Patents

Literature

116results about How to "Improve dispensing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

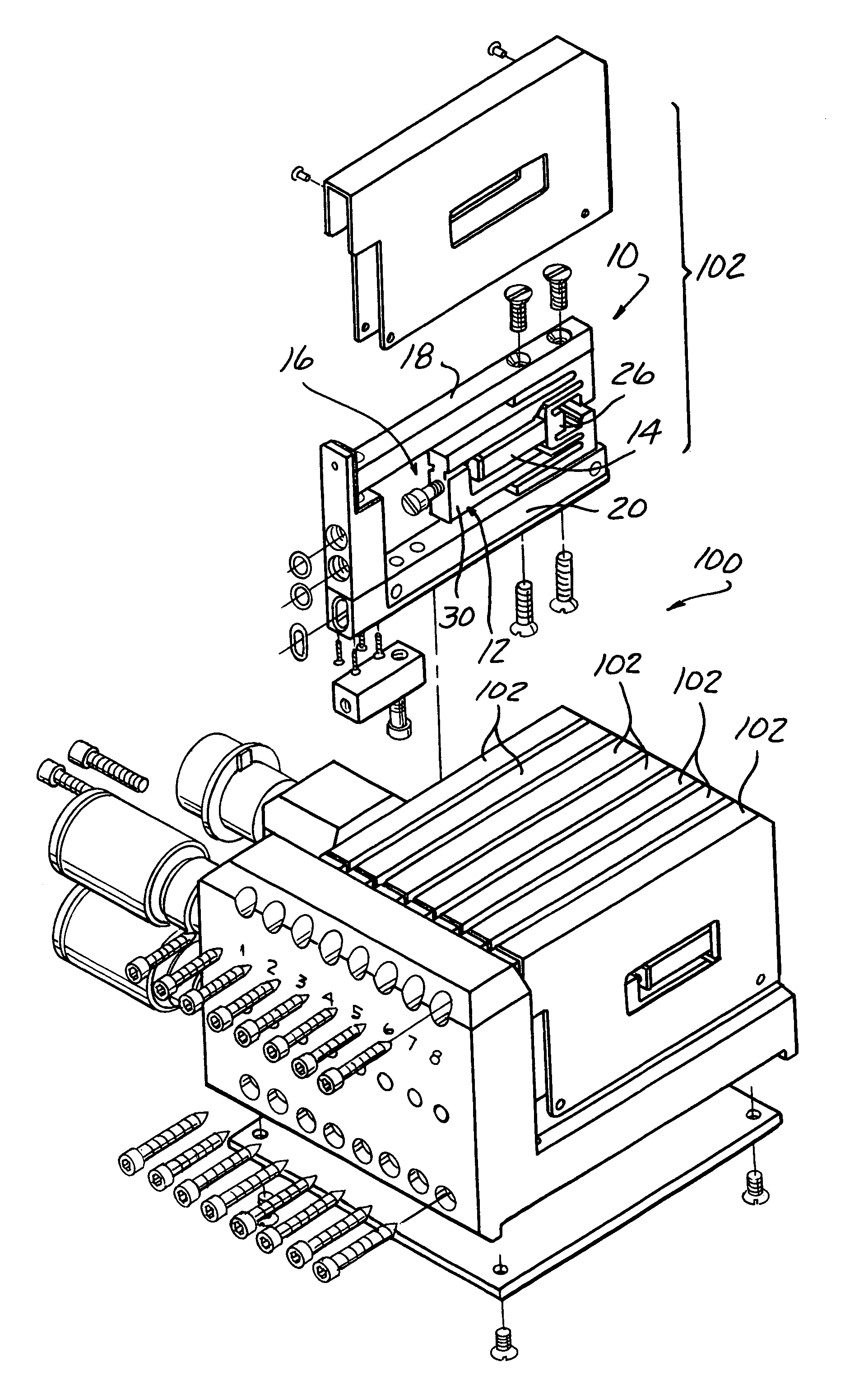

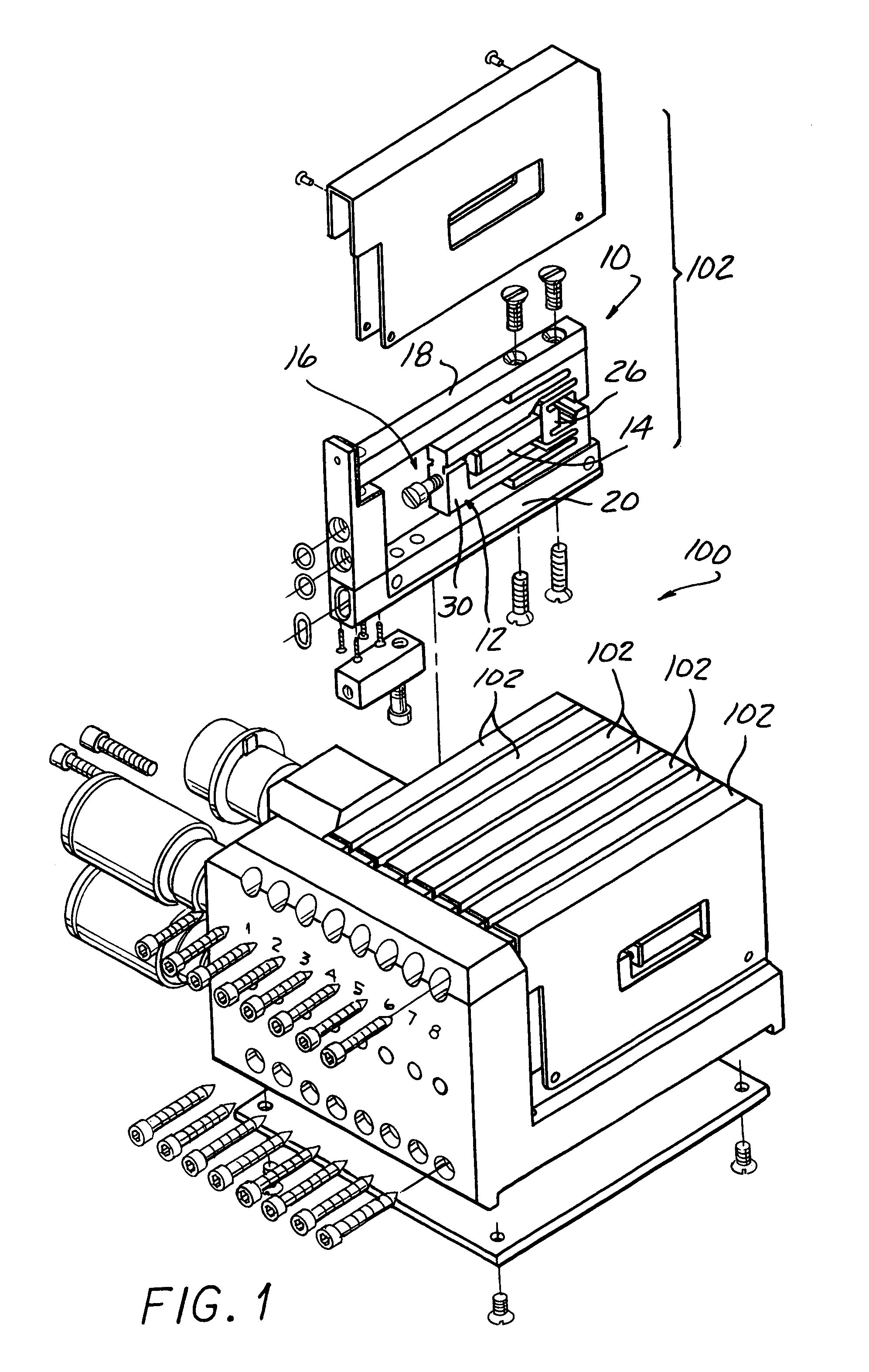

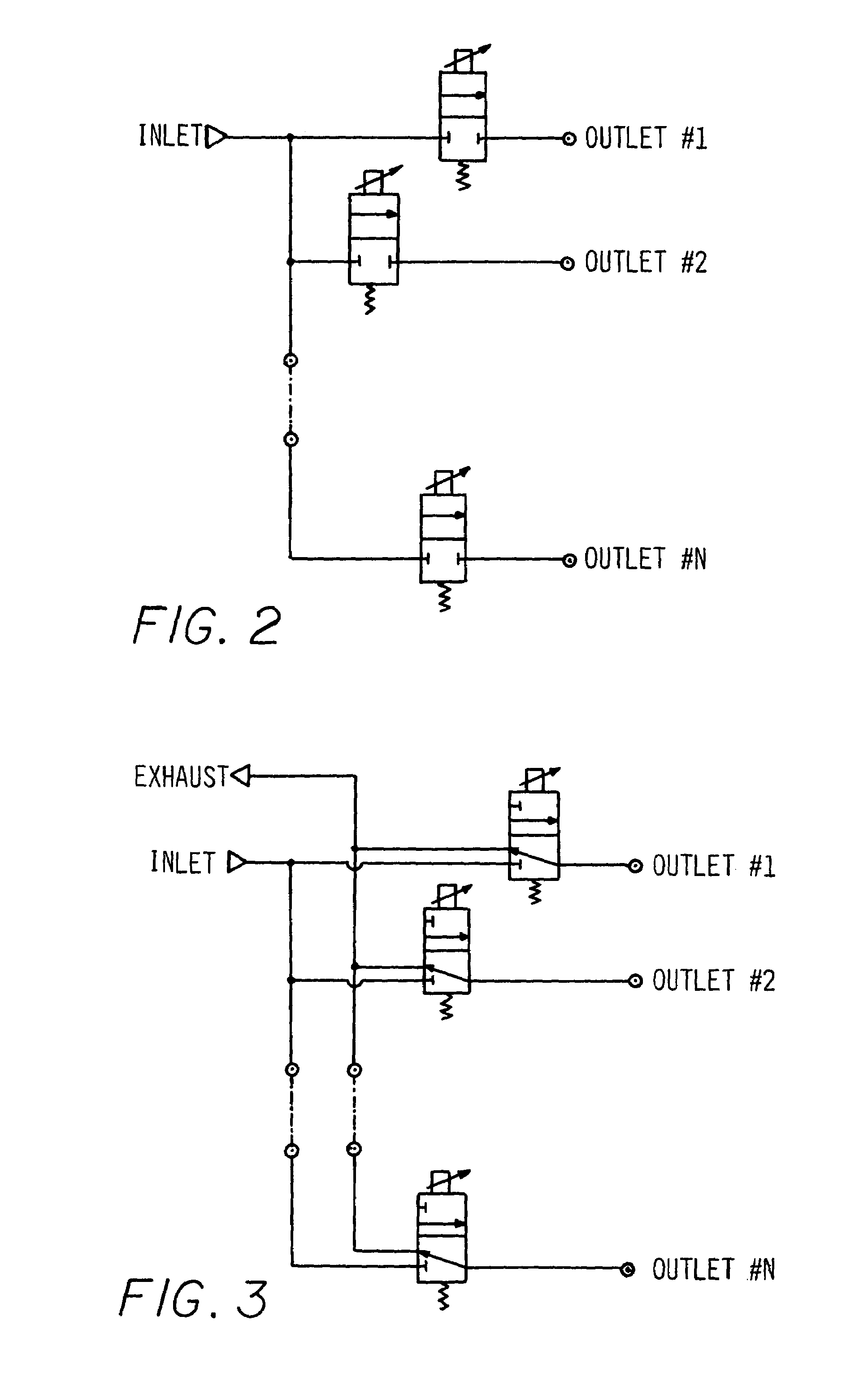

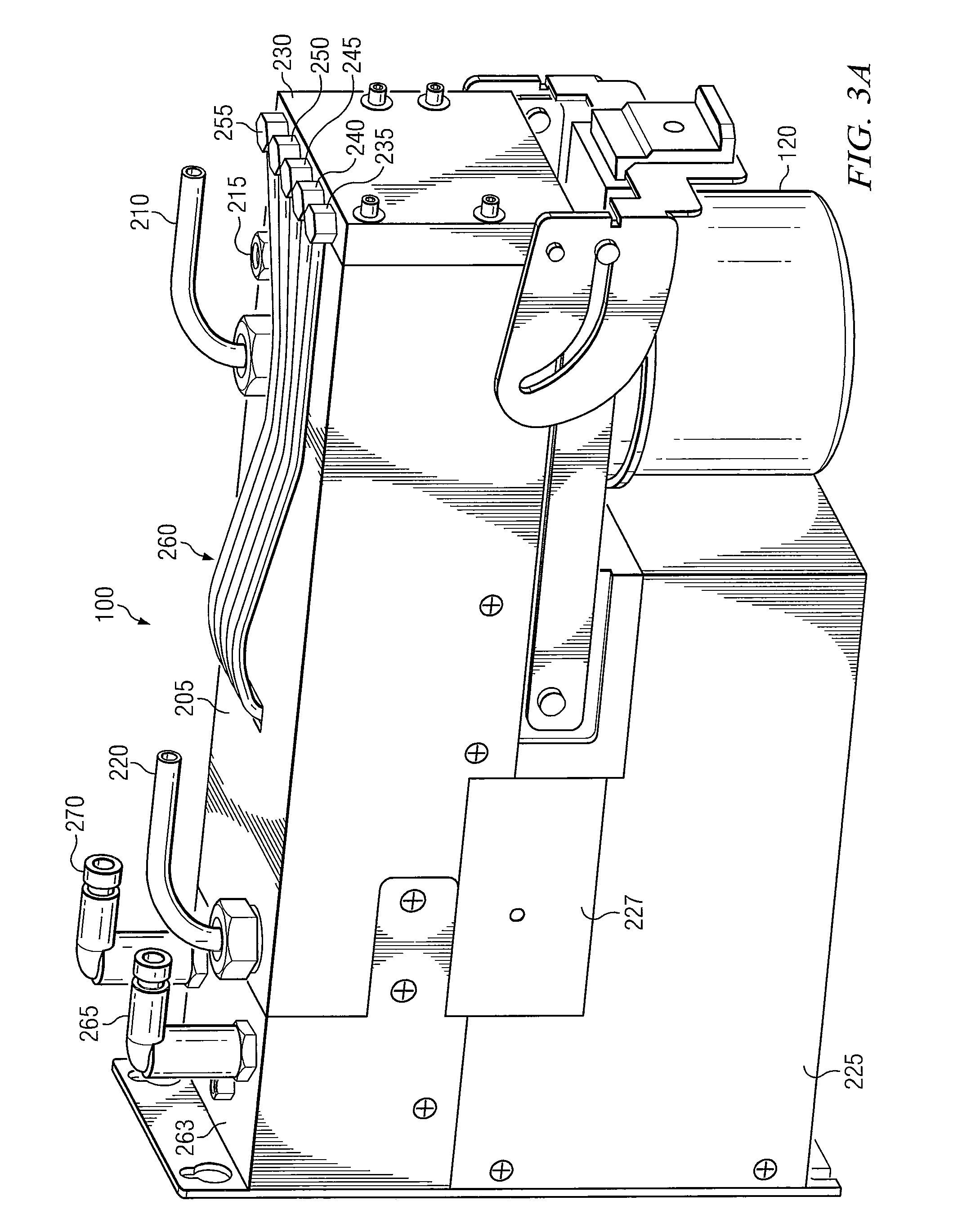

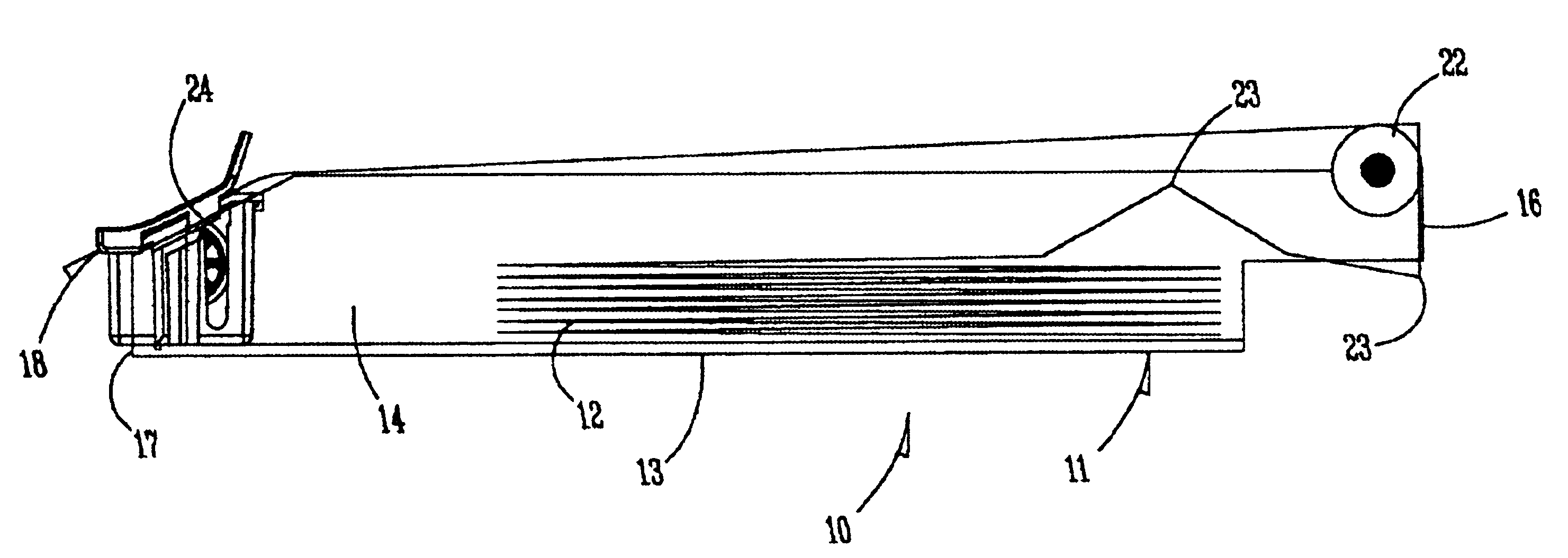

Piezo-electric actuated multi-valve manifold

InactiveUS7040349B2Avoid flowEnabling useOperating means/releasing devices for valvesServomotor componentsMulti-valveControl flow

An apparatus controls flow of a fluid from at least one inlet port to at least one outlet port. A support has a rigid, non-flexible portion, at least one pivotable relatively rigid, non-flexible, folded-back arm portion extending from the rigid portion, at least one surface connected to folded-back arm portion for movement relative to the support, and a rigid, non-flexible force transfer member operably positioned for driving the pivotable folded-back arm portion with a loss of motion of less than 40%. An electrically operated actuator operably engages between the rigid portion and the force transfer member to pivot the folded-back arm portion in response to an electrical activation of the actuator. A manifold includes a fluid passage communicating with at least one valve seat and operably engageable with respect to at least one corresponding valve body for movement between a closed position and an opened position.

