Door of front-loading washer and assembly method thereof

A drum washing machine and assembly method technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of difficulty in satisfying the visual experience of different users, cumbersome assembly process of door glass, low reliability and durability, etc., and achieve improvement Assembly process, satisfactory visual experience, good durability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

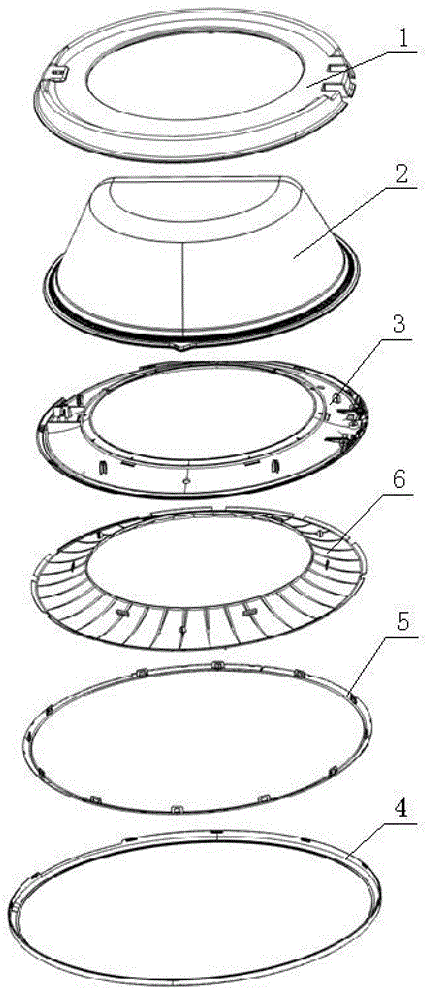

[0059] Such as figure 1 Shown is an exploded view of the door body of the drum washing machine provided in this embodiment.

[0060] The door body of a drum washing machine provided in this embodiment includes an inner frame 1, a transparent basin 2, a middle frame 3, and an outer frame 4 arranged sequentially from the inside of the door body to the outside of the door body. A window screen 5 is arranged between the outer frame 4 and the middle frame 3 , and a decorative part 6 is arranged between the window screen 5 and the middle frame 3 .

[0061]Both the outer frame 4 and the window screen 5 are fixedly connected to the middle frame 3 by clamping, and the transparent basin 2 is fixed by welding the inner frame 1 and the middle frame 3, that is, the After the welding of the inner frame 1 and the middle frame 3 is completed, the movement of the transparent pot 2 located between the inner frame 1 and the middle frame is restricted, so that the transparent pot 2 is fixed. Th...

Embodiment 2

[0081] Figure 9 , Figure 10 , Figure 11 They are respectively the assembly drawing of the door body of the drum washing machine provided in this embodiment, the A-A sectional view and the B partial structural view.

[0082] Such as Figure 12 Shown is a flow chart of the door assembly method of the drum washing machine provided in this embodiment.

[0083] A method for assembling a door body, used for assembling the door body of the drum washing machine, the method for assembling the door body is implemented according to the following steps:

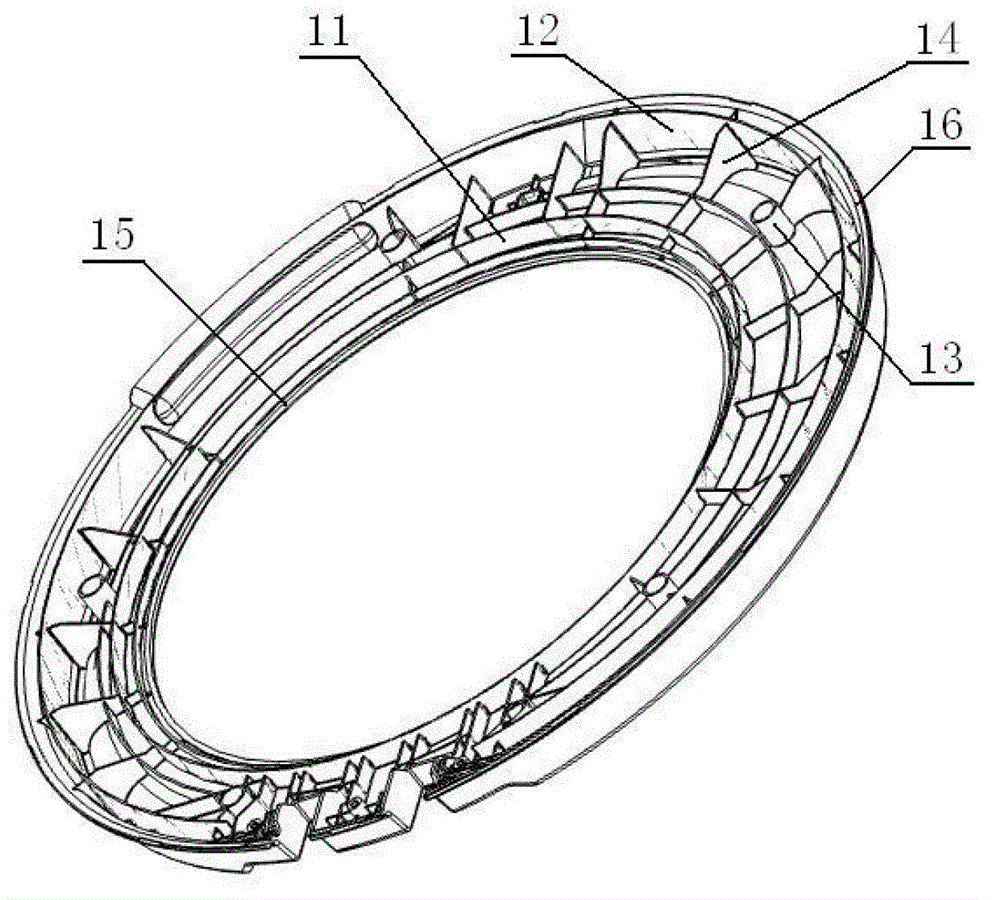

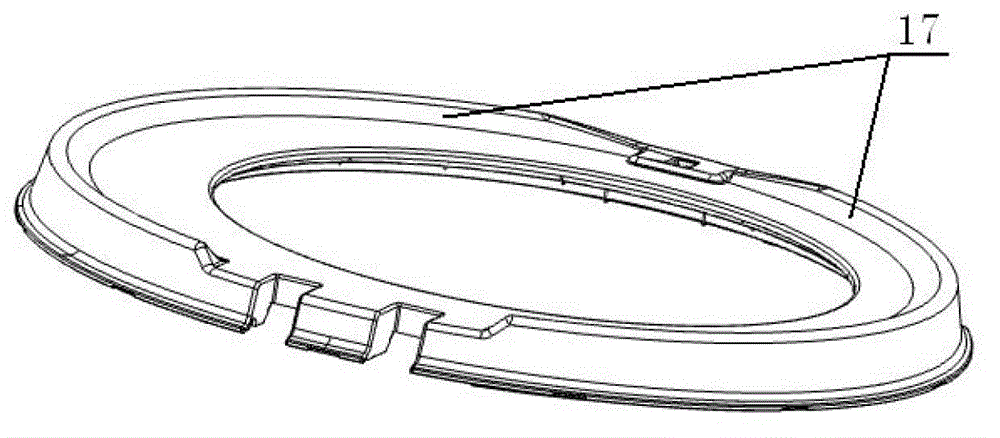

[0084] Step S00: placing the inner frame 1, the transparent basin 2, the middle frame 3, door hinges and other accessories in an assembly machine for positioning. When positioning, the transparent basin 2 is located between the inner frame 1 and the middle frame 3, and the middle frame claw 39 is inserted into the circular clamp post 13 for positioning, and the door hinge is located on one side of the inner frame 1. side.

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com