Patents

Literature

16968 results about "Electric arc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electric arc, or arc discharge, is an electrical breakdown of a gas that produces a prolonged electrical discharge. The current through a normally nonconductive medium such as air produces a plasma; the plasma may produce visible light. An arc discharge is characterized by a lower voltage than a glow discharge and relies on thermionic emission of electrons from the electrodes supporting the arc. An archaic term is voltaic arc, as used in the phrase "voltaic arc lamp".

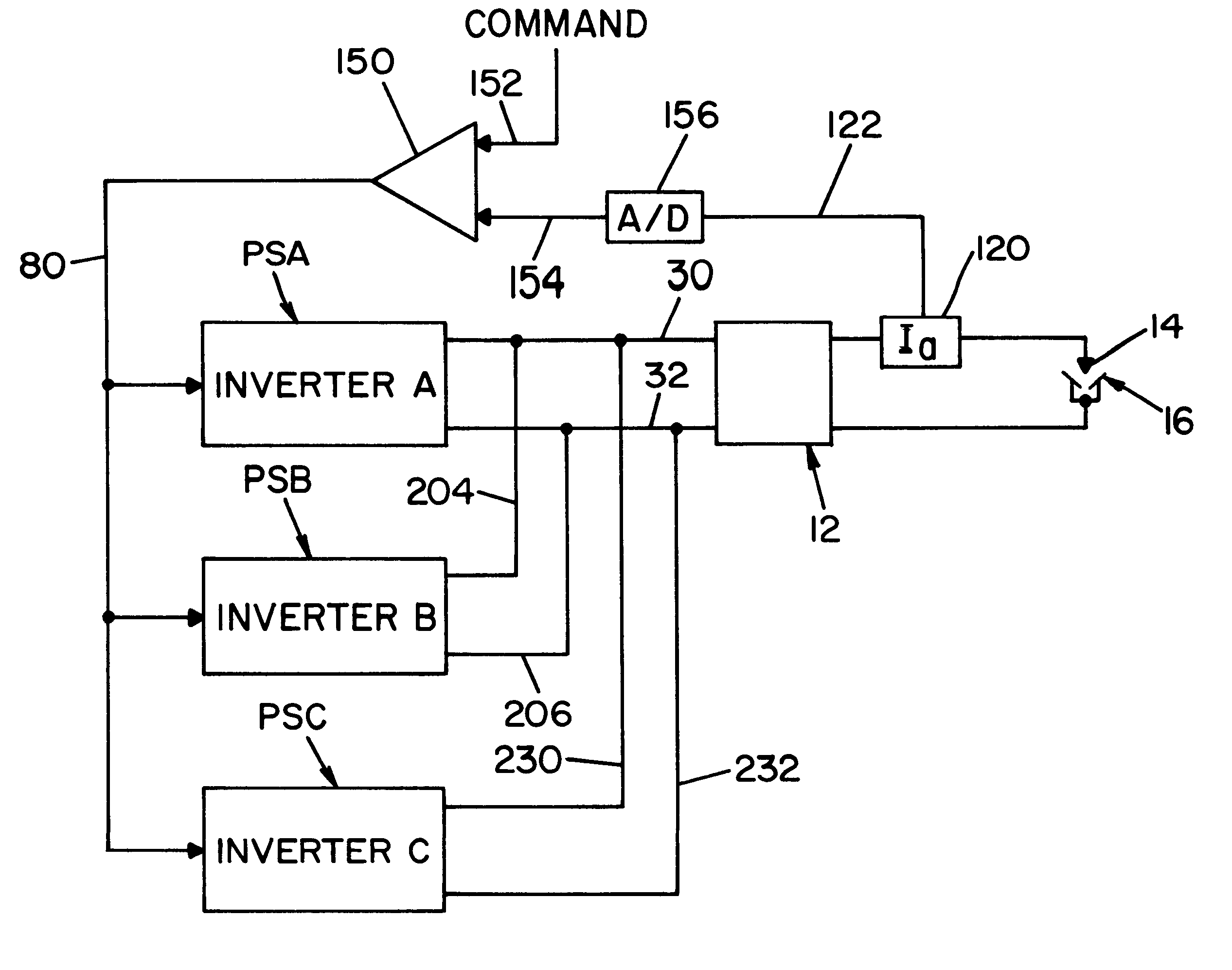

Electrosurgical generator

InactiveUS6923804B2Improving impedanceIncrease resistanceSurgical instruments for heatingSurgical instruments for aspiration of substancesResonant inverterConstant power

An electrosurgical generator which provides a constant power output particularly suited for cutting arc formation at an active electrode which exhibits a dynamic active surface area of varying geometry. Essentially constant power-based control is achieved through the utilization of a d.c. link voltage the level of which functions to establish the amplitude of the output of an RF resonant inverter. A dual loop feedback control is described wherein output power based control signals are slowly introduced at low gain, while link voltage based controls are comparatively rapidly applied. Enhanced development of a controlling d.c. link voltage is achieved through the utilization of an input network incorporating a power factor correction stage.

Owner:COVIDIEN AG

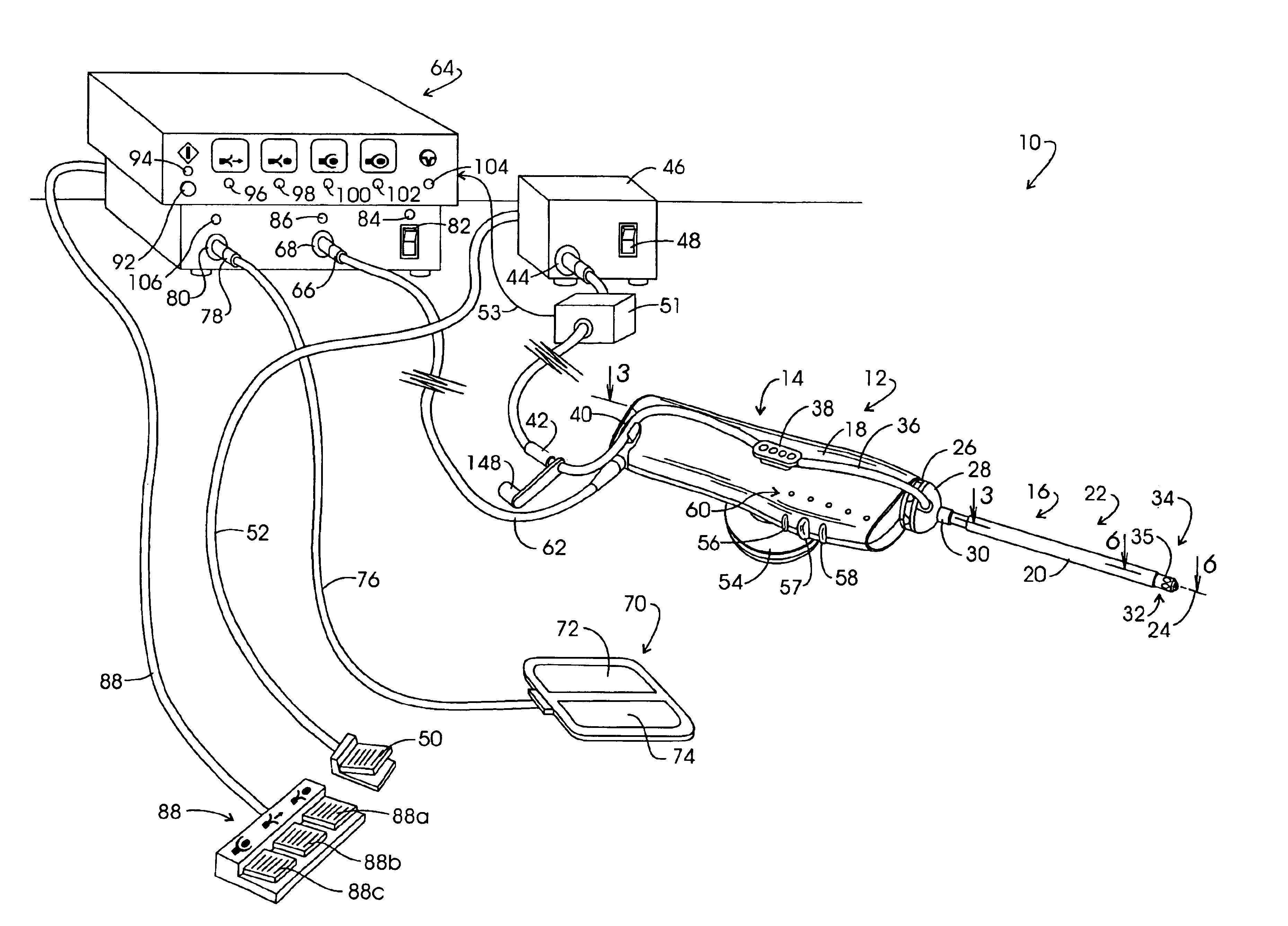

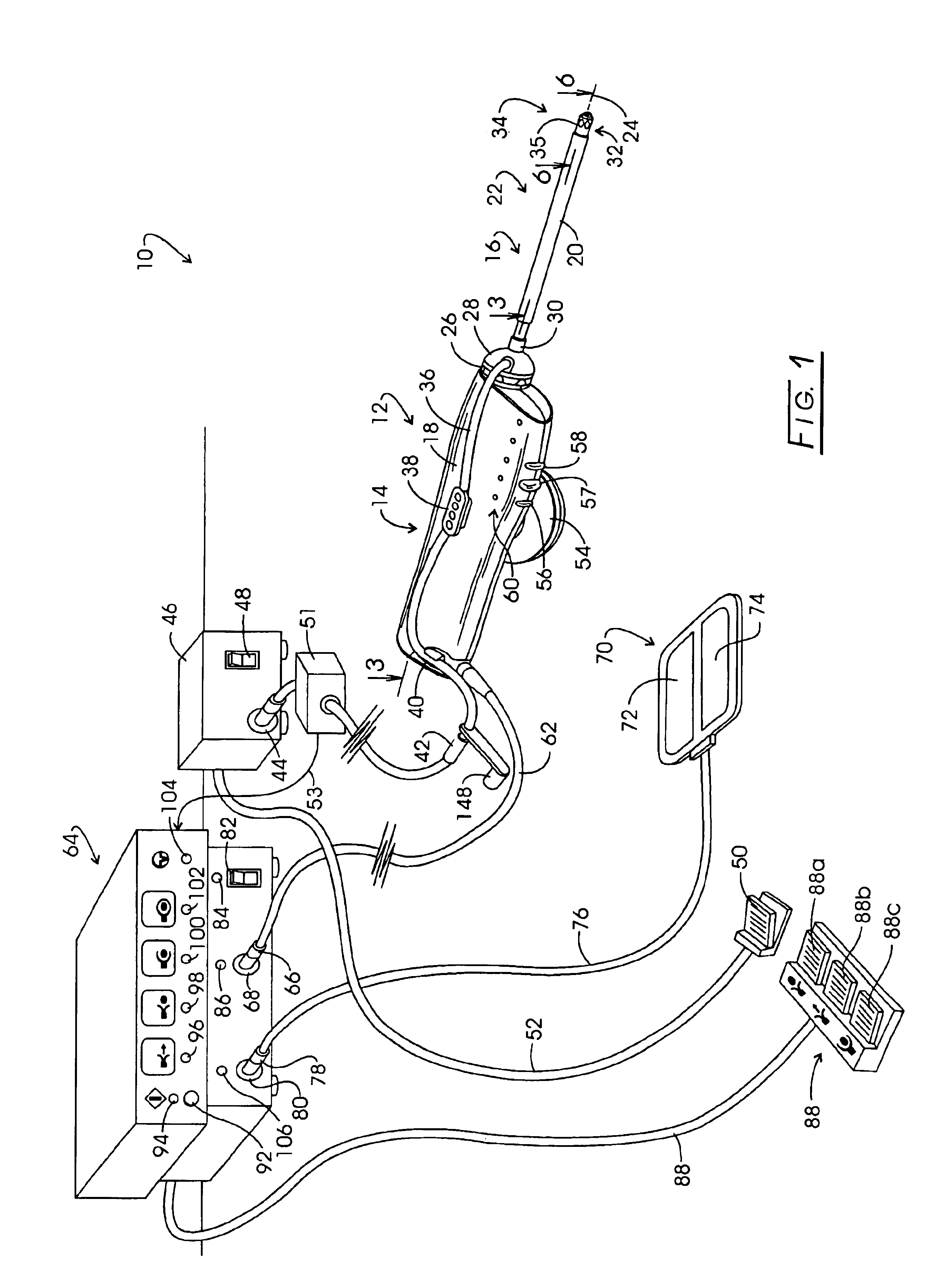

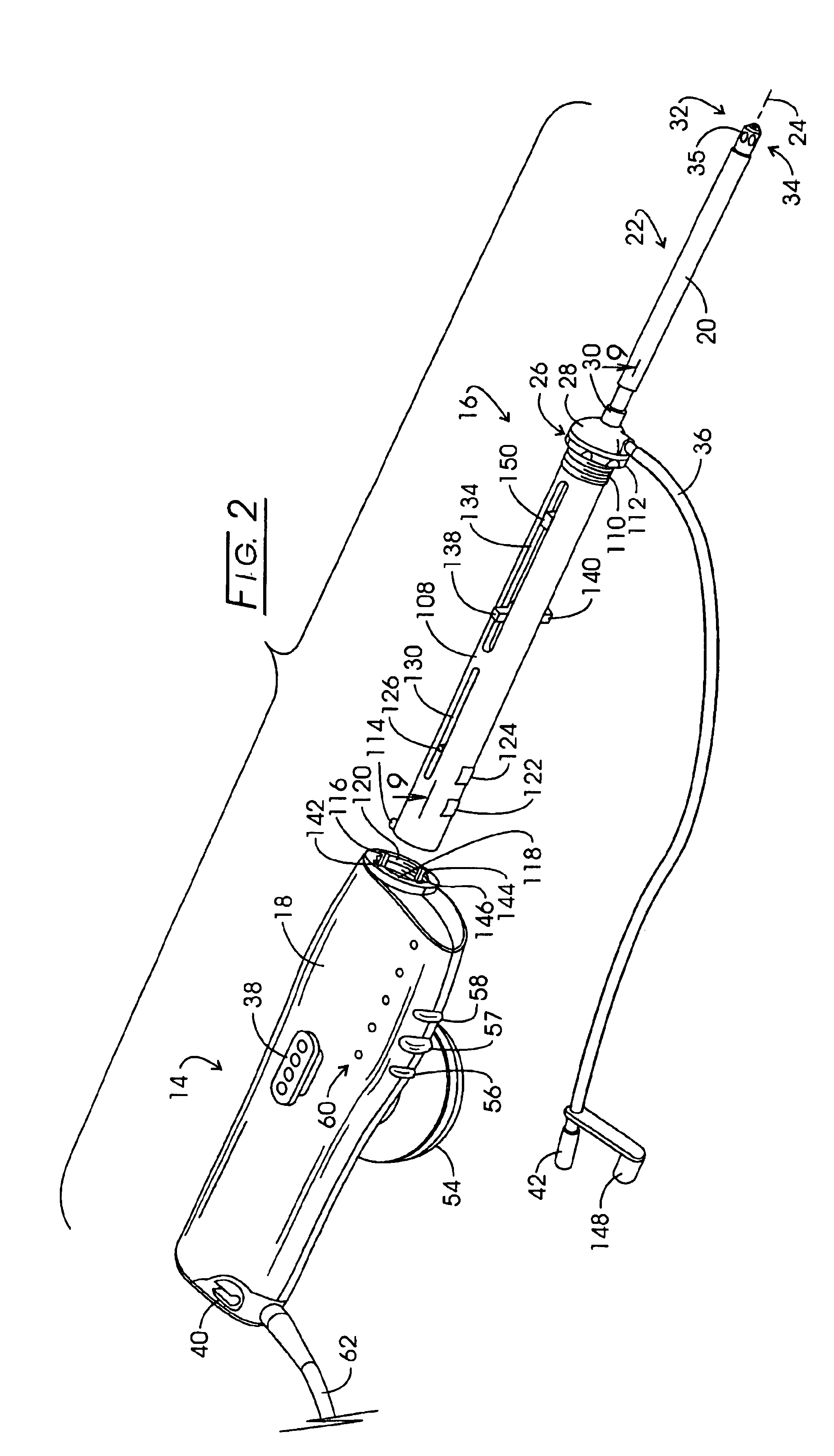

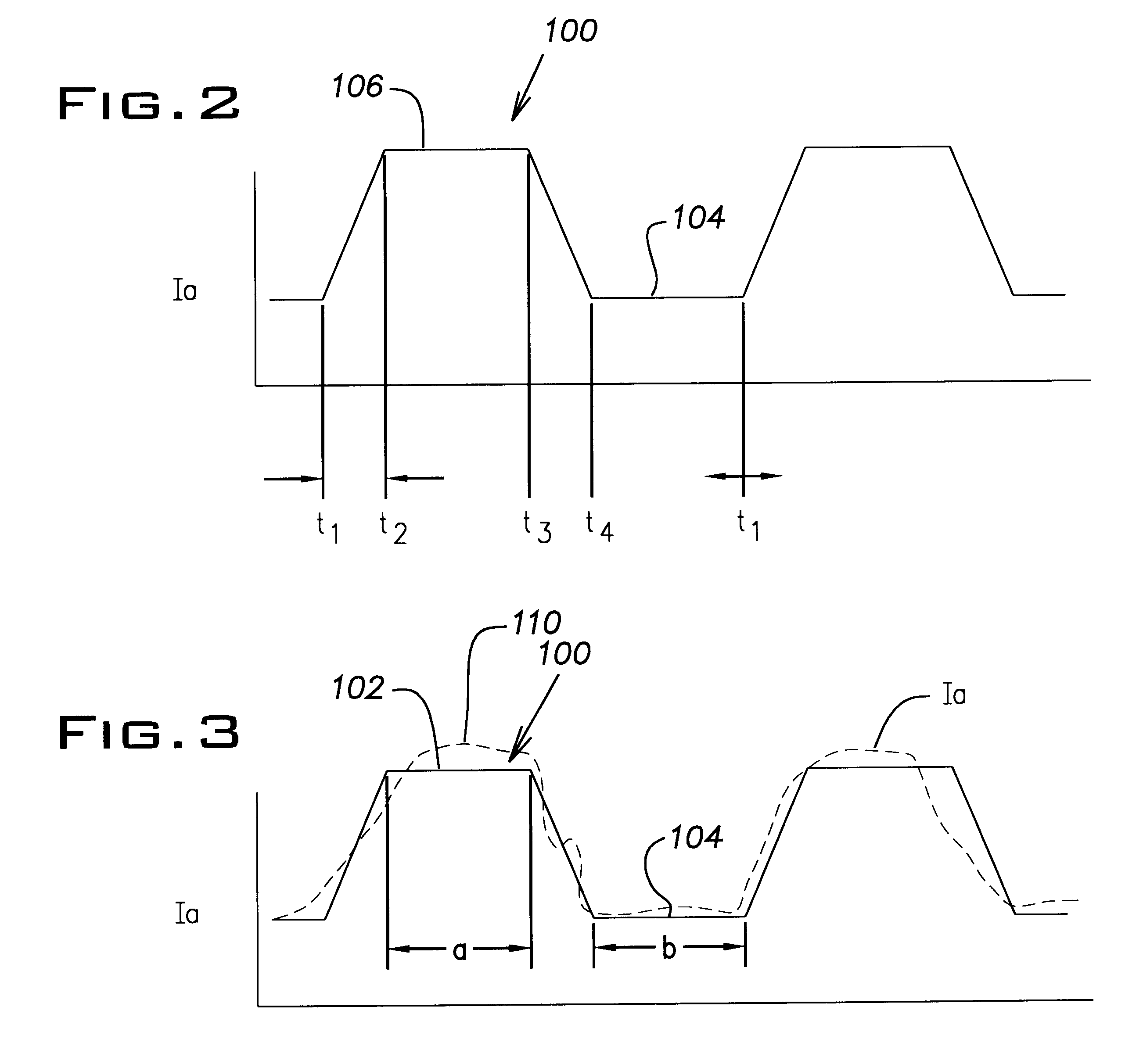

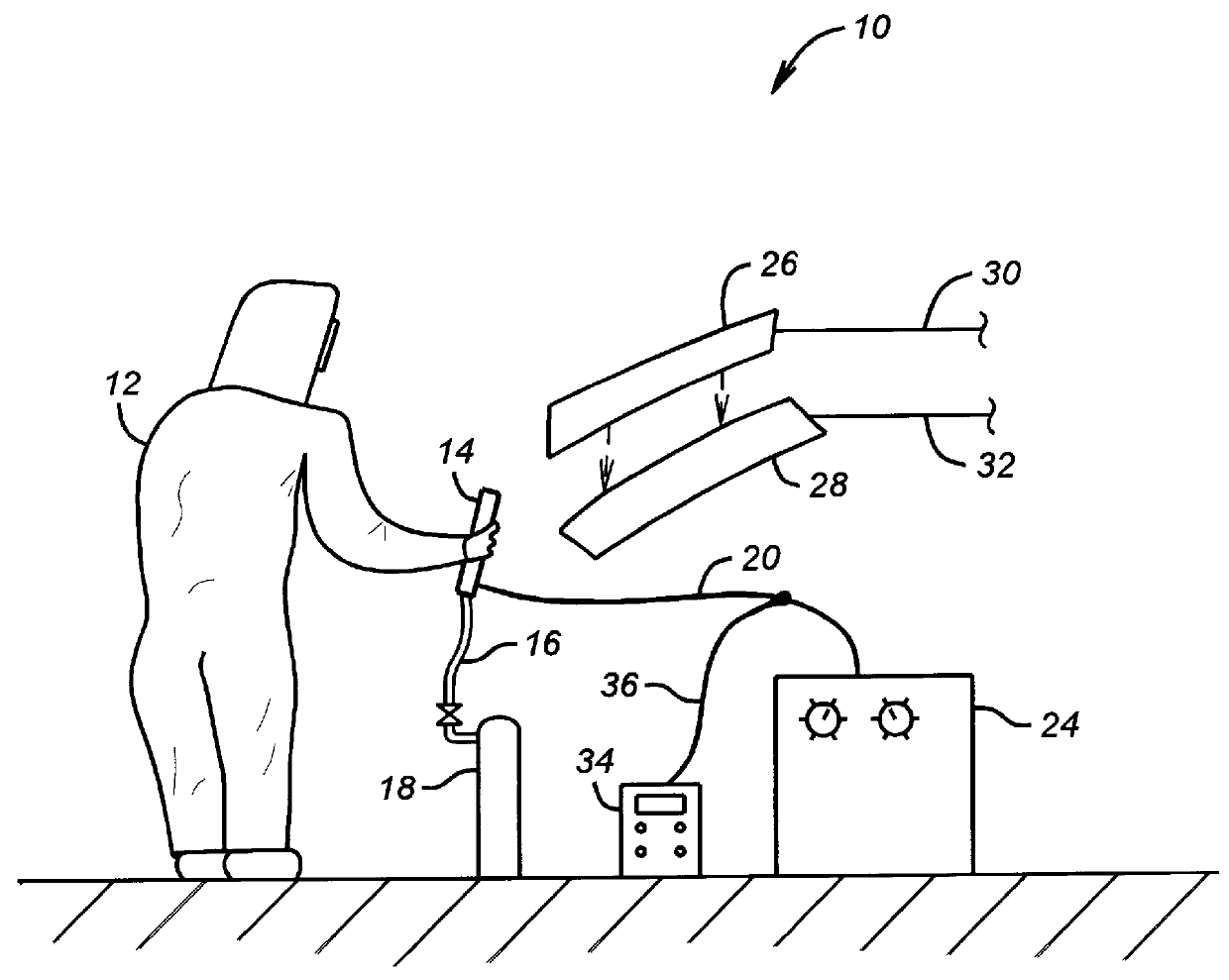

Monitor for electric arc welder

InactiveUS6441342B1Rapid data acquisition rateSufficient memoryArc welding apparatusWave shapeSimulation

A monitor for an electric arc welder as the welder performs a selected arc welding process by creating actual welding parameters, such as arc current and arc voltage, between an advancing welding wire and a workpiece, where the process involves an arc and is defined by a series of rapidly repeating wave shapes constituting a weld cycle with a cycle time, the wave shapes are each segmented into time states having command signals corresponding to the actual parameters and a time duration. The monitor selects a specific wave shape state, reads one of the actual parameters, compares the actual read parameter with a function of the command signal corresponding to the actual parameter, and uses-the comparison to generate a characteristic of the welding process during the selected state.

Owner:LINCOLN GLOBAL INC

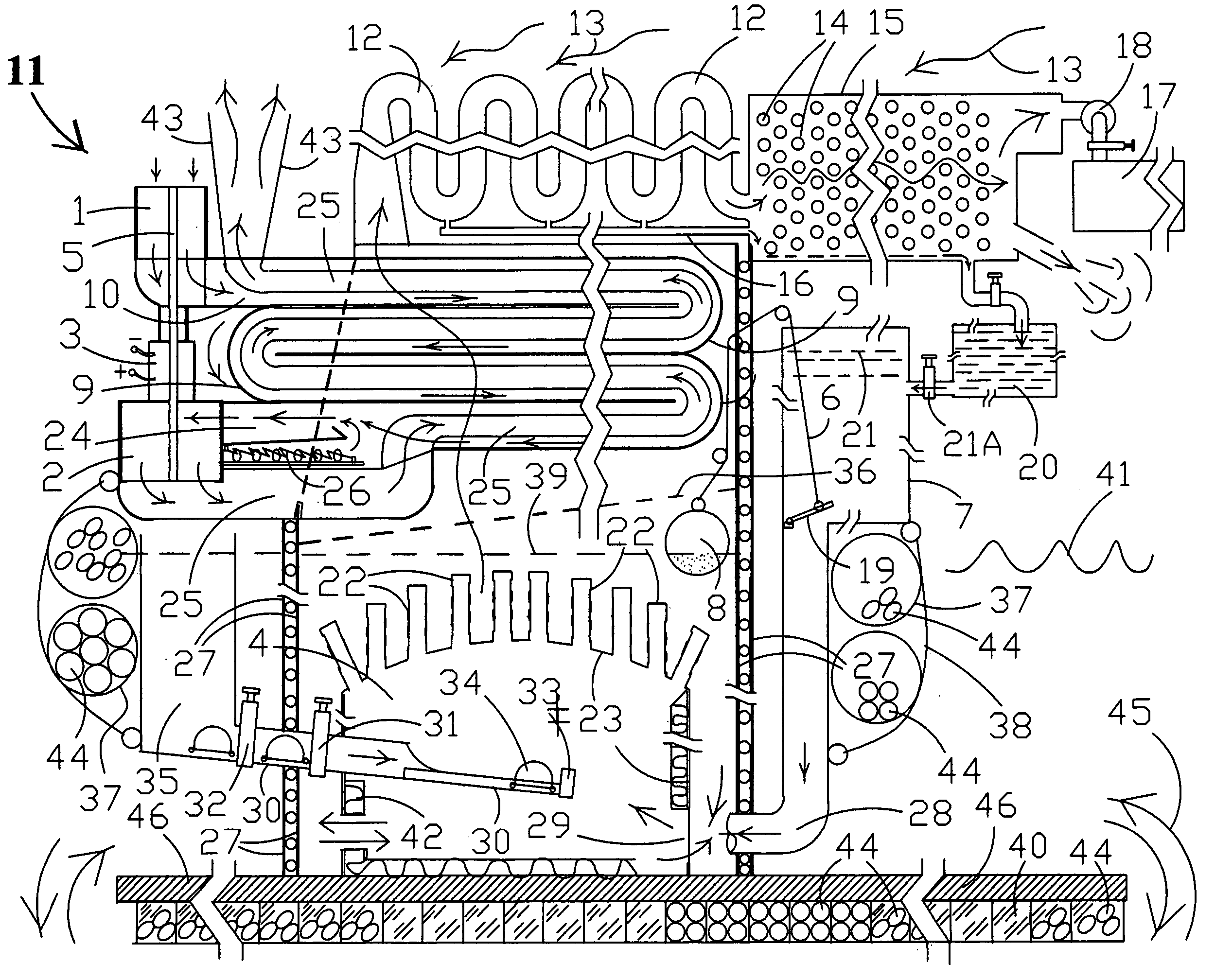

Heat energy recapture and recycle and its new applications

InactiveUS20050120715A1Increase the atmosphereGood sunshineEngine fuctionsEfficient propulsion technologiesThermal energyDistillation

What has been created is a plurality and a variety of processes and a variety of devices correspondingly supportive to each process, wherein, a new partnership between; (1) a heat absorbing radiator compressed air pipes / tubes and (2) a gas turbine engine or a reciprocating piston engine,—is used to recapture and reconvert the, otherwise wasted, heat energies expelled by engines, by factories, by smelting plants, by distillation plants, by chillers / coolers / freezers, by cooking ovens, by lamps / stoves, by trash burners, and the heat energies created by the solar heat on the desert / ocean water,—into electric power and finally into hydrogen-deuterium fuel,—by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow, to further drive and re-drive the same engine; wherein, in order to capture fusion heat energy the hydrogen bomb is detonated in the deep ocean to catch the flames by the water and the hot water is used to energize the compressed air inside the heat absorbing radiator pipes; wherein, in order to produce fusion energy, an abundant electric arc is passed across liquid deuterium or across gaseous deuterium by the electro-plasma torch and sparkplug in the internal combustion engine, and by detonating a dynamite inside a liquid deuterium; wherein diamond is produced by placing carbon inside the hydrogen bomb; and wherein, deuterium fusion flame is used first in smelting glass to large sizes before running an engine.

Owner:CHRISTIAN SCHOOL OF TECH CHARITABLE FOUND TRUST

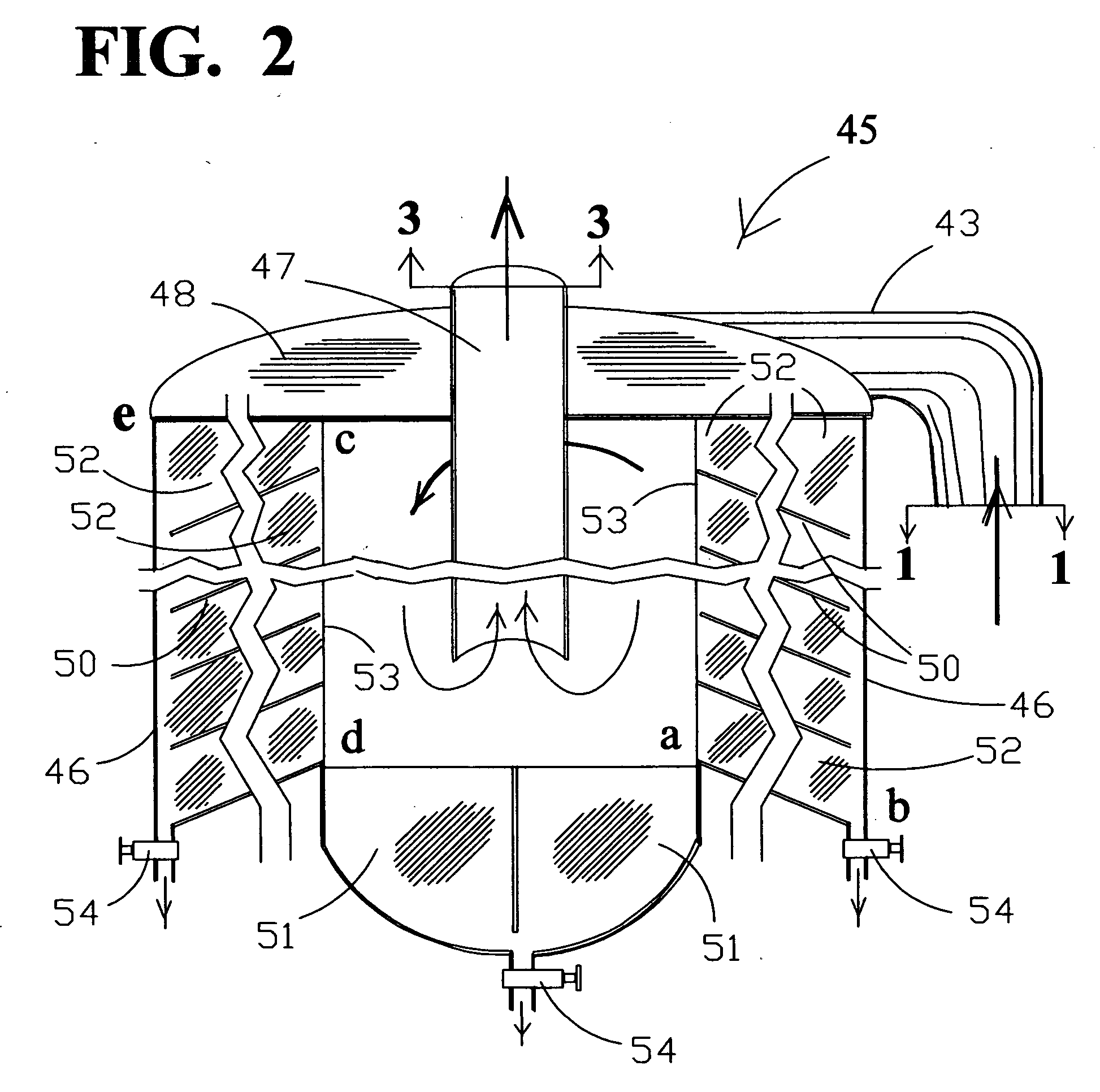

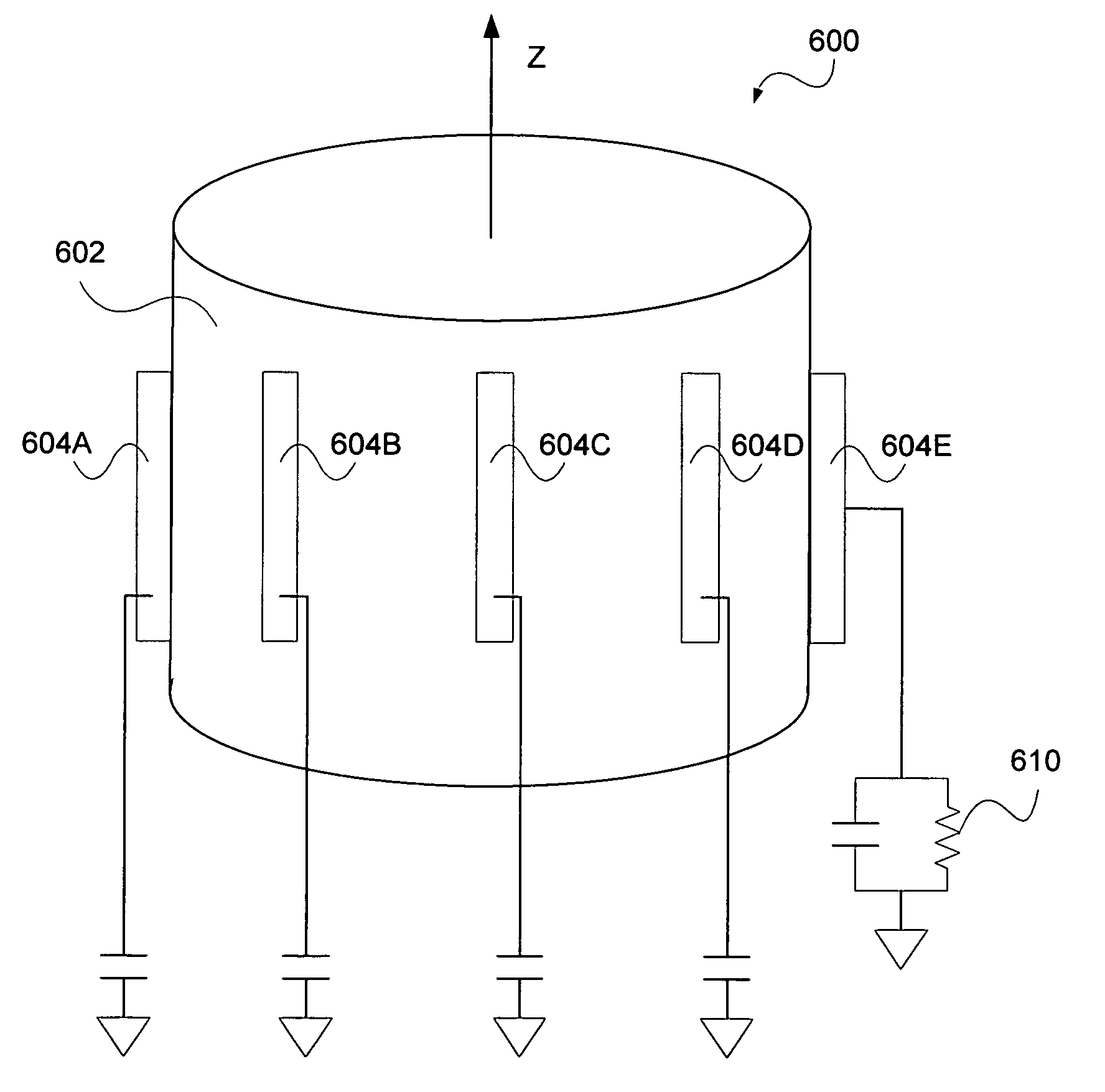

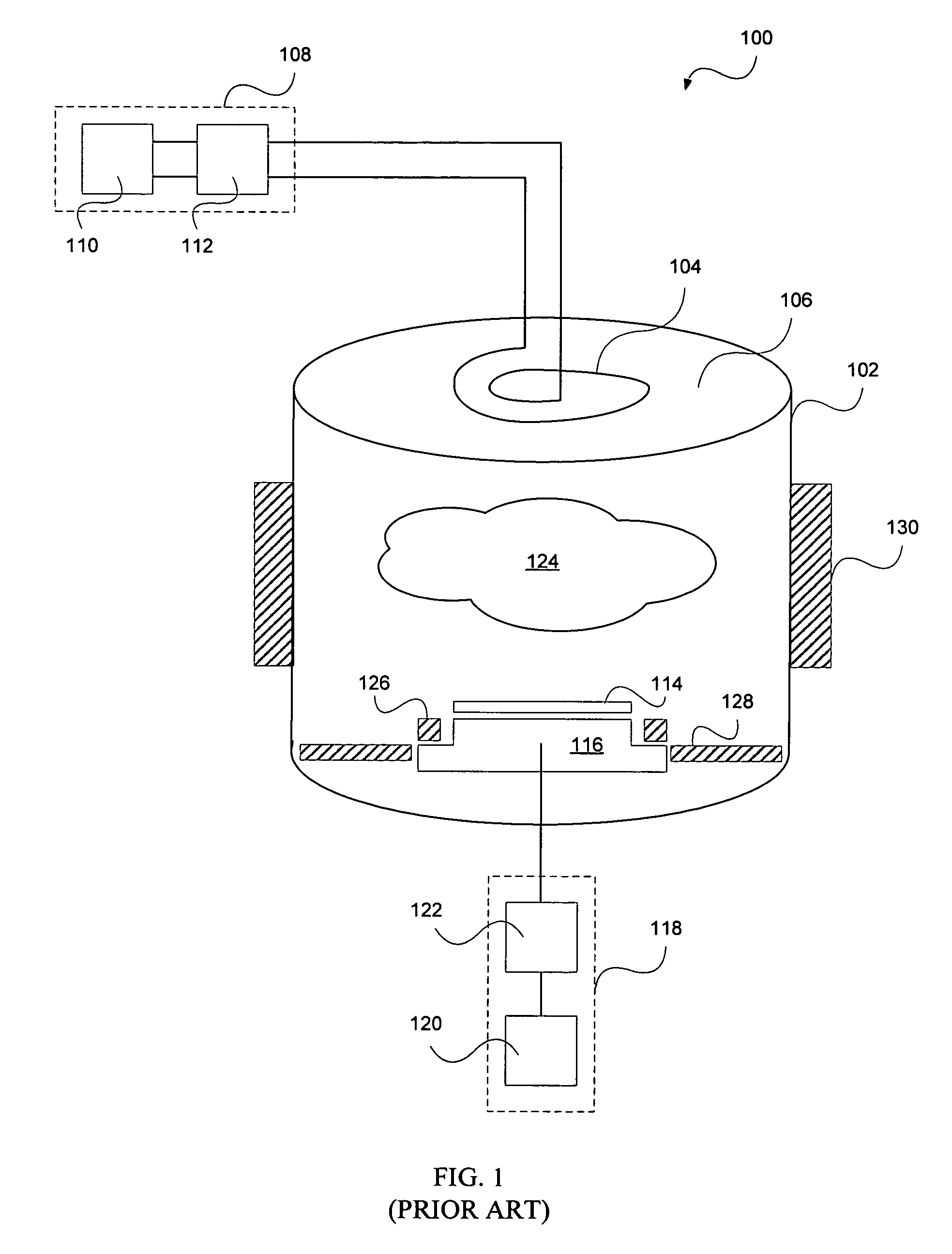

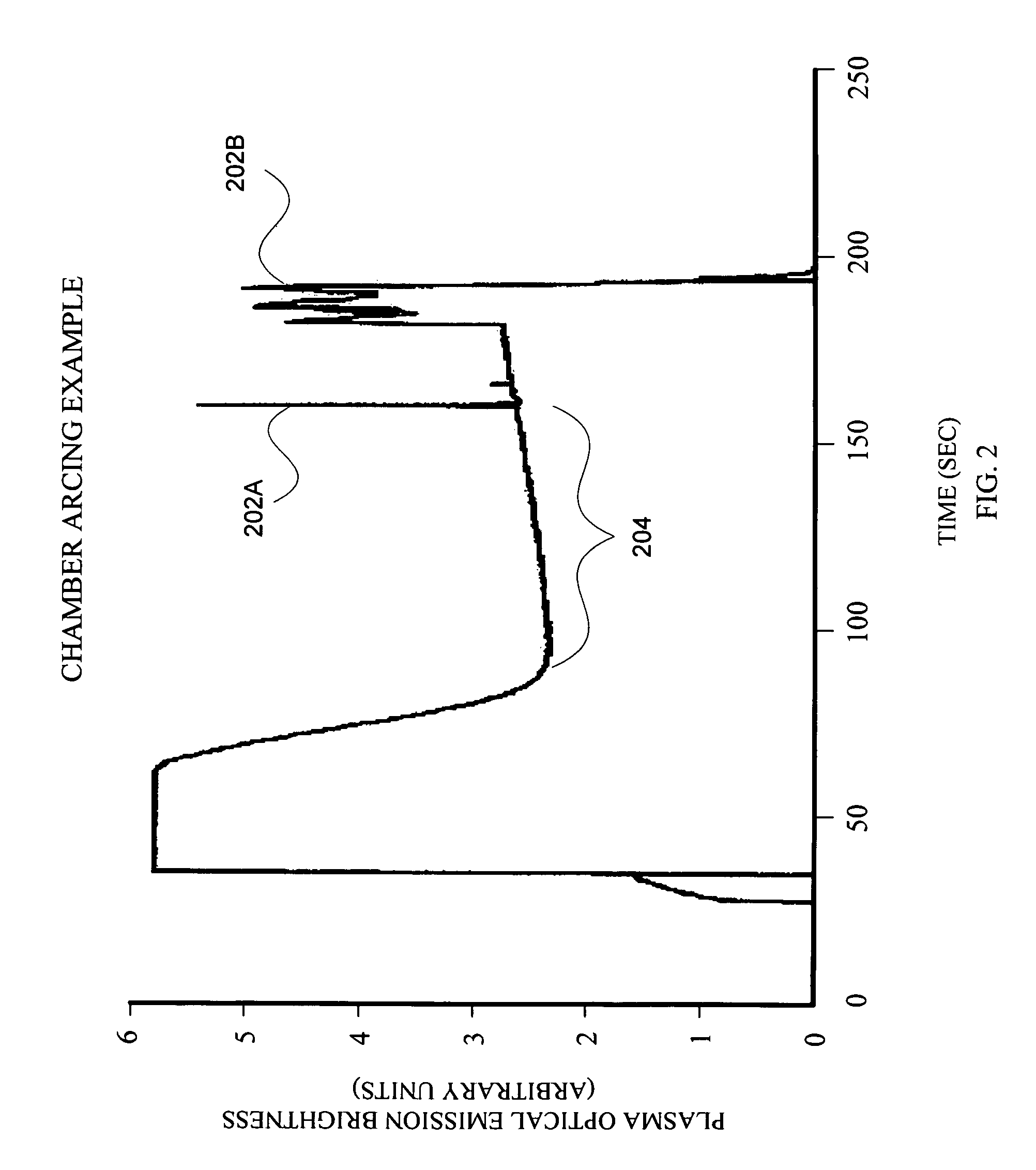

Minimizing arcing in a plasma processing chamber

InactiveUS7611640B1Arc eliminationElectric discharge tubesDecorative surface effectsEngineeringRf filters

A plasma processing chamber for processing a substrate to form electronic components thereon is disclosed. The plasma processing chamber includes a plasma-facing component having a plasma-facing surface oriented toward a plasma in the plasma processing chamber during processing of the substrate, the plasma-facing component being electrically isolated from a ground terminal. The plasma processing chamber further includes a grounding arrangement coupled to the plasma-facing component, the grounding arrangement including a first resistance circuit disposed in a first current path between the plasma-facing component and the ground terminal. The grounding arrangement further includes a RF filter arrangement disposed in at least one other current path between the plasma-facing component and the ground terminal, wherein a resistance value of the first resistance circuit is selected to substantially eliminate arcing between the plasma and the plasma-facing component during the processing of the substrate.

