Patents

Literature

71 results about "Manifold vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manifold vacuum, or engine vacuum in an internal combustion engine is the difference in air pressure between the engine's intake manifold and Earth's atmosphere. Manifold vacuum is an effect of a piston's movement on the induction stroke and the choked flow through a throttle in the intake manifold of an engine. It is a measure of the amount of restriction of airflow through the engine, and hence of the unused power capacity in the engine. In some engines, the manifold vacuum is also used as an auxiliary power source to drive engine accessories and for the crankcase ventilation system.

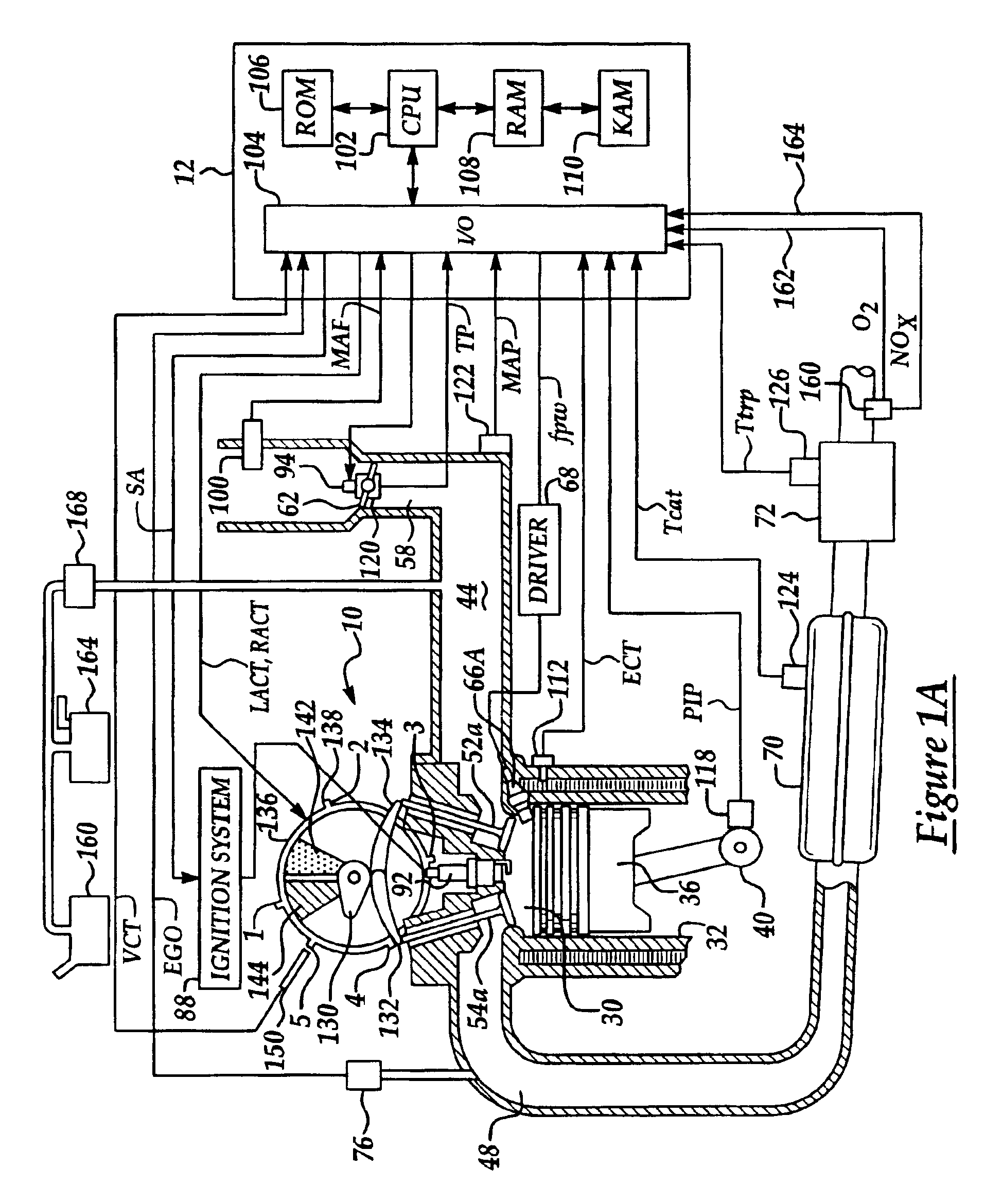

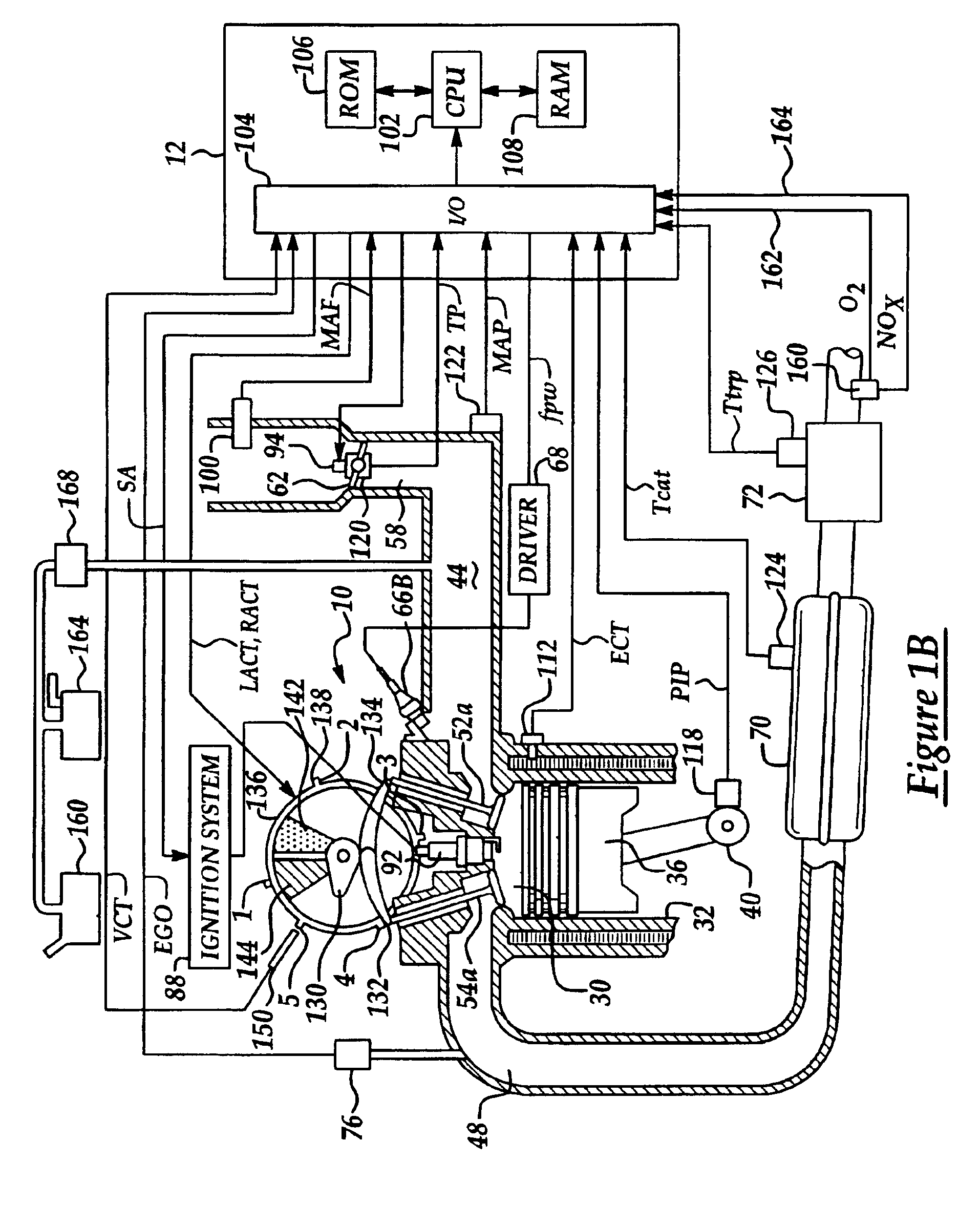

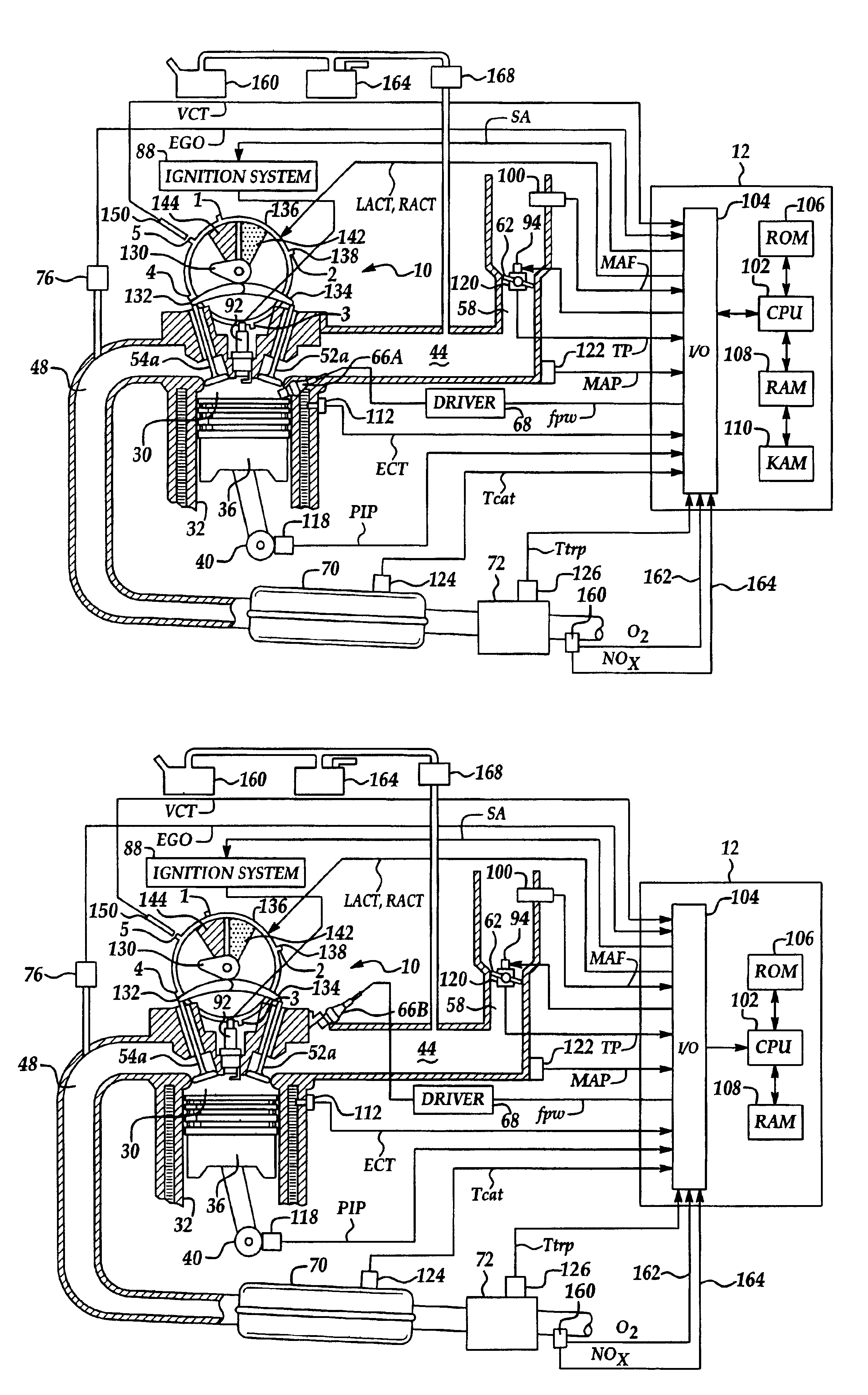

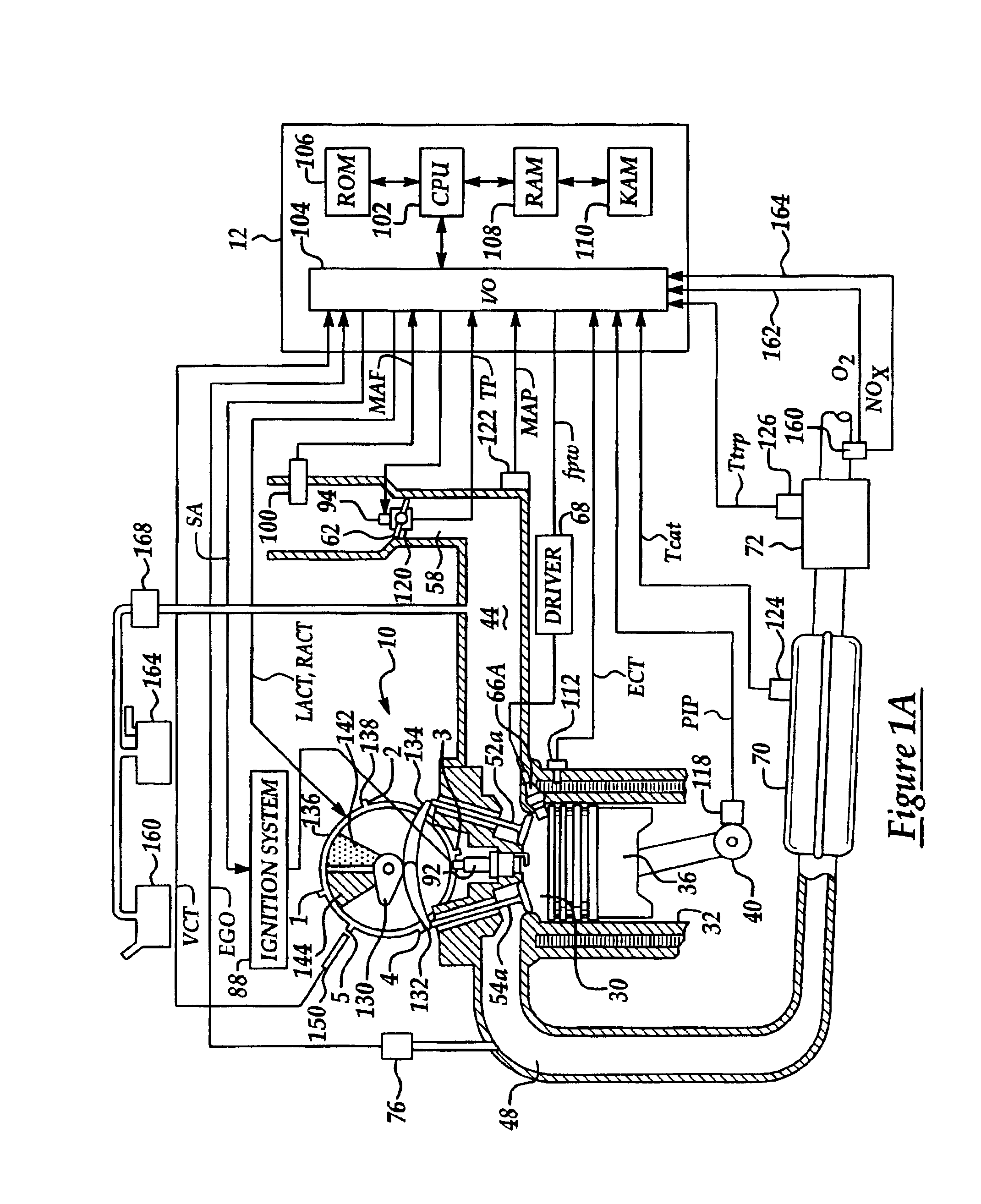

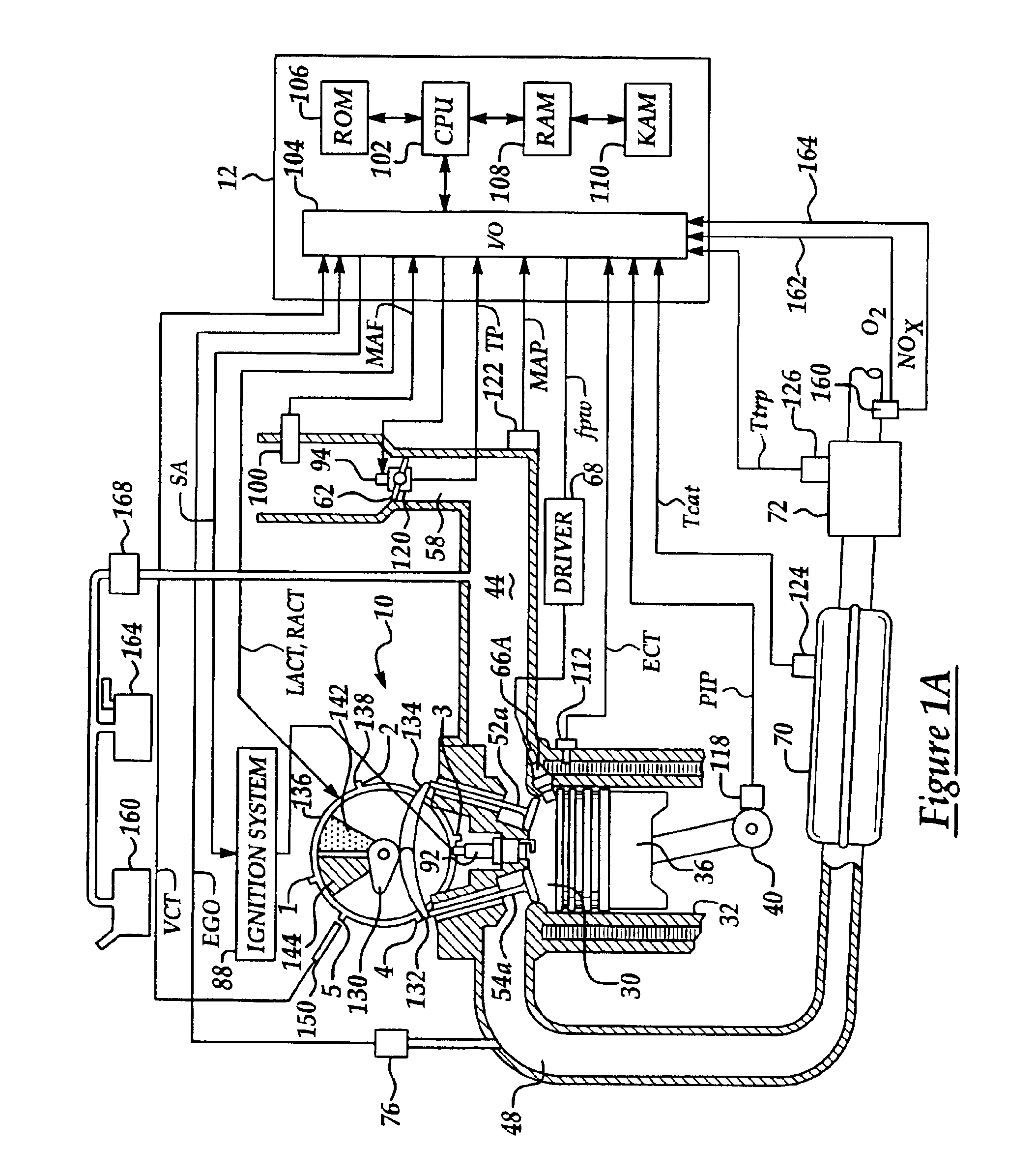

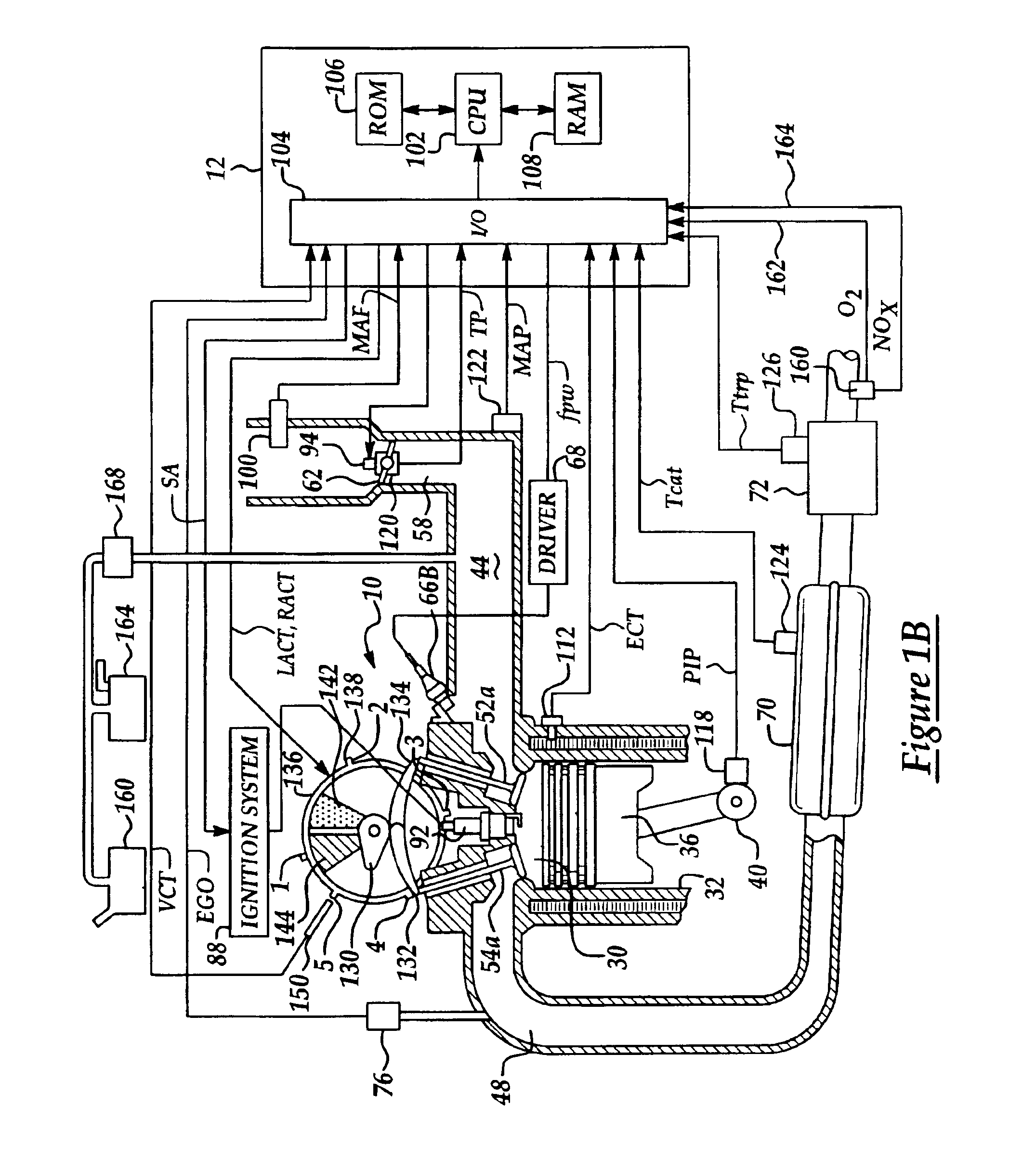

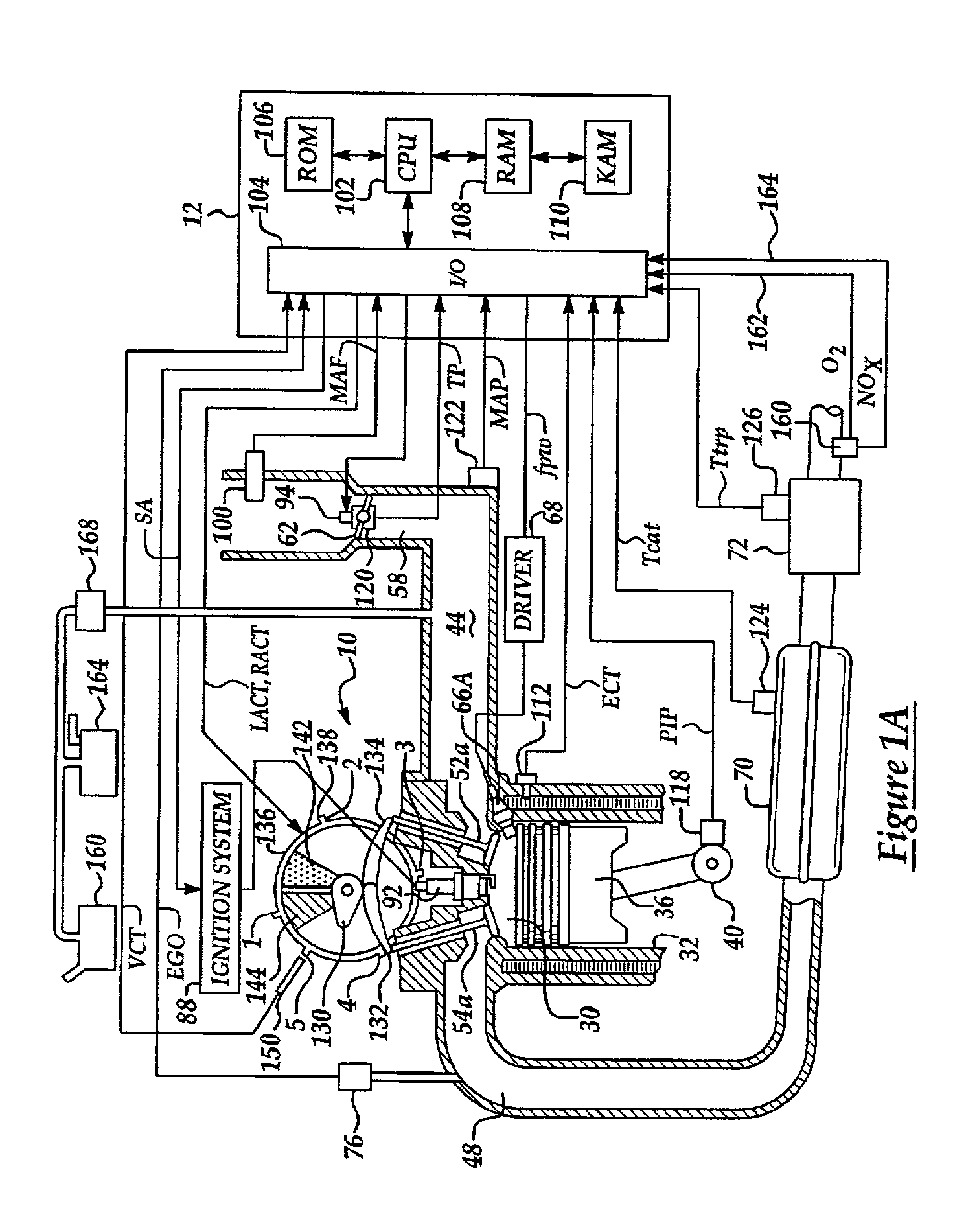

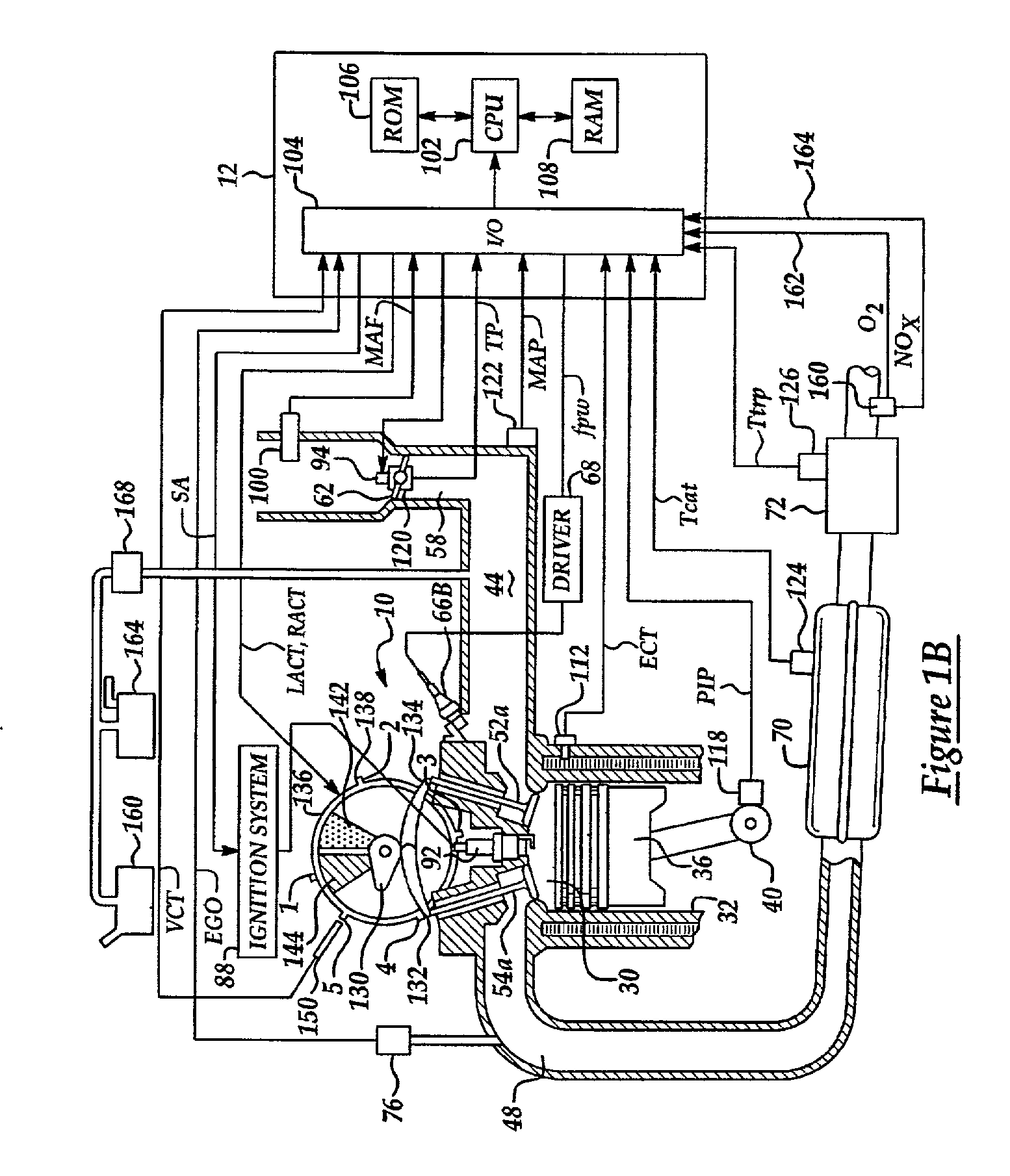

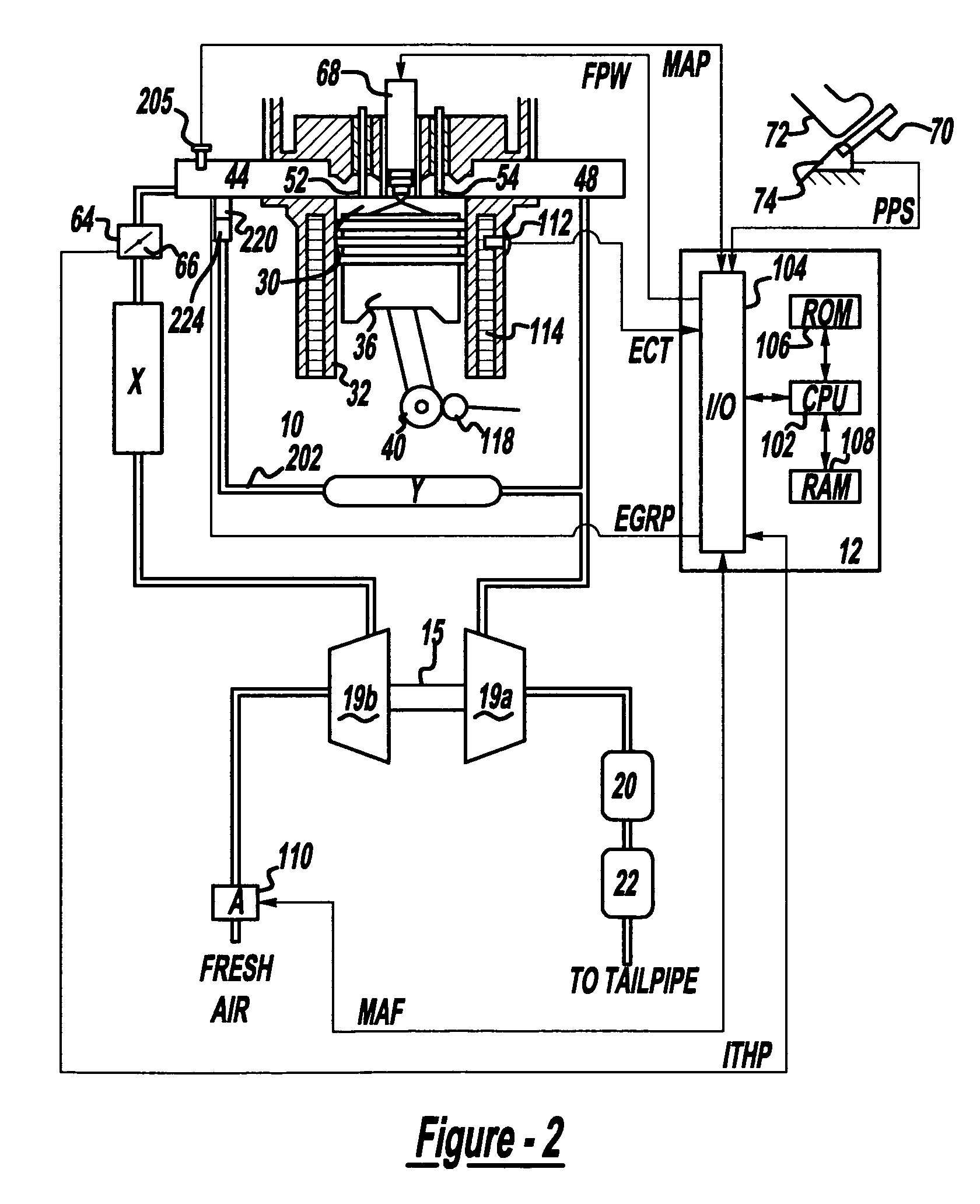

Method for rapid catalyst heating

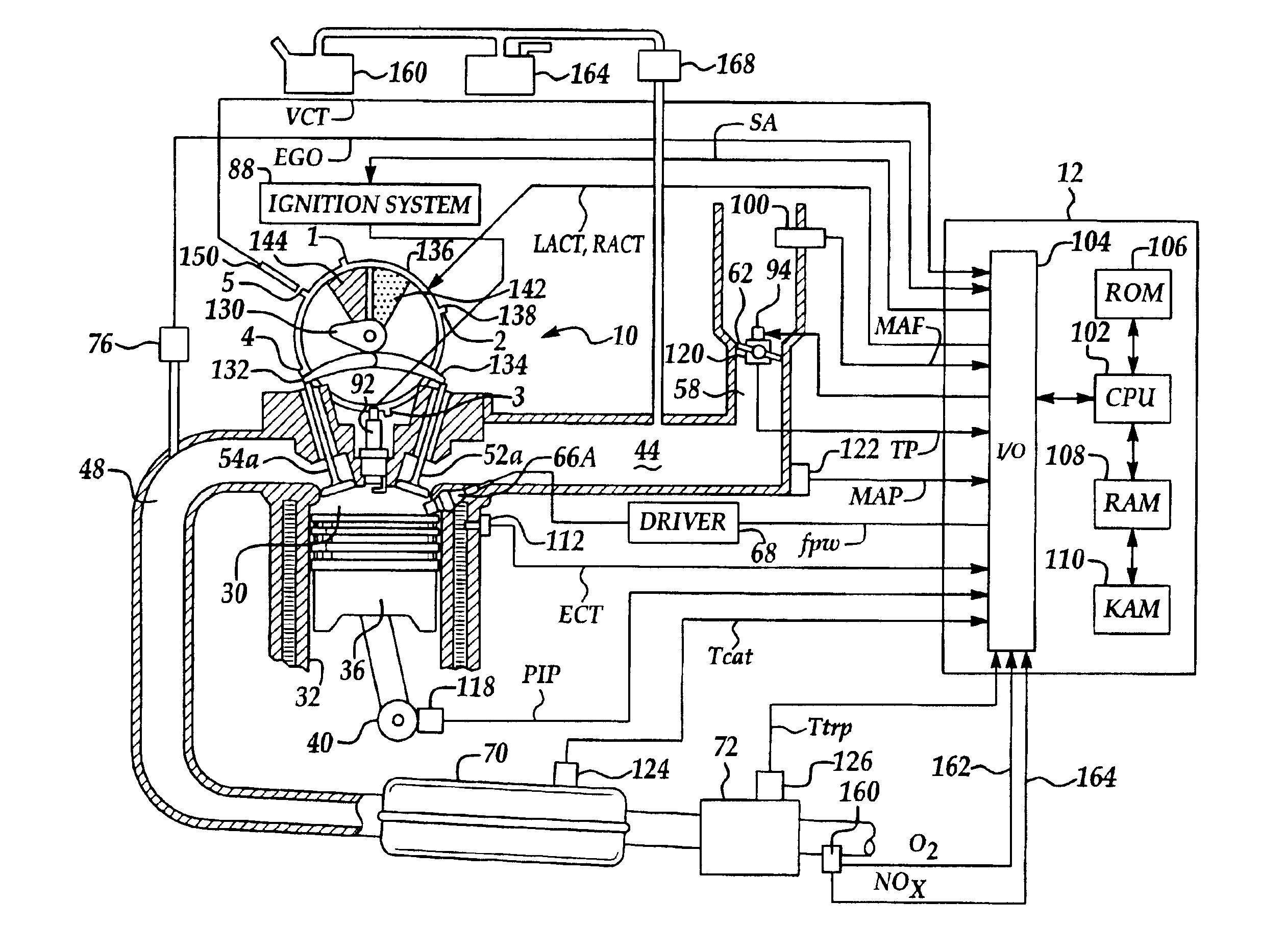

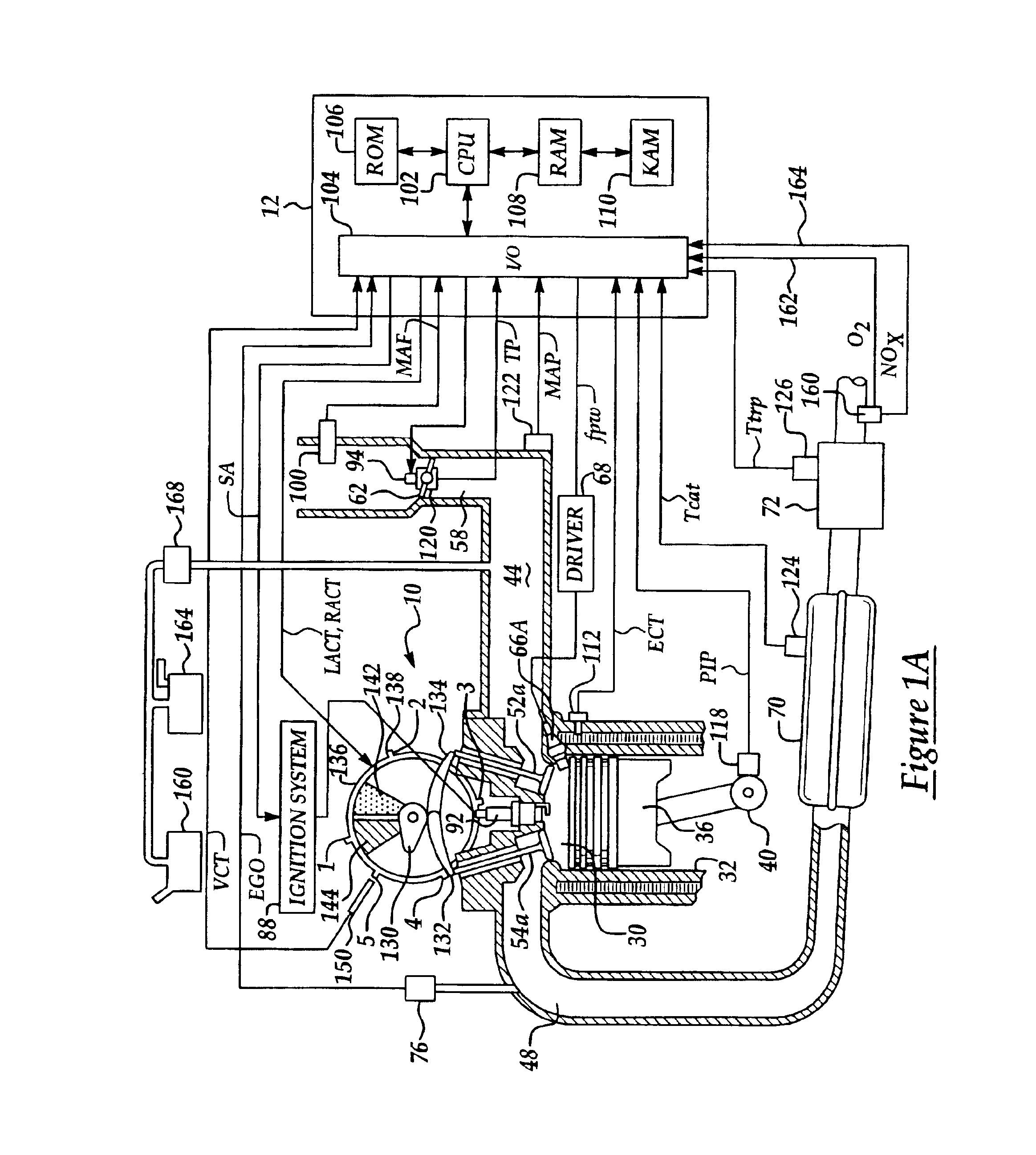

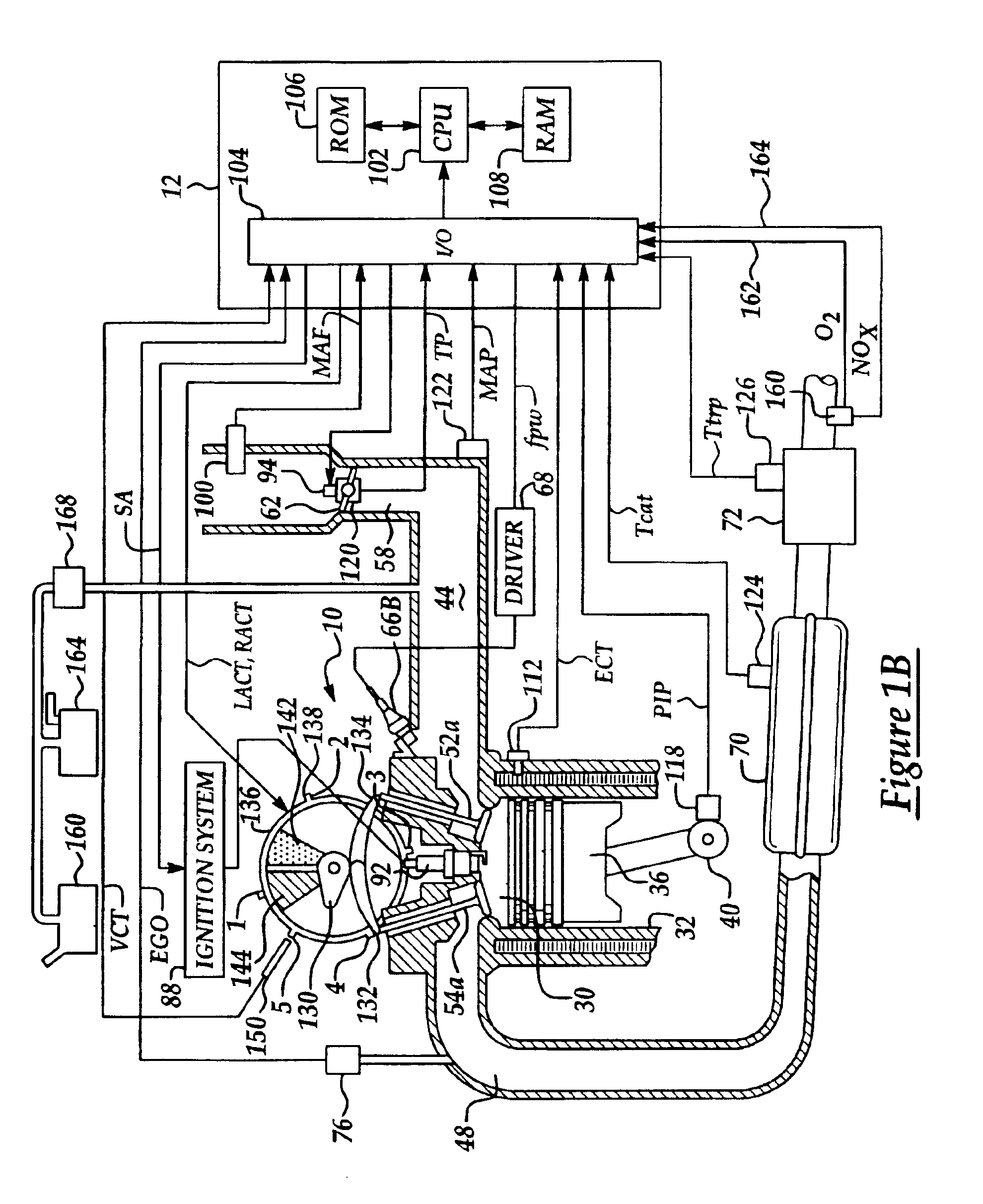

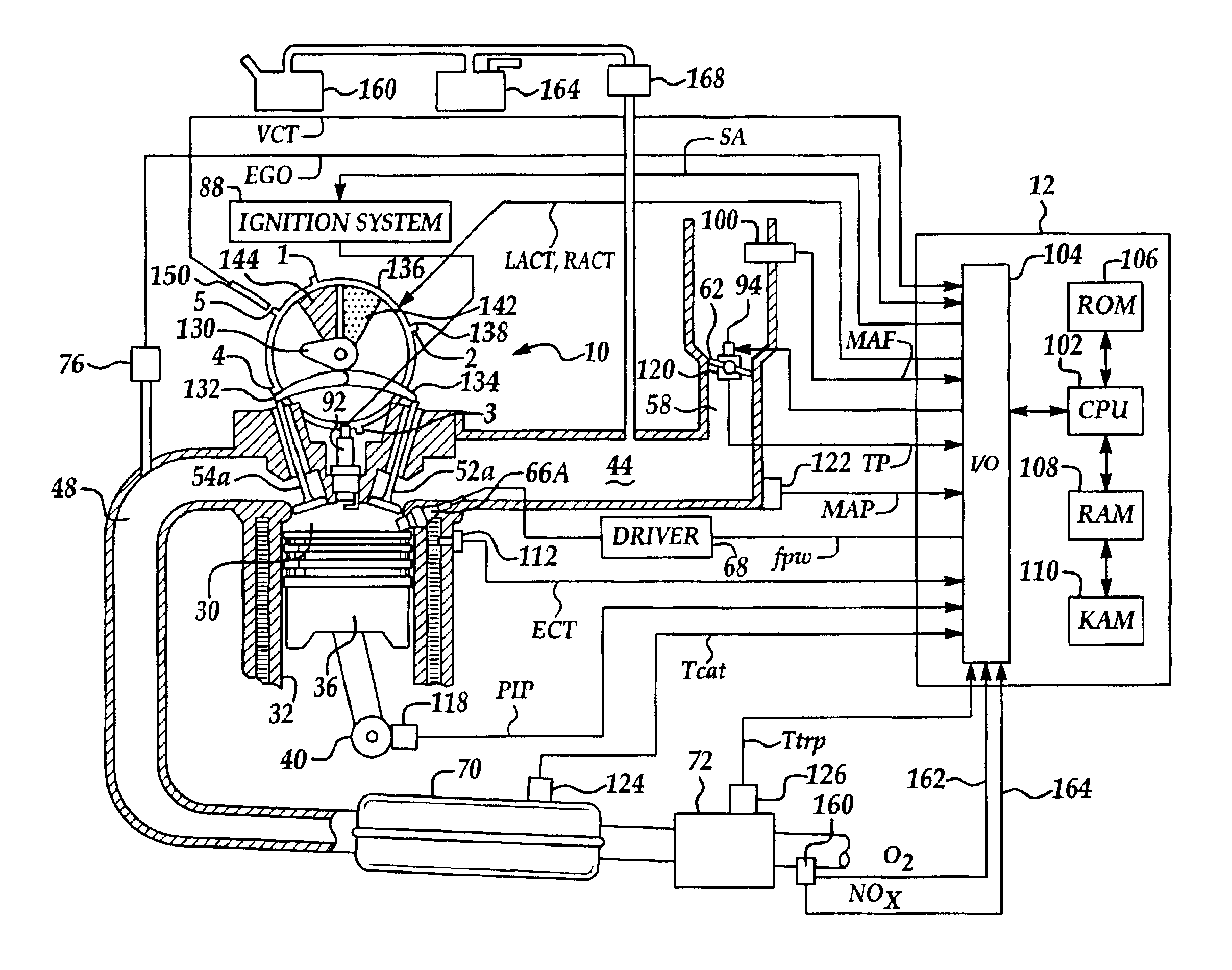

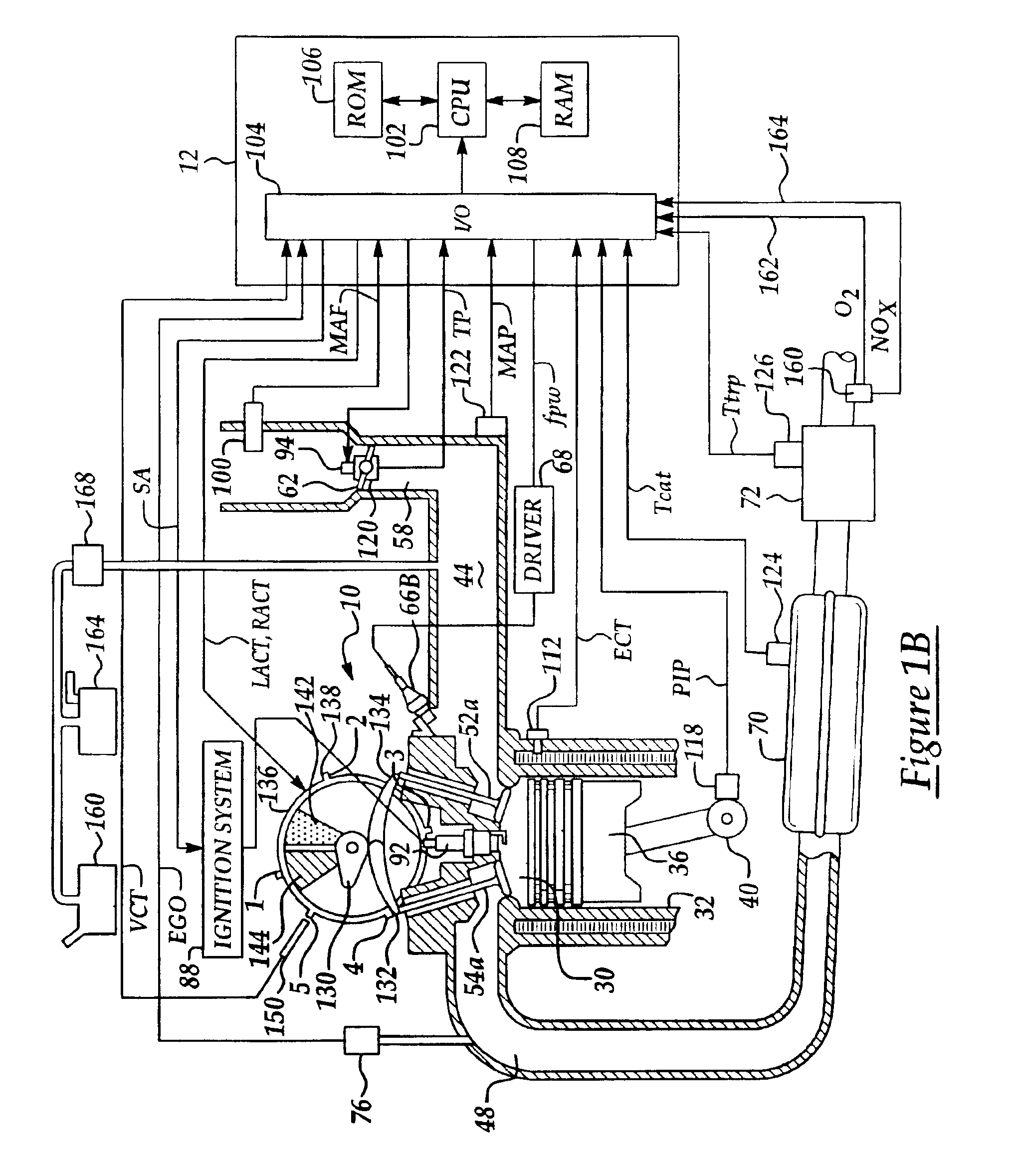

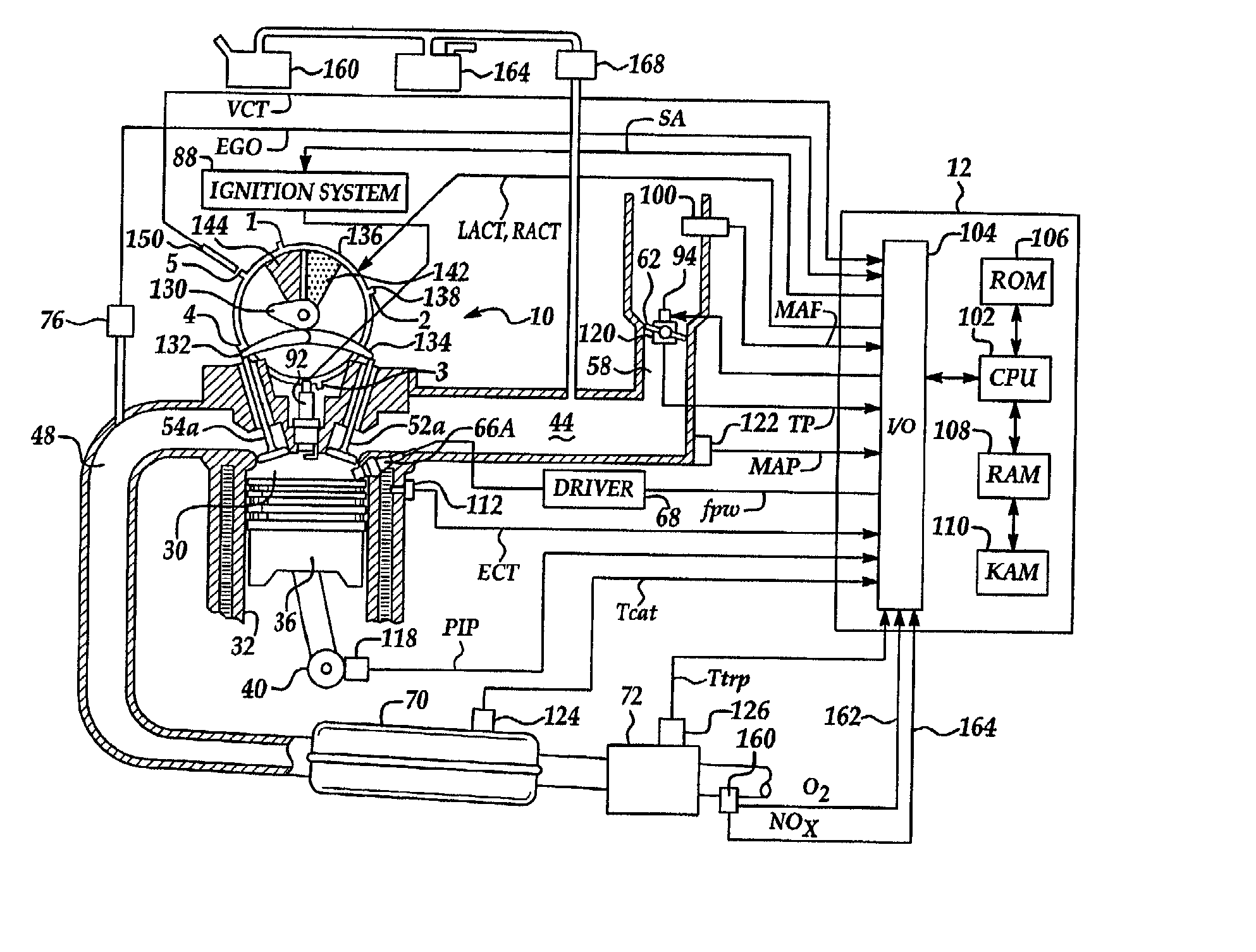

