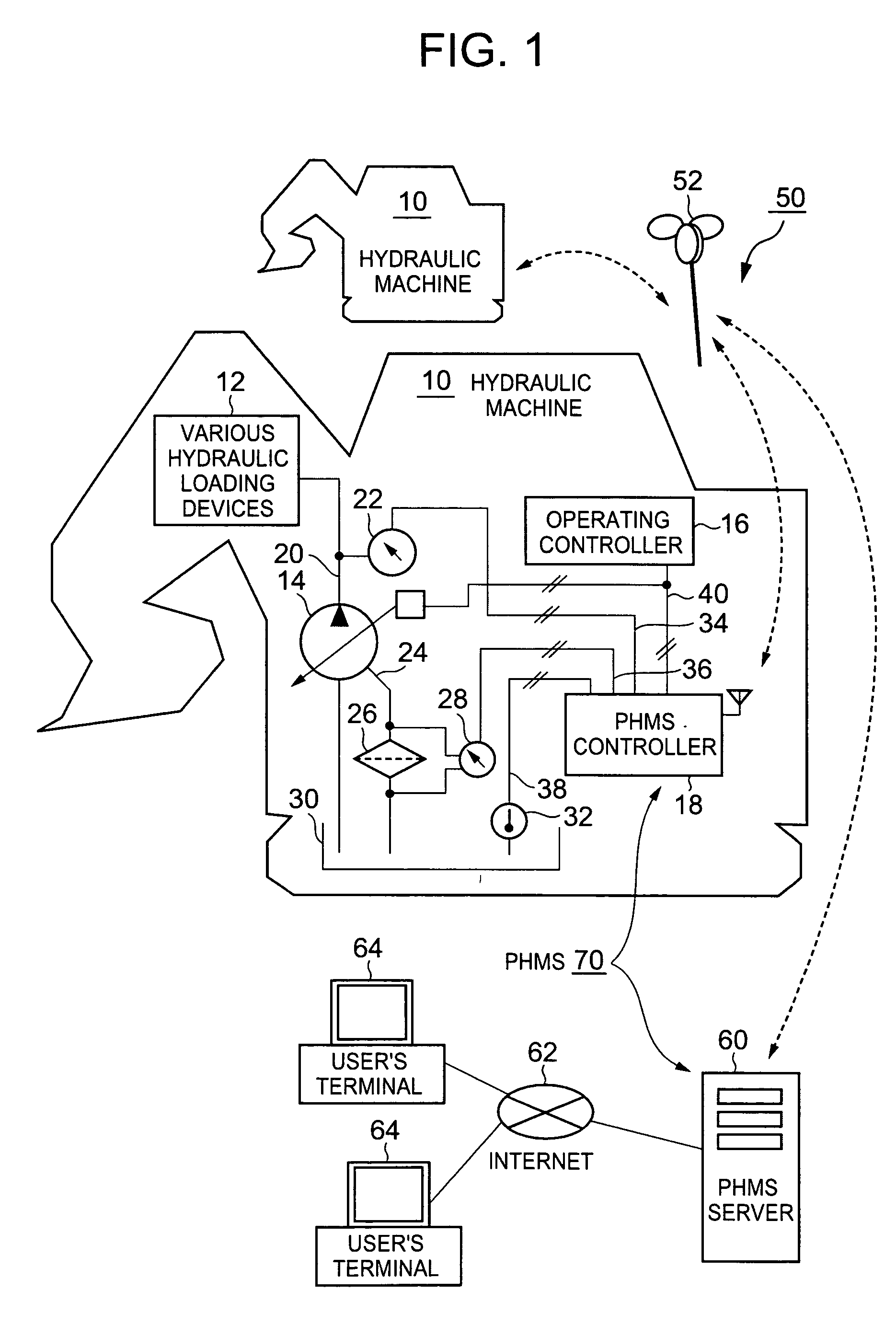

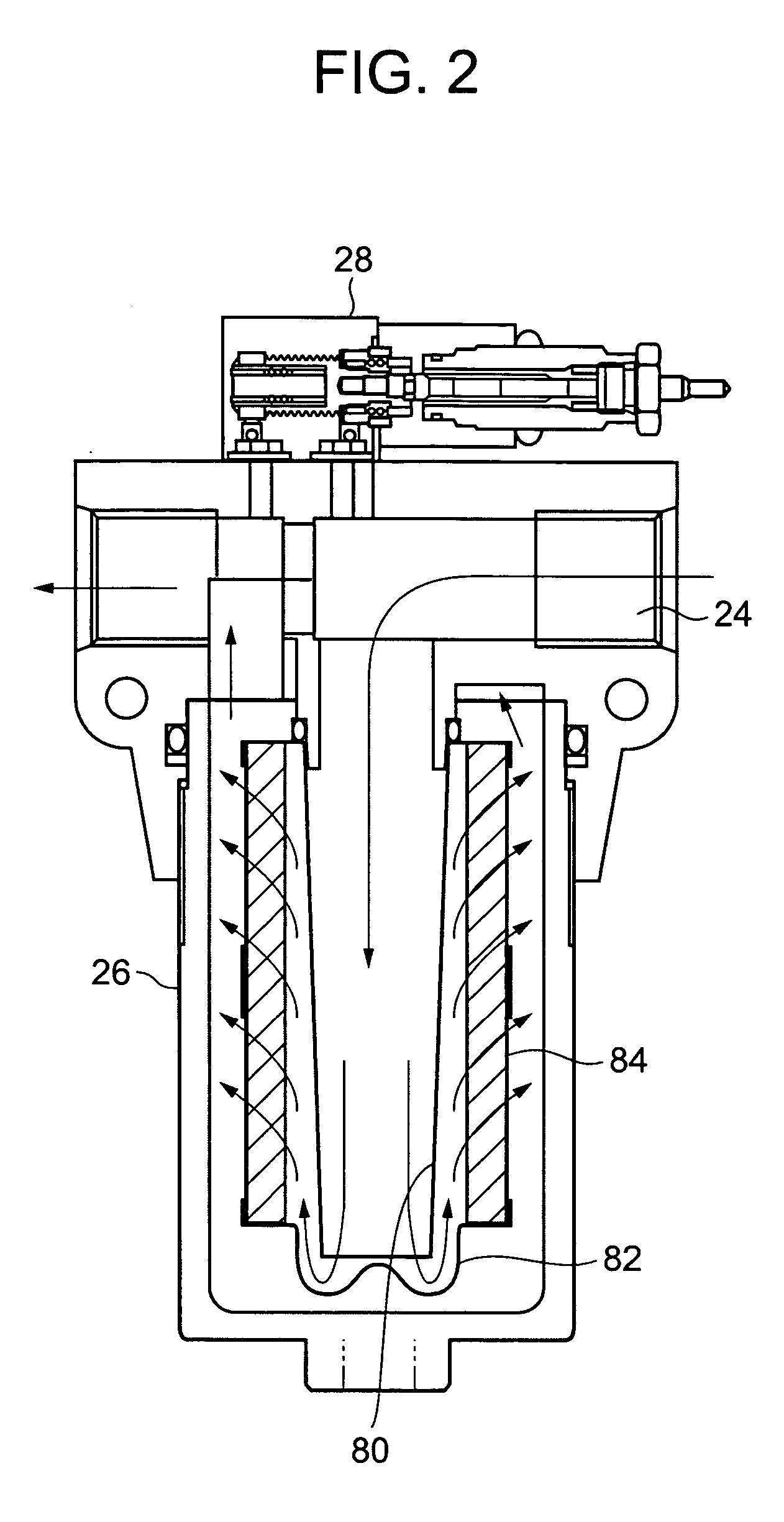

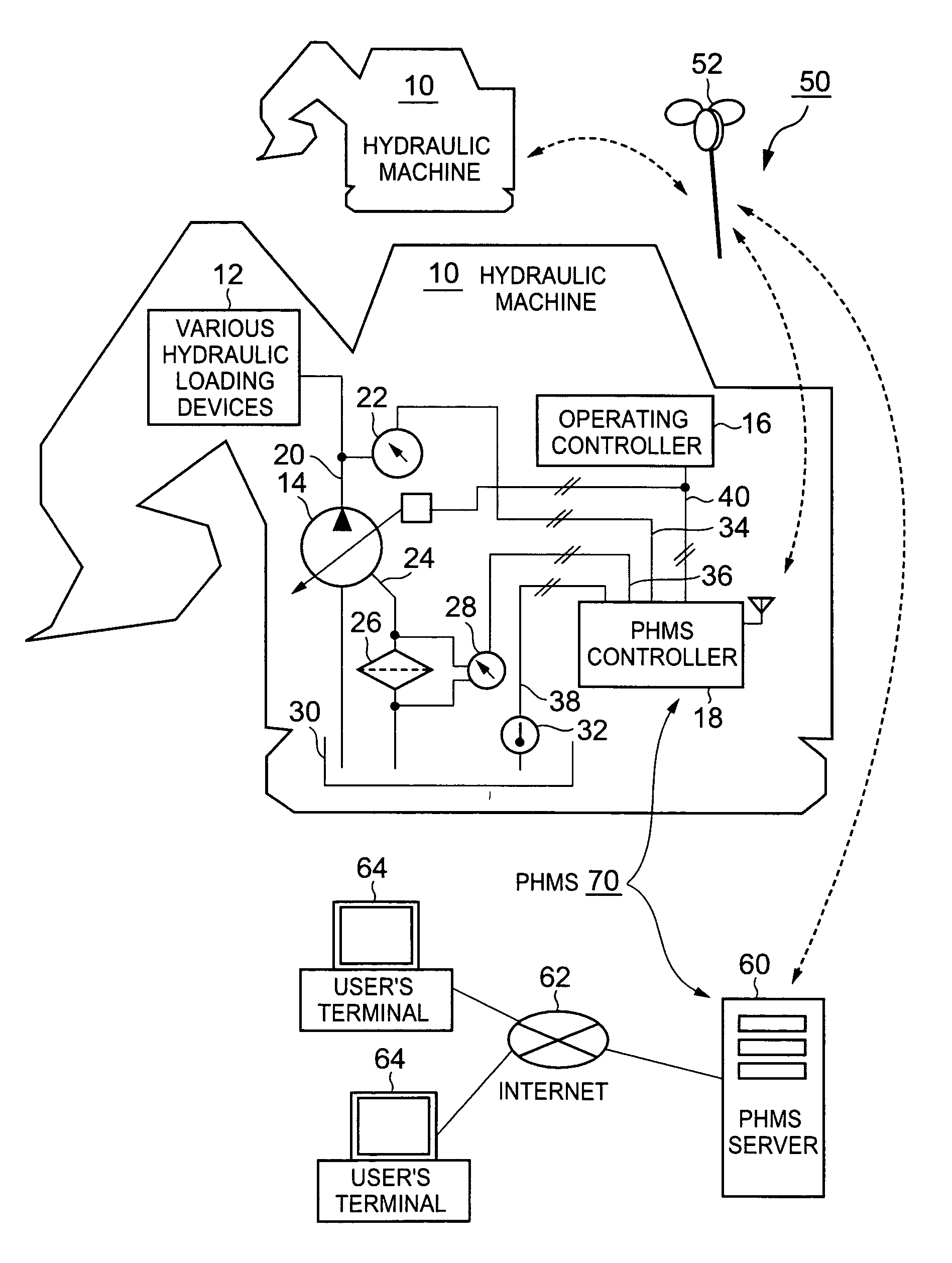

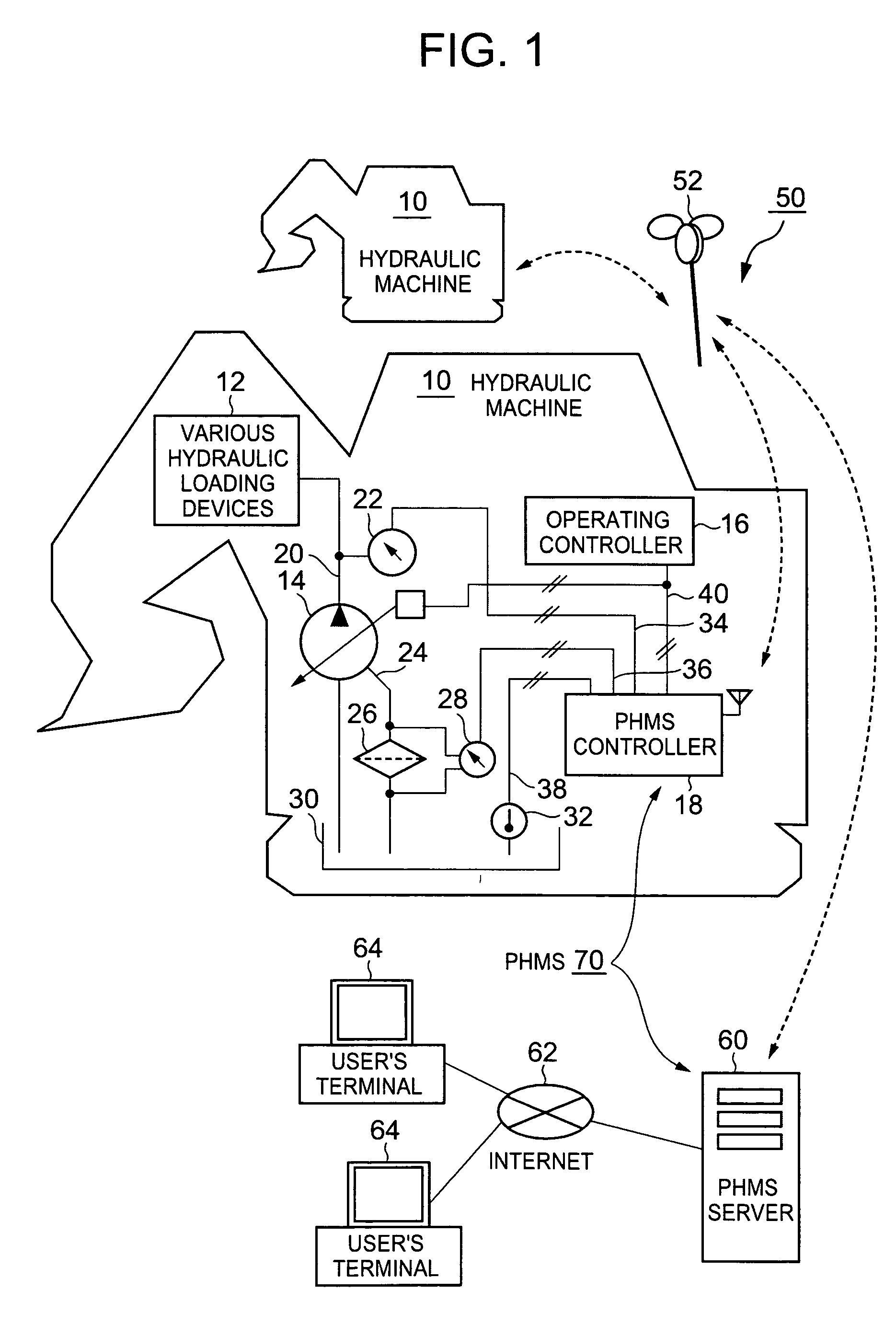

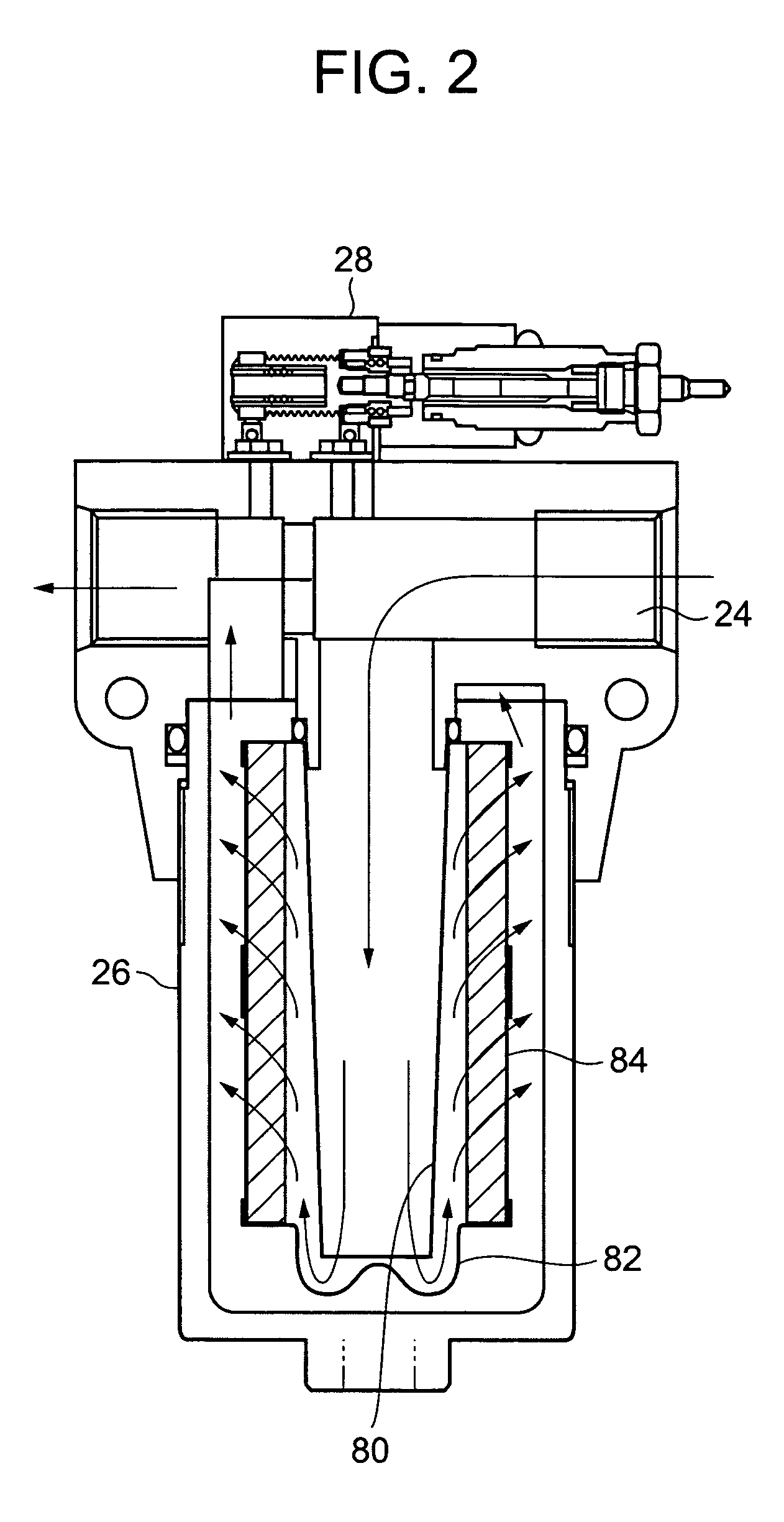

Hydraulic machine, system for monitoring health of hydraulic machine, and method thereof

InactiveUS20050262838A1Improve reliabilityAvoid failureFluid-pressure actuator safetyMachine part testingDifferential pressureCorrelation function

In a hydraulic machine, hydraulic pump failure is detected and the pump lifespan is estimated before the pump failure occurs. The discharge pressure 122, oil temperature 126, and drain filter differential pressure 120 are measured, a correlative relationship 128 between the filter differential pressure and the discharge pressure is determined, and a representative filter differential pressure 130 is calculated from this correlative relationship. Using an oil temperature-differential pressure correlation function, the representative differential pressure value 130 is corrected so that the variable component 132 caused by the oil temperature 126 is eliminated therefrom. The long-term trend and the short-term trend of the increase over time of the corrected differential pressure is calculated. A pump failure is predicted or the pump lifespan is estimated based on the degree of deviation between the long-term trend and the short-term trend.

Owner:KOMATSU LTD

Hydraulic machine, system for monitoring health of hydraulic machine, and method thereof

InactiveUS7082758B2Improve reliabilityFluid-pressure actuator safetyMachine part testingDifferential pressureCorrelation function

In a hydraulic machine, hydraulic pump failure is detected and the pump lifespan is estimated before the pump failure occurs. The discharge pressure 122, oil temperature 126, and drain filter differential pressure 120 are measured, a correlative relationship 128 between the filter differential pressure and the discharge pressure is determined, and a representative filter differential pressure 130 is calculated from this correlative relationship. Using an oil temperature-differential pressure correlation function, the representative differential pressure value 130 is corrected so that the variable component 132 caused by the oil temperature 126 is eliminated therefrom. The long-term trend and the short-term trend of the increase over time of the corrected differential pressure is calculated. A pump failure is predicted or the pump lifespan is estimated based on the degree of deviation between the long-term trend and the short-term trend.

