Patents

Literature

17205results about How to "Improve assembly efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

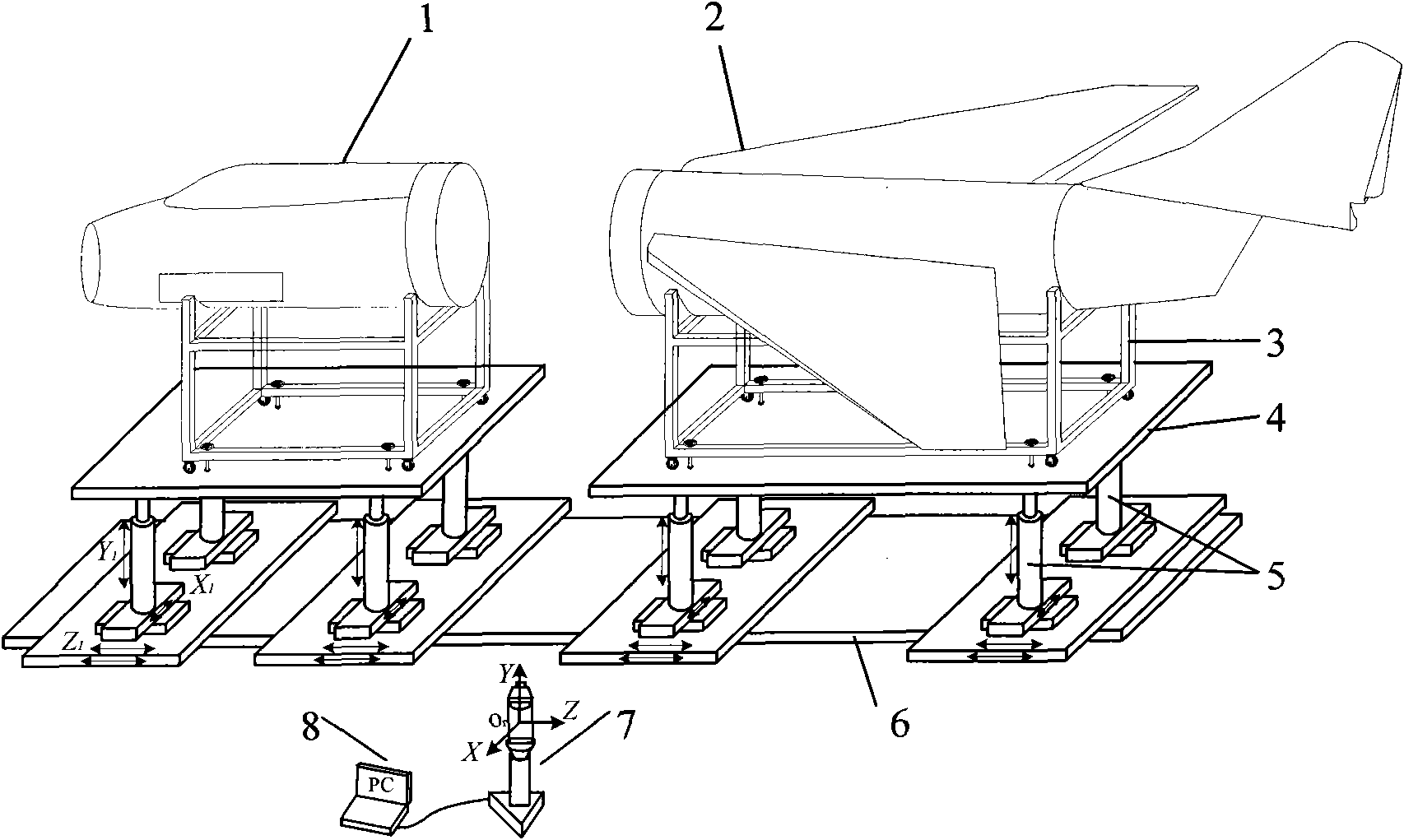

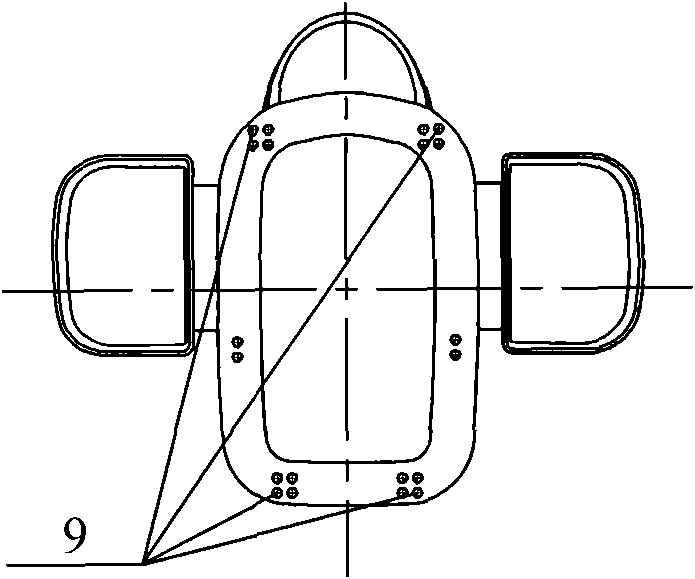

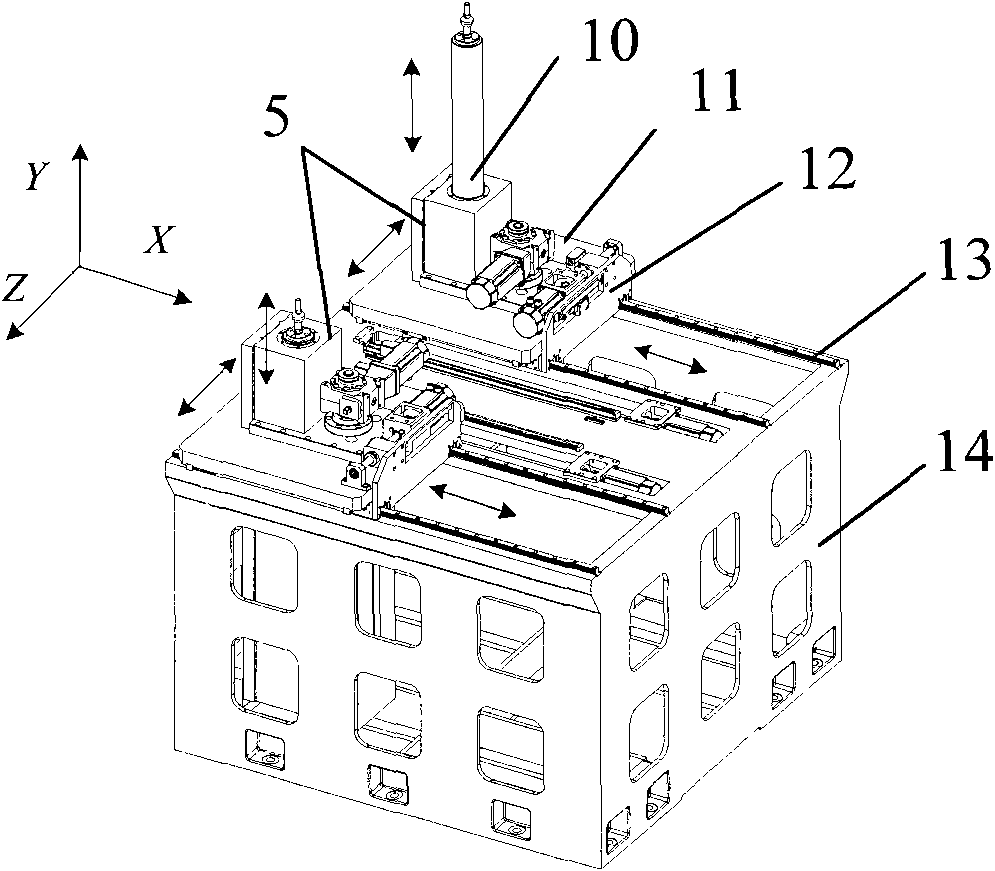

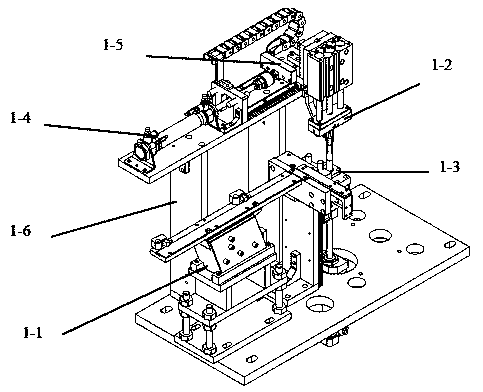

Airplane component attitude adjusting and butting system based on four numeric control positioners, attitude adjusting platform and mobile bracket and corresponding method

InactiveCN102001451ARealize digital positioningRealize dockingAircraft assemblyLaser trackerFuselage

The invention discloses an airplane component attitude adjusting and butting system based on four numeric control positioners, attitude adjusting platform and mobile bracket and a corresponding method. The system comprises a mobile bracket, an attitude adjusting platform, numeric control positioners, a numeric control positioner group guide rail, an upper computer, a ball hinge connection mechanism and a laser tracker. The attitude adjusting and butting method includes the following steps: 1) the mobile bracket is fixed onto the attitude adjusting platform and is supported by the numeric control positioner; 2) fuselage is arranged in place; 3) a site assembly coordinate system and a local coordinate system solidified on the fuselage are established; 4) the current attitude of fuselage A is measured and calculated; 5) motion path of the numeric control positioner is planned; 6) the attitude of the fuselage A is adjusted; 7) coordinates of a butt hole are measured and target attitude offuselage B is calculated; 8) the current attitude of fuselage B is calculated; 9) the attitude of the fuselage B is adjusted; 10) fuselage is butted; 11) the system is reset; 12) the mobile bracket is removed. The invention has the advantages that digitalized attitude adjusting and butting of airplane components are realized and adaptability is strong.

Owner:ZHEJIANG UNIV

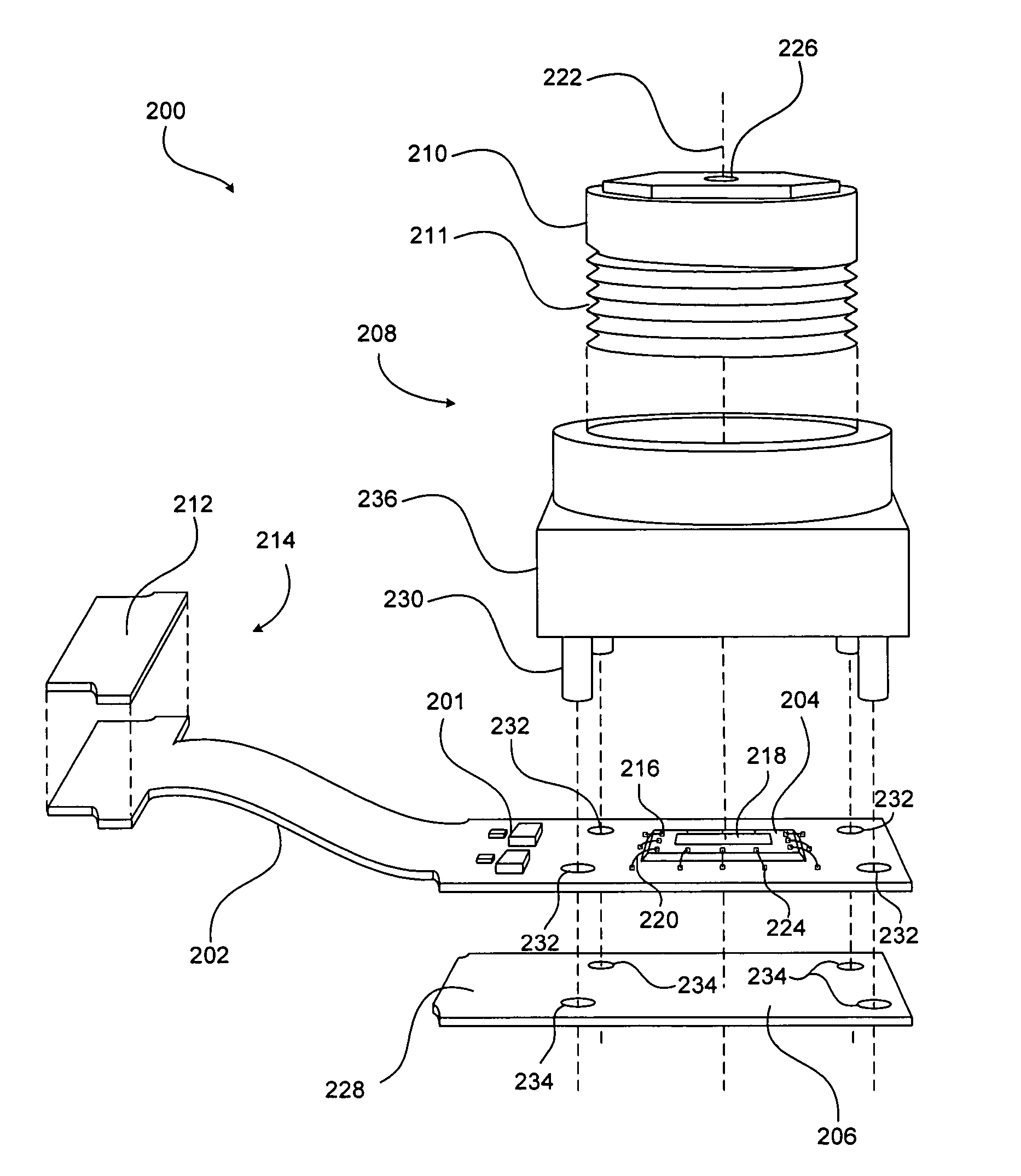

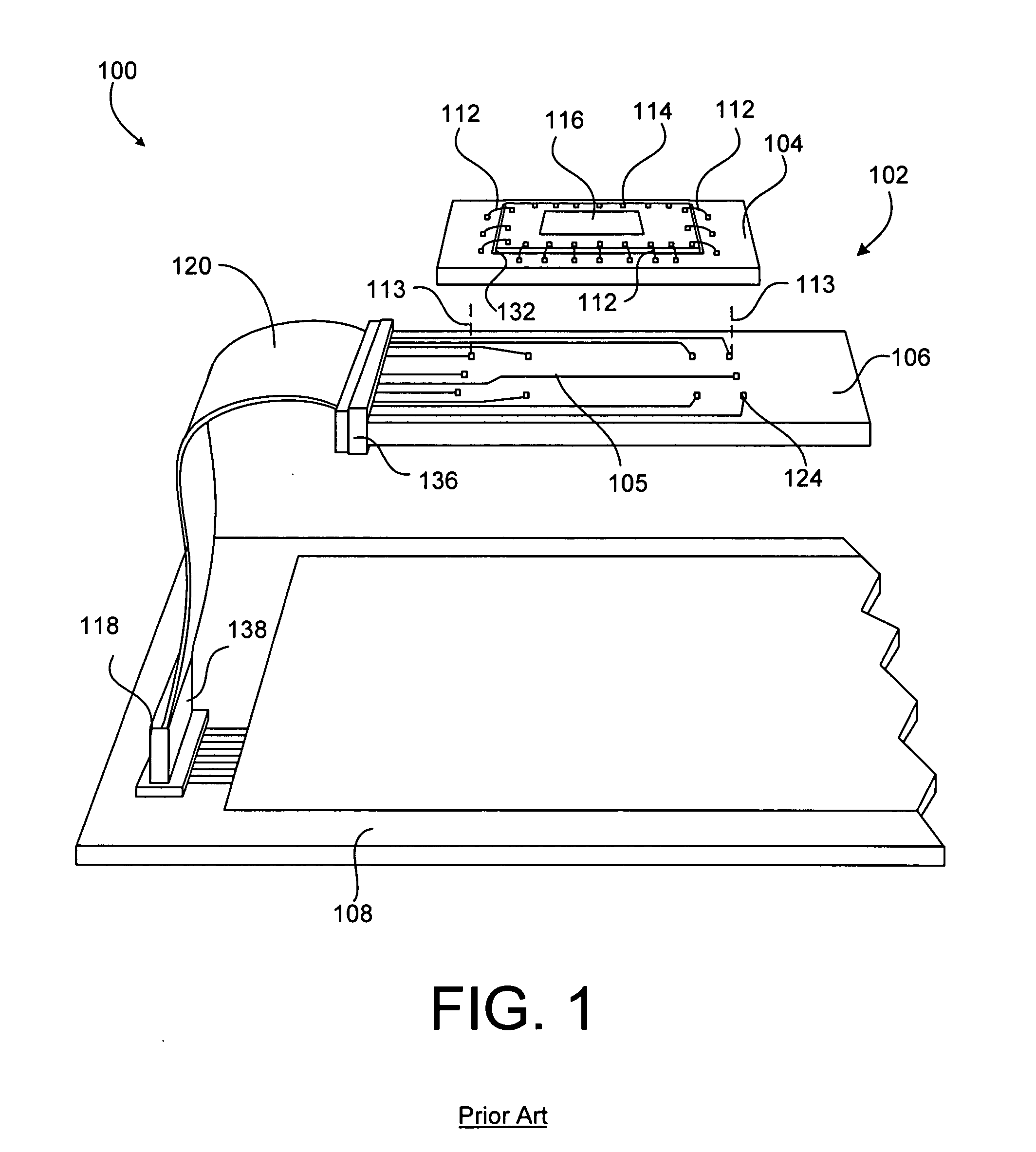

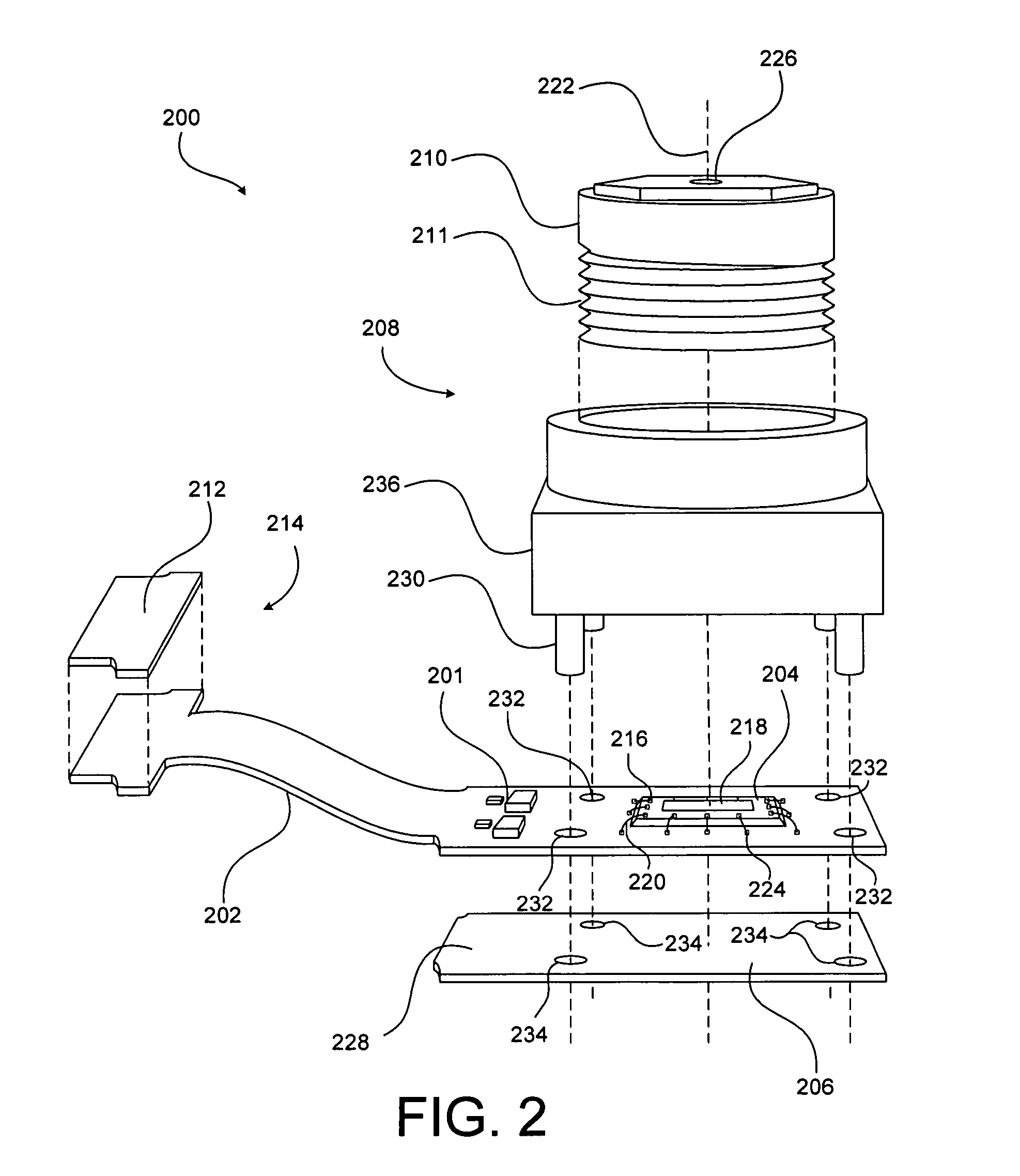

System and method for mounting an image capture device on a flexible substrate

ActiveUS20050285973A1Facilitates fastImprove assembly efficiencyTelevision system detailsSolid-state devicesAdhesiveFlexible circuits

A digital camera module includes an image capture device mounted on a flexible circuit substrate. In one embodiment of the digital camera module, the image capture device is mounted directly (e.g., by an adhesive) on the flexible circuit substrate. A stiffener (e.g., a piece of circuit board material) is mounted to the back of the flexible circuit substrate to support wire bonding of the image capture device onto the flexible circuit substrate and / or to support the mounting of additional components (e.g., a lens housing).

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD

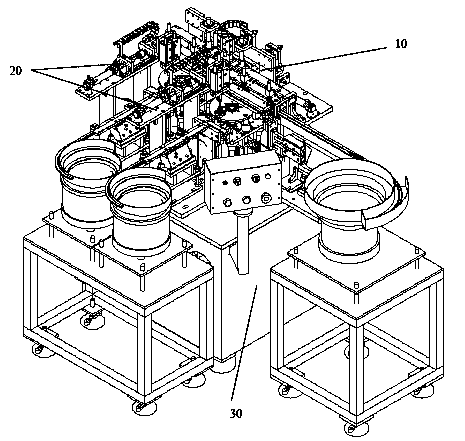

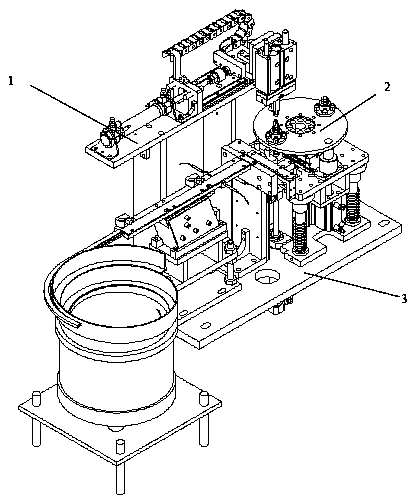

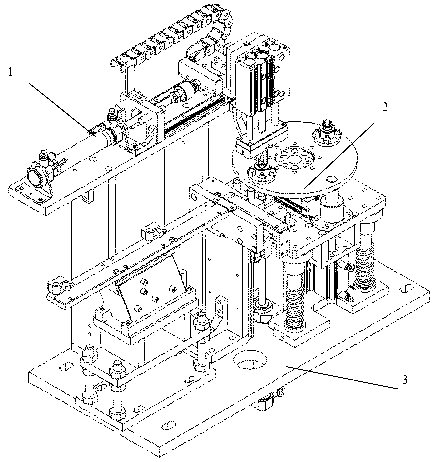

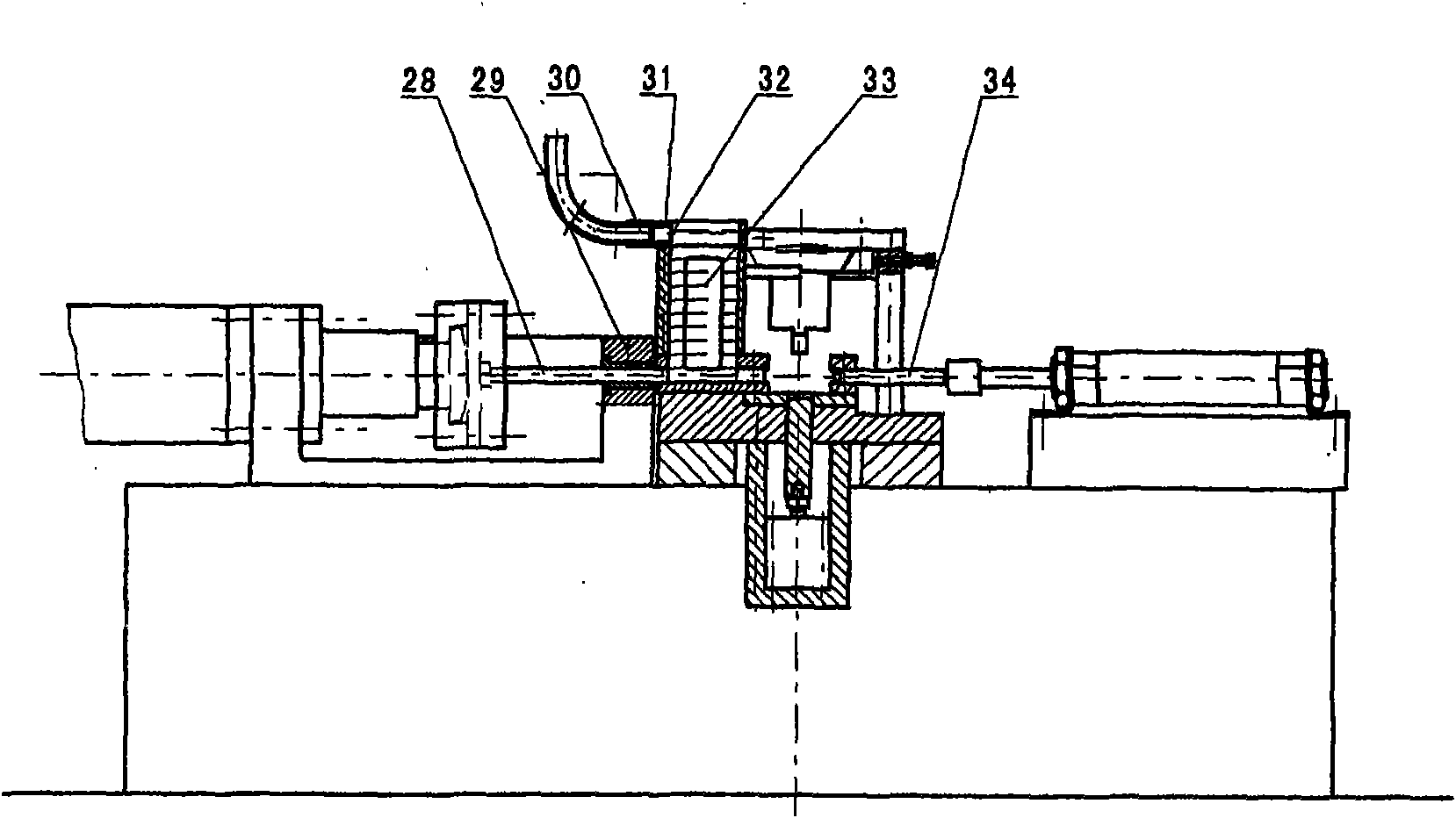

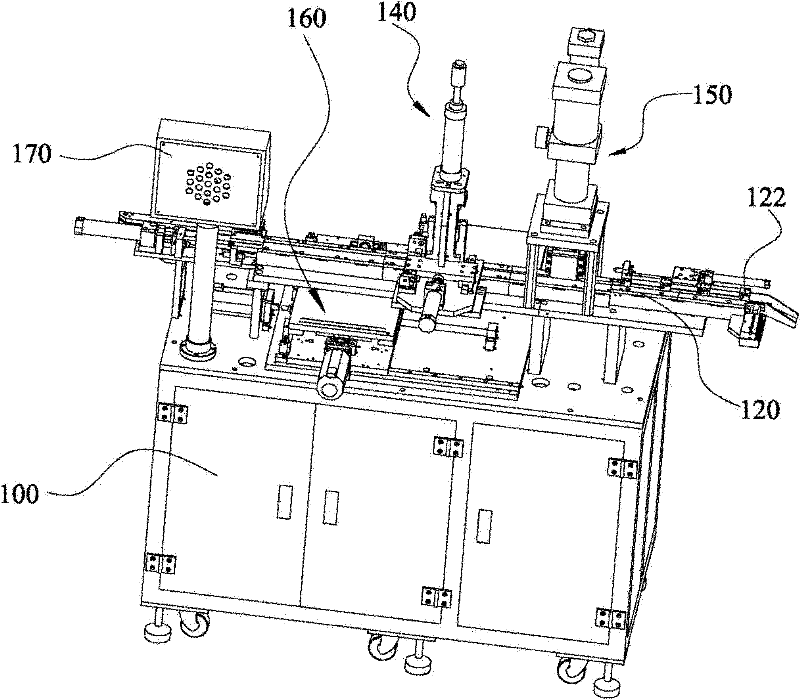

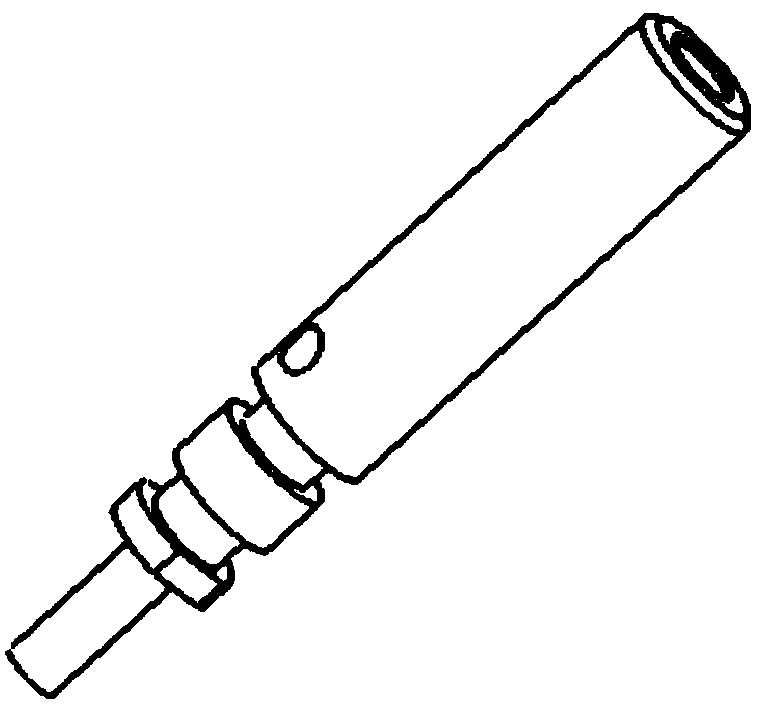

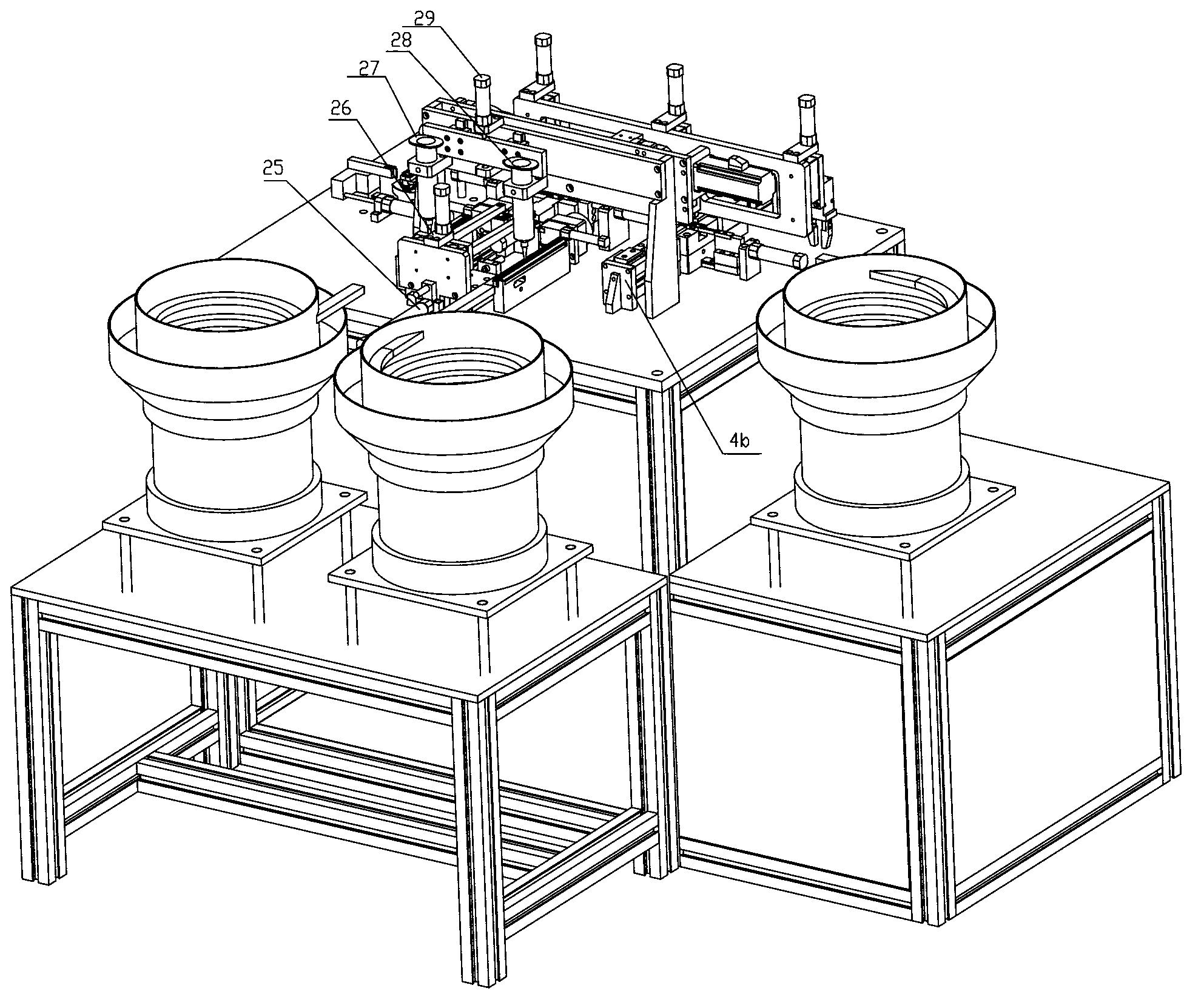

Automatic assembling device and assembling method for valve rod sealing rings

InactiveCN103465005ASmall support ringImprove assembly efficiencyMetal working apparatusEngineeringAssembly automation

