Patents

Literature

96results about How to "Increase arc voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

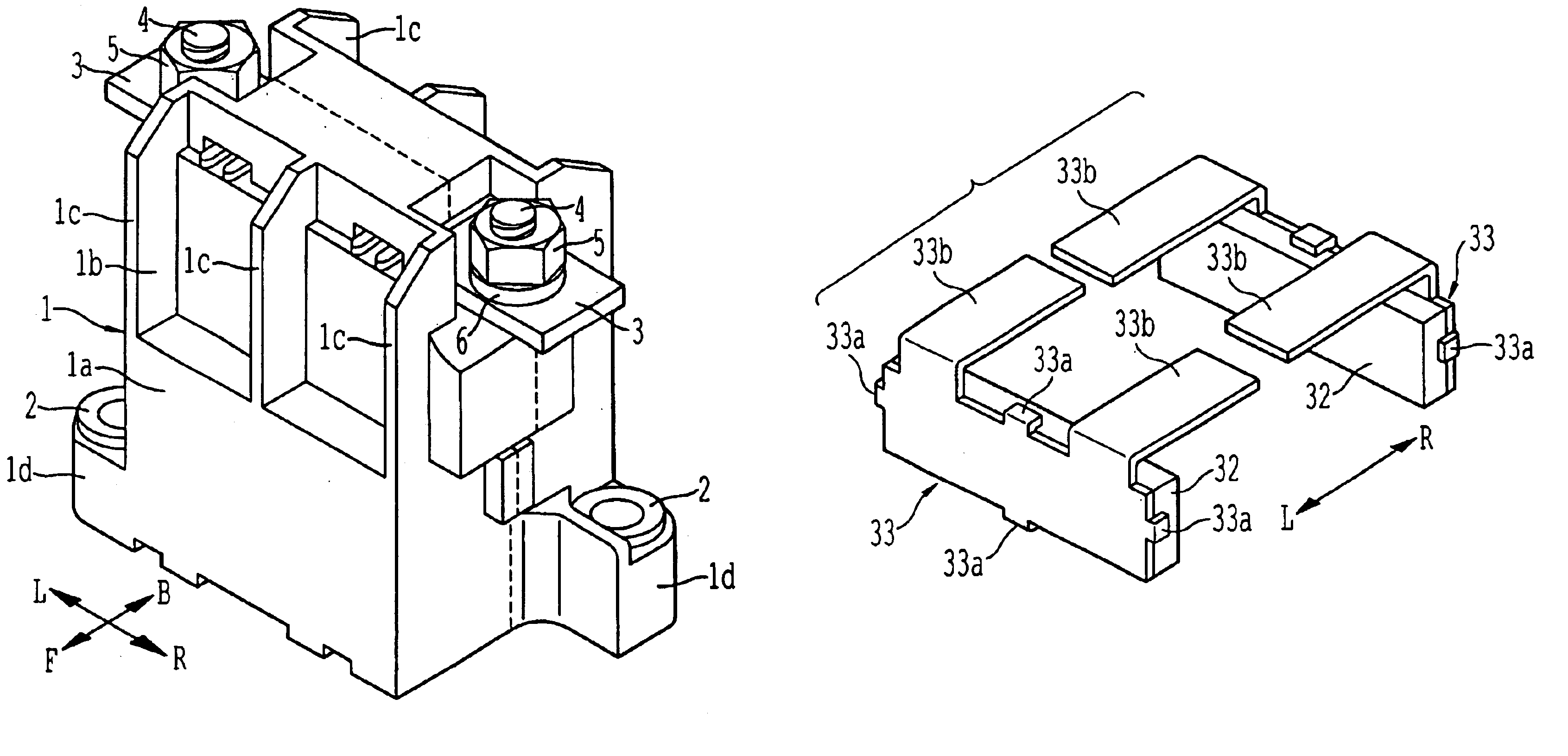

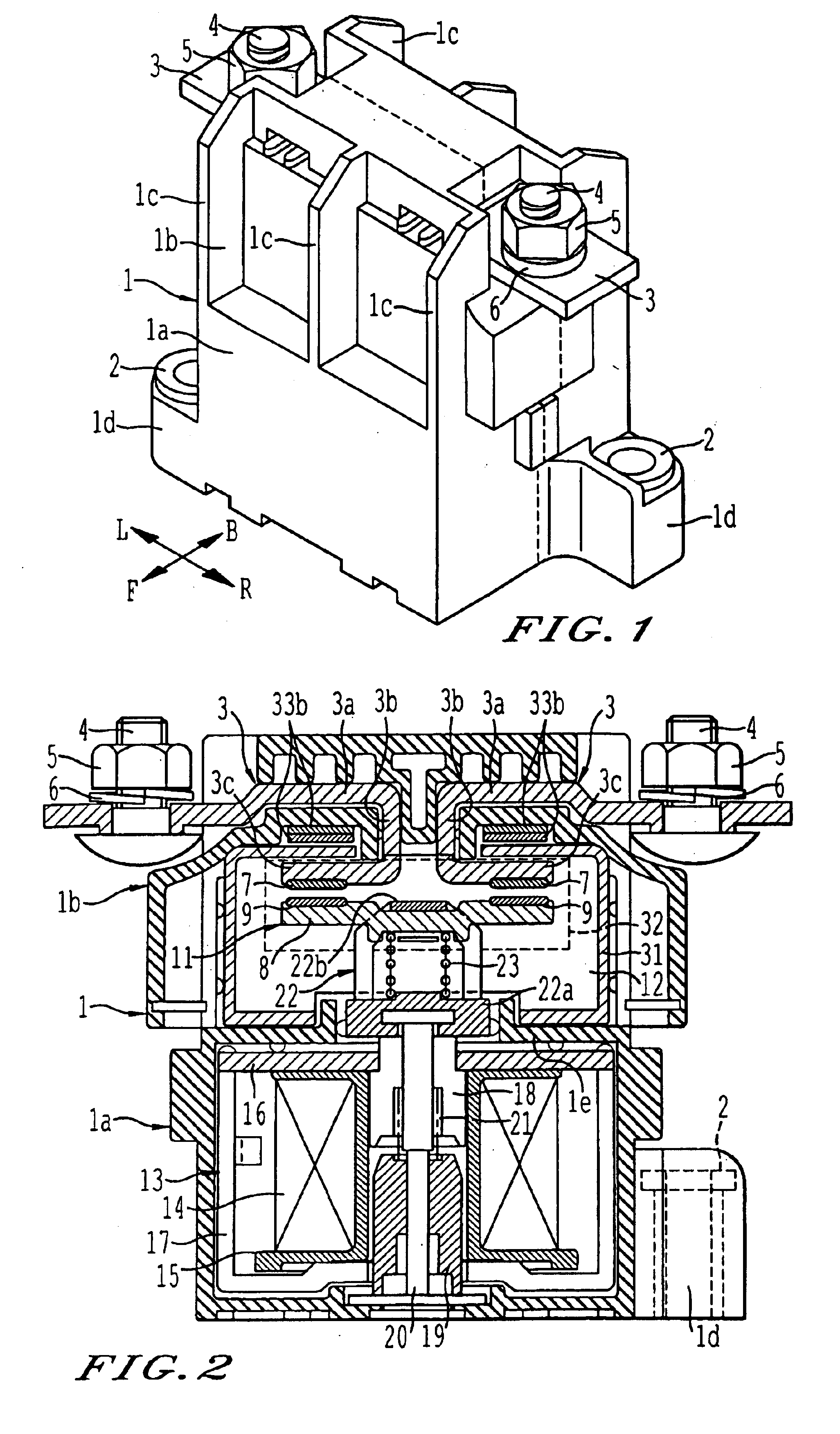

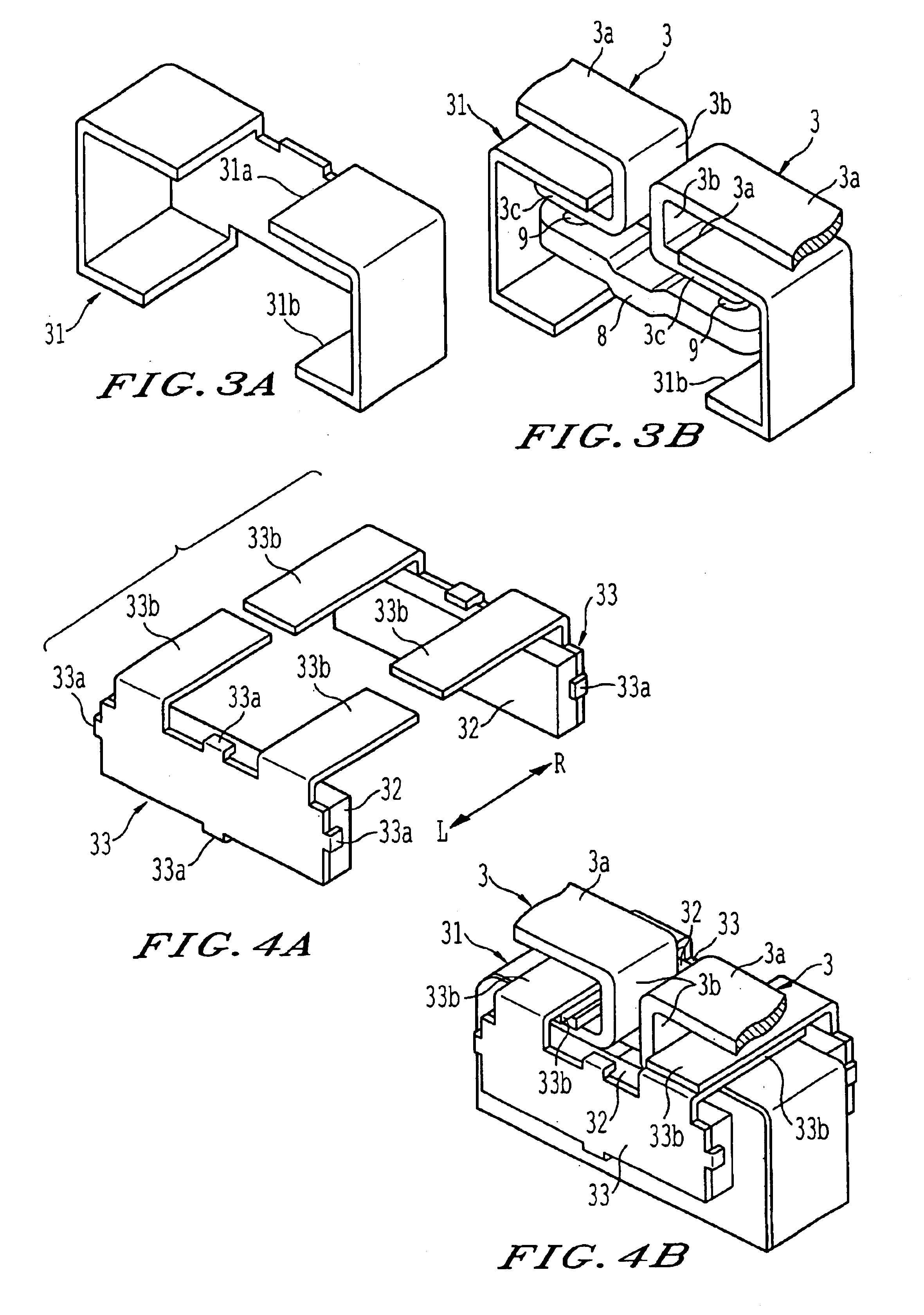

Contactor

InactiveUS6700466B1Increase arc lengthIncrease arc voltageHigh-tension/heavy-dress switchesAir-break switchesEngineeringMagnet

A contact apparatus is provided having a permanent magnet disposed in a region where a fixing contact point is mounted to a fixing contact and a movable contact to which a movable contact point is mounted. An arc generated between both the contact points is moved in a lateral direction by the magnetic force of the permanent magnet and stretched. An arc-extinguishing member which is heated by the arc for generating arc-extinguishing gas is provided such as to surround the fixing contact point and the movable contact point.

Owner:MATSUSHITA ELECTRIC WORKS LTD

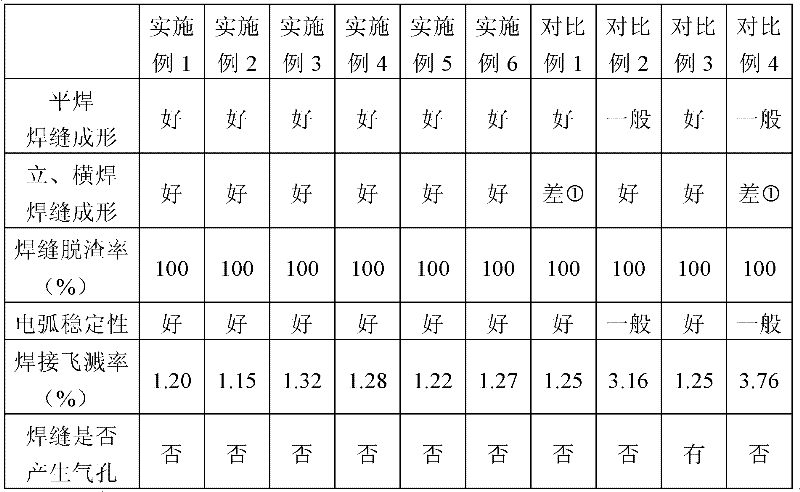

Flux-cored wire for austenitic stainless steel all-position welding

ActiveCN102229029AGood workmanshipGood slag removalWelding/cutting media/materialsSoldering mediaElectrolysisPotassium

The invention relates to a flux-cored wire for austenitic stainless steel all-position welding, and the flux-cored wire is composed of a flux core and an external stainless steel belt, wherein, the flux core accounts for 22-24wt% of the flux-cored wire, and the flux core comprises the following components in percentage by weight: 20-23% of metal chromium powder, 7-8.5% of metal nickel powder, 2-4% of electrolytic manganese metal, 3-4% of aluminium powder, 0.5-1% of ferrotitanium, 32-34% of rutile, 1-2% of quartz, 2-4% of zircon sand, 4-6% of albite, 2-4% of potassium feldspar, 1-1.5% of cryolite, 1-1.5% of lithium carbonate, 0.1-0.5% of bismuth oxide and the balance of iron powder. The ratio of the albite to the potassium feldspar in the flux core is 1.2-2, the sum of the albite and the potassium feldspar is not more than 10wt% of the flux core, the external stainless steel belt is the austenitic stainless steel 304L, the carbon content is less than 0.025wt%, the diameter of the flux-cored wire is 0.9-1.2mm, and the flux-cored wire can be used for realizing the austenitic stainless steel all-position welding.

Owner:北京远达国际工程管理咨询有限公司 +1

Welding process

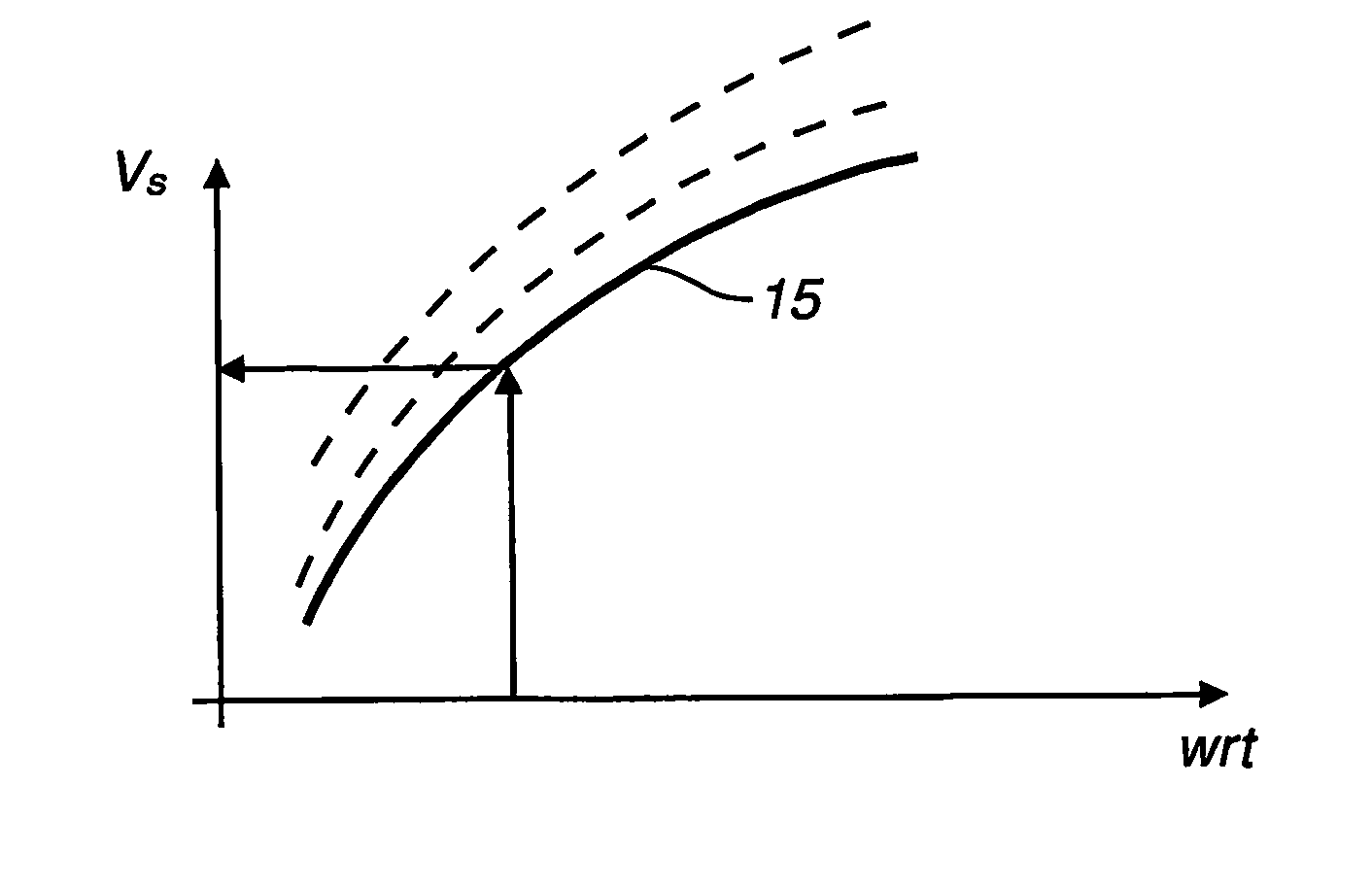

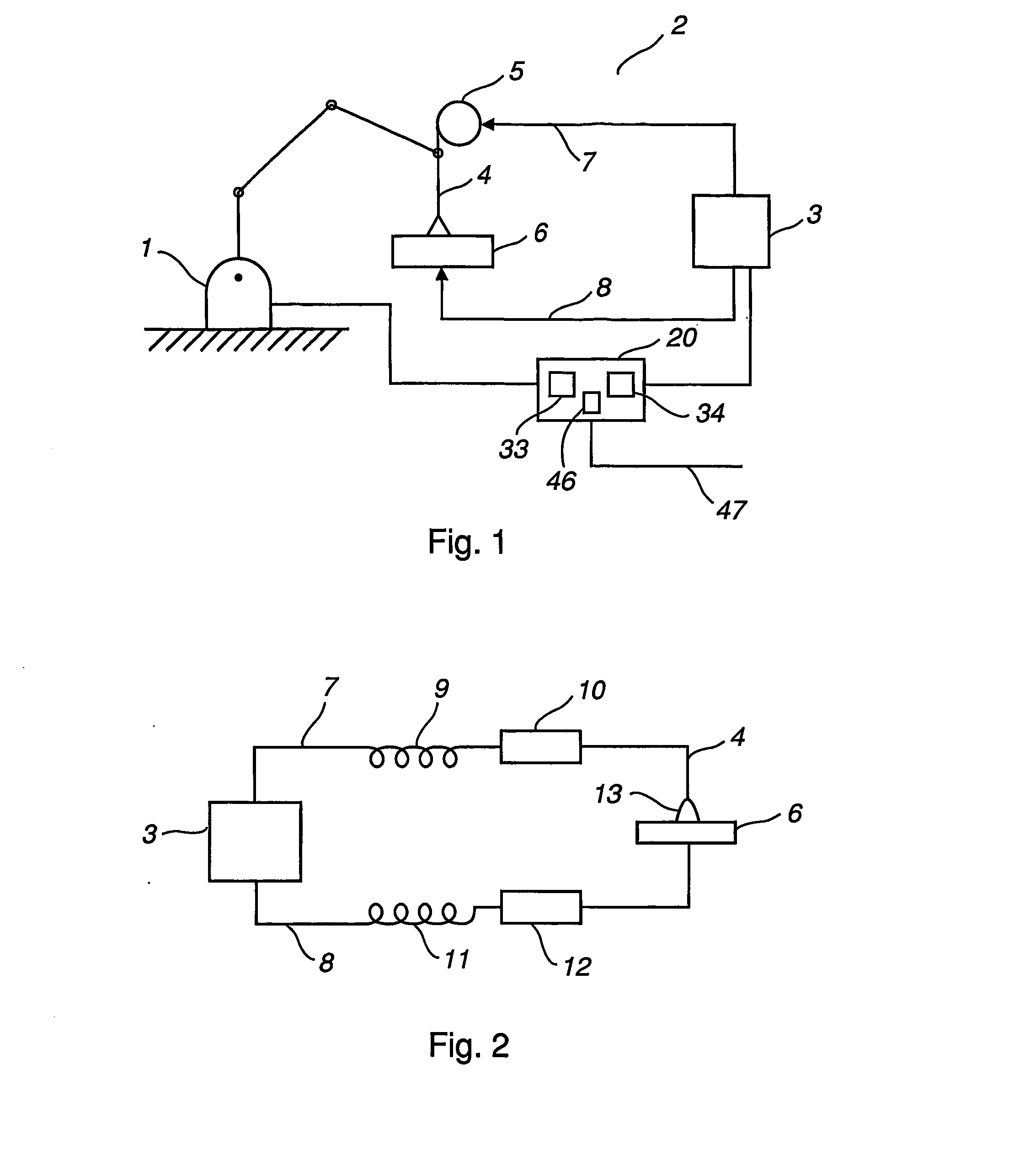

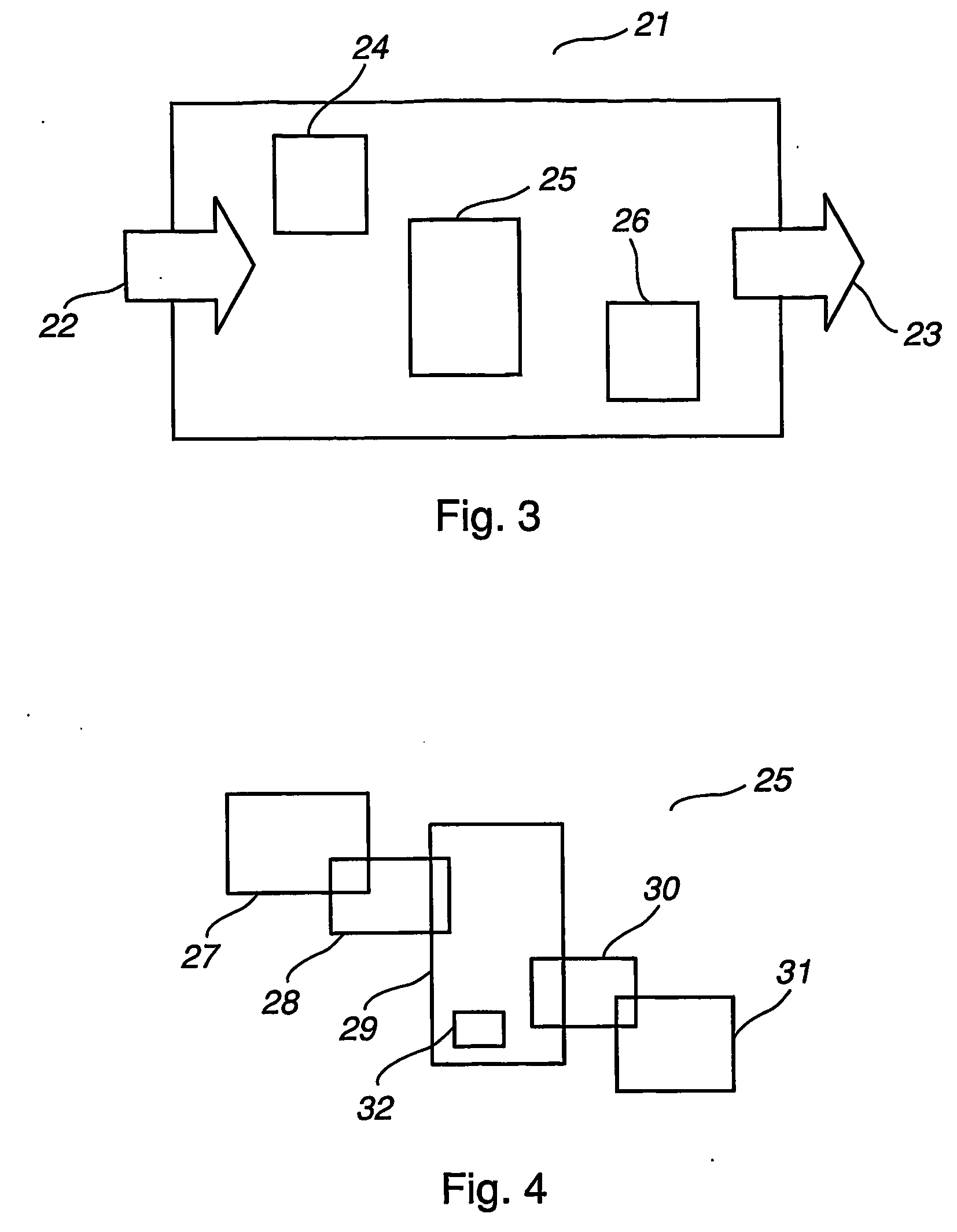

InactiveUS20070181548A1Increase arc voltageReduce arc voltageArc welding apparatusControl systemComputer memory

An arc welding system including an electric circuit including a power source, a welding torch with a consumable welding wire, a workpiece and a control system including a computer, memory and elements for tuning the arc welding system.

Owner:ABB (SCHWEIZ) AG

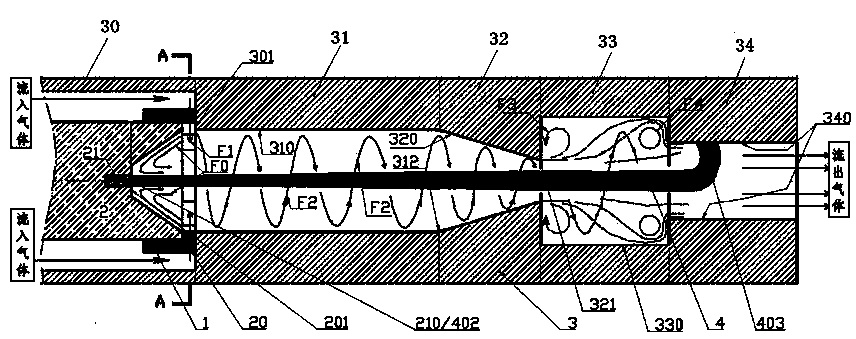

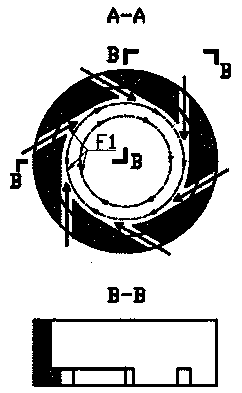

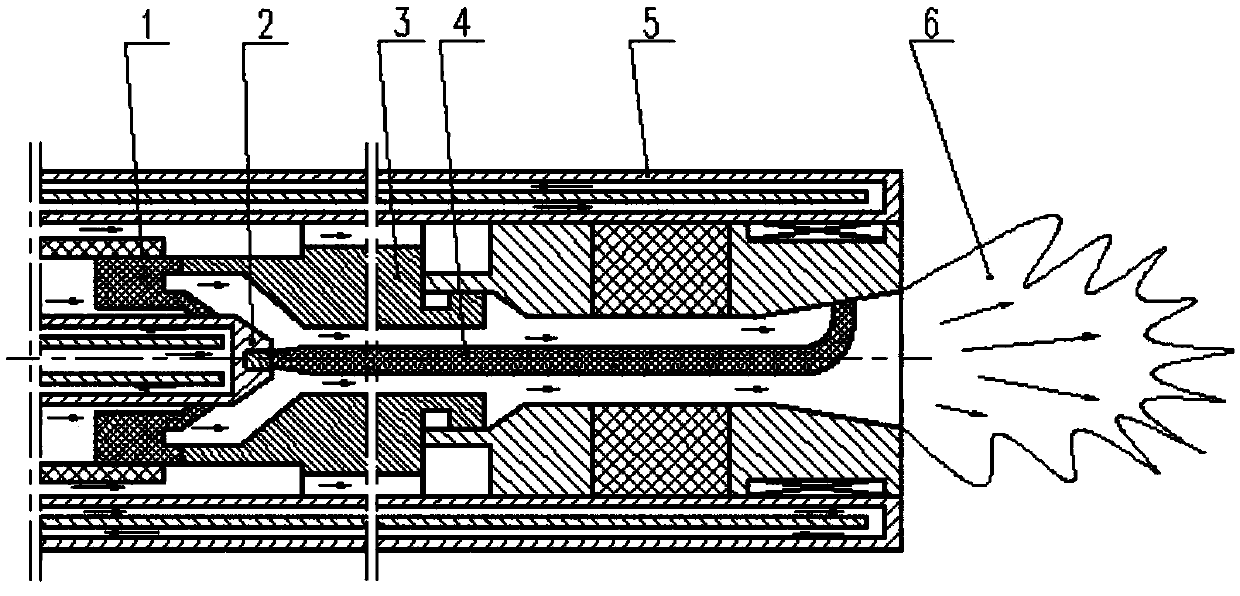

Arc plasma torch having arc channel with abnormal diameter

ActiveCN103354695AIncrease arc voltageIncrease arc powerPlasma techniqueStraight tubeMaterials science

Provided by the invention is an arc plasma torch having an arc channel with an abnormal diameter. The arc plasma torch comprises an anode, a cathode, and an annular gas whirlcone. The anode is a circular tube with an abnormal inner bore diameter; the cathode is arranged in the inner bore of the anode circular tube; the gas whirlcone is arranged between the cathod front end and the anode; and the gas whirlcone, the cathode, and the inner bore of the anode circular tube are arranged coaxially. One end, provided with the cathode, of the anode circular tube serves as a gas inflow end and the other end serves as a gas outflow end; the anode circular tube is successively divided into a gas lead-in segment, a straight tube segment or reducing segment, a contraction segment, a groove segment and a nozzle segment; inner bores of the straight tube segment or reducing segment, the contraction segment, the groove segment and the nozzle segment of the anode circular tube forms an anode arc channel. And a tangential air flow channel is arranged at an annular wall of the gas whirlcone and is used for guiding gas into the inner bore of the gas whirlcone to generate an eddy air flow. According to the invention, the provided an arc plasma torch with the simple structure enables the arc power, the electrode life, and the energy utilization rate to be substantially improved.