Owner:KOMATSU LTD

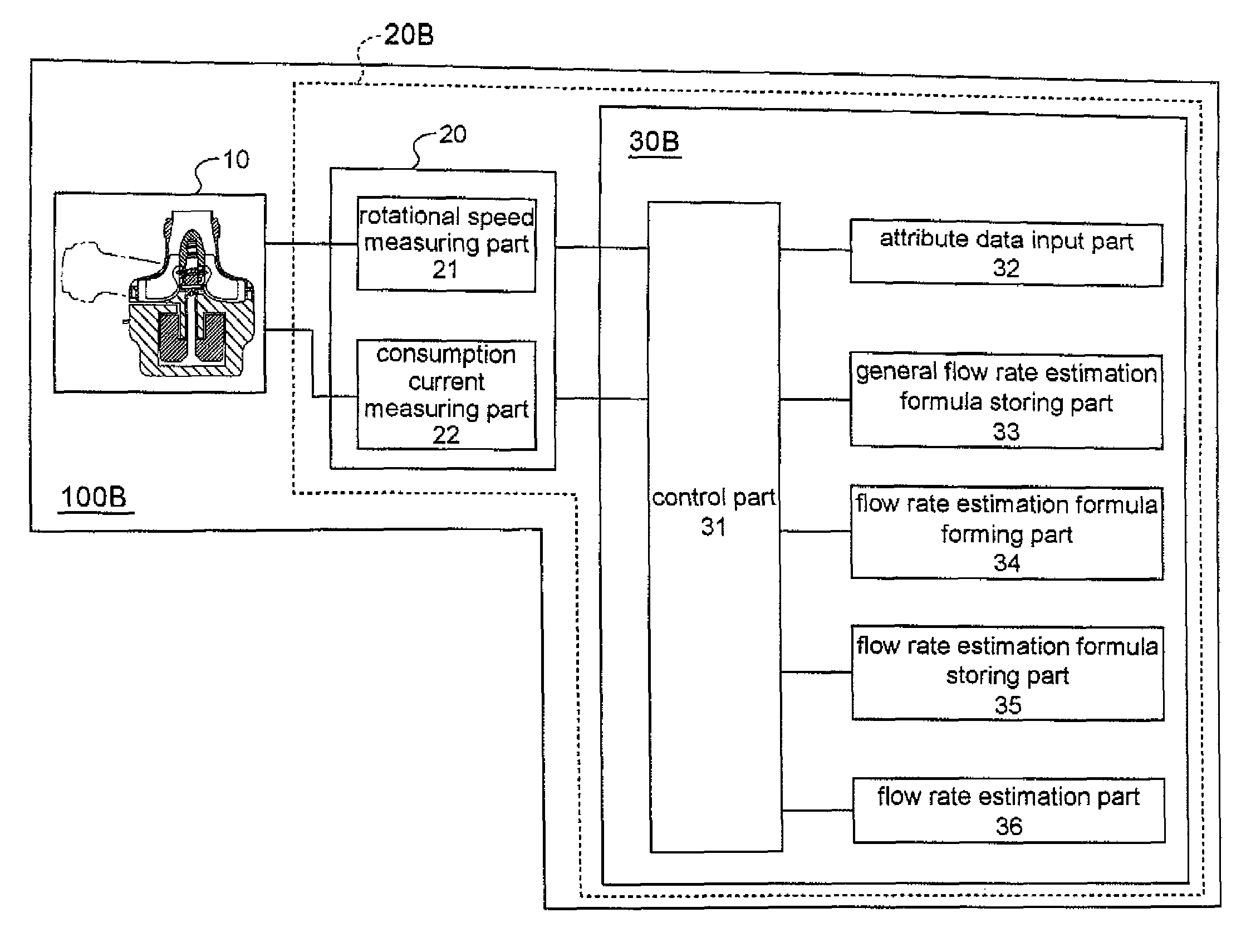

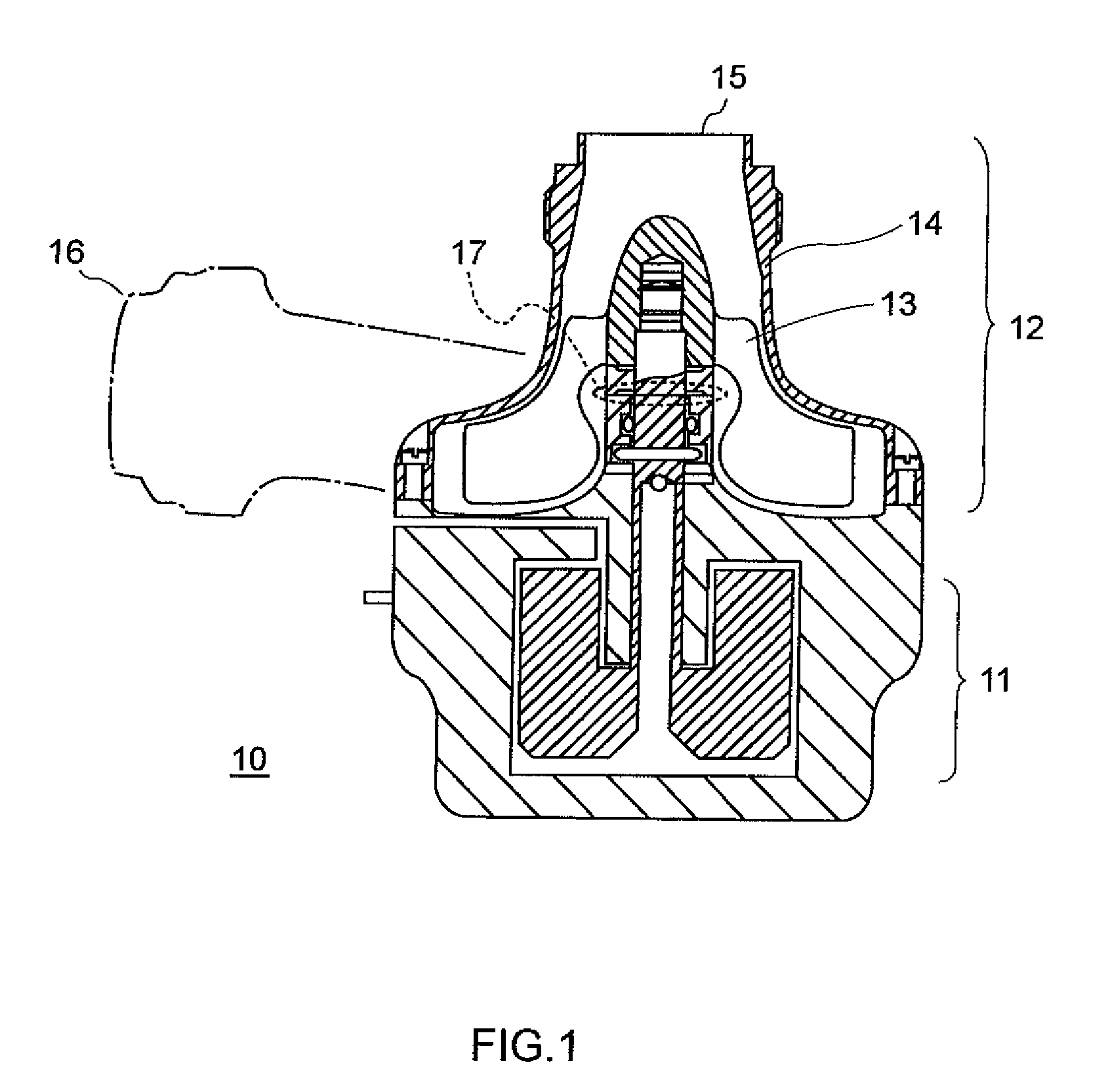

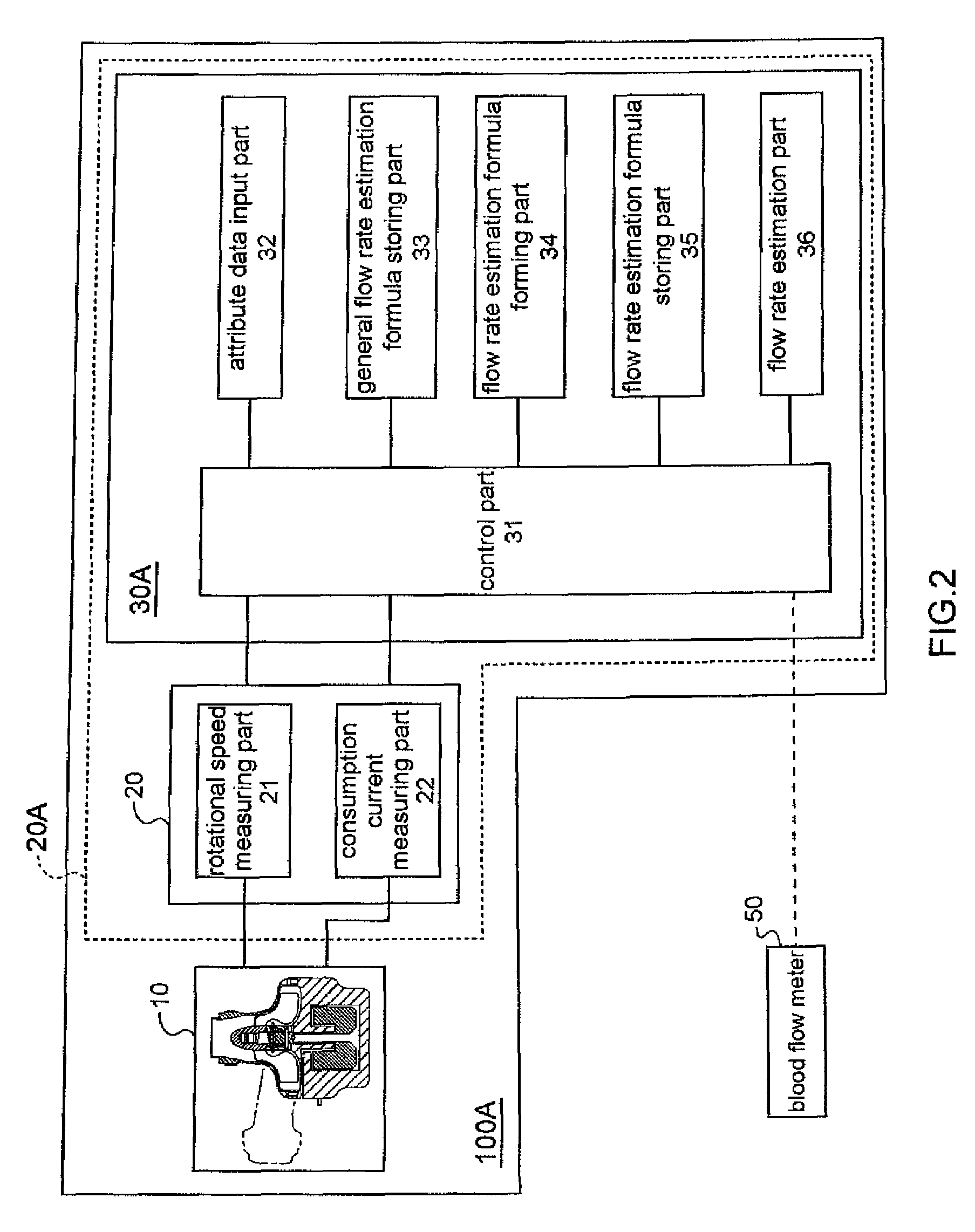

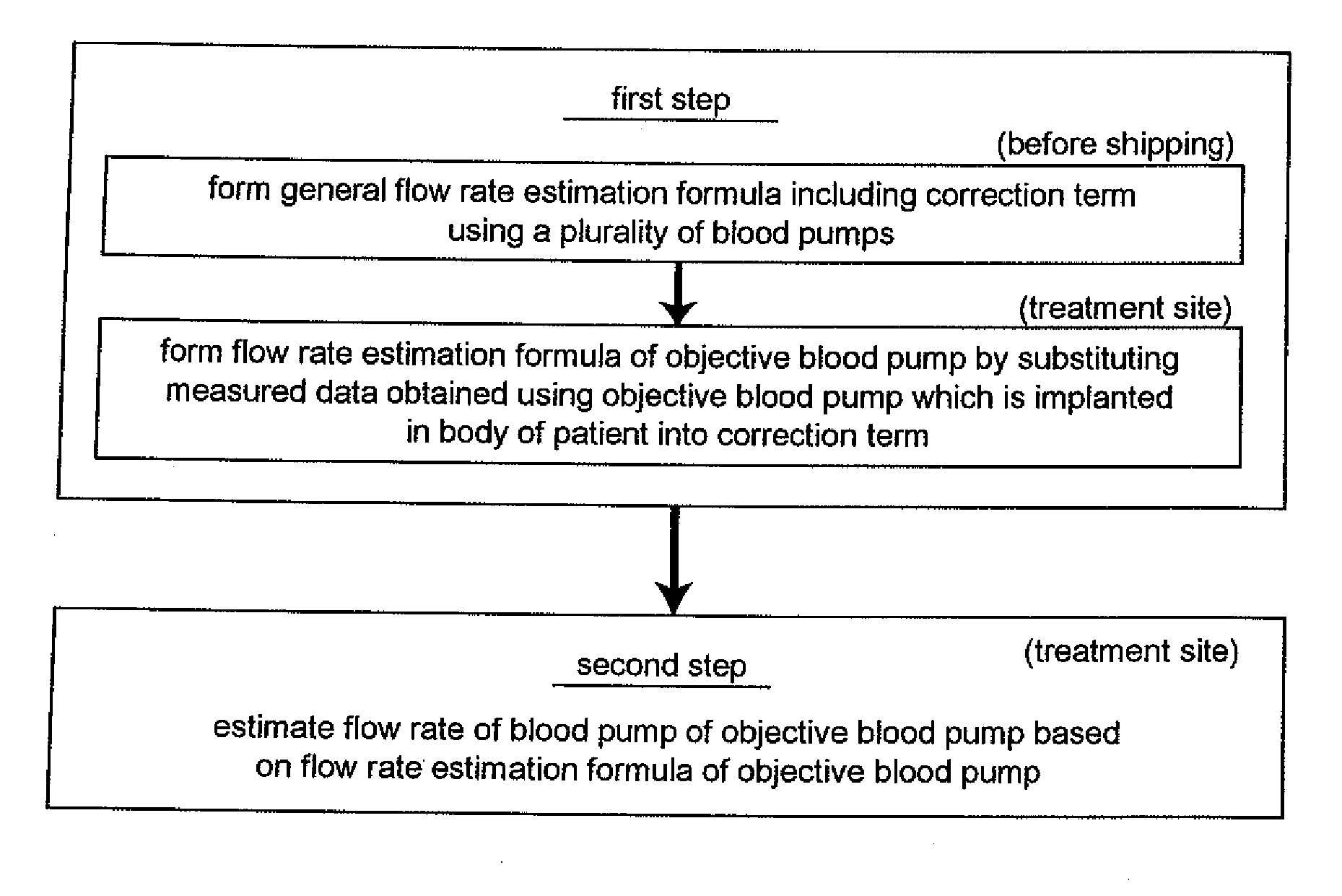

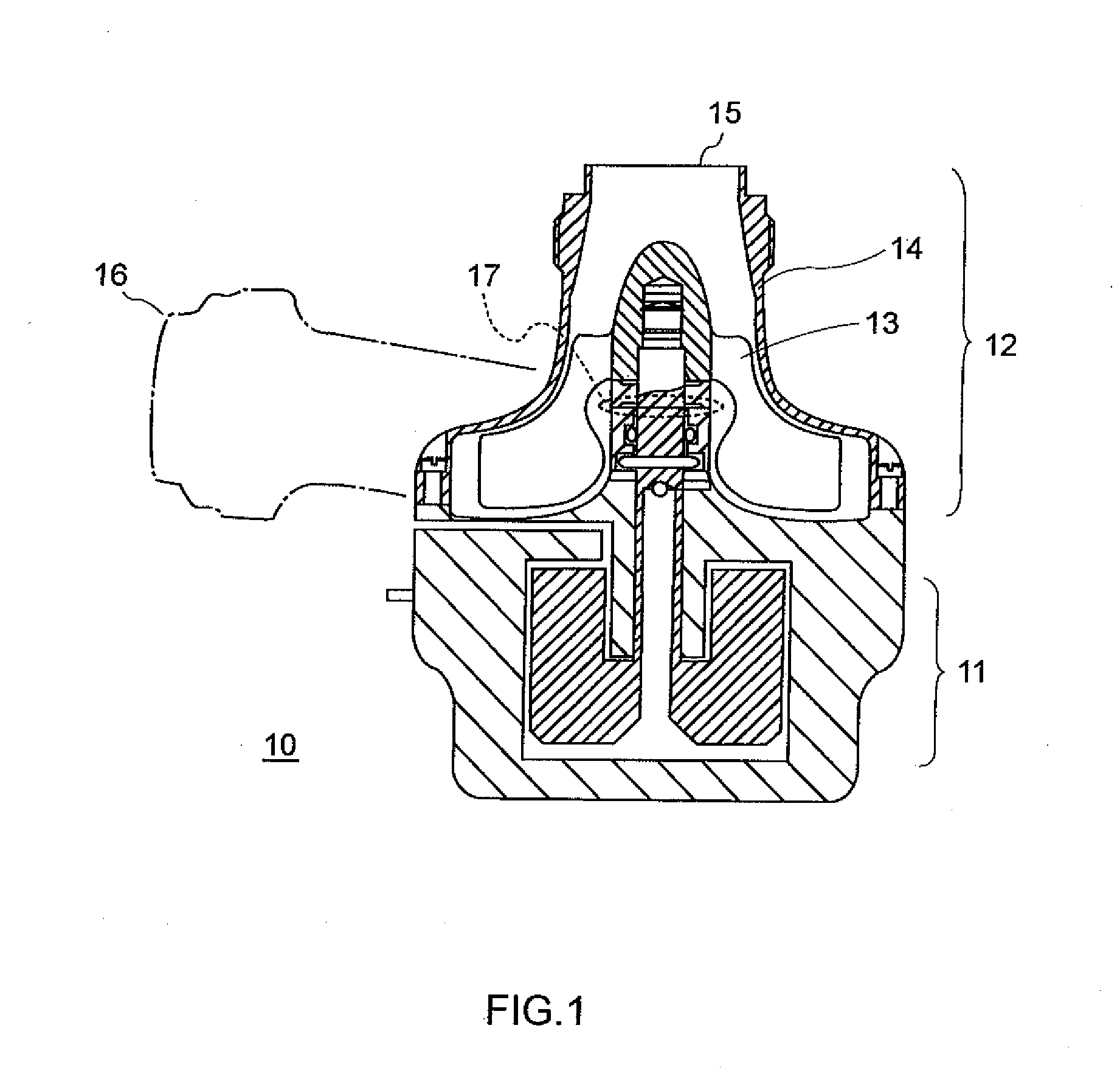

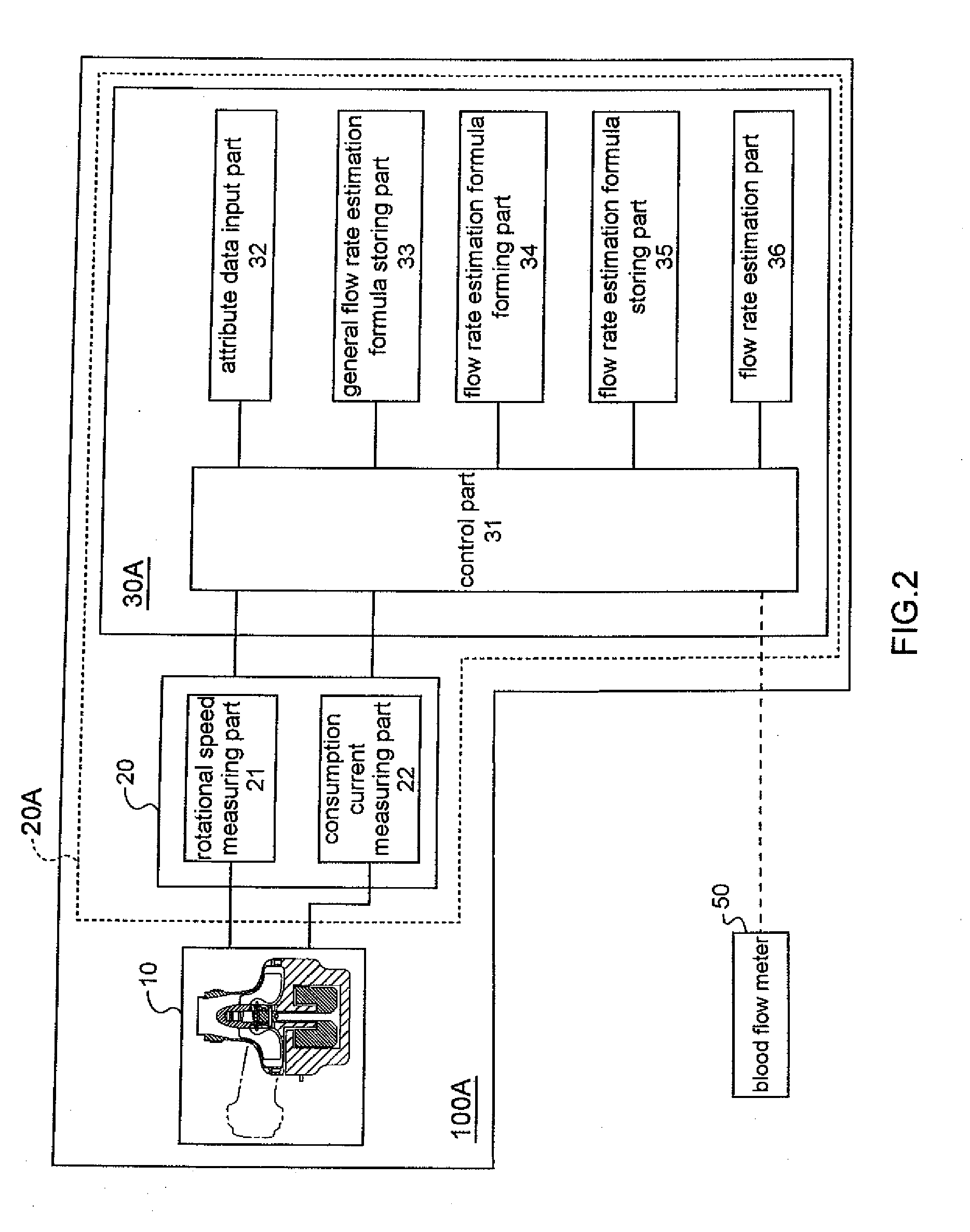

Flow rate estimation method of blood pump

ActiveUS7497116B2Effectively suppress the lowering of accuracy of a flow rate estimation resultImprove accuracyVehicle testingMedical devicesEstimation methodsBlood pump

In a flow rate estimation method of a blood pump, a general flow rate estimation formula which includes a correction term is formed based on a plurality of blood pumps. Measured data obtained from an objective blood pump implanted inside a patient is substituted into the correction term, thus forming a flow rate estimation formula of the objective blood pump. The flow rate Q of the objective blood pump is estimated based on the flow rate estimation formula and the values of the rotational speed N and the consumption current I of the motor of the objective blood pump, and the attribute data Z of the blood of the patient.

