Patents

Literature

1433 results about "Production automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

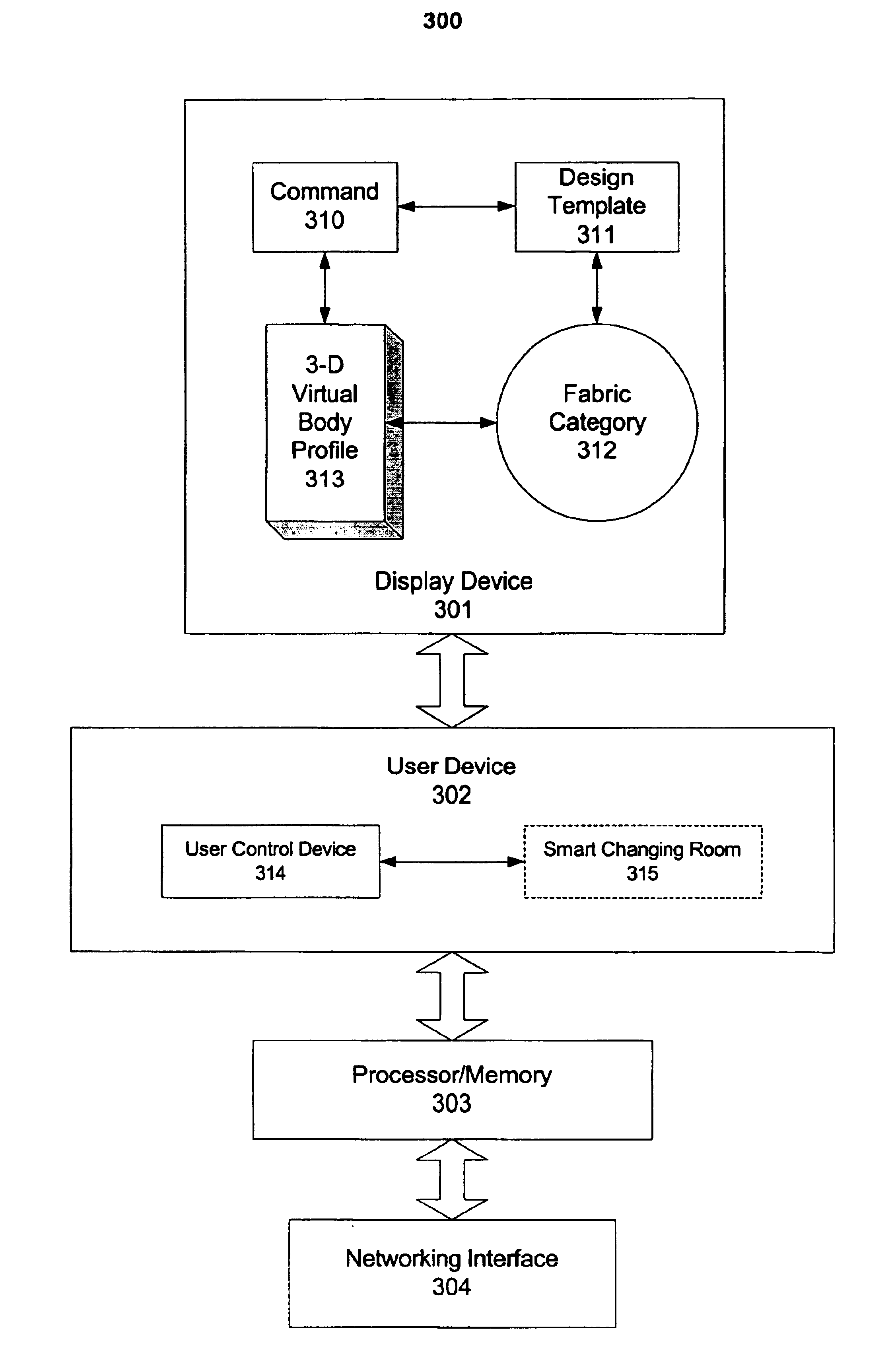

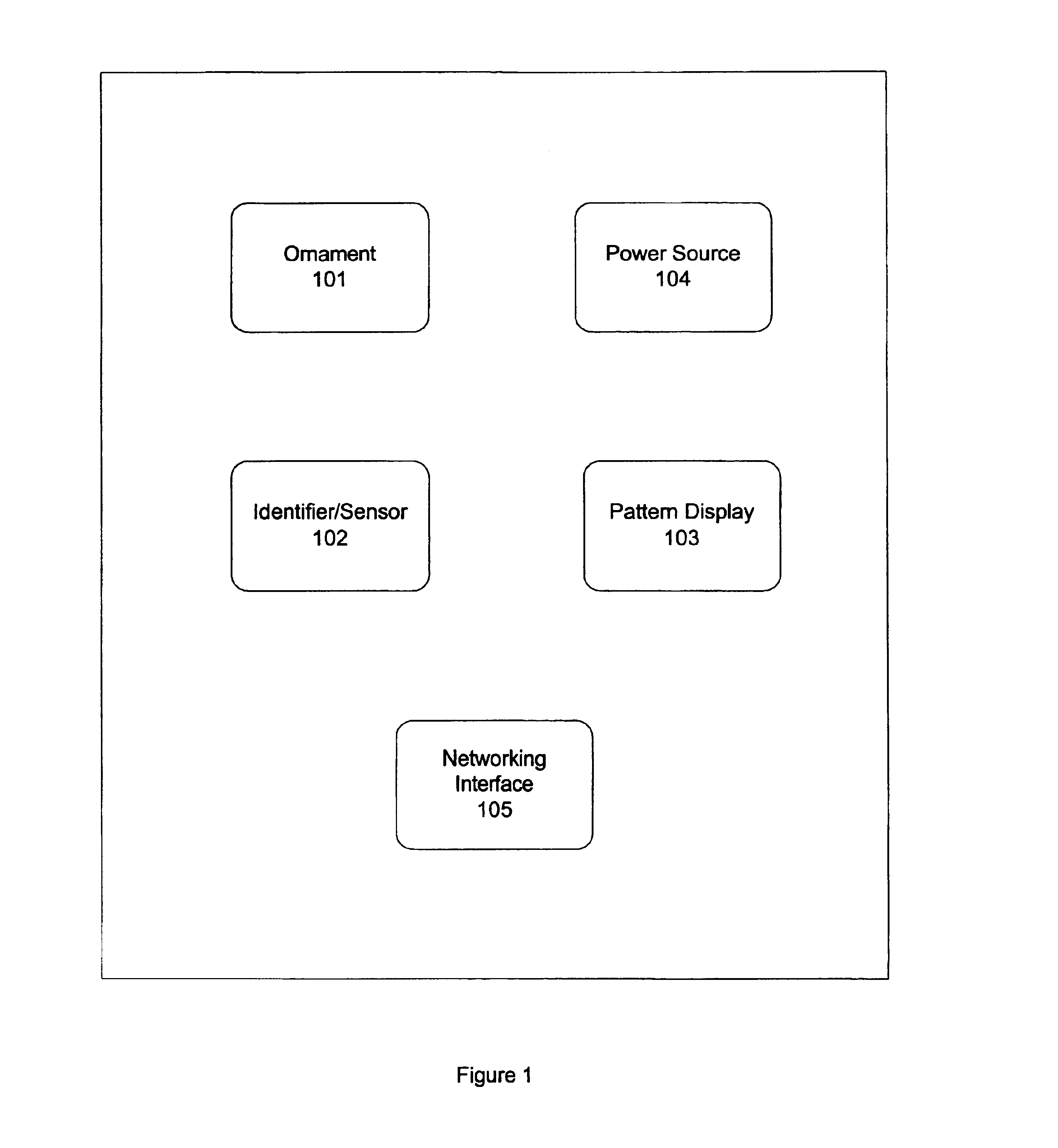

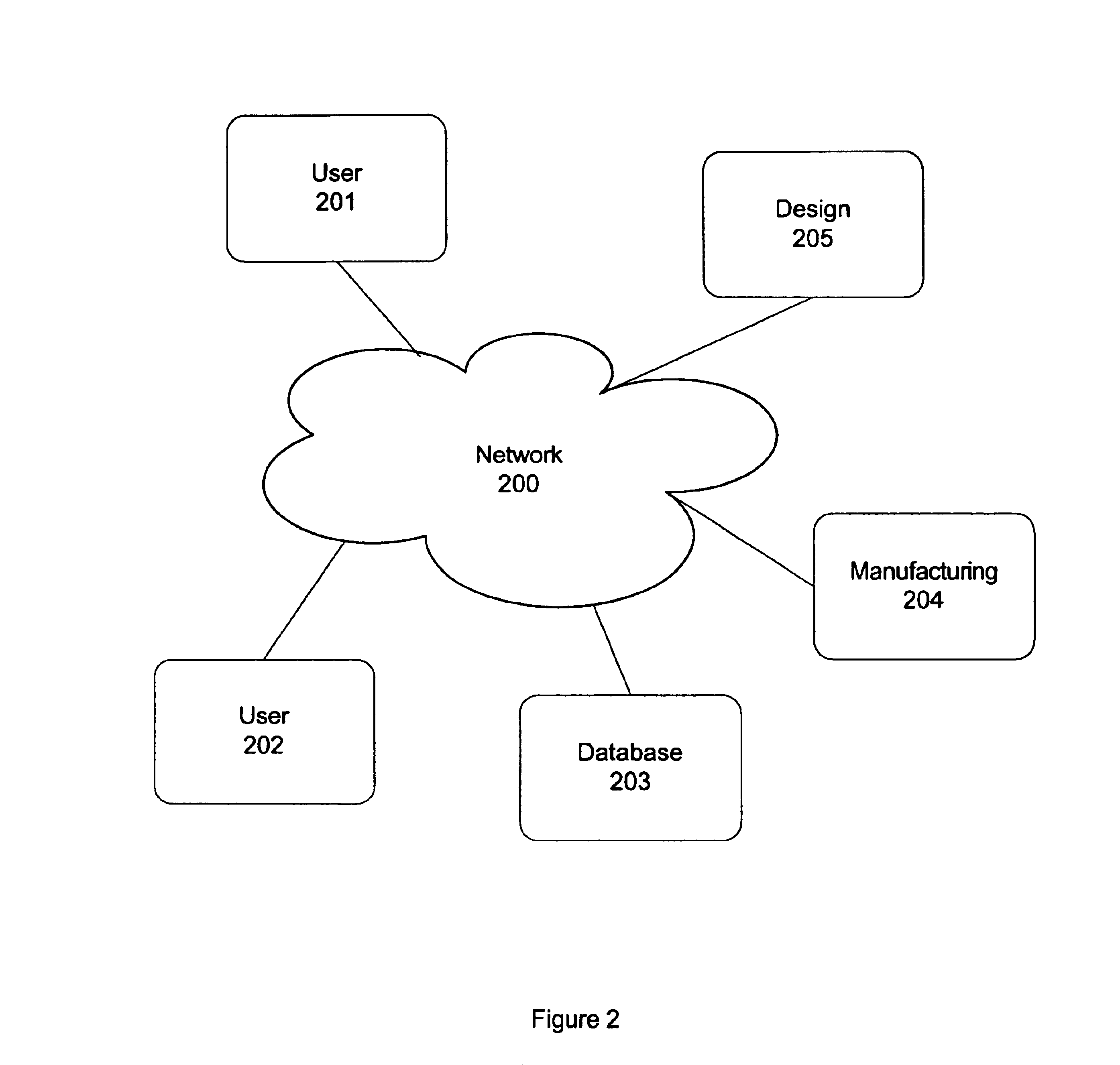

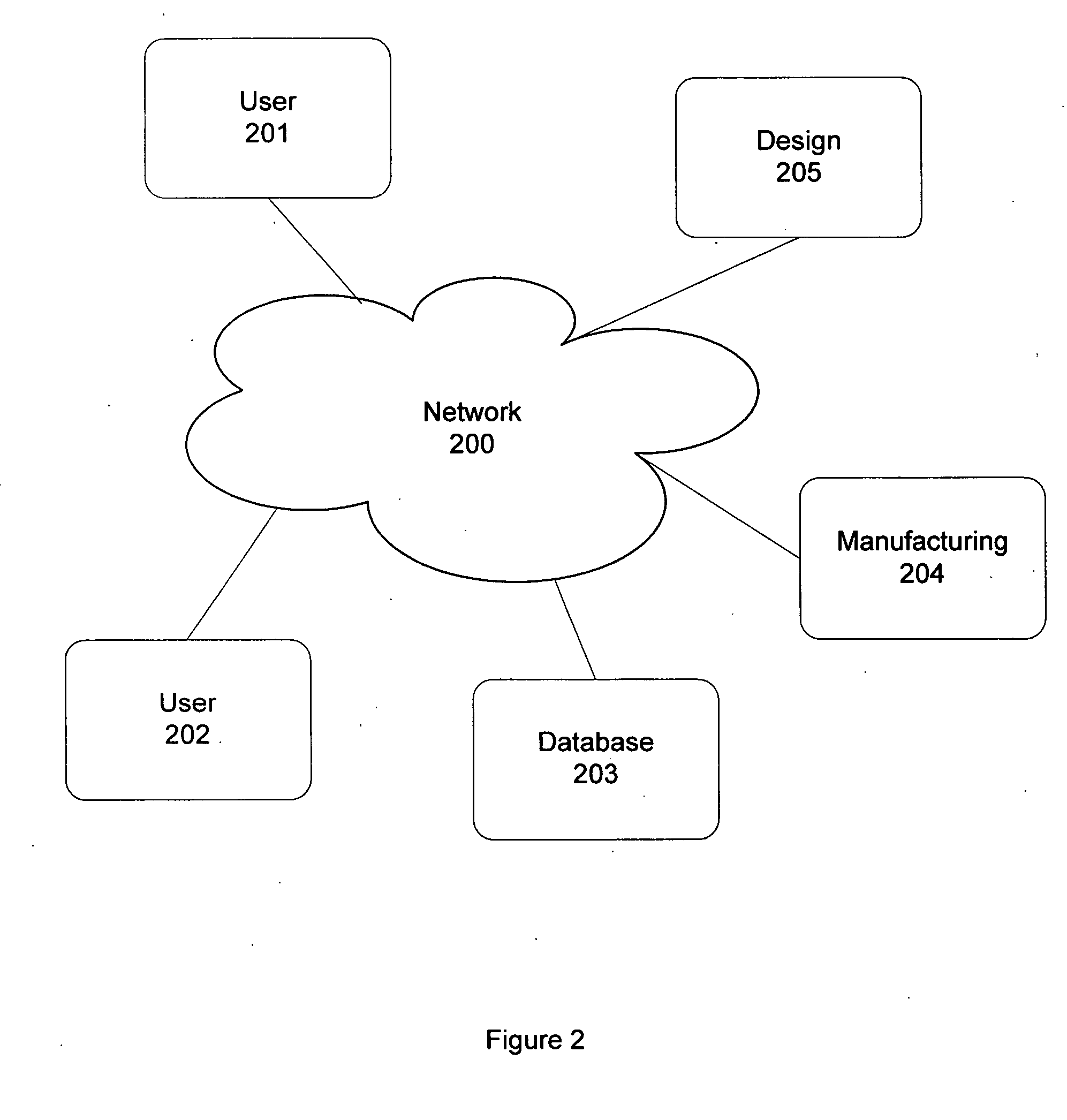

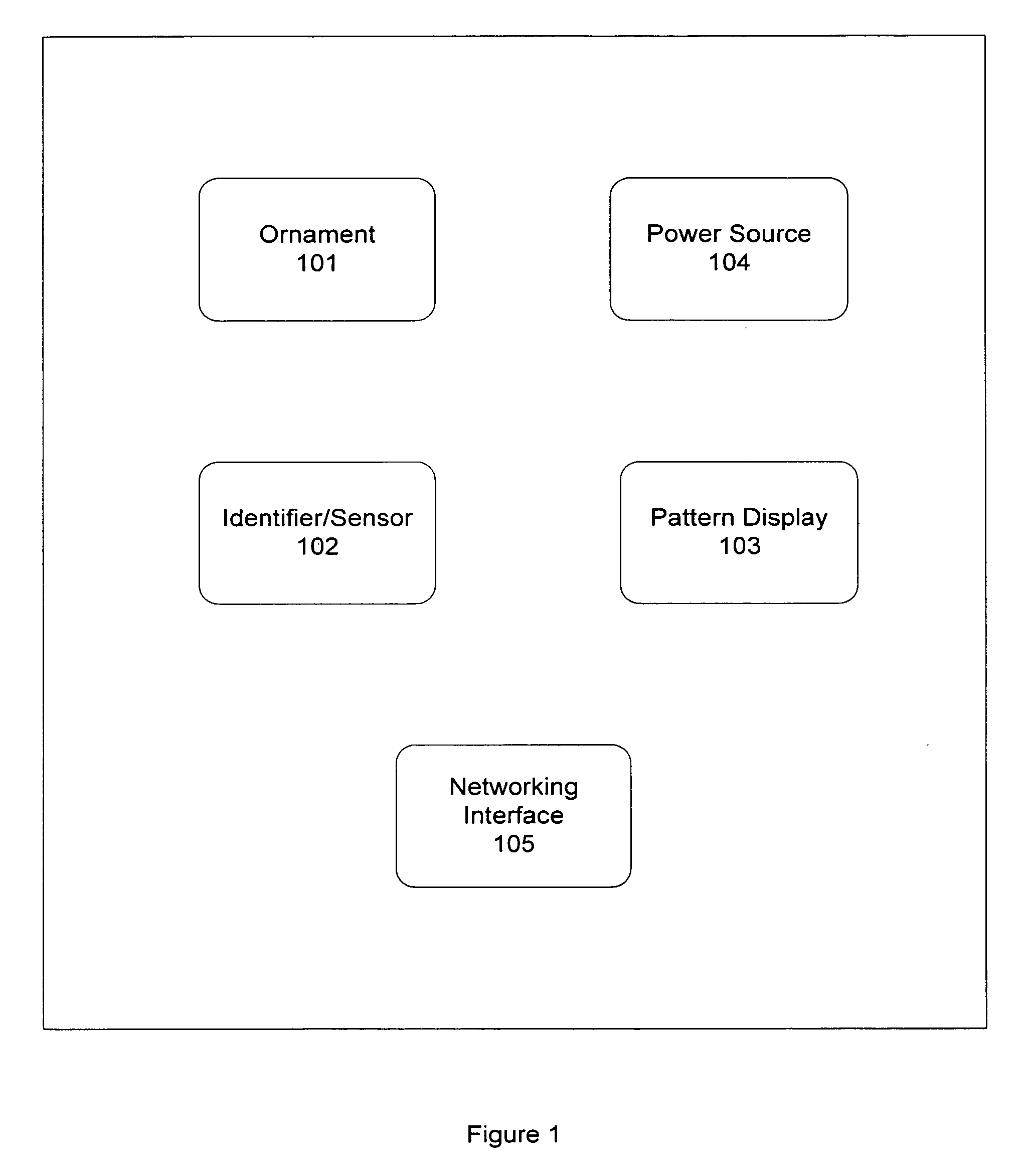

Reconfigurable garment definition and production method

InactiveUS6882897B1Efficient integrationSimple designGarmentsSurgeryLine sensorComputer Aided Design

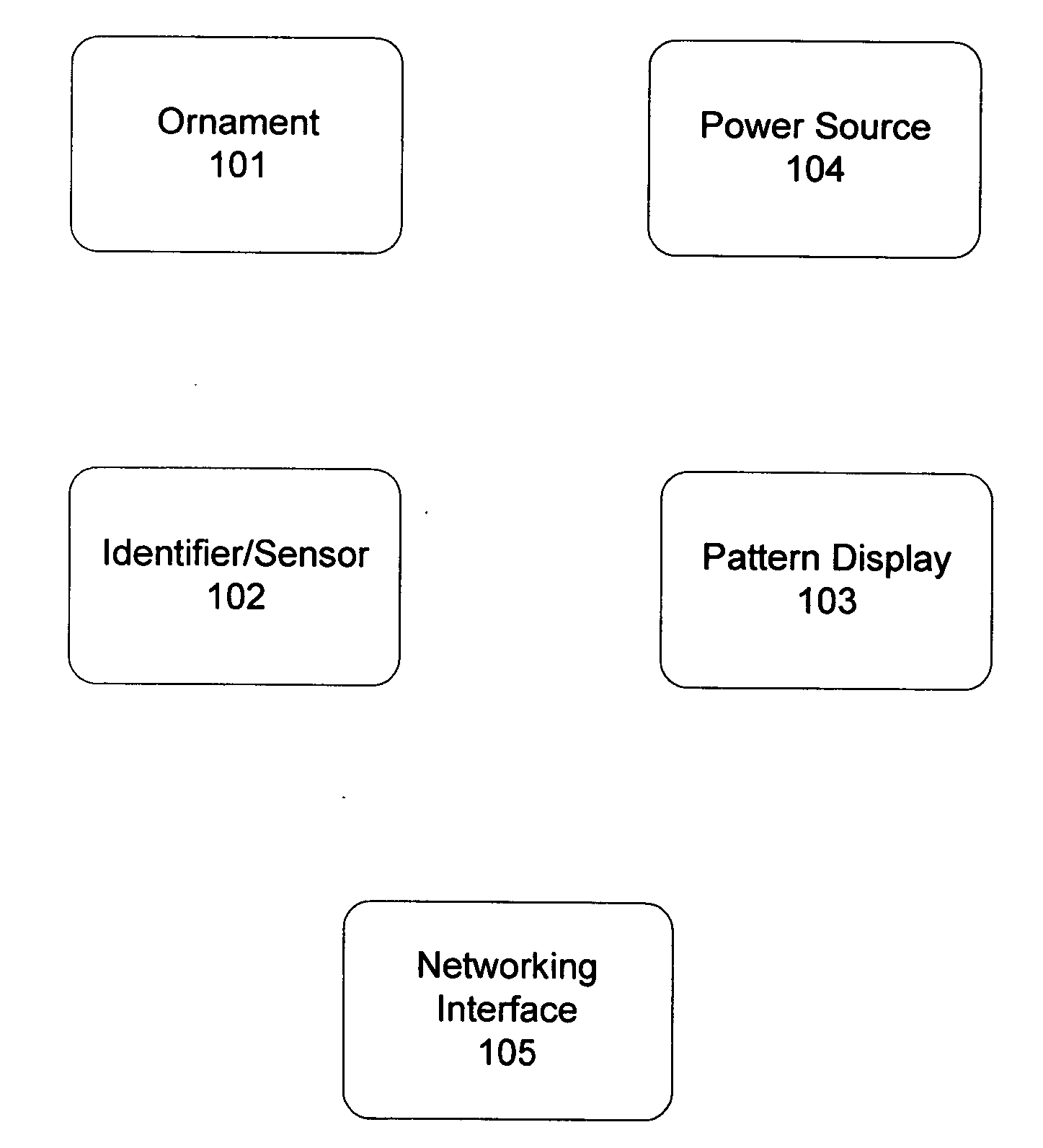

Computer-aided design and manufacture software and hardware automate garment and fashion definition and production. Configurable garment includes ornamental element, pattern display, and personal identifier and wireless sensor electronics.

