Patents

Literature

7331 results about "Crank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crank is an arm attached at a right angle to a rotating shaft by which reciprocating motion is imparted to or received from the shaft. It is used to convert circular motion into reciprocating motion, or vice versa. The arm may be a bent portion of the shaft, or a separate arm or disk attached to it. Attached to the end of the crank by a pivot is a rod, usually called a connecting rod (conrod). The end of the rod attached to the crank moves in a circular motion, while the other end is usually constrained to move in a linear sliding motion.

Reciprocating machine & other devices

InactiveUS20120227389A1Improve power densityImprove efficiencyLiquid coolingCasingsCombustionReciprocating motion

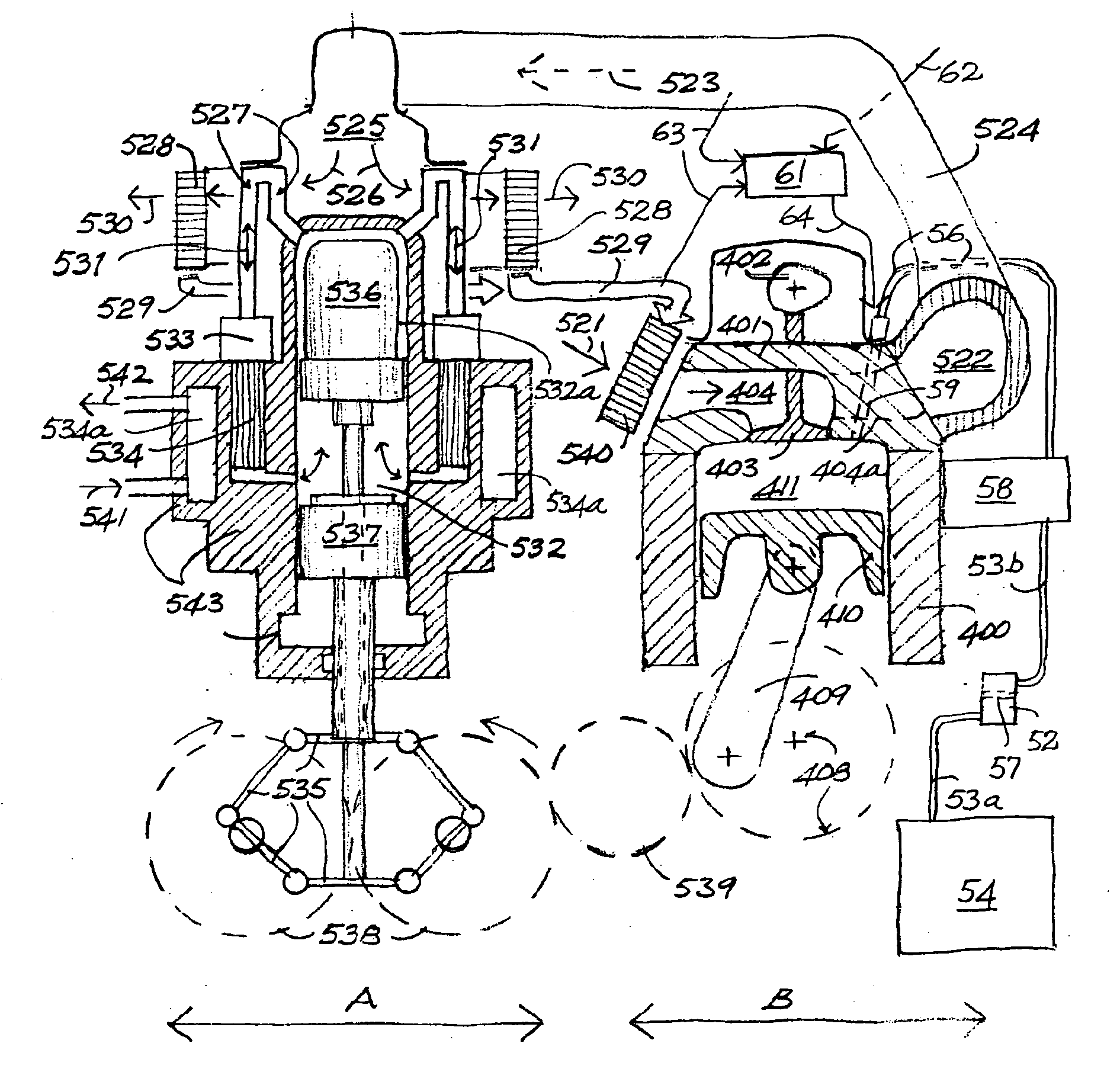

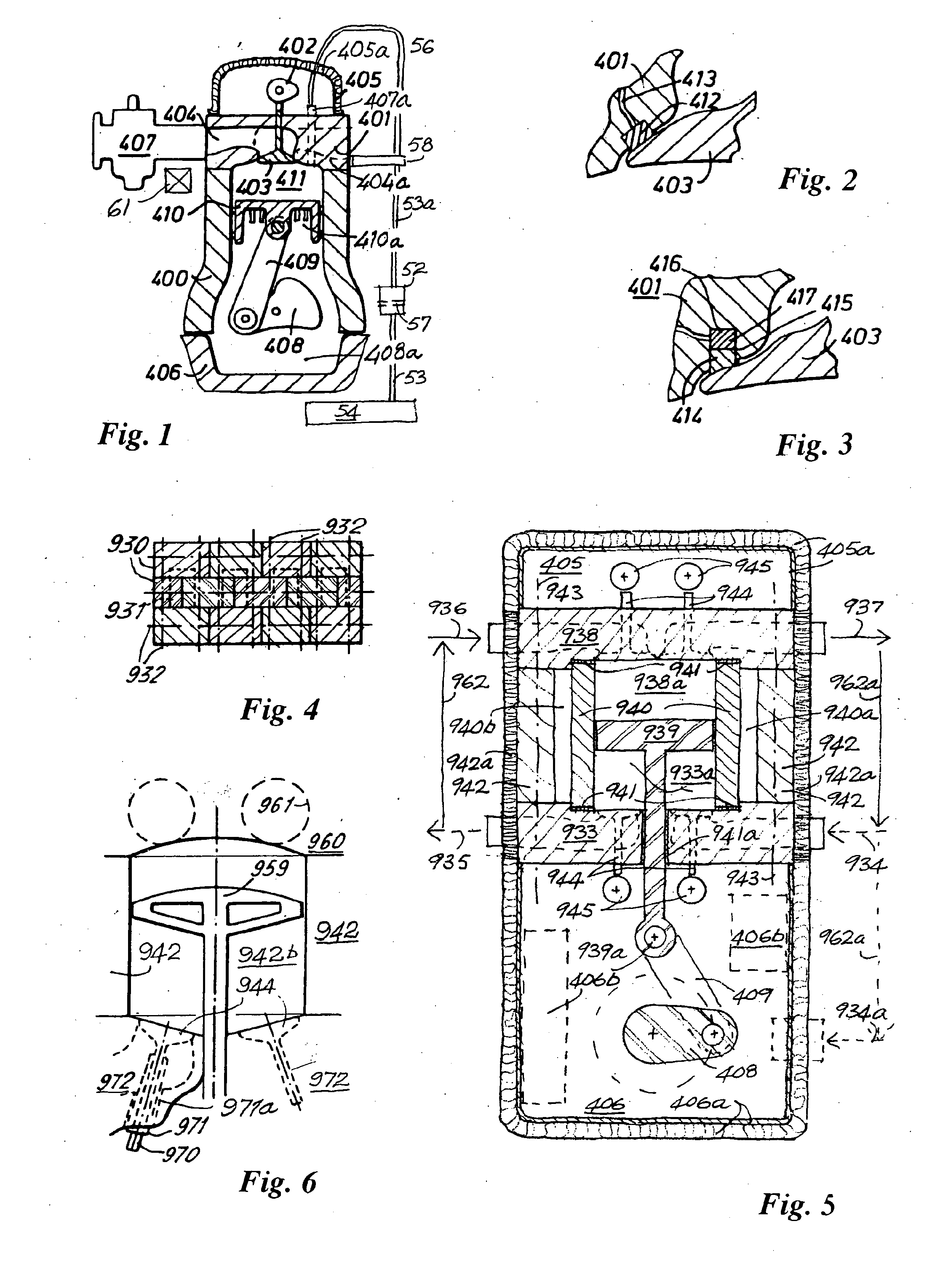

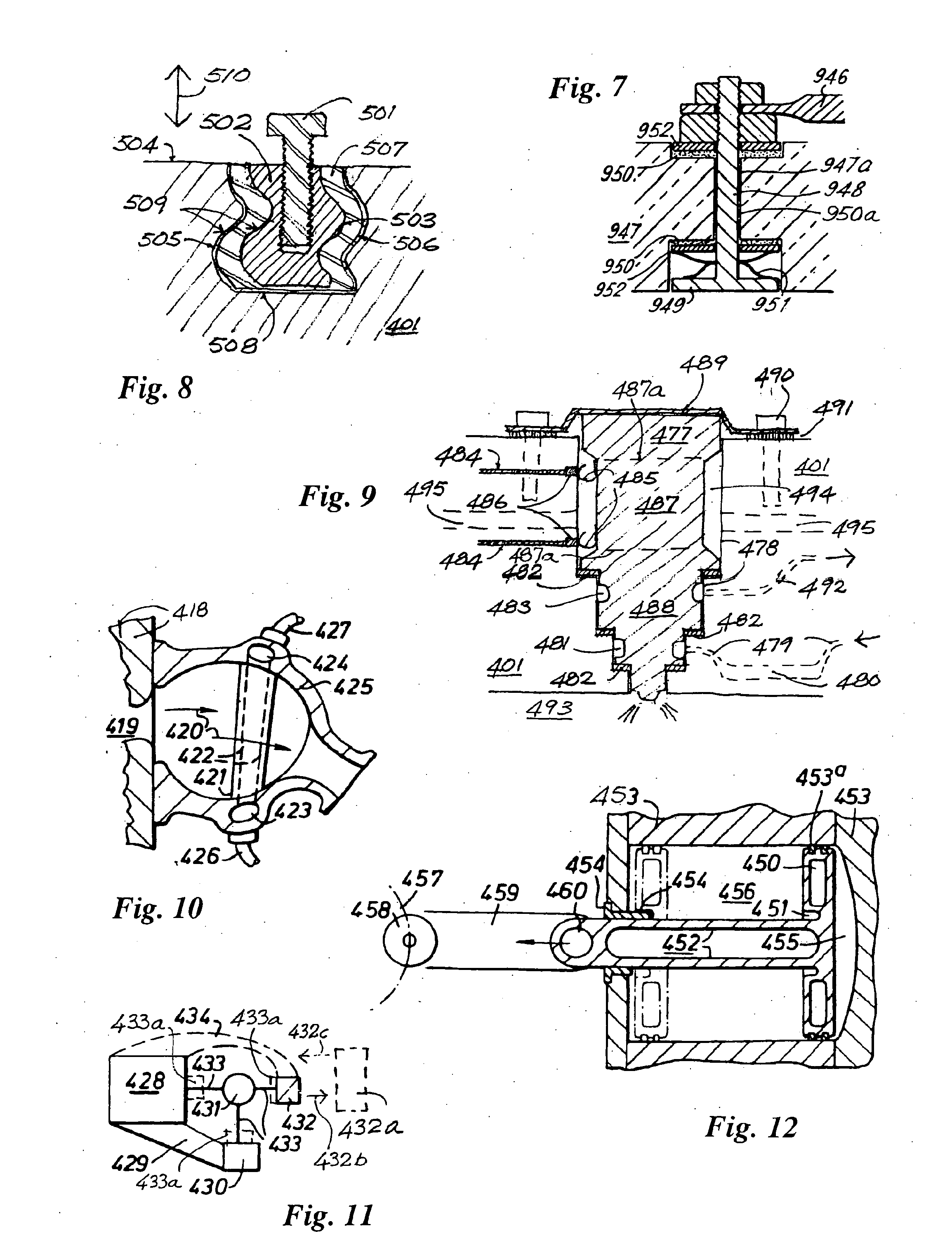

The disclosure relates to reciprocating fluid working devices including internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, a single piston reciprocating between a pair of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components which reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Also disclosed are improved vehicles, aircraft, marine craft, transmissions and exhaust emission systems suited to the engines of the invention.

Owner:HINDERKS MITJA VICTOR

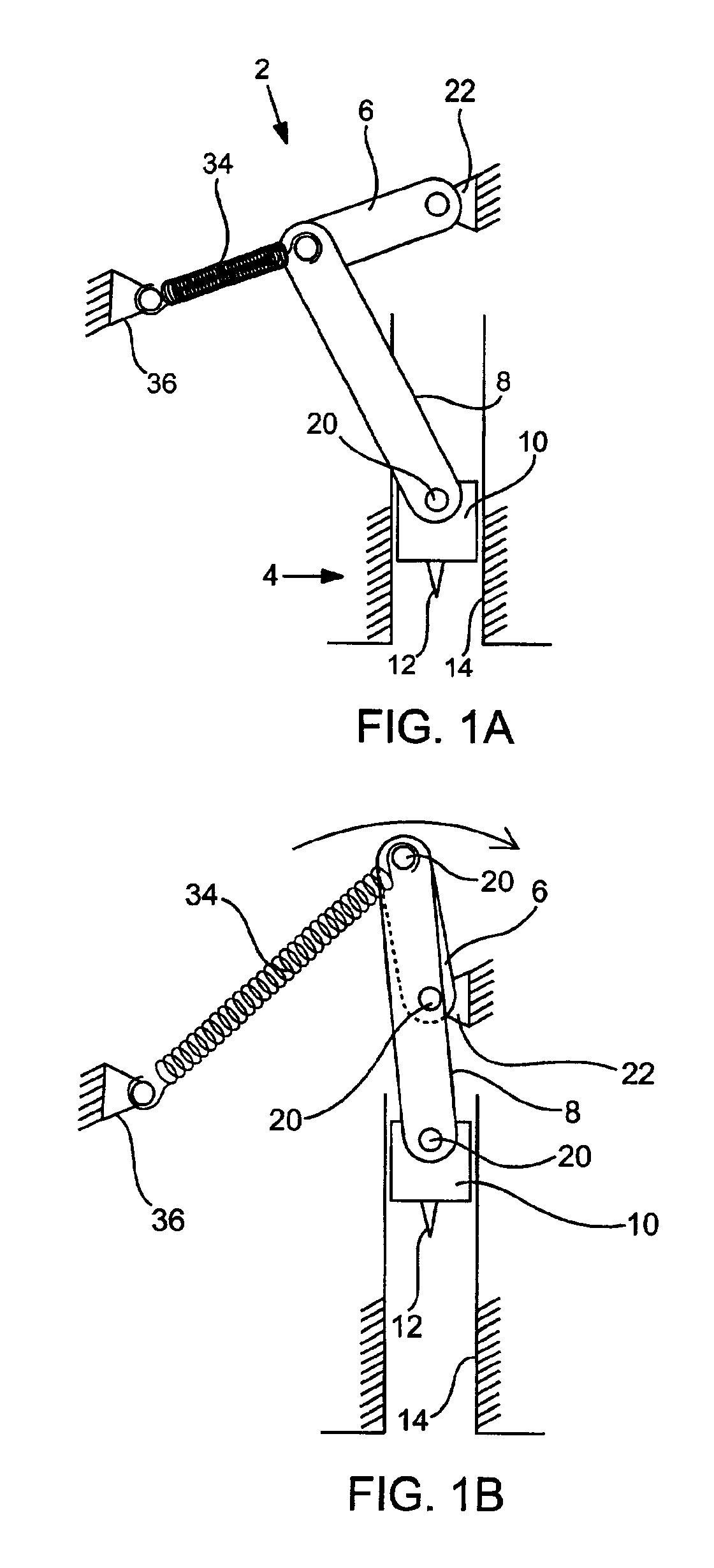

Lancing device with automatic stick and return

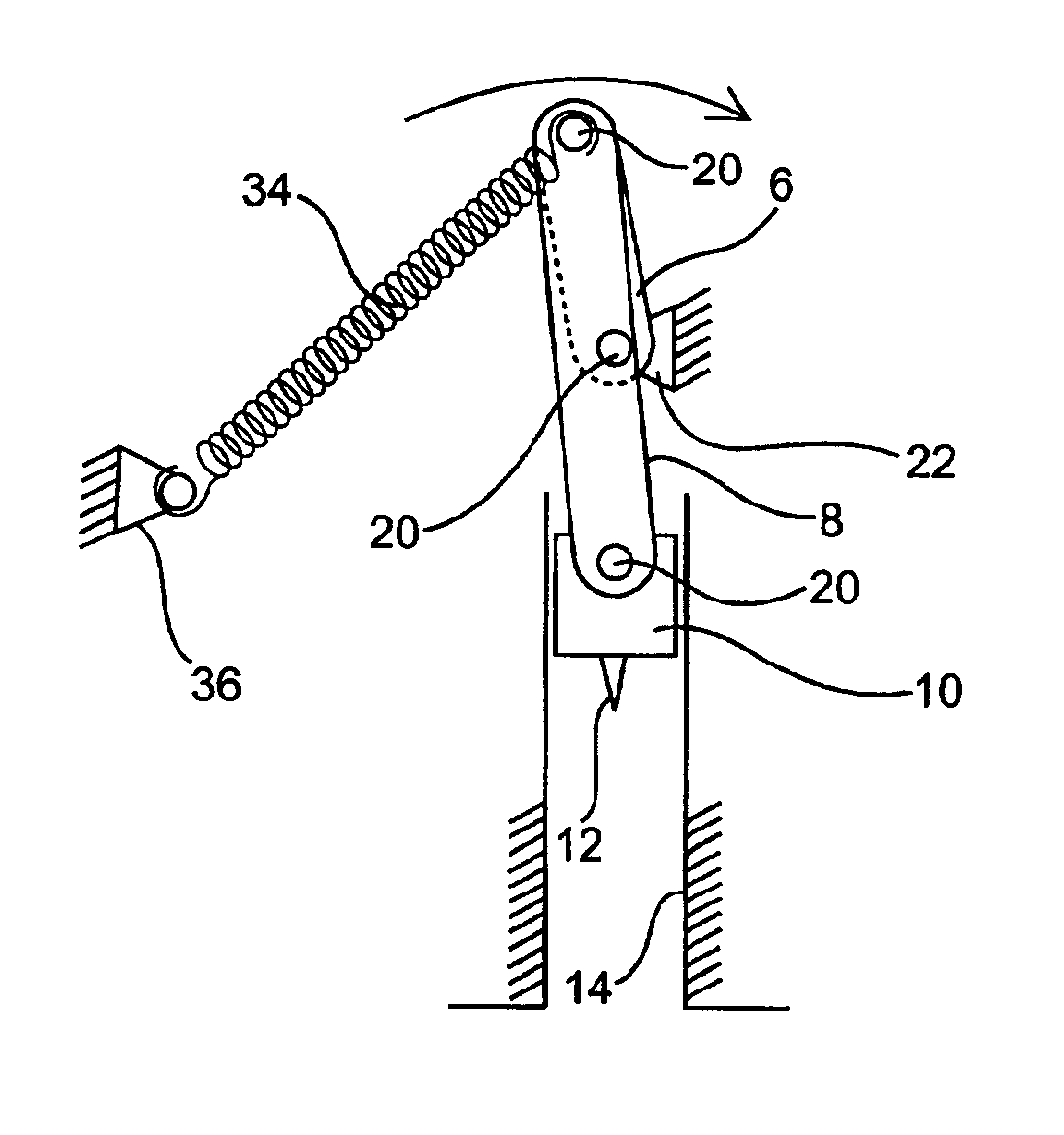

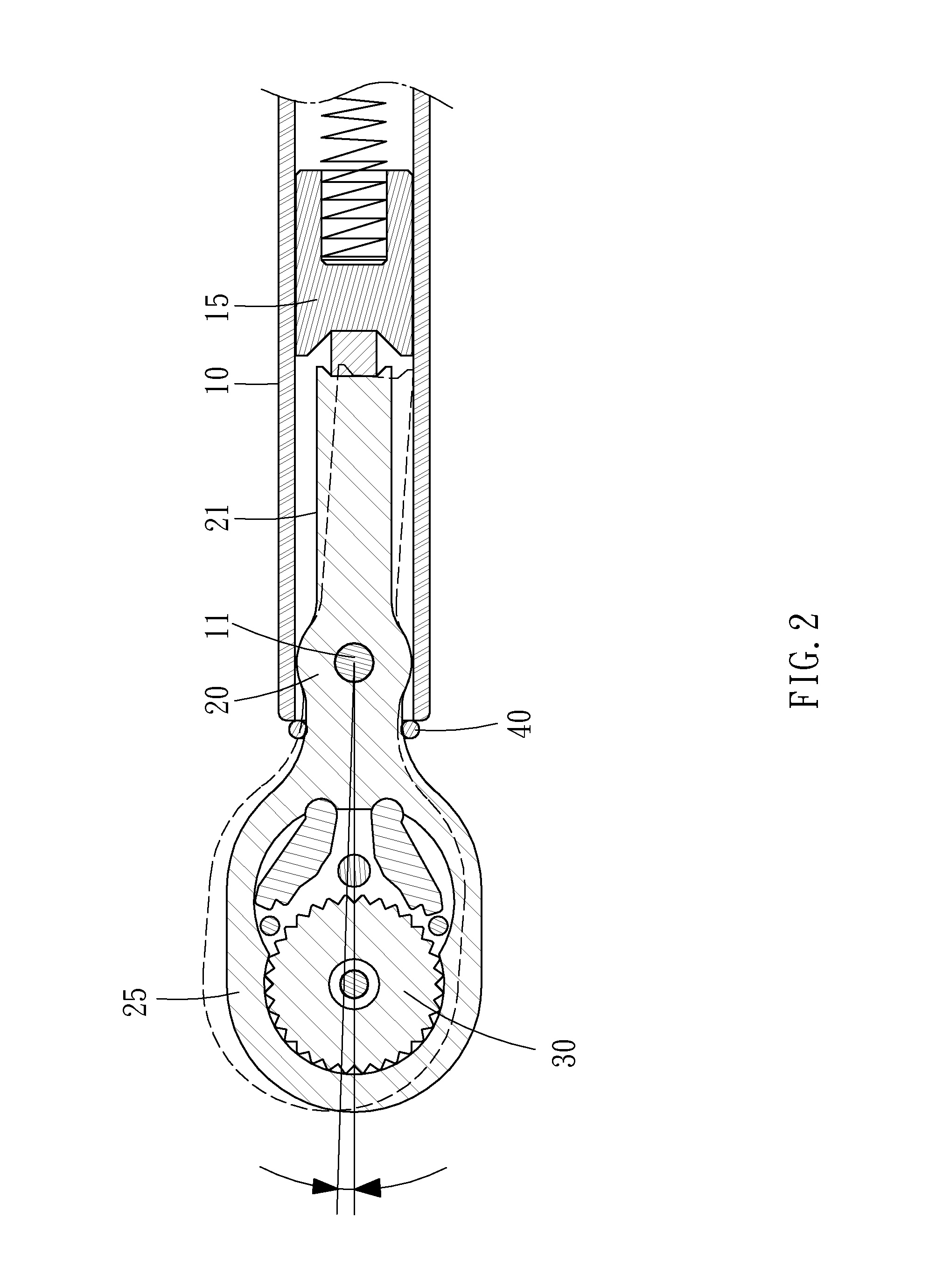

A lancing device with automatic stick and lance return features is disclosed. A drive mechanism within the unit comprises a slider-crank linkage combination. It is biased by a spring member to cause automatic firing once a crank member advanced by a user causes movement of an internal linkage member beyond its fully-cocked position. After firing, the lance is withdrawn so as not to pose a threat of secondary injury to the user. In use, the device is substantially silent though its course of operation. Yet, its configuration lends itself to producing a very quick, virtually painless stick with minimal recoil or shock to the device.

Owner:LIFESCAN IP HLDG LLC

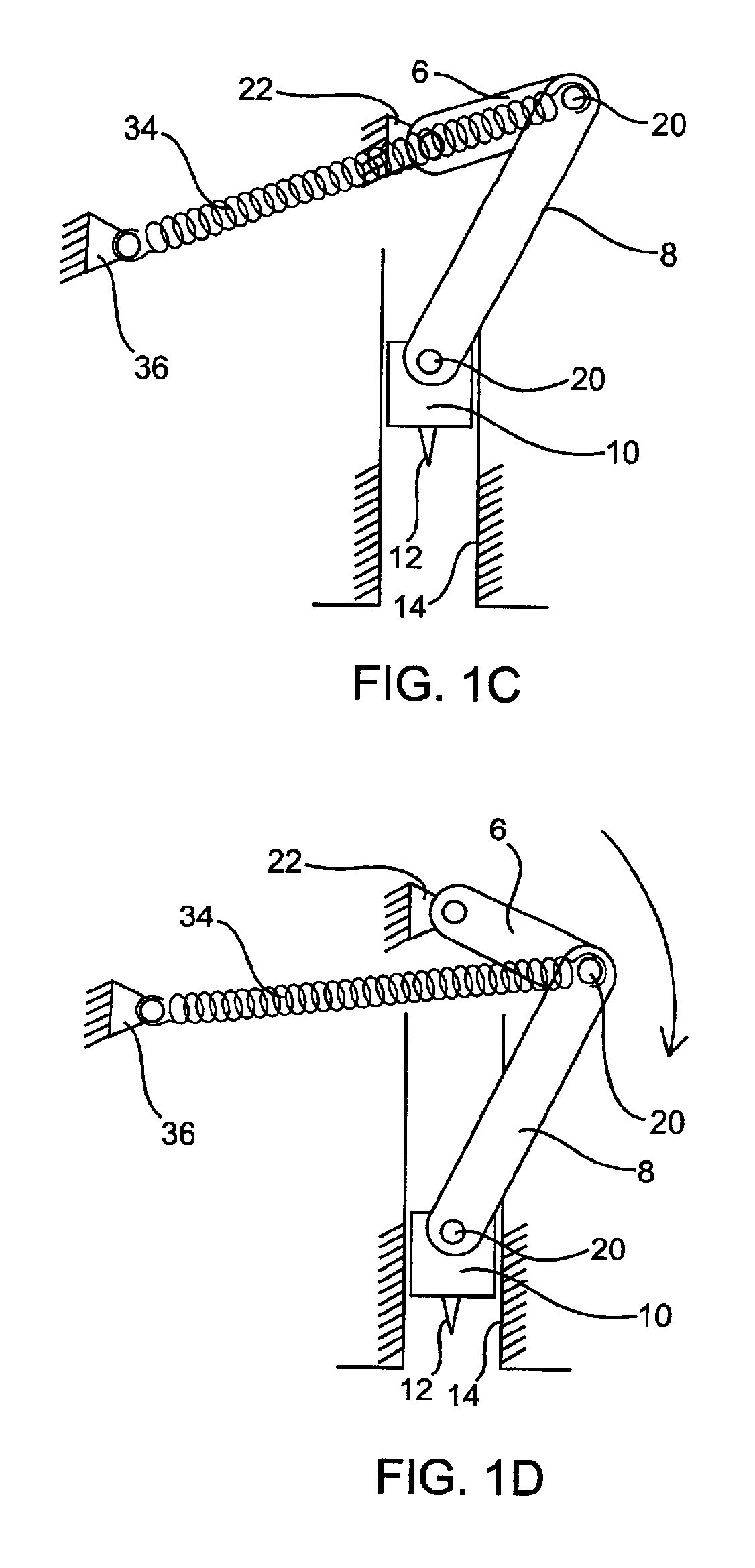

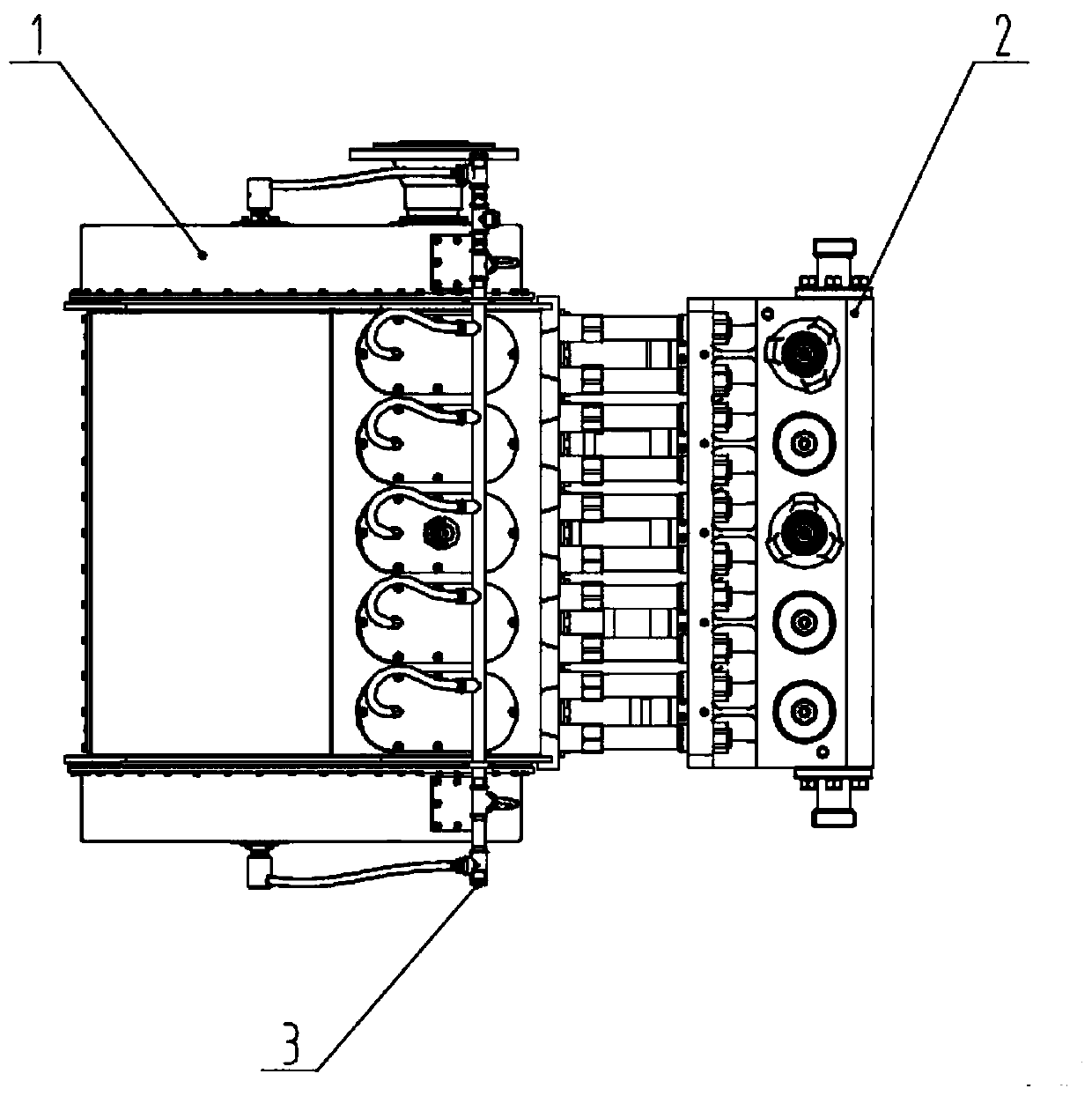

Light five-cylinder plunger pump

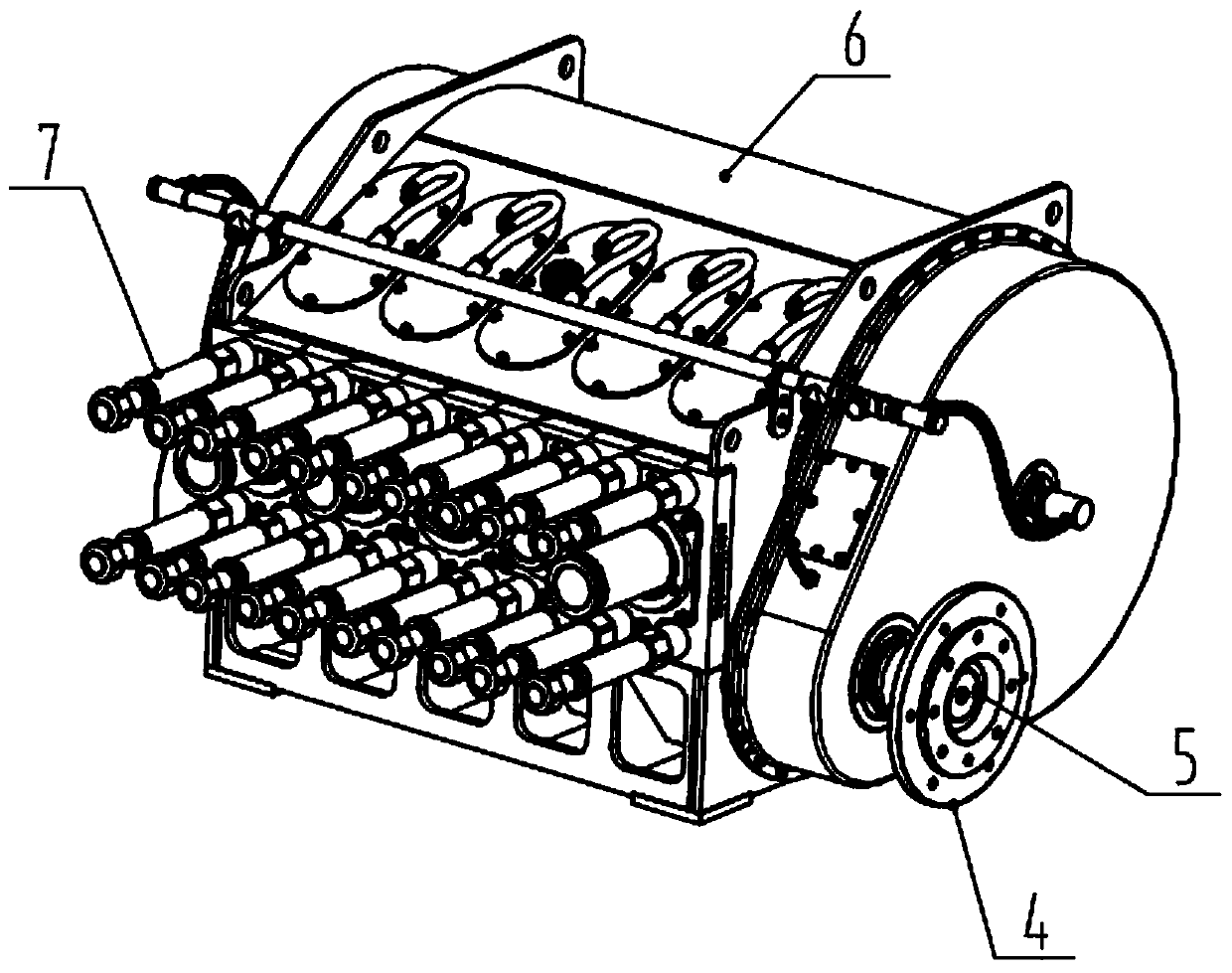

PendingCN111441925AIncreased stroke distanceIncrease rated input powerCrankshaftsPositive displacement pump componentsCrankGear wheel

The invention discloses a light five-cylinder plunger pump. The light five-cylinder plunger pump comprises a power end assembly and a hydraulic end assembly, wherein the power end assembly is connected with the hydraulic end assembly; the cylinder spacing of the light five-cylinder plunger pump is 9in; the power end assembly comprises a crank shaft, the crank shaft comprises six crank necks and five crank throws, the crank necks and the crank throws are fixedly connected, the distance between rotating centers of the crank necks and the crank throws is 101.6 mm, and the stroke distance of the light five-cylinder plunger pump is 203.2 mm. According to the light five-cylinder plunger pump, power is increased by increasing stroke, reducing transmission ratio and improving bearing capacity, andmeanwhile, dead weight is reduced by reducing the cylinder spacing, the tooth number of a big gear and the tooth thickness of the big gear and a pinion. The light five-cylinder plunger pump meets conditions of working in the area with severe well cementing operation conditions in aspects of weight and power simultaneously, and working efficiency is increased.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Internal combustion engine

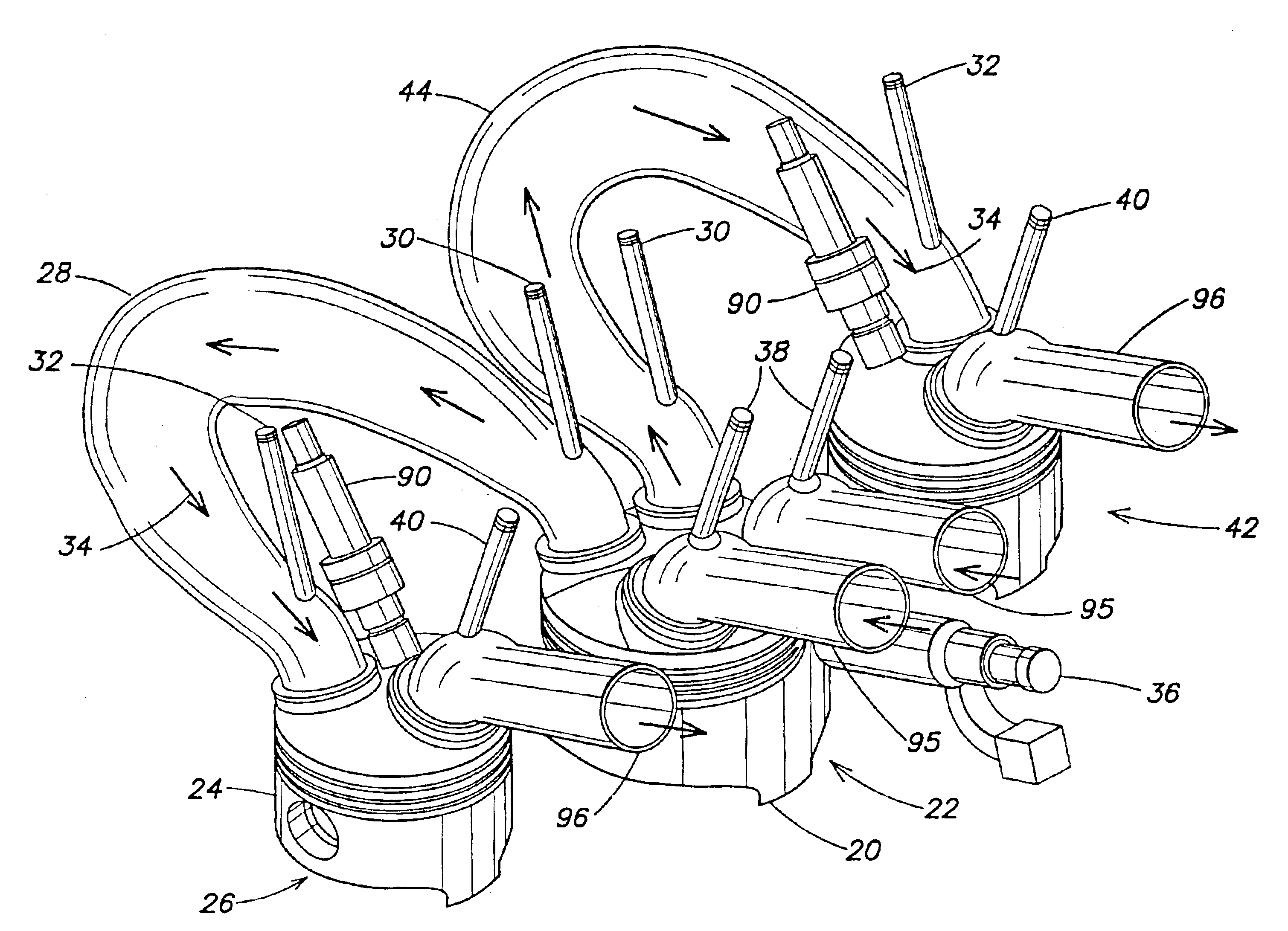

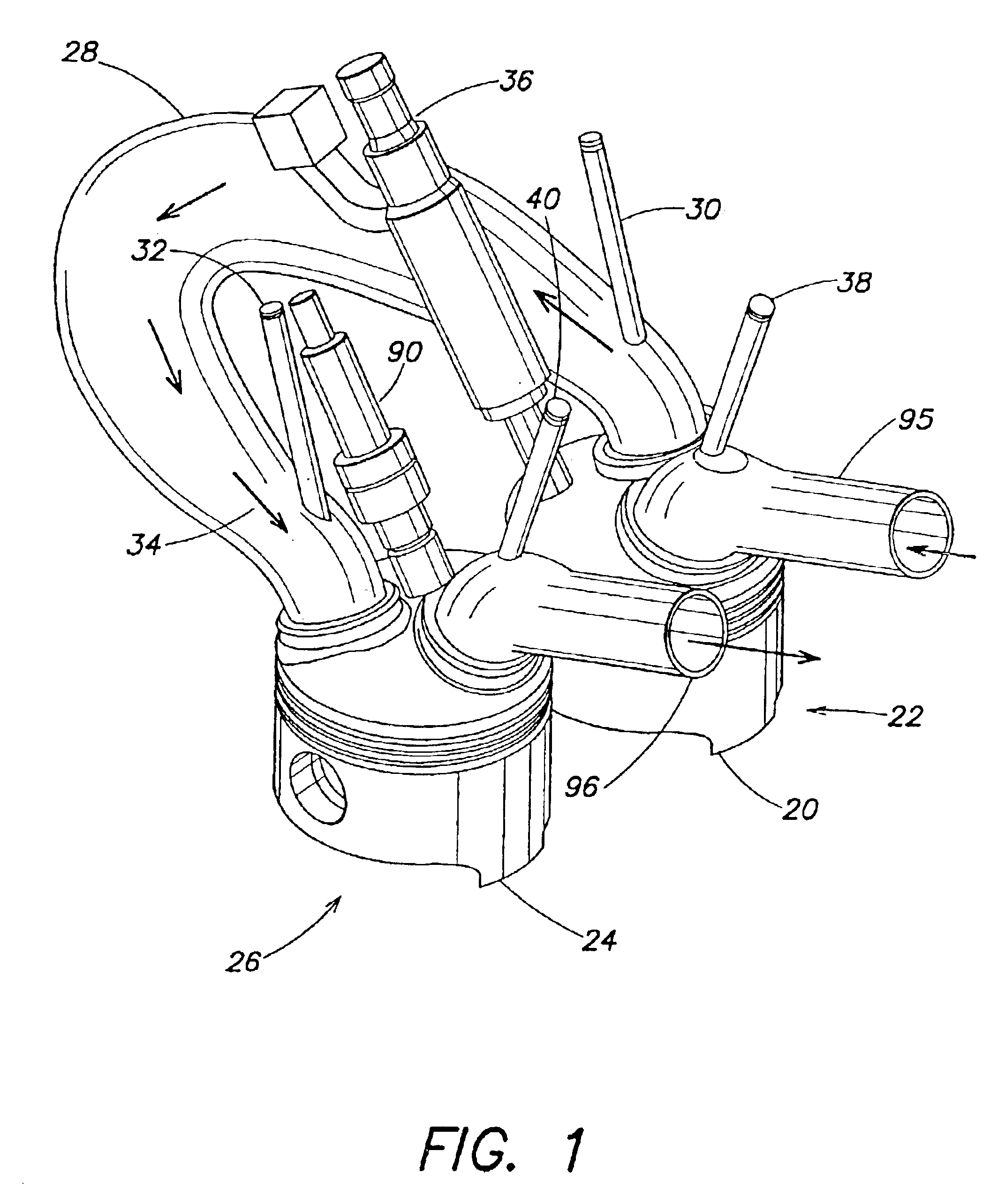

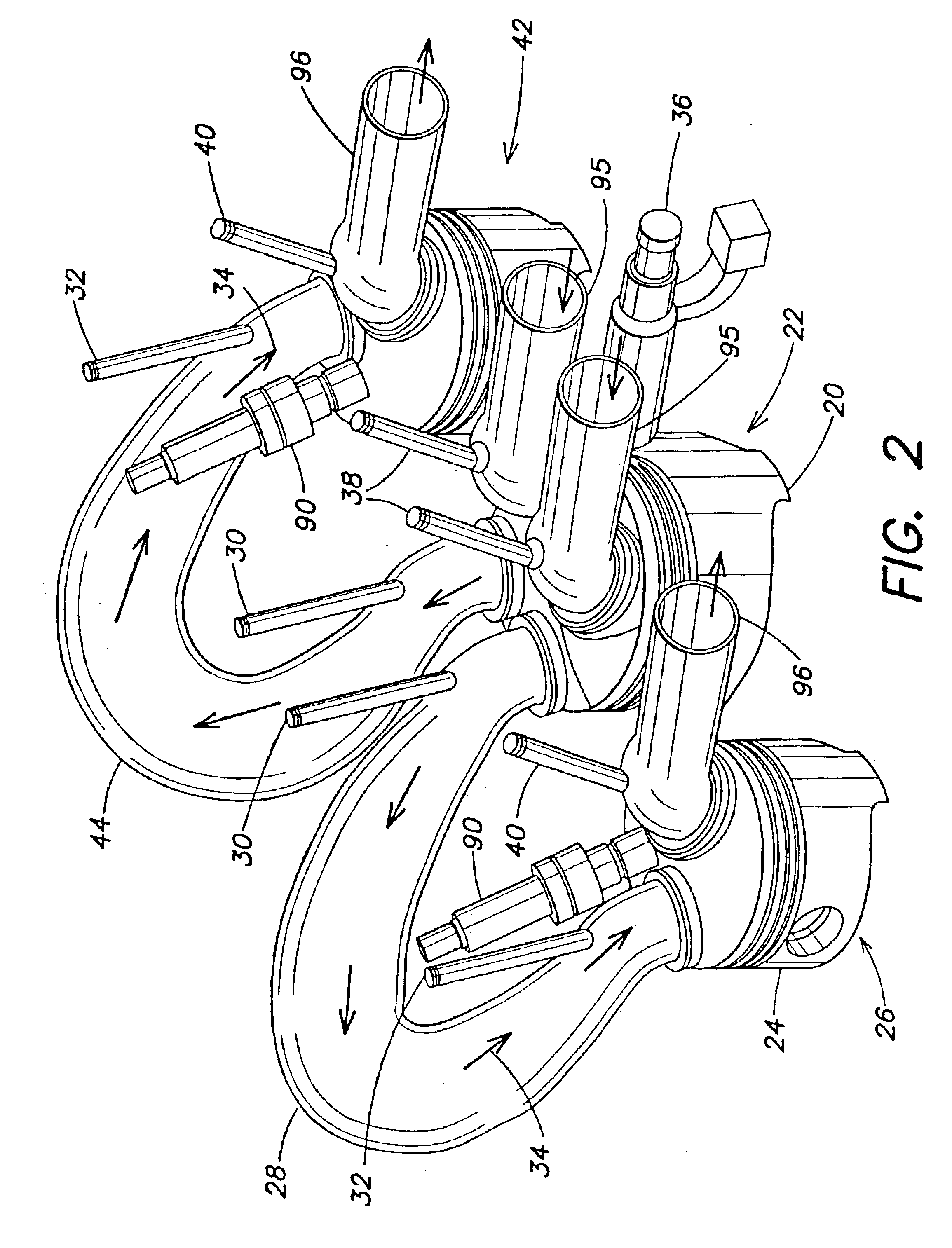

InactiveUS6880501B2Easy to implementLower emission levelsCombustion enginesEngineeringInternal combustion engine

An internal combustion engine that has a pair of cylinders each having a reciprocating piston connected to a crank shaft by a connecting rod. One of the cylinders is adapted for an air and fuel intake and a compression strokes only, and the other of the cylinders adapted for at least power and exhaust strokes. A conduit exists for transfer of gases from the one into the other cylinder after the compression stroke. The conduit has means for isolating gases in the conduit intermediate the compression and power strokes. Furthermore, the conduit is designed to prevent the transfer of liquefied fuel from the one cylinder to the other.