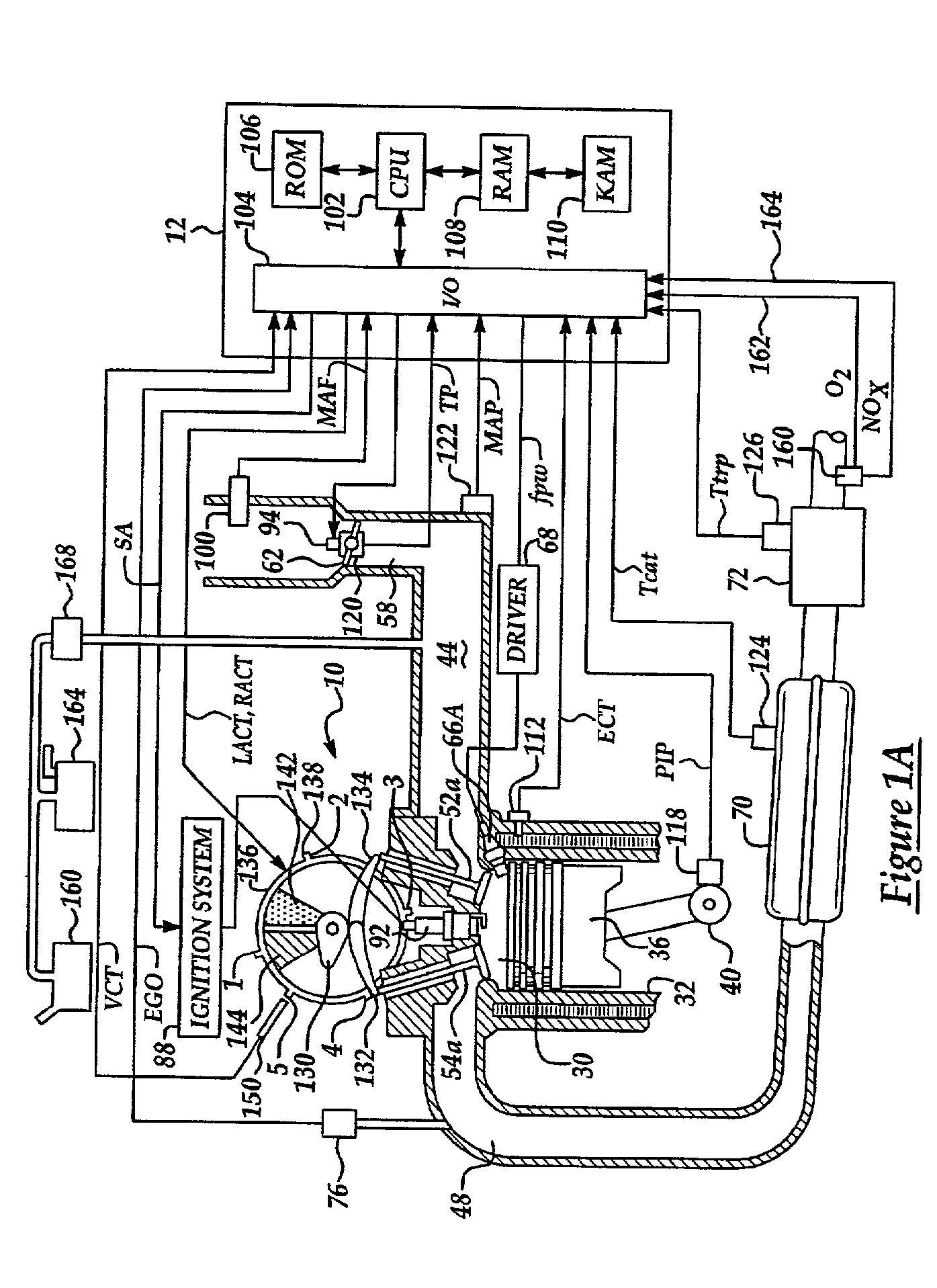

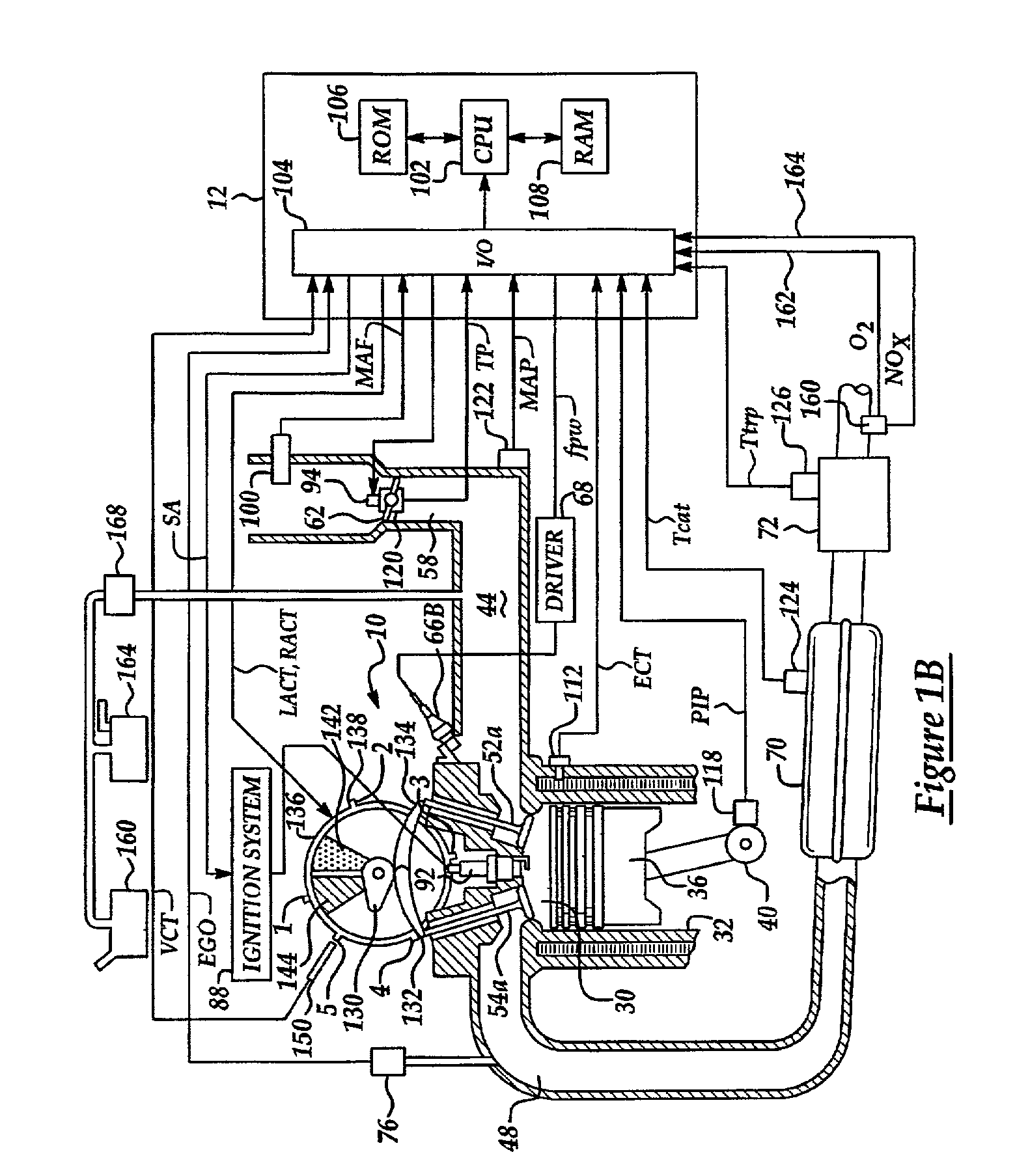

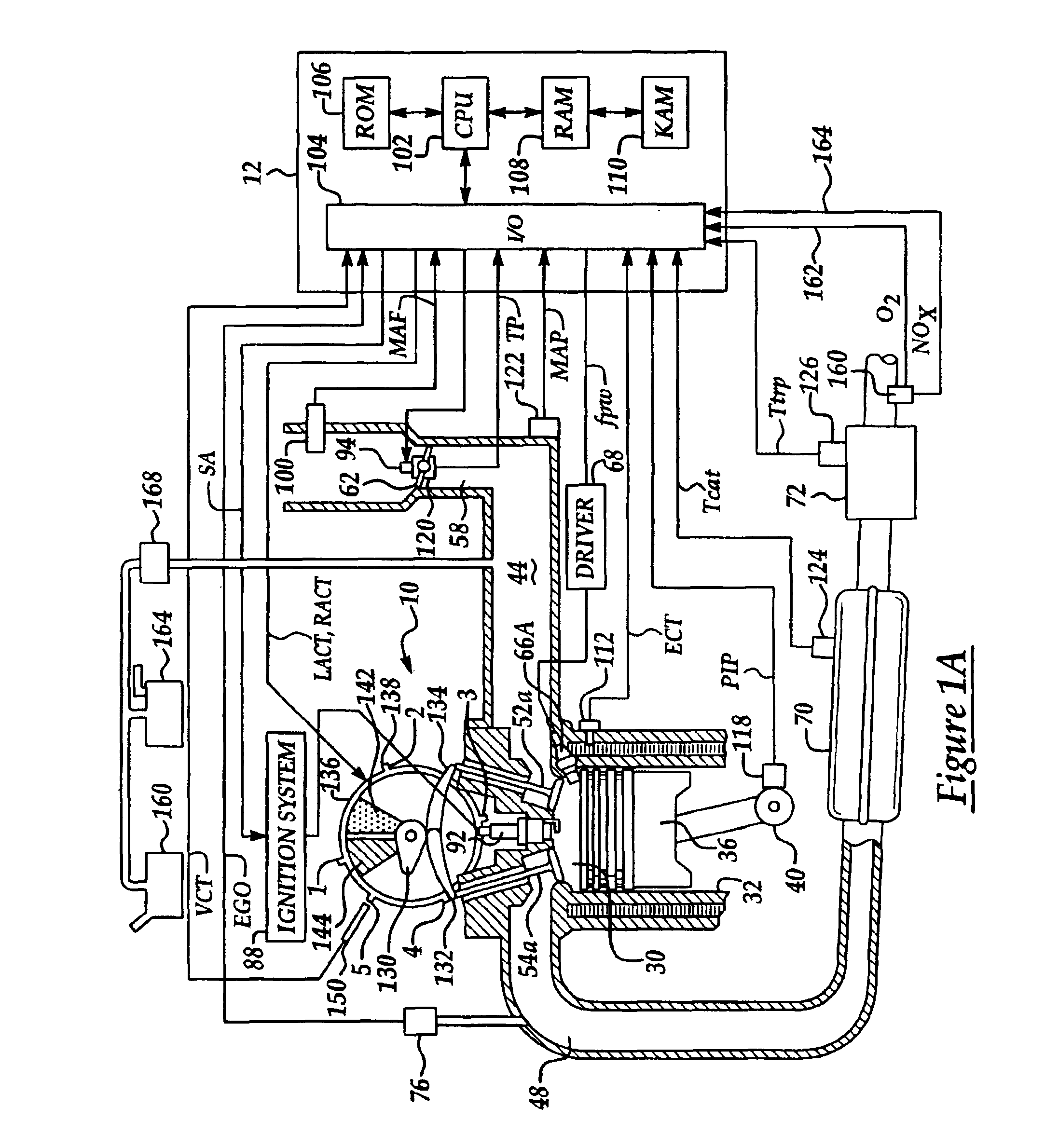

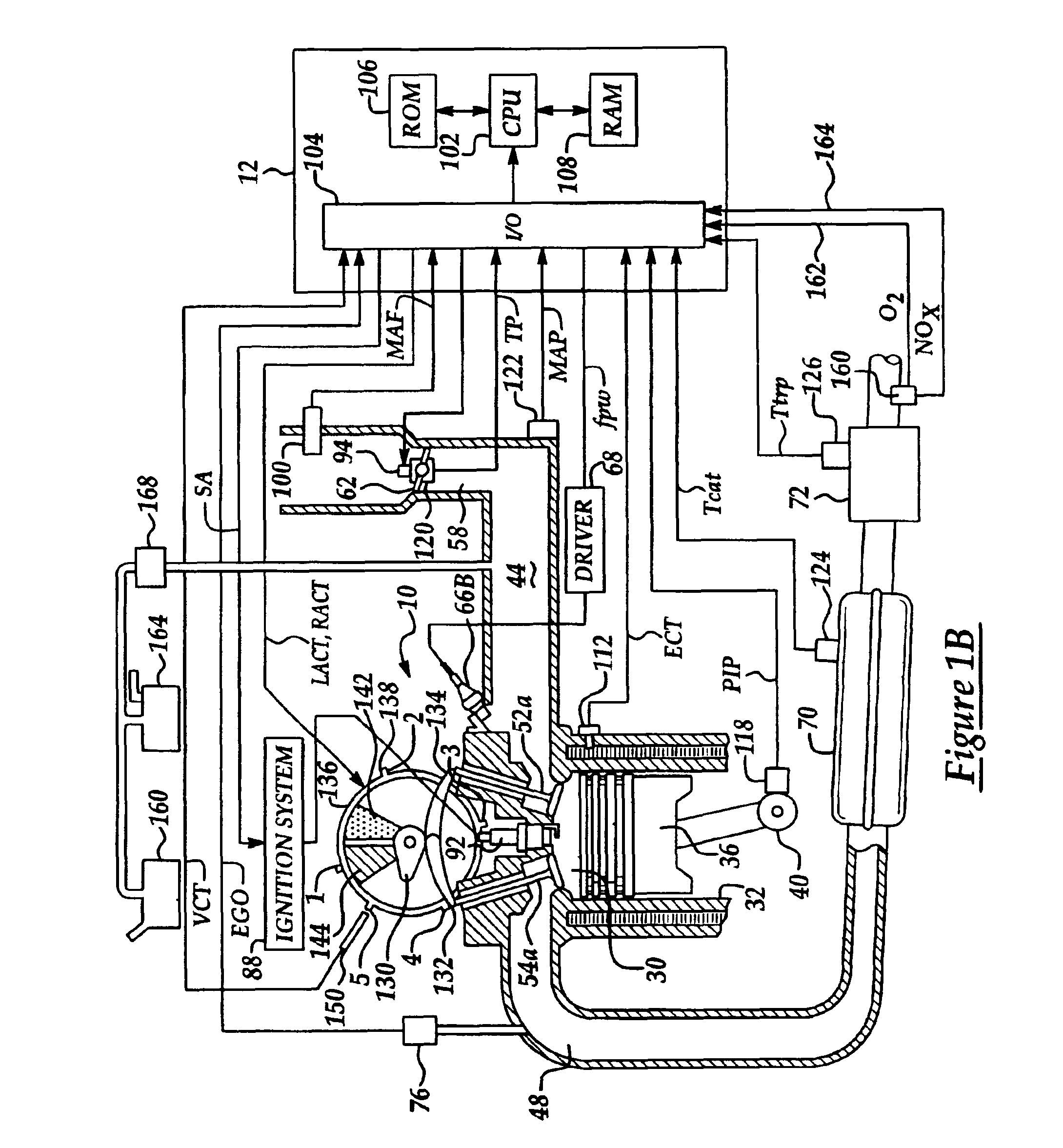

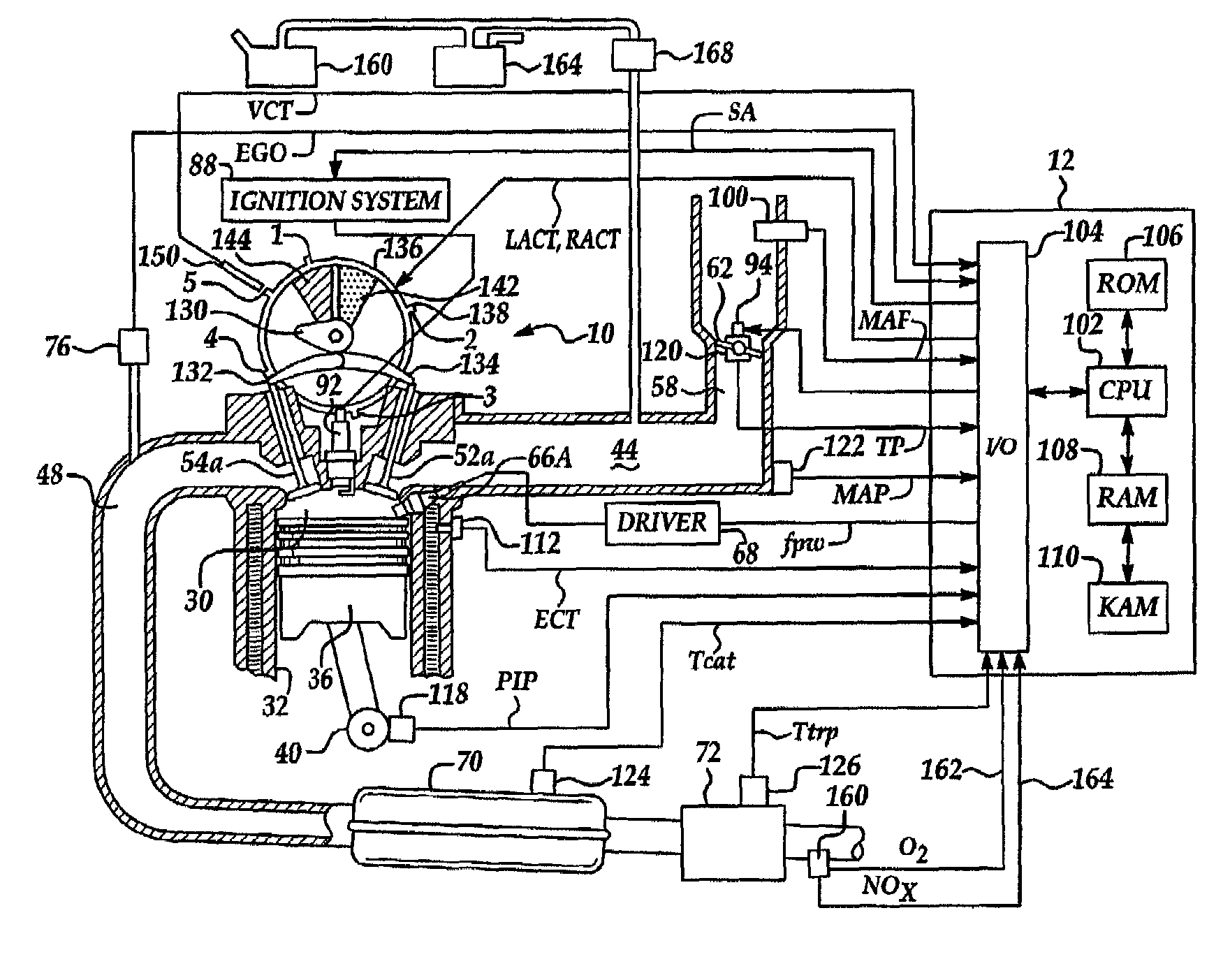

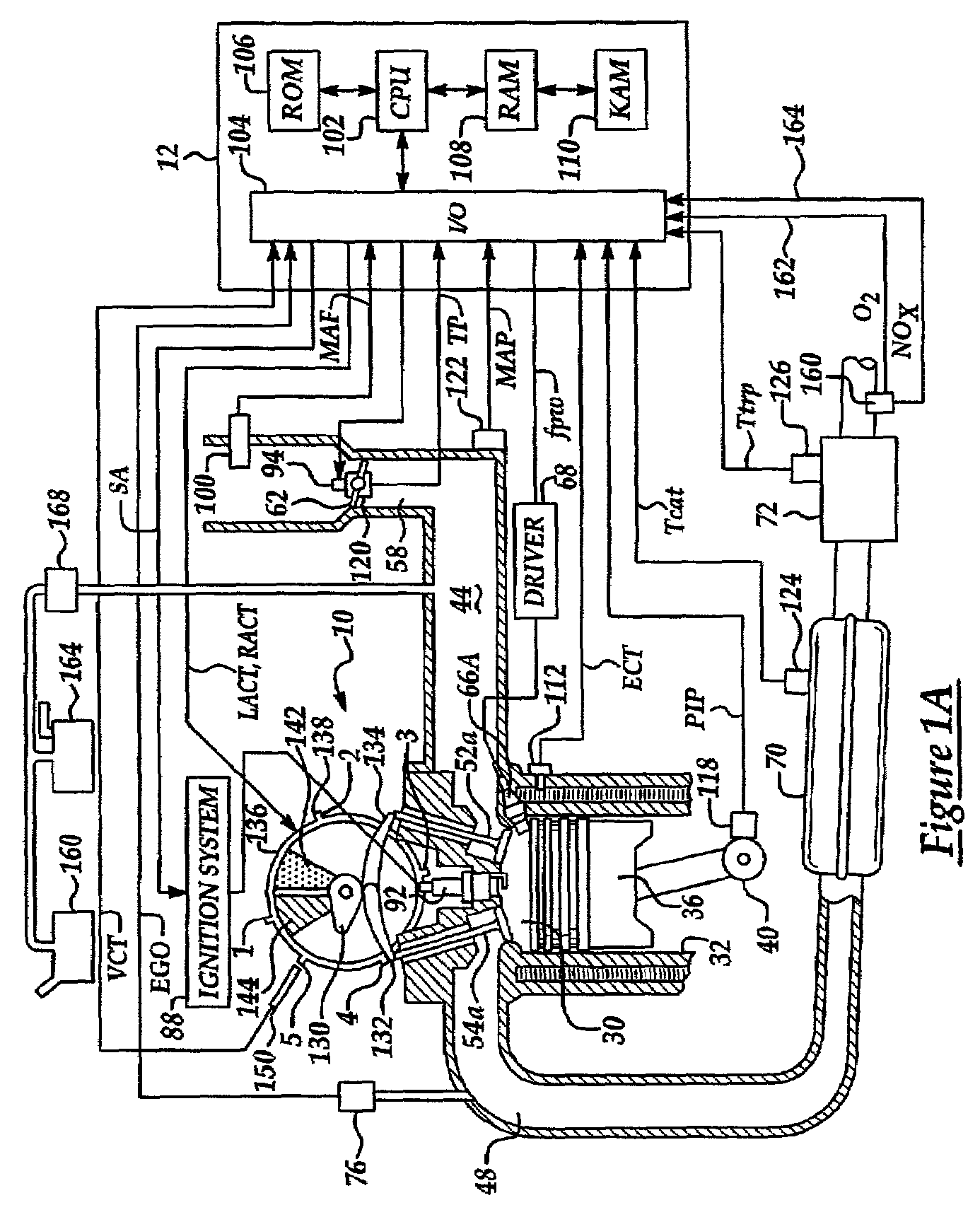

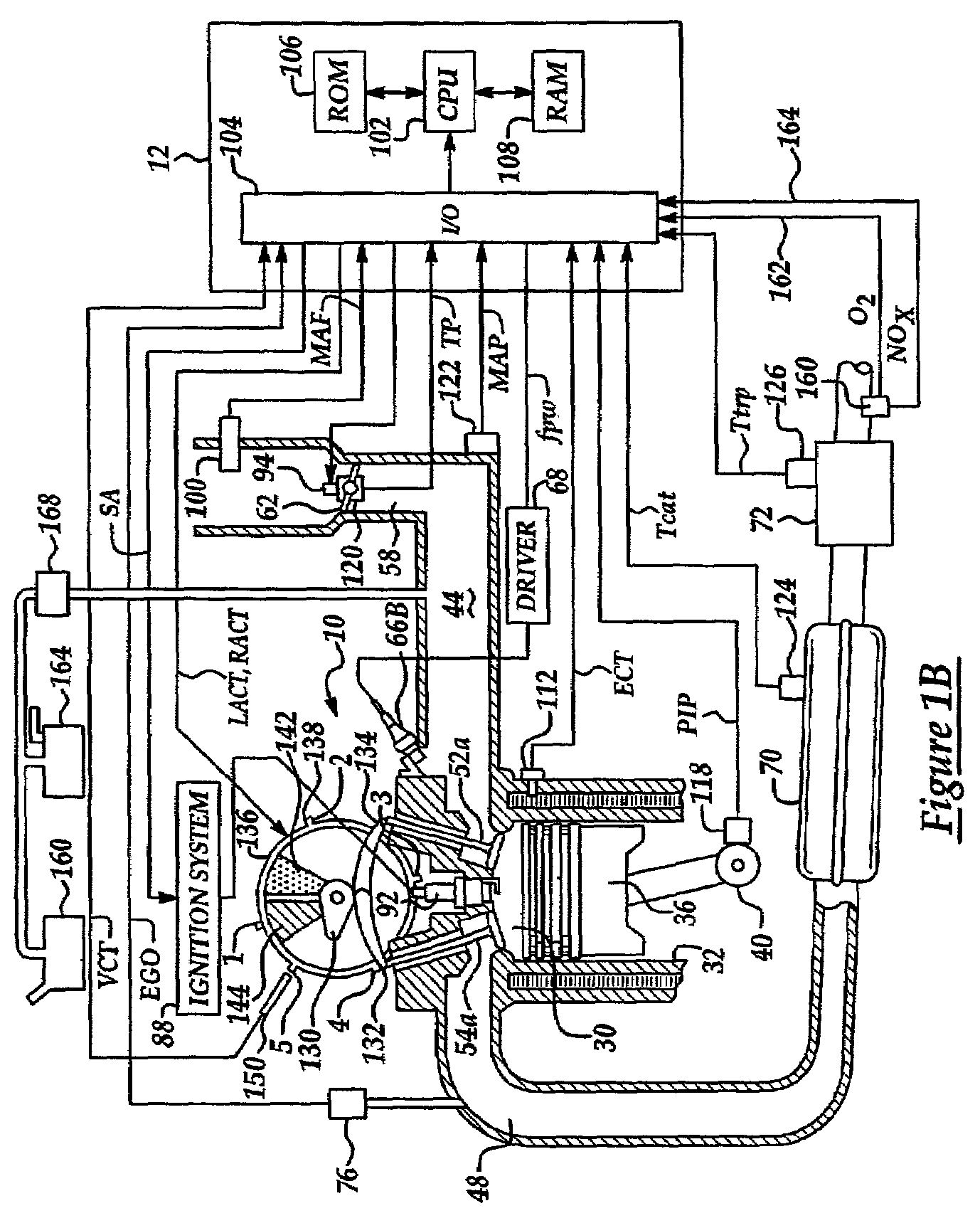

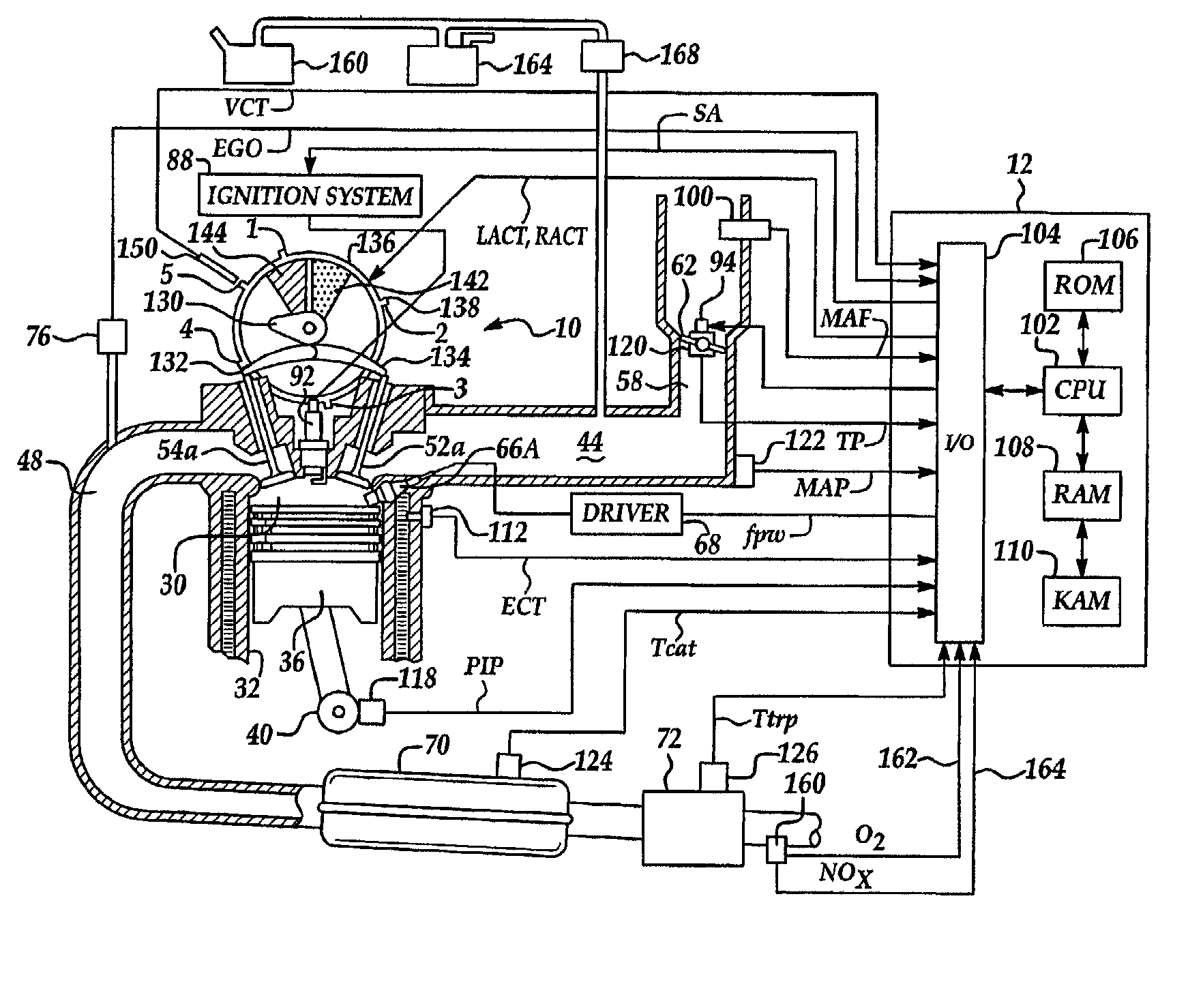

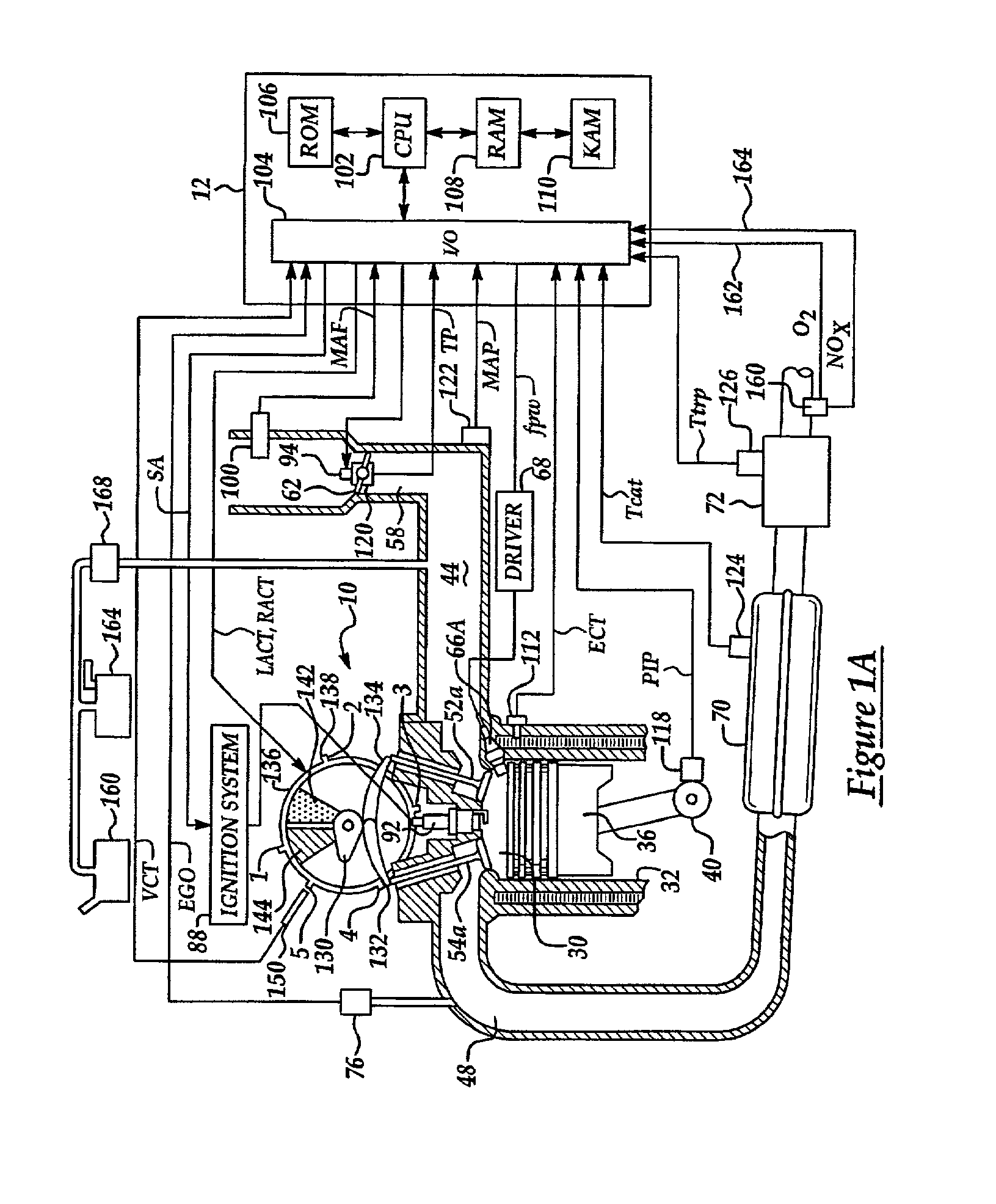

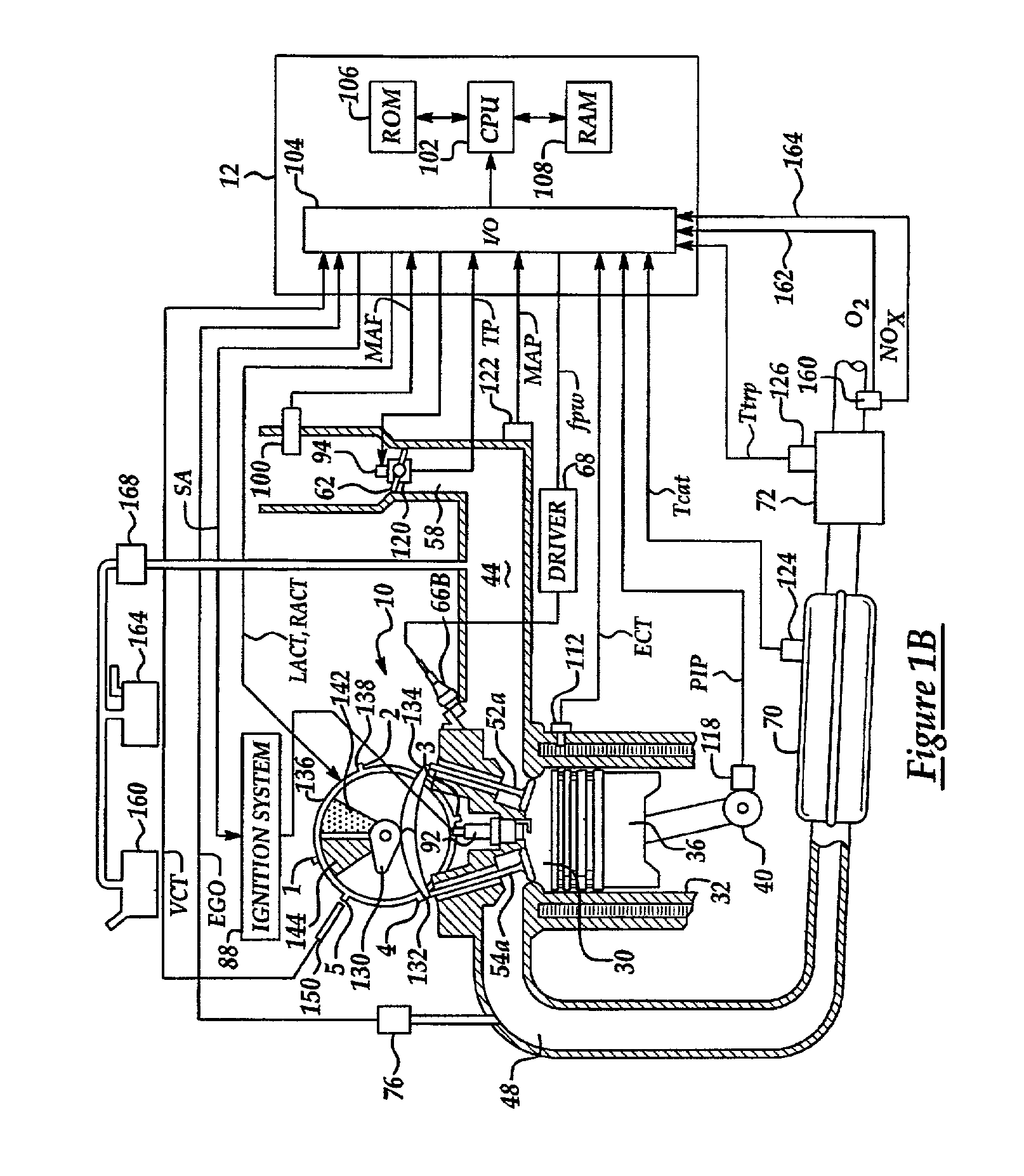

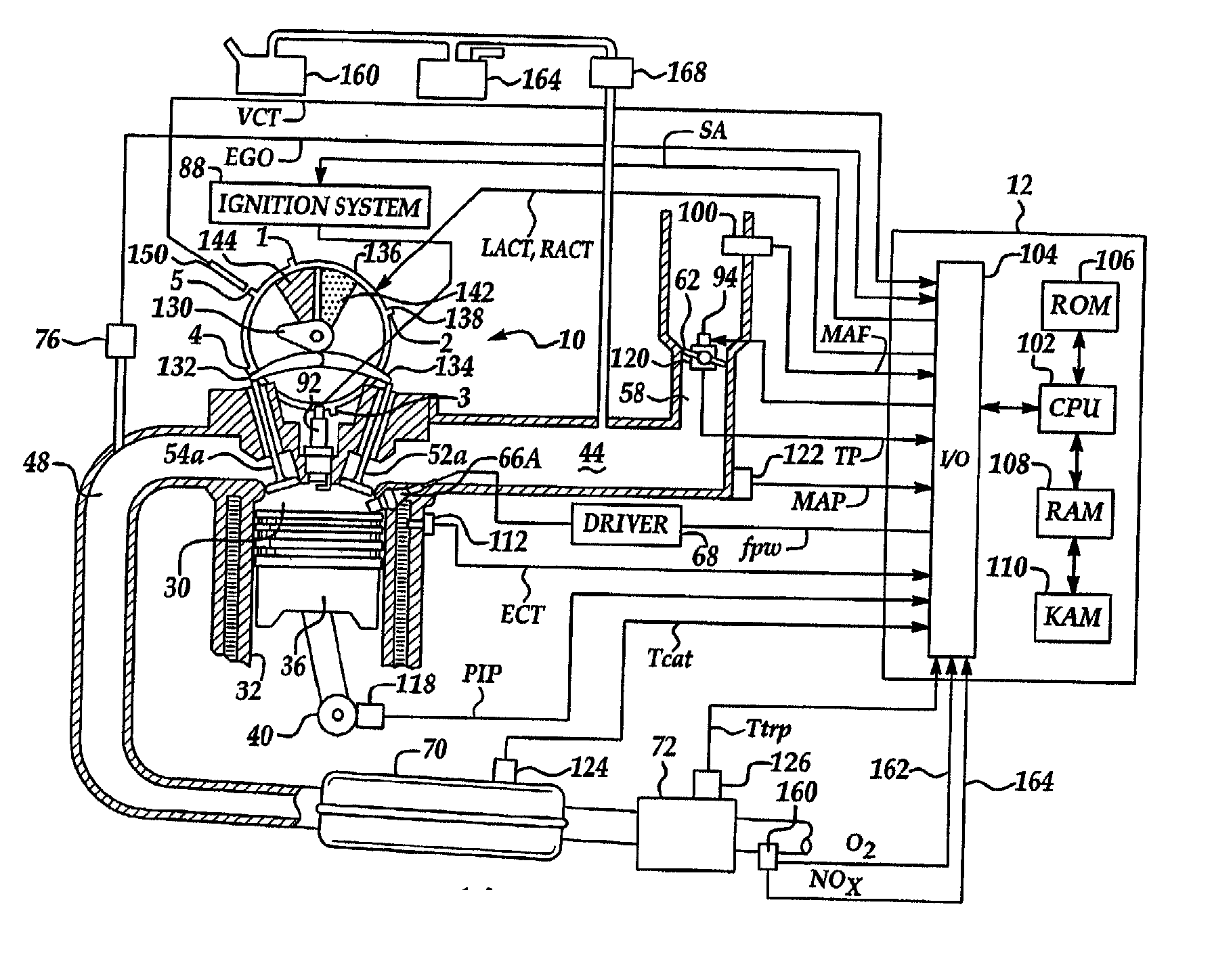

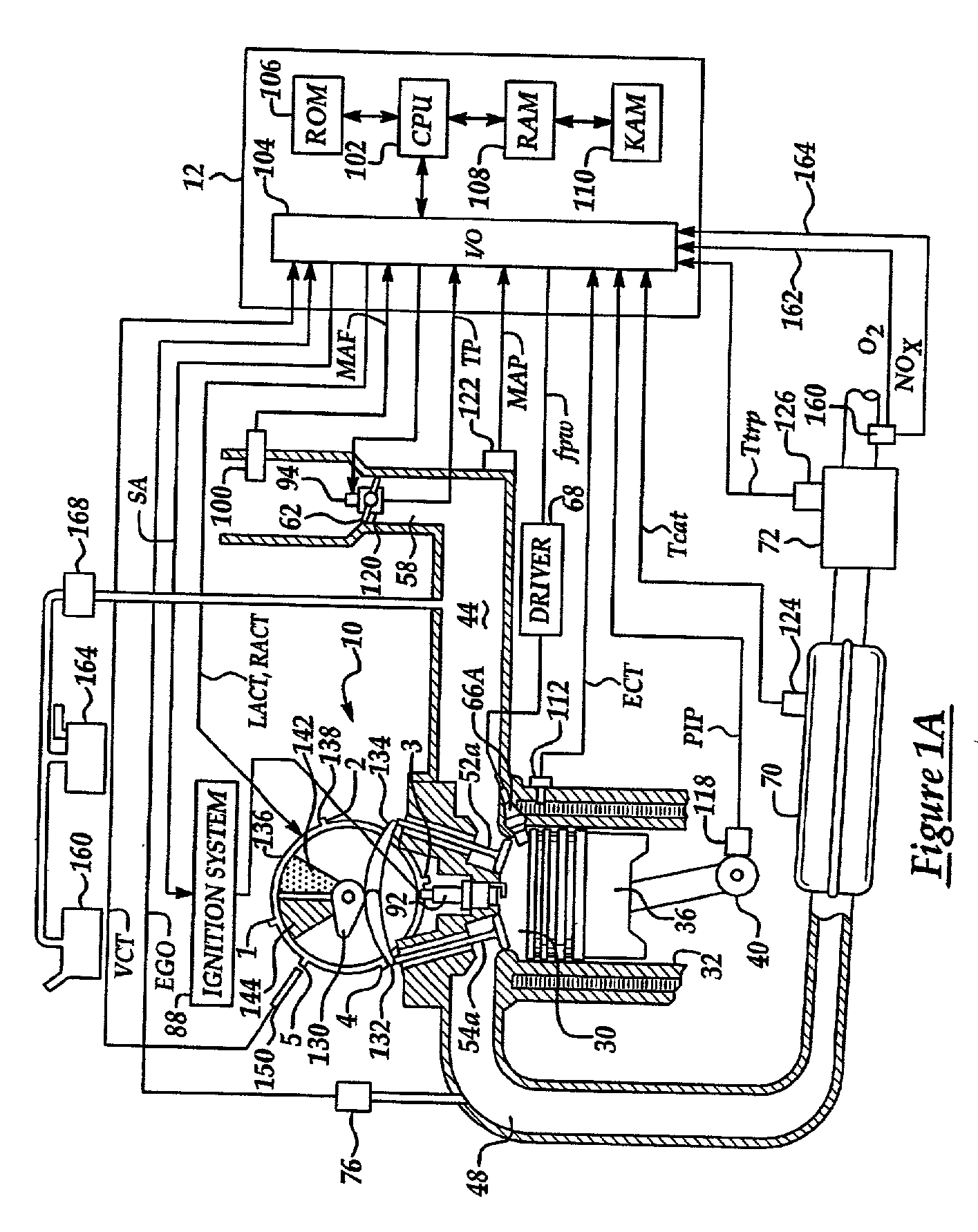

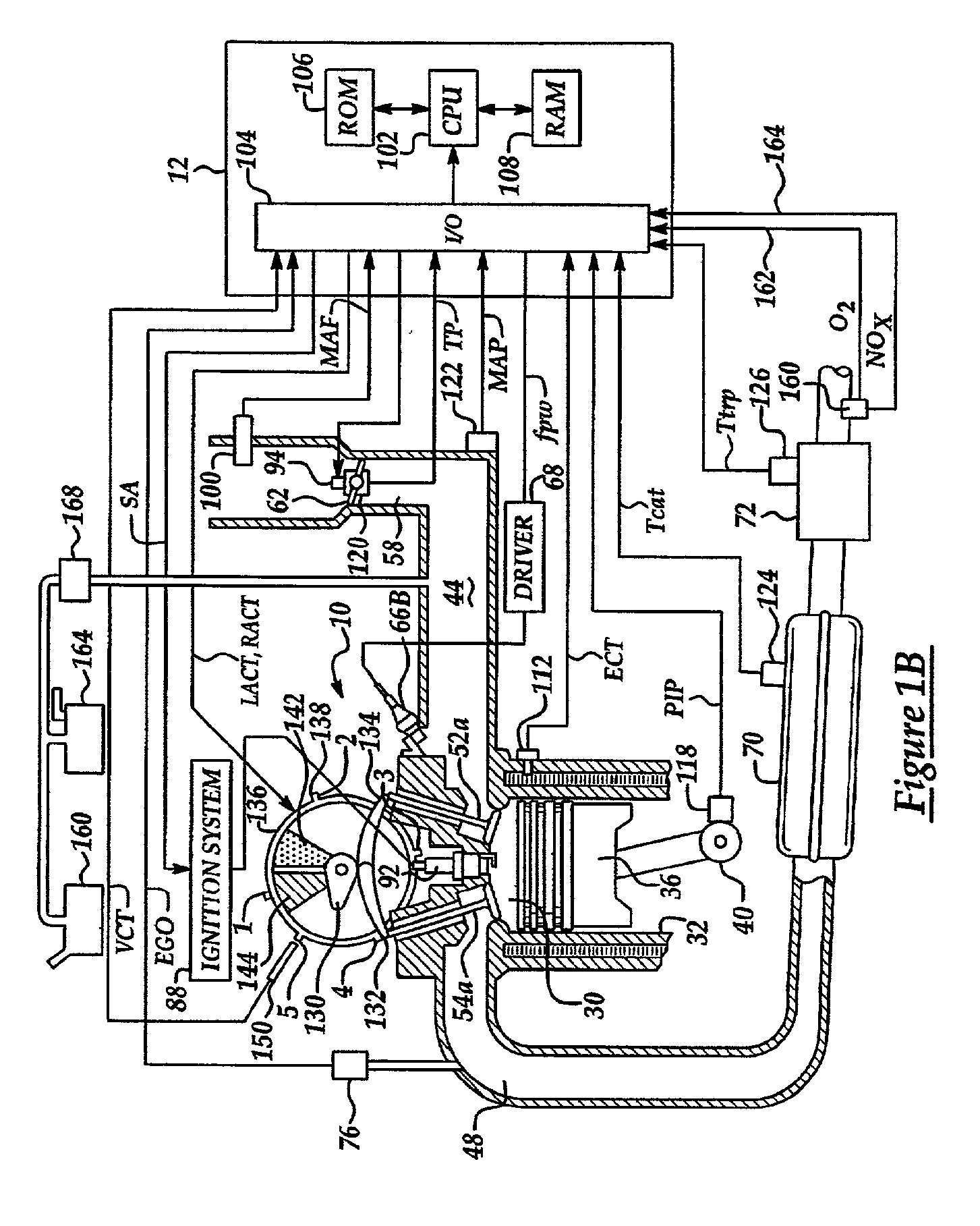

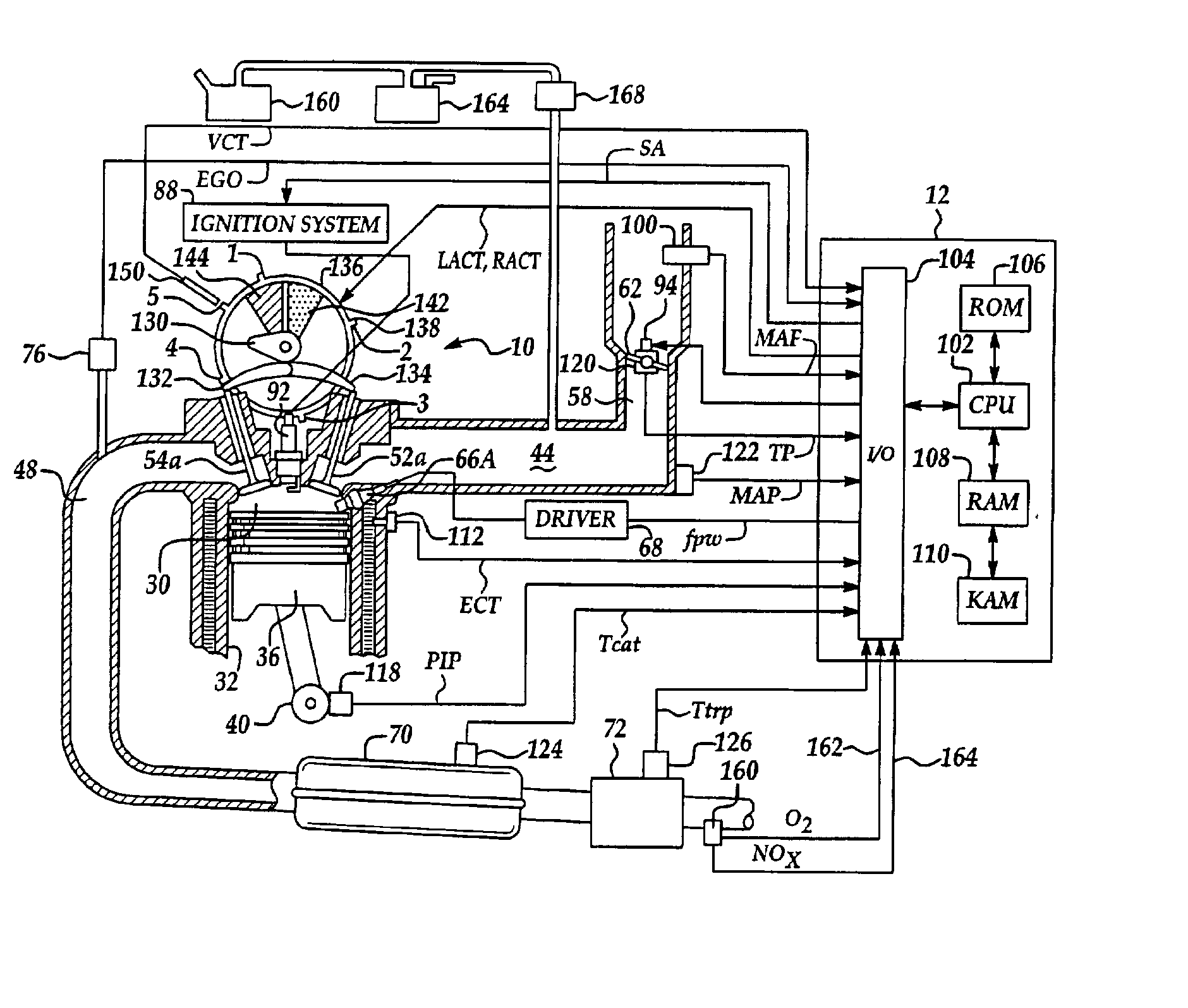

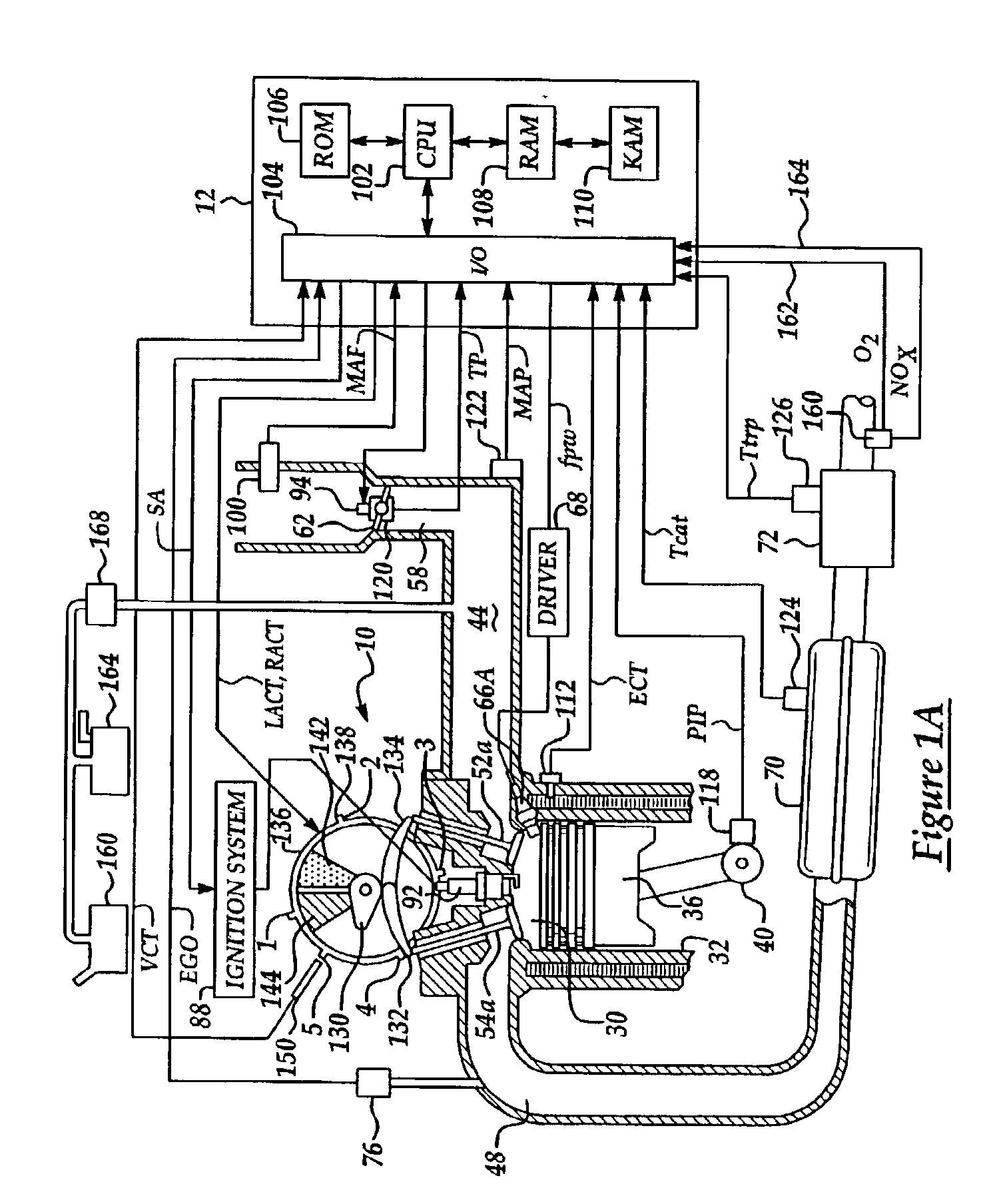

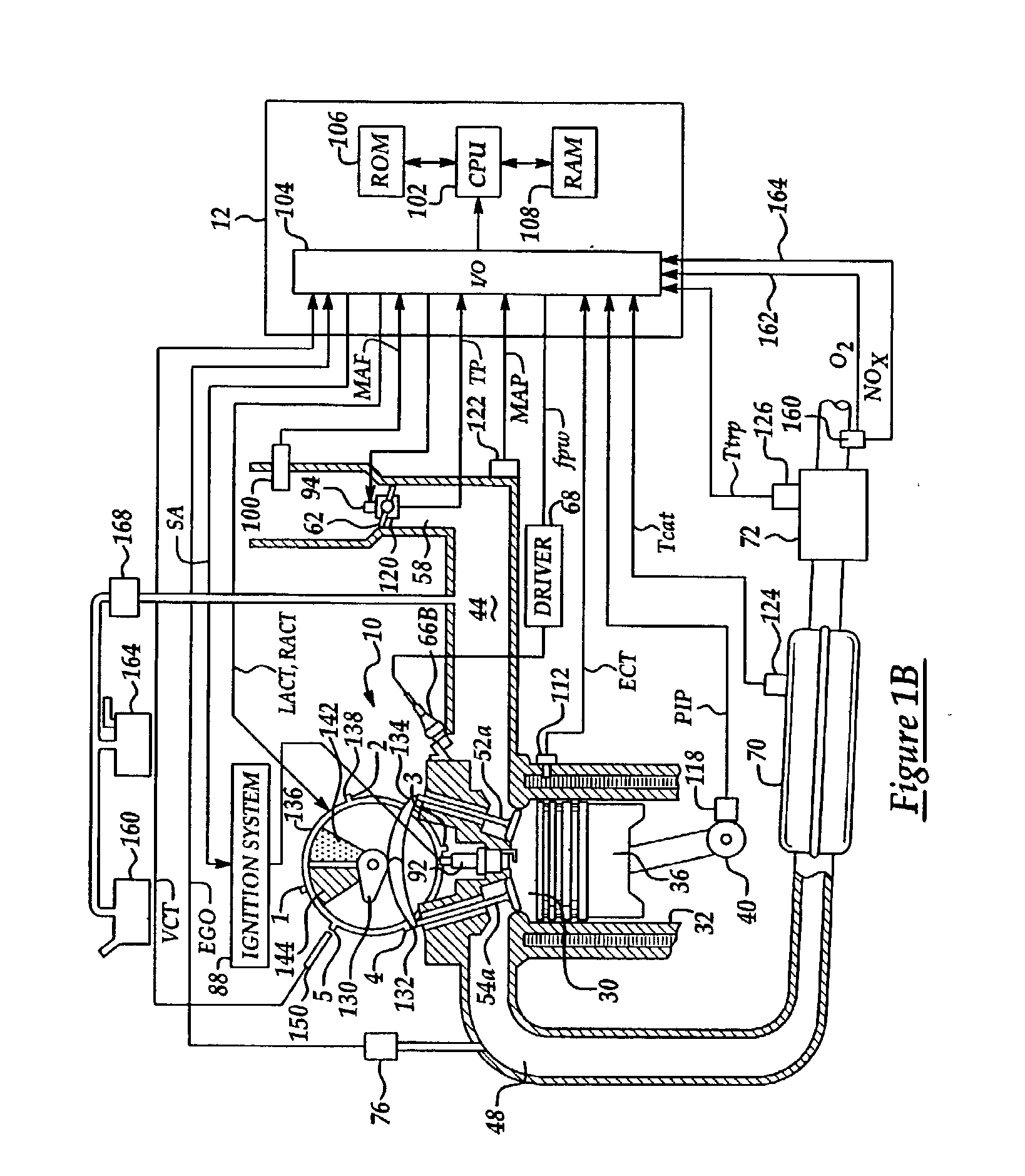