Owner:FERNANDEZ DENNIS S

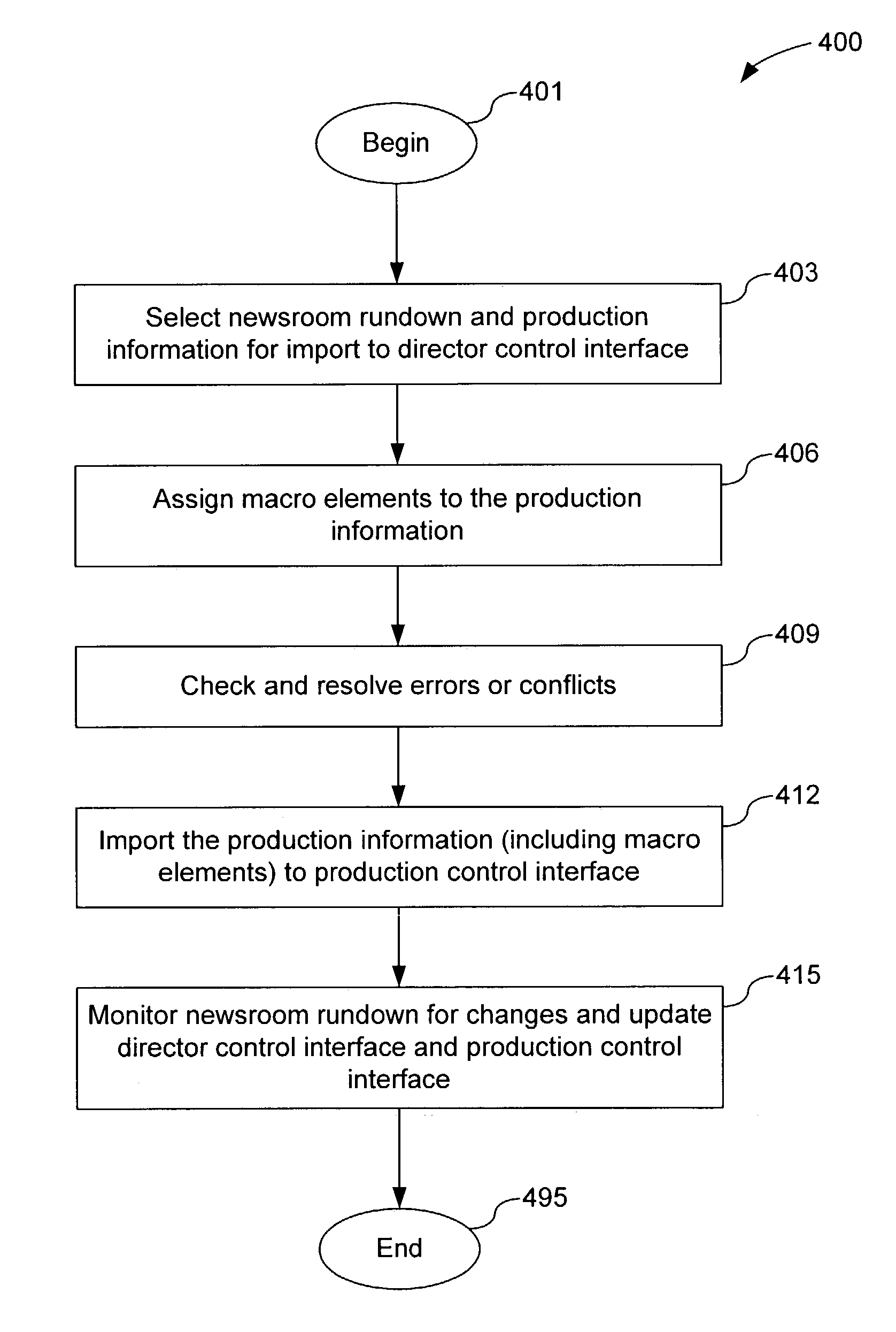

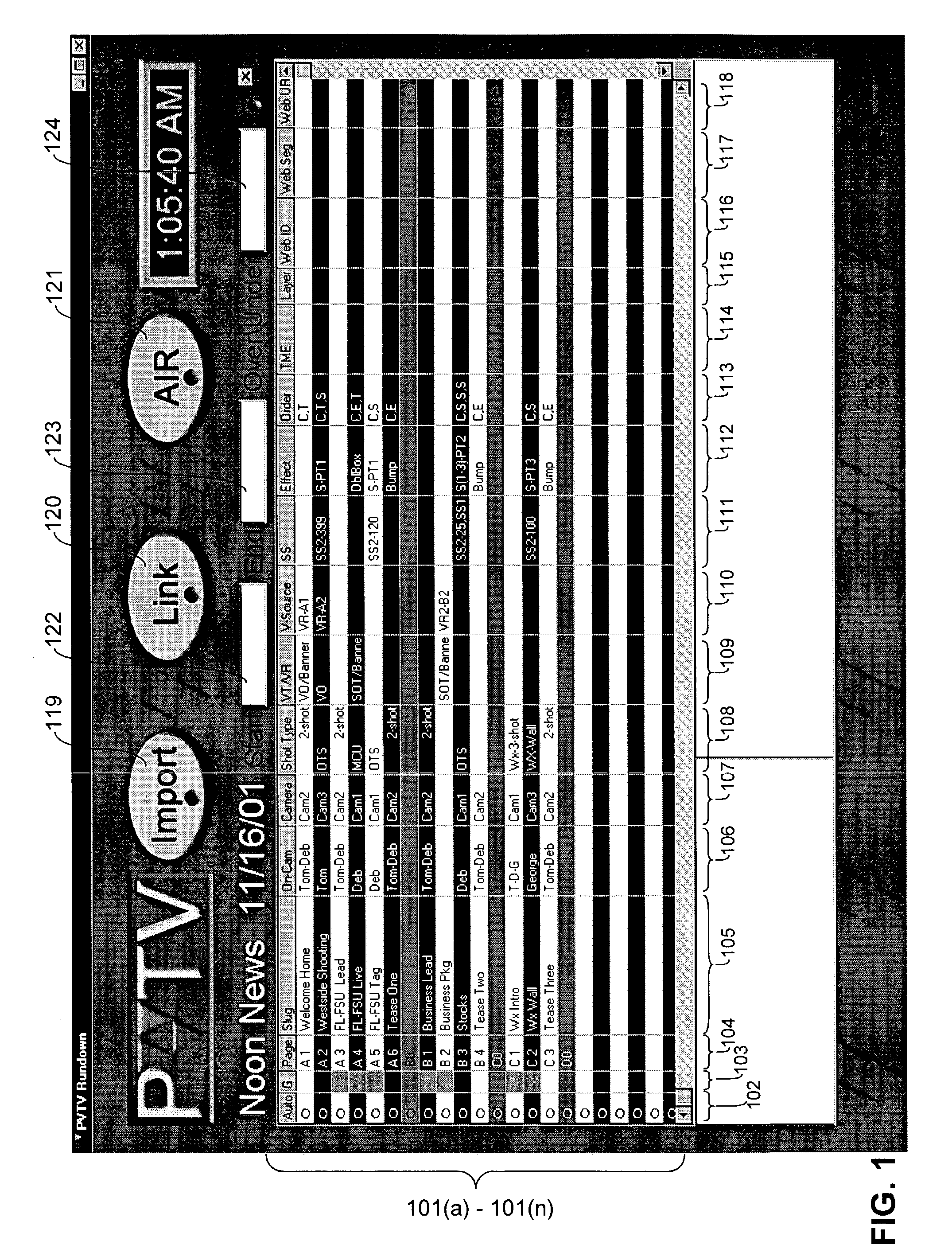

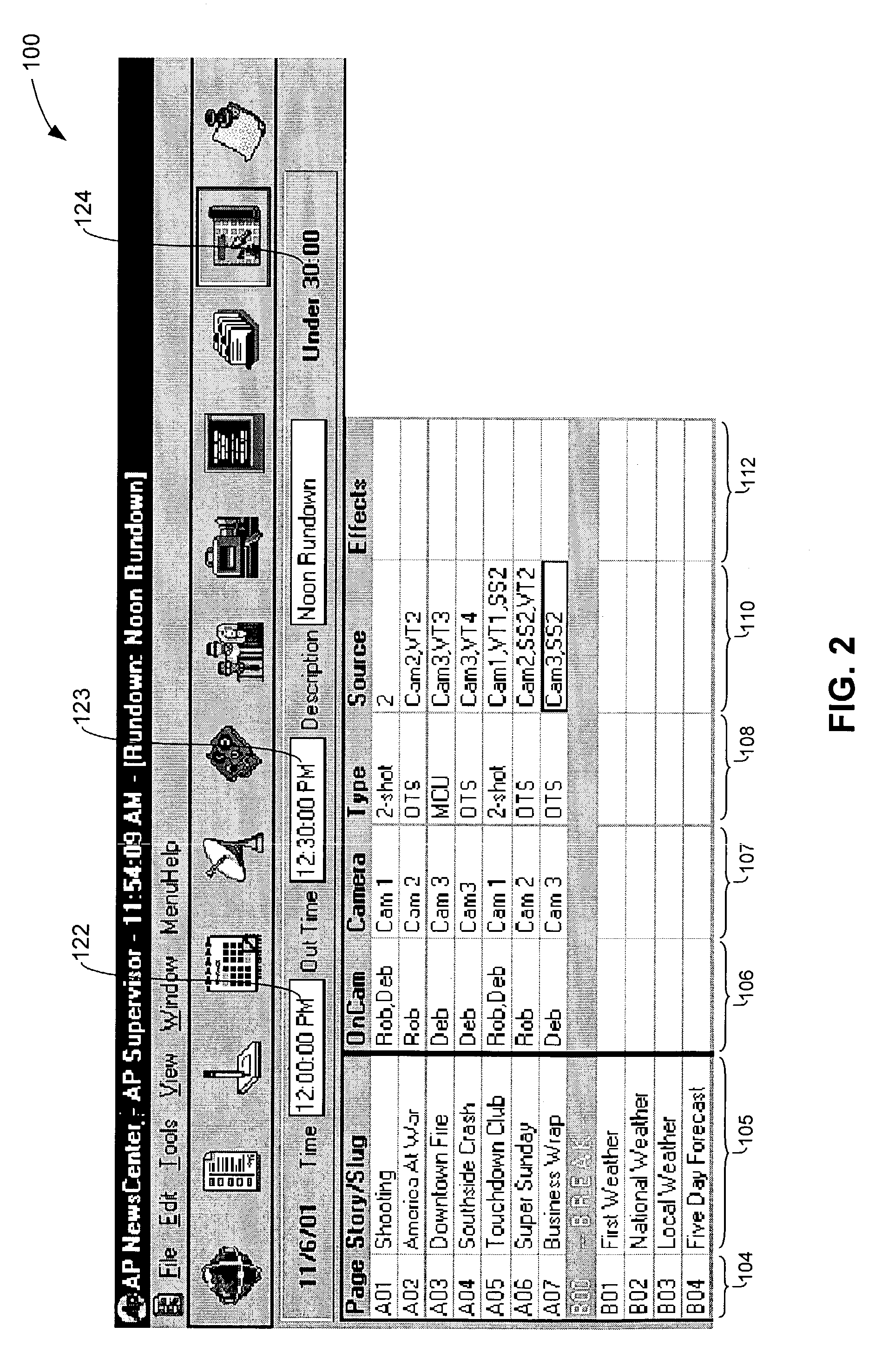

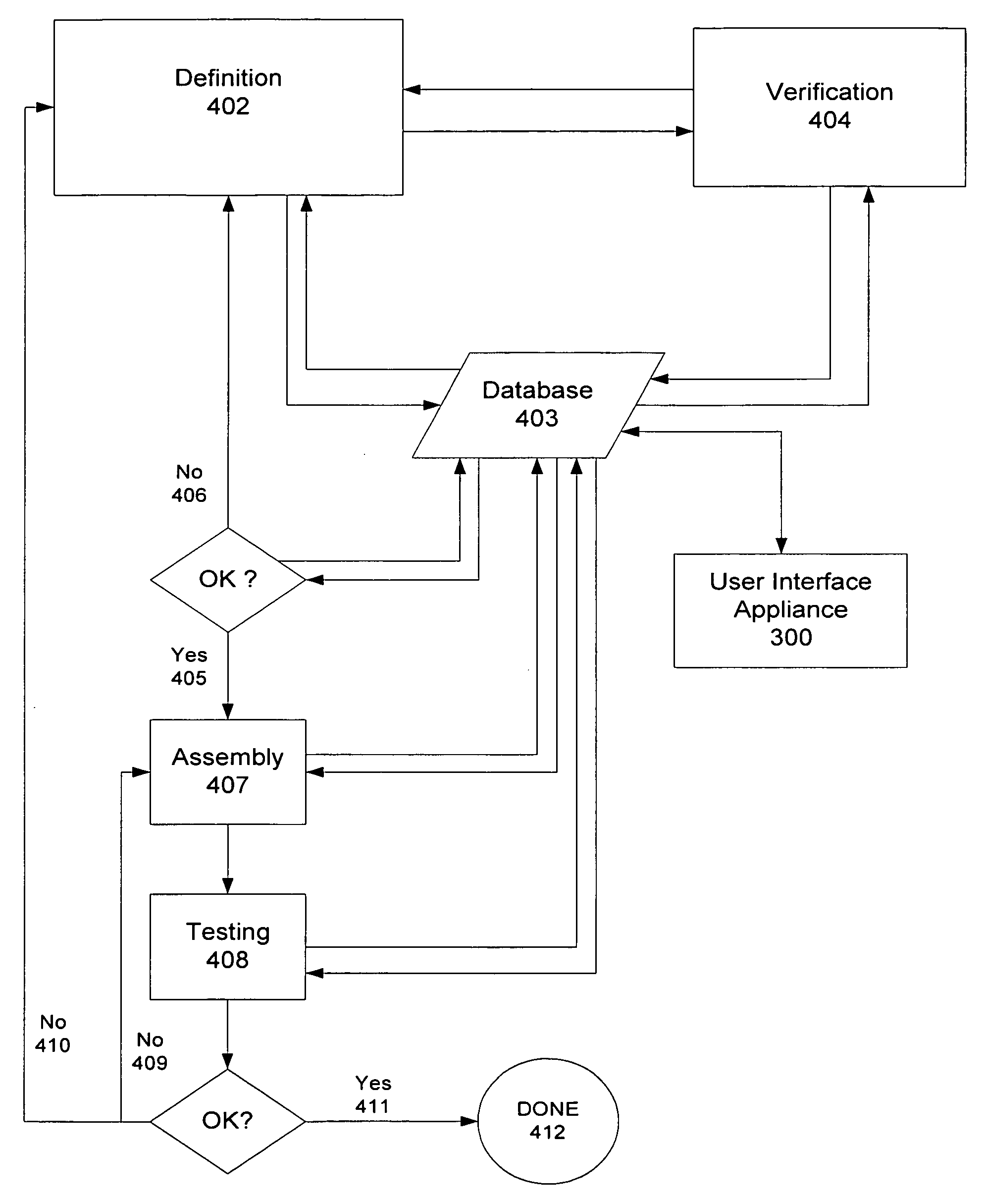

Director interface for production automation control

InactiveUS7835920B2Reduce errorsTelevision system detailsRecord information storageControl systemProduction control system

A director control interface is provided to extract production information from a newsroom information management system and populate a production control system. The director control interface enables the director to build a show, but mitigate errors and check for conflicts during the building process. In an embodiment, the director control interface automatically selects macro elements, which are executed on the production control system. The director can override the selection process and choose the macro elements. The director control interface monitors the newsroom information management system for rundown changes, evaluates the changes, and updates the production control system either automatically or with approval from the director. The director control interface is compatible with any type of newsroom information management system as long as it can extract the requisite information.

Owner:MAGNOLIA LICENSING LLC

Reconfigurable garment definition and production method

Computer-aided design and manufacture software and hardware automate garment and fashion definition and production. Configurable garment includes ornamental element, pattern display, and personal identifier and wireless sensor electronics.

Owner:FERNANDEZ DENNIS S

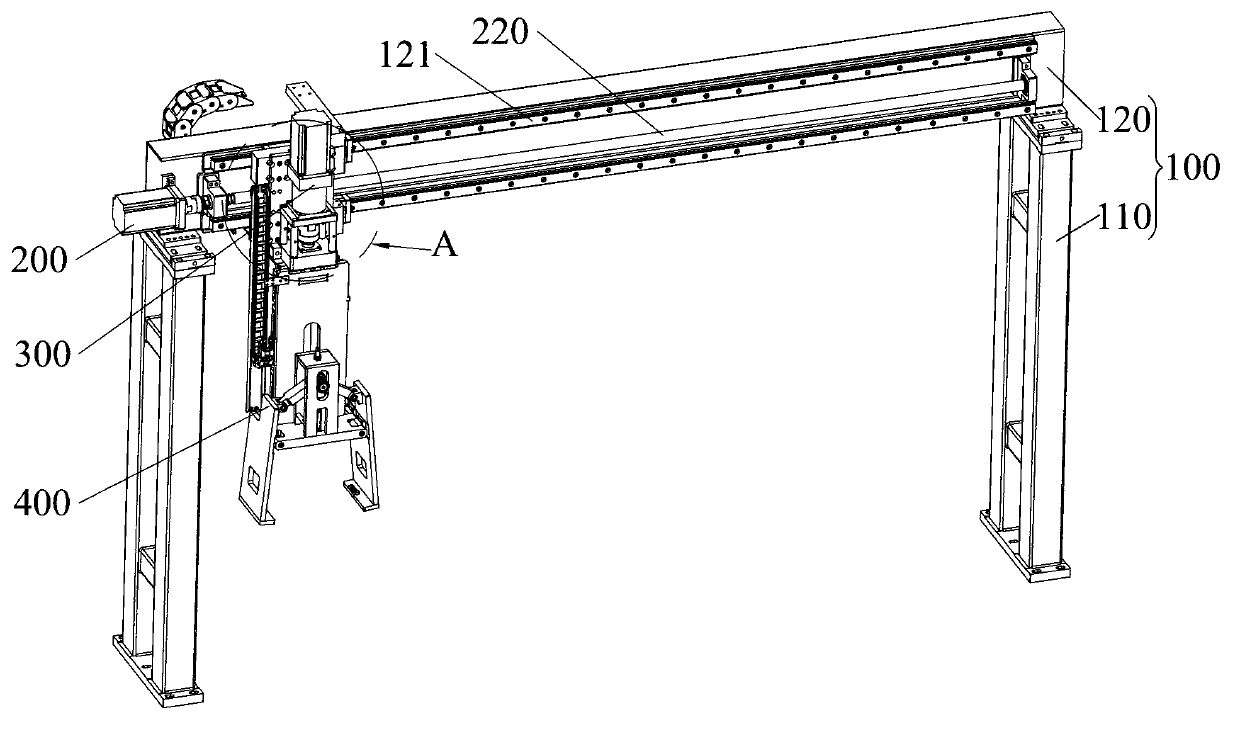

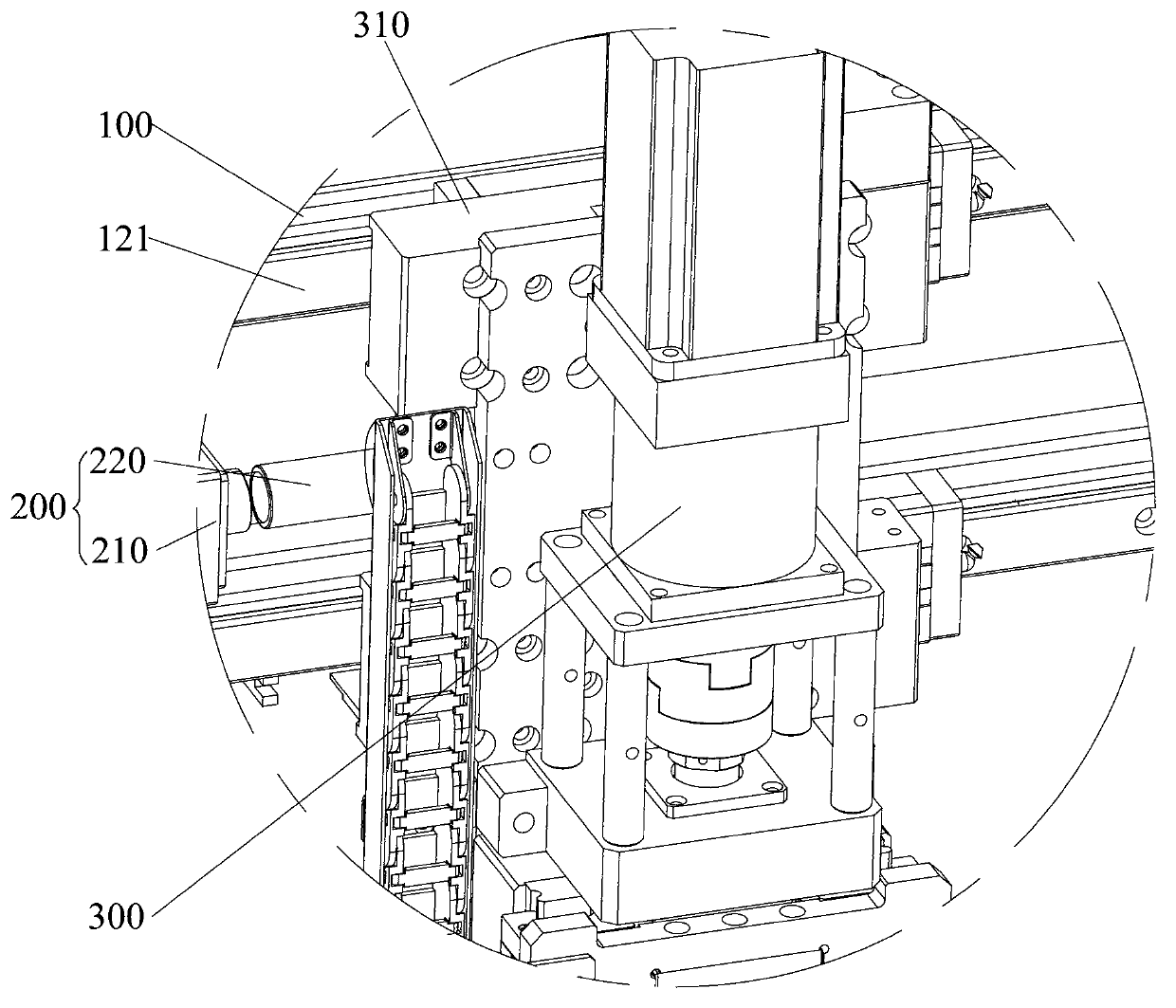

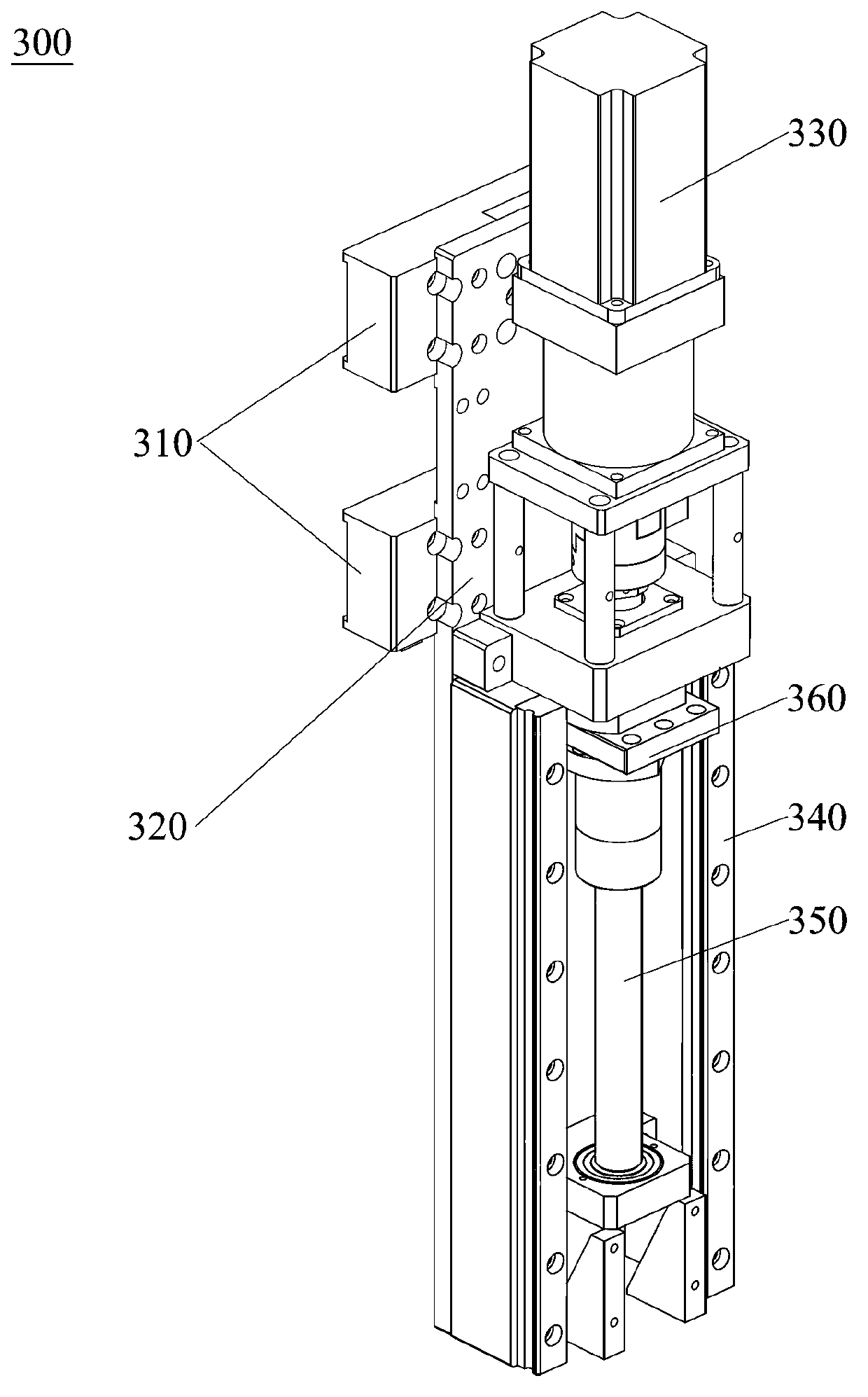

Mechanical arm

ActiveCN103213120AImprove qualityEasy to moveProgramme-controlled manipulatorGripping headsRobotic armElectrical and Electronics engineering

The invention relates to battery production equipment, in particular to a mechanical arm for carrying battery clamps. The mechanical arm comprises a support, a horizontal driving mechanism, a vertical driving mechanism and a clamping mechanism, wherein the vertical driving mechanism is installed on the support in a horizontally-sliding mode, and the horizontal driving mechanism is installed on the support and drives the vertical driving mechanism to horizontally move; the vertical driving mechanism drives the clamping mechanism to move up and down; the clamping mechanism comprises a bearing plate, a pushing unit and at least two jaws, and the bearing plate is connected with the output end of the vertical driving mechanism; and the pushing unit is arranged on the bearing plate and pushes the two jaws to be opened or closed. The mechanical arm is used for carrying the battery clamps so as to replace manual carrying, so that the production efficiency is increased, the battery quality is optimized, and the production automation is benefited.

Owner:DONGGUAN TEC RICH ENGINEERING CO LTD

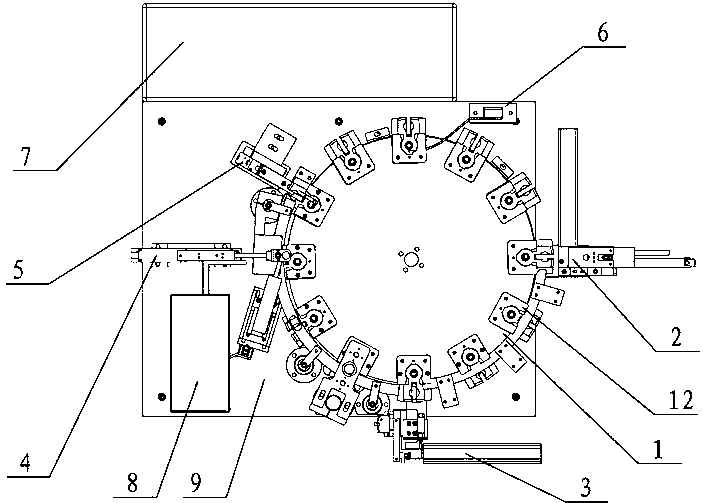

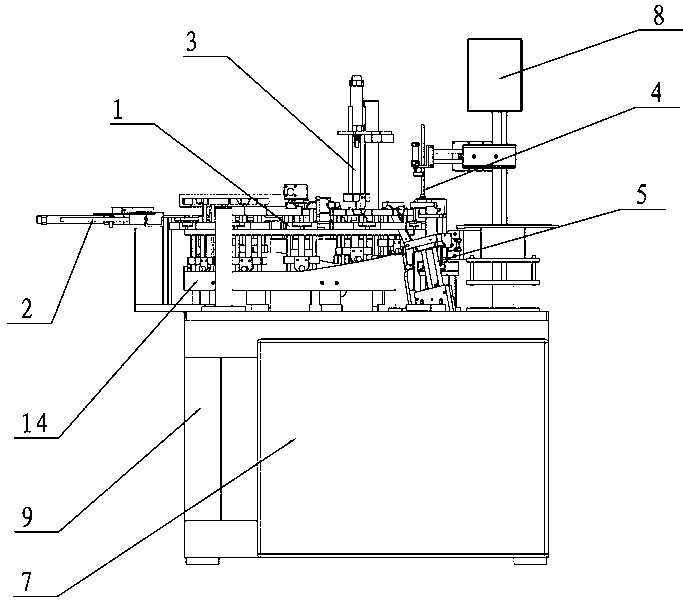

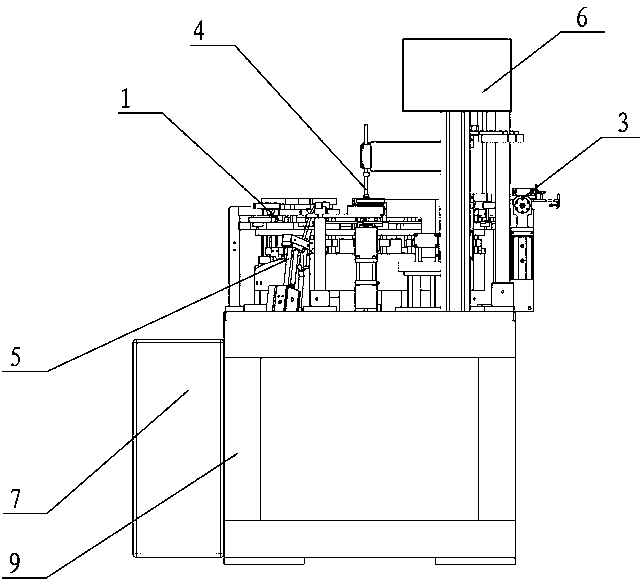

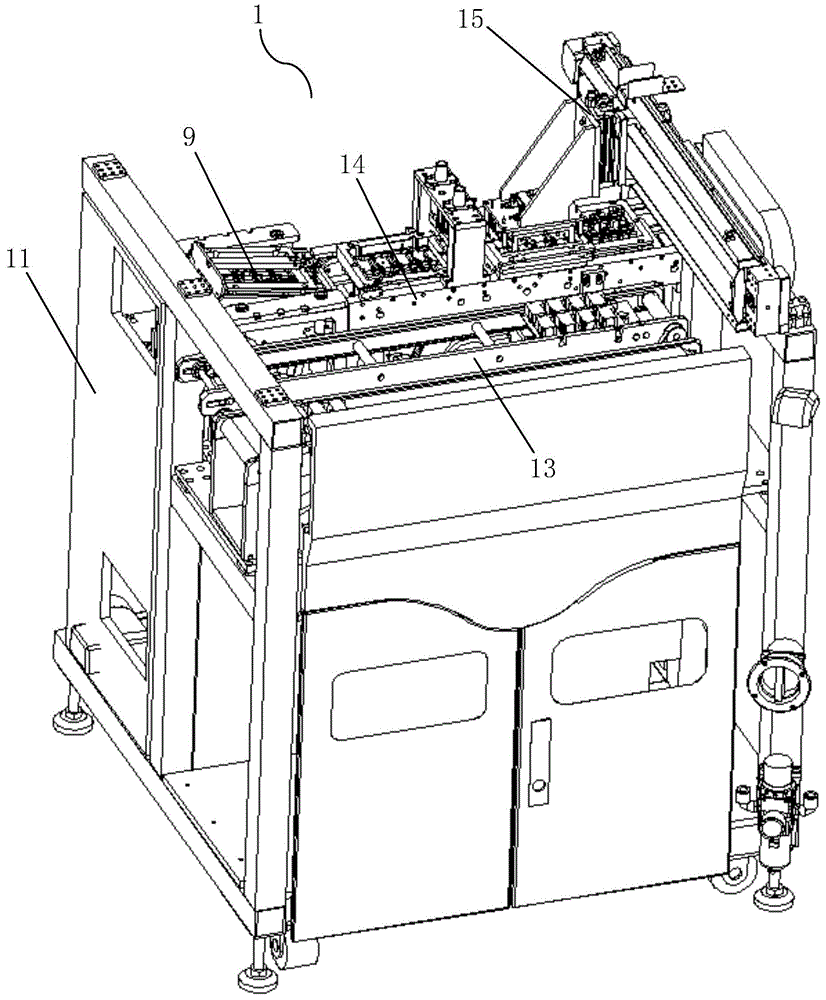

Cap assembling device

InactiveCN103252635AImprove assembly efficiencyImprove production automationMetal working apparatusFastening meansOutput deviceBottle cap

The invention relates to a cap assembling device which is used for assembling kettle caps, bottle caps and other combined type caps. The cap assembling device is characterized in that a cap combining device comprises a divided plate, a plurality of locating components are arranged on the divided plate along the periphery, and a concave-convex station sliding rail is arranged below the divided plate in a surrounding mode and located at the position which is aligned to the locating components vertically. The locating components comprise screening blocks, locating pads, and a guide assembly which is arranged below the screening blocks and the locating pads and used for changing the vertical distance between the locating pads and the screening blocks. The screening blocks and the locating pads are used for locating raw materials, and the lower end of the guide assembly is connected with the station sliding rail. The cap combining device in a divided plate mode is used, connection of upper caps and lower caps is controlled intelligently and finished automatically, and a lower cap conveying device, an upper cap conveying device, a paster conveying device, an output device and the like are combined, so that the complete process from feeding to output of finished products of kettle caps is finished orderly and compactly. Production automation is improved, and assembling efficiency of the kettle caps, the bottle caps and other combined type caps is improved.

Owner:德清中科金融信息技术研究院 +1

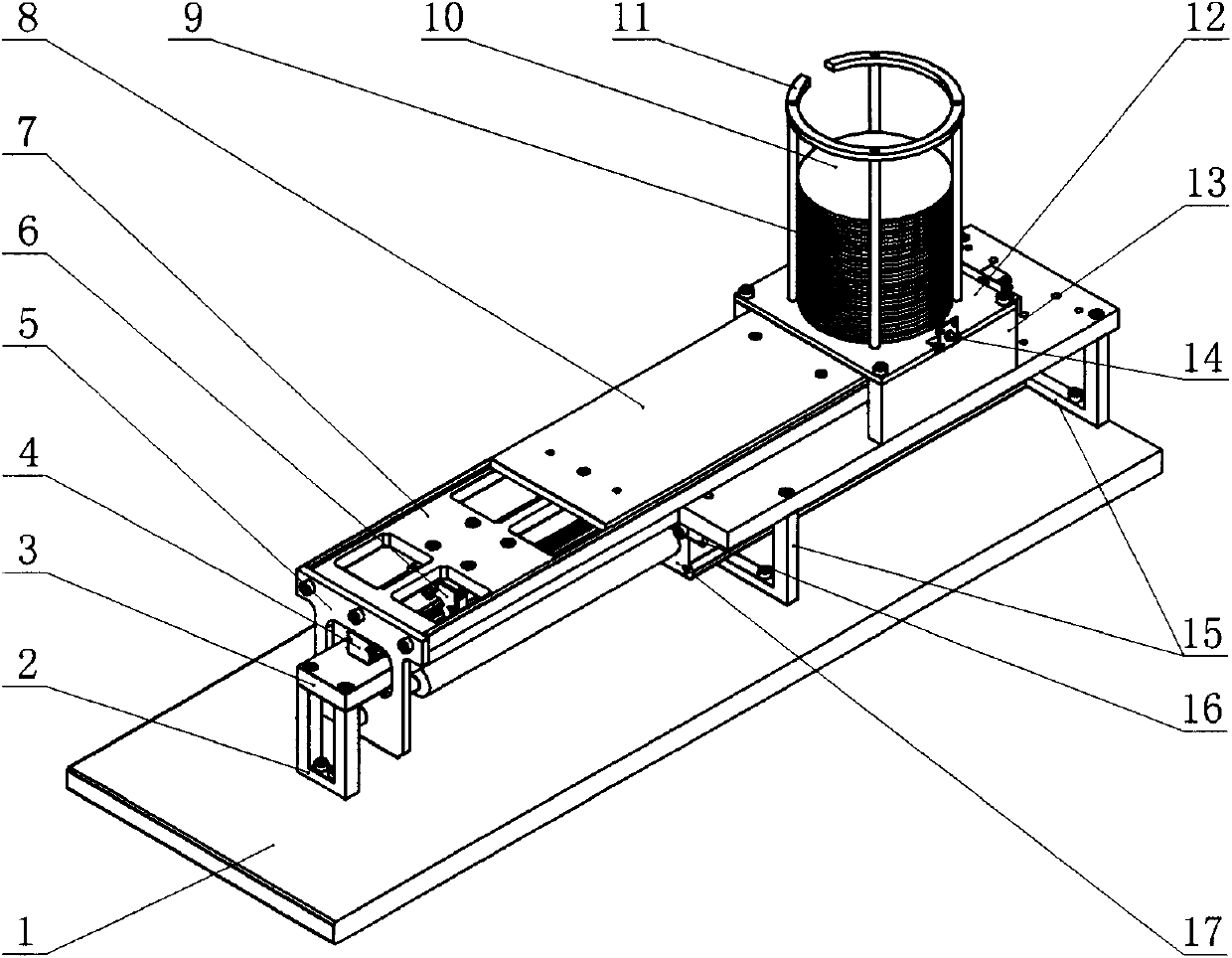

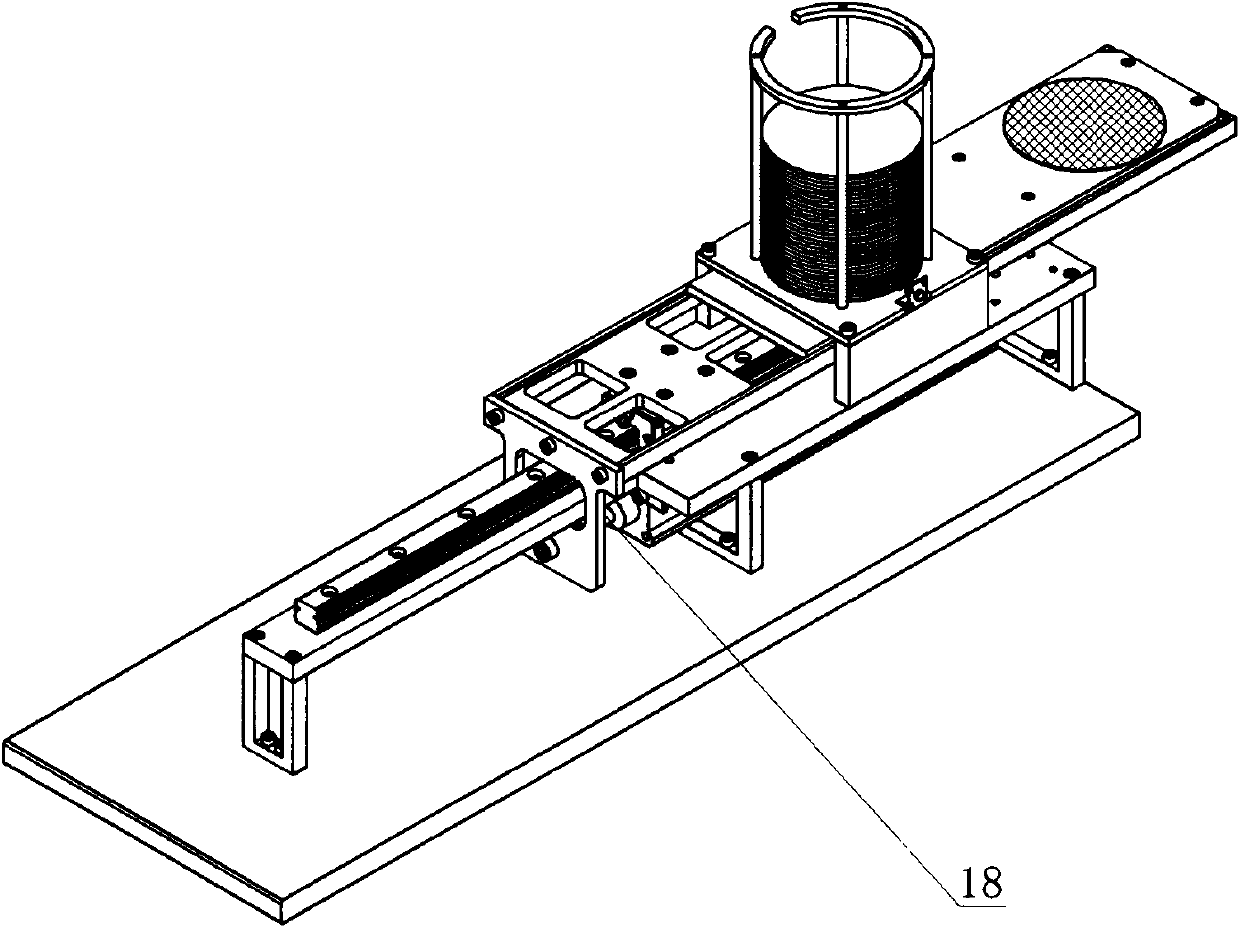

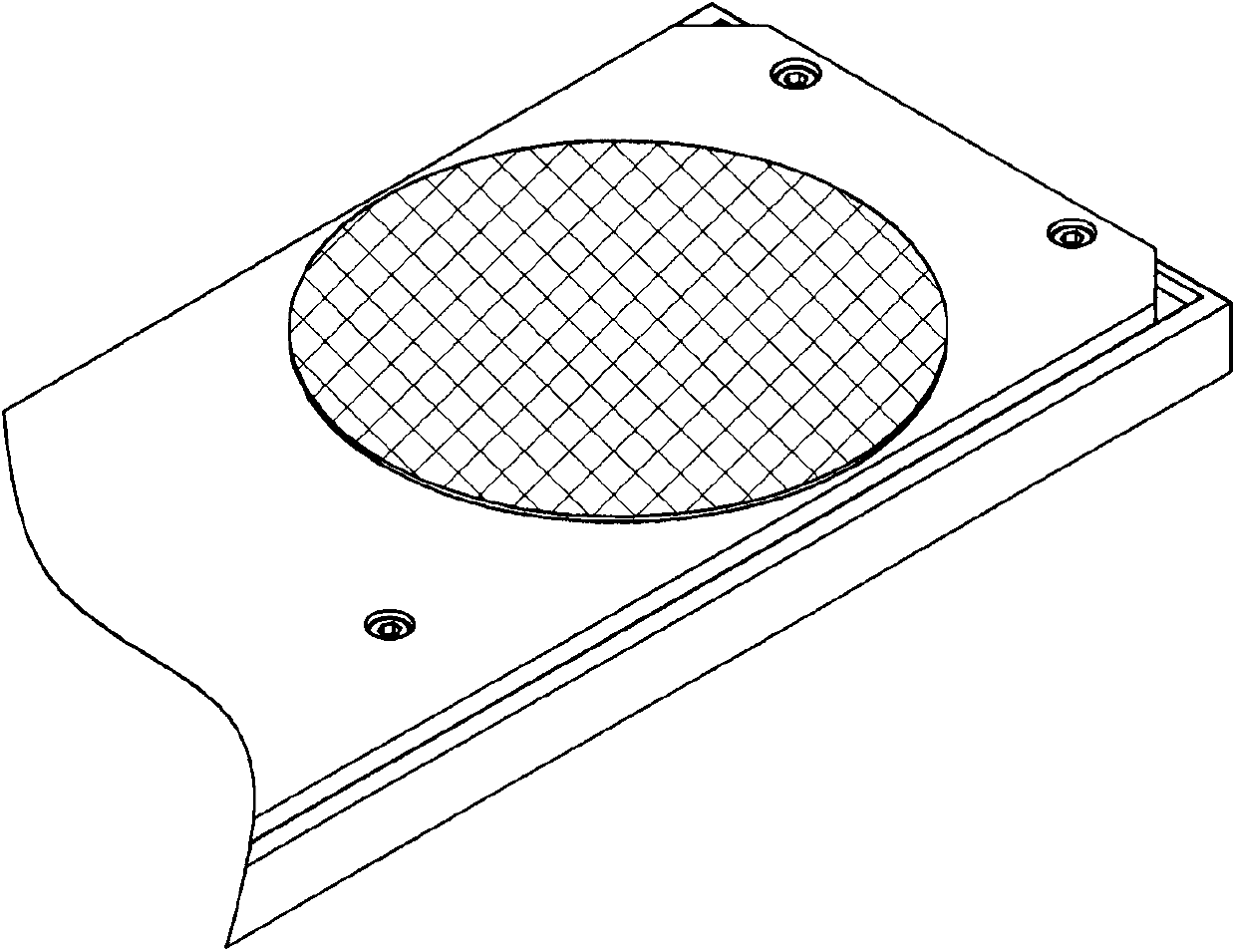

Round sheet automatic feeding mechanism

ActiveCN104003181AAvoid bad phenomenaReasonable structureDe-stacking articlesConveyor partsReciprocating motionComputer engineering