Owner:ANHUI TENGLONG ELECTRIC

Anode of supersonic plasma torch, and supersonic plasma torch

The invention discloses an anode of a supersonic plasma torch, and the supersonic plasma torch. Mainly, the conventional laval-type anode is divided into two parts, wherein one part near a cathode body is called as a basic anode; the other part far away from the cathode body is called an auxiliary anode; and the two parts are isolated by a high-temperature-resistant insulation ceramic chip. The cathode body is fixed on a conductive torch core and is sequentially connected with the basic anode and the auxiliary anode in an axial direction. When the anode works, an arc root is transferred from the basic anode to the auxiliary anode, so that a nozzle of the laval-type basic anode with a complicated structure is protected while an electric arc is lengthened. Therefore, the voltage is increased under the condition that the working current is unchanged. As a result, the energy utilization rate is improved.

Owner:NANJING UNIV OF SCI & TECH

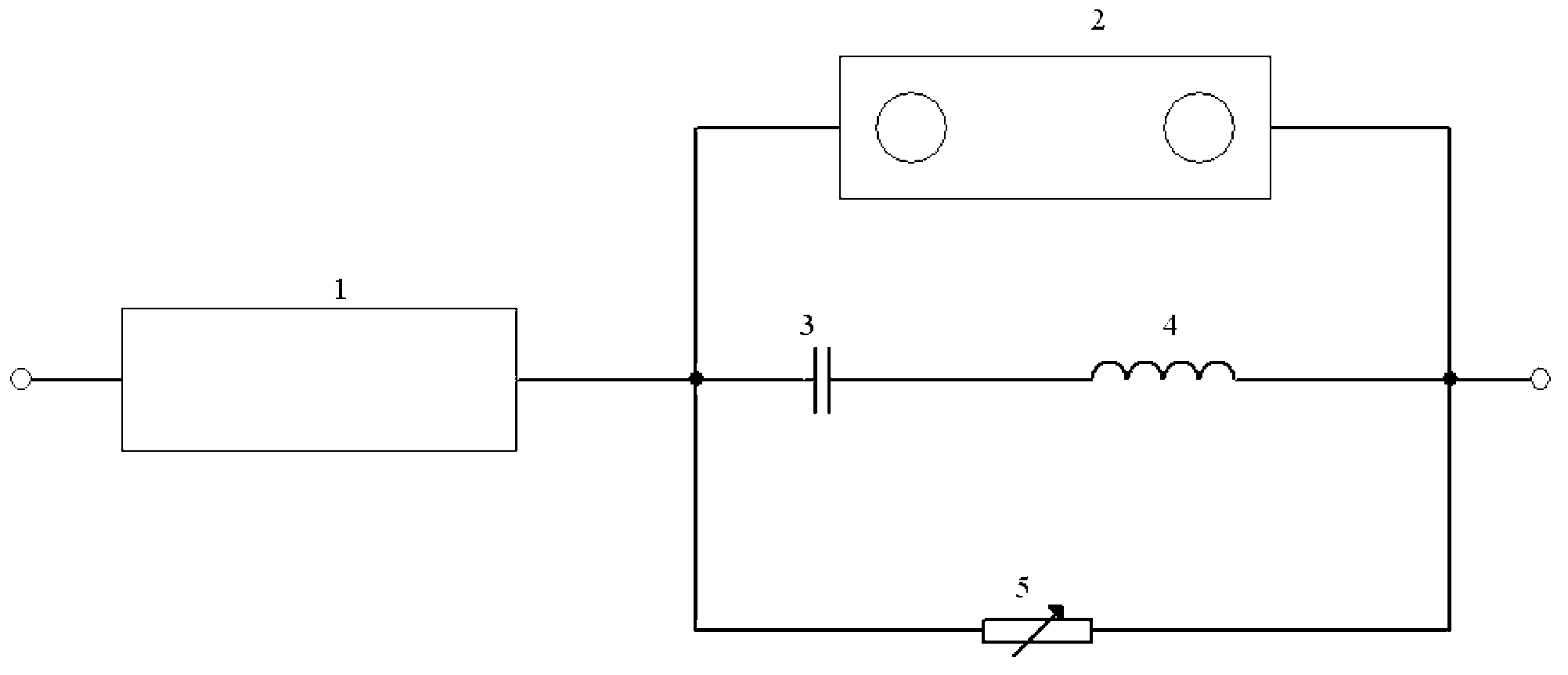

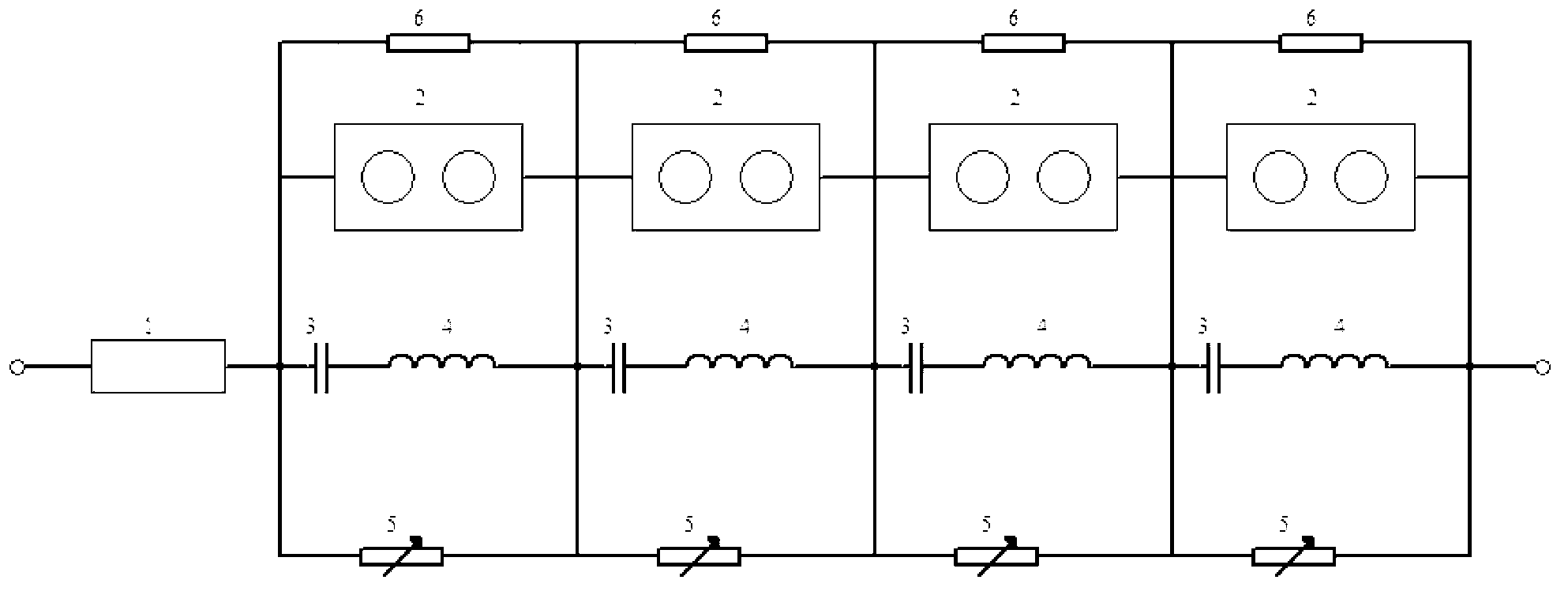

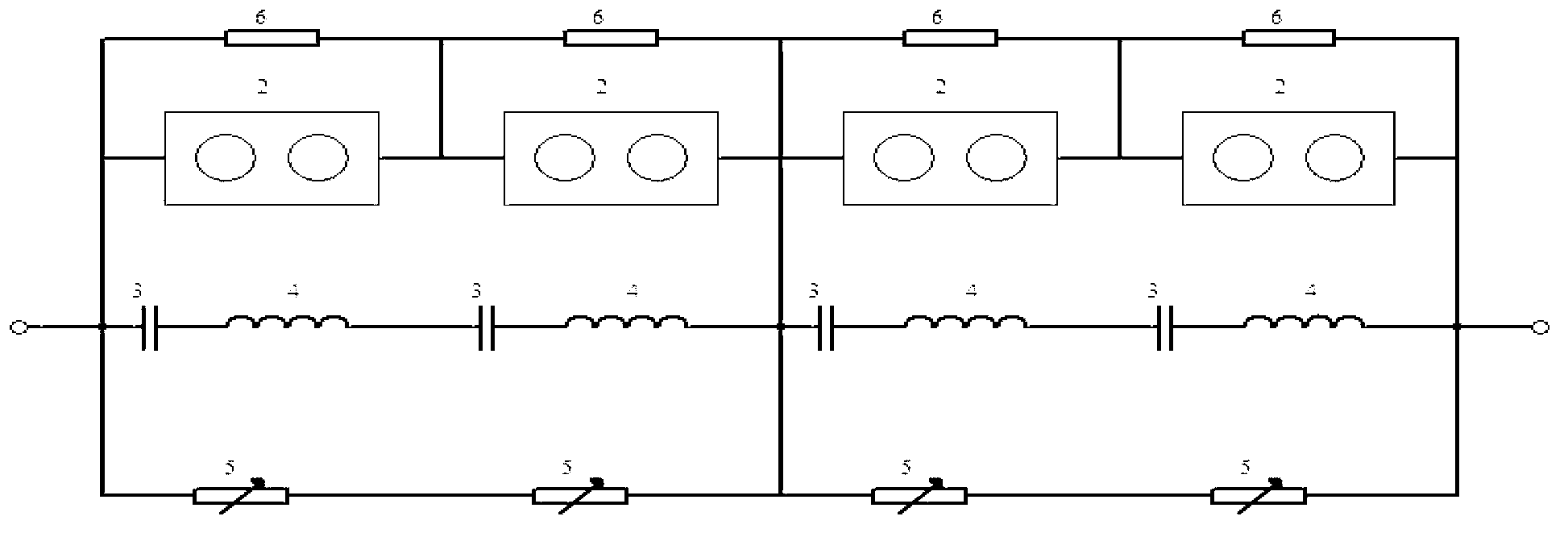

High-voltage direct-current gas breaker based on self-excited oscillation circuit

InactiveCN103296636ASimple structureQuick responseEmergency protective arrangements for automatic disconnectionHigh-tension/heavy-dress switchesCapacitanceNonlinear resistor

The invention discloses a high-voltage direct-current gas breaker based on a self-excited oscillation circuit. By the gas breaker, fault current can be cut off under high nominal voltage classes. The gas breaker comprises a superconducting current limiter and a cut-off module which are in serial connection. The cut-off module comprises gas breaker bodies in parallel connection, a current conversion circuit formed by serial connection of a capacitor and an inductance, and a non-linear resistor oxidation energy absorbing device. The fault current passes the superconducting current limiter first, is limited by the same, and is cut off by the gas breaker bodies. The gas breakers extinguish arc by using self exciting to generate artificial zero crossing points. The high-voltage direct-current gas breaker is fast in response, low in current overload coefficient, simple in structure, low in size, low in overvoltage, safe and reliable, short-circuit current does not exceed current quench of the superconducting current limiter, and other devices can be protected.

Owner:XI AN JIAOTONG UNIV

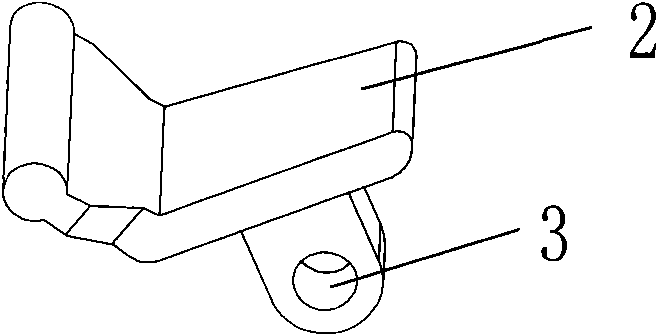

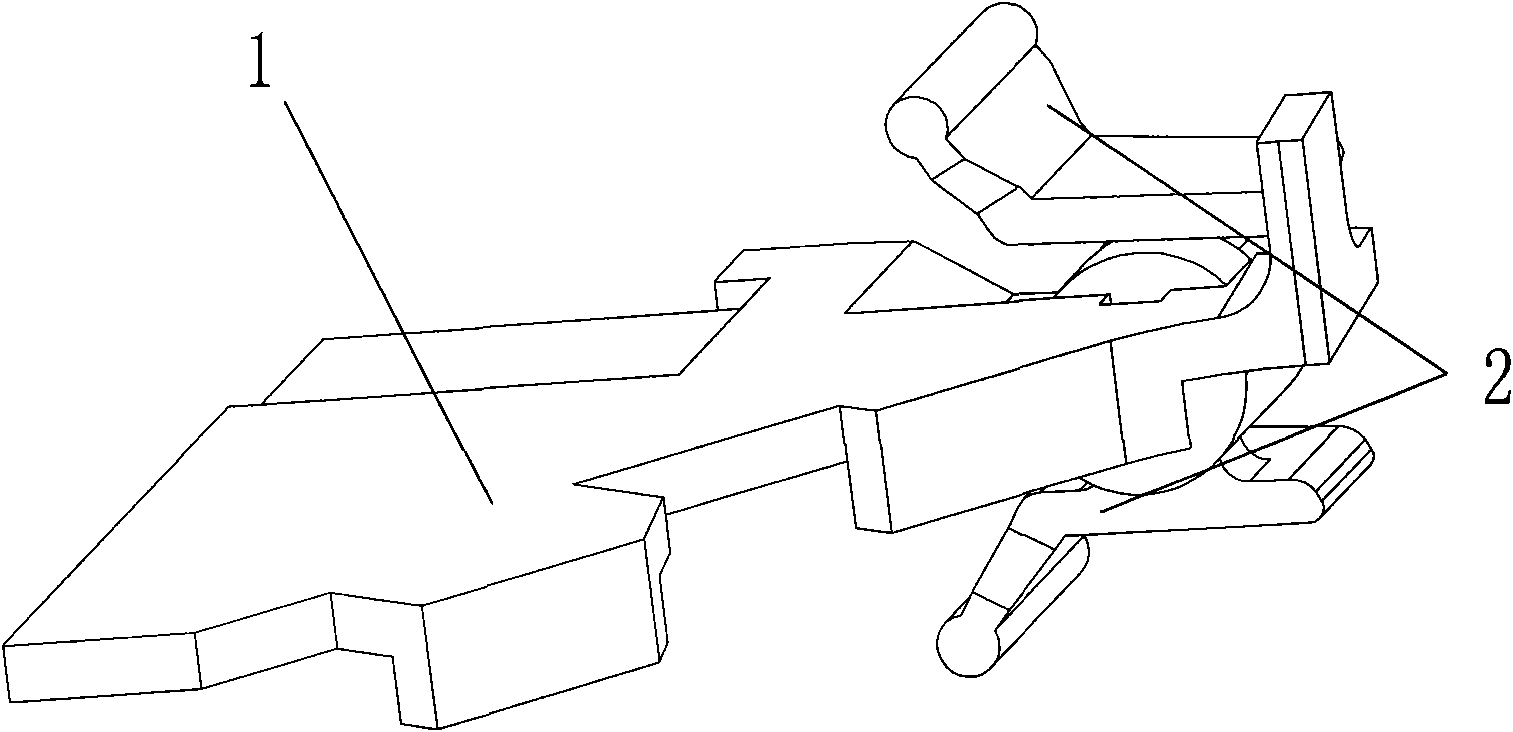

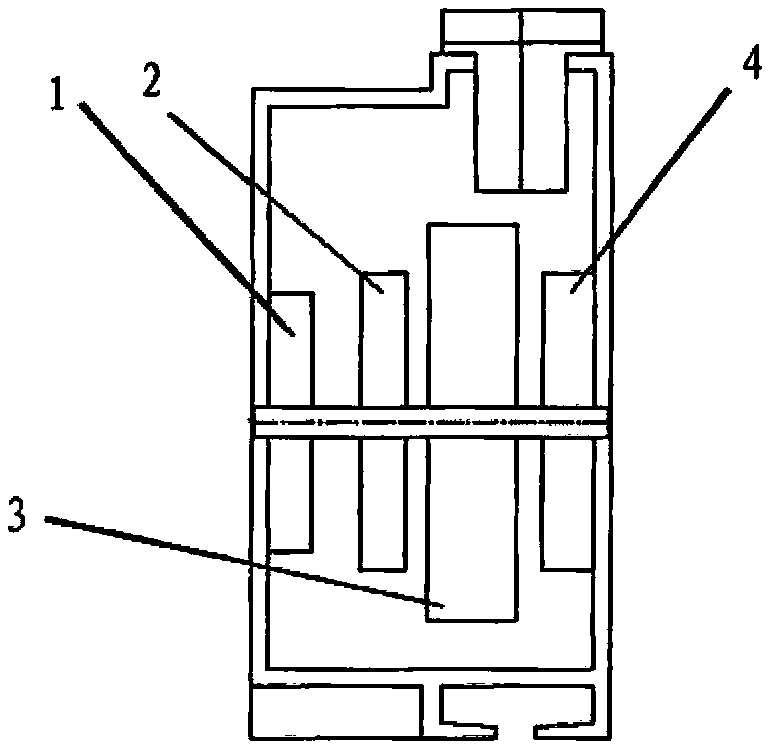

Breaker with forced flash barrier device

InactiveCN102486982AImprove breaking capacityDoes not affect connectionCircuit-breaking switch detailsCurrent limitingBreaking capacity

The invention relates to a breaker with a forced flash barrier device. The breaker comprises a shell, a movable contact and a fixed contact, wherein the shell is internally provided with a lever made of an insulating material and composed of a left moment arm, a right moment arm and a fulcrum, the left moment arm of the lever is inserted into a gap between the movable contact and the fixed contact since the right moment arm is pushed rightwards by the movable contact during the separation process of the movable contact and the fixed contact, and the left moment arm of the lever goes out of the gap between the movable contact and the fixed contact since the left moment arm is pushed leftwards by the movable contact during the closing process of the movable contact and the fixed contact. The breaker is simple in structure and reliable in movement, can quickly cut off an electric arc when the movable contact and the fixed contact are separated so as to improve arc voltage, increase the breaking capacity and the current-limiting capacity of the breaker, widen the application range of the breaker and realize reversible protection.

Owner:BEIJING PEOPLES ELECTRIC PLANT

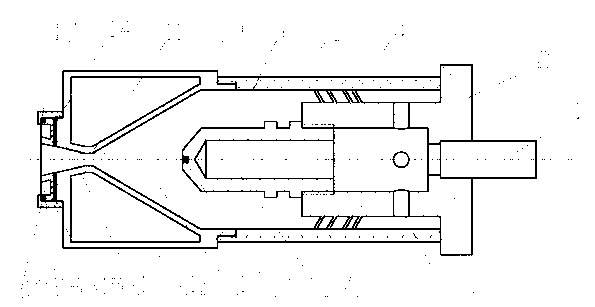

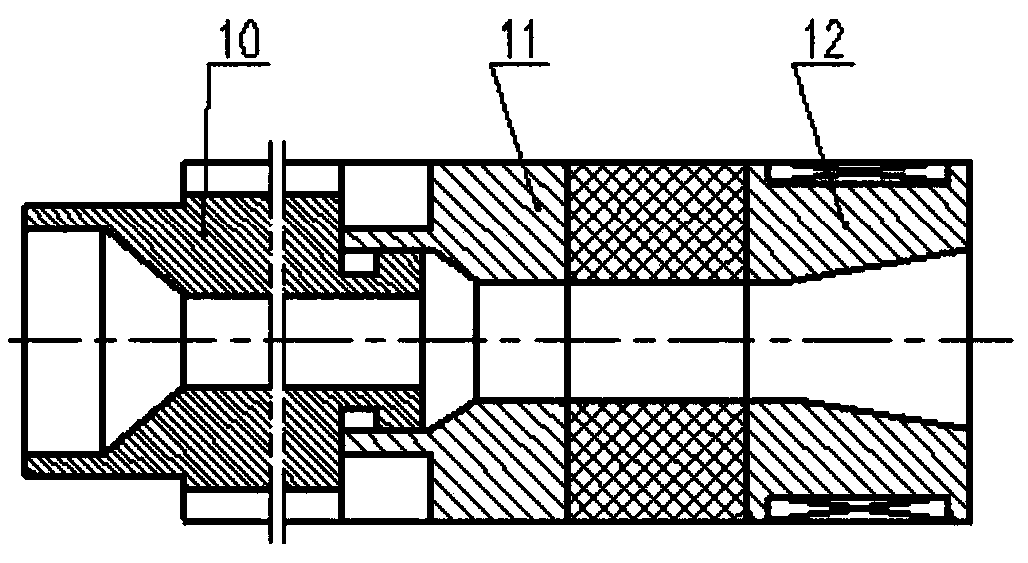

Plasma ignition and combustion stabilization device for IGBT (insulated gate bipolar transistor) rectification power supply

ActiveCN103486579AIncrease arc voltageImprove efficiencyPulverulent fuel combustion burnersLump/pulverulent fuel feeder/distributionCombustion chamberEngineering

The invention discloses a plasma ignition and combustion stabilization device for IGBT (insulated gate bipolar transistor) rectification power supply. The plasma ignition and combustion stabilization device for the IGBT rectification power supply comprises a collision type pulverized coal concentration fractional combustion pulverized coal burner and a plasma spray gun, wherein the plasma spray gun generates high-temperature flame at the temperature of about 4000DEG C to ignite pulverized coal in an inner-layer combustion chamber of the pulverized coal burner; heat released from the burning of the pulverized coal in the inner-layer combustion chamber then ignites pulverized coal in an outer-layer combustion chamber to realize the stable combustion of pulverized coal flame; the collision type pulverized coal concentration fractional combustion pulverized coal burner comprises a primary air dust inlet, a straight pipe section, a taper pipe section, an outer nozzle, a collision concentration block, a collision concentration ring, the inner-layer combustion chamber, the outer-layer combustion chamber, an inner-layer combustion chamber disturbance block, an outer-layer combustion chamber rear disturbance block and an outer-layer combustion chamber front disturbance block; and the plasma spray gun comprises a cathode, a magnetic field coil, a spiral air chamber, an anode, a nozzle and a gun body. The plasma ignition and combustion stabilization device for the IGBT rectification power supply is applied to the starting ignition and the combustion stabilization stage of a pulverized coal fired boiler to replace the traditional big oil gun ignition and combustion stabilization mode, coal is used for replacing oil, and therefore the purpose of saving cost is achieved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

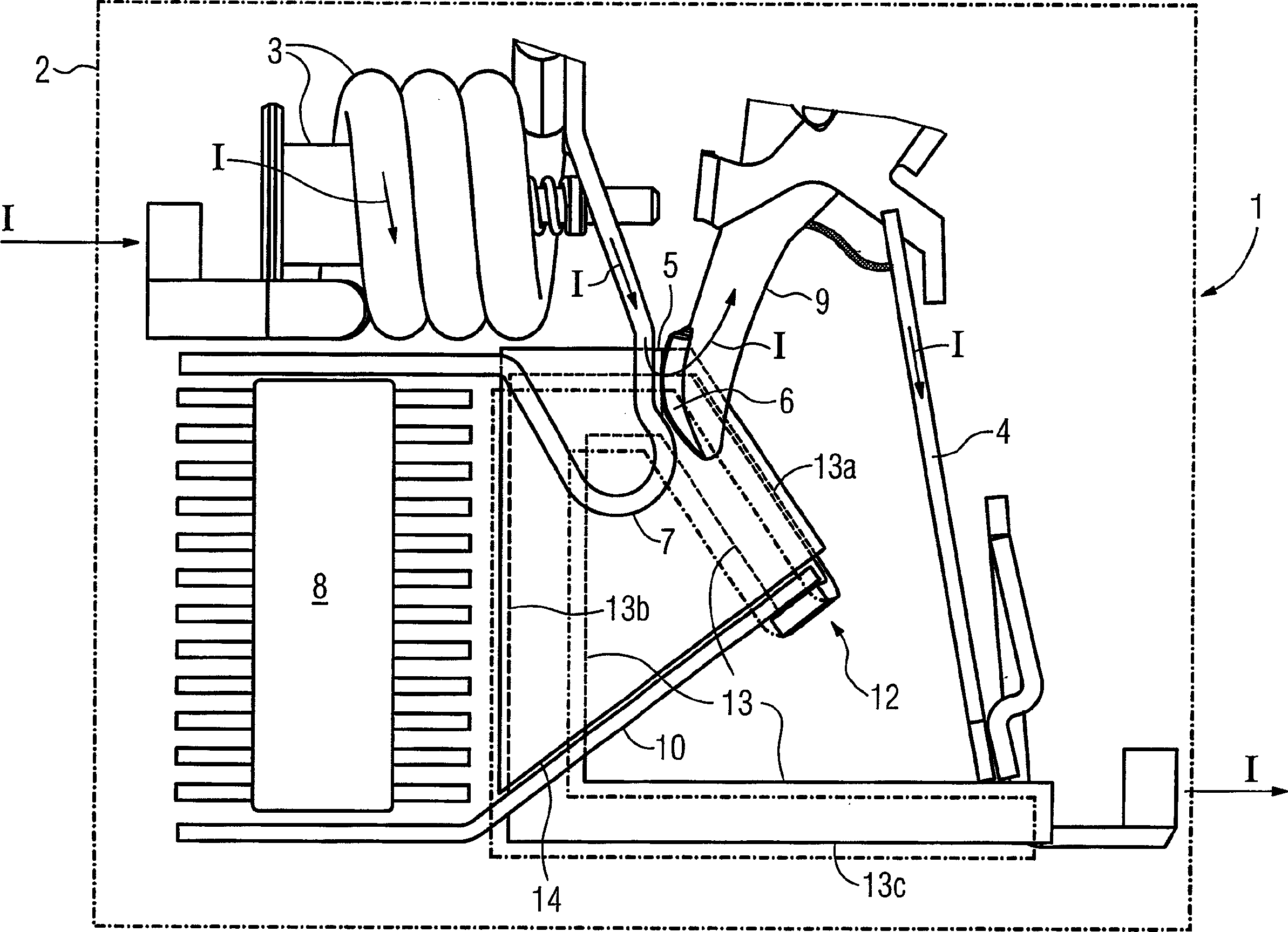

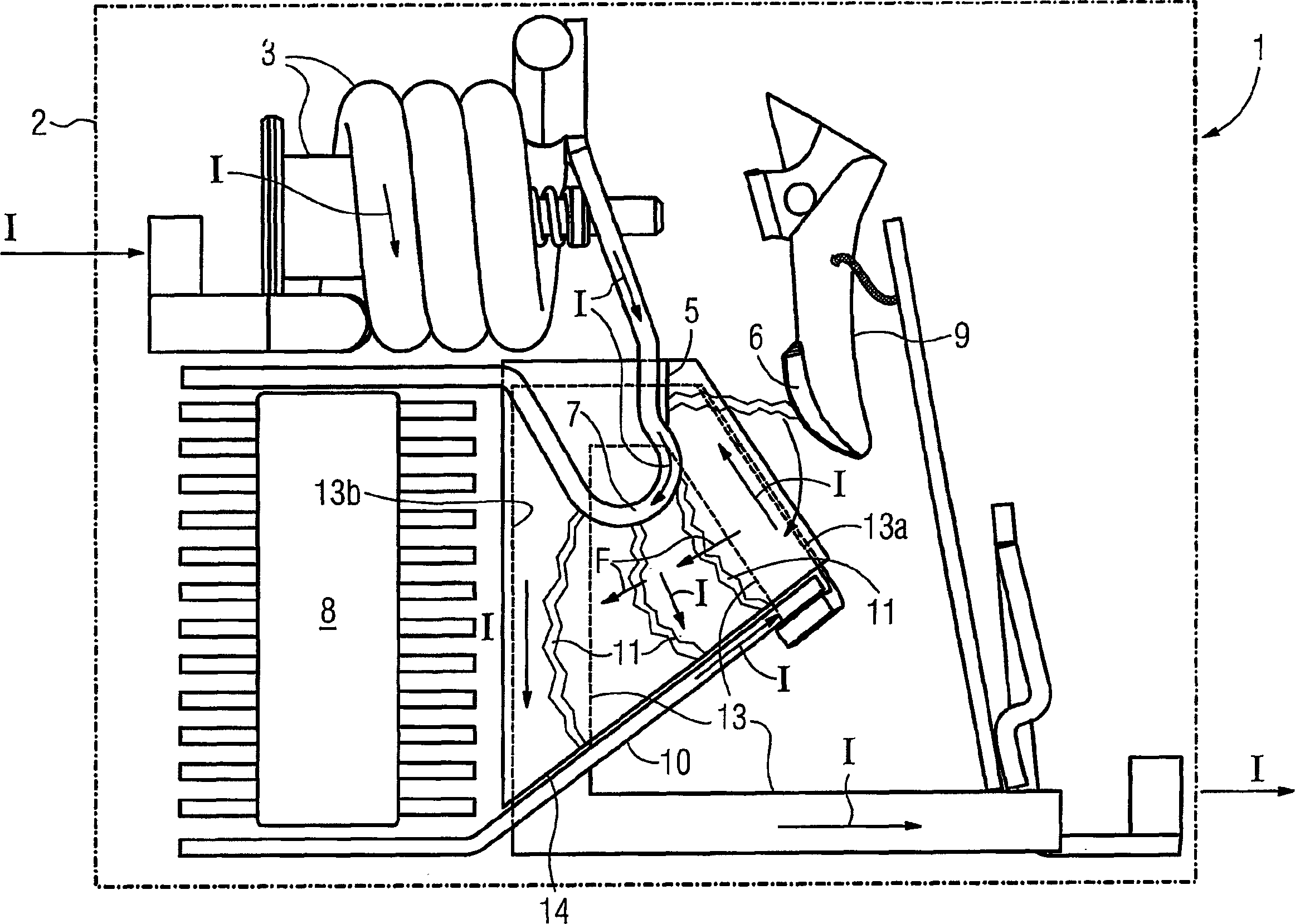

Arc quenching system

ActiveCN1879183AQuickly and effectively extinguishReduced service lifeElectric switchesCircuit-breaking switch detailsElectrical conductorEngineering

The aim of the invention is to create an arc quenching system for a switching device, which ensures low heat build-up and fast quenching of an arc using simple means. Said aim is achieved by providing a current conducting path which comprises an electrically conducting passage to an additional arc guide rail so as to form a conductor loop and is electrically insulated relative to a pair of switching contacts. The conductor loop is not connected to the pair of switching contacts while being arranged in the area of an interrupter chamber such that a current (I) which drives the arc into the arcing chamber is conducted via the current conducting path when the arc commutates from one of the switching contacts to the additional arc guide rail.