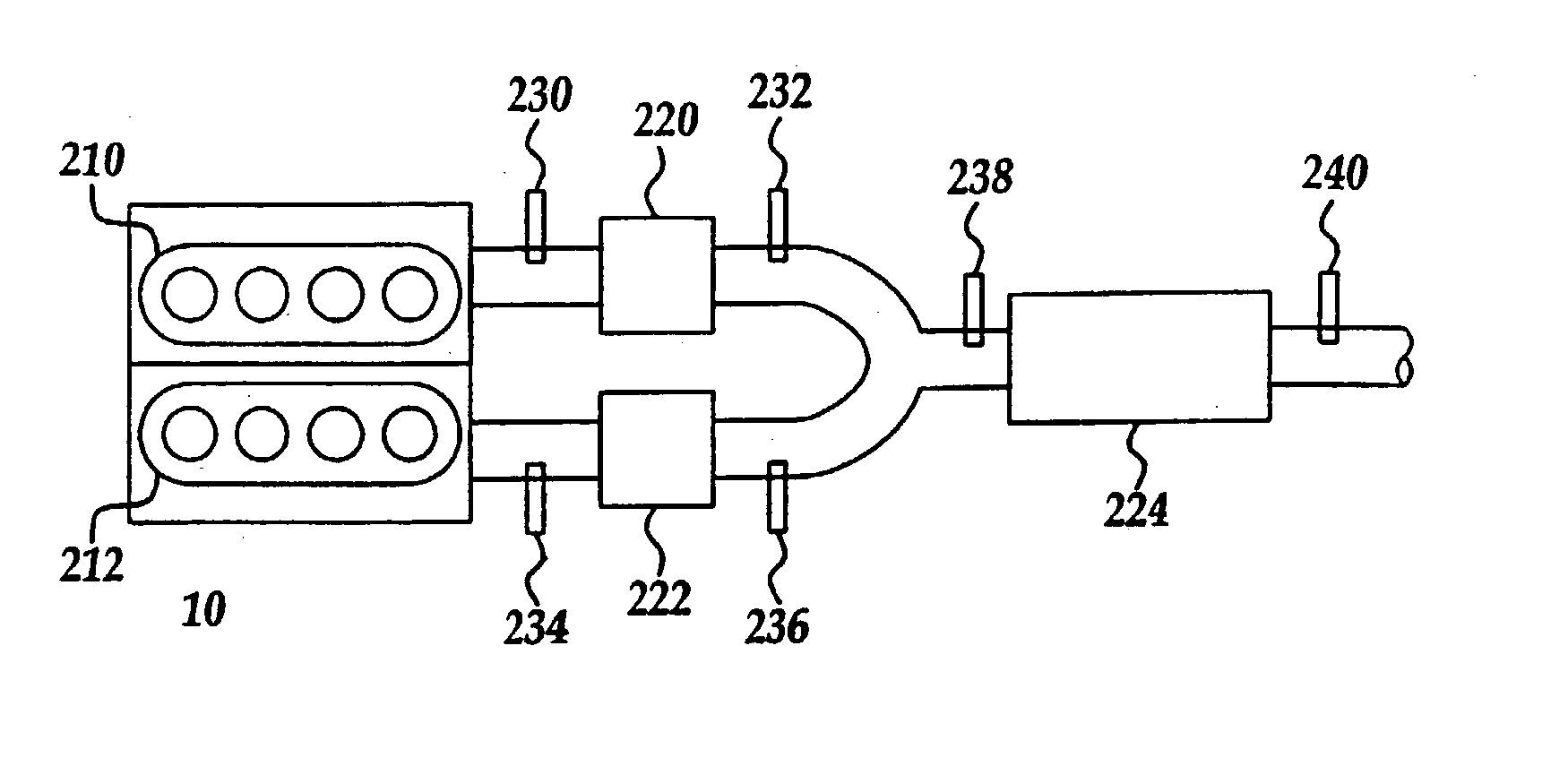

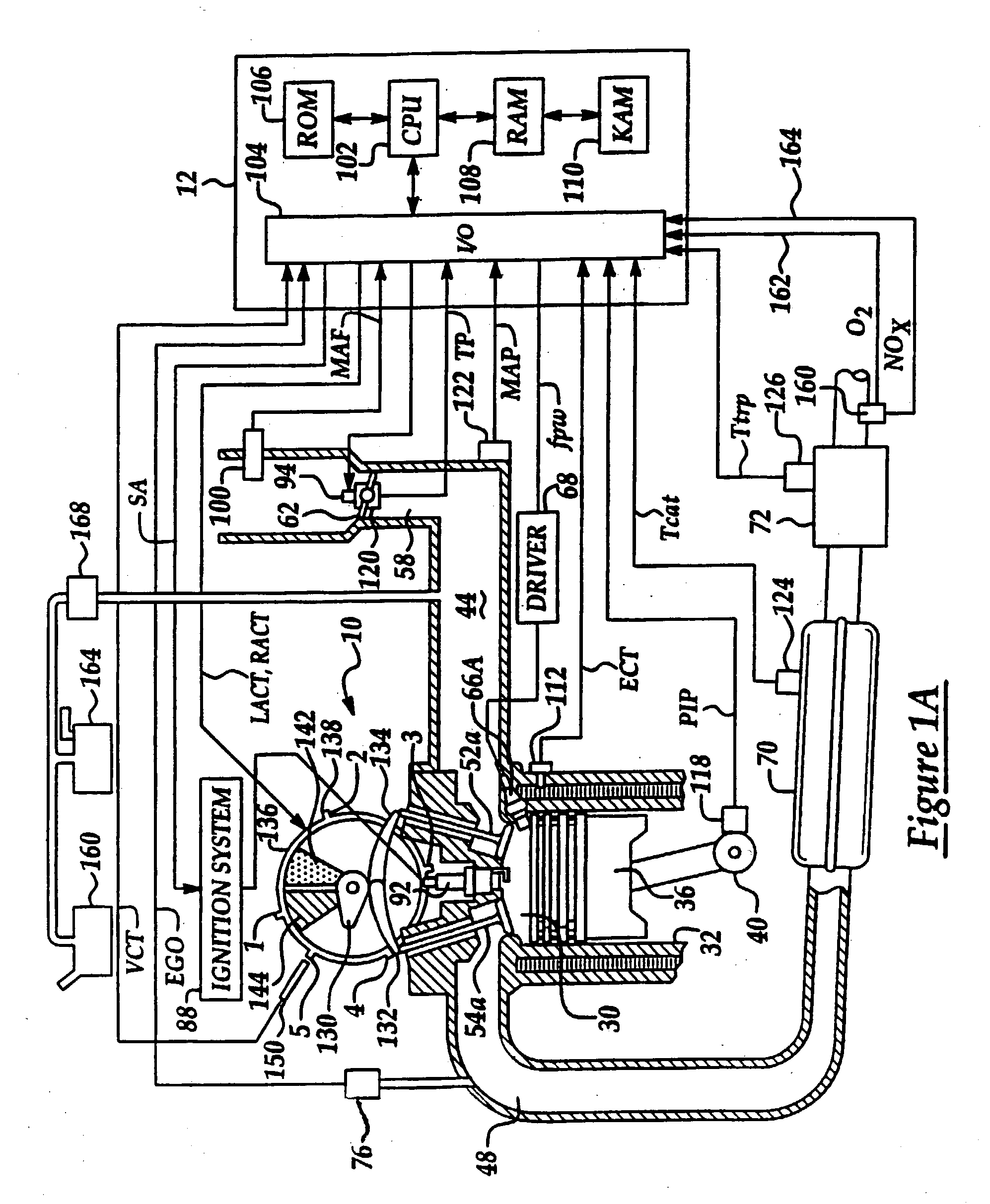

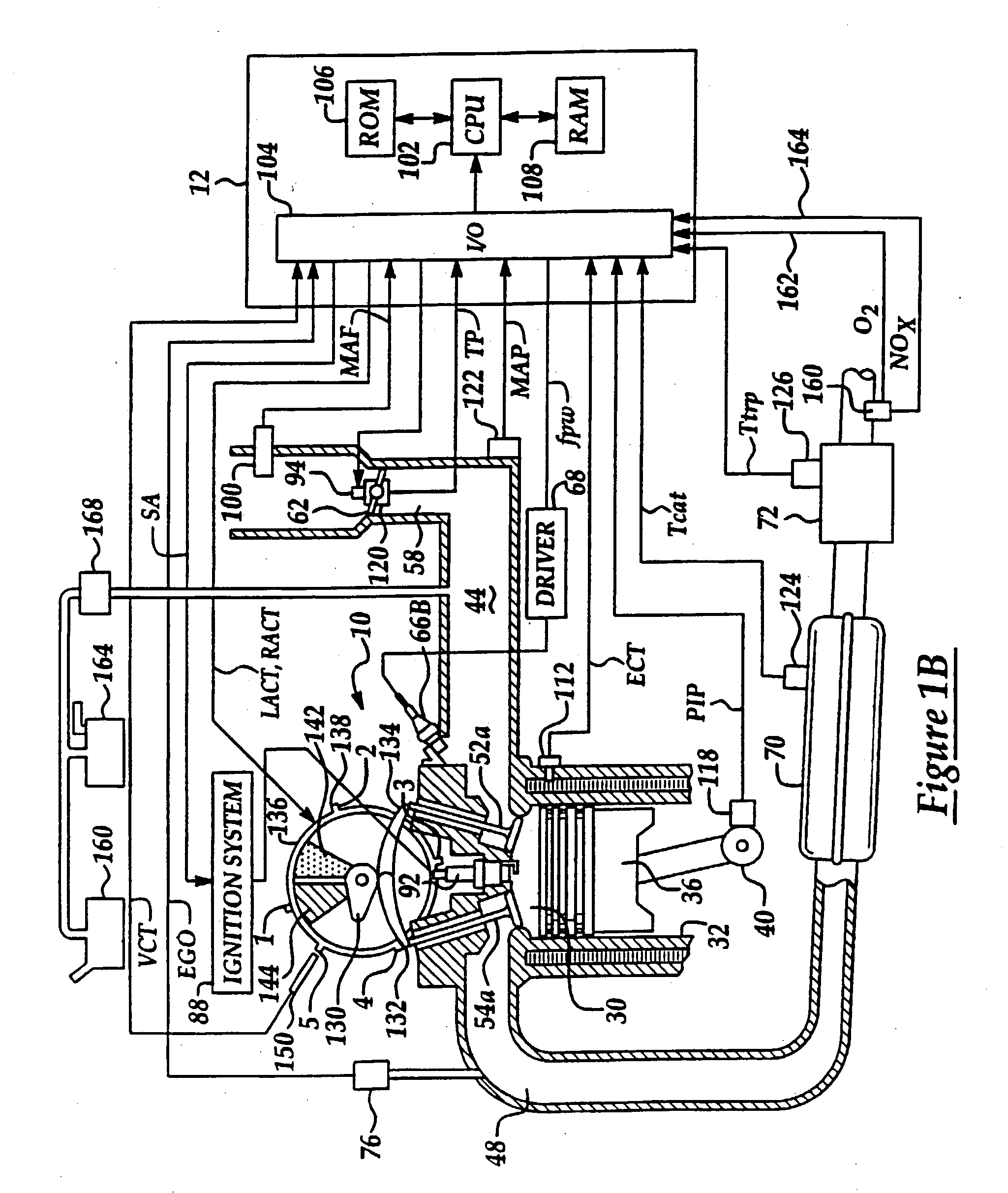

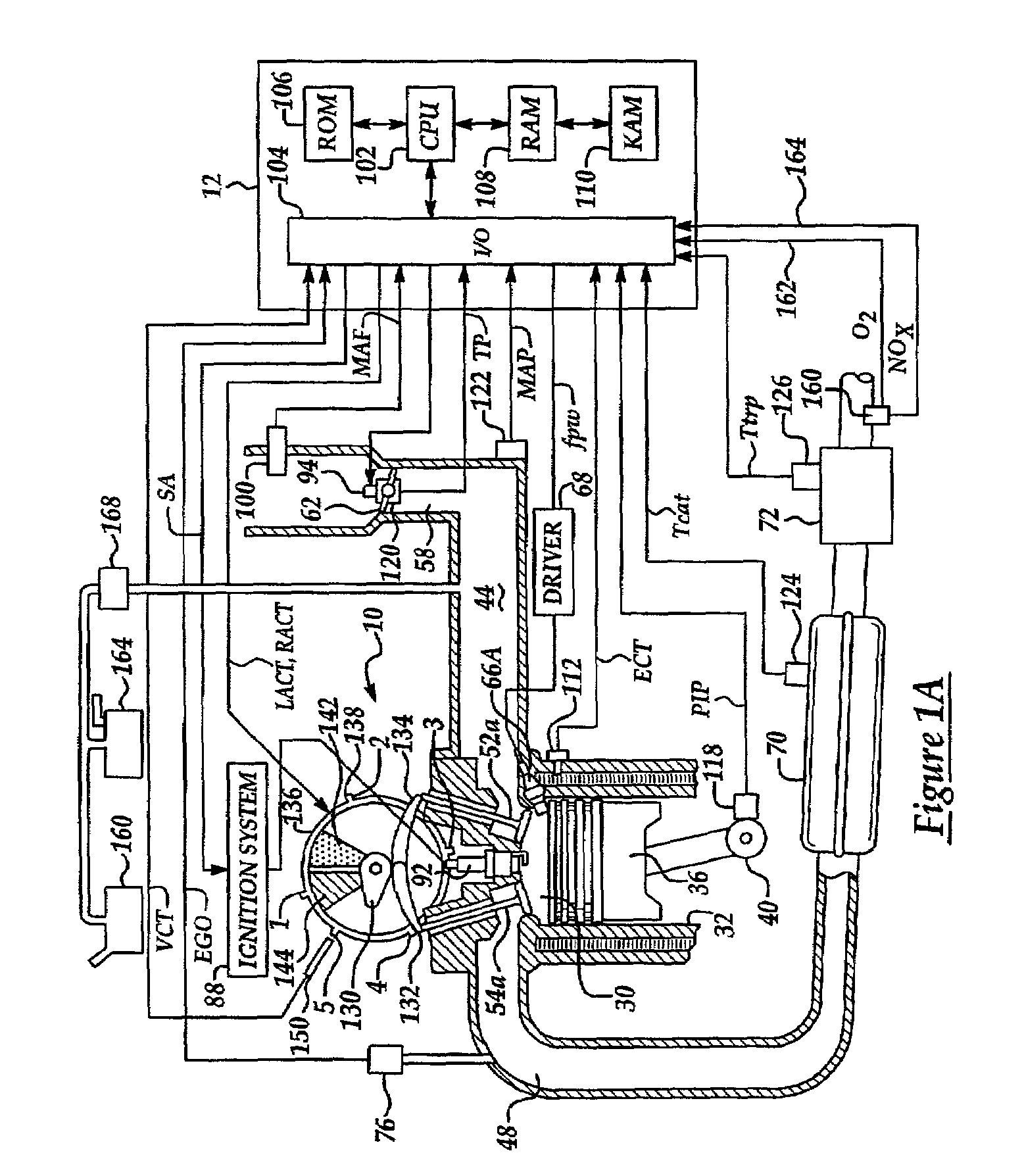

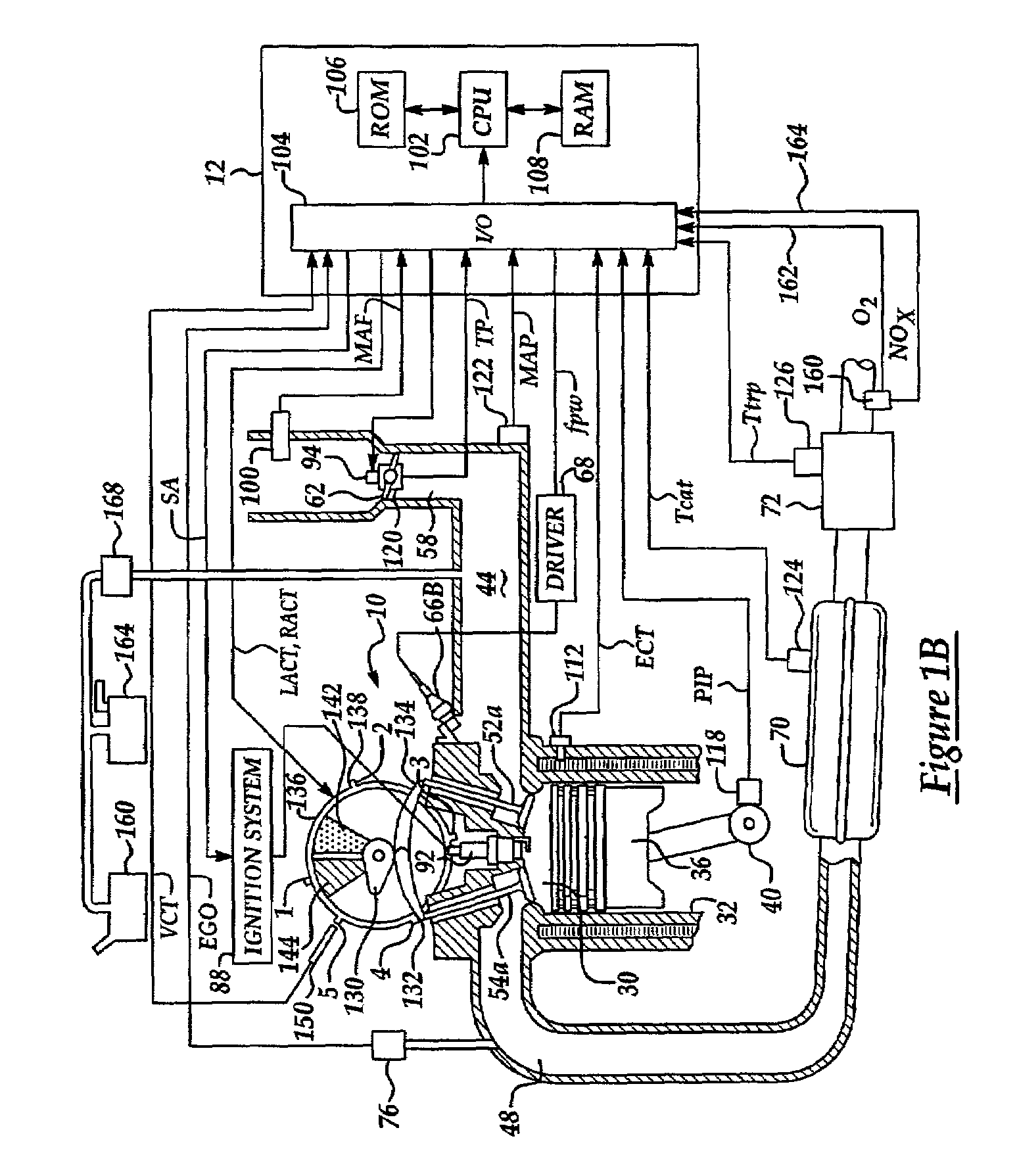

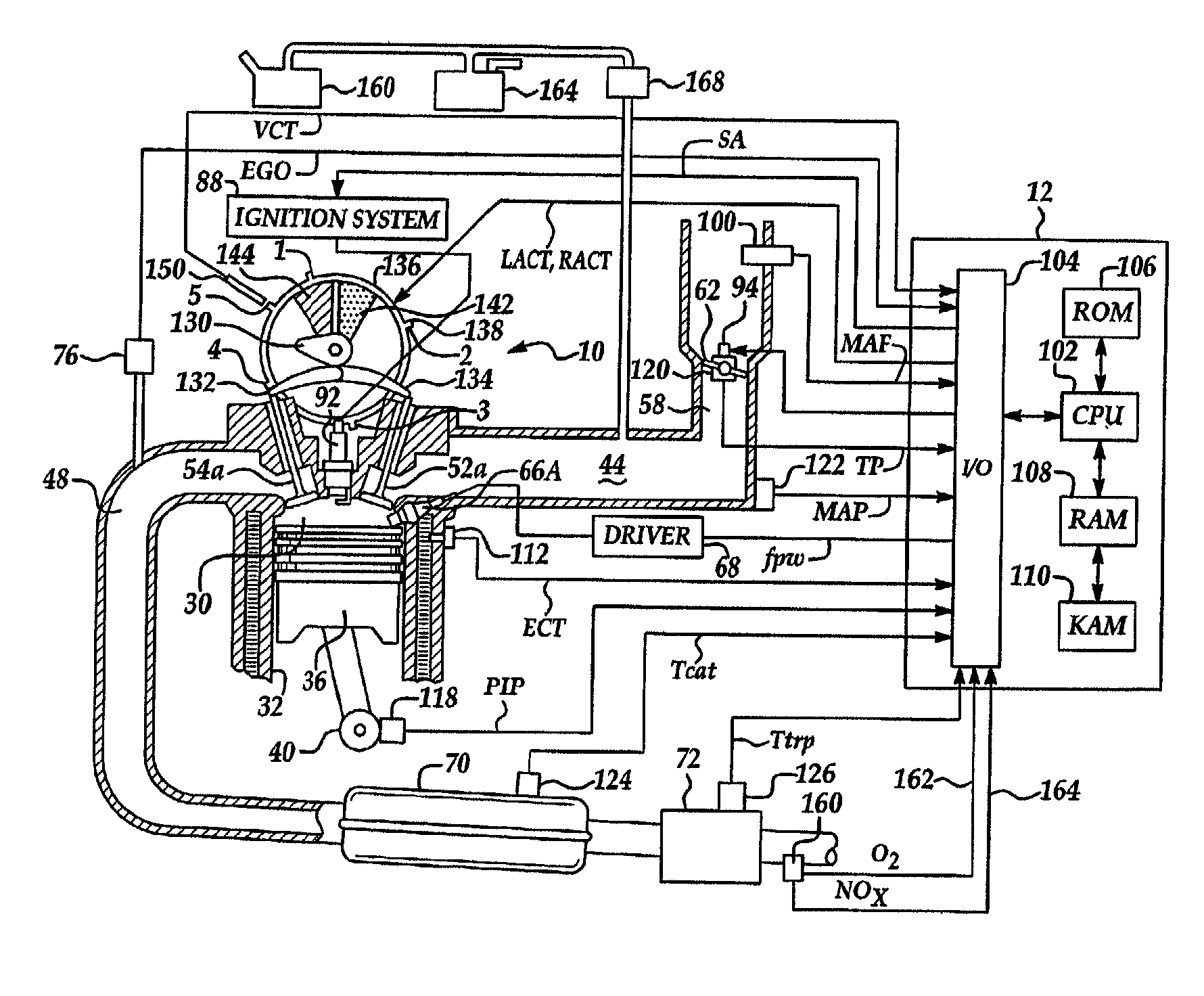

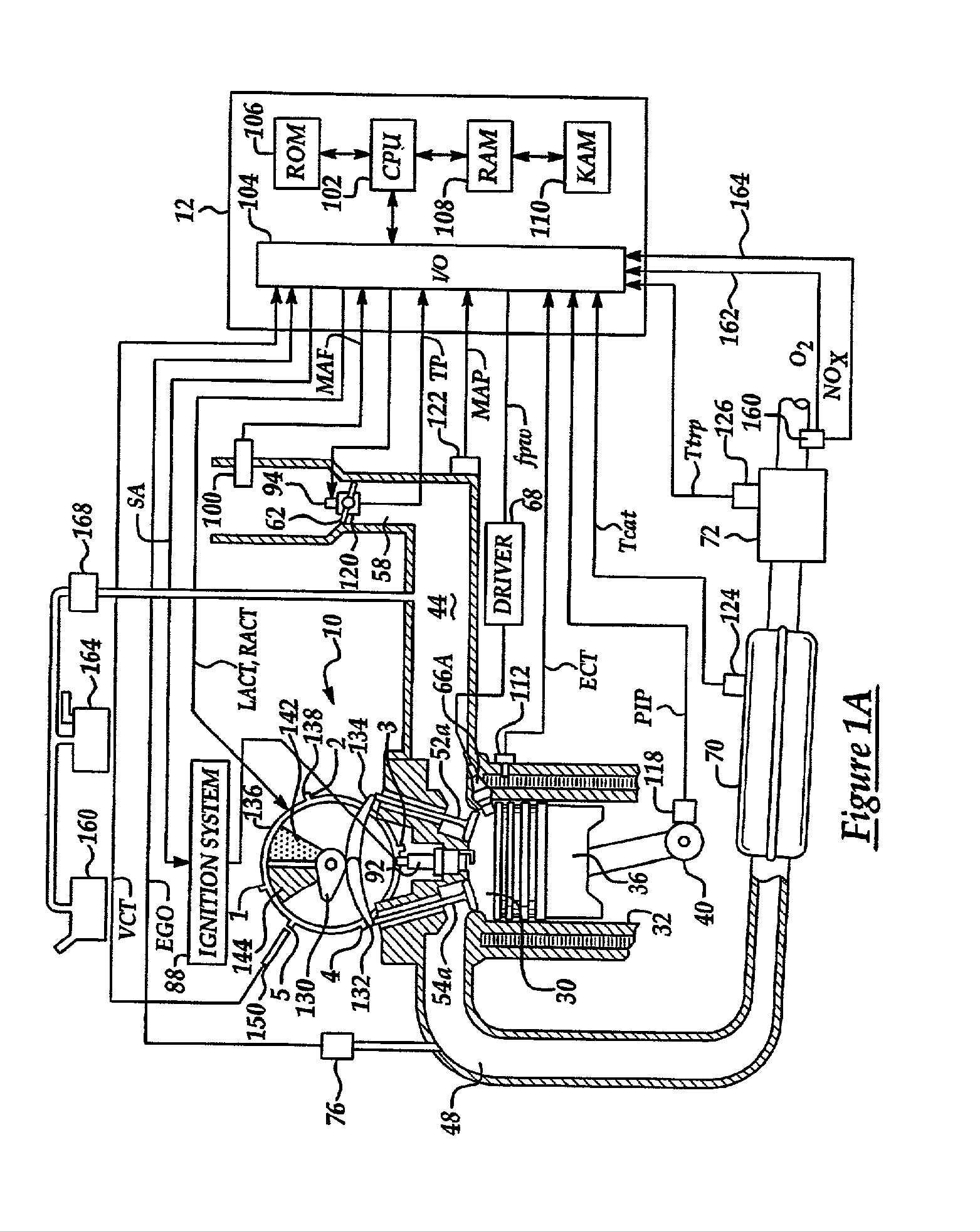

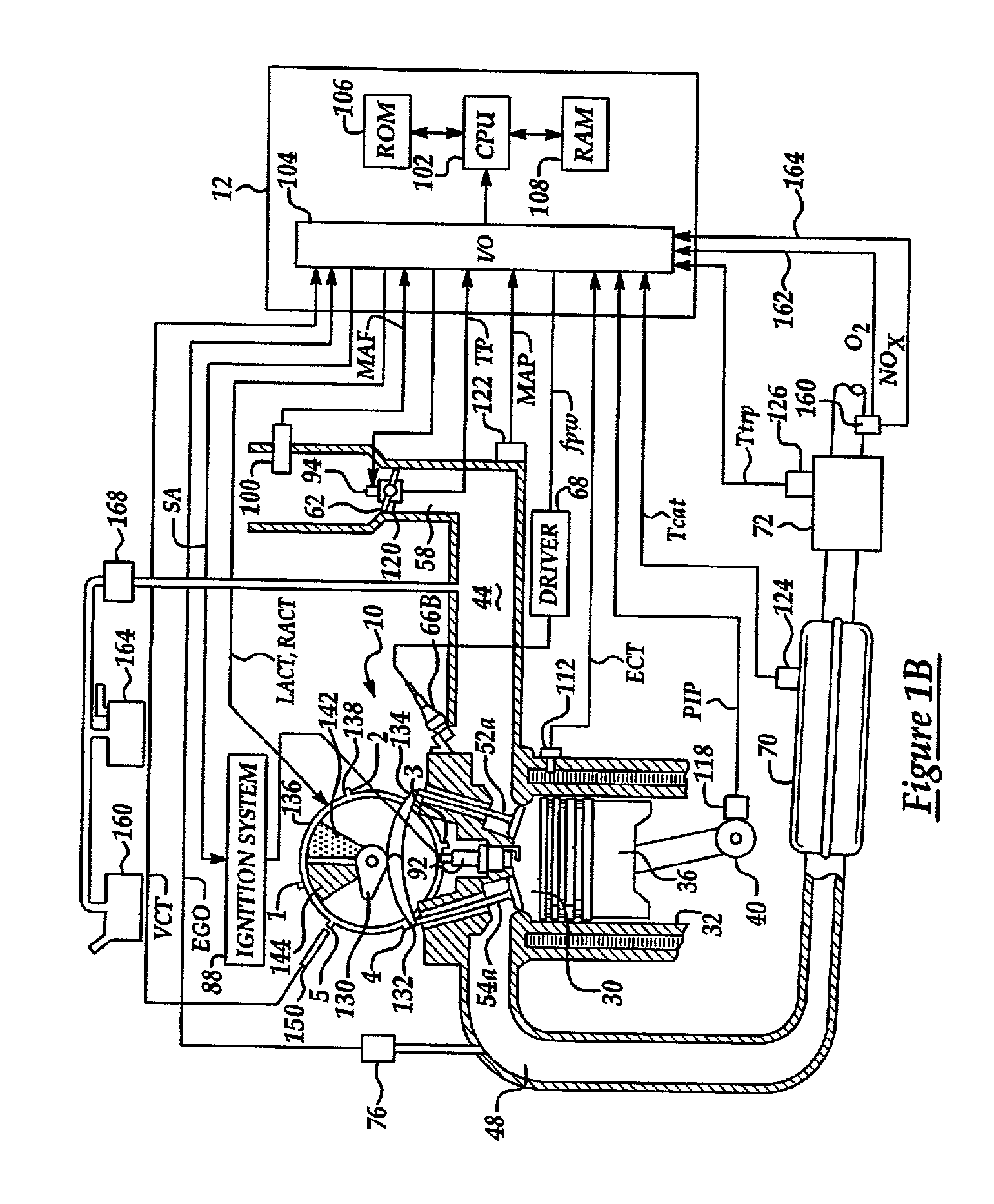

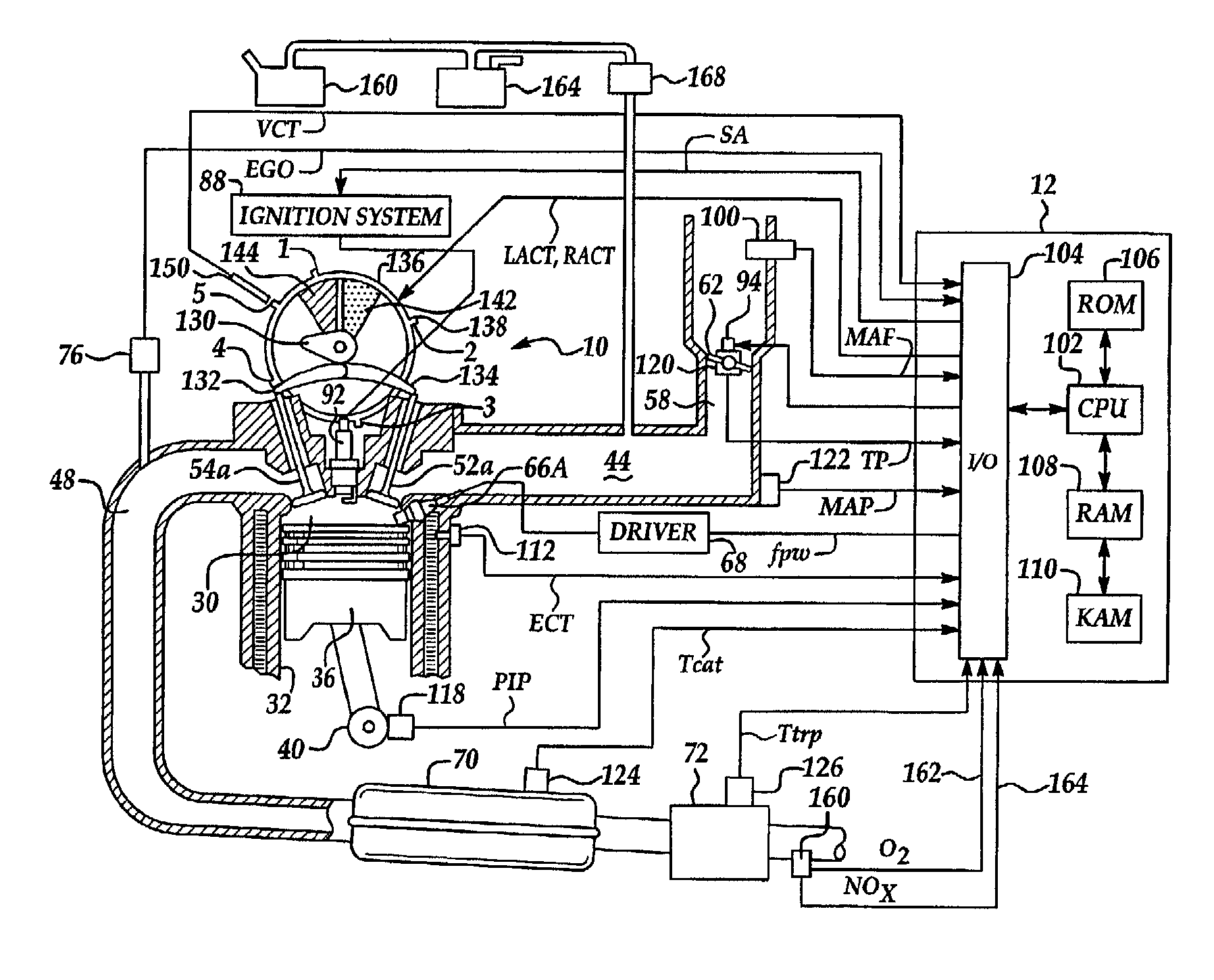

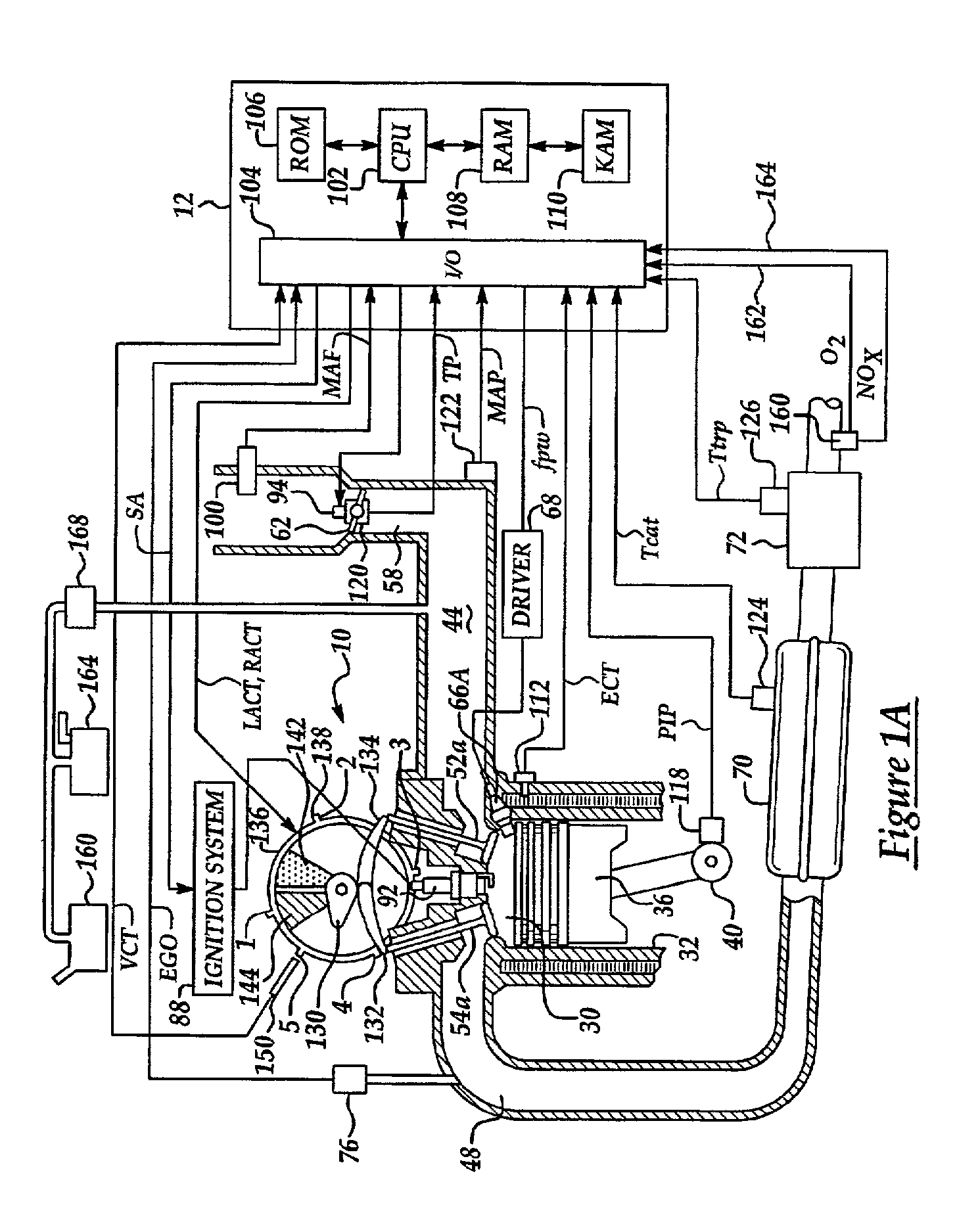

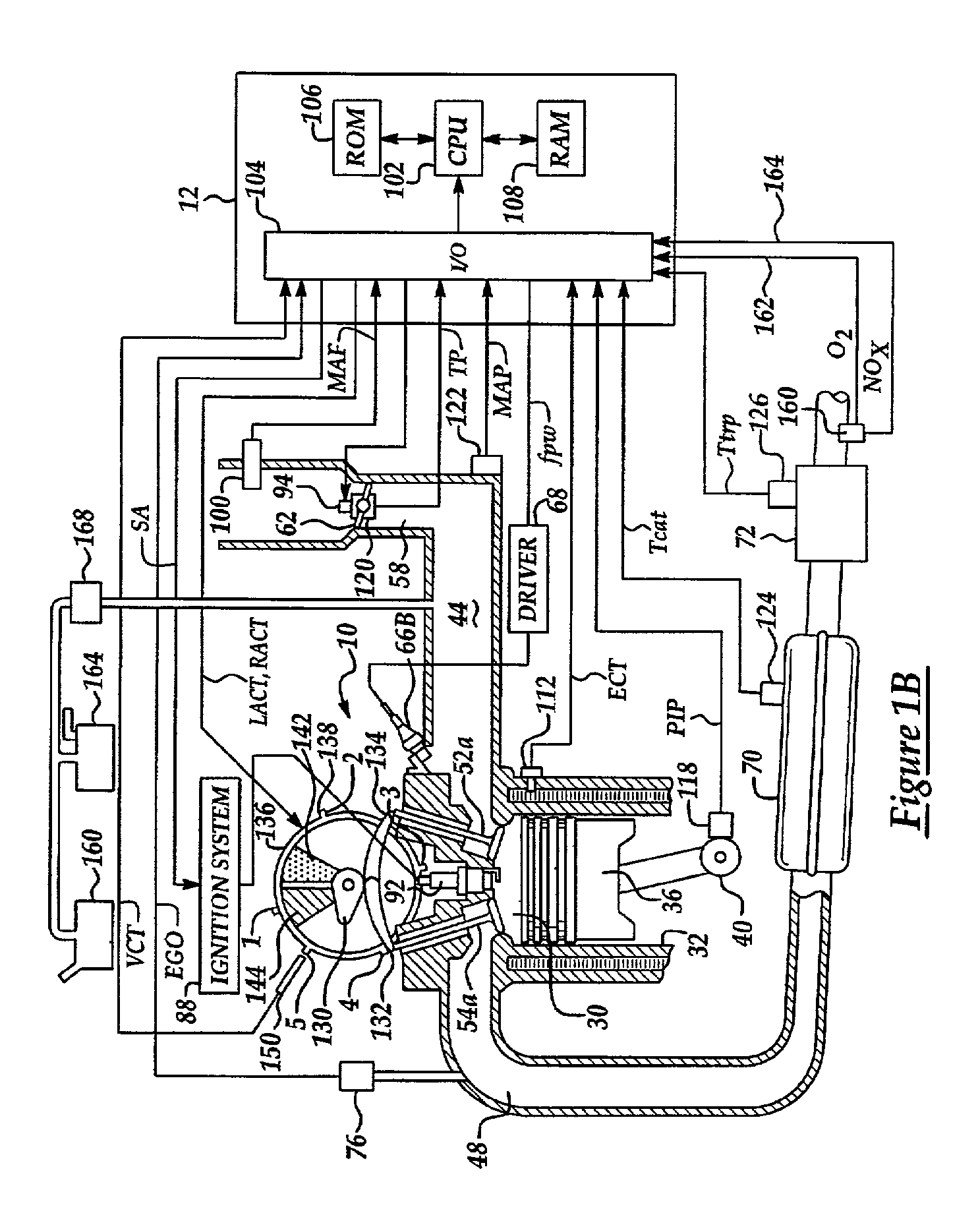

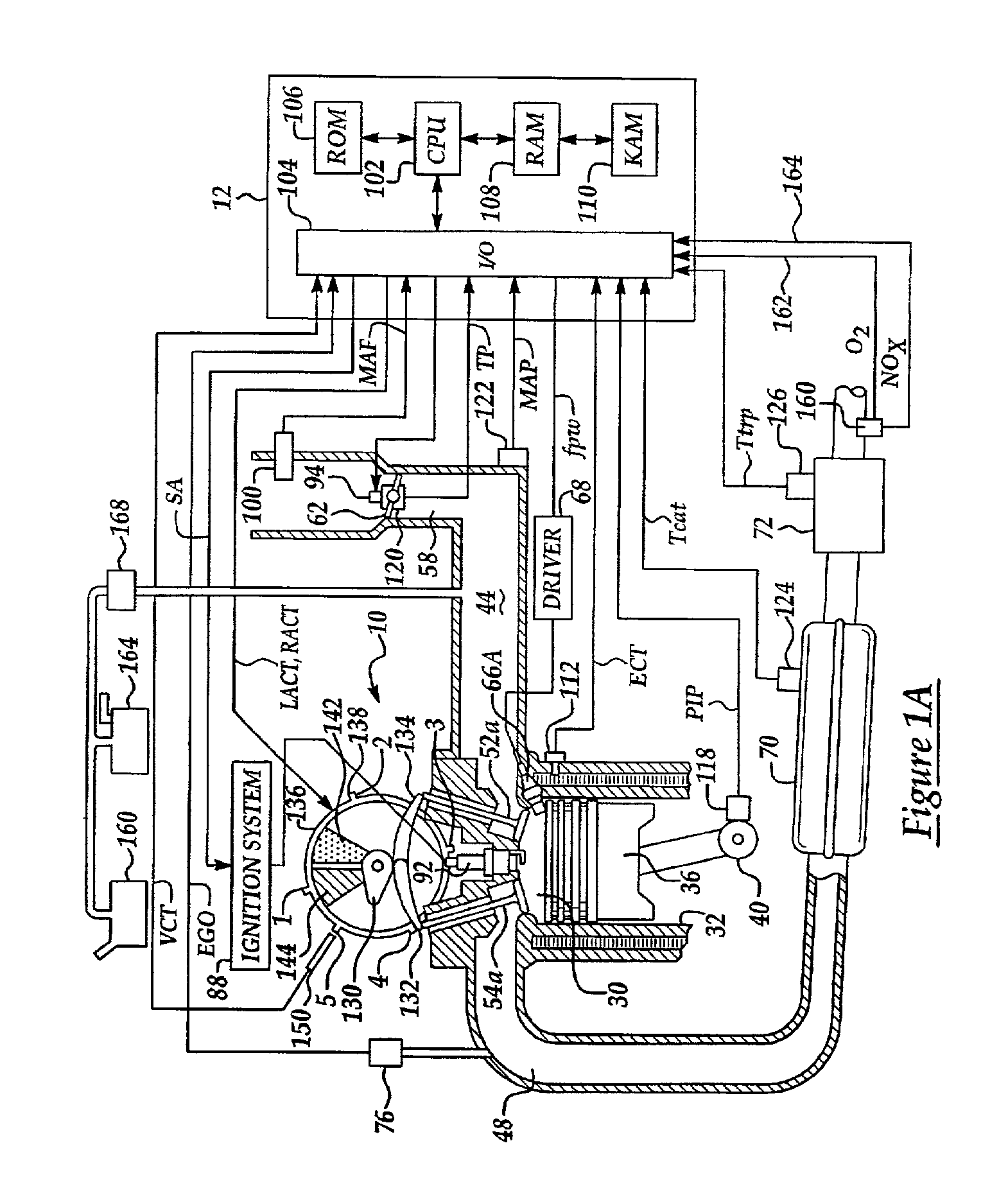

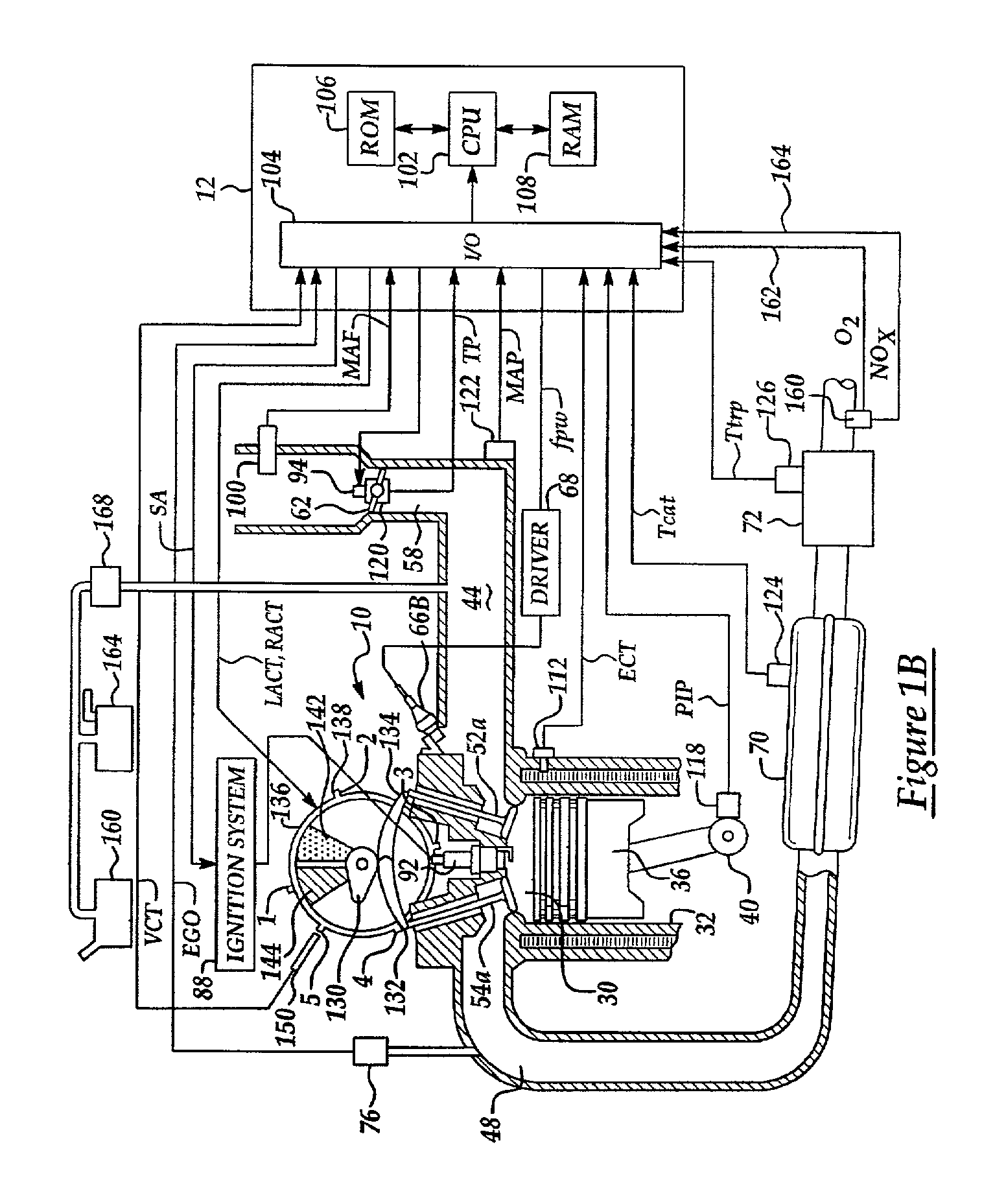

InactiveUS6568177B1High load conditionMore ignition timingElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