Owner:SUN MEDICAL TECH RES

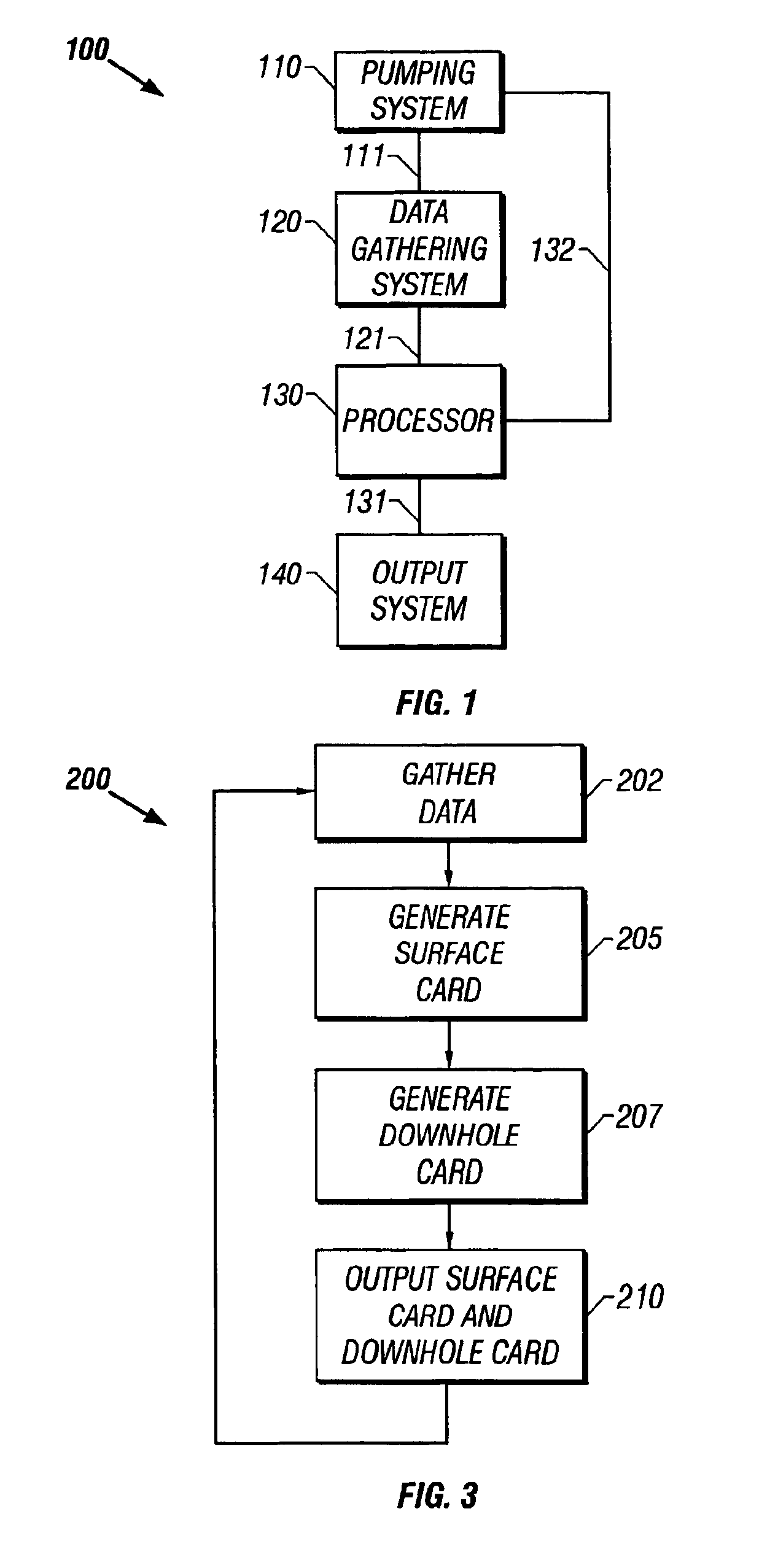

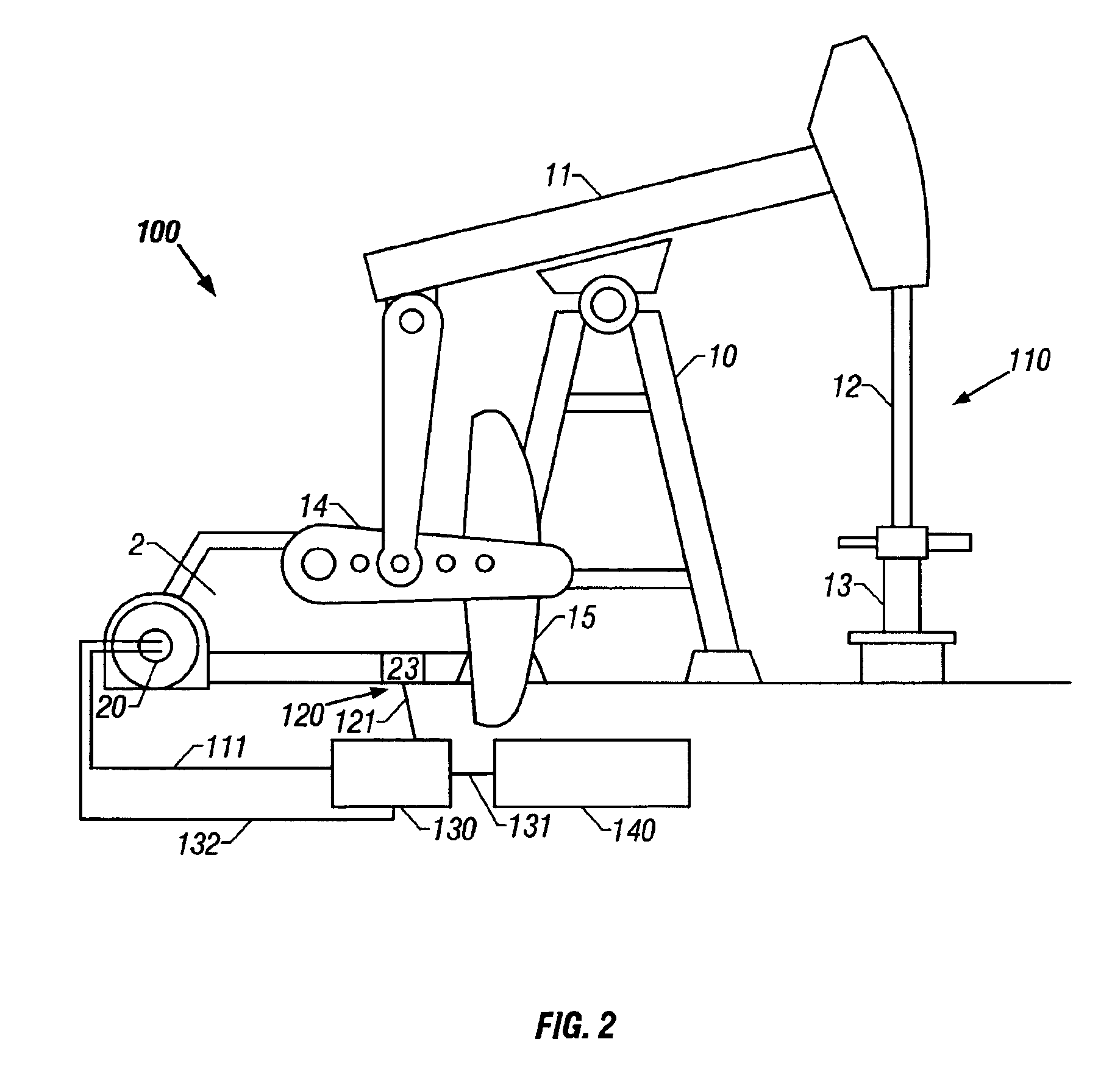

Methods, apparatus and products useful in the operation of a sucker rod pump during the production of hydrocarbons

InactiveUS6857474B2Electric/magnetic detection for well-loggingConstructionsProcess engineeringWellbore

Apparatus, methods and products for monitoring / controlling a reciprocating well producing hydrocarbons from a wellbore, which determine the surface card from a well operating characteristics, determine the downhole card, and display both at the same scale for position.

Owner:RAVDOS HLDG INC

Error volume system and method for a pump

ActiveUS20070125796A1Reduce errorsImprove dispensing accuracyLayered productsPretreated surfacesBiomedical engineering

Owner:ENTEGRIS INC

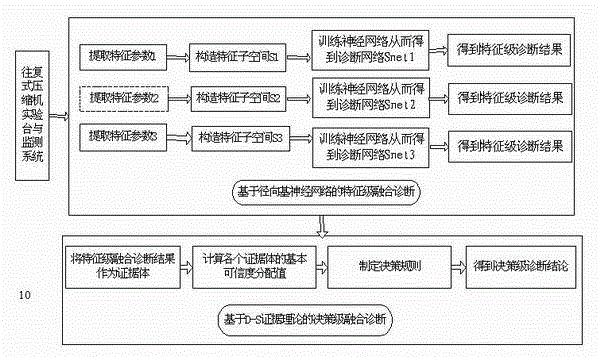

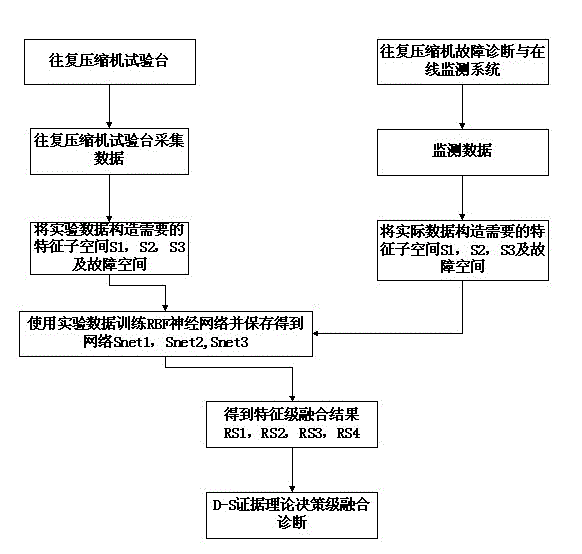

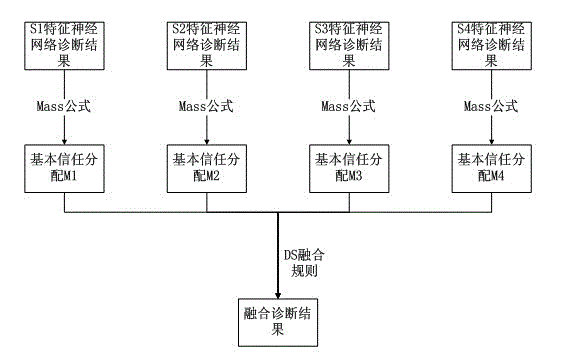

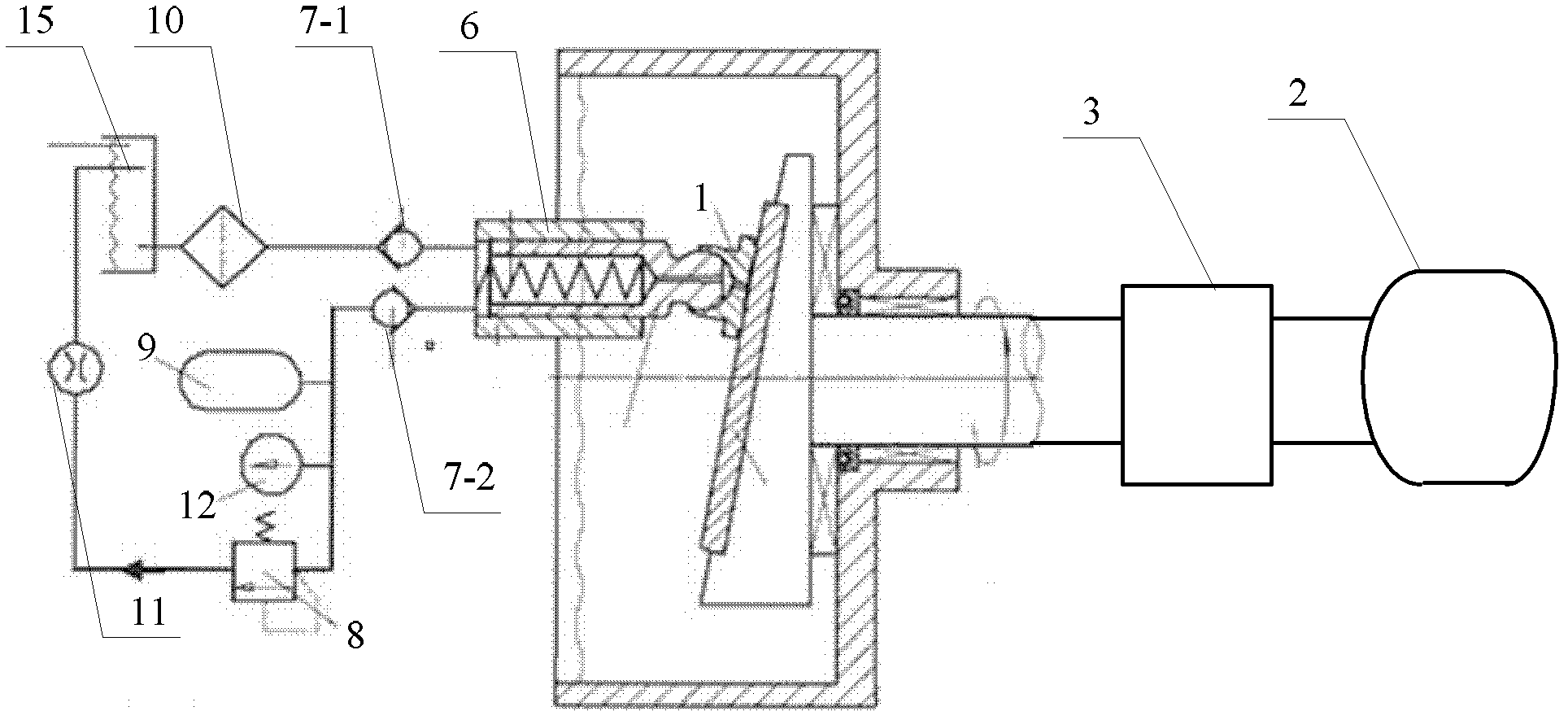

Reciprocating-type compressor fault diagnosis method based on multi-sensor information fusion

ActiveCN103147972APump testingPositive-displacement liquid enginesControl engineeringMultiple sensor

The invention discloses a reciprocating-type compressor fault diagnosis method based on multi-sensor information fusion, and the method is characterized by comprising the following steps of 1, collecting data; 2, constructing a fault characteristic sub-space and a fault space; 3, obtaining a fault diagnosis network; 4, acquiring characteristic fusion diagnosis results; and 5, carrying out D-S evidence theory decision-level fusion diagnosis, and giving out a decision-level diagnosis result. The method has the advantages of convenience in application, high diagnosis accuracy and applicability to a production site of reciprocating-type compressors of petroleum chemical industrial enterprises.

Owner:BEIJING UNIV OF CHEM TECH

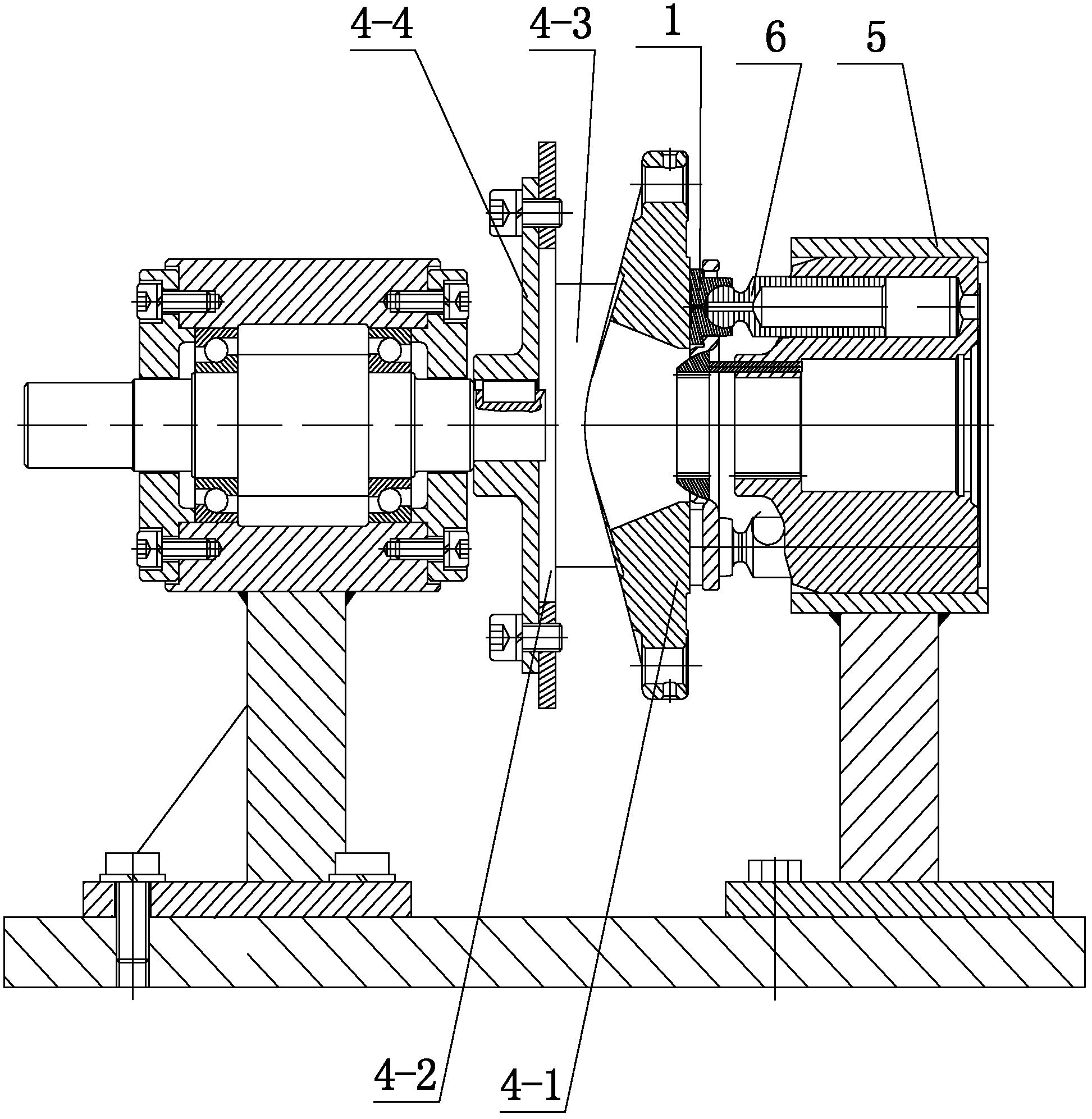

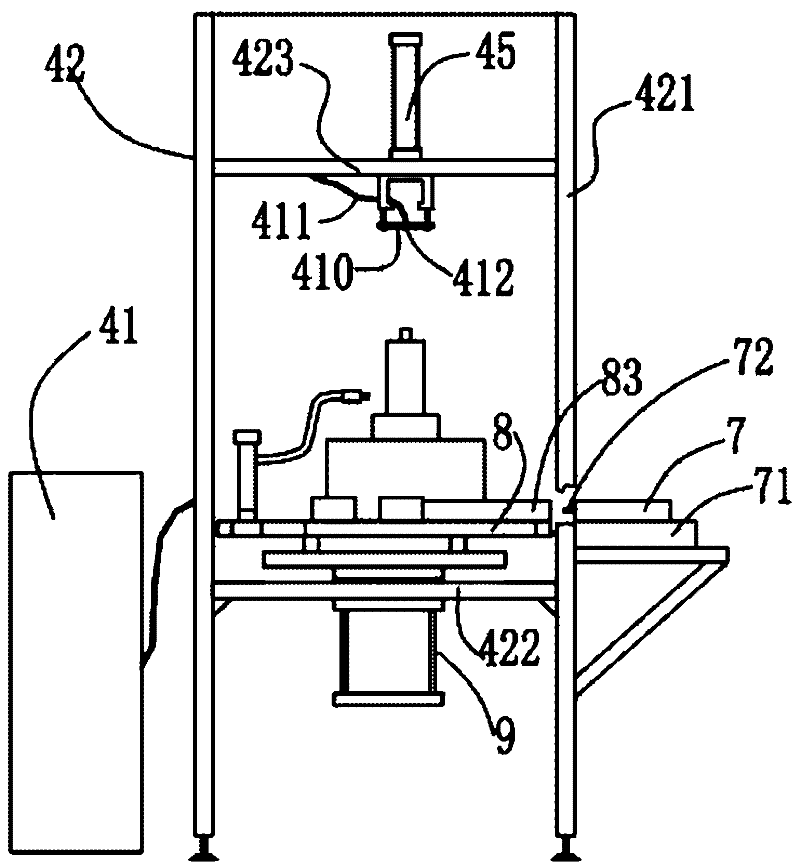

Performance testing device for piston shoe in axial plunger pump

InactiveCN102312830AImprove performanceImprove work performancePump testingPositive-displacement liquid enginesHydraulic cylinderCoupling