The invention discloses an automatic assembling device for valve rod sealing rings. The automatic assembling device comprises an automatic valve rod feeding device and two sets of automatic sealing ring assembling devices, wherein the automatic valve rod feeding device sequentially moves valve rods to positions to be assembled for realizing the automatic feeding of the valve rods; after the automatic valve rod feeding device positions the valve rods and tightly presses the valve rods, the automatic feeding and ring supporting actions of O-shaped sealing rings are respectively completed by the two sets of automatic sealing ring assembling devices, in addition, the supported O-shaped sealing rings are pushed into grooves of the valve rods in the two positions to be assembled of the valve rods, and the automatic assembly of the two sealing rings is completed; finally, the assembled valve rods are conveyed and discharged. The automatic assembling device has the advantages that the assembly automation of the valve rod sealing rings can be realized, the defects of low assembly speed and automation assembly adaption difficulty of manual operation can be overcome, the product qualification rate and the assembly efficiency are greatly improved, and in addition, the work intensity, the labor and the production cost are reduced. The invention also discloses an automatic assembling method for the valve rod sealing rings.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

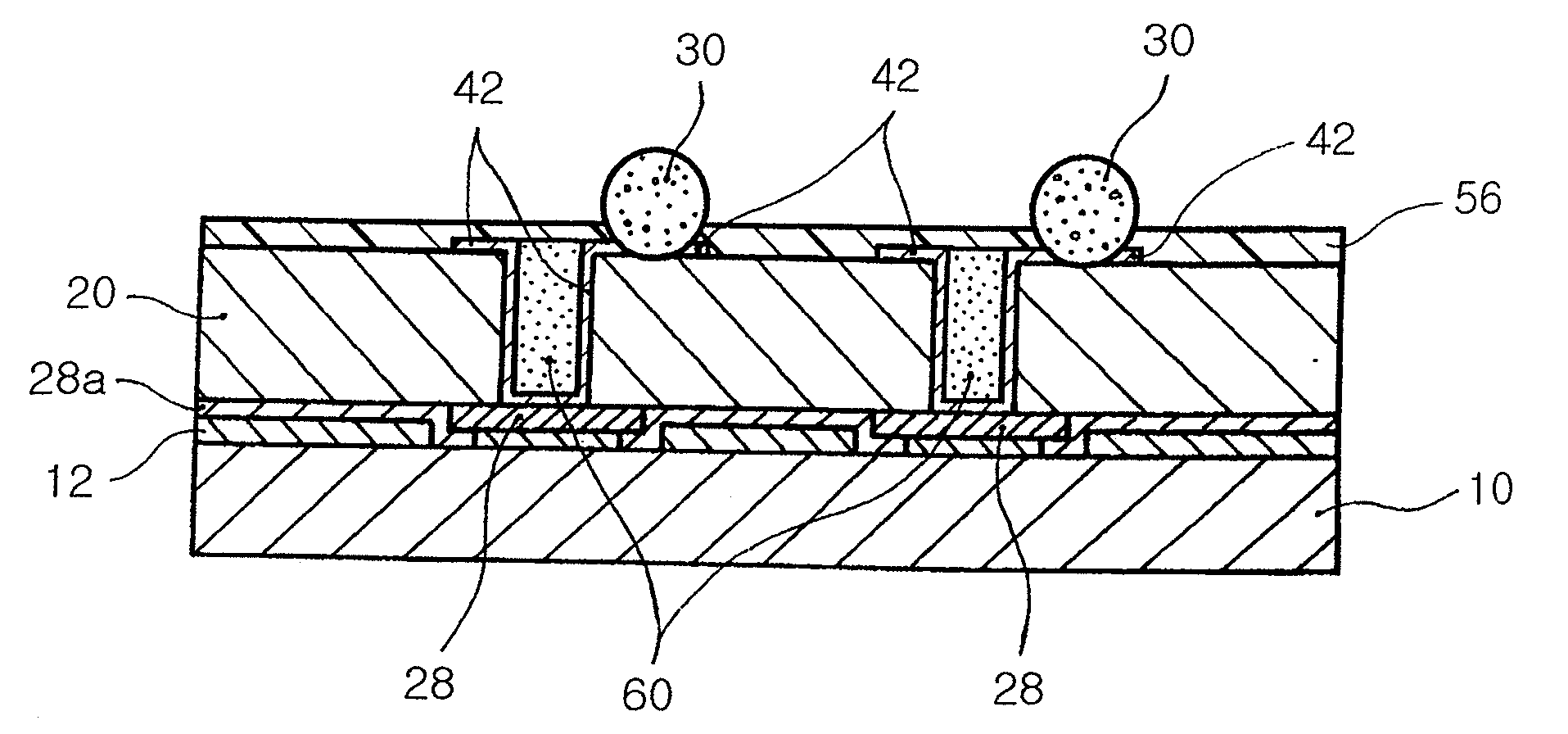

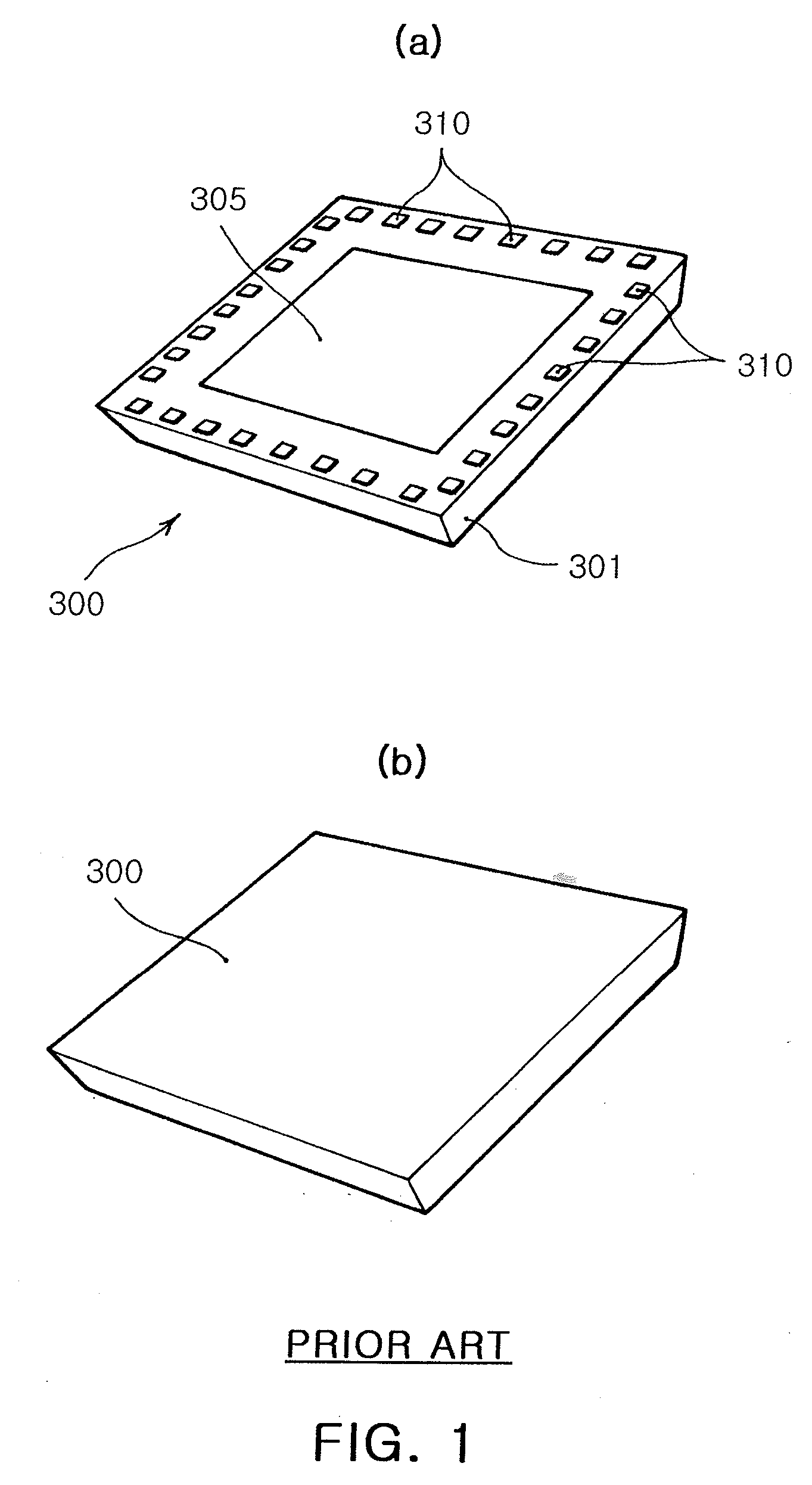

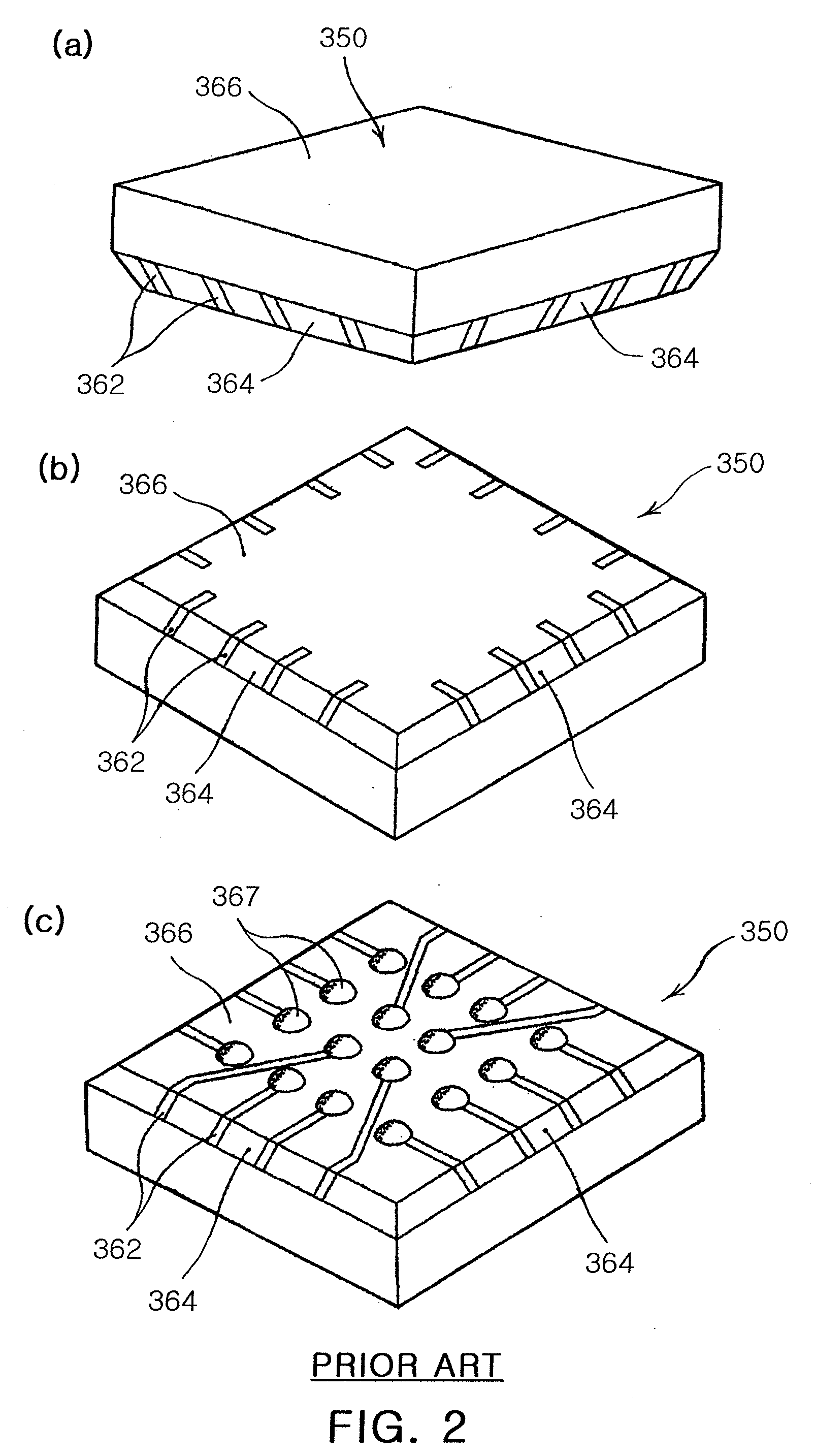

Semiconductor package and method of manufacturing the same

InactiveUS20070249095A1Reduce manufacturing costMinimized in sizeTelevision system detailsSemiconductor/solid-state device detailsCMOSSemiconductor package

Disclosed herein are a semiconductor package used in digital optical instruments and a method of manufacturing the same. The semiconductor package comprises a wafer made of a silicon material and having pad electrodes formed at one side surface thereof, an IR filter attached on the pad electrodes of the wafer by means of a bonding agent, terminals electrically connected to the pad electrodes, respectively, in via holes formed at the other side surface of the wafer, which is opposite to the pad electrodes, and bump electrodes, each of which is connected to one side of each of the terminals. The present invention is capable of minimizing the size of a semiconductor package having an image sensor, which is referred to as a complementary metal oxide semiconductor (CMOS) or a charge coupled device (CCD), through the application of a wafer level package technology, thereby reducing the manufacturing costs of the semiconductor package and accomplishing production on a large scale.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

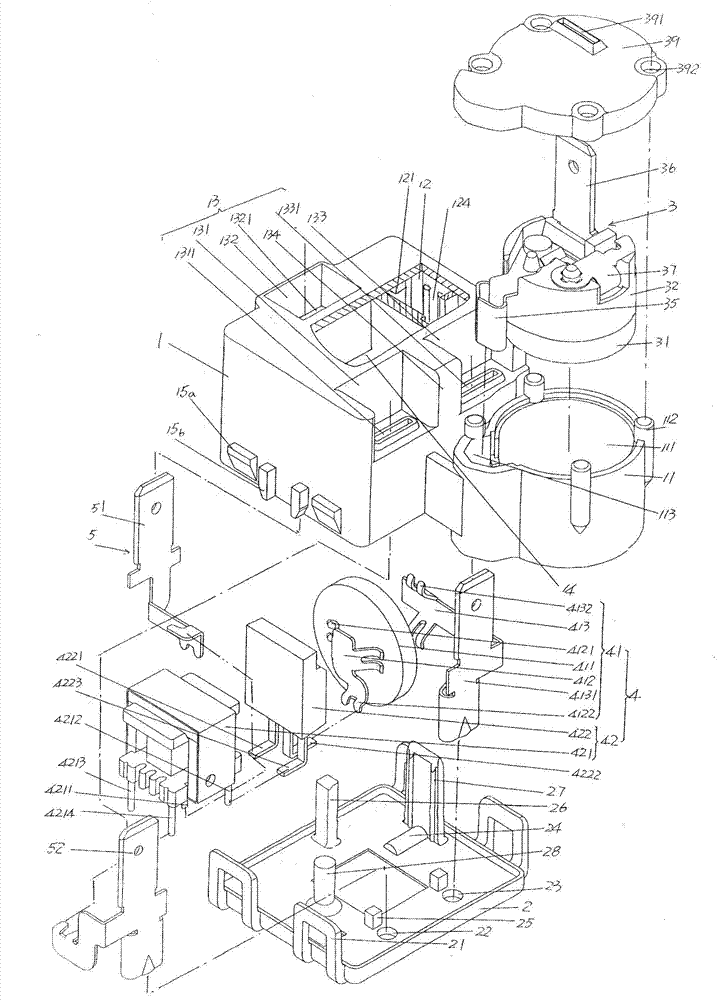

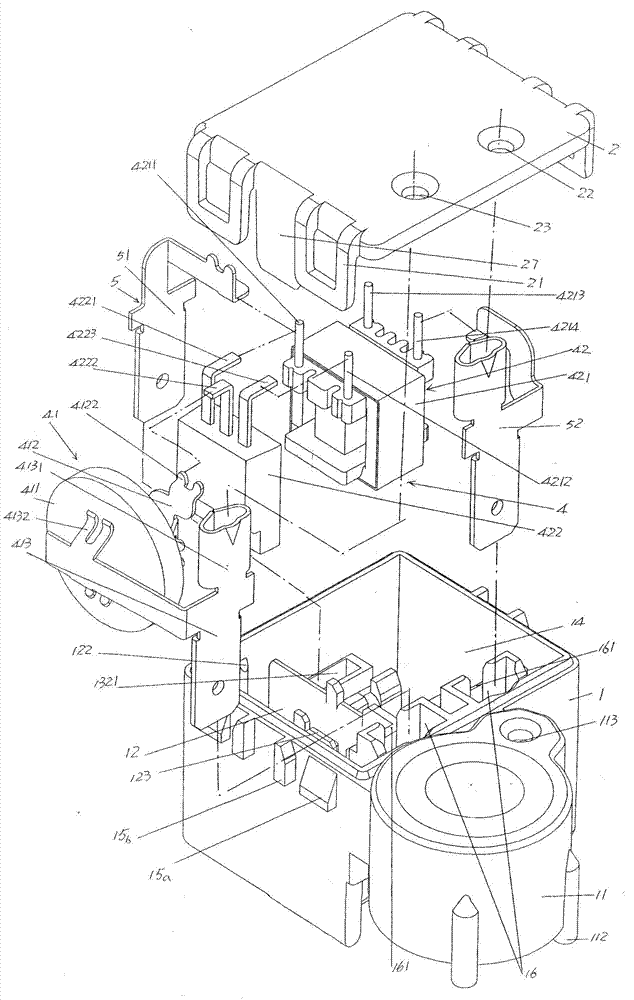

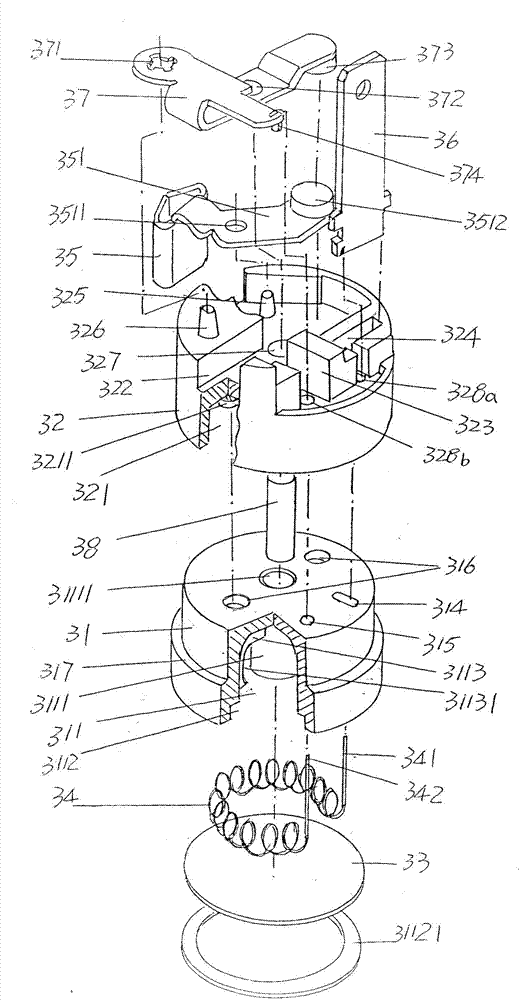

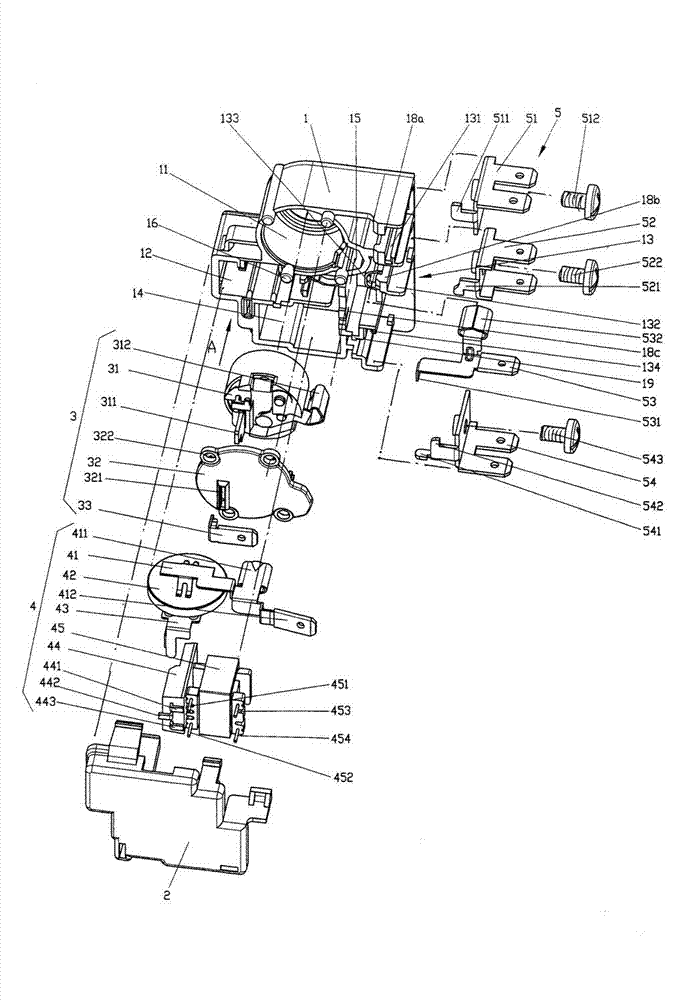

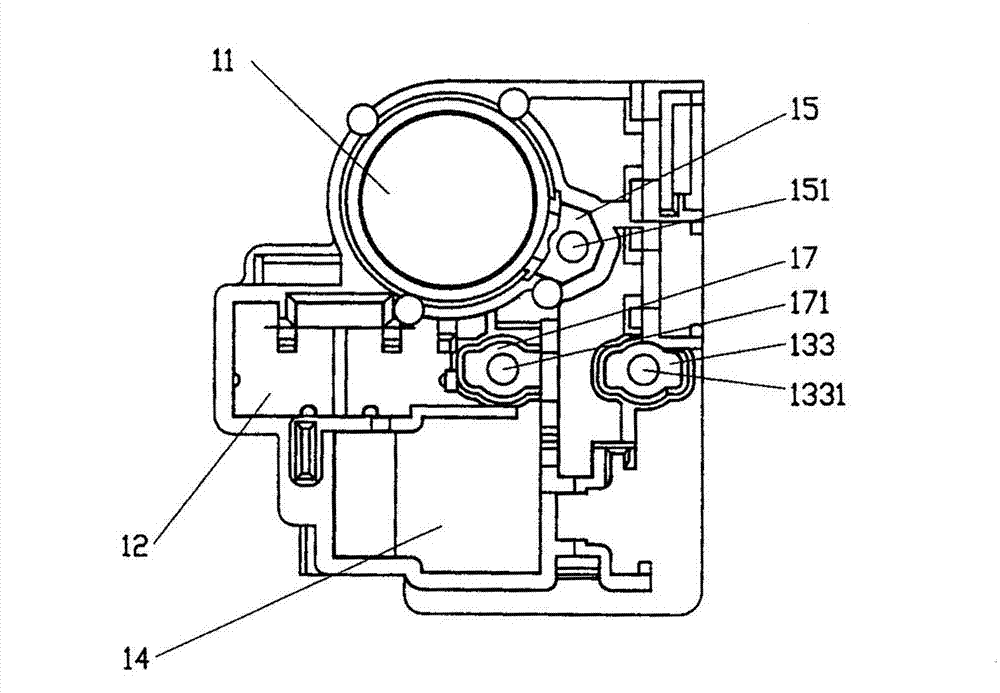

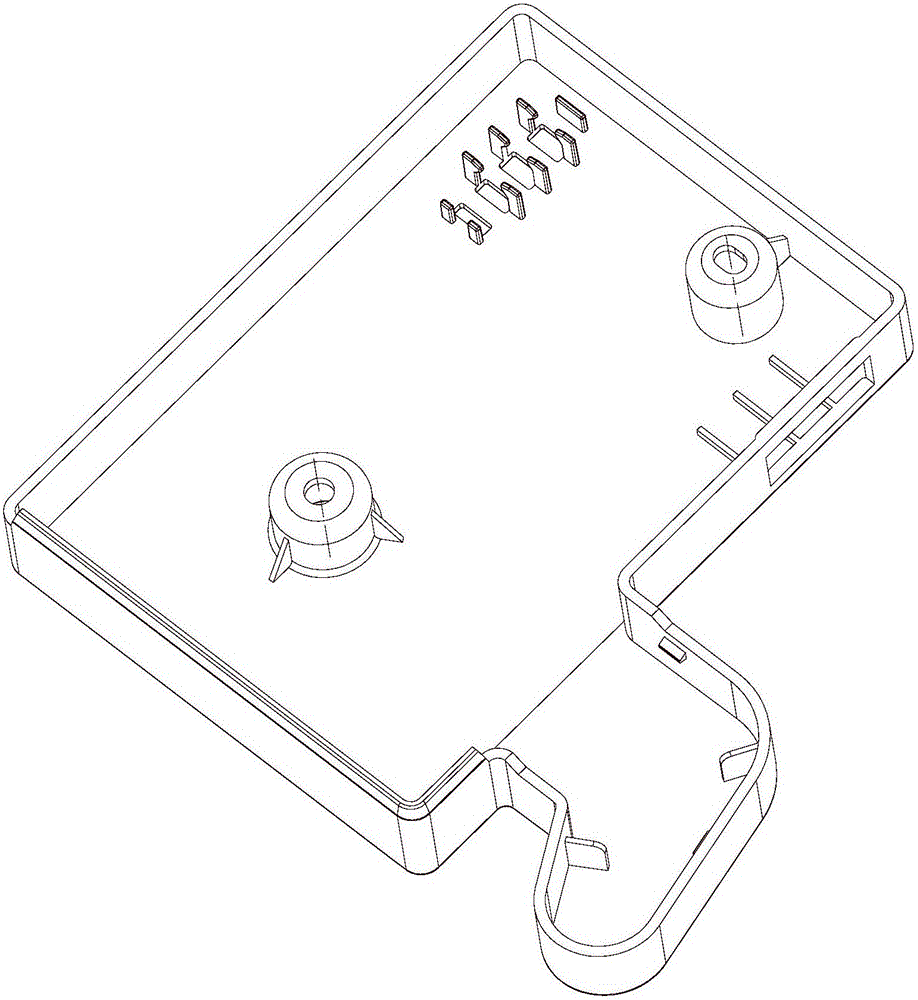

Power-dissipation-free and energy-saving type start protector of single phase AC motor

InactiveCN104734570AReduce volumeSmall footprintSingle-phase induction motor startersEmergency protective circuit arrangementsRefrigeration compressorEngineering

The invention provides a power-dissipation-free and energy-saving type start protector of a single phase AC motor and belongs to the technical field of refrigeration compressors. The power-dissipation-free and energy-saving type start protector comprises a shell, a shell cover, an overload protector, a power-dissipation-free starter and an external terminal mechanism. The shell is provided with an overload protector seat, a power-dissipation-free starter accommodation cavity, an external terminal mechanism cavity and a start controller accommodation cavity. The shell cover is provided with a first three-terminal jack and a second three-terminal jack. The overload protector is arranged in an overload protector accommodation cavity. The power-dissipation-free starter comprises a power-dissipation-free starter body and a start controller. The external terminal mechanism is matched with the external terminal mechanism cavity. The start protector is characterized in that the external terminal mechanism cavity comprises a first insertion cavity, a second insertion cavity and a third insertion cavity, the second insertion cavity is formed in the left side of the shell, and the bottom wall of the second insertion cavity is provided with a second shell insertion groove; the first insertion cavity and the third insertion cavity are formed in the right side of the shell, a first shell insertion groove is formed in the bottom wall of the first insertion cavity, and a third shell insertion groove is formed in the bottom wall of the third insertion cavity; the external terminal mechanism comprises a first insertion piece and a second insertion piece, the first insertion piece is matched with the second shell insertion groove in an inserted mode, and the second insertion piece is matched with the first shell insertion groove in an inserted mode.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

