Patents

Literature

21422 results about "Air compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An air compressor is a device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When tank pressure reaches its engineered upper limit, the air compressor shuts off. The compressed air, then, is held in the tank until called into use. The energy contained in the compressed air can be used for a variety of applications, utilizing the kinetic energy of the air as it is released and the tank depressurizes. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. An air compressor must be differentiated from a pump because it works for any gas/air, while pumps work on a liquid.

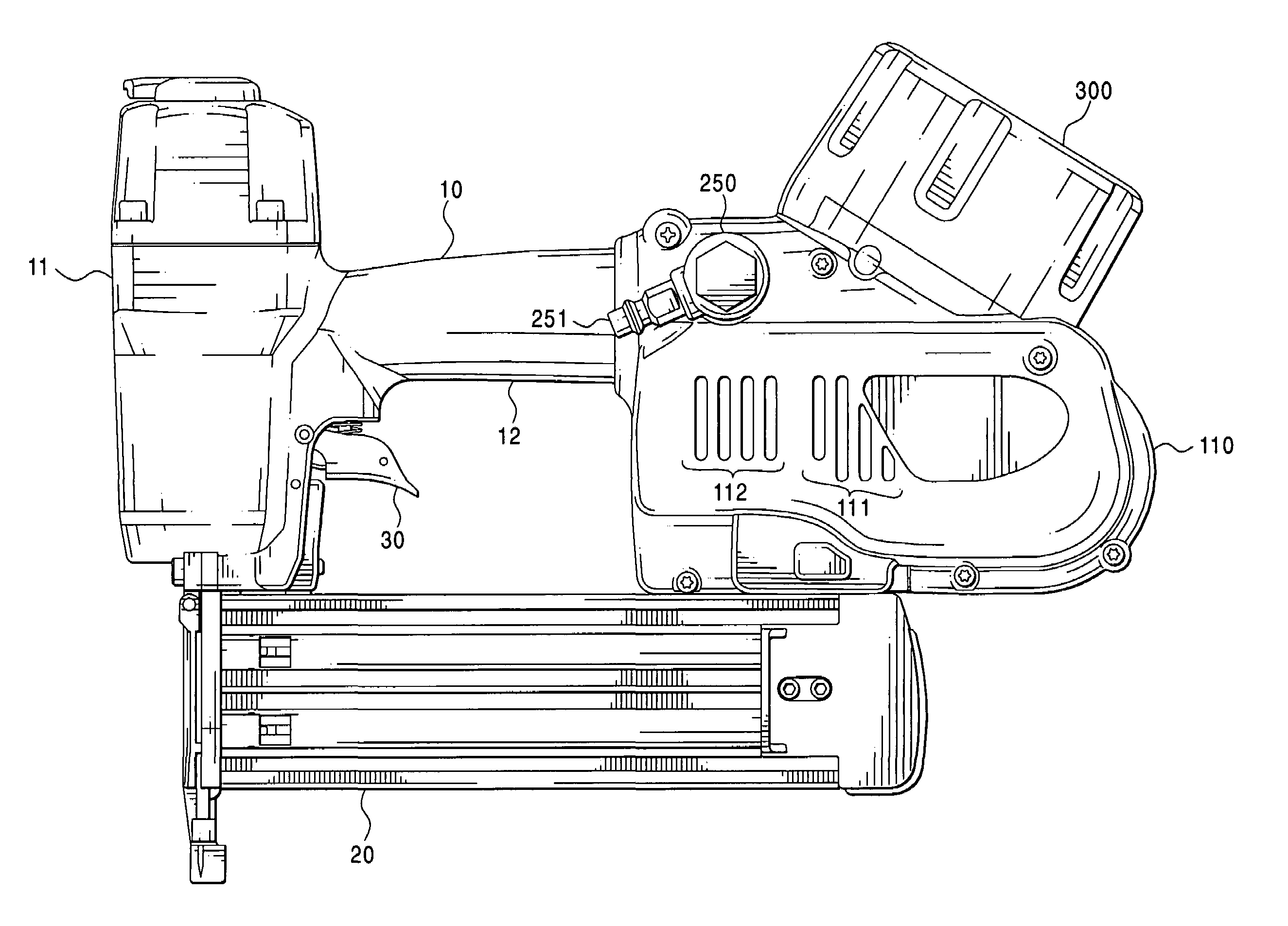

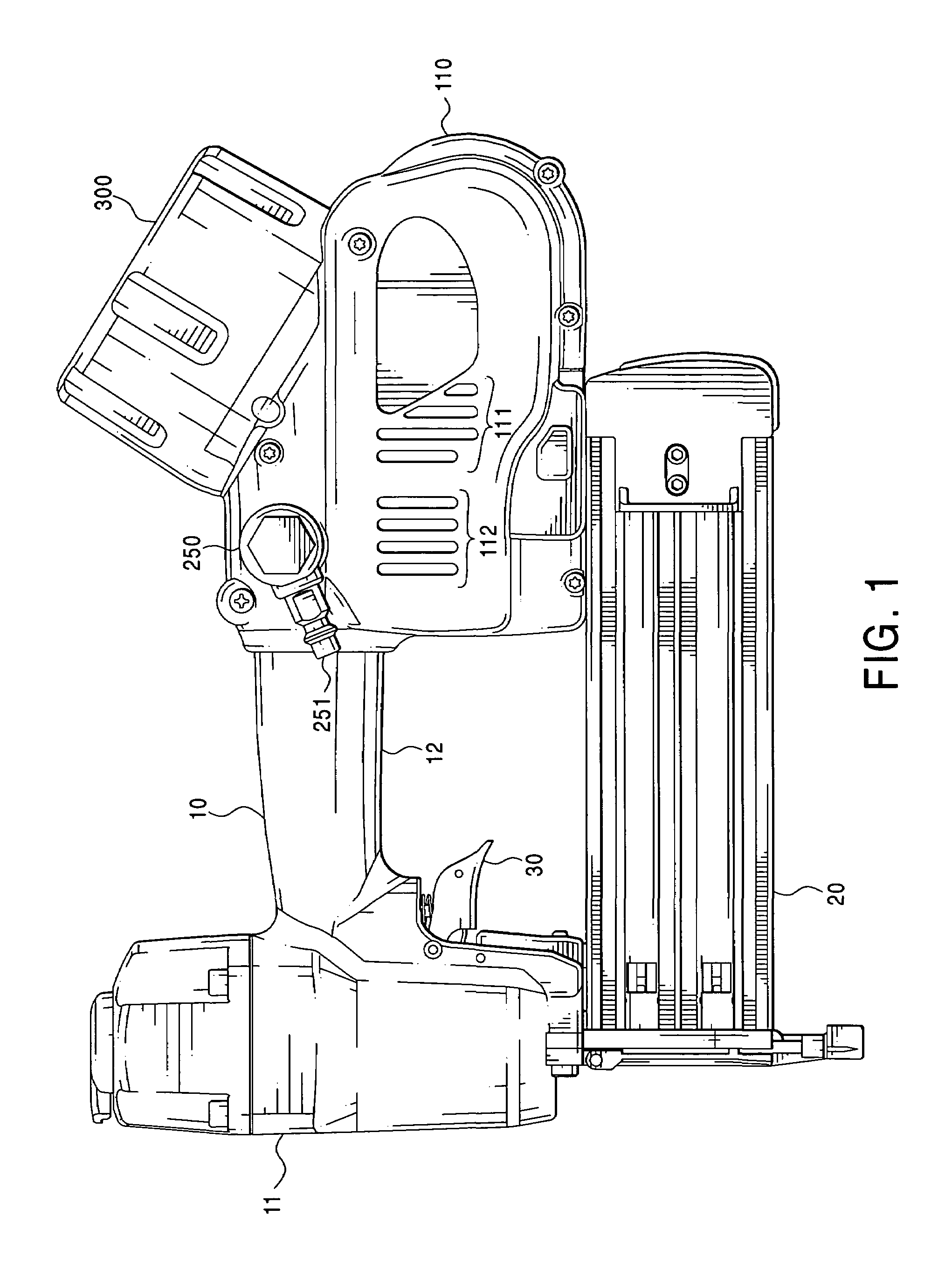

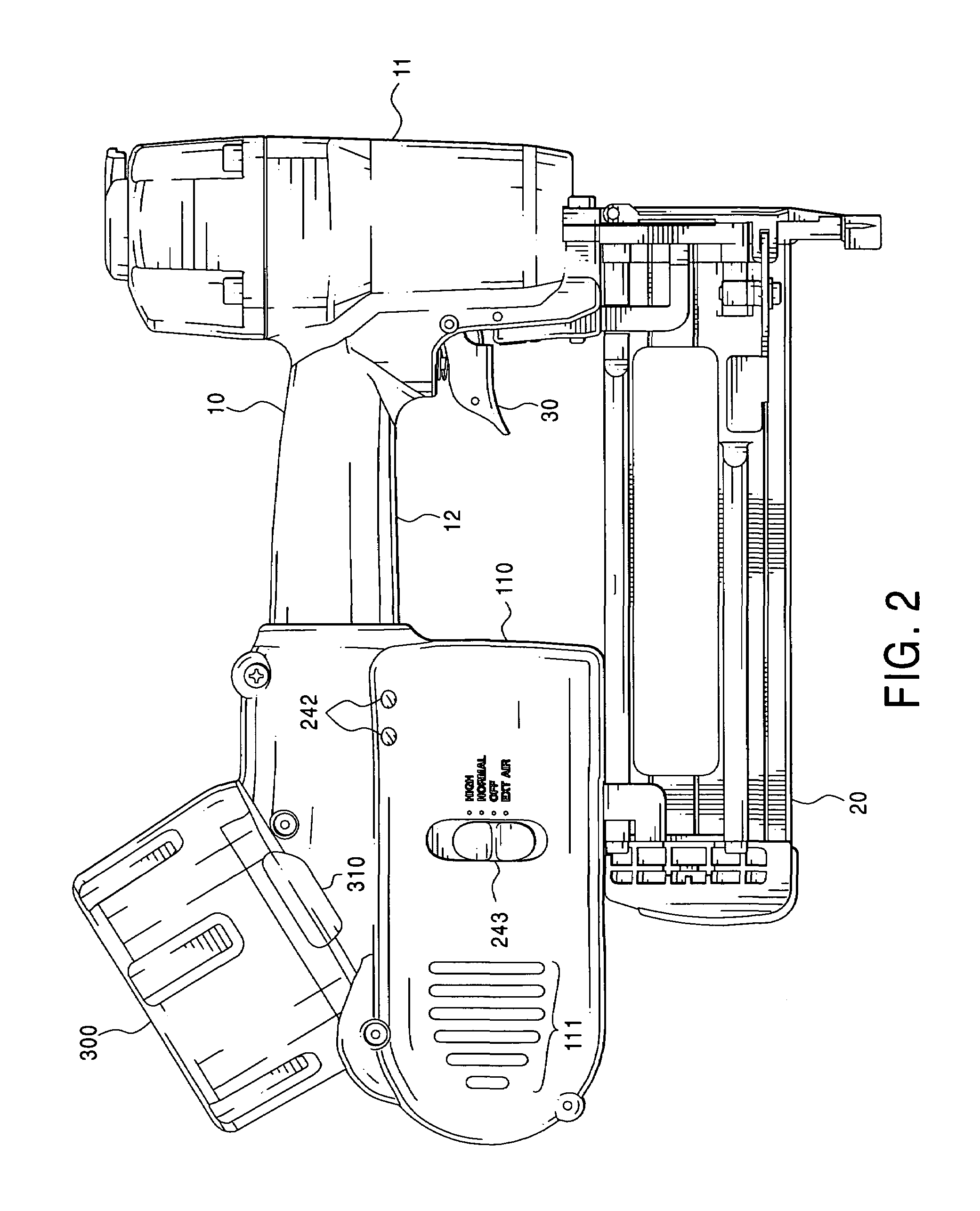

Portable, battery-powered air compressor for a pneumatic tool system

Owner:BLACK & DECKER INC +1

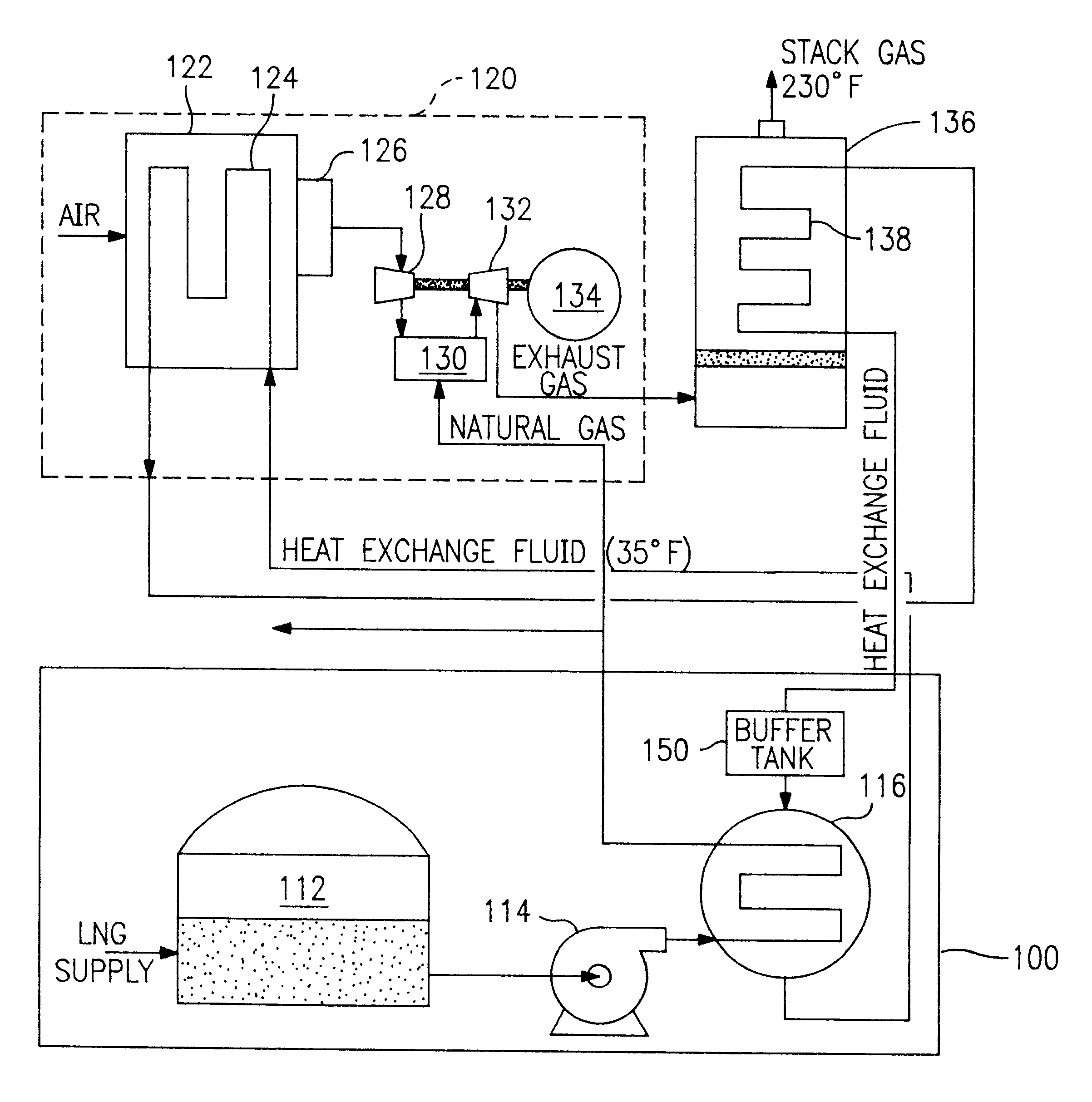

