Curved pinhead rotary positioning device for dispensing

A positioning device and needle technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems that straight needles are difficult to complete the dispensing task, and it is difficult to be convenient, and achieve the effect of improving dispensing efficiency and dispensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

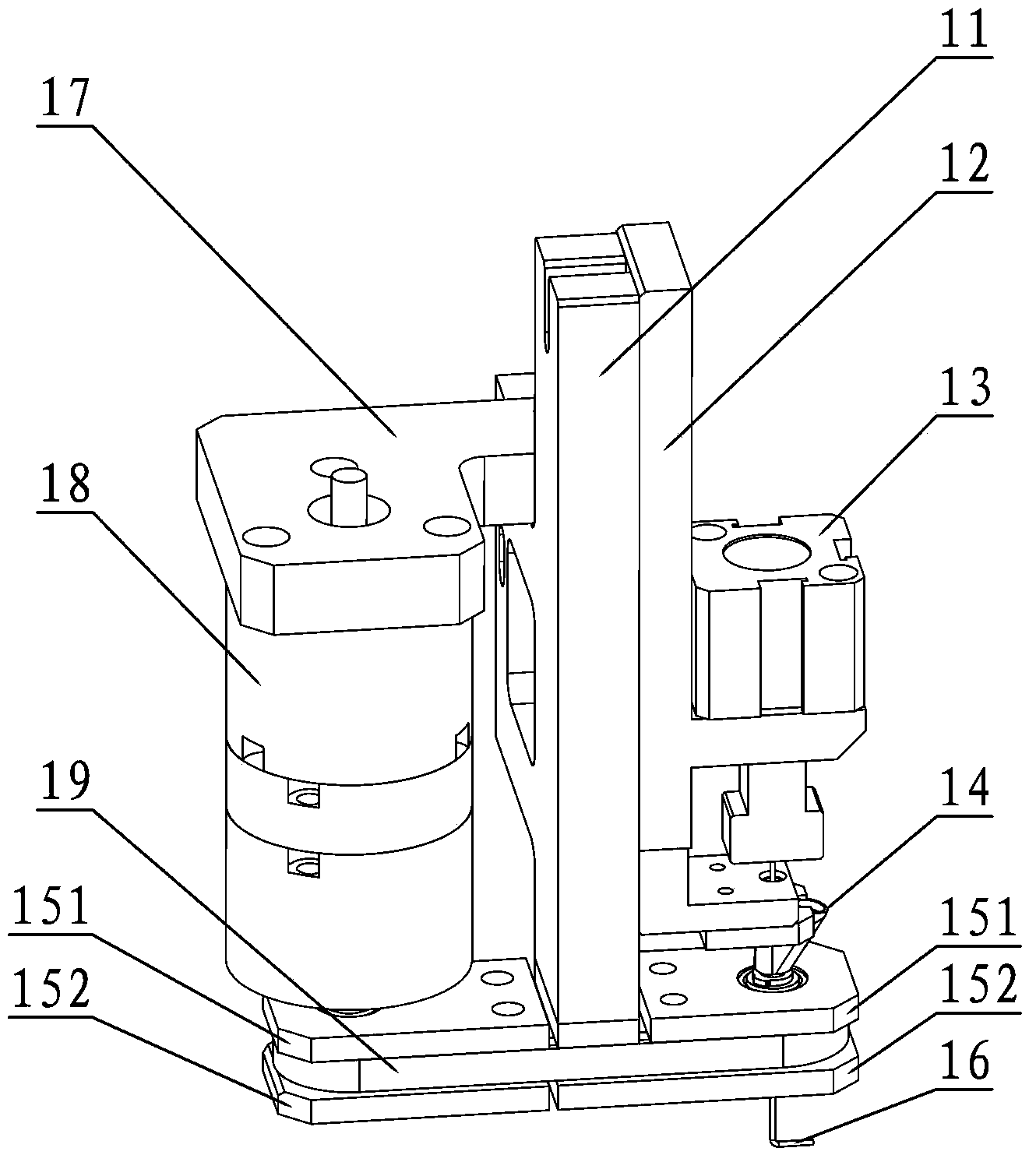

[0019] according to figure 1 , the looper head rotary positioning device for dispensing provided by the present invention includes a bracket 11, a linear cylinder holder 12 installed on the bracket 11, a linear cylinder 13 installed on the linear cylinder holder 12, and a point driven by the linear cylinder 13. Glue valve 14, and the looper head 16 that is installed on the top of dispensing valve 14; Rotation mechanism fixing seat 17 is also installed on the bracket 11, and rotation mechanism 18 is installed on the rotation mechanism fixing seat 17; Rotation mechanism 18 is connected with synchronous wheel one, Two synchronous wheels are installed on the dispensing valve 14, and the first synchronous wheel and the second synchronous wheel are connected by a synchronous belt 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com