Patents

Literature

61117 results about "Welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

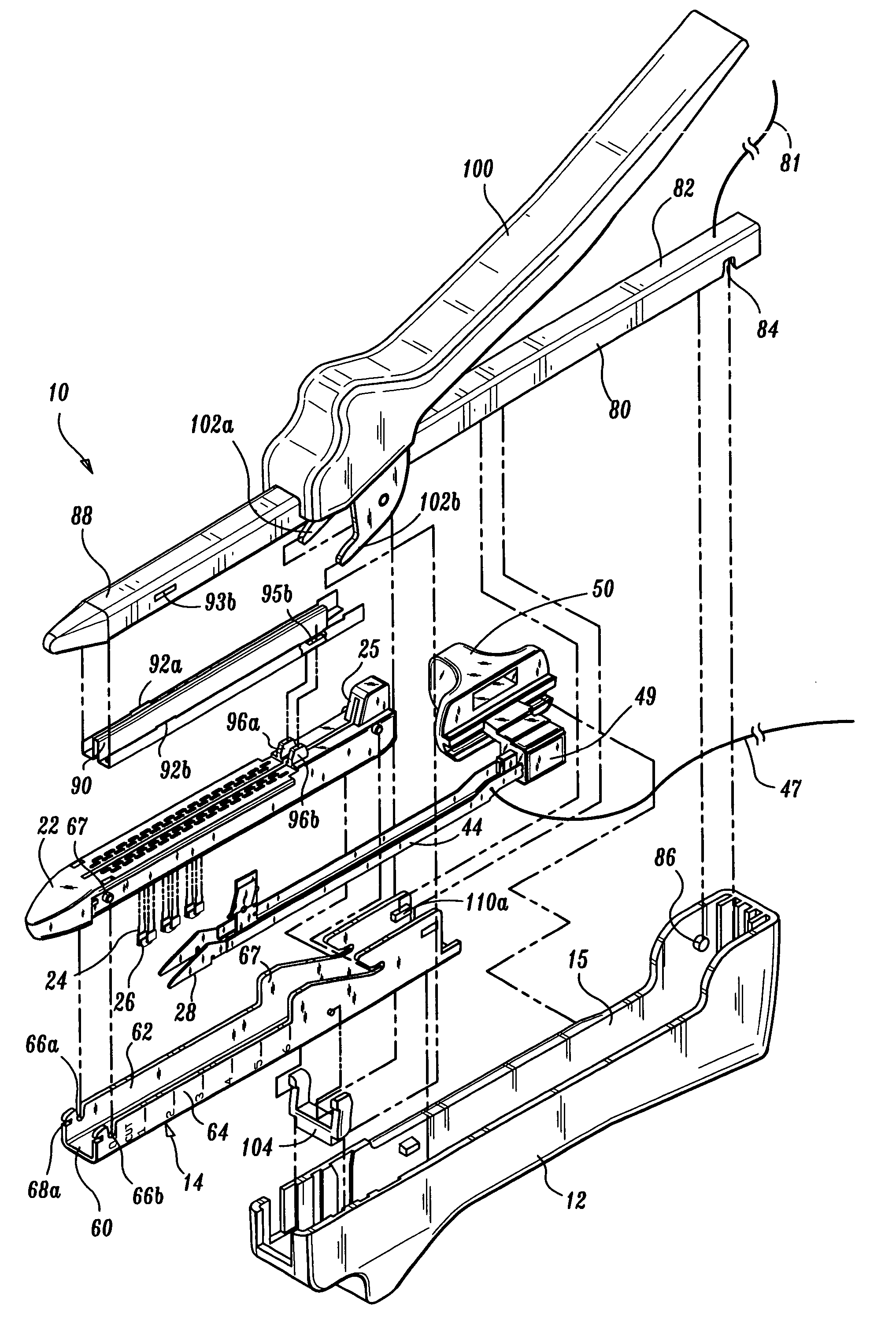

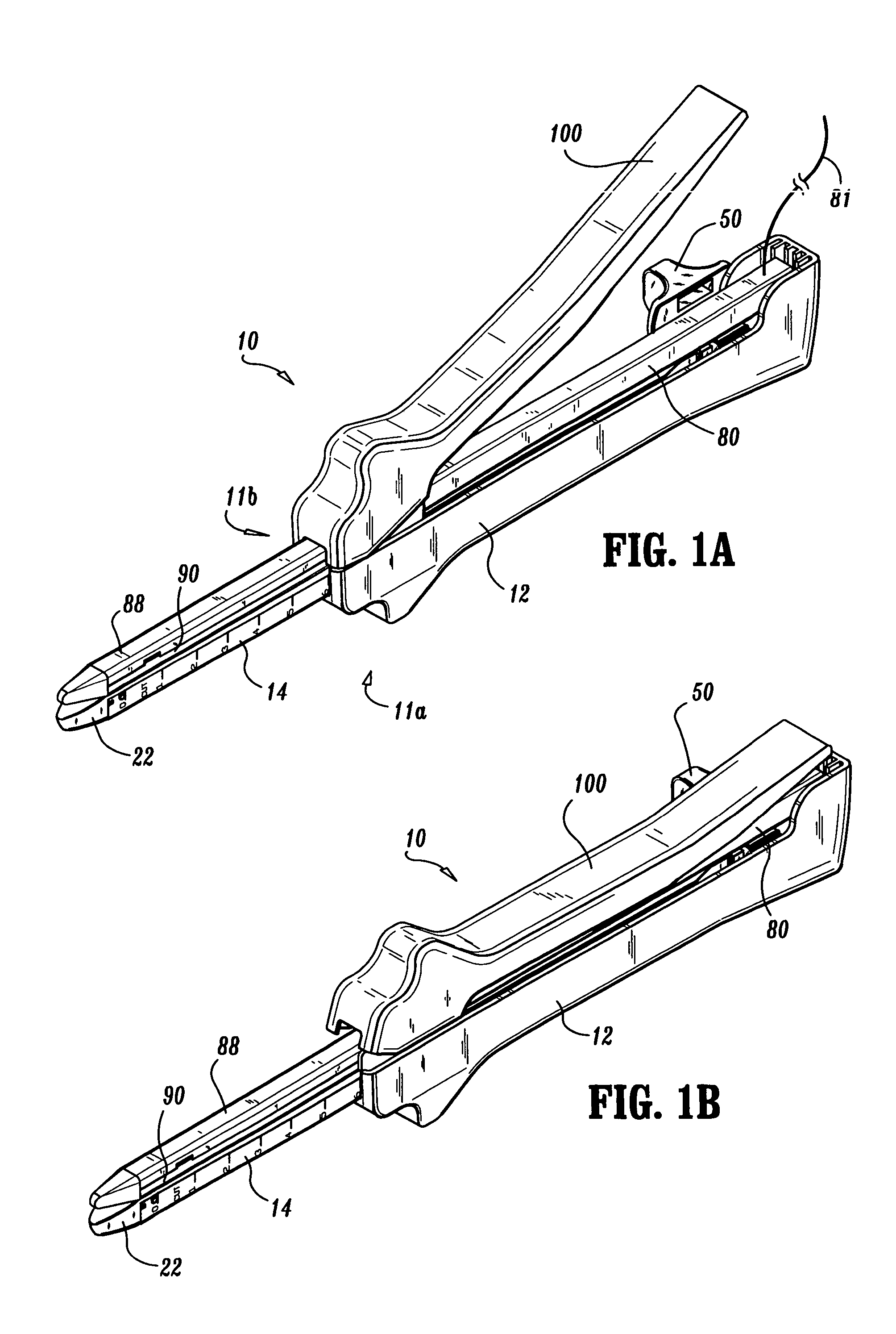

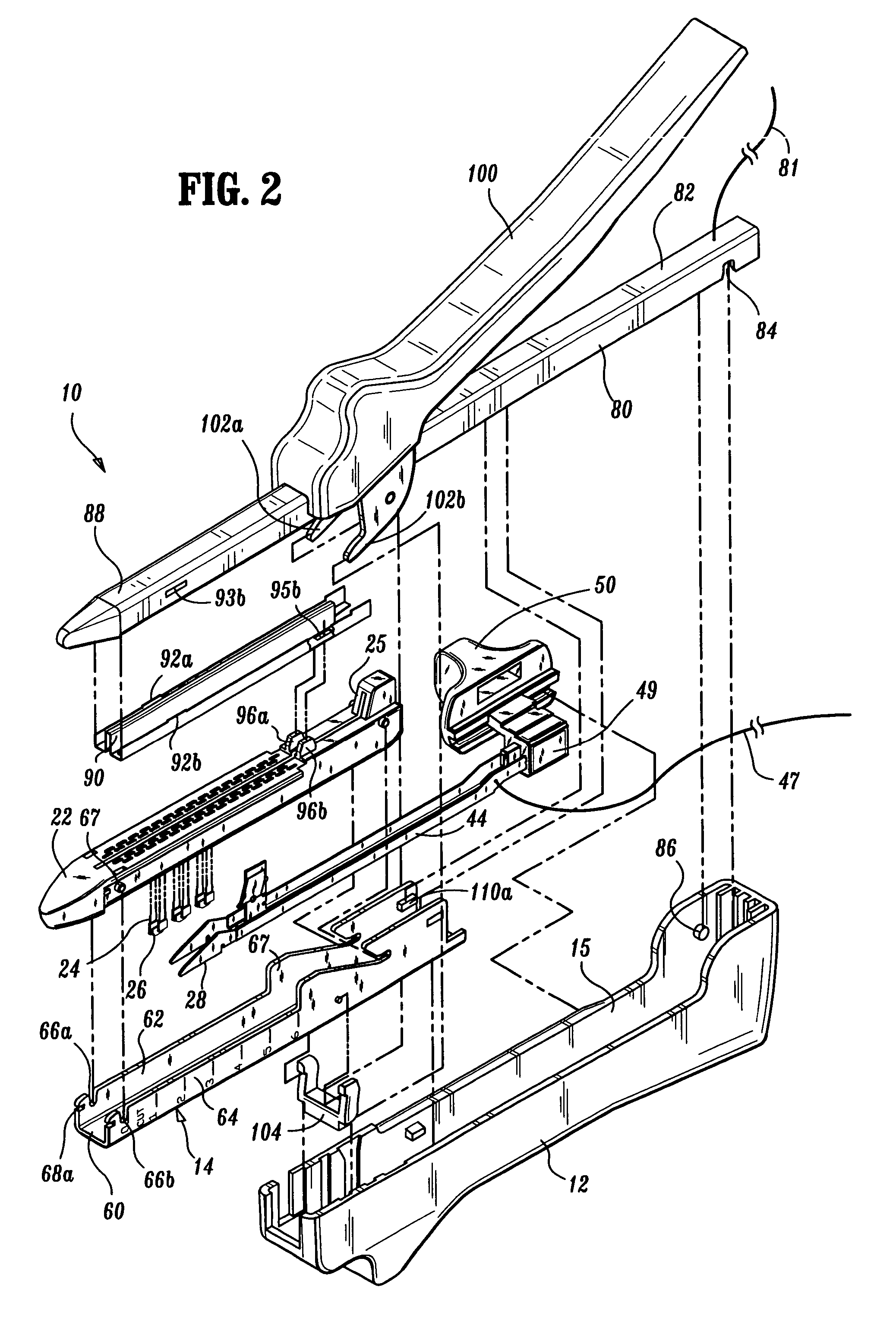

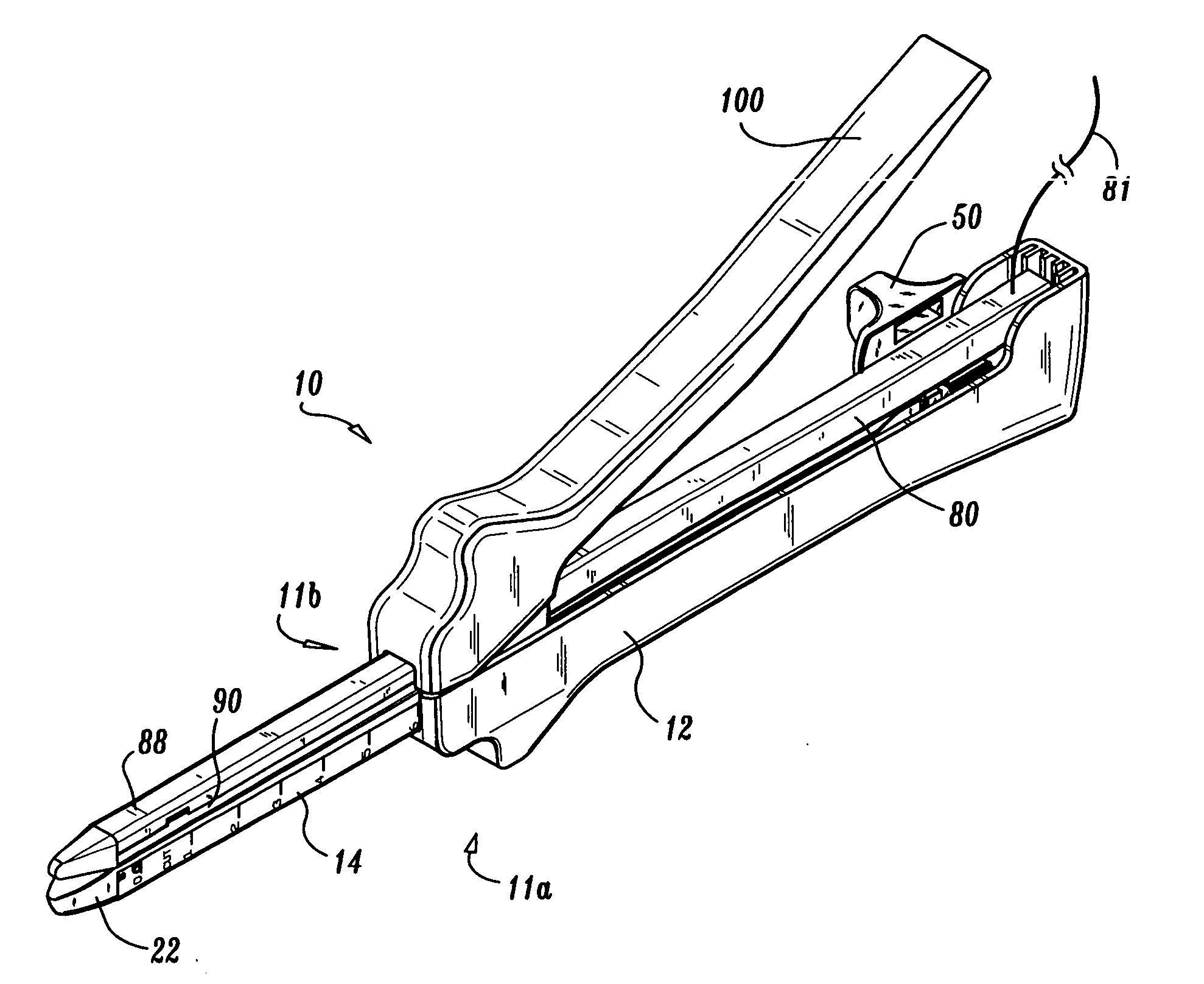

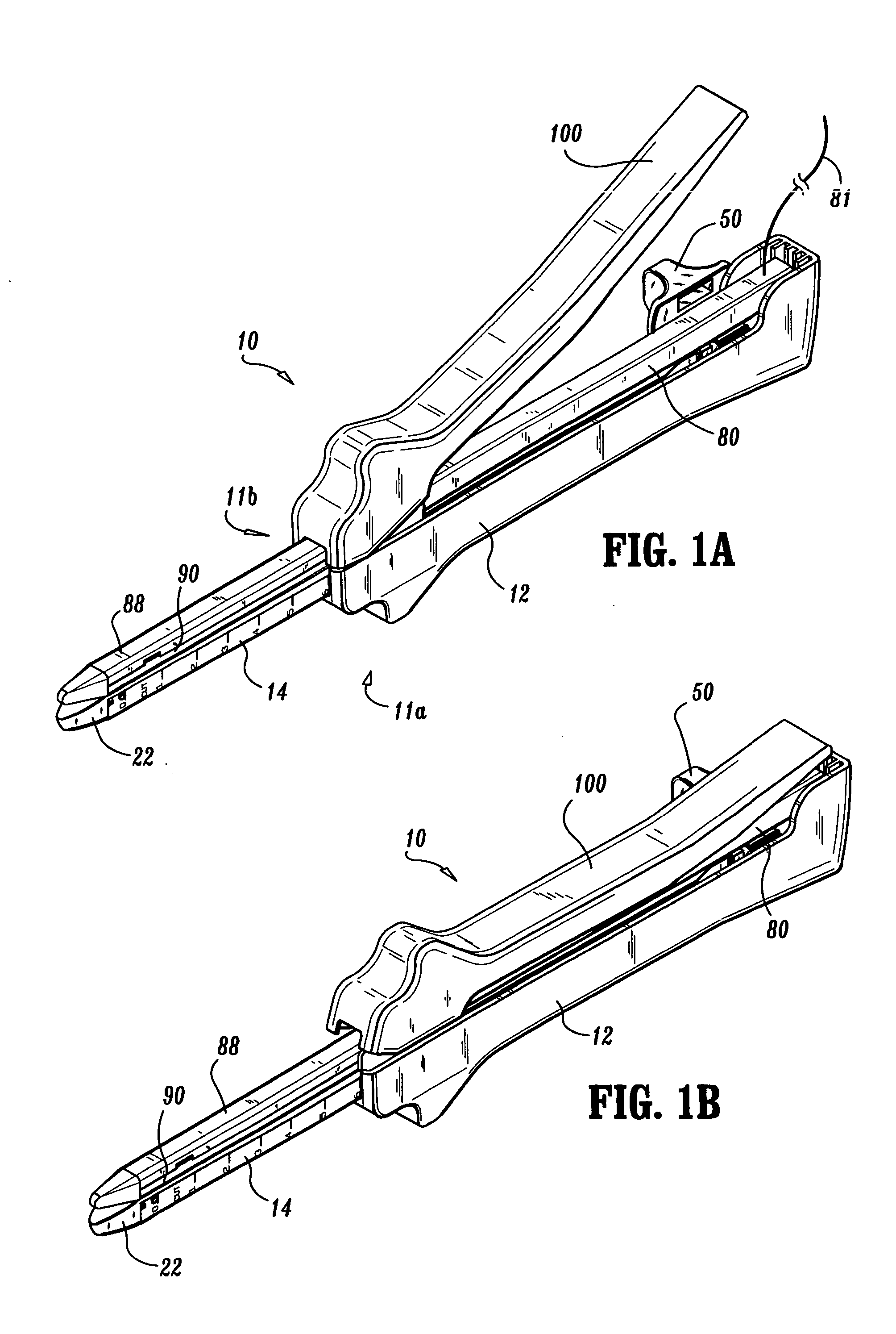

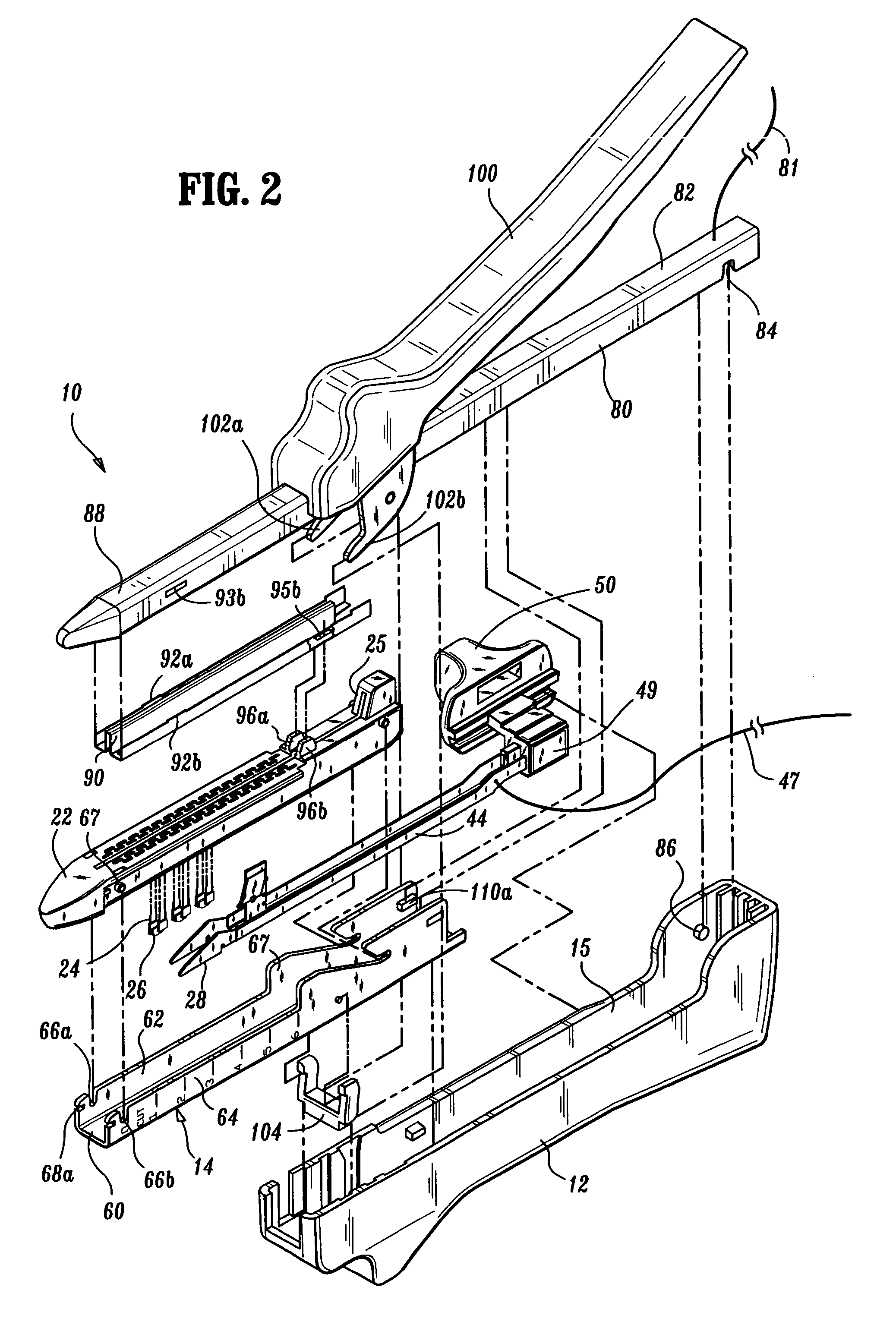

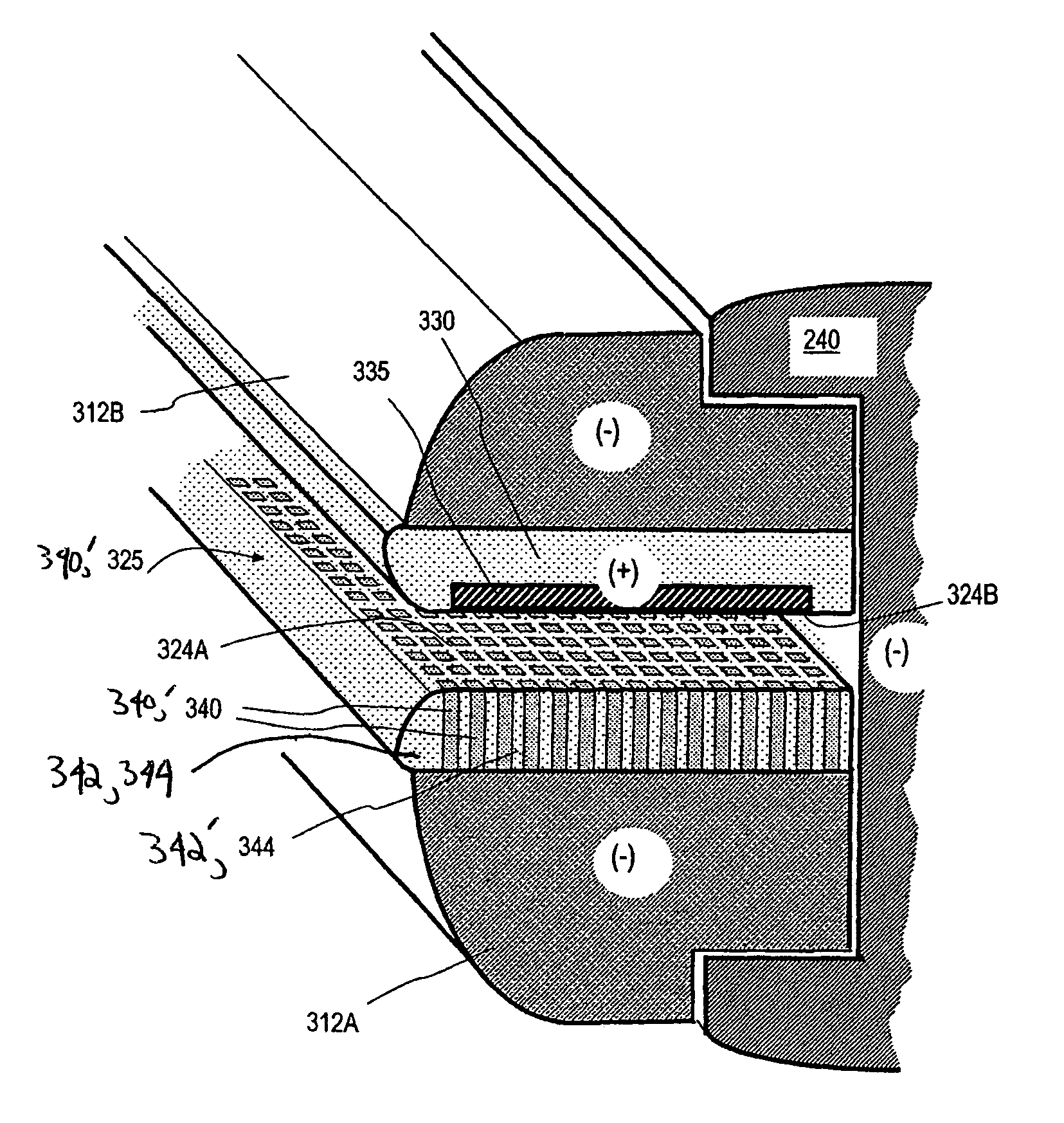

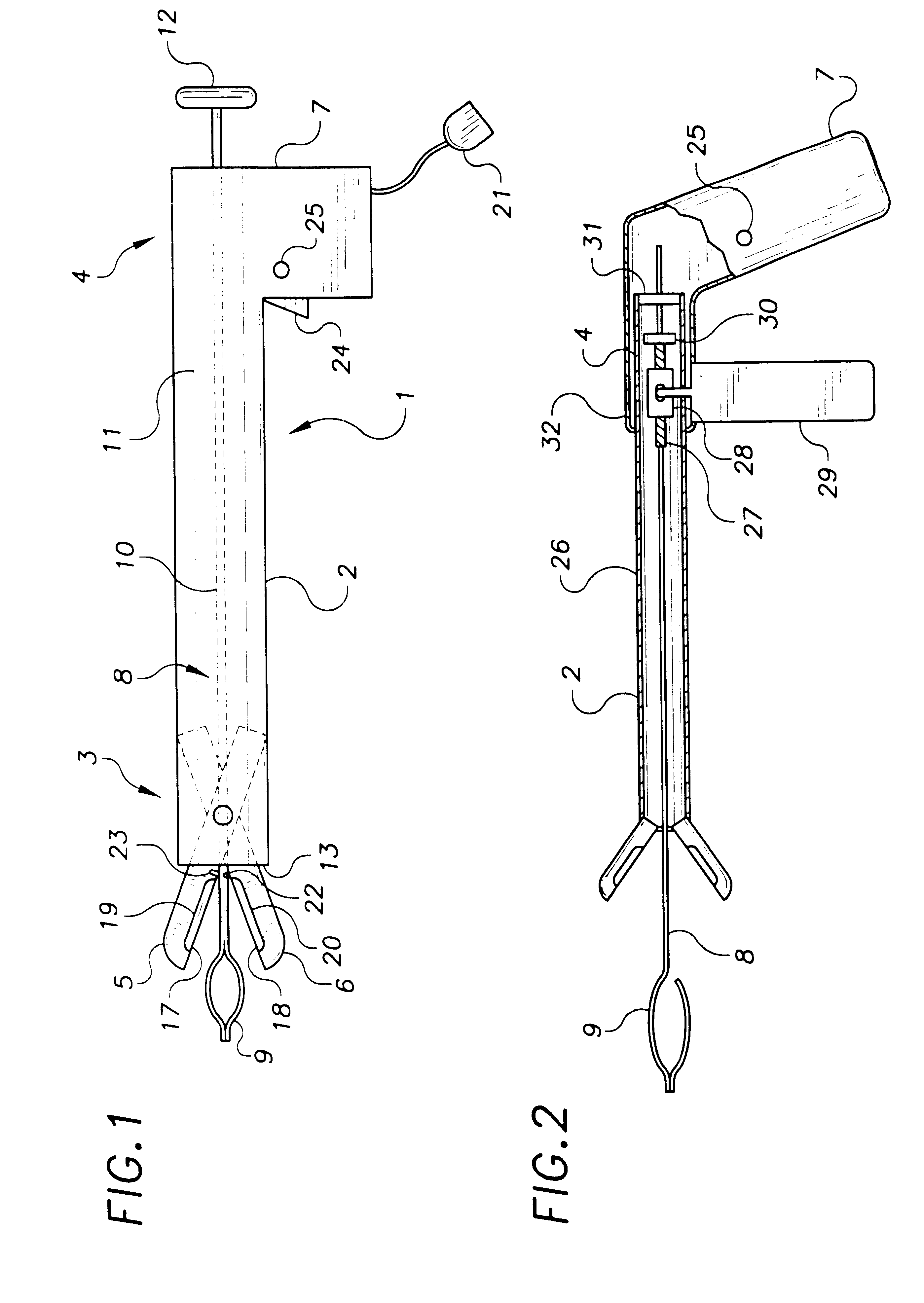

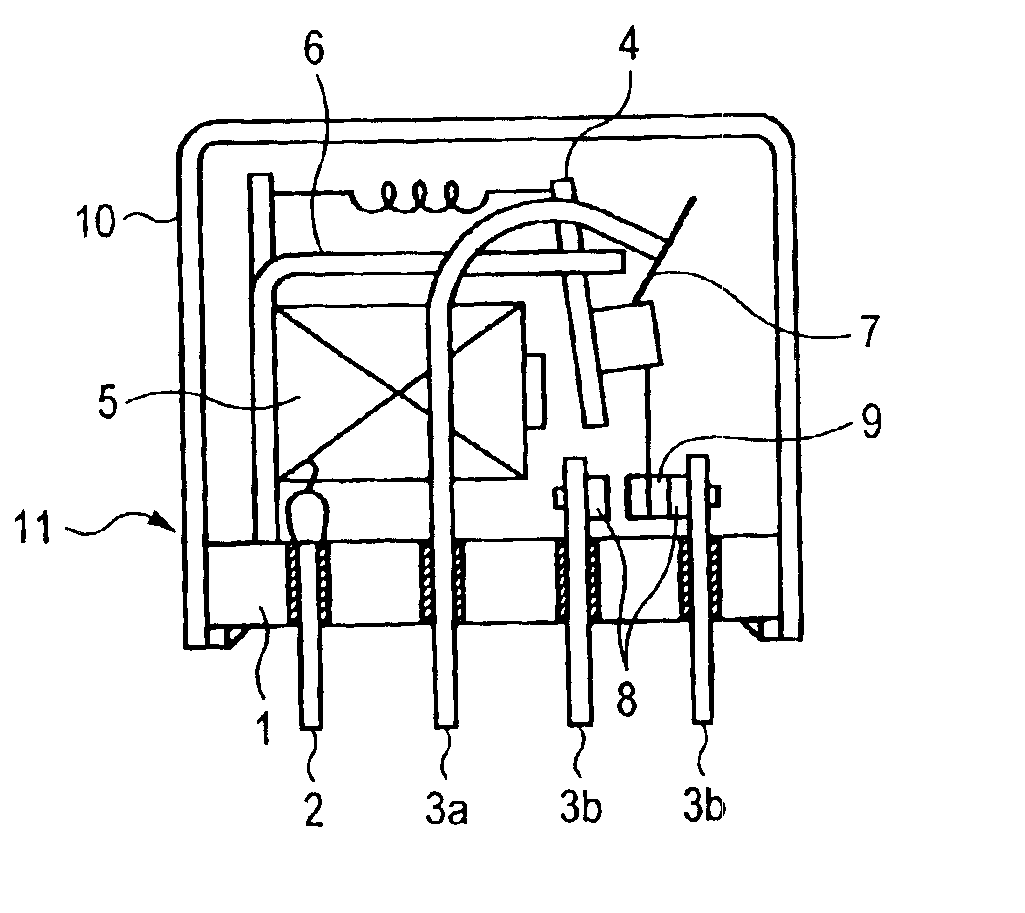

Electrosurgical stapling apparatus

InactiveUS7207471B2Reduces or prevents staple line and cut line bleedingShort and strengthSuture equipmentsStapling toolsStaple lineEngineering

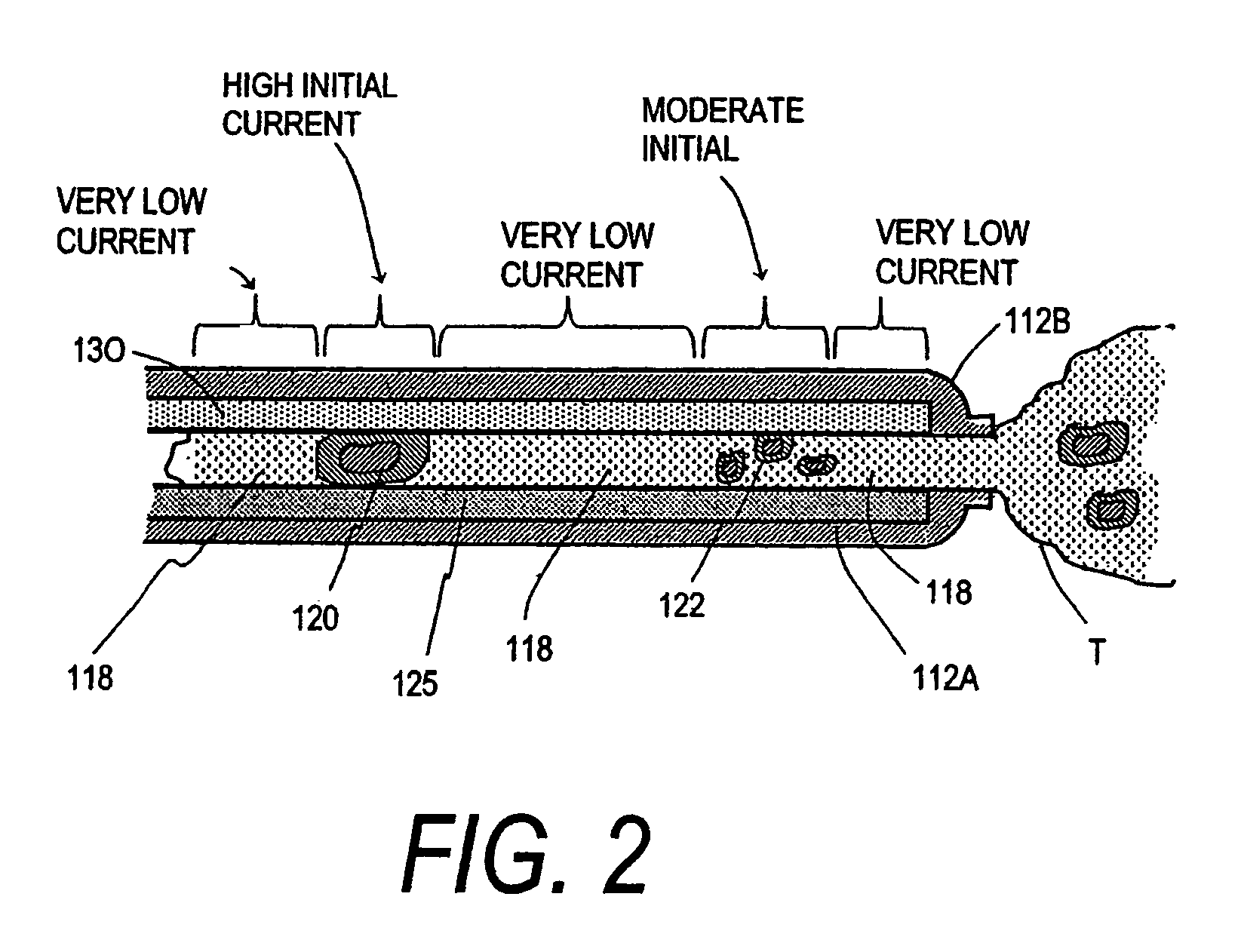

An electrosurgical stapling apparatus is provided which uses thermogenic energy as well as surgical fasteners or staples for strengthening tissue, providing hemostasis, tissue joining or welding. The thermogenic energy also strengthens tissue in proximity to a staple line and knife cut line and provides hemostasis along the staple and cut lines formed by the staples and a knife blade during surgical stapling. The use thermogenic energy provides short-term hemostasis and sealing, and reduces or prevents staple line and cut line bleeding, while the stapling features provide short and long-term tissue strength and hemostasis. The stapling apparatus further substantially reduces or prevents knife cut line bleeding by energizing a knife blade for cauterizing tissue while it is being cut. In one embodiment, energy is applied to the anvil to energize the staples as they make contact with the anvil.

