Patents

Literature

1144results about How to "Guaranteed assembly quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

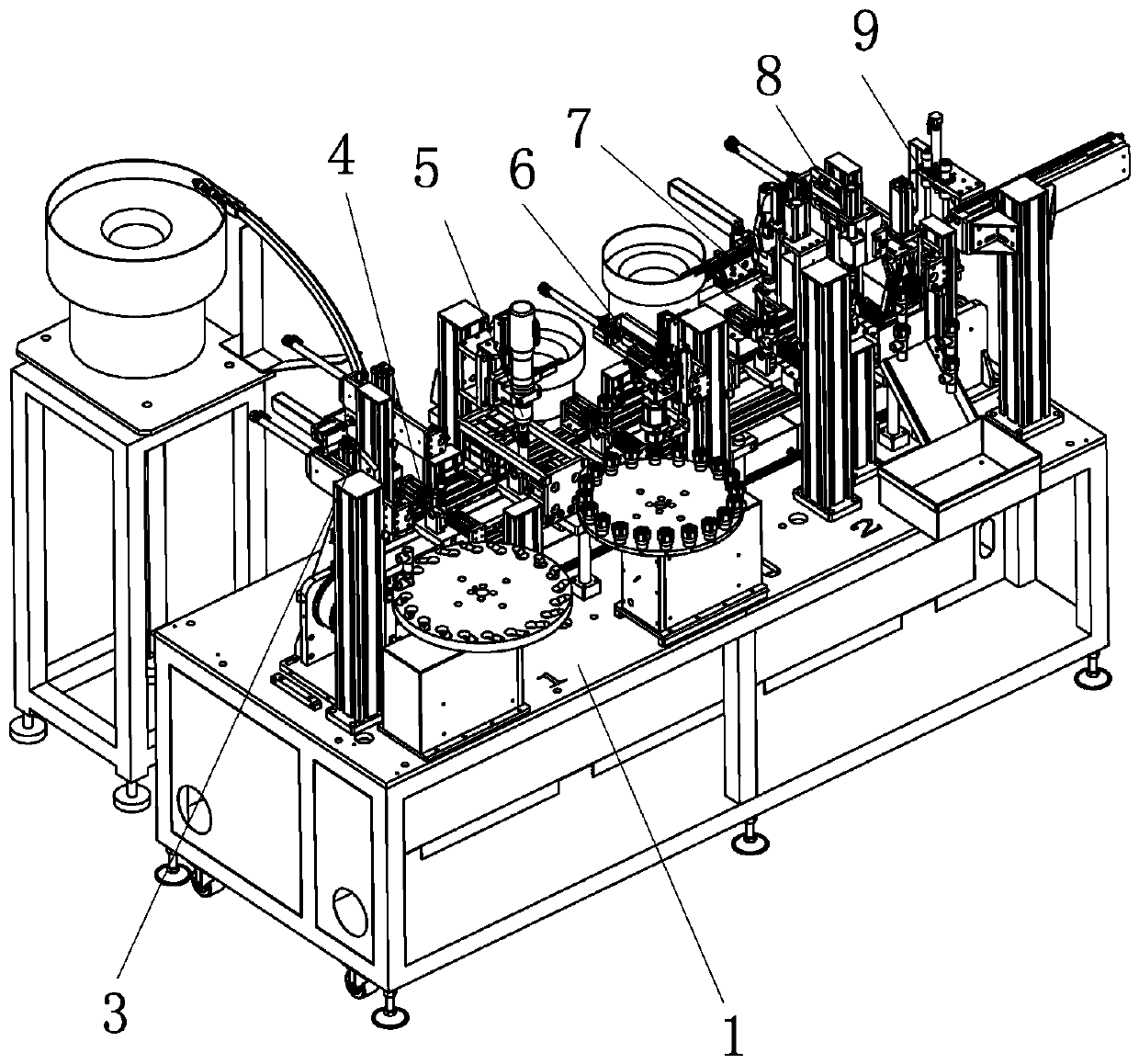

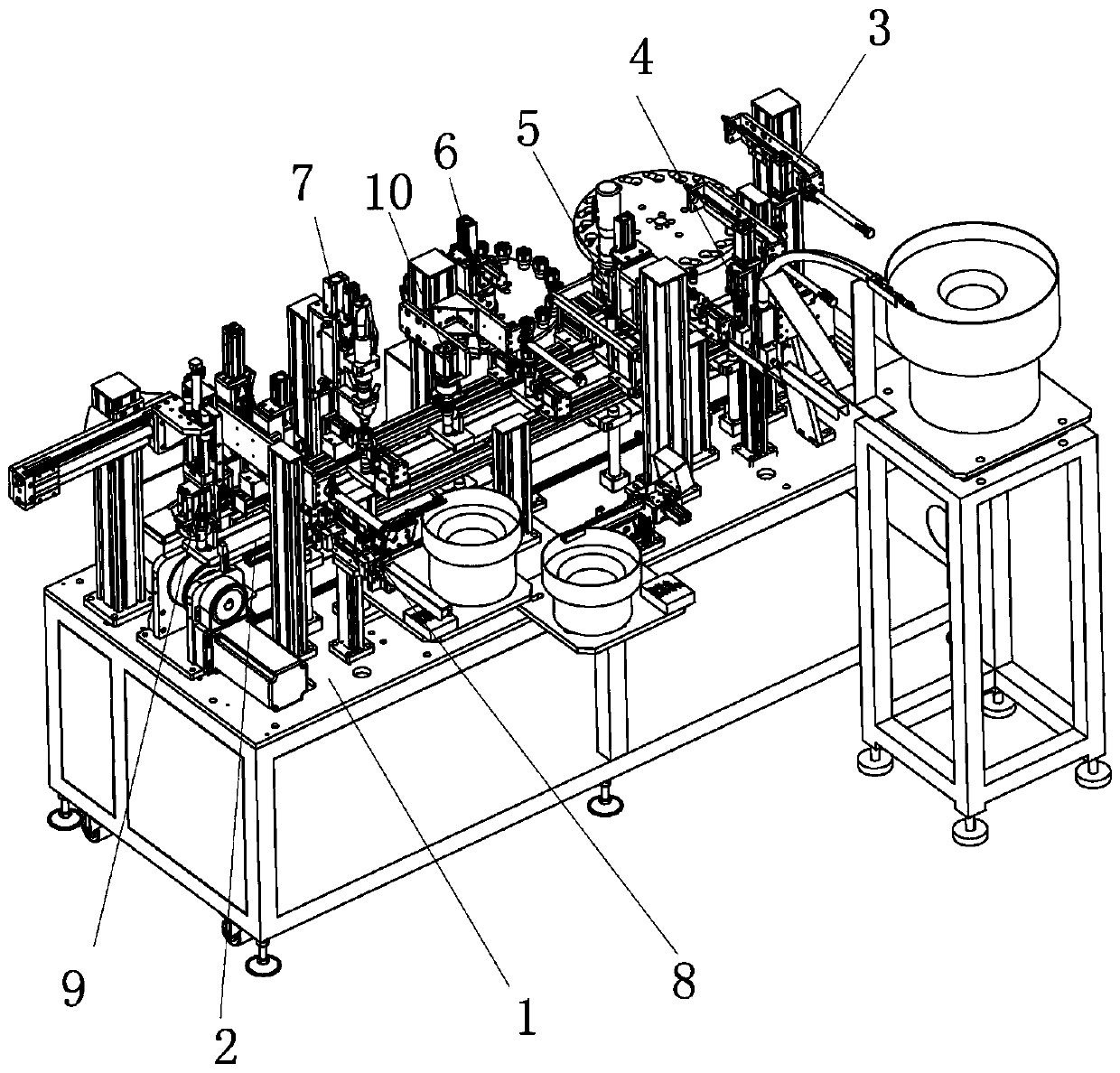

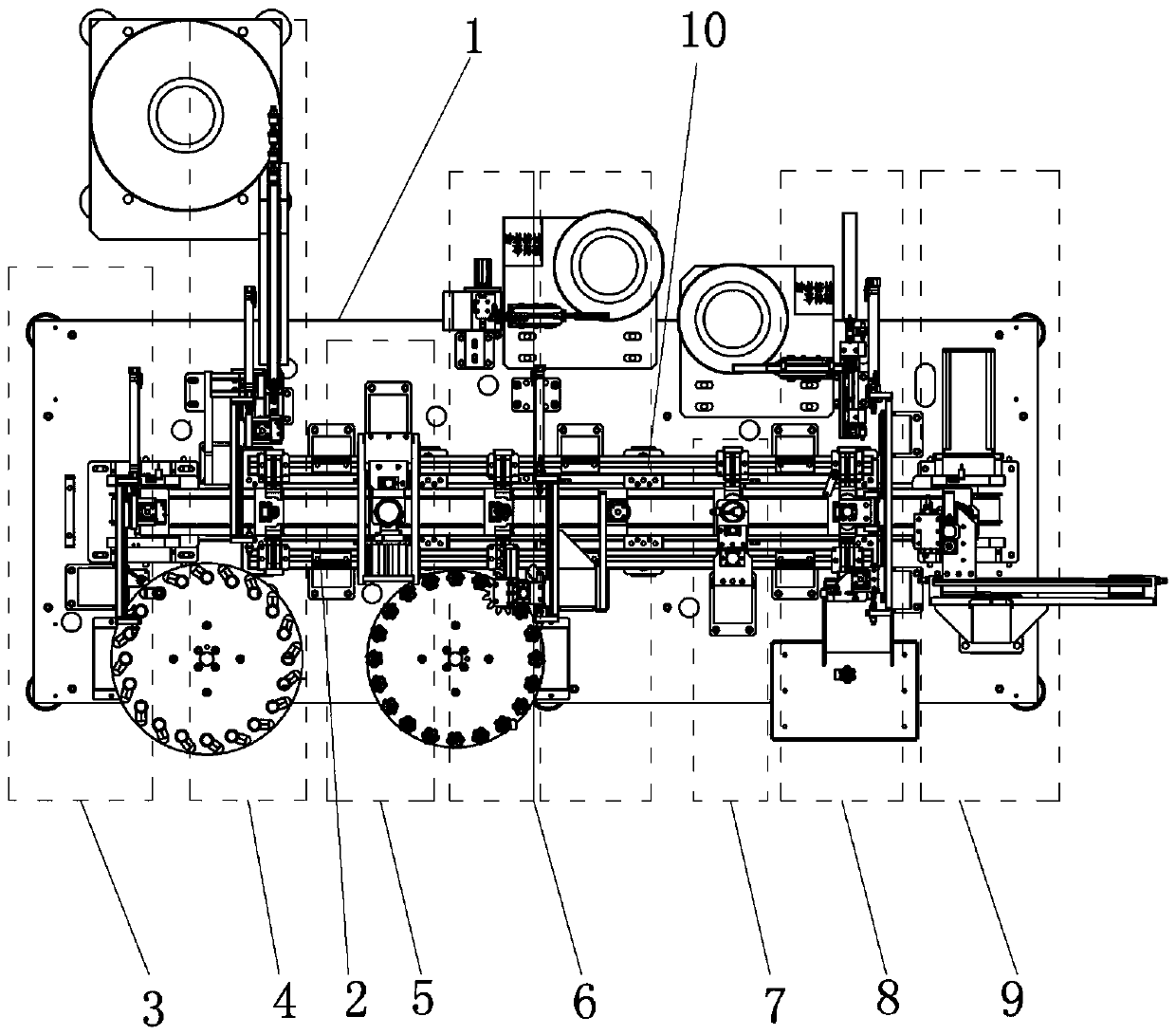

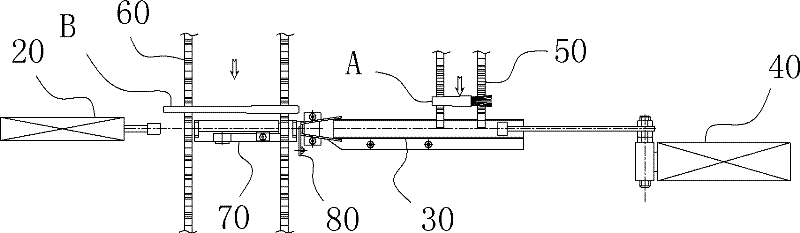

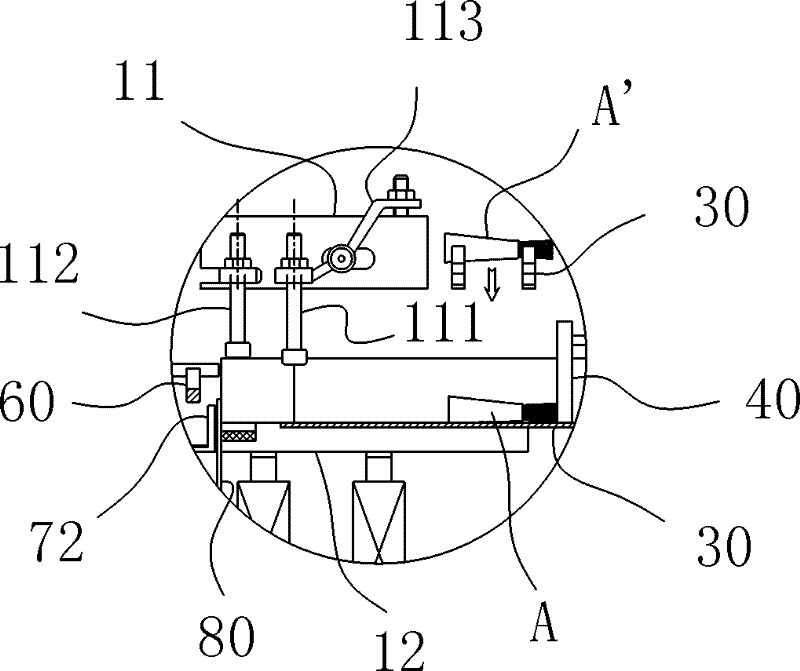

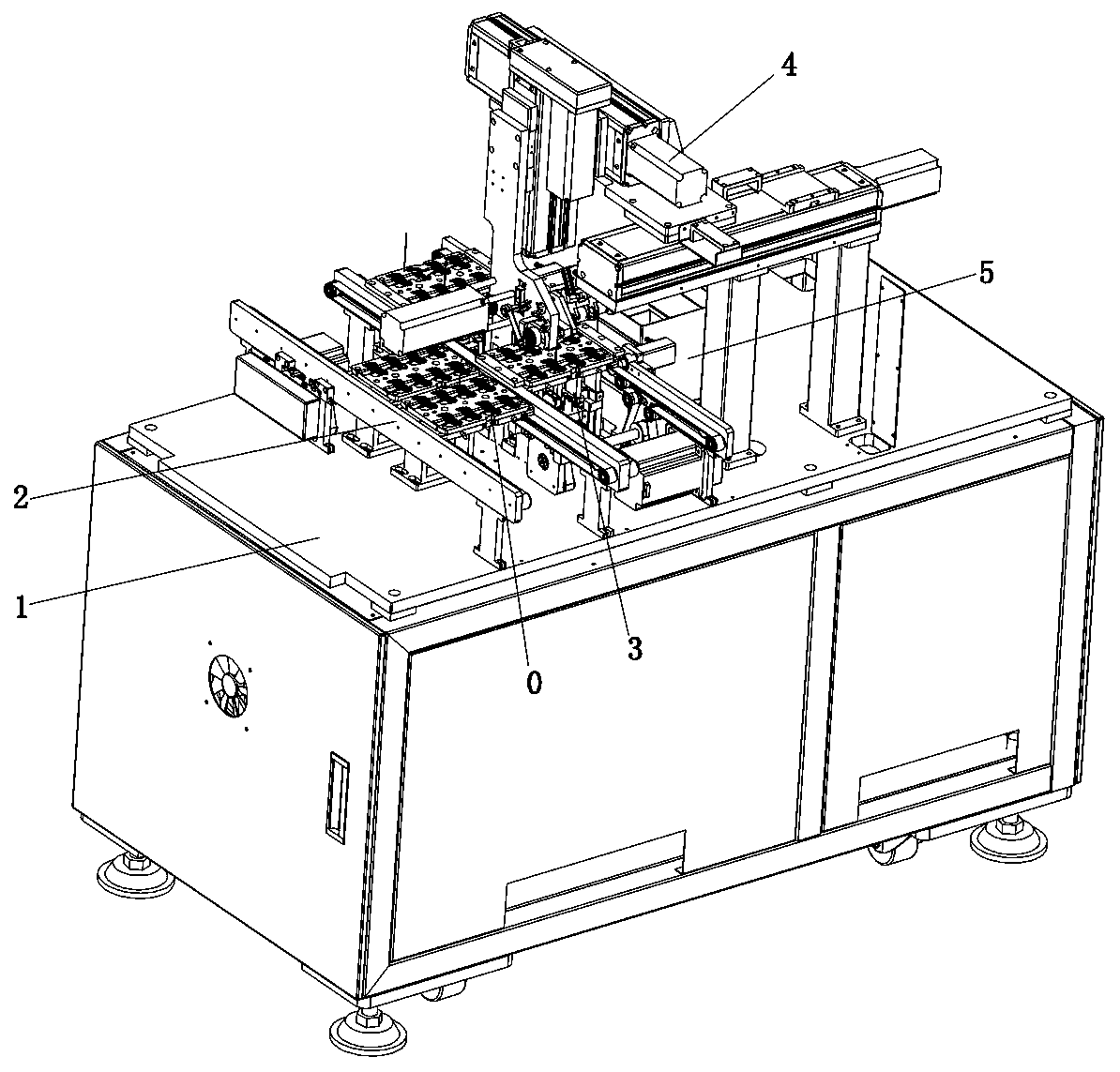

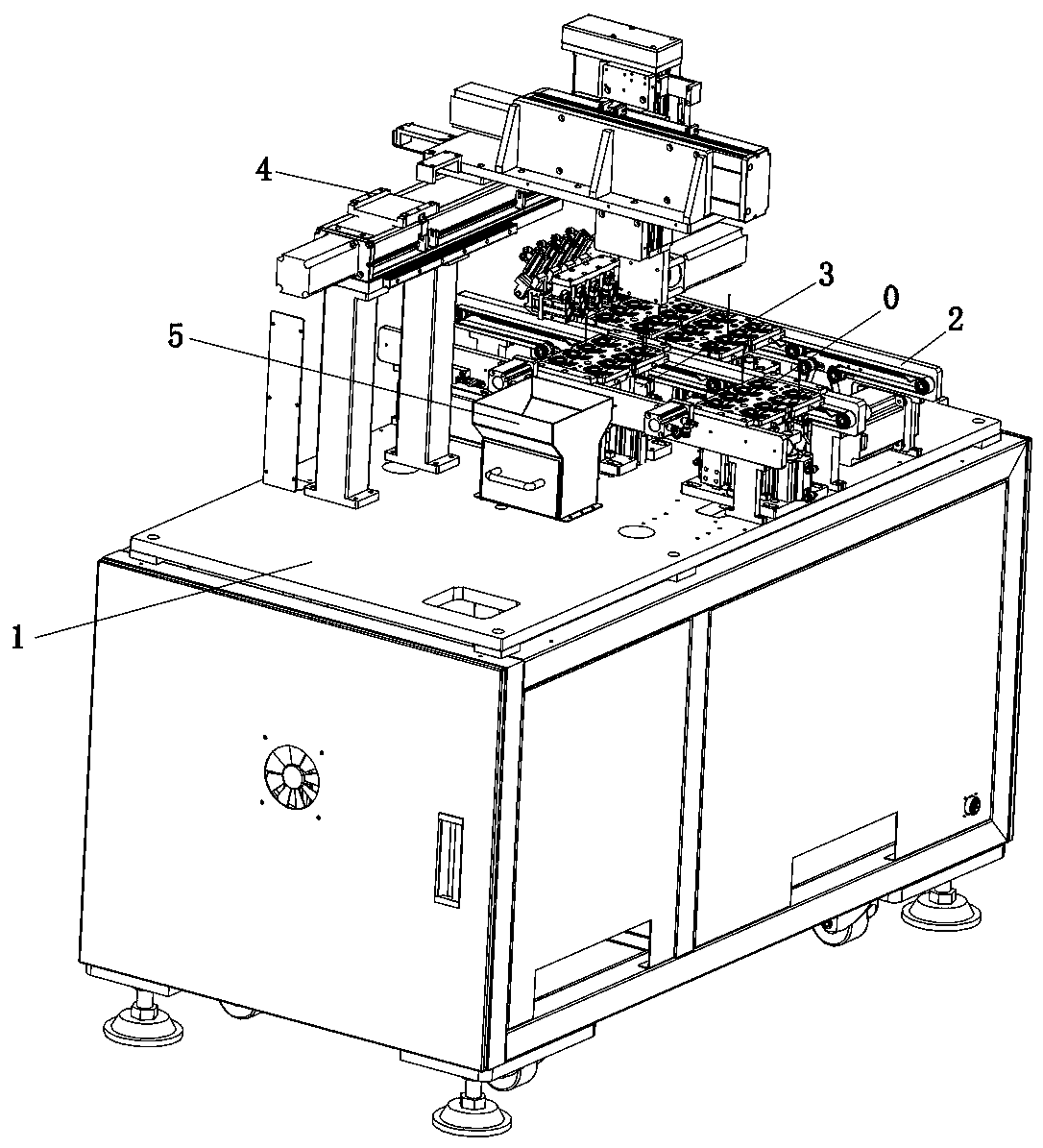

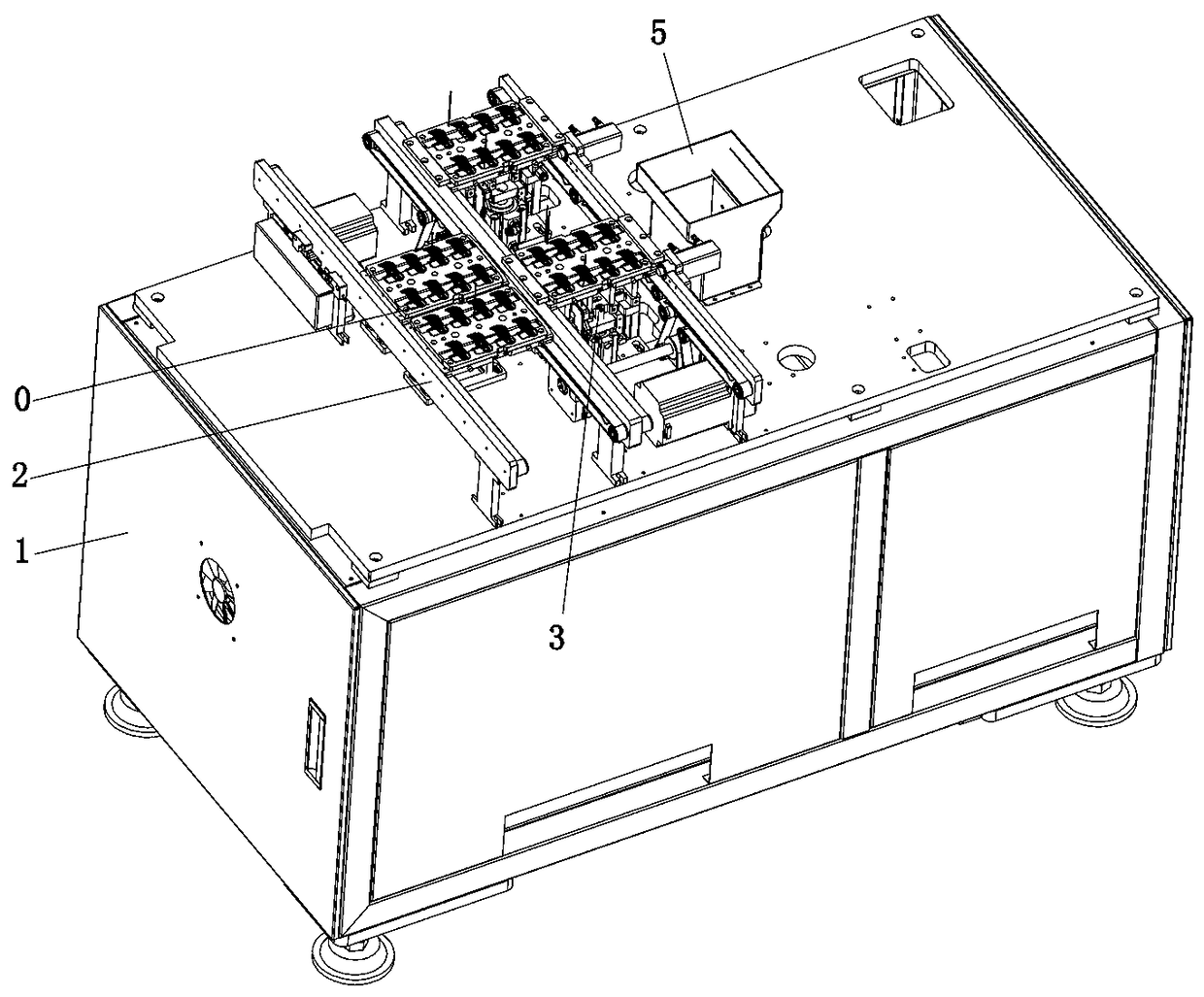

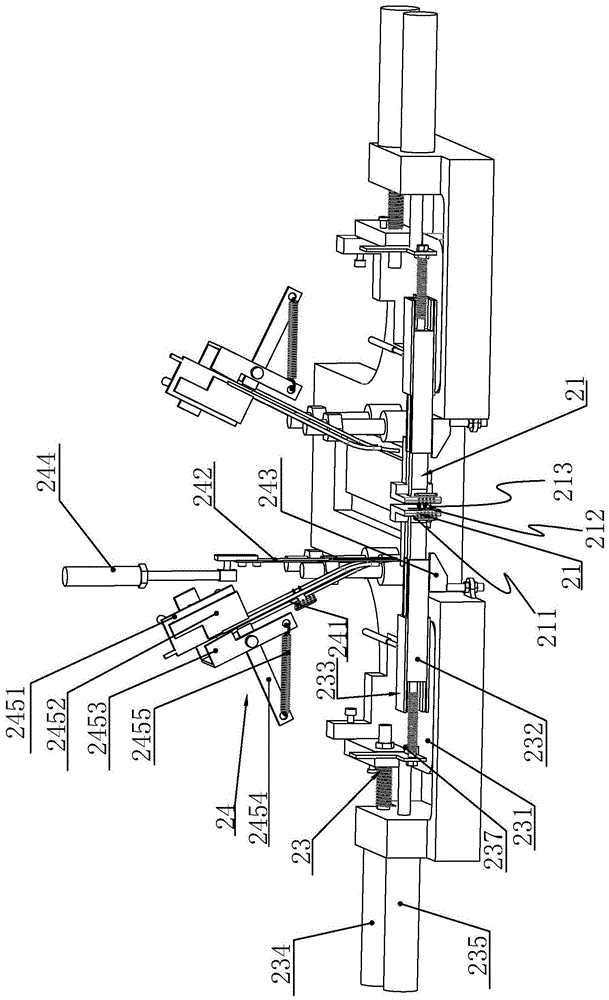

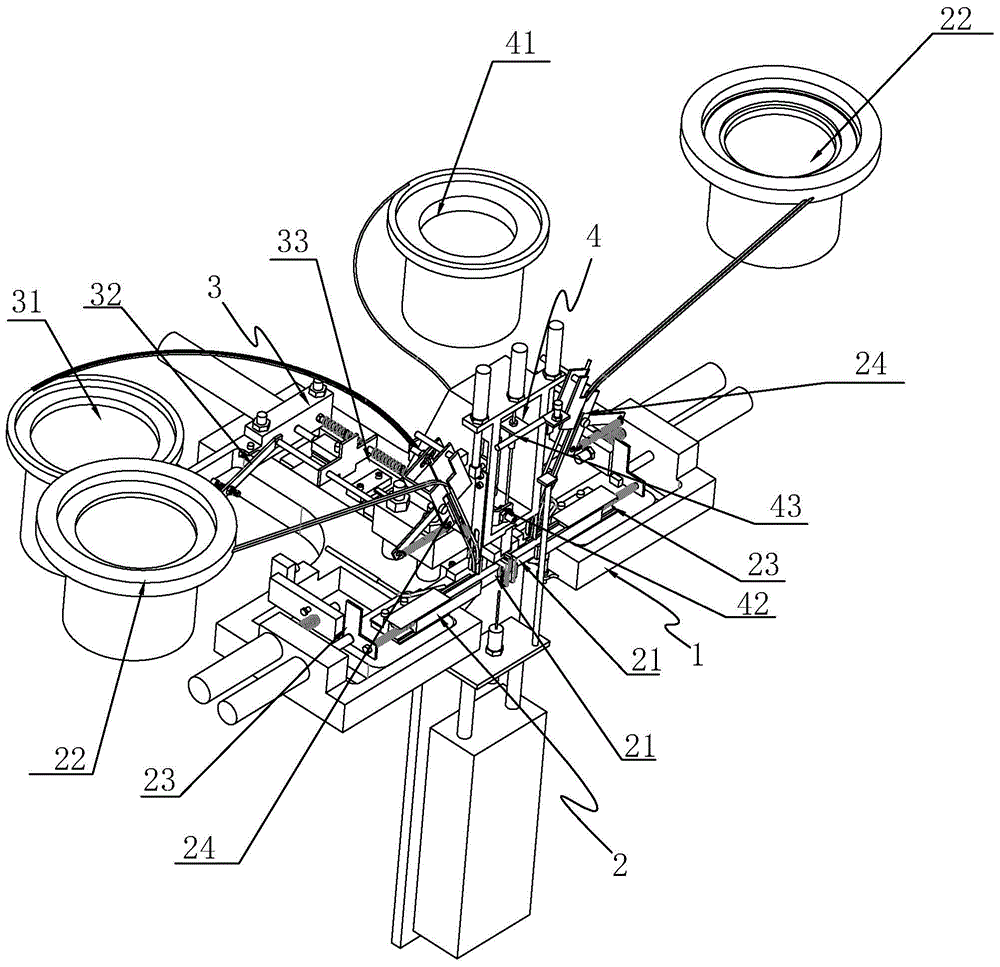

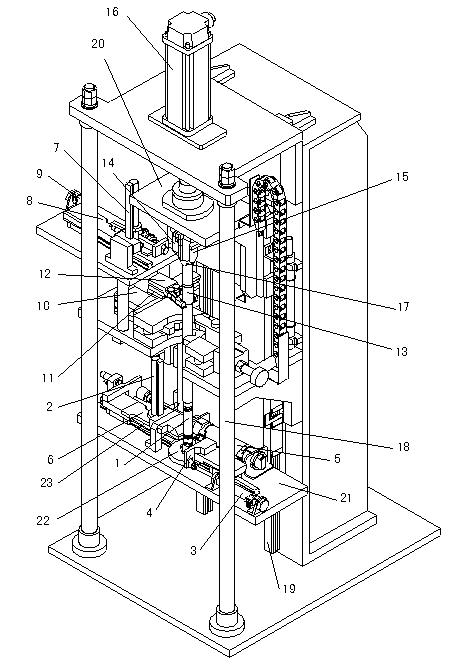

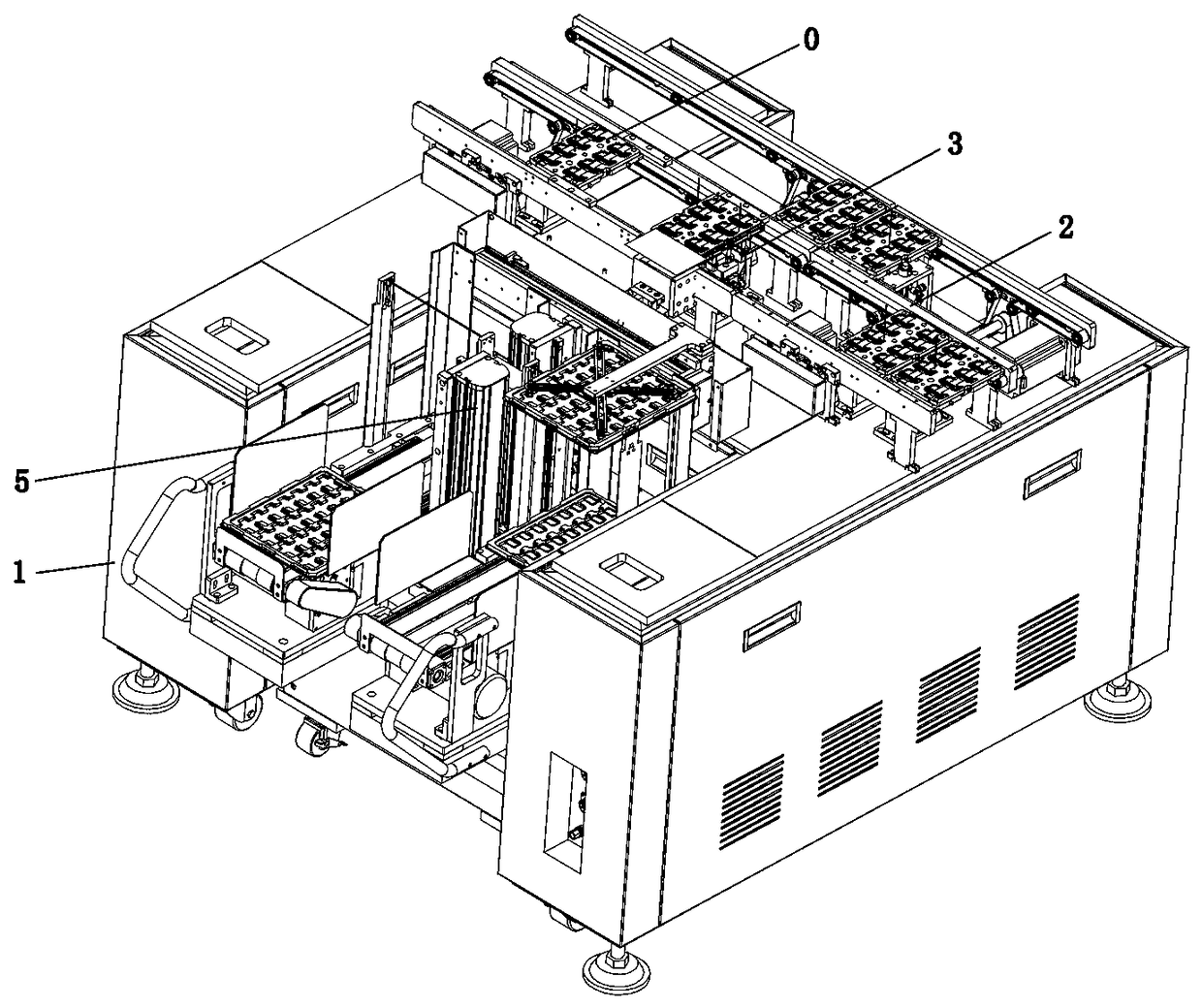

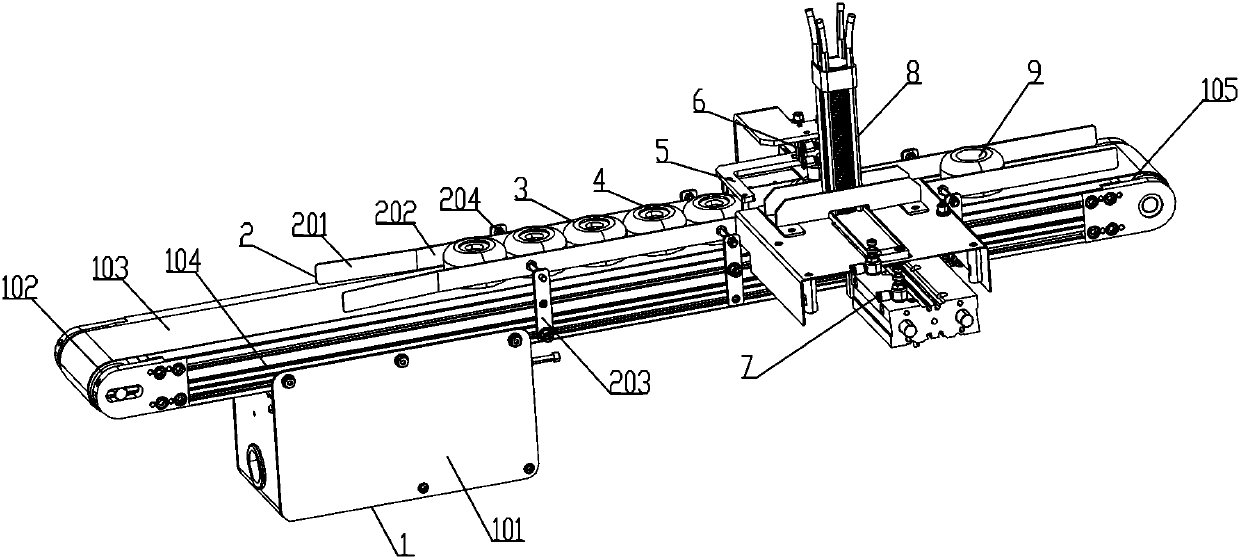

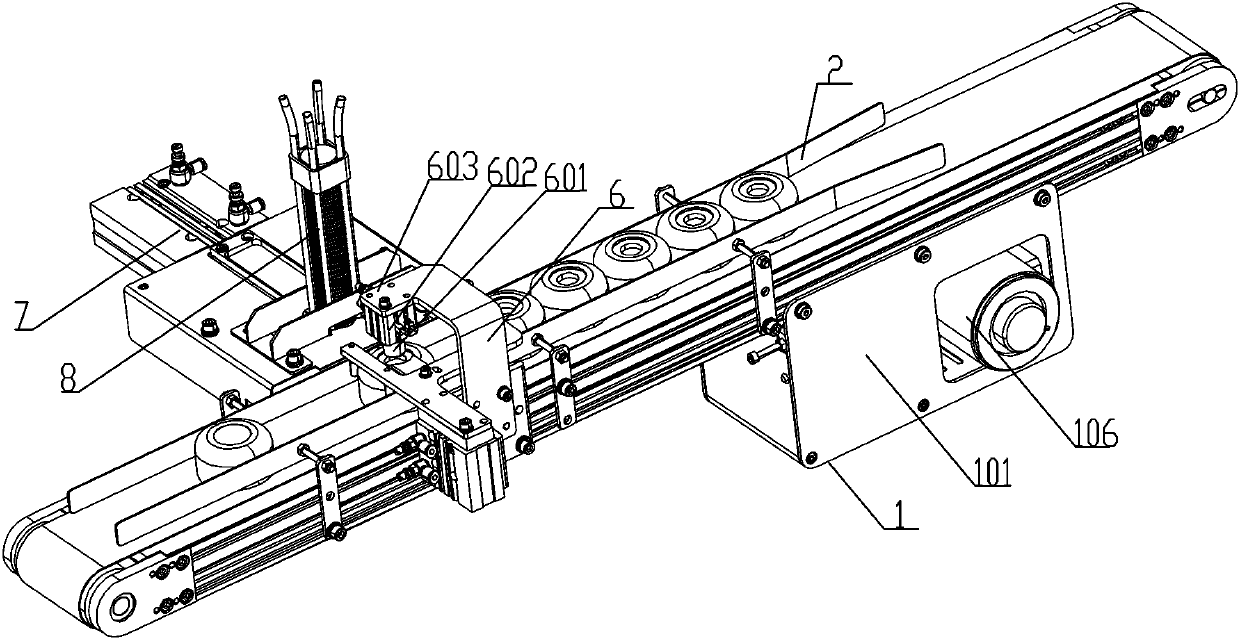

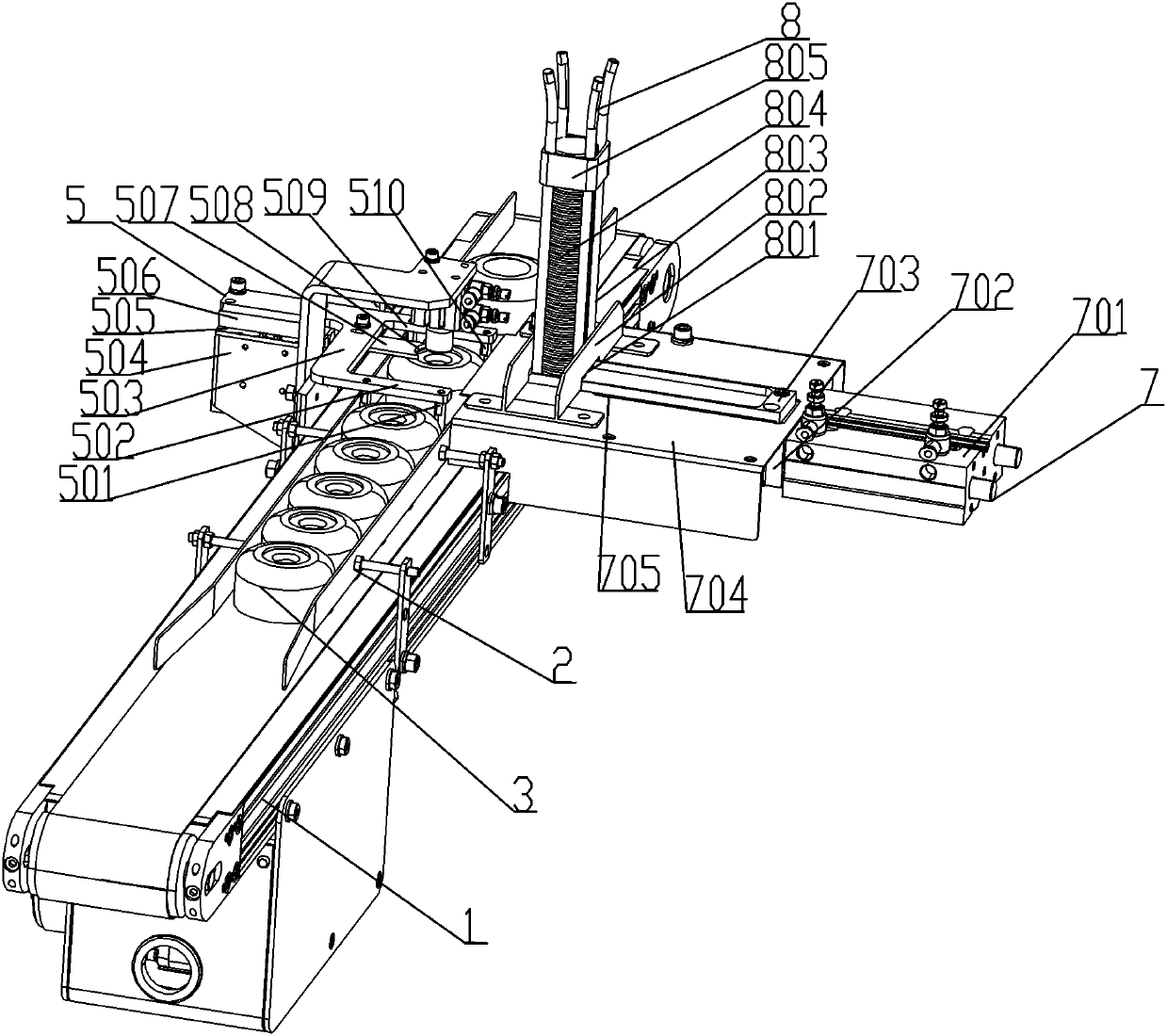

Full automatic angle valve assembly machine

PendingCN108015536ASimple structureReduce manufacturing costAssembly machinesMetal working apparatusLocking mechanismEngineering

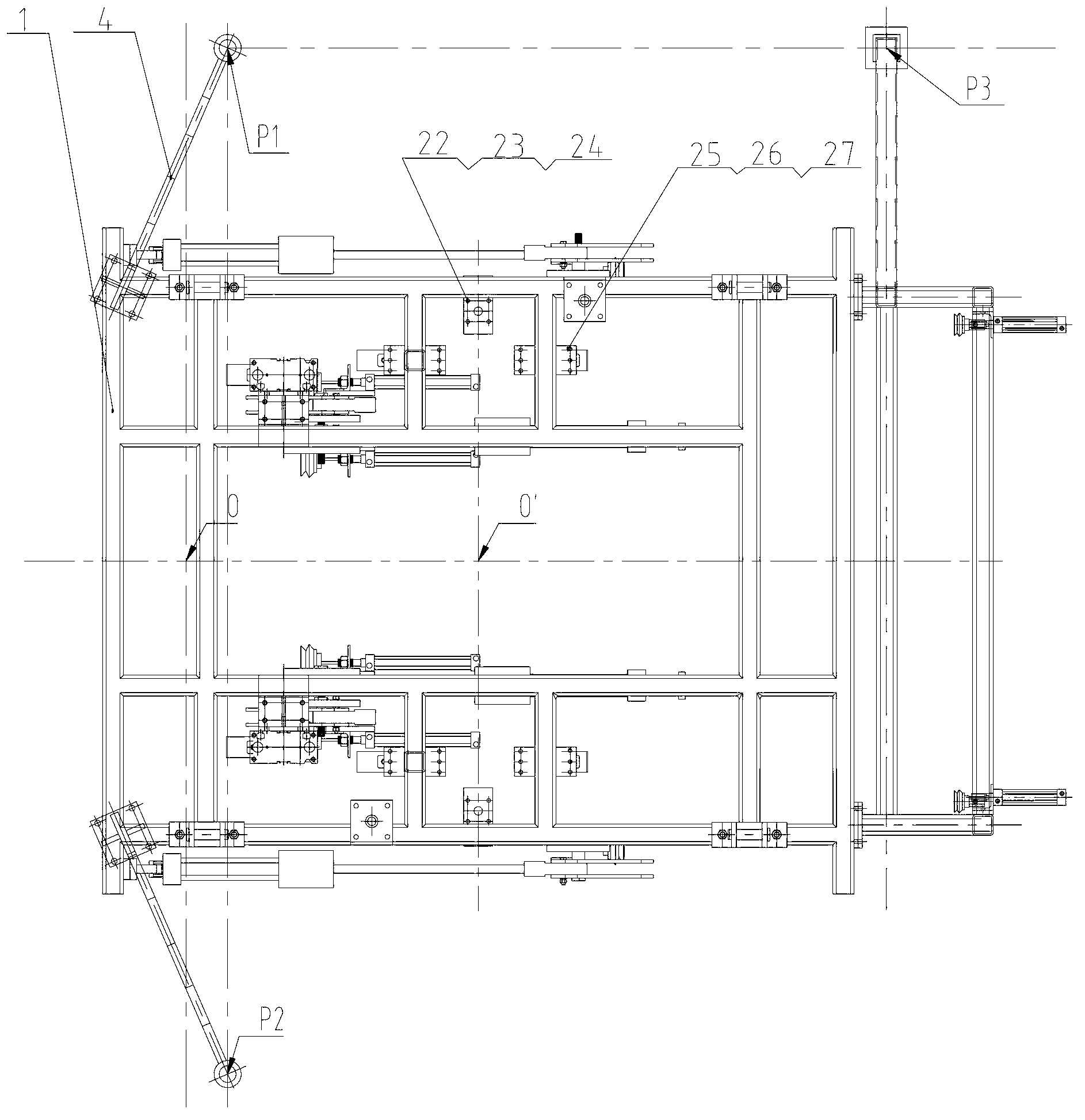

The invention discloses a full automatic angle valve assembly machine which is characterized in that the full automatic angle valve assembly machine comprises a main frame and a material shifting andlocating mechanism arranged above the main frame; a valve body charging mechanism, a valve core charging mechanism, a valve core tightening mechanism, a handle charging mechanism, a screw locking mechanism, a valve cap assembly mechanism and a finished product taking mechanism are sequentially arranged above the material shifting and locating mechanism, wherein the material shifting and locating mechanism comprises a synchronous belt and a plurality of locating seats arranged on the synchronous belt; the synchronous belt is driven to rotate by a servo motor and then drives the locating seats to sequentially enter the various assembly mechanisms; locating rods are arranged above and below the synchronous belt; and guide grooves in the bottoms of the locating seats are located in the surfaces of the locating rods to slide. The full automatic angle valve assembly machin has the beneficial effects that by employing the multiple assembly mechanisms, automatic charging and assembly of various fittings of an angle valve are realized, and when full automatic assembly is realized, the assembly quality of products can be ensured since a standardized flow and operation sequences are adopted.

Owner:FOSHAN SUCCEED AUTOMATIC TECH

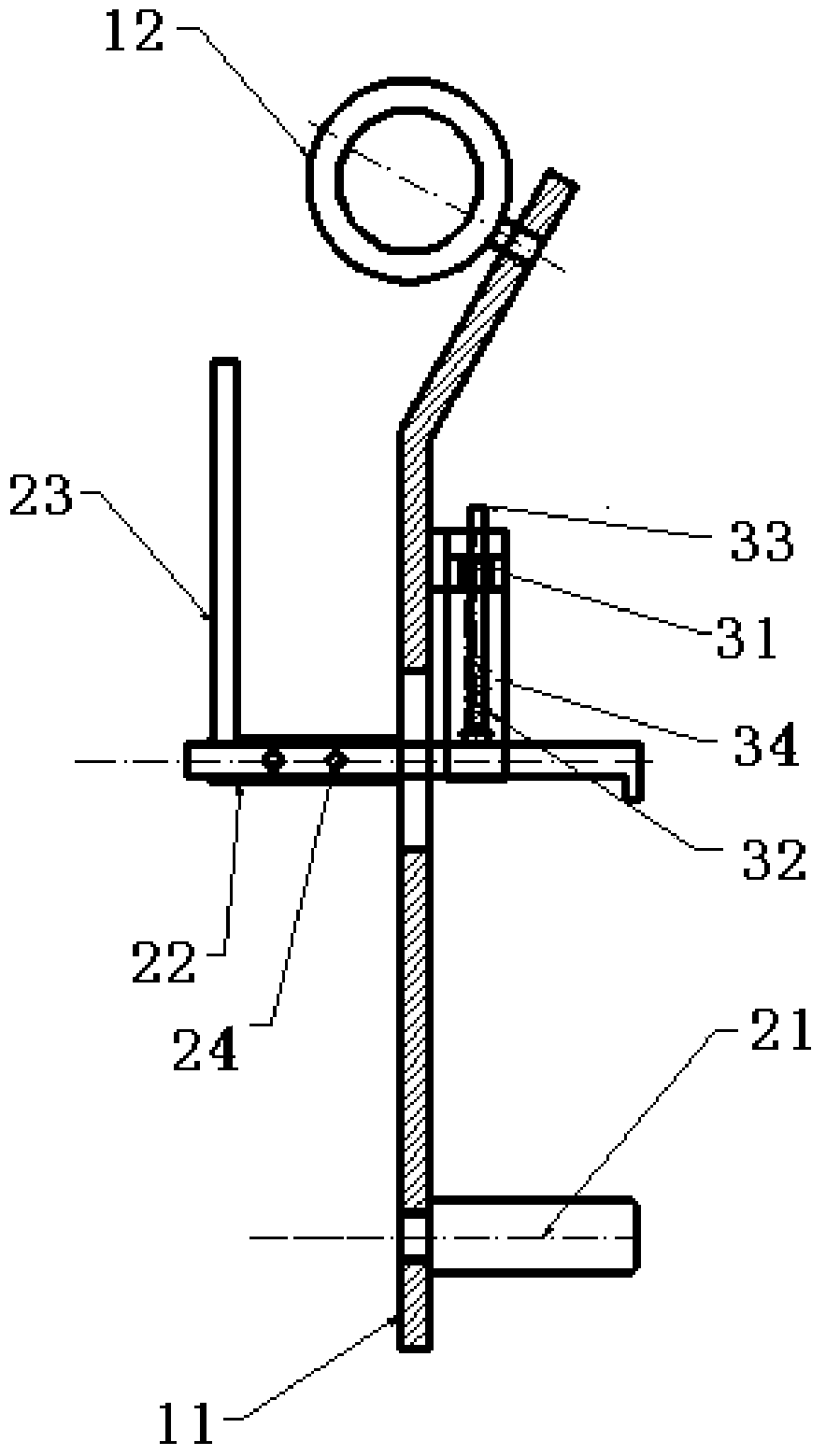

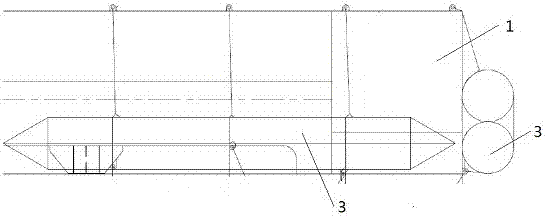