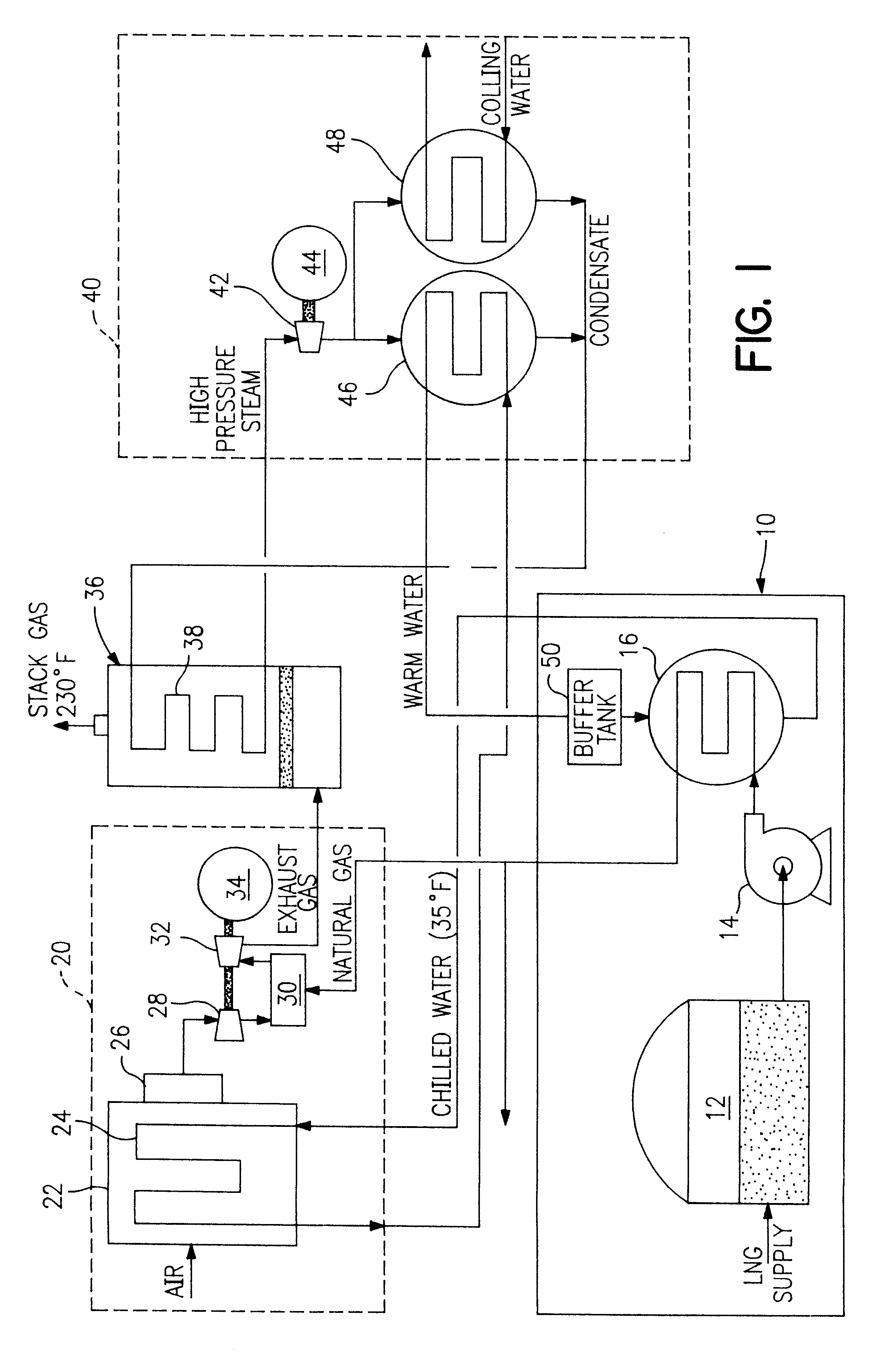

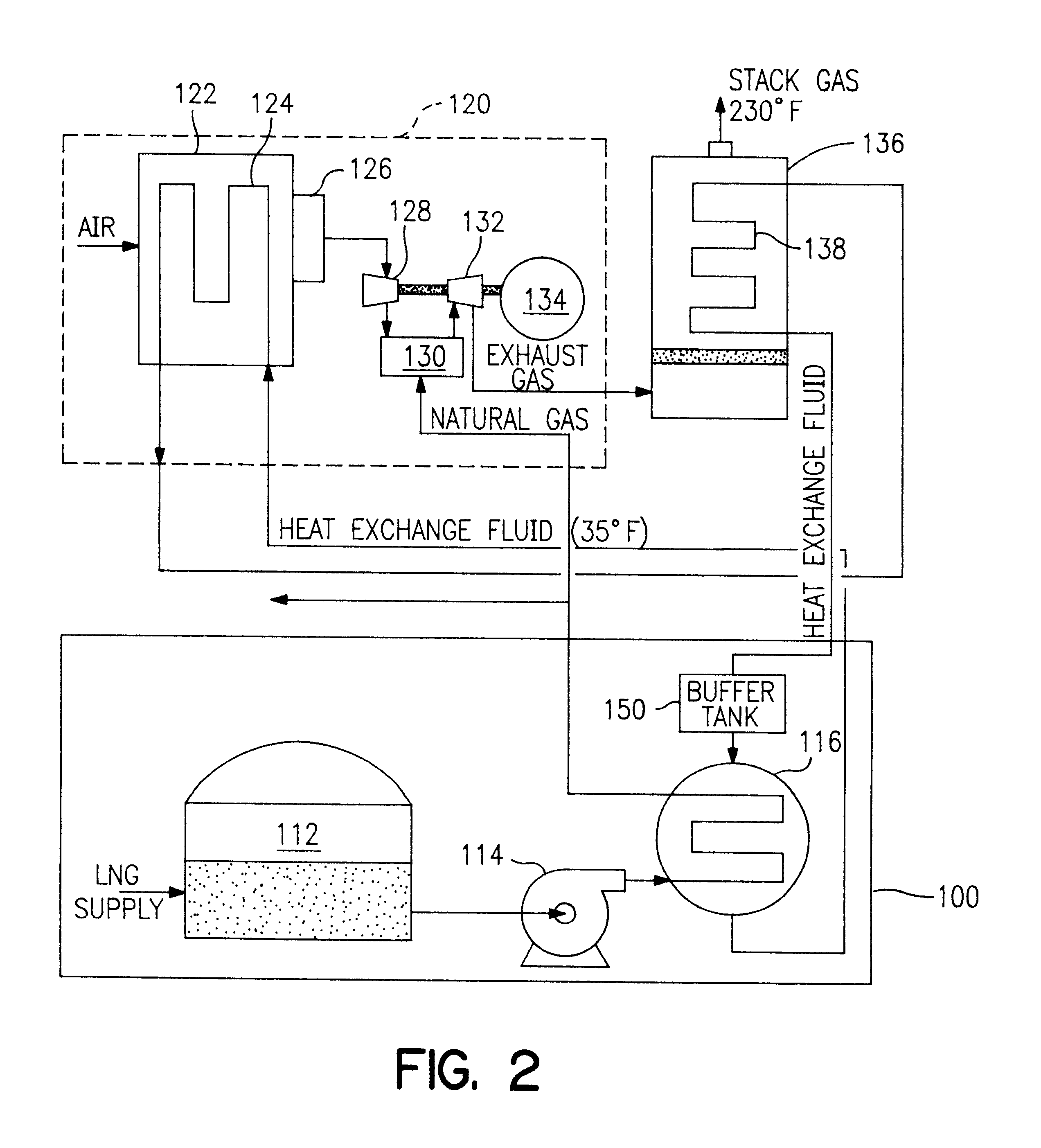

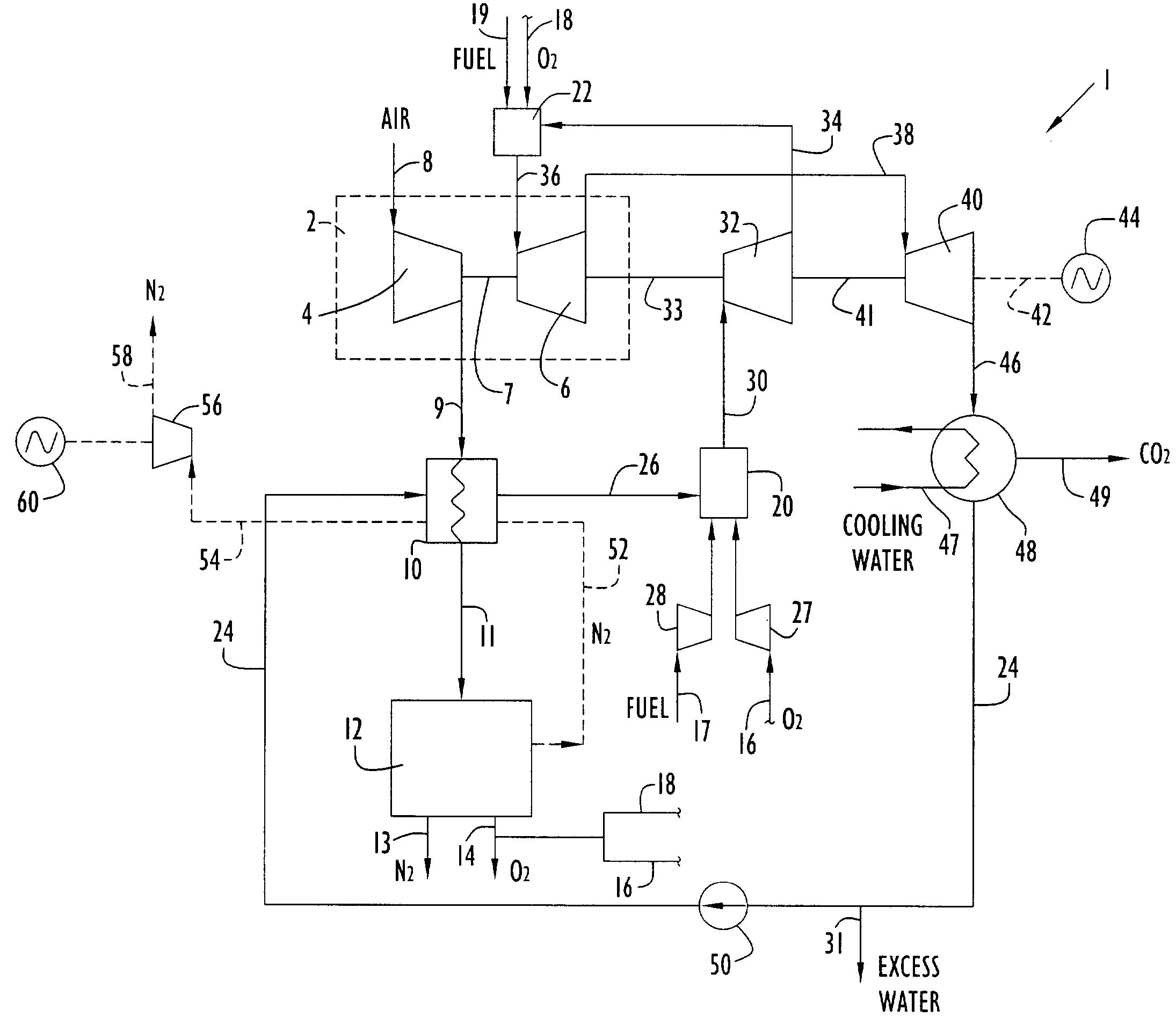

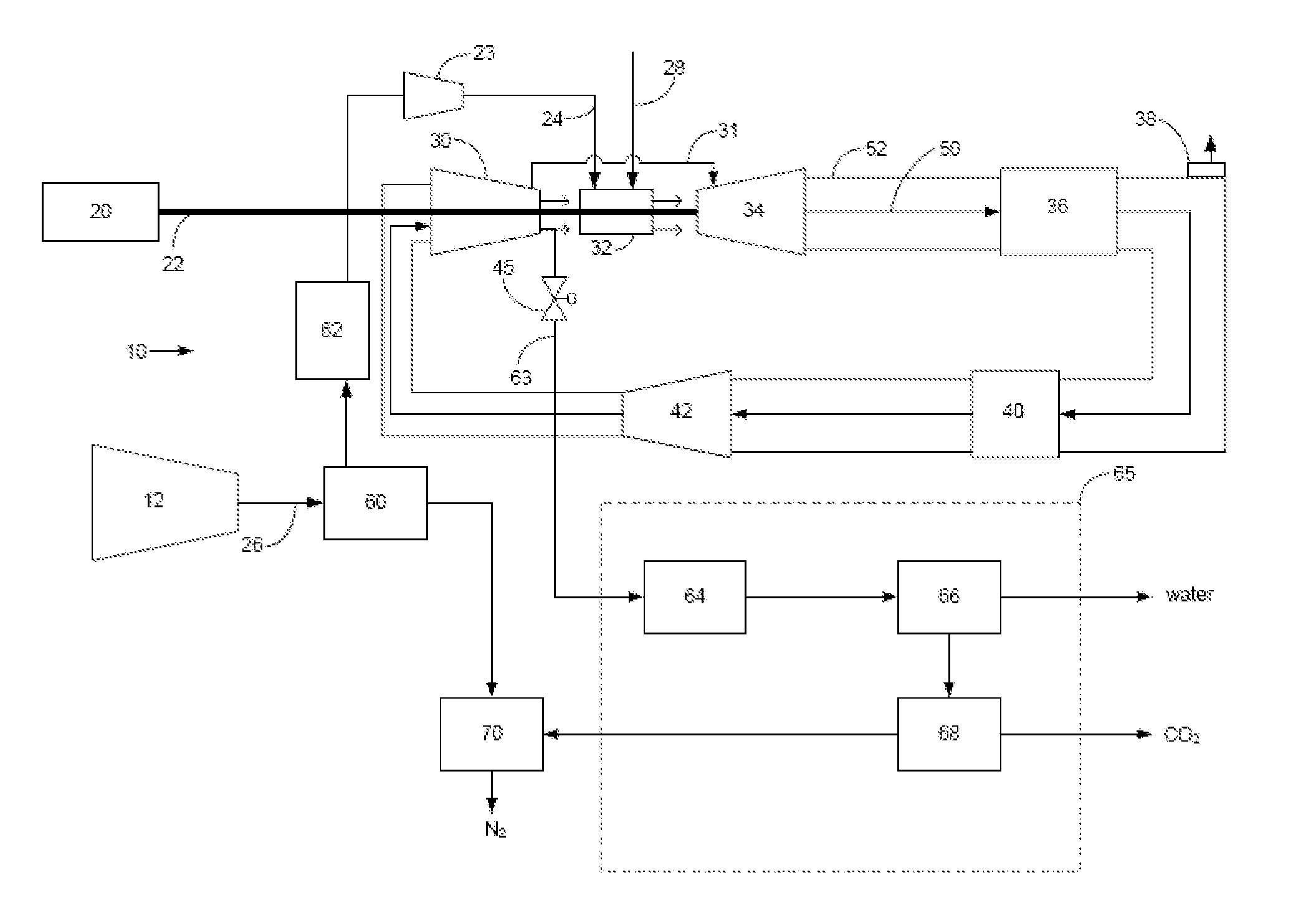

Liquified natural gas (LNG) fueled combined cycle power plant and a (LNG) fueled gas turbine plant

InactiveUS6374591B1Improve efficiencyParts are smallGas handling applicationsGas turbine plantsCombustion chamberPower station

A process and system which improves the capacity and efficiency of a power plant. A LNG supply system fuels the plant. Gasified LNG in a combustor mixes with the air from an air compressor to provide the hot combustion gas for a gas turbine. The expanding LNG is used to chill a heat exchange fluid, e.g. water, which heat exchange fluid cools and densifies the intake air for the air compressor. Subsequently, the heat exchange fluid is used in another heat exchange step and is then re-chilled and recycled to cool and densify the intake air.

