Patents

Literature

40815results about "Electrical control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

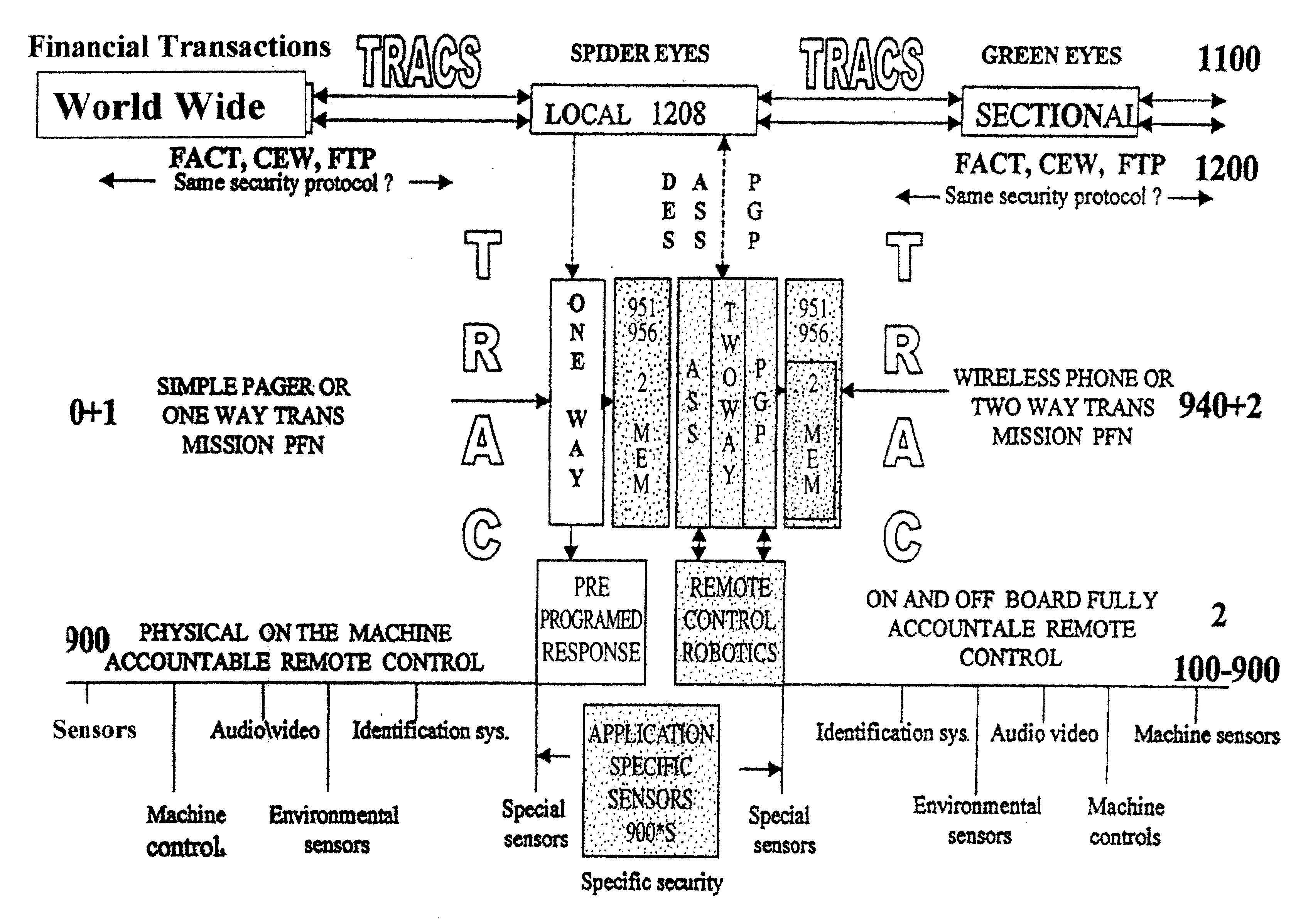

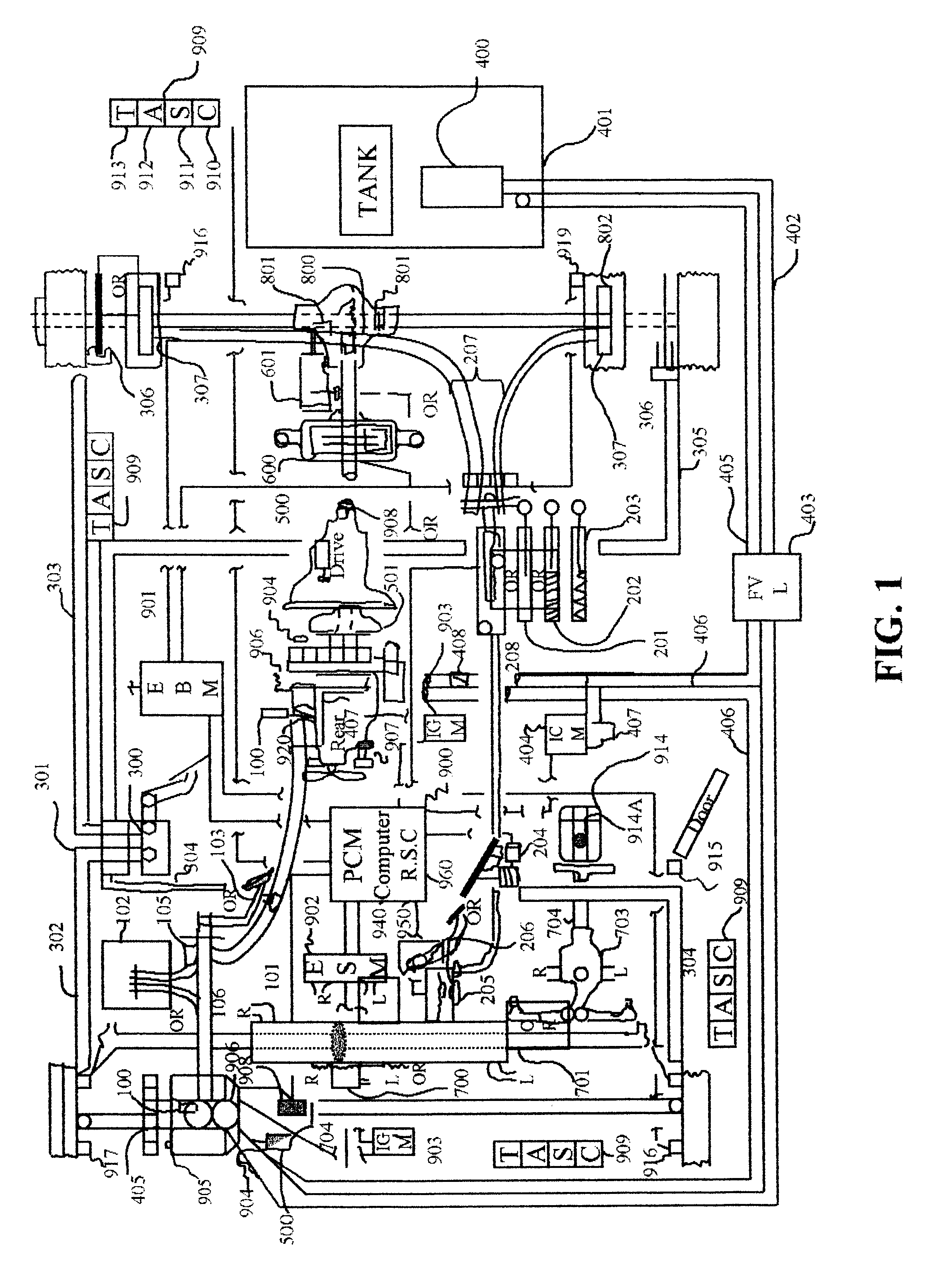

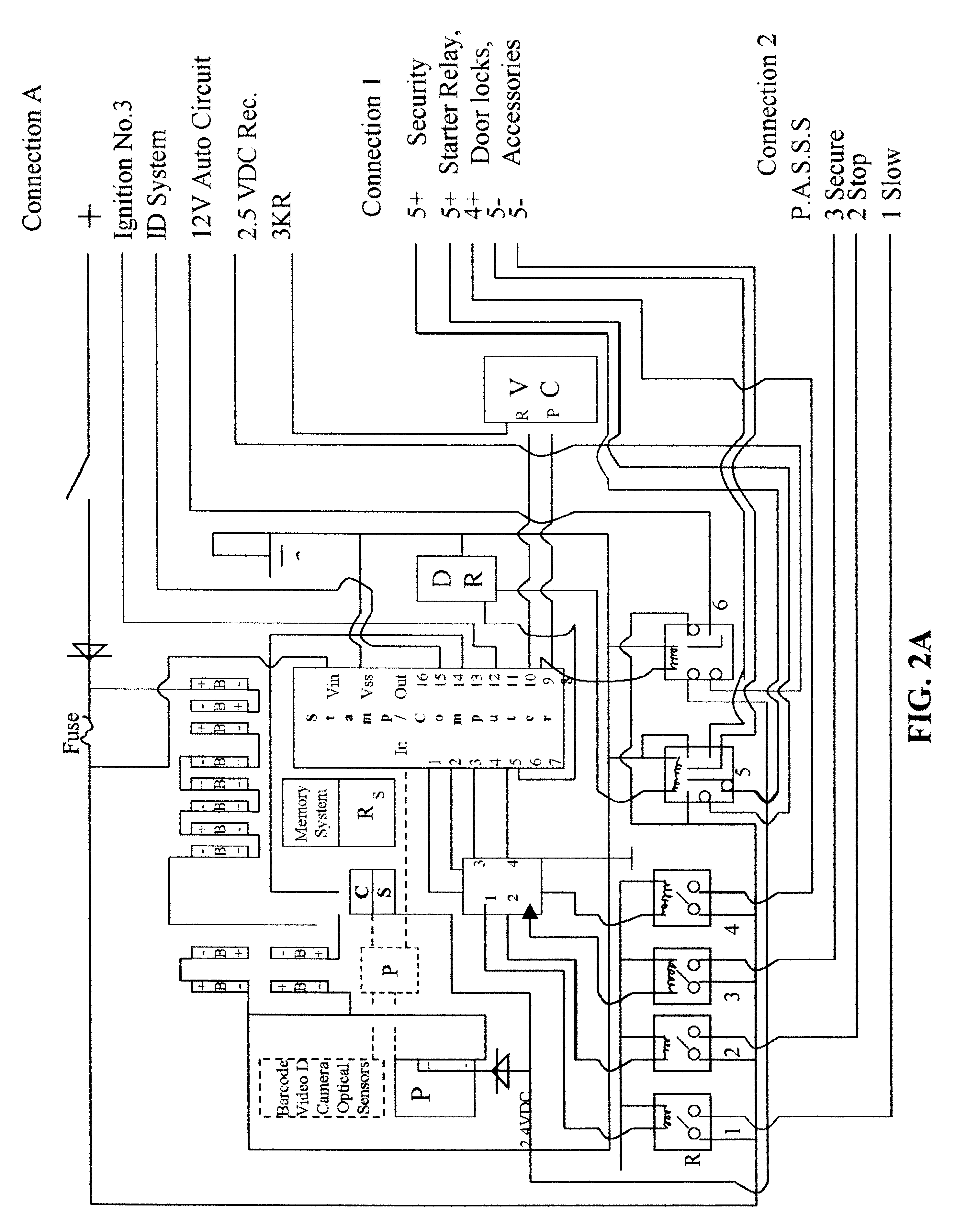

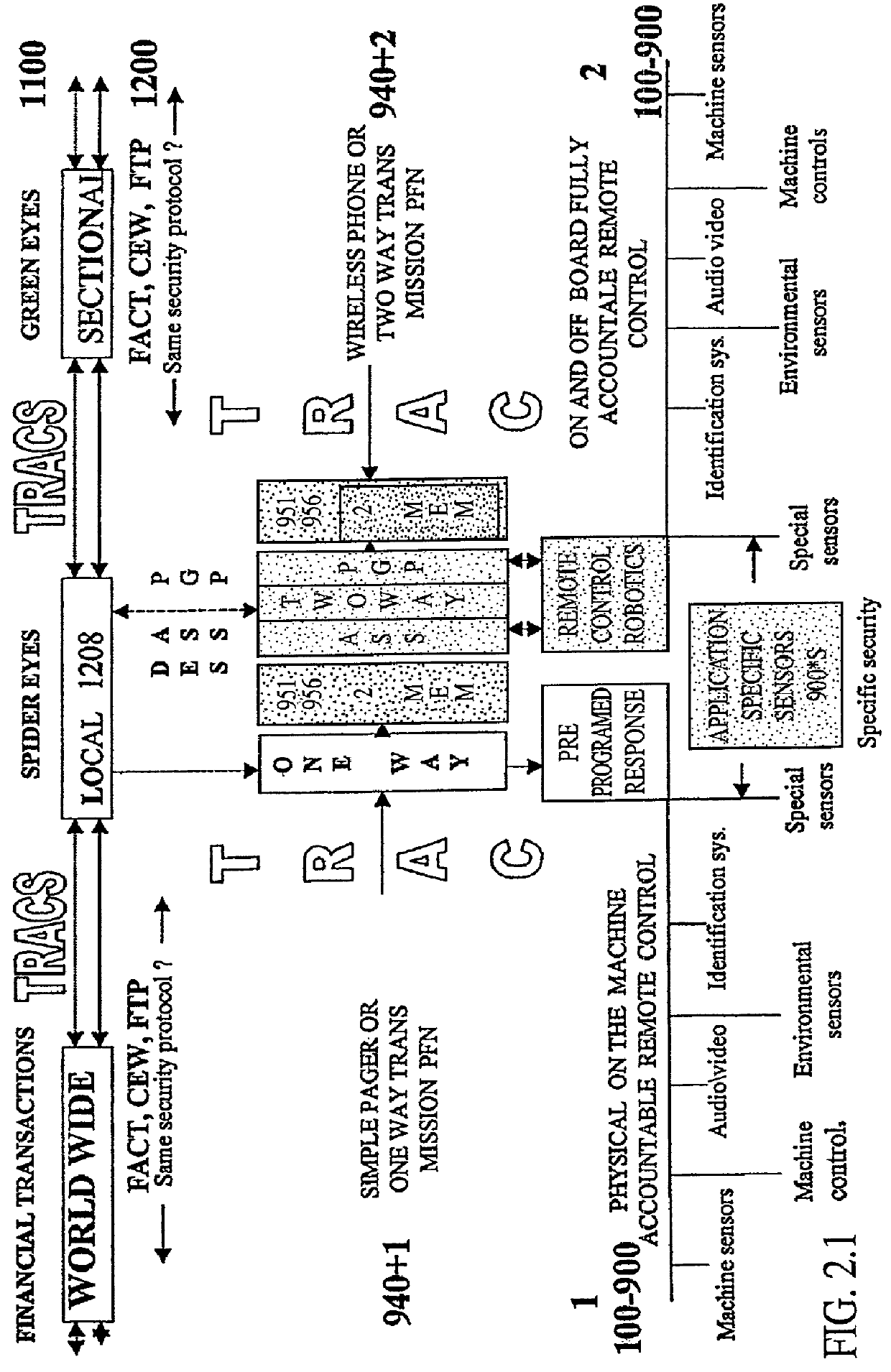

Electrically controlled automated devices to control equipment and machinery with remote control and accountability worldwide

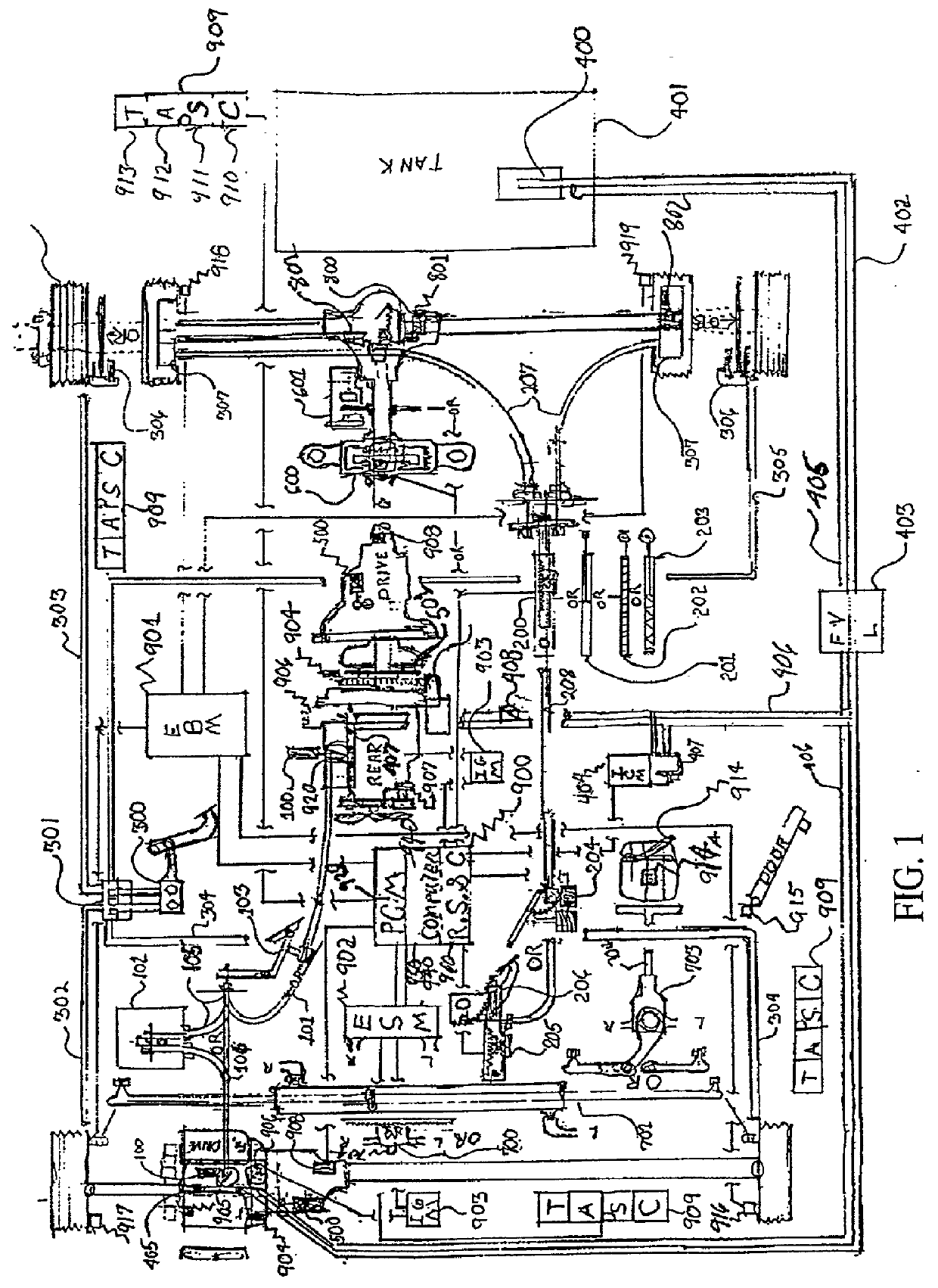

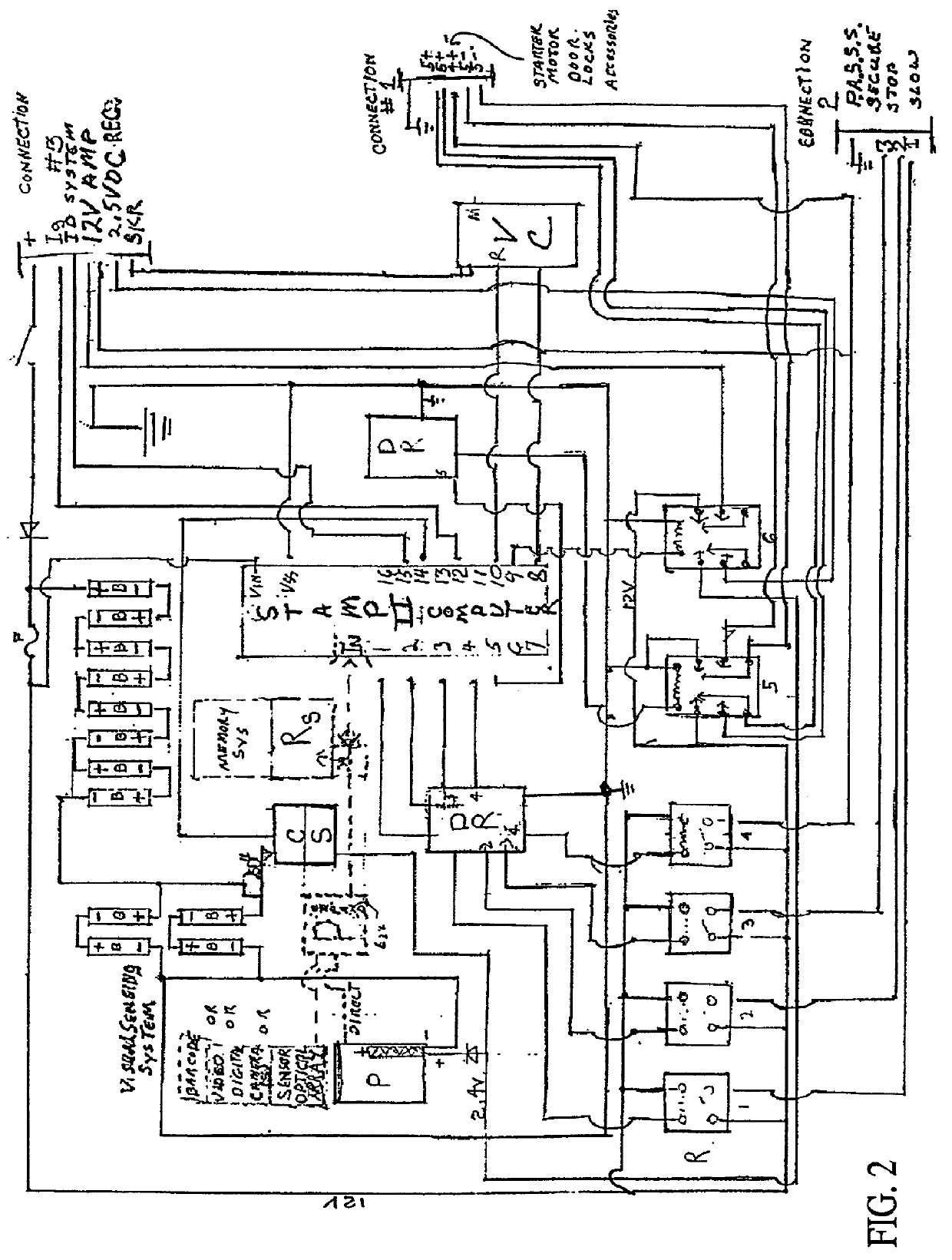

This application describes completely in many unique ways and detail all the devices to reduce a vehicle's speed and / or reduce a machines RPMs and / or stop any piece of equipment's as well as guide it if mobile through automated controls. First to slow it down, and guide it and / or control it if necessary (i.e., other pieces of equipment). Secondly it discusses how to stop any piece of equipment completely. And thirdly, the invention secures it in a safe stationary position either entirely or any number of specific moving parts. Many of these systems are initially here described to slow, reduce speed, steer, stop and / or secure equipment functions. However, they also can be used to increase a piece of equipment's functions. In other words their variations are completely capable to serve any remote or automated controls on a vehicle in the future to provide full robotics systems, e.g., for automated transportation systems, automated manufacturing, etc., either through individually isolated remote control systems and / or interfaced with other off-board systems through communication links, gateway computers, computer networks and the world wide web for inexpensive long distance monitoring and remote control. The invention focuses on the automobile industry but as has always been maintained throughout all these applications these devices and systems are designed to control every piece of equipment. The invention includes various accountable protocols and commercial developments to control speed, brake and steering for an automobile shut down to be performed through automation to a safe controlled secured deactivated state to be considered as a basis for a standard in aggressive vehicle remote control and / or to control and guide a vehicle and / or piece of equipment through many different automated systems.

Owner:KLINE & WALKER

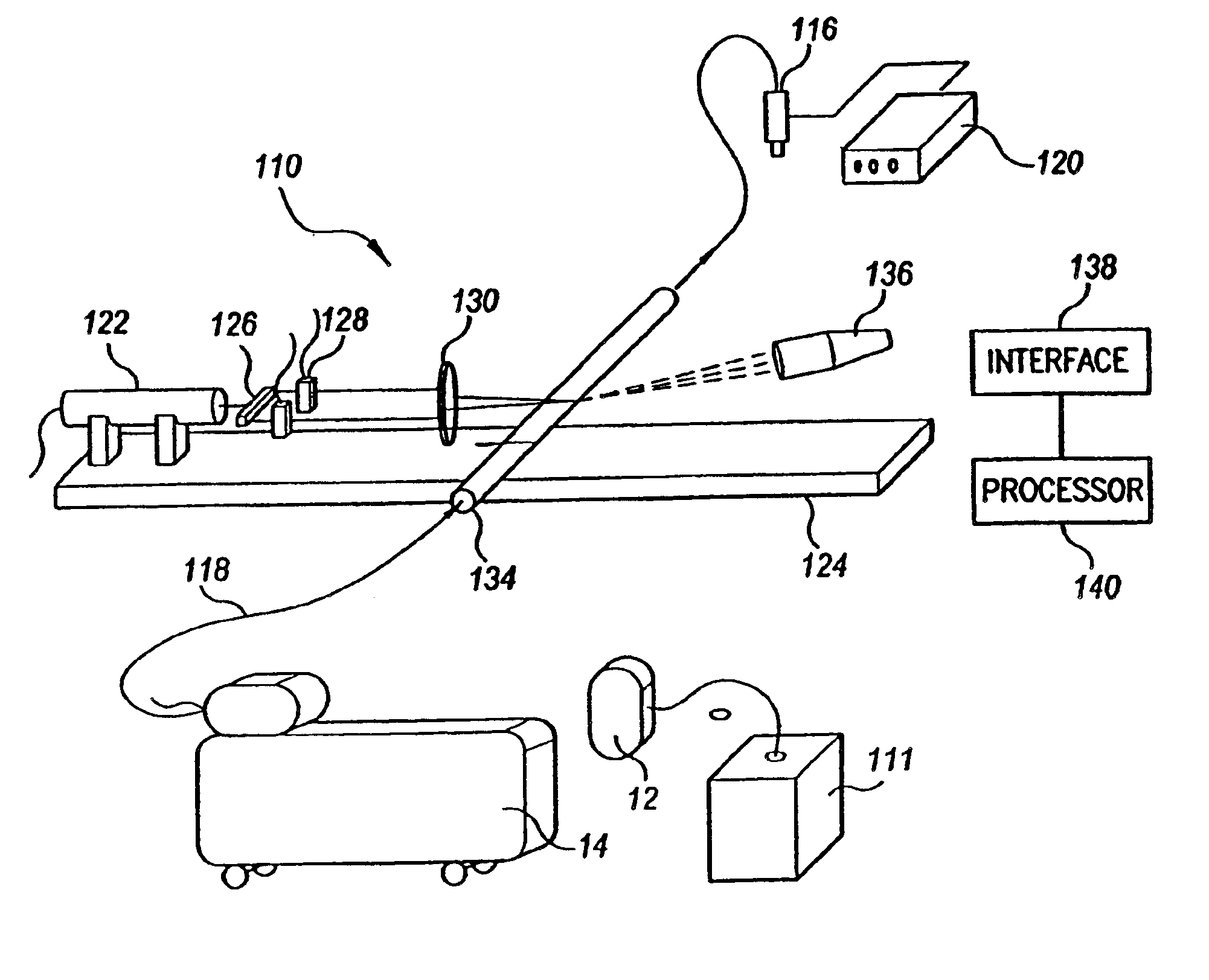

Flow meter

Various embodiments of the present invention provide a flow meter device having a laser Doppler anemometer (LDA) which measures the instantaneous center line velocity of fluid flow in a pipe. The flow meter may process the instantaneous velocity so obtained to compute the volumetric flow rate, mass rate, and / or other flow characteristics (e.g., as instantaneous quantities and / or integrated over a time interval) The flow meter may use an electronic processing method. The electronic processing method may provide essentially an exact solution to the Navier-Stokes equations for any periodically oscillating flow.

Owner:COMBUSTION DYNAMICS

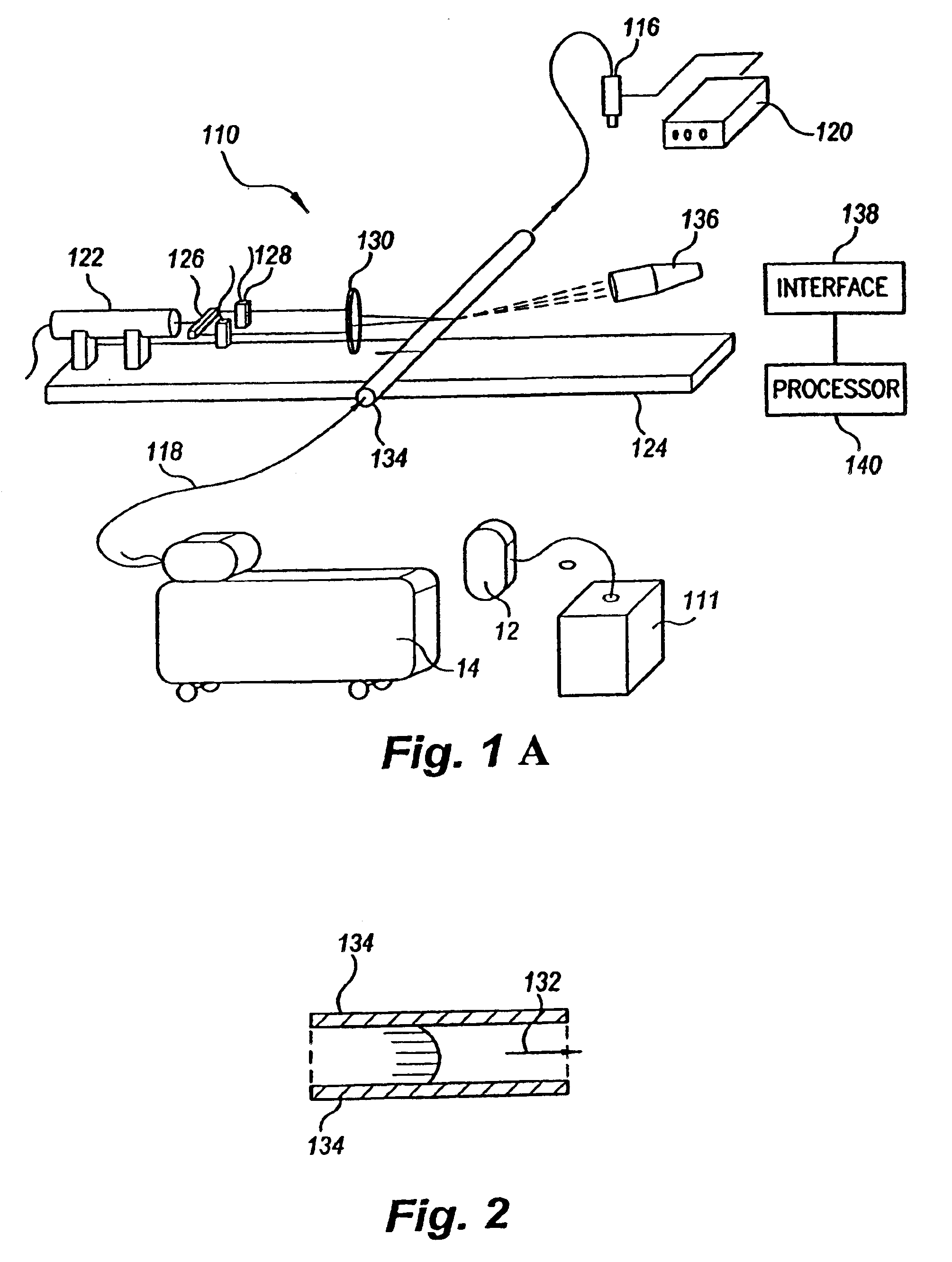

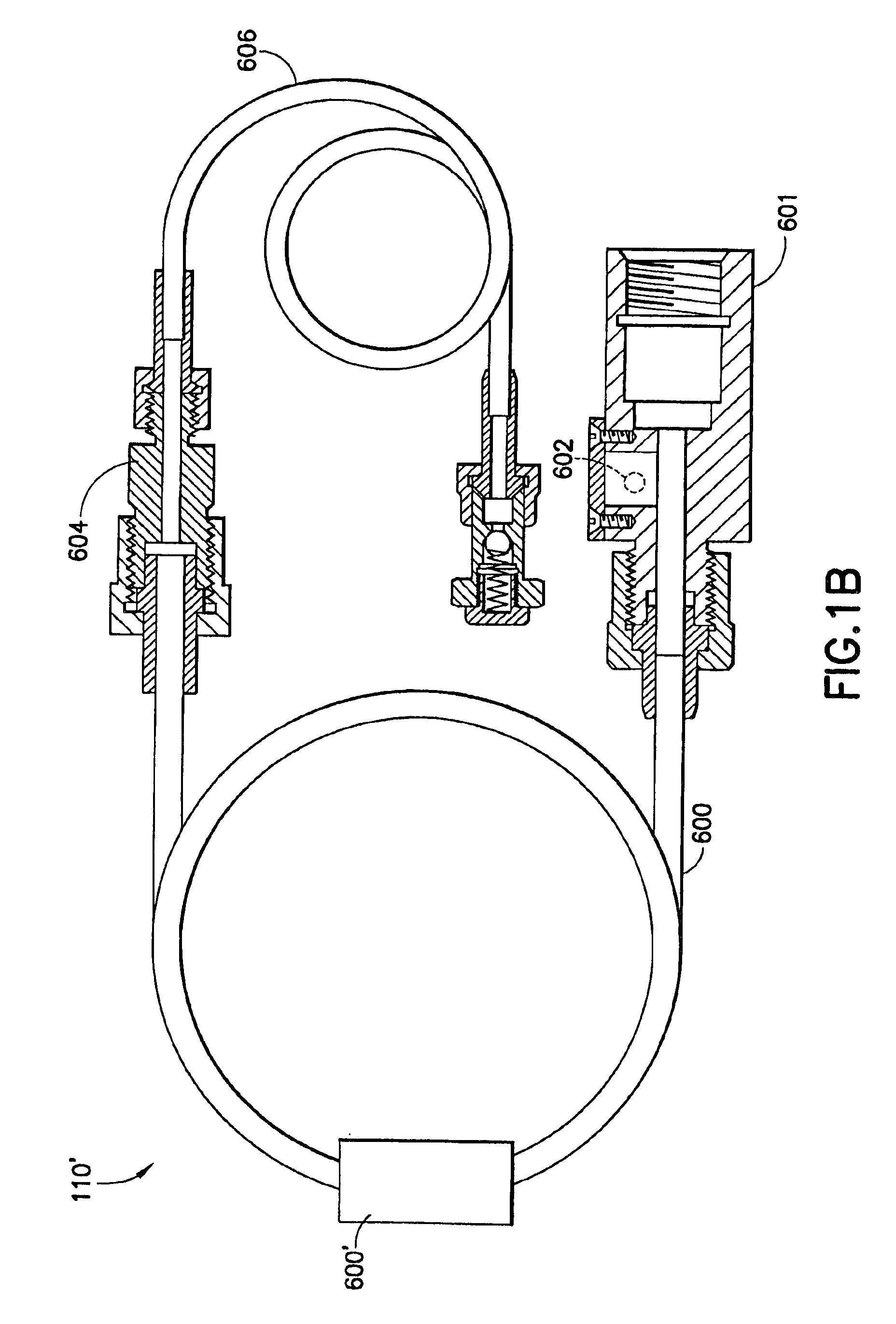

Electrically controlled automated devices to operate, slow, guide, stop and secure, equipment and machinery for the purpose of controlling their unsafe, unattended, unauthorized, unlawful hazardous and/or legal use, with remote control and accountability worldwide

InactiveUS20010056544A1The degree of freedom becomes largerElectrical controlVehicle fittingsRobotic systemsRobotics

This application describes completely in many unique ways and detail all the devices to reduce a vehicle's speed and / or reduce a machines RPM's and / or stop any piece of equipment's as well as guide it if mobile through automated controls. First to slow it down, and guide it and / or control it if necessary (i.e., other pieces of equipment). Secondly it discusses how to stop any piece of equipment completely. And thirdly, the invention secures it in a safe stationary position either entirely or any number of specific moving parts. Many of these systems are initially here described to slow, reduce speed, steer, stop and / or secure equipment functions. However, they also can be used to increase a piece of equipment's functions. In other words their variations are completely capable to serve any remote or automated controls on a vehicle in the future to provide full robotics systems, e.g., for automated transportation systems, automated manufacturing, etc., either through individually isolated remote control systems and / or interfaced with other off-board systems through communication links, gateway computers, computer networks and the world wide web for inexpensive long distance monitoring and remote control. The invention focuses on the automobile industry but as has always been maintained throughout all these applications these devices and systems are designed to control every piece of equipment. The invention includes various accountable protocols and commercial developments to control speed, brake and steering for an automobile shut down to be performed through automation to a safe controlled secured deactivated state to be considered as a basis for a standard in aggressive vehicle remote control and / or to control and guide a vehicle and / or piece of equipment through many different automated systems.