Owner:MASSACHUSETTS INST OF TECH

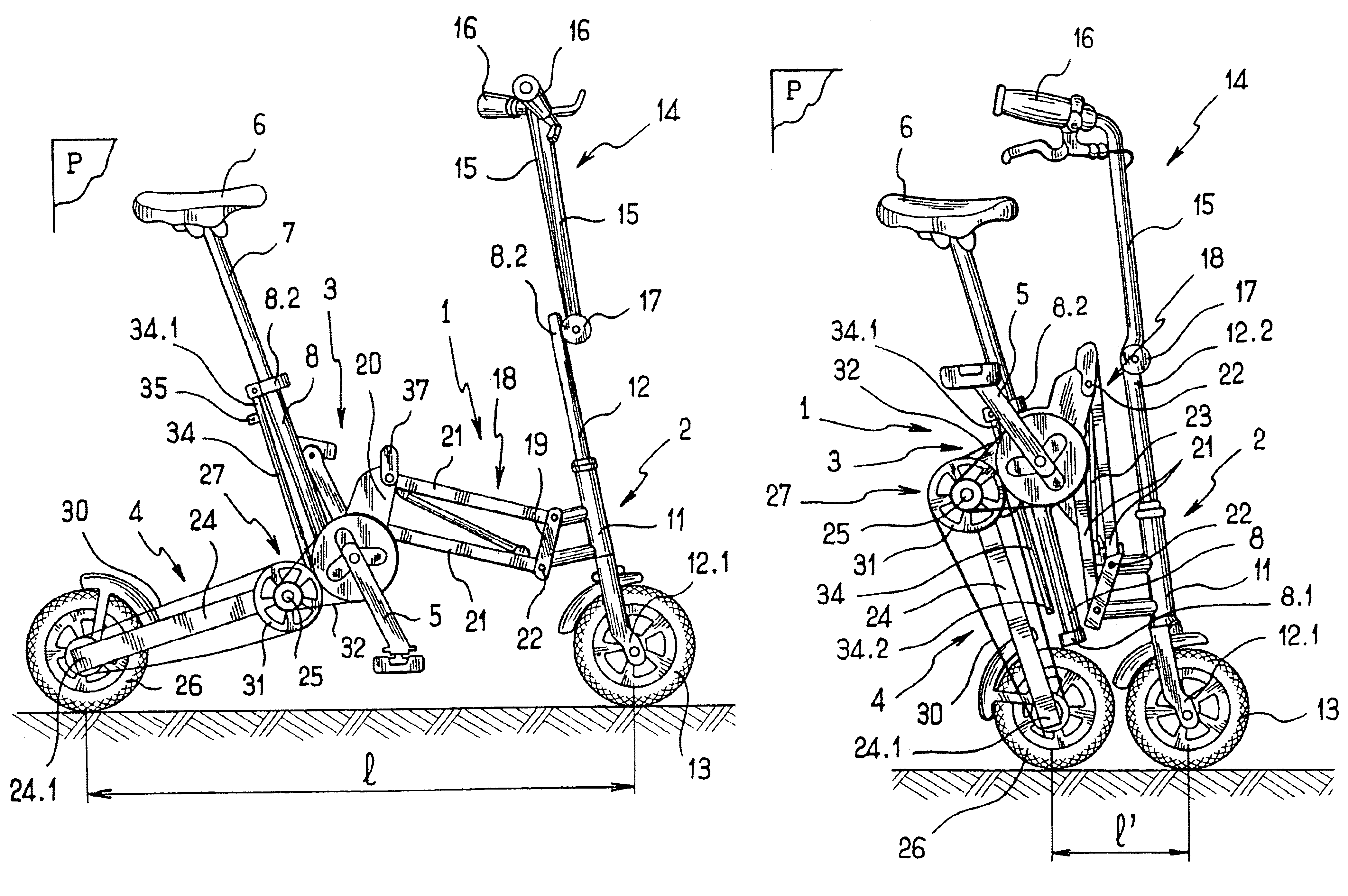

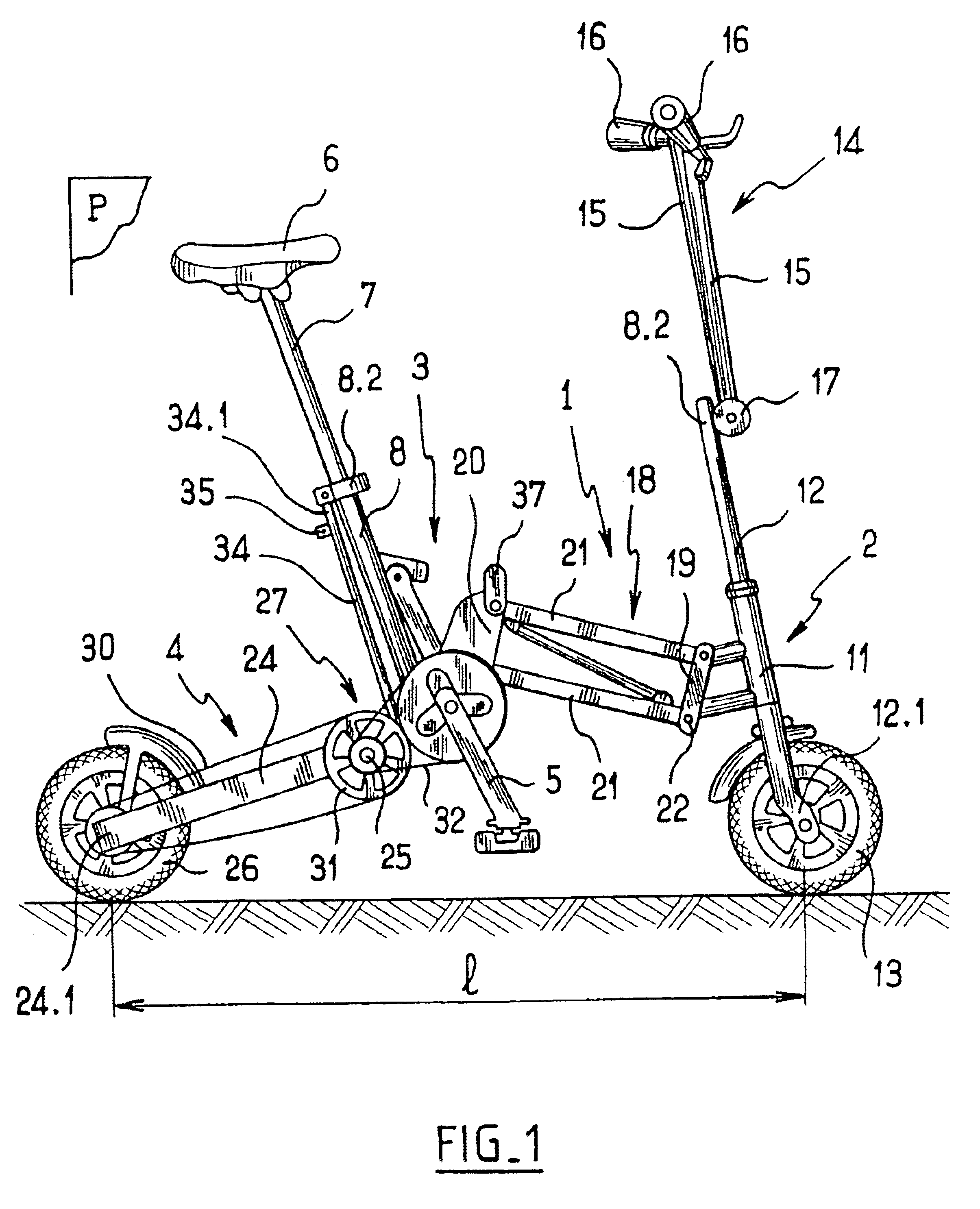

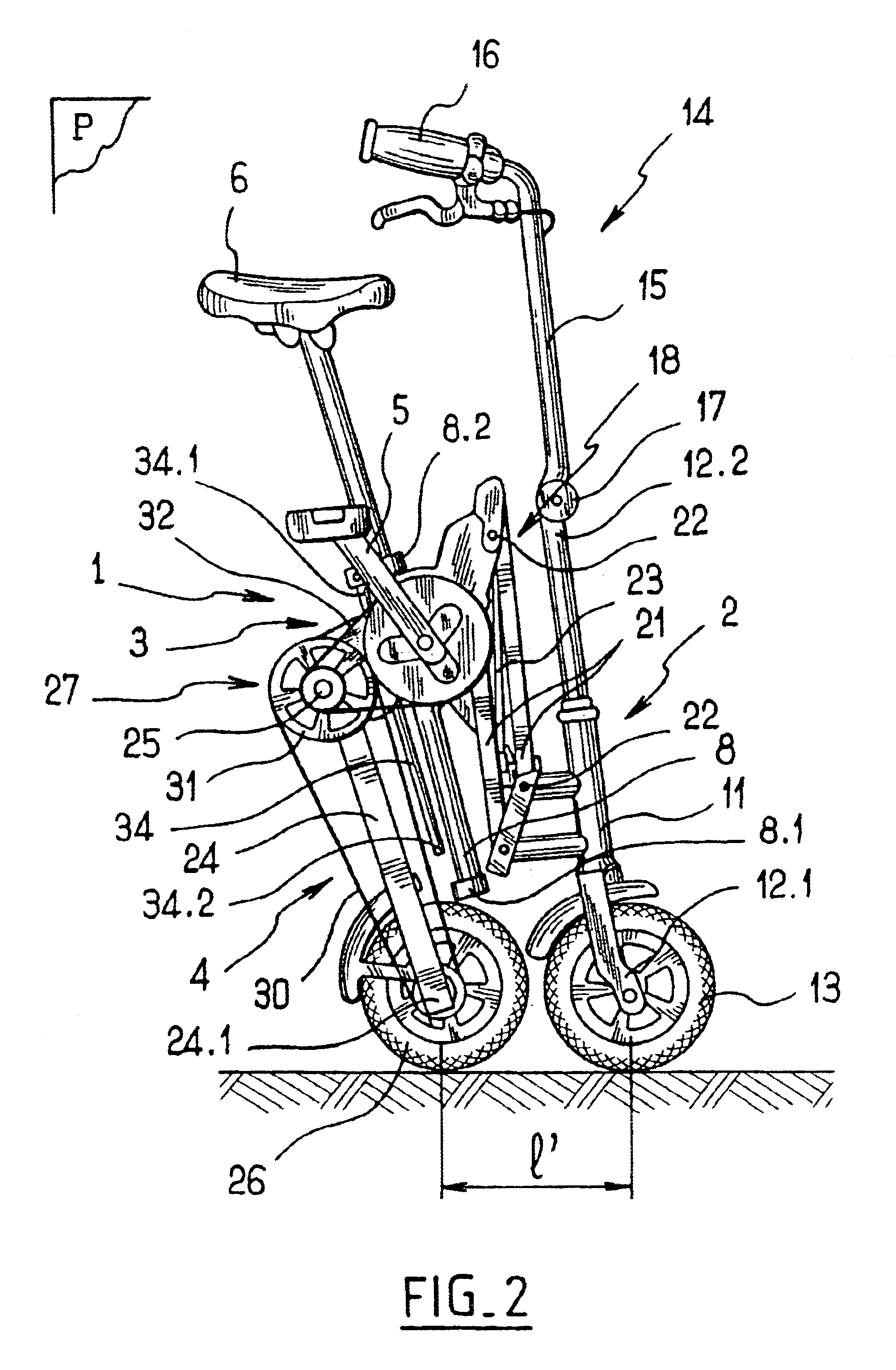

Folding bicycle

InactiveUS6799771B2Length of connection can be constantSimple structurePassenger cyclesWheel based transmissionCrankEngineering

A folding bicycle comprises a frame including a front part whereon is mounted pivoting a steering rod having a lower end provided with a first wheel and an upper end provided with a handlebar, a rear part whereon is mounted a second wheel, and a central part whereon are mounted a saddle and a crankset connected to the rear wheel by transmission elements, such that the saddle, the crankset, the steering rod, the front wheel and the rear wheel are substantially contained in a common plane when the bicycle is unfolded. The frame includes elements articulating the front part and the rear part to the central part to reduce the bicycle wheelbase associated with elements for maintaining at least the front wheel and the rear wheel in the plane.

Owner:MOBIKY

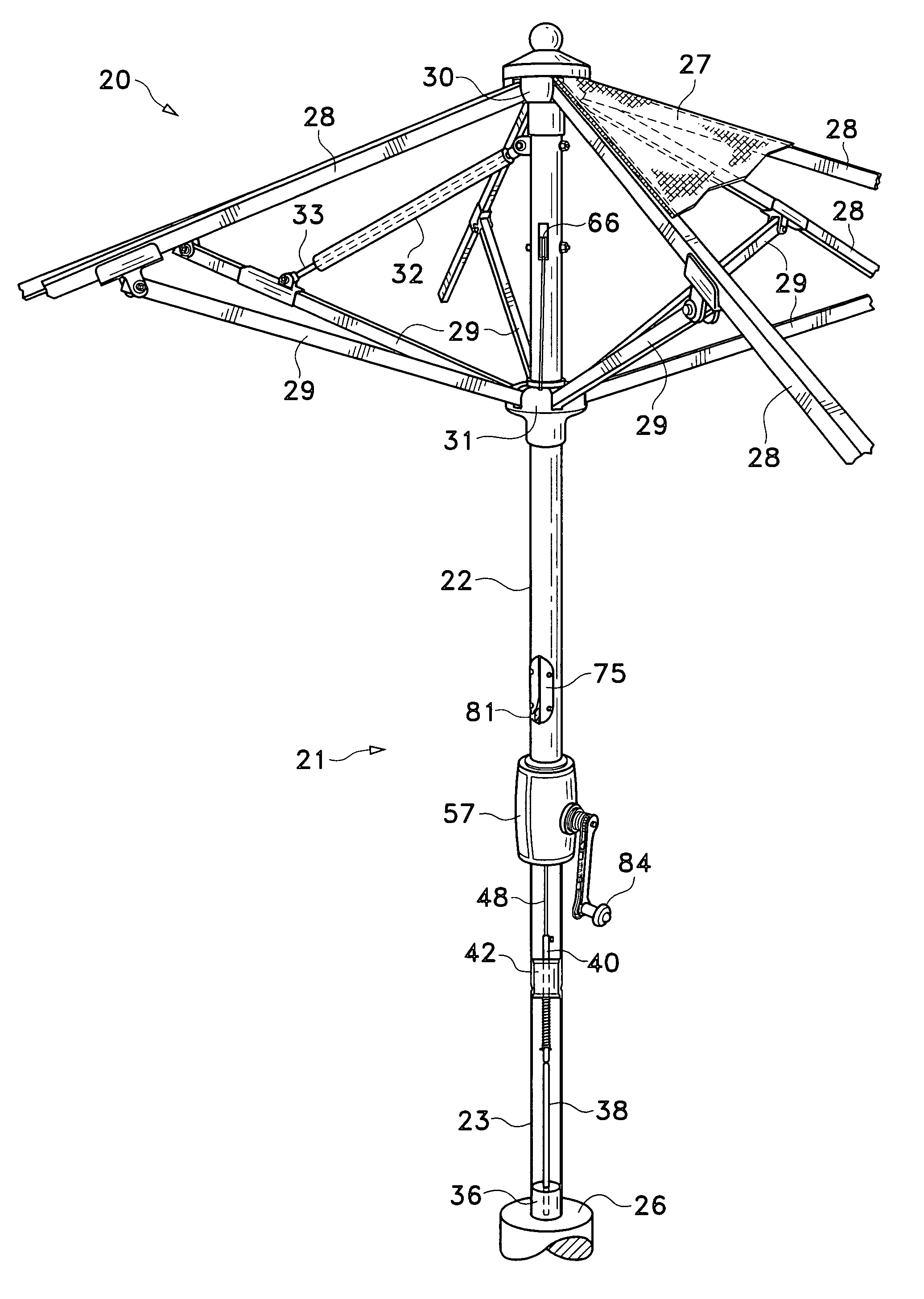

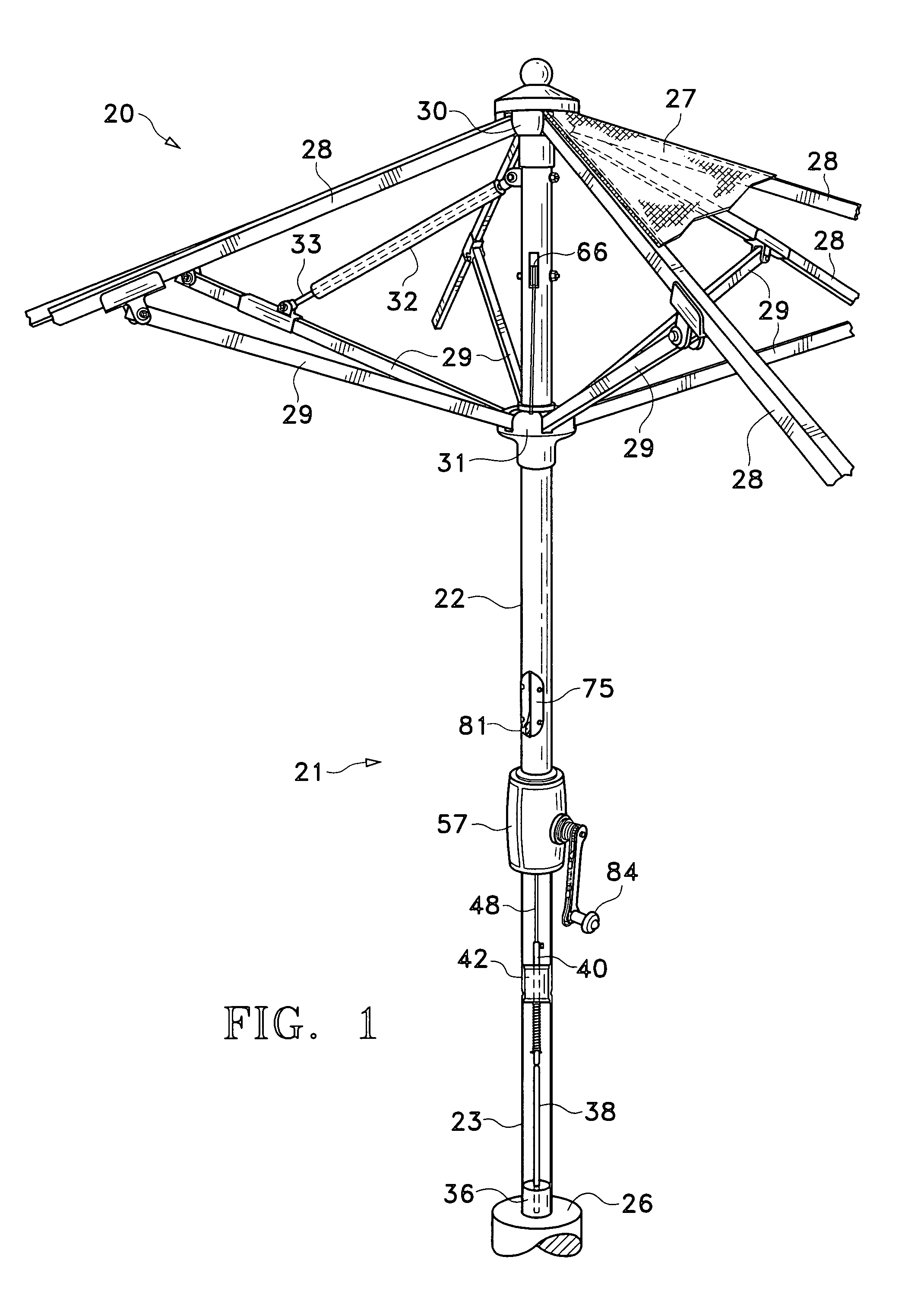

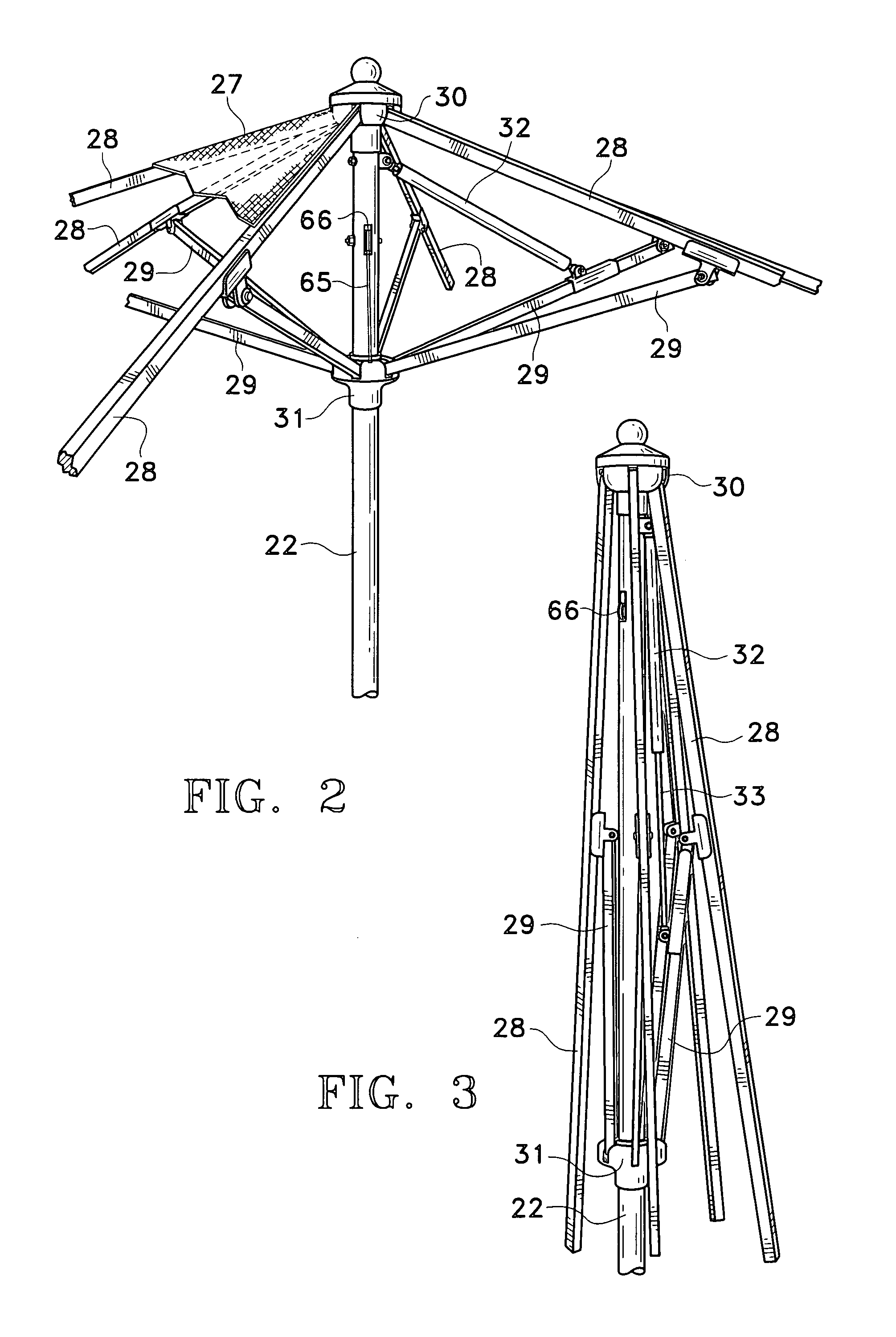

Self closing stationary umbrella

InactiveUS7665477B1Easy to manufacturePerforms betterWalking sticksUmbrellasHydraulic cylinderEngineering

An outdoor umbrella that closes automatically in high wind is disclosed. The wind causes the main support post of the umbrella to flex from the vertical dislodging a plunger from its weight bearing mounting on a rigid rod. The plunger is attached to an actuator rod extending upward within the support post. When the plunger is displaced the actuator rod is caused to move downward thereby activating a releasing ratchet which frees a shaft to rotate and the cable which holds the canopy to unwind. A hydraulic cylinder attached to one of the canopy ribs presses on the rib to close the canopy and maintain the canopy in closed orientation. As the canopy closes a reset mechanism is activated which resets the plunger onto the rigid rod. Once closed the canopy will remain closed until raised by manually rewinding the cable onto the shaft using a hand crank attached to the end of the shaft. A second ratchet assembly incorporated into the hand crank prevents the hand crank from spinning when the umbrella closes.

Owner:HATHAWAY MARTIN

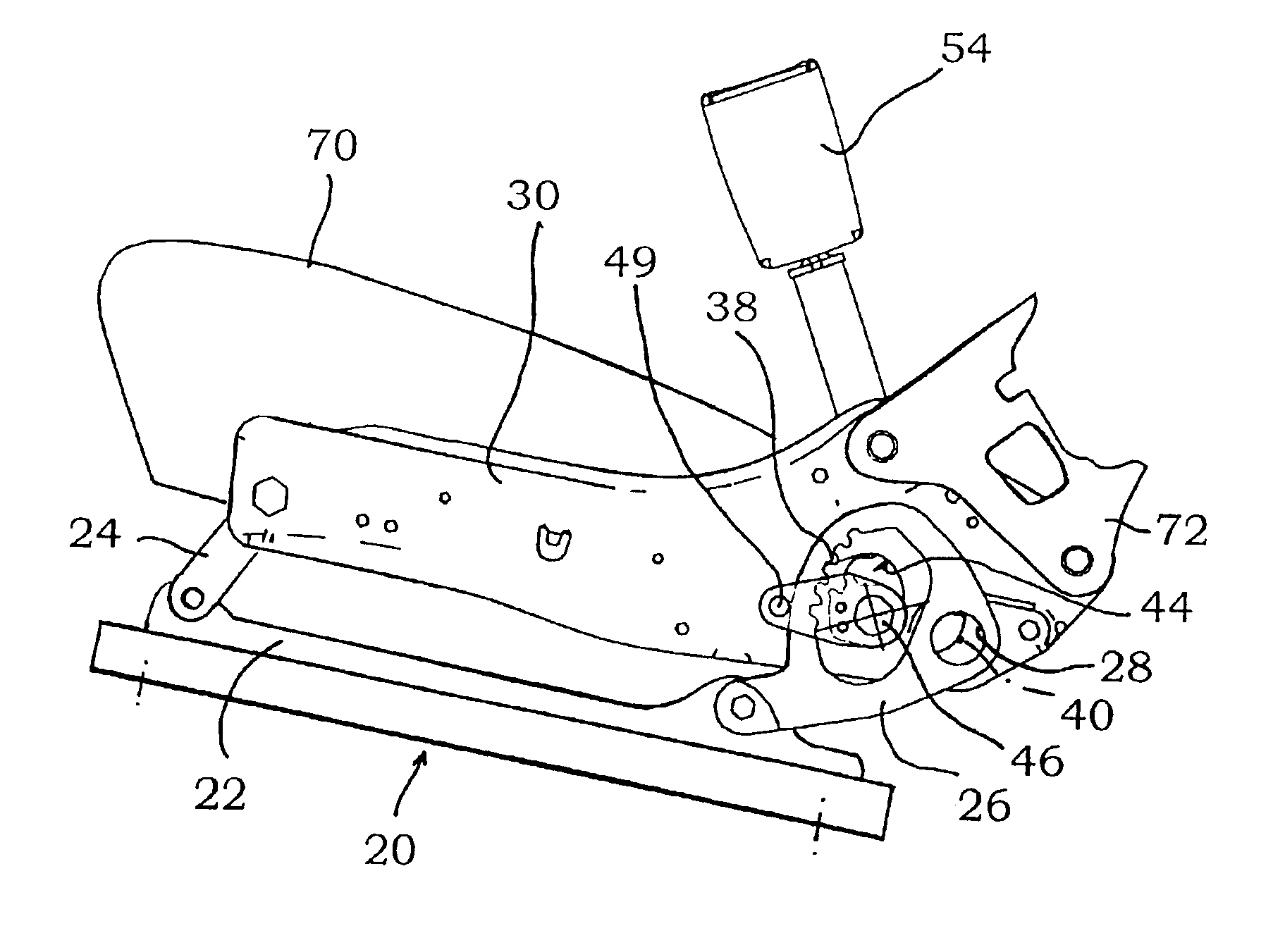

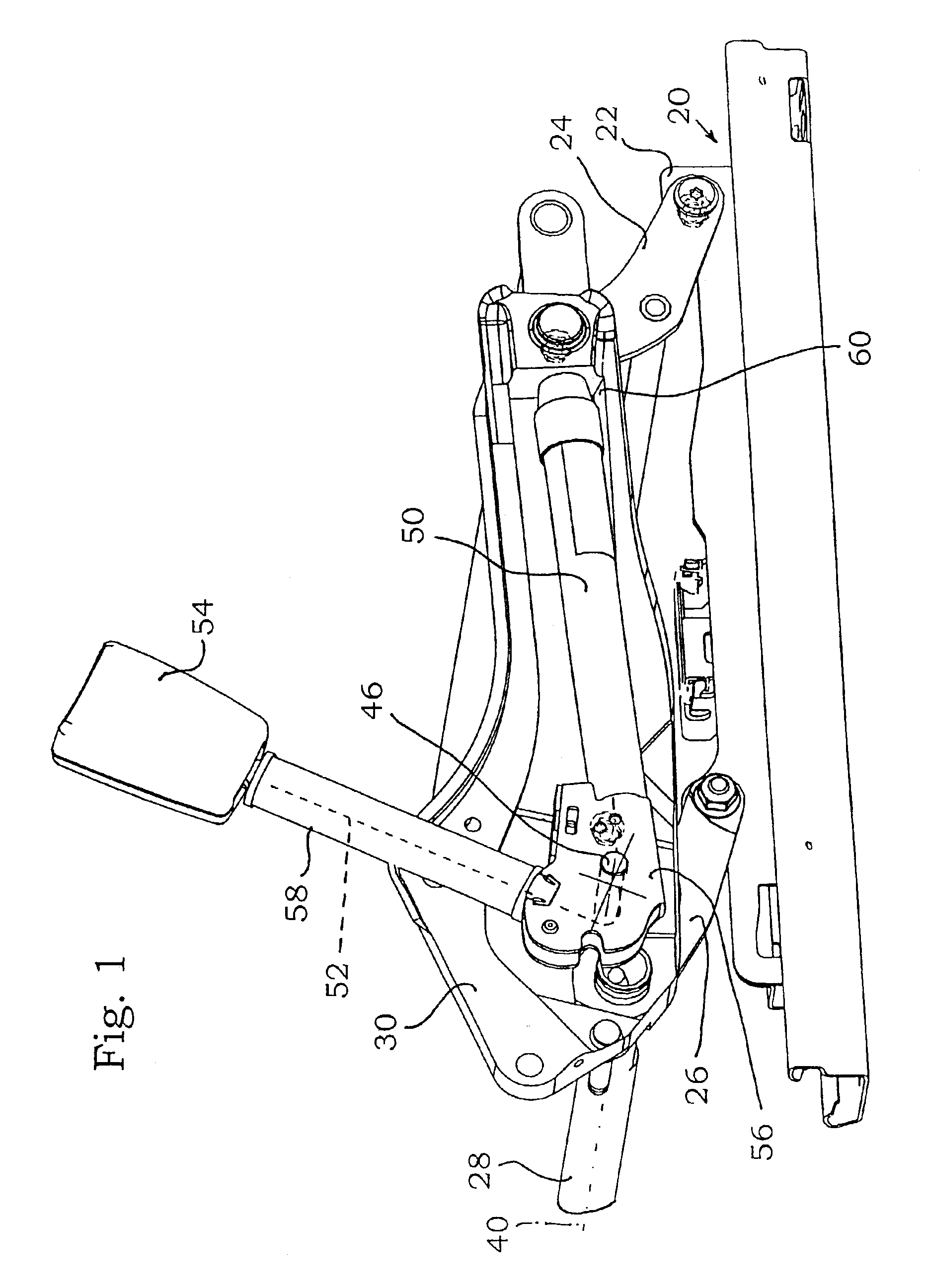

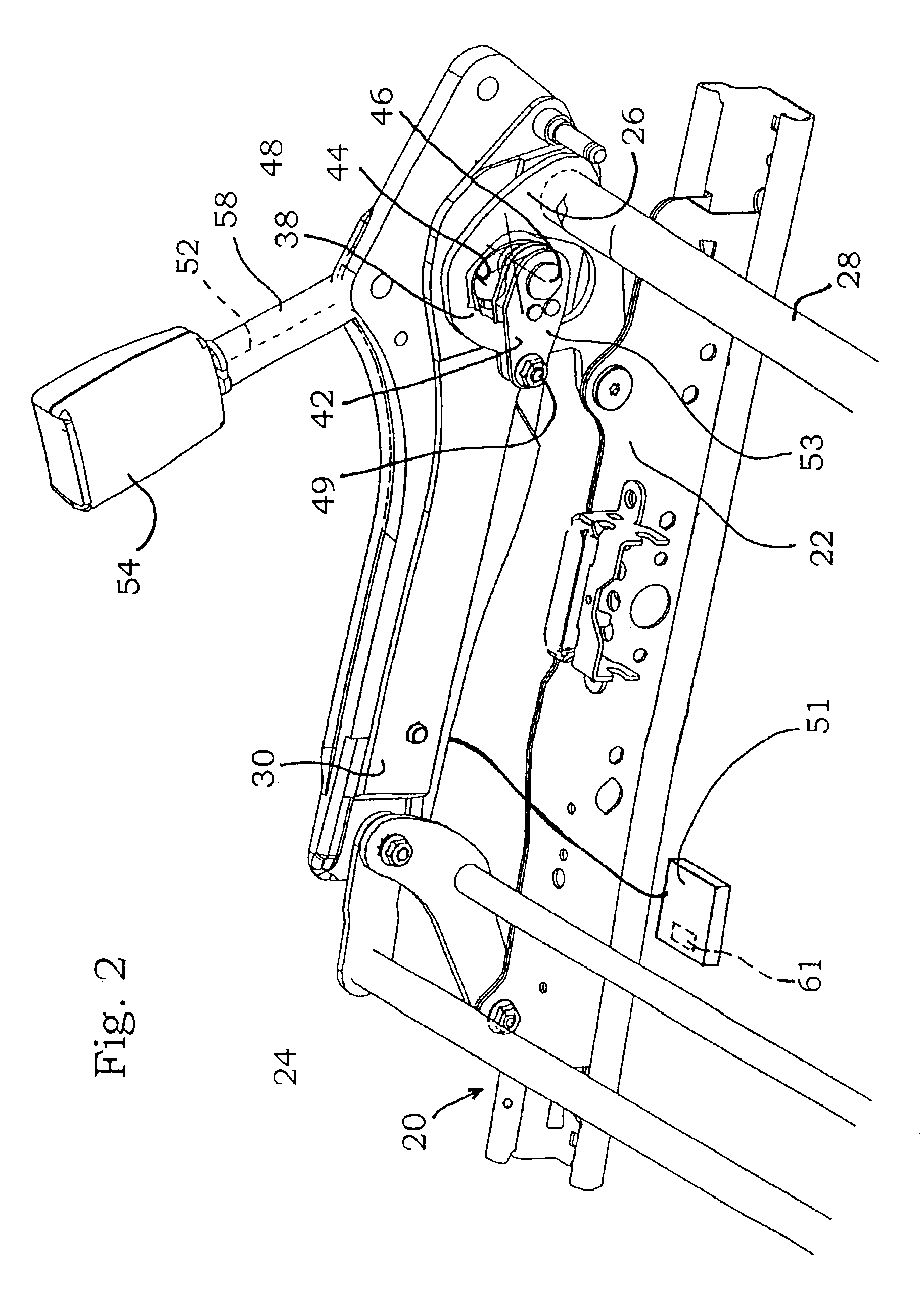

Vehicle seat with a catch on one side and with a retaining device

InactiveUS6902234B2Precise positioningPedestrian/occupant safety arrangementStands/trestlesMobile vehicleNormal load

The motor vehicle seat of a motor vehicle comprises an underframe and a seat carrier that is height-adjustably connected to the underframe through rear oscillating cranks. A catch device is directly assigned to one of the two rear oscillating cranks. A non-rotatable tie bar joins the two rear oscillating cranks so that they are parallel when the vehicle seat is subjected to normal load. A retaining device has a sector gear firmly connected to the other one of the two rear oscillating cranks. An engaging piece which is movably disposed on the seat carrier or on the underframe, is provided with teeth devised for engagement with the sector gear and is disengaged from the sector gear as long as the vehicle seat is subjected to normal load. When the associated motor vehicle is subjected to a crash load an actuator is activated and causes the engaging piece to move into positive mesh with the sector gear. It is activated both for a positive and for a negative acceleration of the vehicle seat in the event of an accident. The teeth of the sector gear are configured in such a manner that their flanks, which are located on either side thereof, are oriented substantially radially relative to the orientation of said sector gear so that, during an accident situation, the sector gear is locked in the two directions of rotation upon engagement of the engaging piece.