The invention discloses a round sheet automatic feeding mechanism. The round sheet automatic feeding mechanism comprises a feed cylinder fixed on the rack and used for stacking up round sheets; a main support plate between the rack and the feed cylinder is provided with a horizontal guide rail; a guide rail slide block is connected with a push plate support plate; a round groove with the depth thereof smaller than the thickness of the round sheet and the diameter in consistence with the diameter of the round sheet is formed in the round sheet push plate; the groove of the round sheet push plate when being moved under the feed cylinder receives the round sheet blank; the size of both the feed cylinder and the groove of the round sheet push plate varies according to the specification of the round sheet, so that automatic blanking of different round sheet is realized. A cylinder for controlling horizontal movement of the sheet push plate is mounted below the main support plate; a cylinder push rod is connected to the push plate support plate through a connecting plate; the cylinder drives the round sheet push plate to do reciprocating motion. The round sheet automatic feeding mechanism has relatively high production automation degree, greatly improves production benefit, is reliable and practical, and solves the problems of great time consumption and low frequency brought by manual separation.

Owner:NANTONG UNIVERSITY

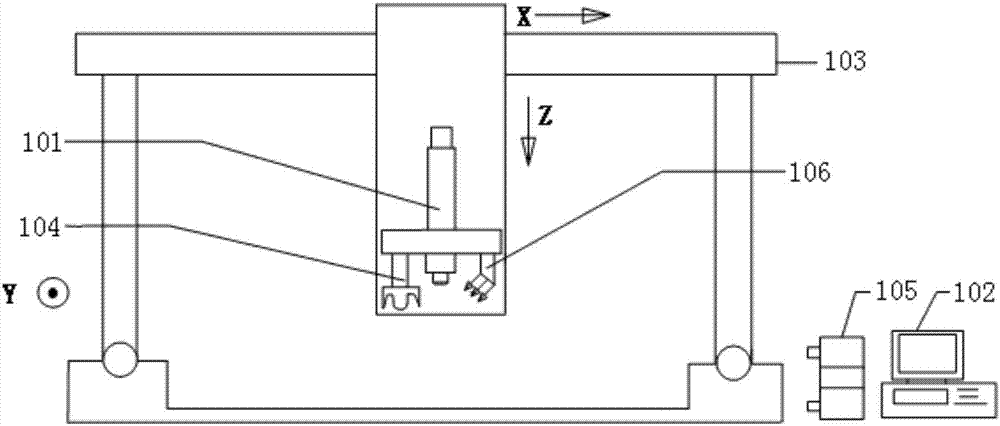

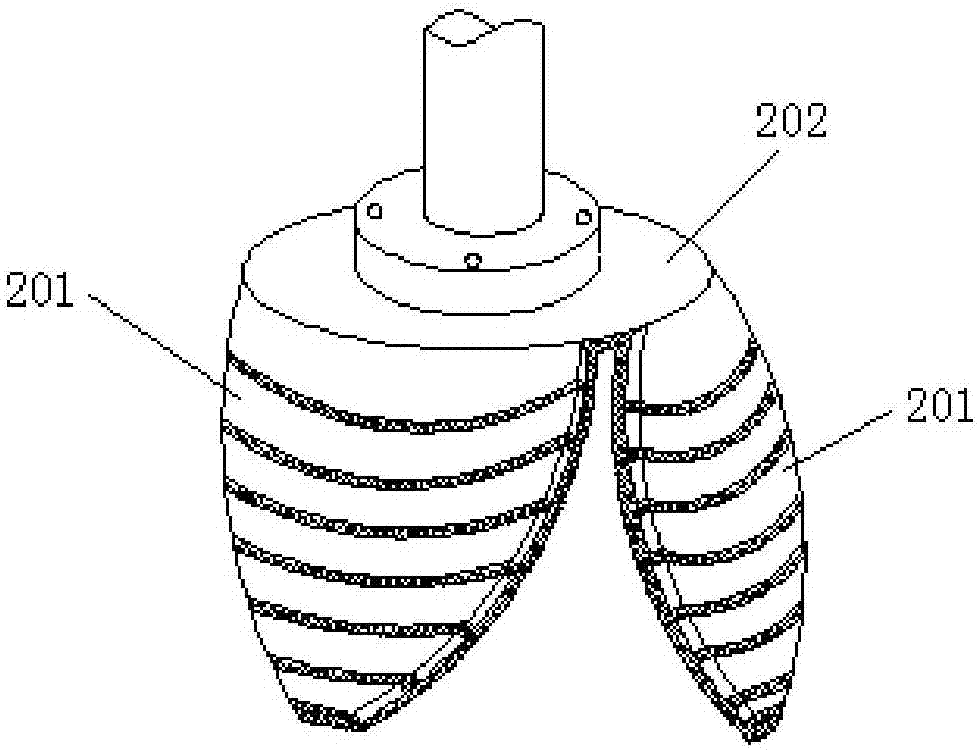

Machine vision based mushroom automatic picking up system and method

ActiveCN107046933AAvoid damageFully automatedProgramme controlProgramme-controlled manipulatorMachine visionControl system

The invention discloses a machine vision based mushroom automatic picking up system and method. The mushroom automatic picking up system includes a camera, a main control system, a motion system, an air bag type mechanical arm, and an air pump. The problem that the efficiency of mushroom manual picking is low, the sorting quality is uneven, and the conventional picking end executors can cause damage to mushroom and are poor in deformation and adaptive capacity can be overcome; the system can process mushroom seedling bed images having complex backgrounds and serious adhesion, and the problem of damage to the mushroom due to picking-up can be solved by the air bag type mechanical arm. The machine vision based mushroom automatic picking up system and method can provide a new method for mushroom industrial and automatic production, can achieve full mushroom production automation from seedling bed management to picking and sorting, can reduce the production cost, and can improve the classification quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

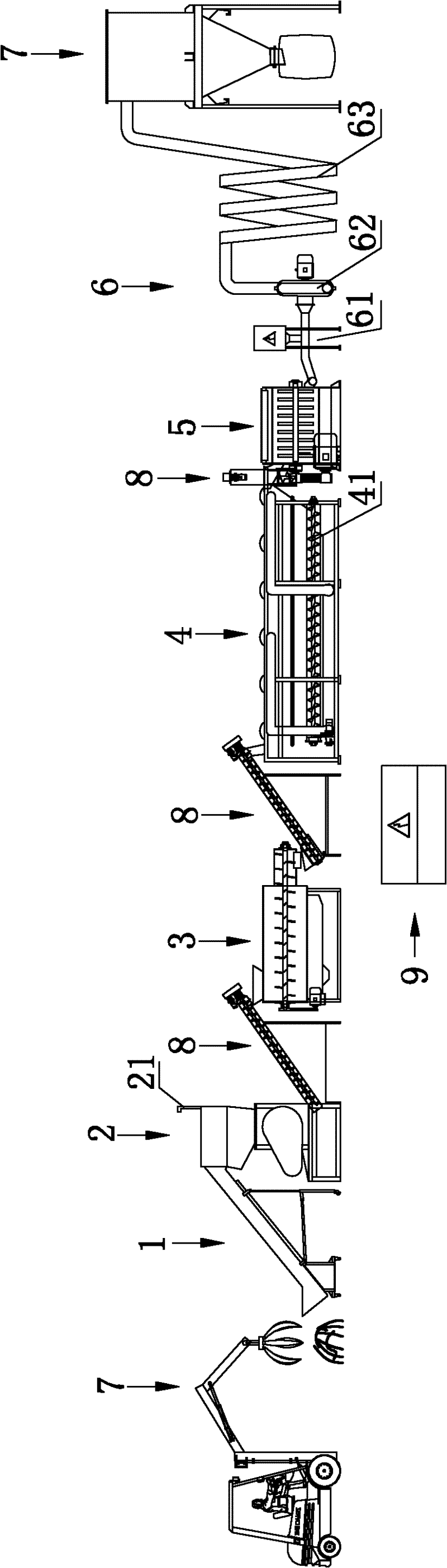

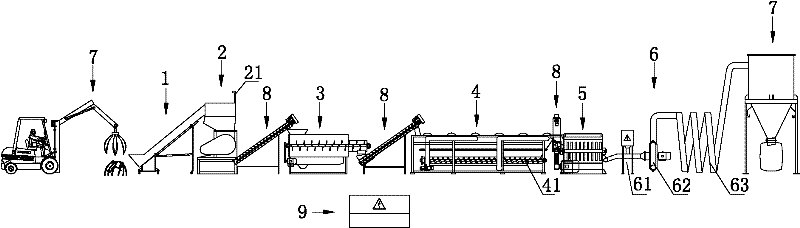

Film crushing washing line

ActiveCN102179883ARelieve pressureImprove efficiencyPlastic recyclingFlat articlesEngineeringWhirlwind

A film crushing washing line comprises, in a working procedure order, a conveyer belt, a crusher for crushing a film conveyed by the conveyer belt, a cleaning machine for cleaning the film and detaching the film from impurities on the film, a washing rinsing machine for thoroughly separating the film from the impurities on the film, a dewaterer for dewatering the cleaned film, a drying system forfurther drying the dewatered film, and a whirlwind storage hopper for bagging. The drying system comprises a heater, a drying pipe, and a blower disposed between the heater and the drying pipe for allowing the film to enter the pipe. With the invention, not only bad production environment for original manual washing is got rid of and human-oriented enterprise idea is embodied; but also productionautomation is realized with greatly improved yield and increased factory benefits; and the recovery and the utilization of waste and old films reduce the dependence on petroleum and the pressure to the environment.

Owner:SUZHOU ZHONGSU REPROCESSING MACHINERY

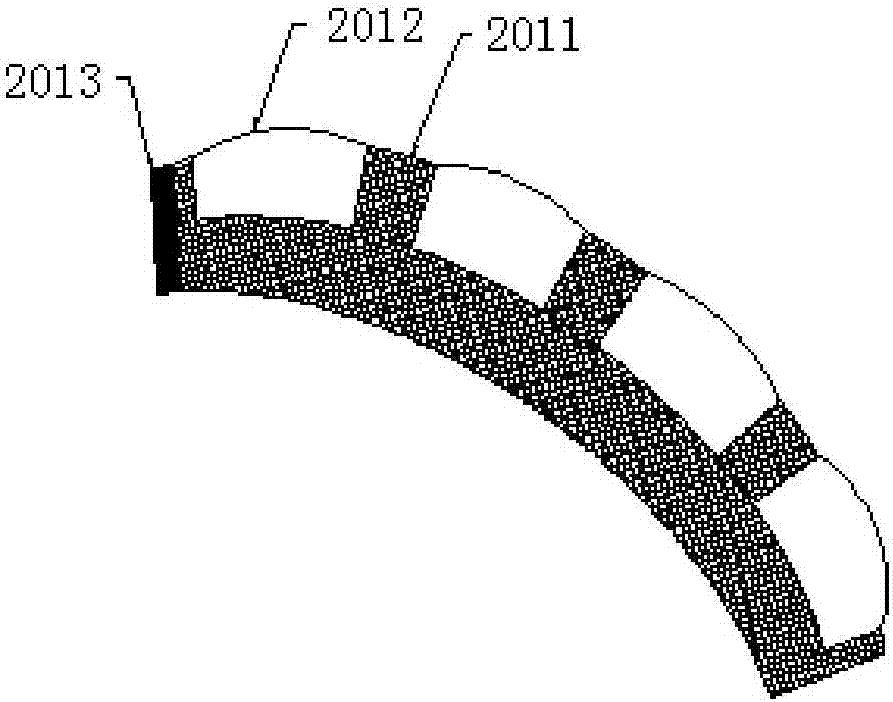

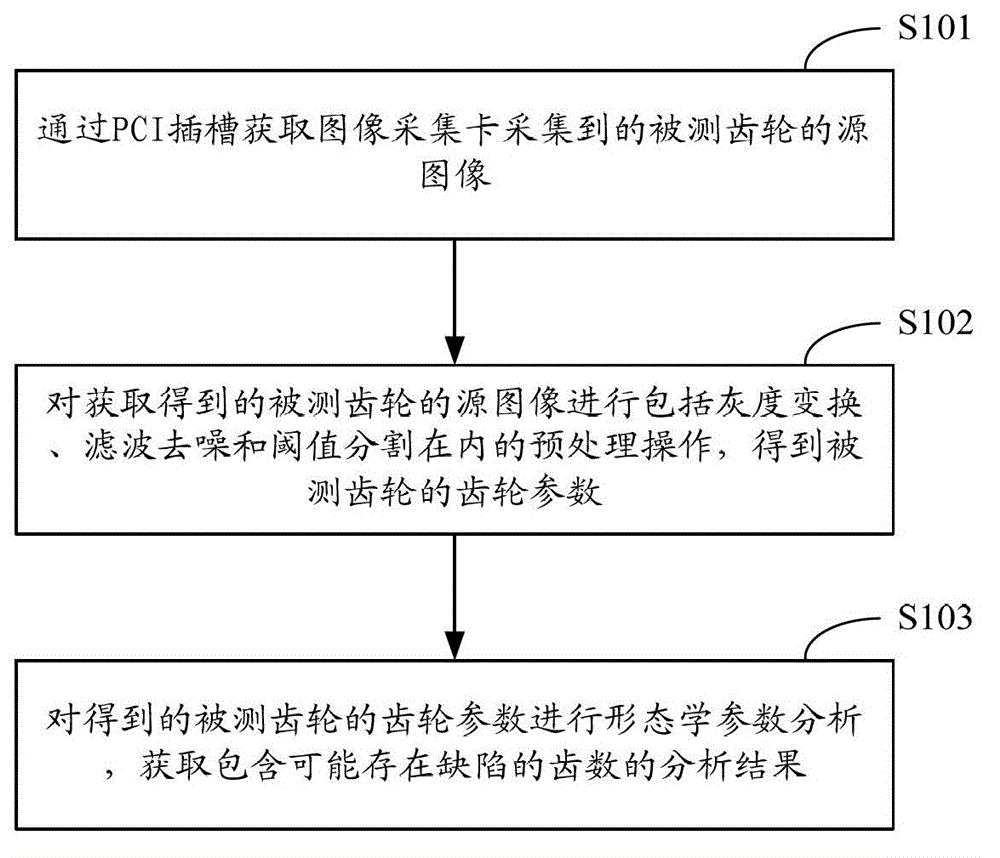

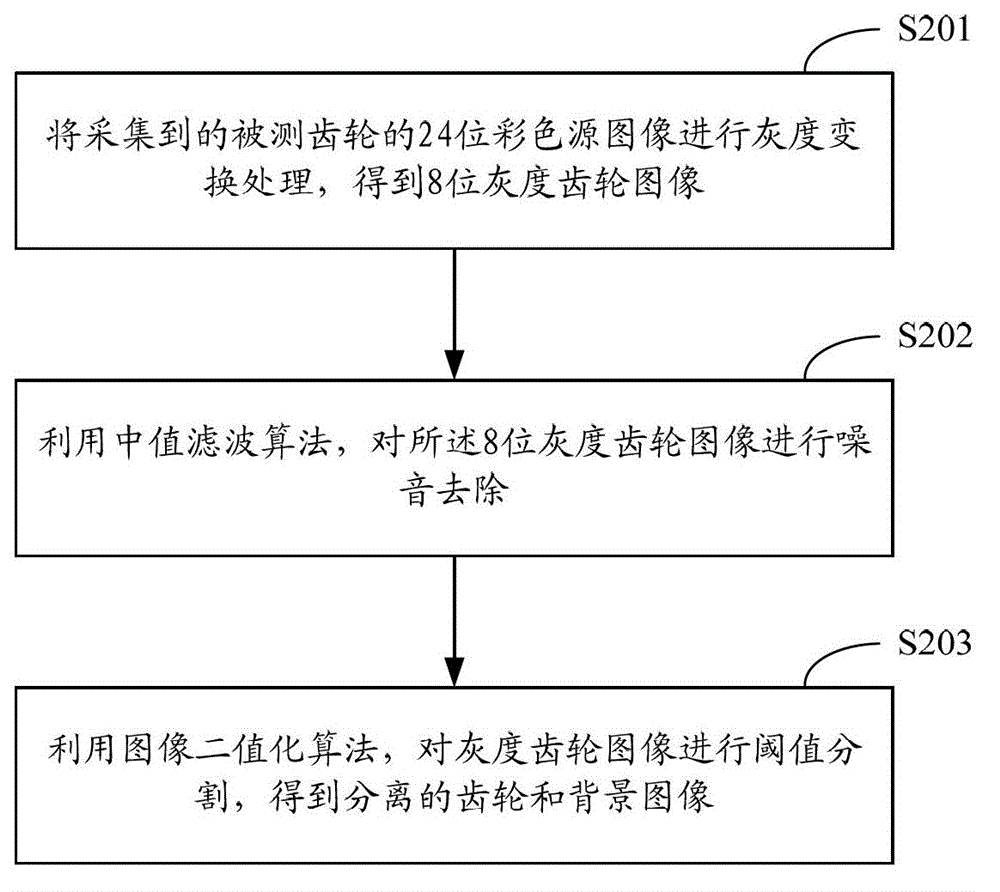

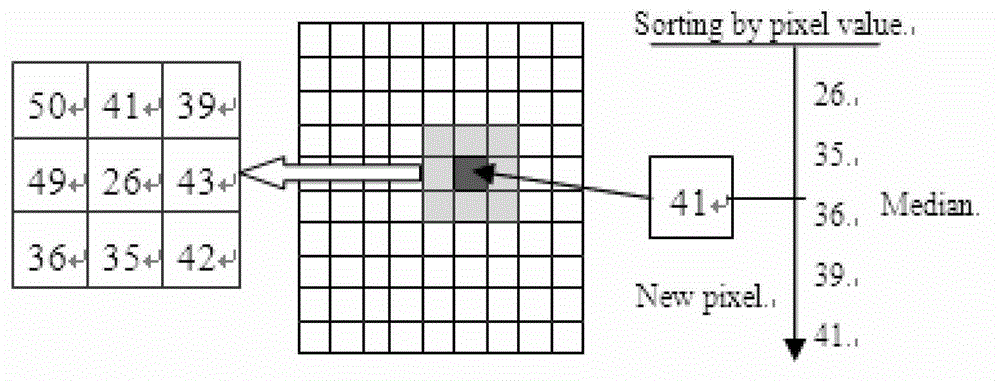

Gear defect detection method and system based on computer vision

ActiveCN102914545AMeet the functional requirements of routine parametric measurementsMeet the functional requirements of the measurementOptically investigating flaws/contaminationUsing optical meansImaging processingNoise reduction

The invention relates to the technical field of image processing and provides a gear defect detection method and system based on computer vision. The method comprises the following steps of: acquiring a source image of a detected gear acquired by an image acquisition card through a peripheral component interconnect (PCI) slot; performing preprocessing operation comprising grey level transformation, filtering and noise reduction and threshold segmentation on the source image of the detected gear, and obtaining gear parameters of the detected gear; and performing morphological parameter analysis on the gear parameters of the detected gear, and acquiring an analysis result of the teeth where the defects possibly exist. The gear defect detection method is high in measurement speed and high in precision, the functional requirements of the conventional gear parameter measurement are met, the production efficiency and production automation degree can be greatly improved in the large-scale industrial production process, the measurement precision requirement in the actual production can be met, the measurement time is only several seconds, the requirement on the measurement speed in industrial measurement can be met, and the method has high theoretical and practical values.

Owner:WEIFANG UNIVERSITY

Reconfigurable garment definition and production method

InactiveUS20080147231A1Efficient integrationSimple designGarmentsSurgeryLine sensorComputer Aided Design

Computer-aided design and manufacture software and hardware automate garment and fashion definition and production. Configurable garment includes ornamental element, pattern display, and personal identifier and wireless sensor electronics.

Owner:FERNANDEZ DENNIS S

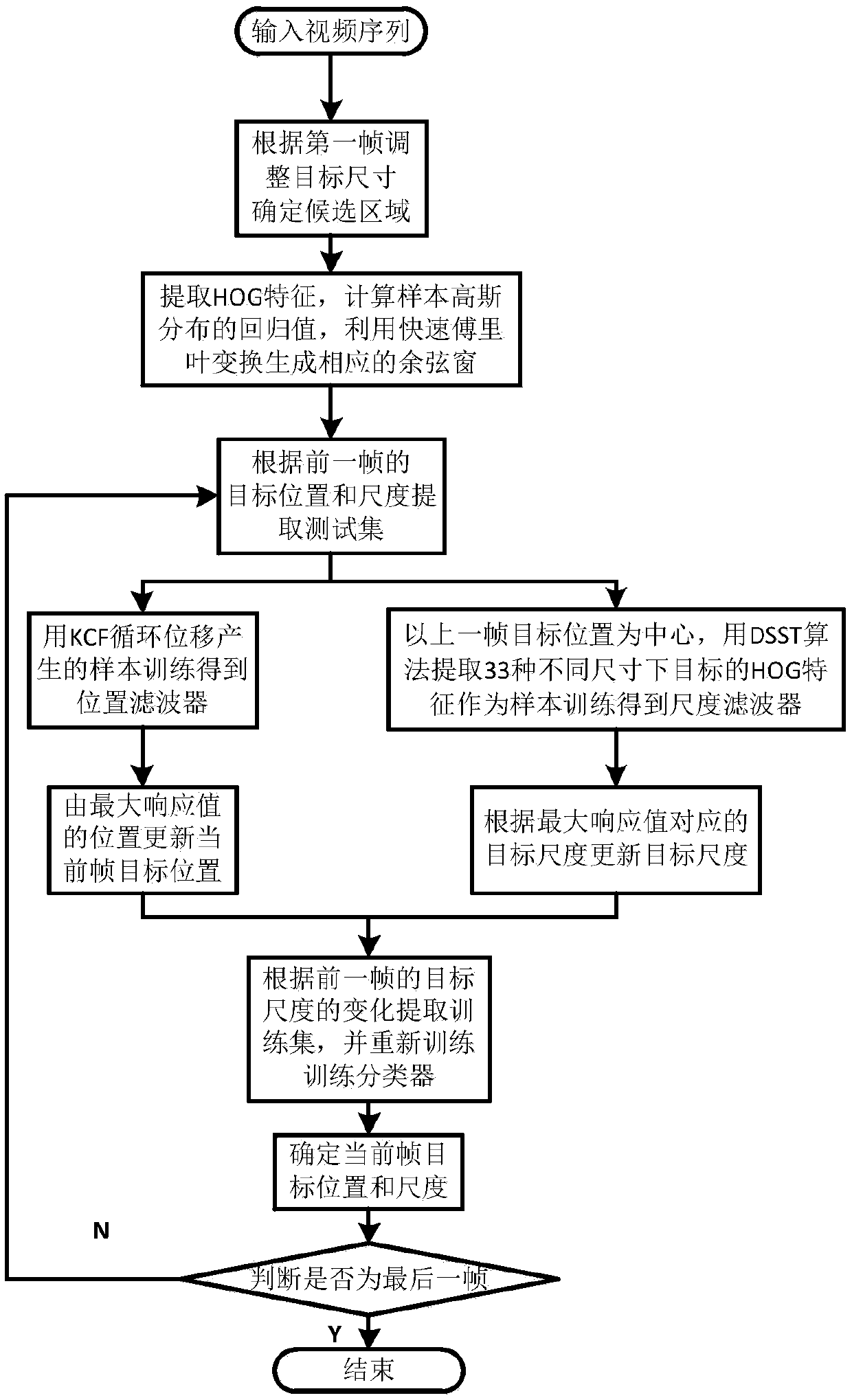

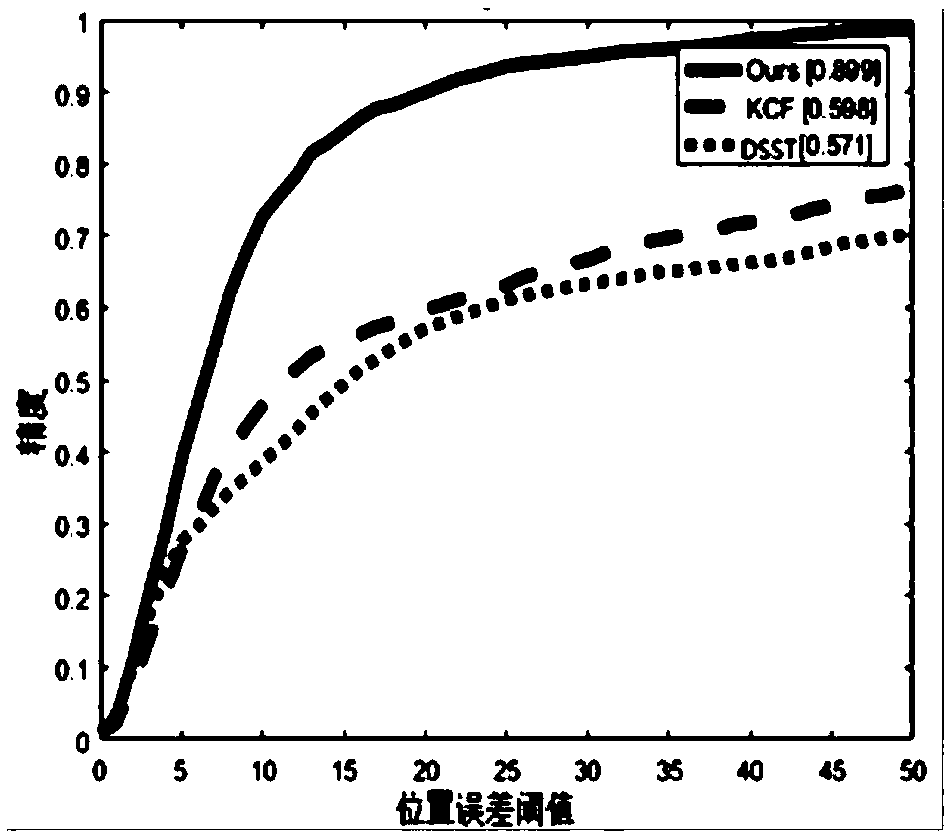

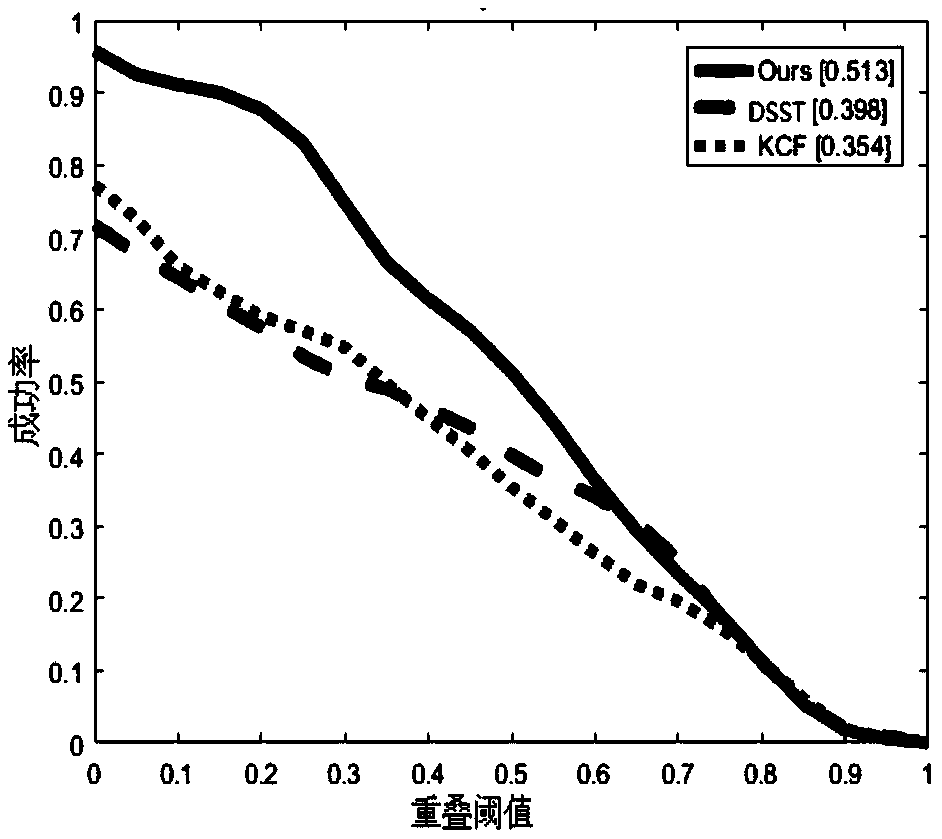

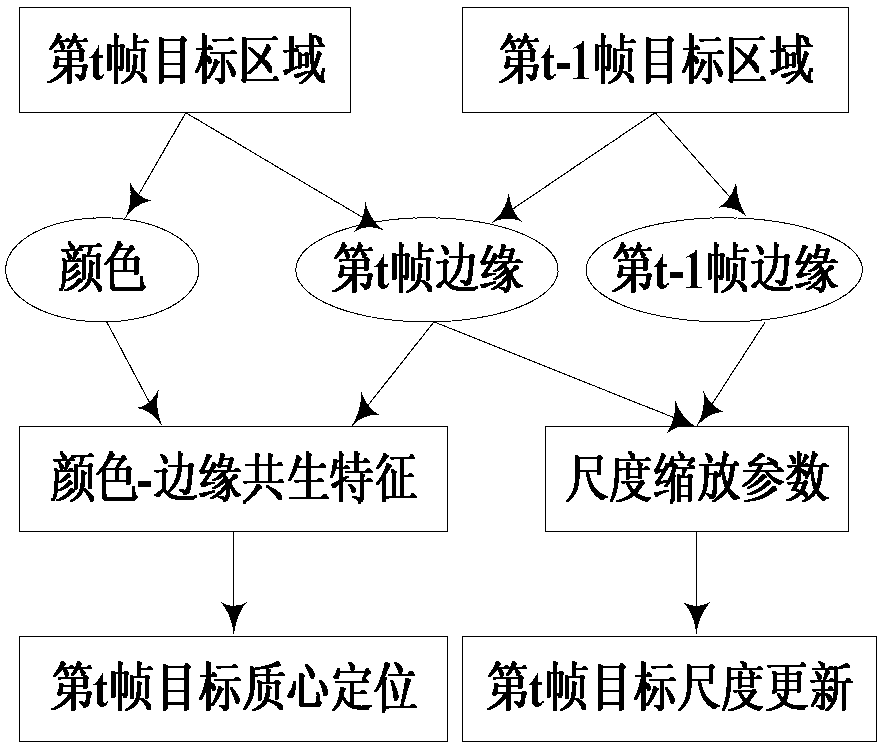

A scale self-adaptive target tracking algorithm based on kernel correlation filtering

PendingCN109685073AImprove performanceSuppress interferenceImage enhancementImage analysisVideo monitoringTrack algorithm

The invention discloses a scale self-adaptive target tracking algorithm based on kernel correlation filtering, and belongs to the field of computer vision. The method comprises the steps of selectinga first frame of to-be-tracked target, and determining as a candidate region; Extracting gradient direction histogram (HOG) characteristics of the candidate area, and carrying out cosine weighting; Performing cyclic shift on the candidate area by using a KCF algorithm to generate a training sample, calculating a response value in a frequency domain according to a position filter obtained by sampletraining and HOG characteristics extracted by the candidate sample, and updating the target position of the current frame; Taking the target position determined by the previous frame as a center to obtain a scale filter, calculating to obtain a response value, and taking the scale corresponding to the maximum response value as the target scale of the current frame; Re-extracting the sample training filter, updating the position filter and the scale filter in a linear interpolation mode, and tracking a subsequent frame; The method can be applied to the fields of intelligent video monitoring, enterprise production automation, intelligent robots and the like.