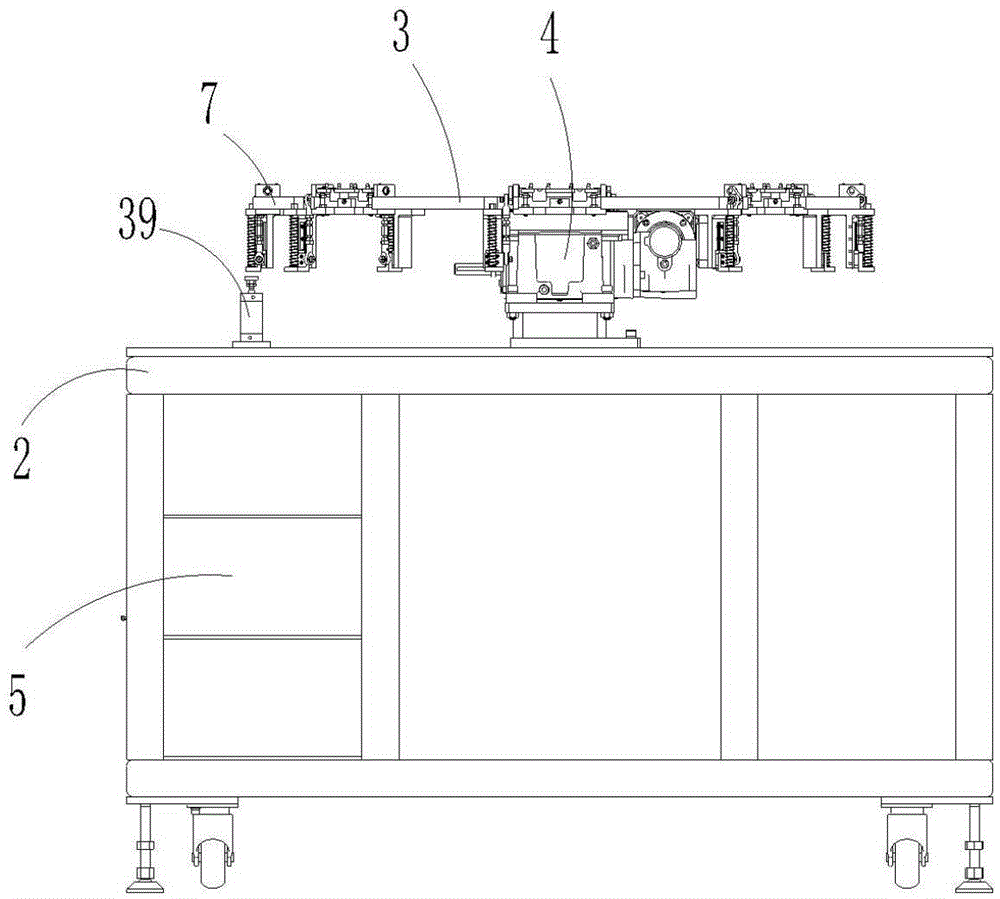

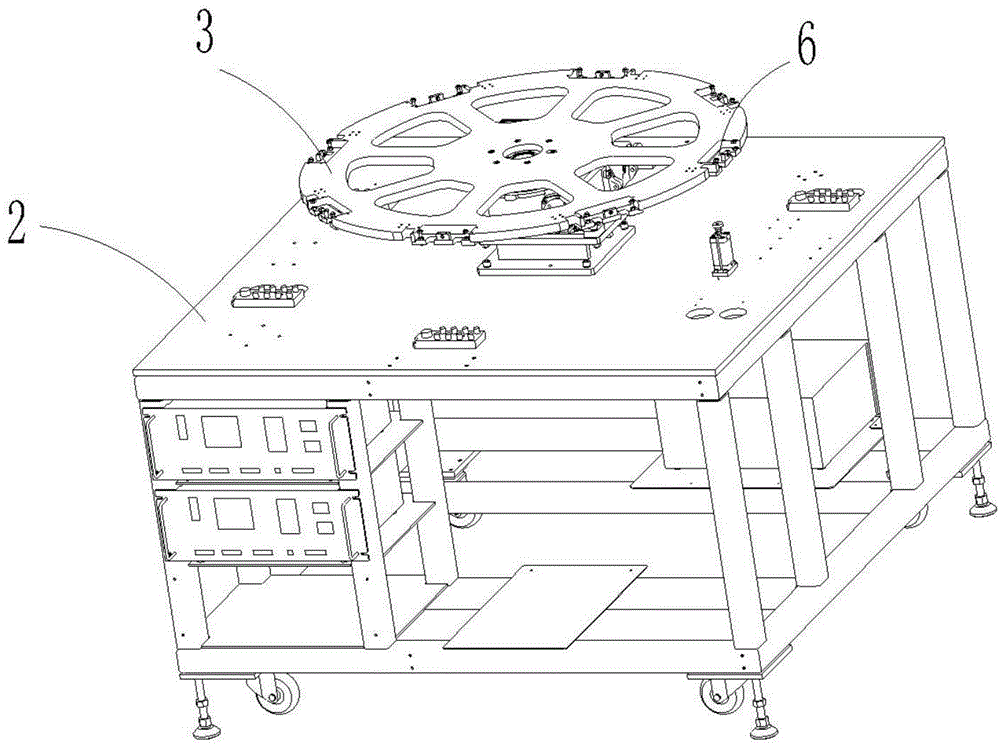

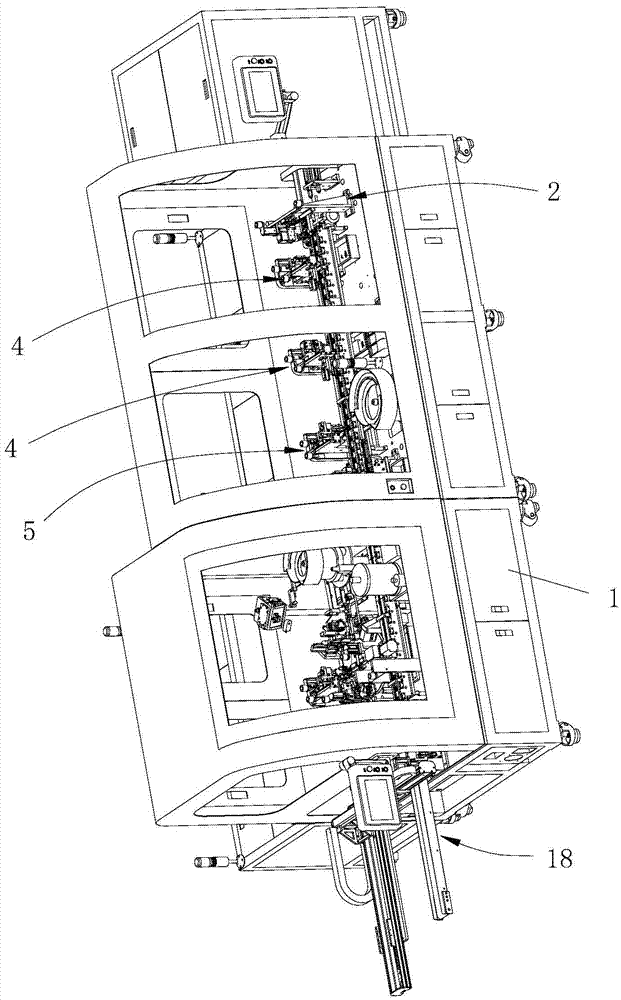

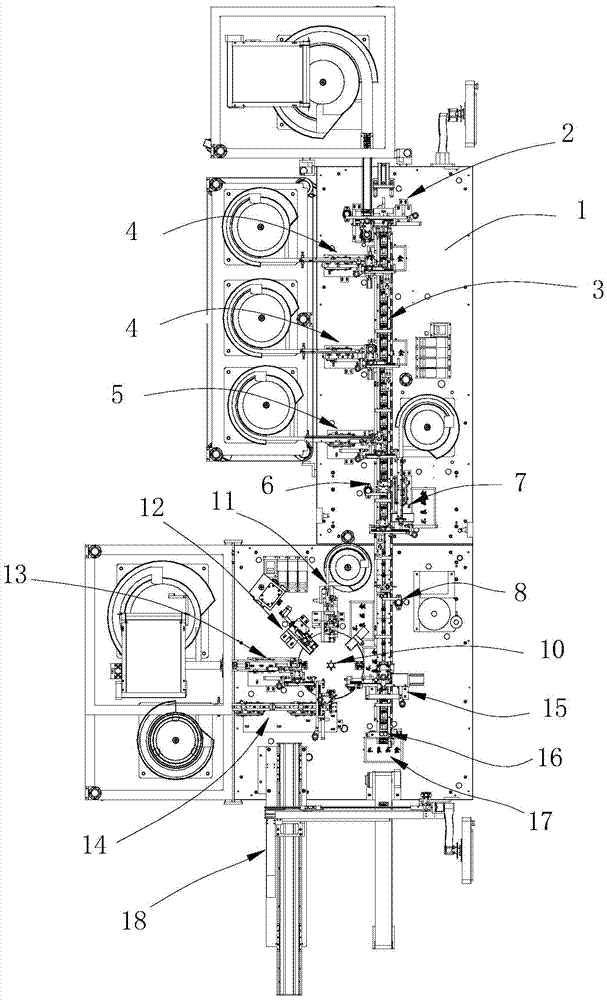

Full-automatic bearing assembly machine

ActiveCN103047300AImprove assembly efficiencyImprove assembly qualityBearing componentsEngineeringTransfer mechanism

The invention discloses a full-automatic bearing assembly machine. The assembly machine comprises a base, a working platform, a assembling station and a press fit station, wherein the assembling station and the press fit station are arranged on the working platform; an inner-ring feeding mechanism is arranged in the front of the assembling station, and a roller assembling mechanism is arranged behind the assembling station; a roller feeding mechanism is arranged behind the roller assembling mechanism; a holder feeding mechanism is arranged on one side of the assembling station; the inner ring of the bearing, the holder and a tapered roller are assembled together to form an inner assembly of the bearing; an assembly transferring mechanism which can convey the inner assembly of the bearing from the assembling station to the press fit station is arranged between the other side of the assembling station and the inner side of the press fit station; a press fit mechanism is arranged on the press fit station; a material discharging passage is arranged outside the press fit station; and a material pushing mechanism is arranged on the material discharging passage. With the adoption of the structure, assemblies of the holder, the tapered roller and the inner ring of the bearing can be performed automatically, and the inner assembly of the bearing is transferred to the press fit station for pressing through the assembly transferring mechanism, so that the assembly efficiency and the assembly quality are improved greatly, and potential safety hazards are eliminated.

Owner:宁波江宸智能装备股份有限公司

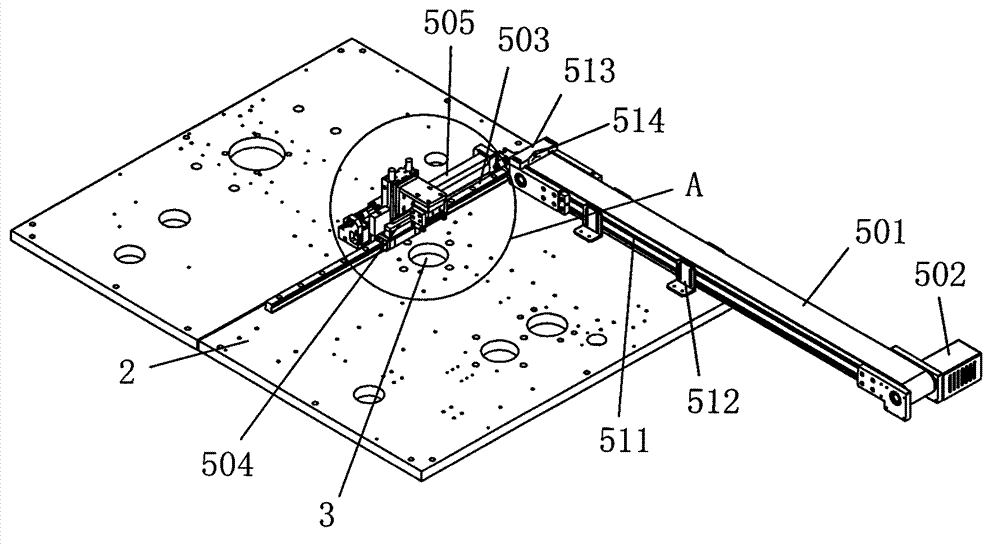

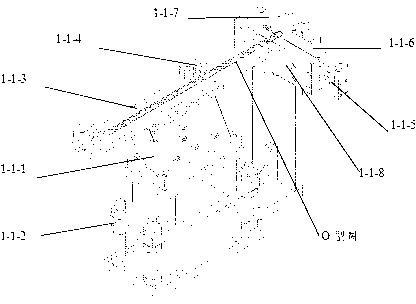

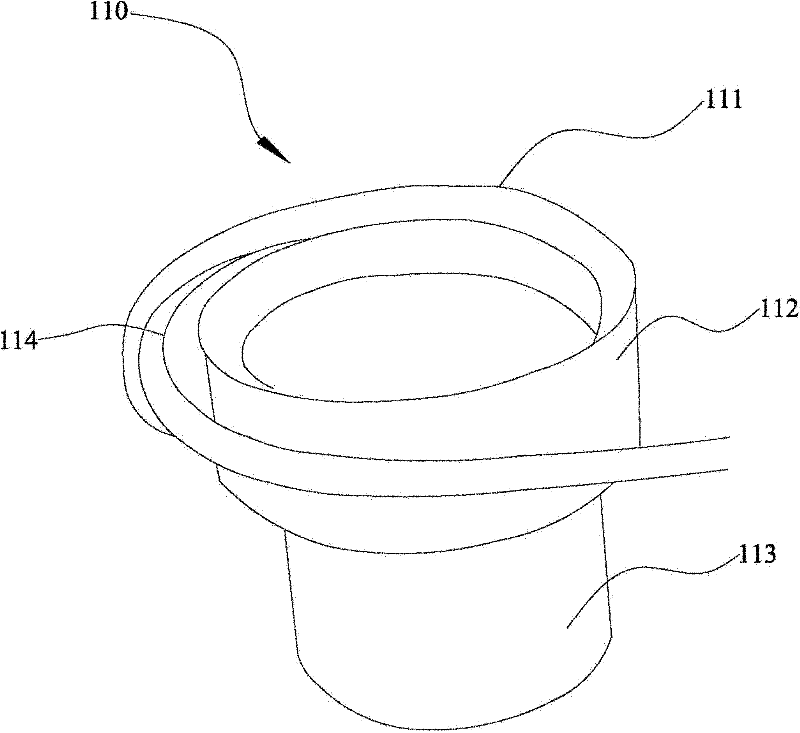

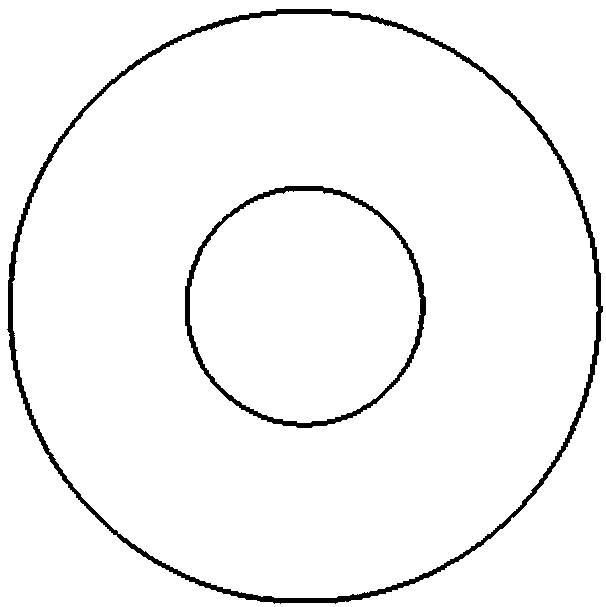

Automatic assembly device and method of O-type sealing ring

InactiveCN103317336ANo damageSmall support ringMetal working apparatusEngineeringUltimate tensile strength

The invention discloses an automatic assembly device of an O-type sealing ring. The automatic assembly device comprises a ring loading and supporting module and a ring moving and releasing module. The ring loading and supporting module forms a feeding station and a ring supporting station, and when a loading device of the O-type sealing ring is located at the feeding station, the O-type sealing ring is delivered to the loading device of the O-type sealing ring by a feeding device of the O-type sealing ring. A loading needle-shaped air cylinder drives the loading device of the O-type sealing ring to move to the ring supporting station, the ring supporting motion is carried out on the O-type sealing ring by a ring supporting device, the O-type sealing ring is delivered to the ring moving and releasing module by the ring supporting device, the ring moving and releasing module enables the supported O-type sealing ring to be delivered to a ring releasing station from the ring supporting station, the ring moving and releasing module breaks away from the supported O-type sealing ring, the supported O-type sealing ring is sleeved at the position of a groove of a workpiece to be assembled, and automatic assembly between the workpiece and the O-type sealing ring is achieved. According to the automatic assembly device, assembly automation of the O-type sealing ring can be achieved, the qualified rate and the assembly efficiency of products are greatly improved, the labor strength is relieved, and the production cost is reduced. The invention further discloses an automatic assembly method of the O-type sealing ring.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

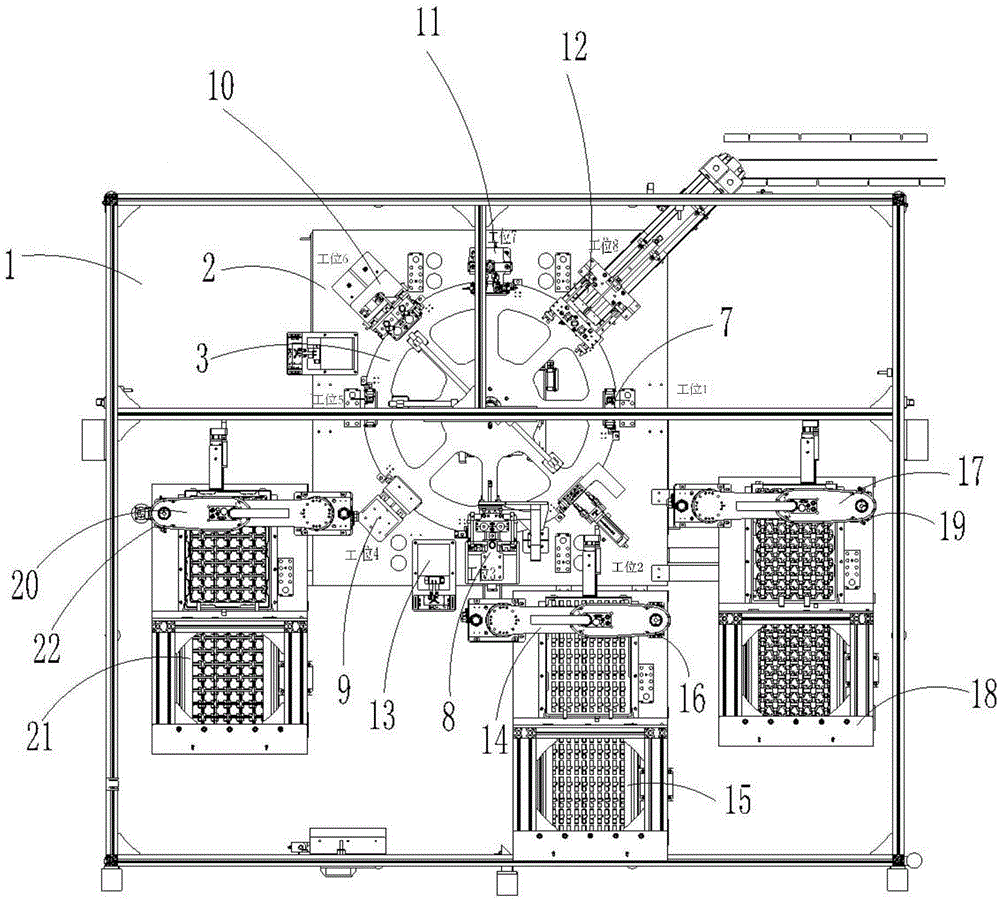

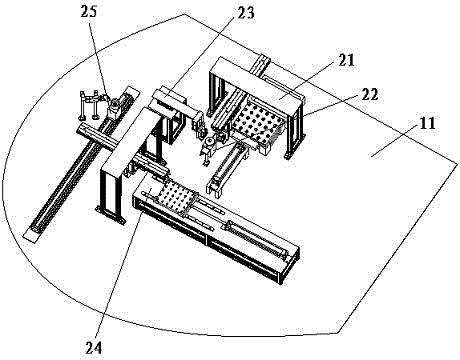

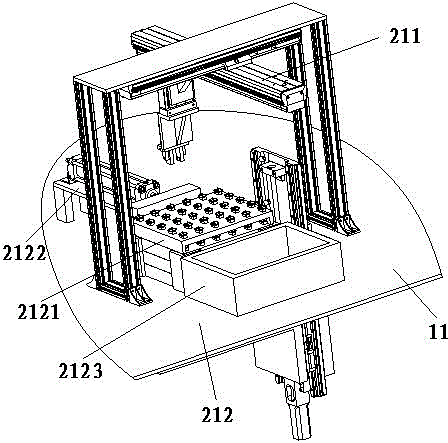

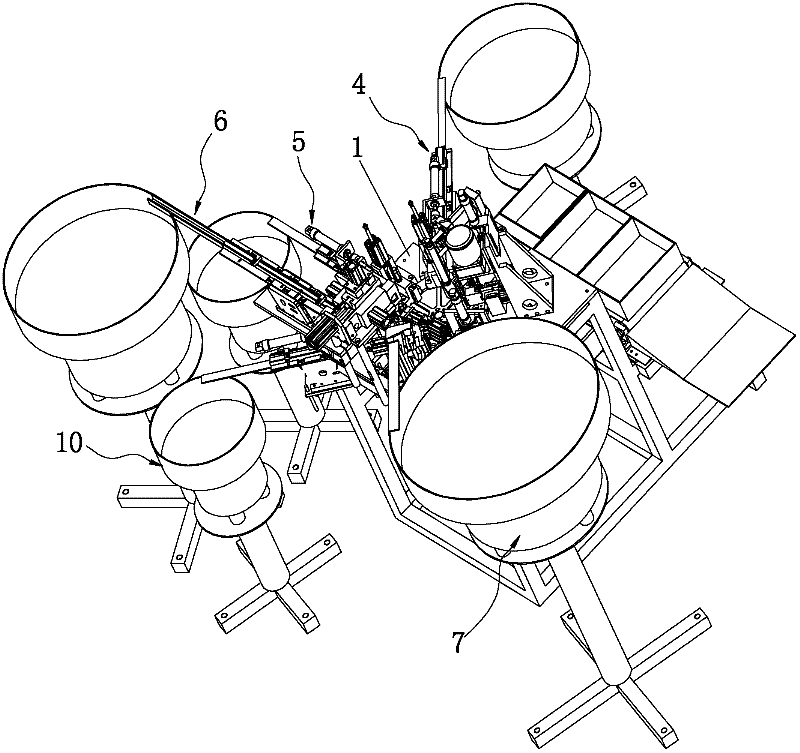

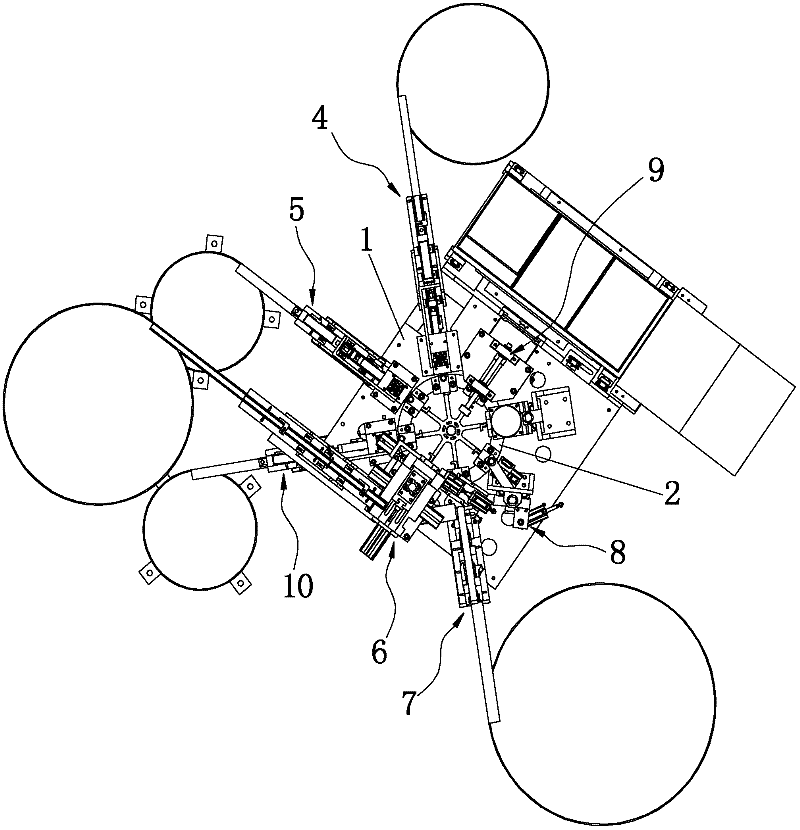

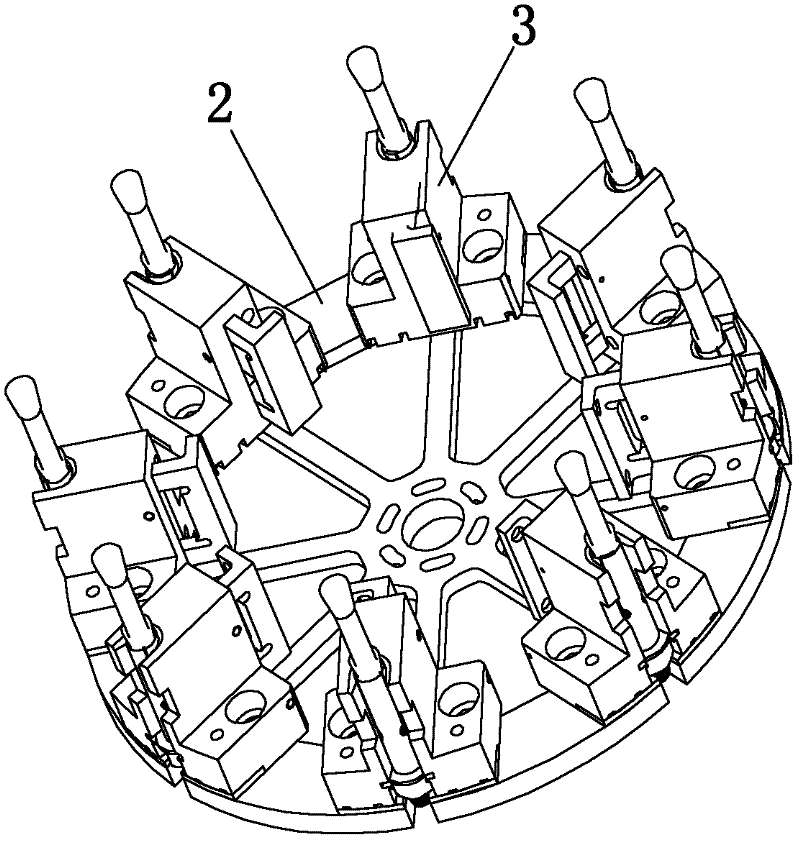

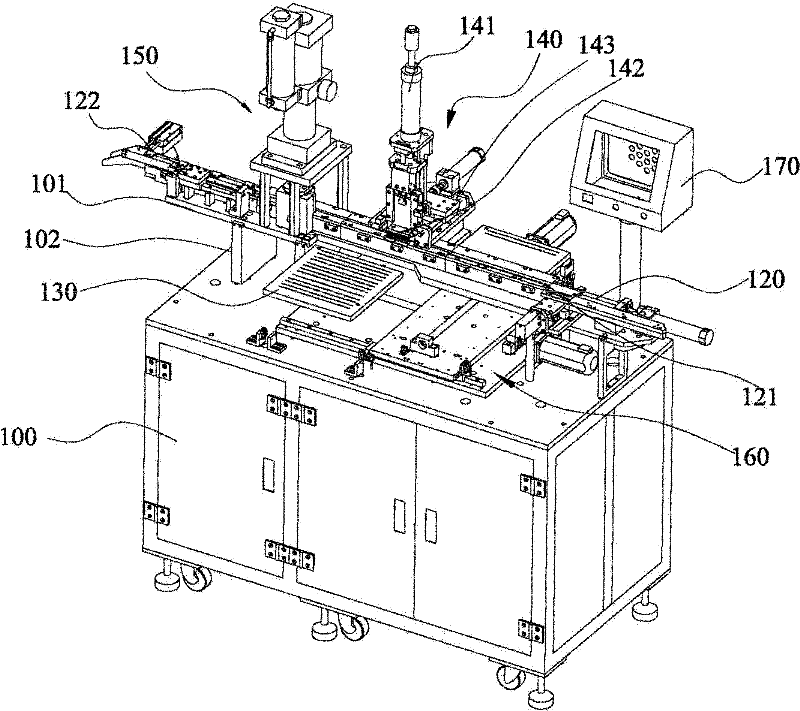

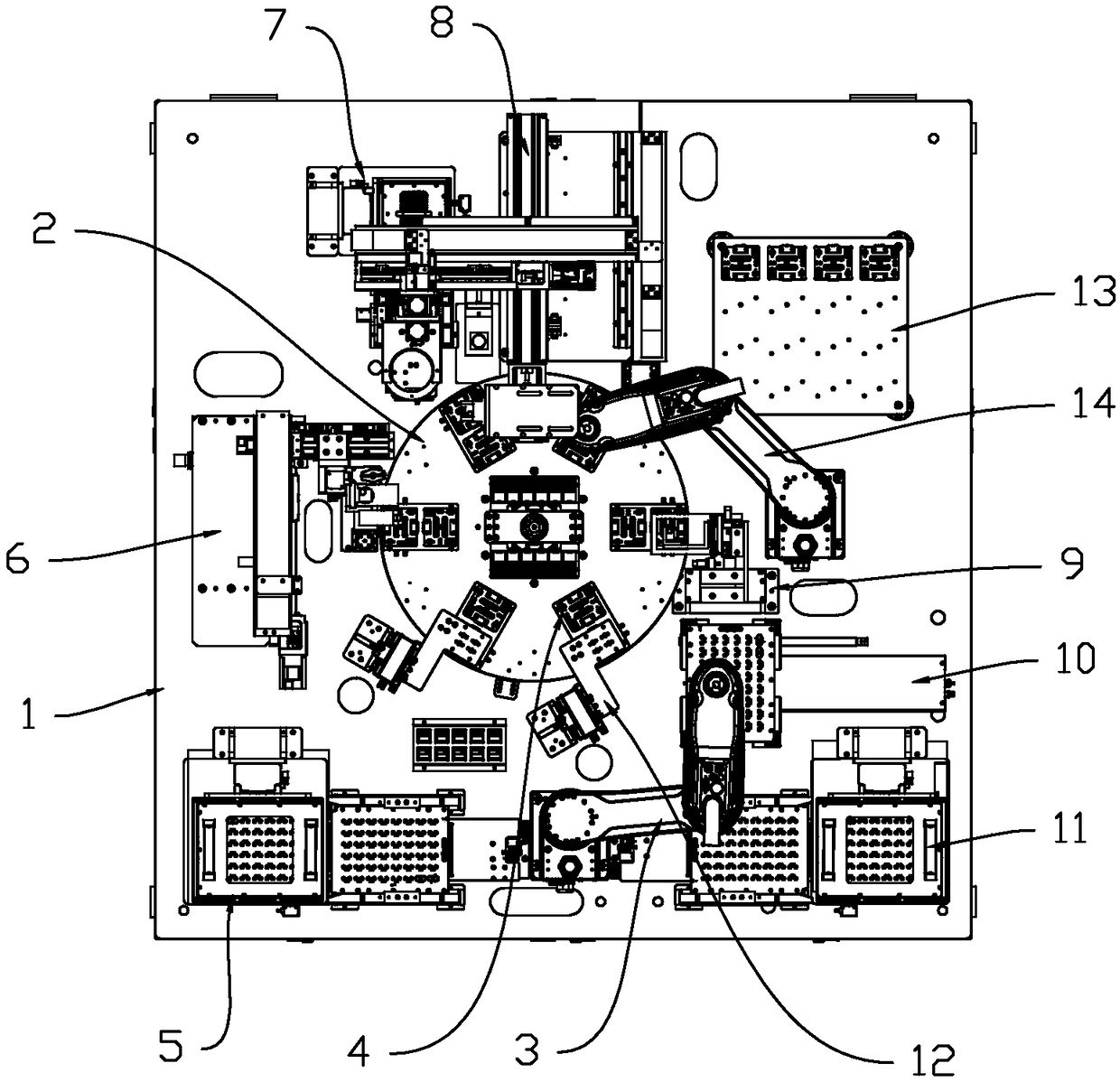

Security industry camera core assembly based automatic assembly system and method

ActiveCN104801968AImprove assembly efficiencyHigh degree of automationAssembly machinesCircular discCore component

The invention relates to automatic assembly systems, particularly to a security industry camera core assembly based automatic assembly system and method. The security industry camera core assembly based automatic assembly system comprises an operation area; an operation frame is arranged in the operation area; an operation disk is arranged above the operation frame, wherein the operation disk and the operation frame are fixed; the rotation of the operation disk is controlled by an indexer; a controller is arranged in the operation frame; the edge of the operation disk is provided with at least six operation position assemblies which are distributed uniformly; the operation area comprises a turnover positioning fixture, a lens feeding robot assembly, a base feeding robot assembly, a lateral side nailing assembly, a PCB (Printed Circuit Board) feeding robot assembly, a rotary table fixture calibration assembly, a PCB nailing assembly, a bolt detection assembly, a discharging assembly and a screw feeding and distribution assembly. According to the security industry camera core assembly based automatic assembly system and method, the assembly efficiency is improved, the degree of automation is high, the product quality is improved, and the labor cost is reduced.