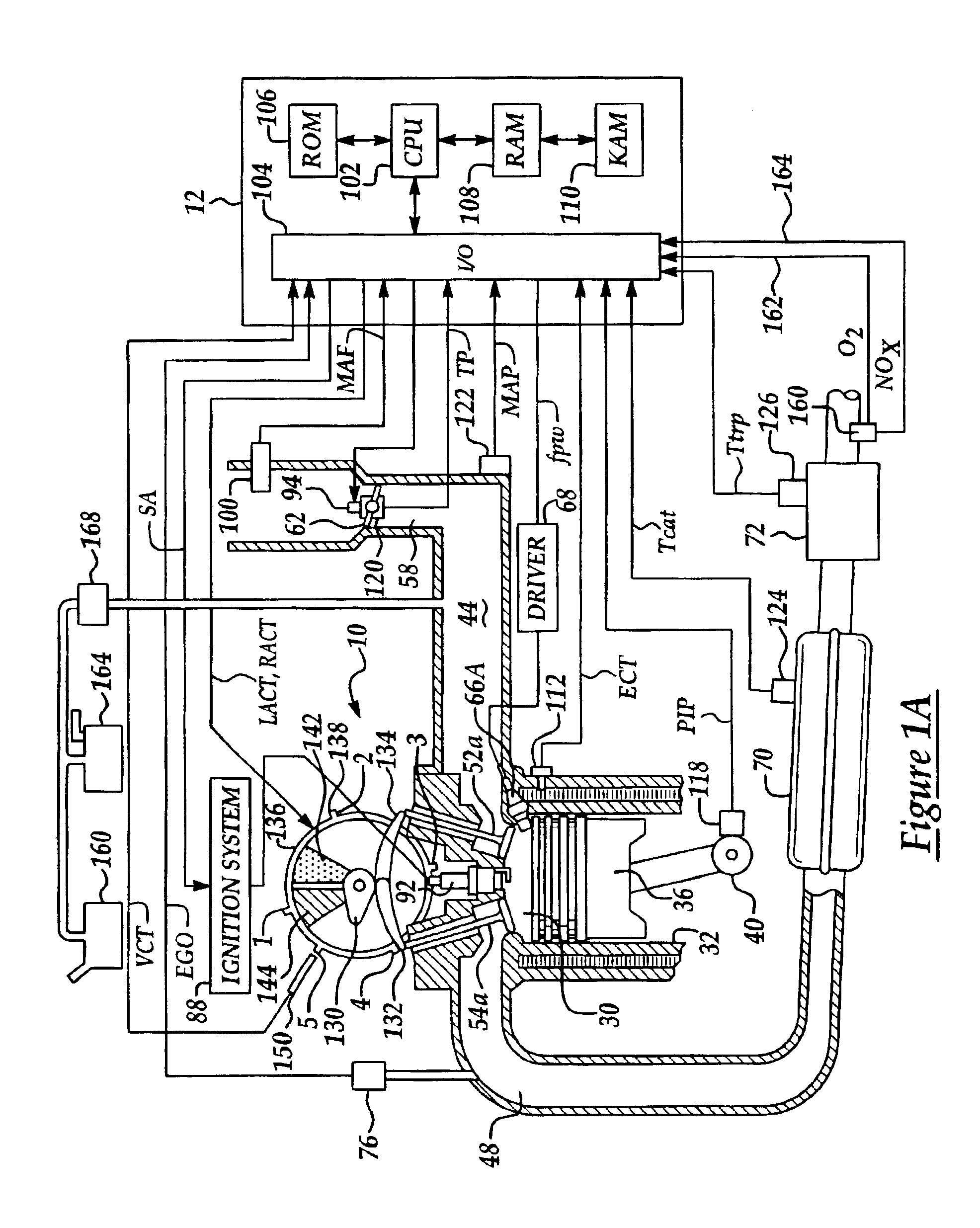

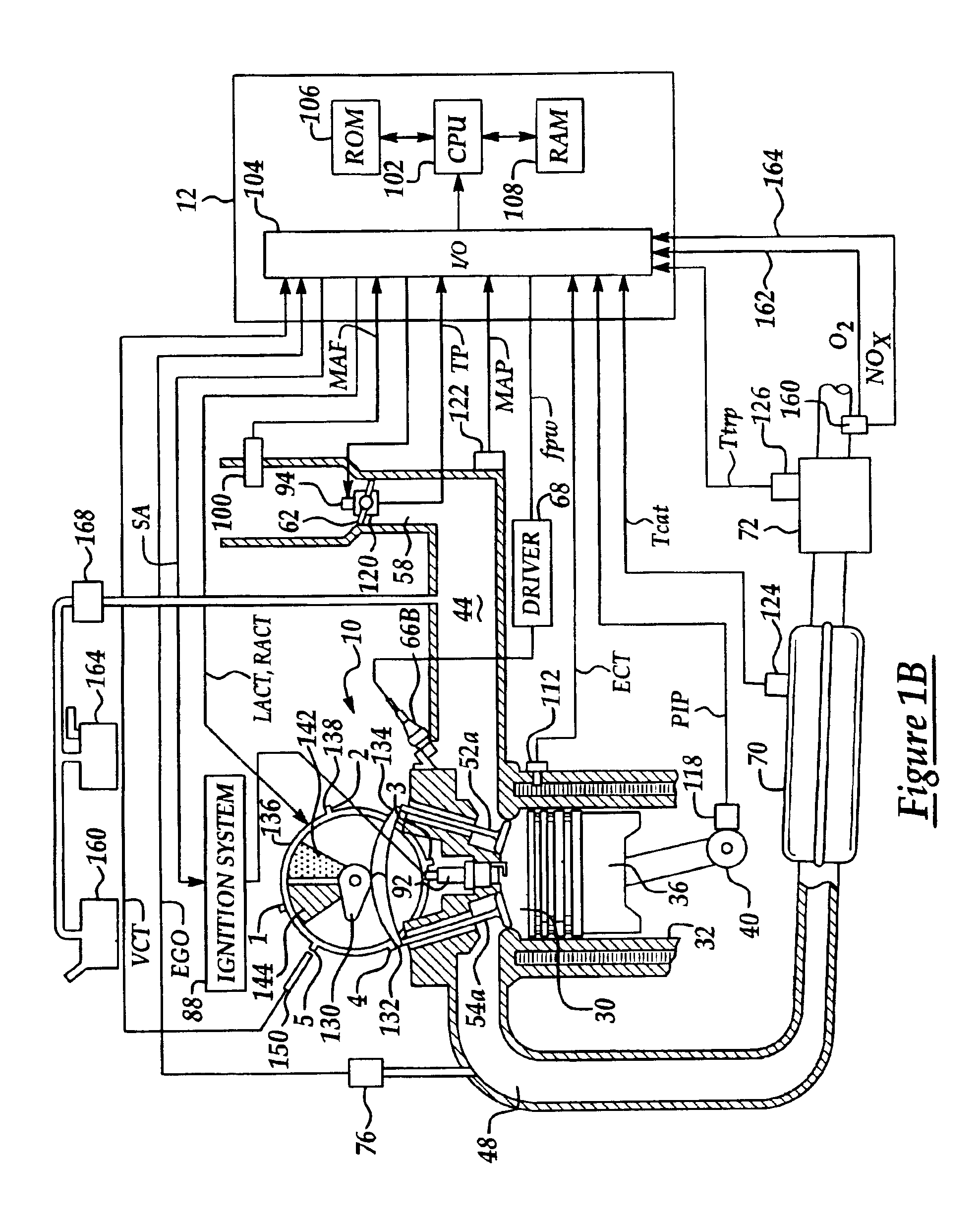

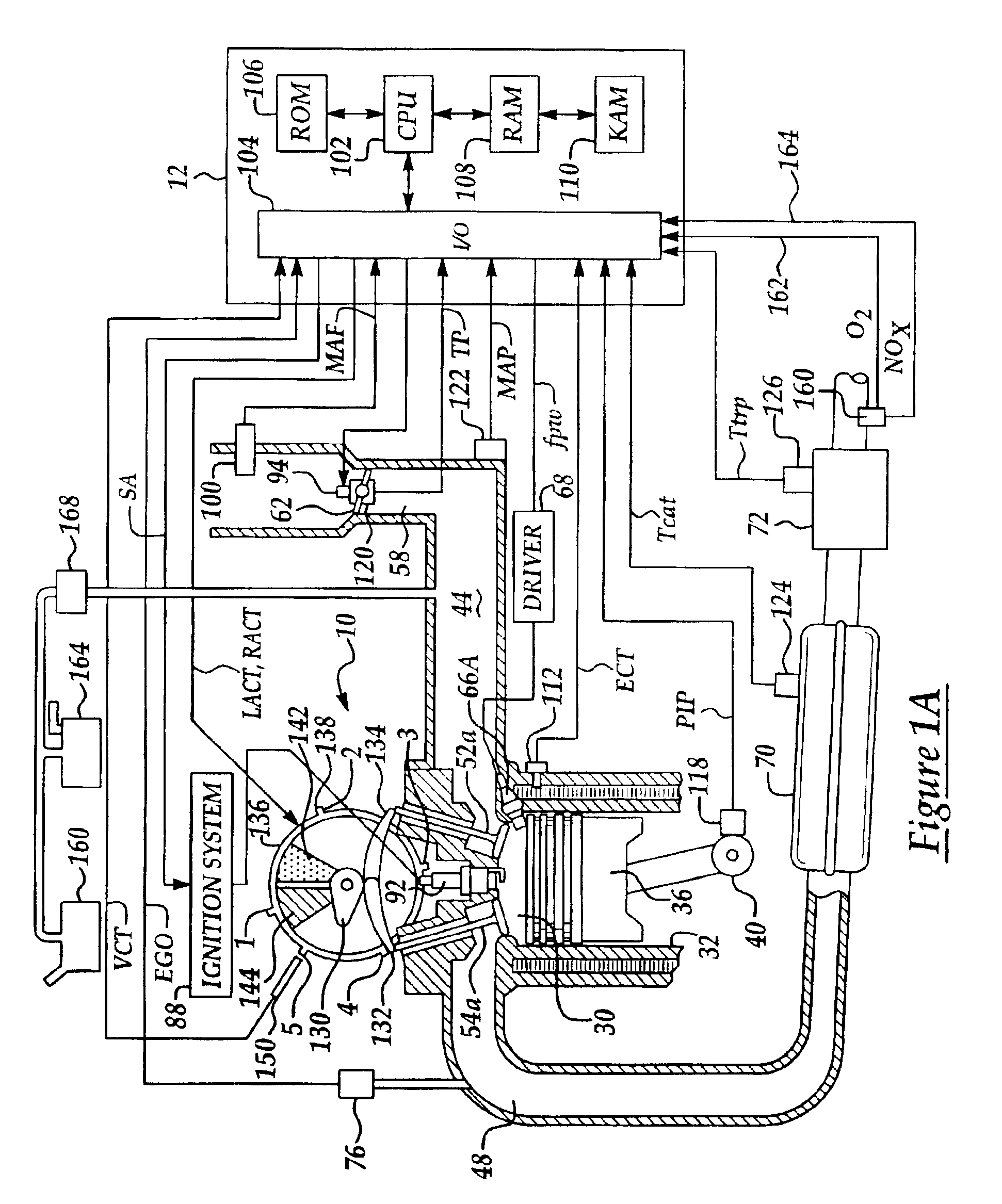

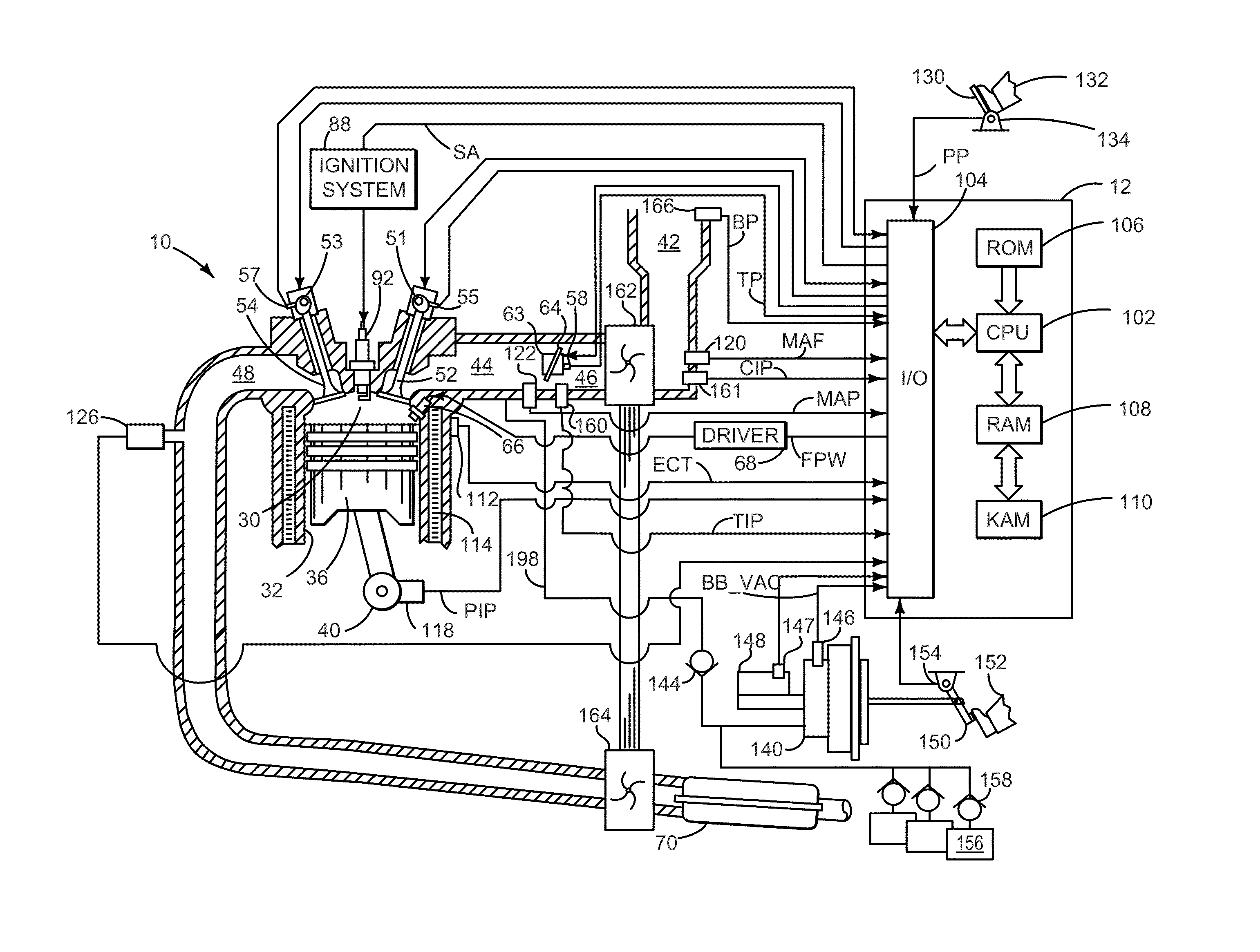

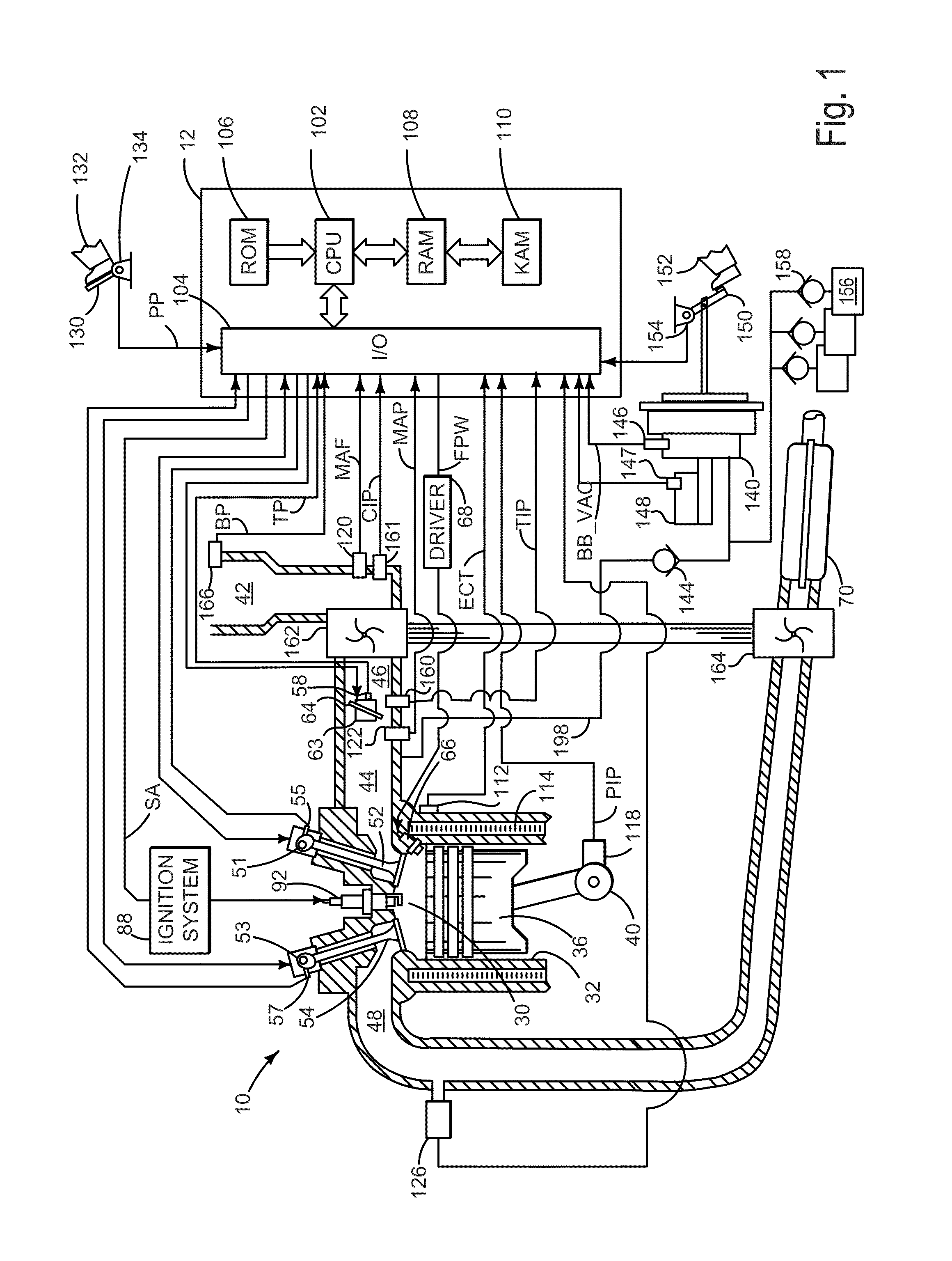

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

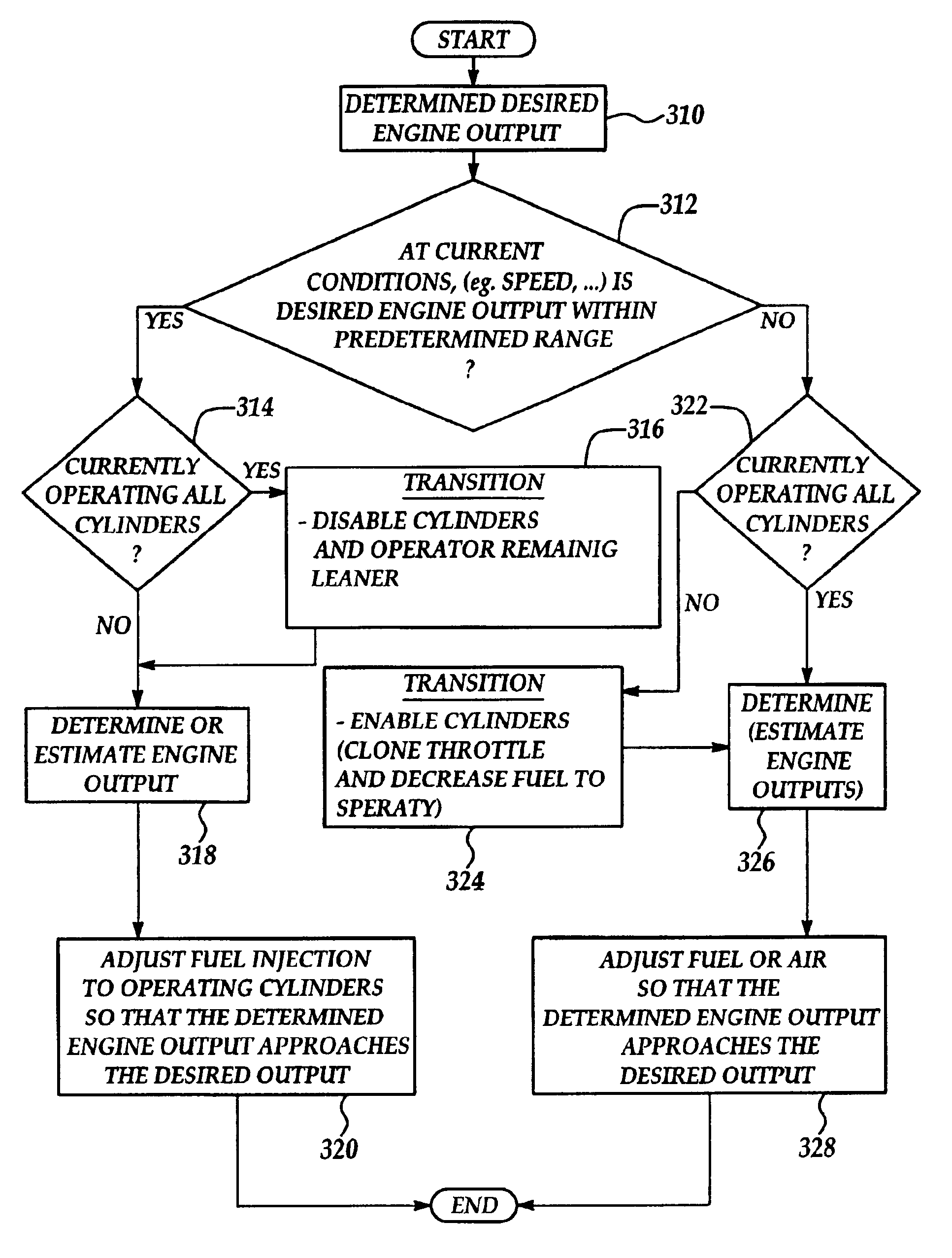

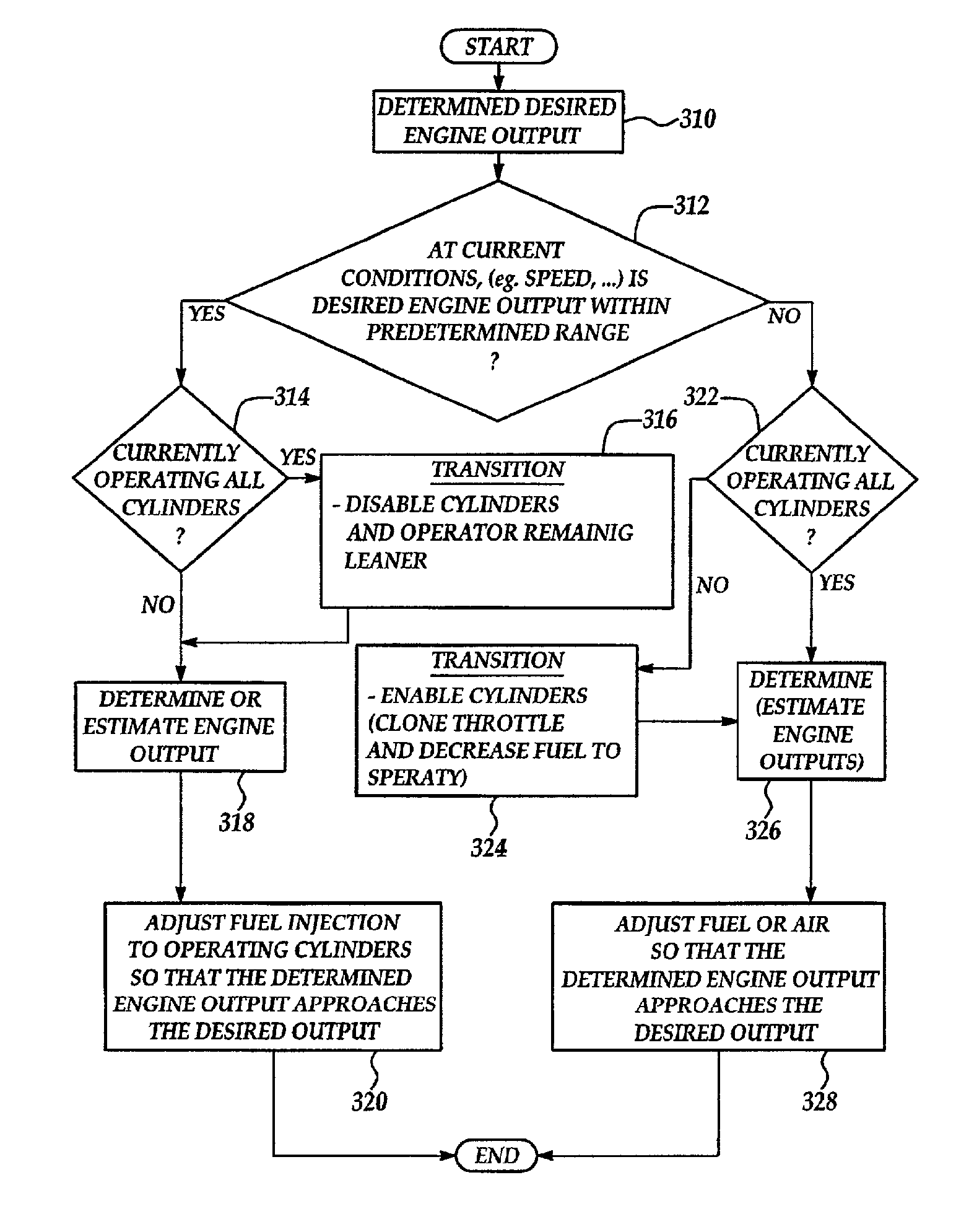

Method to control transitions between modes of operation of an engine

InactiveUS6735938B2Improve carrying capacityFuel to the remaining cylinders is rapidly increasedElectrical controlVehicle fittingsTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

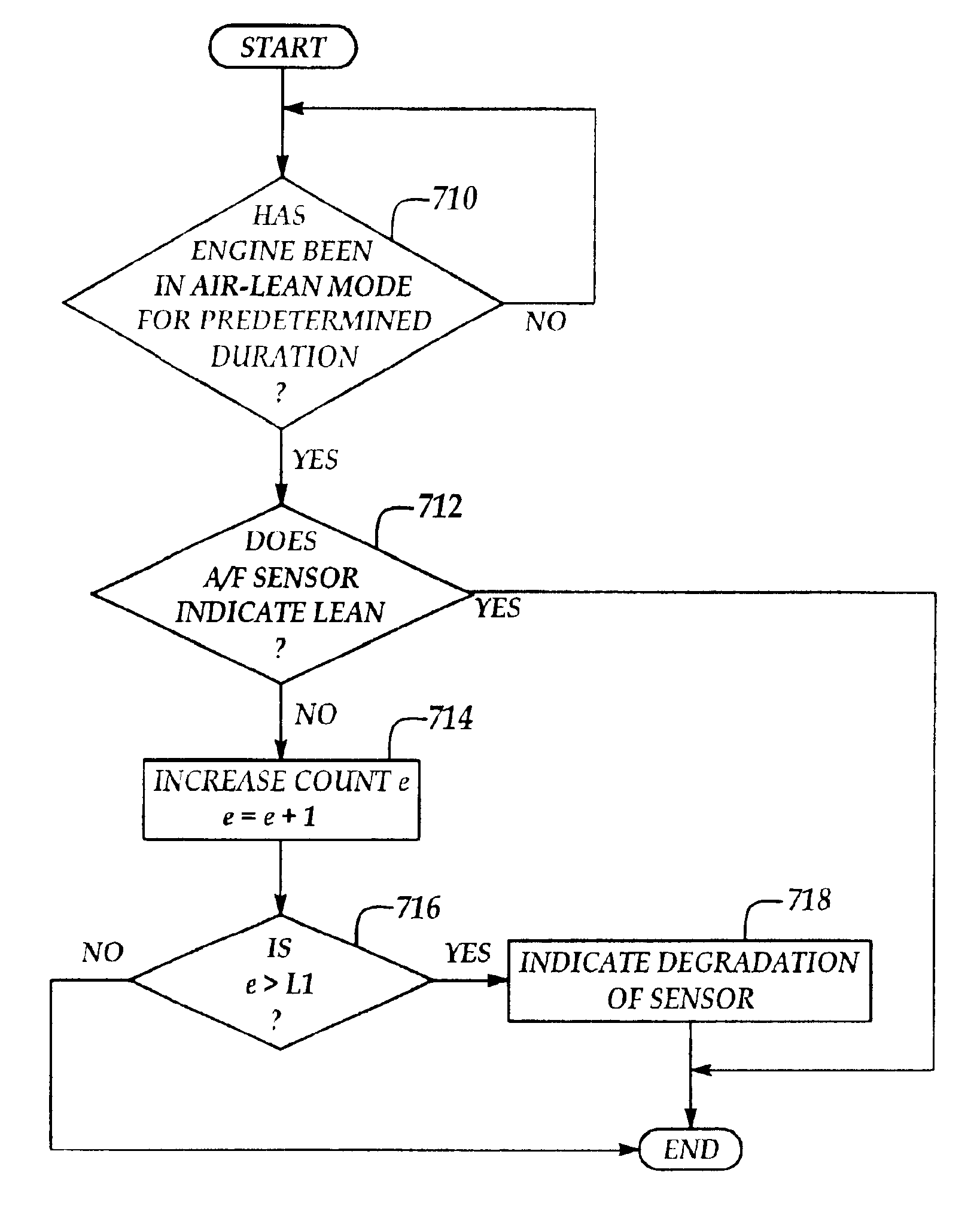

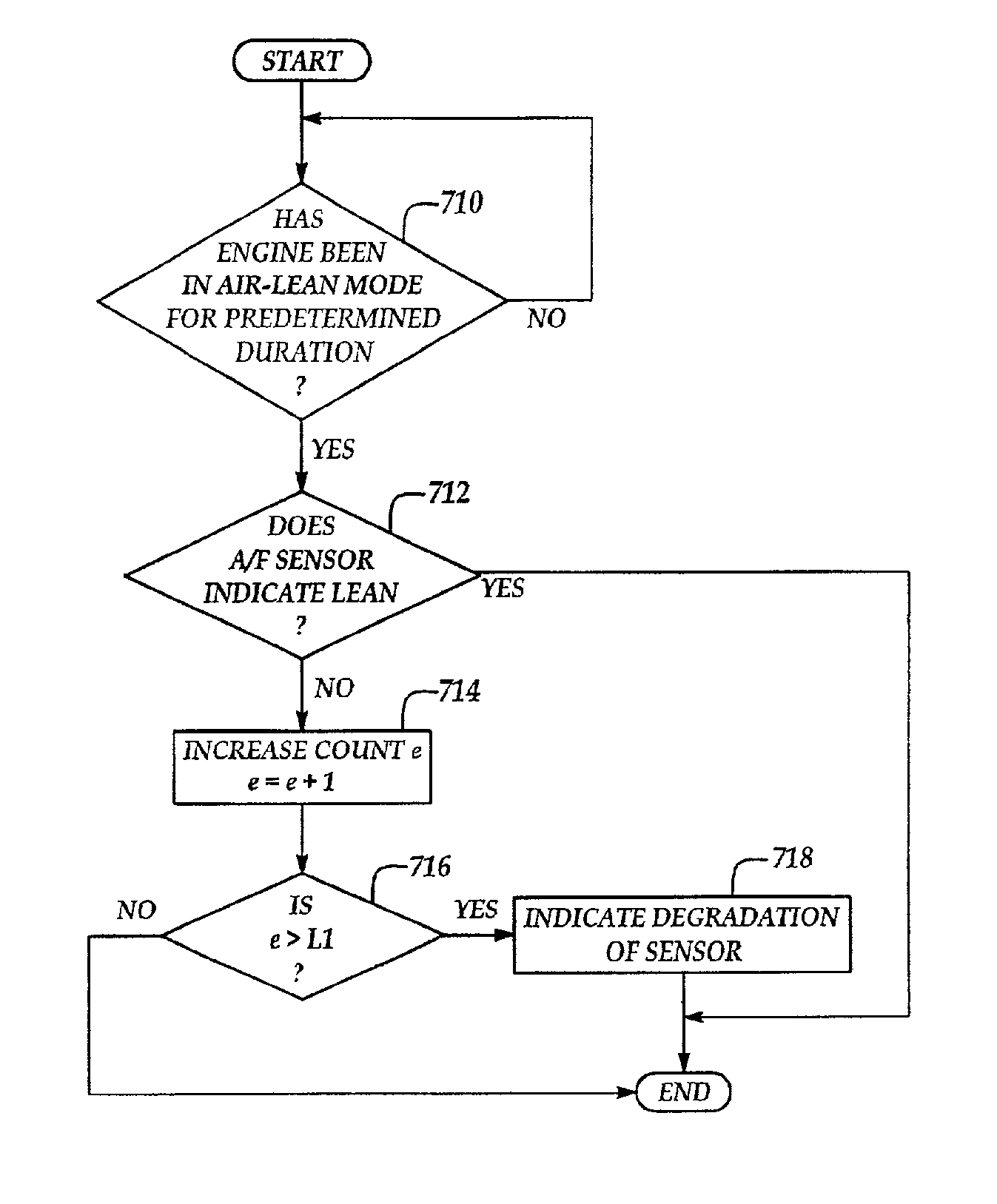

Method for air-fuel ratio sensor diagnosis

InactiveUS6736121B2Avoid false indicationsLow heat generationElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Preservation by Vaporization

ActiveUS20080229609A1Easy to controlImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsIndustrial scaleVacuum chamber

Significant research is being done to develop and improve delivery mechanisms for biopharmaceuticals and vaccines, including pulmonary (inhalation), nasal, transdermal, and oral alternatives. Market projections indicate that the delivery of proteins and vaccines by inhalation and oral formulation has become and will continue to be increasingly important. These delivery mechanisms, to be effective, will require better stabilization of the biologicals so that they can maintain potency and effectiveness at ambient temperatures for extended periods of time. The novel Preservation by Vaporization (PBV) Technology described herein provides cost-effective and efficient industrial scale stabilization of proteins, viruses, bacteria, and other sensitive biologicals, thereby allowing a production of products that are not possible to be produced by existing methods. The suggested new PBV process comprises primary drying under vacuum from a partially frozen state (i.e. slush) at near subzero temperatures followed by stability drying at elevated temperatures (i.e., above 40 degrees Celsius). The new suggested method can be performed aseptically in unit doze format (in vials) and / or in bulk format (in trays, bags, or other containers). The drying can be performed as a continuous load process in a manifold vacuum dryer comprising a plurality (e.g., 30) of vacuum chambers attached to a condenser during the drying.