Owner:TYCO HEALTHCARE GRP LP

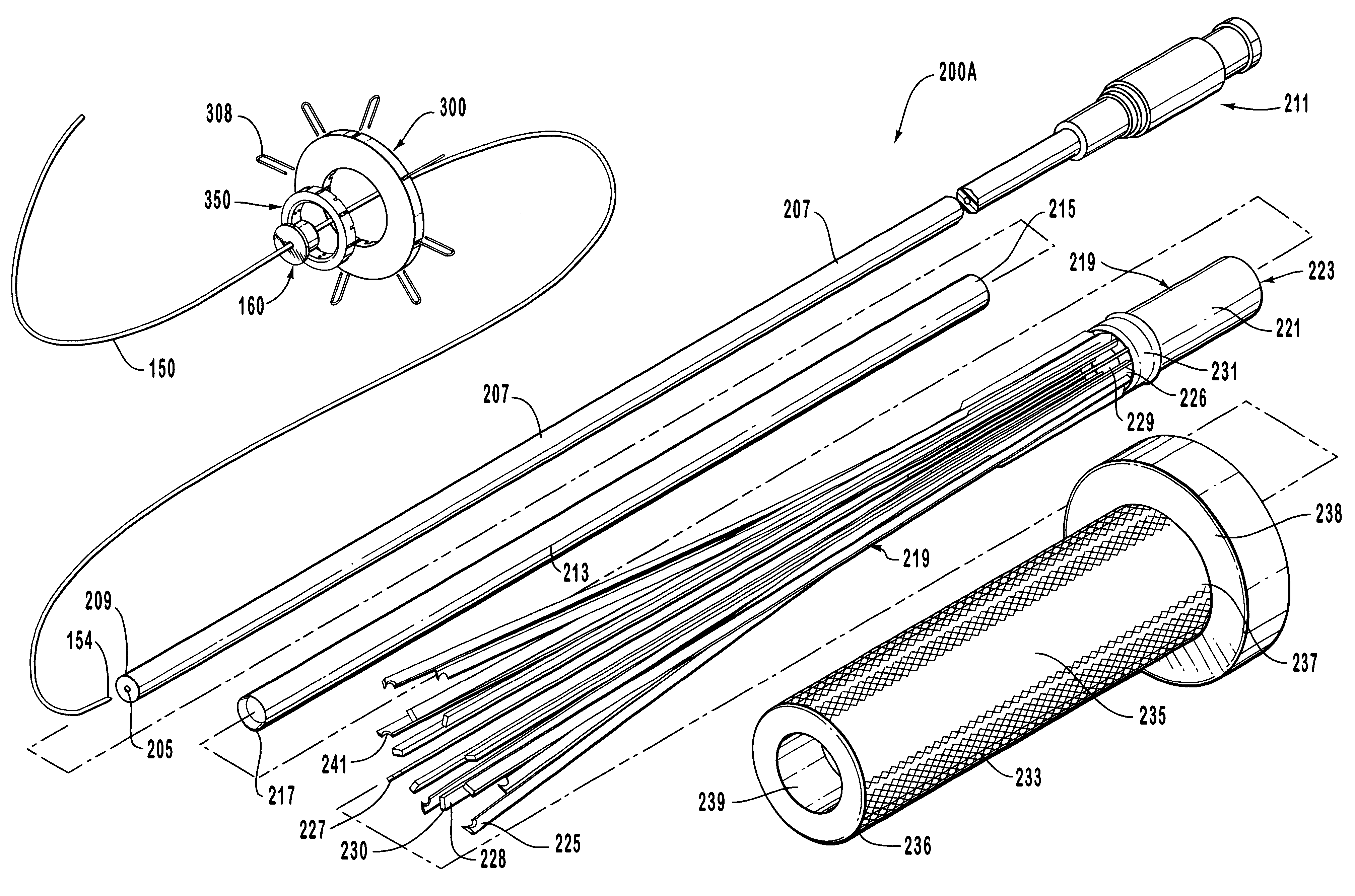

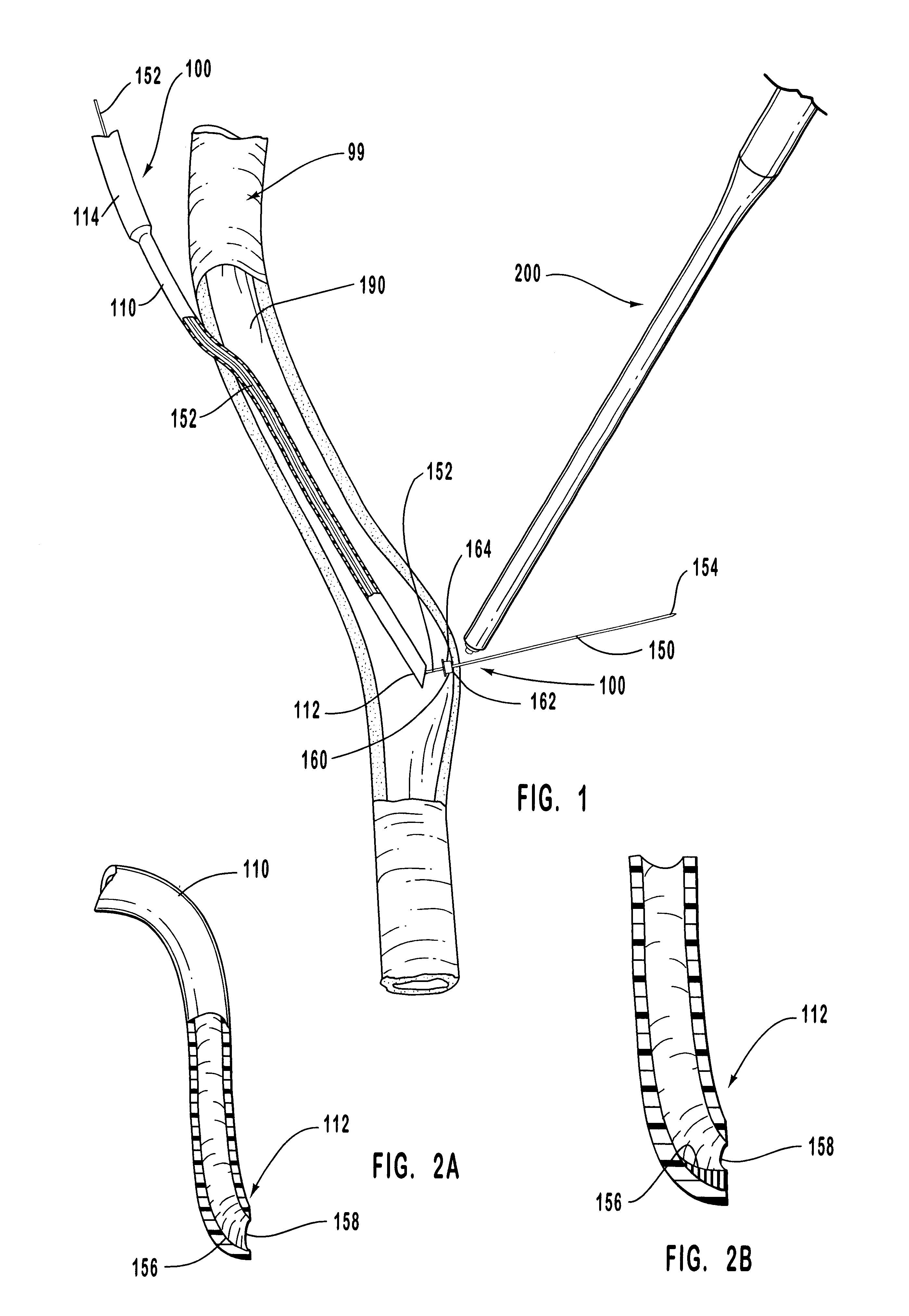

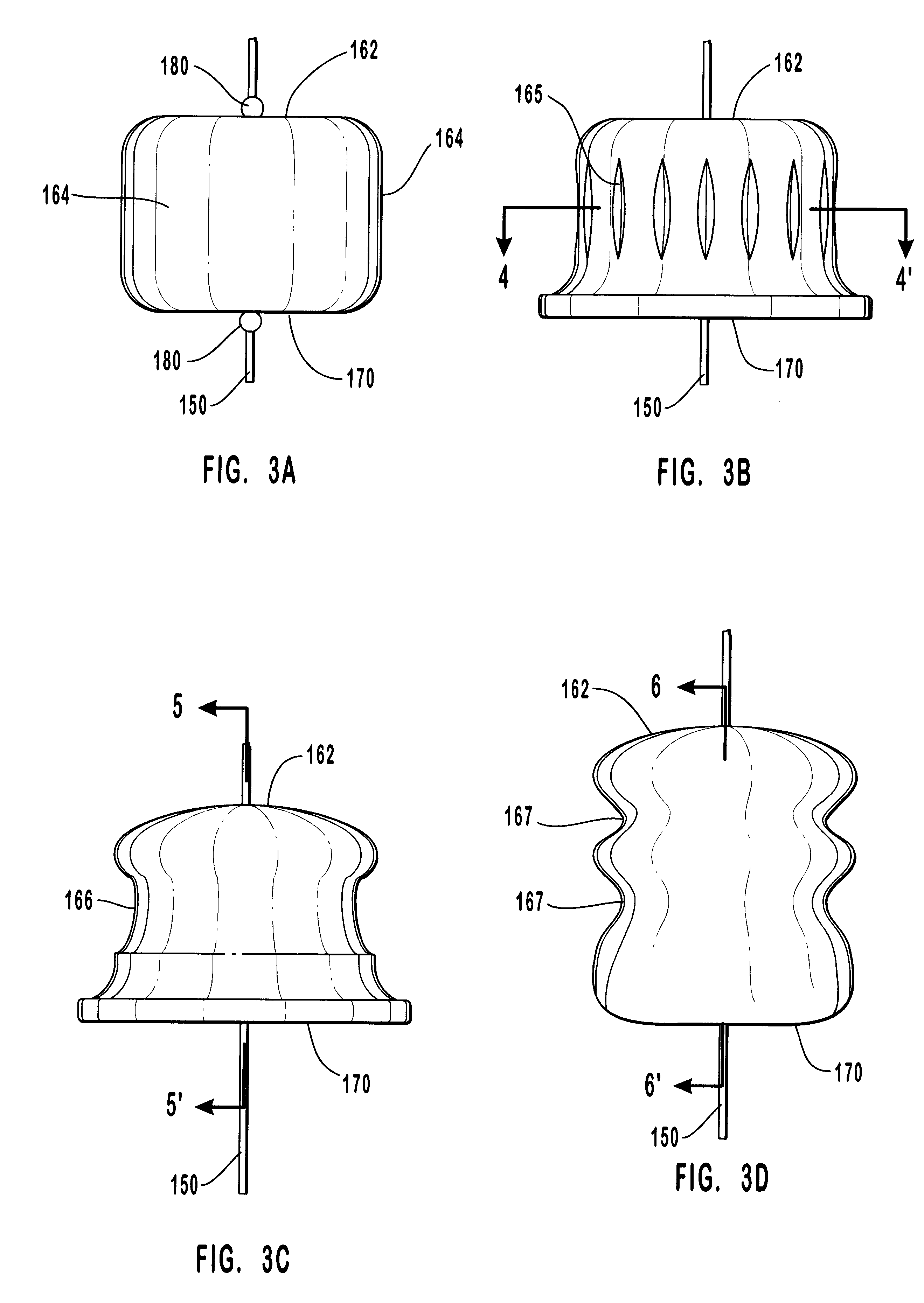

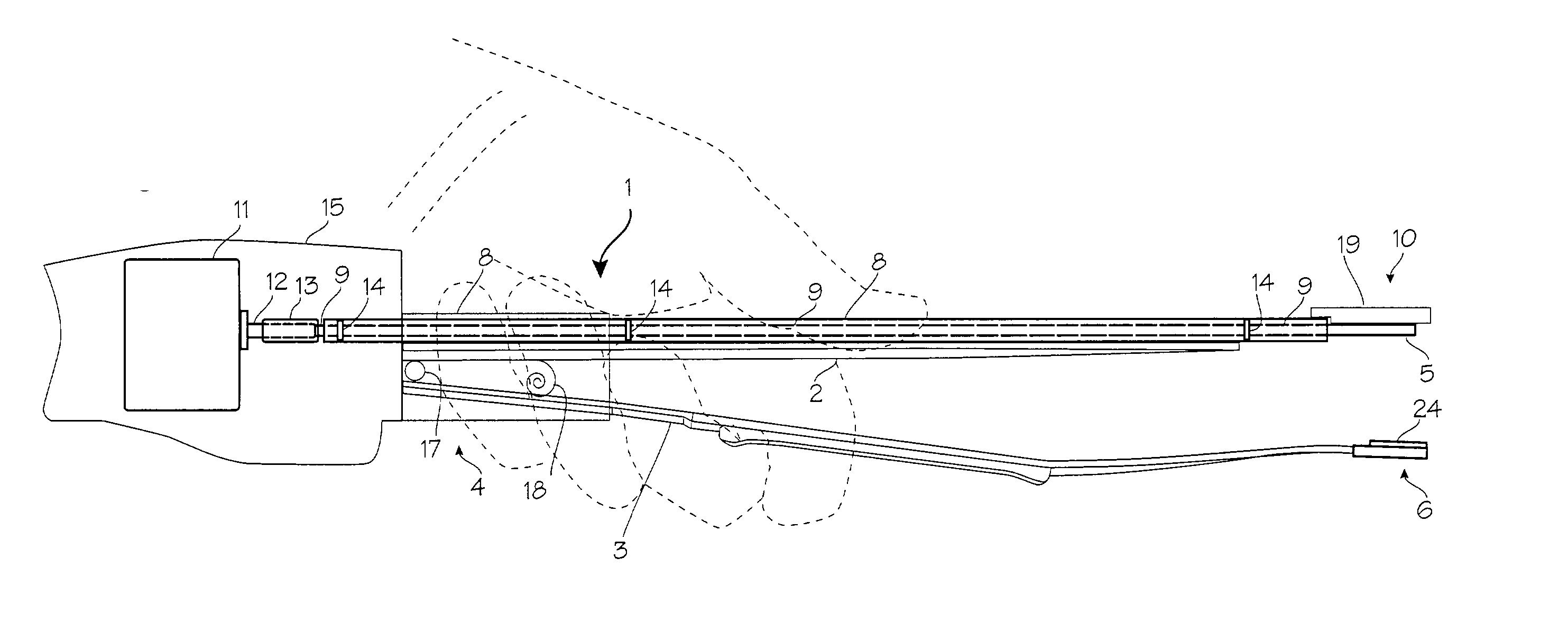

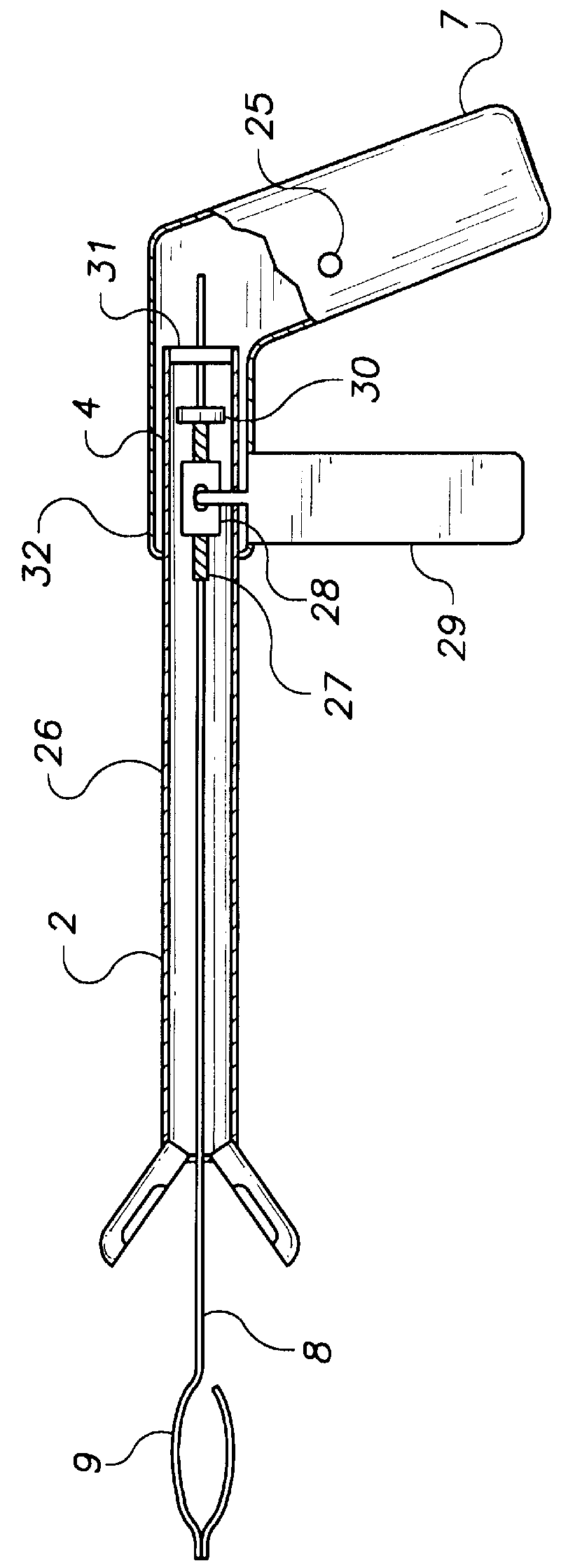

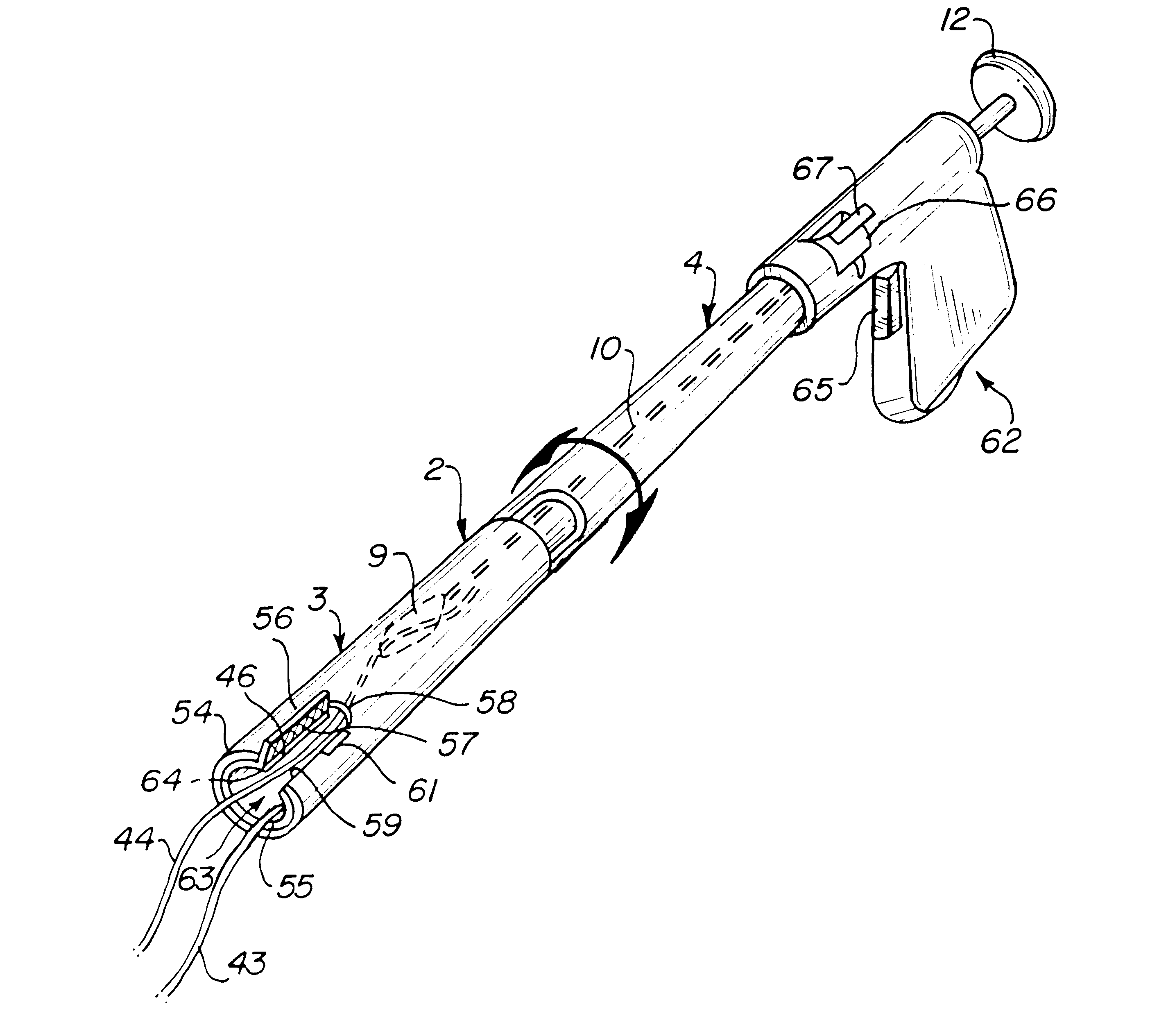

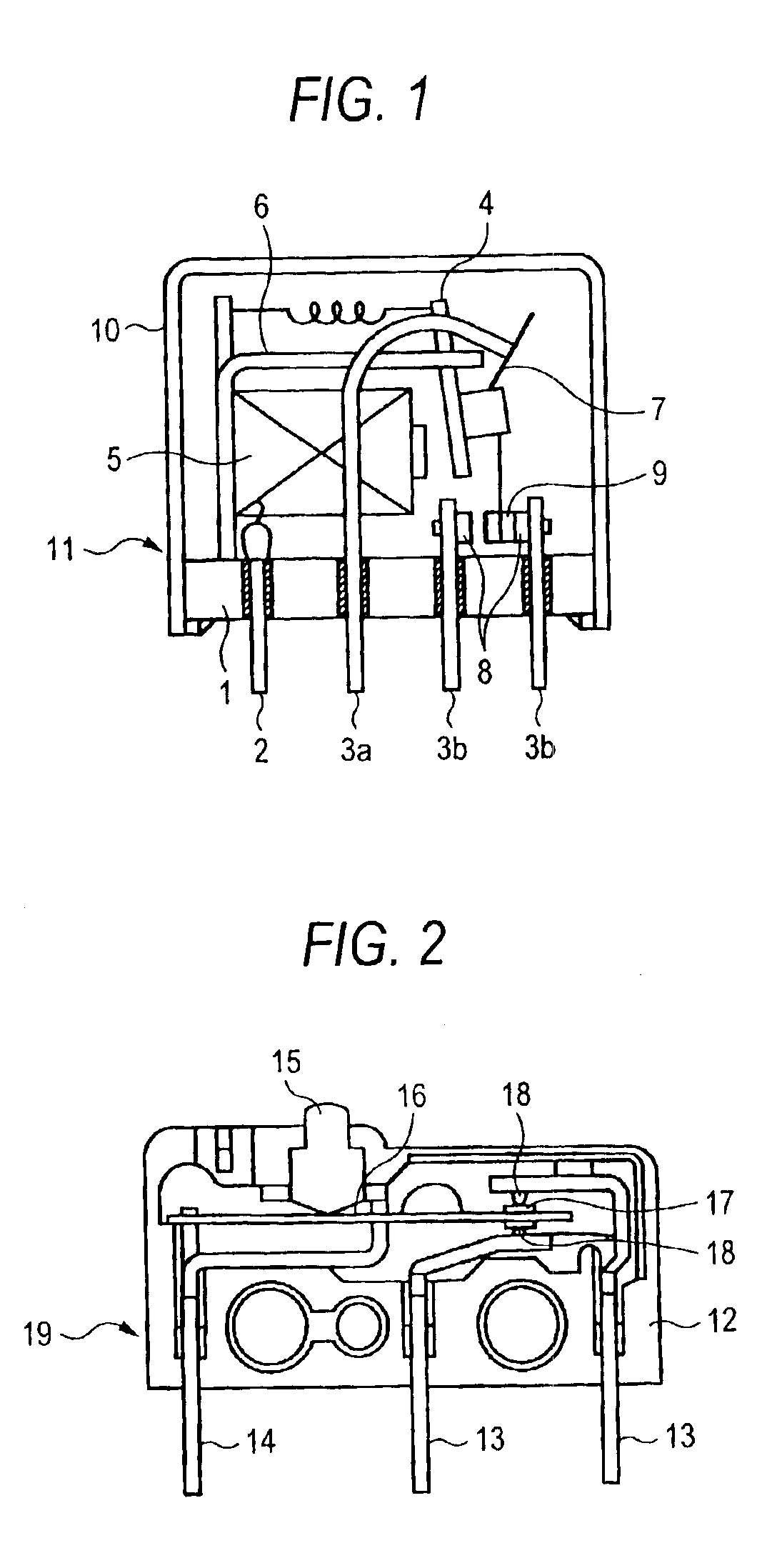

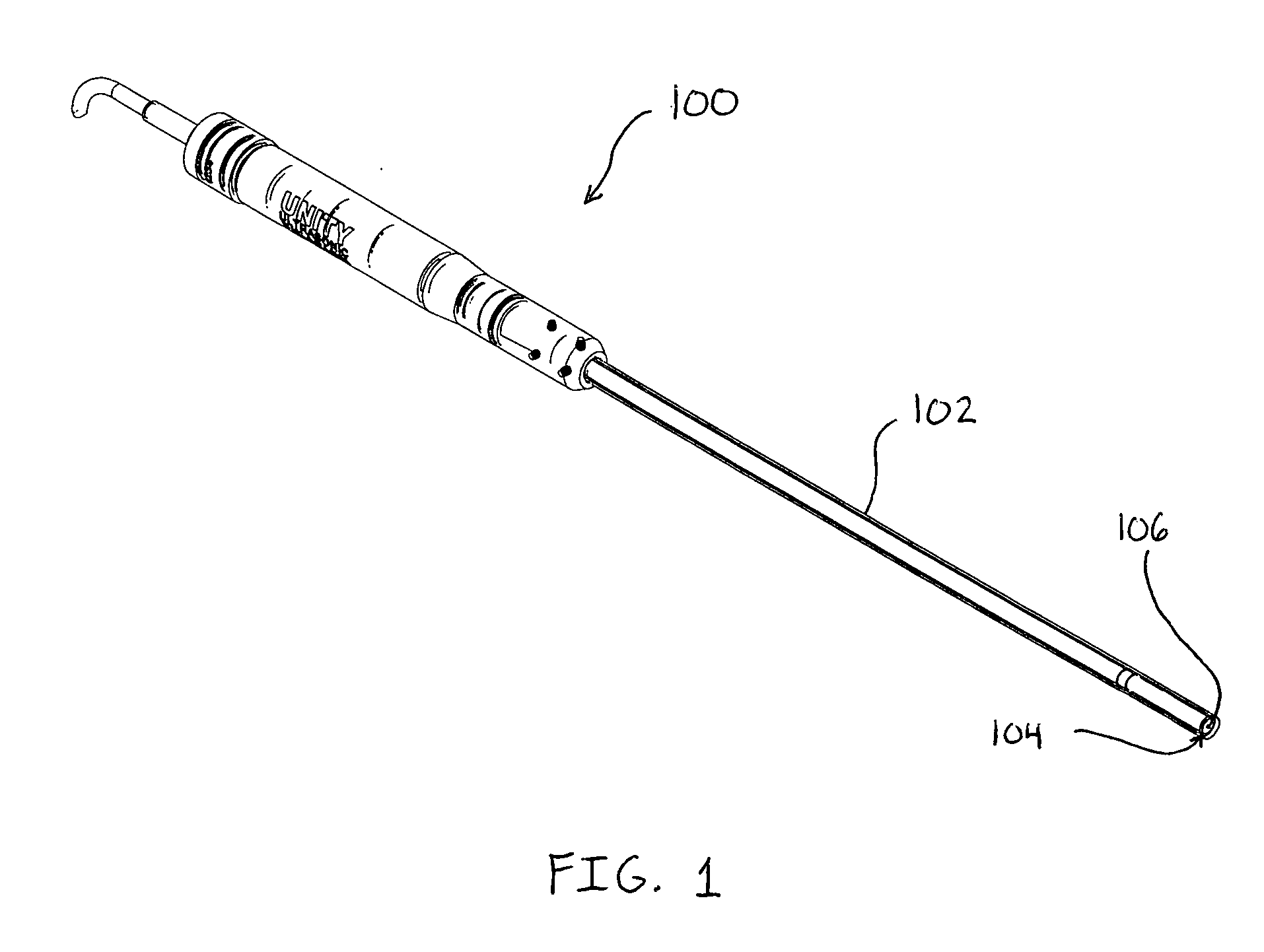

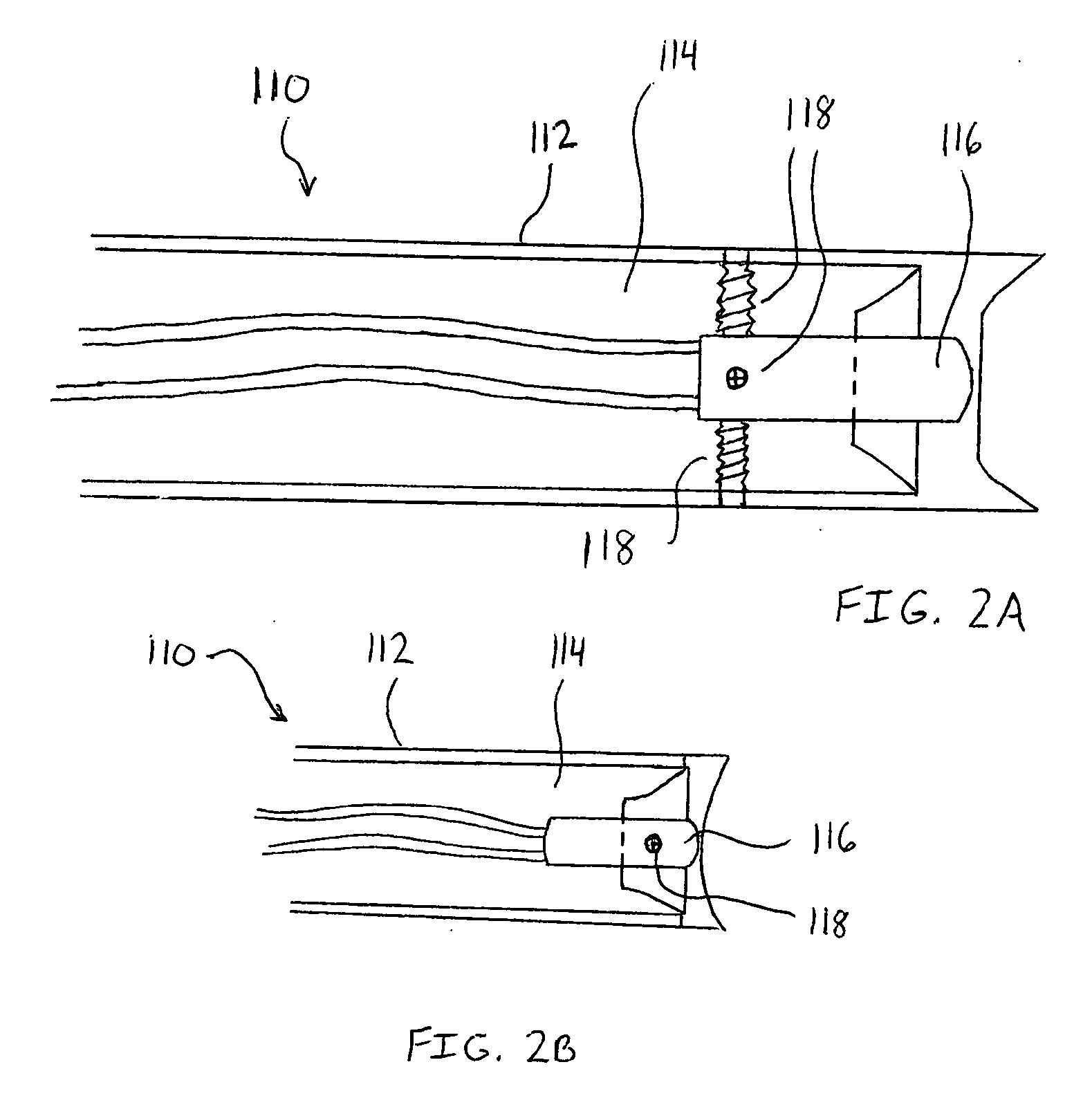

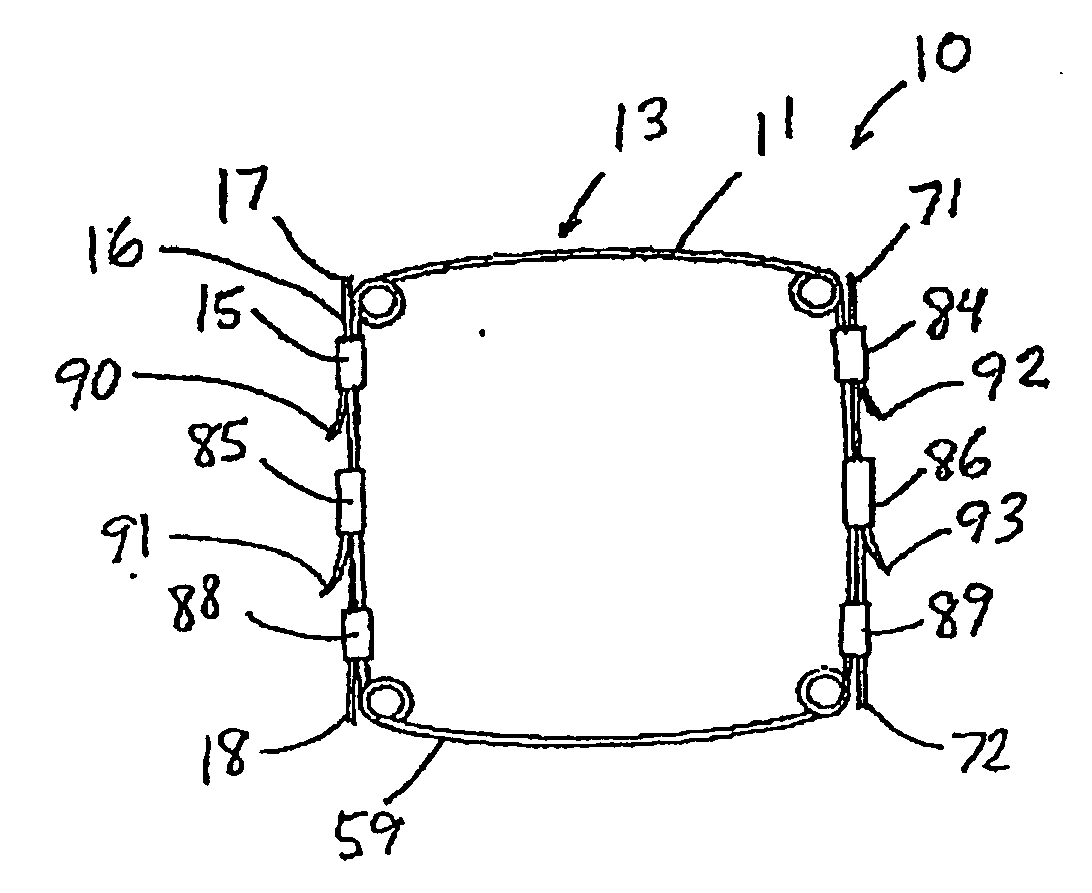

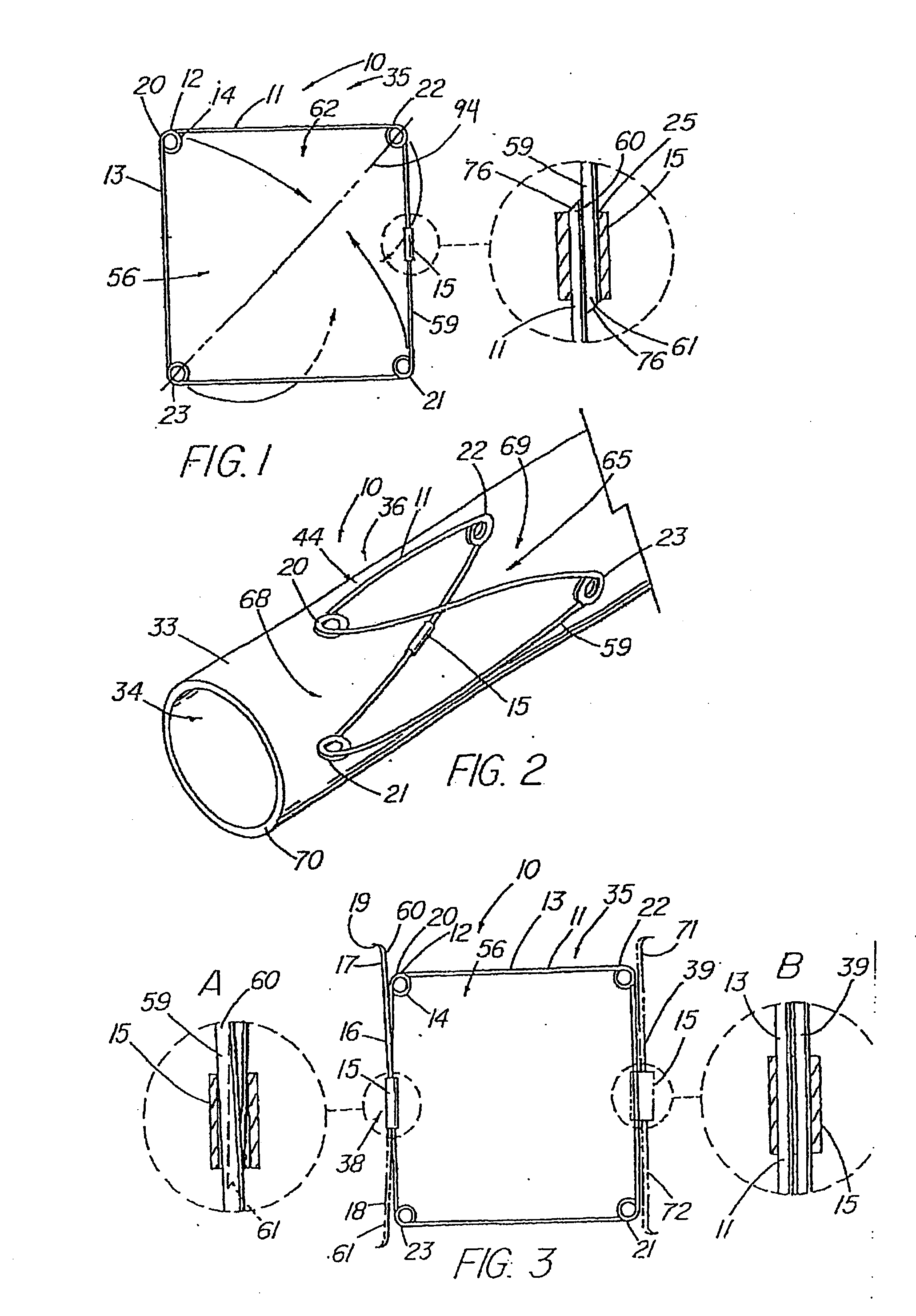

Anastomosis apparatus for use in intraluminally directed vascular anastomosis

InactiveUS6248117B1Surgical needlesSurgical staplesVascular anastomosisMinimally invasive procedures