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

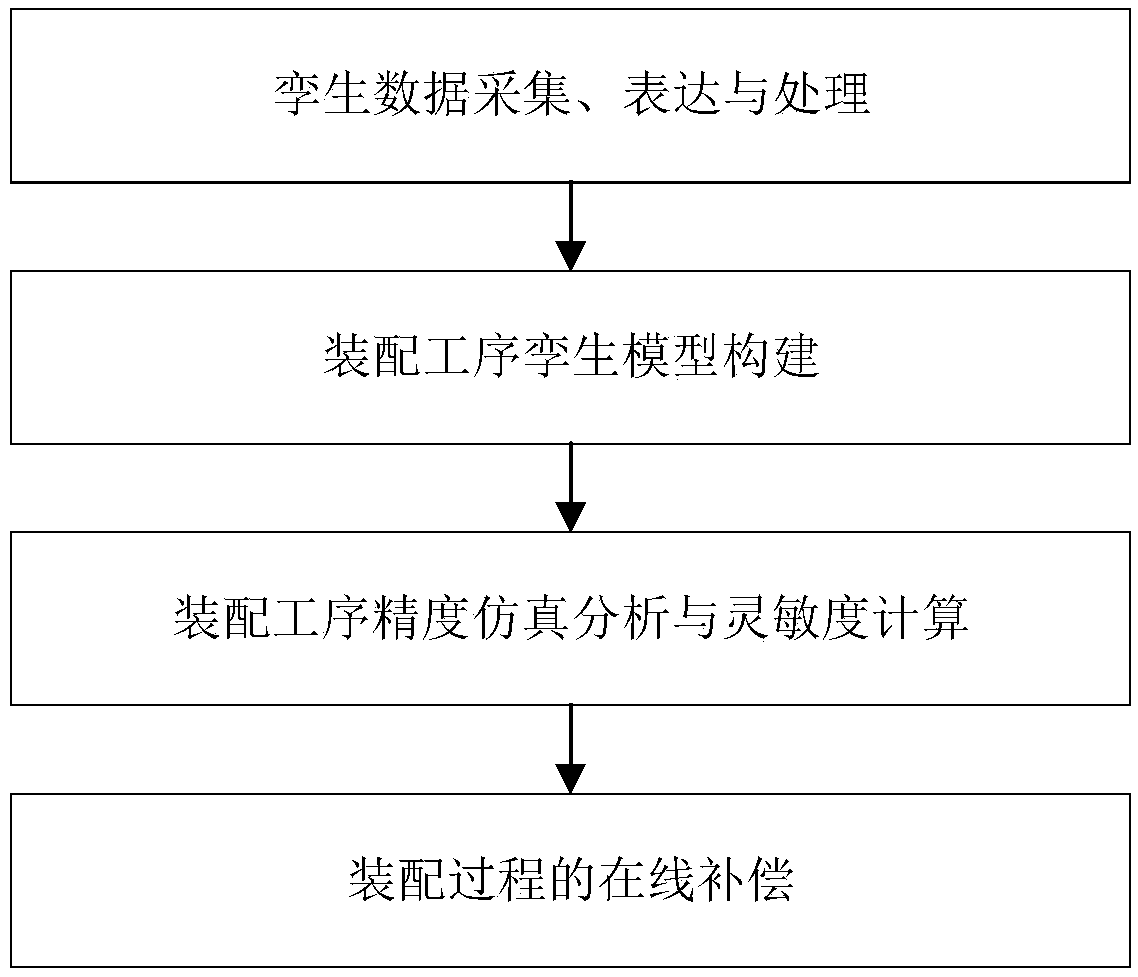

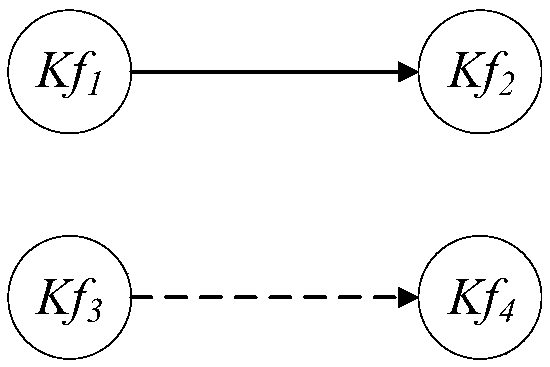

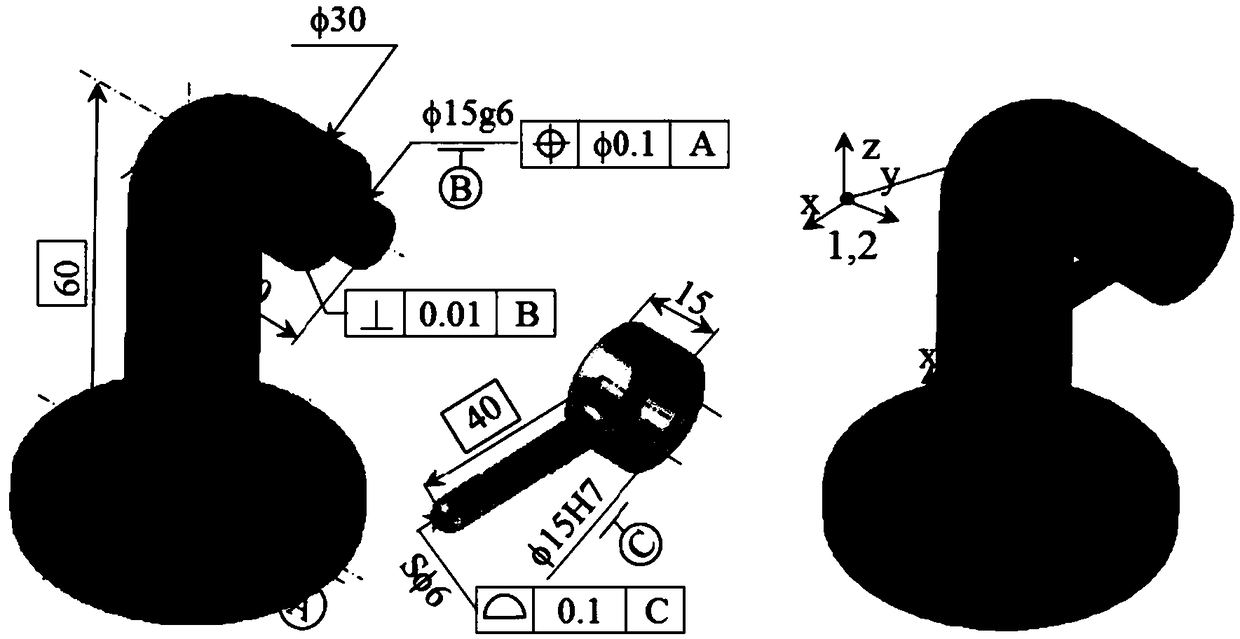

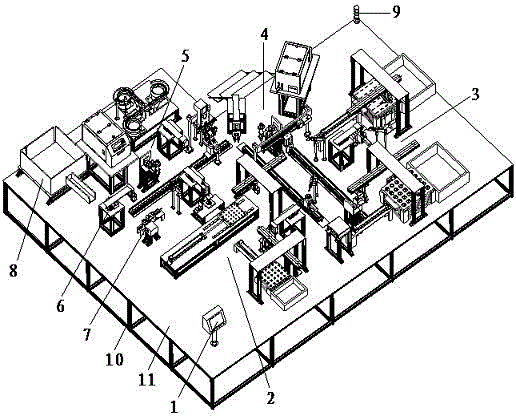

Digital twinning-based assembly precision simulation analysis method and system

InactiveCN109445305ARealize scientific assemblyQuality improvementSimulator controlInformation spacePhysical space

The invention discloses a digital twinning-based assembly precision simulation analysis method and system. According to the digital twinning-based assembly precision simulation analysis method and system, as for key processes in complex product assembly, the twin data of a physical assembly site are collected and processed, and twin data information is expressed and stored; an assembly process model is obtained in a 3D assembly process design system, and the assembly process model is reconstructed based on the twin data, so that an assembly process twin model is generated; the assembly processtwin model is introduced into commercial assembly tolerance analysis software, so that assembly precision simulation and sensitivity calculation can be performed; and the online compensation and precise control of the assembly process are performed according to assembly process precision simulation analysis results. With the digital twinning-based assembly precision simulation analysis method andsystem of the invention adopted, the deep fusion of the physical space and information space of the assembly site can be realized. The method and system are of great significance for realizing the intelligent closed-loop control of a complex product assembly process and improving assembly quality and efficiency.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

LED assembling machine

ActiveCN104889729AImprove assembly efficiencyEasy to operate manuallyAssembly machinesLight guideMan machine

The invention discloses an LED assembling machine which comprises a man-machine controller, a contact pin assembling mechanism, a lamp panel assembling mechanism, a screw screwing-in inversion mechanism, a light guide pillar assembling and welding mechanism, a finished product inversion mechanism, a finished product detection mechanism, a workbin device and an indicating lamp tower, all of which are installed on a workbench face of a box type rack. The contact pin assembling mechanism is installed at the front end of the workbench face, the left side and the right side of the contact pin assembling mechanism are provided with the man-machine controller and the lamp panel assembling mechanism respectively, the rear side of the lamp panel assembling mechanism is provided with the indicating lamp tower, the rear portion on the left side of the lamp panel assembling mechanism is provided with the screw screwing-in inversion mechanism, the light guide pillar assembling and welding mechanism and the workbin device in sequence, the finished product inversion mechanism is arranged on the front side of the workbin device, the finished product detection mechanism is arranged at the front position on the right side of the finished product detection mechanism, a control circuit is arranged inside the box type rack, and steps are arranged on the rear side of the box body rack. In this way, automatic assembly is achieved, the assembling efficiency is improved, and manual operation is simplified.

Owner:桐乡市腾飞家纺股份有限公司

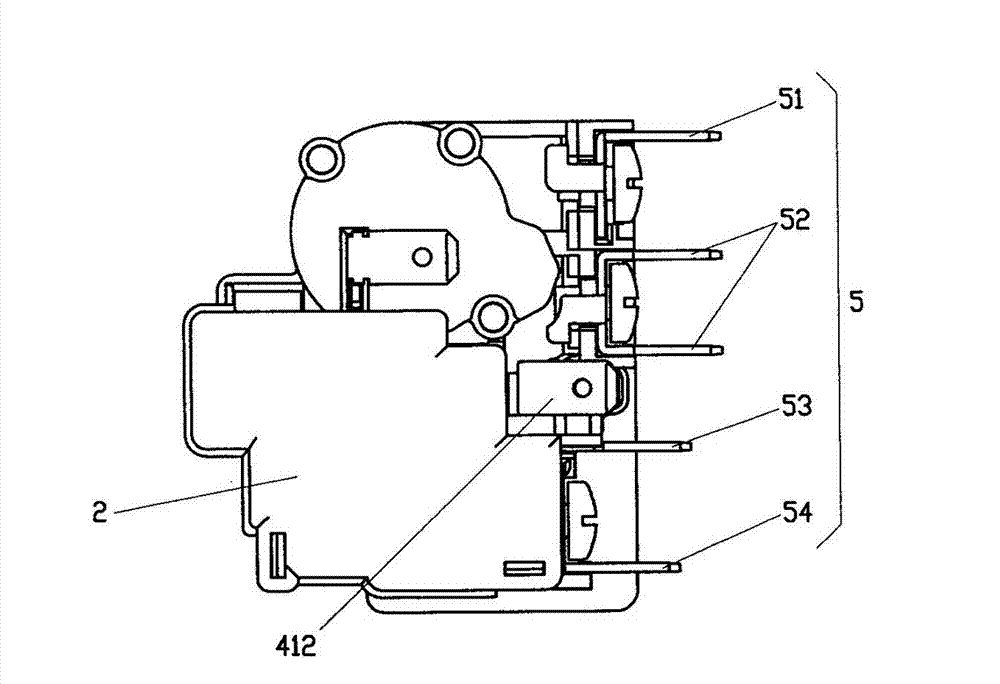

Integrated motor starting and protecting device with improved structure

ActiveCN102386815BSmall footprintMeet the needs of useSingle-phase induction motor startersEmergency protective circuit arrangementsElectric machineMaterial consumption

The invention discloses an integrated motor starting and protecting device with an improved structure, and belongs to the technical field of single-phase alternating current motor starting and protecting devices. The device comprises a shell, a shell cover, an overload protector module, a power consumption-free starter module and an external terminal mechanism, wherein the shell is provided with an overload protector module cavity, a power consumption-free starter module cavity, an external terminal mechanism cavity and a starting controller cavity. The device is characterized in that: the external terminal mechanism cavity comprises a first insert cavity, a second insert cavity, a third insert cavity and a fourth insert cavity; the first, second and third insert cavities are positioned on the same side of the shell; the external terminal mechanism comprises a first insert, a second insert, a third insert and a fourth insert; the first insert is inserted into the first insert cavity; the second insert is inserted into the second insert cavity; the third insert is inserted into the third insert cavity; and the fourth insert is inserted into the fourth insert cavity. The device has the advantages of reducing the material consumption of the external terminal mechanism, meeting industrial production requirements and reflecting resource saving, along with compact structure, convenience for assembly and high assembly efficiency.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

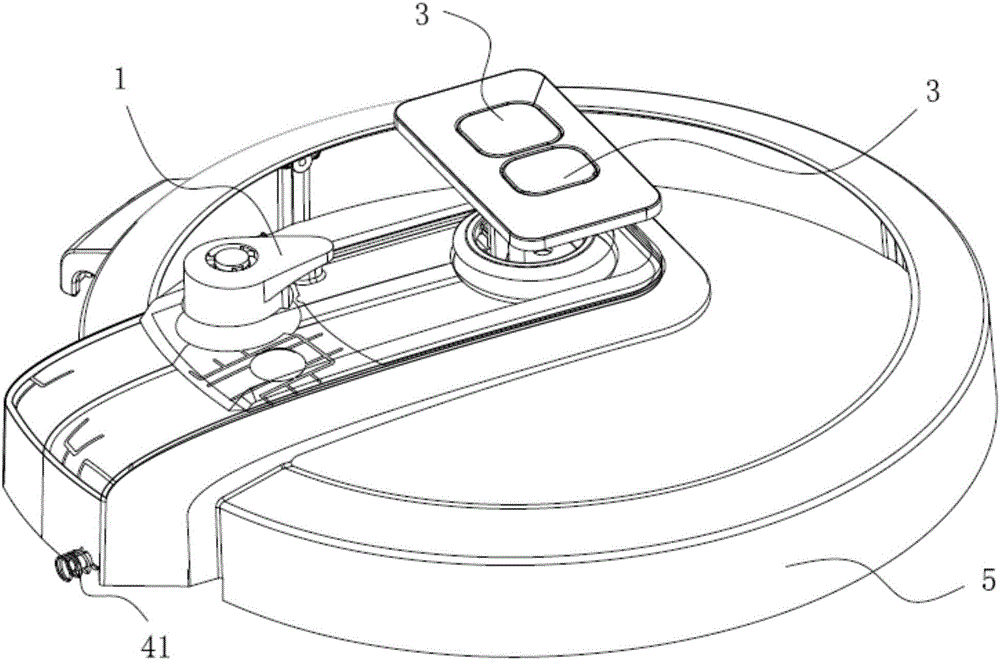

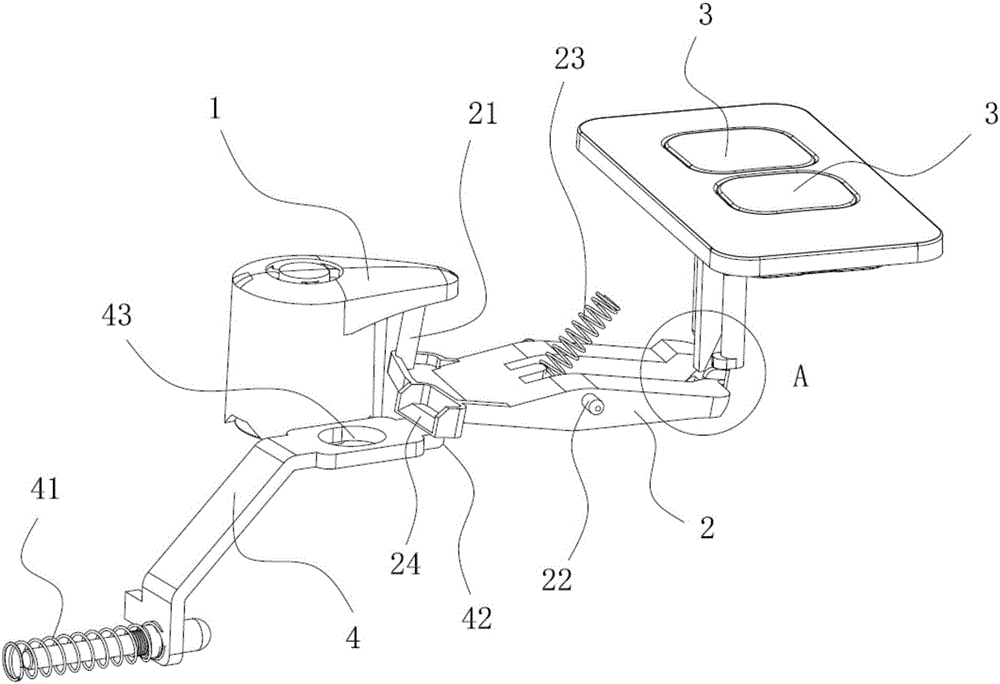

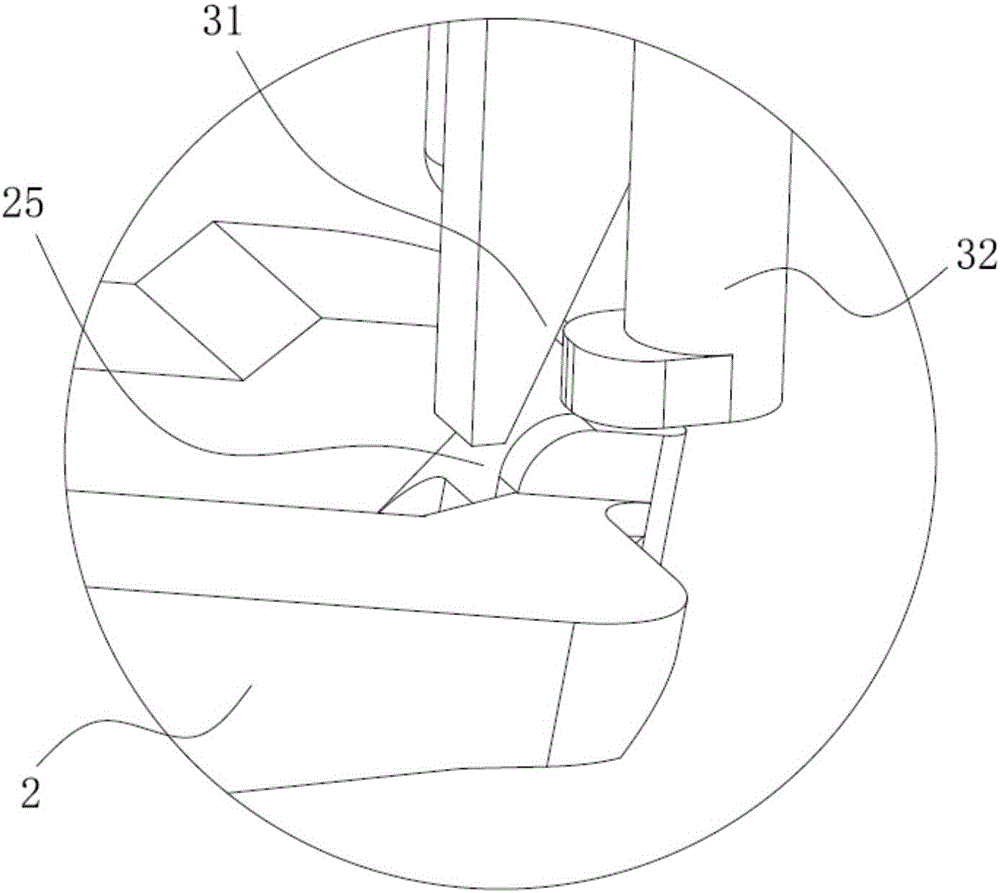

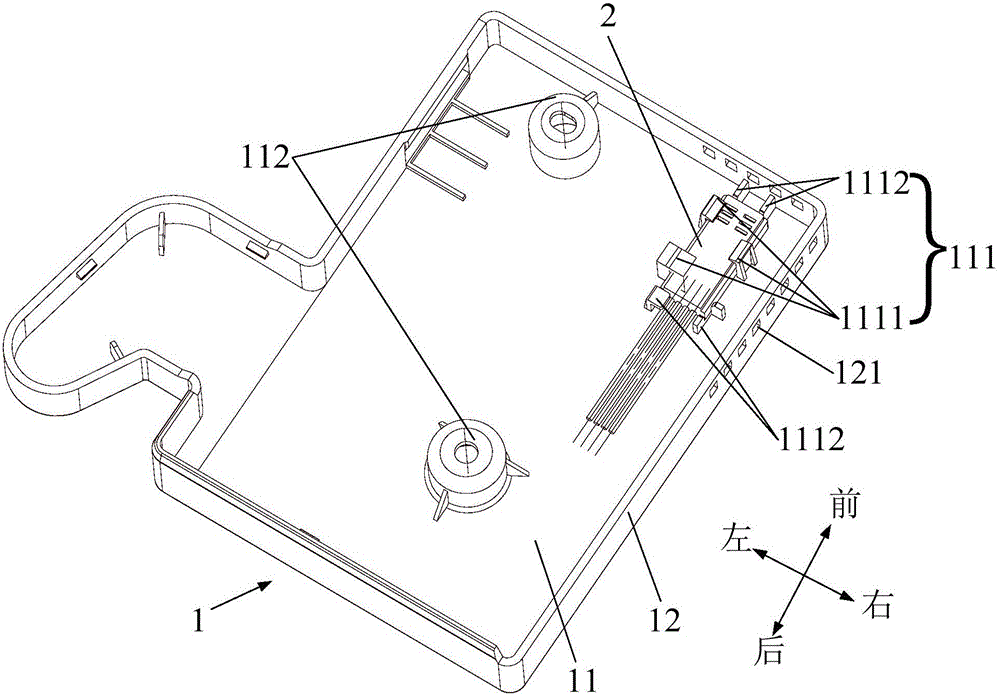

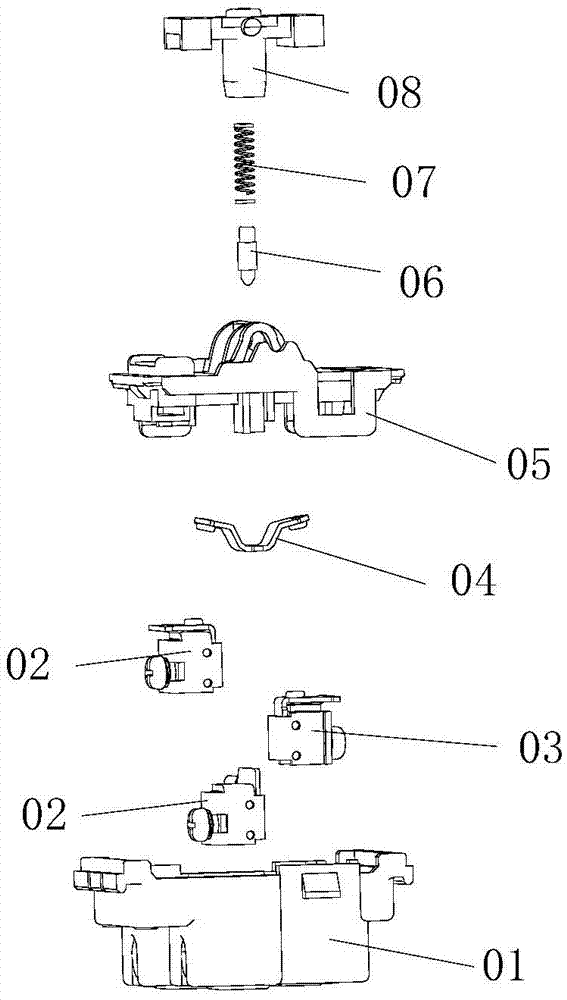

Pot cover assembly and pressure cooker

ActiveCN106539491AImprove assembly efficiencyThe overall structure is simple and reliablePressure-cookersEngineeringHigh pressure

The invention discloses a pot cover assembly and a pressure cooker and belongs to the technical field of pressure cookers. The pot cover assembly and the pressure cooker are designed to solve the problem that the structure of an existing device is complex. The pot cover assembly comprises a pressure-limiting valve and a valve body unbalance mechanism. The valve body unbalance mechanism can eject the pressure-limiting valve continuously after triggered and enable the pressure-limiting valve to be in an exhaust status continuously until the valve body unbalance mechanism is reset, and the electric pressure cooker is restored to a high pressure mode. The pot cover assembly and the valve body unbalance mechanism of the pressure cooker can eject the pressure-limiting valve continuously after the valve body unbalance mechanism is triggered and enable the pressure-limiting valve to be in the exhaust status continuously until the valve body unbalance mechanism is reset. The electric pressure cooker is restored to the high pressure mode only when the pot cover of the electric pressure cooker is opened or rotated. A non-pressure cooking mode is achieved by using the pressure-limiting valve to exhaust continuously. Manual exhaust can also be achieved; the structure is simple and reliable; using is convenient; assembling is easy; the assembling efficiency is high; and the cost is low.

Owner:GREE ELECTRIC APPLIANCES INC

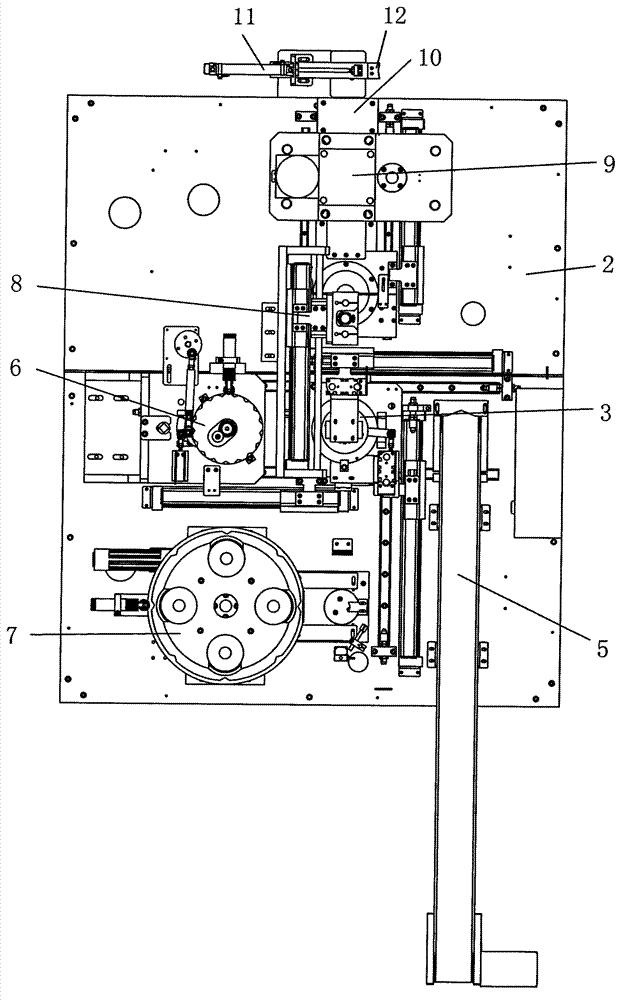

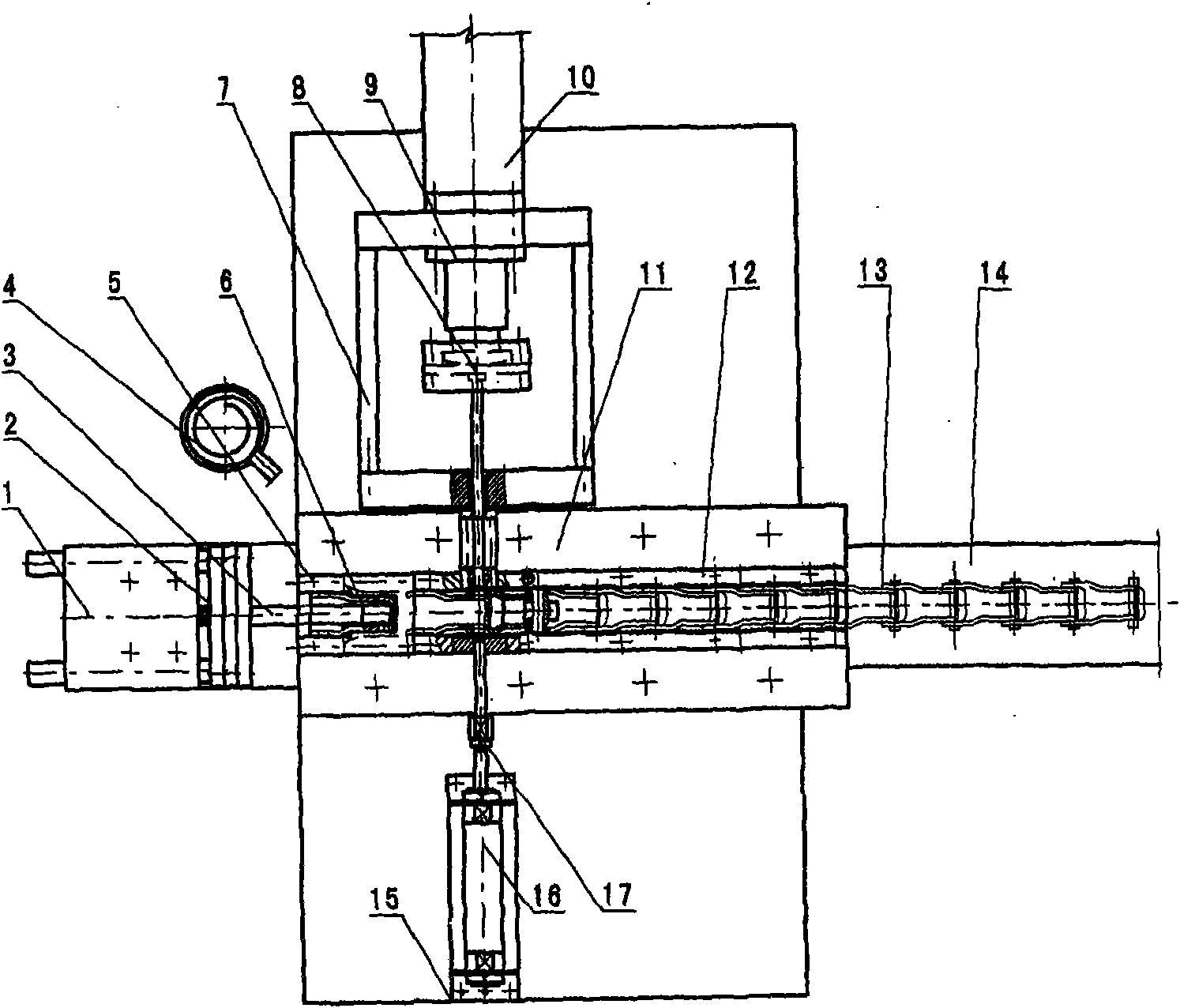

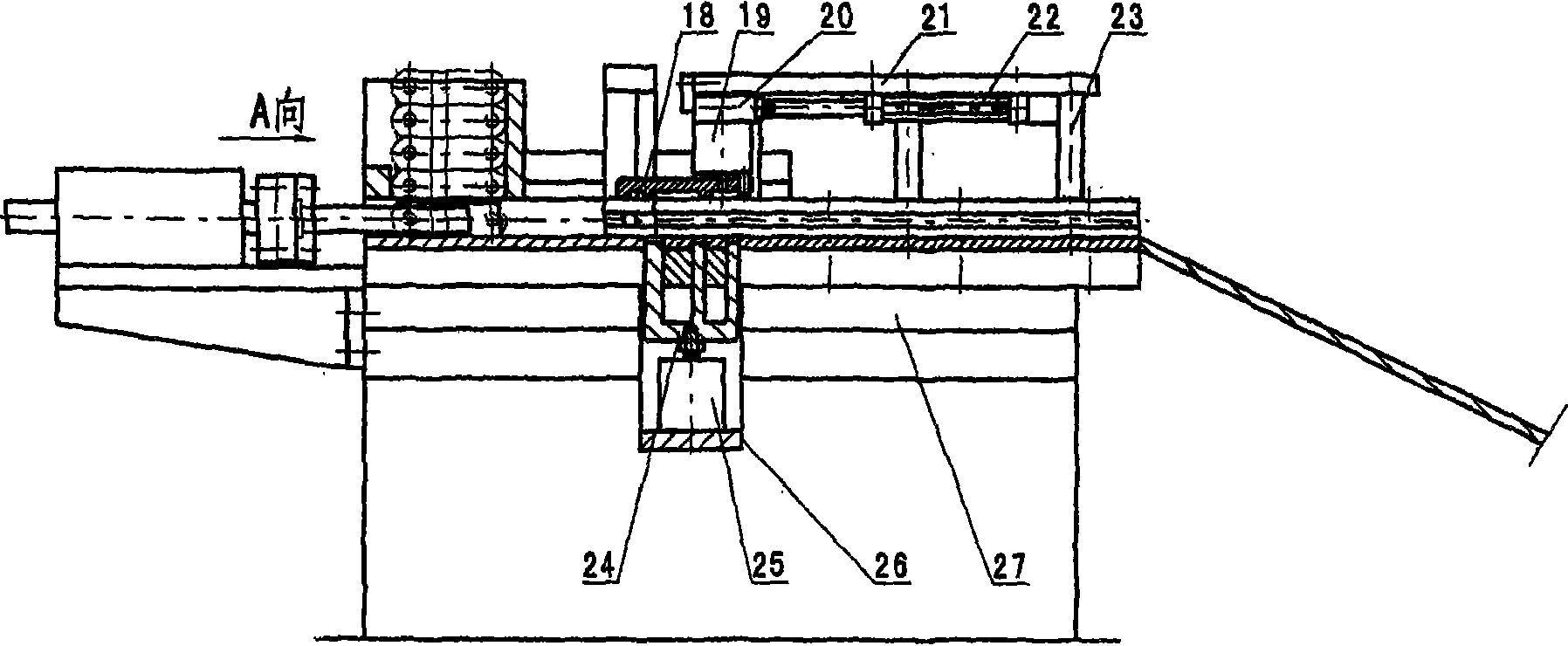

Pintle chain automatic assembly machine

InactiveCN101676049AGood assembly precisionSolve the shortcomings of manual assemblyMetal chainsControl systemEngineering