Owner:UNIVERSAL STABILIZATION TECH INC

Method for split ignition timing for idle speed control of an engine

InactiveUS20030221664A1High load conditionMore ignition timingAnalogue computers for vehiclesElectrical controlTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

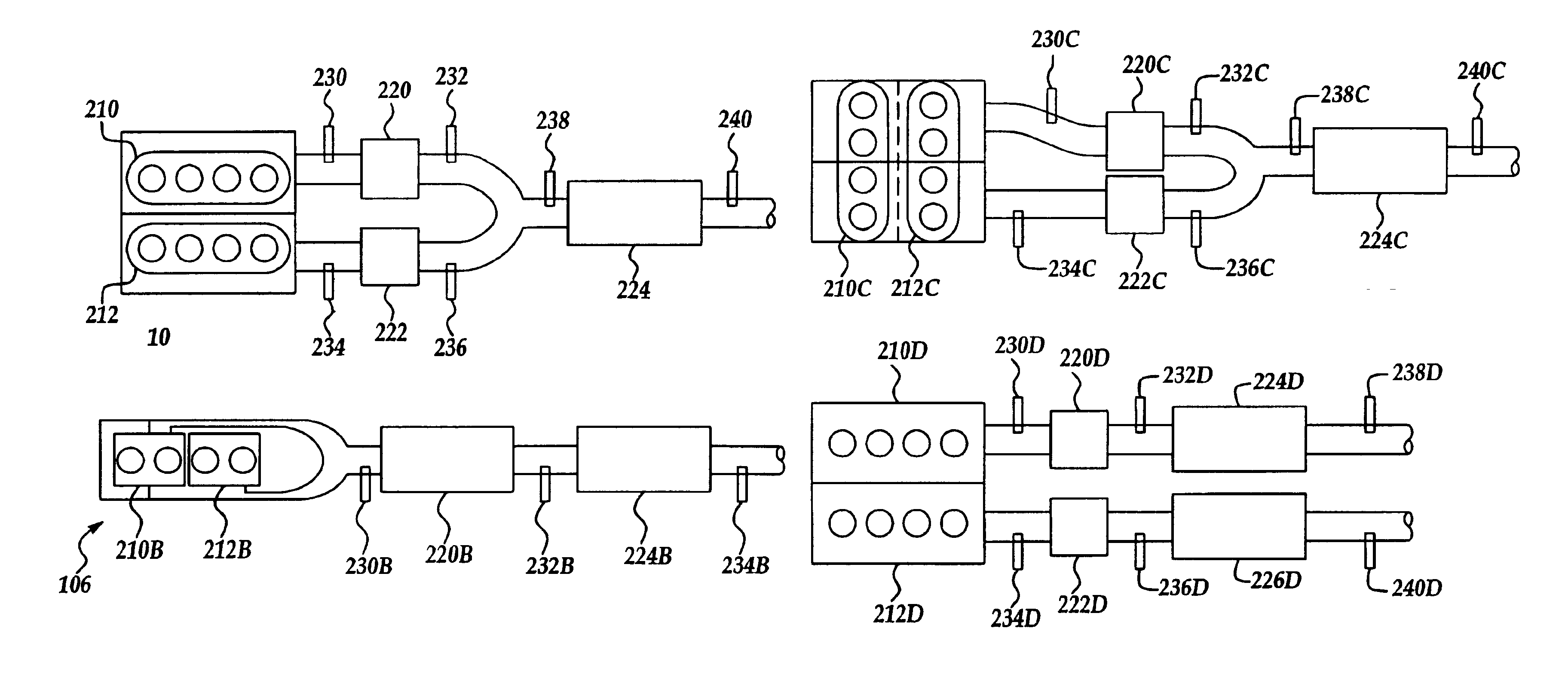

Method to improve fuel economy in lean burn engines with variable-displacement-like characteristics

InactiveUS6758185B2Easy to operateOverall engine torque fallsElectrical controlNon-fuel substance addition to fuelTemperature controlAdaptive learning

Owner:FORD GLOBAL TECH LLC

Overall scheduling of a lean burn engine system

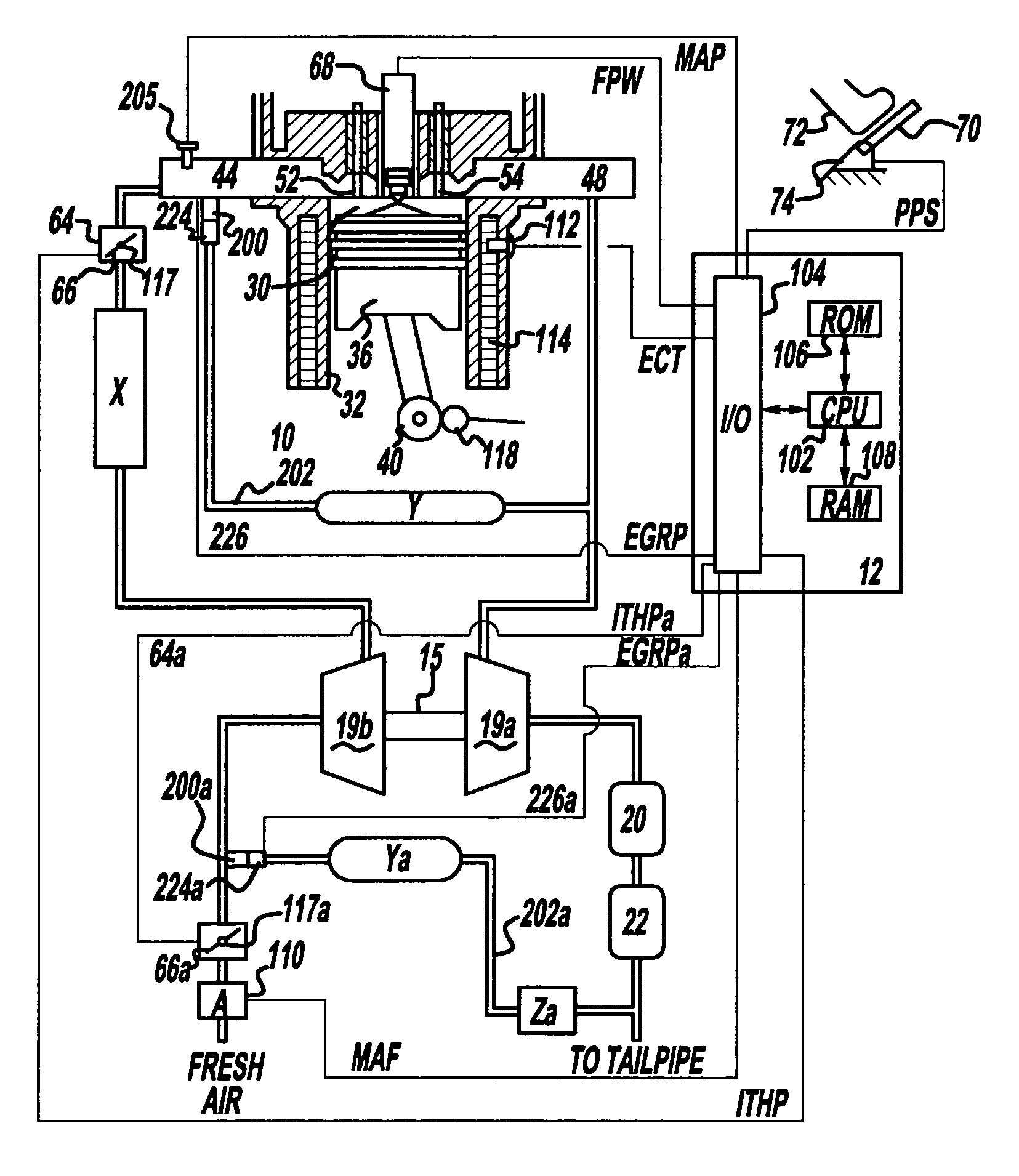

InactiveUS6691669B2Improve carrying capacityFuel to the remaining cylinders is rapidly increasedElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

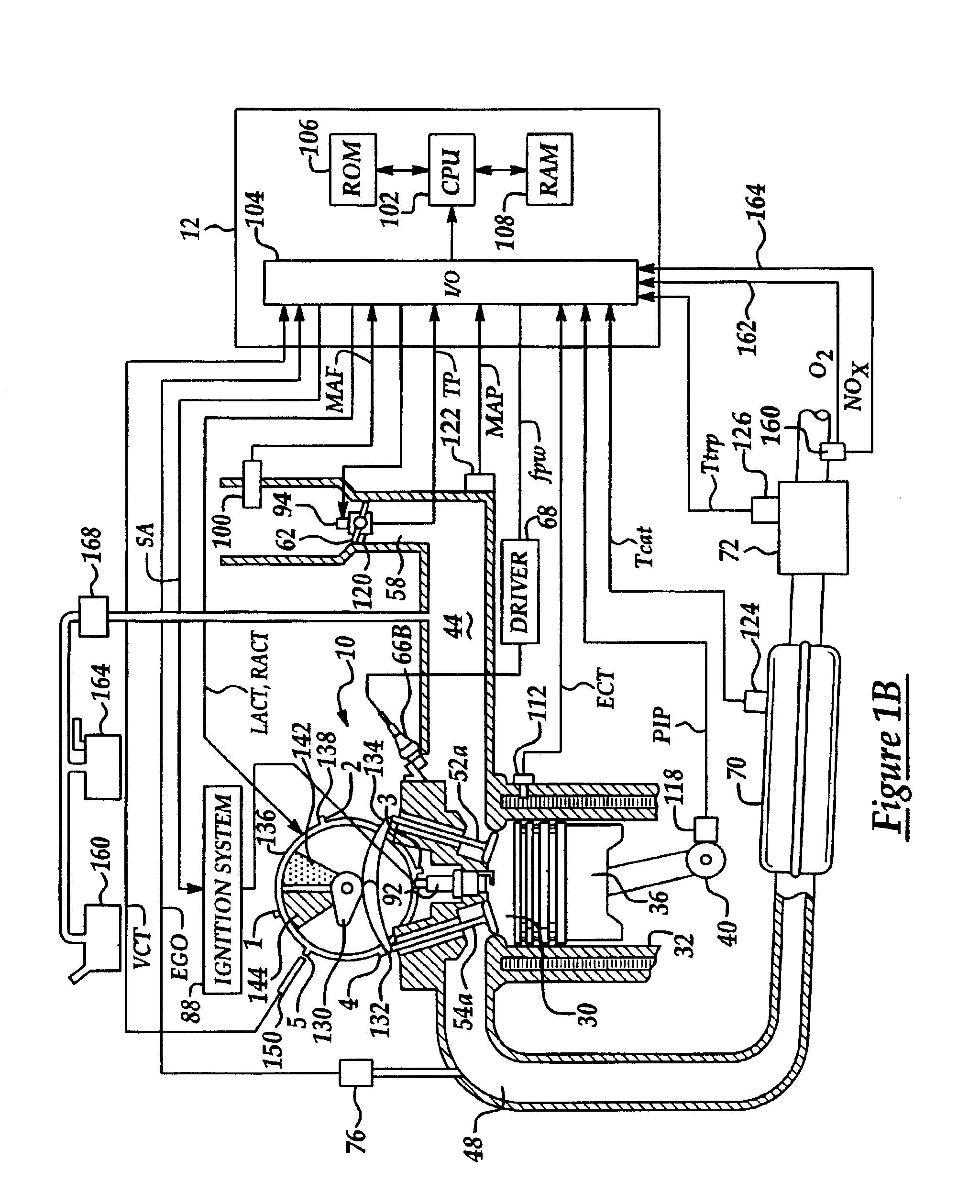

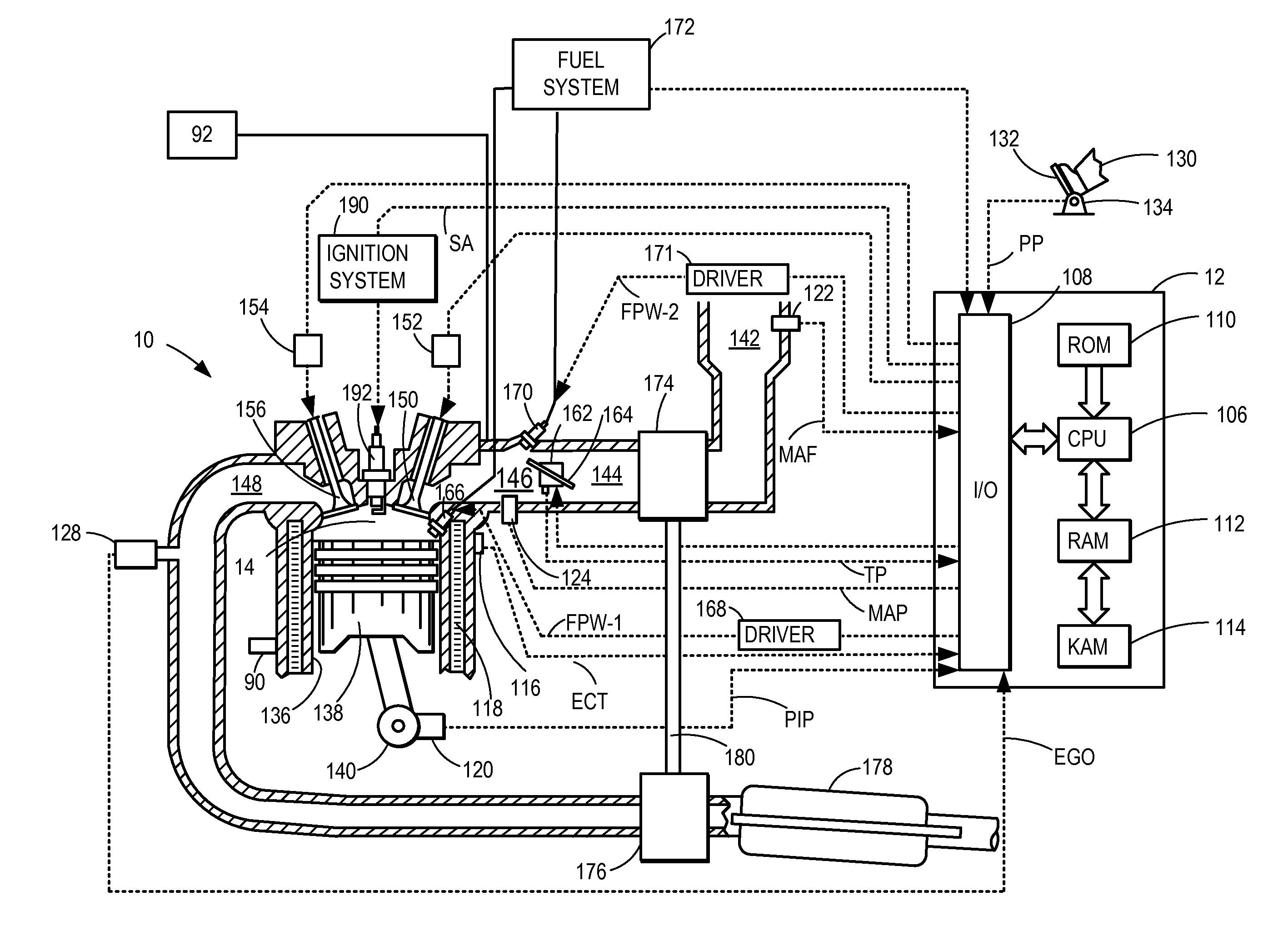

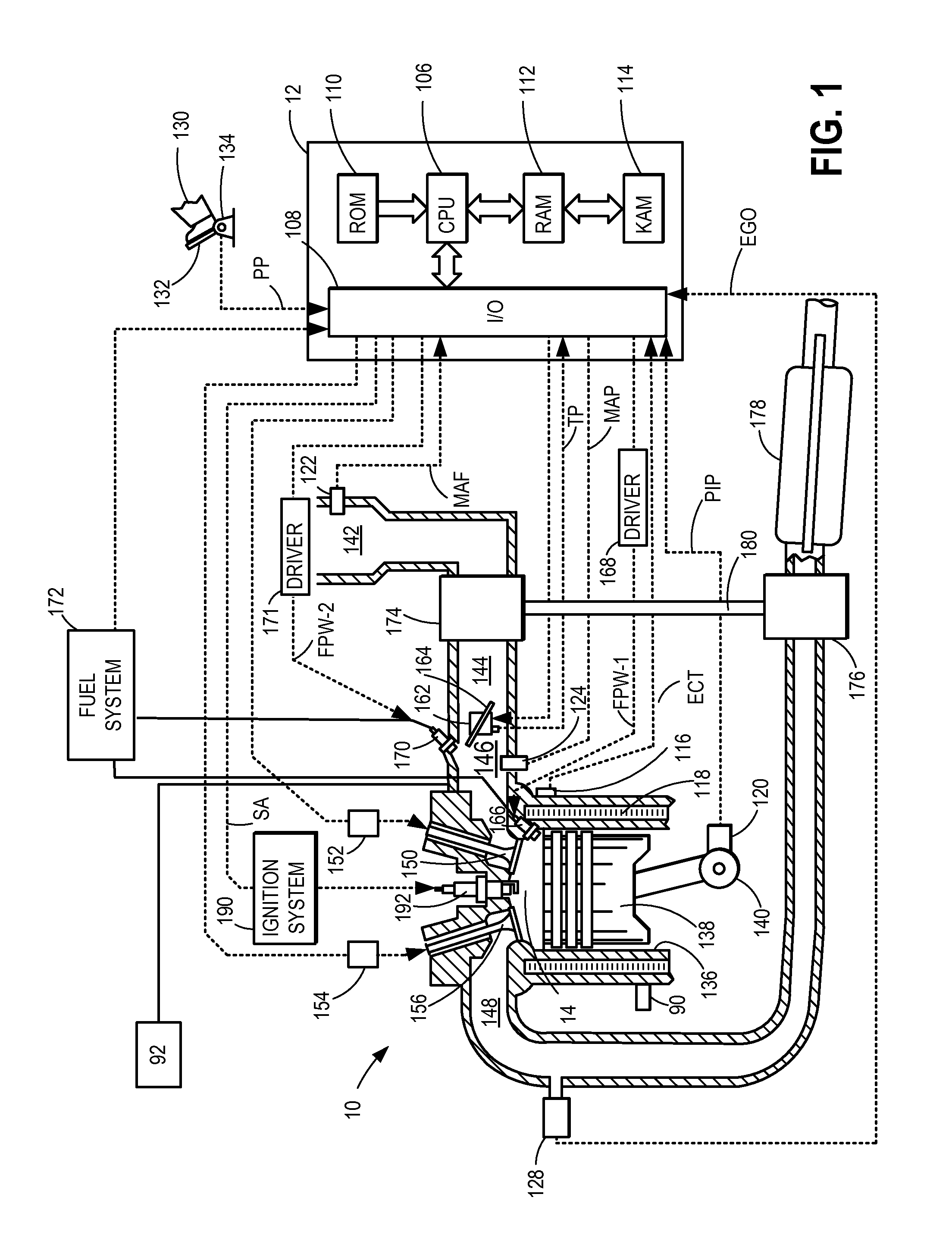

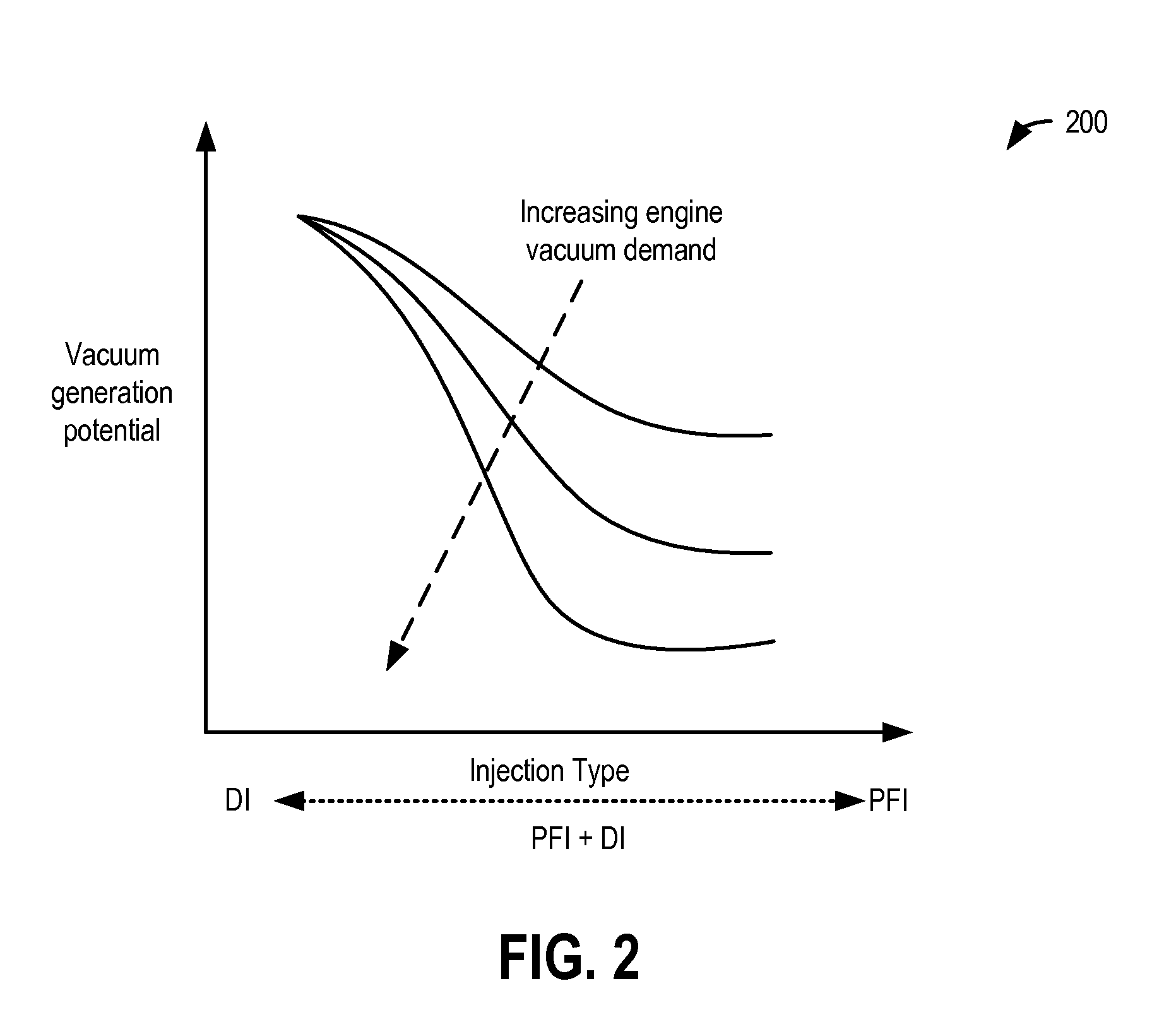

Method and system for vacuum control

ActiveUS20140261301A1Small droplet sizeImprove volumetric efficiencyElectrical controlInternal combustion piston enginesEngineeringCrankcase

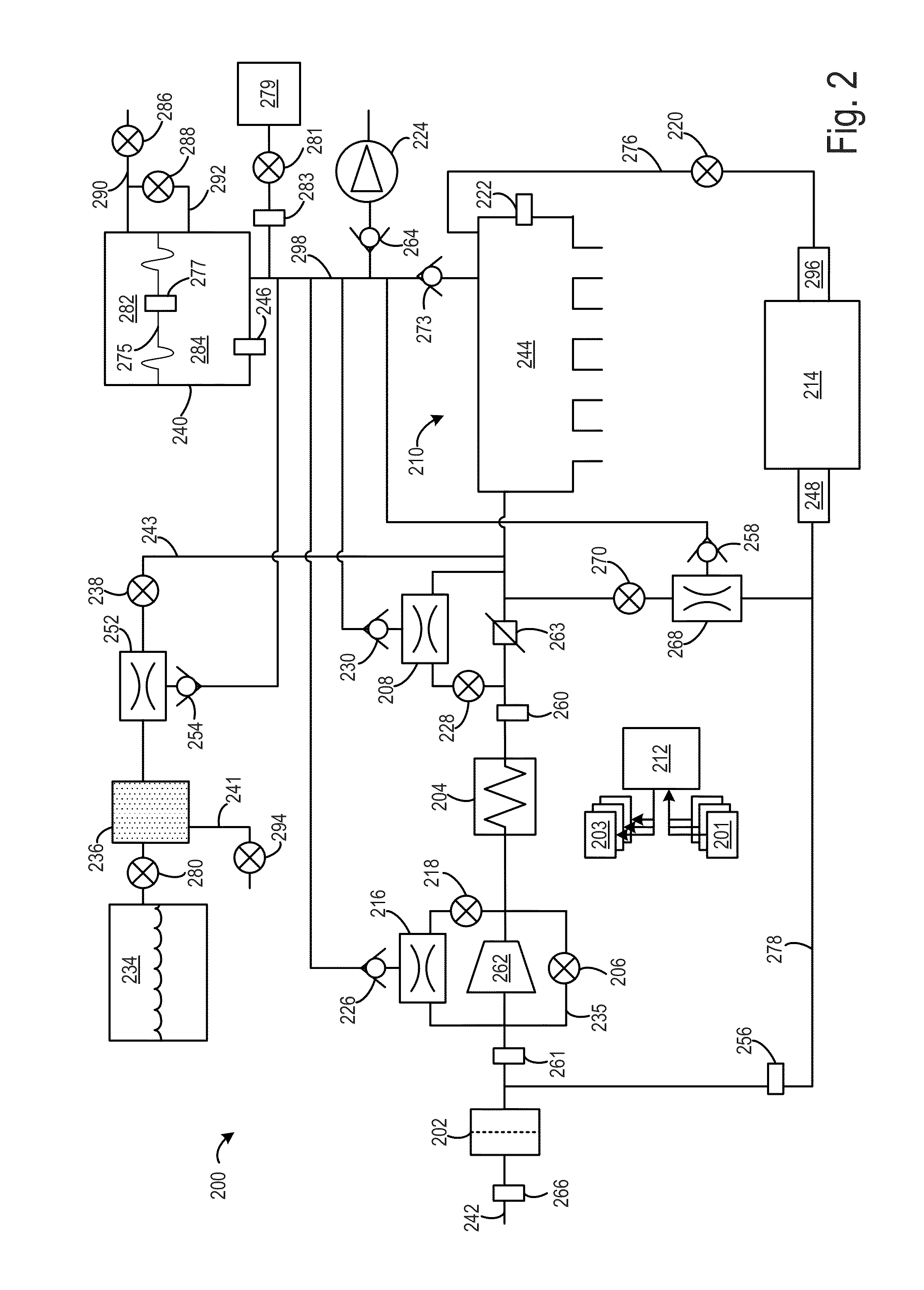

Methods and systems are provided for adjusting a fuel injection split between a direct injection and a port injection based on engine vacuum demand. When more intake manifold vacuum is required, relatively more direct injection is used to take advantage of the associated throttling for generating vacuum. The vacuum may then be used for canister purging, crankcase ventilation, or actuating an engine vacuum consumption device.

Owner:FORD GLOBAL TECH LLC

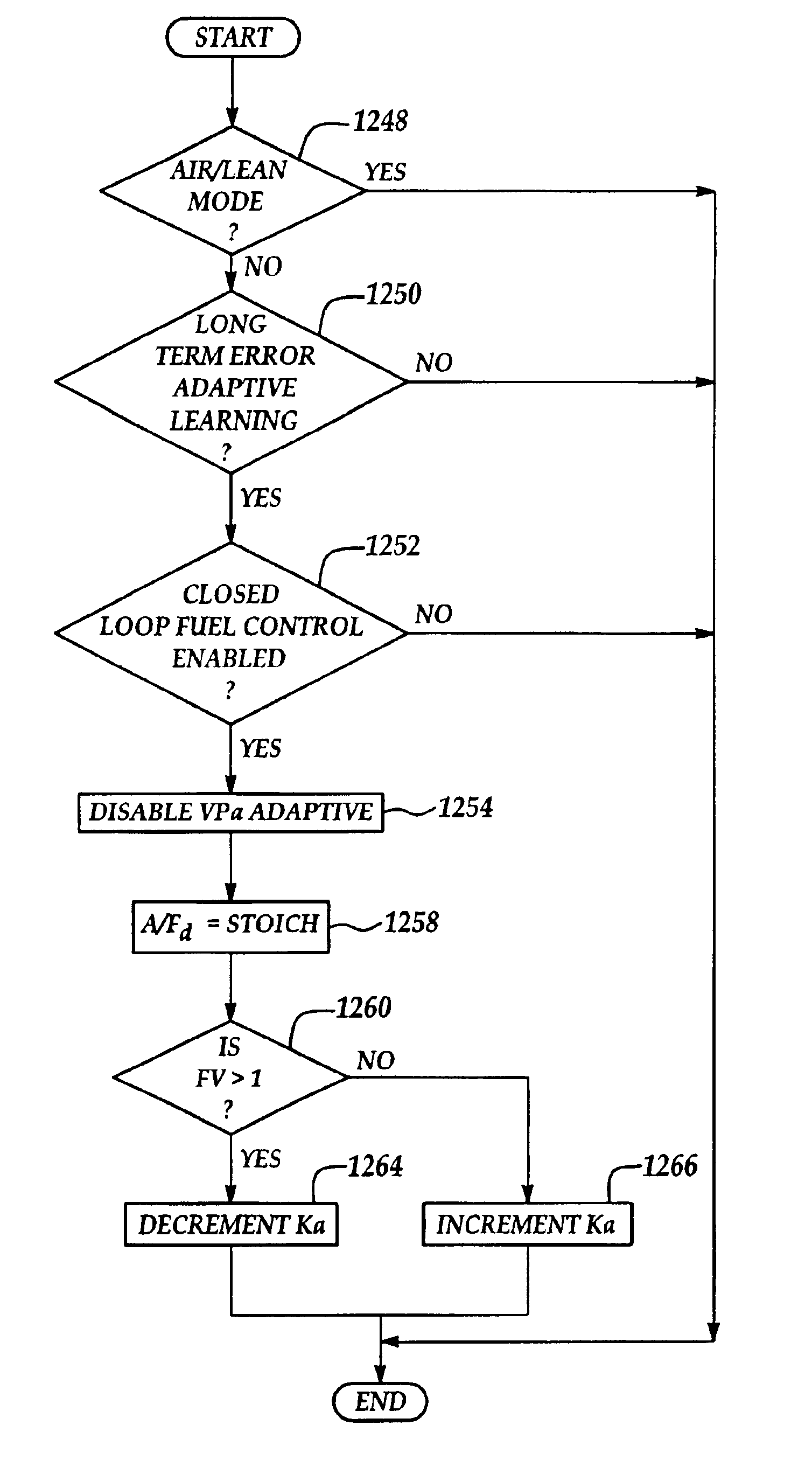

Method and system of adaptive learning for engine exhaust gas sensors

InactiveUS6736120B2Accurate operationLow heat generationElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method to improve fuel economy in lean burn engines with variable-displacement-like characteristics

InactiveUS20030221655A1Accurate air-fuel ratioIncrease in temperature of catalystElectrical controlNon-fuel substance addition to fuelTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method to control fuel vapor purging

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method for controlling the temperature of an emission control device

InactiveUS7111450B2Increase temperatureElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method to control transitions between modes of operation of an engine

InactiveUS20030224907A1Small torqueIncrease loadElectrical controlVehicle fittingsTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Overall scheduling of a lean burn engine system

InactiveUS20030221659A1Efficient engine operationElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Overall scheduling of a lean burn engine system

InactiveUS20030221660A1Improve carrying capacityFuel to the remaining cylinders is rapidly increasedElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method for rapid catalyst heating

InactiveUS20030221418A1Heating fastSolve excessive vibrationElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

Owner:FORD GLOBAL TECH LLC

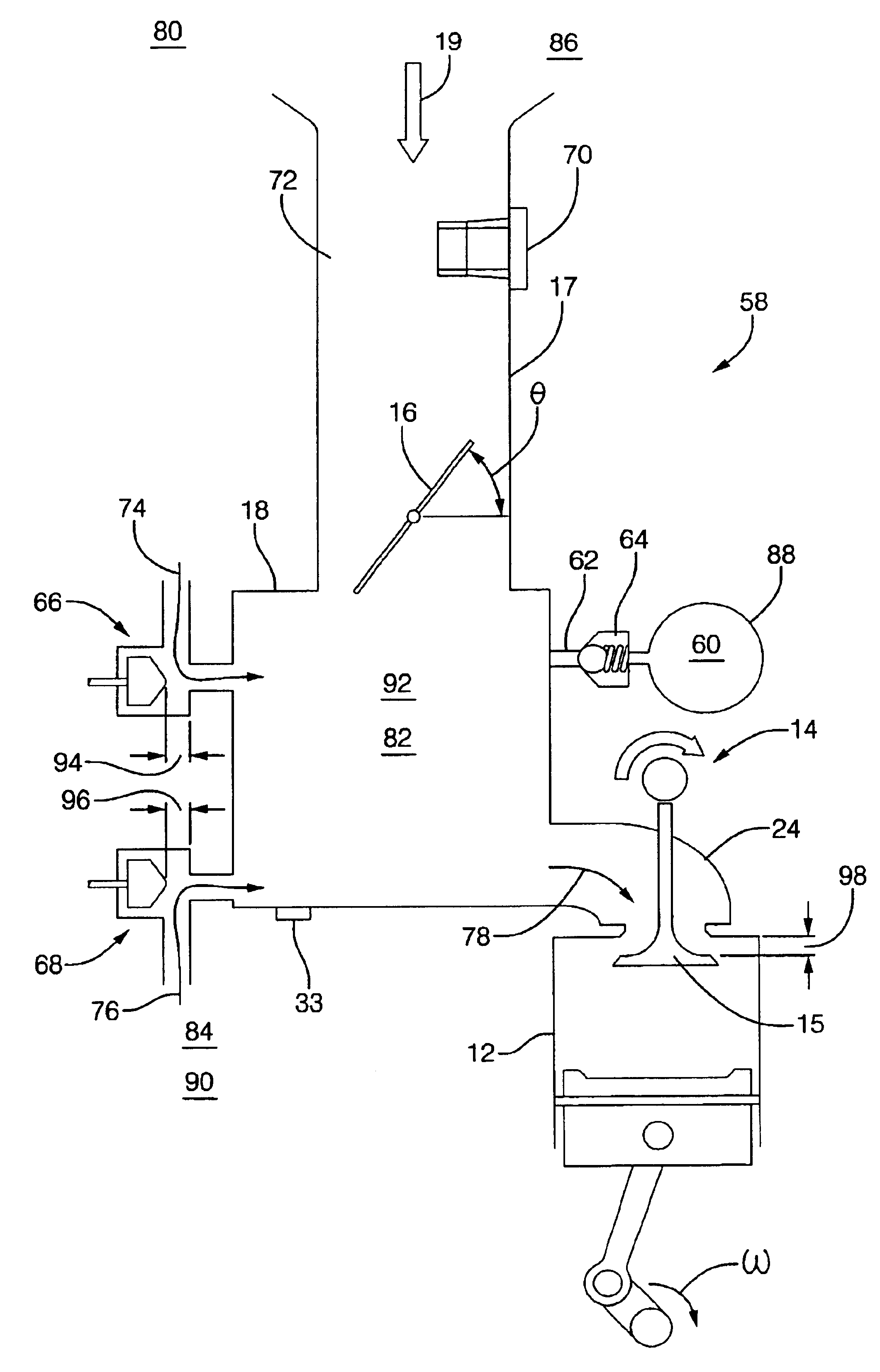

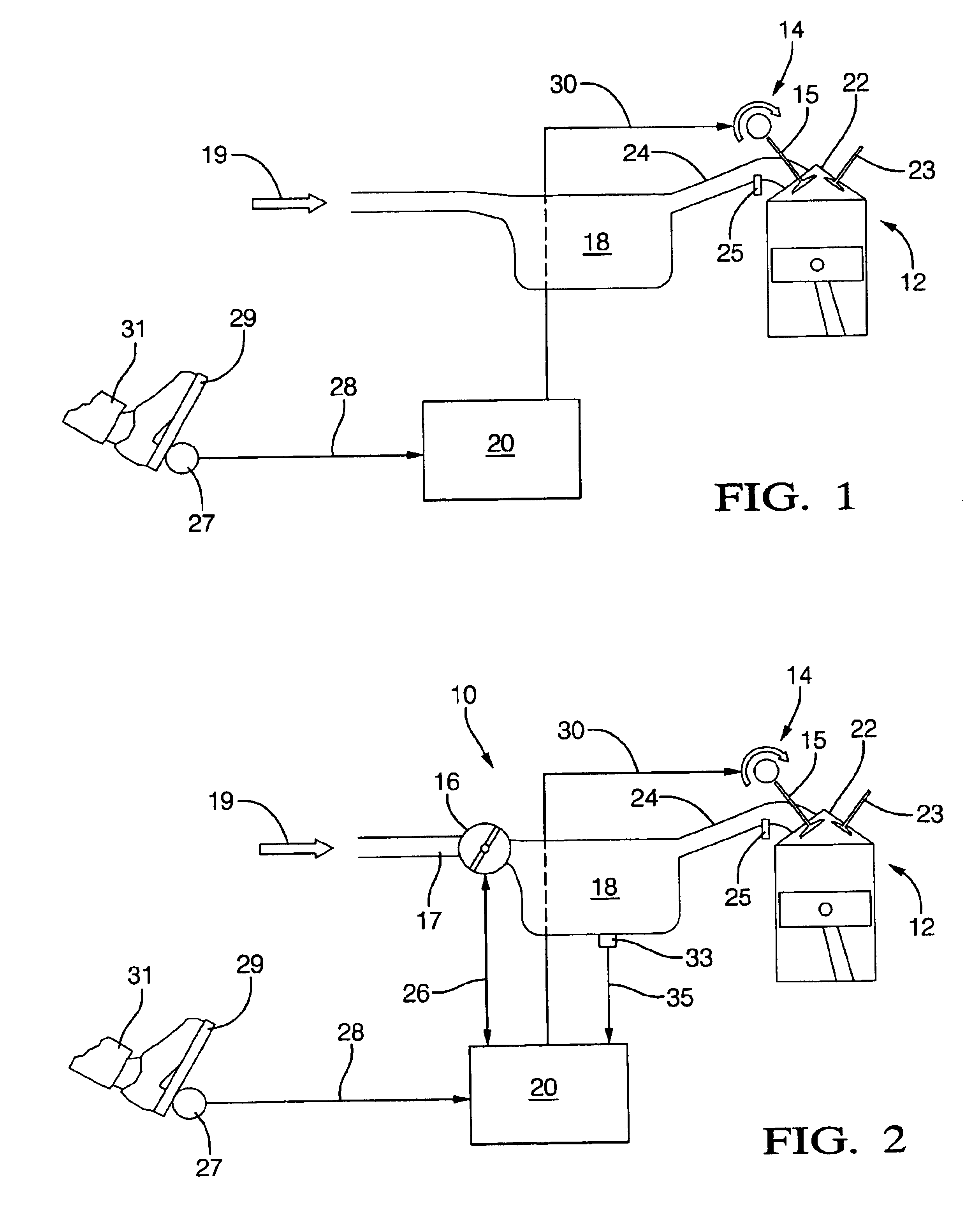

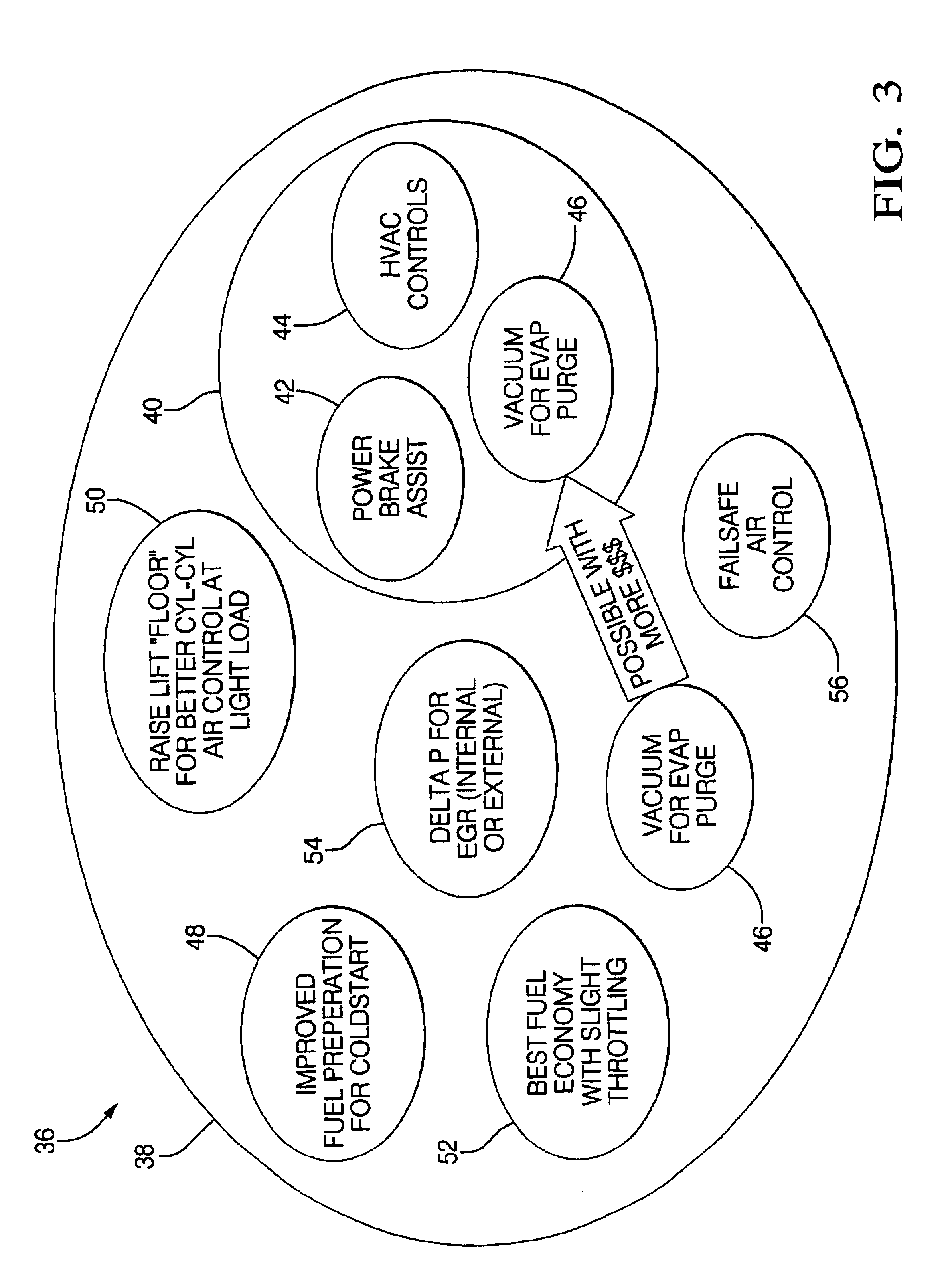

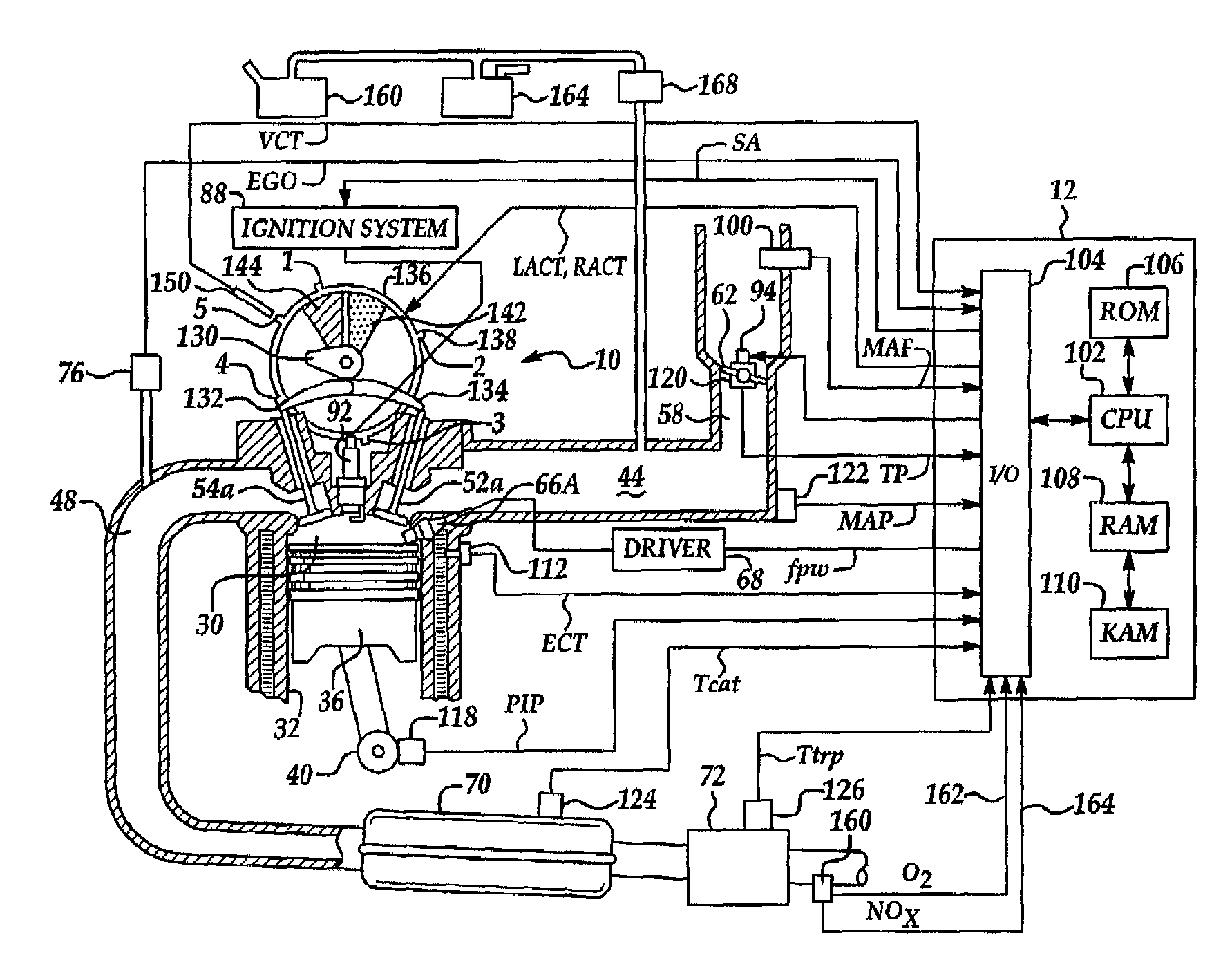

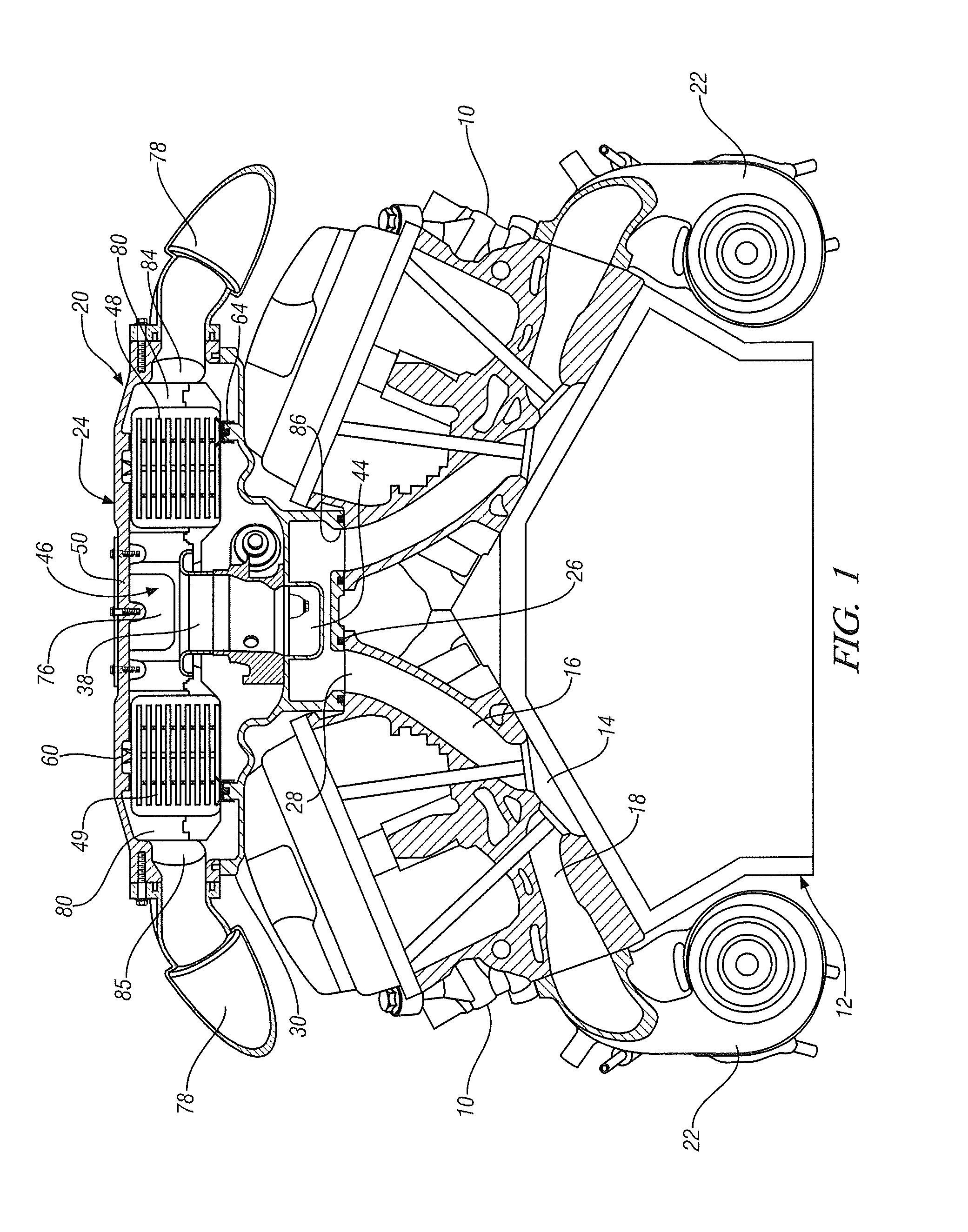

Vacuum management system for engine with variable valve lift

InactiveUS6866020B2Improve fuel economyNon-fuel substance addition to fuelInternal combustion piston enginesVacuum assistedVariable valve timing