Owner:NANJING INST OF TECH

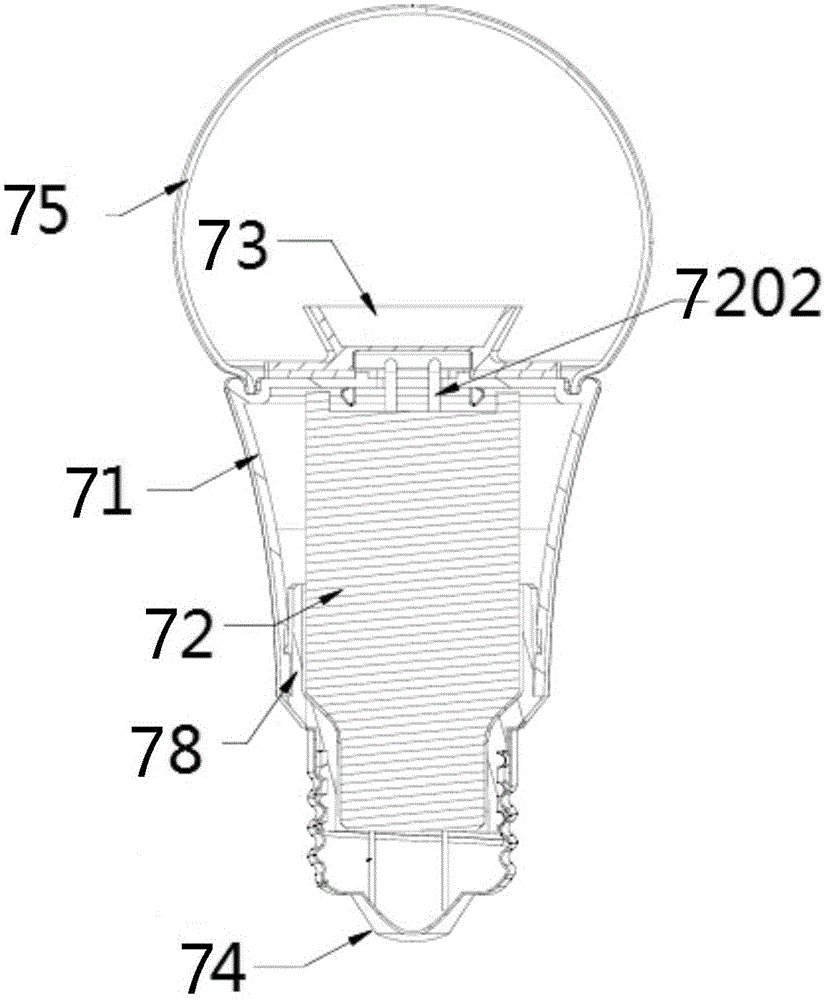

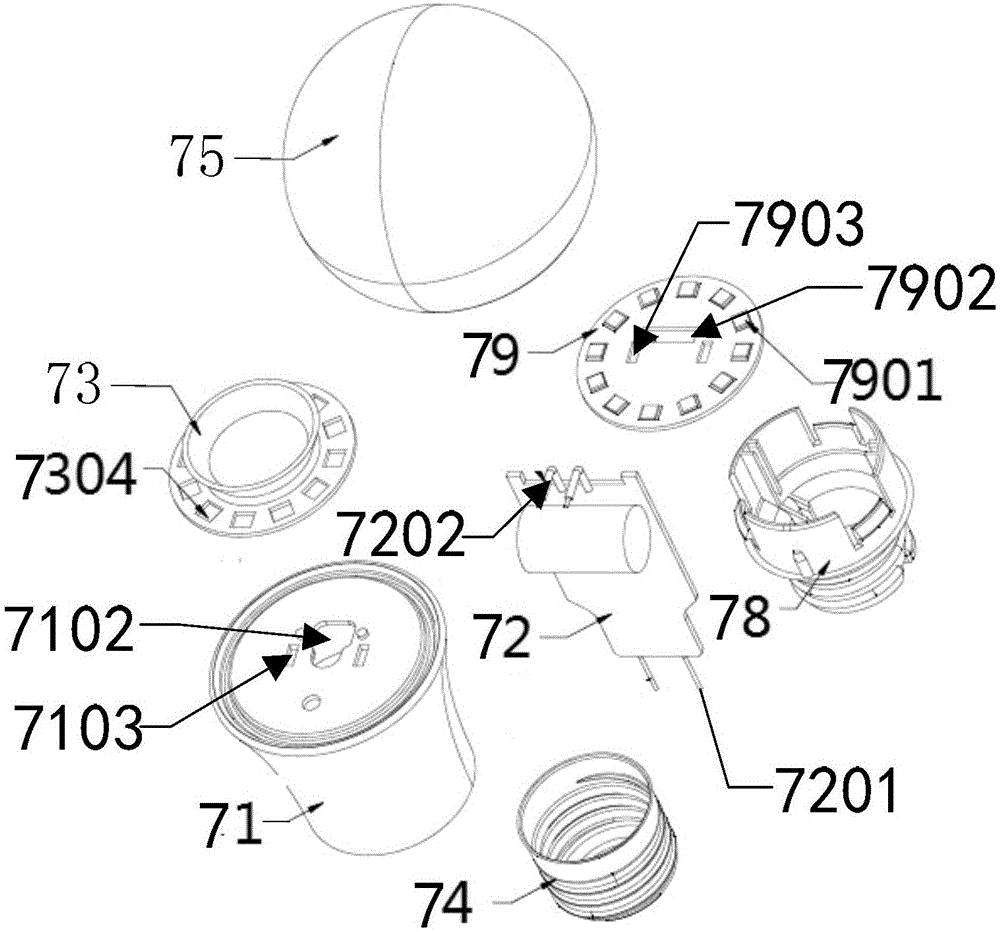

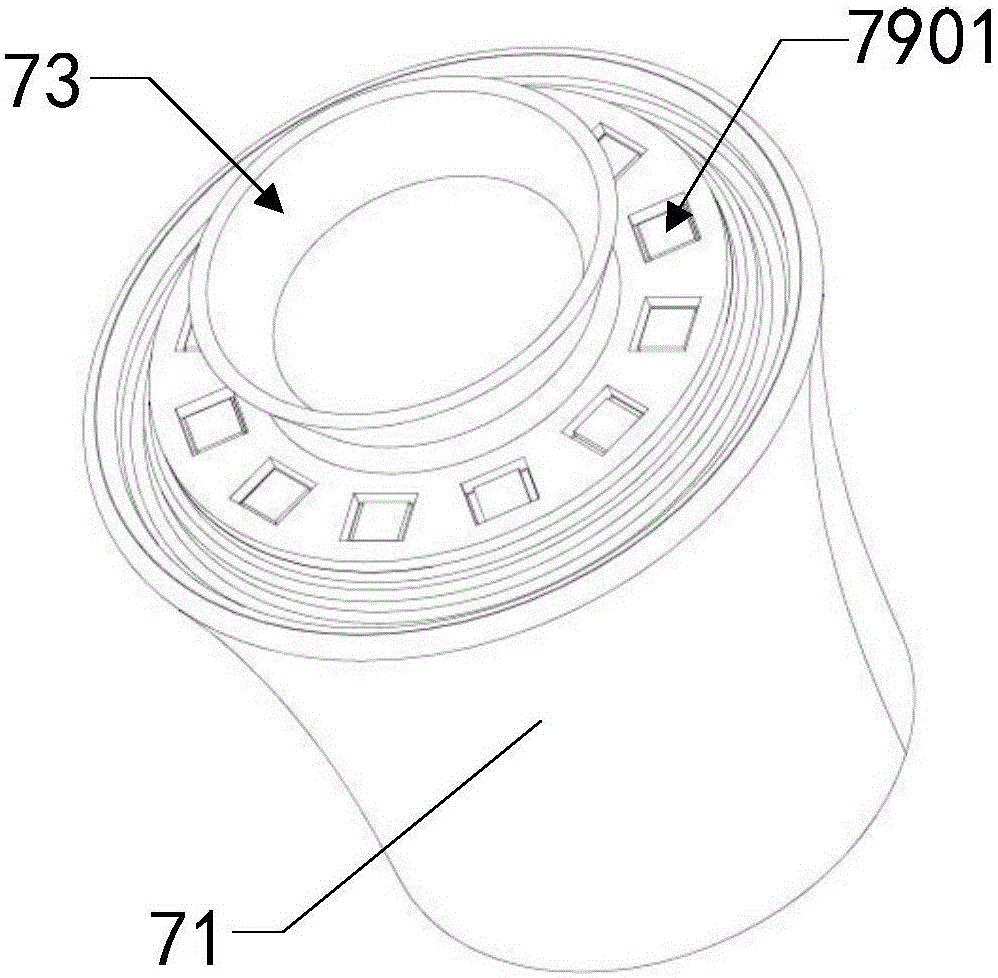

LED bulb lamp

InactiveCN105465663AUniform luminanceAvoid injuryElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLamp shell

The invention discloses an LED bulb lamp which comprises an LED bulb lamp panel and a light processing structure. The LED bulb lamp panel is provided with at least one LED light source, and the light processing structure is arranged on the side, where the LED light sources are located, of the LED bulb lamp panel and is provided with a reflecting face used for changing the direction of light generated by the LED light sources. In this way, uniform transition of the luminance of the LED bulb lamp can be achieved, and the luminance can be distributed by more than 180 degrees; besides, production automation can be easily achieved; users can be prevented from being hurt; as the users can be prevented by through holes from making contact with internal electrified bodies under the condition that a lamp shell is broken, the electric shock risk is greatly lowered.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

Motor housing continuous die

InactiveCN103752698ASimple structureReduce in quantityShaping toolsMetal-working feeding devicesElectric machineryEngineering

A motor housing continuous die comprises an upper die and a lower die, wherein the upper die comprises an upper supporting plate and an upper die base, the lower die comprises a lower supplying plate and a lower die base, multiple stations are sequentially arranged from one side to the other side between the upper die base and the lower die base, a female die and a male fie which correspond are arranged on each station in one time, a material pushing plate and a feeding machine are arranged at the position of the first station, and two sides of each of the other stations are symmetrically provided with a front clamp claw and a rear clamp claw. Two sides of the lower die base are further symmetrically provided with feeding strips, the feeding strips can oppositely or reversely move under the driving of a longitudinal driving mechanism and simultaneously and move back and forth in the length direction of the lower die base under the driving of a transverse driving mechanism, the outer ends of the front and rear clamp claws are respectively fixed on the feeding strips, and the material pushing plate is driven by the feeding strips to move. Due to the fact that the multiple-station progressive die formed through continuous multiple-station stamping is adopted, the production efficiency is high, and the cost is low. In addition, the front and rear clamp claws are driven to perform action and feeding by the feeding strips, complete production automation is achieved, and the operation is safe.

Owner:CIXI LONGSHAN AUTOMOBILE PART

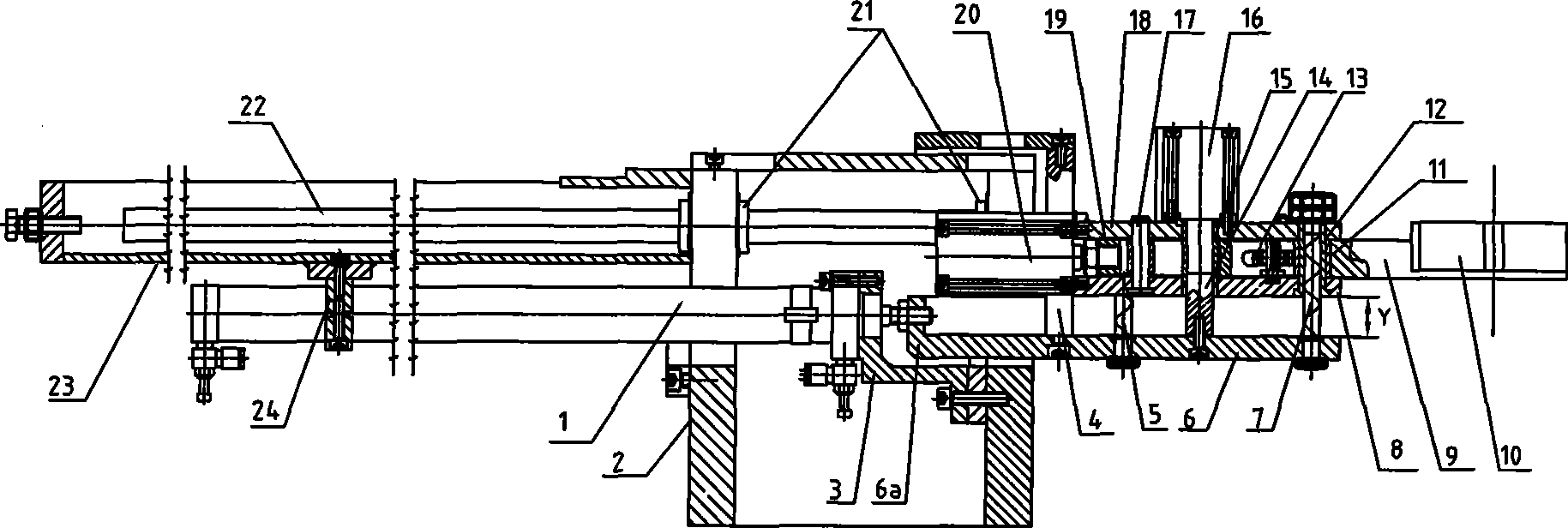

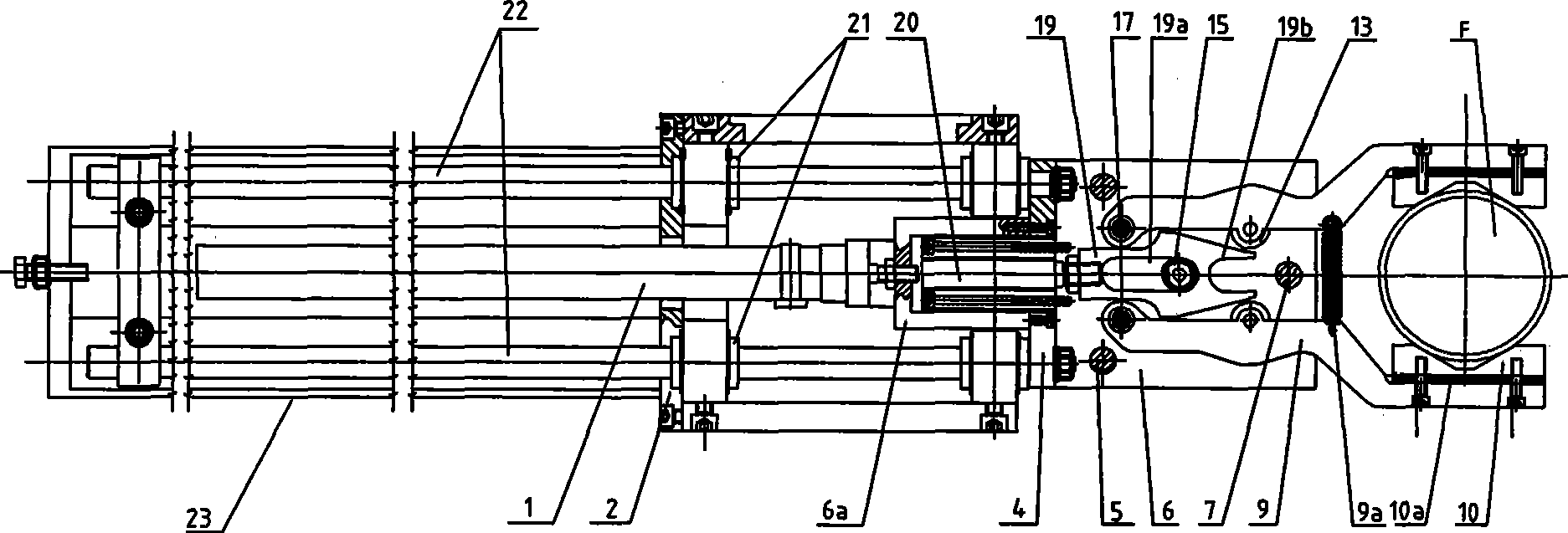

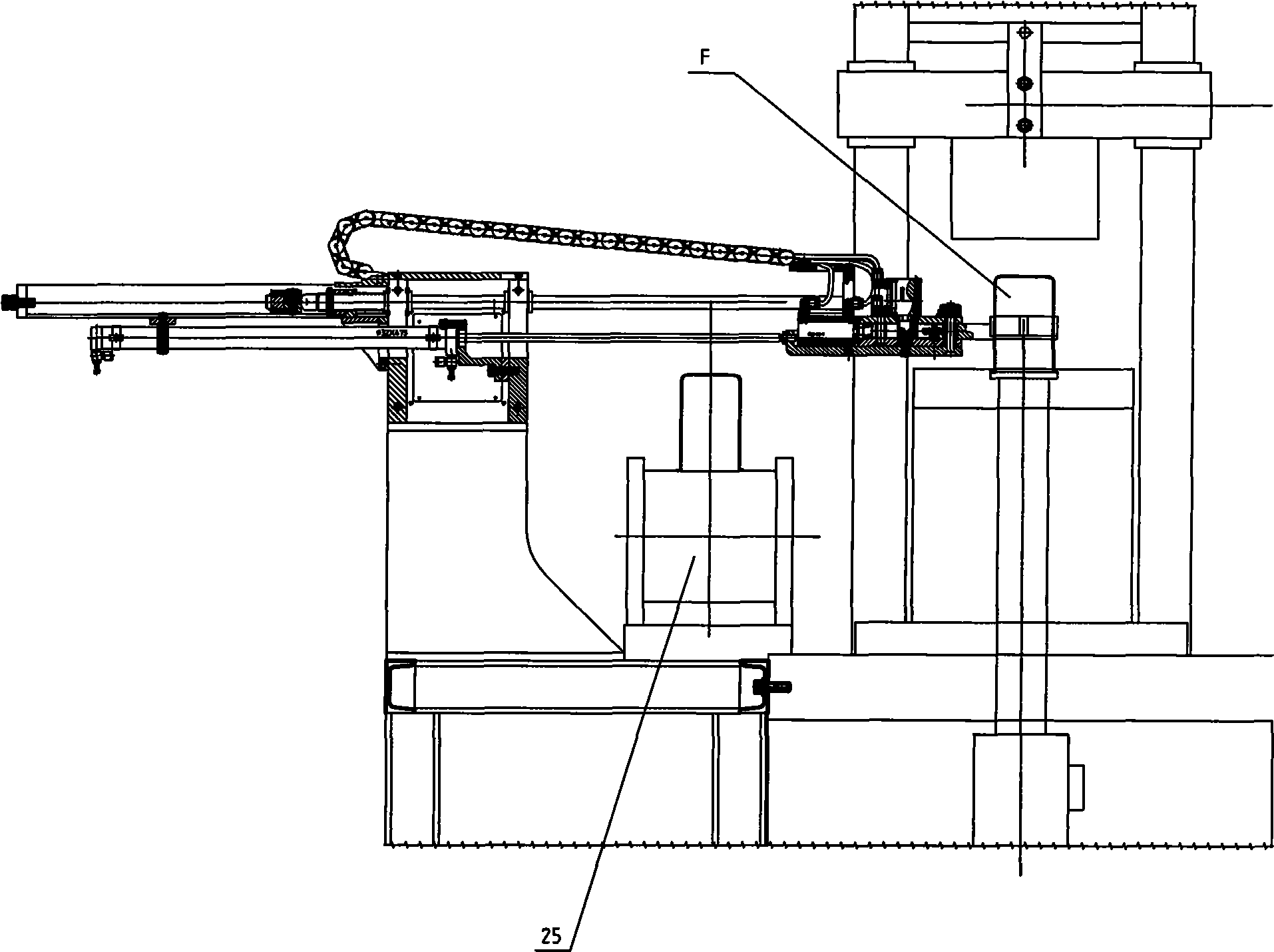

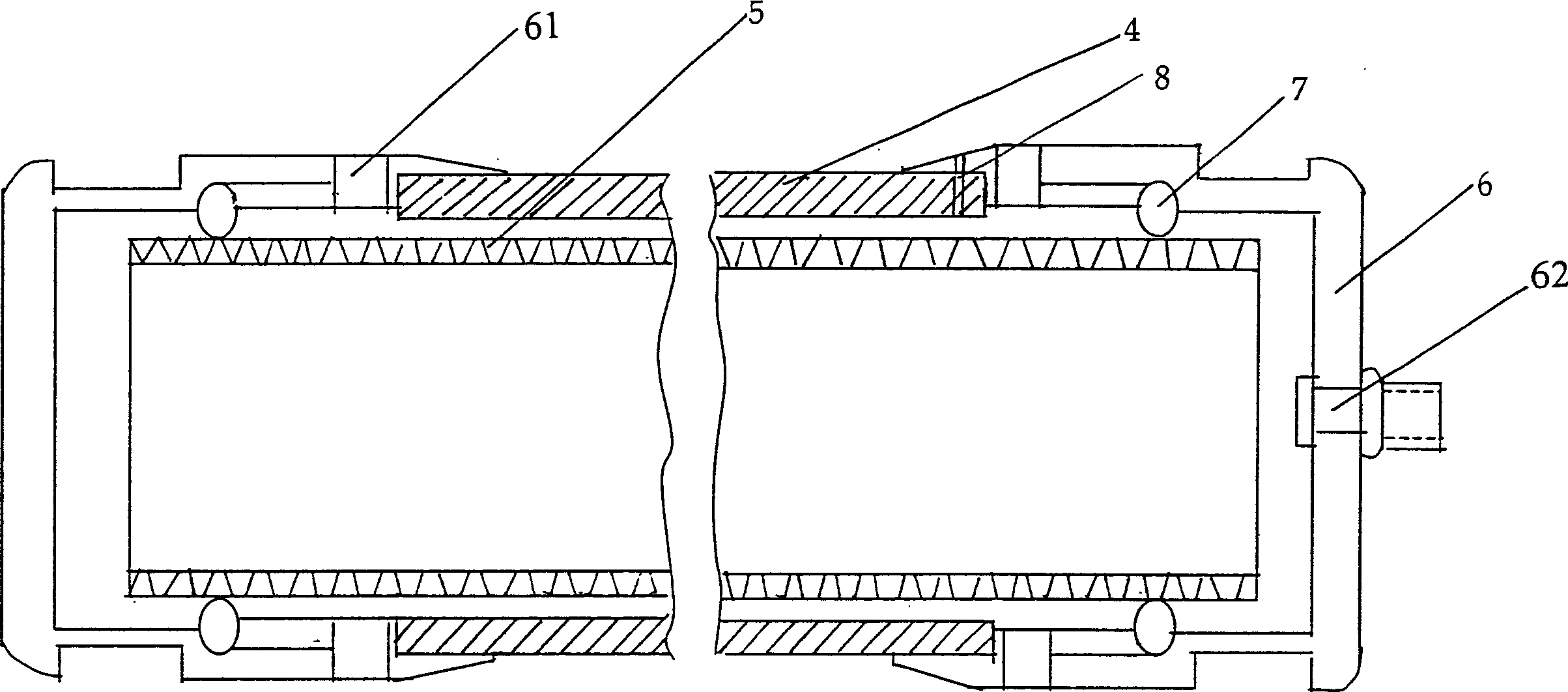

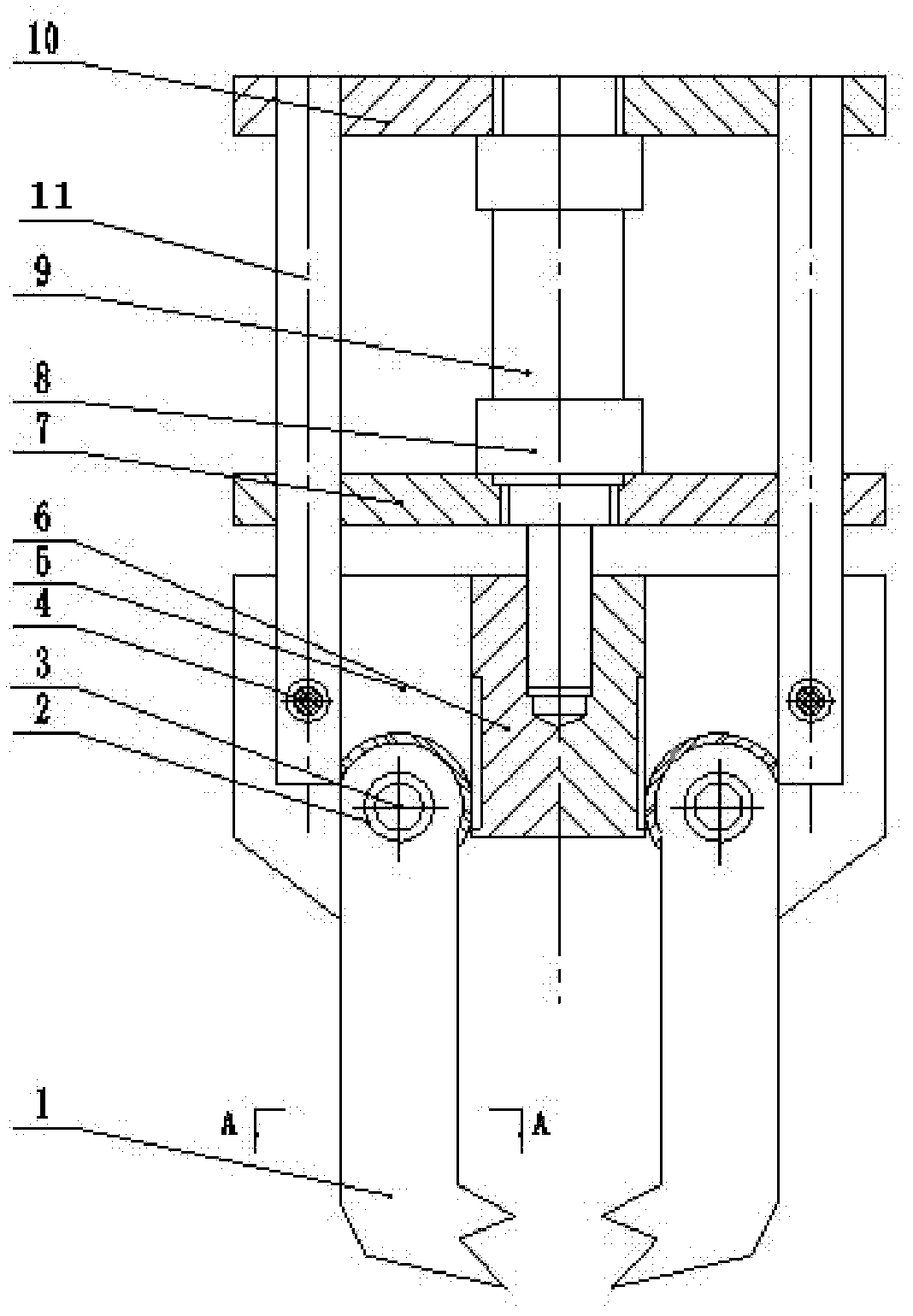

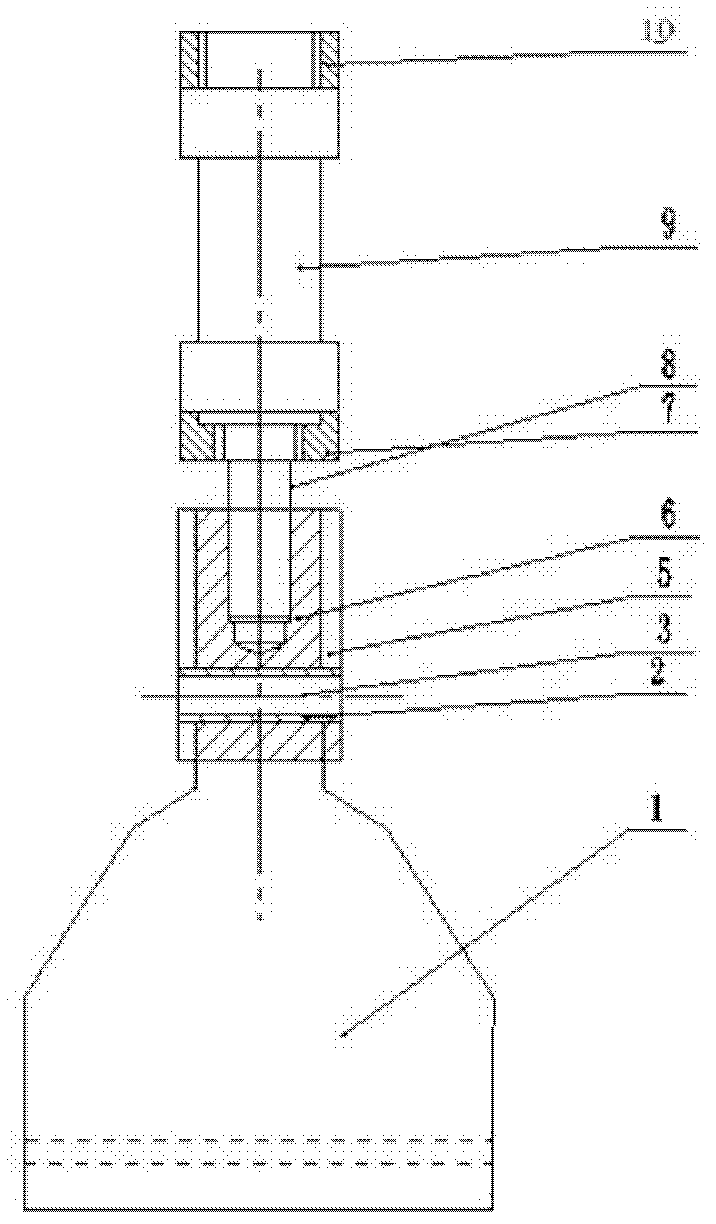

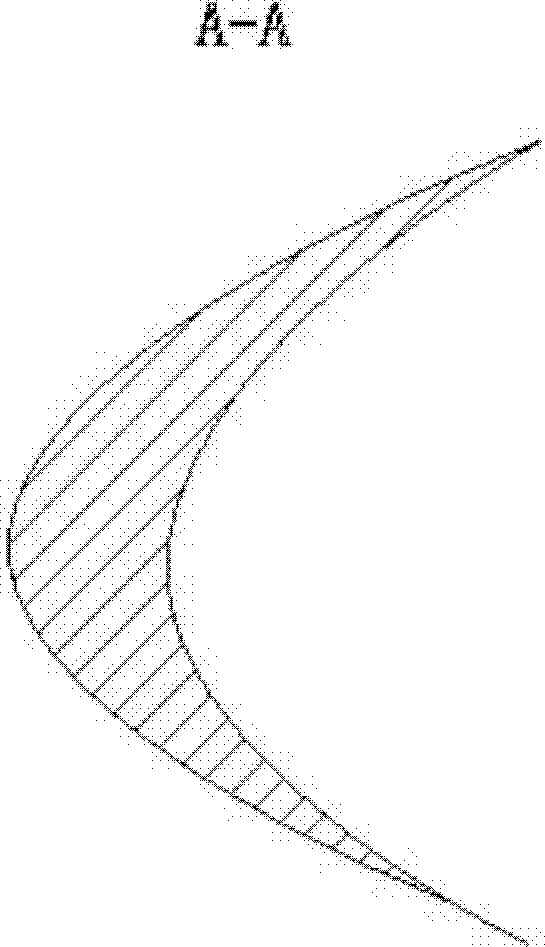

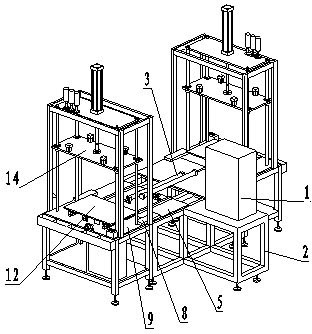

Automatic material-fetching machine for clarifier case formed by stretching

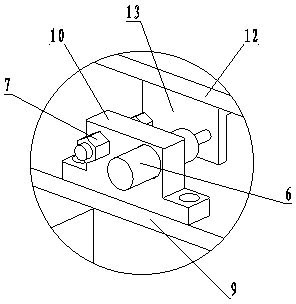

InactiveCN101497087ARealize automated productionIncrease productivityEngineeringMechanical engineering

The invention relates to an automatic stretching material taking machine for a filter shell, wherein a stander (2) is provide with a pair of guide rods (22) which are matched with a linear bearing (21); a piston rod of an arm cylinder (1) is connected with hand rest base plates (6a,6) which are connected with an upright plate (4); upper parts of the hand rest base plates are connected with the guide rods (22); the hand rest base plates are provided with a grabbing piece cylinder (20), a wedge block (19), a pair of clamping arms (9) and a tension spring (9a); and the inclined plane of the wedge block is matched with a bearing (13) of the clamping arms (9) to allow the clamping arms (9) and claws thereof to stretch and clamp. When a mechanical arm extends in place, the claws of the clamping arms stretch and clamp a workpiece F to lift the workpiece upward by 25mm, and retract the piston rod, and after the workpiece is in place, the claws stretch and put down the workpiece F. The automatic stretching material taking machine for the filter shell has the advantages of realizing automatic production of the filter shell, improving the production efficiency and preventing accidents at work.