A performance testing device for a piston shoe in an axial plunger pump belongs to the technical field of hydraulic elements, and solves the problems that in the prior art a simulator is adopted to carry out the simulation test on the performance parameter of the piston shoe in the plunger pump, the test result has errors, and a piston shoe pair is difficult to be isolated from other friction component pairs when the performance parameter test is carried out in the piston shoe in a practical pump. The performance testing device for the piston shoe in the axial plunger pump comprises a piston shoe, and further comprises a variable frequency motor, a rotating speed and torque sensor, a variable device, a hydraulic cylinder body, a plunger, a flowmeter, a pressure gauge, an oil box and a temperature sensor, wherein the coupling plate of the variable device is fixedly connected with a bottom plate of a support tile of a swash plate through a bolt, the swash plate is supported by the support tile of the swash plate, three screwed holes on each fastening splint are connected with three corresponding screwed holes on one side of the swash plate through the bolts, a waist-shaped slot on each fastening splint corresponds to and is connected with the screwed hole on the side wall of the support tile of the swash plate through bolts, so the swash plate can swing in the support tile of the swash plate. The performance testing device for the piston shoe in the axial plunger pump is used for testing the performance of the piston shoe in the axial plunger pump.

Owner:HARBIN INST OF TECH

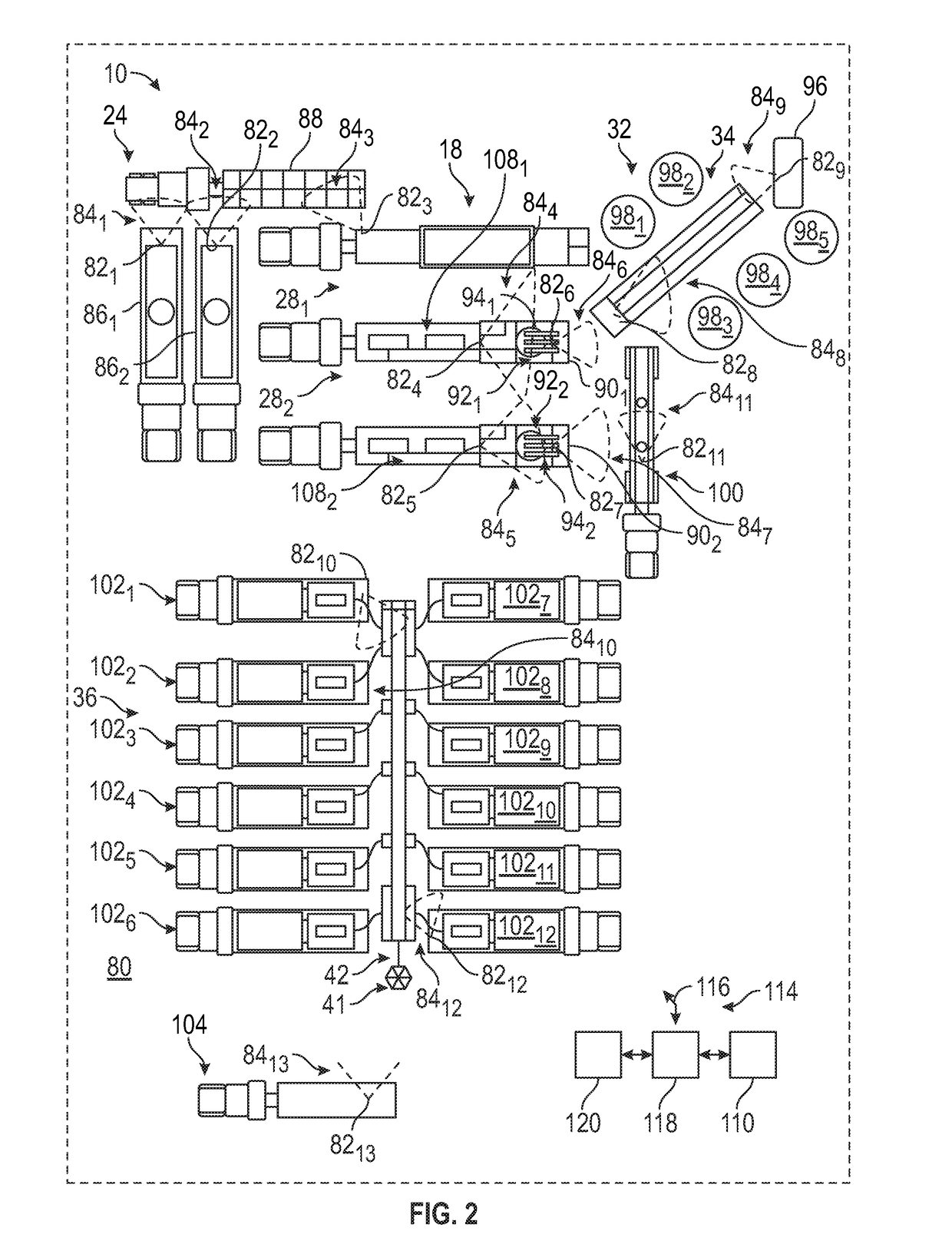

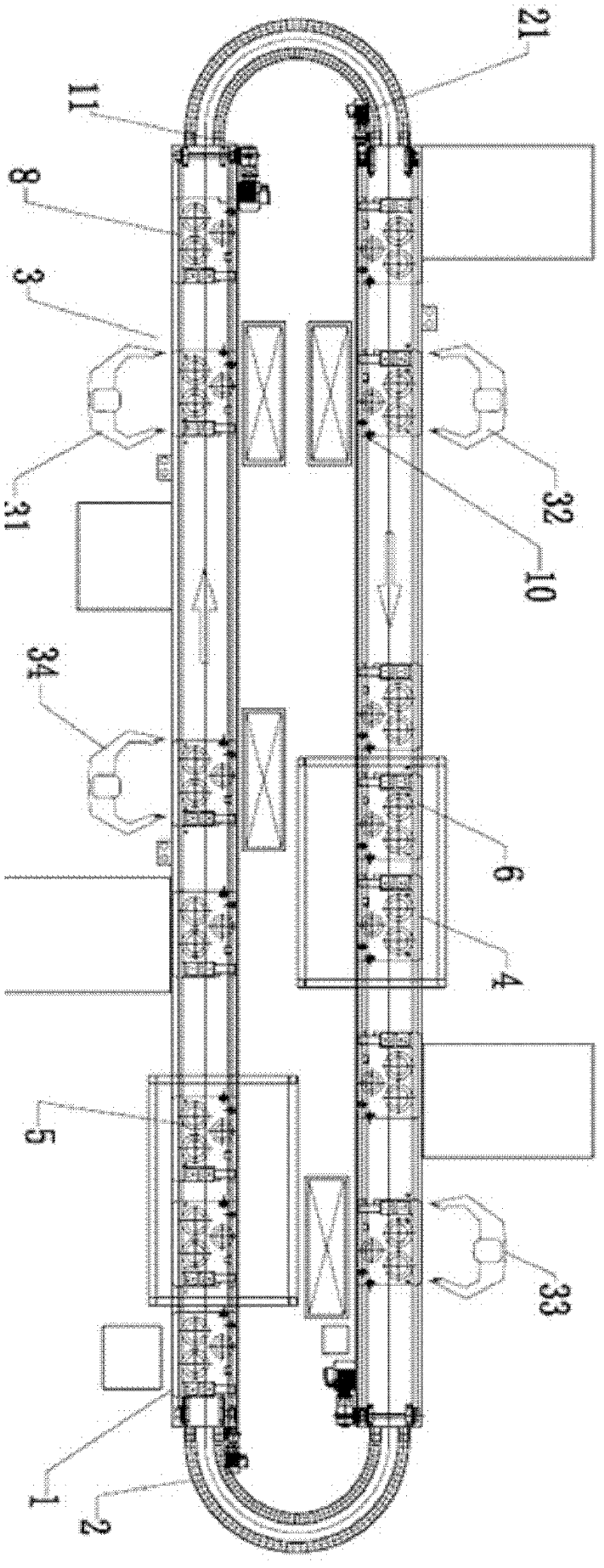

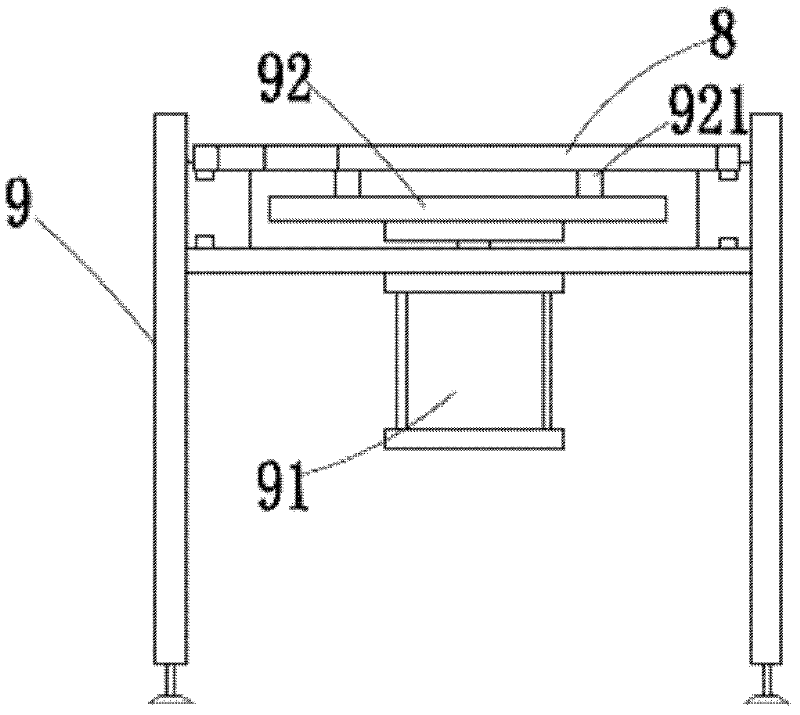

Water pump automatic circulation assembly line

ActiveCN102284860AAccurate detectionOptimizationPump testingAssembly machinesDifferential lineEngineering

The invention discloses an automatic flow assembly line for a water pump. The automatic flow assembly line comprises a circulated flow line mainly consisting of a differential chain line and an arc flat chain line and is characterized in that the circulated flow line is provided with an automatic water pump comprehensive testing platform, an air tightness testing unit, a main sealing automatic pressing table and more than two manual placement stations. The circulated flow line is also provided with circularly delivered tool plates. The automatic water pump comprehensive testing platform, the air tightness testing unit, the main sealing automatic pressing table and the manual placement stations are respectively provided with a tool plate jacking unit and a positioning stopper. In the automatic flow assembly line for the water pump, a part to be assembled can be conveniently placed on the tool plate for corresponding installation during assembly, and different automatic tests can be performed on different stations, so the labor intensity is reduced, and the production efficiency is improved.

