Patents

Literature

114results about How to "Reduce intake noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

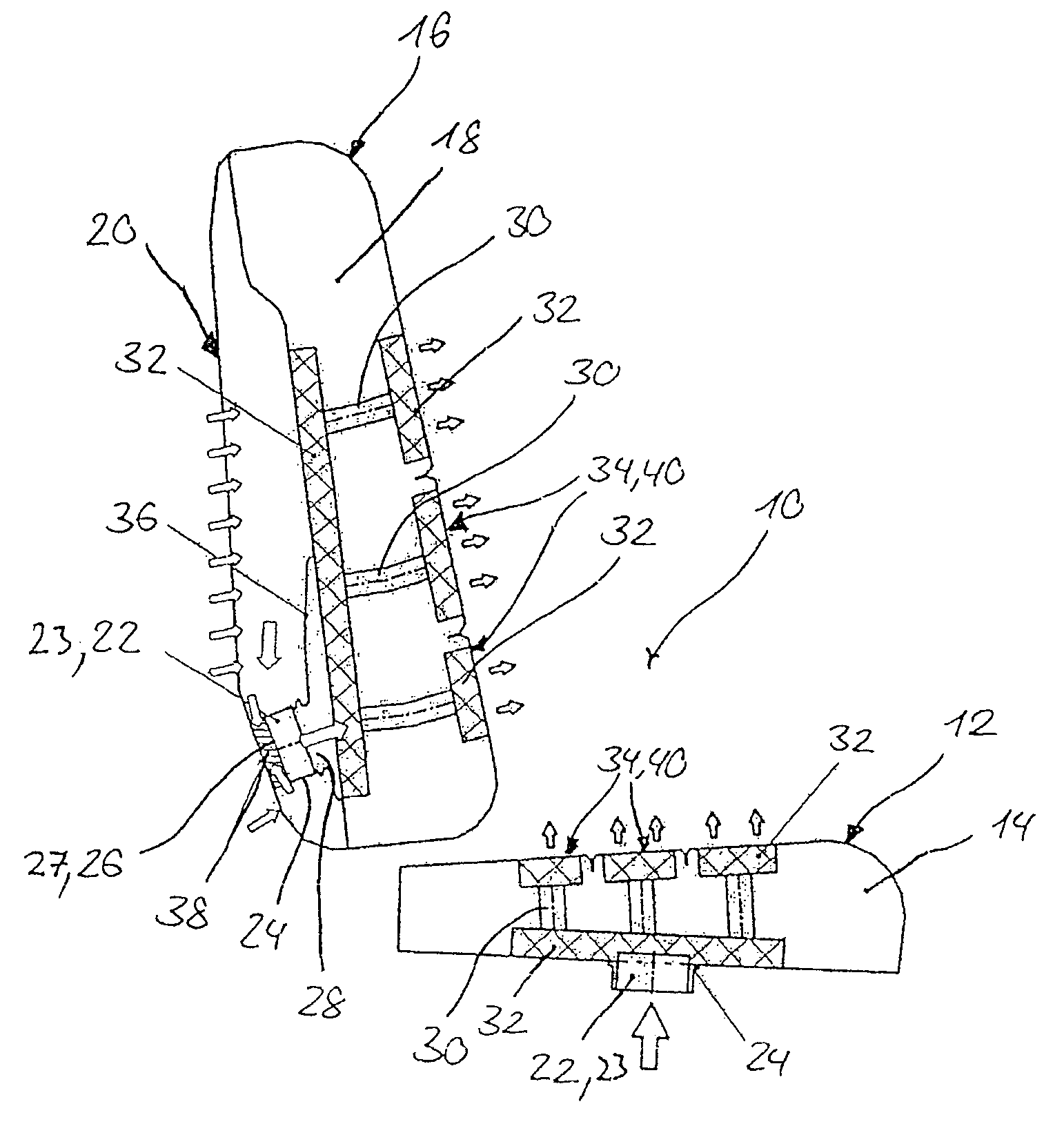

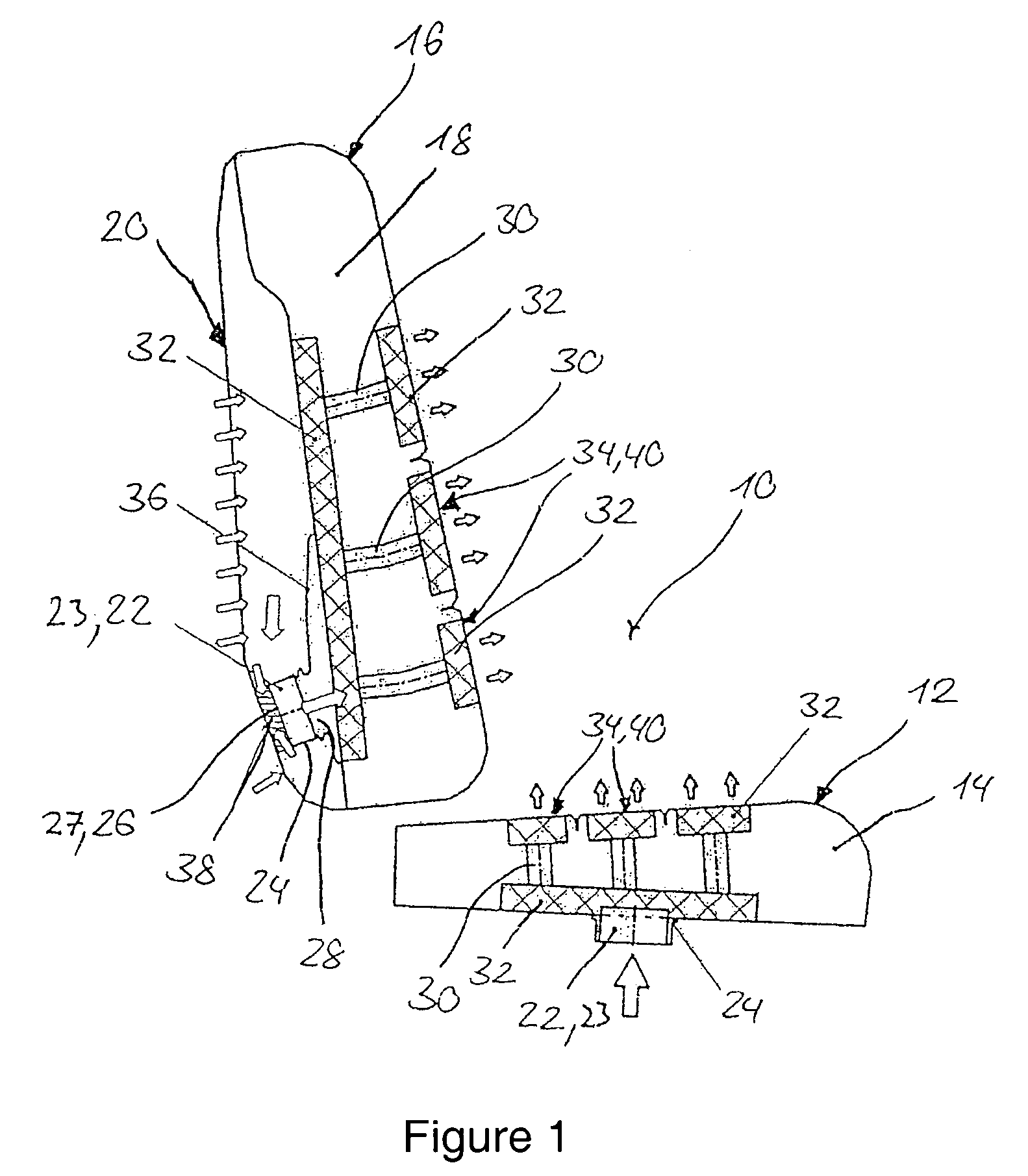

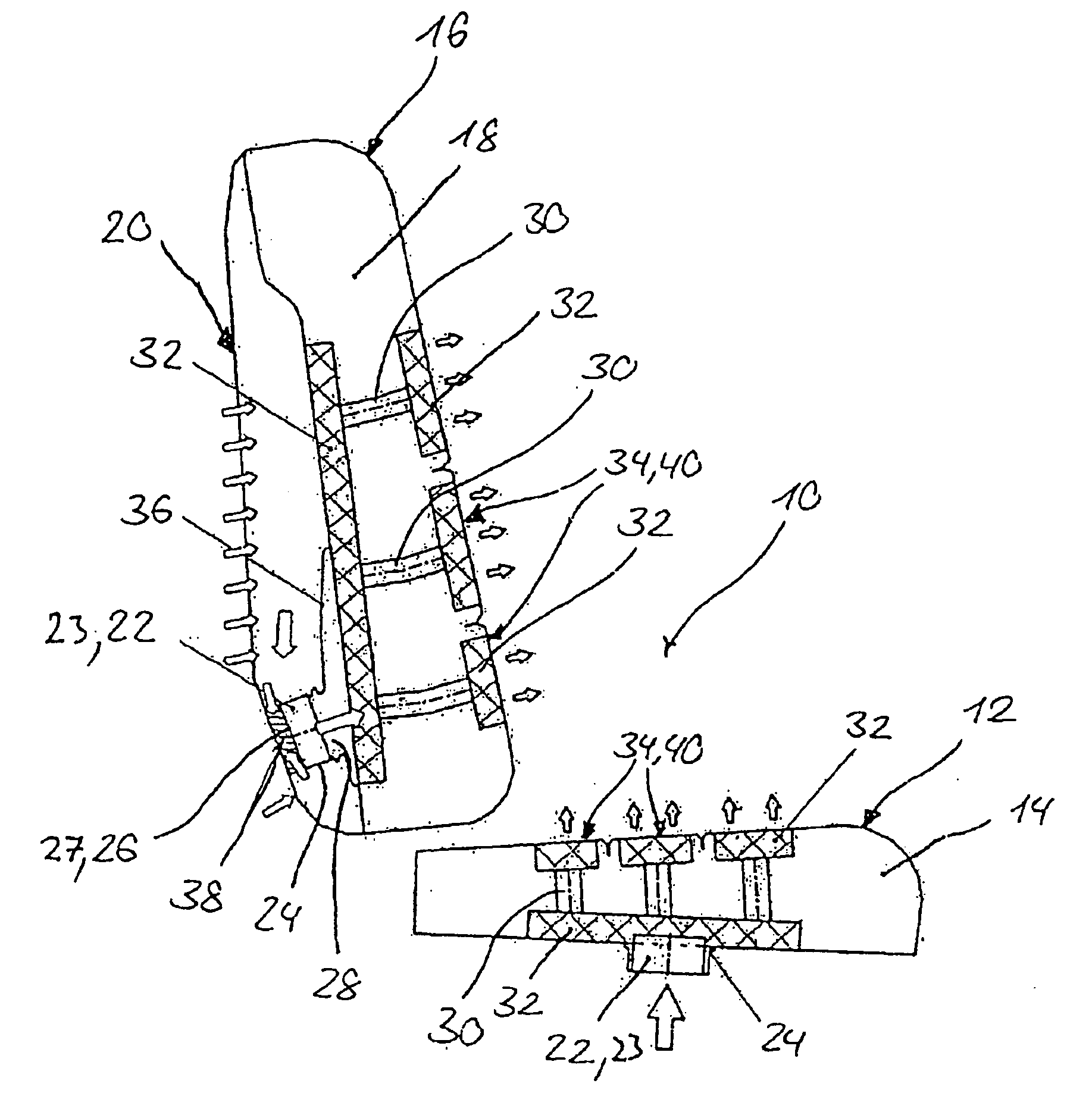

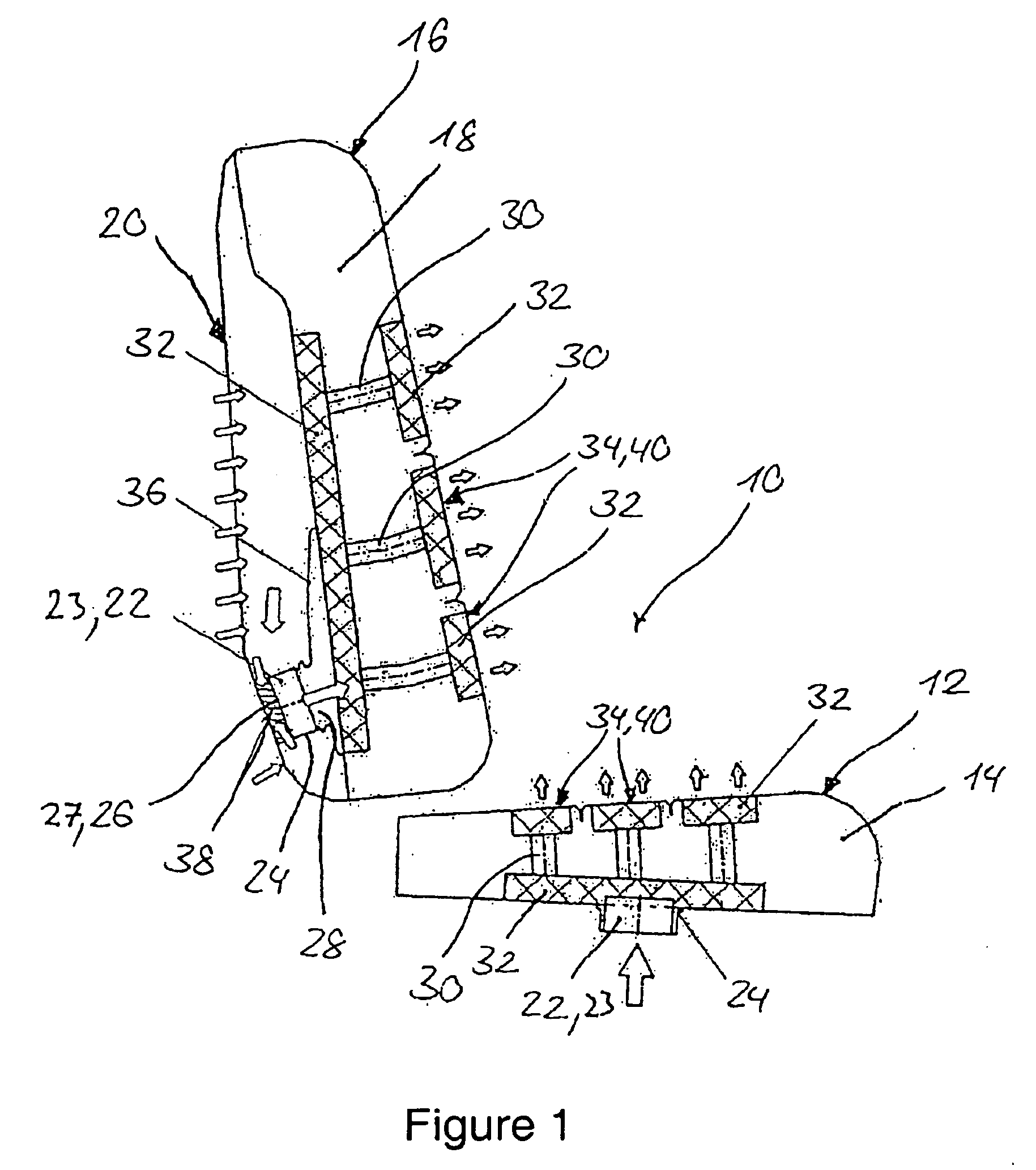

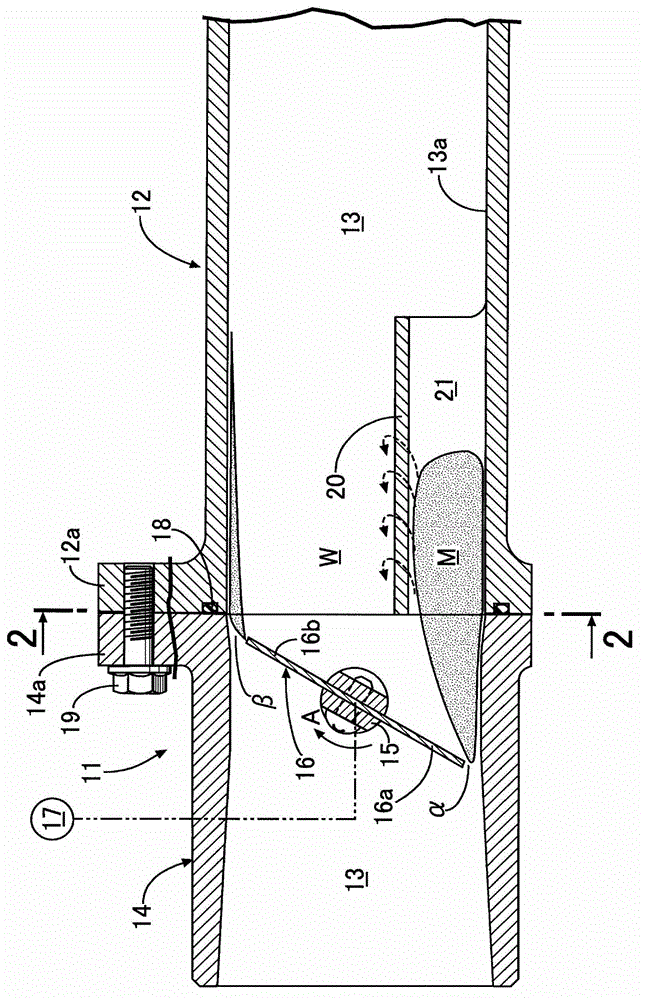

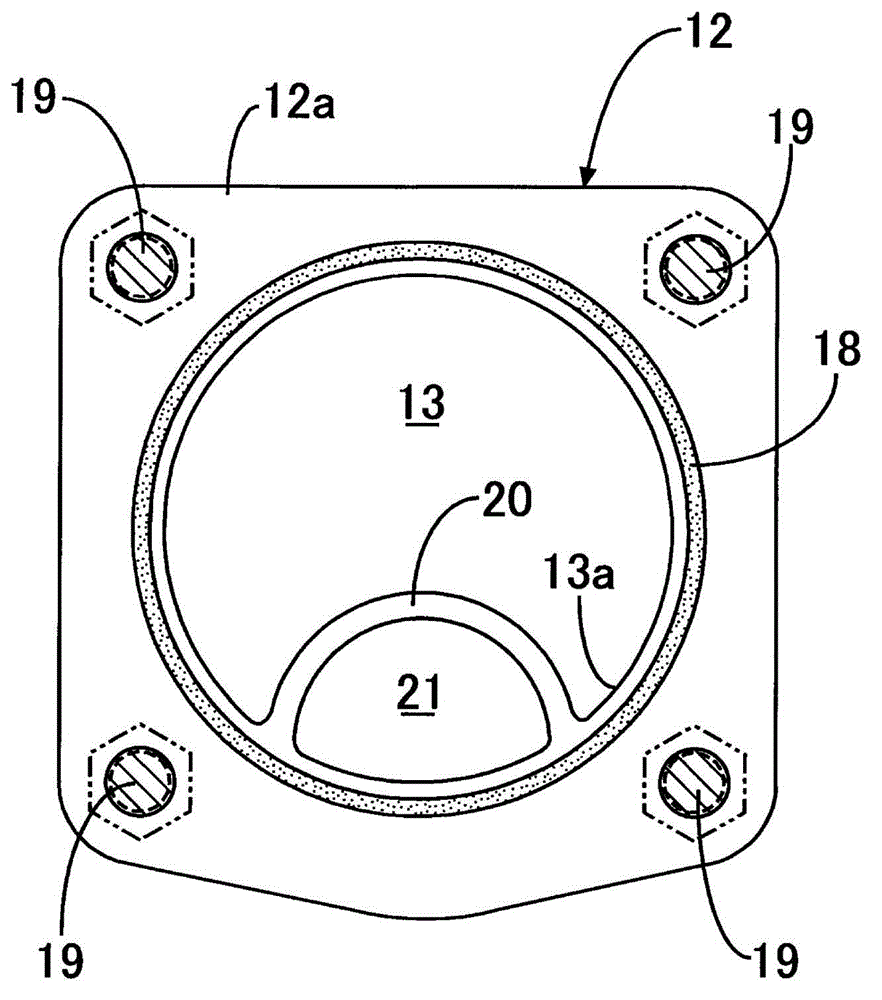

Vehicle seat and associated air conditioning apparatus

ActiveUS6976734B2Reduction in bothersome intake noiseReduce intake noiseSeat heating/ventillating devicesStoolsEngineeringAir conditioning

A vehicle seat with a backrest (16) that has a backrest cushion (18) and a rear backrest cover (20), and an air-handling device that is associated with the backrest (16) and is connected to an air distribution device (30, 32) in the seat. The rear backrest cover (20) is at least partially air permeable, and covers at least one passage (27) of the air-handling device (23). The air exchanged between the environment and the air-handling device (23) passes for the most part through the air-permeable regions of the backrest cover (20).

Owner:GENTHERM GMBH

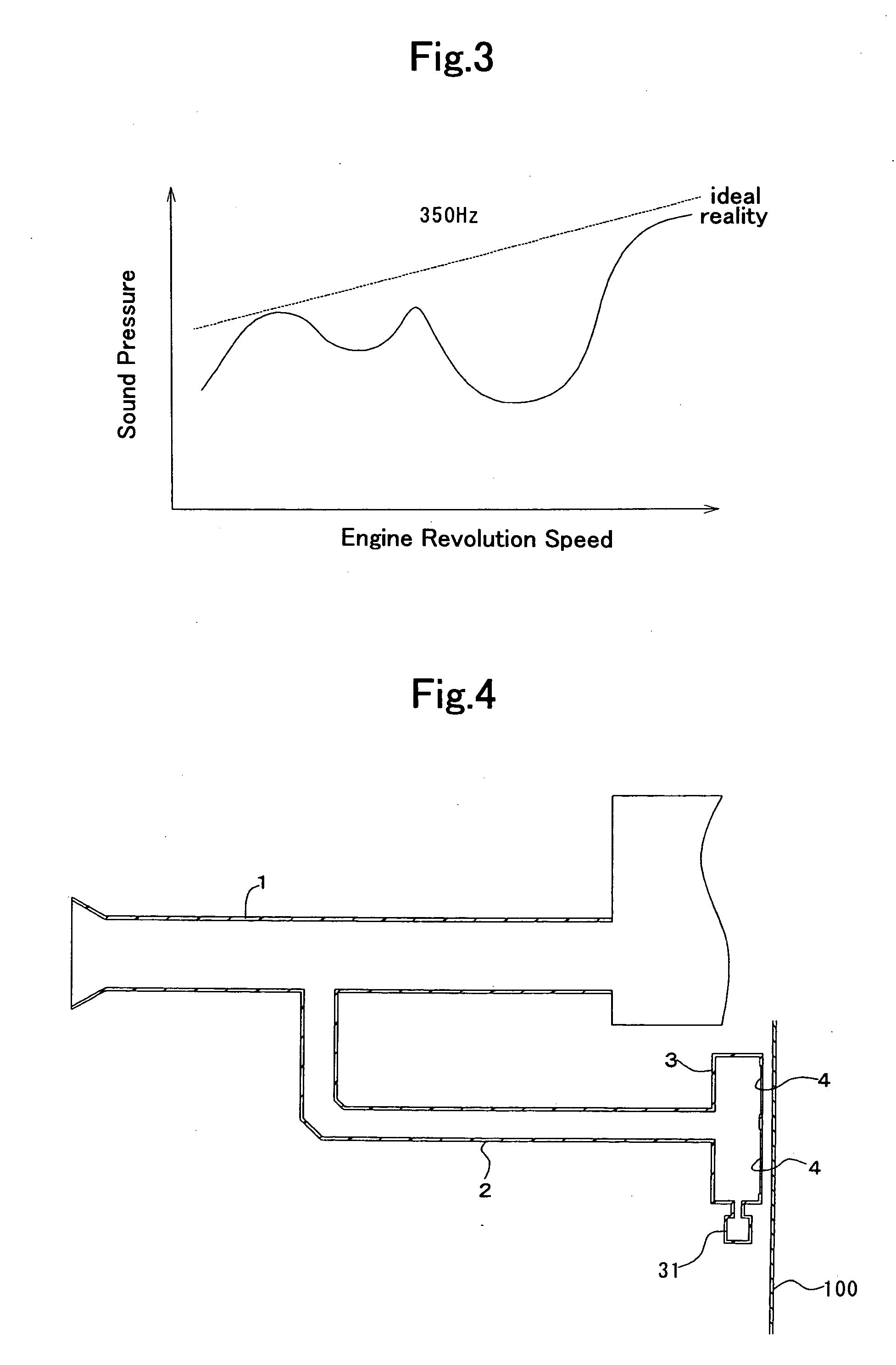

Air intake sound control structure

InactiveUS20070044747A1Low stiffnessIncrease sound pressureMachines/enginesSound producing devicesEngineering

An air intake sound control structure comprises a sound guiding pipe, a sound producing body, and a silencing means. The sound guiding pipe is branched off from a branch portion formed on a part of an air intake flow passage of an automobile, communicating with the air intake flow passage. The sound producing body is held by the sound guiding pipe at the position spaced apart from the branch portion, thereby sealing the sound guiding pipe, and producing a sound at a frequency which corresponds to its own natural vibration frequency by its vibration. The silencing means is disposed on the side of the branch portion of the sound guiding pipe and canceling a sound at a target frequency for suppression out of the air intake sound. The sound generated by the vibration of the sound producing body is transmitted into a vehicle interior.