Owner:BENGBU HAOYE FILTER

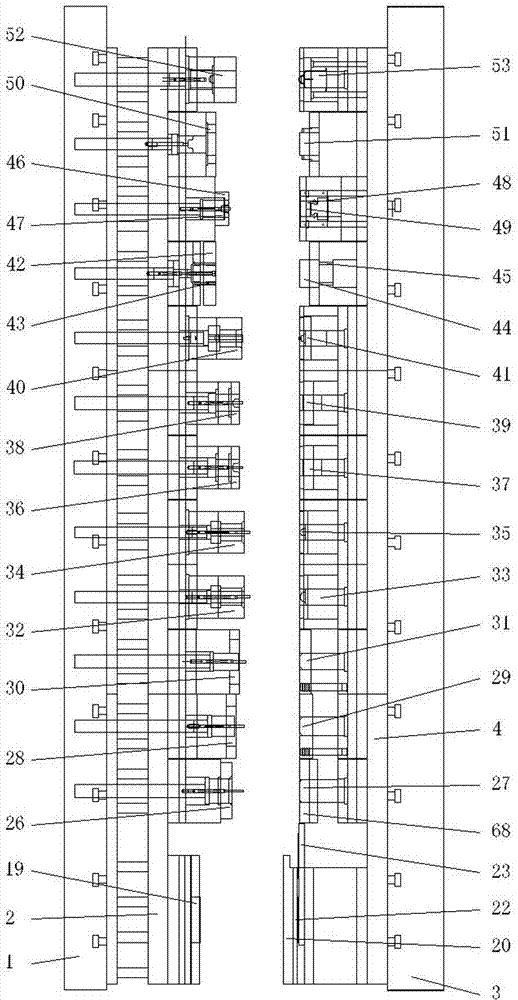

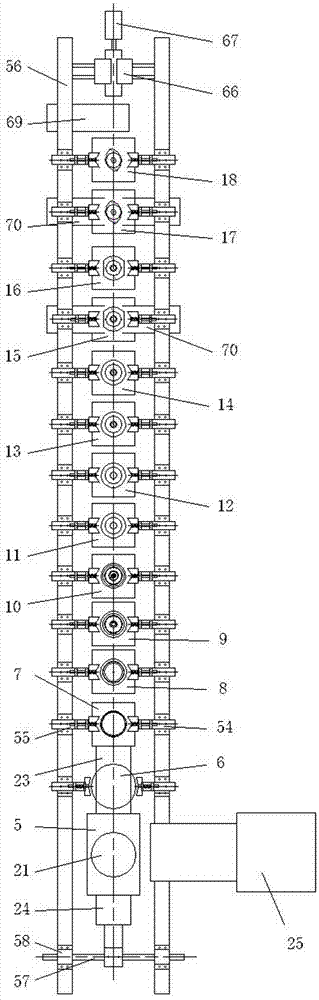

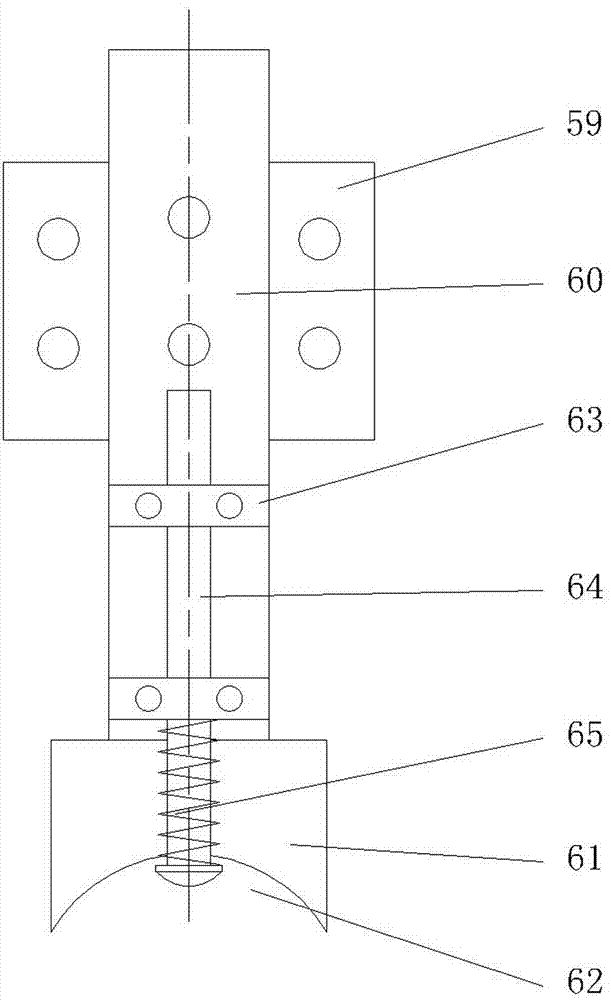

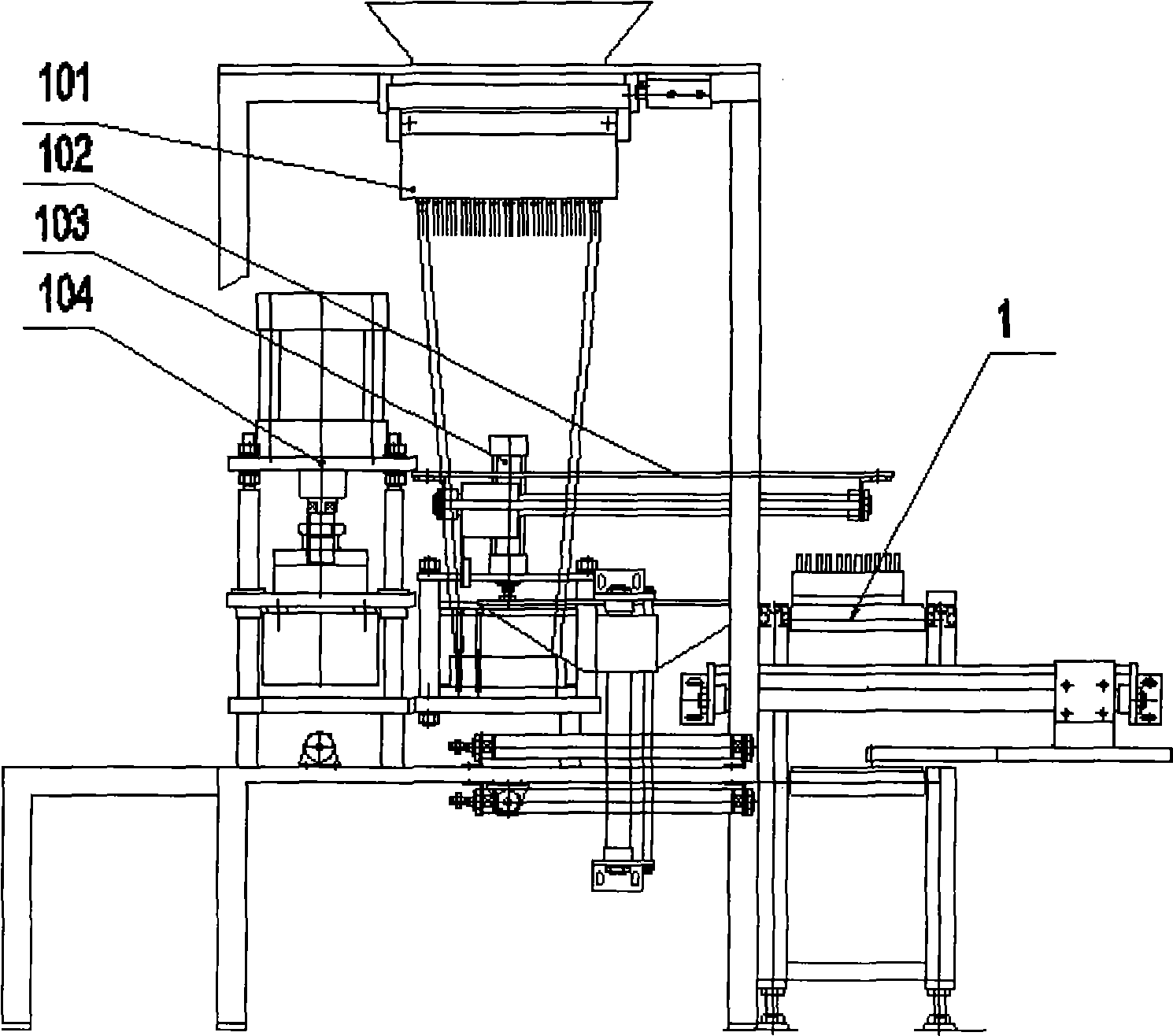

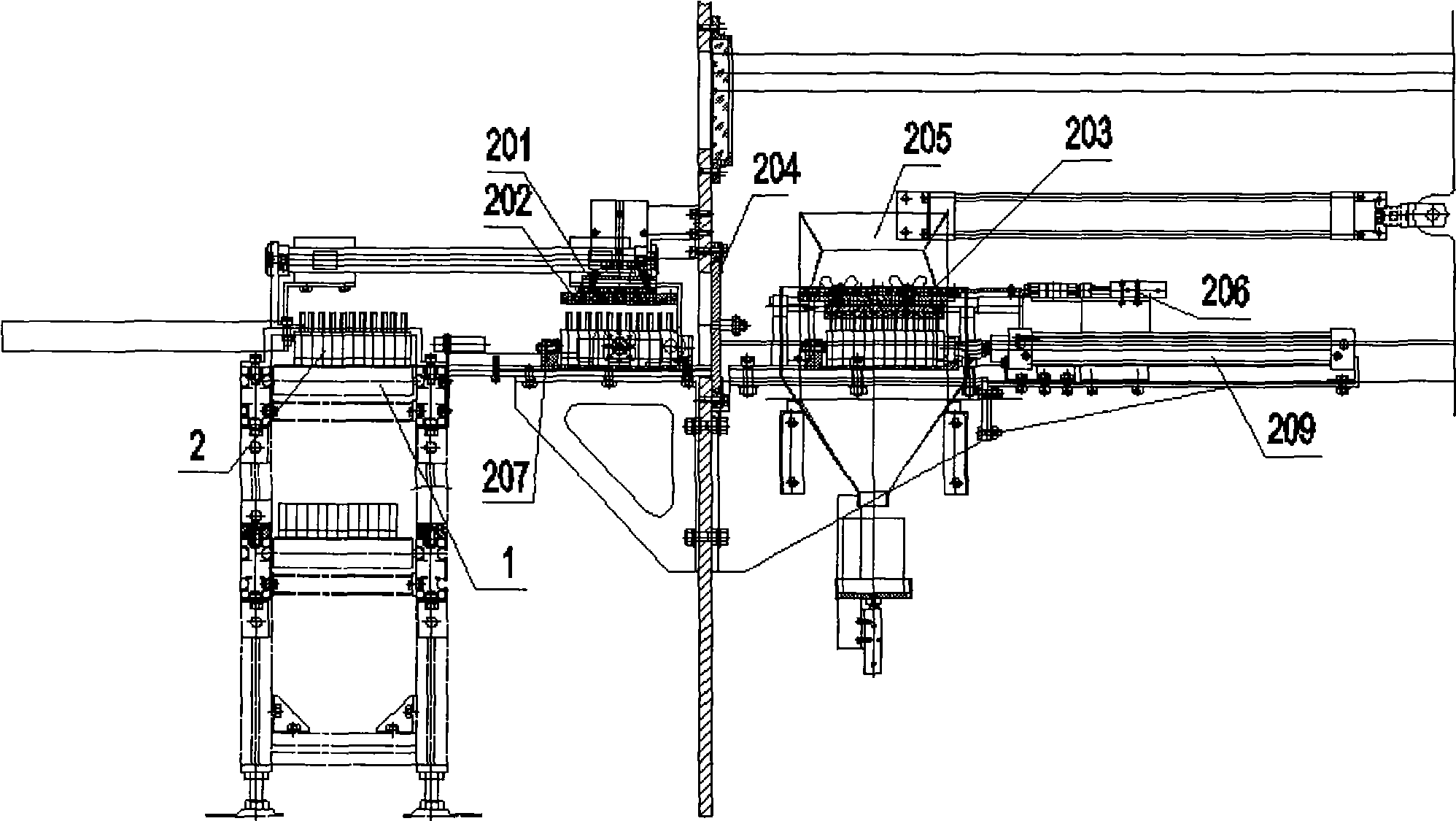

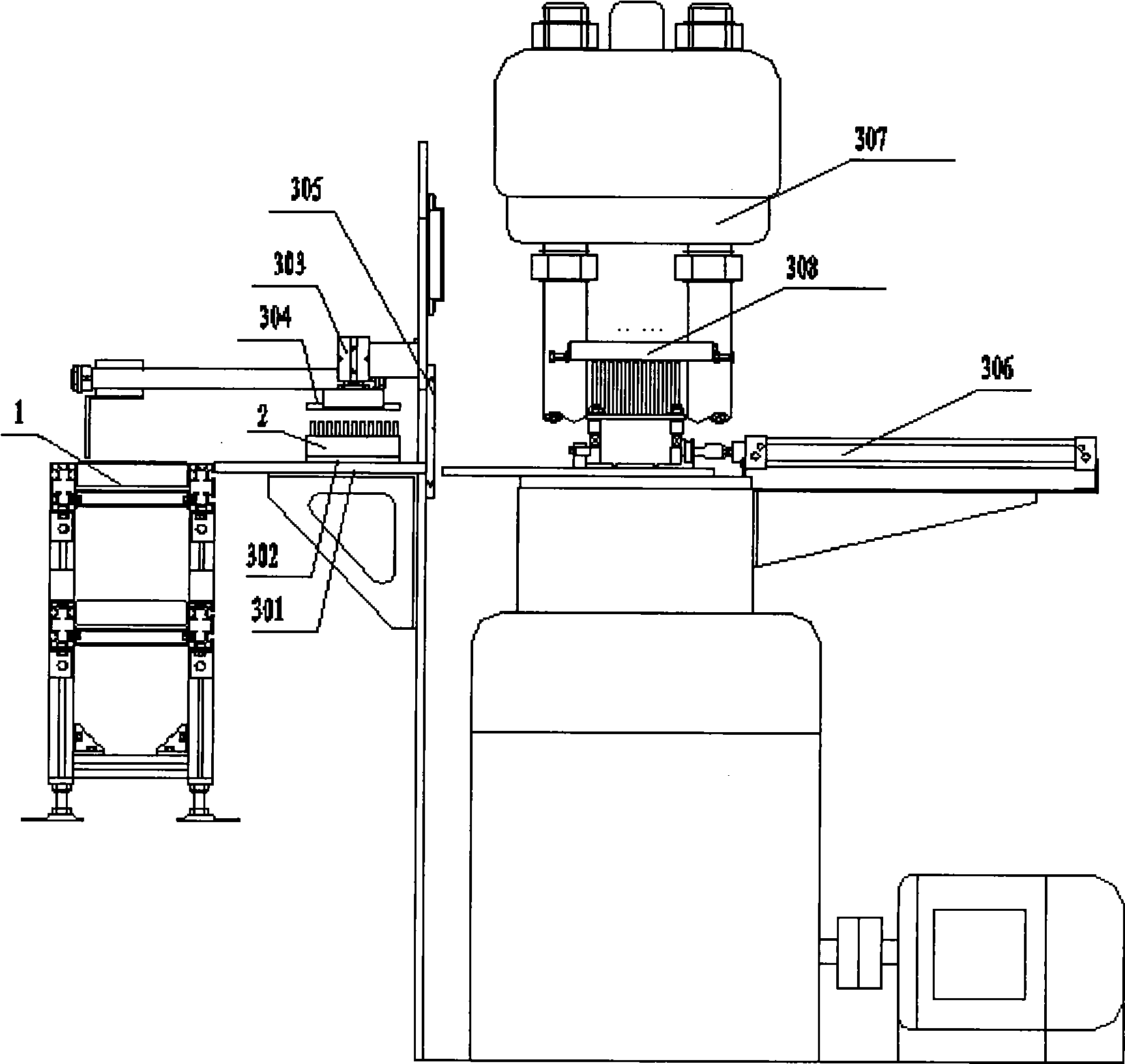

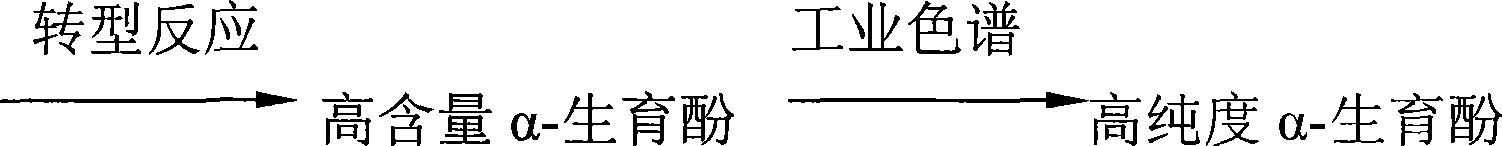

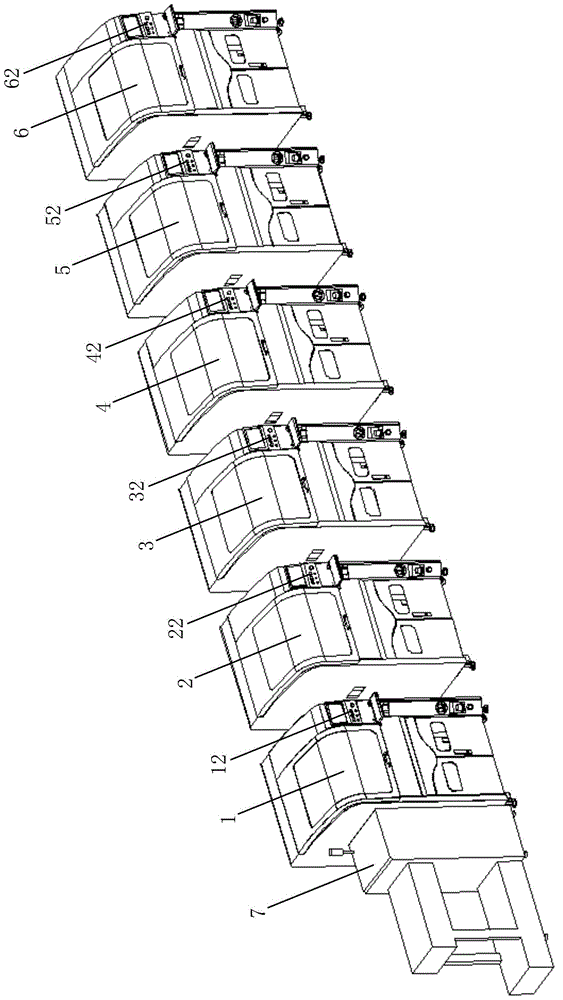

Production line for automatically assembling basal detonator

The invention discloses a production line for automatically assembling basal detonator, comprising a production line for automatically assembling basal detonator, a safety protection image monitor system and a configuration animation control demonstration system on the production line. The production line further comprises a metal shell automatic detonator-arranging machine arranged along a conveyer belt, an automatic charging machine, an automatic pressing machine, an automatic mould-arranging machine, an automatic whipping machine, an automatic detonator-releasing machine, an automatic mould-distributing and mould-transporting device, a PLC control system for controlling work of the apparatuses, and an integral line safety interlocking system. The invention realizes automation for assembling and producing basal detonator and continuous production by application of PLC programmable control, pneumatic principle and electromechanical integration, and realizes operation of hazardous work without a worker.

Owner:YAHUA GROUP MIANYANG INDAL

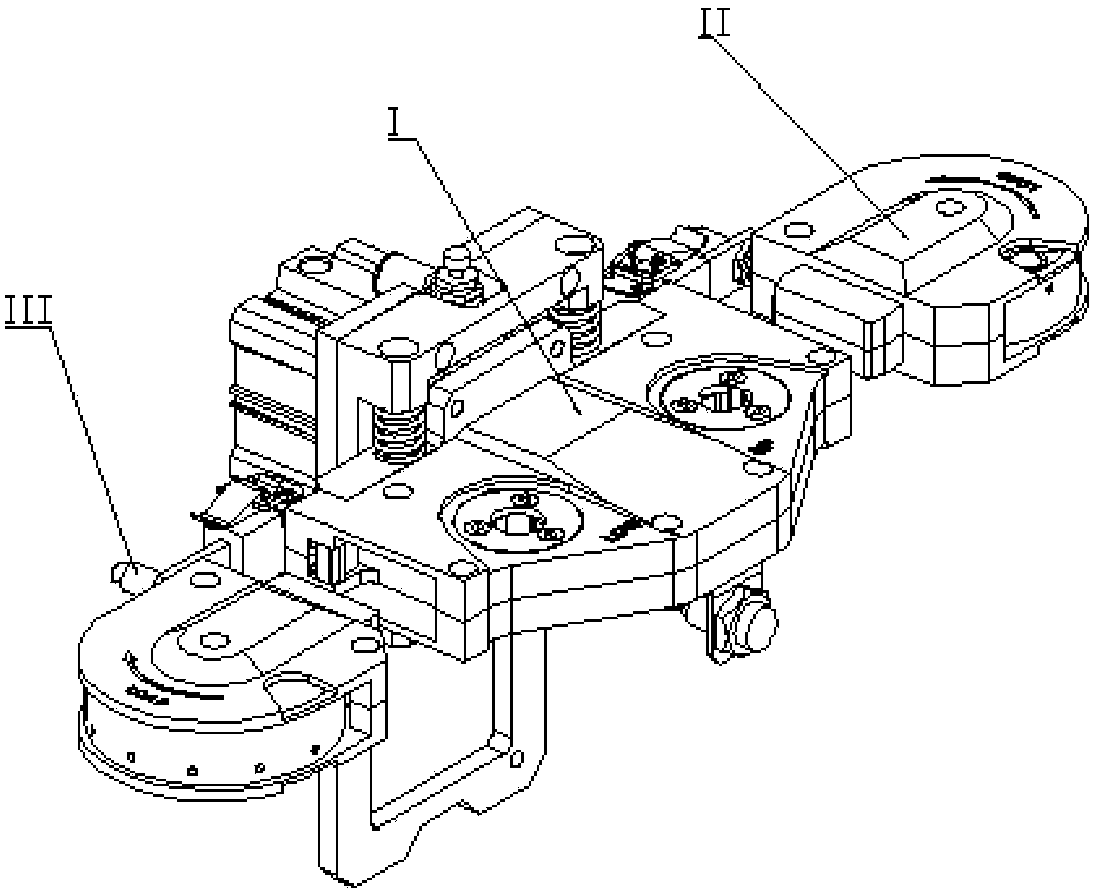

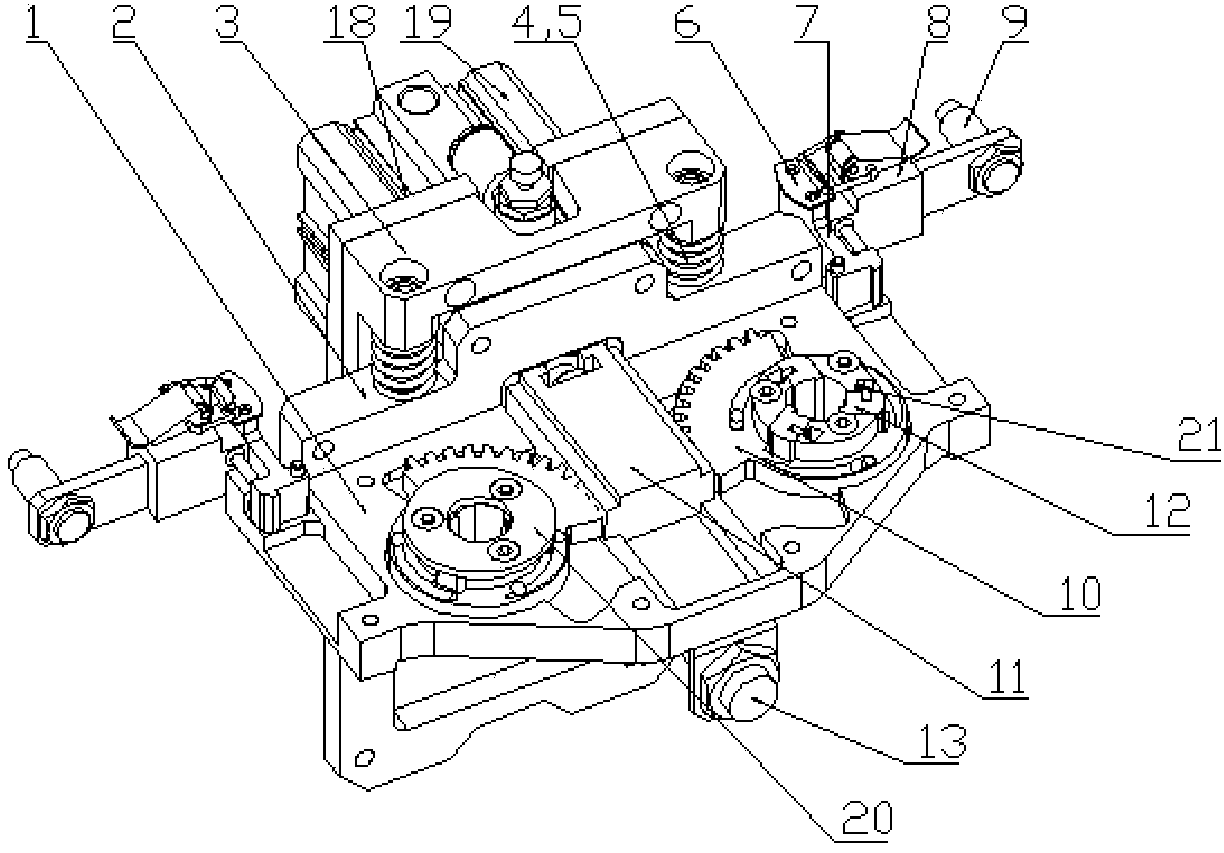

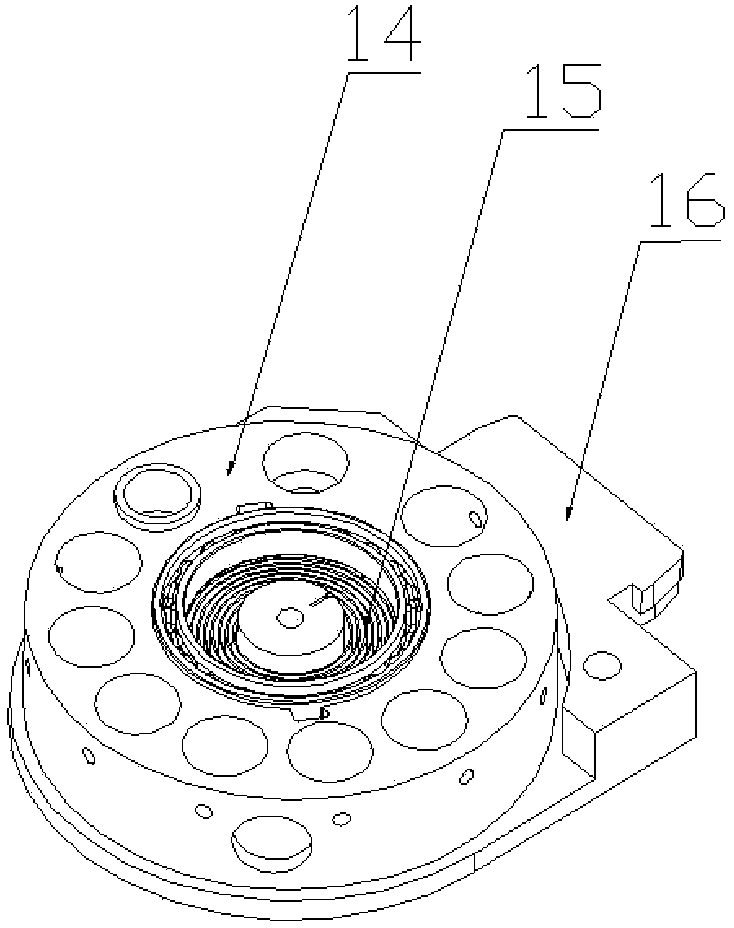

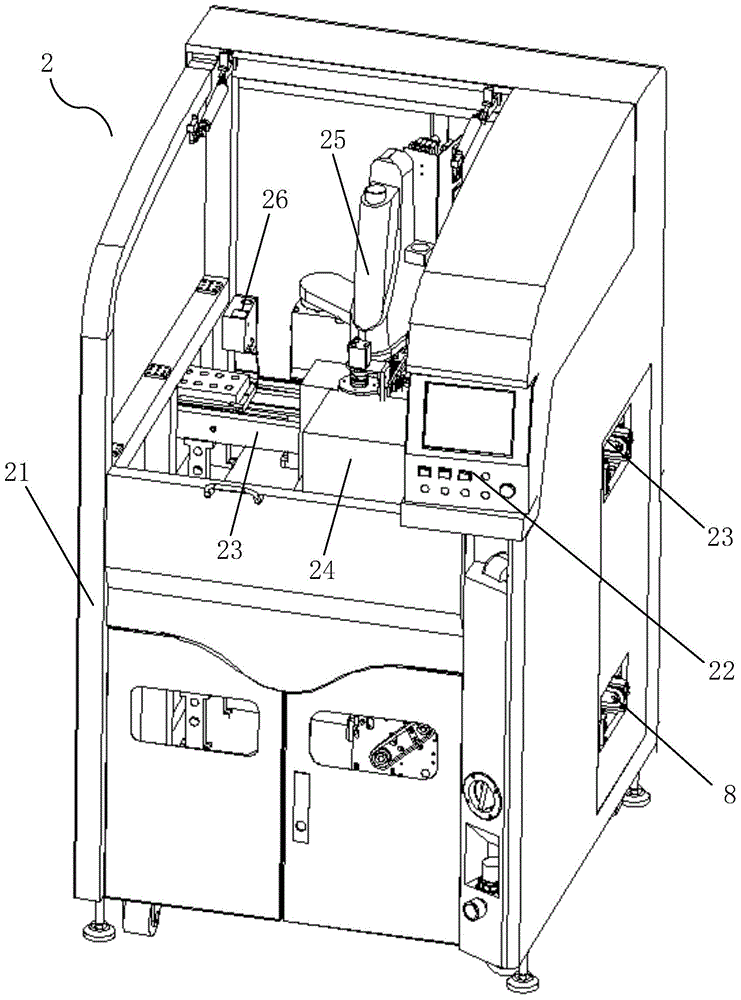

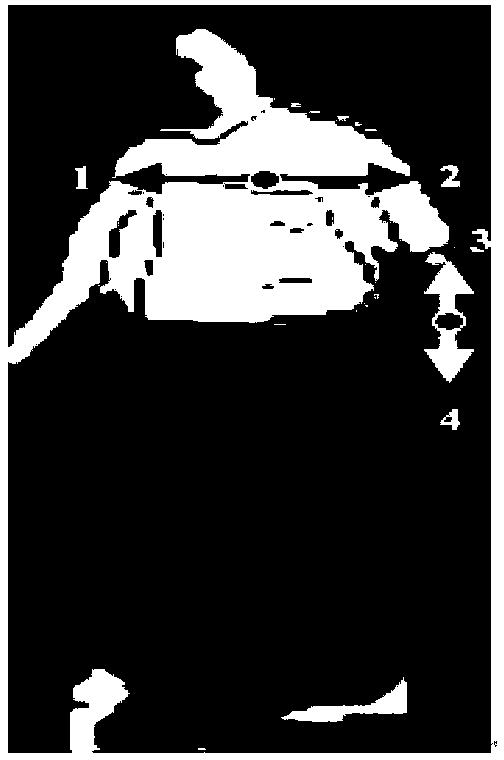

Tapered roller surface defect detection system

InactiveCN103264019AReduce wearEasy to sortOptically investigating flaws/contaminationSortingFace detectionEngineering

The invention discloses a tapered roller surface defect detection system. The tapered roller surface defect detection system comprises a tapered roller end-face detection mechanism and a tapered roller side-face detection mechanism. The tapered roller end-face detection mechanism comprises a feeder, a rotary feeder and an image acquisition device II. The tapered roller side-face detection mechanism comprises 1, a positioning clamp for vertical ordinal falling-off of tapered rollers, 2, a rotation table, 3, an image acquisition device I and 4, a sorting mechanism. The rotation table is located below an outlet of the positioning clamp and is driven by a stepping motor to rotate. One side of the rotation table is provided with the image acquisition device I and the other side of the rotation table is provided with a cylinder II. A push plate II in front of the cylinder II is corresponding to an automatic sorting table. The sorting mechanism receives qualified and unqualified tapered rollers sorted by a movable turnover panel. The tapered roller surface defect detection system effectively improves work efficiency and precision and realizes automatic production.