Owner:SUEZ LNG NA

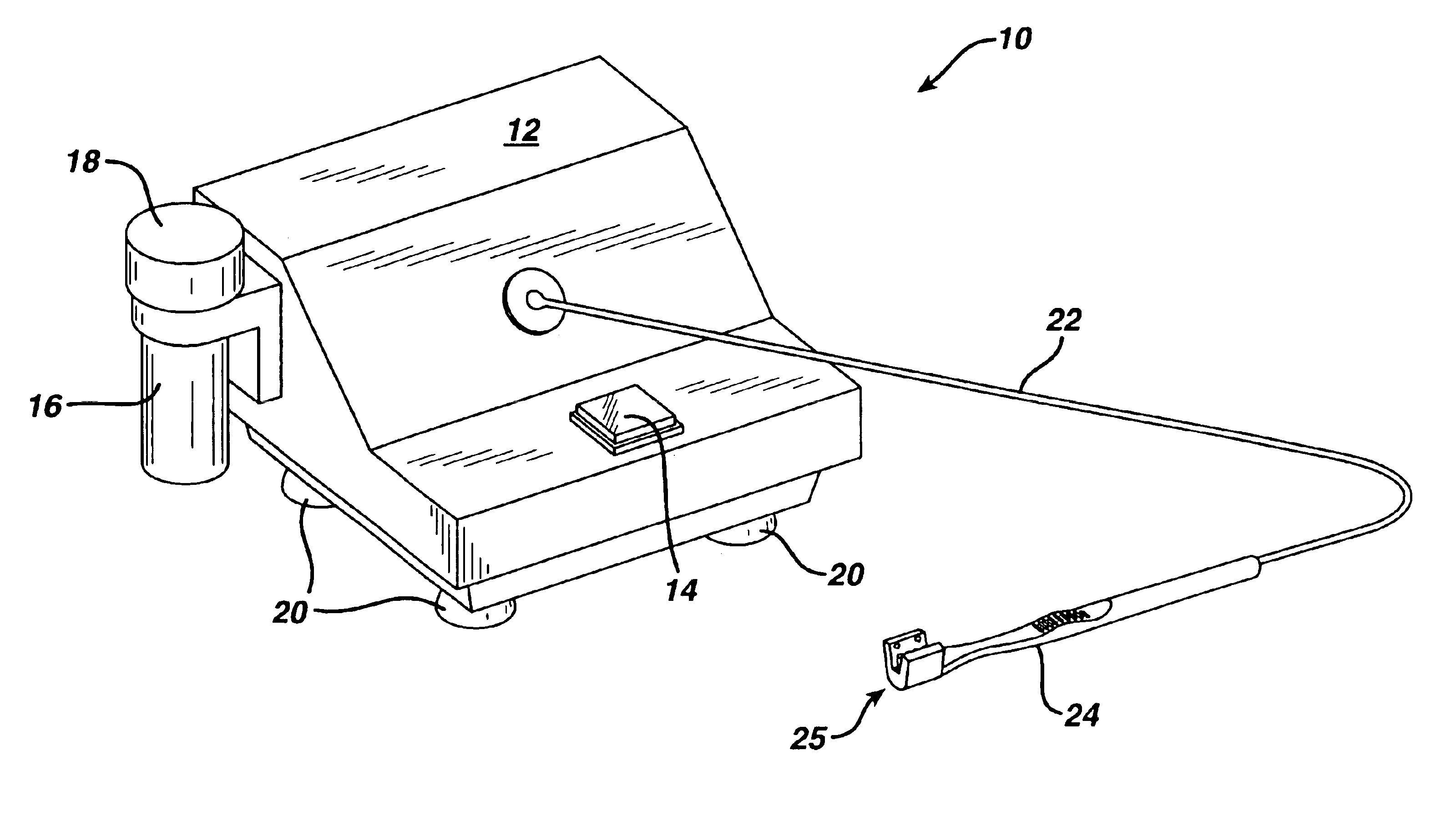

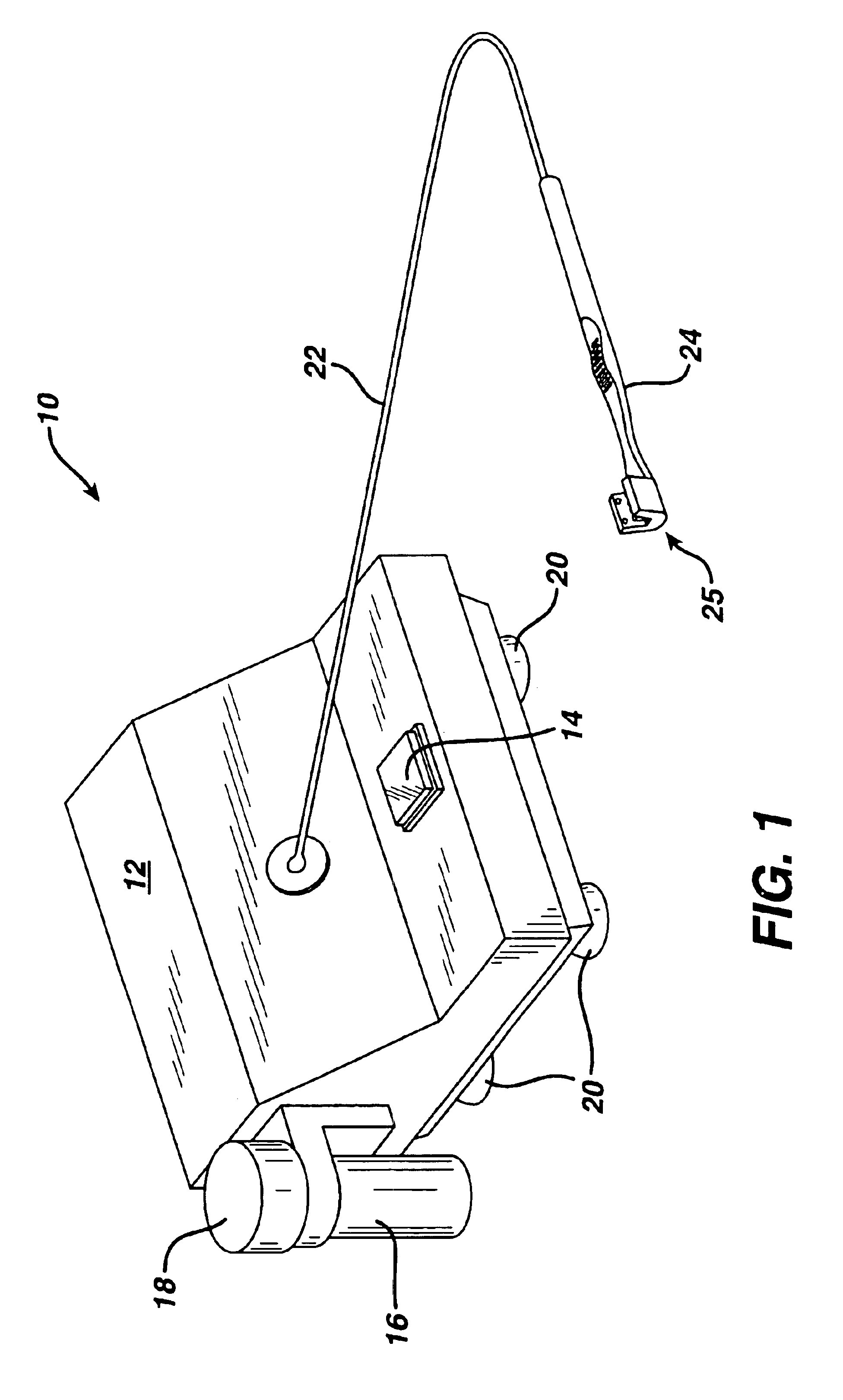

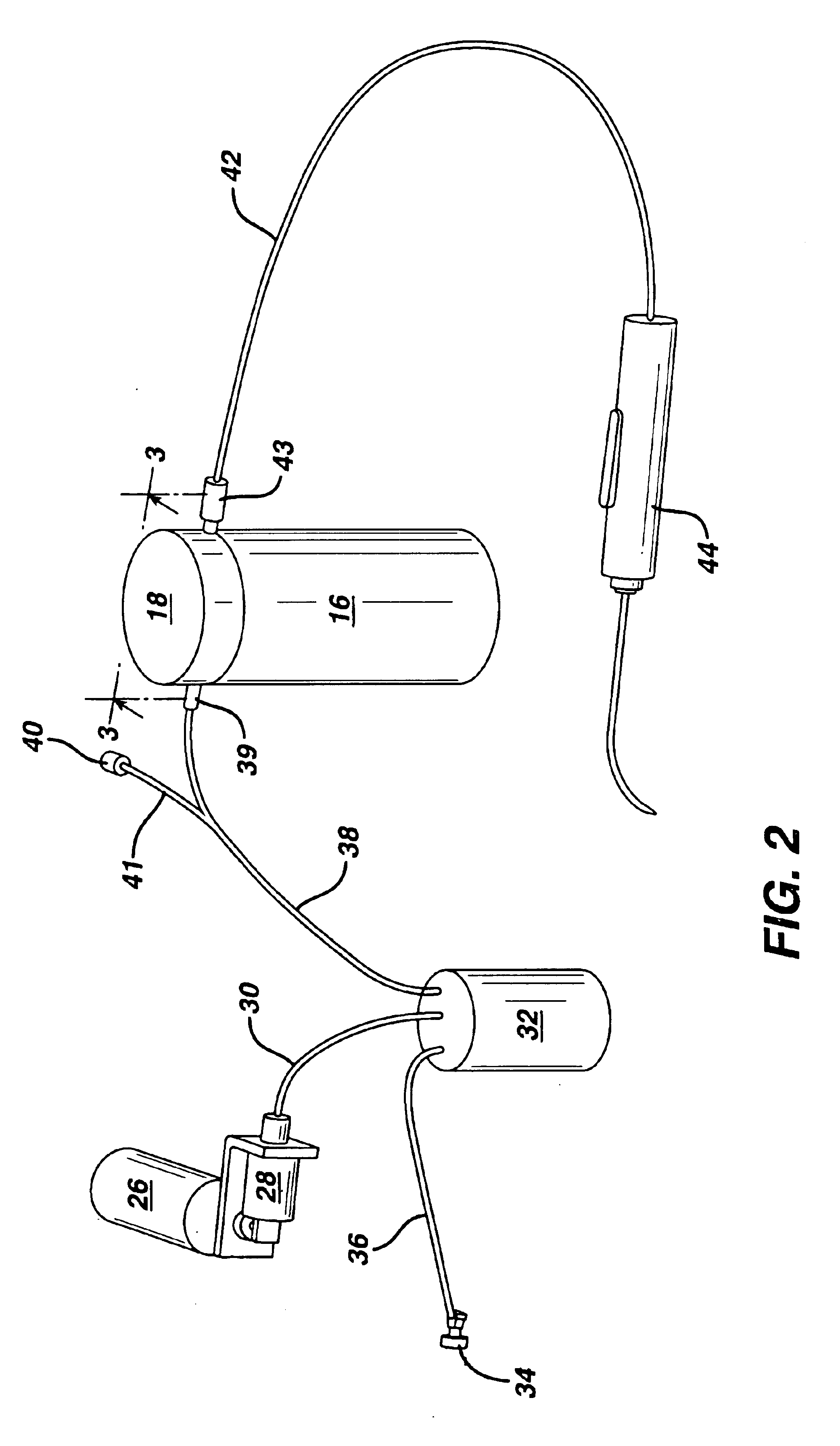

Oral care device

An oral care device includes an electric motor, an air compressor operated by the motor, and an enclosed container for holding a slurry. A first conduit conducts compressed air from the compressor into the container. The compressed air is at a pressure of between about 20 psi to about 50 psi. A second conduit conducts the slurry and air from the container to an applicator from which the slurry and air is sprayed into the oral cavity of a human. The second conduit is at least about 24 inches in length.