Owner:TOYODA GOSEI CO LTD

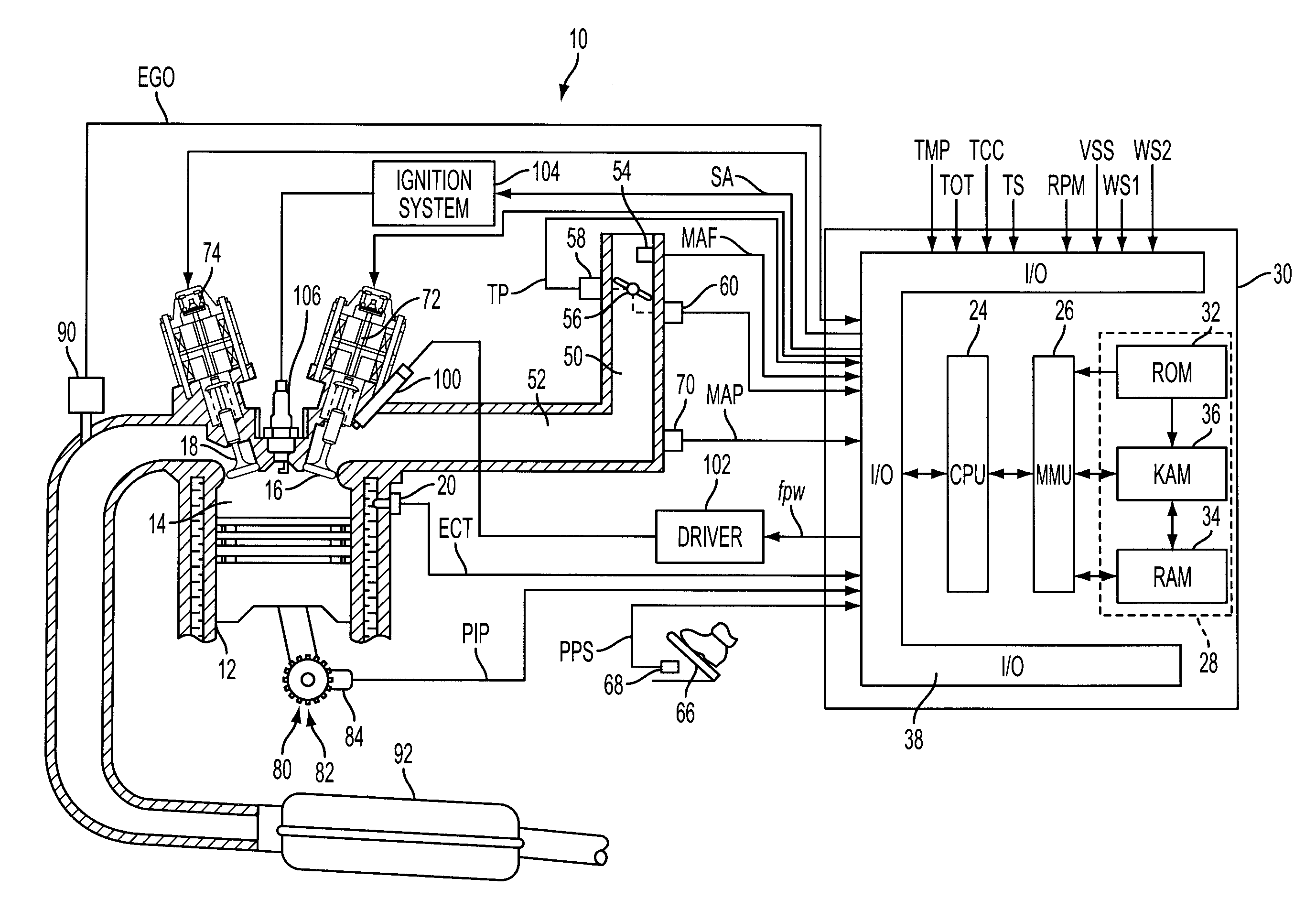

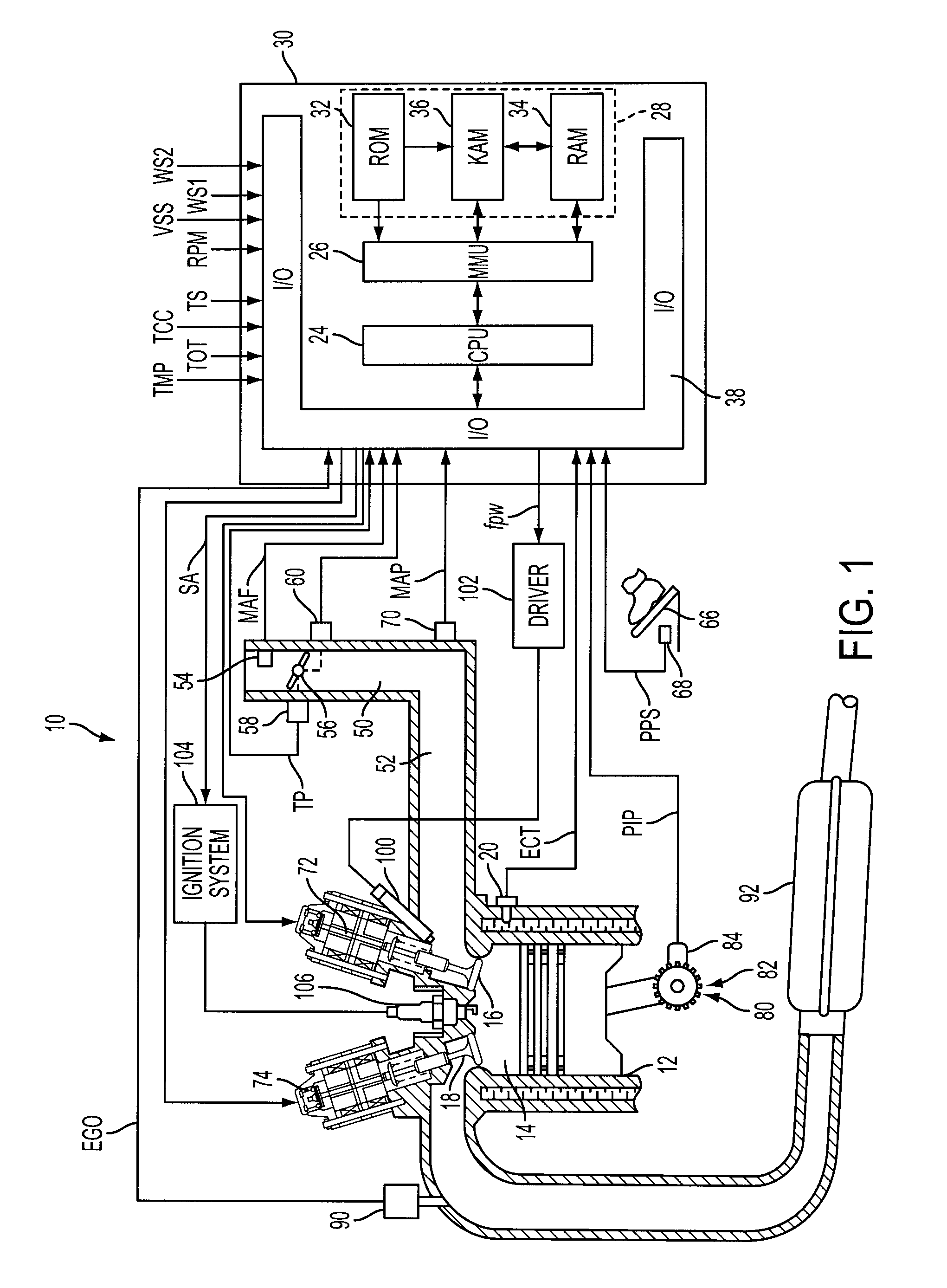

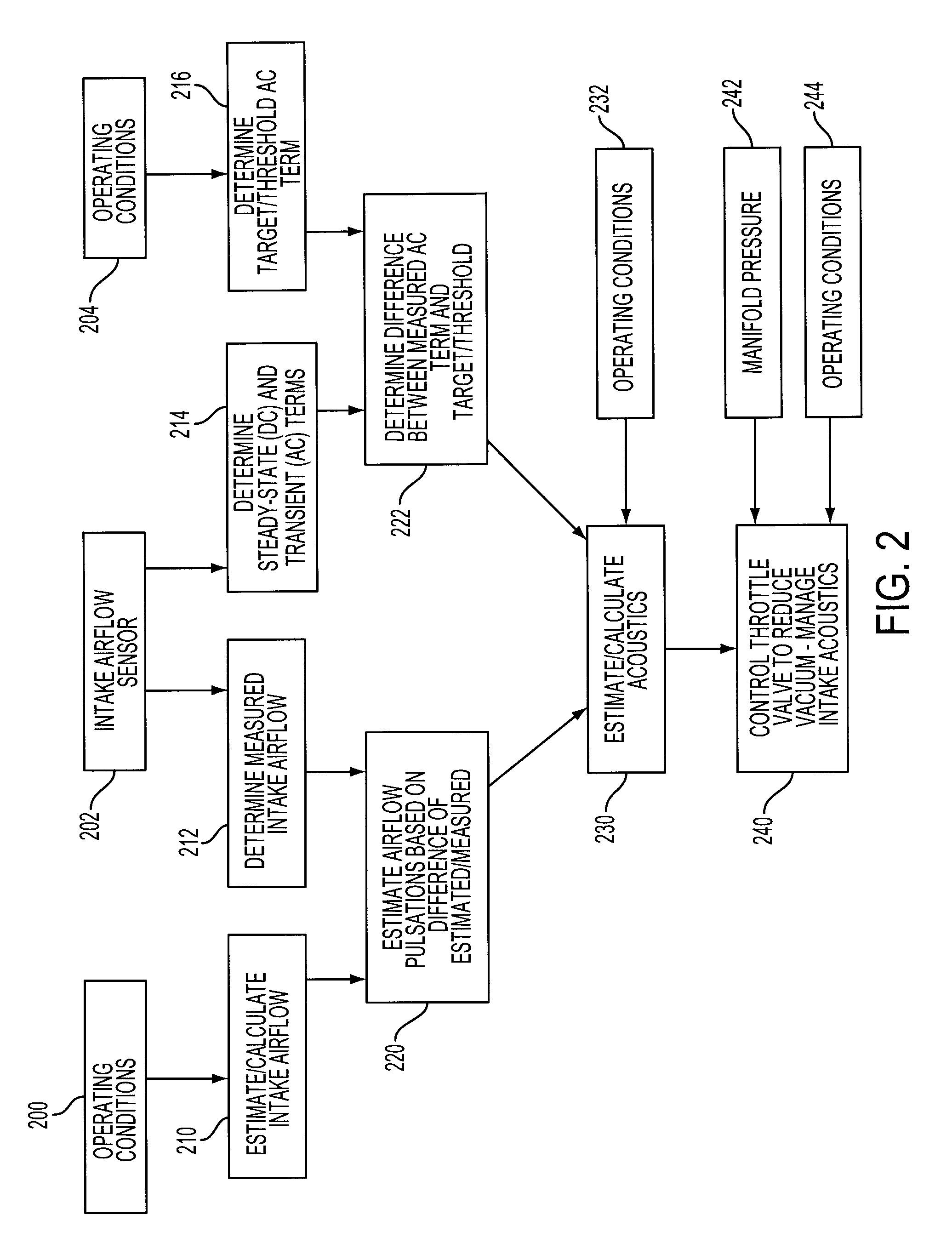

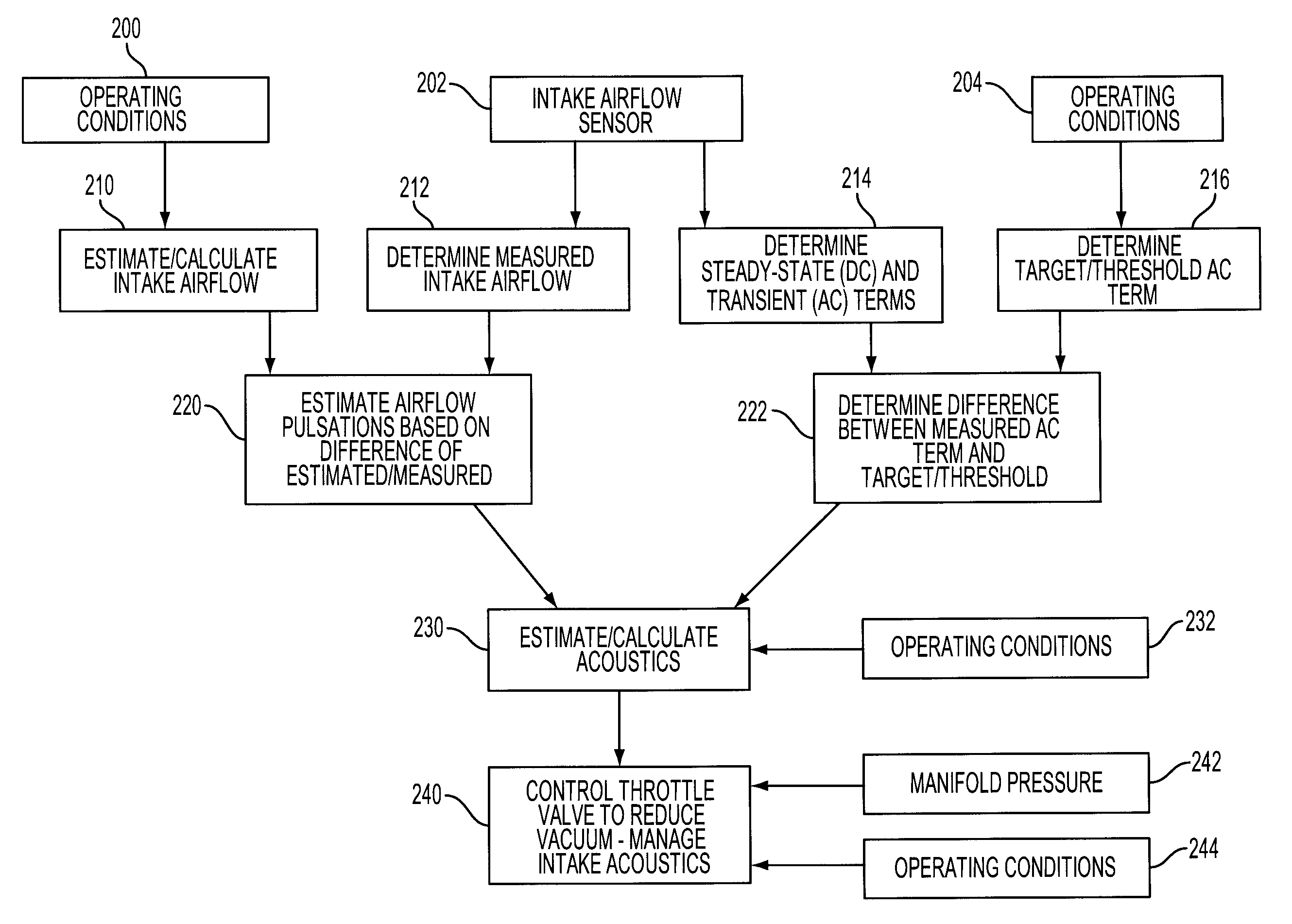

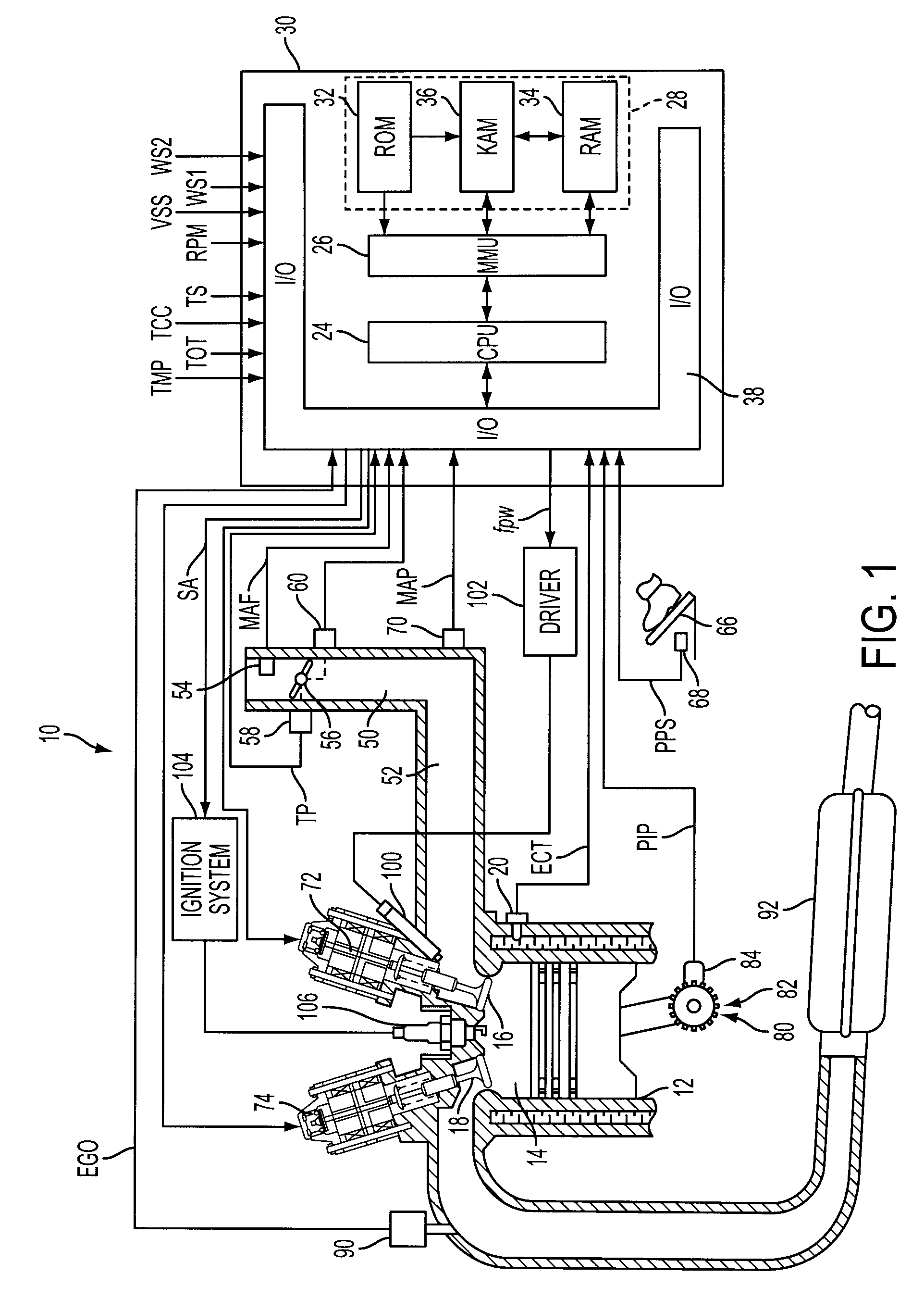

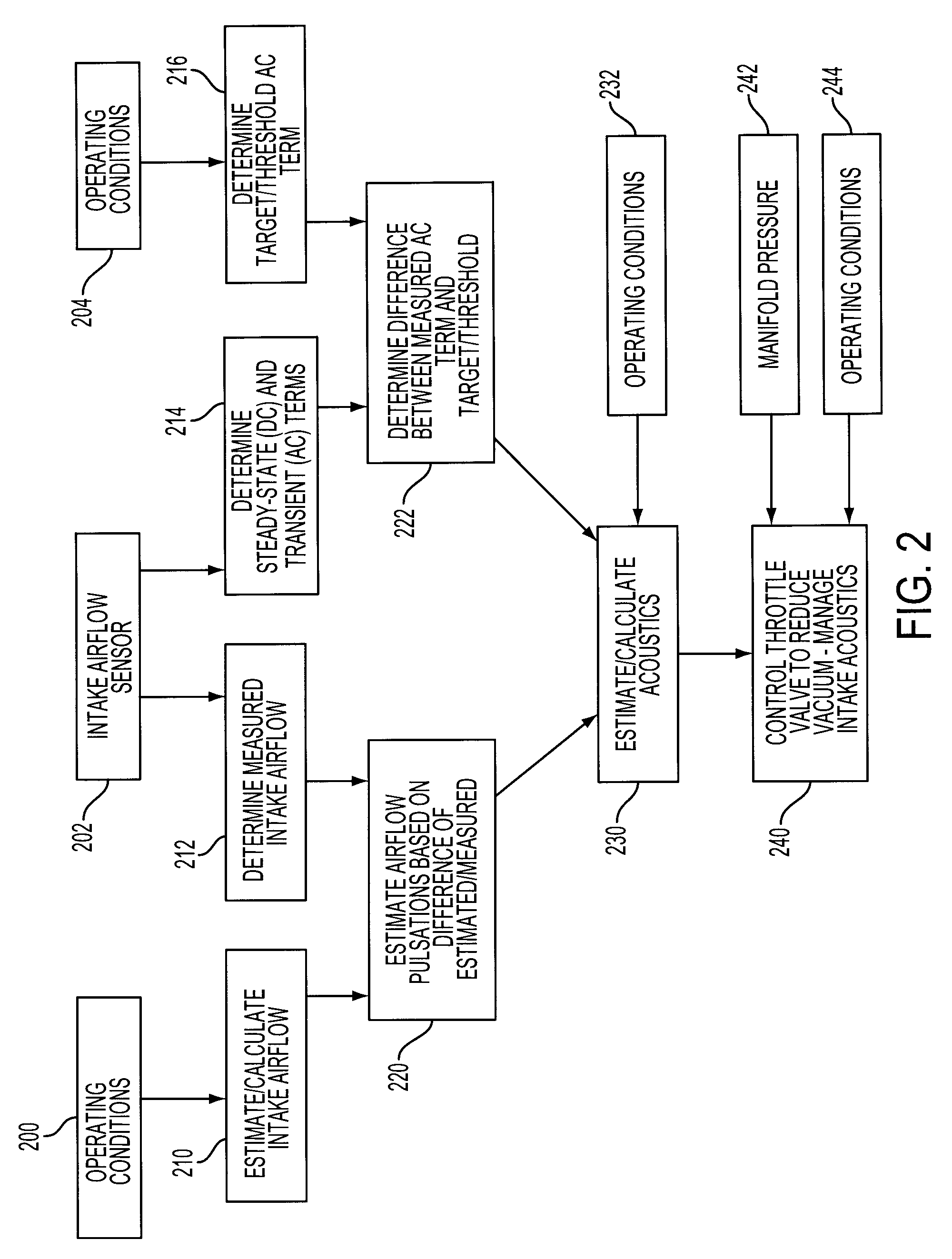

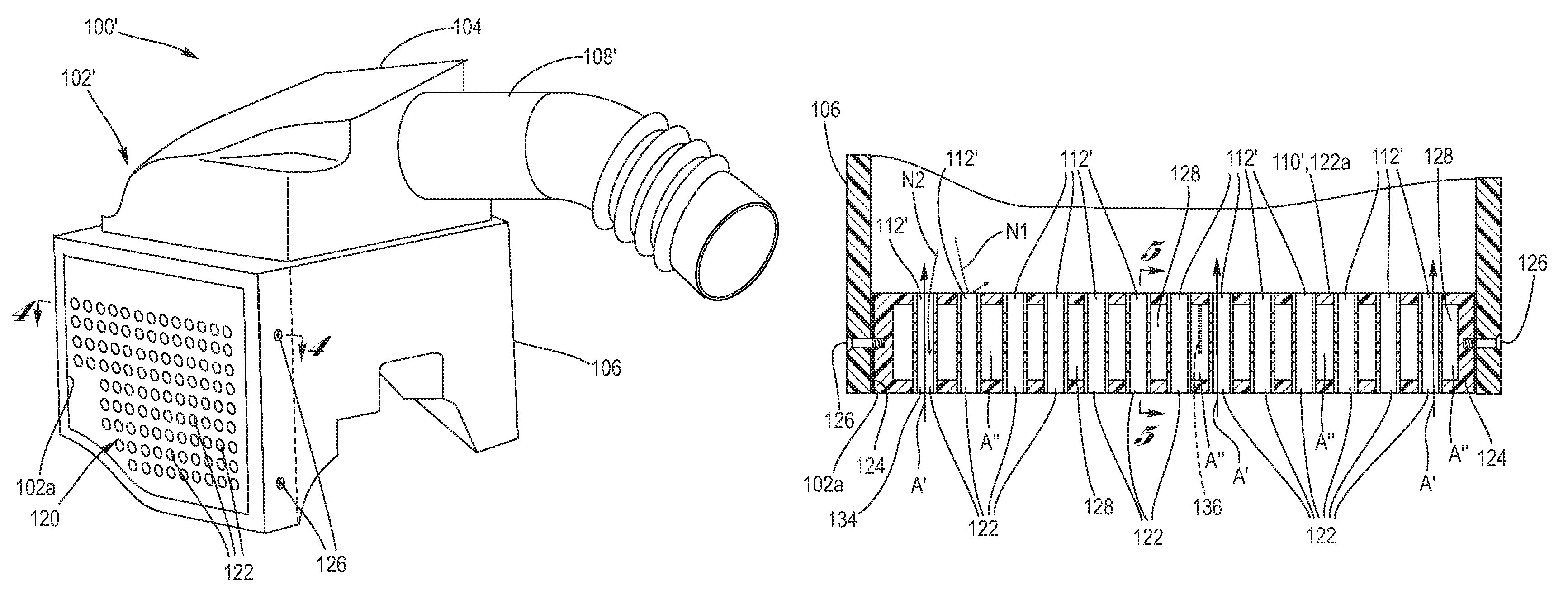

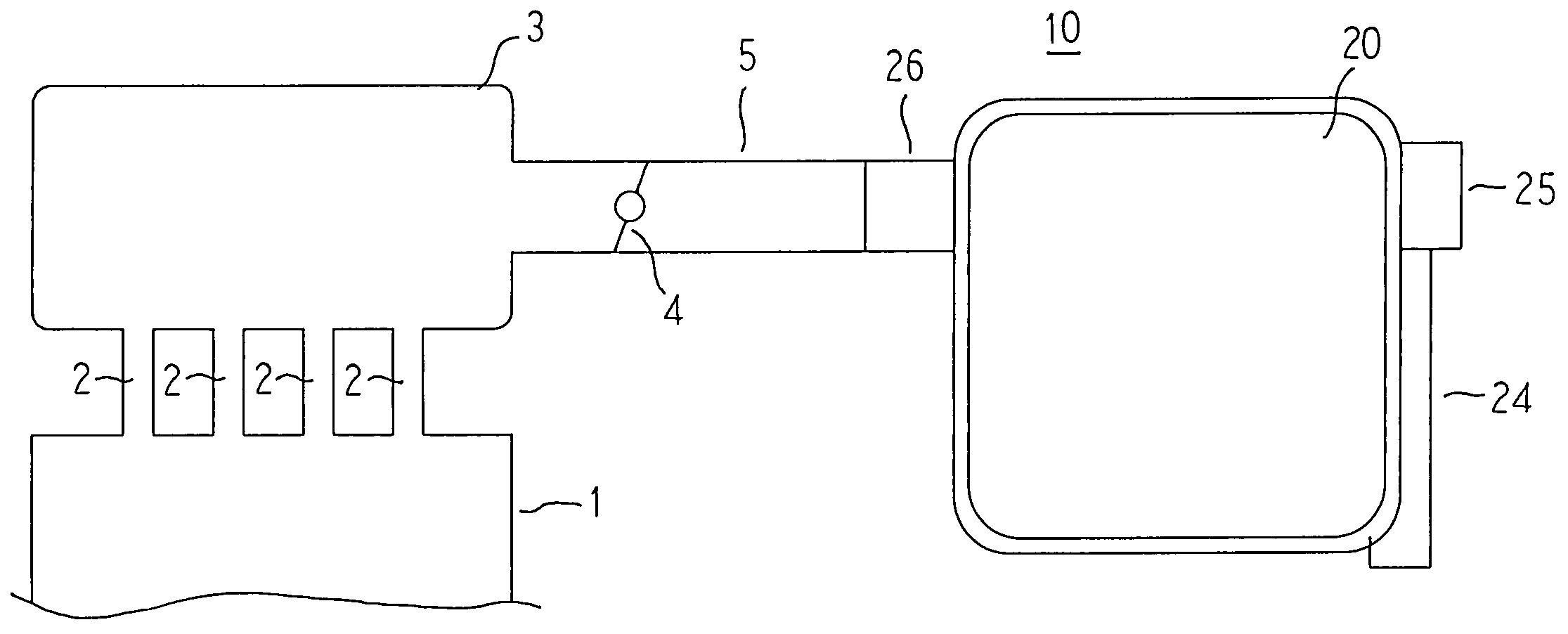

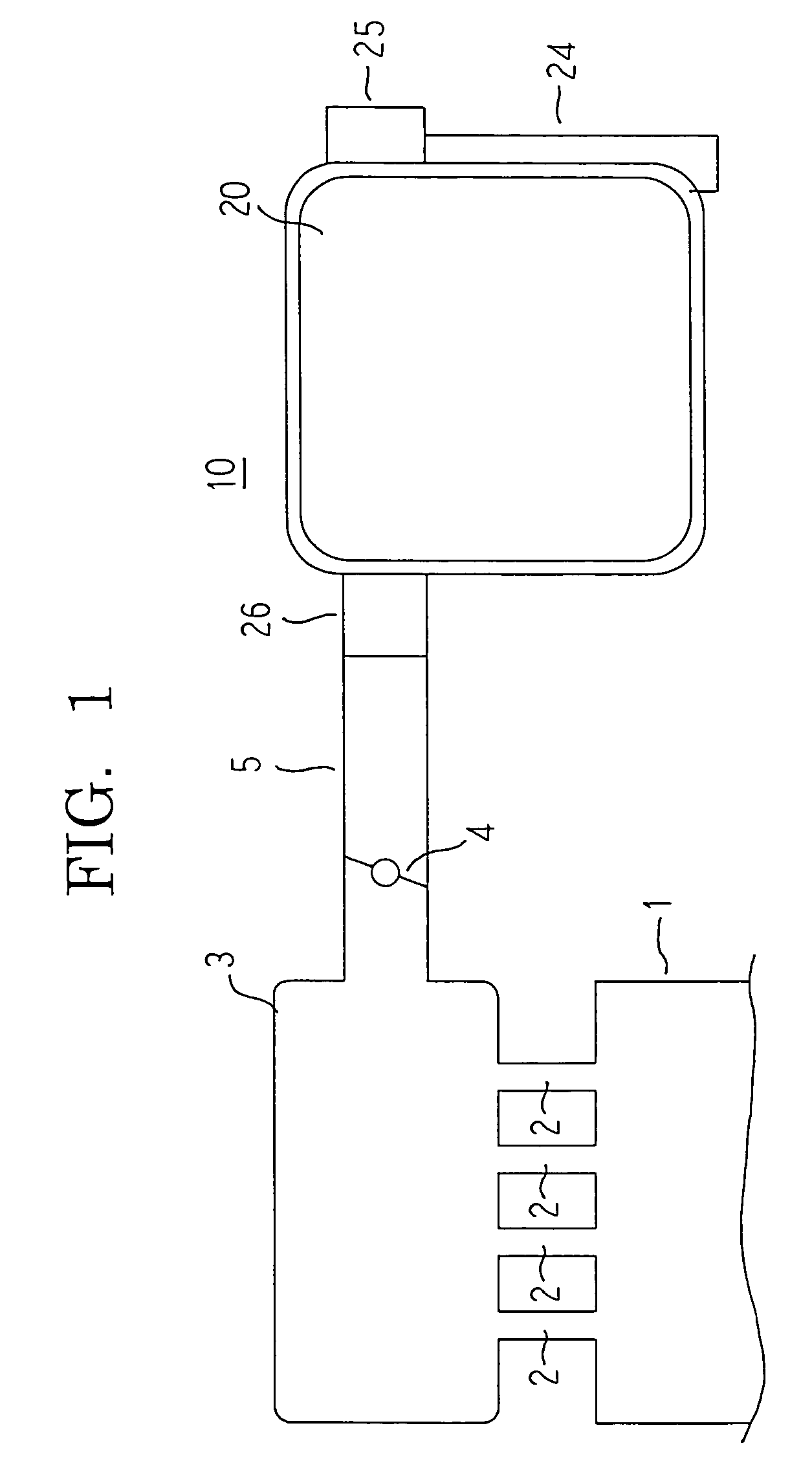

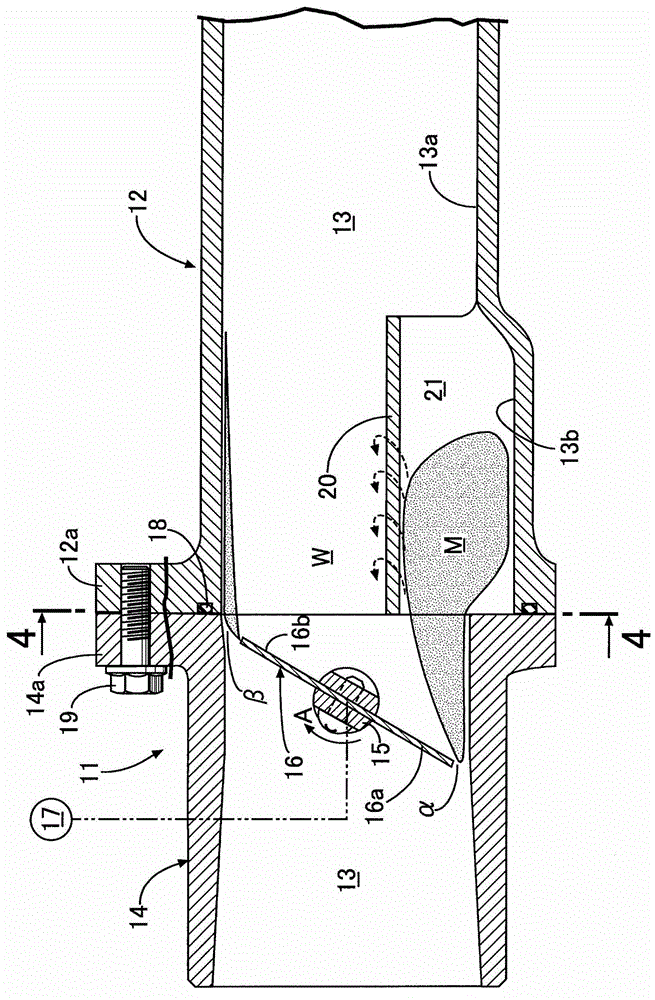

Induction air acoustics management for internal combustion engine

InactiveUS20080066699A1Increase intake vacuumReduce intake noiseInternal combustion piston enginesOutput powerExhaust valveExternal combustion engine

A system and method for controlling an internal combustion engine control an actuator in response to variations of intake airflow relative to an average intake airflow to manage induction acoustics. The system and method may include controlling an actuator, such as a throttle valve, to increase intake manifold vacuum in response to intake airflow. In an engine having electronically actuated intake and / or exhaust valves, intake airflow is estimated based on at least engine speed and valve timing and compared to a measured intake airflow to determine a first difference. The measured airflow is divided into a steady-state and transient term or component with a second difference determined based on the transient component and a target value. Throttle valve position is selectively controlled to increase vacuum in response to a combination of the first and second difference to manage induction acoustics.

Owner:FORD GLOBAL TECH LLC

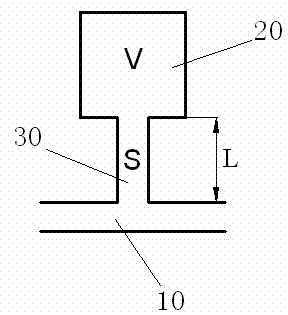

Resonance silencer with dynamically adjusted silencing frequency

InactiveCN102434337ASimple structureEasy to processIntake silencers for fuelEngineeringNoise reduction

The invention aims to provide a resonance silencer with a dynamically adjusted silencing frequency, which is applied to an engine to save space and improve noise reduction effect of the engine. The resonance silencer with the dynamically adjusted silencing frequency comprises a hollow housing; the housing is provided with a connecting hole used for being communicated with an engine air inlet pipeline; a resonance cavity communicated with the connecting hole is arranged in the housing; and the resonance cavity can be changed in volume under the control of an engine control unit. The resonance silencer with the dynamically adjusted silencing frequency is simple in structure, easy to manufacture and process and small in volume, and can save engine space. The volume of the resonance cavity is dynamically adjusted by the engine control unit to realize the aim of reducing induction noise at different rotation speeds.