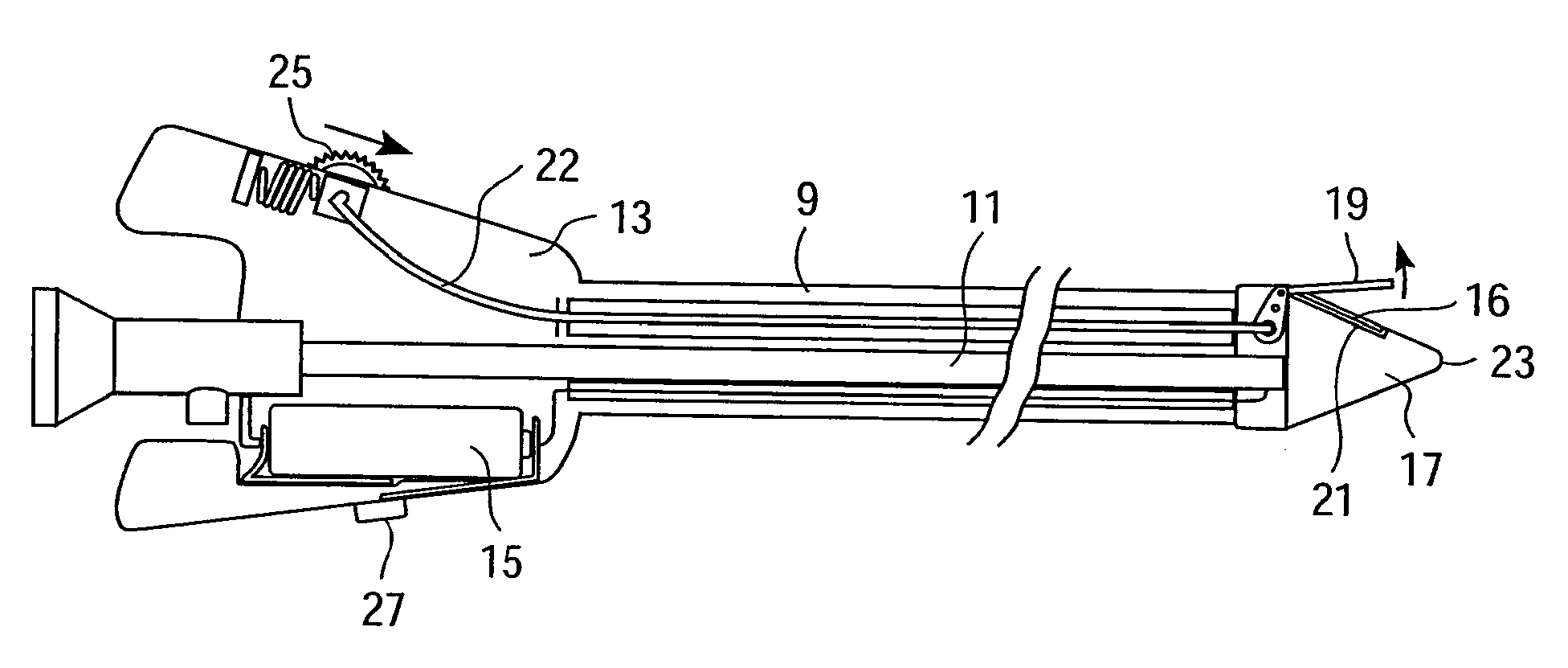

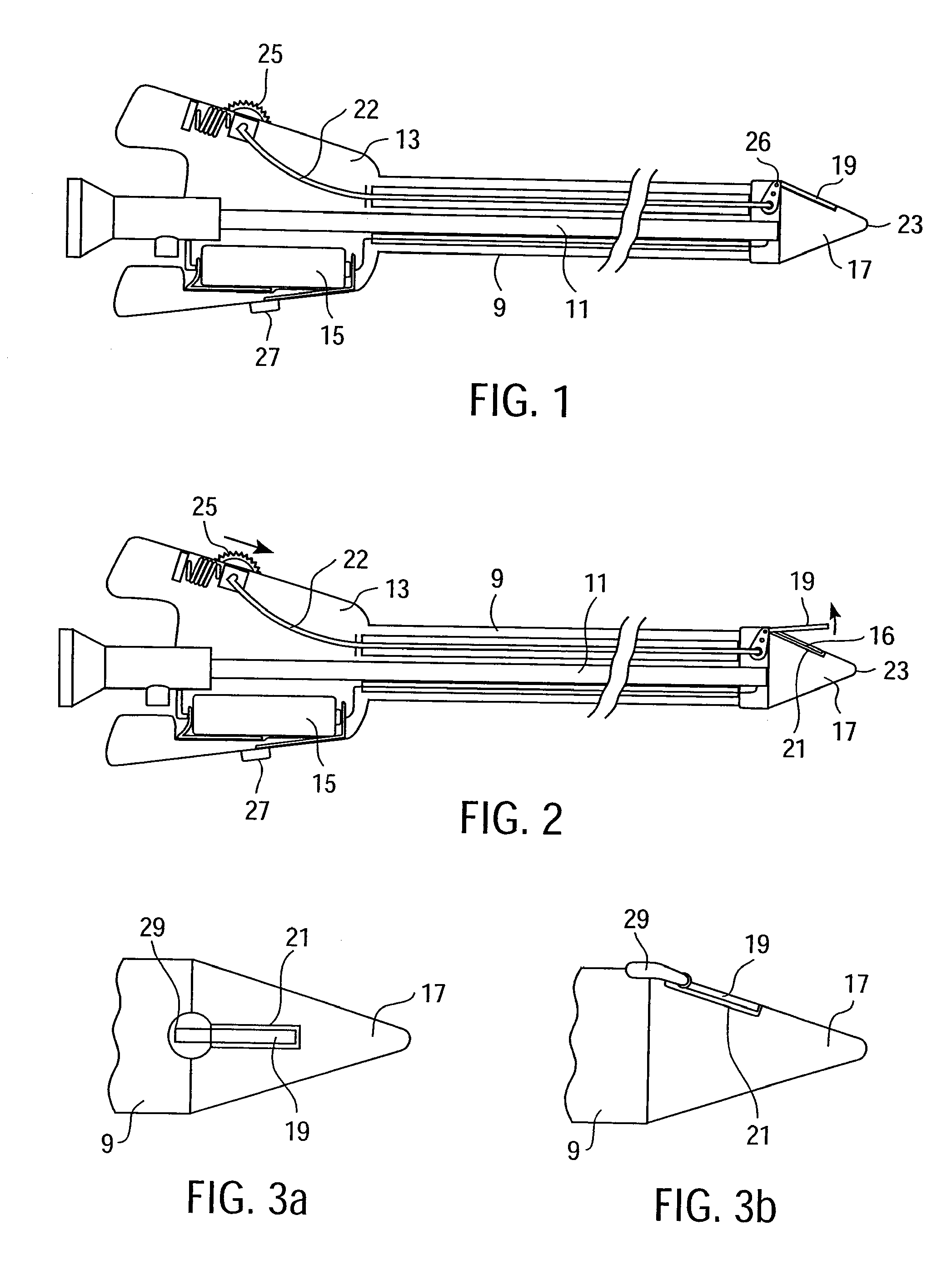

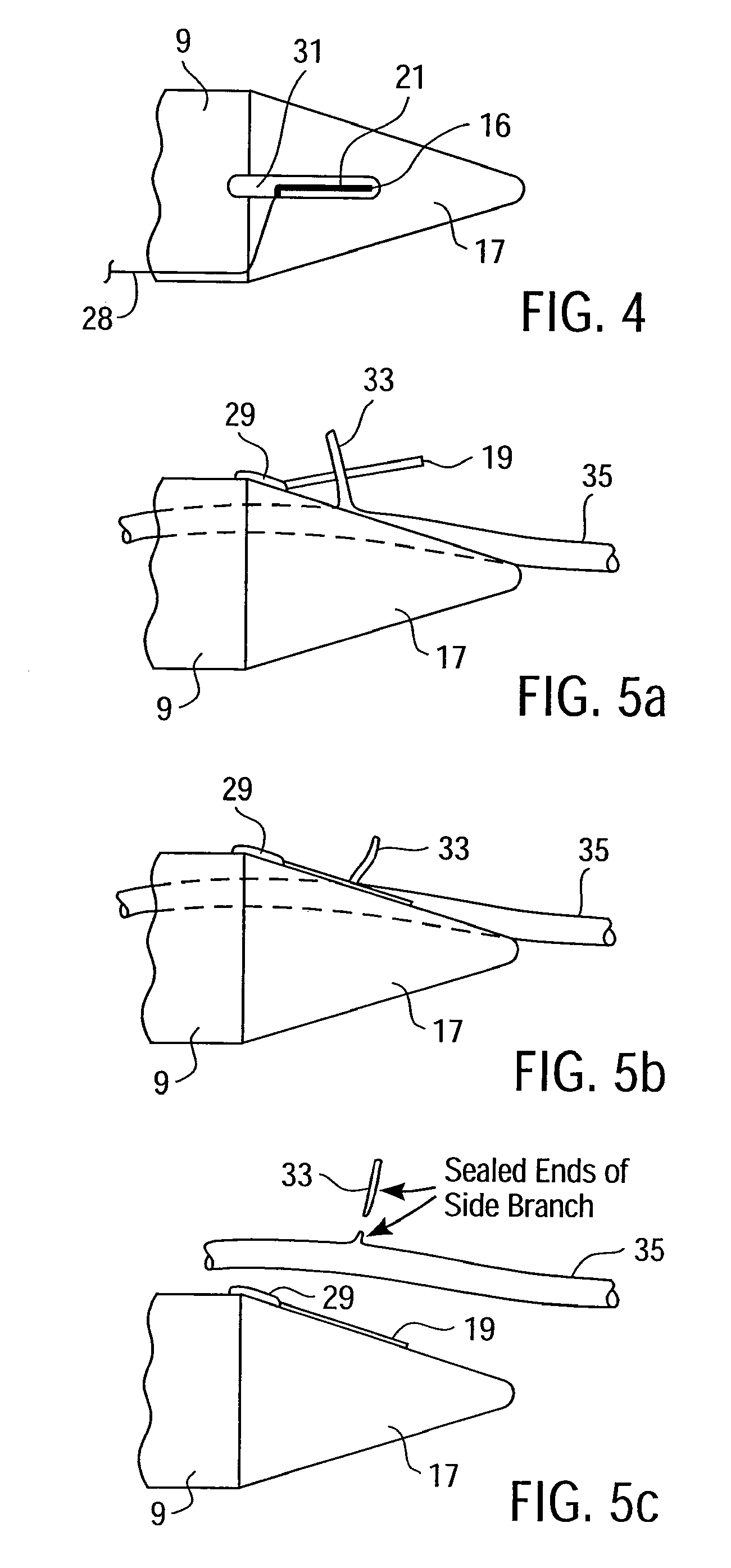

The present invention relates to new and useful apparatus for use with an intraluminally directed anvil apparatus for intraluminally directed vascular anastomosis of an end of a graft vessel to the wall of a receiving blood vessel that is performed according to a minimally invasive procedure. The intraluminally directed vascular anastomosis does not require the interruption of blood flow in the receiving blood vessel and it is versatile enough to suitably combine a variety of cutting, welding, soldering, sealing, and joining techniques such as stapling. The intraluminally directed anvil apparatus comprises an anvil and a wire used for signaling the optimal anastomosis site; this signaling can be performed when the initial exploration is performed. The intraluminally directed anvil apparatus is typically used with a catheter.

Owner:VITAL ACCESS CORP

Electrosurgical stapling apparatus

InactiveUS20050159778A1Reduces or prevents staple line and cut line bleedingShort and strengthSuture equipmentsStapling toolsStaple lineEngineering

An electrosurgical stapling apparatus is provided which uses thermogenic energy as well as surgical fasteners or staples for strengthening tissue, providing hemostasis, tissue joining or welding. The thermogenic energy also strengthens tissue in proximity to a staple line and knife cut line and provides hemostasis along the staple and cut lines formed by the staples and a knife blade during surgical stapling. The use thermogenic energy provides short-term hemostasis and sealing, and reduces or prevents staple line and cut line bleeding, while the stapling features provide short and long-term tissue strength and hemostasis. The stapling apparatus further substantially reduces or prevents knife cut line bleeding by energizing a knife blade for cauterizing tissue while it is being cut. In one embodiment, energy is applied to the anvil to energize the staples as they make contact with the anvil.

Owner:TYCO HEALTHCARE GRP LP

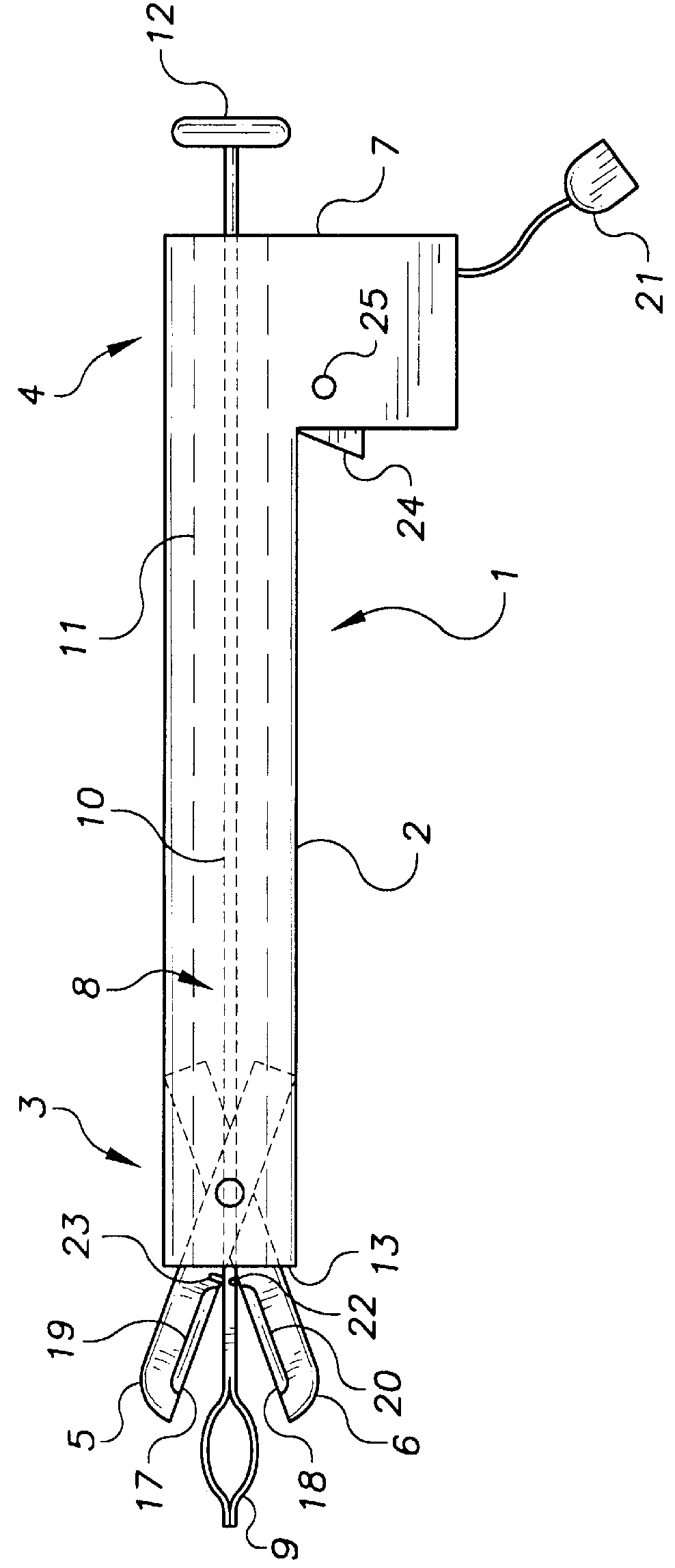

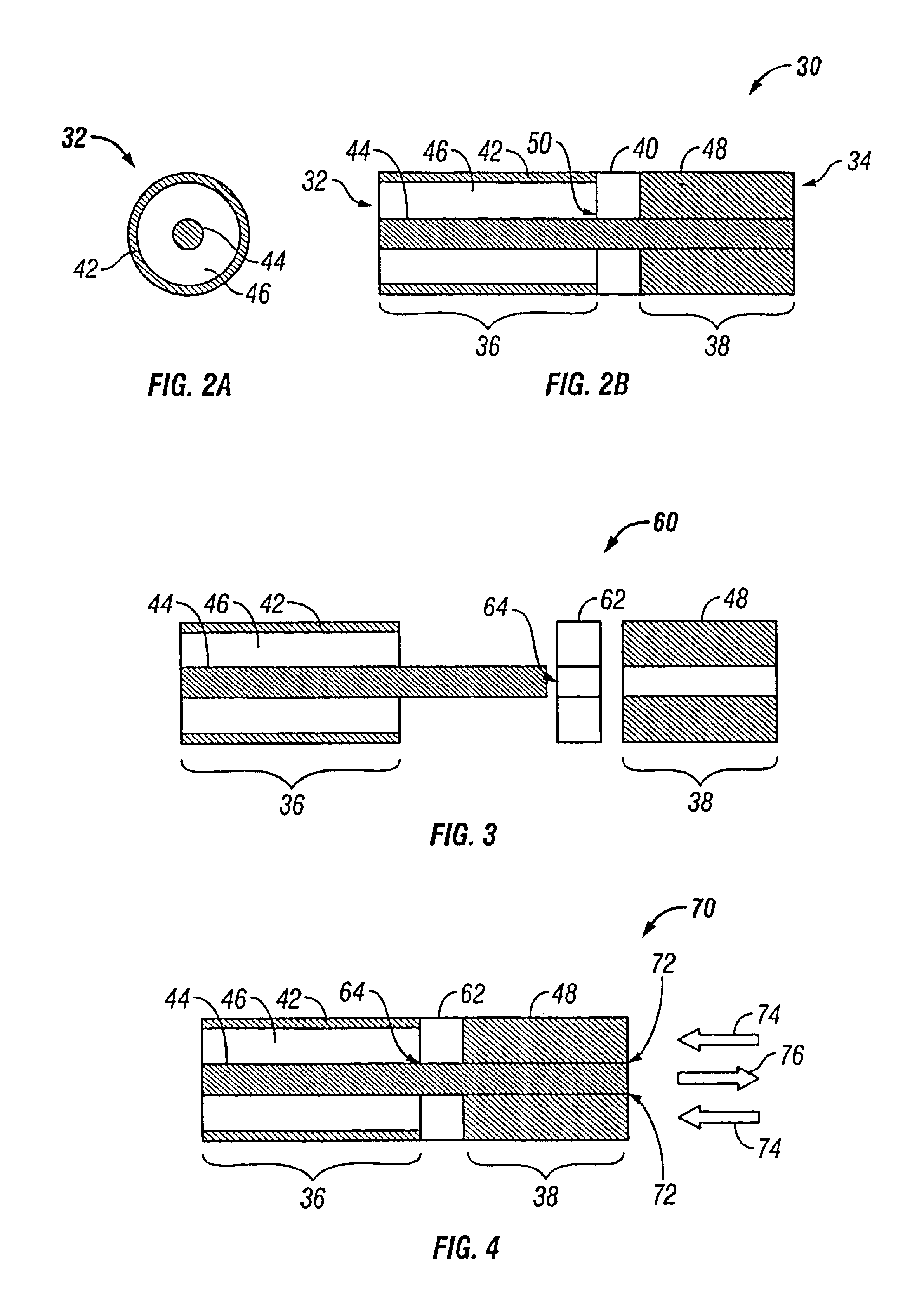

Ultrasonic forceps

Ultrasonic forceps adapted for use in open surgical forceps. The device is provided in the form of traditional open surgery forceps or tweezers, and the transmitting rod which transmits ultrasonic vibration from a proximally located transducer to the distally mounted welding horn runs through a lumen in one of the arms of the forceps.

Owner:STARION INSTR

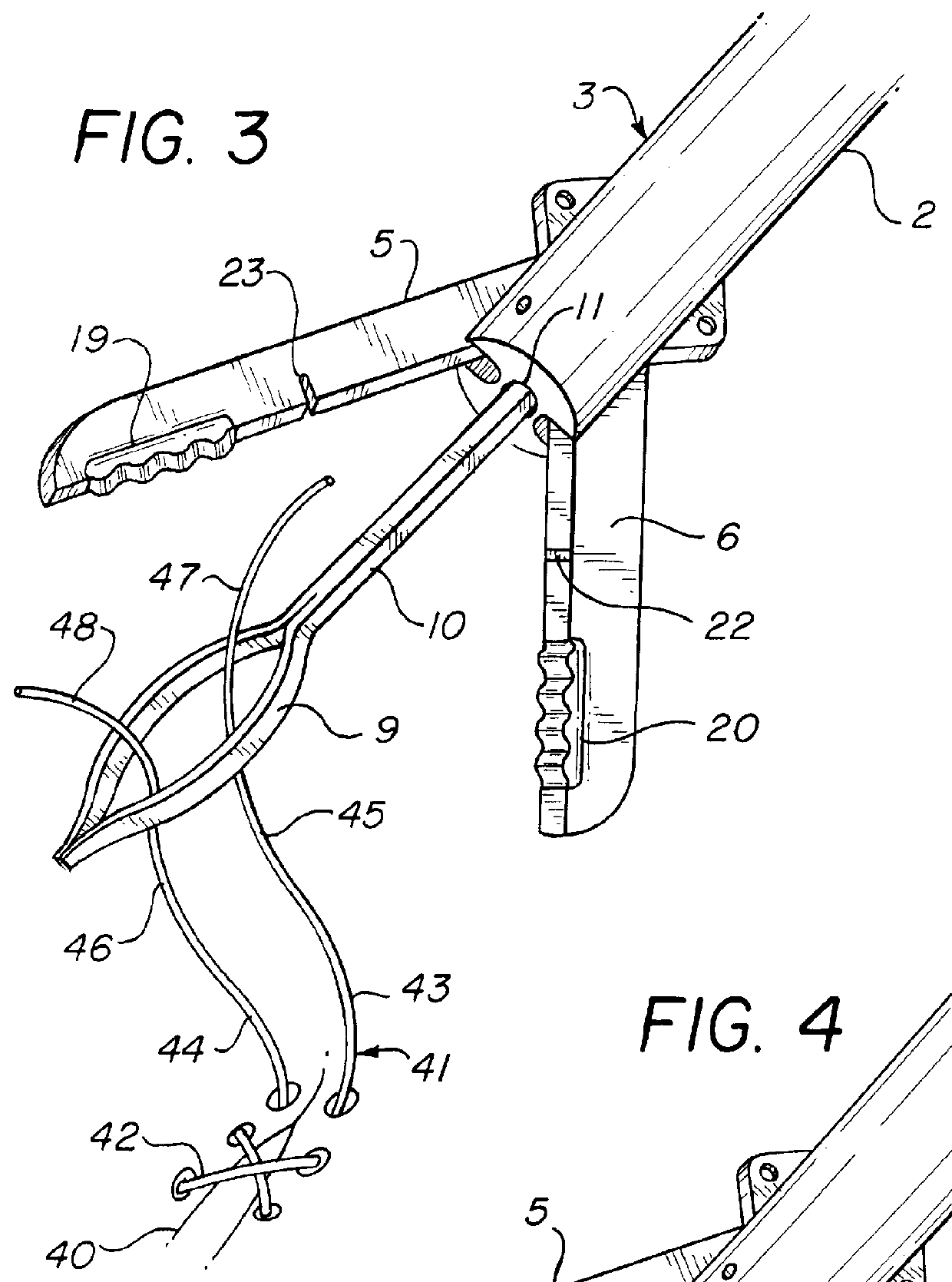

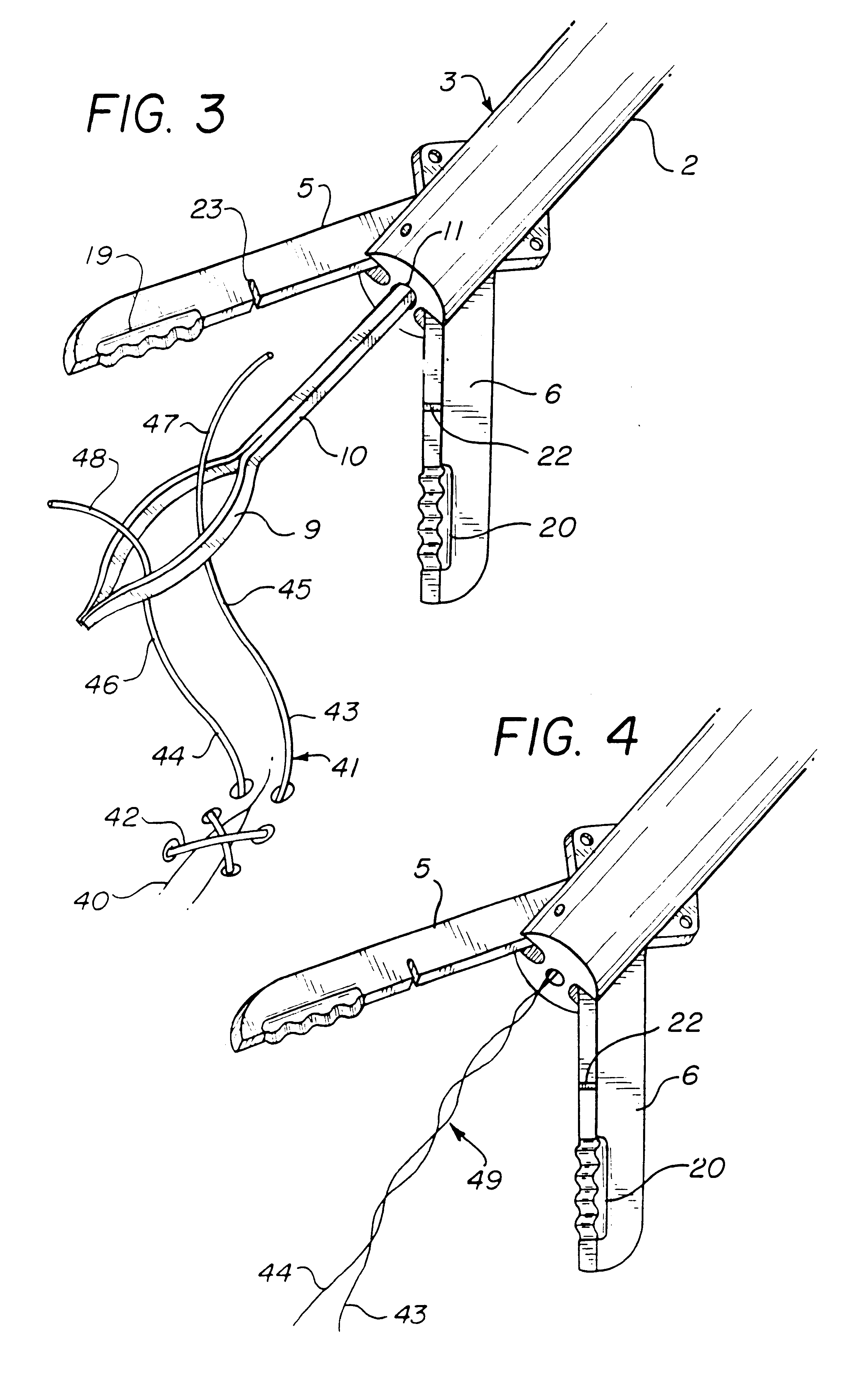

Suture welding device

Devices for welding suture segments in lieu of tying knots in sutures applied during endoscopic surgery. The devices provide for snaring loose suture ends and drawing the suture ends into a space between heating surfaces, and provide for closing the heating surfaces

Owner:MICROLINE SURGICAL INC

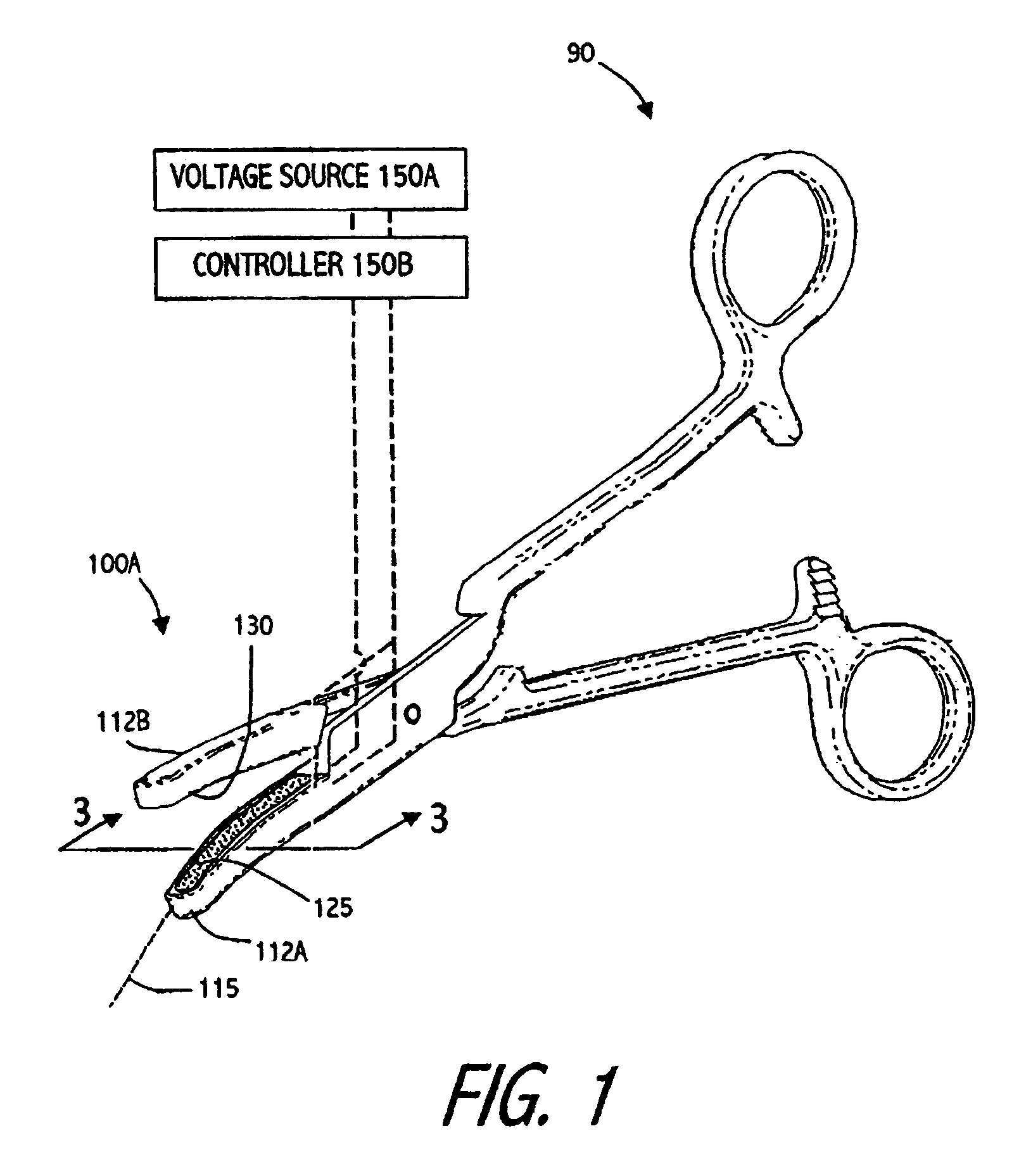

Electrosurgical instrument and method of use

ActiveUS7955331B2Effective “weld” in tissueAvoid flowSurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceHigh intensity

A particular embodiment of the invention provides an electrosurgical working end for performing high strength welding of tissue comprising a body having a tissue contacting energy delivery surface. The body includes pixel portions and non-pixel portions distributed within the tissue contacting surface. The pixel portions comprise a positive temperature coefficient of resistance (PTCR) material with at least one pixel portion configured to switch Rf current on and off in the at least one pixel portion responsive to tissue temperature adjacent the at least one pixel portion. The pixel portions can be configured to be coupled to an Rf current source such as an Rf generator. The pixelated energy delivery surfaces are capable of highly localized modulation of Rf energy application to the engaged tissue to create high strength tissue welds.

Owner:ETHICON ENDO SURGERY INC

Dissection and welding of tissue

InactiveUS7534243B1Facilitates concentrating compression forceEndoscopesBlunt dissectorsTissue solderingBlood vessel

A tissue dissector and method for welding and severing blood vessels includes advancing the tip of a tissue-dissecting surgical instrument through tissue, with a tissue welder substantially concealed within the tip during tissue dissection. Blood vessels encountered in the tissue being dissected are selectively captivated and compressed in substantial contact with the tissue welder to elevate the temperature of the compressed tissue sufficiently to hemostatically weld and sever the compressed blood vessel.

Owner:MAQUET CARDIOVASCULAR LLC

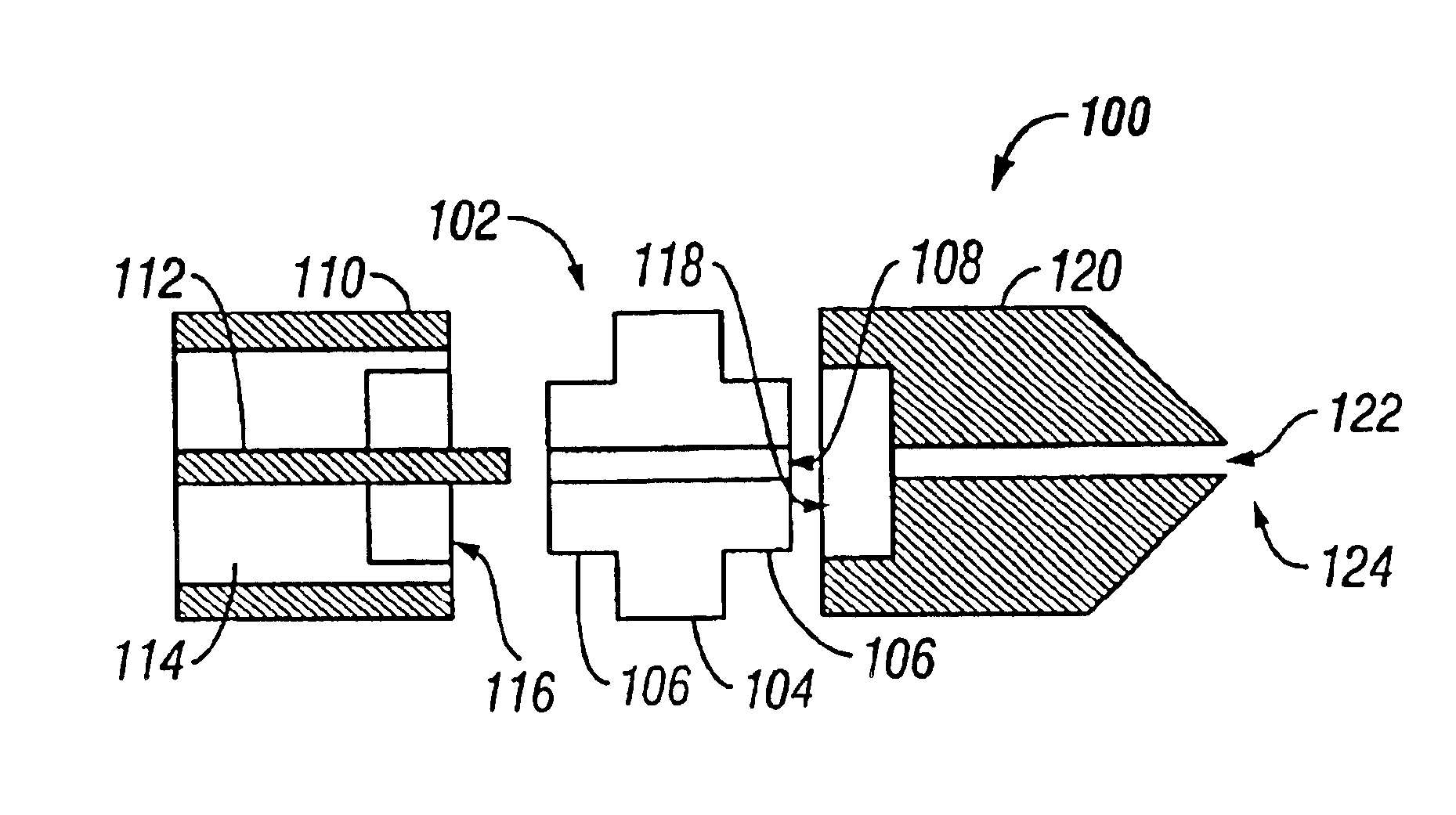

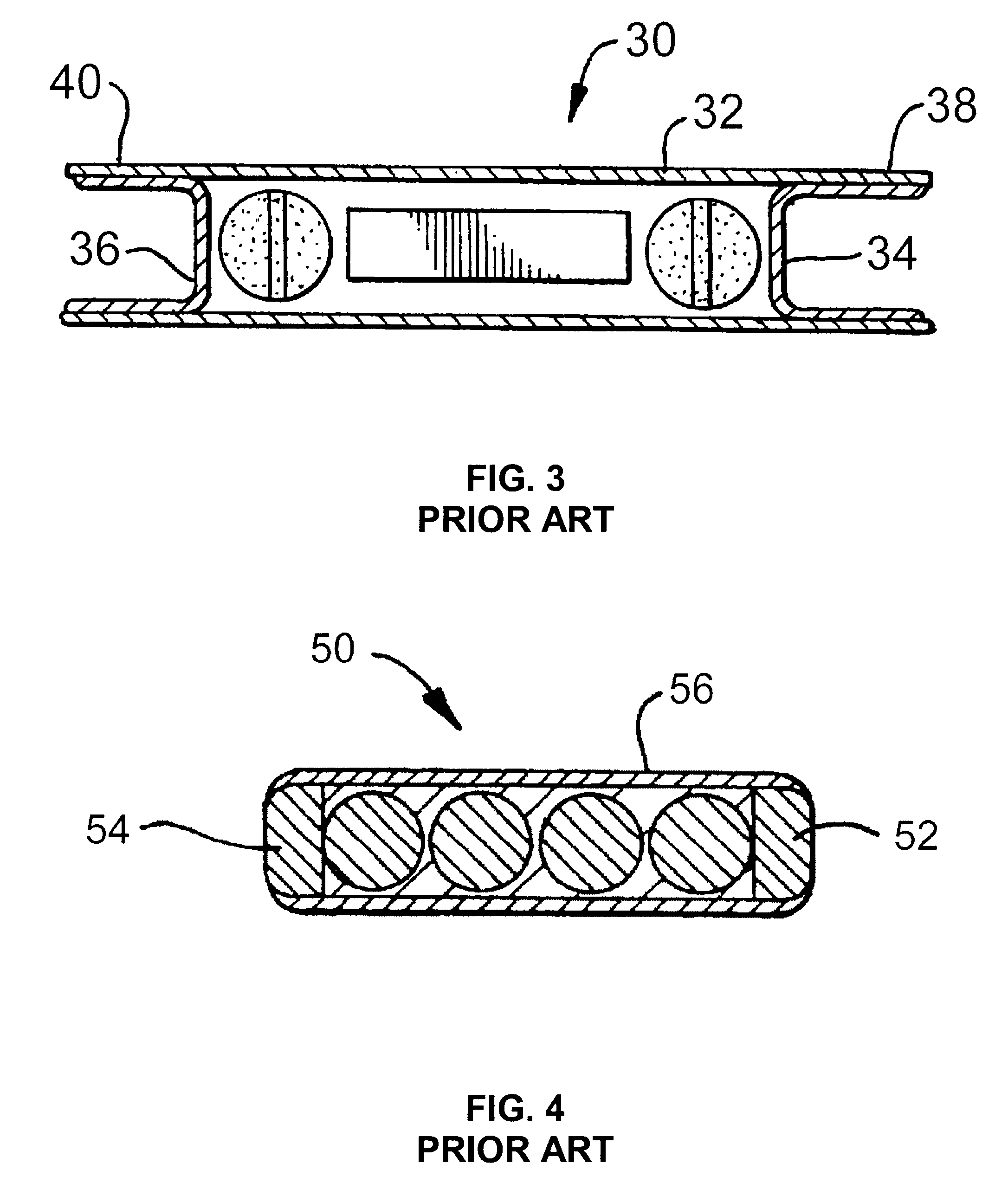

High-strength microwave antenna assemblies

InactiveUS6878147B2Avoid mechanical failureSurgical needlesSurgical instruments for heatingAntenna designElectrical conductor

Various high-strength microwave antenna assemblies are described herein. The microwave antenna has a radiating portion connected by a feedline to a power generating source, e.g., a generator. The antenna is a dipole antenna with the distal end of the radiating portion being tapered and terminating at a tip to allow for direct insertion into tissue. Antenna rigidity comes from placing distal and proximal radiating portions in a pre-stressed state, assembling them via threaded or overlapping joints, or fixedly attaching an inner conductor to the distal portion. The inner conductor is affixed to the distal portion by, e.g., welding, brazing, soldering, or by adhesives. A junction member made from a hard dielectric material, e.g., ceramic, can be placed between the two portions and can have uniform or non-uniform shapes to accommodate varying antenna designs. Electrical chokes may also be used to contain returning currents to the distal end of the antenna.