Owner:LUOYANG JIUDE BEARING MOLD TECH

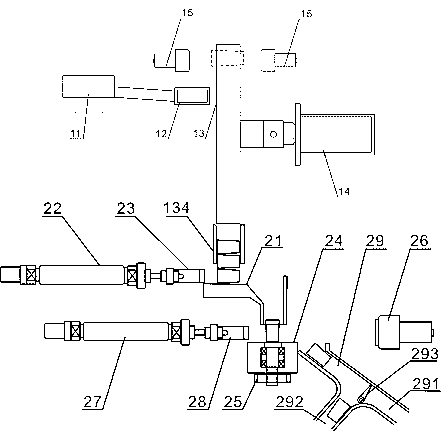

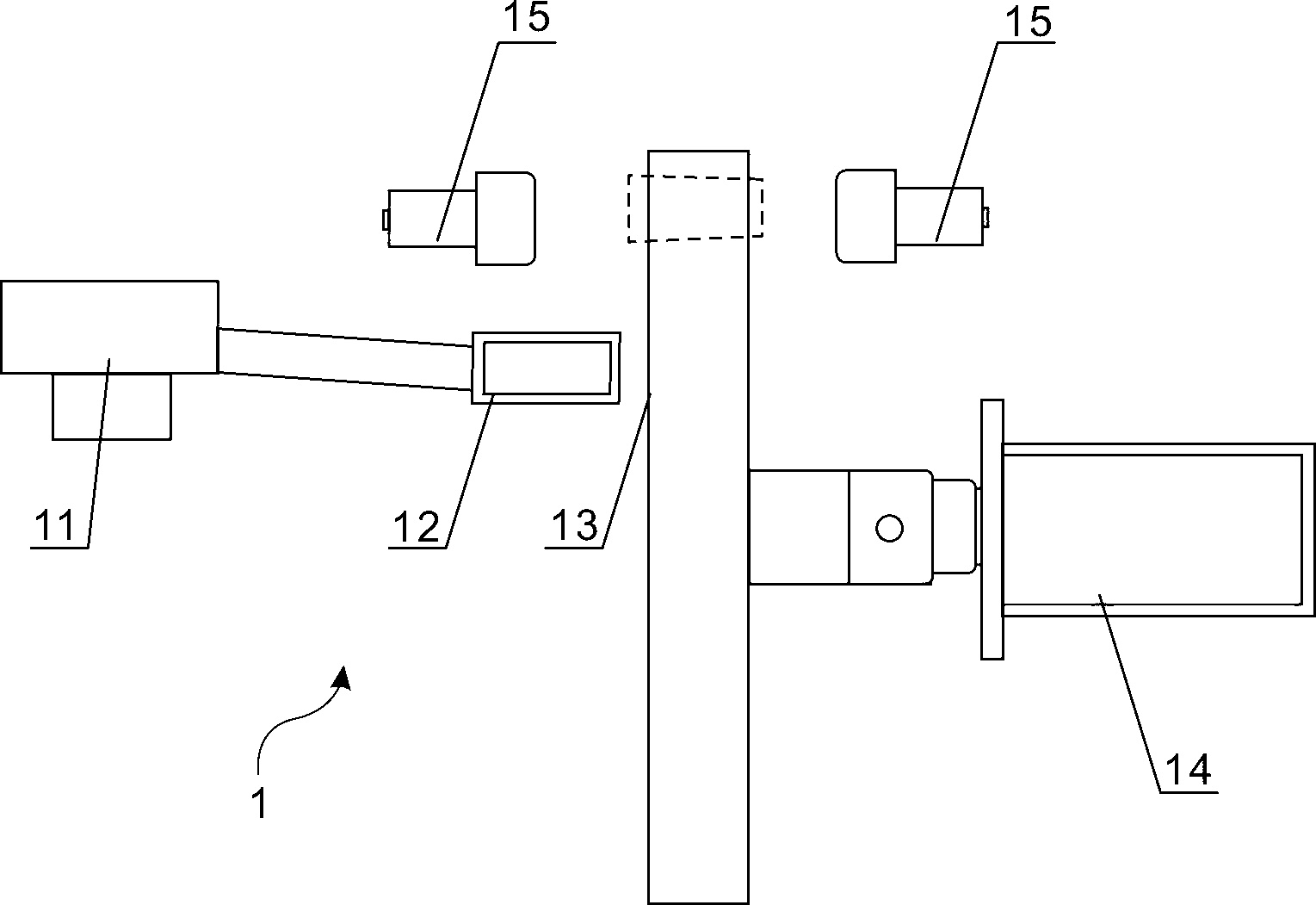

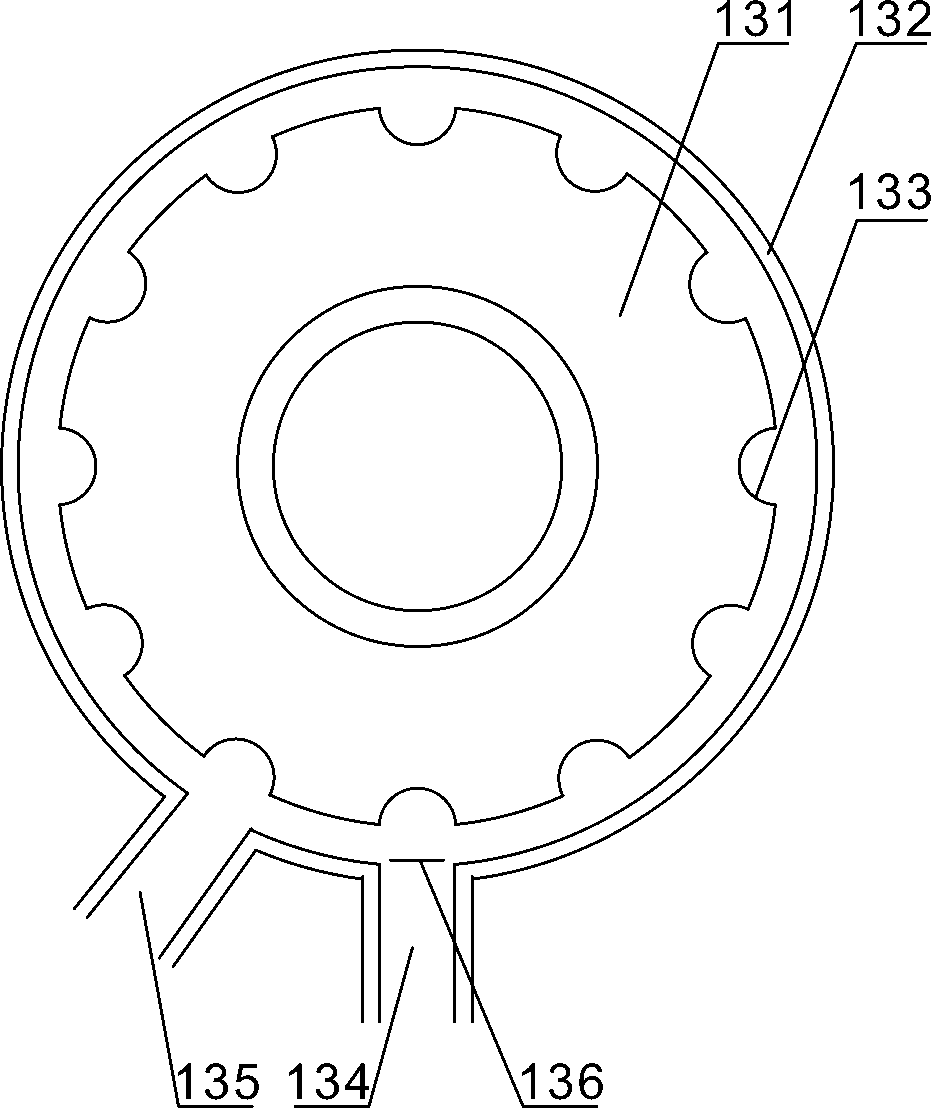

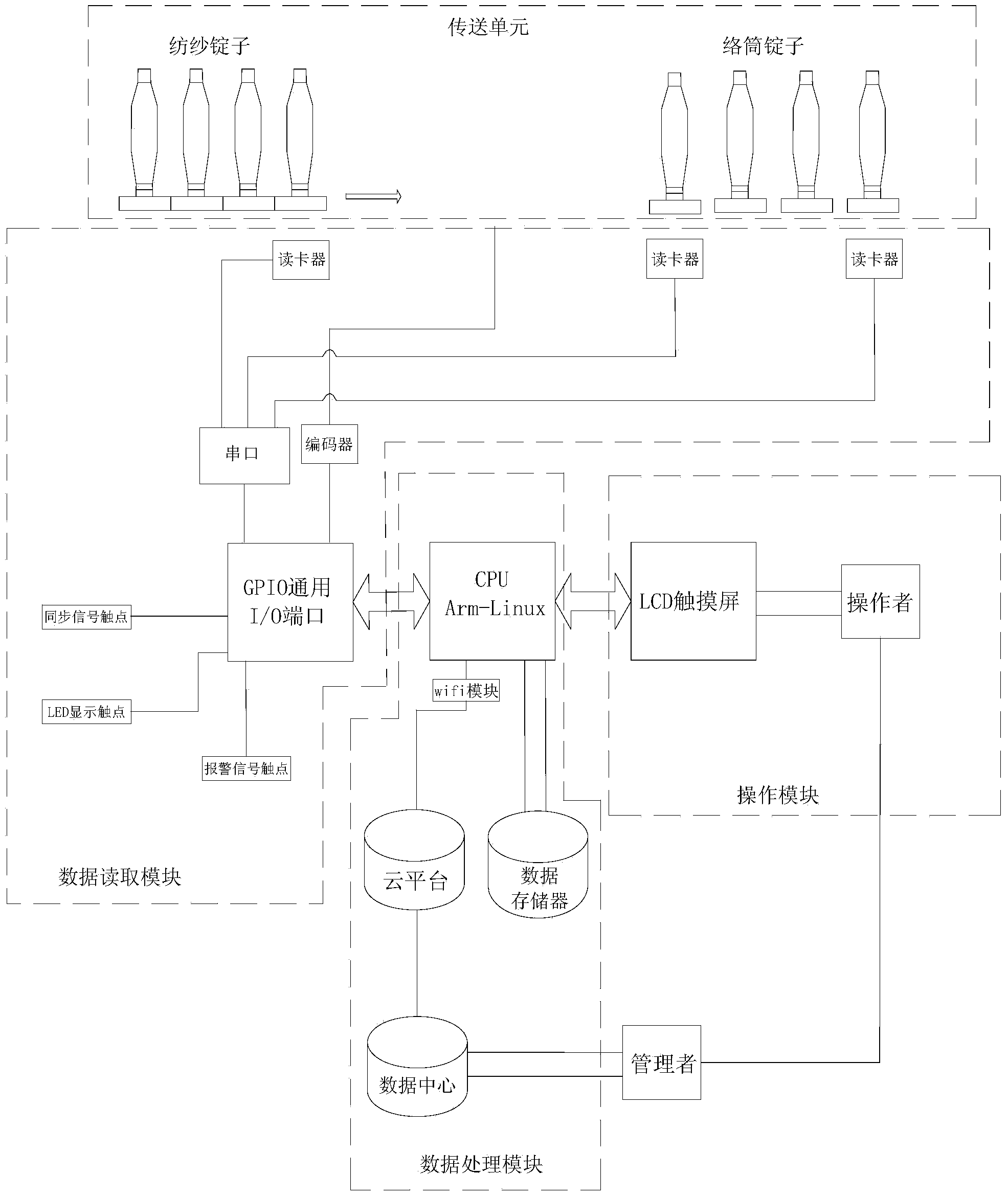

Textile production automated management system and management method thereof

InactiveCN104049615AFind out exactlyImprove spinning qualityTextiles and paperTotal factory controlYarnBobbin

The invention discloses a textile production automated management system and a management method thereof. The management method includes the steps that each spinning spindle and / or spooling spindle of a transport unit are respectively provided with an RFID radio frequency tag module with coded message, the RFID radio frequency tag modules corresponding to each specific spinning spindle position and / or each specific spooling spindle position are respectively provided with a card reader, and therefore tag information and working condition information corresponding to all spinning spindles and / or spooling spindles are obtained and transmitted to a data processing module to be stored, analyzed and processed. According to the system and method, bobbin positioning and quality online monitoring can be carried out rapidly, quality conditions of spun yarn can be checked in real time, the production automation level is improved, labor intensity is relieved, labor productivity is raised, and automated management of quality of spun yarn is achieved.

Owner:ZHANJIANG ZHONGZHAN TEXTILE

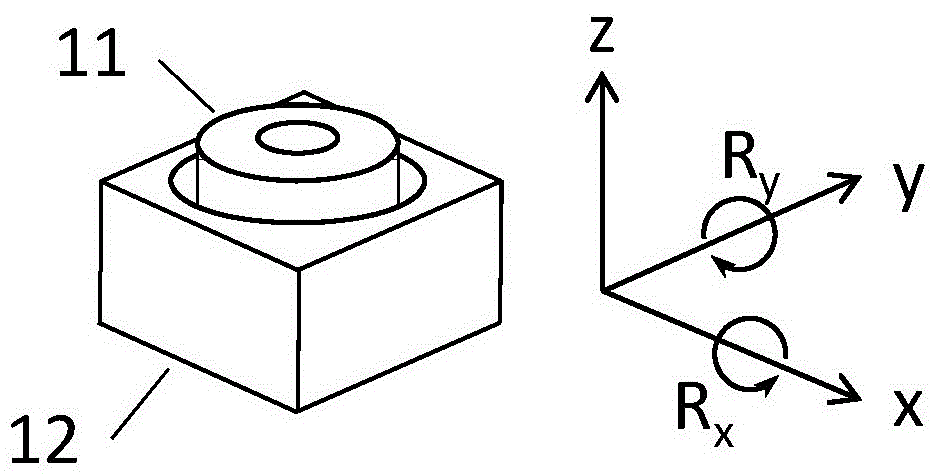

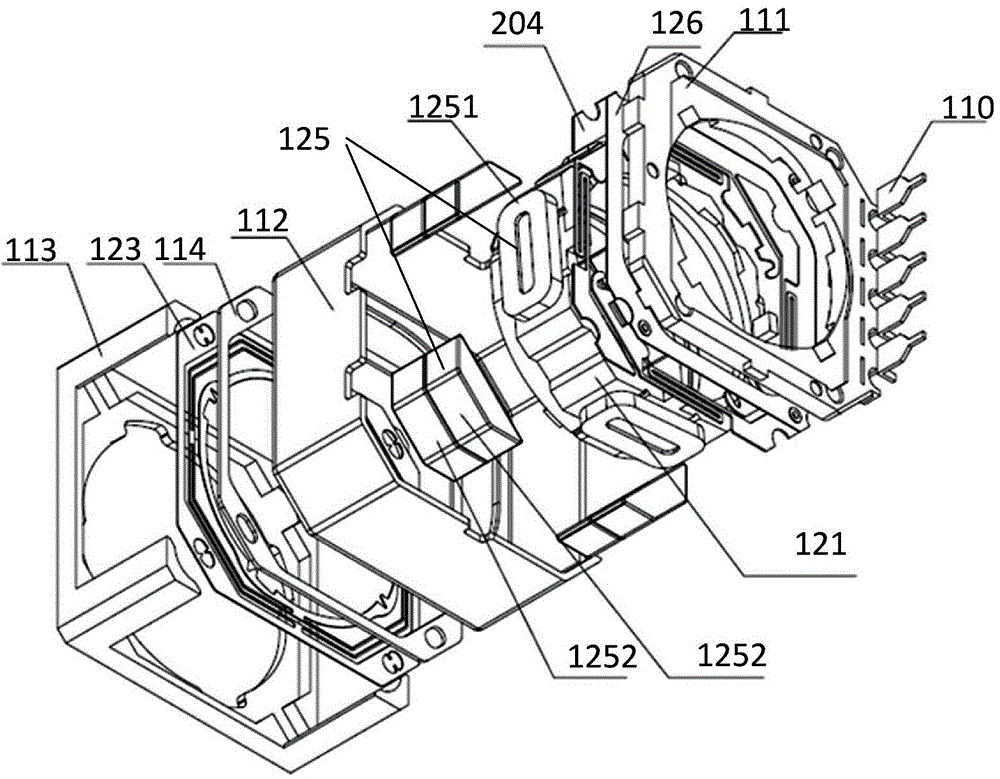

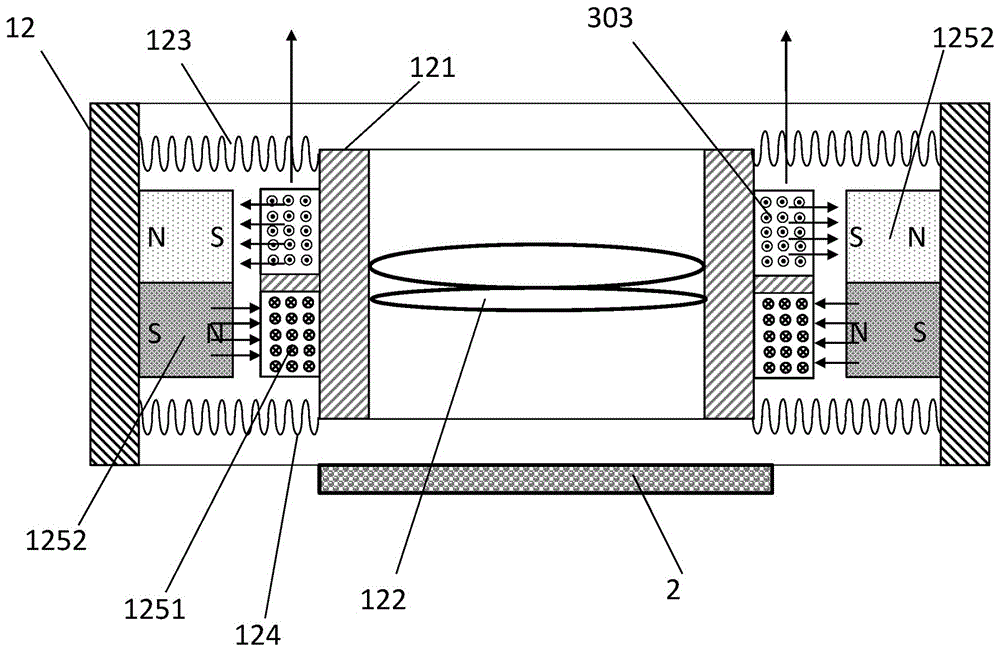

Camera module based on camera lens tilt controllable motor and quick focusing sensor, and control method

InactiveCN106303264AReduce production automation equipment requirementsImprove experienceTelevision system detailsColor television detailsCamera lensCamera module

The invention provides a camera module based on a camera lens tilt controllable motor and a quick focusing sensor, and a control method, relates to the technical field of micro-camera modules, and solves the problem of camera lens initial mounting position error or additional parasitic deflection generated in the camera lens moving process required by auto-focusing and after movement. The camera module comprises a focusing motor and a phase auto-focusing image sensor, wherein the focusing motor comprises a motor stator and a motor rotor arranged in the motor stator; the motor stator comprises a camera lens mount; more than three groups of electromagnetic drivers which are used for driving a camera lens part to do parallel movement vertical to the axis of the phase auto-focusing image sensor and do tilt deflection motion vertical to the X direction and the Y direction of the axis, are arranged between the outside wall of the camera lens mount and the inner wall of the motor stator. The production automation equipment requirement of a PDAF (phase detection auto focus) camera can be reduced, and a back-end adjusting and correcting technology and a process requirement are simplified, so that production yield is increased and the production cost is reduced.

Owner:DONGGUAN PRECISION PHOTONICS LTD

Spinning forming method and device based on laser heating

InactiveCN106424286AImprove heating efficiencyGood process flexibilityShaping toolsProcess equipmentSpinning

The invention discloses a spinning forming method and device based on laser heating. The spinning forming device is characterized by comprising a numerically-controlled spinning machine, spinning process equipment, a laser device, a light guide system, a six-degree-of-freedom robot machining system, a laser machining head, a temperature measuring device and the like. The spinning forming device conducts high-accuracy flexible control over a heating area according to the characteristics of high laser heating speed, accurate and controllable heating parts and temperatures and high degree of freedom and accurate control of the six-degree-of-freedom robot machining system, and spun blanks can be dynamically and locally heated while the spinning process equipment is not heated. The purposes of improving the material spinnability and reducing damage to the spinning machine are achieved. Meanwhile, closed-loop control over the heating temperature and laser output is realized, and realization of production automation is realized. The spinning forming method and device based on laser heating have the advantages of being high in production efficiency, good in process stability, high in forming precision, convenient to operate and the like.

Owner:JIANGSU UNIV OF TECH

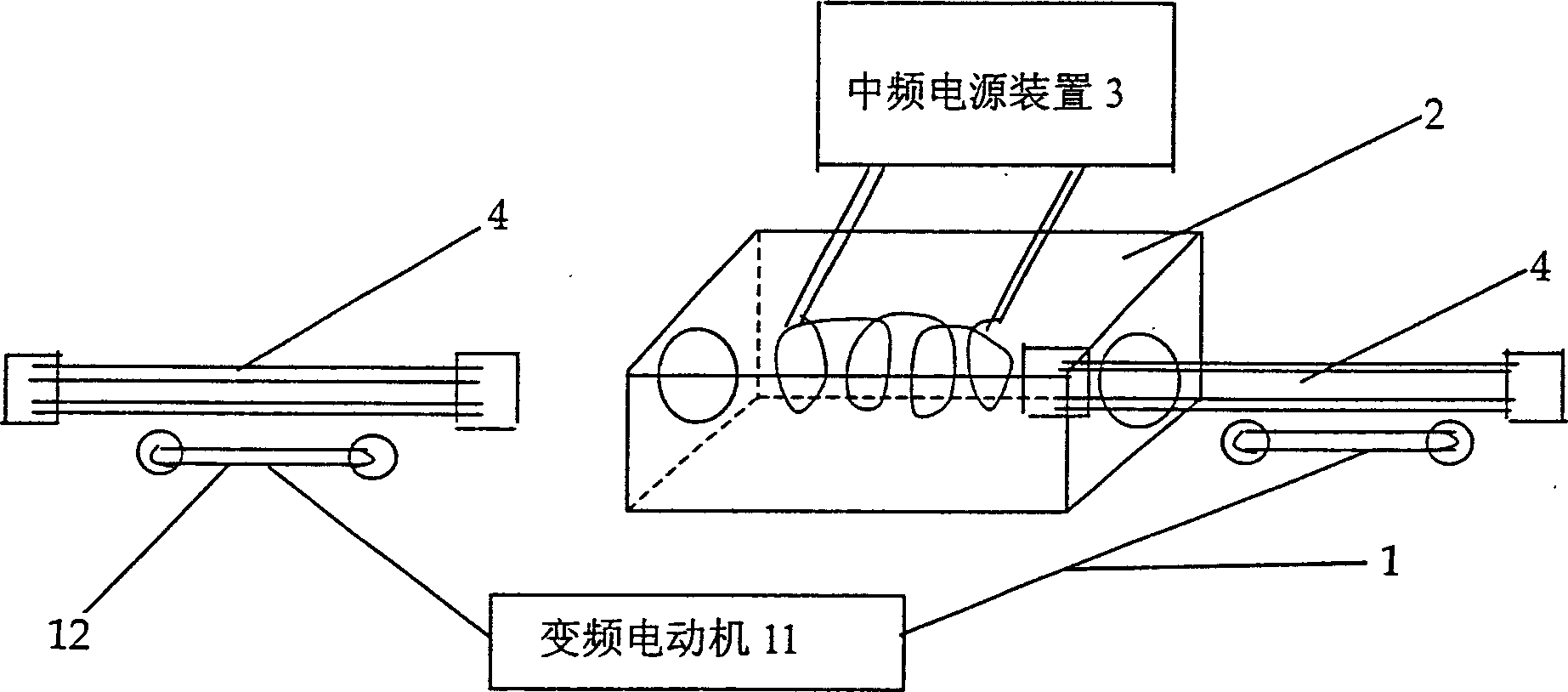

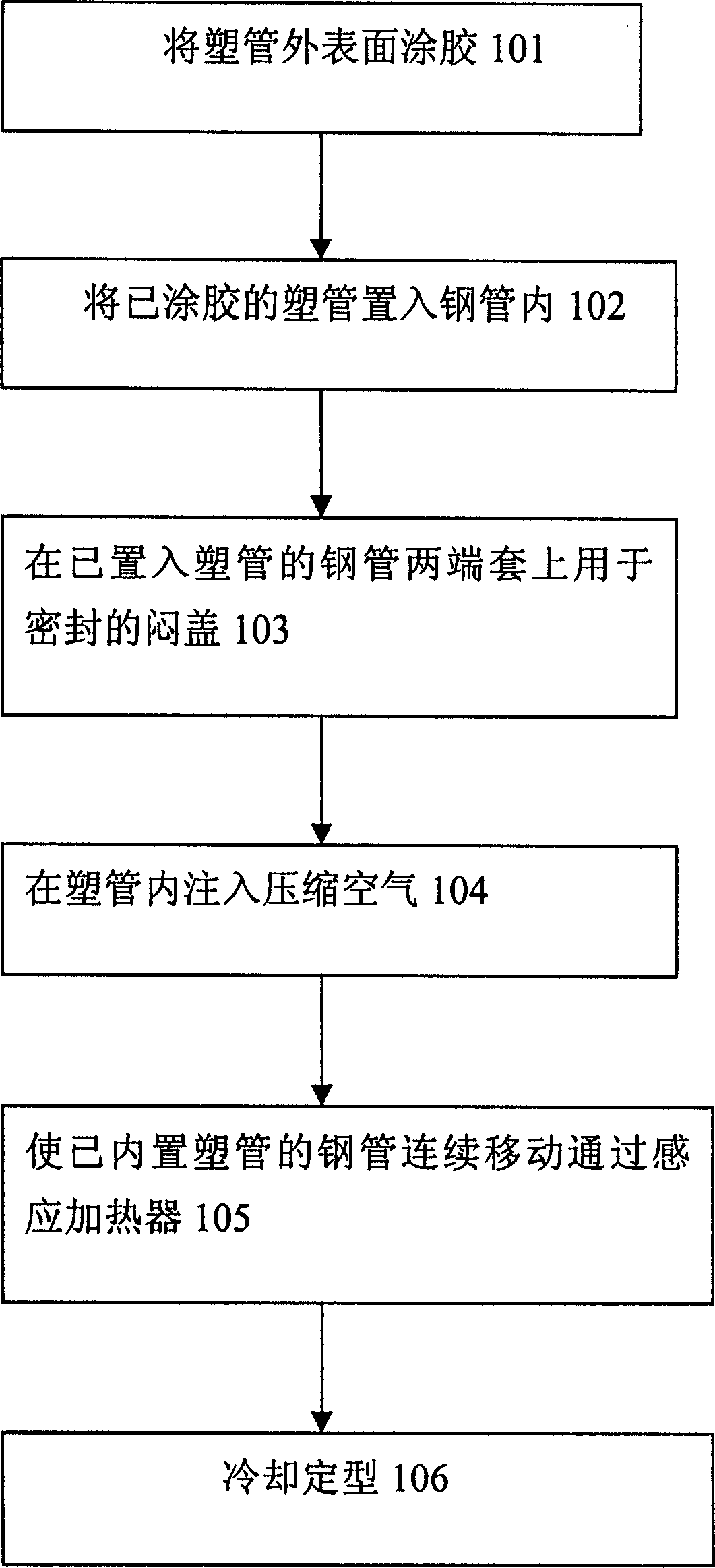

Manufacturing method plastic lining composite steel pipe and its manufacturing equipment

A technology for manufacturing plastic-lined composite steel pipe includes such steps as coating adhesive on the external surface of a plastic pipe, putting the plastic pipe in a steel pipe, sealing both ends of steel pipe by two blank covers, injecting compressed air into the plastic pipe, moving the steel pipe through an induction heater, and cooling for formation. Its advantages are high productivity and no damage to the coated zinc layer of steel pipe.