Owner:KLINE & WALKER

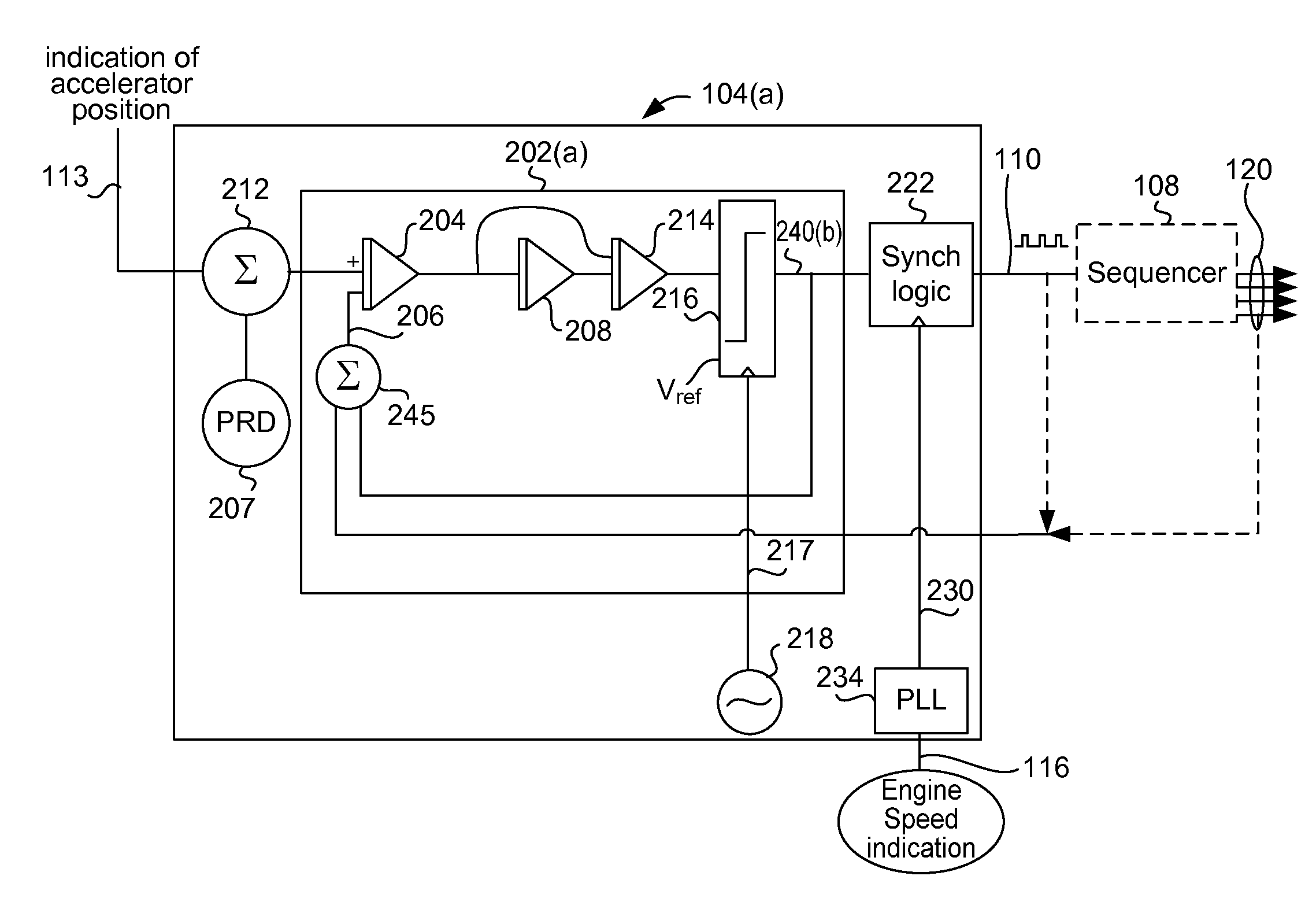

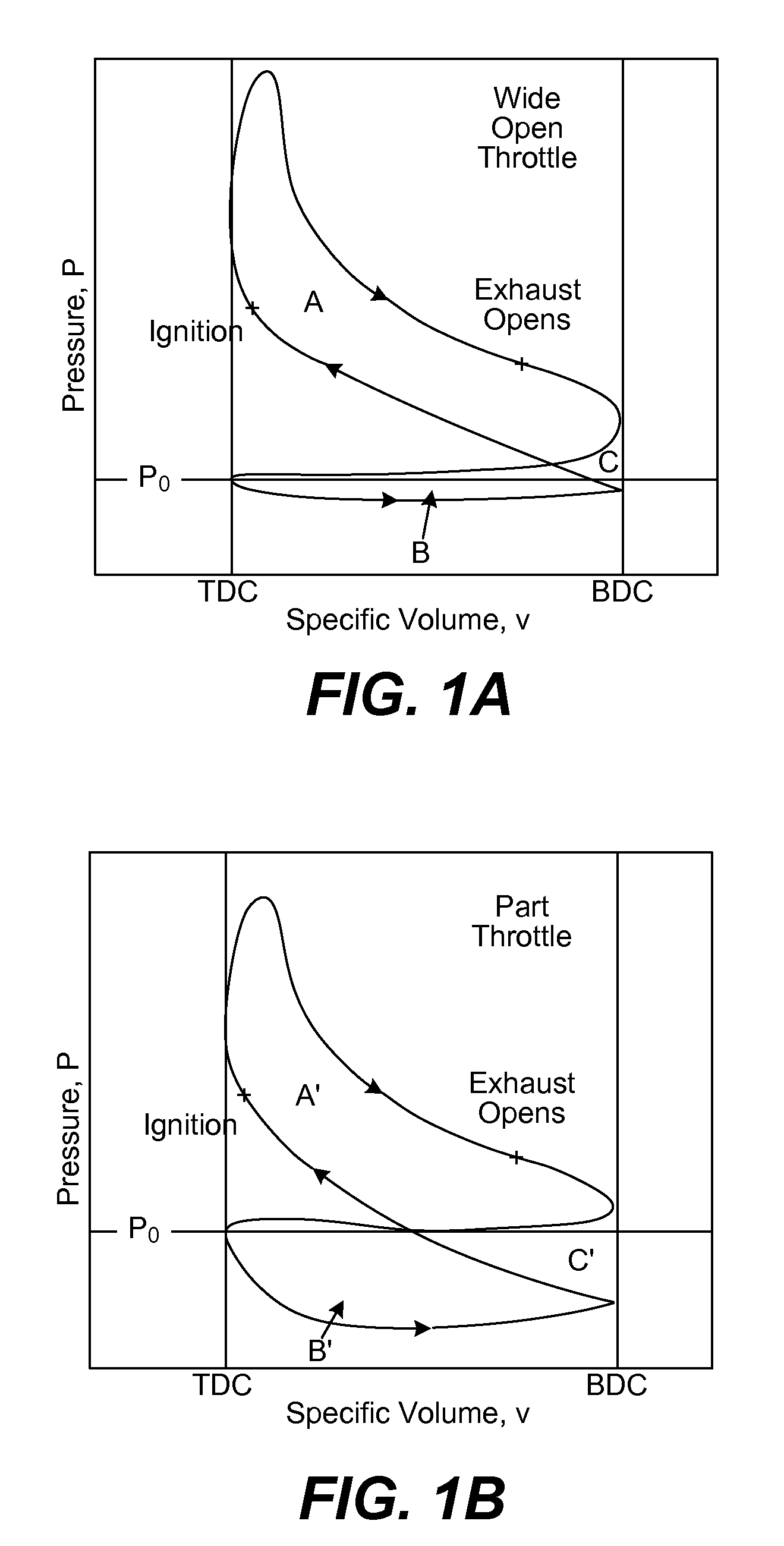

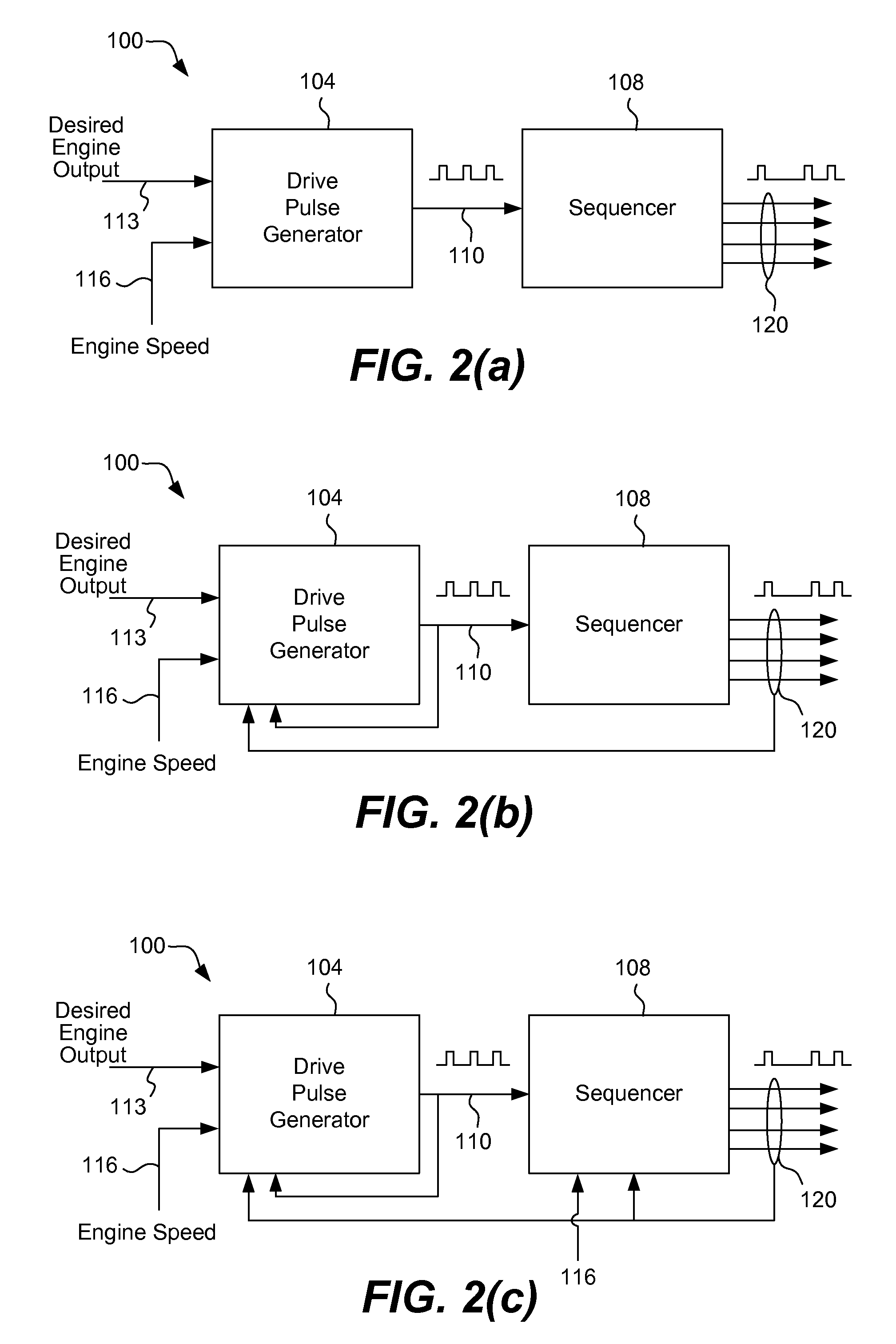

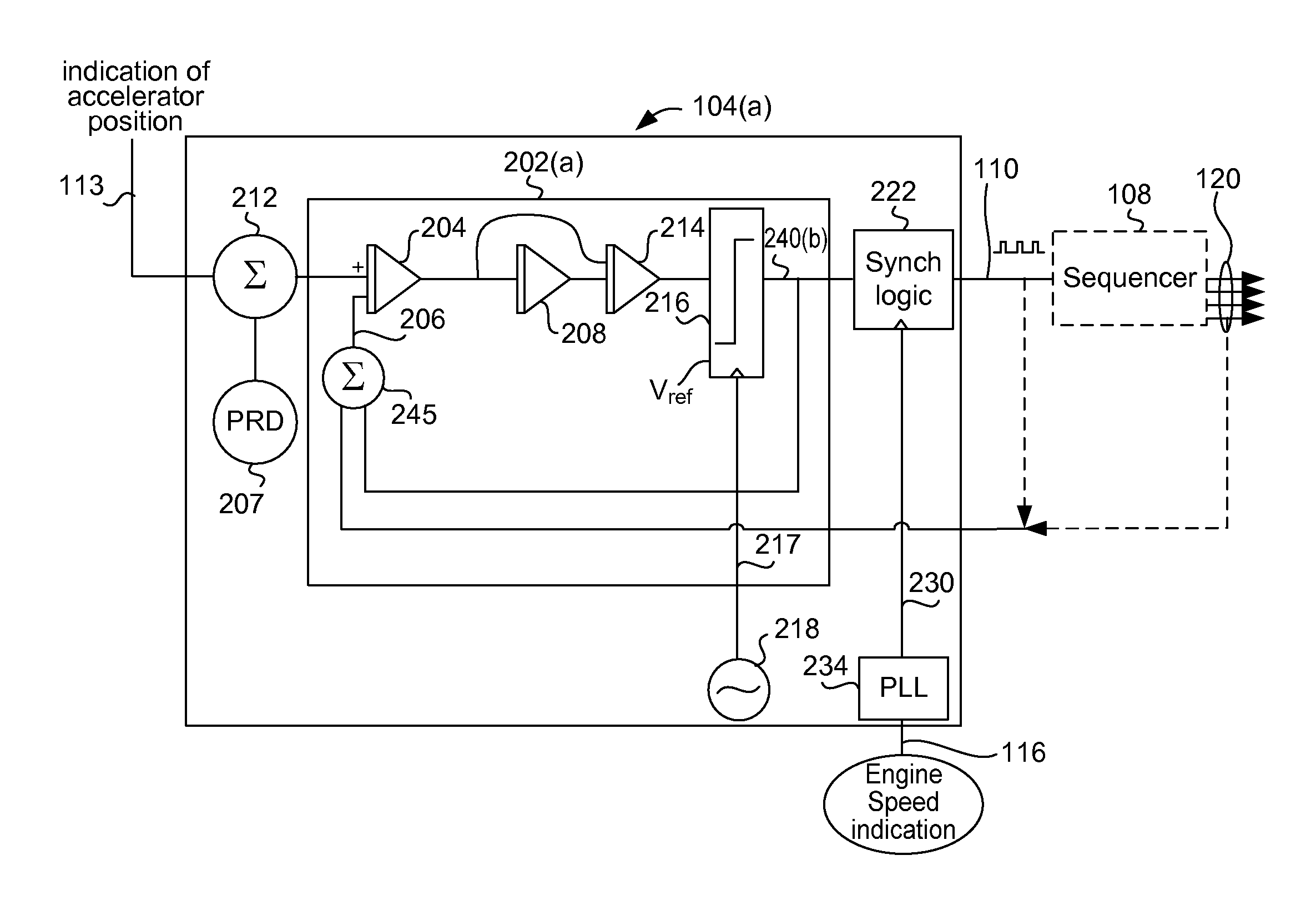

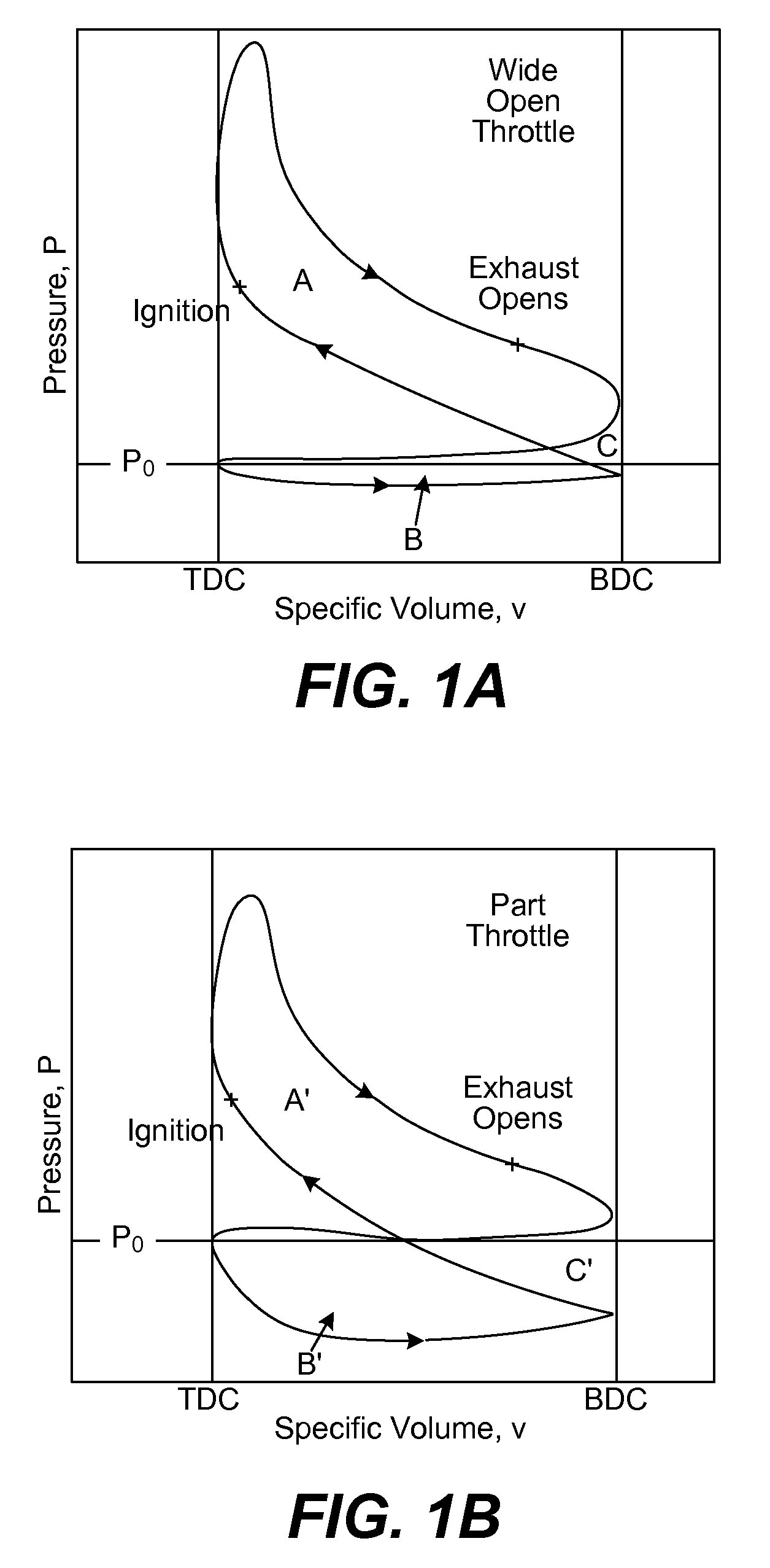

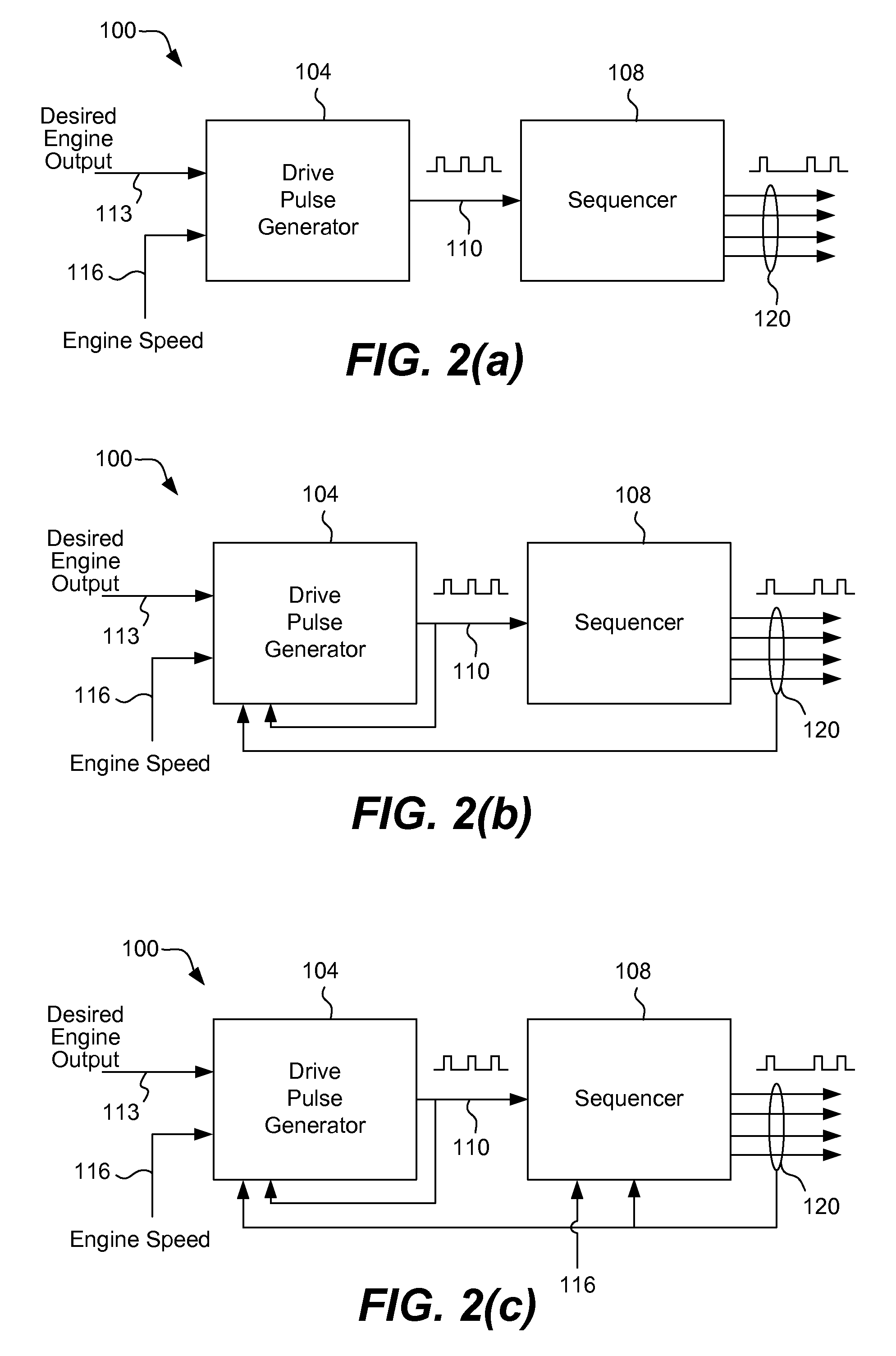

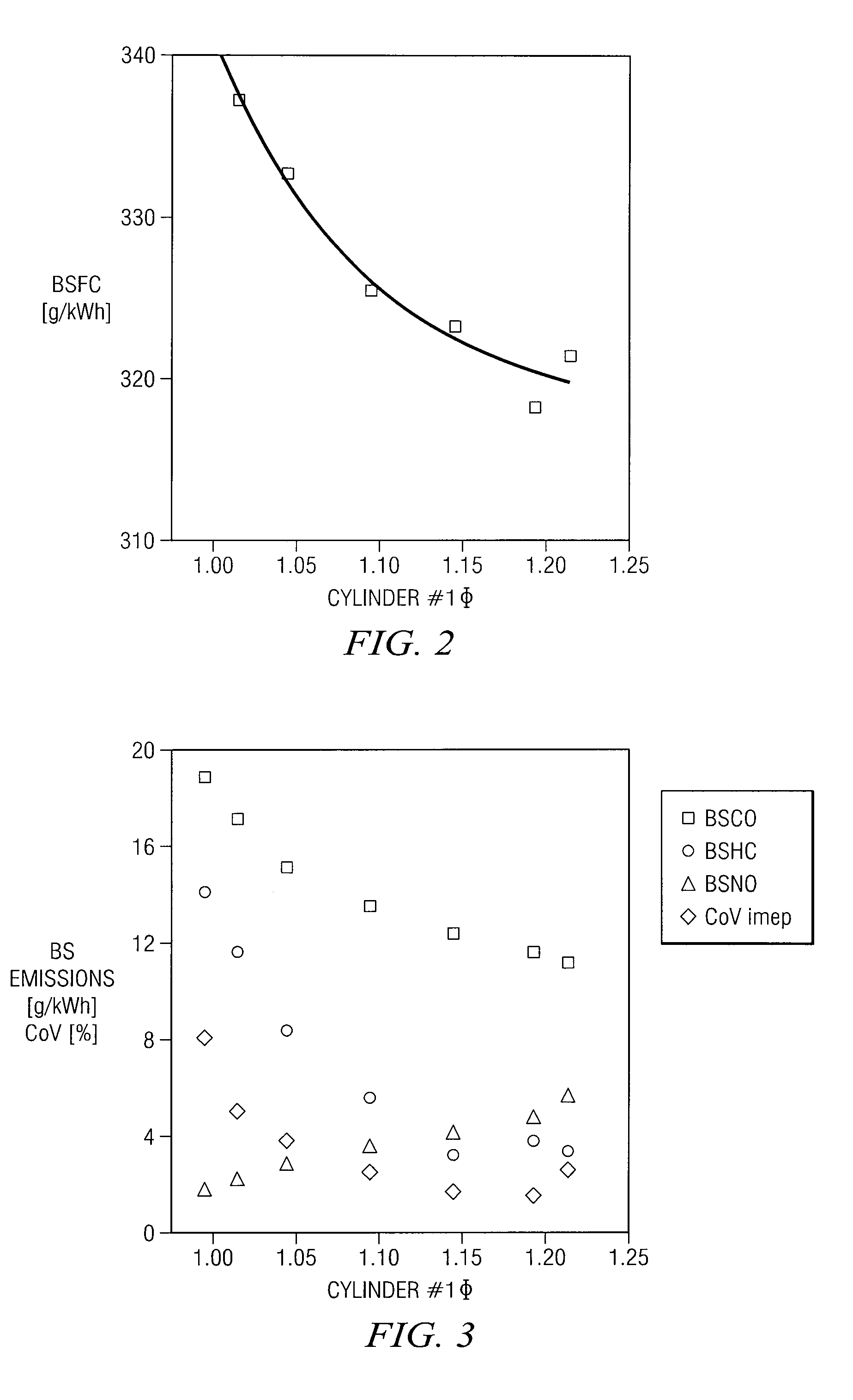

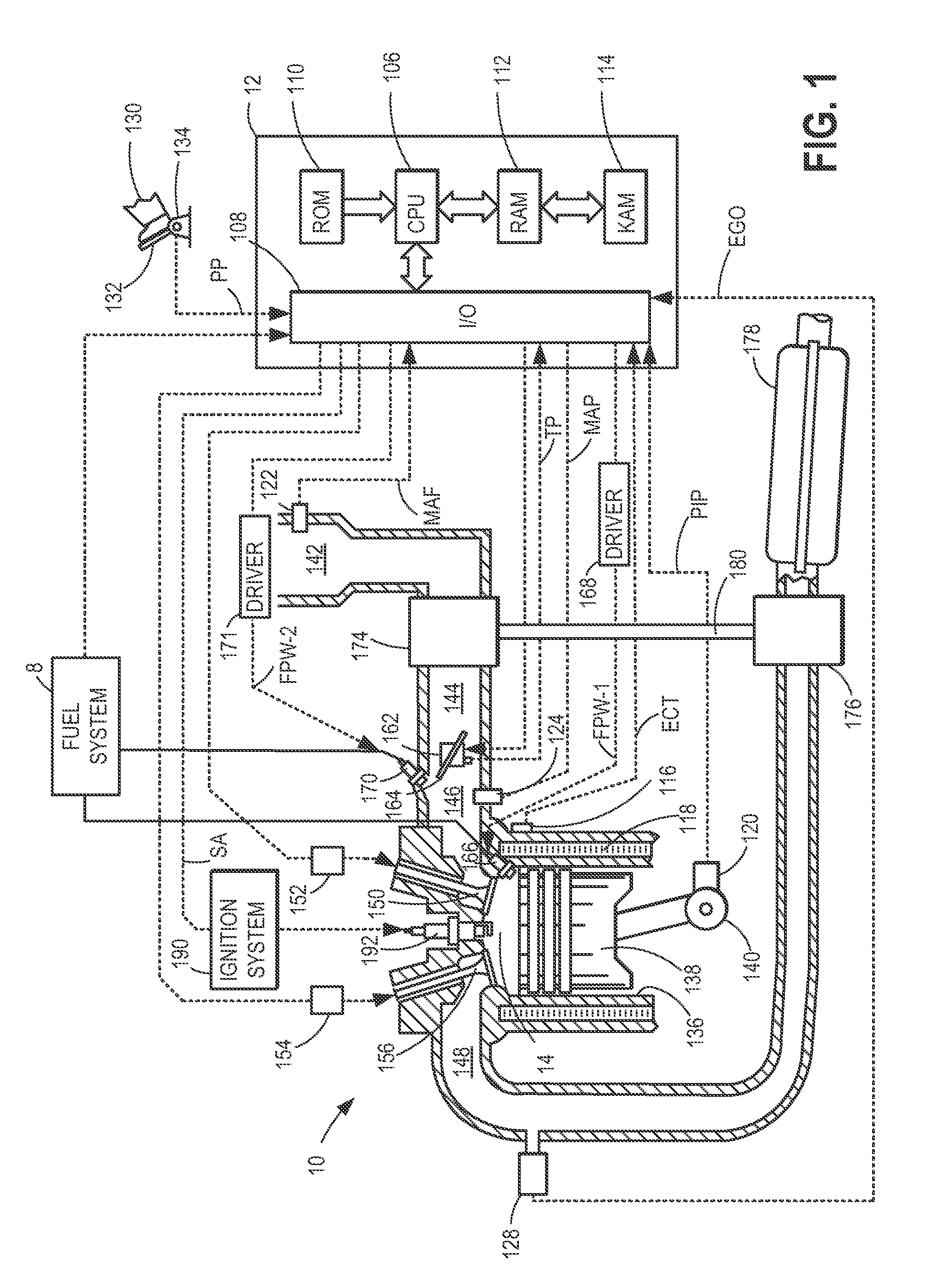

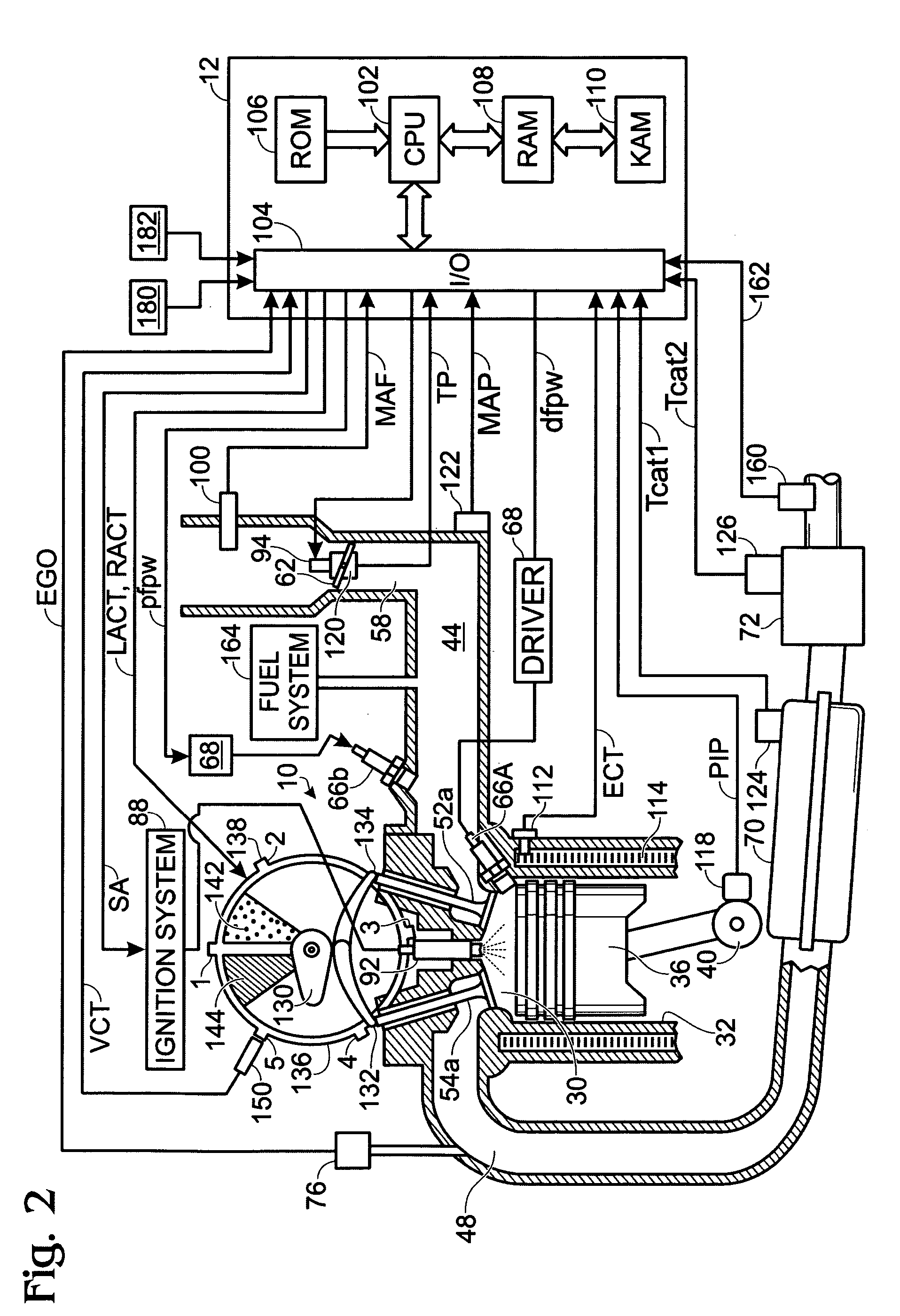

Internal combustion engine control for improved fuel efficiency

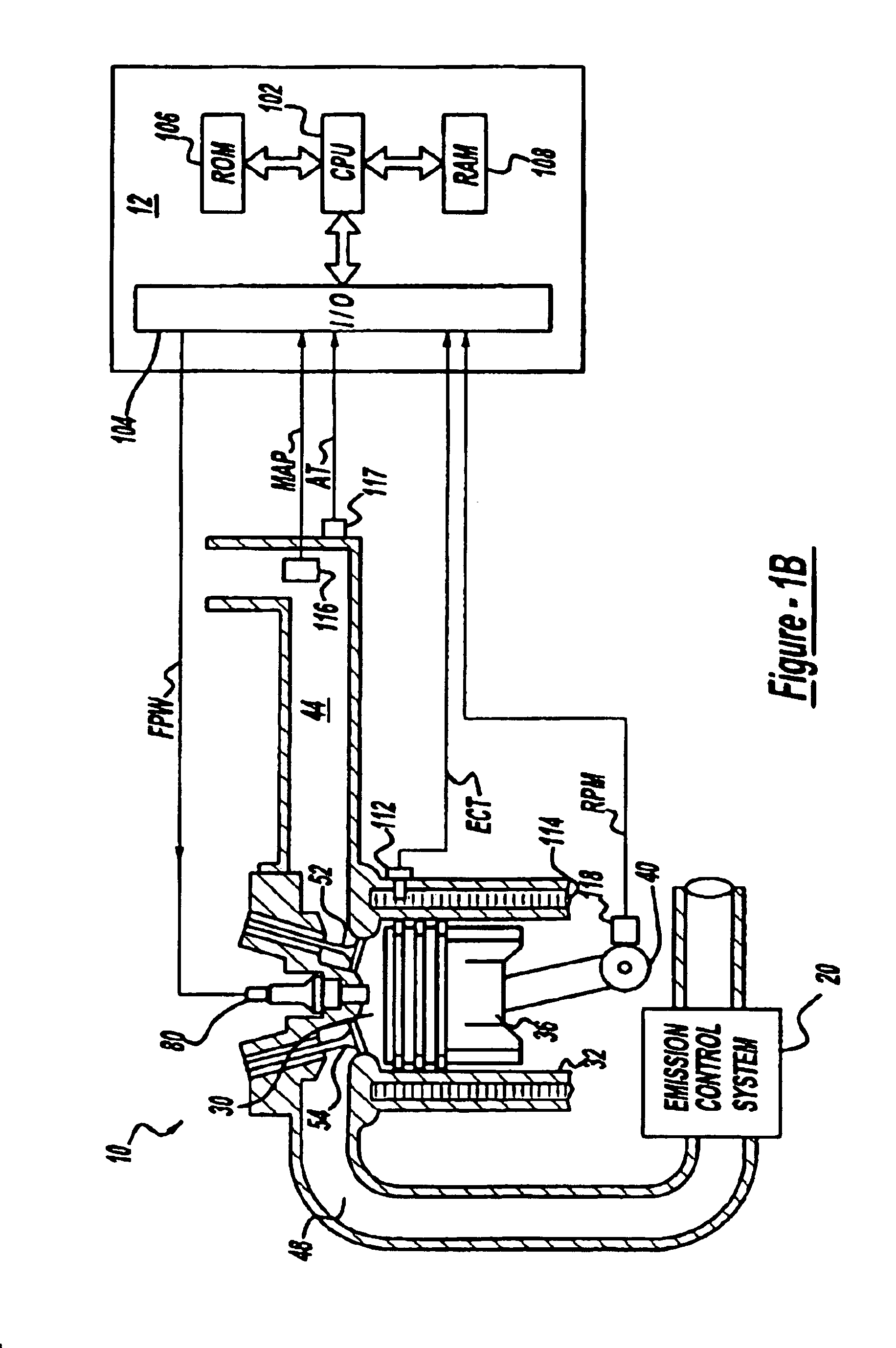

ActiveUS7577511B1Smoother and precise controlReduce probabilityElectrical controlInternal combustion piston enginesExternal combustion engineWork cycle

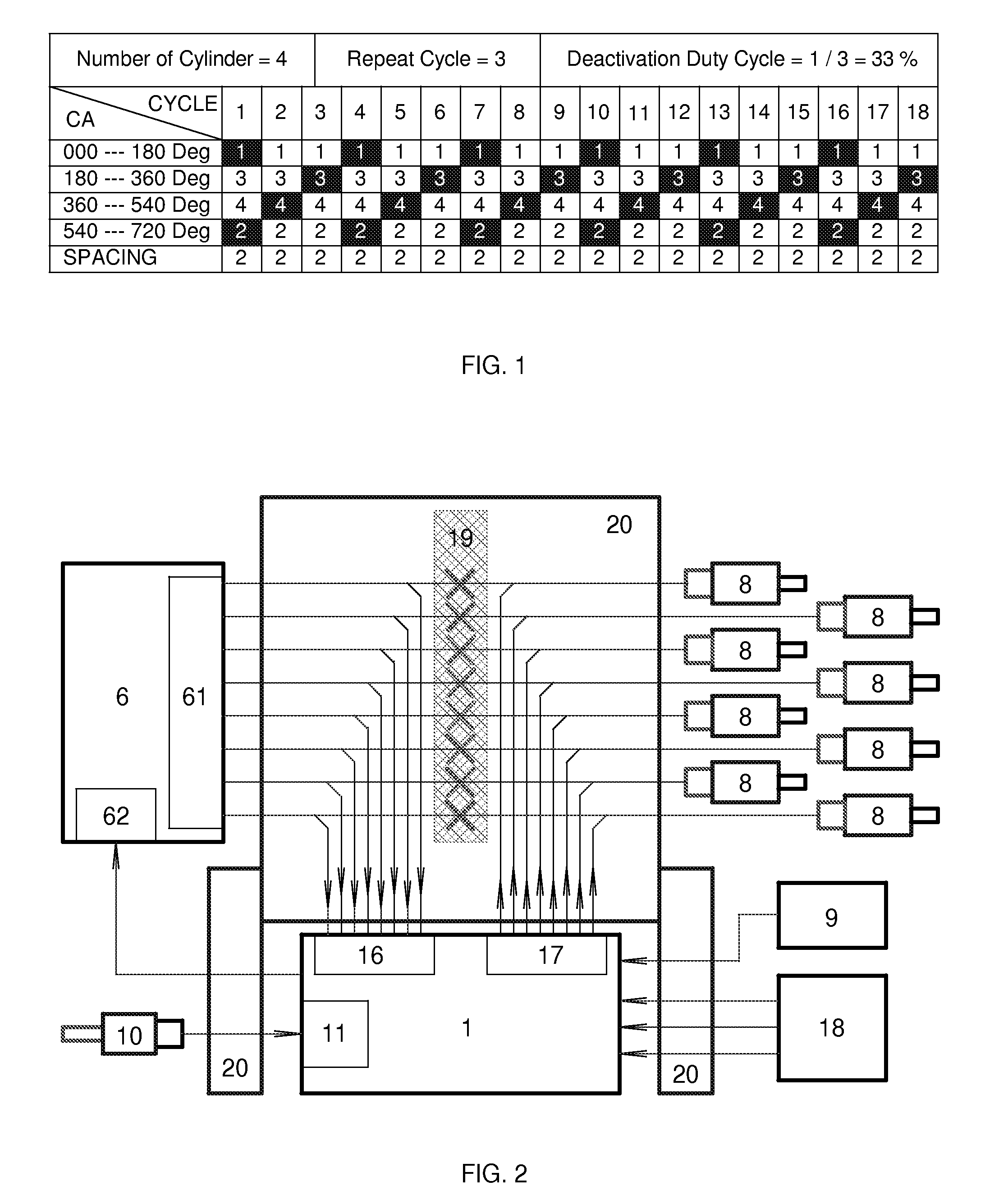

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

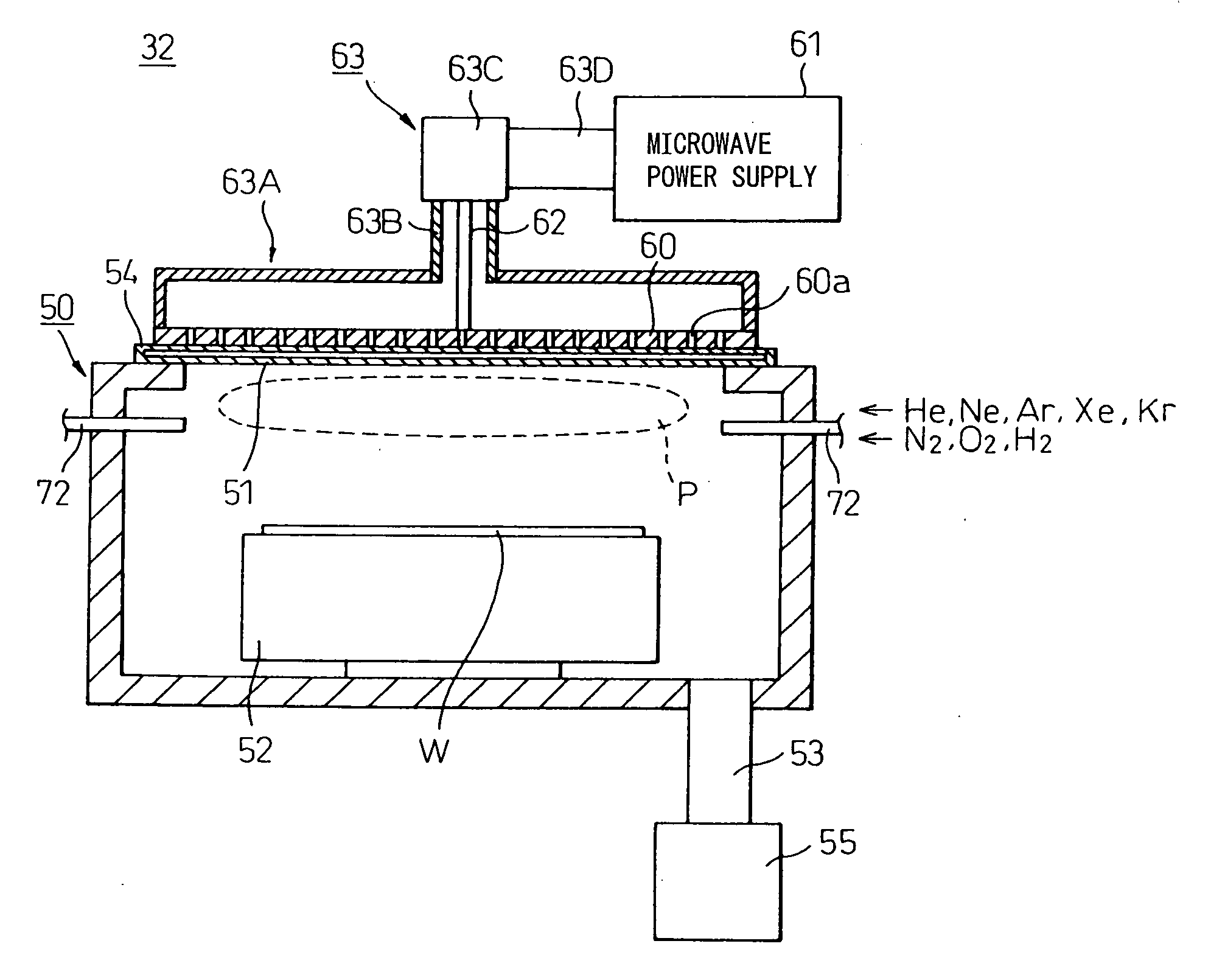

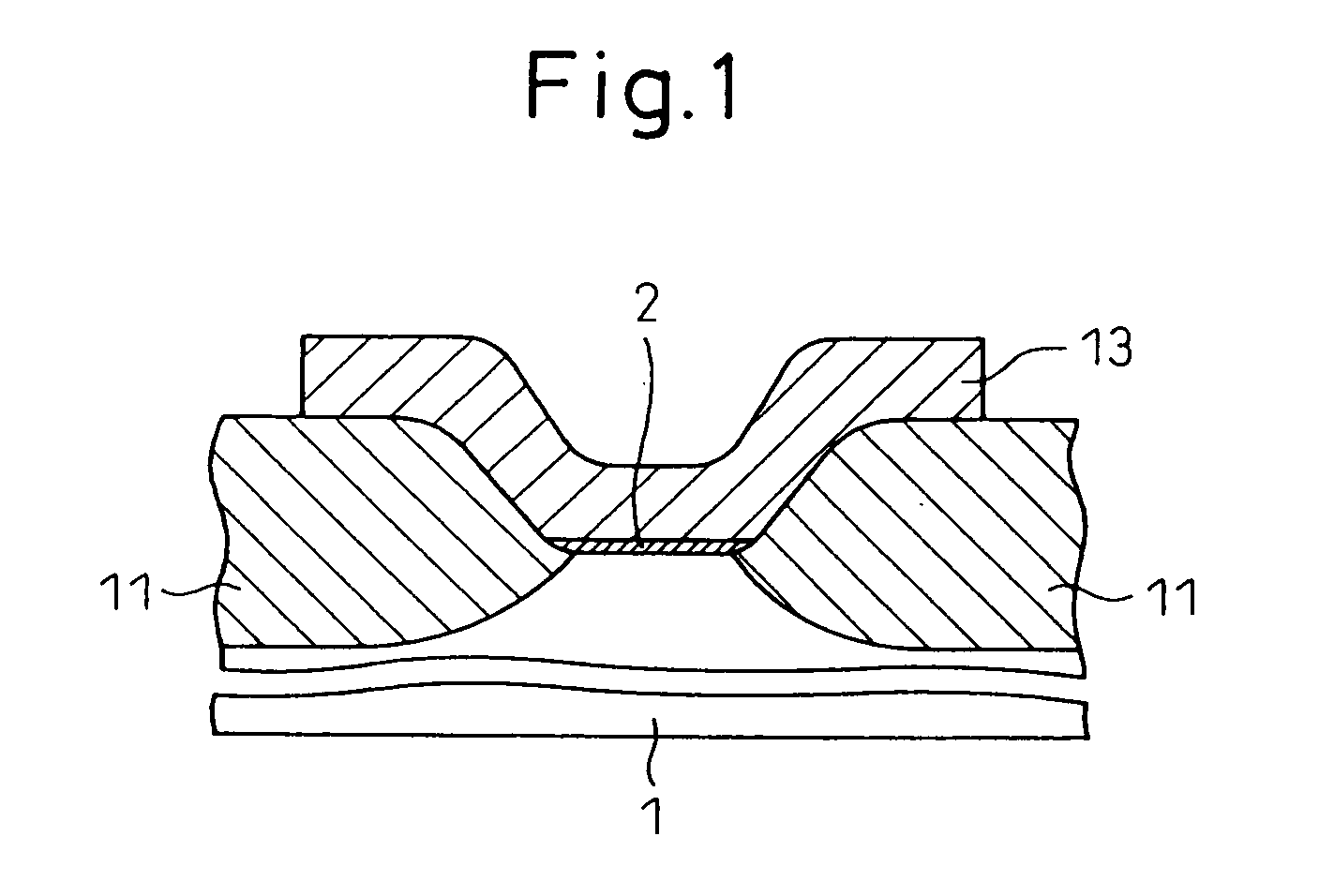

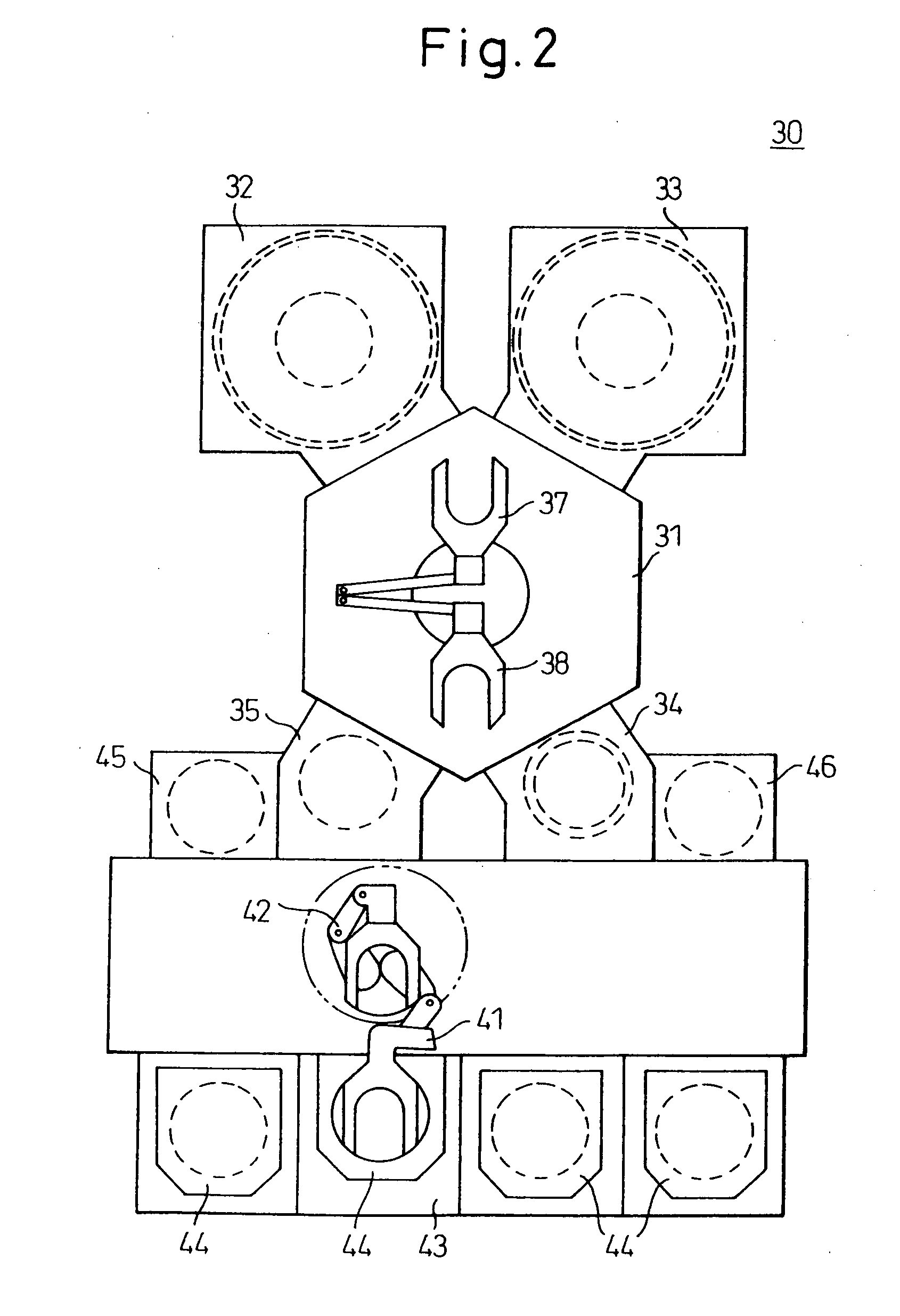

Method for forming insulation film

InactiveUS20050161434A1Quality improvementIncreasing the thicknessElectrical controlDecorative surface effectsSubstrate surfaceElectron

In a process involving the formation of an insulating film on a substrate for an electronic device, the insulating film is formed on the substrate surface by carrying out two or more steps for regulating the characteristic of the insulating film involved in the process under the same operation principle. The formation of an insulating film having a high level of cleanness can be realized by carrying out treatment such as cleaning, oxidation, nitriding, and a film thickness reduction while avoiding exposure to the air. Further, carrying out various steps regarding the formation of an insulating film under the same operation principle can realize simplification of the form of an apparatus and can form an insulating film having excellent property with a high efficiency.