Owner:COVIDIEN LP

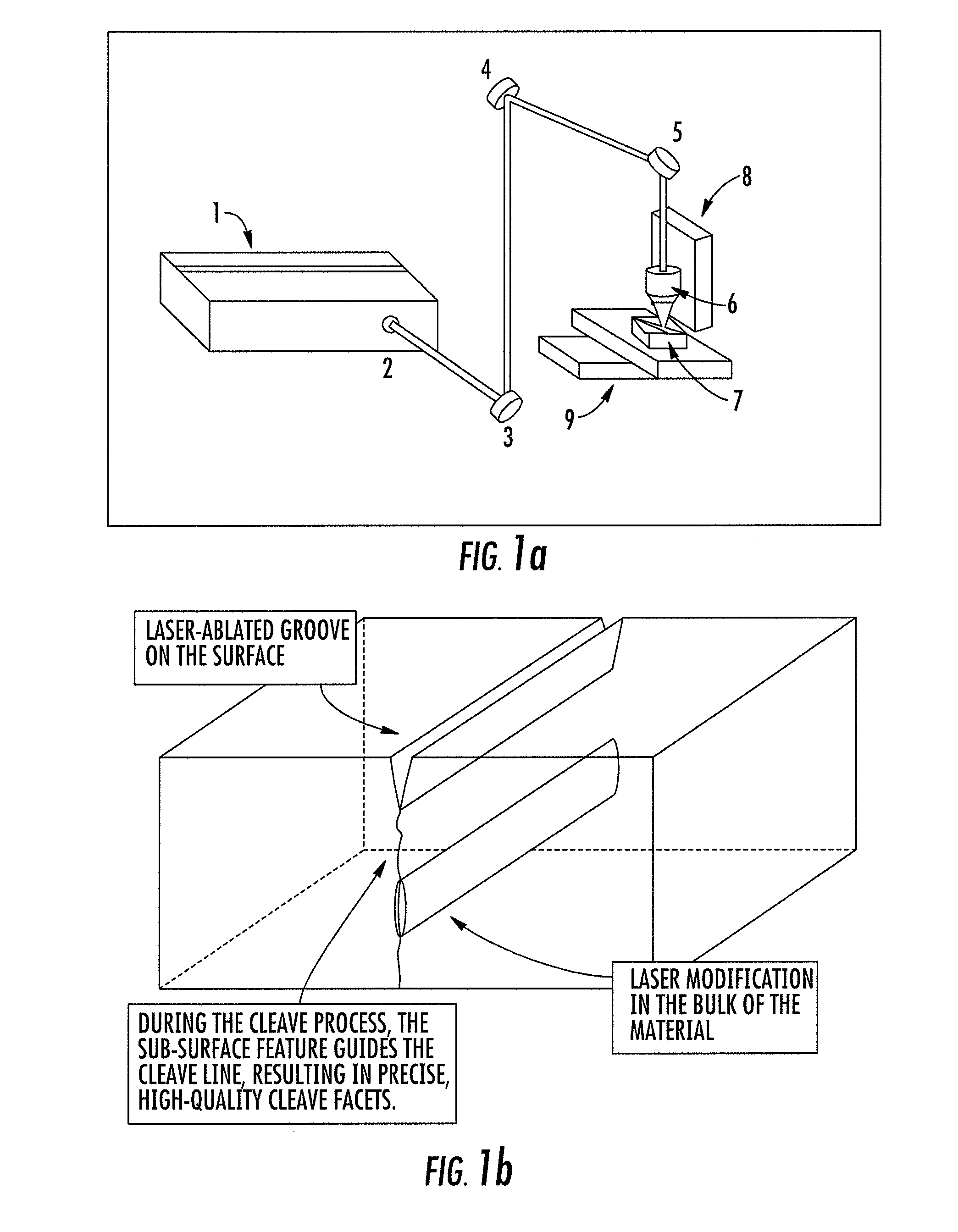

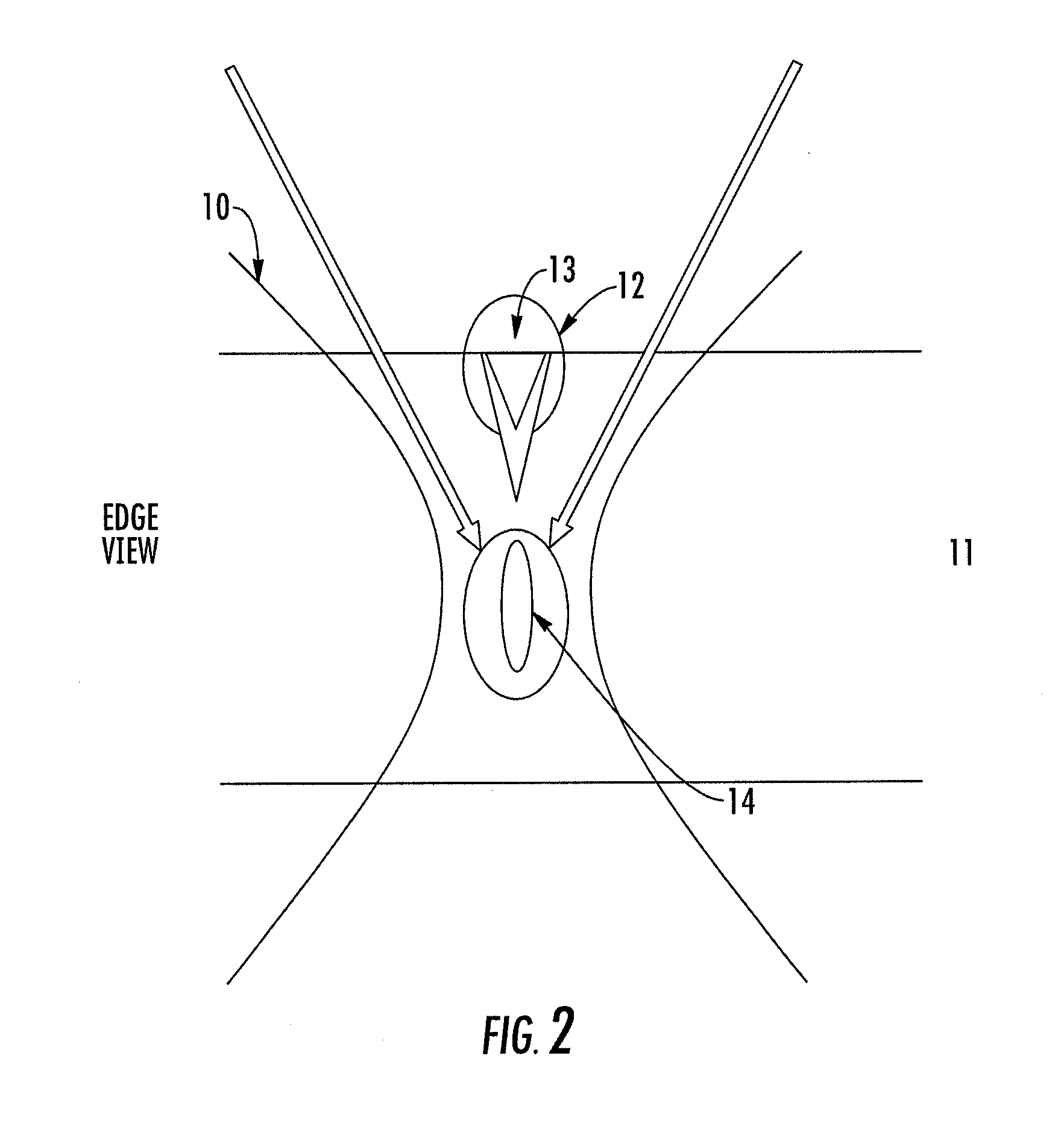

Transparent material processing with an ultrashort pulse laser

InactiveUS20100025387A1Reduce quality problemsPoor precisionSemiconductor/solid-state device manufacturingFine working devicesLight beamOptoelectronics

Methods, devices, and systems for ultrashort pulse laser processing of optically transparent materials are disclosed, with example applications in scribing, marking, welding, and joining. For example, ultrashort laser pulses create scribe features with one pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with correctly aligned illumination. Reflective marks may also be formed with control of laser parameters. A transparent material other than glass may be utilized. A method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. In some embodiments of transparent material processing, a multifocus beam generator simultaneously forms multiple beam waists spaced depthwise relative to the transparent material, thereby increasing processing speed.

Owner:IMRA AMERICA

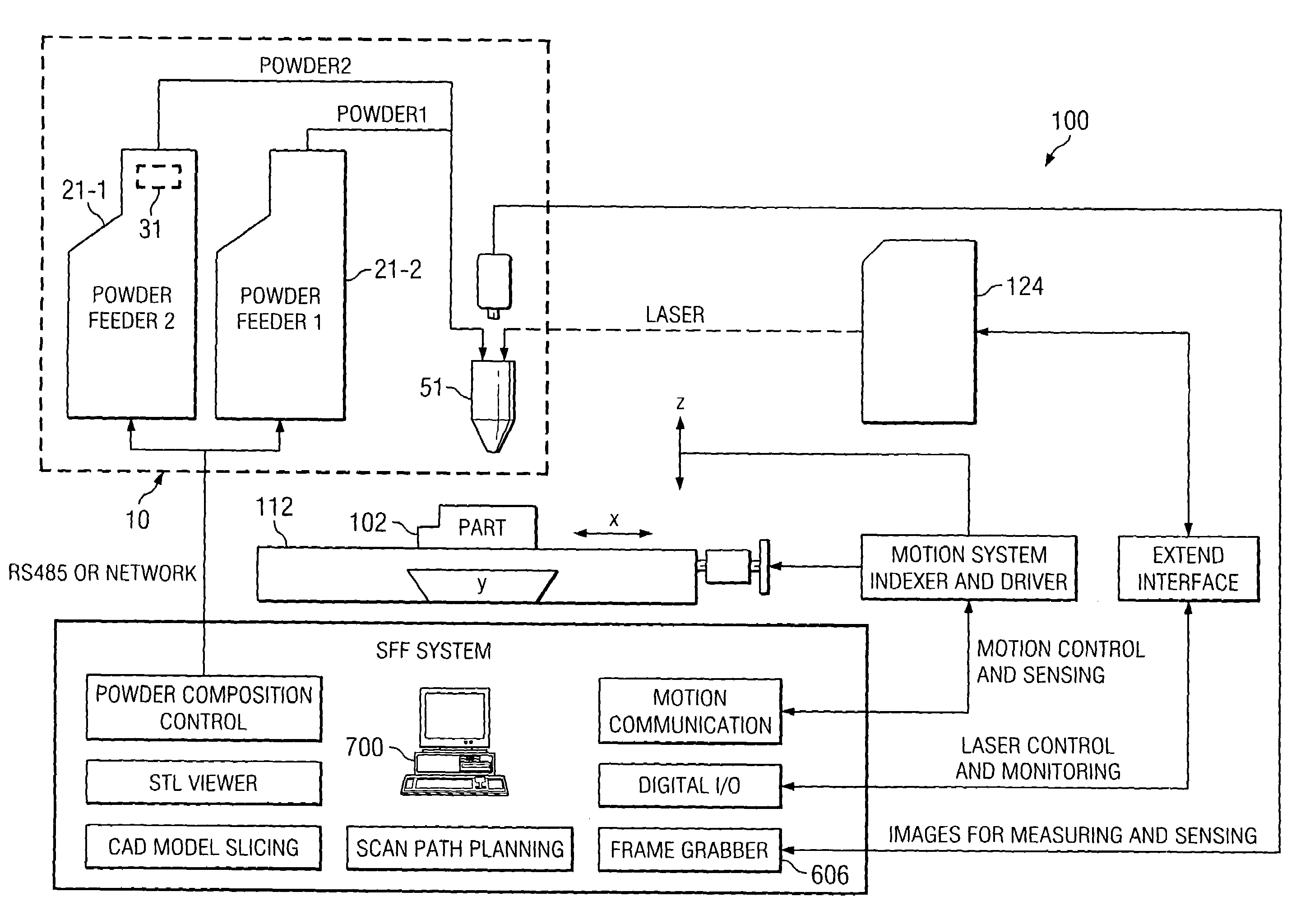

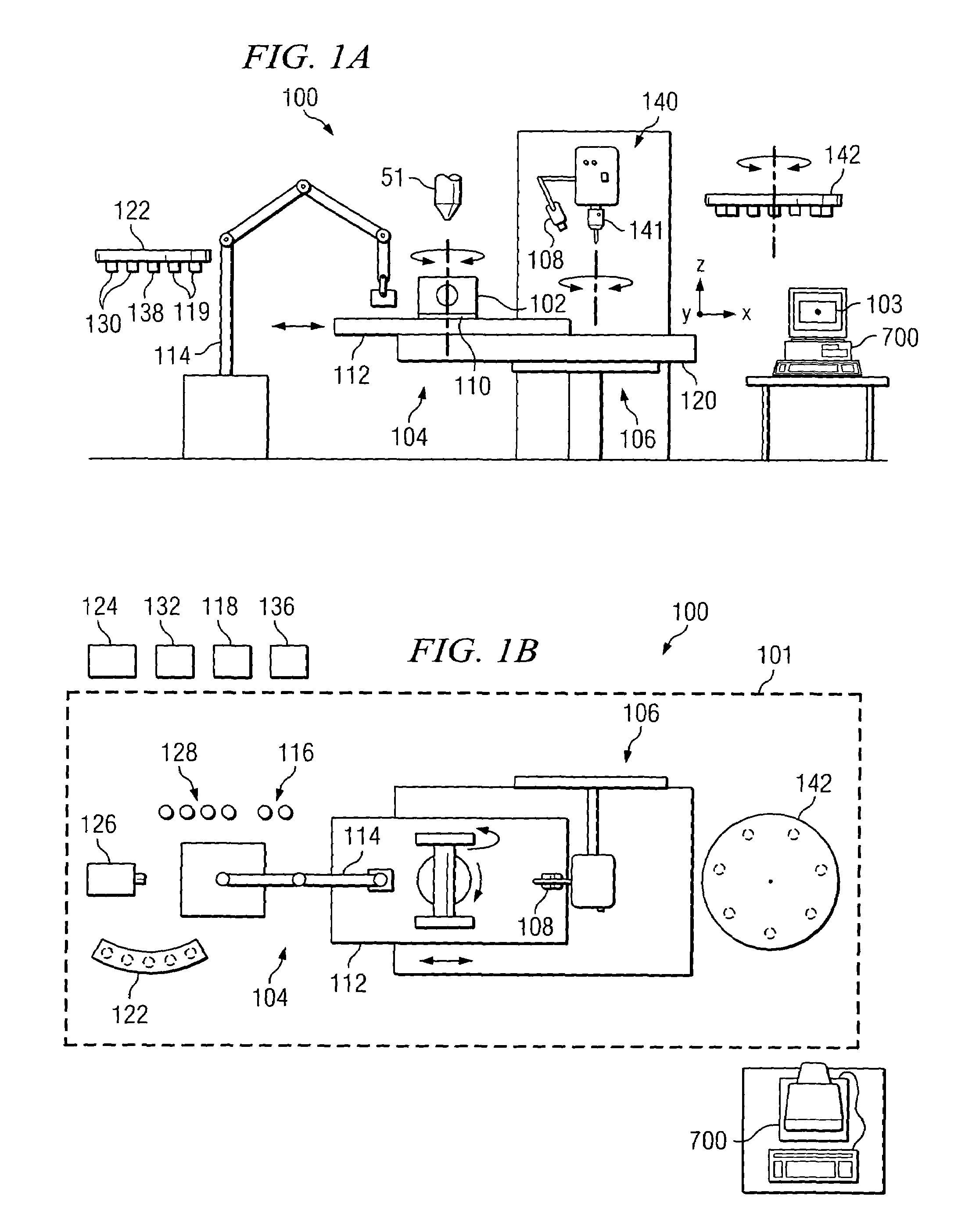

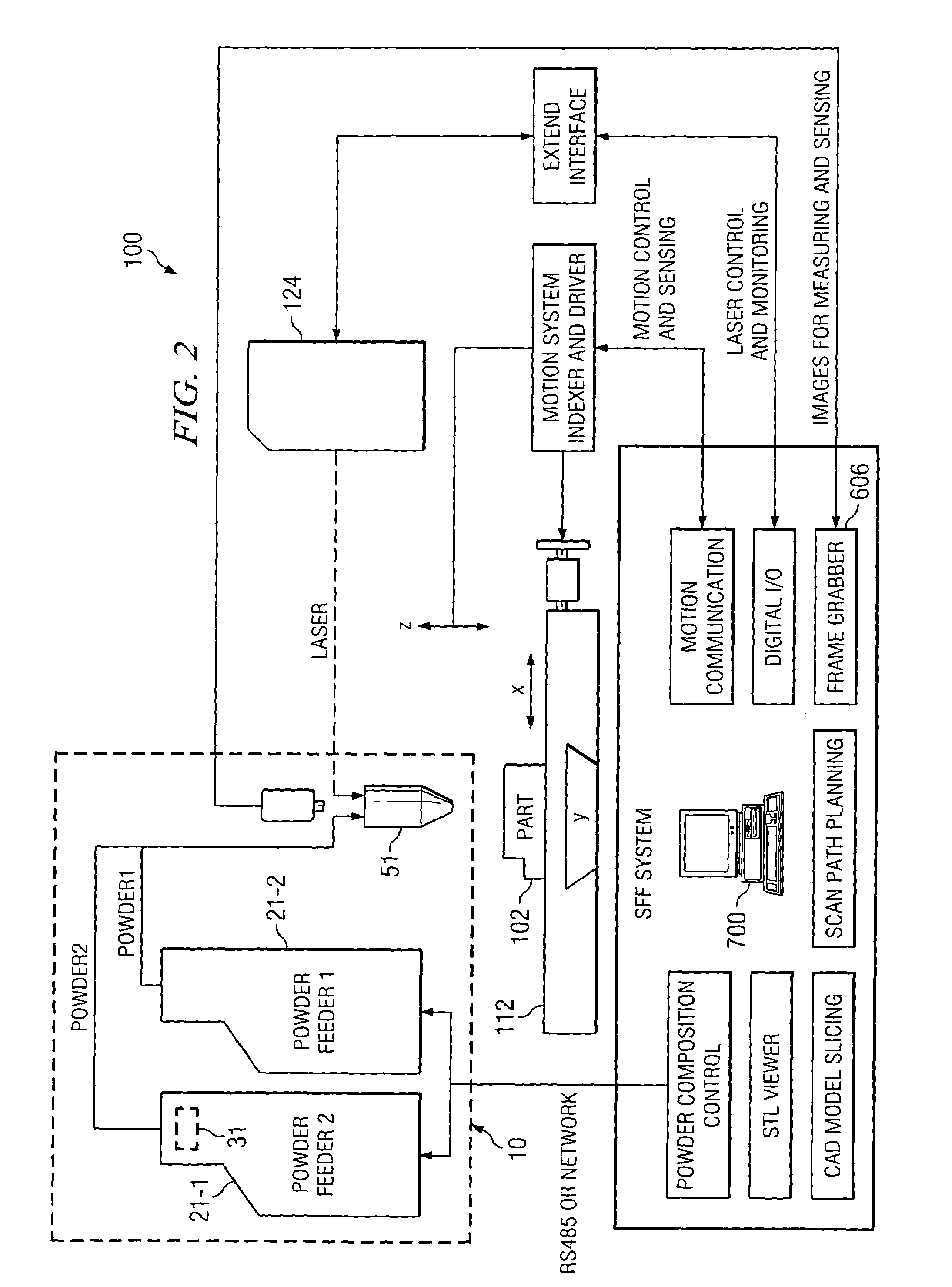

System and method for fabricating or repairing a part

InactiveUS7020539B1Improve accuracyHigh geometric accuracyAdditive manufacturing apparatusTool changing apparatusMulti axisMachining

According to one embodiment of the invention, a system for fabricating a part includes a computer operable to control the fabrication of a three-dimensional part using a solid CAD model, a deposition station operable to deposit successive two-dimensional layers of material to fabricate the three-dimensional part, and a machining station operable to remove at least a portion of one or more of the deposited two-dimensional layers of material. The deposition station includes a substrate on which to fabricate the three-dimensional part, a welding-based deposition system having a welding torch, a laser-based deposition system having a laser head, a plasma powder cladding system having a plasma torch, and a multi-axis robot operable to, when directed by the computer, utilize one of the welding-based deposition system, laser-based deposition system, and plasma powder cladding system to deposit any of the two-dimensional layers of material. The machining station includes a multi-axis milling machine and an automatic tool changer. The milling machine is operable to, when directed by the computer, select from a plurality of machining tools associated with the automatic tool changer for use in the milling machine.

Owner:SOUTHERN METHODIST UNIVERSITY

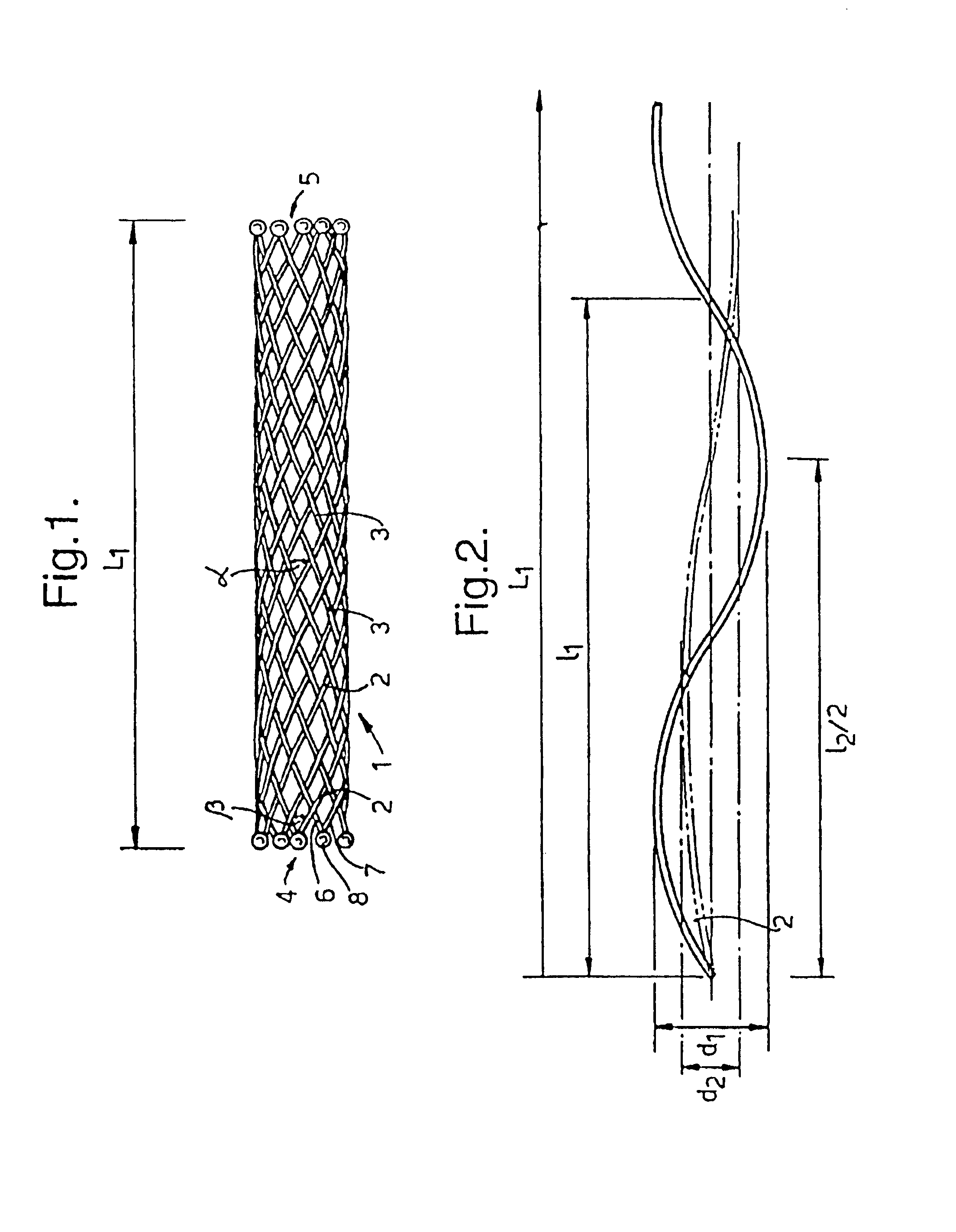

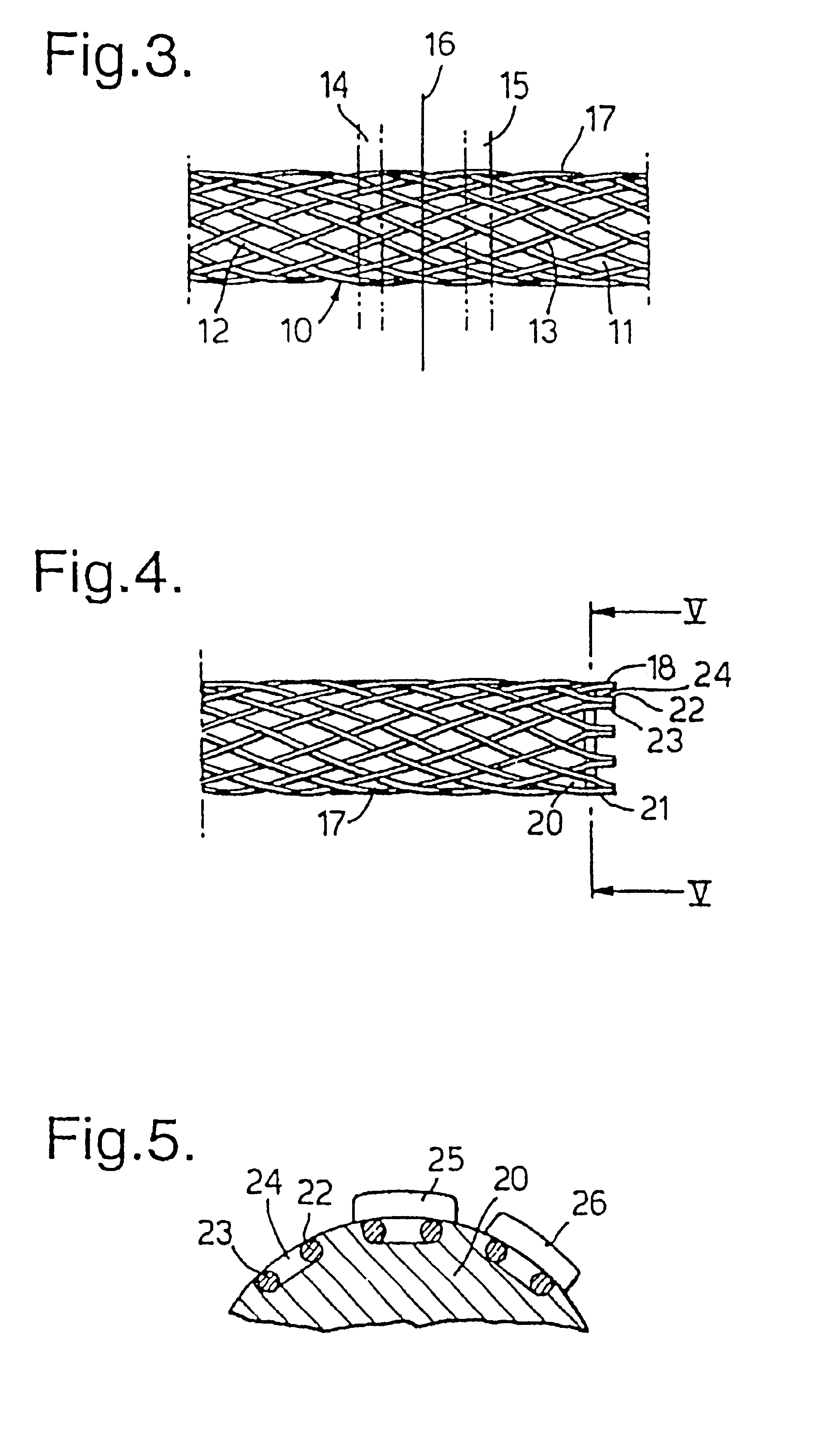

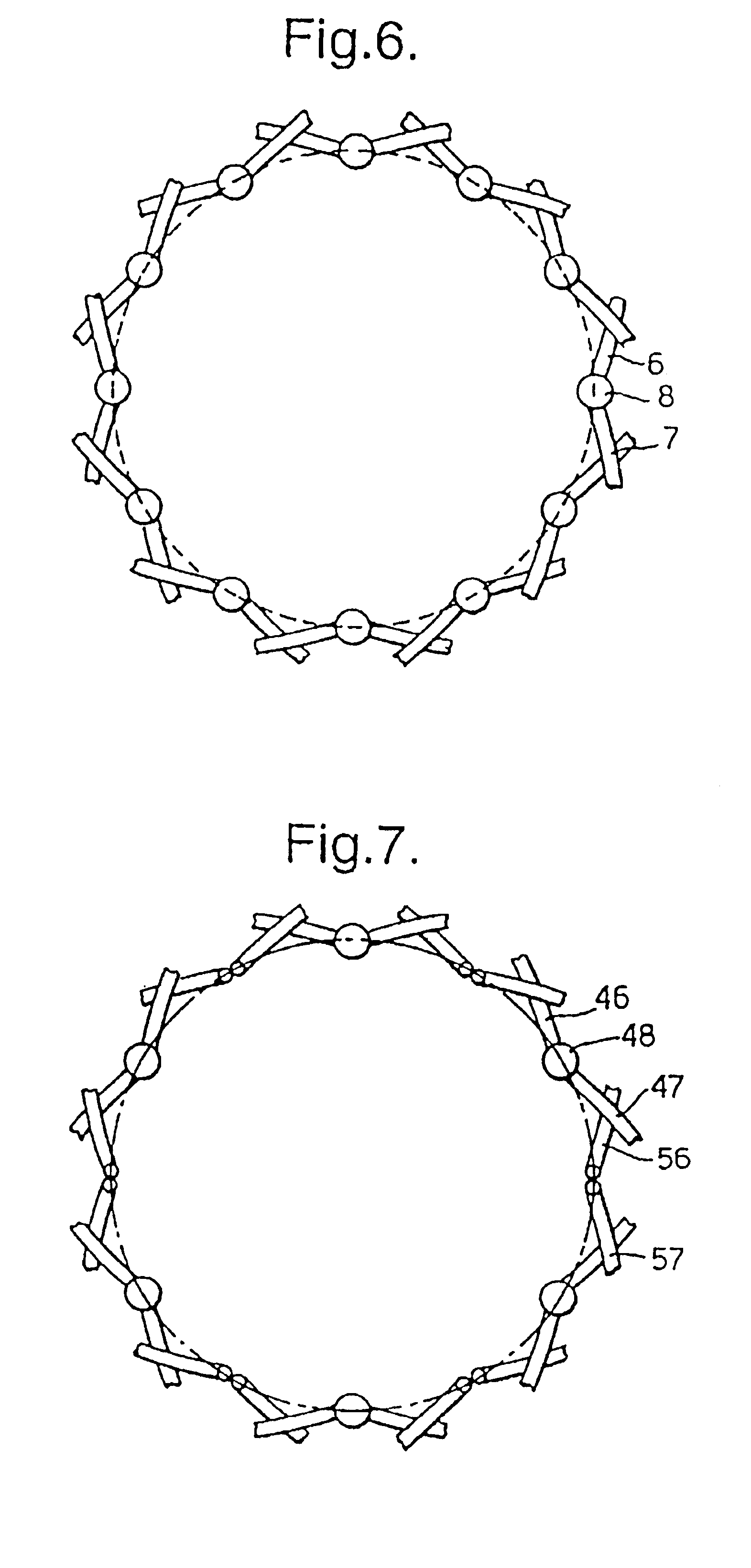

Biocompatible crosslinked coating and crosslinkable coating polymer composition for forming such a coating

A braided stent (1) for transluminal implantation in body lumens is self-expanding and has a radial expanded configuration in which the angle α between filaments is acute. Some or all of filaments (6,7) are welded together in pairs at each end (4,5) of the stent to provide beads (8), thereby strengthening the stent and assisting its deployment from a delivery device. The stent is preferably completely coated using a biocompatible polymeric coating, said polymer preferably having pendant phosphoryl choline groups. A method of making the stent by braiding and welding is described as well as a delivery device for deploying the device.The present invention provides a biocompatible crosslinked coating and a crosslinkable coating polymer composition for forming such a coating. The biocompatible crosslinked coating may be formed by curing a polymer of 23 mole % (methacryloyloxy ethyl)-2-(trimethylammonium ethyl) phosphate inner salt, 47 mole % lauryl methacrylate, 5 mole % γtrimethoxysilyl propyl methacrylate and 25 mole % of hydroxy propyl methacrylate. The crosslinkable coating polymer may include 23 mole % (methacryloyloxy ethyl)-2-(trimethylammonium ethyl) phosphate inner salt, 47 mole % lauryl methacrylate, 5 mole % γtrimethoxysilyl propyl methacrylate and 25 mole % of hydroxy propyl methacrylate.<?insert-end id="INS-S-00001" ?>