Owner:SHANGHAI WEIBANG PIPELINE

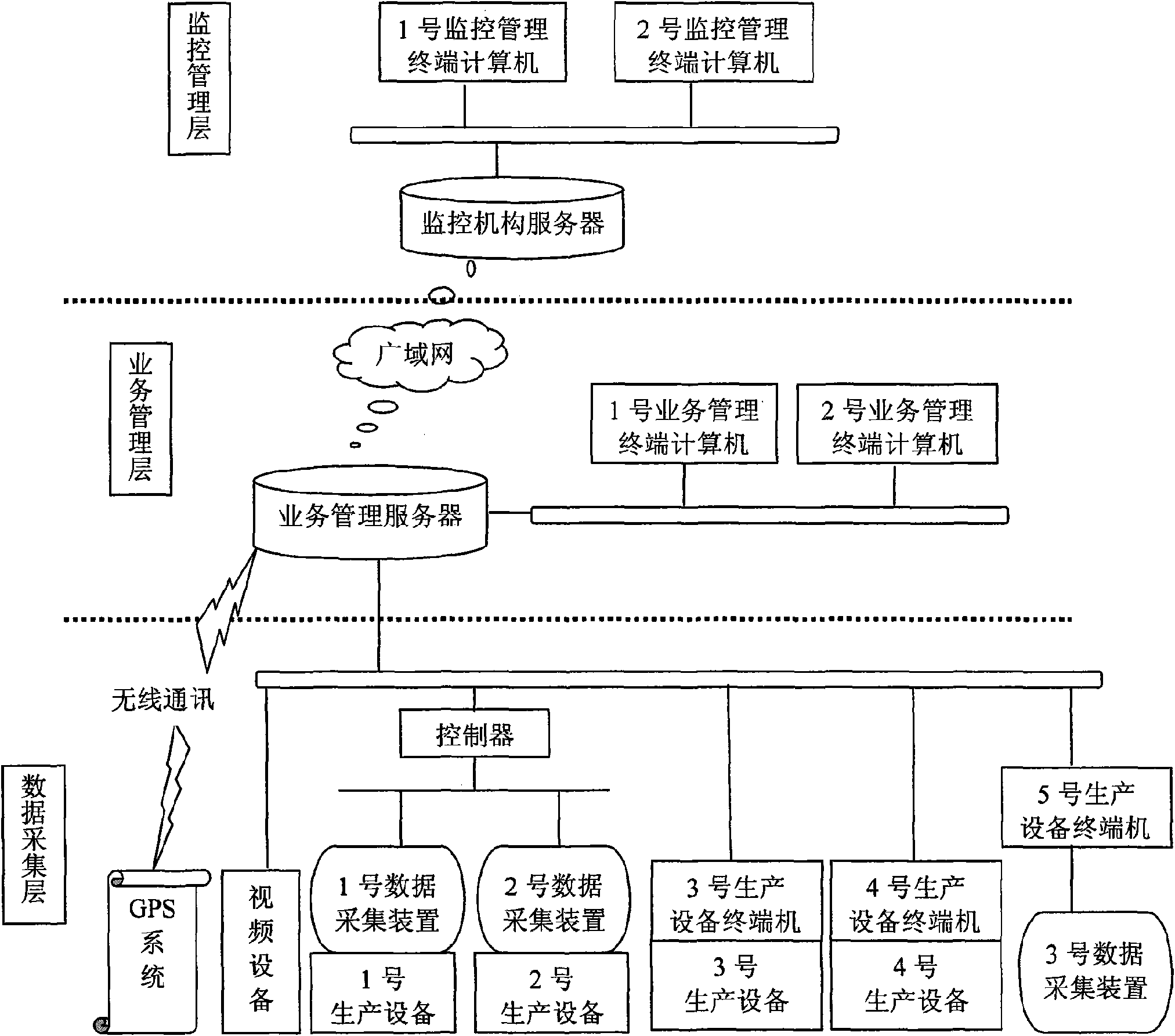

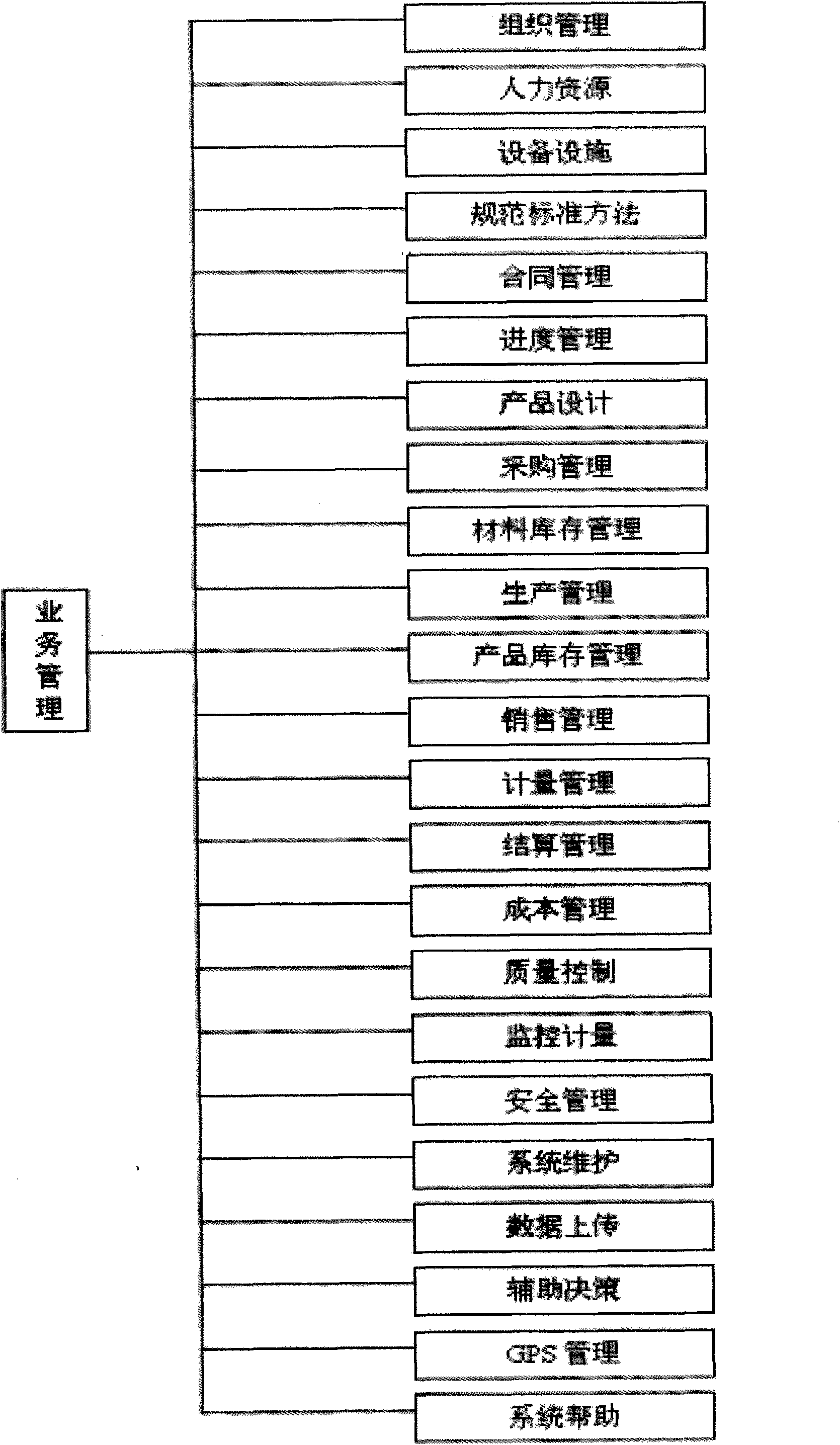

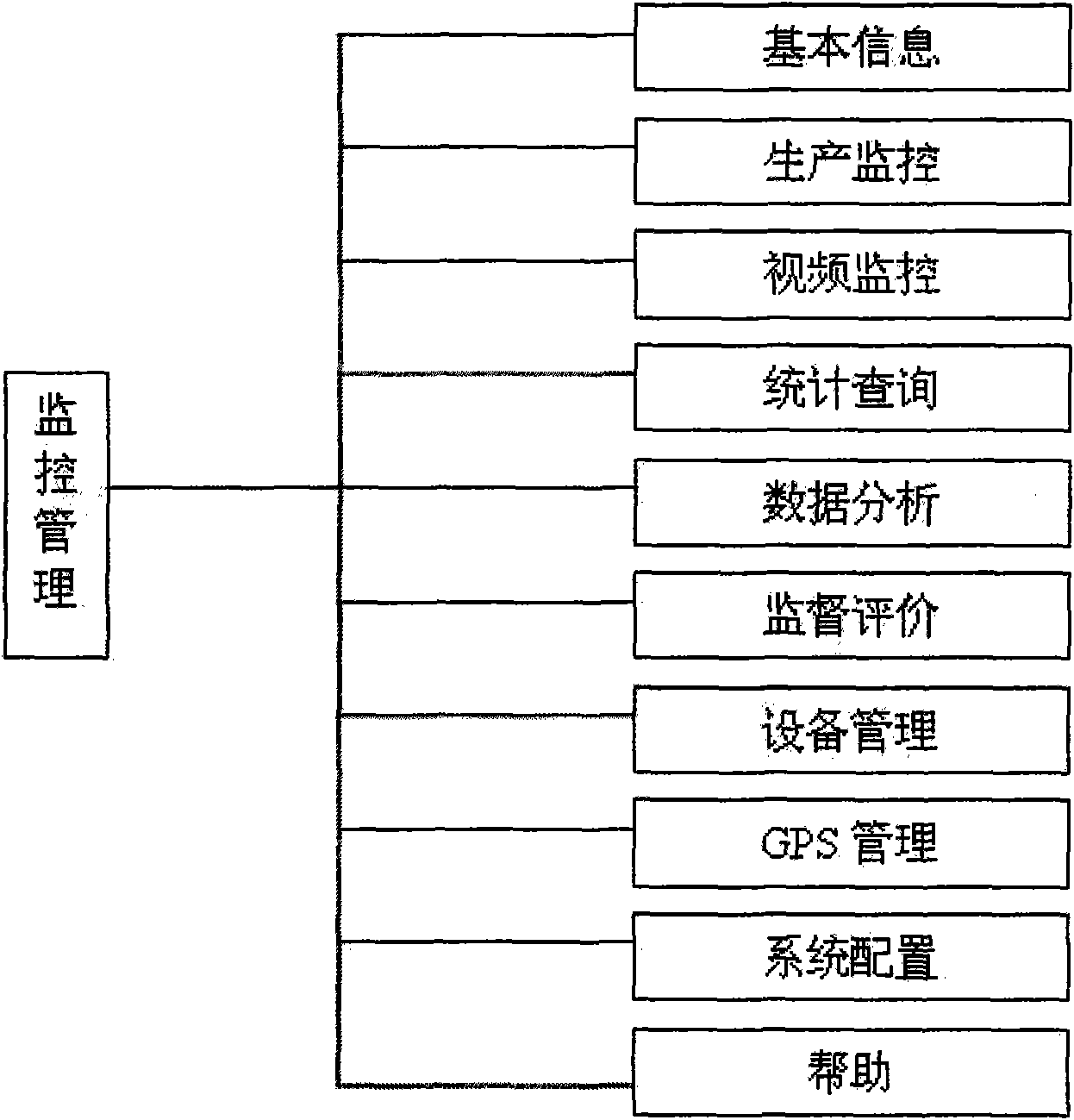

Integrated managing and controlling system and method of mass production enterprise

InactiveCN101667271AImprove securityImprove reliabilityResourcesStructure of Management InformationIT service management

The invention provides an integrated managing and controlling system and a method of mass production enterprises in transportation construction industry; the system comprises two parts, namely, hardware and software; the hardware includes a plurality of production devices, a plurality of production device terminal computers, a plurality of data collectors, a plurality of controllers, a plurality of video devices, a plurality of dippers or GPS satellite positioning devices, a plurality of service management terminal computers, a plurality of monitoring management terminal machines, a service management server and a monitoring mechanism server; the software includes data collecting software, service management software, monitoring management software, service management database software andmonitoring management database software; the integrated managing and controlling system of mass production enterprises is divided into three layers based on structure; the first layer is a data collecting layer, the second layer is a service management layer and the third layer is a monitoring management layer. The system and the method are scientifically and rationally designed, and creative, not only improve the production automation level and production continuity, but also guarantee the systematicness, visibility and reliability of intelligent operation of the whole production; meanwhile,the system and the method can prevent resource loss, reduce production cost and improve economic benefits.

Owner:石庆生 +1

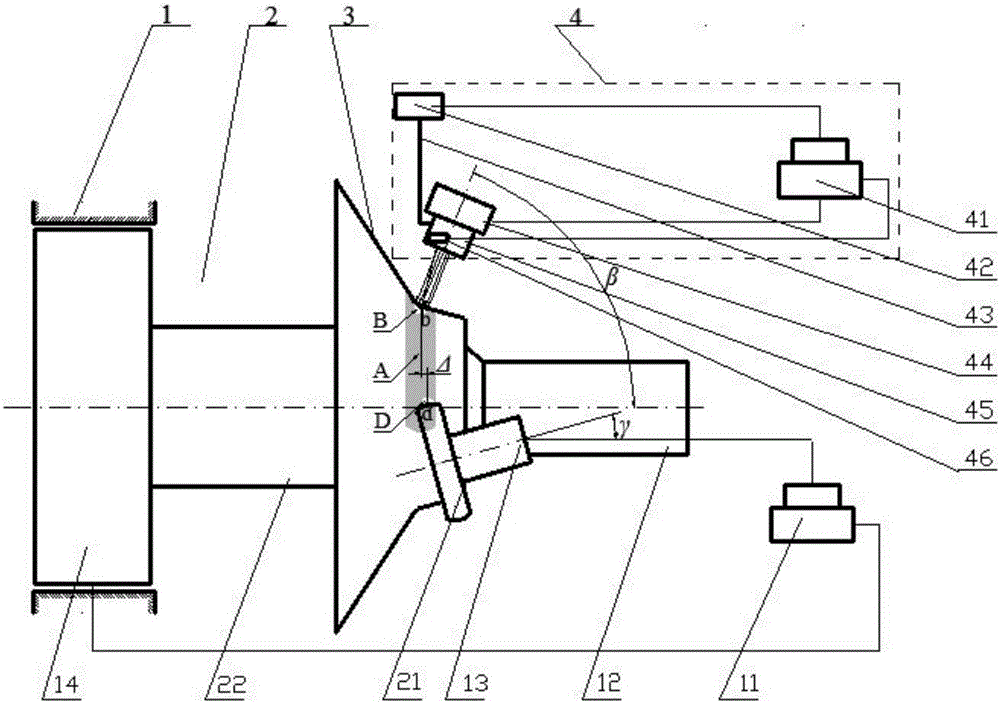

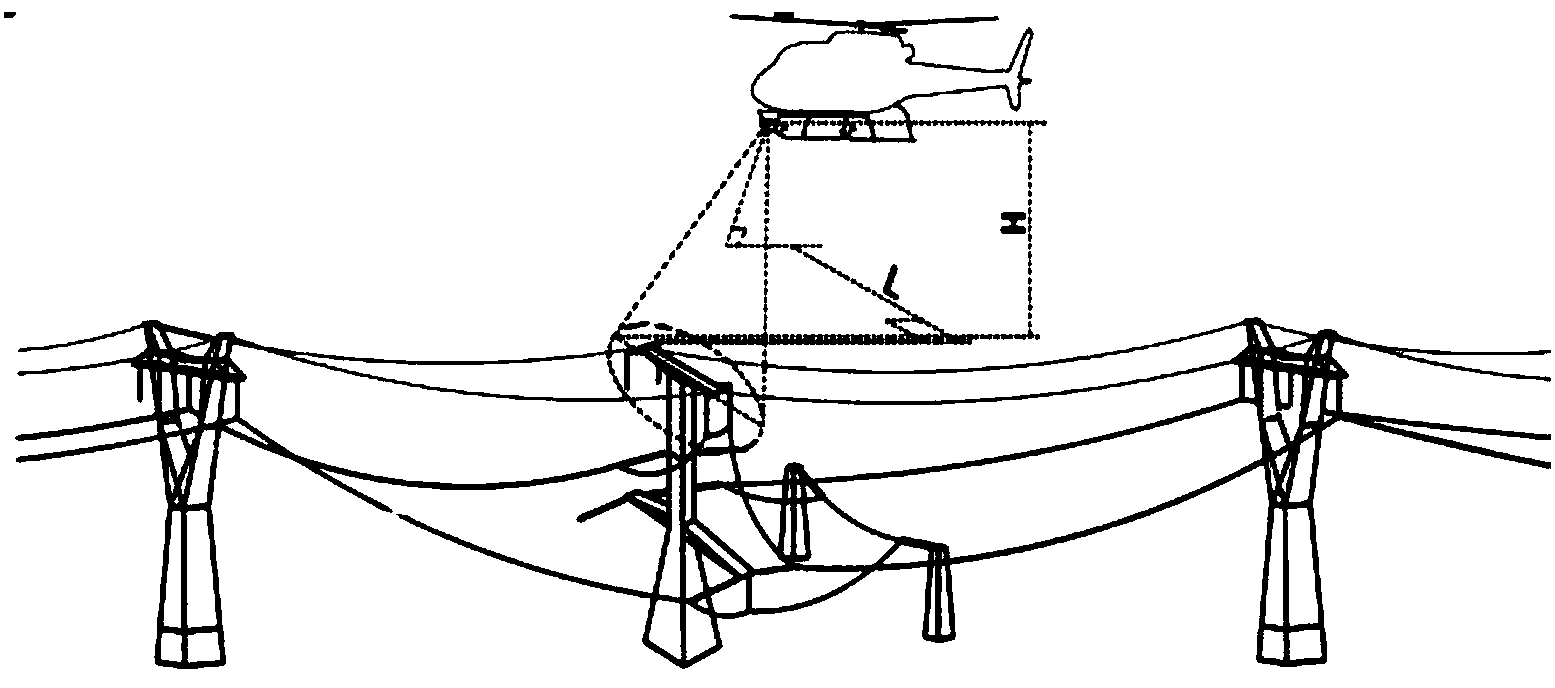

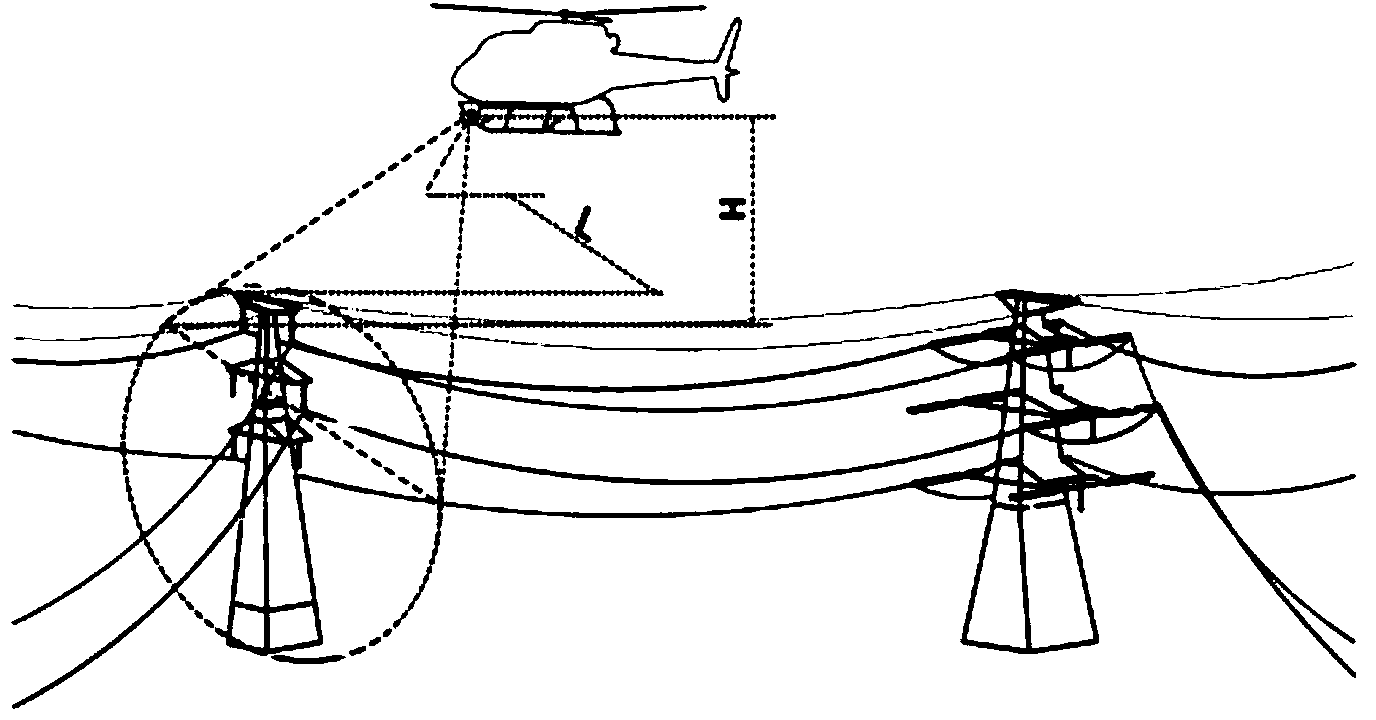

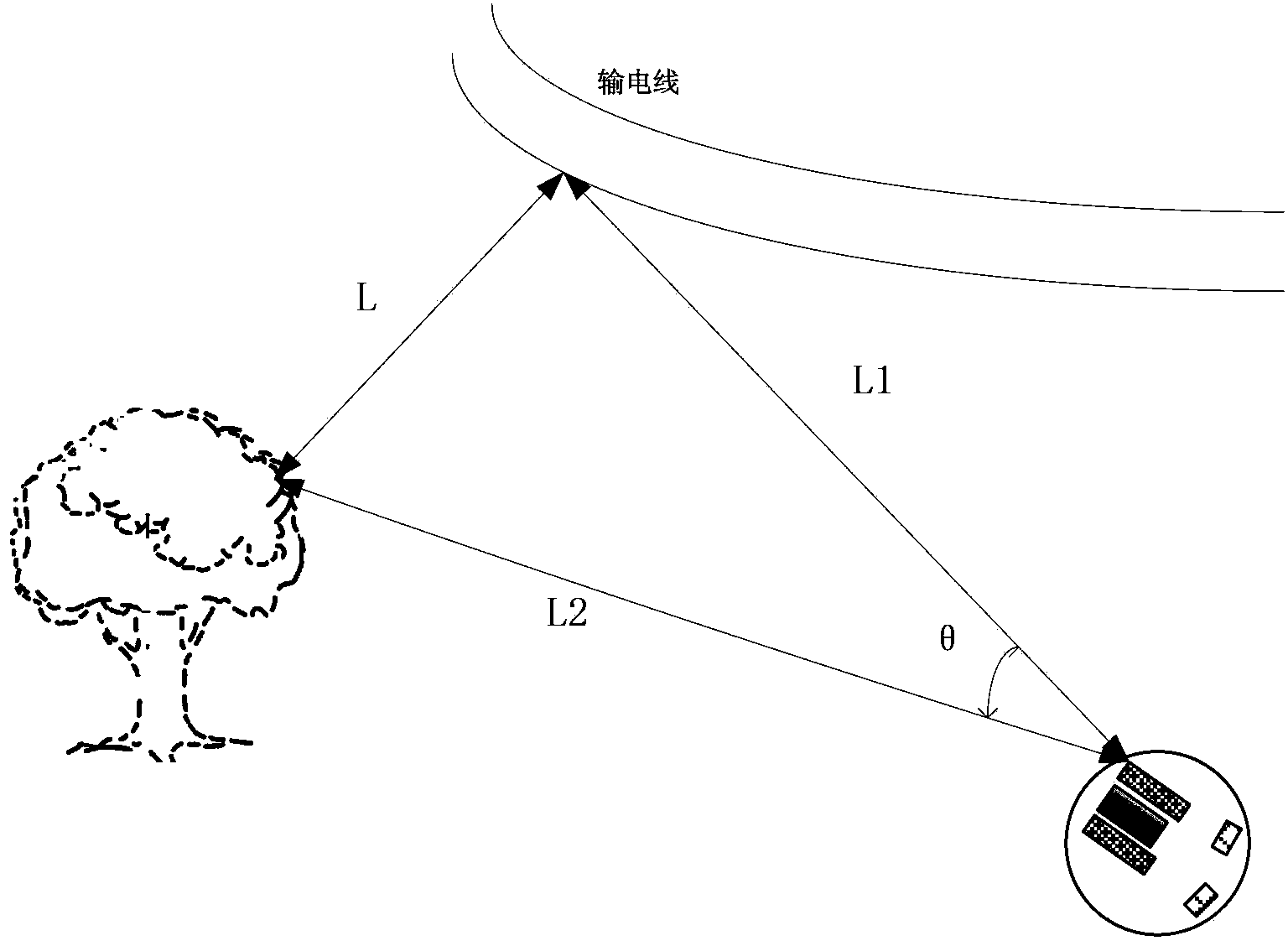

Airborne photoelectric measurement apparatus of dimensions and spacing of electric transmission line and target, and method thereof

InactiveCN103353297AReduce labor intensityQuality improvementOptical rangefindersMeasurement deviceEngineering

The invention relates to an airborne photoelectric measurement apparatus of the dimensions and the spacing of an electric transmission line and a target, and a method thereof, and belongs to the electrical line detection field. The apparatus comprises an unmanned plane, a photoelectric stabilized gondola and a ground system; and the photoelectric stabilized gondola is connected to the unmanned plane, and the ground system controls the unmanned plane and the photoelectric stabilized gondola through radio communication. The method comprises the steps of flight on a line, adjustment motion, measurement, acquisition and transmission. The apparatus has the advantages of flexible motion, simple operation and economy, and the exploitation of the airborne photoelectric automatic measurement apparatus of the remote target dimension and the spacing of the electric transmission line and the target through the combination of the photoelectric stabilized gondola and the design of a laser measurement system in the gondola greatly reduces the line inspection labor intensity of a worker, reduces the running and maintenance costs of electric transmission, improves the inspection work quality and the technological level of scientific management, enhances the electric production automation comprehensive capability, creates high economic and social benefits, and is of great significance.