Owner:THE GILLETTE CO

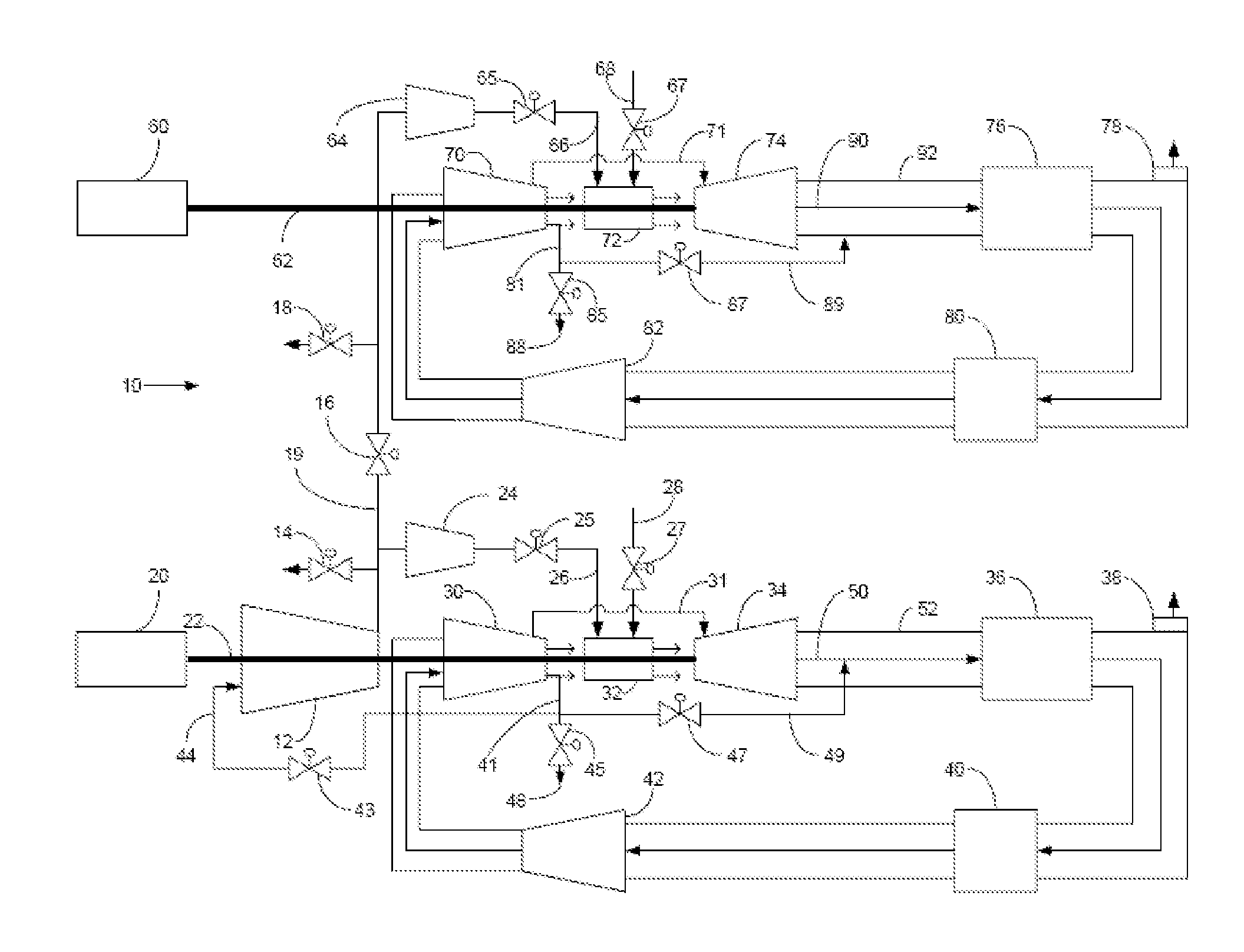

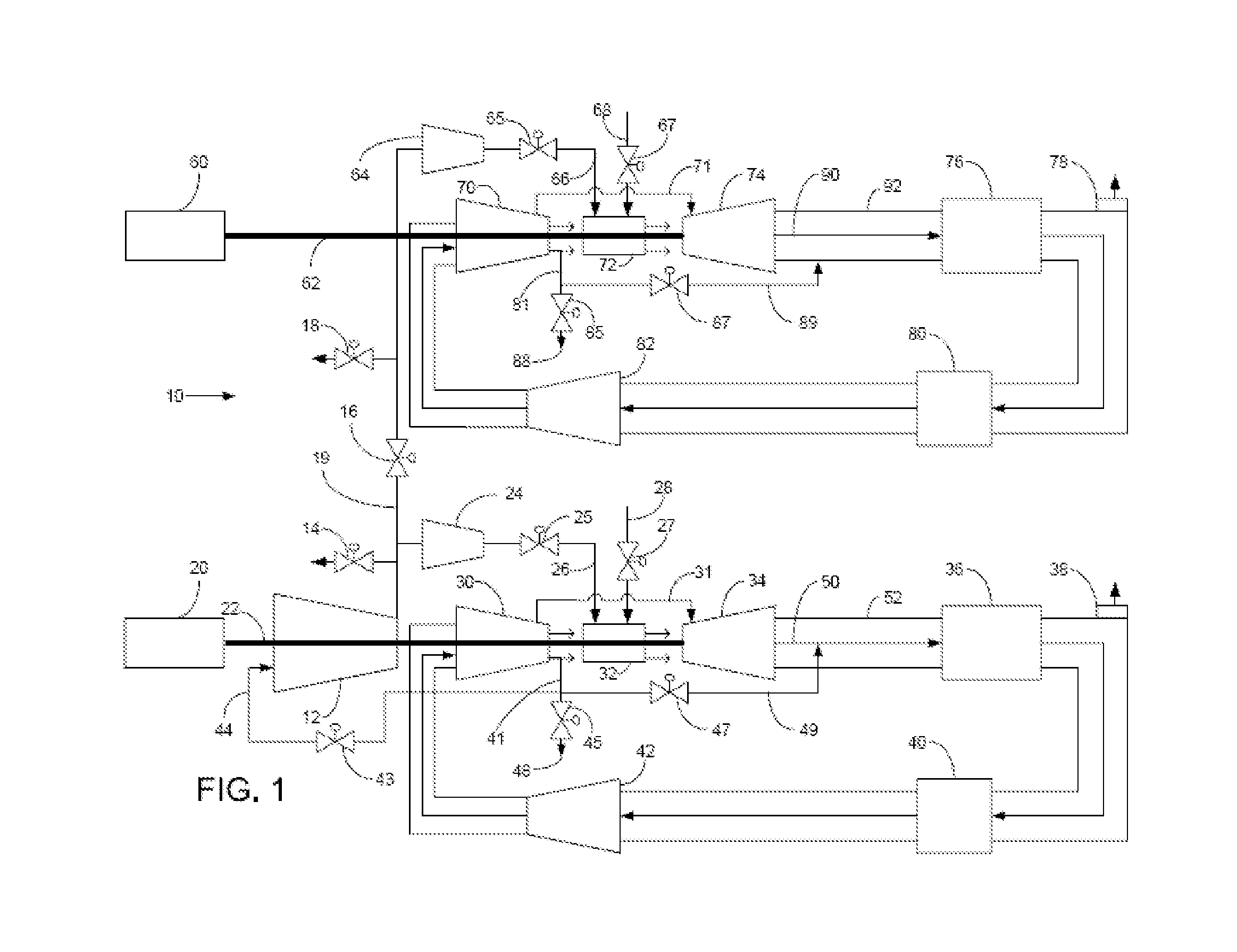

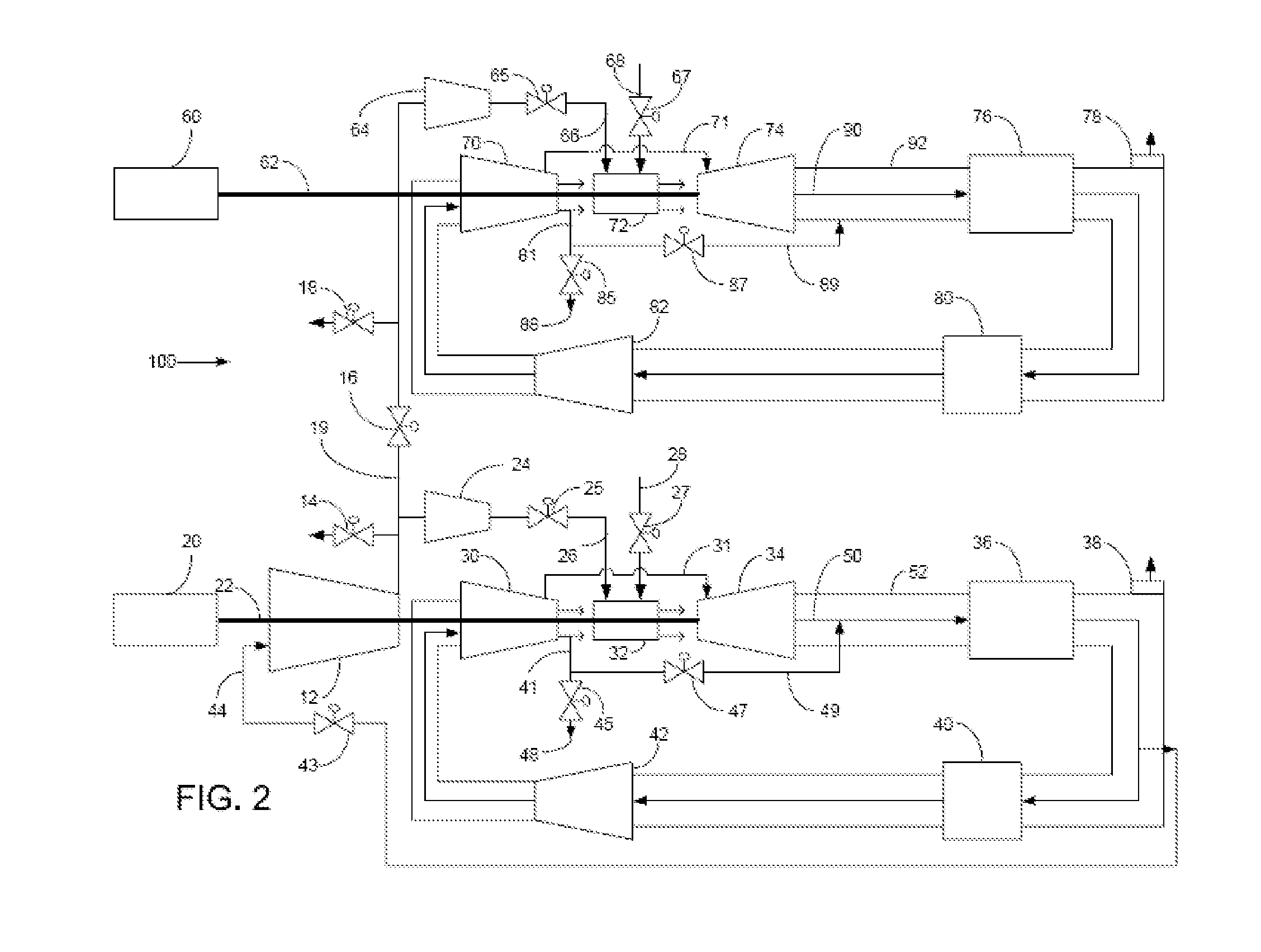

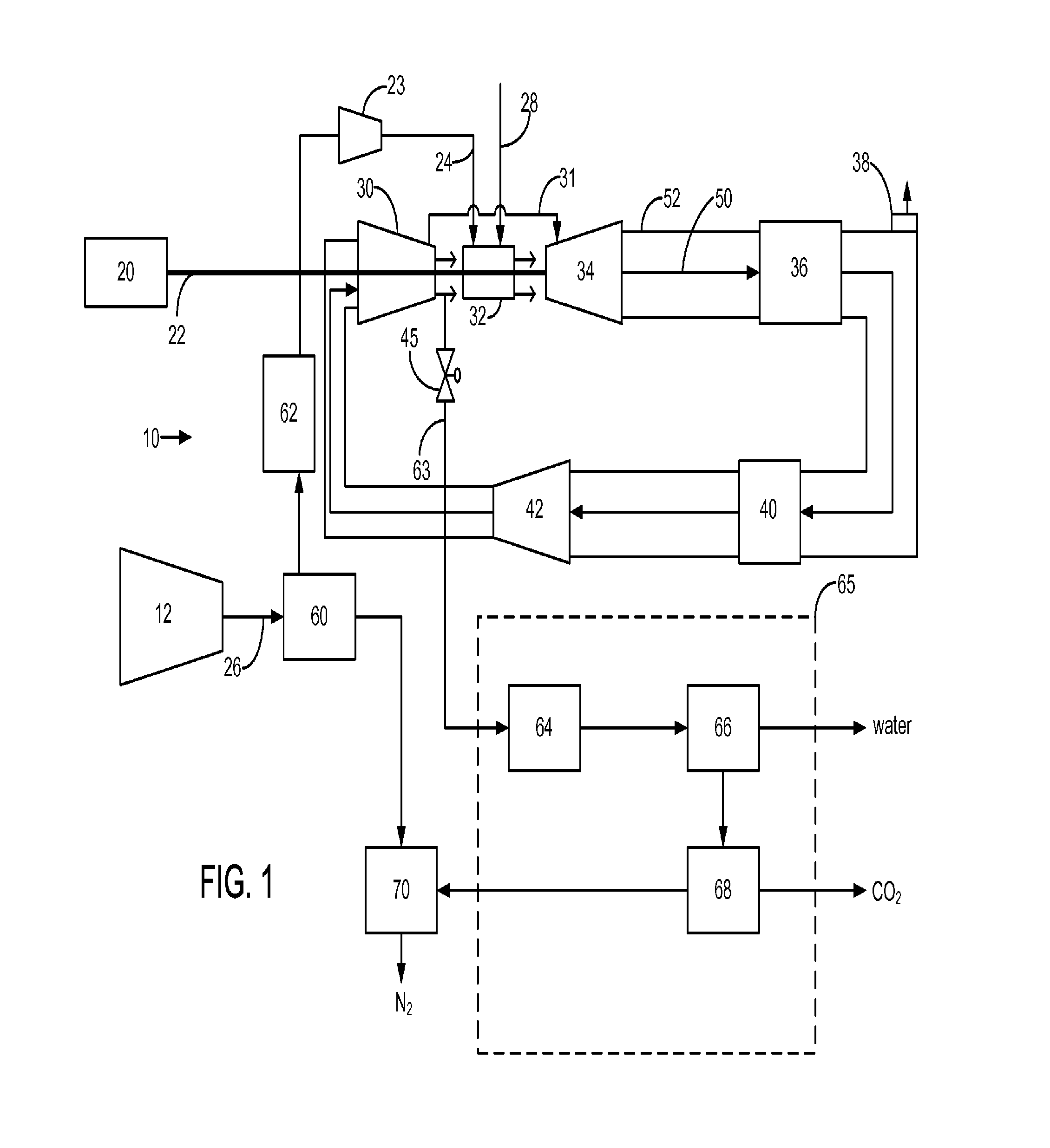

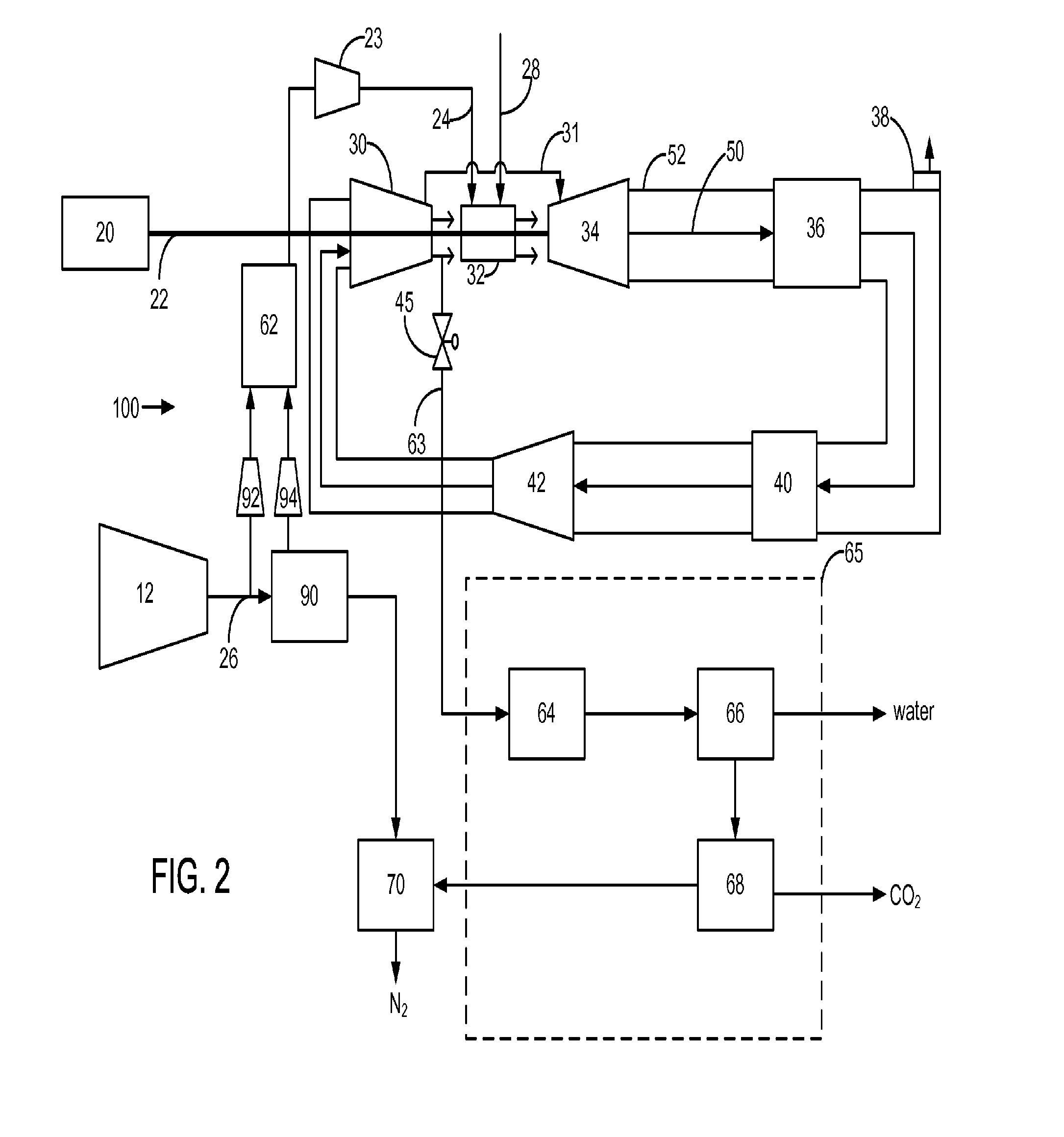

Integrated air separation and oxygen fired power generation system

An integrated air separation and oxygen fired power generation system includes an air separation unit and a gas turbine including an air compressor to provide compressed air for the air separation unit. The system further includes a gas turbine expander and at least one additional turbine to drive the air compressor, as well as at least one combustion unit to provide drive gas for expander and additional turbine(s). A portion of oxygen produced by the air separation unit is delivered to the combustor(s) to facilitate production of drive gas for use by the expander and additional turbine(s). Turbine inlet temperatures are controlled by recycling water or steam to the combustor(s).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