A vacuum management system for an engine with variable valve lift includes a vacuum control valve at the entrance to the intake manifold to increase vacuum within the manifold as needed and preferably only when it can be done without impairing fuel economy or engine performance. Vacuum may then be used for any of various vacuum-assisted devices and functions, for example, boosting a vehicle braking system. The numerical relationships among important operating parameters are determined in a laboratory, and a programmable engine control module (ECM} is provided with algorithms and tables of such values by which the ECM is able to vary valve lift and vacuum control valve position to provide optimum flow across the intake valves and optimum manifold vacuum under all engine operating conditions.

Owner:DELPHI TECH INC

Preservation by vaporization

ActiveUS9469835B2Maximize potencyMaximize viabilityBioreactor/fermenter combinationsBiological substance pretreatmentsIndustrial scaleVacuum chamber

Significant research is being done to develop and improve delivery mechanisms for biopharmaceuticals and vaccines, including pulmonary (inhalation), nasal, transdermal, and oral alternatives. Market projections indicate that the delivery of proteins and vaccines by inhalation and oral formulation has become and will continue to be increasingly important. These delivery mechanisms, to be effective, will require better stabilization of the biologicals so that they can maintain potency and effectiveness at ambient temperatures for extended periods of time. The novel Preservation by Vaporization (PBV) Technology described herein provides cost-effective and efficient industrial scale stabilization of proteins, viruses, bacteria, and other sensitive biologicals, thereby allowing a production of products that are not possible to be produced by existing methods. The suggested new PBV process comprises primary drying under vacuum from a partially frozen state (i.e. slush) at near subzero temperatures followed by stability drying at elevated temperatures (i.e., above 40 degrees Celsius). The new suggested method can be performed aseptically in unit doze format (in vials) and / or in bulk format (in trays, bags, or other containers). The drying can be performed as a continuous load process in a manifold vacuum dryer comprising a plurality (e.g., 30) of vacuum chambers attached to a condenser during the drying.

Owner:UNIVERSAL STABILIZATION TECH INC

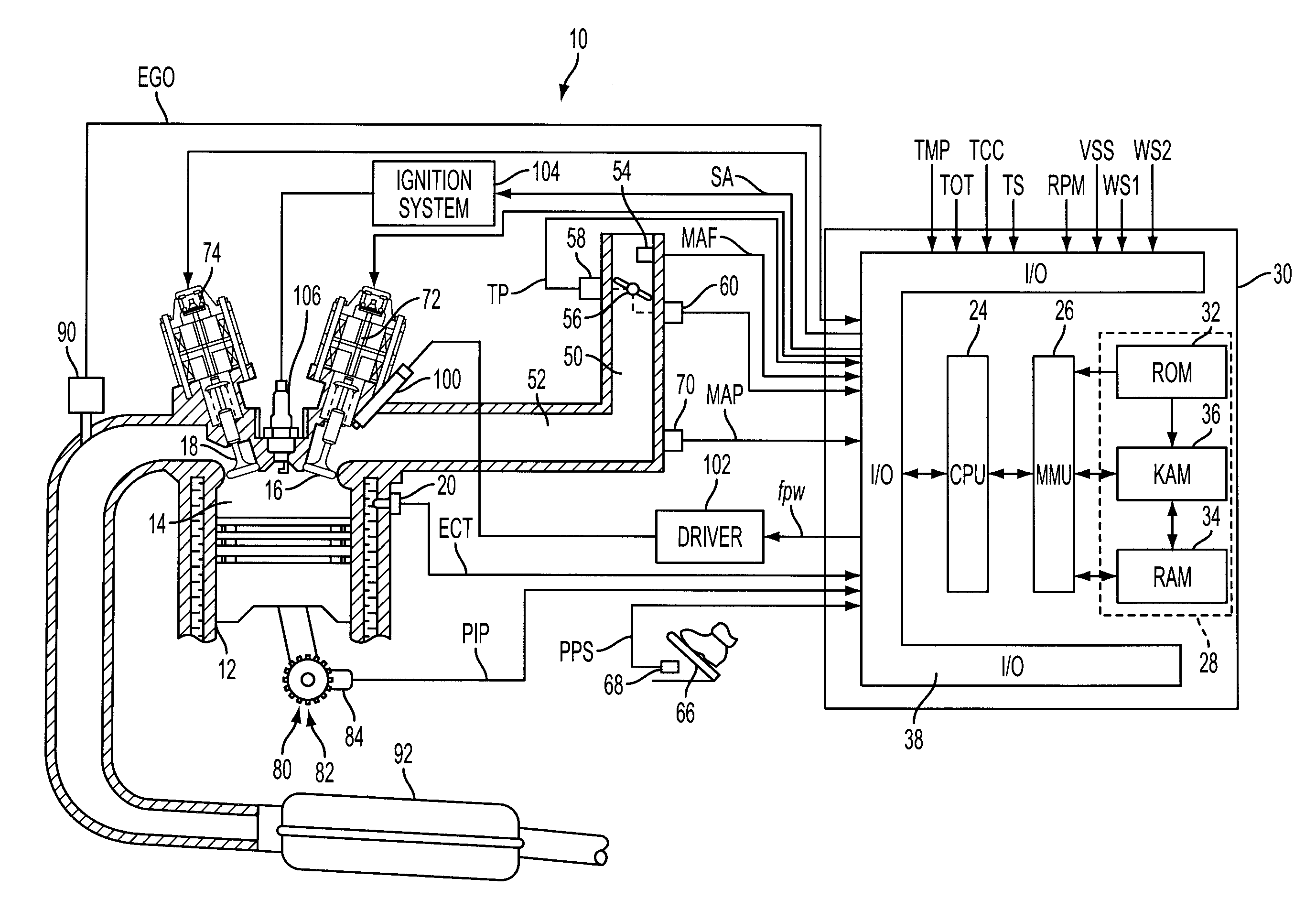

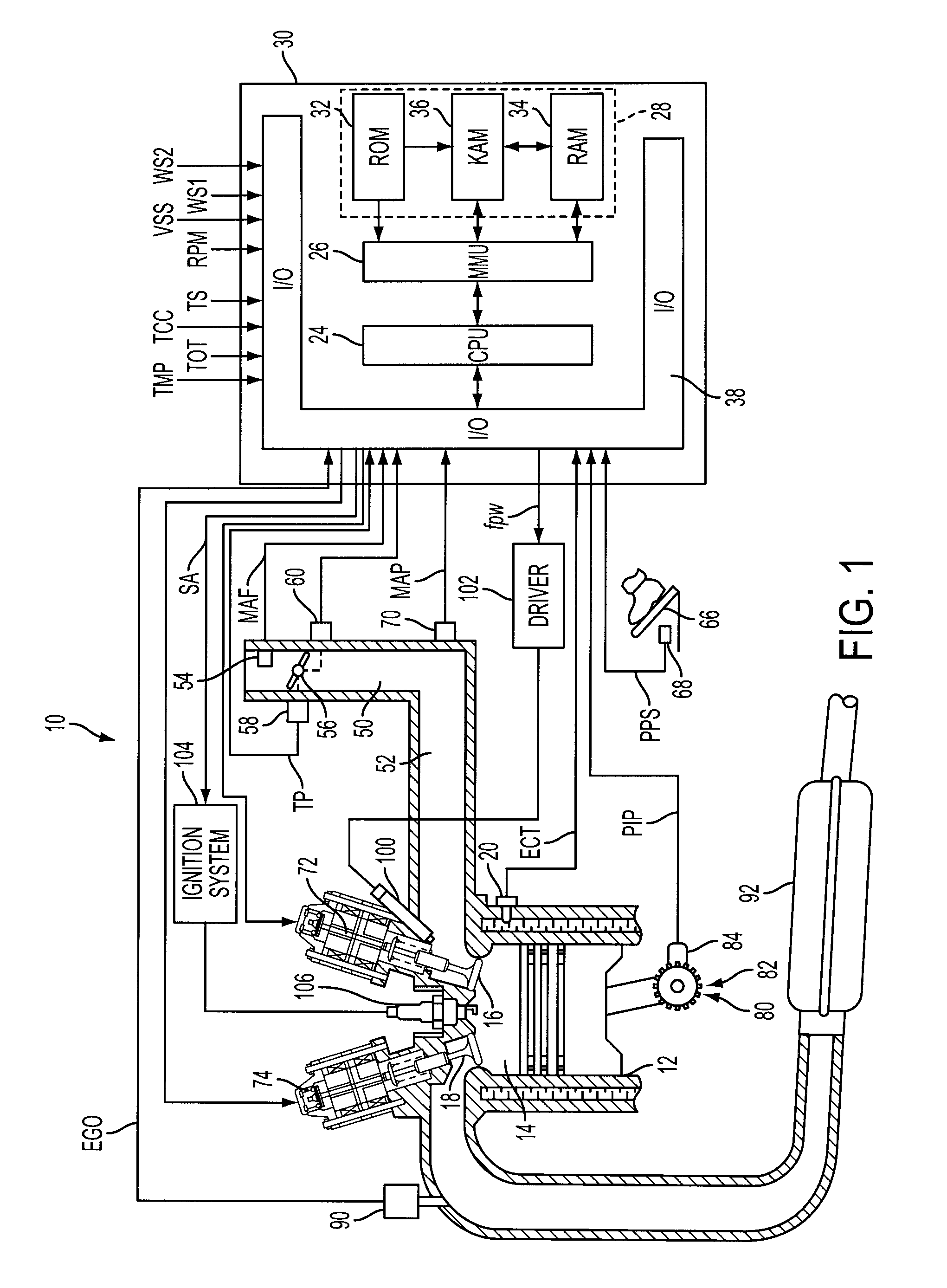

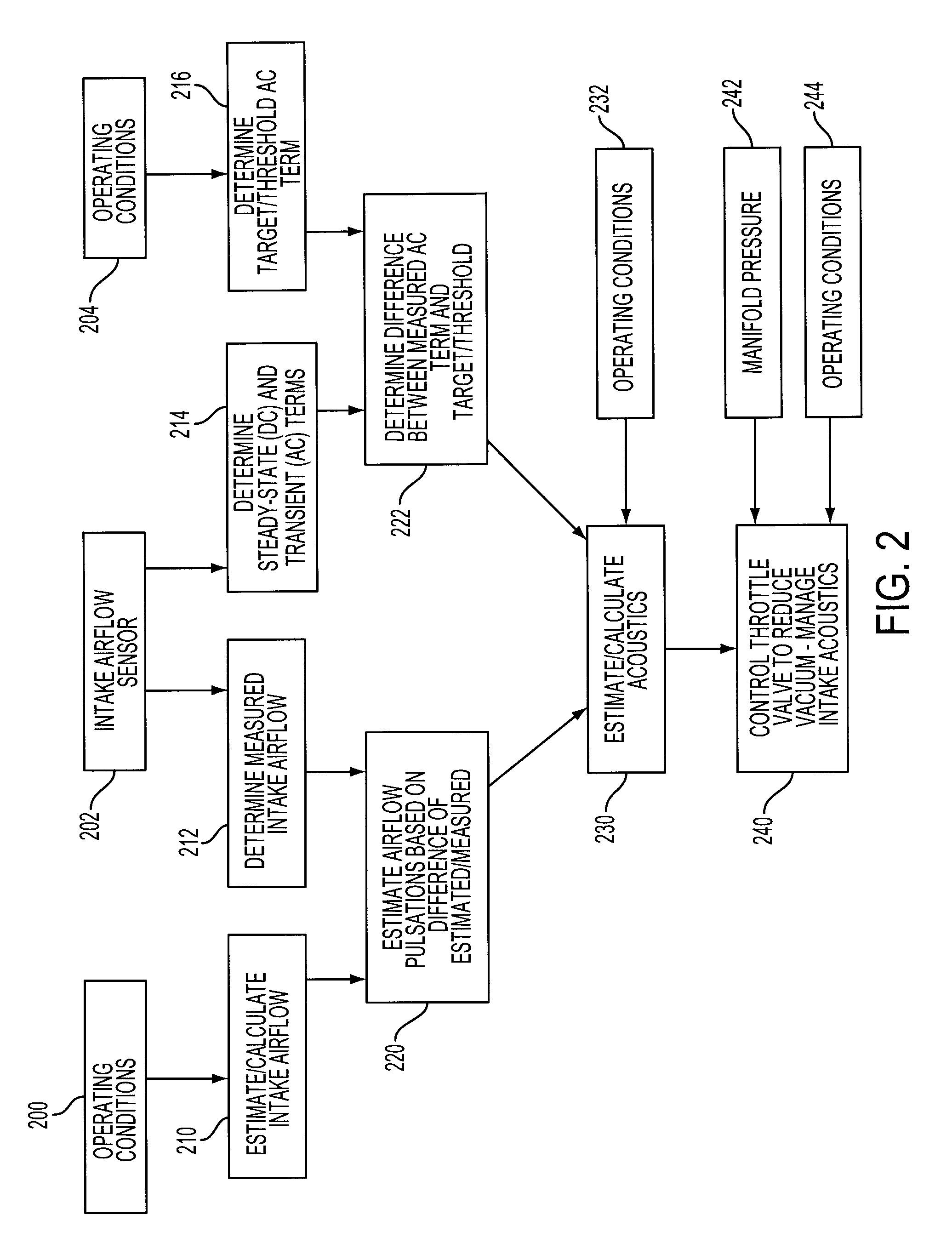

Induction air acoustics management for internal combustion engine

InactiveUS20080066699A1Increase intake vacuumReduce intake noiseInternal combustion piston enginesOutput powerExhaust valveExternal combustion engine

A system and method for controlling an internal combustion engine control an actuator in response to variations of intake airflow relative to an average intake airflow to manage induction acoustics. The system and method may include controlling an actuator, such as a throttle valve, to increase intake manifold vacuum in response to intake airflow. In an engine having electronically actuated intake and / or exhaust valves, intake airflow is estimated based on at least engine speed and valve timing and compared to a measured intake airflow to determine a first difference. The measured airflow is divided into a steady-state and transient term or component with a second difference determined based on the transient component and a target value. Throttle valve position is selectively controlled to increase vacuum in response to a combination of the first and second difference to manage induction acoustics.

Owner:FORD GLOBAL TECH LLC

Method for controlling an engine to obtain rapid catalyst heating

InactiveUS7032572B2Analogue computers for vehiclesElectrical controlTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method for controlling the temperature of an emission control device

InactiveUS20030221419A1Small torqueIncrease loadElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

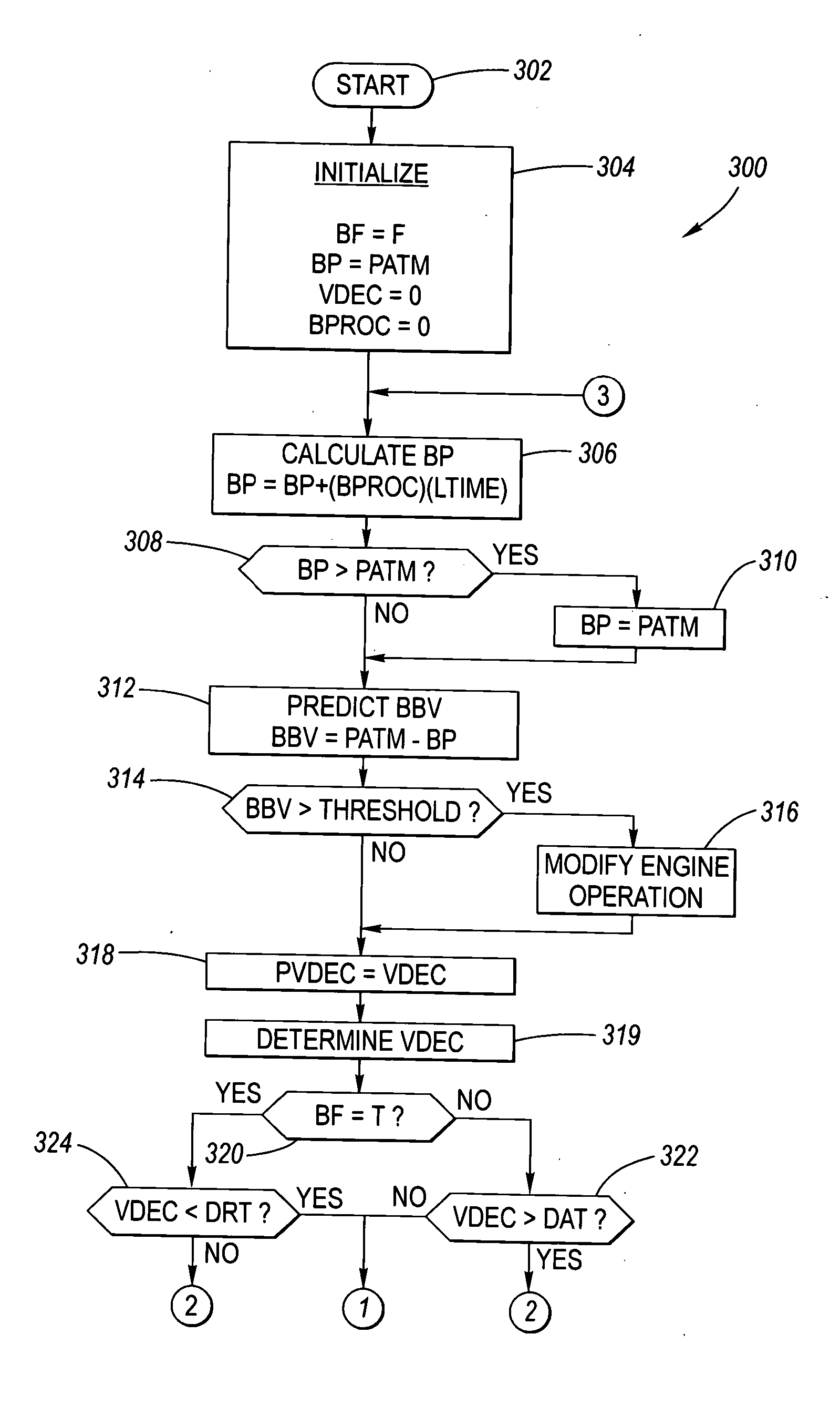

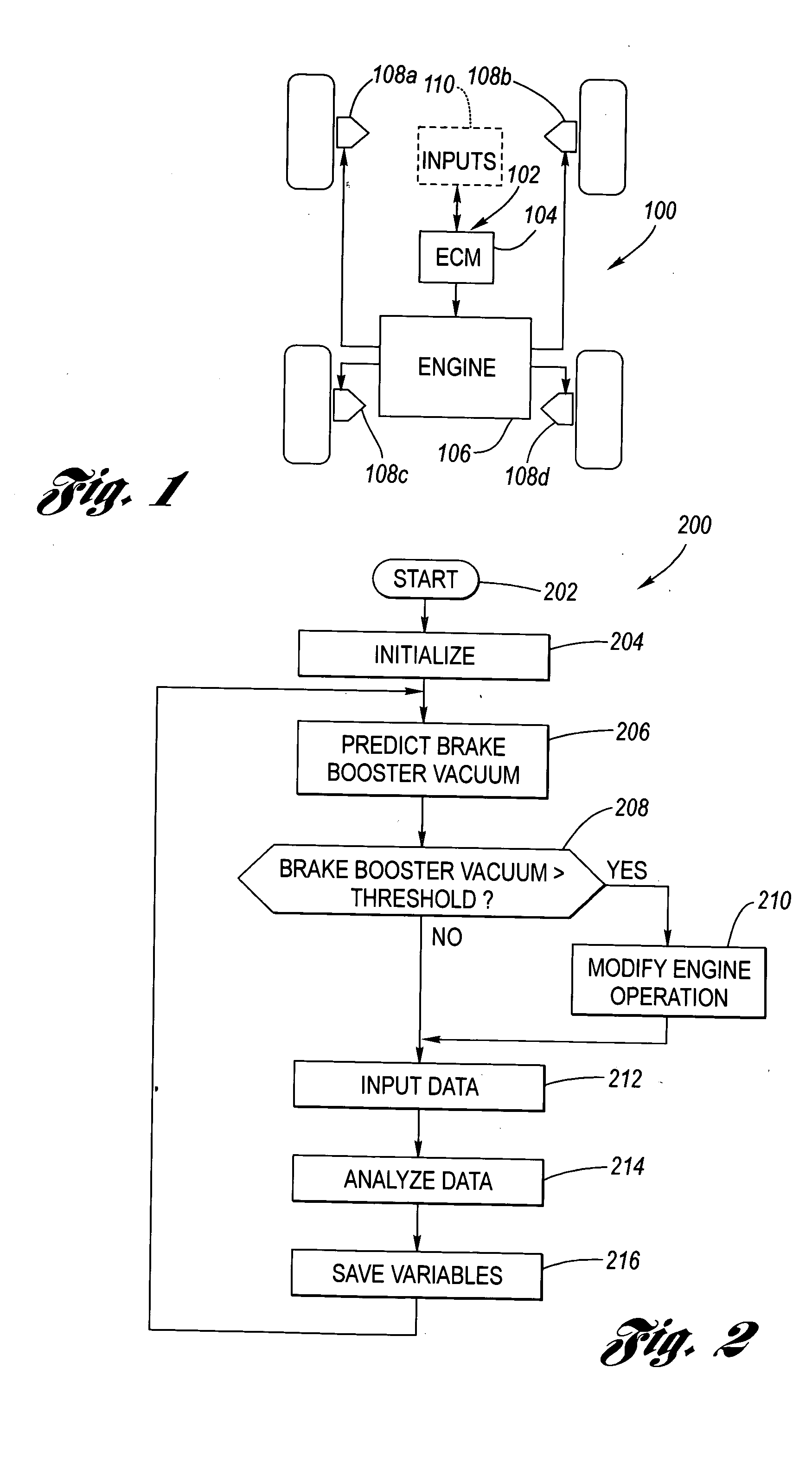

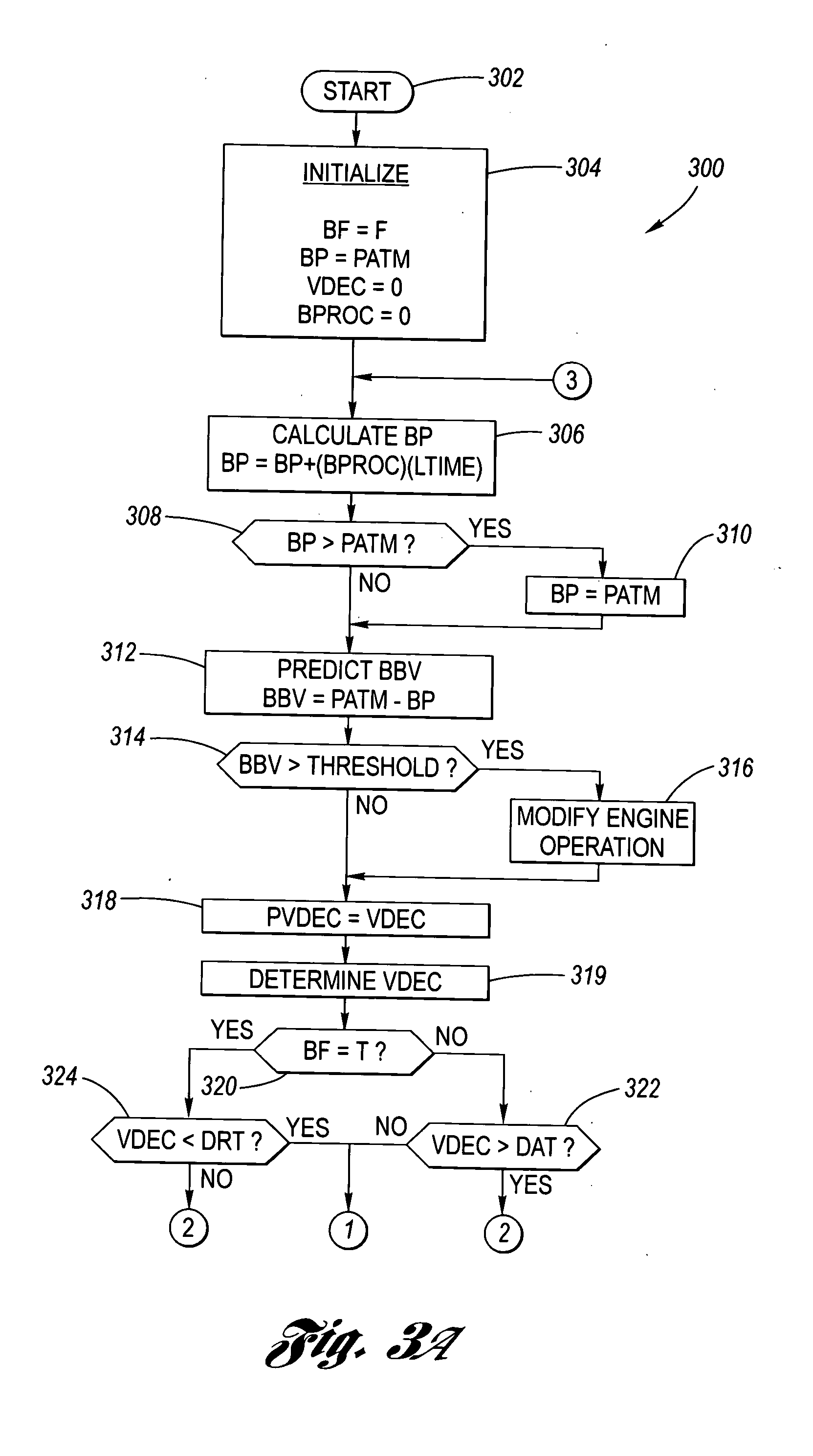

Brake booster vacuum prediction algorithm and method of use therefor

InactiveUS20050218716A1Improve intake manifold vacuumElectrical controlBraking action transmissionPrediction algorithmsMotorized vehicle

An algorithm residing in, for example the ECM of a motor vehicle, which predicts brake booster vacuum for vehicles using vacuum for brake pedal assist. The predicted brake booster vacuum is compared to a calibrated brake booster vacuum threshold to determine if adequate brake booster vacuum is available to meet vehicle braking requirements, whereupon engine operation can be modified, as necessary, to improve intake manifold vacuum such that brake booster vacuum requirements for vehicle braking are better satisfied.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and system of adaptive learning for engine exhaust gas sensors

InactiveUS20030221679A1High load conditionMore ignition timingElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

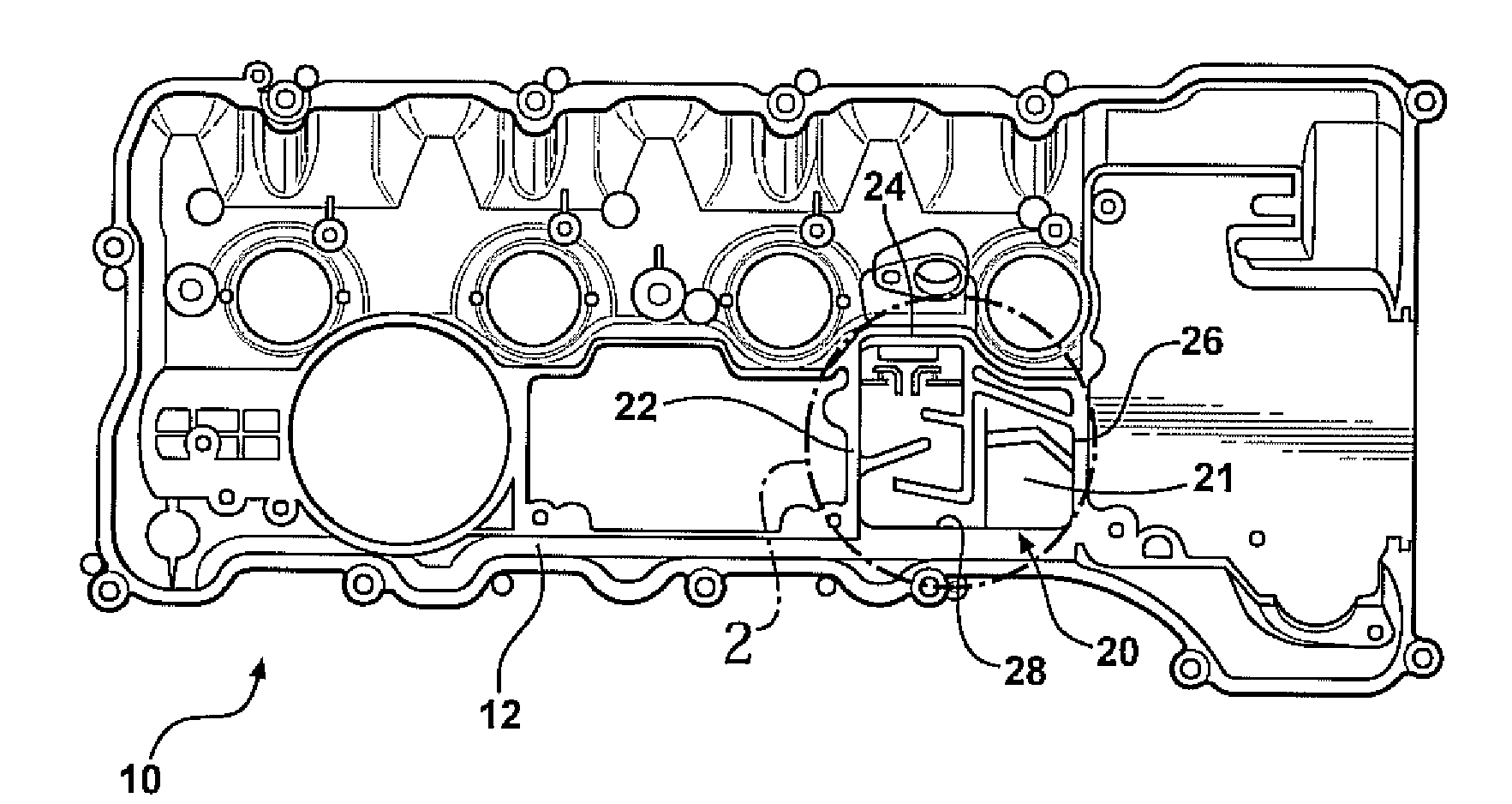

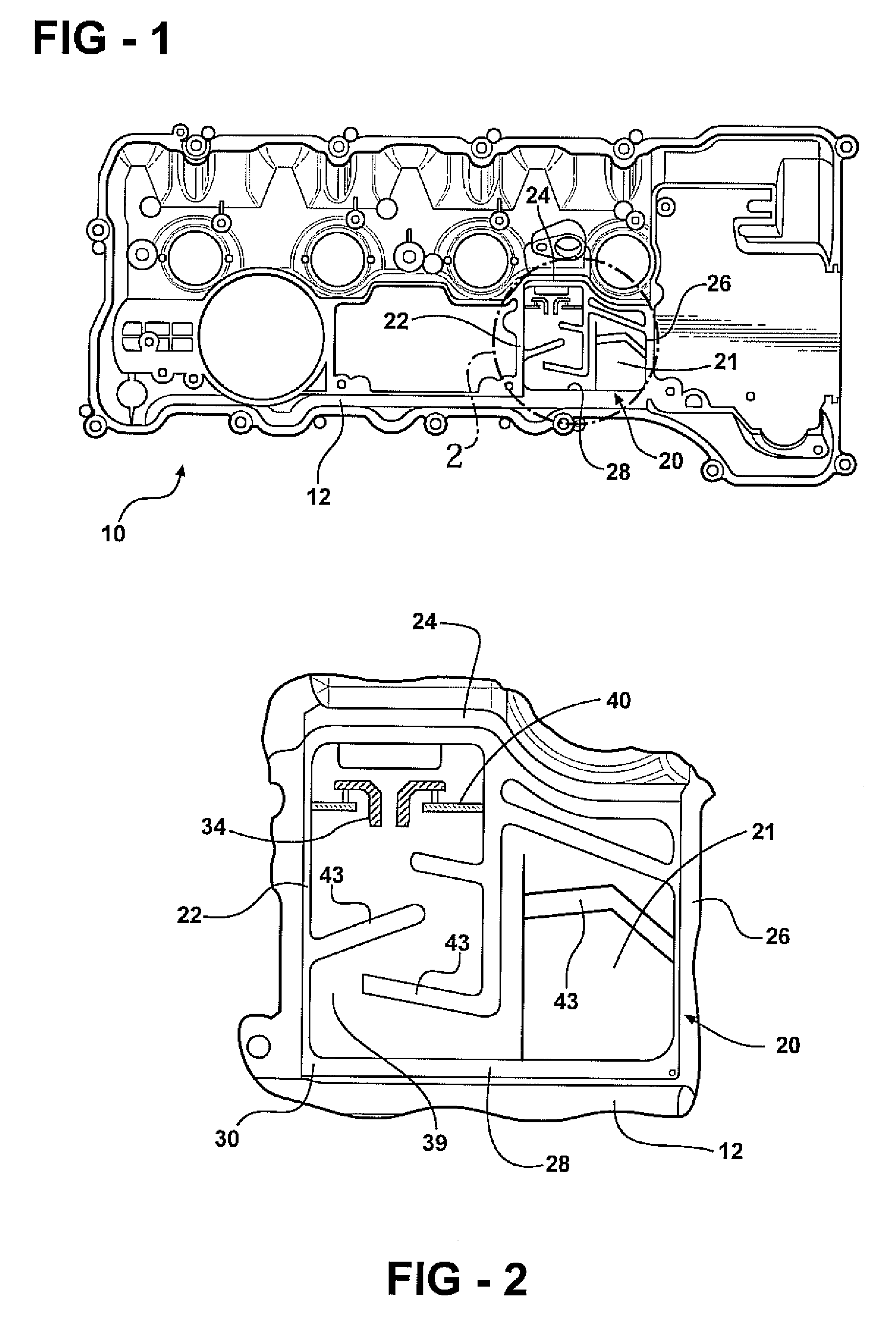

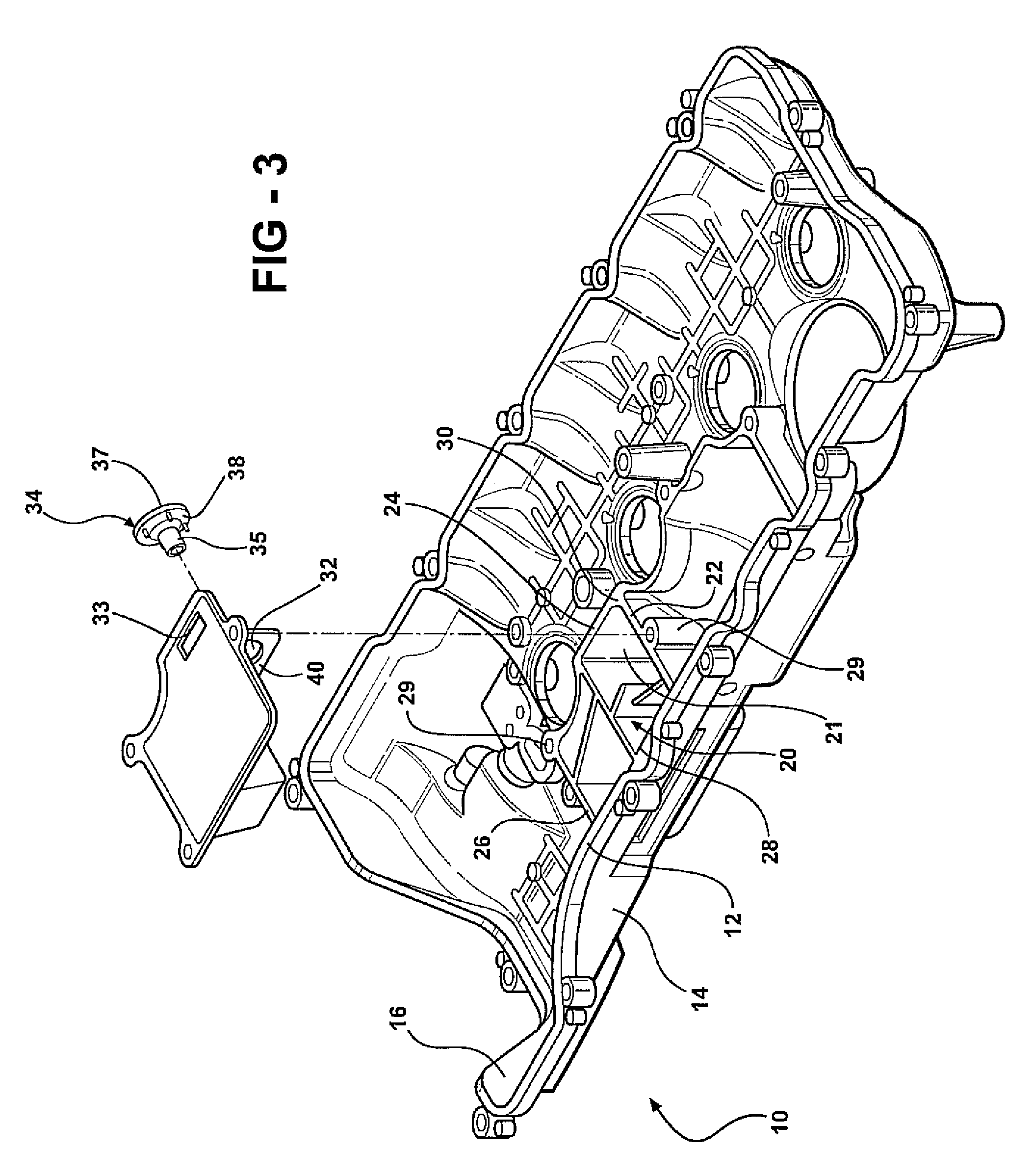

Engine head cover assembly having an integrated oil separator and a removable cover

A head cover assembly for covering a crankcase of an internal combustion engine includes a head cover, a removable cover, a valve, and an integral oil separator. The oil separator includes a labyrinth that defines a flow path that separates oil from crankcase gases passing therethrough. The valve includes a tubular body presenting a passage for which manifold vacuum may draw crankcase gas from the oil separator. The cover includes an aperture. The tubular body is disposed through the aperture such that the outer tube surface is spaced apart from the inner edge of the aperture to define a gap in which separated oil may drain back into the engine for recycling.