Plugging device of pen head and pen holder

InactiveCN102225674AGood production efficiencyStable working conditionPen repairingPackaging toiletriesEngineeringYield rate

The invention belongs to the field of pen manufacturing and in particular relates to a plugging device of a pen head and a pen holder. The plugging device comprises a clamping mechanism for fixing the pen head and a pen holder pushing mechanism for pushing the pen holder; the pen head and the pen holder are horizontally arranged in the pushing direction of the pen holder pushing mechanism when being assembled. By using the plugging device, the assembling quality and the production yield rate can be guaranteed while the plugging assembling efficiency of the pen head and the pen holder is improved; and the apparatus can run stably and reliably.

Owner:卫青山

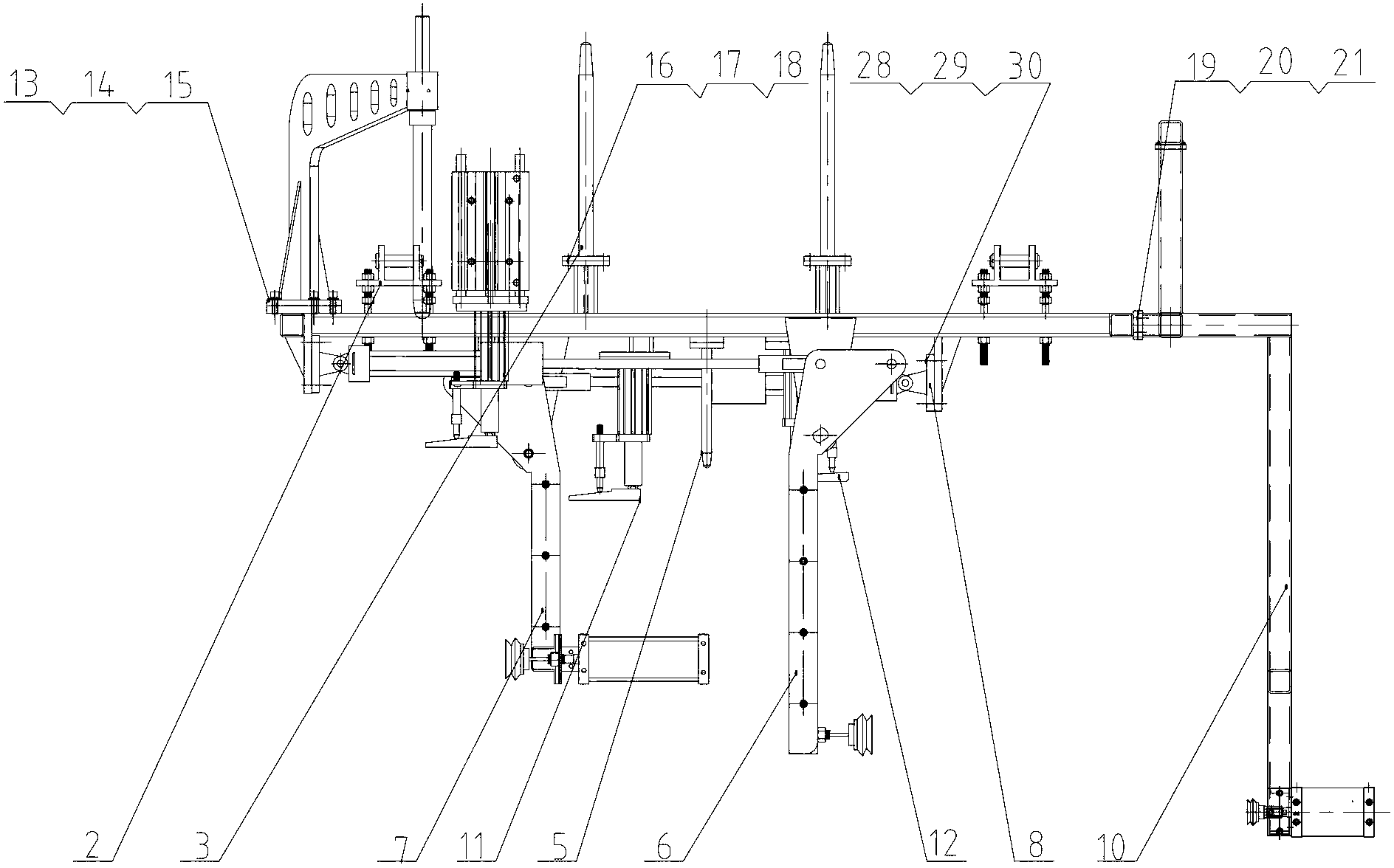

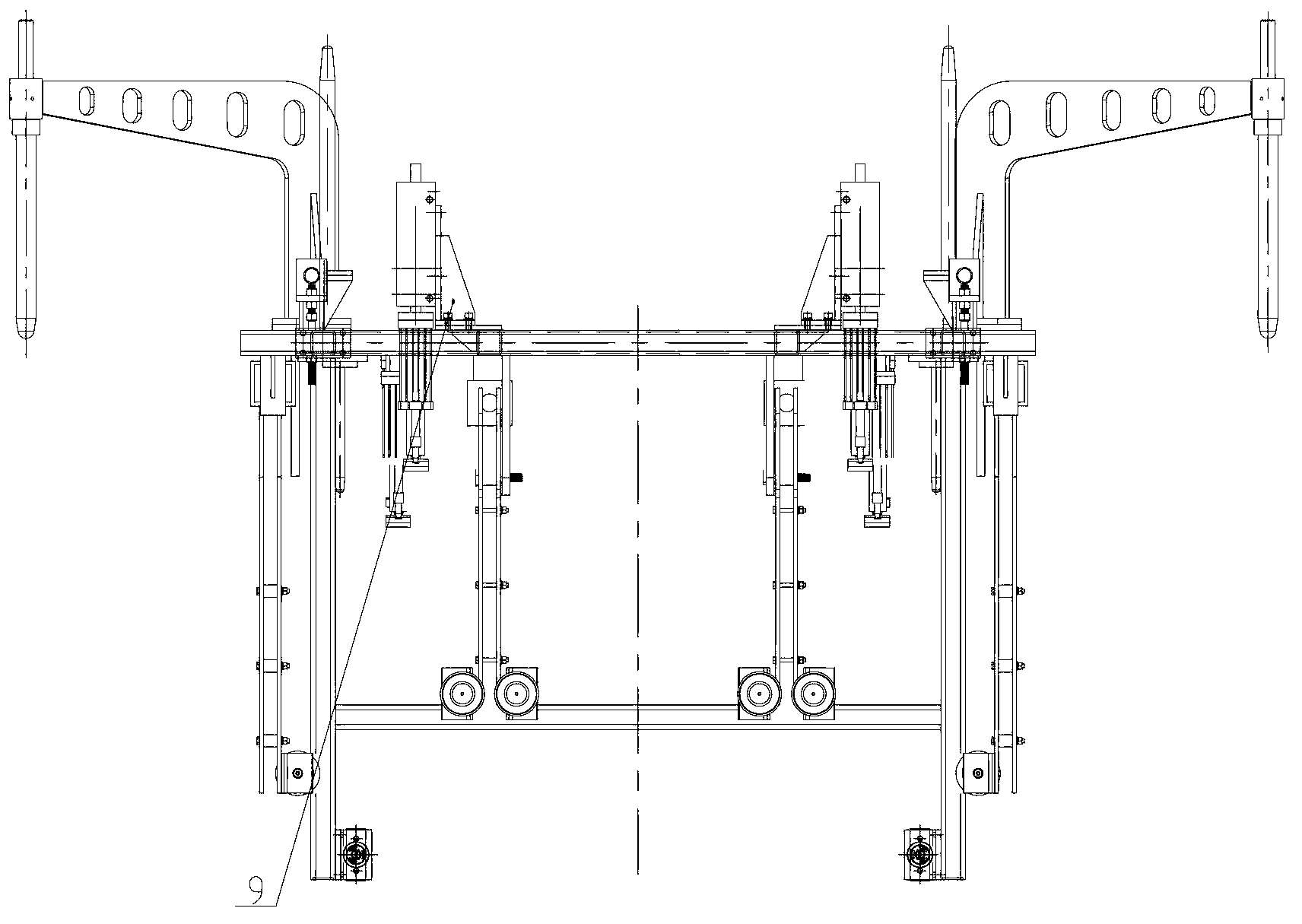

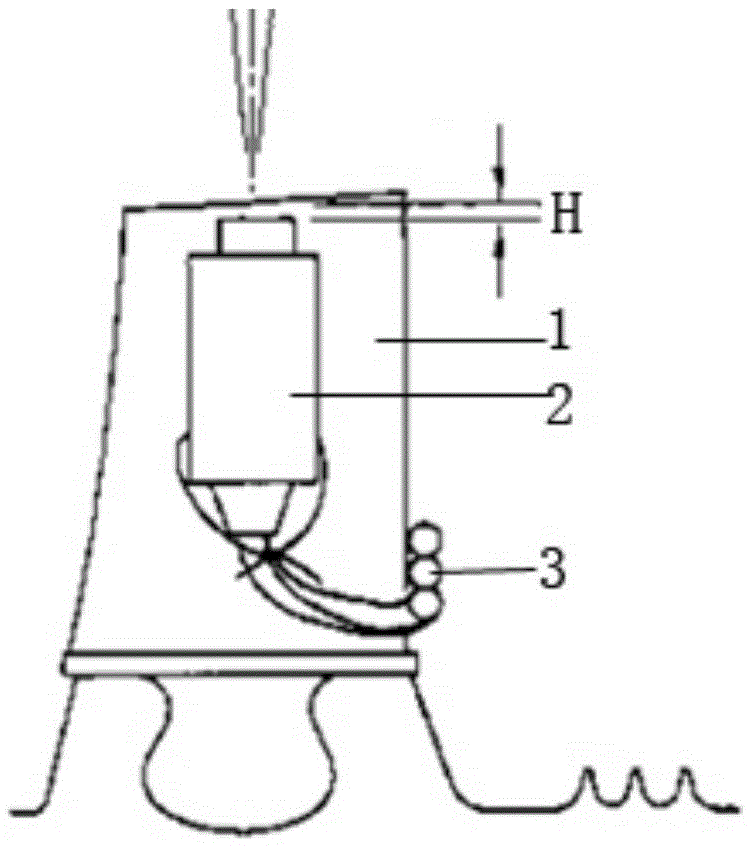

Front and rear cover on-line spreader of high-top twin truck cab

InactiveCN103224191AAvoid deformationMeet the requirements of block tailor welding processLoad-engaging elementsTruckFront cover

The present invention discloses a front and rear cover on-line spreader of high-top twin truck cab, including a spreader frame and spreader up and down positioning mechanisms mounted on the spreader frame, front and rear cover positioning mechanisms, a bottom surface supporting mechanism of front and rear cover and a rear side supporting mechanism of rear cover: the spreader up positioning mechanism positions between the spreader frame and the hoist; the spreader down positioning mechanism positions between the spreader frame and the pre-installed fixture; the front cover positioning mechanism positions between the front cover and the spreader frame; the rear cover positioning mechanism positions between the rear cover and the spreader frame; the bottom surface supporting mechanism of front cover supports the front cover in lifting; the bottom surface supporting mechanism of rear cover supports the rear cover in lifting; the rear side supporting mechanism of rear cover supports the rear cover in lifting. According the invention, the positioning and supporting mechanisms of the front and rear cover are reasonably disposed so that the workpiece could be conveniently grabbed on-line for lifting, improving the assembly efficiency of high-top twin truck cab, ensuring the assembly quality of products.