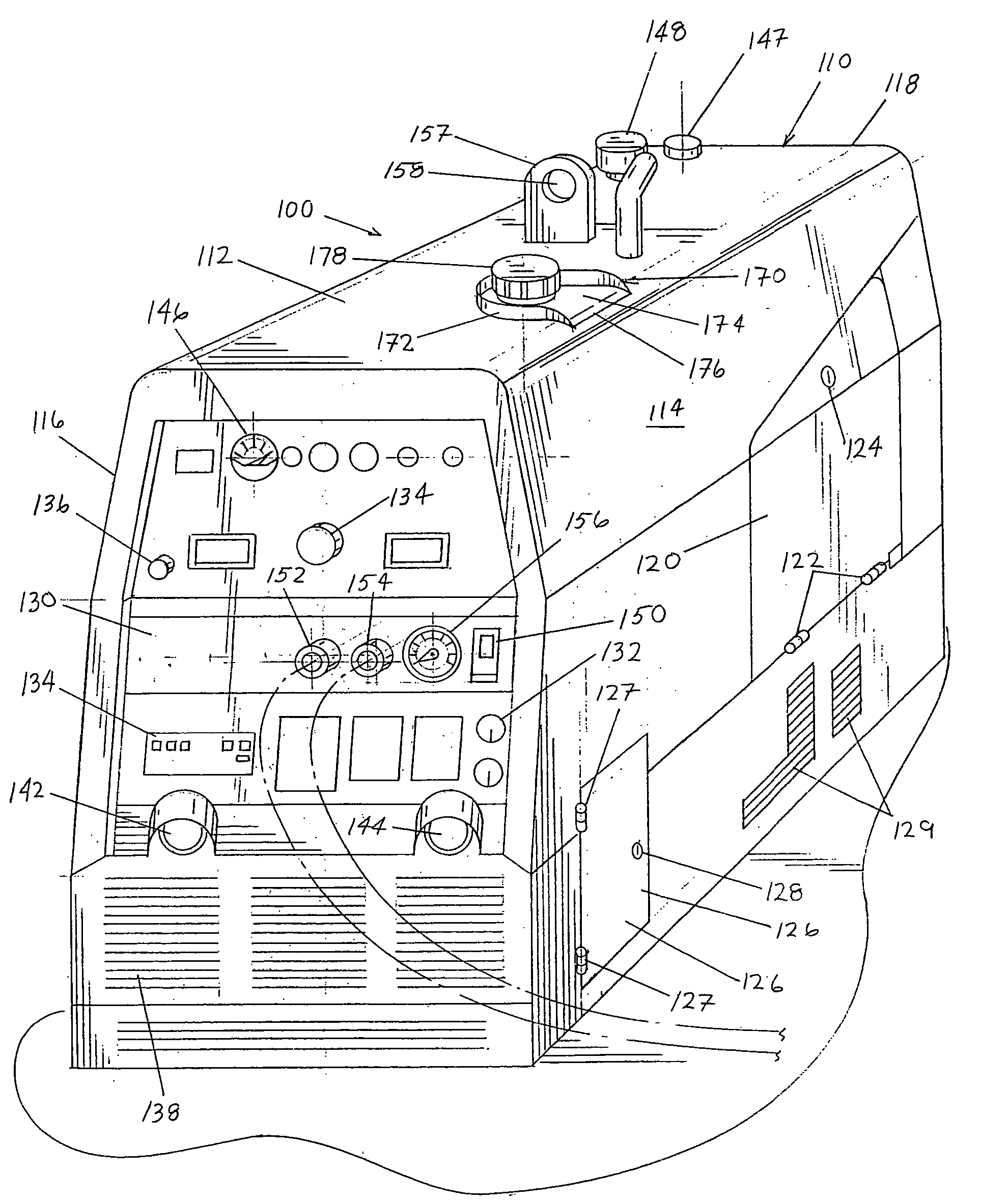

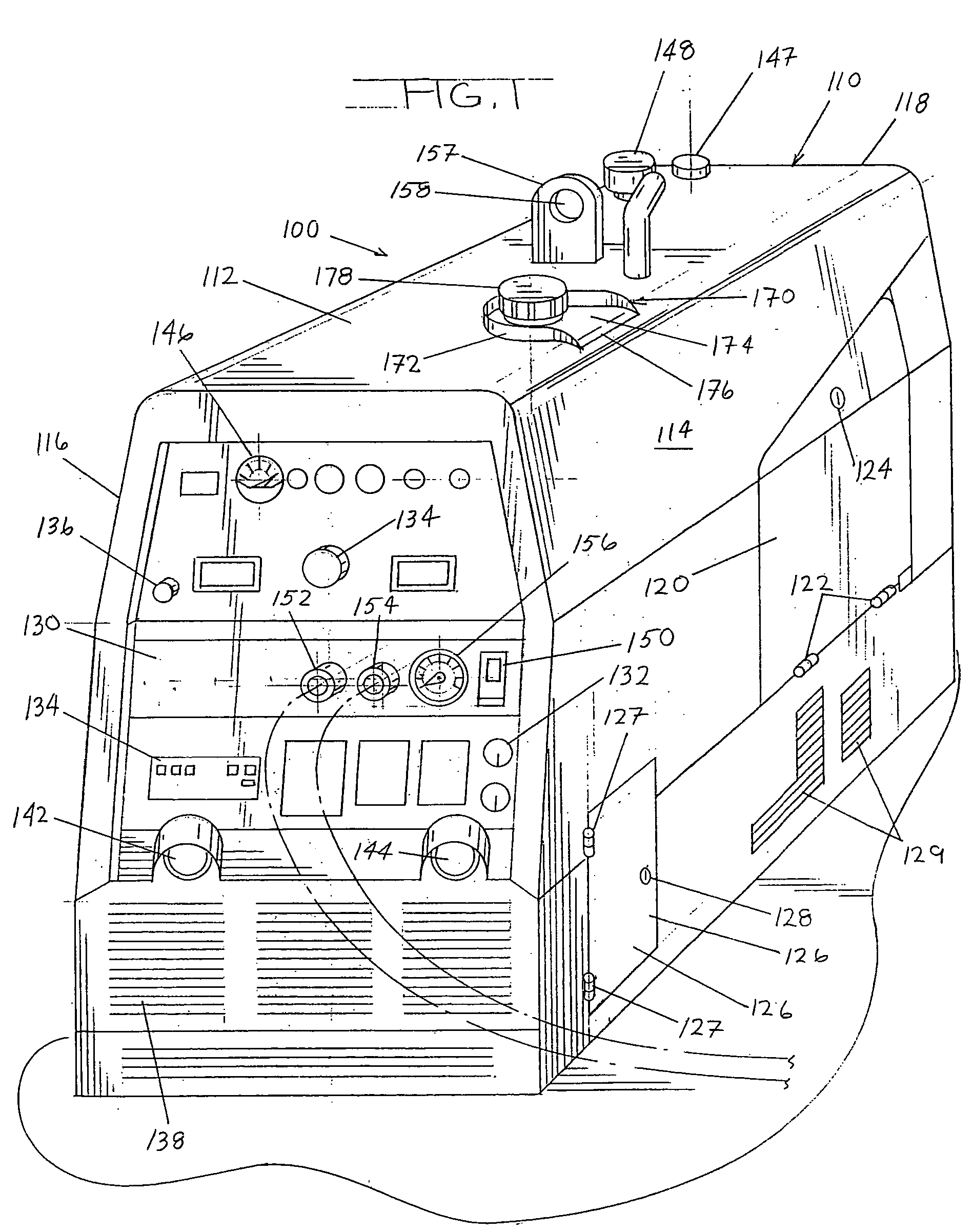

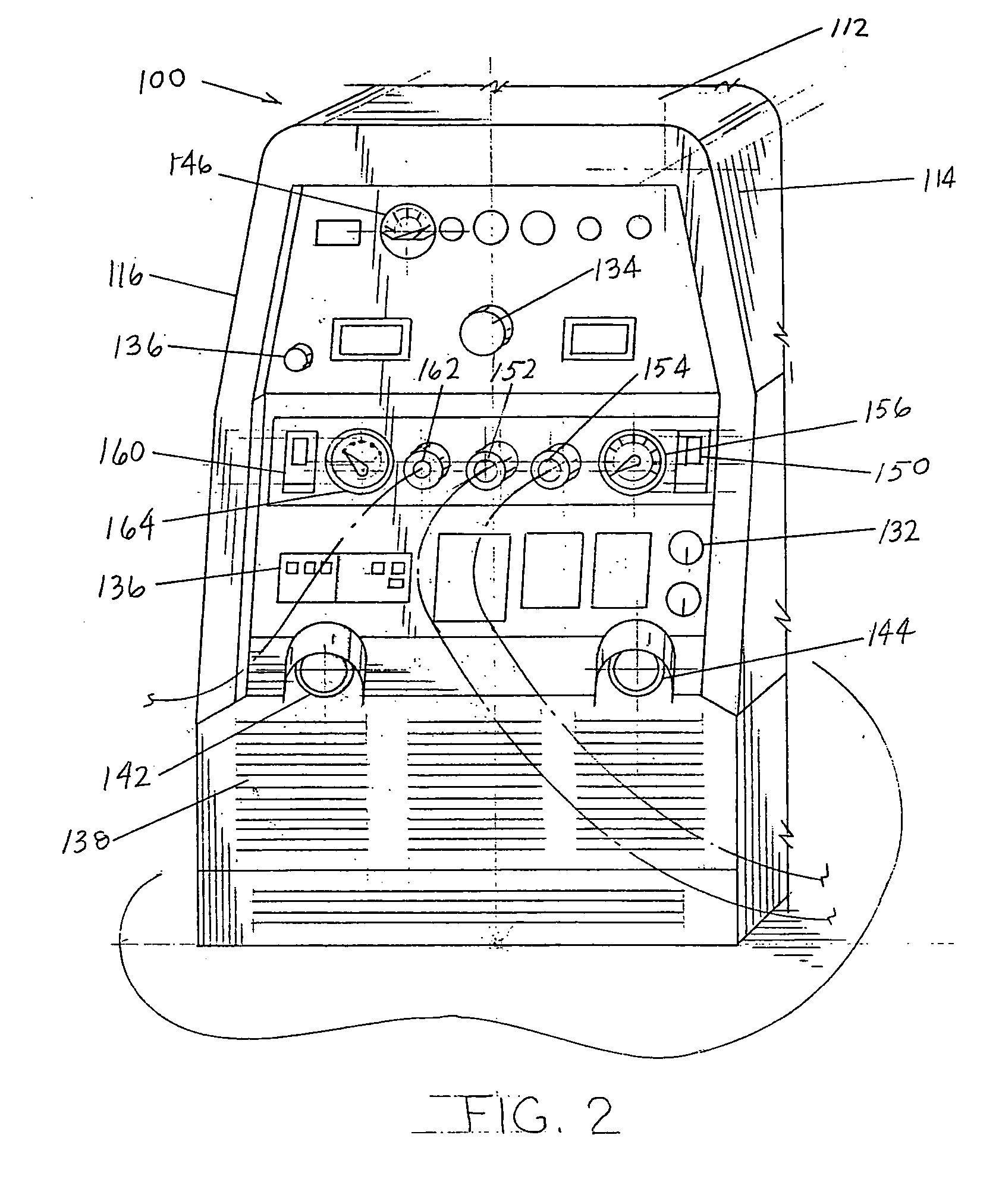

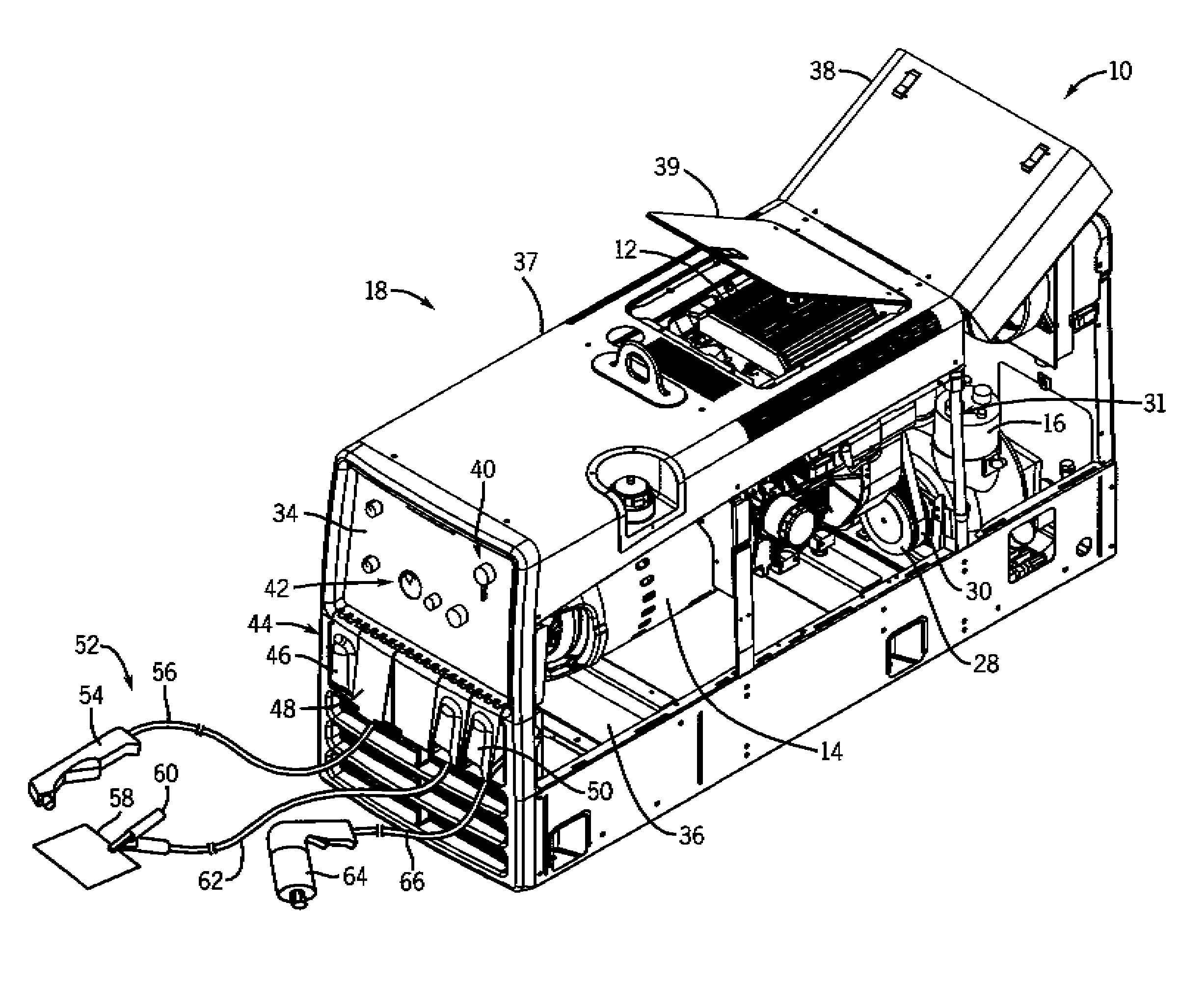

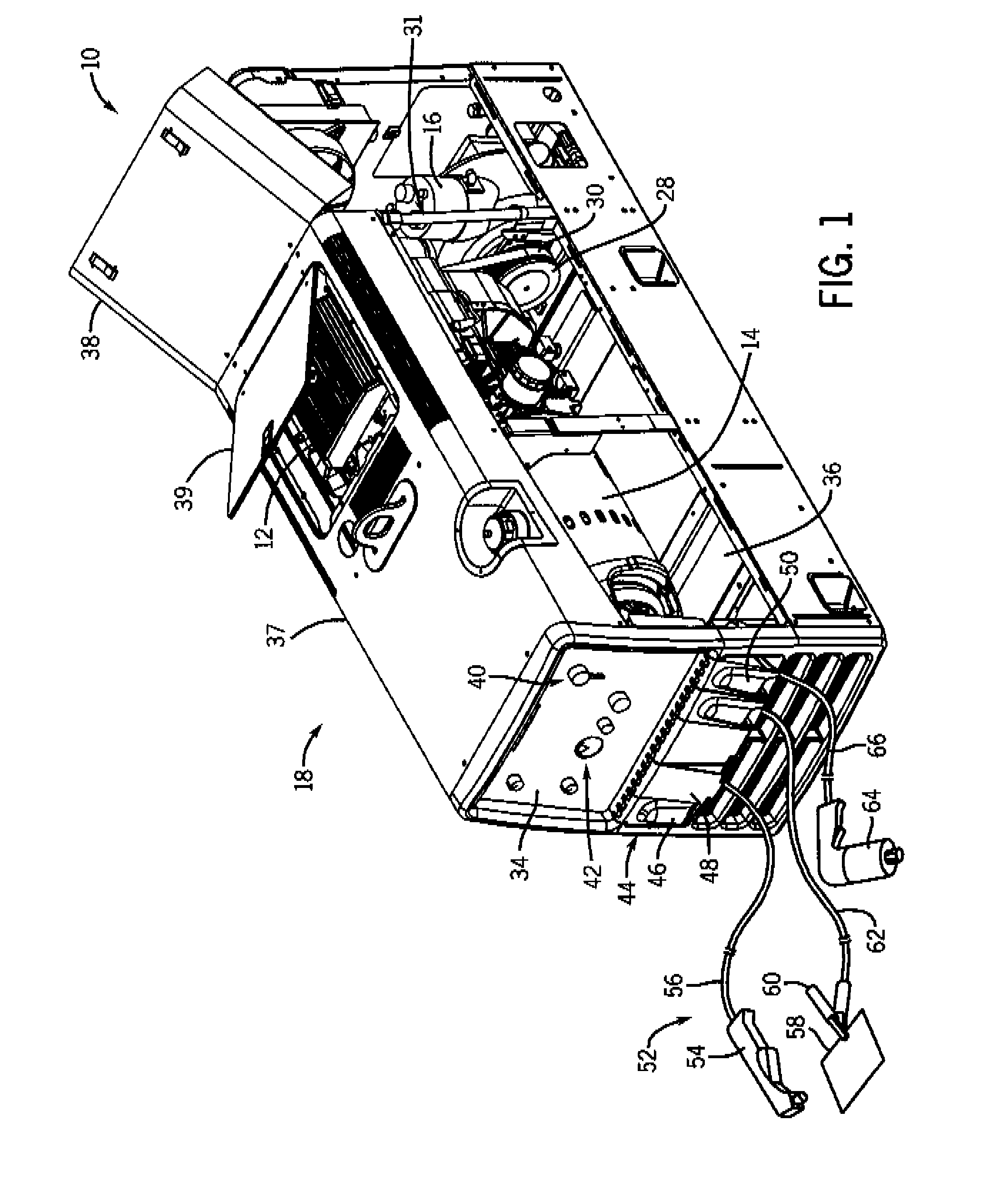

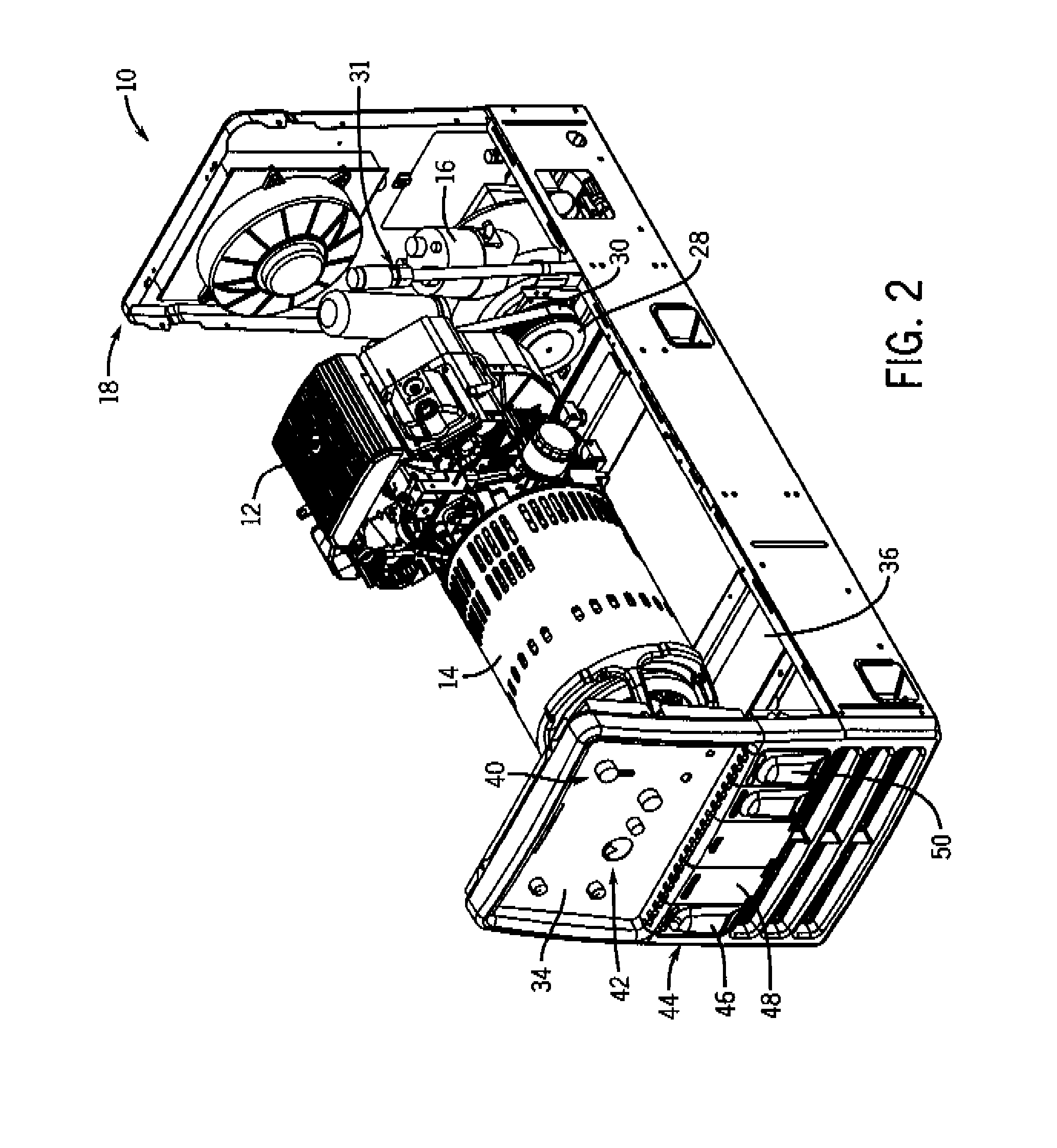

Integrated engine welder and hydraulic pump

InactiveUS20060027547A1Easy to transportImproves ease of designElectric discharge heatingWelding coupling meansHydraulic pumpAir compressor

An integrated welder, generator and hydraulic unit that includes a housing that at least partially contains components of a welder, generator and a hydraulic pump. An engine, an electric current generator, and a hydraulic pump are at least partially mounted in the housing. The electric current generator is at least partially connected to the engine to be at least partially driven thereby. The hydraulic pump can be at least partially powered by the electric current generator or the fuel powered engine during the operation of the engine. The integrated welder, generator and hydraulic unit can also include an air compressor.