Owner:SIEMENS AG

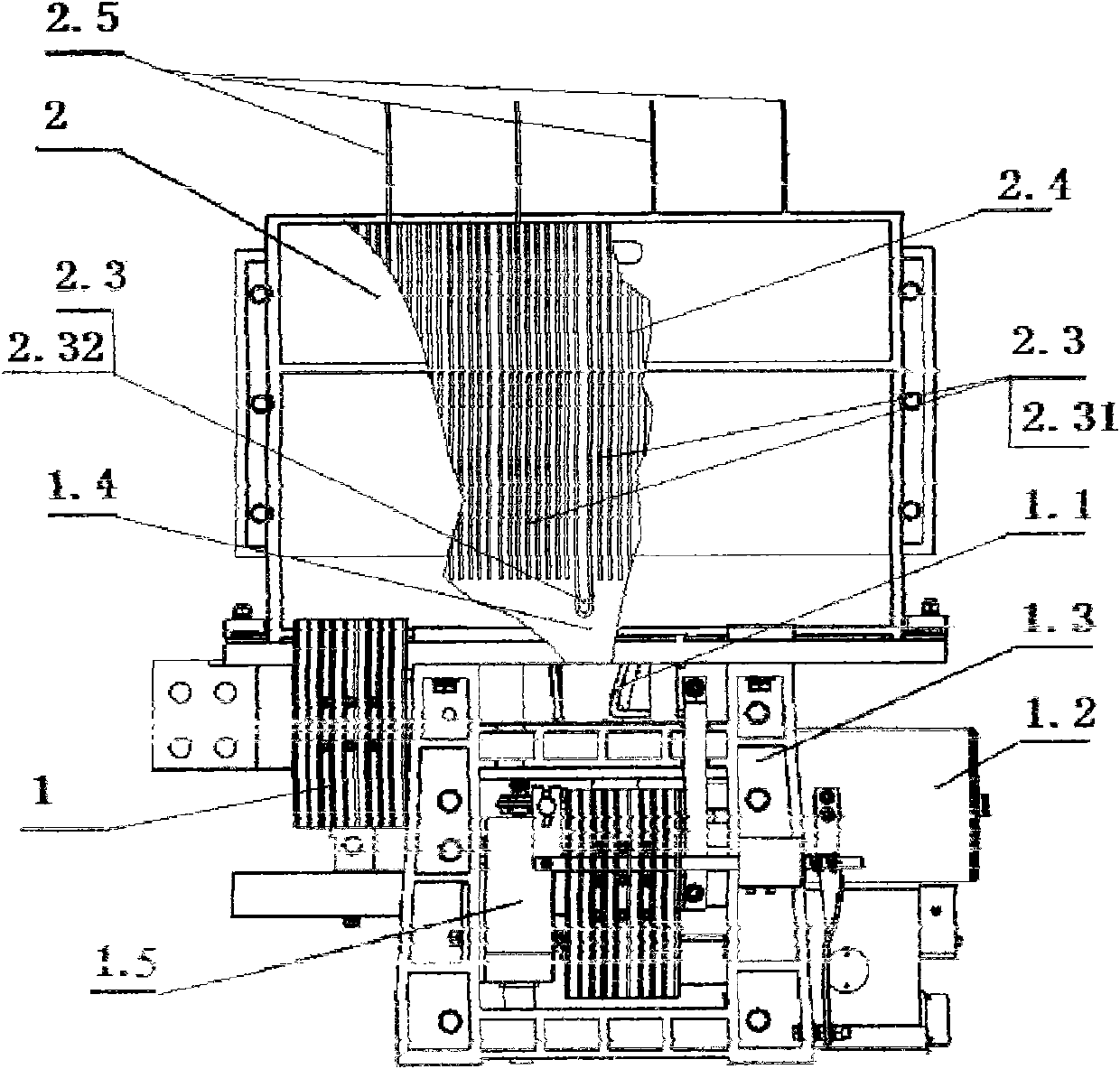

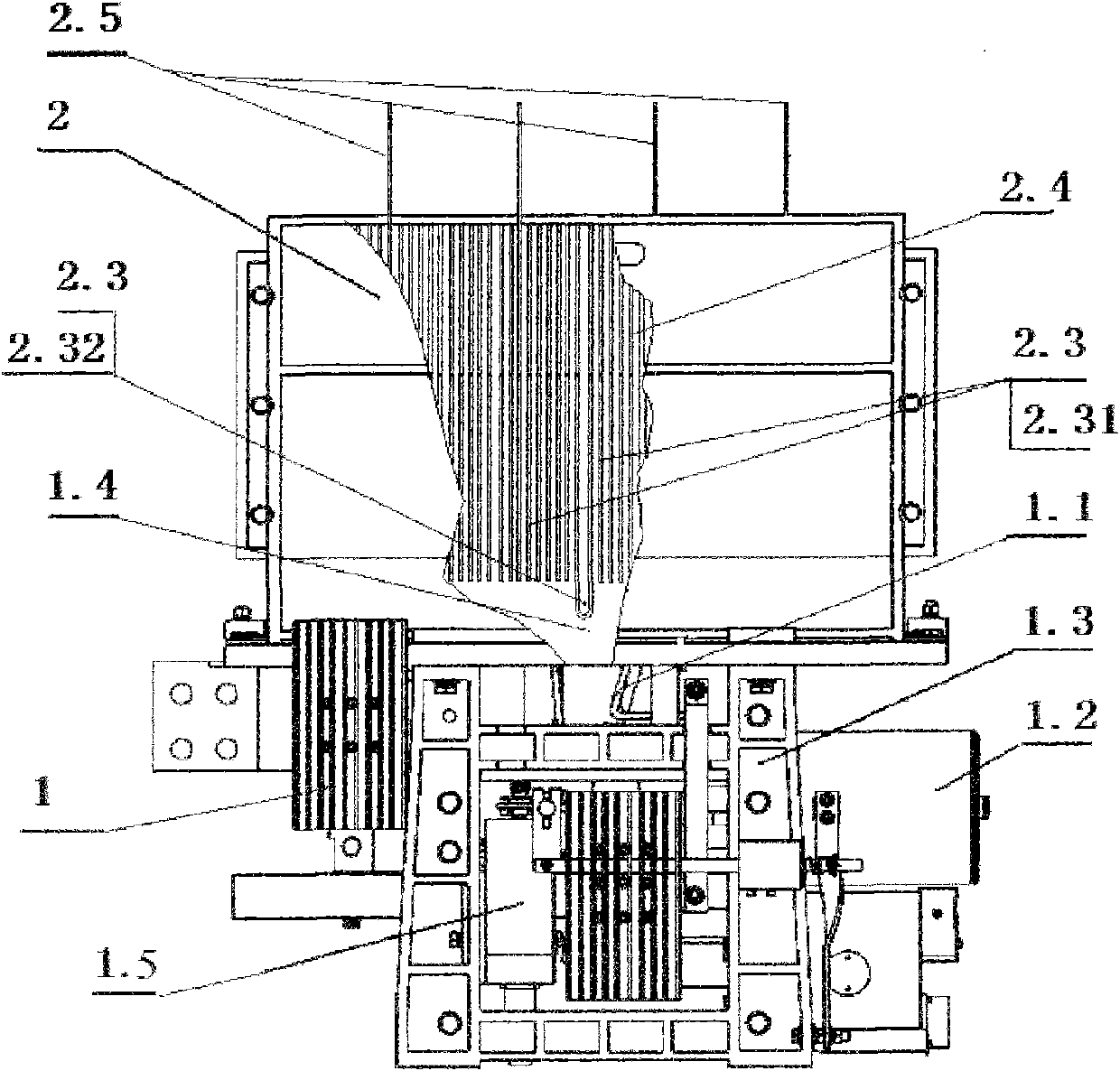

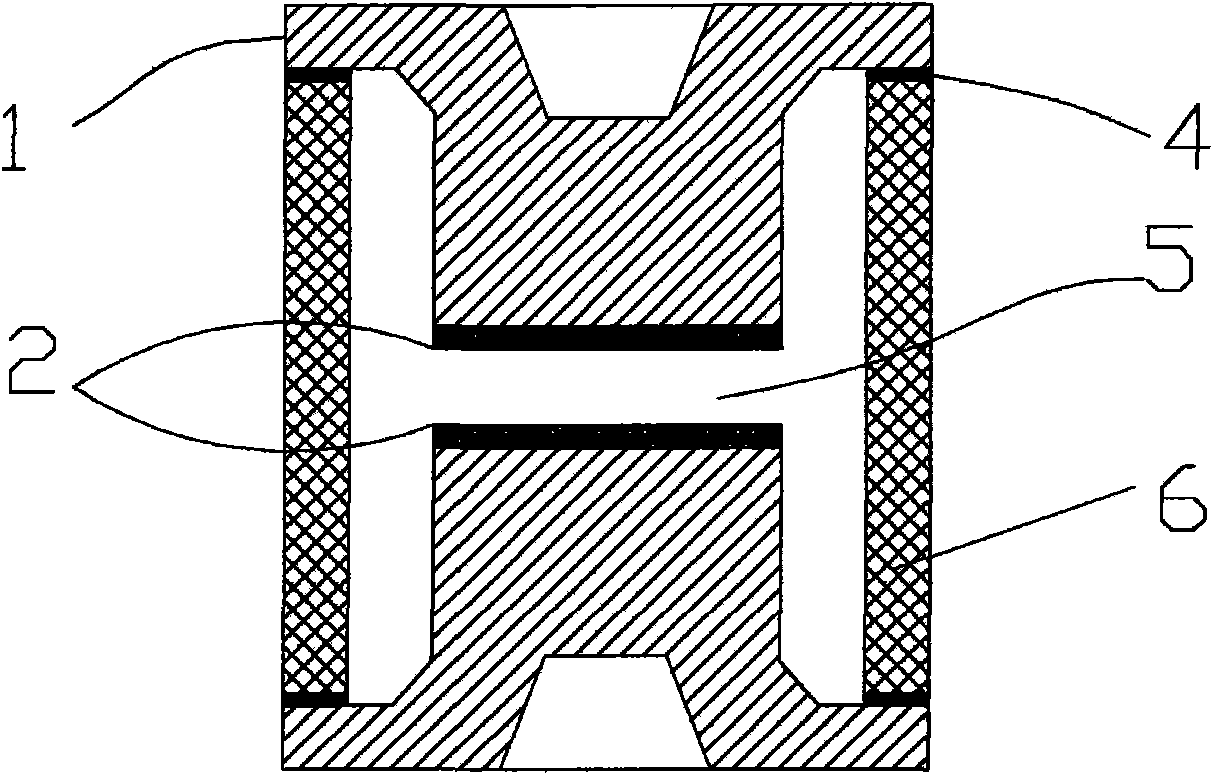

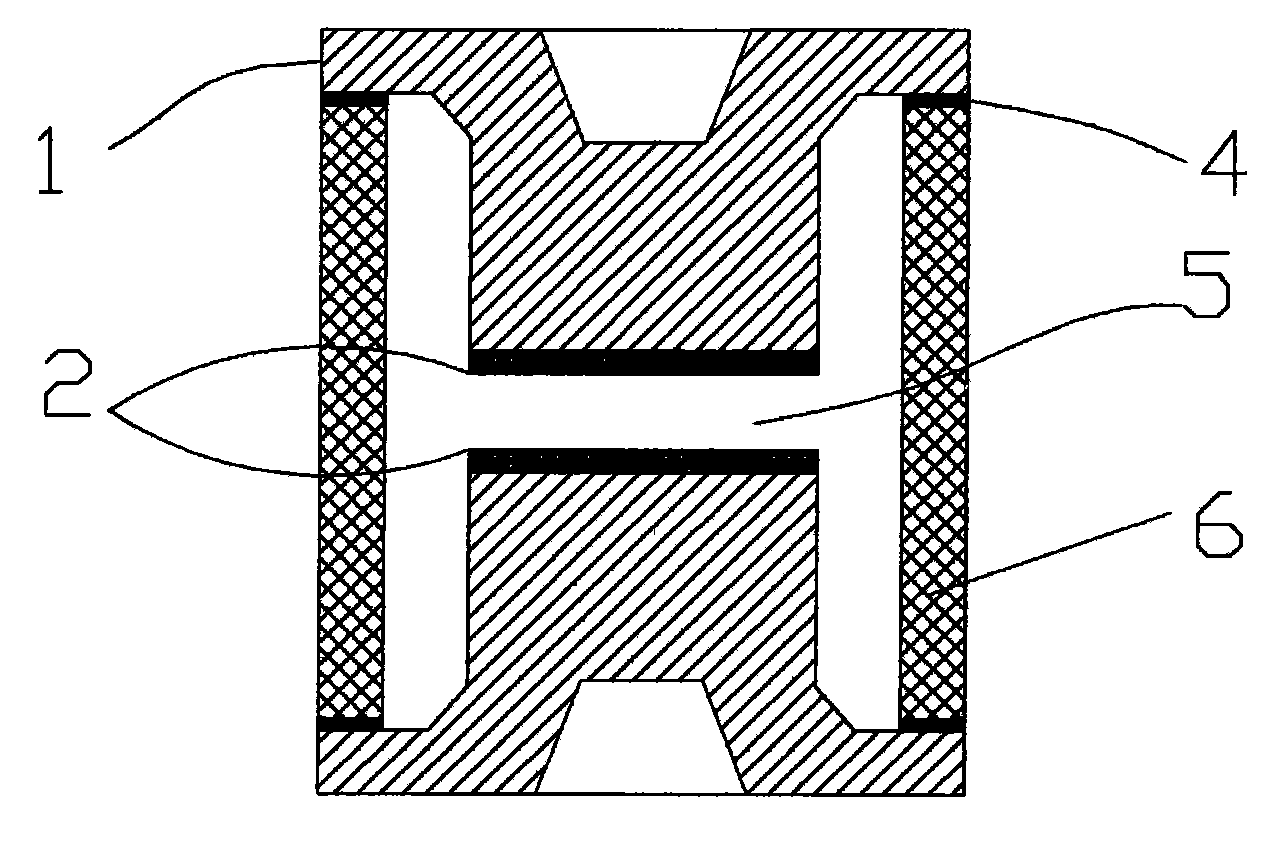

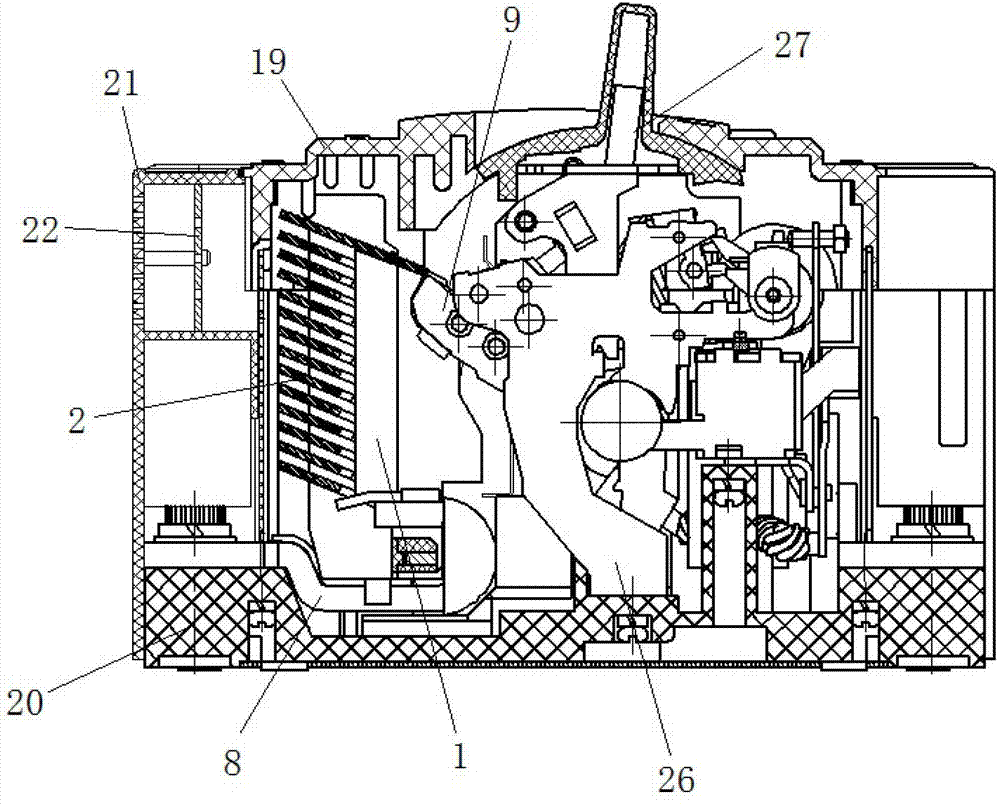

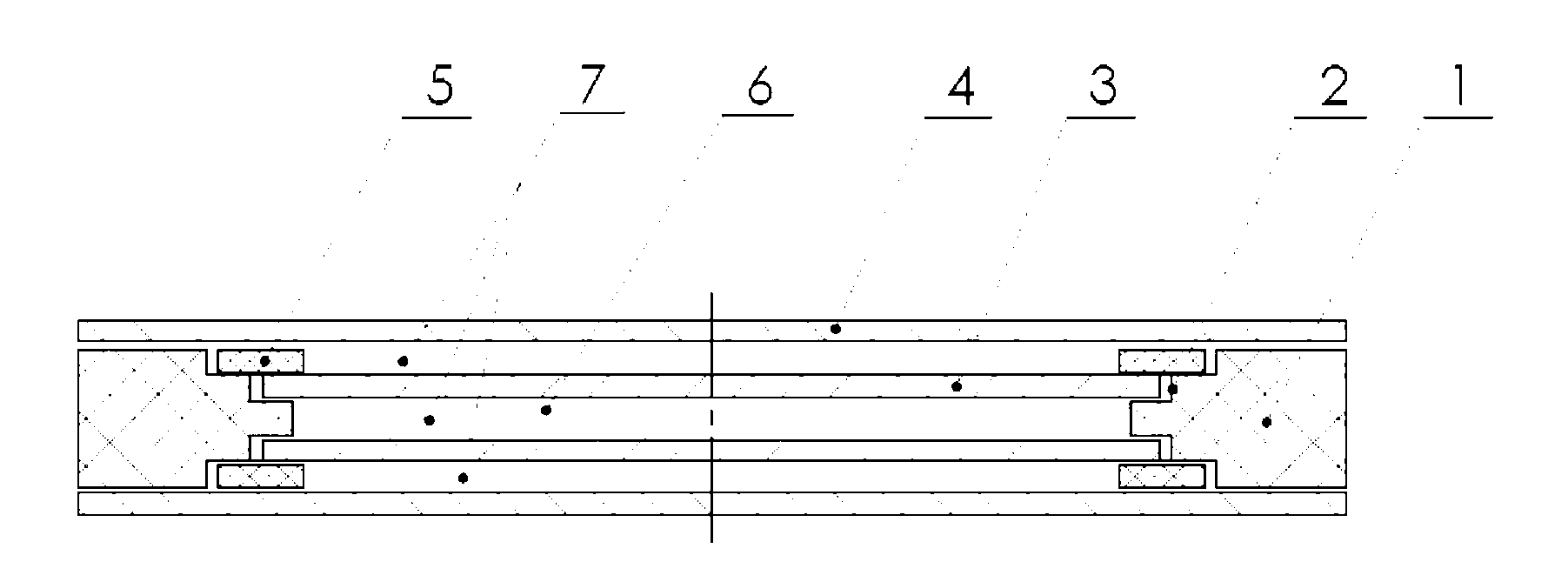

Non-polar hydrogen mixed gas DC (direct-current) arc extinction system for DC contactor

ActiveCN102592890AEasy accessIncrease contactElectric switchesElectromagnetic relay detailsBreaking capacityArc extinction

The invention discloses a non-polar hydrogen mixed gas DC (direct-current) arc extinction system for a DC contactor. The DC arc extinction system comprises a moving contact, four pairs of moving and static arc striking contacts, a static contact, a grid group and a permanent magnet. The non-polar hydrogen mixed gas DC arc extinction system is non-polar, namely the arc extinguishing property can not be influenced by the change of the current direction. According to the non-polar hydrogen mixed gas DC arc extinction system, the arc striking contacts strike electric arc to smoothly move along a track of the arc striking contacts, the arc striking contacts, the grid group and the permanent magnet are reasonably arranged, and the electric arc between the moving contact and the static contact is better and rapidly extinguished, thus the short circuit caused by sudden reversing of current is solved, and the breaking capacity is further improved. Hydrogen or a hydrogen mixed gas can be inflated into the non-polar hydrogen mixed gas DC arc extinction system for realizing arc extinguishing.

Owner:BEIHANG UNIV

Ultralow-hydrogen type high efficiency iron powder welding rod for low alloy high streagth steel

InactiveCN1657224AImprove low temperature toughnessGood pressure coating processWelding/cutting media/materialsSoldering mediaIron powderHydrogen

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

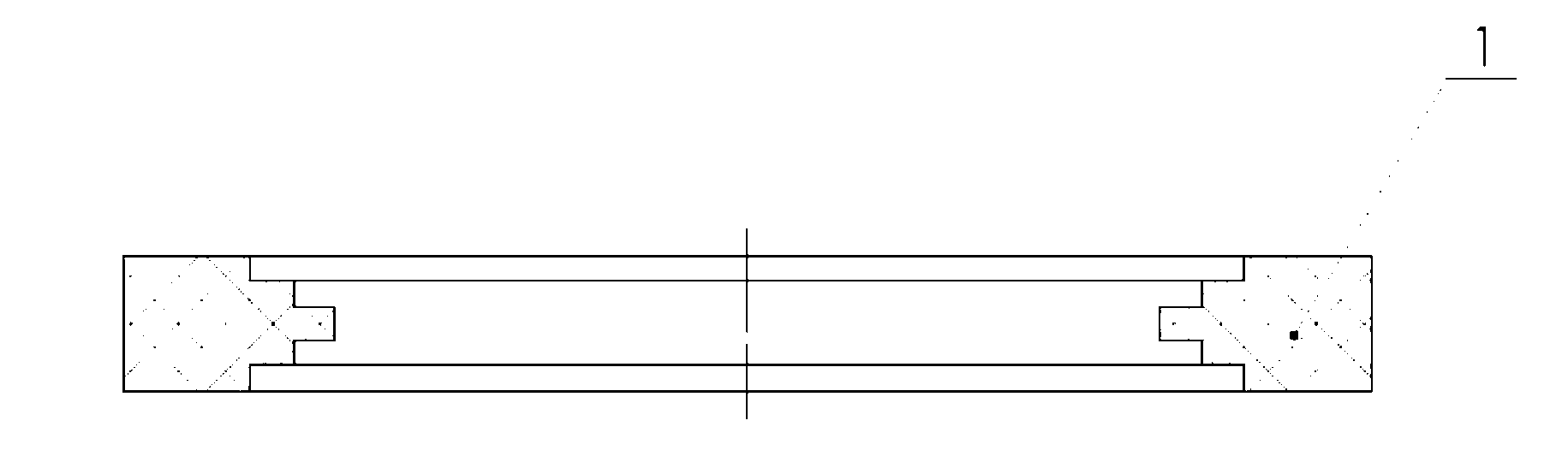

Direct current quick breaker

ActiveCN101908450AEasy accessEffectively build up arc voltageElectric switchesCircuit-breaking switch detailsEngineeringCircuit breaker

The invention relates to a direct current quick breaker, in particular to a direct current quick breaker with high requirement for short circuit breaking current. The breaker comprises a breaker body and an arc extinguish chamber, wherein the arc extinguish chamber comprises a pair of insulated shells and an arcing ring; the cavity of the arc extinguish chamber comprises a metal grid, an insulated grid and a transverse clapboard; the metal grid and the insulated grid are positioned in the middle of the arc extinguish chamber; the transverse clapboard is positioned on the upper part of the arc extinguish chamber; one side, which faces the bottom of the arc extinguish chamber, of the metal grid is a lower side provided with a notch having a downward opening; and two types of metal grids, namely a straight-panel metal grid and a U-shaped metal grid are provided. The breaker has the advantages of quickly establishing arc voltage, reducing the resistance of electric arc entering the arc extinguish chamber, lengthening electric arc, shortening arcing time, enhancing arc extinguishing capability of the arc extinguish chamber, along with simple structure, small overall dimension, convenient assembly and maintenance and the like.