Owner:PARKER INTANGIBLES LLC

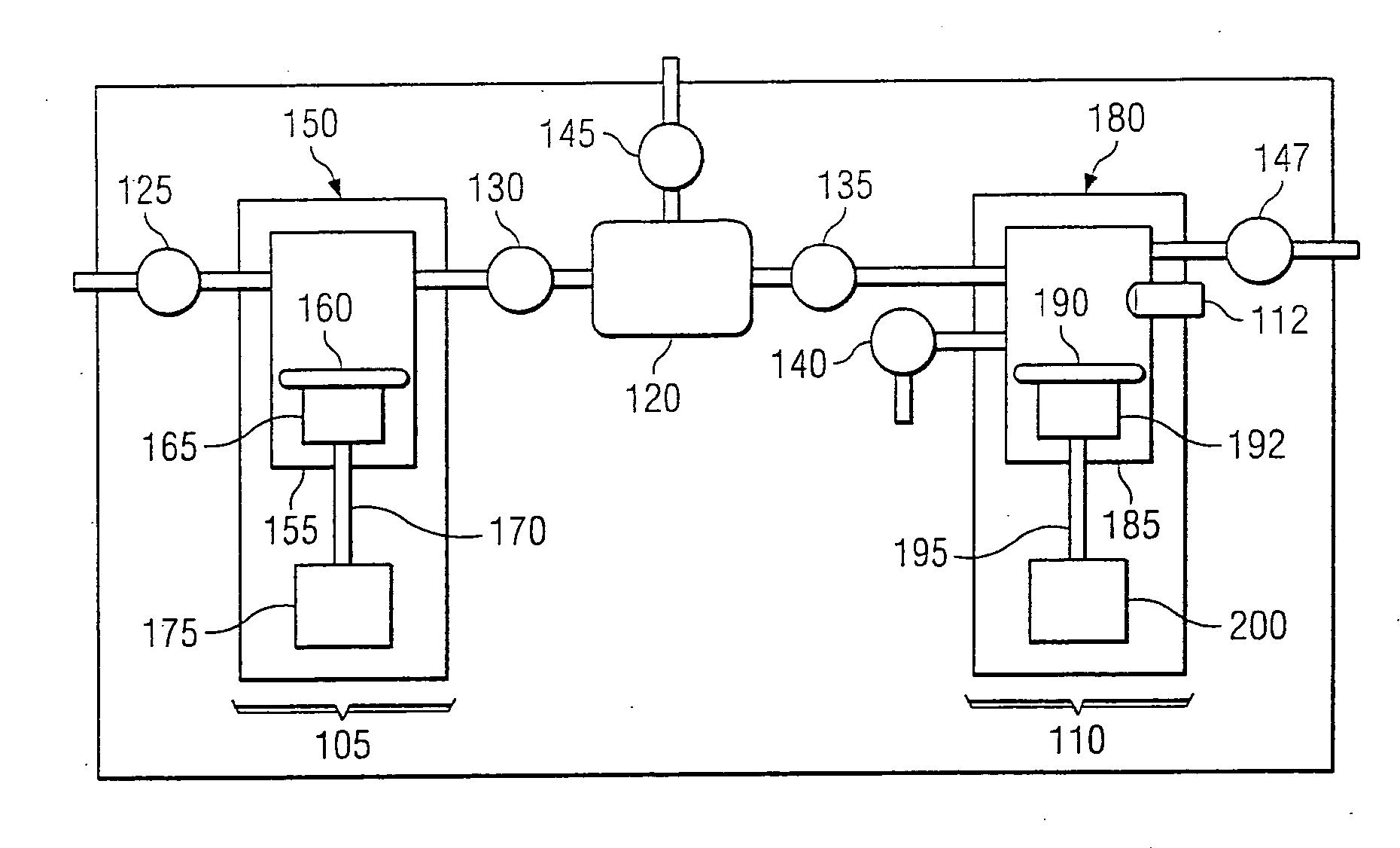

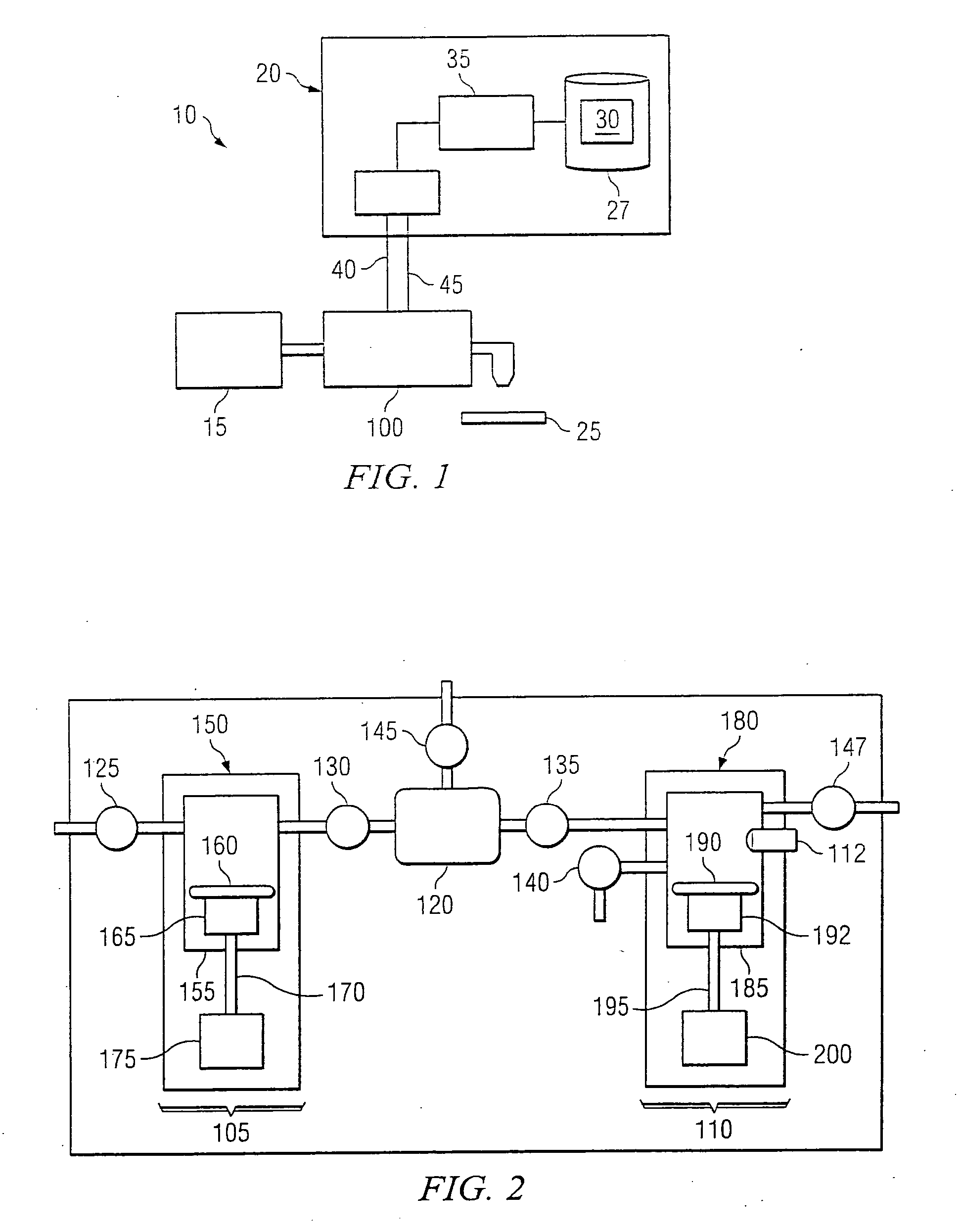

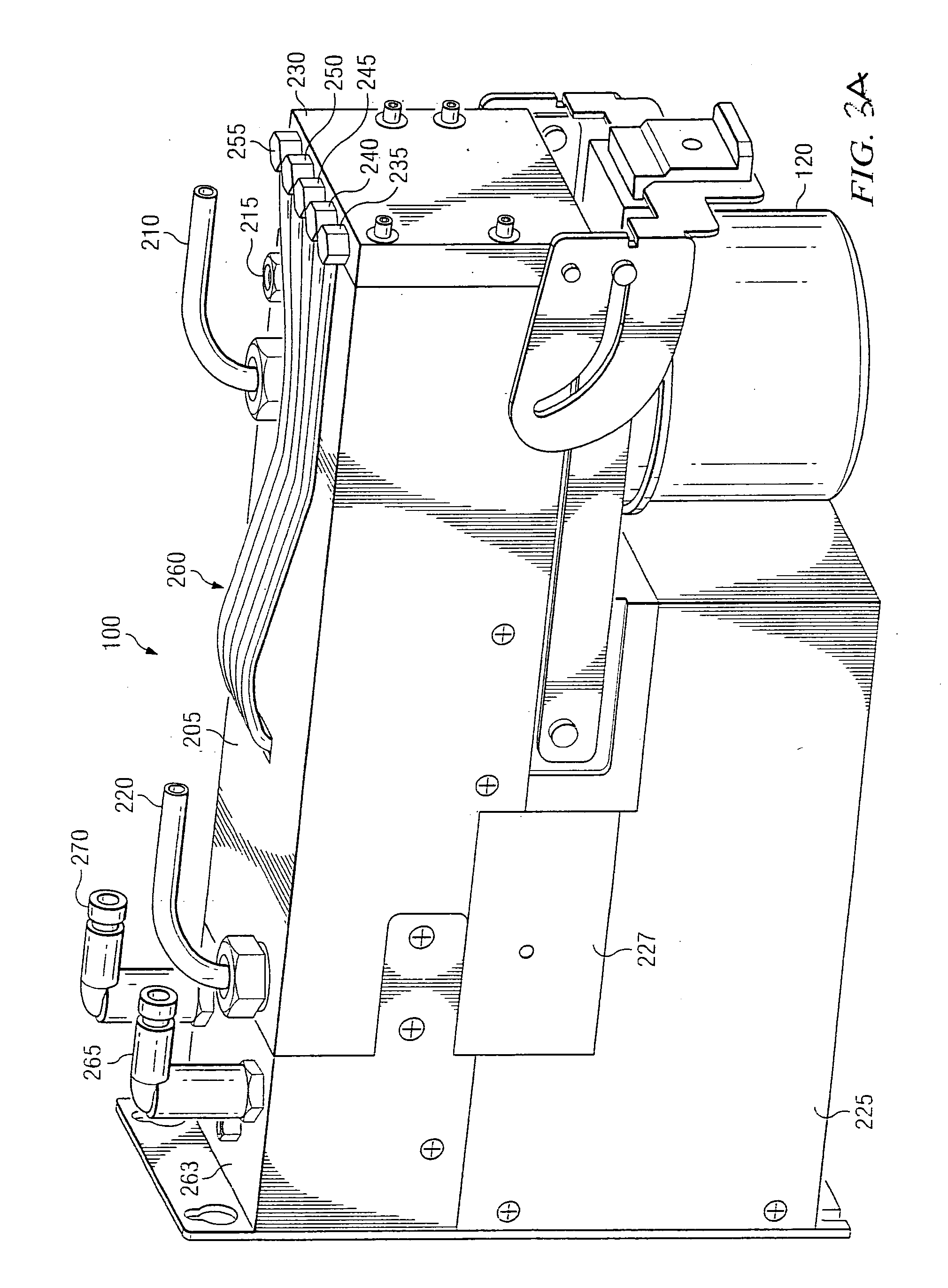

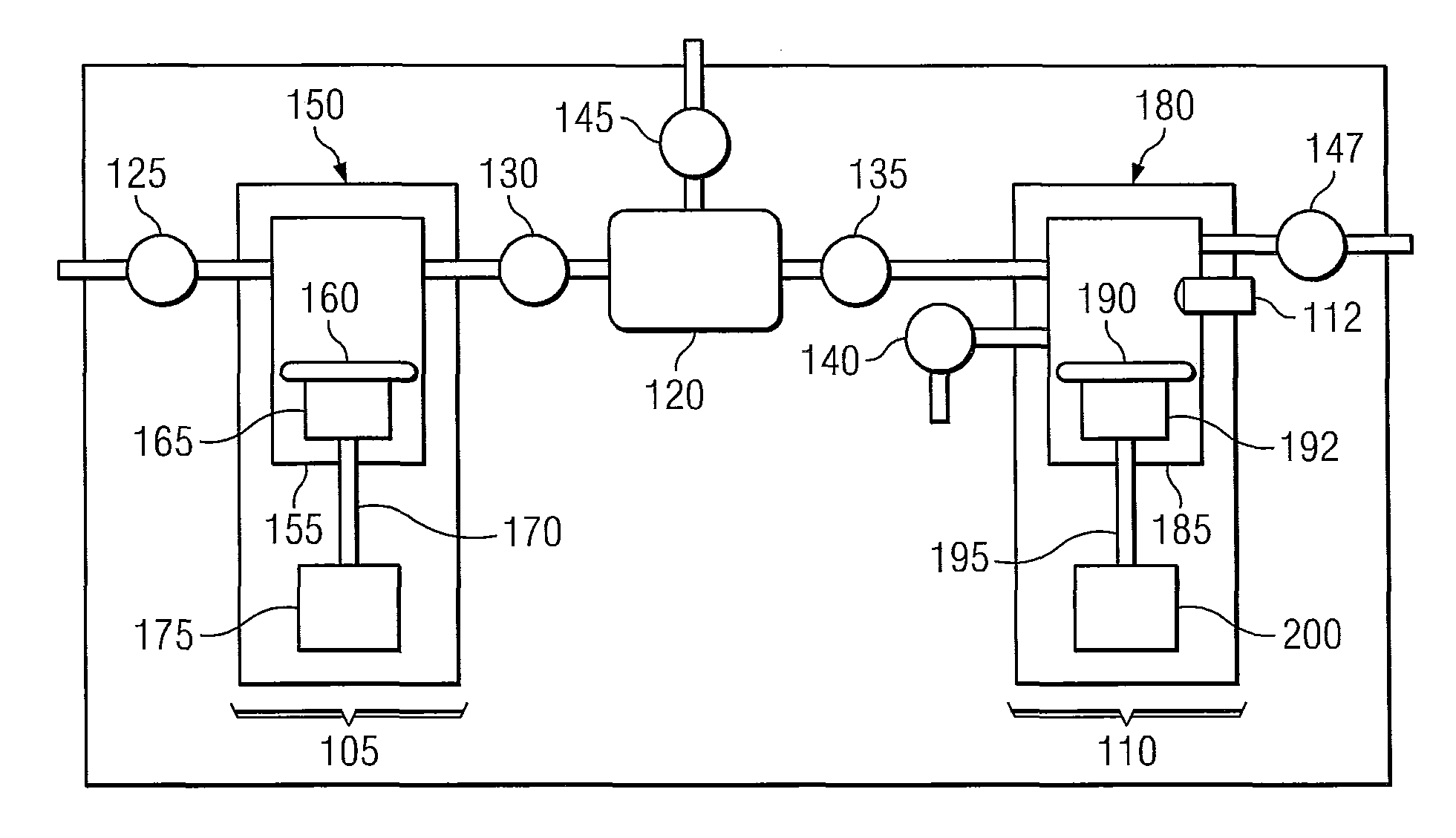

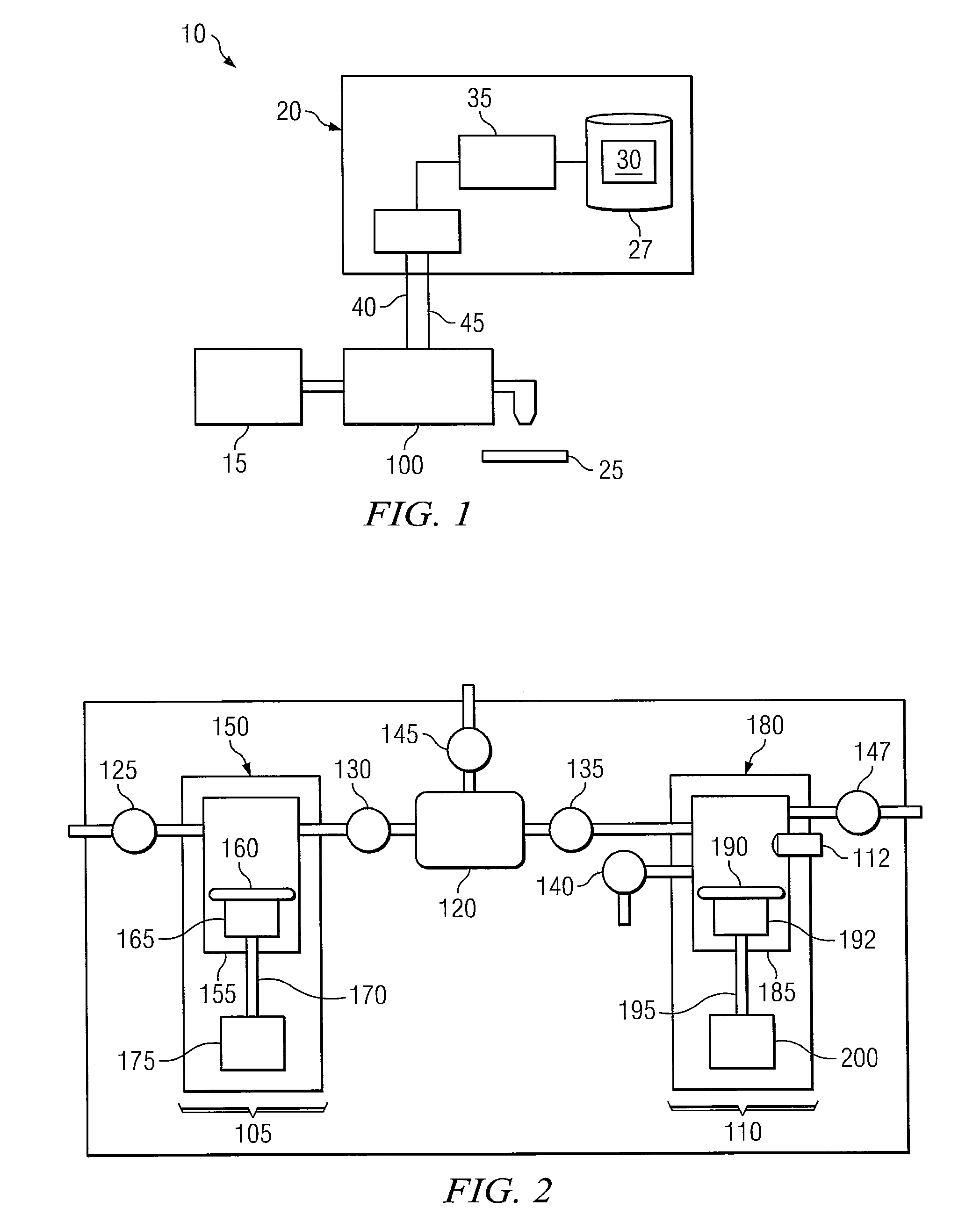

Error volume system and method for a pump

ActiveUS20070125796A1Reduce errorsImprove dispensing accuracyLayered productsPretreated surfacesBiomedical engineering

Owner:ENTEGRIS INC

Error volume system and method for a pump

ActiveUS7897196B2Reduce errorsImprove dispensing accuracyLayered productsPretreated surfacesEngineeringMechanical engineering

Owner:ENTEGRIS INC

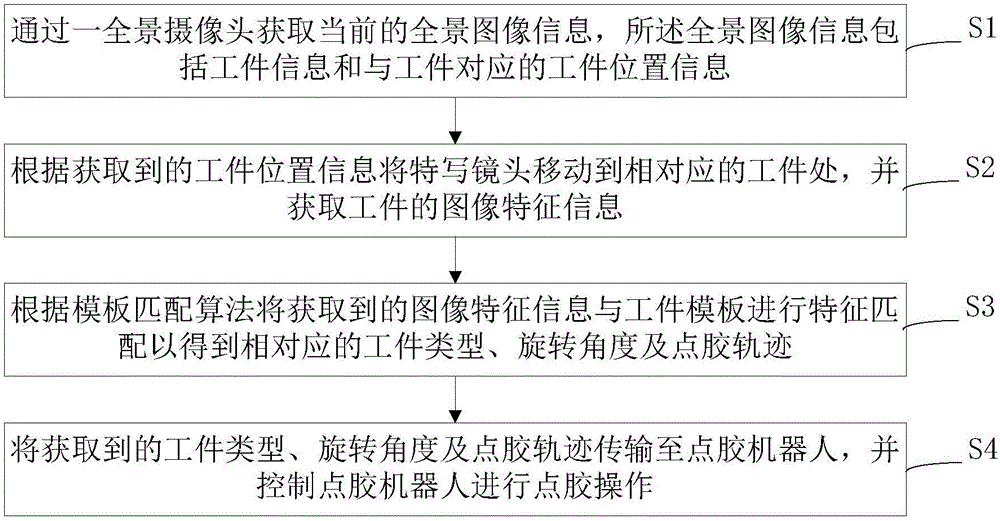

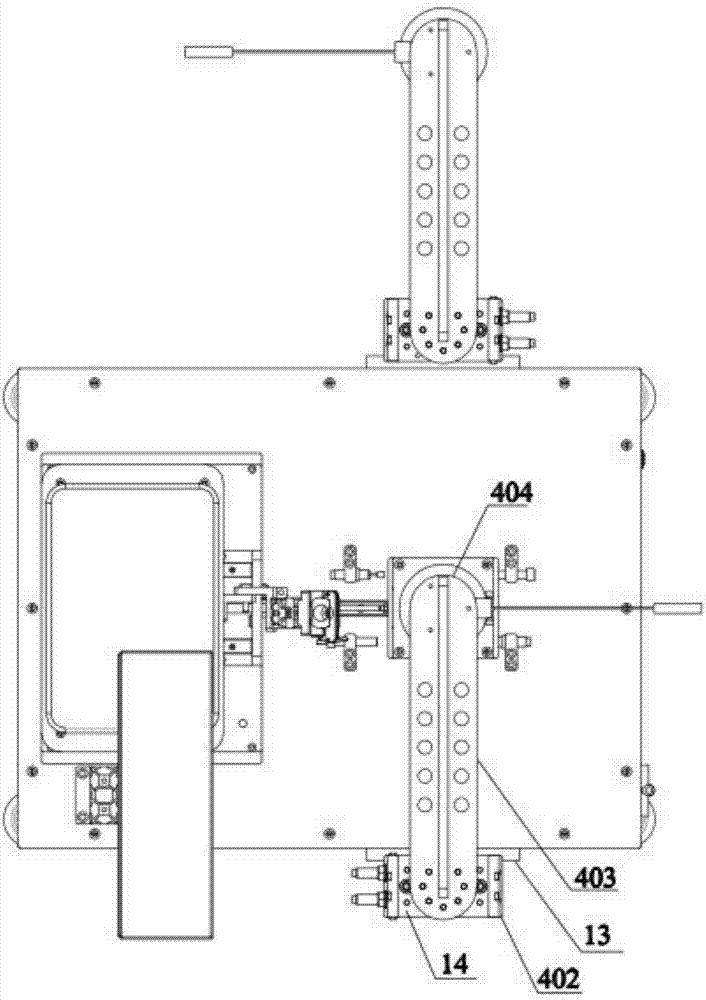

Automatic dispensing method and device based on double cameras

InactiveCN106733525AImprove adaptabilitySkip the pre-positioningLiquid surface applicatorsCoatingsTemplate matchingImaging Feature

The invention discloses an automatic dispensing method and device based on double cameras. The method comprises the following steps: S1: through a panoramic camera, obtaining current panoramic image information, wherein the panoramic image information comprises workpiece information and workpiece position information corresponding to a workpiece; S2: according to the obtained workpiece position information, moving a close-up shot to the corresponding workpiece, and obtaining image feature information of the workpiece; S3: according to a template matching algorithm, carrying out feature matching on the obtained image feature information and a workpiece template to obtain a corresponding workpiece type, rotary angle and dispensing trajectory; S4: transmitting the obtained workpiece type, rotary angle and dispensing trajectory to a dispensing robot, and controlling the dispensing robot to carry out a dispensing operation. According to the intelligent dispensing robot subjected to visual guidance based on the double cameras, the workpiece type can be automatically identified, the dispensing trajectory can be automatically positioned, a mechanical arm is guided to carry out a dispensing operation, and dispensing quality is automatically identified.