Owner:LINCOLN GLOBAL INC

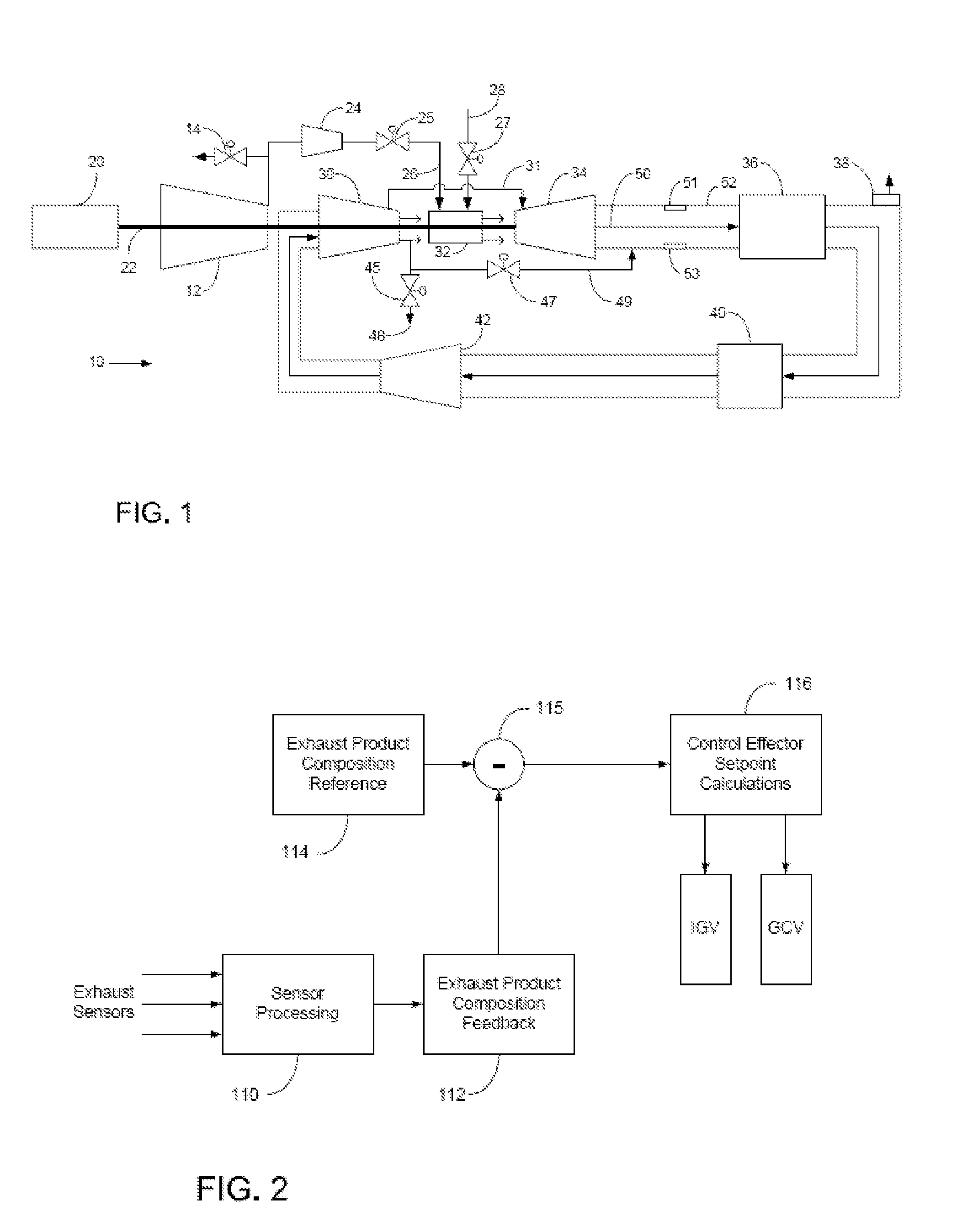

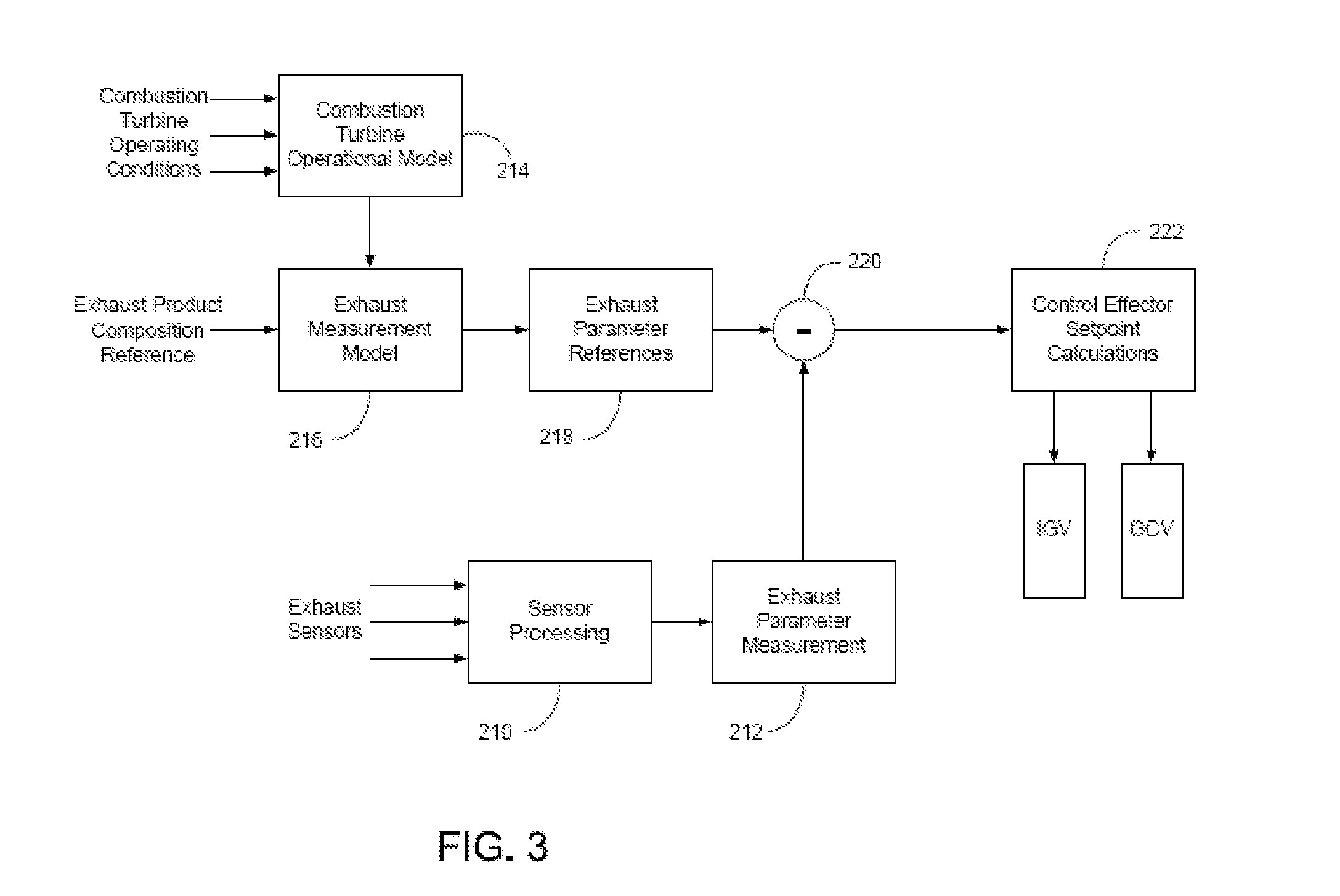

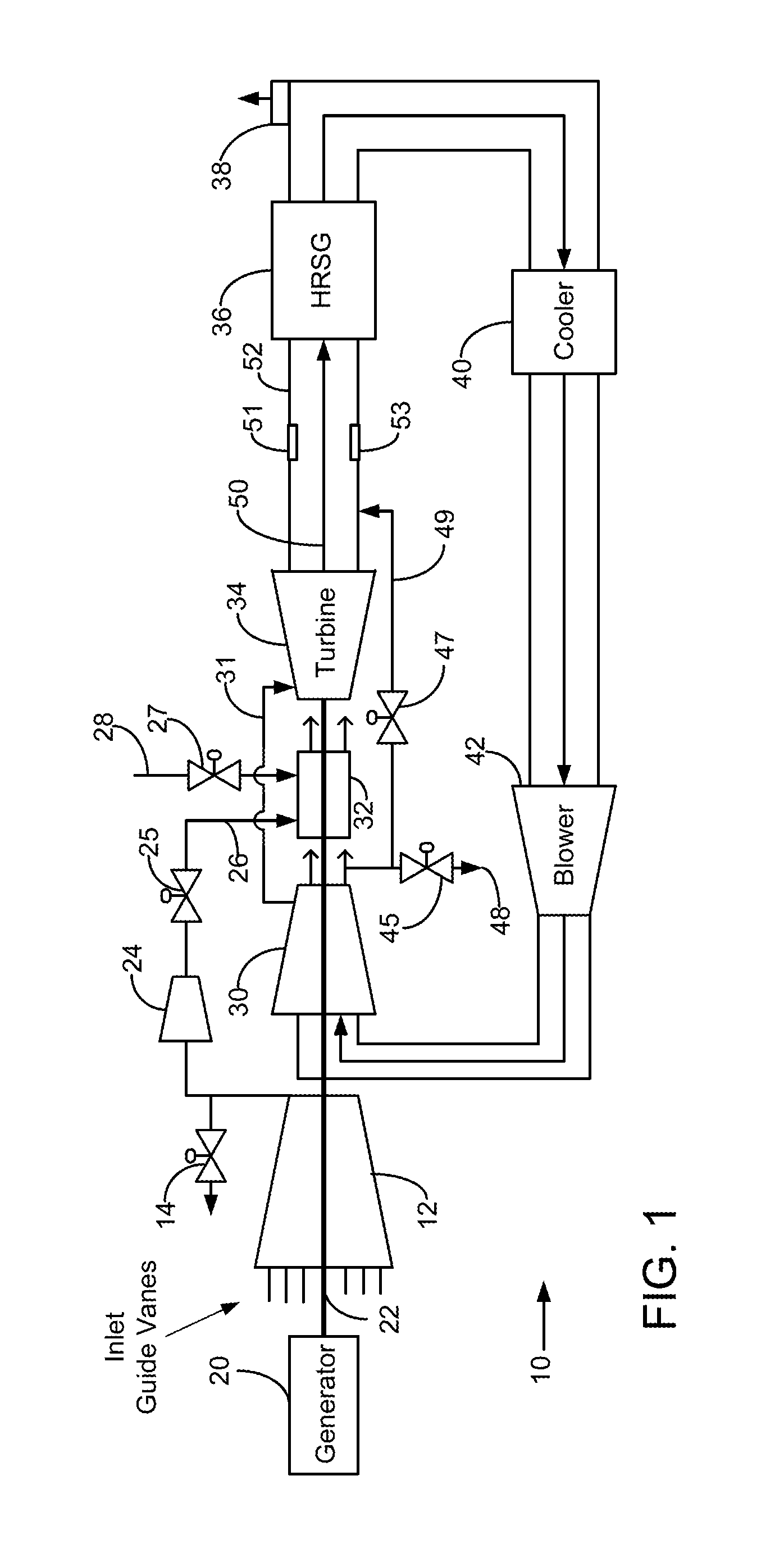

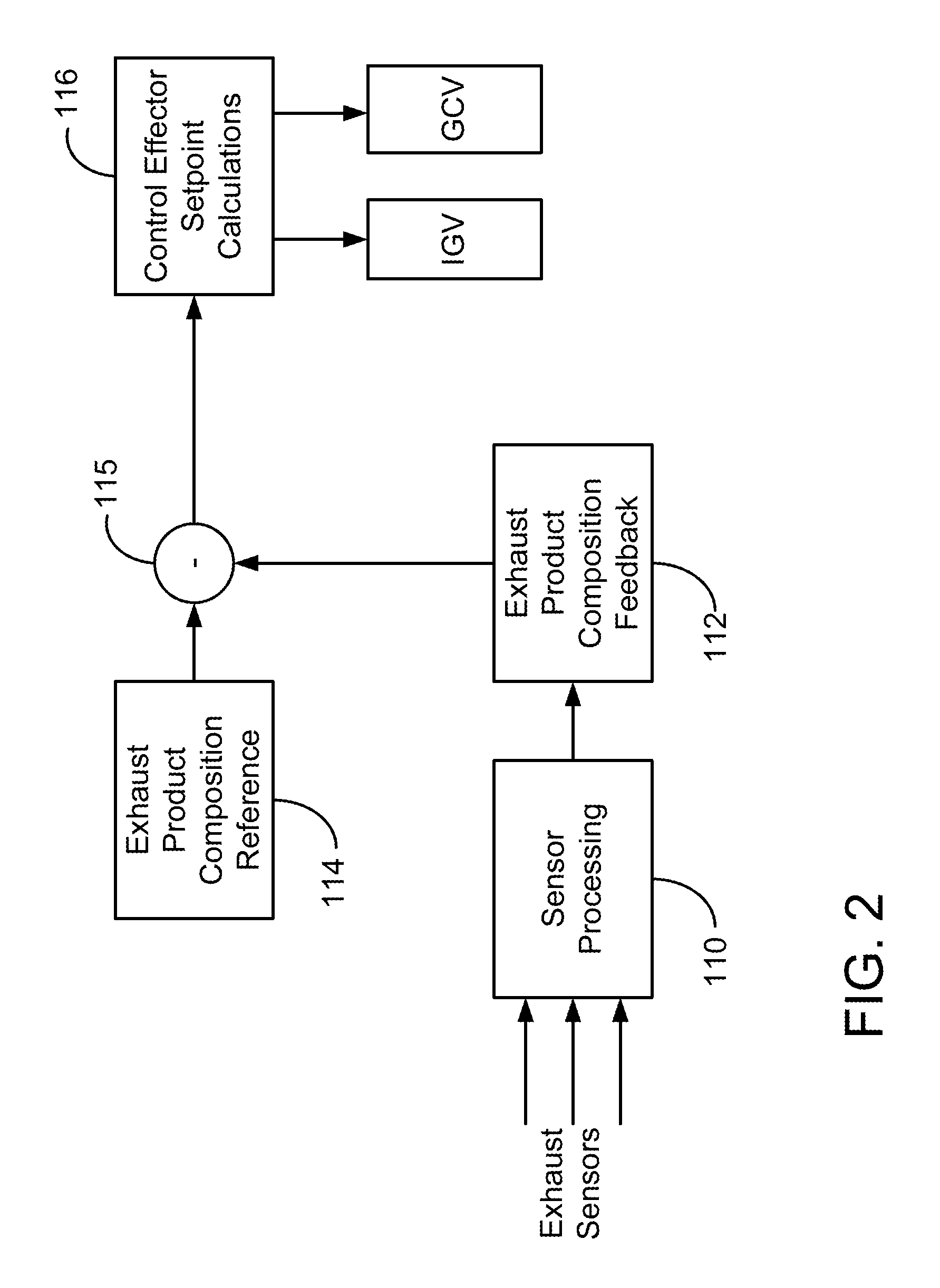

Power plant and control method

Ambient air is compressed into a compressed ambient gas flow with a main air compressor. The compressed ambient gas flow having a compressed ambient gas flow rate is delivered to a turbine combustor and mixed with a fuel stream having a fuel stream flow rate and a portion of a recirculated gas flow to form a combustible mixture. The combustible mixture is burned and forms the recirculated gas flow that drives a turbine. The recirculated gas flow is recirculated from the turbine to the turbine compressor using a recirculation loop. At least one emission level is measured by at least a first emission sensor in the recirculated gas flow and at least a first control signal is generated. The fuel stream flow rate is adjusted based on the at least a first control signal to achieve substantially stoichiometric combustion.