Owner:JUNHE PUMPS HLDG

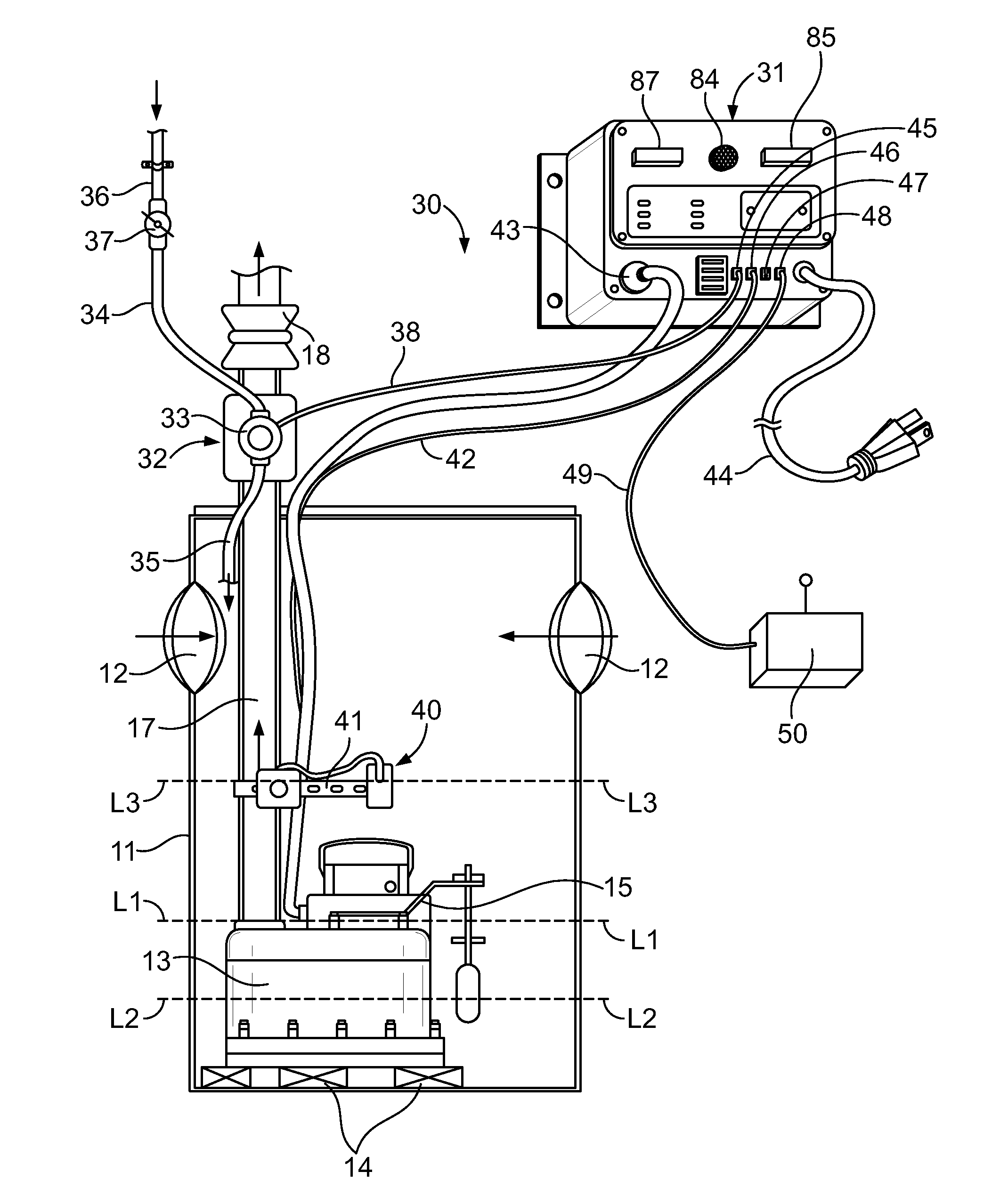

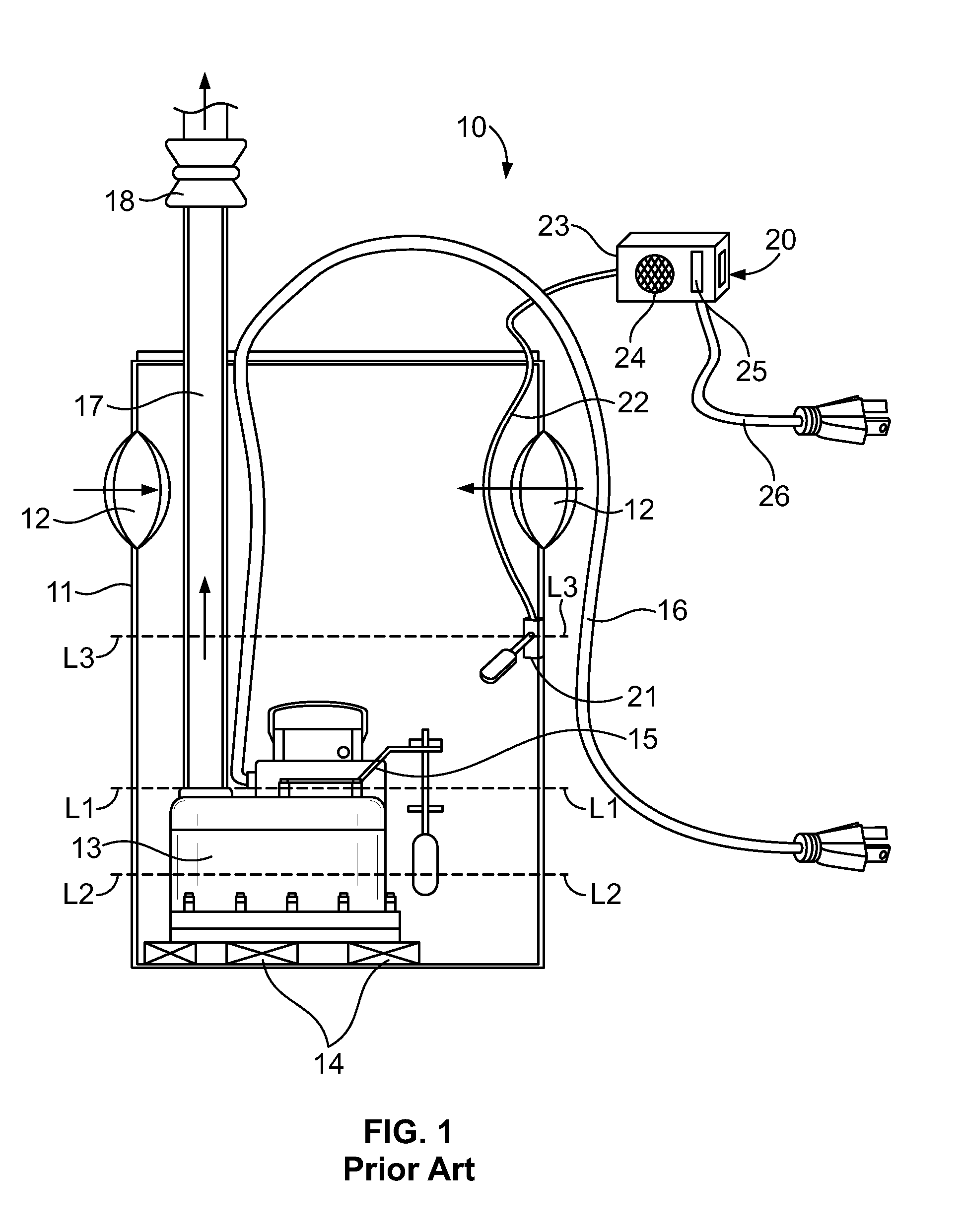

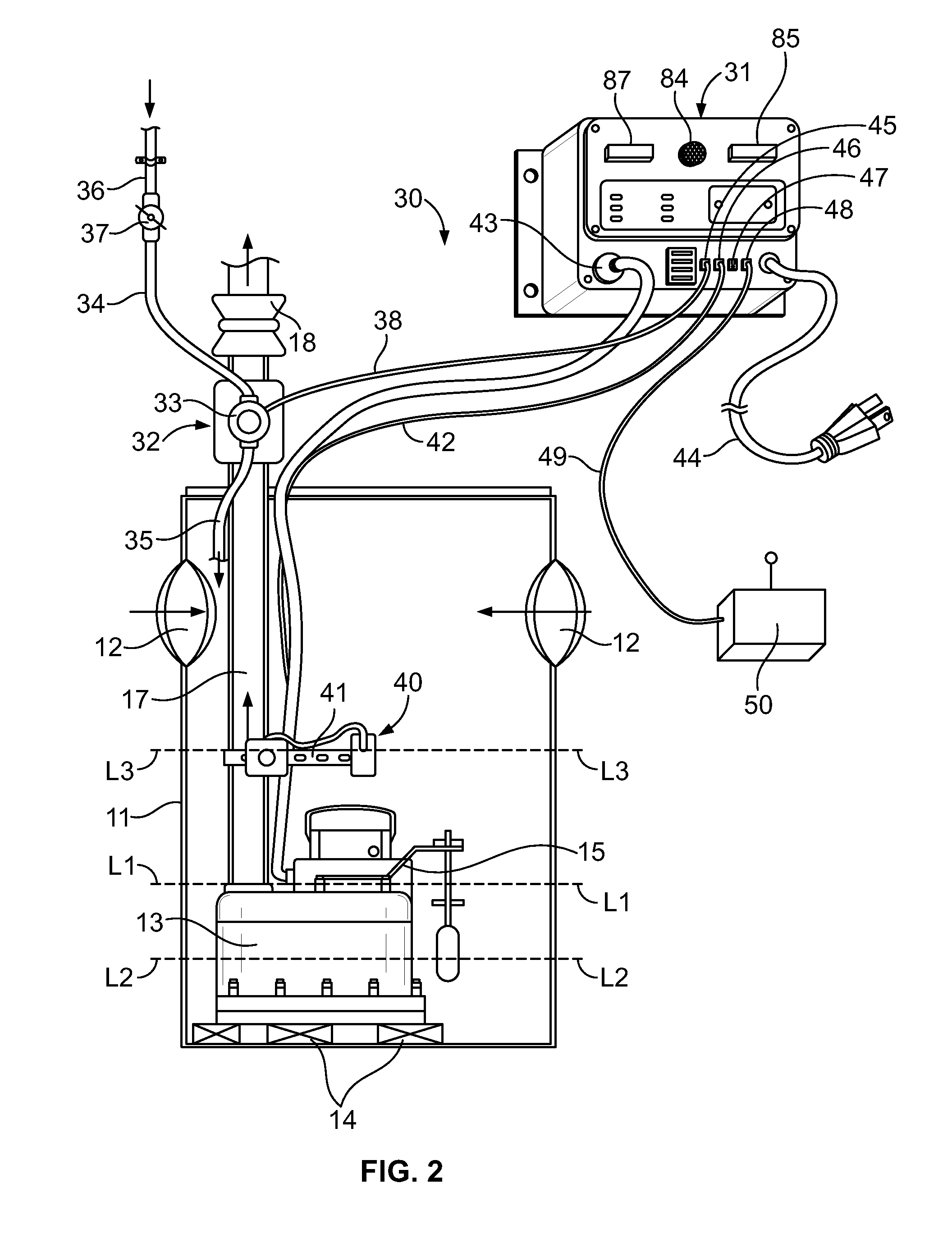

Test and monitoring system for a sump pump installation operable from a remote location

An automated system for monitoring and testing a sump pump installation includes an electrically-actuated valve which admits liquid to the liquid container in response to a valve control signal. A test control module includes a test control circuit which when actuated supplies a valve control signal to initiate a test cycle during which liquid is admitted to the container to cause the liquid level in the container to rise, after which the sump pump discharges liquid from the container until a predetermined event terminates the test cycle. An indicator circuit indicates in response to completion of the test cycle whether the test was successful or unsuccessful. A communications circuit is included which receives and verifies control signals addressed to the system from an external originator to allow a test cycle to be remotely initiated in the event of impending severe weather or other threats.

Owner:SCHWEITZER ENGINEERING LABORATORIES

Error volume system and method for a pump

ActiveUS7897196B2Reduce errorsImprove dispensing accuracyLayered productsPretreated surfacesEngineeringMechanical engineering