Owner:BIOCOMPATIBLES UK LTD

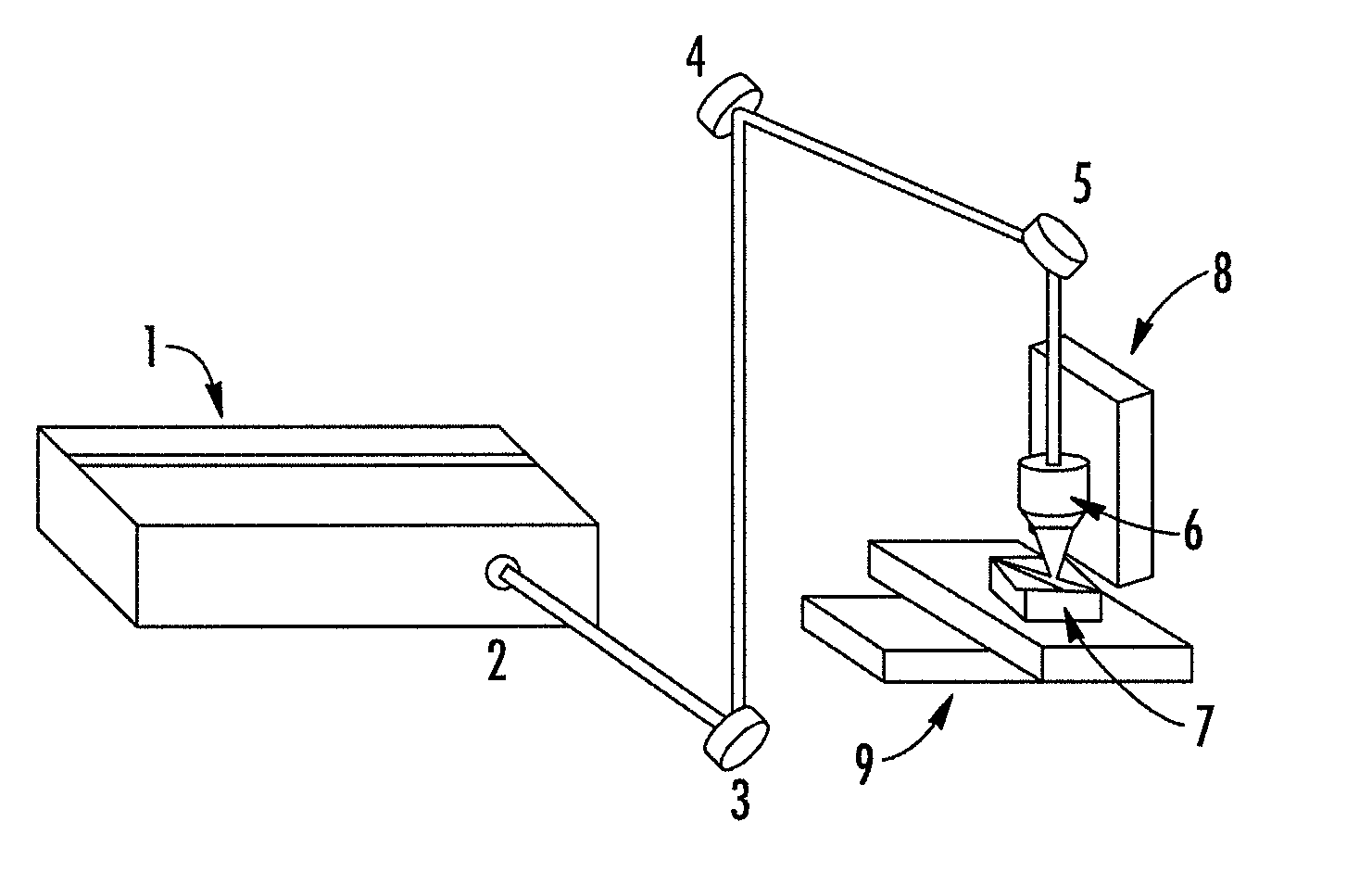

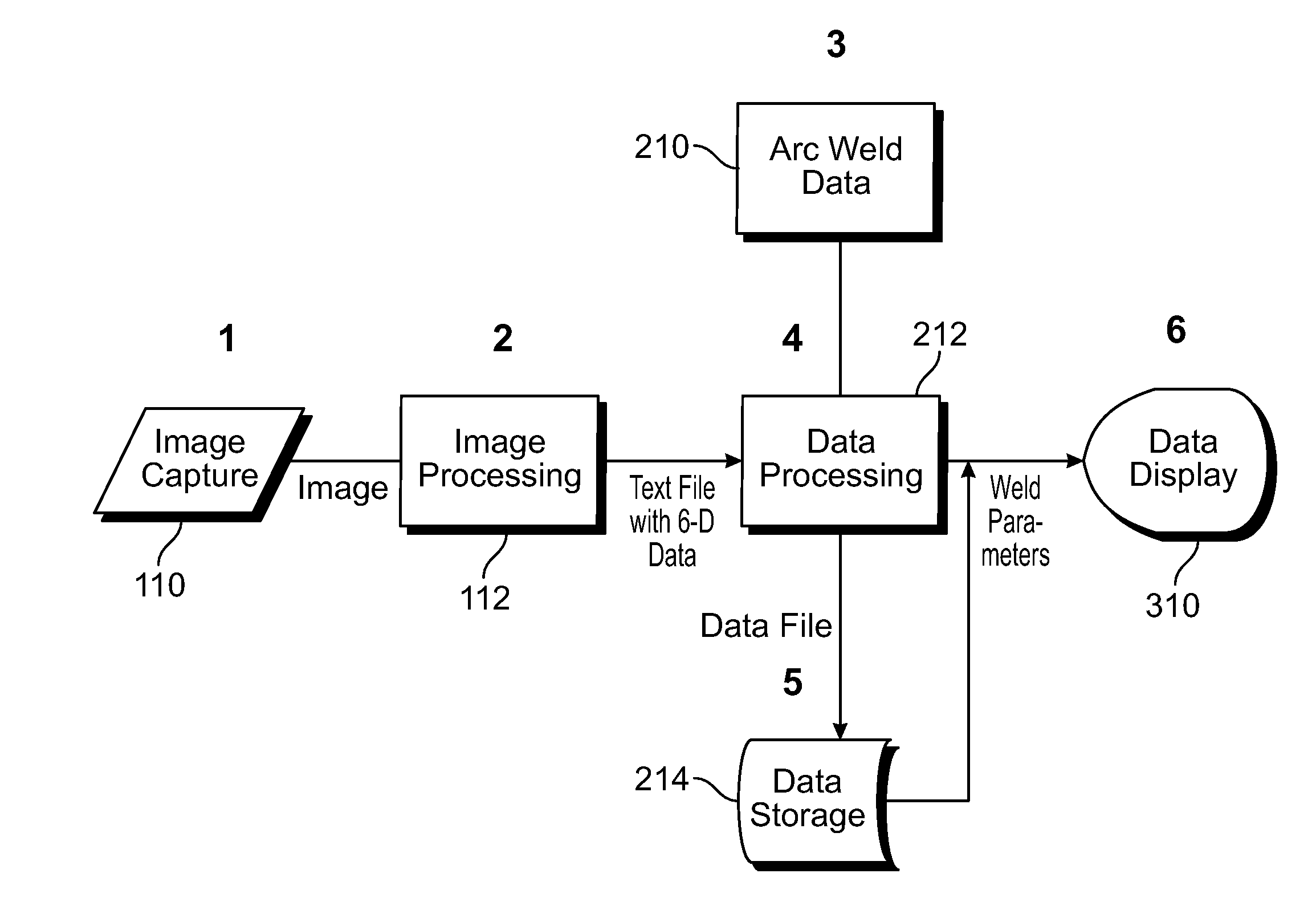

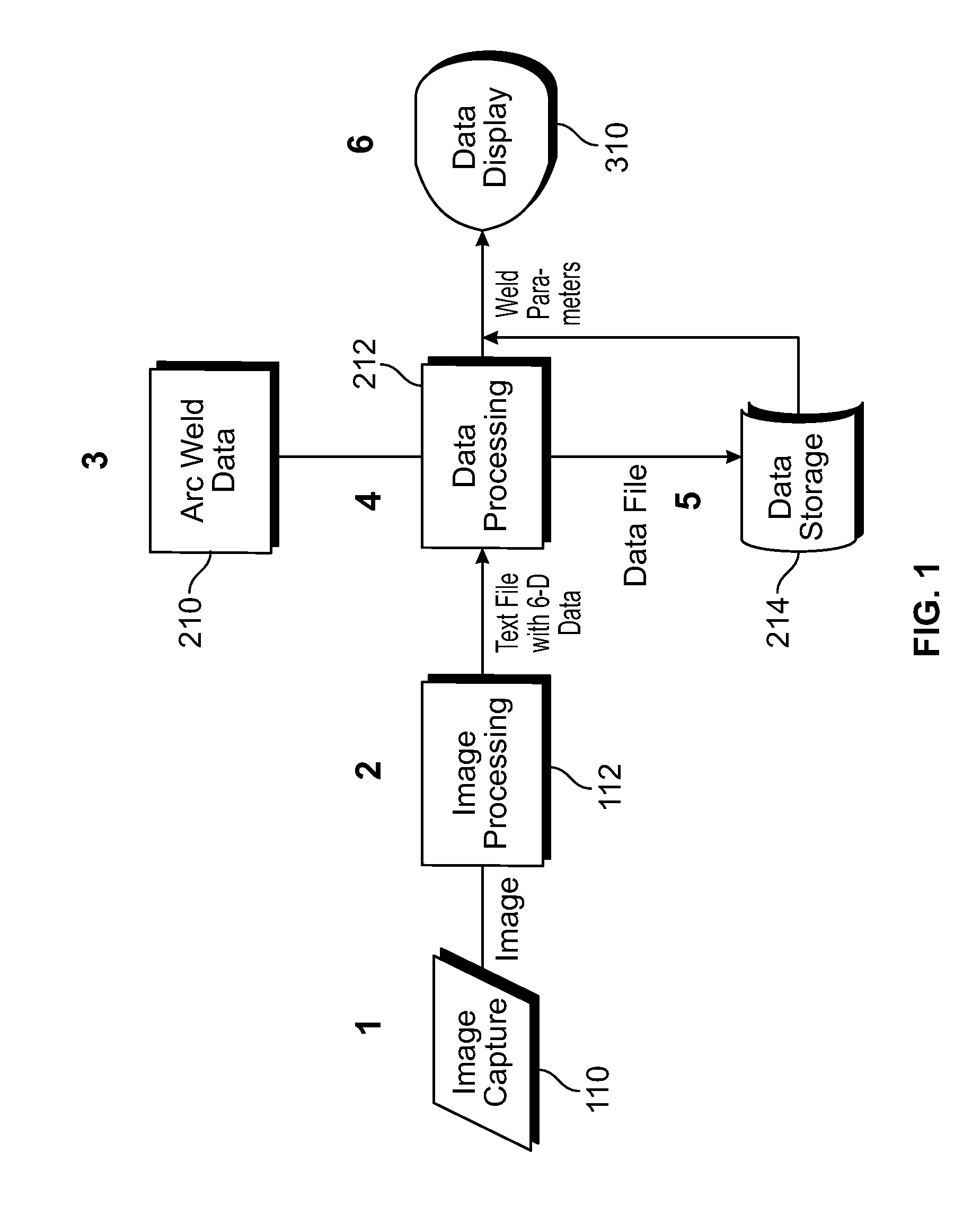

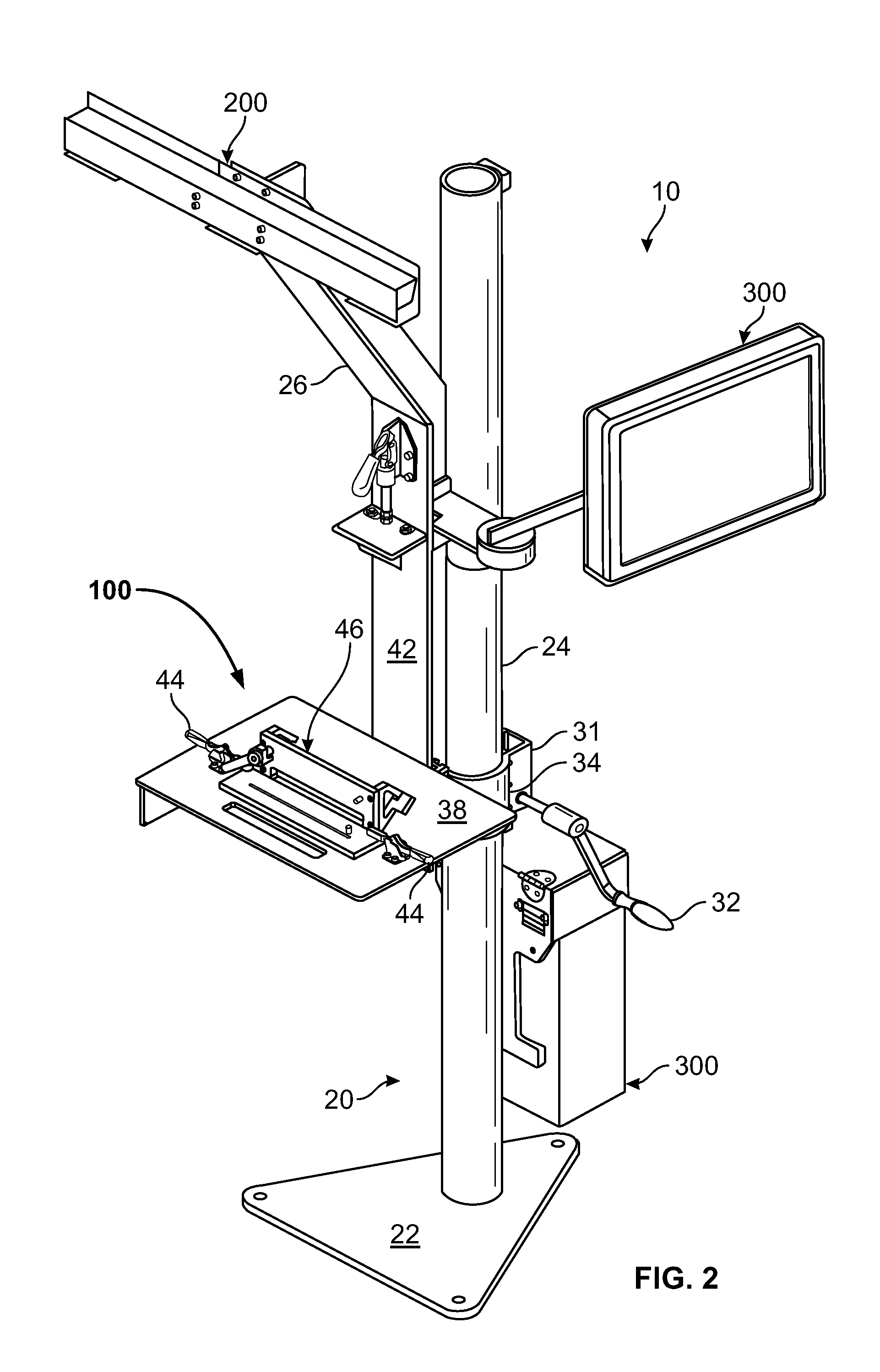

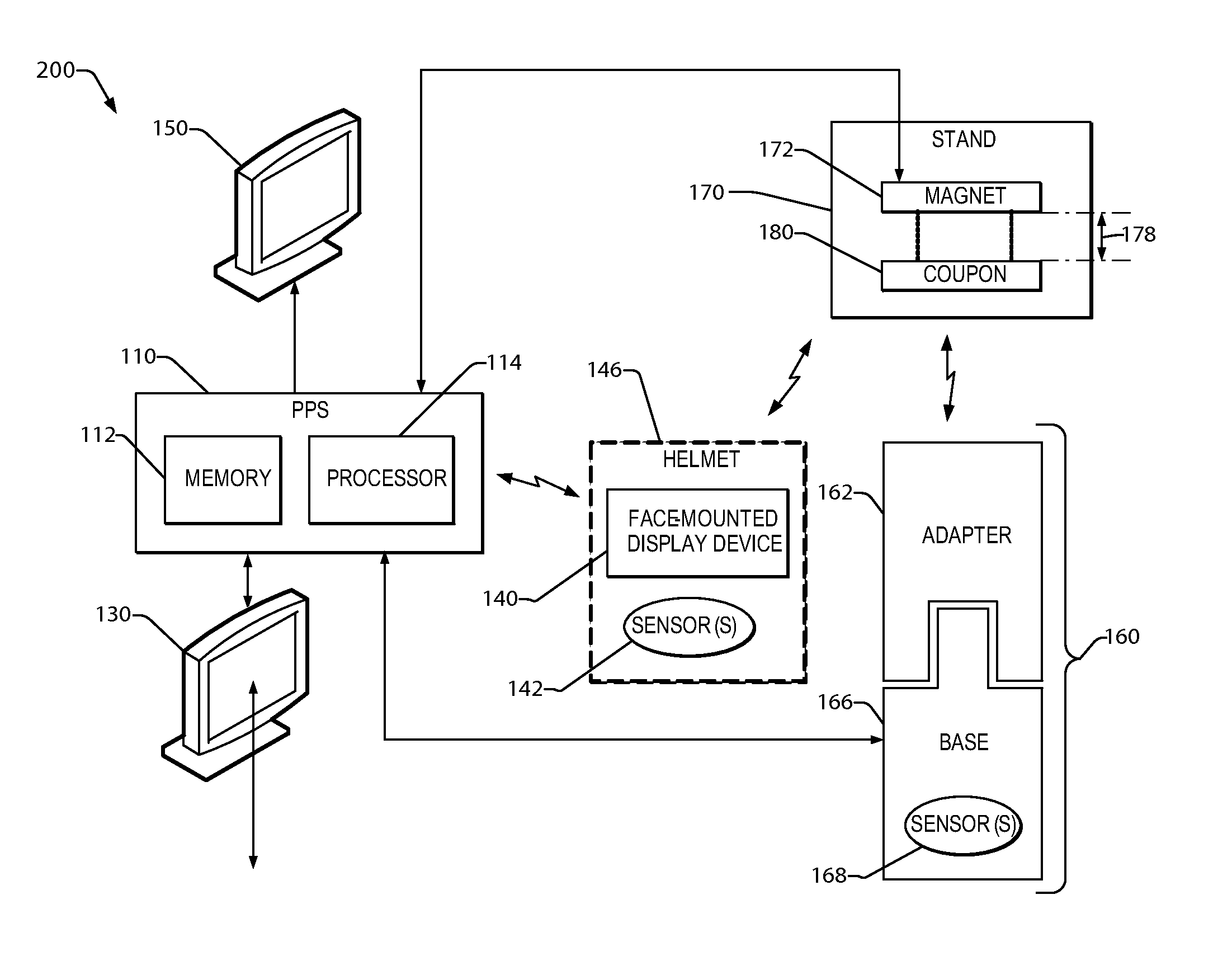

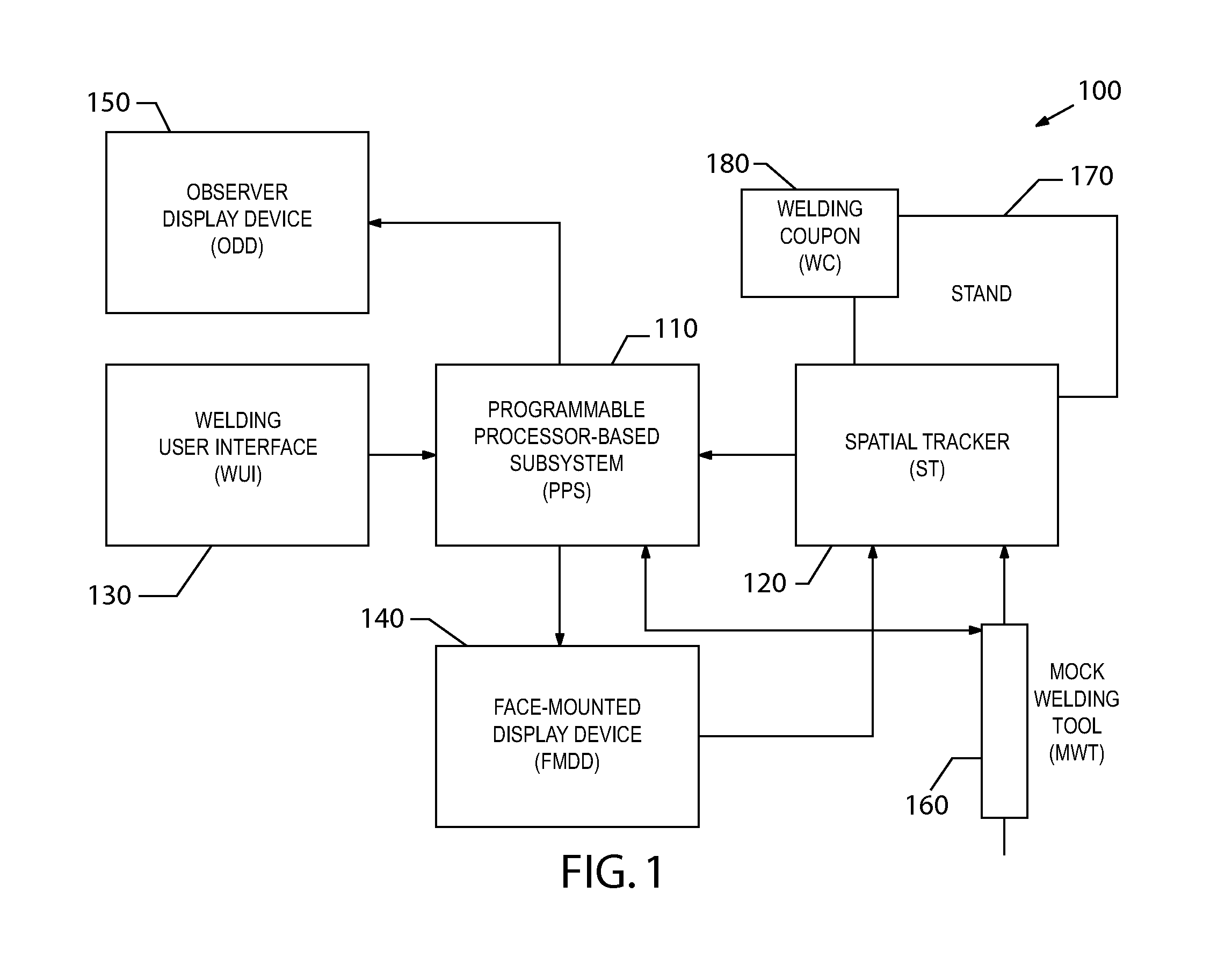

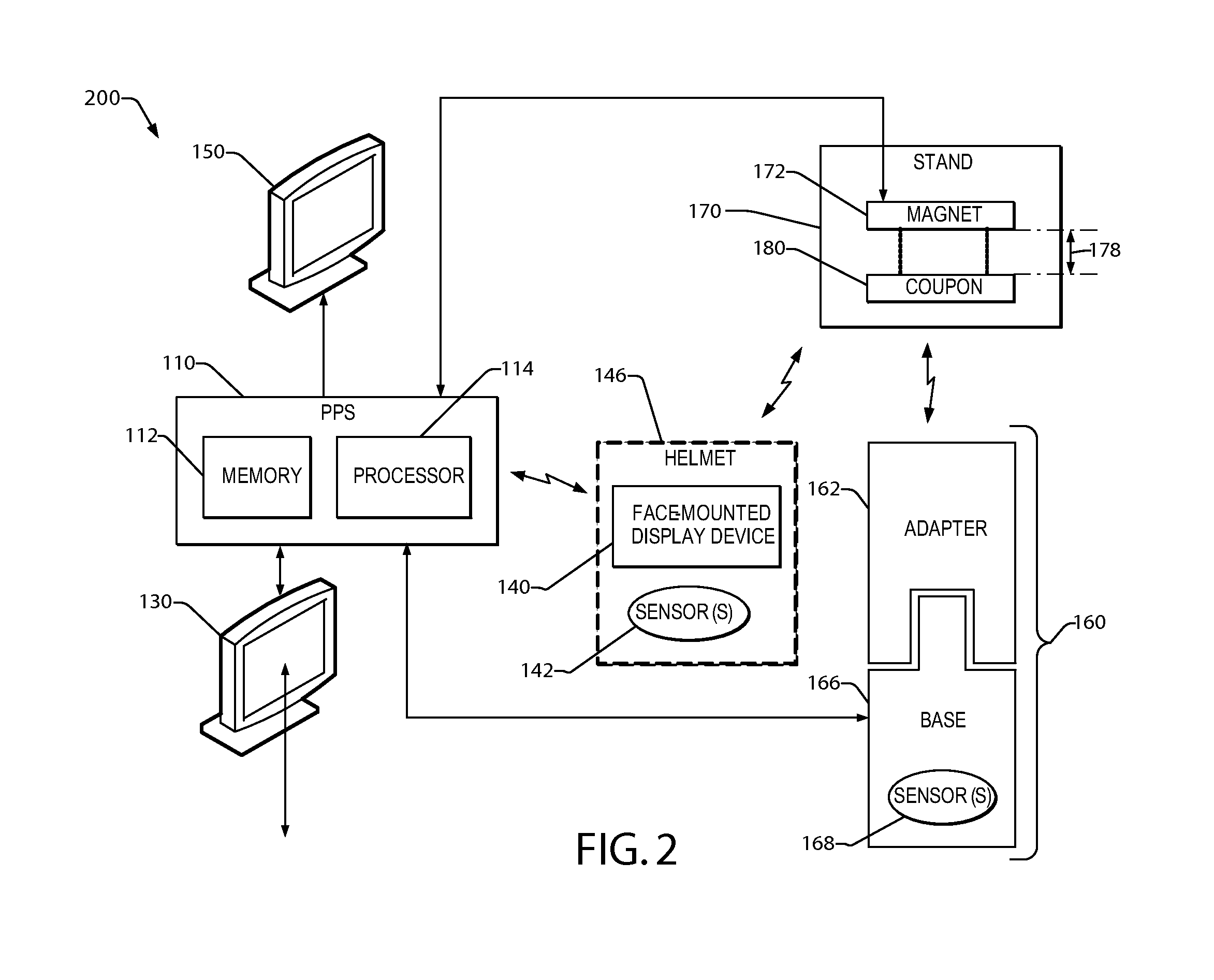

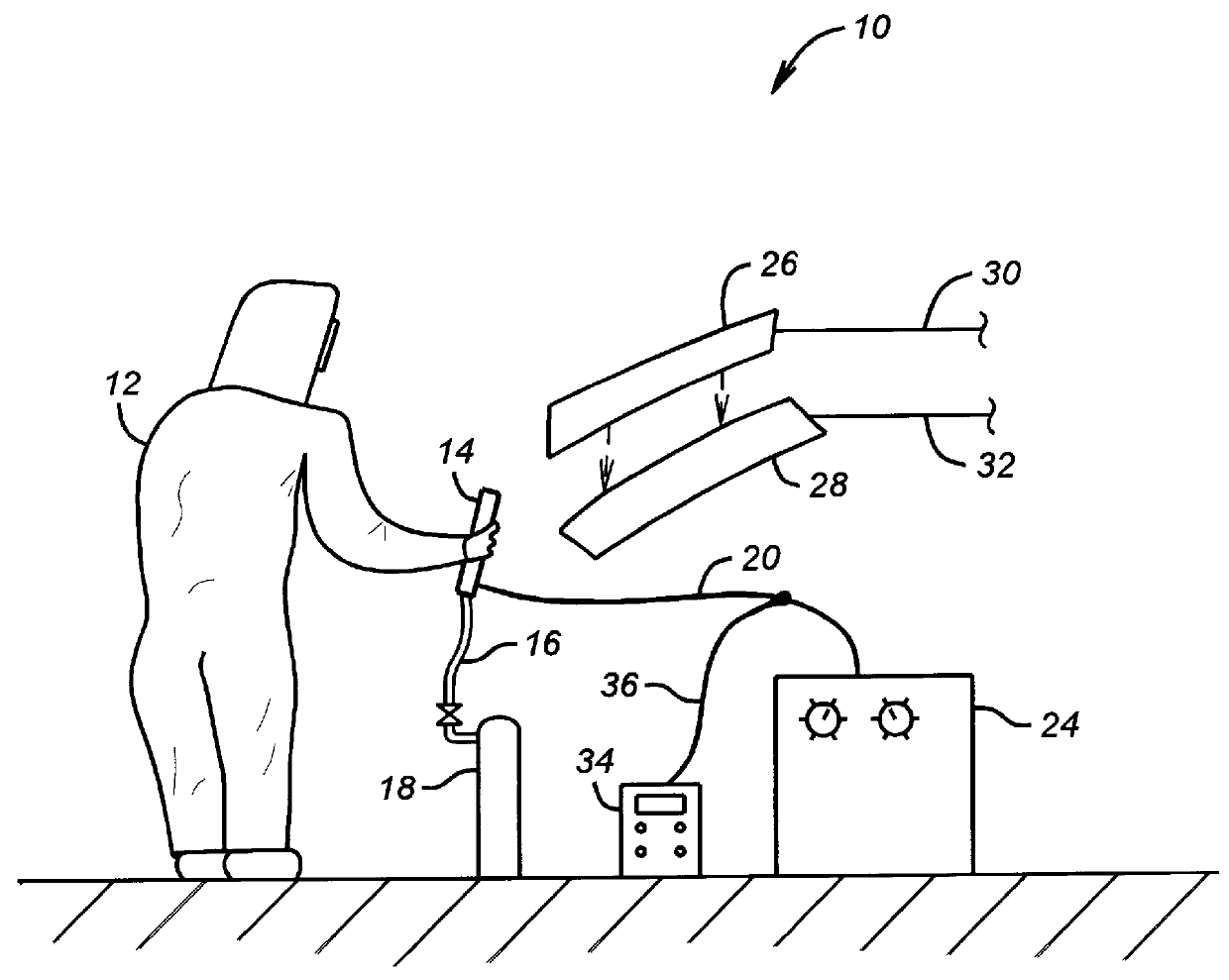

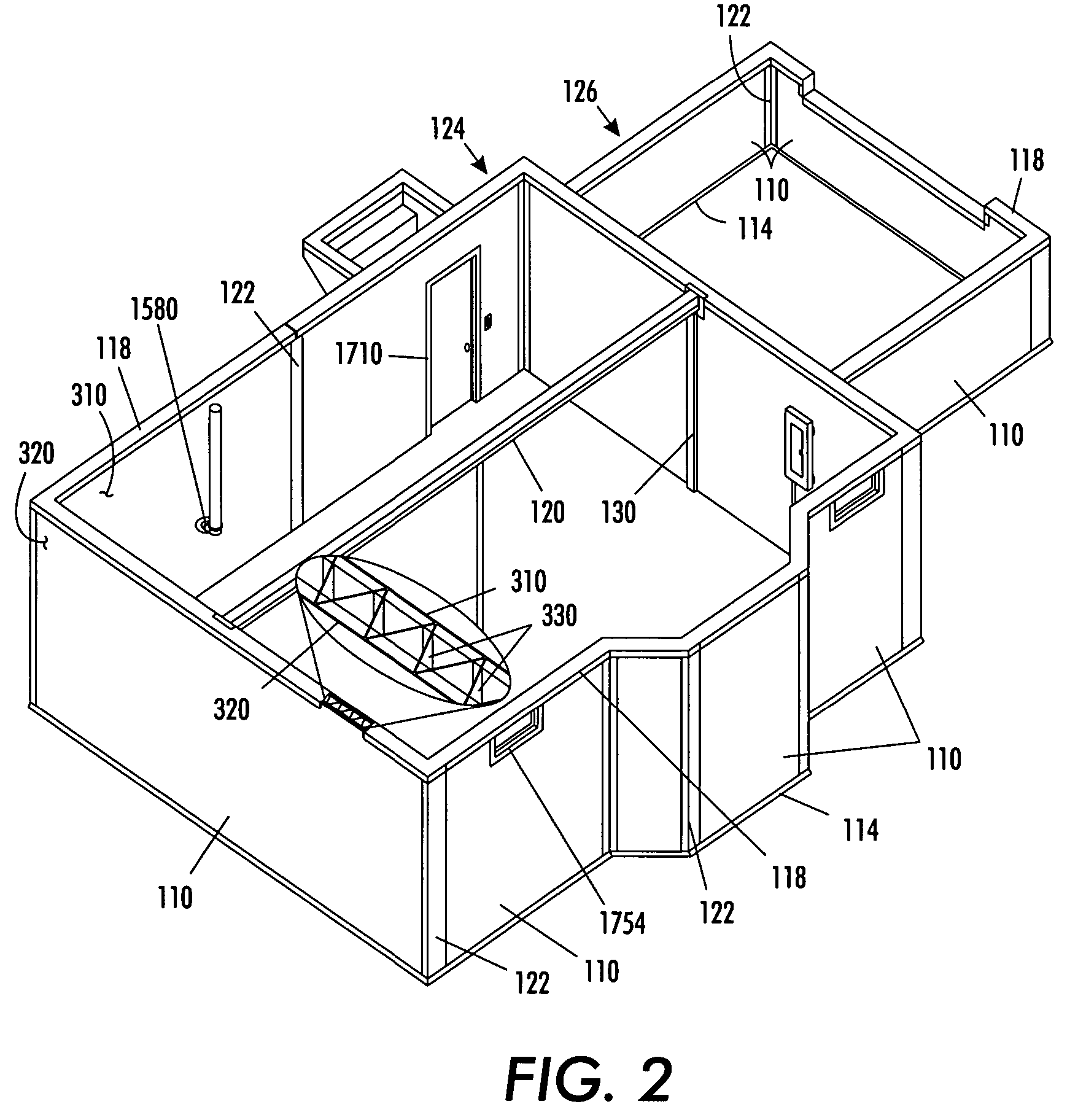

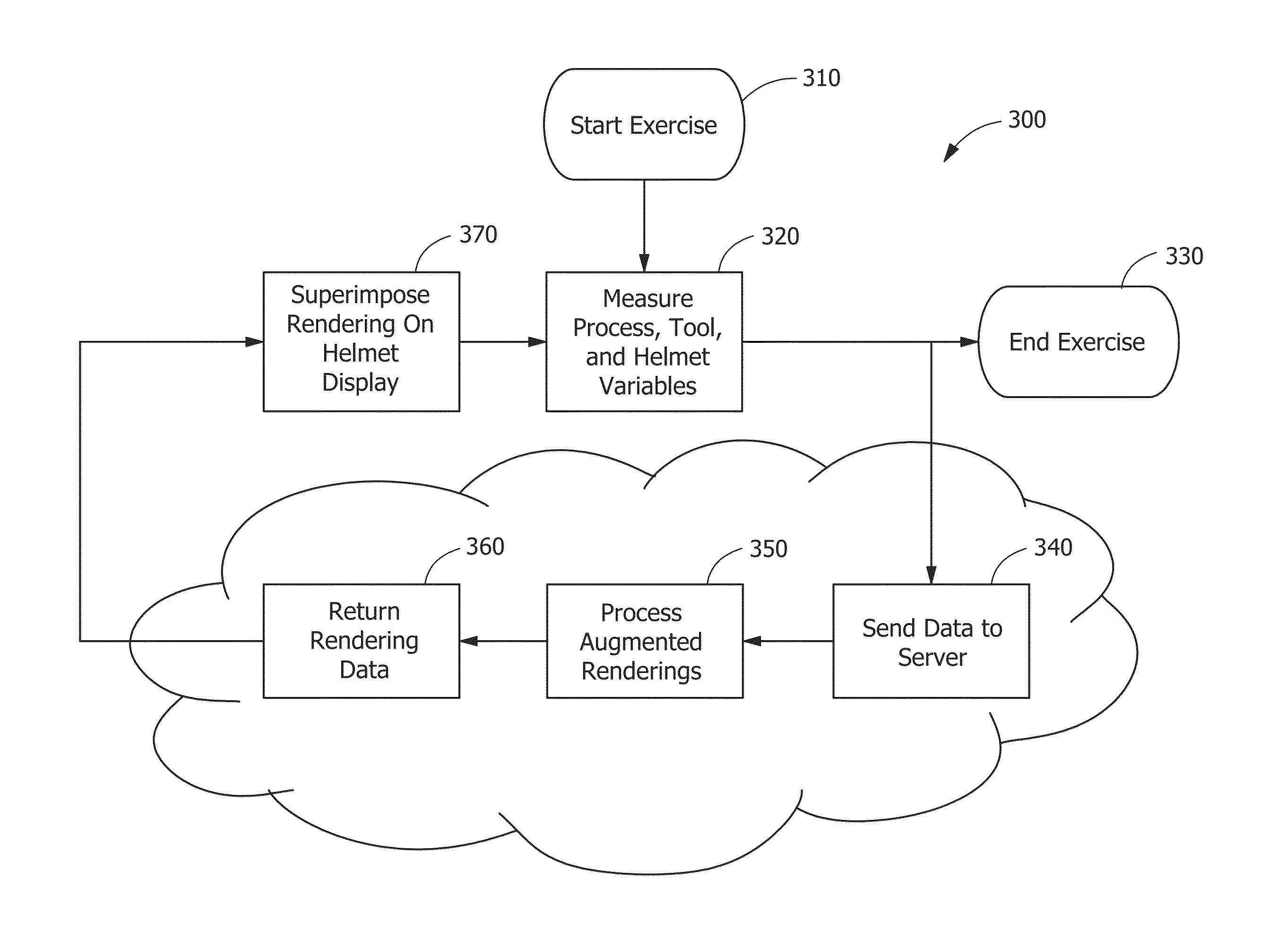

System for characterizing manual welding operations

ActiveUS20120298640A1Improve image signal-to-noise ratioImprove signal-to-noise ratioWelding/cutting auxillary devicesAuxillary welding devicesImage systemWelding

A system for characterizing manual welding exercises and providing valuable training to welders that includes components for generating, capturing, and processing data. The data generating component further includes a fixture, workpiece, at least one calibration devices each having at least two point markers integral therewith, and a welding tool. The data capturing component further includes an imaging system for capturing images of the point markers and the data processing component is operative to receive information from the data capturing component and perform various position and orientation calculations.

Owner:LINCOLN GLOBAL INC

Virtual welding system

ActiveUS20120189993A1Easy to useArc welding apparatusEducational modelsComputer scienceHuman language

Owner:LINCOLN GLOBAL INC

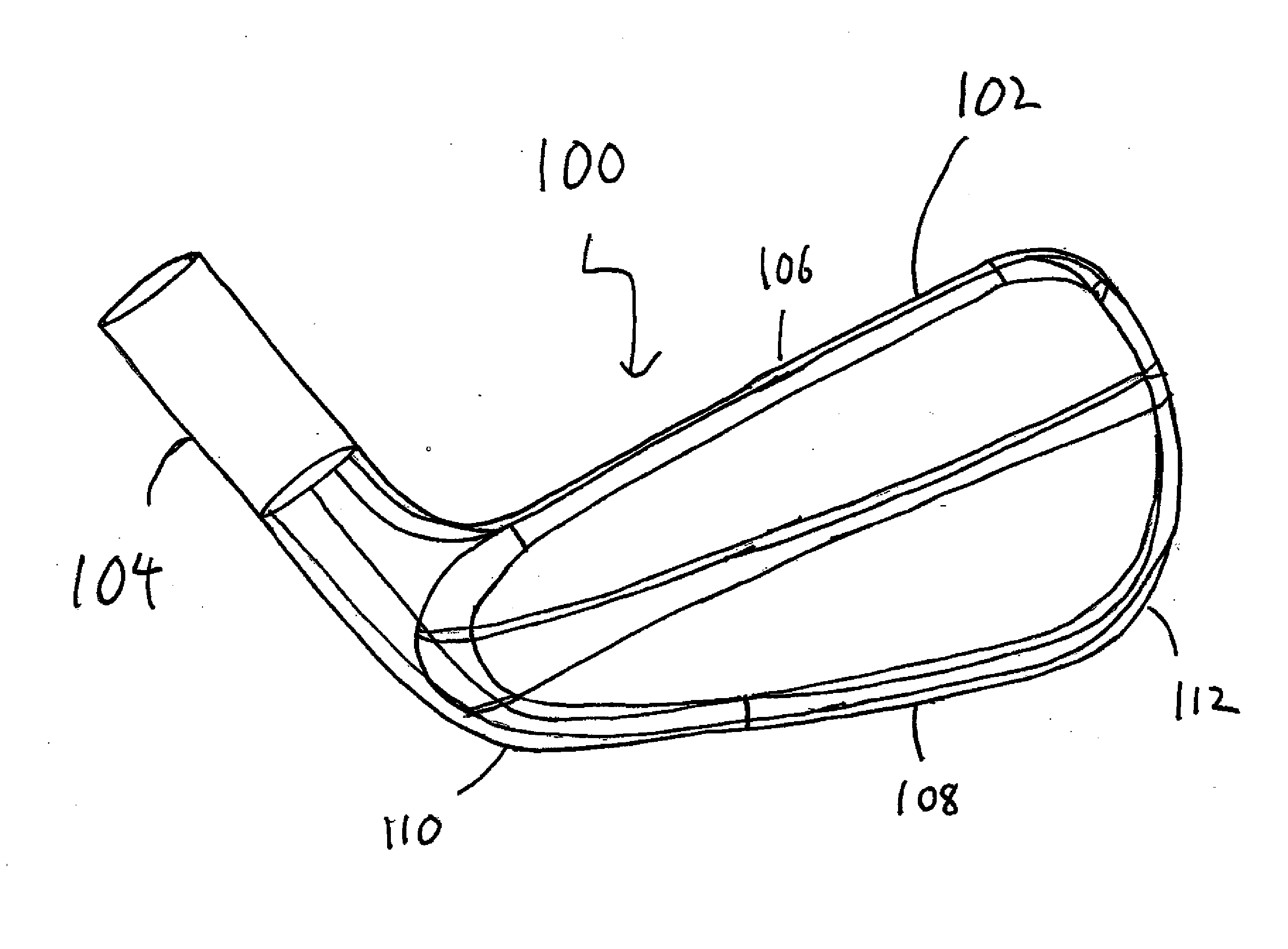

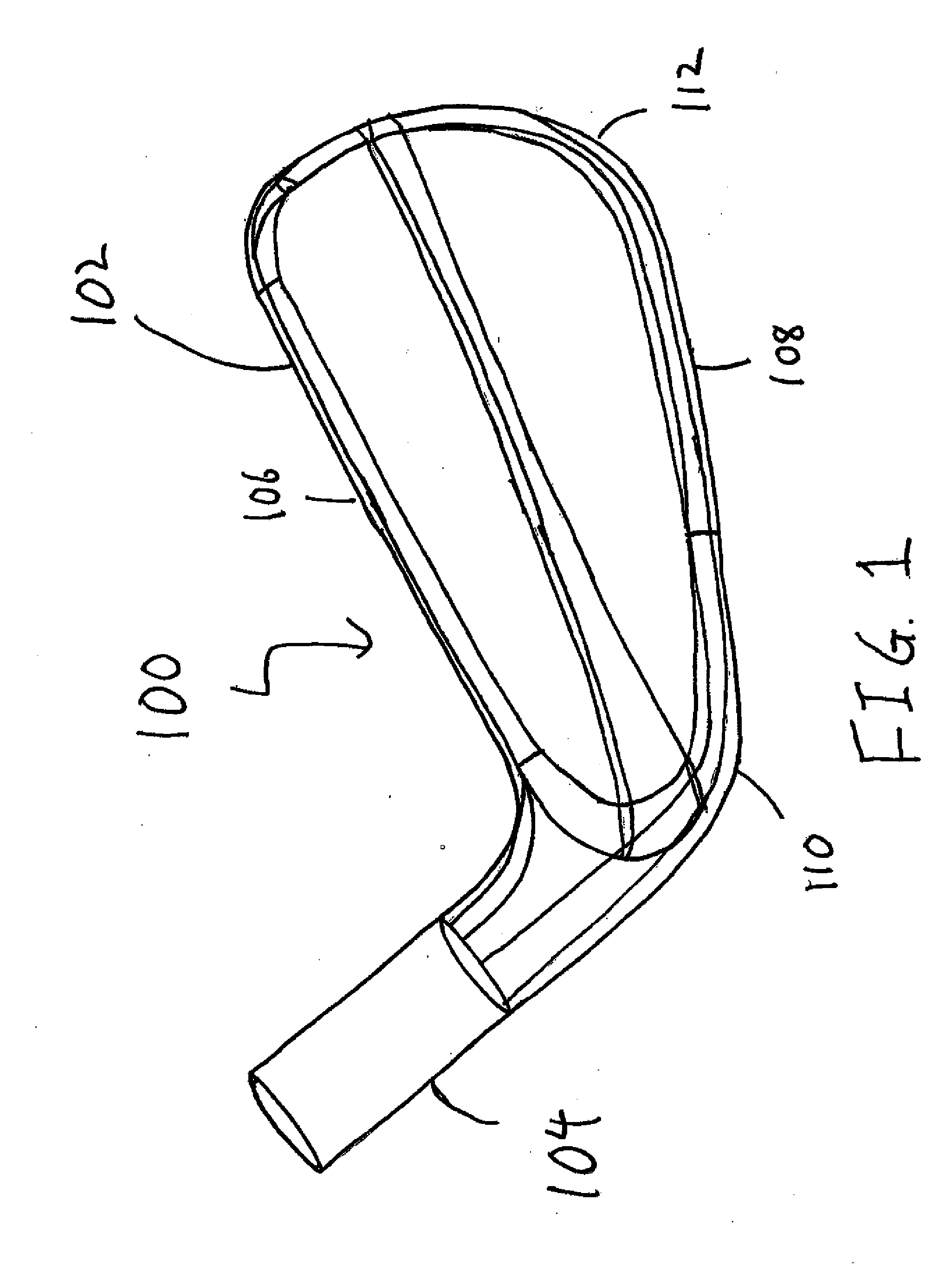

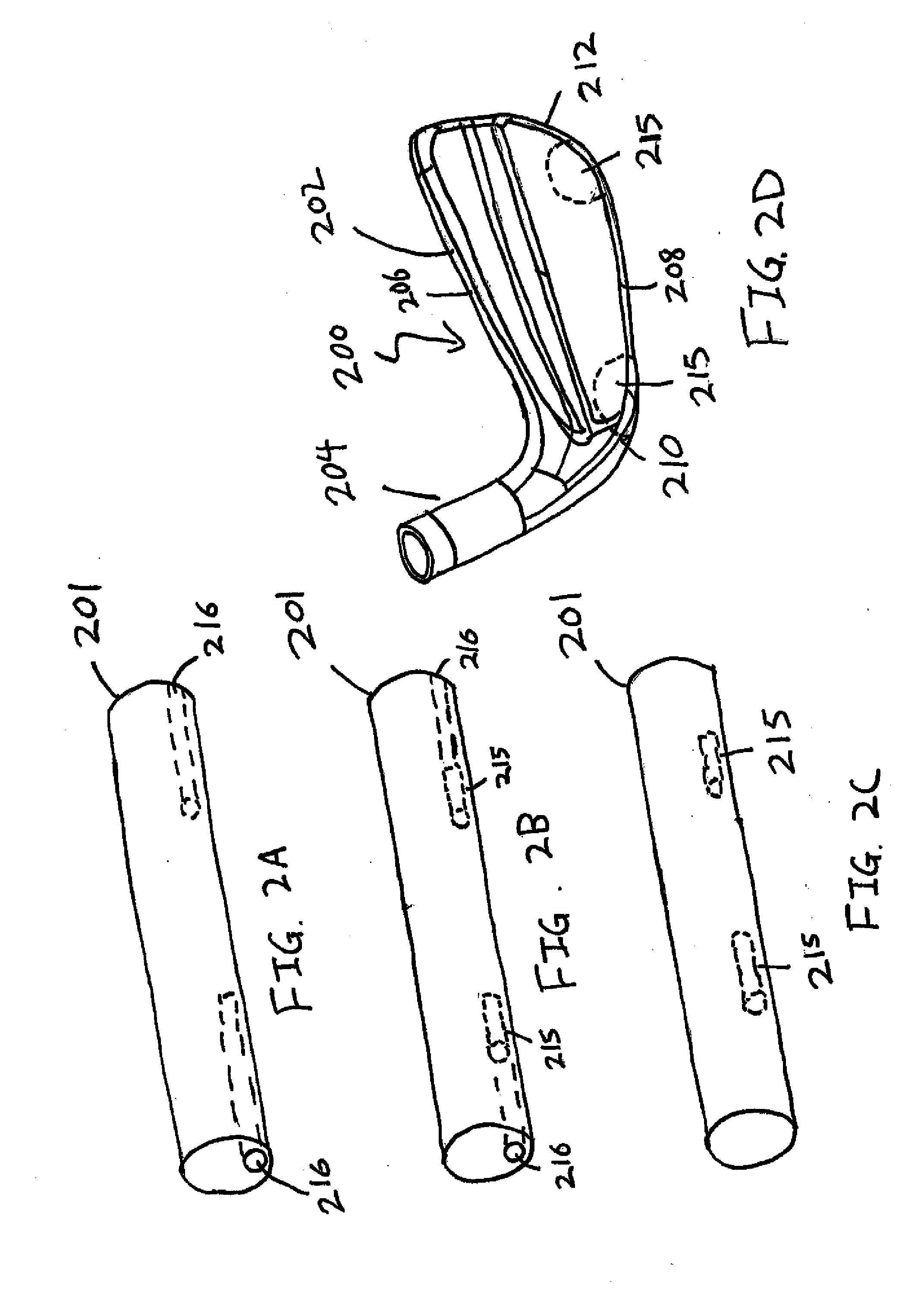

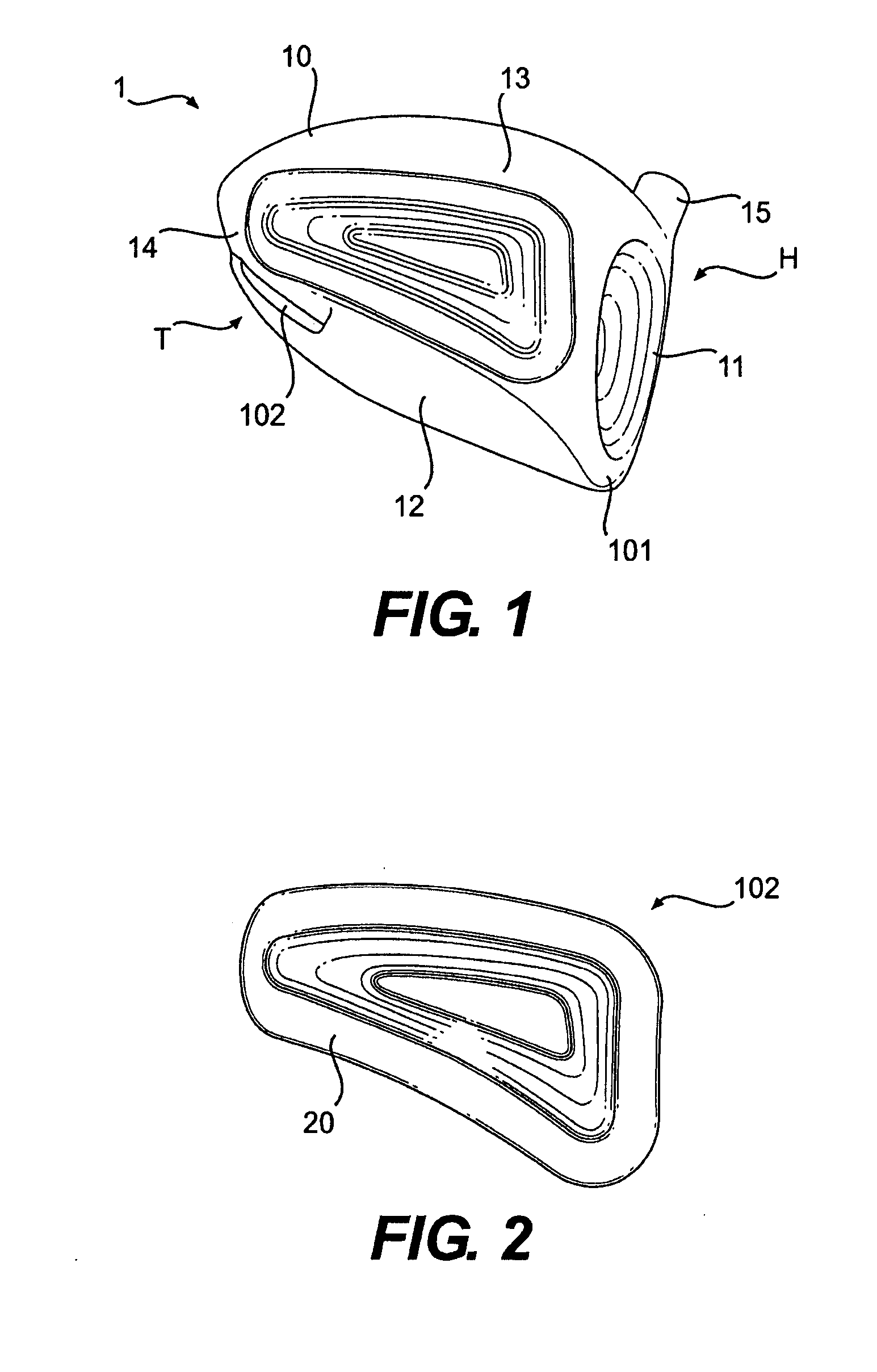

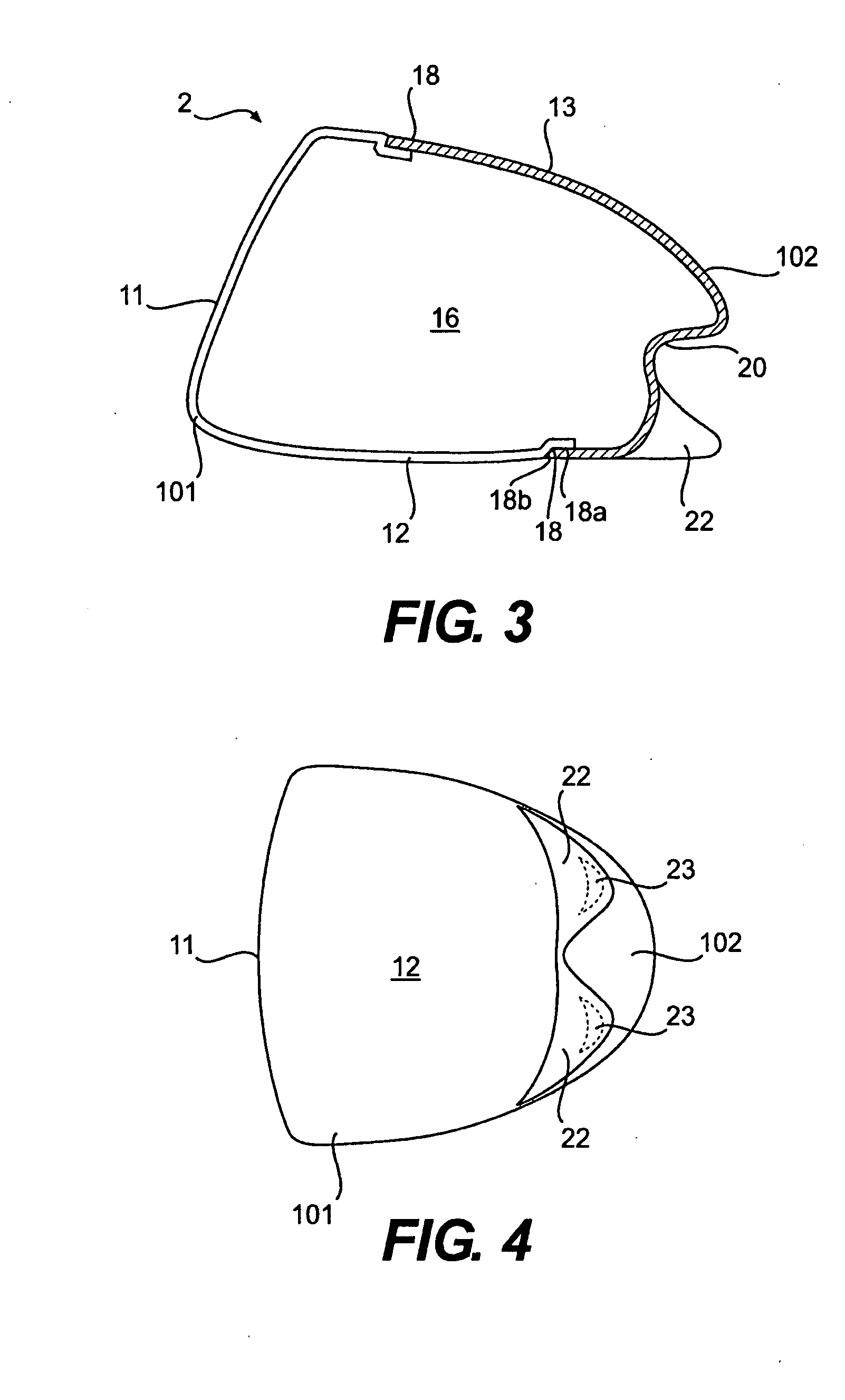

Co-forged golf club head and method of manufacture

A co-forged iron type golf club is disclosed. More specifically, the present invention discloses a co-forged iron type golf club with the body portion made out of a first material and at least one weight adjustment portion monolithically encased within the body portion of the co-forged iron type golf club head without the need for secondary attachment or machining operations. The present invention creates of an iron type golf club head from a pre-form billet that already contains two or more materials before the actual forging process resulting in a multi-material golf club head that doesn't require any post manufacturing operations such as machining, welding, swaging, gluing, and the like.