Owner:HUBEI HUACHANGDA INTELLIGENT EQUIP

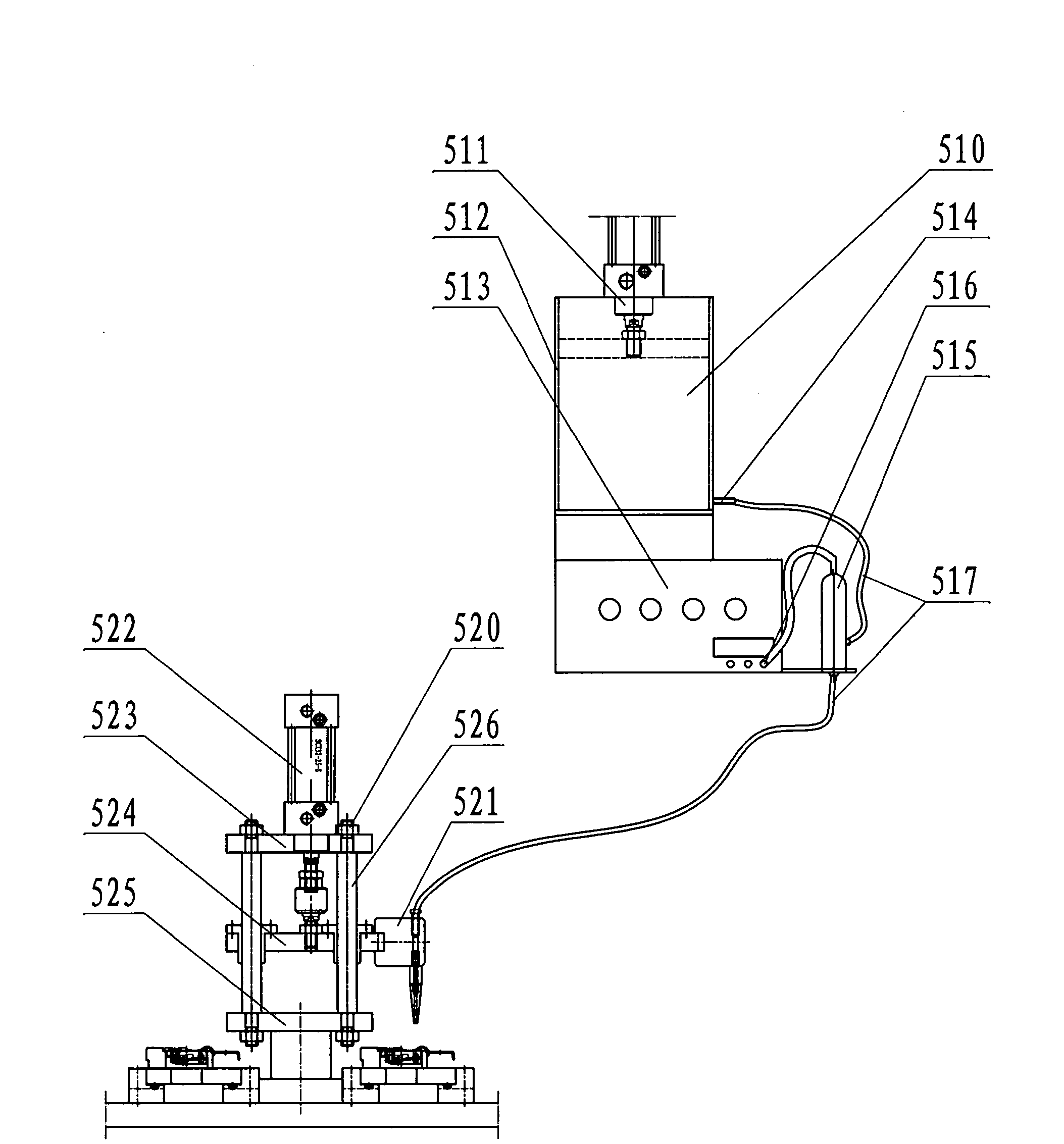

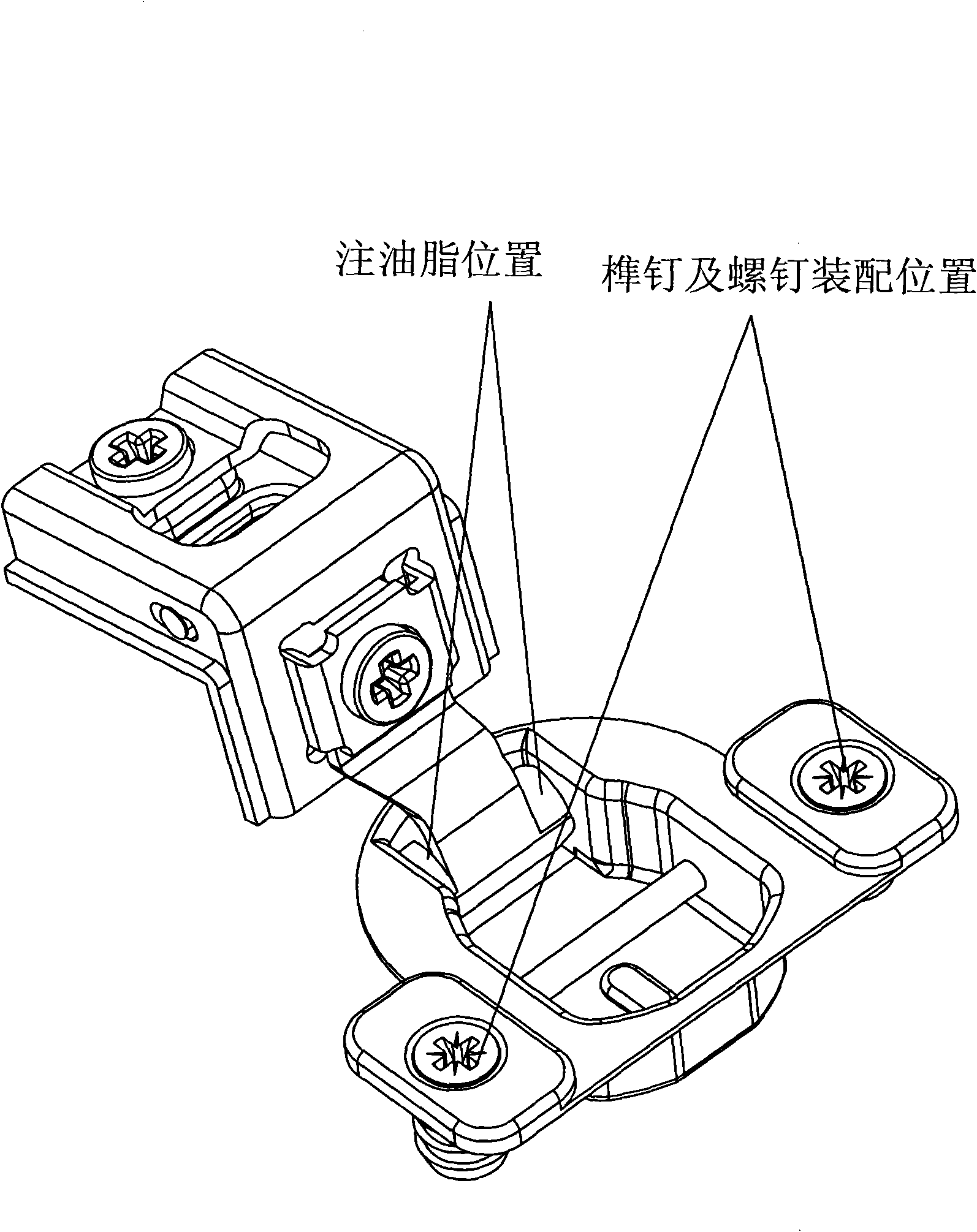

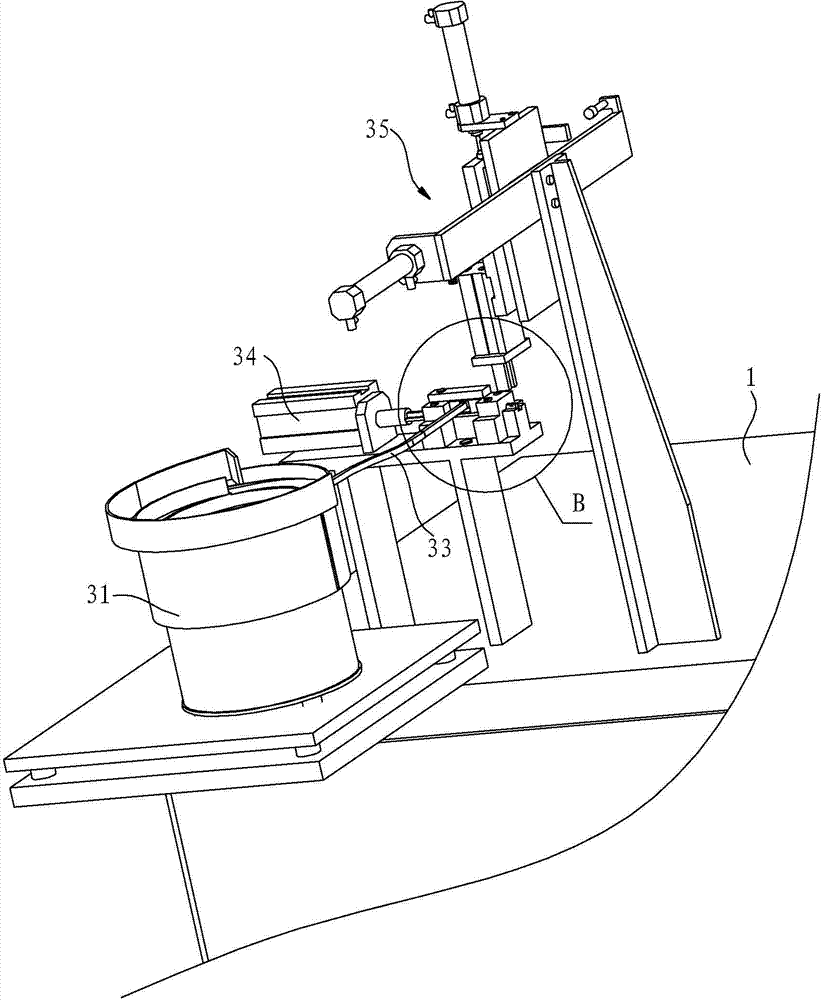

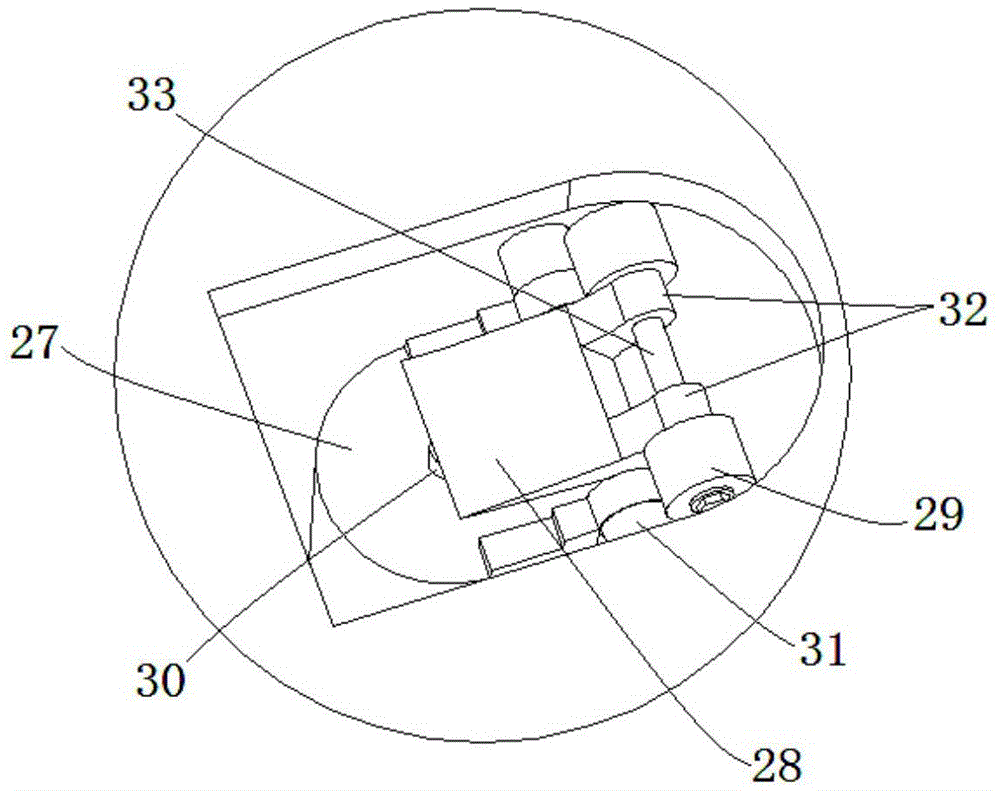

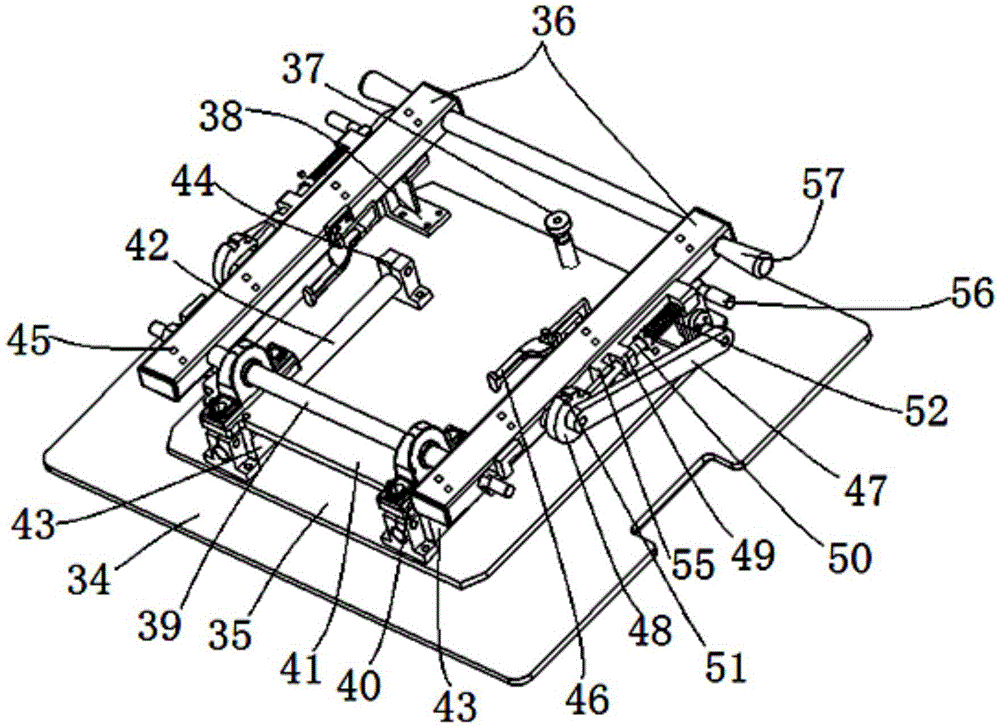

Automatic assembly equipment for hinge pre-installed tenon and oil injection process

InactiveCN102267047ARealize fully automatic assemblyImprove assembly productivityProportioning devicesLubricating pumpsSequence controlQuality assurance

The invention adopts the dowel pressing process, presses the metal screw into the center hole of the plastic dowel, the outer diameter of the screw is slightly larger than the diameter of the center hole of the dowel, and utilizes the elastic deformation and plastic deformation of the plastic dowel to make the screw and the dowel Tightly combined, so that it is firmly fixed on the fixed pocket of the hinge, and at the same time, the quantitative oil injection process is adopted to automatically inject the lubricating grease into the lubricating point quantitatively. The automatic assembly equipment of the present invention includes a dowel grasping mechanism, a dowel vibrating feeding mechanism, a dowel pre-installing mechanism, a screw vibrating feeding mechanism, a grease injection mechanism, a movable clamp cycle stepping and carrying mechanism and a microcomputer control system. Action sequence is controlled by microcomputer control system. The invention realizes the fully automatic assembly of dowel pre-installation and oil injection process, improves the assembly production efficiency and ensures the assembly quality.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

Automatic film tearing machine for accessory assembly

ActiveCN109334215AAvoid position shiftGuaranteed assembly accuracyLamination ancillary operationsLaminationTectorial membraneGlass sheet

The invention discloses an automatic film tearing machine for accessory assembly. The automatic film tearing machine comprises a transmission mechanism, a positioning and supporting mechanism, a filmtearing mechanism and a feed box, wherein the transmission mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at a film-tearing station; the film tearing mechanism is arranged above the film-tearing station; the film tearing mechanism comprises a rotating component, a film clamping component and a pressing component; the film clamping component and the pressing component are respectively connected to the output end of the rotating component; the film clamping component and the pressing component comprise at least two groups, and every two groupsare arranged at an interval; the output ends of the film clamping component and the pressing component are downwards obliquely arranged opposite to each other; the feed box is arranged below the filmtearing mechanism and has an upward opening; after the protective film on gum is torn out by the film tearing mechanism, the torn protective film is put in the feed box. The automatic film tearing machine for accessory assembly disclosed by the invention is applicable to automatic whole line assembly of accessories, multiple films are torn each time, the film tearing efficiency is effectively improved, position offset of the gum or the glass sheet in the film tearing process is effectively avoided, and the assembling precision and quality are ensured.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

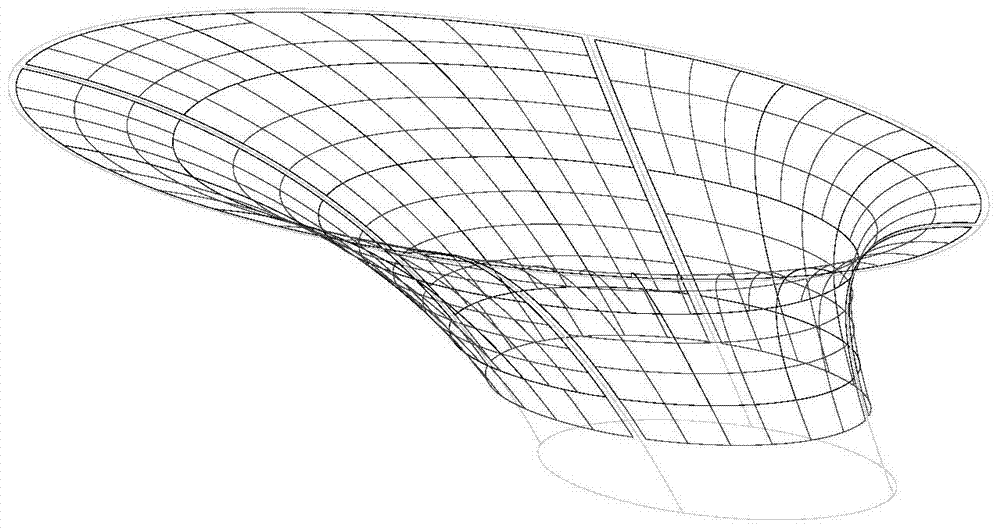

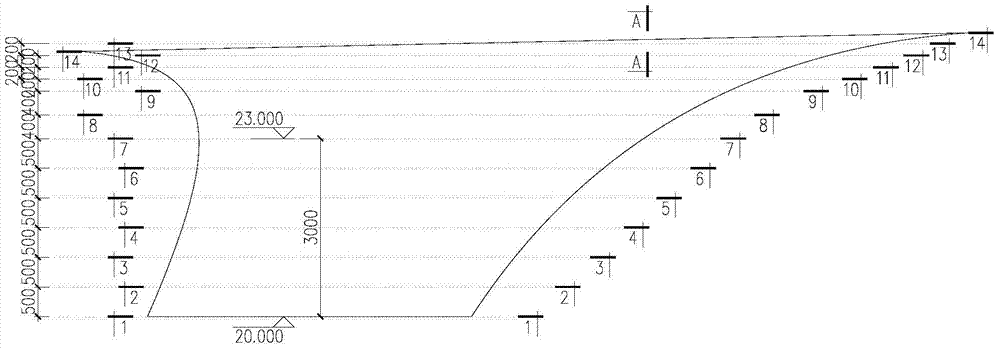

Construction method for using layering method to construct double-curved-surface stainless steel curtain wall

ActiveCN103541474AFast Construction CompletedSafe construction completedWallsBuilding material handlingSurface layerKeel

The invention discloses a construction method for using a layering method to construct a double-curved-surface stainless steel curtain wall. The method includes: building a double-curved-surface stainless steel curtain wall three-dimensional model and deepen drawing; decomposing the double-curved-surface curtain wall structure according to the model and deepen drawing into a surface layer and a keel layer; deepening construction drawings of the surface layer and the keel layer; machining and constructing the surface layer of the double-curved-surface stainless steel curtain wall; cutting and transporting the surface layer; constructing the keel layer of the double-curved-surface stainless steel curtain wall; mounting and seam welding the surface layer; processing the facing of the double-curved-surface stainless steel curtain wall. The construction method has the advantages that the layering method is used to construct the double-curved-surface stainless steel curtain wall, the surface layer with large welding and splicing work load is constructed in a factory, the keel layer is welded on site, filed structural features are combined to adjust and eliminate construction errors reasonably, coordinating and unifying of the curtain wall structure and a main body structure are guaranteed, and accurate curved surfaces and radian smoothness of the curtain wall are guaranteed.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

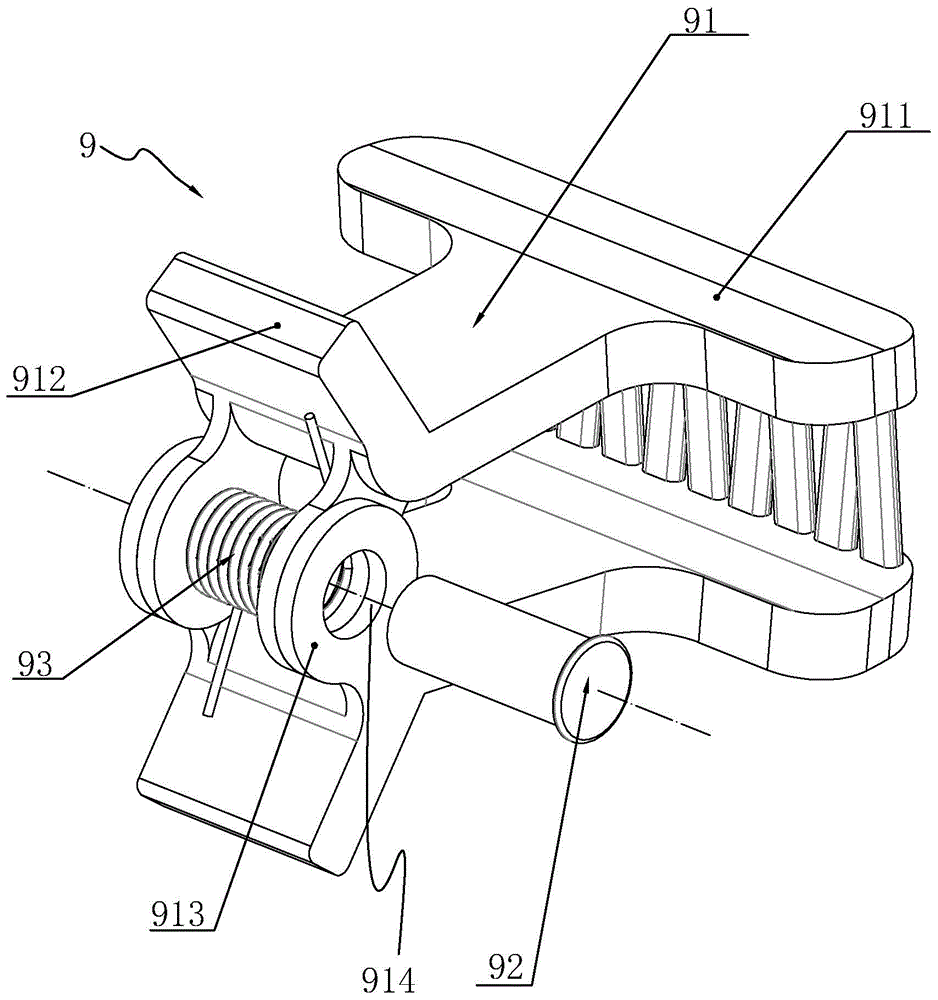

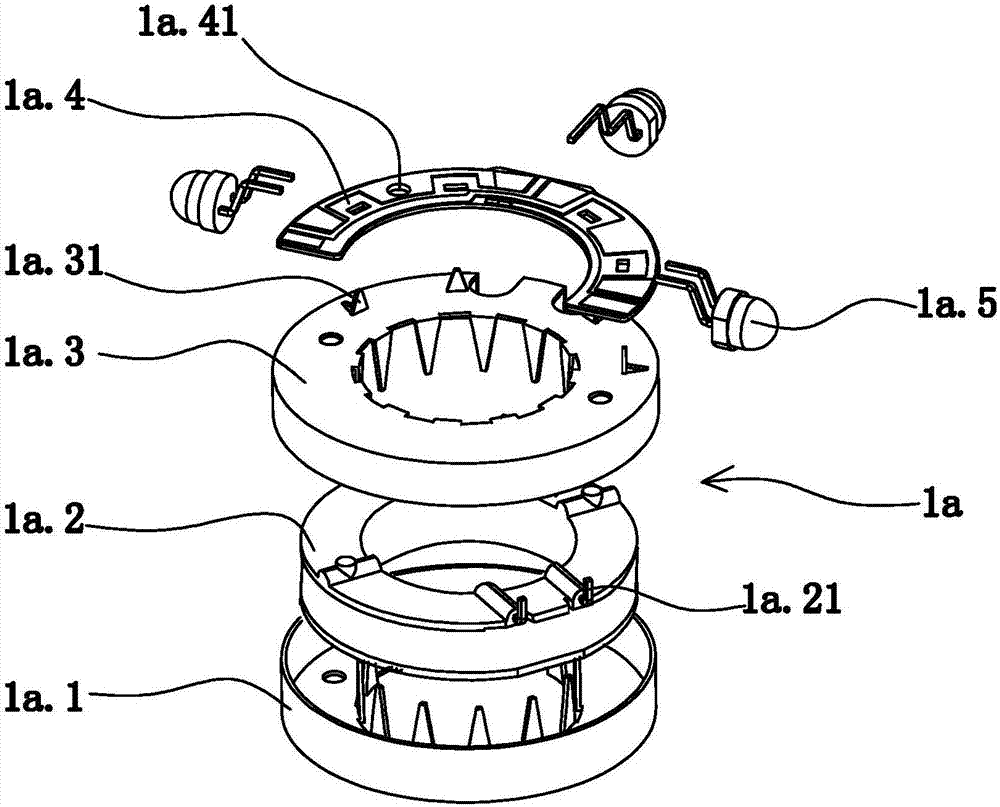

Spring clip automatic assembling machine

ActiveCN104889933AInsertion is stable and reliableThe insertion process is smooth and reliableMetal-working hand toolsEngineeringTorsion spring

The invention relates to a spring clip automatic assembling machine. The machine comprises a rack. A clamping plate splicing unit, a torsion spring compression unit and a pin insertion unit are arranged on the rack. The clamping plate splicing unit comprises a clamping plate splicing seat which comprises two opposite clamping plate clamping seats. Clamping plate body location cavities and pivoting lug stretching ports are formed in the clamping plate clamping seats. The two clamping plate clamping seats are arranged at an interval to form a pivoting lug splicing spacing cavity for a clamping plate upper pivoting lug. The pivoting lug stretching ports are communicated with the pivoting lug splicing spacing cavity and the clamping plate body location cavities. A spring clip blanking port communicated with the clamping plate body location cavities, the pivoting lug stretching ports and the pivoting lug splicing spacing cavity is formed in the clamping plate splicing seat. The pivoting lug splicing spacing cavity comprises a torsion spring feeding port in corresponding fit with the torsion spring compression unit and a pin insertion port in corresponding fit with the pin insertion unit. By means of the machine, the spring clip automatic assembly machine is provided, and the assembly efficiency and the finished product yield of spring clips are improved effectively.

