Construction method of integrally rotating, drawing up and slipping large steel arch structure

A construction method and giant technology, applied to building components, building structures, roofs, etc., can solve the problems of unfavorable stress state and large influence degree of the structure, so as to achieve clear force magnitude, safety guarantee, and avoid uncertainty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

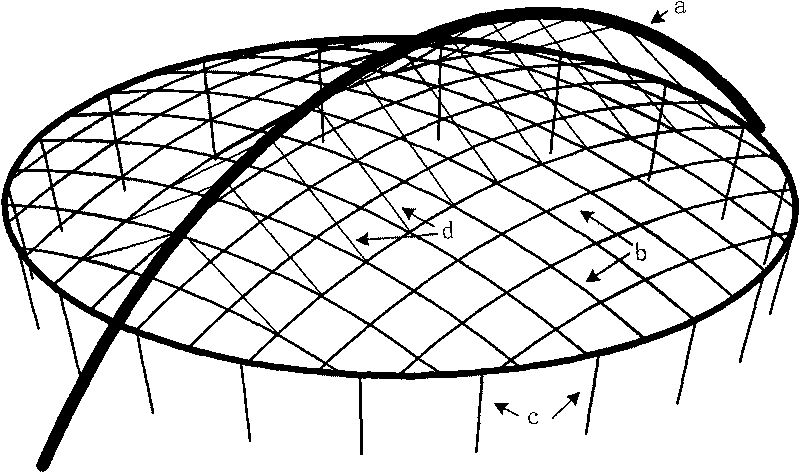

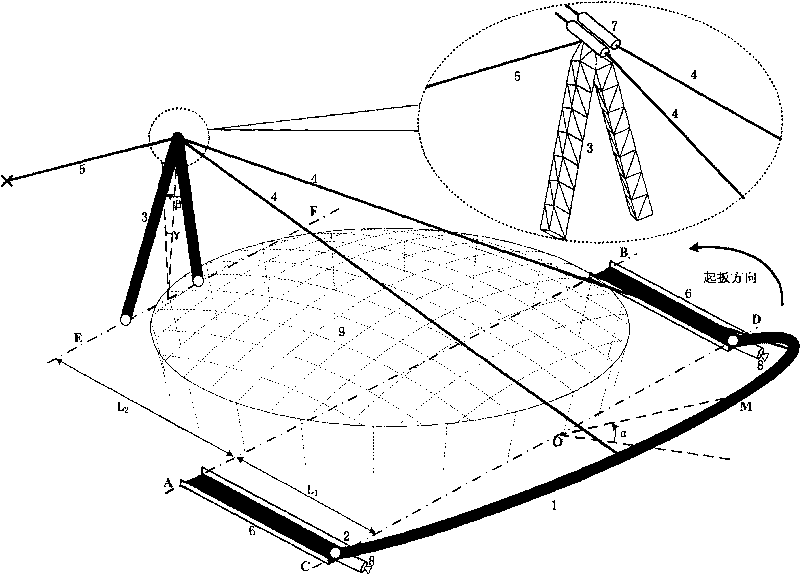

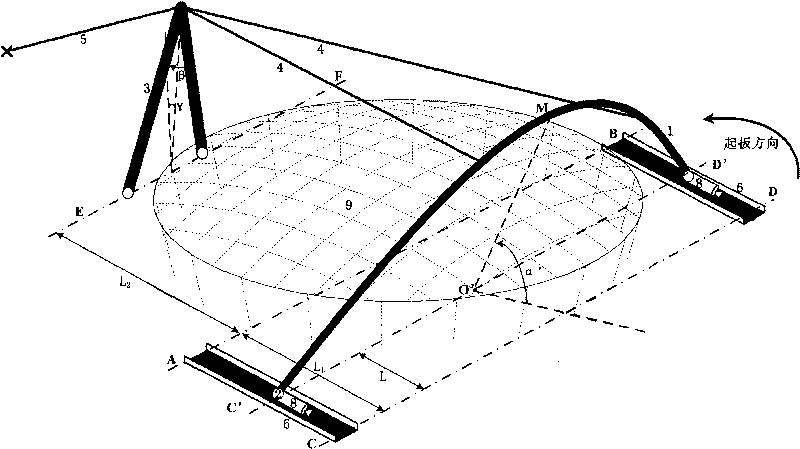

[0053] Step (1): Set up the construction environment required by the overall rotation-lifting-sliding method; figure 2 As shown, when the giant steel arch is at the construction target position, the line connecting the two arch feet is recorded as the axis (AB); specifically follow steps (1.1) to (1.4);

[0054] Step (1.1): Assemble the giant steel arch 1: At a distance L parallel to the axis (AB) 1 Assemble a giant steel arch at a distance of L 1 The giant steel arch does not collide with the roof structure during the lifting process; the giant steel arch is assembled on the ground; the arch foot 2 is hinged to the foundation; the connection between the two arch feet of the giant steel arch in the completed state of assembly is the axis (CD);

[0055] Step (1.2): erect the A-shaped support frame 3, install the lifting rope 4, the back cable 5, and the through-heart tension jack 7, and proceed according to steps (1.2.1) to (1.2.3):

[0056] Step (1.2.1): At a distance L pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com