Owner:C ROB HAMMERSTEIN GMBH & CO KG

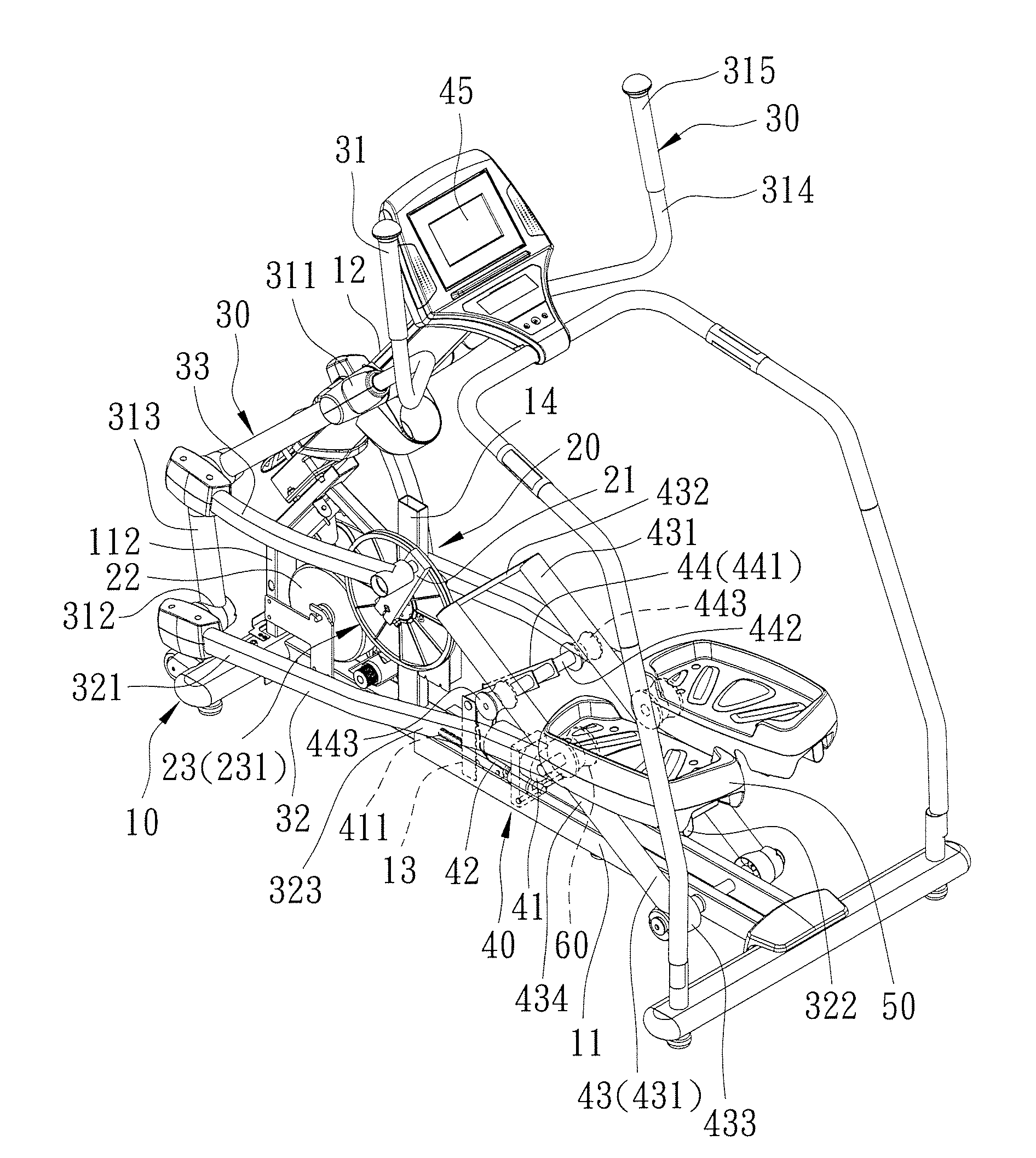

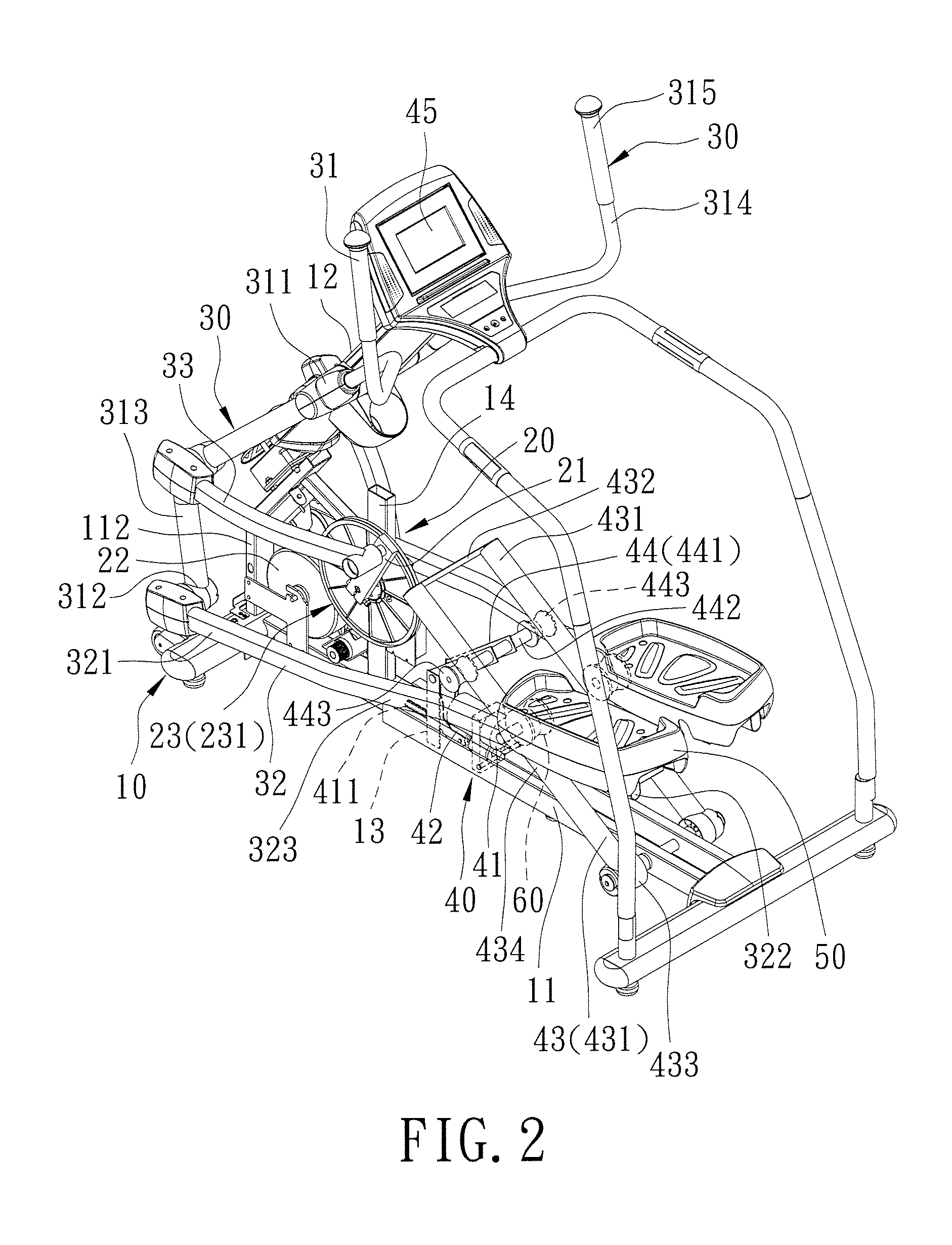

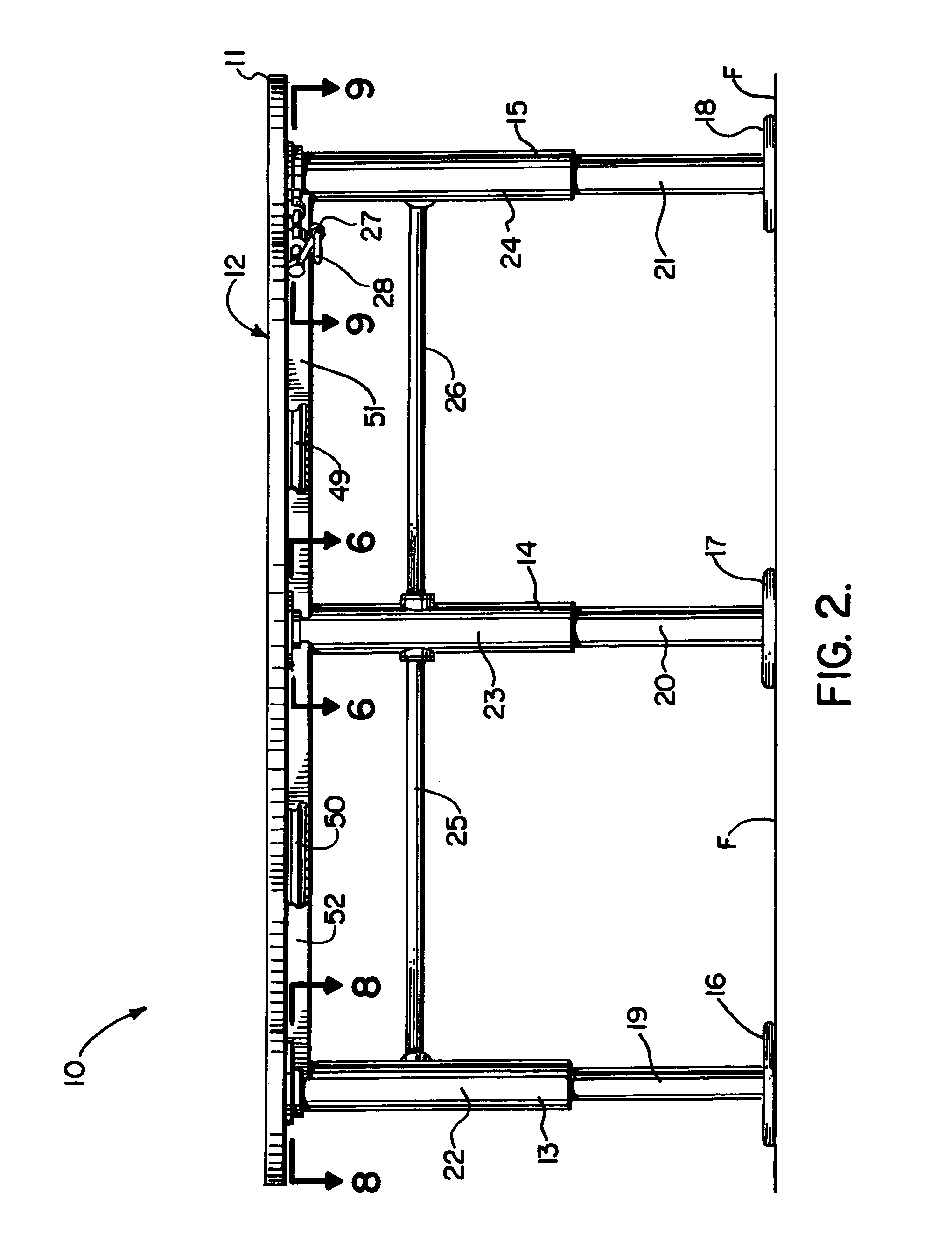

Exercising device

InactiveUS20120077645A1Train different muscle groupsMovement coordination devicesMuscle exercising devicesCrankClassical mechanics

An exercising device includes left and right linking units each having a swing link pivotally mounted on a front support of a frame, a crank link coupling a crank arm to the swing link, and a pedal link connected to a lower end of the swing link, and left and right foot engaging pedals each mounted on a rear linkage end of the pedal link to be movable along an elliptical path with rotation of the crank arms. A sloping ramp member has an inclined surface to guide the foot engaging pedals to simulate stair climbing during the elliptical movement of the foot engaging pedals through left and right rollable anti-friction members mounted under the foot engaging pedals and rollably engaged with the inclined surface.

Owner:SUPERWEIGH ENTERPRISE

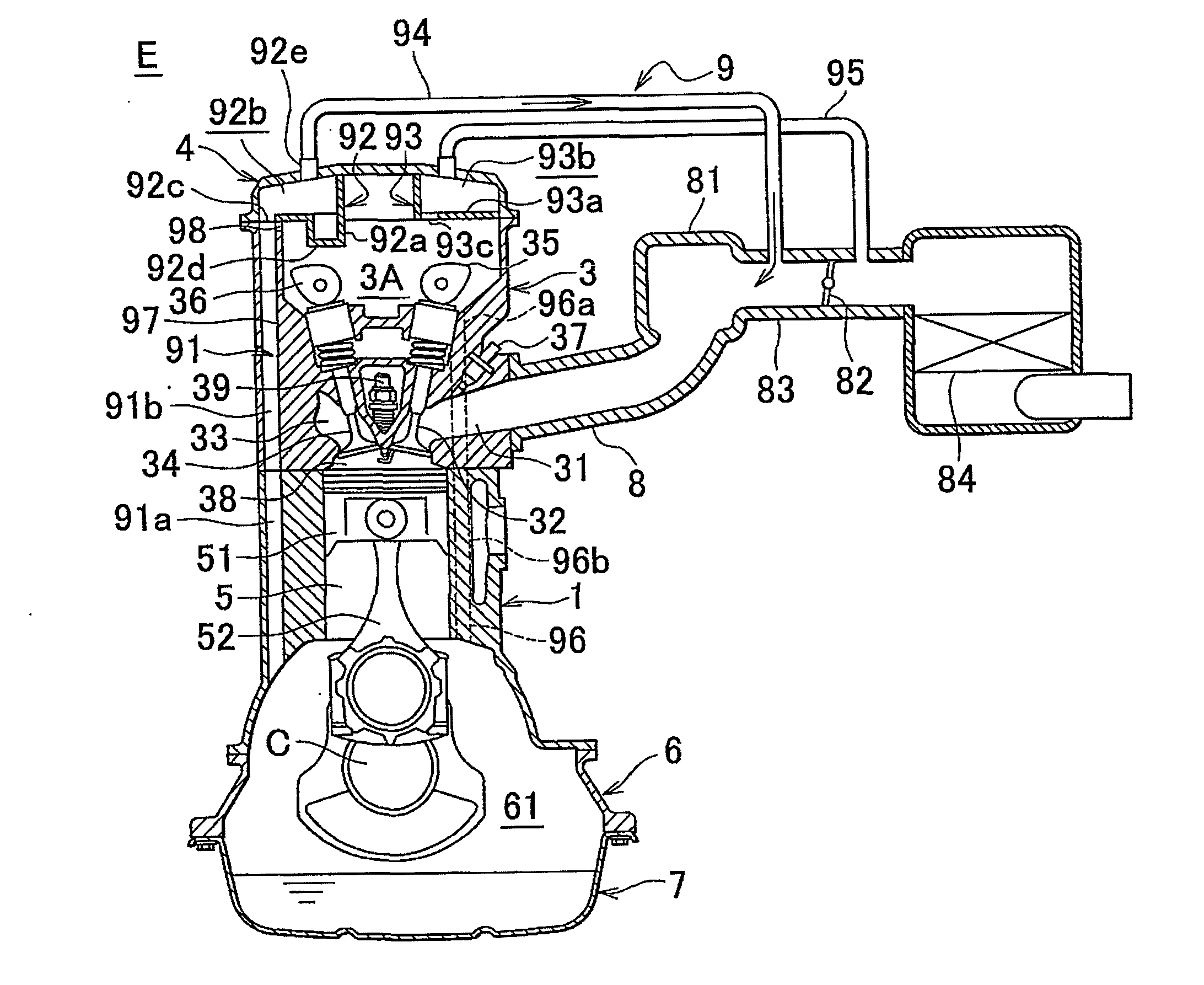

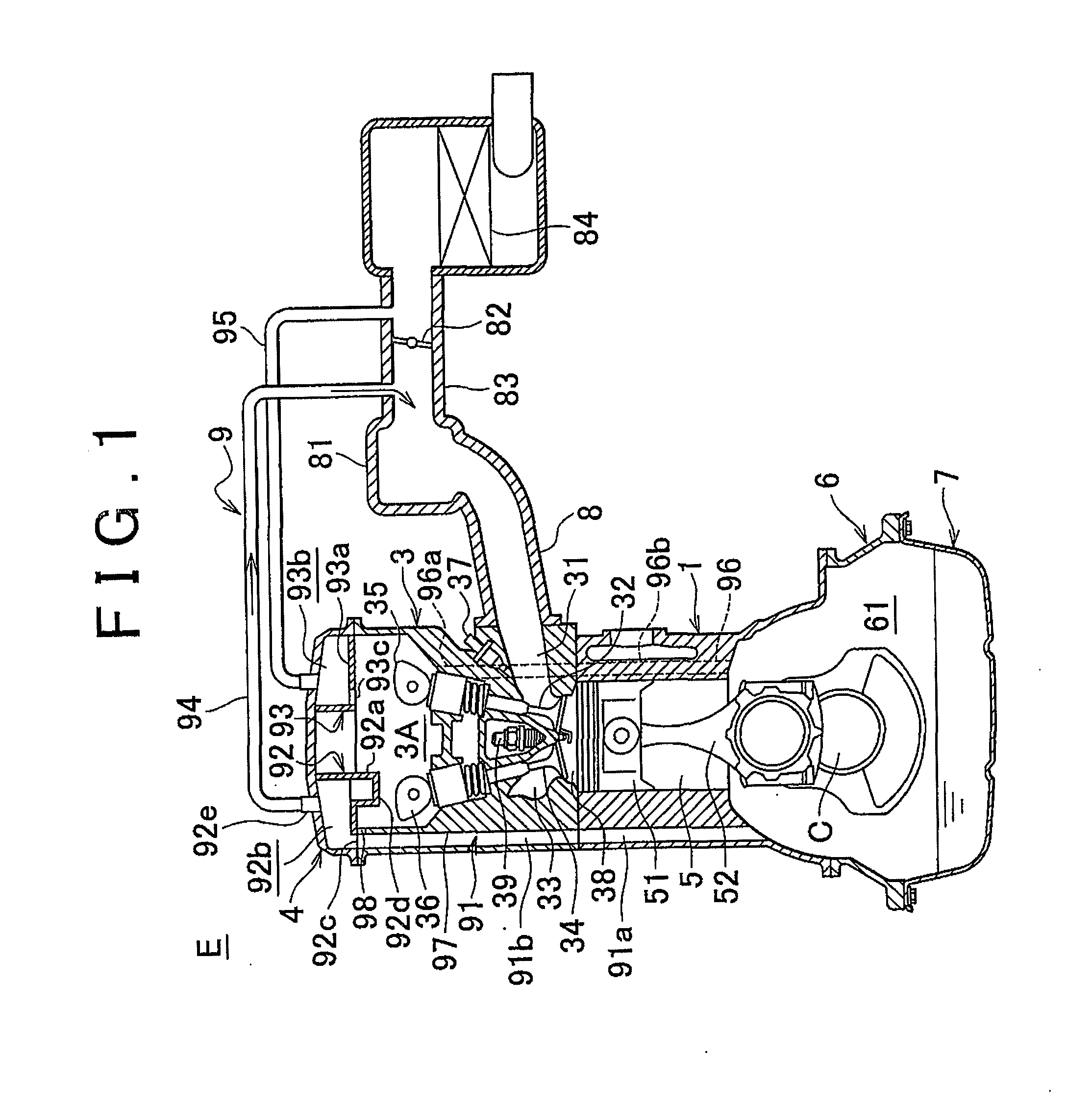

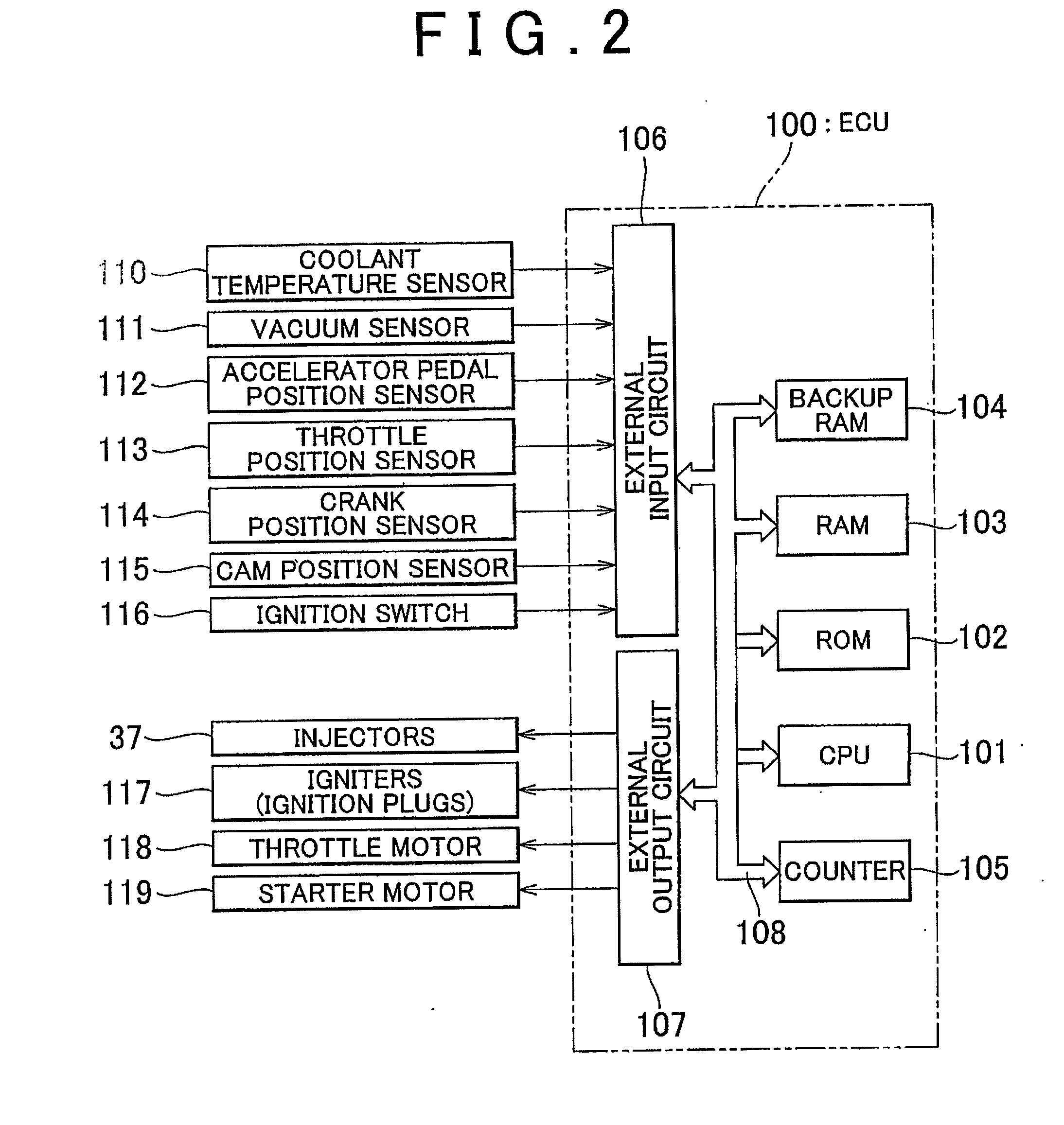

Positive crankcase ventilation system, cylinder head used for positive crankcase ventilation system, internal combustion engine including positive crankcase ventilation system, and positive crankcase ventilation method

InactiveUS20100101514A1Reduce manufacturing costSimple processCylinder headsCombustion enginesCylinder headEngineering

A blow-by gas collection passage (91) extends in a cylinder block (1) and a cylinder head (3). A crank chamber (61) is connected to an oil separator (92) through the blow-by gas collection passage (91). A cutout portion is formed in an upper end portion of a wall portion (97) of the blow-by gas collection passage (91), and the oil separator (92) contacts an upper surface of the cylinder head (3) to form a connection portion (98) through which the blow-by gas collection passage (91) is connected to a cam chamber (3A). Thus, new air in the cam chamber (3A) flows into the blow-by gas collection passage (91) at an inlet portion of the oil separator (92) through the connection portion (98) to dilute the blow-by gas.

Owner:TOYOTA JIDOSHA KK

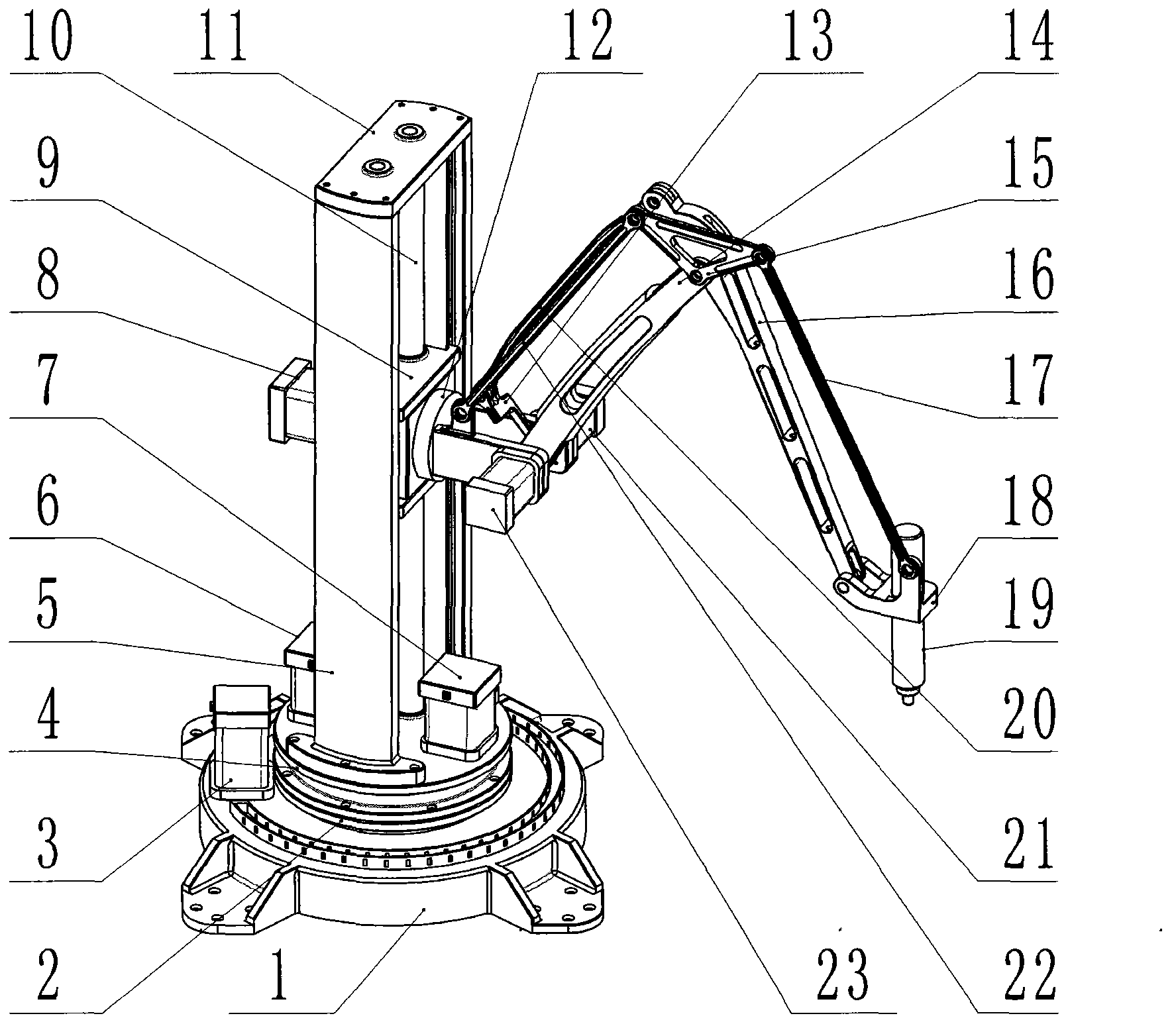

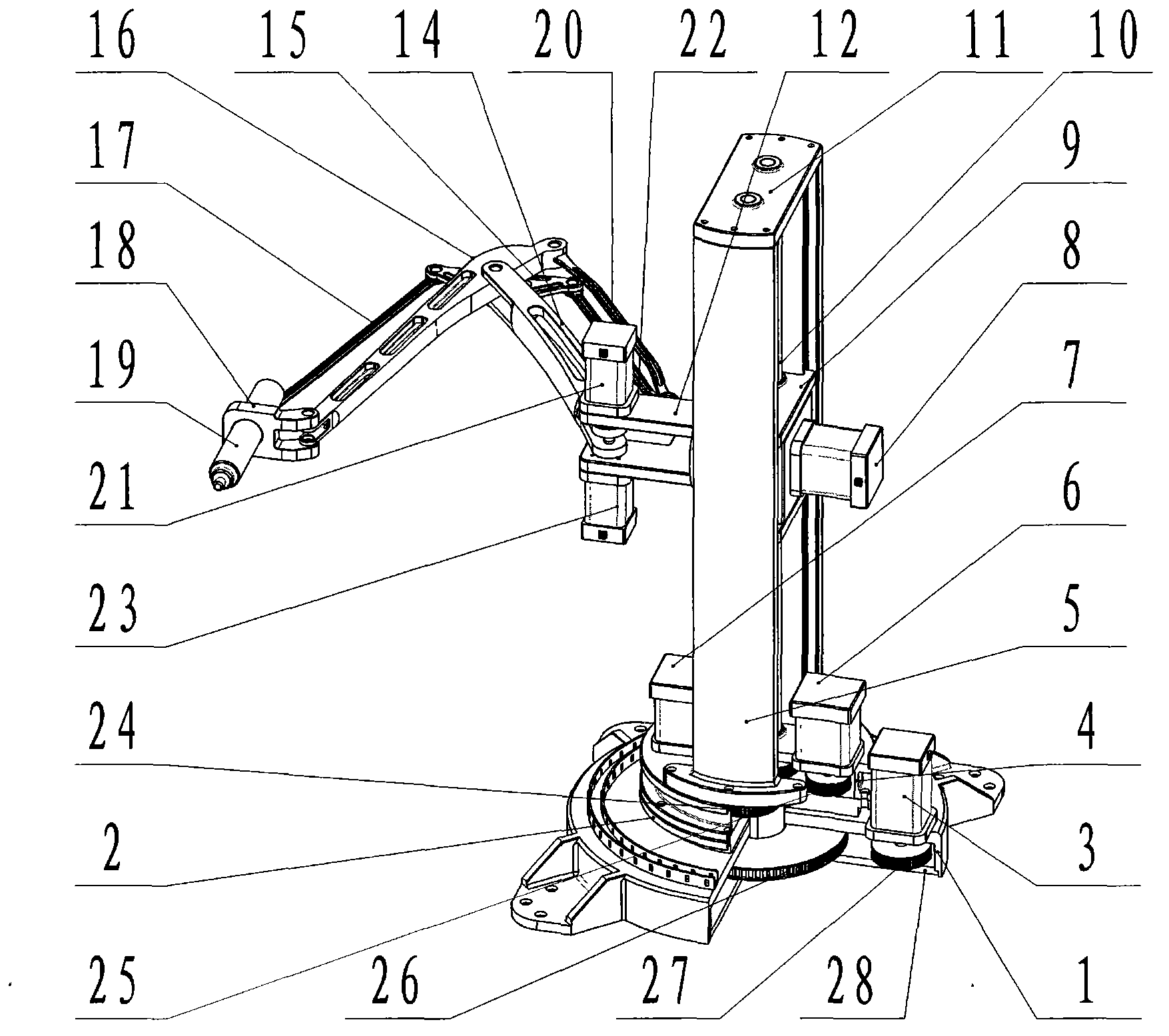

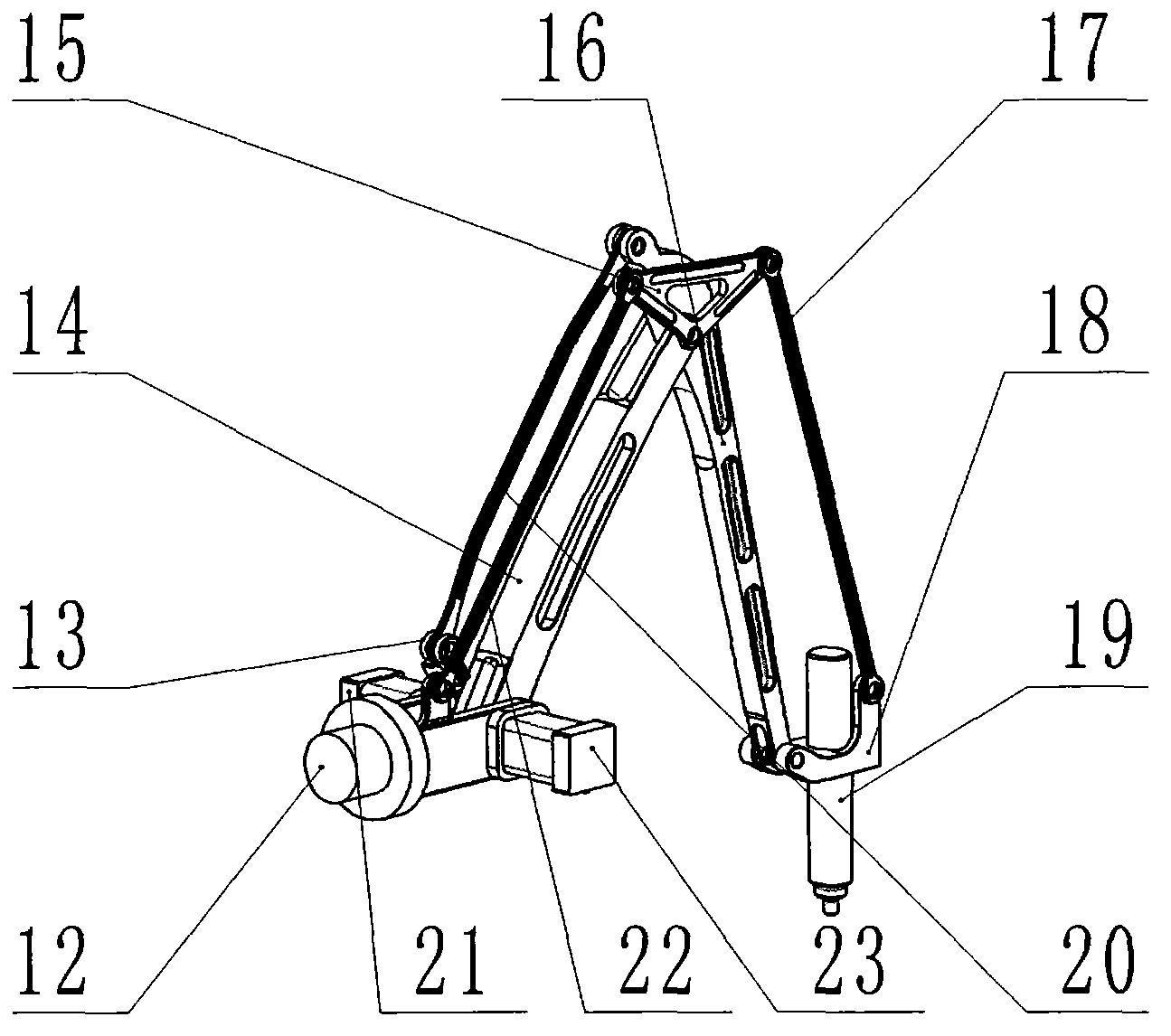

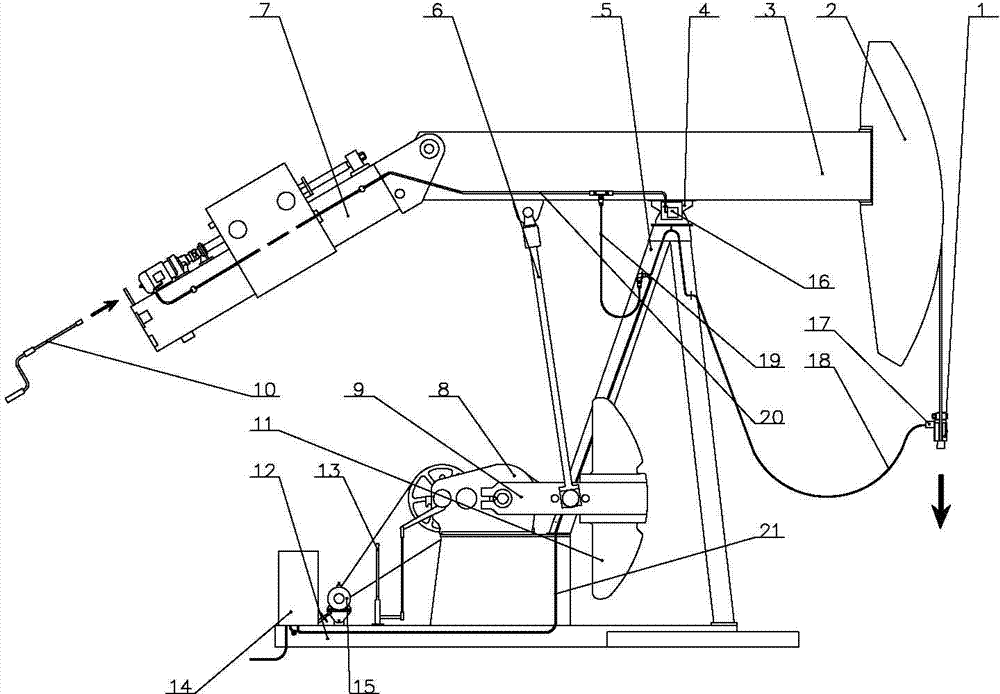

Rotary table upright type five-freedom-degree mixed-connecting spray painting robot

The invention relates to a rotary table upright type five-freedom-degree mixed-connecting spray painting robot which is large in work space and has certain flexibility. The rotary table upright type five-freedom-degree mixed-connecting spray painting robot comprises a foundational series-connection movement unit and a tail end parallel-connection spray painting operation unit. The foundational series-connection movement unit has two rotation freedom degrees and a movement freedom degree and is composed of a machine body rotation joint, a machine body lifting movement joint and a horizontal rotation joint. The tail end parallel-connection spray painting operation unit has two movement freedom degrees and is a plane parallel-connection mechanism composed of a large arm, a small arm, a connecting rod, a crank, a movable platform and the like. The rotary table upright type five-freedom-degree mixed-connecting spray painting robot has the advantages of being wide in work range, small in number of driving joints, compact in structure, easy to manufacture, convenient to control, capable of enabling the modularization to be achieved easily and the like.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

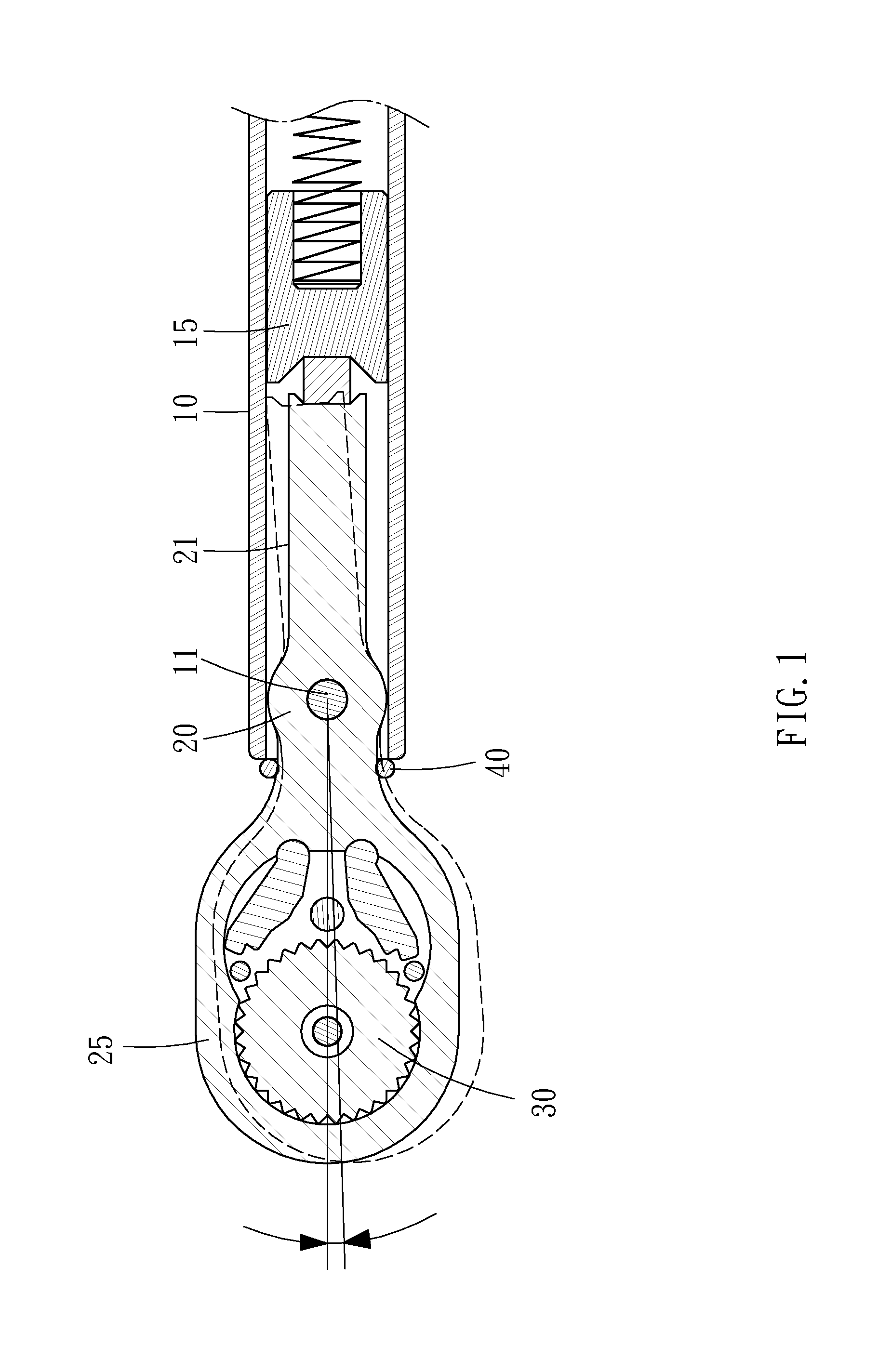

Robust Torque-Indicating Wrench

A torque-indicating wrench includes a handle, a strain gauge, a lever, a head and a driving mechanism. The strain gauge is placed in the handle. The lever including a first end inserted in and pivotally connected to the handle and abutted against the strain gauge and a second end placed out of the handle. The head includes a tubular portion non-pivotally placed around and on the handle. The driving mechanism includes a bit-rotating element pivotally placed in the head and formed with a crank pivotally connected to the second end of the lever.