Owner:LAM RES CORP

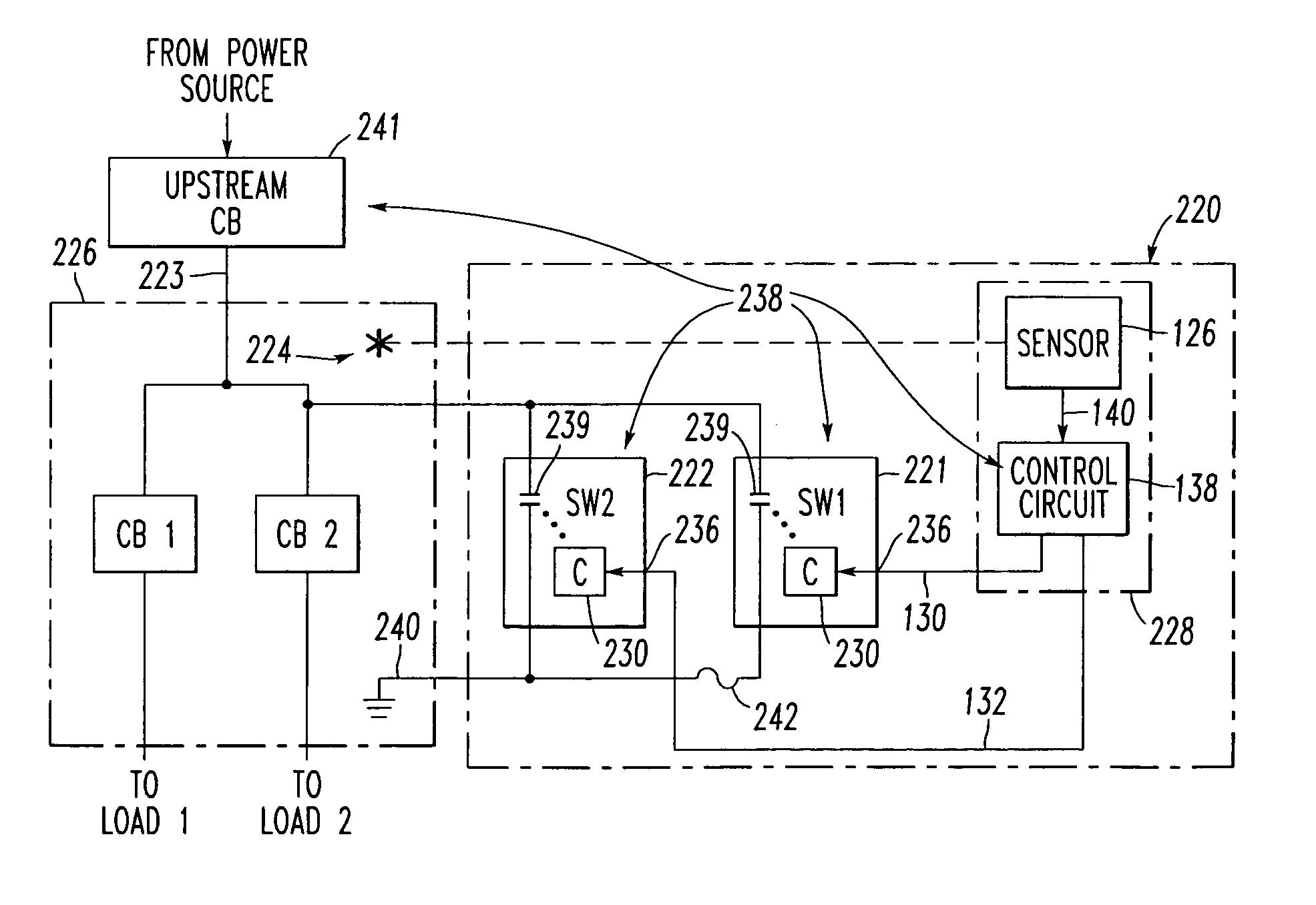

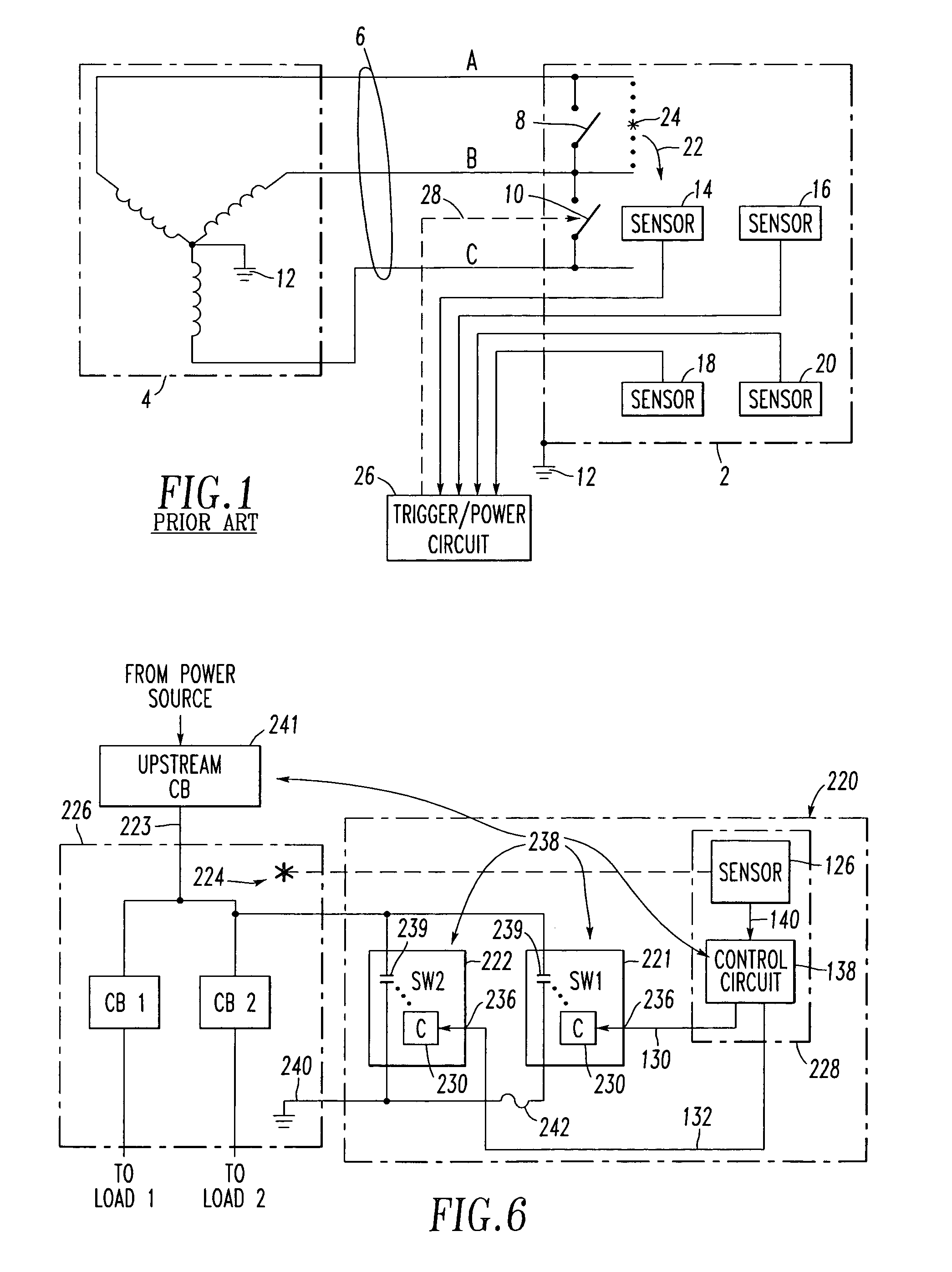

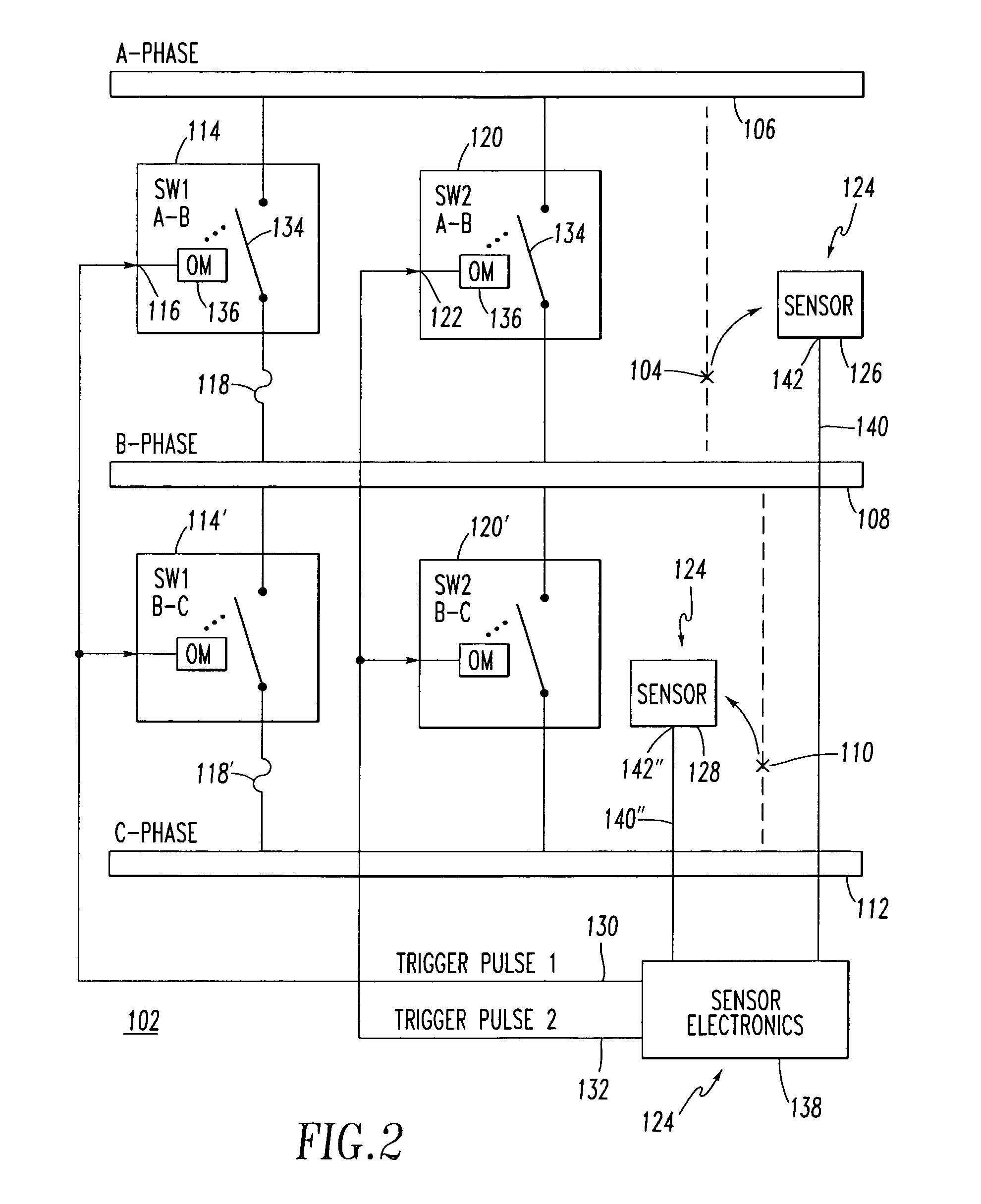

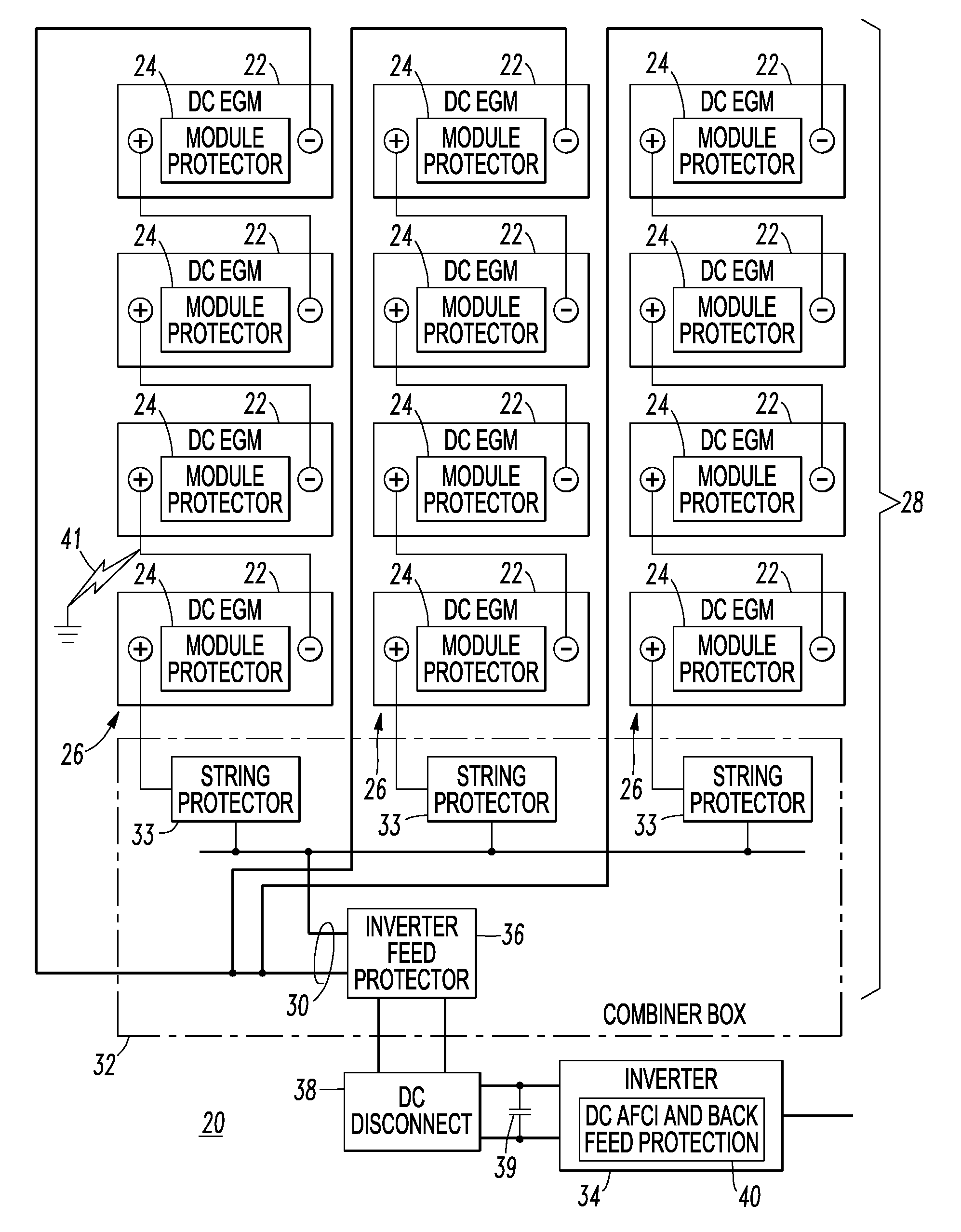

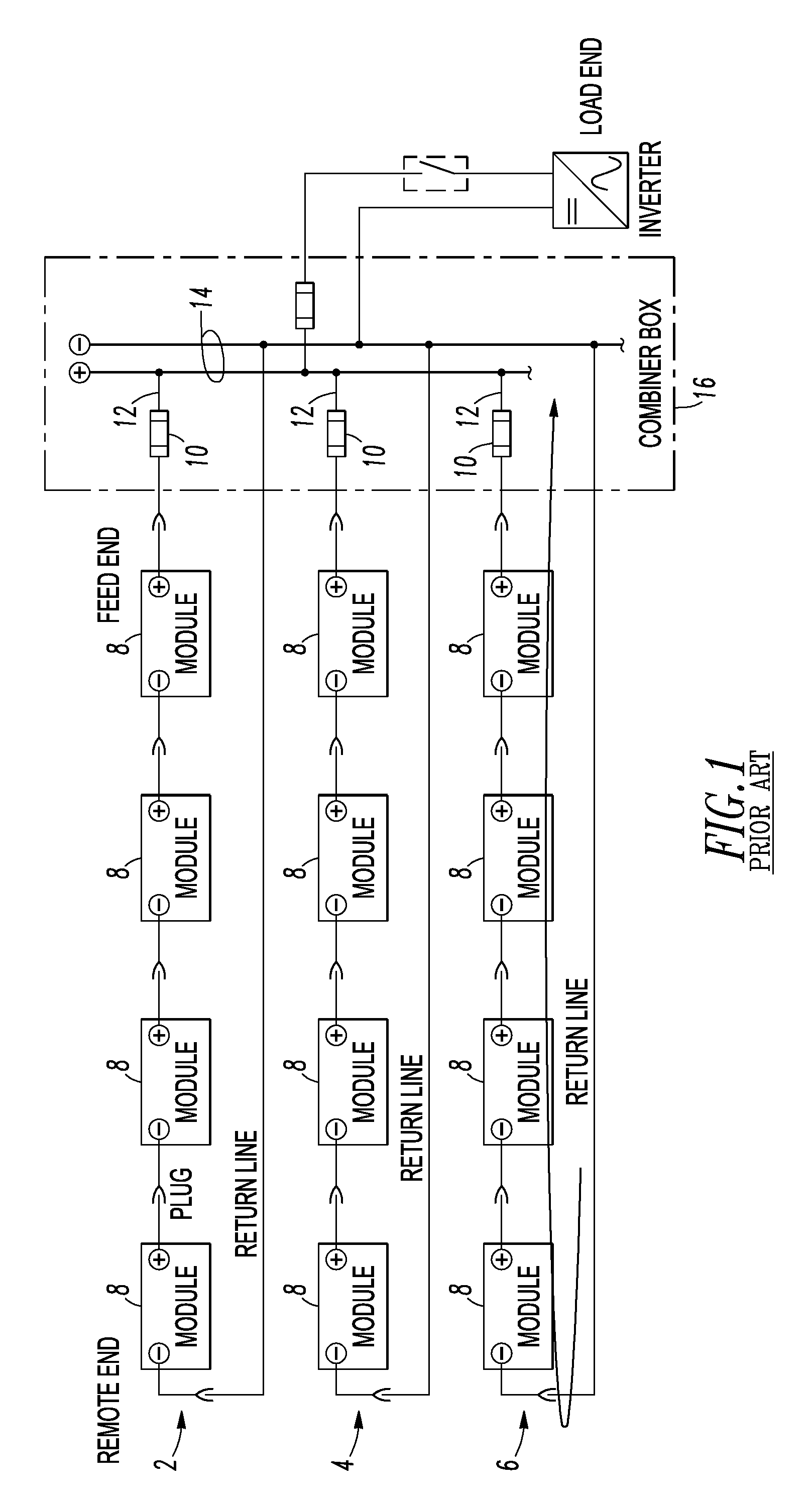

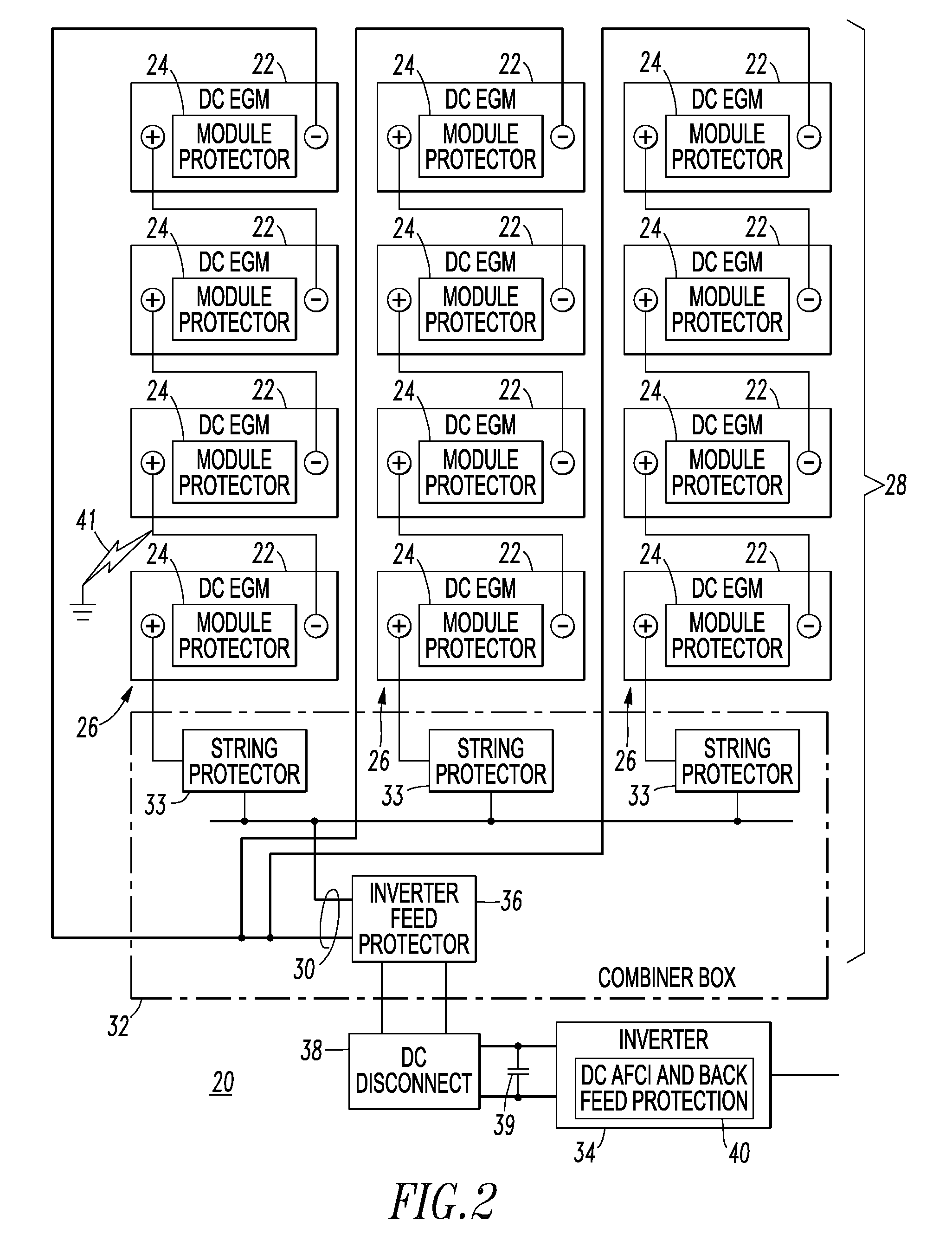

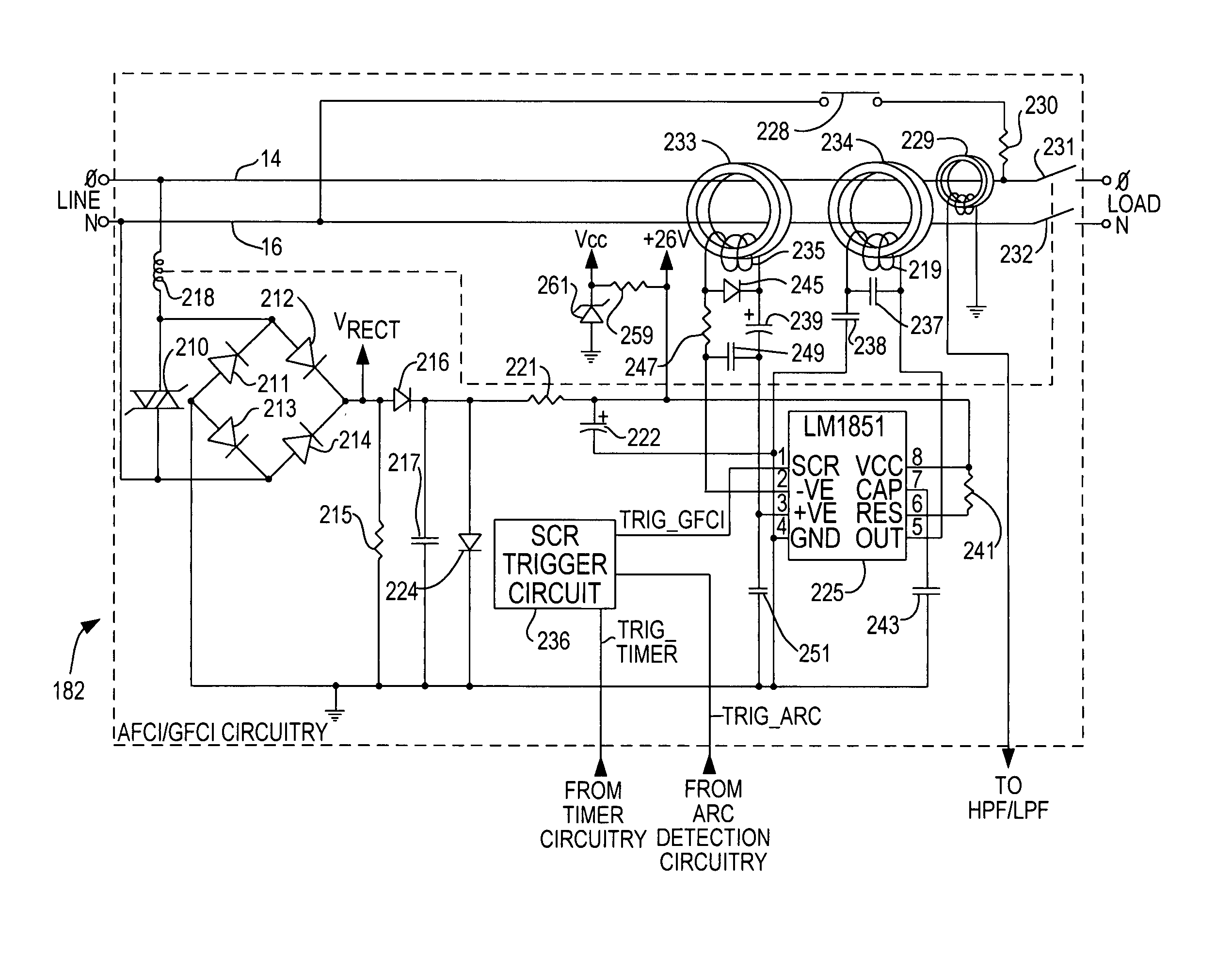

System for eliminating arcing faults and power distribution system employing the same

ActiveUS7145757B2Emergency protective arrangement detailsElectric switchesElectricityDistribution system

Owner:EATON INTELLIGENT POWER LTD

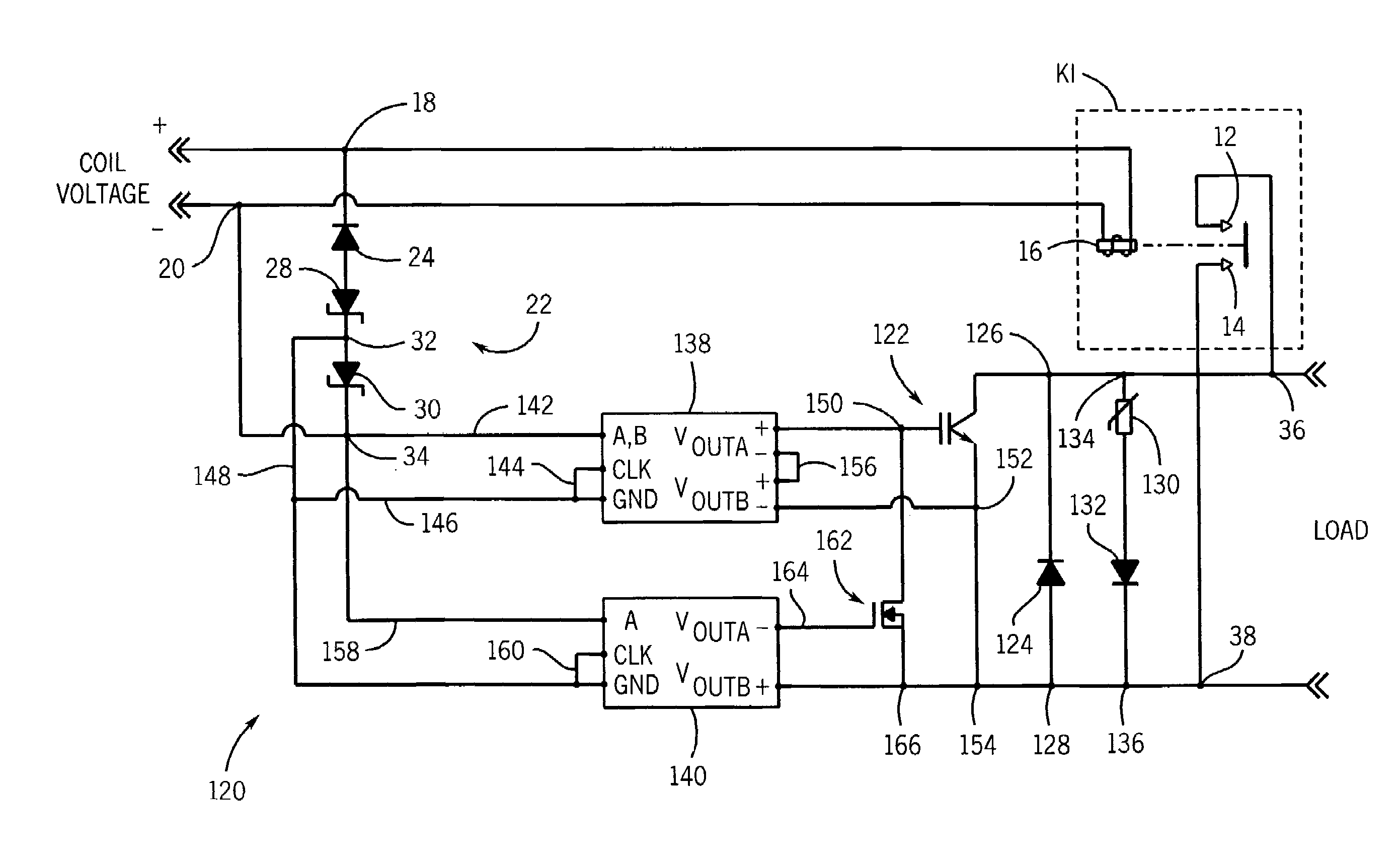

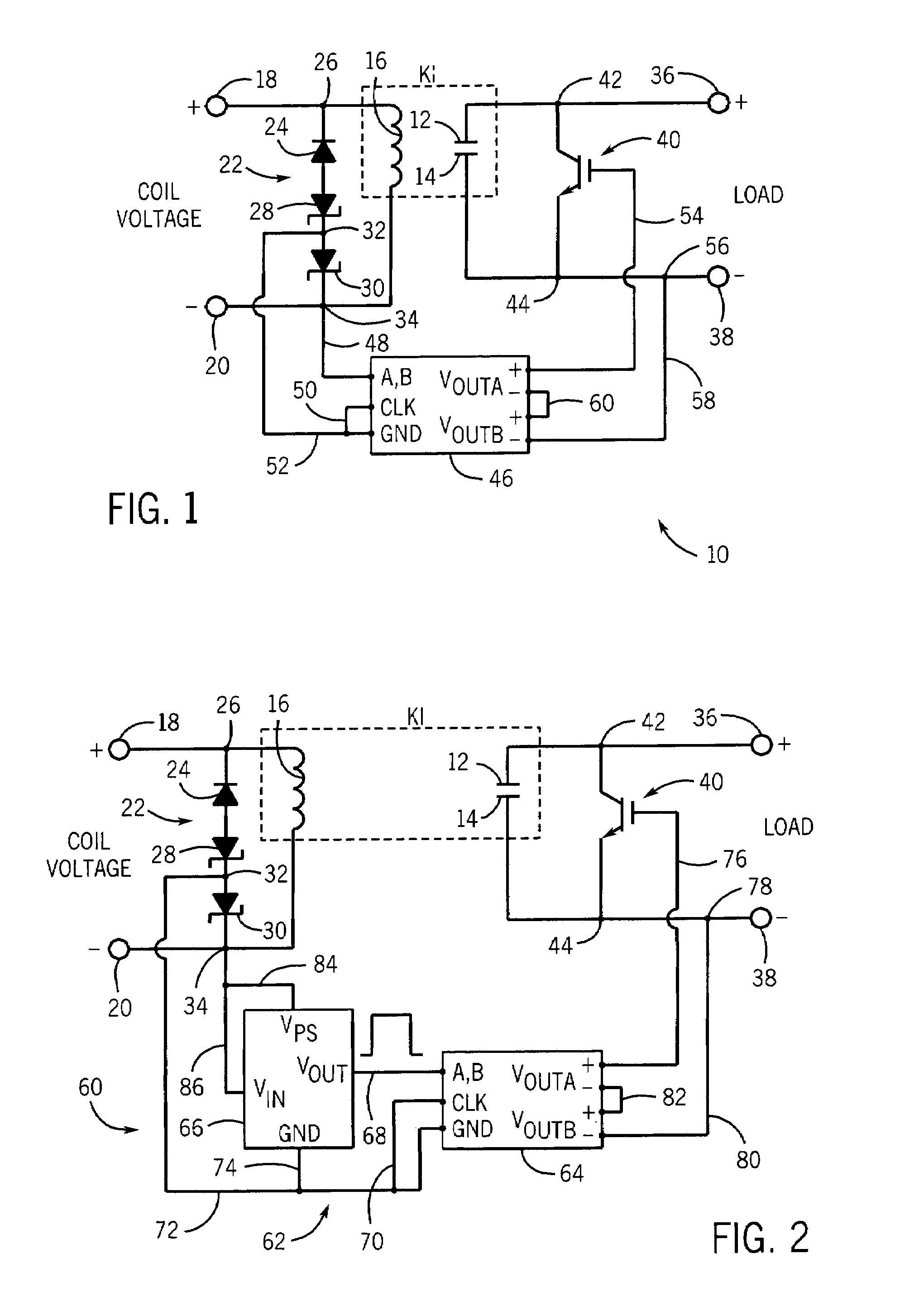

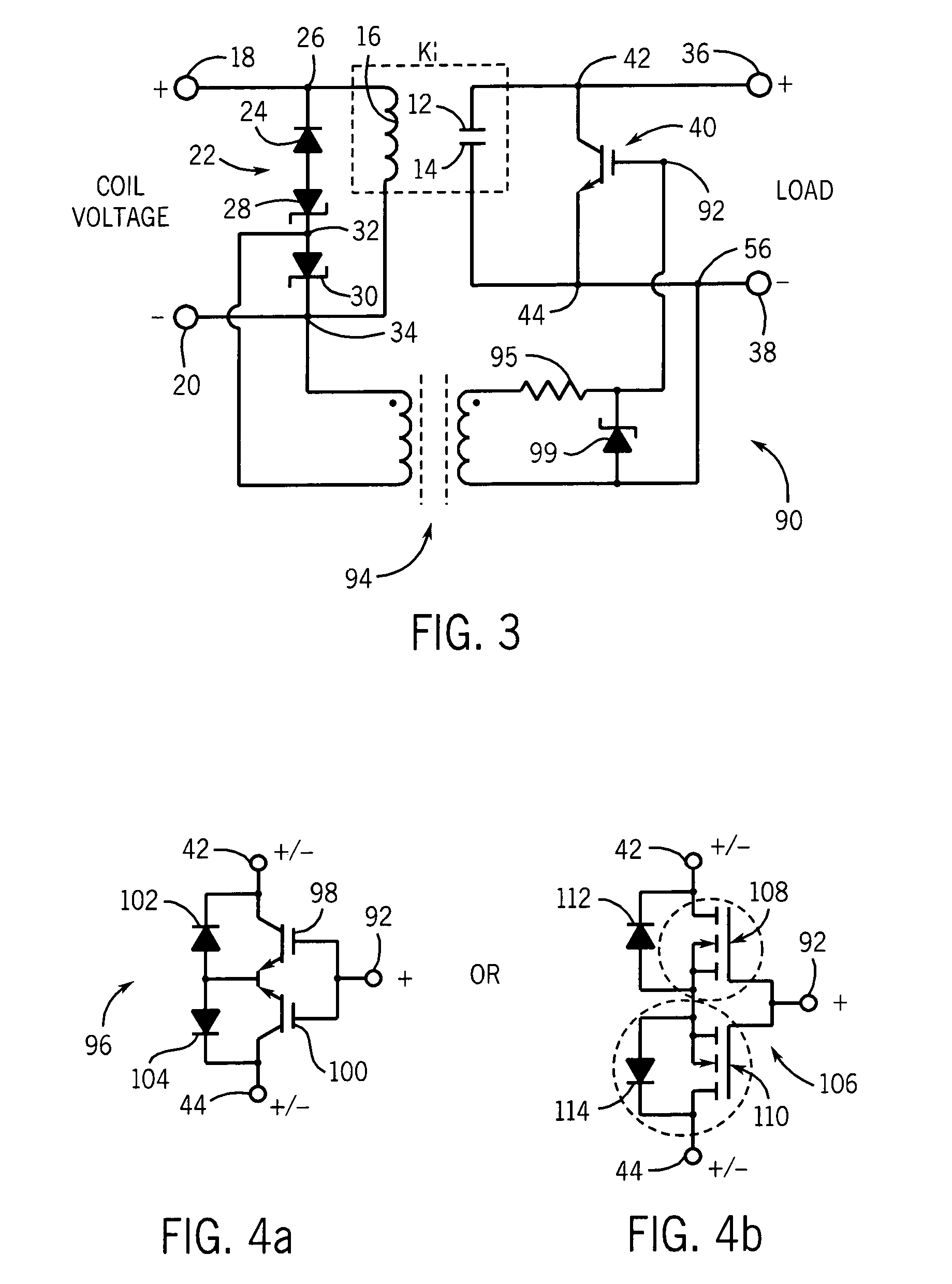

Bypass circuit to prevent arcing in a switching device

ActiveUS7342754B2Increased size and weightMinimize and eliminate potentialElectric switchesEmergency protective arrangements for automatic disconnectionElectric currentSolid-state

A device is provided for preventing arcing between contacts of a switching device as the contacts of the switching device are opened. The device includes a coil suppression circuit connected in parallel with the coil. The coil suppression circuit dissipates the energy stored in the coil in response to the de-energization of the coil. A first solid state switch has a gate operatively connected to the coil suppression circuit and is connected in parallel with the contacts. The first solid state switch is movable between an open position preventing the flow of current therethrough and a closed position in response to the dissipation of energy by the coil suppression circuit.