Owner:CHERY AUTOMOBILE CO LTD

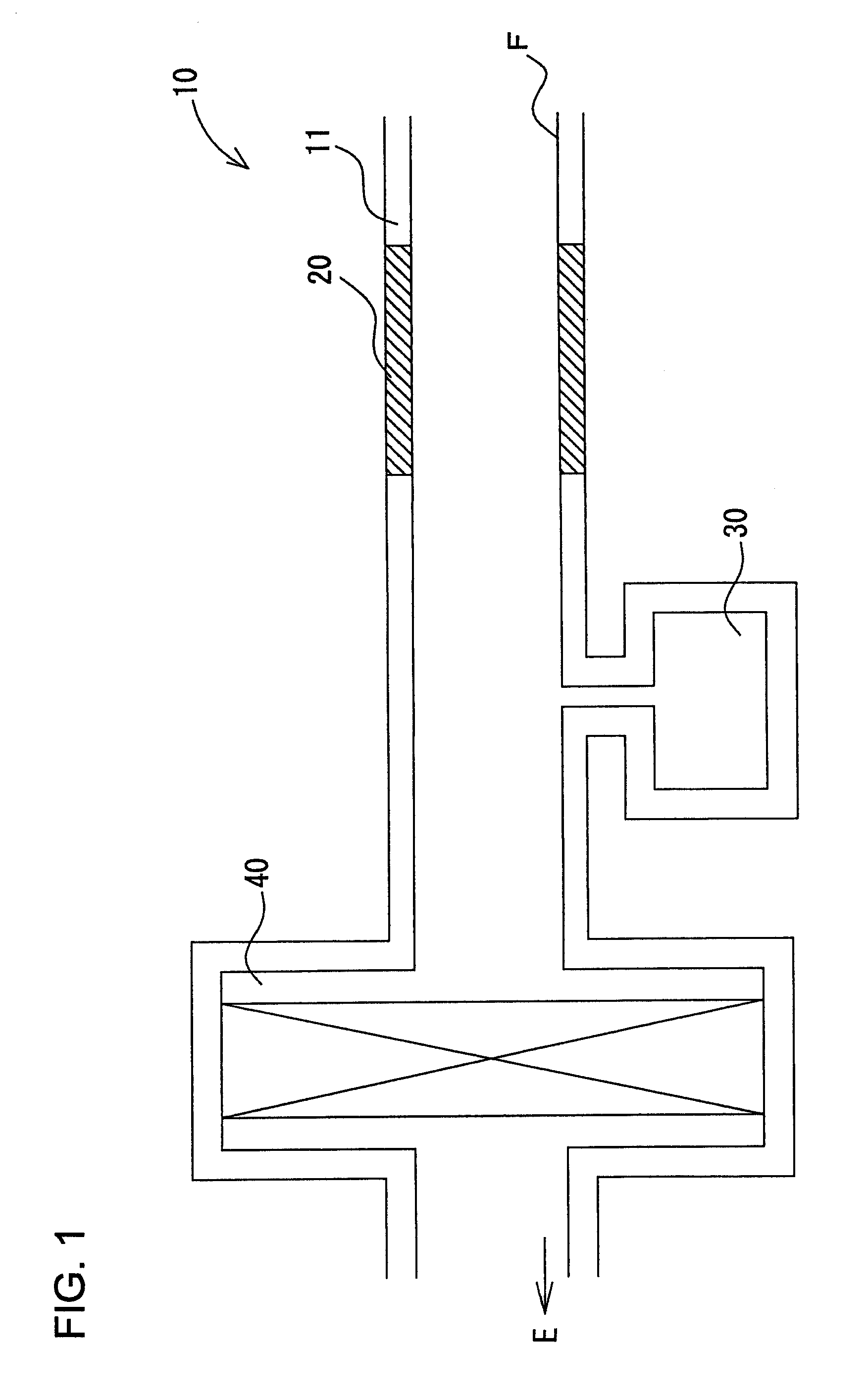

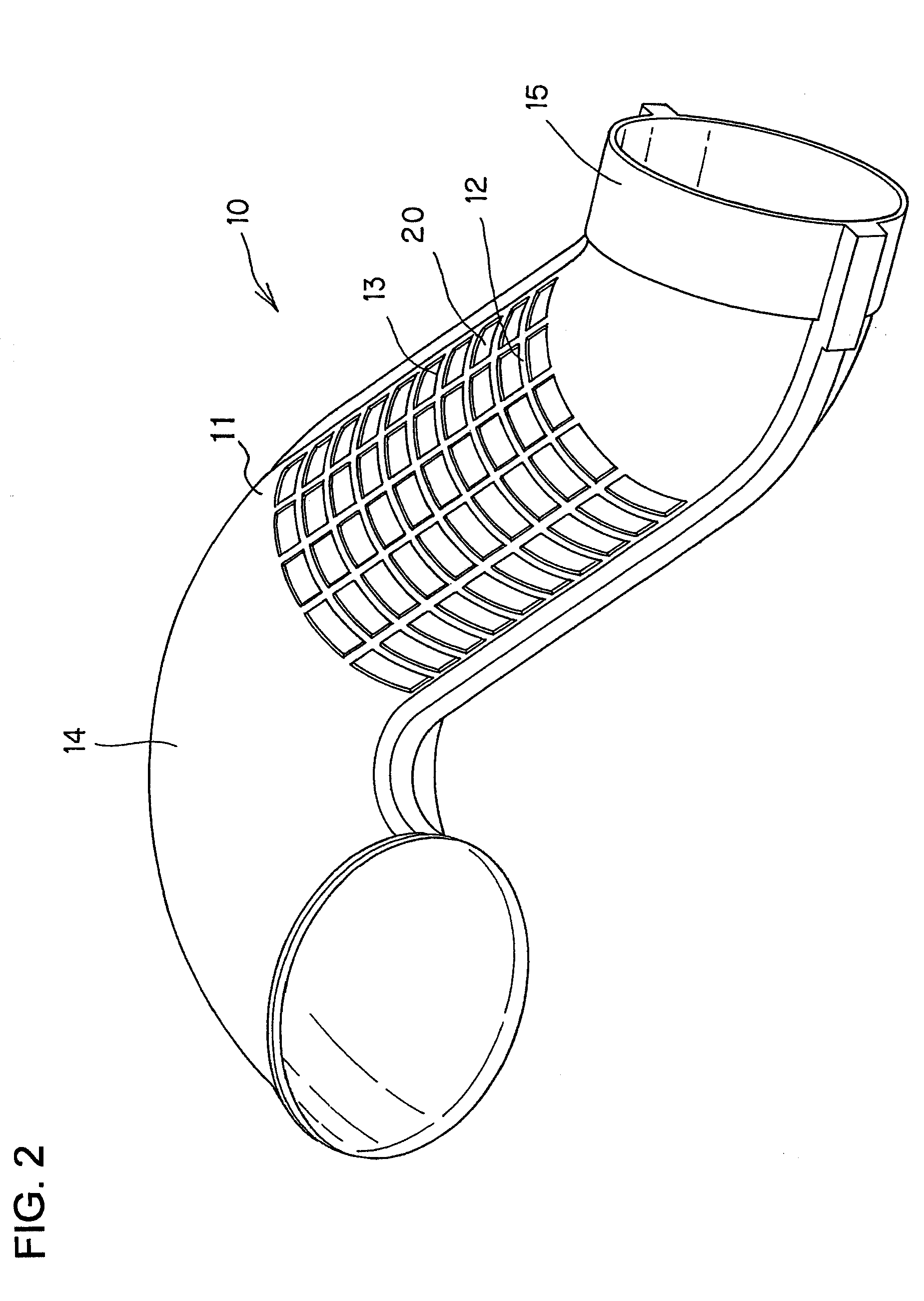

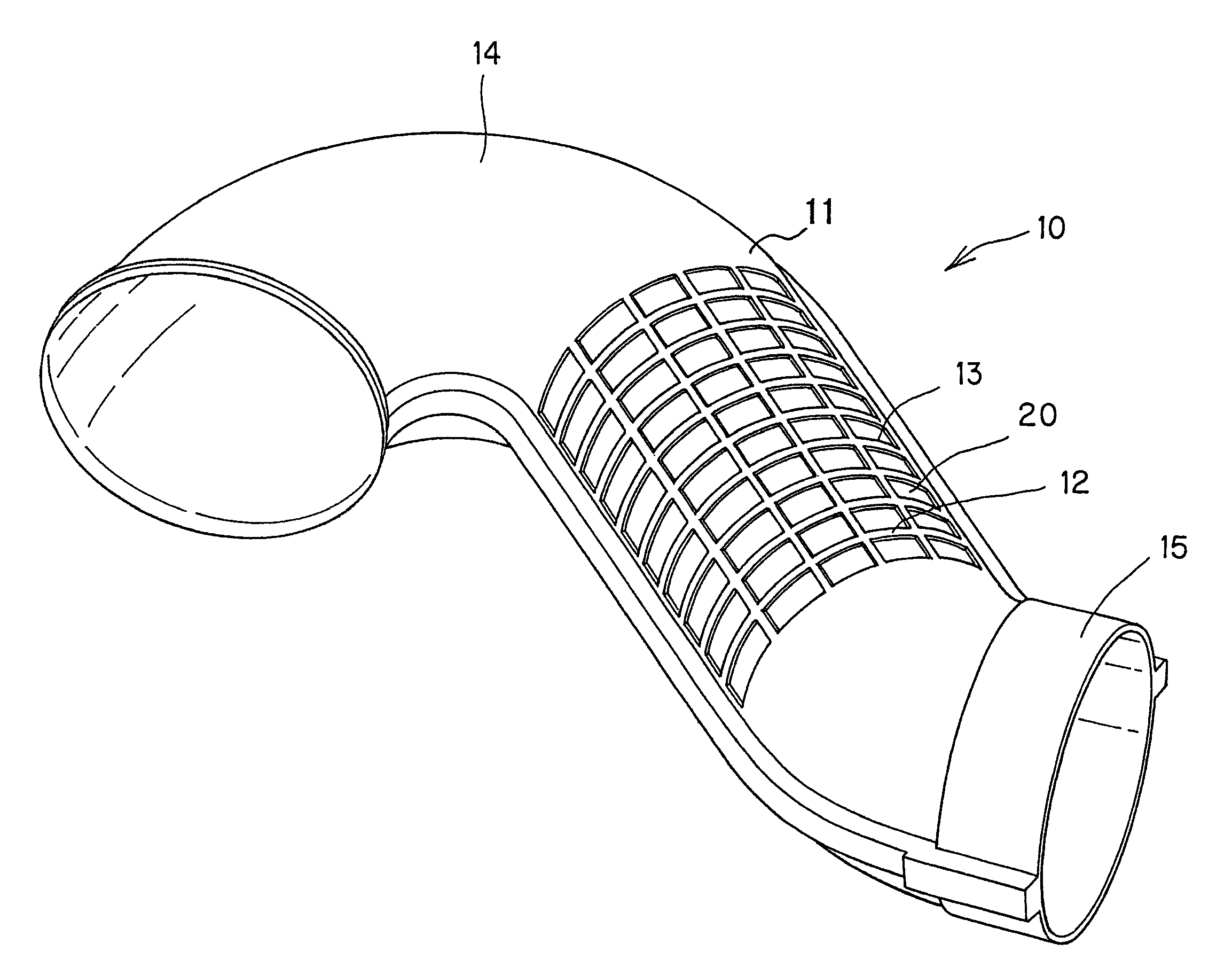

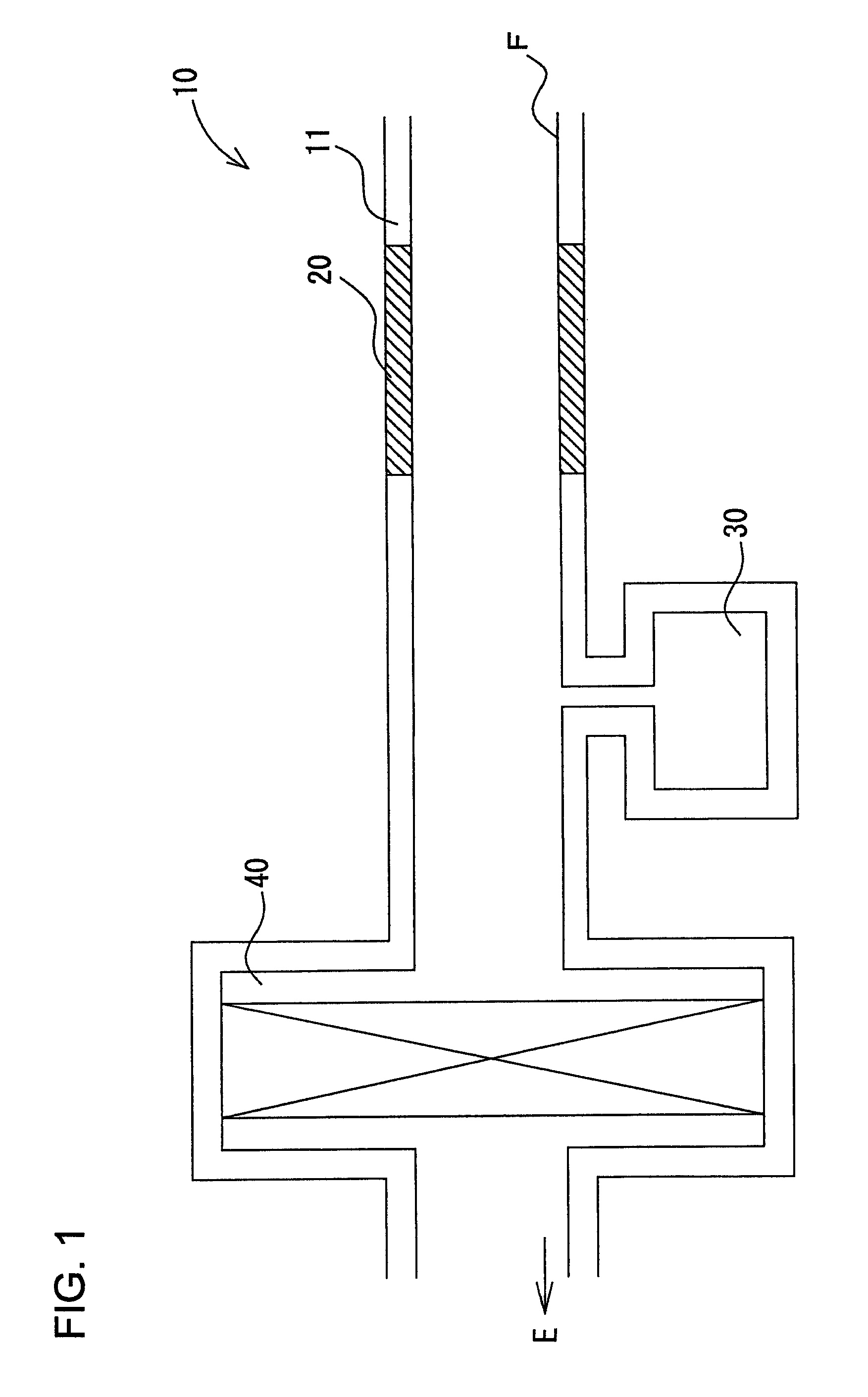

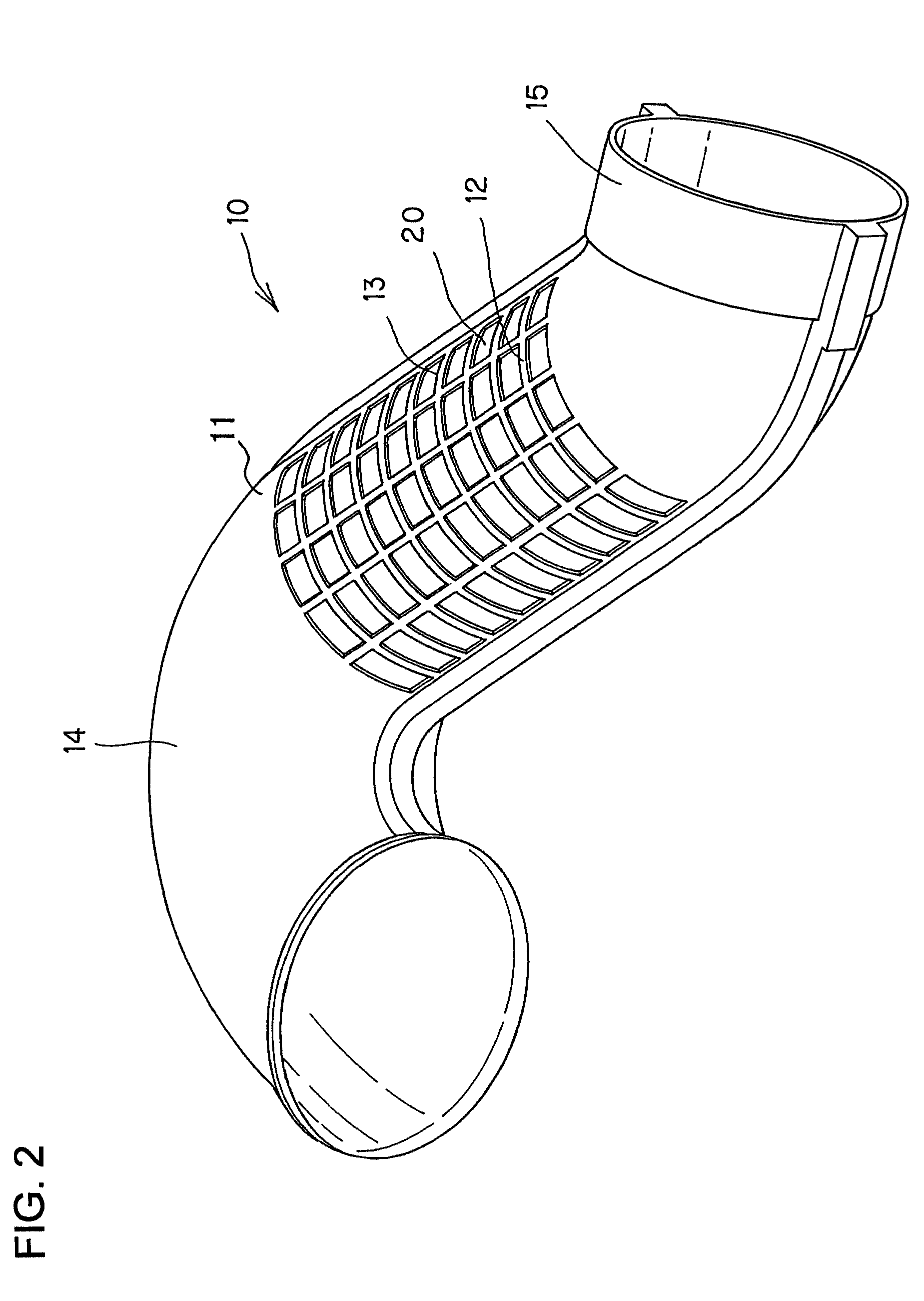

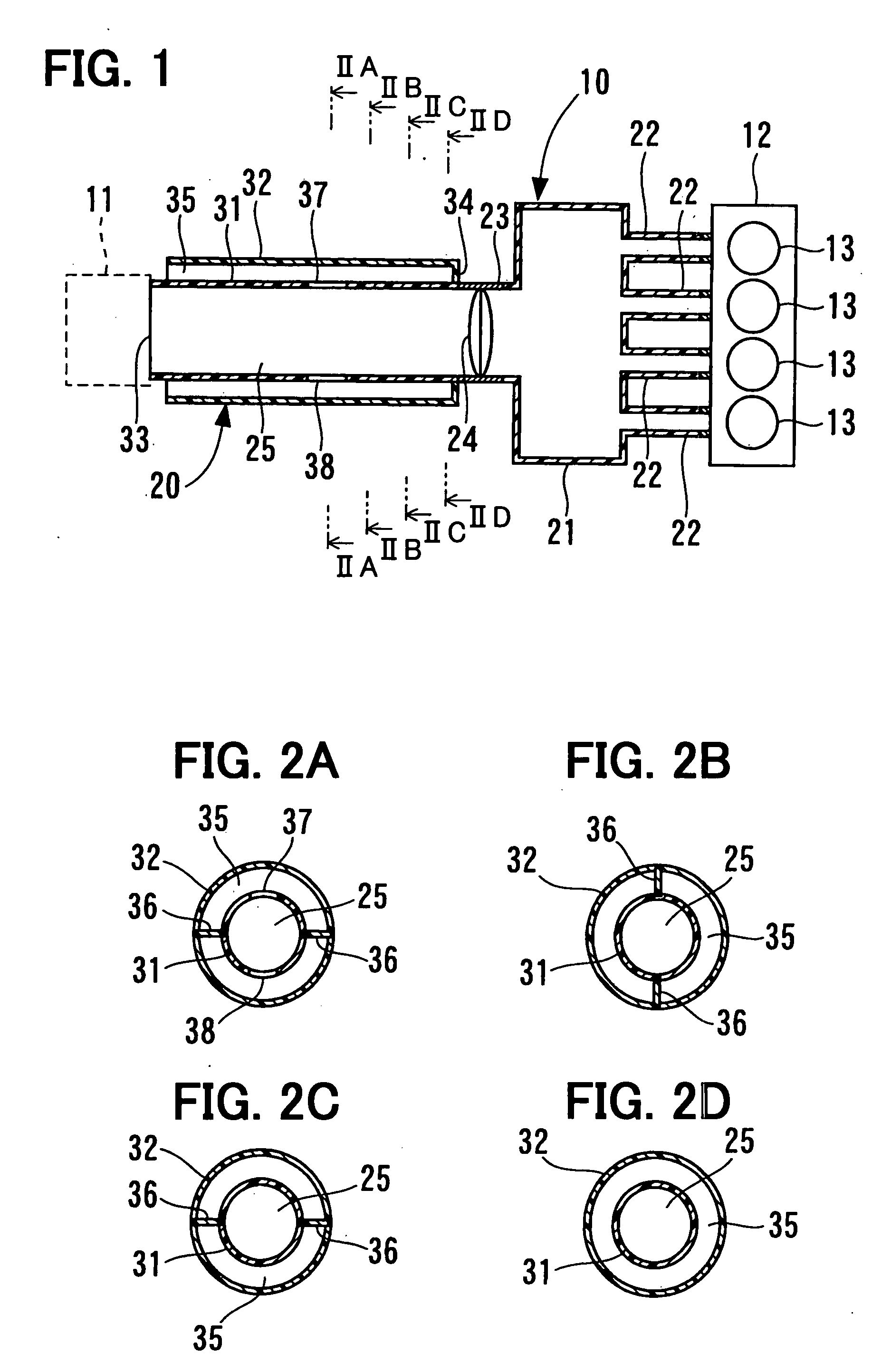

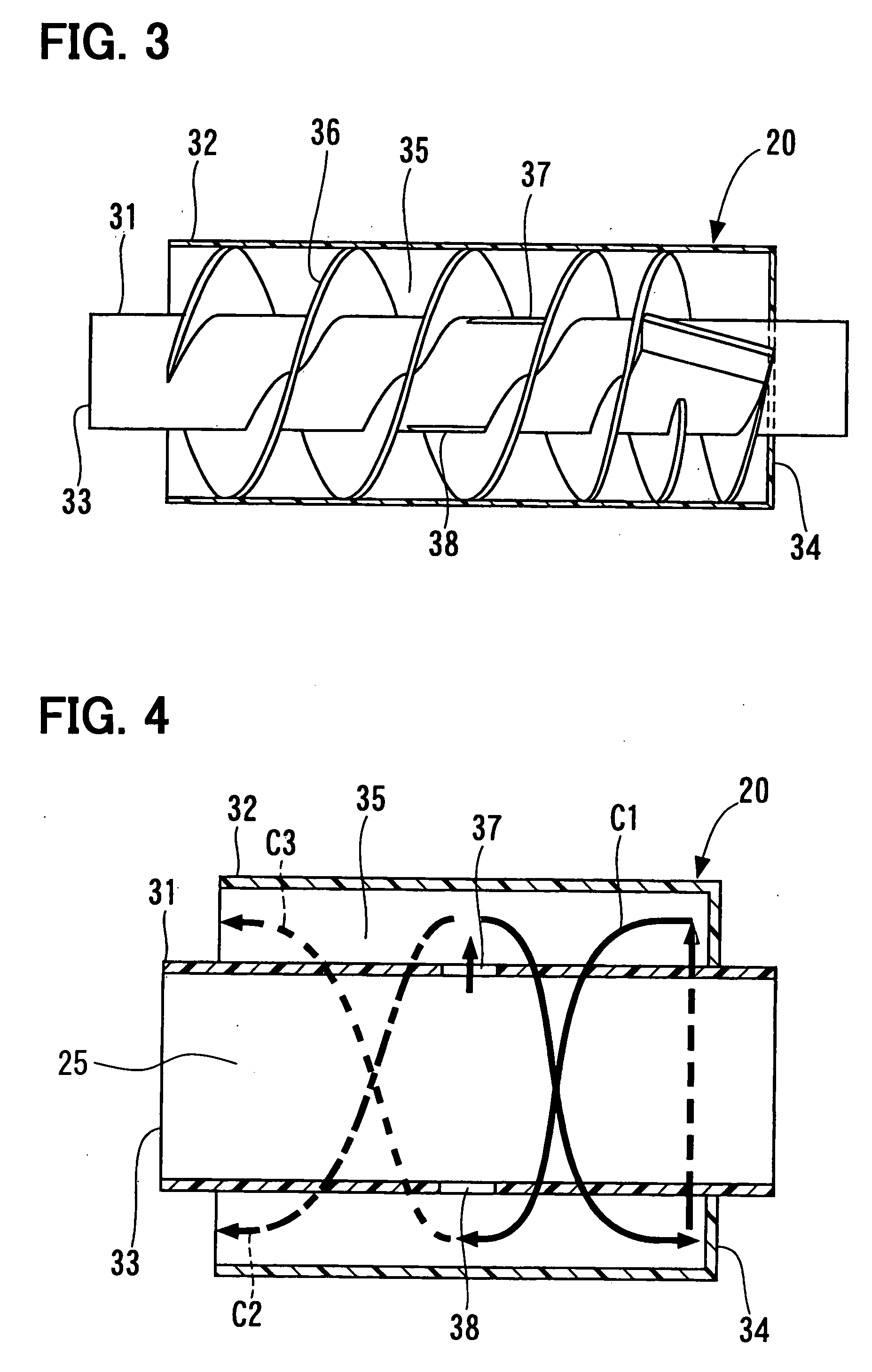

Intake duct

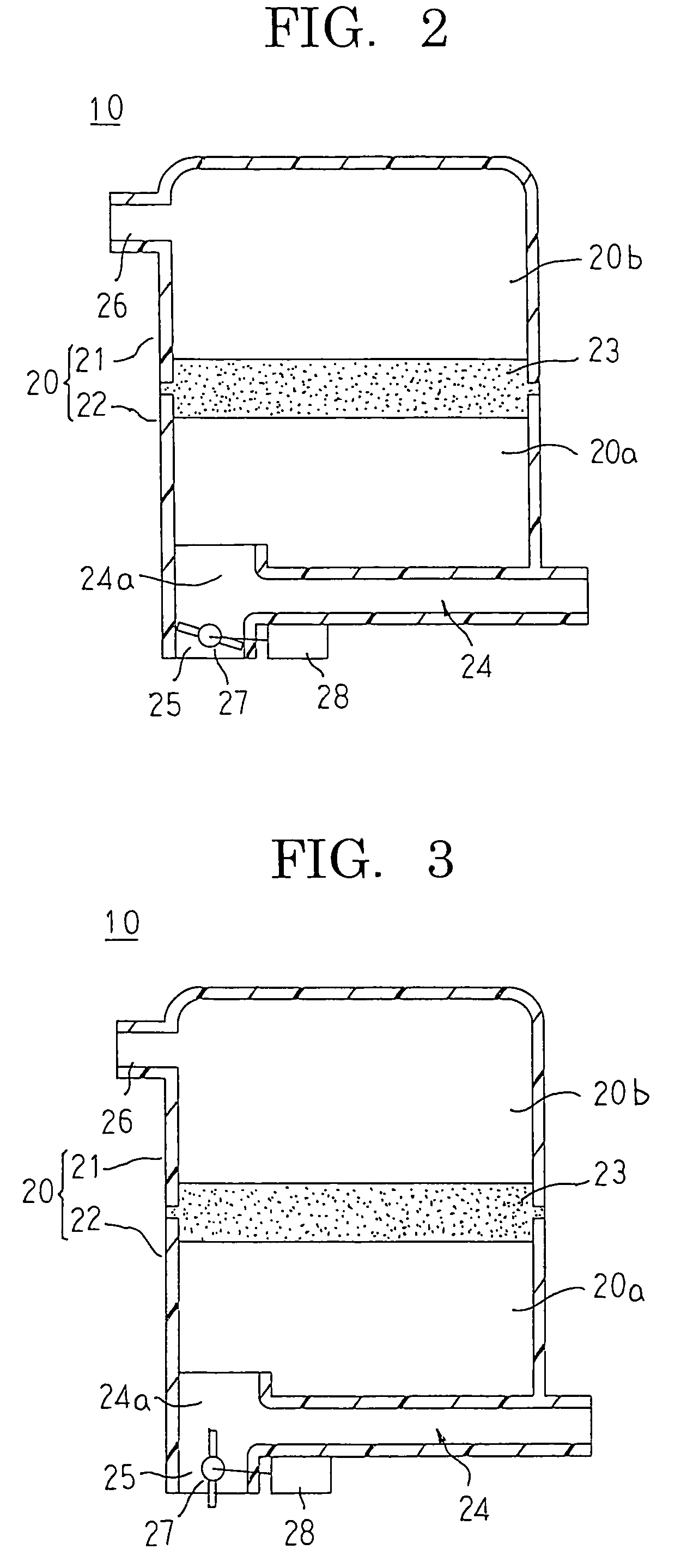

ActiveUS20090293832A1Reduce intake noiseSmall outer diameterSilencing apparatusMachines/enginesFiberHigh density

[Object] The object of the present invention is to provide an intake duct having waterproof function without increasing parts count.[Means of Solution] An intake duct 10 for air intake from the outside to an internal combustion engine E includes a duct wall 11 made of a resin in a tubular form. The duct wall 11 includes a waterproof and humidity-transparent component 20 having a water-repellent layer 21 made of high-density fiber and a waterproof and humidity-transparent layer 22 made of fine porous film laminated to each other.

Owner:ROKI CO LTD

Intake duct

ActiveUS8132552B2Reduce intake noiseSmall outer diameterSilencing apparatusMachines/enginesFiberHigh density

The object of the present invention is to provide an intake duct having waterproof function without increasing parts count.An intake duct 10 for air intake from the outside to an internal combustion engine E includes a duct wall 11 made of a resin in a tubular form. The duct wall 11 includes a waterproof and humidity-transparent component 20 having a water-repellent layer 21 made of high-density fiber and a waterproof and humidity-transparent layer 22 made of fine porous film laminated to each other.

Owner:ROKI CO LTD

Induction air acoustics management for internal combustion engine

InactiveUS7464674B2Increase intake vacuumReduce intake noiseElectrical controlInternal combustion piston enginesExhaust valveActuator

A system and method for controlling an internal combustion engine control an actuator in response to variations of intake airflow relative to an average intake airflow to manage induction acoustics. The system and method may include controlling an actuator, such as a throttle valve, to increase intake manifold vacuum in response to intake airflow. In an engine having electronically actuated intake and / or exhaust valves, intake airflow is estimated based on at least engine speed and valve timing and compared to a measured intake airflow to determine a first difference. The measured airflow is divided into a steady-state and transient term or component with a second difference determined based on the transient component and a target value. Throttle valve position is selectively controlled to increase vacuum in response to a combination of the first and second difference to manage induction acoustics.

Owner:FORD GLOBAL TECH LLC

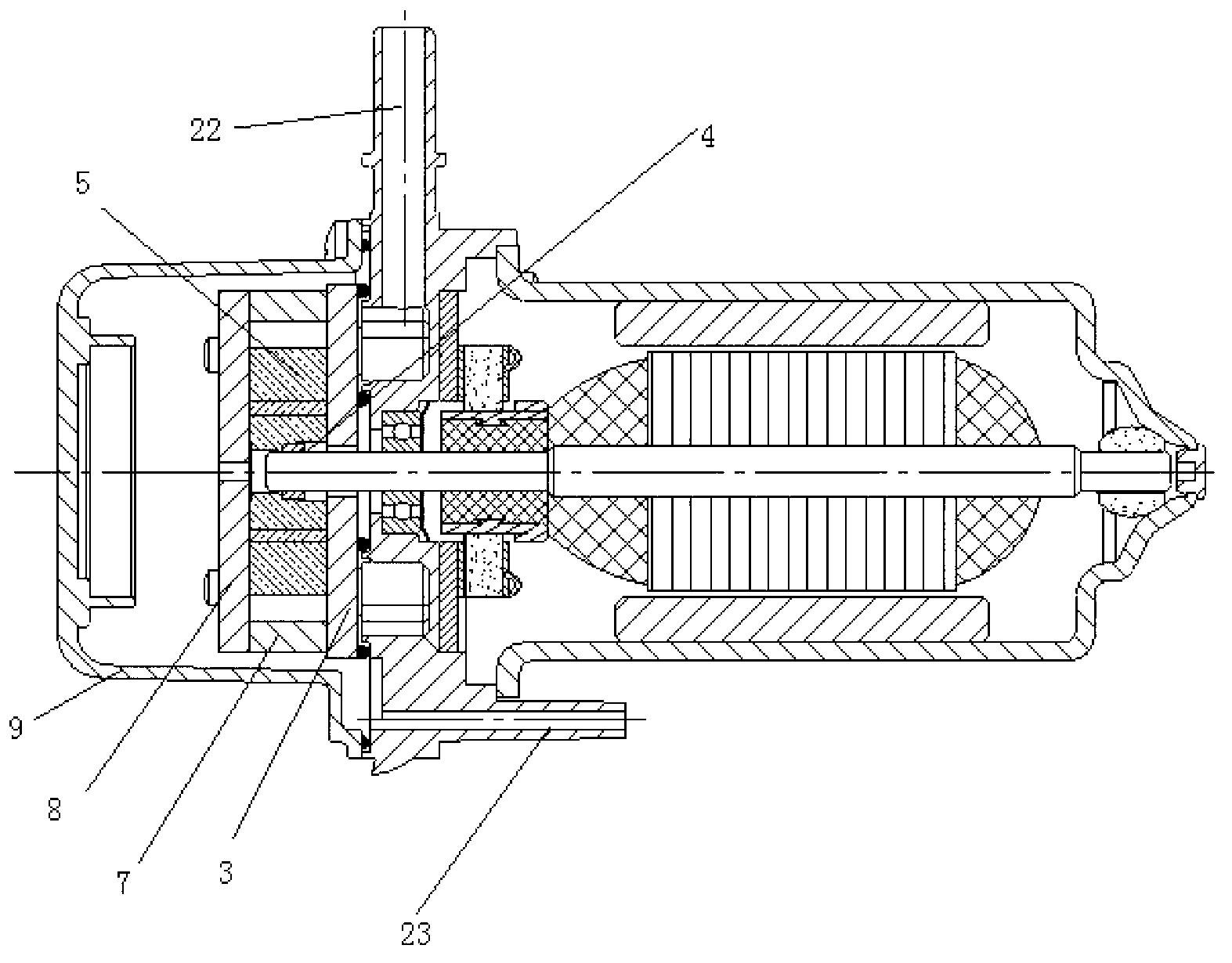

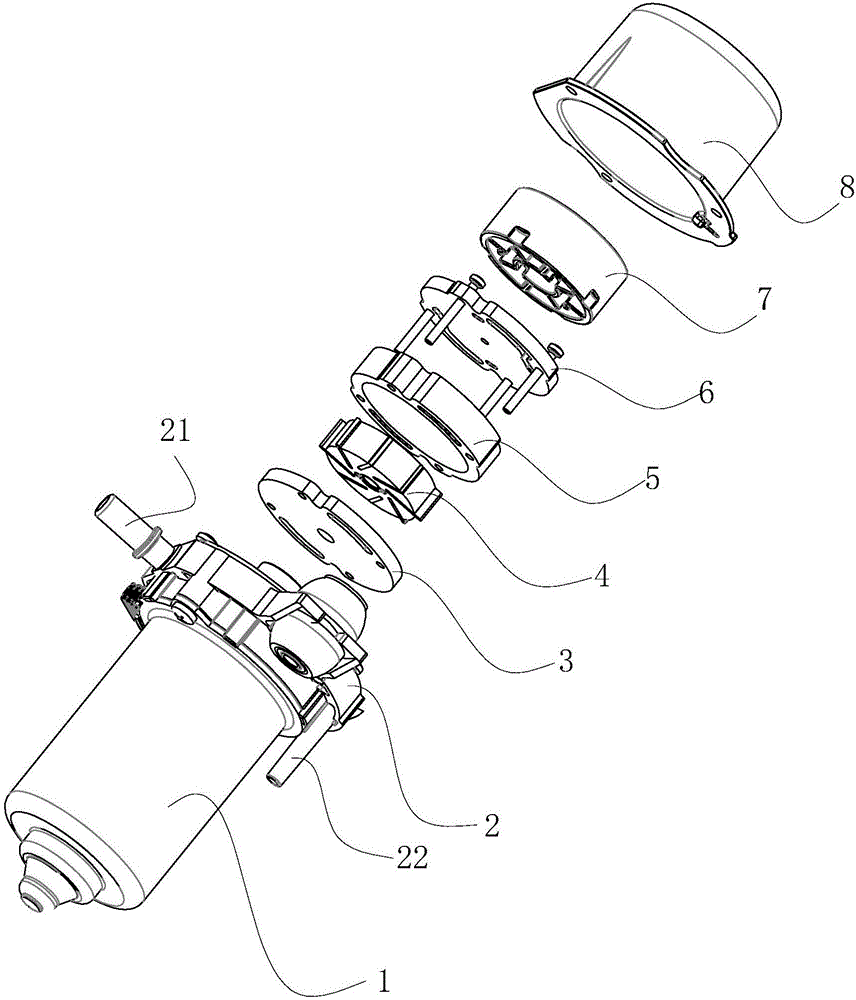

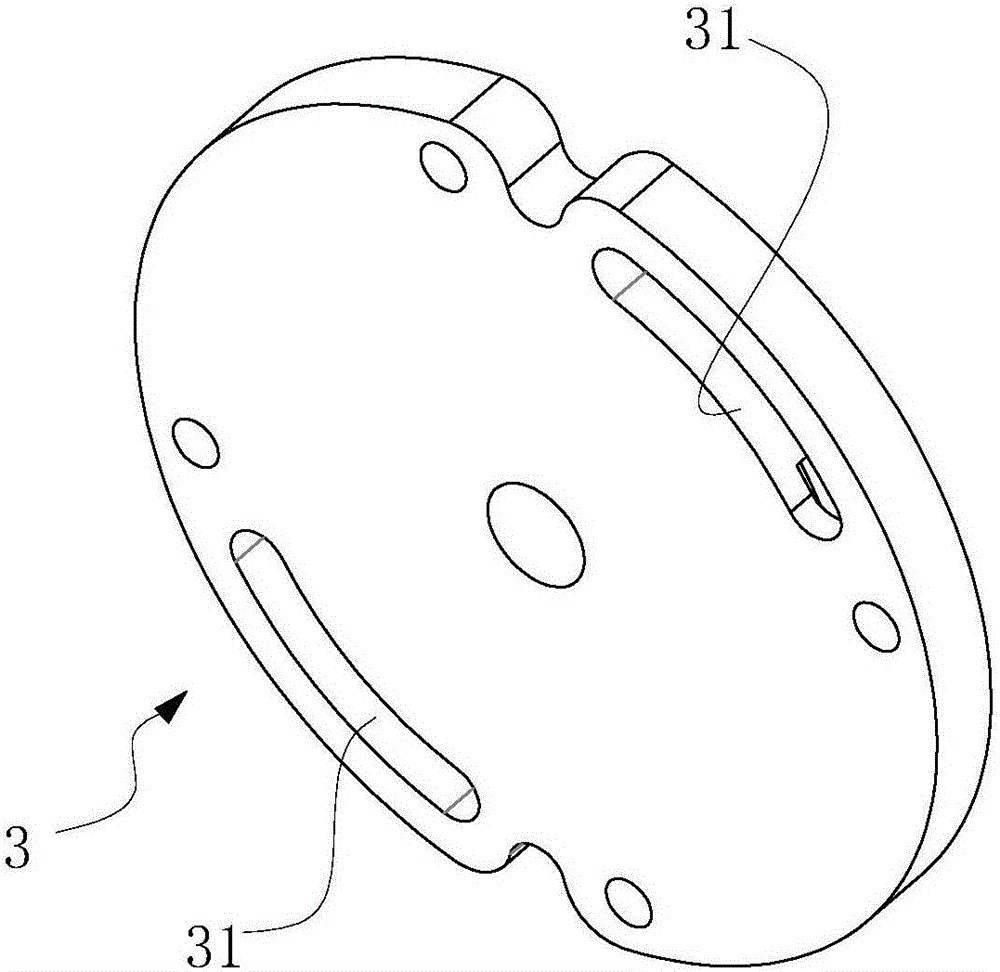

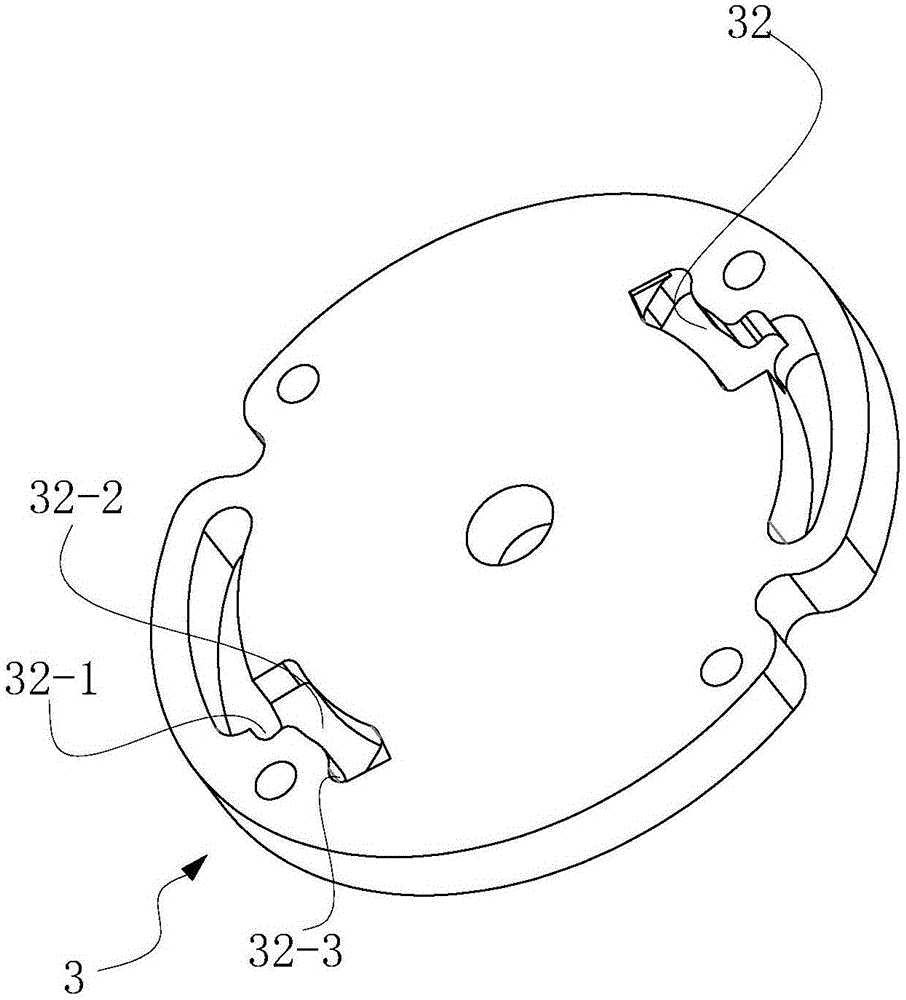

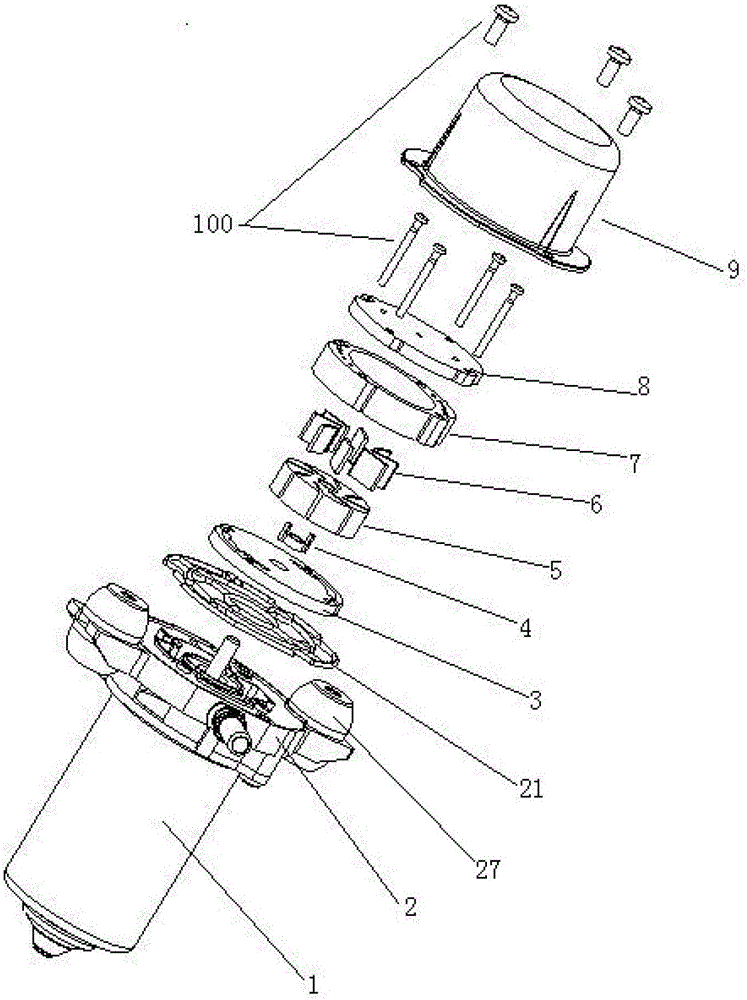

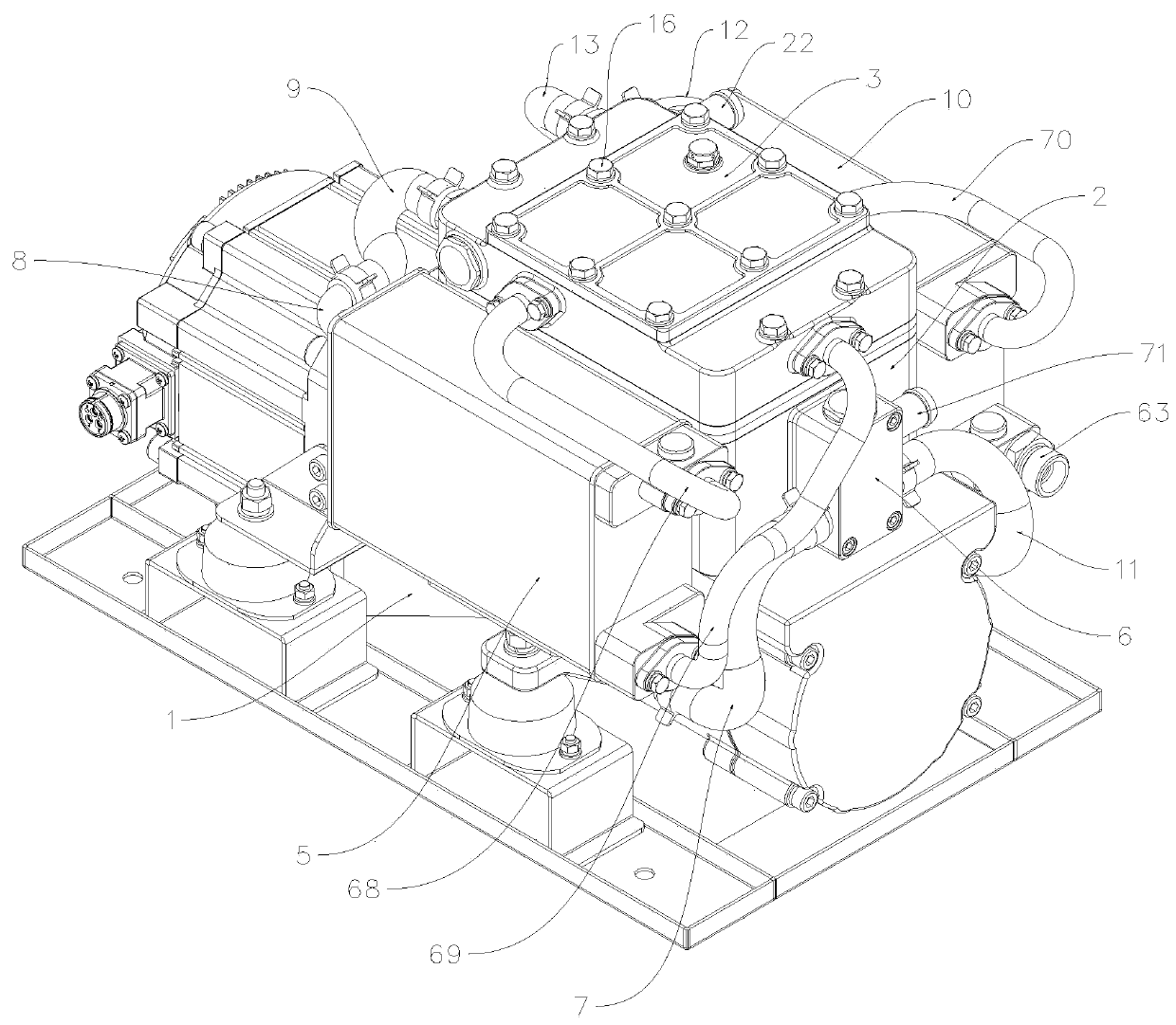

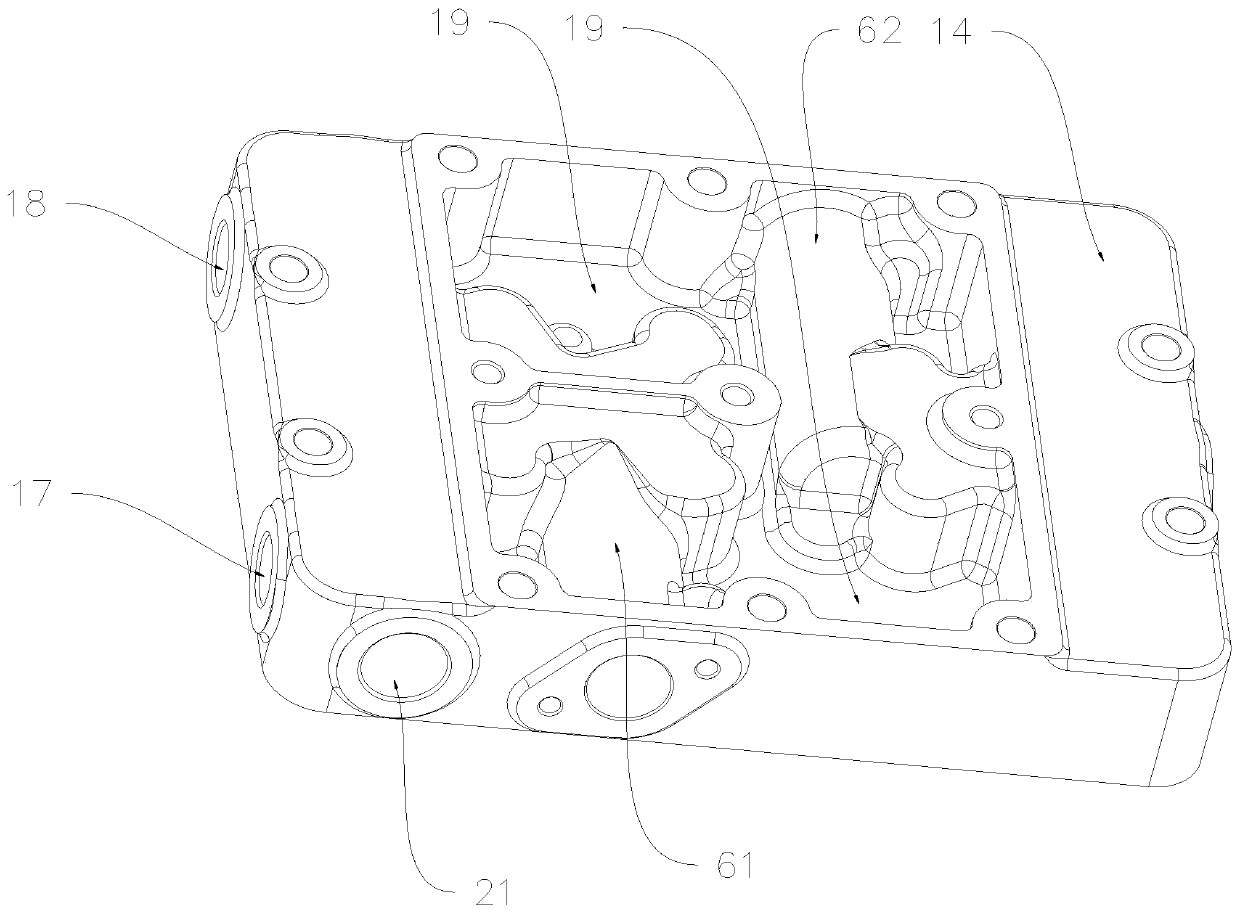

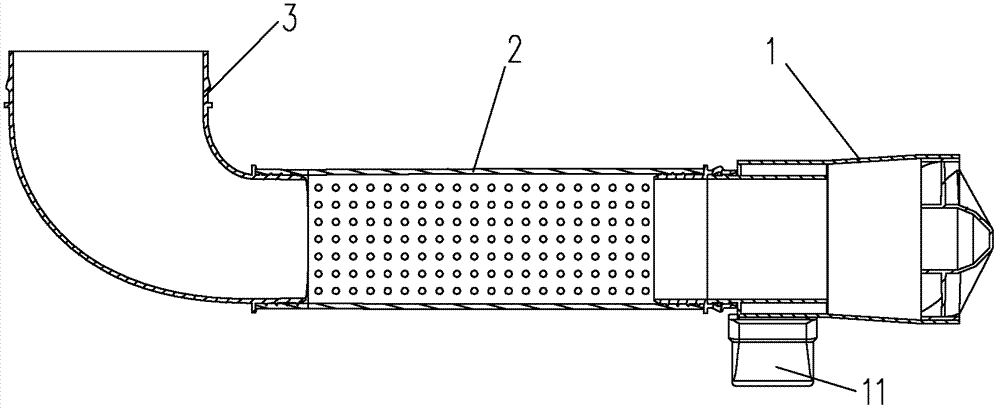

Electronic vacuum pump for new energy vehicle brake vacuum booster

ActiveCN103306979AImprove vacuum efficiencyIncrease air intakeMachines/enginesPumpsVacuum pumpEnergy consumption

The invention discloses an electronic vacuum pump for a new energy vehicle brake vacuum booster. The electronic vacuum pump comprises a motor assembly, a supporting base, a pump chamber lower cover, a driving sleeve, a pump rotor, blades, a pump chamber, a pump chamber upper cover, a pump body cover and fixing pins, wherein a left side air feeding slot of the pump chamber lower cover, a left side air feeding through hole of the pump chamber and a left side air feeding slot of the pump chamber upper cover are communicated with one another to form an air passageway; a right side air feeding slot of the pump chamber lower cover, a right side air feeding through hole of the pump chamber and a right side air feeding slot of the pump chamber upper cover are communicated with one another to form an air passageway; a flow guide slot of the pump chamber lower cover is communicated with an inner cavity of the pump chamber; an air discharging slot of the pump chamber upper cover is communicated with the inner cavity of the pump chamber; the flow guide slot of the pump chamber lower cover and the air discharging slot of the pump chamber upper cover are symmetric. When the vacuum pump works, an air path with four air inlets and two air outlets is formed; therefore, the air feeding resistance is greatly reduced, and the air feeding amount of the pump chamber is increased; under the equal energy consumption, the vacuumizing efficiency of the vacuum pump provided by the invention is higher.