Owner:MATATAKITOYO TOOL

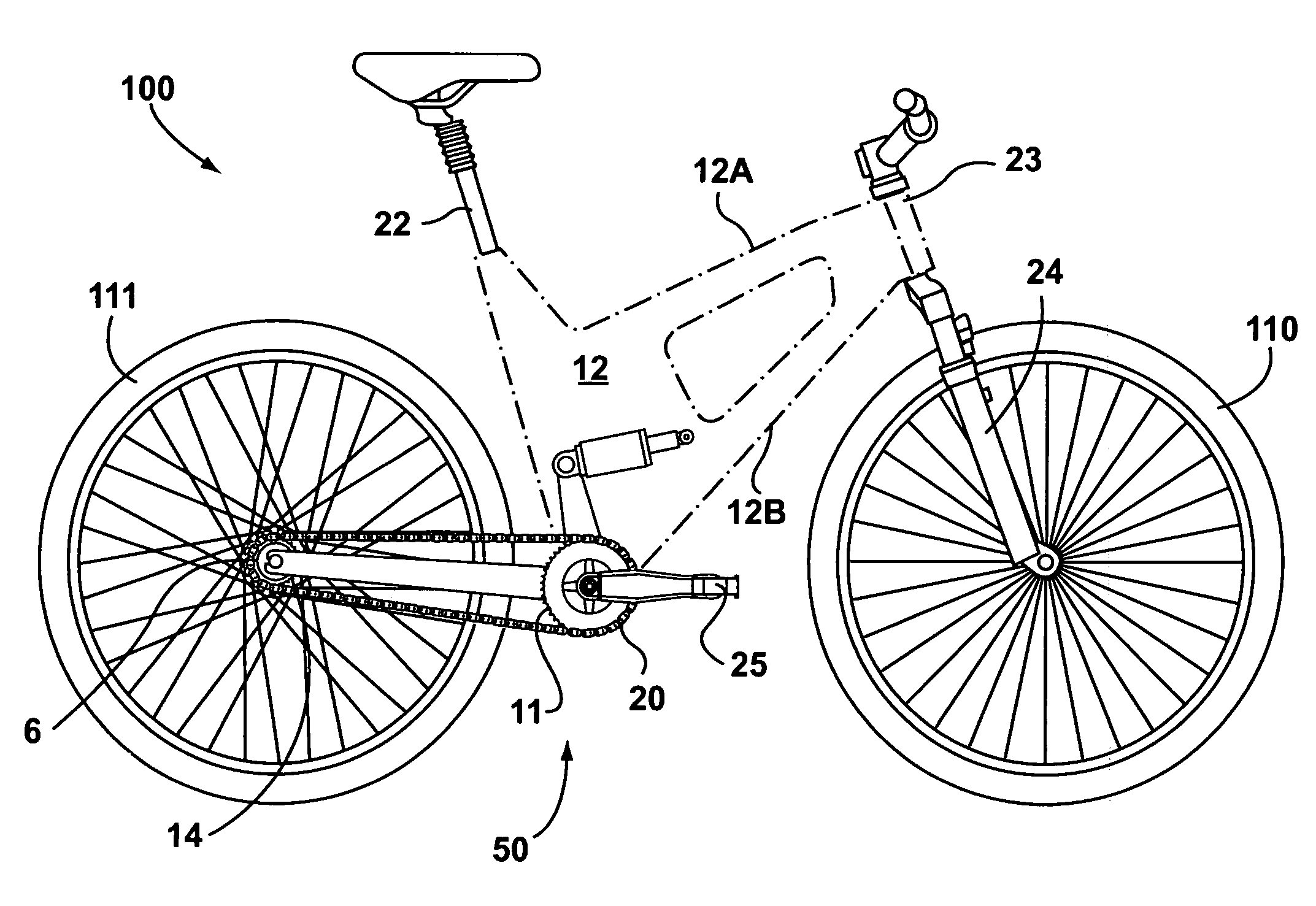

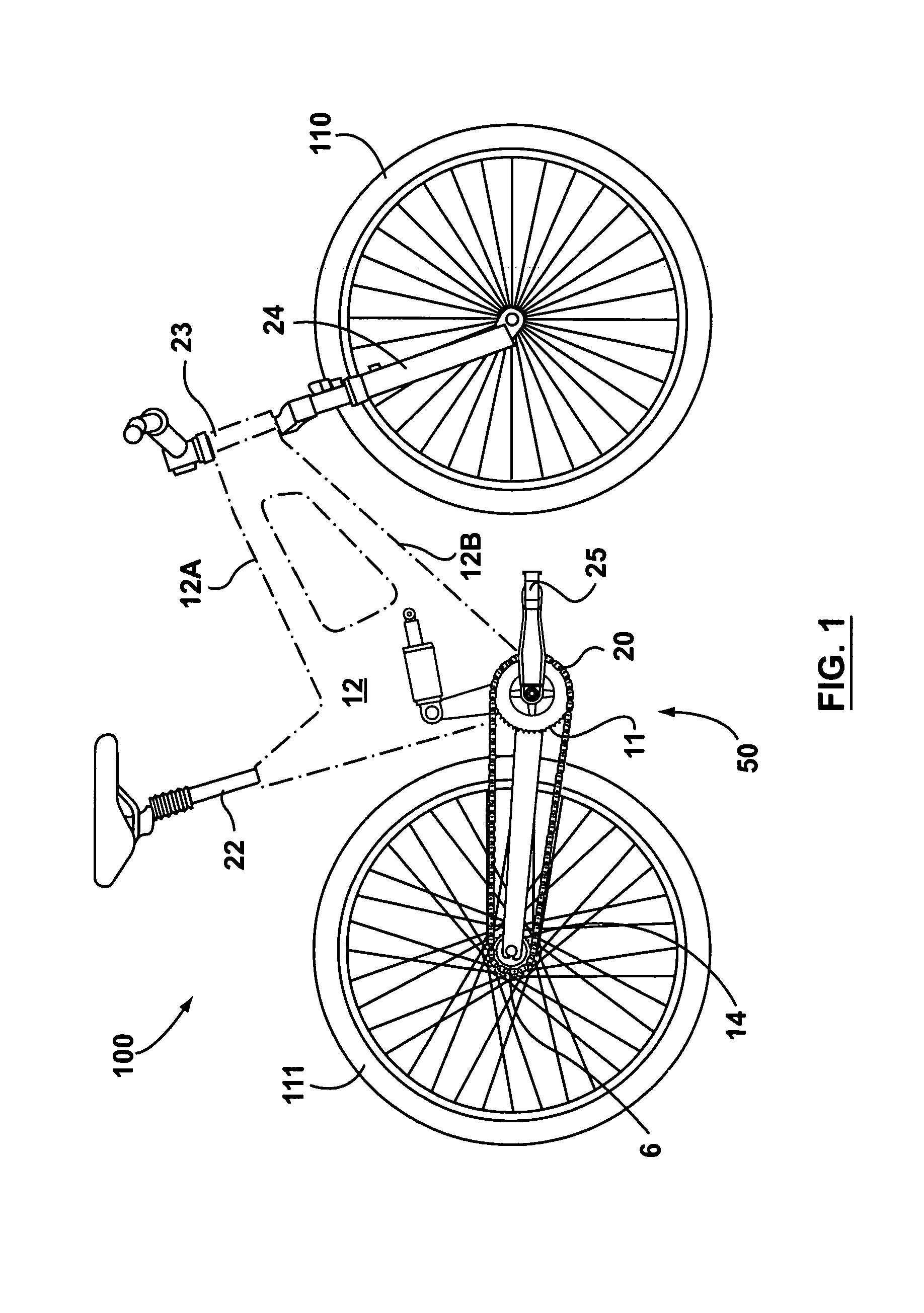

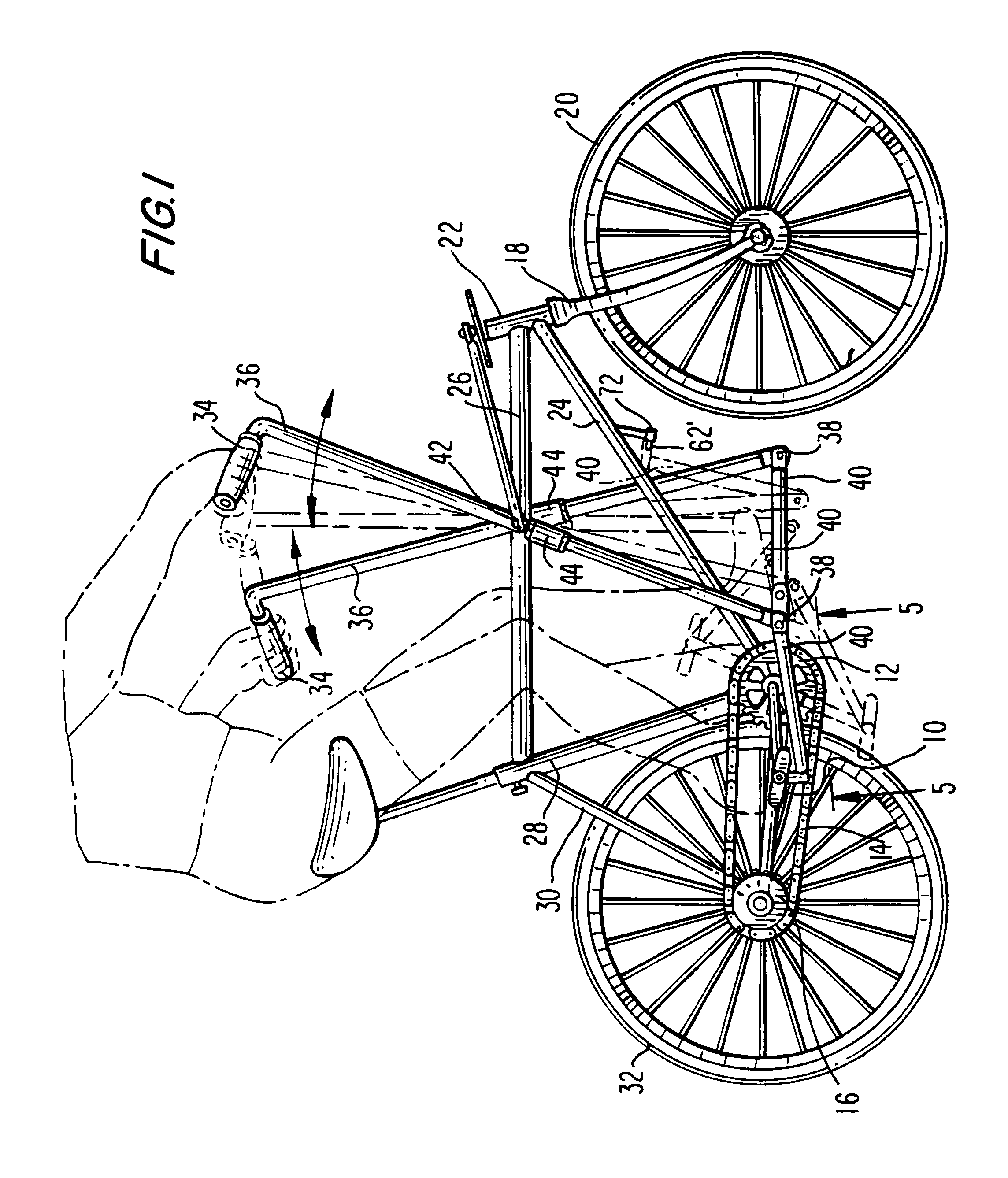

Cantilever rear suspension for a bicycle

ActiveUS7104562B2Reduce unwanted playIncrease surface areaPassenger cyclesChildren cyclesRotational axisEngineering

A bicycle is equipped with a rear wheel suspension having a swing arm with one or more generally cantilevered side arms, which are capable of withstanding bending and torsional loads and isolating said loads from the rider. A bottom portion of the bicycle frame includes a pedal sleeve. A pedal or crank assembly rotates within the pedal sleeve about a rotational axis with a fixed location relative to the frame. The swing arm is pivotally secured to the frame for movement about the rotational axis. A shock-absorbing element is connected between the swing arm and the frame.

Owner:GINGL MANFRED

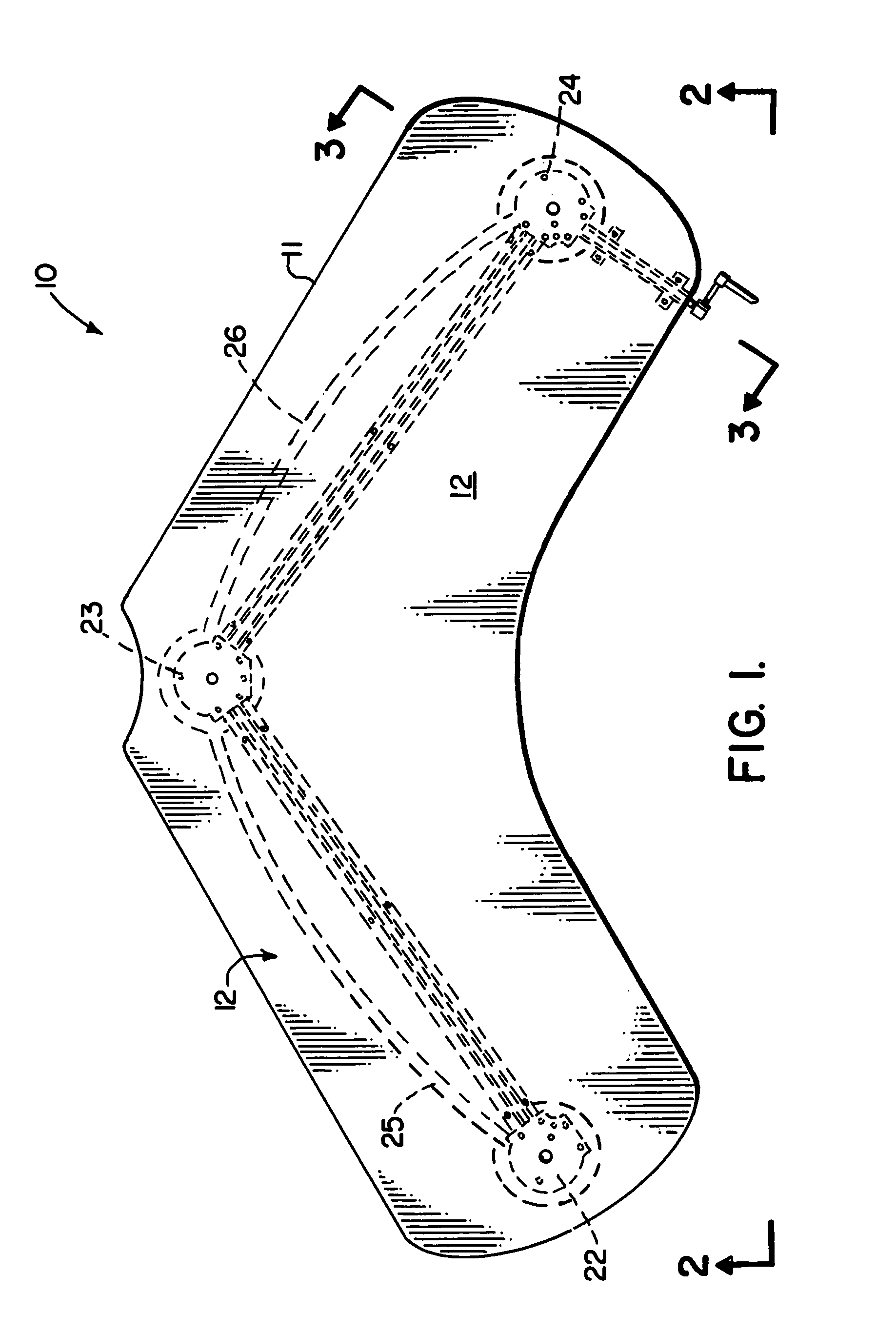

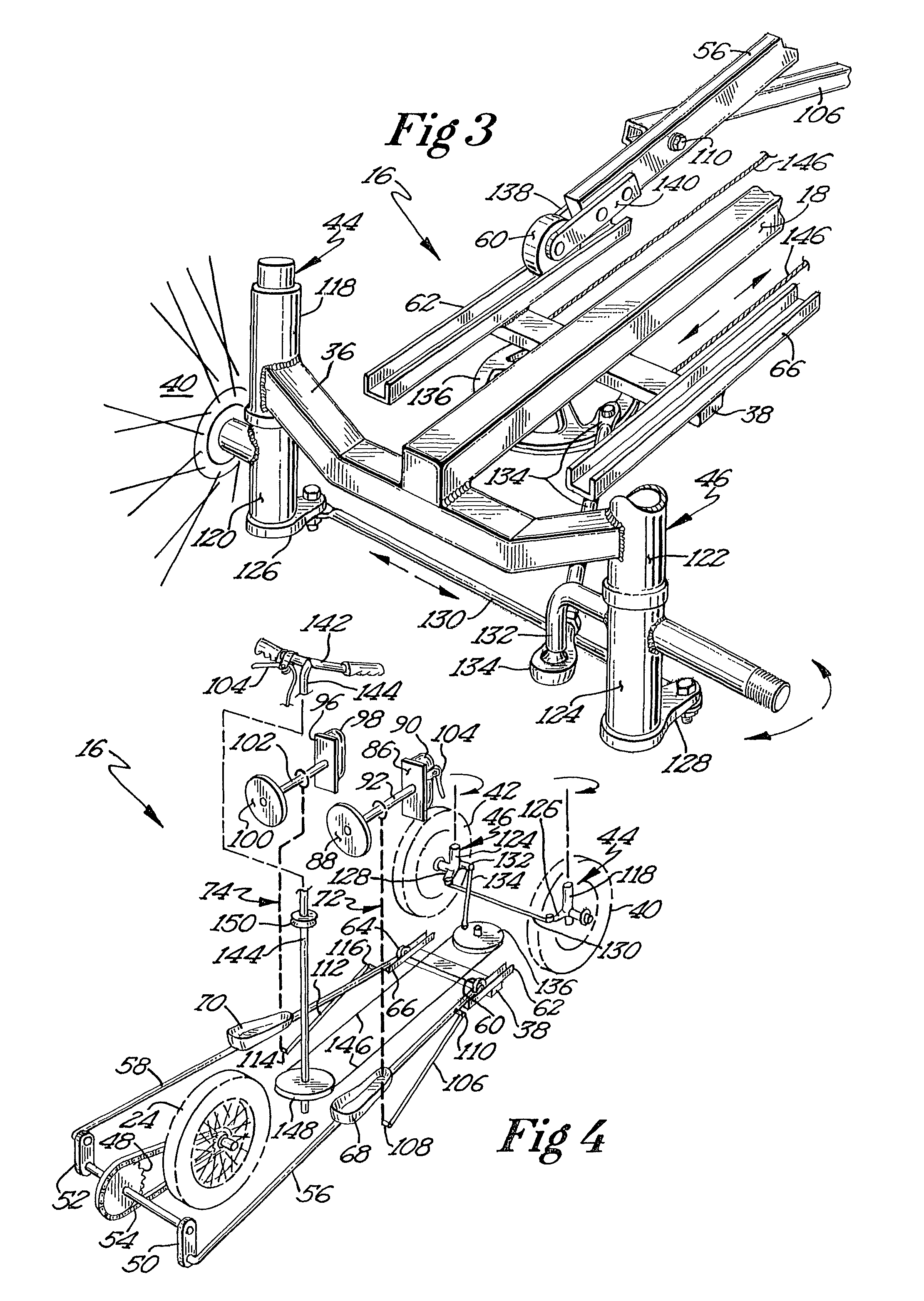

Adjustable height table with multiple legs operable by a single crank

An improved elevating table apparatus provides a plurality of at least three telescoping legs that support a table top having an underside and an upper surface that provides a work surface upon which can be placed computers, office equipment and the like. A gear cluster is provided at the top of each leg that includes a plurality of gears, preferably bevel gears, that are engaged during use. Each leg has a hollow interior that holds a generally vertically extending, externally threaded rod, the rod having an upper end portion with a gear that forms a part of the gear cluster and a lower end portion that threadably engages a section of the leg. A single crank provides a drive shaft with a gear that forms a part of one of the gear clusters. A plurality of connecting linkages or connecting rods are provided that connect a center of the gear clusters to each of a pair of side gear clusters. When the single crank is rotated, all of the gear clusters and connecting rods or linkages rotate, each connecting rod or linkage having a gear at a connecting rod or linkage end portion that forms a part of a gear cluster. In this fashion, the crank can be rotated in one rotational direction that extends the length of each of the legs and elevates the table top. When the crank is rotated in an opposite rotational direction, all of the legs shorten in length so that the table top is lowered.

Owner:BAKER MFG

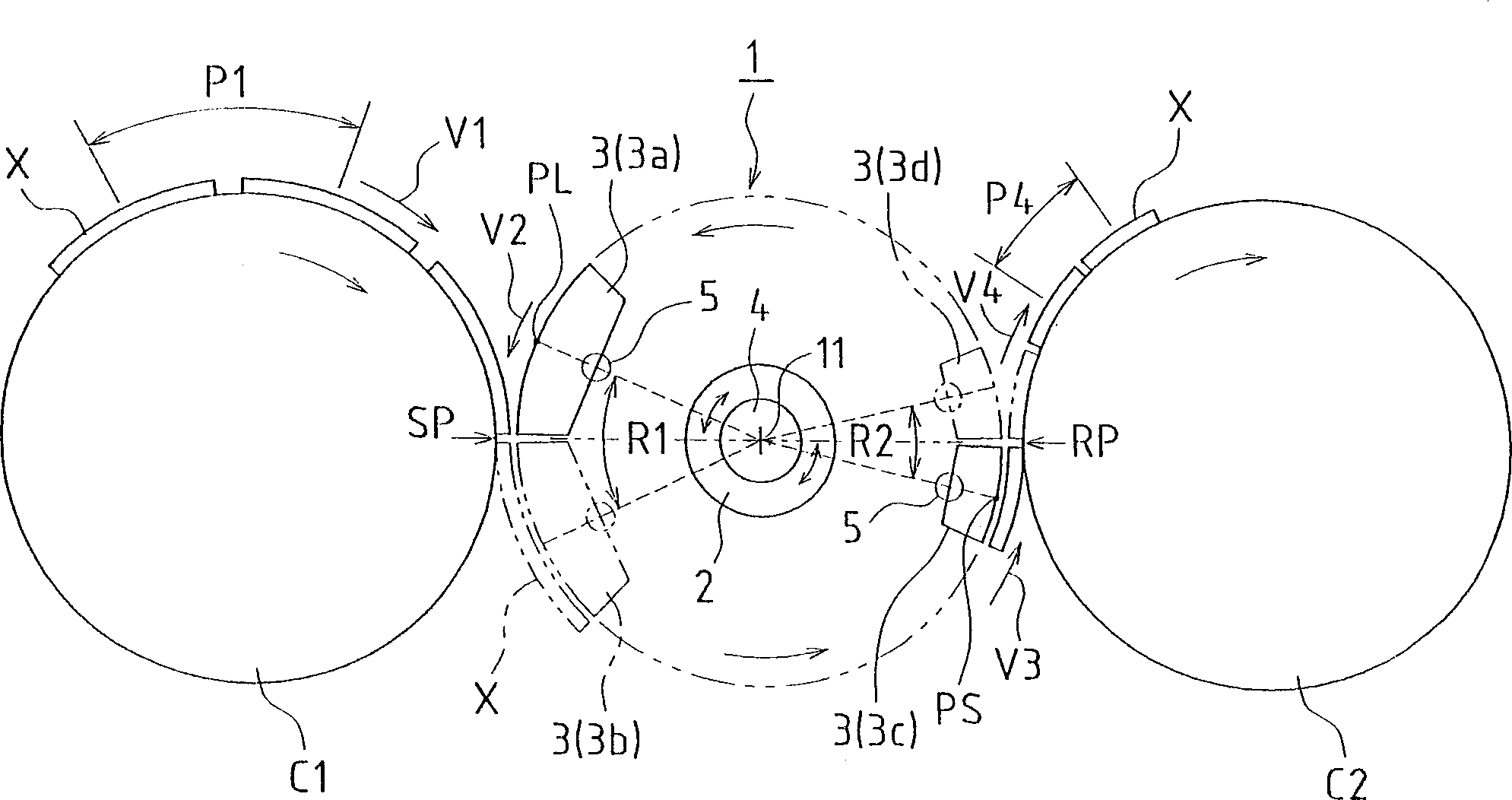

Method and device for transportation

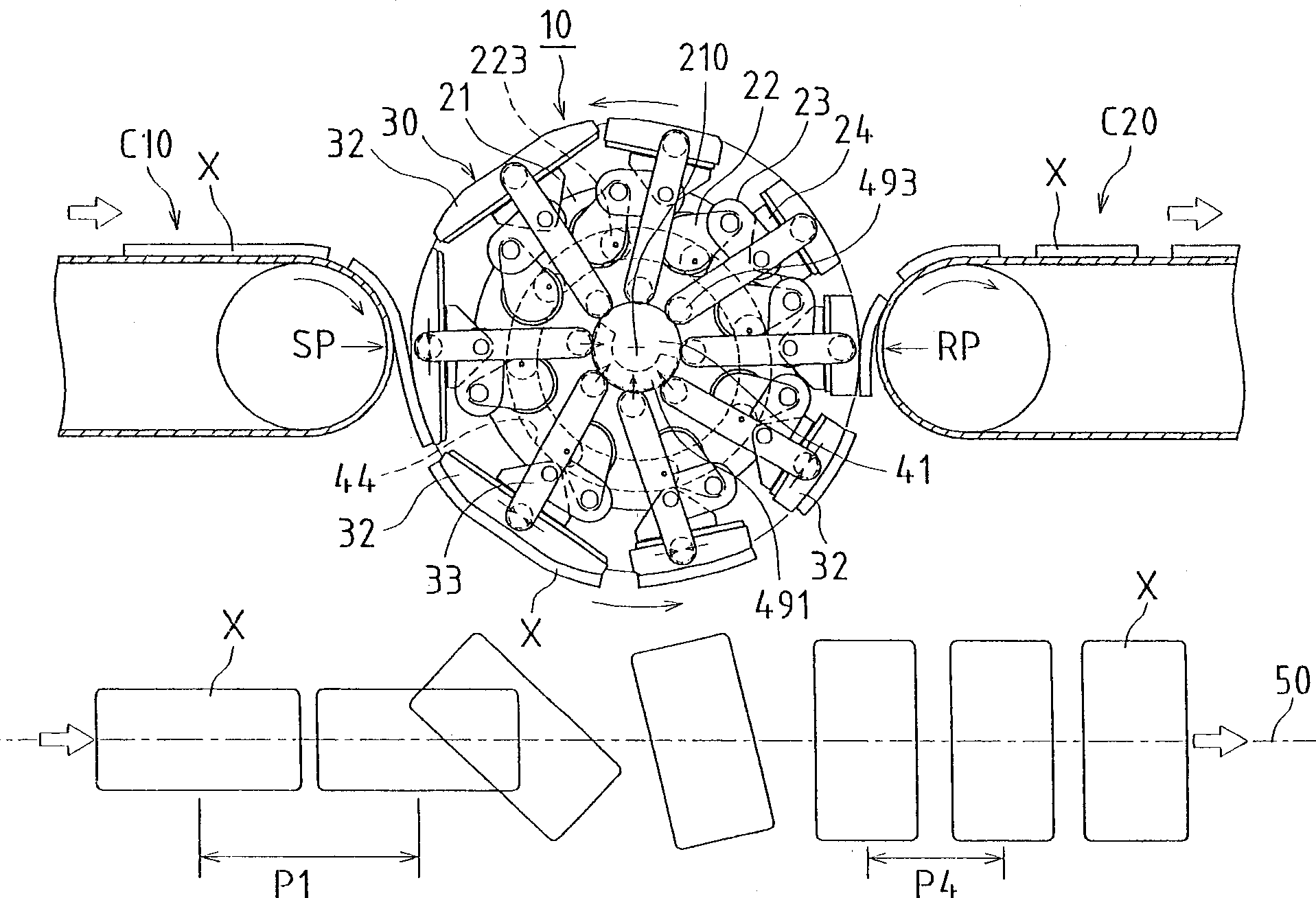

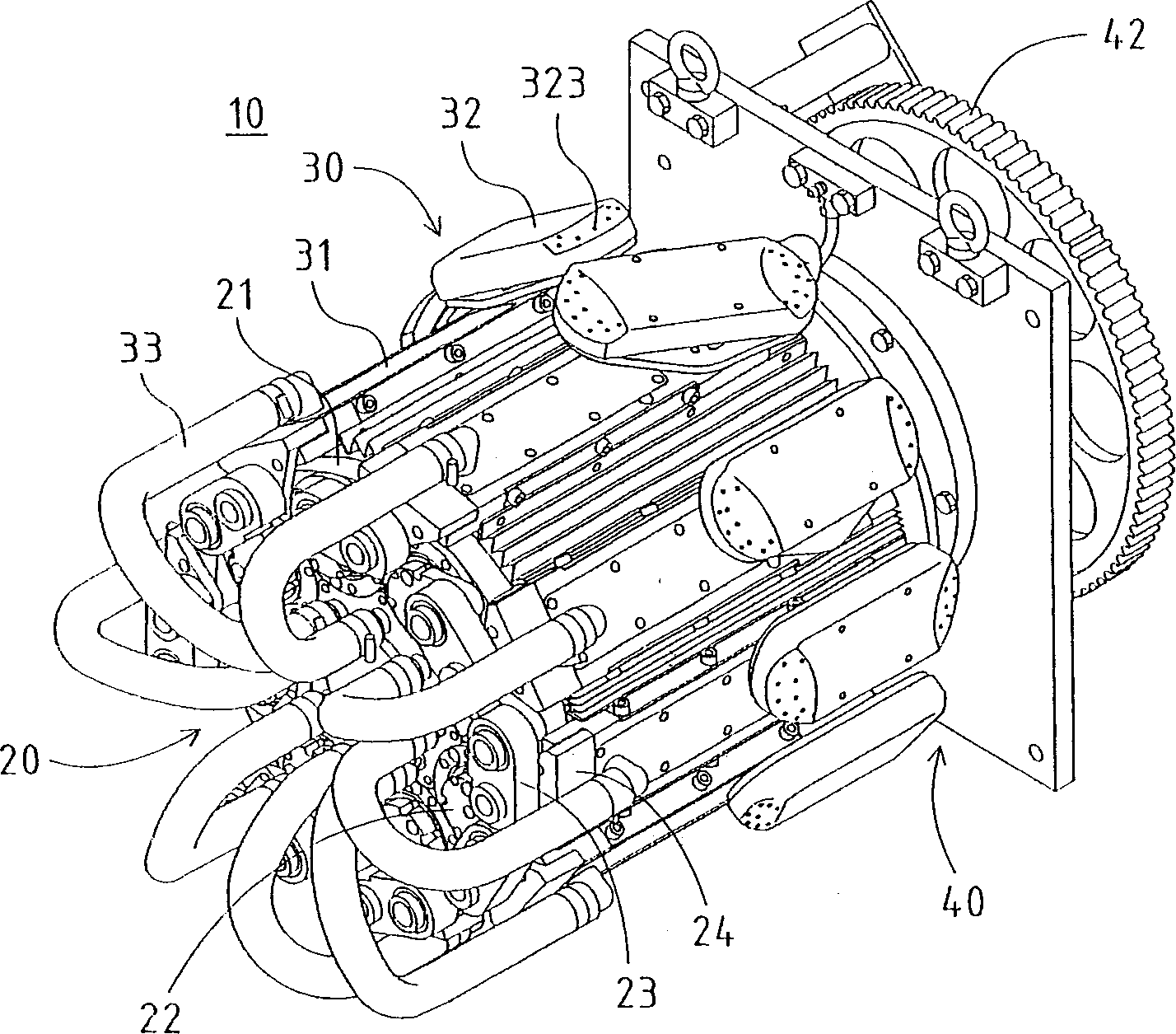

A transportation device (10) comprising crank arms (22) installed rotatably on a drive wheel (21), link levers (23) each having one end pin-connected to the tip of each of the crank arms (22), and swing parts (30) each having the other end pin-connected to each of the link levers (23) and held at a specified distance from a rotating shaft (210) of the drive wheel (21), wherein a speed changing cam roller (223) is installed on the crank arm (22) projectedly at a position apart from the rotating center thereof, and the transmission cam roller (223) is engaged for guiding with a transmission cam groove (44) formed eccentrically with respect to the rotating shaft (210) of the drive wheel (21), whereby the tips of the crank arms (22) are swung with in one rotation frequency of the drive wheel (21), and the angular velocities of the link levers and the swing part (30) connected thereto are increased or decreased periodically relative to the angular velocity of the drive wheel (21).

Owner:ZUIKO CORP

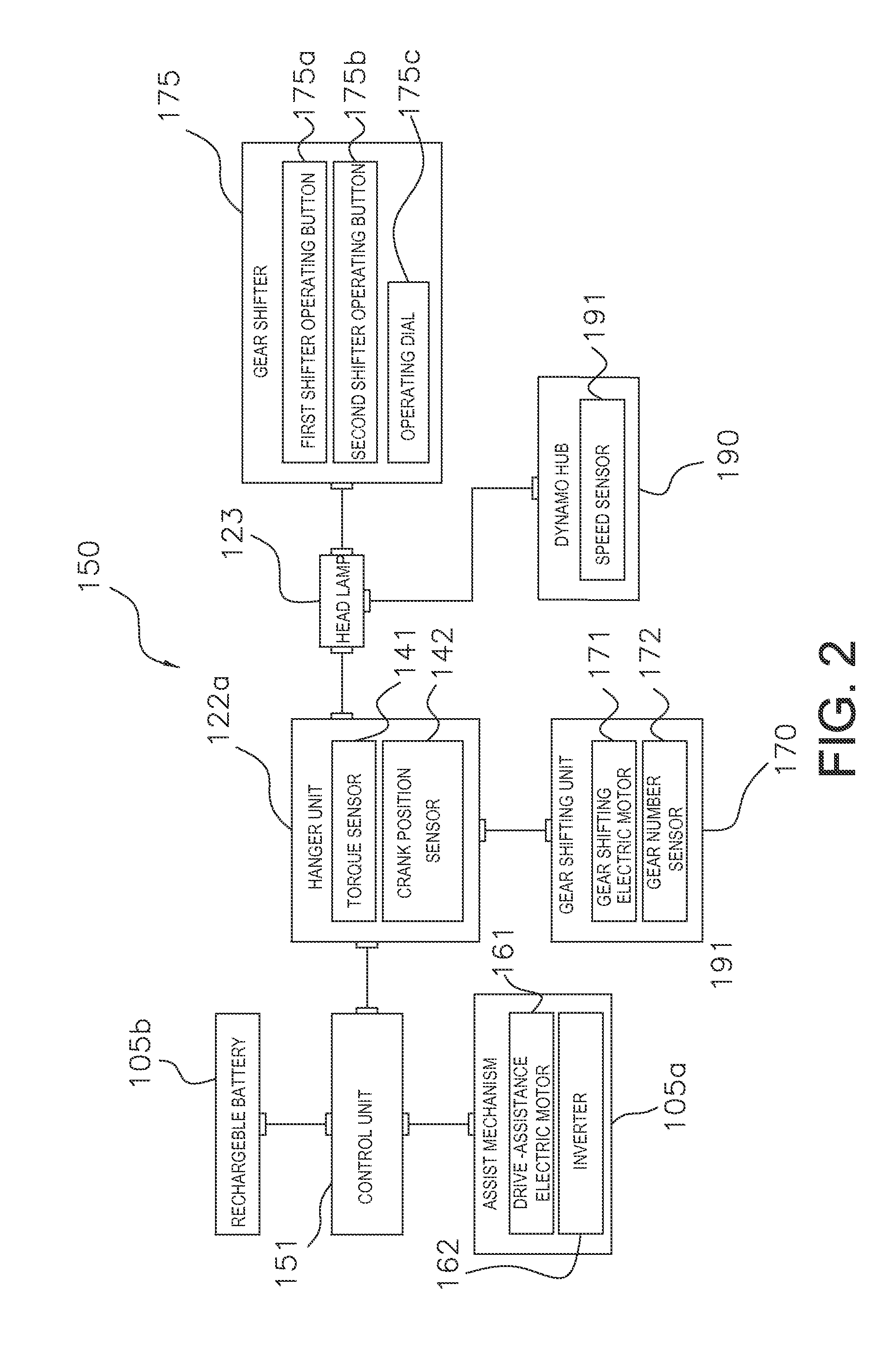

Bicycle drive apparatus

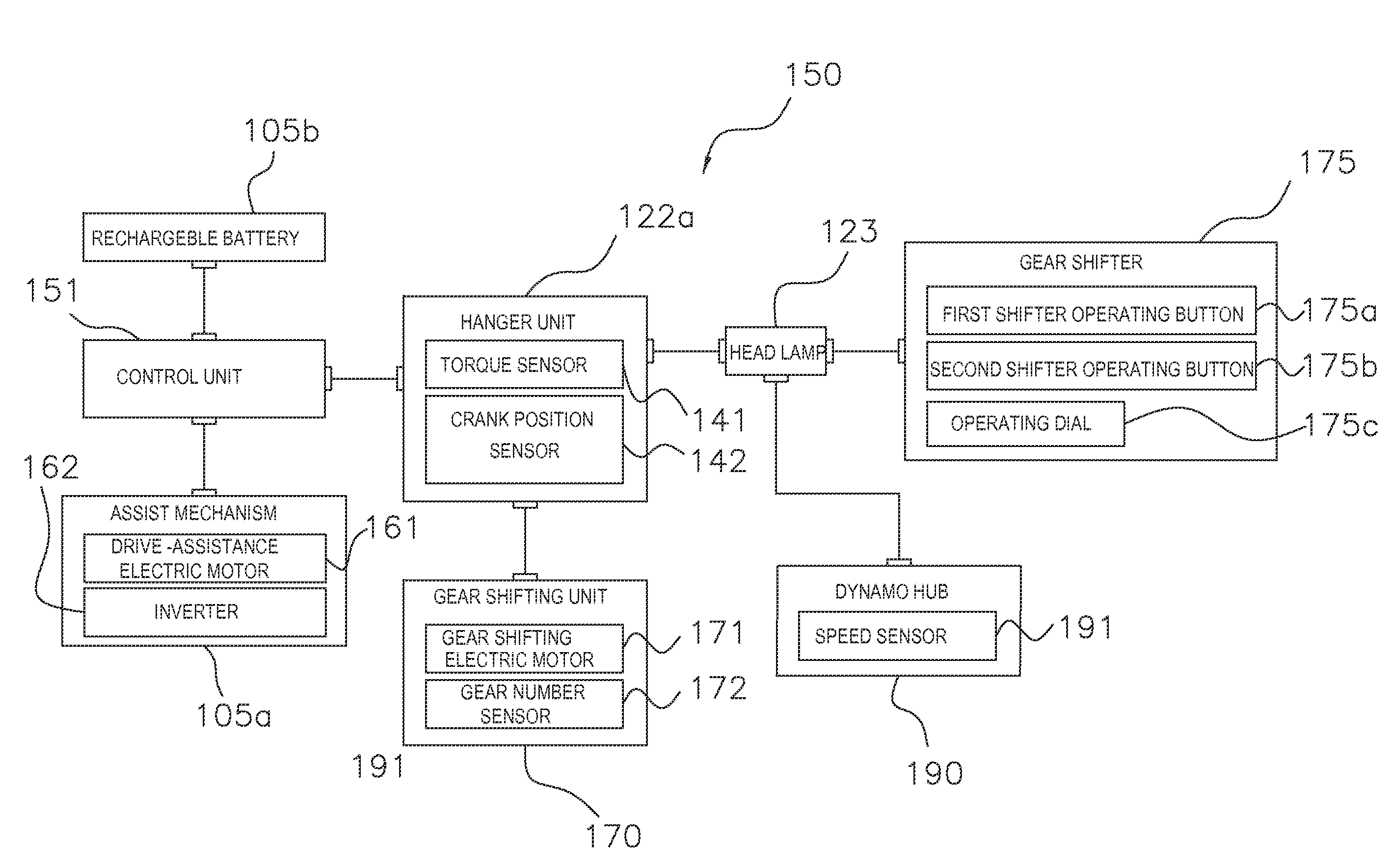

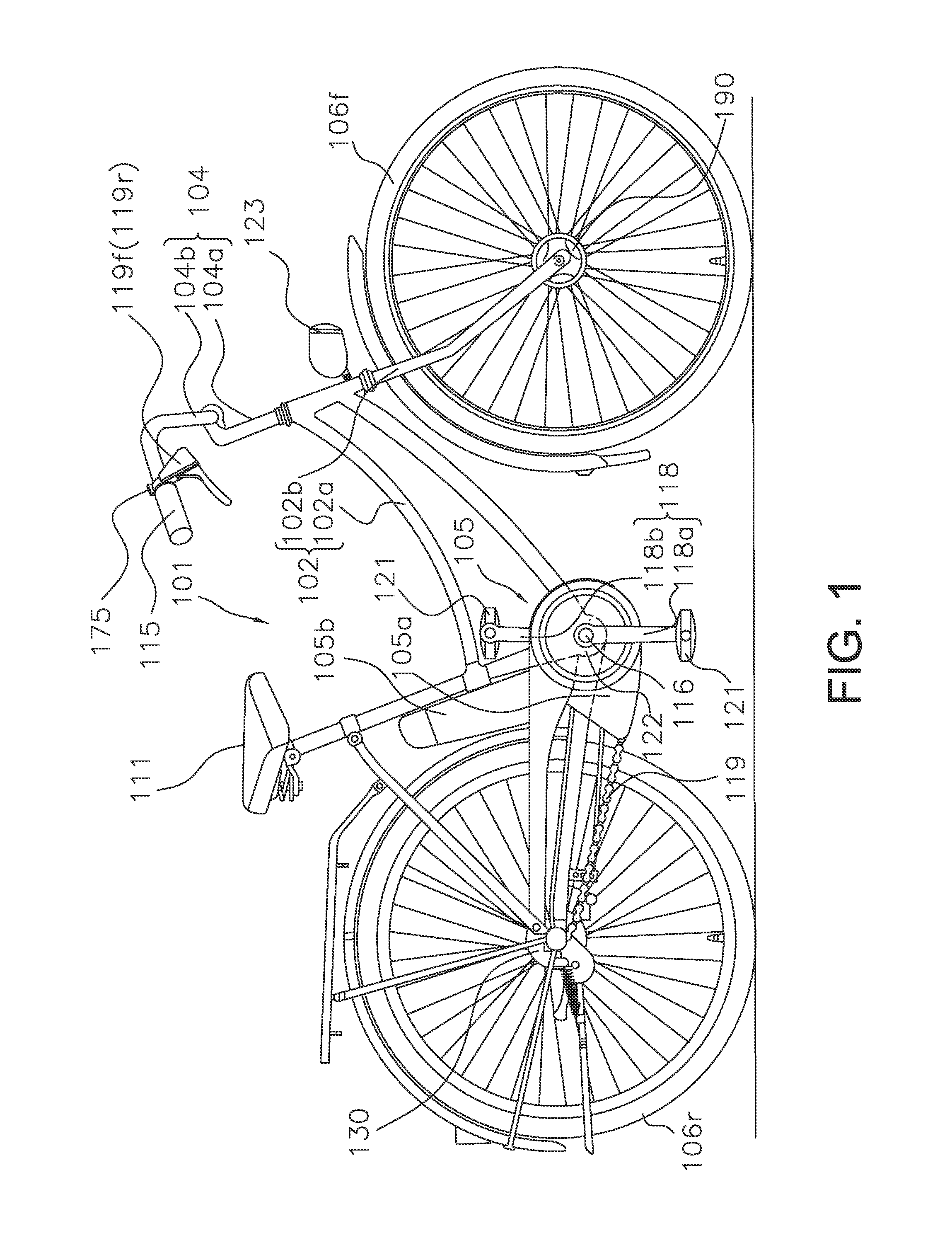

ActiveUS20130054065A1Guaranteed uptimeTension of chain is smallDigital data processing detailsCycle control systemsMicrocomputerTop dead center

A bicycle drive apparatus includes a bicycle crankset, a bicycle transmission, a drive assistance electric motor and a microcomputer. The microcomputer includes an output control section. The output control section has a first control and a second control that makes an output of the drive assistance electric motor smaller than an output of the drive assistance electric motor occurring during the first control only upon determining a crank arm of the bicycle crankset is positioned within a prescribed range of at least one of a top dead center position and a bottom dead center position of the bicycle crankset. The output control section is configured to vary the output of the drive assistance electric motor according to a pedaling force. The output control section switches from the first control to the second control upon receiving a shift command to shift the transmission.