Owner:EATON INTELLIGENT POWER LTD

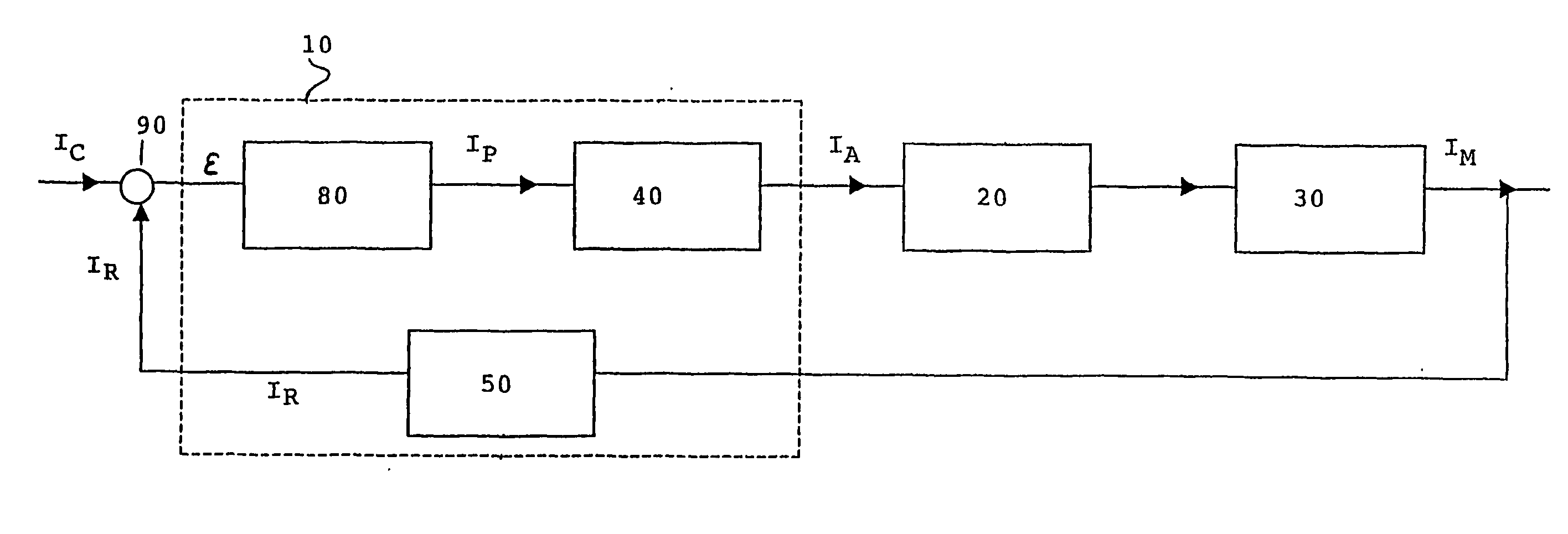

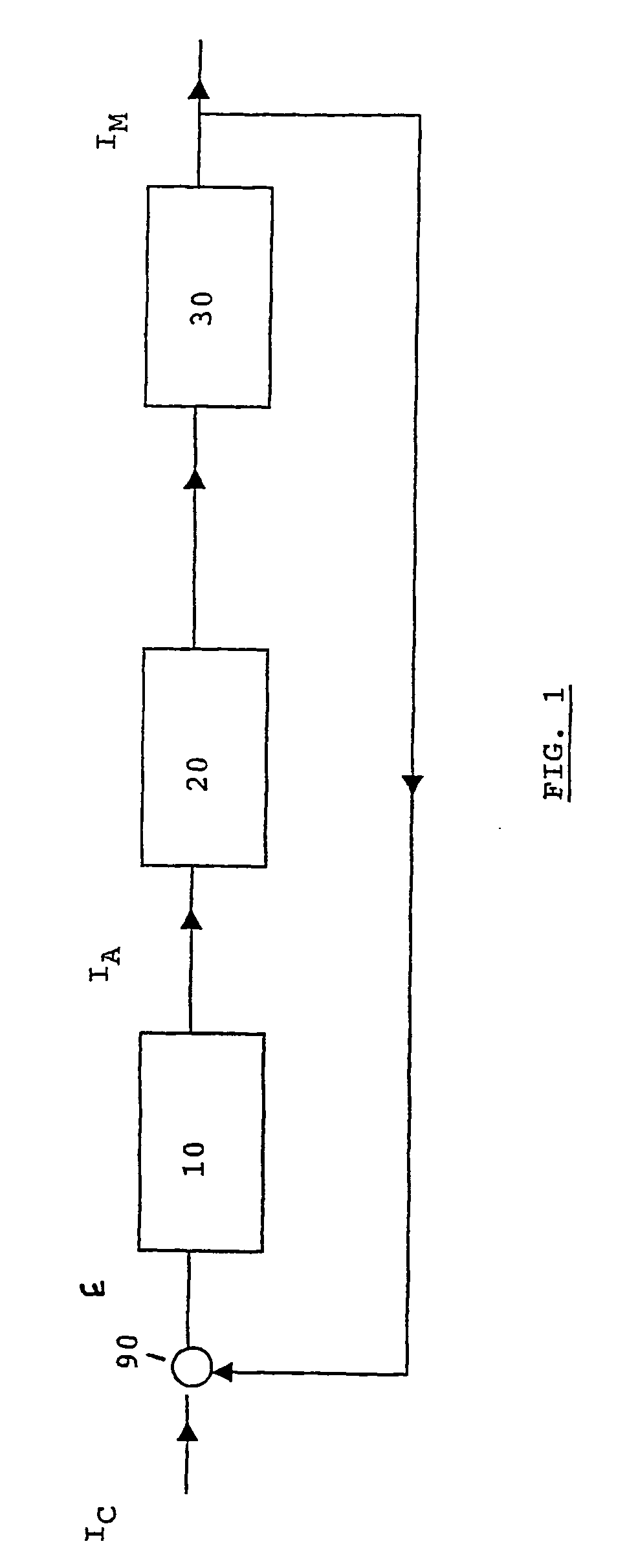

Device and method for regulating intensity of beam extracted from a particle accelerator

InactiveUS6873123B2Thermometer detailsStability-of-path spectrometersParticle acceleratorAccelerated particle

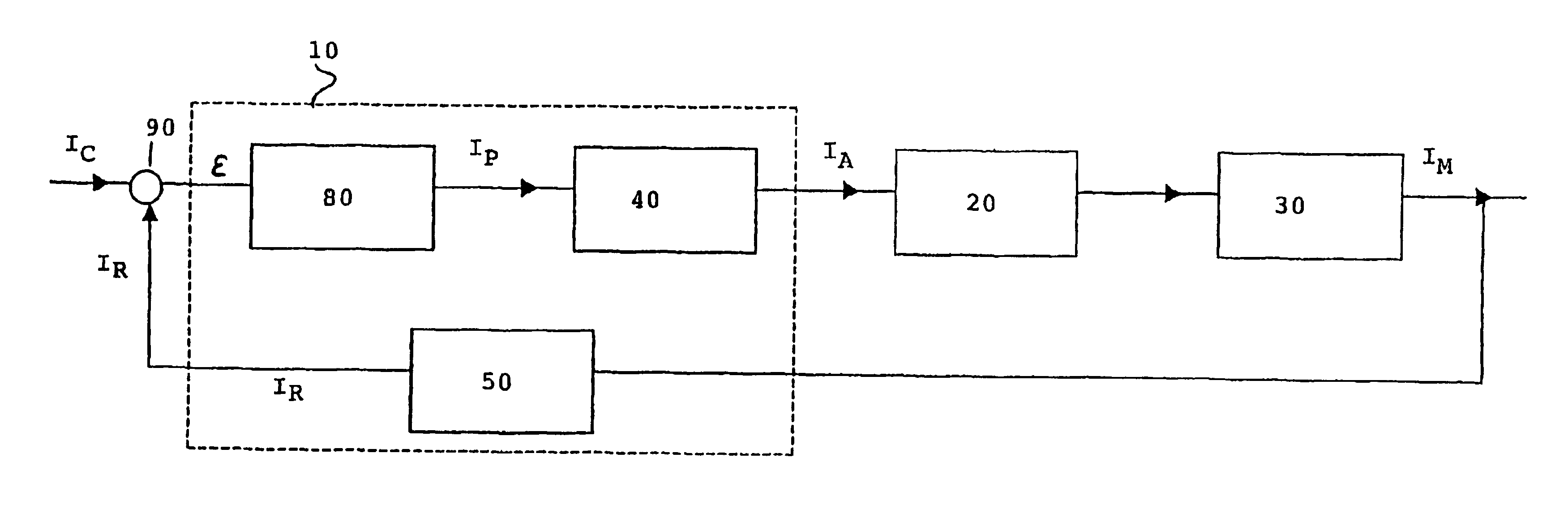

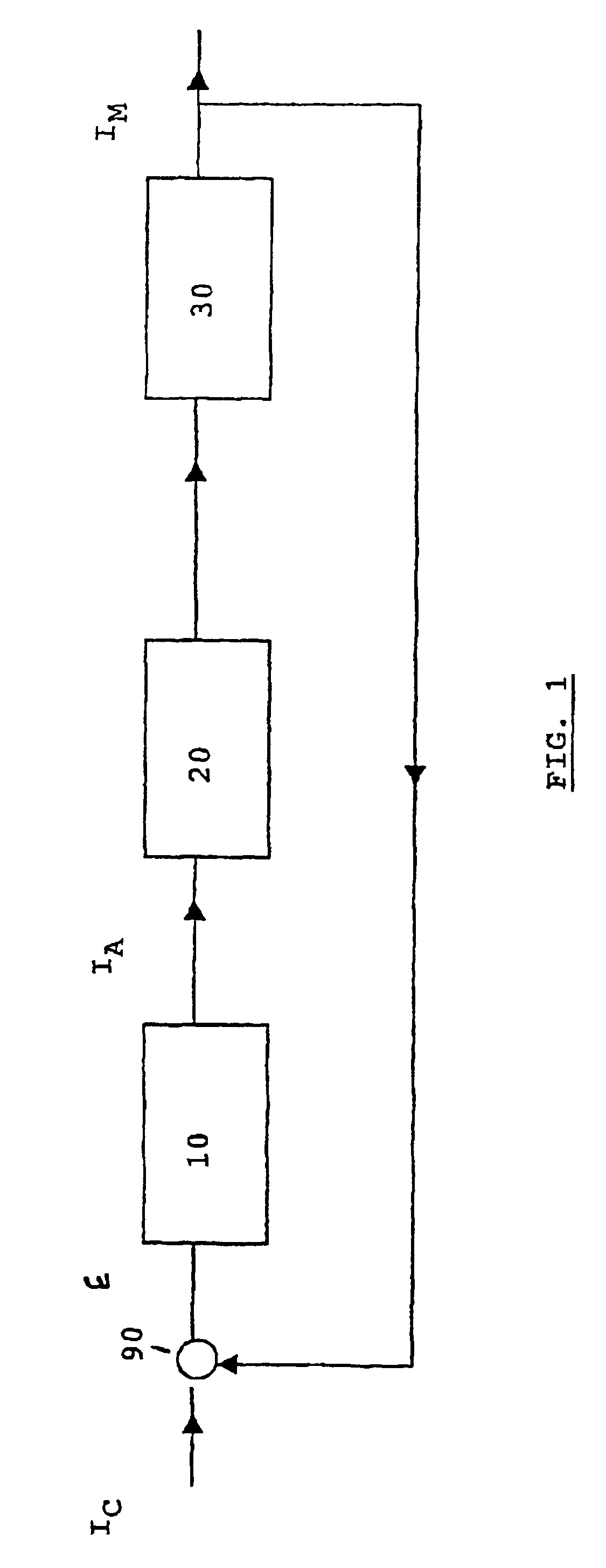

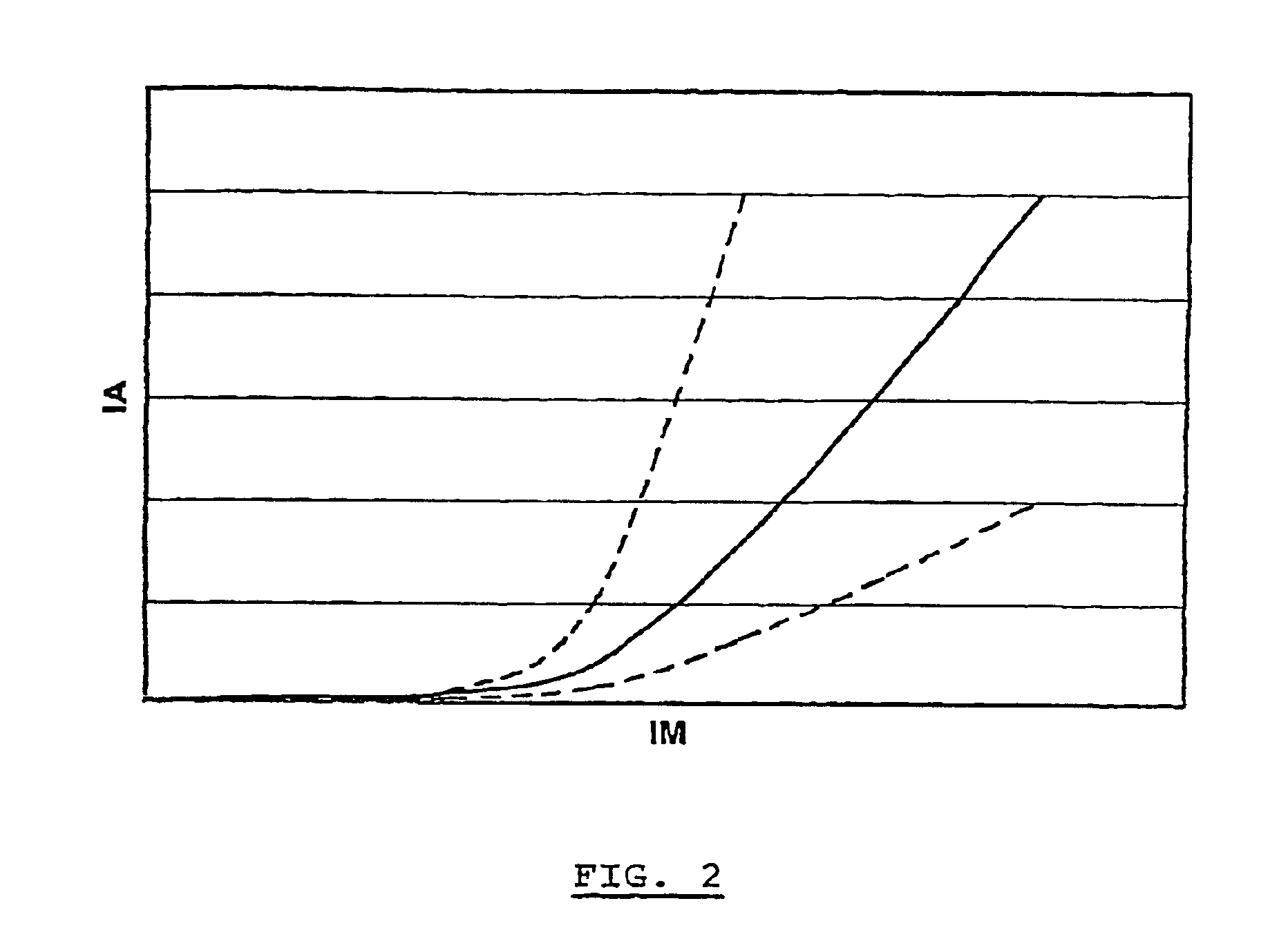

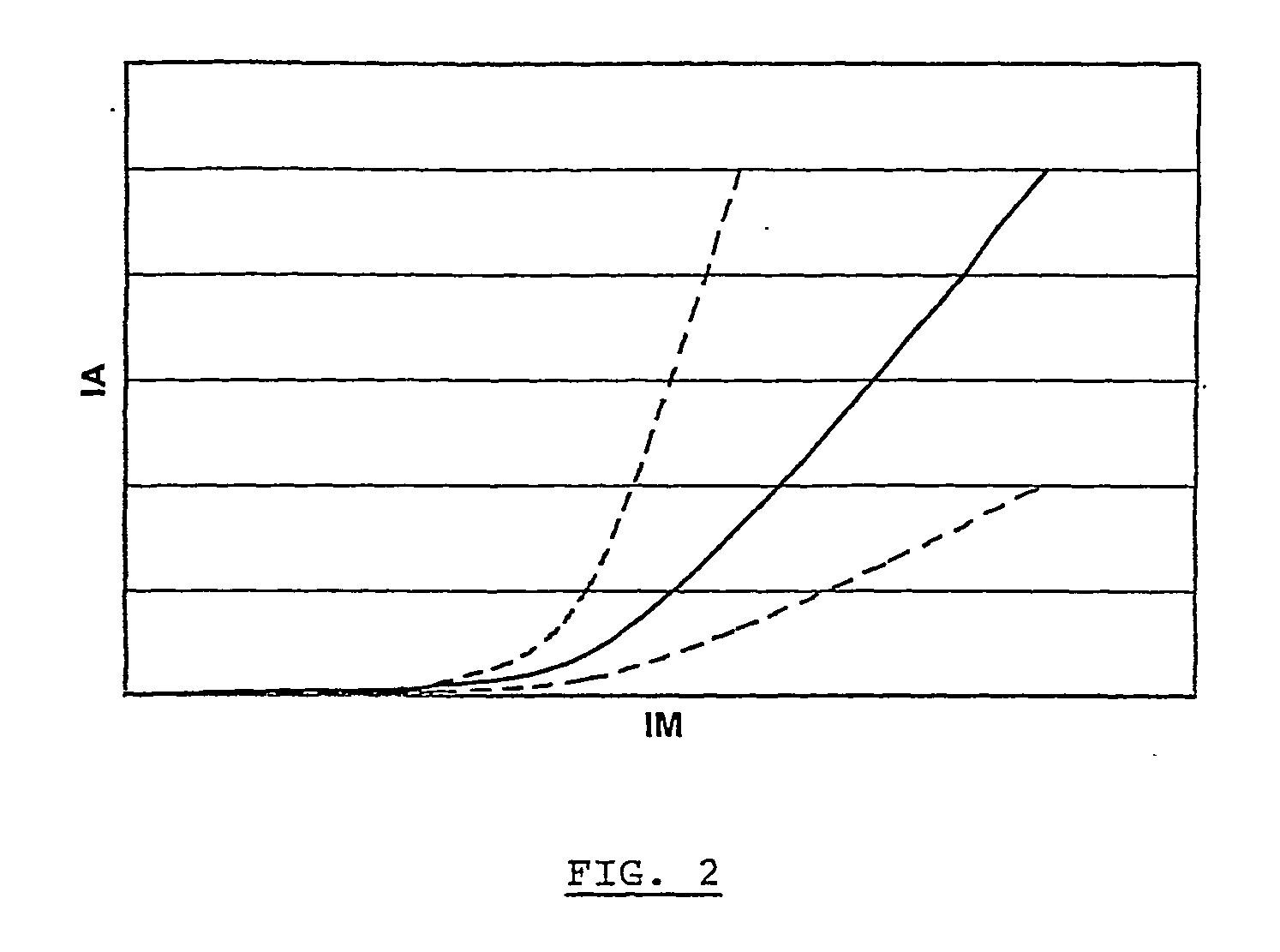

The invention concerns a device (10) for regulating the intensity of a beam extracted from a particle accelerator, such as a cyclotron, used for example for protontherapy, said particles being generated from an ion source. The invention is characterized in that it comprises at least: a comparator (90) determining a difference ε between a digital signal IR representing the intensity of the beam measured at the output of the accelerator and a setpoint value IC of the beam intensity: a Smith predictor (80) which determines on the basis of the difference ε, a correct value of the intensity of the beam IP; an inverted correspondence table (40) supplying, on the basis of the corrected value of the intensity of the beam IP, a setpoint value IA for supply arc current from the ion source (20).

Owner:ION BEAM APPL

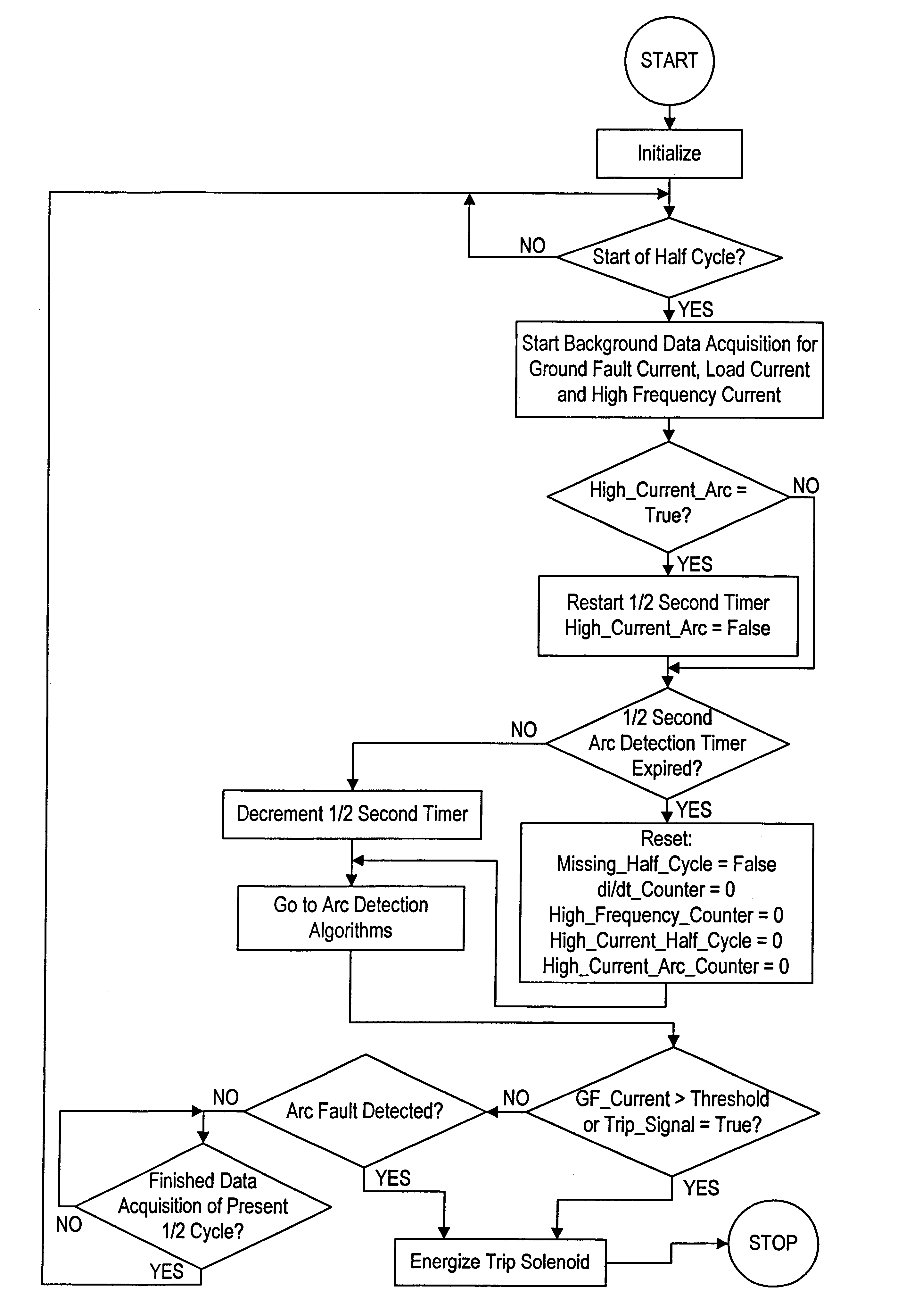

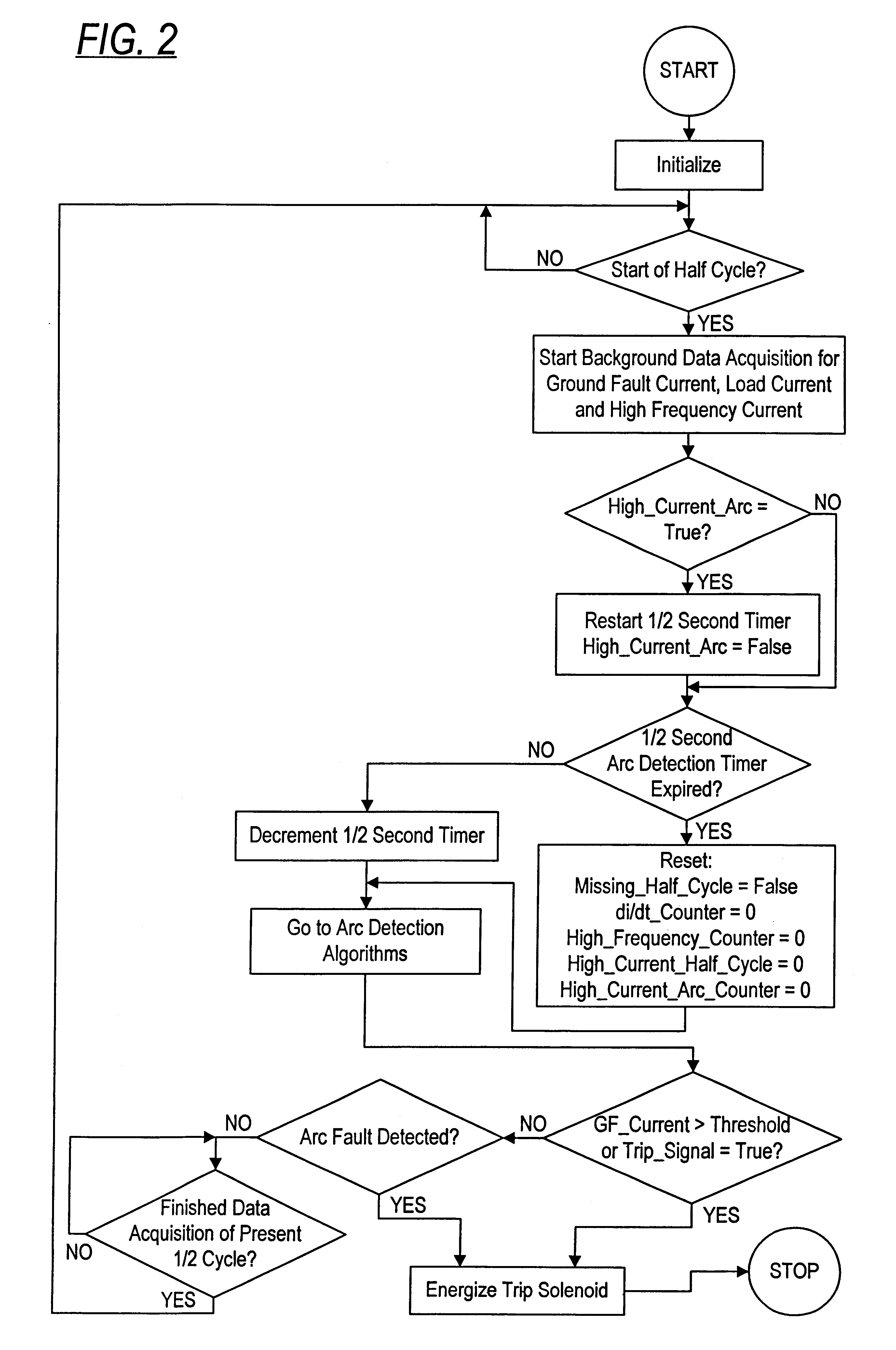

Direct current arc fault circuit interrupter, direct current arc fault detector, noise blanking circuit for a direct current arc fault circuit interrupter, and method of detecting arc faults

ActiveUS20110141644A1Emergency protective arrangement detailsArrangements responsive to excess currentCurrent sensorPeak current

A direct current arc fault circuit interrupter includes separable contacts and a trip circuit to trip open the contacts. The trip circuit includes a number of alternating current sensors structured to sense a current flowing through the separable contacts, a number of filter circuits cooperating with the AC current sensors to output a number of AC signals, a number of peak detectors cooperating with the filter circuits to output a number of peak current signals, and a processor cooperating with at least the peak detectors. The processor inputs the number of peak current signals as a plurality of peak current signals or inputs the number of peak current signals and determines the plurality of peak current signals. The processor also determines if the peak current signals exceed corresponding predetermined thresholds for a predetermined time, and responsively causes the contacts to trip open.

Owner:EATON INTELLIGENT POWER LTD

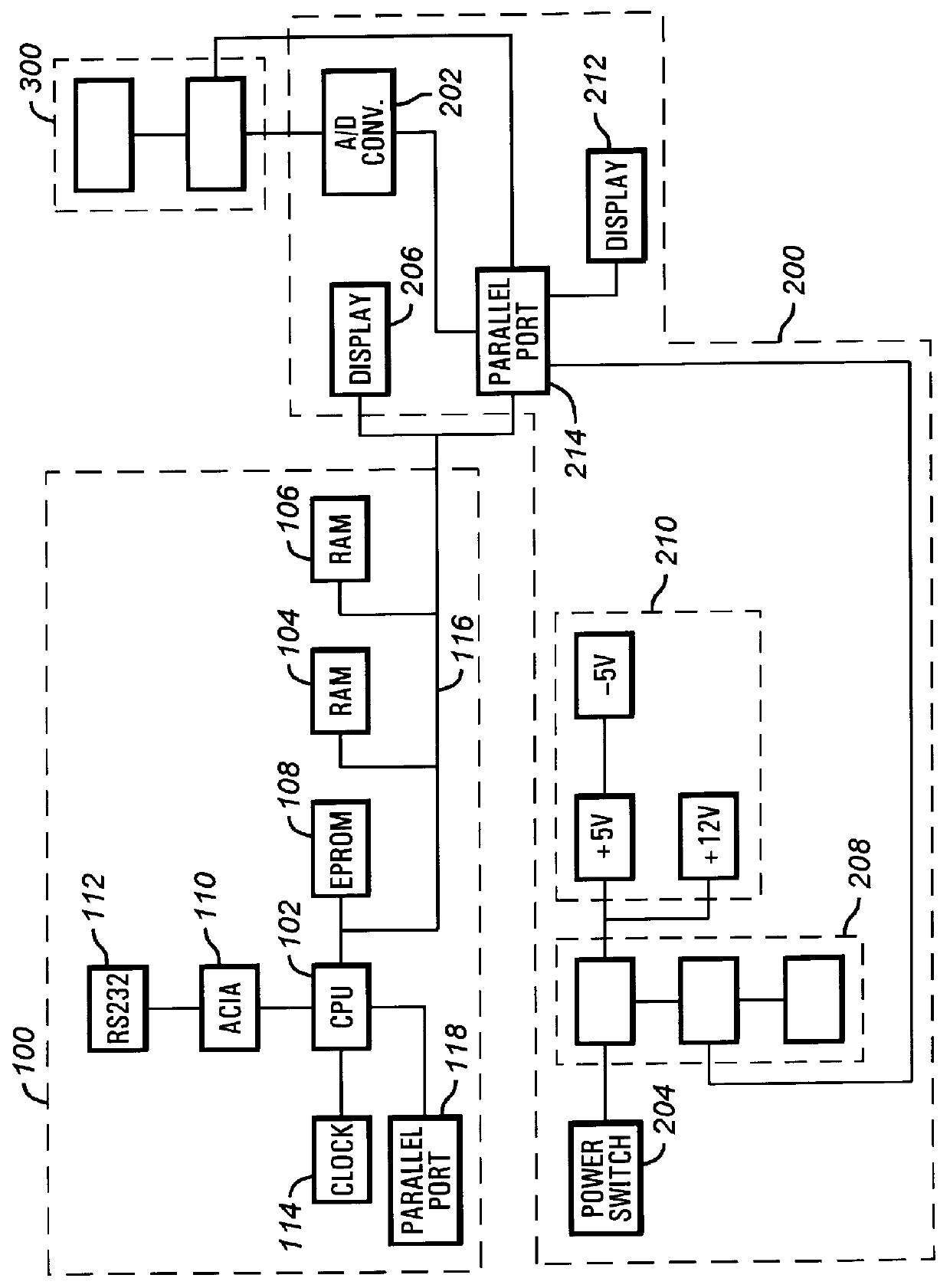

Methods and apparatus for welding performance measurement

InactiveUS6051805AStreamlined operationMaximize efficiencyArc welding apparatusAverage currentControl circuit

Methods and apparatus are provided for determining the duty cycle, average amperage, and / or the number of arc starts during a welding operation. The apparatus comprises first and second circuits, the first circuit being a CPU control circuit, and the second circuit being an arc time sensor circuit which is programmed to measure amperage, welding wire feed speed and preferably gas flow rates while welding. A ratio of the cumulative welding time during the audit to the total on-time provides a measurement of the efficiency of the welding arc. The welding deposition efficiency may then be calculated using the average amperage and welding duty cycle as measured and calculated by the apparatus. The number of arc starts where the arc on-time is in excess of one second may also provide a useable measurement in giving secondary information on the overall efficiency of the welding operation.