Owner:杭州力视科技有限公司

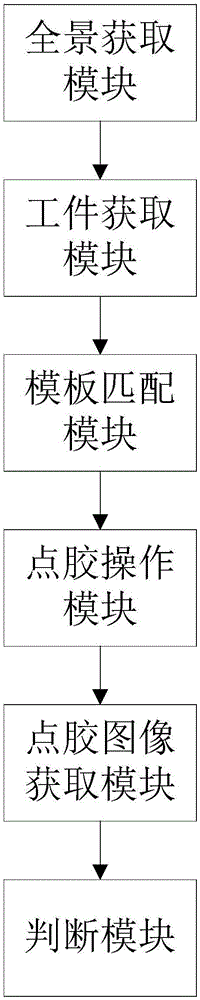

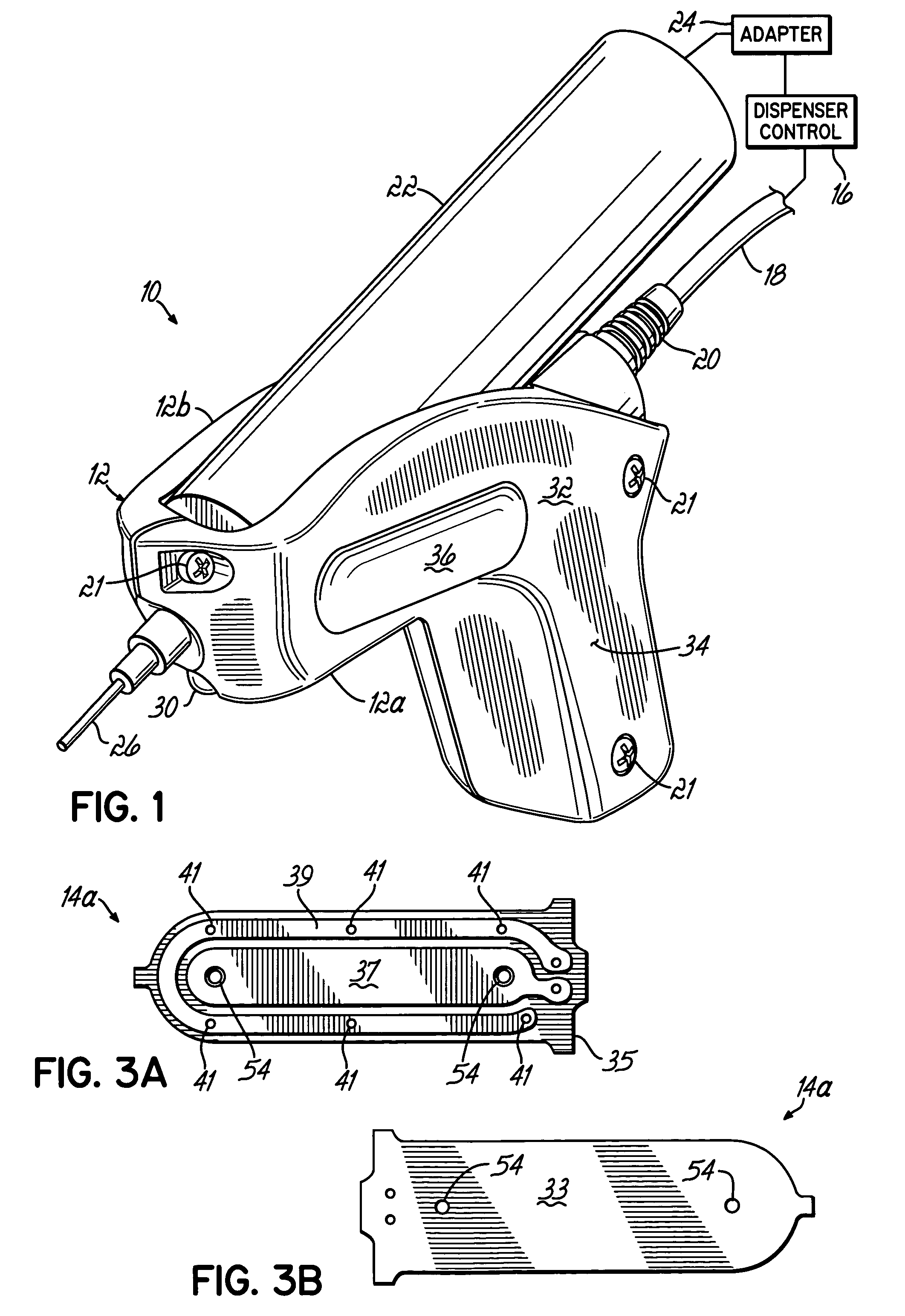

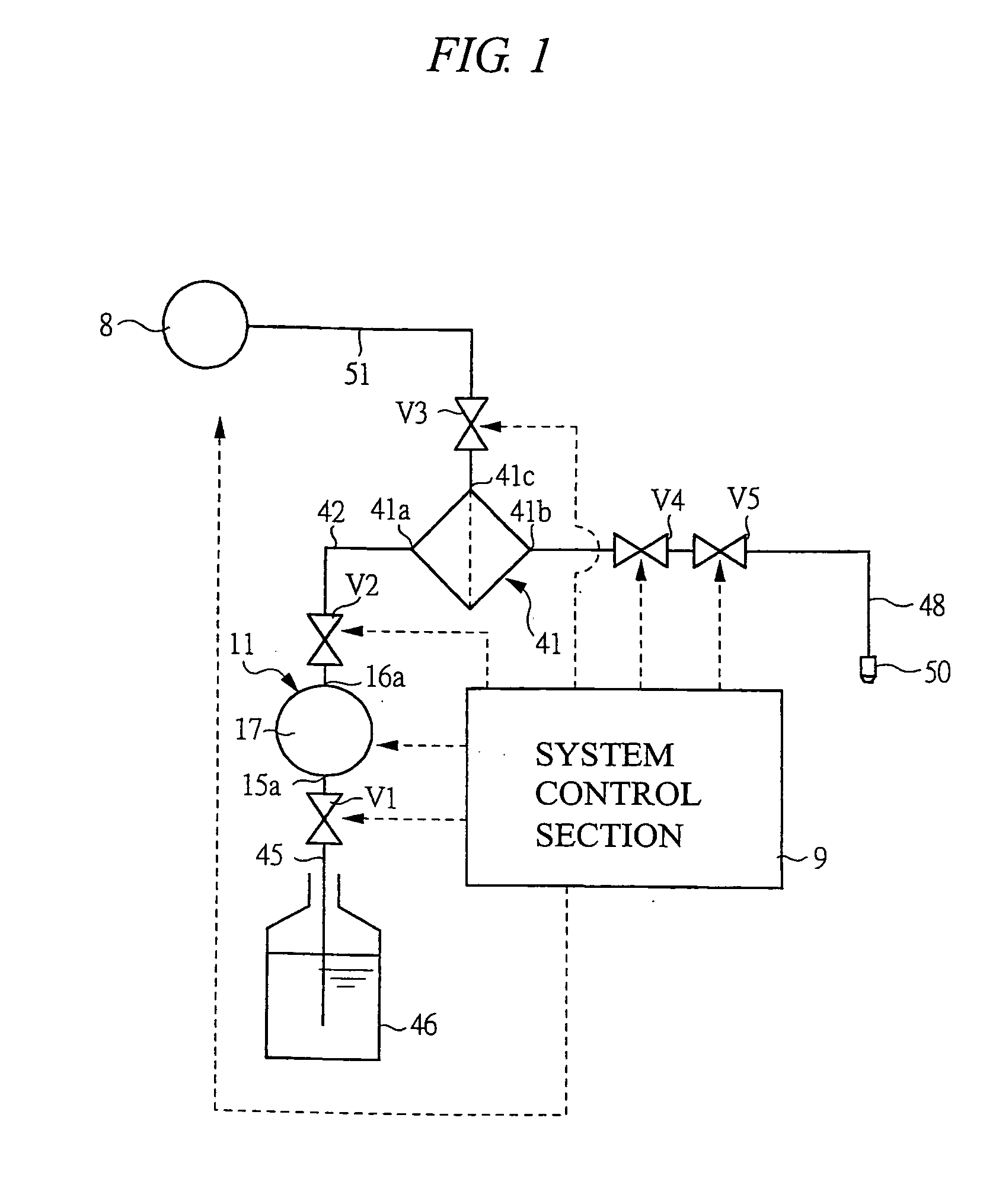

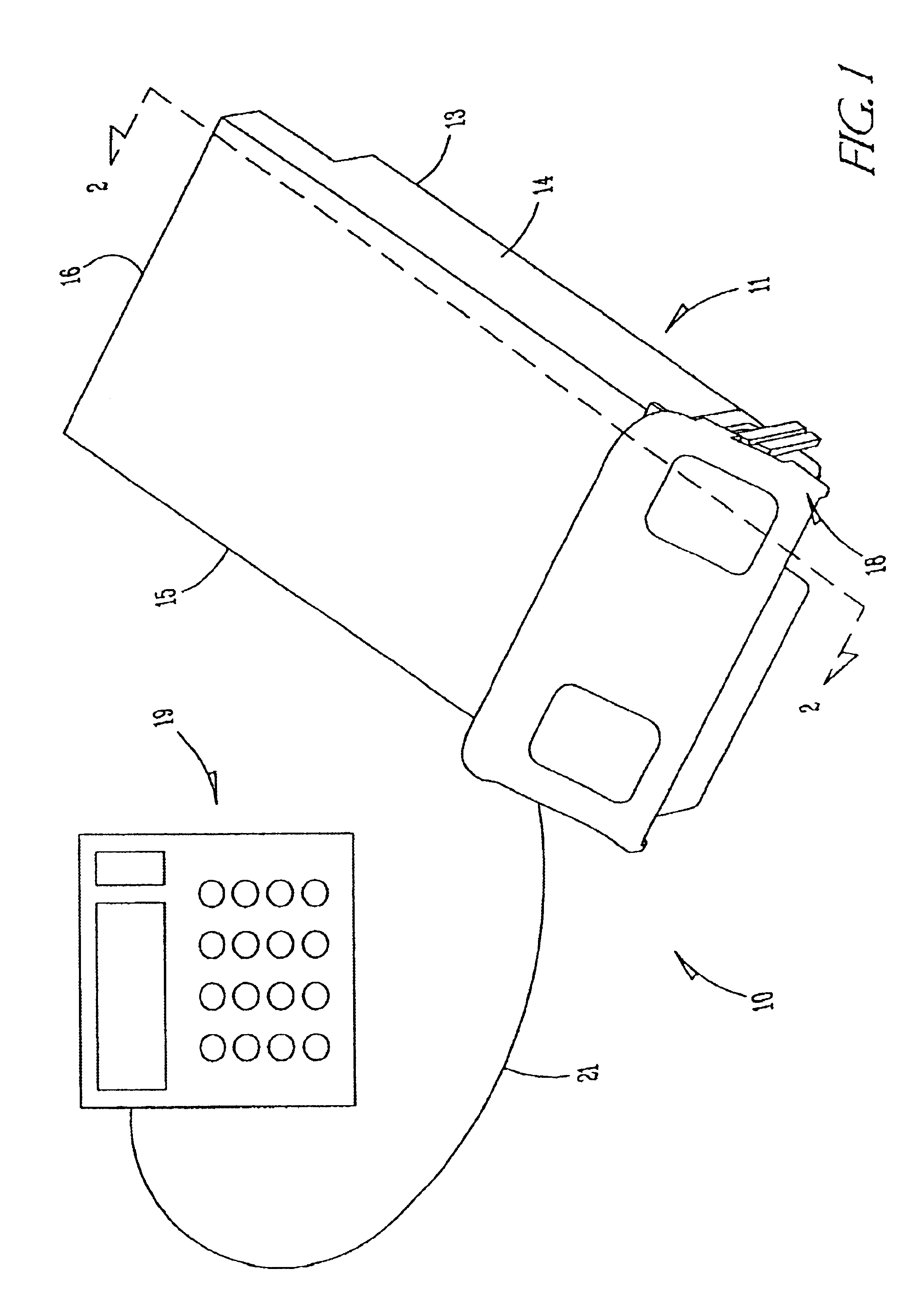

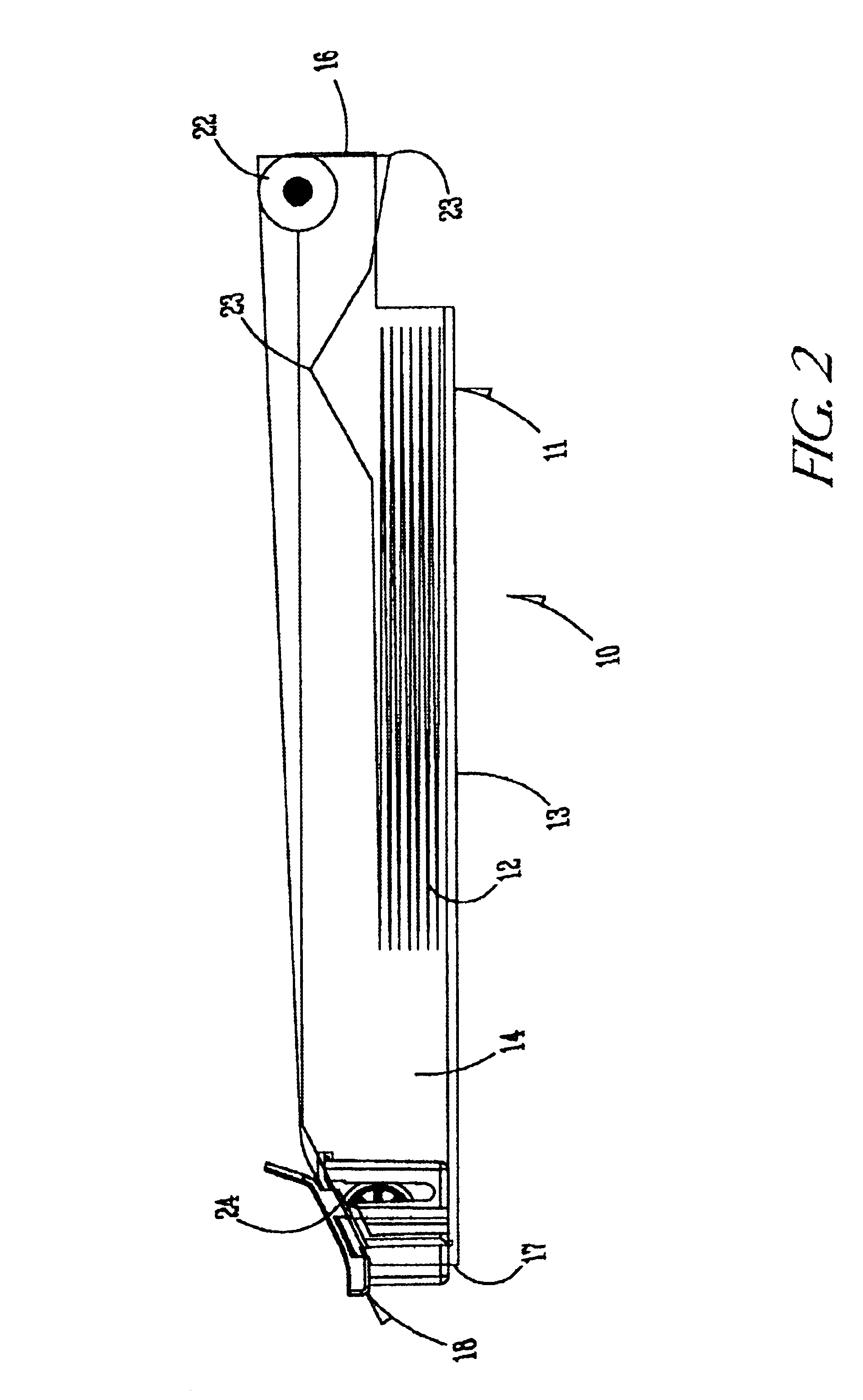

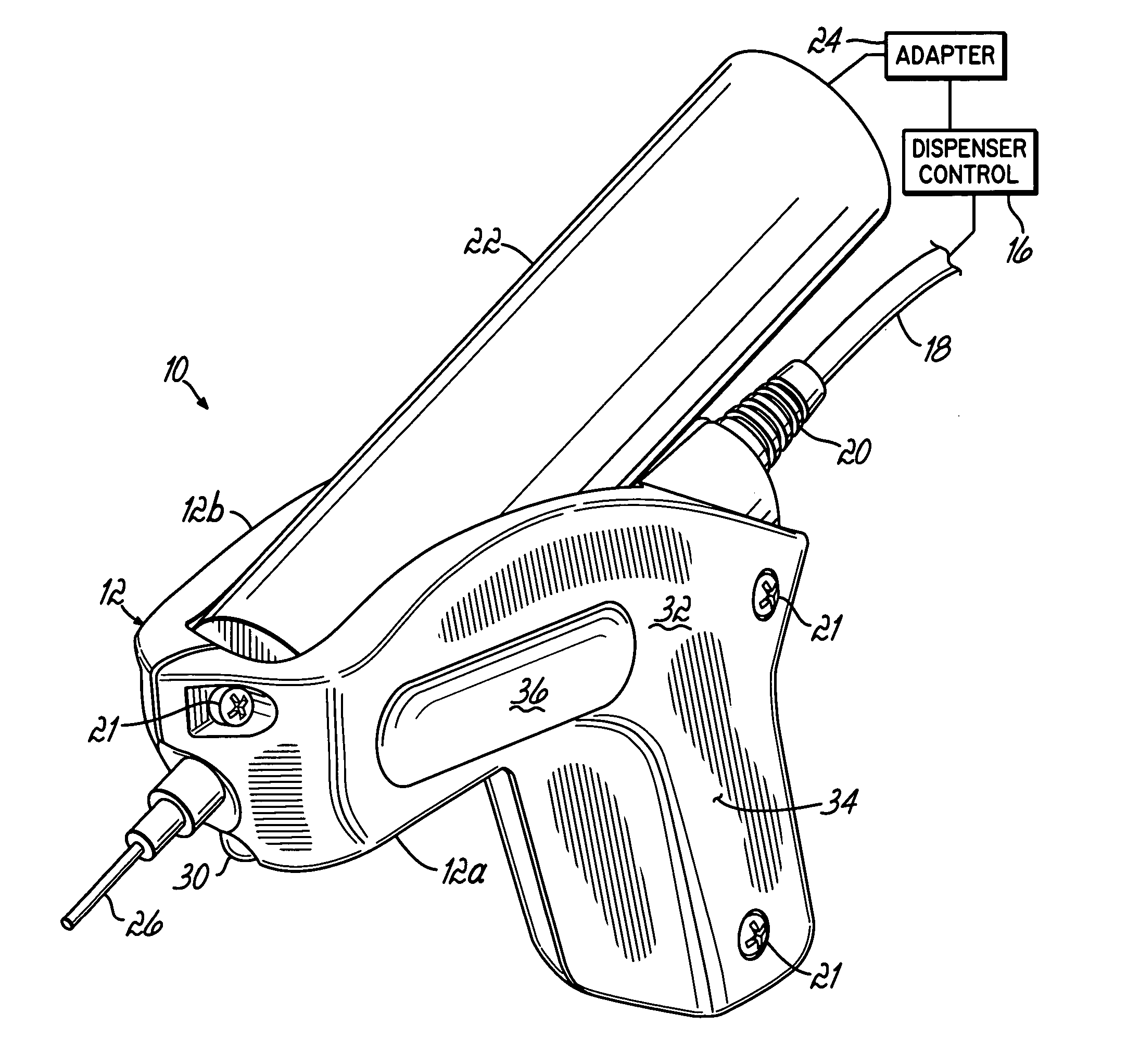

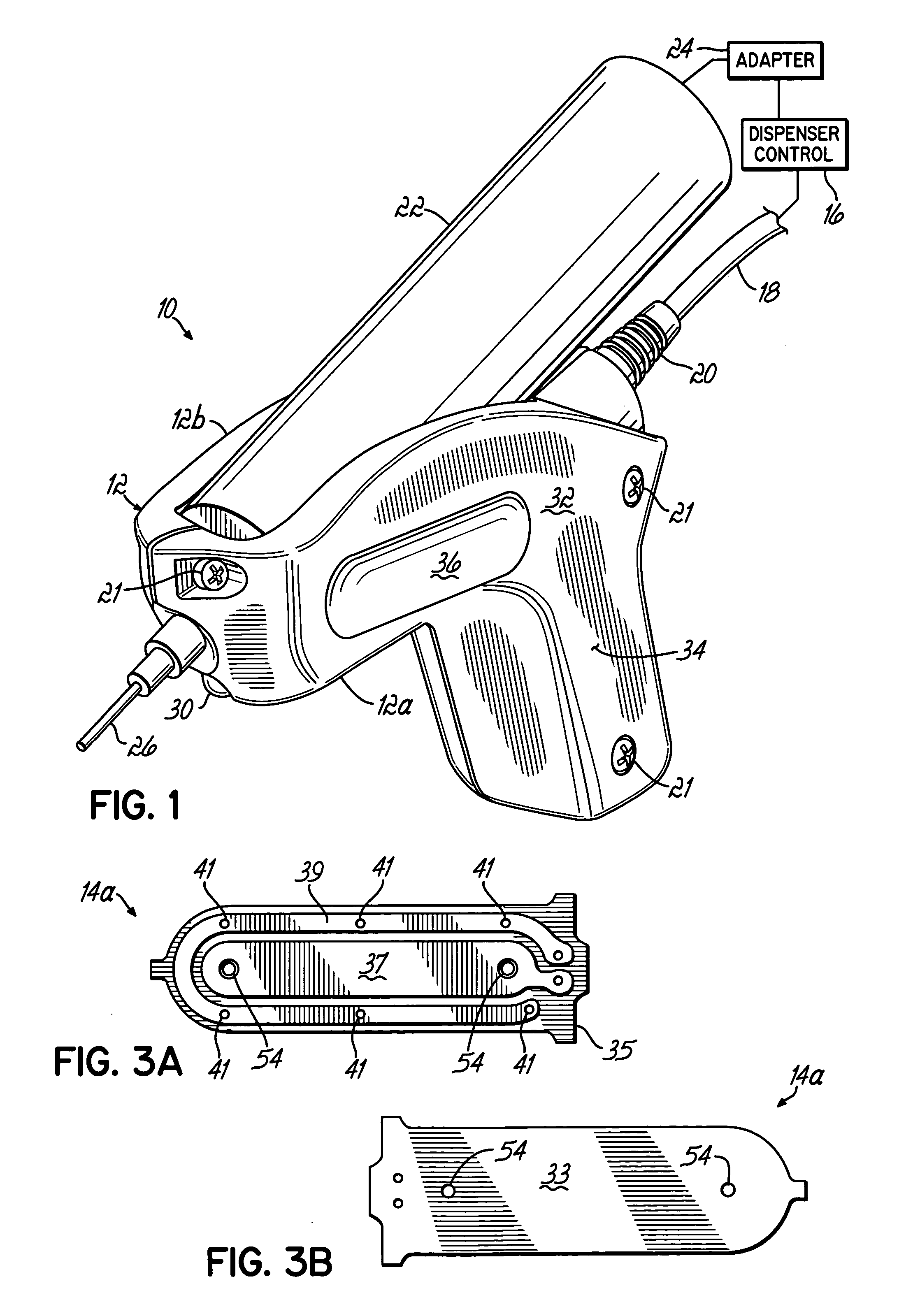

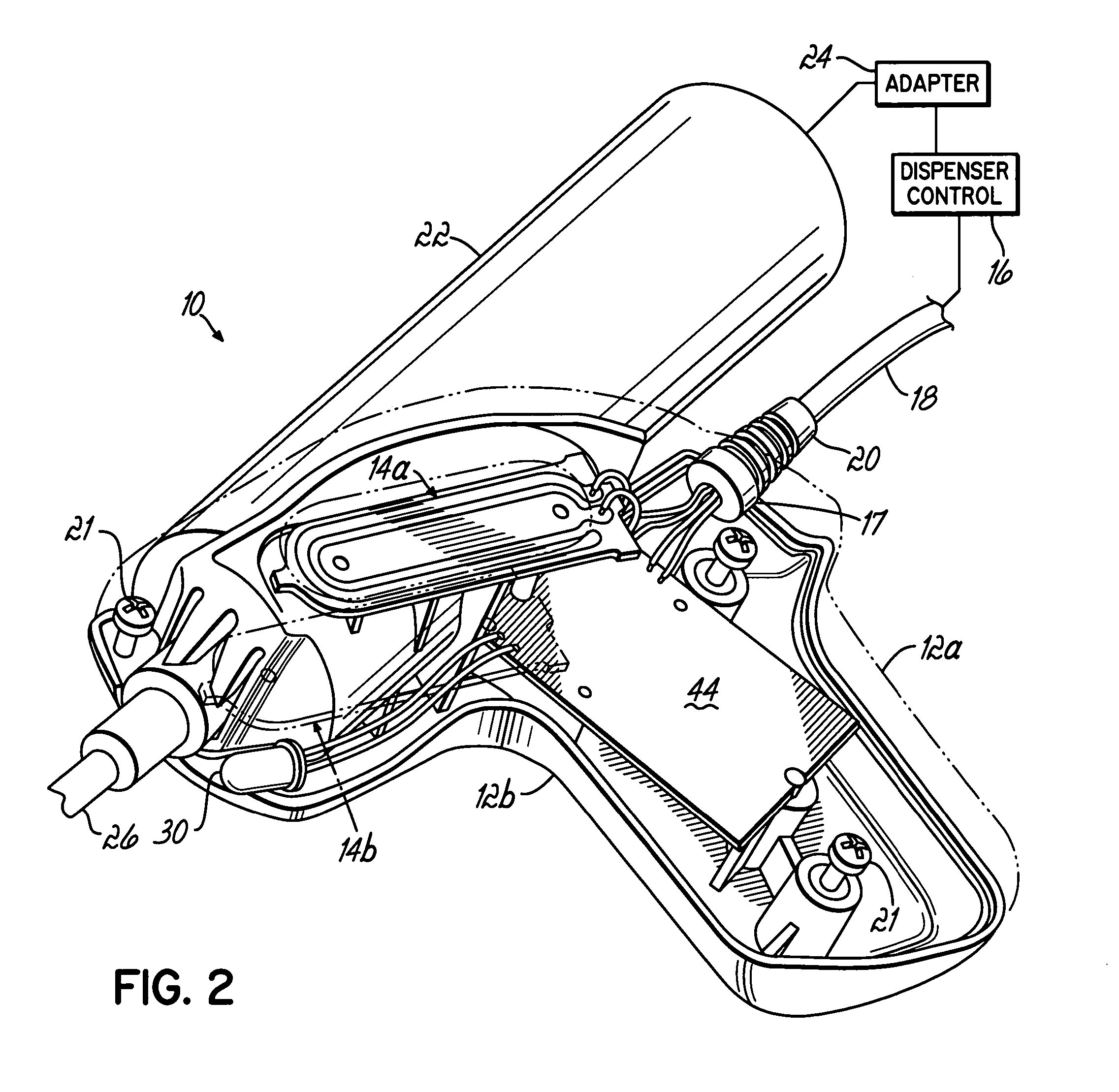

Hand-held fluid dispenser system and method of operating hand-held fluid dispenser systems

InactiveUS6938795B2Improved hand gripReduce stress and fatigueOpening closed containersBottle/container closureProximity sensorHand held

Owner:NORDSON CORP

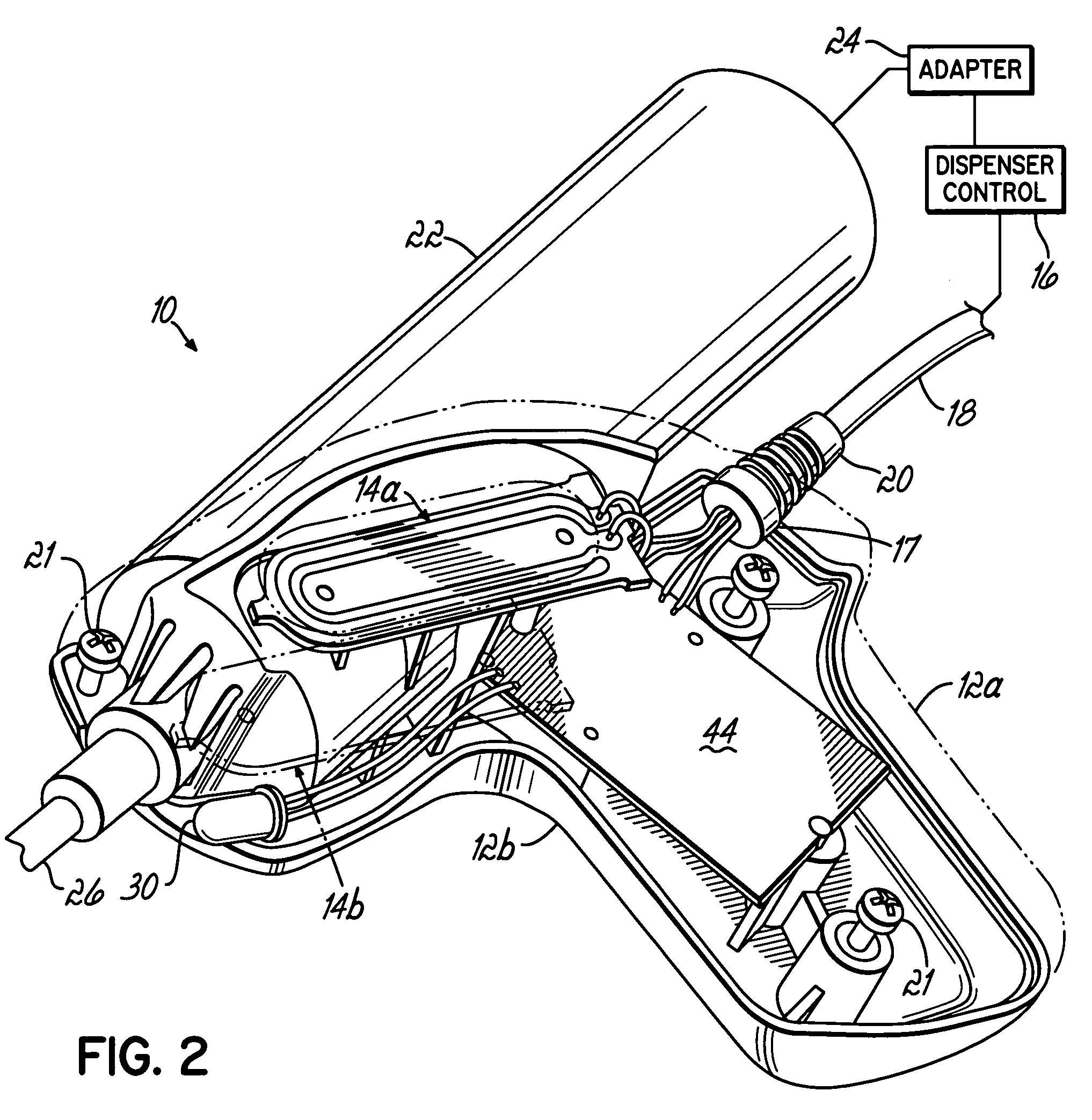

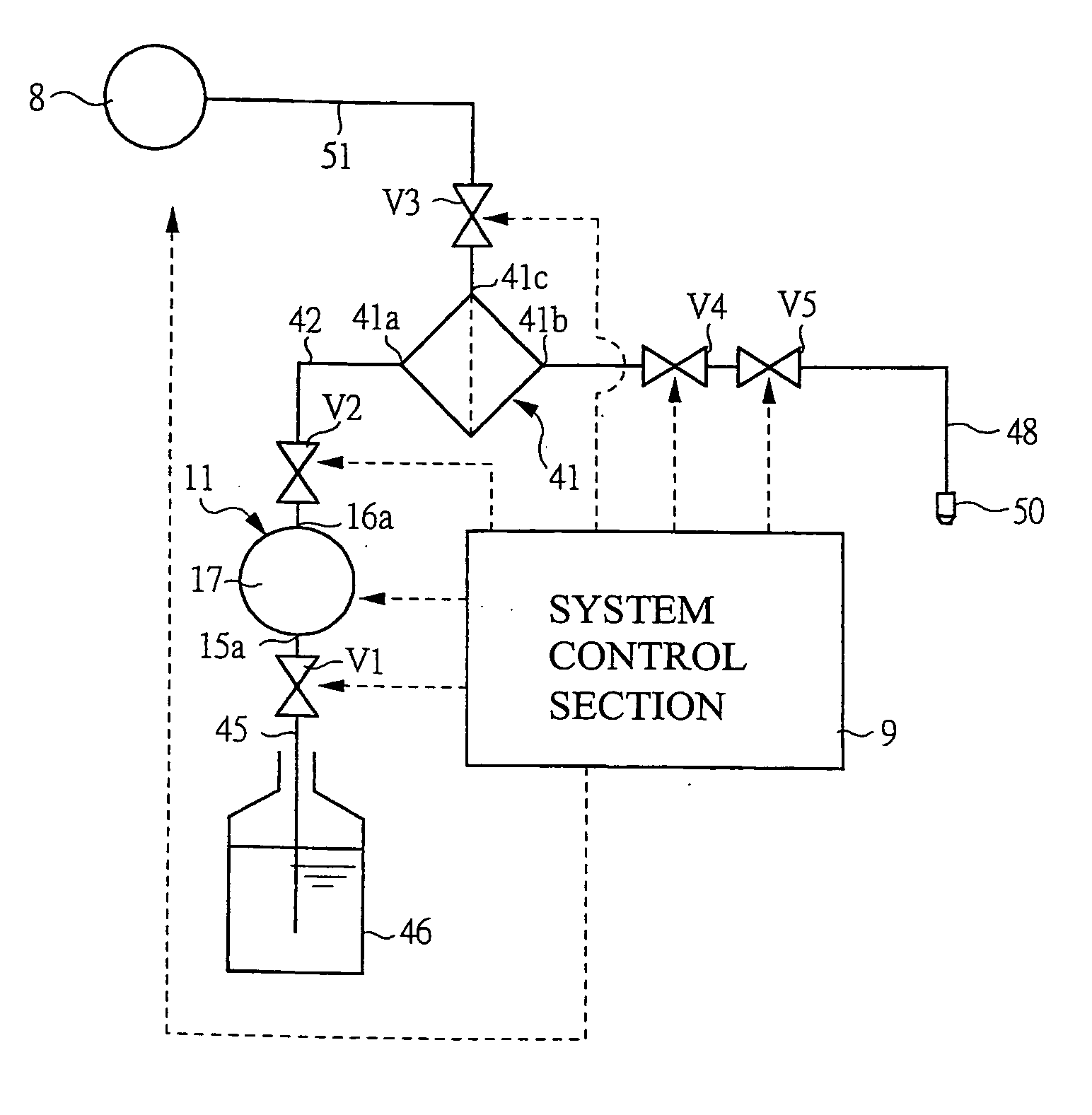

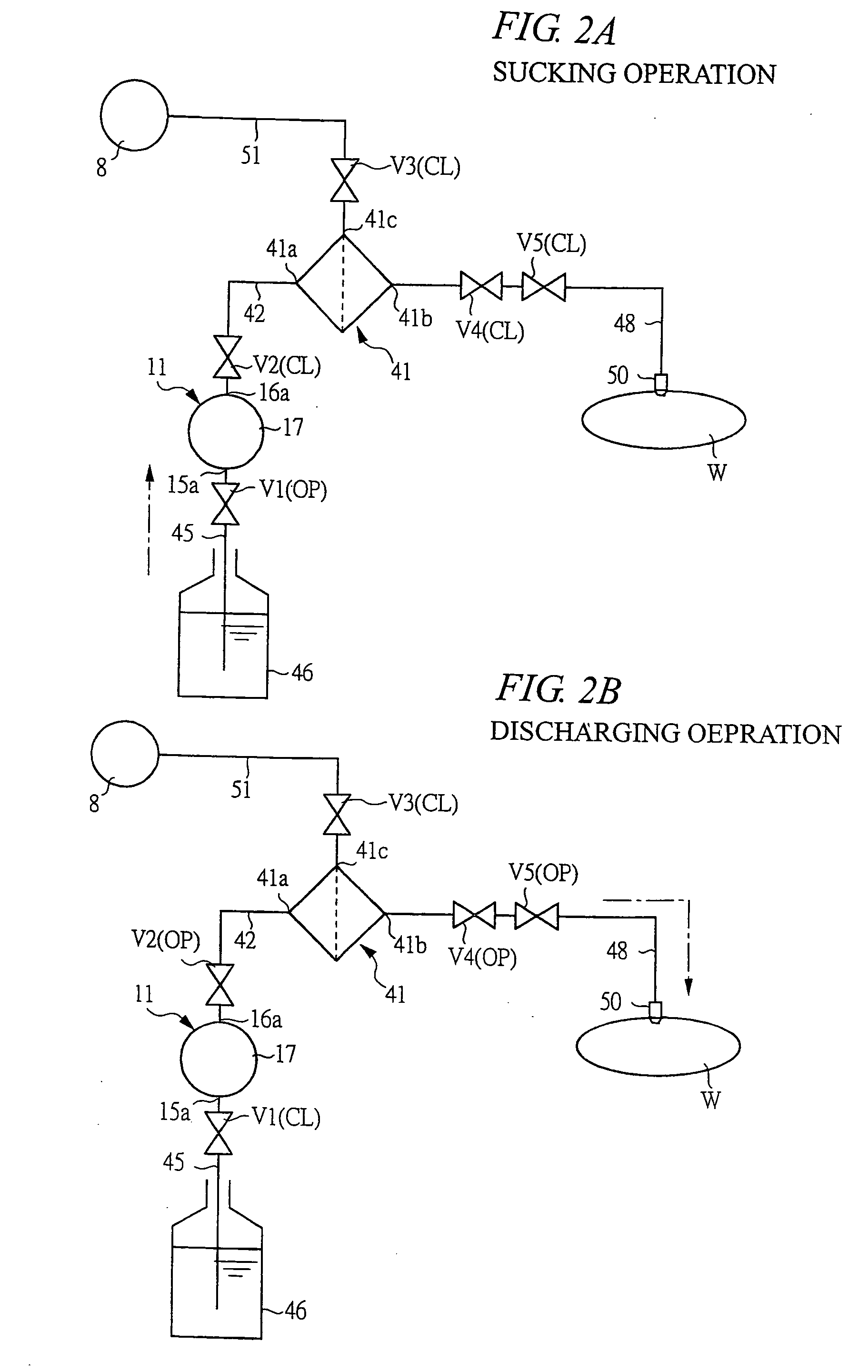

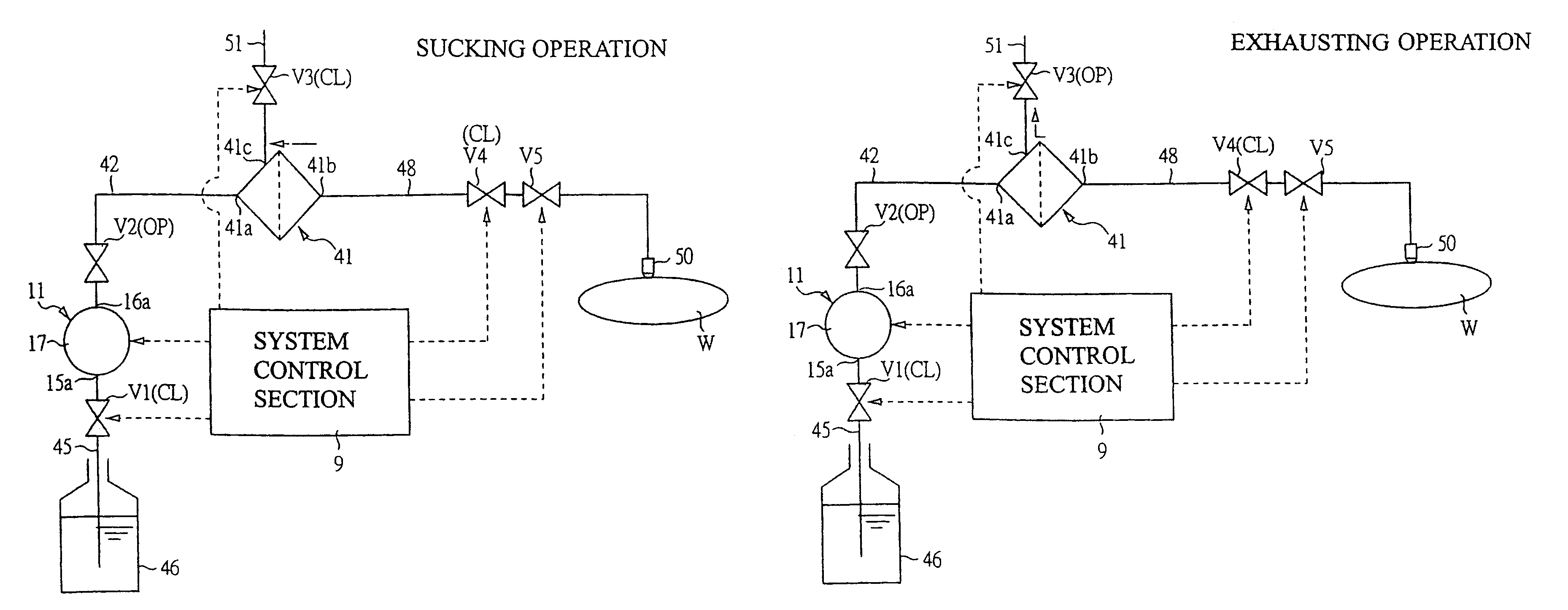

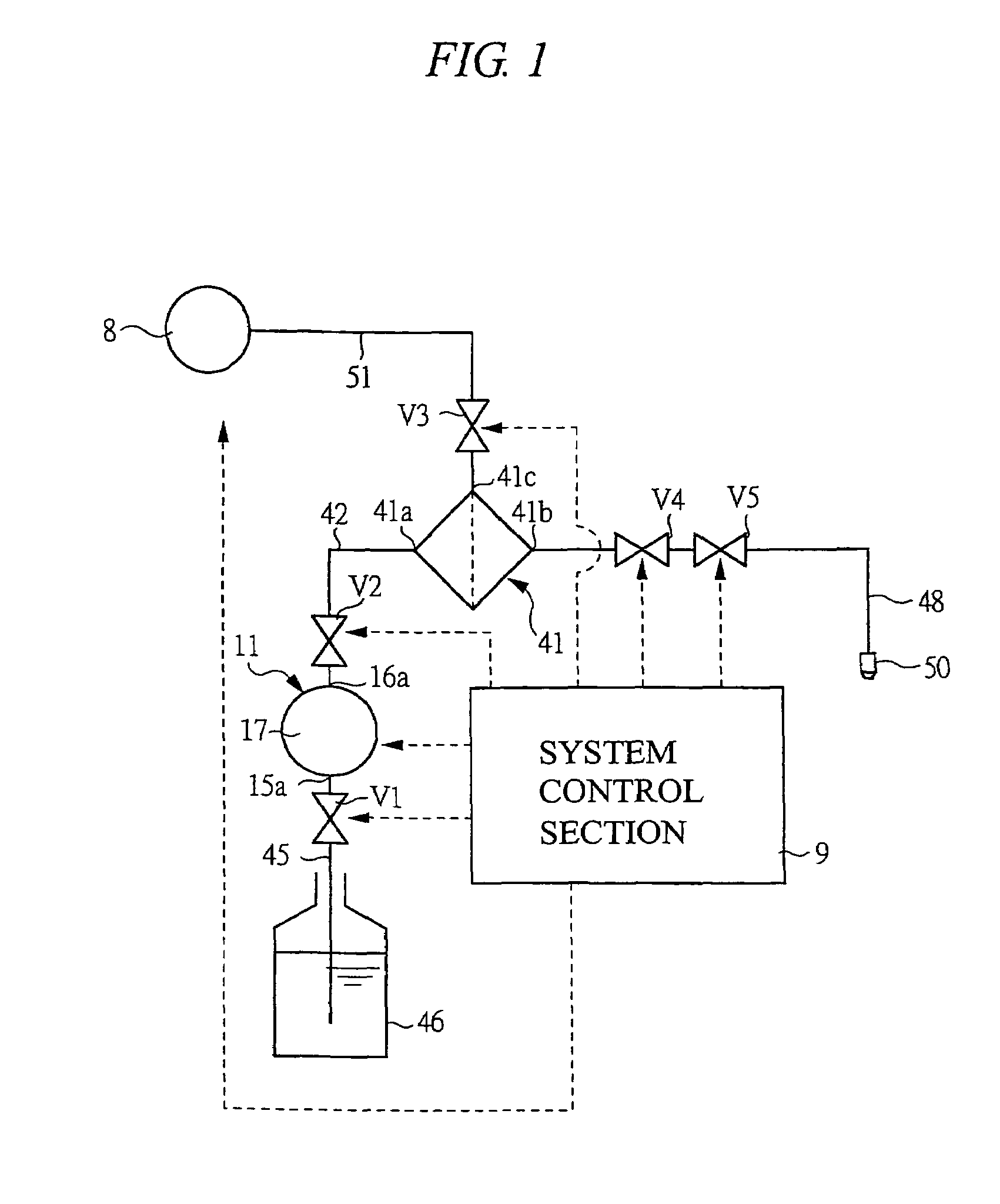

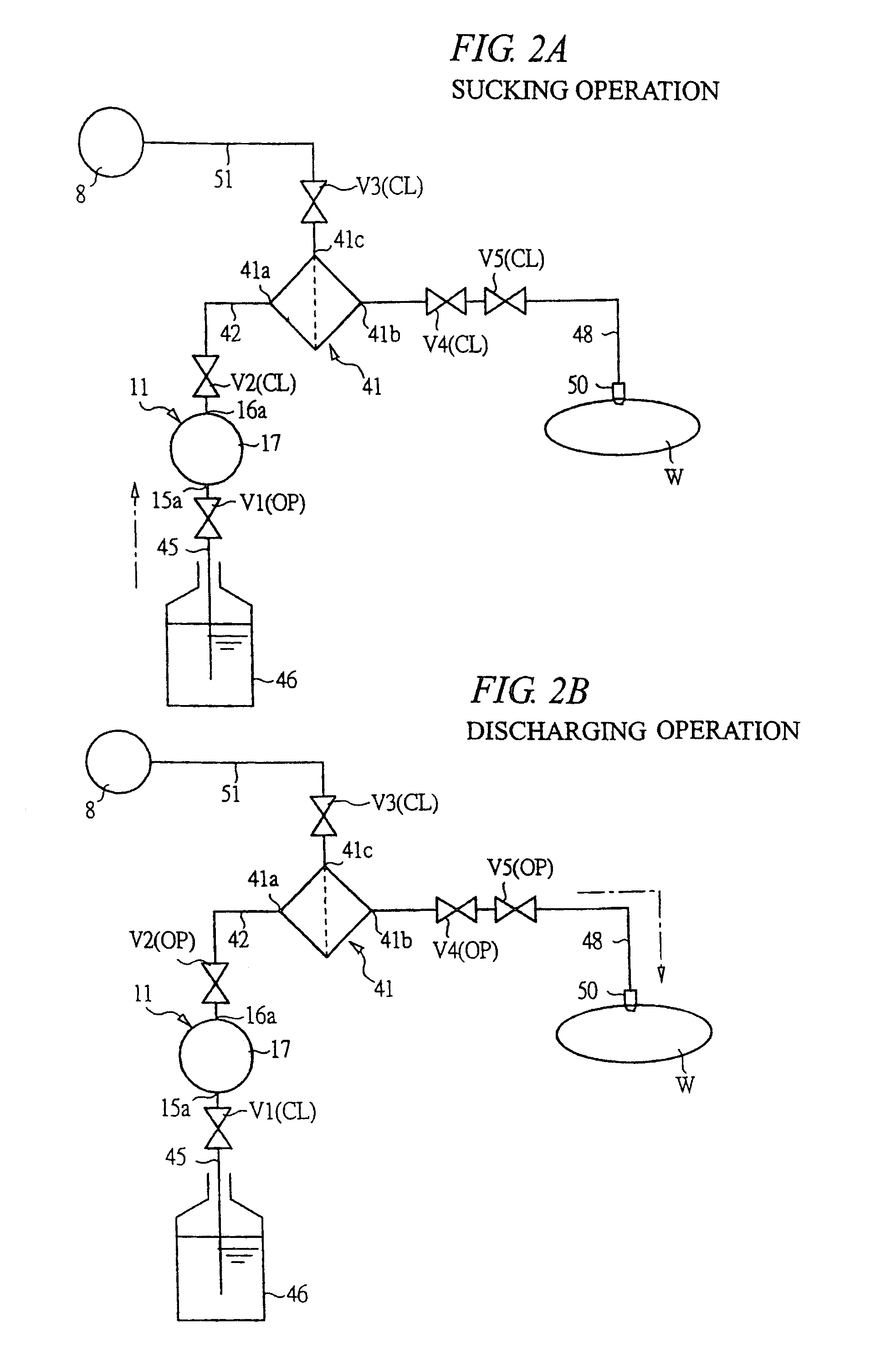

Liquid medicine supplying device and method for venting air from liquid medicine supplying device

InactiveUS20050175472A1Improve dispensing accuracyQuality improvementLiquid surface applicatorsFlexible member pumpsCompound (substance)Engineering

The amount of chemical liquids dispensed by a chemical liquid supply apparatus is stabilized and dispensing accuracy is remarkably improved. A pump discharges a liquid accommodated in a liquid tank. A filter is connected to the pump through a pump outlet flow path to which a pump discharge-side valve for opening / closing the flow path is provided. A dispensing nozzle (liquid dispense portion) is connected to the filter through a liquid discharge flow path to which a discharge valve for opening / closing the flow path is provided. A vacuum source communicates with the filter through an exhaust flow path to which a deaeration valve for opening / closing the flow path is provided.