The invention relates to a pintle chain automatic assembly machine, belonging to the technical field of chain manufacturing machinery. The invention aims to provide a pintle chain automatic assembly machine which is suitable for the assembly production process of pintle chains and has good precision control and high production efficiency. The technical key of the pintle chain automatic assembly machine in that the assembly machine comprises a frame, a link plate feeding mechanism, a link plate positioning mechanism, a pin-penetrating mechanism, a chain element moving mechanism, a PLC automaticcontrol system and a discharging plate, wherein the link plate feeding mechanism comprises a double-cylinder feeding air cylinder (1) and a feeding pole (3) which are arranged in the front of the frame (27) and a link plate-feeding box (5); the link plate positioning mechanism comprises a positioning air cylinder (25) and a positioning block (24) which are arranged below the platen of the frame;the chain pin feeding and pin-penetrating mechanism comprises a pin-pressing air cylinder (10) and a pin-introducing air cylinder (16) which are arranged on the two sides of the parallel track of theplaten of the frame and a vibration pin-distributing disk (4), a pin-sending hose (30) and a pin-collecting box (32) which are arranged on the platen of the frame; the chain element moving mechanism comprises a moving air cylinder (22) and a chain element-pressing air cylinder (19) which are arranged above the platen of the frame; the discharging plate (14)is arranged on the backside of the platenof the frame.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

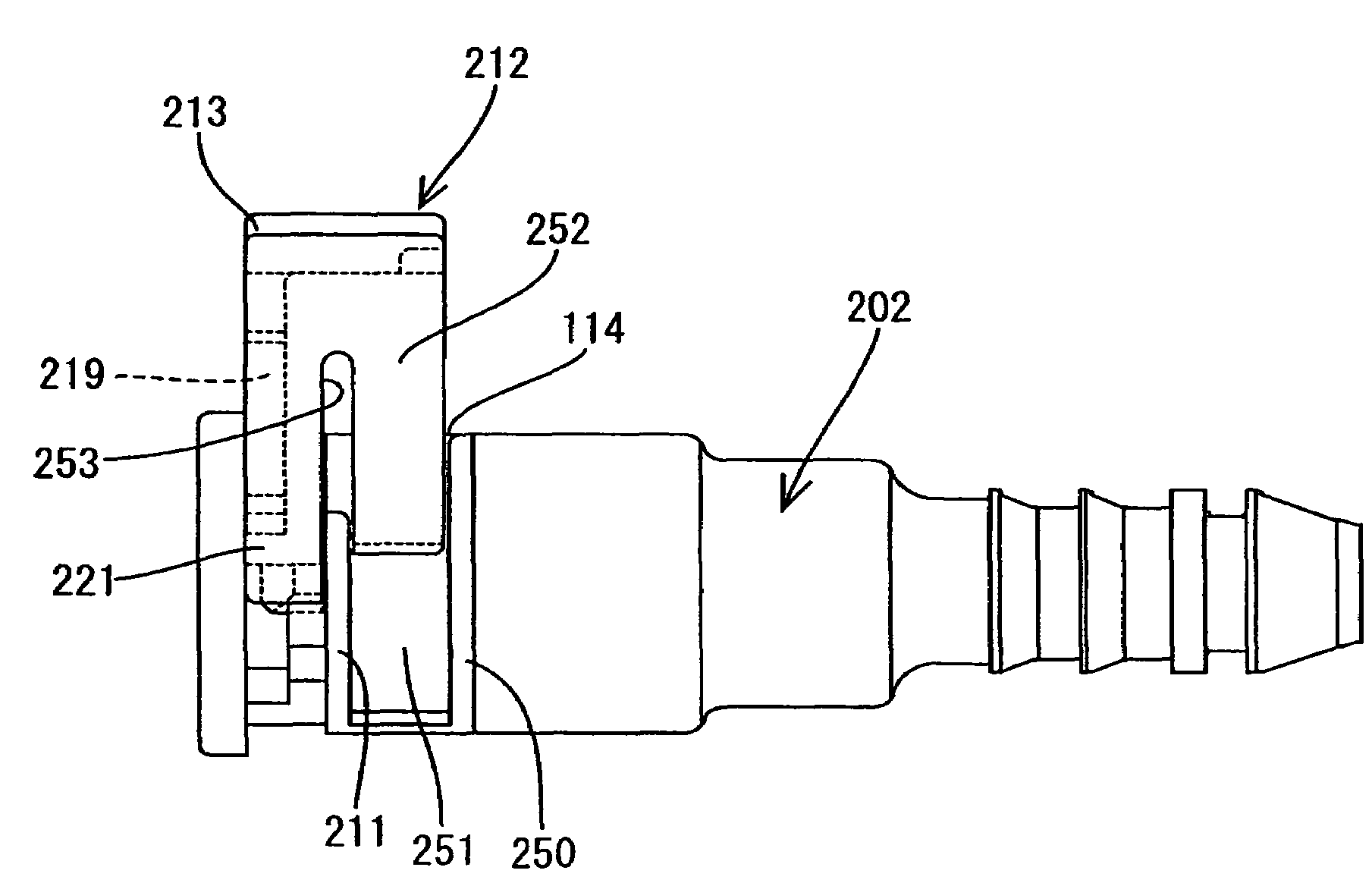

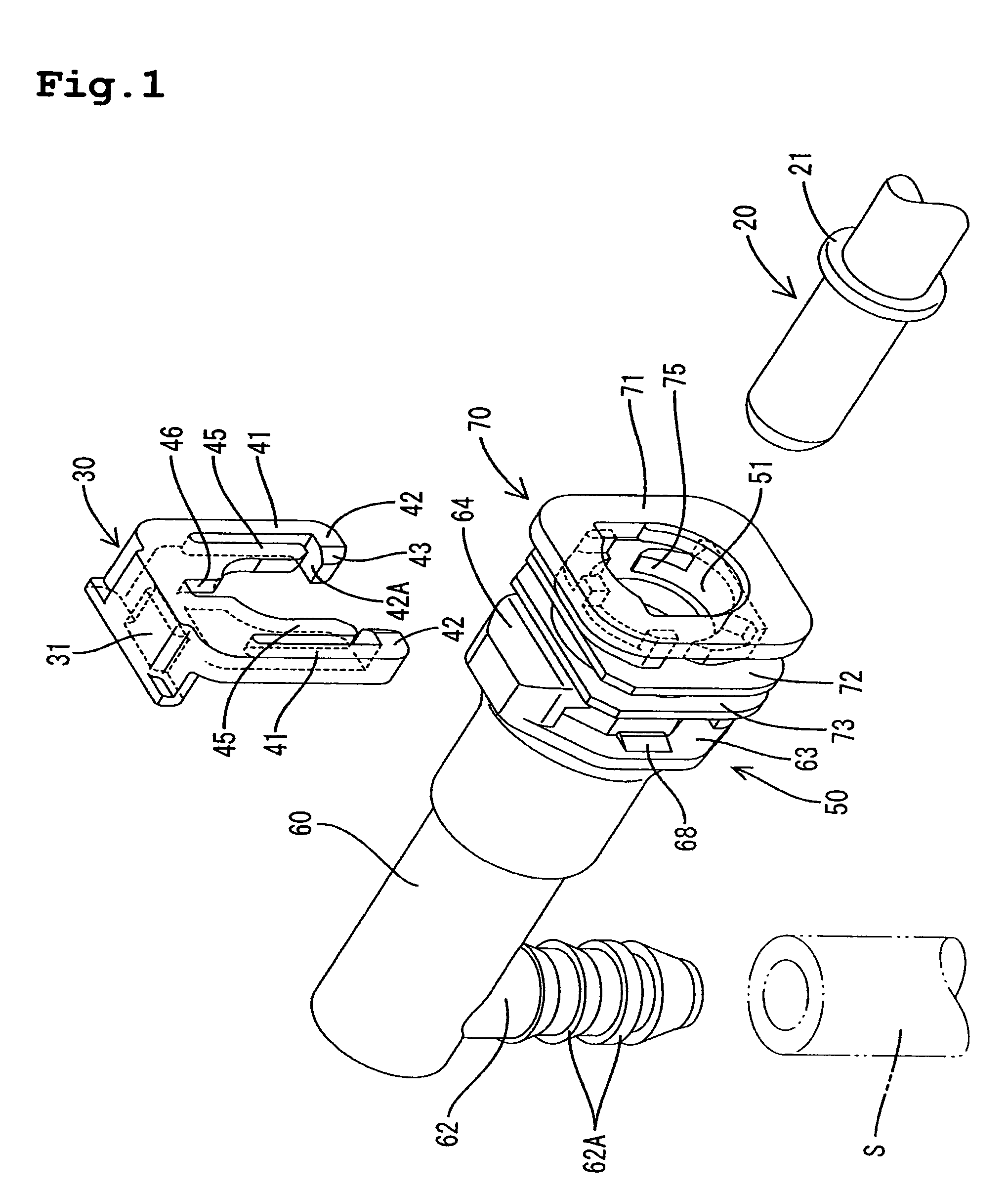

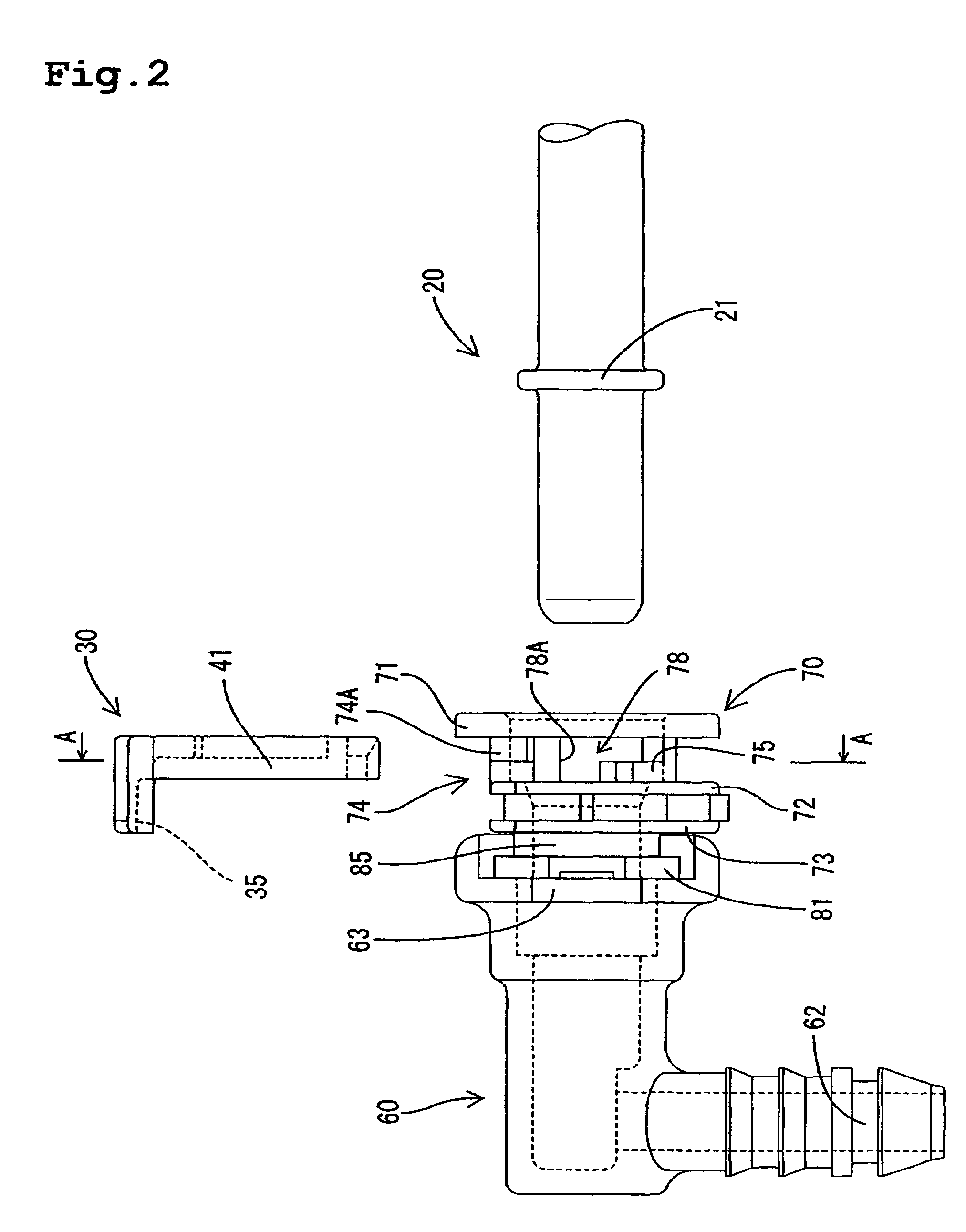

Pipe joint

ActiveUS7464970B2Improve assembly efficiencyPossible to selectPipe couplingsCouplingsEngineeringFlange

A pipe joint for connecting a rigid pipe with a retaining flange to a tube includes a pipe joint body formed with a through bore and a window in communication with the bore. A tube connector portion may be connected at an angle to a rigid pipe connector portion. A pipe retainer provided with locking pieces can be located in two positions relative to the pipe joint body. The first position allows the retaining flange to pass through the locking pieces. The second position retains the rear of the retaining flange and prevents inadvertent removal of the rigid pipe. The retaining pieces engage the rear of the flange through the window communicating with the bore. The locking direction of the retainer can be altered relative to the tube connector portion to suit different applications and ease assembly.

Owner:TOGO SEISAKUSYO CORP

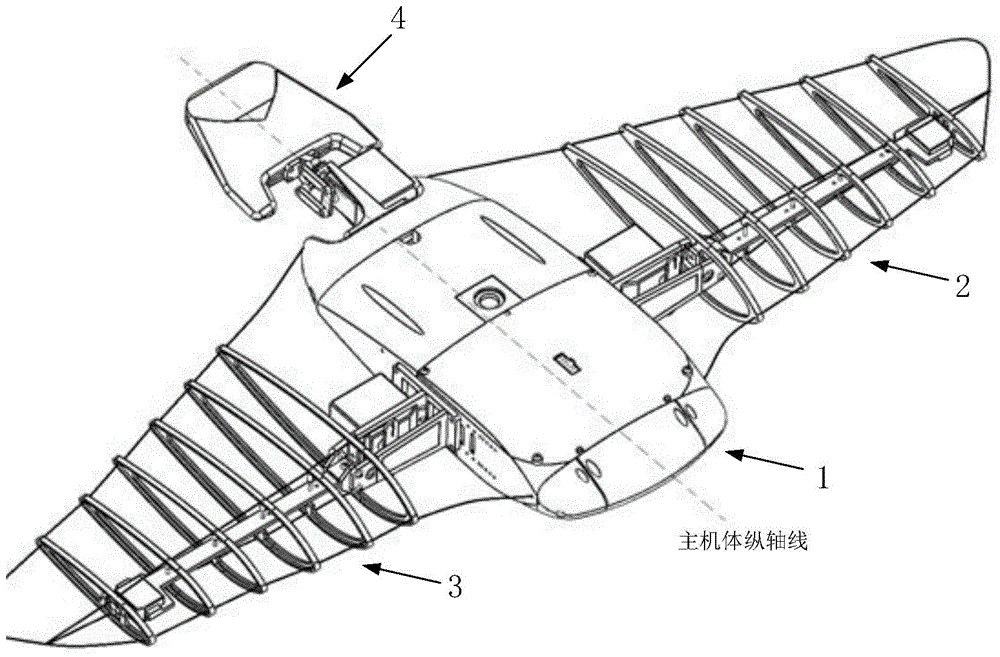

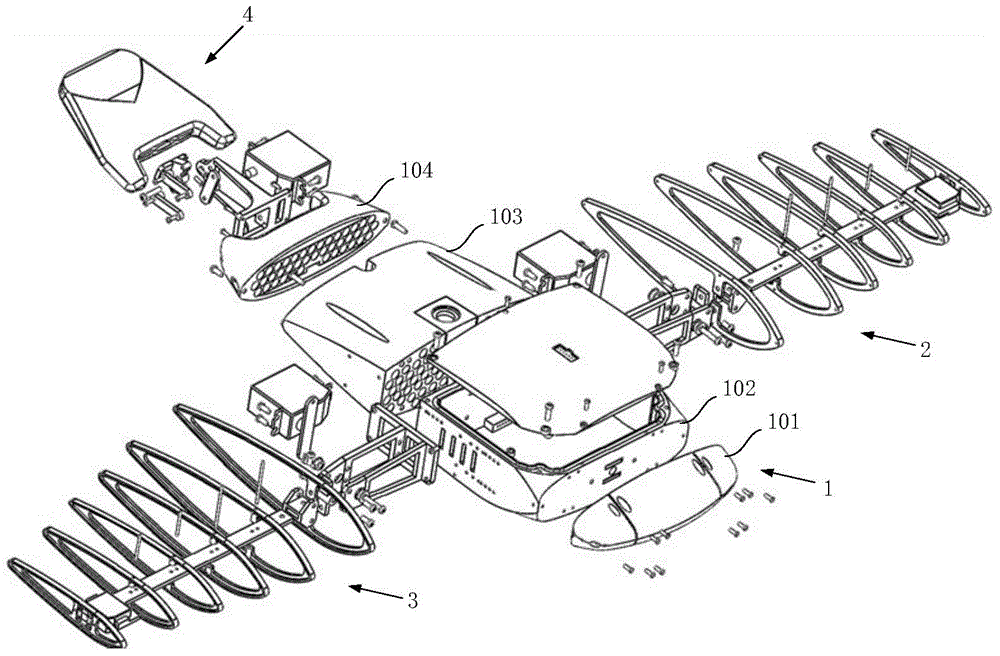

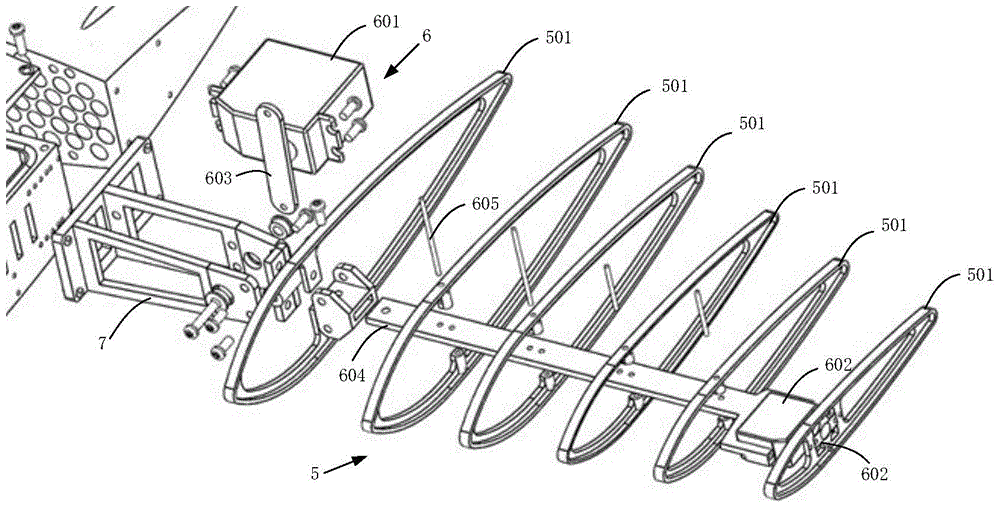

Novel modular bionic underwater robot based on full-flexible pectoral fins

InactiveCN104943839AImprove mobilityImprove concealmentPropulsive elements of non-rotary typePhase differenceBionics

The invention discloses a novel modular bionic underwater robot based on full-flexible pectoral fins. A hydrodynamic module of eagle ray pectoral fins is analyzed, and motion of the pectoral fins is decomposed into vertical bending flapping in the vertical body longitudinal axis direction and twisting motion taking the vertical body longitudinal axis direction as the axis. The whole robot comprises a sectioned main body, a left flexible pectoral fin module, a right flexible pectoral fin module and a tail fin module, and a group module is formed by connecting fin connecting parts; the left and right flexible pectoral fin modules are identical in structure and are in mirror symmetry; a pectoral fin framework adopts a structure similar to that of a plane rib, a symmetrical airfoil is taken as the basic shape, and the pectoral fin modules with streamline sections are spliced through serial connection of straight pectoral fin trunk bones and steel wires. A large steering engine and a small steering engine are arranged at the root and the tip of each pectoral fin to control vertical flapping and twisting motion of each pectoral fin. Through adjustment of motion amplitude, motion frequency and phase difference of the two steering engines of each pectoral fin, different pectoral fin motion postures can be realized, and fish body motion can be finished better.

Owner:BEIHANG UNIV

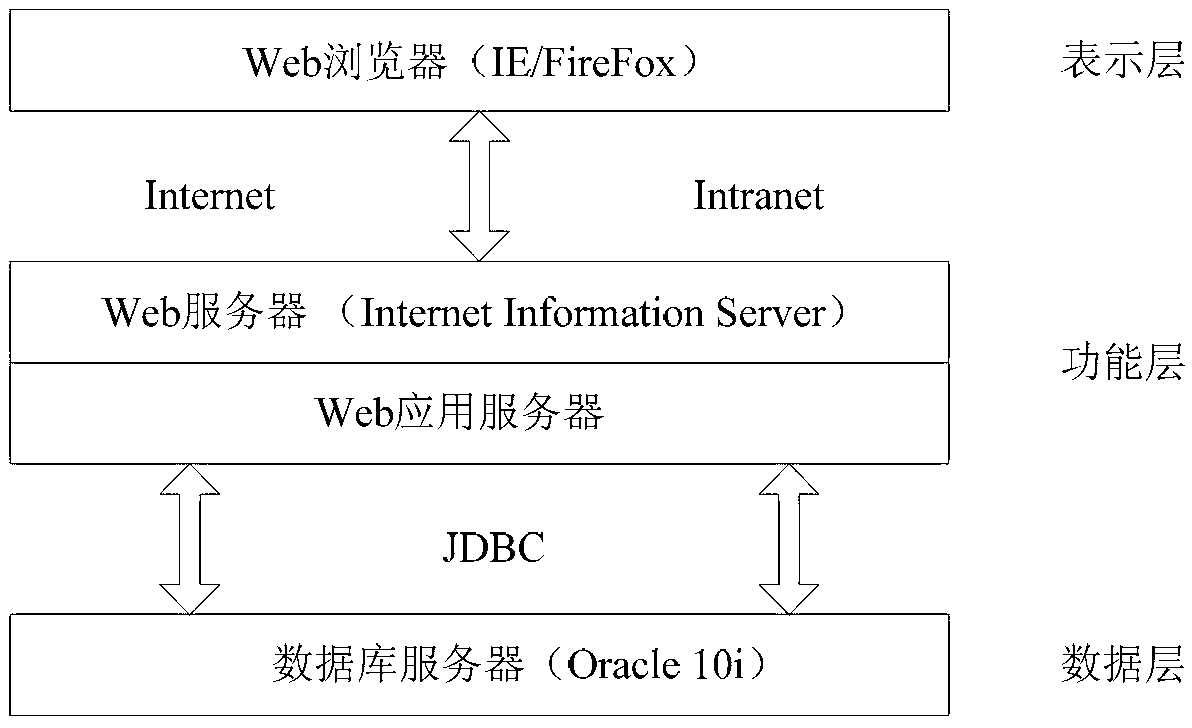

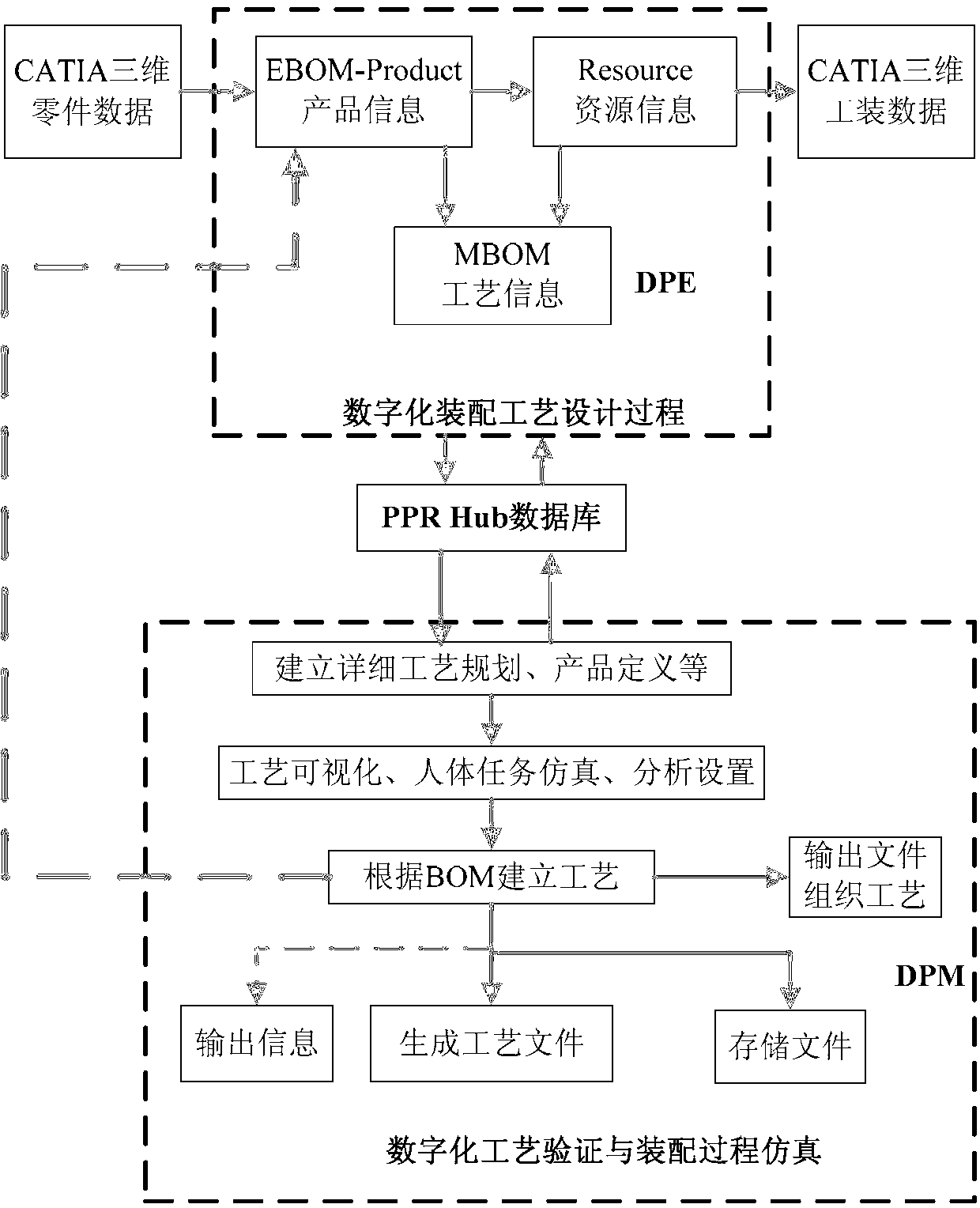

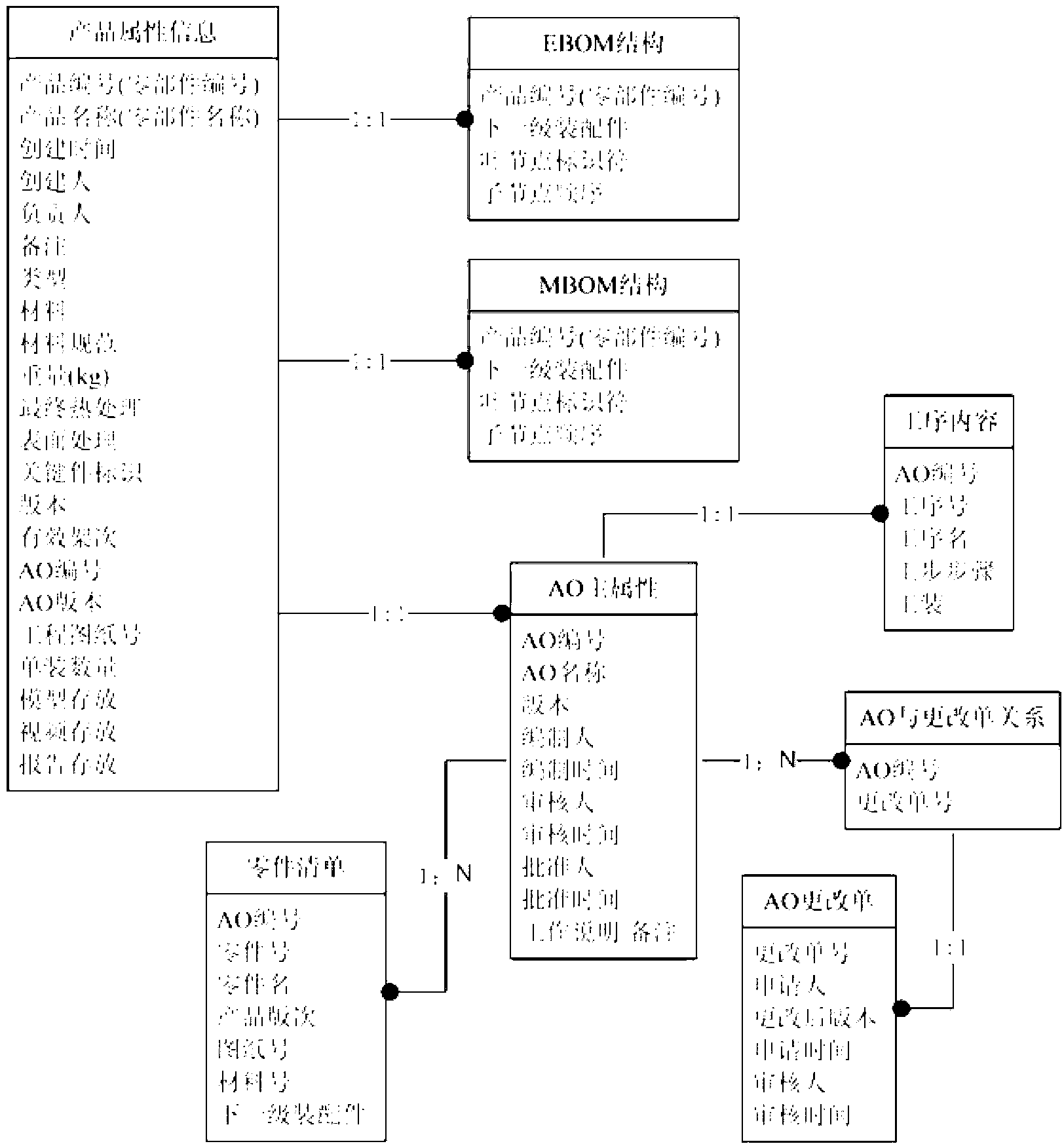

Aircraft assembly data visualization method based on Web

ActiveCN103020393ARealize online browsingReduce redundancySpecial data processing applicationsBill of materialsSimulation

The invention relates to an aircraft assembly data visualization method based on Web. The method comprises four steps as follows: step 1, setting up system architecture and development environment; step 2, visualization AO (Assembly Order) designing; step 3, assembling process simulation; and step 4, using in an assembly site. The method is used for realizing visual online browse of data such as BOM (Bill of Material), AO, product information and the like, and the assembly quality and the working efficiency of aircrafts are increased. The method has a better practical value and a wide application prospect in the aircraft industry.