Owner:AIR LIQUIDE CANADA

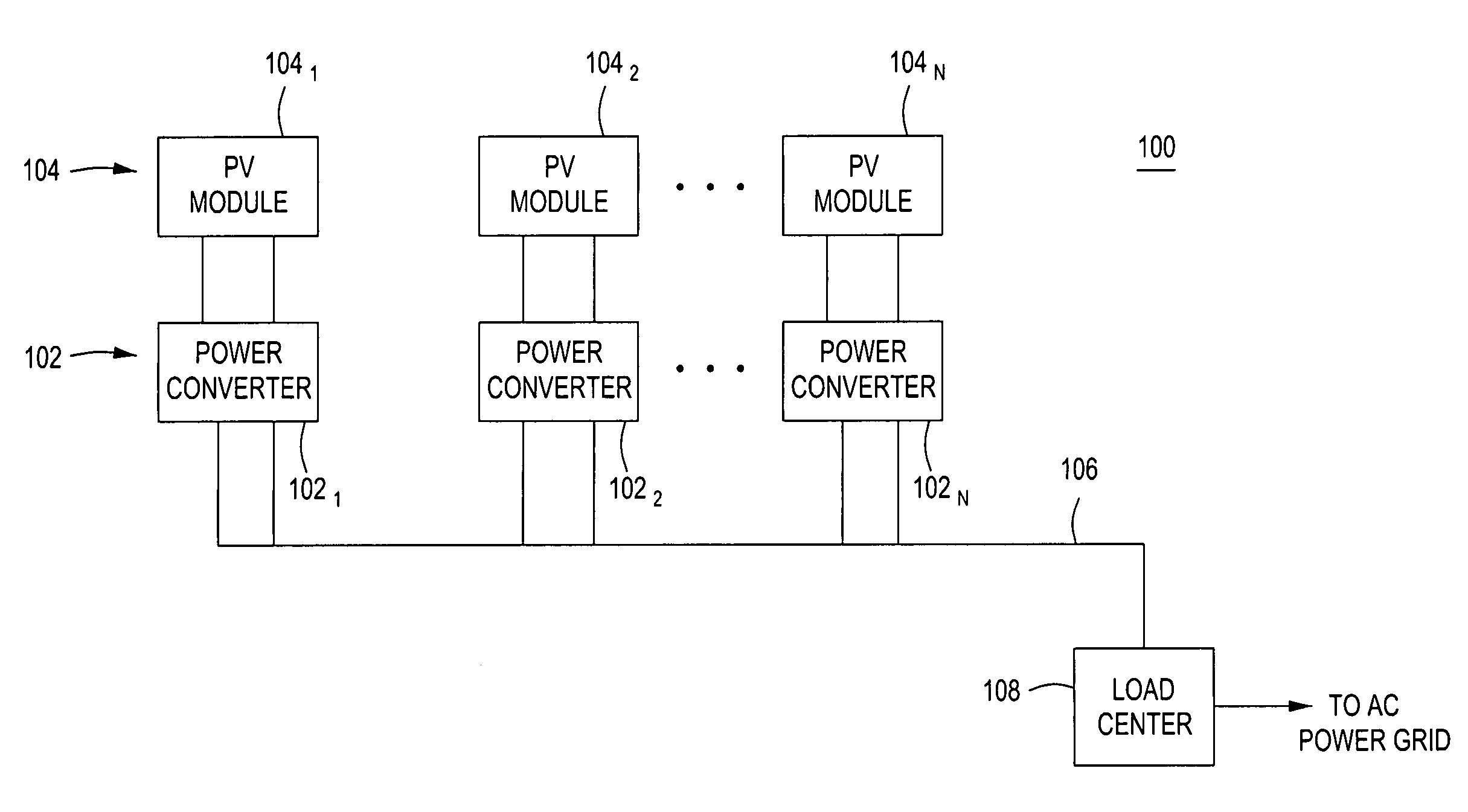

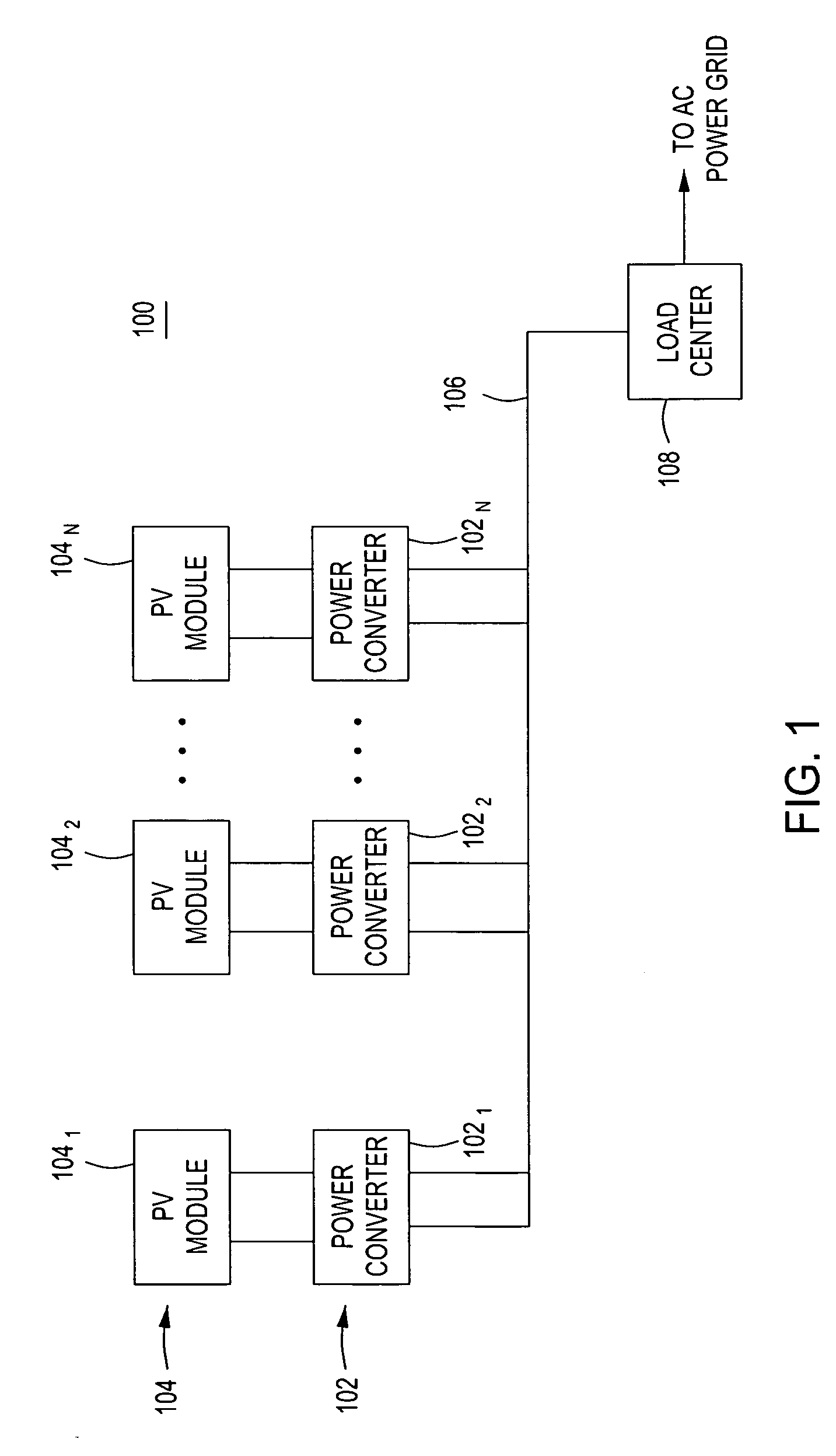

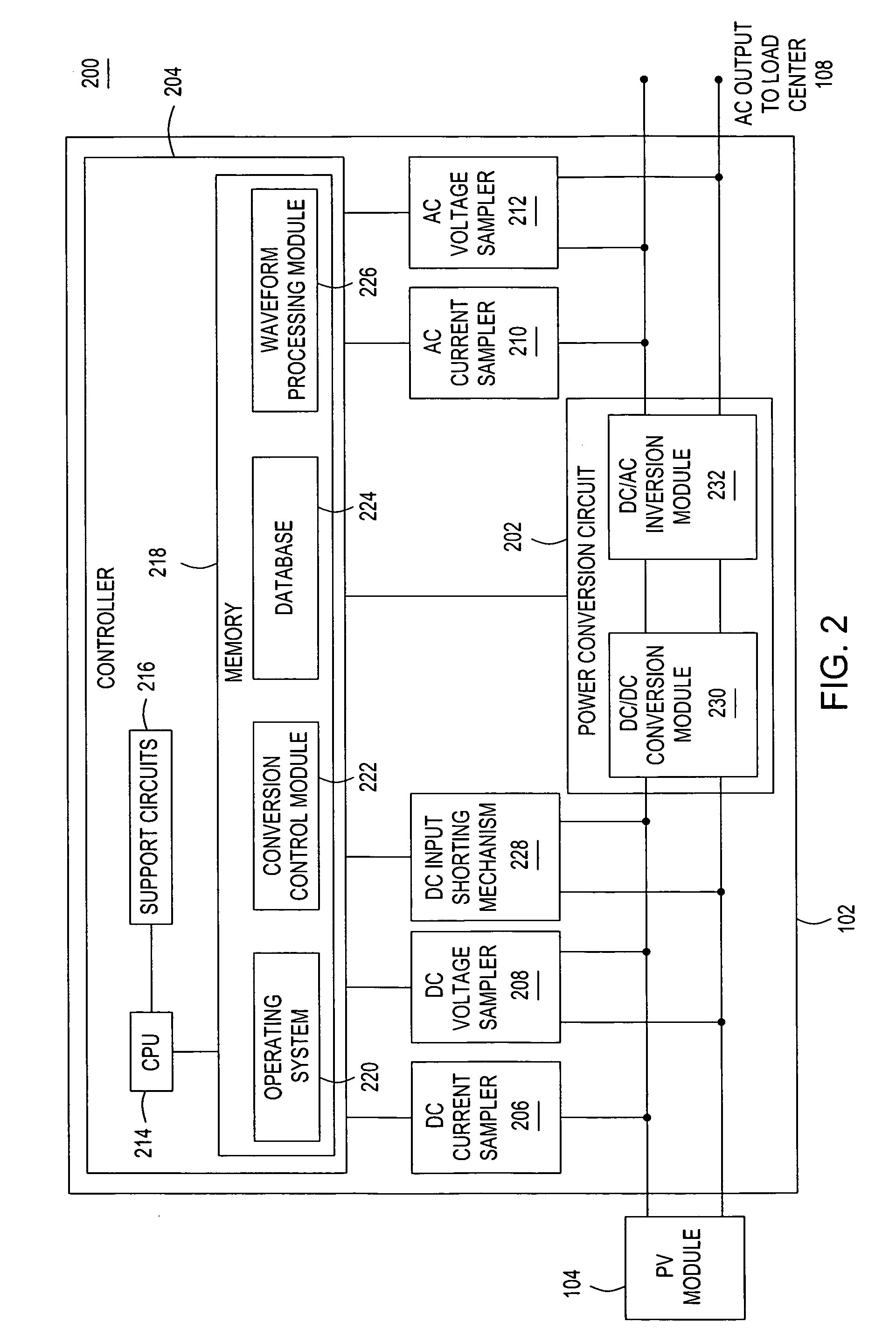

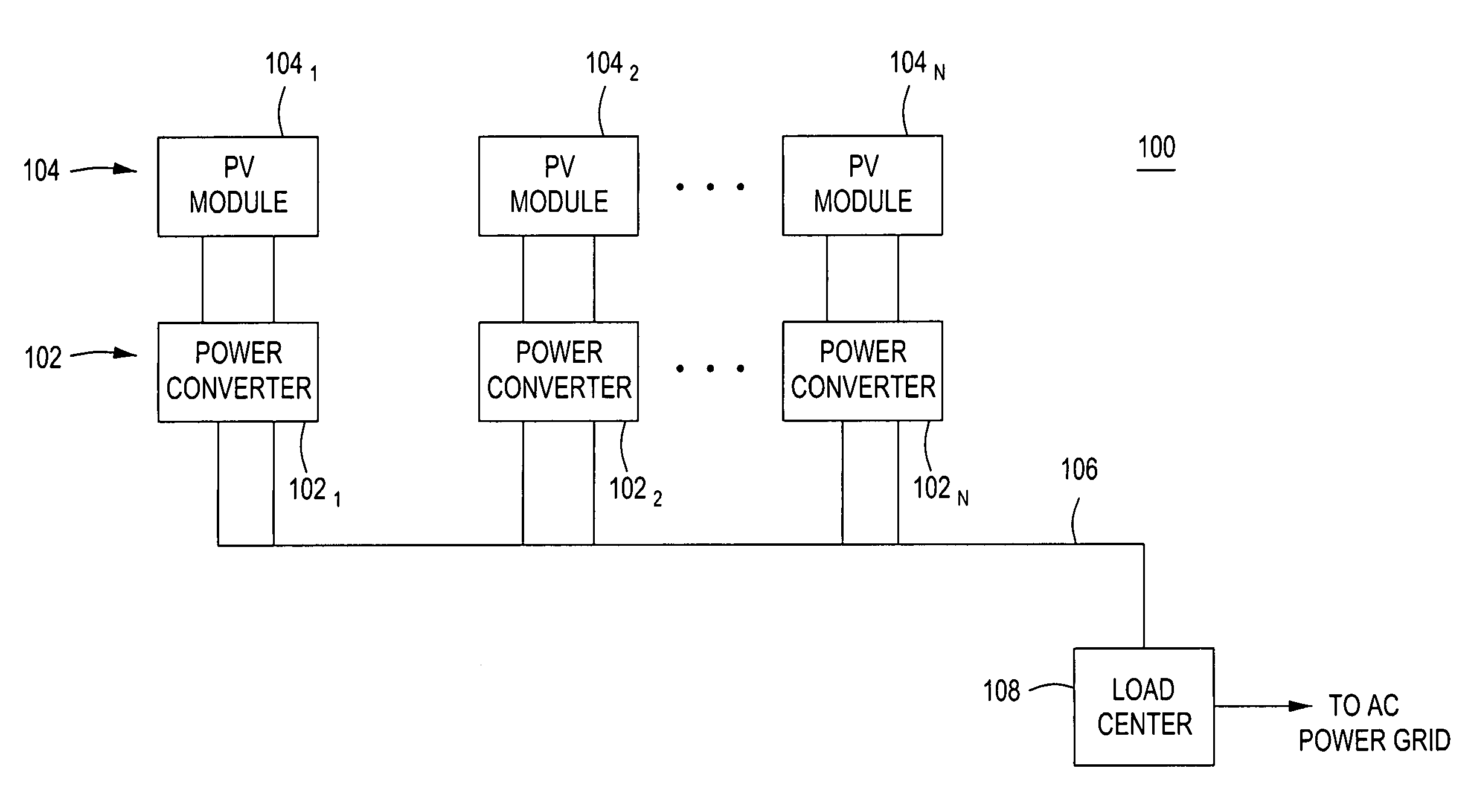

Method and apparatus for detection and control of dc arc faults

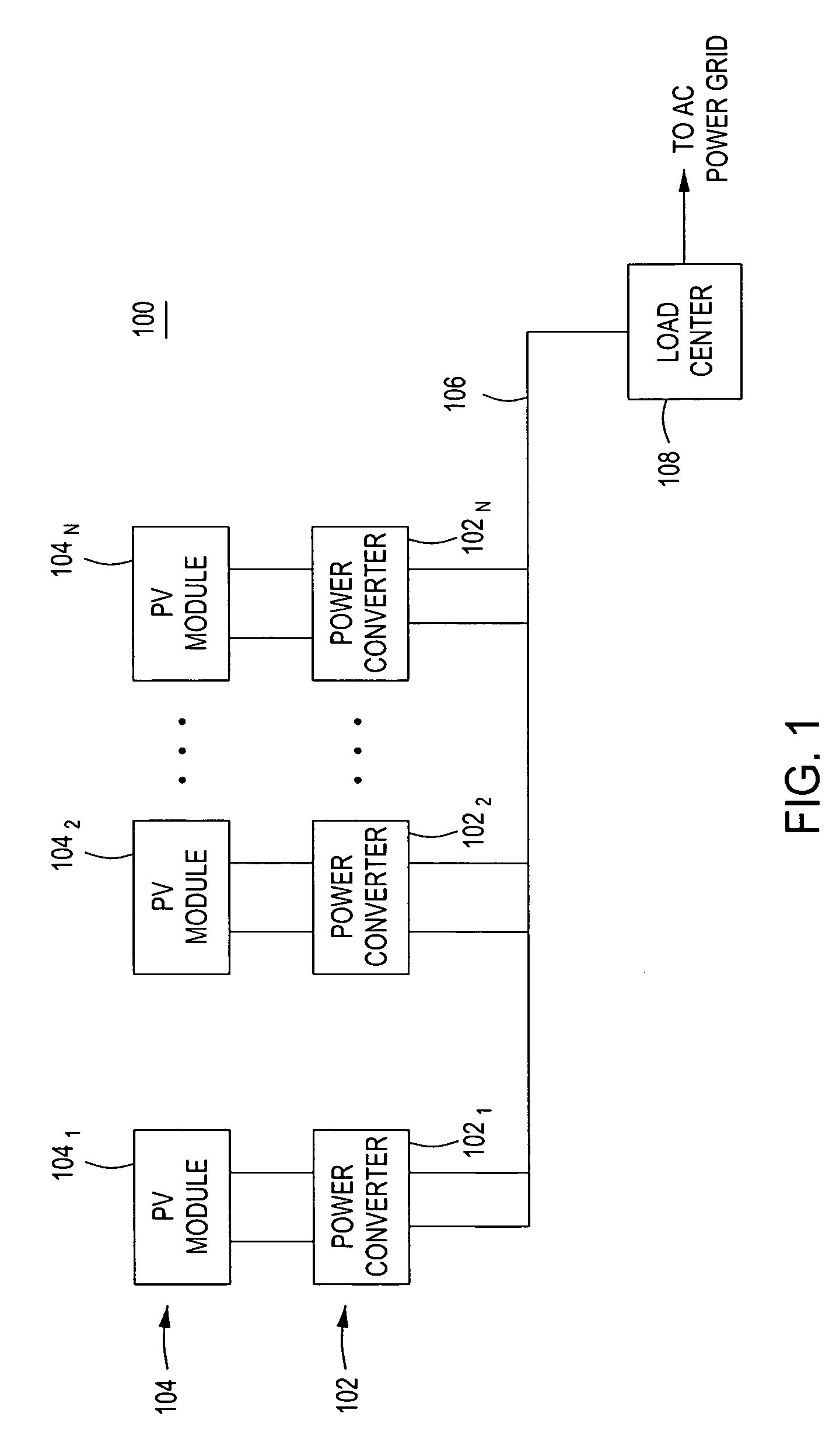

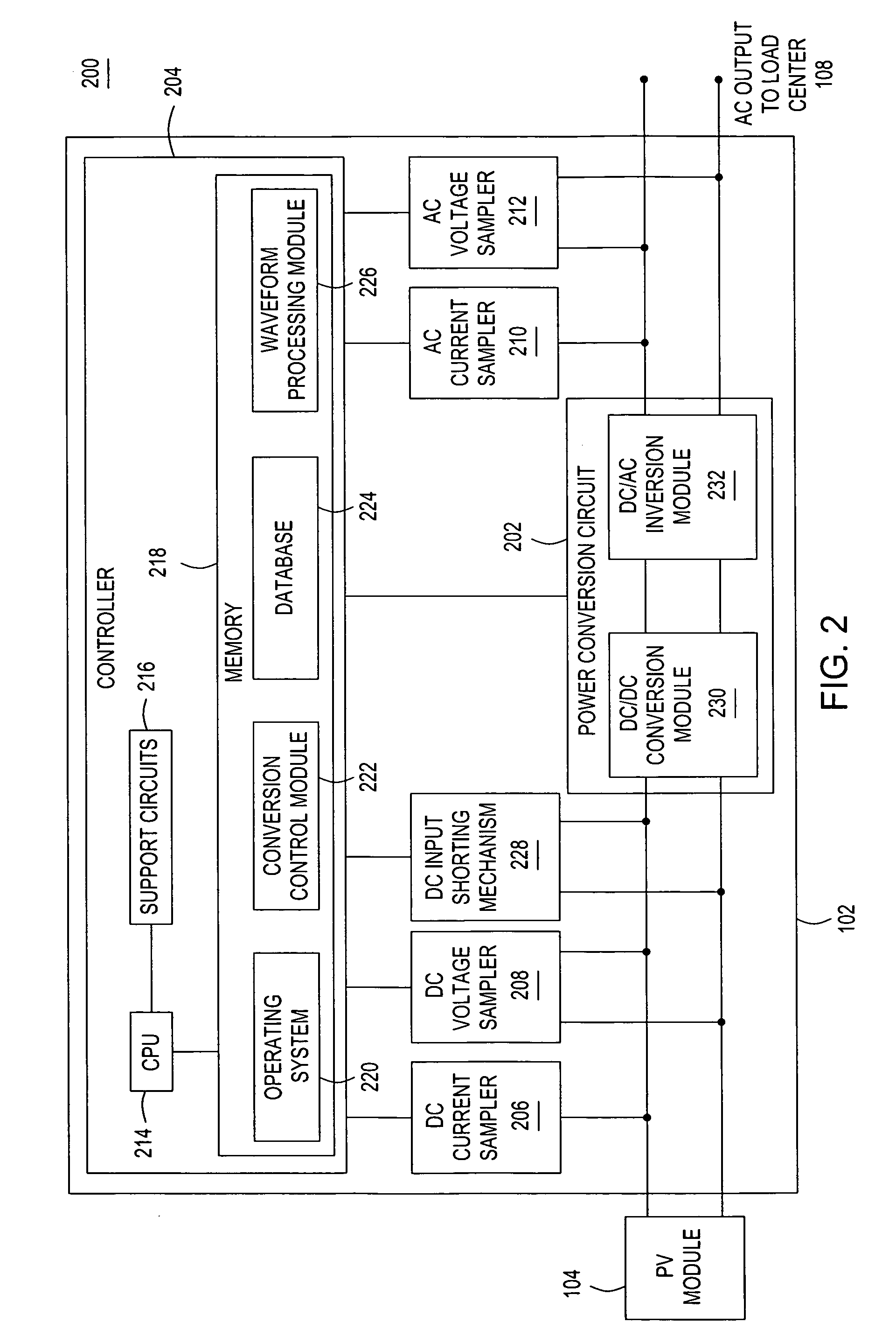

ActiveUS20110019444A1Testing dielectric strengthPhotovoltaic monitoringReliability engineeringElectric arc

A method and apparatus for managing DC arc faults. At least a portion of the method is performed by a controller comprising at least one processor. In one embodiment, the method comprises analyzing a signature of a signal of a power converter and determining, based on analysis of the signature, whether an arc fault exists.

Owner:ENPHASE ENERGY

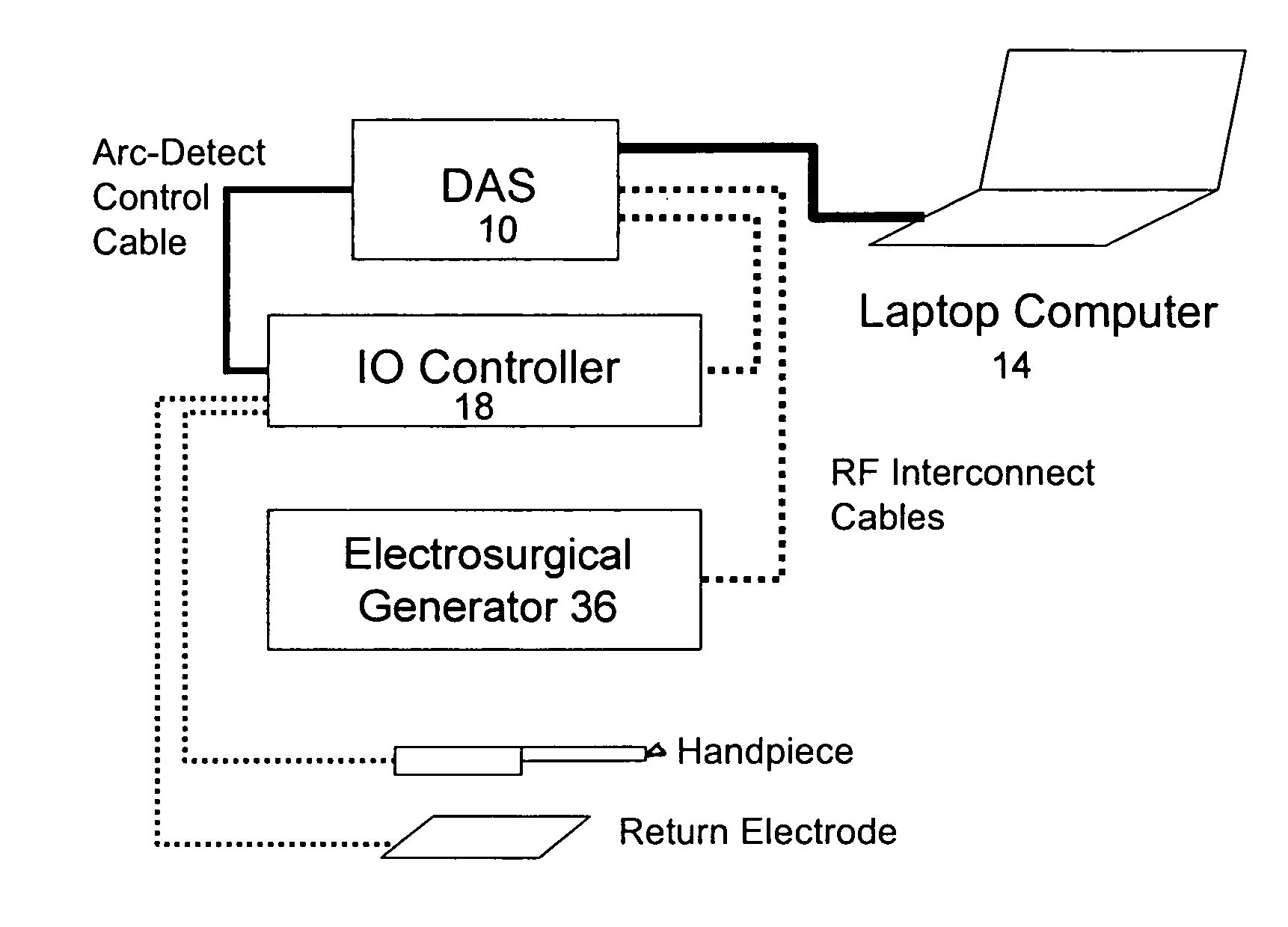

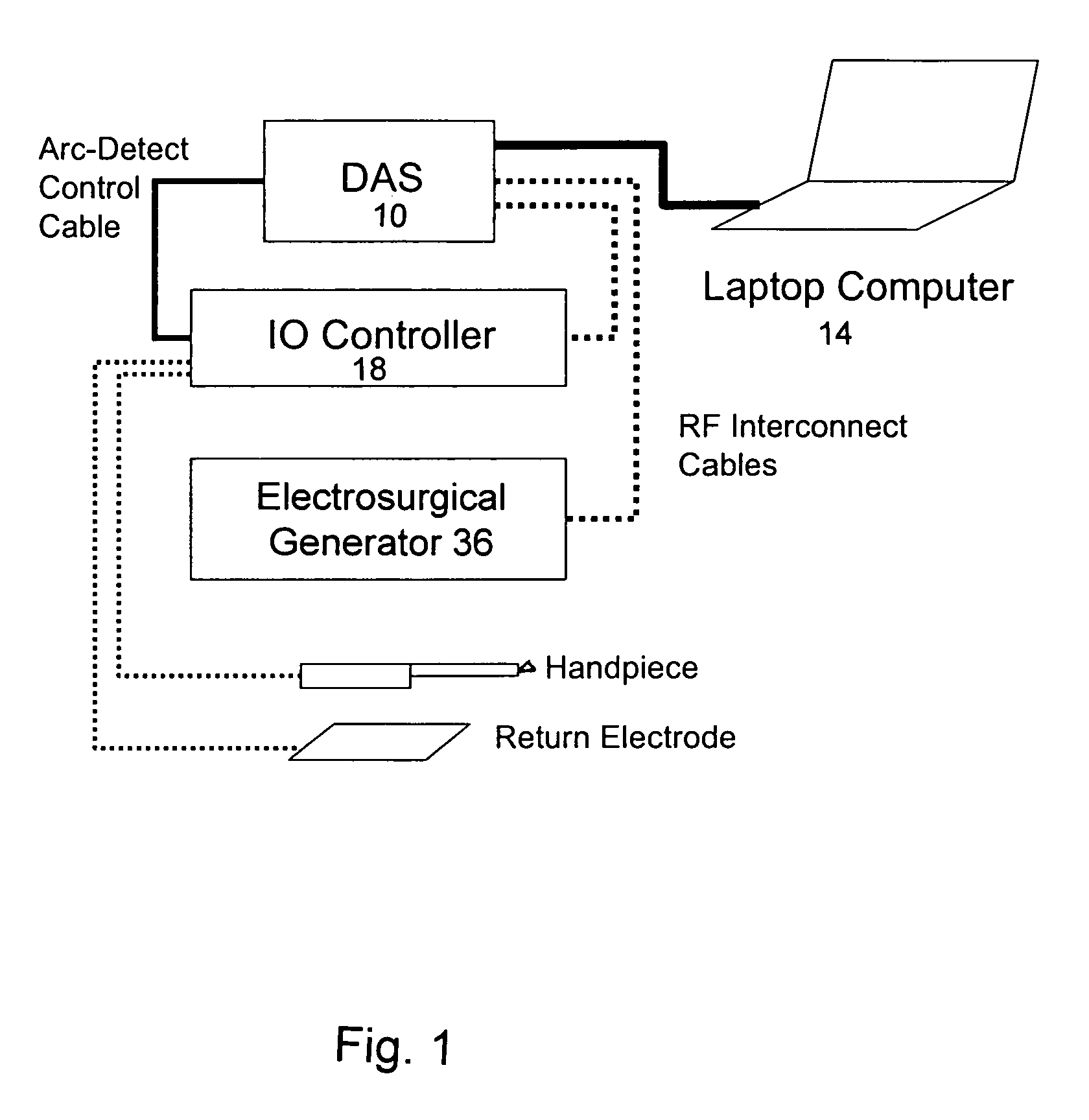

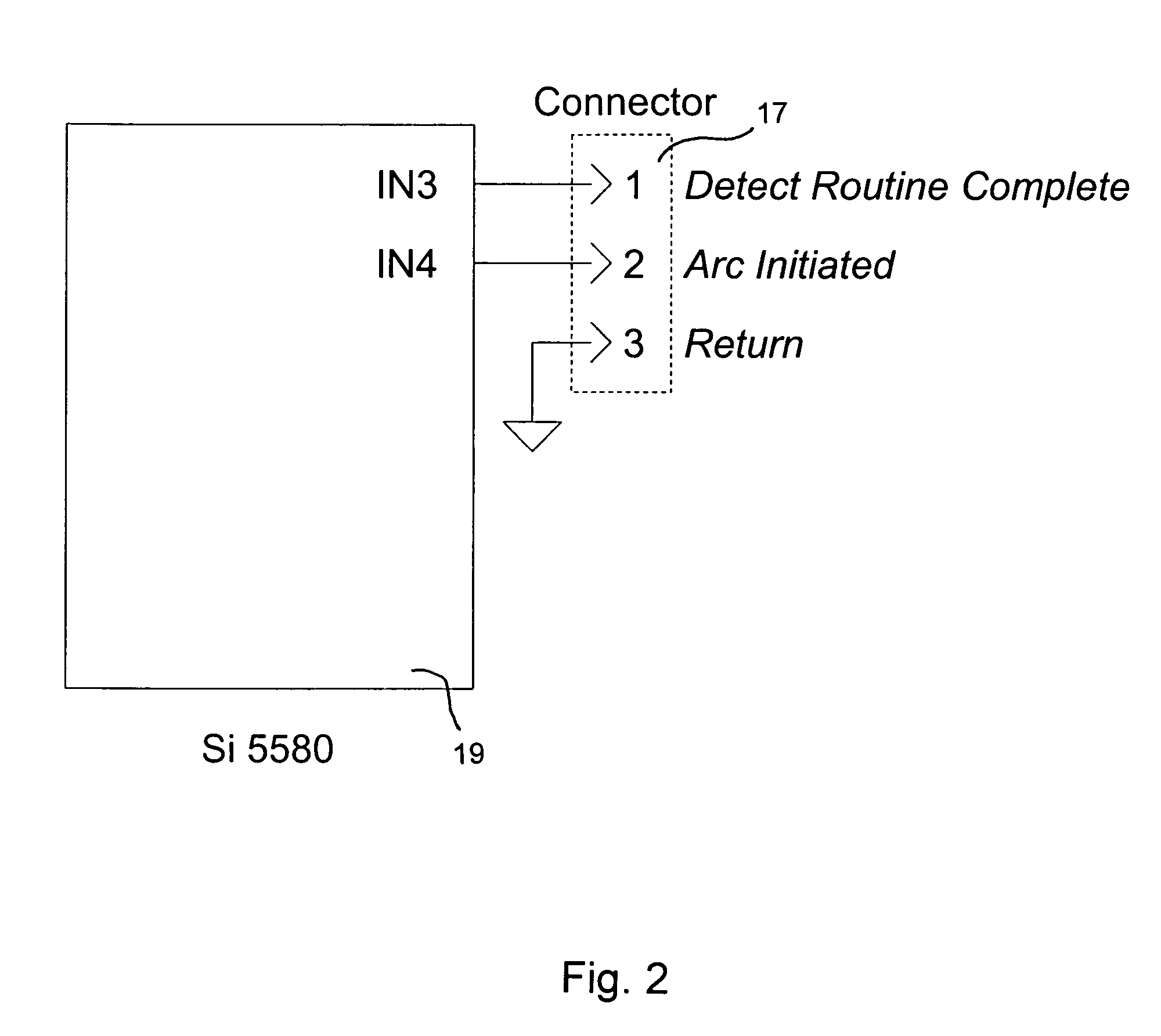

Devices and methods for controlling initial movement of an electrosurgical electrode

ActiveUS7060063B2Effect separationCatheterSurgical instruments for heatingData acquisitionBiomedical engineering

An electrosurgical electrode assembly having a cutting device including a catheter with a proximal and distal end, and an electrode carried on the distal end of the catheter. A controller is connected to the cutting device. A data acquisition system is connected to the controller and is capable of monitoring voltage and current output. A microprocessor may also be connected to the data acquisition system for processing voltage and current data from the data acquisition system. A generator is also connected to the data acquisition system. The controller initiates movement of the electrode upon arc initiation at the electrode. Methods of using the devices herein are also disclosed.

Owner:CILAG GMBH INT

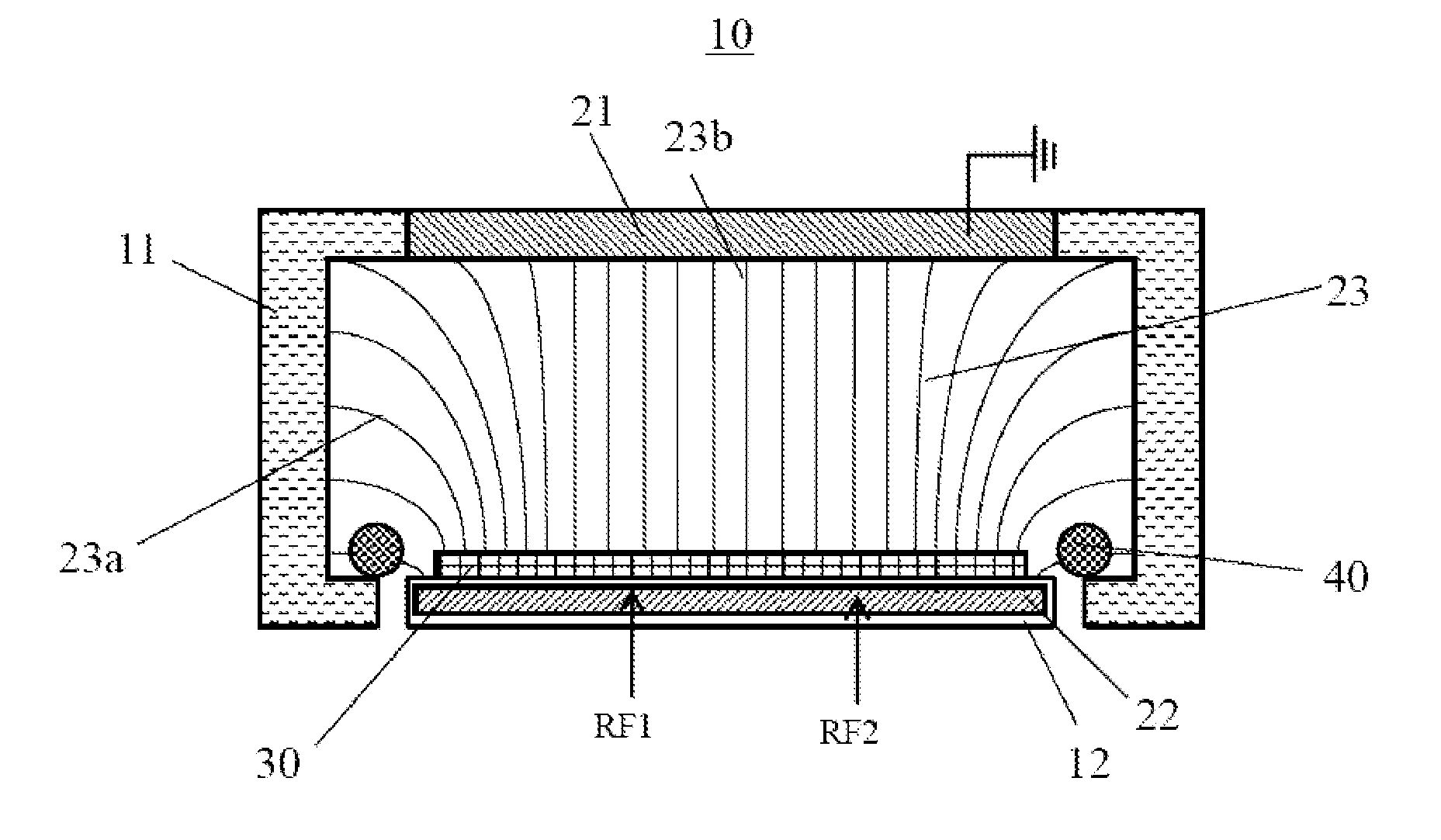

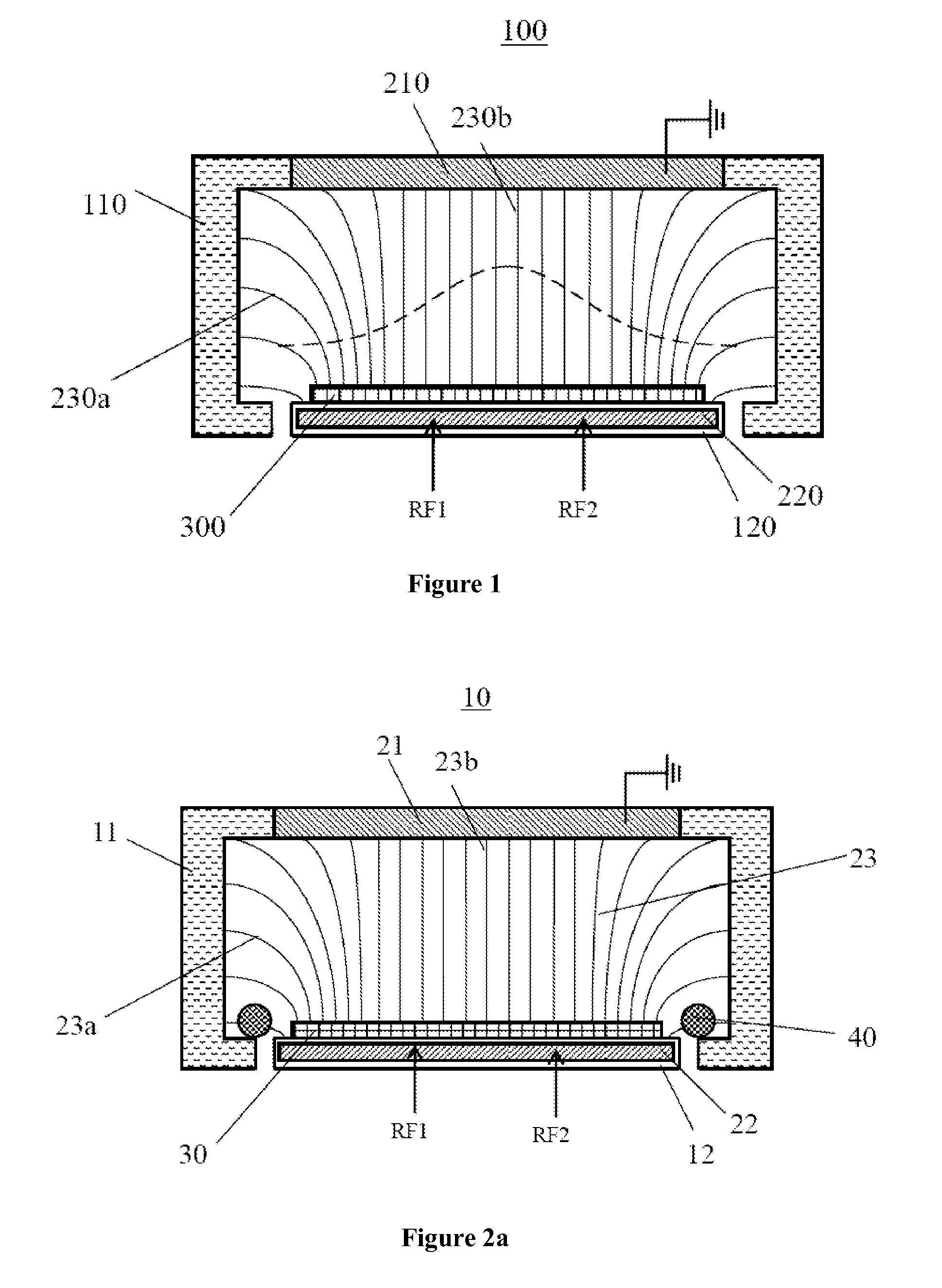

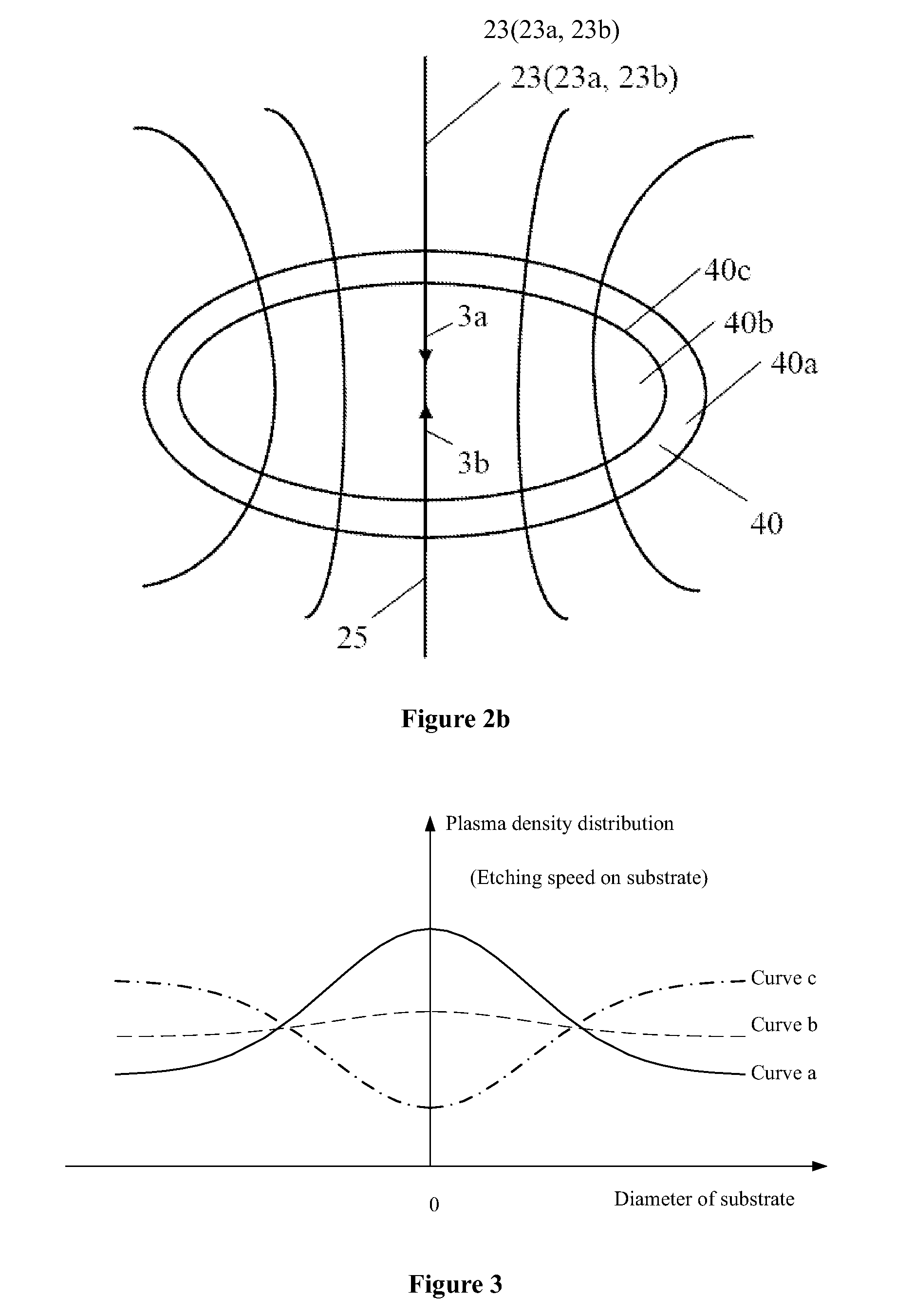

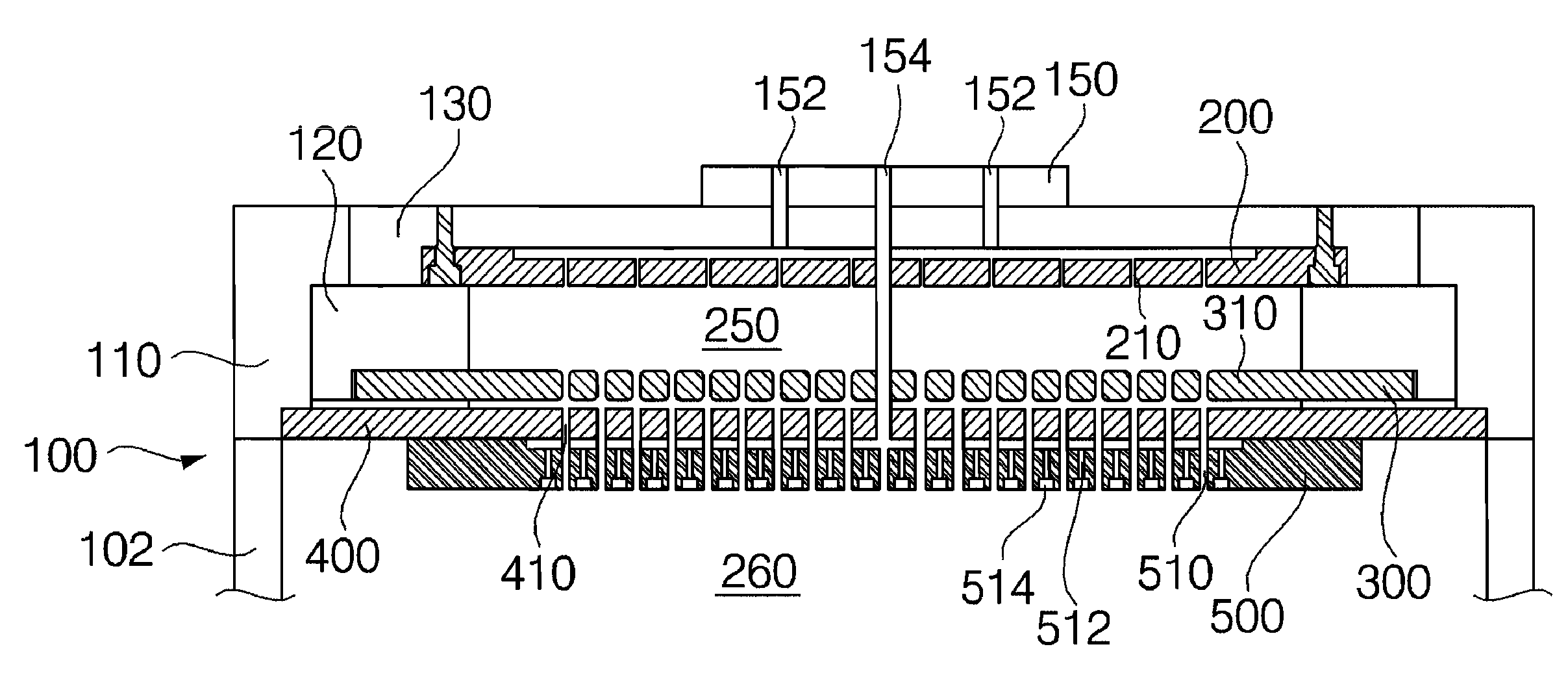

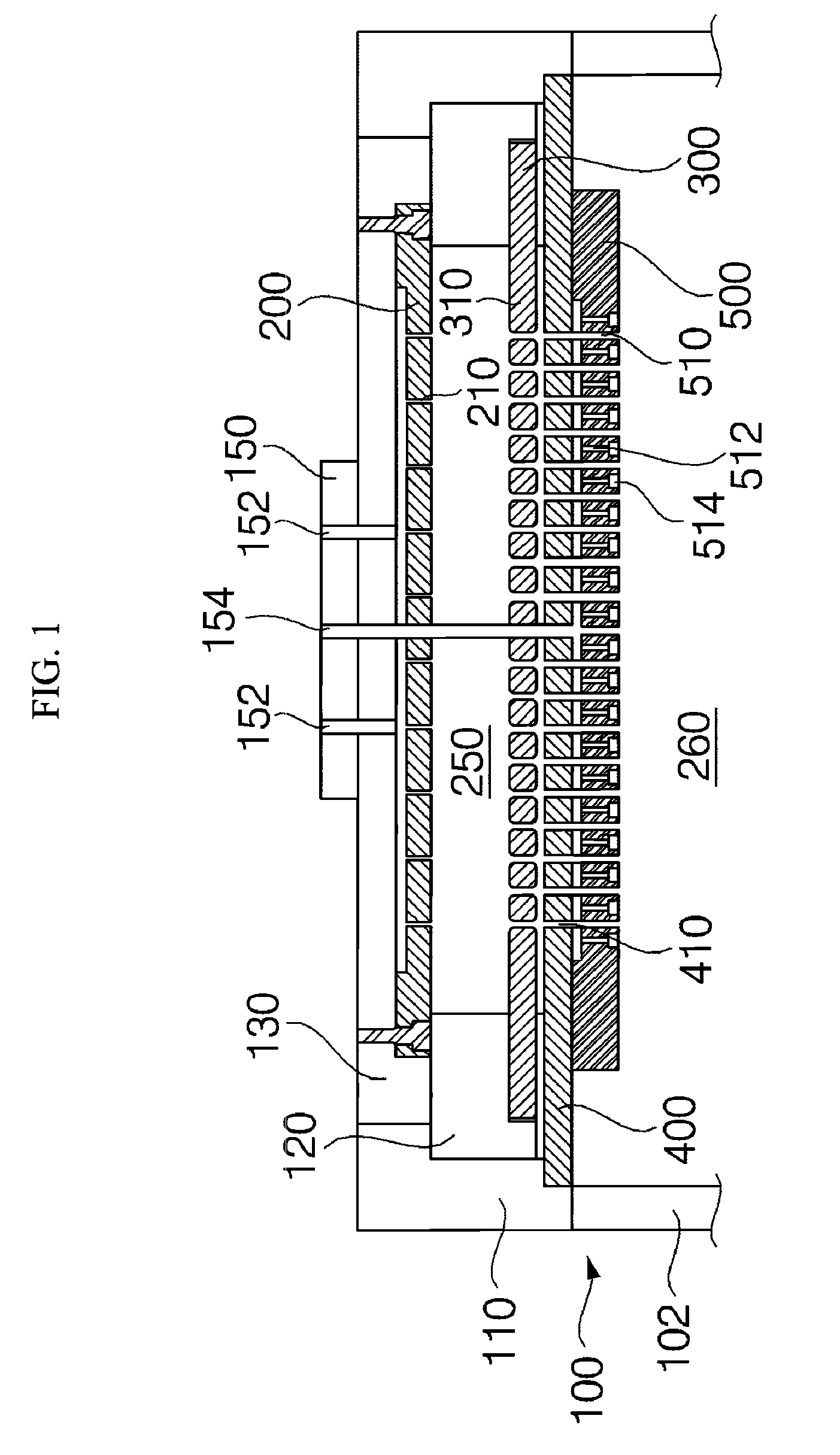

Capacitive-coupled plasma processing apparatus and method for processing substrate