Owner:KOGANEI

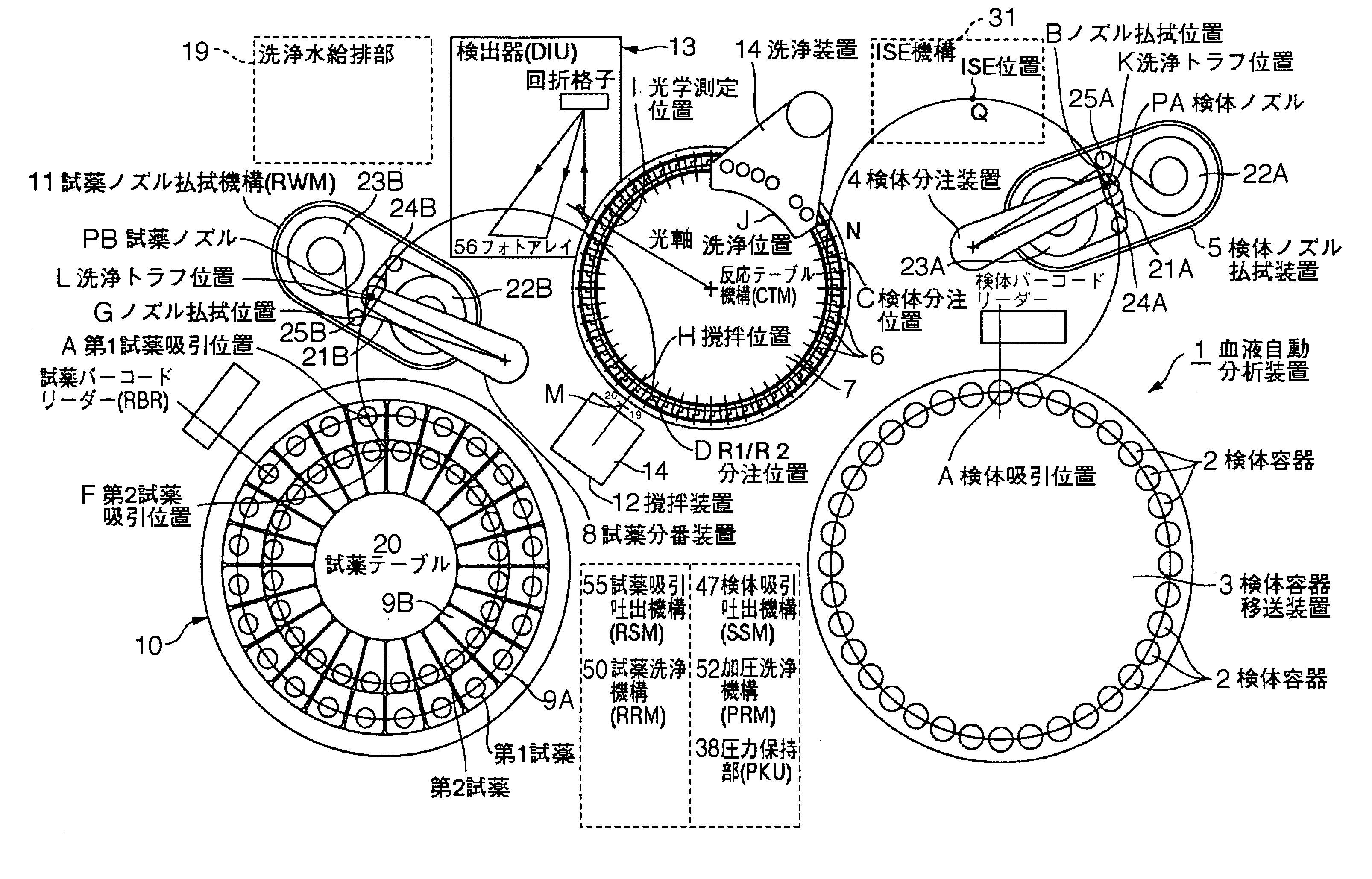

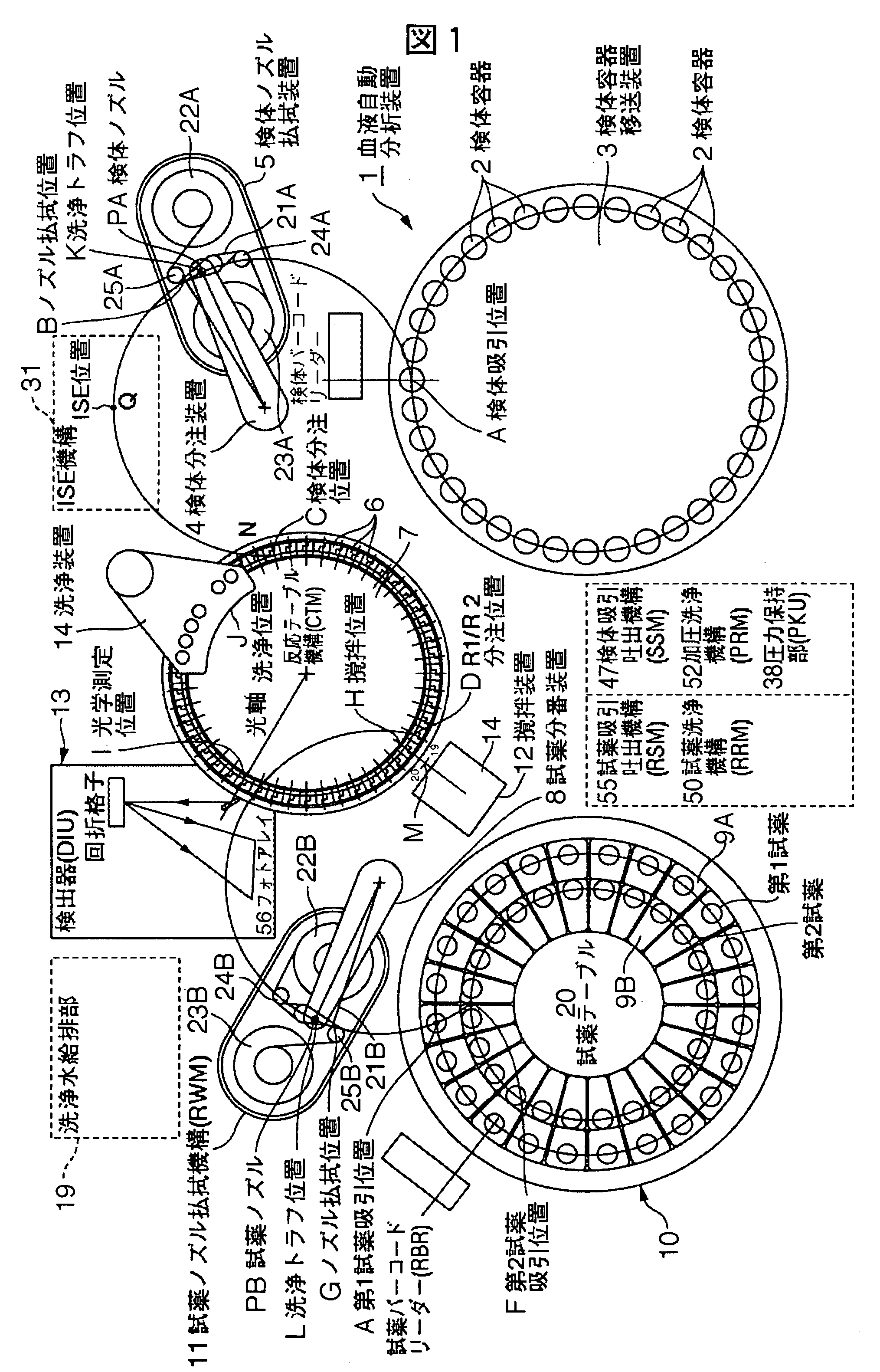

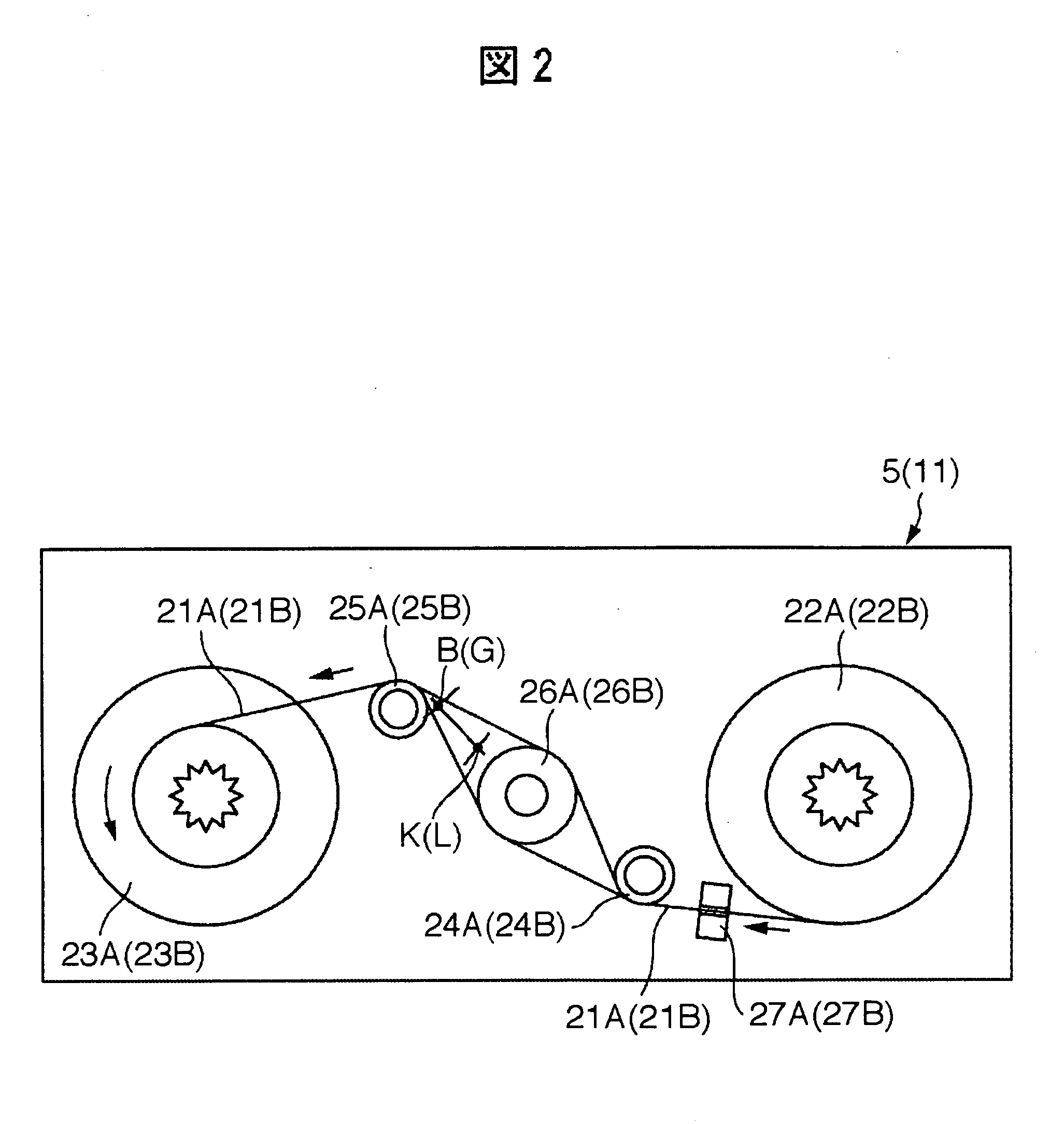

Automatic blood analyzer

InactiveUS20070166194A1Accurately controlMeasure of reliabilityMaterial analysis by optical meansBiological testingSyringeBiomedical engineering

This relates to an automatic blood analyzer that enables to test many items by using a small quantity of blood from infants and critically ill patients that is not possible for tests by conventional automatic blood analyzers, and obtains highly accurate measured data useful for early curative effect. Between the sample nozzle of the sample dispensing device and the washing water supply line, two dispensing lines of a dispensing line by a micro syringe that performs dispensing of more than a prescribed quantity and a pressure dispensing line that performs dispensing of less than a prescribed quantity, and a wipeout device that wipes out the outer surface of each dispensing nozzle are placed before and after a working of dispensing of the sample and the reagent.

Owner:NITTEC CO LTD

Sealing piston for syringe

InactiveUS20050043689A1Efficiency problemImprove dispensing accuracyIntravenous devicesEngineeringPiston

The present invention is directed to a sealing piston for syringe. The sealing piston includes a first sealing element, a second sealing element, and a third sealing element. The second sealing element is elastic and expandable. One end surface of the second sealing element is connected with the first sealing element, and another end surface of the second sealing element is connected with the third sealing element for constraining the second sealing element. The present invention not only effectively resolves the air-leakage problem of a conventional syringe, but also enhances dispensing accuracy.

Owner:LITE ON IT

Ticket counting dispenser

InactiveUS6871755B2Accurate countImprove accuracyCoin-freed apparatus detailsFunction indicatorsOptical sensingMechanical engineering

A storage, display and dispensing apparatus for tickets of various sizes that accounts for the tickets dispensed during a selected time period. The apparatus includes a bin housing for storing a pack of tickets, a ticket dispensing assembly through which the tickets are dispensed and includes a friction wheel assembly that is actuated as tickets pass through the ticket dispensing assembly. An optical sensing element is also employed to sense indicia on the tickets to coact with the friction wheel assembly to provide a ticket count.

Owner:SCHAFER SYST

Chemical liquid apparatus and deaerating method

InactiveUS7594801B2Improve dispensing accuracyQuality improvementLiquid surface applicatorsFlexible member pumpsExhaust valveLiquid tank

The amount of chemical liquids dispensed by a chemical liquid supply apparatus is stabilized and dispensing accuracy is remarkably improved. A pump discharges a liquid accommodated in a liquid tank. A filter is connected to the pump through a pump outlet flow path to which a pump discharge-side valve for opening / closing the flow path is provided. A dispensing nozzle (liquid dispense portion) is connected to the filter through a liquid discharge flow path to which a discharge valve for opening / closing the flow path is provided. A vacuum source communicates with the filter through an exhaust flow path to which a deaeration valve for opening / closing the flow path is provided.

Owner:KOGANEI

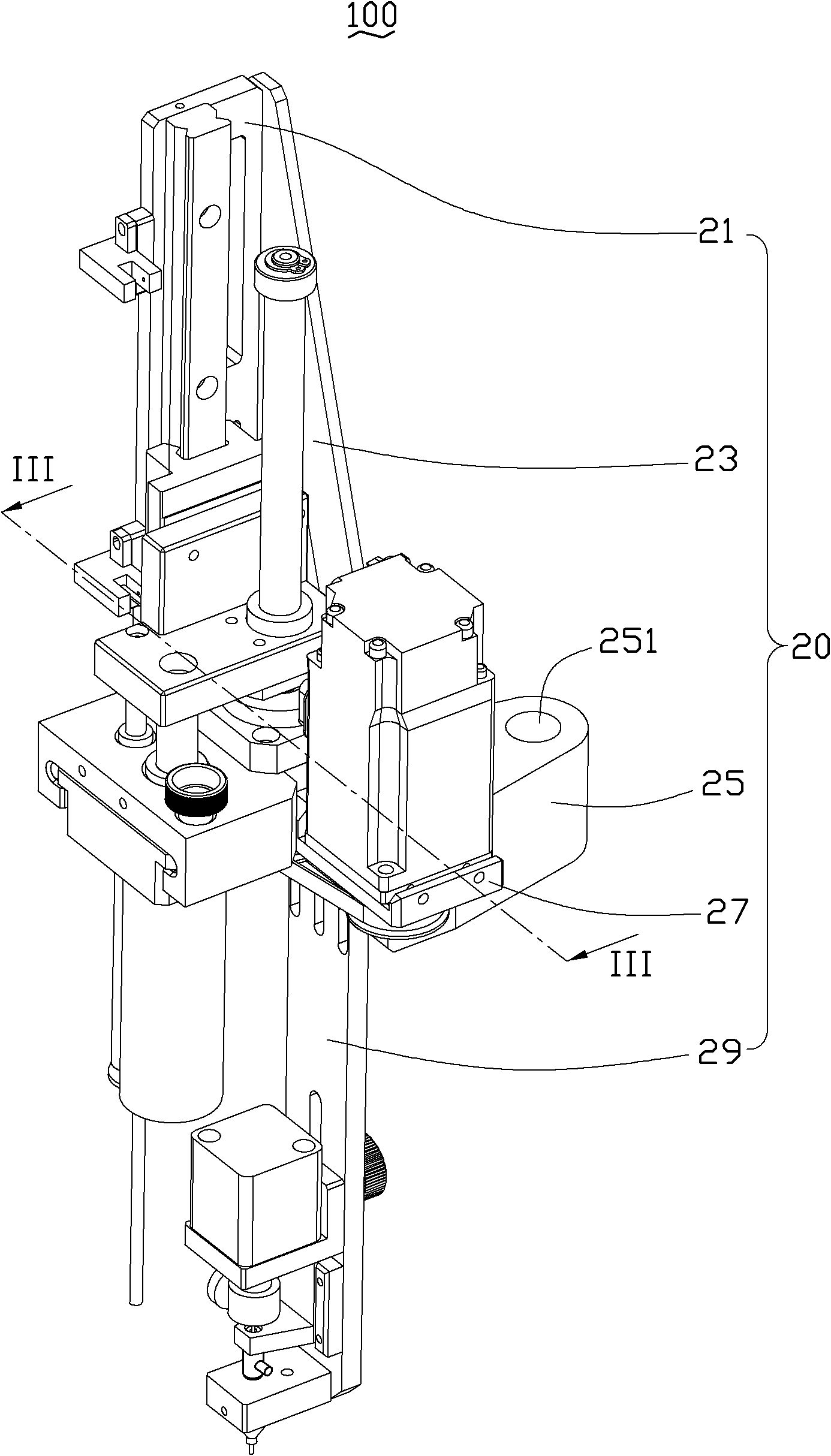

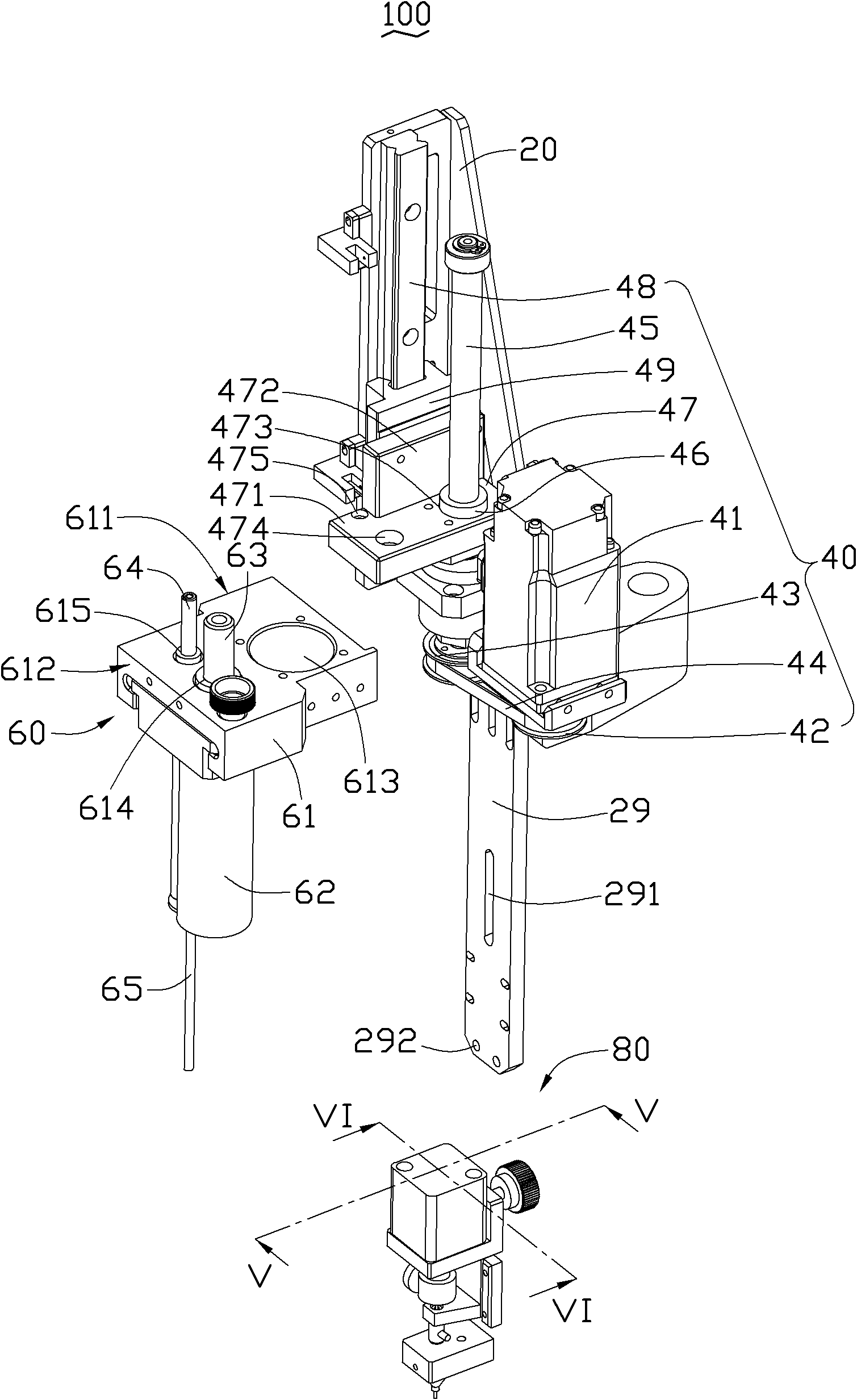

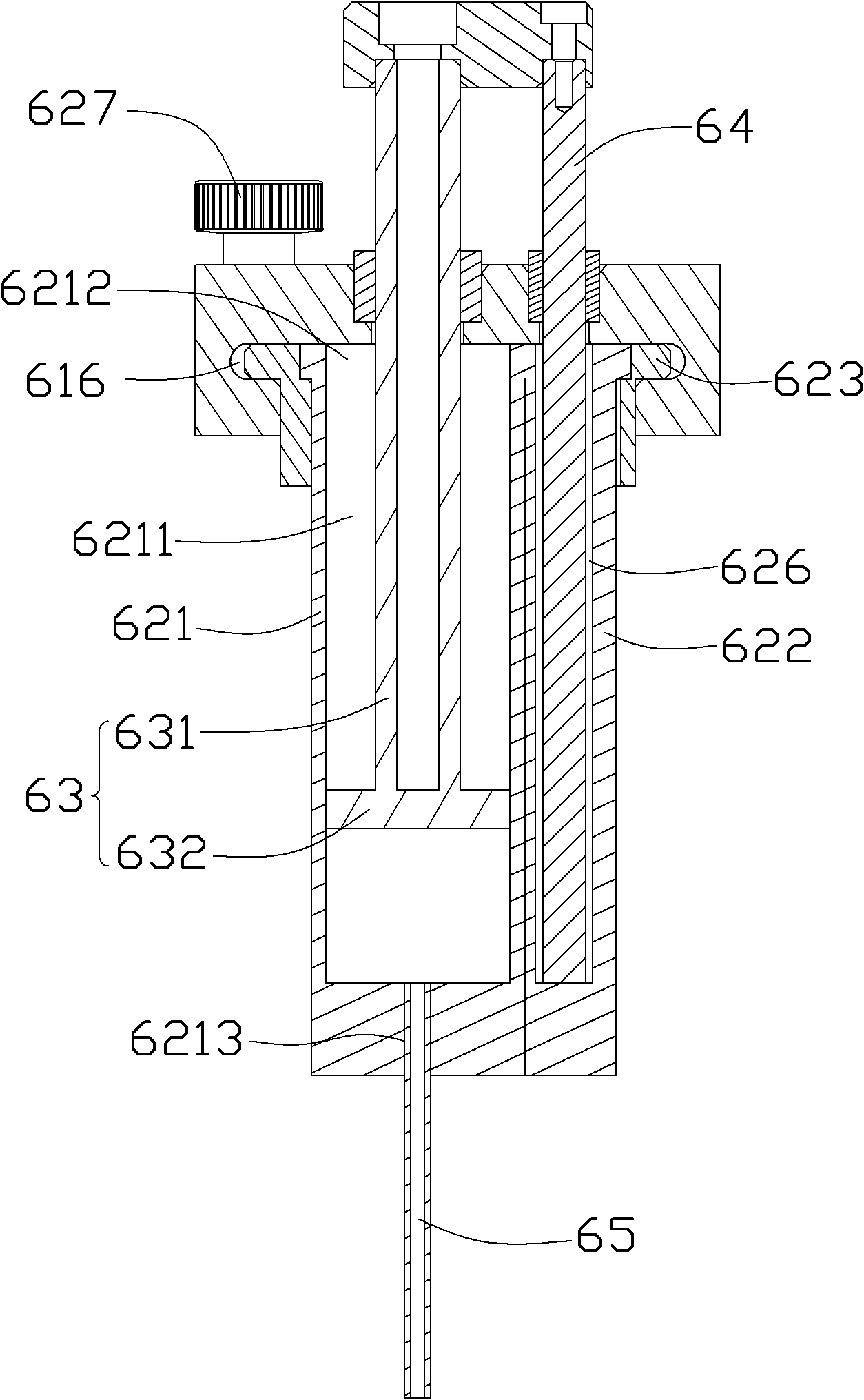

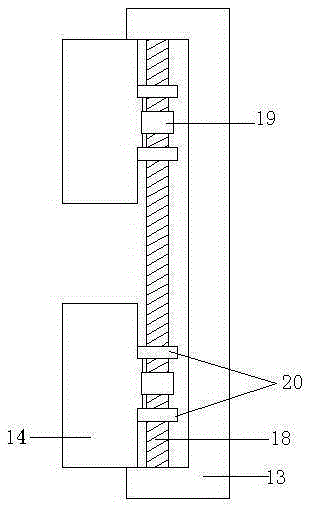

Adhesive dispensing device

InactiveCN102247943AImprove dispensing accuracyFast glue break responseLiquid surface applicatorsCoatingsEngineeringSyringe needle