Owner:BEIHANG UNIV

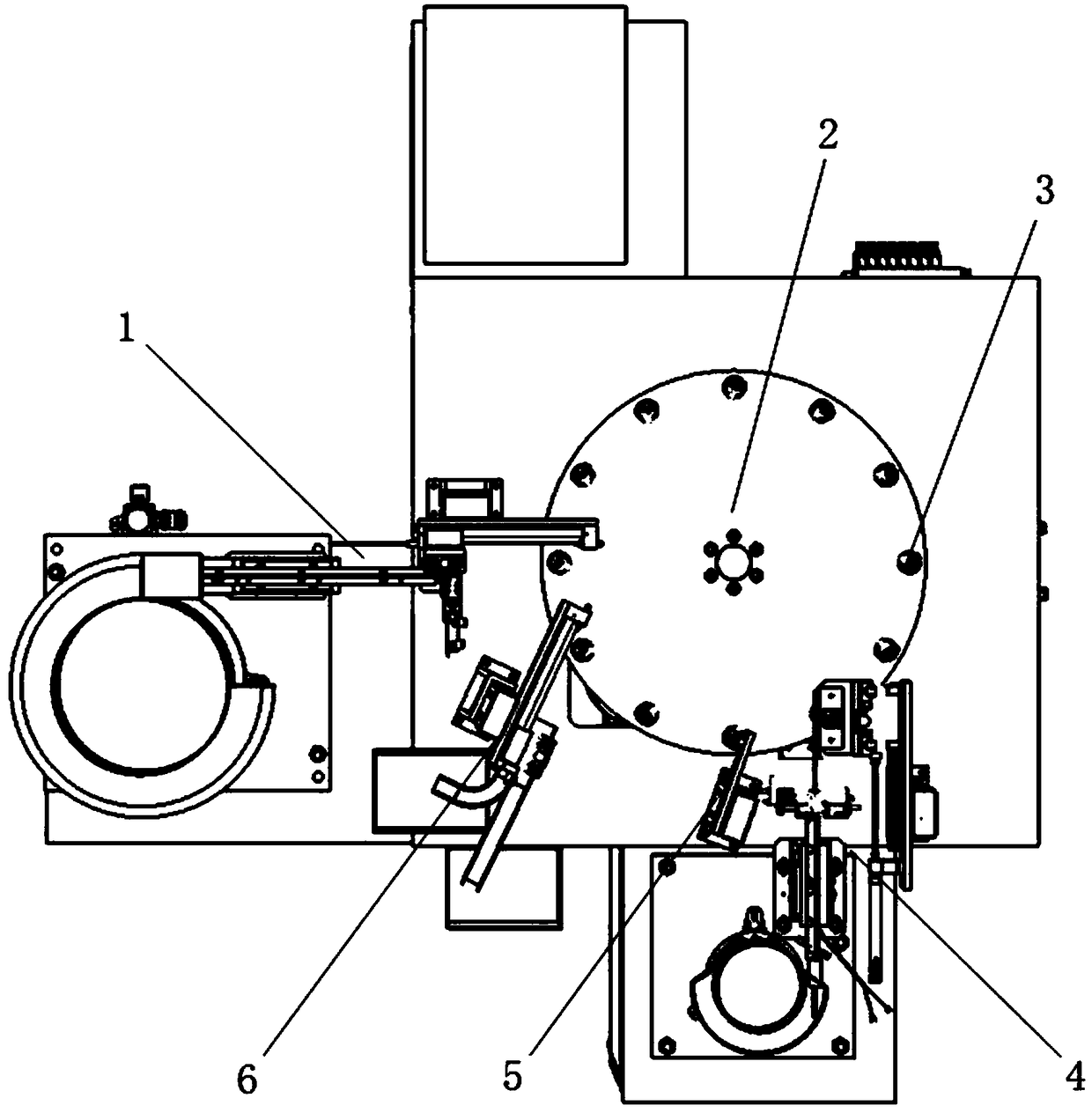

Expansion bolt automatic assembly machine

The invention discloses an automatic expansion bolt assembling machine, comprising a rack and a cam divider rotary table which is arranged on the rack and provided with a plurality of fixtures at intervals. The automatic expansion bolt assembling machine also comprises a nut feeding device, a shim feeding device, an expansion tube feeding device, a bolt feeding device, a rotary assembling device and a finished product discharging device which are all arranged on the rack, wherein the nut feeding device is used for feeding nuts into the fixtures; the shim feeding device is used for feeding shims into the fixtures; the expansion tube feeding device is used for feeding expansion tubes into the fixtures; the bolt feeding device is used for feeding bolts into the fixture; the rotary assemblingdevice is used for assembling the nuts, the shims, the expansion tubes and the bolts which are fed into the fixture; and the finished production discharging device is used for unloading an assembled finished product; and the automatic expansion bolt assembling machine also comprises a spring shim feeding device which is arranged between the shim feeding device and the expansion tube feeding device on the rack and is used for feeding spring shims into the fixtures. Therefore, all the components of an expansion bolt are automatically assembled into the expansion bolt; and the automatic expansion bolt assembling machine has the advantages of high assembling efficiency, stable product quality and the capability of effectively improving the product percent of pass.

Owner:DONGGUAN YIXIN AUTOMATION EQUIP

Hinged cover and refrigerator

ActiveCN105115221AExclude the impact of detectionImprove accuracyDomestic cooling apparatusLighting and heating apparatusEngineeringMoisture sensor

The invention provides a hinged cover and a refrigerator, wherein the hinged cover is used for the refrigerator; a door body and a box body of the refrigerator are connected by virtue of a hinge; and the hinged cover is mounted on the hinge. The hinged cover is characterized in that the hinged cover is provided with a top wall and a side wall, wherein the top wall and the side wall are enclosed to form an accommodating chamber; a vent hole is formed in the side wall; and a mounting part for mounting a temperature and humidity sensor is arranged in the accommodating chamber. According to the technical scheme, the influence of the door body or the box body on detection of the temperature and humidity sensor can be eliminated, and dust in water drops or air can be prevented from dropping onto the temperature and humidity sensor through the vent hole, thereby improving the detection accuracy of the temperature and humidity sensor.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

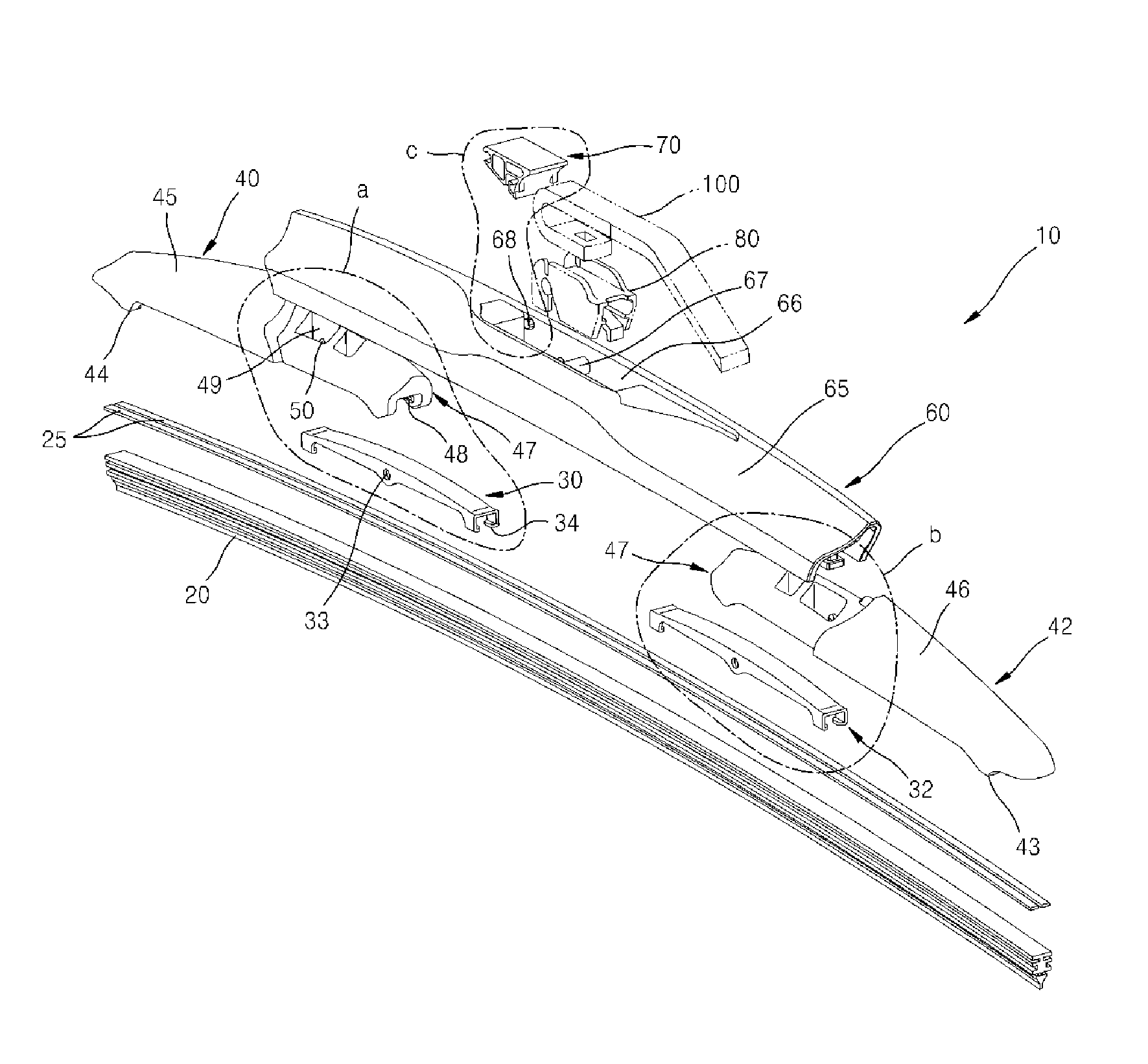

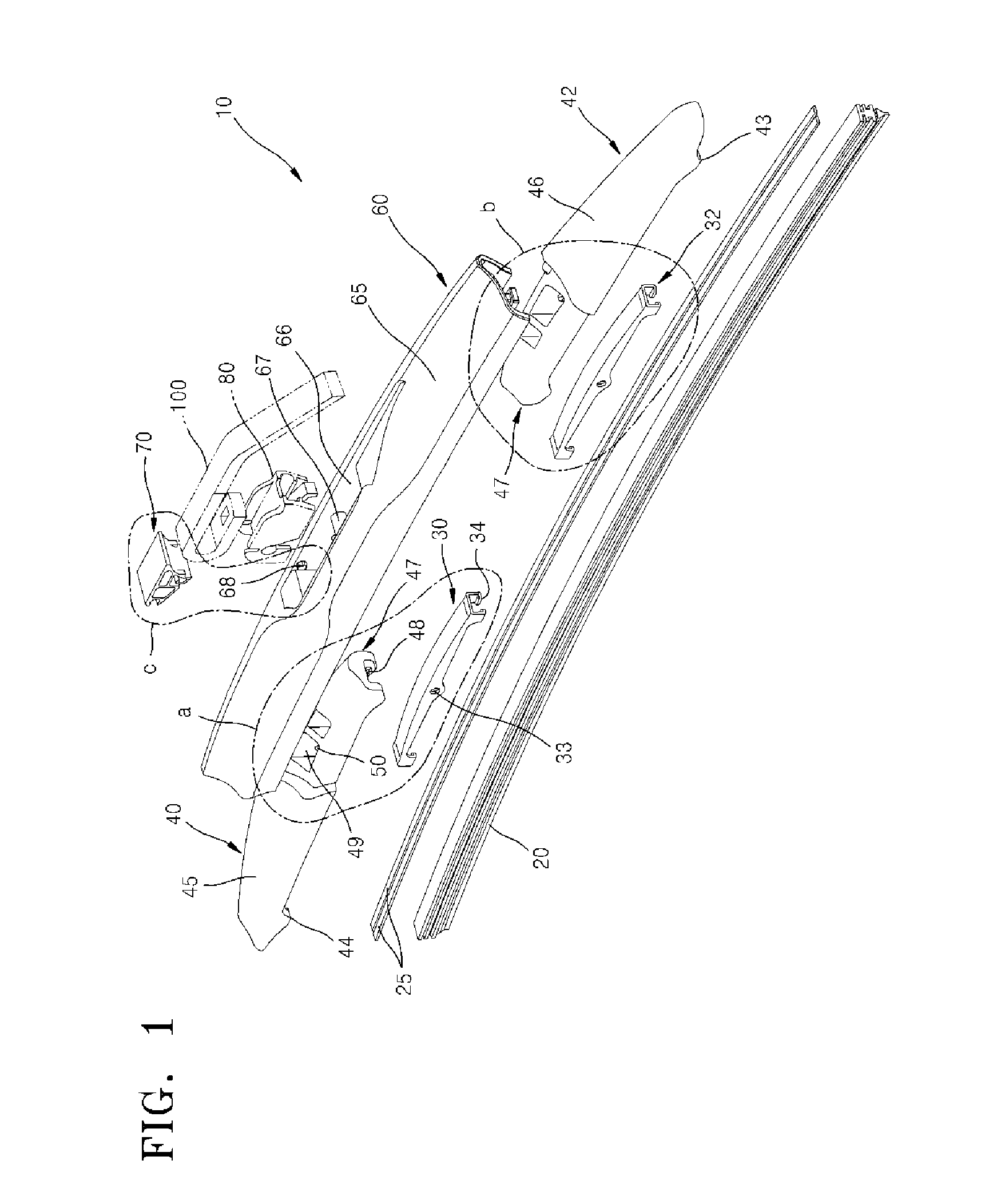

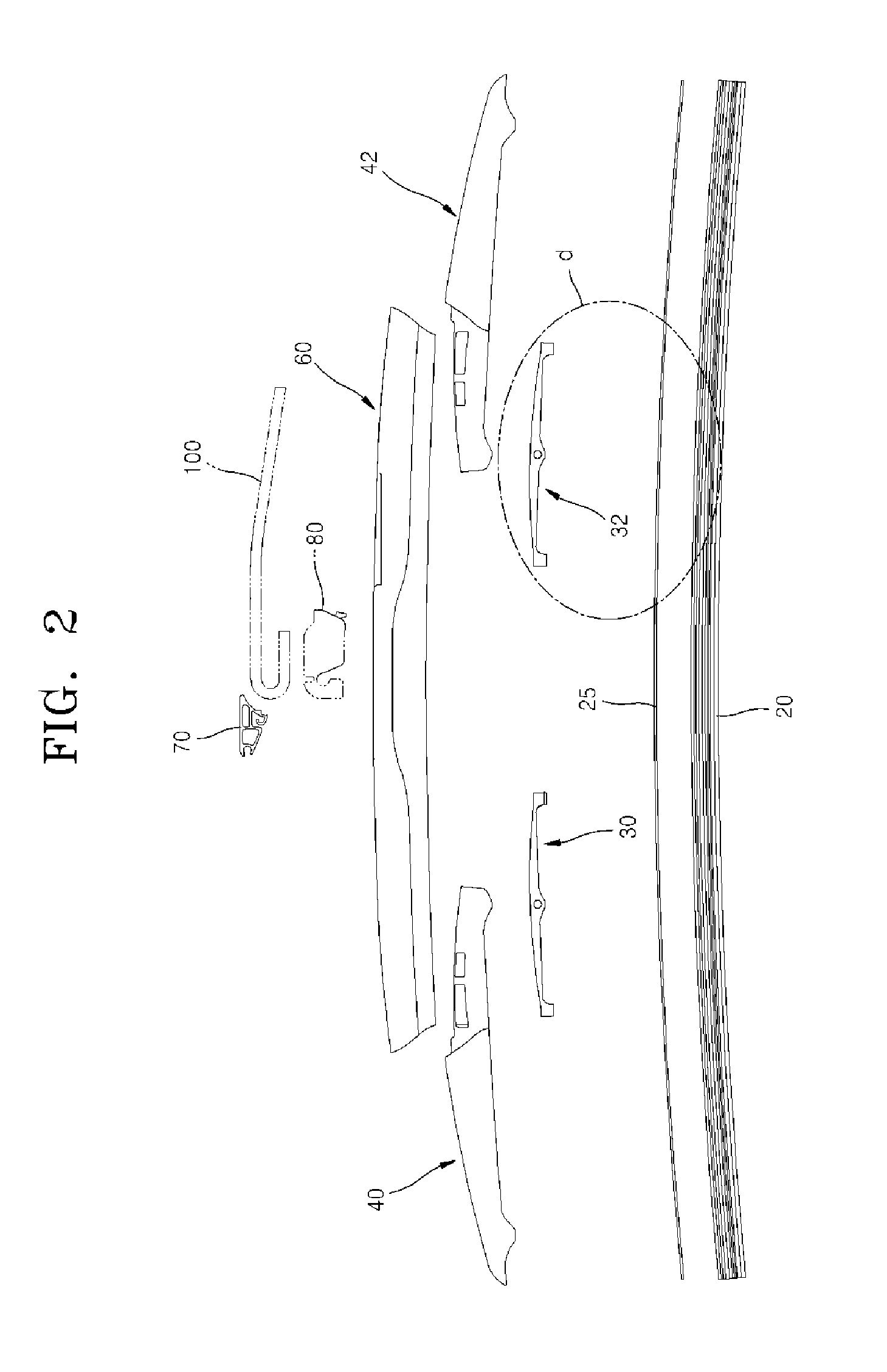

Wiper for vehicle having improved assembling efficiency and reduced weight

ActiveUS8181308B2Improve assembly efficiencyReduce weightWindow cleanersVehicle cleaningEngineeringMechanical engineering

Owner:DYAUTO

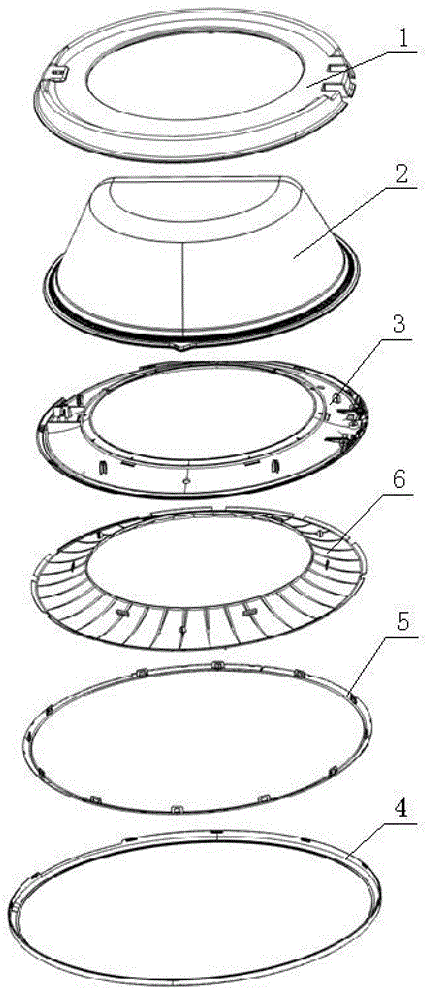

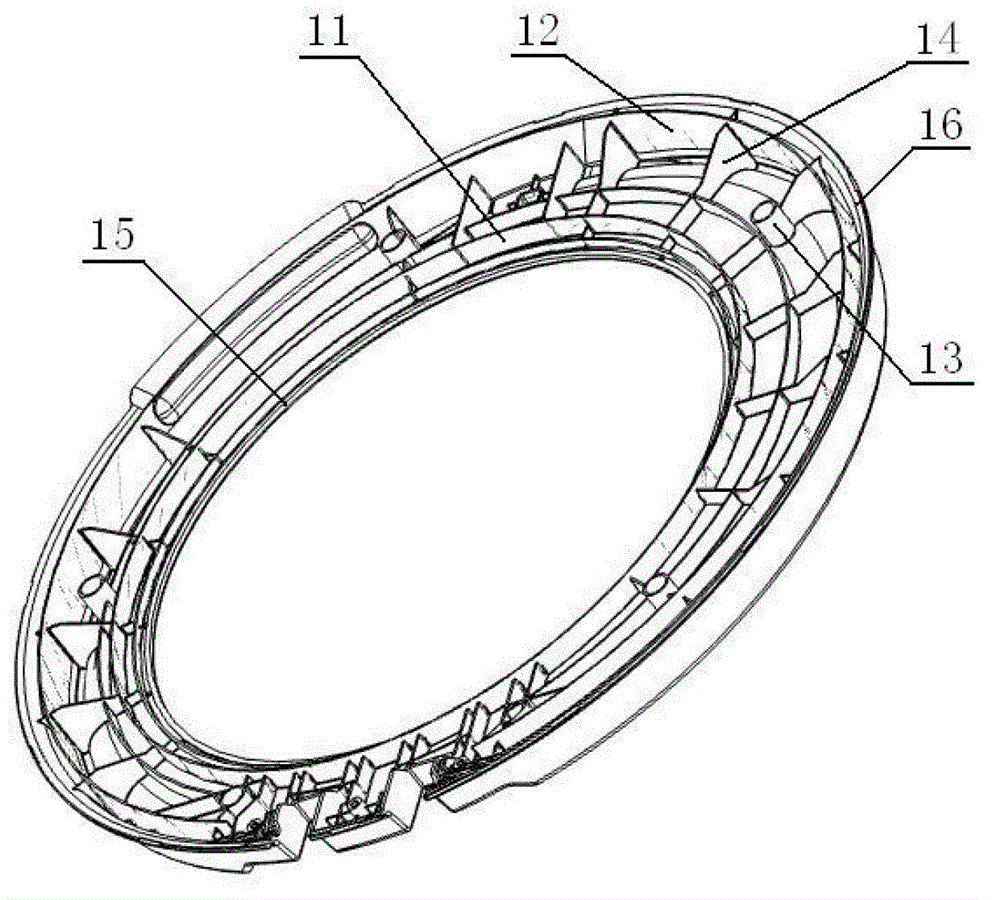

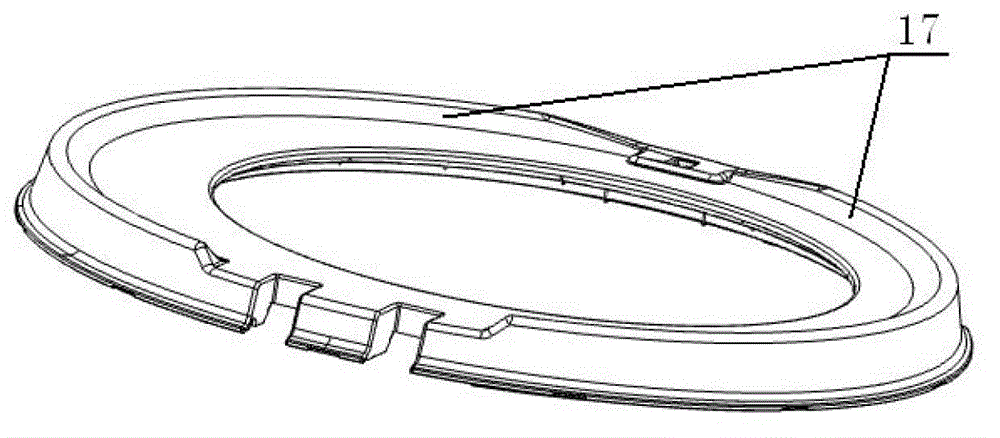

Door of front-loading washer and assembly method thereof

ActiveCN104372569AImprove reliabilityIncreased durabilityOther washing machinesTextiles and paperEngineeringFront loading

The invention discloses a door of a front-loading washer and belongs to the field of parts for front-loading washers. The door comprises an inner frame, a transparent basin, a middle frame and an outer frame which are arranged in order from inside of the door to the outside of the door; a window screen is disposed between the outer frame and the middle frame; the middle frame is in welded connection with the inner frame; the outer frame and the window screen are fastened to the middle frame; a decoration is provided between the window screen and the middle frame. The door is compact in structure and convenient to mechanically assemble; parts of the door are flexible to combine and select; personalized needs of different users can be met. An assembly method of the door includes assembling the parts of the door by plastics welding; production is highly effective; products are more reliable and durable.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD

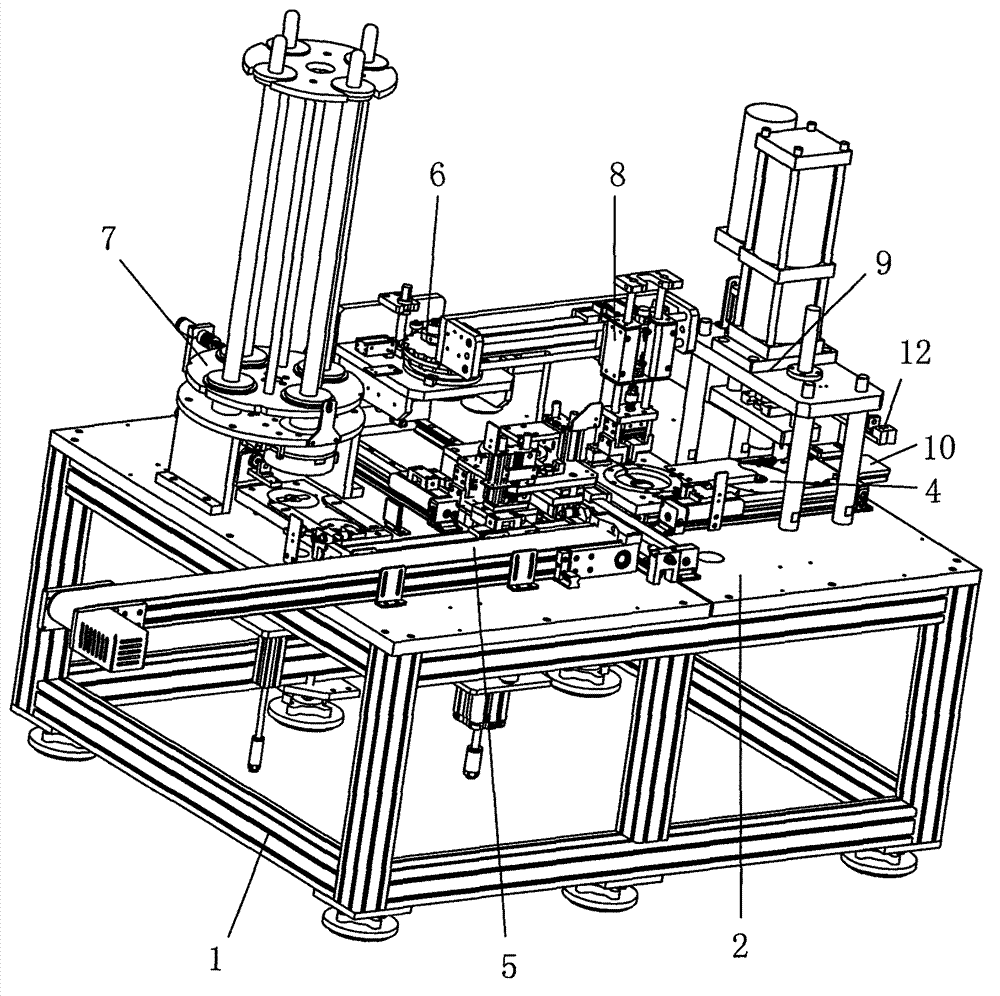

Automatic assembly machine for wall control switch

ActiveCN105448562AHigh degree of automationImprove assembly efficiencyAssembly machinesElectric switchesEngineeringControl switch

The invention discloses an automatic assembly machine for a wall control switch. The automatic assembly machine comprises a rack, a trough conveyer device, a base feeding mechanism, a side terminal feeding assembly mechanism, a medium terminal feeding assembly mechanism, a terminal missing detection mechanism, a wane feeding assembly mechanism, an oil adding mechanism, a rotary plate mechanism, a bullet feeding mechanism, a spring feeding assembly mechanism, a pressure plate feeding assembly mechanism, a transition part feeding assembly mechanism, a transition part component assembly mechanism, a switch conduction detection mechanism, a defective product discharge mechanism and a finished product discharge mechanism, wherein the trough conveyer device, the base feeding mechanism, the side terminal feeding assembly mechanism, the medium terminal feeding assembly mechanism, the terminal missing detection mechanism, the wane feeding assembly mechanism, the oil adding mechanism, the rotary plate mechanism, the bullet feeding mechanism, the spring feeding assembly mechanism, the pressure plate feeding assembly mechanism, the transition part feeding assembly mechanism, the transition part component assembly mechanism, the switch conduction detection mechanism, the defective product discharge mechanism and the finished product discharge mechanism are arranged on the rack. According to the automatic assembly machine for the wall control switch, various components of the wall control switch can be automatically assembled into a finished product of the wall control switch; the automatic degree and the assembly efficiency are high; the quality of the product is stable; and the qualified rate of the product can be effectively improved.