Owner:金华市晨帆饰品有限公司

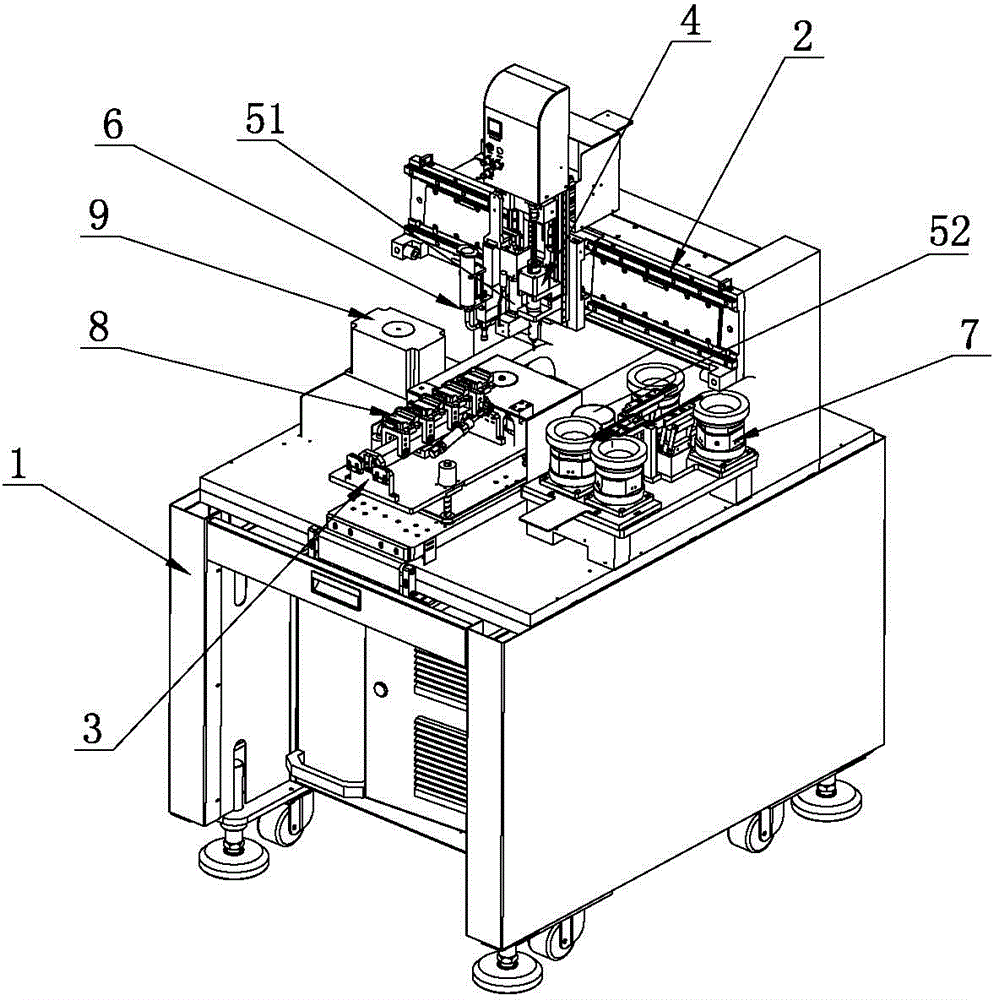

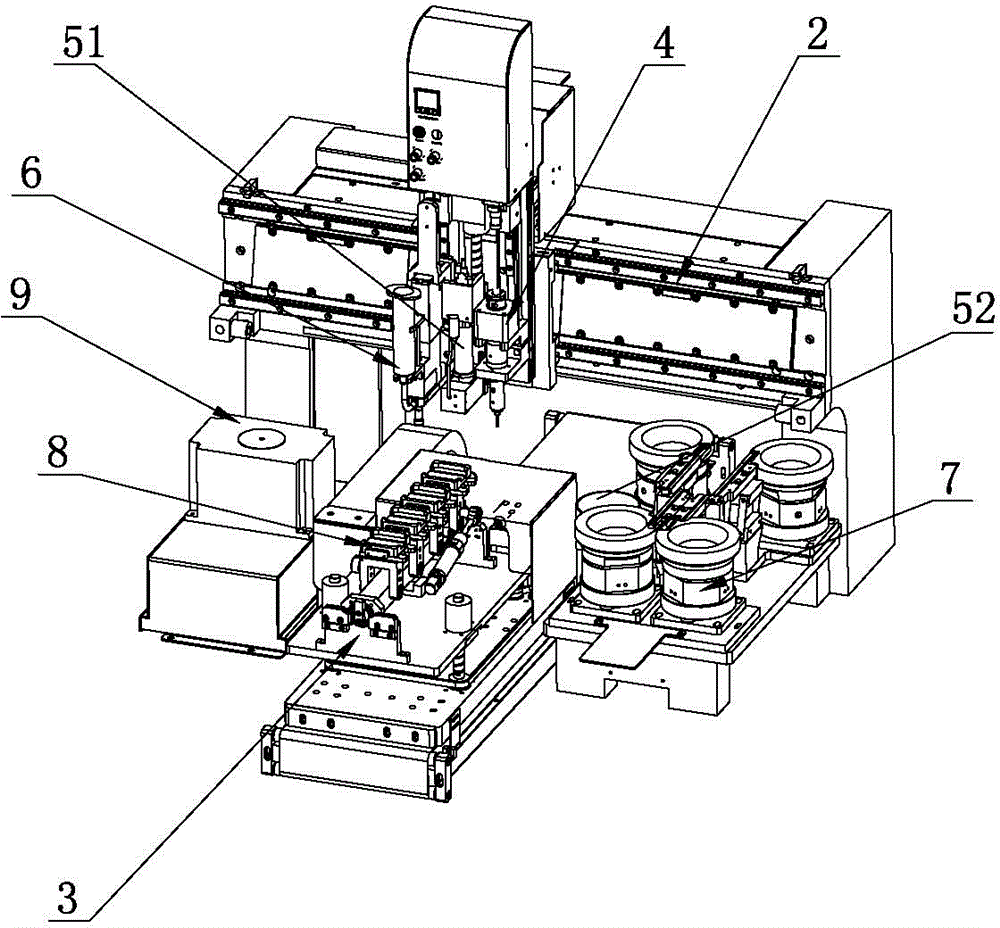

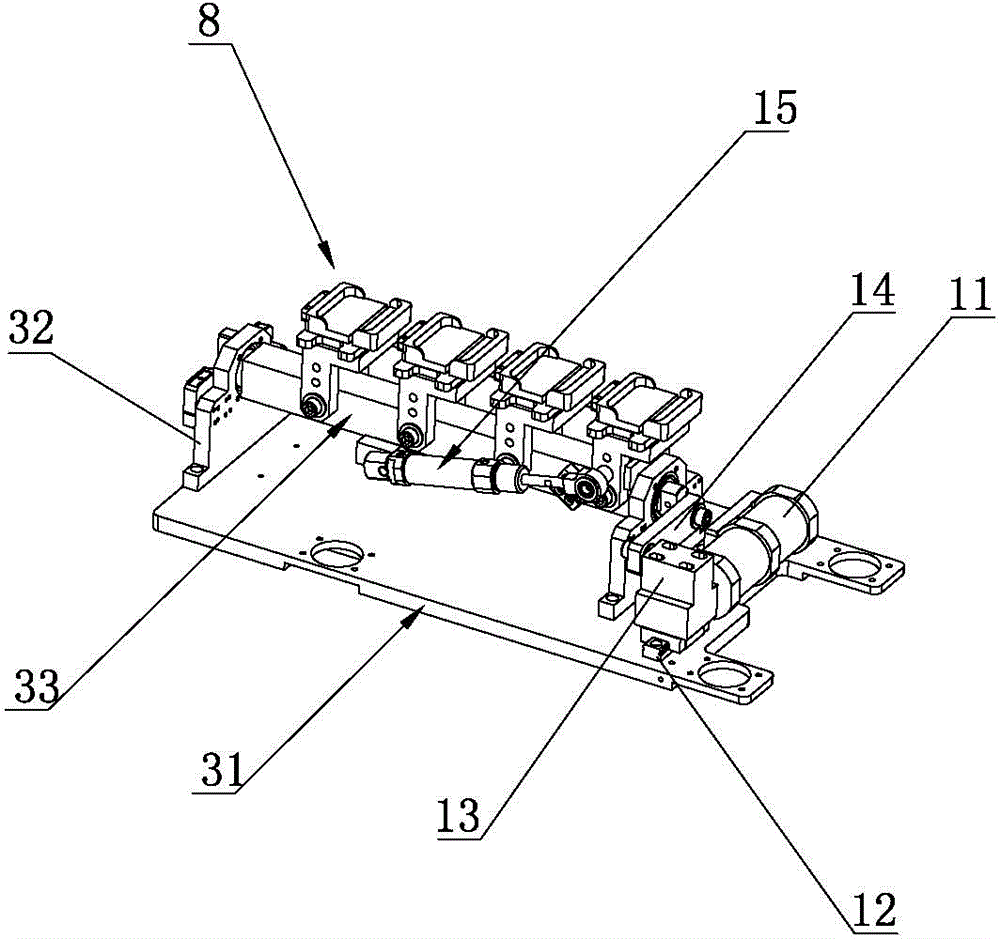

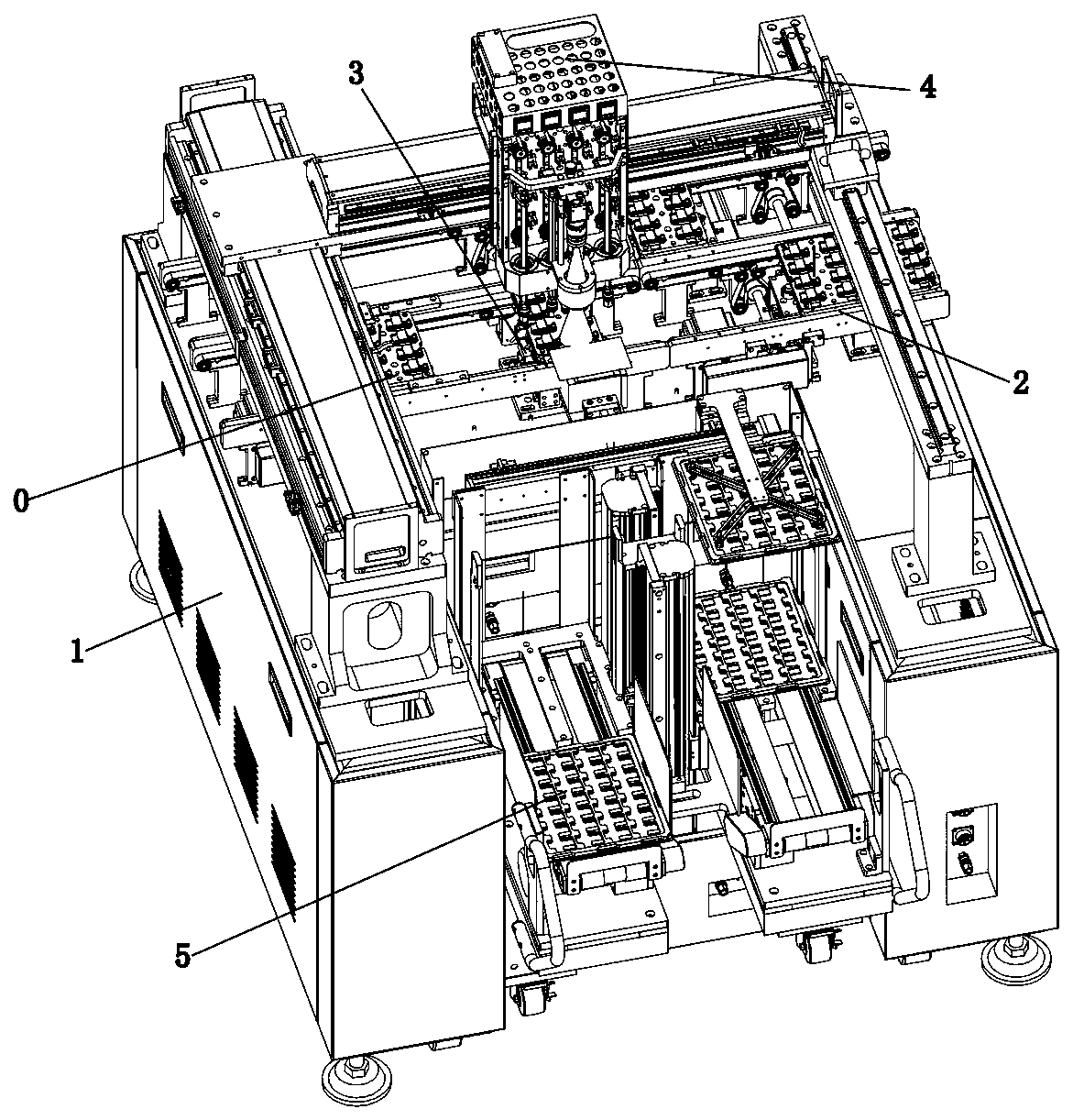

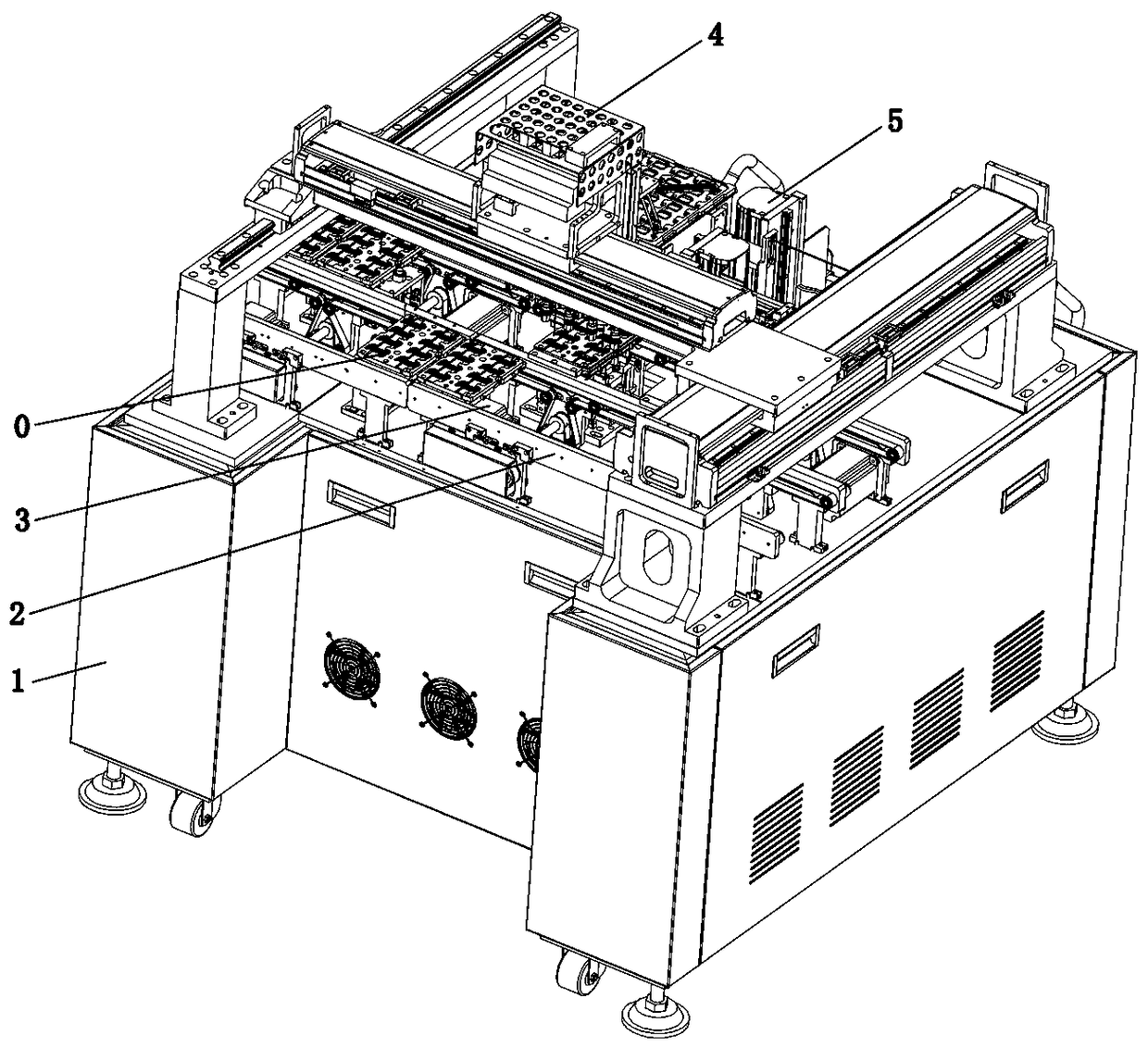

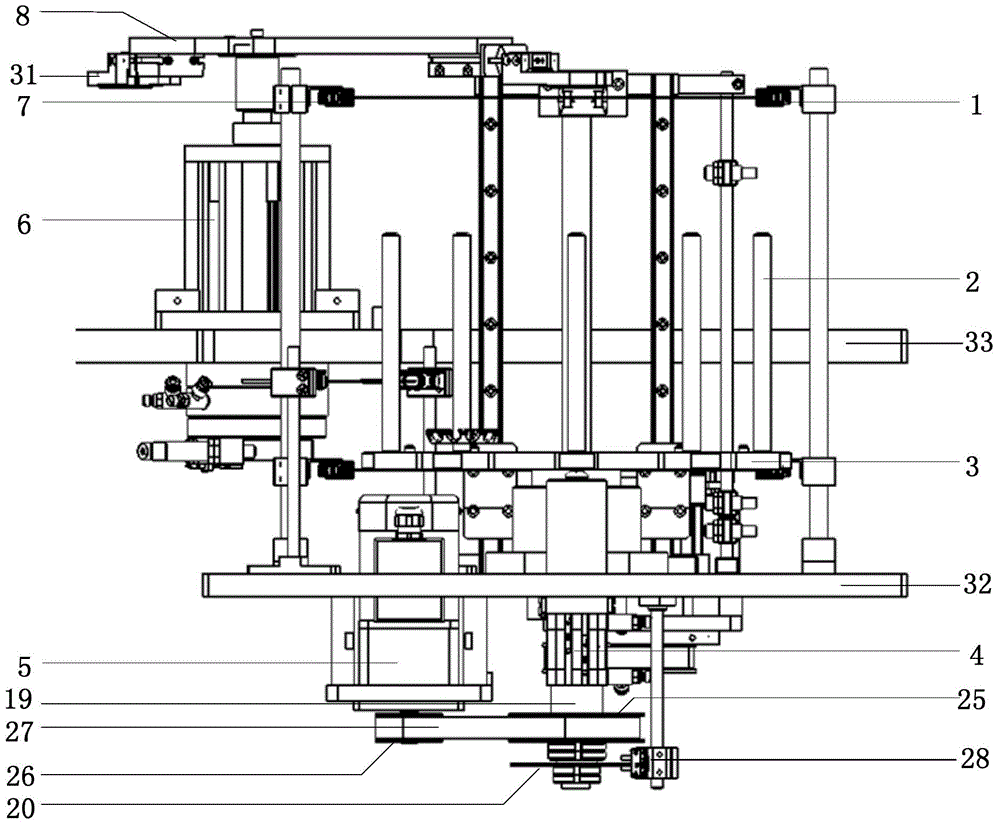

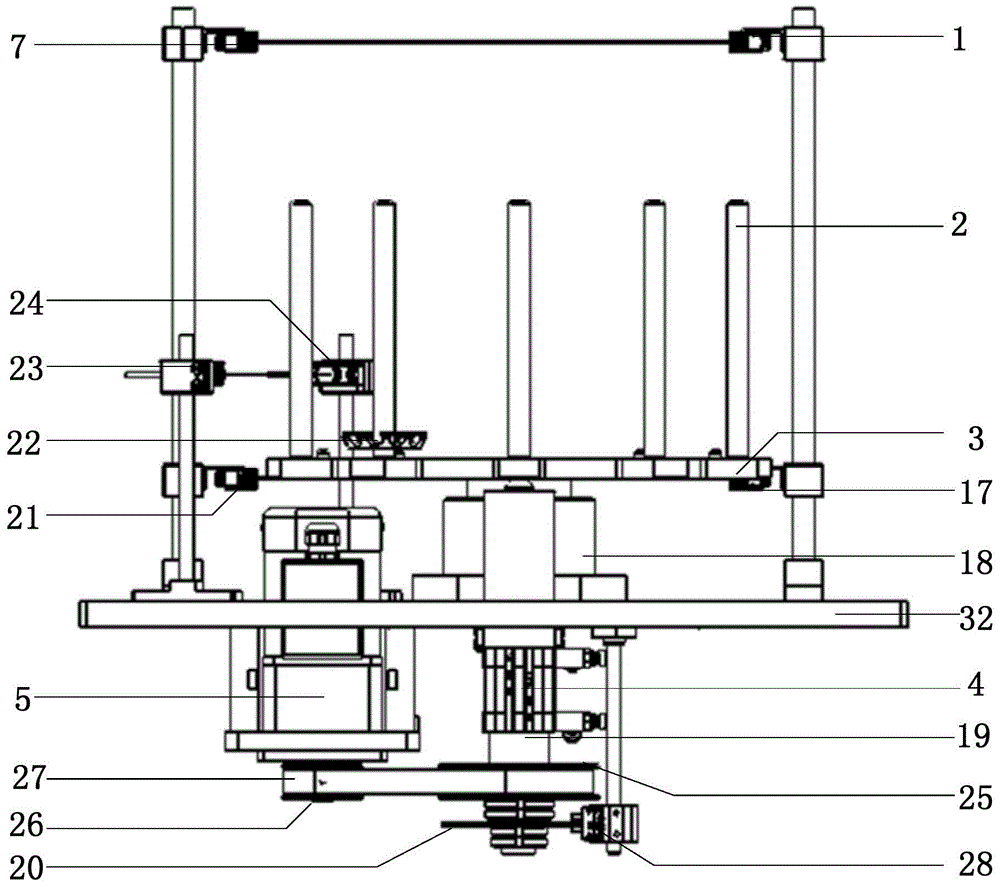

Multifunctional full-automatic assembling machine

ActiveCN104607939AImprove assembly efficiencyGuaranteed assembly qualityAssembly machinesReciprocating motionMaterial supply

The invention relates to the technical field of automatic assembling equipment, in particular to a multifunctional full-automatic assembling machine which comprises a machine frame. An X-axis feeding device is arranged on the machine frame, a multi-angle inclining clamp for adjusting the mounting angle of a workpiece is arranged on the machine frame, the X-axis feeding device is provided with a high-precision vacuum nozzle device, and the multi-angle inclining clamp is located below the high-precision vacuum nozzle device; an upper CCD detector and a glue dispensing mechanism are arranged on the high-precision vacuum nozzle device, an automatic material supply device is arranged on one side of the multi-angle inclining clamp, a lower CCD detector is arranged on the automatic material supply device, and the high-precision vacuum nozzle device moves between the automatic material supply device and the multi-angle inclining clamp in a reciprocating mode through the X-axis feeding device. By means of the multifunctional full-automatic assembling machine, materials are assembled on different mounting faces of workpieces, automatic assembling is achieved, assembling efficiency is improved, and assembling quality is guaranteed.

Owner:DONGGUAN ANDA AUTOMATIC EQUIP

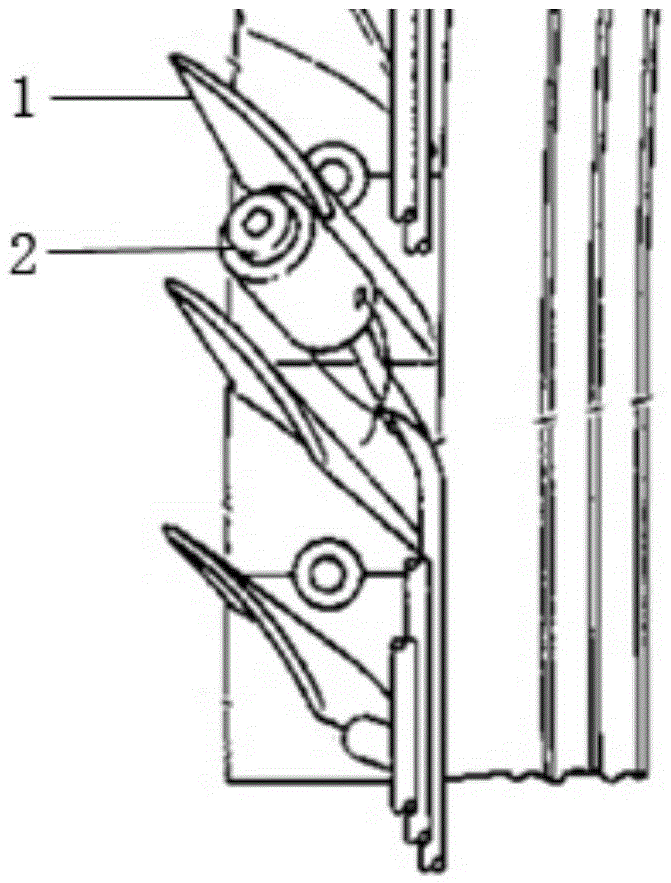

Machining process for low-pressure first-stage stationary blades of gas turbines

ActiveCN103028917AGuaranteed Design RequirementsGuaranteed assembly qualityWire cuttingRadial surface

The invention discloses a machining process for low-pressure first-stage stationary blades of gas turbines, which belongs to the technical field of blade machining. The machining process for low-pressure first-stage stationary blades of gas turbines includes: step 1: a Z-shaped blade blank is formed by wire cutting; step 2: auxiliary heads are respectively welded on the inner and outer rings of the blade; step 3: rough machining is carried out; step 4: semifinishing is carried out; step 5: four times of finish machining are carried out on the air passage part, and finish machining is carried out on the radial face of the blade; step 6: the wire cutting method is adopted to remove the auxiliary heads of the outer and inner rings, and the inner ring surface, the outer ring surface and the inner radial surface of the blade are then machined. Under the premise of guaranteeing product design requirements and assembly quality, the machining process for low-pressure first-stage stationary blades of gas turbines strive for strict process control, a complete machining process, simple machining operation, integrated difficult point machining and critical control on key factors, thus effectively guaranteeing the quality of products and increasing the production efficiency.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

Cable fixing clamp and cable fixing device employing cable fixing clamp

InactiveCN102889430AReduce stressAvoid deformationPipe supportsElectrical apparatusEngineeringMechanical engineering

Owner:XUJI GRP +2

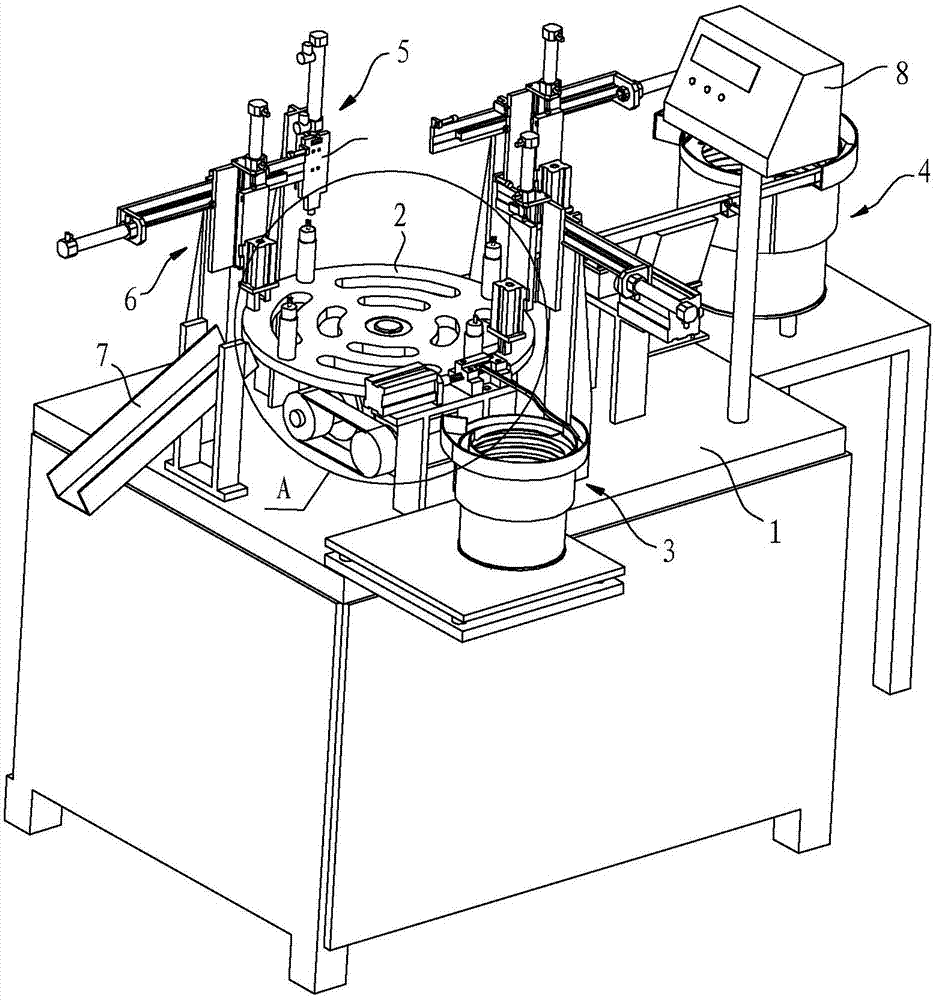

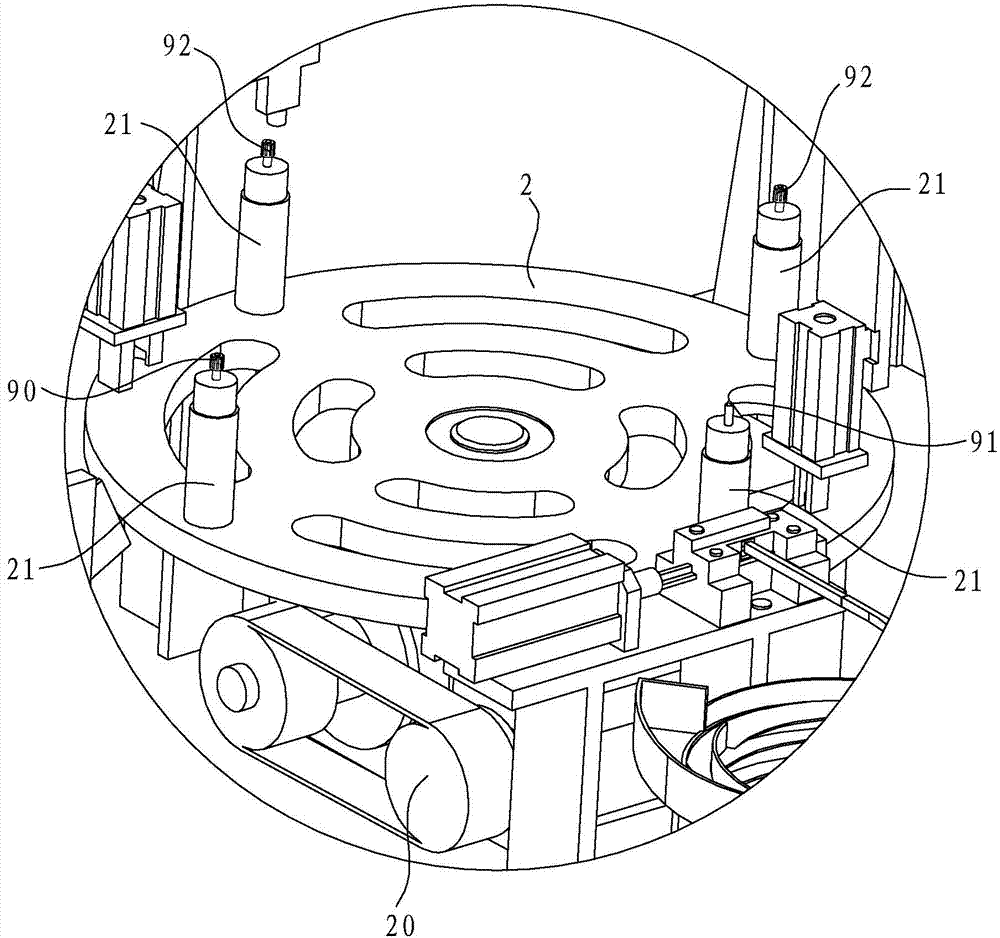

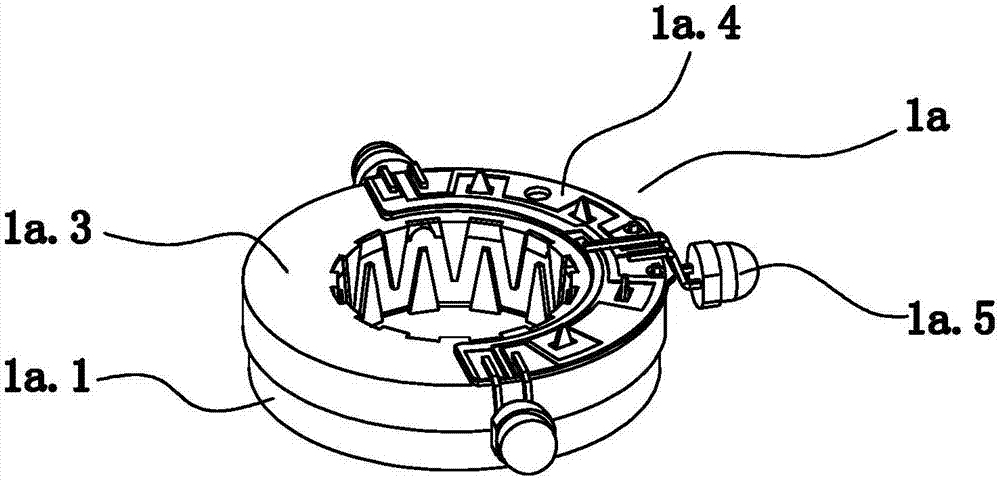

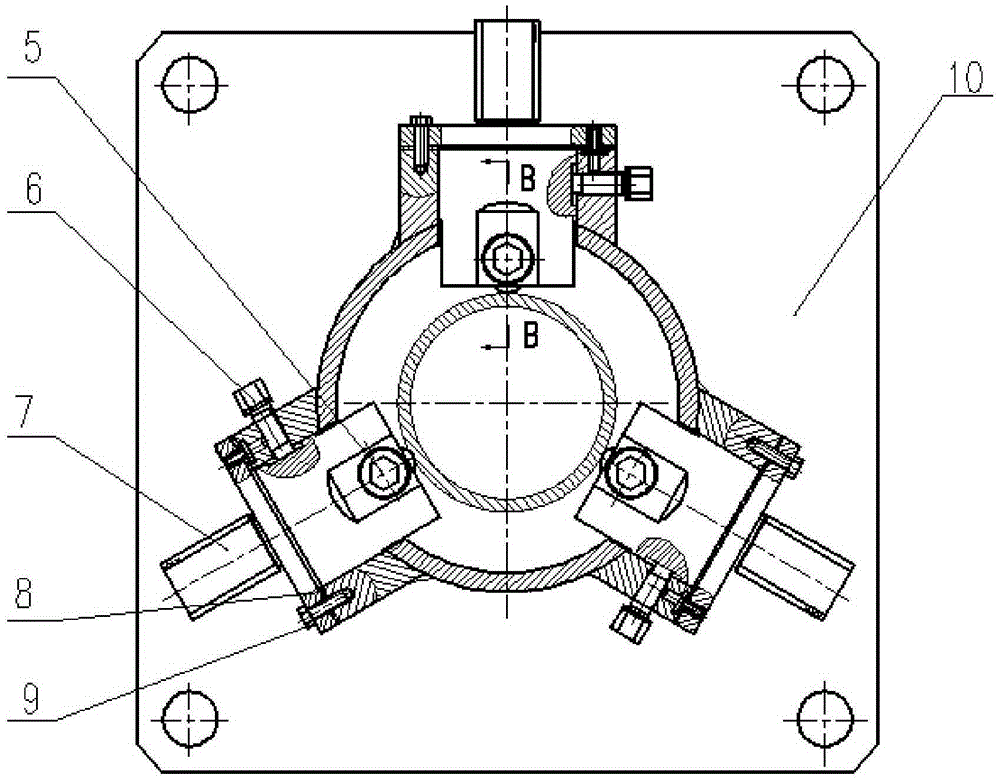

Automatic assembling tool of impeller lining and agate of water meter

ActiveCN103921107AImprove assembly efficiencyConcentricity winsMetal working apparatusImpellerEngineering

The invention provides an automatic assembling tool of an impeller lining and agate of a water meter. The automatic assembling tool is characterized by comprising a work table, a rotating plate, an agate conveying mechanism, a lining conveying mechanism, a lining pressing mechanism, a discharge clamping mechanism, an output material channel and a controller. The rotating plate is arranged on the work table and rotates intermittently. The agate conveying mechanism conveys the agate to the agate assembling station. The lining conveying mechanism conveys linings to the lining assembling station. The lining pressing mechanism presses the linings and the agate on the agate and lining assembling station to form agate and lining assembling bodies. The discharge clamping mechanism unloads the agate and lining assembling bodies on the agate and lining assembling body output station, and the unloaded agate and lining assembling bodies fall into the output material channel. The automatic assembling tool has the advantages that conveying of the agate and the linings, assembling of the linings and the agate and unloading of the agate and lining assembling bodies are finished automatically, manual assembling can be replaced, and therefore the assembling efficiency is improved greatly, and the assembling quality can be ensured.