Owner:CHANGCHUN UNIV OF SCI & TECH +3

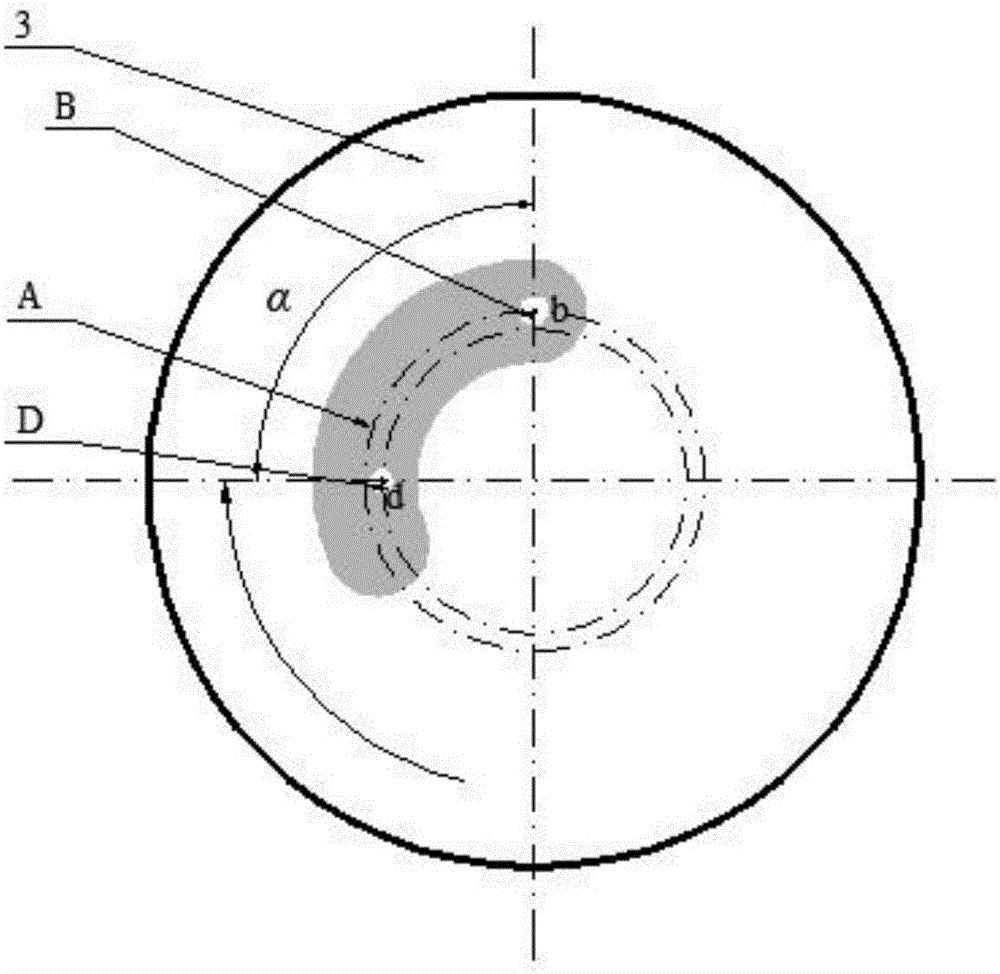

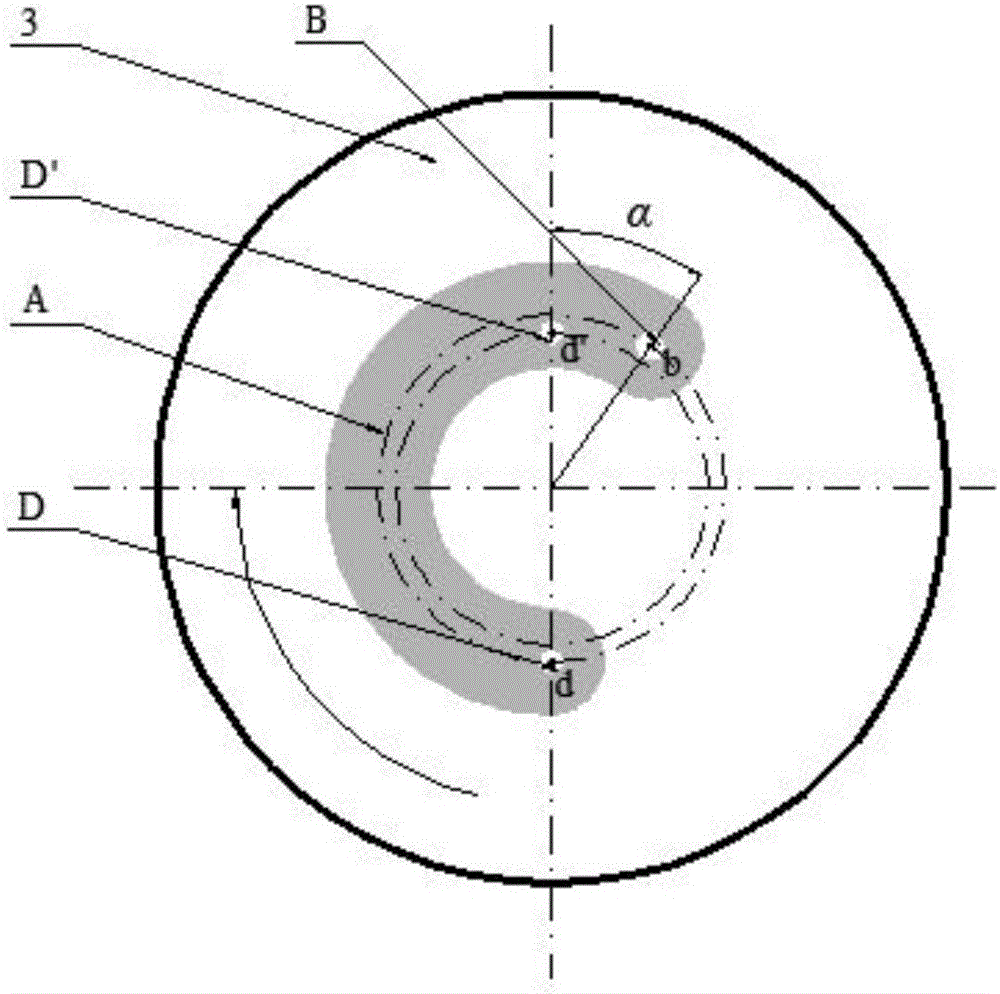

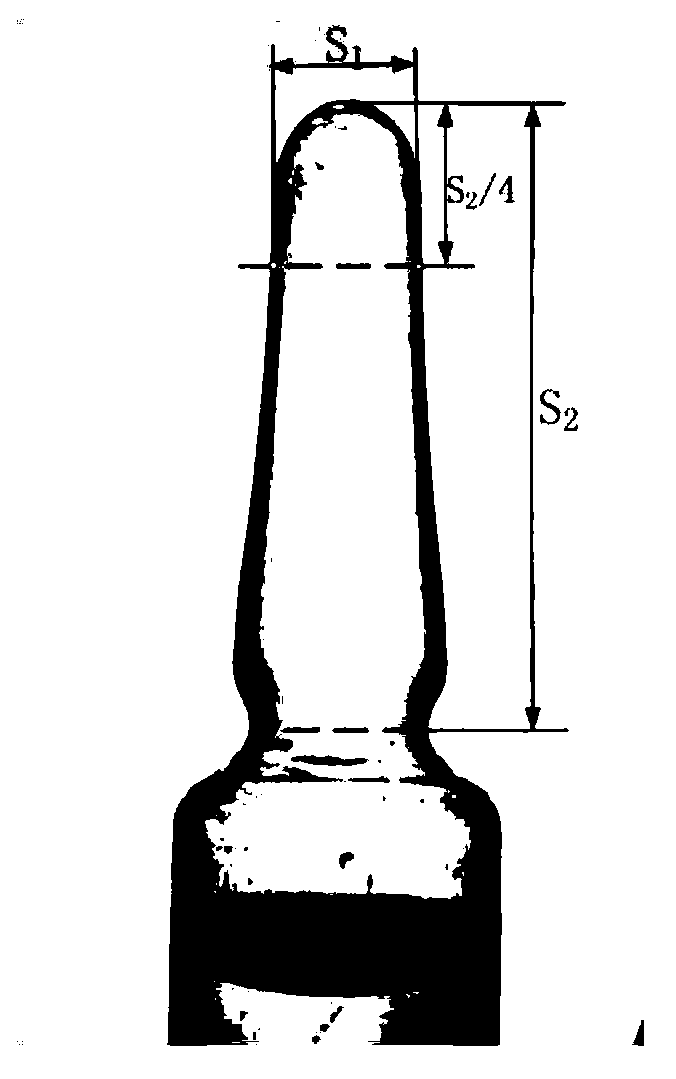

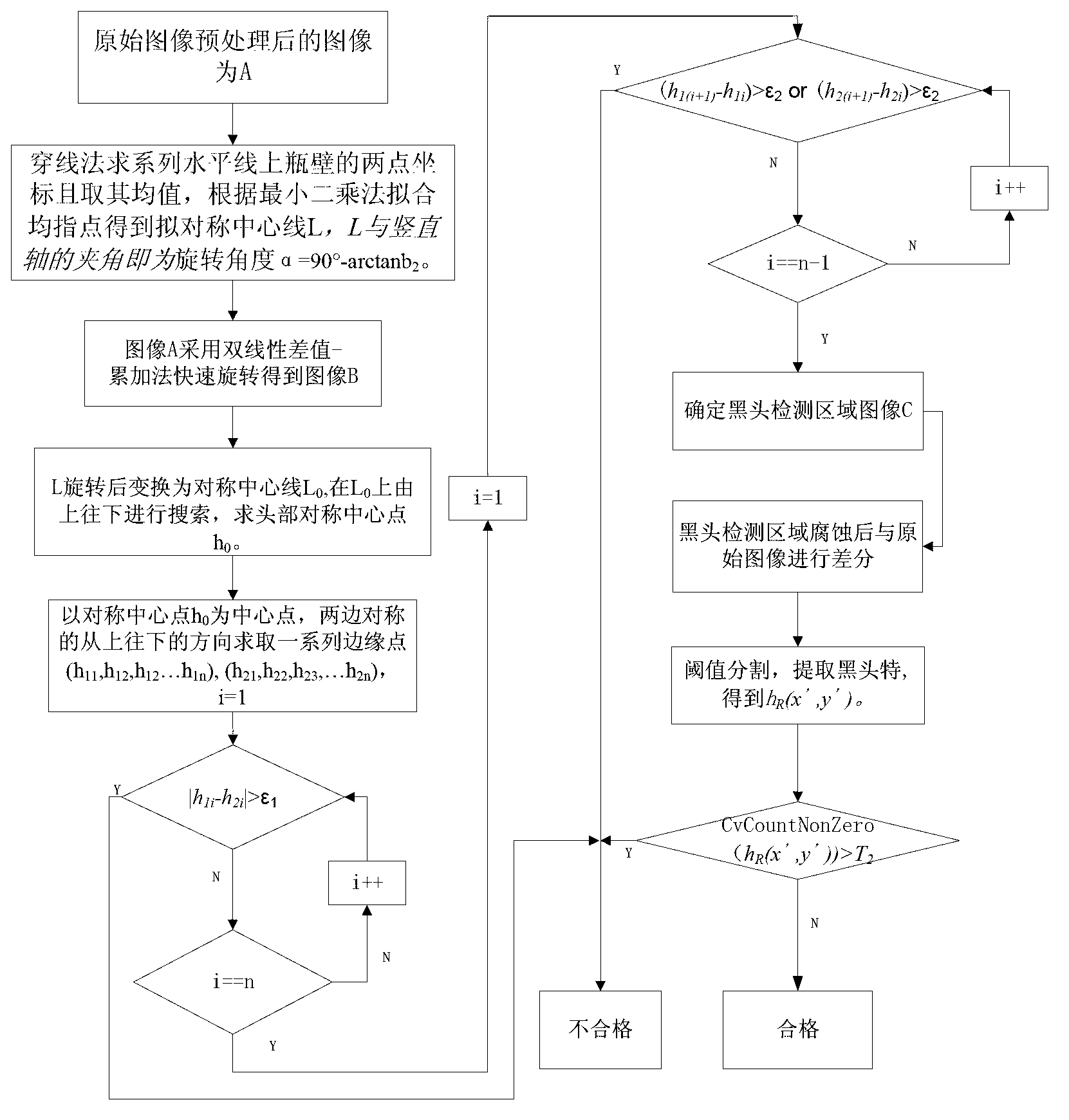

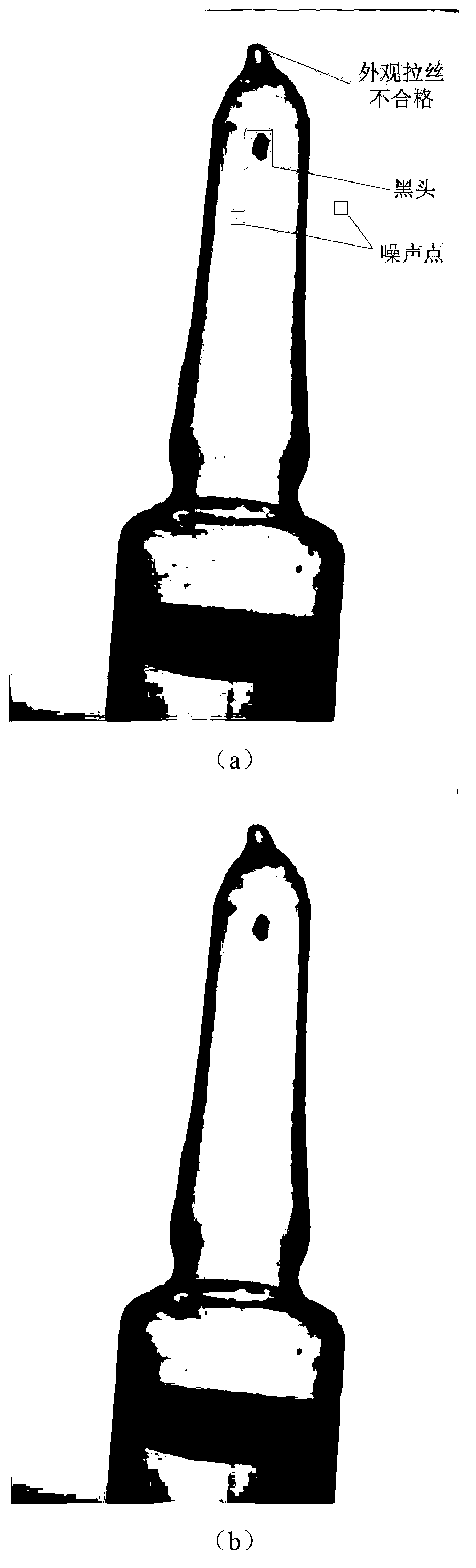

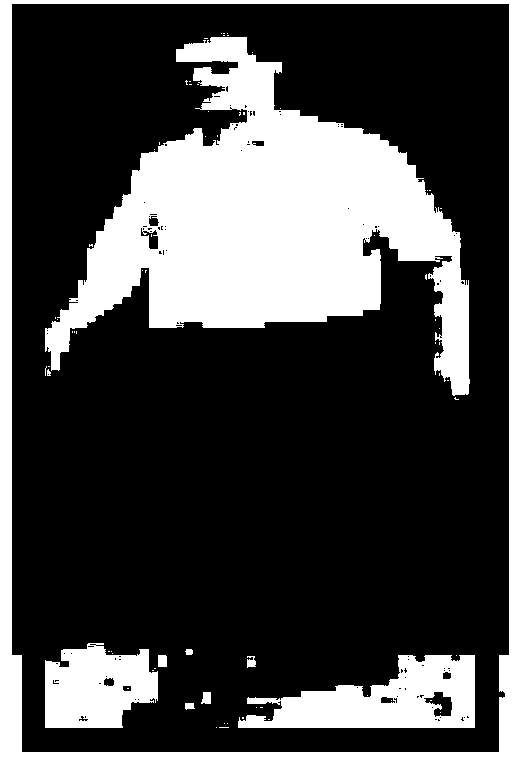

Method for detecting ampoule bottle appearance quality through medical visual inspection robot

ActiveCN103018253AImplement automatic detectionSave resourcesOptically investigating flaws/contaminationSpin imageSymmetry line

The invention discloses a method for detecting ampoule bottle appearance quality through a medical visual inspection robot. The method comprises the steps of (1) acquiring an ampoule bottle image, and preprocessing the image through a median filter; (2) solving an ampoule bottle mimic symmetry line by employing a threading method to obtain a rotating angle alpha; (3) rotating the image by using a bilinear interpolation-summation method; (4) solving a symmetry center line, wherein the intersection of the symmetry center line and the head is a symmetry center point h0; (5) solving a head edge point; (6) enabling the outer curve at the head of the ampoule bottle to have the characteristic of a symmetrical variable trend in a lower parabola shape, and judging whether the ampoule bottle appearance wire-drawing quality is qualified; (7) positioning a black head detection rectangular area; (8) judging whether the black head ampoule bottle appearance is qualified by employing a difference method; and (9) integrating the appearance drawing and black head quality detection result. According to the method, the problems that the manual detection efficiency is low, the consistency is low and the leakage detection rate is high and the like are overcome, and the degree of automation and product quality of the ampoule bottle medicine production are improved.

Owner:HUNAN UNIV

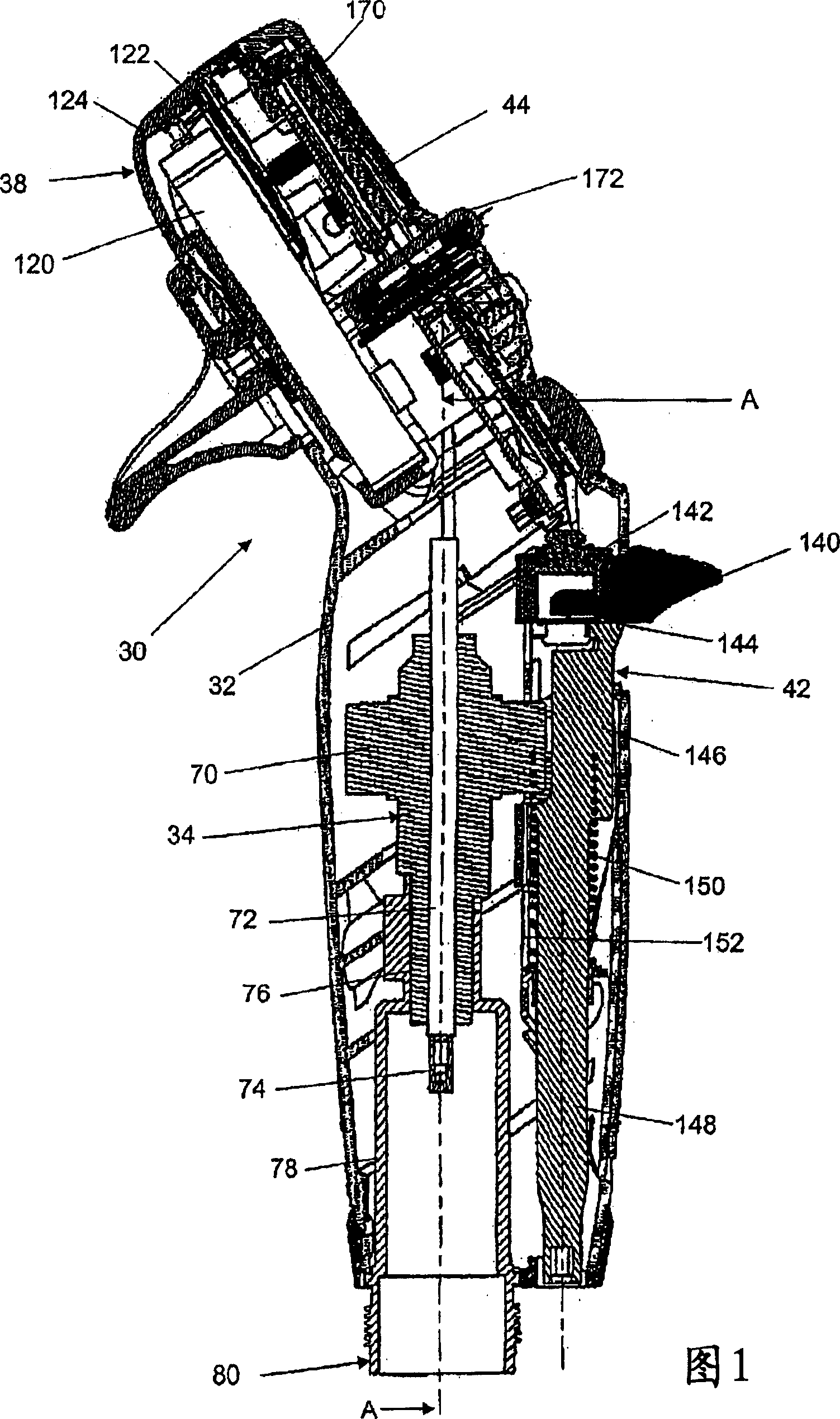

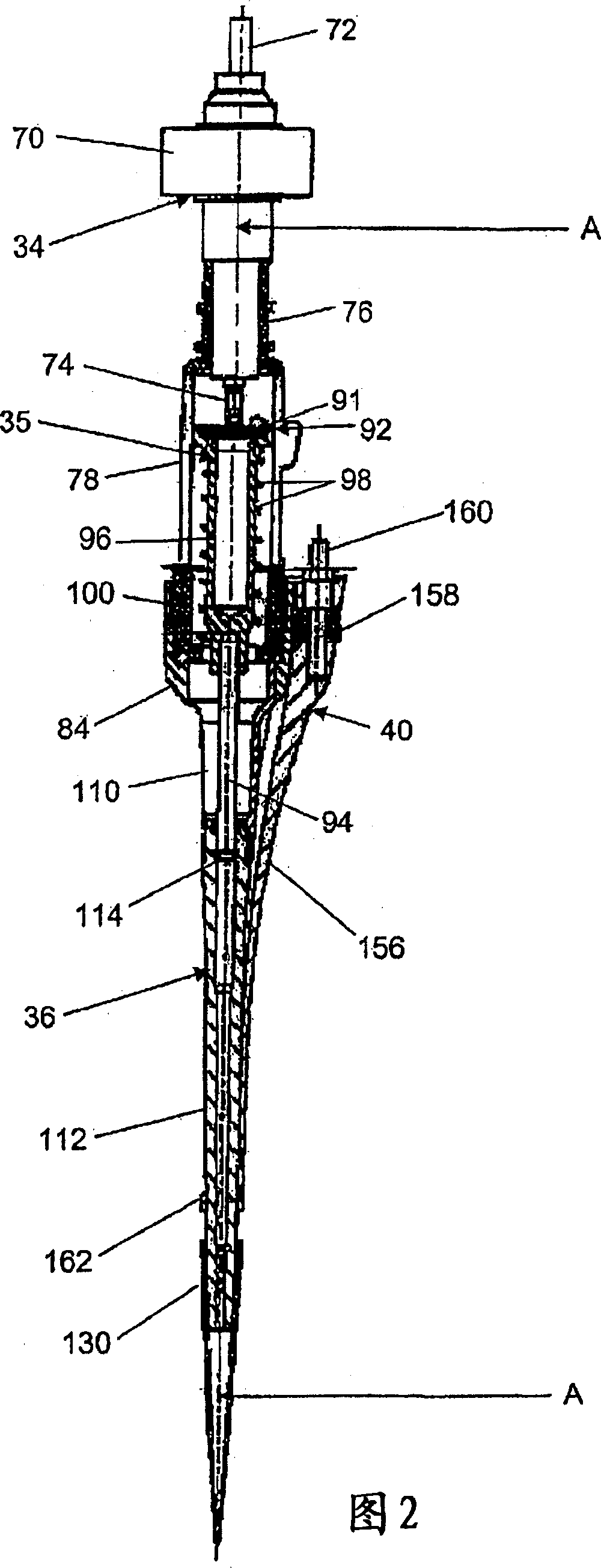

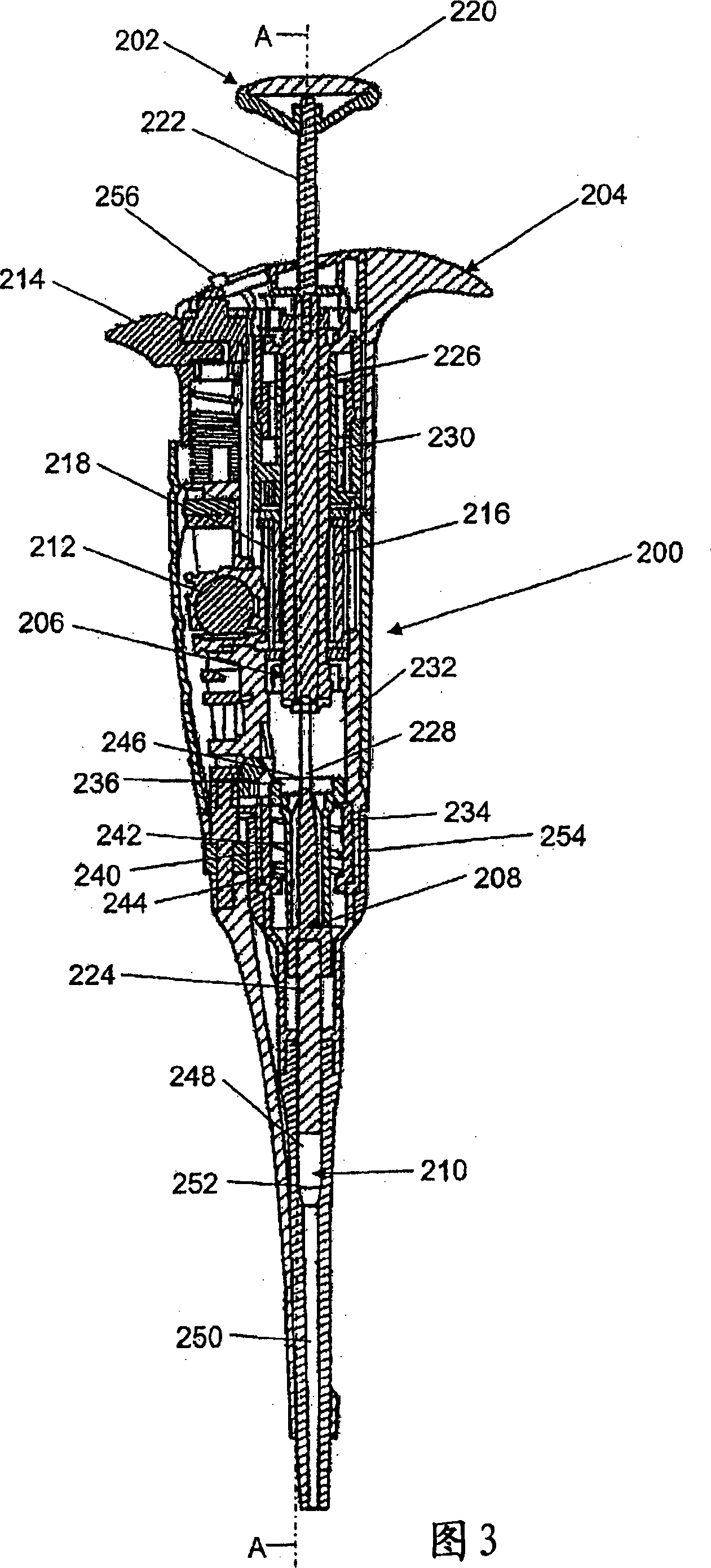

System and method for accurate measuring volume of liquid in a pipette

A pipette control system (220) comprises a computing device (230) with a pipetting module and a first communication interface (234); and a pipette (30) with a sampling tube, a piston assembly, a piston drive mechanism, a second communication interface (190) and a microprocessor. The pipetting module has a computer code to define an operation to be performed by the pipette, and the first interface sends electronic signals to the second interface to define the operation. - A pipette control system (220) comprises a computing device (230) with a pipetting module and a first communication interface (234); and a pipette (30) with a sampling tube, a piston assembly, a piston drive mechanism, a second communication interface (190) and a microprocessor. The pipetting module has a computer code to define an operation to be performed by the pipette, and the first interface sends electronic signals to the second interface to define the operation. The microprocessor is coupled to the second communication interface and controls the piston drive mechanism to perform the pipette operation defined by the electronic signals. The operation is selected from an update installed software operation, a serial number entry operation, a calibration operation, a production automation operation, a data transfer operation, an execute program operation, a new mode integration operation or a servicing operation. - Independent claims are included for the following: - (1) a method of using the interface in a display of the computing device; - (2) and a method of responding to user inputs to a user interface presented in the display of the device.

Owner:GILSON SAS

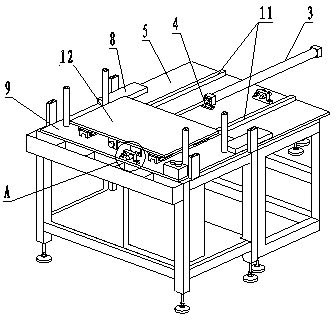

Novel pneumatic mechanical claw

The invention discloses a novel pneumatic mechanical claw. The novel pneumatic mechanical claw comprises a fixing plate, a finger, a guide mechanism and a pneumatic cylinder, wherein the finger is mounted on the fixing plate, a lower end of a connecting plate in the guide mechanism is fixed on the fixing plate through a fastening bolt, a rack is embedded in the middle part of the fixing plate, a pneumatic cylinder telescopic shaft is connected with the rack in the fixing plate, one end of the finger is provided with a round hole in which a sliding sleeve is arranged, the finger is connected with the fixing plate by penetrating a mandrel through the round hole, the same end is provided with an external circle coaxial with the round hole, the external circle is provided with a plurality of tooth, and the toot and the rack in the fixing plate are in gear-rack connection; the guide mechanism comprises the connecting plate, an upper guide plate and a lower guide plate, the middle and two ends of each of the upper guide plate and the lower guide plate are respectively provided with holes; the middle holes are all equipped with a fixed column, the connecting plate is connected with the upper guide plate and the lower guide plate after penetrating through the holes at two ends. The work piece is tightened and loosened by using the mechanical principle; and the novel pneumatic mechanical claw is mechanical and automatic in production, time-saving and labor-saving, simple in structure and convenient for use.

Owner:李阳阳

Independent automatic electrode cap replacement unit

ActiveCN103465006AEasy upgrade functionImprove efficiencyMetal working apparatusResistance welding apparatusElectricityChanging equipment

The invention relates to the field of automatic production of automobiles, in particular to an independent automatic electrode cap replacement unit comprising an electrode cap removal unit, an electrode cap storage unit and a sensing detection unit. The electrode cap storage unit and the sensing detection unit are disposed on two sides of the electrode cap removal unit and are connected in a quick plugging manner. The sensing detection unit comprises an electrode cap removal detection sensor, two electrode cap amount detection sensors and two travel detection sensors. The independent automatic electrode cap replacement unit has the advantages that the unit which is highly modular can be combined with any automatic grinder to allow for automatic die repair and cap replacement, and the function can be updated for customers still replacing caps with hands; the twist and pull cap removal technology is utilized innovatively, efficiency and reliability are improved greatly, upper and lower electrode caps are removed respectively with the cap replacement unit in different rotation directions, the risk of electrode bar looseness due to cap removal torque can be reduced, the electrode cap storage unit can be removed freely, and the size of the whole cap replacement unit is reduced.

Owner:上海卡格机电设备有限公司

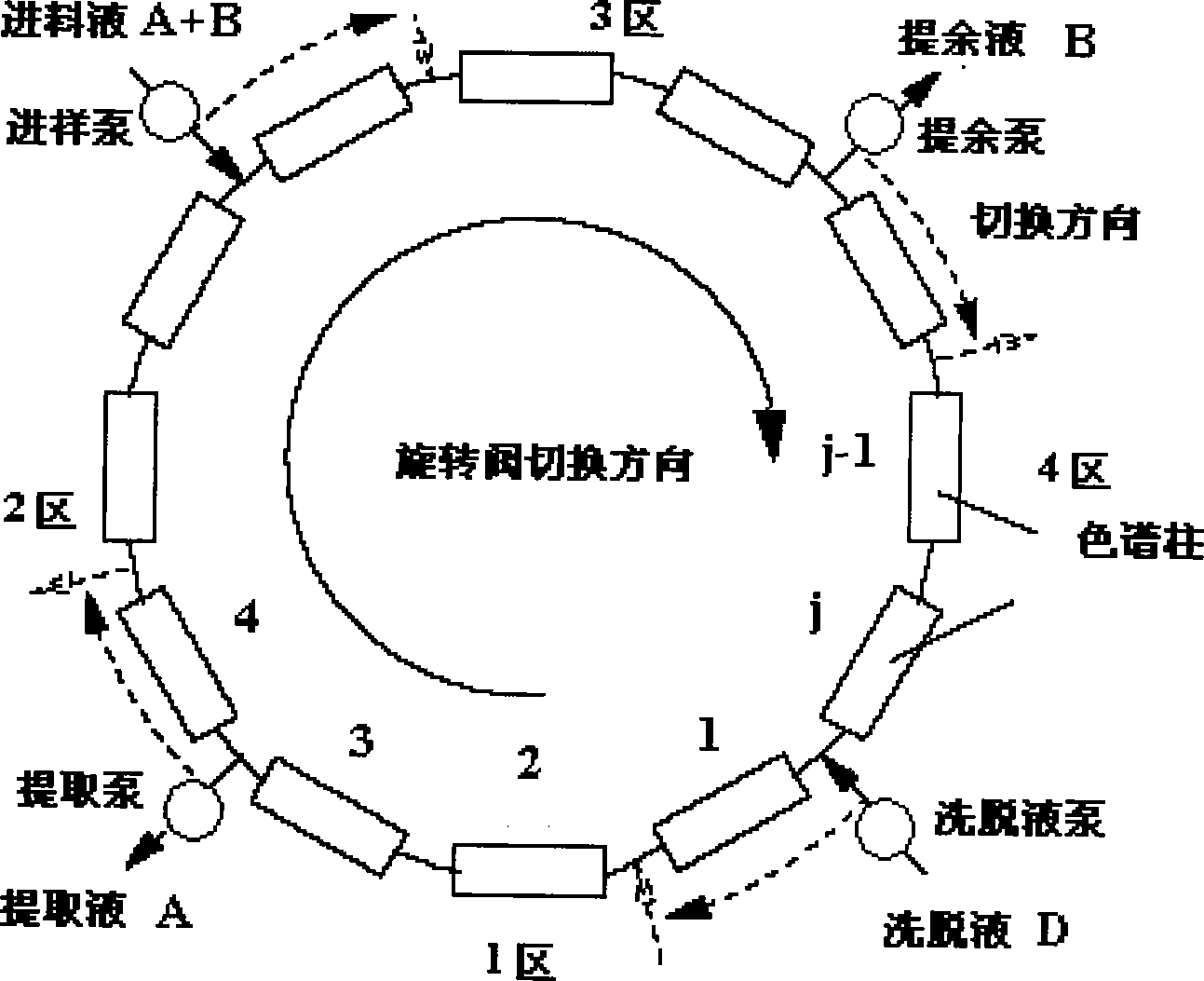

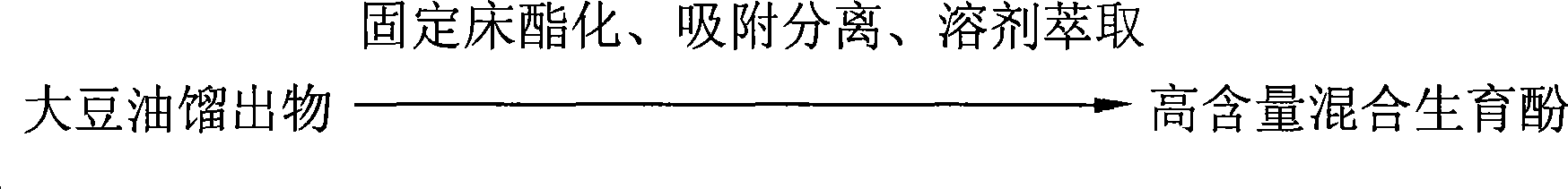

Method for separating single tocopherol from mixed tocopherol

InactiveCN101220018AReduce consumptionHigh purityOrganic chemistryChemical reactionSimulated moving bed

The invention relates to a method for separating single tocopherol from mixed tocopherol, which takes the mixed tocopherol with a content of 50 percent to 100 percent as a raw material and adopts a four-area simulated moving bed chromatography system to separate a d-alpha-tocopherol, a d-beta-tocopherol, a d-gamma-tocopherol and a d-delta tocopherol with the purity and yield all more than 98 percent. As the simulated moving bed chromatography separation is a continuous process, the method has the advantages of high degree of production automation, simple technique, high production efficiency, continuous production and stable product quality. As an adsorbent and a solvent have low consumption, the whole separating device does not relate to chemical reactions.

Owner:ZHEJIANG UNIV

Glue dispensing lamination device for lamp

ActiveCN102536981AGuaranteed assembly qualityReduce installation and positioning operationsFastening meansEngineeringMechanical engineering

A glue dispensing lamination device for a lamp completes glue dispensing and lamination for the lamp at the same station and comprises a lamination tooling, a glue dispensing worktable, a glue dispensing robot and a workpiece moving mechanism. The glue dispensing robot is fixed onto a robot mounting frame, the workpiece moving mechanism, the lamination tooling and the glue dispensing worktable respectively comprise two portions which are bilaterally symmetric and mutually independent, and the glue dispensing worktable on the same side is positioned on the inner side of the lamination tooling and connected with the lamination tooling through a connecting plate. By the aid of the glue dispensing lamination device, the capacity of an existing device is sufficiently used, production automation degree and production efficiency of lamp assembly are improved, and the quality of the lamp is ensured.

Owner:MIND ELECTRONICS APPLIANCE CO LTD

Novel multifunctional PCB production automation system

ActiveCN104822230AReduce labor intensityReduce in quantityLiquid surface applicatorsInsulating layers/substrates workingAdhesiveEngineering

The invention relates to a novel multifunctional PCB production automation system, comprising an automatic feeding system, a fully-automatic two-dimensional code sticking system, a height measuring system, an automatic adhesive dispensing curing system, an online automatic board-splitting cutting system, and a finished product sorting recovery system. The input ends and output ends of the above systems are connected in sequence. Control centers disposed on the above systems are connected with each other. The input end of the automatic feeding system is also provided with a large PCB feeding device. The large PCB feeding device is connected with the control center of the automatic feeding system. Thus, two-dimensional code marking on each PCB unit on a large PCB can be automatically completed, and good product detection, and cutting of the large PCBs can be automatically completed. The system can automatically complete finished products of PCB units, and the system is powerful in functions, high in automation degree, high in production efficiency, low in labor intensity, low in production cost, and high in qualified rate, and has assurance in product quality. A reversed design is used, thereby effectively preventing dusts generated in a cutting process from falling on the PCB, so the finished products are clean.

Owner:ZHUHAI ZHIXIN AUTOMATIC TECH CO LTD

Target tracking method based on correlation of space-time-domain edge and color feature

ActiveCN103065331AEnhanced Color DifferencesEasy extractionImage analysisVideo monitoringTime domain

The invention discloses a target tracking method based on correlation of space-time-domain edge and color feature. The target tracking method based on correlation of space-time-domain edge and color feature comprises the following steps: (1) selecting a tracked target area; (2) extracting the edge outline of the target and calculating the direction angle of the edge; (3) along the two orthogonal directions of horizontal direction and vertical direction, conducting statistics of edge-color symbiosis character pairs, and building a target edge-color correlation centroid model; (4) selecting the centroids of the edge-color pairs with high confidence coefficient to conduct probability weighting, so as to gain a transfer vector of a target centroids in a current frame; (5) conducting statistics of histograms of target edge distances between adjacent frames, conducting probability weighting of the successfully matched distance change rates between the adjacent frames so as to gain a target dimension scaling parameter. By means of the target tracking method based on correlation of space-time-domain edge and color feature, a target tracking in a crowded scene, a shelter, and a condition that the target dimension changes is achieved, and robustness, accuracy and instantaneity of the tracking are improved. The target tracking method based on correlation of space-time-domain edge and color feature has a wide application prospect in the video image processing field, and can be applied to the fields such as intelligent video monitoring, enterprise production automation and intelligent robot.

Owner:南京雷斯克电子信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com