Owner:中国船舶重工集团公司第七一二研究所

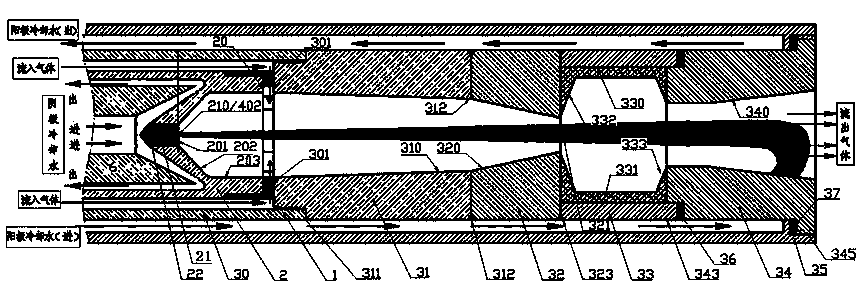

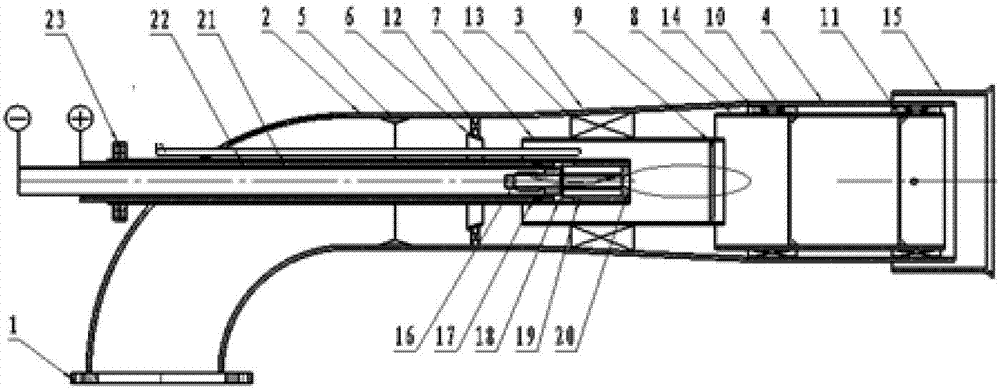

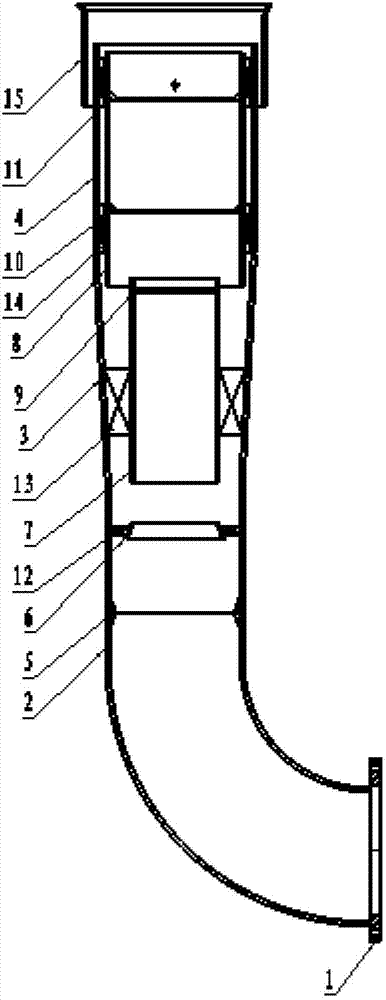

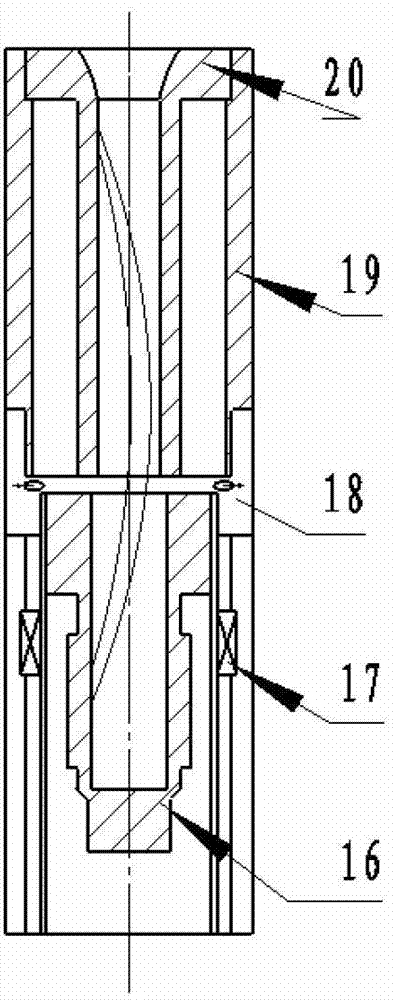

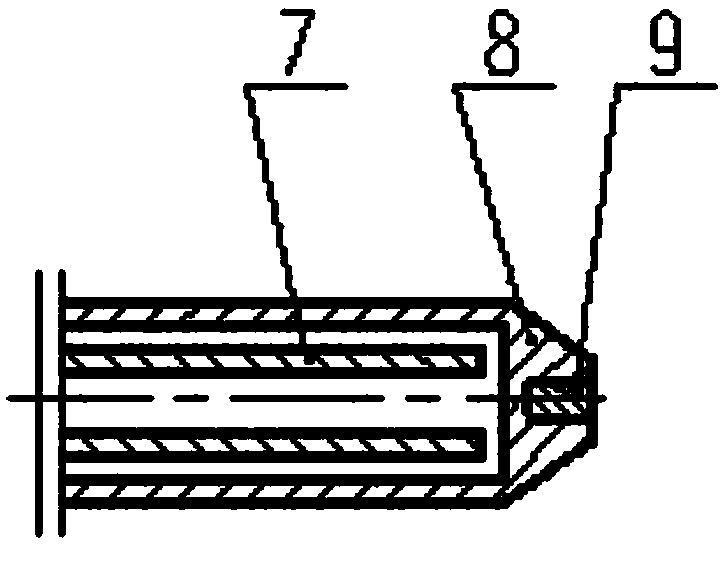

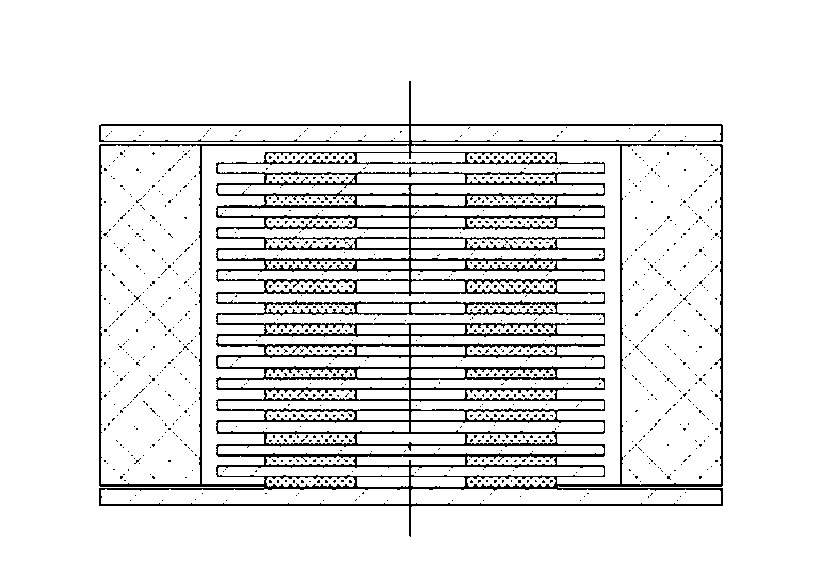

200KW non-transferred arc plasma generator and arc-striking method

ActiveCN102625561AIncrease distanceIncrease arc voltagePlasma techniquePlasma generatorRadioactive waste

Disclosed are a 200KW non-transferred arc plasma generator and an arc-striking method. A negative pole and an insulating sleeve, a clearance, a small positive pole and an adjustable insulating seat, a main gas ring, a second positive pole, an outside seal, an adjusting nut and a big positive pole are arranged sequentially along the injecting direction. The negative pole is of solid red copper, an outer ring of the negative pole is a stainless steel sleeve, and a cooling waterway is formed between the negative pole and the stainless steel sleeve. Each positive pole is of red copper with a center hole and a cooling waterway, a threaded junk ring and a special-shaped flange which can be adjustably connected at an axial direction are arranged outside each positive pole. Inert gases serving as assistant gases are ventilated to the top of the small positive pole; and main gases and protection gases are screwed in the second positive pole and the top of the big positive. The negative pole of the direct current power is connected with the negative pole of the plasma generator; the positive pole of the direct current power is connected with three positive poles of the plasma generator, and each positive pole is provided with an arc-transferring switch. Multiple positive poles are used for increasing the arc pressure, so that the power can be reached to 200KW. The main gases and protection gases are screwed in to produce stable and uniform arcs. Water-cooling is used for meeting the cooling requirements for high powers. The negative poles are arranged at the rearmost end to guarantee convenient installation and replacement. Control parameters can be altered by distance adjustment, so that the service life is prolonged. The 200KW non-transferred arc plasma generator and the arc-striking method can be used for waste detoxifying treatment, fire-resistant heat-insulating material melting production for ore smelting, radioactive waste treatment and funeral-interment and cremation industry.

Owner:CHENGDU JINCHUANGLI SCI & TECH

High-intensity arc voltage gas electrical discharge tube

InactiveCN101882757AIncrease arc voltageOvervoltage arrestors using spark gapsHydrogenHigh intensity

The invention discloses a high-intensity arc voltage gas electrical discharge tube, which comprises electrodes and a hollow ceramic tube, wherein the electrodes and the hollow ceramic tube are welded to form a sealed cavity, and a mixture of nitrogen gas and hydrogen gas is mainly filled in the cavity, wherein the nitrogen gas accounts for less than 90 percent of the total volume, and a gap between the two electrodes of the gas electrical discharge tube is larger than 0.5mm. After the technical scheme is adopted, the arc voltage of the gas electrical discharge tube can be improved to 26V or higher than 26V. When the gas electrical discharge tube is applied to fields such as power supplies and the like, the effect of no follow current can be realized without the combination of a plurality of gas electrical discharge tubes, and the invention brings convenience for users.

Owner:SHENZHEN BENCENT ELECTRONICS CO LTD

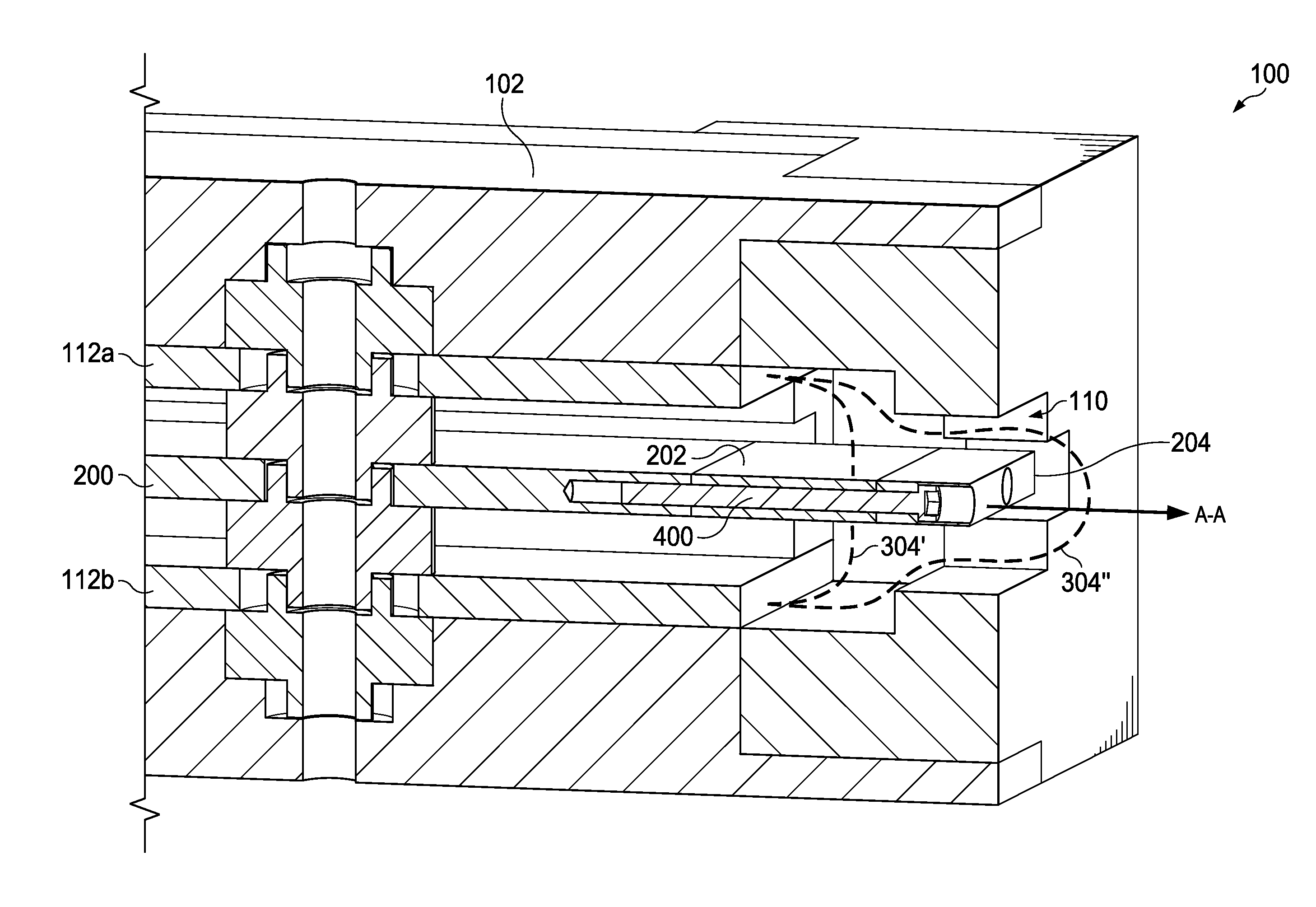

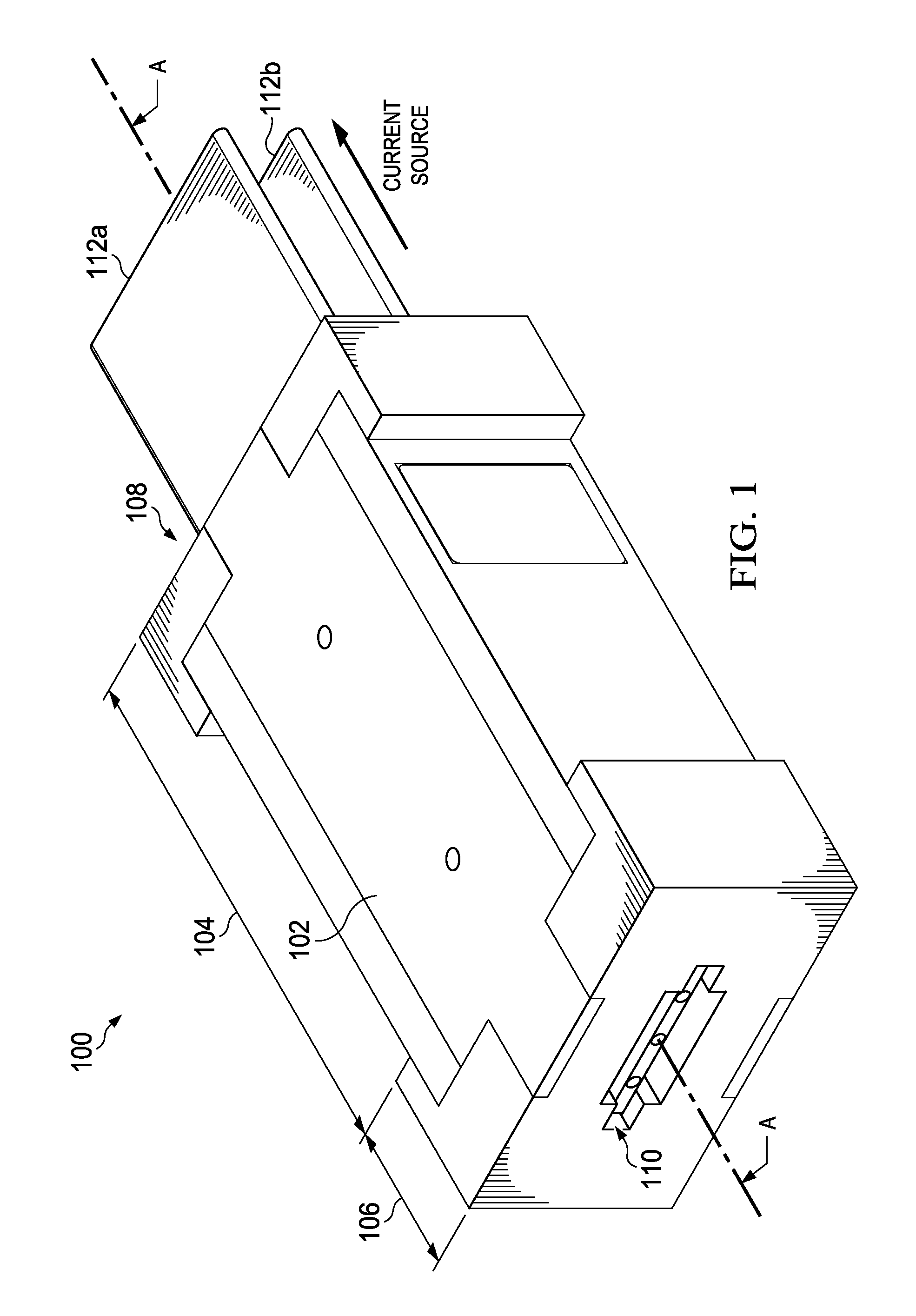

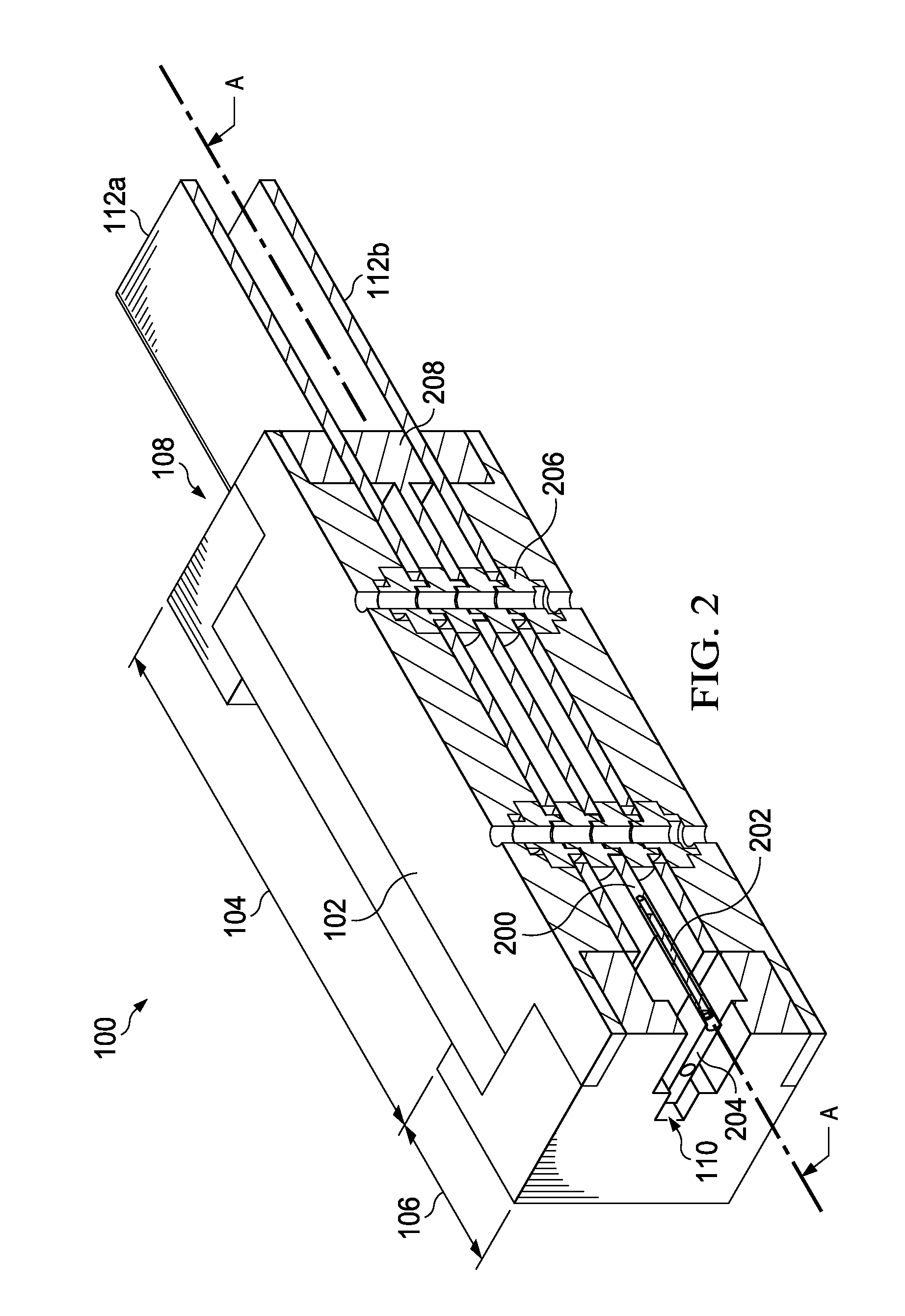

Bus end arc interrupter

ActiveUS20160190780A1Increase arc voltageTotal current dropNon-enclosed substationsBus-bar/wiring layoutsElectrical conductorControl theory

Method and system for controlling and limiting the damage caused by arcs formed on exposed conductors in electrical distribution equipment involve using the tendency of an arc to move in a direction away from a current source and toward the terminal ends of the conductors. An arc interruption device, or arc interrupter, is placed over the terminal ends of the conductor to capture the arc as it travels toward the terminal ends of the conductors. Within the arc interrupter, the shape of the arc is conformed to geometries designed to stretch and extend the arc to the point where it can no longer be sustained and is extinguished.

Owner:SCHNEIDER ELECTRIC USA INC

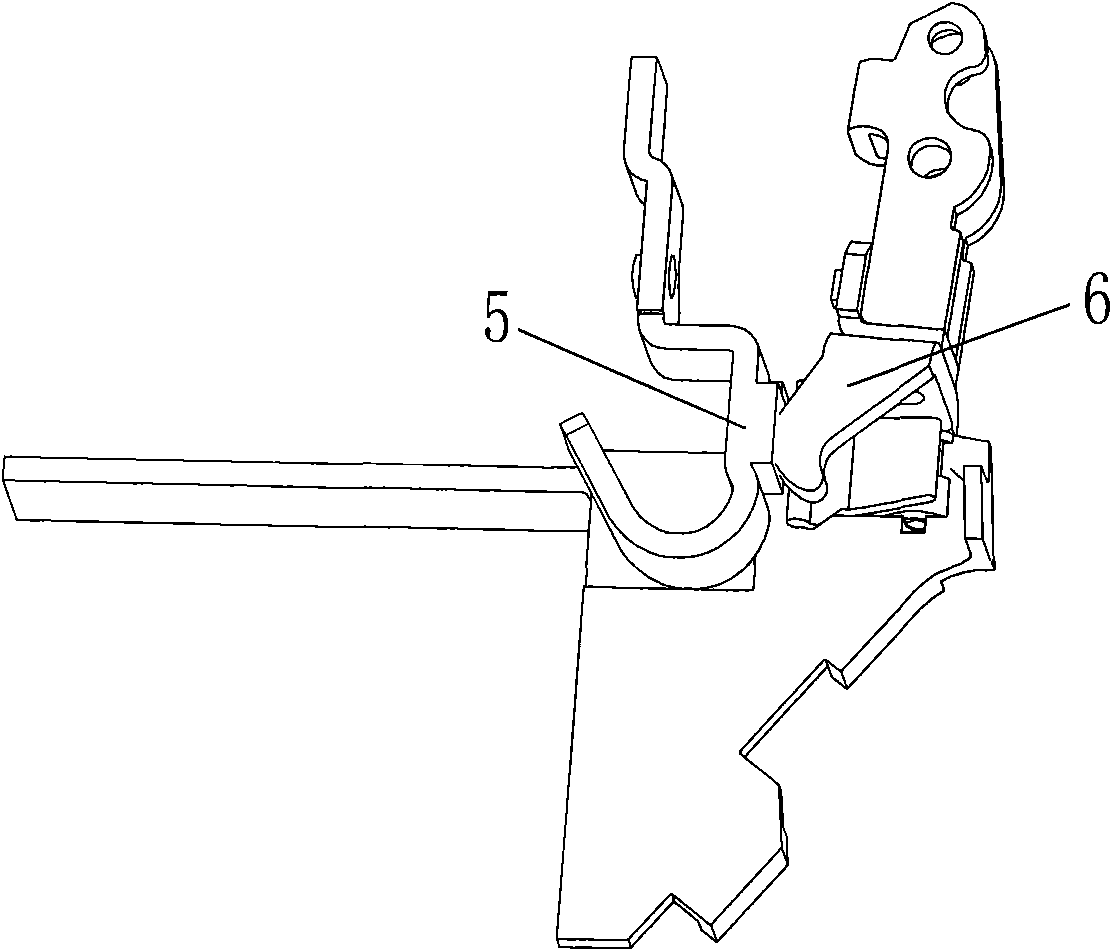

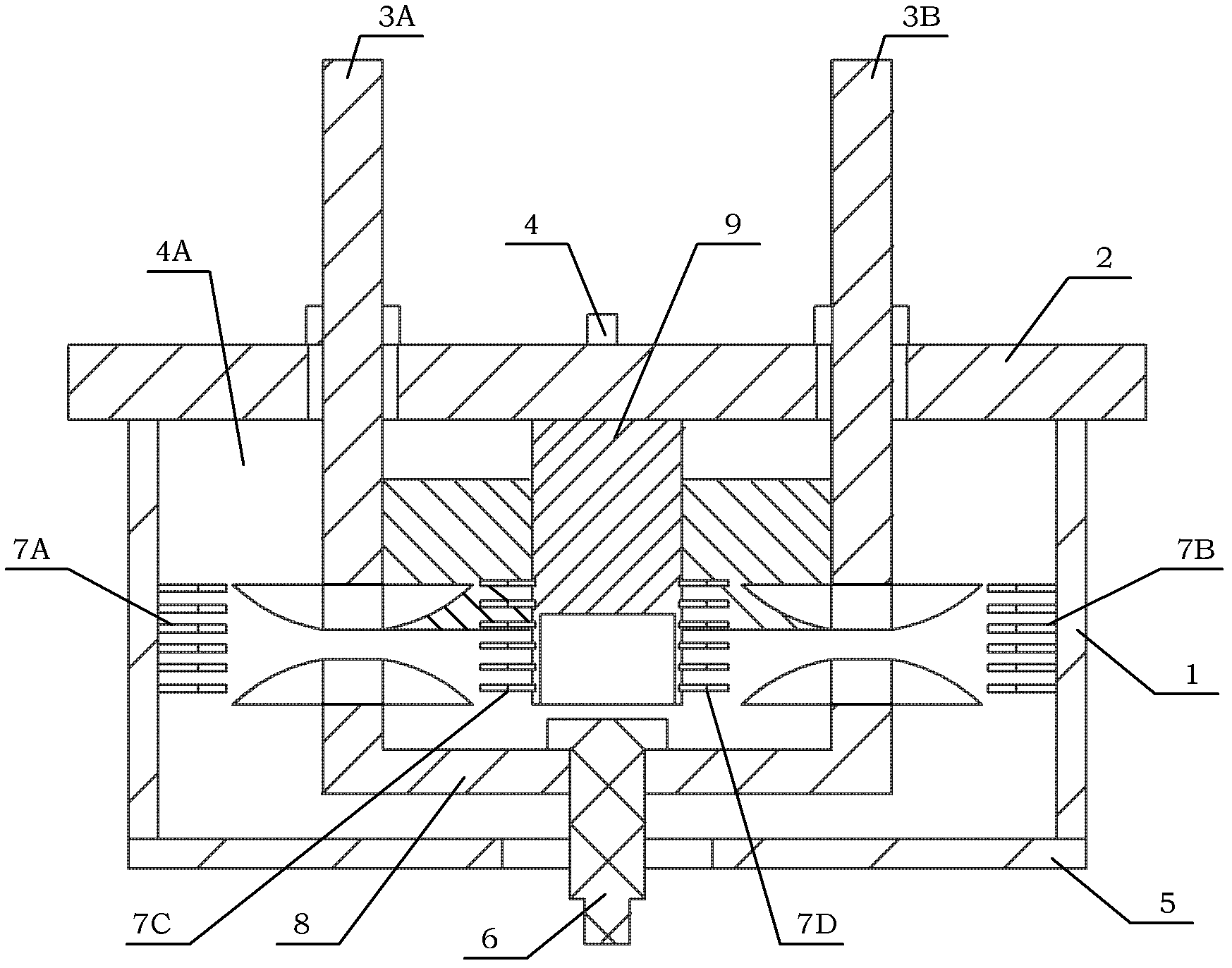

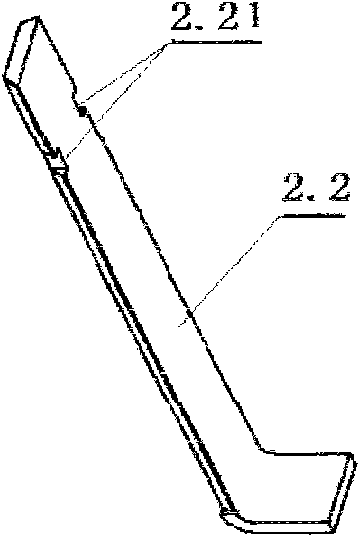

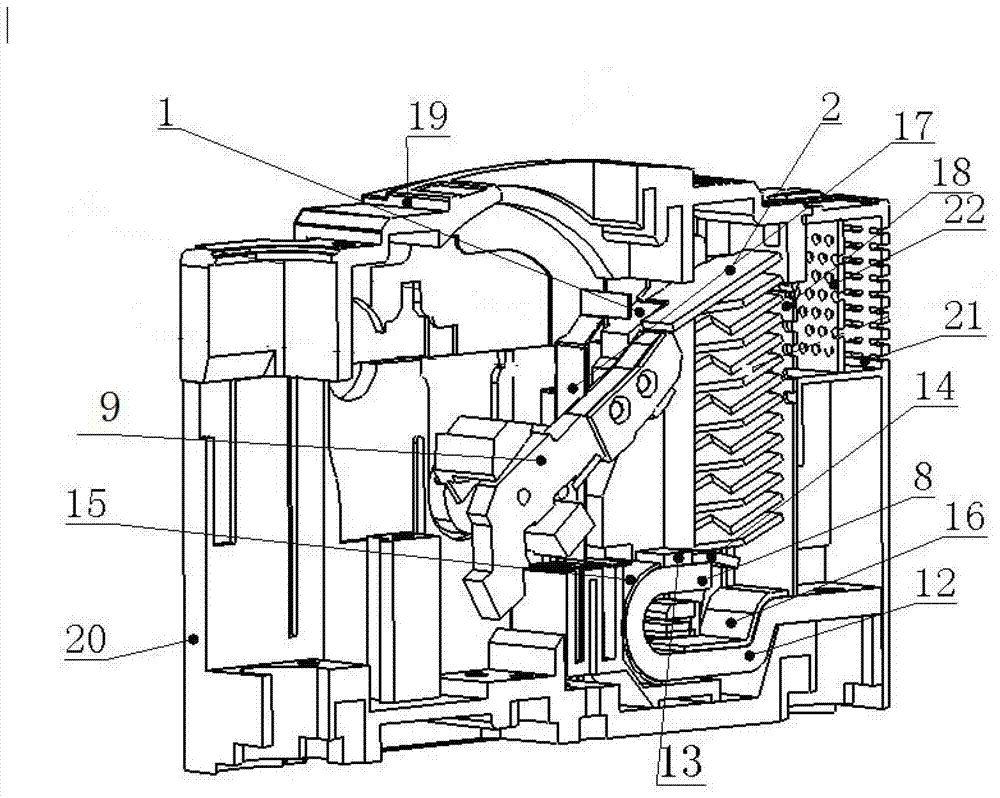

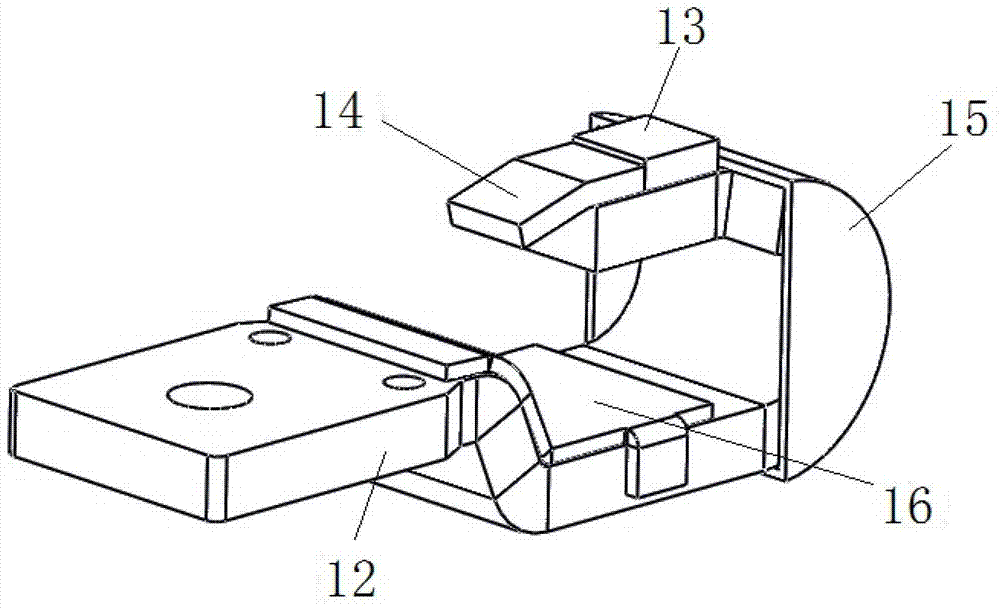

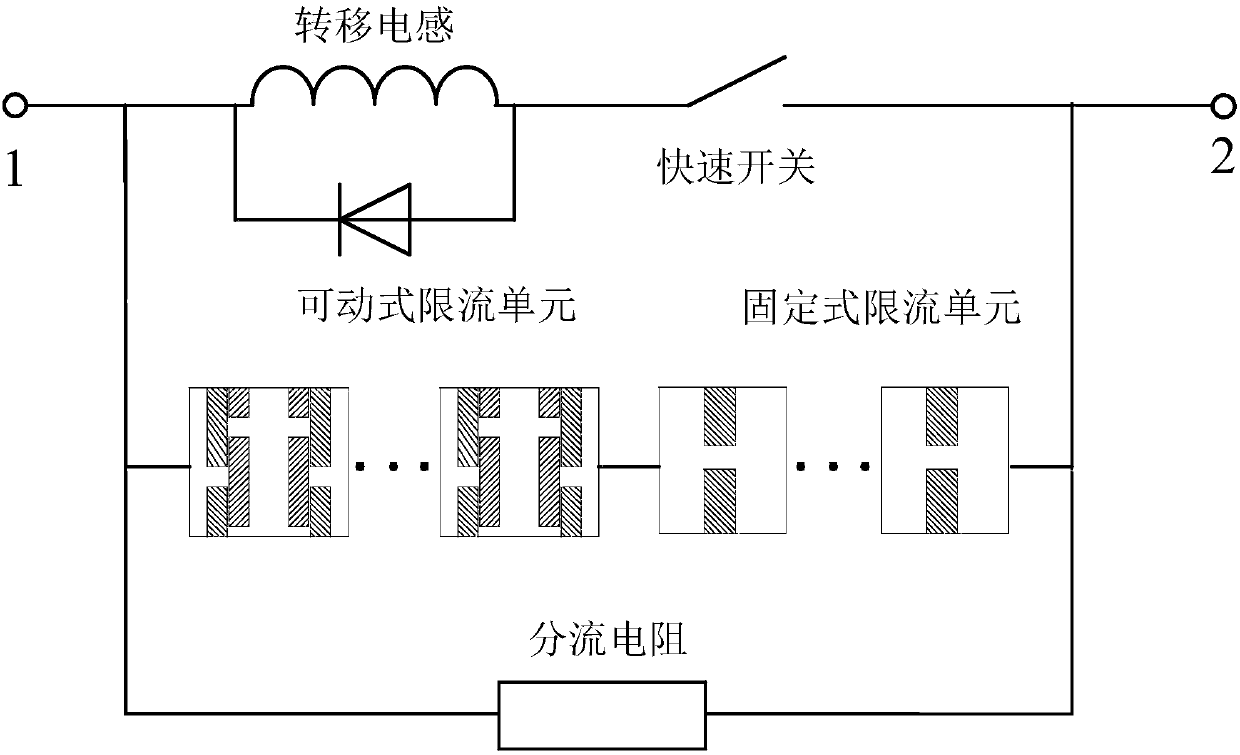

Arc guiding and extinguishing apparatus and DC breaker using same

ActiveCN102931041AImprove arc extinguishing performanceImprove arc extinguishing effectCircuit-breaking switch detailsDc circuit breakerElectric current