ActiveUS20130032574A1Adjust electric field strengthIncrease the electric field strengthElectric discharge tubesDecorative surface effectsCapacitanceHigh pressure

The present invention relates to a capacitive-coupled plasma processing apparatus, wherein an electric field regulating element, i.e., an “electric field lens”, is arranged in the reaction chamber to generate a regenerated electric field in a direction opposite to that of the original radio frequency electric field in the reaction chamber, so that the non-uniformity of etching rate on the surface of the substrate of the plasma incurred by the original radio frequency electric field is decreased; and the electric field regulating element, i.e., the “electric field lens”, further decreases the equivalent quality factor Q value of the reaction chamber, expands the radio frequency band, and prevents high-voltage electric arcing. The present invention further provides a method for processing the substrate using the processing apparatus.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

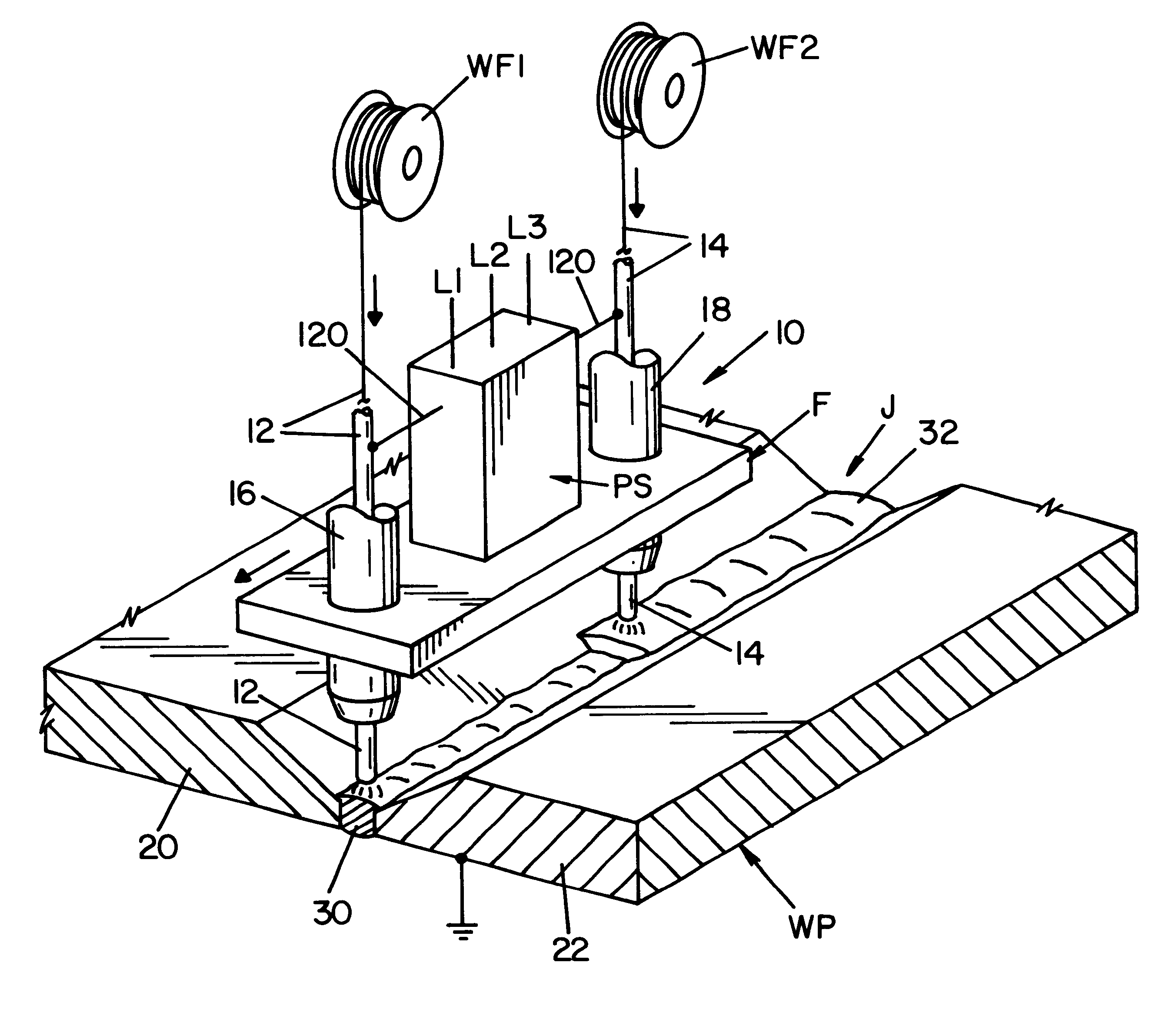

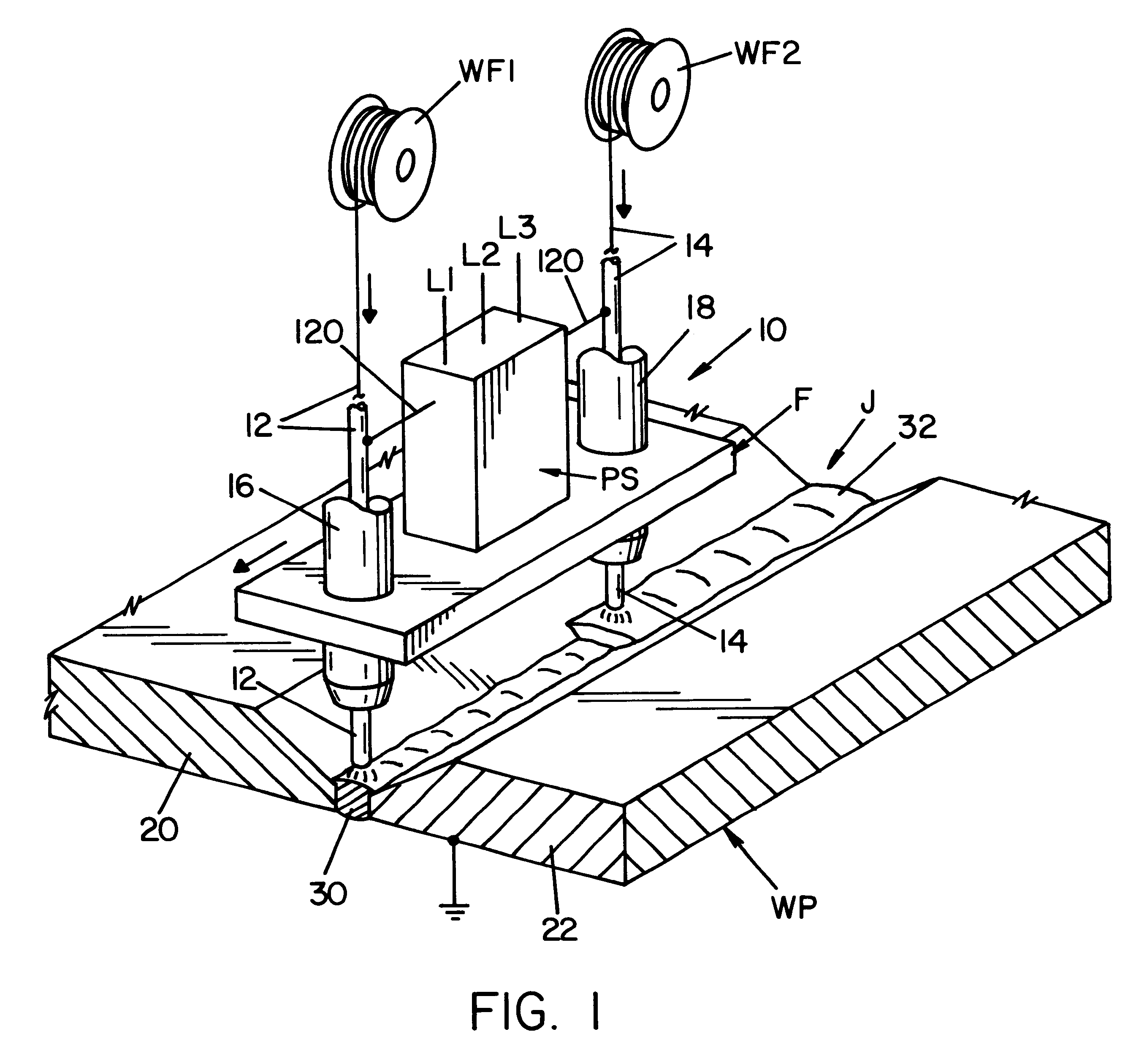

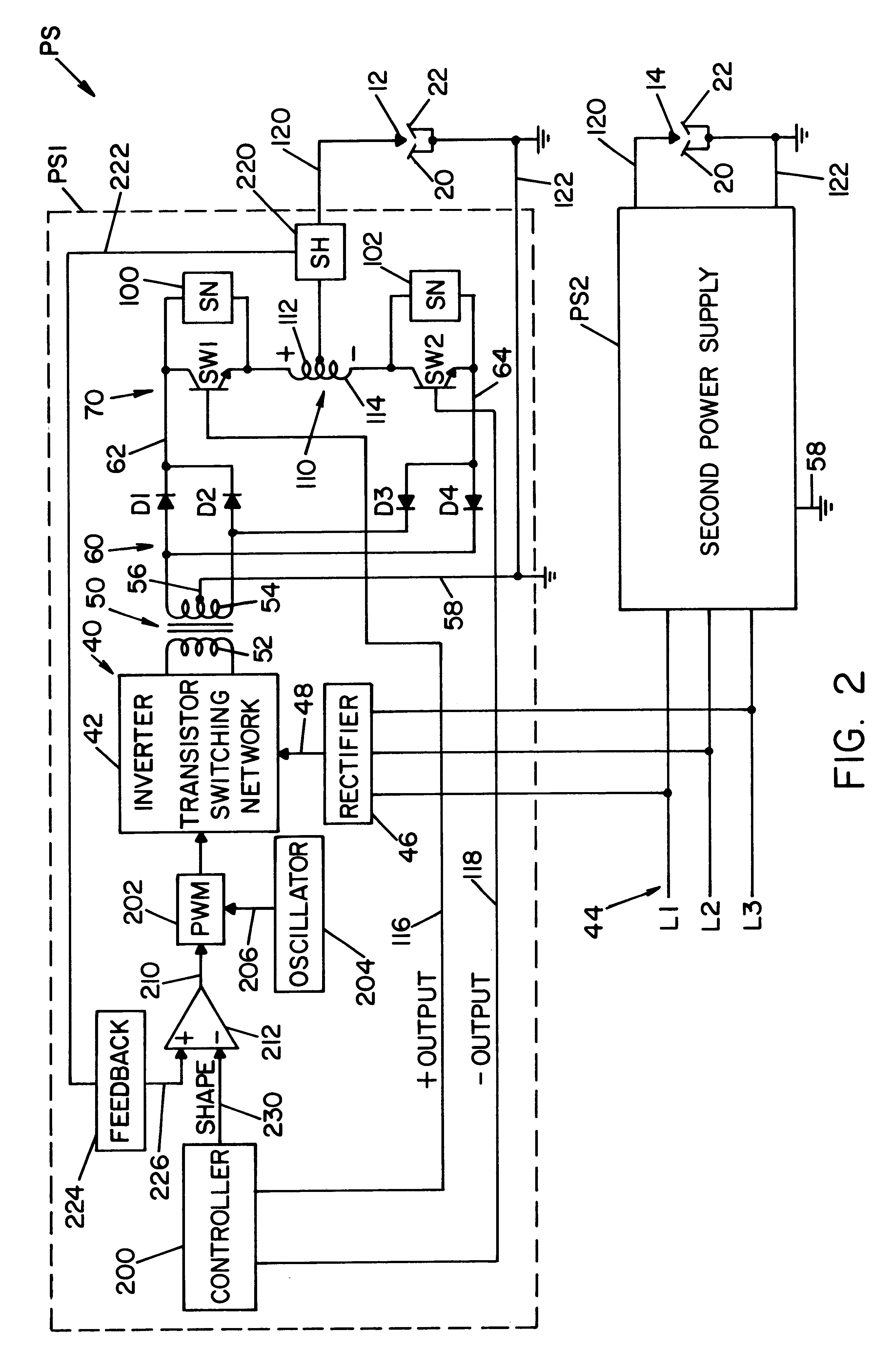

Tandem electrode welder and method of welding with two electrodes

An electric arc welding apparatus comprising at least a first consumable electrode and a second consumable electrode movable in unison along a welding path between the edges of two adjacent, mutually grounded plates, a first power supply for passing a first welding current at a first low frequency between the first electrode and the two plates, a second power supply for passing a second welding current at a second low frequency between the second electrode and the two plates, where each of the power supplies includes a three phase voltage input operated at line frequency, a rectifier to convert the input voltage to a DC voltage link and a high frequency switching type inverter converting the DC voltage link to a high frequency AC current, an output rectifier circuit to provide a positive voltage tenninal and a negative voltage terminal, and an output switching network operated at a given low frequency for directing a pulsating welding current at the given low frequency from the two terminals across one of the electrodes and the plates, and a circuit for independently adjusting the given low frequency so the value of the first low frequency of the first power supply is different from the second low frequency of the second power supply.

Owner:LINCOLN GLOBAL INC

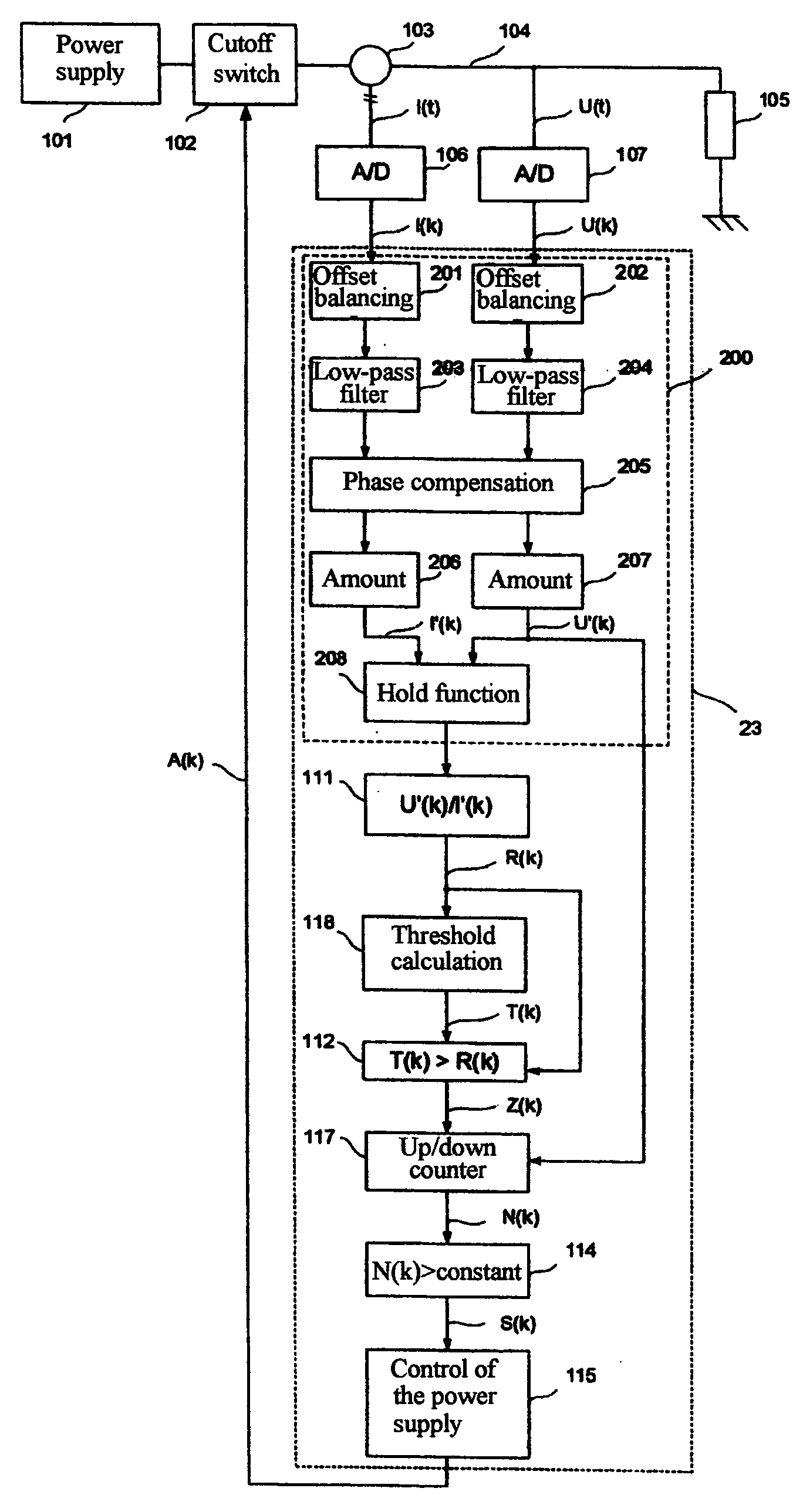

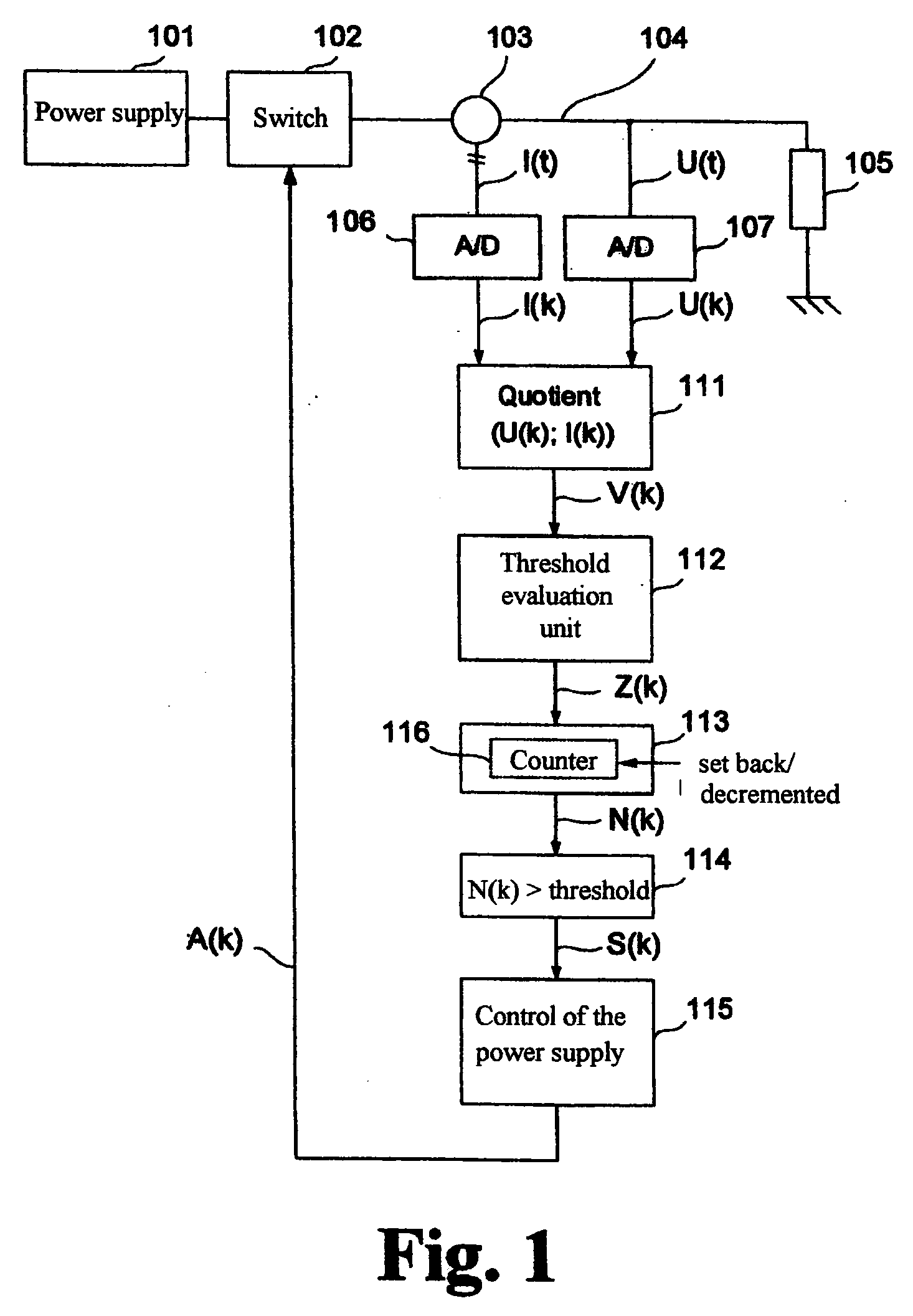

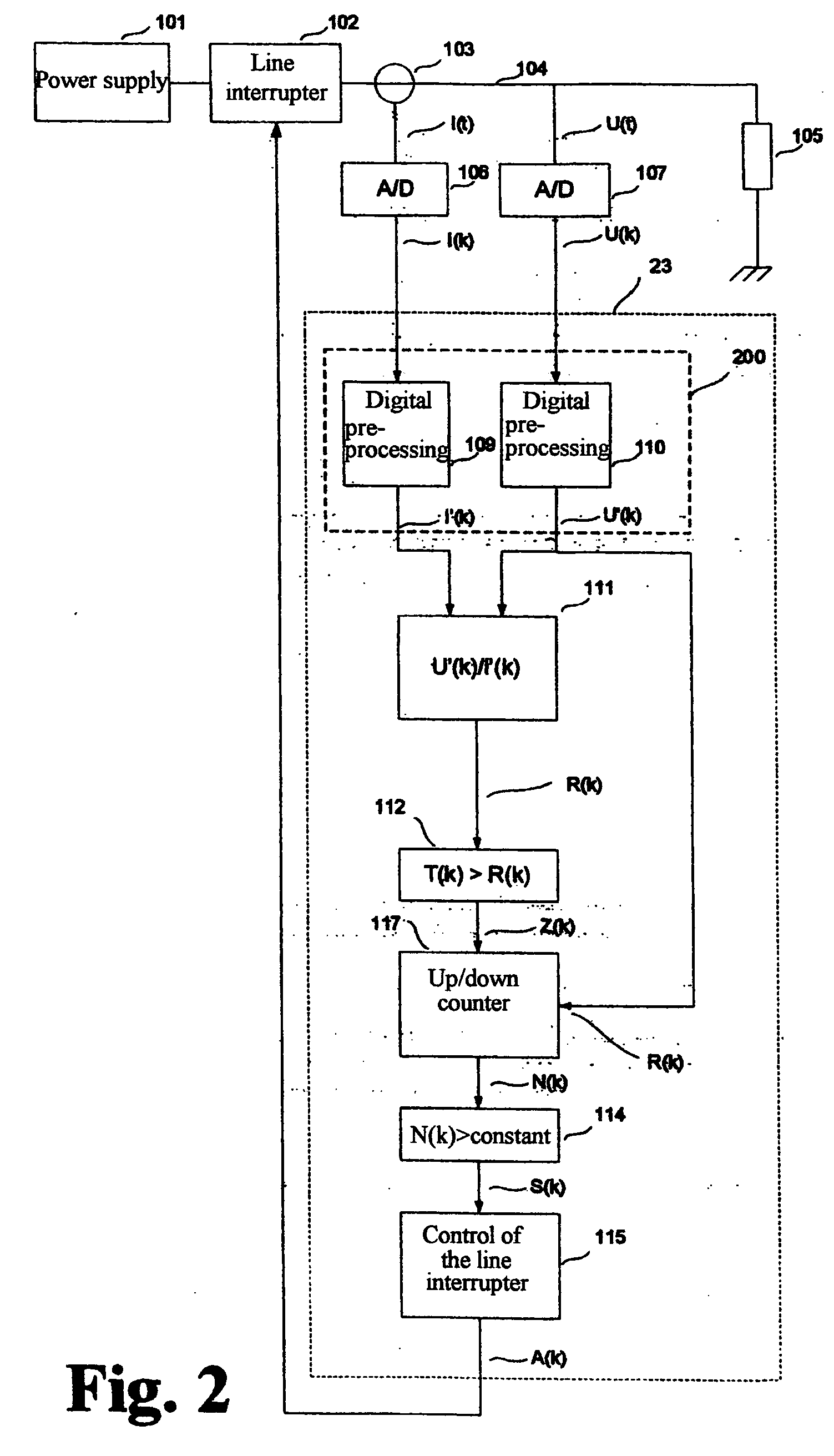

Method and device for the detection of fault current arcing in electric circuits

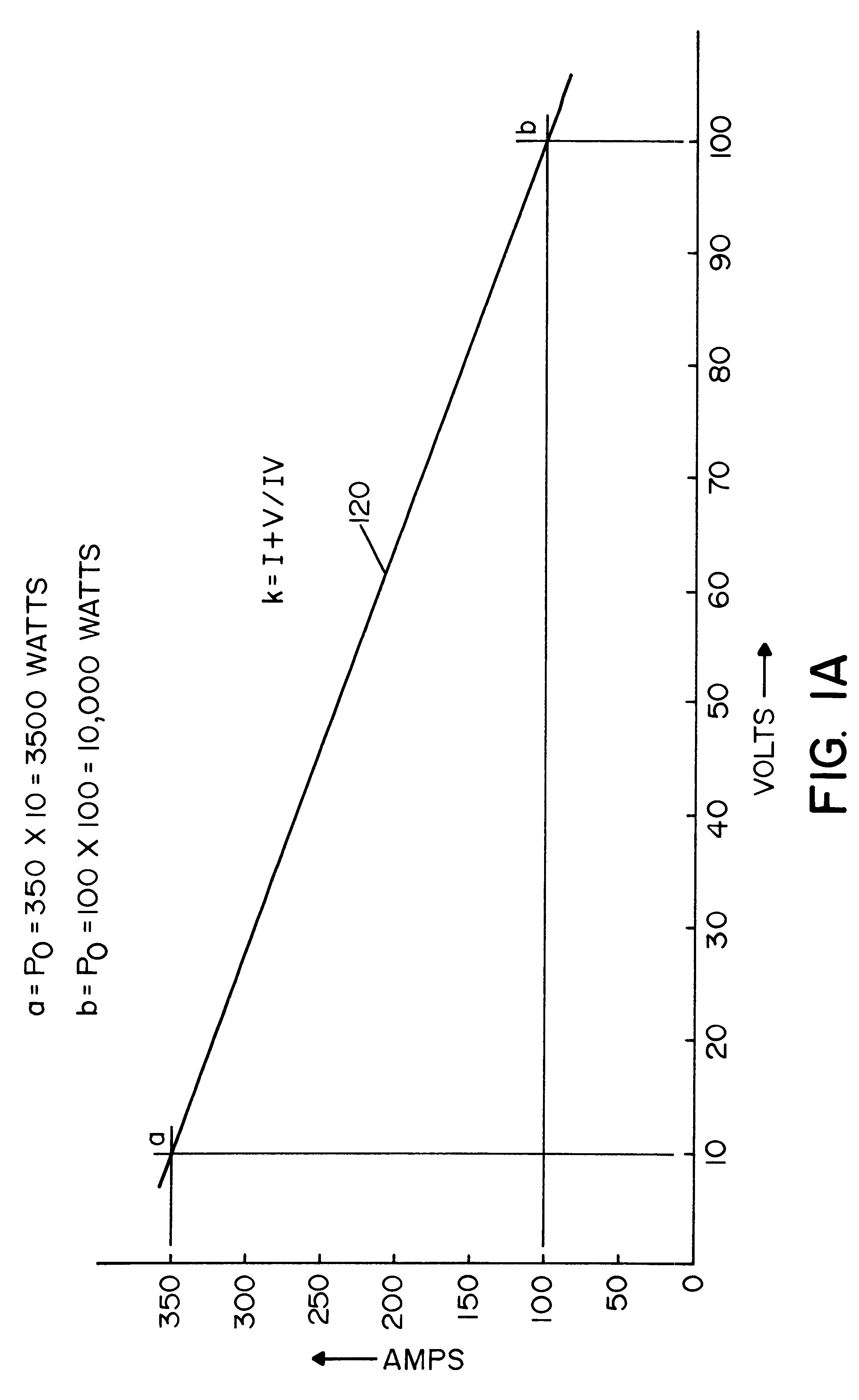

ActiveUS20060109009A1Reduces erroneous triggeringReduce sensitivityTesting dielectric strengthCurrent/voltage measurementConstant powerElectrical current

The invention is directed to a method and a device for detecting fault current arcing in electric circuits for consumers with relatively constant power consumption, particularly in onboard aircraft power supplies. The object of the invention is to find a novel possibility for detecting arc faults in electric lines of consumers with a relatively constant power consumption which appreciably reduces erroneous triggering of safeguards without compromising the reliability of switching off in the event that arcing actually occurs. This object is met, according to the invention, in that a voltage value is measured simultaneous with the current measurement, a ratio is formed of the current measurement values and voltage measurement values that are detected in parallel, and an indicator signal is generated for detected arcing when changes in the ratio of current measurement values and voltage measurement values exceed a predetermined threshold value.

Owner:JENOPTIK ADVANCED SYST GMBH

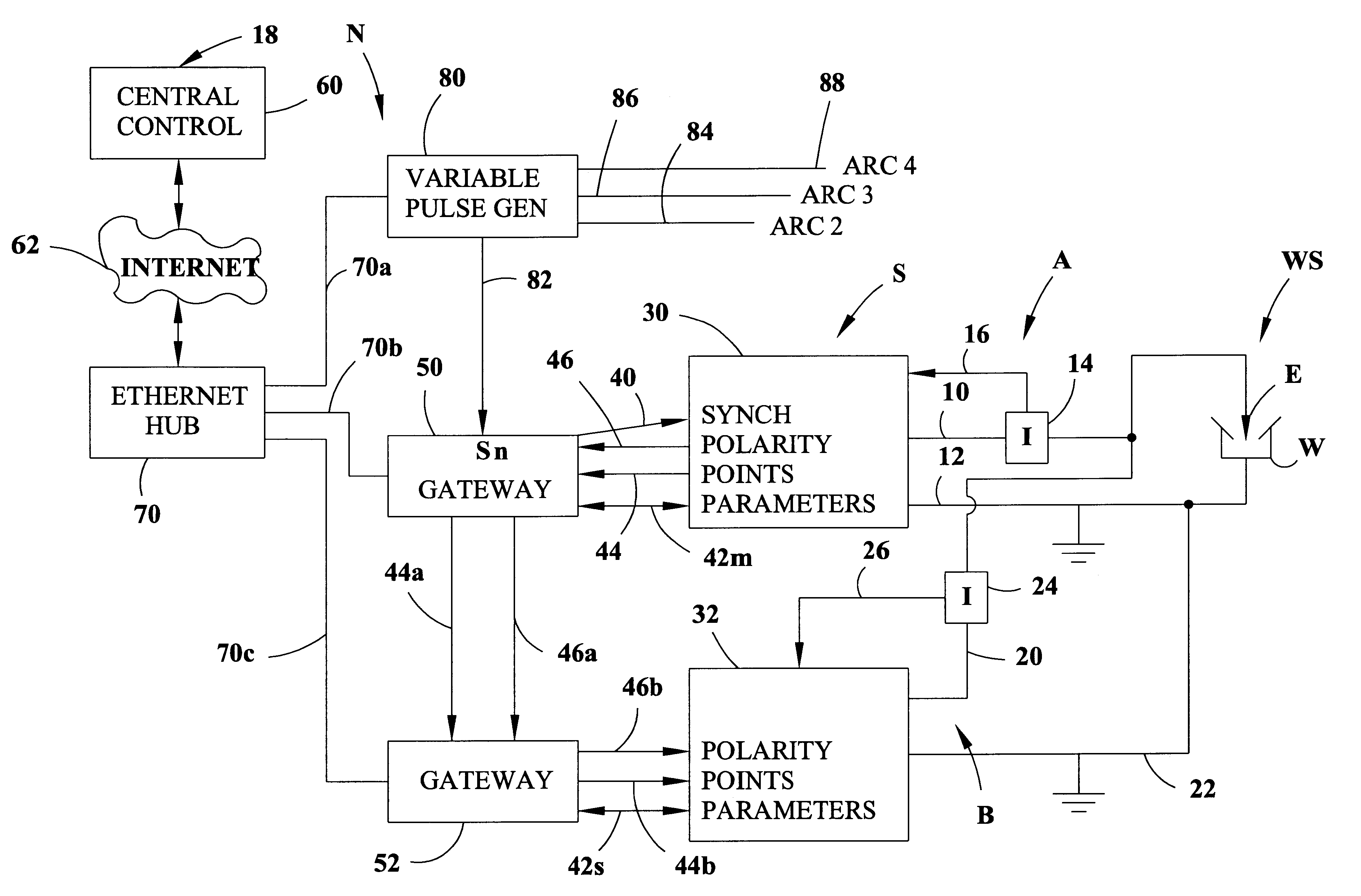

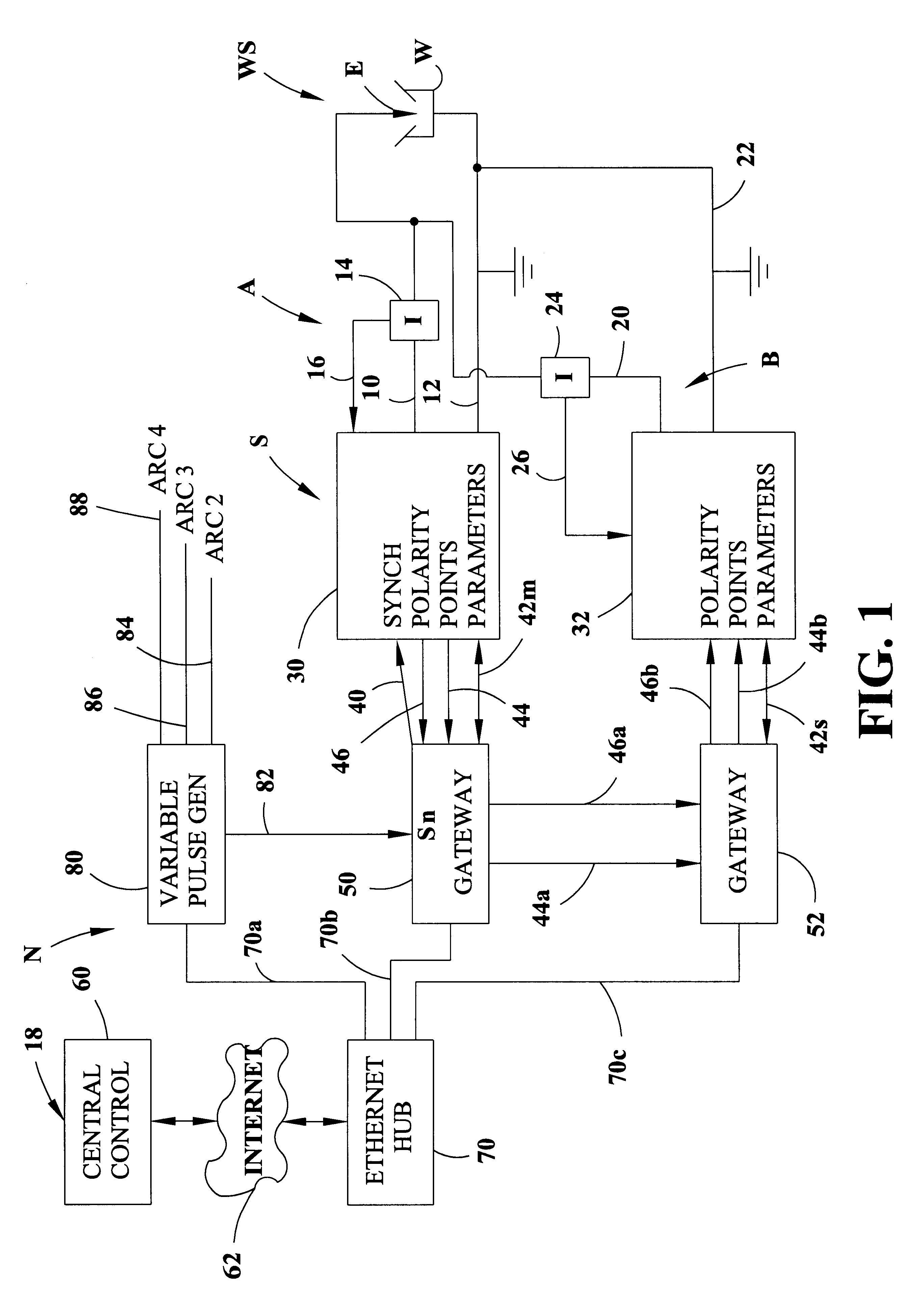

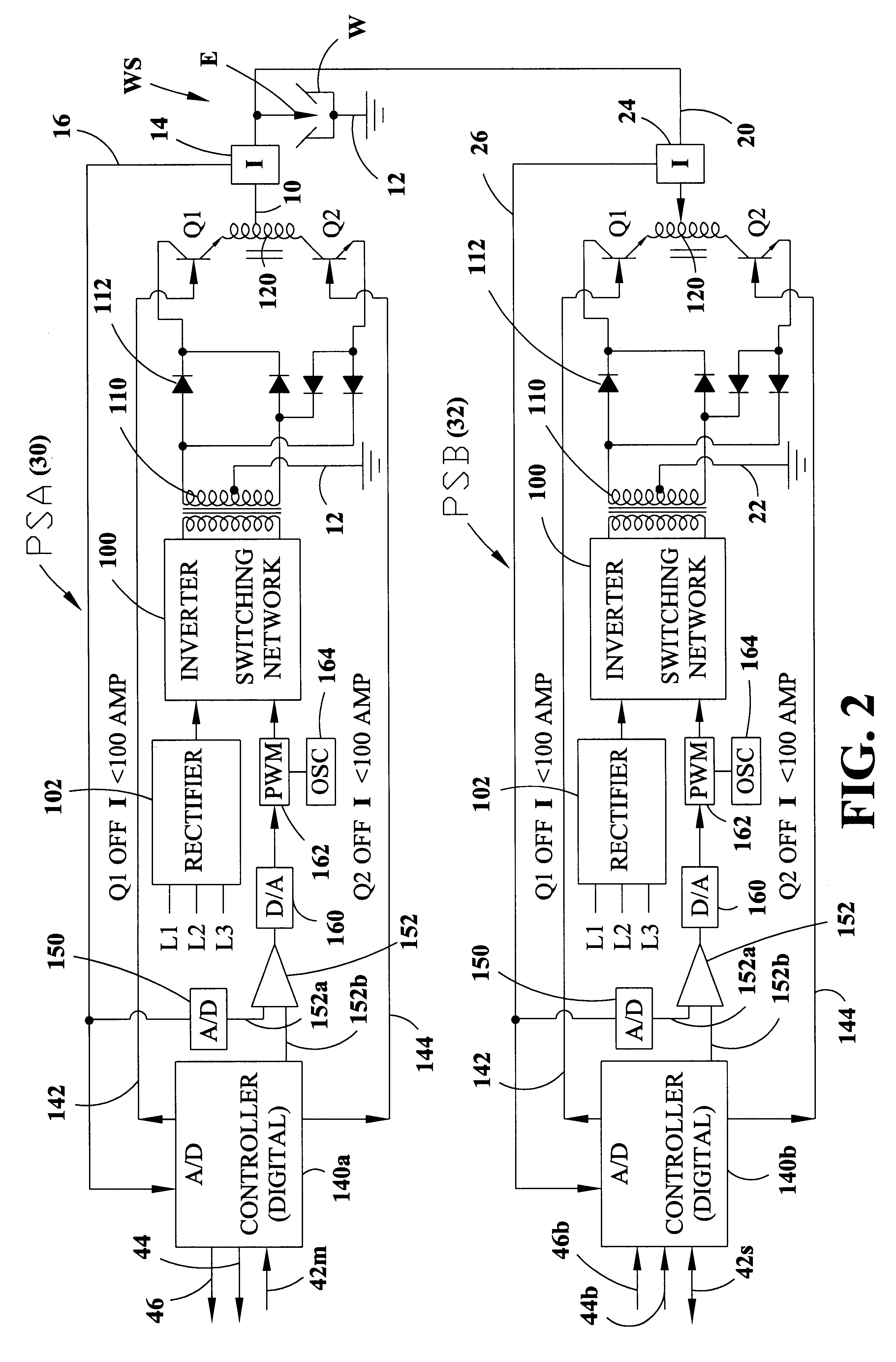

Electric arc welding system

InactiveUS6472634B1Prevent and reduce electrode interferenceLarge capacityElectric discharge heatingArc welding apparatusPower flowDigital interface

An electric arc welding system for creating an AC welding arc between an electrode and a workpiece wherein the system comprises a first controller for a first power supply to cause the first power supply to create an AC current between the electrode and workpiece by generating a switch signal or command with polarity reversing switching points in the first controller, with the first controller operated at first welding parameters in response to first power supply specific parameter signals to the first controller. The system has at least one slave controller for operating a slave power supply to create an AC current between the electrode and workpiece by reversing polarity of the AC current at switching points where the slave controller is operated at second welding parameters in response to second power supply specific parameter signals to the slave controller. An information network connected to the first controller and the slave controller and containing digital first and second power supply specific parameter signals for the first controller and the slave controller and a digital interface connects the first controller with the slave controller to control the switching points of said second power supply by the switch signal or command from the first controller.