Owner:常州市东南电器电机有限公司

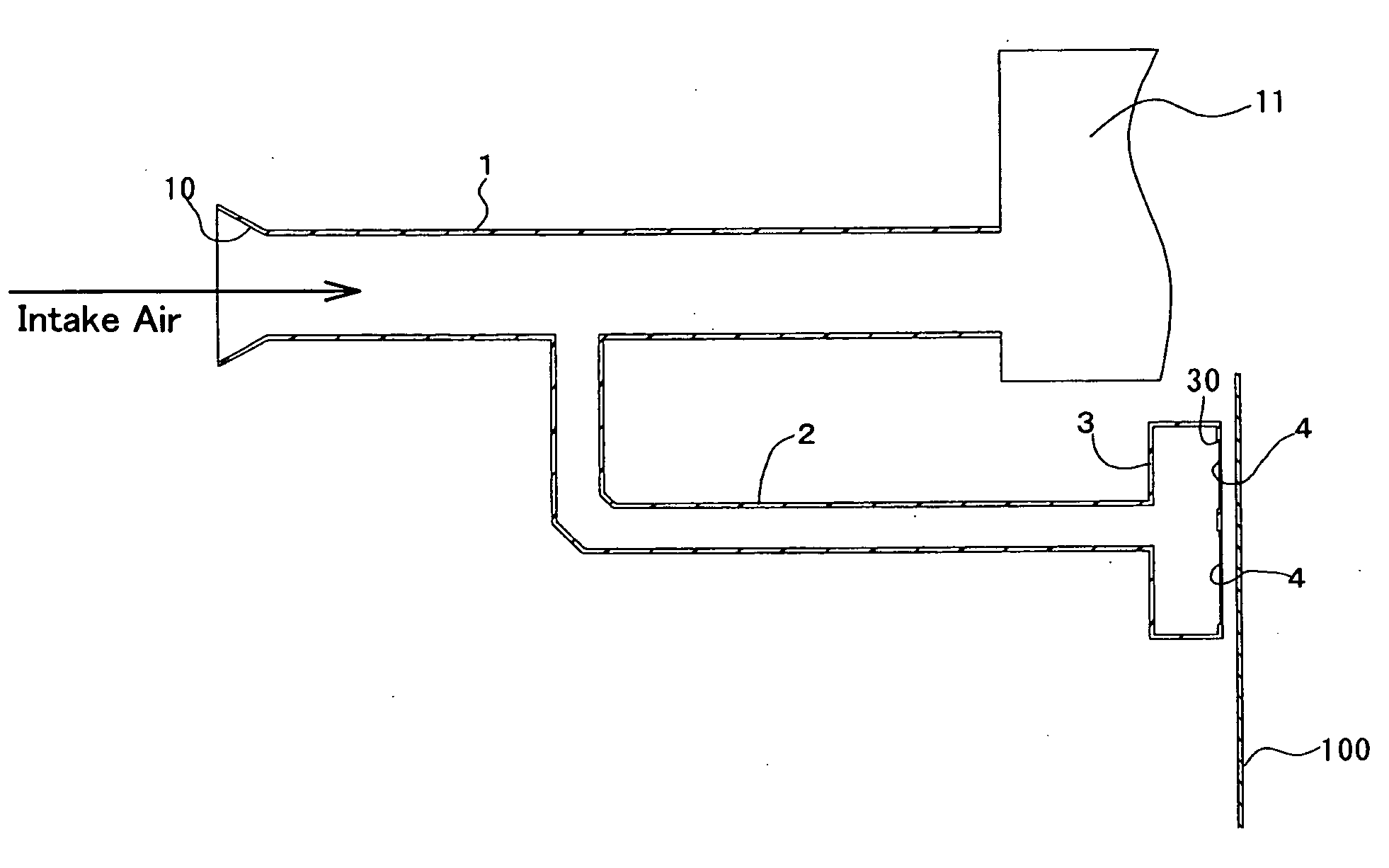

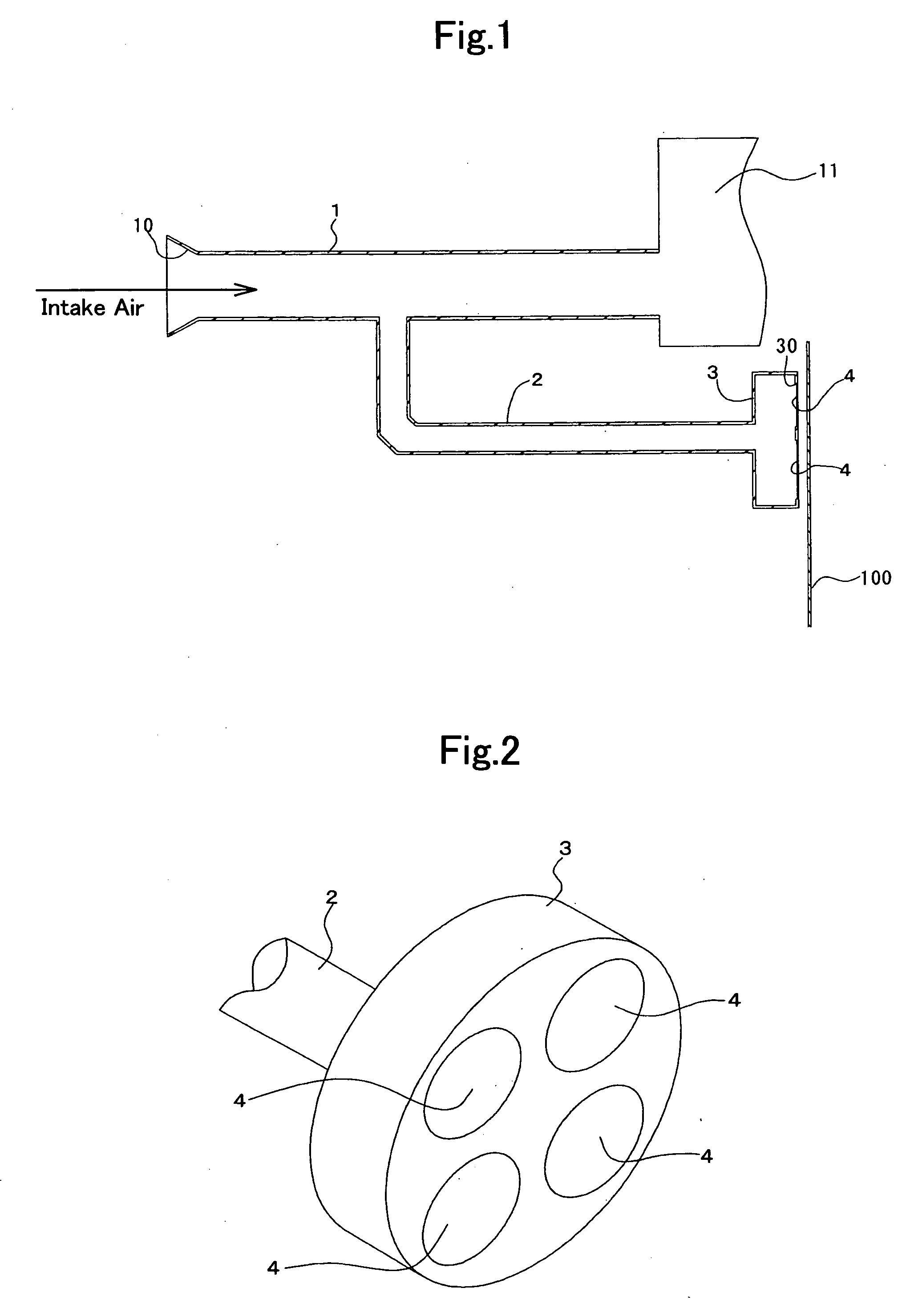

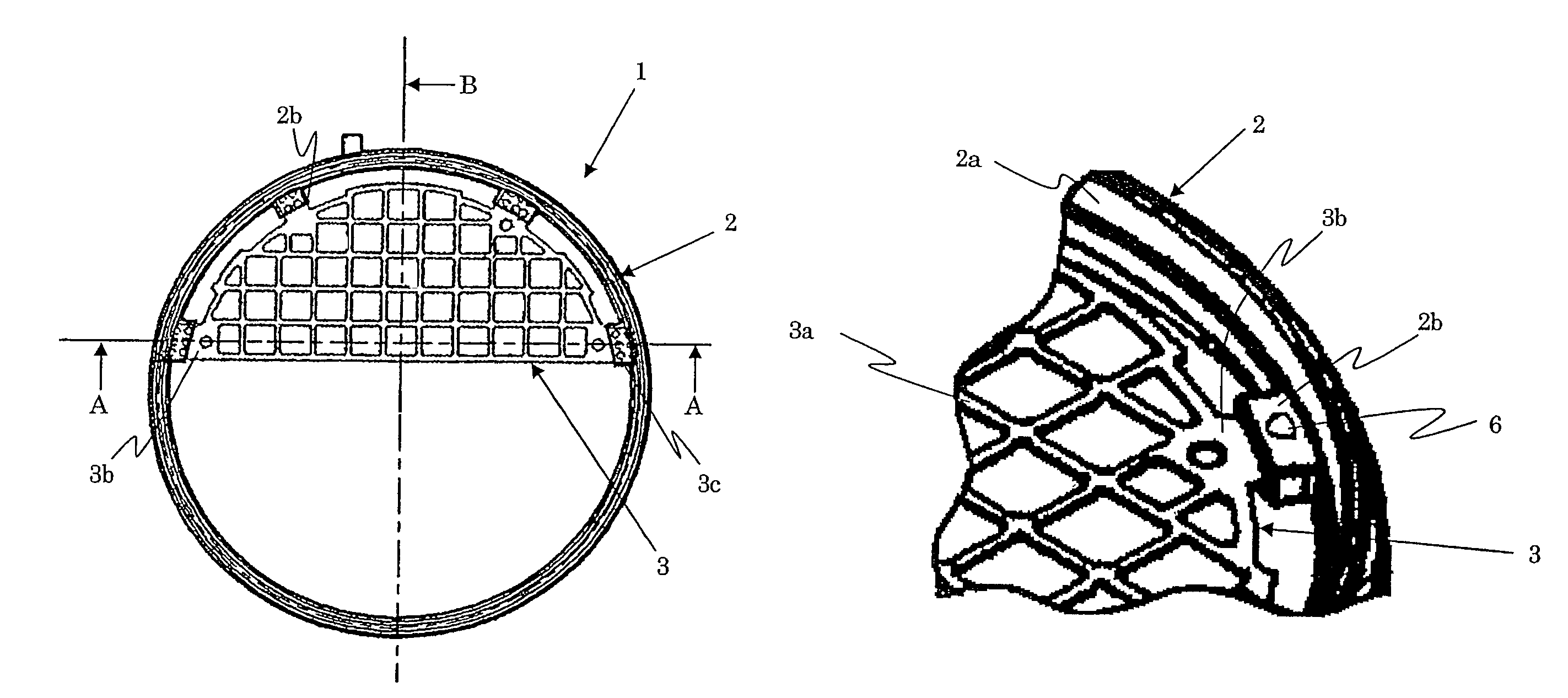

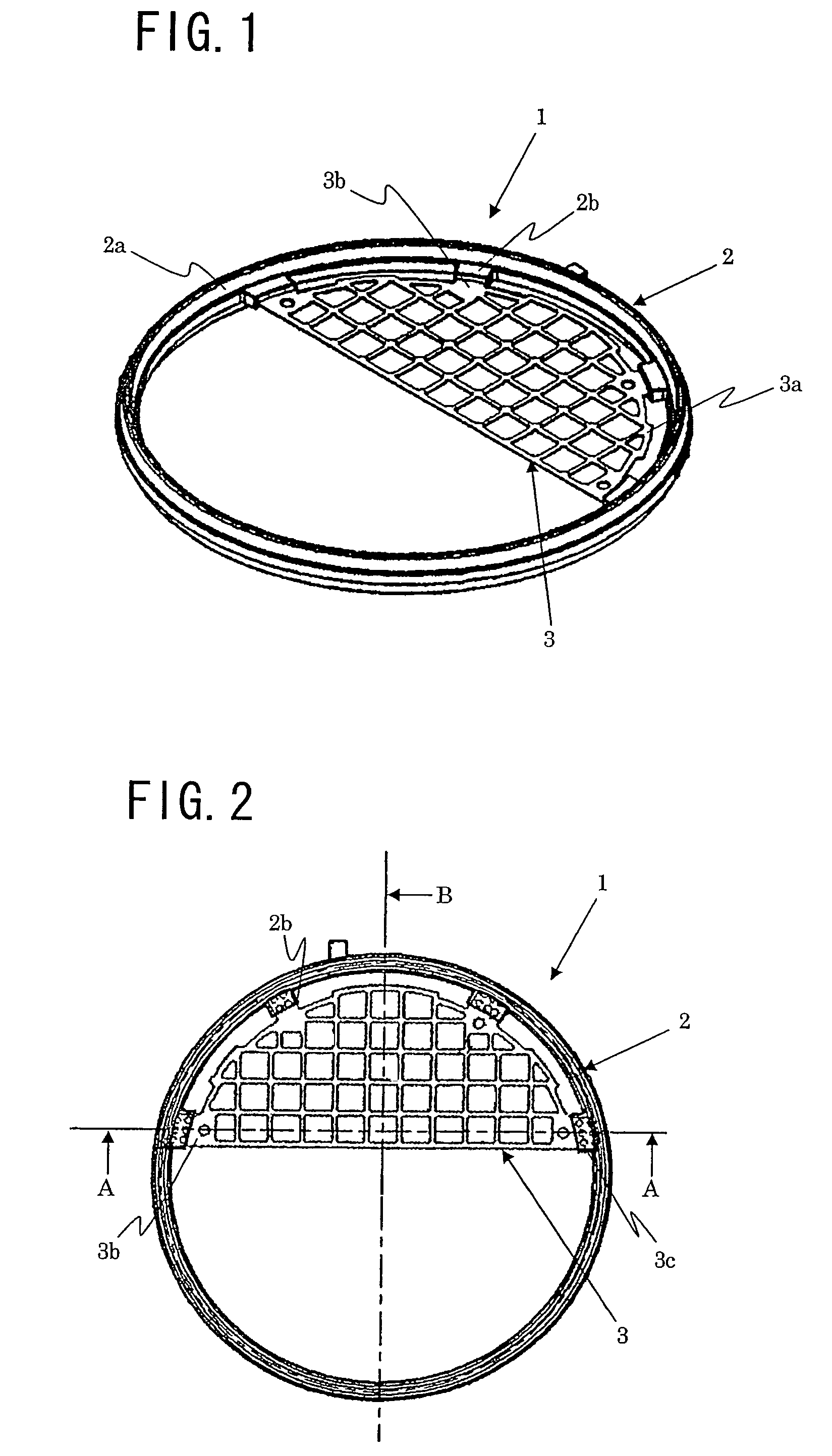

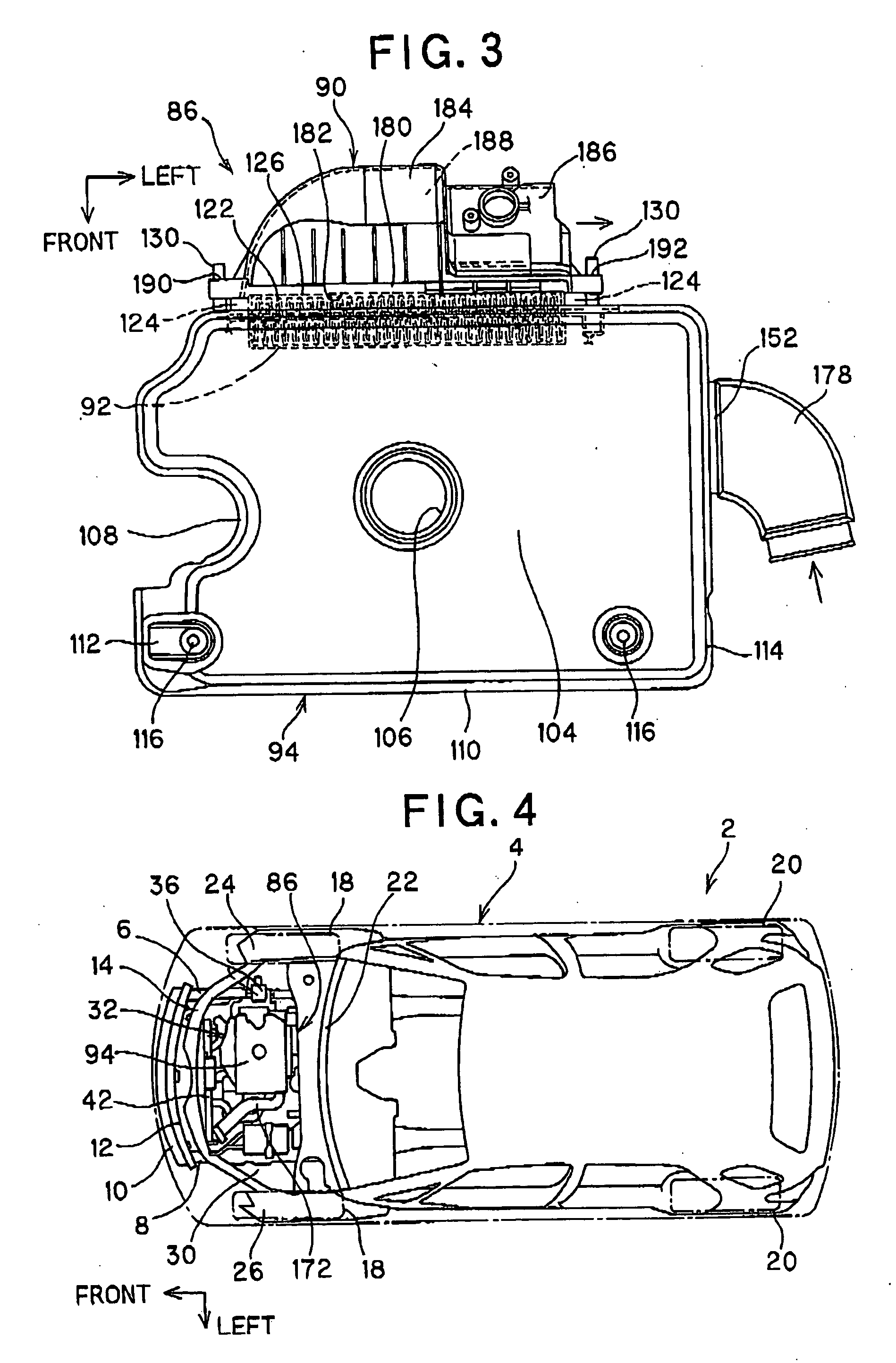

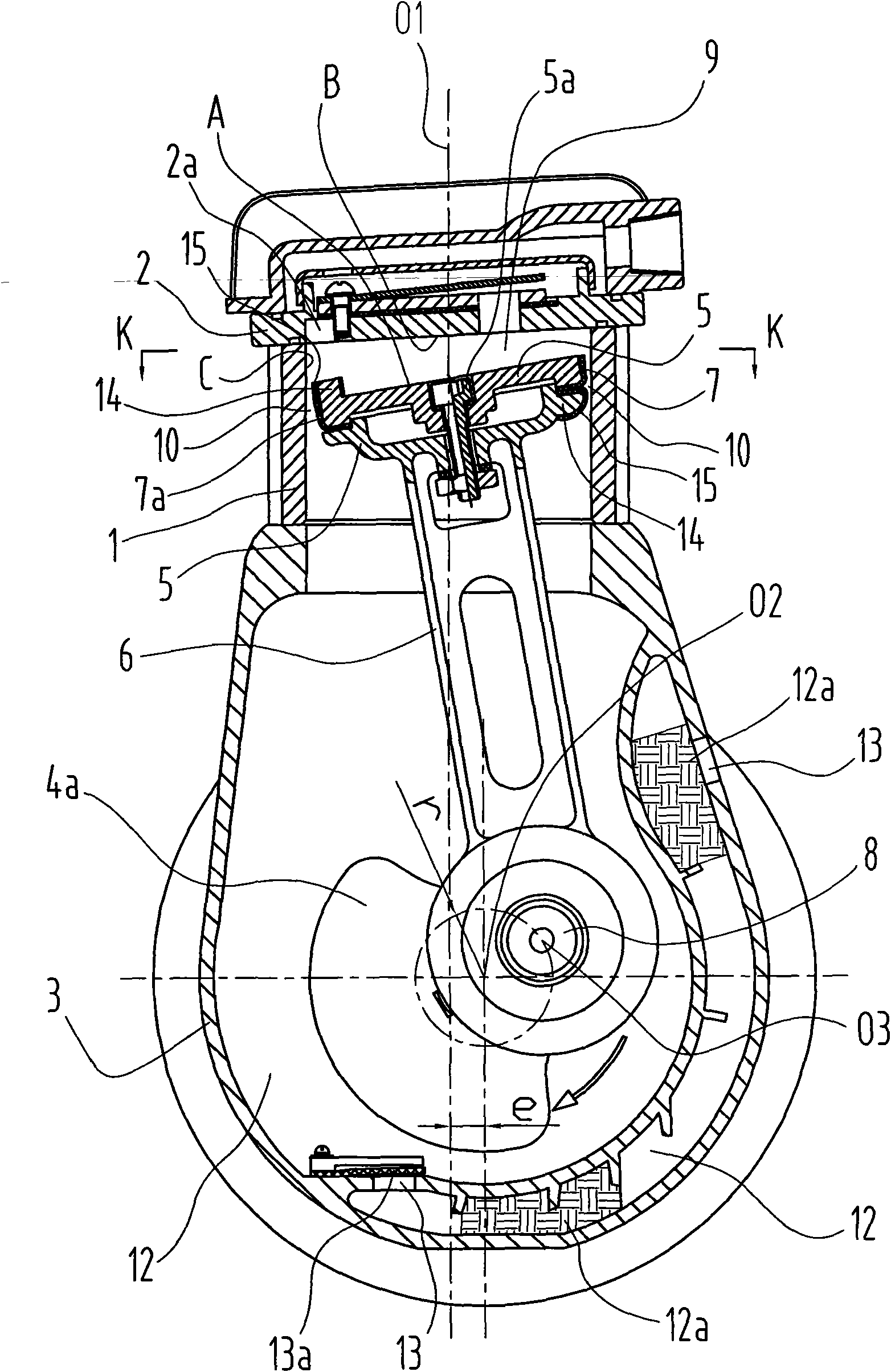

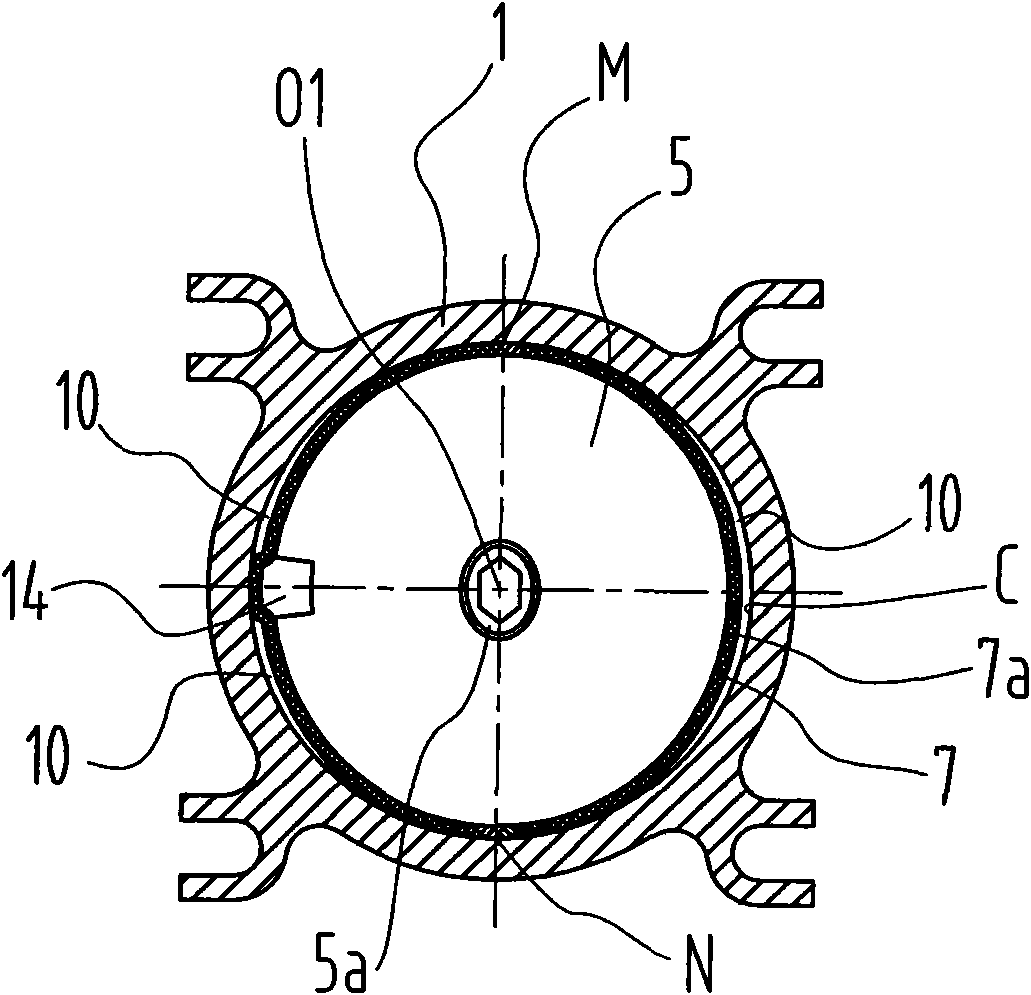

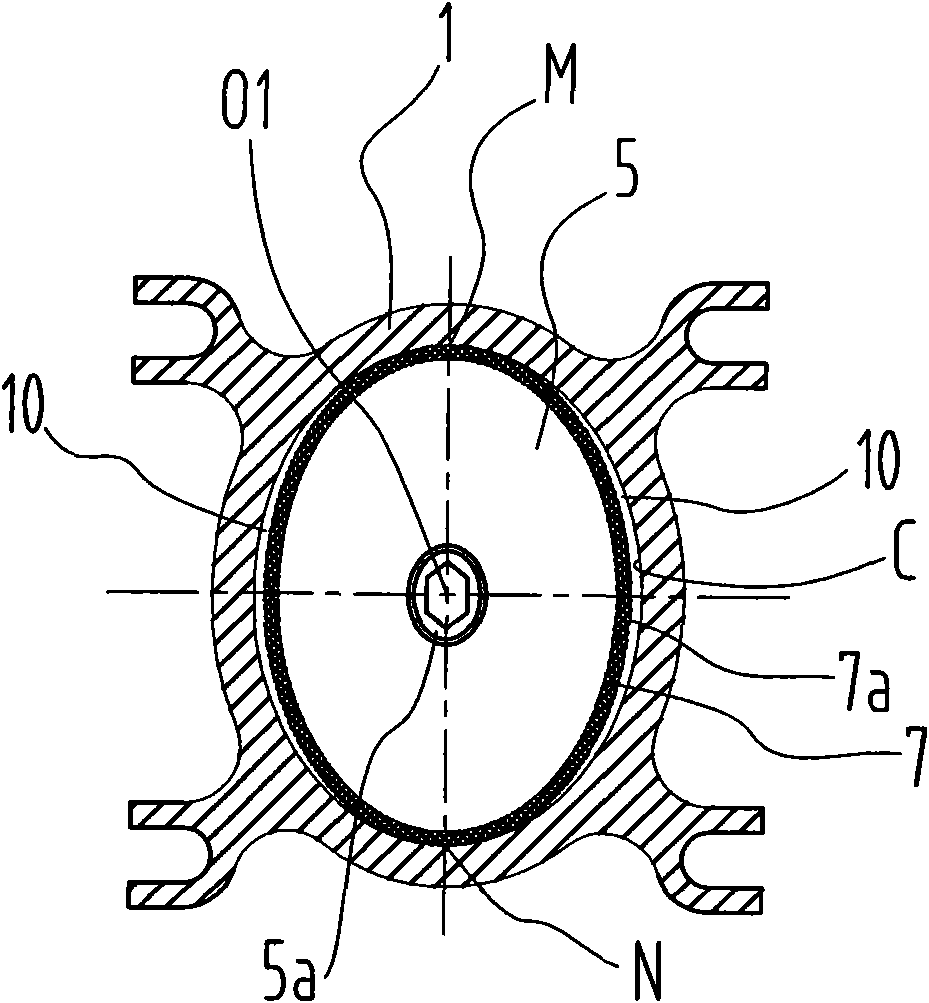

Air intake noise reducing device, internal combustion engine fitted with the same and structure for fitting the same to the internal combustion engine

ActiveUS7730997B2Less assemblyReduce intake noiseProportioning devicesSilencing apparatusMan-hourEngineering

The present invention provides an air intake noise reducing device, an internal combustion engine fitted with the air intake noise reducing device and a structure for fitting the air intake noise reducing device to the internal combustion engine. The air intake noise reducing device comprises a gasket (2) comprising a ring member (2a) held by connecting surfaces of an air intake passage (100) and protrusion holding portions (2b) extending from the ring member (2a) toward a center of the air intake passage (100); and a net member (3) comprising a net (3a) for rectifying intake air and connecting protrusions (3b) extending outward from the net (3). The connecting protrusions (3b) are held in the protruding holding portions (2b) such that the ring member (3) is firmly secured to the gasket (3). The air intake noise reducing device constituted by in the above-mentioned manner can reduce assembly man-hours without deteriorating a sealing property of the air passage.

Owner:KOKOKU INTECH CO LTD

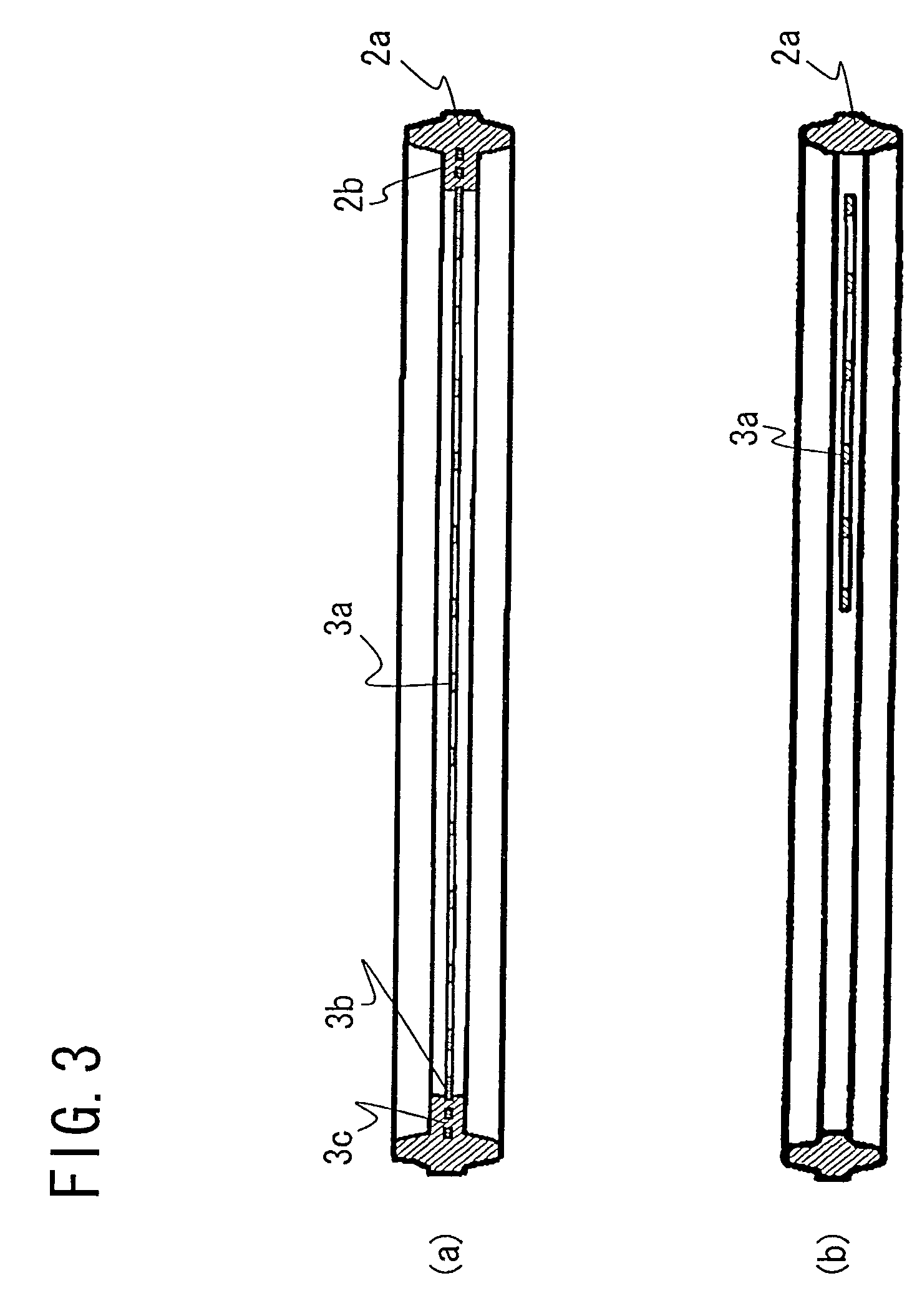

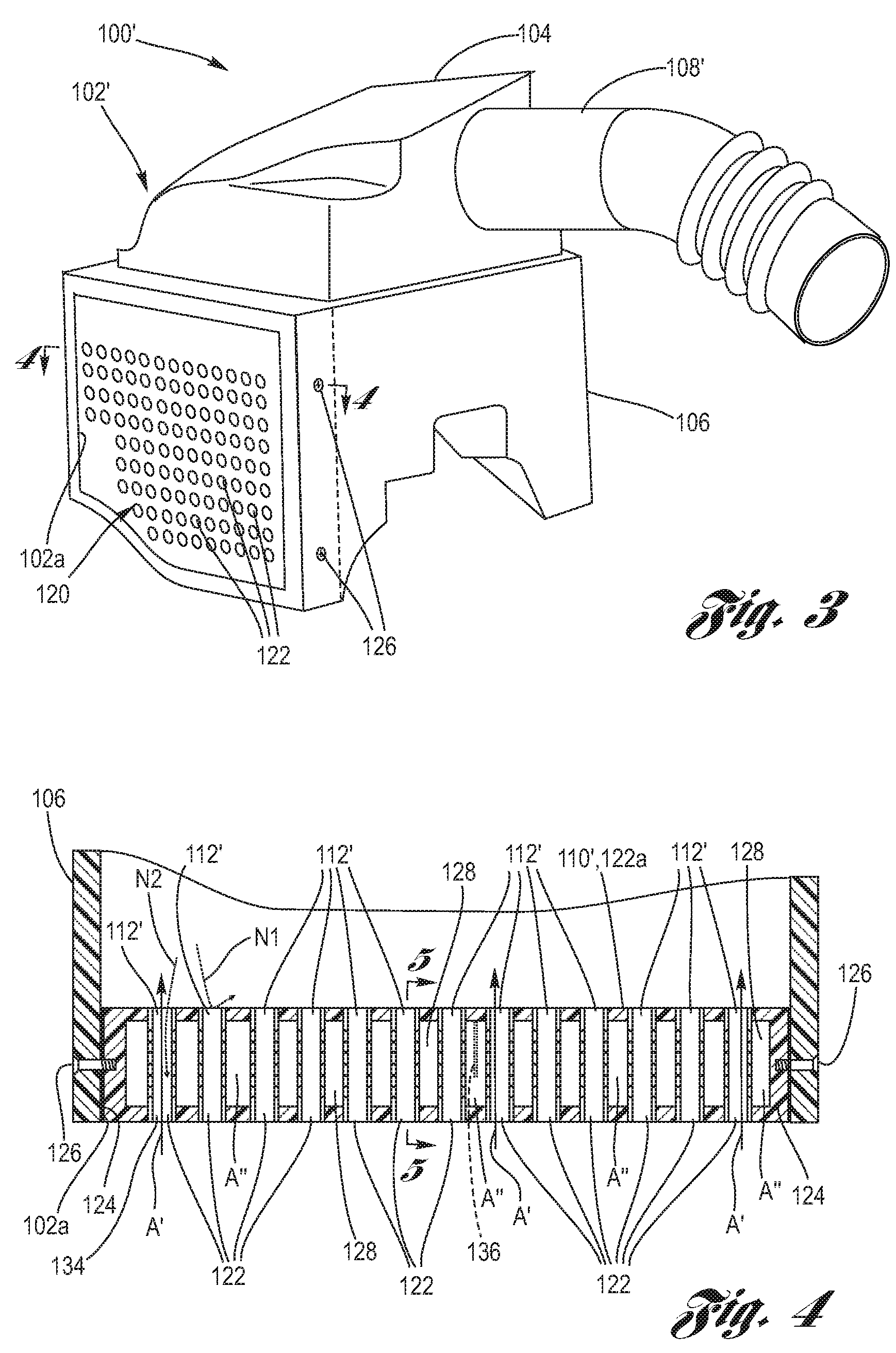

Air induction housing having a perforated wall and interfacing sound attenuation chamber

InactiveUS7694660B2Audibility of minimizedHigh levelExhaust apparatusSilencing apparatusUltrasound attenuationDiagnostic Radiology Modality