Owner:SHIMANO INC

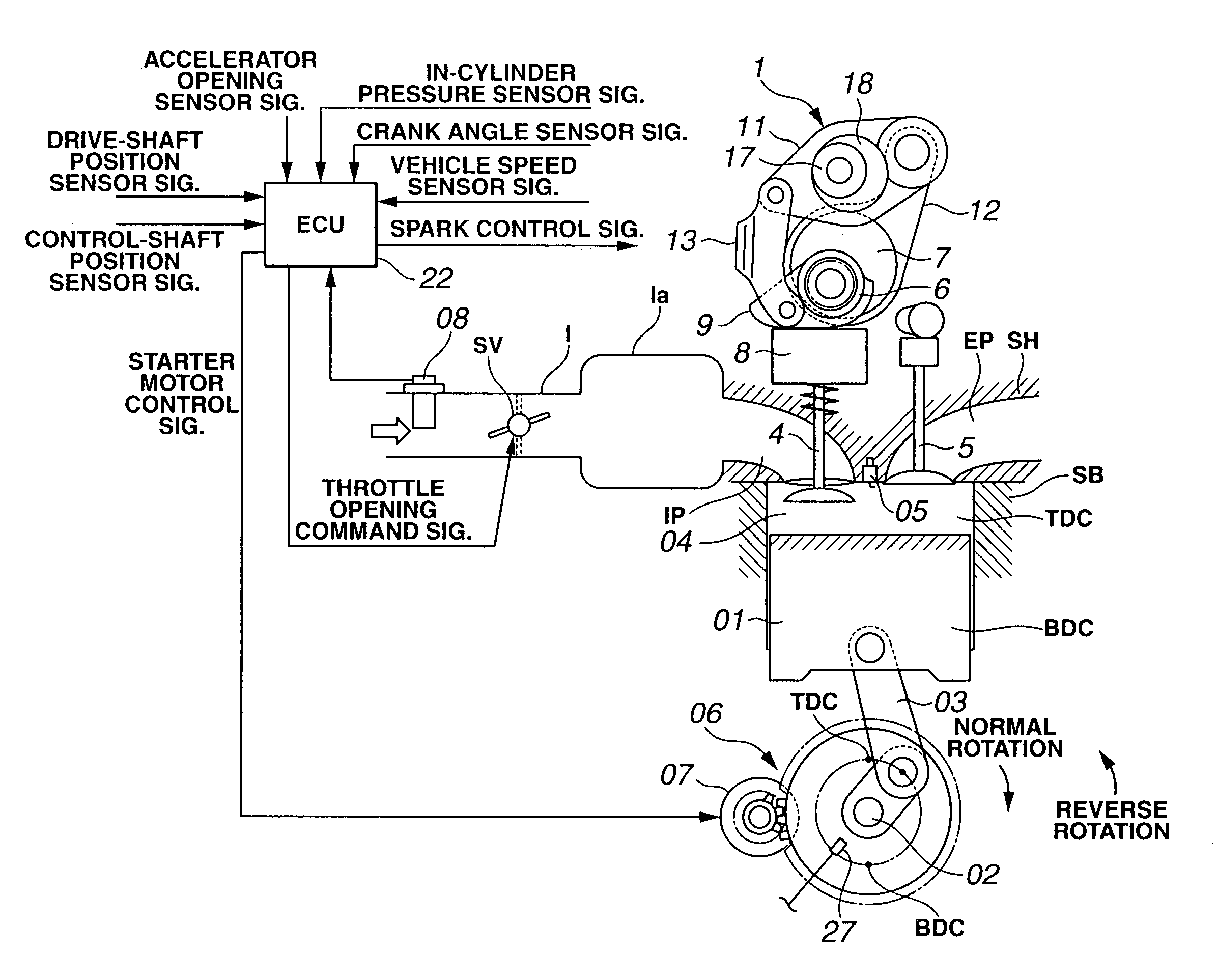

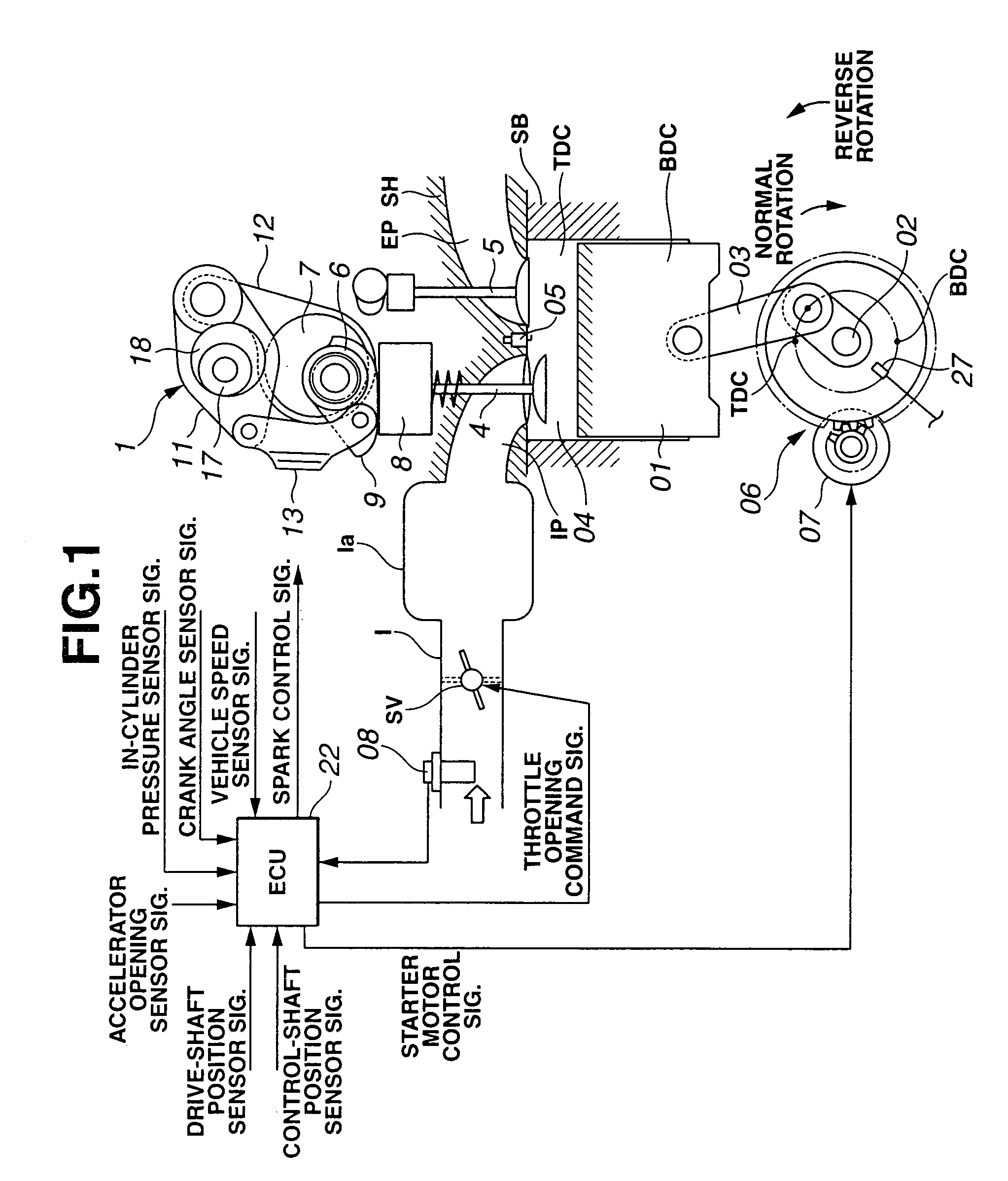

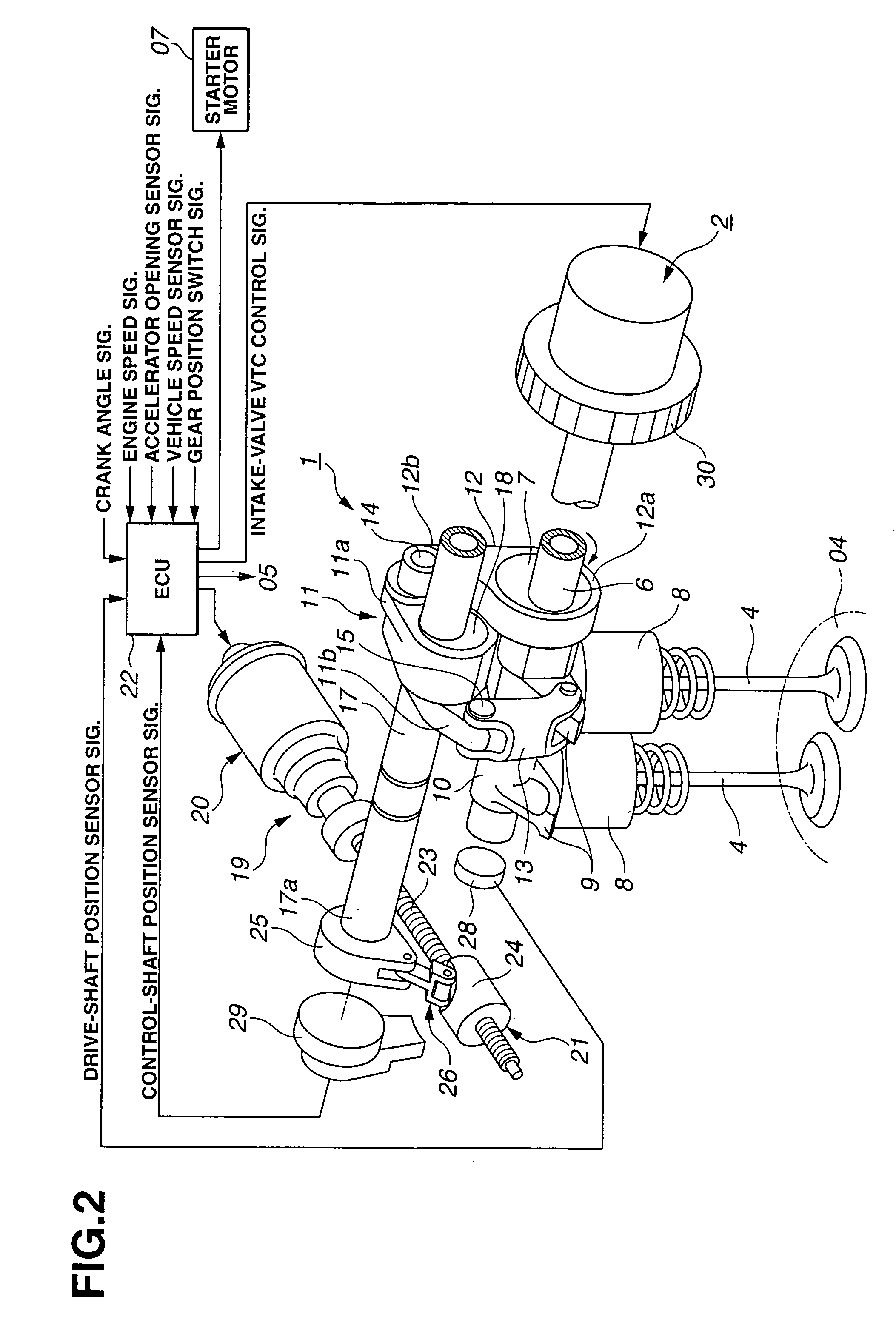

Engine start control apparatus

InactiveUS7191746B2Preventing an excessive in-cylinder pressure riseReduce electricity loadValve arrangementsElectrical controlInlet valveEngineering

Owner:HITACHI LTD

Method of operating a supercharger

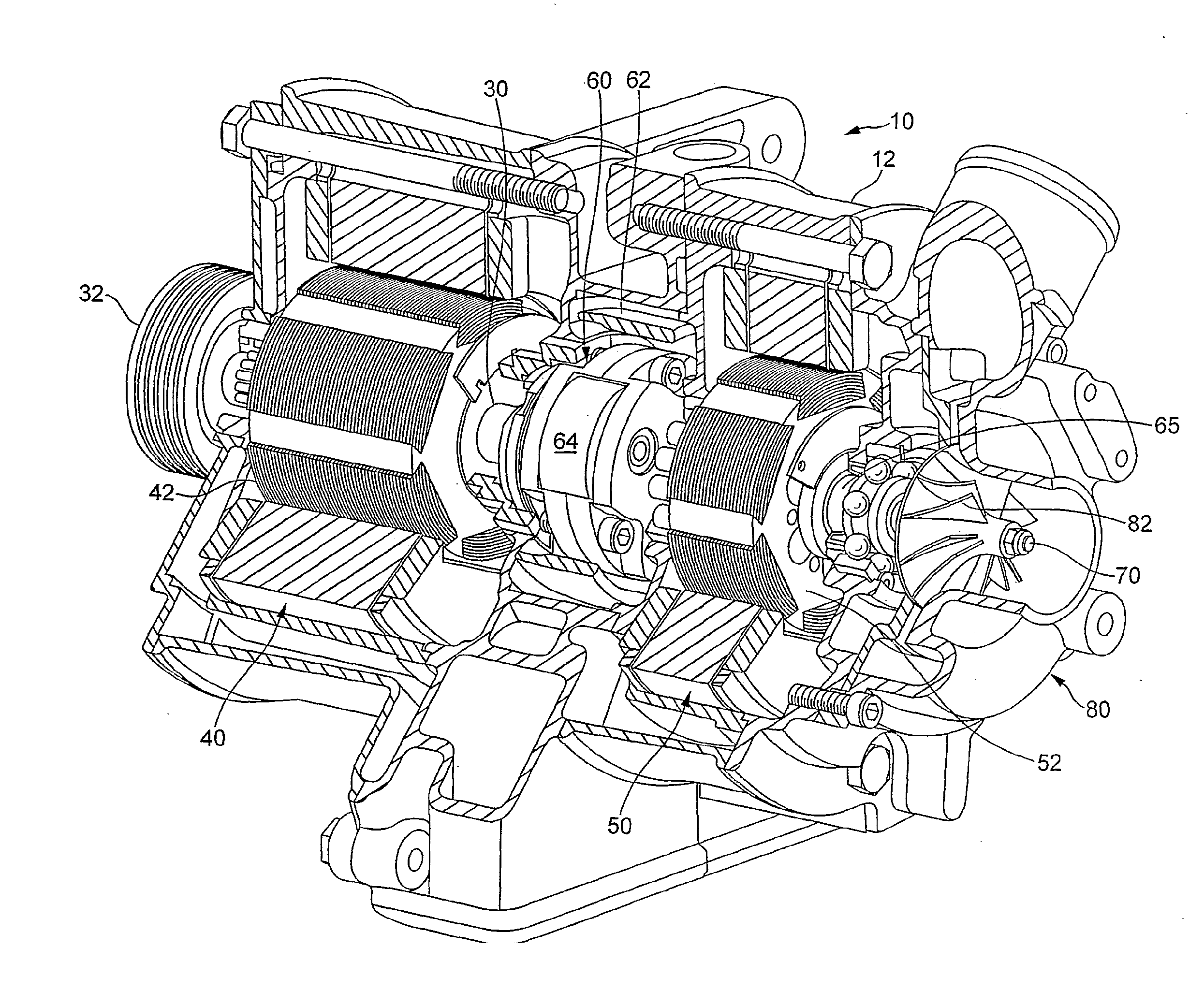

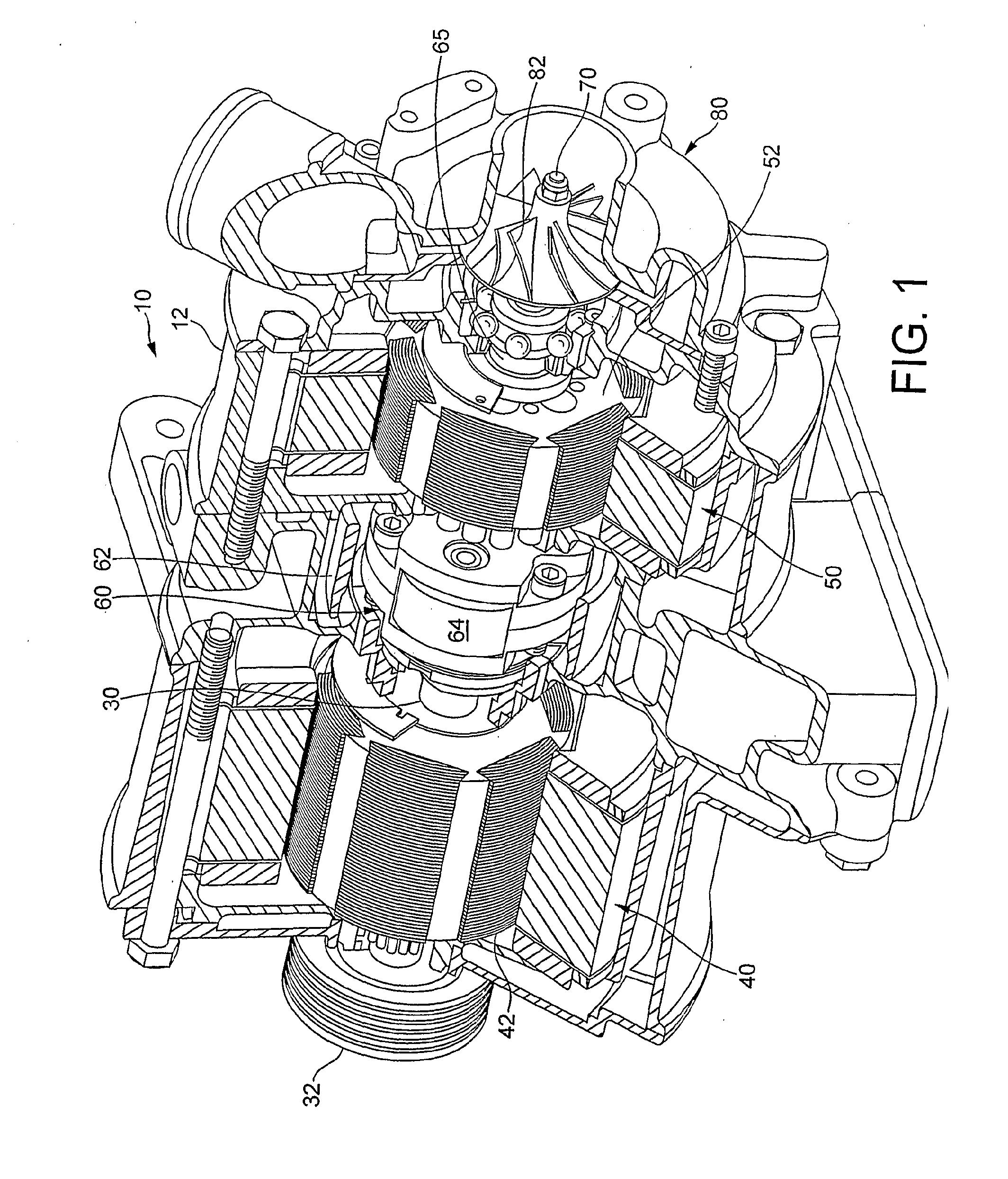

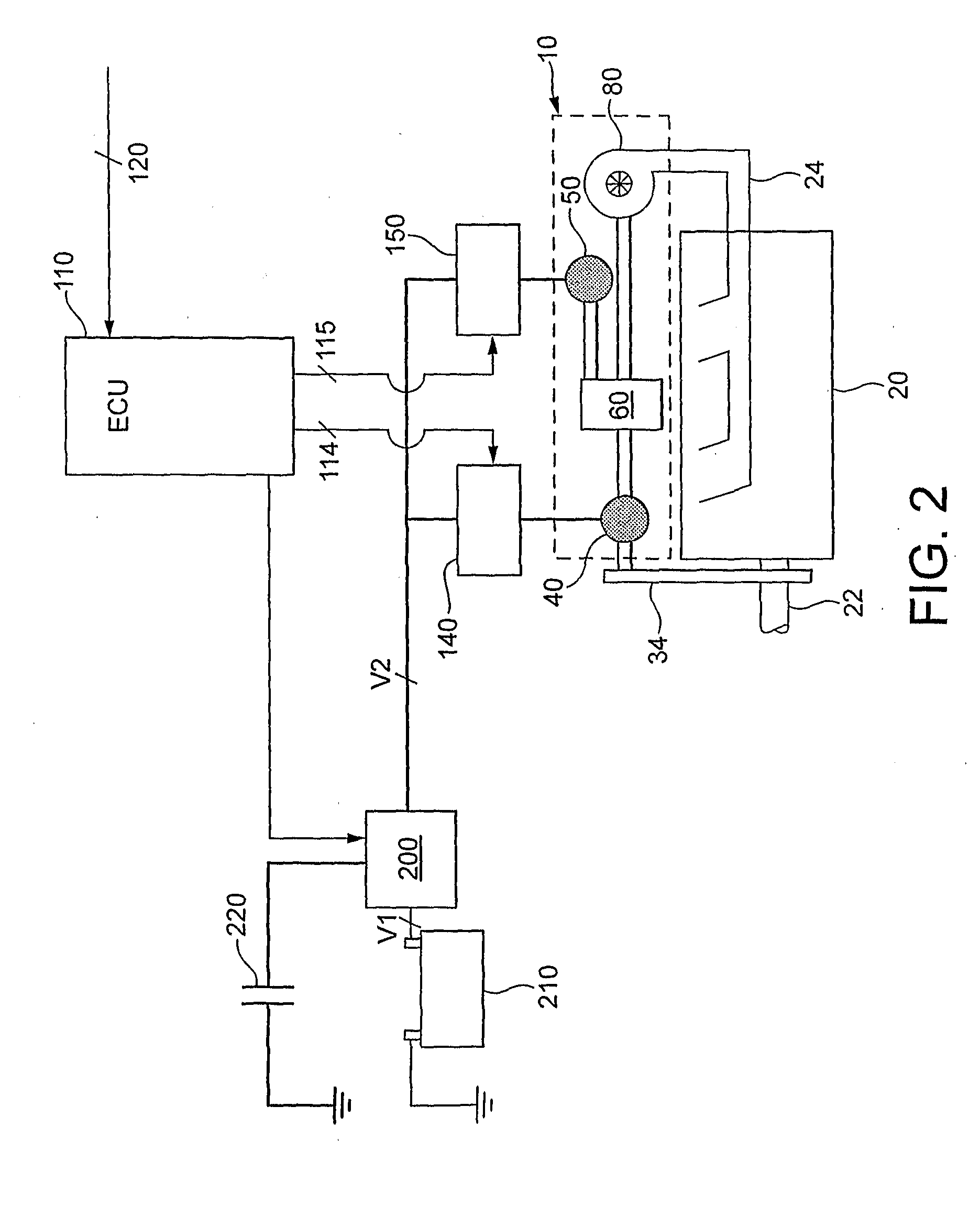

ActiveUS20100275890A1Constant speedReduce cycle variationCombustion enginesPlural diverse prime-mover propulsion mountingCrankshaftElectric generator

A method of operating a supercharger (10) for an automotive engine (20) is disclosed. A supercharger (10) has an input shaft (30) for coupling to a crank shaft (22) of the engine and also for coupling to the rotor of a first electrical machine (40) and the annulus of an epicyclic gear train (60). An output shaft (70) is connected to a compressor (80) and a sun gear of the epicyclic gear train (60). A carrier carrying planet gears of the epicyclic gear train (60) is connected to the rotor of a second electrical machine (50). The first electrical machine (40) is selectively operable to supply electrical energy to the second electrical machine (50). The second electrical machine (50) is selectively operable as a motor or a generator to accelerate or decelerate the compressor (80), thereby tending to increase or decrease the power output of the engine. The first electrical machine (40) is selectively operable as a motor or a generator to control the torque transmitted from the input shaft (30) back to the crank shaft (22) caused by operation of the second electrical machine (50).

Owner:NEXXTDRIVE LTD +1

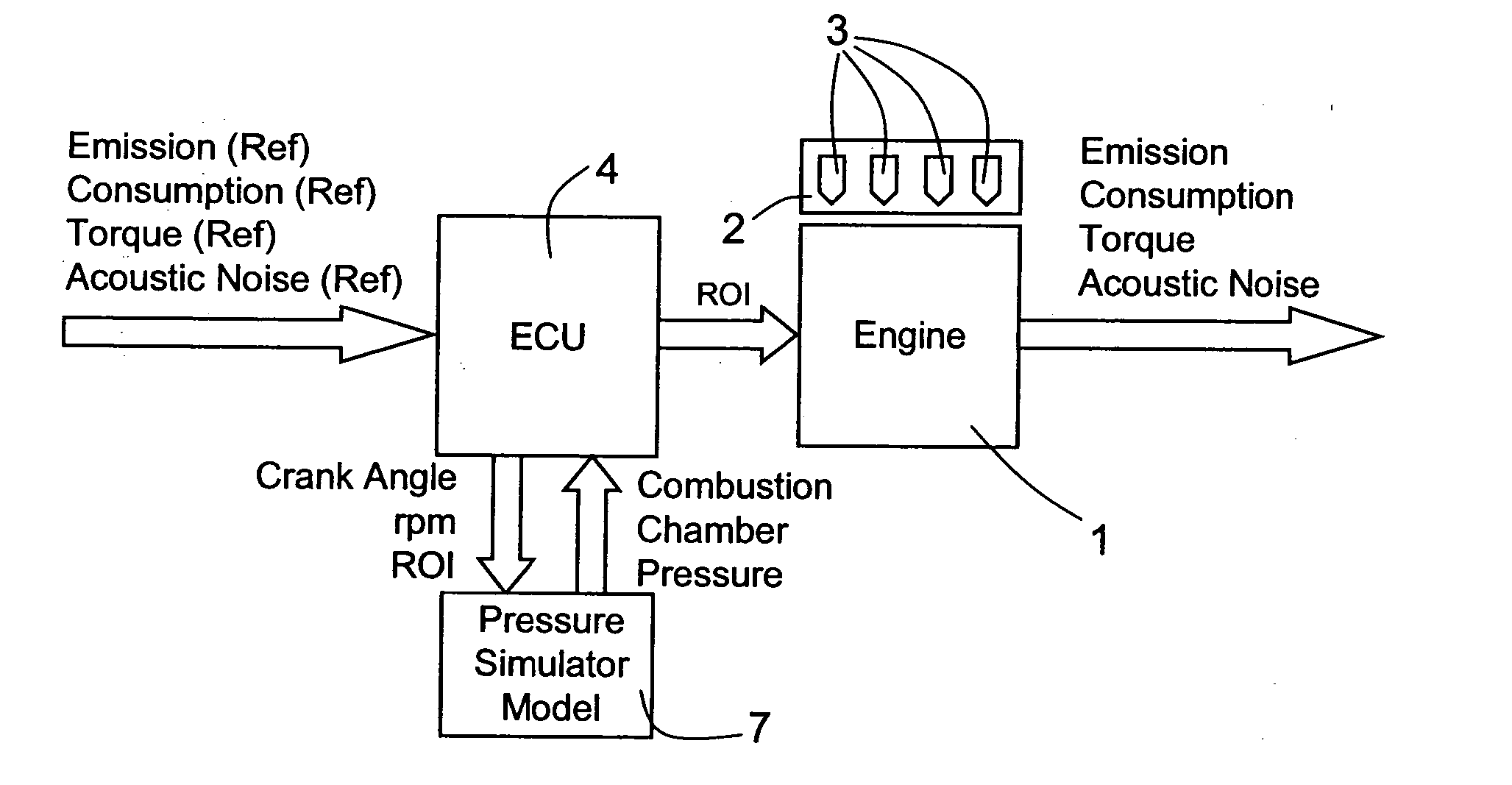

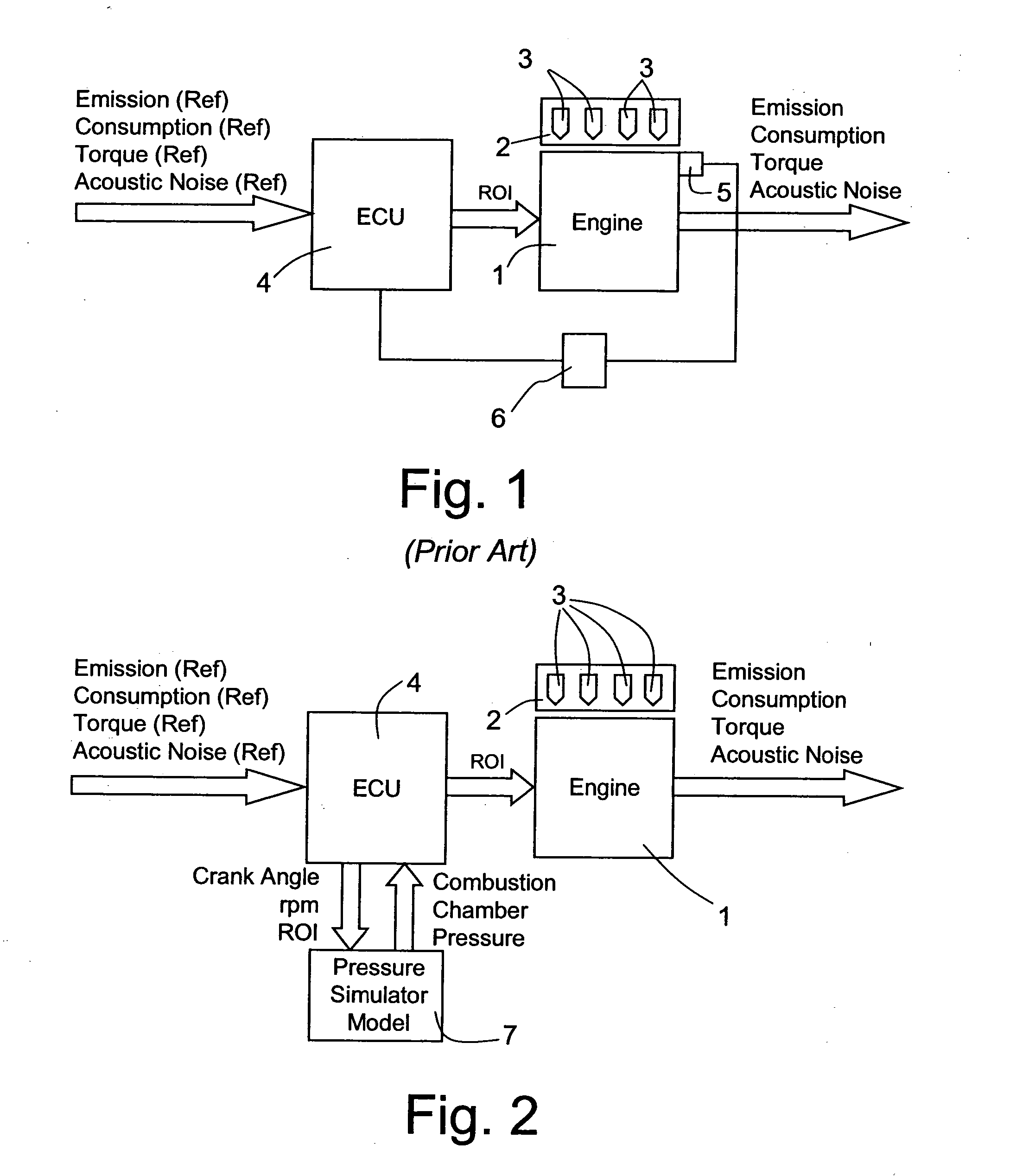

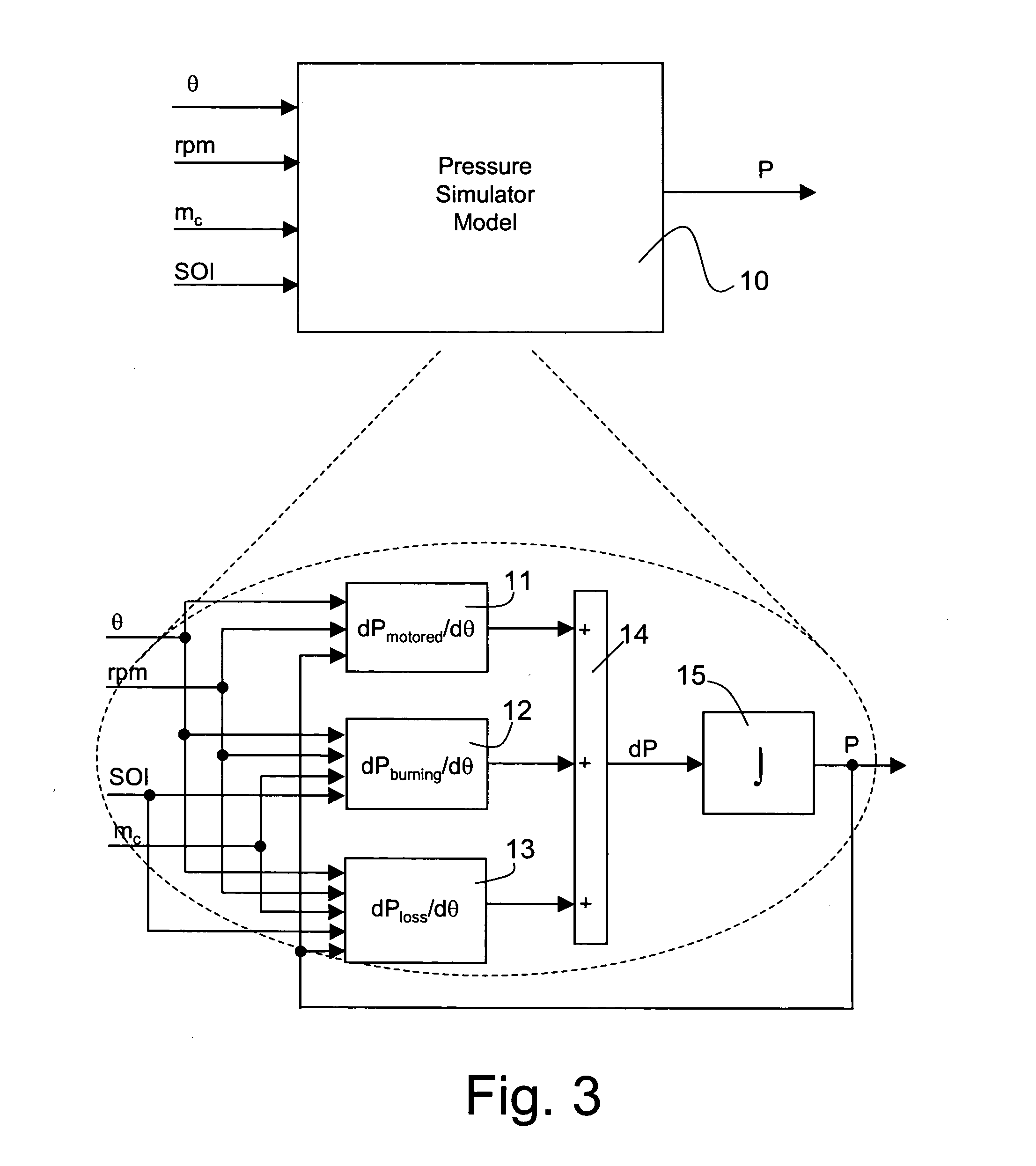

Method and device for determining the pressure in the combustion chamber of an internal combustion engine, in particular a spontaneous ignition engine, for controlling fuel injection in the engine

A method is described for controlling fuel injection in an spontaneous ignition engine equipped with an electronically controlled fuel injection system and with an electronic control unit receiving engine quantities comprising the pressure in the combustion changer of the engine and closed-loop controlling the fuel injection system on the basis of the pressure in the combustion chamber, in which the pressure in the combustion chamber is determined as a function of engine kinematic quantities such as the engine speed and the crank angle and of the fuel injection law, which is defined by the quantity of fuel injected and by the crank angle at the start of injection.

Owner:STMICROELECTRONICS SRL

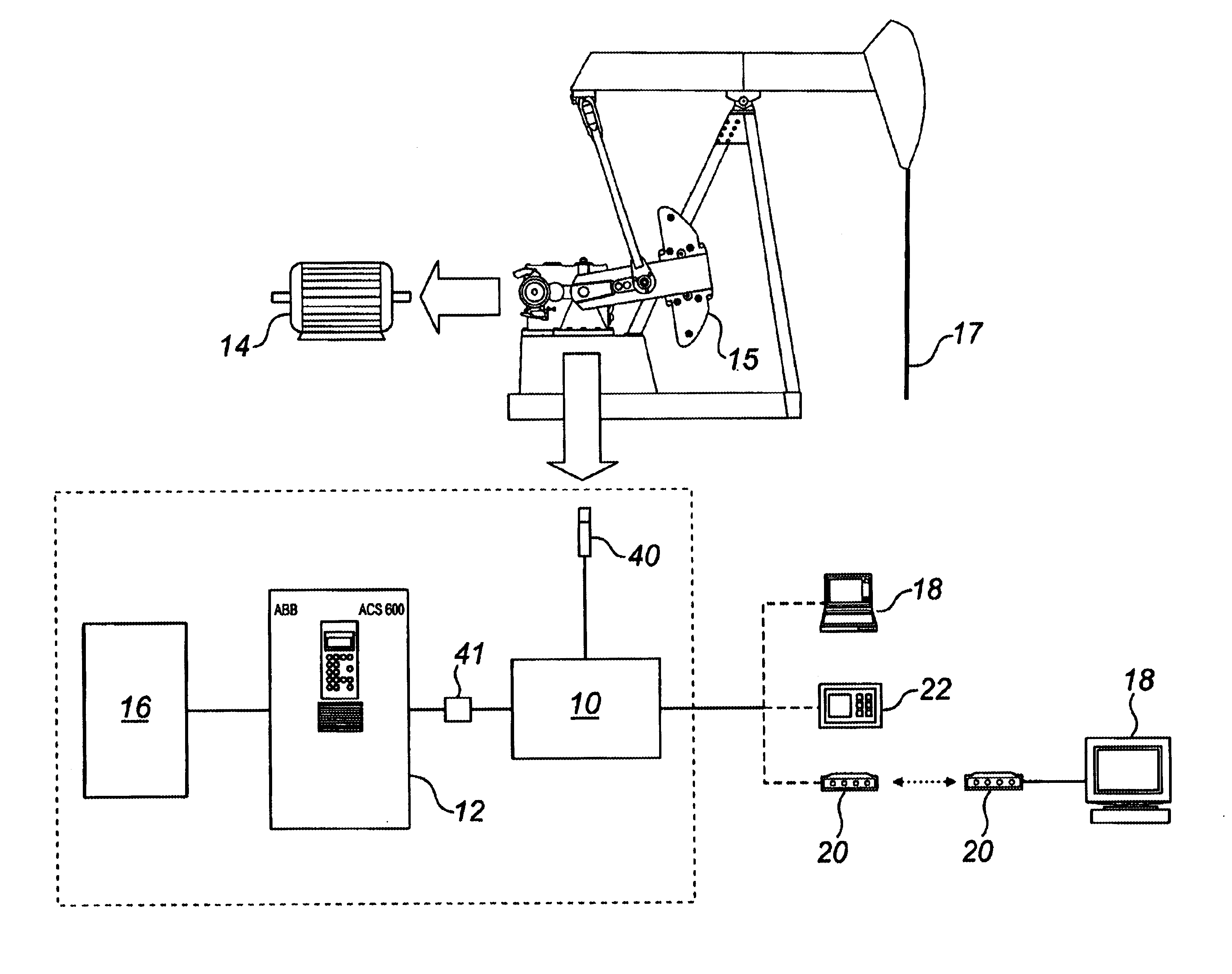

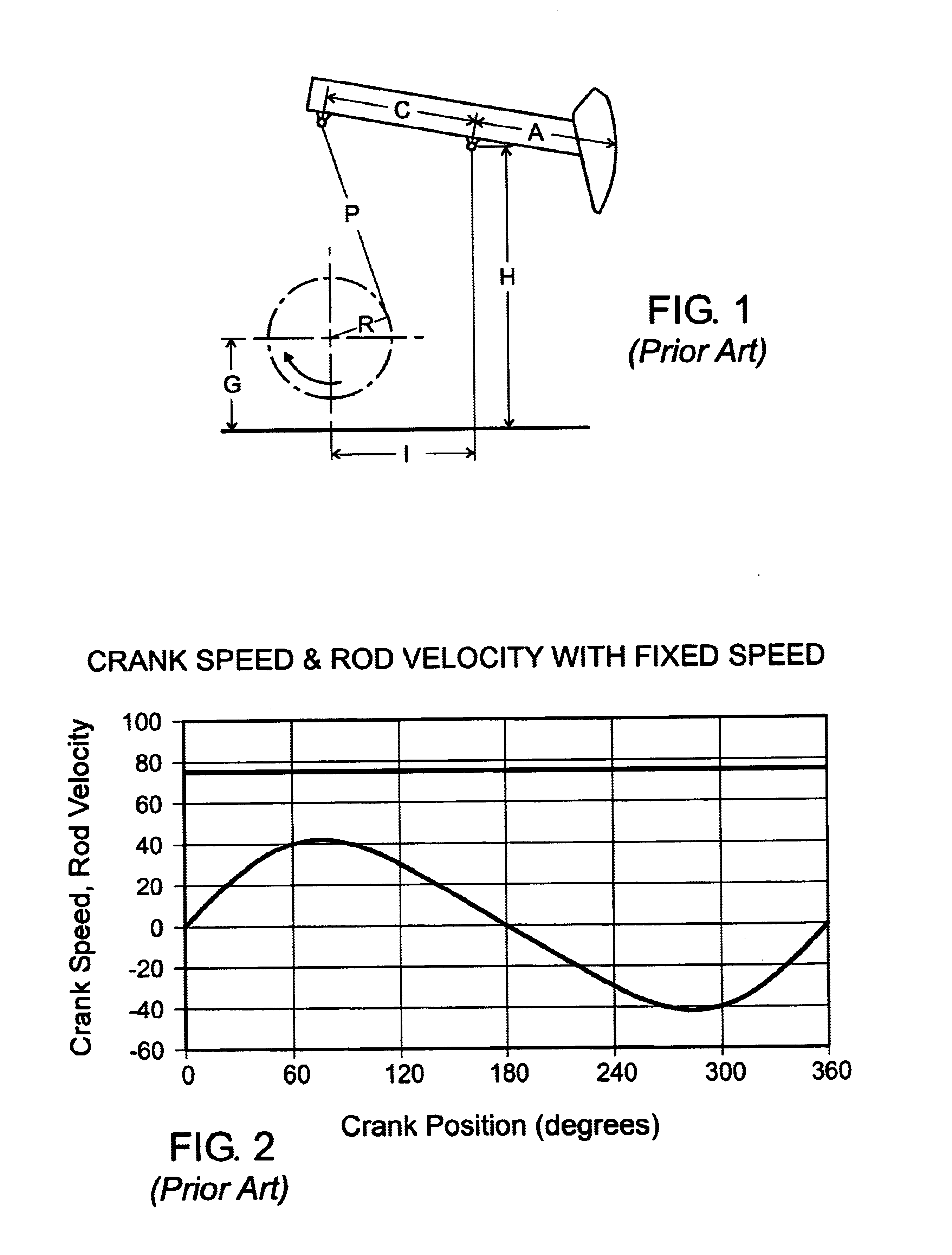

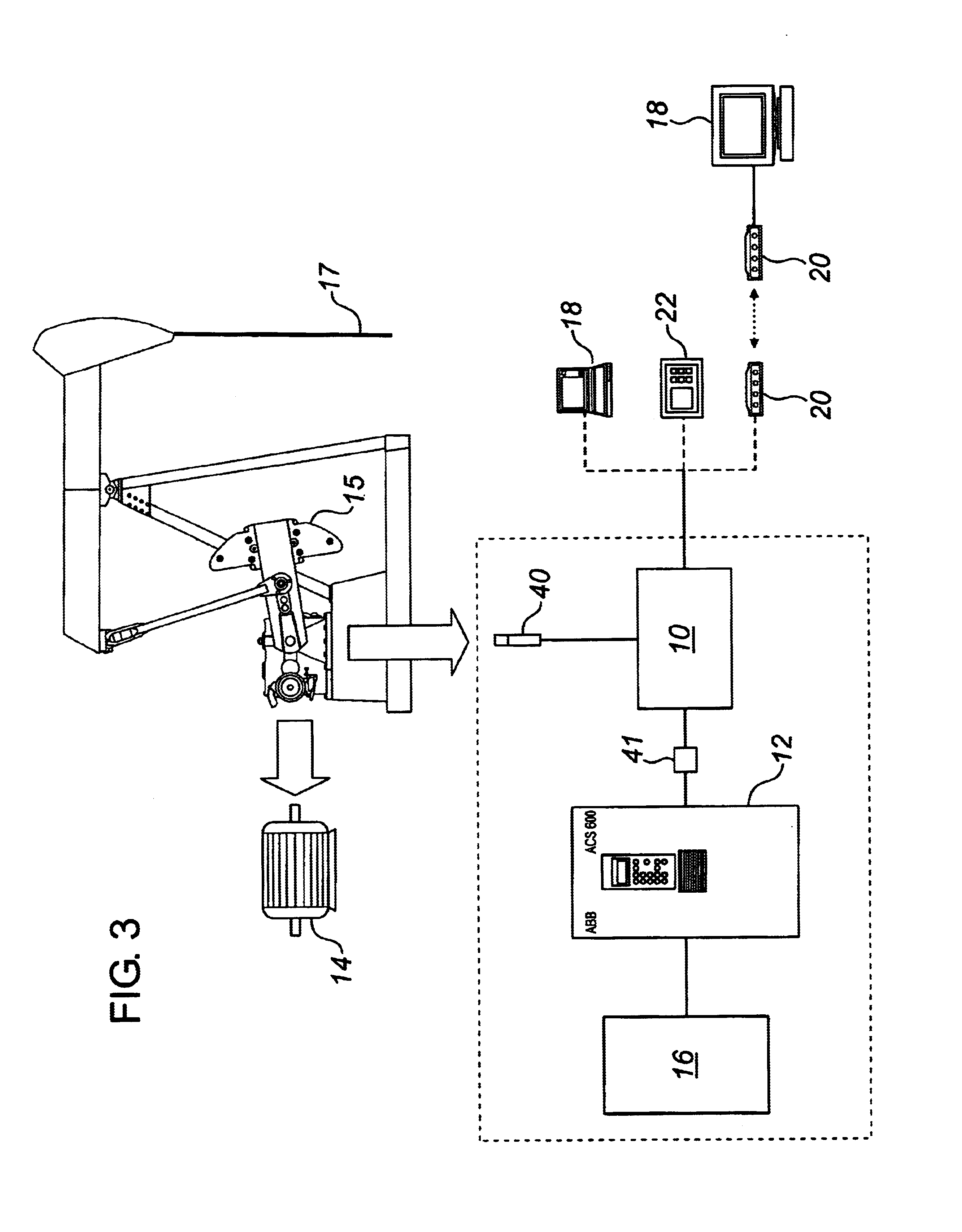

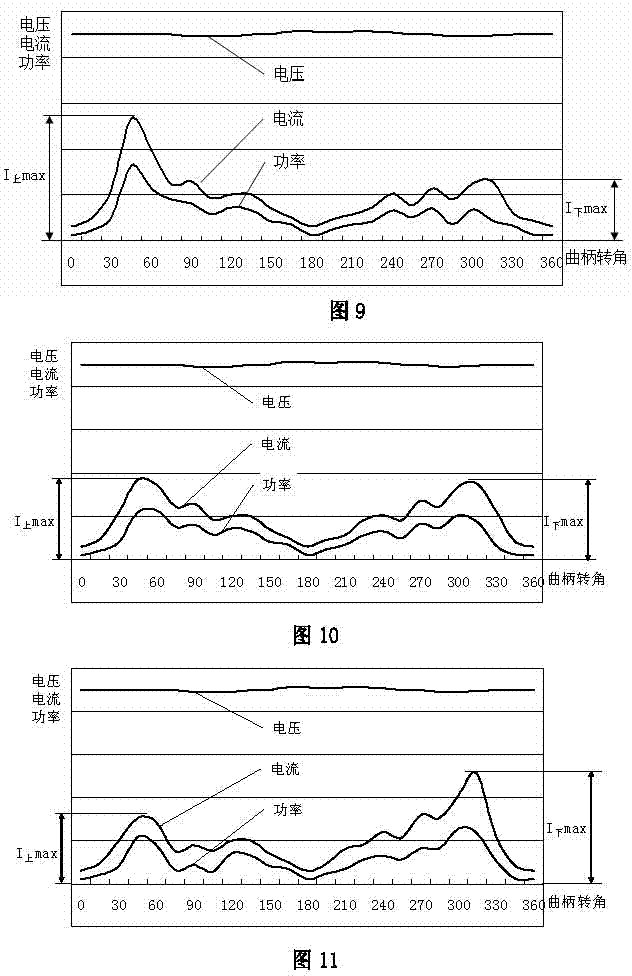

Reciprocating pump control system

A pumpjack speed control system includes a user interface, a controller and a variable speed drive. The user interface includes a mathematical representation of the pumpjack geometry which permits the conversion of rod speed profiles to crank speed profiles.