Owner:LINCOLN GLOBAL INC

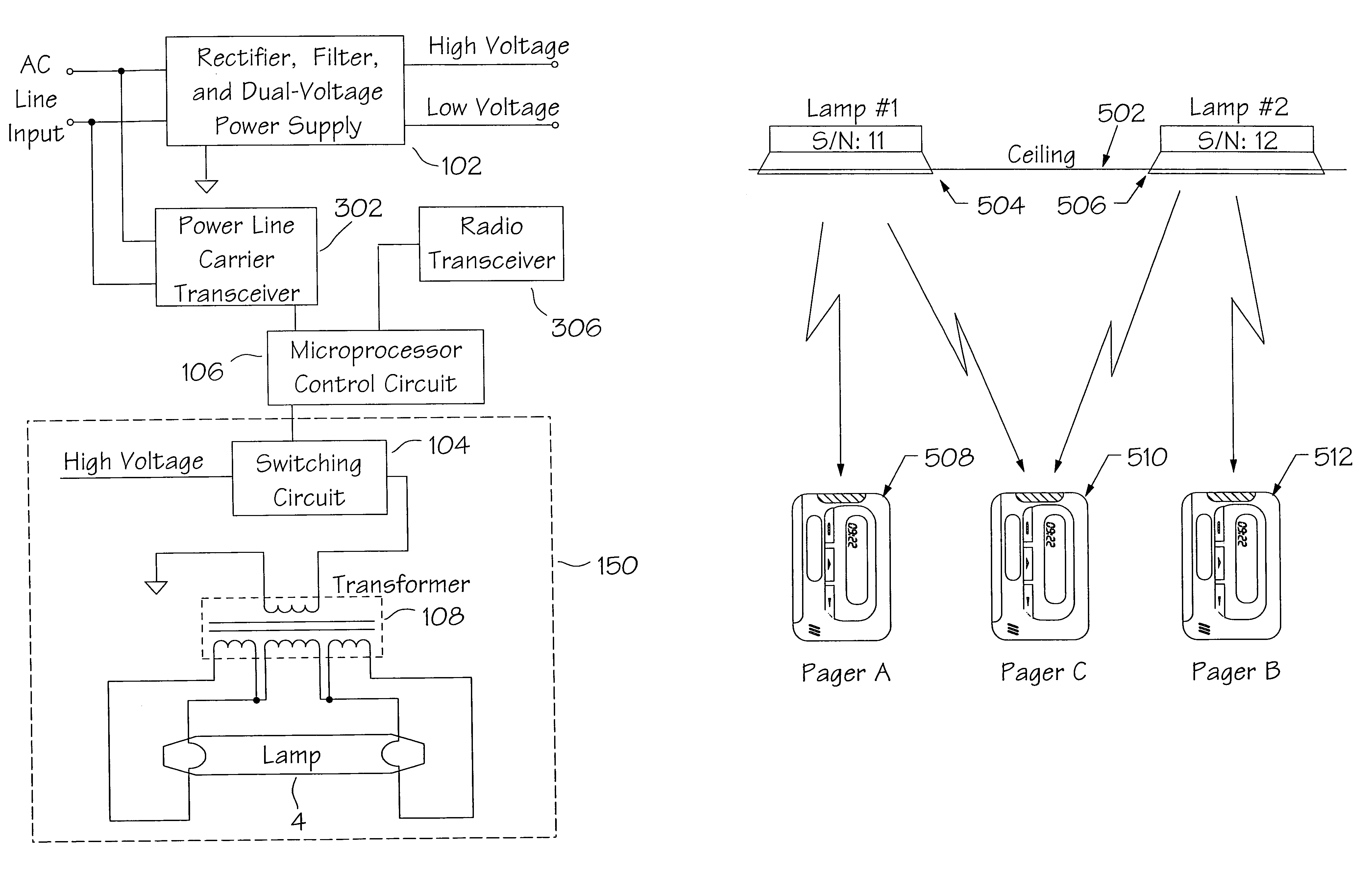

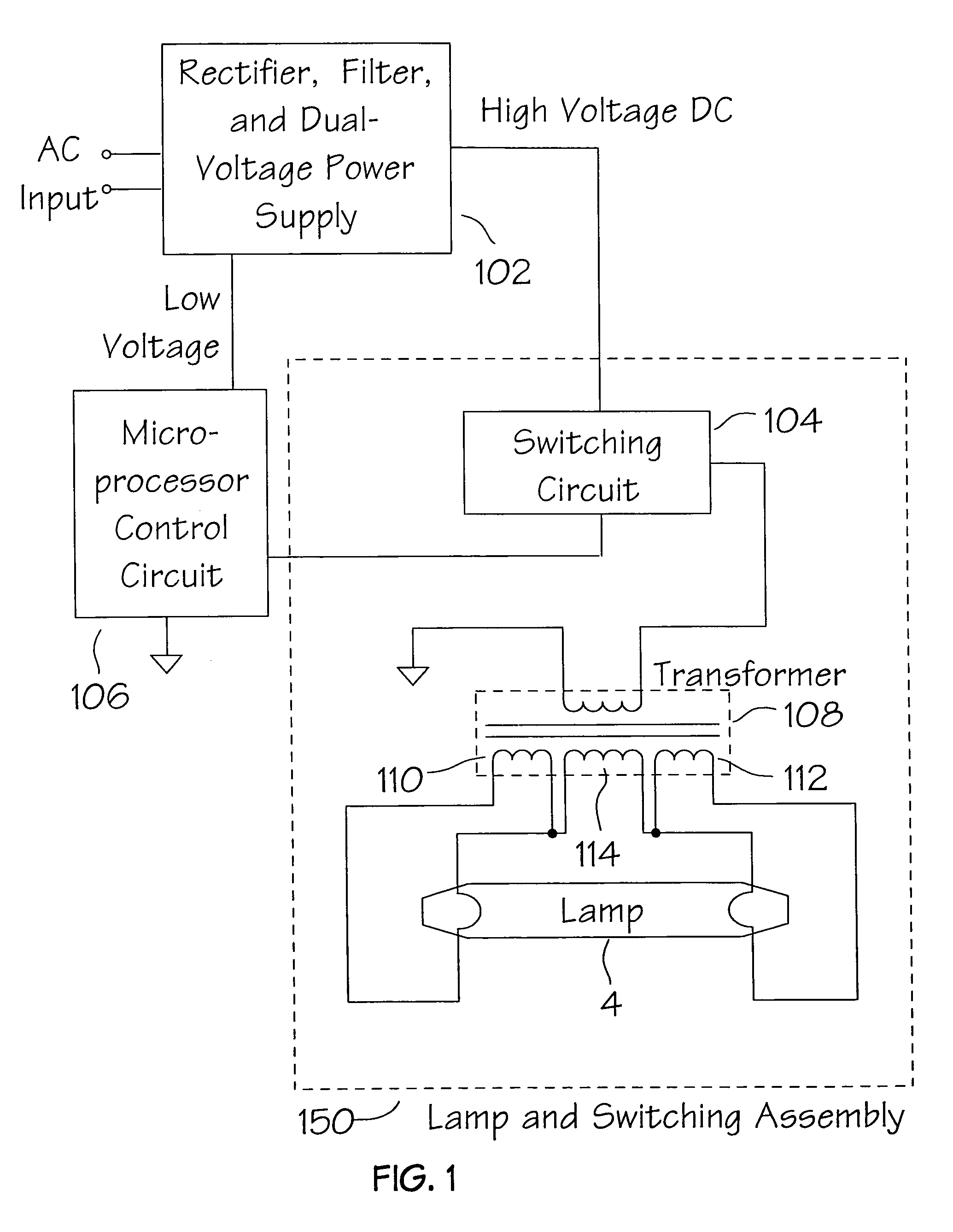

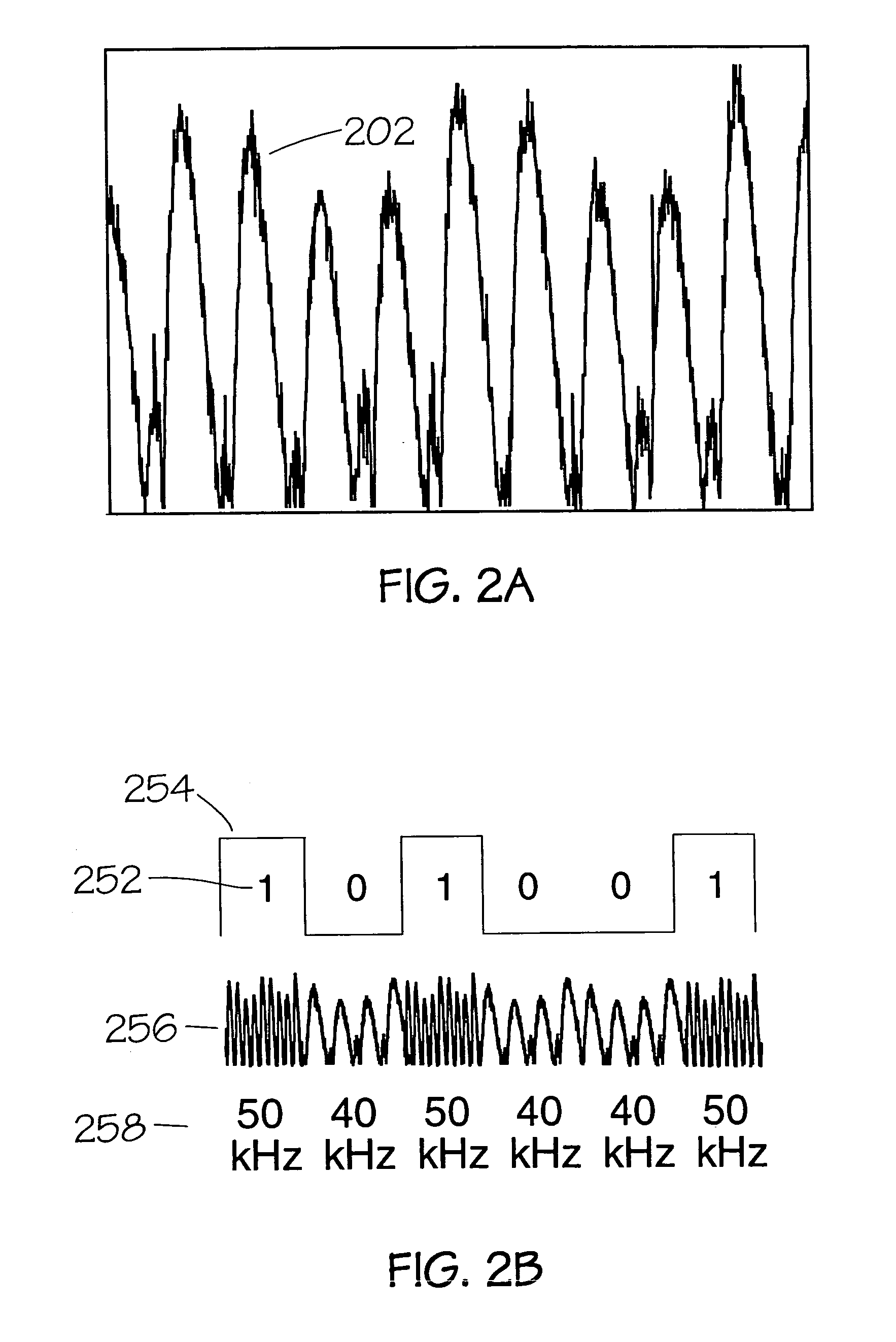

Method and apparatus for the zonal transmission of data using building lighting fixtures

This invention relates to the zonal transmission of data by the modulation of the light output of arc lamps or discharge lamps; including the visible or invisible light output of fluorescent lamps, mercury vapor lamps, high or low-pressure sodium lamps, metal-halide based lamps, or other arc or discharge lamps. The method results in an easily installed, easily maintained, and economical to purchase, optical-wave communications system which exploits the existing infrastructure of a building or facility to facilitate the transmission of data in individual zones; thereby facilitating the transmission of wide-area as well as zonal-specific data to compatible receivers, and further facilitating the determination of location of remote devices or users, and the delivery or exchange of information or data, utilizing limited range transmission techniques.

Owner:CONVERGENCE WIRELESS A CALIFORNIA CORP

Method and apparatus for detection and control of dc arc faults

A method and apparatus for managing DC arc faults. At least a portion of the method is performed by a controller comprising at least one processor. In one embodiment, the method comprises analyzing a signature of a signal of a power converter and determining, based on analysis of the signature, whether an arc fault exists.

Owner:ENPHASE ENERGY

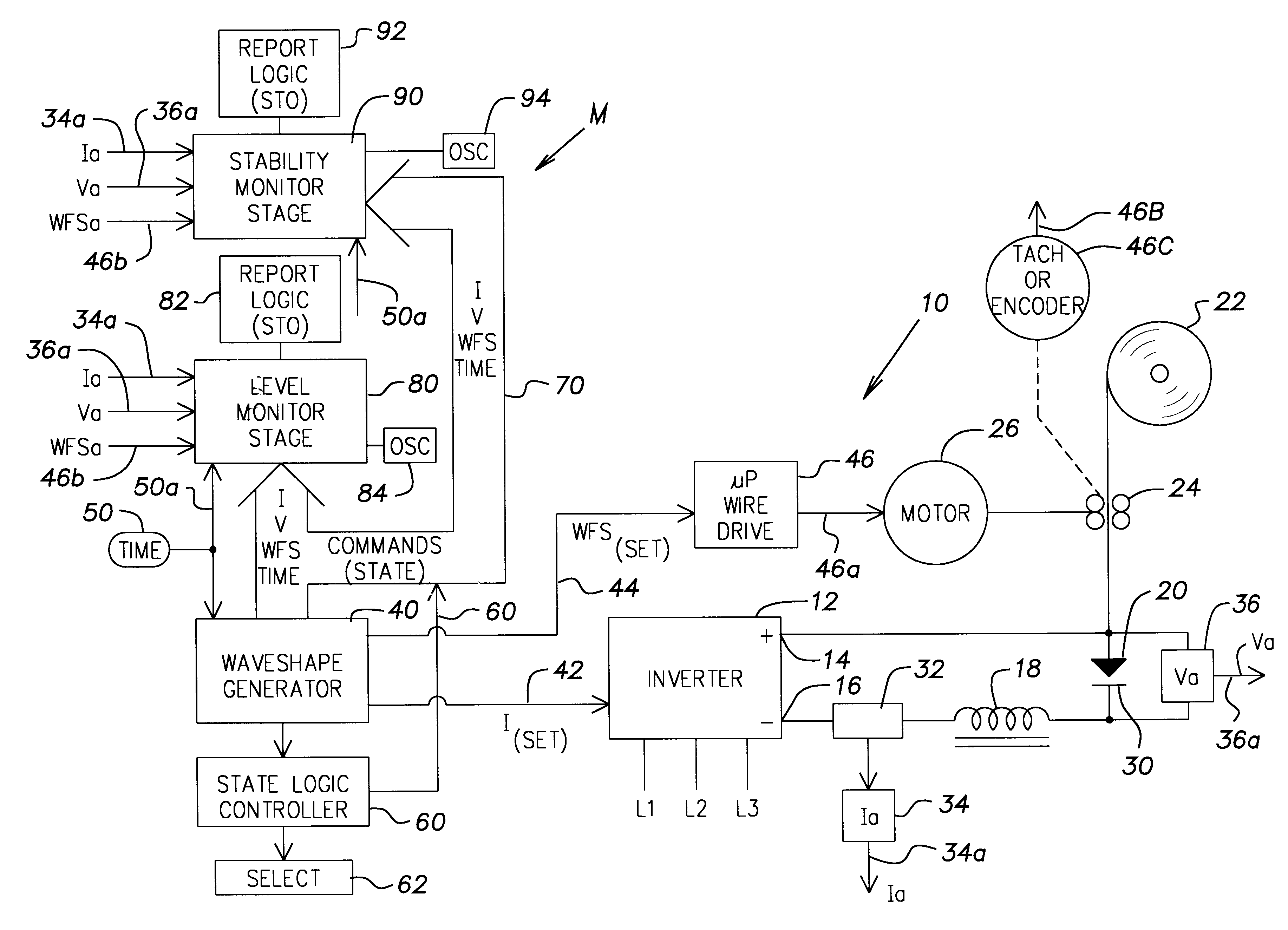

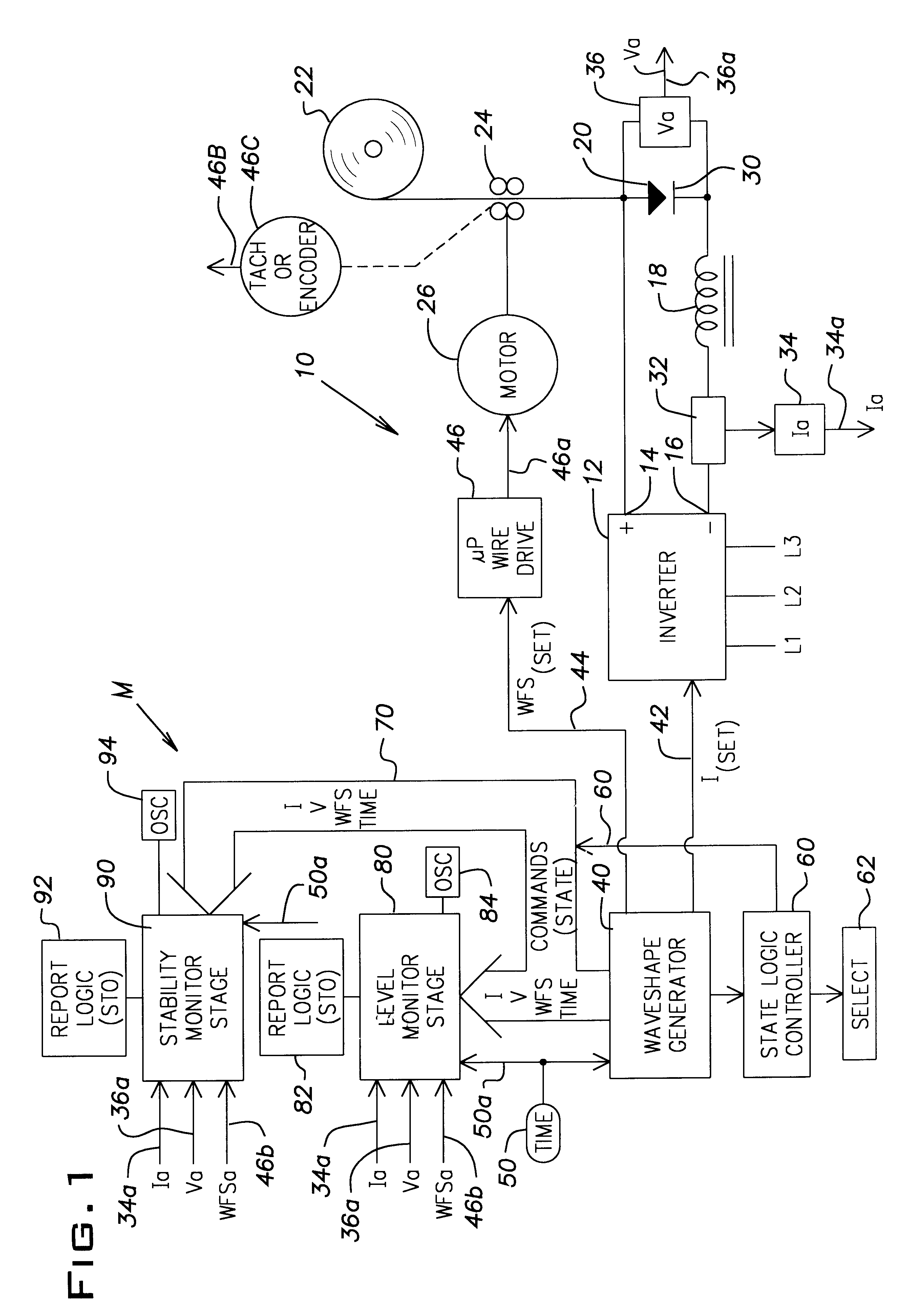

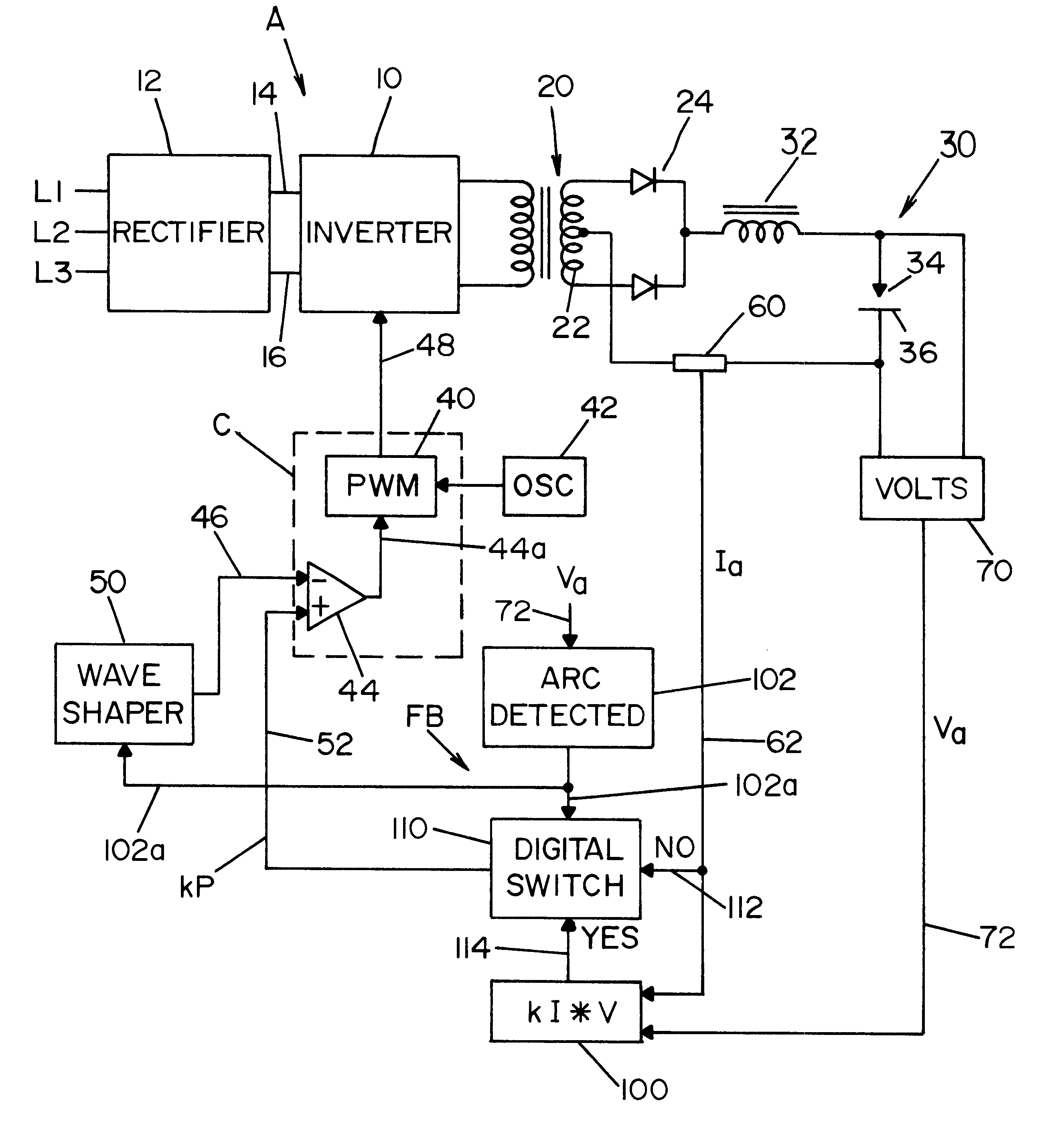

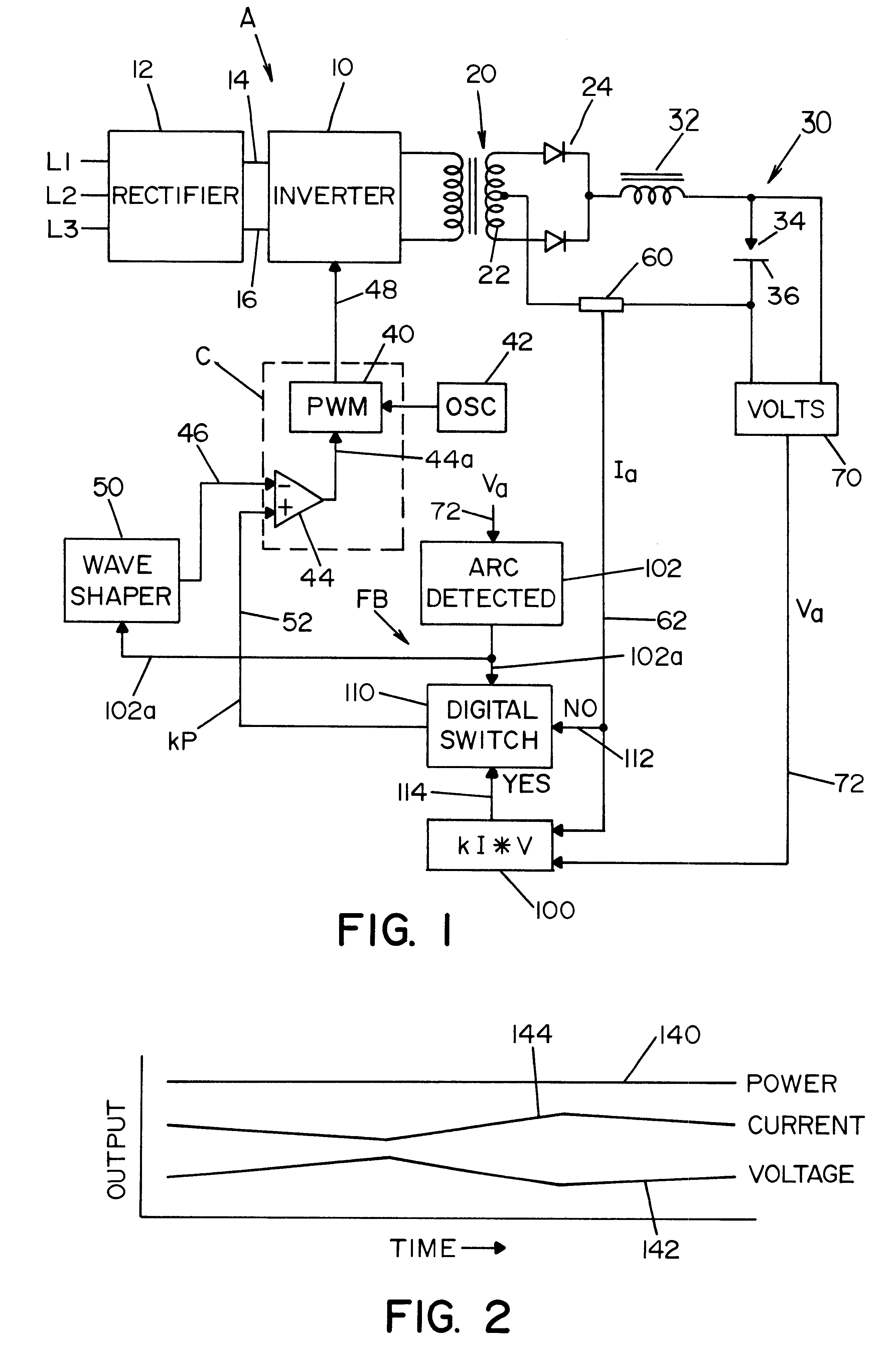

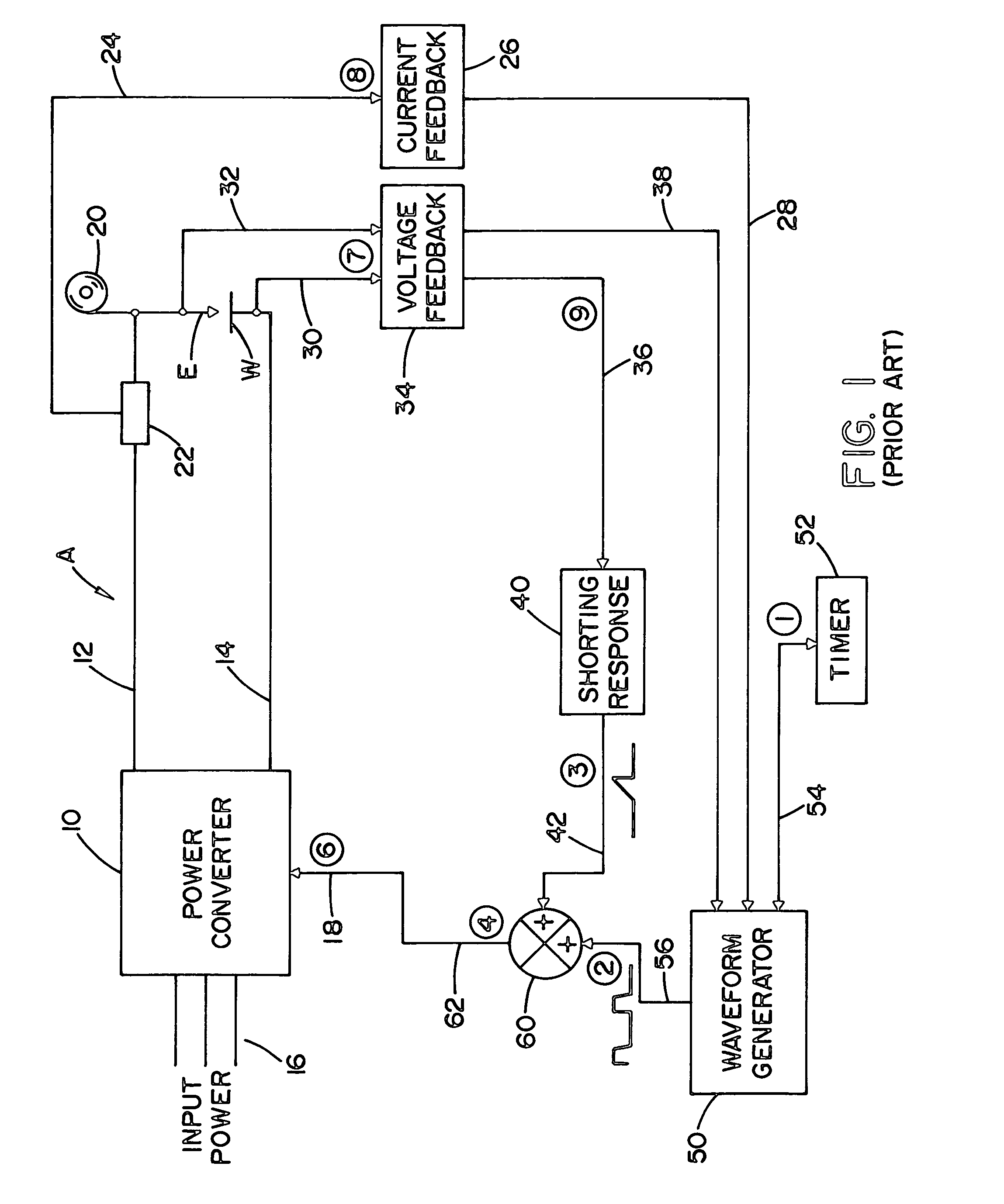

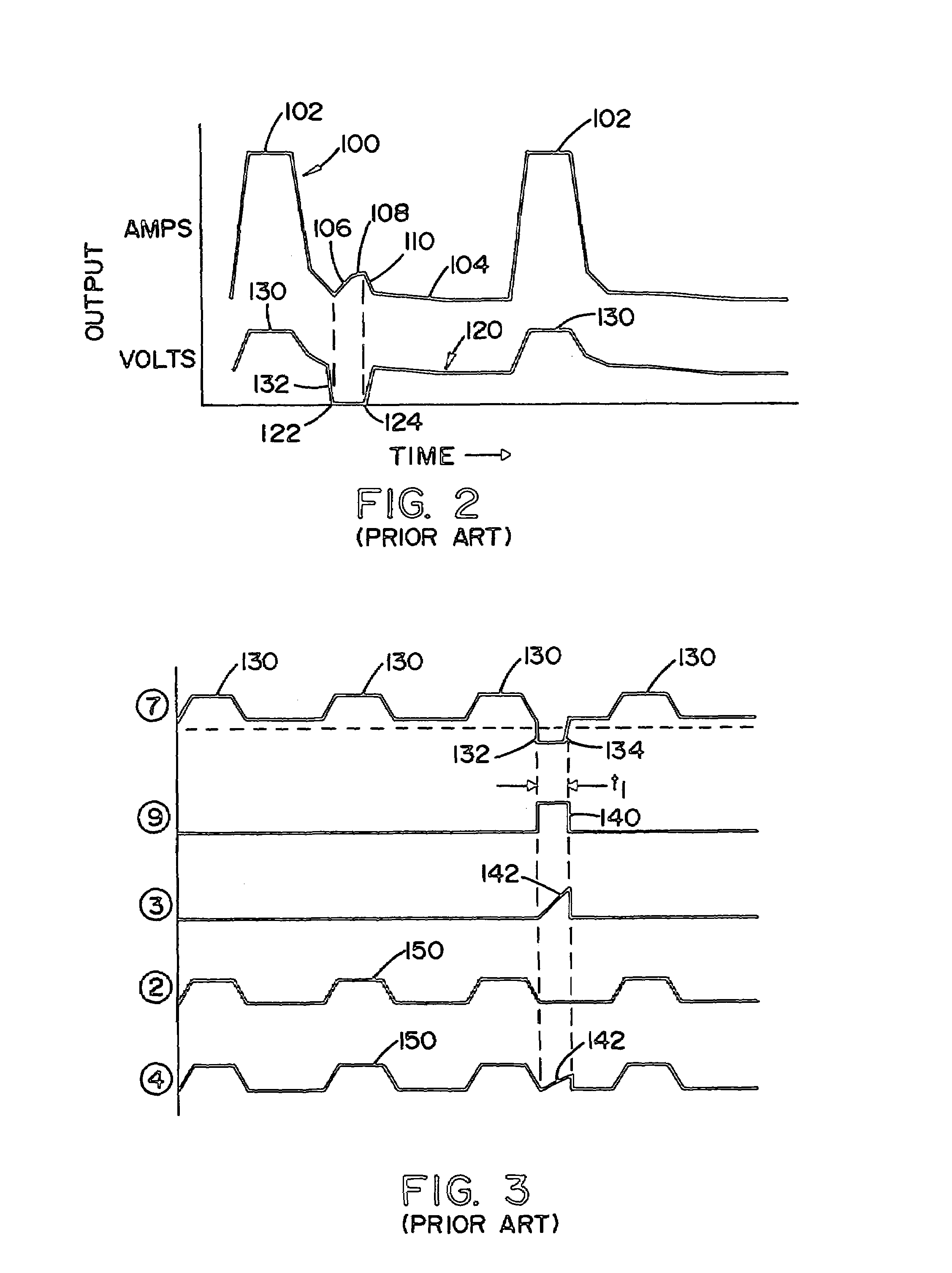

System and method for controlling an electric arc welder

InactiveUS6498321B1Inhibit currentRealize automatic adjustmentArc welding apparatusControl signalControl system

A control system for an electric arc welder performing a welding process between an electrode and a workpiece, which system comprises: a high speed switching type power supply with a controller operated at a switching frequency of at least about 10 kHz with an input current control signal to adjust the output current of the power supply; a first sensor sensing the actual arc voltage; a second sensor sensing the actual arc current; a first circuit for creating a power signal representing the desired real time power level at progressive times during the welding process; a second circuit for creating a function of the sensed actual voltage and the sensed actual current; and a third circuit for adjusting the current control signal in accordance with the difference between the power signal and the function of the actual voltage and current, preferably arc power.

Owner:LINCOLN GLOBAL INC

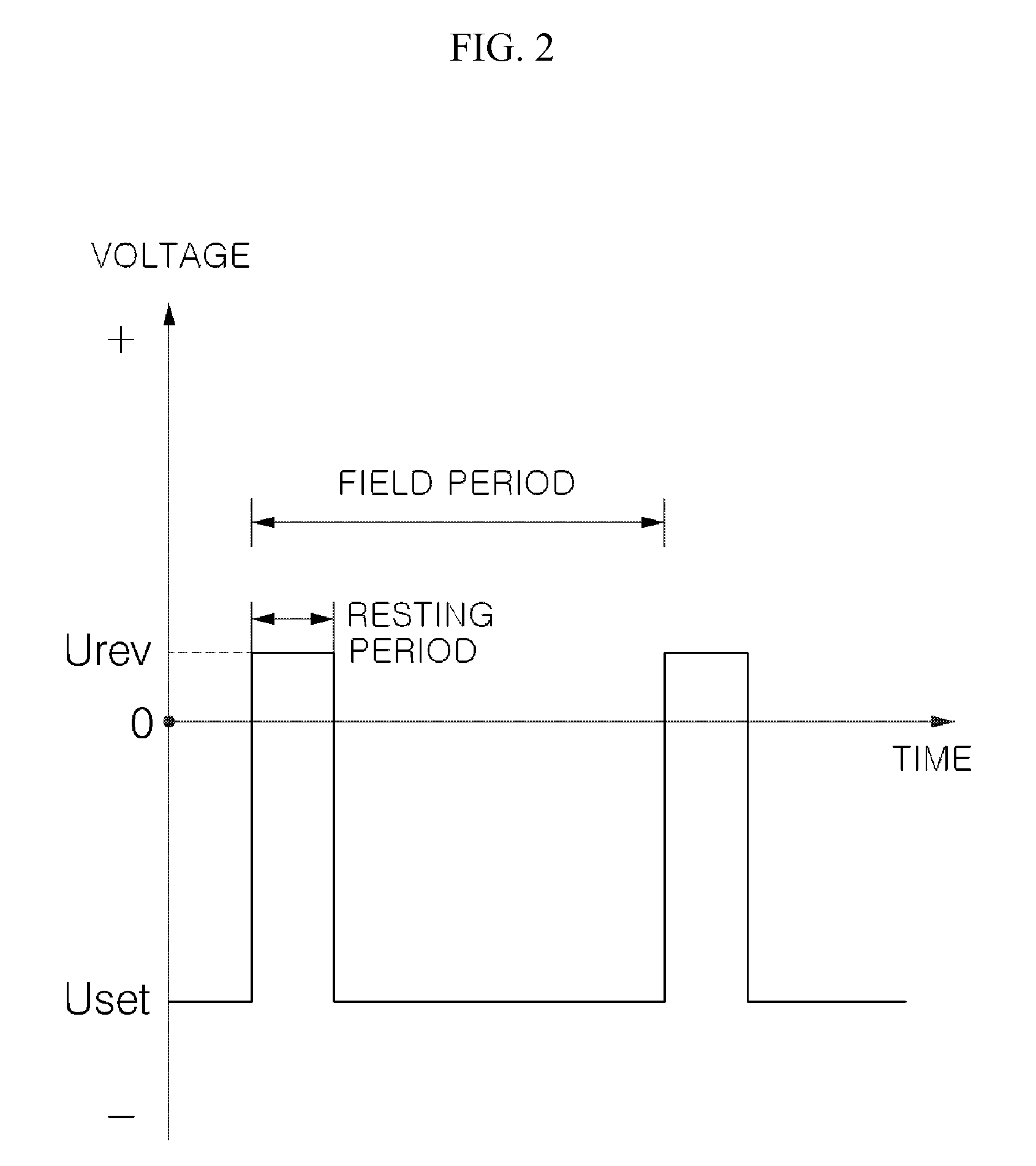

Apparatus for generating remote plasma

ActiveUS20100096367A1Eliminate chargeImprove film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaPulsed DC

Provided is an apparatus for generating remote plasma, which can improve thin-film quality by preventing an arc at a bias electrode. The apparatus includes a radio frequency (RF) electrode installed inside an upper portion of a chamber, a bias electrode installed apart from the RF electrode, and including a plurality of through holes through which plasma passes, wherein a bias power is supplied to the bias electrode, a plasma generating unit formed between the RF electrode and the bias electrode, wherein a plasma gas is supplied to the plasma generating unit, and a ground electrode installed under and spaced apart from the bias electrode, and including plasma through holes corresponding to the through holes of the bias electrode, wherein a pulsed DC bias of a second voltage level, which has a first voltage level periodically, is applied to the bias electrode.