The invention discloses an arc guiding and extinguishing apparatus, as well as a DC breaker using the arc guiding and extinguishing apparatus. The arc guiding and extinguishing apparatus comprises a U-shaped motor groove and an arc extinguishing cover component which are mutually connected, wherein a U-shaped magnet yoke is arranged in a hollow cavity of the U-shaped motor groove; a magnetic material block is respectively arranged on each side of the upper sides of two sidewalls of the magnet yoke; and a reversed U-shaped magnetic path is formed by the magnetic material blocks and an arc extinguishing grid sheet in the arc extinguishing cover component. The magnetism generated by the current in a conductive circuit in the U-shaped magnet yoke and the reversed U-shaped magnetic path has a strong magnetic blowing force on the arc which is instantly generated when a movable contact and a static contact are released from contact, so as to blow the arc into the arc extinguishing cover component to extinguish the arc. With the adoption of the arc guiding and extinguishing apparatus, as well as the DC breaker using the arc guiding and extinguishing apparatus, the problem that the arc guiding effect on the arc near to the dynamic contact by the arc guiding device in the prior art is poor is solved; and the arc guiding and extinguishing apparatus, as well as the DC breaker using the arc guiding and extinguishing apparatus is excellent in arc guiding effect, strong in arc extinguishing ability, short in arc spraying distance and wide in application range for all arcs between the dynamic contact and the static contact.