Owner:ACUSHNET CO

Suture welding device

Devices for welding suture segments in lieu of tying knots in sutures applied during endoscopic surgery. The devices provide for snaring loose suture ends and drawing the suture ends into a space between heating surfaces, and provide for closing the heating surfaces.

Owner:MICROLINE SURGICAL INC

Direct current load breaking contact point constitution and switching mechanism therewith

InactiveUS6934134B2Contact materialsCircuit-breaking switches for excess currentsElectrical resistance and conductanceElectrical polarity

The invention intends to provide a direct current load breaking contact point constitution that can make and break an electrical circuit under both direct current loads of direct current resistance load and direct current inductance load over a long period of time without causing problems such as ① the conduction defect due to the consumption of the contact point, ② the locking due to material transfer from one contact point to the other contact point, ③ the welding between the contact points, and ④ the abnormal arc continuation, and a direct current load breaking switching mechanism such as a relay, a switch and so on that has the contact point constitution. The direct current load breaking contact point constitution according to the invention comprises a movable contact point and a stationary contact point that face each other; wherein the movable contact point is made of AgSnO2In2O3 alloy that contains at least Ag, 8 to 15% by weight in total of metal oxides including SnO2 and In2O3, 6 to 10% by weight of SnO2 and 1 to 5% by weight of In2O3; the stationary contact point is made of AgZnO alloy that contains at least Ag and 7 to 11% by weight of ZnO; and polarity of a movable side is (+) and that of a stationary side is (−).

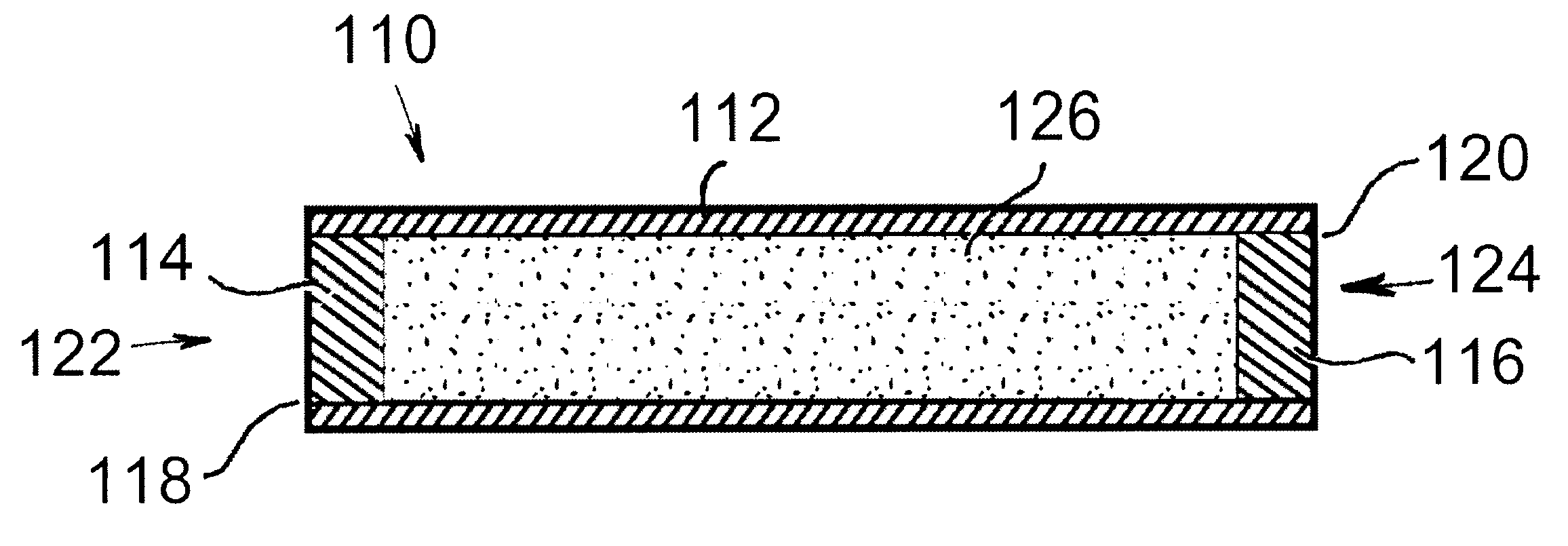

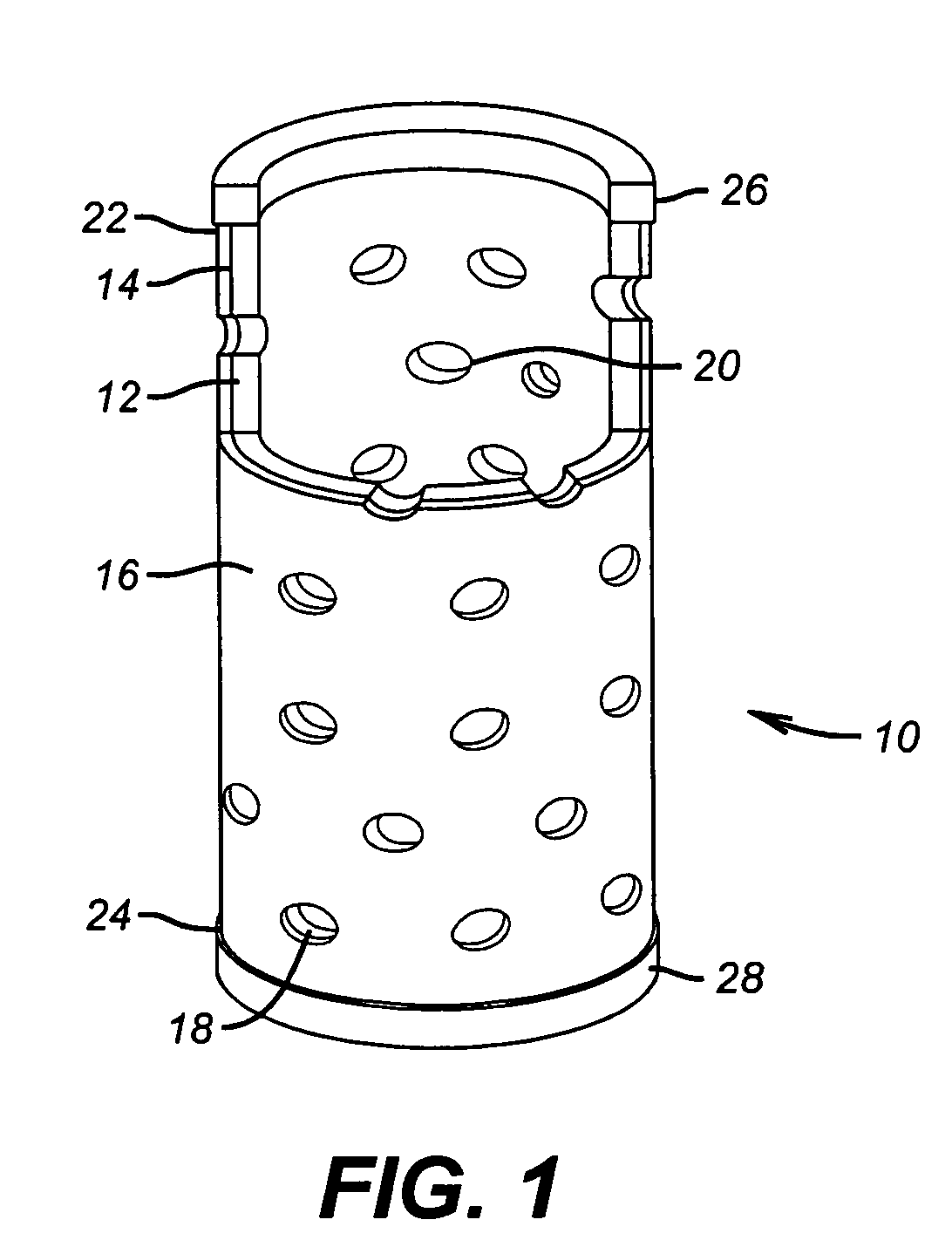

Bioabsorbable brachytherapy device

InactiveUS6575888B2Controlled release rateMinimally shieldsRadioactive preparation formsX-ray/gamma-ray/particle-irradiation therapyBrachytherapy deviceRadiopaque medium

A bioabsorbable brachytherapy device includes a tubular housing with sealed ends and an enclosed radioactive material. The radioactive material includes a radioisotope, such as palladium-103 or iodine-125. The tubular housing is made from a biocompatible and bioabsorbable polymeric material, and is sealed by means such as heat welding or solvent fixing. The device may further include a radiopaque medium and one or more therapeutic drugs.

Owner:FERRING BV

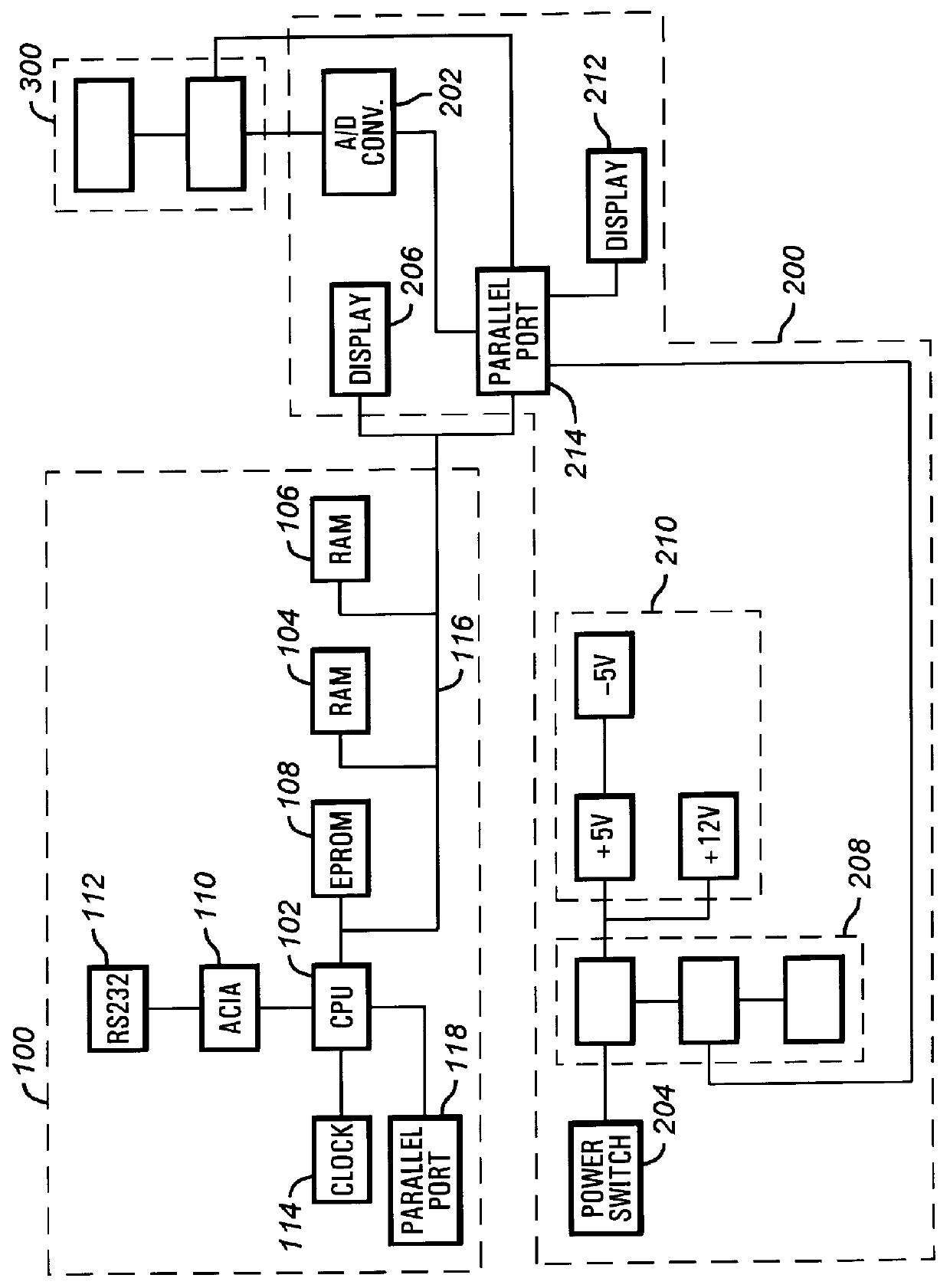

Methods and apparatus for welding performance measurement

InactiveUS6051805AStreamlined operationMaximize efficiencyArc welding apparatusAverage currentControl circuit

Methods and apparatus are provided for determining the duty cycle, average amperage, and / or the number of arc starts during a welding operation. The apparatus comprises first and second circuits, the first circuit being a CPU control circuit, and the second circuit being an arc time sensor circuit which is programmed to measure amperage, welding wire feed speed and preferably gas flow rates while welding. A ratio of the cumulative welding time during the audit to the total on-time provides a measurement of the efficiency of the welding arc. The welding deposition efficiency may then be calculated using the average amperage and welding duty cycle as measured and calculated by the apparatus. The number of arc starts where the arc on-time is in excess of one second may also provide a useable measurement in giving secondary information on the overall efficiency of the welding operation.

Owner:AIR LIQUIDE CANADA

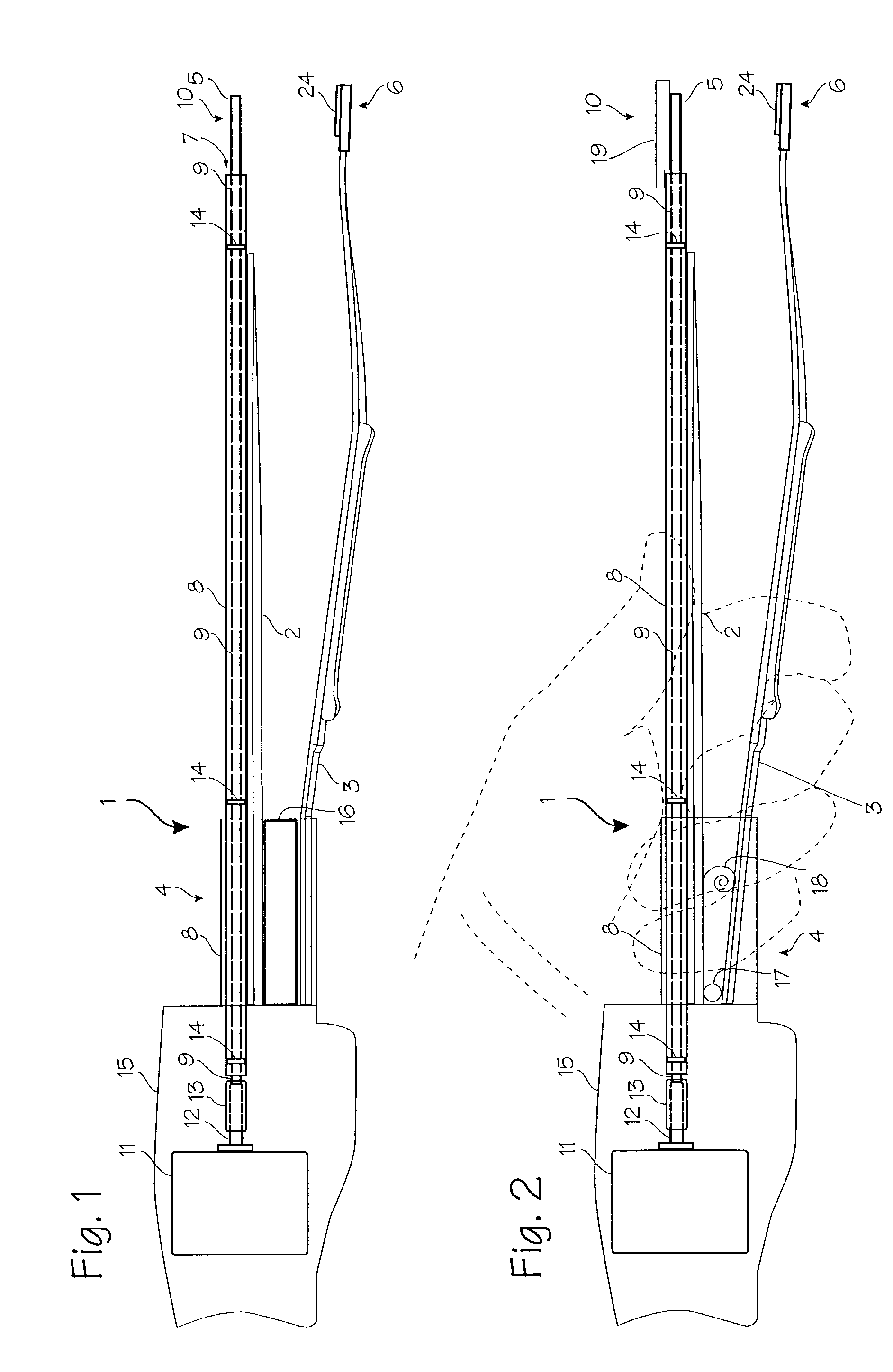

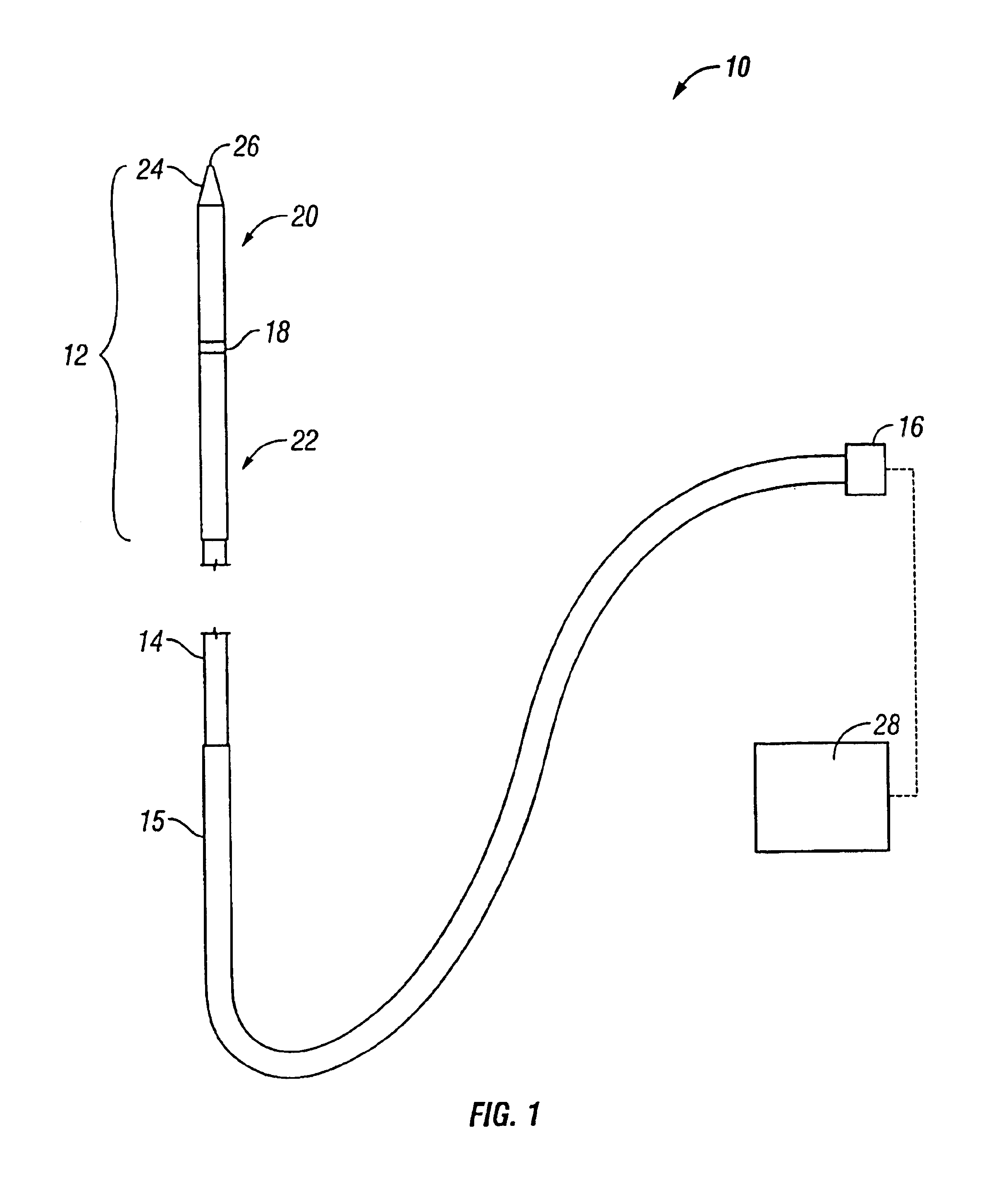

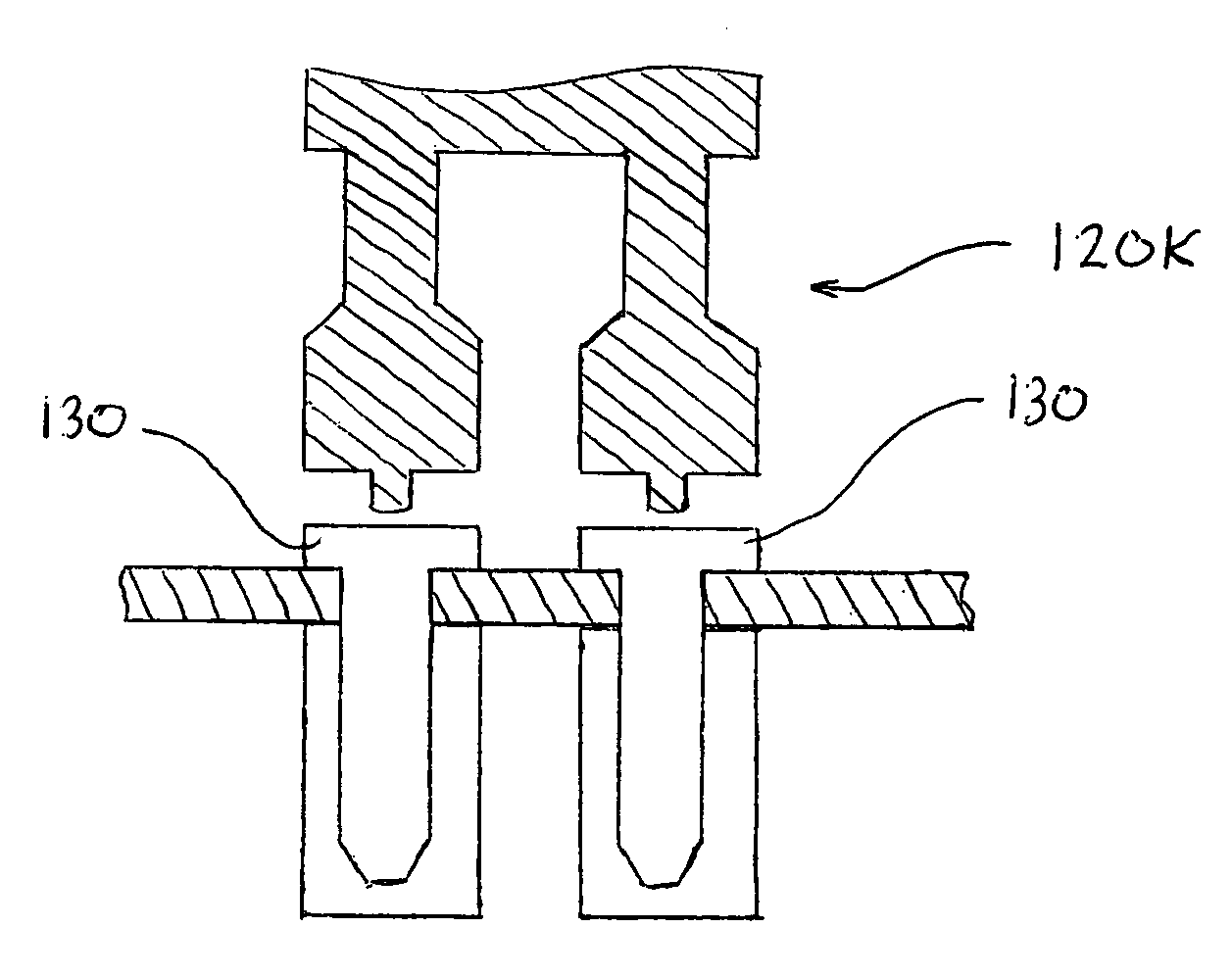

Methods and devices for trauma welding

ActiveUS20070270833A1Process stabilityStabilizing a fractured boneSuture equipmentsInternal osteosythesisMedicineFractured bone

The present invention provides a method for stabilizing a fractured bone. The method includes positioning an elongate rod in the medullary canal of the fractured bone and forming a passageway through the cortex of the bone. The passageway extends from the exterior surface of the bone to the medullary canal of the bone. The method also includes creating a bonding region on the elongate rod. The bonding region is generally aligned with the passageway of the cortex. Furthermore, the method includes positioning a fastener in the passageway of the cortex and on the bonding region of the elongate rod and thermally bonding the fastener to the bonding region of the elongate rod while the fastener is positioned in the passageway of the cortex.

Owner:P TECH

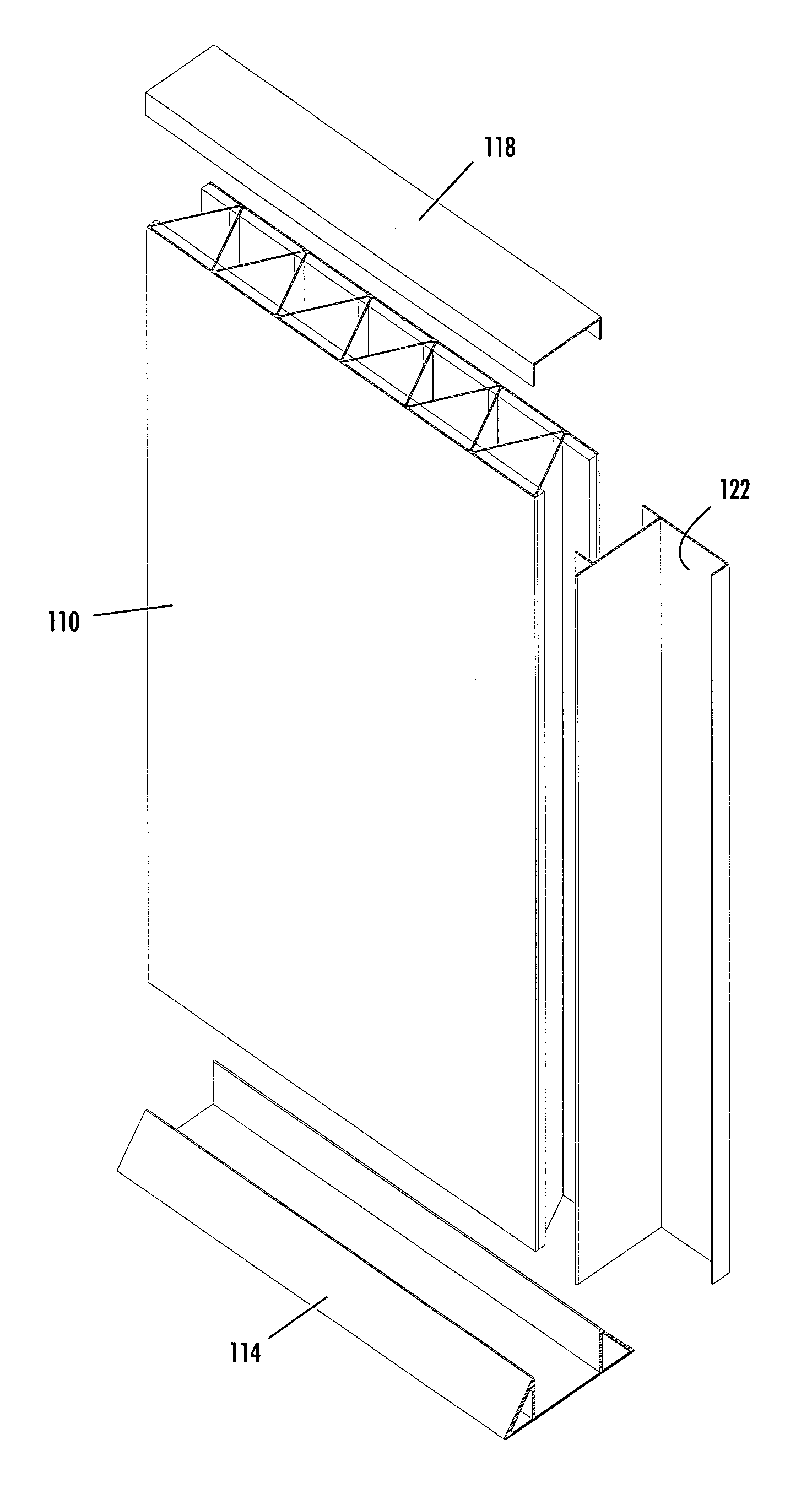

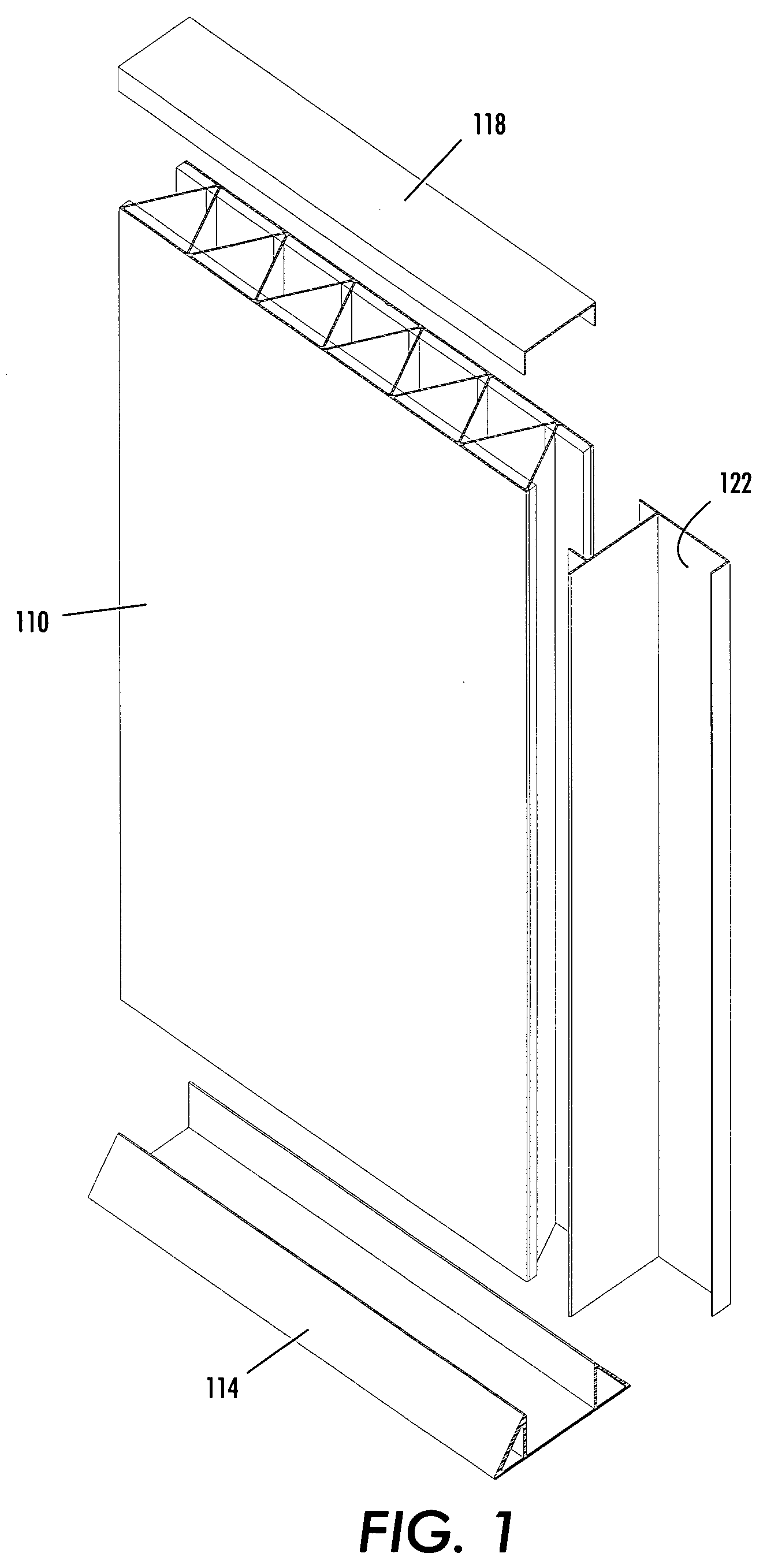

Modular structure for building panels and methods of making and using same

The present invention is a polymeric panel system and method for production and use thereof, enabling the rapid construction of a building foundation wall or other structure and in particular a below-grade foundation. The polymeric foundation system includes polymeric wall panels and other components suitable for withstanding lateral and end compression loads. The walls include two parallel faces separated by a series of webs or ribs, where the webs and faces of the wall panels may be formed of a similar polymer material such as polyvinylchloride (PVC). The wall panels and / or other components may be extruded so as to enable the rapid production of sections of wall panels, where the panels may be cut to length and then affixed to adjacent panels to form a foundation wall. The method of affixing adjacent panels may include welding, gluing or other techniques and may be performed on the job site or in a pre-fabrication facility. Furthermore, the wall panels may be co-extruded with an insulating material inserted in the voids between the parallel faces so as to provide improved thermal performance of the foundation as well.