Owner:ENTEGRIS INC

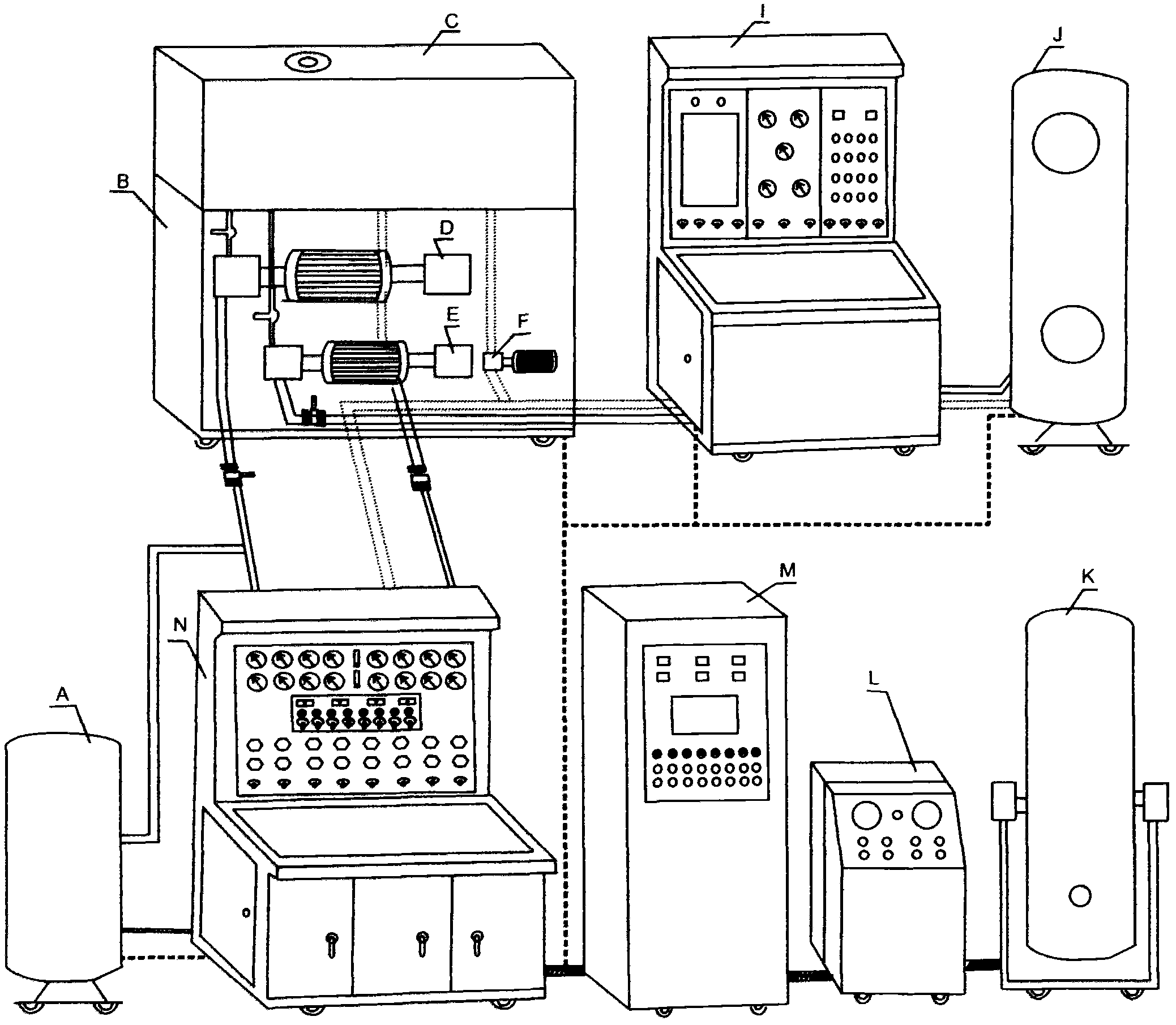

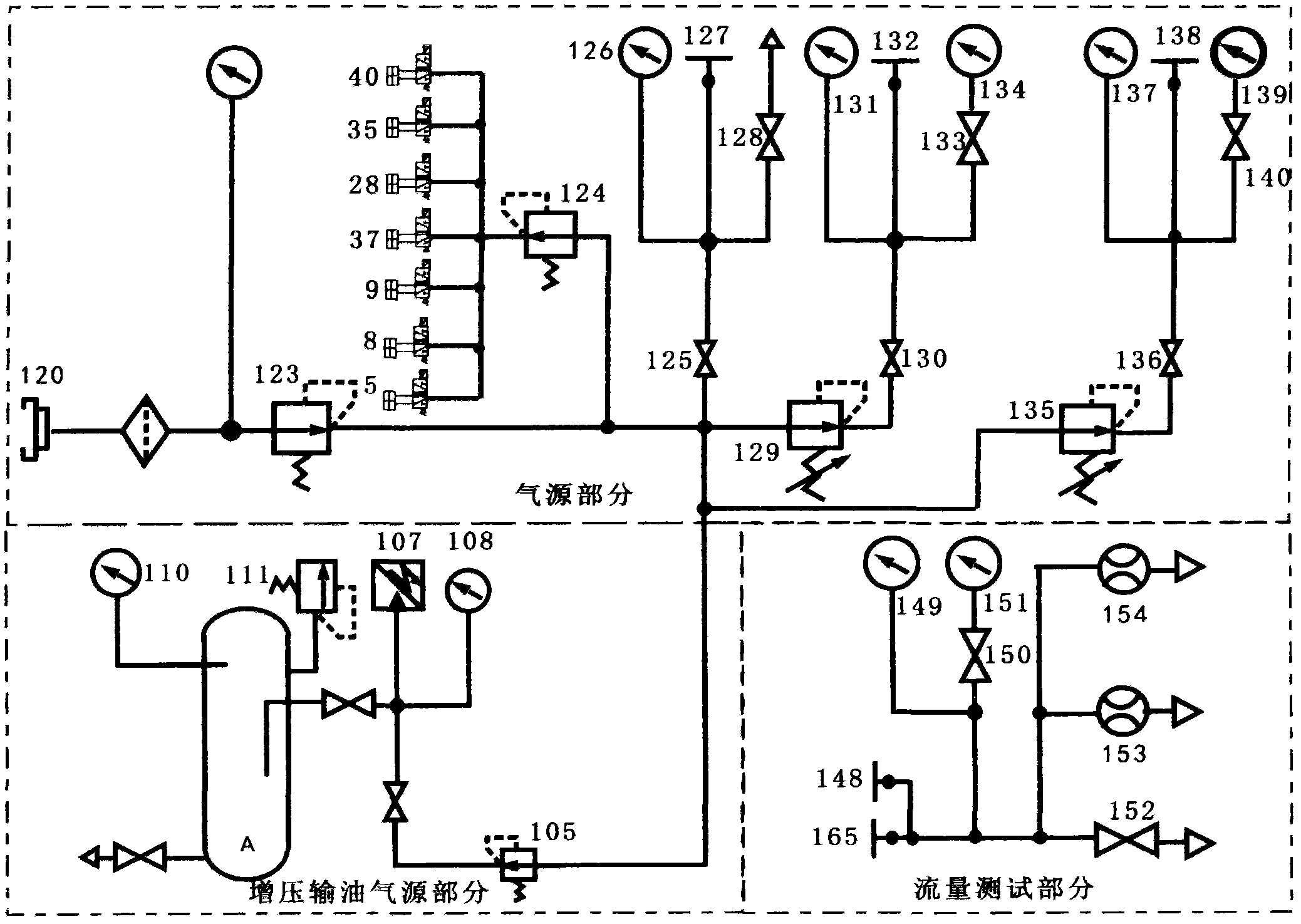

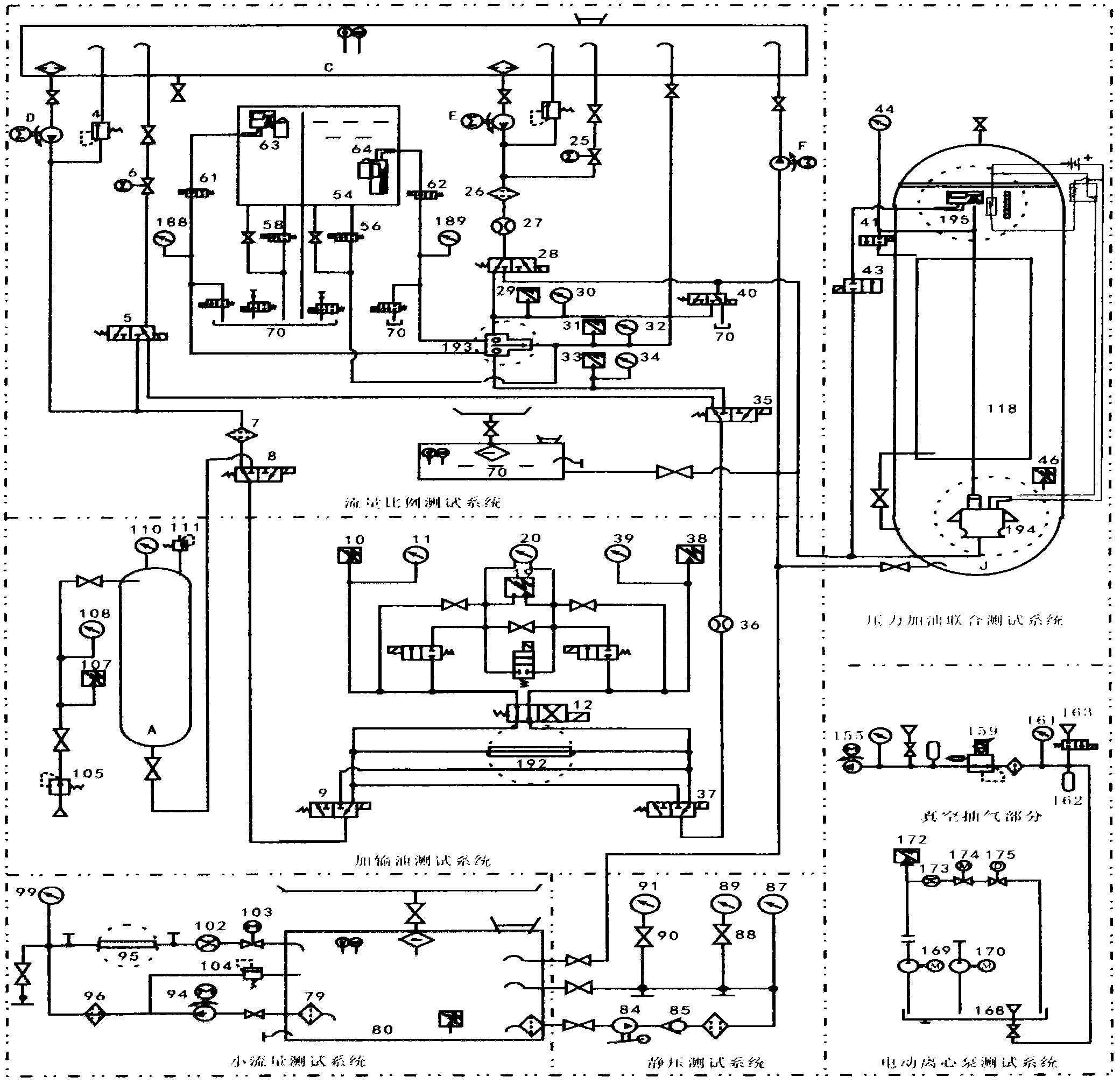

Integrated testing system for aviation fuel accessories

InactiveCN102589860AReduce purchasing costsLower requirementMachine part testingPump testingAviationAircraft fuel system

The invention relates to an integrated testing system for aviation fuel accessories. The integrated testing system comprises an electric control cabinet, a mechanical operating platform, an integrated pump station, a flow proportion testing platform, a pneumatic testing system and a fuel testing system, wherein the mechanical operating platform is connected with a pressurizing oil delivery gas storage tank through the pneumatic testing system; the integrated pump station is connected with the fuel testing system through an oil delivery pipeline; the pneumatic testing system is connected with the fuel testing system through a pneumatic pipeline; the flow proportion testing platform is connected with a pressure refueling joint testing oil tank; and the electric control cabinet is electrically connected with the mechanical operating platform, the integrated pump station, the flow proportion testing platform, the pneumatic testing system, the fuel testing system, the pressurizing oil delivery gas storage tank and the pressure refueling joint testing oil tank. The integrated testing system can perform performance test on all accessories of an aircraft fuel system, is high in integrity,convenient to maintain, compact in structure, small in occupation area and low in cost and expenditure, and is in accordance with specific using environment and support conditions under the field condition of an aviation equipment support army.

Owner:QINGDAO CAMPUS AVIATION ENG COLLEGE OF THE PEOPLES LIBERATION ARMY NAVY

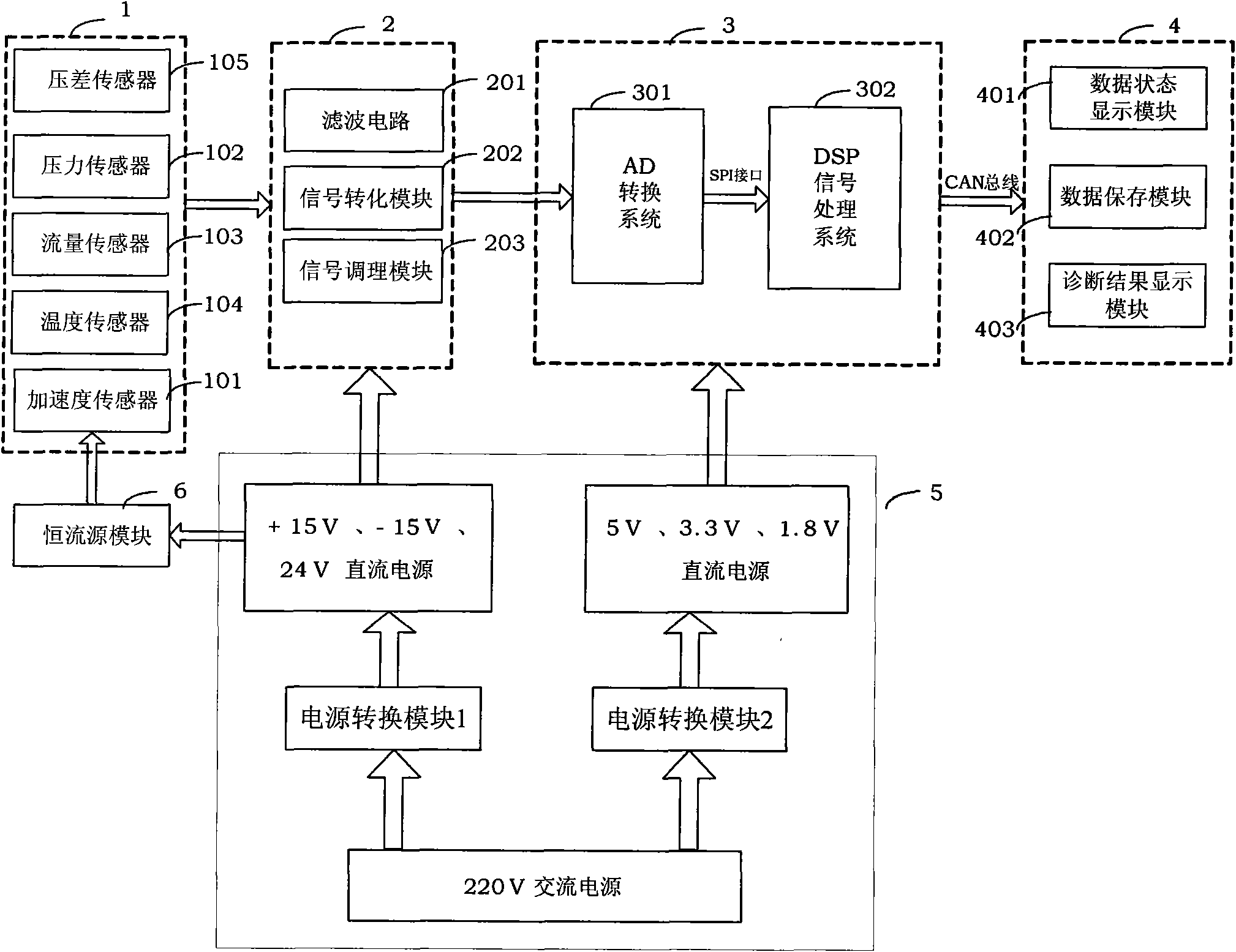

Airborne hydraulic pump source fault diagnosis system based on DSP

InactiveCN101581295AAchieve rapidityRealize requirementsPump testingPositive-displacement liquid enginesData processing systemSignal conditioning

The invention discloses an airborne hydraulic pump source fault diagnosis system based on a DSP, comprising a data acquisition system, a signal conditioning system, a signal processing system, a host computer display system, a power supply system and a constant flow source module; wherein, the signal processing system consists of an A / D converting system and a DSP system; a DSP TMS 320F2812 chip is selected by a DSP data processing system, and fault diagnosis is carried out on an airplane pumping source system in the signal processing system, finally, the data mode and diagnosis results are transmitted into the host computer display system to be displayed by a CAN bus. The invention adopts the embedded DSP system with small volume and high reliability, adapts to flexibility requirement on the airplane and meets the special requirements of the airborne fault diagnosis system, thus improving the real-time property and accuracy of the fault diagnosis system.

Owner:BEIHANG UNIV

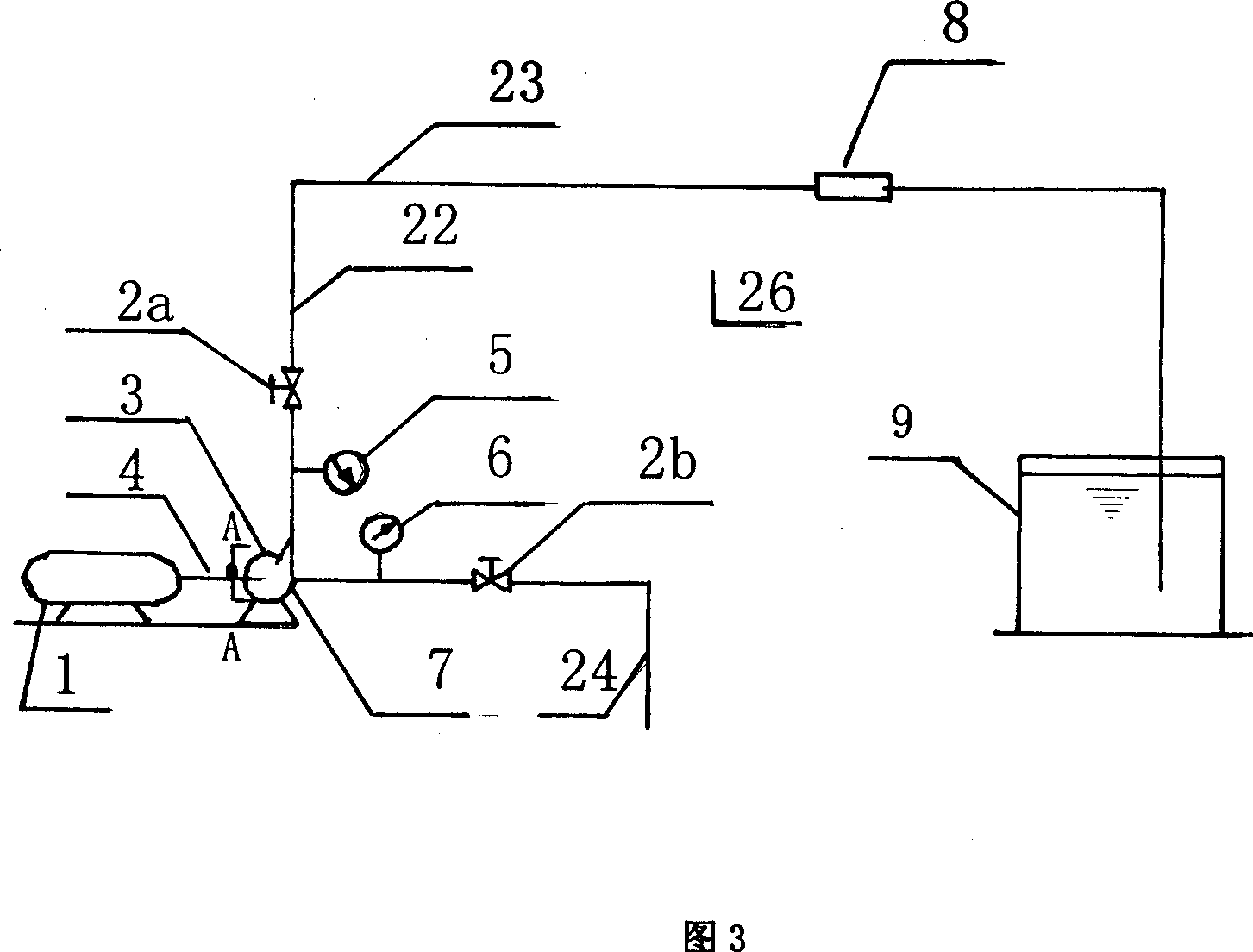

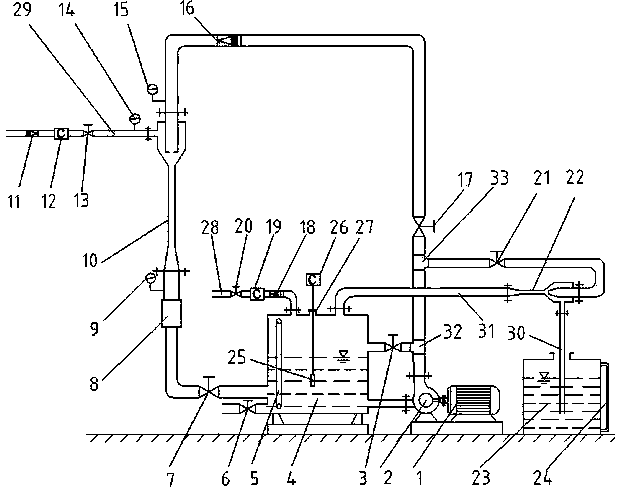

Multifunctional testing table for property and application of liquid and gas jet pump

InactiveCN103410718AThe overall structure is simple and reliableEasy to adjustPump testingPositive-displacement liquid enginesLiquid jetEngineering

The invention discloses a multifunctional testing table for property and application of a liquid and gas jet pump and belongs to the technical field of ejecting. The multifunctional testing table is composed of a testing system and a medicine feeding system. The testing system comprises a main water tank, a centrifugal pump unit, the liquid and gas jet pump, a testing parameter measuring instrument, a connection pipeline and a gate valve. The medicine feeding system is formed by a main water tank, a centrifugal pump unit, a medicine feeding box, a liquid and liquid jet pump, a pipeline and a gate valve. The multifunctional testing table can perform liquid and gas jet pump performance testing and can perform simulation study on structural size optimization and actual application of the liquid and gas jet pump by utilizing waste gas absorbing simulation experiments and oxygenating aeration experiments of the liquid and gas jet pump.