Owner:TOKYO ELECTRON LTD

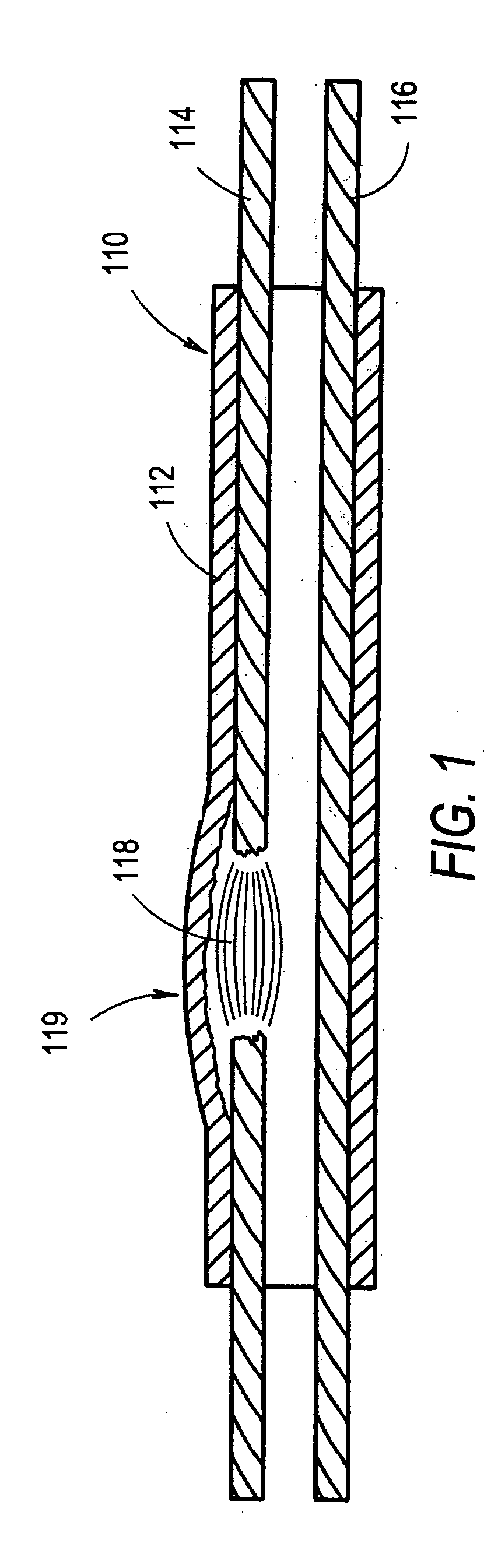

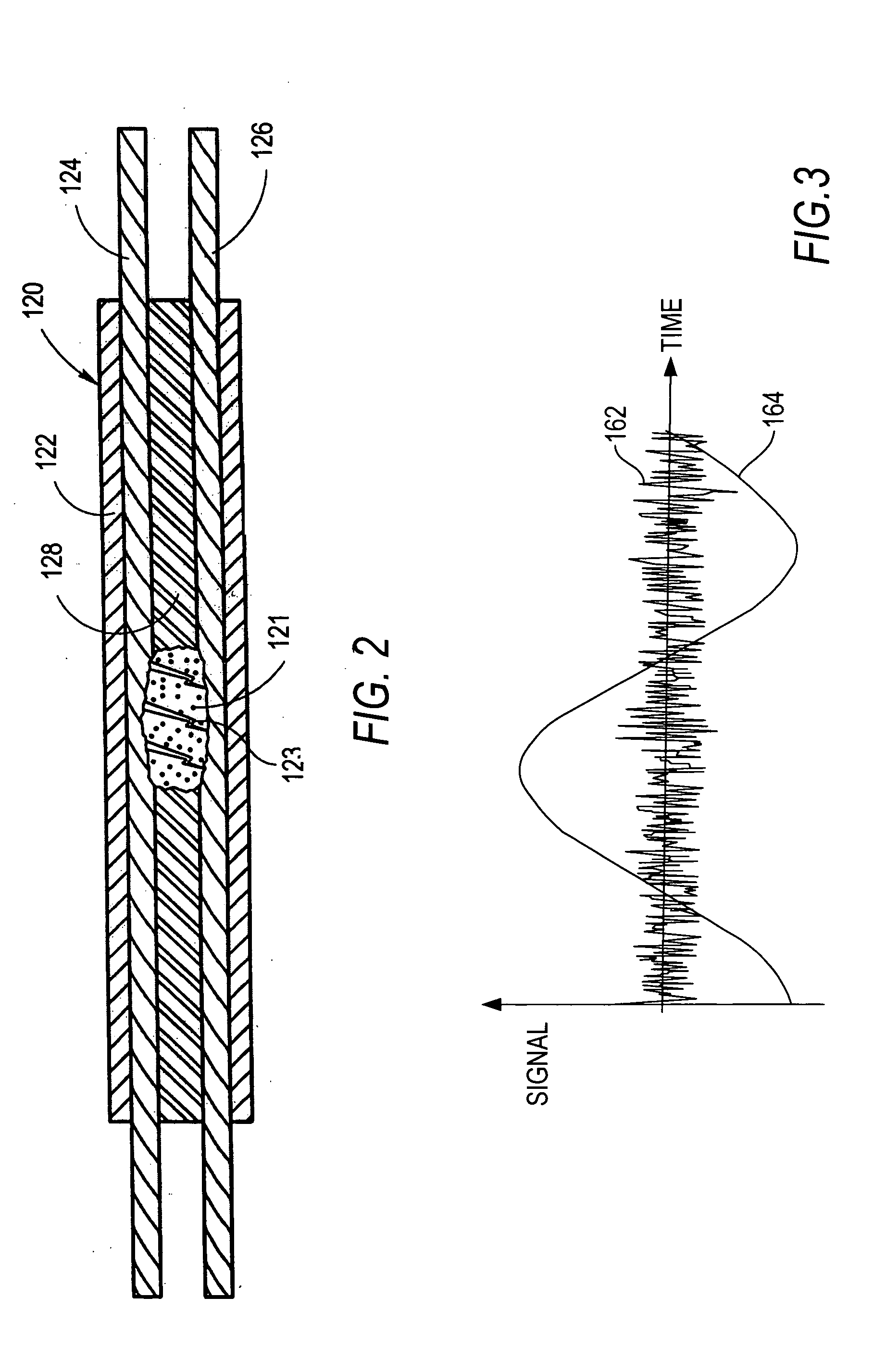

Method and apparatus for electric arc welding

An electric arc welding apparatus for depositing molten metal from an advancing welding wire into a weld puddle in an open root between two juxtapositioned plates where the root extends in a welding path and is formed by converging walls terminating in generally parallel walls spaced to define a gap, which apparatus comprises a contact holder with a wire outlet, a switching power supply directing welding current to the wire as the wire passes from the outlet toward the open root, with the advancing wire defining an electrode stick out between the contact holder and the weld puddle, a circuit for sensing the length of the stick out, and control means for adjusting the welding current as a function of the sensed stick out length.

Owner:LINCOLN GLOBAL INC

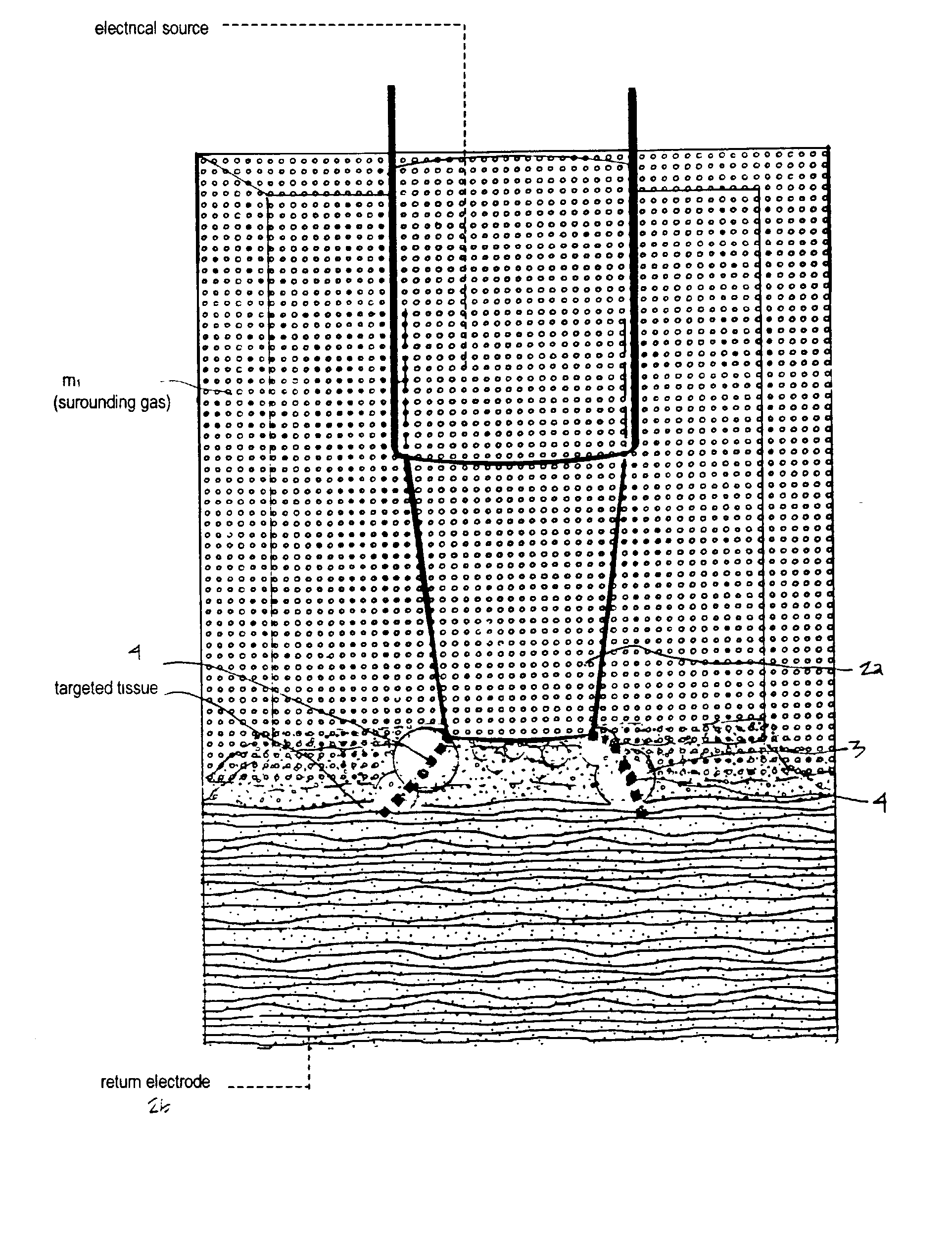

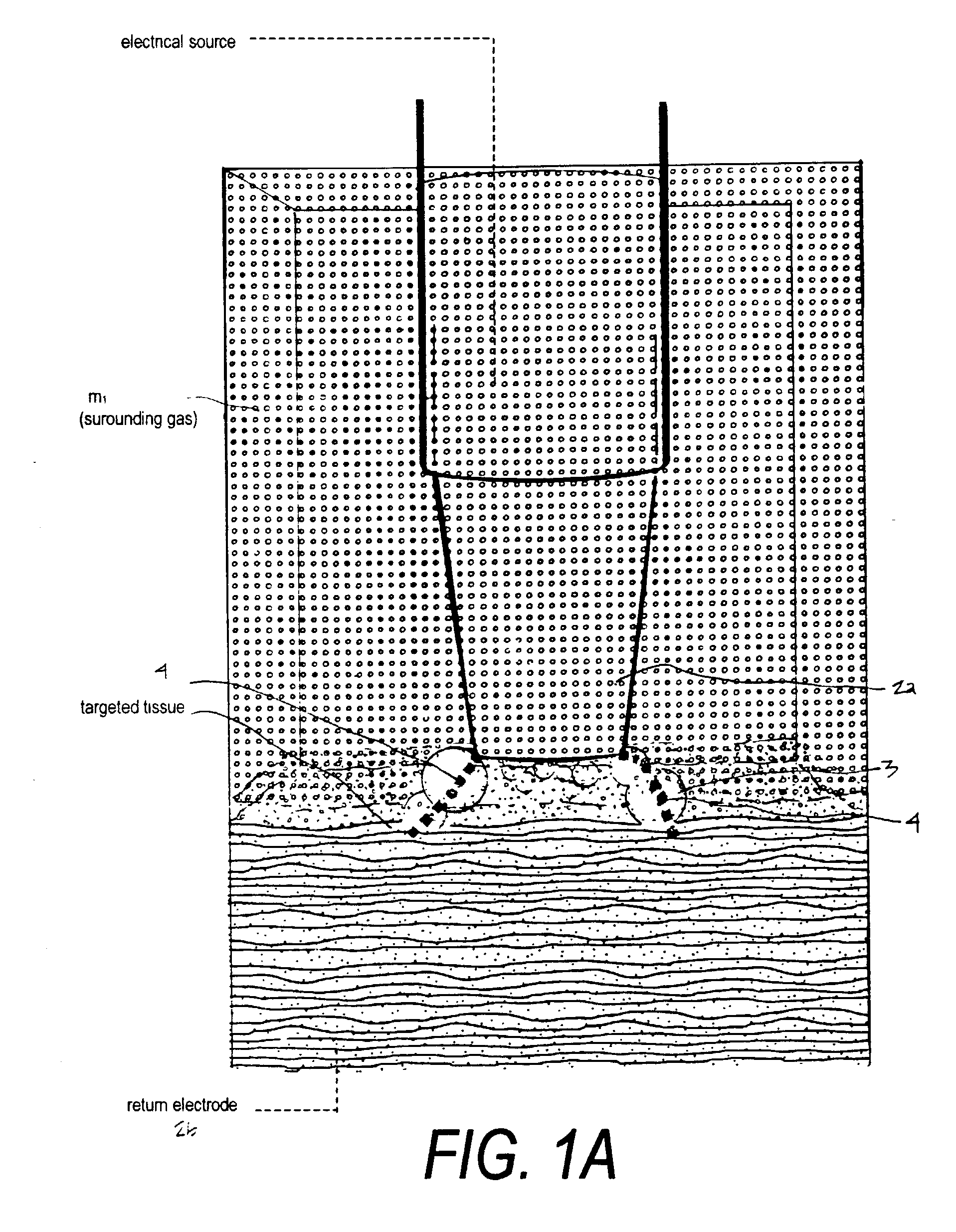

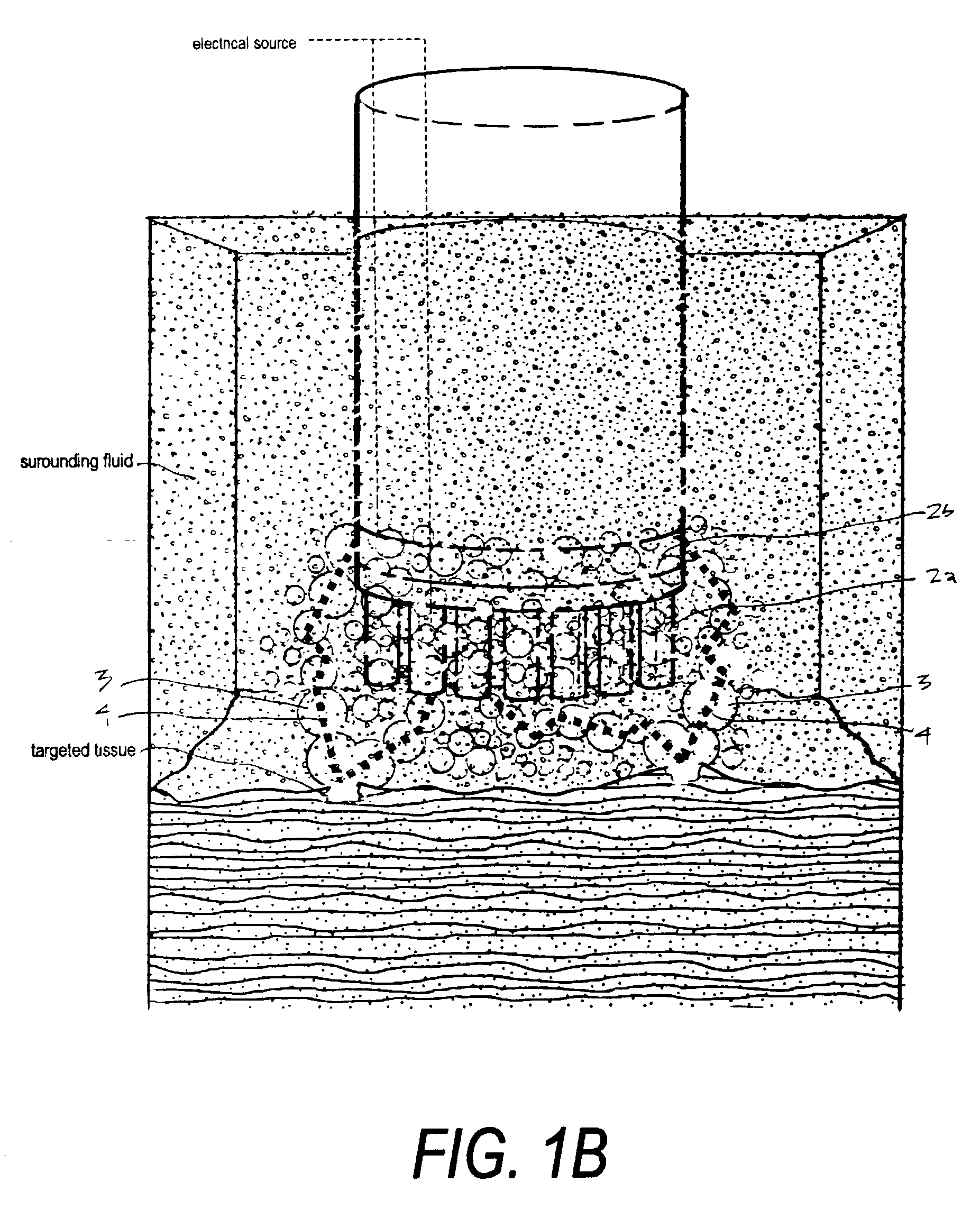

Electrical discharge devices and techniques for medical procedures

InactiveUS20030125727A1Enhance electron avalancheDiagnosticsSurgical instrument detailsTarget tissueMedical procedure

A medical instrument coupled to first and second energy means and a computer controller for the controlled volumetric removal of thin tissue layers. The system provides a source for introducing a gas to controllably form and capture transient gas volumes in a microchannel structure at the working surface of the instrument that interfaces with a targeted tissue site. Each of the microchannel features of the working surface carries an electrode element coupled to the electrical source. The energy may be applied to the targeted site in either of two modes of operation, depending in part on voltage and repetition rate of energy delivery. In one mode of energy application, electrical potential is selected to cause an intense electrical arc across the transient ionized gas volumes to cause an energy-tissue interaction characterized by tissue vaporization. In another preferred mode of energy delivery, the system applies selected levels of energy to the targeted site by means of an energetic plasma at the instrument working surface to cause molecular volatilization of surface macromolecules thus resulting in material removal. Both modes of operation limit collateral thermal damage to tissue volumes adjacent to the targeted site. Another preferred embodiment provides and an ultrasound source or other vibrational source coupled to the working end to cause cavitation in fluid about the working end.

Owner:RELIGN CORP

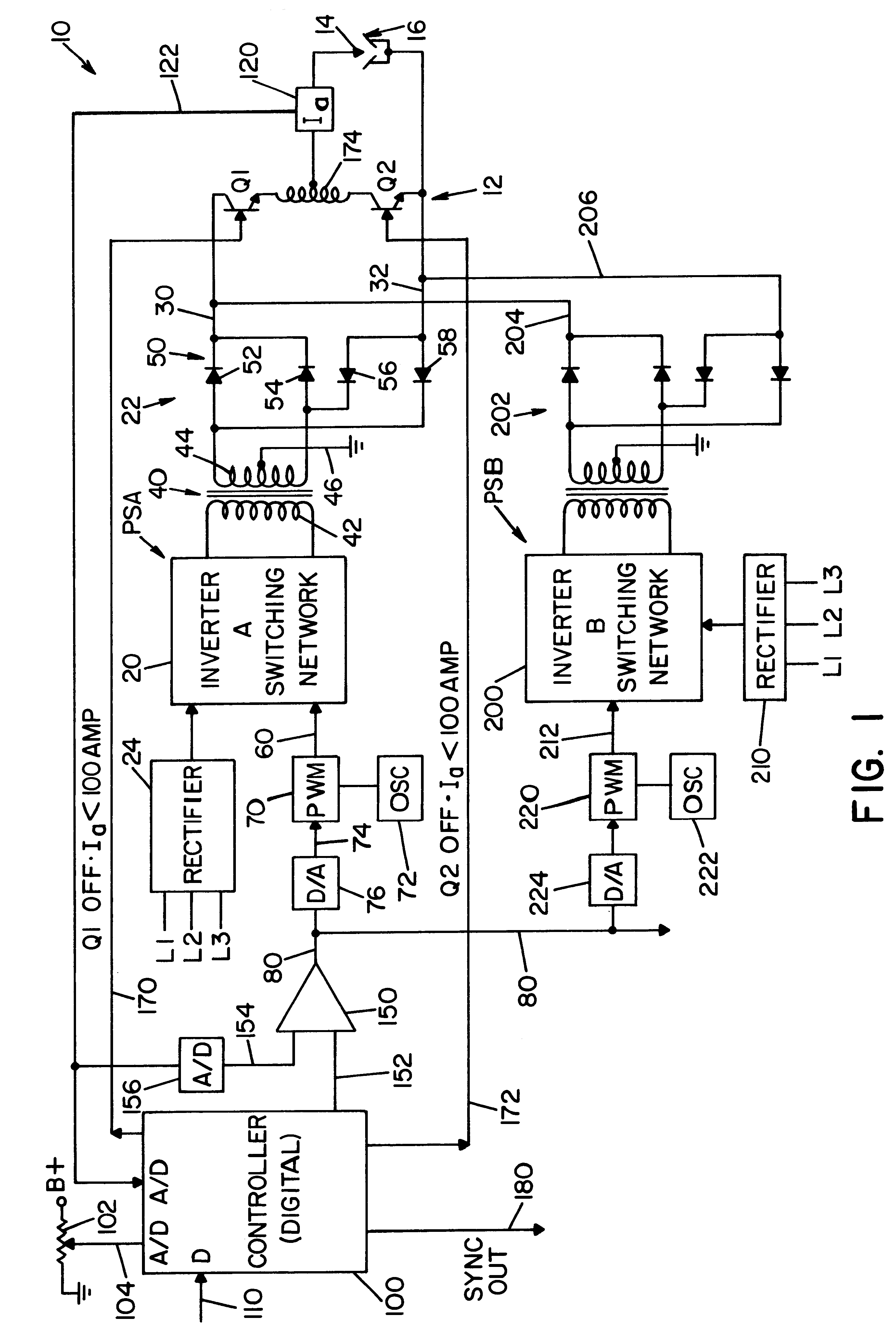

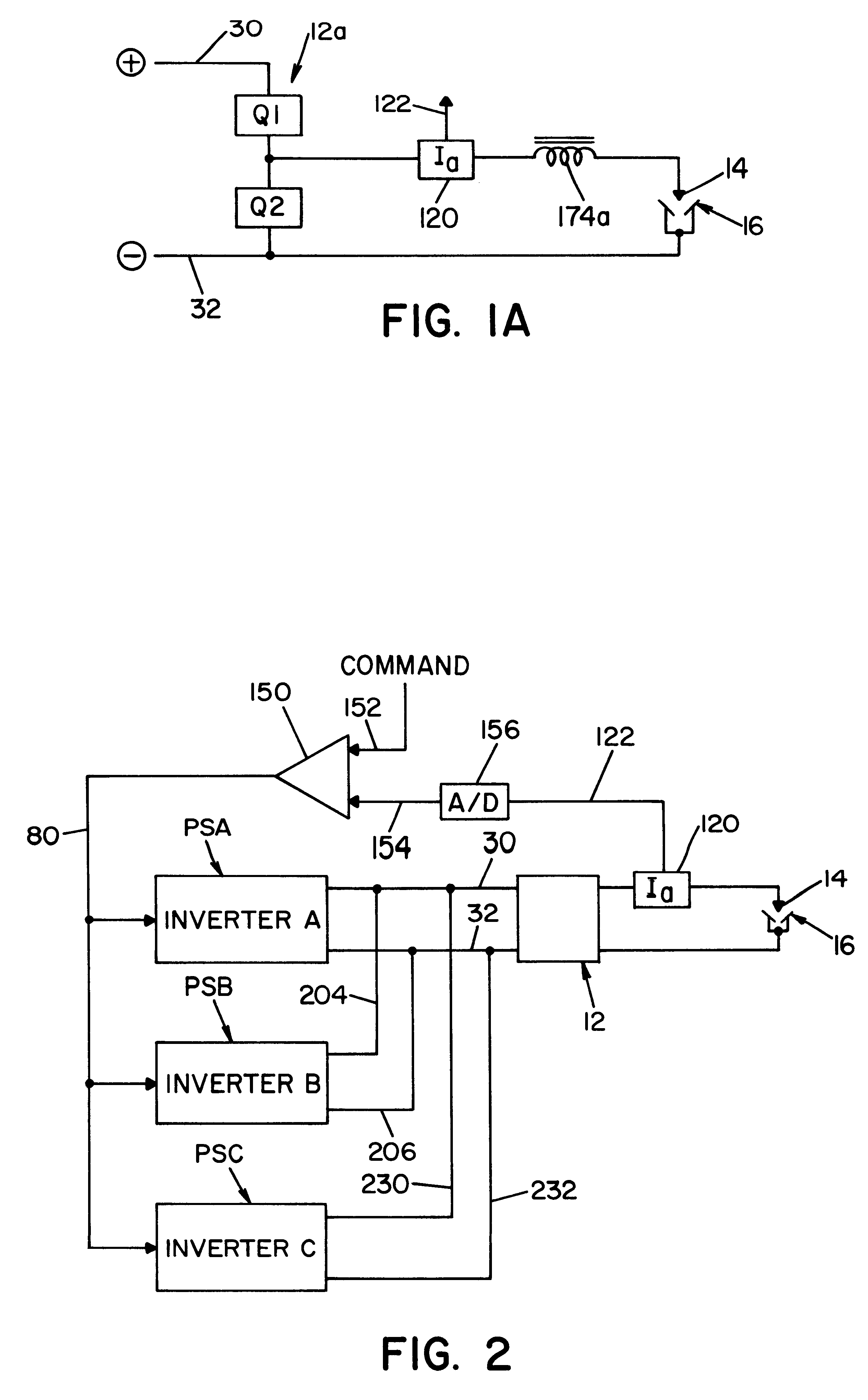

Electric ARC welder with a plurality of power supplies

An electric arc welder comprising a plurality of power supplies connected to a single welding station with a D.C. input for passing an arc welding current across an electrode and workpiece, each of the power supplies including a switching type inverter with an output D.C. current determined by a signal applied to the input of the power supply, a circuit connecting the output D.C. currents in parallel at the input of the welding station, a feedback circuit including a sensor for creating a current signal representing the arc current, a command signal source, and a circuit for creating a master current signal based upon the sensed current signal and the command signal, and a circuit for applying said master current signal to the input of the plurality of power supplies whereby the D.C. current to the D.C. input of the welding station is equally shared by the power supplies.

Owner:LINCOLN GLOBAL INC

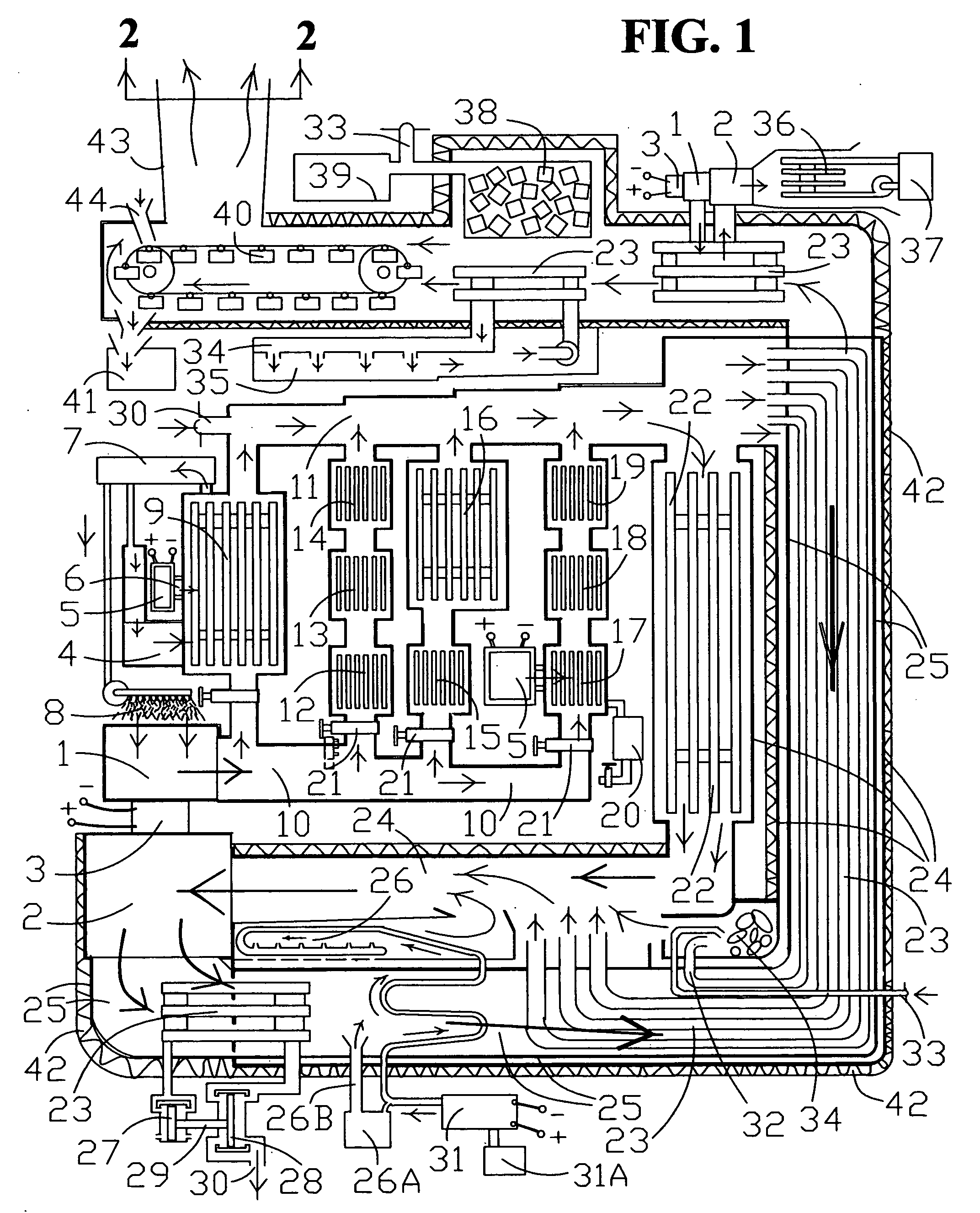

Device and method for regulating intensity of beam extracted from a particle accelerator

InactiveUS20040155206A1Thermometer detailsElectrode and associated part arrangementsElectric arcParticle accelerator

The invention concerns a device (10) for regulating the intensity of a beam extracted from a particle accelerator, such as a cyclotron, used for example for protontherapy, said particles being generated from an ion source. The invention is characterised in that it comprises at least: a comparator (90) determining a difference epsilon between a digital signal IR representing the intensity of the beam measured at the output of the accelerator and a setpoint value IC of the beam intensity: a Smith predictor (80) which determines on the basis of the difference epsilon, a corrected value of the intensity of the beam IP; an inverted correspondence table (40) supplying, on the basis of the corrected value of the intensity of the beam IP a setpoint value IA for supplying arc current from the ion source (20).

Owner:ION BEAM APPL

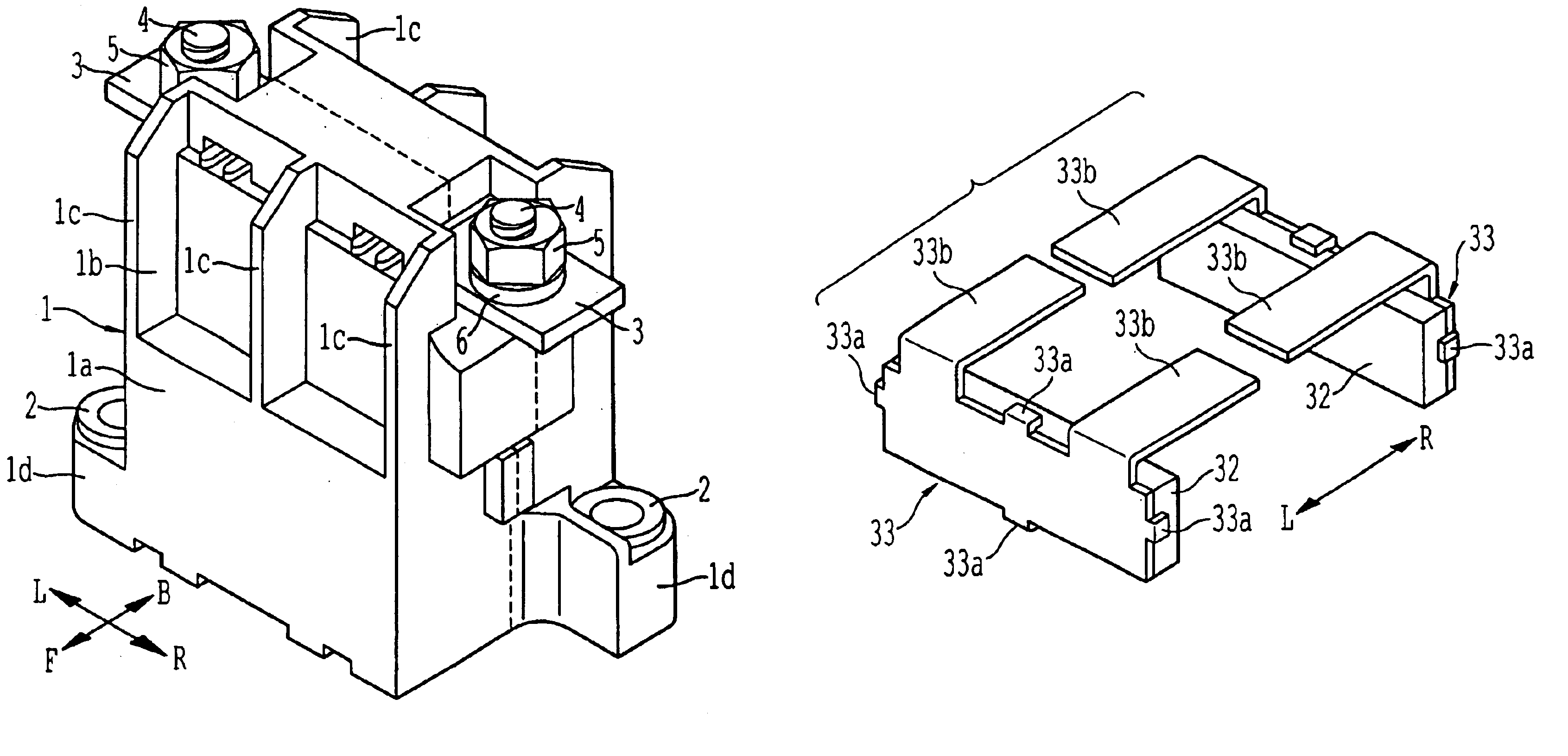

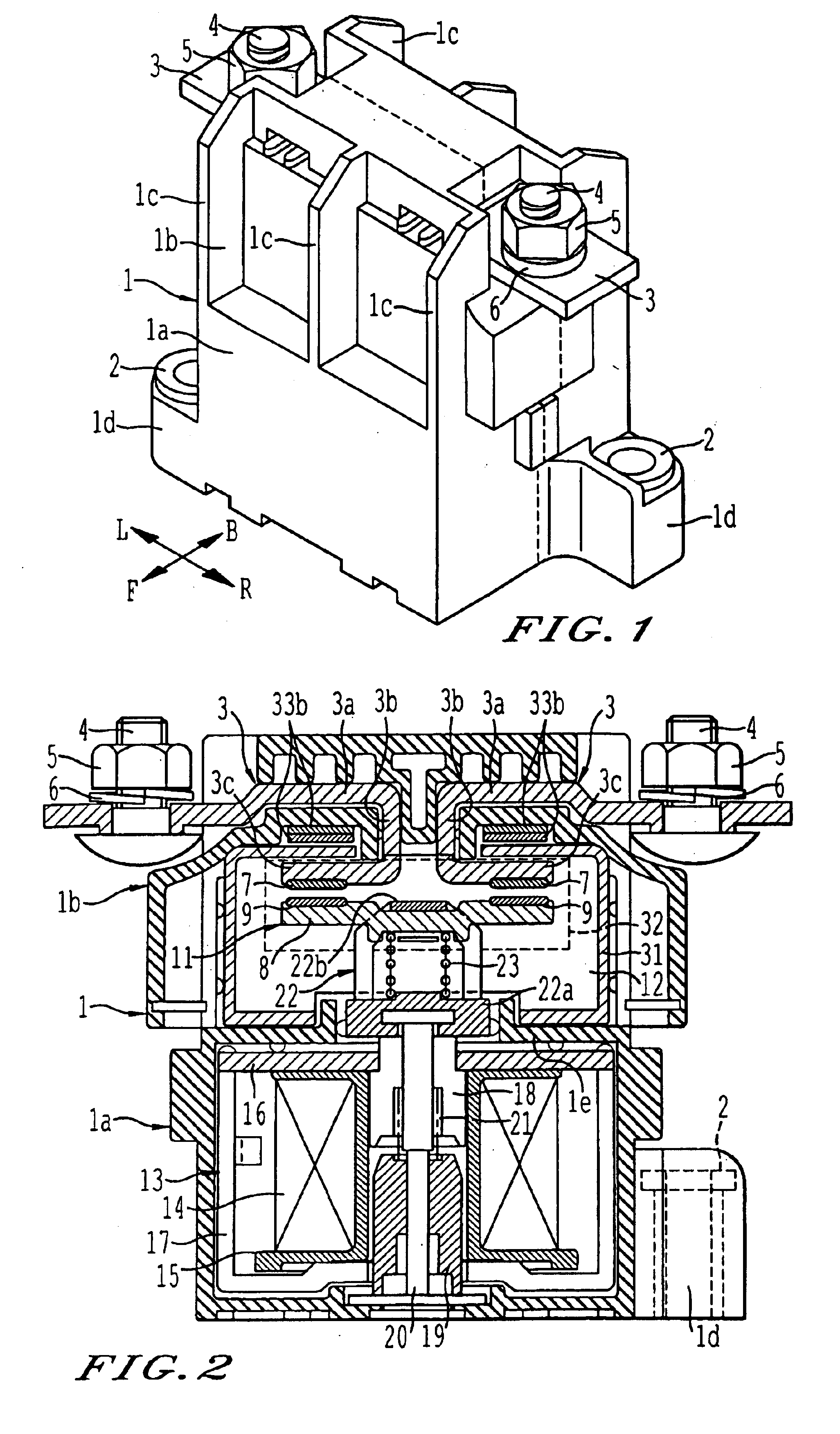

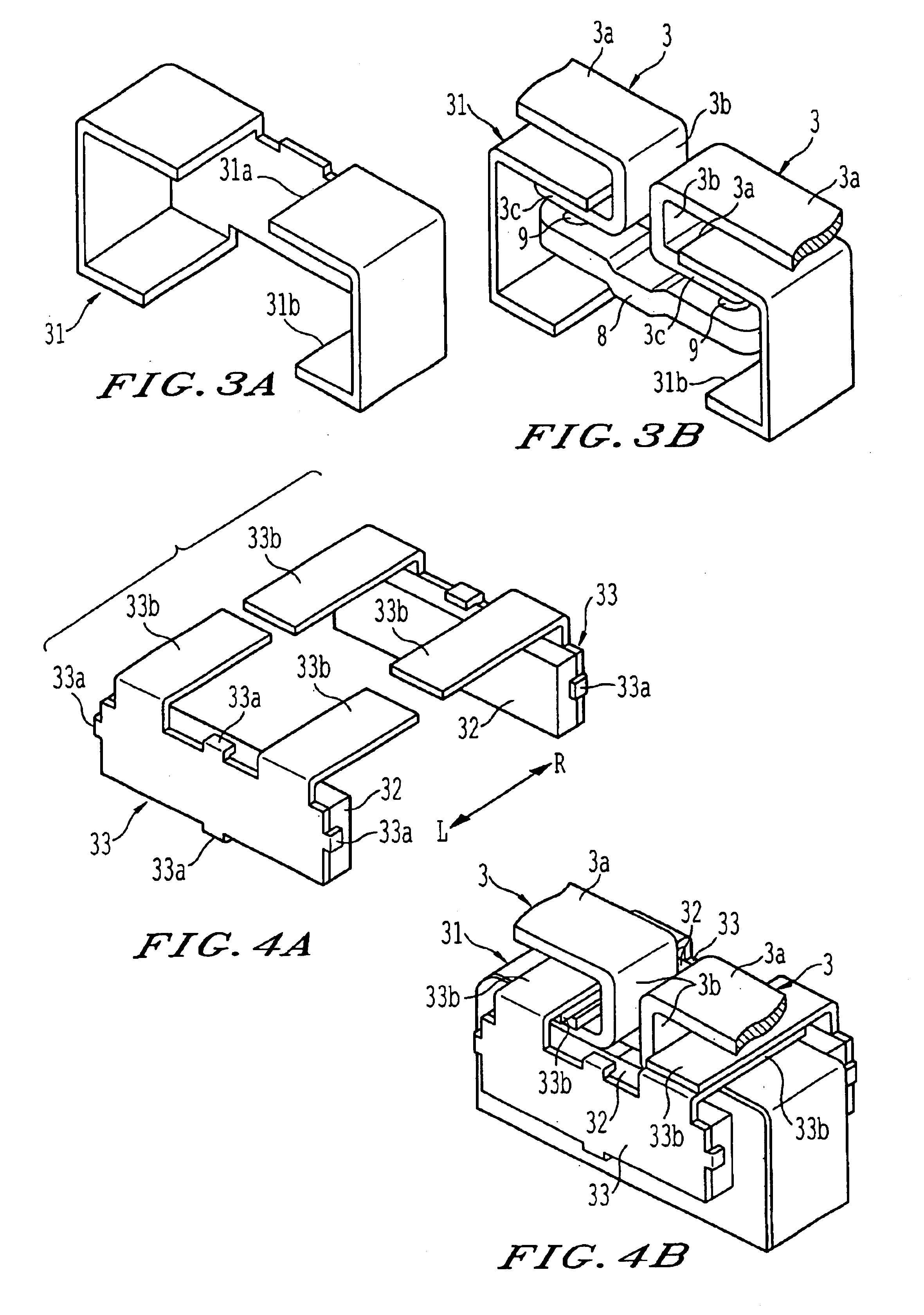

Contactor

InactiveUS6700466B1Increase arc lengthIncrease arc voltageHigh-tension/heavy-dress switchesAir-break switchesEngineeringMagnet

A contact apparatus is provided having a permanent magnet disposed in a region where a fixing contact point is mounted to a fixing contact and a movable contact to which a movable contact point is mounted. An arc generated between both the contact points is moved in a lateral direction by the magnetic force of the permanent magnet and stretched. An arc-extinguishing member which is heated by the arc for generating arc-extinguishing gas is provided such as to surround the fixing contact point and the movable contact point.