Owner:1123050 ALBERTA +1

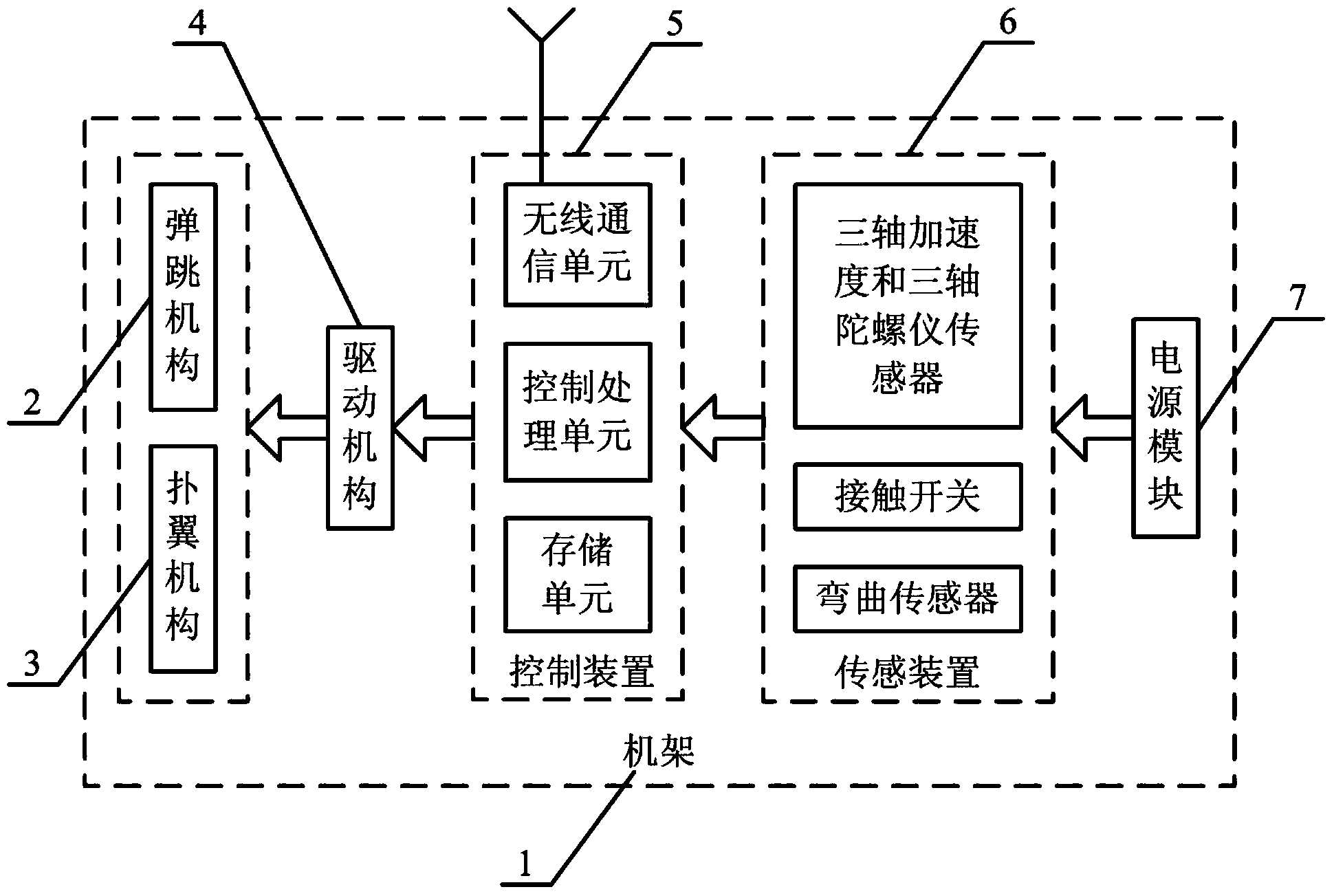

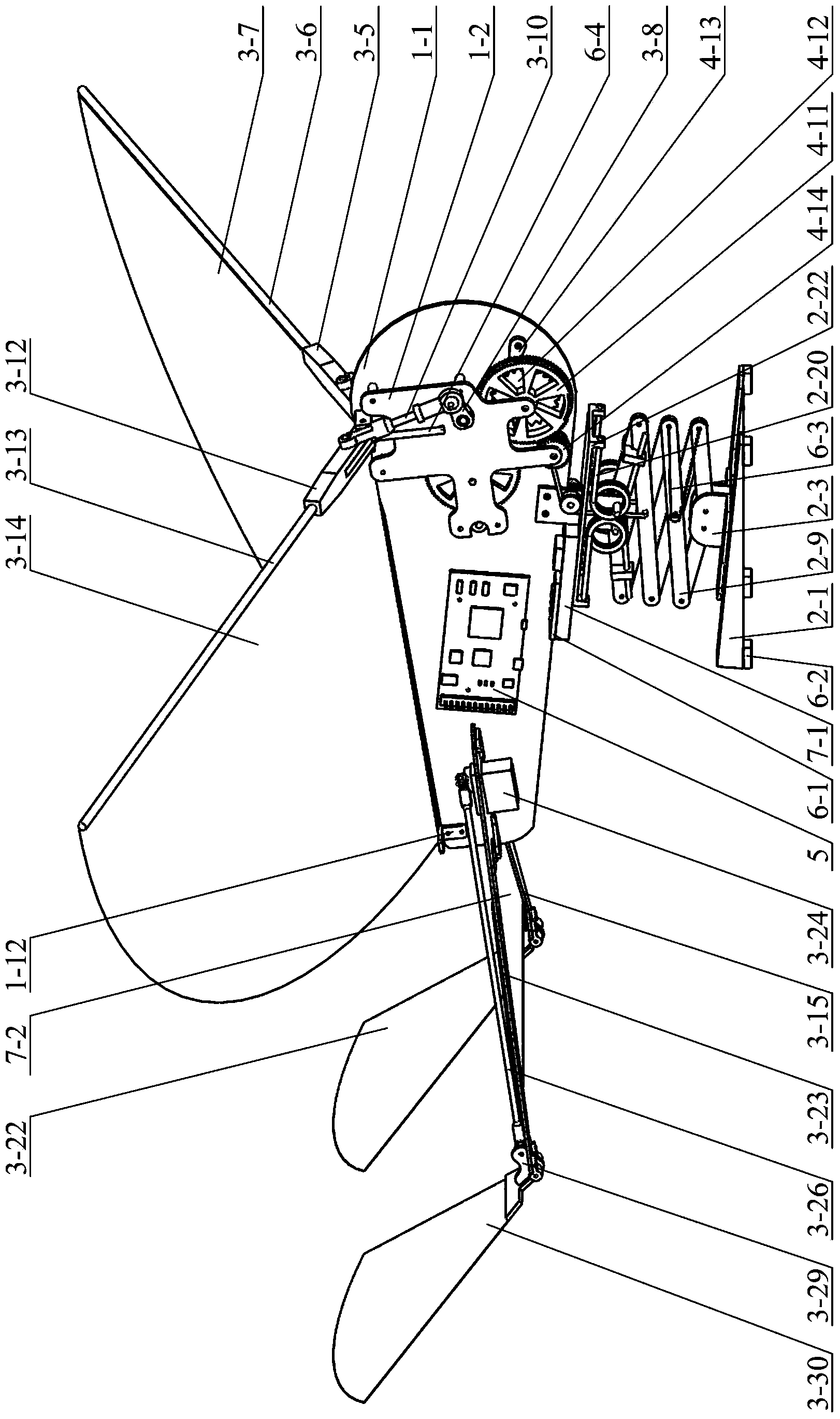

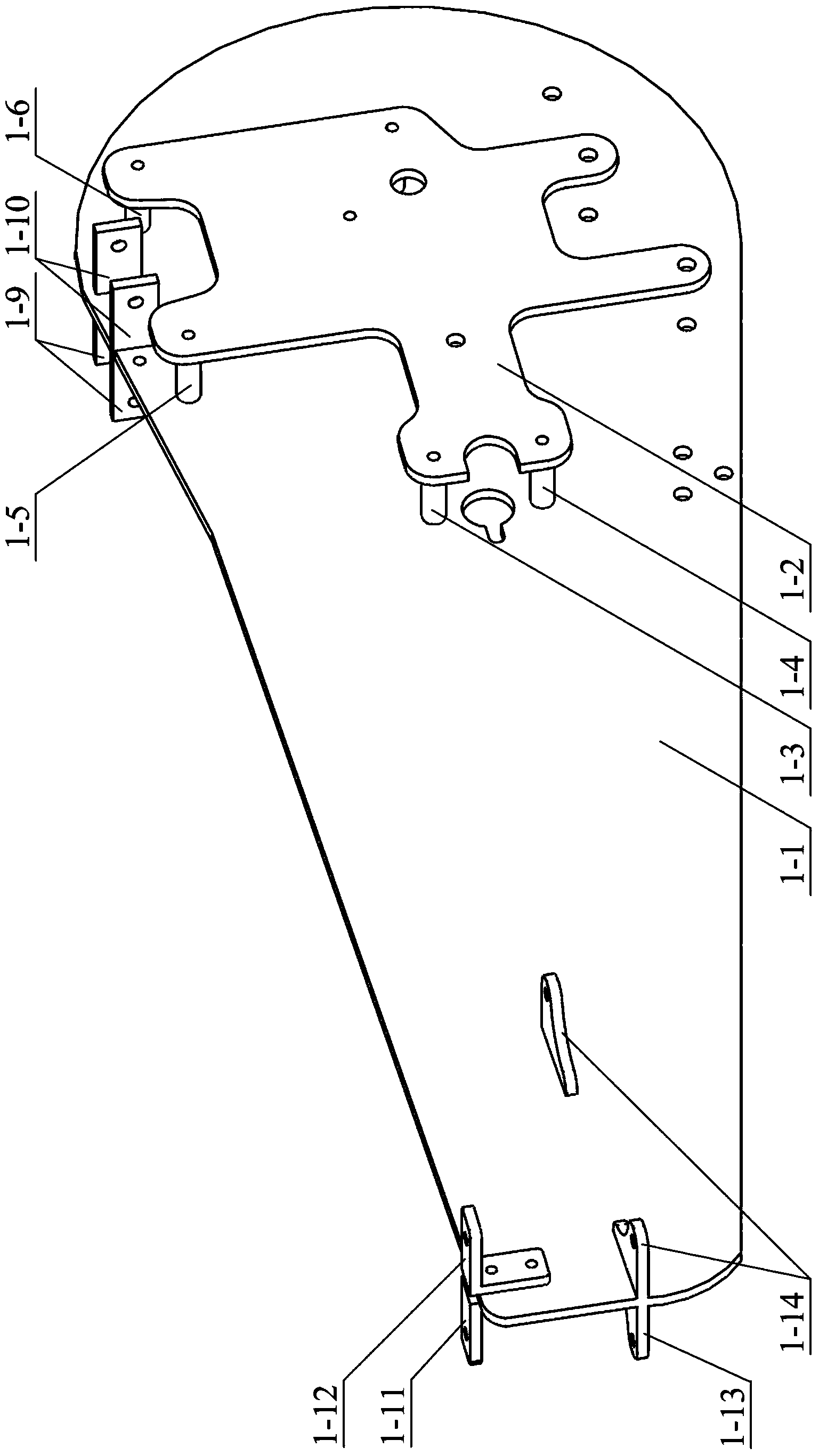

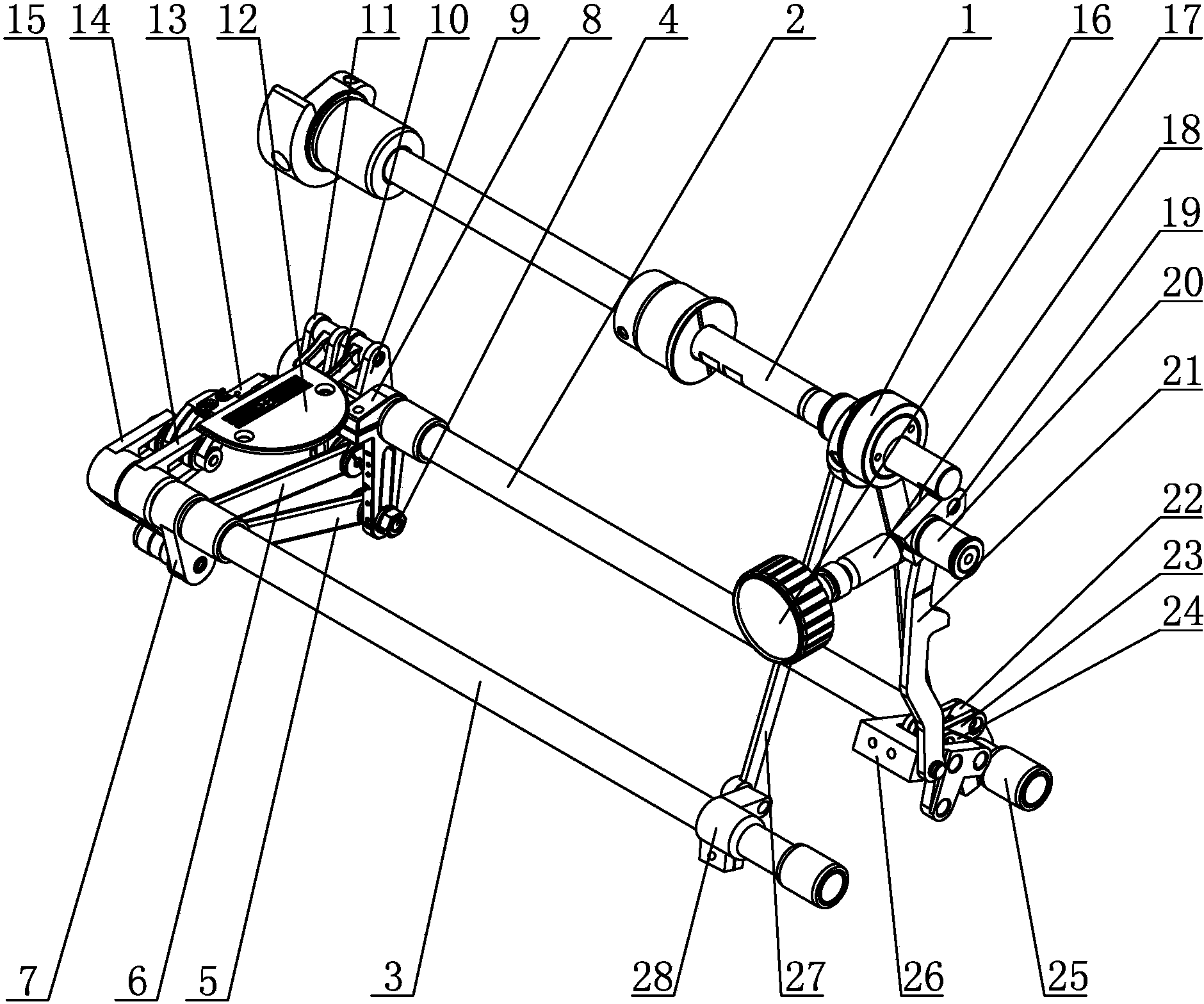

Bionic wing-flapping and bouncing multi-mode movement robot

The invention discloses a bionic wing-flapping and bouncing multi-mode movement robot which comprises a rack, a bouncing mechanism, a wing-flapping mechanism and a driving mechanism, wherein the bouncing mechanism, the wing-flapping mechanism and the driving mechanism are arranged on the rack. The bouncing mechanism comprises feet, a folding mechanism, a torsional spring frame and a winch wheel. The wing-flapping mechanism comprises two wing mechanisms and two tail wing mechanisms, wherein the two wing mechanisms and the two tail wing mechanisms are respectively symmetrical in a left-right mode. The driving mechanism comprises a driving motor, a gear transmission mechanism and a ratchet mechanism. The gear transmission mechanism comprises an input gear and an output gear meshed with the input gear. The output gear comprises a tooth-incomplete gear, a crank gear connected with a crank, and a winch wheel gear connected with the winch wheel. The crank gear is meshed with the half side, with complete teeth, of the tooth-incomplete gear, and the winch wheel gear is meshed with the half side, with incomplete teeth, of the tooth-incomplete gear. The driving mechanism with the single motor drives the wing mechanisms and the bouncing mechanism to work, the complexity and the whole mass of the robot are effectively reduced, and the feasibility of the multi-mode movement robot is improved.

Owner:SOUTHEAST UNIV

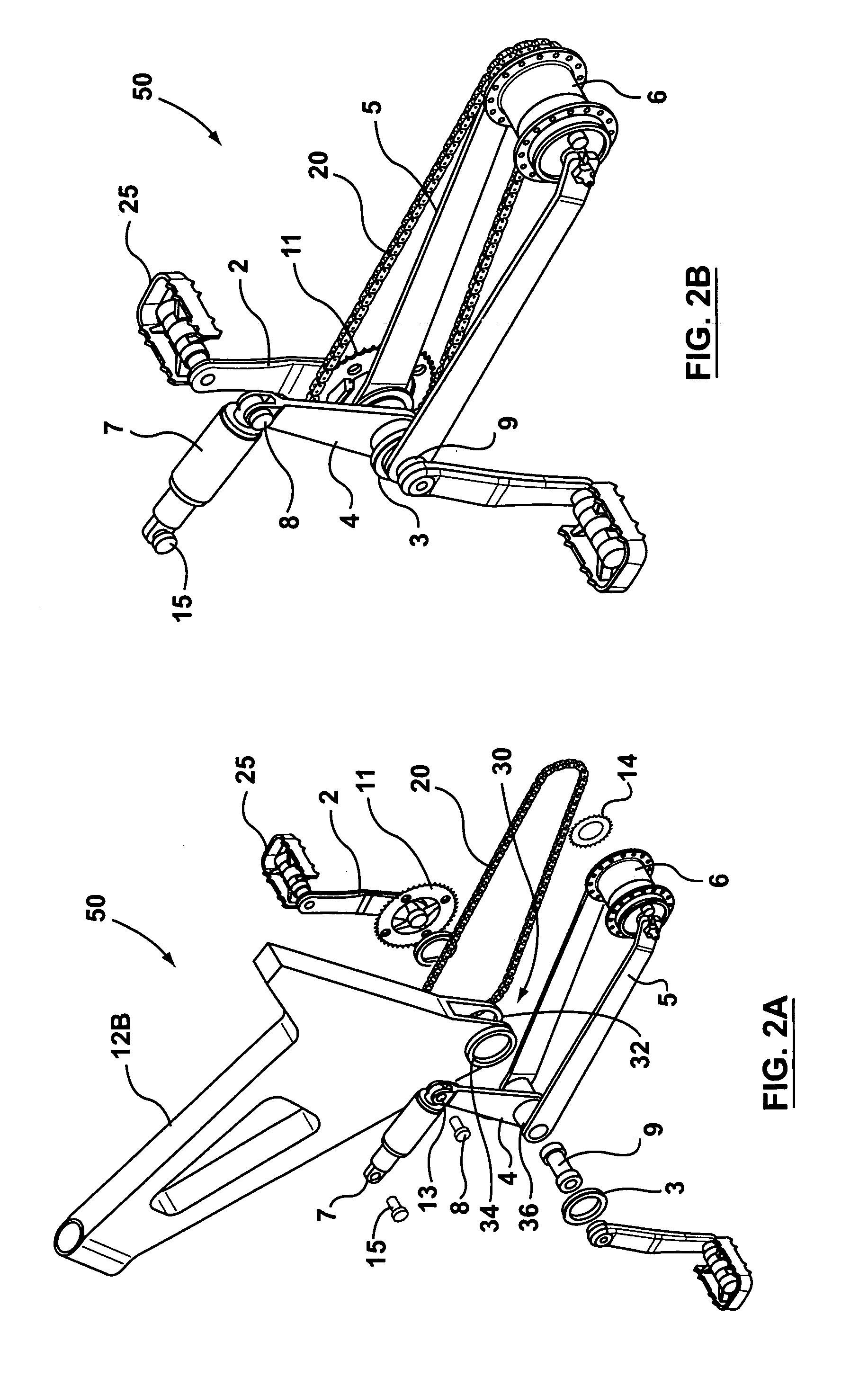

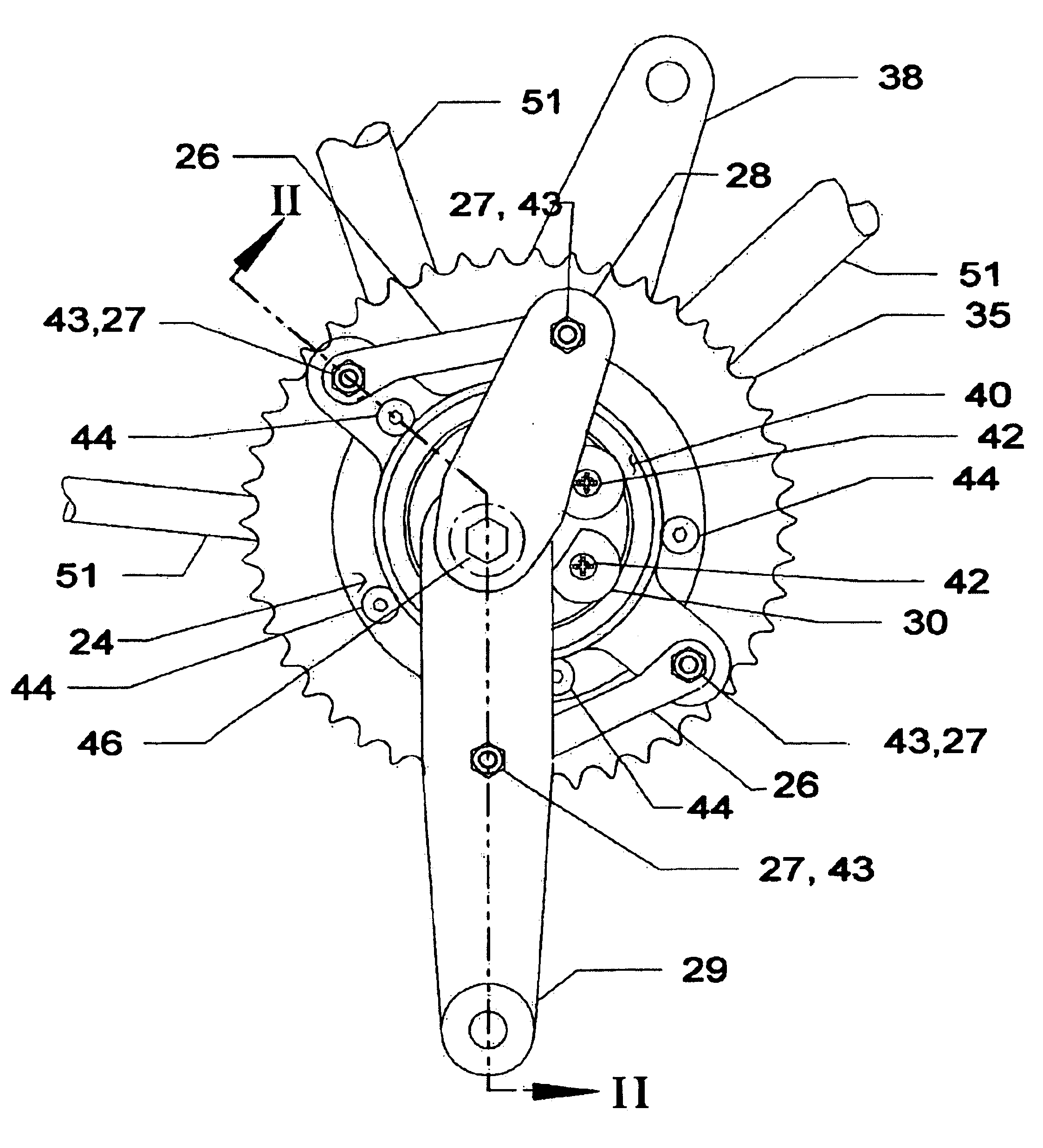

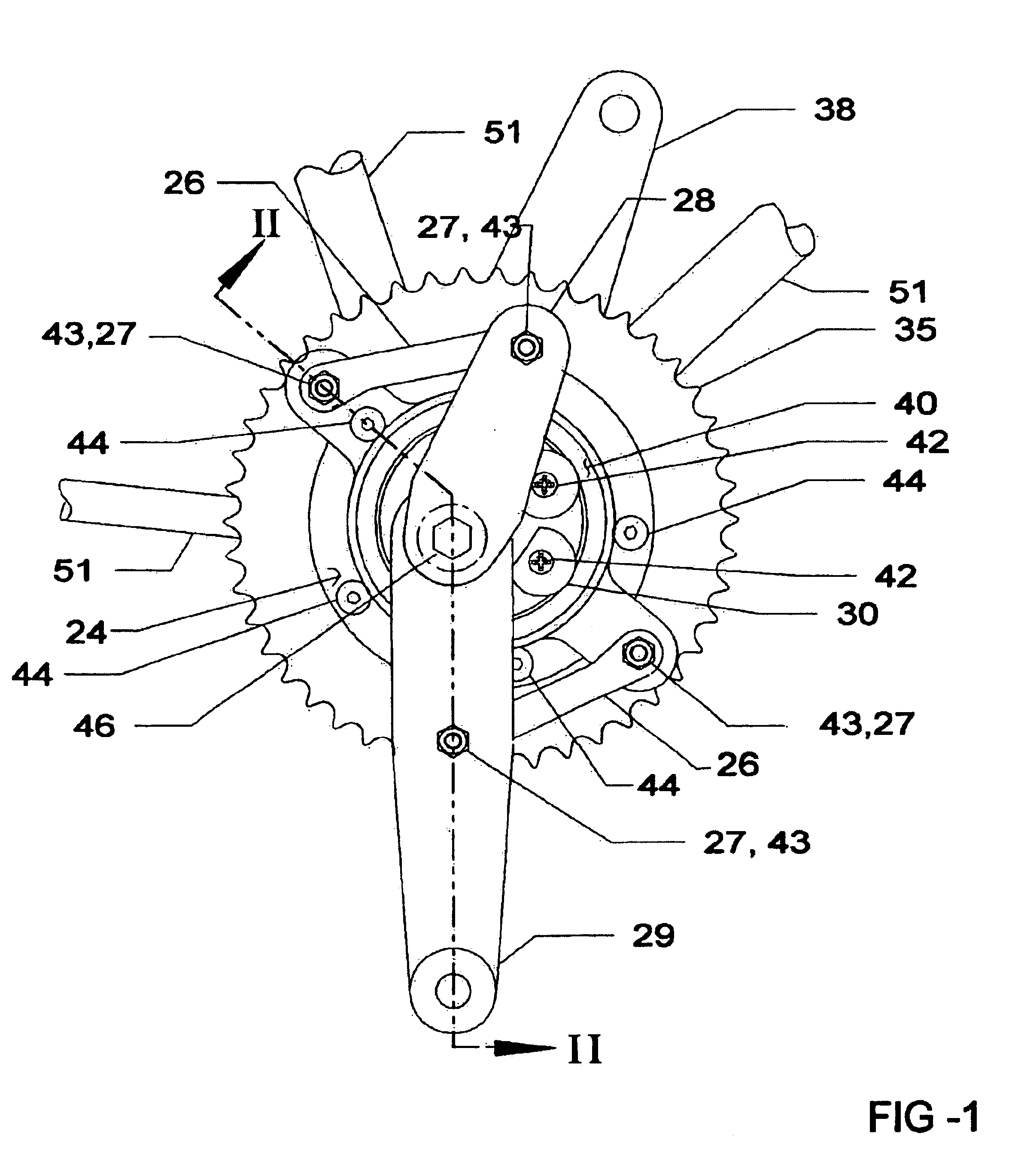

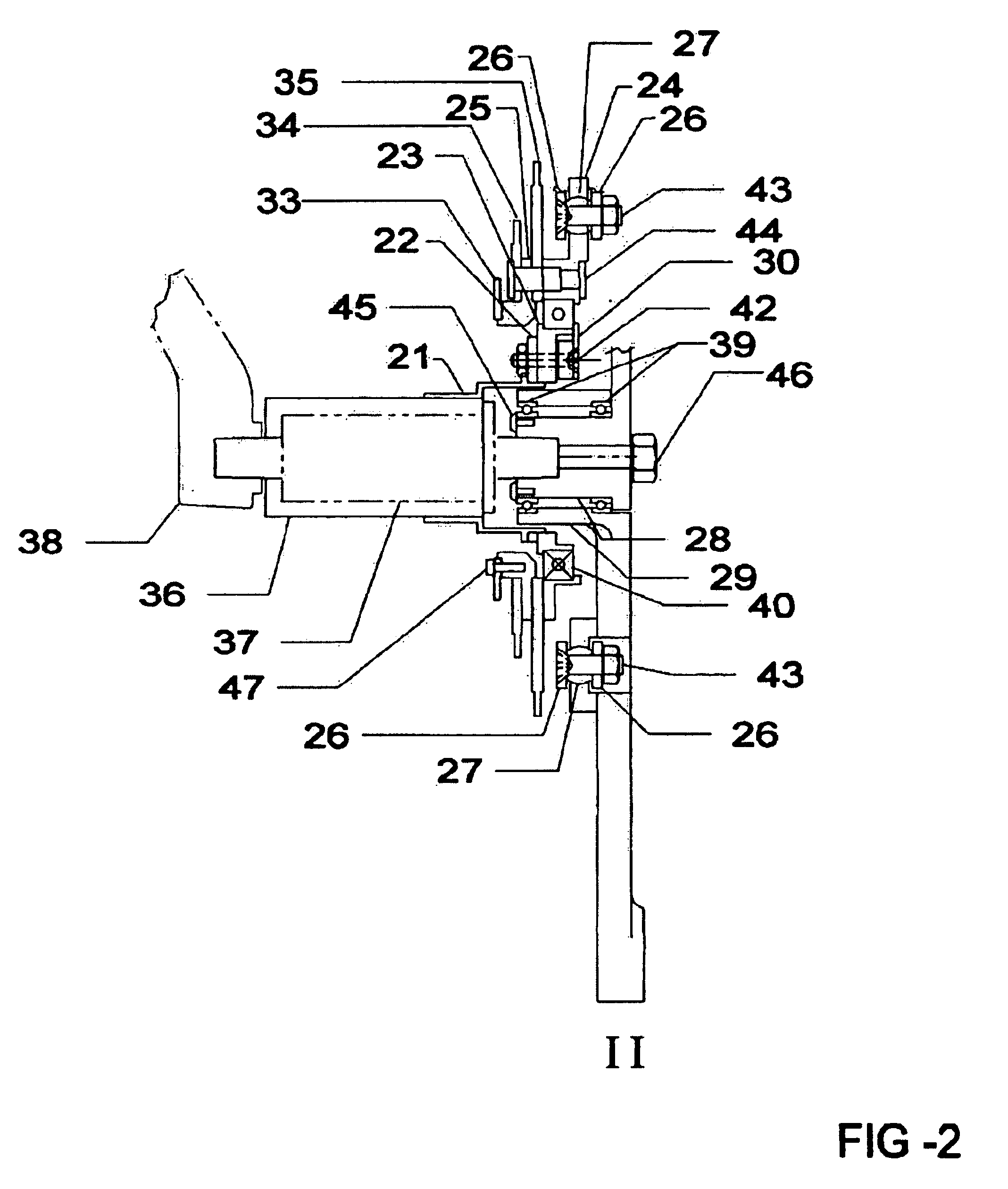

Pedal drive mechanism

A pedal drive mechanism that provides continuous, uninterrupted torque to the drive chain or belt. The continuous torque effect is a result of establishing two separate but connectively joined axes of rotation that transmit pedal crank force to the drive chain (55). The assembly of a right pedal crank (29) rotative mounted about left pedal output crank (28) are connectively fastened (46) to the left pedal crank (38) through the bottombracket bearing (37) defines the first axis of rotation. The assembly of the chain sprockets (35, 34 and 33), sprocket interface (25) and sprocket support (24) are rotatively mounted by a sealed bearing (40) about a bearing inner race support (23) and eccentric flange (22) establish a second axis of rotation. The fixtures of these two axes of rotation are connectively joined by articulating links (26) with self-aligning sealed bearings (27).