Owner:TOYOTA MOTOR CO LTD

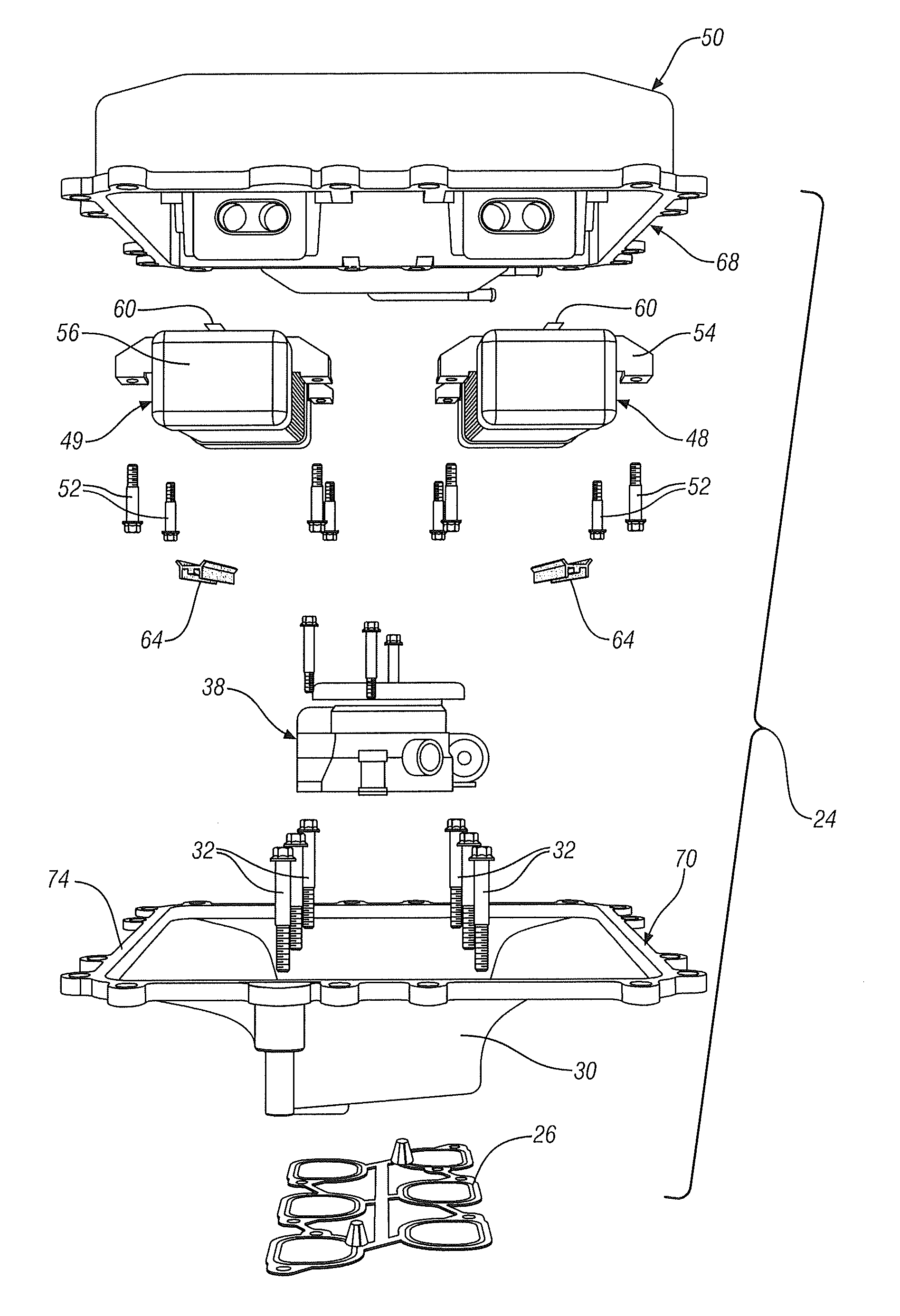

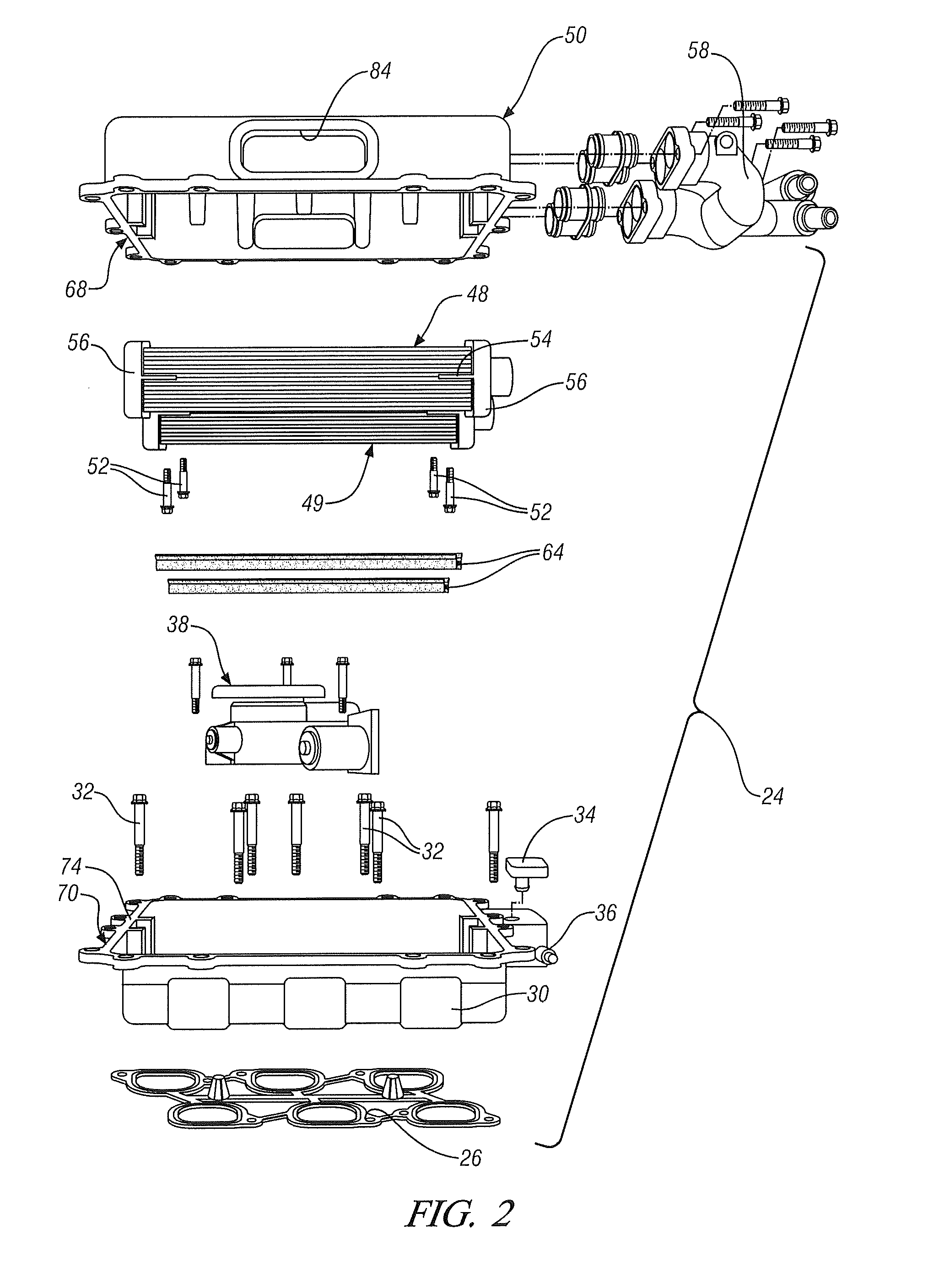

Intake System for an Internal Combustion Engine

ActiveUS20120167860A1Internal combustion piston enginesThermal treatment of fuelCombustionExternal combustion engine

The intake system includes an integrated airflow cooler module comprising a lower manifold assembly and a throttle body fluidly connected to, and disposed within the lower manifold assembly to meter combustion air into a lower manifold volume of the lower manifold assembly. An upper manifold assembly is configured for assembly to the lower manifold assembly to define a manifold volume therebetween and a heat exchanger is disposed in the manifold volume, between the upper manifold assembly and the lower manifold assembly and between a combustion air inlet in the integrated airflow cooler module and the throttle body.

Owner:GM GLOBAL TECH OPERATIONS LLC

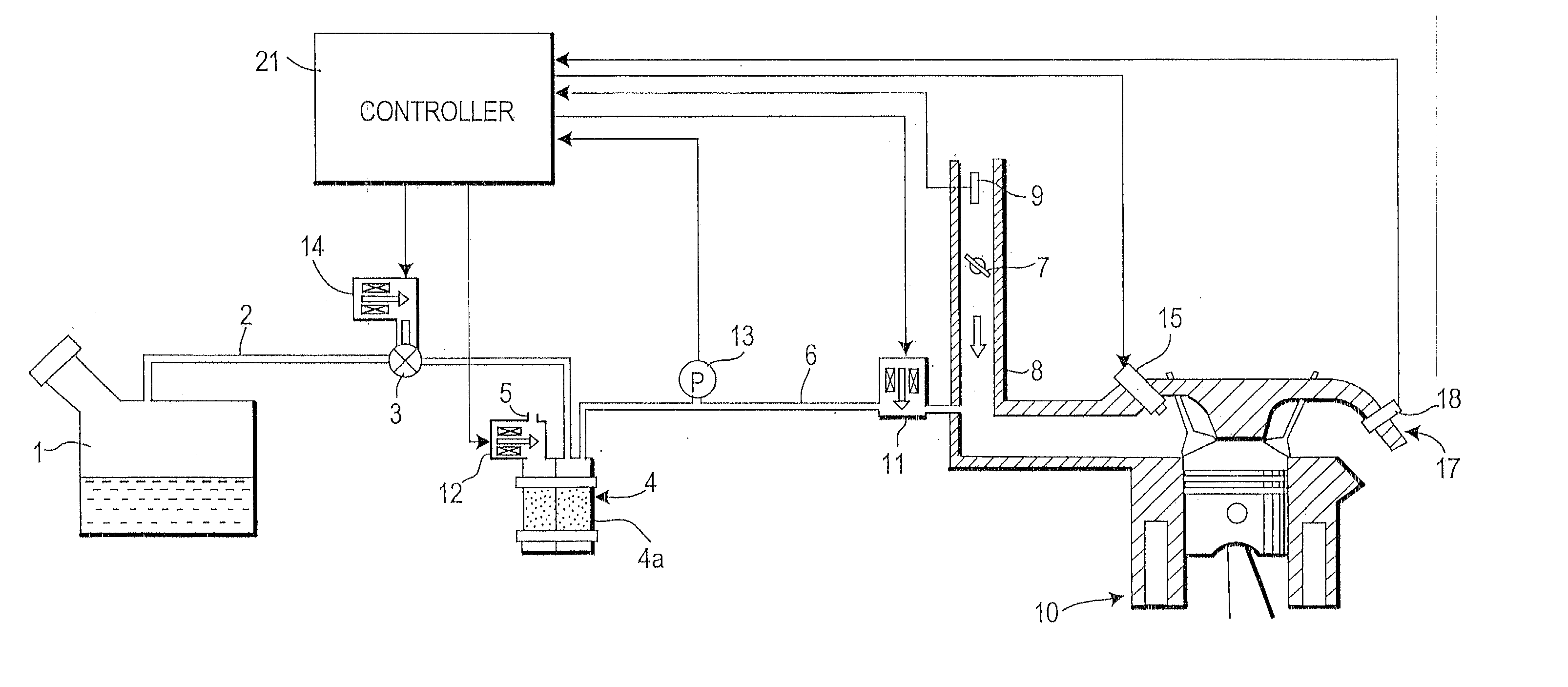

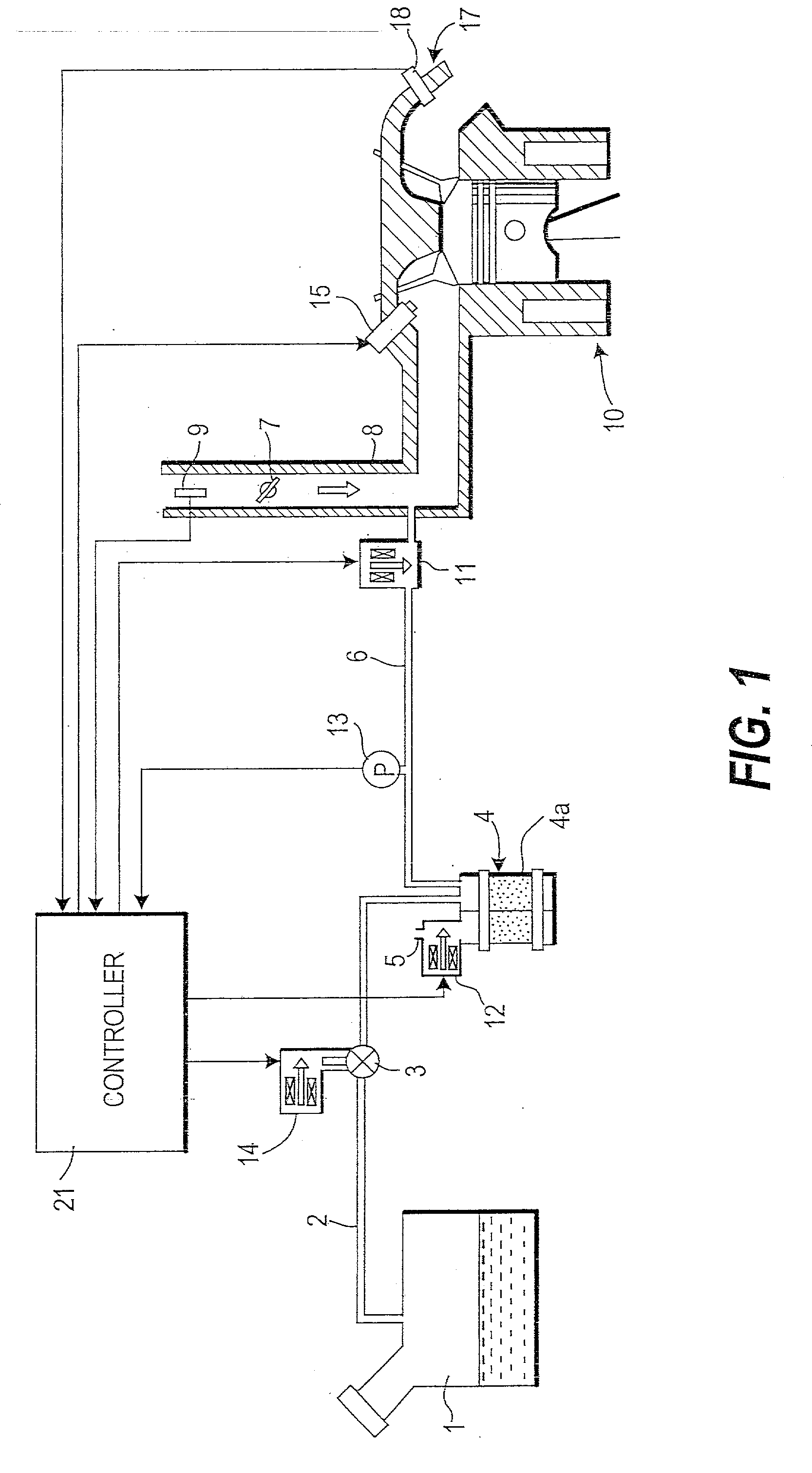

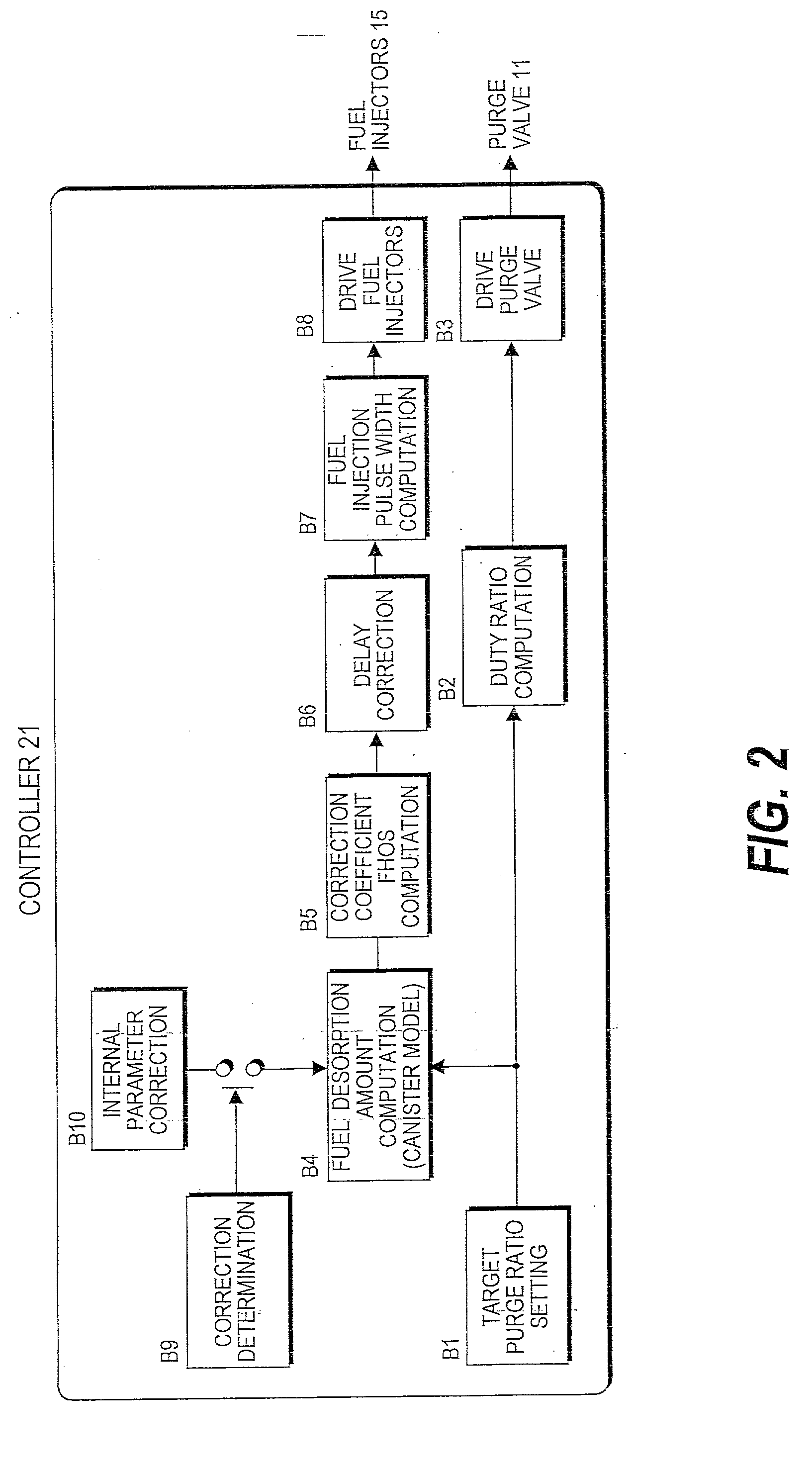

Fuel vapor emission control device for an engine

InactiveUS20020129797A1Large amount of cleaningDecreased air-fuel ratioElectrical controlNon-fuel substance addition to fuelActivated carbonDesorption

Fuel vapor adsorbed by activated carbon 4a in a canister 4 is introduced to an engine 10 by a manifold vacuum in an intake air passage 8, and burnt. The controller 21 estimates the fuel amount desorbed from the canister 4 during purge, using a canister model (physical model) comprising an equation which computes the adsorption amount and an equation which computes the desorption amount from the adsorption amount and purge rate. An injection pulse width output to injectors 15 is corrected to reduce an air-fuel ratio fluctuation due to the supply of this desorbed fuel to the engine 10.

Owner:NISSAN MOTOR CO LTD

Brake booster fault diagnostics

InactiveUS20140137544A1Simple conditionsBraking action transmissionRotary clutchesDiagnostic methodsAutomotive engineering

Methods and systems for indicating brake booster degradation when braking is suspended may include comparing expected brake booster vacuum with measured brake booster vacuum, and indicating a fault when the difference between the two values exceeds a threshold. In one example, the expected brake booster vacuum is computed differently depending on whether intake manifold vacuum or vacuum from one or more vacuum-powered pumps dominates evacuation of the brake booster. Expected brake booster vacuum may be computed based on expected brake booster mass air flow and brake booster volume; when measured brake booster vacuum is less than intake manifold vacuum, expected brake booster mass air flow may be computed as a function of intake manifold vacuum and measured brake booster vacuum, whereas expected brake booster mass air flow may be computed based on flow characteristics of the pump(s) when measured brake booster vacuum is not less than intake manifold vacuum.

Owner:FORD GLOBAL TECH LLC

Method for air-fuel ratio sensor diagnosis

InactiveUS20030221682A1Small torqueIncrease loadElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

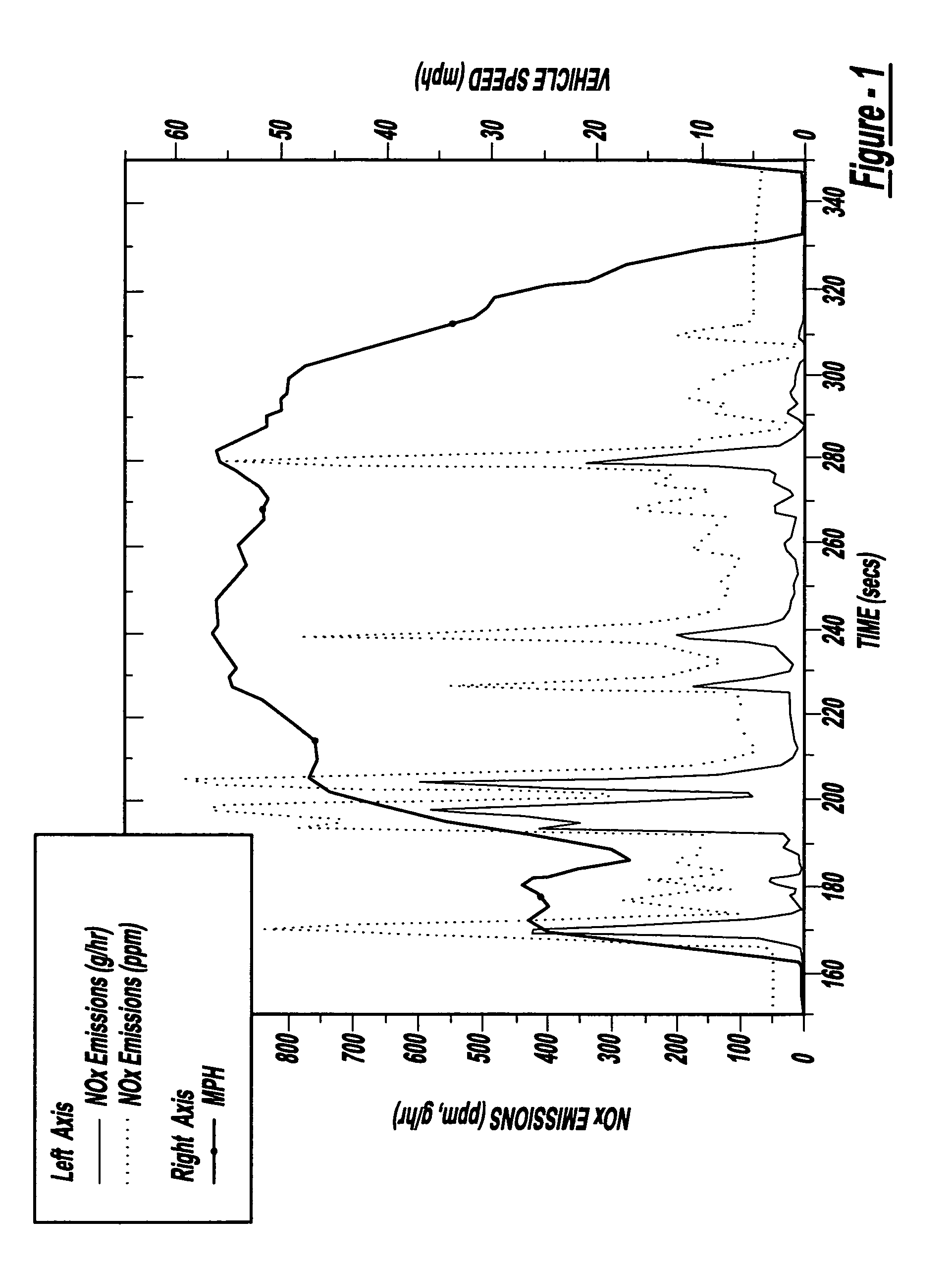

System and method for reducing NOx emissions during transient conditions in a diesel fueled vehicle with EGR

InactiveUS7273045B2Electrical controlNon-fuel substance addition to fuelCombustion chamberDual stage

The present invention is a dual-stage fuel injection strategy for compression ignition engines in which 15-40% of the fuel is injected into the combustion chamber no later than about −20 to −30 CA ATDC and as early as IVC. The remaining fuel is then injected in one or more fuel pulses, none of which start before about −20 to −30 CA ATDC. The fuel injected early in the compression stroke forms a lean mixture that burns with low soot and low NOx emissions. The combustion of that fuel serves to increase in-cylinder temperature such that the ignition delay of subsequent fuel injection pulses is short. This mode is utilized when it is predicted that a NOx spike is imminent. Various other alternative methods for reducing NOx spikes are also disclosed such as specialized EGR systems that can provide EGR with low manifold vacuum.

Owner:FORD GLOBAL TECH LLC

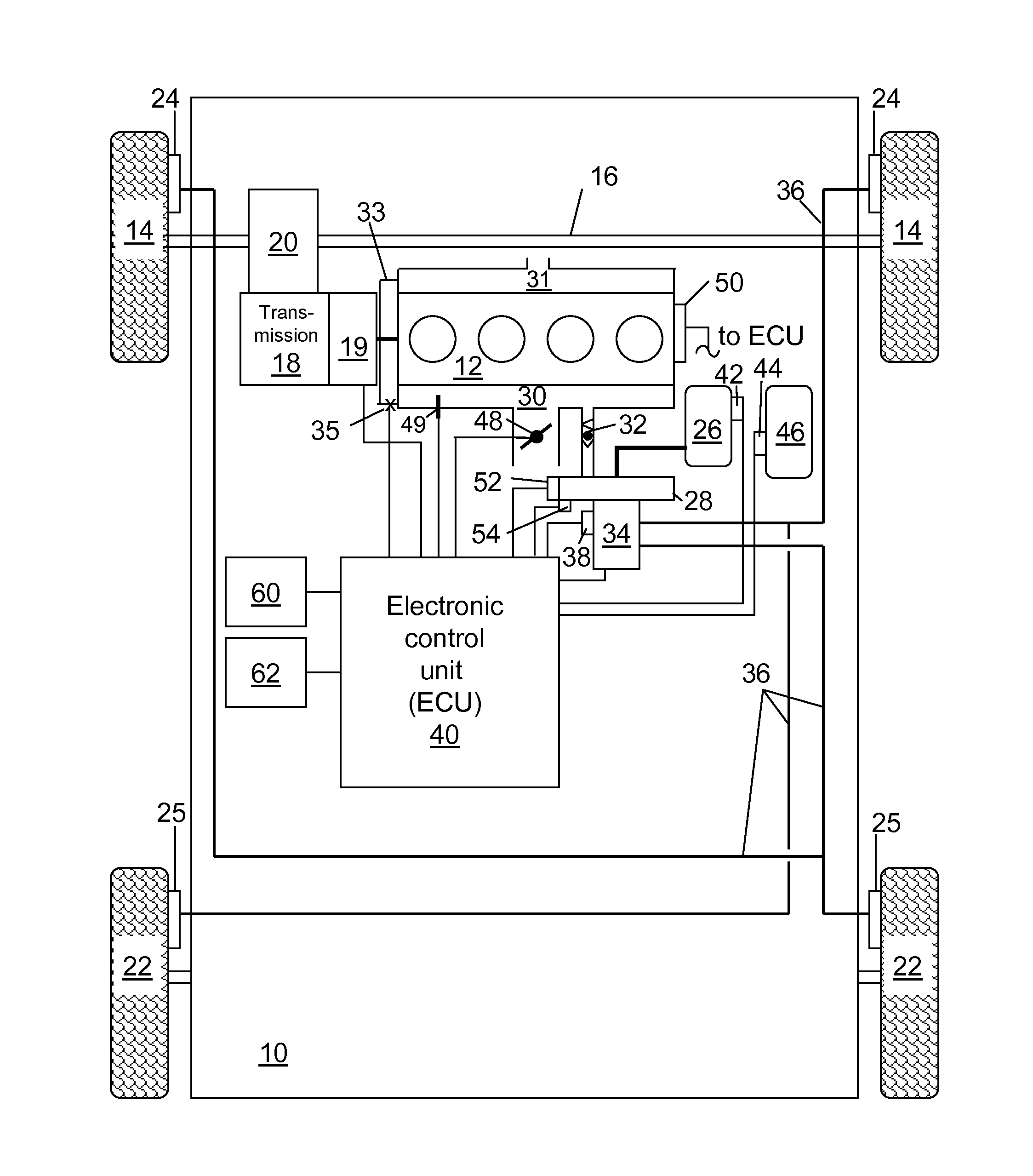

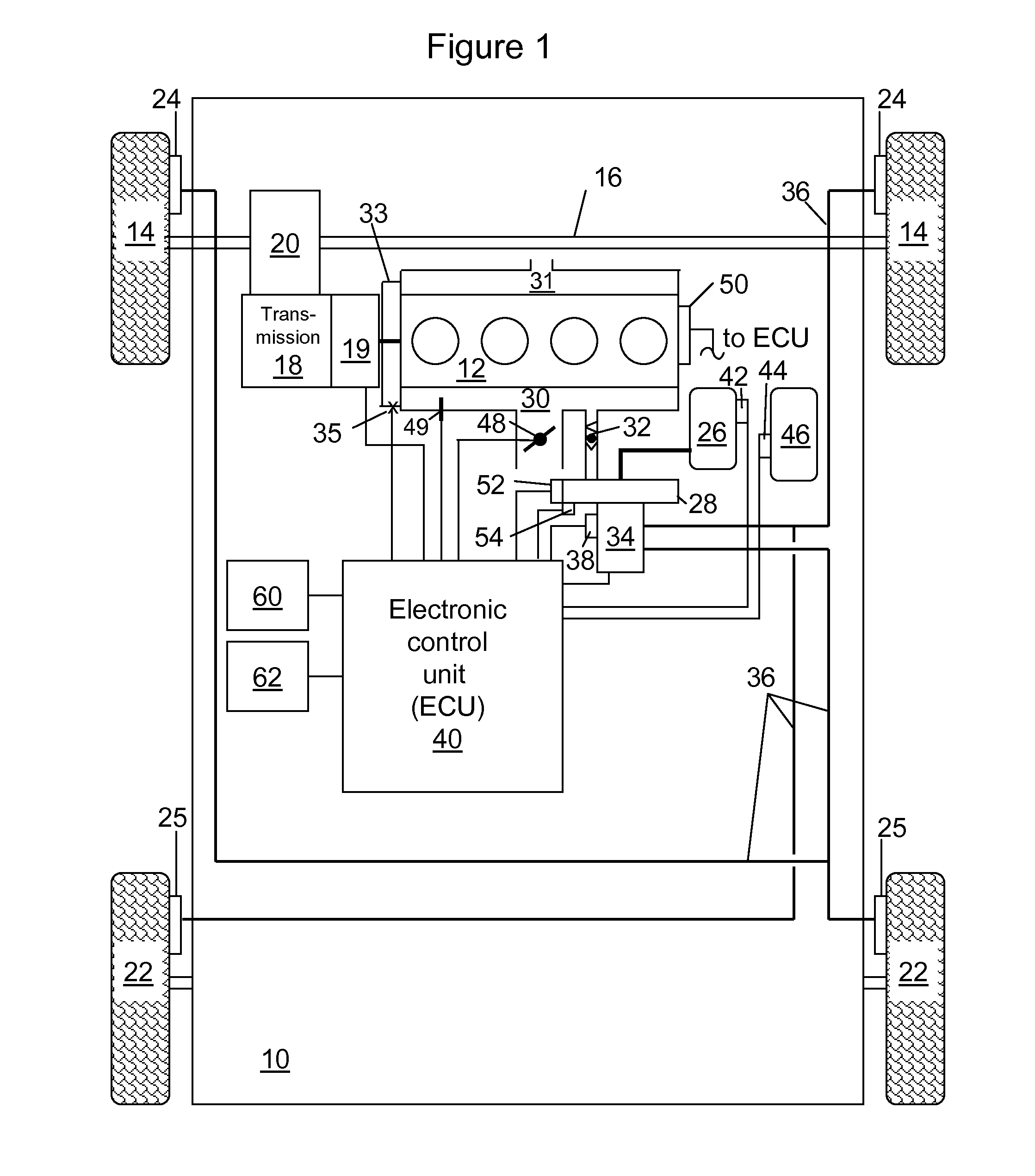

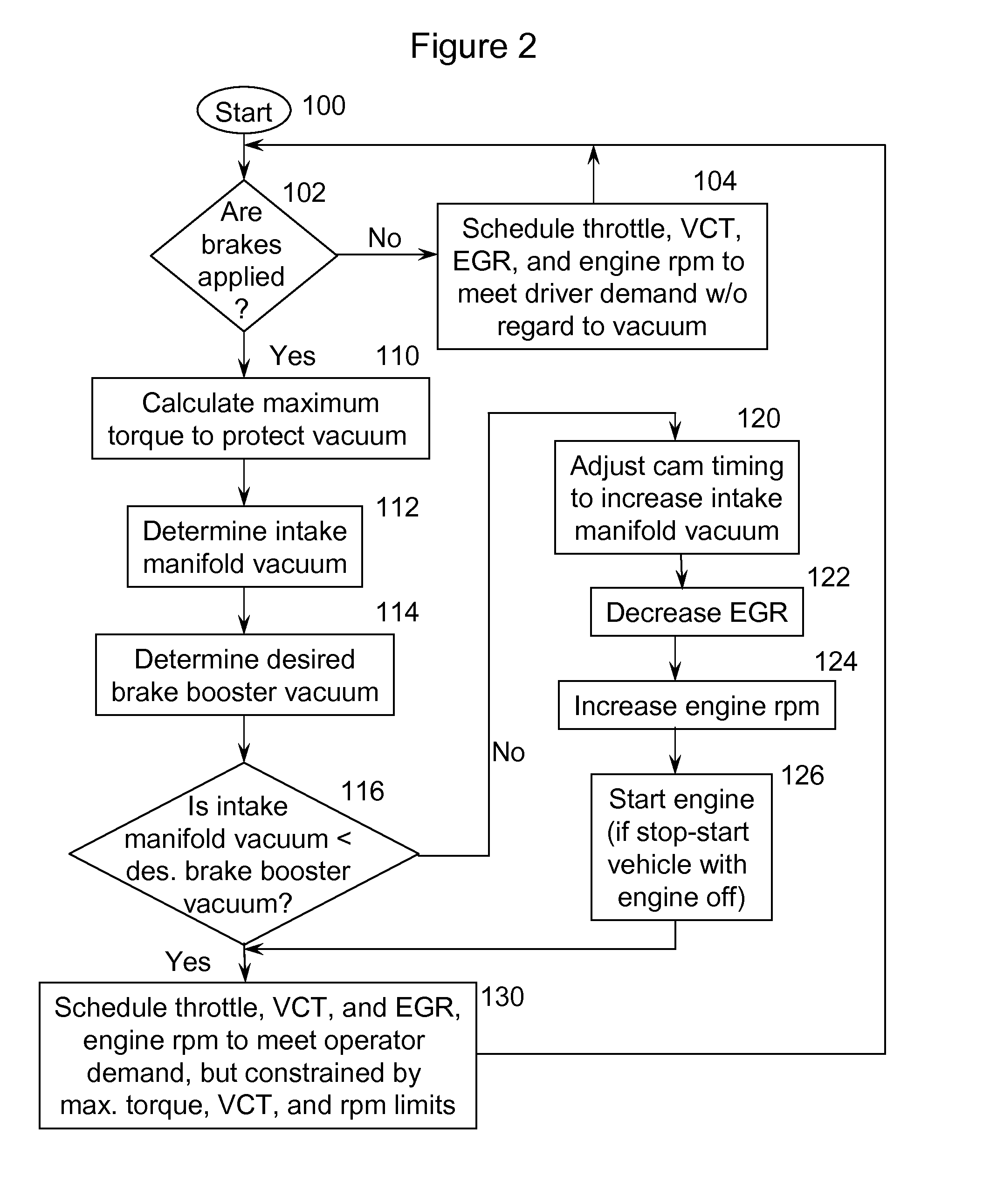

Vacuum Boost For Vehicle Braking

InactiveUS20120116656A1Increase engine speedIntake manifold vacuum is increasedAnalogue computers for vehiclesElectrical controlVacuum assistedCam

Power brakes are typically vacuum assisted, with the vacuum provided from the intake manifold. If the engine is commanded to operate for a long period at a condition with low intake manifold vacuum, the vacuum within the brake booster may drop to a level which is marginal or insufficient for a present or subsequent braking operation. To ensure sufficient vacuum in the intake manifold to provide to the brake booster, the engine may be commanded to operate at a condition to increase intake manifold vacuum by one of: adjusting cam timing, increasing engine speed, and increasing EGR. In the case of a stop-start vehicle, the engine speed is increased from zero to a condition that provides the desired vacuum.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com