Owner:DONGGUAN YI CHENG AUTOMATIC EQUIP

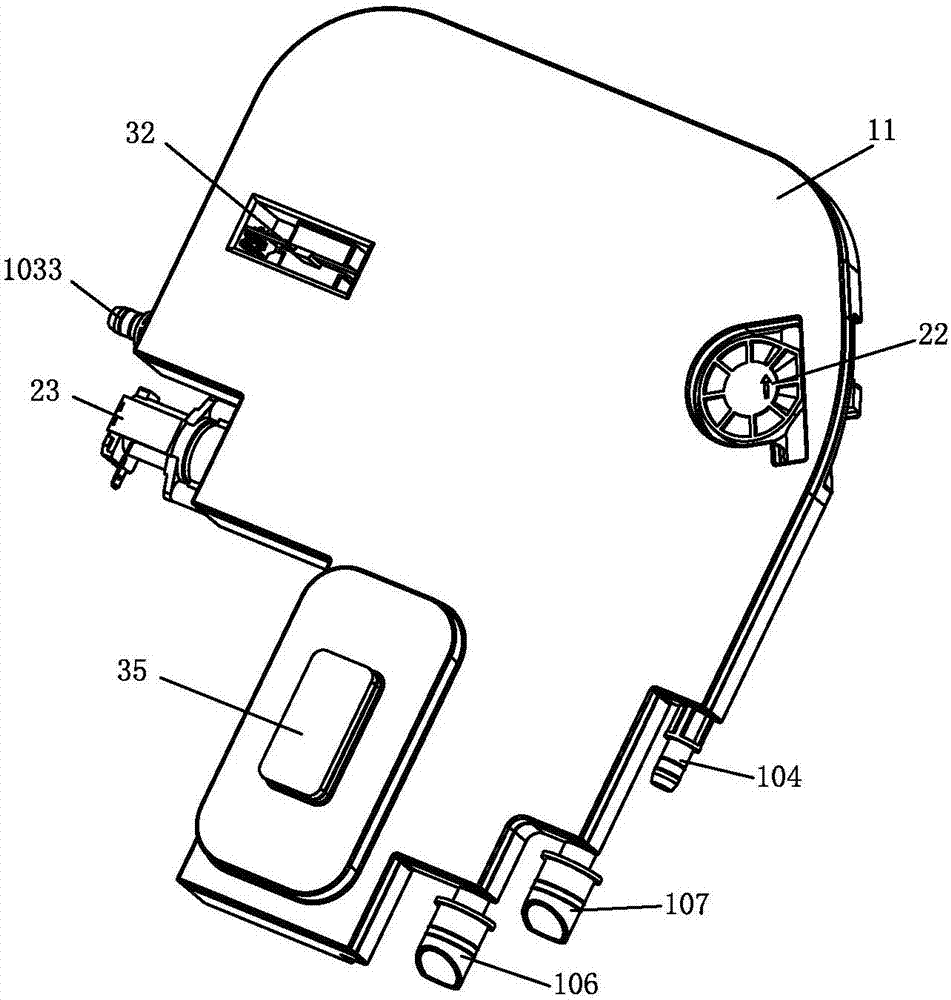

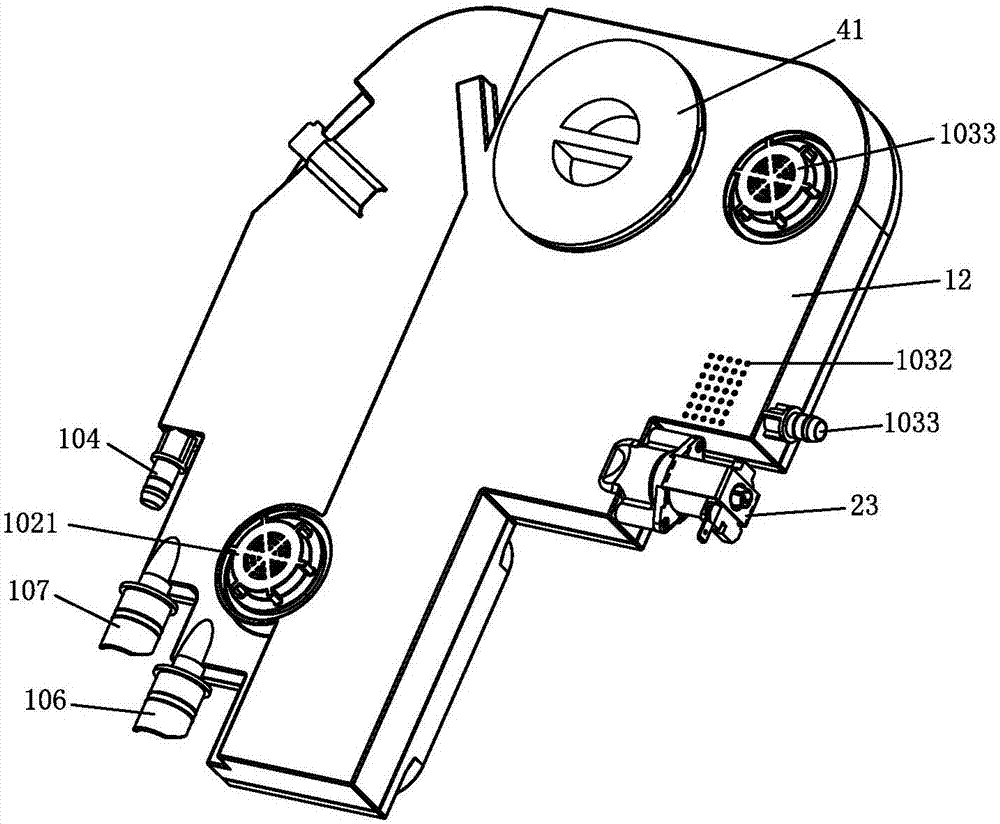

Respirator and softener assembly for dish washing machine

PendingCN106963318ASolve the problem of too small to install a water softenerSave spaceTableware washing/rinsing machine detailsSoftened waterEngineering

The invention relates to a respirator and softener assembly for a dish washing machine. The assembly comprises a body composed of an upper respirator and softener piece and a lower respirator and softener, a salt cavity and a resin cavity are formed in the body and adjacent to each other in a spaced mode, a water inlet device interface is arranged at the position, corresponding to a softened water outlet end of the resin cavity, on the body, and a respirator interface is arranged at the position, corresponding to the salt cavity, on the body. By means of the innovated design, the respirator, the water inlet device and a water softener are integrated to form the respirator and softener assembly, space is greatly saved, the respirator and softener assembly can be vertically installed in the dish washing machine, and the problem that the bottom spaces of a water tank dish washing machine, a table type dish washing machine, a drawer dish washing machine, a small dish washing machine and the like are small and accordingly water softeners cannot be installed is solved.

Owner:中山市吉相电器有限公司

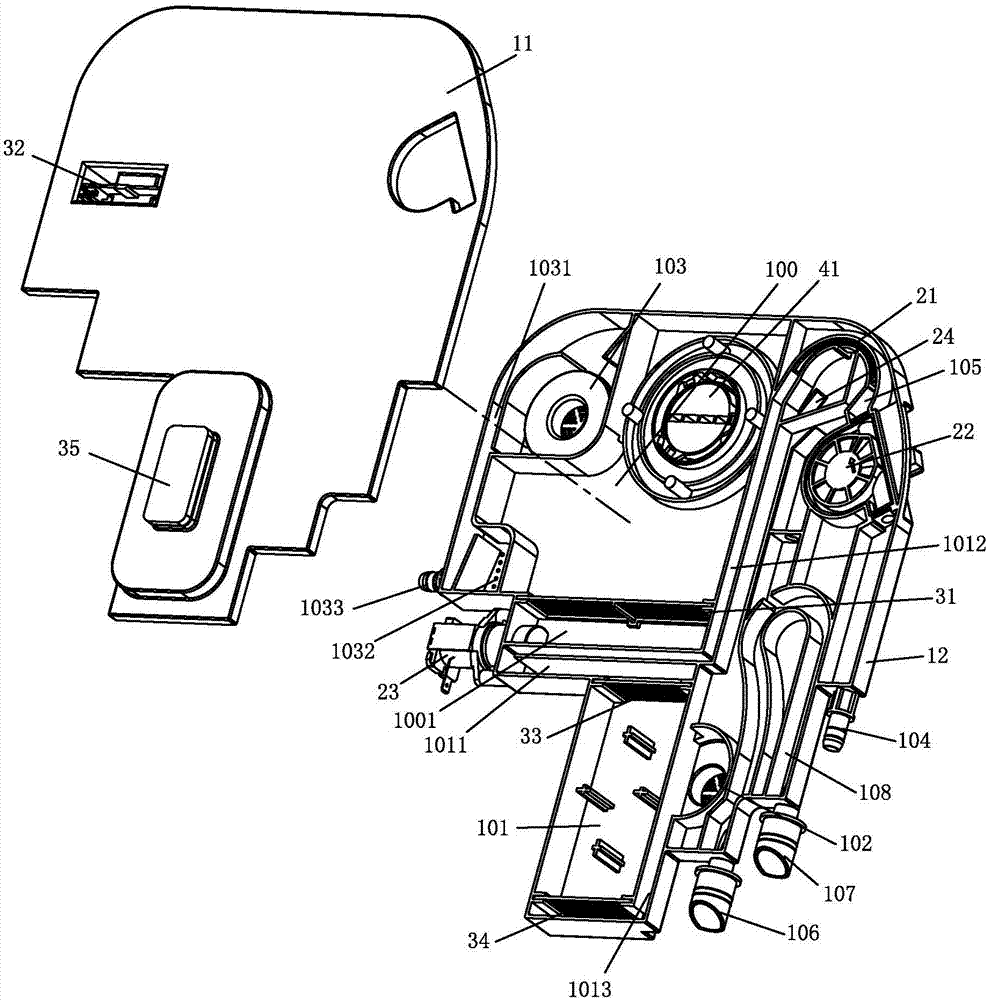

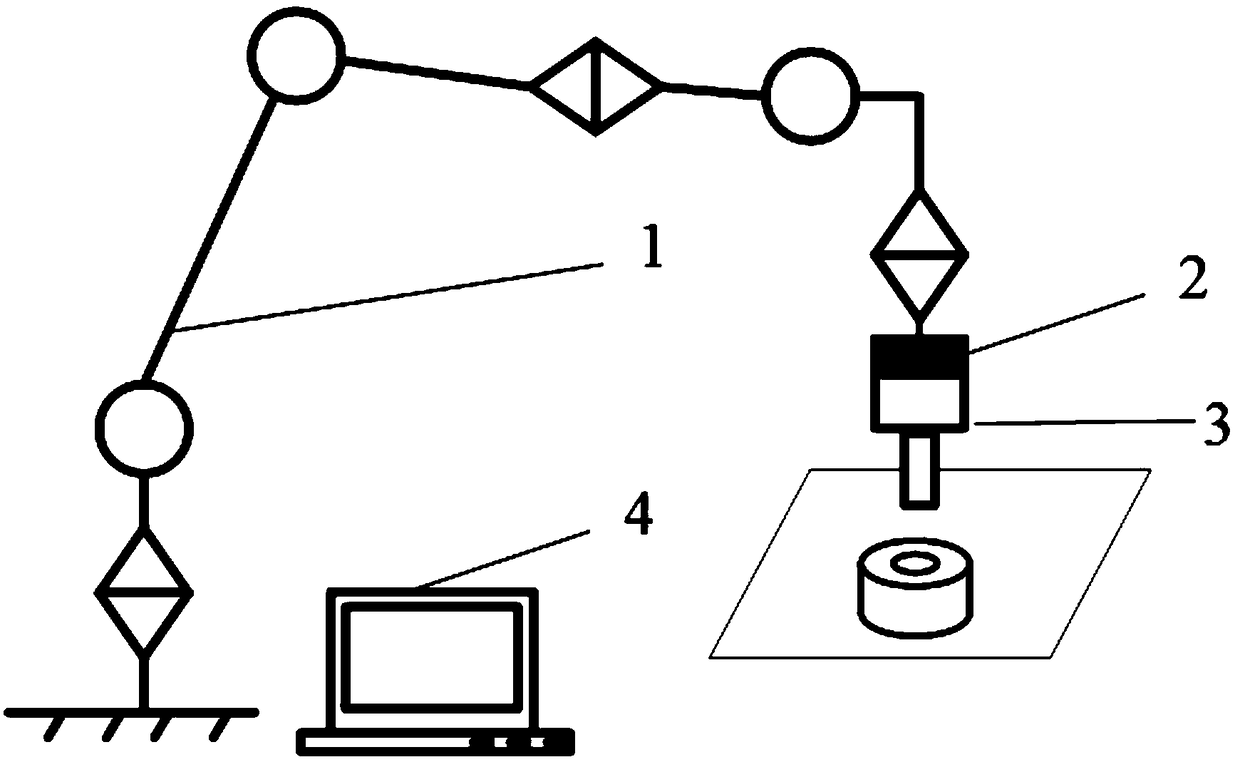

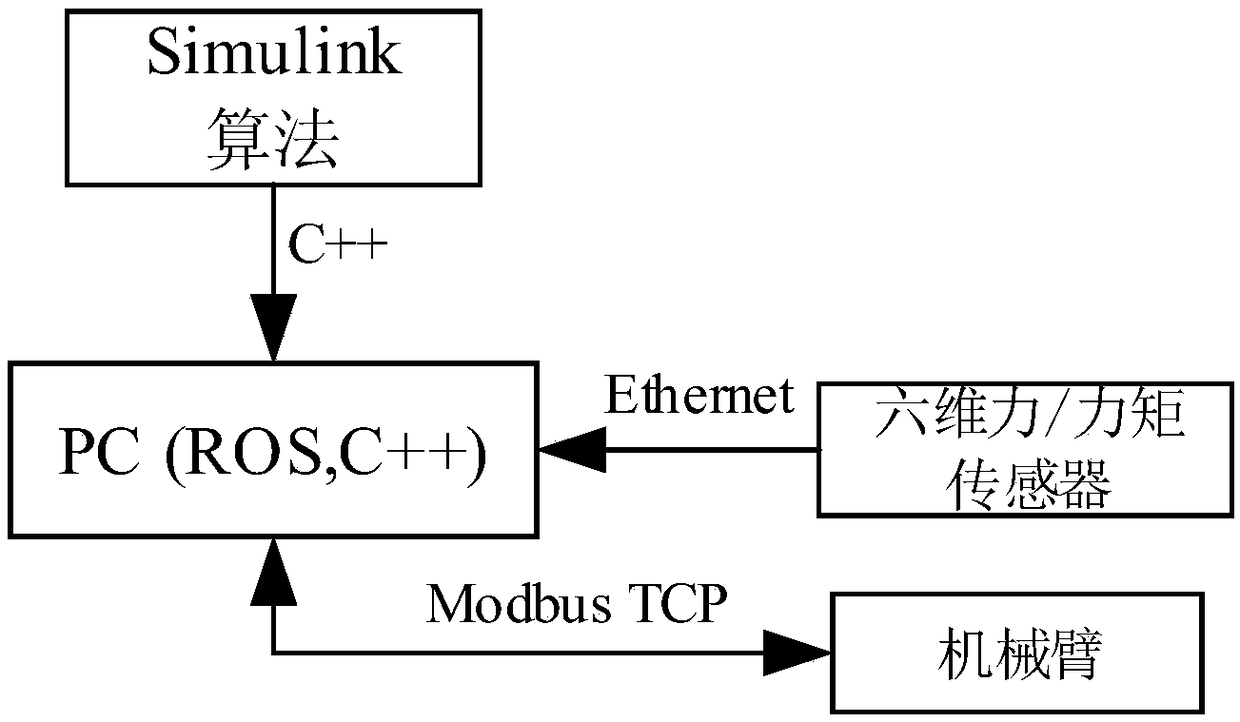

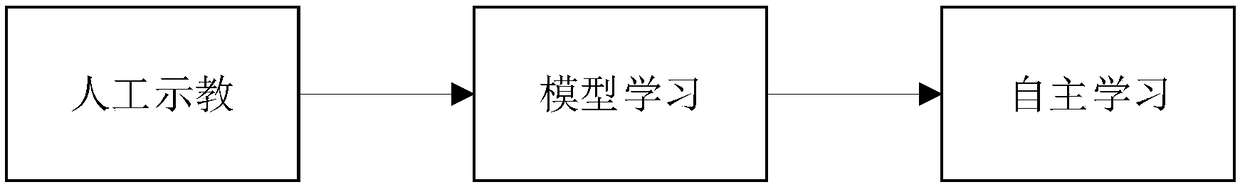

Robot shaft hole assembly system and method based on teaching learning

ActiveCN109382828AAvoid Calibration WorkLower application thresholdProgramme-controlled manipulatorMetal working apparatusTorque sensorAssembly systems

The invention discloses a robot shaft hole assembly system and method based on teaching learning. The system comprises a mechanical arm, a six-dimensional force / torque sensor, a passive flexible RCC device and a PC upper computer, wherein the mechanical arm is a multi-axis mechanical arm, the six-dimensional force / torque sensor is arranged at the tail end of the mechanical arm, the passive flexible RCC device is arranged on the six-dimensional force / torque sensor, the passive flexible RCC device is provided with a clamping tool used for clamping a to-be-assembled component, and the PC upper computer can achieve real-time communication with the mechanical arm and six-dimensional force / torque sensor. Firstly, a manual teaching recorder completes the assembly of task data, an assembly skill model is trained by adopting a learning algorithm, then under a control command of the PC upper computer, the mechanical arm carries a pin component to perform shaft hole assembly, and a control systemestablished by the PC upper computer is based on an ROS platform. The robot shaft hole assembly system and method based on teaching learning have the advantages that a flexible behavior of a person when an assembly task is completed is imitated by combining teaching learning, so that the automatic flexible assembly operation of a robot is achieved, and the operation requirements can be met well.

Owner:武汉库柏特科技有限公司

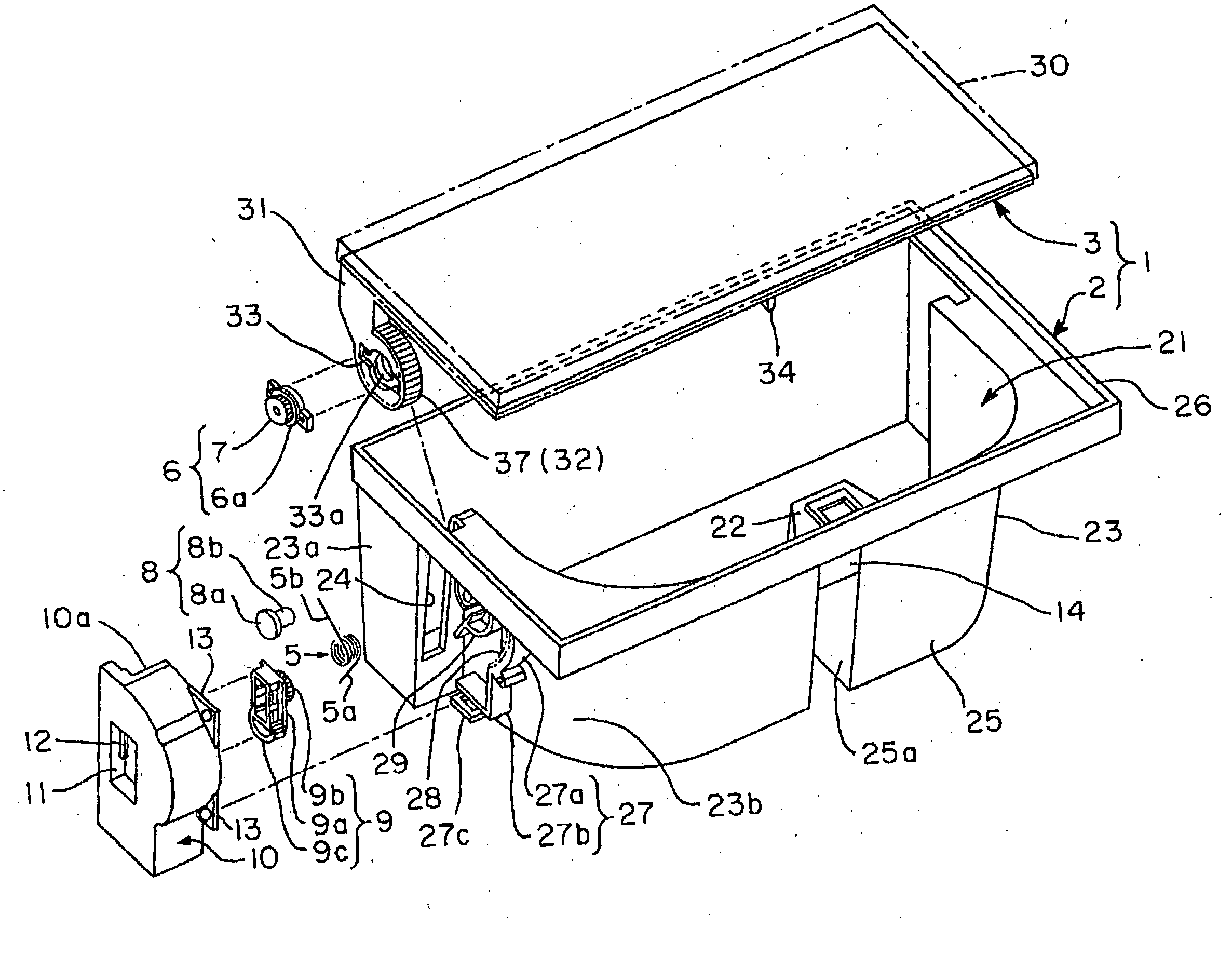

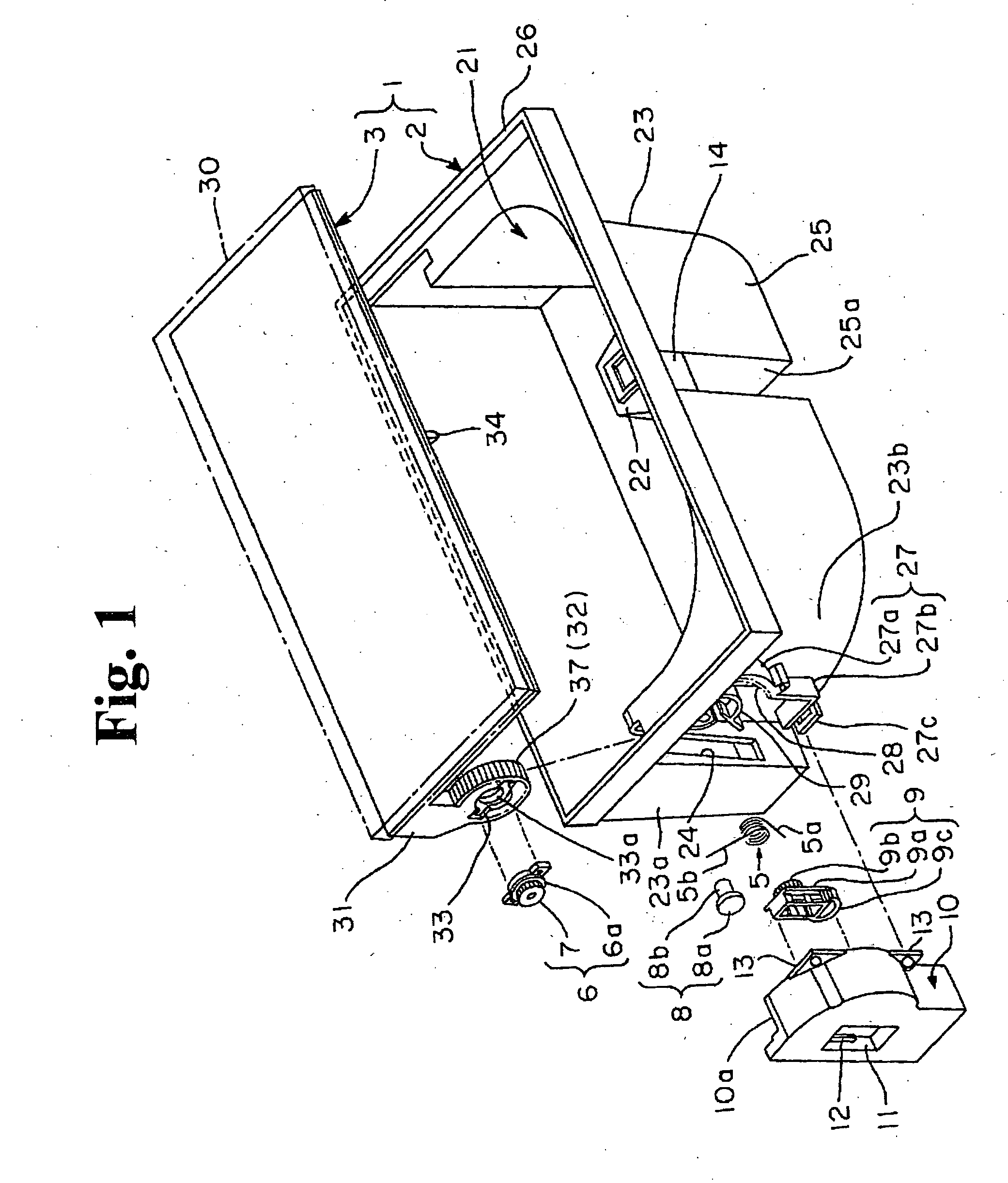

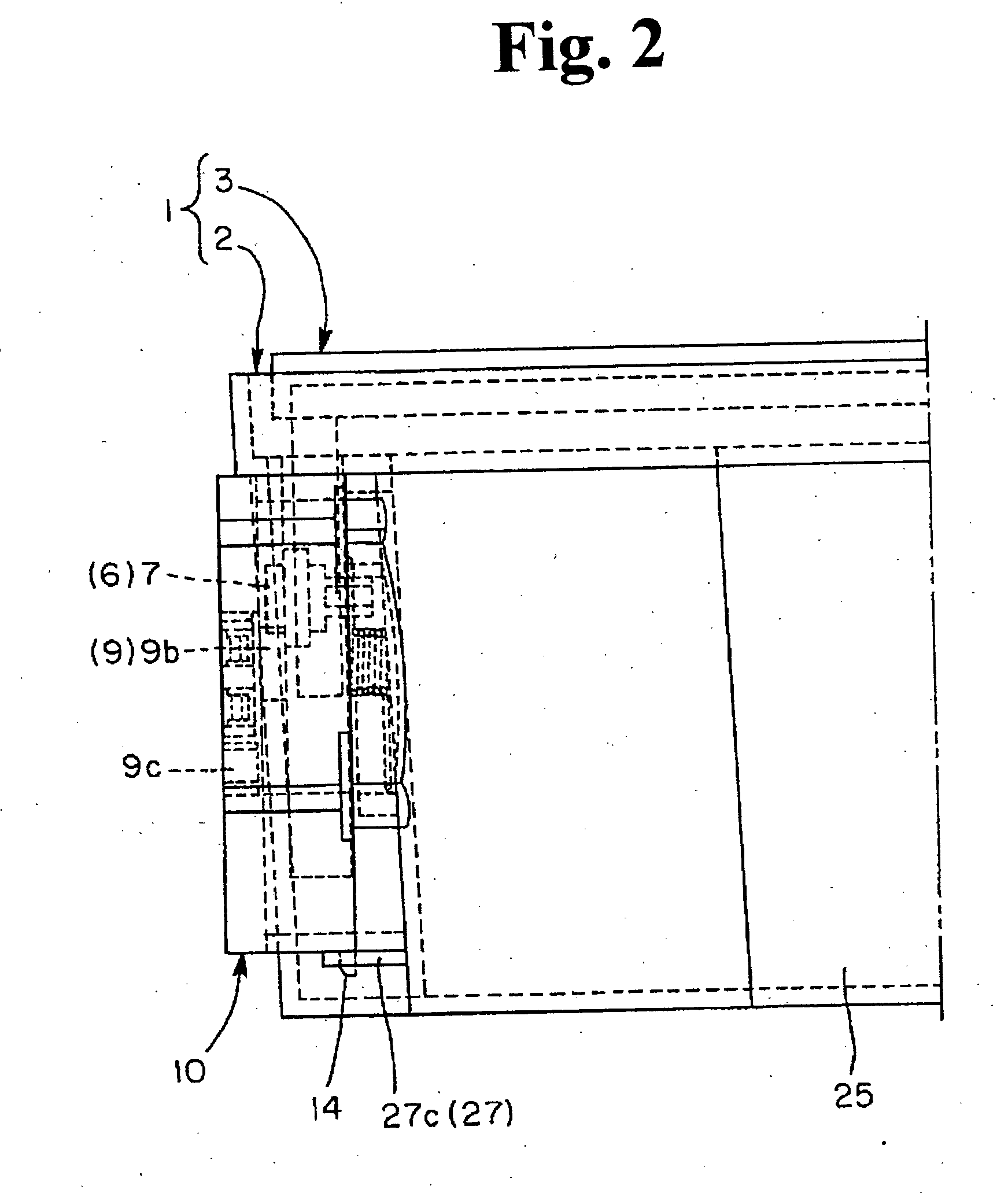

Door operating mechanism and unit

InactiveUS20070034636A1Easy constructionImprove assembly efficiencyPassenger spaceLidsEngineeringMechanical engineering

Owner:NIFCO INC

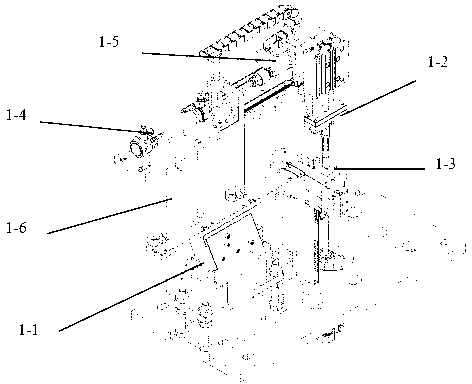

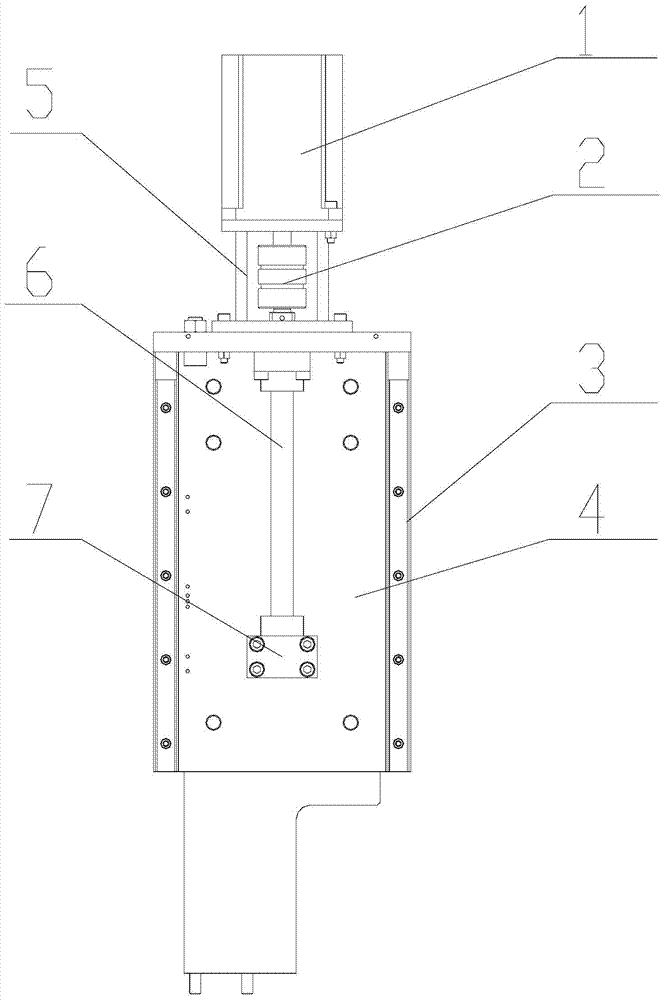

Automatic needle inserting machine

ActiveCN102412494AImprove assembly efficiencyReduce labor intensityContact member assembly/disassemblyControl systemNeedle insertion

The invention provides an automatic needle inserting machine, comprising a rack, a feeding mechanism, a transmission rail, a needle inserting plate, a needle inserting mechanism, a needle pressing mechanism and a control system for controlling all the mechanisms to act, wherein the needle inserting plate is detachably fixed on a movable component; the needle inserting mechanism comprises a lifting cylinder, a suctioning disc detachably fixed on the lifting cylinder and a horizontal sliding platform for fixing the lifting cylinder. The automatic needle inserting machine is characterized in that a piece to be inserted is conveyed out by the feeding mechanism and is conveyed to the needle inserting mechanism by the transmission rail; the needle inserting mechanism takes a needle by the needle inserting plate and inserts the needle into the piece to be inserted; the inserted needle is pressed and fixed by the needle pressing mechanism; all the actions are controlled by the control system;therefore, in the piece to be inserted, the steps from feeding to needle insertion are carried out automatically respectively, so that the assembling efficiency is greatly improved, and the labor intensity is reduced. The automatic needle inserting machine is suitable for batch production; simultaneously, the needle inserting plate and the suctioning disc are detachable and can move relatively, so that the needle taking is convenient; and for different pieces to be inserted, only corresponding needle inserting plates and suctioning discs need to be replaced, so that the automatic needle inserting machine is convenient and fast.