Owner:DOUGLAS ROBERT B

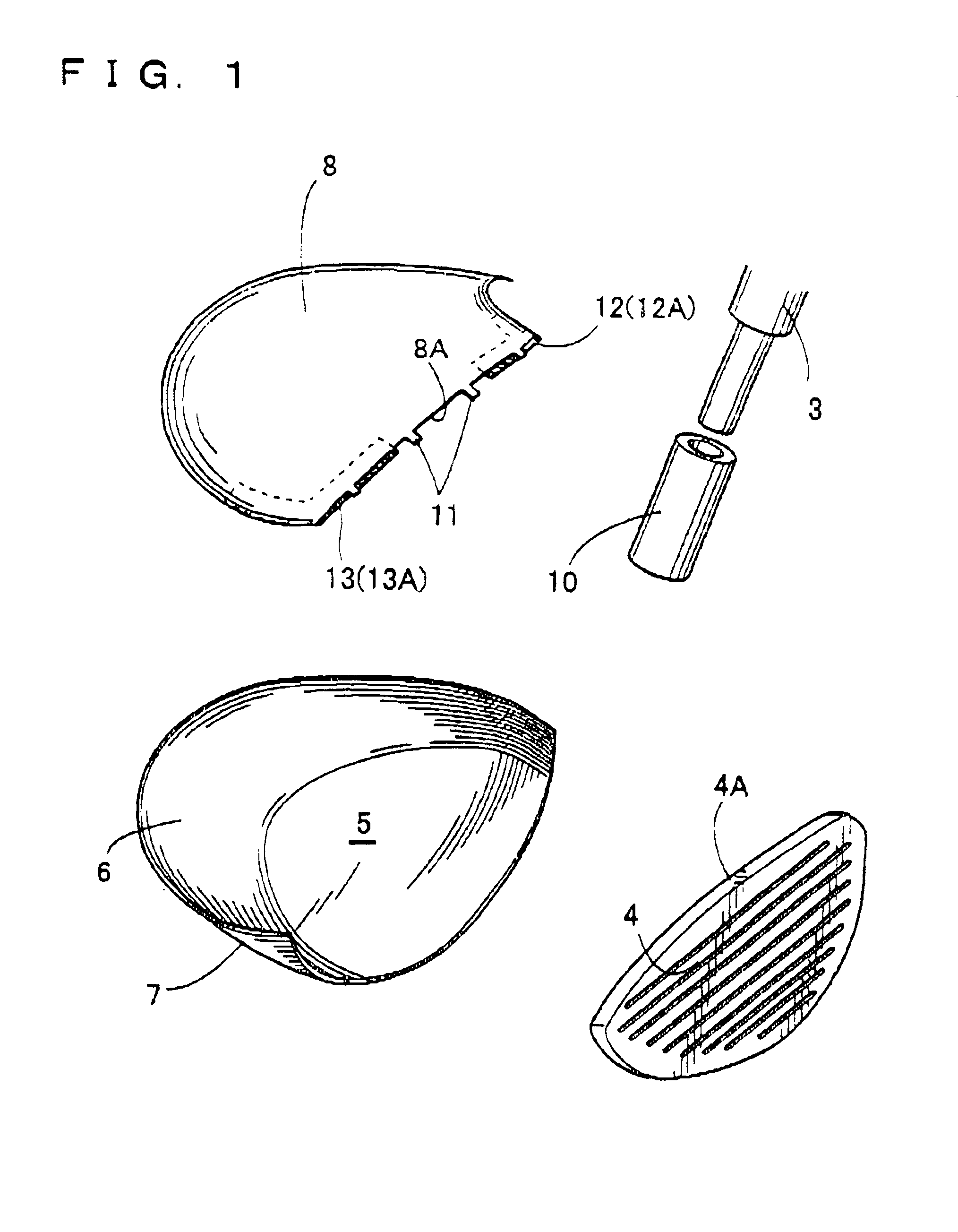

Golf club head

InactiveUS20080039228A1Improved playing characteristicProvide integrityGolf clubsRacket sportsAdhesiveEngineering

A hollow golf club head with a concave portion is disclosed and claimed. The club head includes a metallic portion and a light-weight portion, which may be formed of plastic, composite, or the like. The concave portion allows the club designer to make a club head having very thin portions while still maintaining the requisite structural integrity. Convex bulges may optionally be provided to house weight inserts to enhance the playing characteristics of the golf club. The metallic portion of the club head may take on the appearance of a frame, into which several light-weight inserts are positioned. These light-weight inserts may be positioned in the crown, skirt, and sole of the club head. The club head may be formed by co-molding, eliminating the need for welding or adhesives, freeing mass to be used in more beneficial ways. The club head may be large to increase playability and forgiveness. The club head may include one or more light-weight inserts to manipulate the playing characteristics of the resulting golf club. These inserts may have attachment surfaces that are relatively angled such that the inserts are subjected to compressive forces rather than shear forces upon impact with a golf ball during a golf swing.

Owner:COBRA GOLF

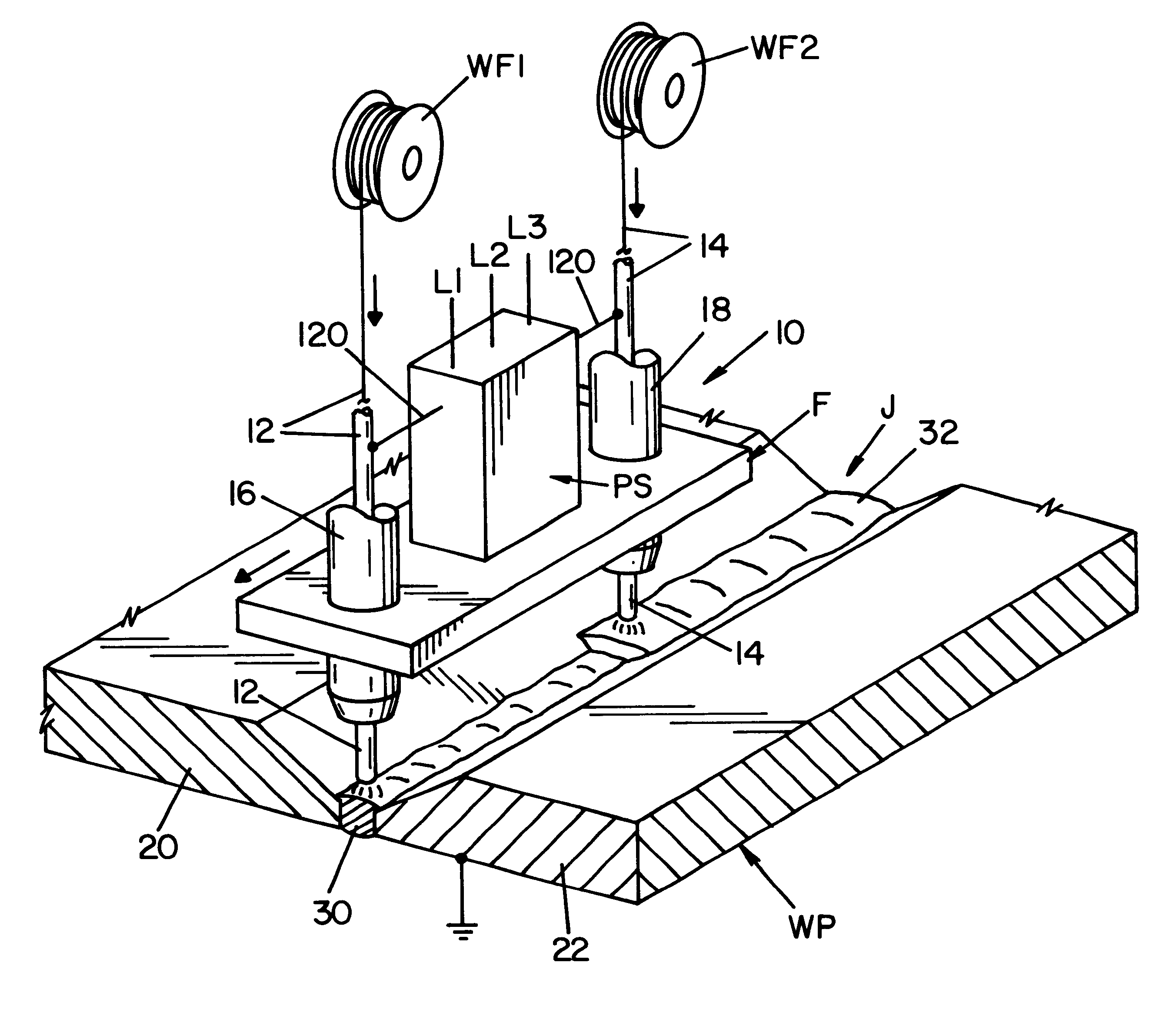

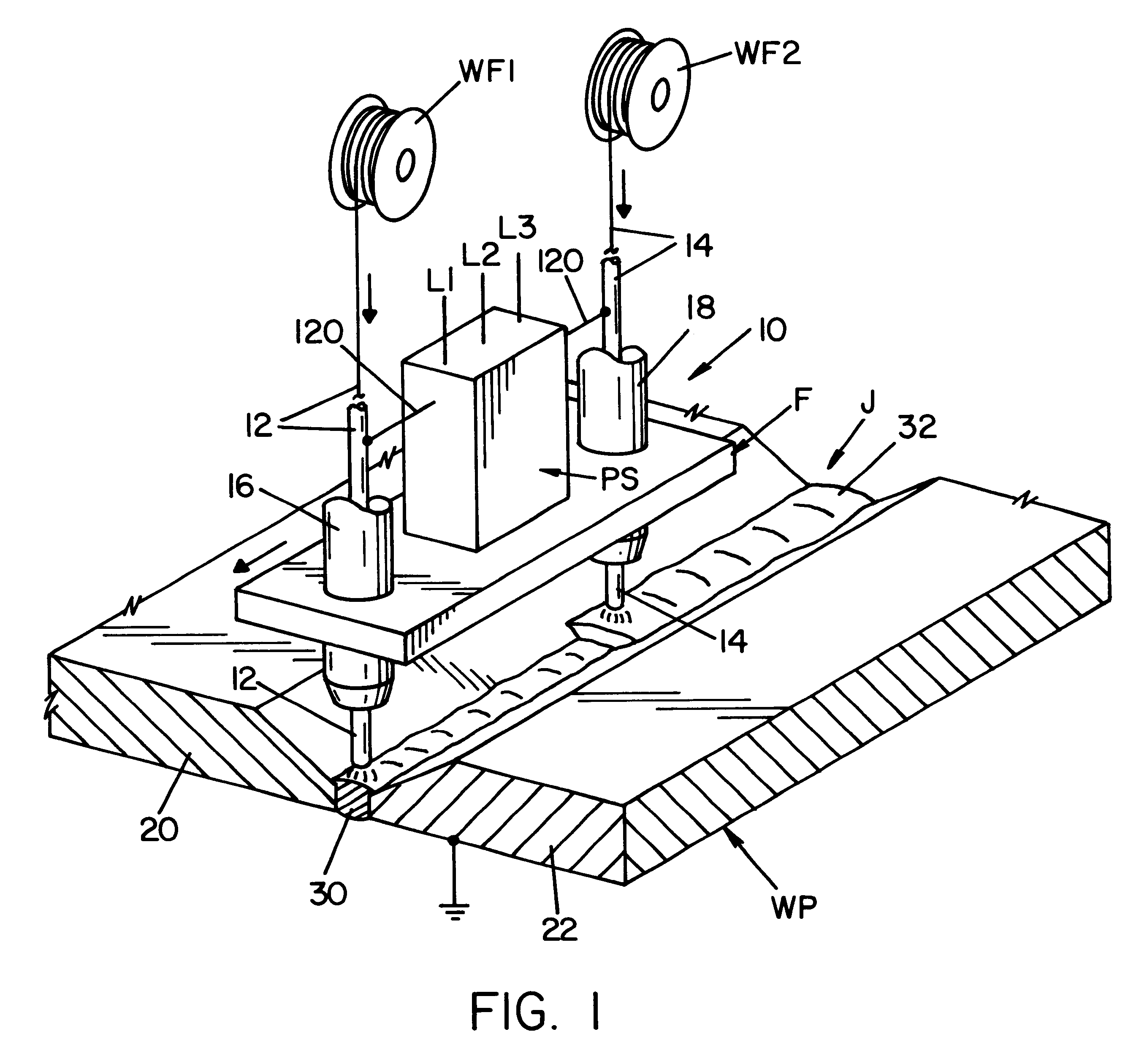

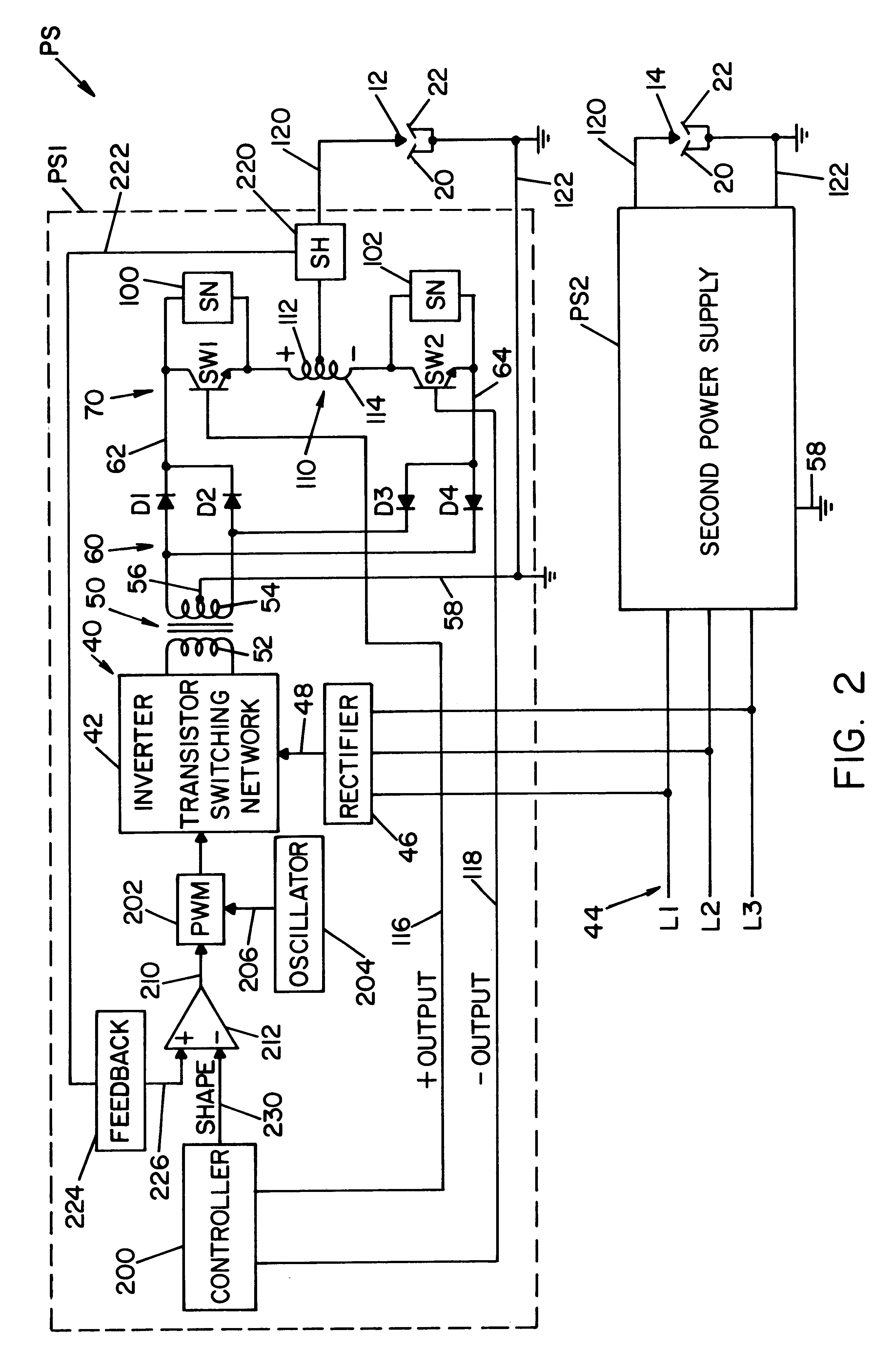

Tandem electrode welder and method of welding with two electrodes

An electric arc welding apparatus comprising at least a first consumable electrode and a second consumable electrode movable in unison along a welding path between the edges of two adjacent, mutually grounded plates, a first power supply for passing a first welding current at a first low frequency between the first electrode and the two plates, a second power supply for passing a second welding current at a second low frequency between the second electrode and the two plates, where each of the power supplies includes a three phase voltage input operated at line frequency, a rectifier to convert the input voltage to a DC voltage link and a high frequency switching type inverter converting the DC voltage link to a high frequency AC current, an output rectifier circuit to provide a positive voltage tenninal and a negative voltage terminal, and an output switching network operated at a given low frequency for directing a pulsating welding current at the given low frequency from the two terminals across one of the electrodes and the plates, and a circuit for independently adjusting the given low frequency so the value of the first low frequency of the first power supply is different from the second low frequency of the second power supply.

Owner:LINCOLN GLOBAL INC

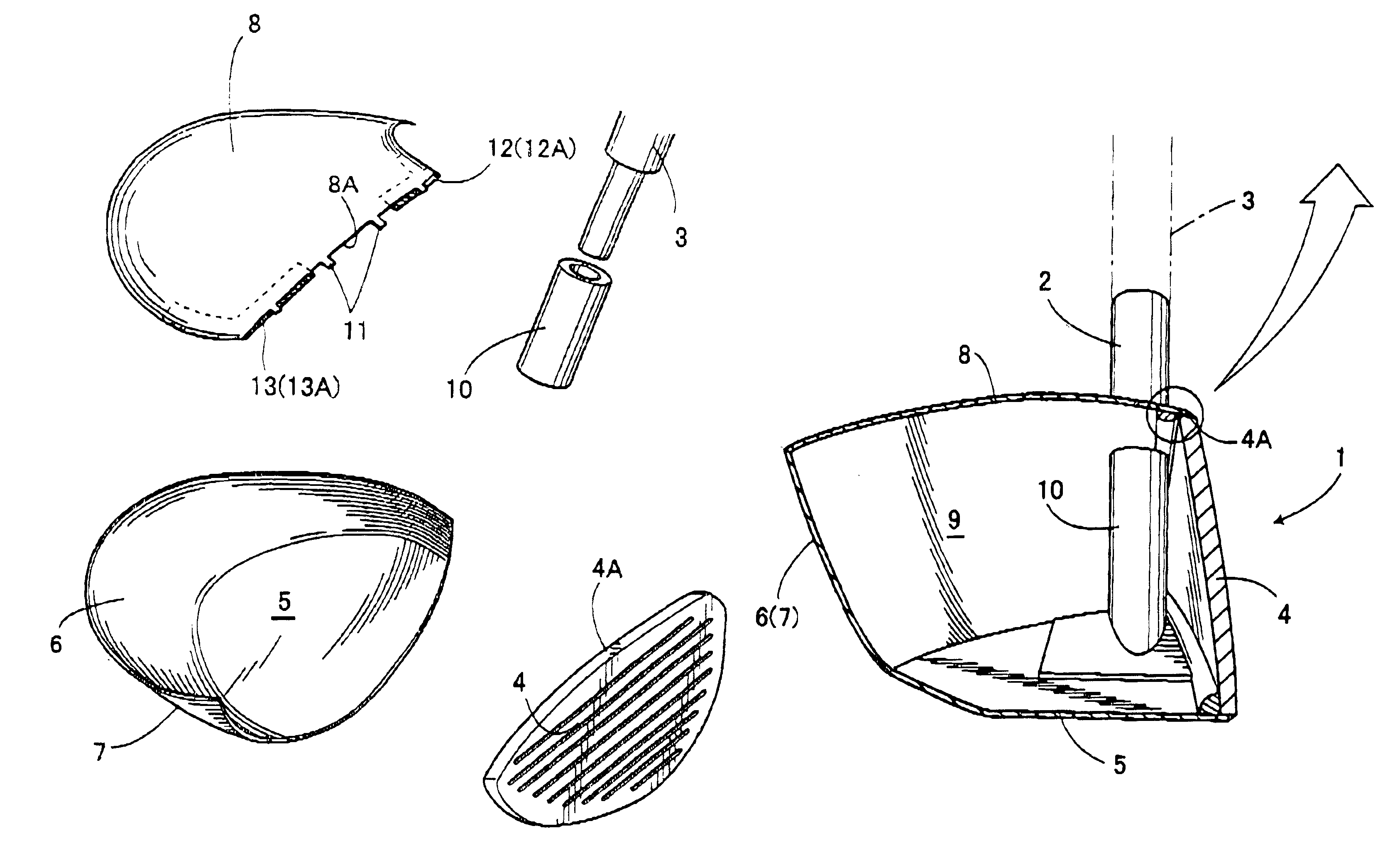

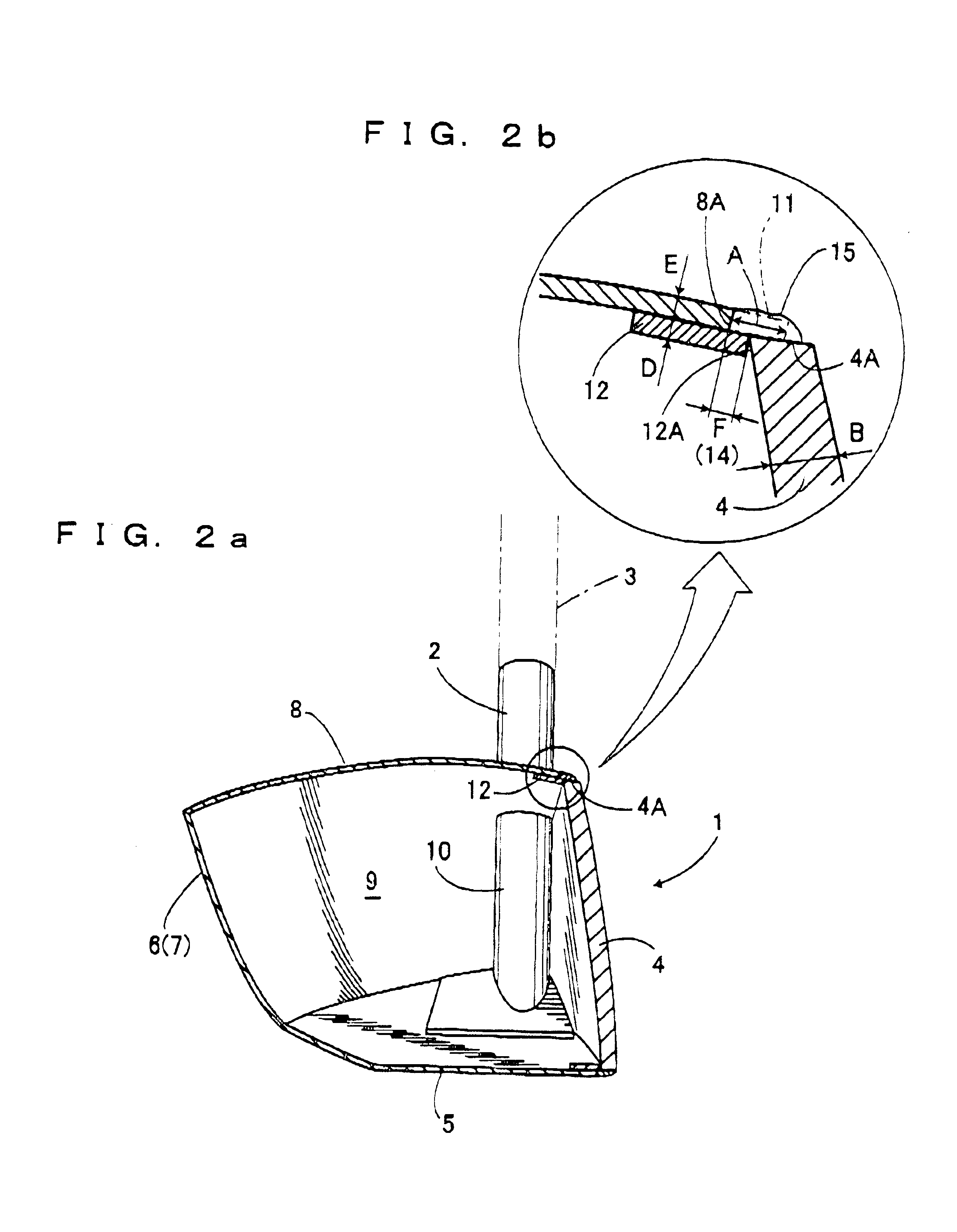

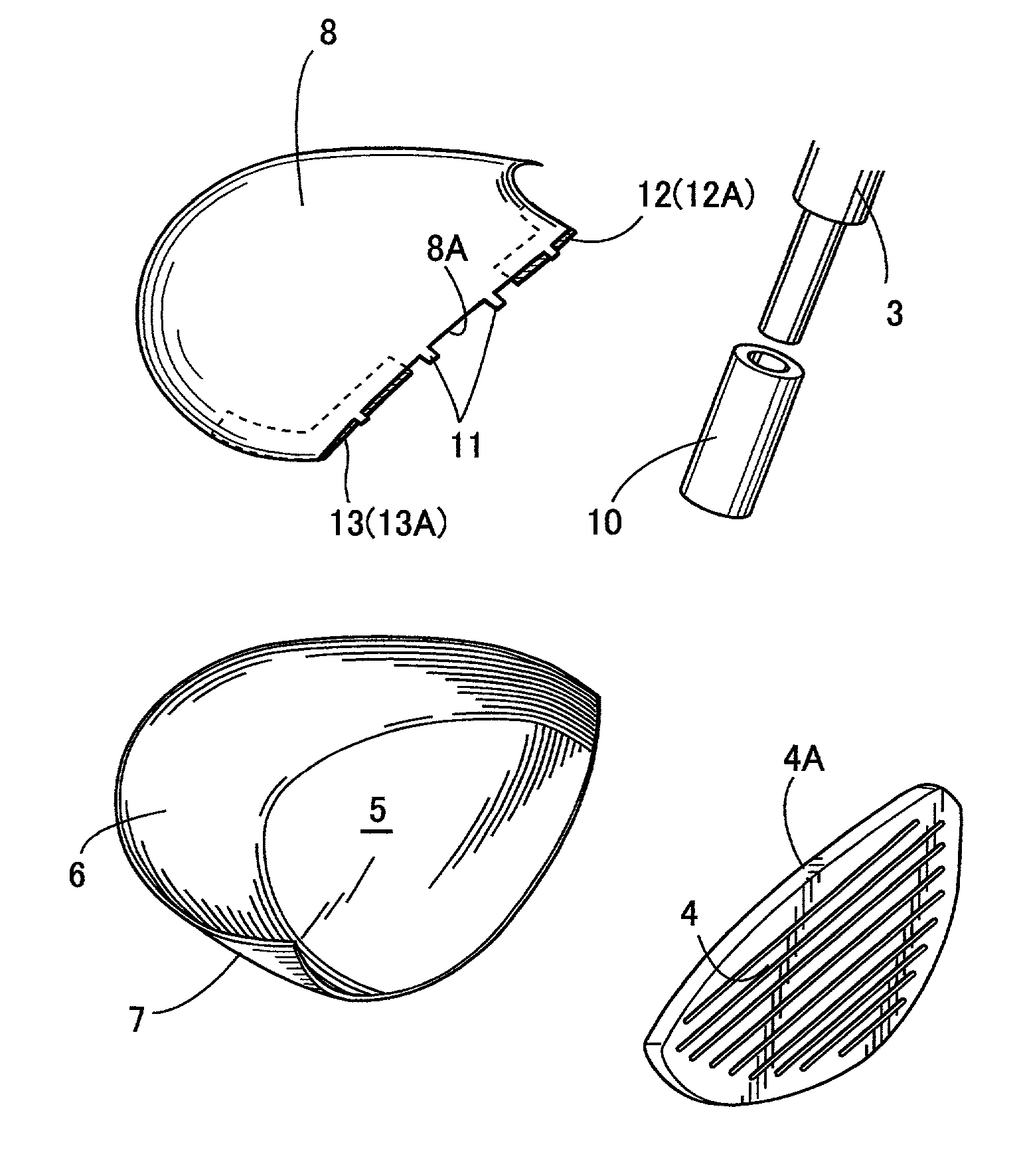

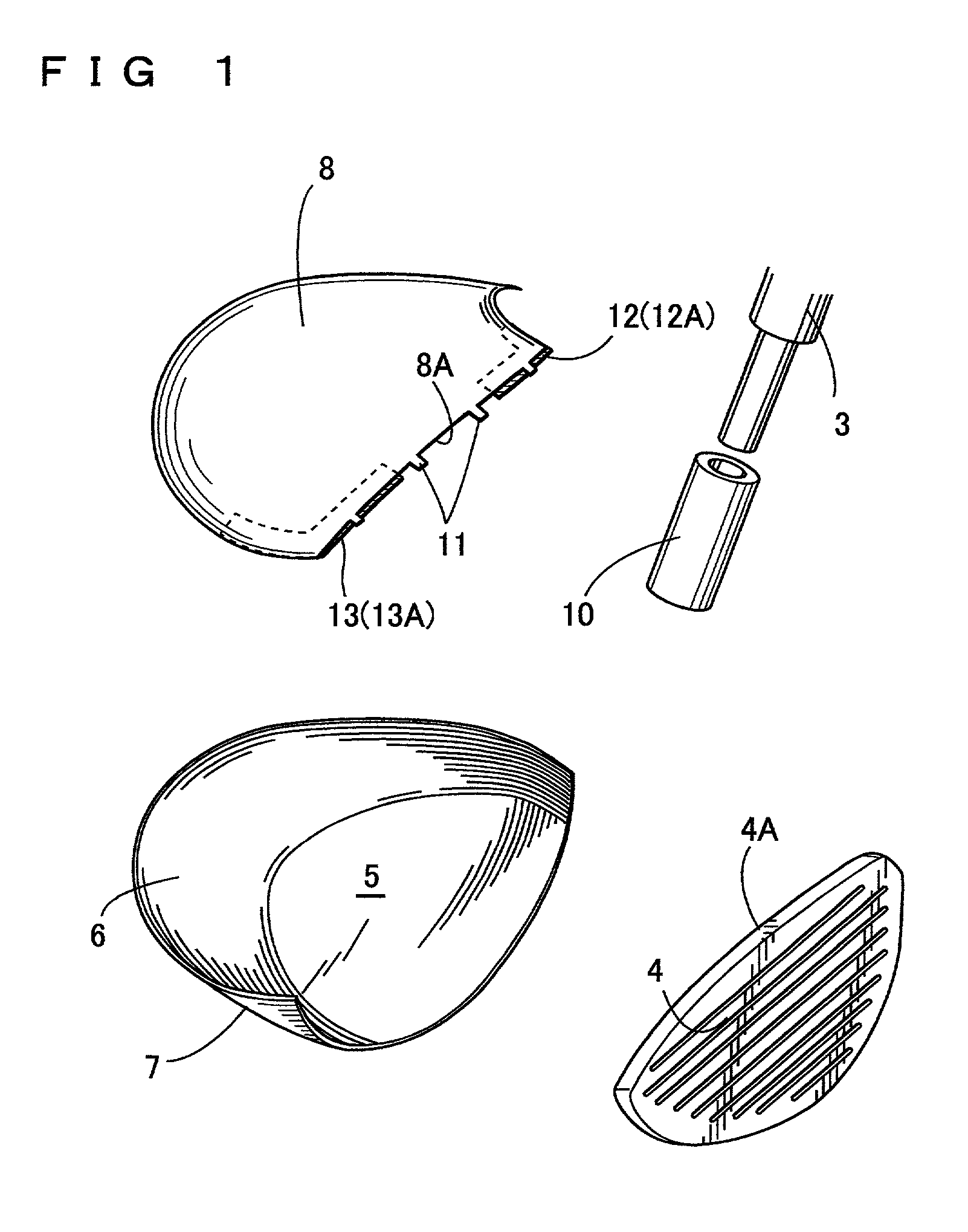

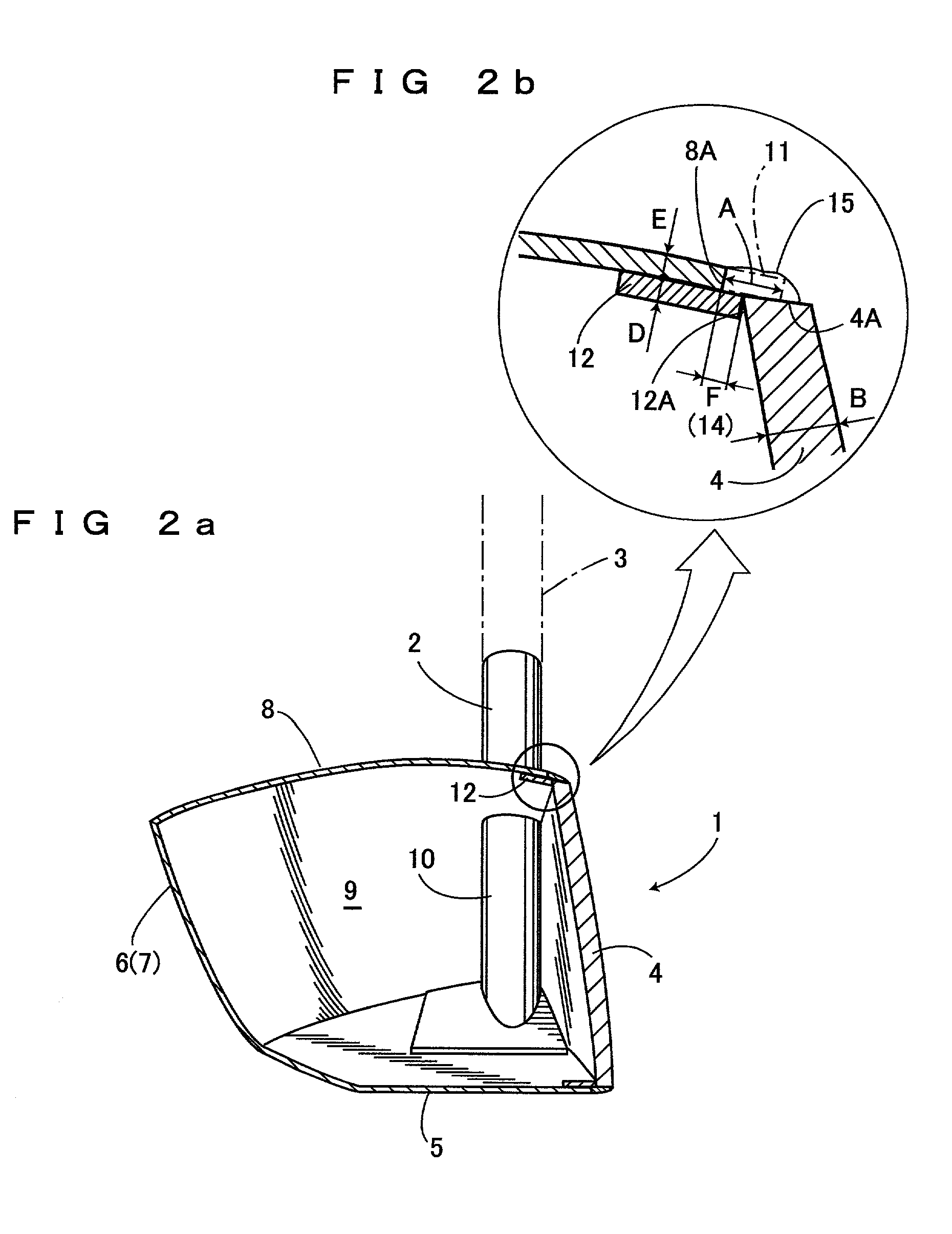

Golf club

Owner:THE YOKOHAMA RUBBER CO LTD +1

Golf club

A golf club which comprises a head which is less deformable by the heat in welding. Separate reinforcing members 12 and 13 are provided on inner surface of a front edge 8A of a crown shell 8. Thus, the front edge 8A side is thickened and then the upper edge 4A of the face shell 4 is joined to the front edge 8A of the crown shell 8, by welding. The front edge 8A of the crown shell 8 is formed with a plurality of projections 11 which are anchored by the upper edge 4A of the face shell 4. front edge 8A of the crown shell 8 is thickened by adding the thickness of the reinforcing members 12, 13 to the thickness of crown shell 8 itself. Thus, thermal deformation and the sinking of the front edge 8A at the time of welding can be prevented, thus enabling the upper edge 4A to be joined to the front edge 8A as designed.