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

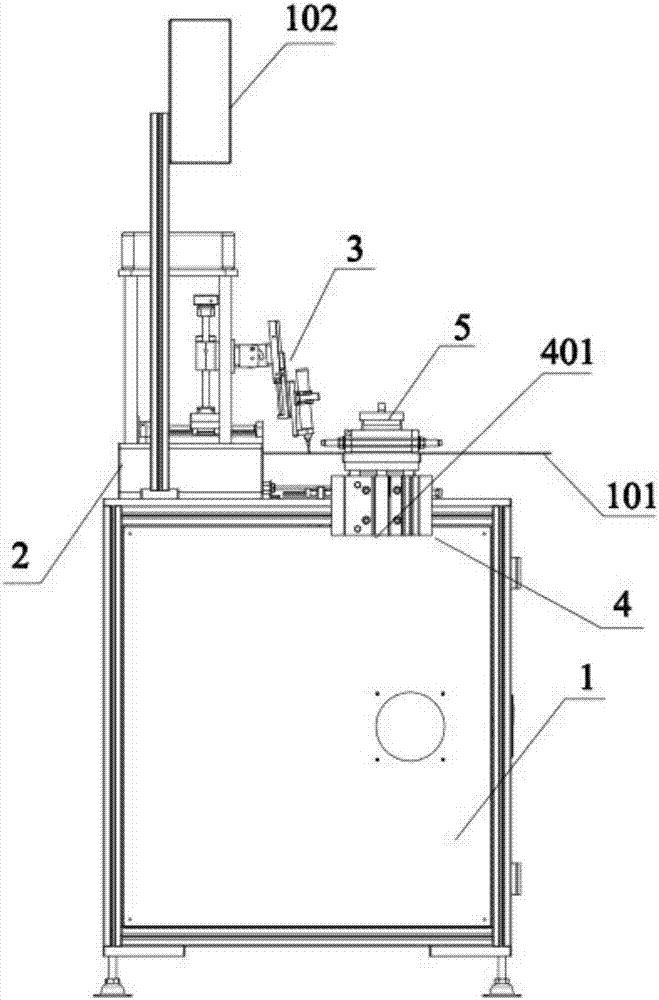

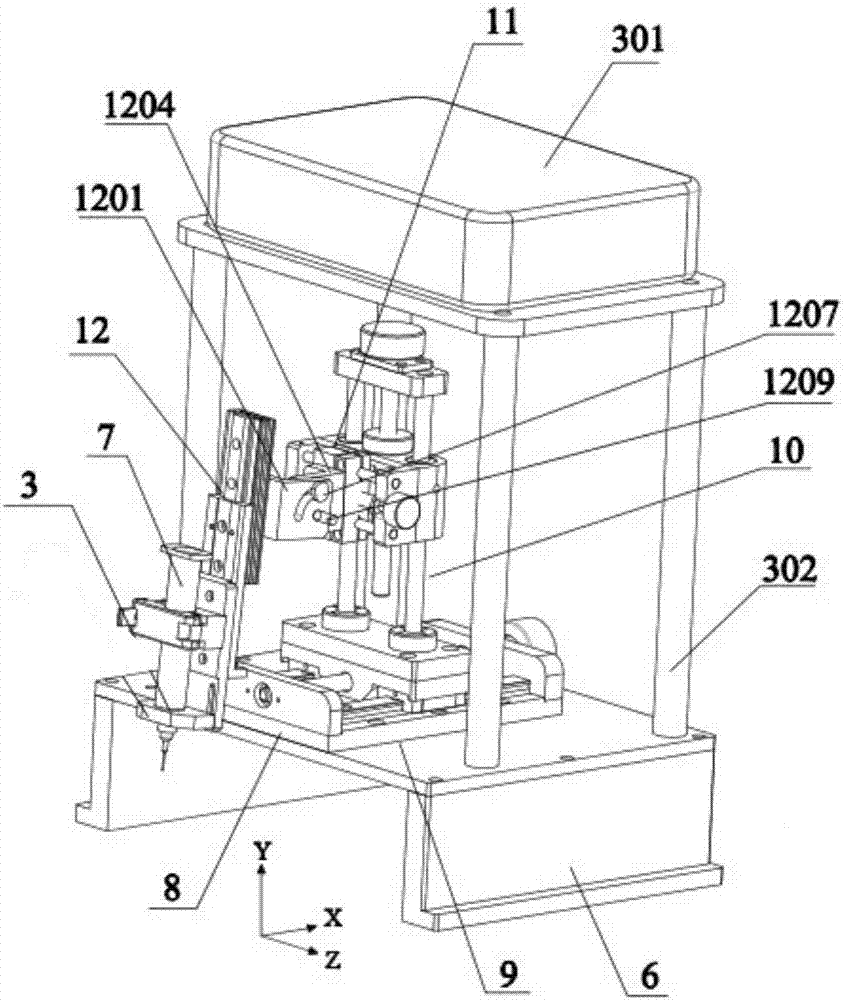

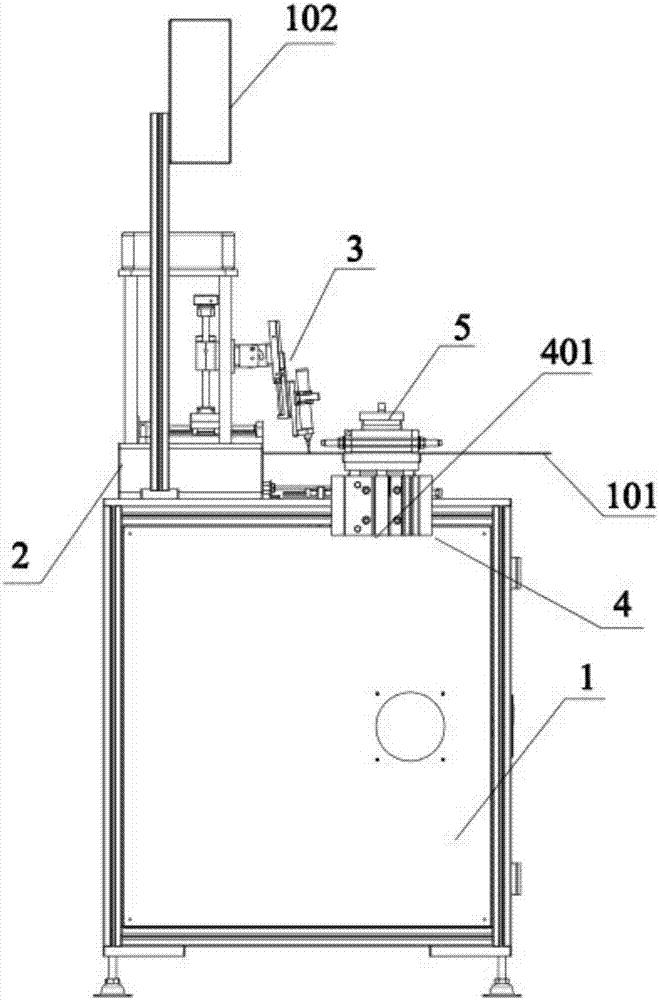

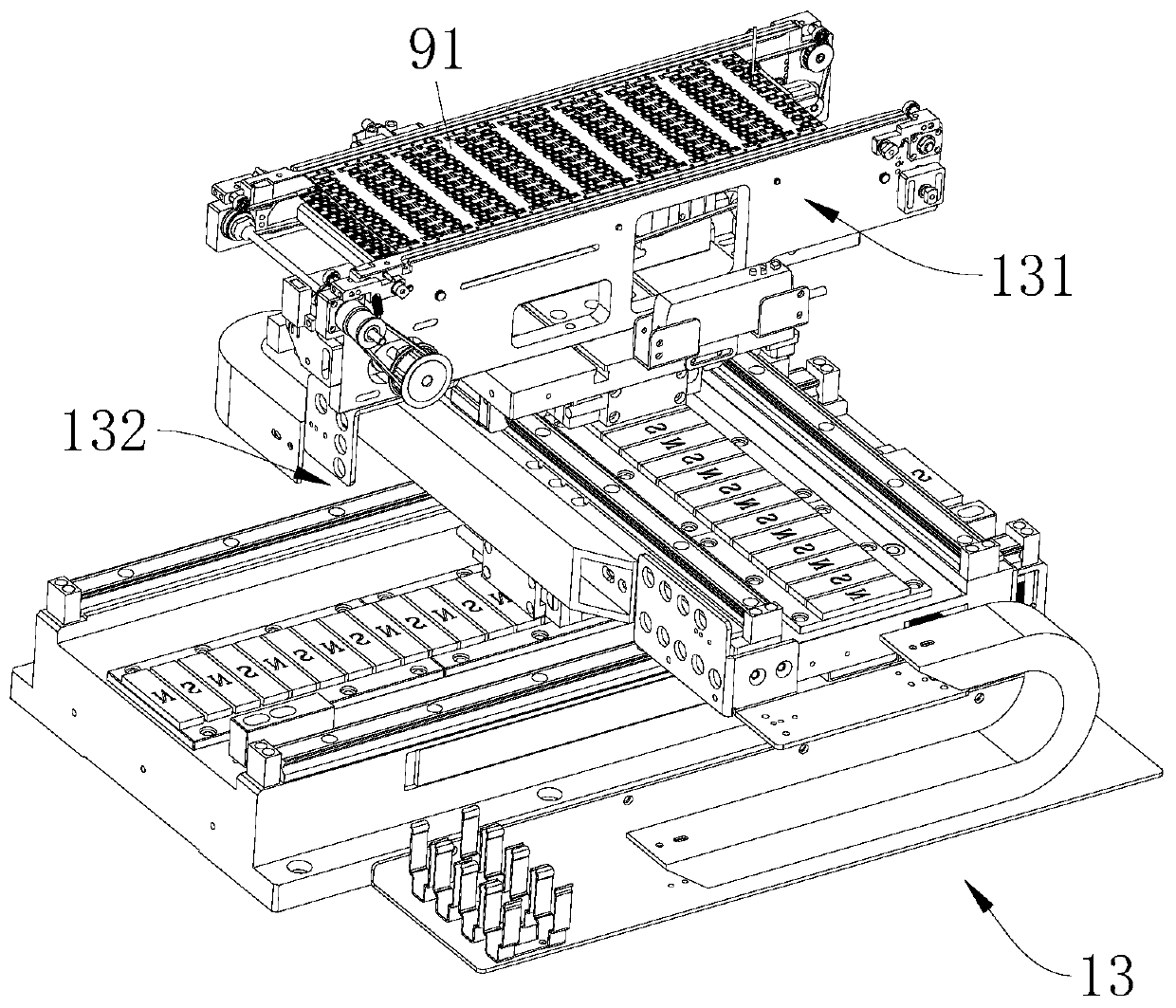

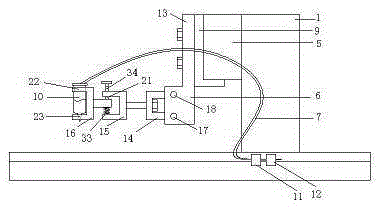

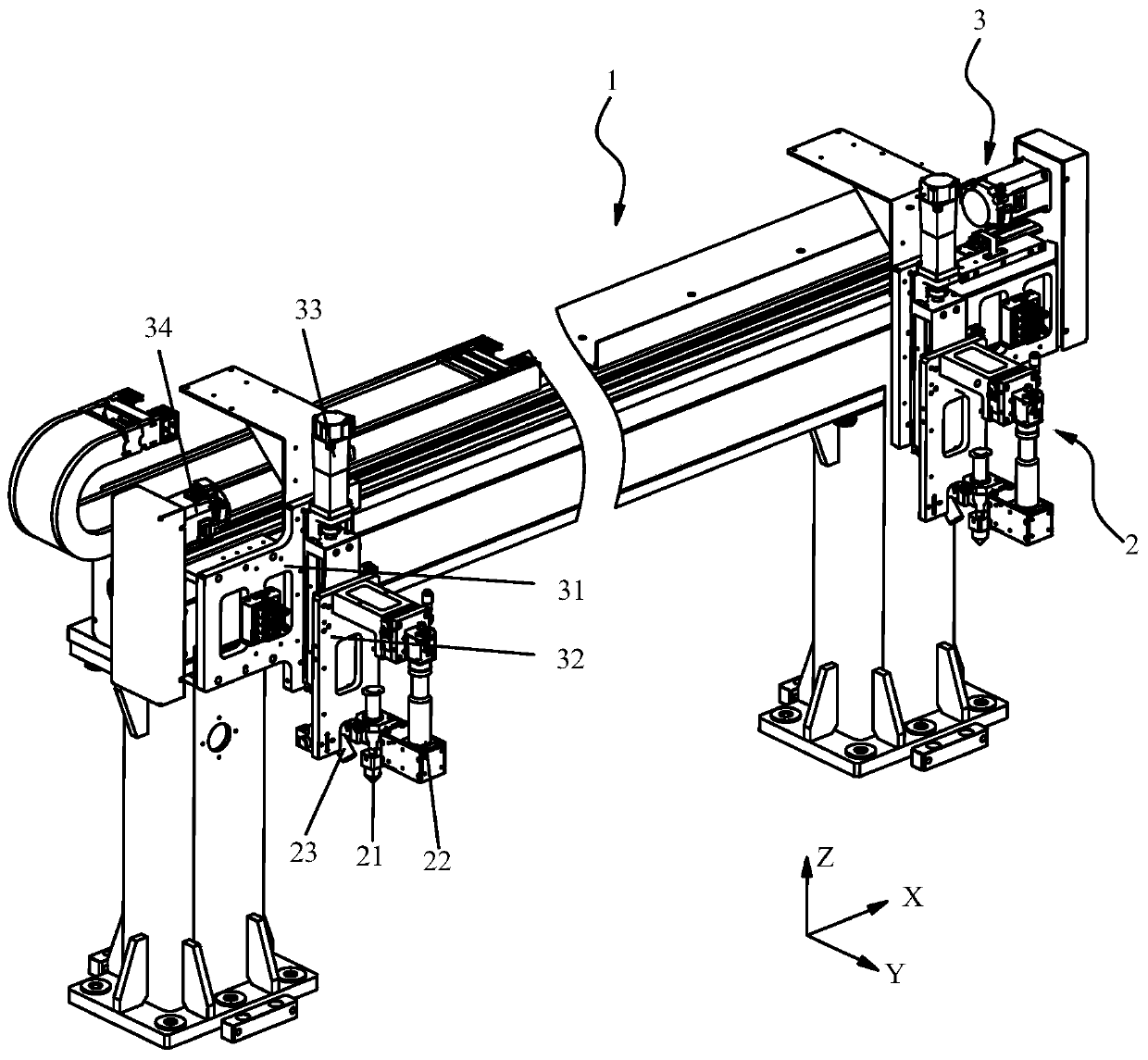

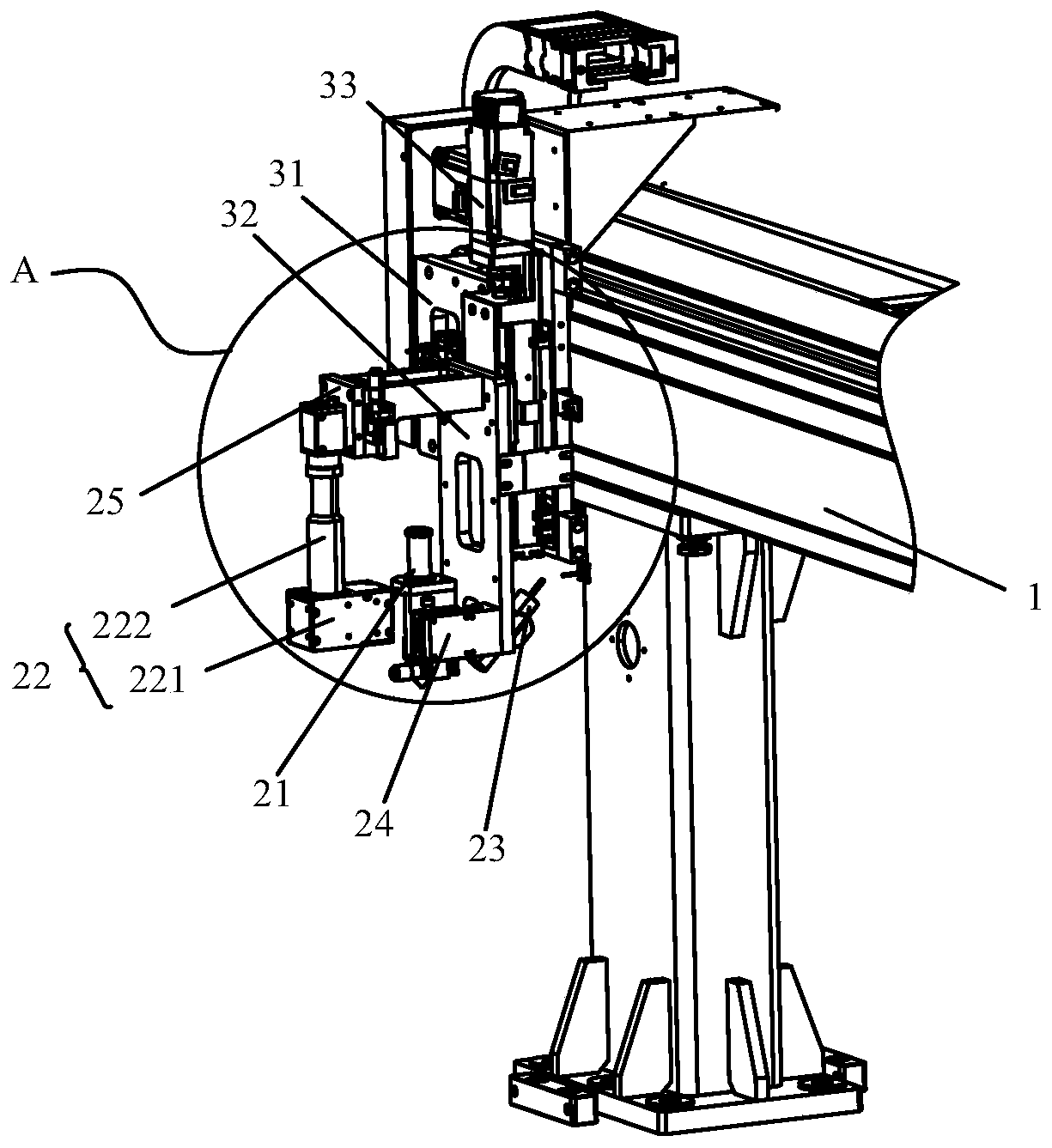

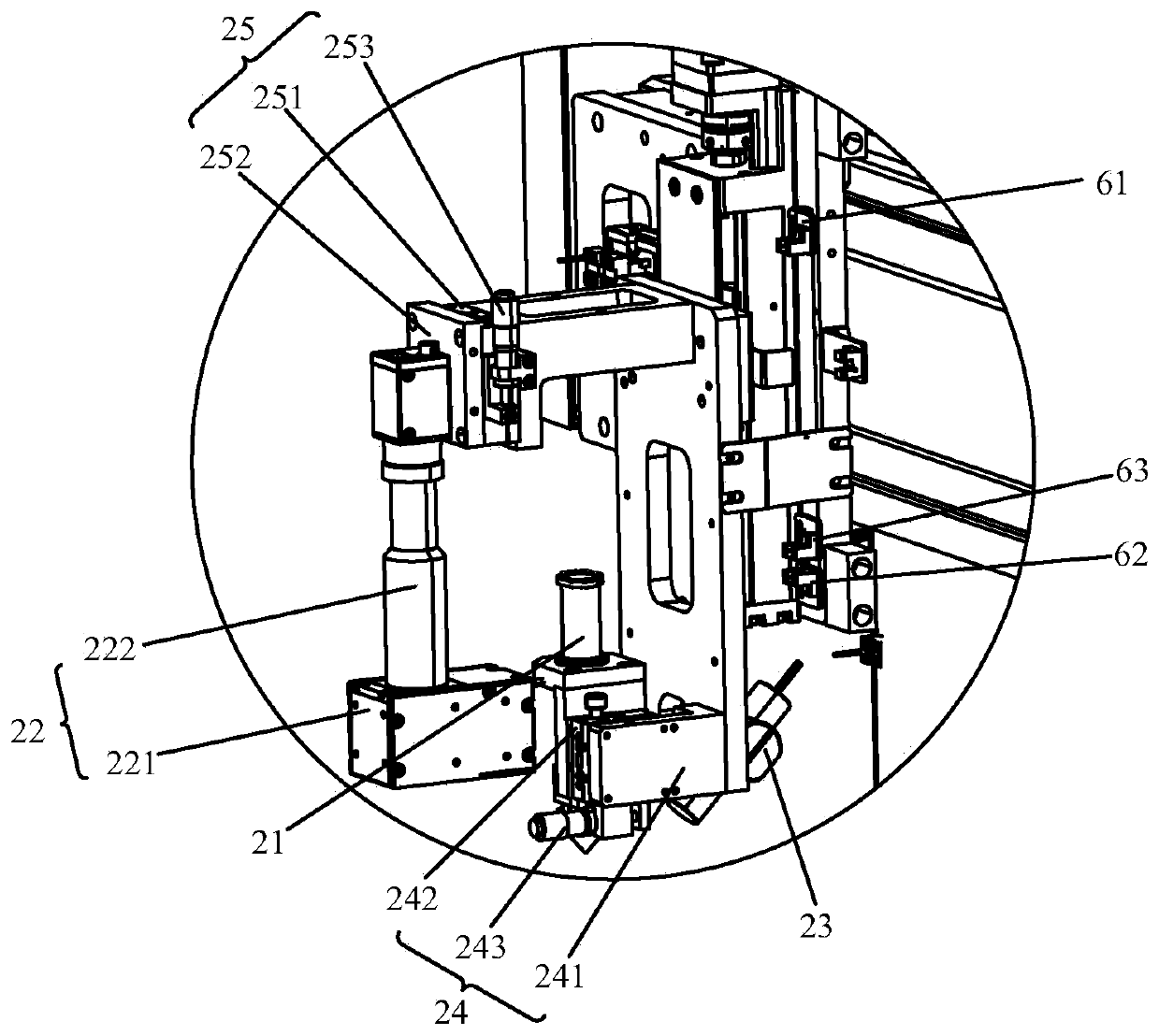

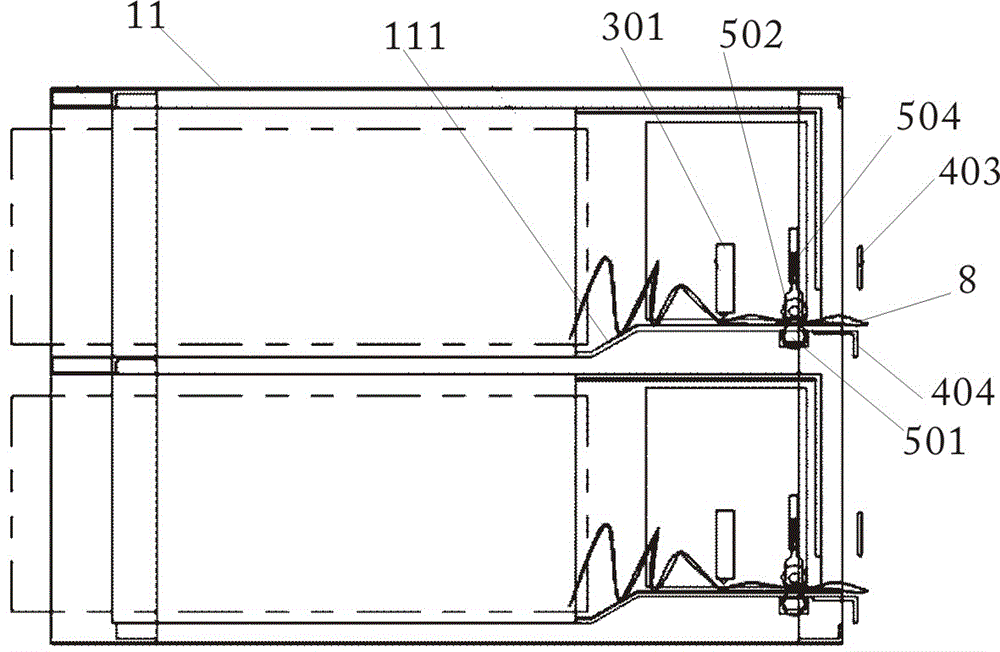

Dispensing machine with dispensing head assembly

InactiveCN107537733AFlexible moving processImprove dispensing qualityLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The present invention provides a dispensing machine with a dispensing head assembly, which includes a control cabinet and a dispensing unit located on the control cabinet, the control cabinet includes a working table and a control mechanism, and the dispensing unit includes the The dispensing head assembly electrically connected to the control mechanism, the transmission device, the positioning device for limiting the positioning of the product to be dispensed, and the driving dispensing head assembly can move the dispensing tube along the X-axis, Y-axis, and Z-axis respectively Drive mechanism; in this way, through the cooperation of the first drive mechanism, the second drive mechanism and the third drive mechanism, the flexible movement of the dispensing head assembly in the three-axis direction can be realized. By setting the fourth drive mechanism, the dispensing head assembly can be controlled. Rotating, it can effectively dispensing work on the parts that are difficult to dispensing, such as the corners of the dispensing product. Reliable and improve the quality of the product.

Owner:柏跃龙

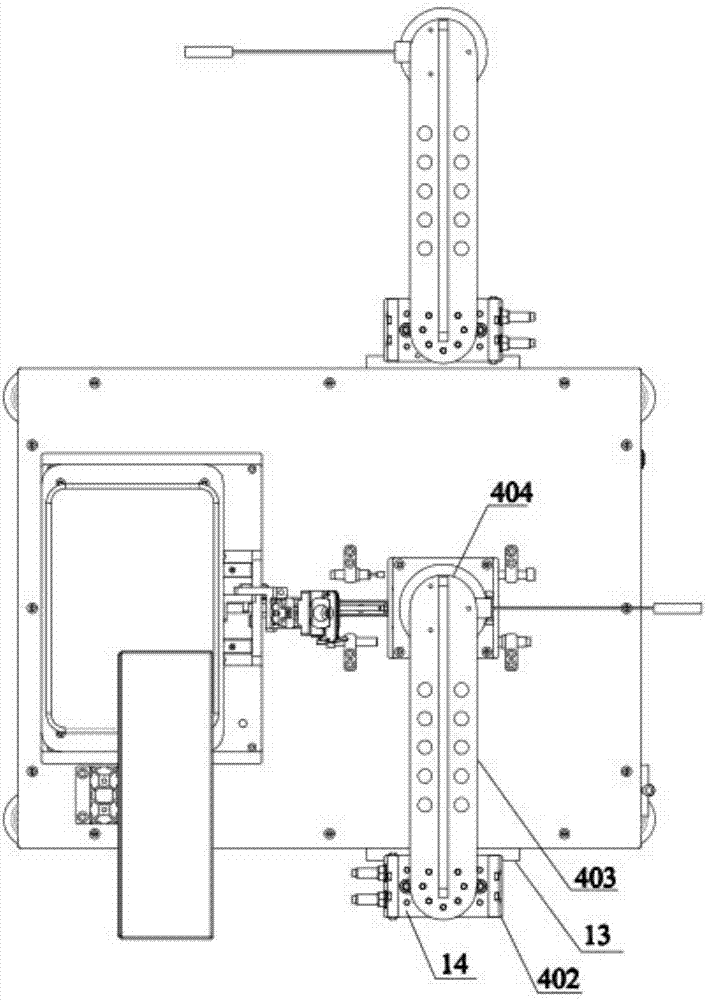

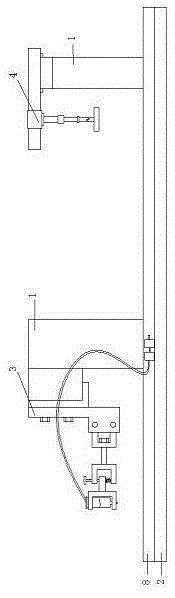

Full-automatic glue dispenser

InactiveCN107398398AImprove dispensing qualityEffective dispensingLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a fully automatic dispensing machine, which includes a control cabinet and a dispensing unit, the control cabinet includes a working table and a control mechanism, and the dispensing unit includes a dispensing device, a transmission device and a positioning device electrically connected to the control mechanism; dispensing The device includes a fixed base, a dispensing tube and a dispensing tube driving mechanism. The dispensing tube driving mechanism includes a first driving mechanism for controlling the movement of the dispensing tube along the X-axis direction, a second driving mechanism for controlling the movement of the dispensing tube along the Y-axis direction, The third driving mechanism that moves in the Z-axis direction and the fourth driving mechanism that controls the rotation of the dispensing hose; the transmission device includes a lifting cylinder, a rotating cylinder, a rotating arm and a grabbing mechanism, and the positioning device includes a stopper and is connected with the stopper the first axis of rotation. The invention aims to solve the problems that the dispensing tube of the existing dispensing machine is difficult to be accurately aligned and cannot be flexibly controlled during three-axis movement.

Owner:柏跃龙

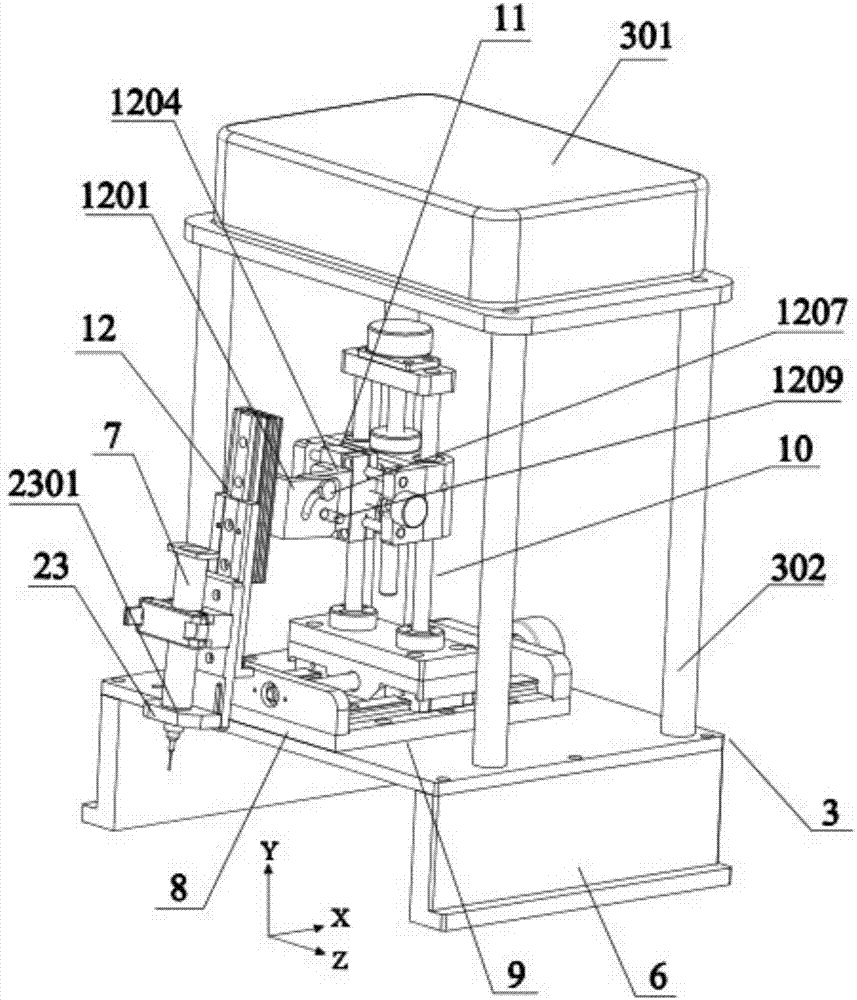

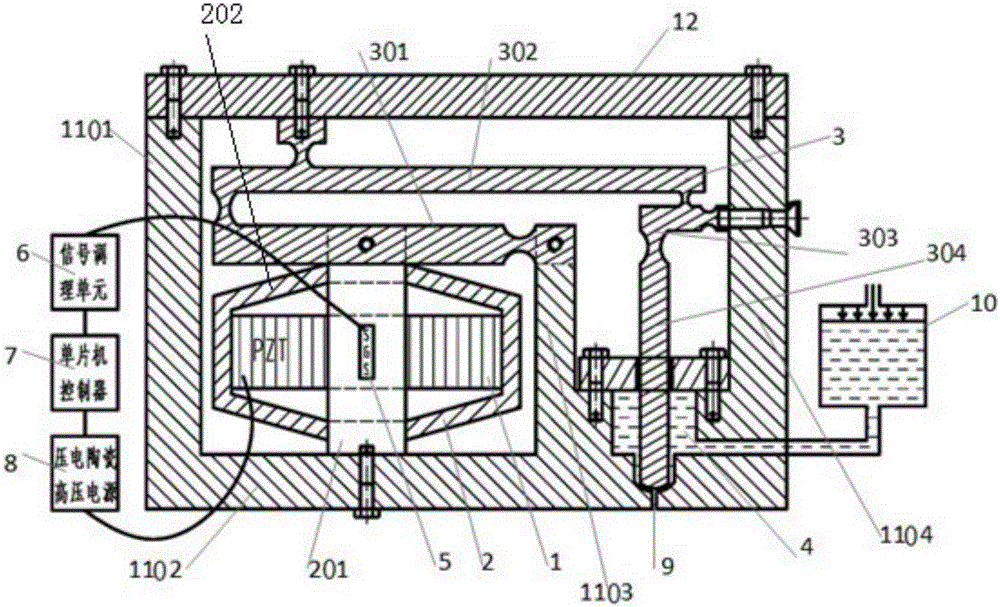

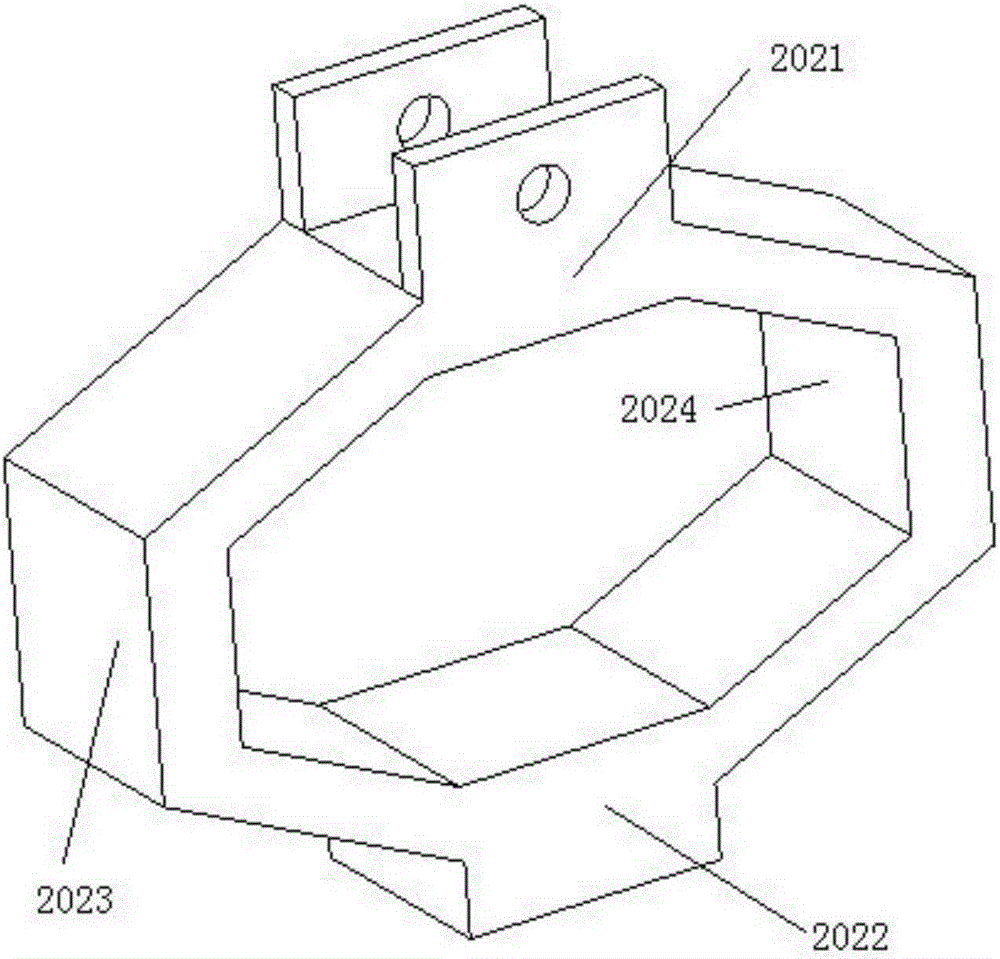

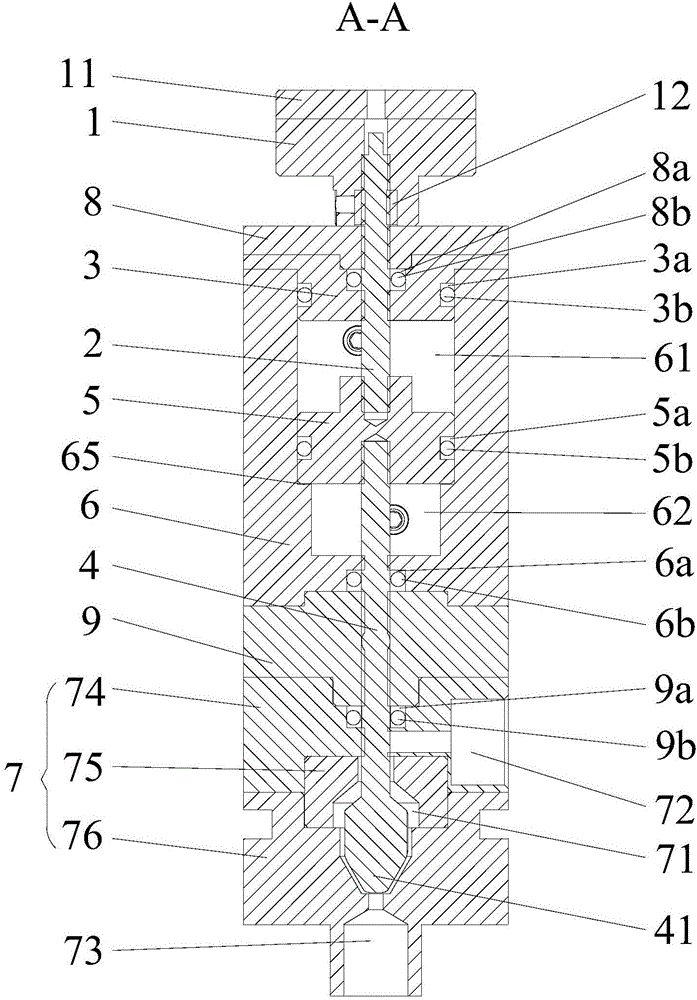

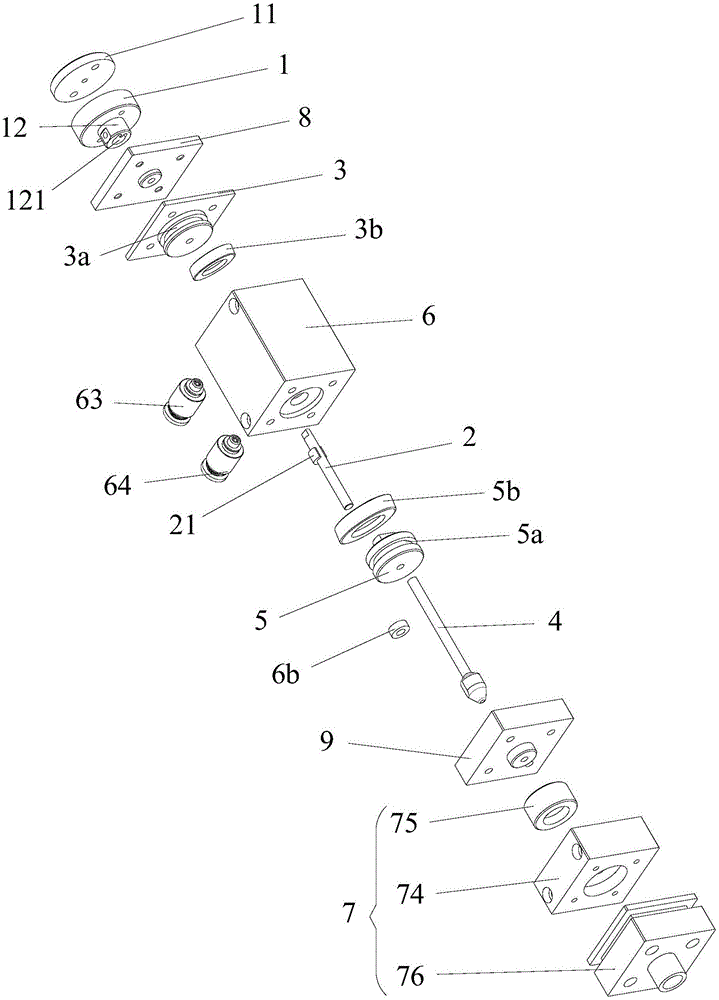

Piezoelectric injection type precise quantification dispensing device and dispensing method thereof

InactiveCN105289934AAccurate and controllable displacementImprove dispensing accuracyLiquid surface applicatorsCoatingsElectricityInterference fit

The invention relates to the field of electronic packaging, and particularly relates to a piezoelectric injection type precise quantification dispensing device and a dispensing method thereof. A piezoelectric stack PZT driver is inlaid in a primary amplifying mechanism in interference fit; the piezoelectric stack PZT driver is connected with a piezoelectric ceramic high voltage power supply; sheet metal is adhered to the primary amplifying mechanism, and an SGS strain gage is adhered on the sheet metal; the SGS strain gage is connected with a signal conditioning unit; a thrice-amplifying mechanism is arranged above the primary amplifying mechanism and comprises a lower plate, an upper plate, a connecting rod and a firing pin; the same ends of the upper plate and the lower plate are flexibly connected, and the lower plate is also connected with the upper part of the body of an elastic amplifying mechanism; the firing pin is inserted into a hole in a cover plate above a cavity of a machine base, a sealing ring is arranged in the hole, and the firing pin extrudes a glue solution in the cavity to be ejected from a nozzle. The device realizes quartic amplification of slight elongation produced by the piezoelectric stack PZT driver, the piezoelectric stack PZT driver is used as a power to achieve injection type non-contact dispensing, and the dispensing quality is improved.