Owner:TOKYO ELECTRON LTD

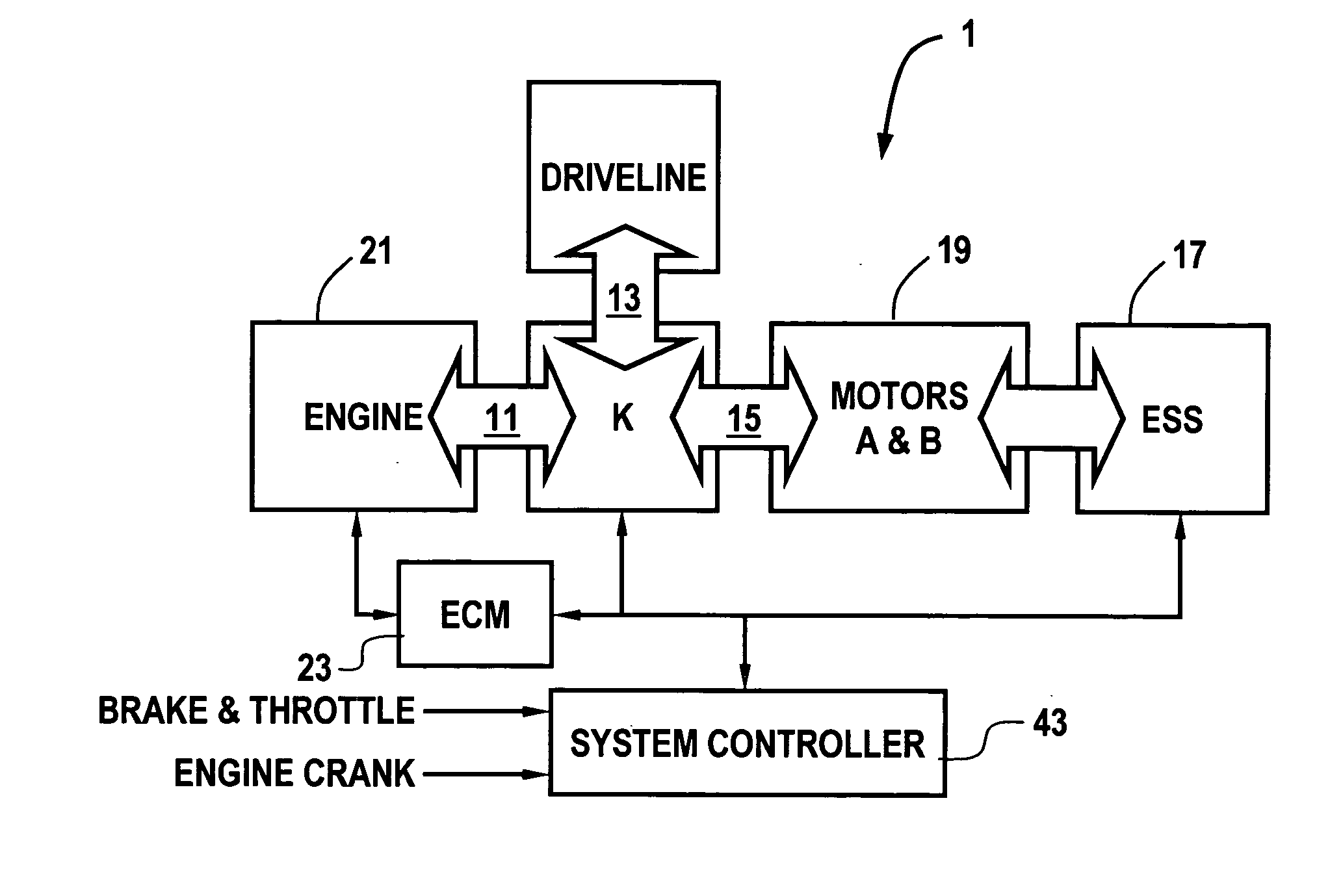

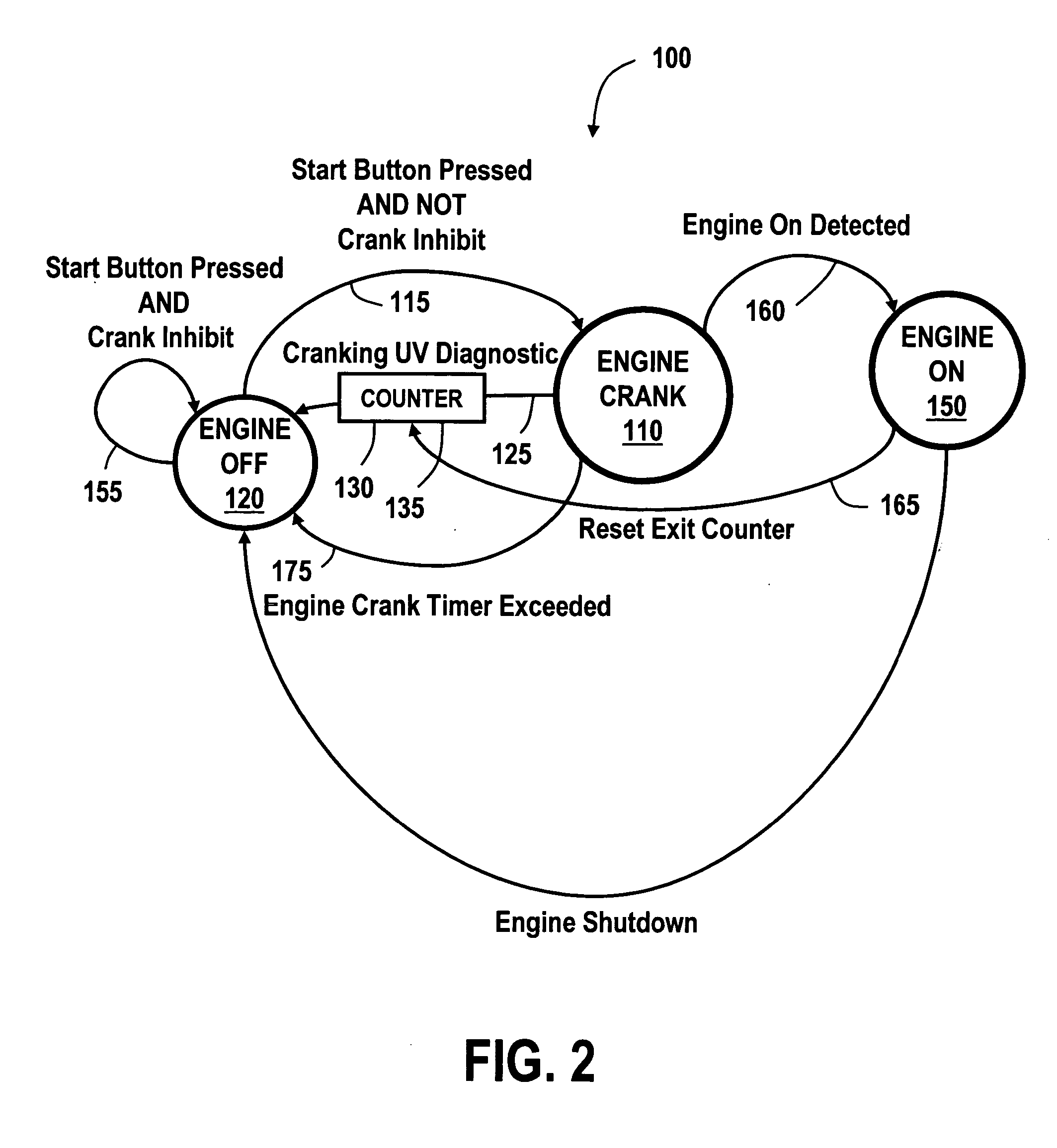

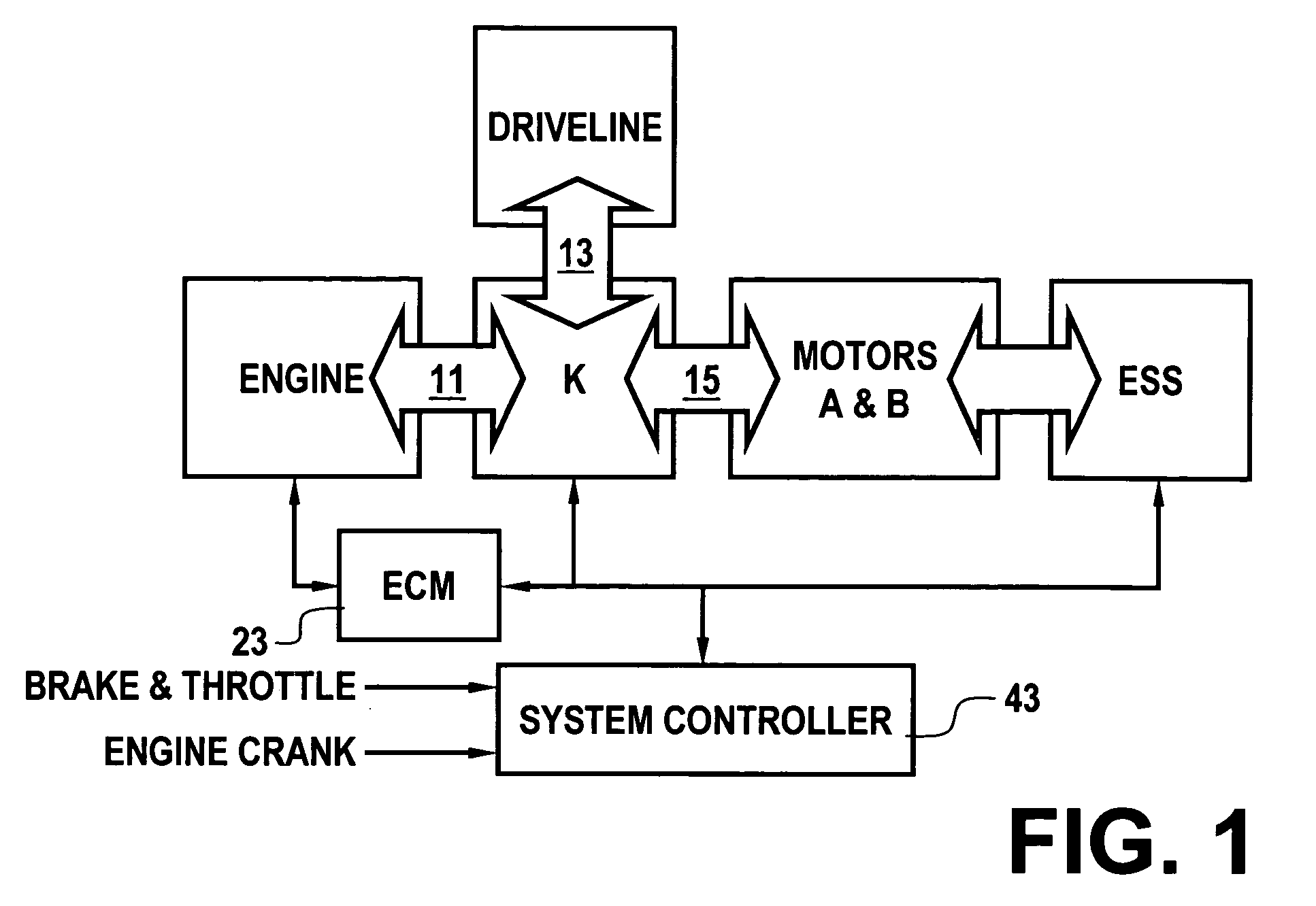

Method of undervoltage protection during engine cranking

ActiveUS20050256617A1Reduce the amount requiredImprove protectionHybrid vehiclesAnalogue computers for vehiclesElectric machineEngineering

A method for controlling the cranking of an engine of a vehicle powertrain system having a rechargeable energy storage system that is adapted to provide electric power to an electric machine, wherein the system is adapted to exit from the engine crank state as a function of an output voltage of the energy storage system to the electric machine during the crank state, if the output voltage is less than a crank undervoltage threshold for a predetermined crank time. According to the method, the crank undervoltage threshold is a function of the number of failed start attempts, generally decreasing as a function of the number of failed start attempts. The predetermined crank time is a function of a magnitude of a difference between the output voltage and the crank undervoltage threshold.

Owner:GM GLOBAL TECH OPERATIONS LLC

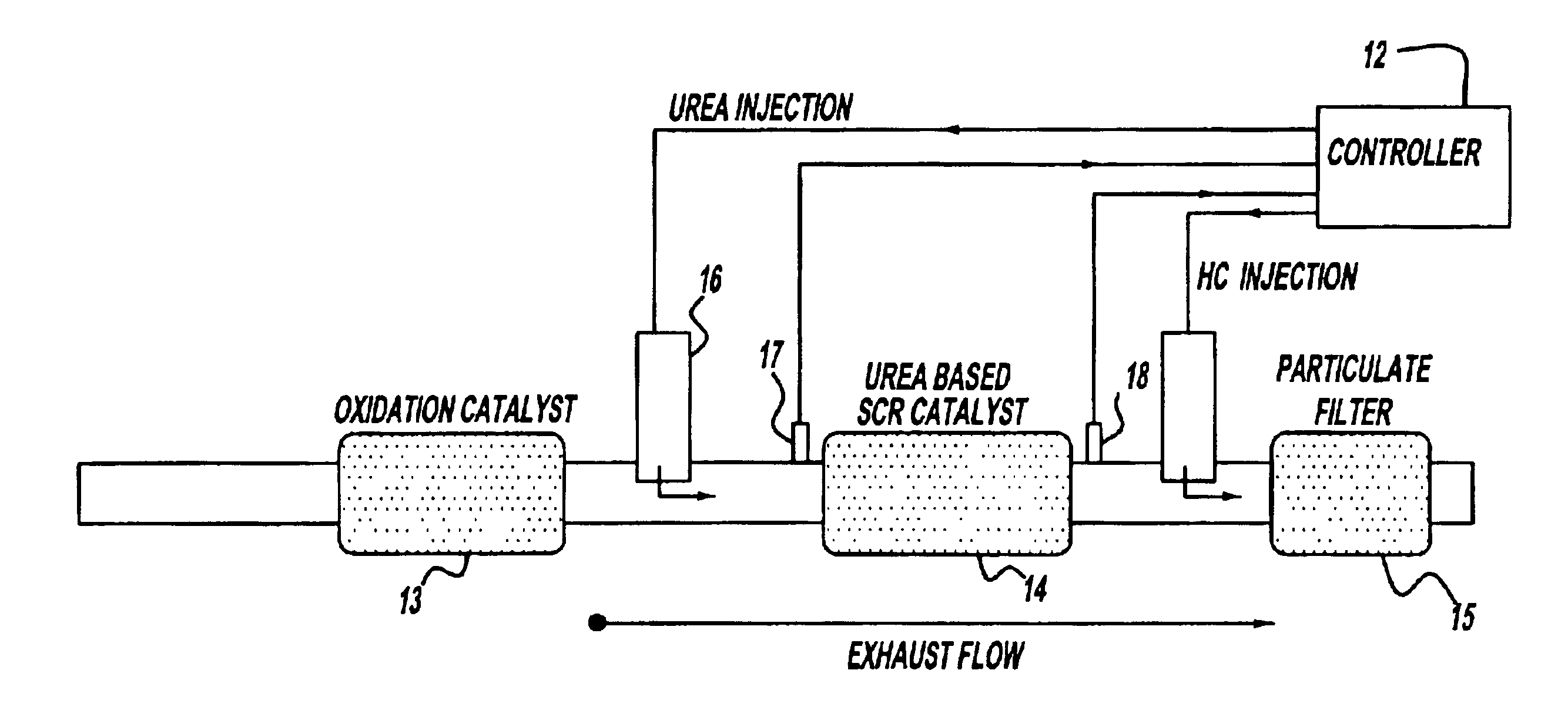

Exhaust gas aftertreatment systems

InactiveUS6928806B2Improve NOx conversion efficiencyHigh operating temperatureElectrical controlInternal combustion piston enginesExhaust fumesSystem configuration

A system for effective NOx and particulate matter control in a diesel or other lean burn internal combustion engine is presented. The system includes a urea-based SCR catalyst having an oxidation catalyst coupled upstream of it and a particulate filter coupled downstream of the SCR catalyst. This system configuration results in improved NOx conversion due to fast SCR catalyst warm-up and higher operating temperatures. Additionally, placing the particulate filter last in this system configuration reduces tailpipe ammonia emissions as well as prevents any thermal damage to the SCR catalyst due to the particulate filter regeneration.

Owner:FORD GLOBAL TECH LLC

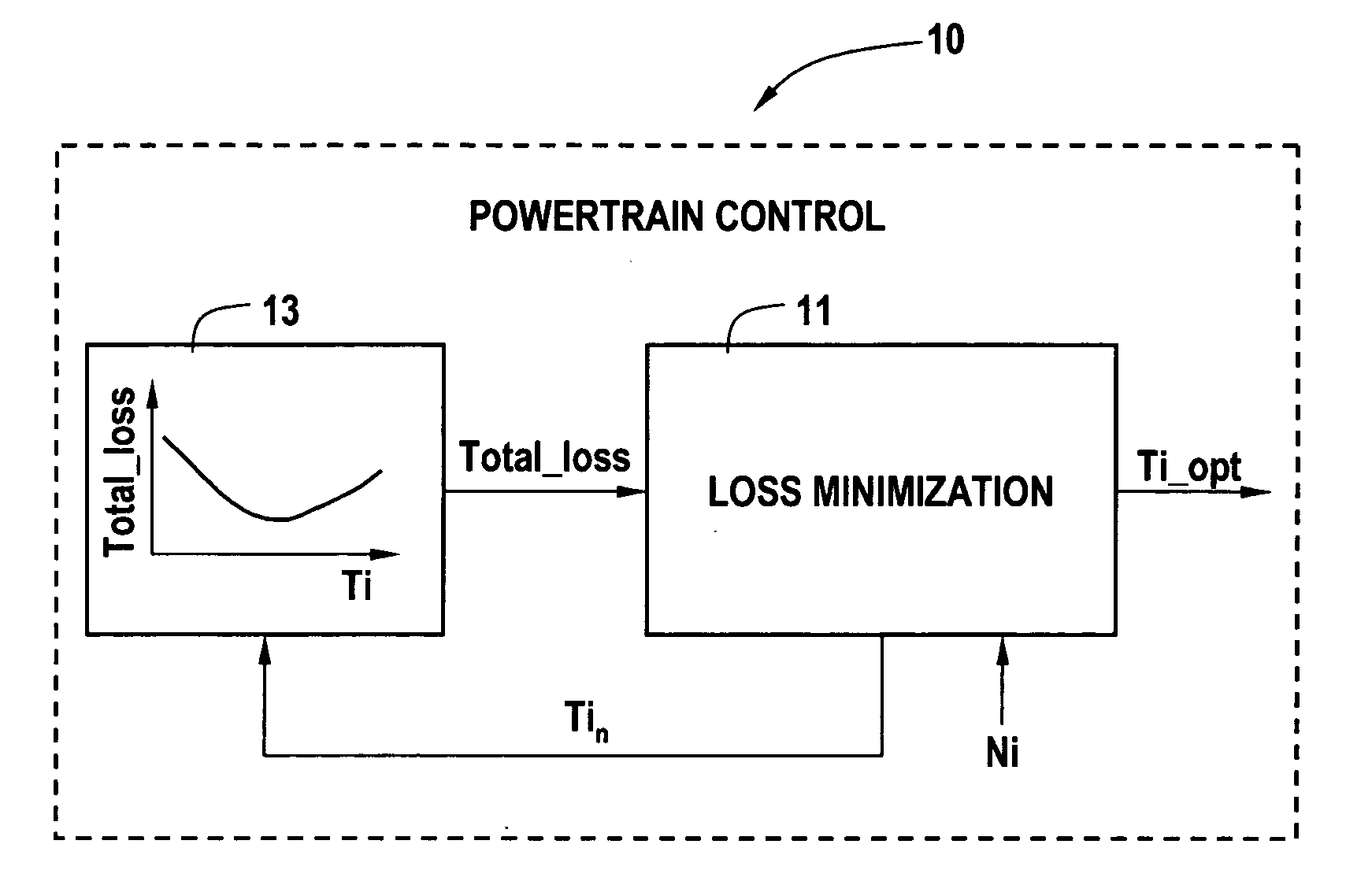

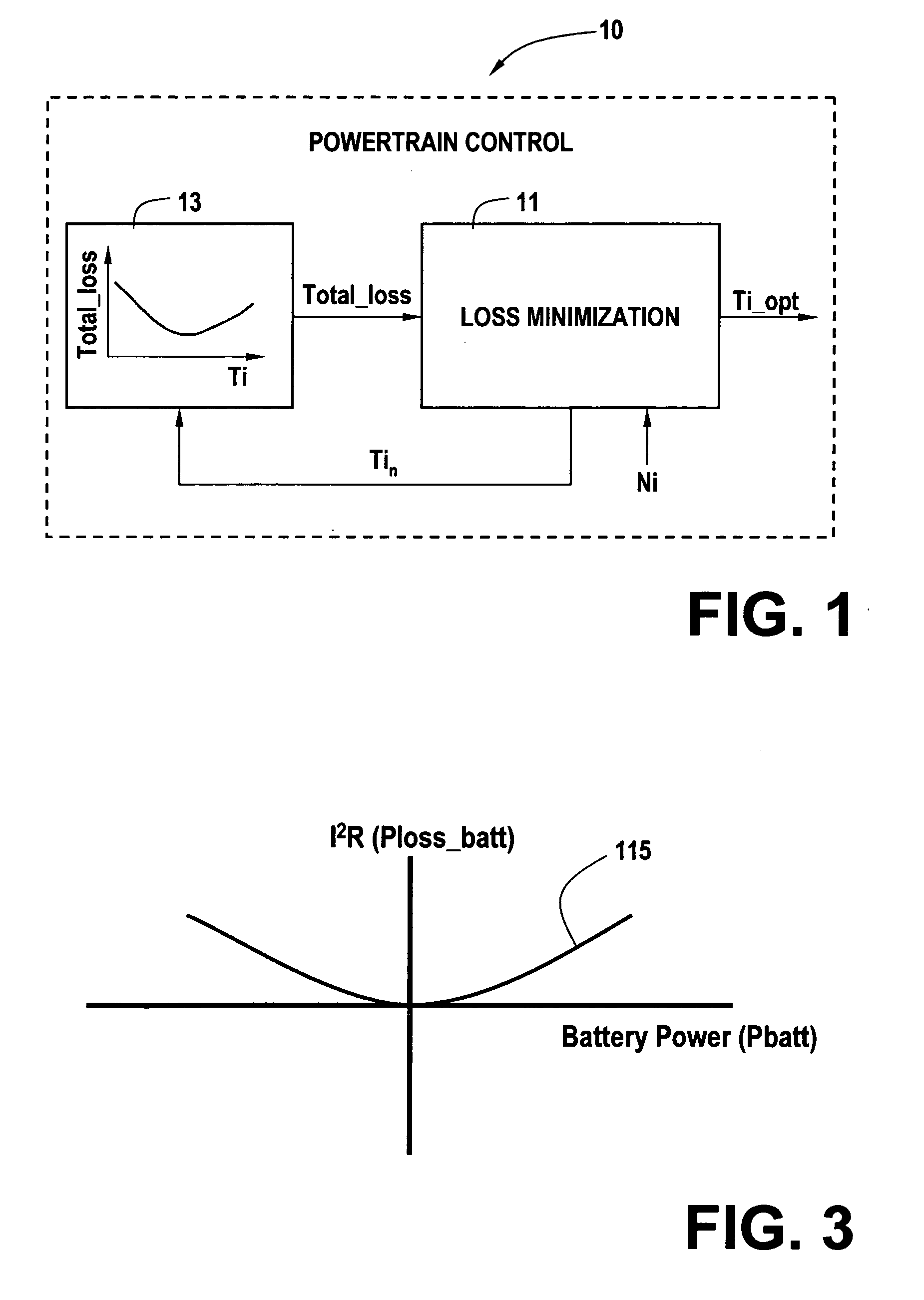

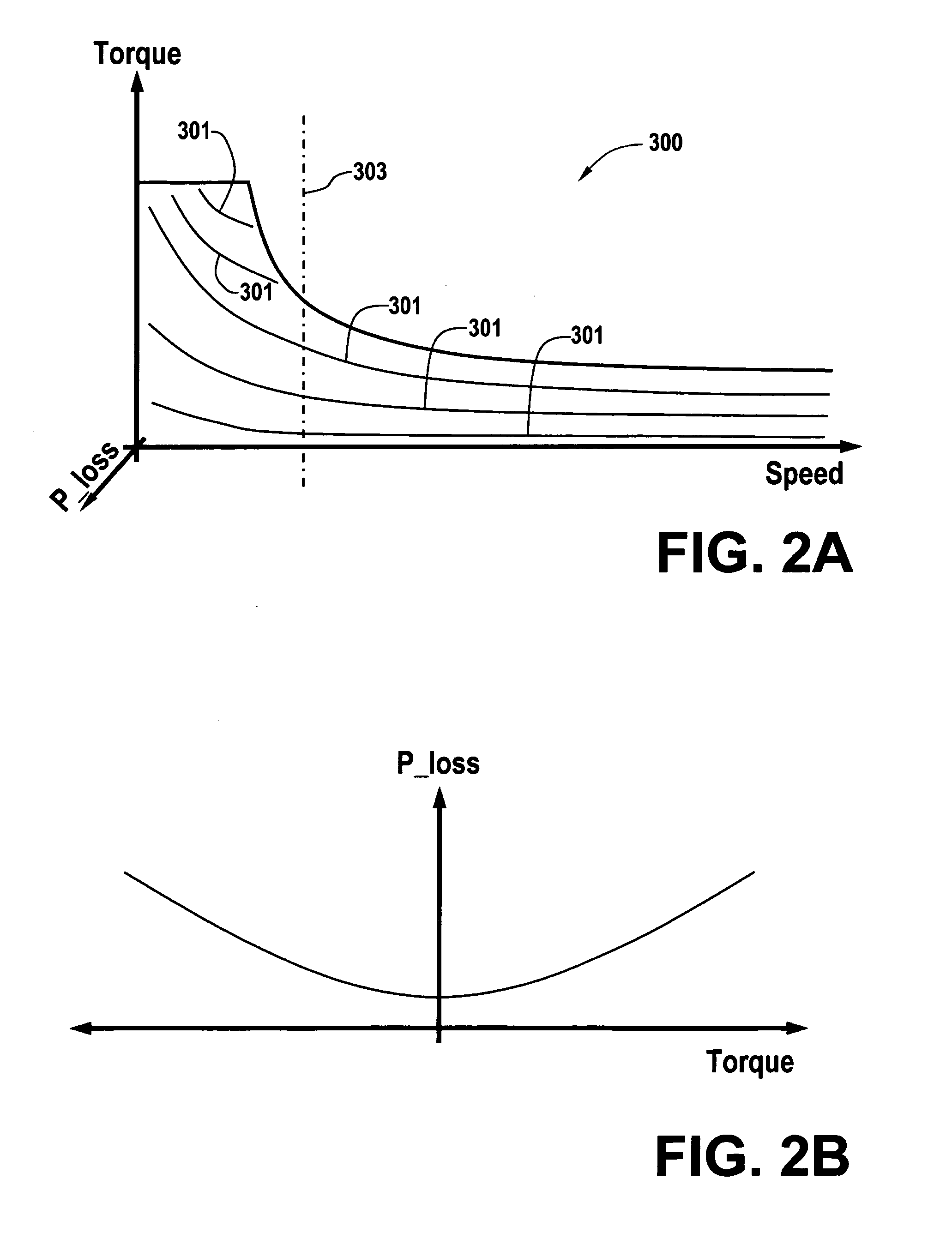

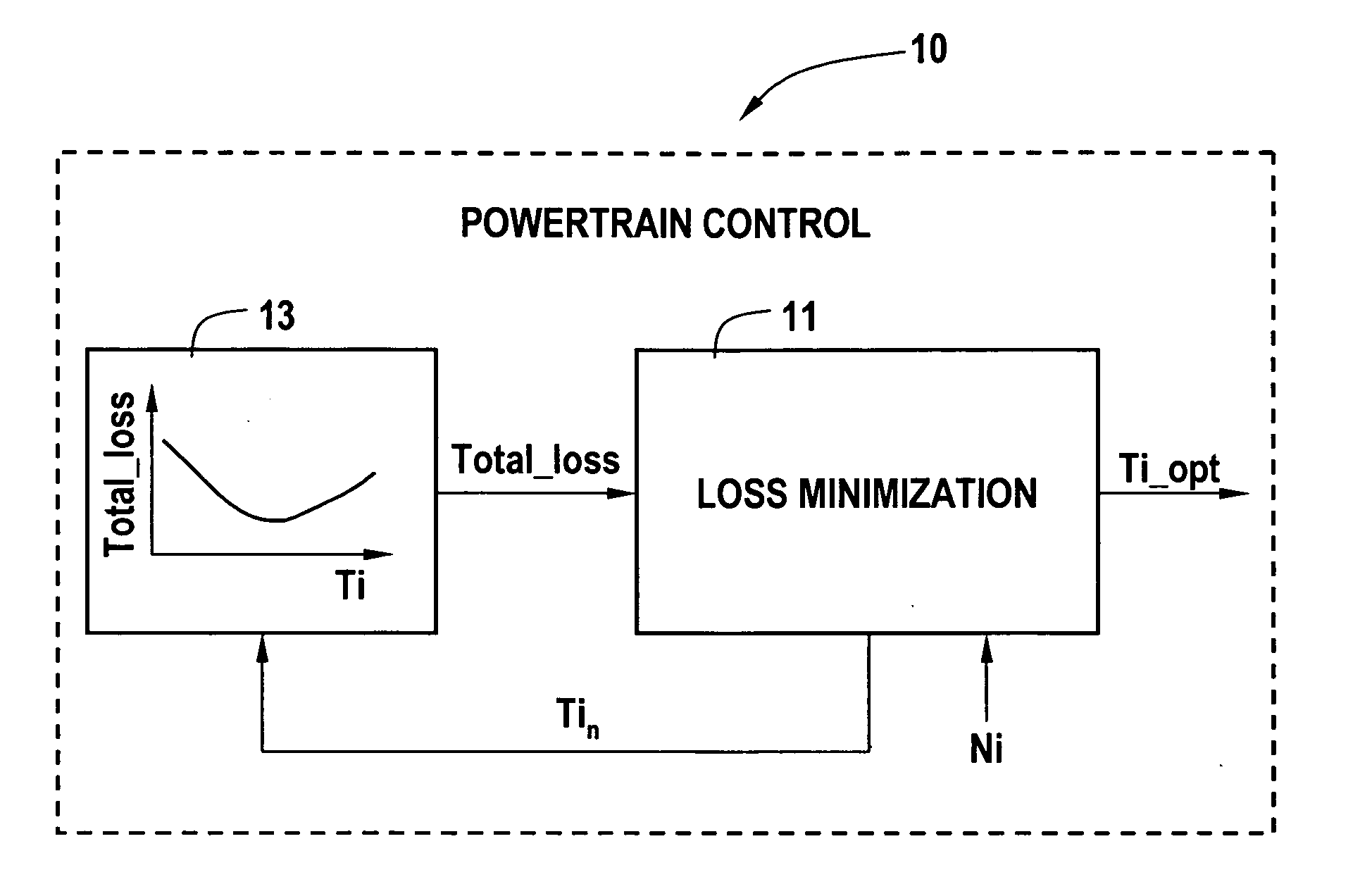

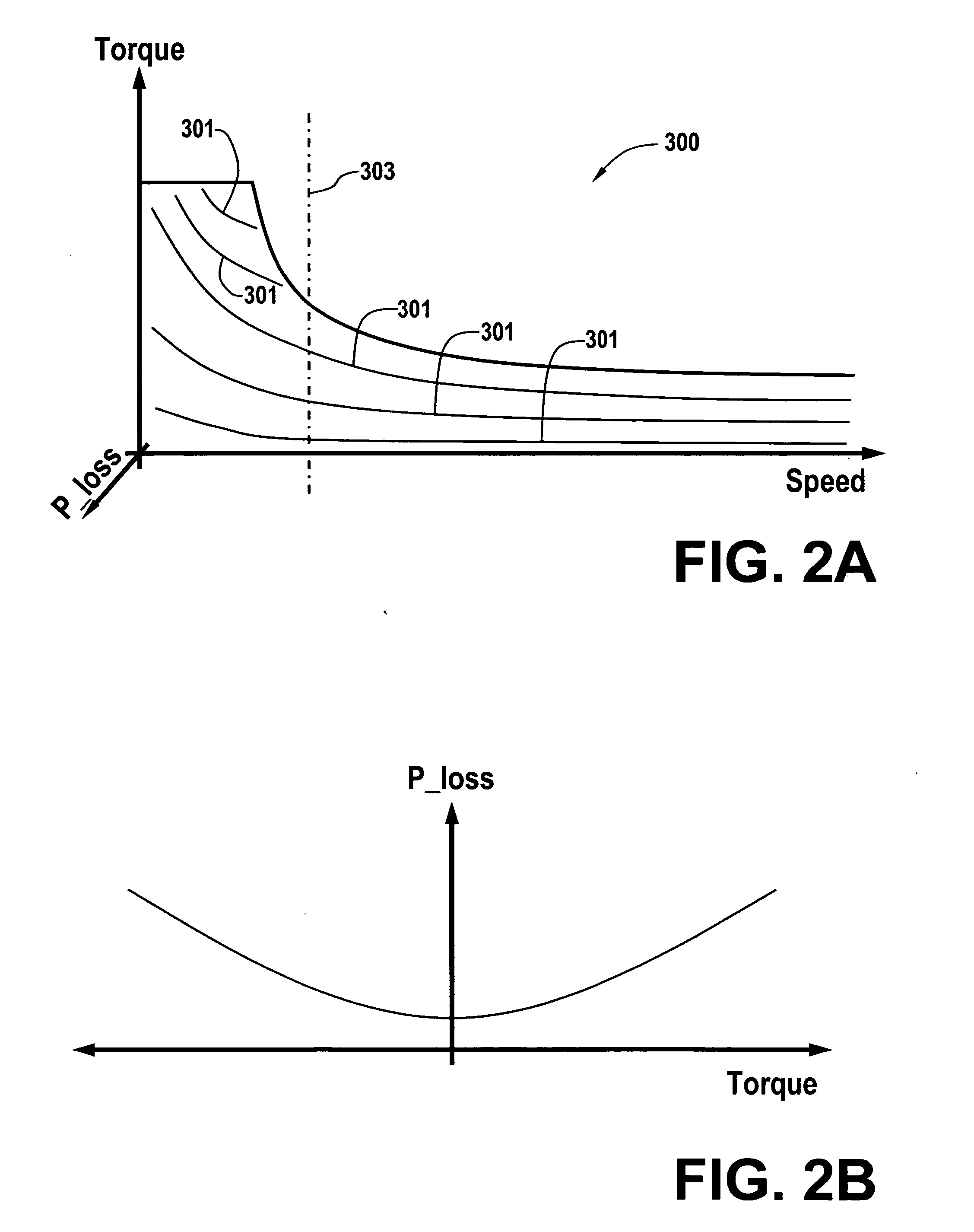

Cost structure method including fuel economy and engine emission considerations

ActiveUS20070093953A1Analogue computers for vehiclesElectrical controlOperating pointPowertrain control

A powertrain control selects engine operating points in accordance with power loss minimization controls. Power loss contributions come from a variety of sources including engine power losses. Engine power losses are determined in accordance with engine operating metrics such as power production per unit fuel consumption and power production per unit emission production. Engine power losses are combined in accordance with assigned weighting into a single engine power loss term for use in the power loss minimization control and operating point selection.