Owner:深圳市君灏精密工业有限公司

Automatic screw and nut combination locking device

ActiveCN103537892AReduce assembly man-hoursImprove accuracy and efficiencyMetal working apparatusEngineeringSlide plate

The invention is applicable to the field of assembly technologies for screws and nuts, and discloses an automatic screw and nut combination locking device which comprises a fixing assembly and a sliding assembly. The sliding assembly comprises a sliding plate, the sliding plate is slidably connected to the fixing assembly, and a sliding plate driving assembly is arranged on the fixing assembly; a screw locking assembly and a nut locking assembly are connected onto the sliding plate, the screw locking assembly comprises a screwdriver, a screw rotation driving assembly and an axial driving assembly, the screw rotation driving assembly is used for driving the screwdriver to peripherally rotate, and the axial driving assembly is used for driving the screwdriver to vertically slide; the nut locking assembly comprises a nut locking sleeve and a nut rotation driving assembly, the nut rotation driving assembly is used for driving the nut locking sleeve to rotate, and the screwdriver and the nut locking sleeve are coaxially arranged. The automatic screw and nut combination locking device has the advantages that a screw and a nut can be assembled at one station, so that the product assembly working hours can be greatly reduced, the assembly efficiency and the assembly precision can be improved, the cost can be reduced for an enterprise, and the core competitiveness of the enterprise can be improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

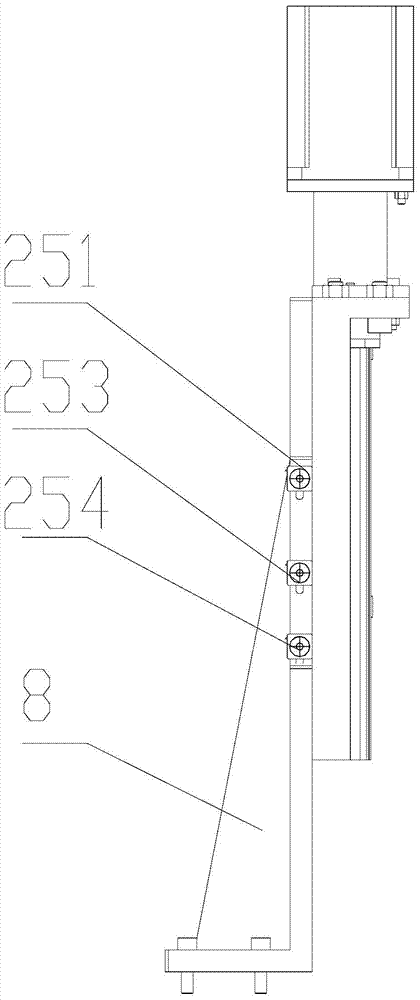

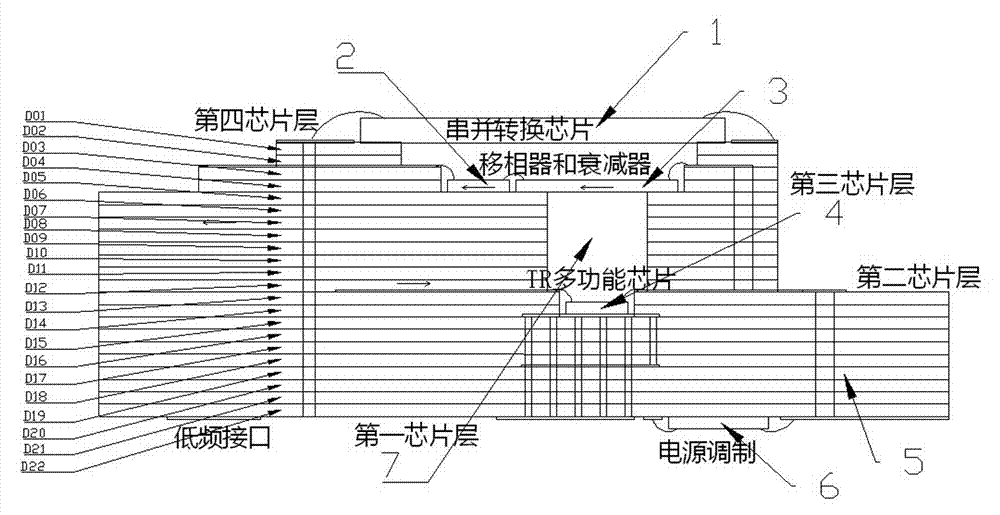

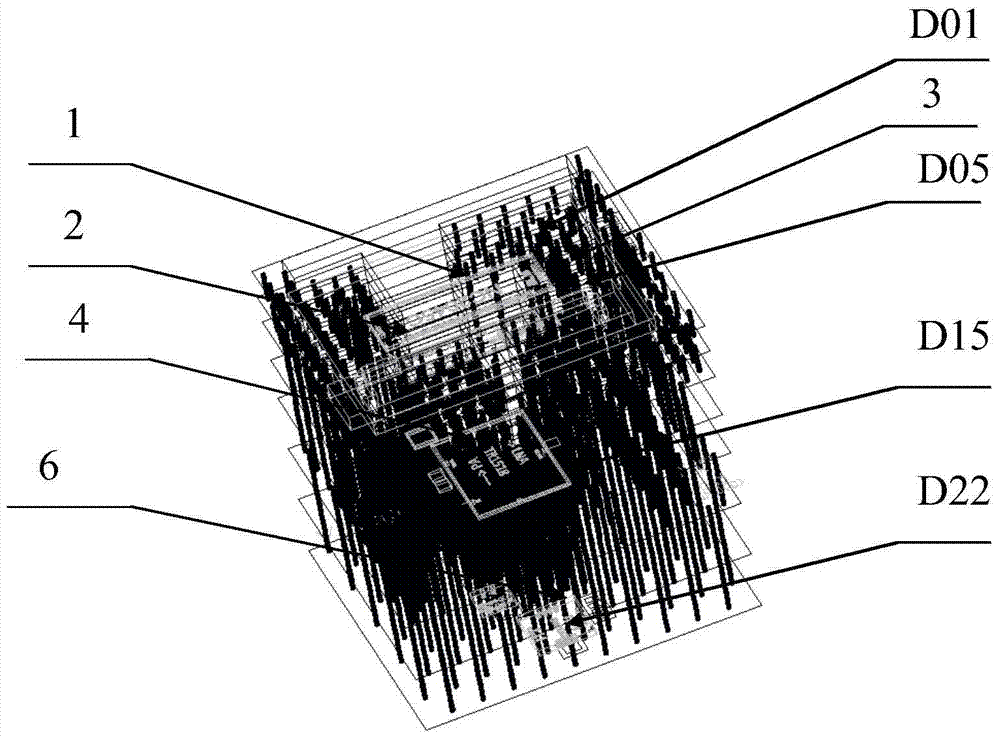

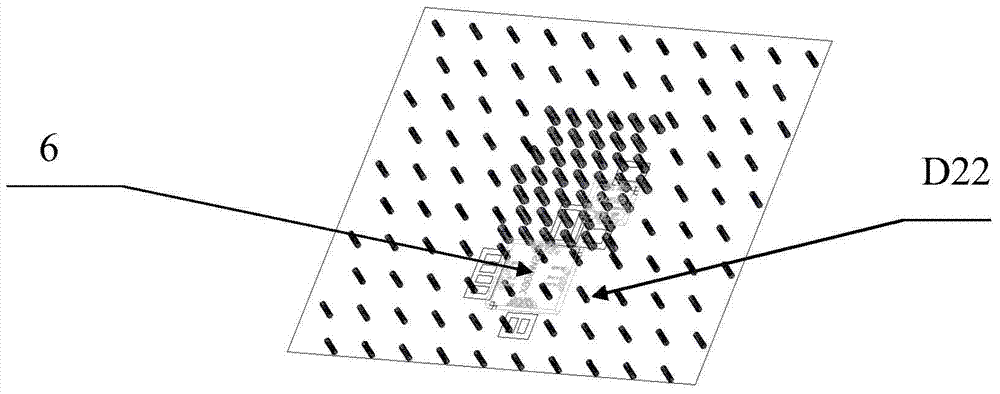

3D assembling method for integrally integrating chips of T/R assembly

InactiveCN104332413AHighly integratedLow costSolid-state devicesSemiconductor/solid-state device manufacturingHigh densityThree-dimensional space

The invention provides a 3D assembling method for integrally integrating chips of T / R assembly, and aims to provide a T / R assembly which has advantages of reliable performance, higher density, more functions, high signal transmission speed, better performance and relatively lower cost. The 3D assembling method is realized through a solution which comprises the steps of performing z-direction expansion on a planar circuit with printed circuit patterns to a green ceramic chip laminate of a three-dimensional circuit through interlayer vertical interconnection; vertically packaging an active device in a rectangular chamber (7) of the green ceramic chip laminate (5), placing a power supply modulator on the back surface of the bottom of the green ceramic chip laminate, and inputting an outer signal from a low-frequency interface at the back surface of the green ceramic chip laminate to a pad of the green ceramic chip laminate (5); performing radio frequency connection among chips through a metal wire bonding vertical interconnection structure among the green ceramic chip laminates, accurately aligning and laminating the green ceramic laminates in a Z direction, and then sintering at a temperature of 900 DEG C, thereby preparing a three-dimensional circuit low-temperature co-sintered ceramic LTCC substrate which is used for high-density circuits with no three-dimensional space interference and is internally provided with a passive element and can be equipped with bare chips or package chips on the surface.

Owner:10TH RES INST OF CETC

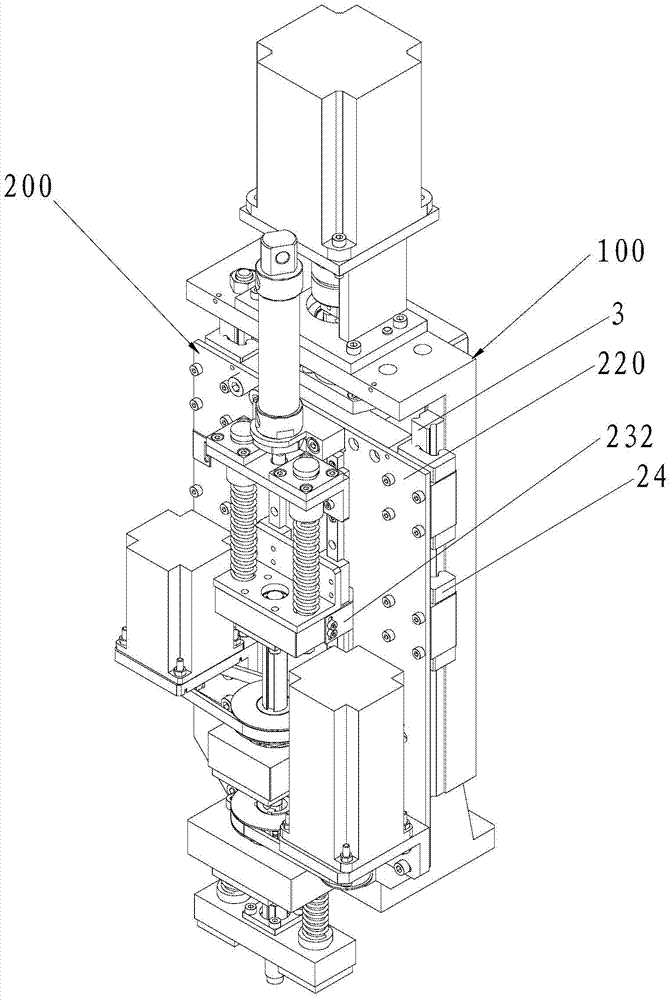

O-shaped sealing ring automatic assembly device and method

InactiveCN108655689AAssembly precisionAccurate assembly tasksMetal working apparatusEngineeringMechanical engineering

The invention discloses an O-shaped sealing ring automatic assembly device and method. The device comprises a sleeve automatic loading module, an O-shaped sealing ring automatic loading module, an automatic detecting module, a finished product sorting module, all of which are arranged on the outer side of a revolving worktable module in the peripheral direction in sequence; the sleeve automatic loading module and the O-shaped sealing ring automatic loading module are in supply connection with the revolving worktable module; the automatic detecting module detects the assembly effect of O-shapedrings on the revolving worktable module in real time; and the finished product sorting module is used for realizing sorting of qualified and unqualified products through chutes according to the detecting result of the automatic detecting module. The device is simple in structure and convenient to use; and through motions of three arc plates on clamping jaws of a three-jaw cylinder and pressing plates with the same apertures as the diameters of sleeves, the clamping and assembly of the O-shaped sealing rings are achieved, the automatic assembly task of the O-shaped sealing rings can be finished with high quality, a lot of manpower and costs are saved, the assembly efficiency is quickly accelerated, and the production demands are met.

Owner:NANJING KANGNI NEW ENERGY AUTO PARTS CO LTD +1

Mobile phone camera LED part automatic assembly machine

PendingCN108857381AImprove assembly efficiencyImprove assembly accuracyMaterial gluingAssembly machinesManipulatorAdhesive

The invention discloses a mobile phone camera LED part automatic assembly machine. The mobile phone camera LED part automatic assembly machine comprises a worktable. The worktable is provided with a rotating disc device and a manipulator arm for feeding and discharging. The rotating disc device is provided with a plurality of auxiliary jigs for placing camera end covers, and a camera end cover feeding device, an adhesive dispensing device, an LED part feeding device, an LED assembly device, a finished product detecting mechanism, a defective product placement area and a finished product discharging device are arranged on the worktable in sequence and surround a rotating disc. A plurality of overturn mechanisms are arranged between the camera end cover feeding device and the rotating disc device. After the camera end covers and LED parts are placed on charging trays, the manipulator arm places the obtained camera end covers on overturn devices, and the overturn devices rotate to overturn the camera end covers and place the camera end covers on the auxiliary jigs; and then through the processes of automatic adhesive dispensing, LED part assembly and the like, and higher assembly efficiency and assembly precision can be achieved. The mobile phone camera LED part automatic assembly machine is used in the field of industrial automation.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

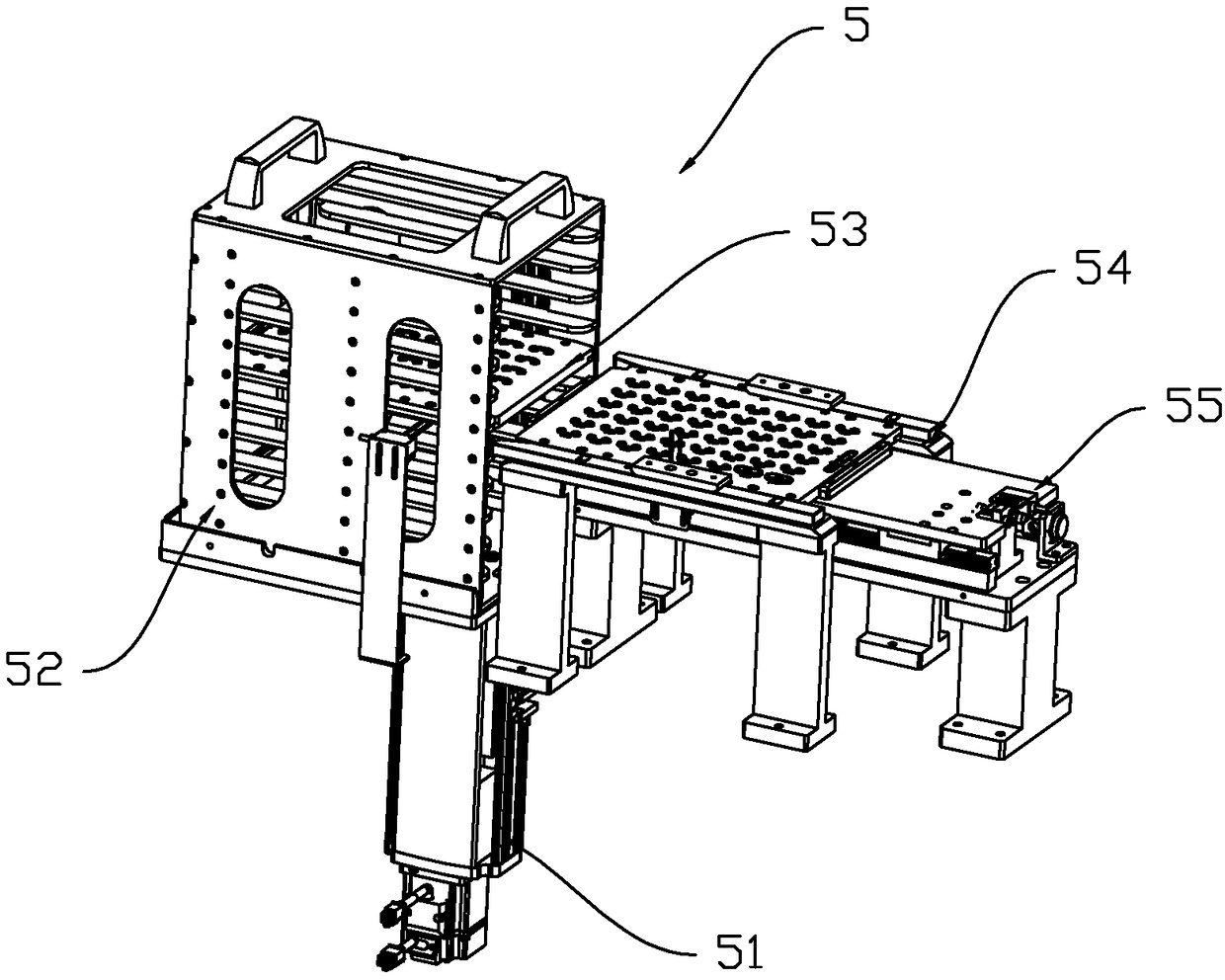

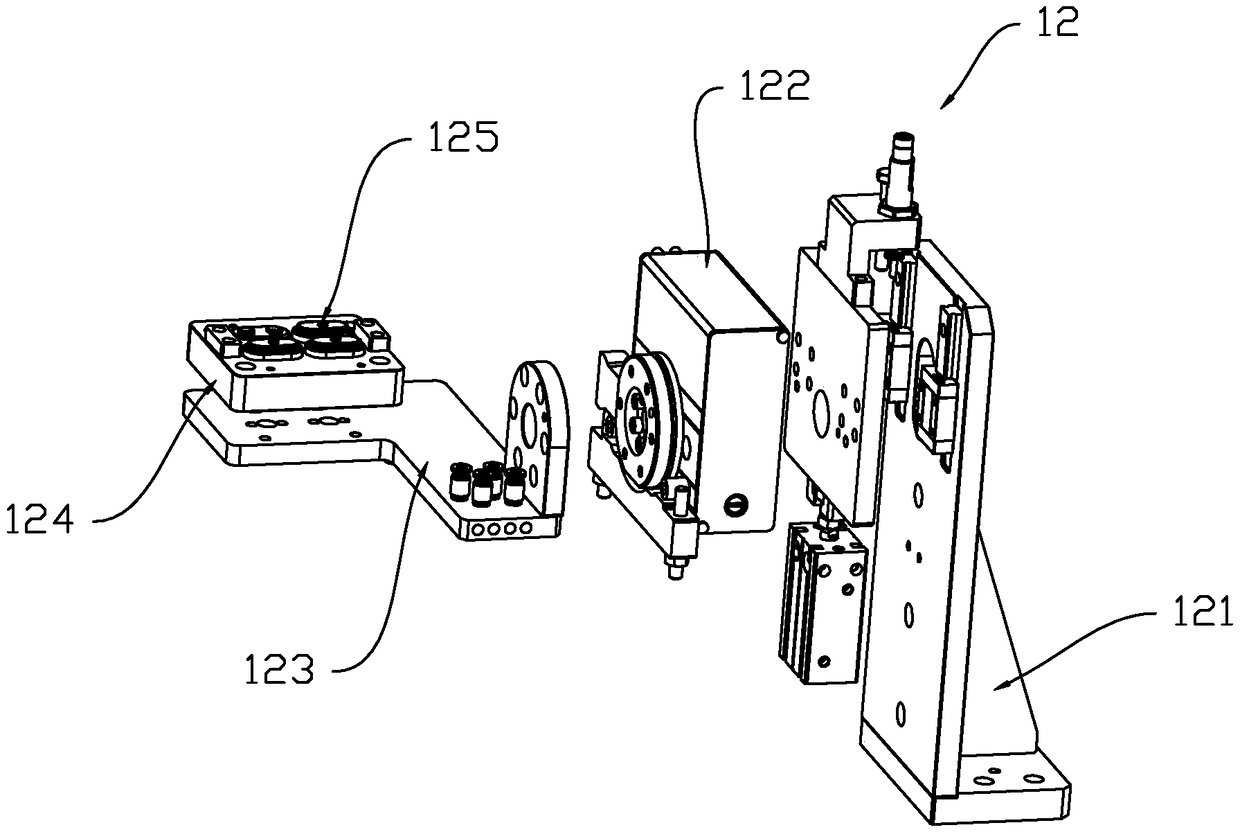

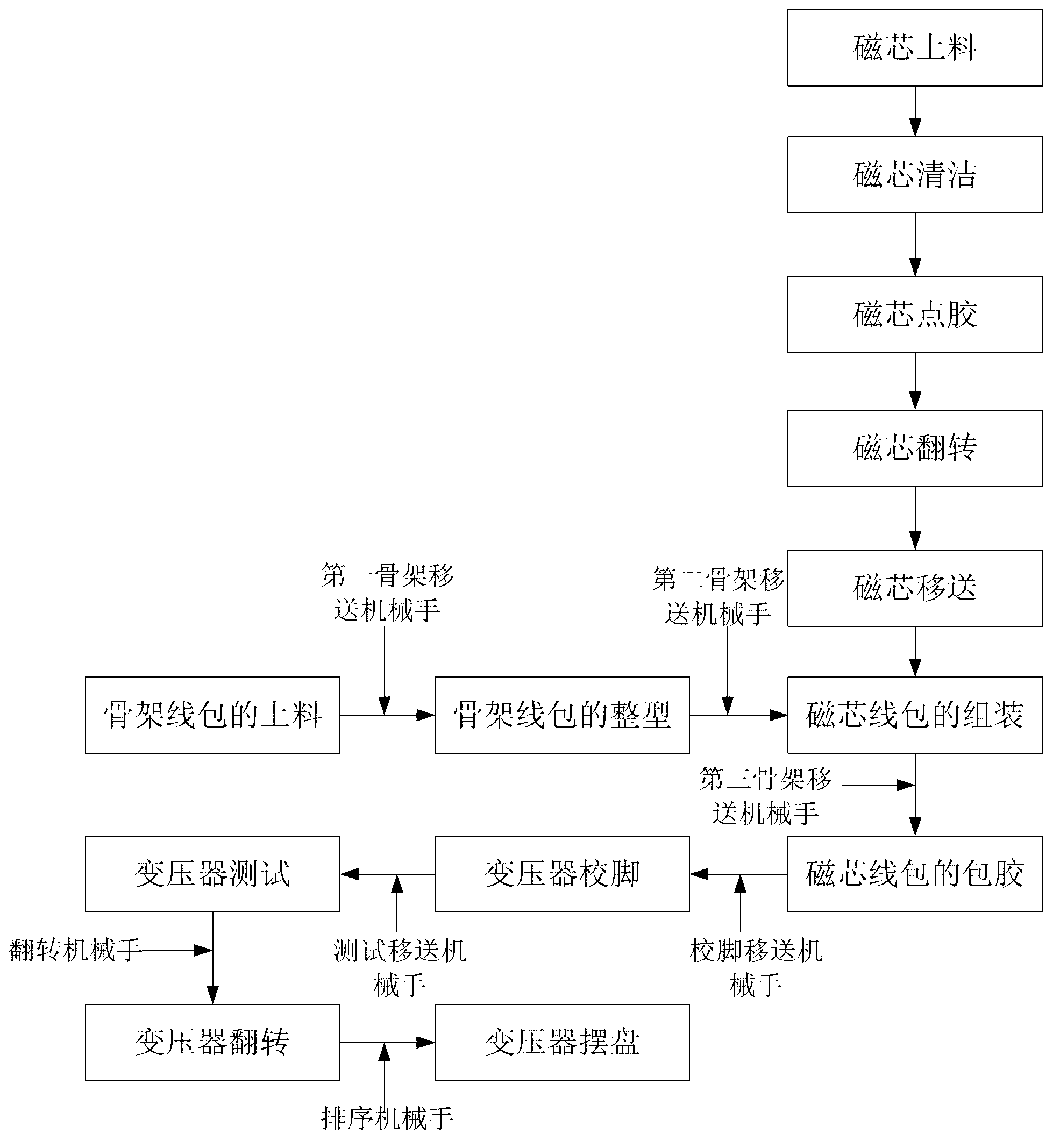

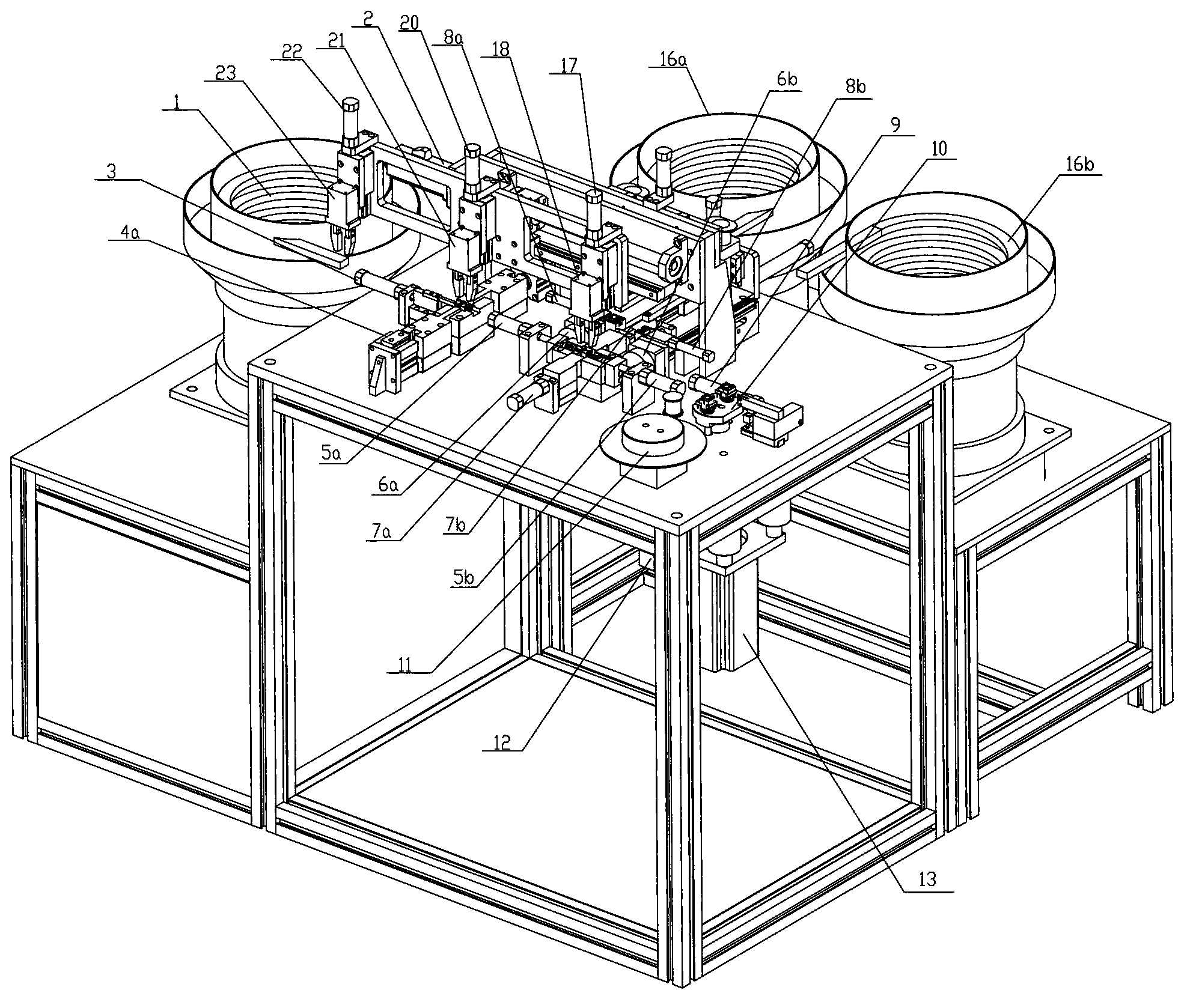

Assembly method and assembly production line of transformer

ActiveCN102842416AImprove assembly efficiencyMinimize impact on product qualityCoils manufactureProduction lineTransformer

The invention discloses an assembly method and an assembly production line of a transformer. The assembly method comprises the following steps: a shaping step implemented by use of an inner shaping clamp which is automatically sleeved in a middle hole of a skeleton wire packet and a front shaping cylinder and a back shaping cylinder which clamp the skeleton wire packet from the front side and the back side; a magnetic core skeleton assembling step of starting a left assembling cylinder and a right assembling cylinder to push the left magnet core and the right magnet core to be sleeved in the middle hole; and a tape wrapping step of winding the tape on a loading turntable around the outer peripheries of the left magnet core and the right magnetic core by driving a tape wrapping fixture to be rotated preset circles. With the adoption of the assembly method and the assembly production line of the transformer, shaping of the skeleton wire packet, assembling of the magnetic core skeleton and tape wrapping of the magnetic core skeleton can be at least completed, the assembling efficiency can be increased greatly, and the influence of the human factors on the product quality can be reduced.

Owner:SUIZHOU RUISHUO ELECTRONIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com