Owner:JONES EARLE H

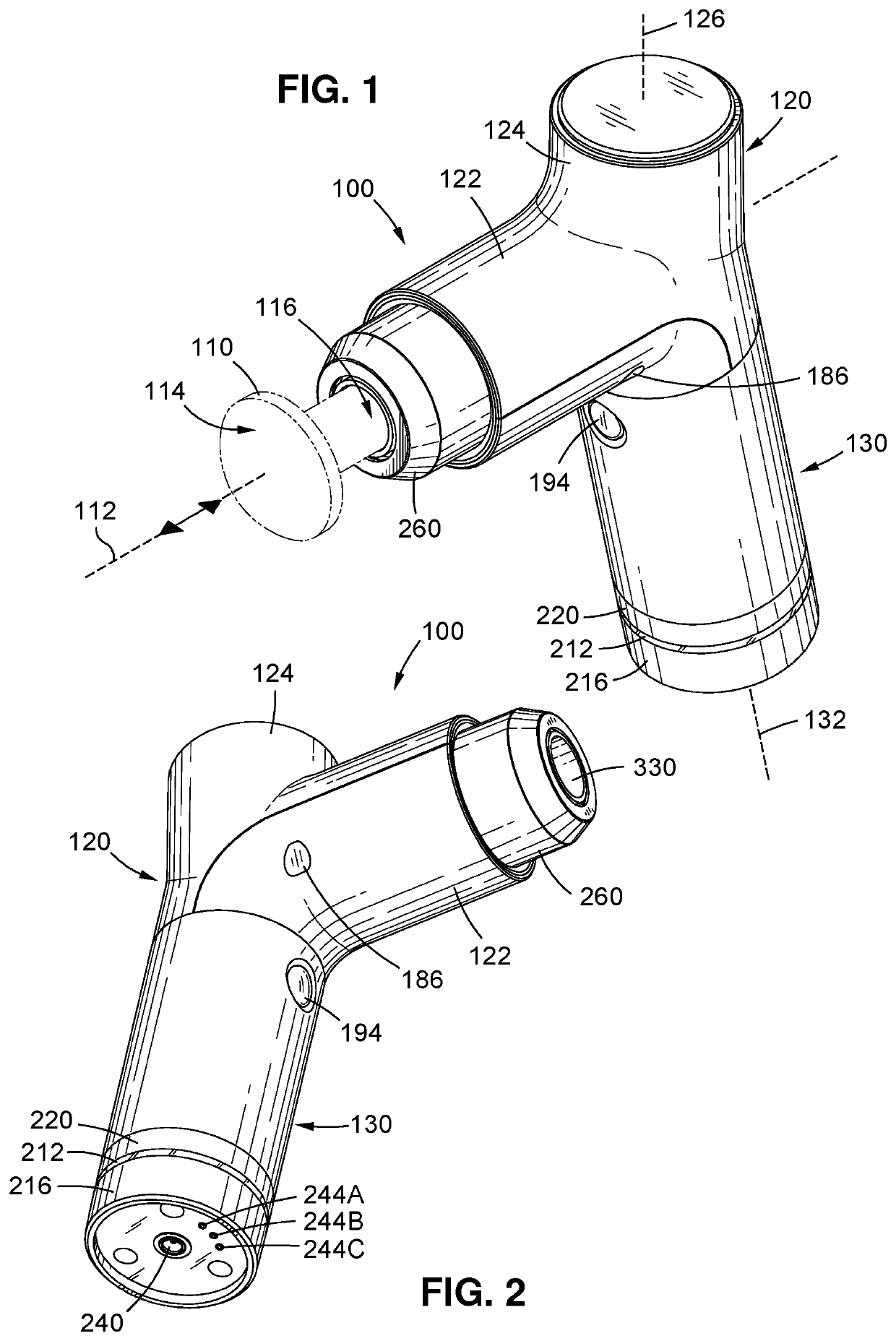

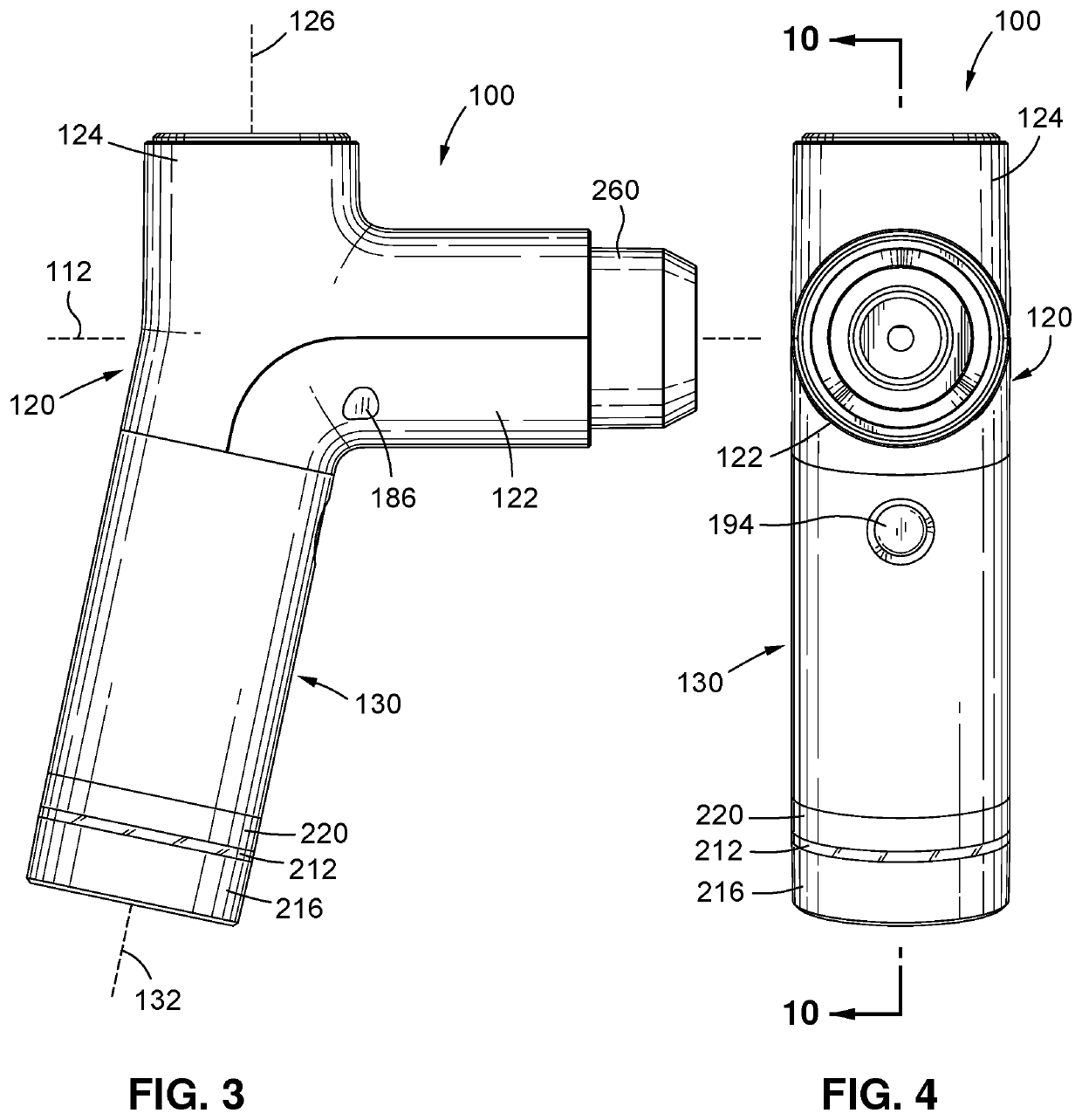

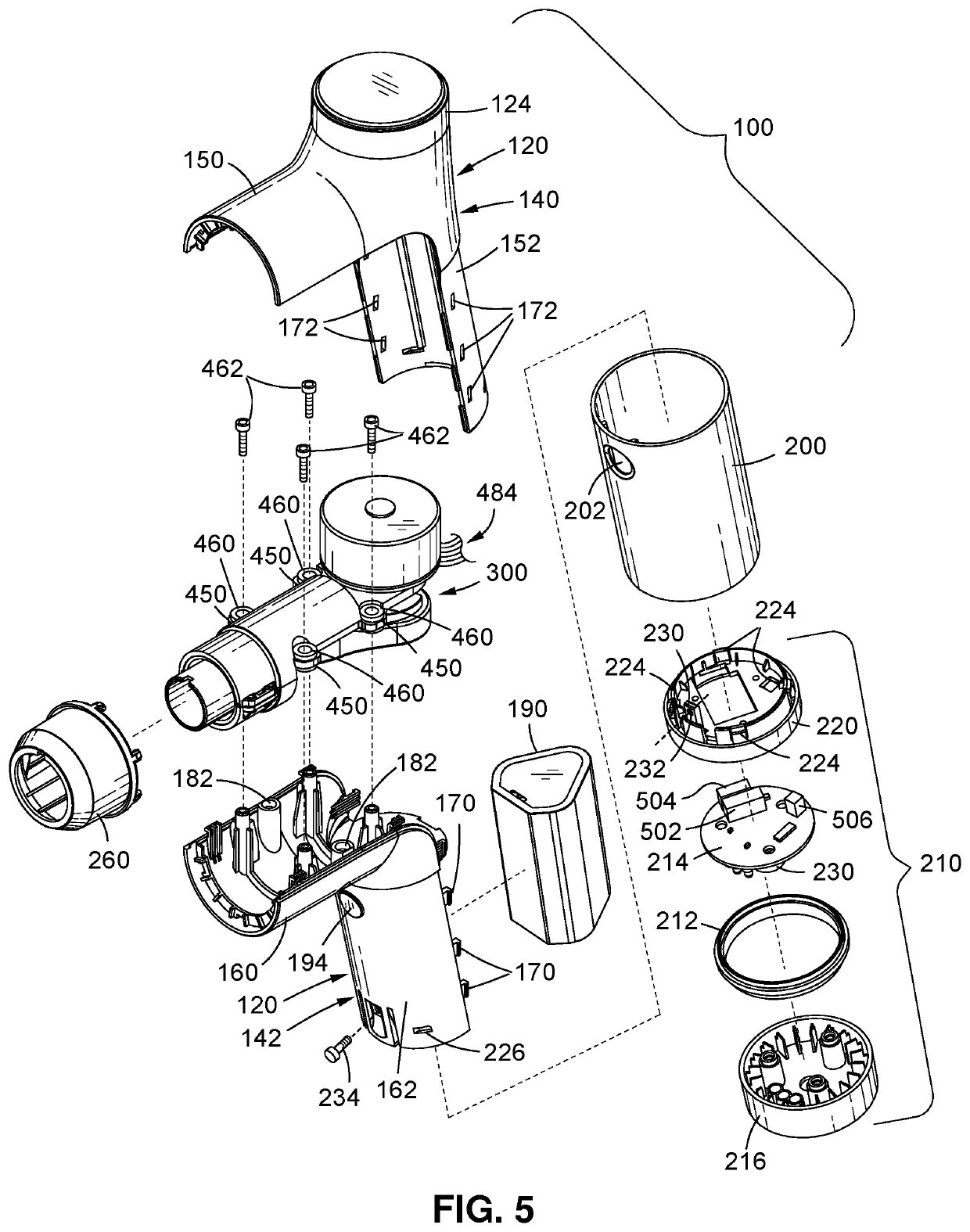

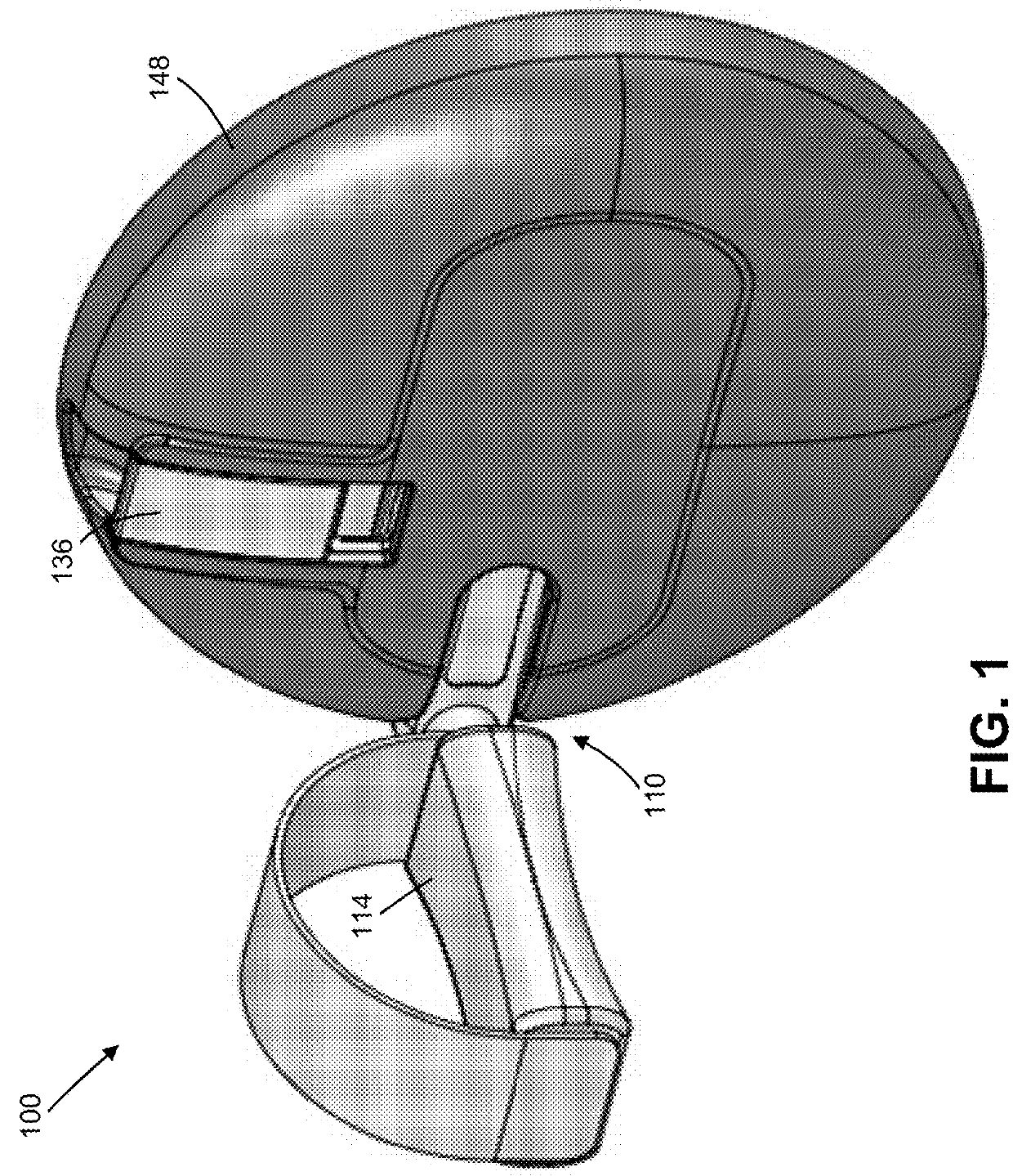

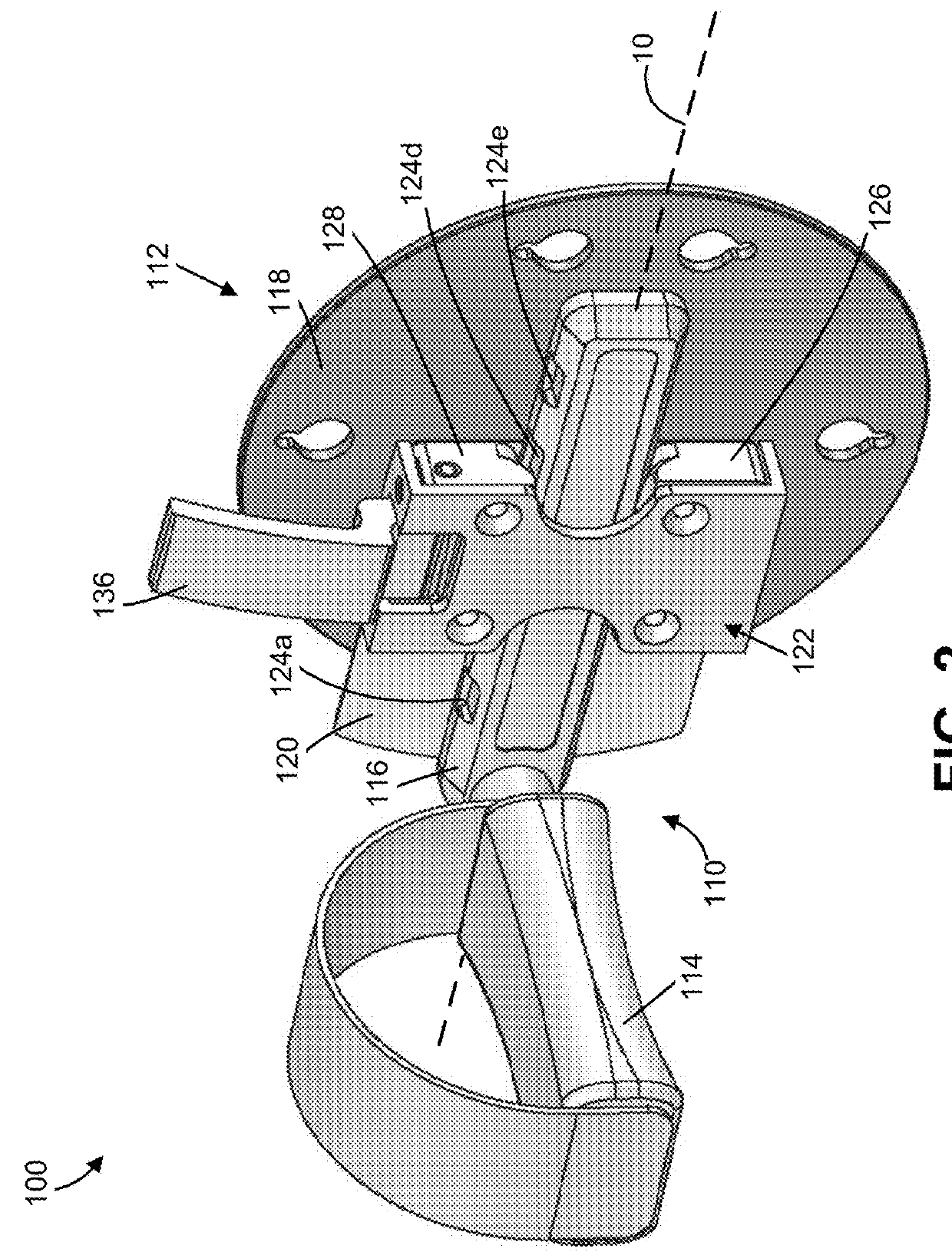

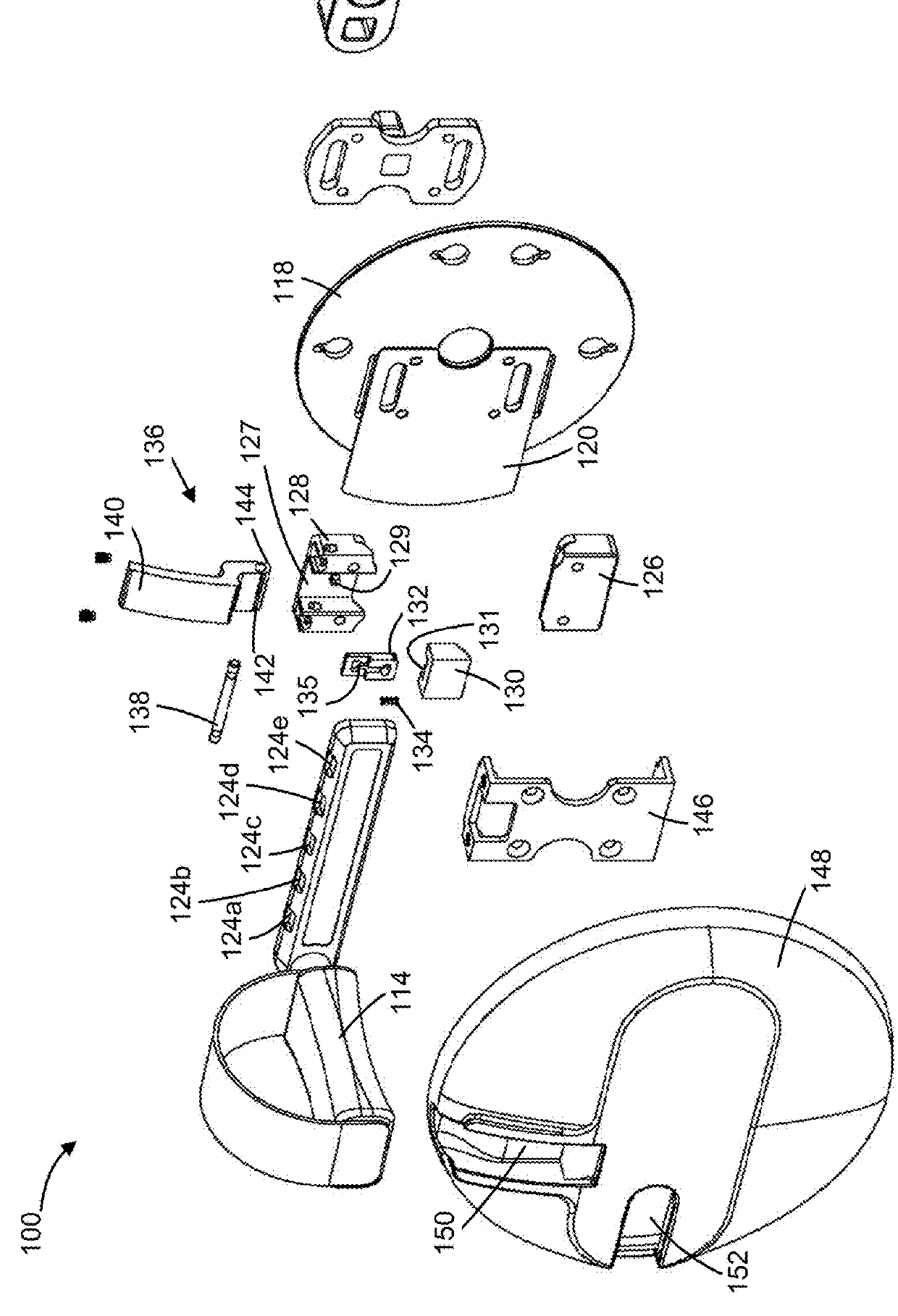

Motor and piston assembly for percussive massage device

ActiveUS10993874B1Chiropractic devicesVibration massagePhysical medicine and rehabilitationReciprocating motion

A self-contained reciprocation mechanism is coupleable within an enclosure of a percussive massage device and is configured to receive an applicator head for stimulating a user's muscles. The self-contained reciprocation mechanism includes a spatial positioning bracket, a semi-cylindrical bracket, a piston, a motor, a crank, and a reciprocation linkage. The spatial positioning bracket is configured to receive the other interconnected components of the self-contained reciprocation mechanism and position said components relative to each other at close predetermined tolerances to assure that the interconnected components are properly positioned to provide consistent operating characteristics. The self-contained reciprocation mechanism is coupled within the enclosure using screws which extend through mounting tabs of the spatial positioning bracket.

Owner:HYPERICE IP SUBCO LLC

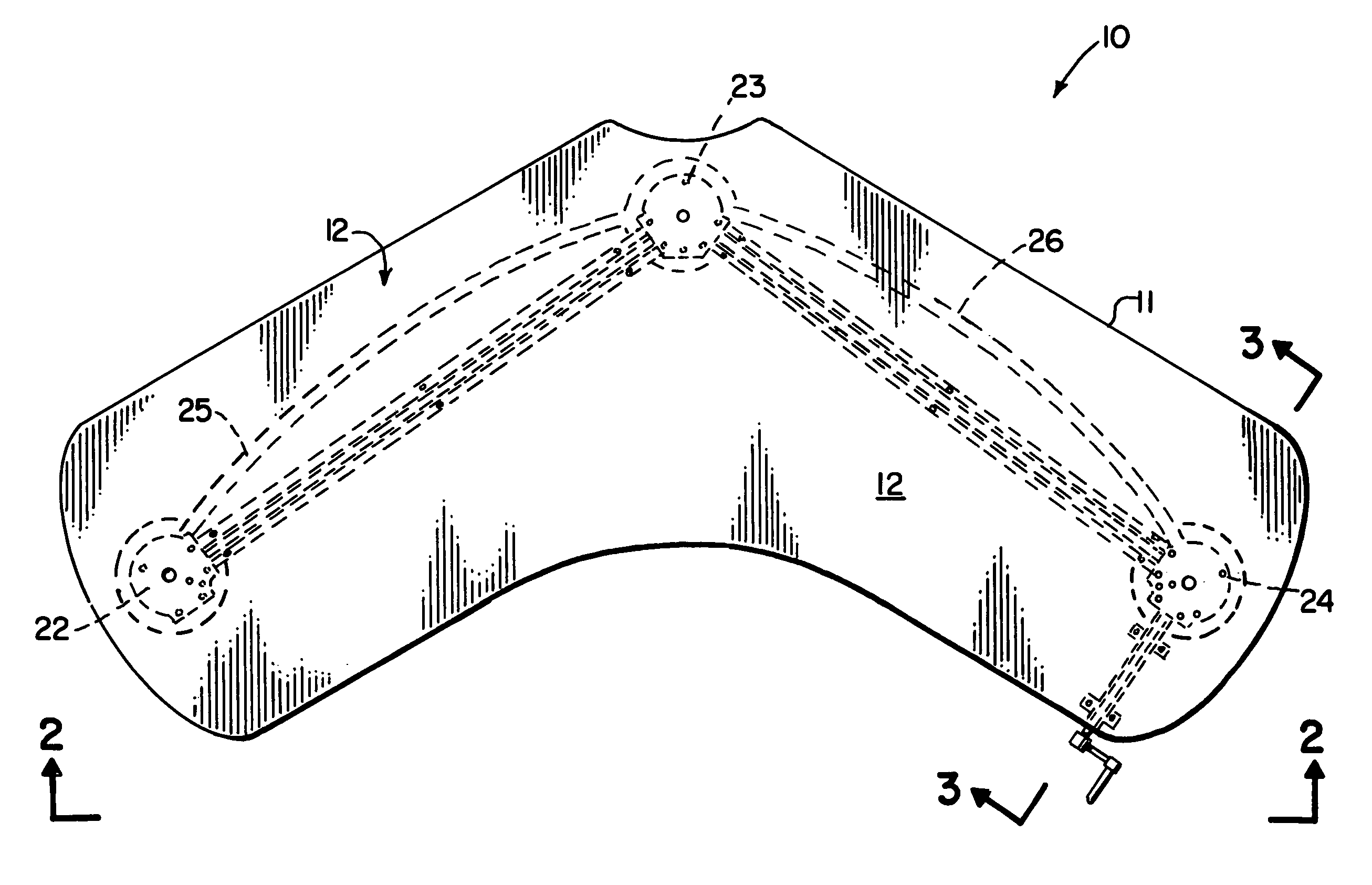

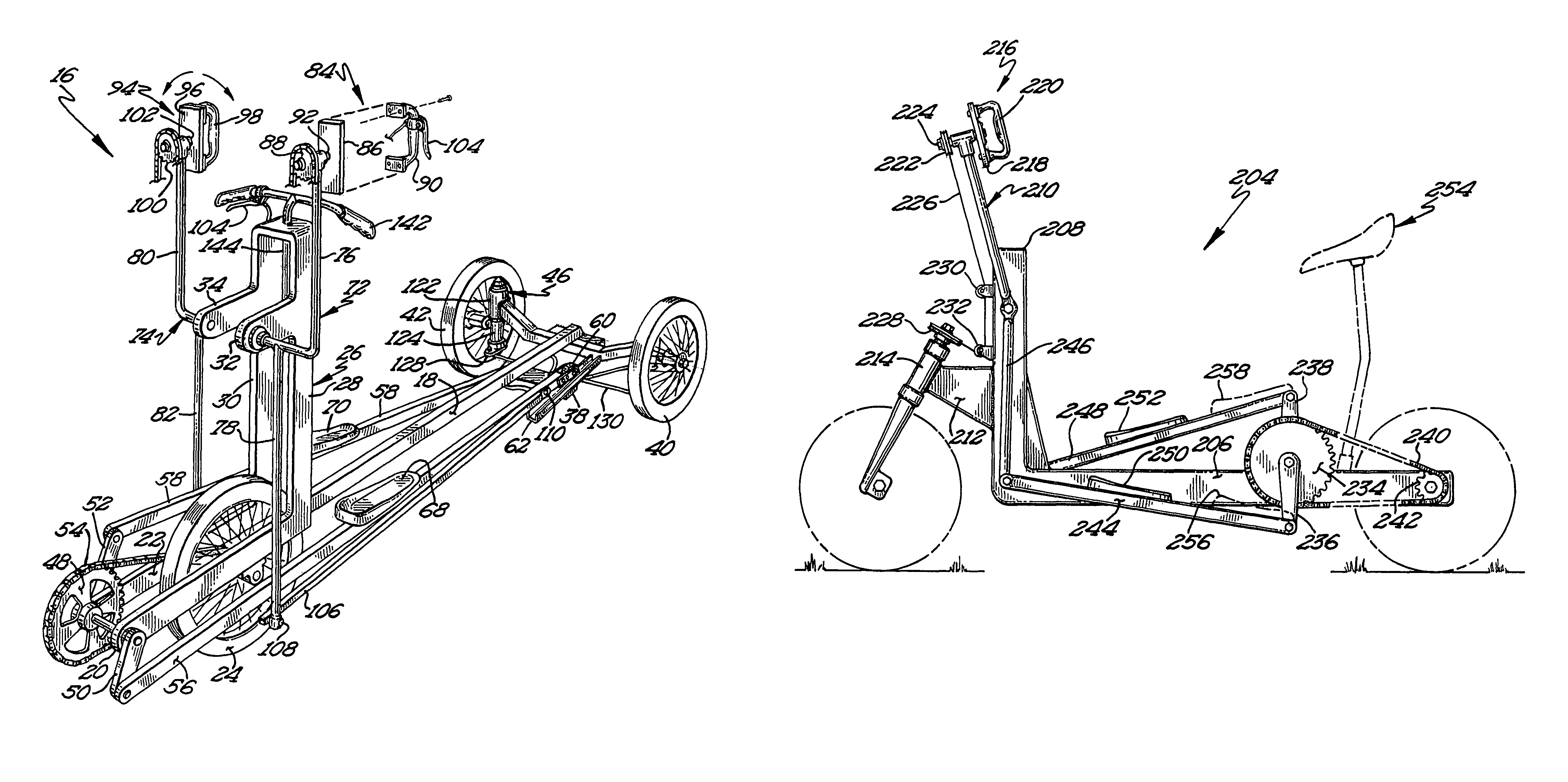

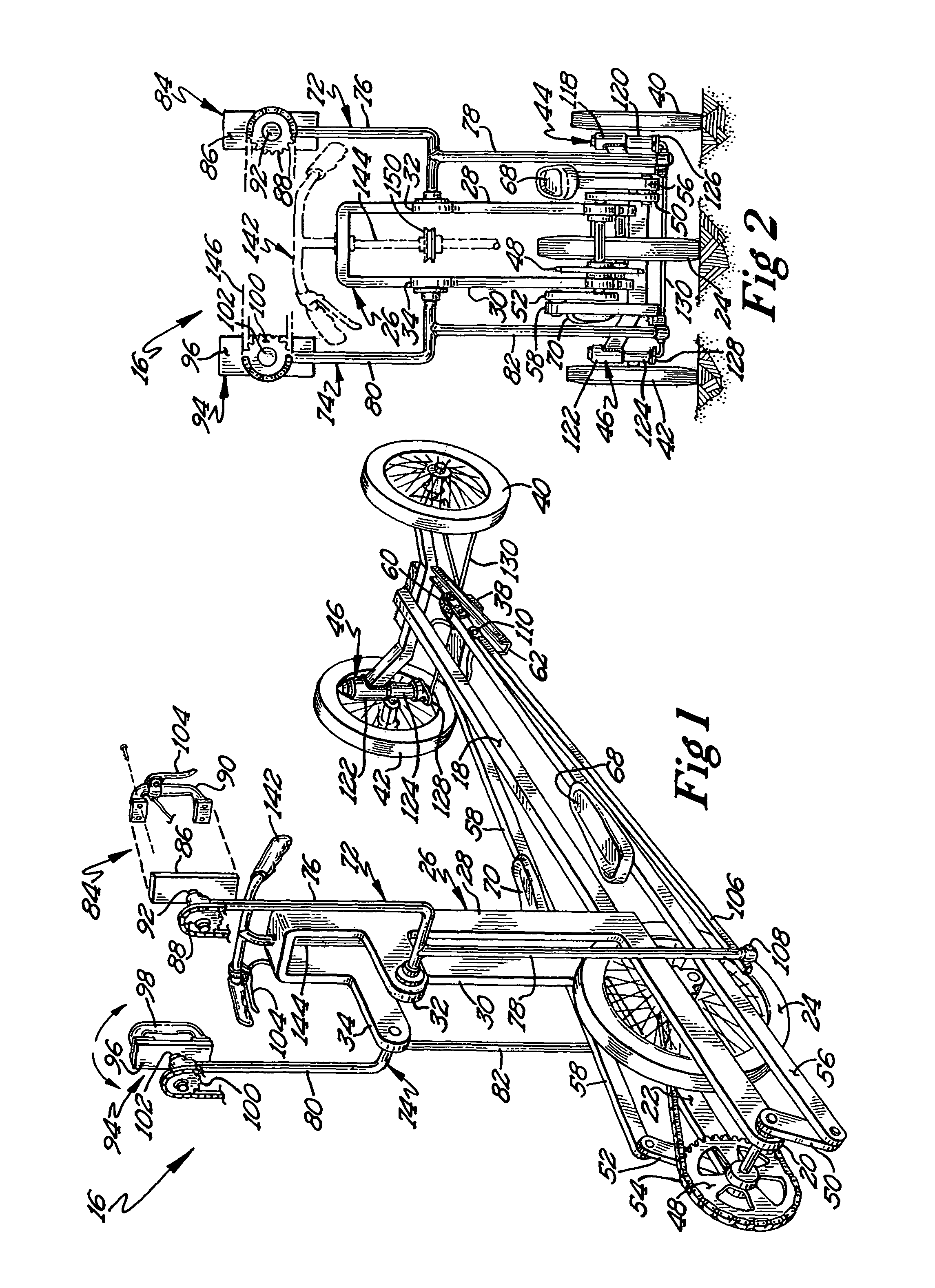

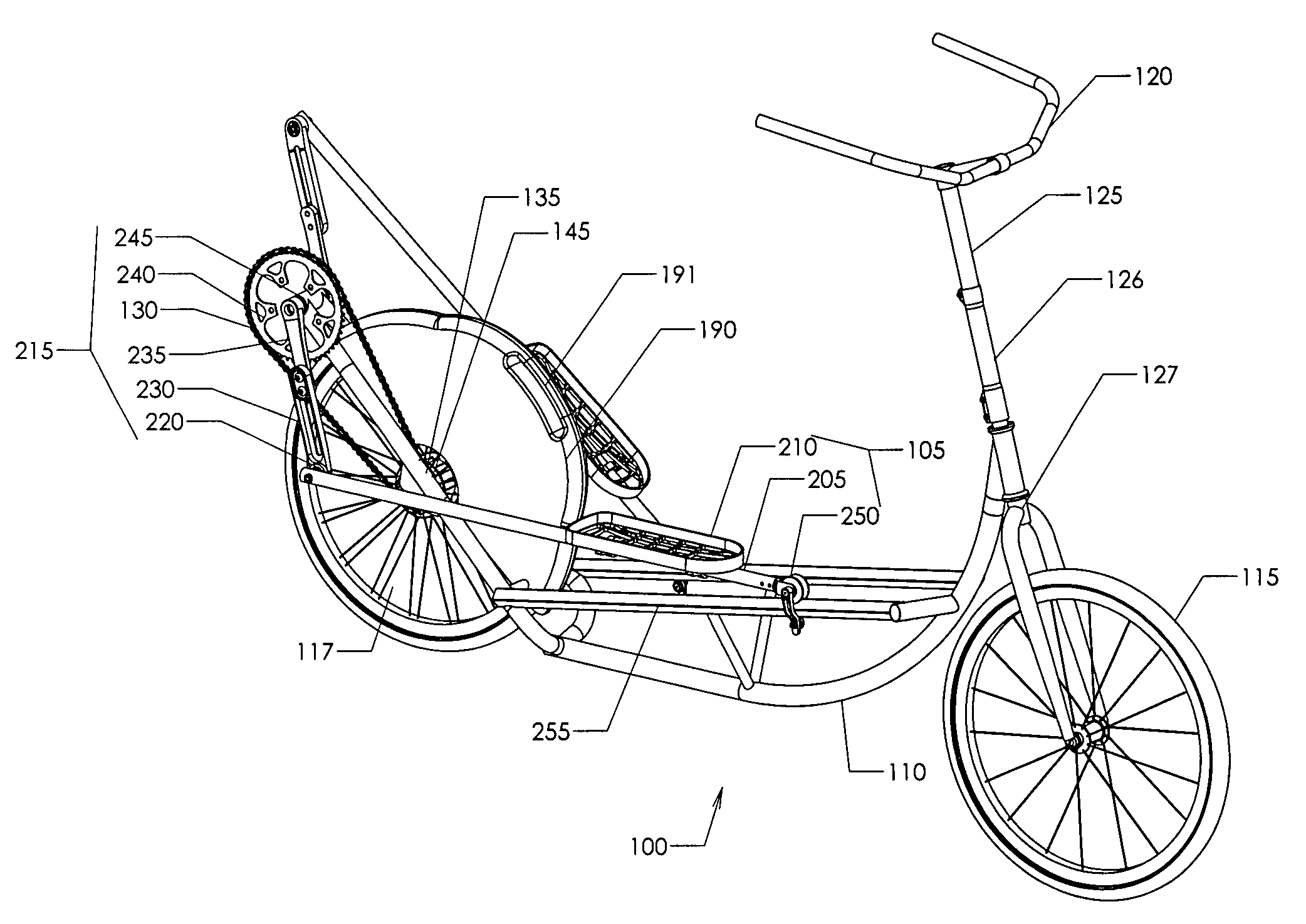

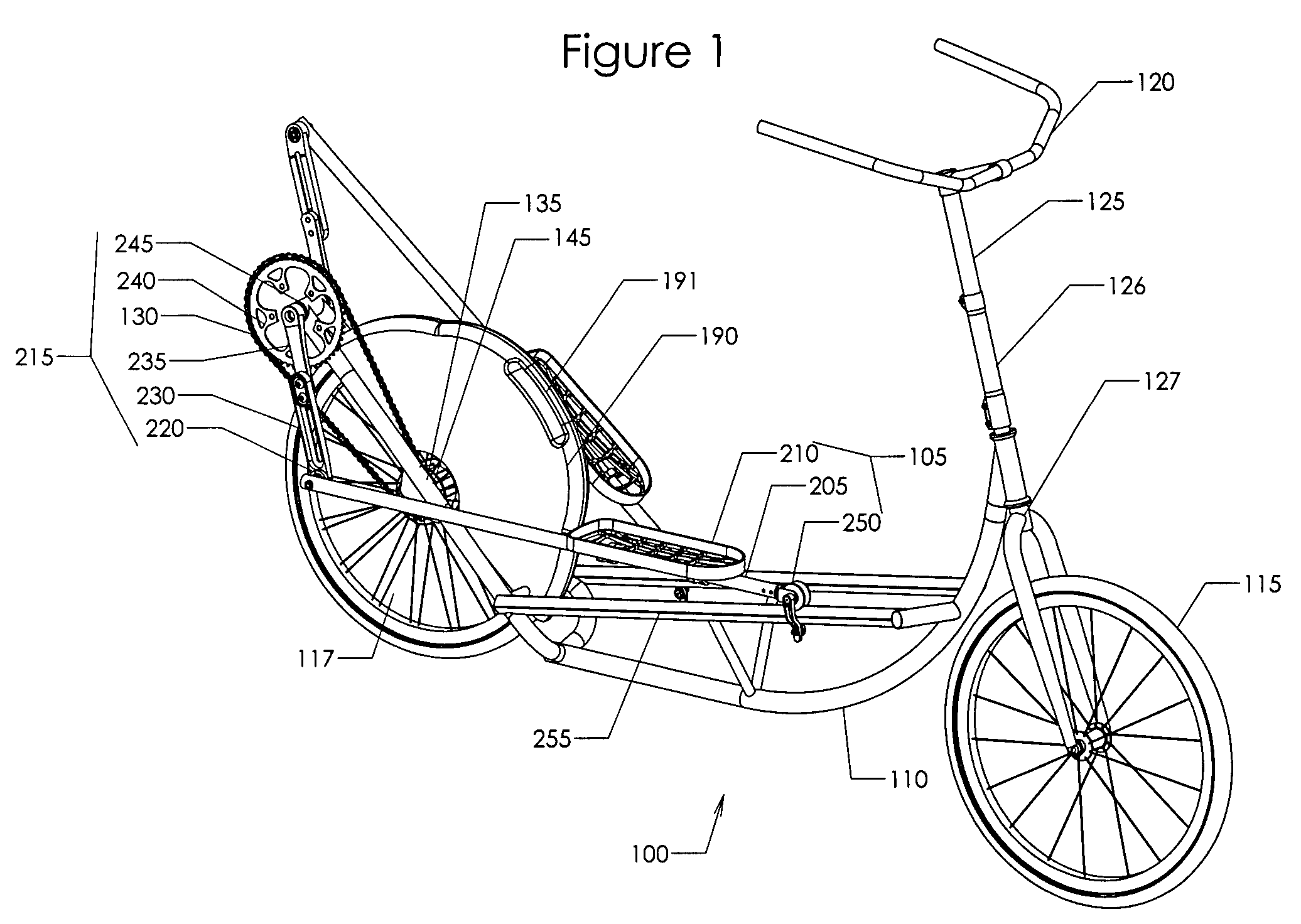

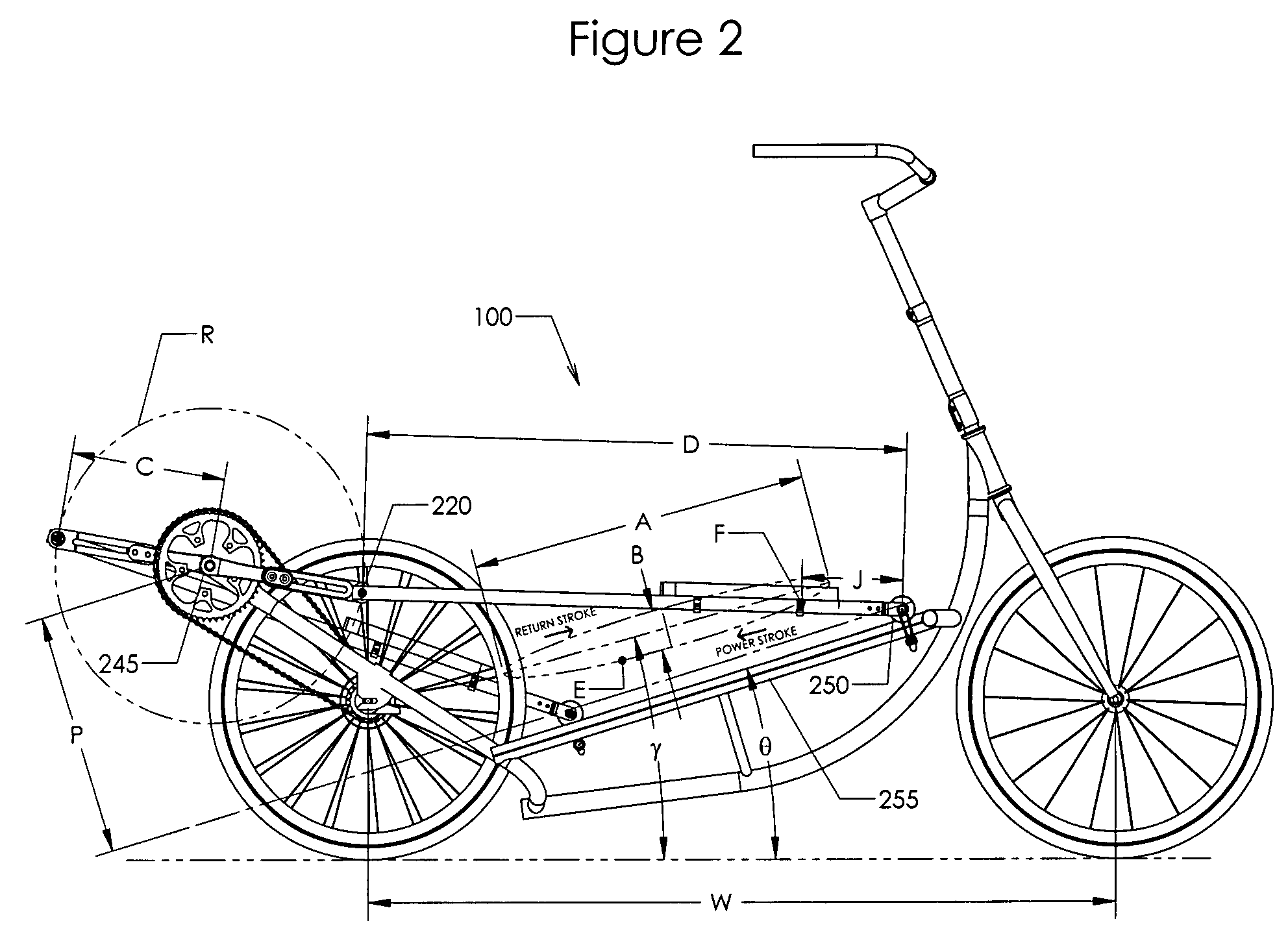

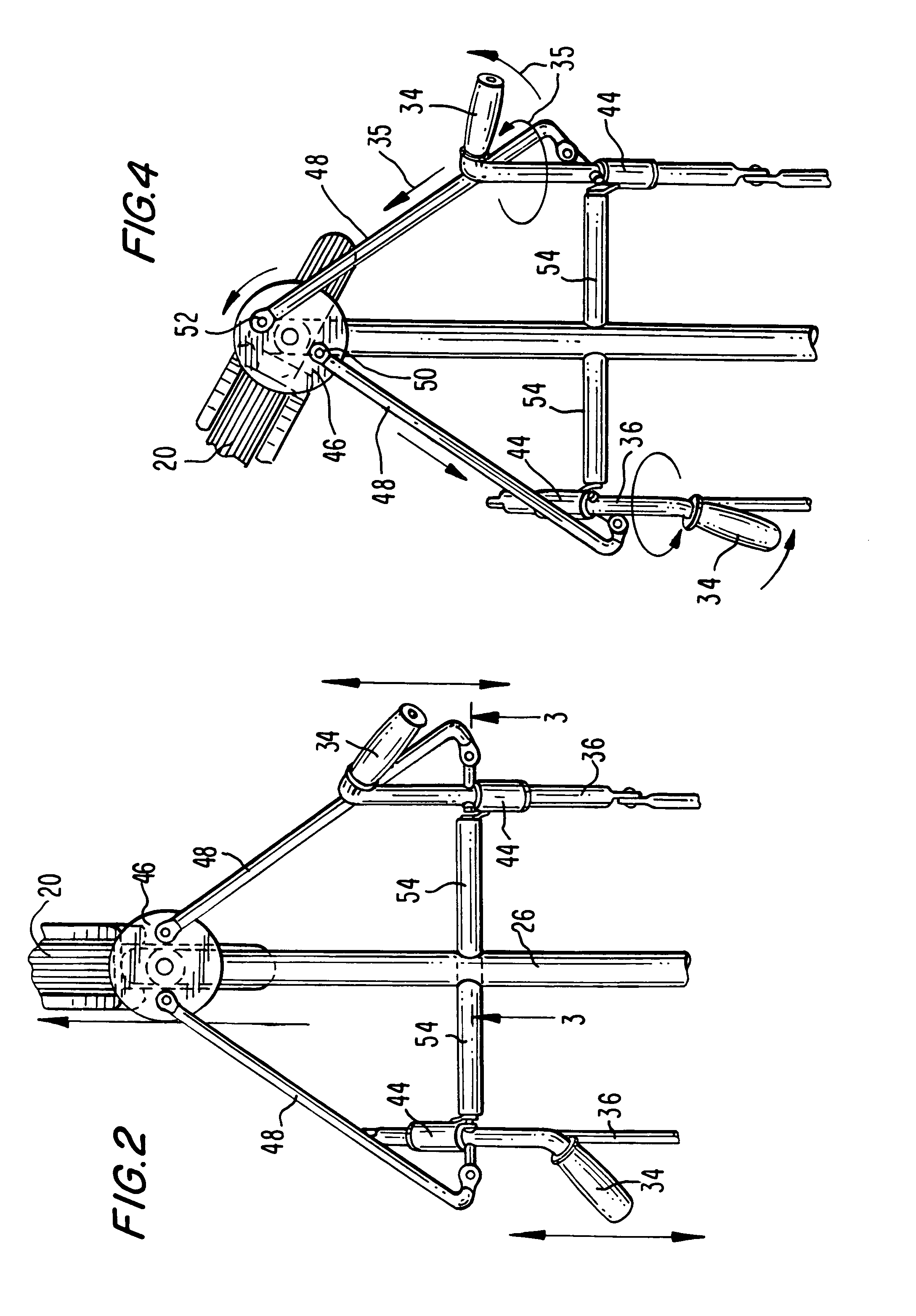

Recreational vehicle with elliptical drive

InactiveUS7967313B1Easy to useExtended service lifeCyclesFoot-driven leversPush and pullReciprocating motion

A wheeled vehicle includes a pair of leg driven skis and hand operated levers for simultaneously applying power to a crank and drive sprocket to propel the vehicle. A pair of controllers, one at the top of each thrust lever, include handles that are pushed and pulled to reciprocate the levers and may simultaneously be rotated through wrist and forearm action to steer the vehicle. Auxiliary steering is provided through a handlebar mounted to the vehicle separately from the thrust levers. The skis are operatively coupled to their associated levers, either directly through a pivotal connection or indirectly through an elongate link rotatably coupled at one end to the lever and at the other end to the ski.