Owner:安徽格太信控科技有限公司

Apparatus for pressing clamp springs and spider on shaft lever of constant speed shaft

ActiveCN102848176AHigh degree of automationGuaranteed assembly qualityAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention relates to an apparatus for pressing clamp springs and a spider on a shaft lever of a constant speed shaft, which comprises a bracket, an upper seat and a lower seat, wherein the upper seat is mounted on a guide rail on the bracket; the lower seat is fixedly mounted on the bottom of the bracket; the bracket is fixedly provided with a clamping cylinder and a lifting cylinder; a piston rod of the lifting cylinder is provided with a finger cylinder; the bracket is provided with an upper push plate cylinder and an upper clamp spring feeding shaft which are arranged above the clamping cylinder; the upper seat is connected with an electric cylinder fixed on the bracket; the bottom surface of the upper seat is provided with a press head sleeve lifting cylinder; a piston rod of the press head sleeve lifting cylinder is connected with a press head sleeve; the lower seat is provided with a support plate cylinder, a lower push plate, a lower push plate cylinder and a lower clamp spring feeding shaft; the lower push plate is connected with a piston rod of the lower push plate cylinder; and a piston rod of the support plate cylinder is connected with a support plate. The apparatus can finish the assembling of the fixed-end clamp spring, the movable-end spider and the movable-end clamp spring on the shaft lever of the constant speed shaft in one step, is high in automation degree and ensures the assembling quality.

Owner:济南易恒技术有限公司

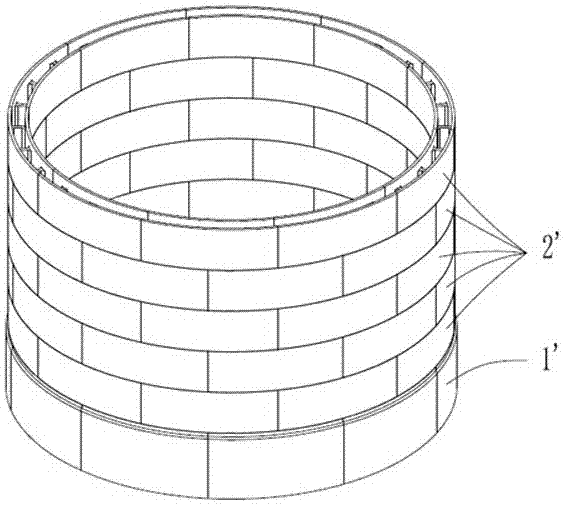

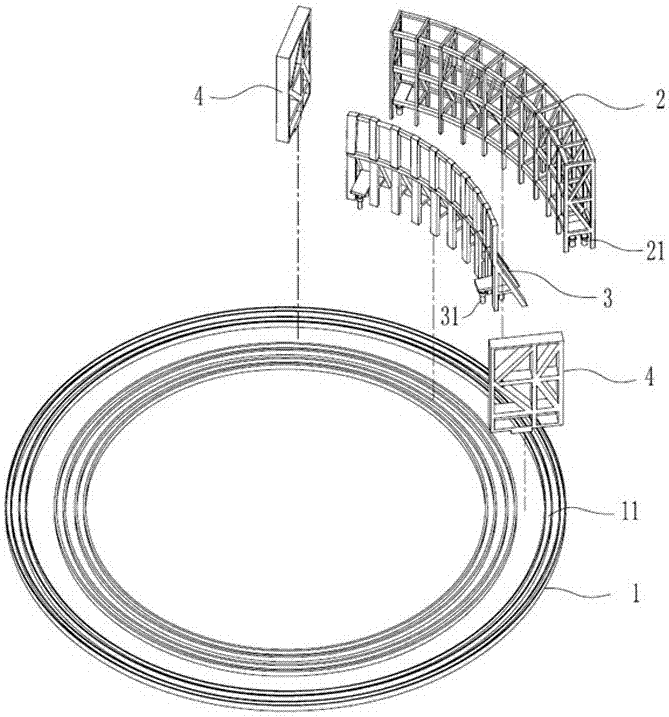

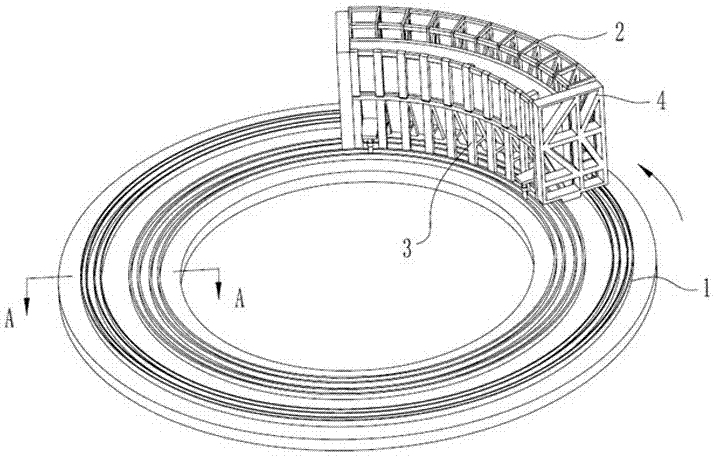

Sliding formwork component and open caisson blade foot layer sliding formwork construction method applying sliding formwork component

PendingCN107575023AGuaranteed vertical accuracyGuaranteed assembly qualityForms/shuttering/falseworksCaissonsSteel barBuilding construction

The invention discloses a sliding formwork component. The sliding formwork component comprises a sliding way, an outer template, an inner template, two side templates and a plurality of connecting fixing pieces. The sliding way is provided with a plurality of sliding grooves for installation of the outer template and the inner template. A plurality of outer stand bars are arranged at the bottom ofthe outer template. The outer stand bars are arranged on the outer side of the sliding way and can be installed and move along the sliding grooves. A plurality of inner stand bars are arranged at thebottom of the inner template. The inner stand bars are arranged on the inner side of the sliding way and can be installed and move along the sliding grooves. The side templates are arranged on the two side edges of the inner template and the two side edges of the outer template and are connected with the inner template and the outer template through the connecting fixing pieces. The invention further discloses an open caisson blade foot layer sliding formwork construction method. The method comprises the steps of field leveling, sliding way installing, steel bar bundling, template installing,concrete pouring, side template dismounting, template sliding and the like. According to the sliding formwork component and the method, the linear vertical perpendicularity after blade foot construction is finished can be ensured, and accordingly the assembling quality of upper-layer open caisson standard segments is guaranteed.

Owner:中铁科建有限公司

Automatic precise assembly machine

InactiveCN109317967AReduce the frequency of replacement and retransmissionAvoid position shiftAssembly machinesEngineeringGlass sheet

The invention discloses an automatic precise assembly machine. The automatic precise assembly machine comprises a conveying mechanism, a positioning and support mechanism, an assembly mechanism and aloading mechanism; the conveying mechanism is horizontally arranged on the frame; a synchronous belt is arranged on the inner side of the conveying mechanism; a tool for loading materials is placed onthe synchronous belt; at least two through grooves are formed in the tool; materials to be assembled are placed in the through grooves; and the assembly modules once absorb multiple materials from the loading mechanism, and assemble the materials to fittings in the through grooves of the tool. Through downward absorption fixation and flexible support of glass sheets, the displacement of the glasssheets in the assembly process is prevented, so that the assembly precision is guaranteed, the pressure crushing condition of the glass sheets is prevented, the loading and unloading time is shortened, the centralized unloading and loading of multiple products once are realized, the tray replacing and reloading time is shortened, and the overall production capacity is effectively improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

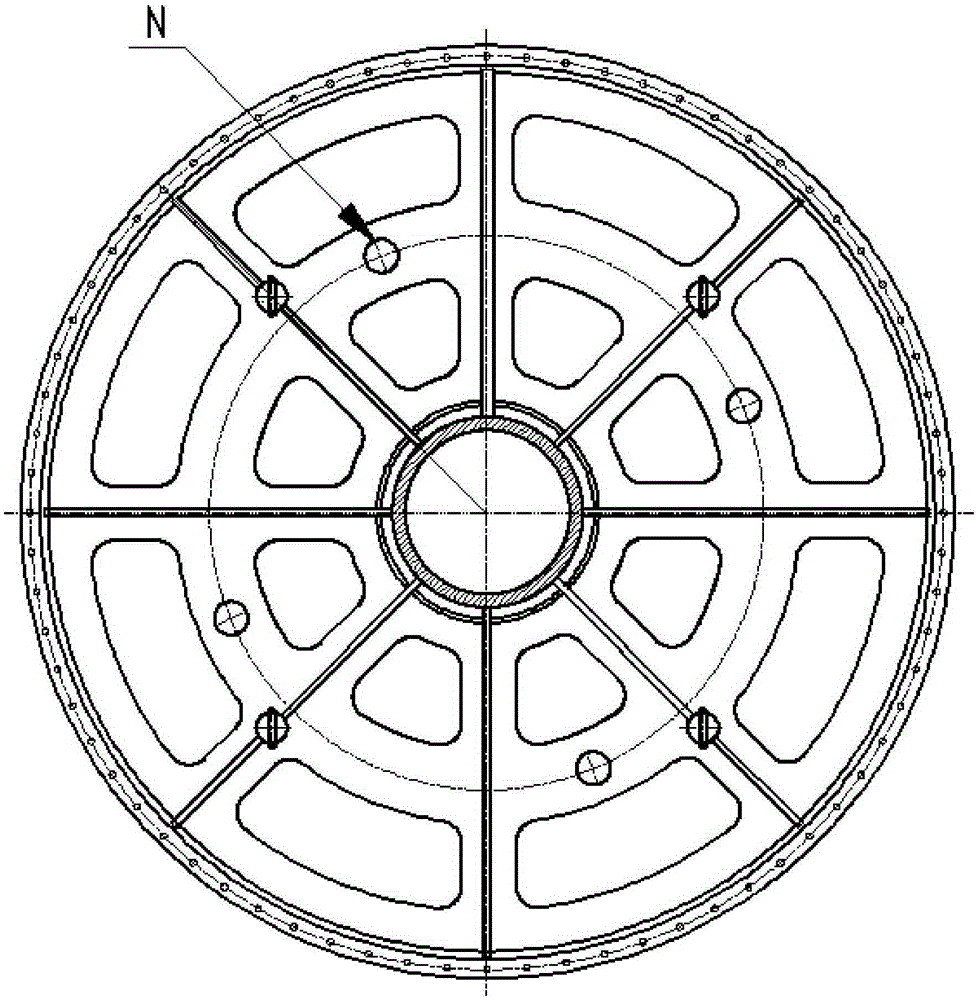

Assembling device for luminous wheel product

InactiveCN107052791AImprove assembly efficiencyGuaranteed assembly qualityAssembly machinesMetal working apparatusWork in processEngineering

The invention discloses an assembling device for a luminous wheel product, and aims to provide an assembling device for the luminous wheel product, which can automatically assemble the luminous wheel product to effectively improve assembly efficiency and guarantee the assembly quality. The assembling device comprises a rack and an upper cover semi-finished product assembling mechanism, wherein the upper cover semi-finished product assembling mechanism comprises a first dividing disc which is rotatably arranged on the rack along a first vertical rotating shaft, and a finished product luminous wheel assembling mechanism; the finished product luminous wheel assembling mechanism includes a second dividing disc which is rotatably arranged on the rack through a second vertical rotating shaft, an upper cover automatic feeding work position, a PCB board feeding work position, an LED lamp bead feeding work position, a PCB board pressing rivet work position, an LED welding work position, a semi-finished product transport work position, a lower cover automatic feeding work position, a coil feeding work position, upper cover and lower cover pressing rivet work positions and a coil welding work position.

Owner:浙江美佳尼精密科技有限公司

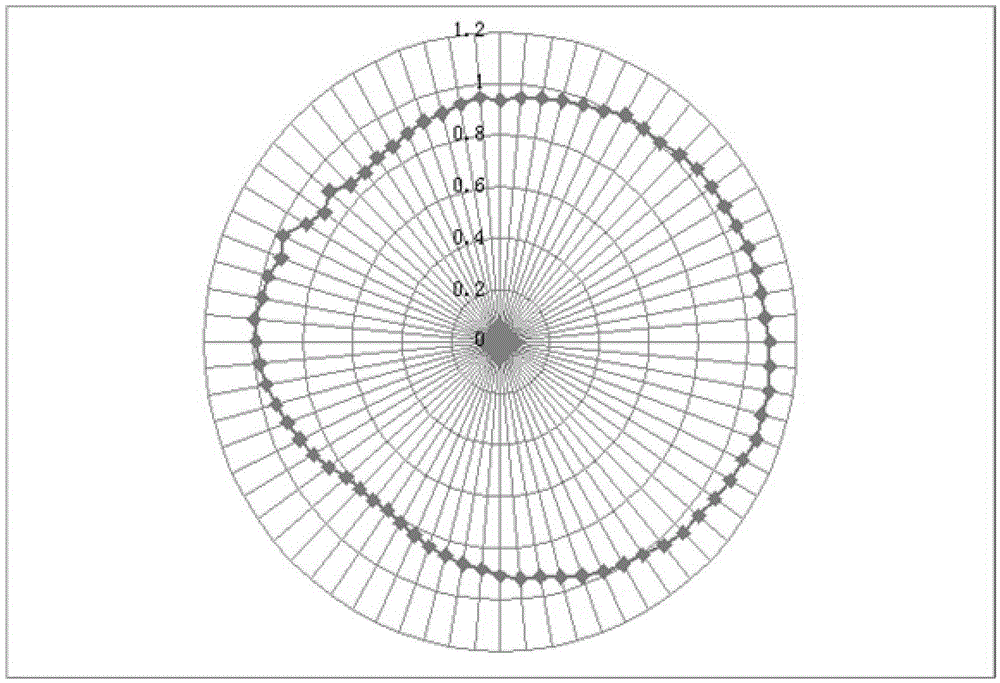

Non-contact engine turbine blade tip radial gap measurement method

InactiveCN105466329AUnderstanding Gap DistributionAdjust machining accuracyUsing electrical meansCoaxial cableMicrometer

A non-contact engine turbine blade tip radial gap measurement method belongs to the gas turbine technology field. The method is characterized by calibrating a sensor and a micrometer before measurement and inputting a curve during protocolling and calibration into a computer; fixing the sensor to any one blade of a high pressure turbine rotor and making an induction end of the sensor and a blade tip flush so as to form a space to be measured H with an inner ring surface of a high pressure turbine case; uniformly fixing coaxial cables connected to the sensor to a turbine rotor and winding at least one circle along an engine rotation direction; fixing an angle rotation encoder to a manual rotating shaft of an engine assembling bench, recording an angle position as a starting position and adjusting a measured initial point; setting an angle ratio i between the rotation encoder and an engine rotation table, rotating the engine rotor through a signal collected by the computer and the manual rotating shaft, observing and recording a blade tip gap value of a current angle position till that the sensor is rotated to an initial position so that case inner ring surface periphery measurement is completed. By using the method, 360 degree gap measurement in the whole case can be realized.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

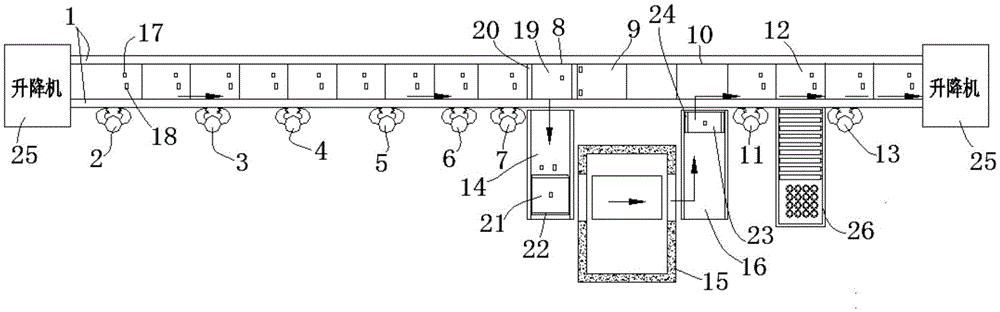

Automatic assembly line for automobile seats and assembly method

ActiveCN105537928AGuaranteed assembly qualityReduce labor intensityAssembly machinesVehicle componentsProduction lineNoise detection

The invention discloses an automatic assembly line for automobile seats and an assembly method. The automatic assembly line comprises a work table and conveying chains arranged on the two sides of the work table, and the work table is sequentially provided with a sliding rail set assembly station, a cushion set assembly station, a backrest set assembly station, a protection plate and safety belt buckle assembly station, a headrest assembly station, a wire arranging station, a first transferring station, a transitioning station, a second transferring station, an appearance function detection station, a repair station and a packaging station; a noise detection conveying work table located the side led to a sound insulation testing chamber is arranged on the side part of the first transferring station, and a noise detection outputting work table led to the second transferring station is arranged on the other side of the sound insulation testing chamber. According to the automatic assembly line, the labor intensity is lowered, the work efficiency is improved, the operation is orderly, errors and neglected assembly occur hardly, and the assembly quality of the seats can be guaranteed.