Owner:GM GLOBAL TECH OPERATIONS LLC

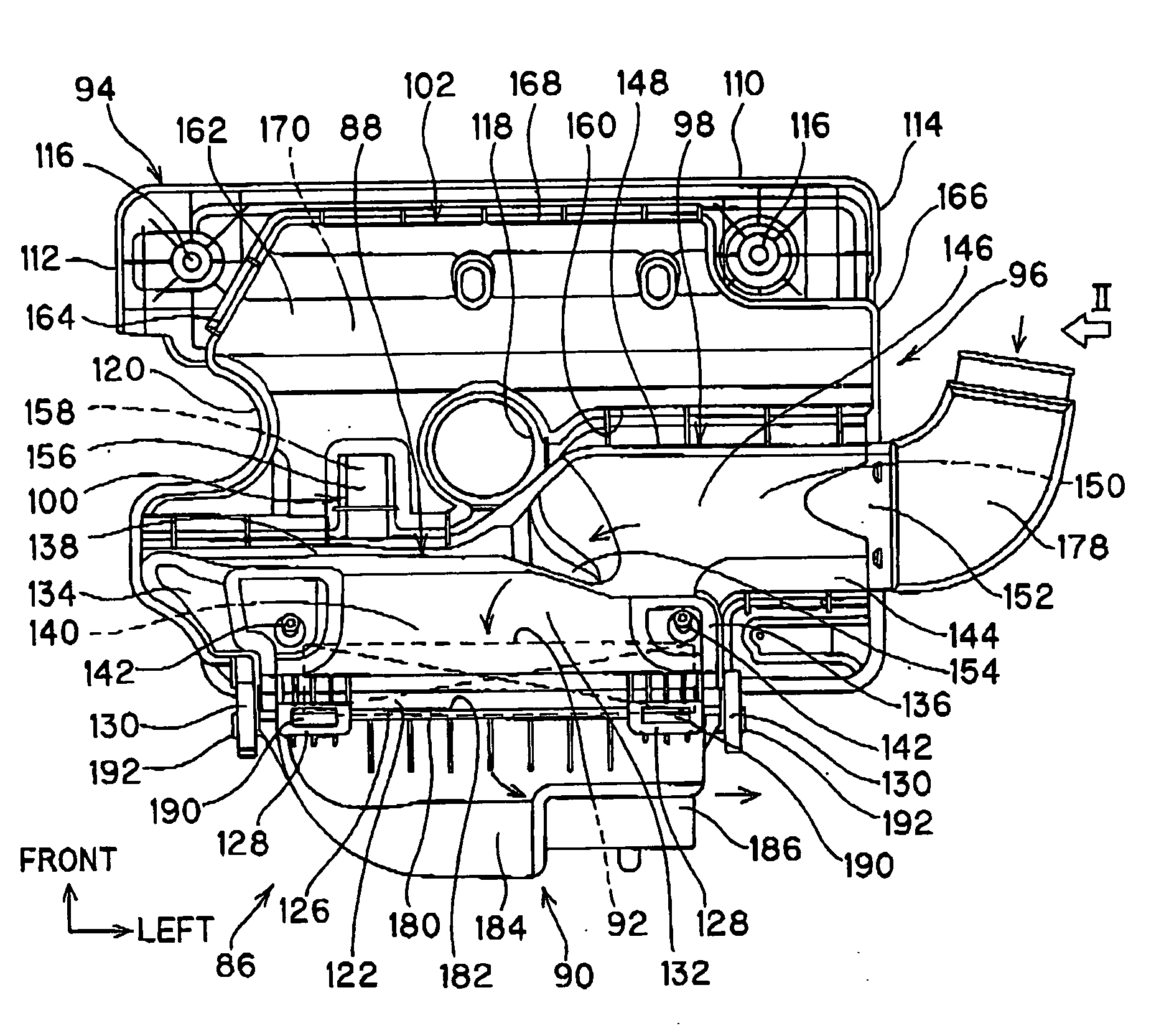

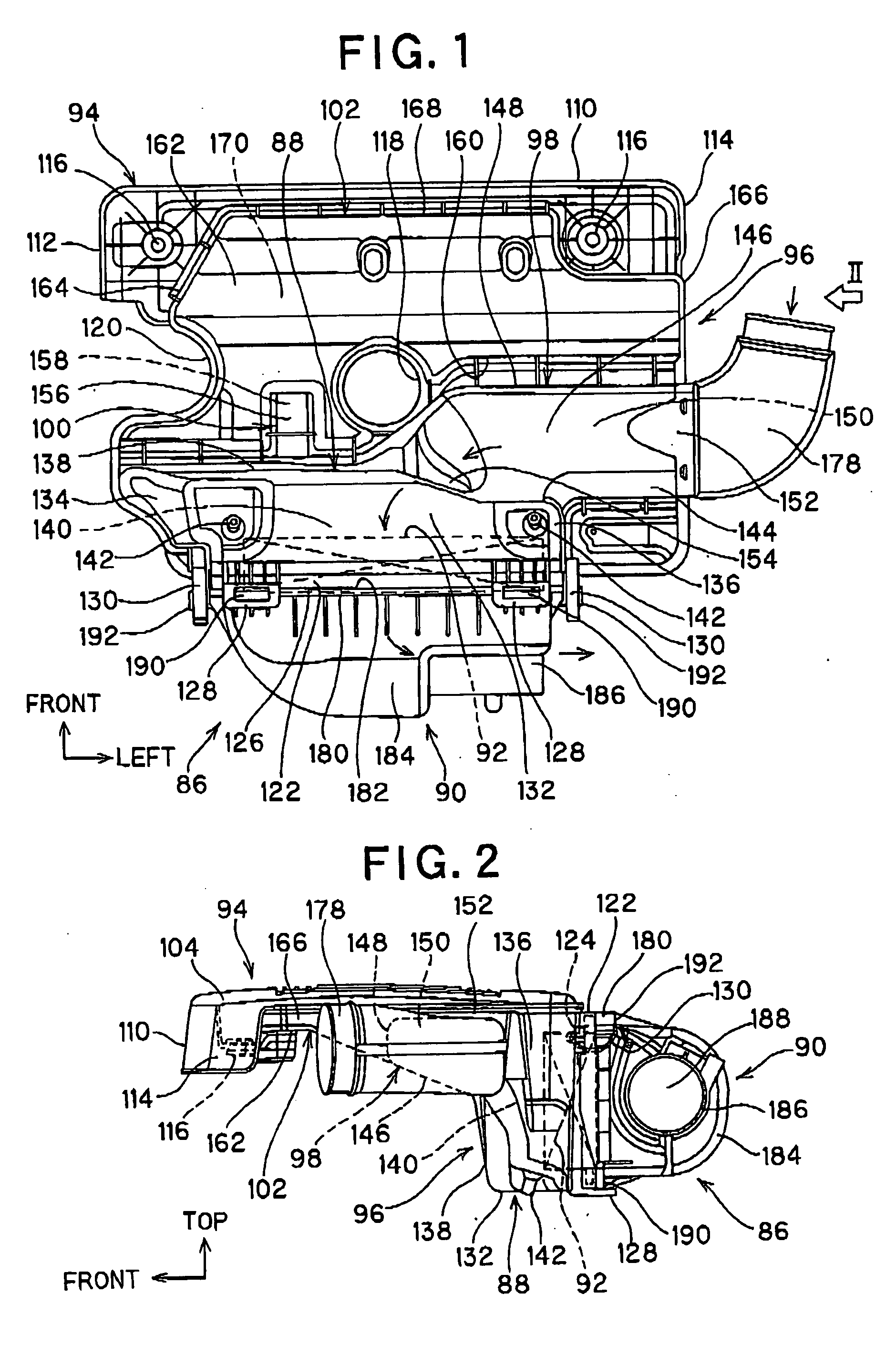

Intake system of engine

ActiveUS20070012276A1Increase resistanceImprove engine performanceNon-fuel substance addition to fuelMachines/enginesFull widthLower half

The purpose of the intake system, which is disposed in a limited space above the engine, is to improve engine performance by preventing increase in both temperature and resistance of intake air, and also to reduce noise of the intake air. In the intake system, a rear wall extending downwardly is formed in a lower half body that is joined to a rear end of an engine cover, and a mounting frame section for attaching an element is formed in a rear wall section. An upstream-side casing is formed forward of the rear wall section. An intake duct has a downstream end connected to a front surface of the upstream-side casing adjacent to a transmission. Further, the intake duct extends widthwise of the vehicle and has an upstream end opened to the side edge of the engine cover adjacent to the transmission. A resonance chamber casing is joined to the side departing from the transmission through a communication pipe forward of the upstream-side casing. The resonance chamber casing is formed to extend along the full width of the engine cover so as to cover the front of the intake duct.

Owner:SUZUKI MOTOR CORP

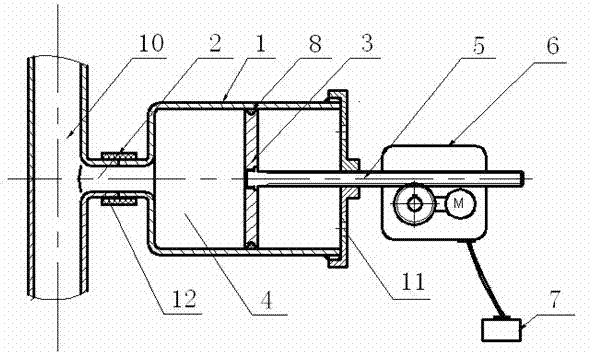

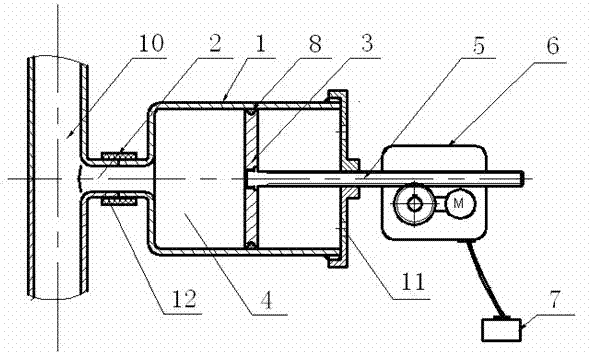

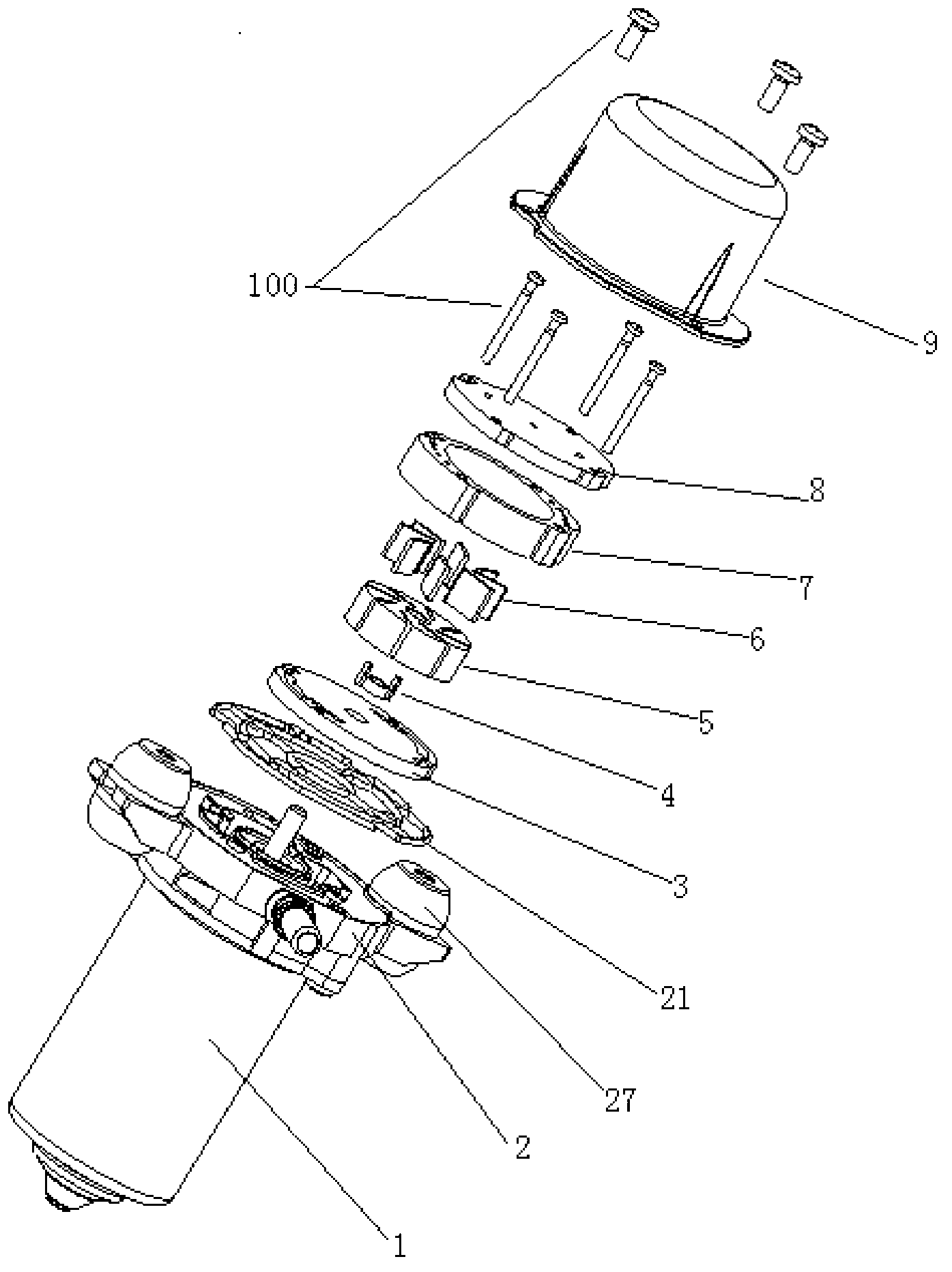

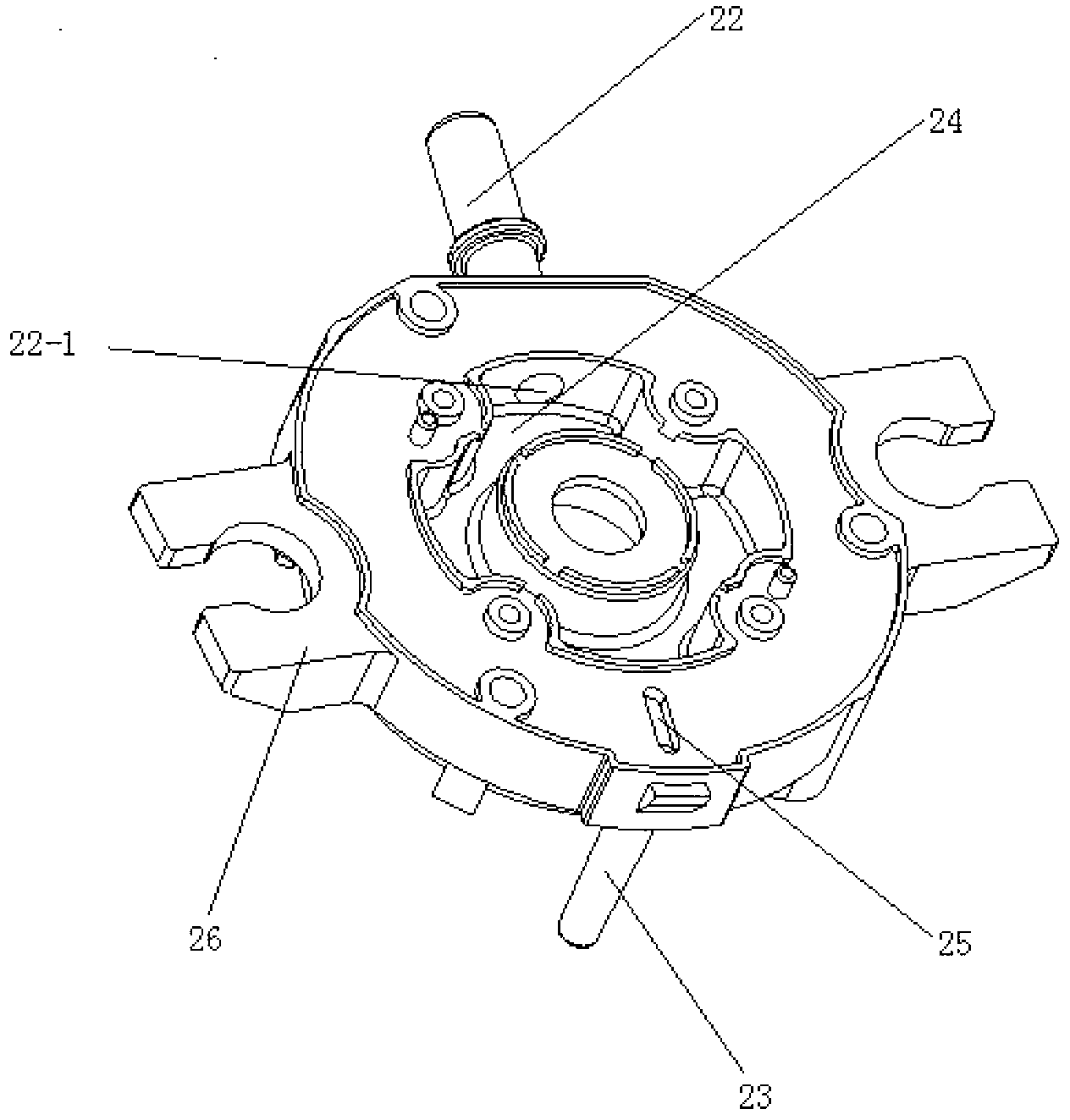

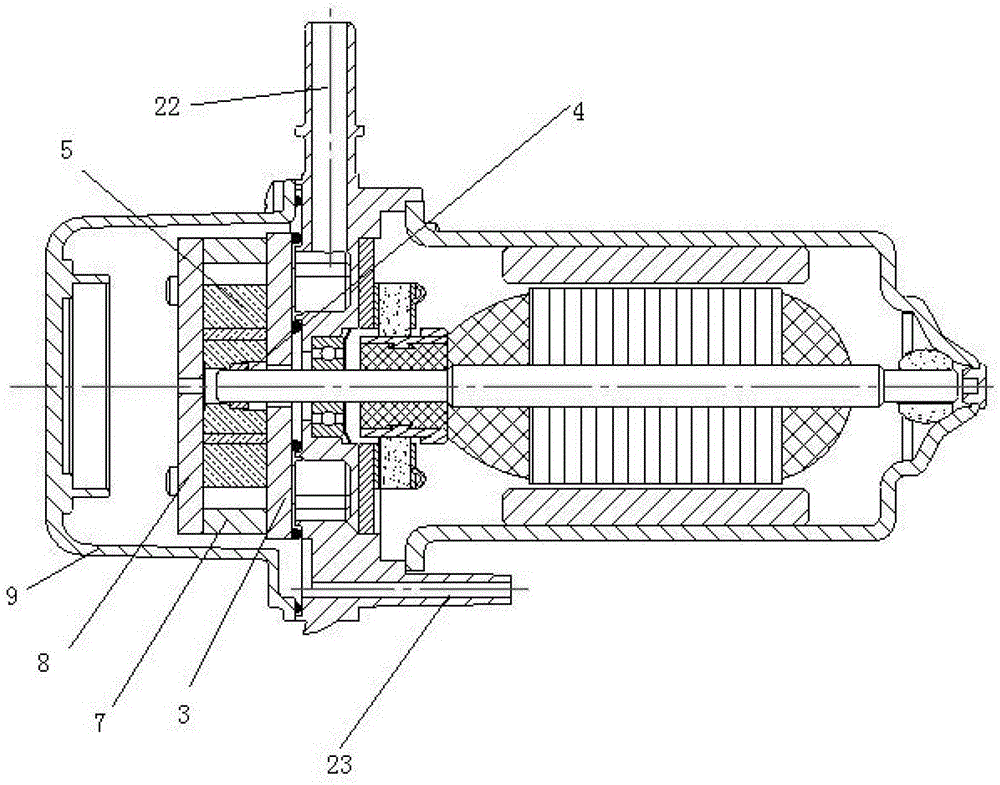

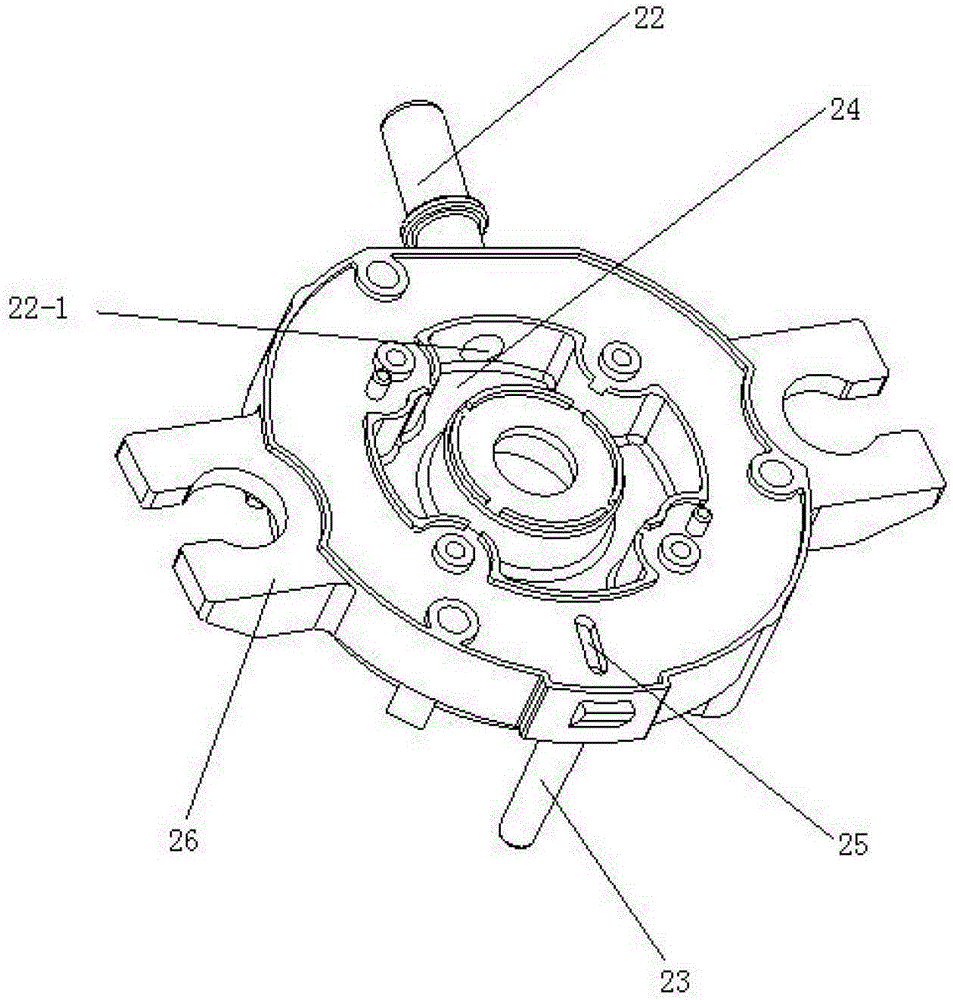

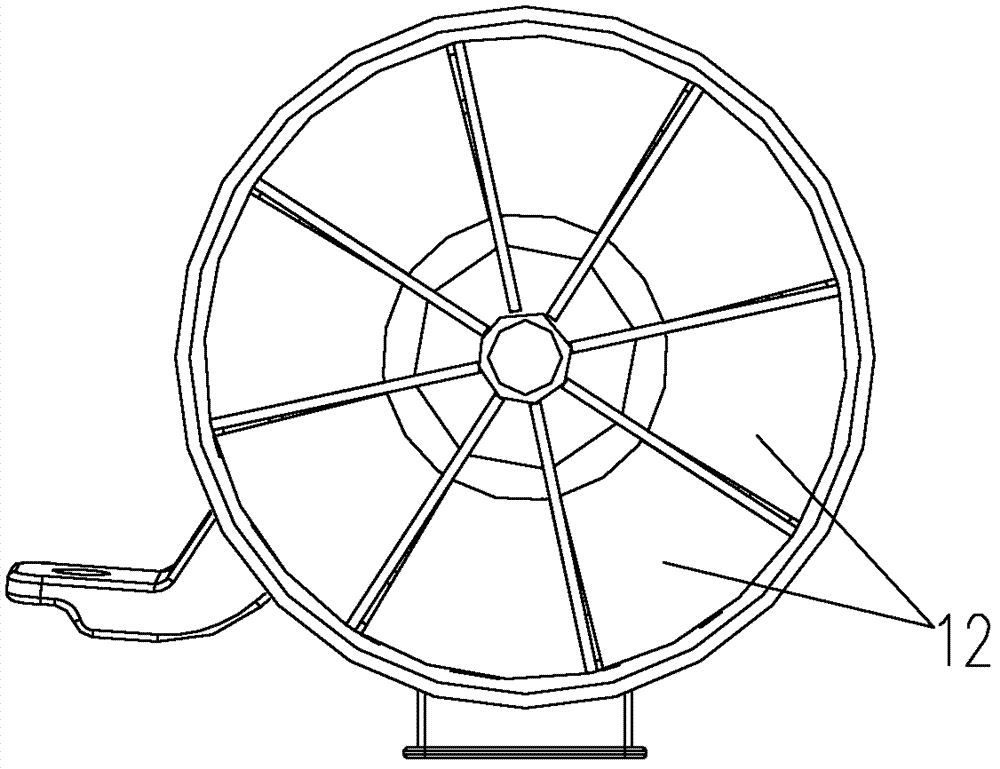

Low-noise automobile electronic vacuum pump

ActiveCN106401959AReduce intake noiseSolve the problem of uneven airflowRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsLow noisePump chamber

The invention discloses a low-noise automobile electronic vacuum pump. The low-noise automobile electronic vacuum pump comprises a motor assembly, a supporting base, a pump chamber lower cover, a driving sleeve, a pump rotor, blades, a pump chamber, a pump chamber upper cover, a silencing part, a pump body cover and a fixing pin. Multiple air chambers evenly distributed in the circumferential direction of the cylinder wall of the silencing sleeve and a converging cavity located in the center are formed in the silencing part. The air chambers include the air inlet air chamber, the buffering air chamber and the air outlet air chamber according to functions. According to the above structure, air flow enters the silencing part from two exhaust ports in the pump chamber upper cover, air flow flowing out from each exhaust port and entering the silencing part sequentially passes through the buffering air chamber and the air outlet air chamber and is converged at the converging cavity after flowing out of the air outlet air chamber, the air flow flows out of an outlet of the converging cavity and flows out after being further buffered through the space between the silencing sleeve and the pump body cover, and finally, the air flow flows out of the silencing part and is exhausted from an air outlet pipe. By means of the structure of the air chambers and the converging cavity, an air way is lengthened, the air flow is buffered, and the effect of effectively lowering noise is achieved.

Owner:常州市东南电器电机有限公司

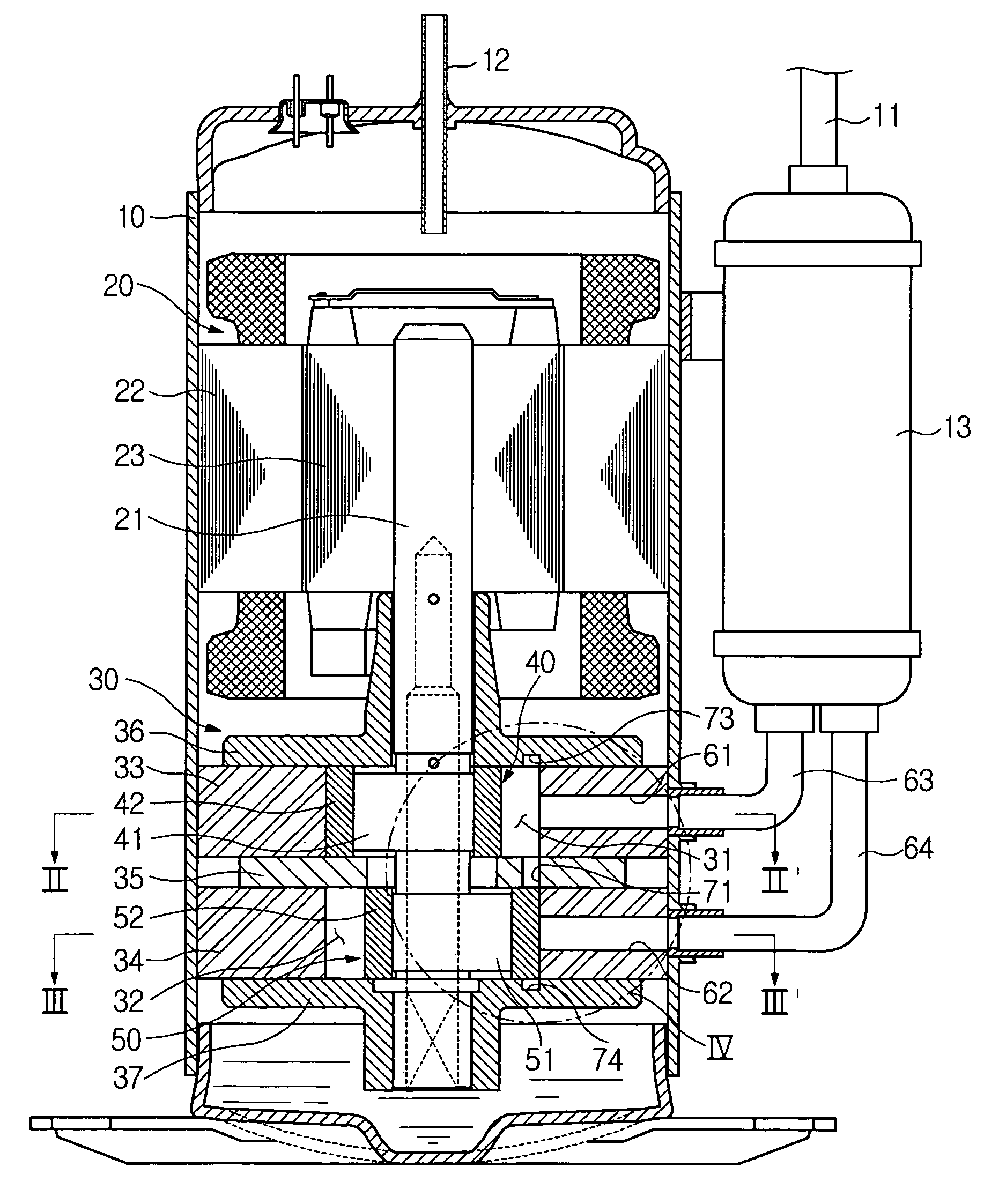

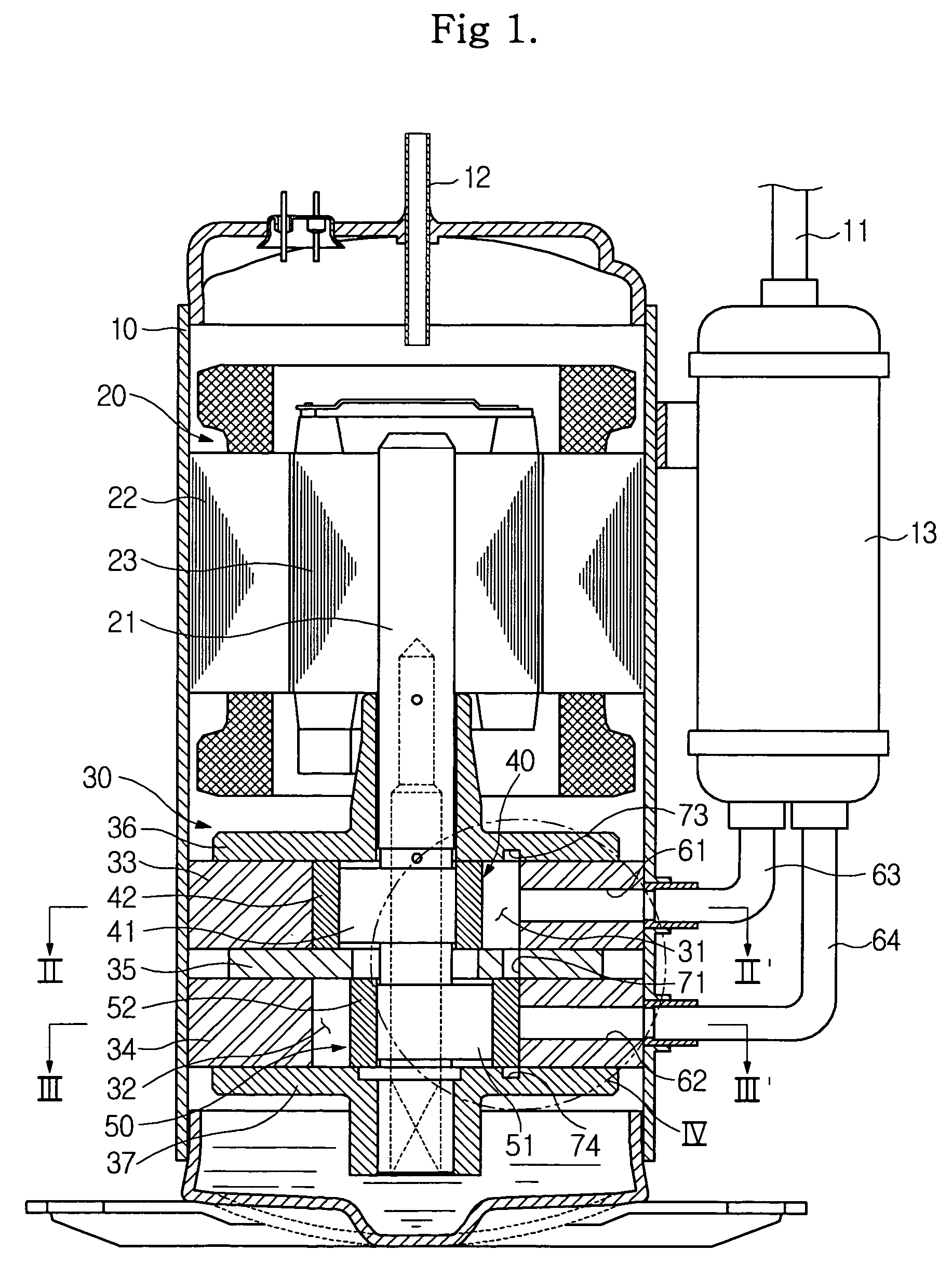

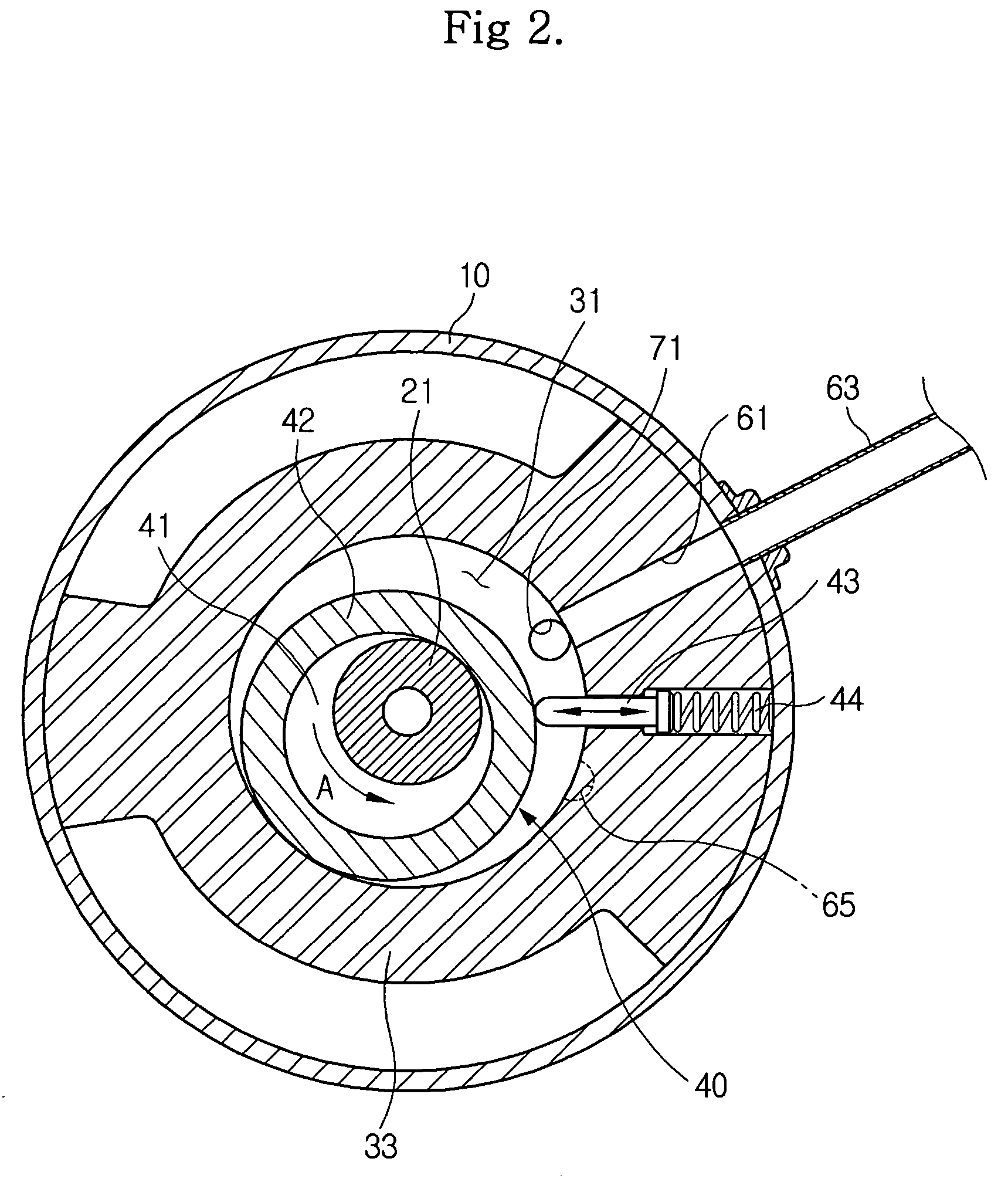

Multi-cylinder rotary type compressor

InactiveUS20060056988A1Reduce intake lossIncrease the areaRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringElectrical and Electronics engineering

A multi-cylinder rotary type compressor designed to reduce intake loss and noise. The multi-cylinder compressor includes first and second compressing compartments partitioned from each other; first and second intake ports communicated with the first and second compressing compartments, respectively; and a communication hole located adjacent to the first and second intake ports to communicate the first compressing compartment with the second compressing compartment.