Owner:GM GLOBAL TECH OPERATIONS LLC

Internal combustion engine control for improved fuel efficiency

ActiveUS8131447B2Undesirable vibration reductionConvenient amountElectrical controlInternal combustion piston enginesCombustion chamberWork cycle

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

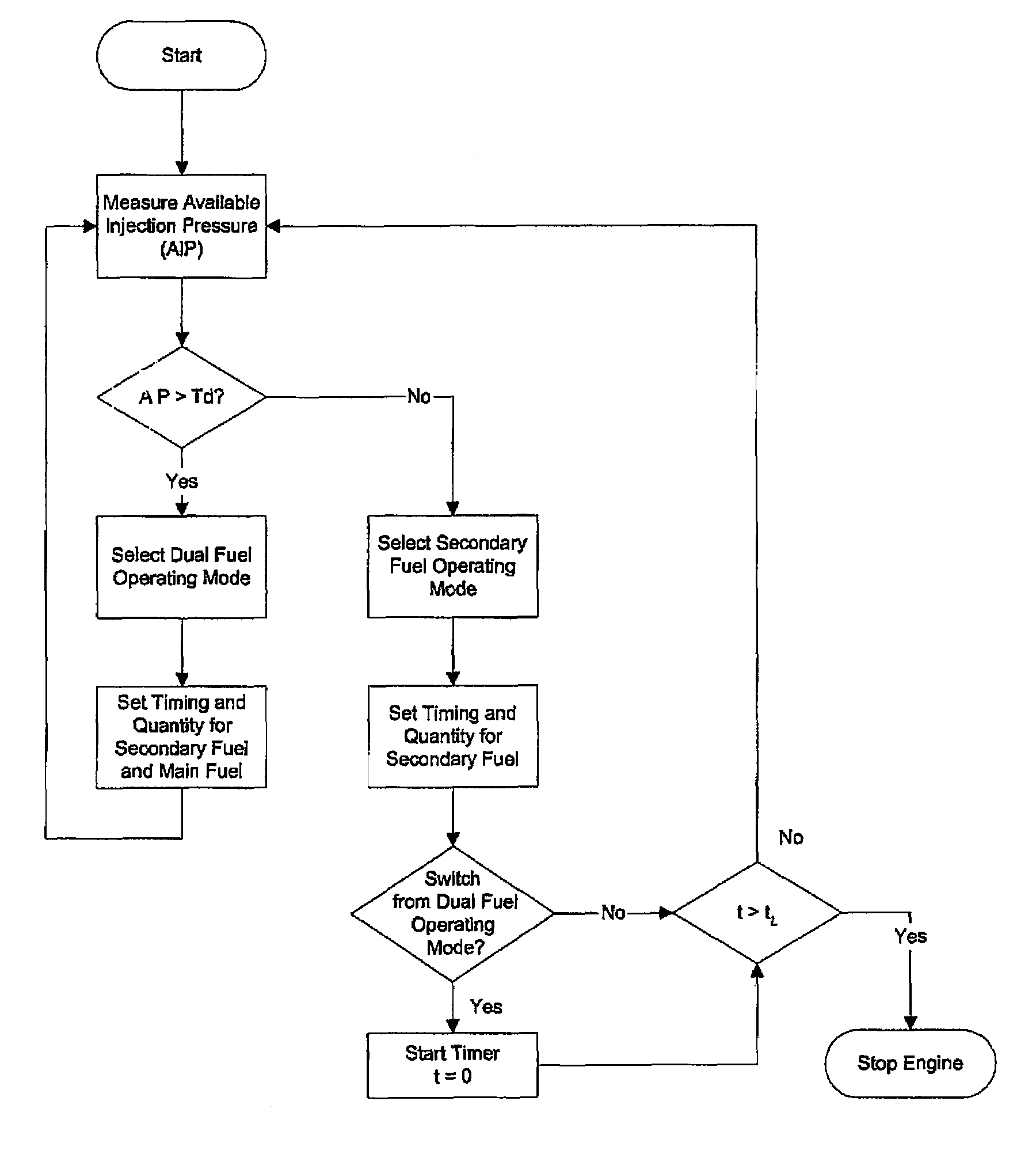

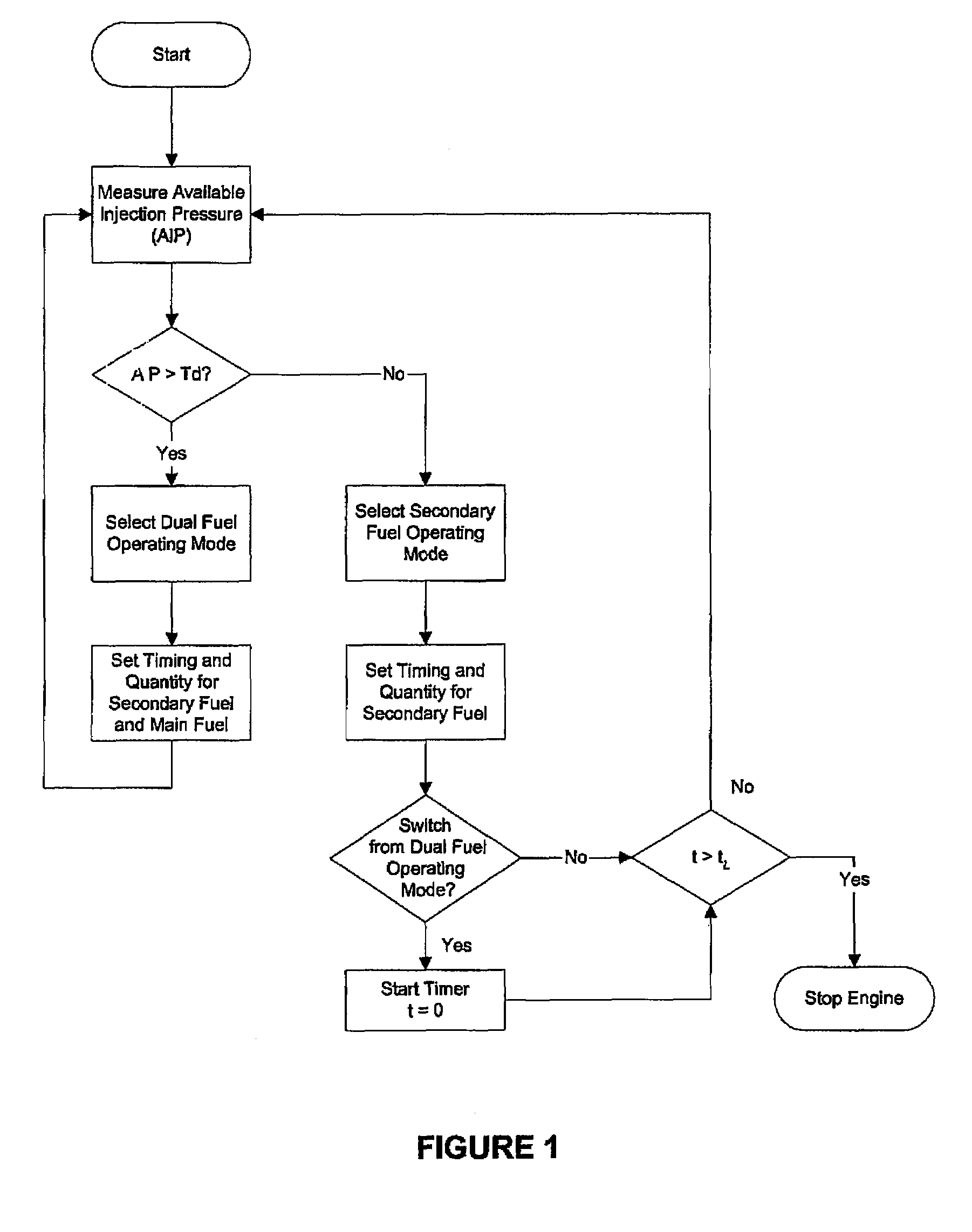

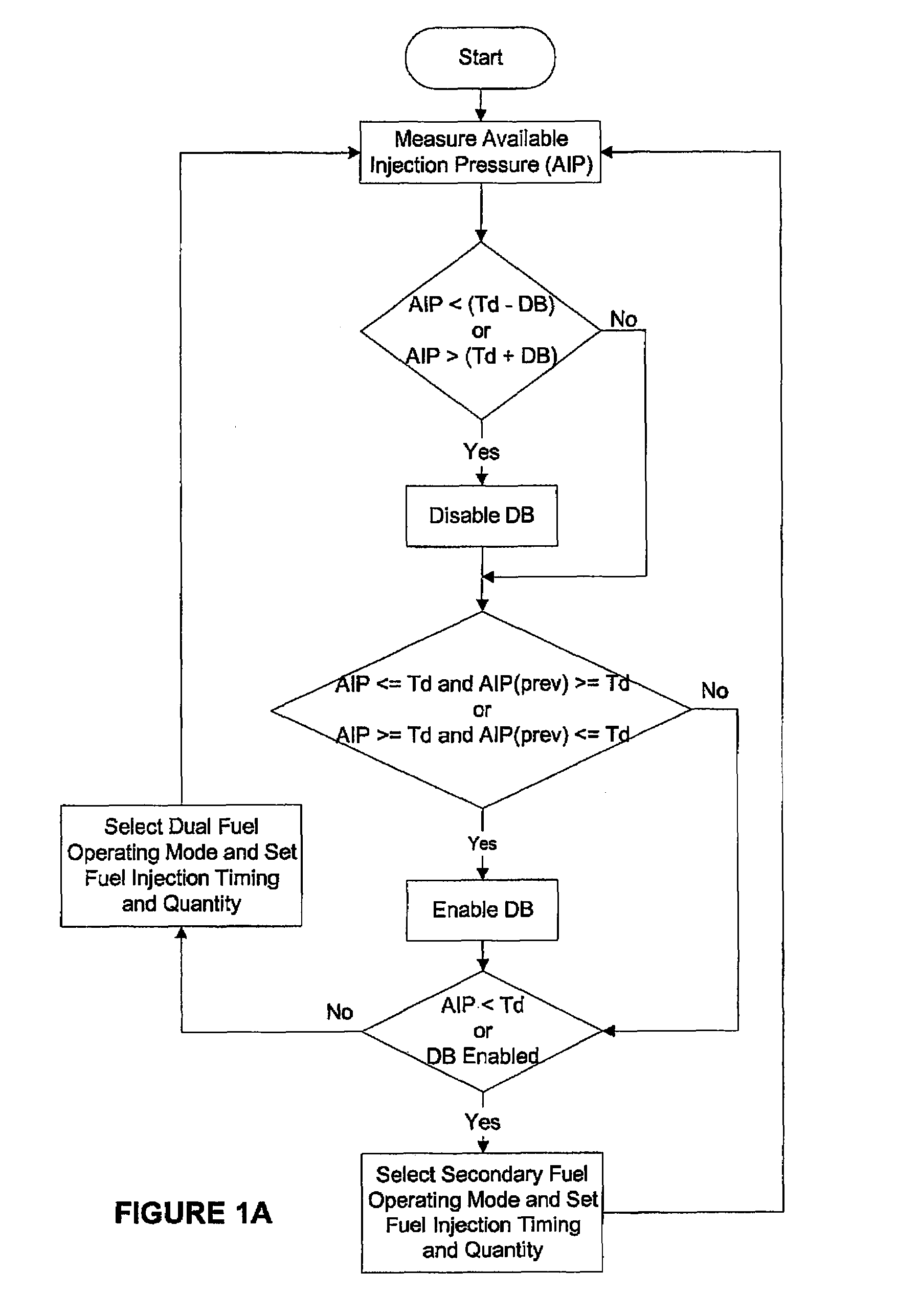

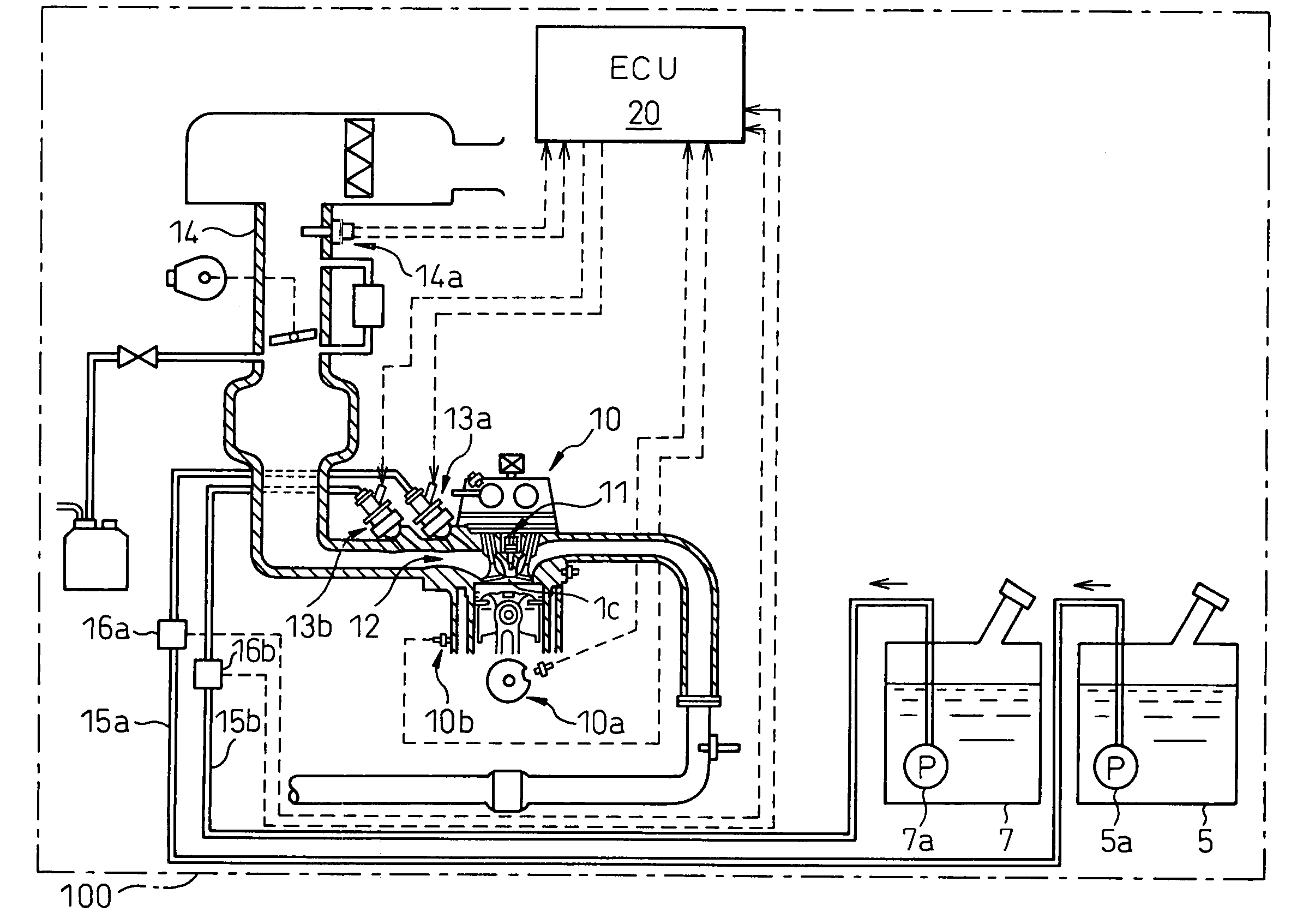

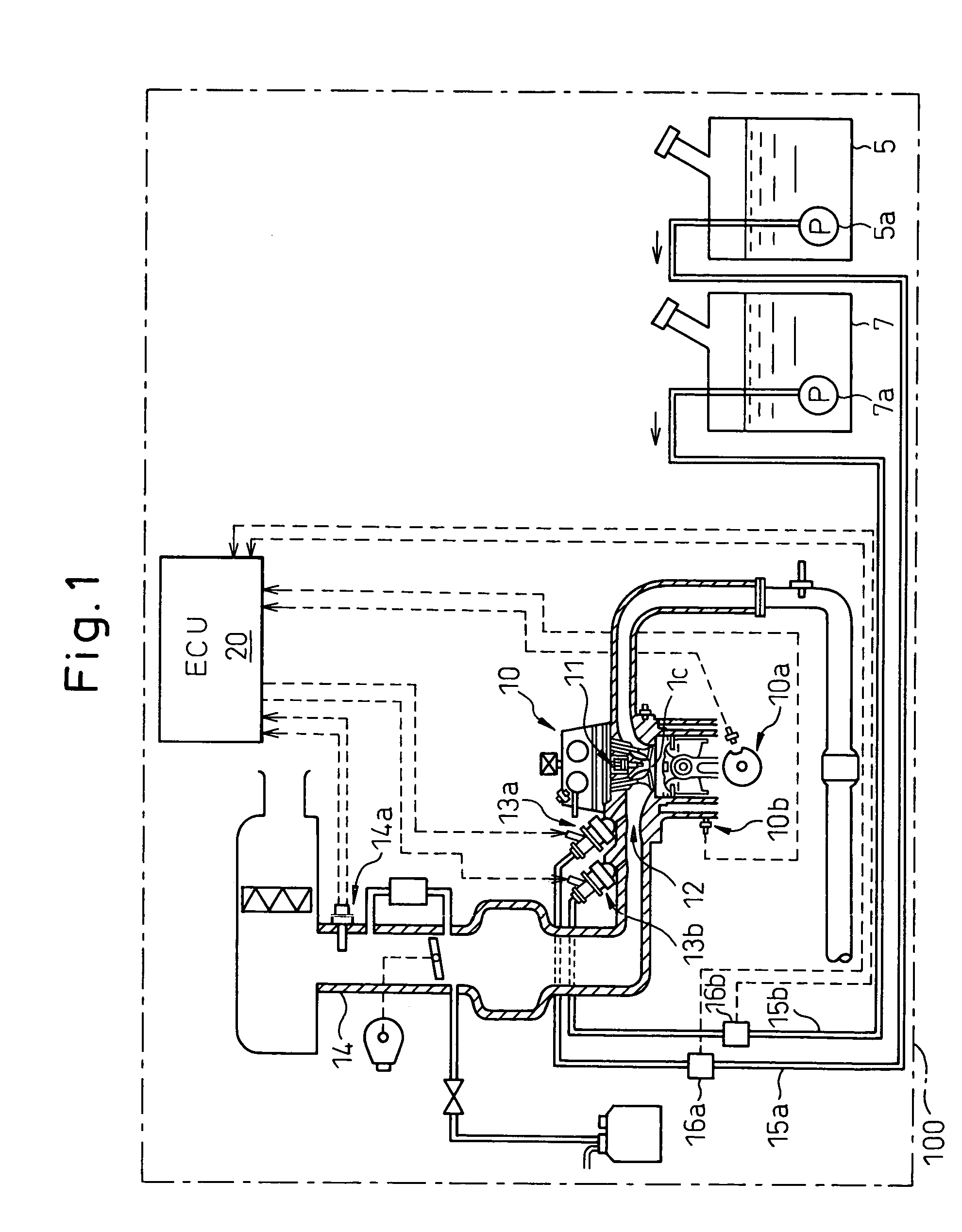

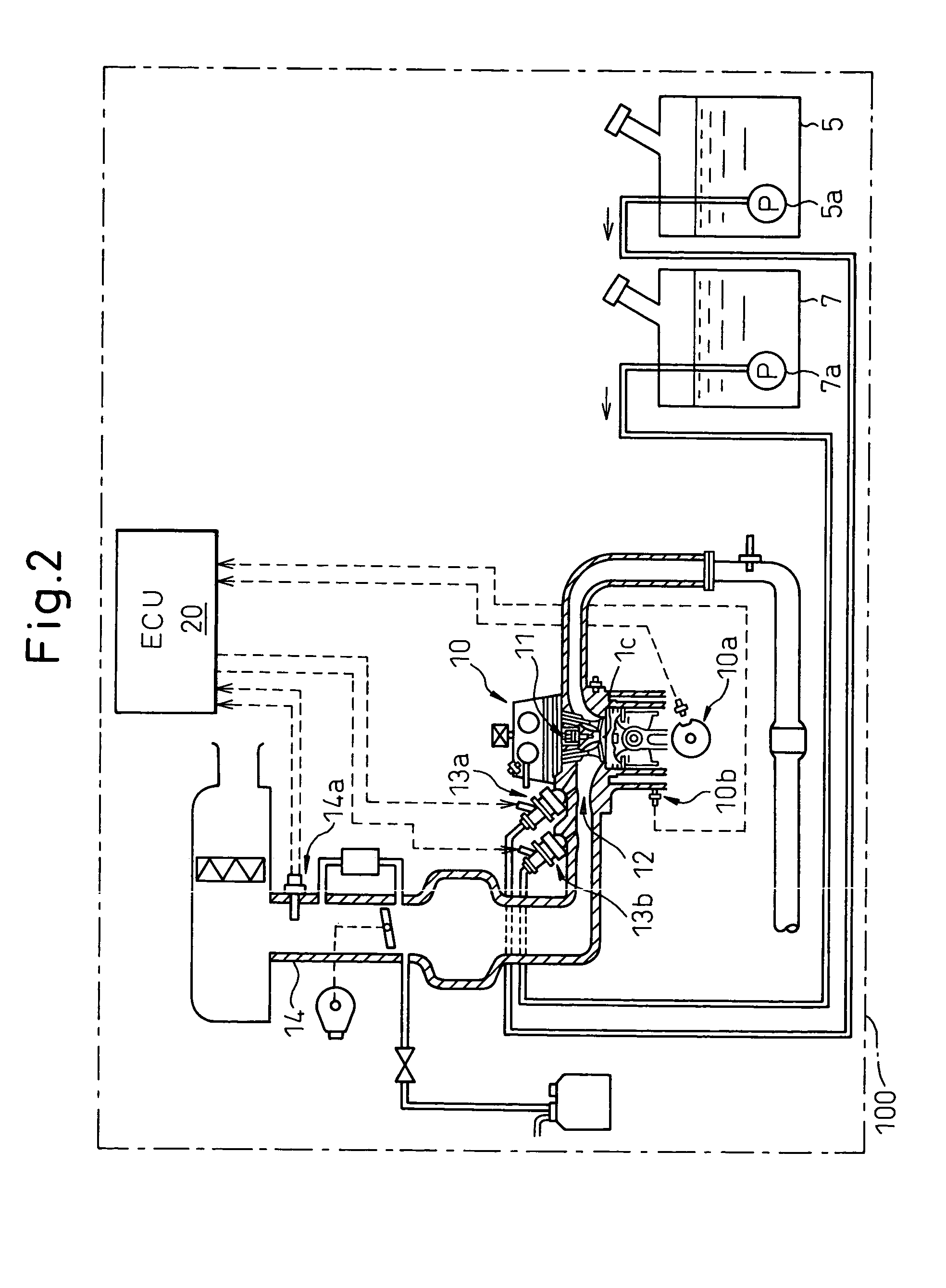

Method and apparatus for operating a dual fuel internal combustion engine

ActiveUS7627416B2Reduce modificationShorten the timeElectrical controlInternal combustion piston enginesCombustion chamberElectronic controller

In an internal combustion engine that can burn two fuels, the main fuel may become unavailable, either temporarily or until the main fuel is replenished. The present apparatus determines when to fuel an engine with main fuel and secondary fuel, or secondary fuel alone. The apparatus includes a main-fuel supply system comprising a main-fuel injection valve that introduces main fuel into an engine combustion chamber; a secondary-fuel injection system comprising a secondary-fuel injection valve that introduces secondary fuel directly into the combustion chamber; a pressure sensor associated with the main-fuel supply system for determining injection pressure inside the main-fuel injection valve; and an electronic controller in communication with the pressure sensor and programmable to separately command actuation of the secondary-fuel and the main-fuel injection valve when injection pressure is greater than a predetermined threshold, and to otherwise command actuation of the secondary-fuel injection valve and not the main-fuel injection valve.

Owner:WESTPORT FUEL SYST CANADA INC

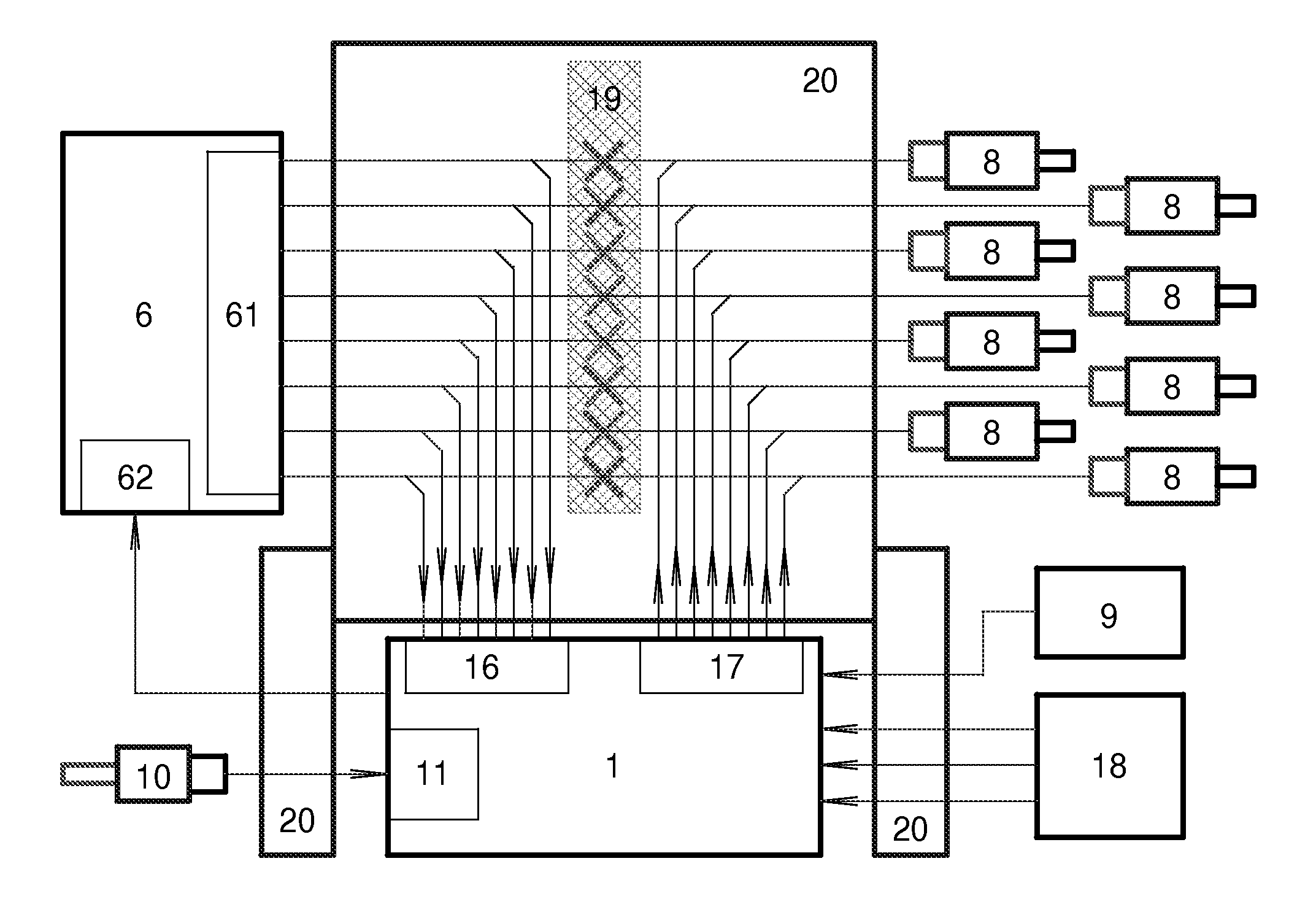

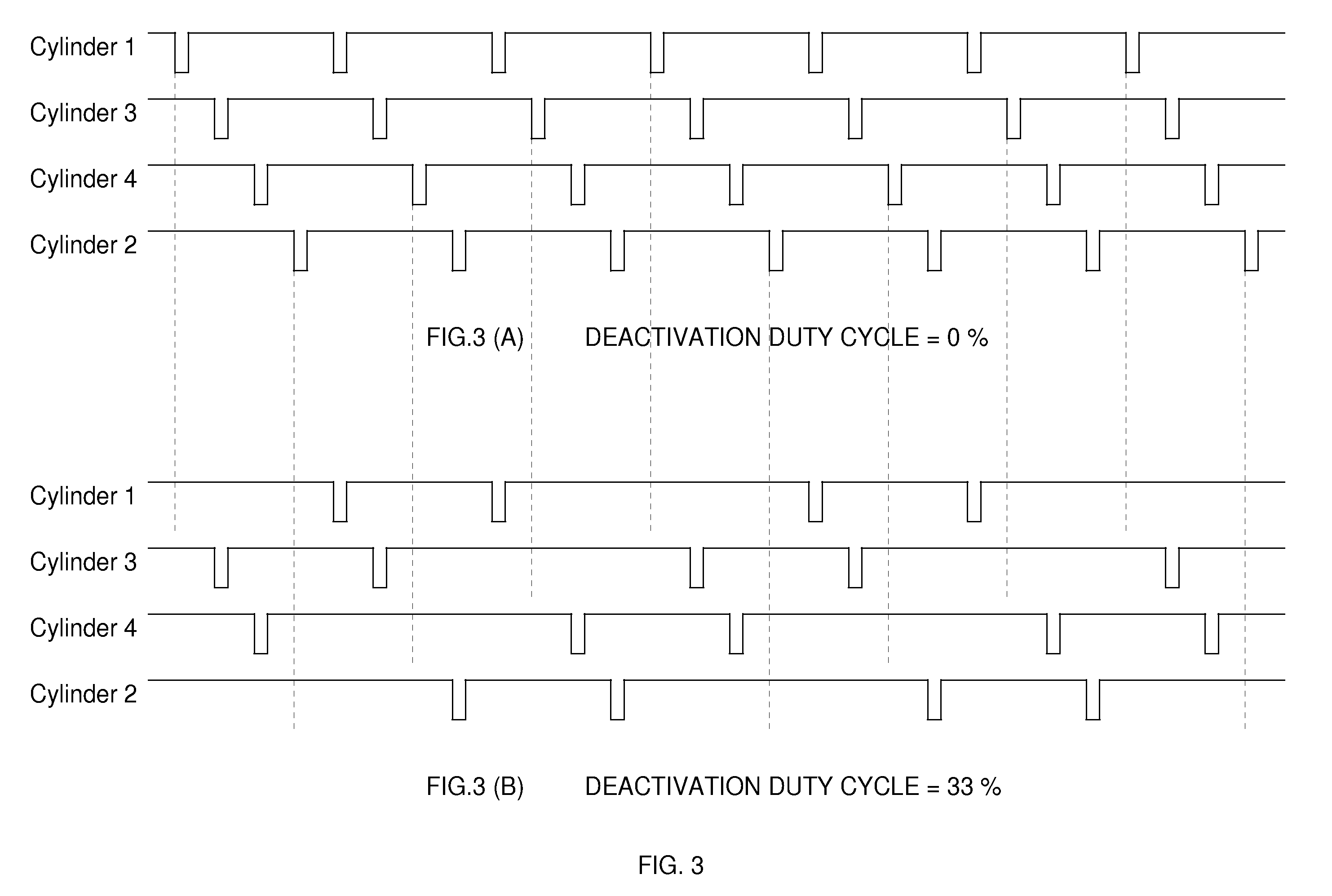

Dynamic Cylinder Deactivation with Residual Heat Recovery

InactiveUS20100050993A1Improve conversion efficiencyElectrical controlMachines/enginesEngine efficiencyFuel efficiency

Cylinder deactivation is a proven solution to improve engine fuel efficiency. The present invention is related to Dynamic Cylinder Deactivation (DCD) solution to conventional internal combustion engine. DCD is an energy saving method based on engine thermodynamics and residual heat recovery. It deactivates all the cylinders within the engine alternatively and dynamically, totally different from traditional sealed-valves cylinder deactivation solutions. DCD has many advantages over traditional sealed-valves cylinder deactivation. Thermodynamic efficiency gain, residual heat recovery, high Lambda and “Air-Hybrid” are the most attractive features of DCD. DCD also makes engine displacement variable.