Owner:WUHU RUITAI AUTO PARTS

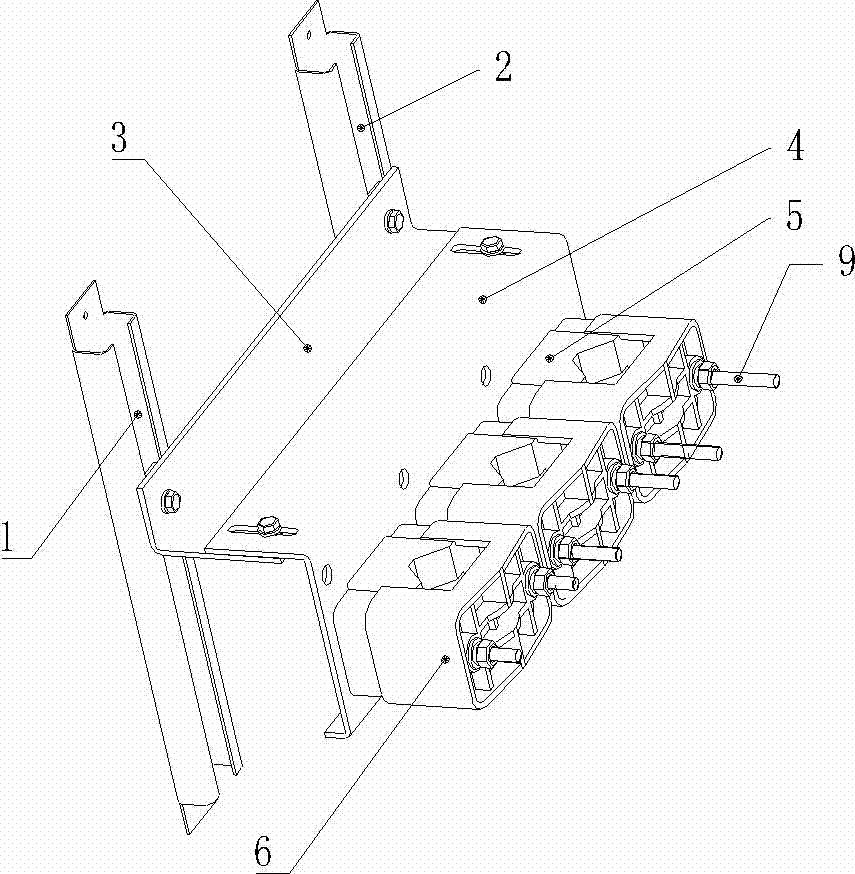

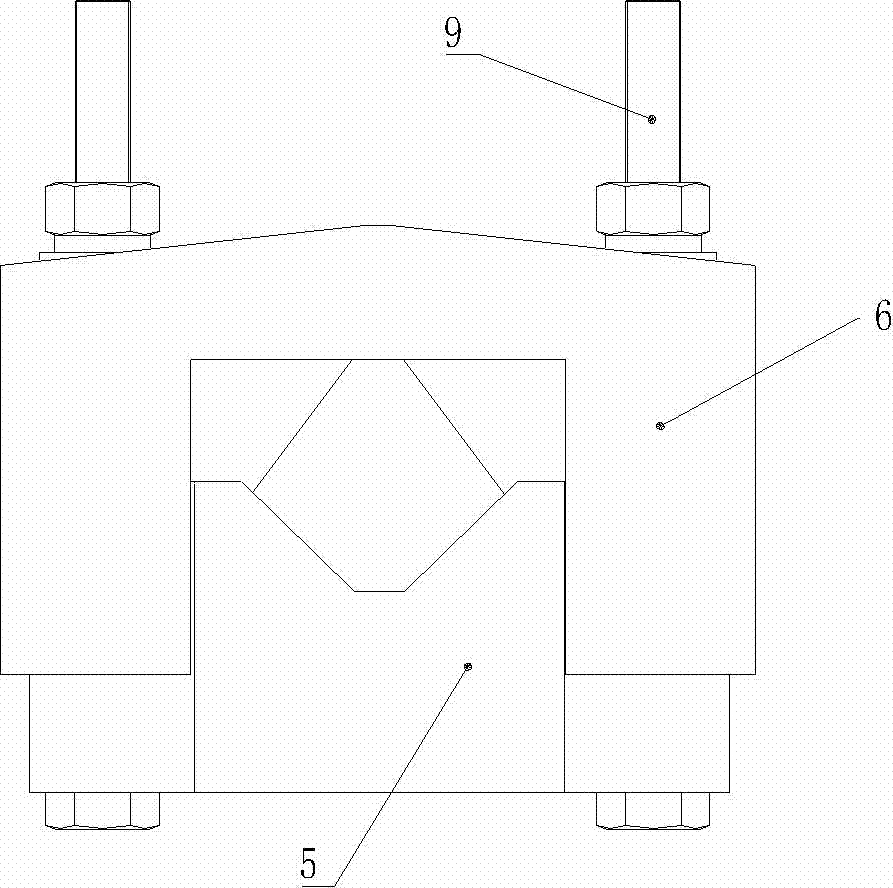

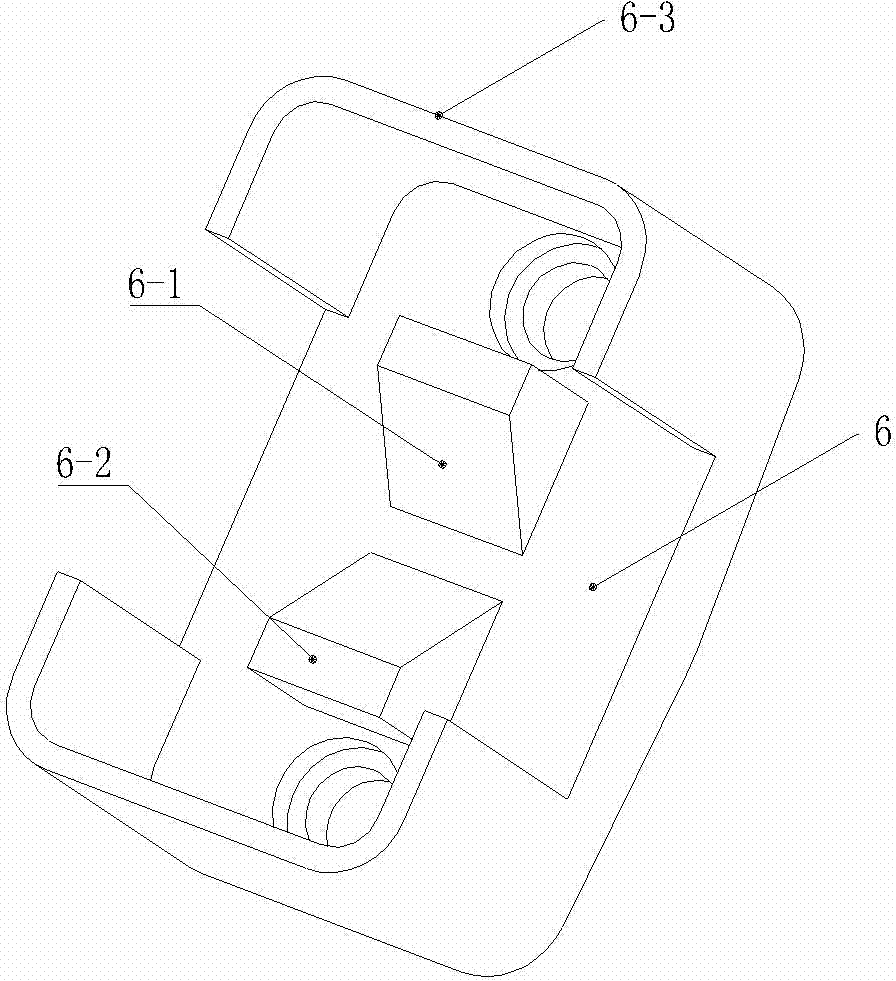

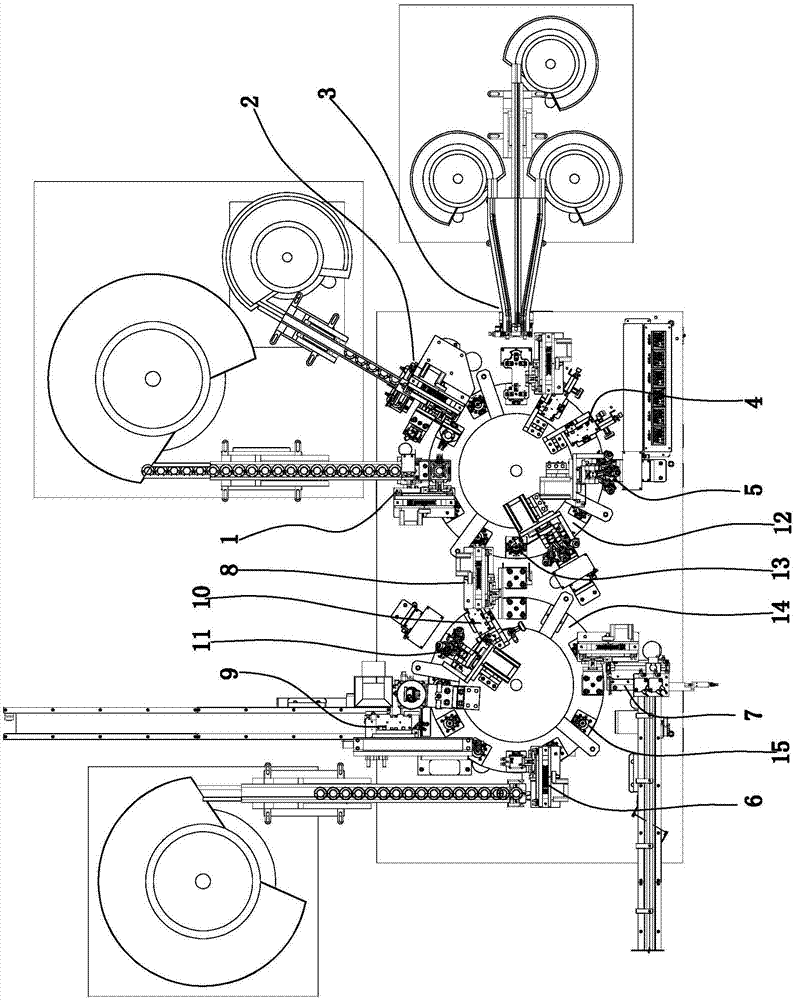

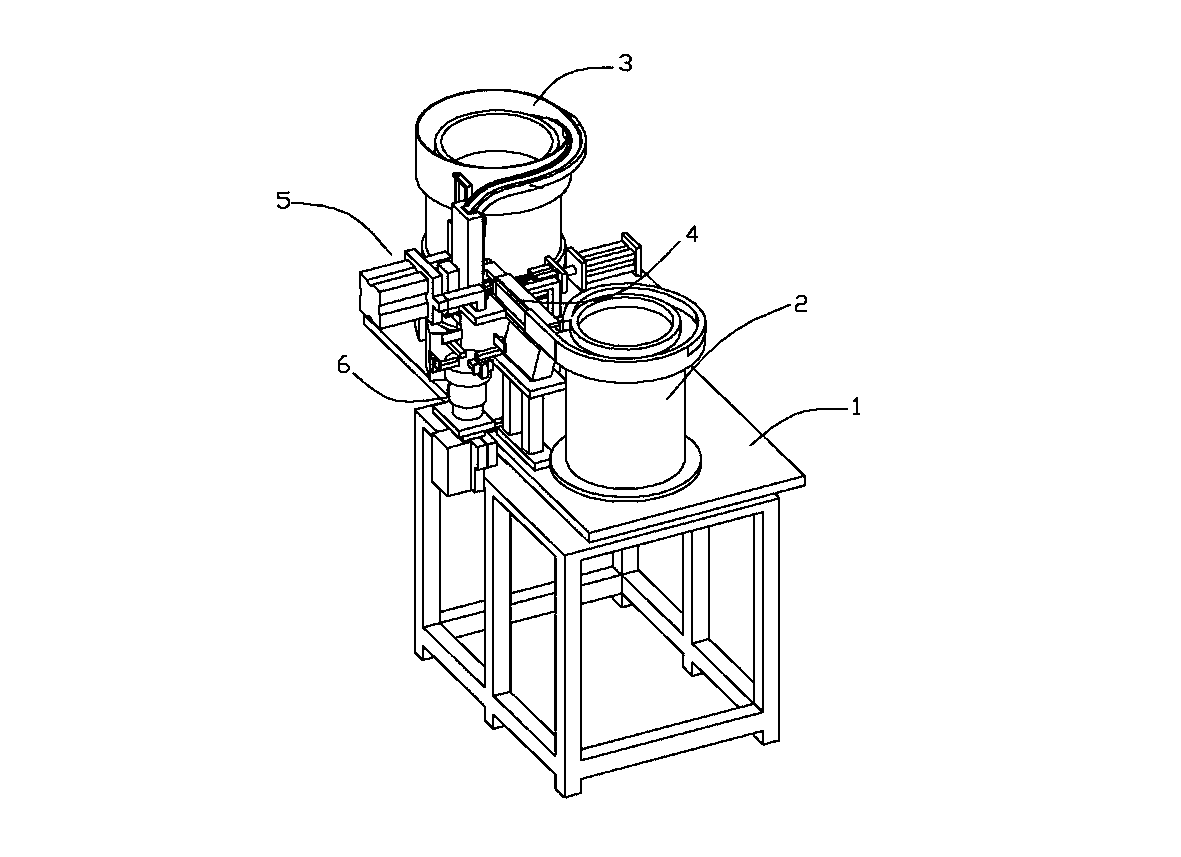

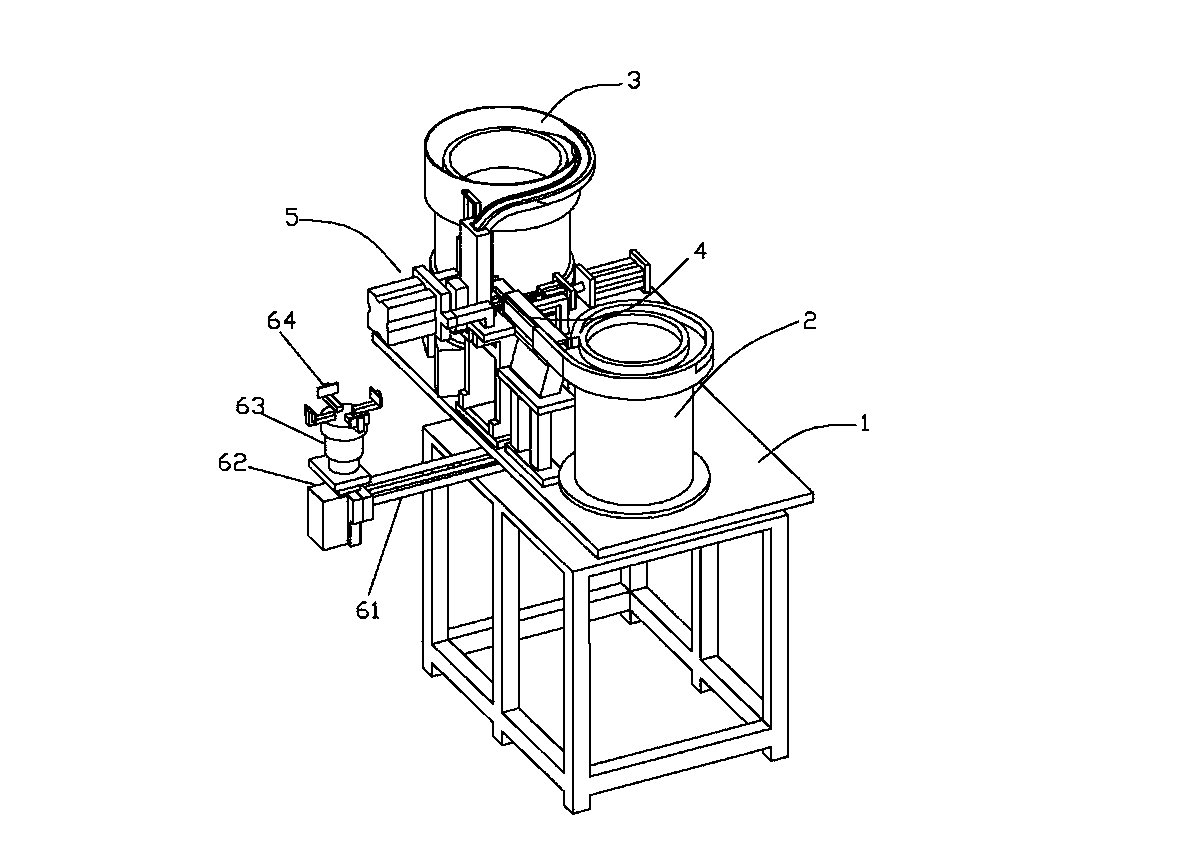

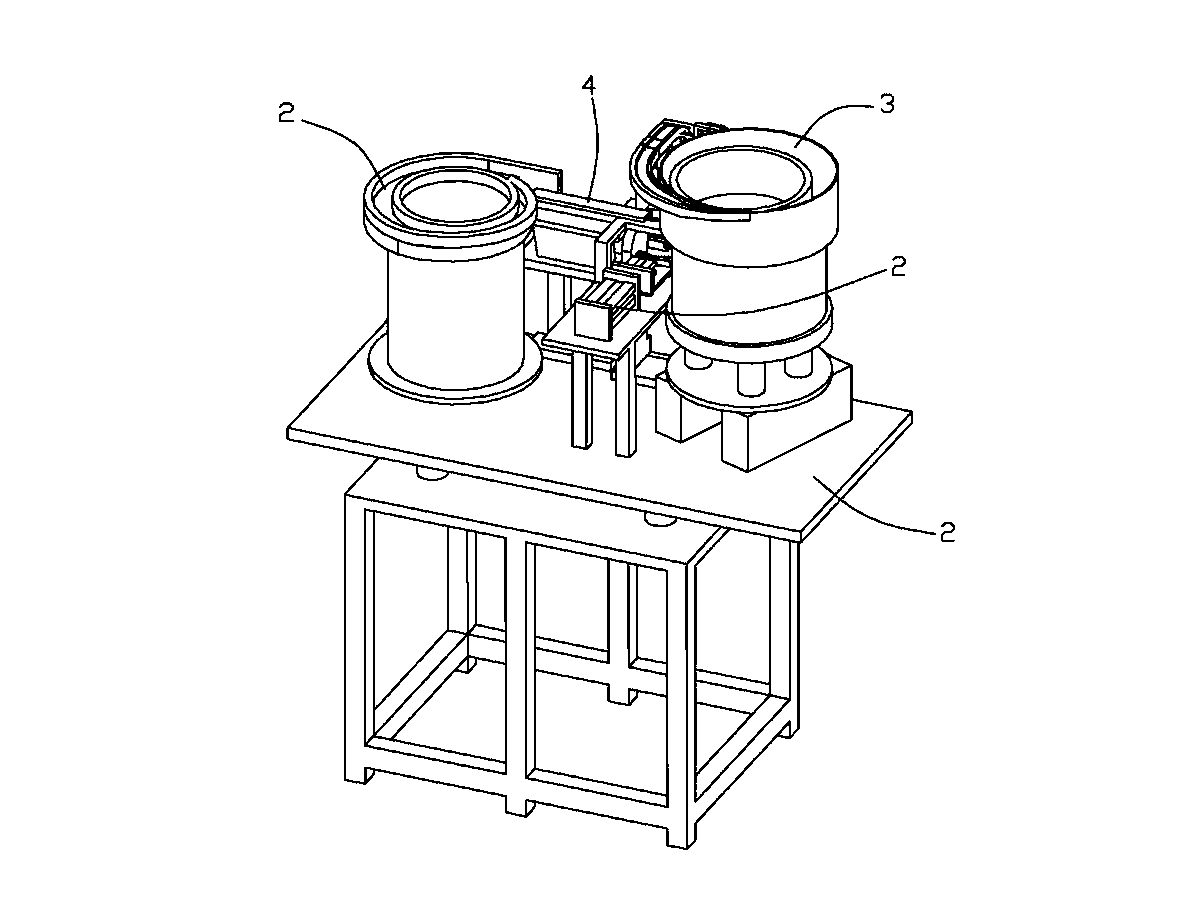

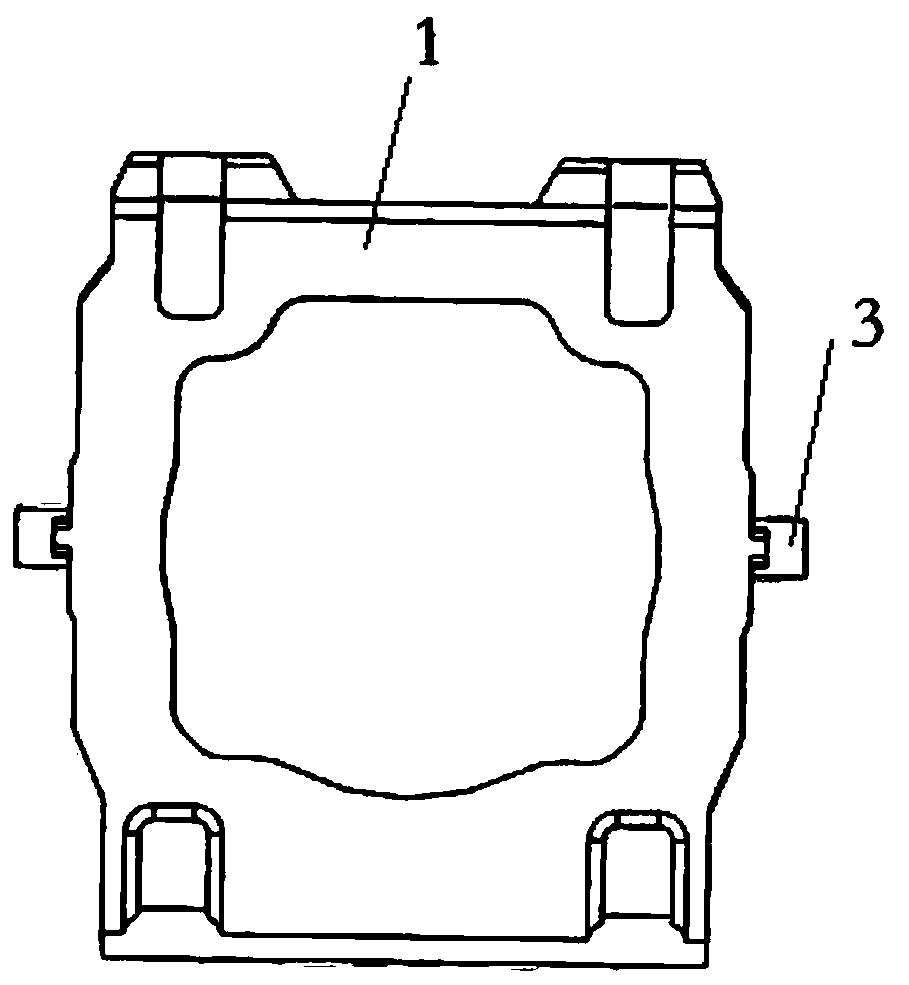

Automatic installation device of switch socket junction box connecting sheet

InactiveCN103269006AFast assemblyCost-effectiveContact member assembly/disassemblyEngineeringJunction box

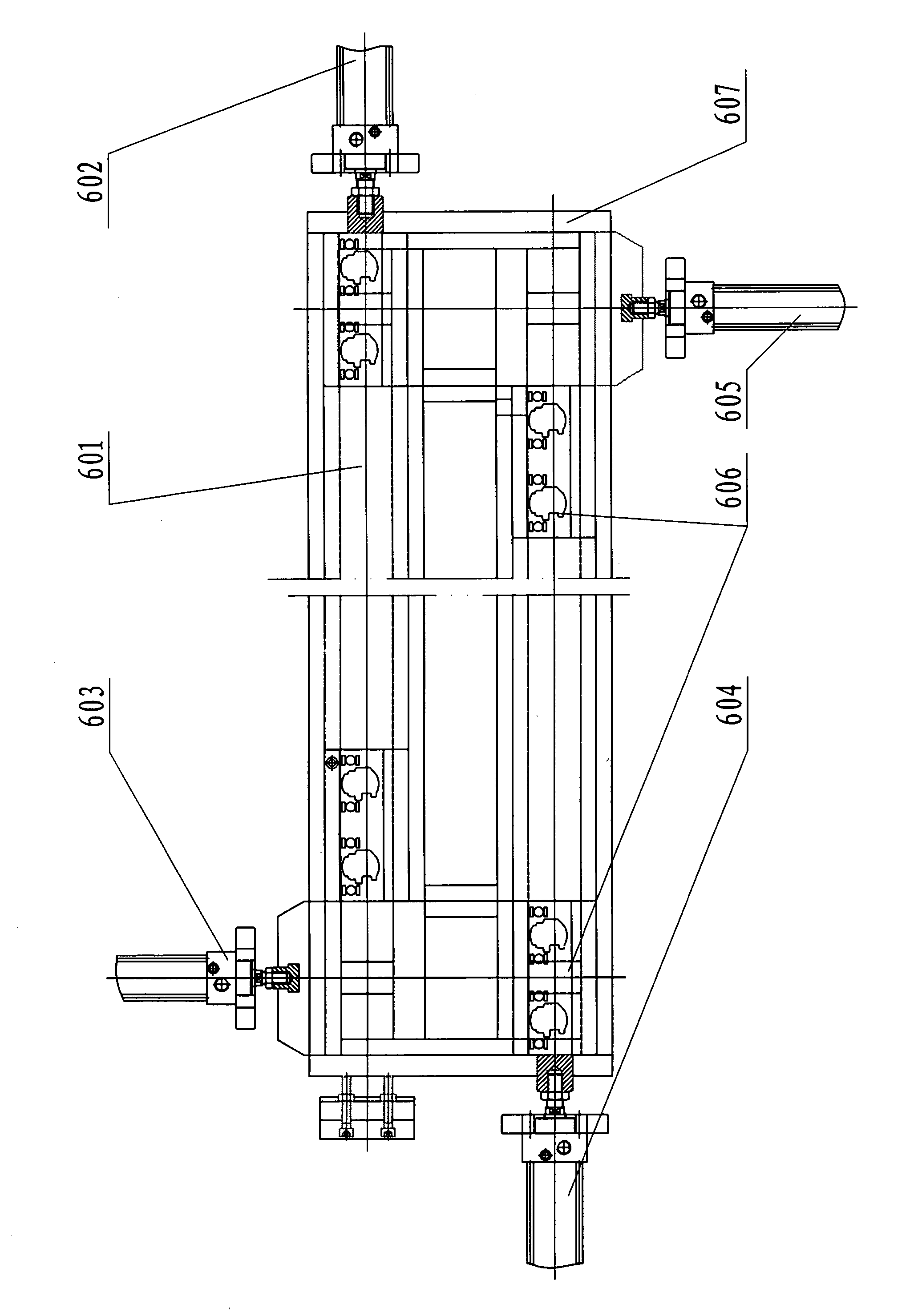

The invention relates to an automatic installation device of a switch socket junction box connecting sheet. The automatic installation device of the switch socket junction box connecting sheet comprises a rack 1, wherein a vibration disc, a tool mechanism 5 and a junction box pushing mechanism 6 are arranged on the rack 1, the vibration disc comprises a connecting sheet vibration disc 2 and a fastening buckle vibration disc 3, the connecting sheet vibration disc 2 and the fastening buckle vibration disc 3 are communicated with the tool mechanism 5, and the junction box pushing mechanism 6 is arranged below the tool mechanism 5. An ejector block pushed by an air cylinder is matched with a locking block to achieve fixing of the connecting sheet, the installation process of the whole connecting sheet does not need manual operation, labor cost is greatly saved, installation speed is improved, and cost performance of products is improved.

Owner:罗邦君

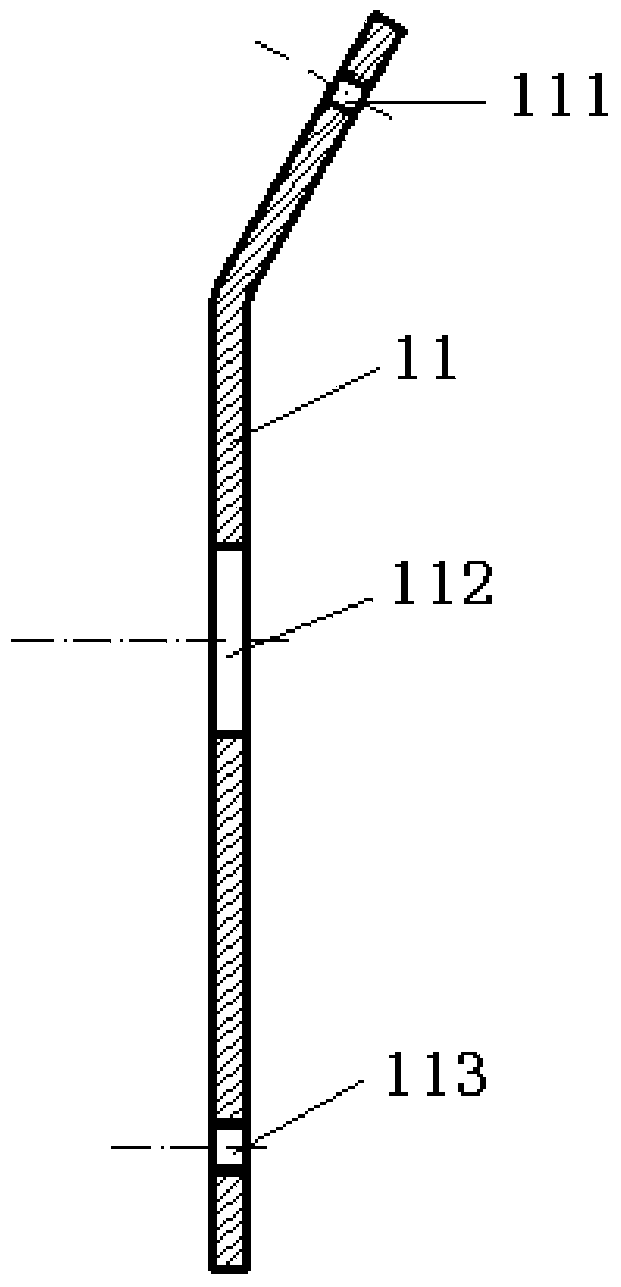

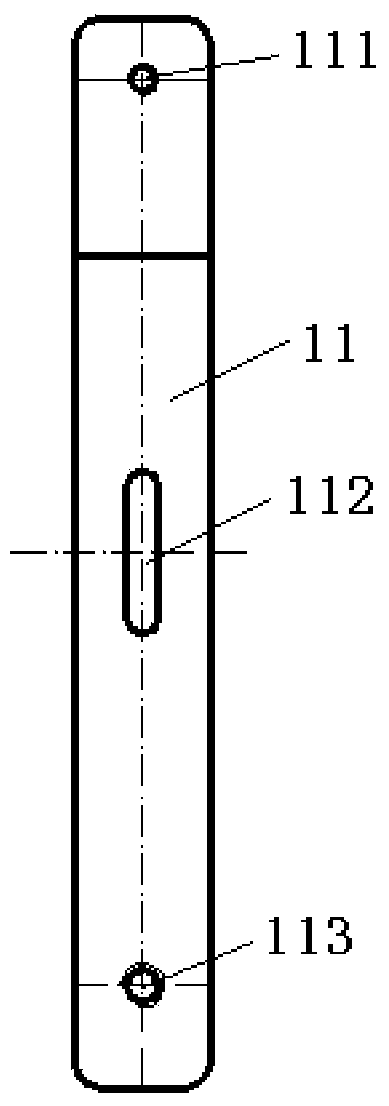

Belt pulley lifting appliance of engine

The invention discloses a belt pulley lifting appliance of an engine. The lifting appliance comprises a shaped plate lifting assembly and a belt pulley locking assembly, wherein the shaped plate lifting assembly comprises a shaped plate and a lifting ring, the middle of the shaped plate is provided with a long-strip-shaped falling-prevention handle punch, and the lifting ring is fixed on the upper end of the shaped plate; the belt pulley locking assembly comprises a falling-prevention handle assembly and a pin shaft, wherein the falling-prevention handle assembly comprises a hinged base and a falling-prevention handle, the hinged base is axially provided with first hinging holes at interval, and one end of the hinged base is horizontally fixed on the side surface of the falling-prevention handle punch of the shaped plate; the falling-prevention handle comprises a horizontal rod and a vertical rod which are fixed in a right-angle end part manner, the outer end part of the horizontal rod is provided with a clamping hook which downward extends, and the axial interval of the horizontal rod is provided with a second hinging hole; one end of the pin shaft is fixed on the lower end of the shaped plate. The lifting appliance provided by the invention has the advantages that the operation is convenient and rapid, the labor intensity of a worker is lightened, the assembly quality is guaranteed, and meanwhile, the production efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

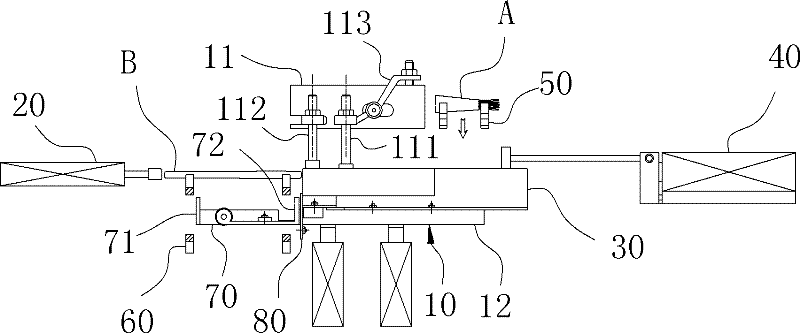

Automatic bottle cap and top cap positioning and assembly line and operation method thereof

InactiveCN111250956AImprove assembly efficiencyGuaranteed assembly qualityMetal working apparatusAssembly lineStructural engineering

The invention provides an automatic bottle cap and top cap positioning and assembly line and an operation method thereof. The automatic bottle cap and top cap positioning and assembly line comprises aconveyor for conveying a bottle cap; the feeding end of the conveyor is provided with a feeding guide structure; the tail end of the feeding guide structure is provided with a positioning mechanism for positioning the wine cap; a pushing device for pushing a top cap to be fed is installed on one side face of the portion where the positioning mechanism is located; the pushing device is matched with a storage mechanism used for storing the top cap to achieve automatic cap feeding; and a pressing mechanism used for pressing the top cap is arranged on the other side face of the portion where thepositioning mechanism is located. The automatic bottle cap and top cap positioning and assembly line can be used for automatically pressing and assembling a cover plate at the top of the bottle cap and automatically positioning and pressing the cover plate, so that the assembly efficiency is greatly improved, and the assembly quality is guaranteed.

Owner:CHINA THREE GORGES UNIV

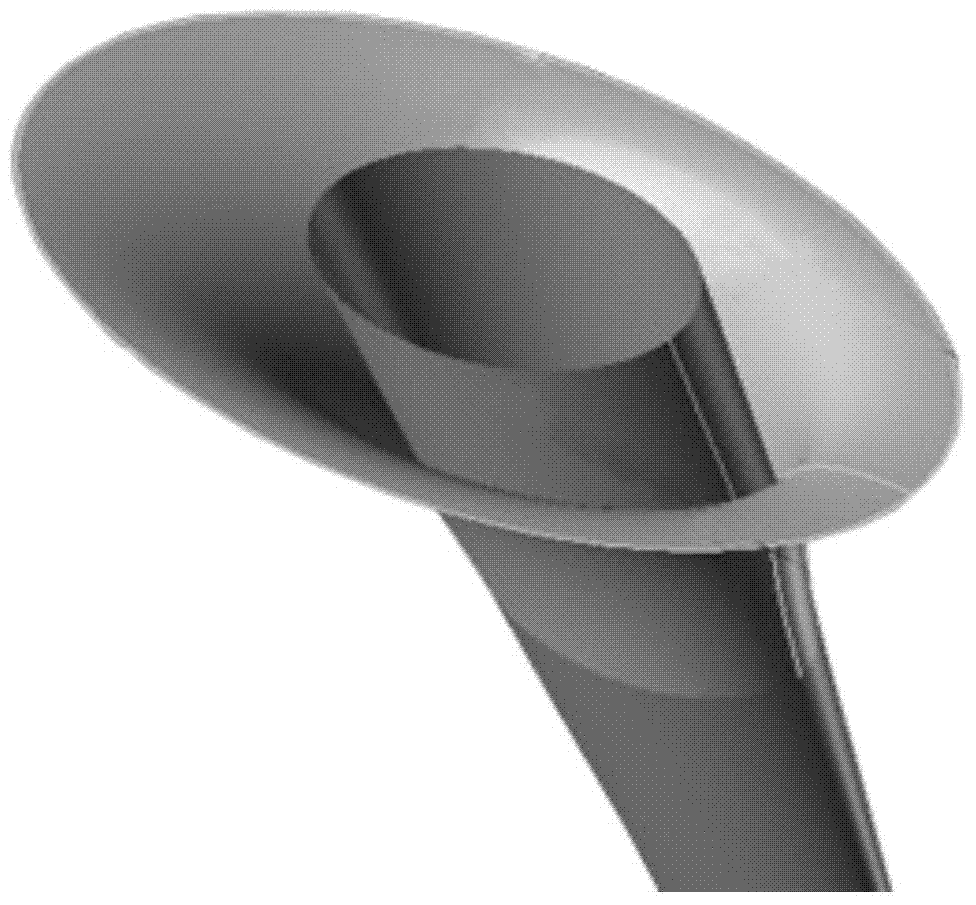

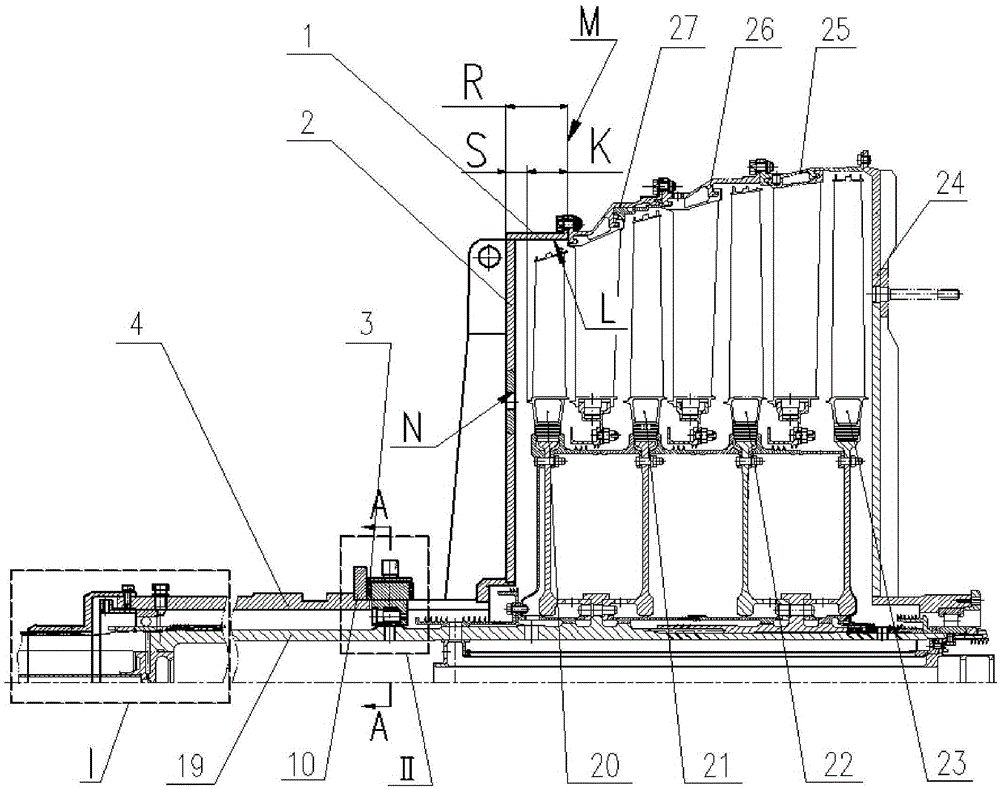

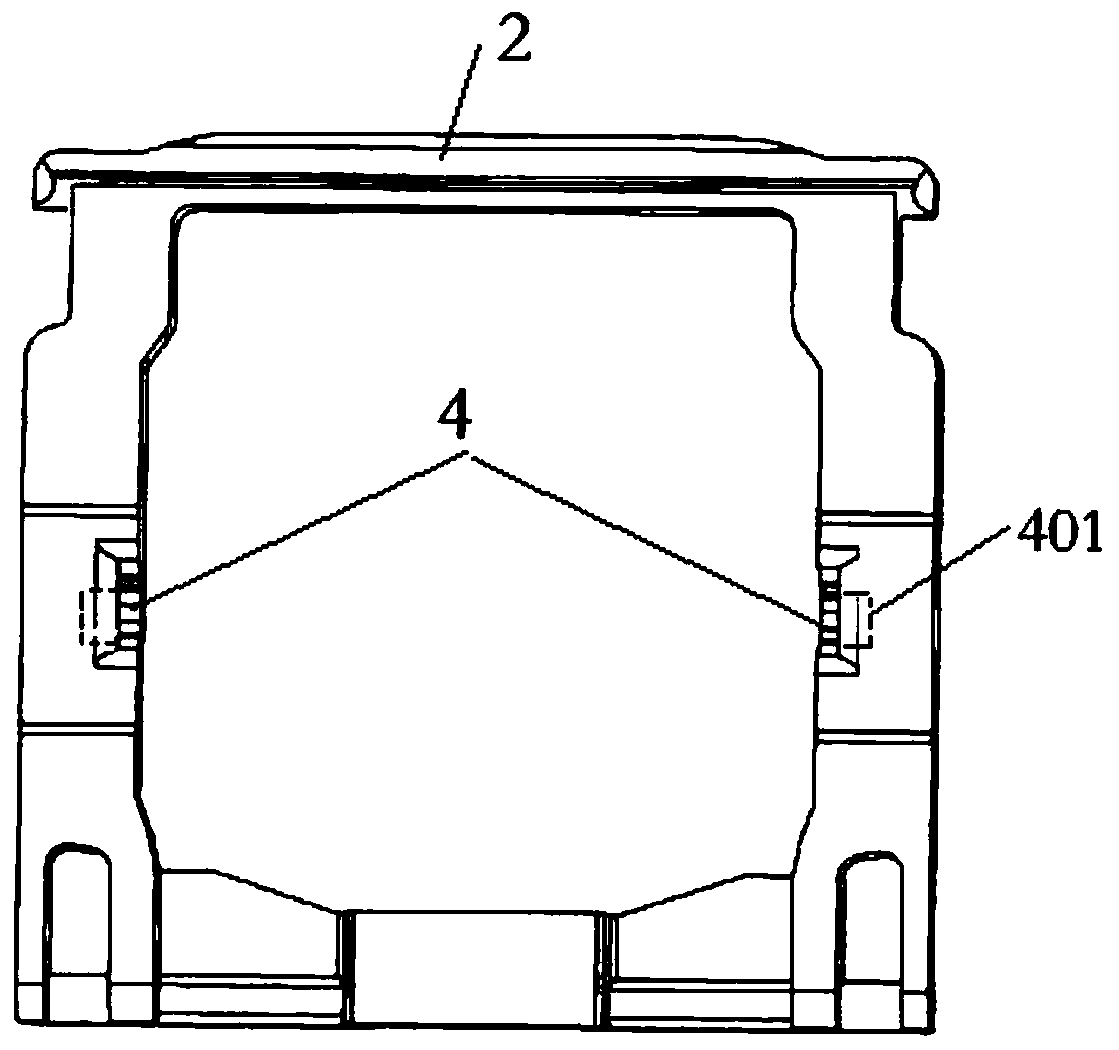

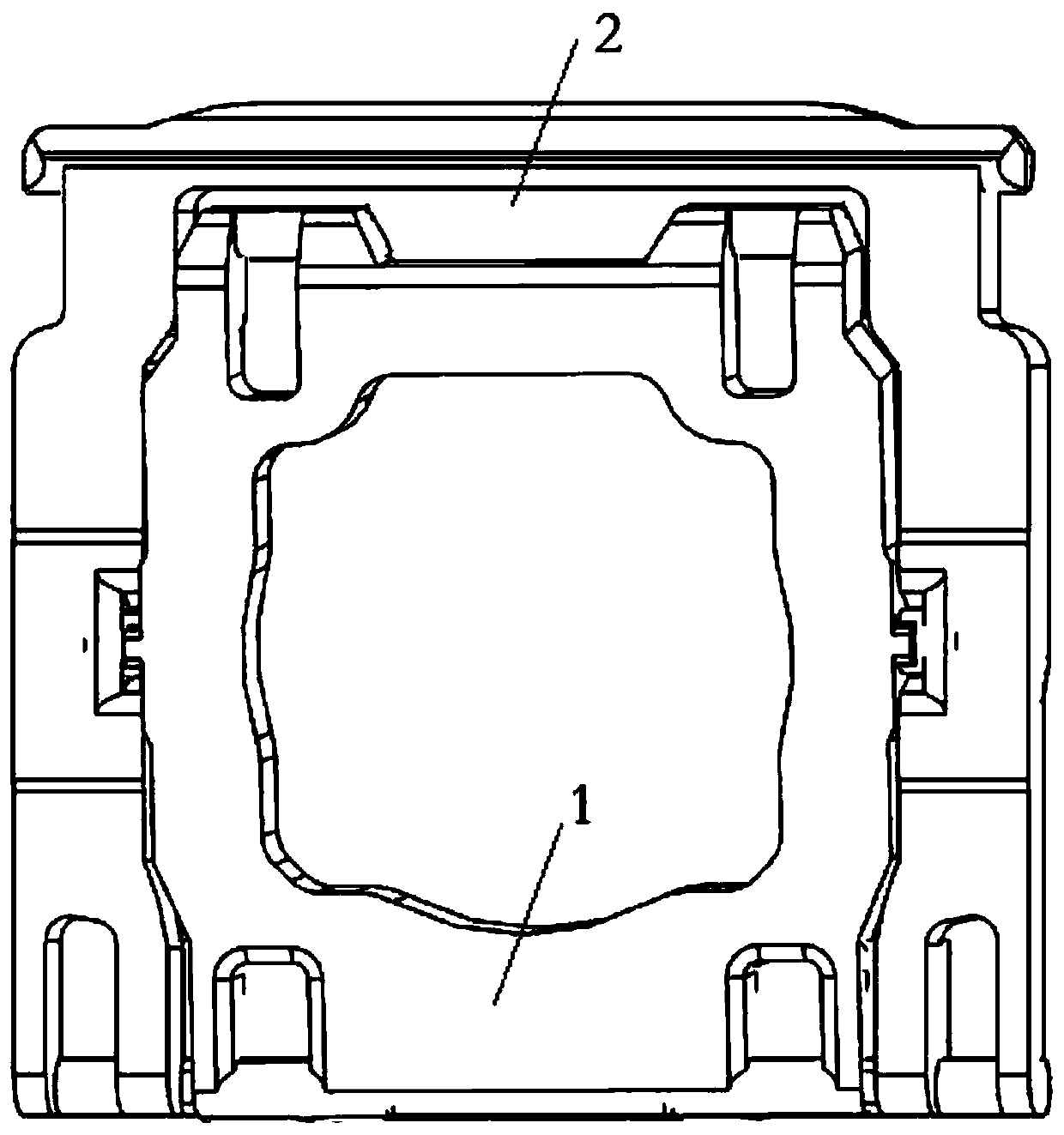

Assembly device for engine turbine

ActiveCN105397465AImprove assembly accuracyImprove assembly reliabilityMetal working apparatusRadial positionEngineering