Owner:SAMSUNG ELECTRONICS CO LTD

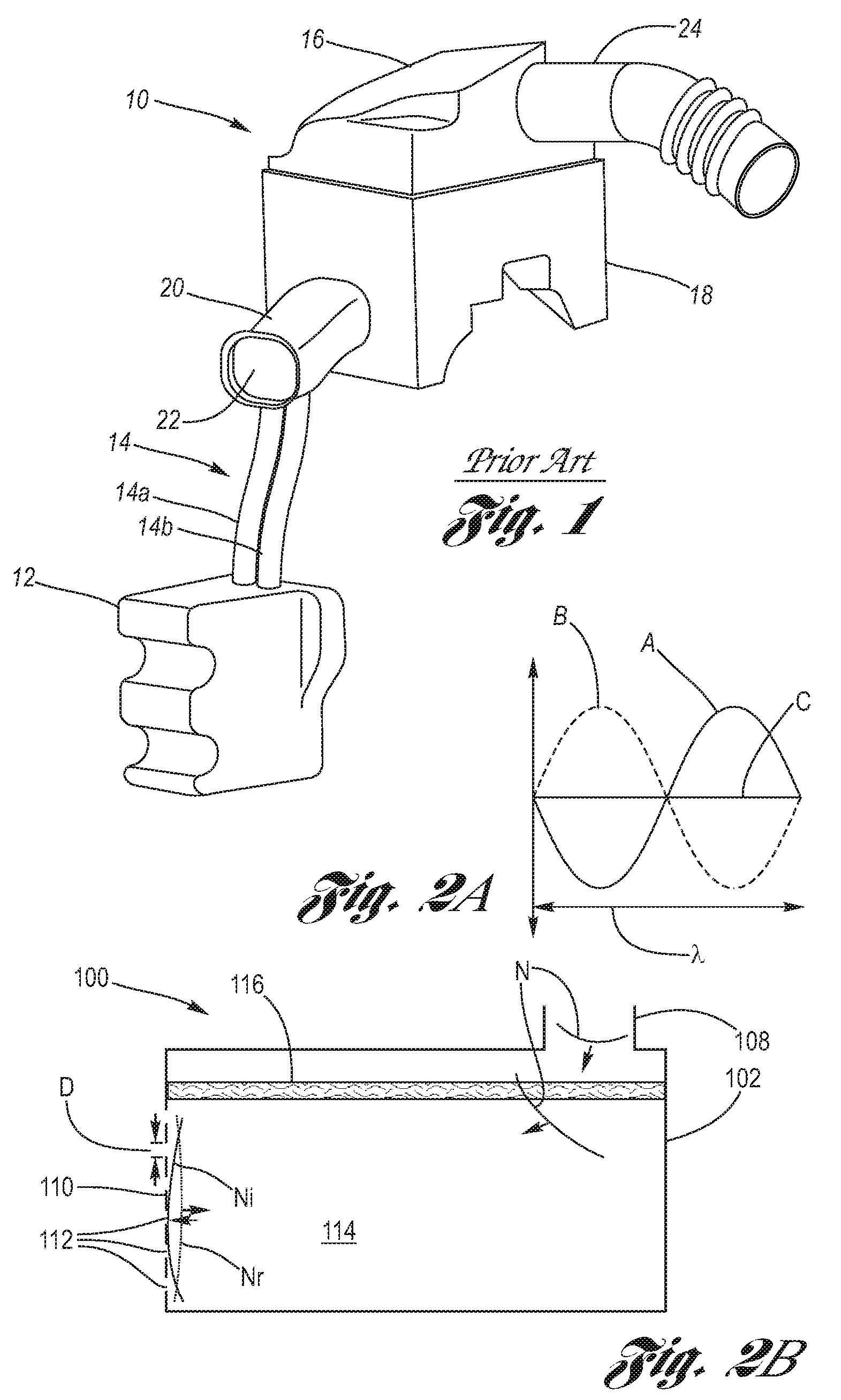

Resonator for vehicle

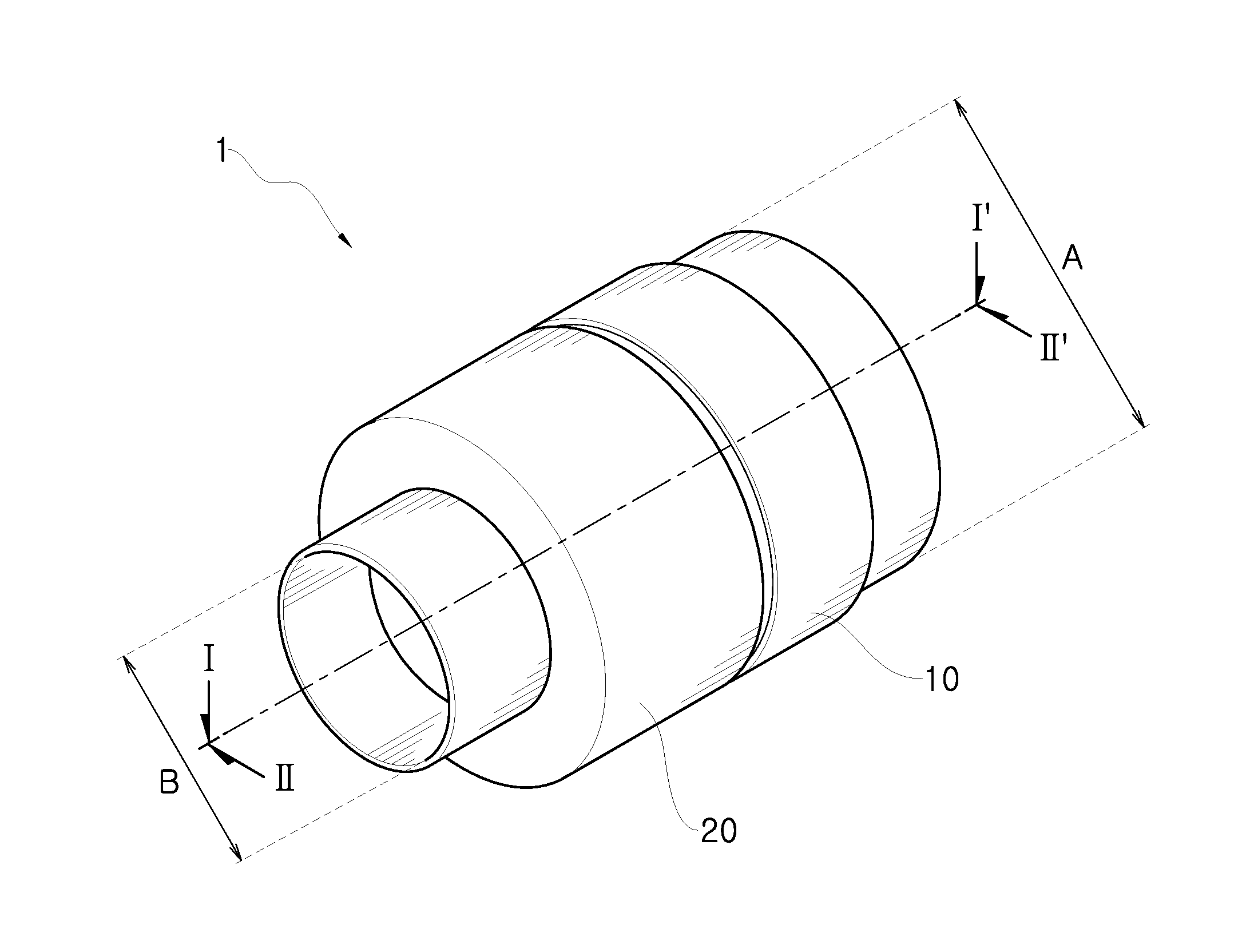

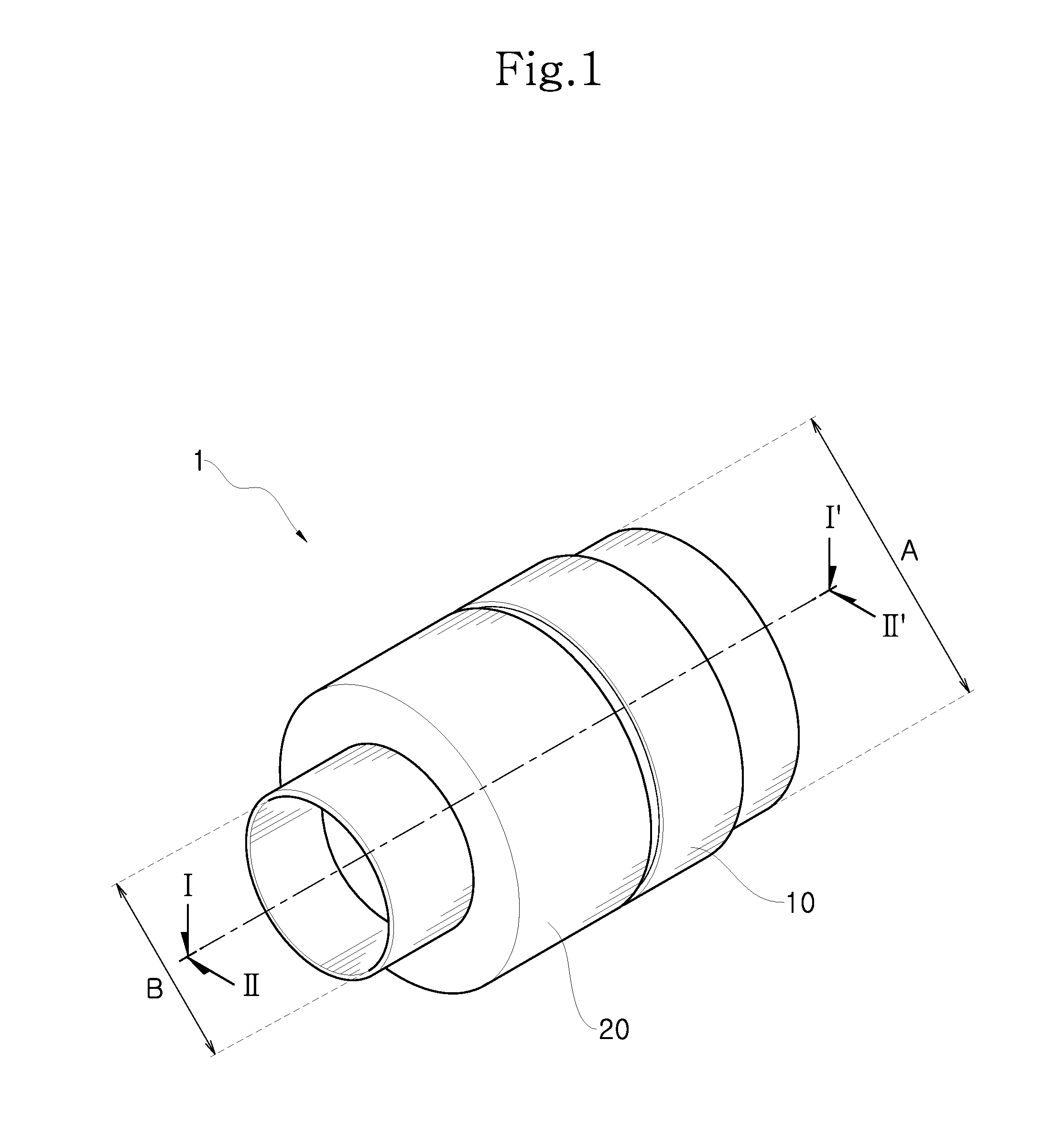

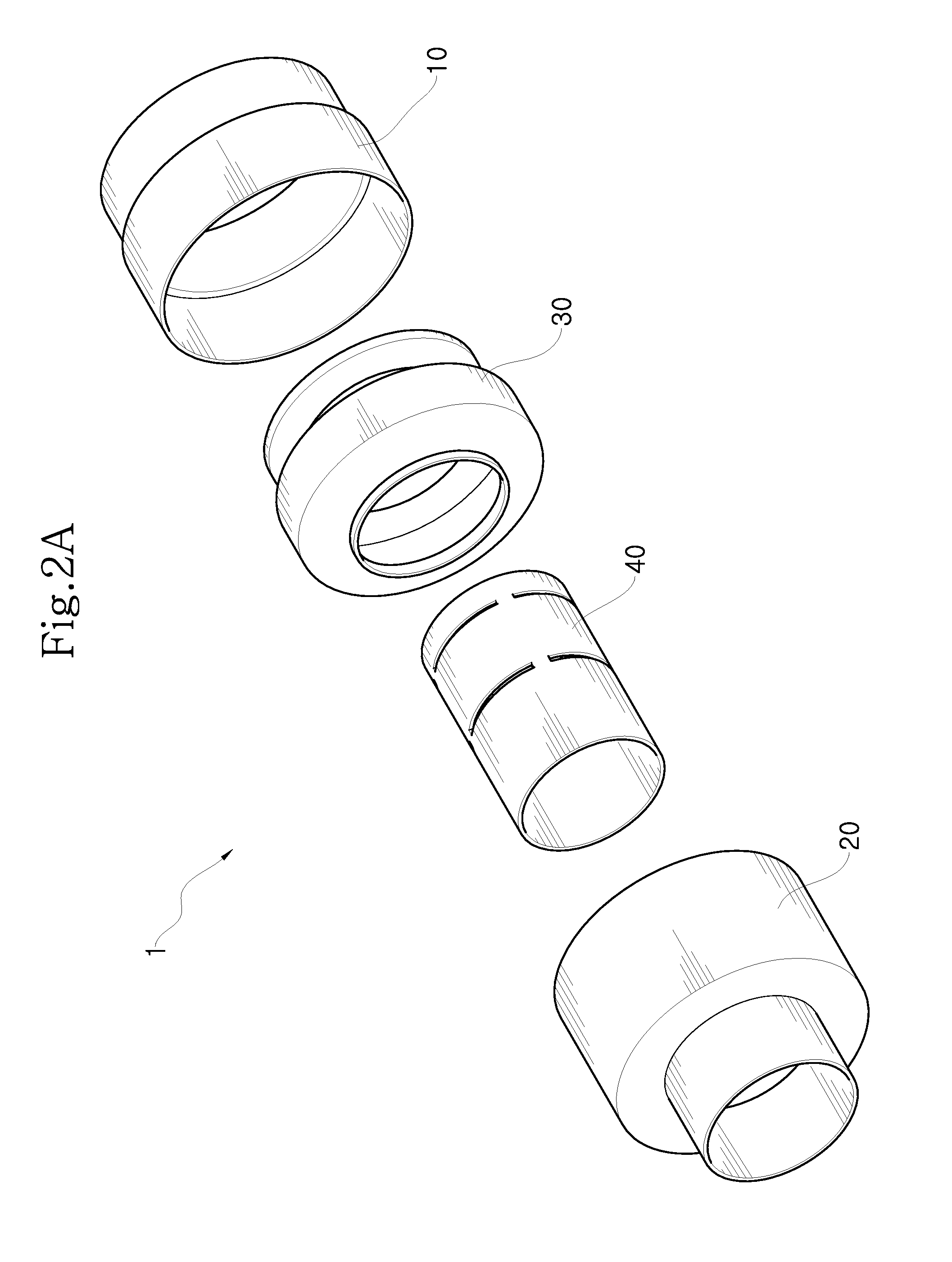

ActiveUS20150226163A1Enhance degree of frequency tuning freedomReduce intake noiseMachines/enginesIntake silencers for fuelEngineeringResonator

A resonator for a vehicle, which reduces intake noise by using a resonance chamber for frequency tuning, includes an outer pipe having a first outer pipe with an inlet for introducing external air and a second outer pipe with an outlet for discharging the air introduced into the inlet to outside, an inner pipe disposed inside the outer pipe and having a plurality of slits for giving a passage of air, and an expansion pipe inserted between the outer pipe and the inner pipe to partition a space between the outer pipe and the inner pipe into a plurality of spaces and thus partition the resonance chamber into a plurality of regions.

Owner:COOPER STANDARD AUTOMOTIVE & IND INC

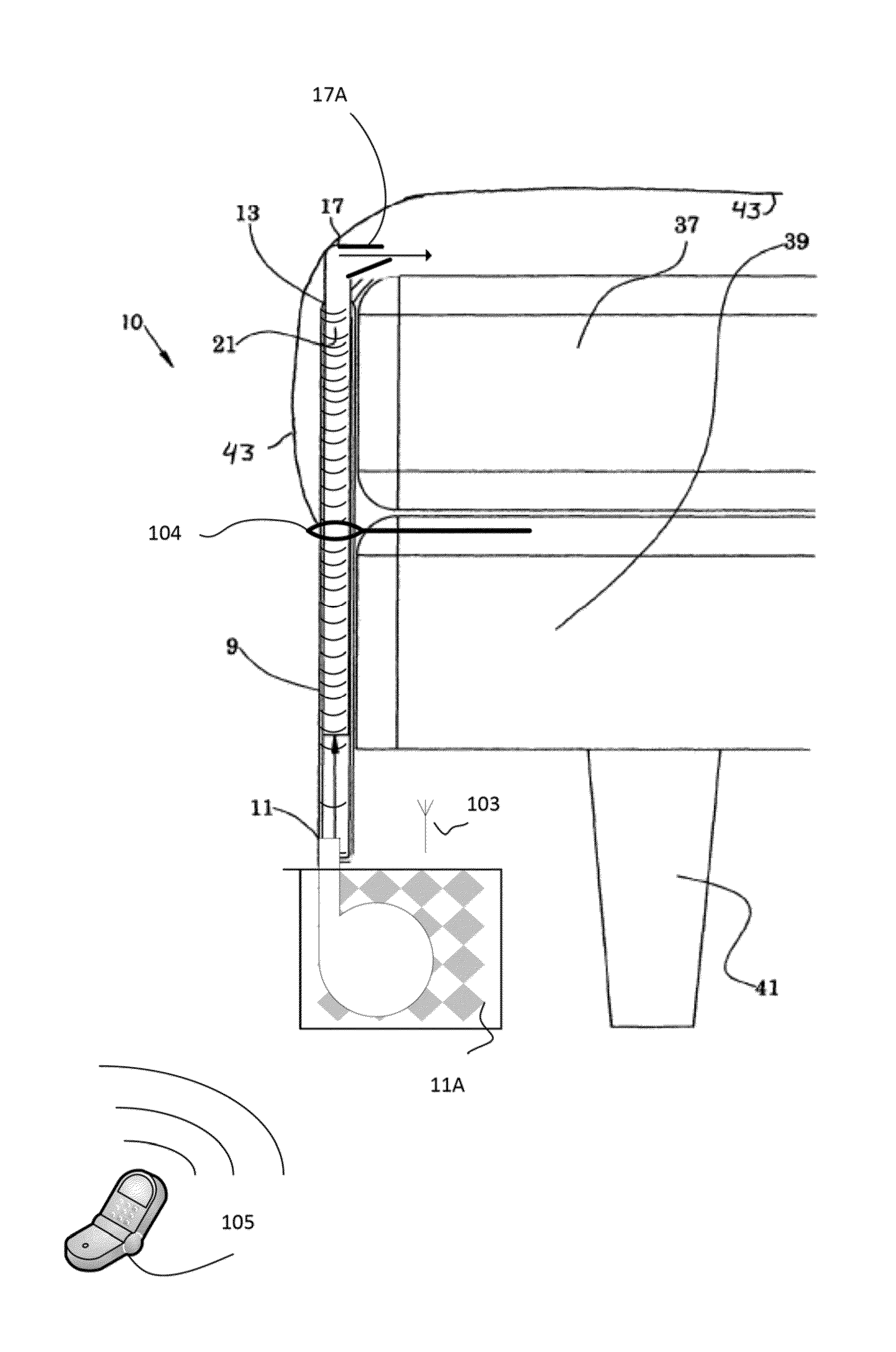

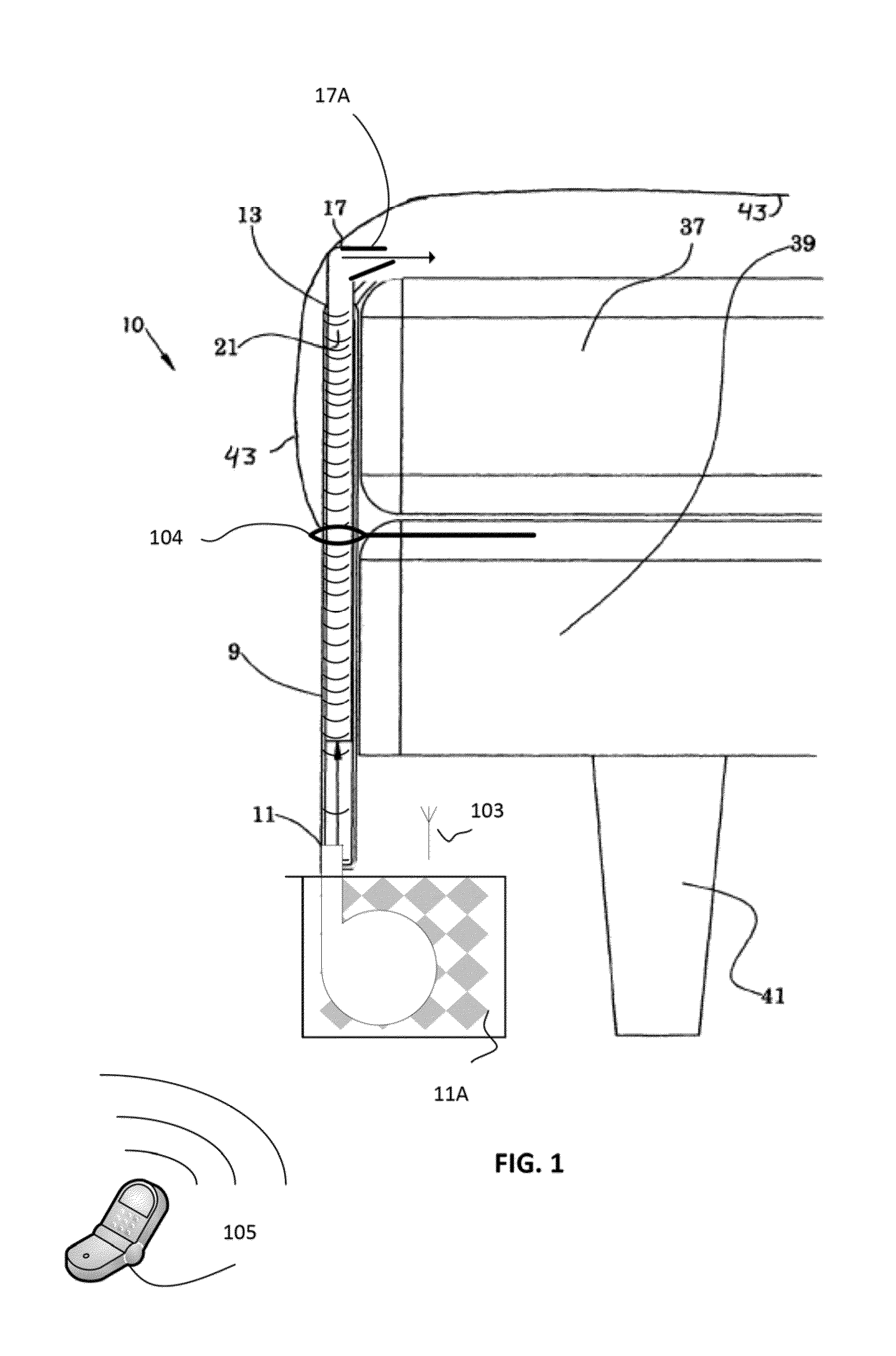

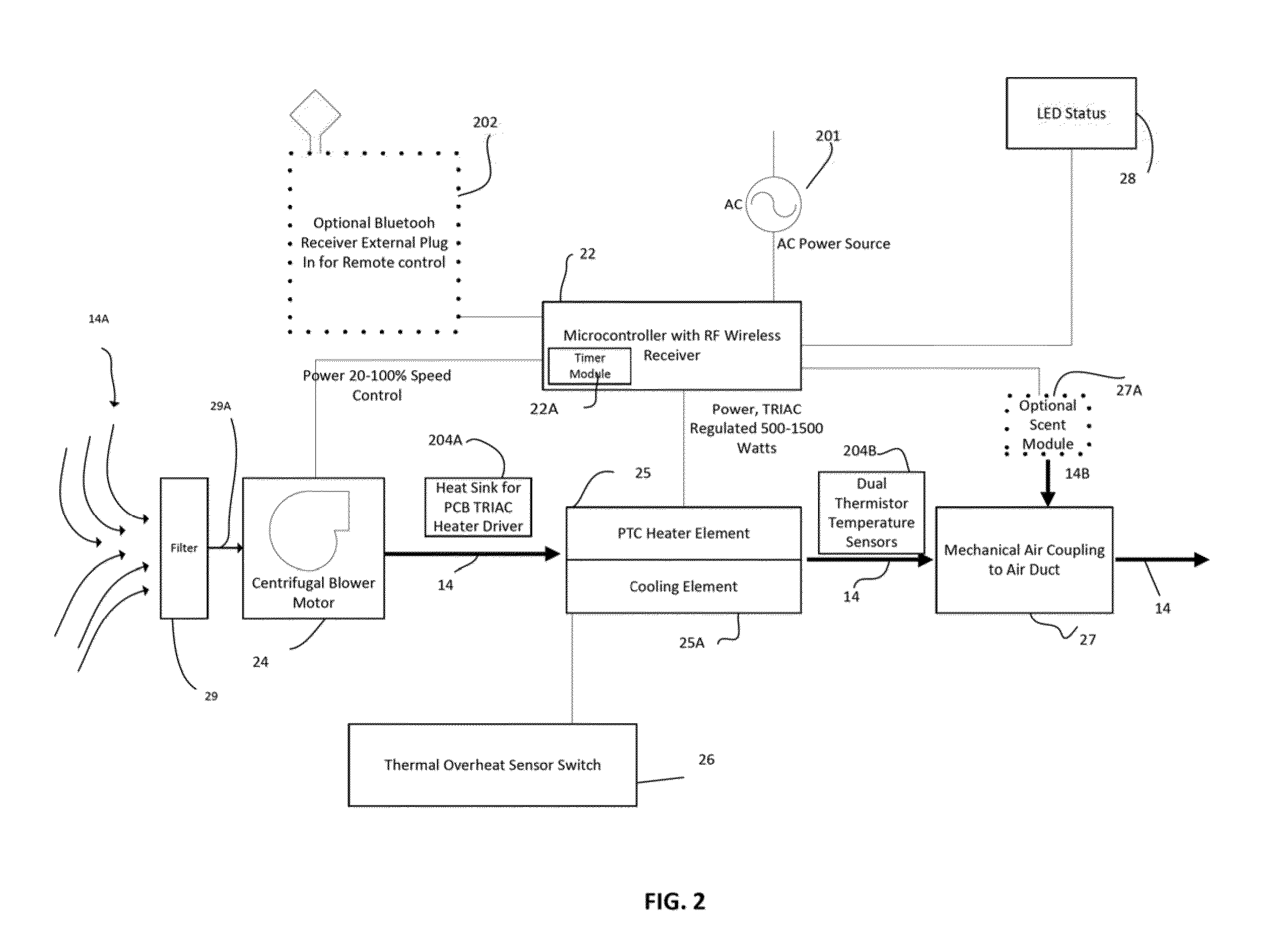

Forced Air Apparatus for Conditioning a Volume of Air

InactiveUS20150121619A1Minimize flow noiseReduce intake noiseStuffed mattressesSpring mattressesElectric heatingAirflow

An apparatus for conditioning a volume of air is provided. The apparatus includes a housing having an electric heating element; a high-pressure variable-speed centrifugal blower for providing constant velocity air flow. The apparatus also includes a controller adaptable to control the electric heating element and the high pressure variable speed blower to raise the temperature within the zone by substantially 15 degrees, or more, in substantially 7 minutes or less. The apparatus also includes an air output flange for disposition between the zone and an air duct disposed between the housing and the air output flange.

Owner:ARAMLI MARK

Piston valve air suction non-lubricated air compressor

InactiveCN101776061ARelieve the intensity of knockingHigh working reliabilityPositive displacement pump componentsPositive-displacement liquid enginesCrankcaseAir compressor

The invention belongs to the technical field of compressors, in particular to a piston valve air suction non-lubricated air compressor which comprises a cylinder, a cylinder cover, a crank case, a piston and a connecting rod, wherein the piston is fastened and connected with the connecting rod or is made together with the connecting rod, the piston is provided with a sealing ring and is arranged in the cylinder, and the peripheral surface of the sealing ring and the inner hole wall surface of the cylinder form an air suction channel of the compressor by adopting an offset cylinder or oblique piston or simultaneously adopting the offset cylinder and the oblique piston when in air suction so as to achieve the effect of controlling the air suction by the piston valve. Because an air inlet one-way valve of the traditional compressor is discarded, the structure is simplified, quick-wear parts are reduced, the working reliability is improved, the mechanical noise source and the clearance volume of the compressor are reduced and the volumetric efficiency is improved. In addition, the crank case is used as an air inlet anechoic room, the piston is provided with a guide member and a buffer member which can release the knock strength of the piston to the cylinder, therefore, the noise of the compressor can be effectively lowered.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

Electronic vacuum pump for brake vacuum booster of new energy vehicles

ActiveCN103306979BImprove vacuum efficiencyIncrease air intakeMachines/enginesPumpsNew energyPump chamber

The invention discloses an electronic vacuum pump for a new energy vehicle brake vacuum booster. The electronic vacuum pump comprises a motor assembly, a supporting base, a pump chamber lower cover, a driving sleeve, a pump rotor, blades, a pump chamber, a pump chamber upper cover, a pump body cover and fixing pins, wherein a left side air feeding slot of the pump chamber lower cover, a left side air feeding through hole of the pump chamber and a left side air feeding slot of the pump chamber upper cover are communicated with one another to form an air passageway; a right side air feeding slot of the pump chamber lower cover, a right side air feeding through hole of the pump chamber and a right side air feeding slot of the pump chamber upper cover are communicated with one another to form an air passageway; a flow guide slot of the pump chamber lower cover is communicated with an inner cavity of the pump chamber; an air discharging slot of the pump chamber upper cover is communicated with the inner cavity of the pump chamber; the flow guide slot of the pump chamber lower cover and the air discharging slot of the pump chamber upper cover are symmetric. When the vacuum pump works, an air path with four air inlets and two air outlets is formed; therefore, the air feeding resistance is greatly reduced, and the air feeding amount of the pump chamber is increased; under the equal energy consumption, the vacuumizing efficiency of the vacuum pump provided by the invention is higher.

Owner:常州市东南电器电机有限公司

Engine air intake apparatus

InactiveUS7287503B2Engine output during high-speed operation to be improvedReduce intake noiseCombination devicesIsotope separationLow speedValve actuator

An air cleaner chamber is configured such that a filtering member is held between an air cleaner cover and an air cleaner case. A low-speed operation air intake passage and a high-speed operation air intake passage share an outlet passage portion near a dusty space, and are molded integrally on the air cleaner case using a synthetic resin. A passage switching valve is disposed so as to switch an aperture area of the high-speed operation air intake passage. In addition, a valve actuator for driving the passage switching valve is mounted to the air cleaner case.