Owner:MATSUSHITA ELECTRIC WORKS LTD

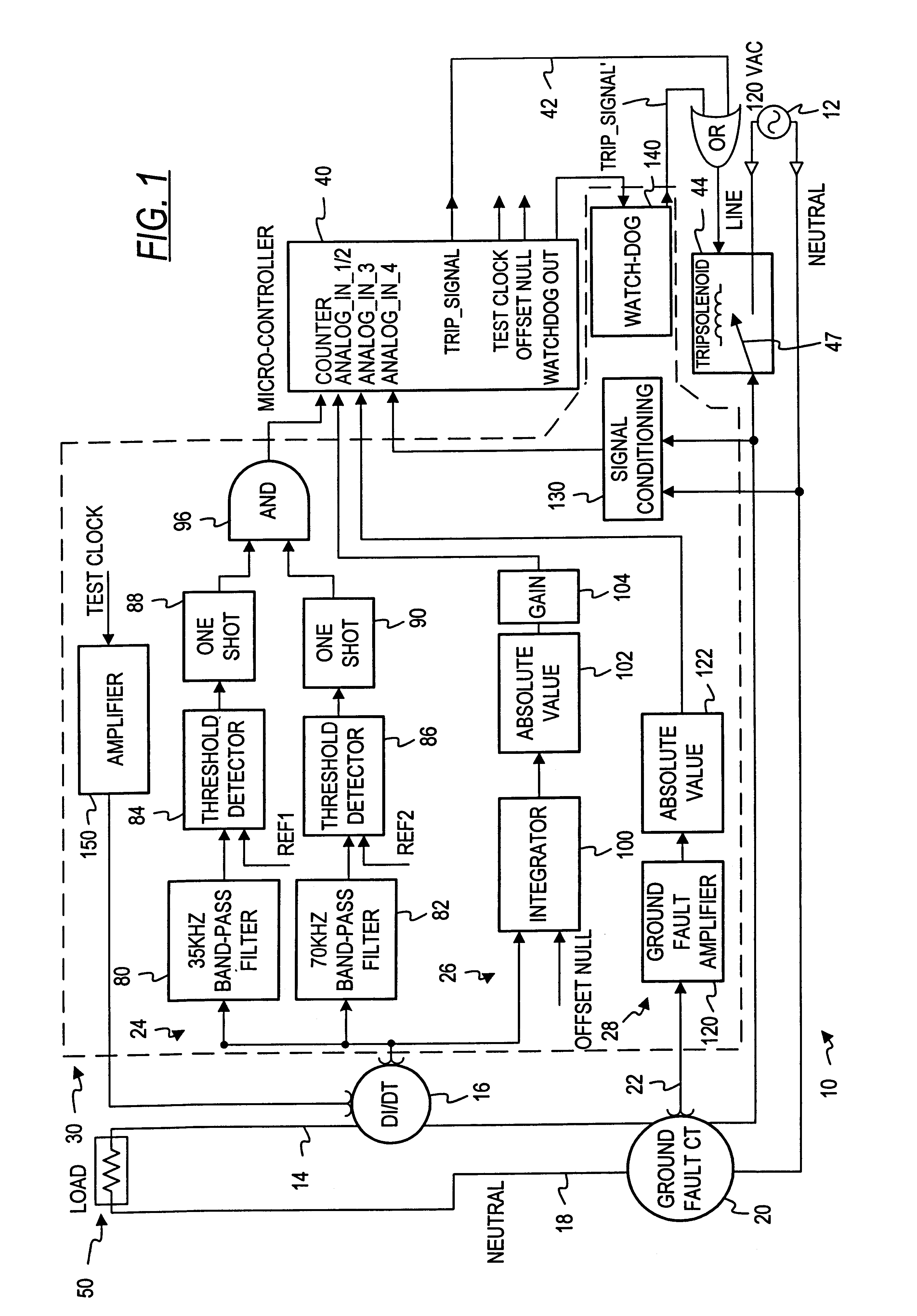

Arc fault detection system

InactiveUS6259996B1Reliably detectsGuaranteed uptimeLevel controlNoise figure or signal-to-noise ratio measurementBroadband noiseSystems analysis

An arc fault detector system detects arcing faults in an electrical distribution system by monitoring one or more conductors and producing an input signal representing one or more electrical signal conditions in the circuit to be monitored. This input signal is processed to develop signals representing the electrical current flow through the monitored circuit and broadband noise signal components. The system analyzes these signals to determine whether an arcing fault is present, and if so, outputs a trip signal which may be used directly or indirectly to trip a circuit breaker or other circuit interruption device.

Owner:SQUARE D CO

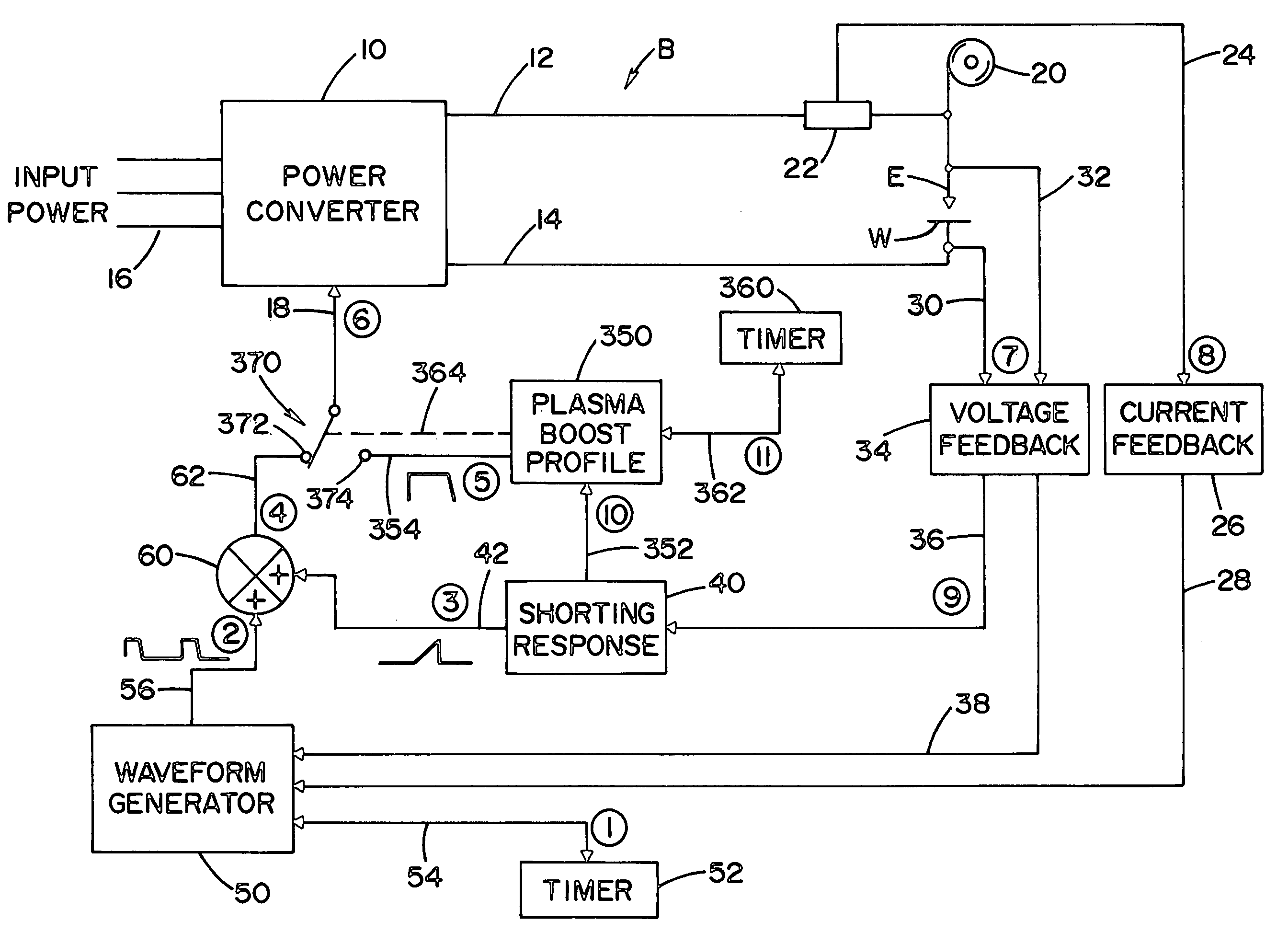

Pulse welder and method of using same

ActiveUS7304269B2Reduce arc forcePromote shorting eventsCoin-freed apparatus detailsArc welding apparatusPower flowEngineering

An electric arc welder for performing a pulse welding process by a current between an advancing electrode and workpiece where the welder comprises a short detecting circuit for creating a short signal upon occurrence of a short circuit between the advancing electrode and the workpiece and a boost circuit to create a plasma boost pulse after the short circuit is cleared during the time period when the welder is not outputting the peak pulse current.

Owner:LINCOLN GLOBAL INC

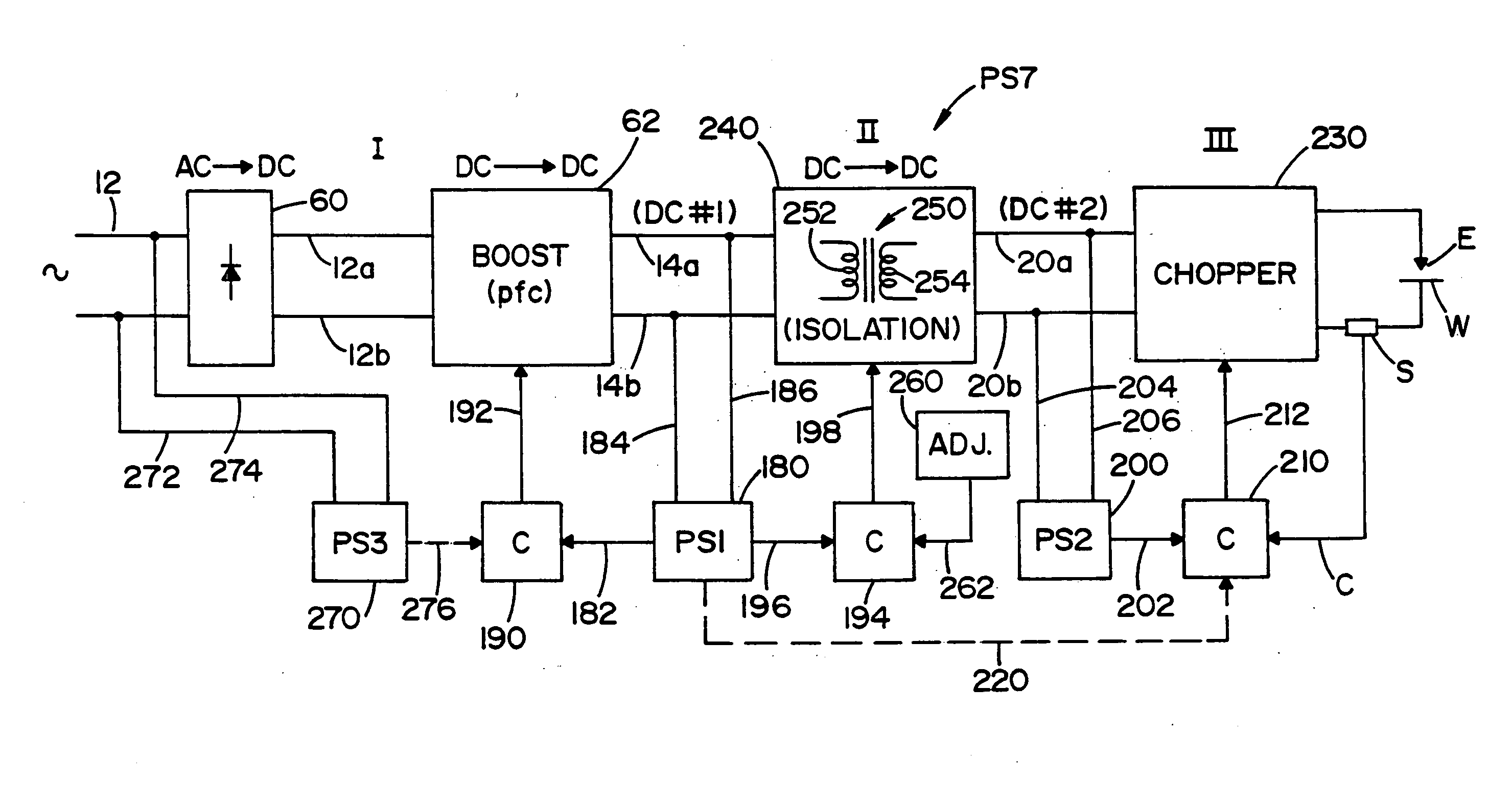

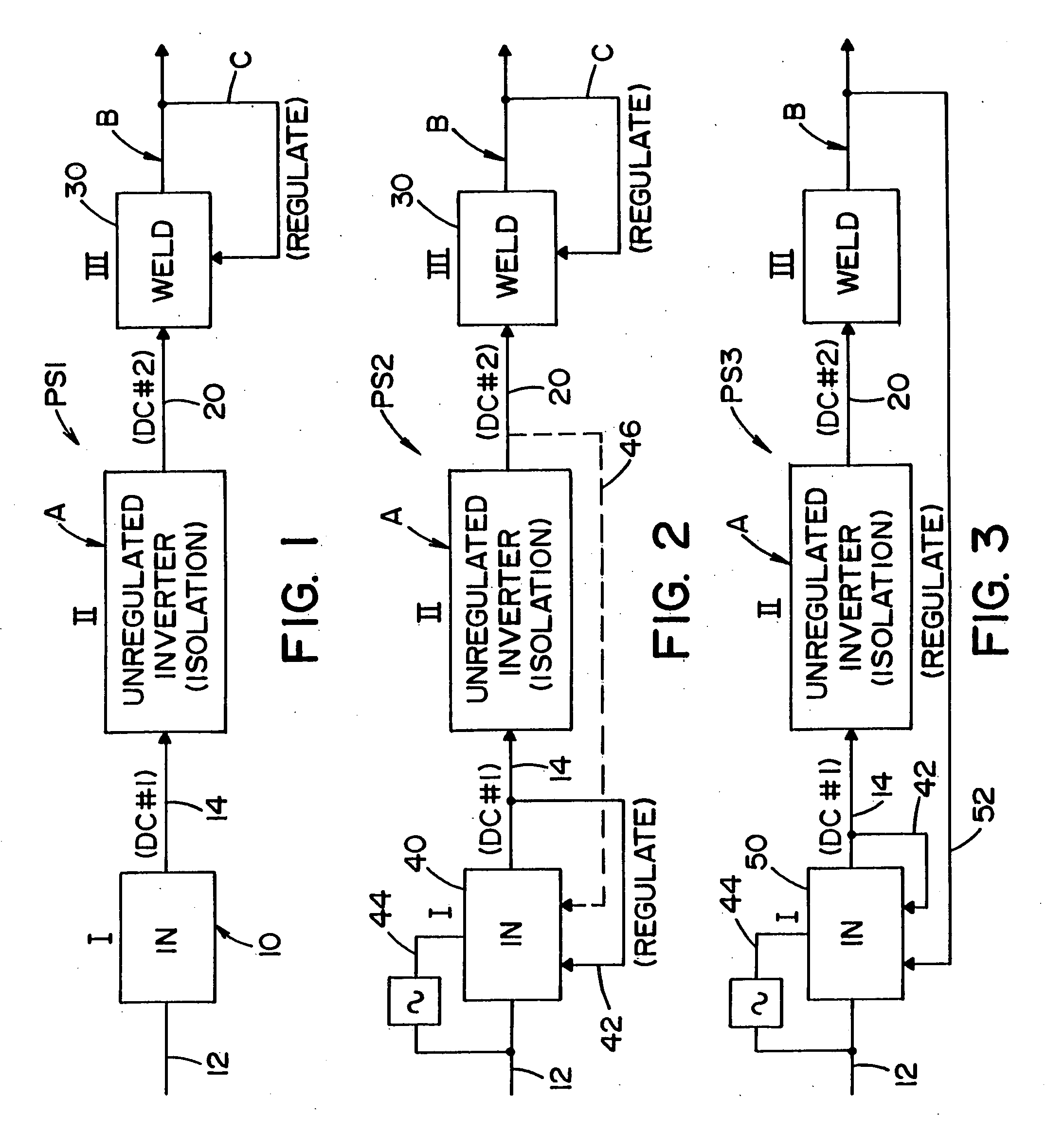

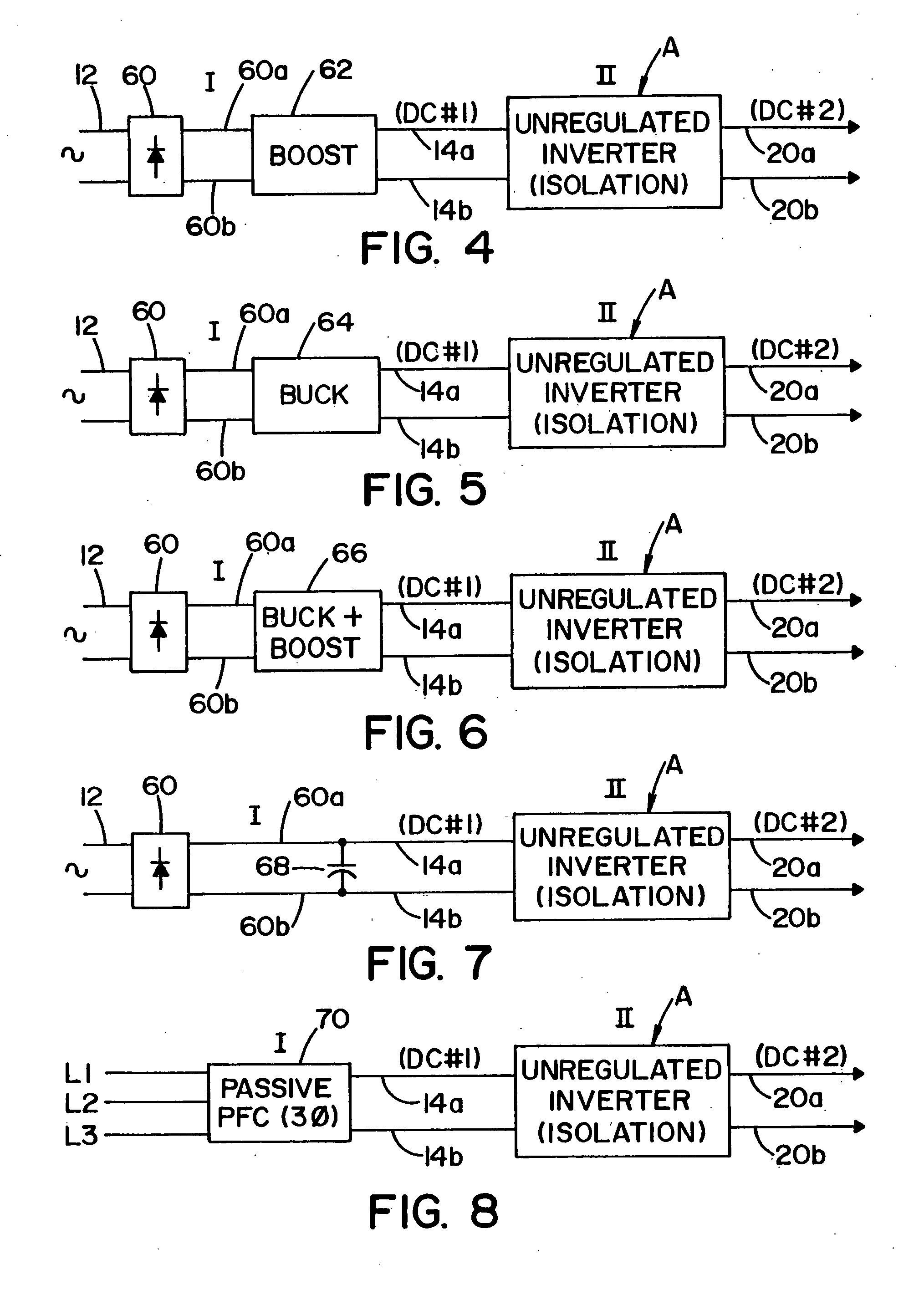

Three stage power source for electric ARC welding

ActiveUS20060213890A1Fast switching speedImprove portabilityEfficient power electronics conversionAc-dc conversionSoft switchingEngineering

A three stage power source for an electric arc welding process comprising an input stage having an AC input and a first DC output signal; a second stage in the form of an unregulated DC to DC converter having an input connected to the first DC output signal, a network of switches switched at a high frequency with a given duty cycle to convert the input into a first internal AC signal, an isolation transformer with a primary winding driven by the first internal high frequency AC signal and a secondary winding for creating a second internal high frequency AC signal and a rectifier to convert the second internal AC signal into a second DC output signal of the second stage, with a magnitude related to the duty cycle of the switches; and, a third stage to convert the second DC output signal to a welding output for welding wherein the input stage has a regulated DC to DC converter with a boost power switch having an active soft switching circuit.

Owner:LINCOLN GLOBAL INC

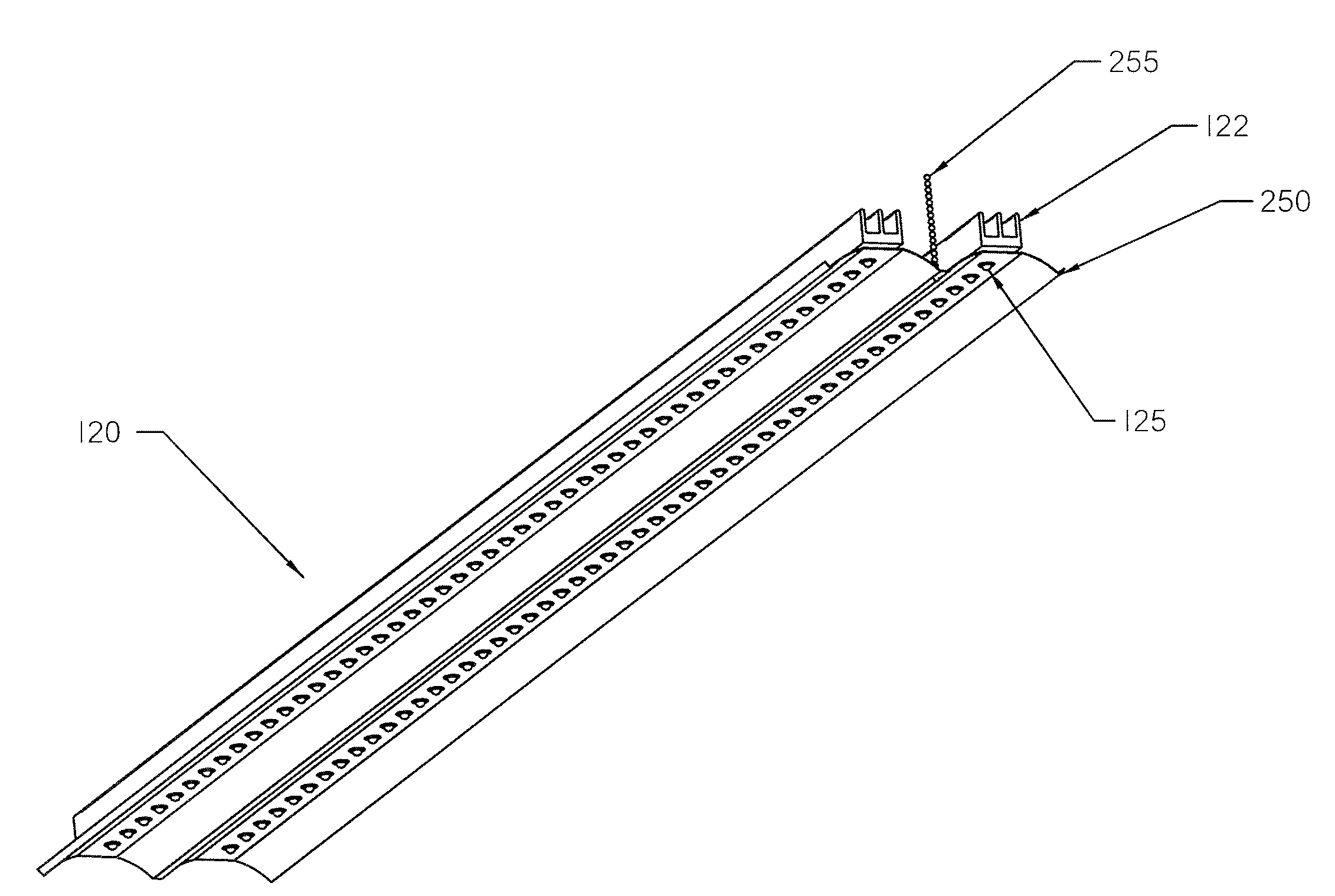

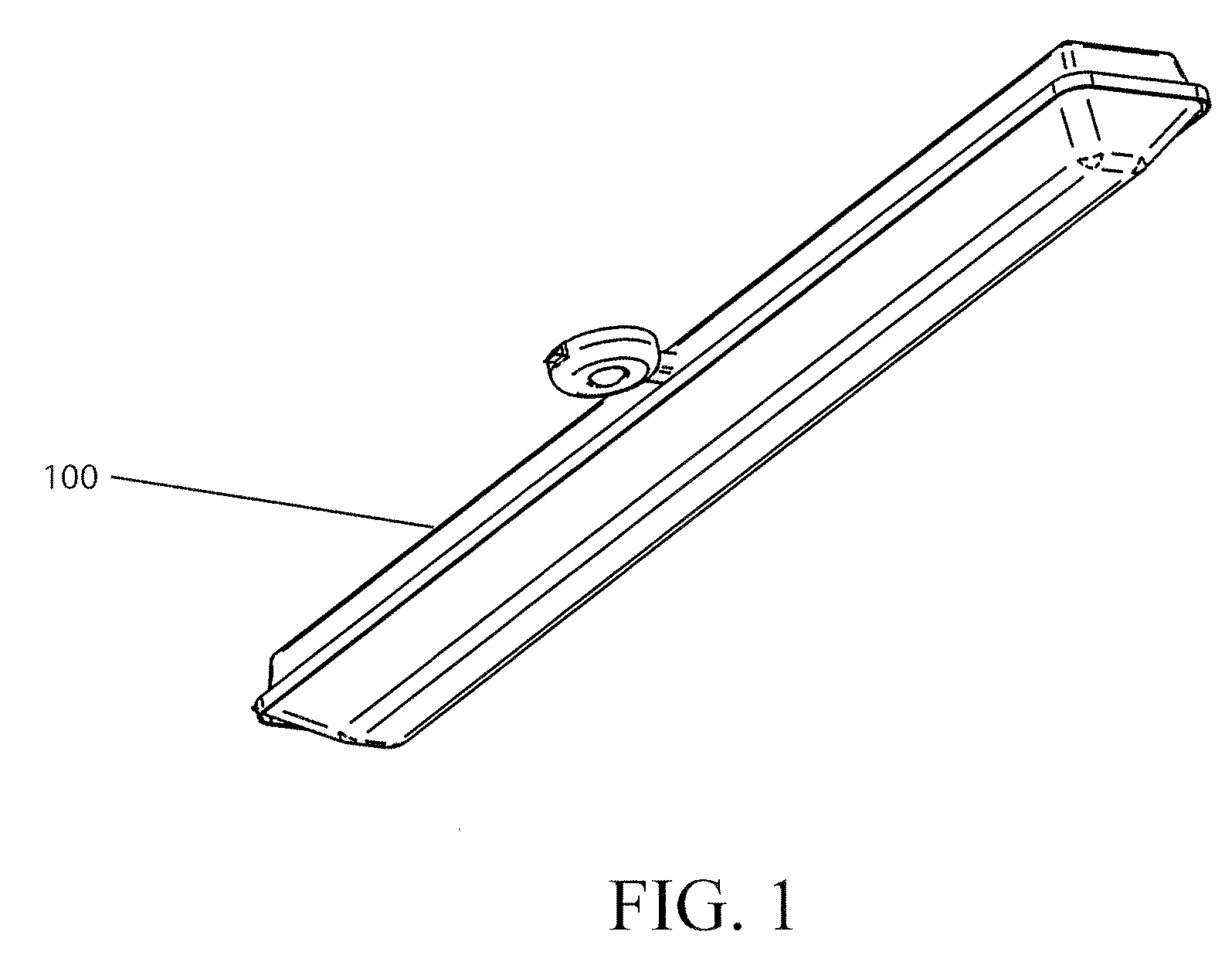

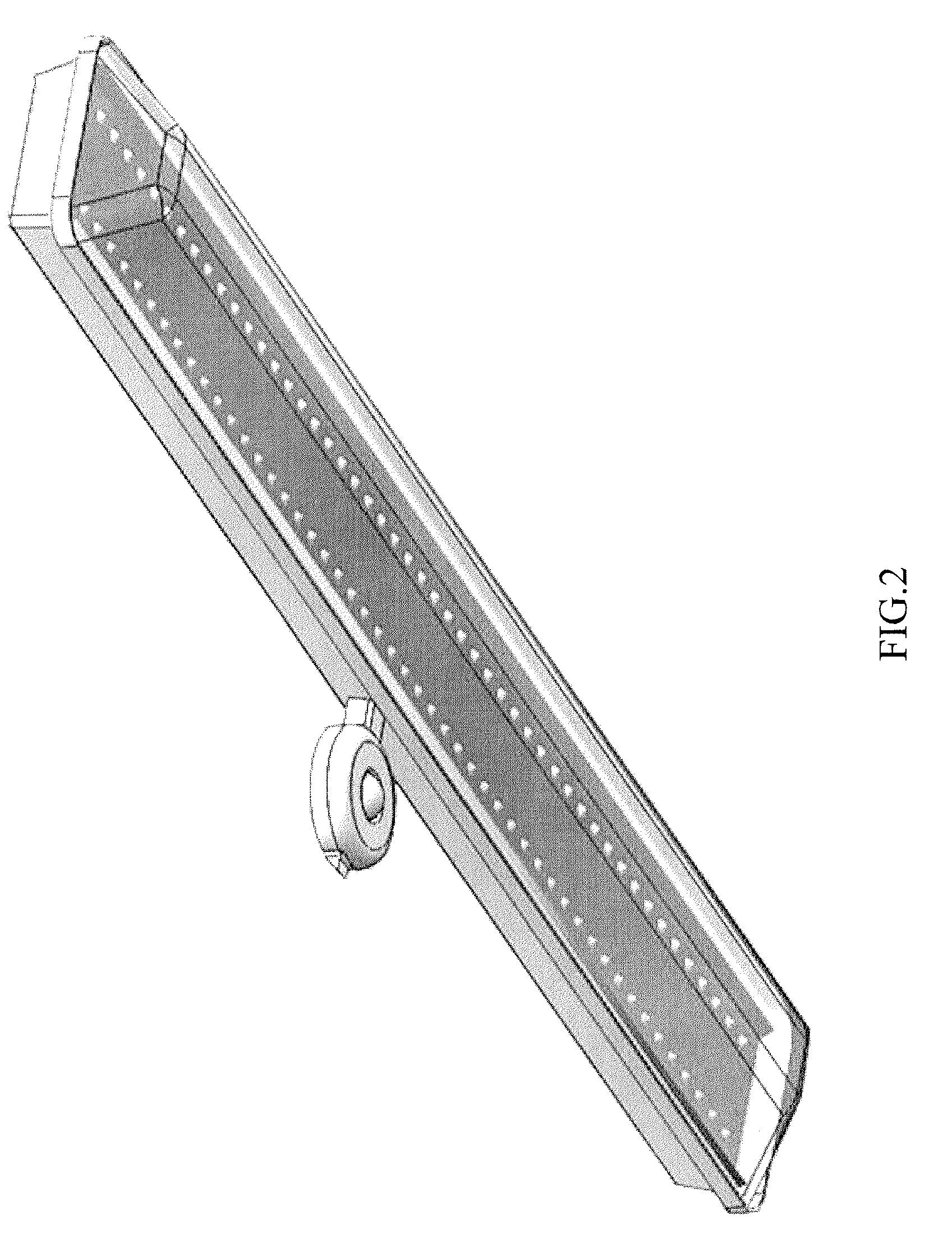

Solid-state lighting fixtures

ActiveUS20090046457A1Easy to changeTurn easilyLight source combinationsPoint-like light sourceFluorescenceEffect light

Owner:EVERHART ROBERT L

Electrical power outlet strip

InactiveUS20050286184A1Improve immunityHigh-frequency energyCoupling device detailsEmergency protective arrangement detailsElectric forceElectrical devices

The power strip of the present disclosure includes an arc fault circuit interrupter (AFCI) to interrupt power to electrical devices plugged into the power strip when arcing is detected and, when combined with a transient voltage surge suppressor (TVSS) device and / or a ground fault circuit interrupter (GFCI) also can provide transient voltage surge suppression and ground fault protection. The power strip here disclosed can include an AFCI by itself or an ACFI in combination with a GFCI.

Owner:LEVITON MFG

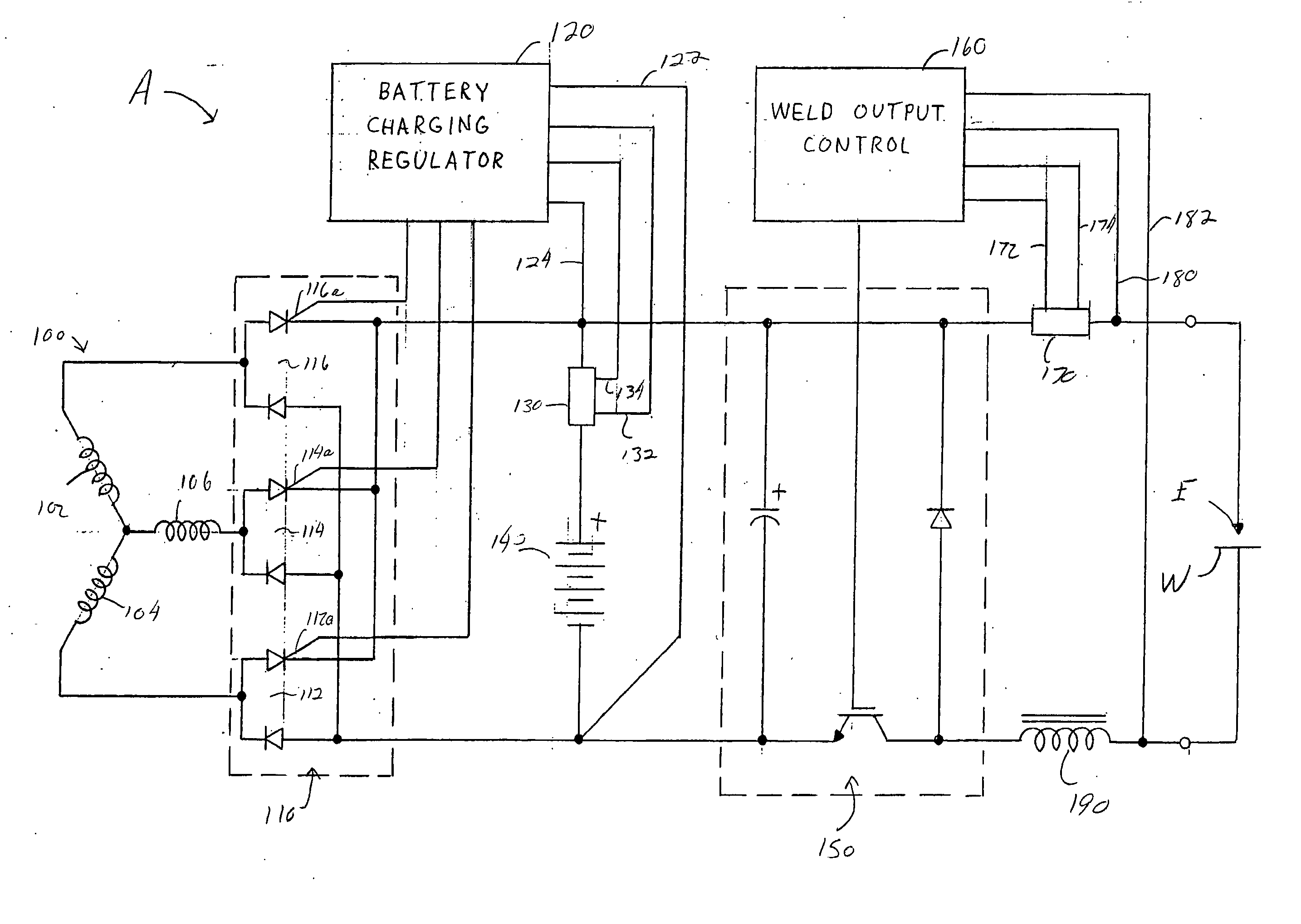

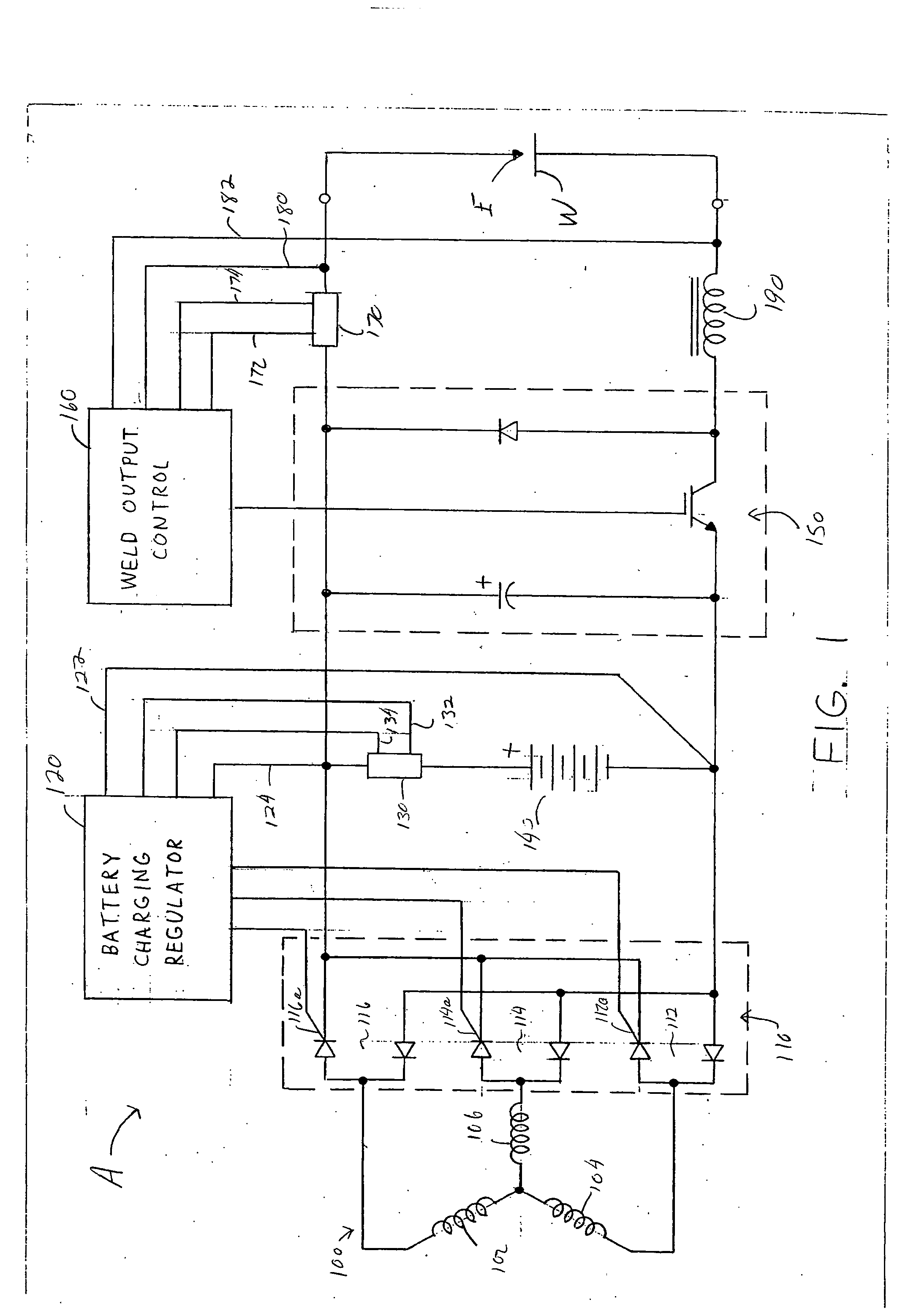

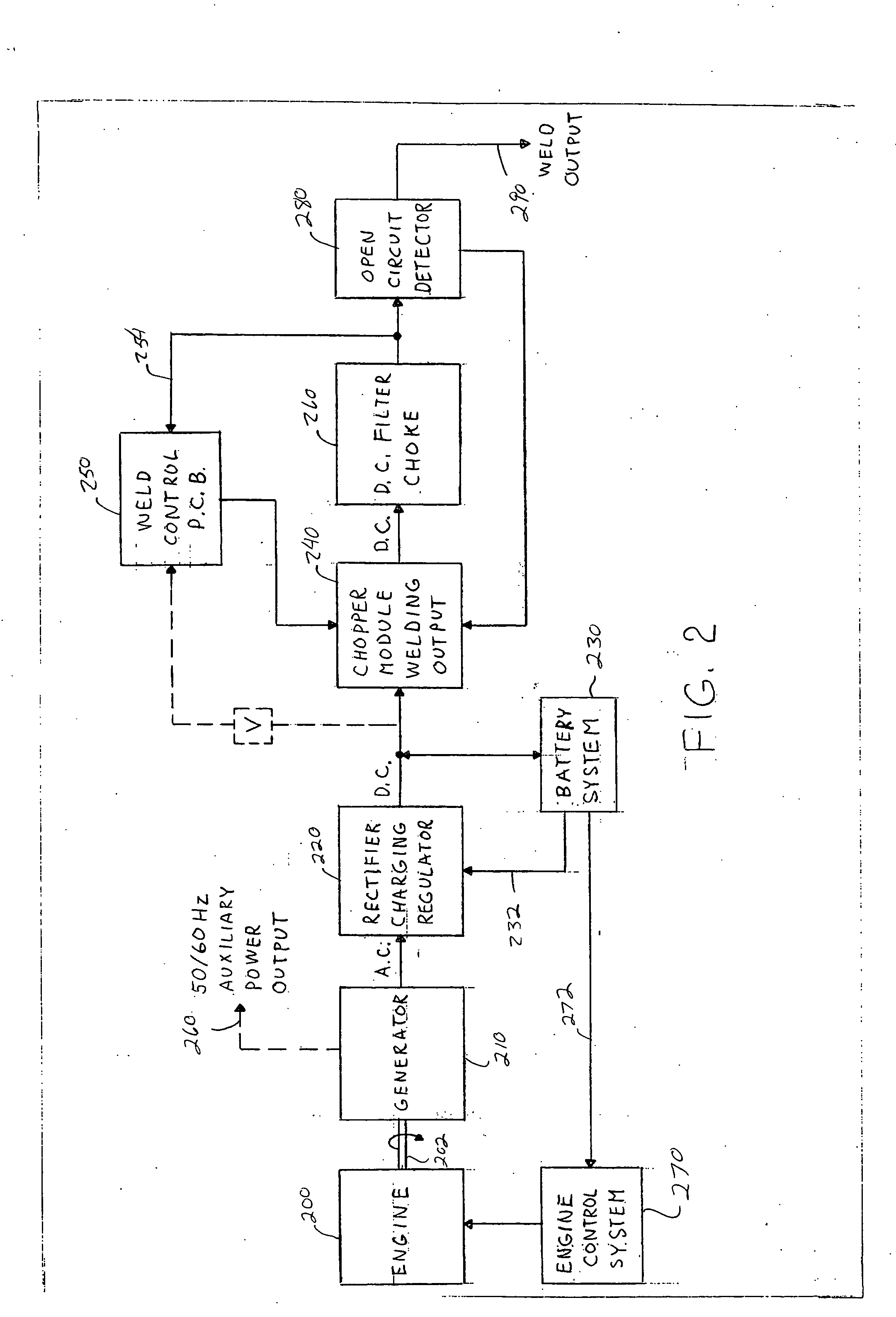

Hybrid powered welder

ActiveUS20060037953A1Improve energy efficiencyReduce noiseElectric discharge heatingArc welding apparatusStored energyFuel cells

An electric arc welder that includes a energy storage device and non-battery power source for the formation of an electric arc. The welder also includes battery charging circuit that controls the charging of the energy storage device by the non-battery power source. The non-battery power source can include an engine driven electric generator, power grid or a fuel cell.

Owner:LINCOLN GLOBAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com