Owner:ZHAO YUANPING +1

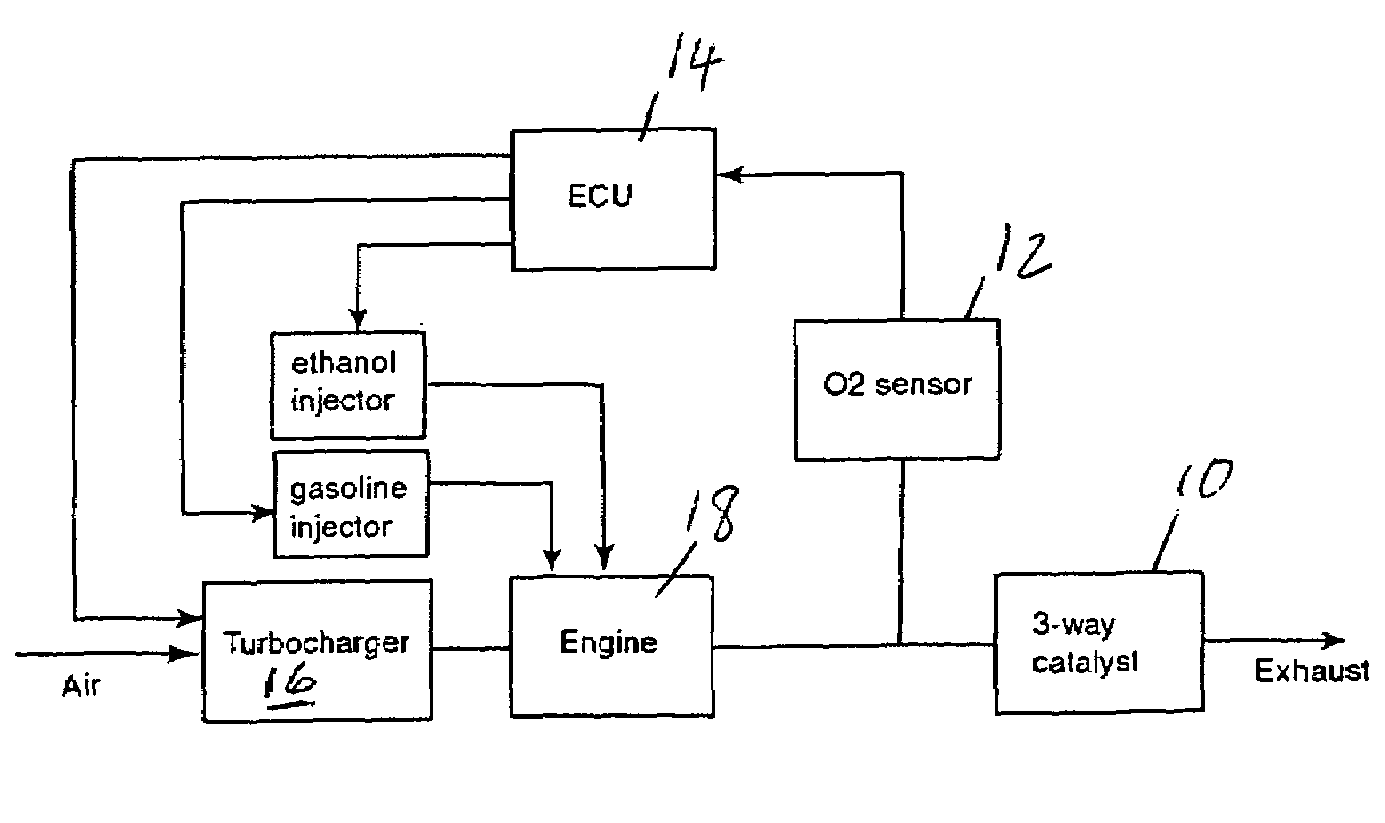

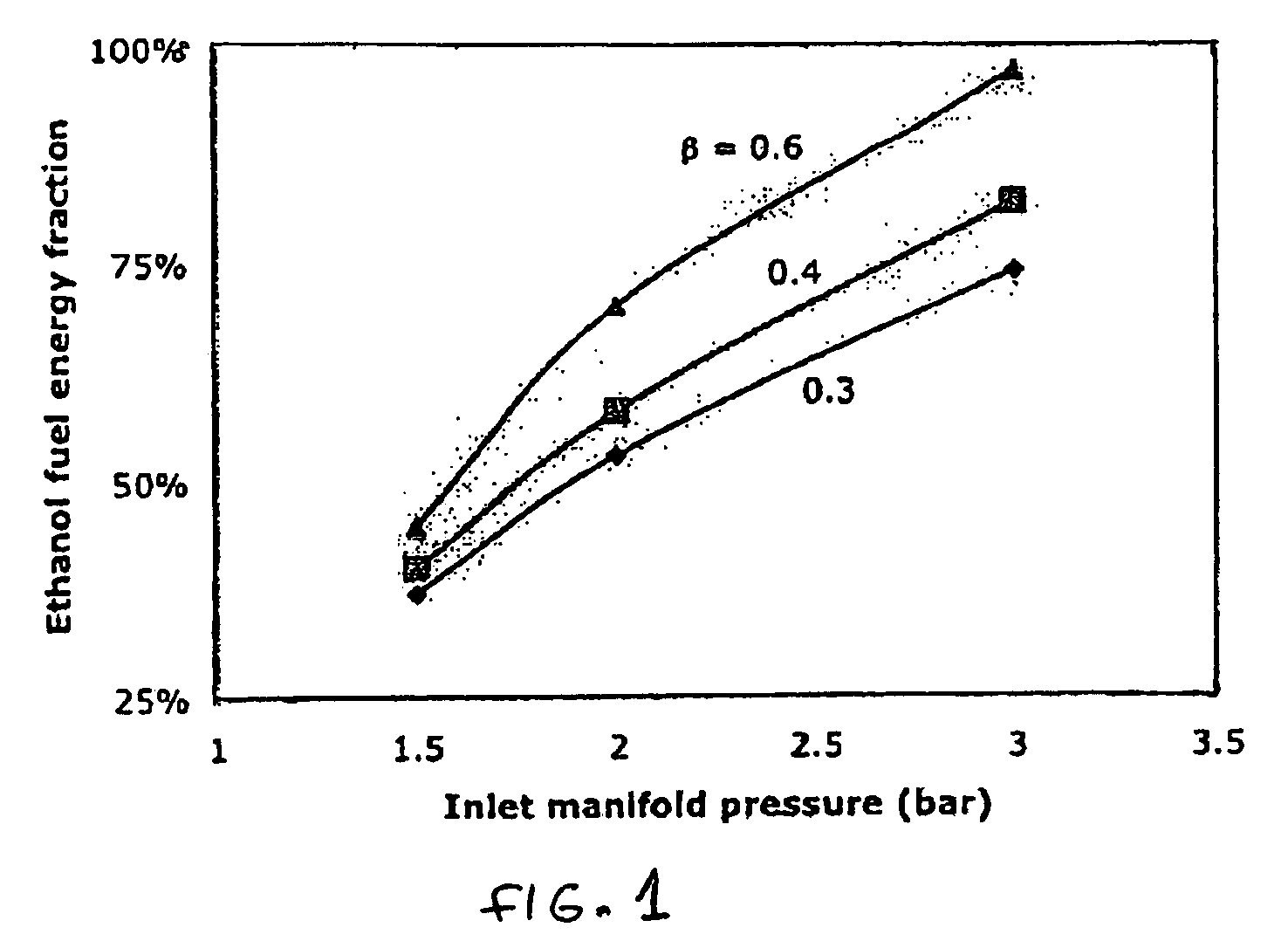

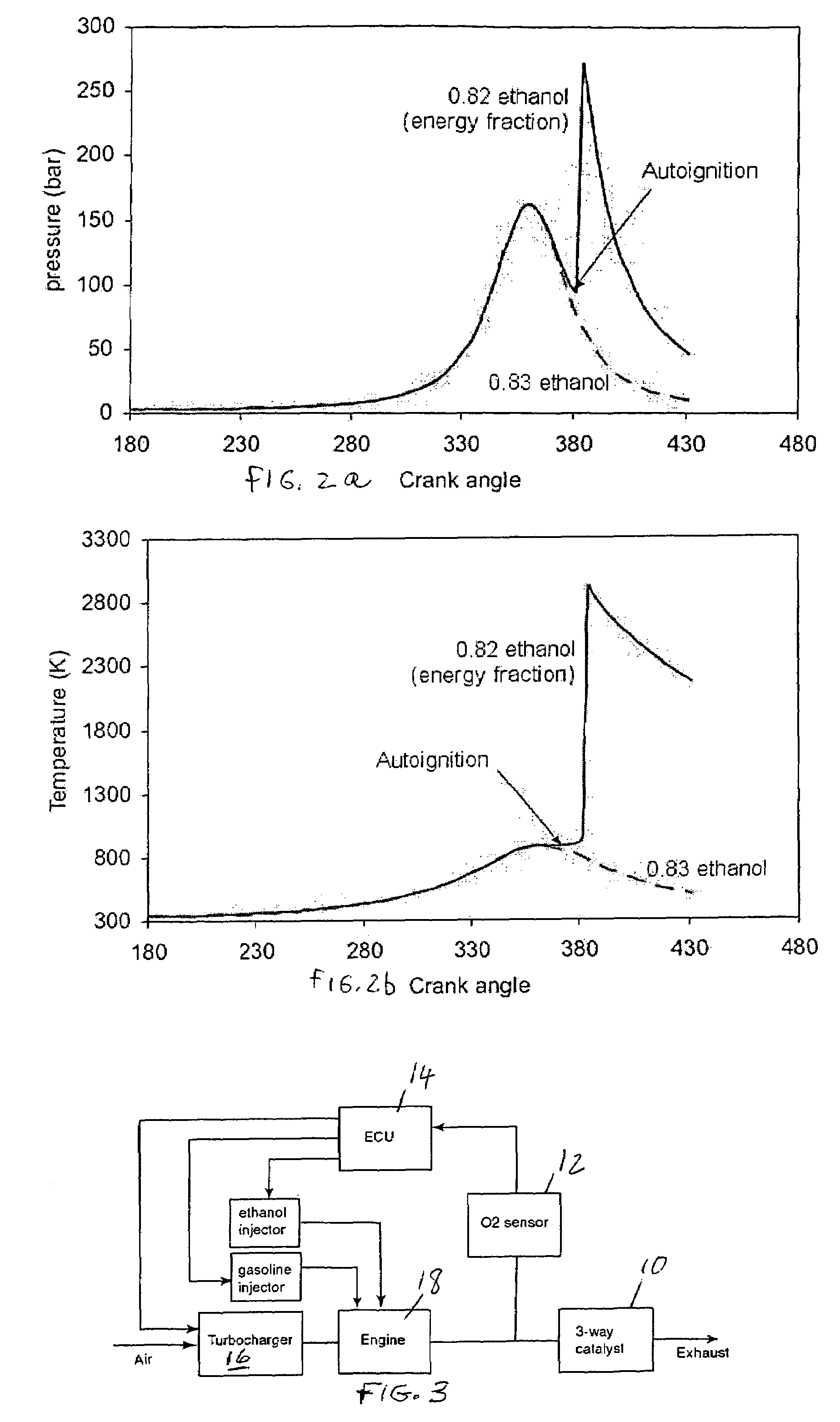

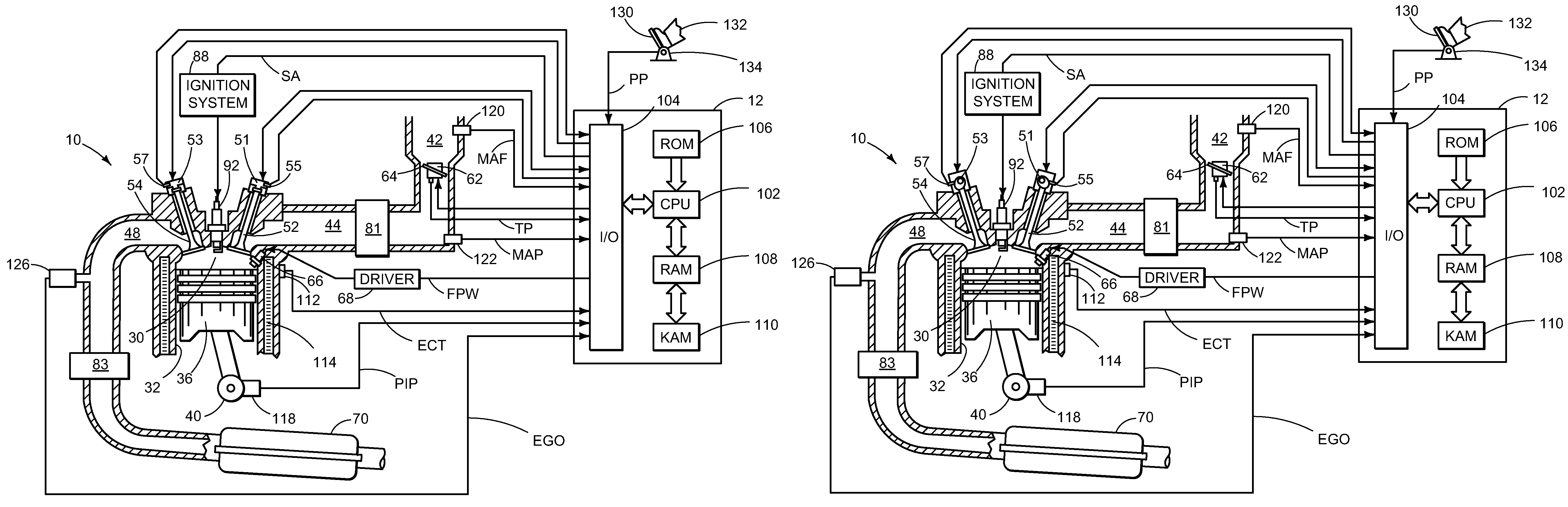

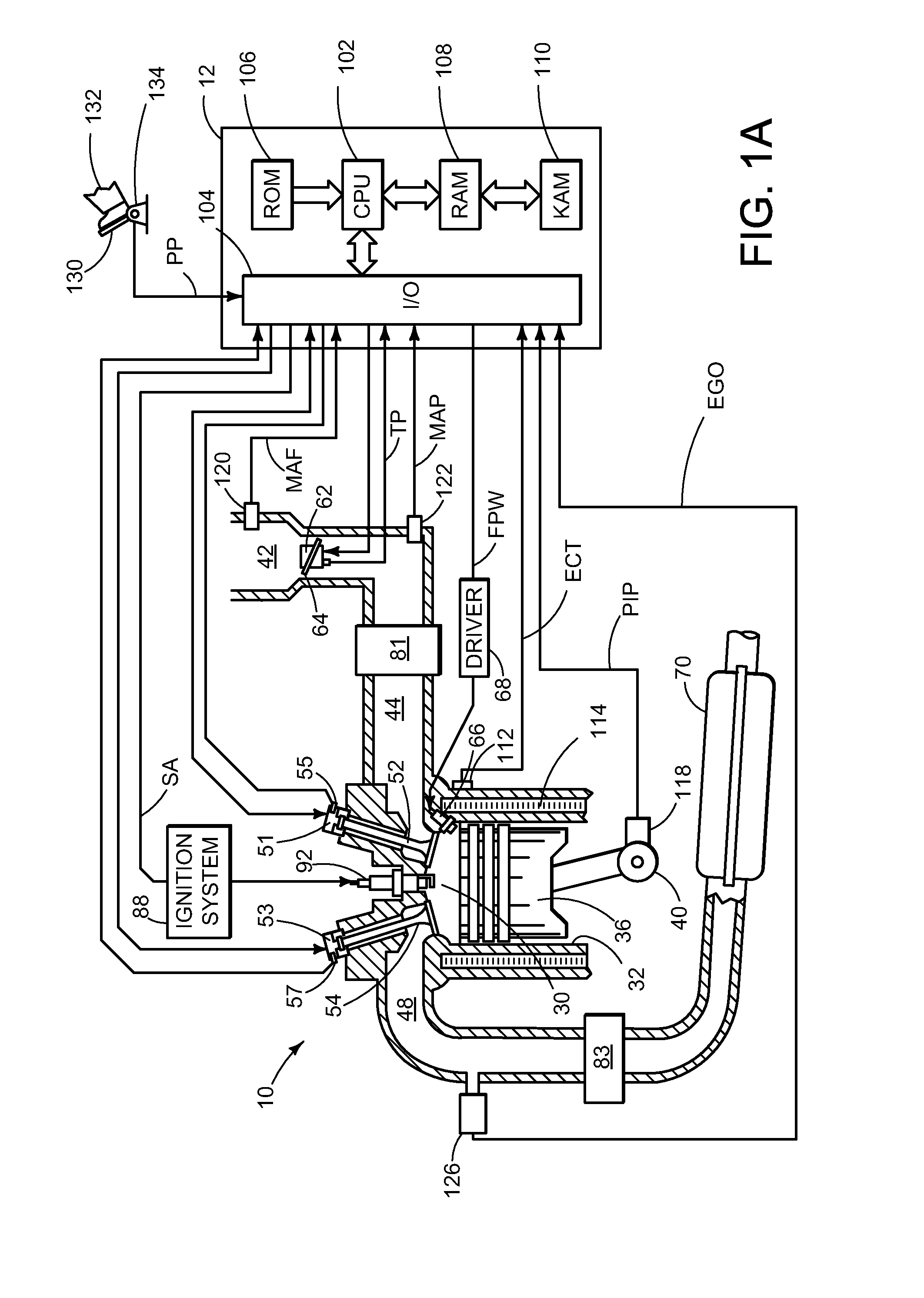

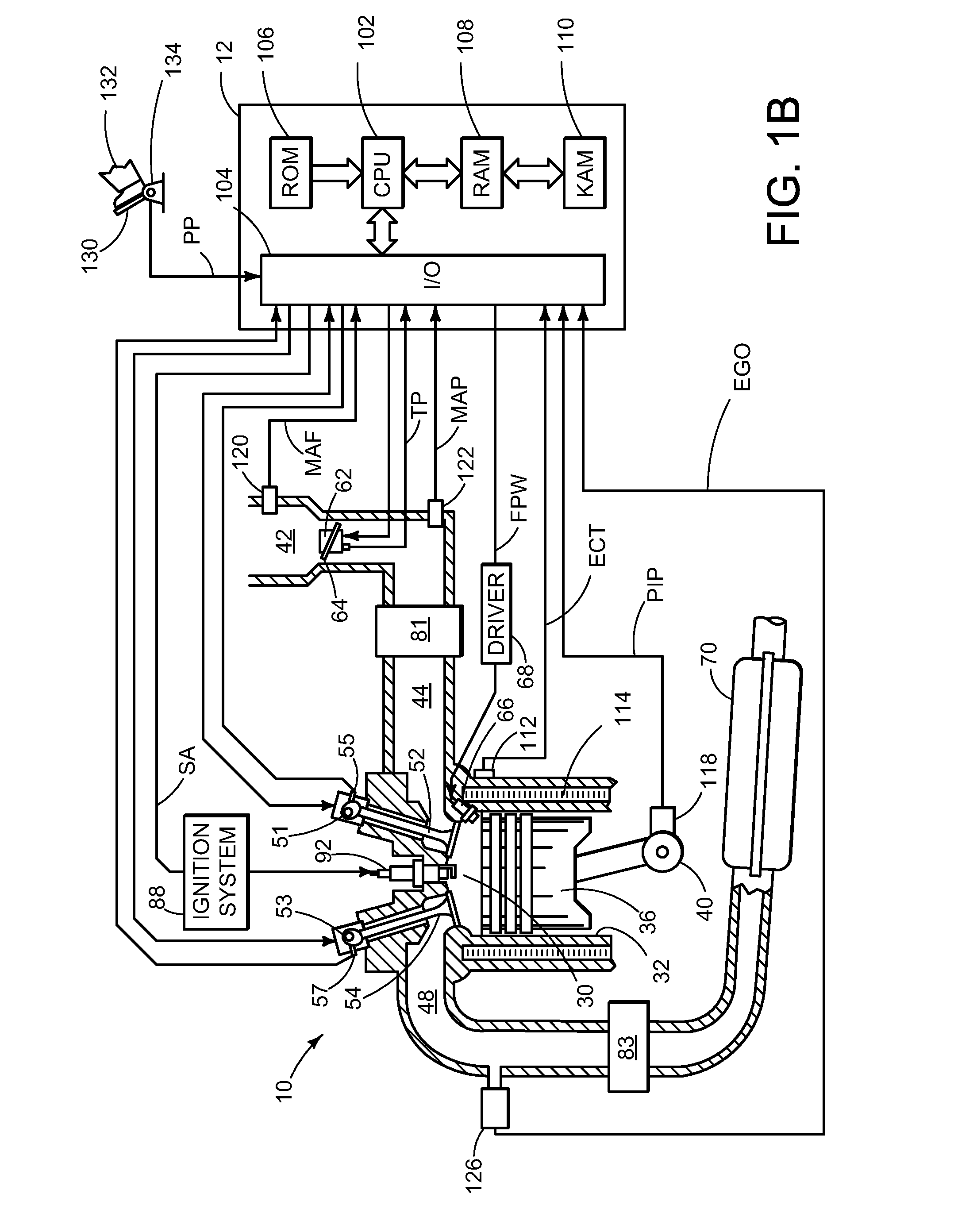

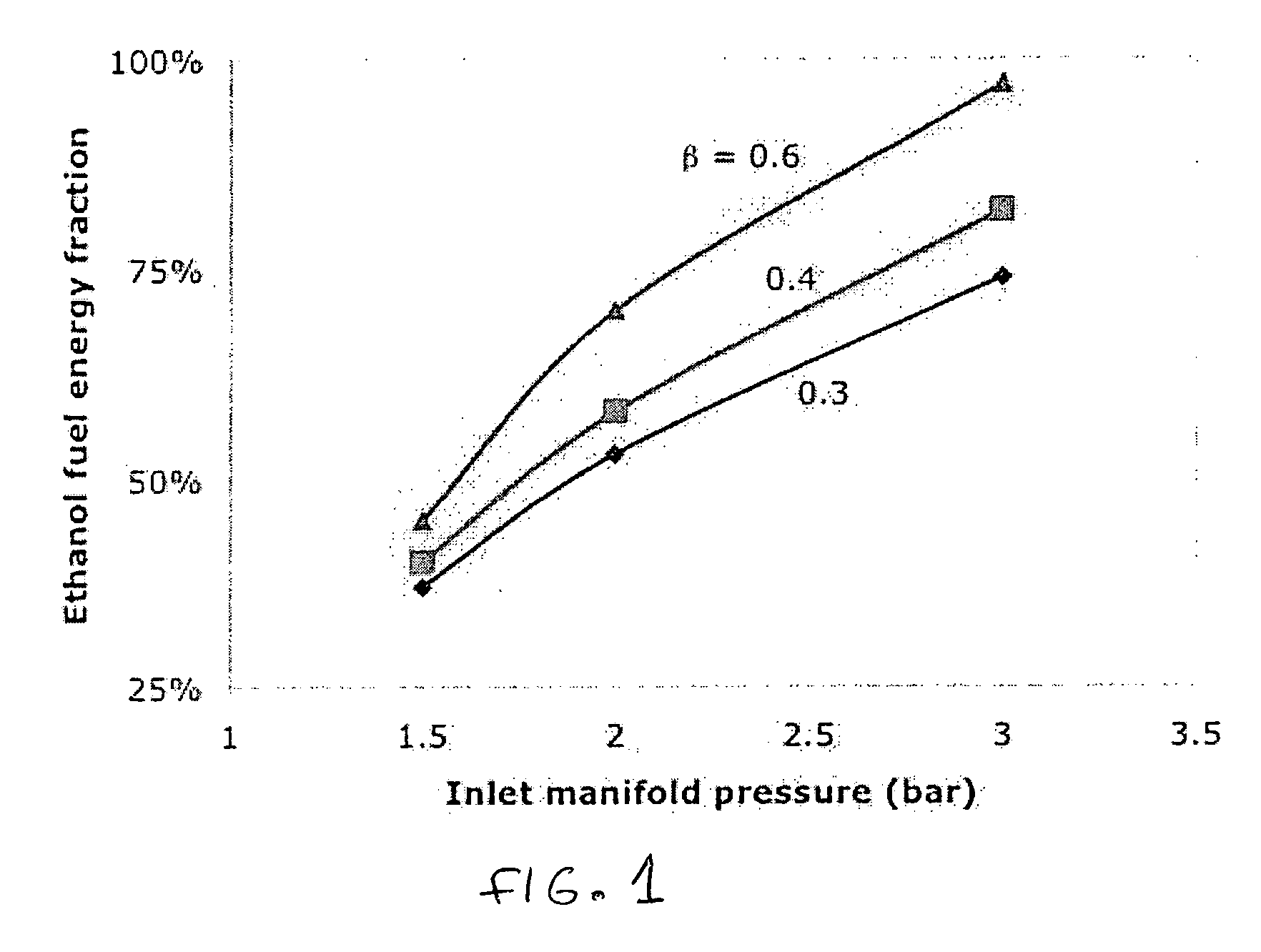

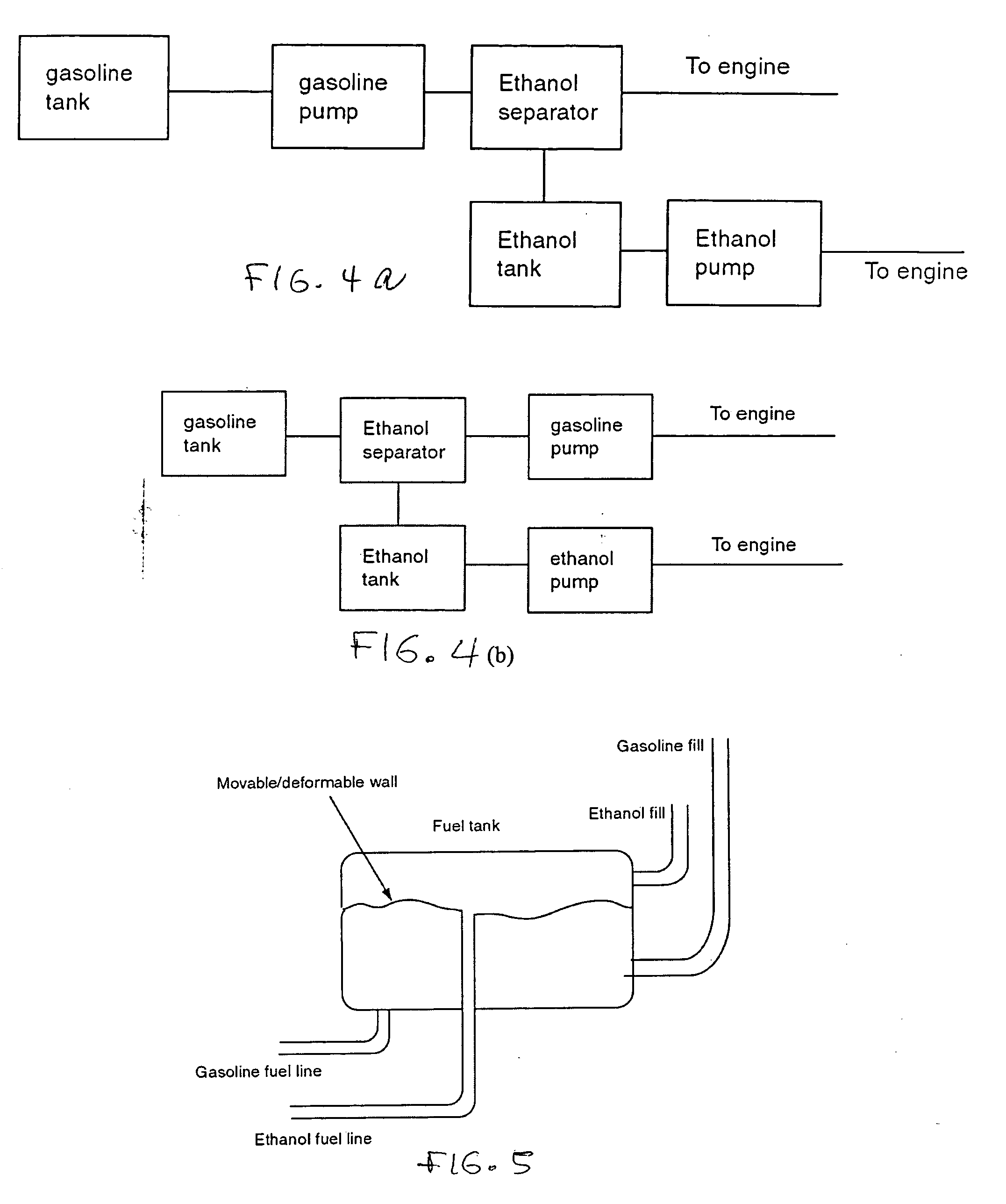

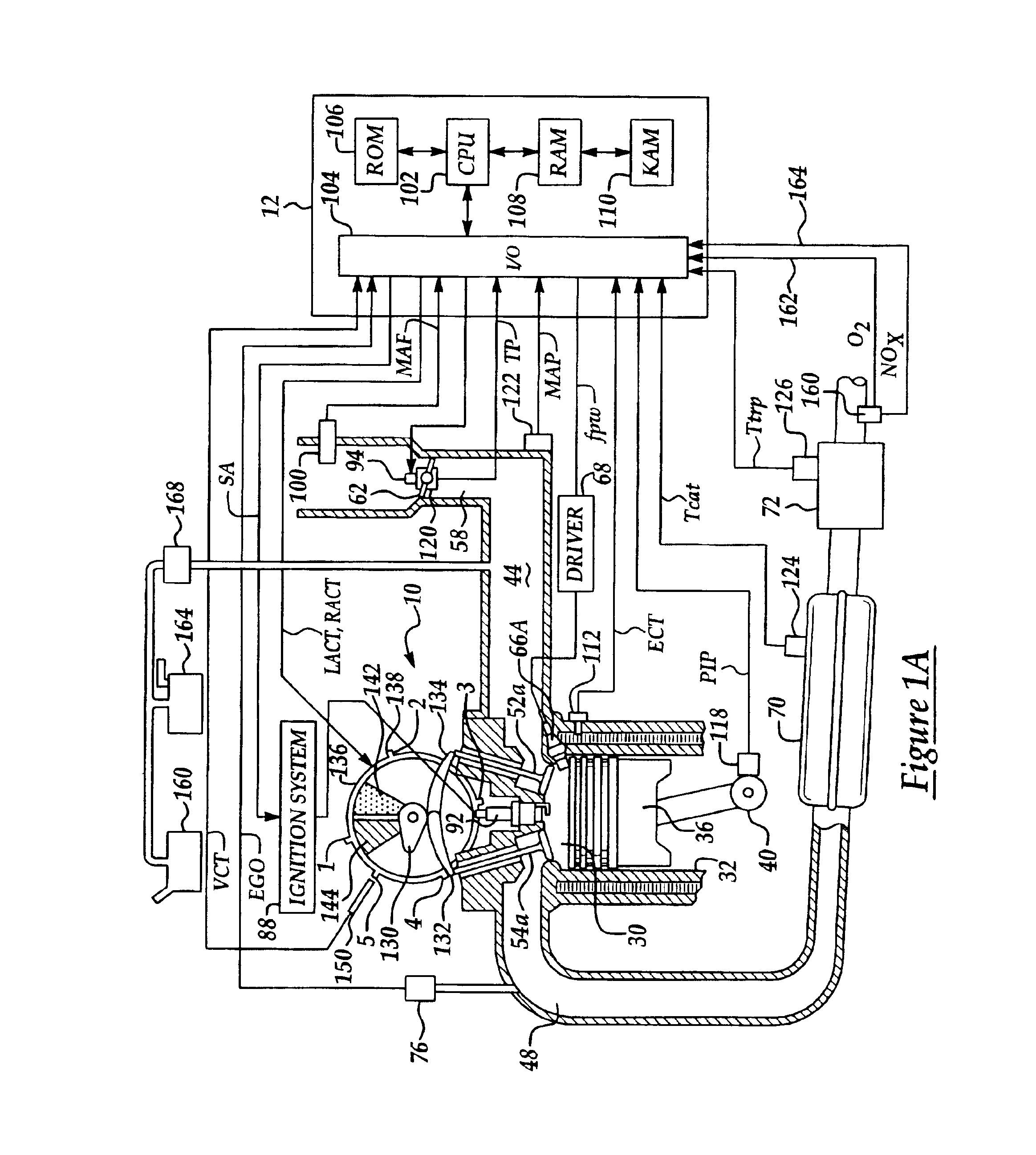

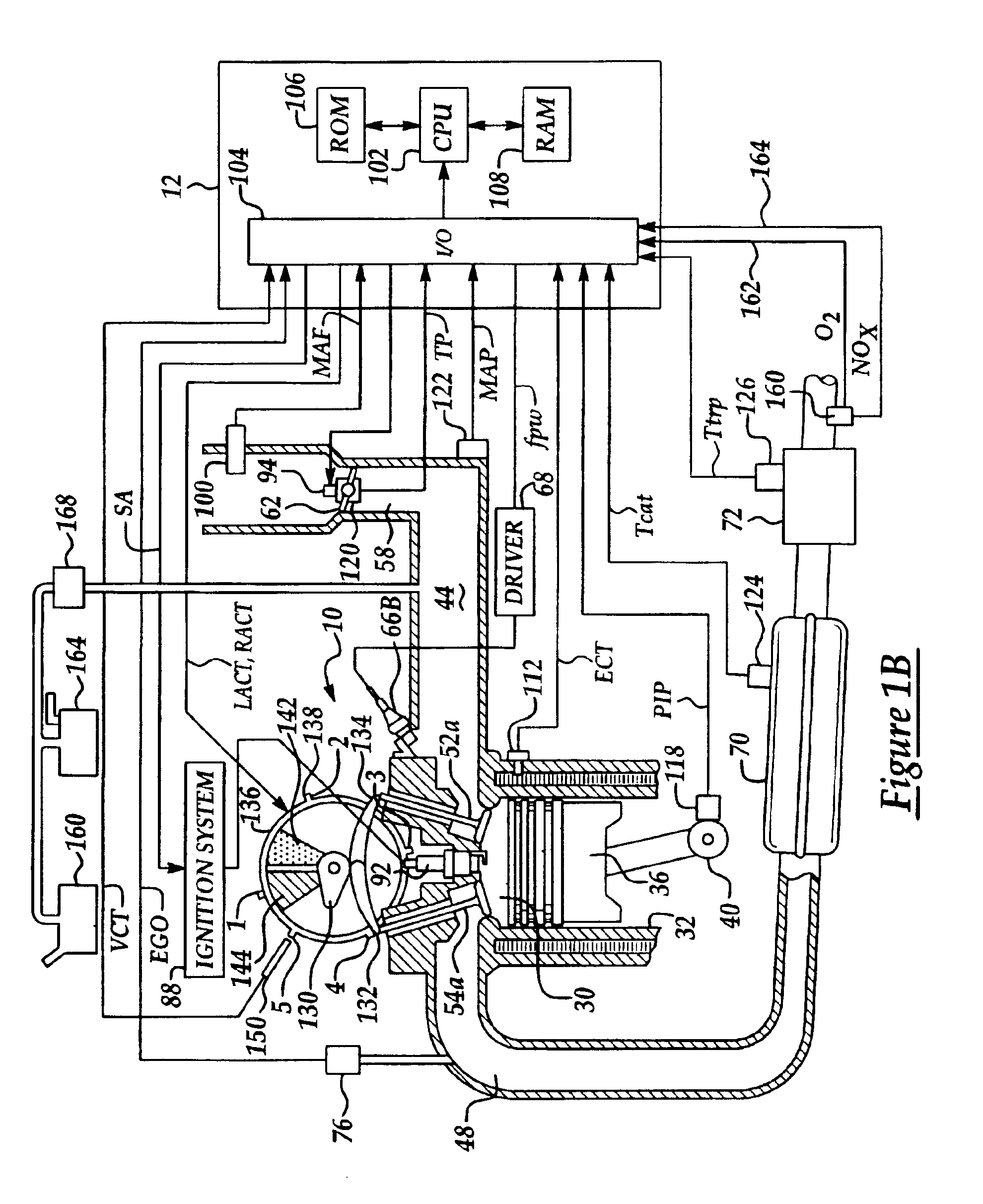

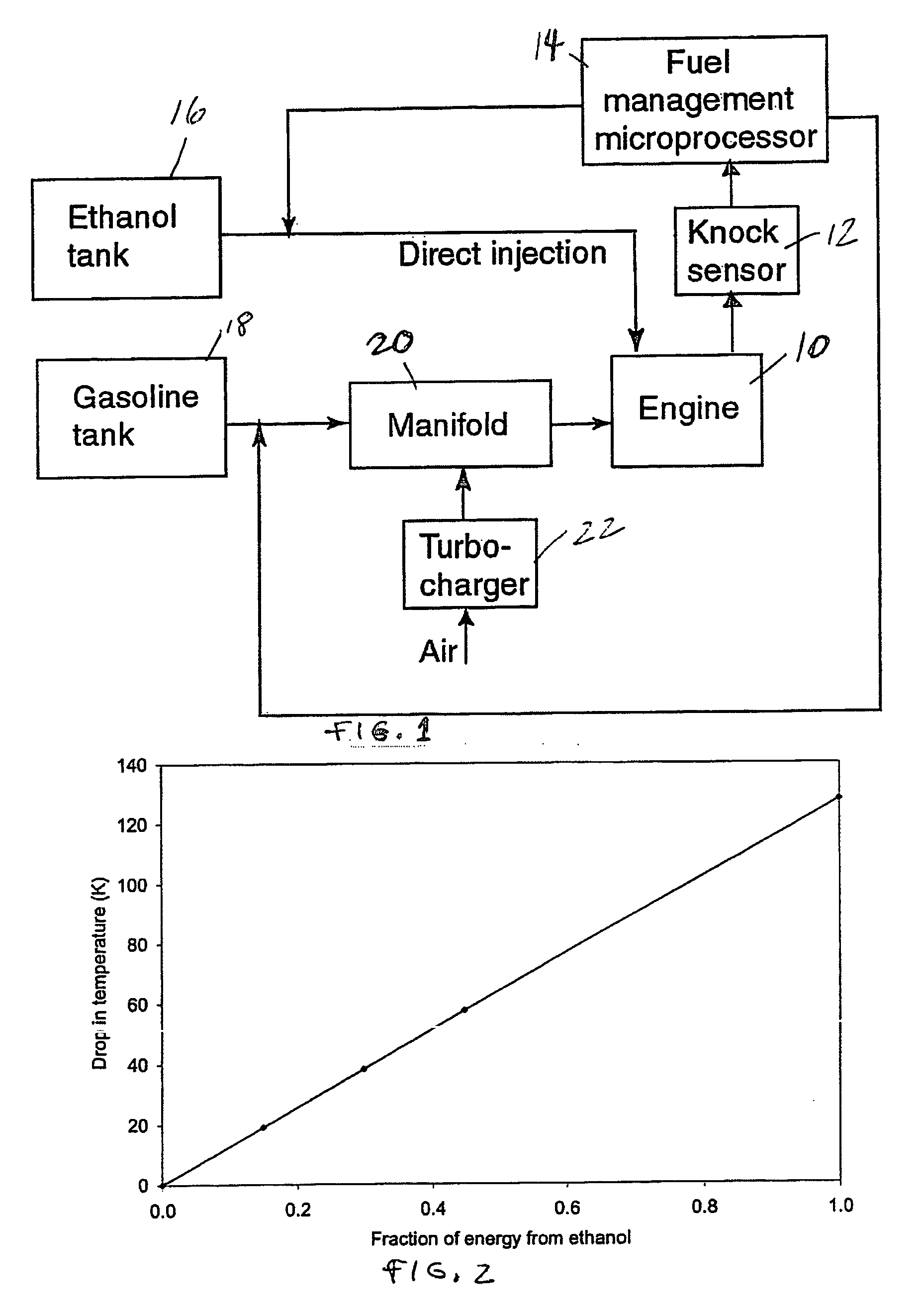

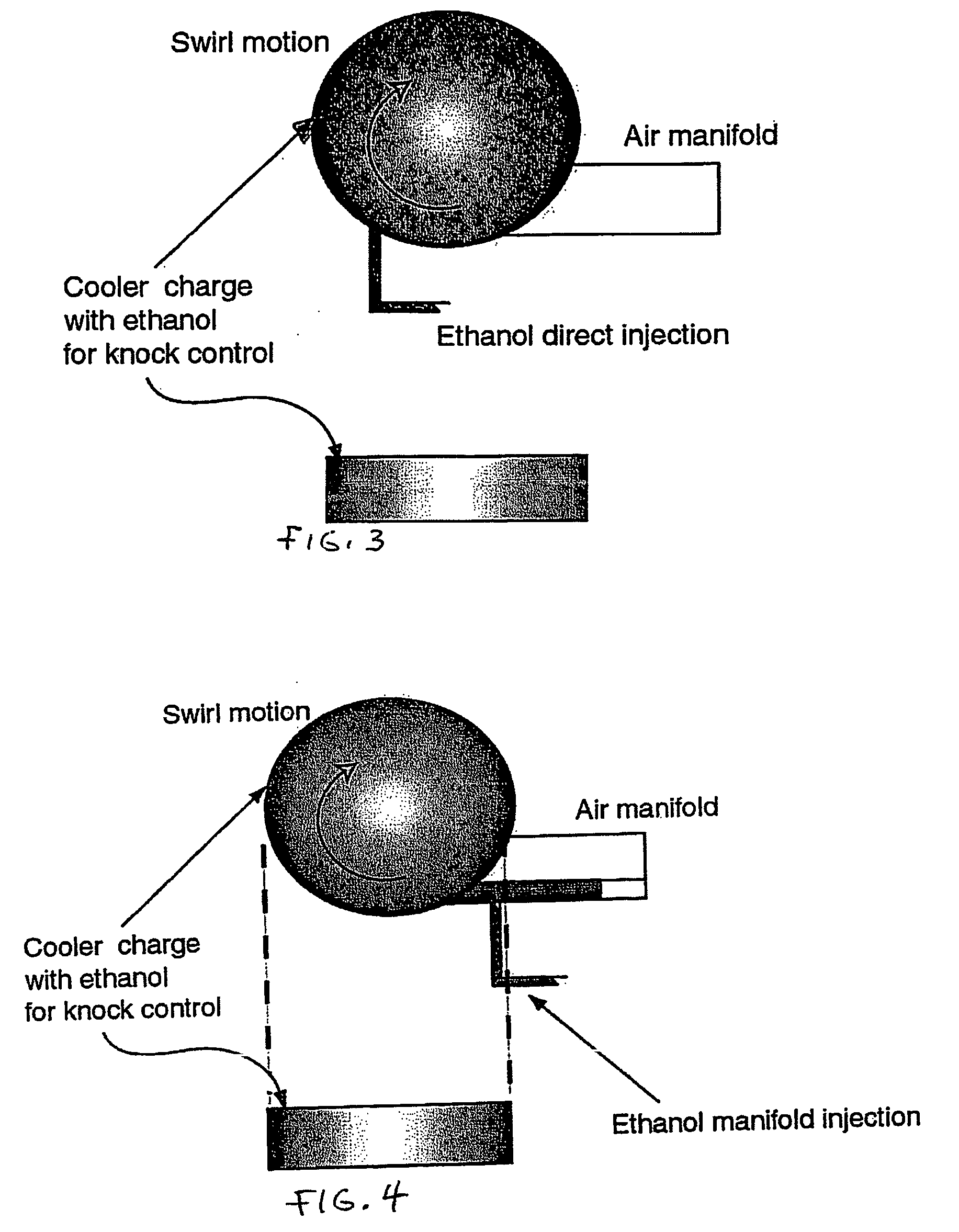

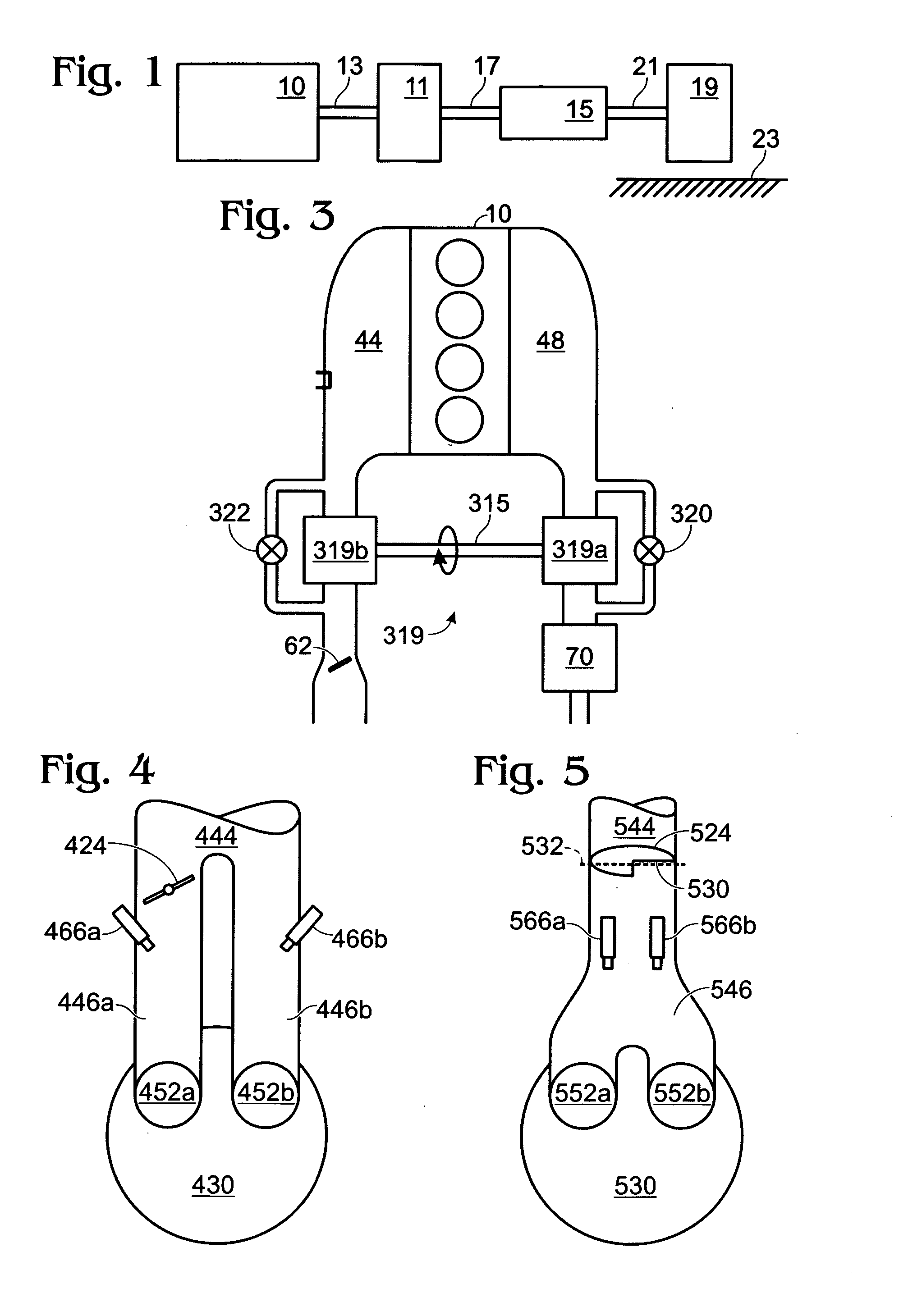

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

InactiveUS7225787B2Save gasImprove engine efficiencyElectrical controlNon-fuel substance addition to fuelEngineeringProcess engineering

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

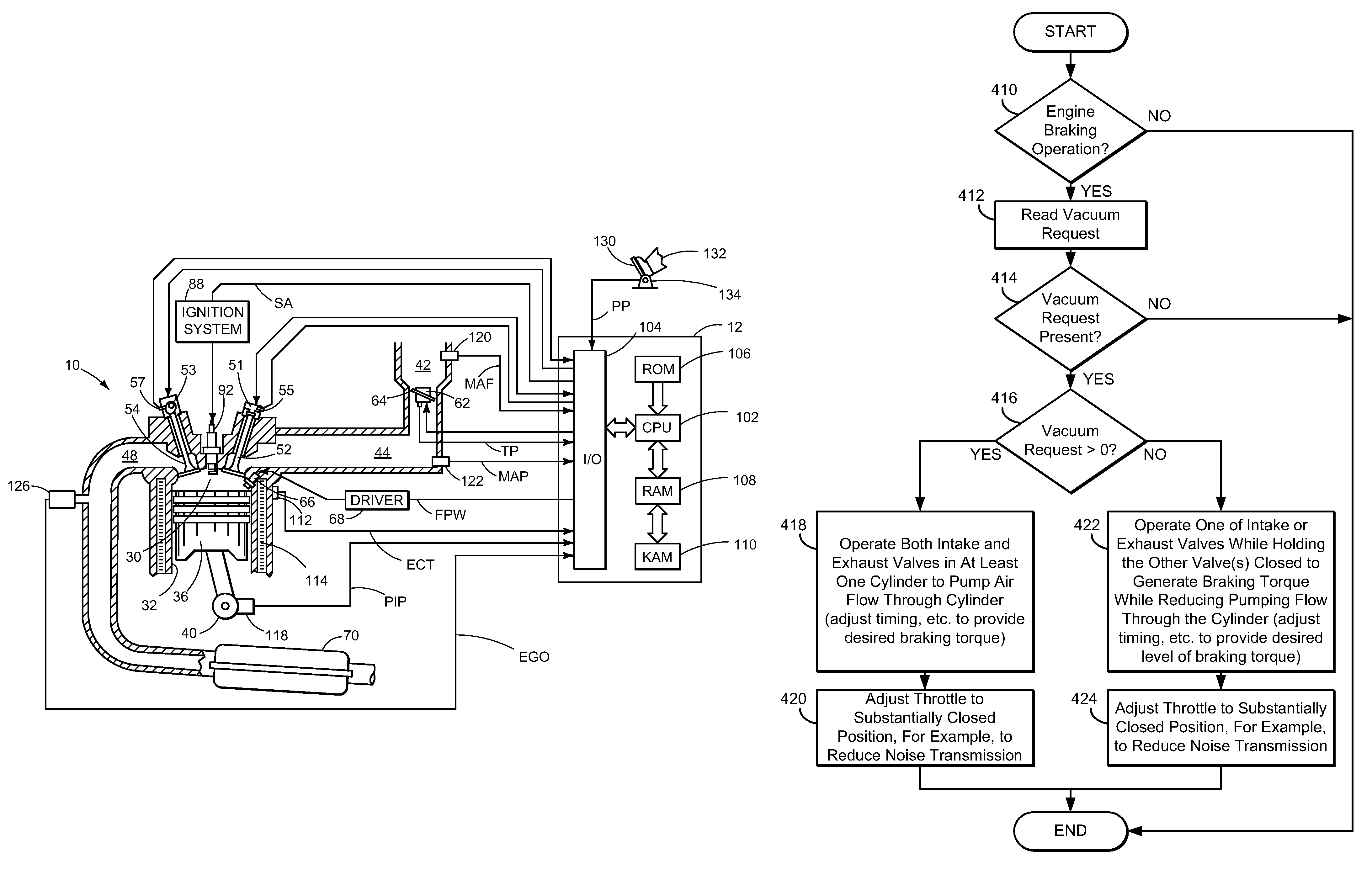

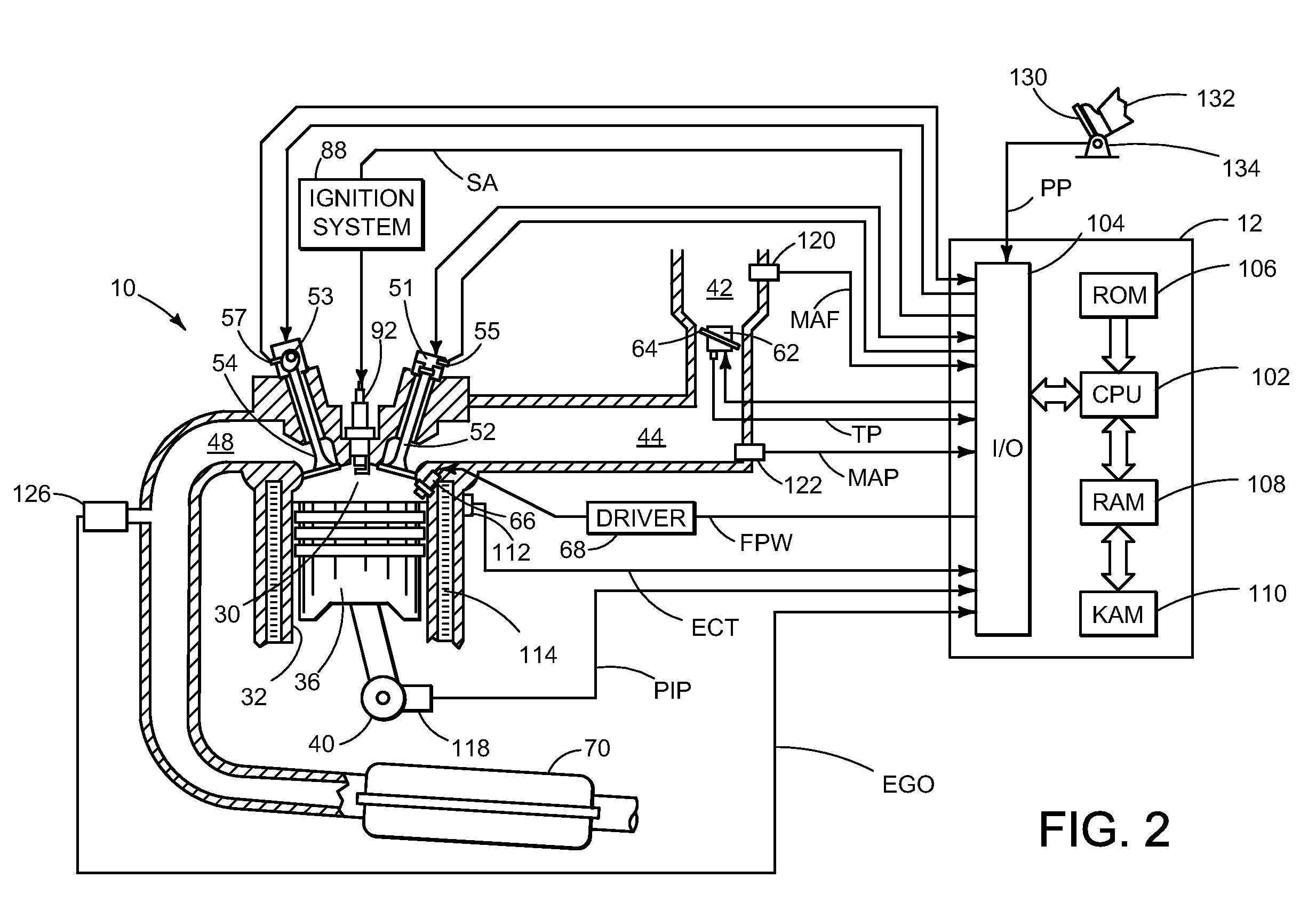

Vehicle braking control

ActiveUS7930087B2Reduced effectivenessImprove fuel economyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

A method of operating an engine for a vehicle having at least a first cylinder, the method comprising of operating the first cylinder to provide at least one of compression braking and expansion braking by holding one of an intake valve and an exhaust valve of the first cylinder closed while opening, closing, and opening the other of the intake valve and the exhaust valve during a cycle of the first cylinder and during a first vacuum level of an intake manifold upstream of the first cylinder; and operating the first cylinder to provide at least one of compression braking and expansion braking by operating both the intake valve and the exhaust valve of the first cylinder during a cycle of the first cylinder to allow at least some air to flow through the first cylinder during a second vacuum level of the intake manifold.