Owner:HENAN POLYTECHNIC UNIV

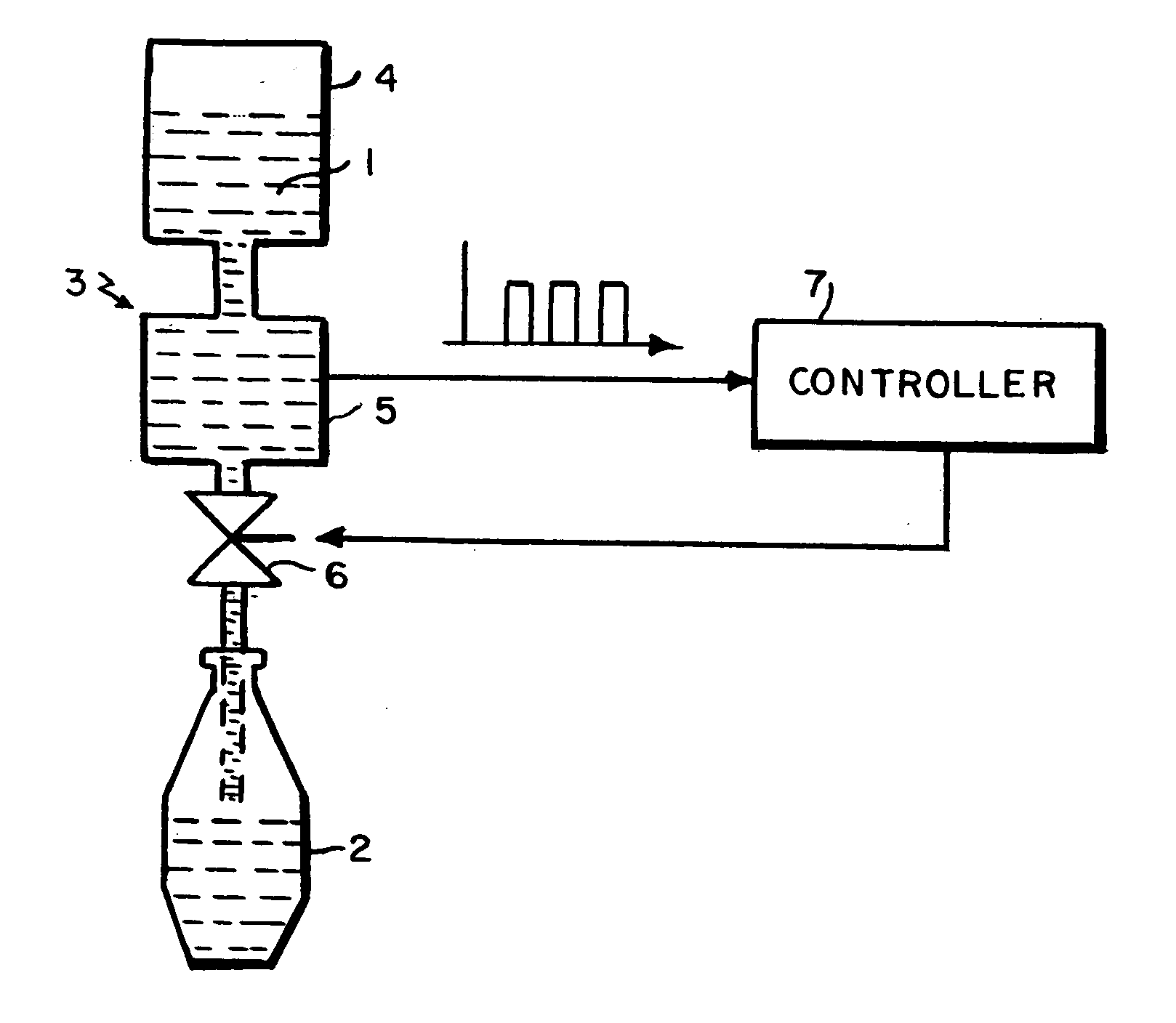

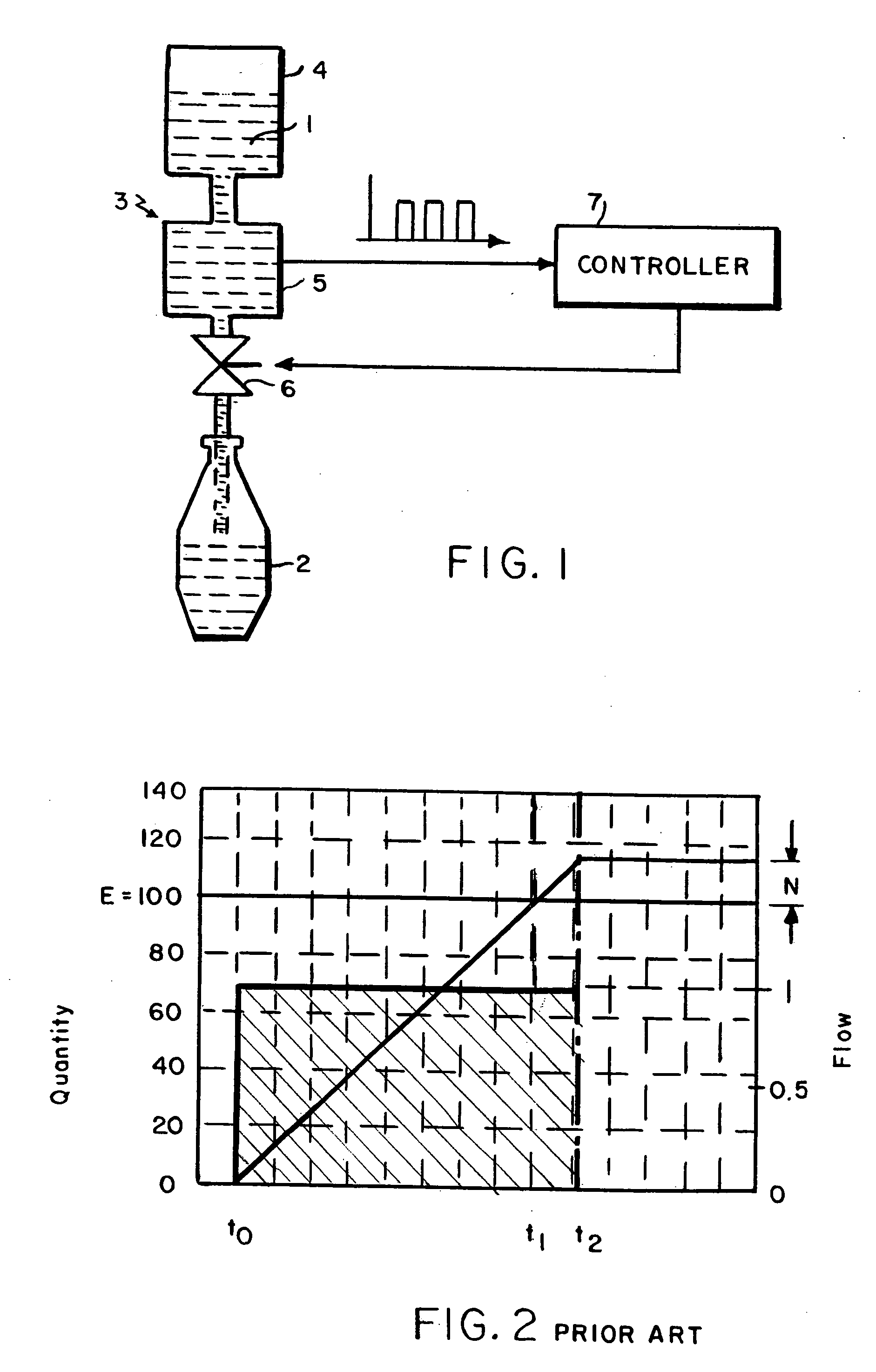

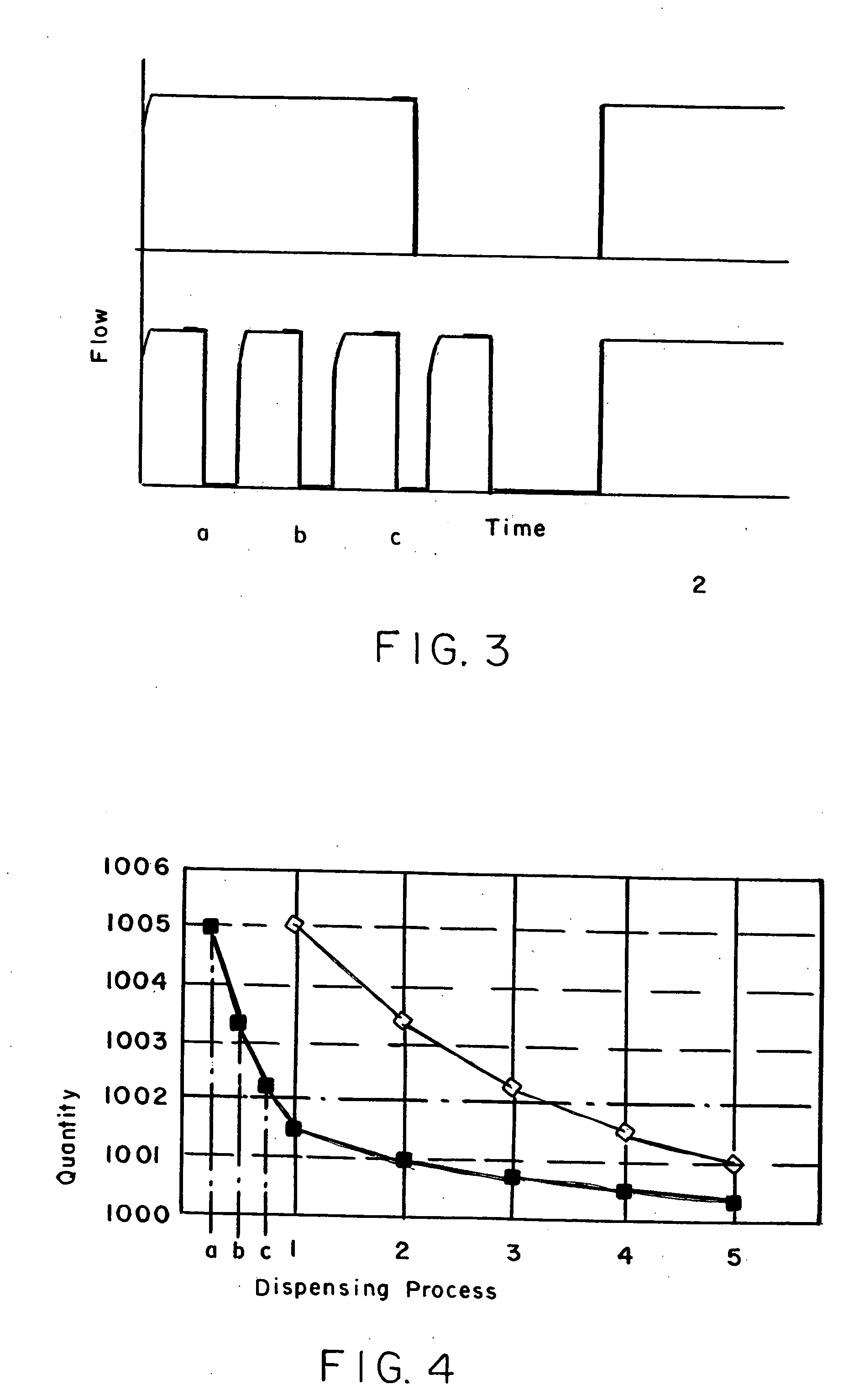

Method for filling a container with a liquid or pourable substance

InactiveUS20050173016A1Improve dispensing accuracyLiquid fillingVolume/mass flow measurementEngineeringBiomedical engineering

A method for dispensing a specific minimum amount of a liquid or pourable substance into a container to fill the container, in the course of which the amount of the dispensed substance is measured and a valve is close to terminate the filling process as soon as the amount of the dispensed substance has reached a defined final value in which the substance is dispensed into a first container in several dispensing steps. During an initial dispensing step, the filling process is interrupted by the closing of the valve so as to permit determination of the tailing of the substance that occurs during the closing of the valve, while for a subsequent dispensing step the valve is opened to resume the filling process, with the final value for terminating the subsequent dispensing step being established by factoring-in a tailing value of the substance that was determined in a preceding dispensing step during the closing of the valve. In this fashion, greater accuracy is achieved in filling the container with the substance especially upon restarting the dispensing system employed for implementing the method.

Owner:KROHNE MESSTECHNICK GMBH & CO KG

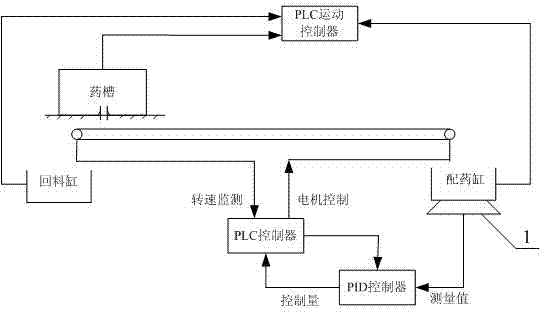

Automatic dispensing system based on PLC and application method

ActiveCN103754556AImprove dispensing accuracyTo achieve the purpose of precise automatic drug graspingConveyorsControl devices for conveyorsDrive motorEngineering

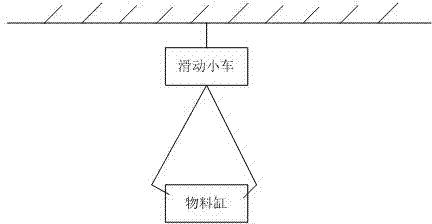

The invention discloses an automatic dispensing system based on a PLC and an application method. The automatic dispensing system based on PLC comprises a PLC controller, a PID controller, a drug tank, a conveying belt, a drive motor, a return cylinder, a dispensing cylinder, an electronic scale, a PLC move controller and a sliding trolley. The PLC controller controls the sliding trolley to take the needed drugs from a drug storage and send the drugs to the drug tank; the drugs in the drug tank drop into the conveying belt through vibration and are sent to the dispensing cylinder through the conveying belt; the electronic scale is mounted under the dispensing cylinder and is monitored at real time through the PLC controller so as to precisely measure the weight of the drugs in the dispensing cylinder. The automatic dispensing system based on the PLC and the application method achieves the purpose of automatically filling the prescription precisely.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

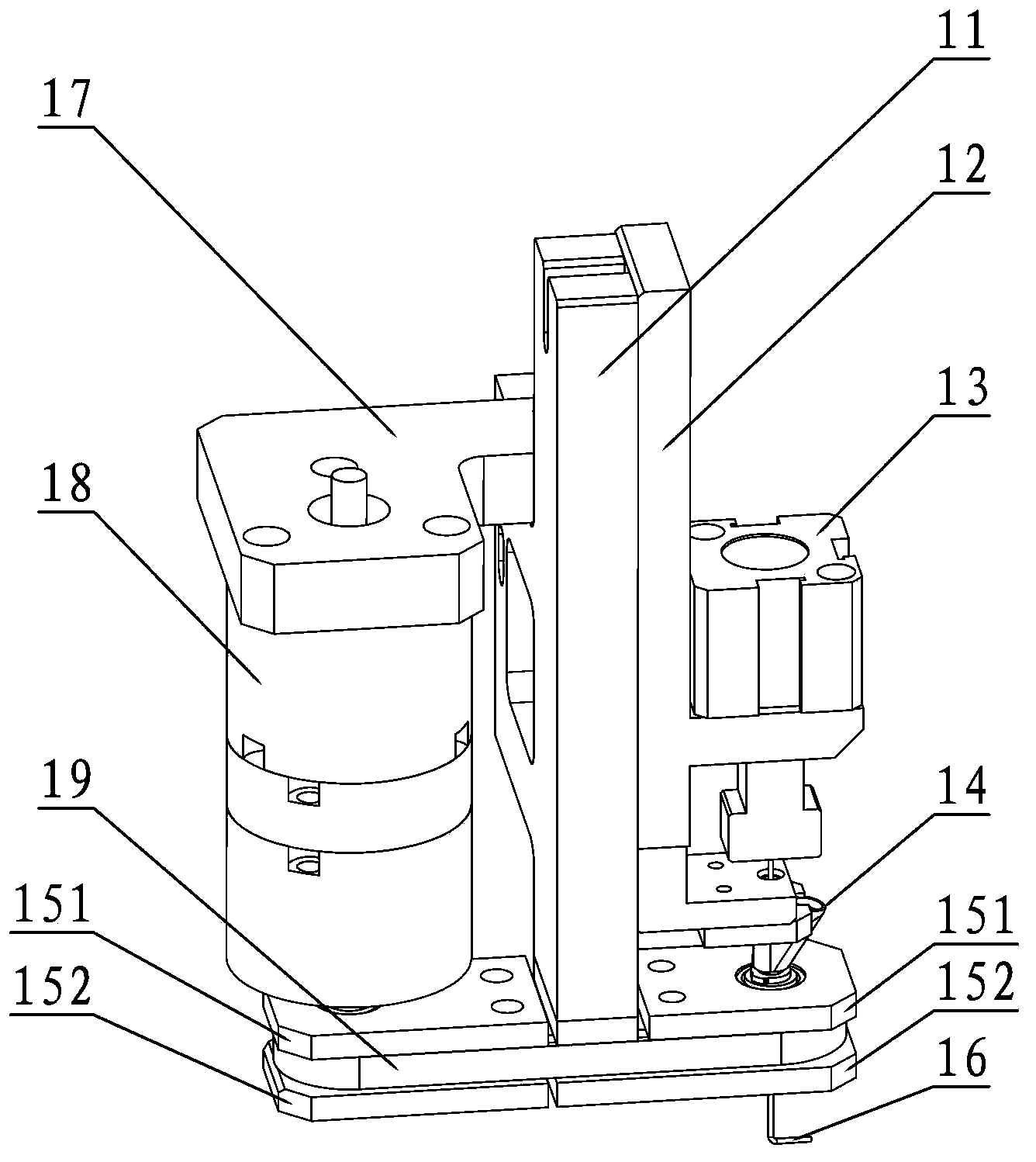

Die bonder

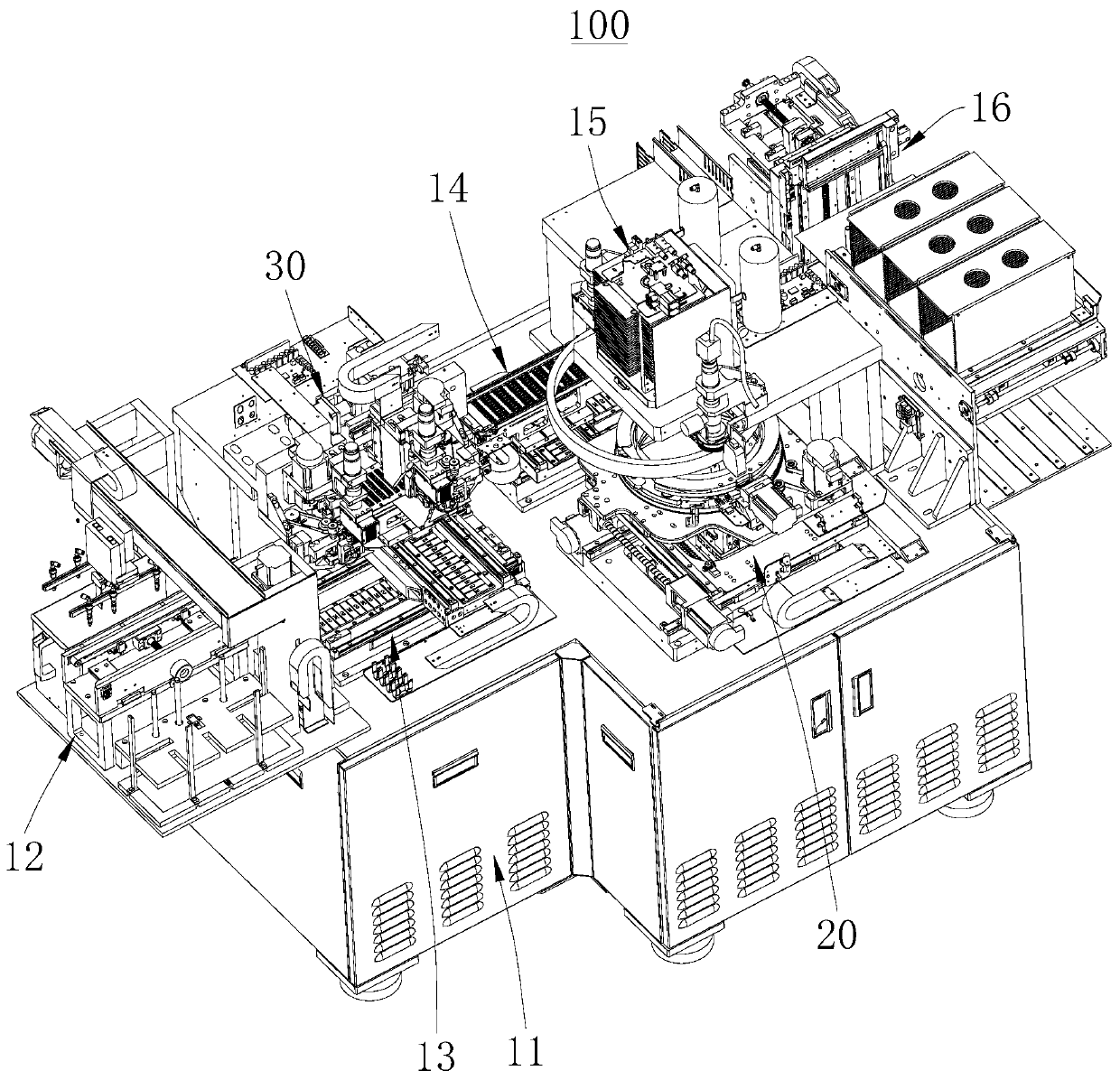

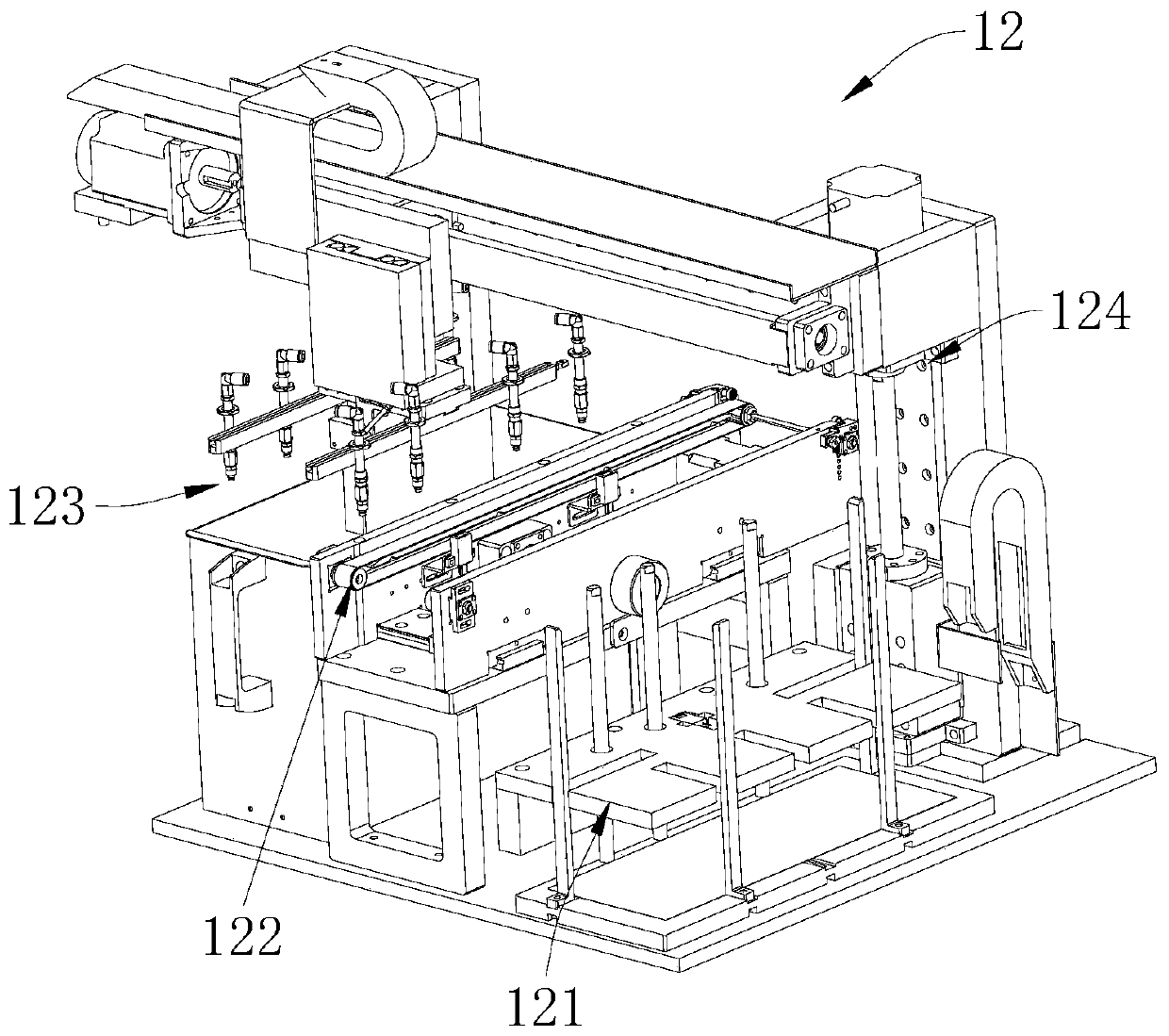

ActiveCN111370350AGuaranteed dispensing accuracyEnsure dispensing qualitySemiconductor/solid-state device manufacturingWaferingElectric machinery

The invention provides a die bonder. The die bonder comprises a rack; a dispensing device; a dispensing shifting mechanism; a feeding mechanism; a die bonding swing arm device; a crystal supply platform; a die bonding displacement mechanism; and a material receiving mechanism. The die bonding swing arm device comprises a rotating frame, a plurality of die bonding swing arms, a lifter and a die bonding motor, and each die bonding swing arm is provided with a suction nozzle; the dispensing device comprises a plurality of dispensing modules. The invention provides a die bonder. According to the invention, the plurality of dispensing modules are combined with the plurality of die bonding swing arms, so that the operation speeds of the plurality of dispensing modules can be adjusted to be matched with the operation speeds of the plurality of die bonding swing arms on the premise of ensuring the dispensing precision and quality and ensuring the wafer taking and placing precision, the idle time of each dispensing module and each die bonding swing arm is reduced, and the die bonding efficiency is greatly improved.