Owner:MITSUBISHI ELECTRIC CORP

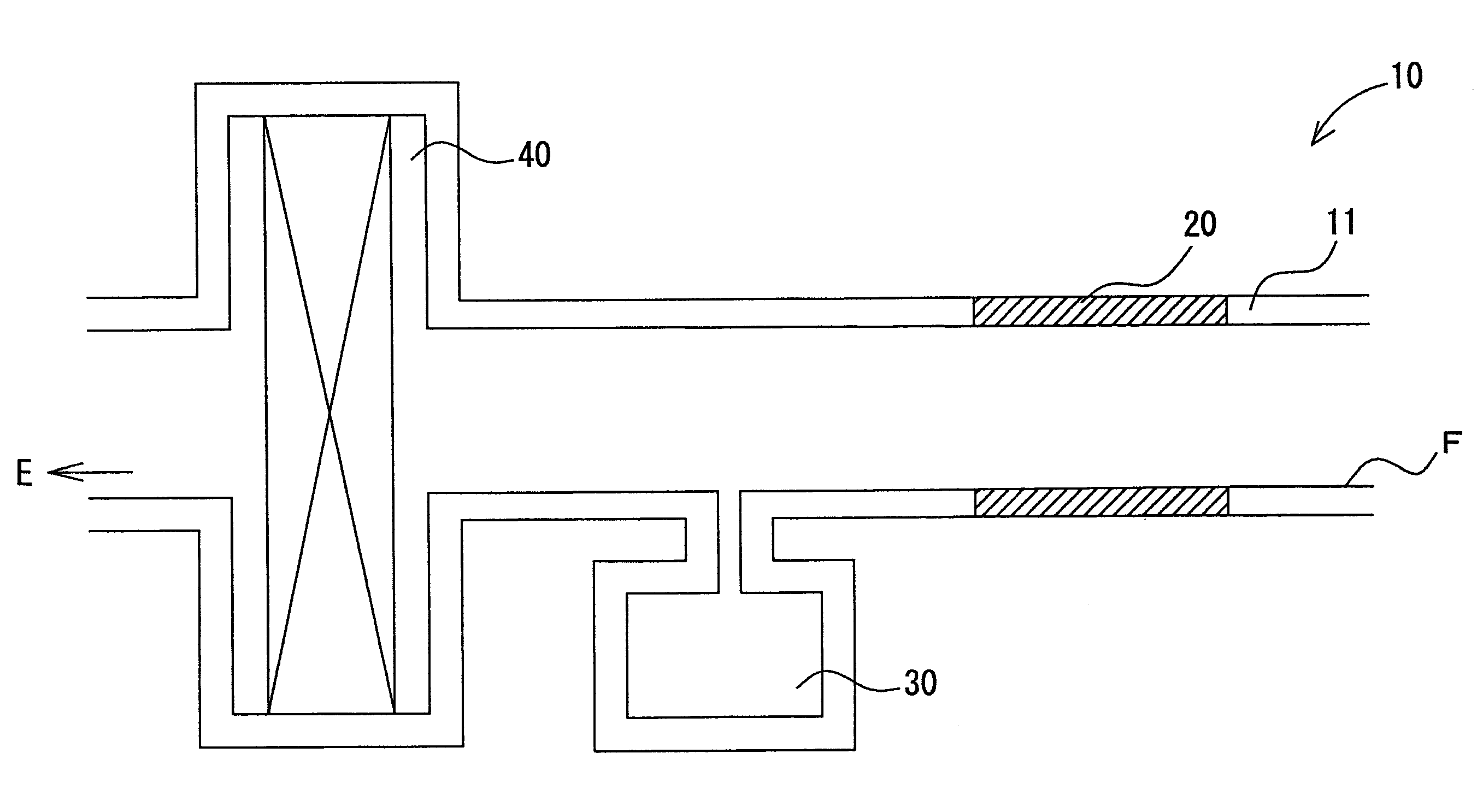

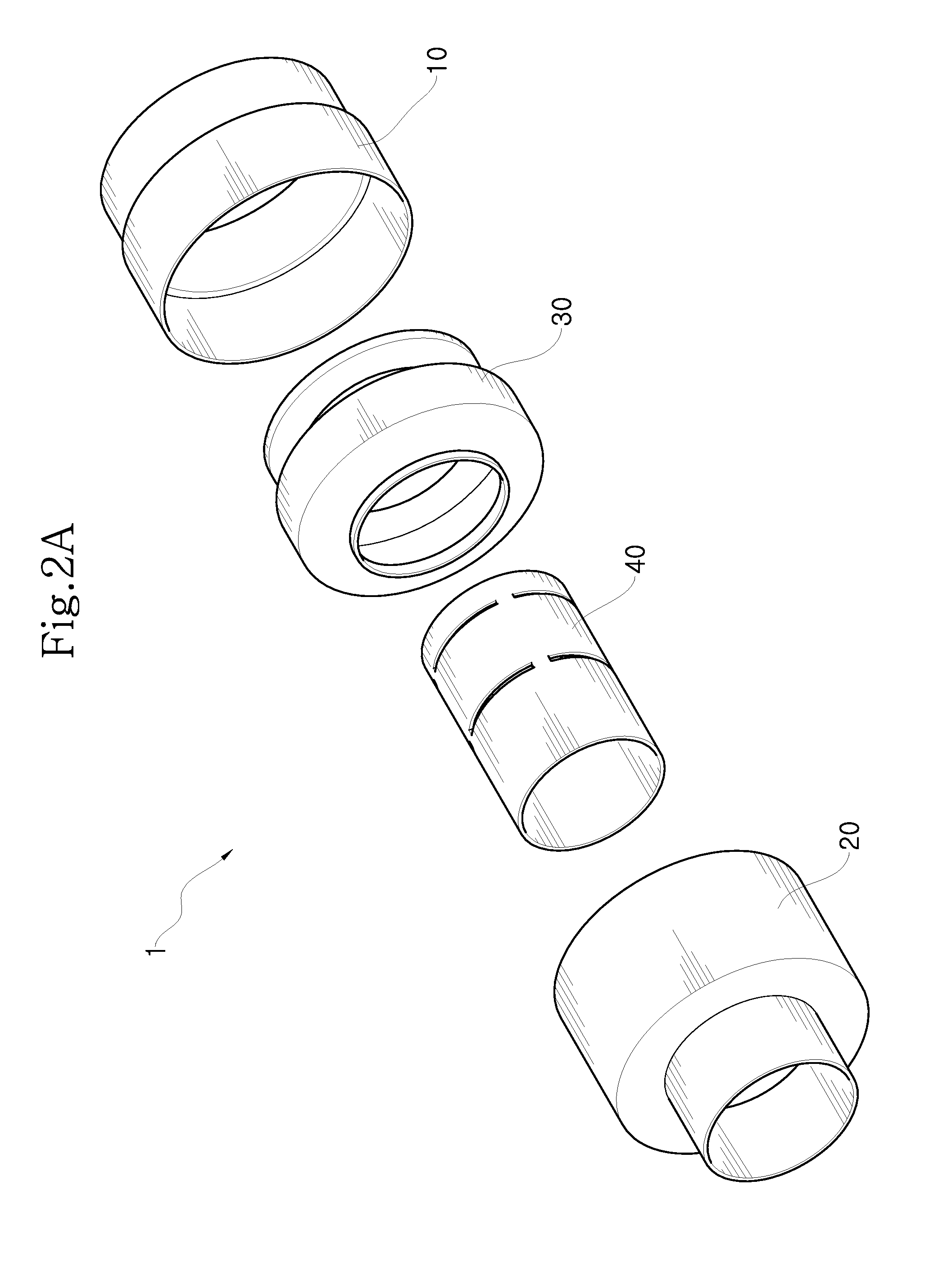

Air inlet

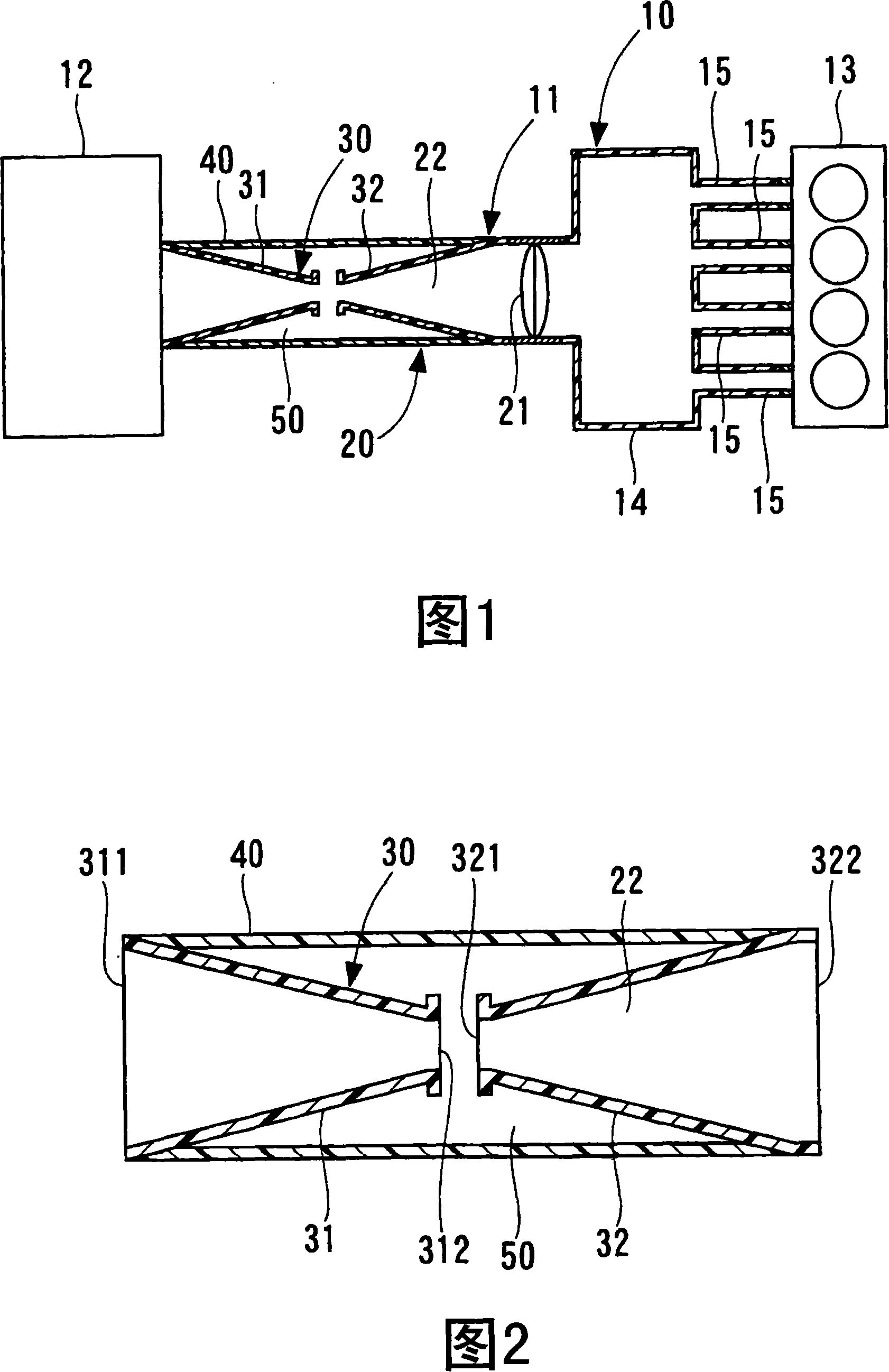

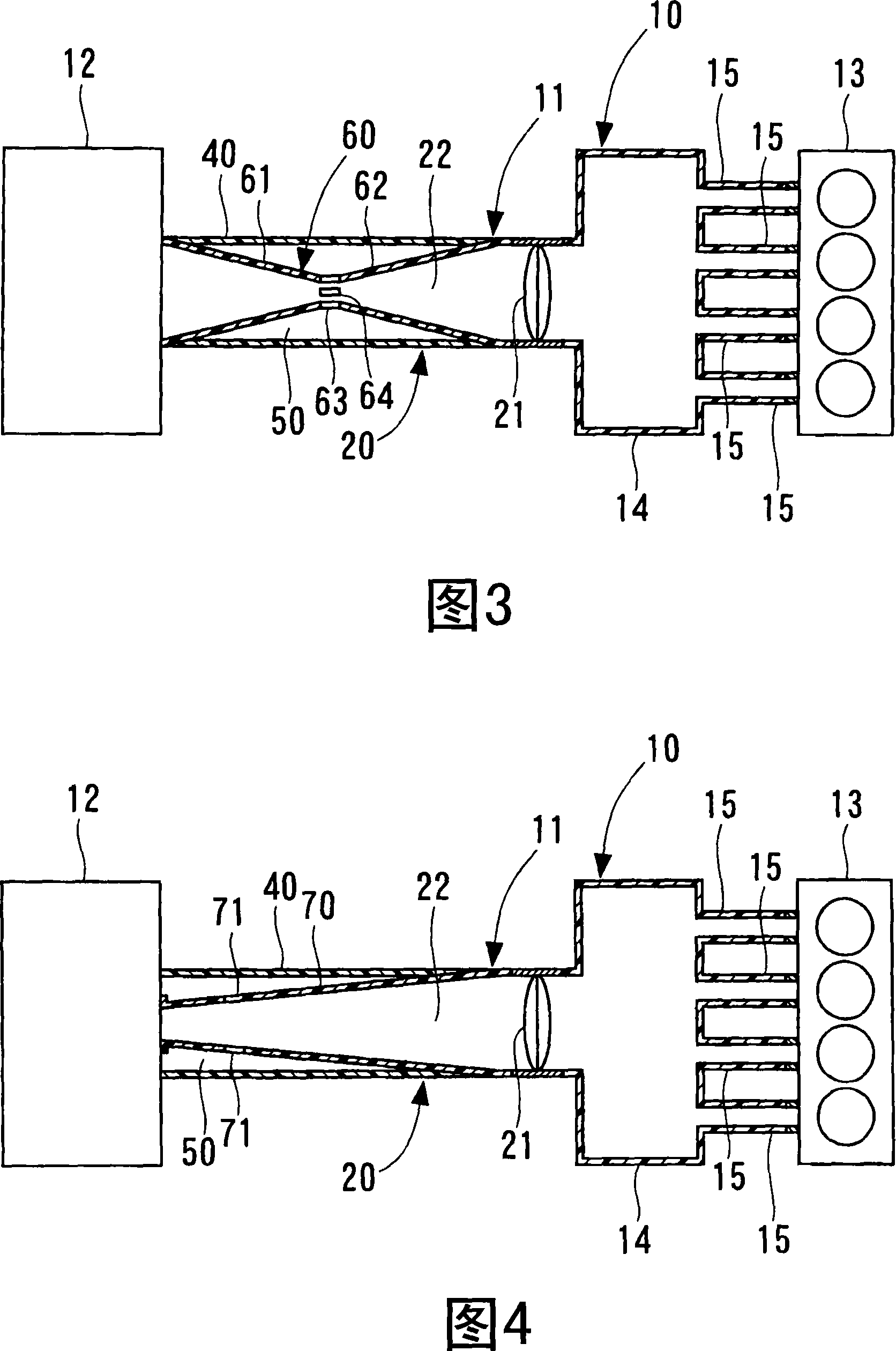

InactiveCN101113702AReduce intake noiseEasy to installMachines/enginesIntake silencers for fuelSurge tankInlet channel

The device (11) has an internal tube element (30) defining an inlet channel (22) that connects an inlet (12) and a surge tank (14), where a diameter of the element rises gradually, when the element extends in a direction of a surge tank-sided end section of the element, where the end section is connected with the tank. An outer tube element (40) covers an outer peripheral side of the element (30), and defines a resonator (50) between the elements, where the resonator is connected with the channel by a connecting hole.

Owner:DENSO CORP

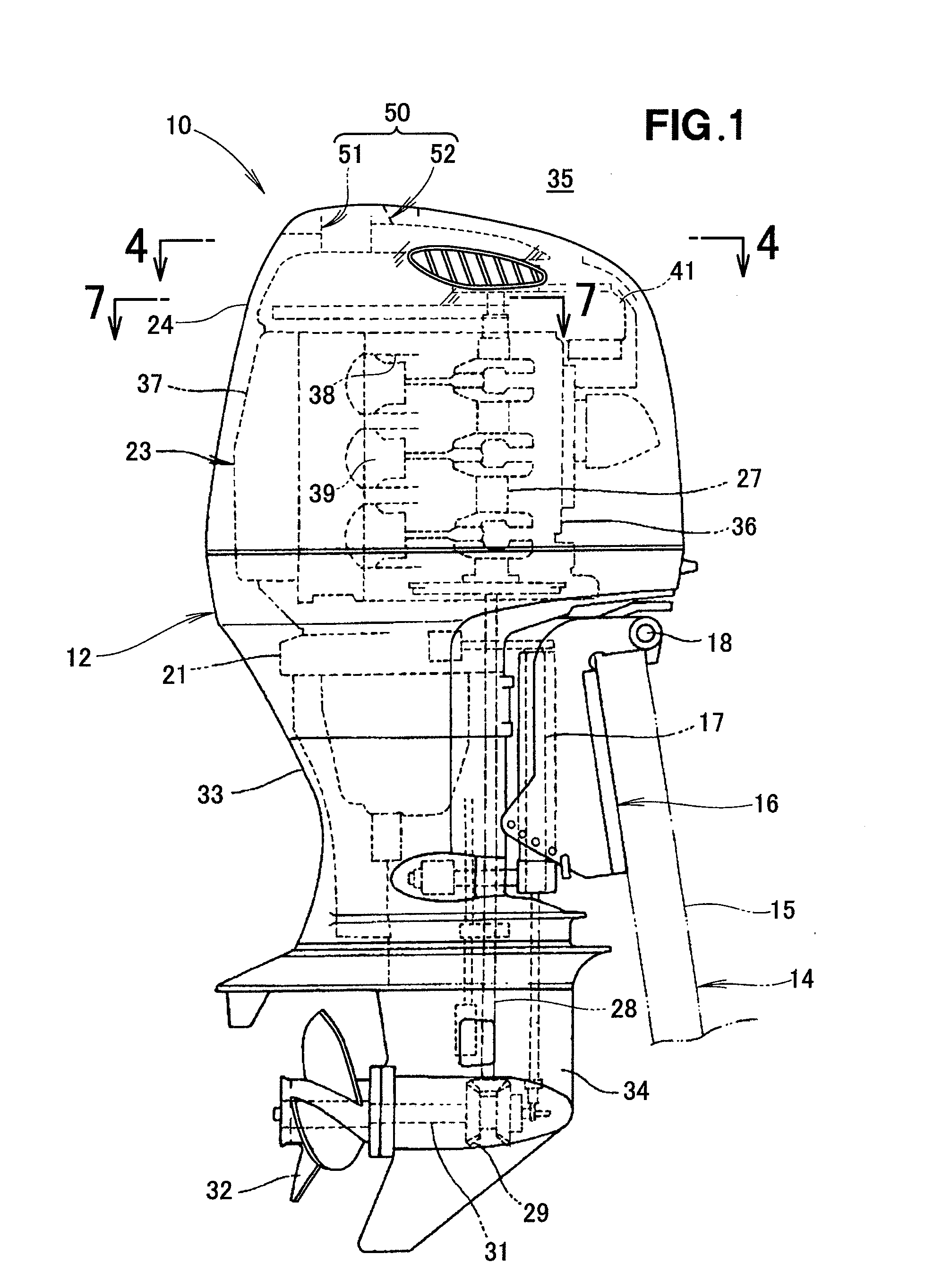

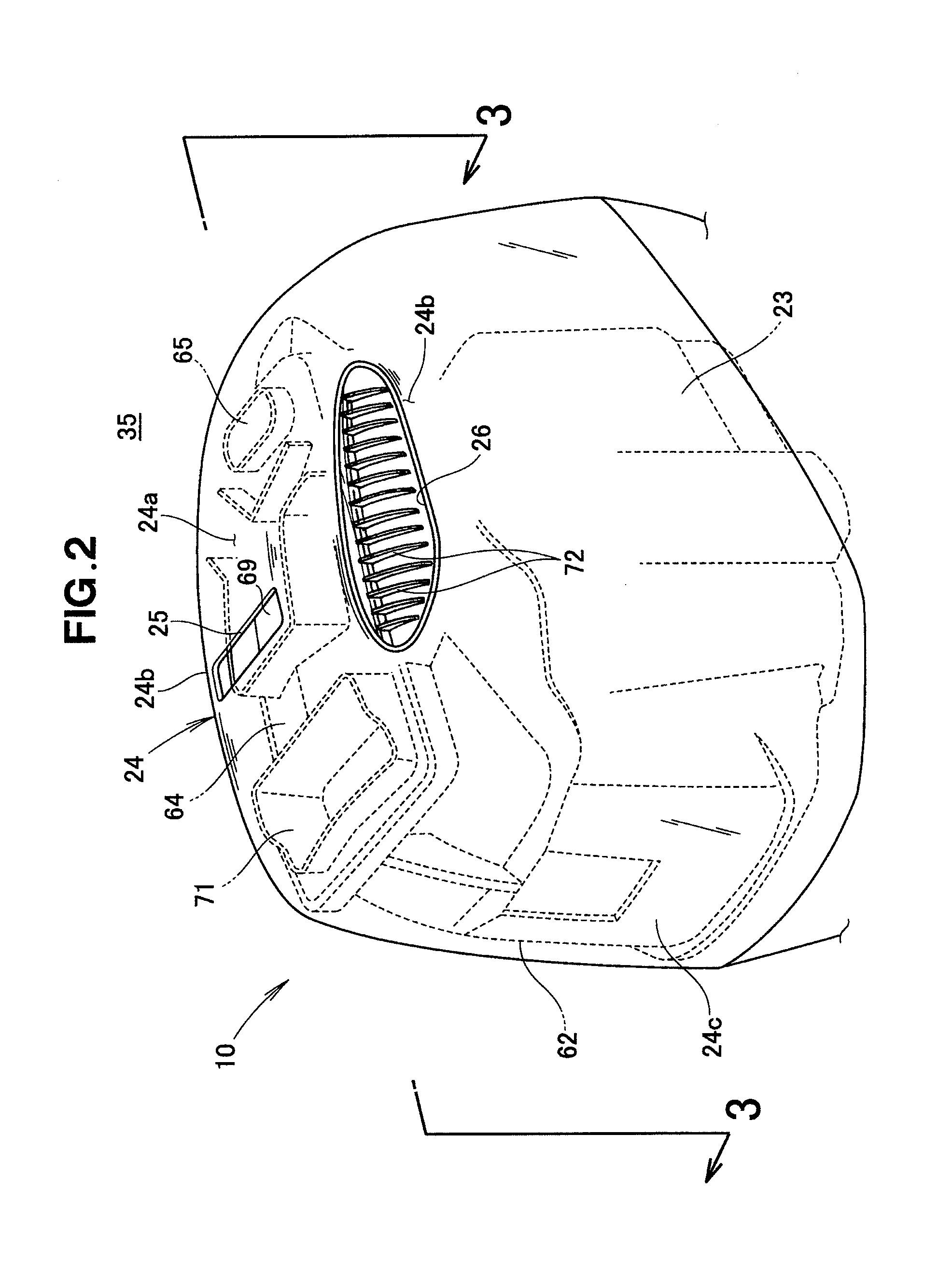

Outboard engine unit

ActiveUS8851945B2Area coveredMinimize entryPropulsion power plantsCombustion-air/fuel-air treatmentPerpendicular directionAerospace engineering

An outboard engine unit capable of efficiently cooling the interior of an engine cover is disclosed. The outboard engine unit includes a cooling opening capable of guiding air to an interior from an upper part of the engine cover, a first intake channel having a first outlet open to an upper front end and communicating with the opening, a partition wall disposed so as to be oriented substantially in a perpendicular direction below the first outlet; and a second intake channel extending substantially in the perpendicular direction along a rear wall of the engine cover rearward of the partition wall. The outboard engine unit is configured so that air directed from the cooling opening to the interior of the engine cover is directed to the throttle unit via the second cooling air intake channel.

Owner:HONDA MOTOR CO LTD

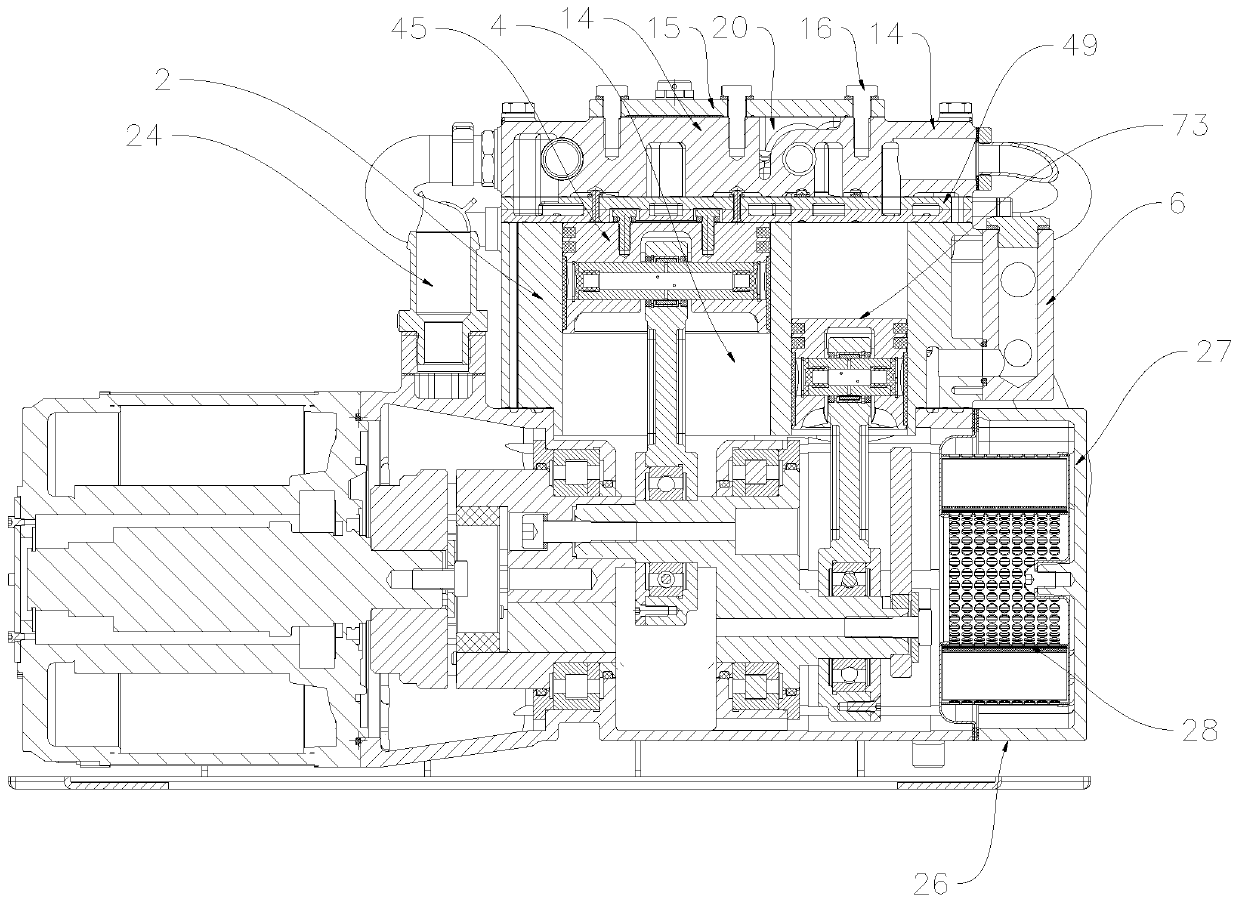

Oil-free piston type air compressor for new energy vehicle

ActiveCN110107473AExtended service lifeImprove lubrication statusPositive displacement pump componentsMulti-stage pumpsCylinder headEngineering

The invention relates to the technical field of air compressors, and discloses an oil-free piston type air compressor for a new energy vehicle. The oil-free piston type air compressor for the new energy vehicle comprises a crank case, a cylinder body and a cylinder head assembly, wherein a piston cylinder is arranged in the cylinder body; the cylinder body is arranged above the crank case and is connected with the crank case; the cylinder head assembly is arranged above the cylinder body and is connected with the cylinder body; a low-pressure heat exchanger connected with the crank case is arranged on the front side of the cylinder body; a manifold block connected with the cylinder body is arranged at the right end of the cylinder body and is connected with the low-pressure heat exchangerthrough a first water inlet pipe; a first water outlet is formed in the left end of the low-pressure heat exchanger and is connected with the cylinder head assembly through a first drainage pipe; a high-pressure heat exchanger connected with the crank case is arranged on the back side of the cylinder body; the manifold block and the high-pressure heat exchanger are connected through a second waterinlet pipe; and a second water outlet is formed in the left end of the high-pressure heat exchanger and is connected with the cylinder head assembly through a second drainage pipe. The oil-free piston type air compressor for the new energy vehicle provided by the invention adopts water-cooling and air-cooling double-acting cooling manners so as to be sufficient in cooling and better in effect.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

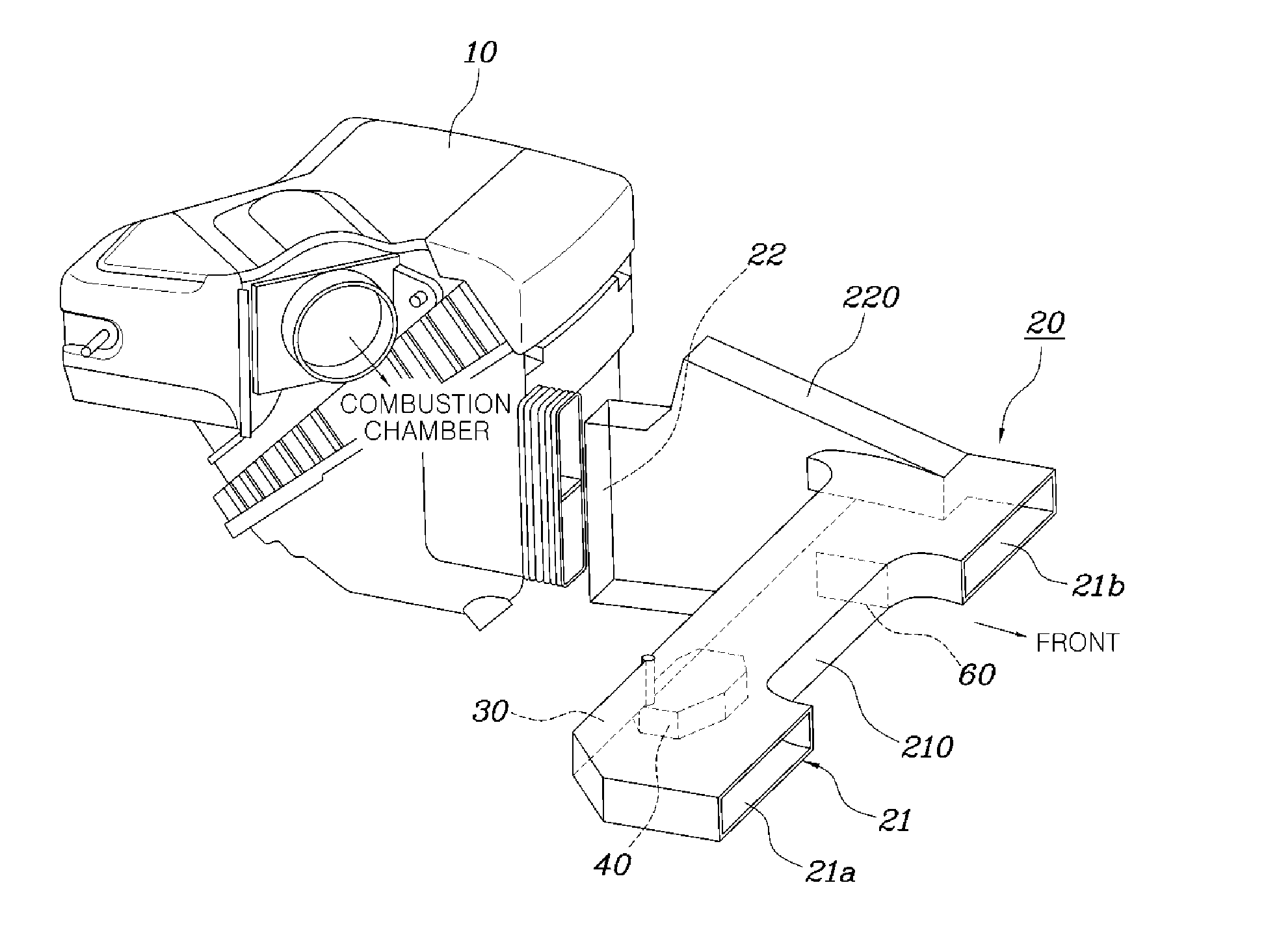

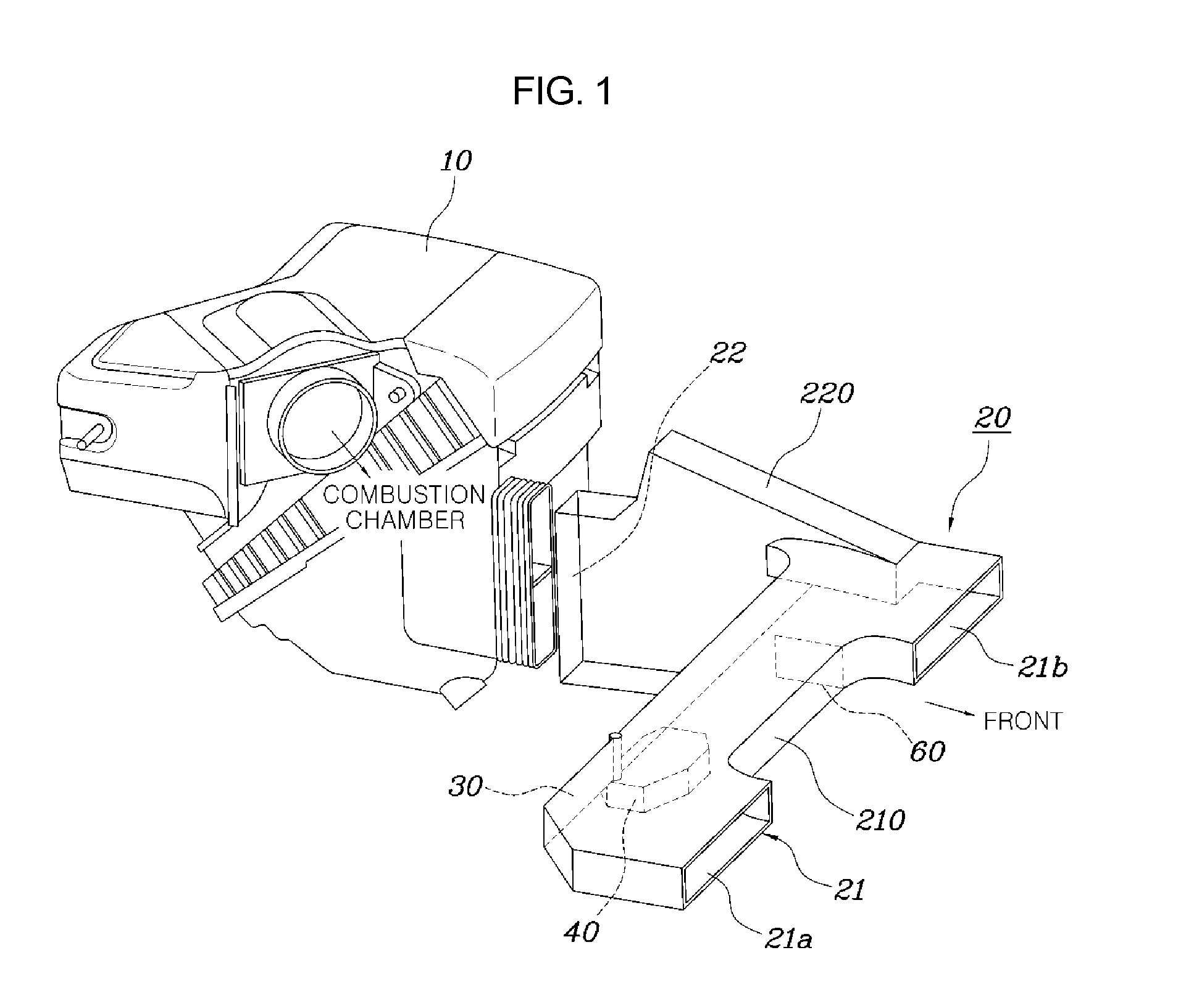

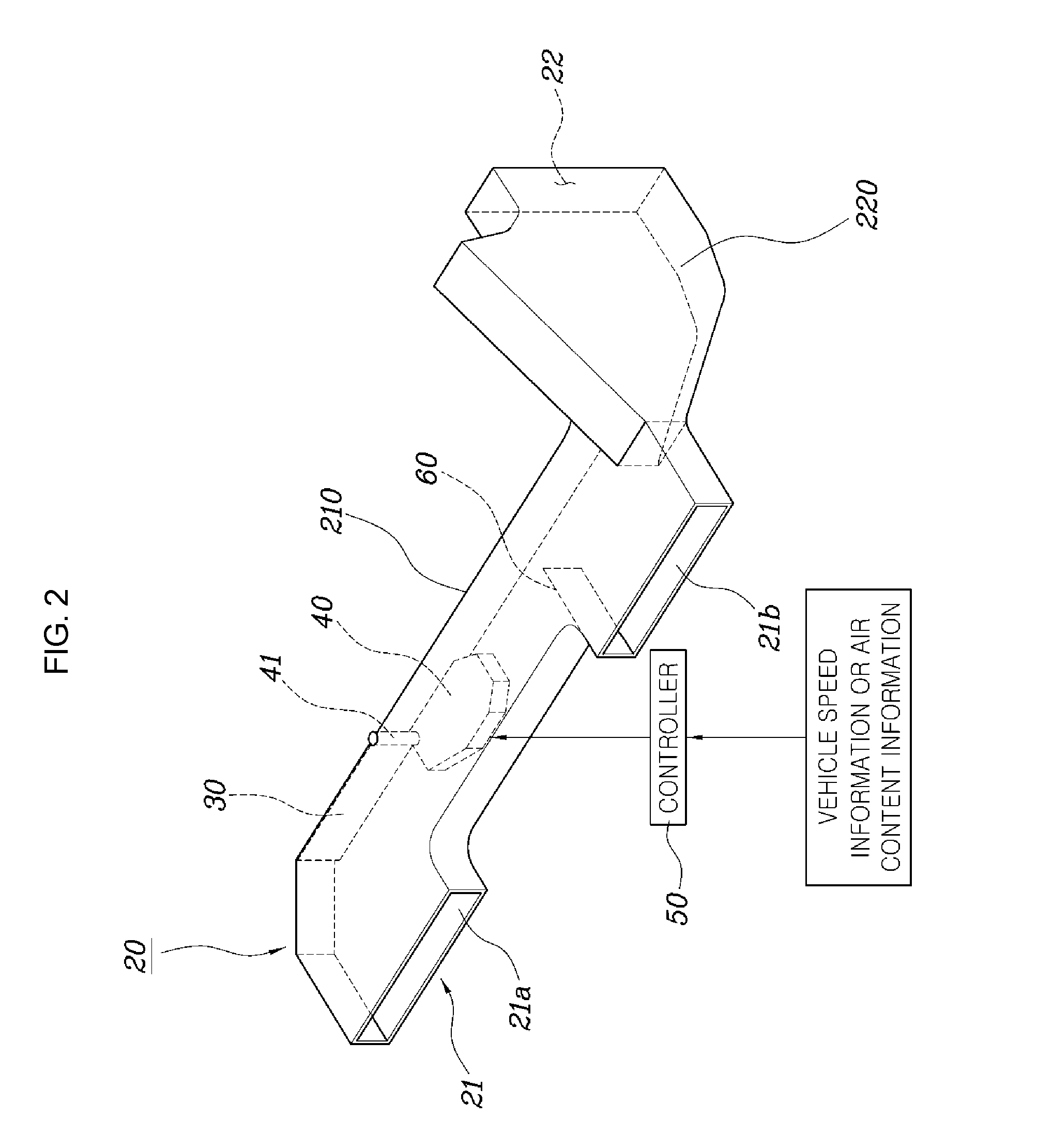

Apparatus for improving cooling efficiency of engine room in vehicle

ActiveUS20160298580A1Improve engine performanceReduced engine temperatureMachines/enginesAir cleaners for fuelIn vehicleFresh air

An apparatus for improving cooling performance of an engine room in a vehicle, may include an air duct connected to an air cleaner to serve as a moving guide of fresh air; a duct flap installed to open and close some section of the air duct and operated to supply all the fresh air introduced into the air duct when the air duct is in a closed state to the air cleaner and discharge some of the fresh air introduced into the air duct when the air duct is in an opened state to a space of a high temperature part of the engine room; and an actuator supplying power to the duct flap to perform an opening and closing operation of the duct flap.

Owner:HYUNDAI MOTOR CO LTD

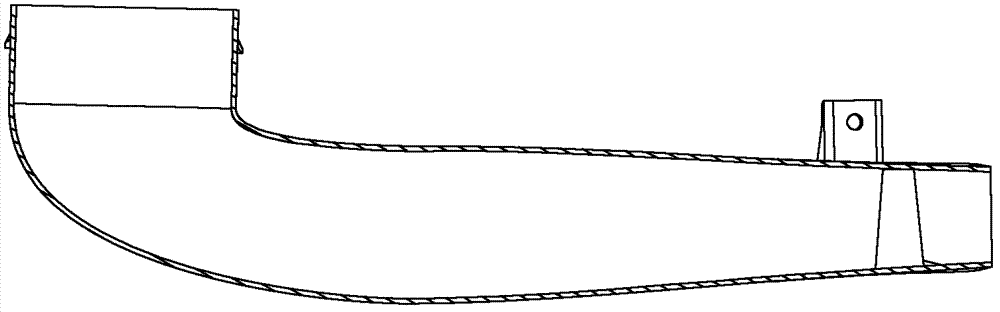

Air inlet pipe

InactiveCN103089498AIncrease dust holding capacityReduce intake noiseInternal combustion piston enginesAir cleaner and silencer combinationAir filterEngineering

The invention discloses an air inlet pipe which is connected with an air filter of an automobile and comprises a swirling pipe section (1), a noise reduction pipe section (2) and an air guide pipe section (3) which are sequentially connected. The swirling pipe section (1) is used for filtering impurities in inlet airflow, the noise reduction pipe section (2) is used for reducing air inlet noise, and the air guide pipe section (3) is communicated with the air filter and used for guiding the inlet airflow flowing out of the noise reduction pipe section (2) into the air filter. By the aid of the technical scheme, the air inlet noise is effectively reduced, the dust holding capacity of an air inlet system can be improved, and the air inlet pipe has the advantages of compact structure, light weight and convenience in assembly, and easily realizes industrialization.