Owner:FORD GLOBAL TECH LLC

Internal combustion engine

ActiveUS6990956B2Accurate calculationElectrical controlInternal combustion piston enginesMultifuelEngineering

An internal combustion engine, in which multiple kinds of fuels are fed to a cylinder from multiple fuel injectors each corresponding to each of multiple kinds of fuels at a target mixing ratio determined according to a running condition, includes an actual fuel mixing ratio calculator calculating an actual fuel mixing ratio of fuel fed to cylinder. The actual fuel mixing ratio calculator at first calculates actual fuel injection quantity of each fuel injection by adding or subtracting predetermined stuck-on-wall fuel to or from each quantity of fuel injected from each fuel injector, and then calculates an actual fuel mixing ratio of fuel fed to cylinder on the basis of the calculated actual fuel injection quantity of each fuel injector.

Owner:TOYOTA JIDOSHA KK

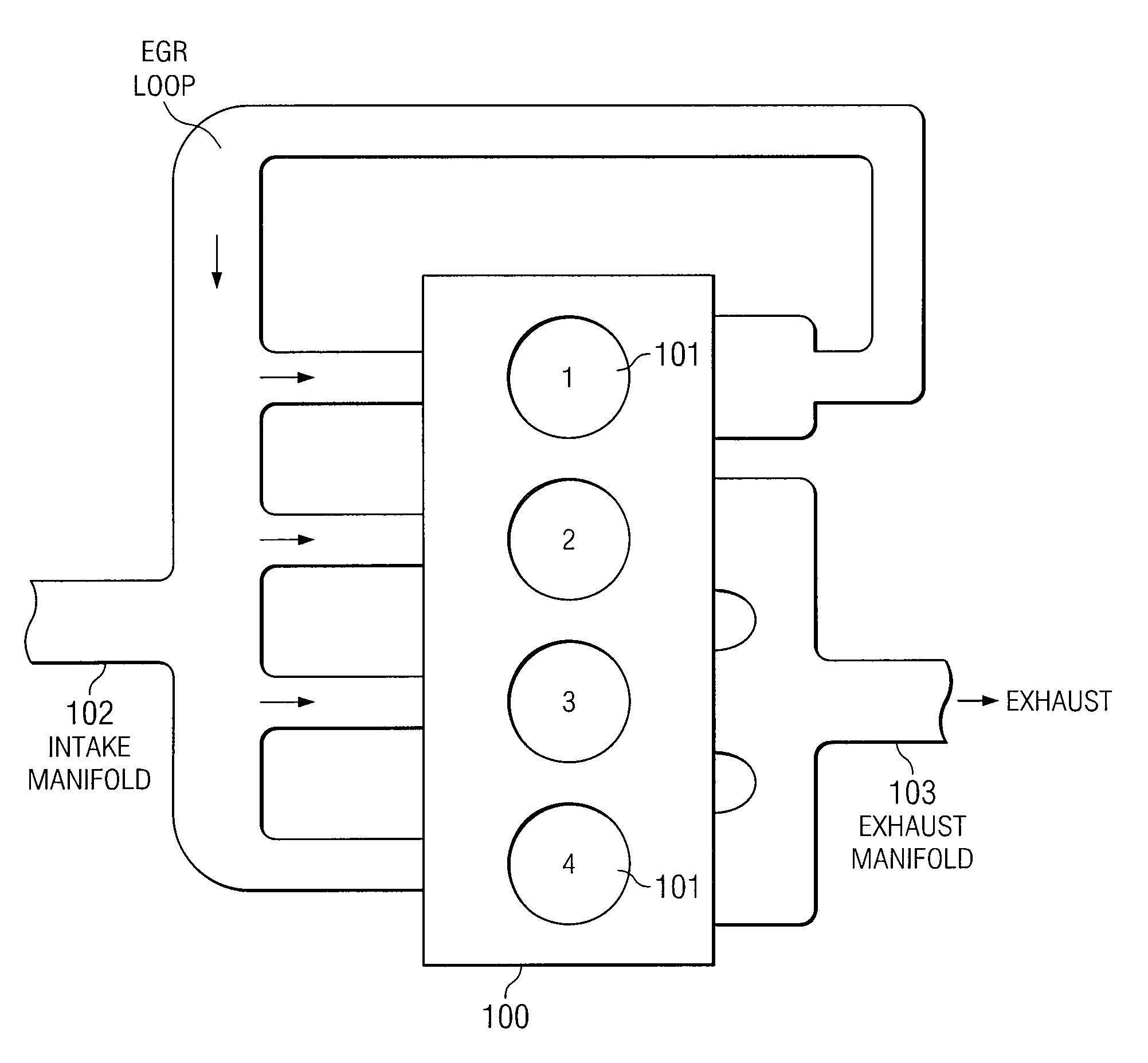

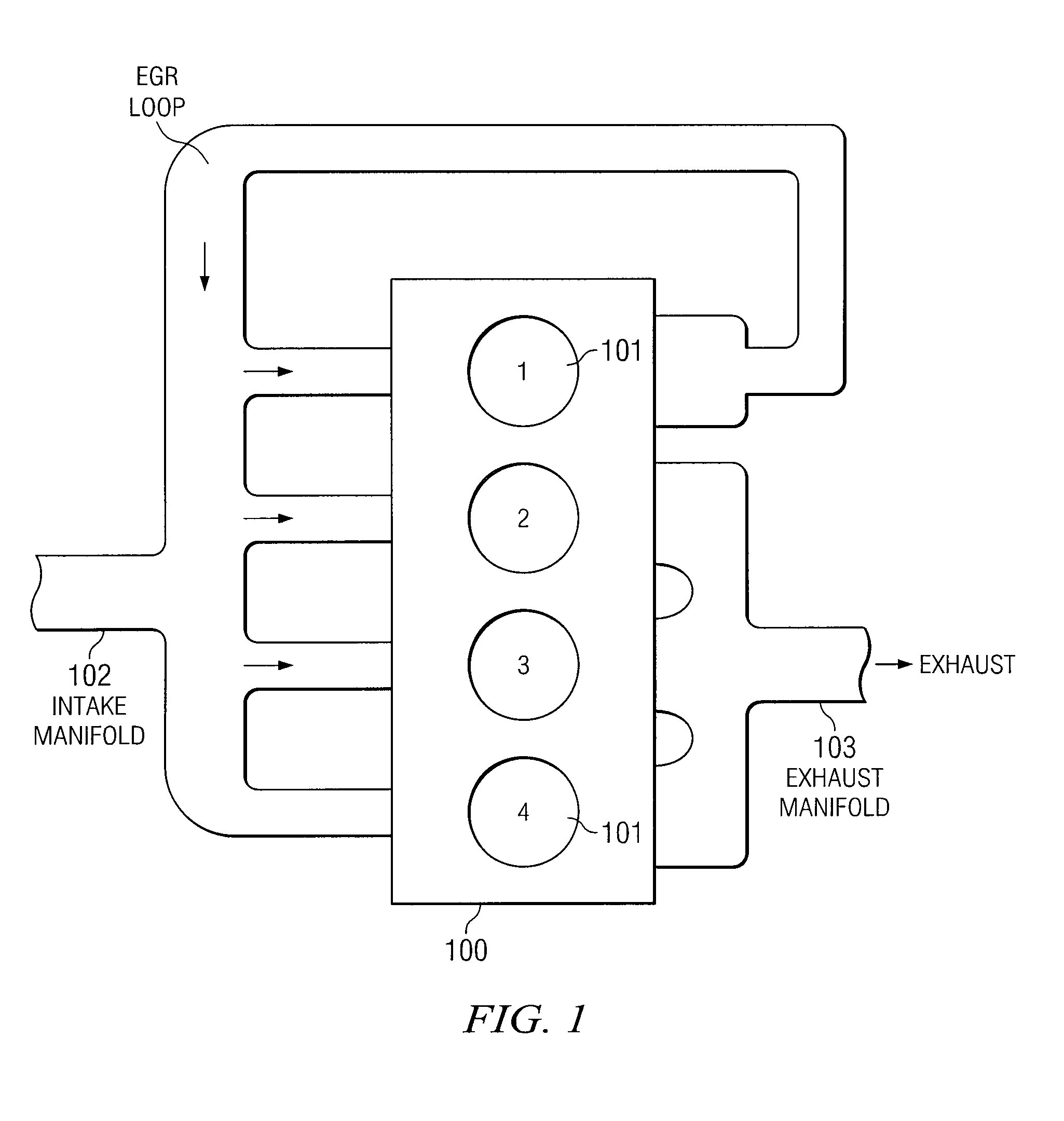

Egr system with dedicated egr cylinders

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

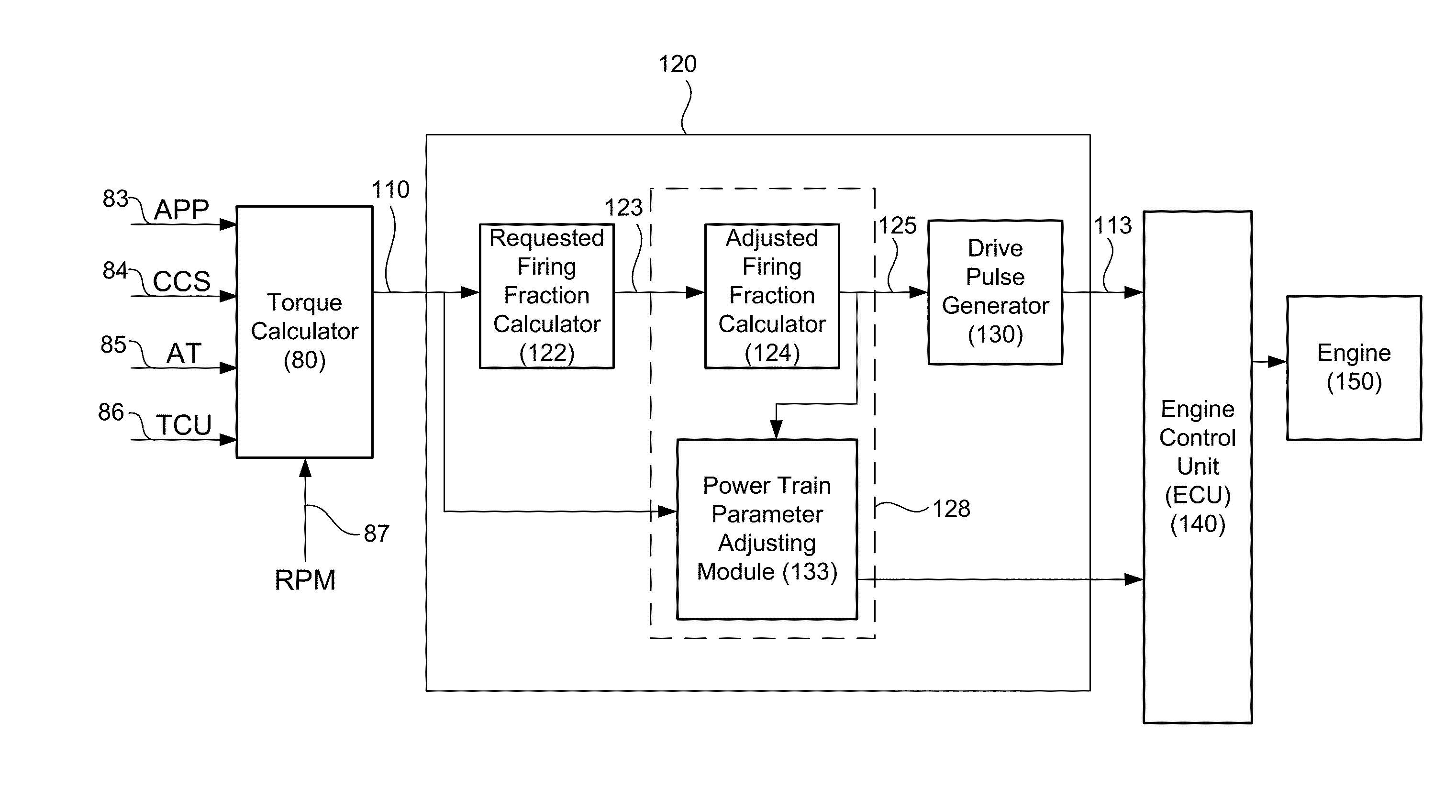

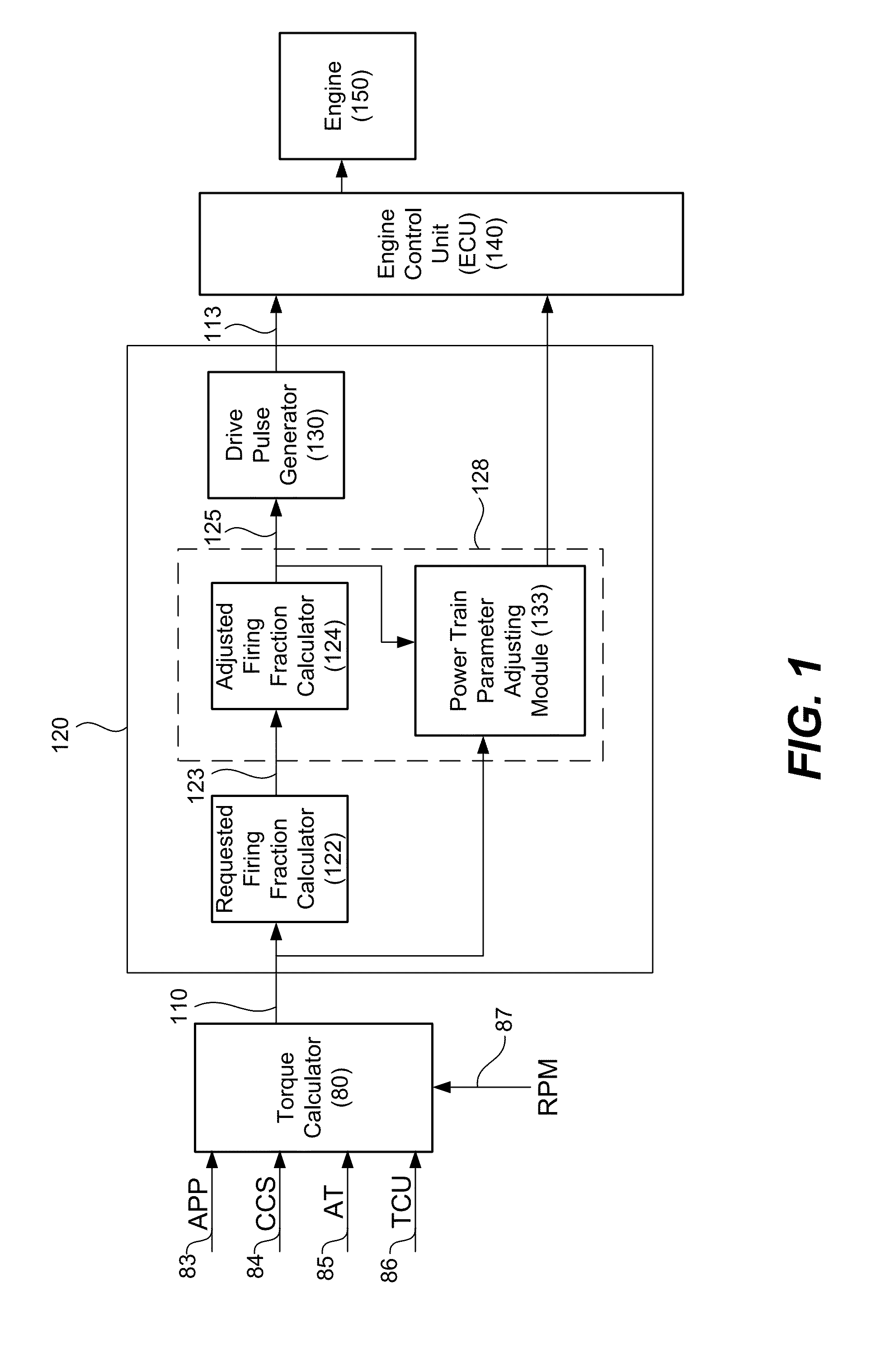

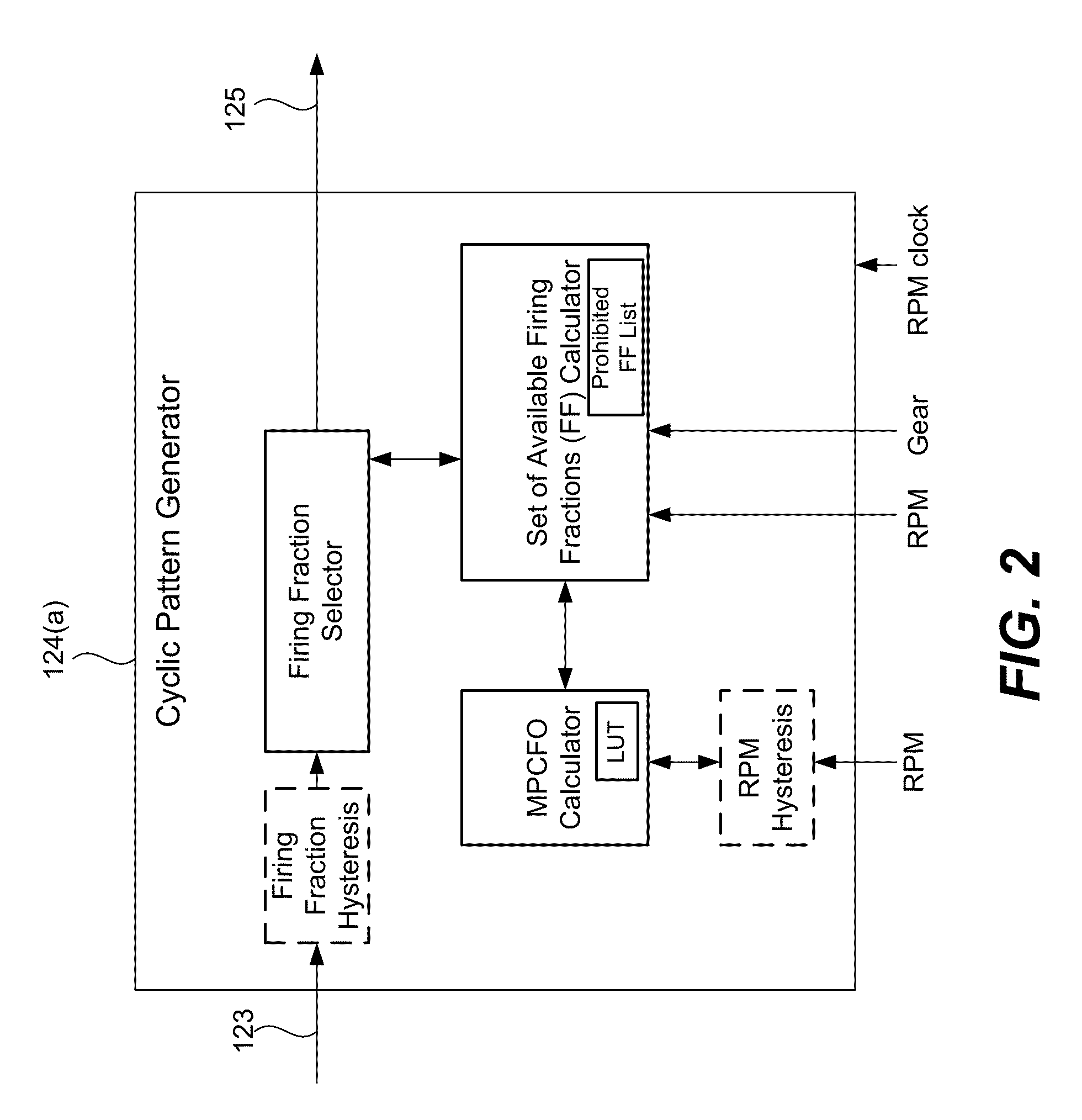

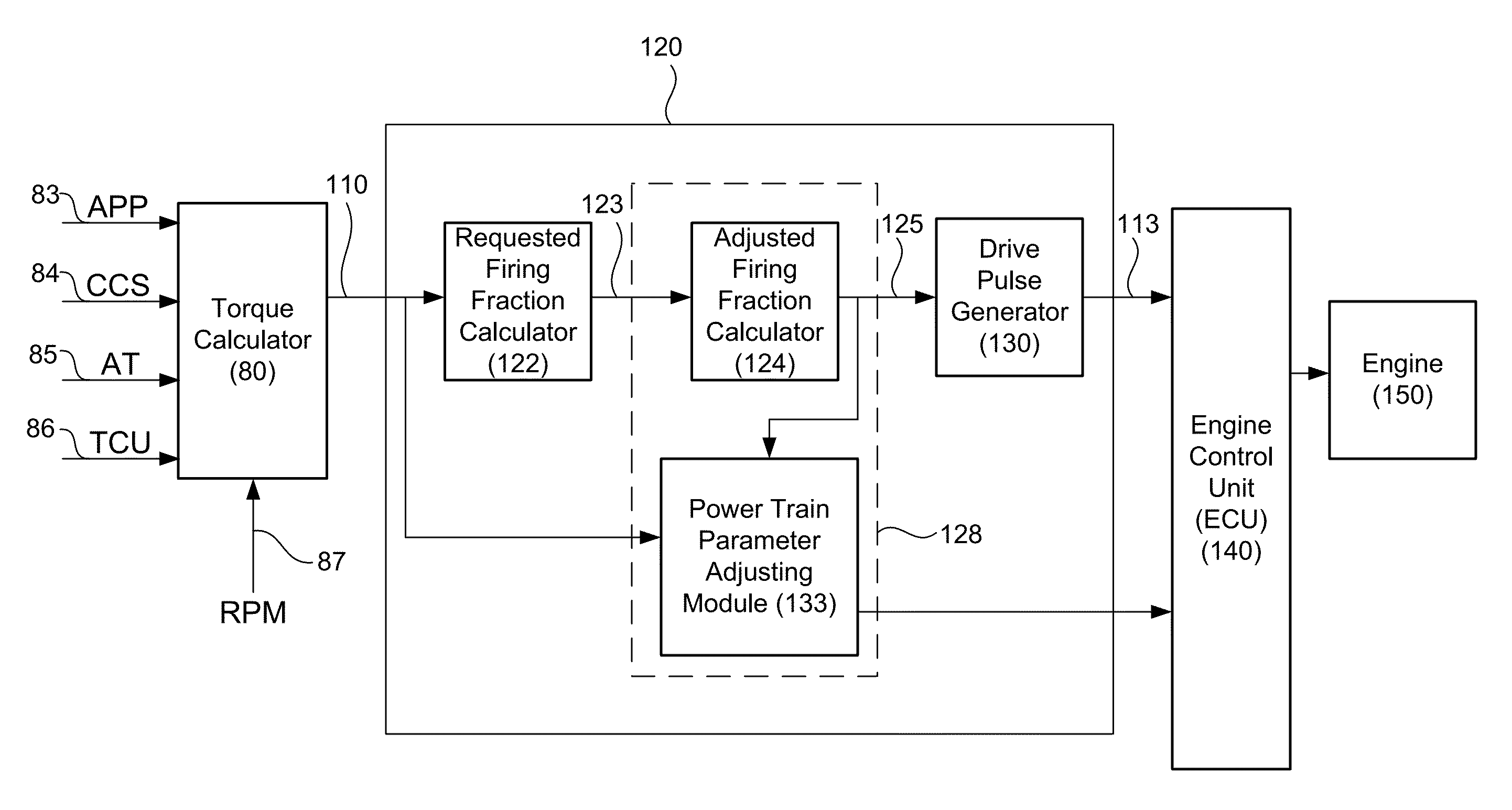

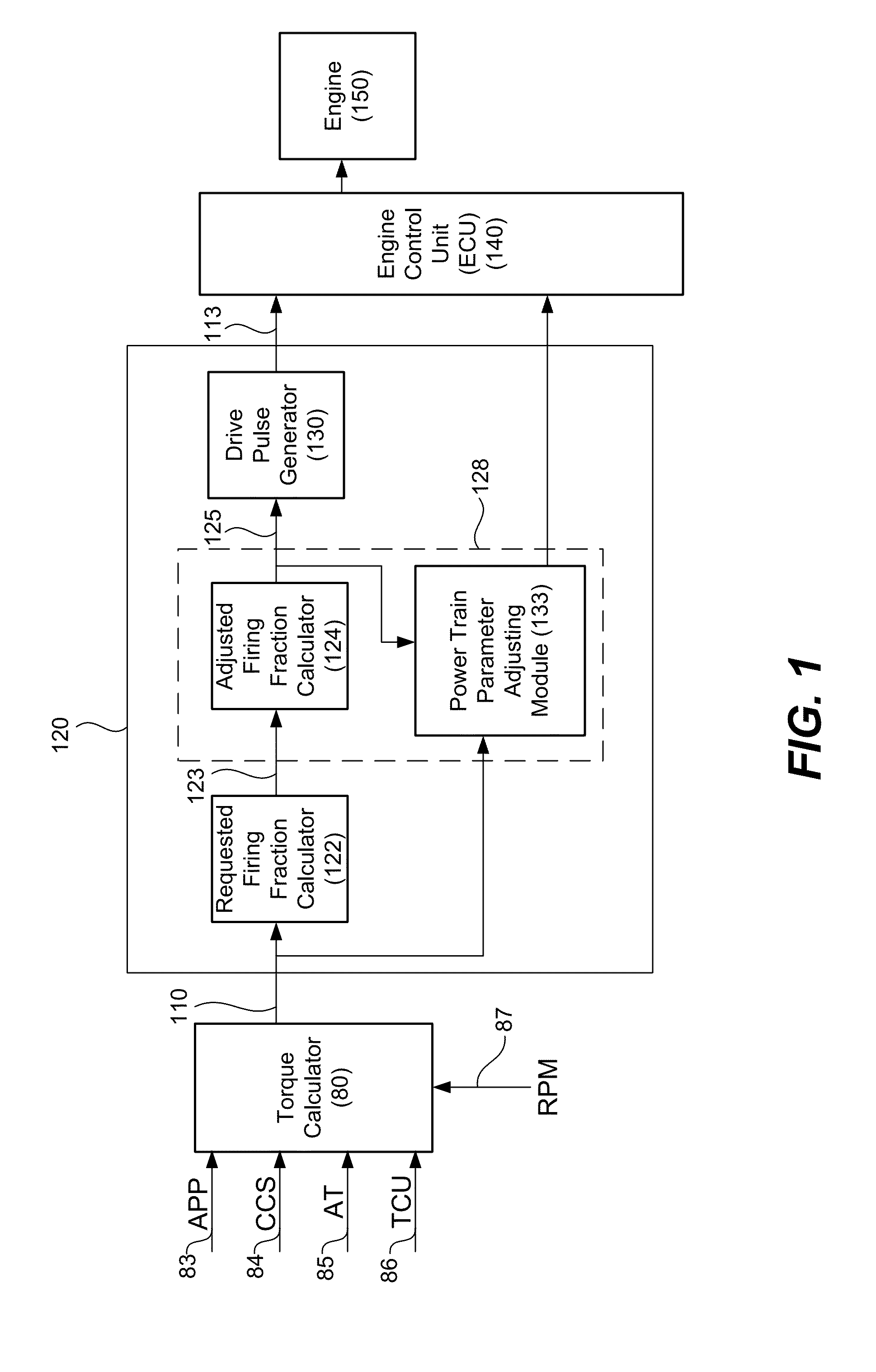

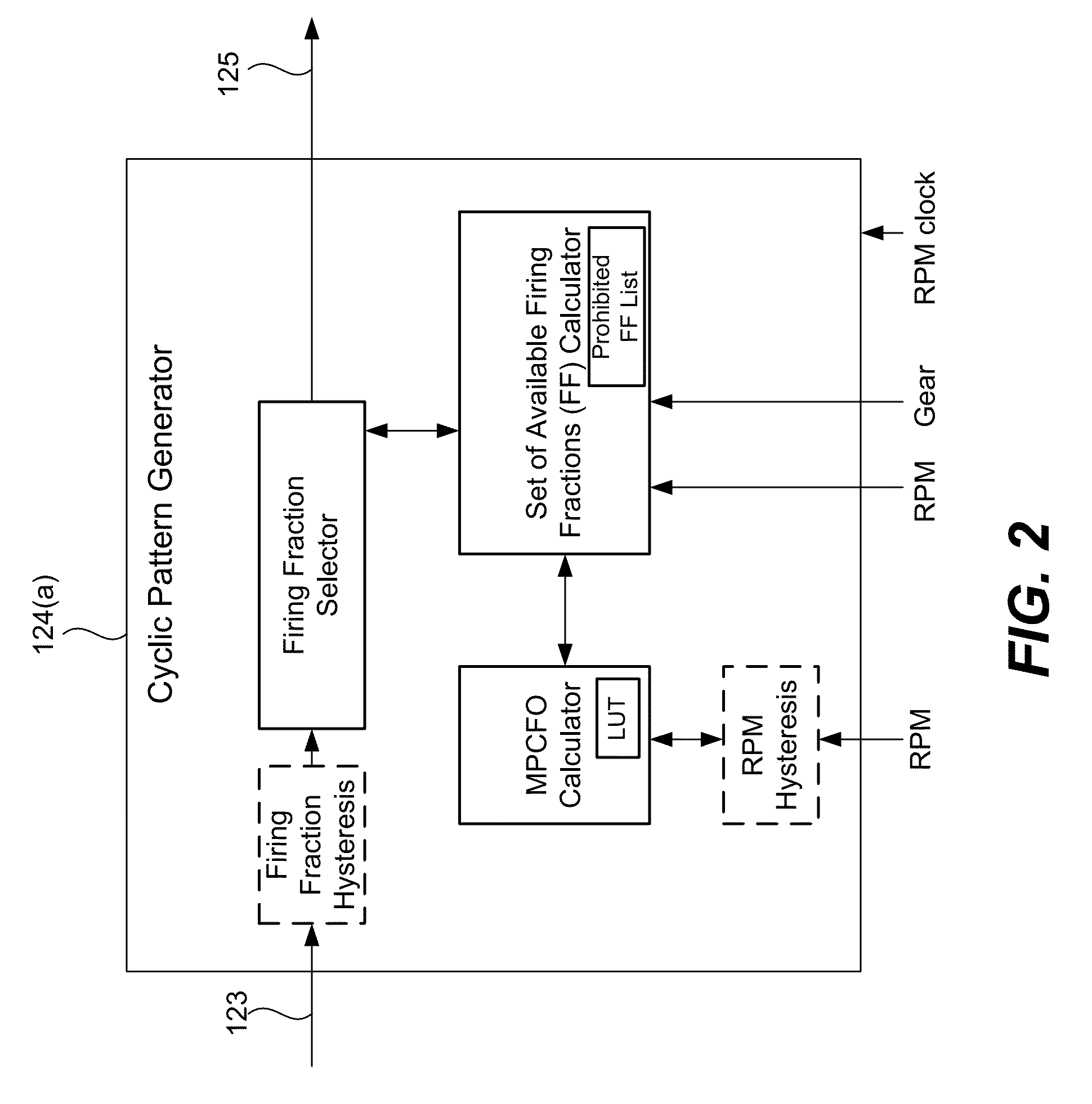

Firing fraction management in skip fire engine control

ActiveUS20130092127A1Reduce generationReduce probabilityElectrical controlOutput powerFire controlIgnition control

In various described embodiments skip fire control is used to deliver a desired engine output. A controller determines a skip fire firing fraction and (as appropriate) associated engine settings that are suitable for delivering a requested output. In one aspect, the firing fraction is selected from a set of available firing fractions, with the set of available firing fractions varying as a function of engine speed such that more firing fractions are available at higher engine speeds than at lower engine speeds. The controller then direct firings in a skip fire manner that delivers the selected fraction of firings.

Owner:TULA TECH INC

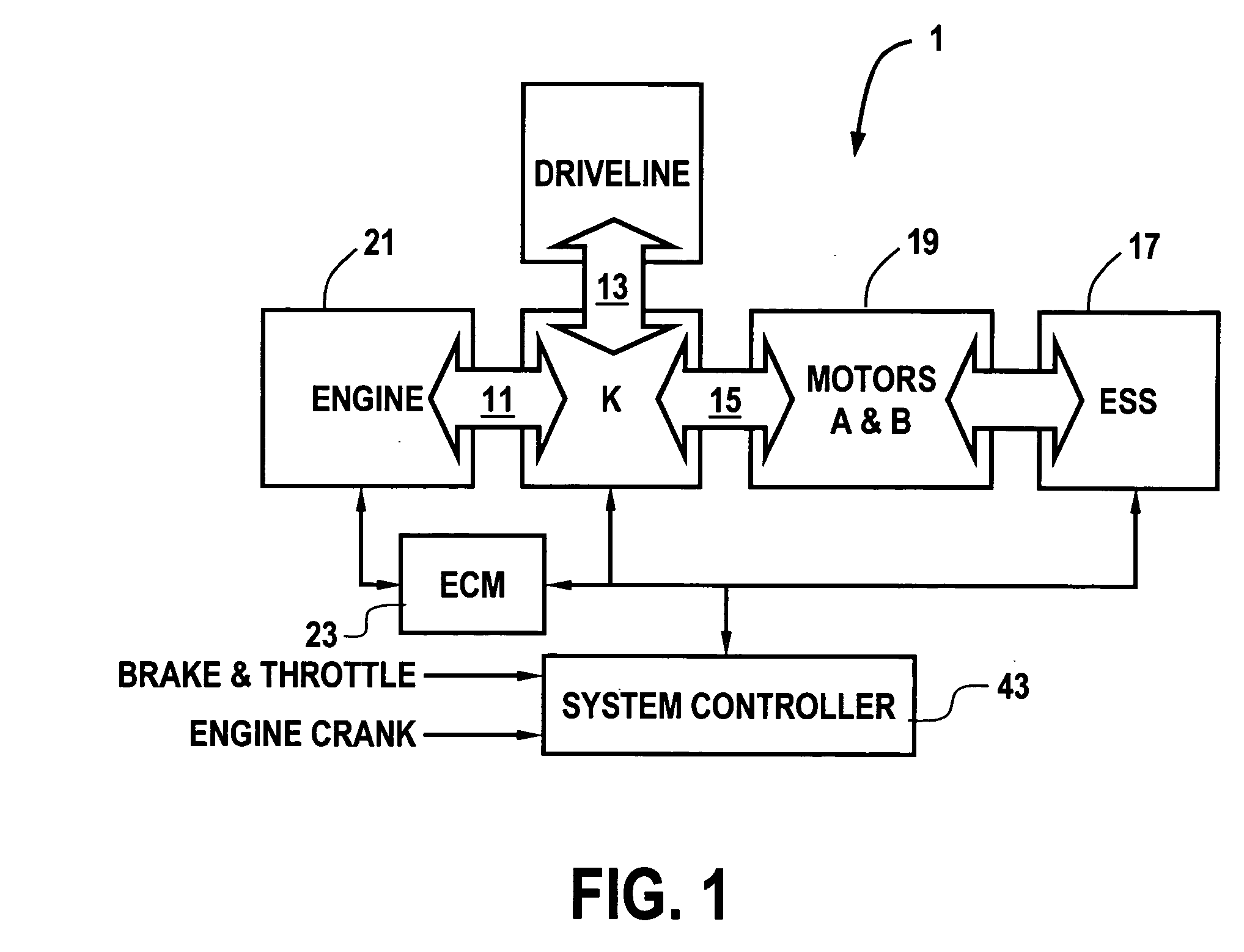

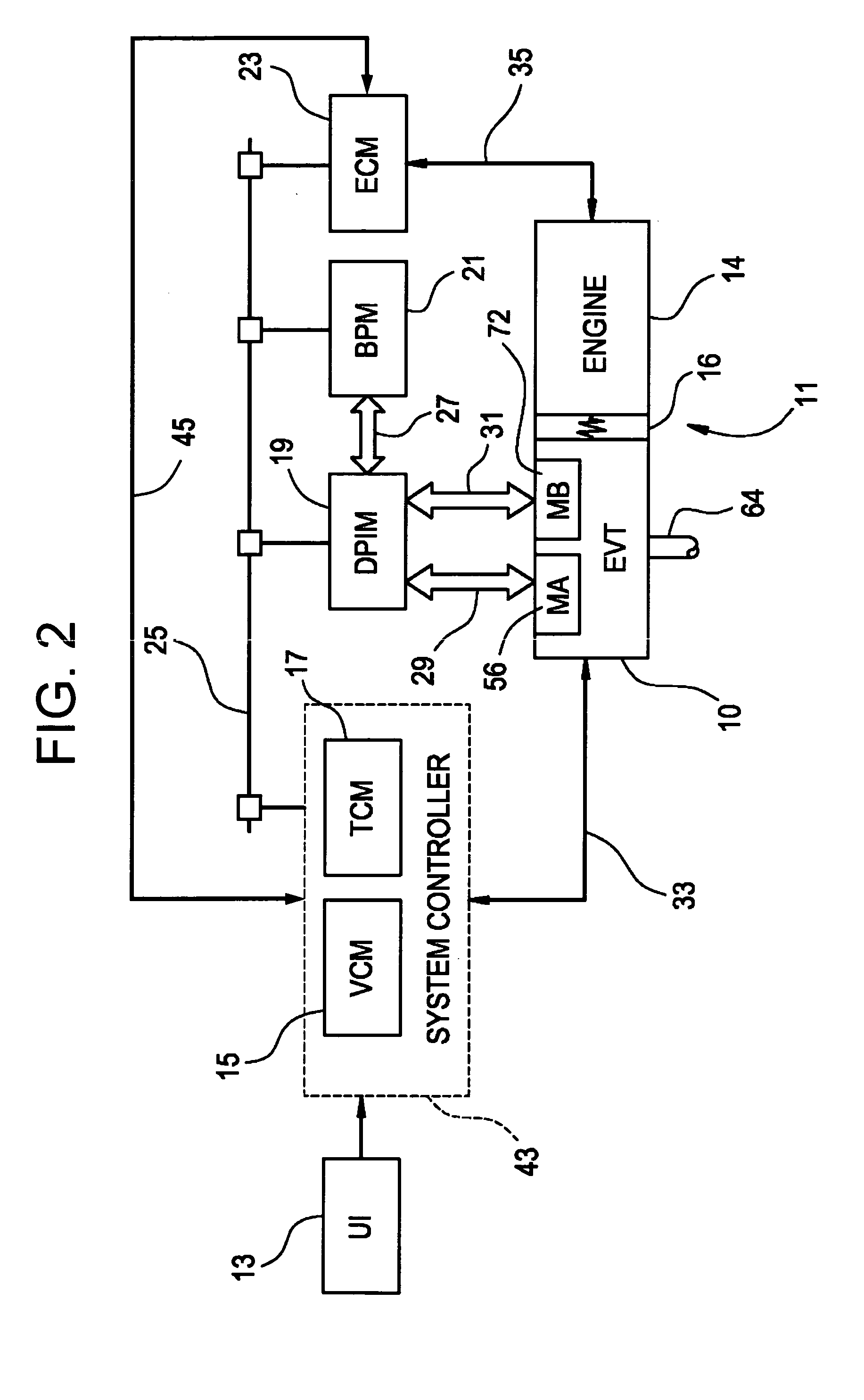

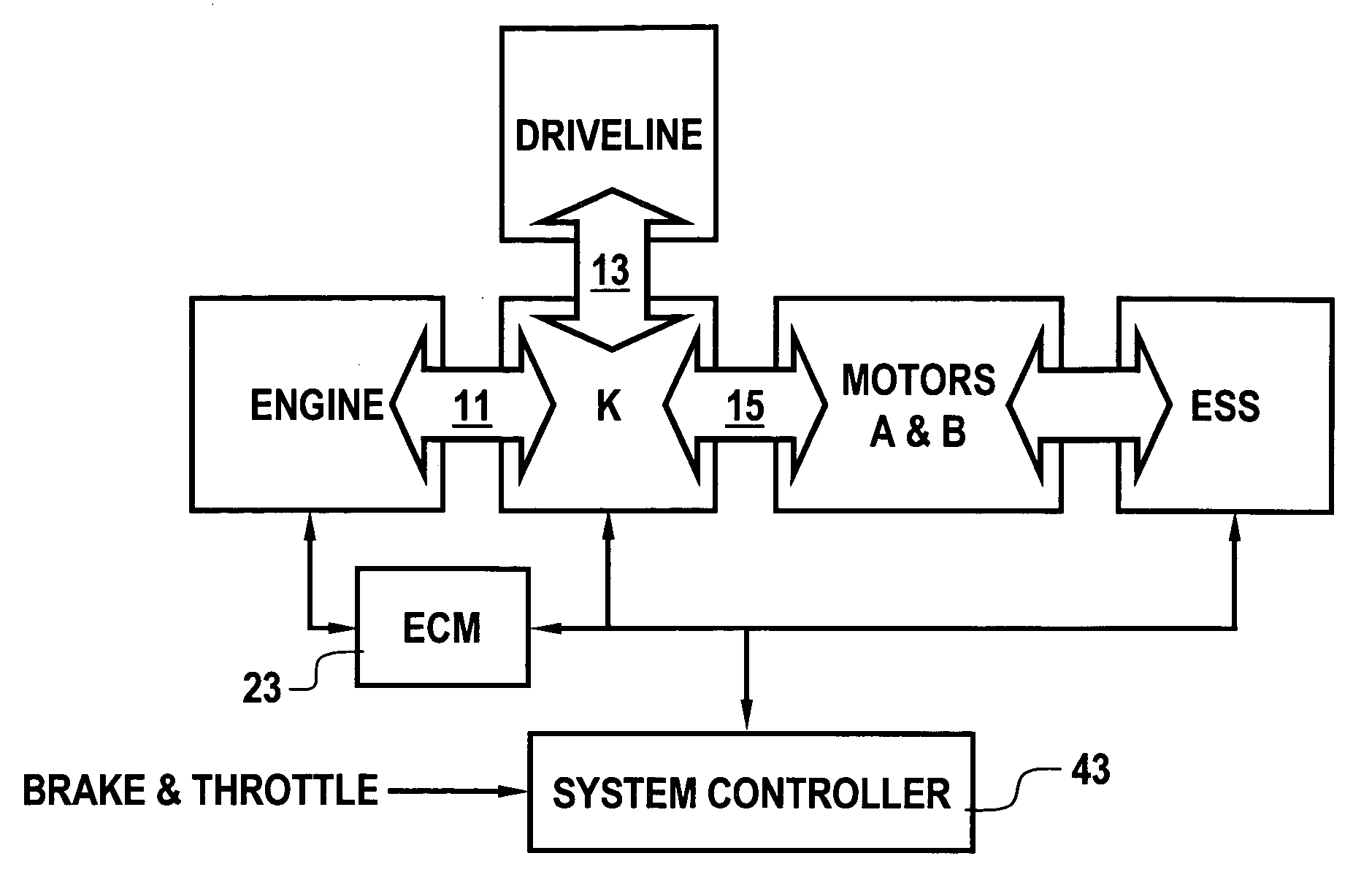

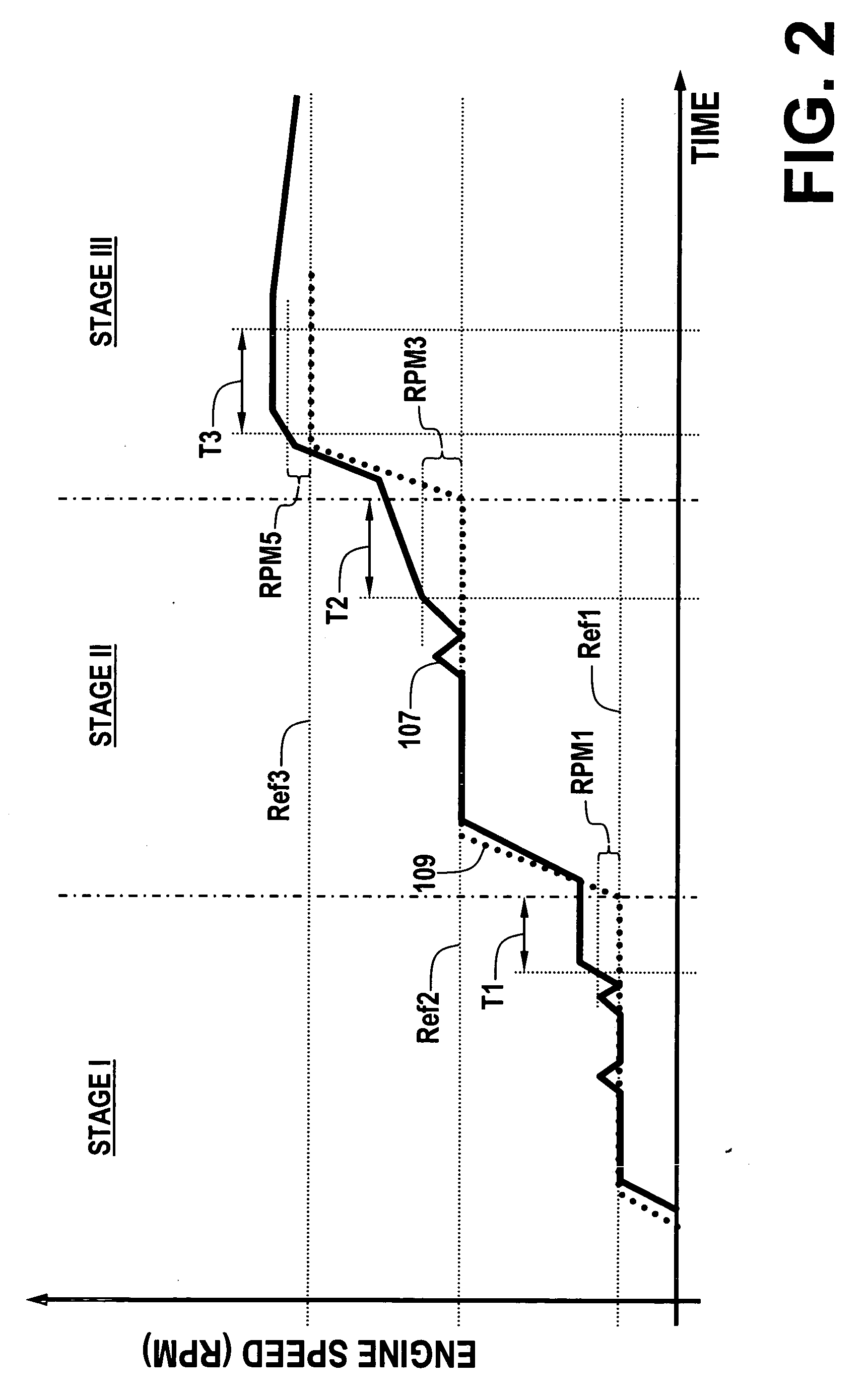

Method for active engine stop of a hybrid electric vehicle

ActiveUS20050255968A1Increased durabilityImprove smoothnessHybrid vehiclesElectrical controlElectric machineResonance