Owner:GENERAL ELECTRIC CO

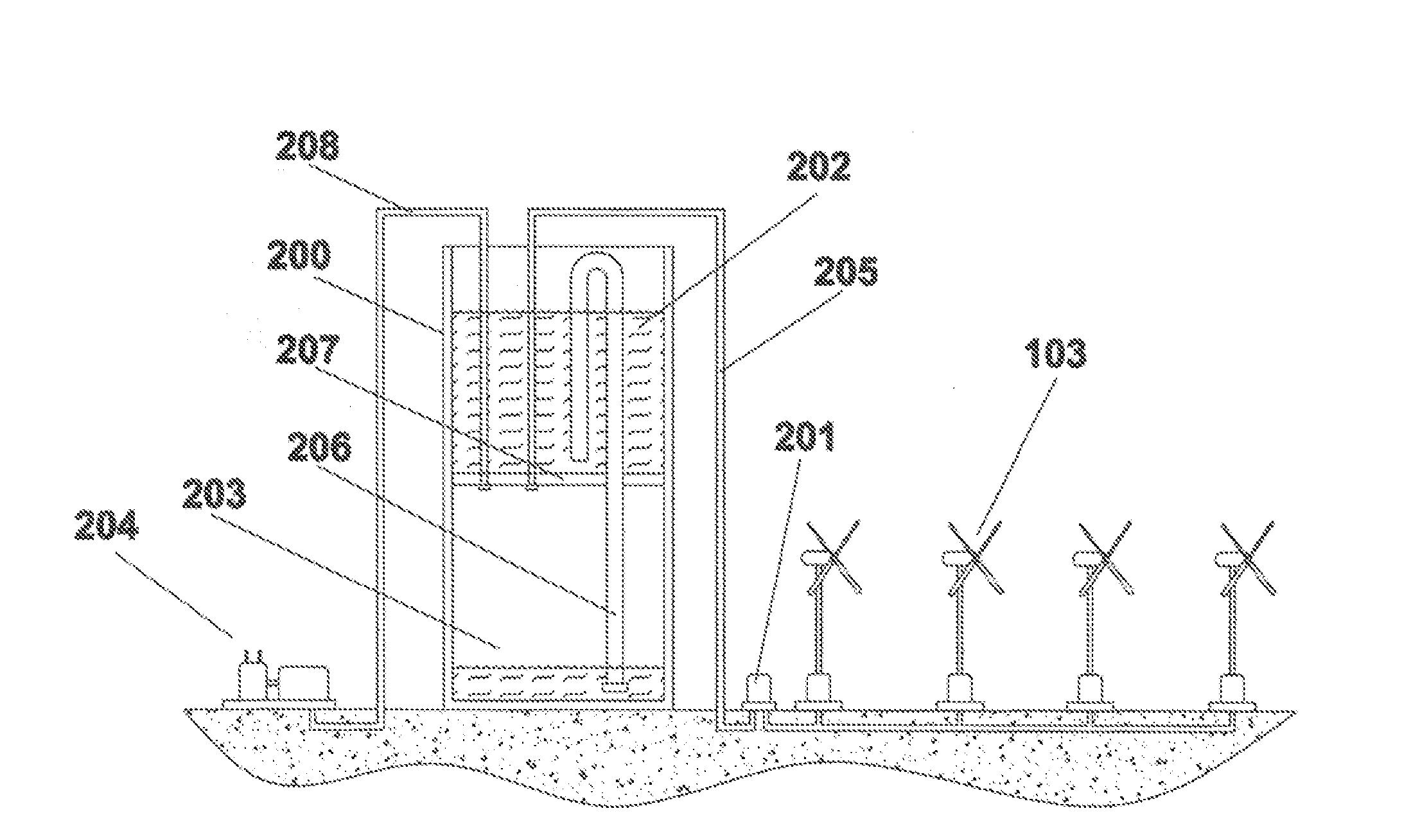

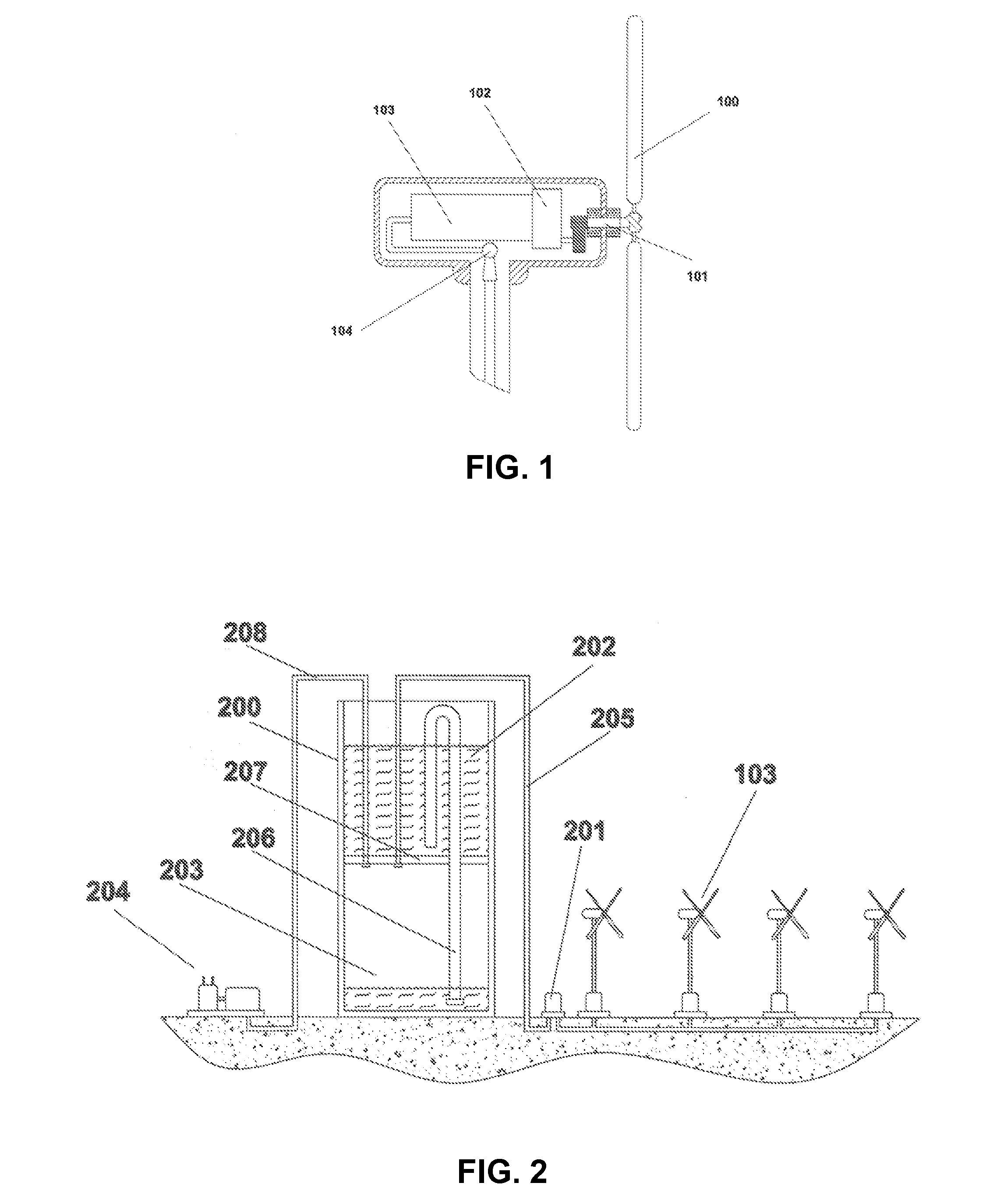

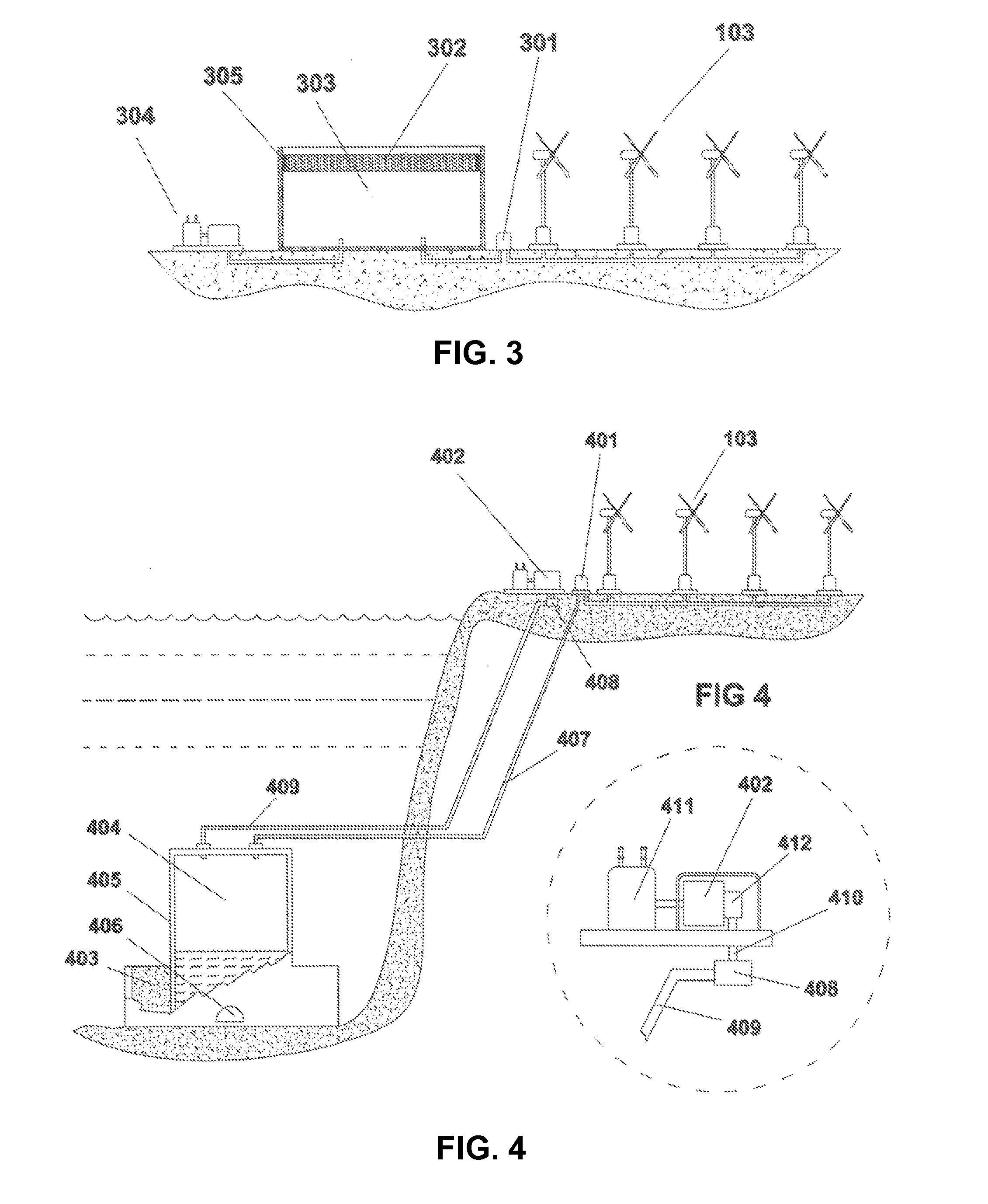

Integrated wind-power electrical generation and compressed air energy storage system

InactiveUS20090021012A1Prevent over-pressurization of the storage unitFrequency stabilityWind energy with garvitational potential energySteam accumulatorsThermal energy storageEngineering

The present invention relates to a method and apparatus for using wind energy to compress air or pressurize a fluid as a means of storing energy. Compressed air or pressurized fluid is generated directly by the wind turbines, thereby avoiding the energy losses that occur when wind power is used first to generate electricity to run an electrically powered air compressor. The compressed air or pressurized fluid is stored by means of expanding a volume at constant or nearly constant pressure. This method avoids energy losses that would otherwise result from compressional heating; while also allowing lower pressures to be employed, reducing the cost of the containment facility and avoiding the need to locate facilities in geographically favored locations where underground storage is available. The invention permits both large and small-scale storage at low cost per unit of energy stored, thereby avoiding the difficulty of using a highly variable and unreliable source of energy such as the wind for electrical power generation. The invention can be used for generation and storage on land, in shallow near-shore waters and in deep-water locations far from shore.

Owner:STULL MARK A +1

Power plant and control method

Ambient air is compressed into a compressed ambient gas flow with a main air compressor. The compressed ambient gas flow having a compressed ambient gas flow rate is delivered to a turbine combustor and mixed with a fuel stream having a fuel stream flow rate and a portion of a recirculated gas flow to form a combustible mixture. The combustible mixture is burned and forms the recirculated gas flow that drives a turbine. The recirculated gas flow is recirculated from the turbine to the turbine compressor using a recirculation loop. At least one emission level is measured by at least a first emission sensor in the recirculated gas flow and at least a first control signal is generated. The fuel stream flow rate is adjusted based on the at least a first control signal to achieve substantially stoichiometric combustion.

Owner:GE INFRASTRUCTURE TECH INT LLC

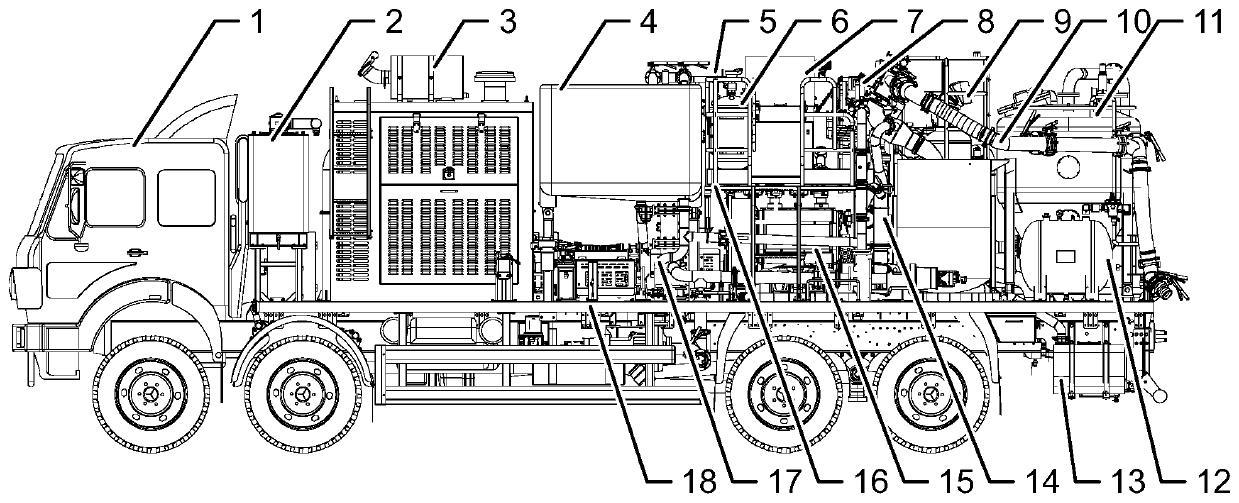

Novel well cementation truck

PendingCN111075391AEasy to operateFlexible and Efficient MobileItem transportation vehiclesSealing/packingDrivetrainWell cementing

The invention discloses a novel well cementation truck, which comprises a loading body, an electrical system, a plunger pump, a clear water manifold, a mud manifold and a high-pressure manifold, wherein the loading body is provided with a cross beam; the cross beam is provided with a hydraulic system, a power transmission system, a metering tank, an operating platform and a mixing system in sequence; the operating platform is provided with a gas path system and an operating system in sequence; the electrical system supplies power to the well cementation truck; the plunger pump, the clear watermanifold, the mud manifold and the high-pressure manifold are all arranged below the operating platform; the clear water manifold supplies water to the plunger pump and the mixing system; the mud manifold provides mud for the plunger pump; the plunger pump injects the mud into a well through the high-pressure manifold; and the well cementation truck also integrates with a steady pressure ash can,an air compressor and an air bottle. The novel well cementation truck has the beneficial effects that a spatial layout is optimized, and the steady pressure ash can, the air compressor and the air bottle are integrated in one well cementation truck. An ash feeding manifold is optimized, so that the steady pressure ash can supplies ashes, and ash supply equipment can be externally connected for supplying ashes. The large-volume air bottle is adopted, and therefore, air can be supplied to other equipment while the requirements of the well cementation truck are met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