Owner:SHENZHEN XINYICHANG TECH CO LTD

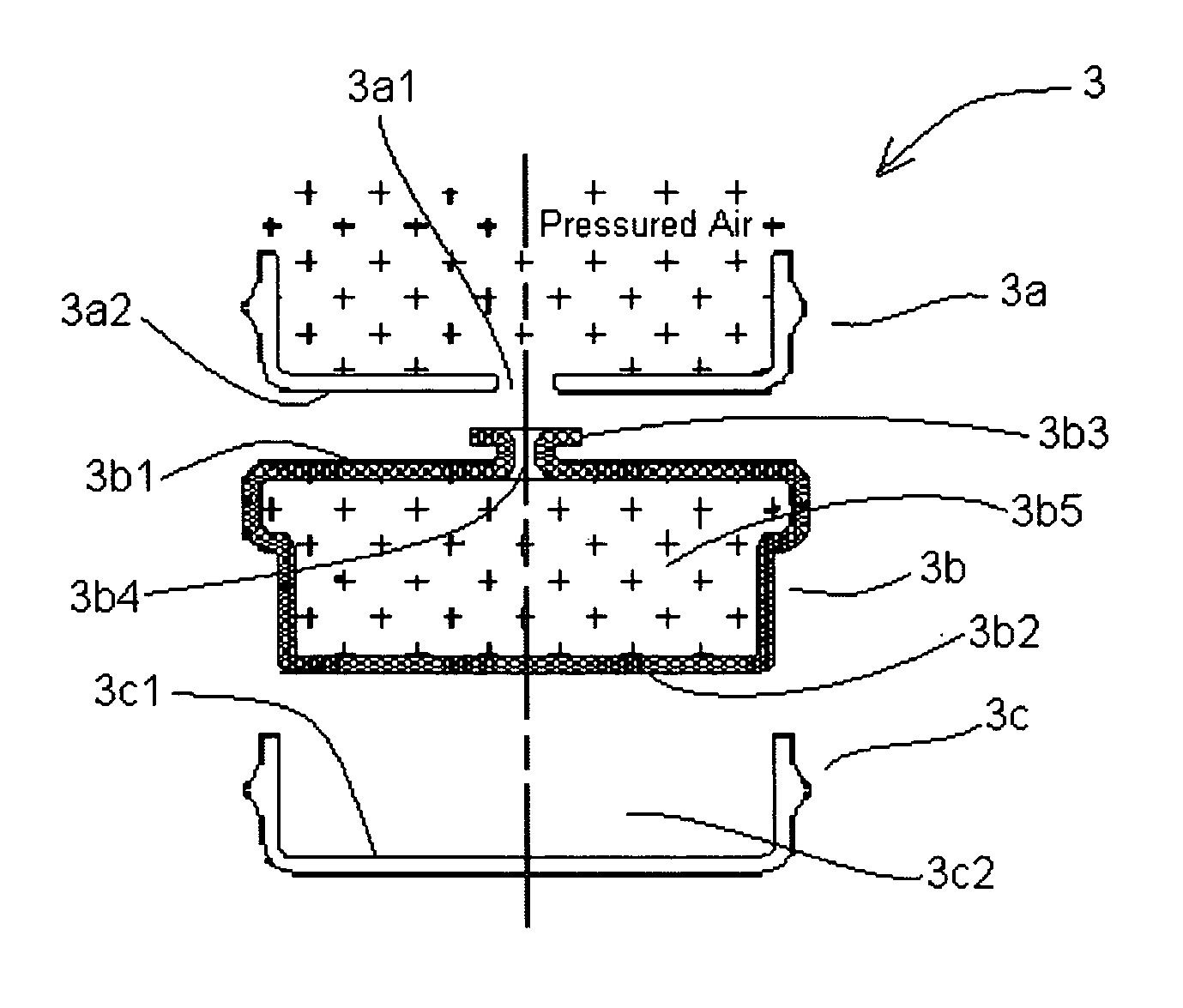

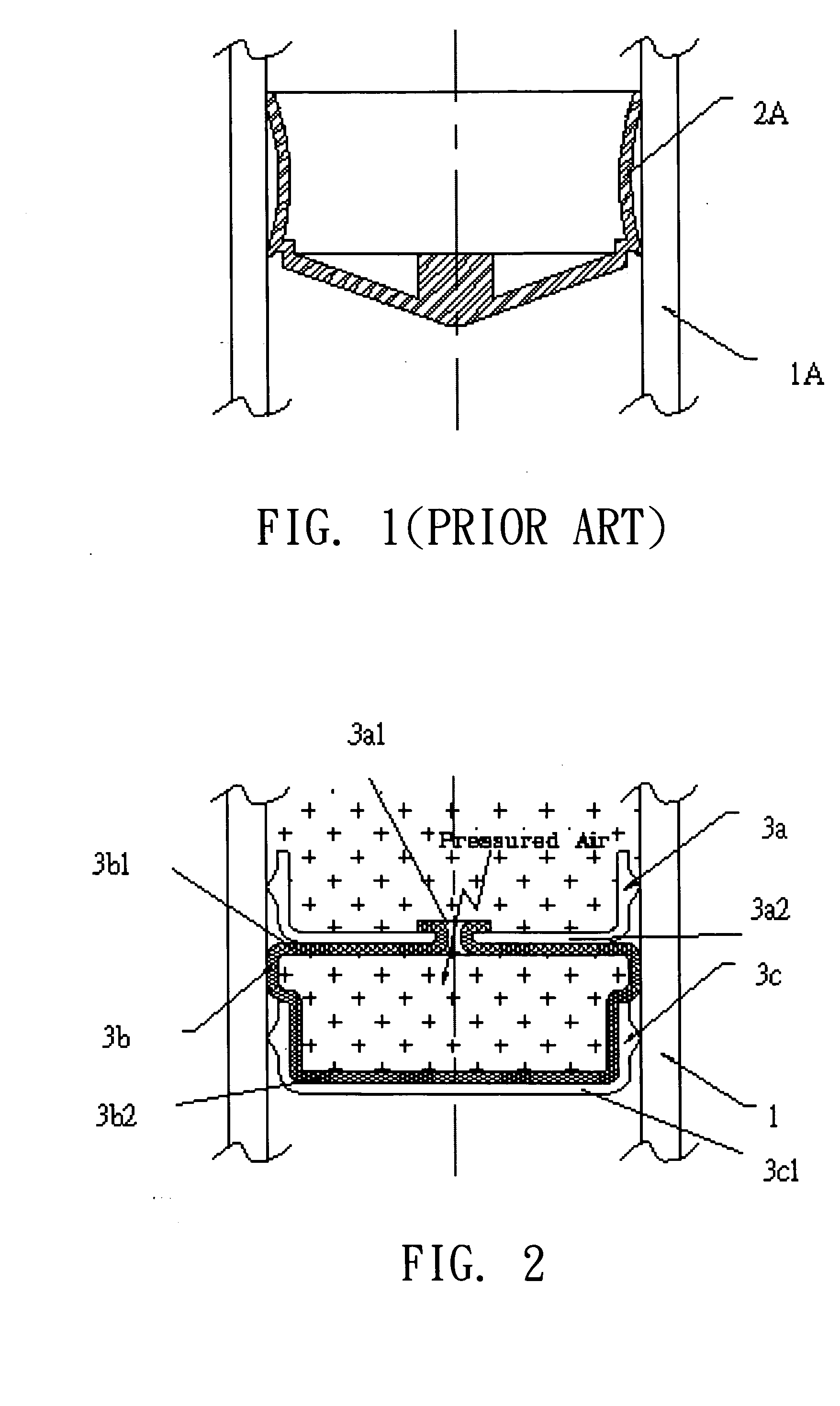

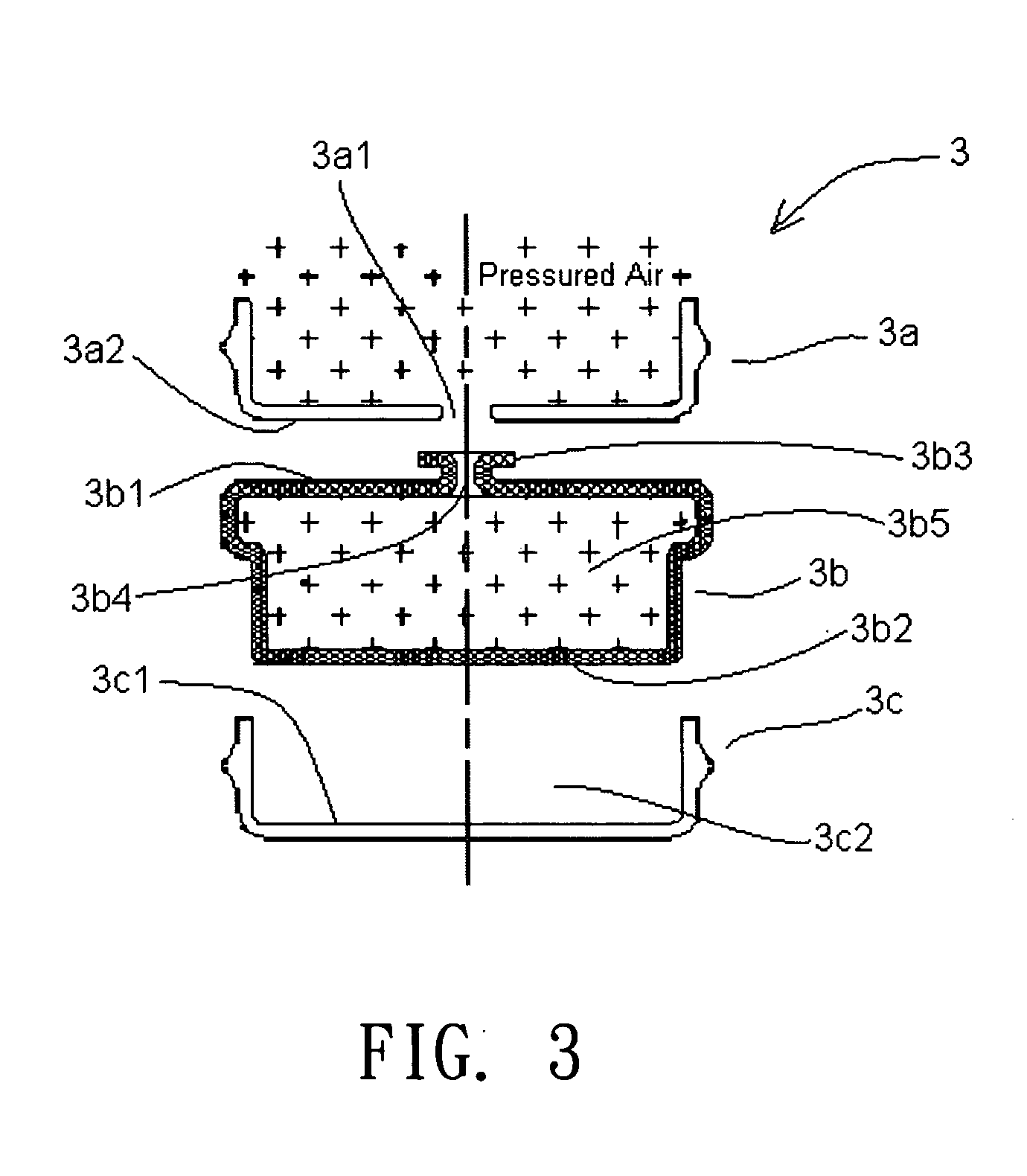

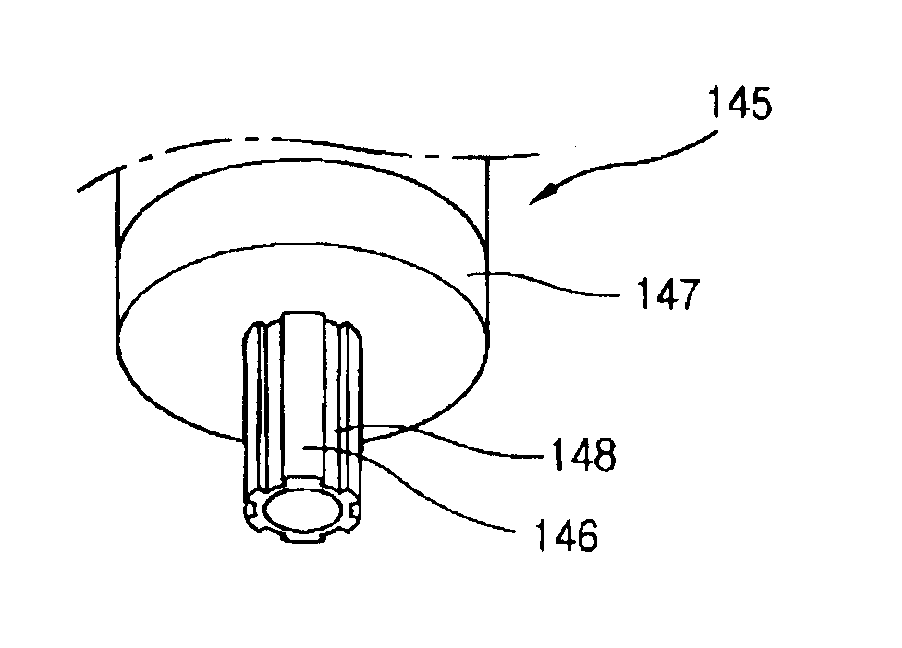

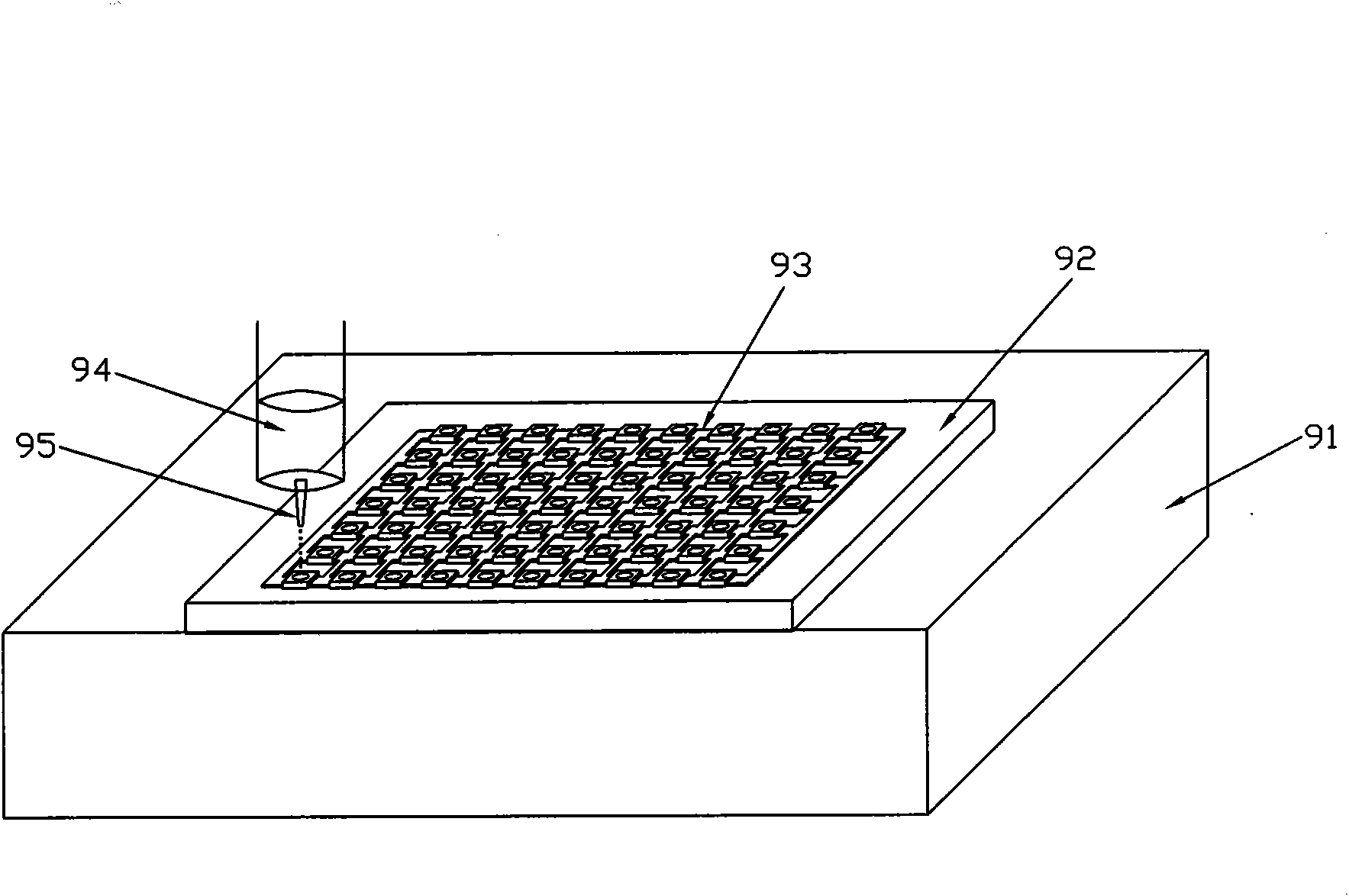

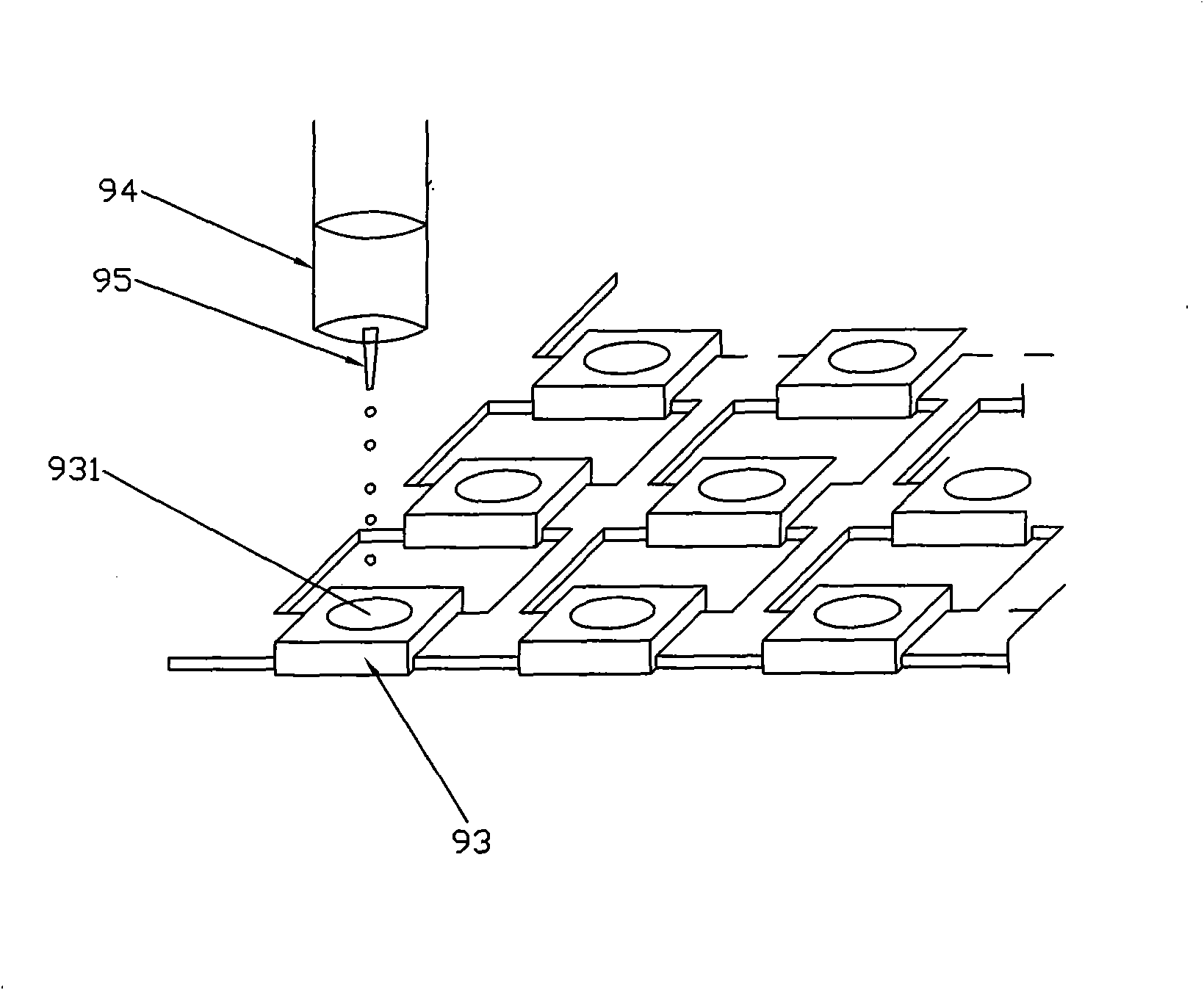

Liquid crystal dispensing apparatus

InactiveUS6874662B2Improve dispensing accuracyLiquid flow controllersSemiconductor/solid-state device manufacturingEngineeringLiquid crystal

A liquid crystal dispensing apparatus includes a liquid crystal material container, a nozzle positioned at a lower portion of the liquid crystal container and having at least one groove formed at an exterior surface thereof, and a valve system for transmitting liquid crystal material from the liquid crystal material container to the nozzle by a gas pressure supplied to the liquid crystal material container.

Owner:LG DISPLAY CO LTD

Hand-held fluid dispenser system and method of operating hand-held fluid dispenser systems

InactiveUS20050109791A1Improved hand gripReduce stress and fatigueOpening closed containersBottle/container closureProximity sensorHand held

A hand-held fluid dispenser having an enclosure for supporting a container holding a fluid to be dispensed, and a method of operating such hand-held fluid dispensers. A first proximity sensor is located inside the enclosure immediately adjacent one side of the enclosure, and a second proximity sensor is located inside the enclosure immediately adjacent an opposite side of the enclosure. An actuation circuit is supported inside the enclosure and is electrically connected to the first and second proximity sensors. The actuation circuit produces an actuation signal in response to detecting opposed digits of an operator being simultaneously in close proximity to the first and second proximity sensors.

Owner:NORDSON CORP

Rotary positioning device for glue-dispensing bent needle head

InactiveCN103567120AImprove efficiencyImprove dispensing efficiencyLiquid surface applicatorsCoatingsEngineeringSyringe needle

Owner:SUZHOU NEW STAR PRECISION MECHANISM

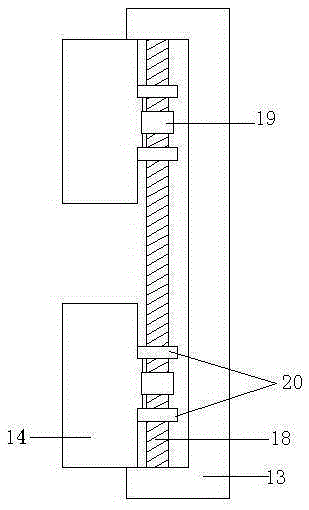

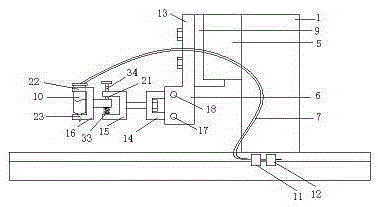

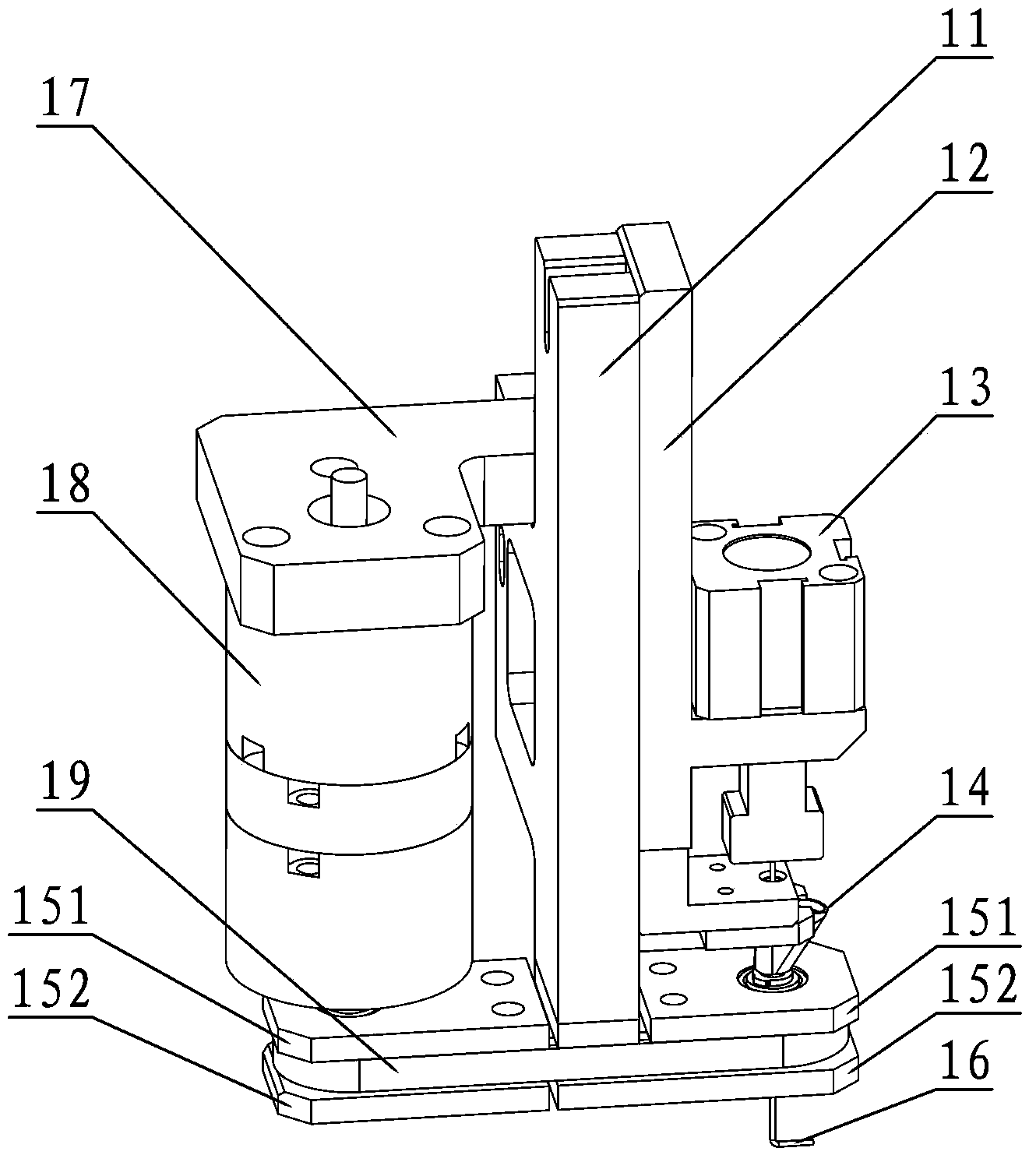

Dispensing and detection device on automatic chip mounting production line

InactiveCN105307417ASimple structureReasonable designPrinted circuit assemblingProduction lineEngineering

The invention provides a dispensing and detection device on an automatic chip mounting production line. The device includes a dispensing device and a CCD detection device, the dispensing device includes a displacement platform, a fixed mechanism and a dispensing mechanism, a lead screw and adjusting bolts are arranged on the fixed mechanism, the CCD detection device includes a two-dimensional mechanical arm, a linear telescopic cylinder and a CCD, a light source fixing seat is arranged on the CCD, and an annular light source and distance sensors are arranged on the light source fixing seat. The dispensing and detection device provided by the invention is simple in structure and reasonable in design, rapidly completes dispensing operation of a plurality of workpieces, and is high in efficiency, the dispensing mechanism performs fine adjustment through adjustment of the lead screw and the adjusting bolts, dispensing precision is high, displacement of the CCD in a horizontal direction is realized through the two-dimensional mechanical arm, photographing detection is performed on dispensing parts one by one, displacement precision is high, and efficiency is high, the distance sensors detect and monitor photographing distance of the CCD, and realize vertical displacement through the linear telescopic cylinder, selection of optimal photographing distance is facilitated, and the annular light source provides a light source for photographing of the CCD.

Owner:JIANGSU HAITIAN MICROELECTRONICS TECH

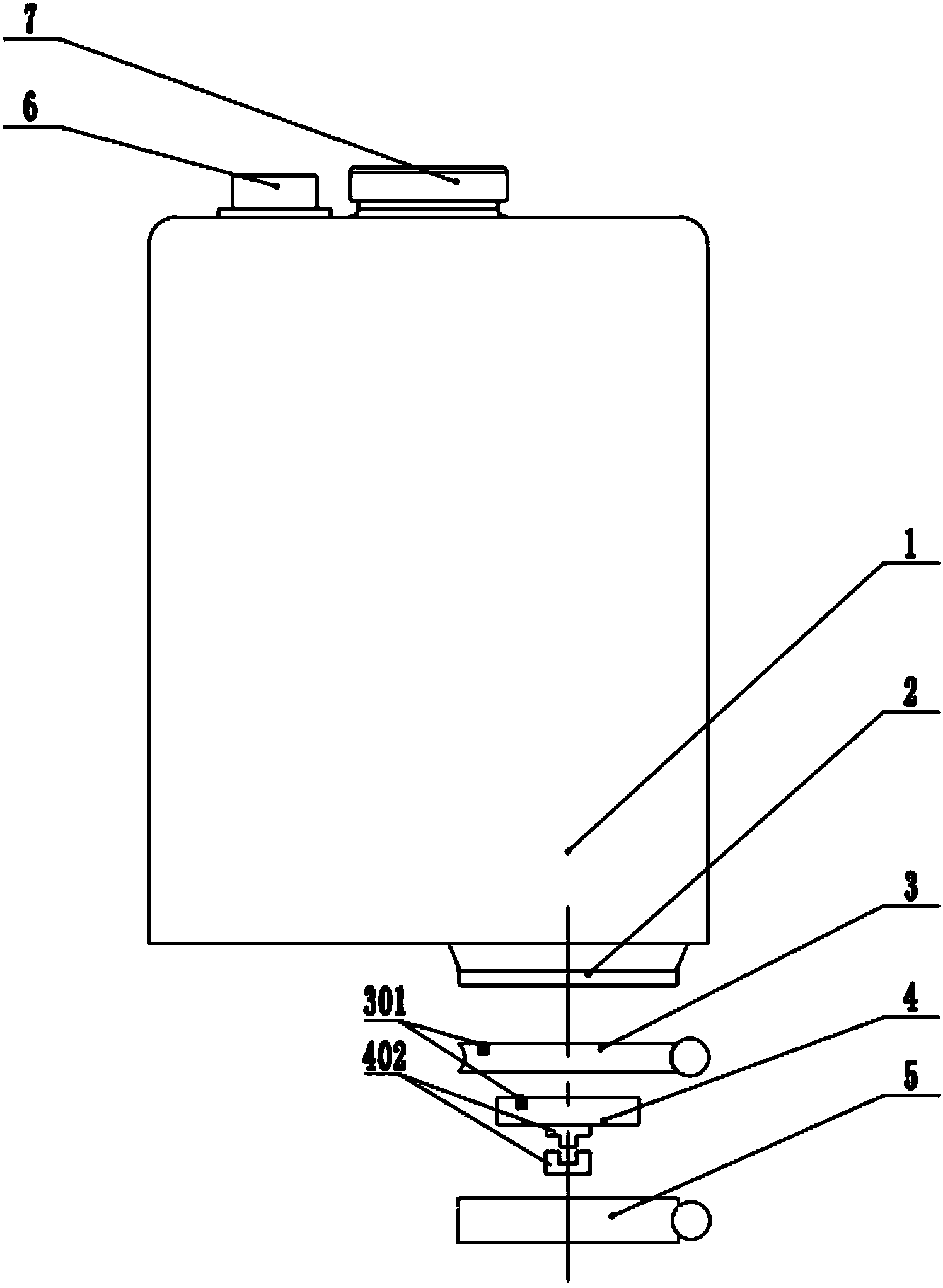

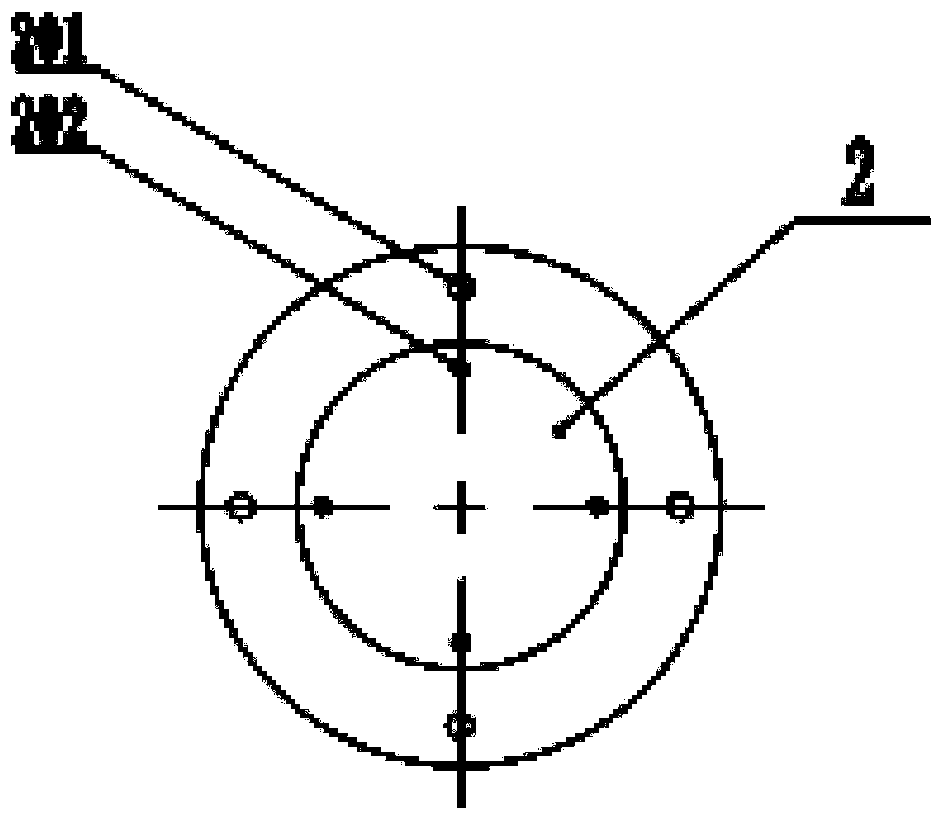

Multi-port double-disc positive-displacement medicine outlet device for concentrated granules of traditional Chinese medicine

ActiveCN103832607AGuarantee the speed of dosingHigh precisionSolid materialTraditional Chinese medicineMedicine tray

The invention relates to a multi-port double-disc positive-displacement medicine outlet device for concentrated granules of traditional Chinese medicine. The multi-port double-disc positive-displacement medicine outlet device mainly comprises a medicine storage tank body, a main medicine discharge outlet, a coarse medicine discharge disc, a fine medicine discharge disc, a medicine outlet base and the like. The multi-port double-disc positive-displacement medicine outlet device has the advantages that rotation of transmission mechanisms corresponding to the medicine outlet discs can be controlled, so that quick, high-precision, constant-number (the quantity of medicine outlet ports) and quantitative (the weight of output medicine) medicine outlet effects can be realized; the multi-port double-disc positive-displacement medicine outlet device is simple in structure and convenient to mount, and environmental requirements of traditional Chinese medicine storage can be met.

Owner:BEIJING UNIV OF TECH

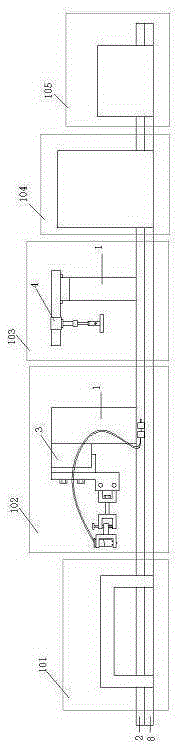

Automatic chip mounting production line

InactiveCN105307471ASimple structureReasonable designElectrical componentsProduction lineEngineering

The invention provides an automatic chip mounting production line, including a loading station, a dispensing station, a CCD detection station, a chip mounting station and a discharging station. The automatic chip mounting production line is characterized in that the production line includes a support, a conveyor belt, a dispensing device and a CCD detection device, a fixed mechanism and a dispensing mechanism are arranged on the dispensing device, a lead screw and adjusting bolts are arranged on the fixed mechanism, the CCD detection device includes a two-dimensional mechanical arm, a linear telescopic cylinder and a CCD, and the CCD is equipped with an annular light source and distance sensors. The automatic chip mounting production line provided by the invention is simple in structure and reasonable in design, rapidly completes dispensing of a plurality of workpieces, and is high in efficiency, the dispensing mechanism performs fine adjustment through adjustment of the lead screw and the adjusting bolts, thereby improving dispensing precision, displacement of the CCD in a horizontal direction is realized through the two-dimensional mechanical arm, so that dispensing parts are detected, displacement precision is high, the distance sensors detect and monitor photographing distance of the CCD, and realize vertical displacement through the cylinder, selection of optimal photographing distance is facilitated, and the annular light source provides a light source for the CCD.