Owner:ANDELI GRP

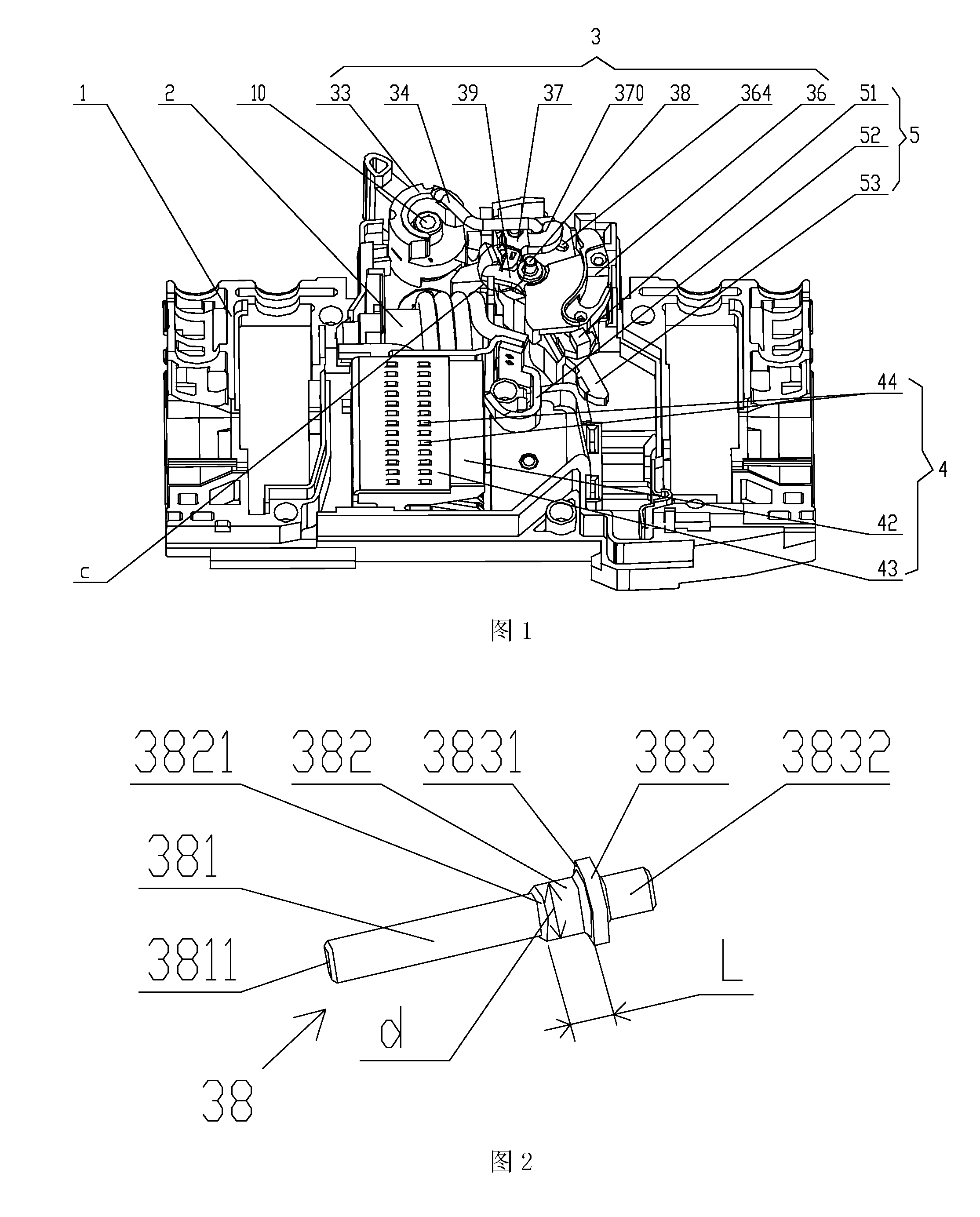

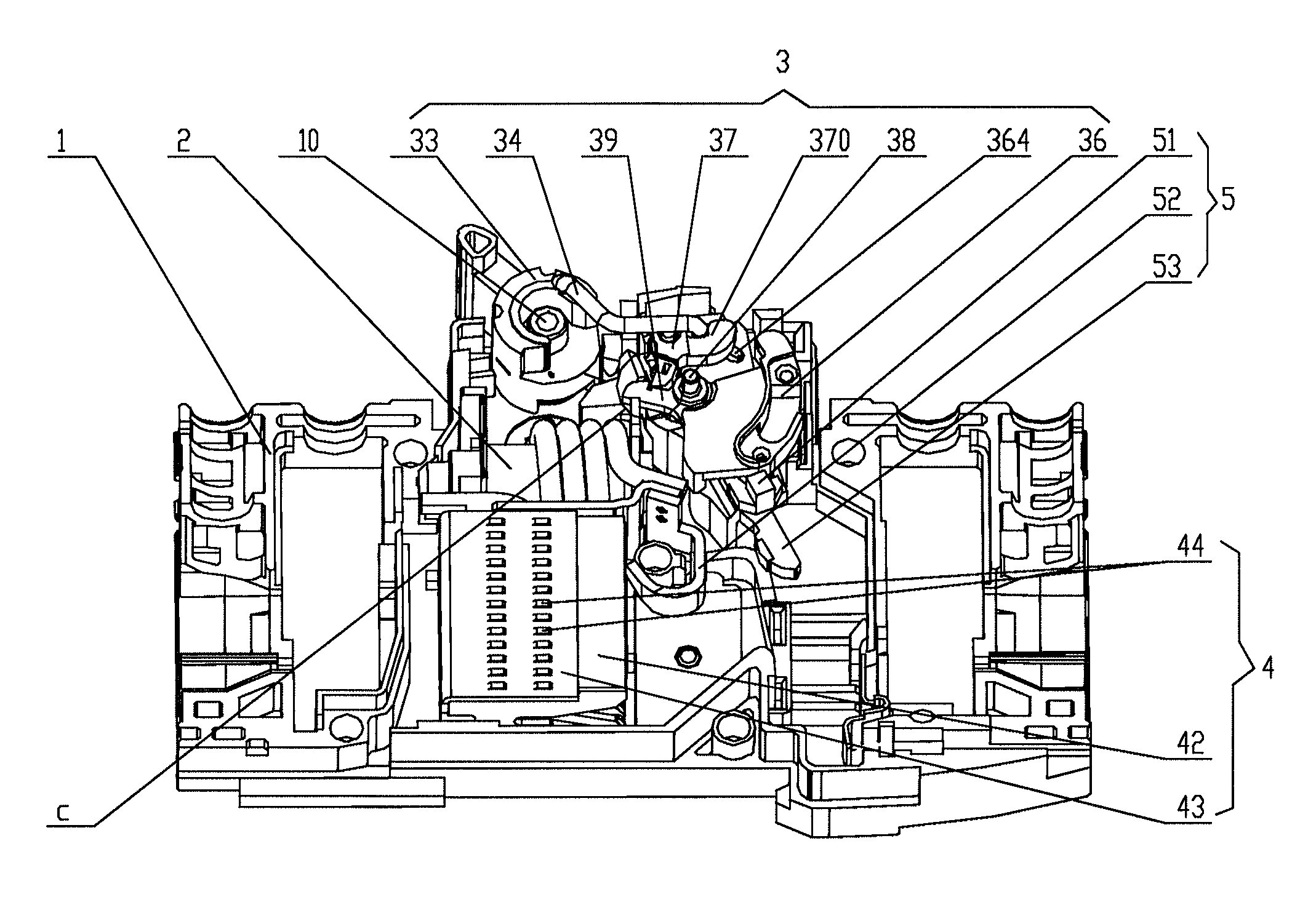

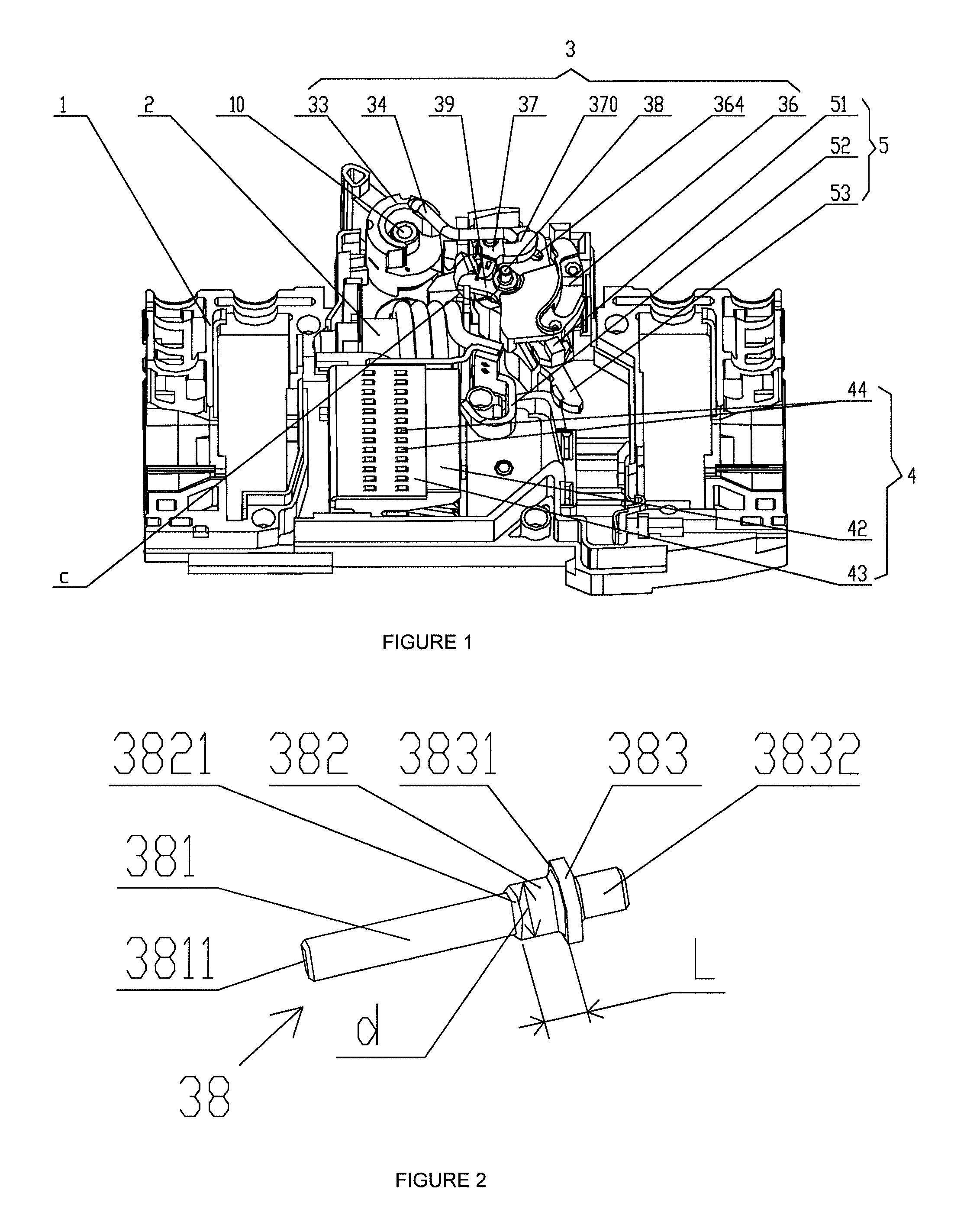

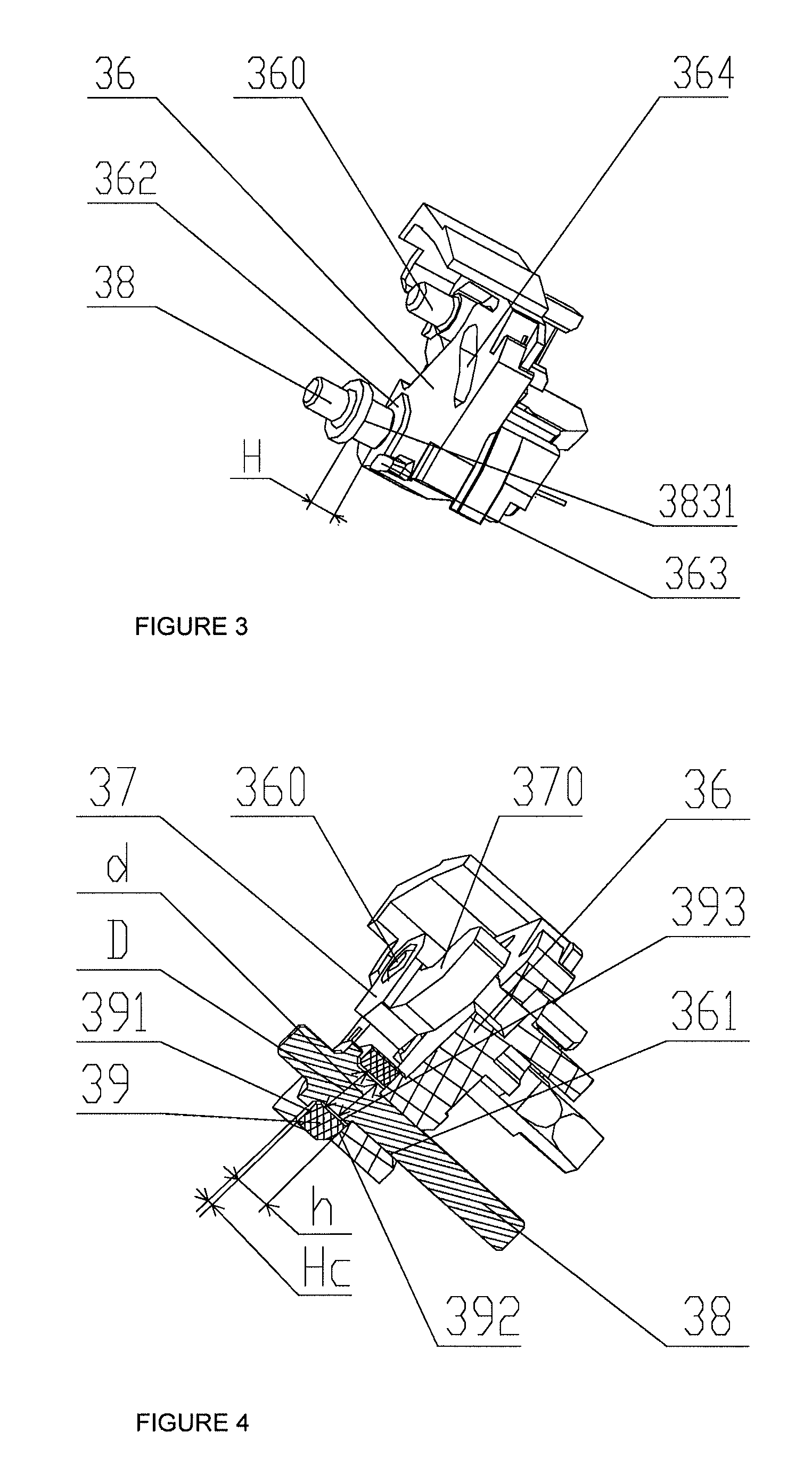

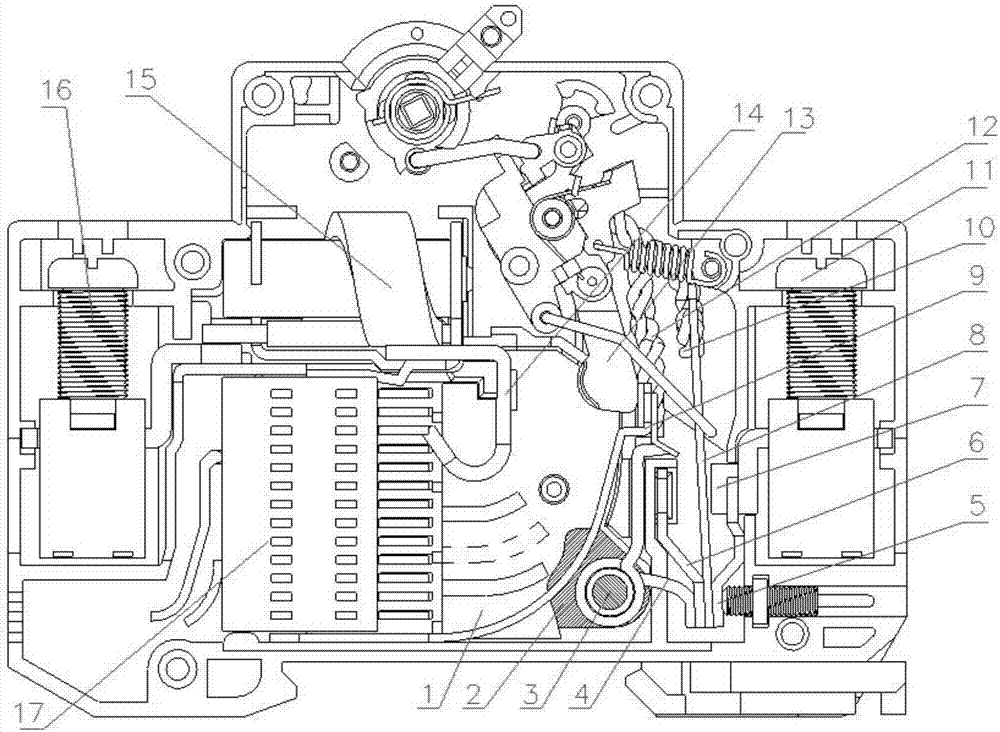

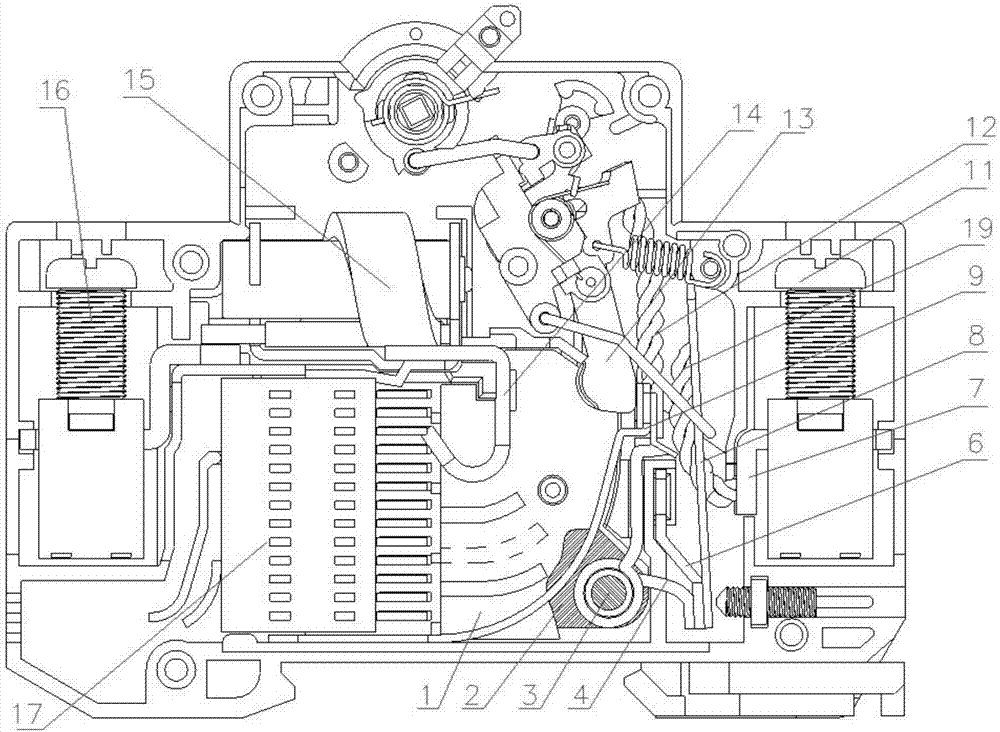

Minitype breaker with high stability

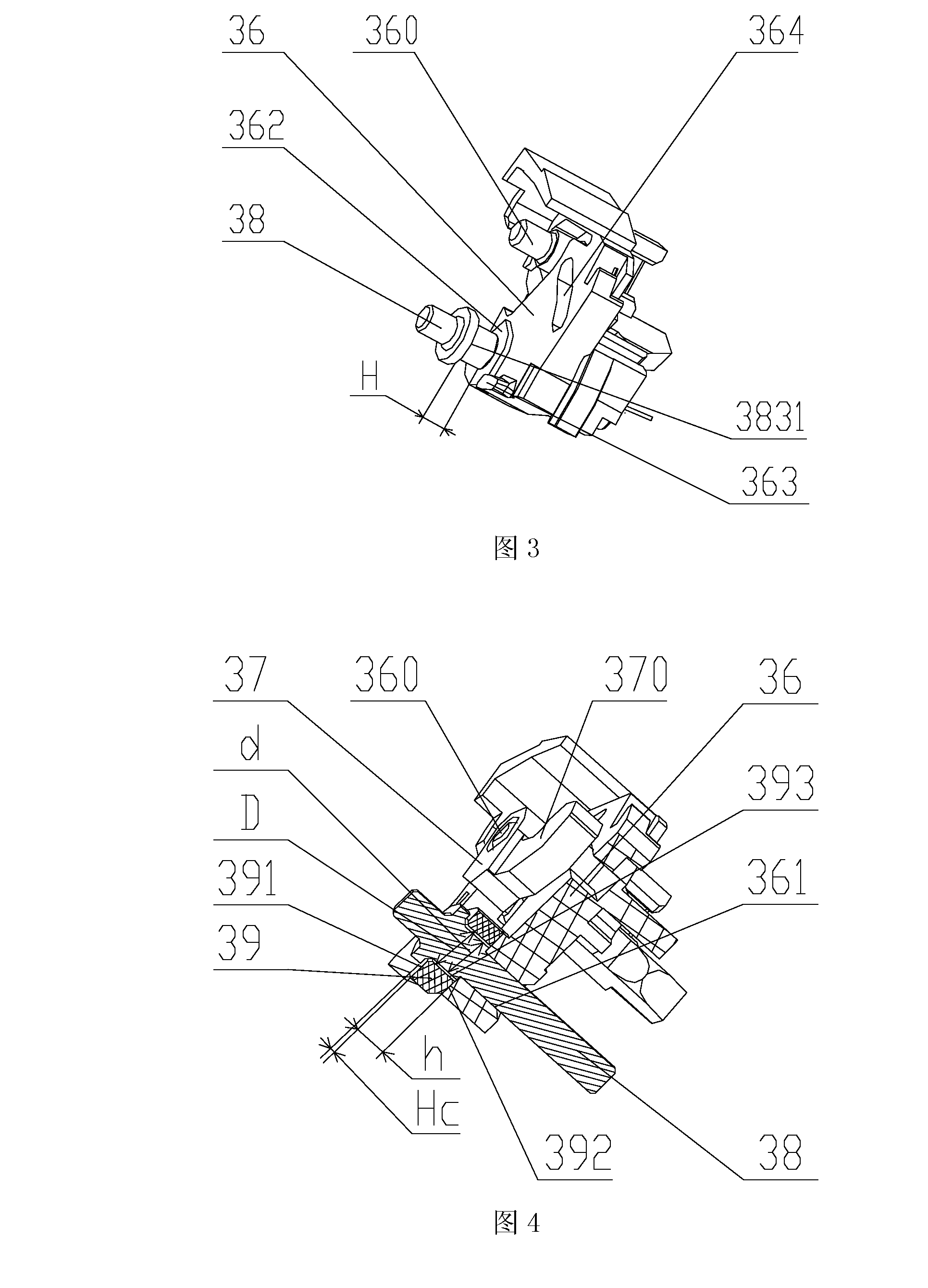

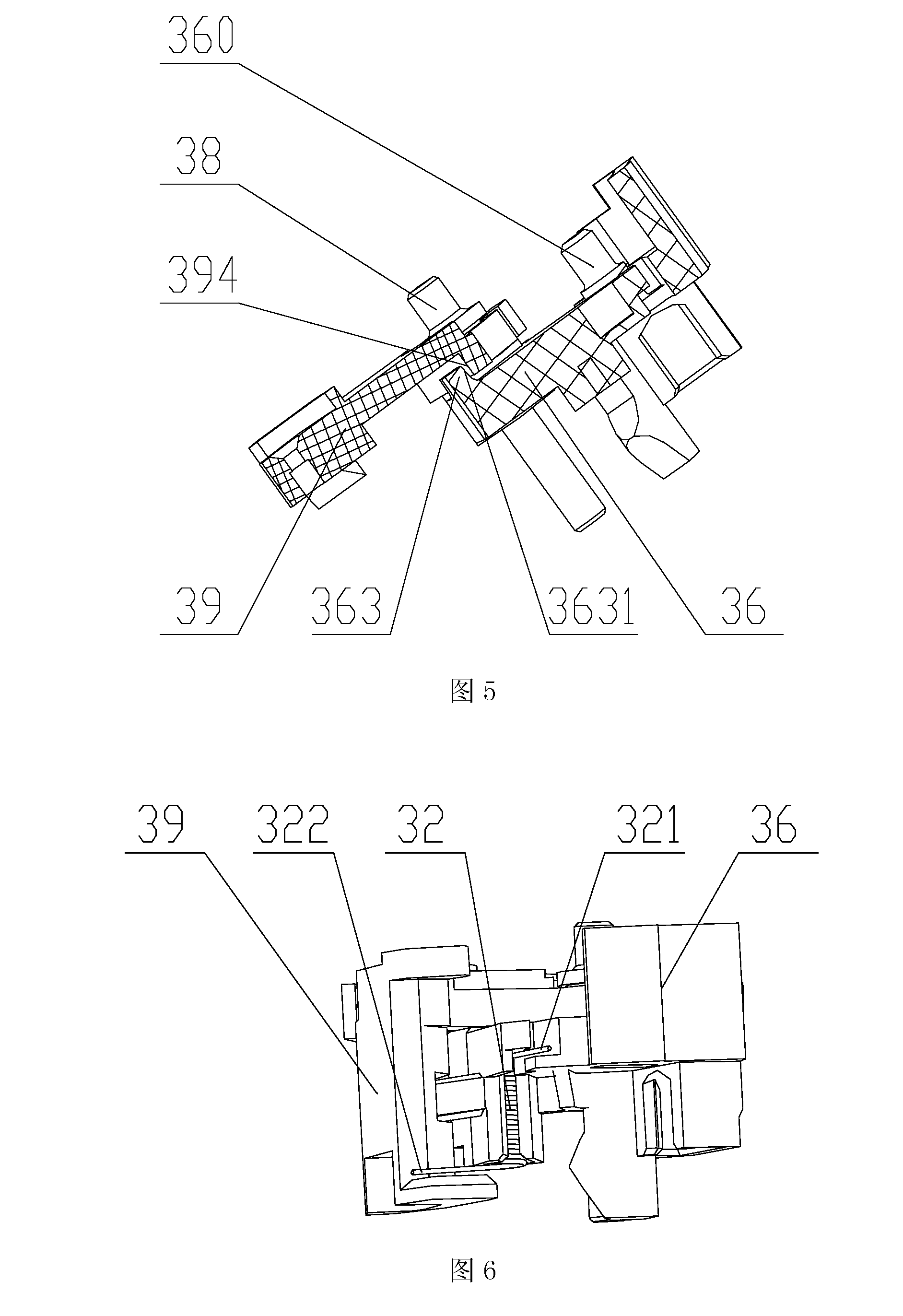

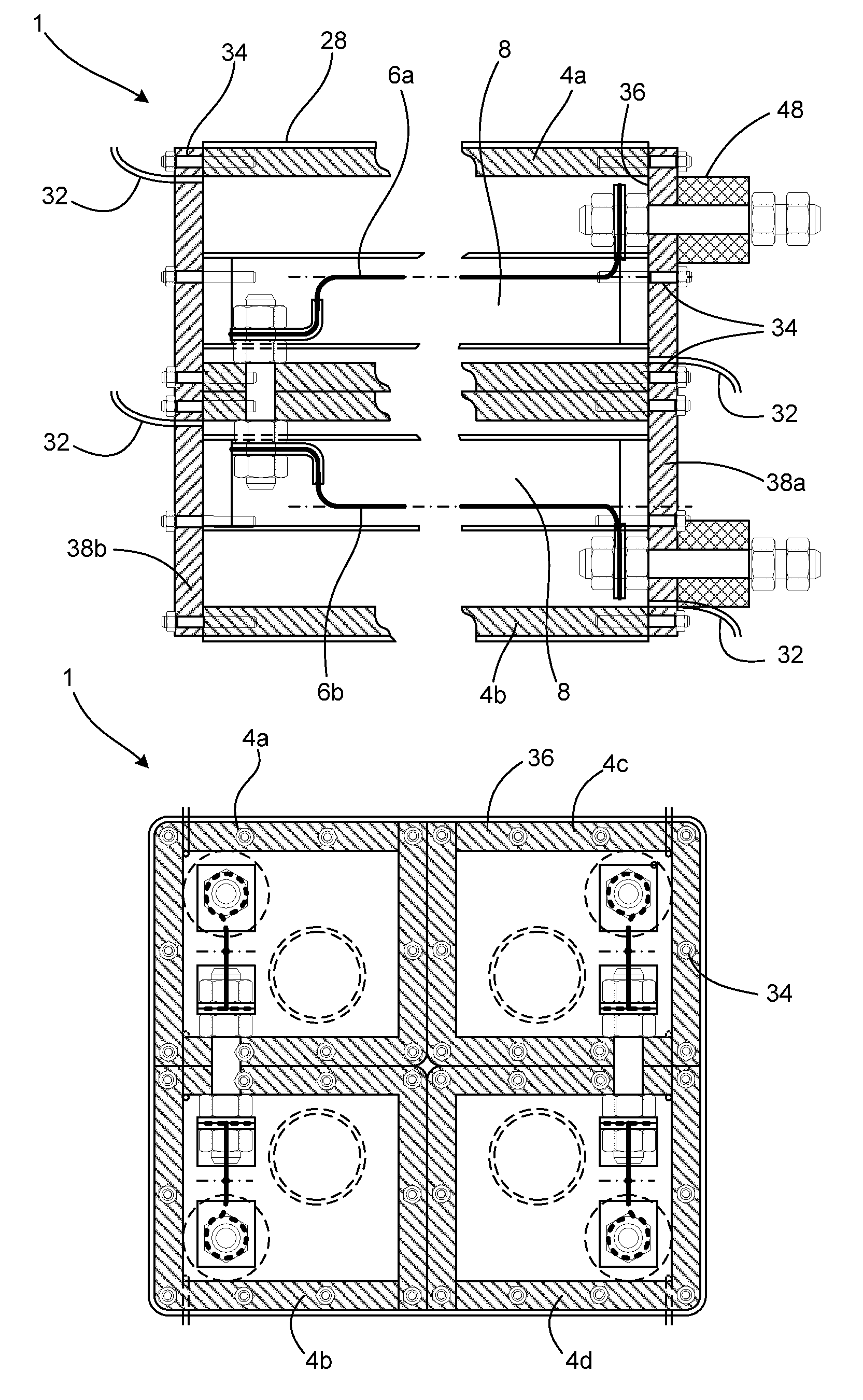

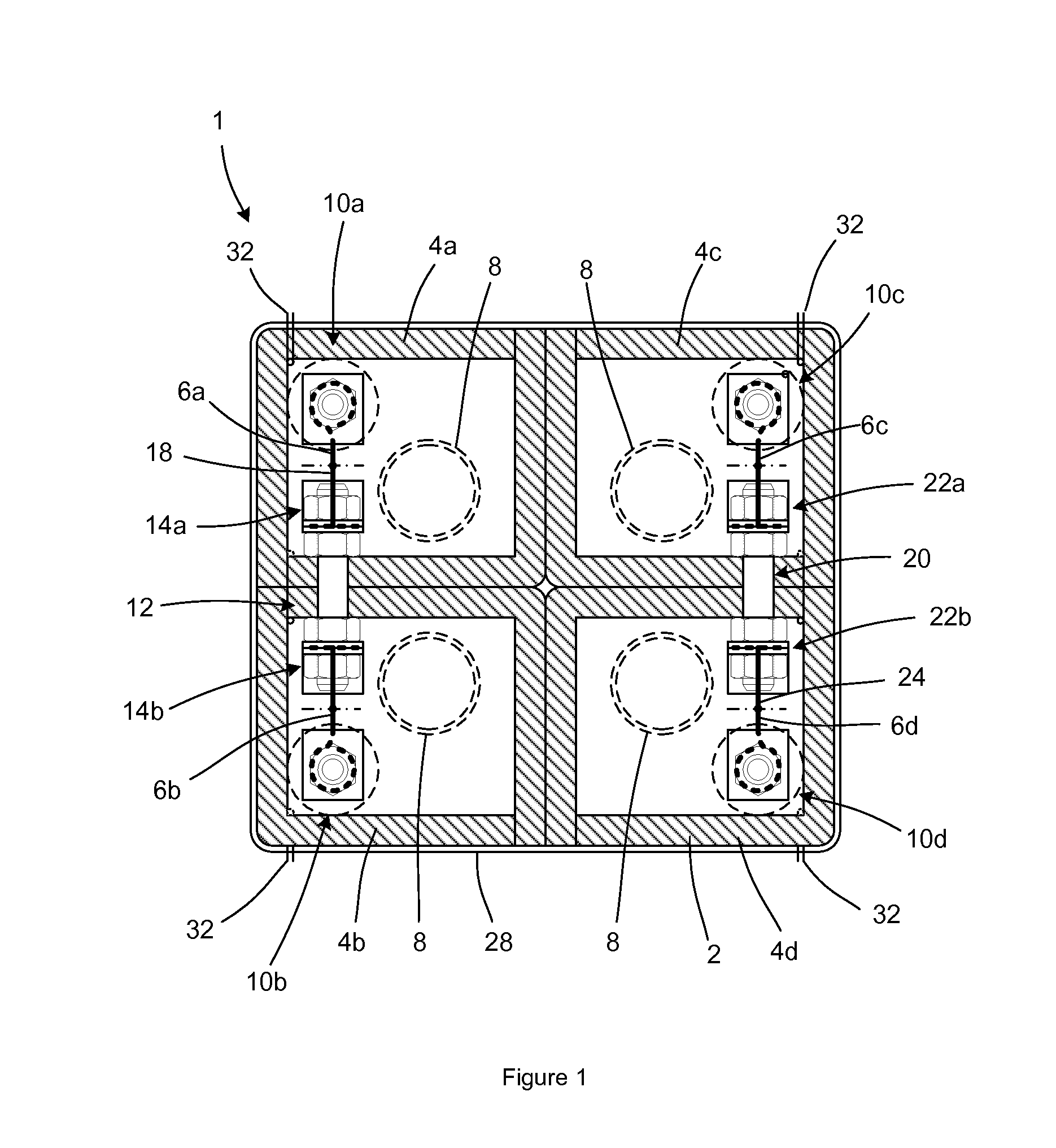

ActiveUS20150255228A1High strengthTripping forceProtective switch detailsEmergency actuatorsEngineeringCircuit breaker

A high-stability miniature circuit breaker includes an operating mechanism, wherein a pivotal shaft of the operating mechanism fixed on a shell includes a first shaft section, a second shaft section and a shaft shoulder; the diameter of the second shaft section is larger than that of the first shaft section, and the diameter of the shaft shoulder is larger than that of the second shaft section. A lever is installed on the first shaft section through a first shaft hole in a pivoting way and used for limiting the axial position of a protruding mesa relative to the pivotal shaft through contact fit between the protruding mesa disposed on the lever and a thrust surface on the second shaft section. A latch assembly is installed on the second shaft section through a second shaft hole in a pivoting way; a first end face fitted with a support surface on the shaft shoulder is disposed at one end of the second shaft hole; and a second end face fitted with the protruding mesa is disposed at the other end of the second shaft hole. A first hasp fitted with a second hasp of the latch assembly is disposed on a connecting rod, the connecting rod is engaged with each other with the latch assembly in the first and second hasp contact and withhold state, and the latch assembly controls a drive rod and the lever not to move relatively; the connecting rod is separated from the latch assembly when the first and second hasps are separated and unbuckled, and the latch assembly is separated from the drive rod, so that the drive rod can slide along a groove of the lever.

Owner:SHANGHAI NOARK ELECTRIC

Fuses

InactiveUS20150054614A1Minimise electric field enhancement factorReduce riskEmergency protective devicesElectrical conductorEngineering

A fuse assembly for interrupting fault current in an external DC circuit. The fuse assembly includes 2n fusible conductor elements, where n is an integer, wherein the fusible conductor elements extend along, and are circumferentially around, a longitudinal axis of the fuse assembly. The fusible conductor elements are connected together in series to define fuse elements and the fusible conductor elements are orientated within the fuse assembly such that current flowing along each fusible conductor element is in the opposite direction to current flowing along the fusible conductor element or fusible conductor elements adjacent to it. The fuse assembly further includes a supply terminal connected to an end of the fuse element and connectible to a DC supply, and a load terminal connected to an opposite end of the first fuse element and connectible to an electrical load.

Owner:GE ENERGY POWER CONVERSION TECH

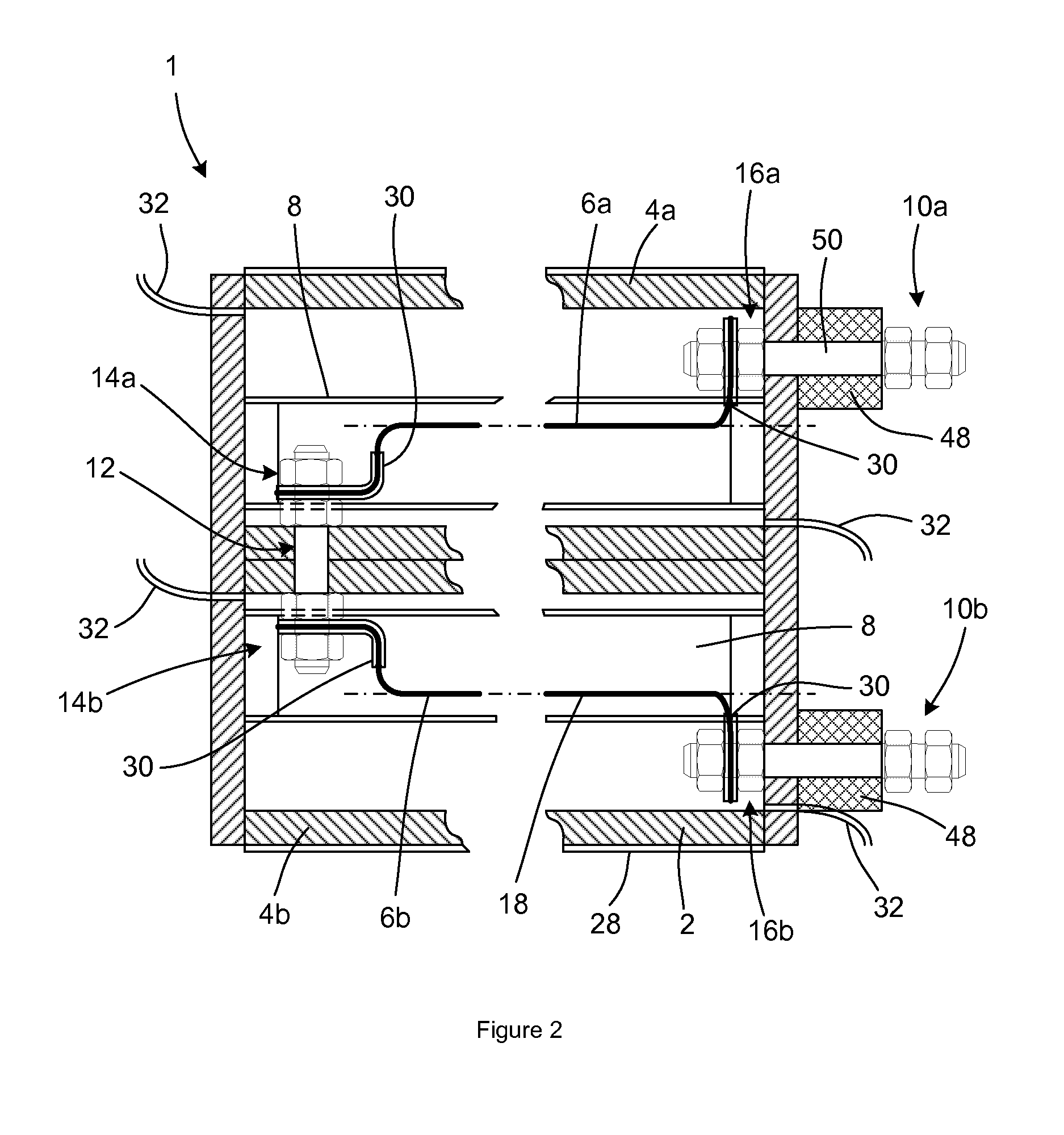

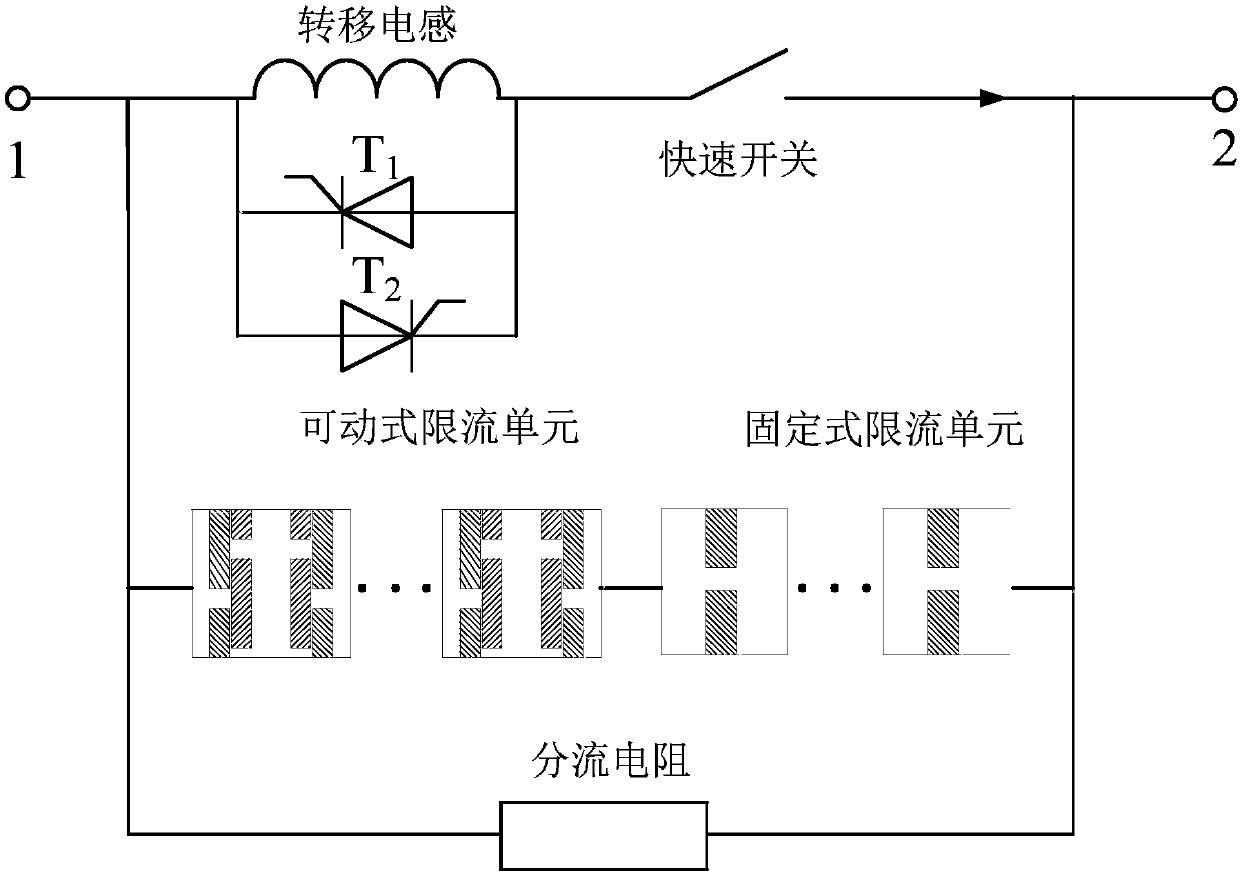

Medium-voltage direct-current fault current limiter and implementation method thereof

InactiveCN107623309ALimited efficiencyLimit fast and efficientEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentElectrical devicesEngineering

The disclosure discloses a medium-voltage direct-current fault current limiter and an implementation method thereof. The current limiter comprises a fast switching branch, a current-limiting unit branch and a shunt resistance branch. The fast switching branch employs a fast mechanical switch to realize rated flowing. The current-limiting unit branch is formed by series connection of a plurality offixed liquid metal current-limiting units and a movable liquid metal current-limiting unit to realize respectively fault current peak limiting and short-circuit energy dissipation. The shunt resistance branch is a resistor; in a current-limiting state, the short-circuit energy is shared and thus the current-limiting unit is protected. According to the disclosure, the parts are reduced and thus the structure becomes simple. Functions of rated high-current carrying and fast short-circuit current limitation are realized simultaneously and rapid transfer and short-circuit energy dissipation problems of the heavy-direct-current fault currents are solved. The limiter and implementation method thereof are especially suitable for limiting the fault current of the medium-voltage direct-current system, so that burdens of various electrical devices like a circuit breaker are reduced.