Owner:EGGERT WILLIAM E

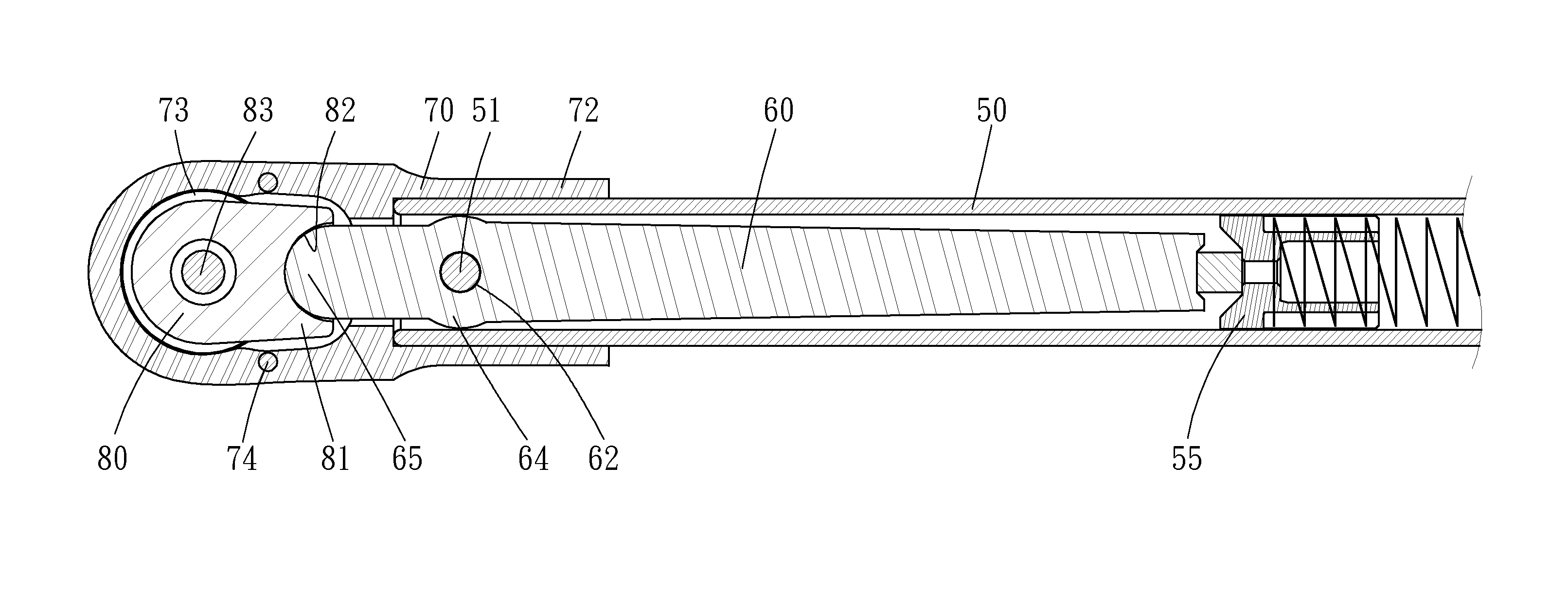

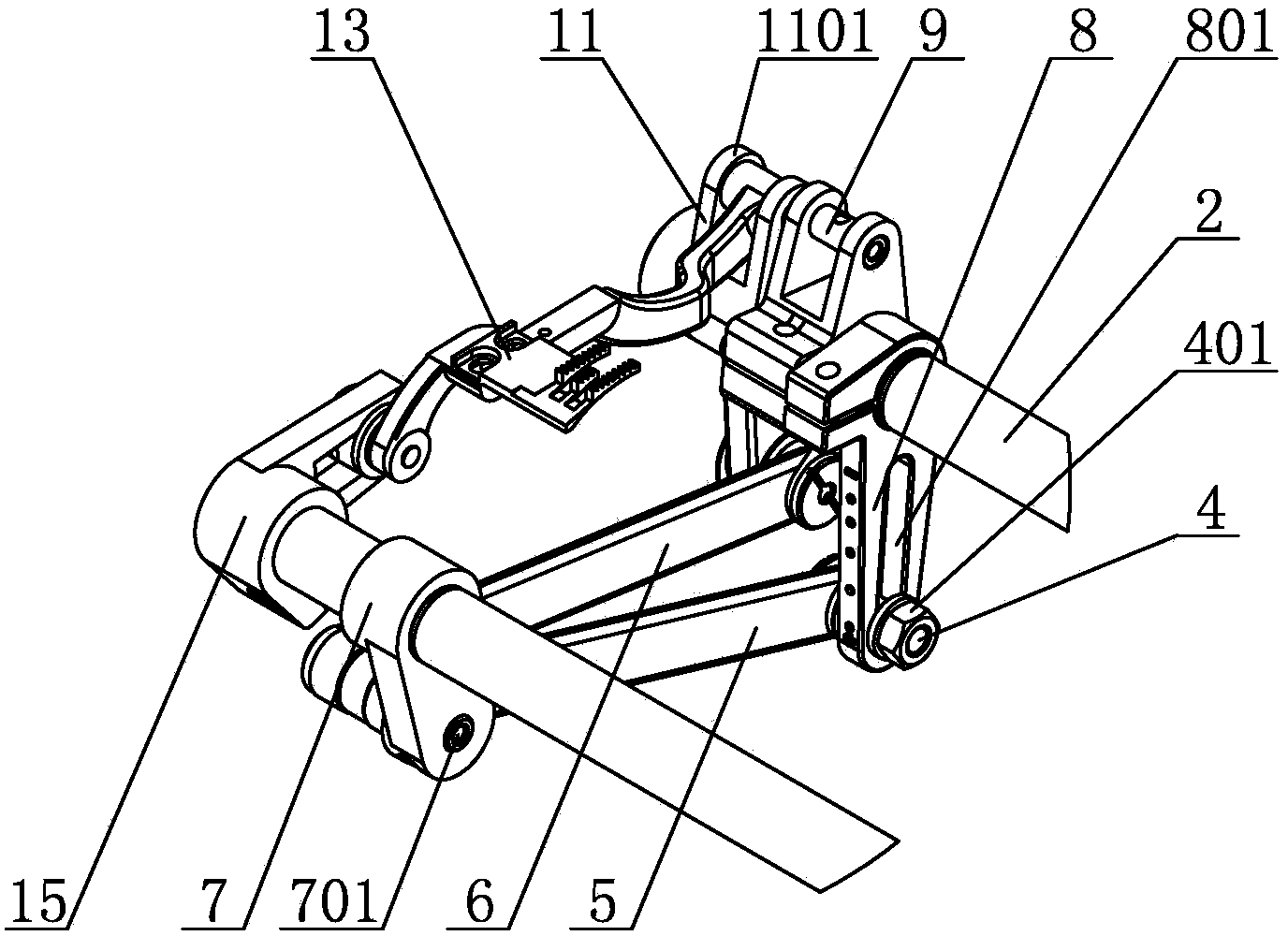

Stationary cycling pedal crank having an adjustable length

An adjustable crank assembly is provided. The adjustable crank assembly includes a crank arm having a surface with a plurality of notches, and a retention block that partially houses the crank arm and allows the crank arm to slide along an axis relative to the retention block. The retention block includes a clamping block and a locking pin, both of which being adapted to selectively engage the crank arm when the retention block is placed in a locked position, and a locking lever for transitioning between a locked position and an unlocked position. The locking lever provides a compressive force to the clamping block when placed in a locked position and a retracting force to the locking pin when placed in an unlocked position.

Owner:MINDBRIDGE INNOVATIONS

Self-propelled vehicle propelled by an elliptical drive train

Owner:PT MOTION WORKS INC

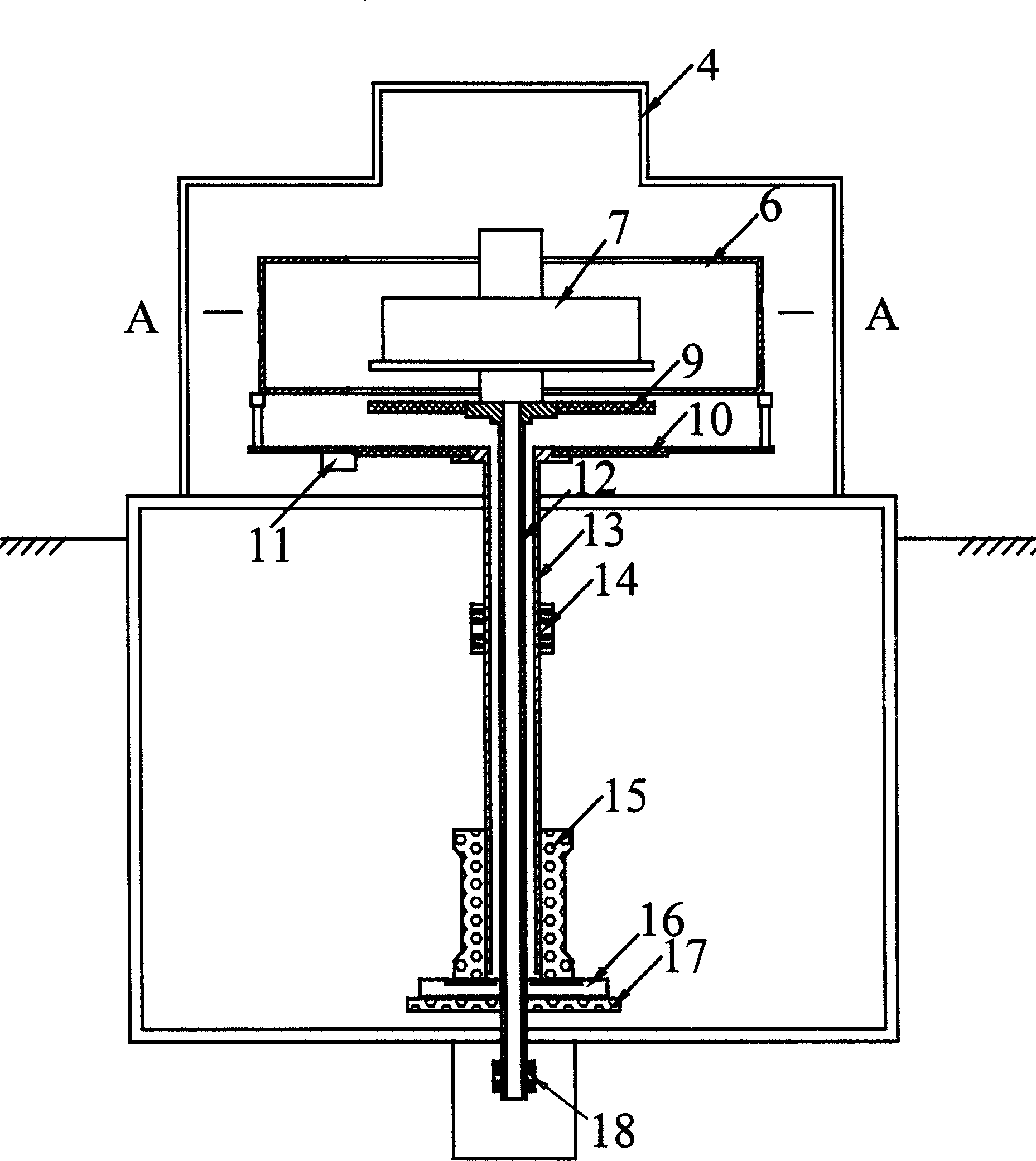

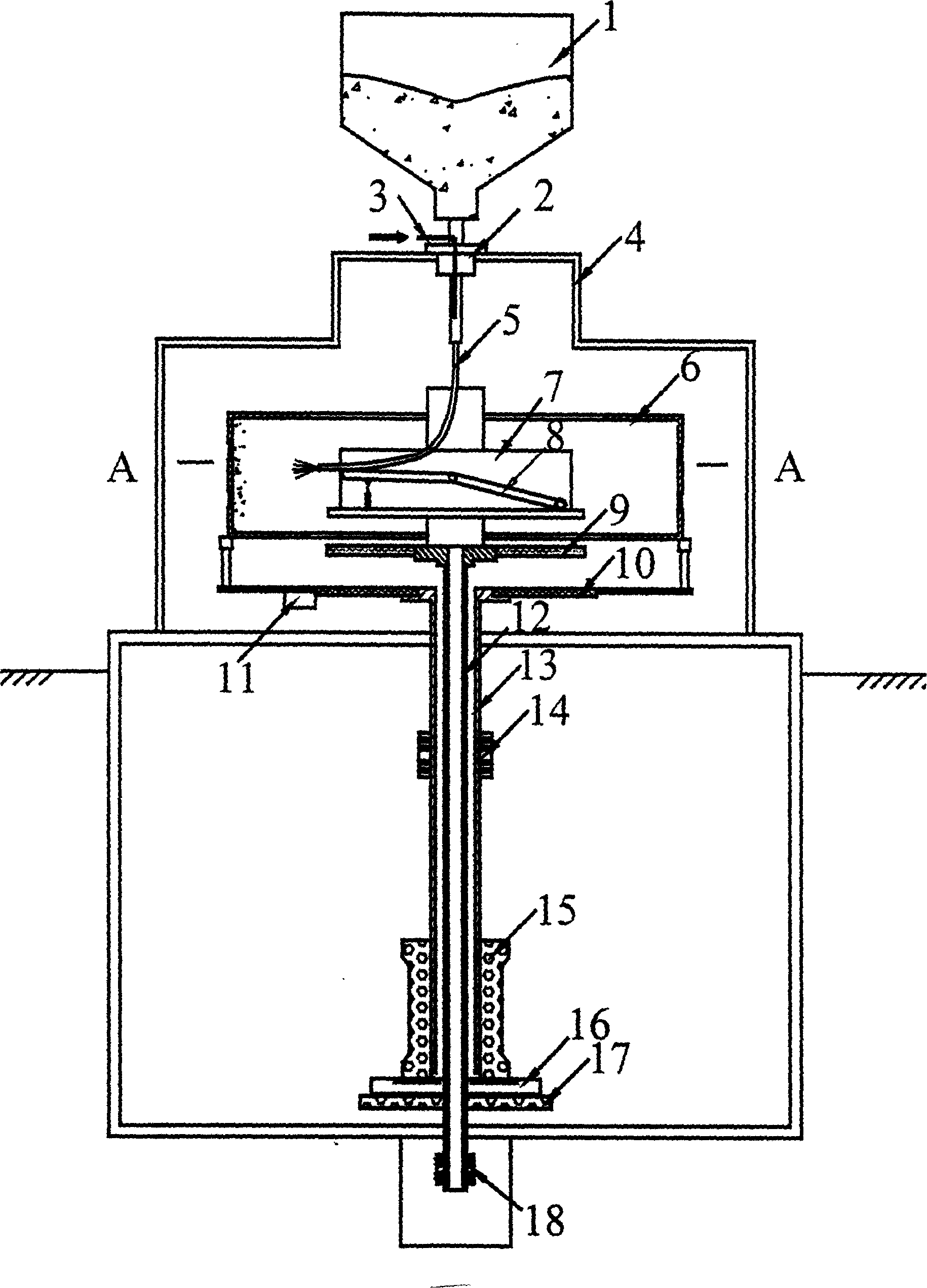

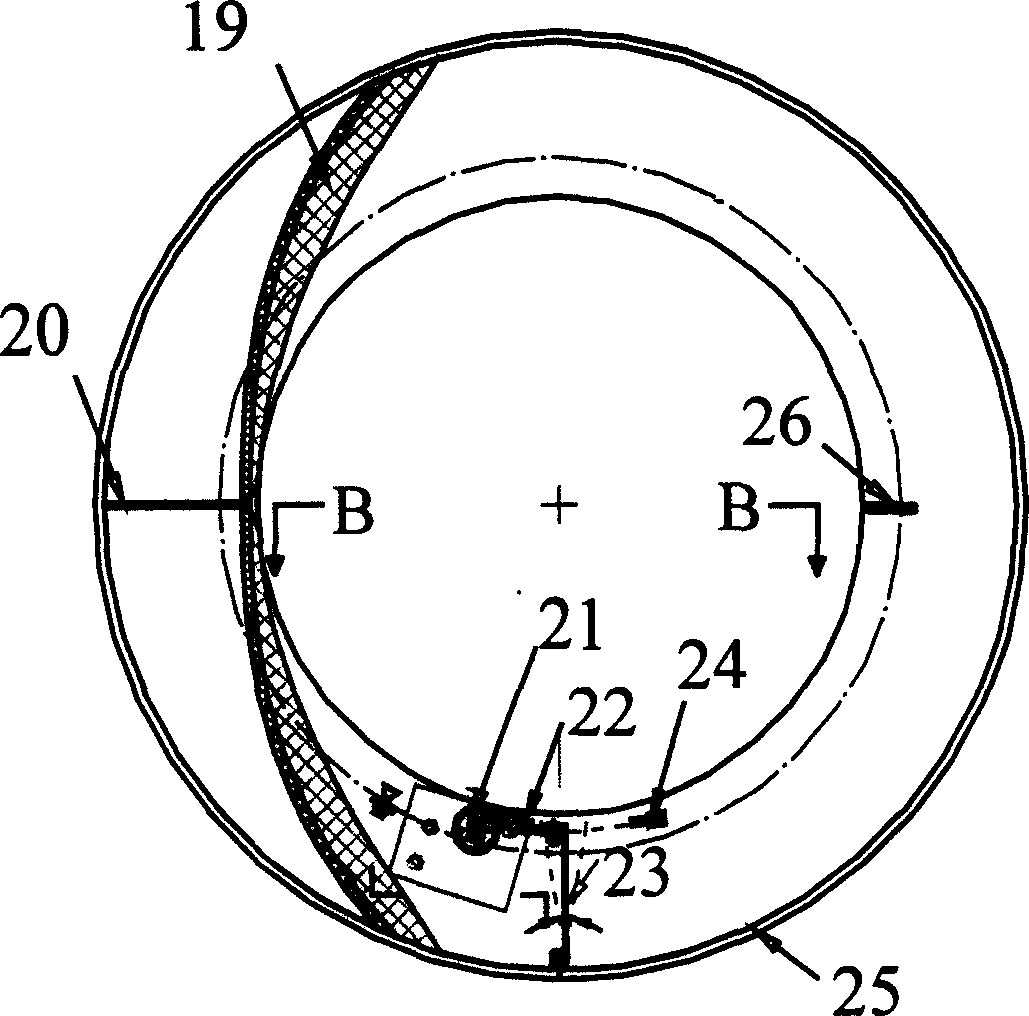

Method for simulating sea waves by using barrel-type centrifugal machine and apparatus therefor

InactiveCN1566916AWide frequency rangeGood wave suppression effectHydrodynamic testingHydraulic modelsSea wavesEngineering

This invention relates to a method and apparatus for imitating sea wave by use of a drum-type centrifuge. The method is the following: to feed water into the drum type groove through the water input system of the centrifuge when it achieves stated centrifugal acceleration; to start the wave generator located in inside wall of the groove to generate moving wave; then to absorb wave through the wave breaker located on the other end of the inside wall. The said apparatus comprises drum-type centrifuge and wave generator and is characterized by the following: the wave generator is located inside the drum type groove with a external diameter of one to three meter, radial depth of twenty to fifty centimeter, axial width twenty to forth centimeter. The said wave generator comprises a crank swing mechanism made up of crank wheel, connecting bar and swing board and servomotor. The said wave breaker is located on side wall of the groove near to swing board with a baffle board in the middle.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

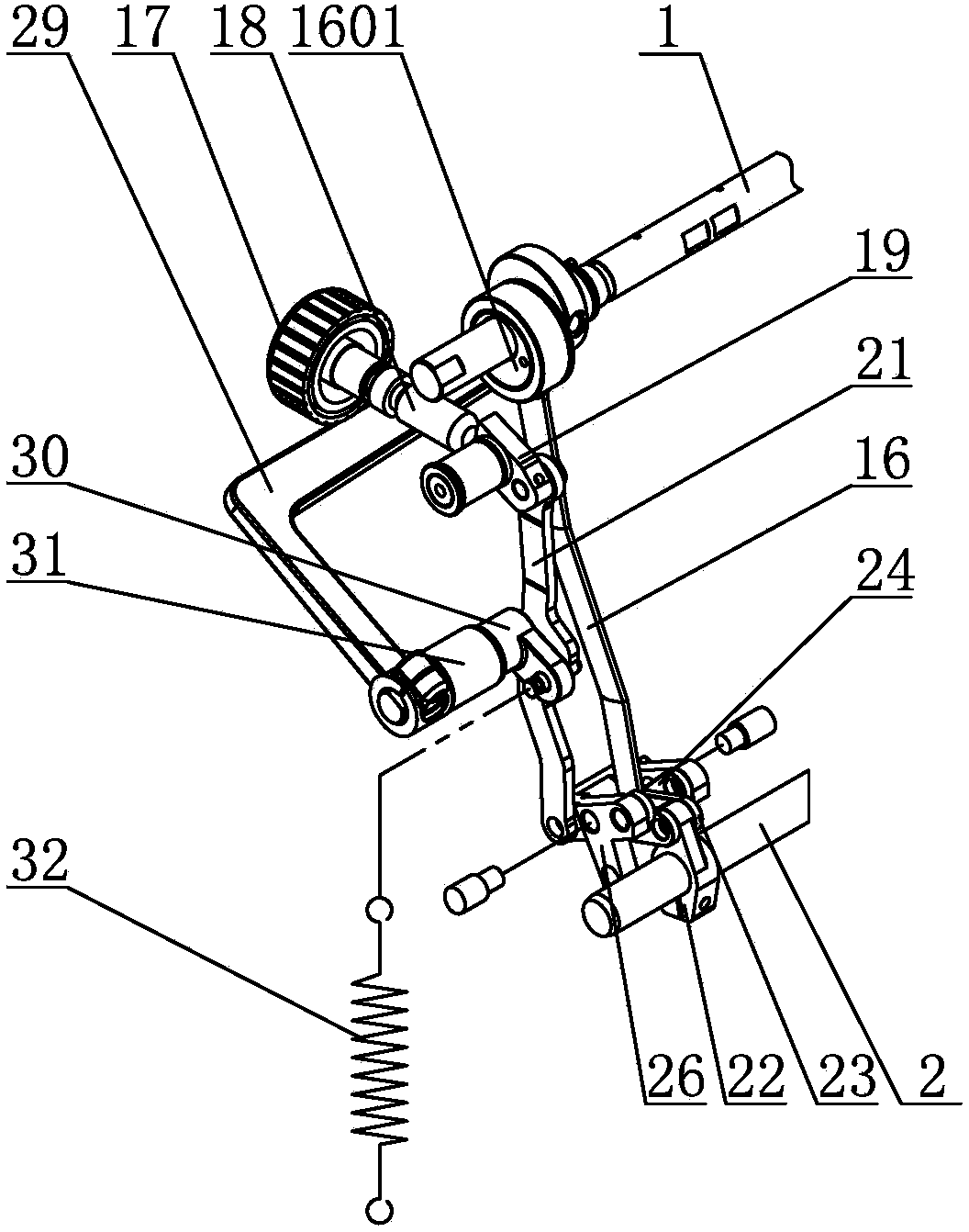

Sewing machine for up-down differential feeding

ActiveCN104233644ASimple structureCombined design is reasonableWork-feeding meansSewing-machine control devicesCrankControl engineering

The invention relates to a sewing machine for up-down differential feeding. The sewing machine comprises a secondary feeding adjusting mechanism, a feeding shaft and a feed lifting rock shaft, wherein the secondary feeding adjusting mechanism comprises a lower differential feeding adjusting crank and a first tooth frame seat which are fixed on the feeding shaft, a lower differential feeding crank which movably sleeves the feeding shaft and a lower differential transmission crank which movably sleeves the feed lifting rock shaft; the first tooth frame seat is connected with a feeding tooth; the lower differential feeding crank is connected with a lower differential feeding tooth; the lower differential feeding adjusting crank, a first lower differential feeding connecting rod, the lower differential transmission crank, a second lower differential feeding connecting rod and the lower differential feeding crank are hinged and linked in sequence; the hinging position between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is adjustable. The hinging position is adjusted so that a force arm relation between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is changed and a relation of swinging and transferring the feeding shaft to the feeding tooth and the lower differential feeding tooth is changed, namely the lower differential feeding adjustment is realized.

Owner:宁波新三合自动化有限公司

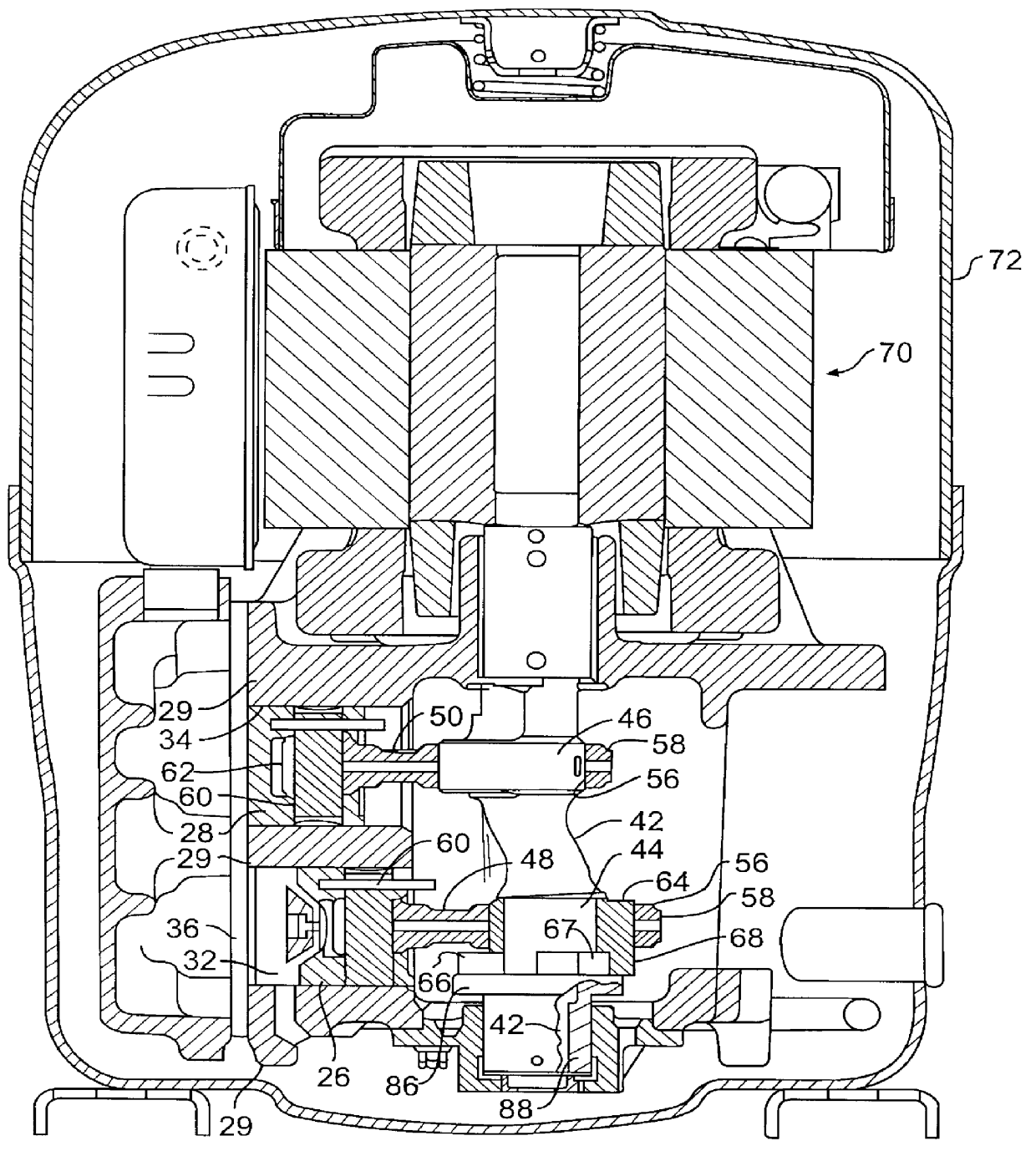

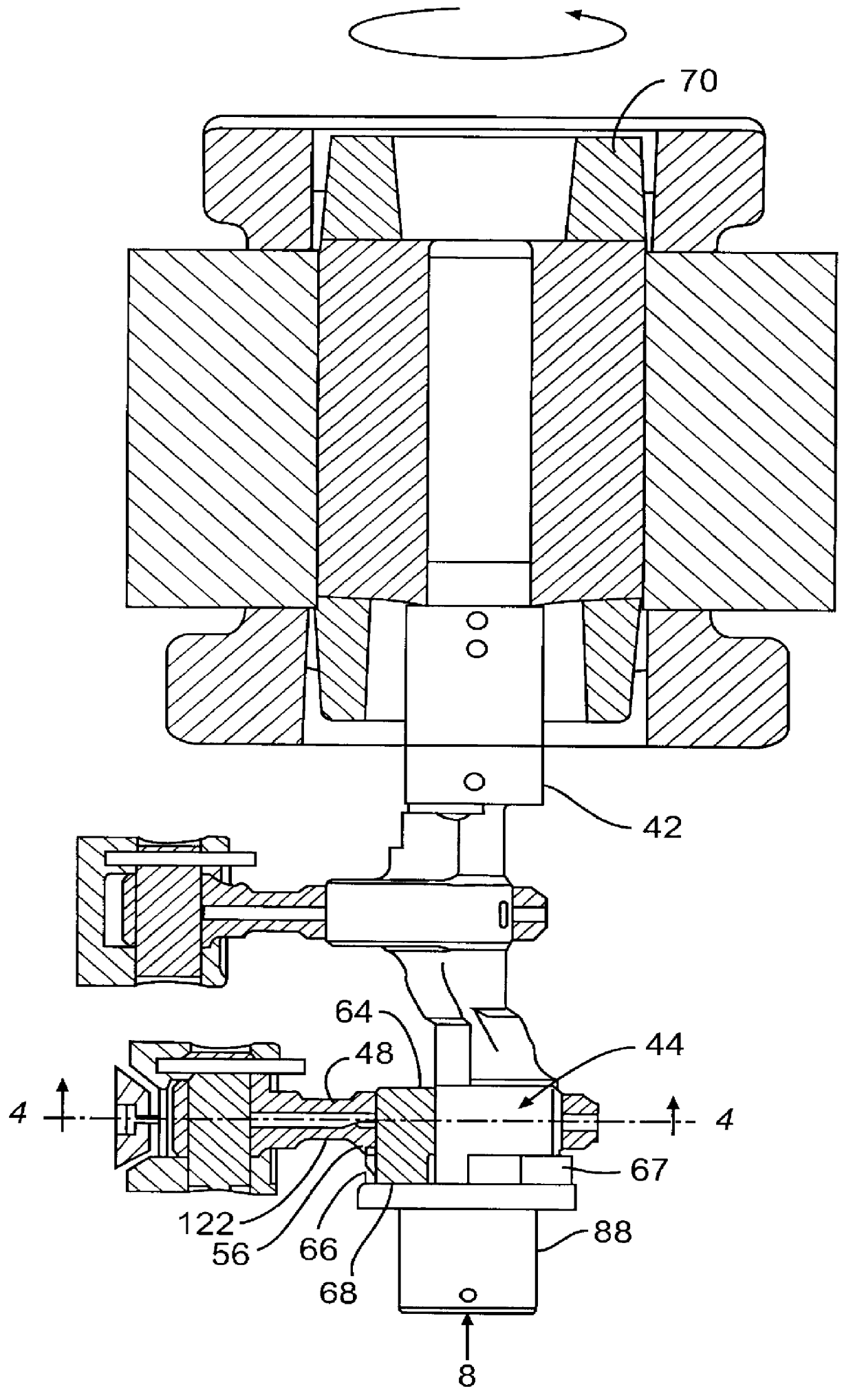

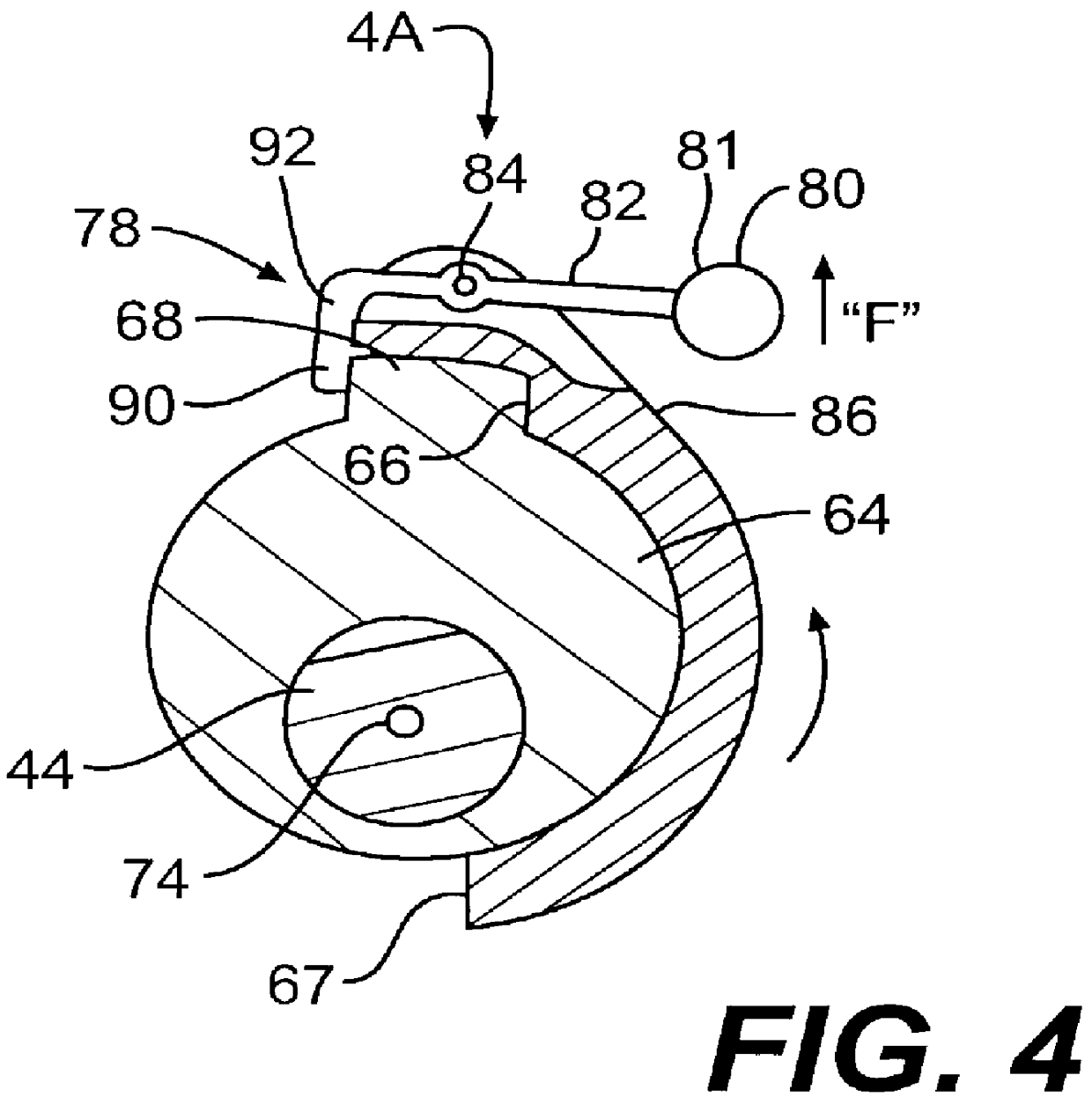

Adjustable crankpin throw structure having improved throw stabilizing means

InactiveUS6092993ACancel noiseReduce capacityFlexible member pumpsWorking fluid for enginesCrankpinCam

A stabilizing structure for a throw adjusting eccentric cam in a two-stage reciprocating compressor is provided. The compressor includes a block that has at least one cylinder with an associated compression chamber and piston, a crankshaft that includes an eccentric crankpin, and a reversible motor for rotating the crankshaft in a forward and a reverse direction. An eccentric, two position cam is rotatably mounted over the crankpin. The cam rotates to and operates at a first position relative to said crankpin when the motor is running in the forward direction and rotates to and operates at a second position relative to said crankpin when the motor is running in the reverse direction. The combined eccentricities of the crankpin and the cam cause the piston to have a first stroke when the motor operates in the forward direction and a second stroke when the motor operates in the reverse direction. There is also provided a control for selectively operating the motor either in the forward direction or in the reverse direction.

Owner:BRISTOL COMPRESSORS INT

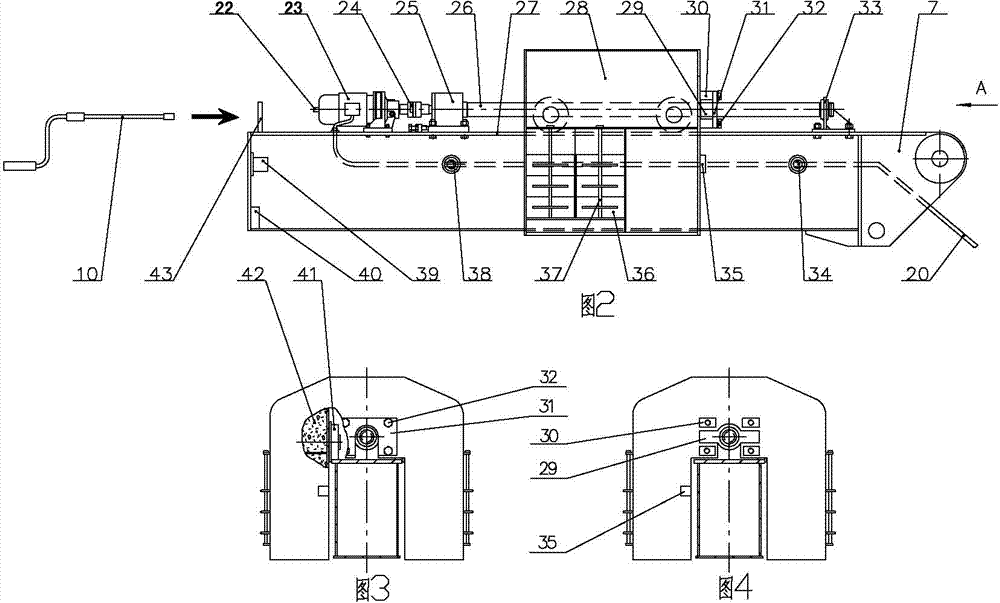

Intelligent oil pumping control method and intelligent oil pumping unit

ActiveCN104775792AMaximize outputCompact and reasonable structureFlexible member pumpsFluid removalReduction driveNetworked system

The invention relates to the technical field of beam-pumping units, in particular to an intelligent oil pumping control method and an intelligent oil pumping unit. The intelligent oil pumping unit comprises a main motor, a speed reducer, a crank, a connecting rod, a walking beam, a balance lifting arm, a bracket, a horse head, a base, a brake device, a beam hanger, a load sensor, a strole process measurer, a safety limiting device and a digital control cabinet, has the characteristics of safety and reliability, realizes the intelligent optimization and adjustment of stroke times and balance of the oil pumping unit, fully exerts the well yield, improves the oil pumping unit well system efficiency, is in seamless joint with an oil field computer network system to realize the data remote transmission and the remote switch well control, simplifies the operation, is convenient and fast, saves the labor, saves the energy, reduces the emission, and improves the economic benefit.

Owner:XINJIANG UYGUR AUTONOMOUS REGION NO 3 MACHINE TOOL WORKS

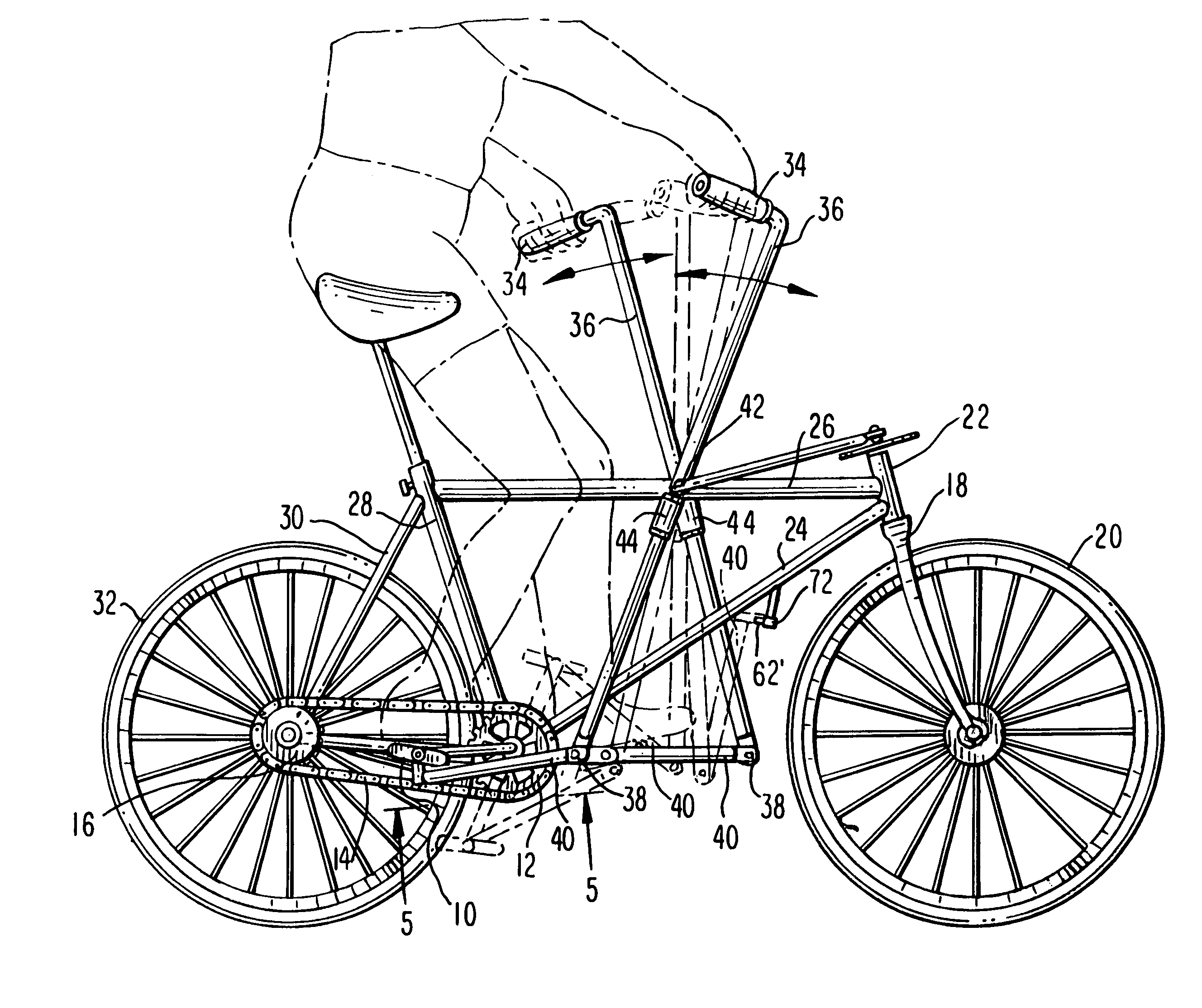

Bicycle propulsion system

ActiveUS7000934B1Reliable and positive forceEasy to useSteering deviceRider propulsionEngineeringMechanical engineering

The disclosure herein provides a two-wheel bicycle system wherein a pair of long levers are arranged on the cross-beam of the frame, to provide the fulcrum for the motion of the levers. The tops of the levers comprise handles perpendicular to such levers, with linkages to a circular and rotatable crank, which rotates in a plane parallel to the ground about a column commonly found in the steering mechanism for such a bicycle. The bottom ends of the levers connect to linking members to connect such levers to the pedals commonly found in such a bicycle. Such linking members are provided so that they are disconnected and then rotatable to be mounted on the diagonal frame piece of the bicycle, when the bicycle is used with hand-operated steering and foot-operated power. Before disconnection, only upper body energy is used to control both steering and powering the bicycle.

Owner:CAPEK WILLIAM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com