Owner:JIANGSU HAITIAN MICROELECTRONICS TECH

Curved pinhead rotary positioning device for dispensing

InactiveCN103567119AImprove efficiencyImprove dispensing efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:SUZHOU NEW STAR PRECISION MECHANISM

Adhesive dispensing mechanism and display screen production line

PendingCN111299086AHigh precisionImprove dispensing efficiencyLiquid surface applicatorsCoatingsProduction lineAdhesive

The invention relates to the technical field of display screen production, and discloses an adhesive dispensing mechanism and a display screen production line. The adhesive dispensing mechanism comprises a portal frame, two sets of adhesive dispensing modules and a moving module, the portal frame forms a space allowing a workpiece to penetrate in the Y direction in the X-Z plane, the two sets of adhesive dispensing modules are arranged at two ends of the portal frame in the X direction respectively and used for adhesive dispensing the workpiece, and the moving module is used for driving the adhesive dispensing modules to move in the X direction and the Z direction relative to the portal frame; and each adhesive dispensing module comprises a adhesive dispensing valve, a CCD detection component and a camera, the position of the adhesive dispensing valve is adjustable relative to the portal frame in the Y direction, the CCD detection component is used for detecting the dispensing quality,and the camera is used for shooting the working state of the adhesive dispensing valve. The adhesive dispensing mechanism disclosed by the invention is high in working efficiency, and the working state of the dispensing valves and the adhesive dispensing quality can be observed in real time. According to the display screen production line disclosed by the invention, through the adhesive dispensing mechanism, the display screen production efficiency is high, the dispensing precision is high, and problems in production can be conveniently observed in real time.

Owner:KUNSHAN SAMON AUTOMATION TECH

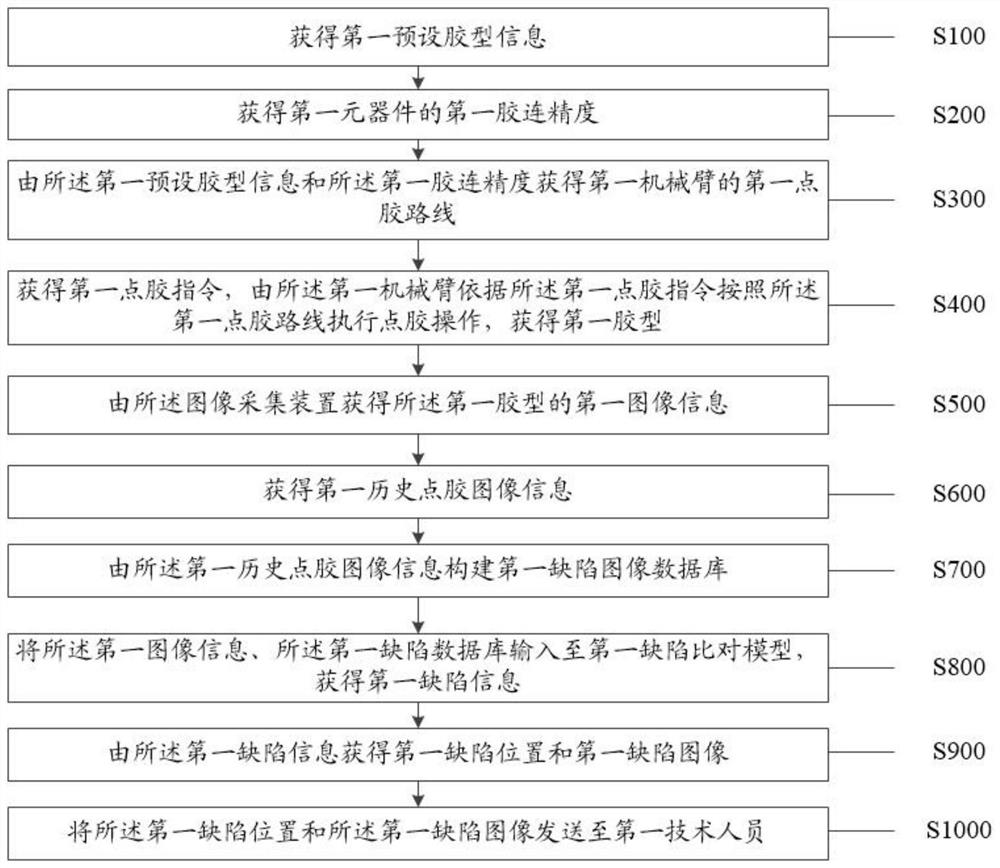

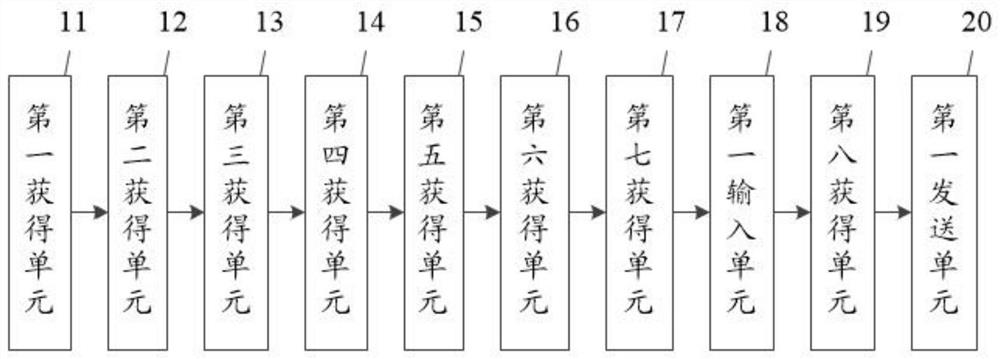

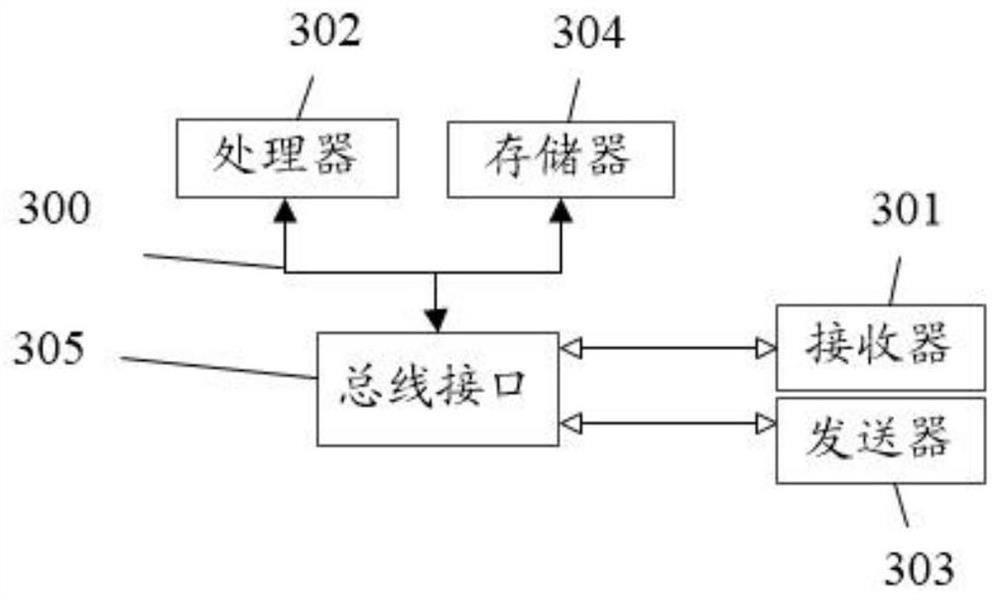

Precise dispensing information processing method and system

ActiveCN112950604ARealize visual inspectionImprove dispensing qualityLiquid surface applicatorsImage analysisInformation processingEngineering

The invention discloses an information processing method and system for precise dispensing, and the method comprises the steps: obtaining first preset glue type information; obtaining the first glue connection precision of the first component; obtaining a first dispensing route of a first mechanical arm according to the first preset glue type information and the first glue connection precision; the first mechanical arm executing dispensing operation according to the first dispensing route, and a first glue type being obtained; obtaining first image information of the first glue type; constructing a first defect image database according to the historical dispensing image information; inputting the first image information and the first defect database into a first defect comparison model to obtain first defect information; and obtaining a first defect position and a first defect image according to the first defect information, and sending the first defect position and the first defect image to a first technician. The technical problems that in the prior art, the intelligent control degree of the dispensing precision is not enough, and defect analysis cannot be conducted in real time are solved.

Owner:SHENZHEN XINLUYUAN ELECTRONICS EQUIP CO LTD

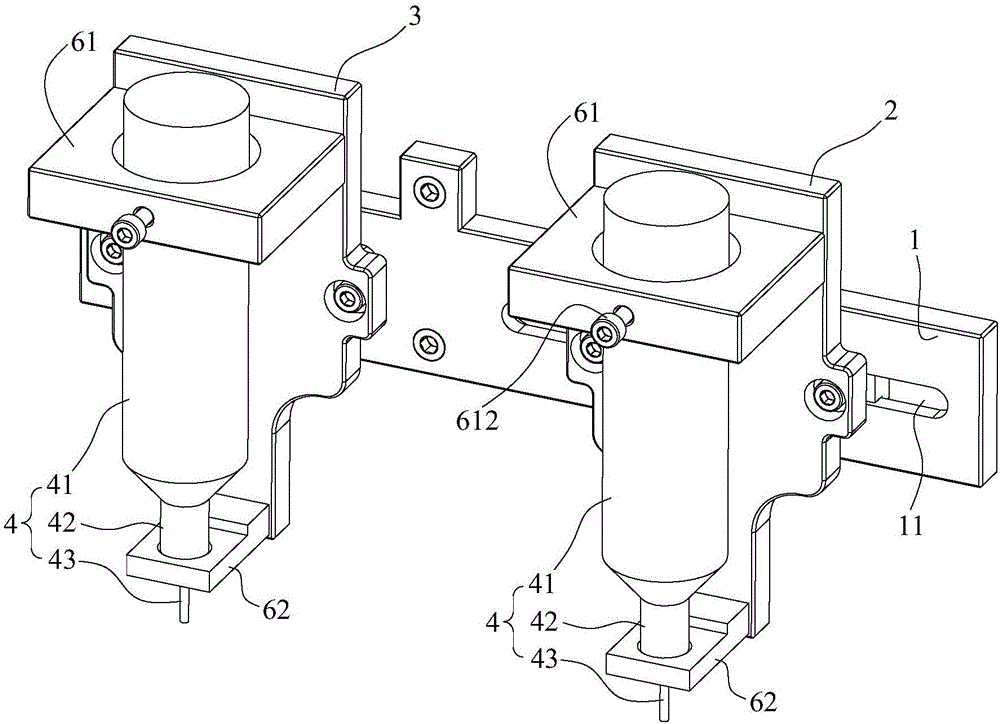

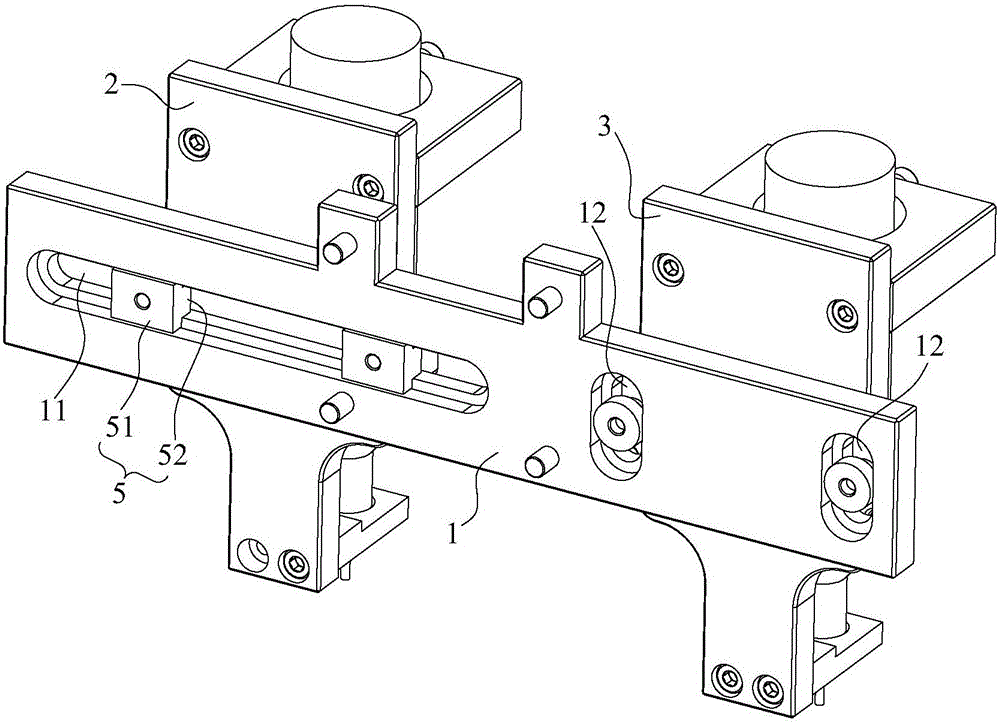

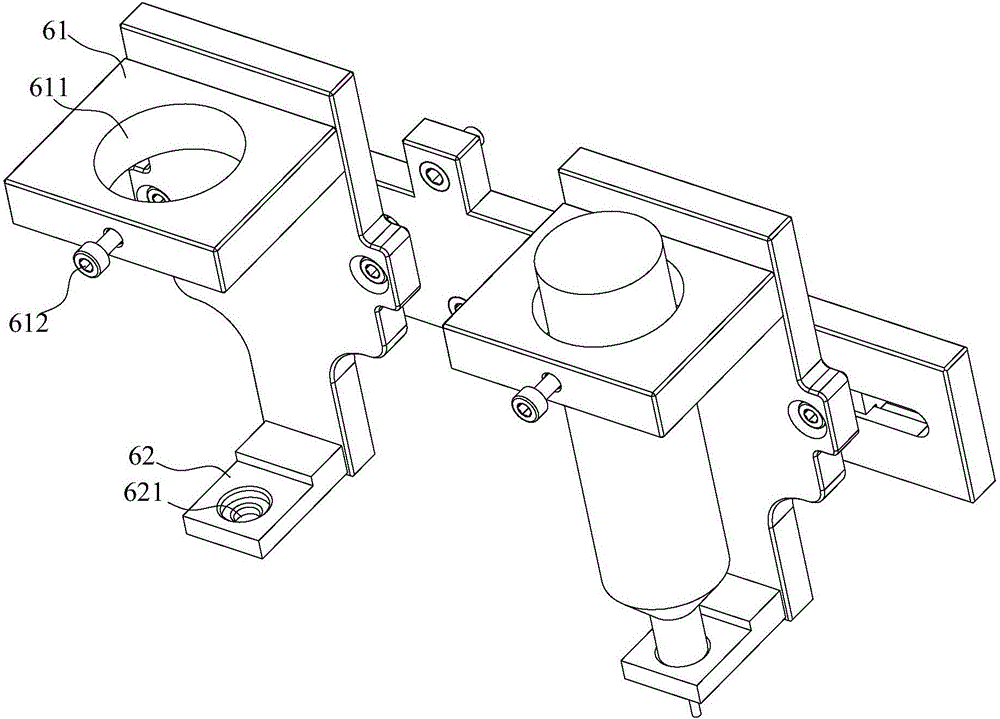

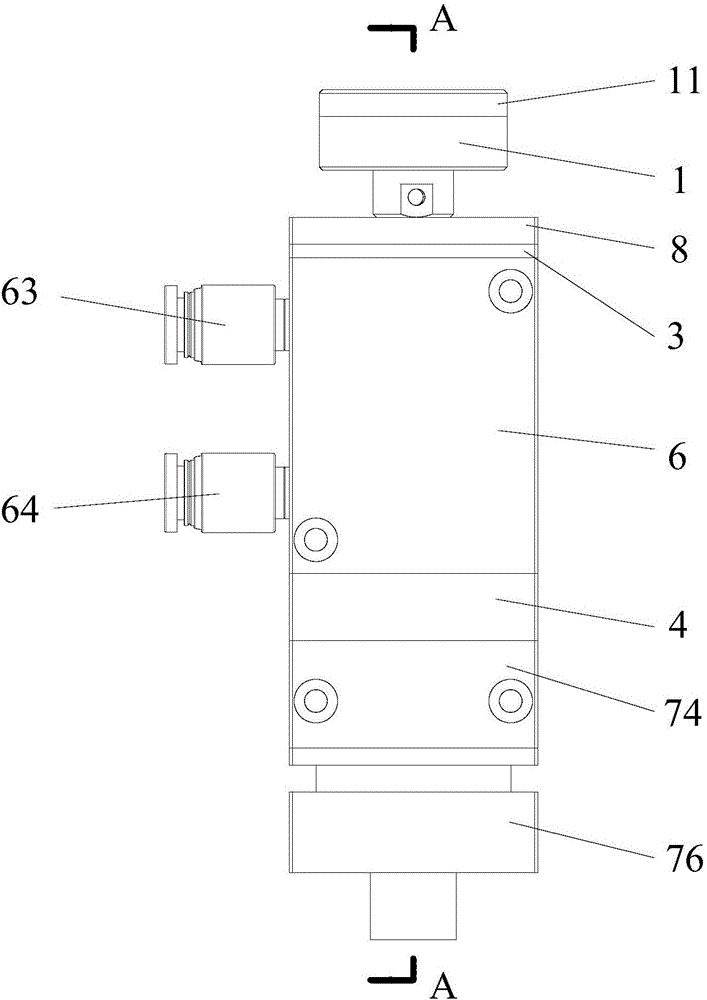

Dispensing jig

InactiveCN106111452AImprove dispensing efficiencyIncreased Versatility and Dispensing AccuracyLiquid surface applicatorsCoatingsInjectorBiomedical engineering

The invention discloses a dispensing jig. The dispensing jig comprises a jig support, a first dispensing support and a second dispensing support. The first dispensing support and the second dispensing support are used for fixing dispensing injectors. The jig support is fixed to a dispensing machine. The first dispensing support can slide along the surface of the jig support in the transverse direction. The second dispensing support can slide along the surface of the jig support in the longitudinal direction. The two dispensing injectors can conduct dispensing on two components at the same time, and the dispensing efficiency is improved. Due to the fact that the first dispensing support can slide along the surface of the jig support in the transverse direction, and the second dispensing support can slide along the surface of the jig support in the longitudinal direction, the position between the first dispensing support and the second dispensing support can be accurately adjusted, the two dispensing positions are accurately adjusted, and universality and the dispensing precision are improved.

Owner:KESEN SCI & TECH DONGTAI CO LTD

Dispensing valve

InactiveCN106799338AImprove dispensing accuracyAccurate and precise adjustmentLiquid surface applicatorsCoatingsEngineeringAtmospheric pressure

The invention discloses a dispensing valve. The dispensing valve comprises a stroke fine tuning rotary knob, an adjusting rod, an adjusting rod fixing base, a plunger rod, a piston, a hollow cylinder body and an adhesive storing body. Accurate dispensing is conducted by controlling the air pressure; in addition, the dispensing quantity can be controlled through the coordinating function between the external stroke fine tuning rotary knob and the adjusting rod; the whole dispensing valve does not need to be disassembled; using is simple and easy; and the service life is long.

Owner:SUZHOU TERUITE ROBOT CO LTD

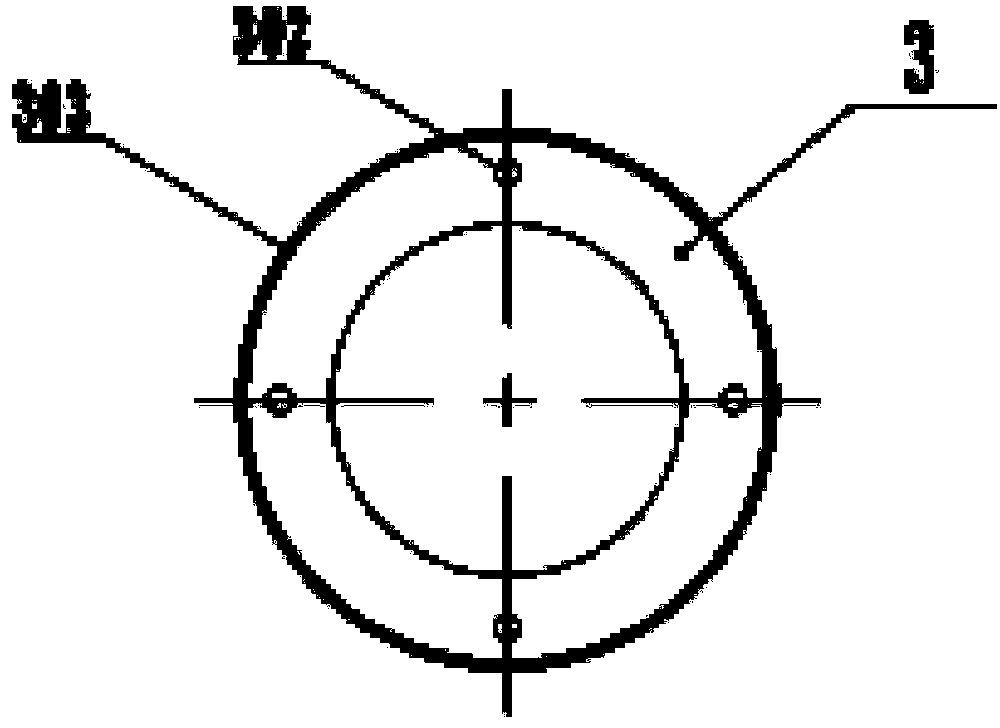

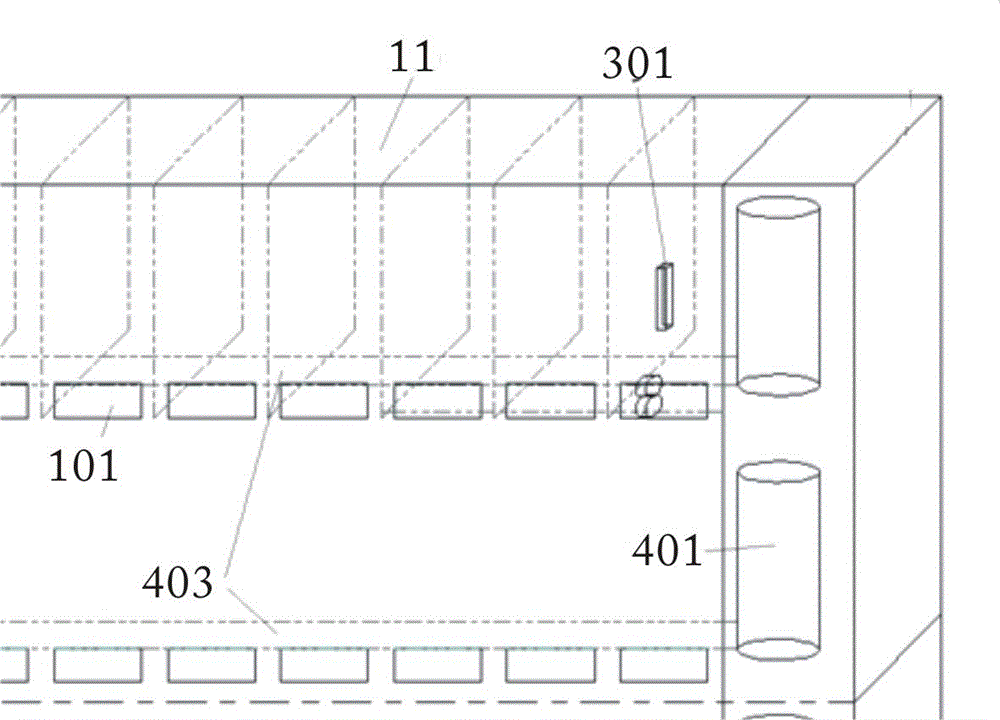

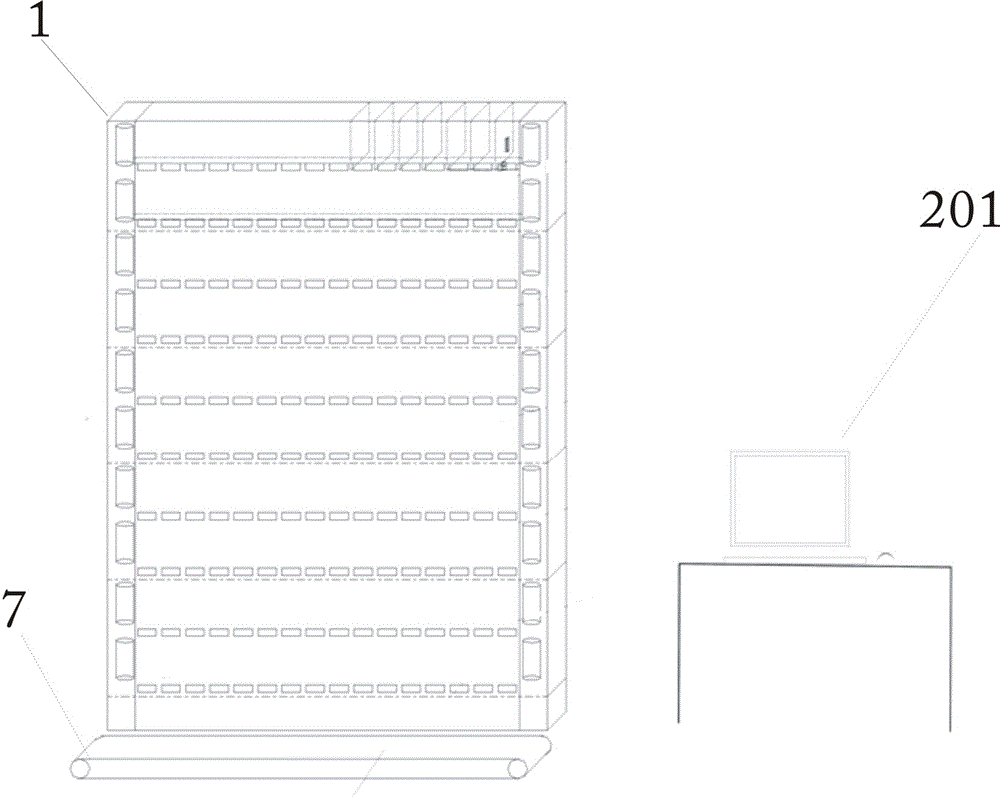

Full-automatic Chinese medicinal granula punch-pack dispensing machine

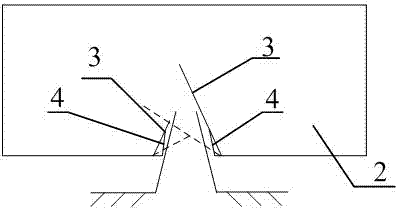

InactiveCN104828317AImprove dispensing accuracyImprove dispensing efficiencyPackaging automatic controlIndividual articlesAutomatic controlMedicine

The invention discloses a full-automatic Chinese medicinal granula punch-pack dispensing machine. The full-automatic Chinese medicinal granula punch-pack dispensing machine comprises a machine cabinet with a plurality of unit medicine boxes, a central controller, a counting mechanism, a cutting mechanism and a medicine discharging mechanism; the cutting mechanism comprises cutters which are arranged in a medicine outlet of each unit medicine box and a linear motor which is connected with the cutters in a driving manner; the linear motor is connected with the central controller by virtue of a signal; the counting mechanism comprises an infrared counting sensor which is matched with each unit medicine box; the infrared counting sensor is connected with the central controller by virtue of a signal; the medicine outlet mechanism comprises a medicine delivery drive wheel which is arranged in each unit medicine box and a speed regulation motor which is connected with the medicine delivery drive wheel in a drive manner; the speed regulation motor is connected with the central controller by virtue of a signal. By adopting the full-automatic Chinese medicinal granula punch-pack dispensing machine, the automatic control of medicine dispensing and medicine distribution can be realized, the dispensing accuracy can be improved, and the dispensing efficiency can be accelerated.

Owner:孙嘉彬

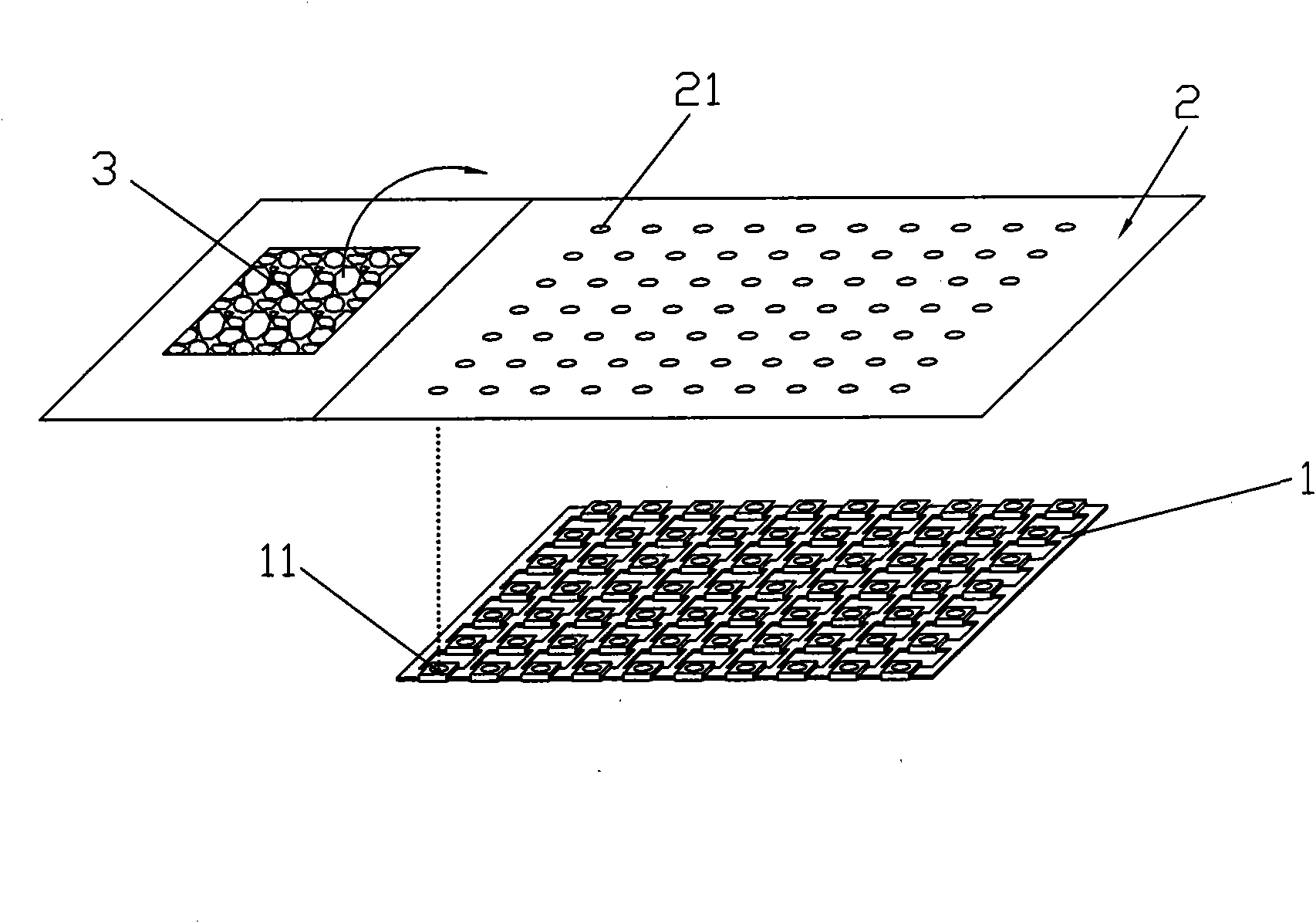

Liquid glue encapsulation device and encapsulation method using same

InactiveCN101670331ADispensing speed is fastImprove dispensing accuracyLiquid surface applicatorsCoatingsEngineering

The invention is applicable to the field of liquid glue encapsulation, and provides a liquid glue encapsulation device which comprises a slice jointed with the product to be encapsulated with liquid glue, and the slice is provided with glue injecting holes that are corresponding to the parts of the product to be encapsulated with liquid glue and have the number being the same as that of the parts.The invention also provides an encapsulation method using the liquid glue encapsulation device, comprising: the slice provided with the glue injecting holes is jointed on the product to be encapsulated with the liquid glue, and the liquid glue is brushed towards the glue injecting holes by a brush or a scraper, so that liquid glue flows into the glue injecting holes and then onto the parts of theproduct to be encapsulated with liquid glue, and the parts of the product to be encapsulated with liquid glue are fully filled with the liquid glue; therefore, the speed and the accuracy rate of adhesive dispense can be improved.

Owner:SHENZHEN REFOND OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com