The invention provides an assembly device for an engine turbine. The assembly device comprises a cylinder body, a bracket disk, a positioning ring and an annular plate, wherein the cylinder body is mounted on a turbine rotor shaft through two bearing devices and can rotate relative to the rotor shaft; the bracket disk is perpendicular to the cylinder body and is fixedly arranged on the cylinder body which is close to one end of the turbine rotor; the positioning ring and the cylinder body are coaxially and fixedly arranged on the bracket disk, and the inner diameter of the positioning ring is used as a mounting radial location reference of a guider; the annular plate is positioned at the outer end of the positioning ring, and the end surface, which is butted to a case of the guider, of the annular plate is used as a mounting axial positioning base of the guider. The cylinder body is mounted on the rotor shaft through the two bearing devices, wherein one bearing device which is close to one end of the turbine rotor is provided with a radial fine tuning structure, and the other bearing device is provided with an axial fine tuning structure; the bracket disk is provided with measuring holes for measuring the distances between front edges of blades. Through the adoption of the assembly device, the precise adjustment of the axial position relation and the radial position relation of a turbine rotor and the guider can be realized, and the assembly of the turbine belt guider and the level by level dynamic equilibrium of the turbine belt guider are realized, so that the assembly precision and the assembly reliability of the turbine belt guider are improved.

Owner:AECC AERO SCI & TECH CO LTD

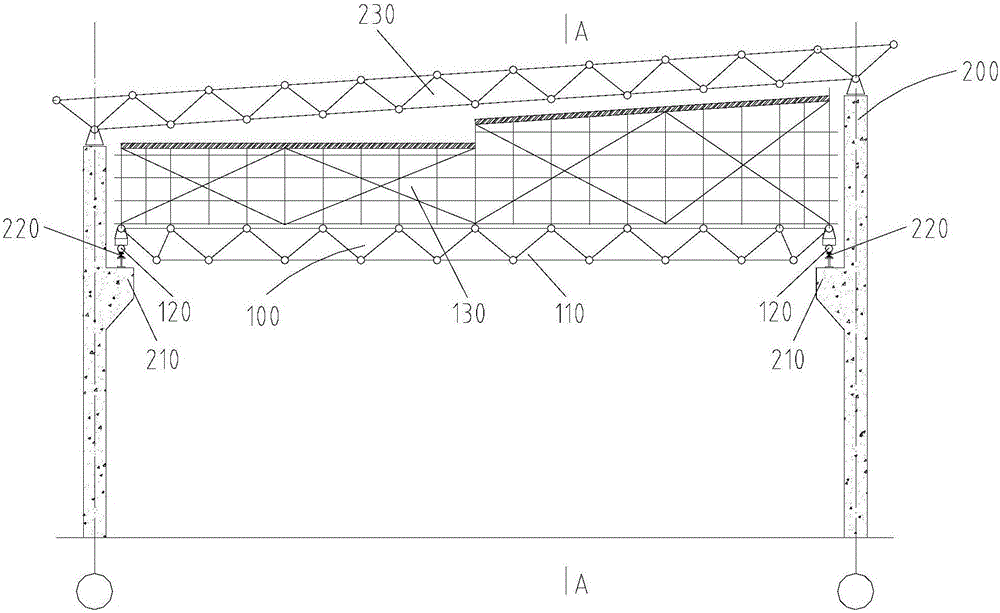

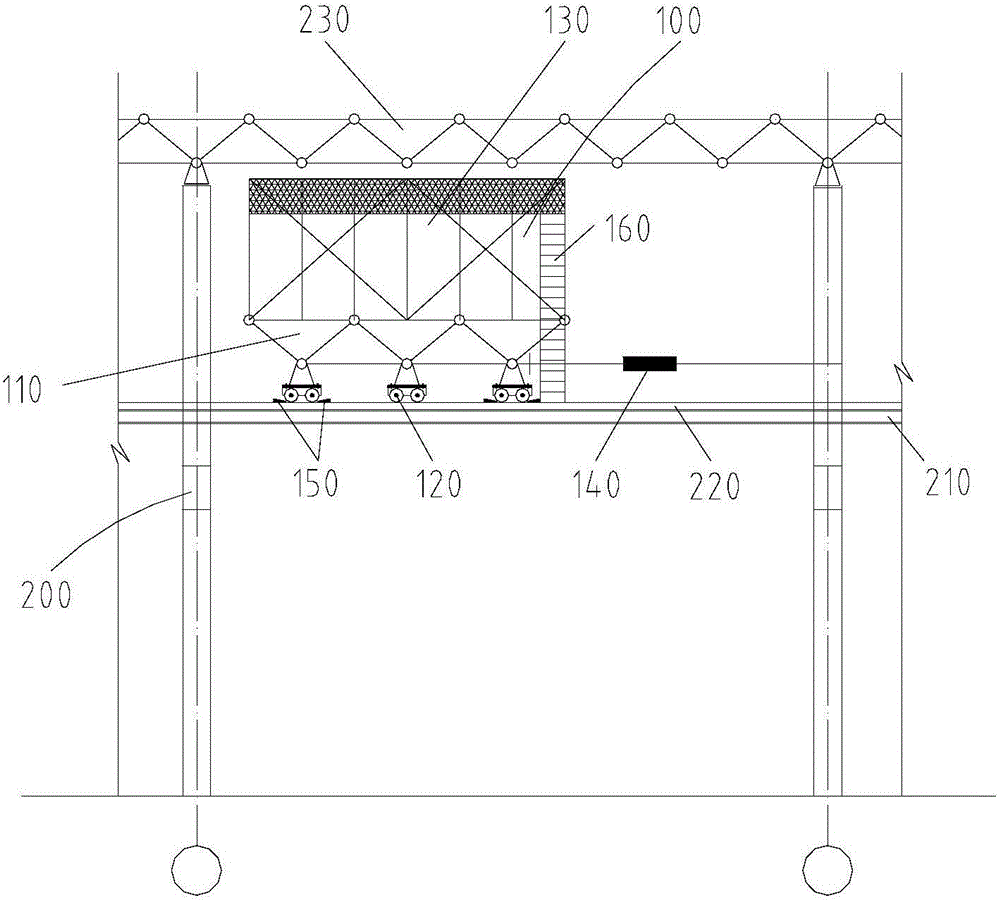

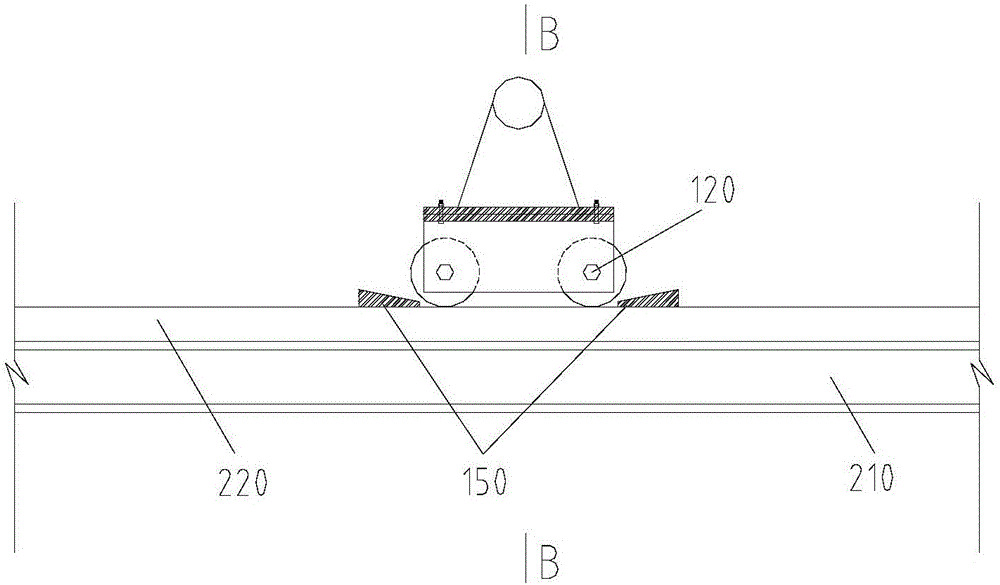

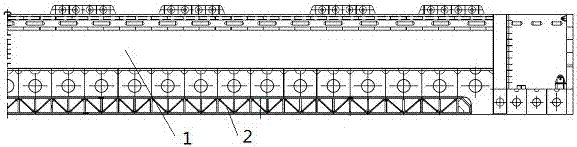

Sliding platform and construction method for separately mounting grid structures on high altitudes

ActiveCN106223595AMeet the requirements of continuous installationGood sliding safetyBuilding support scaffoldsOverhead craneIndustrial Factory

The invention discloses a sliding platform and a construction method for separately mounting grid structures on high altitudes. The sliding platform for separately mounting the grid structures on the high altitudes is arranged in an industrial factory building. The industrial factory building is provided with crane beams, and overhead crane tracks are arranged on the crane beams. The sliding platform for separately mounting the grid structures on the high altitudes comprises a grid structure type sliding platform, a scaffold operating platform and pulling equipment. The grid structure type sliding platform is slidably arranged on the overhead crane tracks via a plurality of sliding rollers; the scaffold operating platform is arranged on the upper surface of the grid structure type sliding platform; the pulling equipment is connected onto the grid structure type sliding platform, so that the grid structure type sliding platform can slide along the overhead crane tracks. The mounting quality of the grid structures, with bolt-sphere joints, of the industrial factory building can be sufficiently guaranteed, the time and labor can be saved, and the safety of staffs for constructing the grid structures on the high altitudes and the safety of construction staffs below the staffs can be guaranteed. The sliding platform and the construction method have the advantages of flexibility, convenience, speediness and low cost. Besides, merits can become obvious along with increase of ratios of the longitudinal lengths to the span of the grid structure.

Owner:CHINA IPPR INT ENG

Automatic assembly machine for scissor foot

PendingCN109920681AFully adapt to assembly needsHigh degree of automationElectric switchesEngineeringHorizontal and vertical

The invention discloses an automatic assembly machine for a scissor foot and belongs to the technical field of scissor-foot assembly. The automatic assembly machine comprises a lower mold capable of horizontal movement, an upper mold capable of both horizontal and vertical movements, a vertically moving cutting mechanism and a stripping mechanism, wherein the lower mold is configured to pre-placeinner and outer shears, the upper mold grasps the inner shear from the lower mold to start assembly, the cutting mechanism is engaged with the lower mold to separate the inner and outer shears from the head material, the groove bottom of an inclined base groove on the lower mole has a thimble protruding toward the open end thereof, the outer shear is placed obliquely through the groove bottom, thelower side of the outer portion of the outer shear is in sliding contact with the top surface of the thimble when the front rotating shaft of the inner shear continues to translate forward after being clamped into the front axle hole of the outer shear such that the rear side of the outer shear is gradually lifted upward to finally enable embedded matching of the rear axle hole of the outer shearand the rear rotating shaft of the inner shear. The automatic assembly machine has a reasonable structure, continuous processes, strong pertinence and high assembly effect and efficiency.

Owner:重庆半步自动化设备有限公司

Automatic feeder of retainers

InactiveCN104310046AReduce labor intensityGuaranteed assembly qualityConveyor partsSlide platePiston

An automatic feeder of retainers comprises a feeding mechanism, a lifting mechanism and a pick-and-place mechanism which are mounted on a support. The feeding mechanism comprises a feeding turnplate, a rotating shaft and a rotating mechanism; hollow rods are evenly distributed on the feeding turnplate; the feeding turnplate is mounted on the rotating shaft; the rotating shaft is mounted on a rack; the rotating shaft is connected with the rotating mechanism. The lifting mechanism comprises a supporting base, a lifting plate, a finger cylinder and a lifting plate lift; a lifting guide rail is disposed on the supporting base; the lifting plate is mounted on the lifting guide rail through a sliding plate; the finger cylinder is disposed on the supporting base; the lifting plate lift is mounted on the supporting base and is connected with the sliding plate. The pick-and-place mechanism comprises a rocking cylinder, a feeding rotating arm and a pick-and-place claw; the pick-and-place claw is mounted on the feeding rotating arm; the feeding rotating arm is connected to a piston of the rocking cylinder; the rocking cylinder is mounted on the rack. The automatic feeder of the retainers has the advantages that automatic feeding of the retainers is achieved, the retainers can be transferred to a press-fitting station, work efficiency is improved, and assembly quality of hub units is guaranteed.

Owner:济南易恒技术有限公司

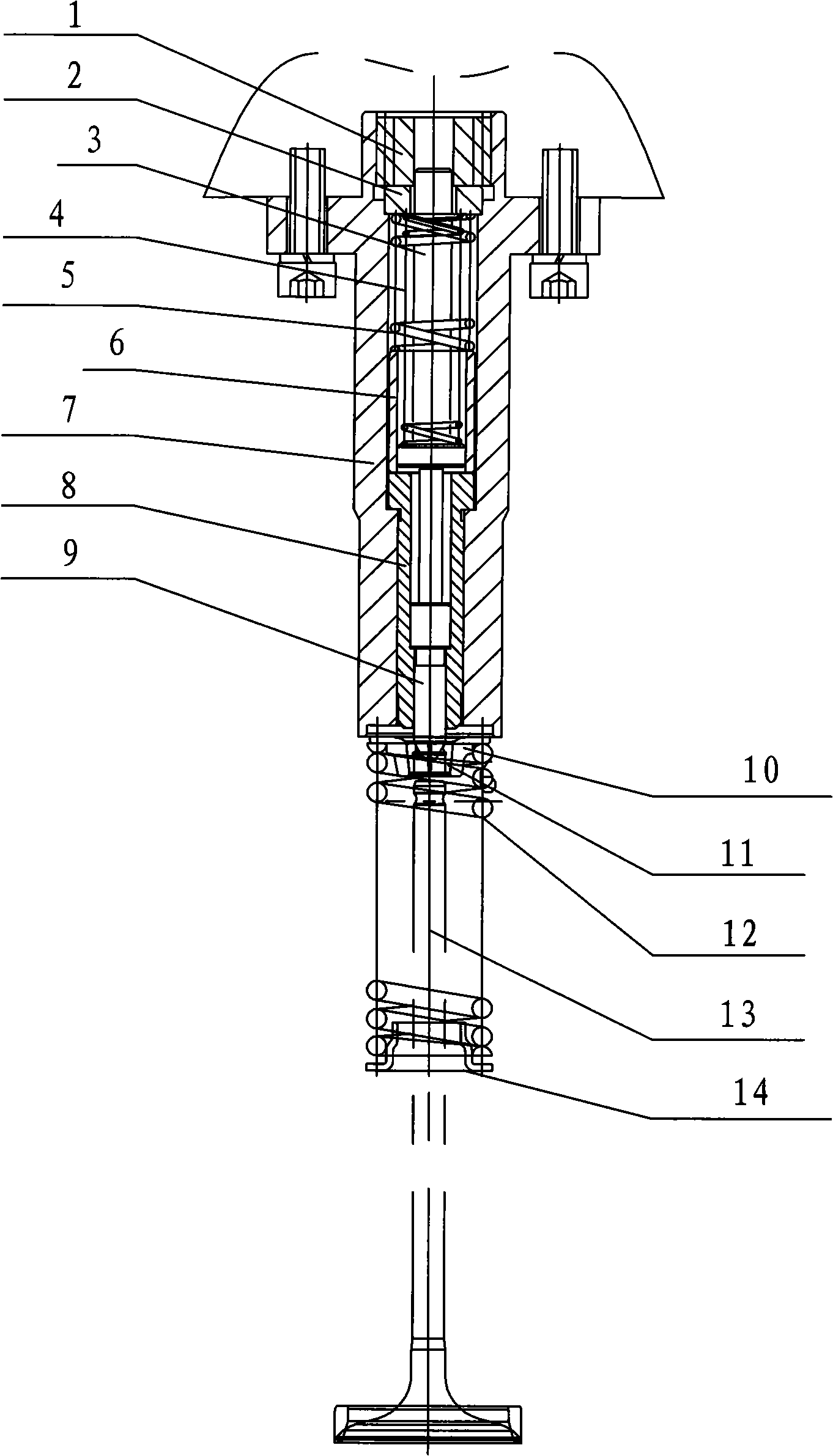

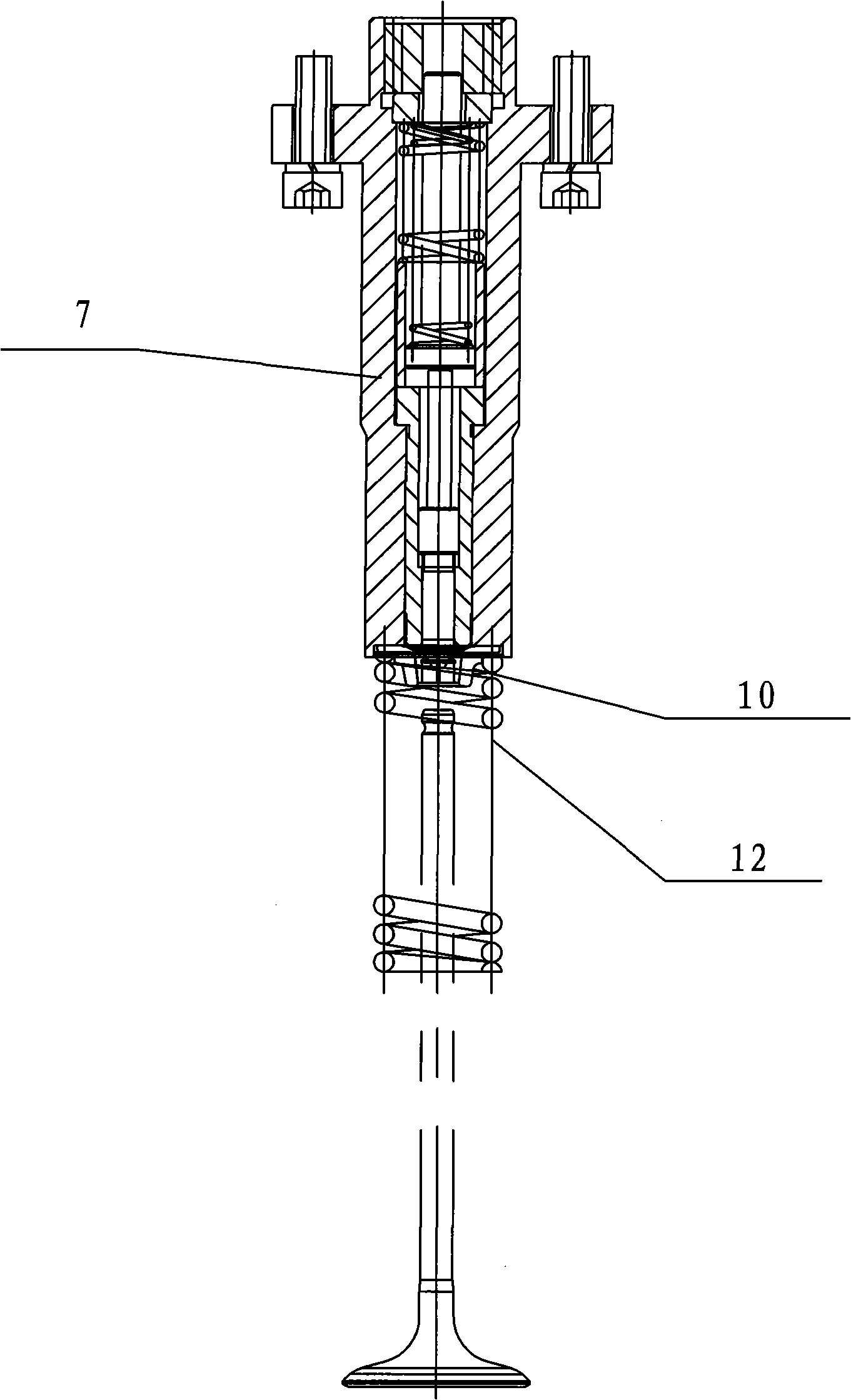

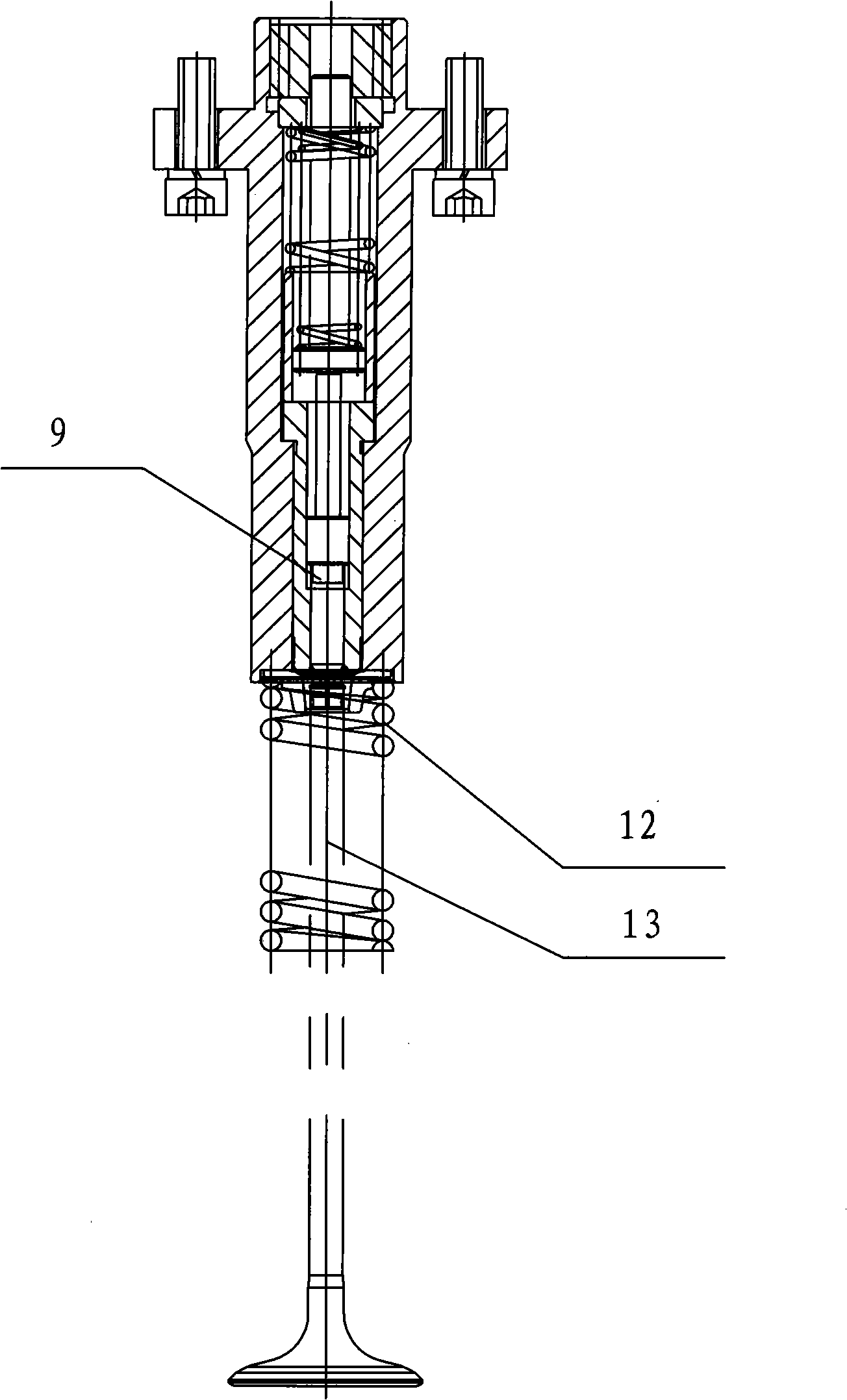

Cylinder cap air valve spring cover, locking plate press-loading head

InactiveCN101279419AStable structureEasy to install and adjustMetal working apparatusEngineeringScrew thread

The invention discloses a cylinder cover valve spring cover and a keeper pressing assembly device, which are characterized in that the invention comprises a pressing head external bushing which is provided with an ejector pin and a pressure head core body; the ejector pin is sheathed with an internal spring and an external spring and a spring pressure cover is sheathed on the ejector pin; a compression plug screw on the ejector pin is connected with the pressing head external bushing by screw thread; a core body sheath is arranged outside the pressure head core body, and the valve spring cover, a valve split collet, a valve spring, a valve ejector pin and related parts for a valve spring retainer are arranged below the core body sheath in sequence. The process of pressing and assembly comprises 6 actions; wherein, the pressing head external bushing is driven to be contacted with the valve spring by Action I; the pressure head core body is driven to be contacted with the ejector pin by Action II; the core body sheath is driven to be contacted with the valve split collet and the side of the pressure head core body is caused to slide into the end part of the valve ejector pin by Action III; the valve split collet is pressed into a space below the end part of the valve ejector pin by Action IV; the valve split collet is pressed into a space below a ring-shaped groove at the end part of the valve ejector pin by Action V; a pressure head is lifted, the valve spring is reset and the valve split collet is clamped into the ring-shaped groove of the valve ejector pin by Action VI.

Owner:DALIAN ZHIYUN AUTOMATION

Method for launching and floating of ship carrying chamber of ship lift

InactiveCN107254869AReasonable designWell consideredVertical ship-liftingMarine engineeringMarine navigation

The invention relates to a method for launching and floating of a ship carrying chamber of a ship lift, and belongs to the field of navigation structures of water conservancy and hydropower engineering. A launching type ship lift ship chamber is located in a reservoir, the ship chamber and the lower portion structure of an upper gate bay are submerged under water, under the normal operation condition of the reservoir, the ship lift does not meet the requirement of unwatering the ship chamber, so that the ship carrying chamber can only adopt integral floating. In order to let the ship carrying chamber enter the ship chamber safely and stably in a floating mode, a method which can make the ship carrying chamber enters the ship chamber in a floating mode needs to be designed. The method for launching and floating of the ship carrying chamber of the ship life includes the following steps of prospecting site conditions of the ship lift, understanding the basic information of the ship carrying chamber, building up an organization mechanism of floating of the ship carrying chamber, understanding the basic requirements the ship carrying chamber needs to meet before launching, preparing safety measures before floating, launching the ship carrying chamber, floating and dragging of the ship carrying chamber, and fixing and positioning the ship carrying chamber after entering the ship chamber in a floating mode. The method for launching and floating of the ship carrying chamber of the ship lift is reasonable in design, and considerate.