Owner:JIANGSU UNIV

Flow rate estimation method of blood pump

ActiveUS20070119246A1Effectively suppress the lowering of accuracy of a flow rate estimation resultImprove accuracyVehicle testingMedical devicesEstimation methodsBlood pump

A flow rate estimation method of a blood pump of the present invention includes a first step which has a step in which a plurality of blood pumps are prepared, and a general flow rate estimation formula which includes a correction term is formed using the plurality of respective blood pumps and a step in which measured data obtained by using the objective blood pump implanted inside a body of a patient is substituted into a correction term, thus forming a flow rate estimation formula of the objective blood pump based on the general flow rate estimation formula, and a second step which estimates the flow rate Q of the blood pump based on the flow rate estimation information formula and the values of N, I and Z of the objective blood pump which are obtained by measuring the rotational speed N of the motor and the consumption current I of the motor of the objective blood pump which is implanted inside the body of the patient, and the attribute data Z of the blood of the patient. Due to the flow rate estimation method of a blood pump of the present invention, it is possible to effectively suppress the deterioration of the accuracy of the flow rate estimation result attributed to the individual difference of the property of the blood pump.

Owner:SUN MEDICAL TECH RES

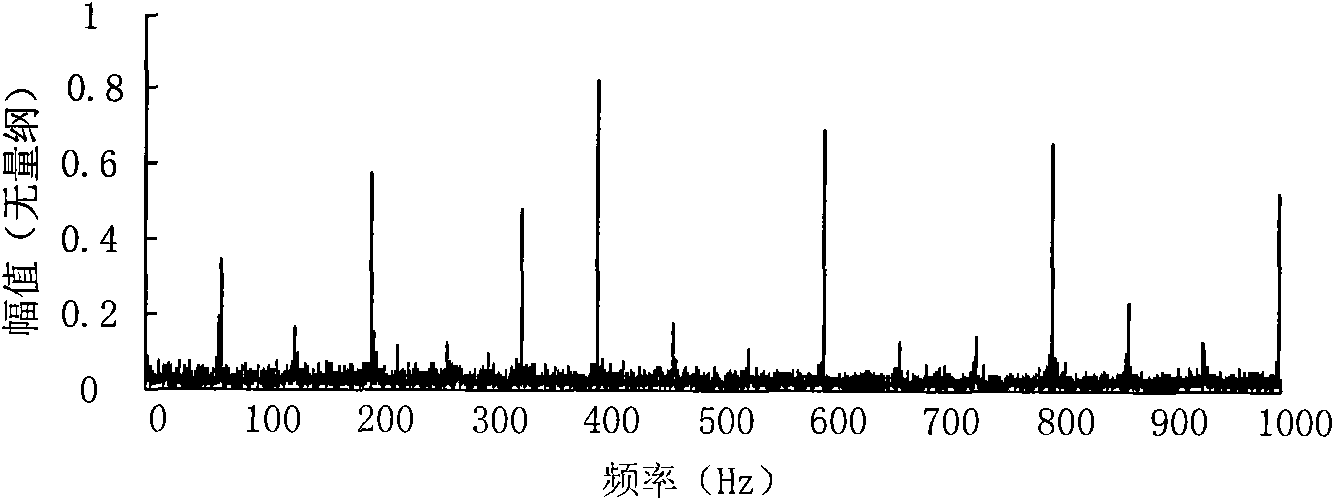

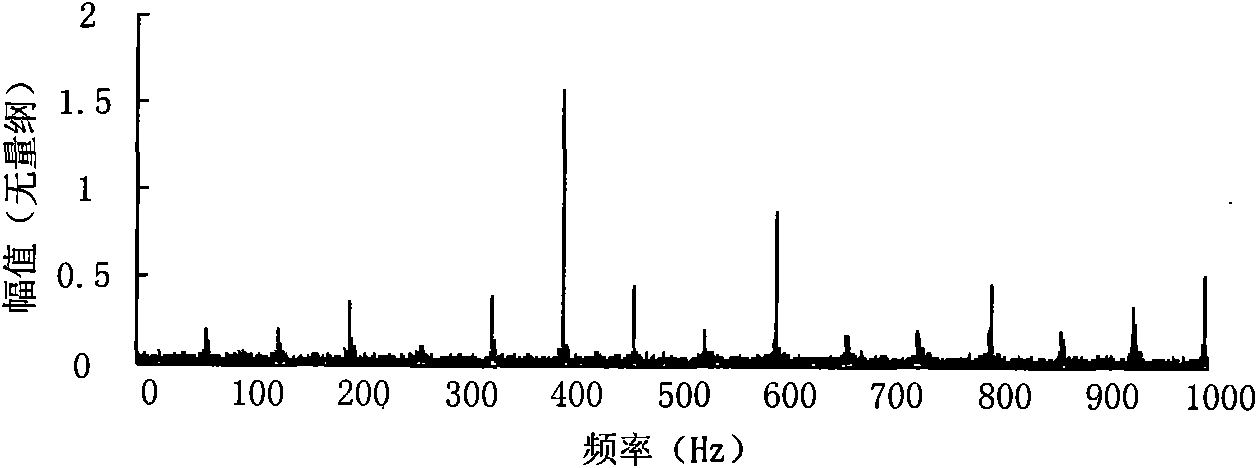

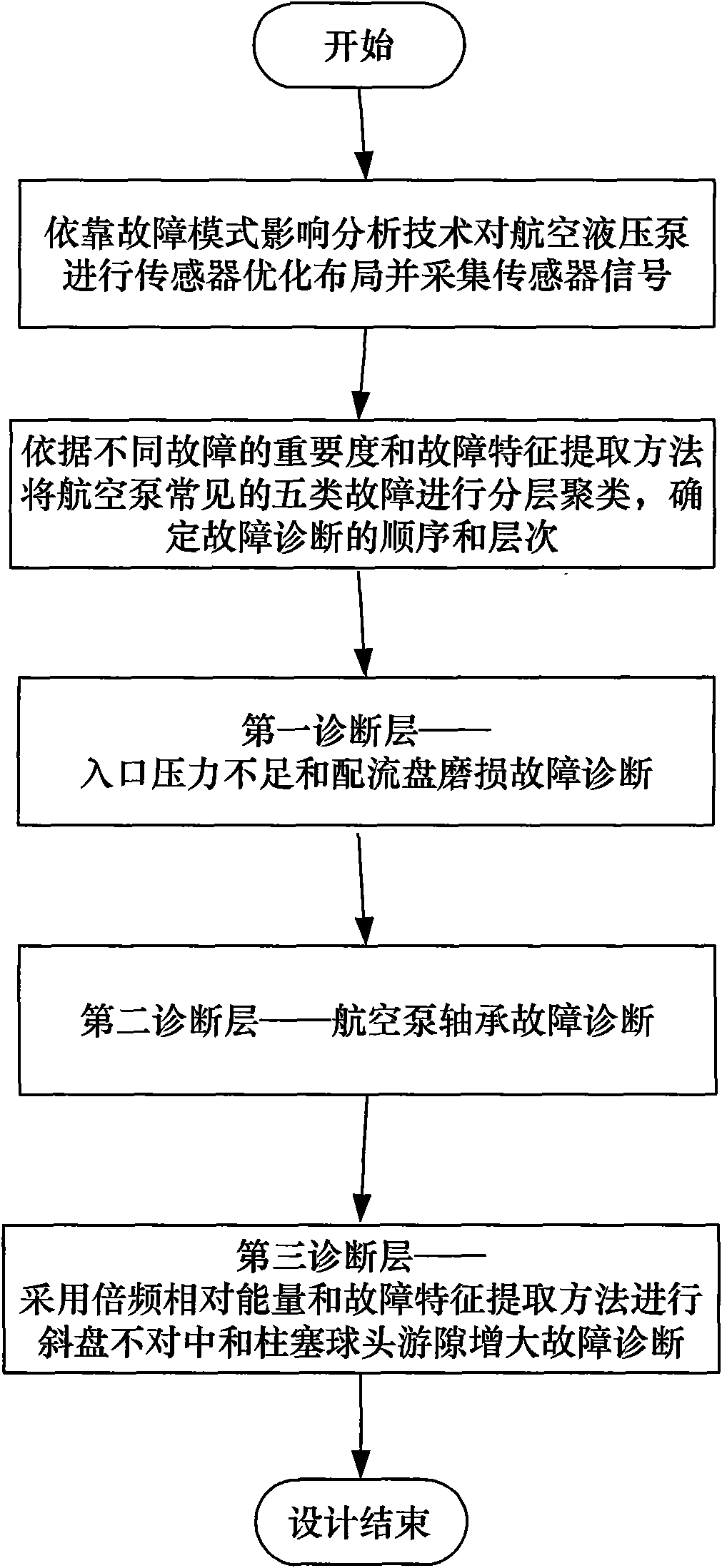

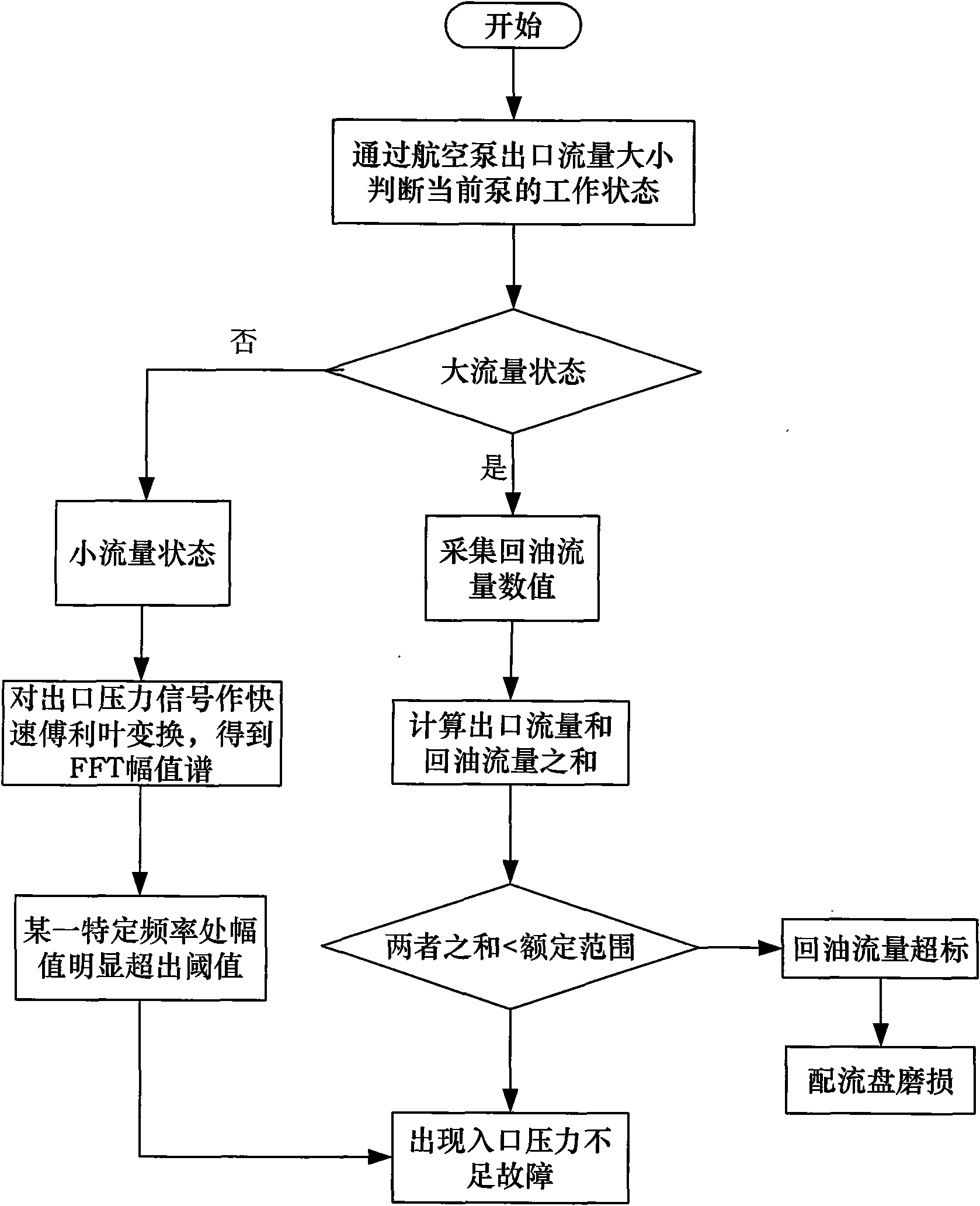

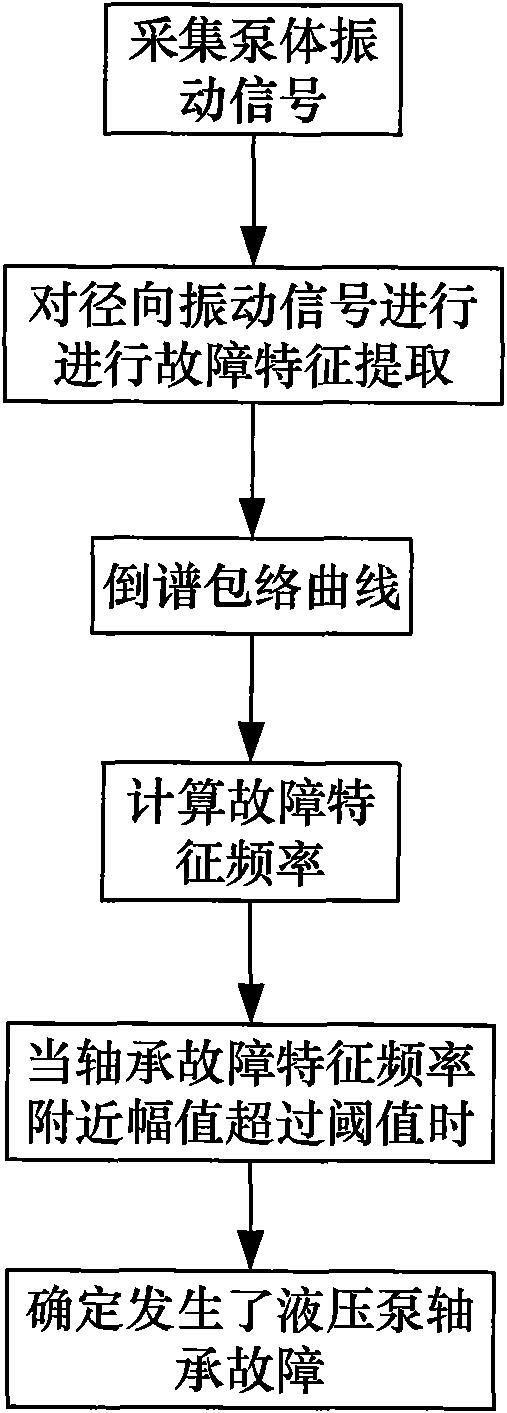

Hierarchical cluster aviation pump multiple fault diagnostic method based on frequency multiplication relative energy sum

InactiveCN101571120AImplement diagnosticsRealize multi-fault high-precision diagnosisPump testingPositive-displacement liquid enginesAviationRelative energy

The invention discloses a hierarchical cluster aviation pump multiple fault diagnostic method based on frequency multiplication relative energy sum. In the method, firstly fault mode effect influence analysis technology is used for carrying out sensor optimal distribution on an aviation hydraulic pump and acquiring sensor signal; then common faults of the aviation hydraulic pump are classified by hierarchical cluster to determine the sequence and hierarchy of fault diagnosis; and finally fault diagnosis of a first diagnosis layer, a second diagnosis layer and a third diagnosis layer is carried out to complete the multiple fault diagnosis on the aviation pump. The method realizes the multiple fault diagnosis of the aviation pump with high accuracy; a extraction method of fault feature and frequency doubling relative energy sum is designed aiming that typical gradual fault of the aviation hydraulic pump is extremely weak at fault initial signature, the method can effectively realize the fault feature extraction of weak signal, and the method is proved to be accurate and efficient by plenty of experiments.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com