Owner:BEIQI FOTON MOTOR CO LTD

Vehicle seat and associated air conditioning apparatus

InactiveUS20060103184A1Reduce intake noiseAvoid problemsSeat heating/ventillating devicesStoolsAir treatmentEngineering

Owner:GENTHERM GMBH

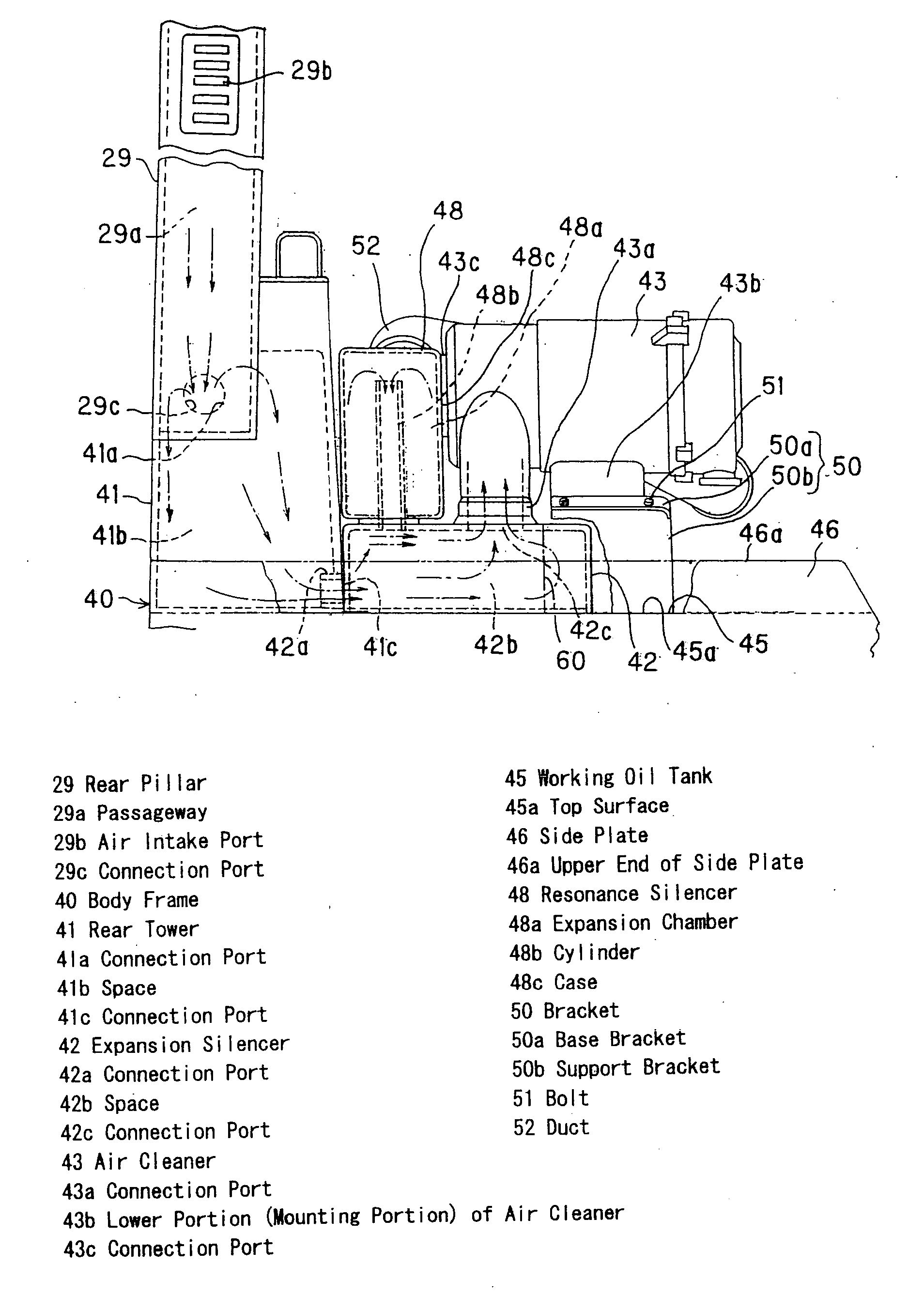

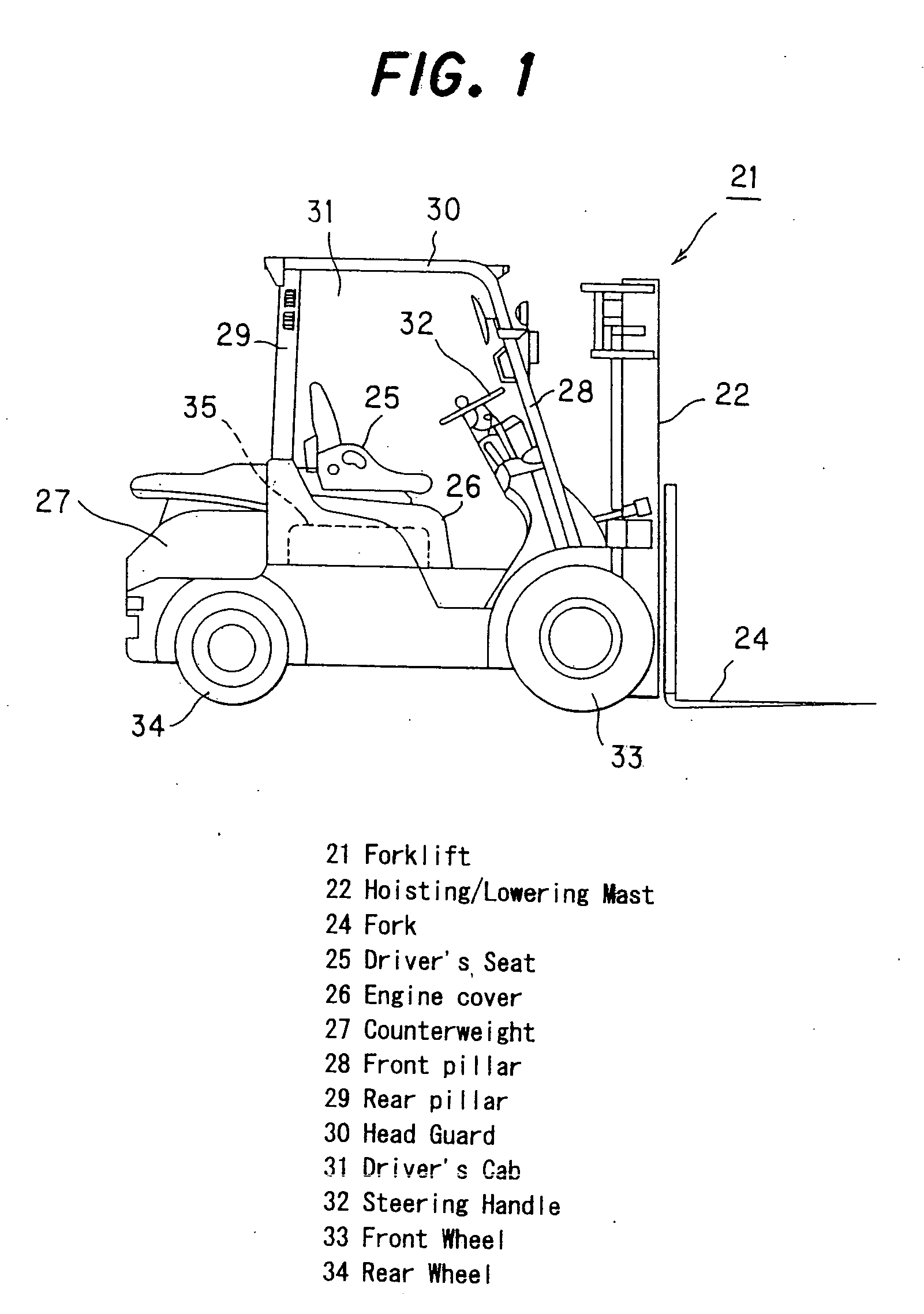

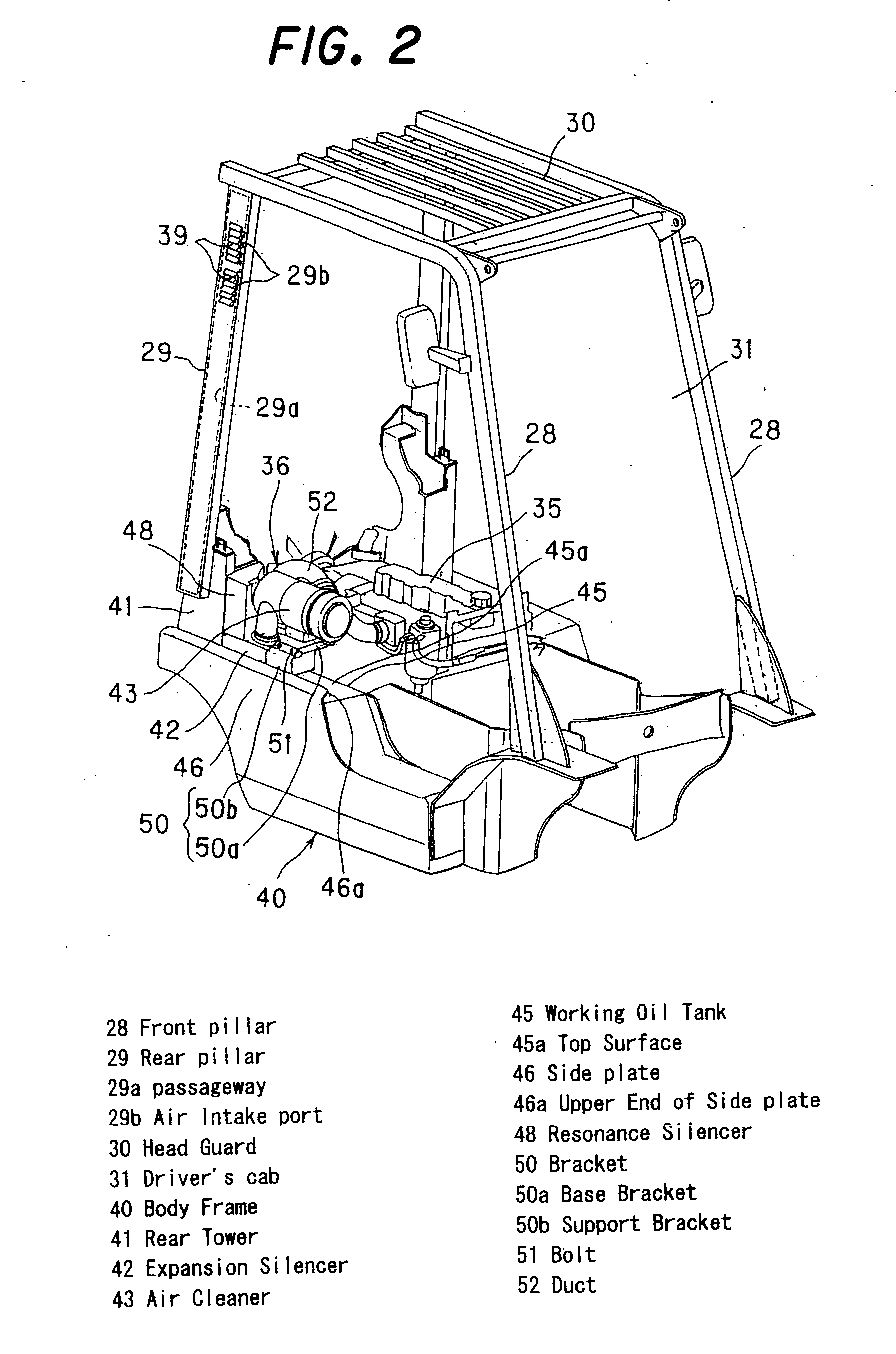

Air intake system and forklift equipped with it

InactiveUS20050022772A1Compact configurationReduce intake noiseLifting devicesMachines/enginesFuel tankEngineering

In an air intake system, a rear tower having a space interiorly is provided on the top surface of a body frame, a rear pillar having a passageway interiorly is mounted on the rear tower, an air intake port communicating with the passageway is provided in the rear pillar, the passageway and the space within the rear tower are connected together, an expansion silencer is connected to the space of the rear tower, and an air cleaner is connected to the expansion silencer. The top surface of a working oil tank is rendered lower than the upper end of a side plate to form a space above the top surface, where the expansion silencer is provided. A base bracket is mounted to the air cleaner, a support bracket is mounted on the side plate, and the base bracket is mounted on the support bracket to support the air cleaner above the expansion silencer.

Owner:MITSUBISHI HEAVY IND LTD +1

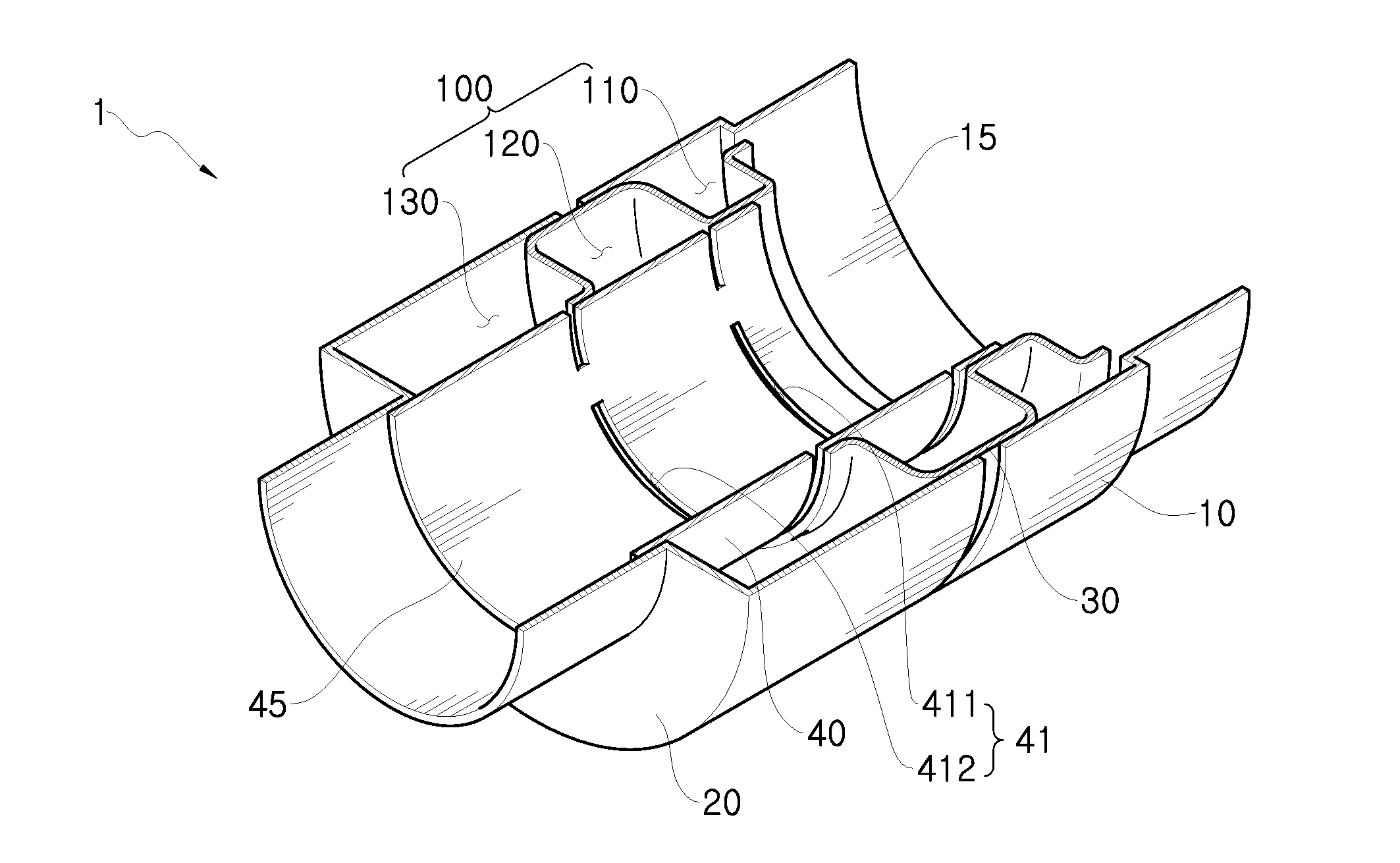

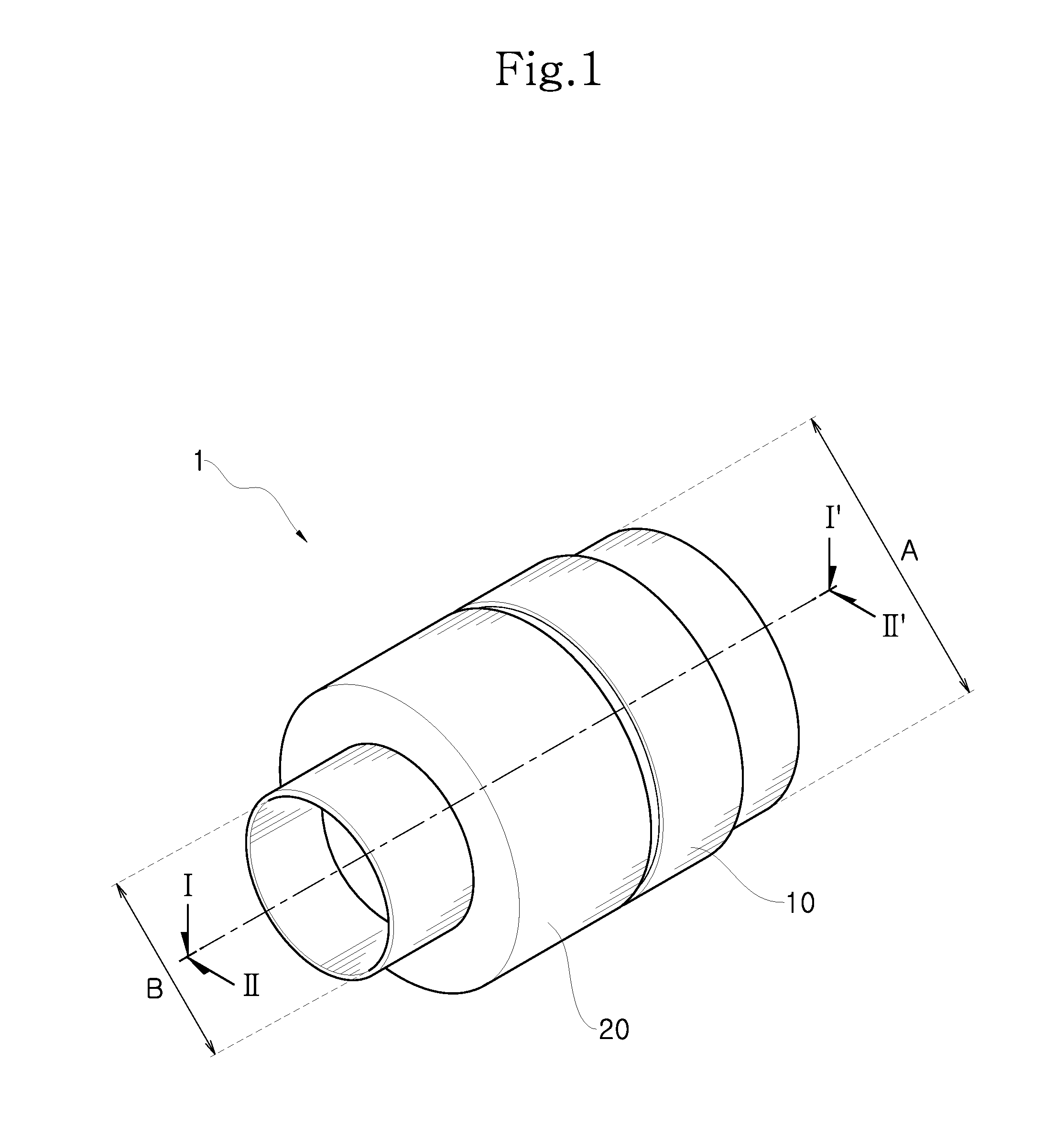

Resonator for vehicle

ActiveUS9309843B2Enhance degree of frequency tuning freedomReduce intake noiseMachines/enginesAir intakes for fuelEngineeringResonator

A resonator for a vehicle, which reduces intake noise by using a resonance chamber for frequency tuning, includes an outer pipe having a first outer pipe with an inlet for introducing external air and a second outer pipe with an outlet for discharging the air introduced into the inlet to outside, an inner pipe disposed inside the outer pipe and having a plurality of slits for giving a passage of air, and an expansion pipe inserted between the outer pipe and the inner pipe to partition a space between the outer pipe and the inner pipe into a plurality of spaces and thus partition the resonance chamber into a plurality of regions.

Owner:COOPER STANDARD AUTOMOTIVE & IND INC

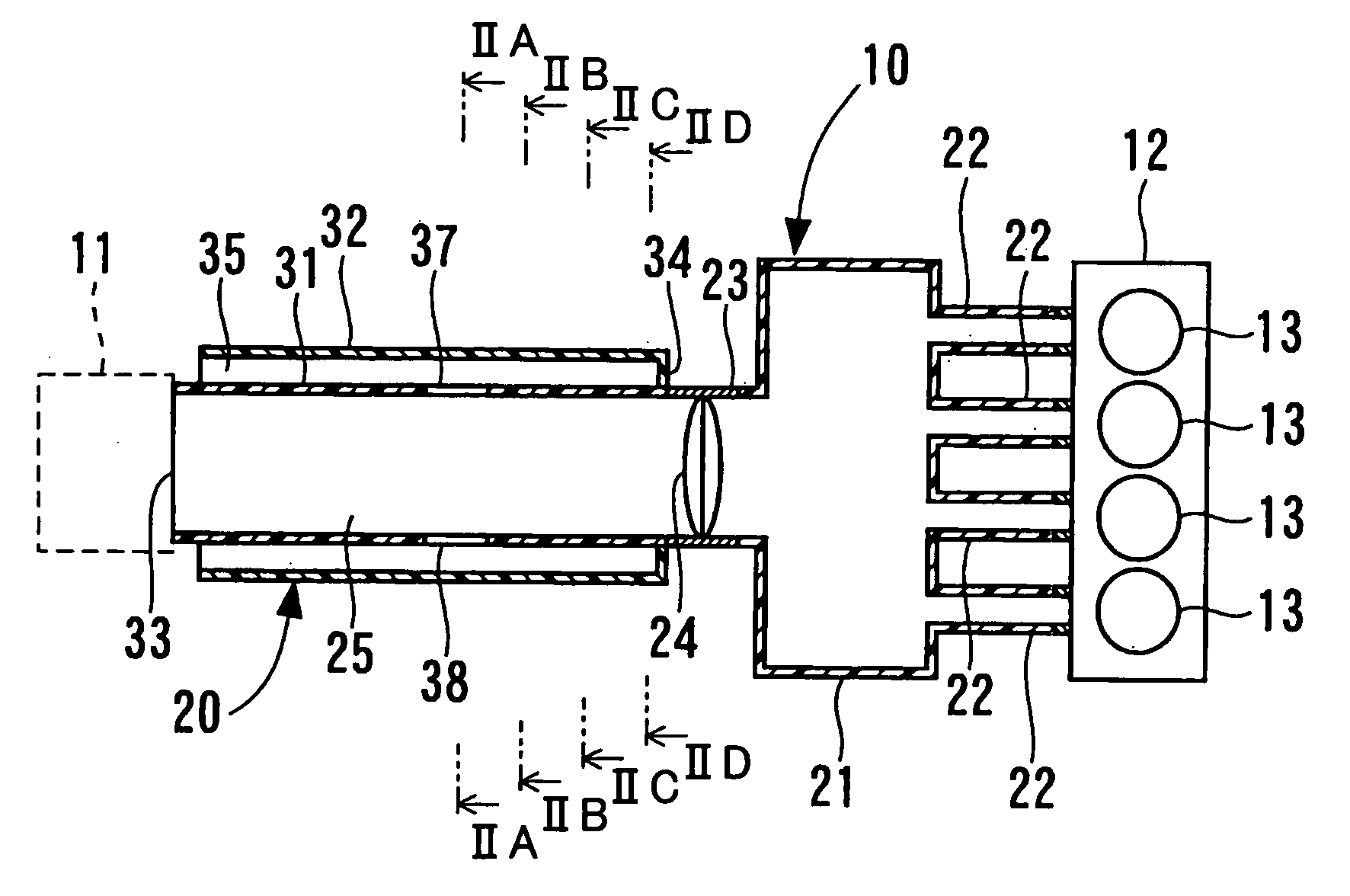

Air intake device

InactiveUS20080156579A1BandwidthReduce the temperatureCombustion enginesAir intakes for fuelSurge tankAtmospheric air

An air intake device includes an inner pipe member having a substantially cylindrical shape and defining therein an air intake passage by a wall portion of the inner pipe member, and an outer pipe member which surrounds a periphery side of the inner pipe member to define therebetween a space. The air intake passage communicates a surge tank with an atmosphere intake port through which air is introduced into the surge tank. The wall portion of the inner pipe member has at least one sound transmission portion through which sound is more readily transferred than other portions of the wall portion. The space has one end which is opening and positioned at a side of the atmosphere intake port, and the other end which is closed and positioned at a side of the surge tank.

Owner:DENSO CORP

Air intake device for internal combustion engine

ActiveCN103061894AReduce intake noiseImprove rigidityEngine controllersMachines/enginesCombustionEngineering

Owner:HONDA MOTOR CO LTD

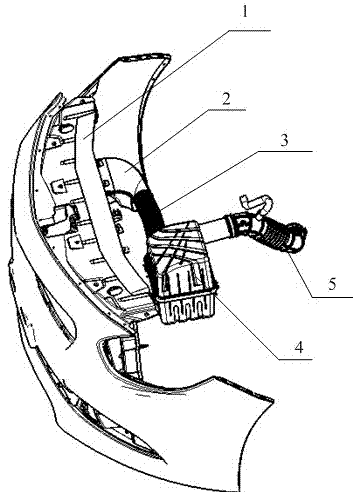

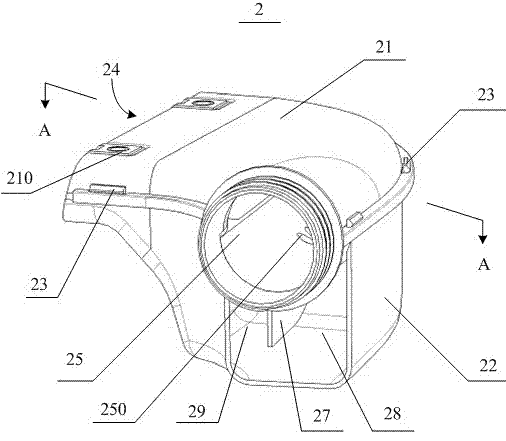

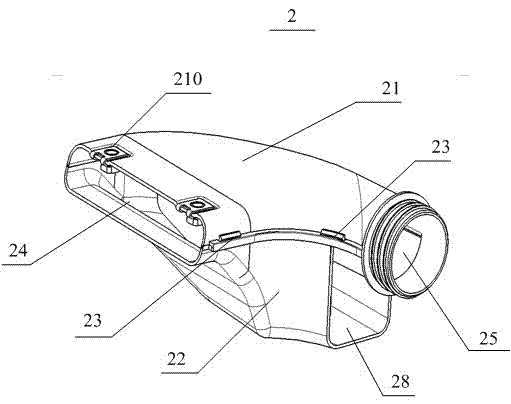

Air feeding structure and system for automobile and corresponding automobile

ActiveCN104727995AStrong filtering functionSufficient air intakeMachines/enginesAir intakes for fuelMechanical engineeringEngineering

The invention discloses an air feeding structure for an automobile. The air feeding structure for the automobile is arranged between an air feeding grid of the automobile and a corrugated tube. The air feeding structure is that an upper part and a lower part are combined to form a cavity; a main air inlet and a tubular body are formed in the cavity; a downwards-inclined flow guide plate is arranged at the main air inlet; a strip-shaped opening is formed in the wall of the tubular body of the flow guide plate; a main air inlet is formed in the lower side edge of the flow guide plate and communicated with the inner part of the tubular body through the strip-shaped opening; a space is formed between the lower side of the flow guide plate and the lower part of the tubular body and is divided into a main cavity and a secondary cavity through a separating plate, wherein the main cavity is communicated with the secondary cavity; a plurality of secondary air inlets are formed in the wall of the tubular body, close to the secondary cavity and used for communicating the secondary cavity with the tubular body. The invention further discloses an air feeding system for the automobile and the corresponding automobile. With the adoption of the air feeding structure, clean air at proper temperature can be provided to an engine.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

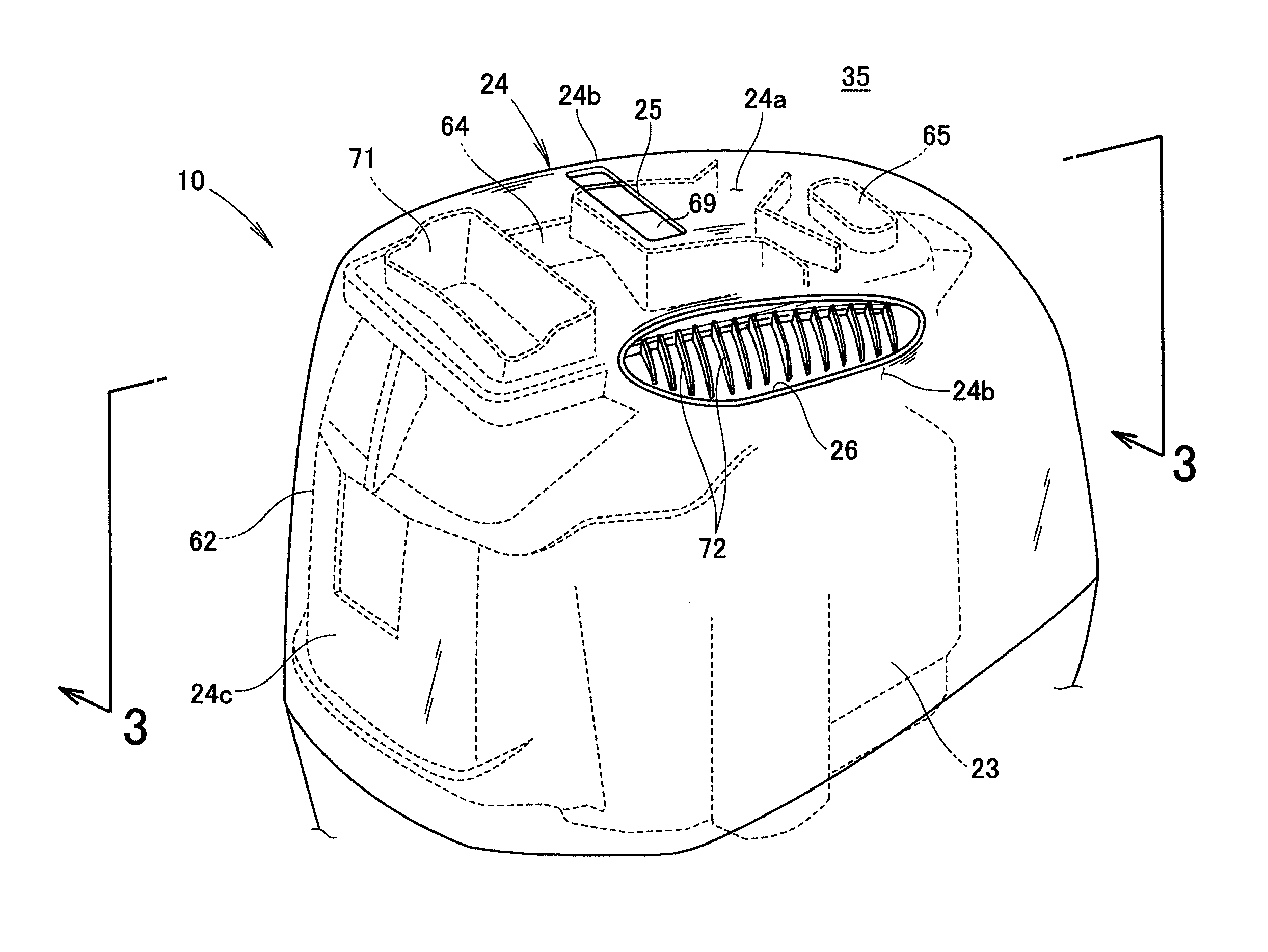

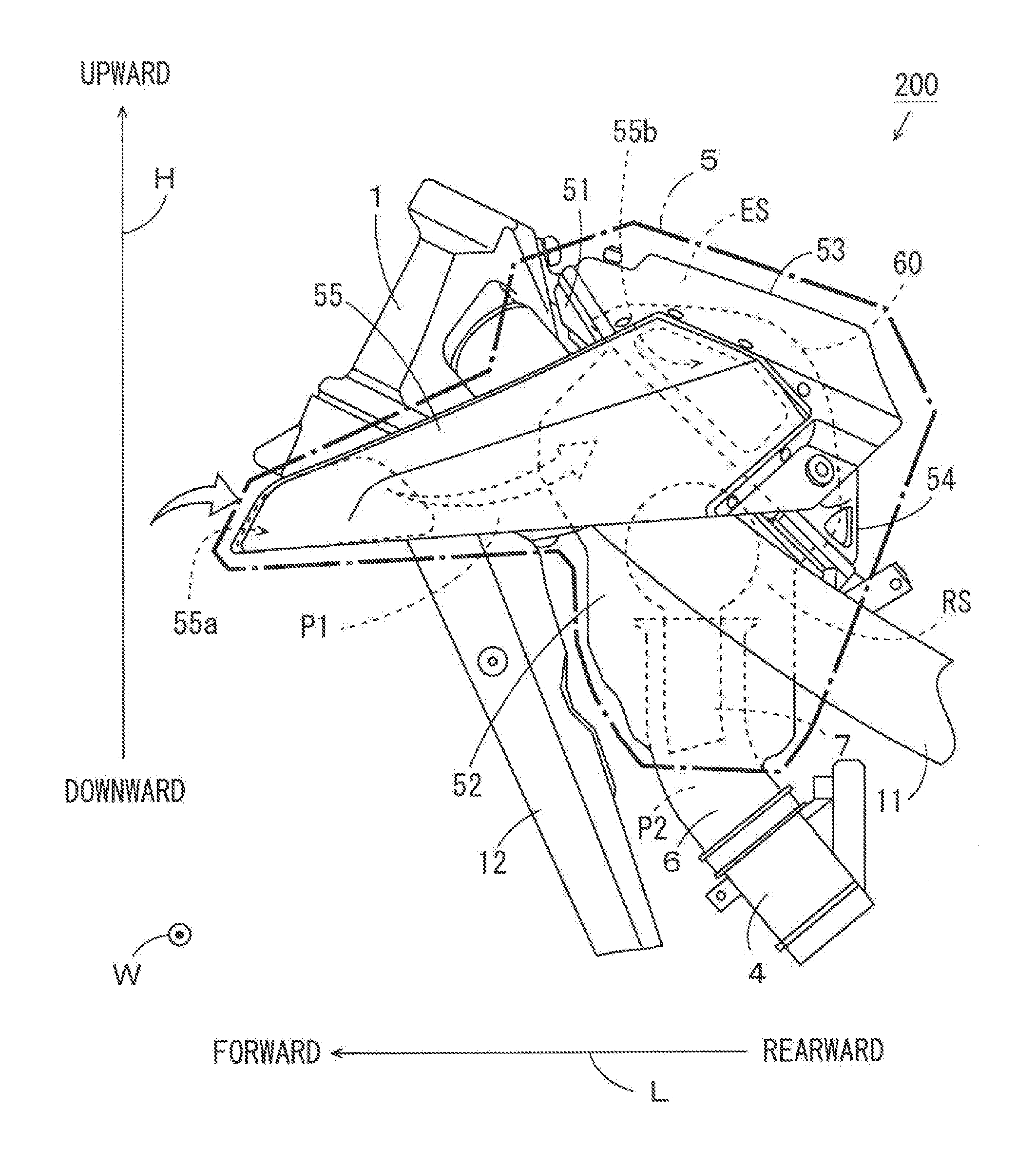

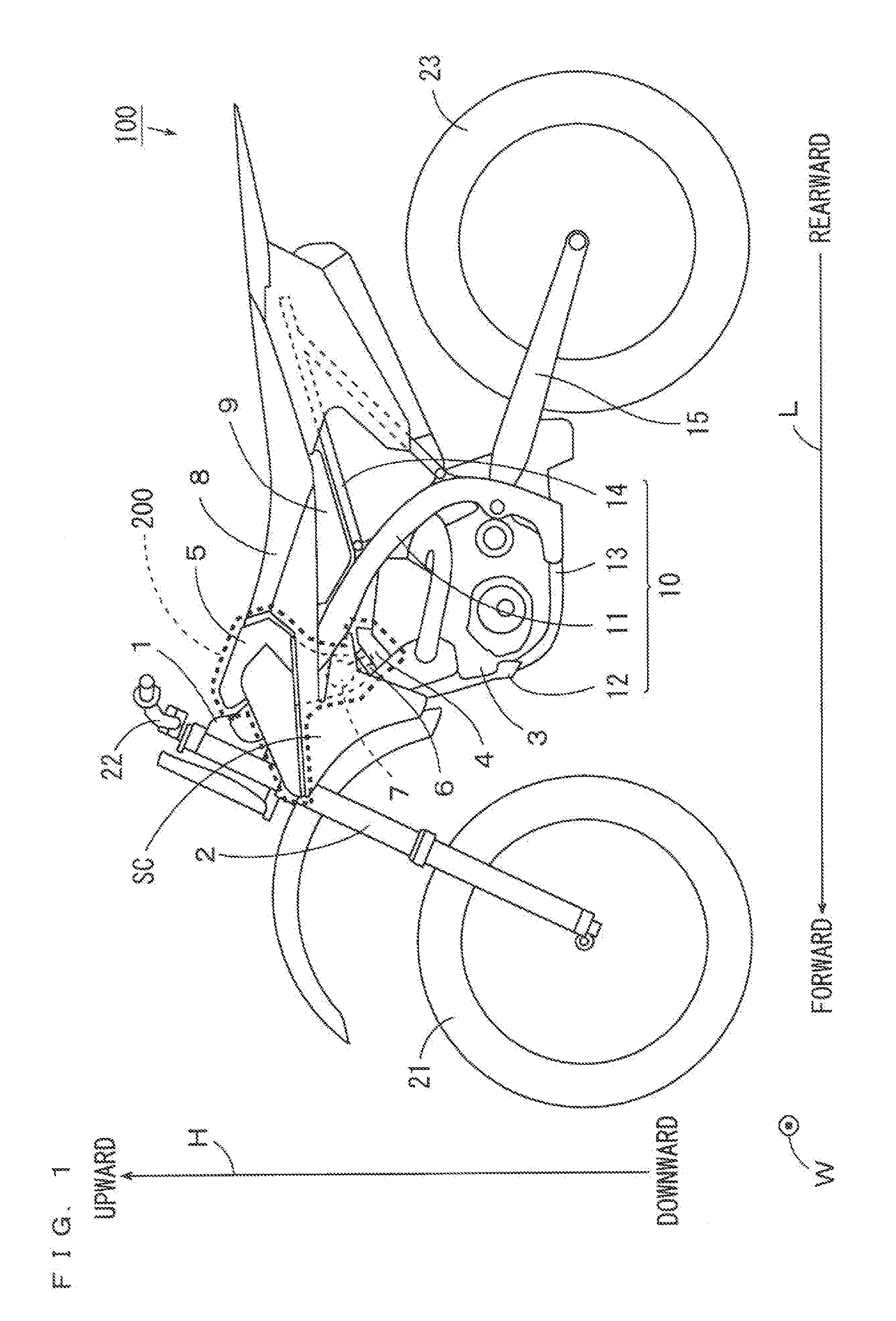

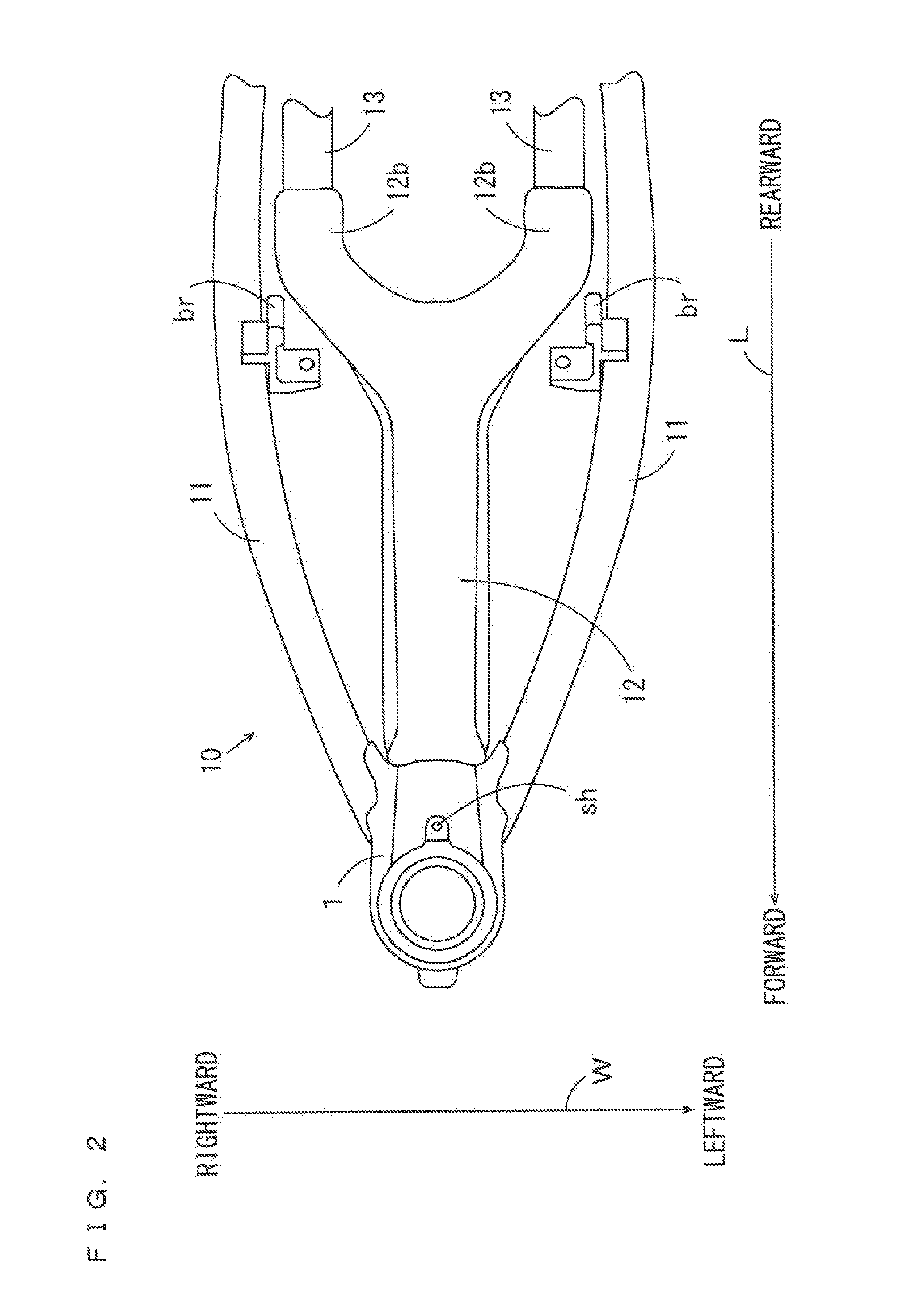

Intake noise reduction device and straddle-type vehicle including the same

ActiveUS20150345440A1Limitation of layoutLimitation of designMachines/enginesAir cleaners for fuelNoise reductionThrottle opening

An intake noise reduction device includes an air cleaner, an intake funnel and a resonator, and is connected to an engine via a throttle body. The resonator is provided inside of the air cleaner. The resonator includes a chamber portion and a pipe portion. The pipe portion is formed to extend downward from the chamber portion, and has an opening end at a lower end. The intake funnel is provided at a lower end of the air cleaner. An opening end of the resonator is inserted into the intake funnel. A cross sectional area of an intake passage between the intake funnel and the pipe portion is set to not less than an opening area of an intake passage of the throttle body opened to a maximum throttle opening.

Owner:YAMAHA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com