A method for providing an active engine stop of the engine of a hybrid electric vehicle. The method utilizes the electric machine to oppose the and rapidly stop the rotation of the engine at a controlled rate. The method includes the calculation of an input speed reduction trajectory using the engine speed when the active engine stop request is made and a predetermined speed reduction interval. The predetermined speed reduction interval is preferably less than a time from the active stop request to the shutoff command to the electric machine. The method provides rapid deceleration of the engine, particularly through the powertrain resonance speed, thereby reducing the amount of vibration energy dissipated through the powertrain and vehicle chassis. The method also removes the electric machine torques from the engine prior to achieving zero engine speed in order to avoid imparting a negative engine speed or counter-rotation of the engine. The method preferably comprises a complementary series of software control functions that allow the vehicle to actively stop the engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

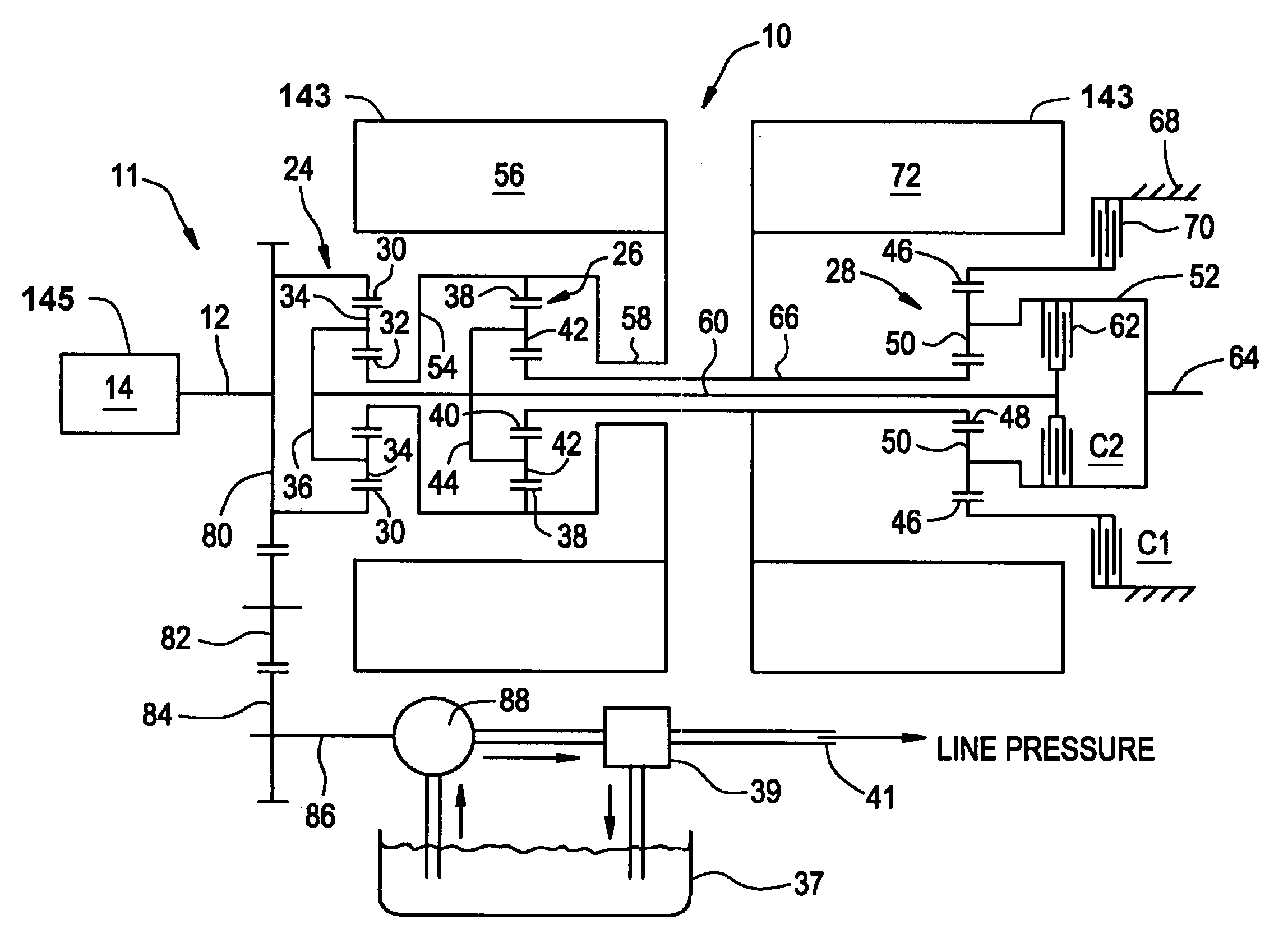

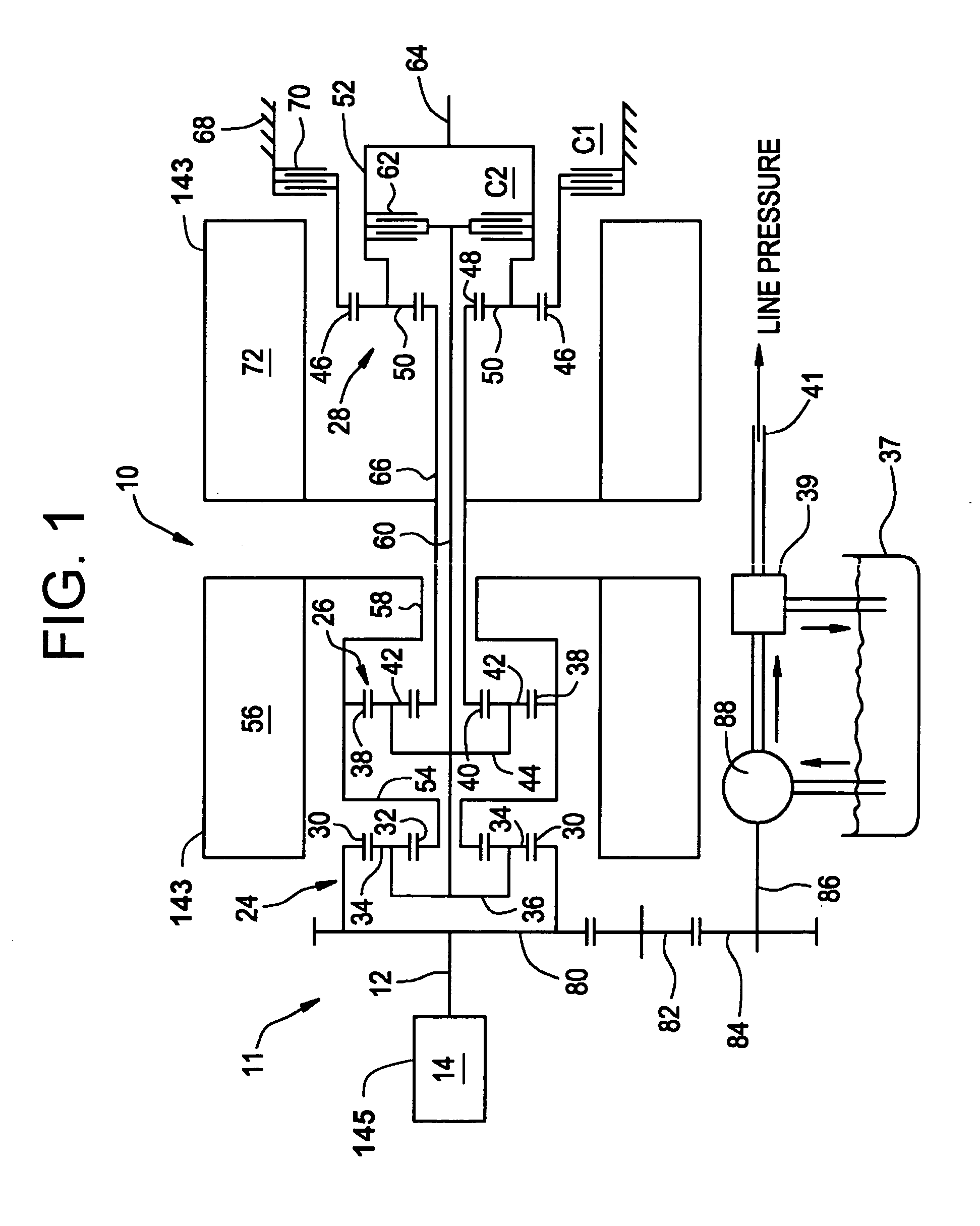

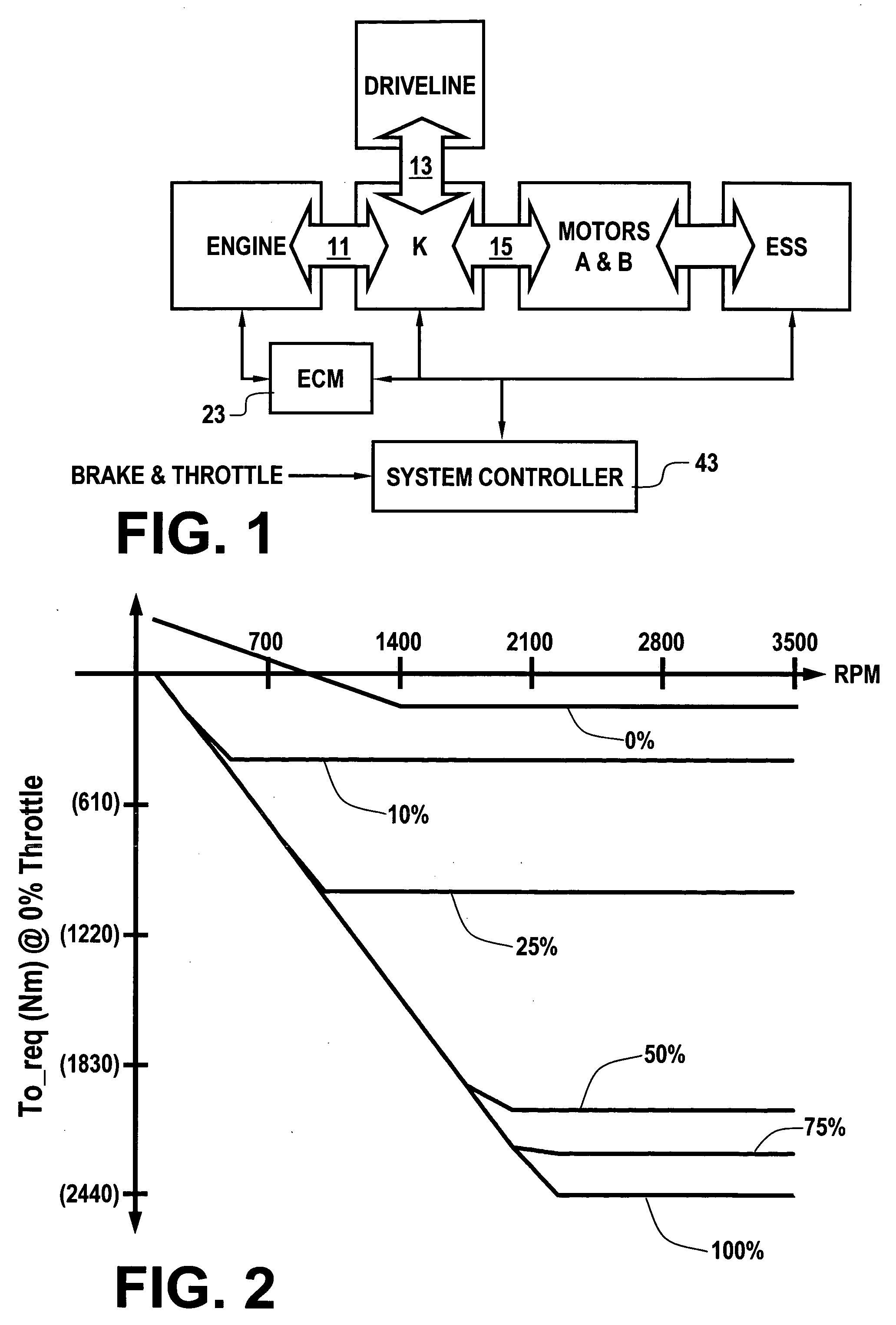

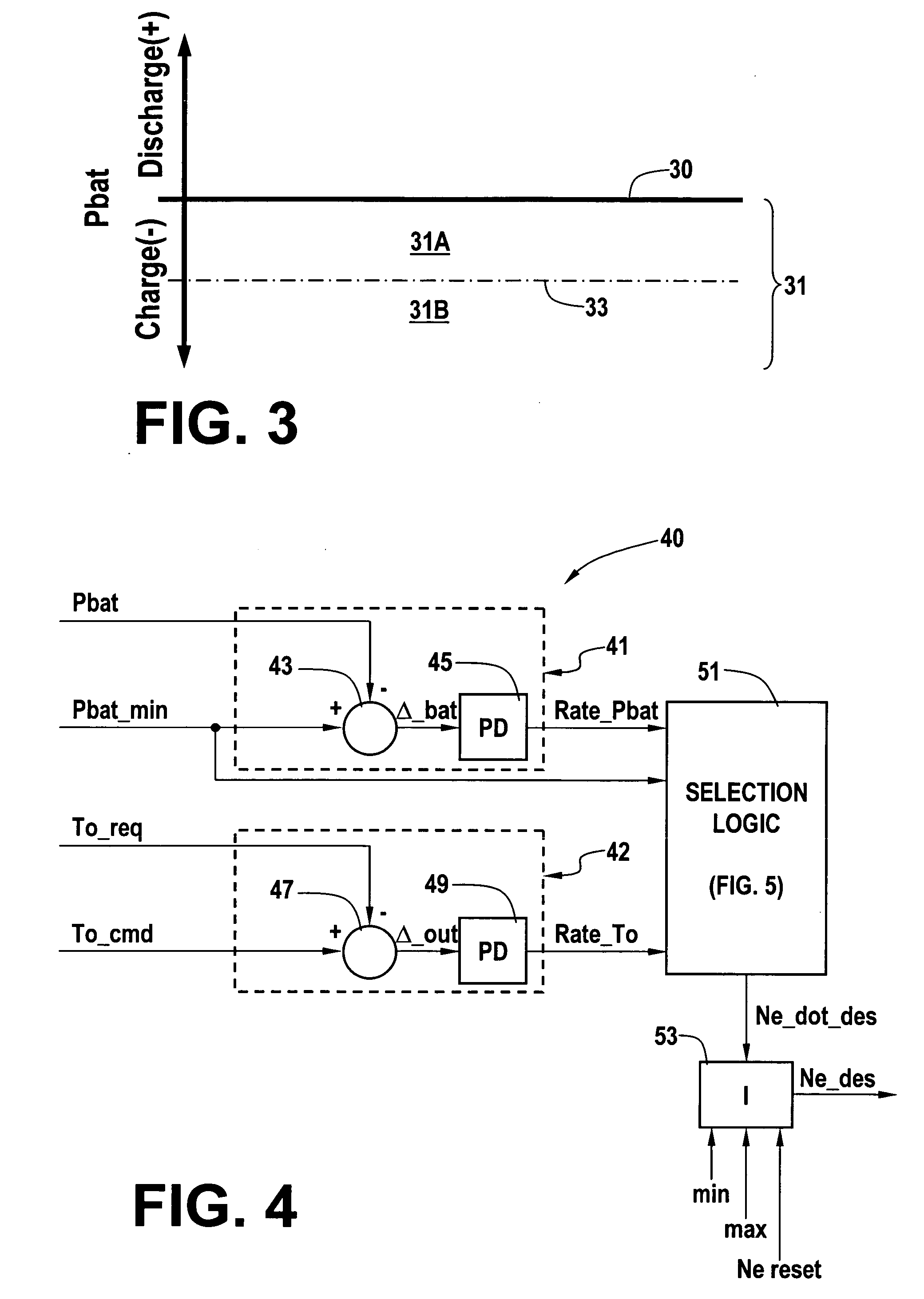

Coordinated regenerative and engine retard braking for a hybrid vehicle

ActiveUS20050255965A1Increases the engine retard braking contributionReduce contributionHybrid vehiclesBraking element arrangementsPower flowGear wheel

A hybrid vehicle includes a powertrain having a retarded diesel engine, an electric machine and energy storage system. The engine and motor are operatively coupled through one or more planetary gearsets and selective coupling paths in accordance with application and release of various torque transfer devices to a drivetrain via an output. Regenerative and retarded engine braking are coordinated to provide priority to energy return to an energy storage system in accordance with predetermined power flow limits. Power flow in excess of the limits are handled by increased engine retard braking contributions via engine speed increases.

Owner:ALLISON TRANSMISSION INC

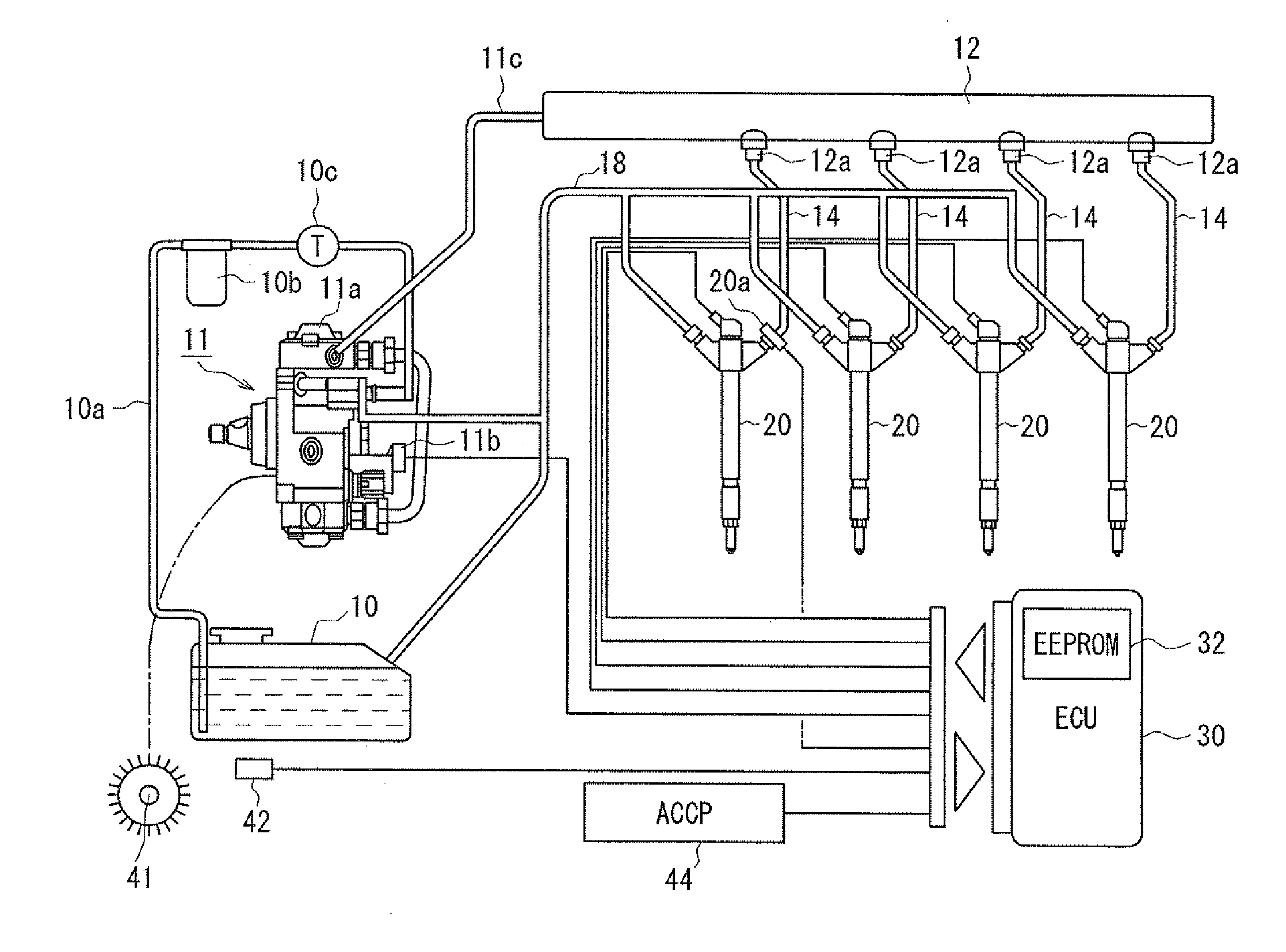

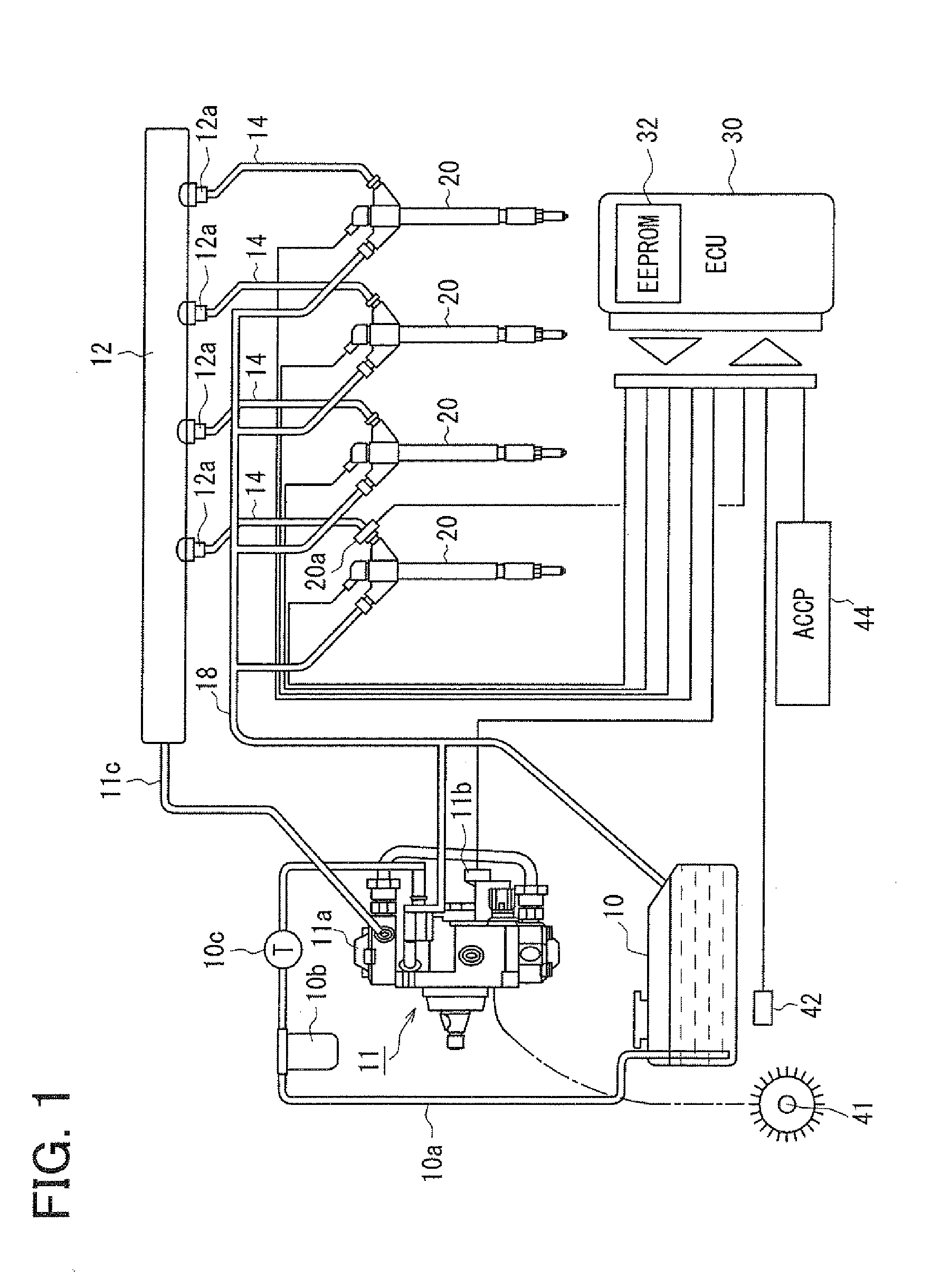

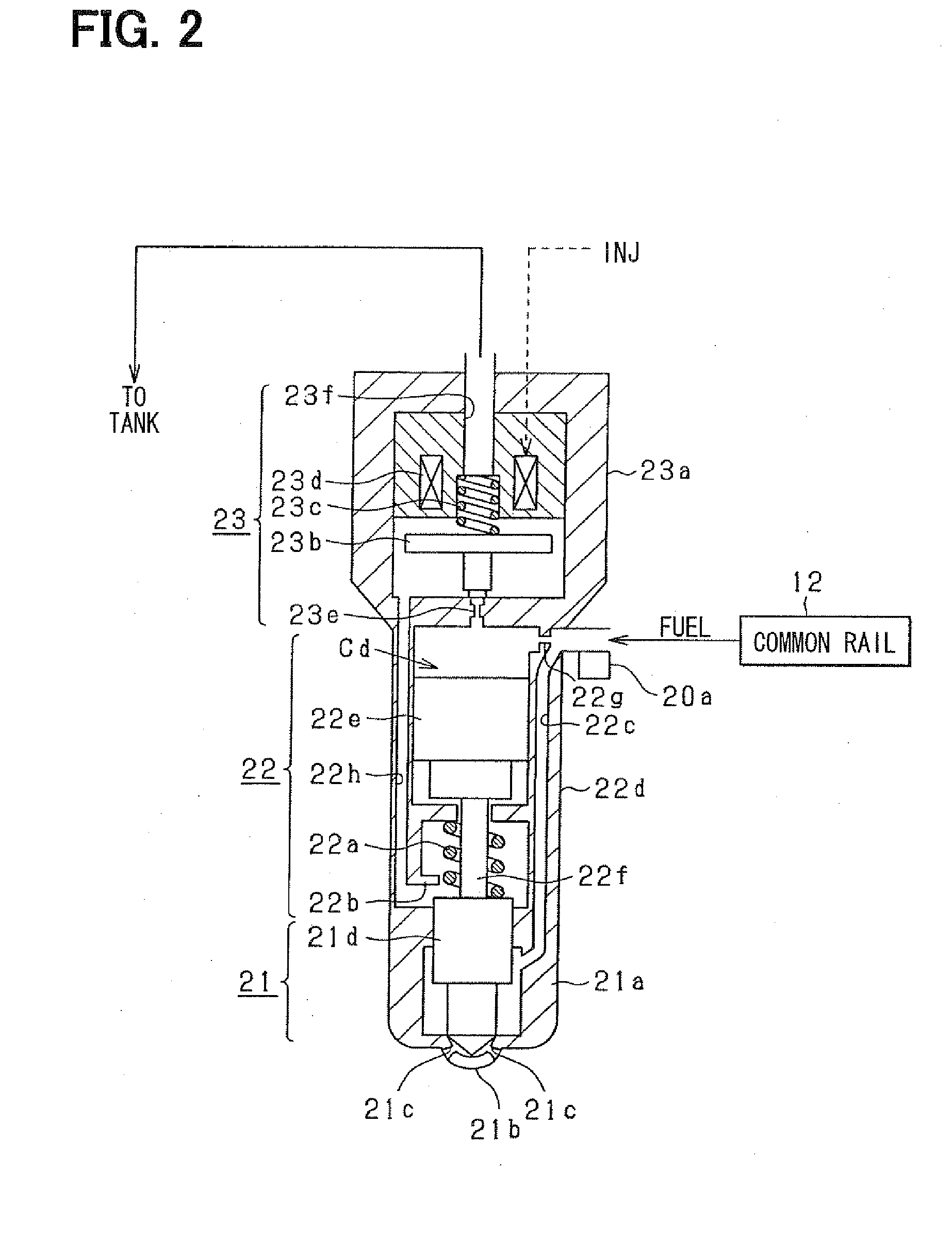

Fuel injection device and adjustment method thereof

ActiveUS20080228374A1Improve accuracyAccurate inductionInternal-combustion engine testingElectrical controlCommon railForce sensor

A fuel injection device (fuel supply system) of a common rail type fuel injection system for an engine includes a pressure sensor disposed in a fuel inlet of an injector for measuring a fuel pressure at a position where the sensor is disposed and an ECU for sensing various kinds of pressure fluctuations associated with the injection including a pressure leak due to an injection operation of the injector and waving characteristics due to actual injection thereof based on sensor outputs from the pressure sensor. The ECU serially obtains the sensor outputs from the pressure sensor at intervals of 20 μsec.

Owner:DENSO CORP

Differential torque operation for internal combustion engine

InactiveUS7503312B2Improve internal efficiencyImprove fuel efficiencyElectrical controlInternal combustion piston enginesInternal combustion engineControl theory

A method of operating an internal combustion engine having a plurality of cylinders including at least a first cylinder and a second cylinder, the method comprising firing the first cylinder and the second cylinder in an alternating sequence; during a first mode, adjusting an operating parameter of the engine to produce a first difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; during a second mode, adjusting the operating parameter of the engine to produce a second difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; and performing the first mode at a higher engine speed than the second mode; wherein the first difference is greater than the second difference.

Owner:FORD GLOBAL TECH LLC

Firing fraction management in skip fire engine control

ActiveUS9086020B2Reduce generationReduce probabilityElectrical controlOutput powerFire controlIgnition control

In various described embodiments skip fire control is used to deliver a desired engine output. A controller determines a skip fire firing fraction and (as appropriate) associated engine settings that are suitable for delivering a requested output. In one aspect, the firing fraction is selected from a set of available firing fractions, with the set of available firing fractions varying as a function of engine speed such that more firing fractions are available at higher engine speeds than at lower engine speeds. The controller then direct firings in a skip fire manner that delivers the selected fraction of firings.

Owner:TULA TECH INC

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

InactiveUS20060102136A1Improve engine efficiencySave gasElectrical controlNon-fuel substance addition to fuelProcess engineeringVaporization

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

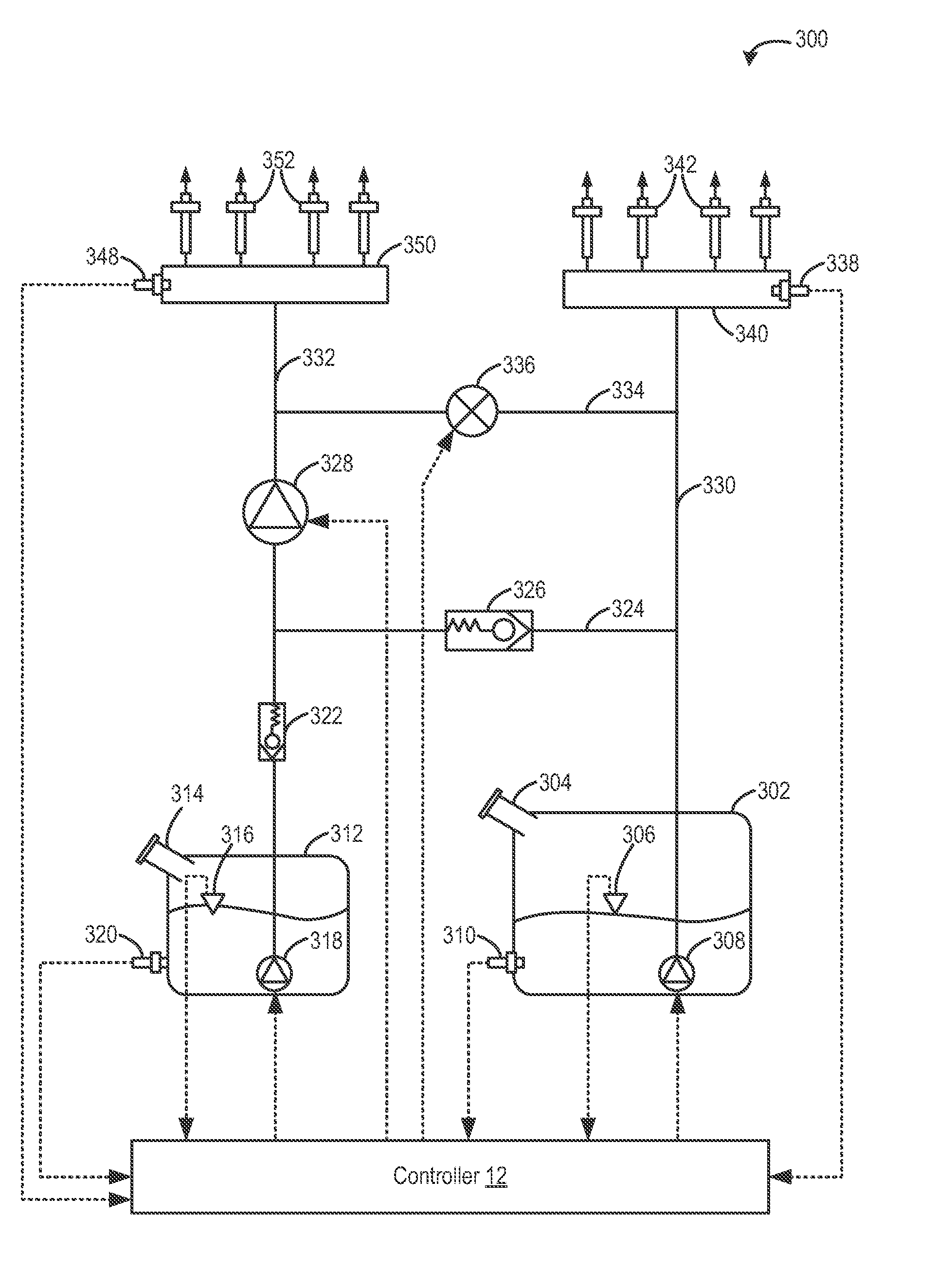

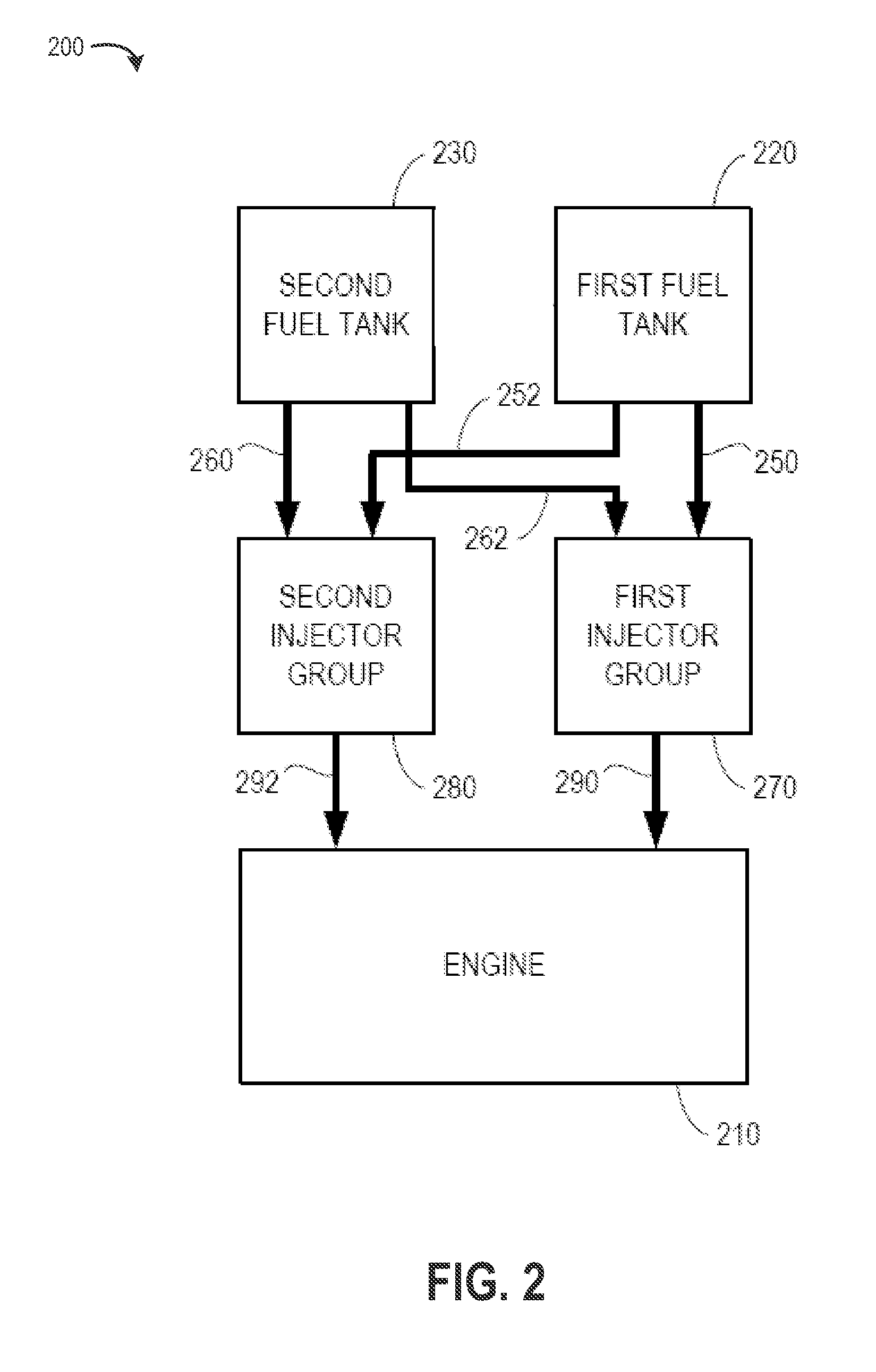

Fuel system for a multi-fuel engine

InactiveUS20120048242A1Reducing high pressure pump degradationReduce degradationElectrical controlInternal combustion piston enginesFuel typeHigh pressure

Methods and systems are provided for operating an engine fuel system including fuels of different fuel types. A first fuel type is delivered for port injection upon circulation through a high pressure pump when direct injection of a fuel is not requested to cool and / or lubricate the high pressure pump.