Owner:THE YOKOHAMA RUBBER CO LTD +1

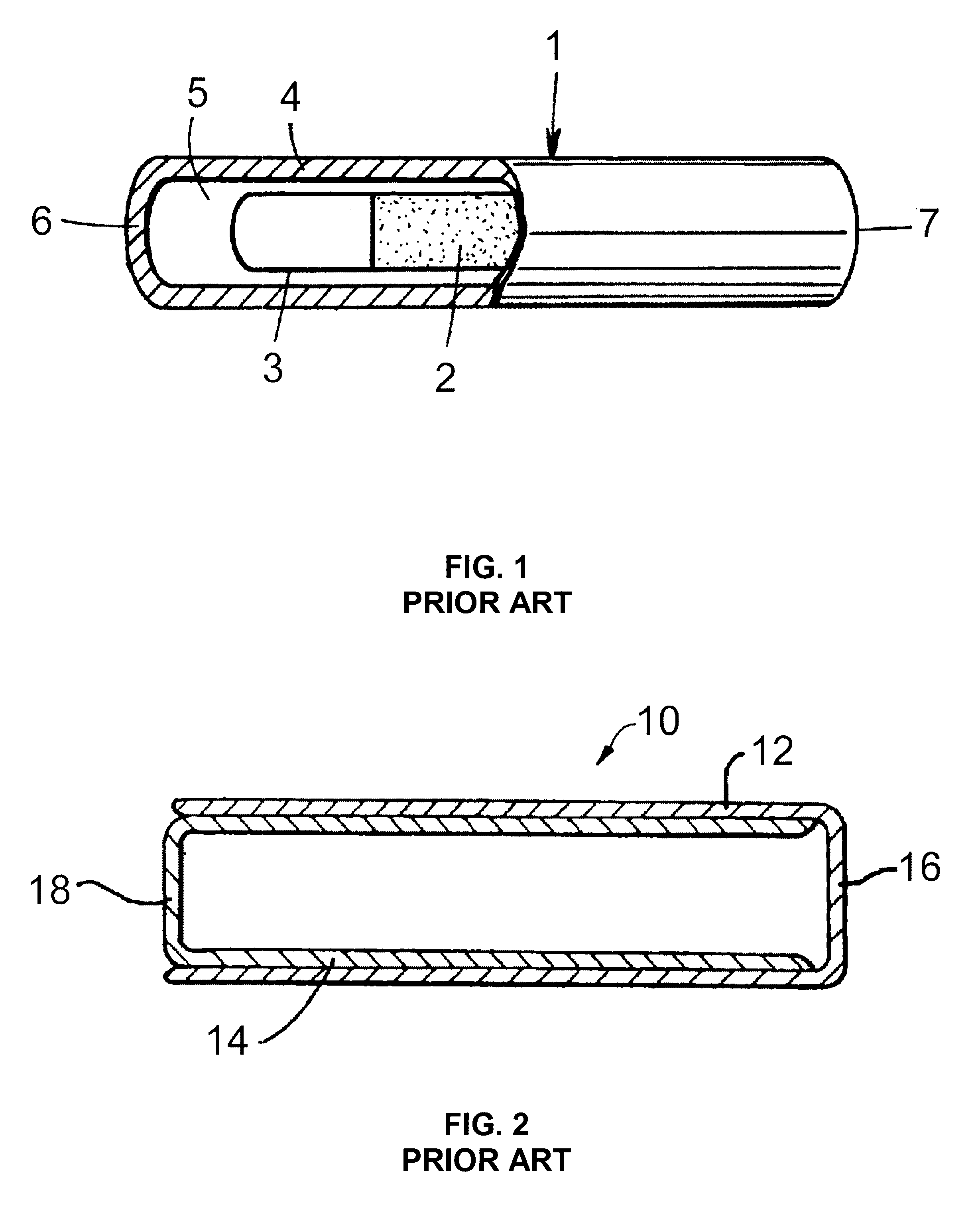

Implantable vascular device

Owner:COOK BIOTECH +2

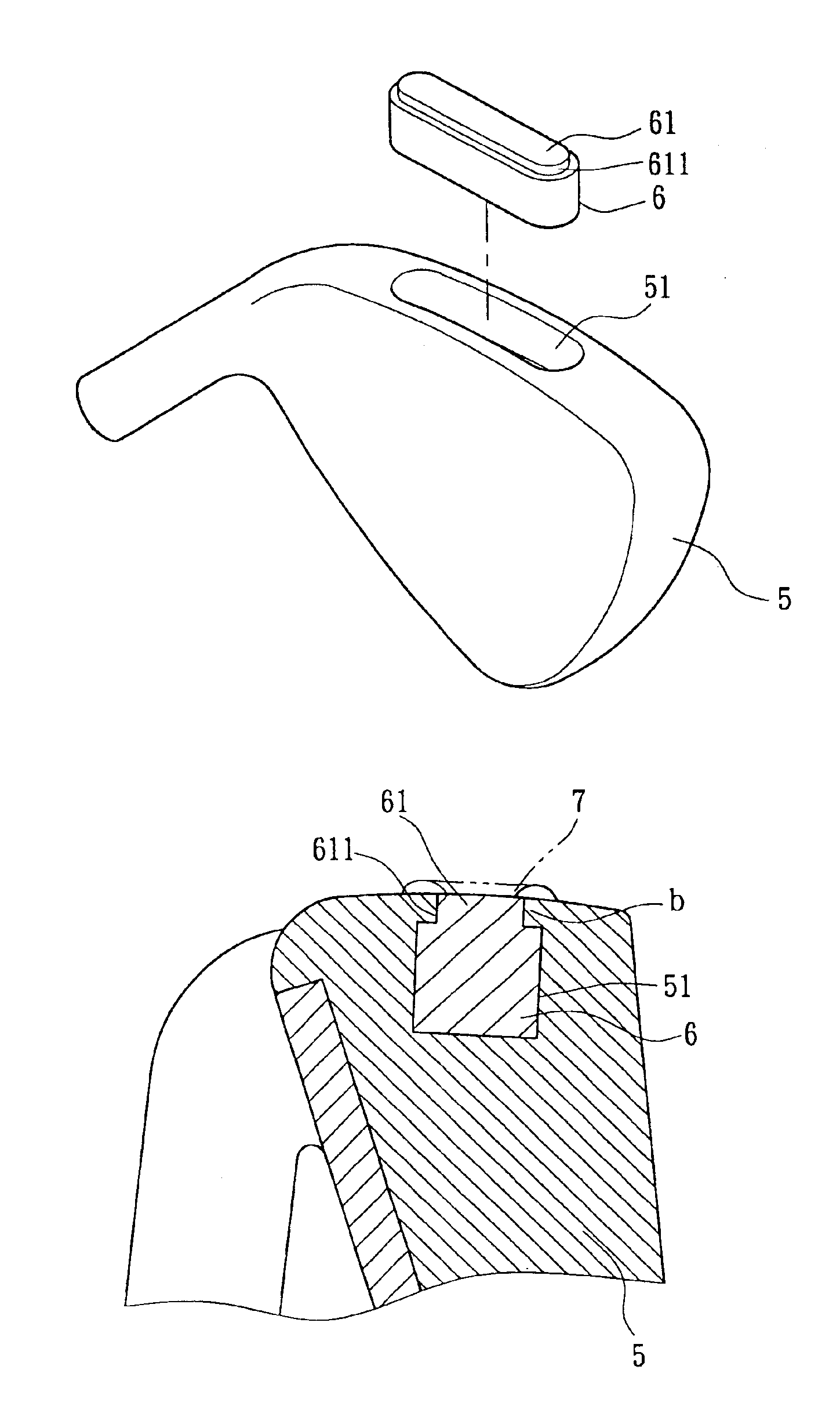

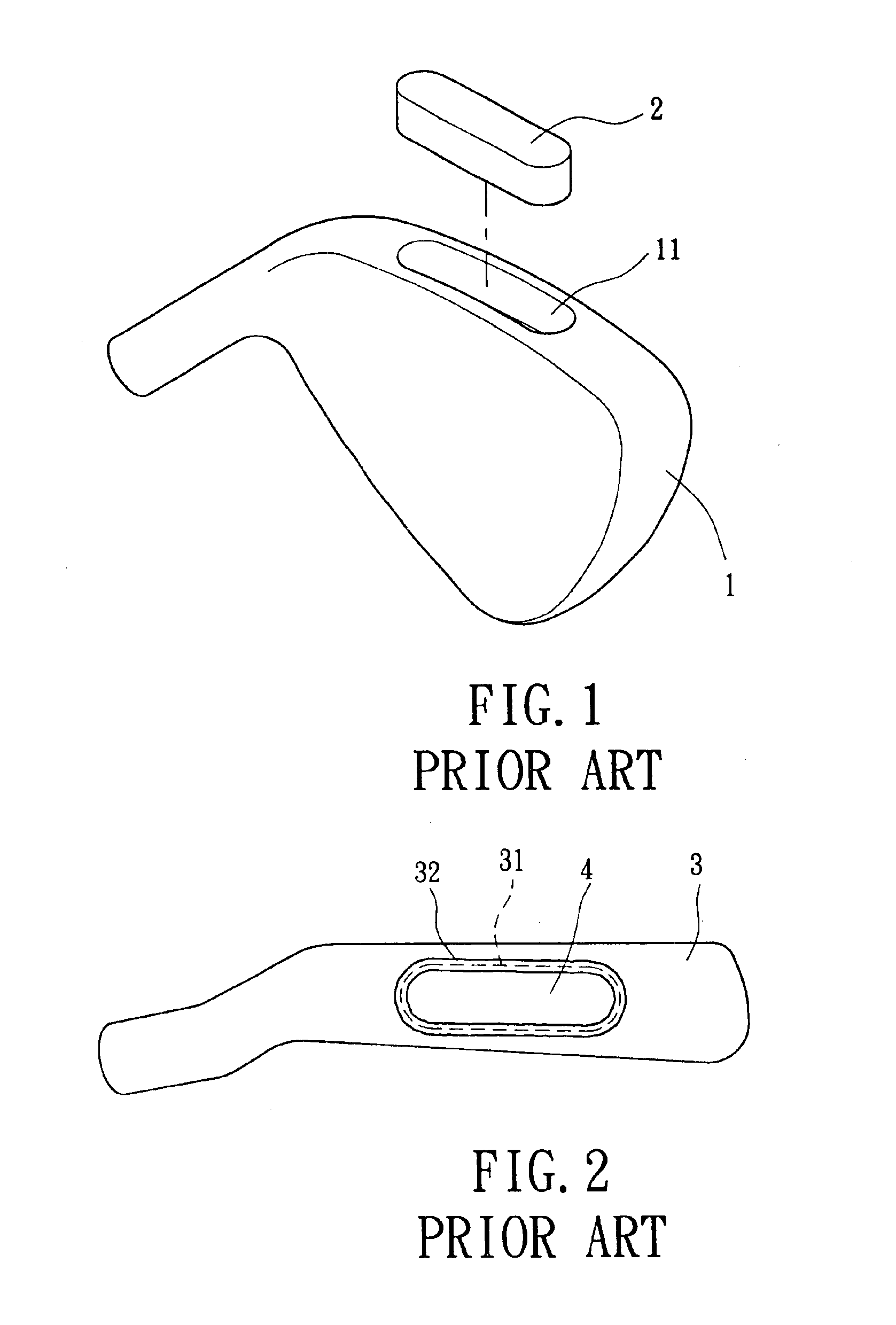

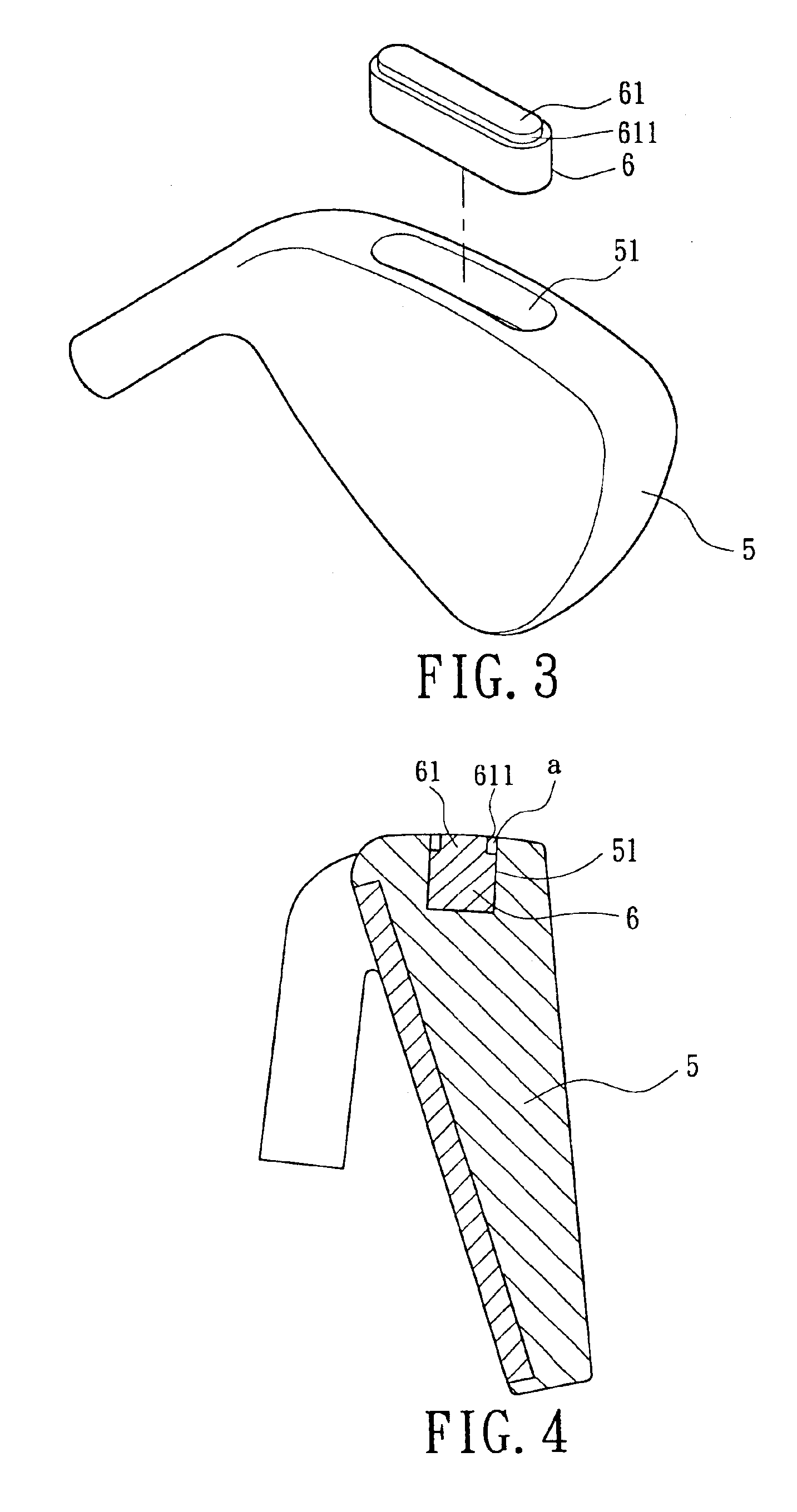

Weight number for a golf club head

A golf club head includes a golf club head body and a weight member. The golf club head member has a recession in which the weight member is mounted. The weight member is securely mounted in the recession of the golf club head body by a welding procedure that uses a welding material. The weight member is made of a material having a melting point higher than that of the golf club head body, avoiding melting of the weight member during the welding procedure. Only a portion of the golf club head body fuses with the welding material while using the welding material for proceeding with the welding procedure for the weight member.

Owner:FUSHENG PRECISION

Method and apparatus for electric arc welding

An electric arc welding apparatus for depositing molten metal from an advancing welding wire into a weld puddle in an open root between two juxtapositioned plates where the root extends in a welding path and is formed by converging walls terminating in generally parallel walls spaced to define a gap, which apparatus comprises a contact holder with a wire outlet, a switching power supply directing welding current to the wire as the wire passes from the outlet toward the open root, with the advancing wire defining an electrode stick out between the contact holder and the weld puddle, a circuit for sensing the length of the stick out, and control means for adjusting the welding current as a function of the sensed stick out length.

Owner:LINCOLN GLOBAL INC

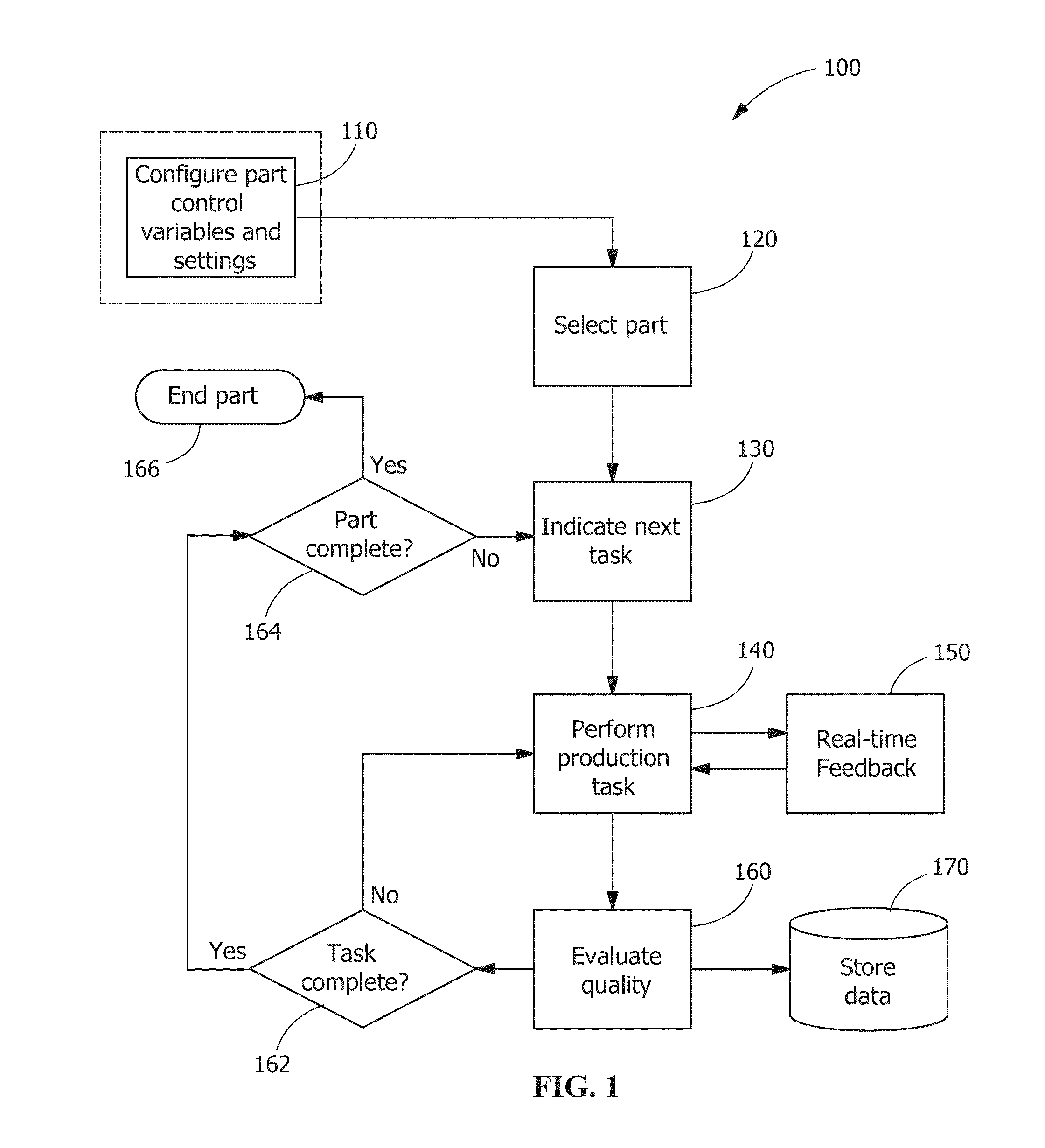

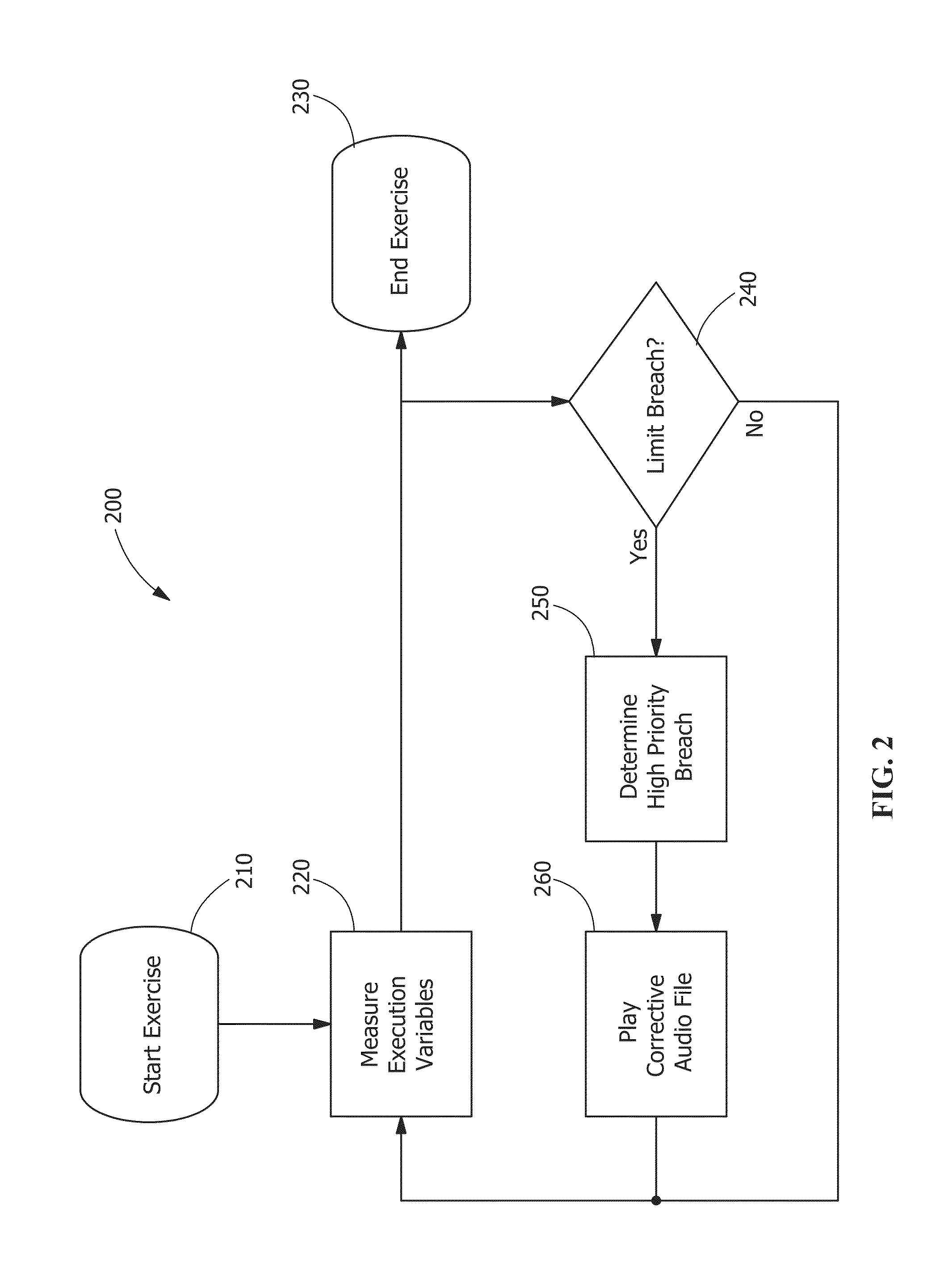

System and method monitoring and characterizing manual welding operations

A system and method for monitoring manual welding that includes a welding system that further includes hardware and software components for gathering and processing data in real time, wherein the data is derived from an actual welding exercise conducted by a welder; providing the system with part information, process variable control targets, and acceptability limits; selecting a part to be welded from the part information; indicating a production task to be completed on the part; performing the indicated production task; providing real-time feedback to the welder performing the task; evaluating the quality of the welder's performance of the task based on the process variable control targets and acceptability limits; if necessary, requiring remedial action with regard to the quality of the performance of the task; and storing data gathered from the evaluation of the performance of the task.

Owner:LINCOLN GLOBAL INC

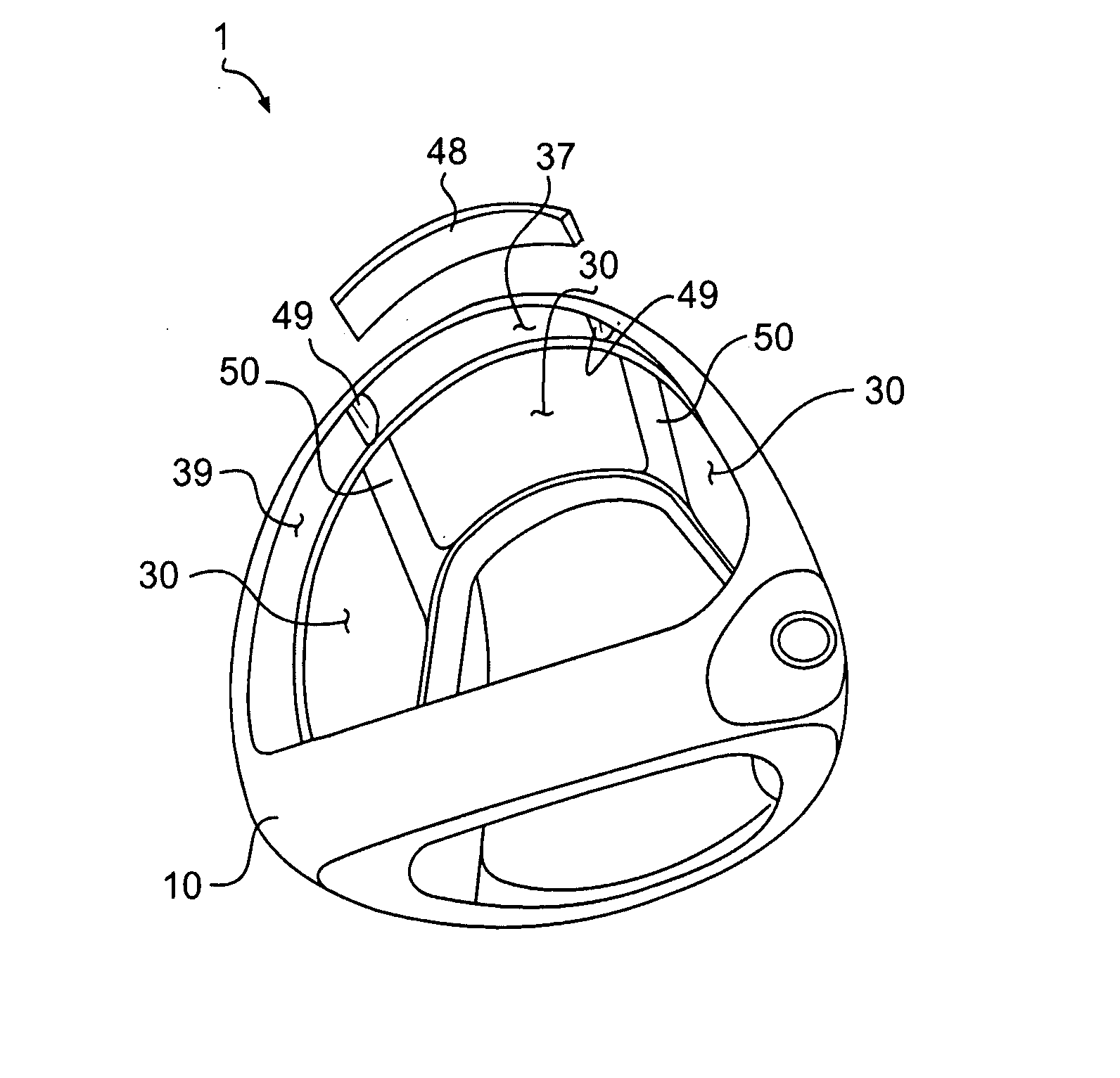

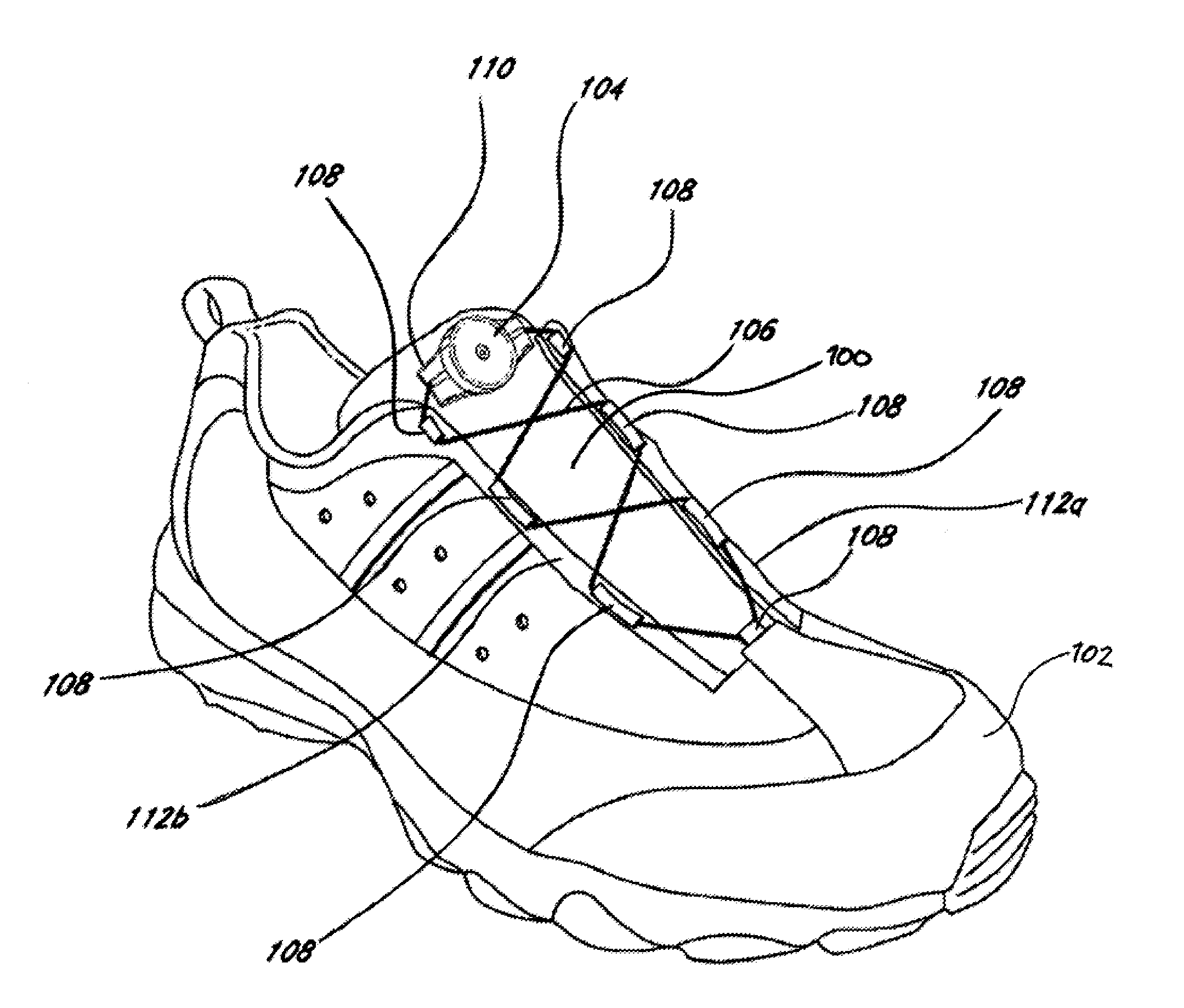

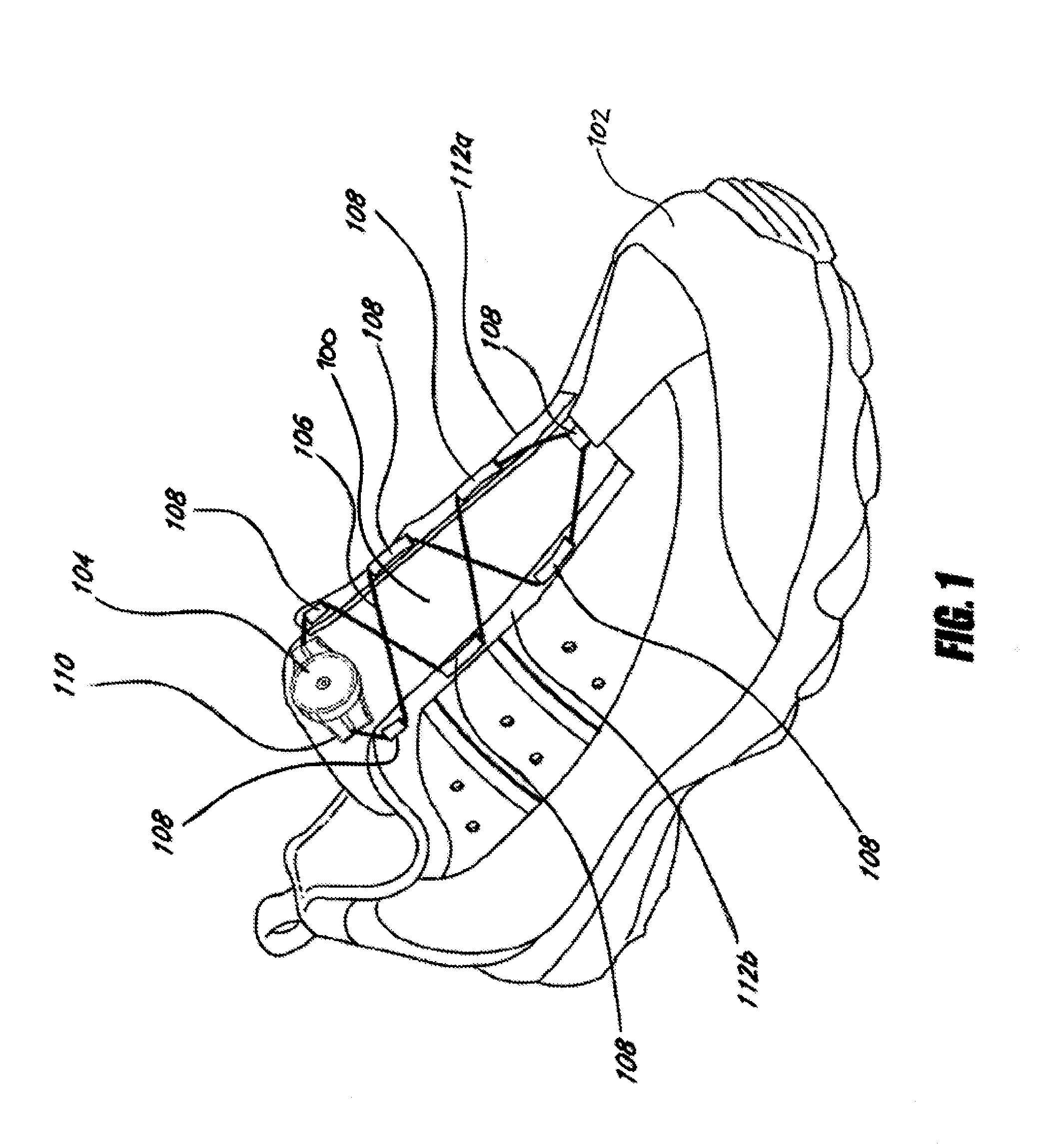

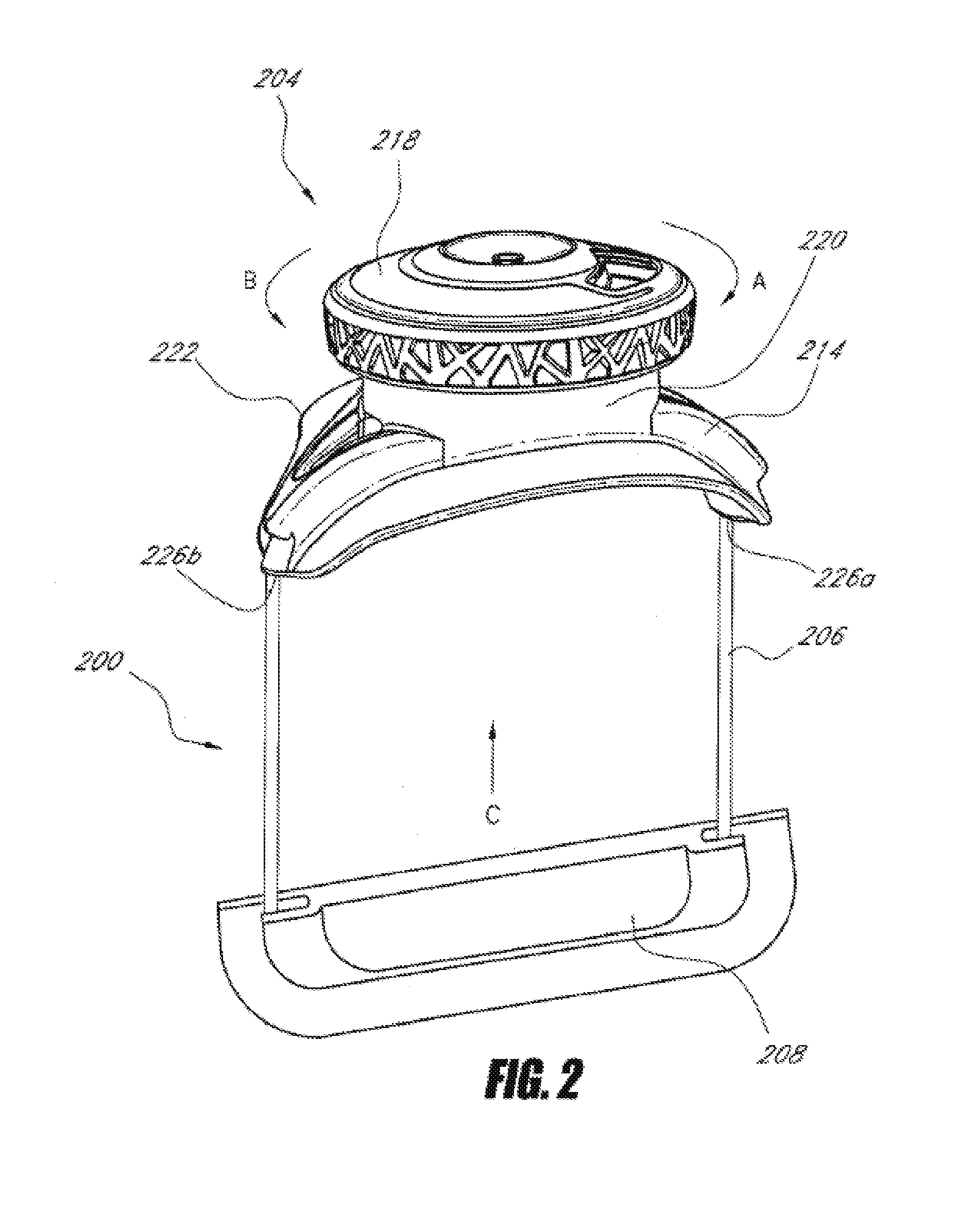

Guides and components for closure systems and methods therefor

ActiveUS20150059206A1Easily and conveniently coupledTighten shoeEyeletsLacing hooksThermoplastic elastomerEngineering

According to an embodiment, a component for attachment to an article includes an upper component that is made of a thermoplastic material having a first melting temperature and a flange member that is molded onto the upper component and made of a thermoplastic elastomer material having a second melting temperature that is lower than the first melting temperature of the upper component. The flange member extends laterally from a bottom end of the upper component so that a bottom surface of the flange member is flush with or positioned axially below a bottom surface of the upper component. The melting temperature of the thermoplastic elastomer material enables the flange member to be directly coupled to the article via heat welding and the like without substantially affecting the upper component.

Owner:BOA TECHNOLOGY

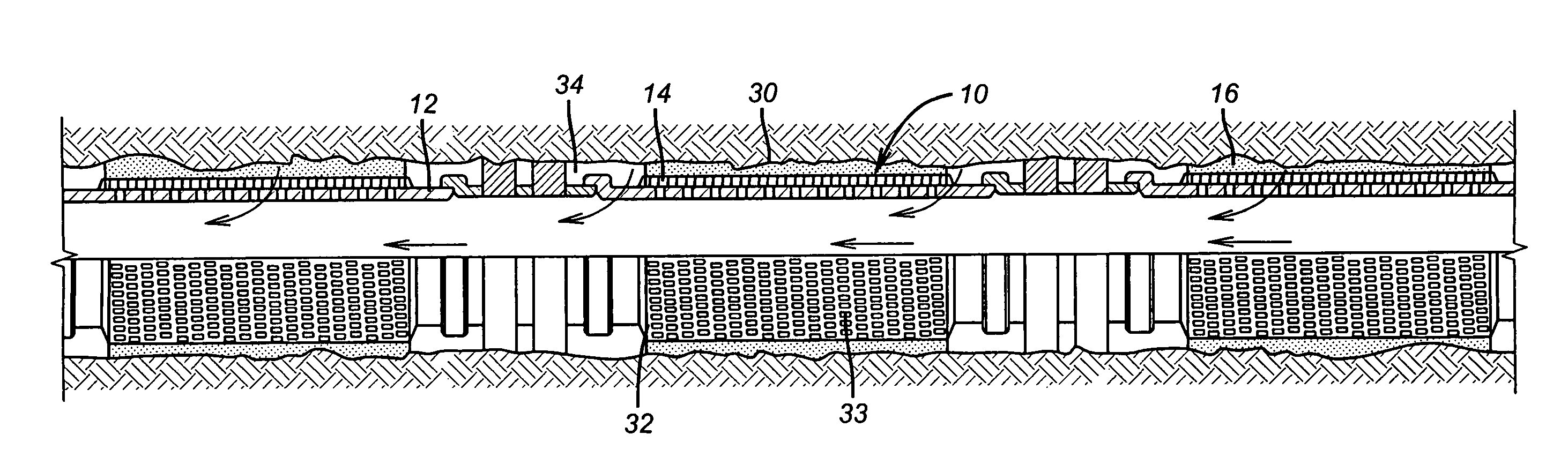

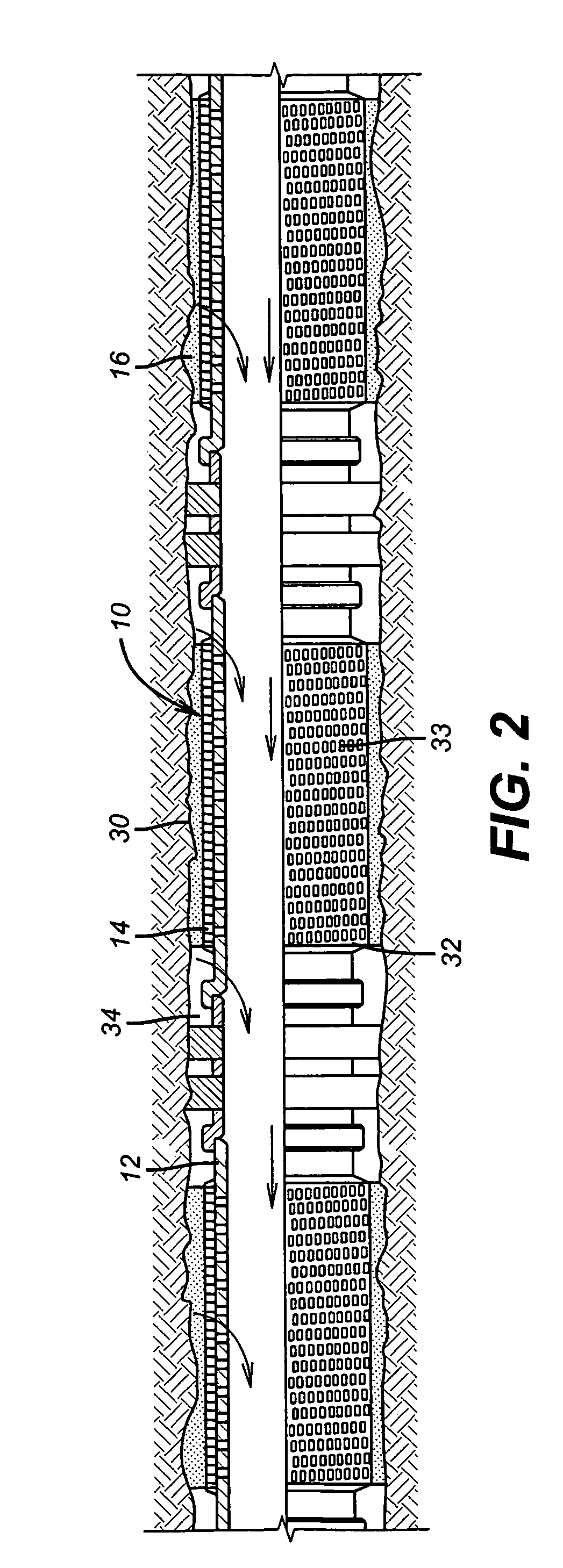

Self-conforming screen

InactiveUS7013979B2Minimizing and eliminating any weldingDrilling rodsFluid removalDrill holeWelding

A screen that conforms to the borehole shape after expansion is disclosed. The screen comprises a compliant outer layer that takes the borehole shape on expansion. The outer layer is formed having holes to permit production flow. The material that is selected preferably swells with prolonged contact to well fluids to further close off annular gaps after expansion. In an alternative embodiment, the screen is not expanded and the swelling of the material alone closes off annular gaps. The outer sleeve is placed over the screen and the screen is placed on a base pipe and initially expanded from within the base pipe to secure the components of the screen assembly for running downhole, while minimizing or eliminating any welding among the layers. A variety of expansion tools can be used to expand the screen or screens downhole.

Owner:BAKER HUGHES HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com