Owner:杭州国电机械设计研究院有限公司

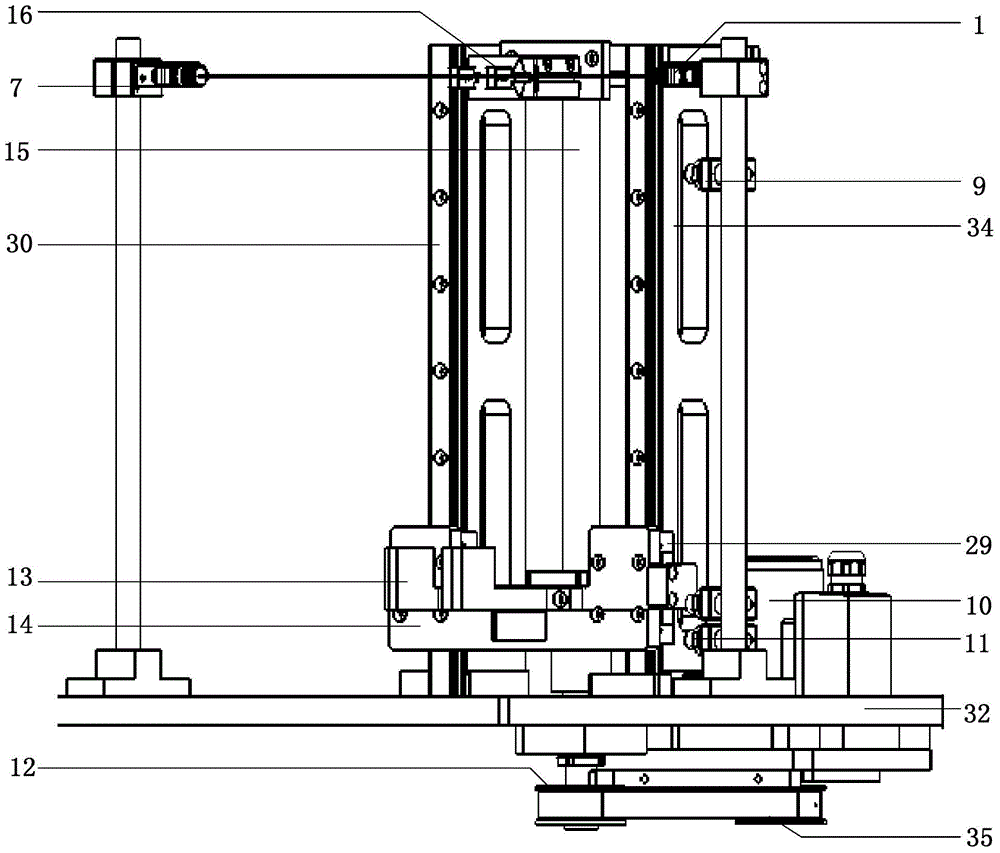

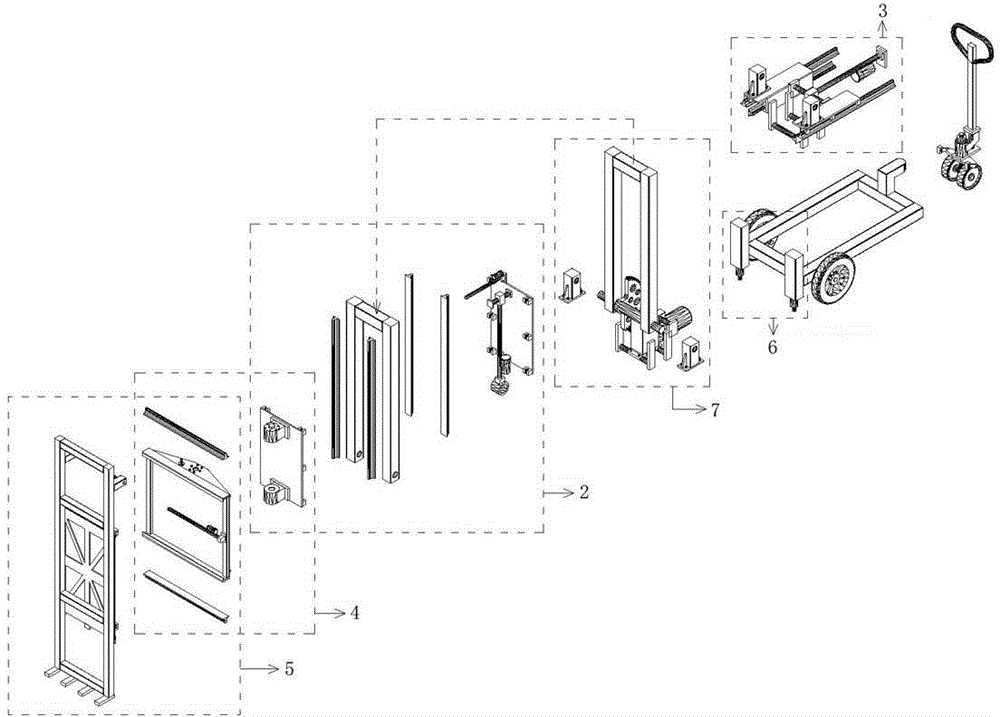

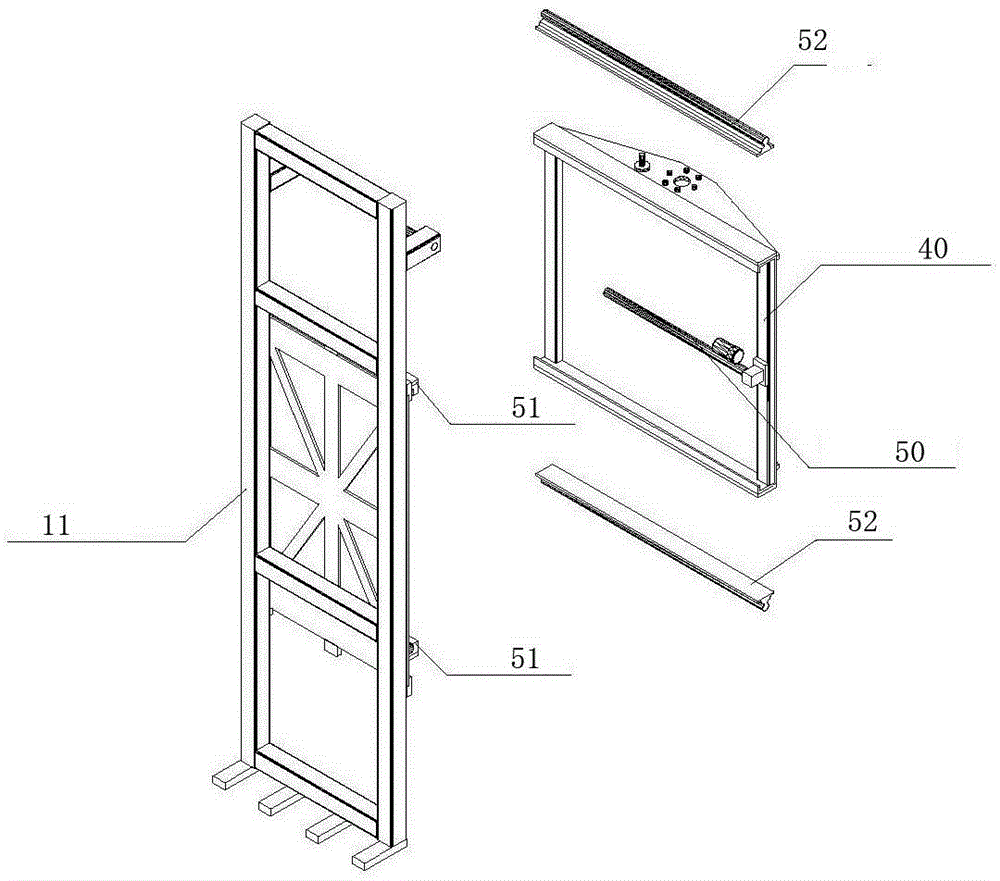

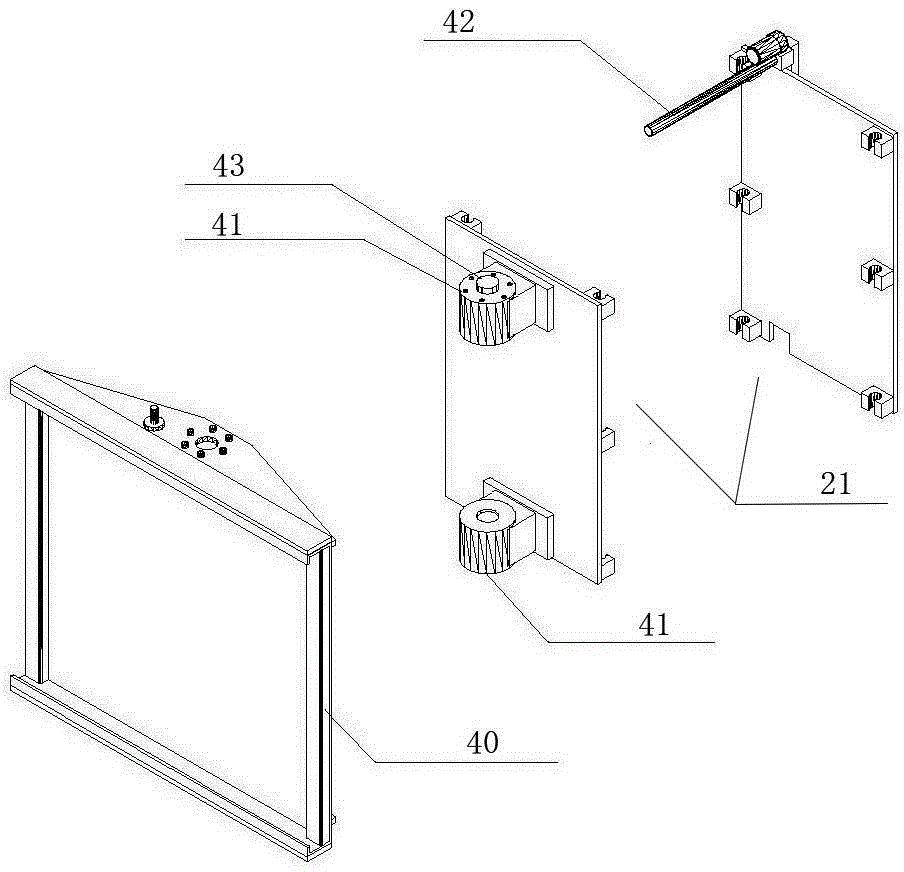

Method for assembling concrete prefabricated wallboards and special mechanical device therefor

ActiveCN104032961AGuaranteed assembly qualityGuaranteed bonding qualityBuilding material handlingEngineeringTranslation system

The invention relates to the technical field of constructional engineering, and in particular relates to a method for assembling concrete prefabricated wallboards and a special mechanical device therefor. The special mechanical device for assembling the concrete prefabricated wallboards is provided with a movable underframe with movable runners, a wallboard supporting rack arranged on the movable underframe for fixedly bundling the wallboards, a vertical lifting system for respectively smoothly lifting the wallboards fixedly bundled on the wallboard supporting rack, a front-back translation system for smoothly moving the wallboards forwards and backwards, a lateral swing system for swinging the wallboards smoothly and laterally, a transverse translation system for moving the wallboards transversely, a lateral adjusting system for adjusting the perpendicularity of assembling surfaces on two sides of the wallboards, and a front elevation aligning system for adjusting the perpendicularity of the surfaces of the wallboards; according to the special mechanical device for assembling the concrete prefabricated wallboards, workers are convenient to construct the wallboards to be a wall, assembly quality and bond quality of the wallboards are effectively ensured, work efficiency of the workers for assembling the wallboards is improved, and labor intensity of the workers for assembling the wallboards is reduced.

Owner:DONGGUAN CAILI BUILDING MAINTAIN TECH

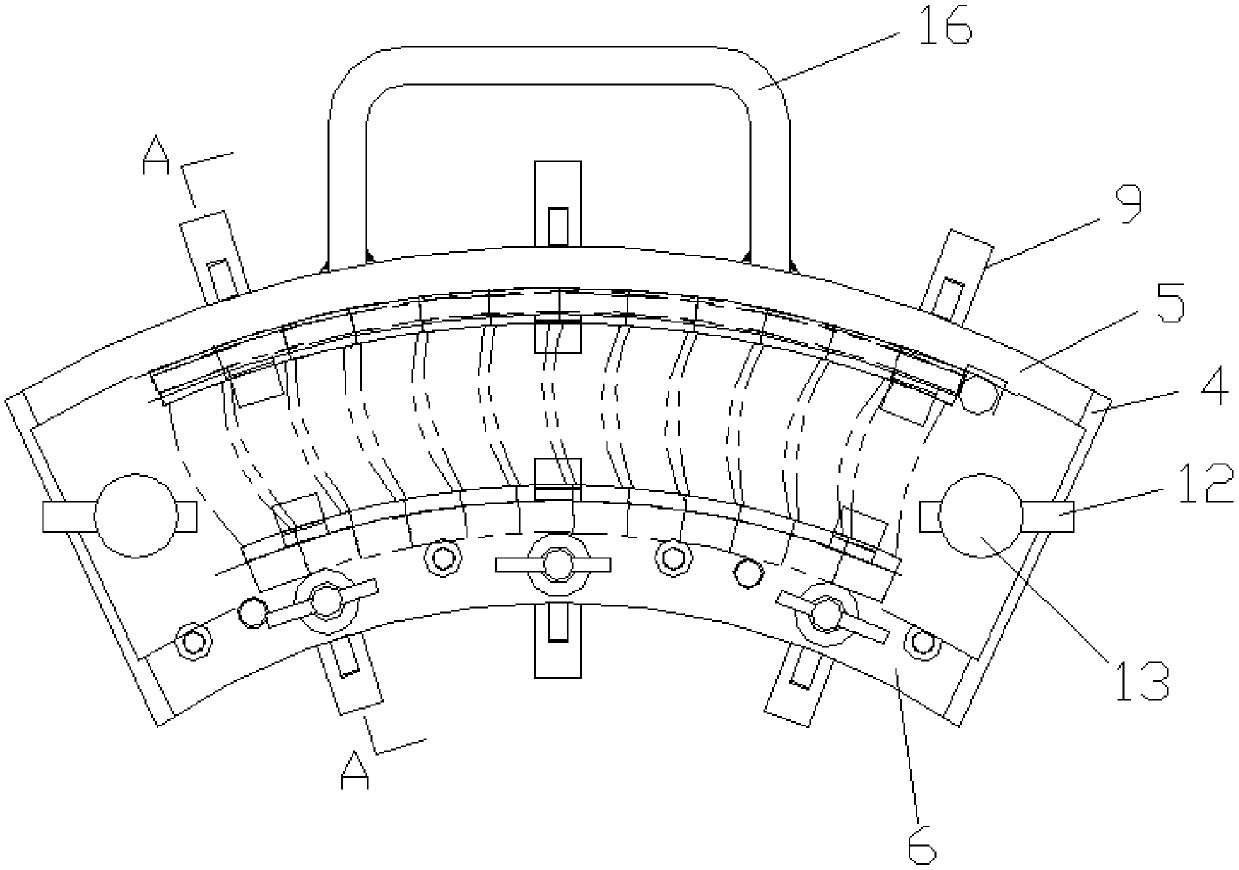

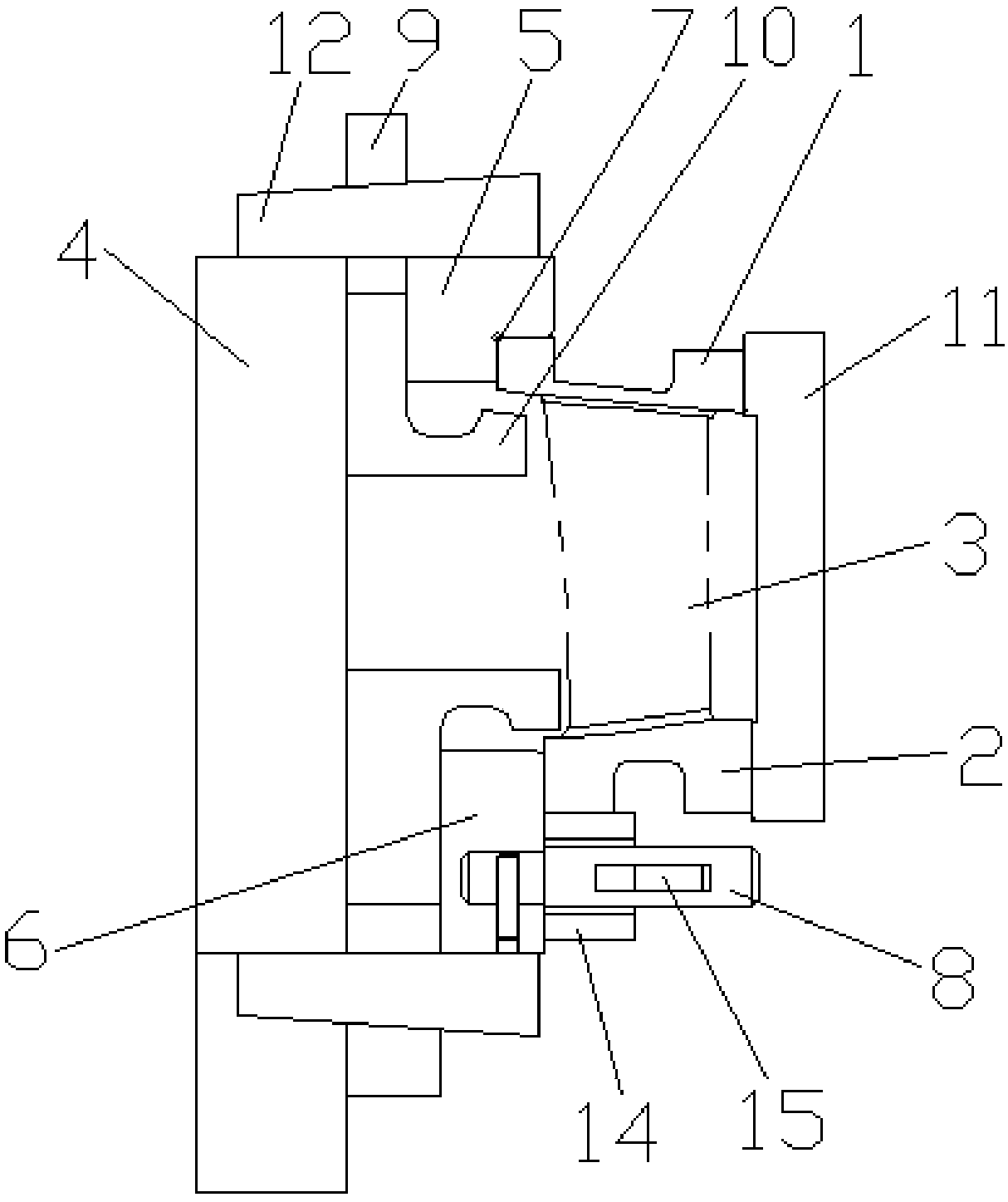

Fan-shaped clamp and method for reducing blade assembly welding deformation

ActiveCN108031944AReduce the influence of welding deformationNo deformationSoldering auxillary devicesEngineeringMechanical engineering

The invention relates to a fan-shaped clamp and method for reducing blade assembly welding deformation. The clamp comprises a base plate, the base plate is provided with an upper edge plate positioning block and a lower edge plate positioning block, a positioning pin is arranged on the lower edge plate positioning block, circumferential pressing blocks are inserted into the upper edge plate positioning block and the lower edge plate positioning block, hook-type parts are arranged at one ends of the circumferential pressing blocks, first locking devices are arranged on the circumferential pressing blocks, an upper pressing block is arranged at the upper end of the base plate, and a second locking device is arranged on the upper pressing block. After welding is carried out through the clampand method, the welding deformation influences are greatly reduced, a reference surface formed after welding is used for appropriately grinding treatment, a good standard is machined through a fan-shaped section assembly edge plate part, the deformation condition does not exist after a fan-shaped section assembly edge plate is machined, the assembly quality is better guaranteed, the position accuracy of a runner part better meets the assembly requirement, and the yield of a welded assembly is greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

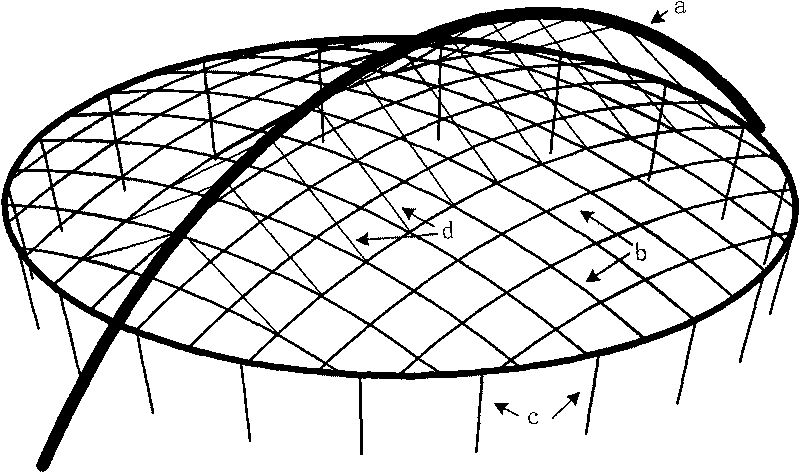

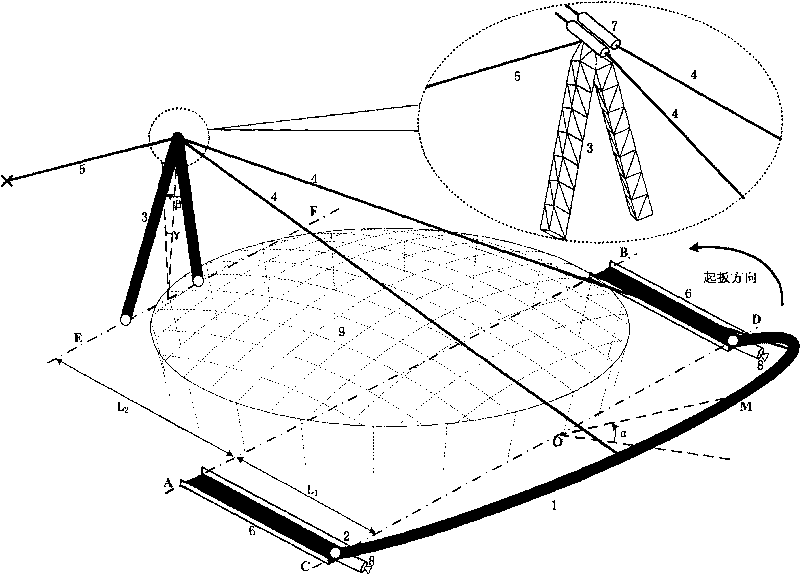

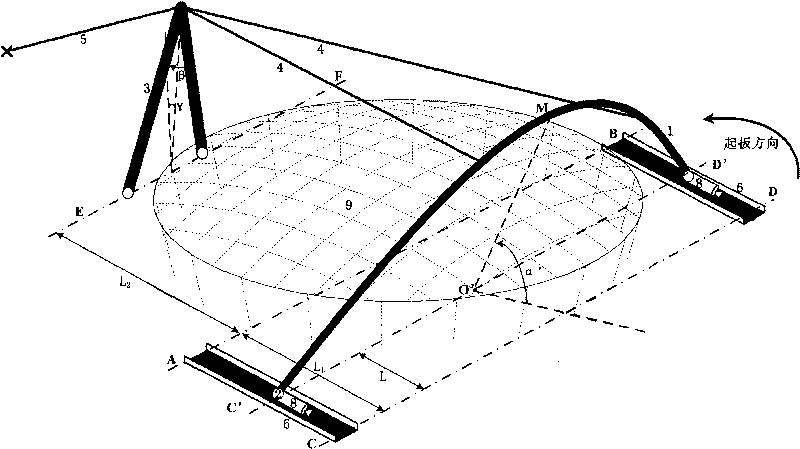

Construction method of integrally rotating, drawing up and slipping large steel arch structure

InactiveCN101725179AThe force size is clearEnsure safetyBuilding roofsBuilding material handlingArch heightBuilding construction

The invention relates to a construction method of integrally rotating, drawing up and slipping a large steel arch structure, belonging to the technical field of construction. The method is realized in a construction environment formed by large steel arches and a series of construction auxiliary equipment according to some steps. The large steel arches are assembled on the ground after parallel movement having a certain distance with a design position, and then rotate and carry out drawing up around two skewback connecting lines; rotation and drawing up of each large steel arch are realized by depending on pulling up a sling by a cross-core jack arranged at the top part of an A-shaped support frame; controlling each large steel arch to slip after rotating and drawing up each large steel arch to a state of a little inclining with a vertical surface so as to boost the jack to force the push force on skewbacks and enable each large steel arch to slowly slip in a grading way by making use of the forward push force of the skewbacks under the deadweight action; at each grading target state position, the slippage of each steel arch is paused so as to carry out regulation of large steel arch height once; and after the skewbacks slip to the design position, the height of each large steel arch is regulated for the last time so as to enable each large steel arch to achieve a design configuration and fix the skewbacks according to the design requirements finally.

Owner:TSINGHUA UNIV

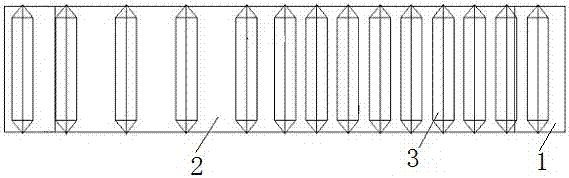

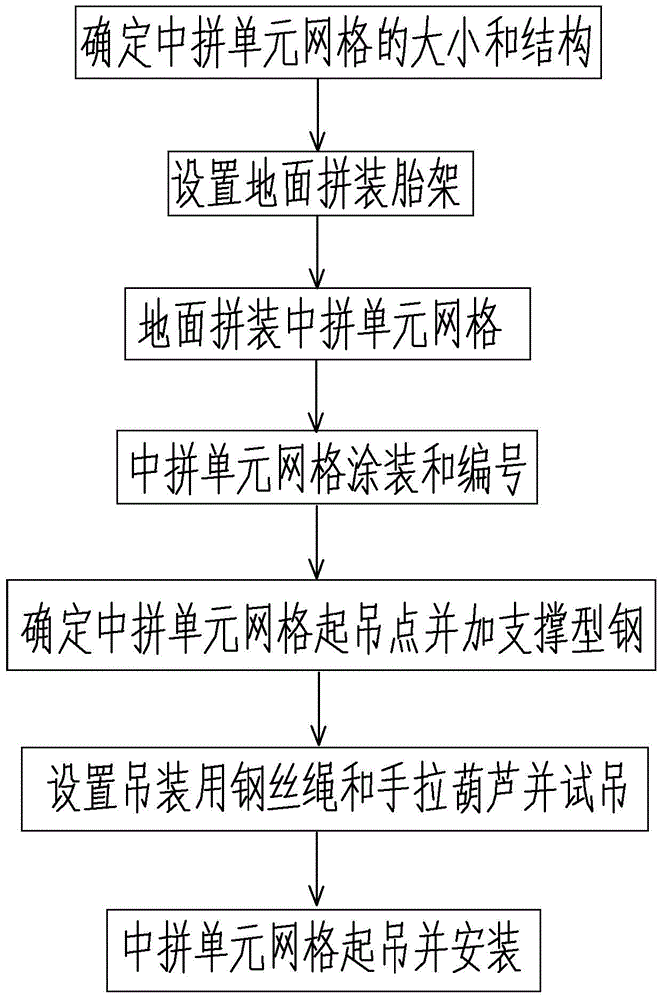

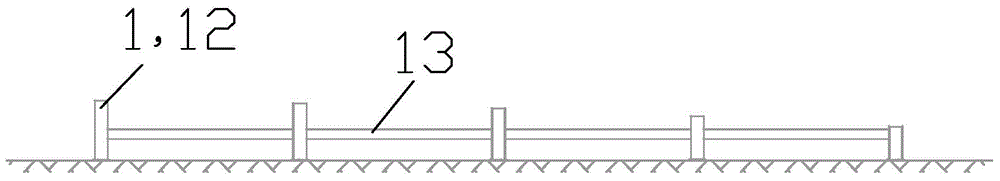

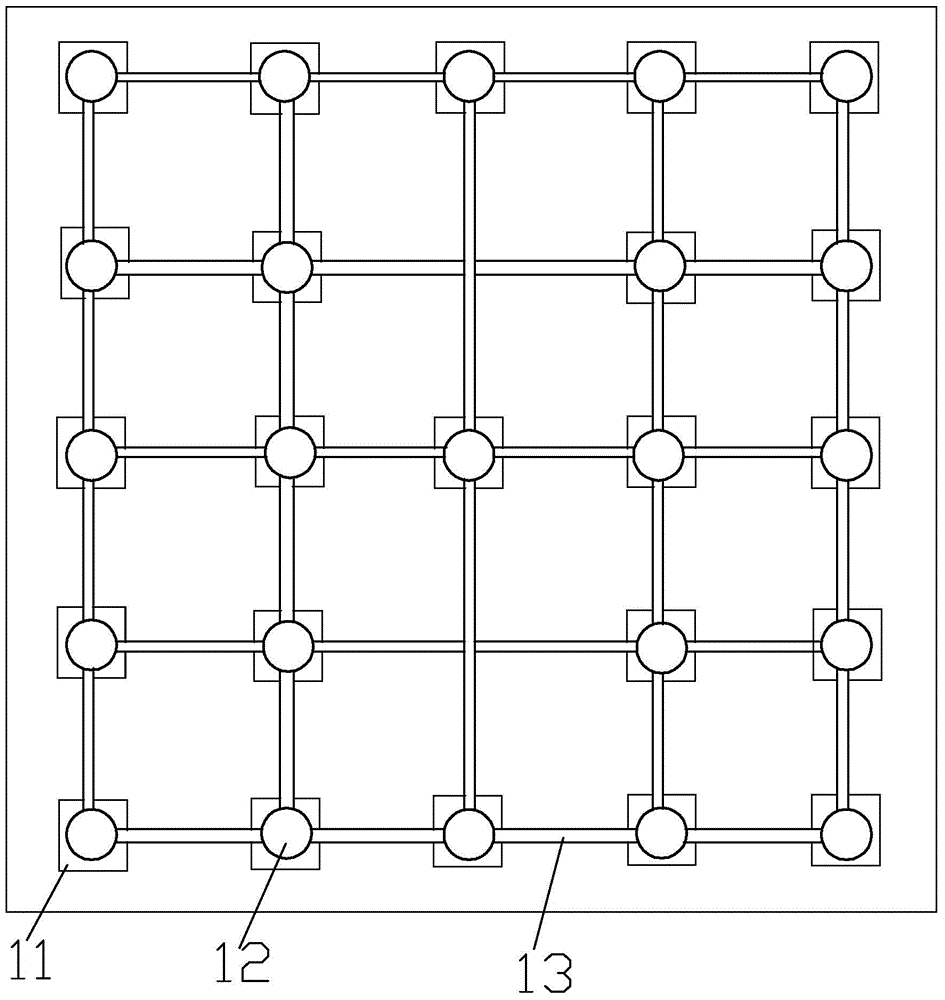

Bolt ball welding ball mixed node large span cantilever grid structure construction method

The invention provides a bolt ball welding ball mixed node large span cantilever grid structure construction method. The method comprises the steps that 1 a bolt ball welding ball mixed node space grid cell, namely the size and structure of a middle-size cell grid are determined according to the design; 2 a ground assembly moulding bed is arranged; 3 ground assembling is conducted on the middle-size cell grid; 4 coating and numbering are conducted on the middle-size cell grid; 5 a lifting point of the middle-size cell grid is determined and support profile steel is added; 6 a steel wire rope used for lifting and a chain block are arranged, and trying of lifting is conducted; 7 the middle-size cell grid is lifted and installed. The construction period can be greatly shortened, the using amount of construction revolving materials is reduced, the construction efficiency is improved, the safe hidden trouble brought by high altitude construction of constructors can be reduced at the same time, and meanwhile the special requirements on loading, span, forms and the like of a large-scale building grid structure can be met conveniently.

Owner:CHANGZHOU NO 1 CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com