Owner:FORD GLOBAL TECH LLC

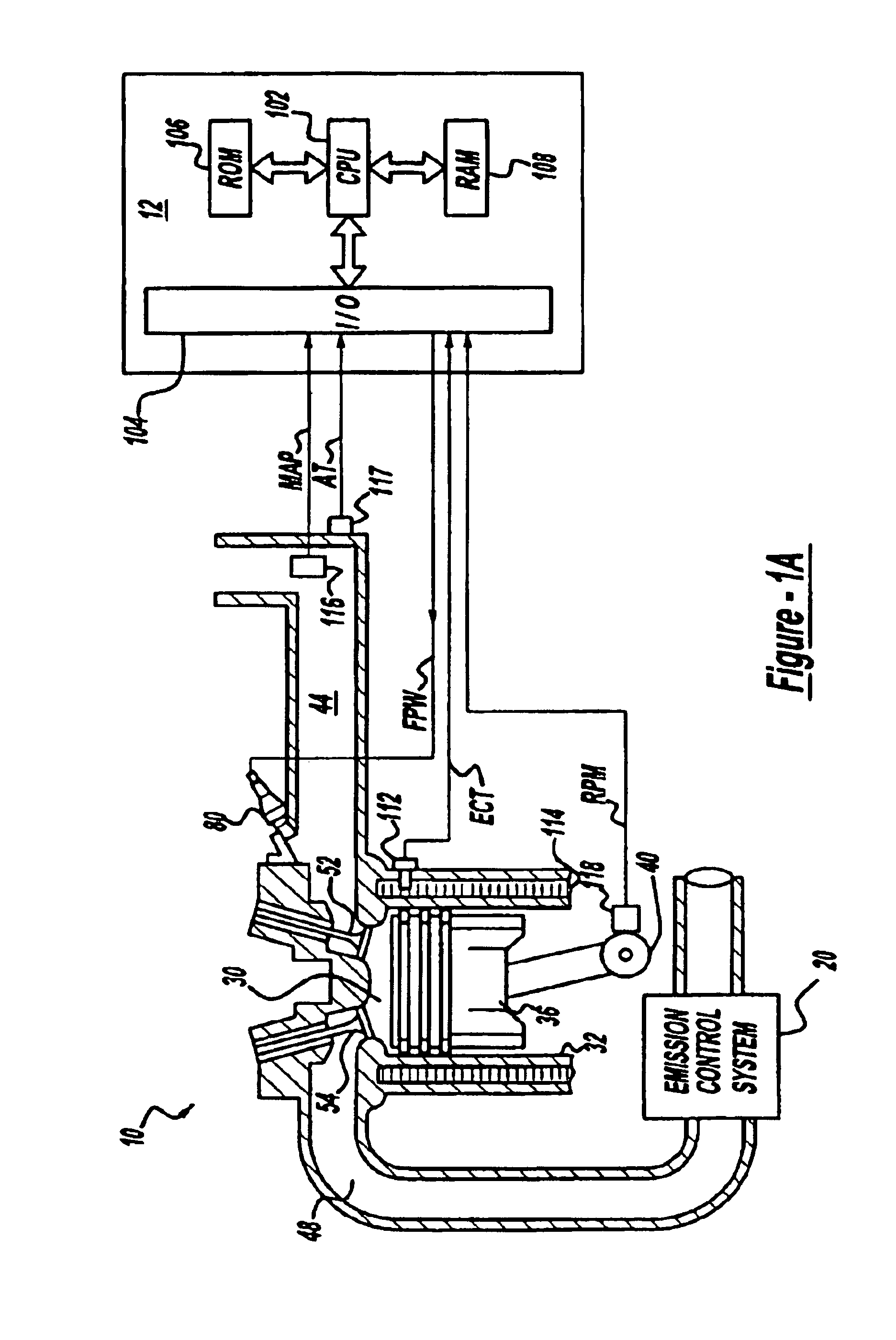

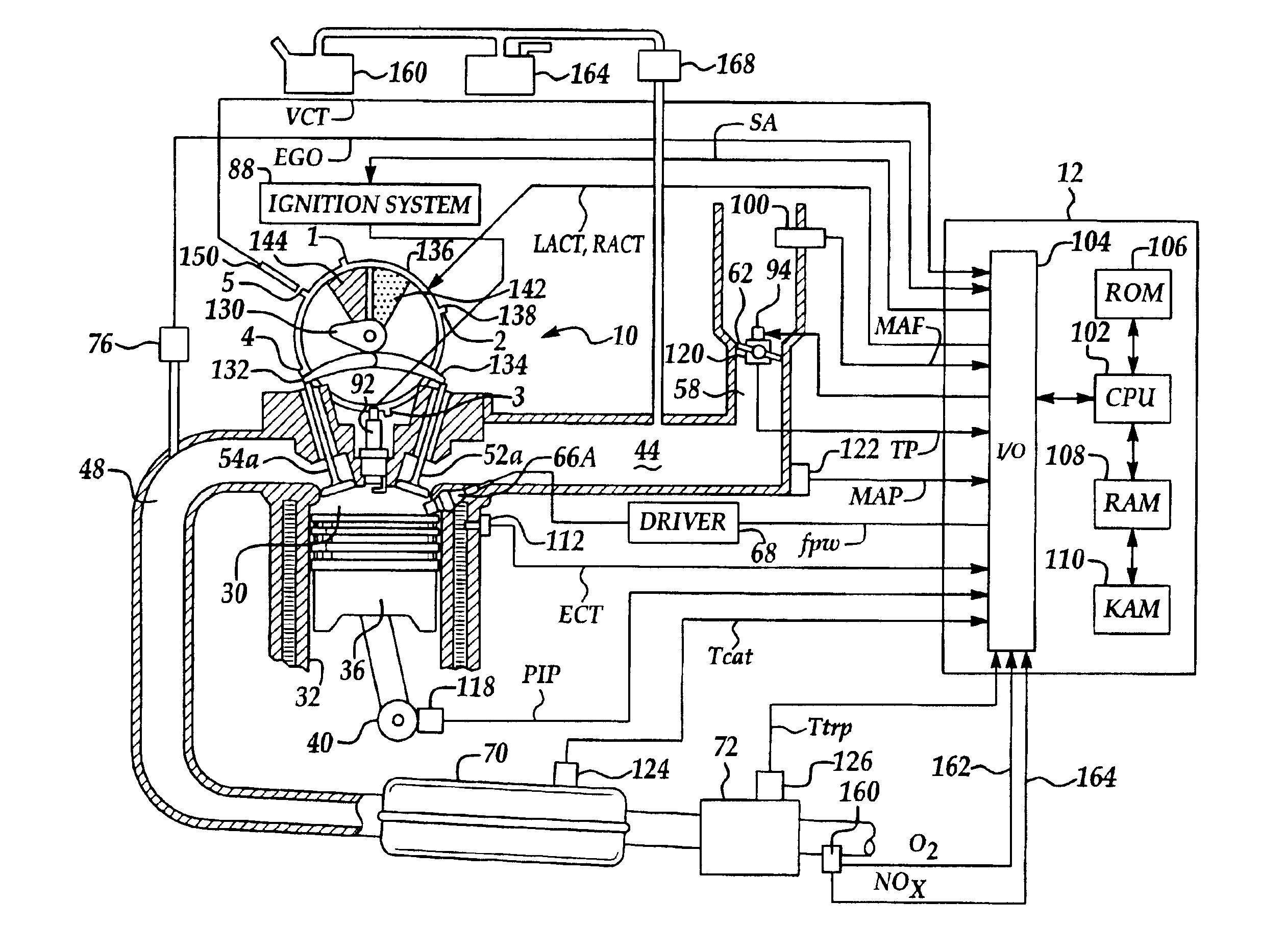

Method for rapid catalyst heating

InactiveUS6568177B1High load conditionMore ignition timingElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Fuel management system for variable ethanol octane enhancehment of gasoline engines

InactiveUS20060102145A1Increase heatMeet cutting requirementsElectrical controlInternal combustion piston enginesEthanol InjectionEngineering

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

Cost structure method including fuel economy and engine emission considerations

ActiveUS20050256633A1Analogue computers for vehiclesElectrical controlOperating pointPowertrain control

A powertrain control selects engine operating points in accordance with power loss minimization controls. Power loss contributions come from a variety of sources including engine power losses. Engine power losses are determined in accordance with engine operating metrics such as power production per unit fuel consumption and power production per unit emission production. Engine power losses are combined in accordance with assigned weighting into a single engine power loss term for use in the power loss minimization control and operating point selection.

Owner:GM GLOBAL TECH OPERATIONS LLC

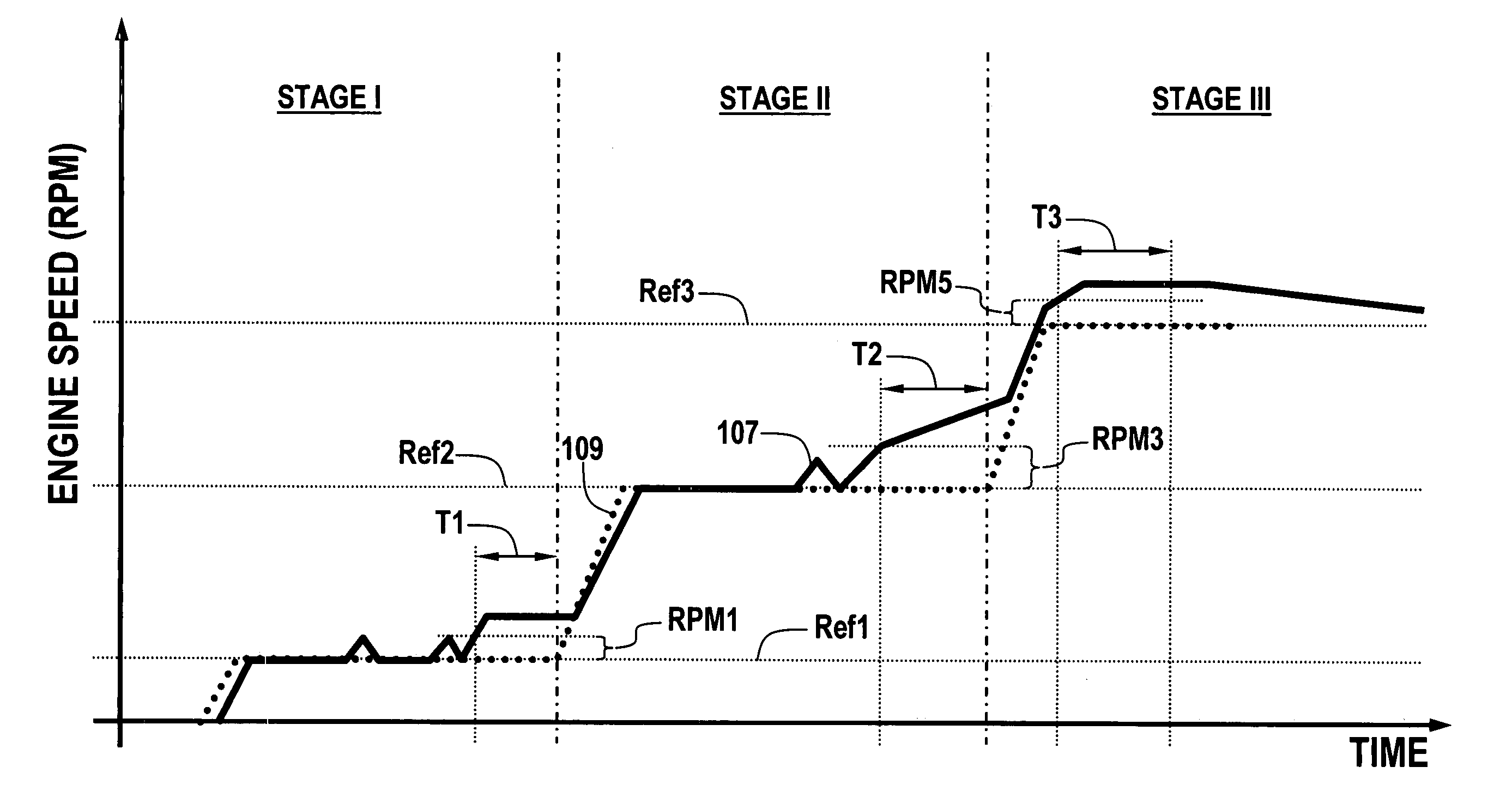

Multi-stage compression ignition engine start

A powertrain includes a diesel compression engine and an electric machine operatively coupled thereto and effective to rotate the engine during engine cranking. Cold engine cranking is accomplished in a staged manner including a first stage wherein the engine is cranked to a first speed below the resonant speed of the coupled engine and electric machine combination for a first duration and thereafter cranked to a second speed above the resonant speed for a second duration. Transition out of cranking at the first and second speeds is accomplished when relative combustion stability is demonstrated. Cranking at the first or second speed is aborted when excessive crank times or if low battery voltages are observed. A third stage is included wherein the engine is cranked to a third speed below the engine idle speed. Transition out of cranking at the third speed is accomplished when relative combustion stability is demonstrated, whereafter normal engine control takes over.

Owner:ALLISON TRANSMISSION INC

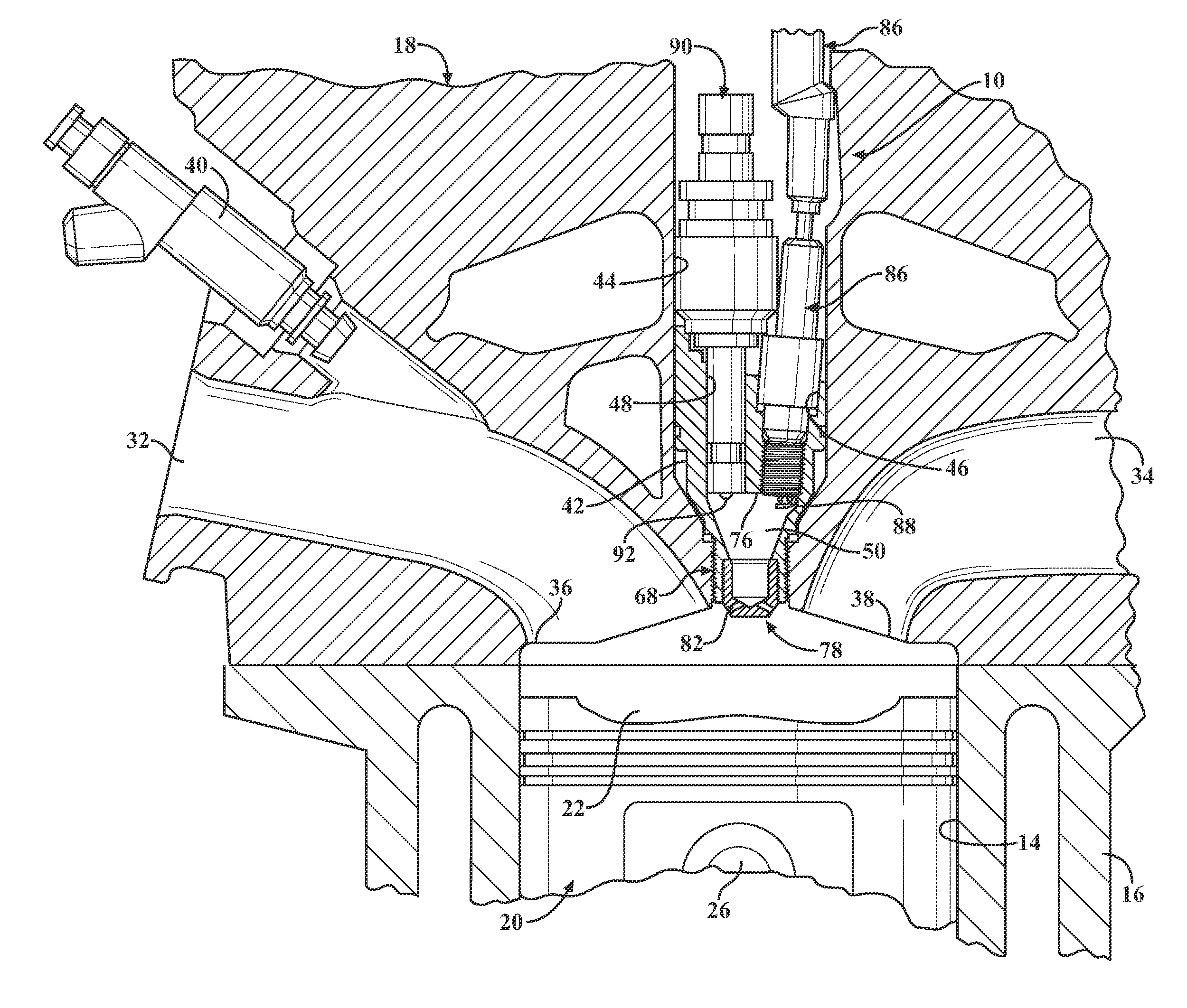

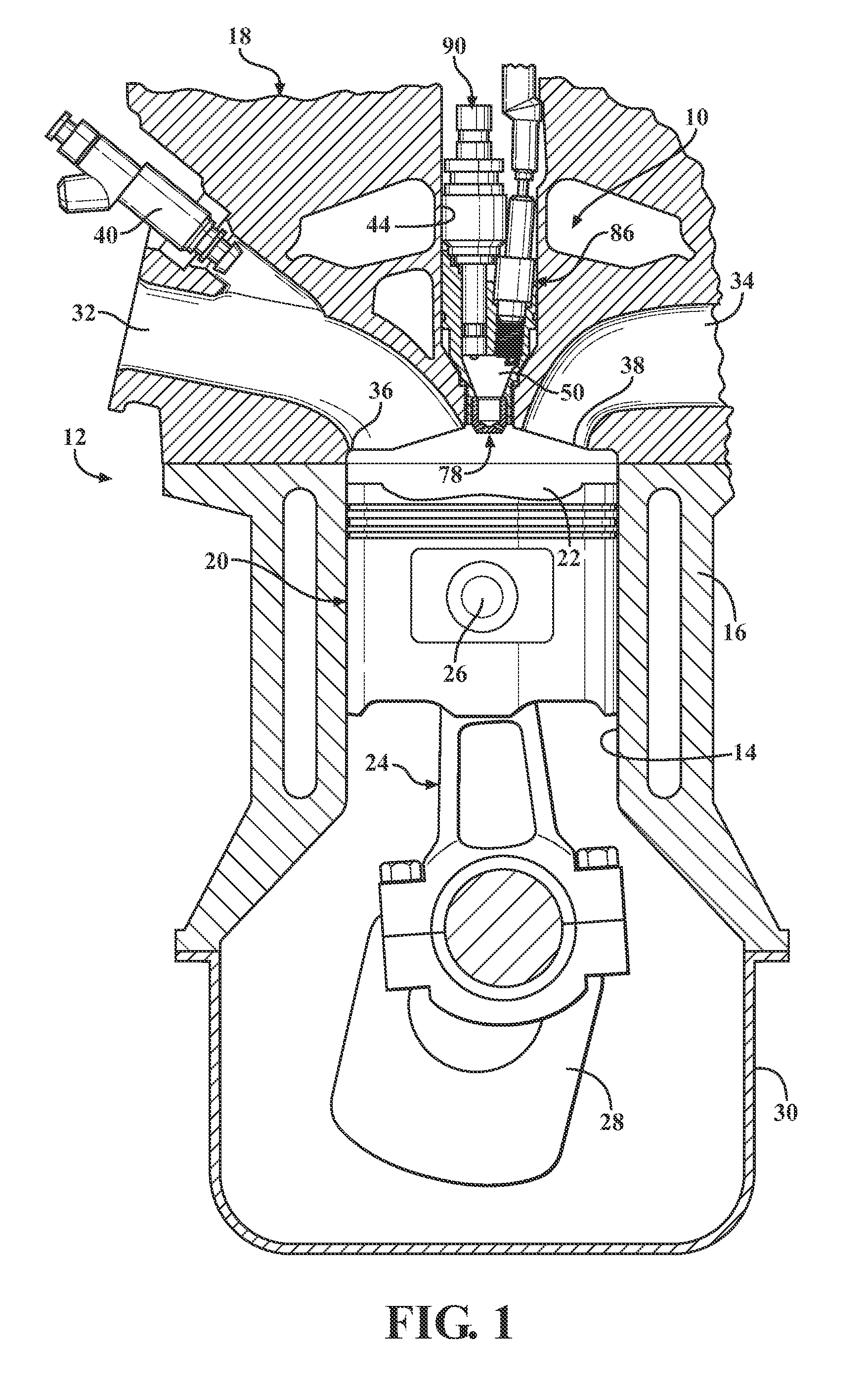

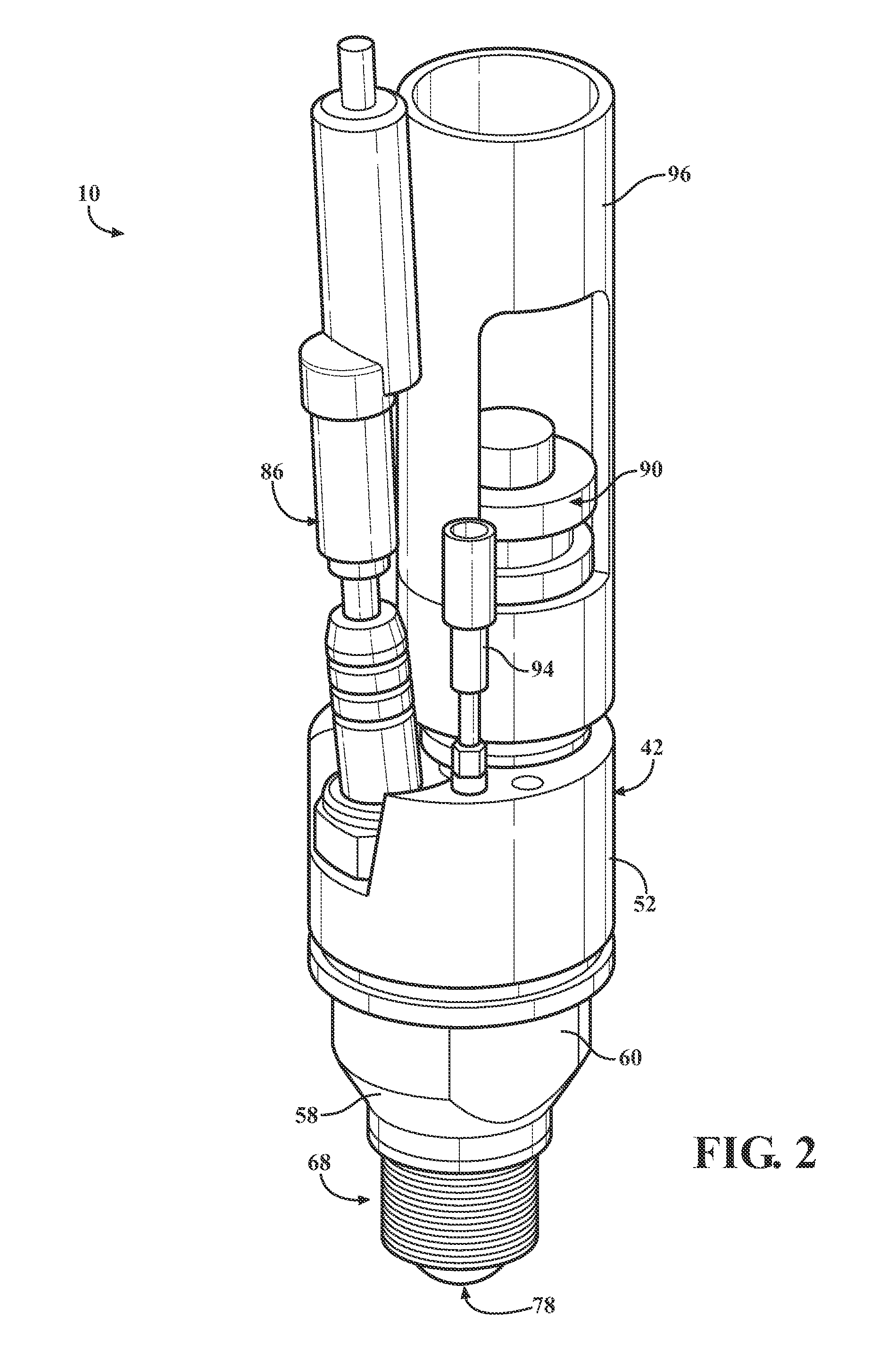

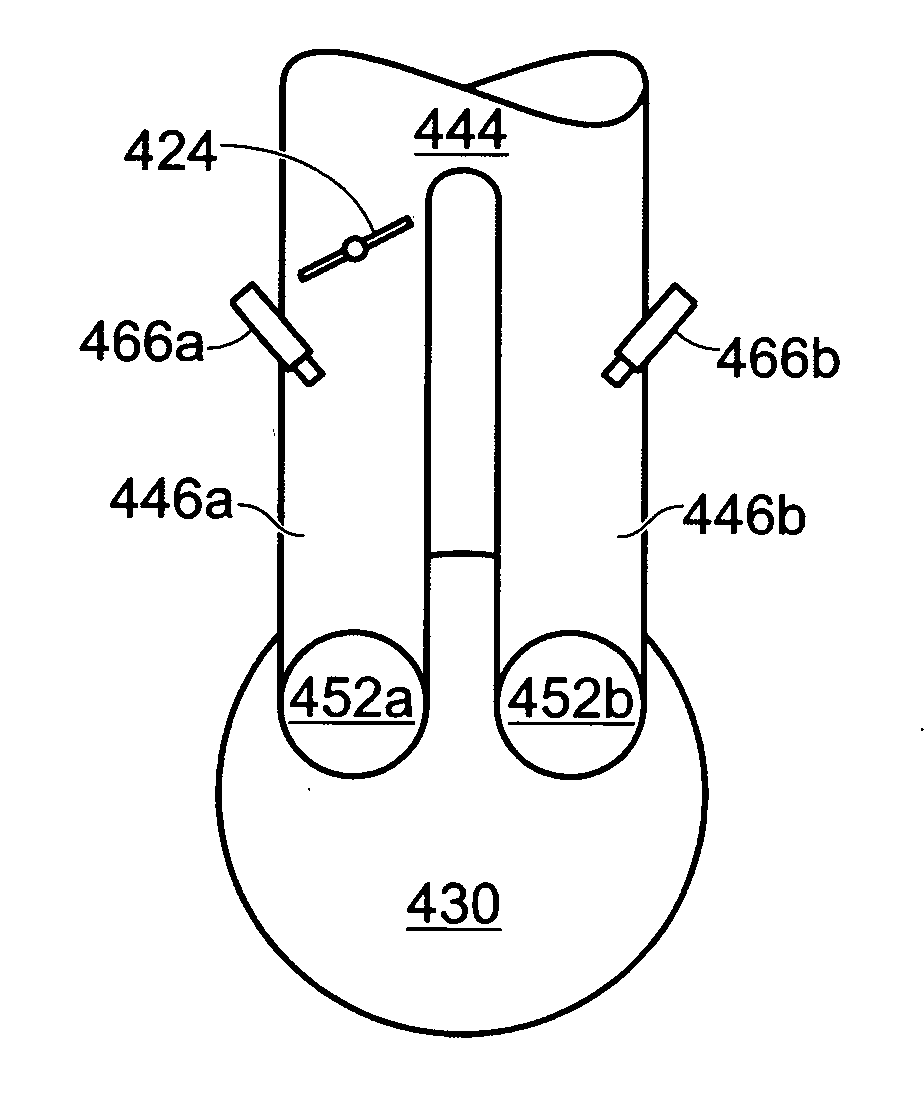

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS20120103302A1Promote flame quenchingHigh-drive cycle (part load) fuel economyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

An ignition system for an internal combustion engine having at least one combustion chamber where the ignition system includes a housing, an ignition device, an injector, and a pre-chamber having a nozzle disposed spaced from the proximal portion of the pre-chamber. The igniter portion of the ignition device and the nozzle of the injector are operatively supported in the proximal portion of the pre-chamber and disposed flush therewith. The igniter portion ignites the fuel in pre-chamber such that partially combusted pre-chamber products are forced through orifices in the pre-chamber nozzle and extinguish, but dispersed through the combustion chamber so as to ignite the main fuel charge therein.

Owner:MAHLE POWERTRAIN

System and method for compensation of fuel injector limits

InactiveUS20070119421A1Reduce injectionGreat alcohol contentElectrical controlInternal combustion piston enginesAutomotive engineeringInjector

A method for an engine configured to deliver an actively varying relative ratio of a first and second fuel via a delivery system having a first and second injector for a cylinder of the engine, where the first fuel has a lesser relative amount of alcohol, the method comprising of varying an amount of injection from the first and second injector with operating conditions, when said variation causes said first injector to approach a first minimum opening condition, increasing injection of said second injector and disabling said first injector, and when said variation causes said second injector to approach a second minimum opening condition, avoiding further reduction of said second injector and decreasing injection of said first injector.

Owner:FORD GLOBAL TECH LLC

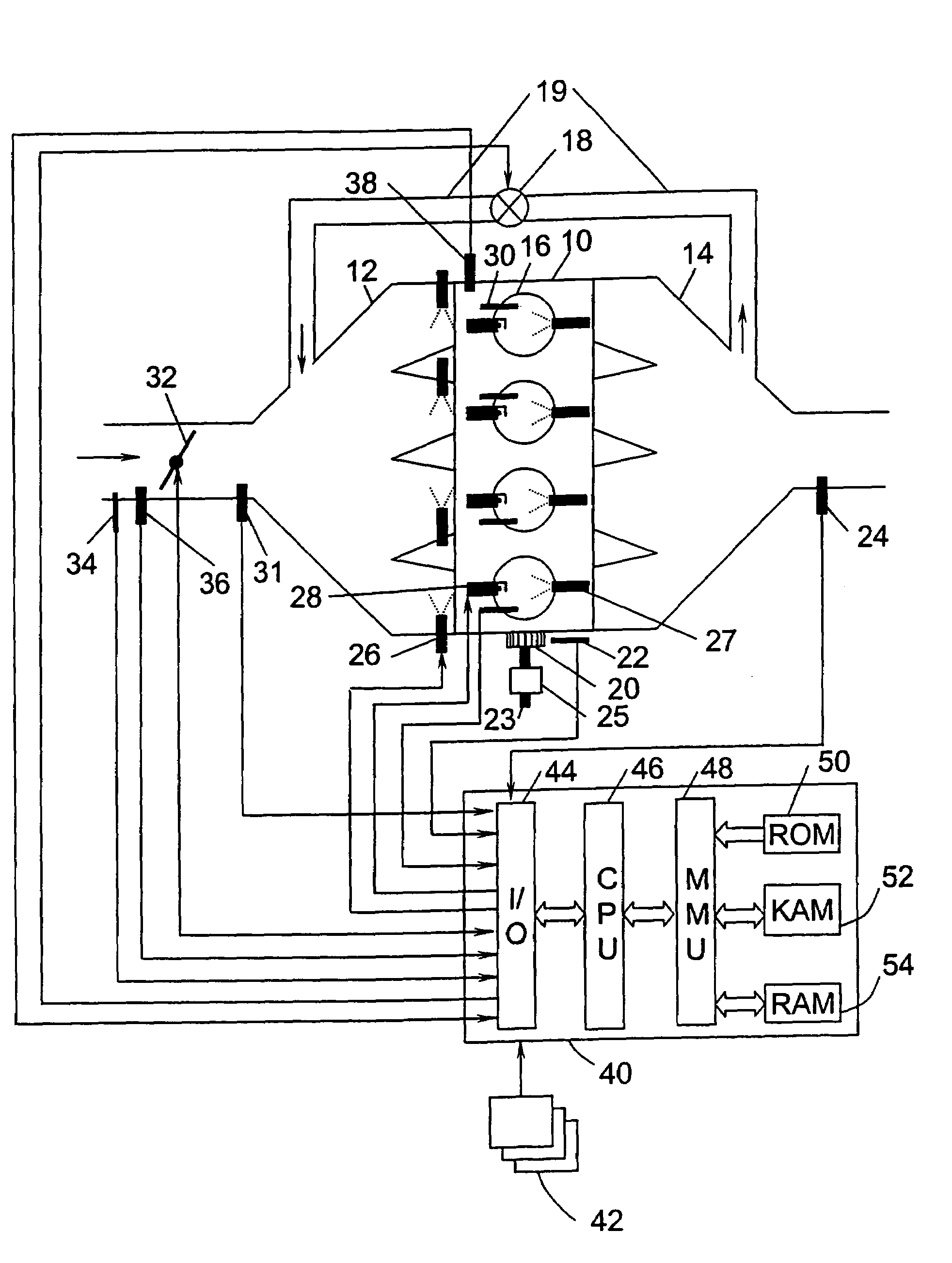

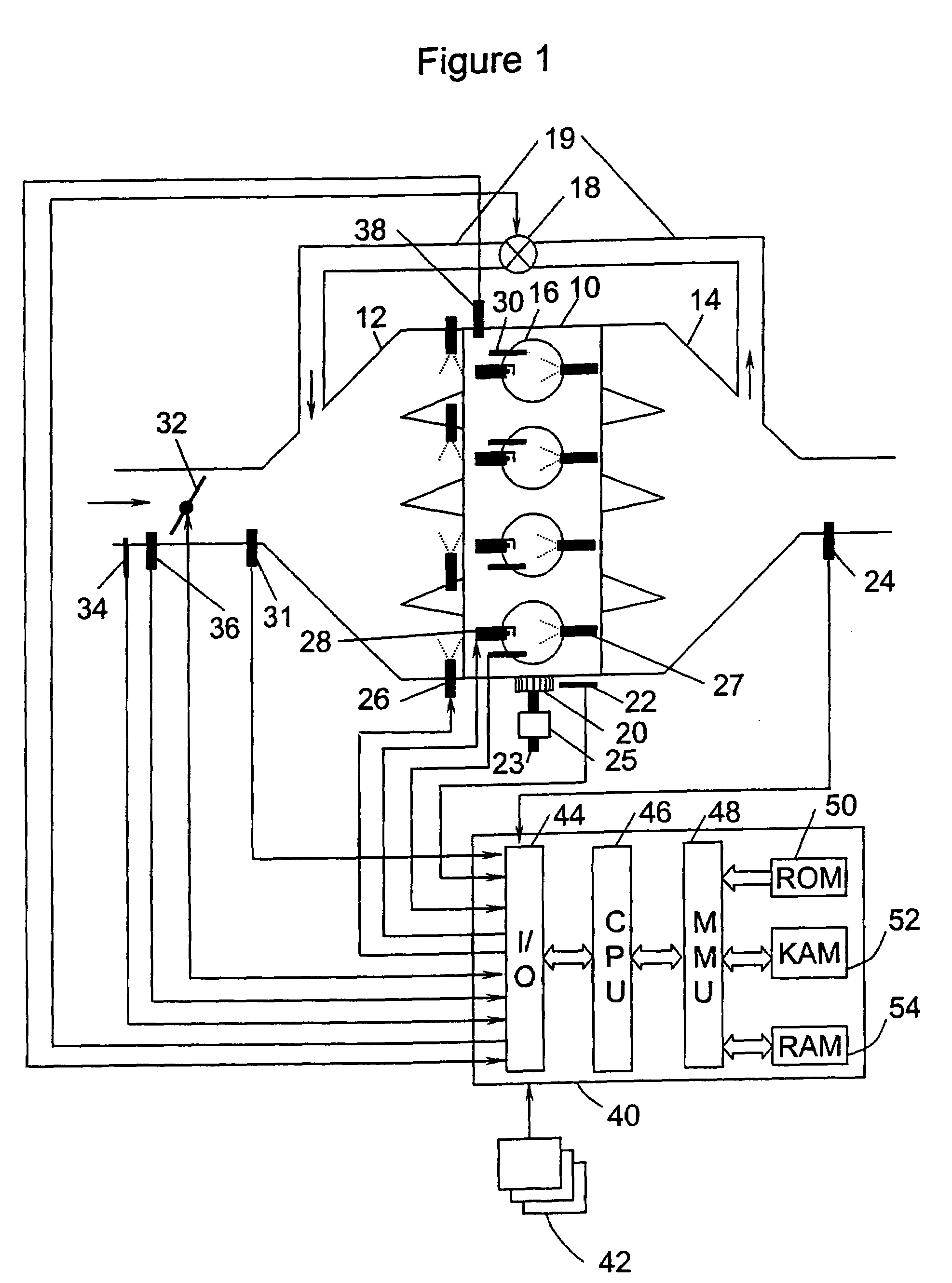

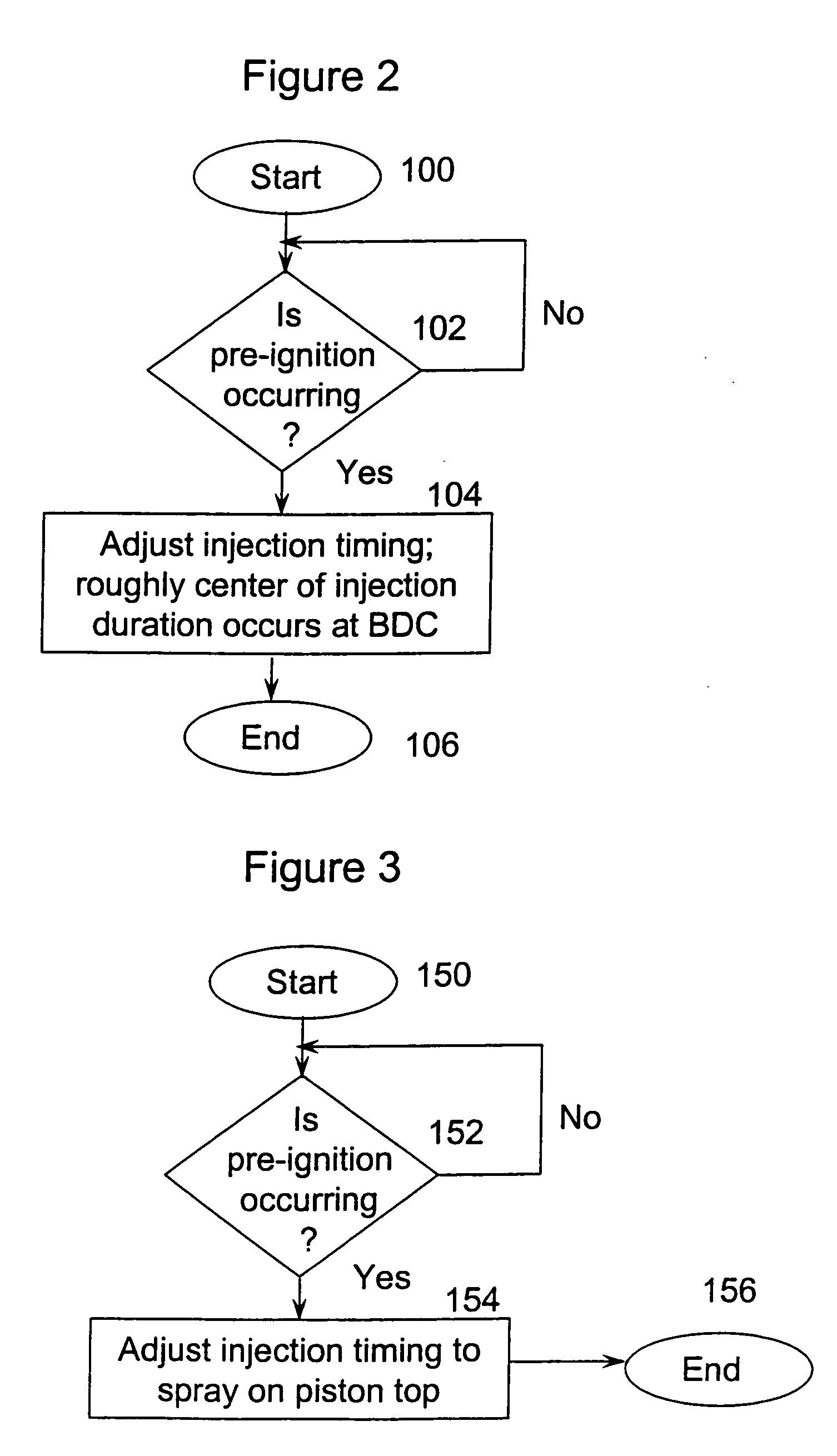

System and method to pre-ignition in an internal combustion engine

ActiveUS7178503B1Mitigate pre-ignitionReduce air densityAnalogue computers for vehiclesElectrical controlCombustion chamberAlcohol fuel

An engine system and method are disclosed for controlling pre-ignition of an alcohol fuel. In one embodiment, the fuel injection timing is adjusted to cause the fuel to avoid combustion chamber surfaces. In another embodiment, the fuel injection timing is adjusted to spray the fuel directly onto the piston surface to cool the piston. Also disclosed is a cylinder cleaning cycle in which engine knock is purposely caused for one to hundreds of engine cycles by adjusting the fuel content away from alcohol toward gasoline. Further measures to cause knock which are disclosed: adjusting spark timing, intake boost, exhaust gas fraction in the cylinder, cam timing, and transmission gear ratio.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com