Owner:XI AN JIAOTONG UNIV +1

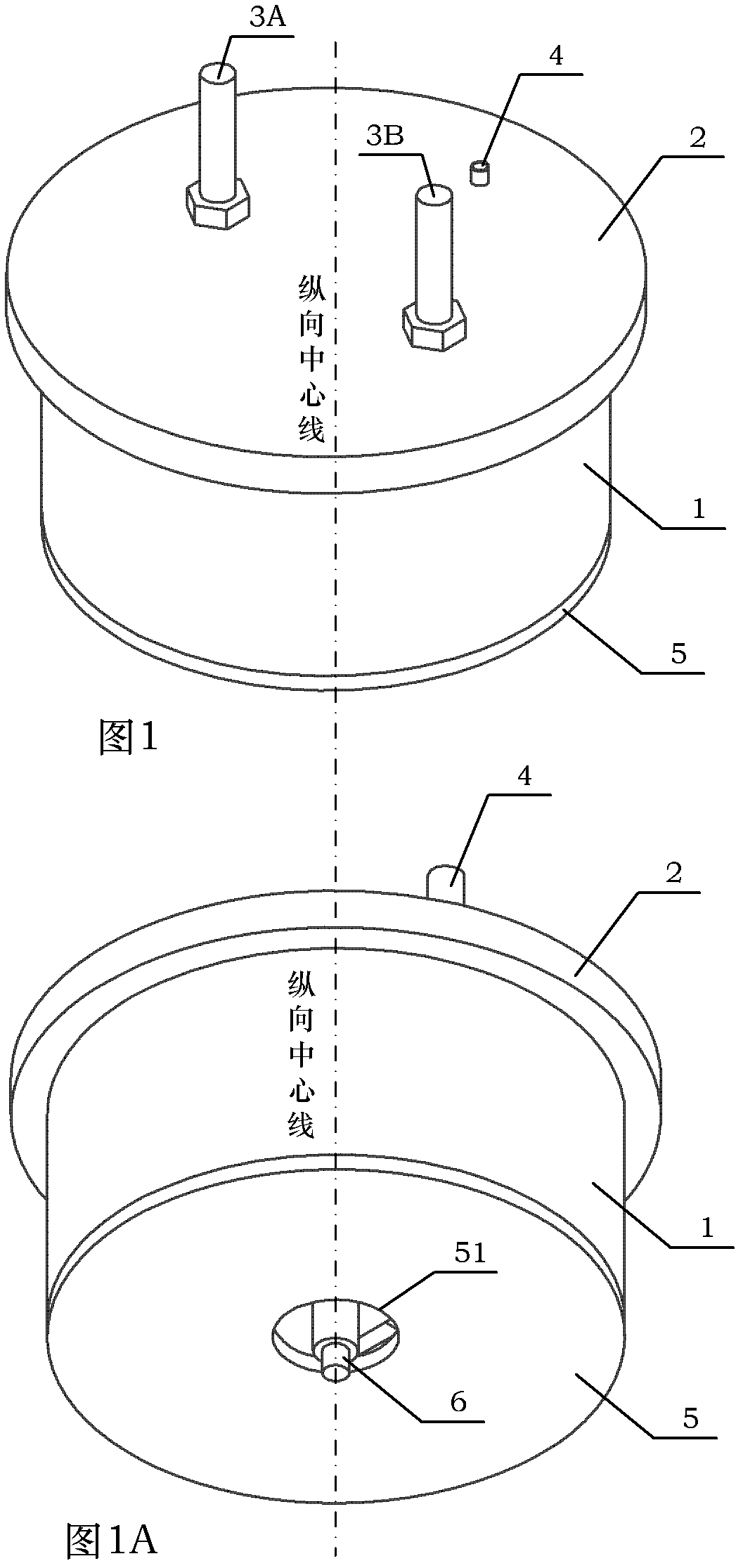

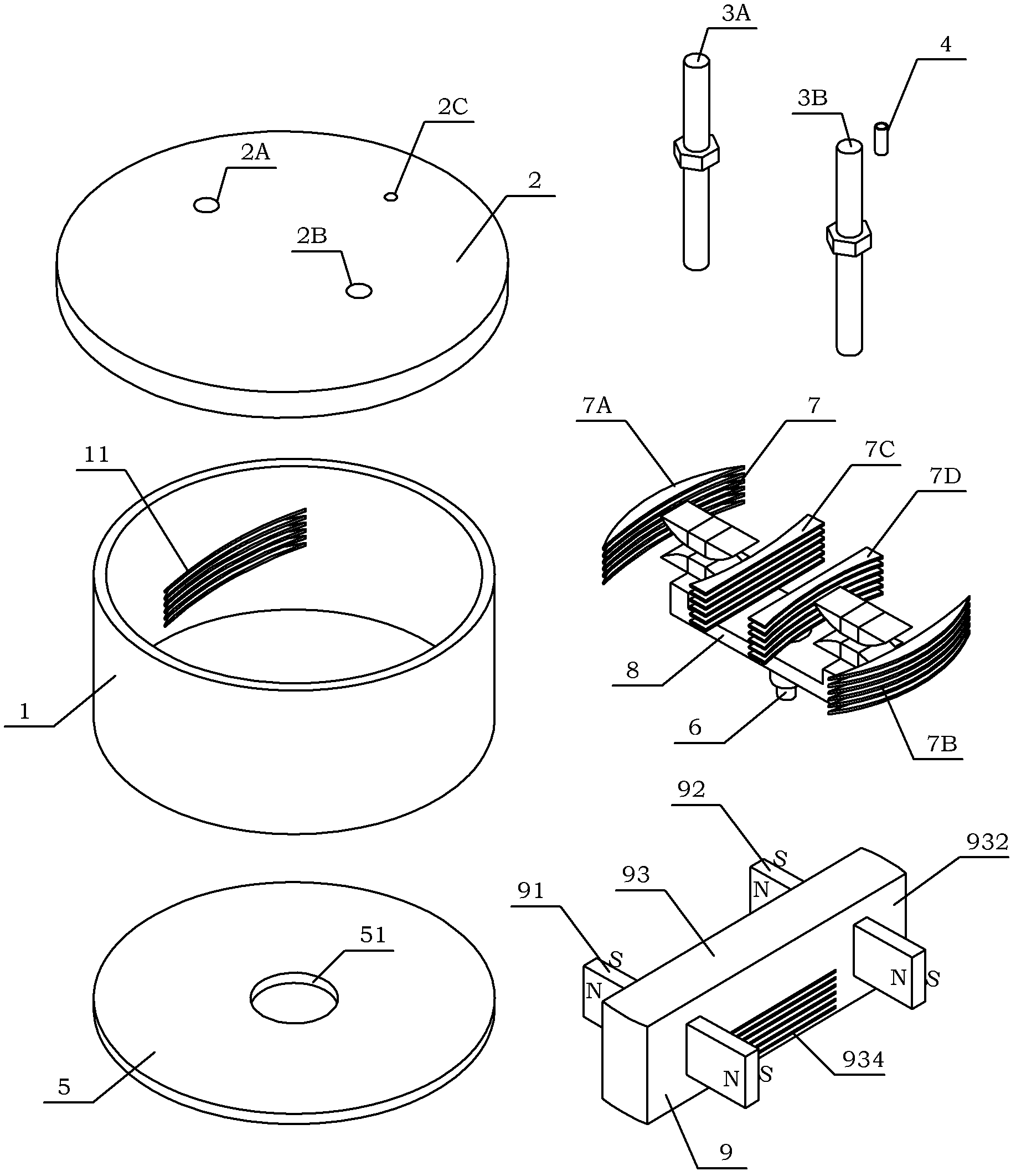

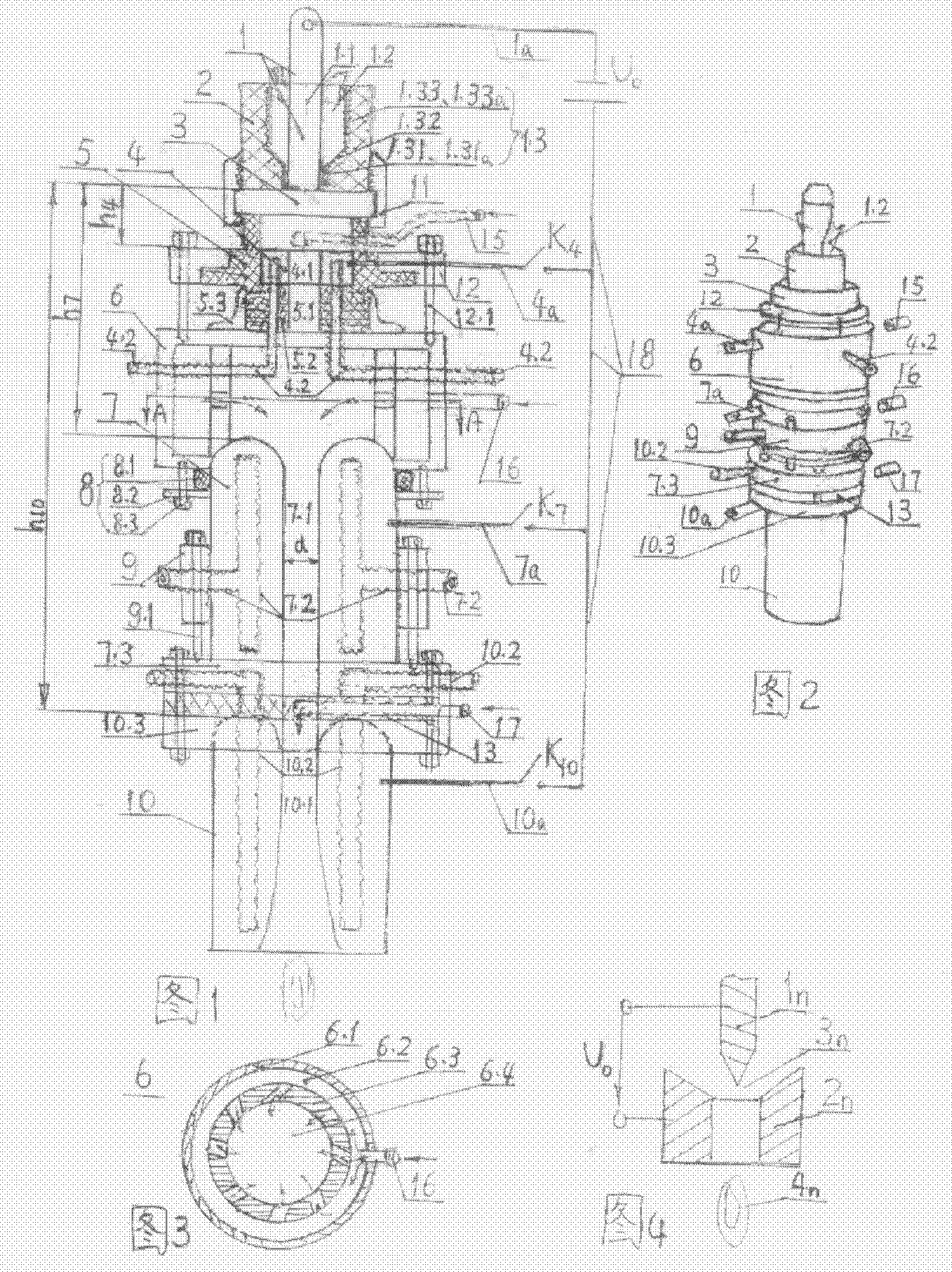

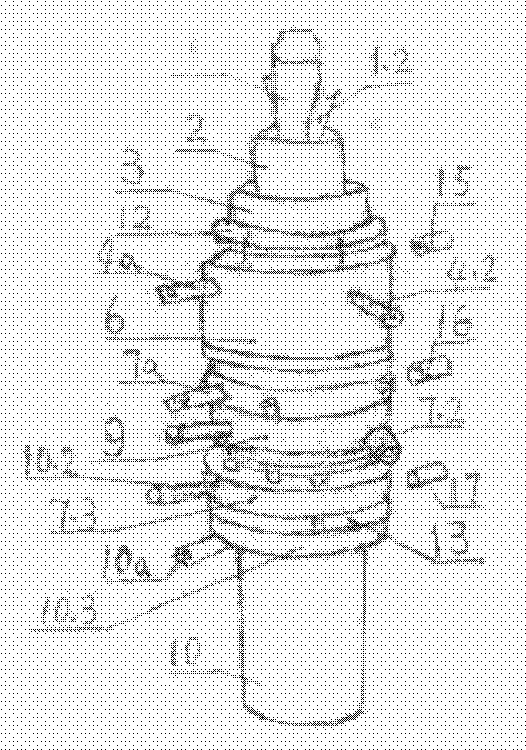

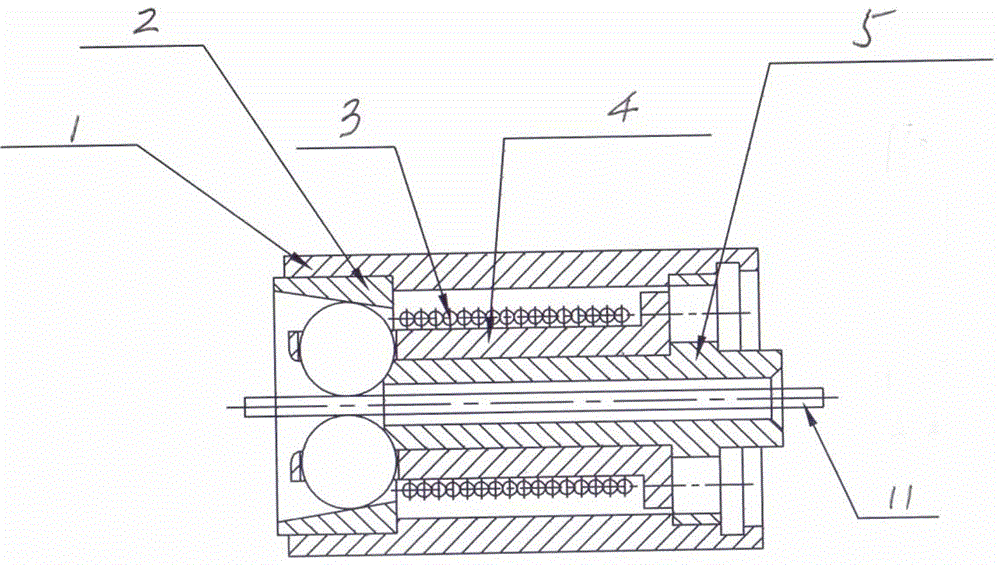

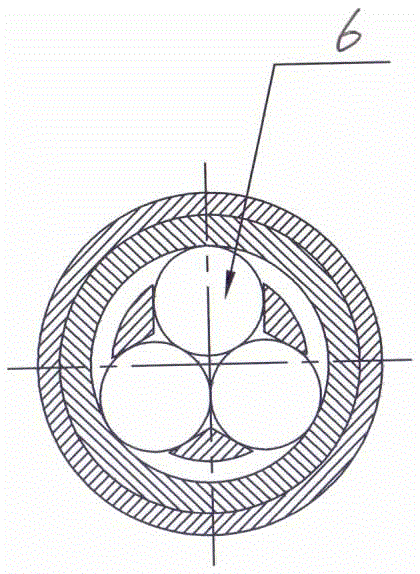

Magnetic rotating arc plasma generator

The invention relates to a magnetic rotating arc plasma generator, and belongs to the technical field of plasma generators. The magnetic rotating arc plasma generator comprises a cathode, a magnetic rotating arc anode, a rotational flow ring and an anode water channel, and is characterized in that the cathode and the magnetic rotating arc anode are arranged in a coaxial manner; the magnetic rotating arc anode comprises an arc starting anode, a transition anode and a main anode, the transition anode comprises a conducting section and an insulating section, and the main anode comprises an electromagnetic coil and a main anode body. The magnetic rotating arc anode is in the shape of a special-shaped circular tube on the whole, one end of the magnetic rotating arc anode is in the shape of a bell mouth, and the middle of the magnetic rotating arc anode is provided with a through hole. The air flow generates a rotational flow through the rotational flow ring, the electromagnetic coil generates an electromagnetic field, the rotational flow and the electromagnetic field compress the arc together and drive the arc to rotate, thereby enabling the root of the arc to rotate with a high speed on the main anode. The magnetic rotating arc plasma generator has the advantages of high arc voltage, low operating current, high electric-thermal conversion efficiency, small electrode ablation amount, small fluctuation range of arc voltage, wide power adjustment range, low operation cost, good disassembly and assembly characteristic, high practicability and the like.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

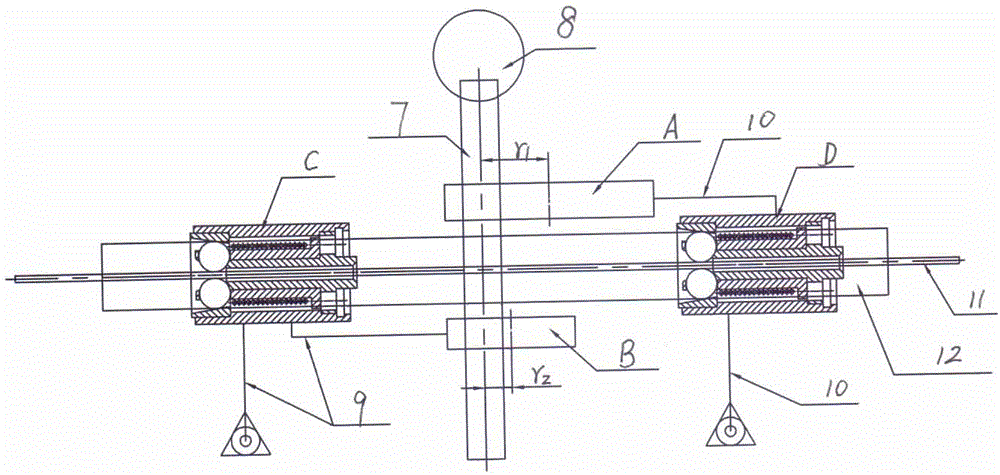

Precise push-pull wire-feeding device

The invention discloses a precise push-pull wire-feeding device. The device is characterized by comprising a double-crank shaft, wherein one end of the shaft is connected to a motor; two homodromously eccentric cams A and B are arranged on the shaft; the eccentric radius of the cam A is r1, the eccentric radius of the cam B is r2, and r1 is not equal to r2; two or more three-steel-ball wire-feeding chucks are arranged front and back and are connected to the cams A and B through different movable connecting rods, respectively; when the motor rotates, the eccentric cams rotate, and the three-steel-ball wire-feeding chucks, supported by different movable connecting rods, perform front-and-back movements synchronized with eccentric movements, respectively. The device disclosed by the invention is reasonable in structure and has a low cost and high reliability.

Owner:NANTONG ZHENKANG WELDING ELECTROMACHINERY

Stainless steel welding rod capable of resisting redness and cracking of coating

InactiveCN111112882AWeaken ruptureHeat dissipation fastWelding/cutting media/materialsSoldering mediaSodium carboxymethylcelluloseSlag (welding)

The invention belongs to the field of welding materials, and particularly relates to a stainless steel welding rod capable of resisting redness and cracking of coating. The stainless steel welding rodcomprises a stainless steel core wire with a longitudinal V-shaped groove formed in the peripheral surface, a copper-plated layer and the coating, wherein the coating comprises the following dry powder components of 10-12% of rutile, 8%-10% of mica, 8%-10% of calcium carbonate, 8%-10% of magnesium carbonate, 5%-7% of nickel carbonate, 3%-5% of white mud, 2%-4% of zirconium oxide, 8%-10% of fluorite, 1%-3% of spodumene, 4%-6% of ferromanganese, 2%-4% of ferrotitanium, 5%-7% of ferrosilicon, 0.2%-0.3% of sodium alginate, 0.15%-0.25% of carboxymethyl cellulose, 1.5%-2% of nano cerium oxide and / or nano yttrium oxide and / or nano lanthanum oxide, and the balance feldspar. According to the stainless steel welding rod, the core wire is small in volume expansion after being heated, the coating strength is high, the welding arc voltage is high, molten drops are in slag wall and jet combined transition, and reddening resistance and cracking resistance of the coating are high.

Owner:ZHENGZHOU UNIV

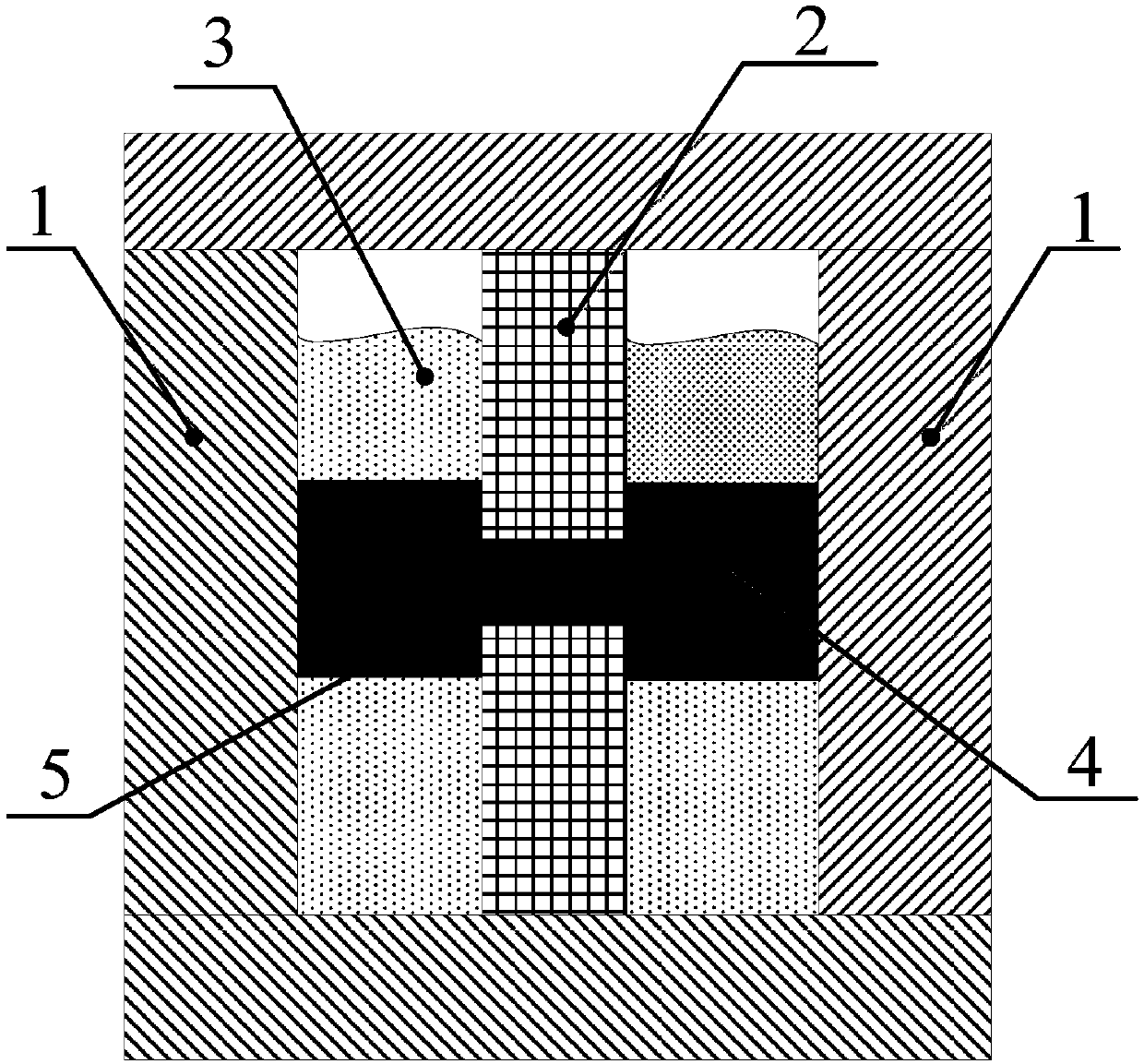

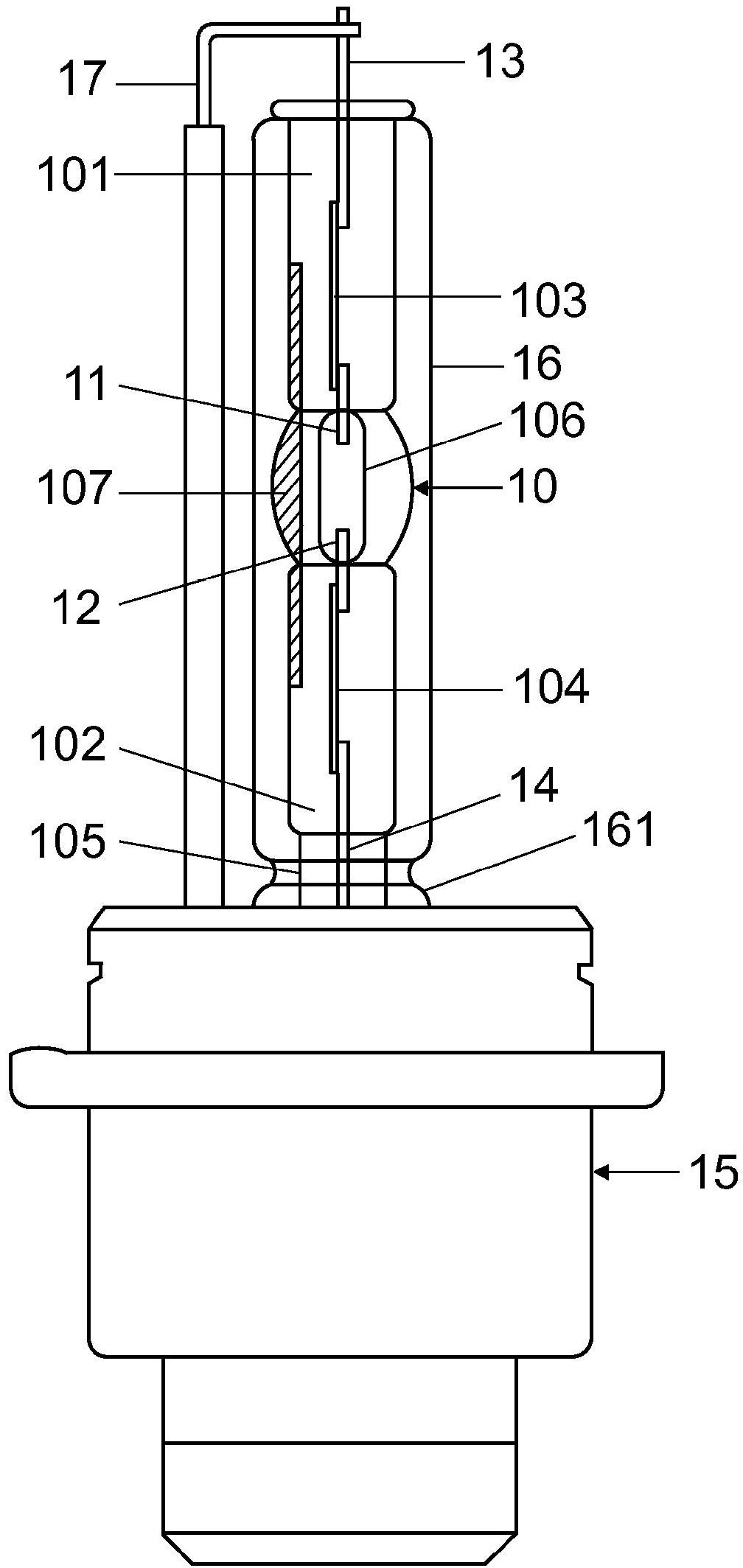

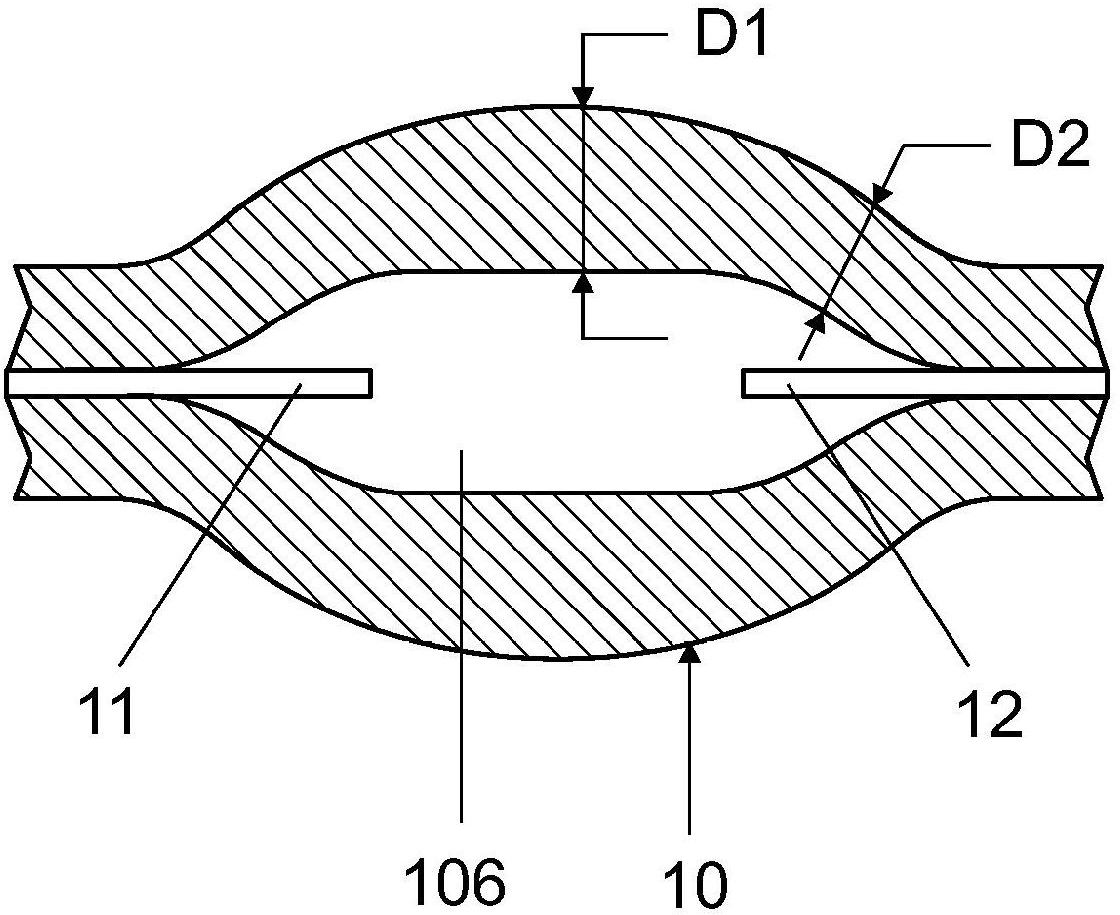

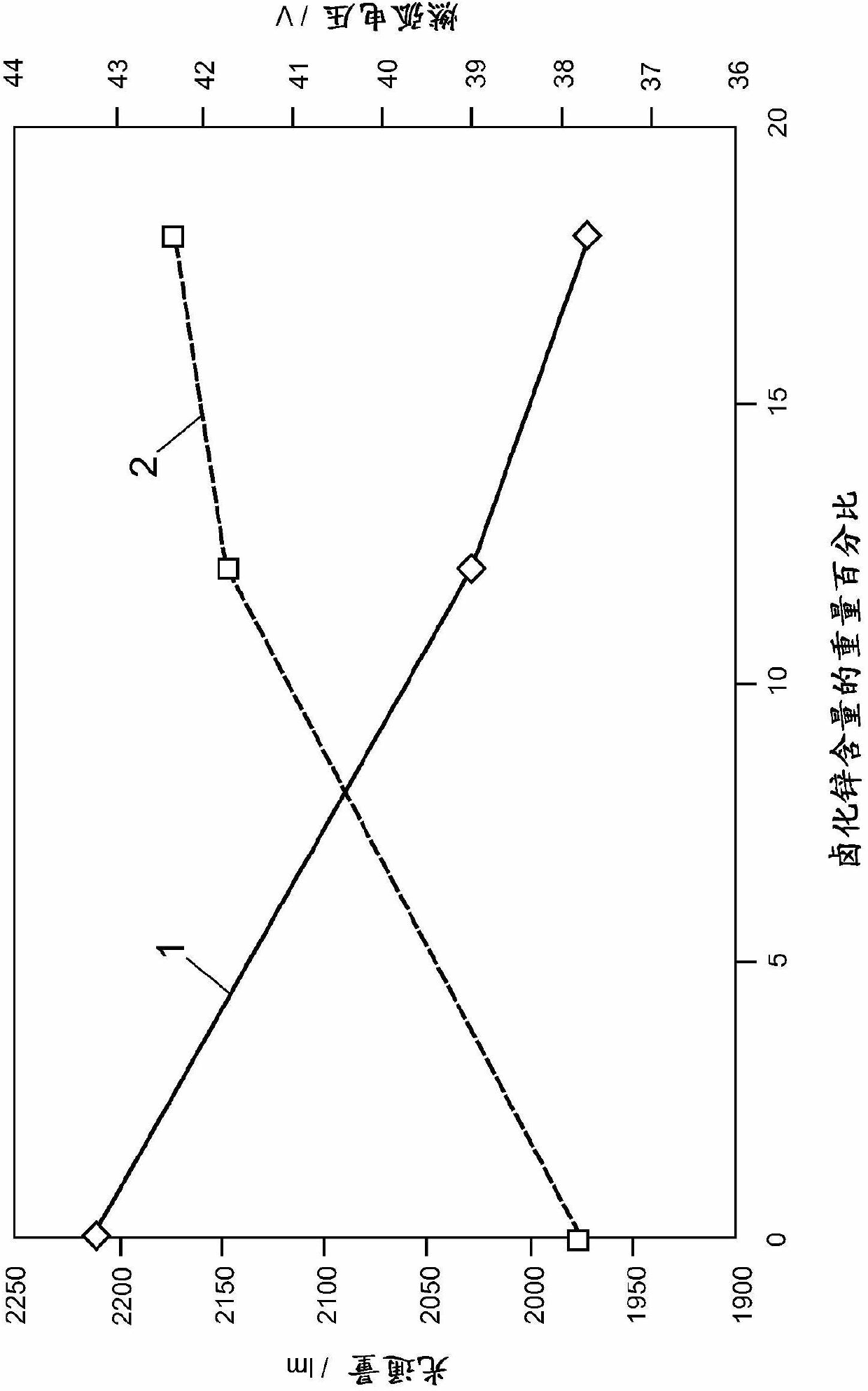

Mercury-free high-pressure discharge lamp with a reduced amount of zinc halide

InactiveCN102687235AIncrease luminous fluxReduce electrical power consumptionGas discharge lampsHigh pressureZinc

The invention relates to a high-pressure discharge lamp for vehicle headlights, comprising a discharge vessel (10) which is sealed in a gas-tight manner and which has a discharge chamber (106). Electrodes (11, 12) and a filling for producing a gas discharge are enclosed in the discharge chamber, wherein the filling is designed as a mercury-free filling that contains at least xenon and halides of sodium, scandium, and zinc. The filling has an amount of zinc halide ranging from 0 mg to 1 mg per 1 cm3 of the discharge chamber volume; the amount of halides that is present in the discharge chamber (106) of the discharge vessel (10) ranges from 8 mg to 15 mg per 1 cm3 of the discharge chamber volume; the cold fill pressure of the xenon ranges from 1.0 megapascal to 1.8 megapascal; and the volume of the discharge chamber (106) of the discharge vessel (10) has a value ranging from 0.015 cm3 to 0.022 cm3.

