Glue dispensing lamination device for lamp

A technology of laminating equipment and adhesive cloth, applied in mechanical equipment, connecting components, etc., can solve the problems of affecting the bonding effect of the lamp housing and the mask, weakening the airtight function of the lamp body, reducing the temperature of the hot melt adhesive, etc. Utilization, easy to engineer mass production, ensure the effect of bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

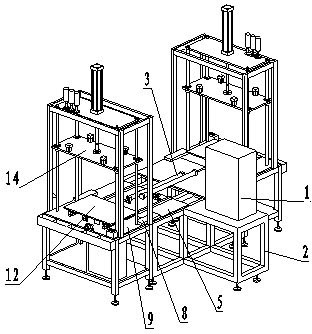

[0017] Referring to Fig. 1, the composition of the present invention includes a pressing tool, a glue-distributing workbench, a glue-distributing robot 1 and a workpiece moving mechanism. Both the glue-distributing workbench and the glue-distributing workbench comprise two parts symmetrically arranged on the left and right and are independent of each other. The glue-distributing workbench 5 on the same side is located on the inner side of the press-fitting tool, and is connected with the press-fitting tool through the connecting plate 8.

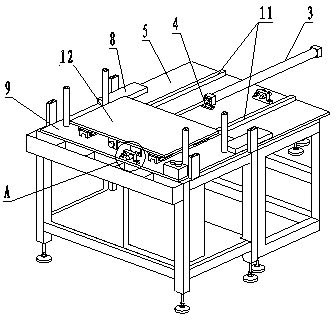

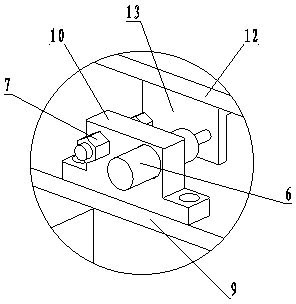

[0018] see figure 1 ,figure 2, image 3 , Figure 4 , the workpiece moving mechanism in the composition of the present invention includes a driving cylinder 3, a slide rail 11, an oil pressure buffer 6 and a block 7, the driving cylinder 3 is fixed on the cylinder mounting seat 4, and the cylinder mounting seat 4 is fixed on the cloth On the glue workbench 5, the slide rail 11 is fixedly installed on the glue cloth workbench 5 and the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com