Owner:OSRAM GMBH

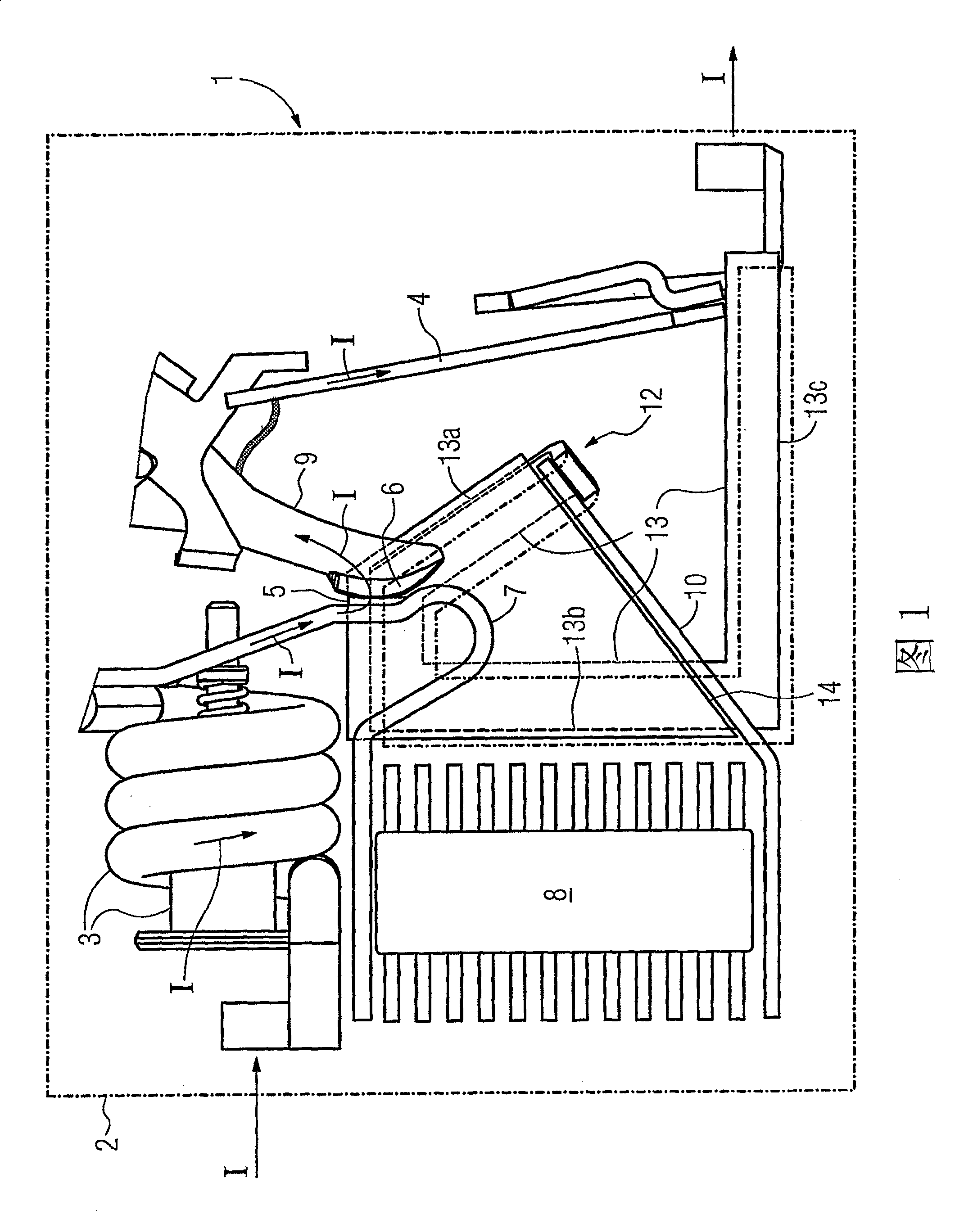

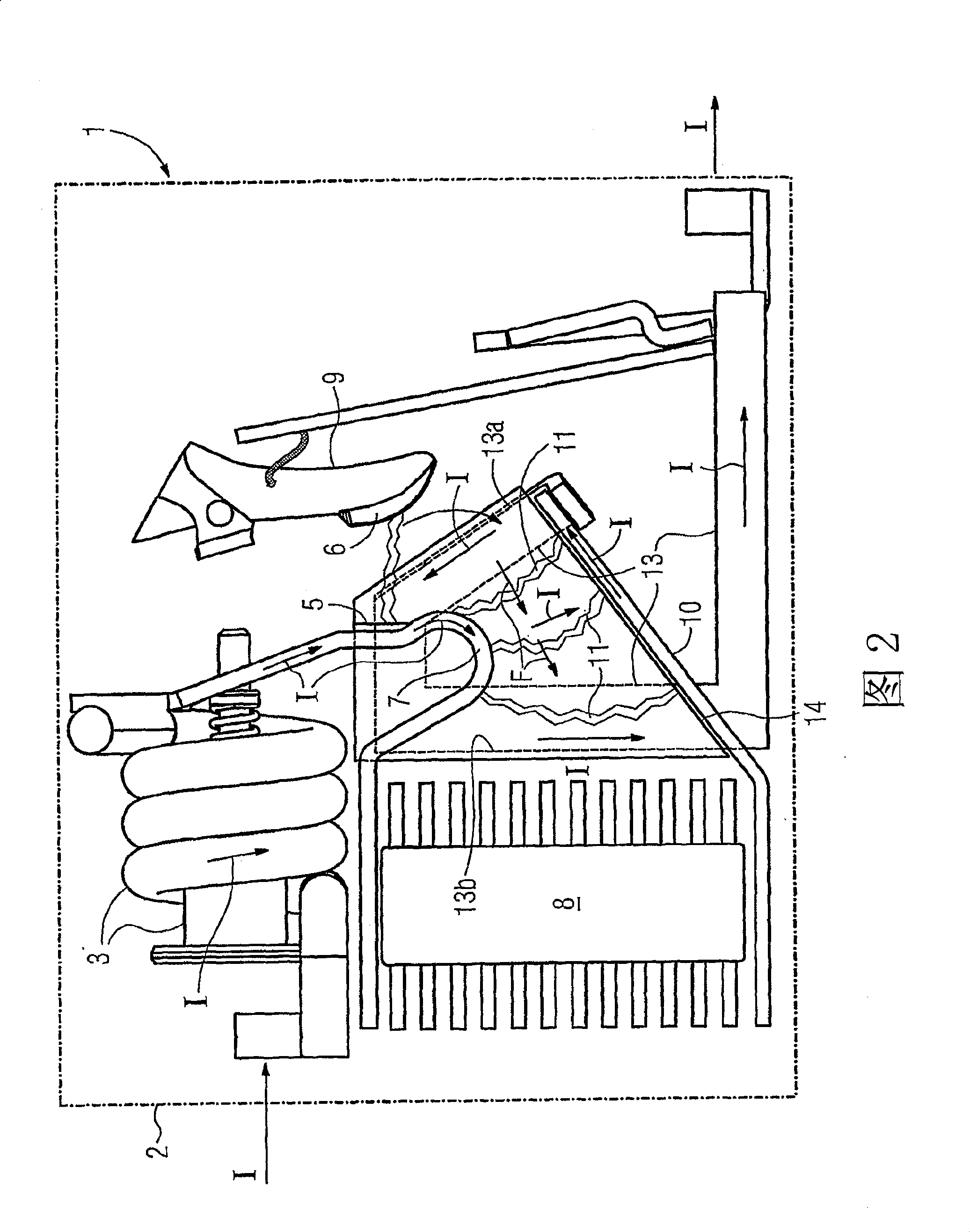

Arc quenching system

ActiveCN100468600CQuickly and effectively extinguishReduced service lifeElectric switchesCircuit-breaking switch detailsElectrical conductorSwitchgear

The aim of the invention is to create an arc quenching system for a switching device (1), which ensures low heat build-up and fast quenching of an arc (11) using simple means. Said aim is achieved by providing a current conducting path (13) which comprises an electrically conducting passage to an additional arc guide rail (10) so as to form a conductor loop (10, 13) and is electrically insulated relative to a pair of switching contacts (5, 6). The conductor loop (10,13) is not connected to the pair of switching contacts (5, 6) while being arranged in the area of an interrupter chamber (12) such that a current (I) which drives the arc (11) into the arcing chamber (8) is conducted via the current conducting path (13) when the arc (11) commutates from one of the switching contacts (5; 6) to the additional arc guide rail (10).

Owner:SIEMENS AG

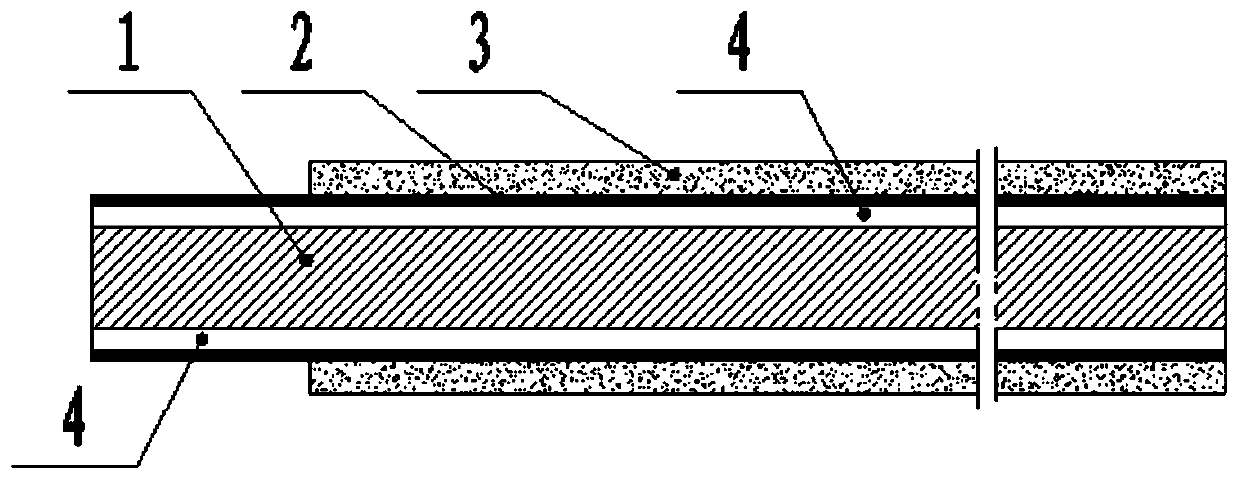

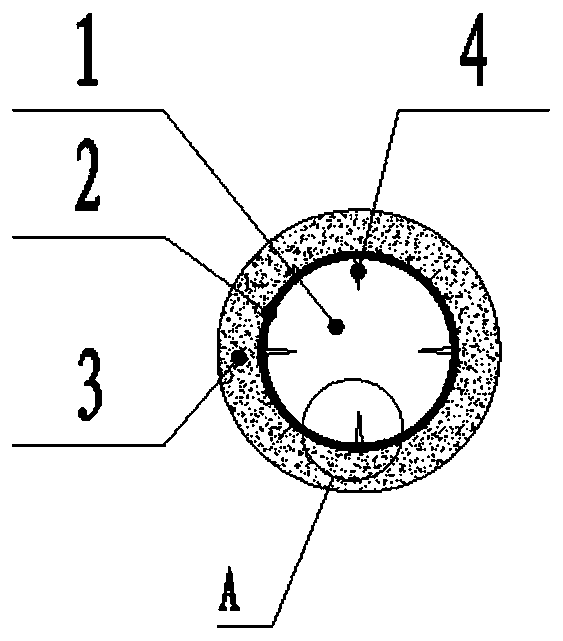

Forming process of moderate-thickness plate no-back-gouging butt joint full-penetration class-I component

InactiveCN104259624AFast molding speedGood effectWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention discloses a forming process of a moderate-thickness plate no-back-gouging butt joint full-penetration class-I component and relates to a moderate-thickness plate tailored-welding forming process. The forming process comprises the steps of preparing plates, cutting the plates to form process grooves, performing tailored welding on the plates, adding ceramic backings, iron liners, clamps and process triangular plates, performing single-side welding on the clamps and the process triangular plates to form single-side welding beads, adding a leading-in arc plate and a leading-out arc plate, welding two moderate-thickness plates, dismounting the ceramic backings, the iron liners, the clamps, the process triangular plates, the leading-in arc plate and the leading-out arc plate, polishing and repairing the single-side welding beads, performing ultrasonic inspection on the single-side welding beads, encoding and marking qualified products and performing next working procedures. The quality of weld joints is guaranteed, butt-jointed plates do not easily deform, production efficiency is high, on-site butt joint operation is quick and easy, lots of manpower resources can be saved, the labor intensity of workers can be reduced, and production cost can be reduced.

Owner:湖北源盛钢构有限公司

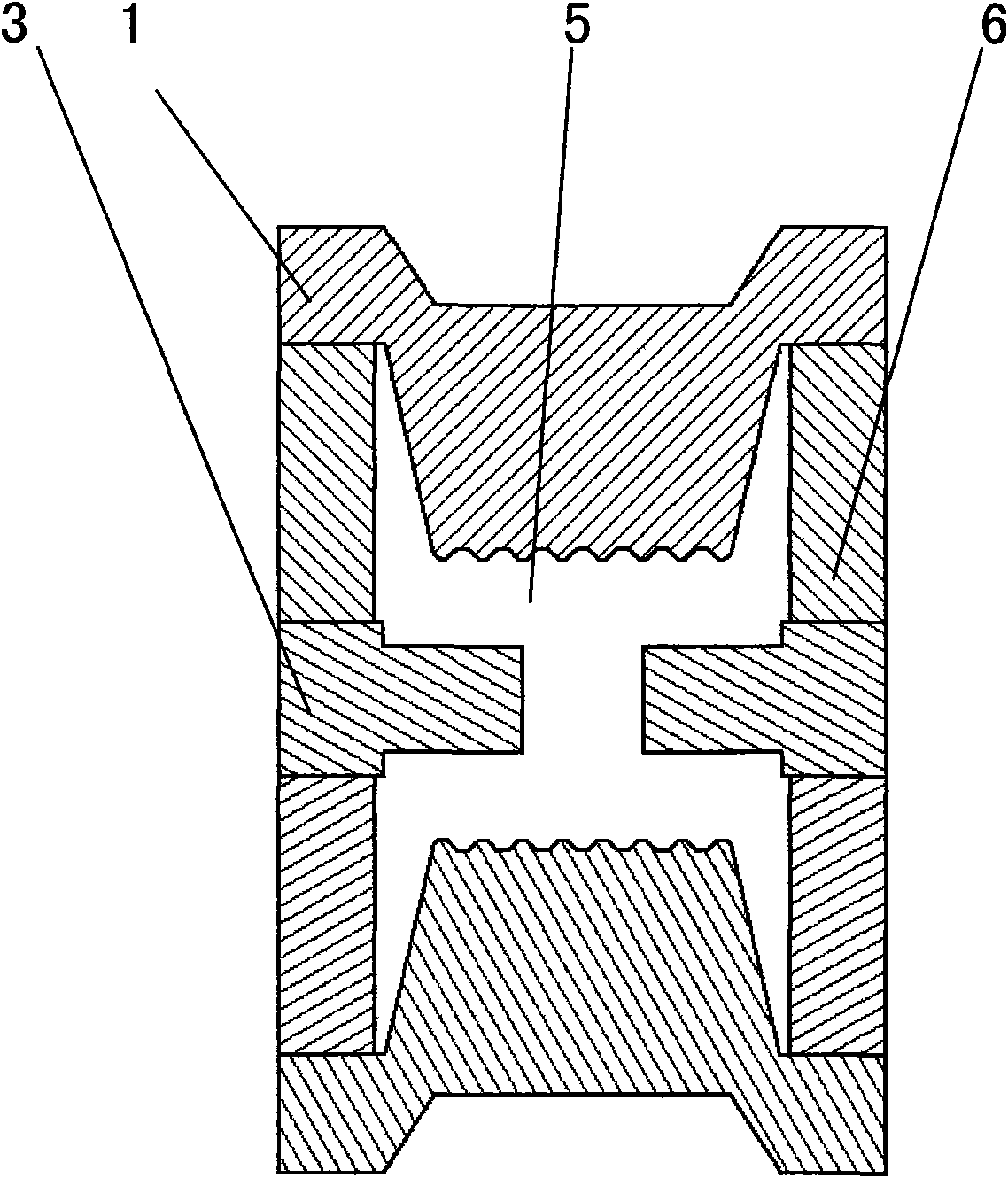

Multi-step porcelain tube and gas discharge tube prepared thereby

ActiveCN103021769AIncrease creep distanceAvoid edge dischargeSolid cathode detailsCold-cathode tubesEngineeringMechanical engineering

The invention discloses a multi-step porcelain tube and a multi-layer gas discharge tube. Steps of the multi-step porcelain tube are provided with first discharge electrodes and second discharge electrodes; insulation porcelain sheets are arranged between the first discharge electrodes and the second discharge electrodes; and cavities formed by the first discharge electrodes, the second discharge electrodes and the insulation porcelain sheets are filled with inert gases. According to the multi-step porcelain tube and the gas discharge tube prepared by utilizing the multi-step porcelain tube, because the porcelain tube in which a plurality of step structures are designed is adopted, creep distances among clearances are increased effectively, and edge discharge among the clearances is prevented to guarantee that three individual discharge clearances are formed in a single-layer discharge tube, so that arc light voltage is doubled; the arc light voltage at a single layer achieves 65V; and the follow current capability is intensified greatly.

Owner:EPCOS ELECTRONICS XIAOGAN

Minitype breaker with high stability

ActiveUS9589743B2Reduced stabilitySimple structureEmergency actuatorsContact driving mechanismsEngineeringCircuit breaker

A high-stability miniature circuit breaker has a pivotal shaft having a first section, a second section and a shoulder. The diameter of the second section is larger than the first section. The shoulder diameter is larger than the second section. A pivoting lever on the first section limits the axial position of a protruding mesa relative to the shaft by contact fit between the mesa and a thrust surface on the second section. A pivoting latch is on the second section. A first end face fits to a support surface on the shoulder. A second end face fits to the protruding mesa at the other end. The latch controls a drive rod and the lever. A connecting rod separates from the latch when latch hasps are separated and the latch separates from the drive rod which slides along a groove of the lever.

Owner:SHANGHAI NOARK ELECTRIC

Magnetic blow-out system, arc extinguishing device, single-pole circuit breaker and multi-pole circuit breaker

The invention provides a magnetic blow-out system, an arc extinguishing device, a single-pole circuit breaker and a multi-pole circuit breaker. The magnetic blow-out system comprises a magnetic blow-out coil used for blowing arcs generated between a moving contact and a static contact of a circuit breaker to an arc extinguishing chamber, the magnetic blow-out coil is arranged on a shunting branch of a circuit breaker main circuit with set current or is connected to the circuit breaker main circuit with set current in series. The current flows through the magnetic blow-out coil when the circuit is connected by the moving contact and the static contact so as to generate magnetic flux. When the contacts are disconnected and arcs are generated, the magnetic blow-out coil can push the arcs to move towards the arc extinguishing chamber due to the magnetic flux generated when the current flow through. The technical scheme is simple in structure and capable of adapting to application occasions with small current. In addition, the magnetic blow-out system has no requirement for the polarity of a wiring terminal, solves a problem that small current is difficult to be disconnected, can be applied to direct current and alternating current occasions, meets requirements of a photovoltaic power generation system and the like for a miniature circuit breaker and adapts to development requirements of a new energy industry in the future.

Owner:ANDELI GRP

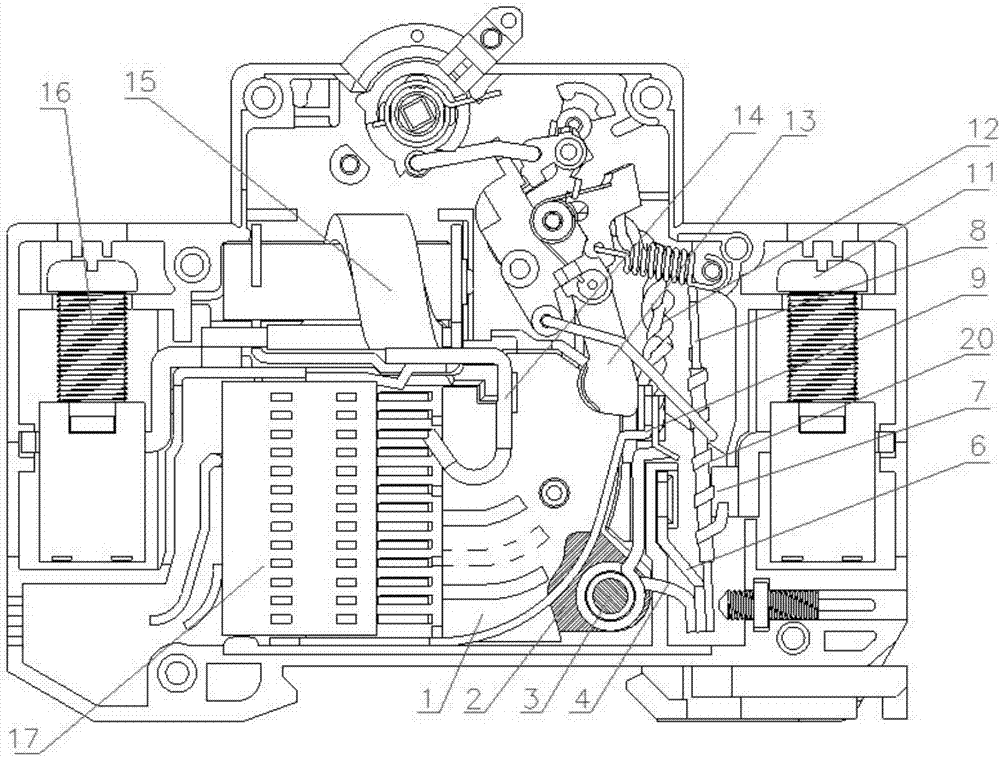

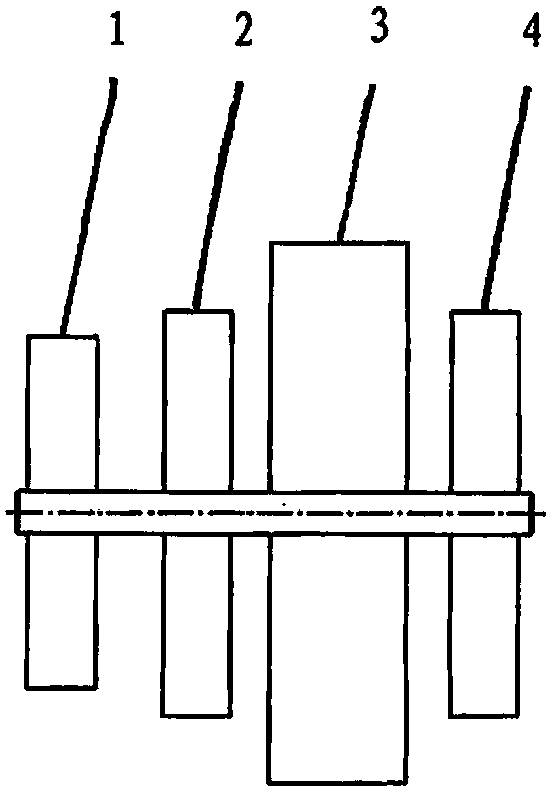

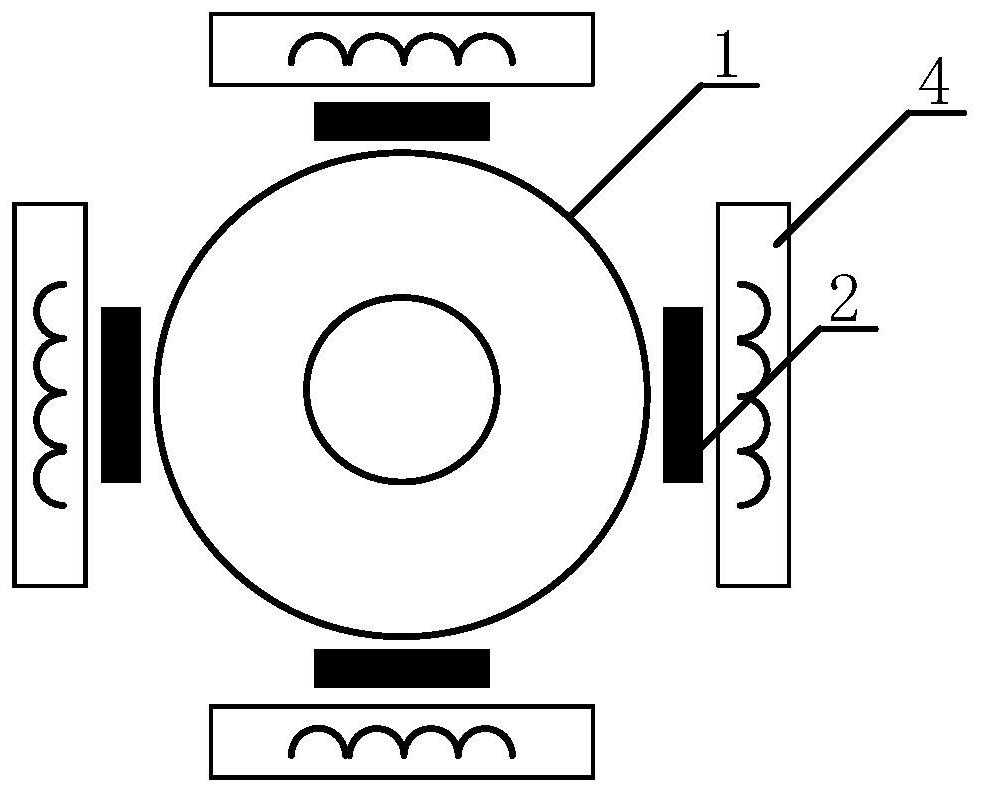

A miniature circuit breaker

ActiveCN104253001AAchieve improvementSimple structureSwitches with electrothermal and electromagnetic releaseCircuit-breaking switch contactsCircuit breakerLinkage concept

The invention describes a miniature circuit breaker, which is characterized in that: the miniature circuit breaker comprises a torsional stretch dual-breaker arc extinguishing system, a linkage transmission mechanism and a tripping mechanism, which are arranged in a same axis, wherein the torsional stretch dual-breaker arc extinguishing system comprises a disc-shaped stationary contact and a disc-shaped moving contact which are provided in the same axis; a movement of the linkage transmission mechanism acts on the disc-shaped moving contact so as to enable the disc-shaped moving contact to simultaneously rotate and translate with respect to the disc-shaped stationary contact; under the action of the tripping mechanism, the disc-shaped stationary contact and the disc-shaped moving contact can be in a locked state or a tripped state.

Owner:SCHNEIDER ELECTRIC IND SAS

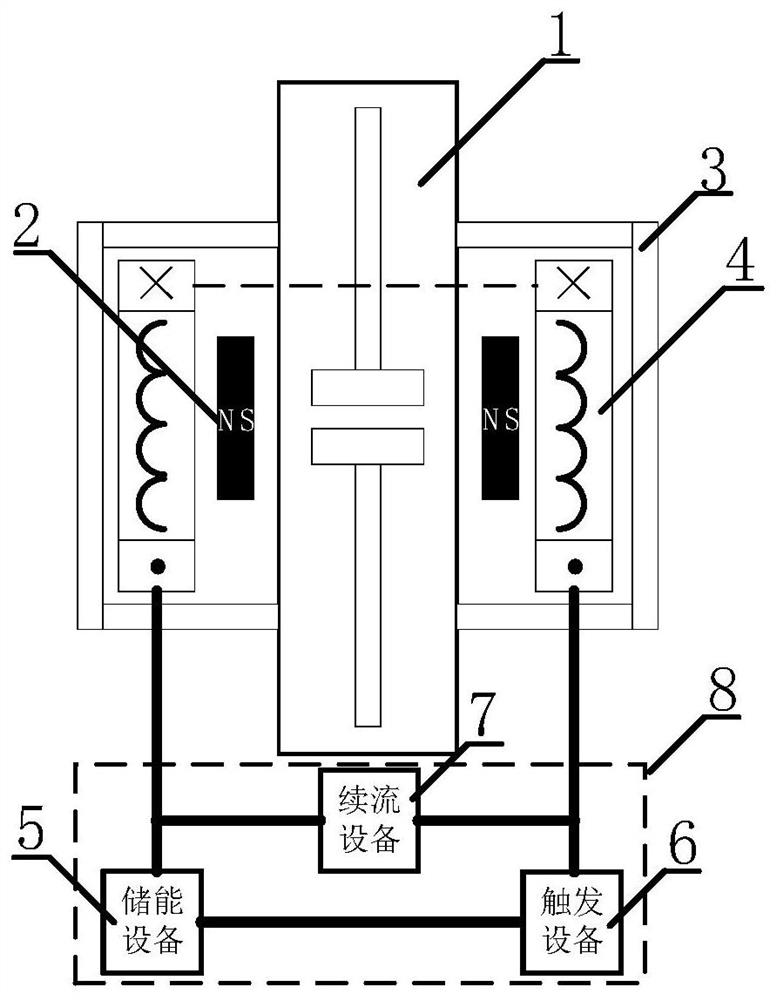

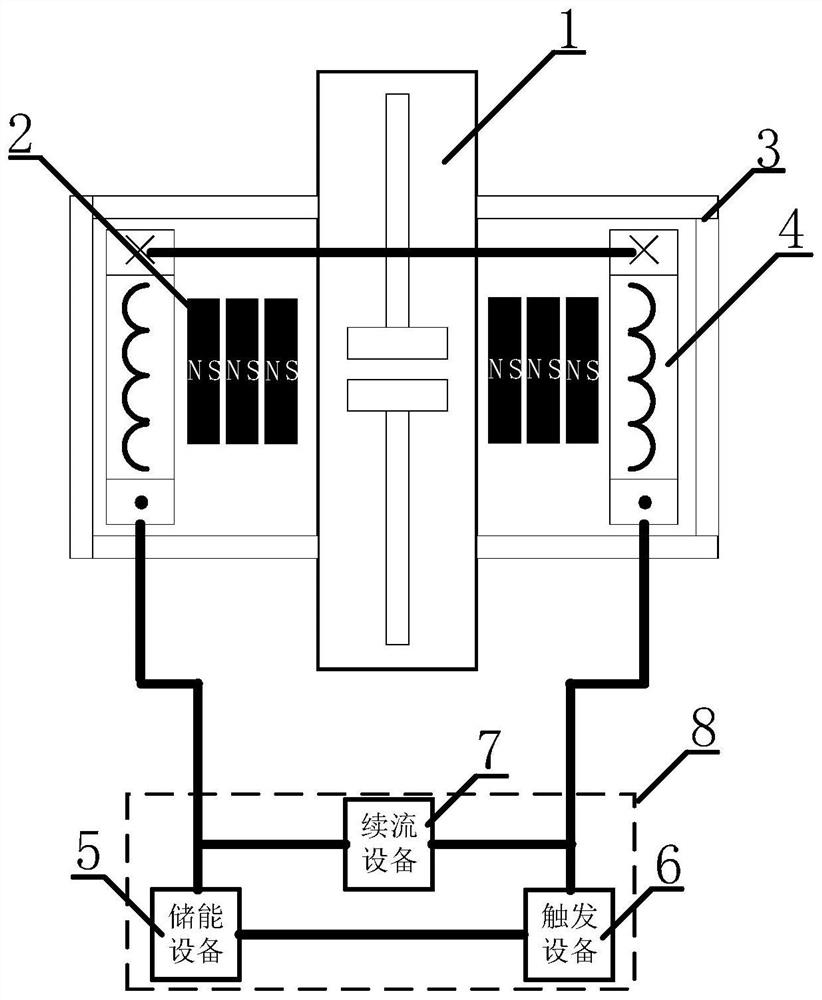

Device for increasing switching arc voltage and control method thereof

ActiveCN112420443AMove quicklyElongated lengthHigh-tension/heavy-dress switchesAir-break switchesArc extinctionElectrical current

The invention provides a device for increasing switching arc voltage and a control method thereof. The device comprises a vacuum arc-extinguishing chamber, permanent magnets, arc-blowing coils and anarc-blowing loop, a switch fracture is arranged in the vacuum arc-extinguishing chamber, the switch fracture comprises a moving contact and a static contact, and an arc voltage is generated when the moving contact and the static contact are separated; the permanent magnets are symmetrically arranged on two sides of the vacuum arc-extinguishing chamber; the arc blowing coils are symmetrically arranged on the two sides of the vacuum arc-extinguishing chamber, are arranged on the outer sides of the permanent magnets and are connected in series; and the arc blowing loop is connected with the arc blowing coils in parallel, and provides currents for the arc blowing coils during working so as to improve the arc voltage.

Owner:NR ELECTRIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com