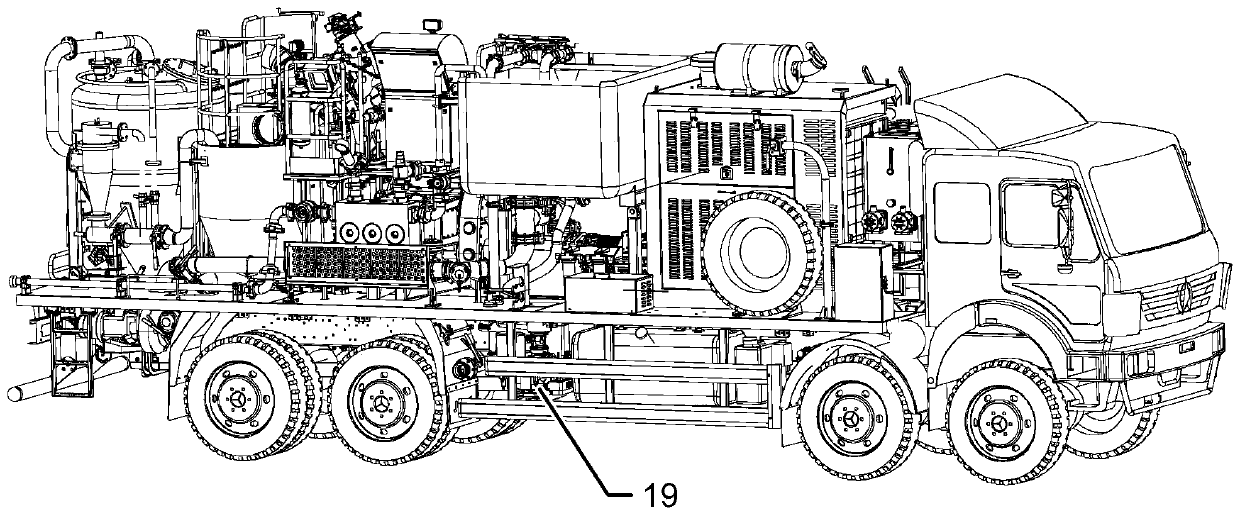

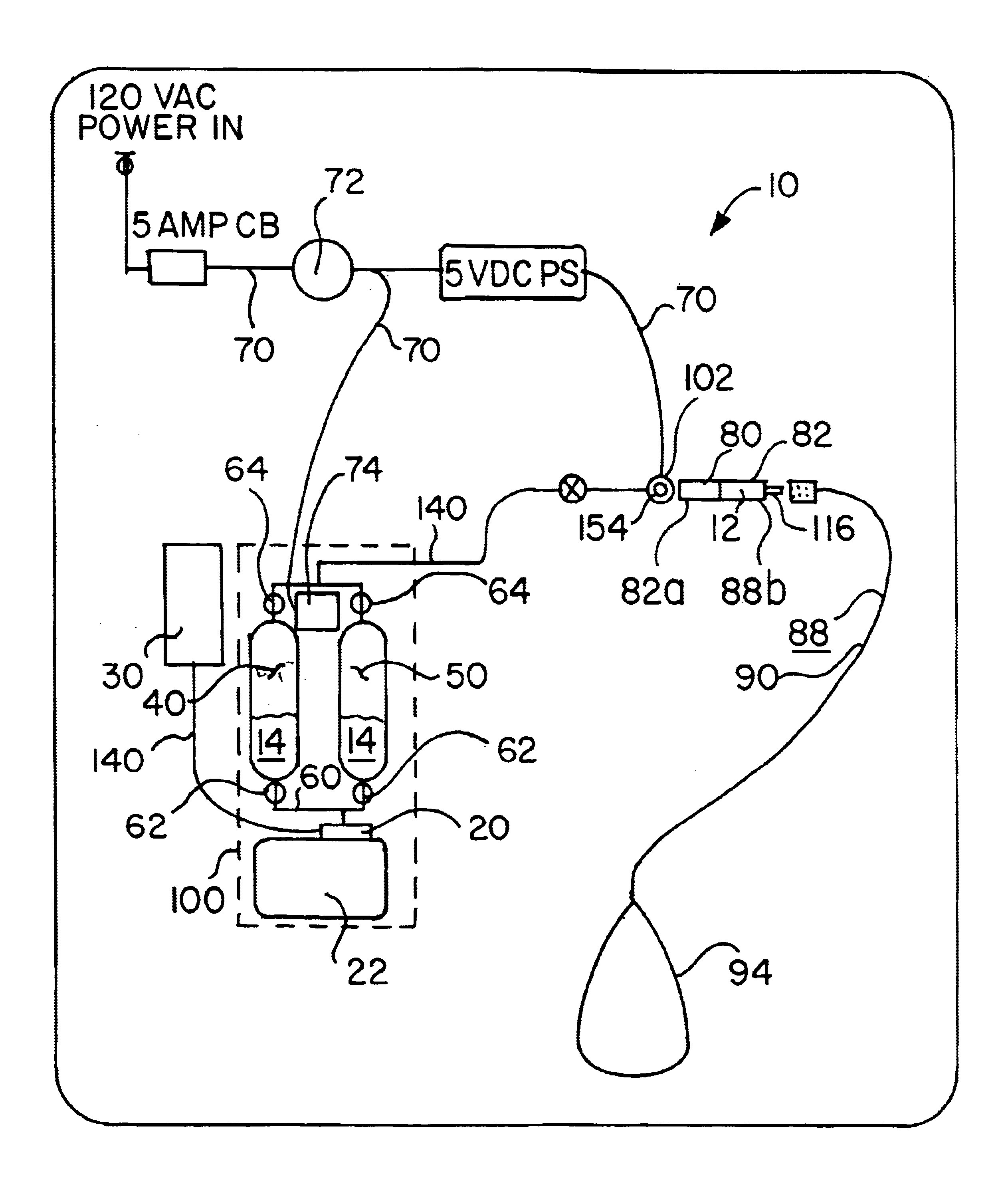

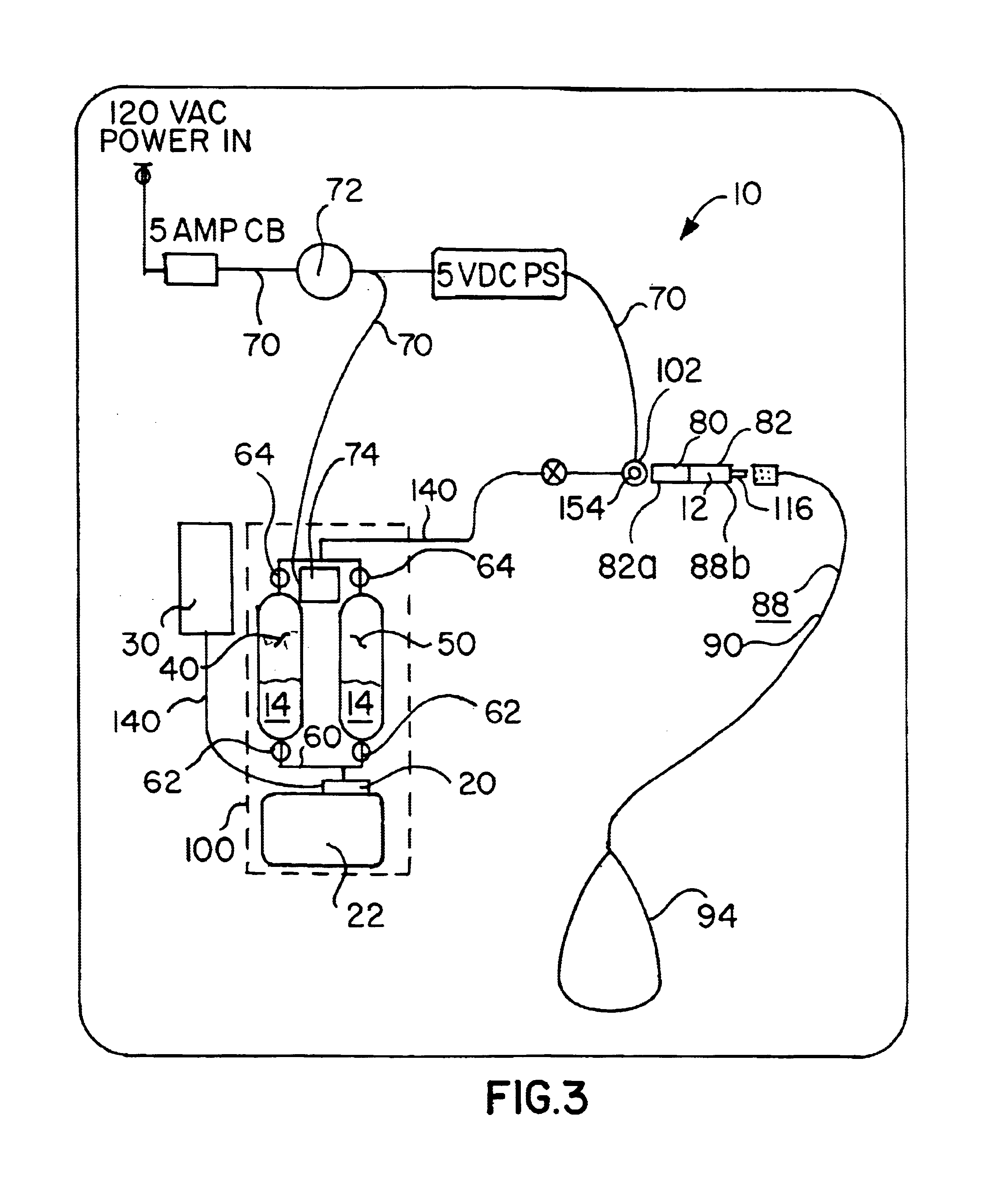

Oxygen concentrating aroma mixing breathable air delivery apparatus and method

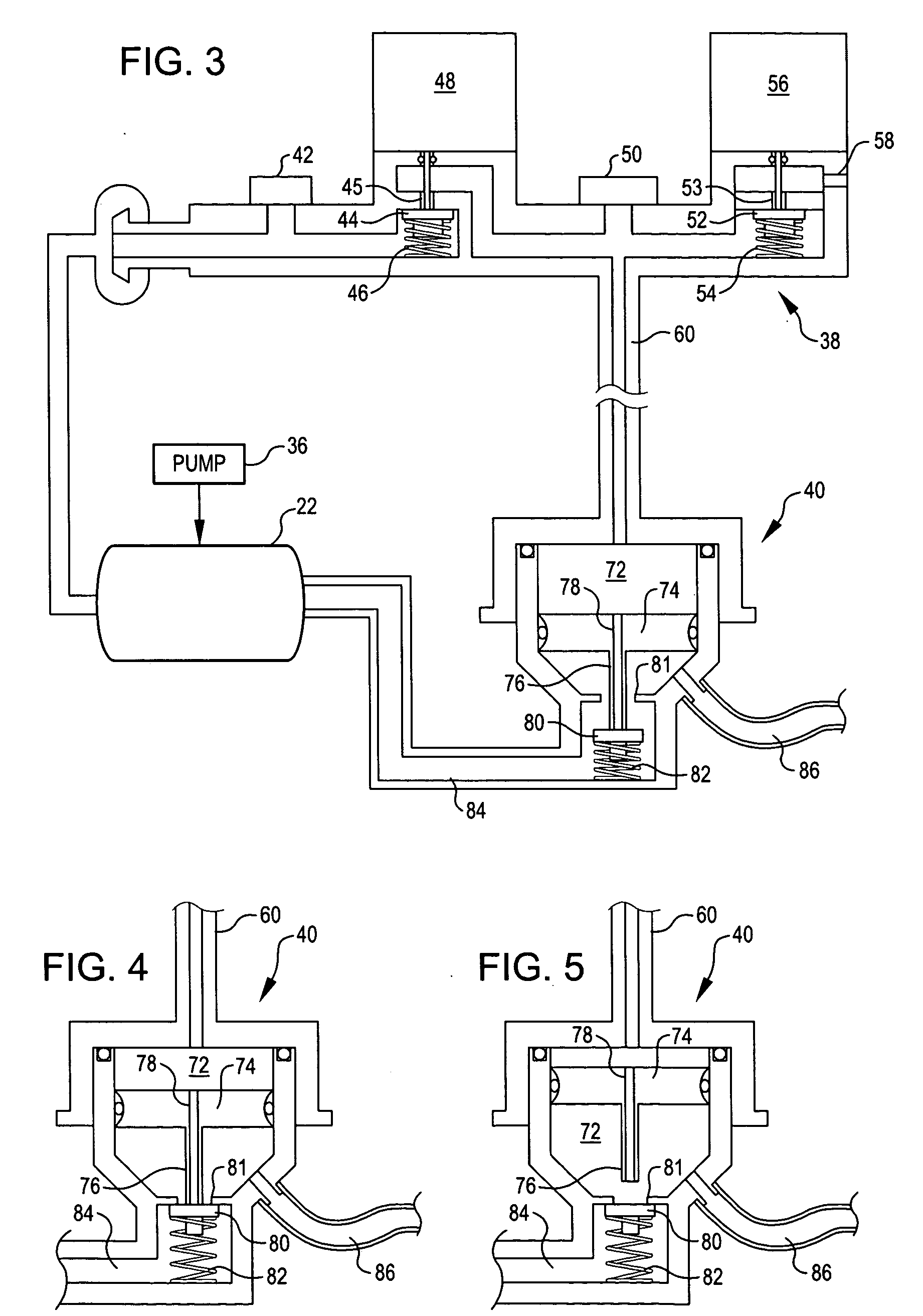

InactiveUS6866041B2Operating means/releasing devices for valvesOther heat production devicesAtmospheric airAir compressor

An apparatus for concentrating the oxygen content of and injecting aroma into a stream of air and delivering the stream of air to the nostrils of a person includes an air intake filter in fluid communication with the air compressor for drawing a stream of air out of the surrounding atmosphere; a sieve bed in fluid communication with the air intake means, each sieve bed containing a quantity of nitrogen absorption material and having sieve bed input and output valve mechanism; so that the sieve bed extracts nitrogen from the air stream so that the proportion of oxygen exiting the sieve bed is elevated, and as the input valve mechanism closes, the sieve bed output valve mechanism opens and vents absorbed nitrogen from the sieve bed to the atmosphere; an aroma chamber containing aroma releasing material in fluid communication with the output valve mechanism.

Owner:EVOLUTION

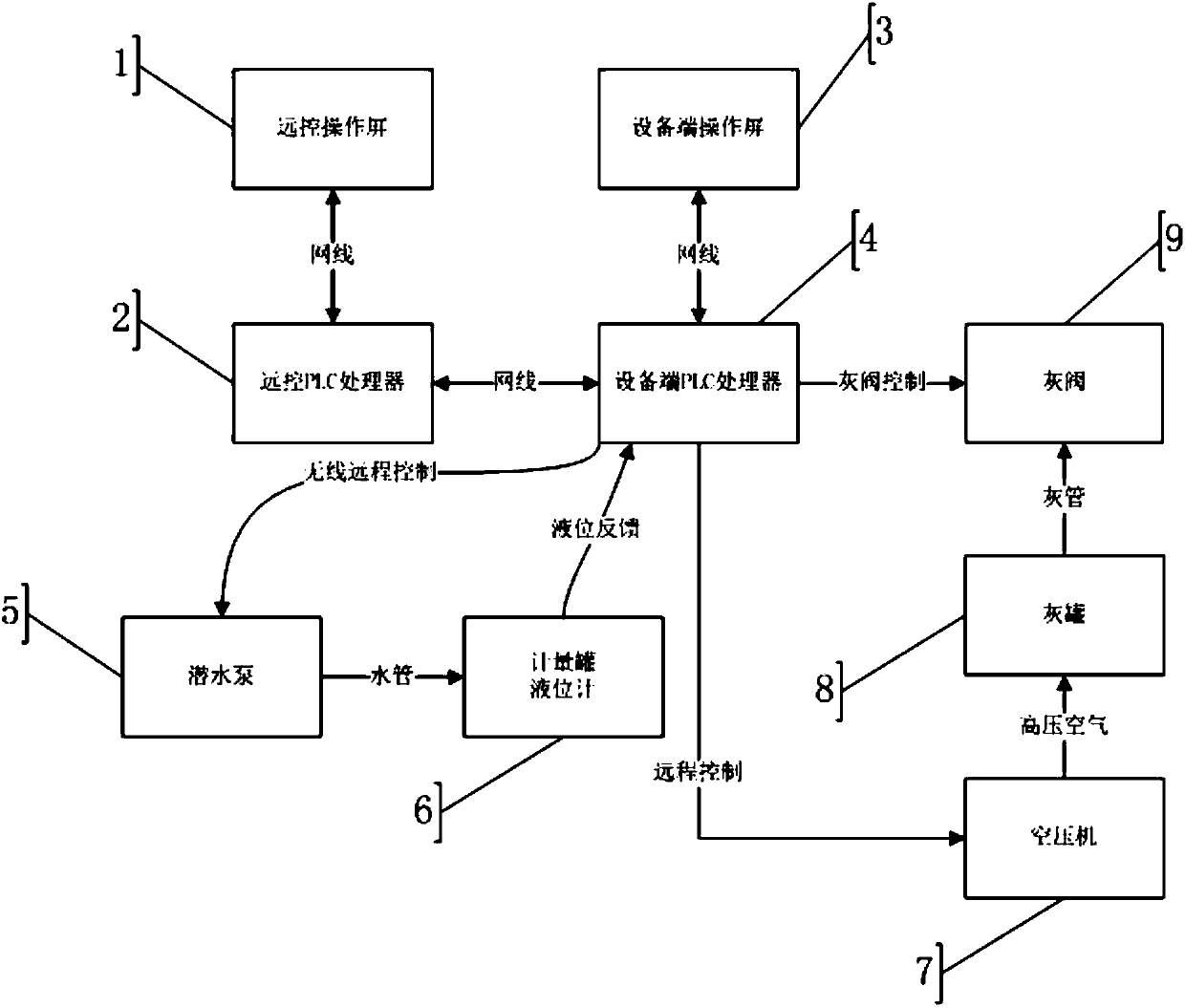

Remote automatic cement supplying control system

PendingCN107656499ARealize remote automatic centralized controlRealize the centralized control of the whole processProgramme control in sequence/logic controllersProportional controlRemote control

The invention belongs to the field of petroleum equipment, and particularly relates to full-automatic intelligent remote controlled well solidifying equipment, and to a remote automatic cement supplying control system for well solidifying equipment. The remote automatic cement supplying control system comprises a control unit, an air compressor, a cement tank and a cement valve. The remote automatic cement supplying control system is characterized in that the control unit comprises an equipment end operating screen, an equipment end PLC processor, a remote control operating screen and a remotecontrol PLC processor; the equipment end operating screen, the equipment end PLC processor, the remote control operating screen and the remote control PLC processor are connected through netting twines; the equipment end PLC processor can remotely control a remote control module for starting and stopping the air compressor, thereby controlling the air compressor through the remote control module;after the air compressor is started, high-pressure air is discharged to the cement tank; the equipment end PLC processor automatically calculates a required cement supplying amount through a preset density of the well solidifying equipment; through comparing the calculated cement supplying amount with a current acquired cement supplying amount, proportion controlling and adjustment of the cementvalve are performed; and furthermore the cement supplying amount of the equipment is controlled.

Owner:CNPC DRILLING RES INST +2

Turbine integrated bleed system and method for a gas turbine engine

InactiveUS20100107594A1Minimizing throttling inefficienciesEfficient extractionEfficient propulsion technologiesGas turbine plantsEngineeringBleed air

A bleed system for a gas turbine engine includes: (a) a bleed air turbine having a turbine inlet adapted to be coupled to a source of compressor bleed air at a first pressure; (b) a bleed air compressor mechanically coupled to the bleed air turbine, and having a compressor inlet adapted to be coupled to a source of fan discharge air at a second pressure substantially lower than the first pressure; and (c) a mixing duct coupled to a turbine exit of the bleed air turbine and to a compressor exit of the bleed air compressor.

Owner:GENERAL ELECTRIC CO

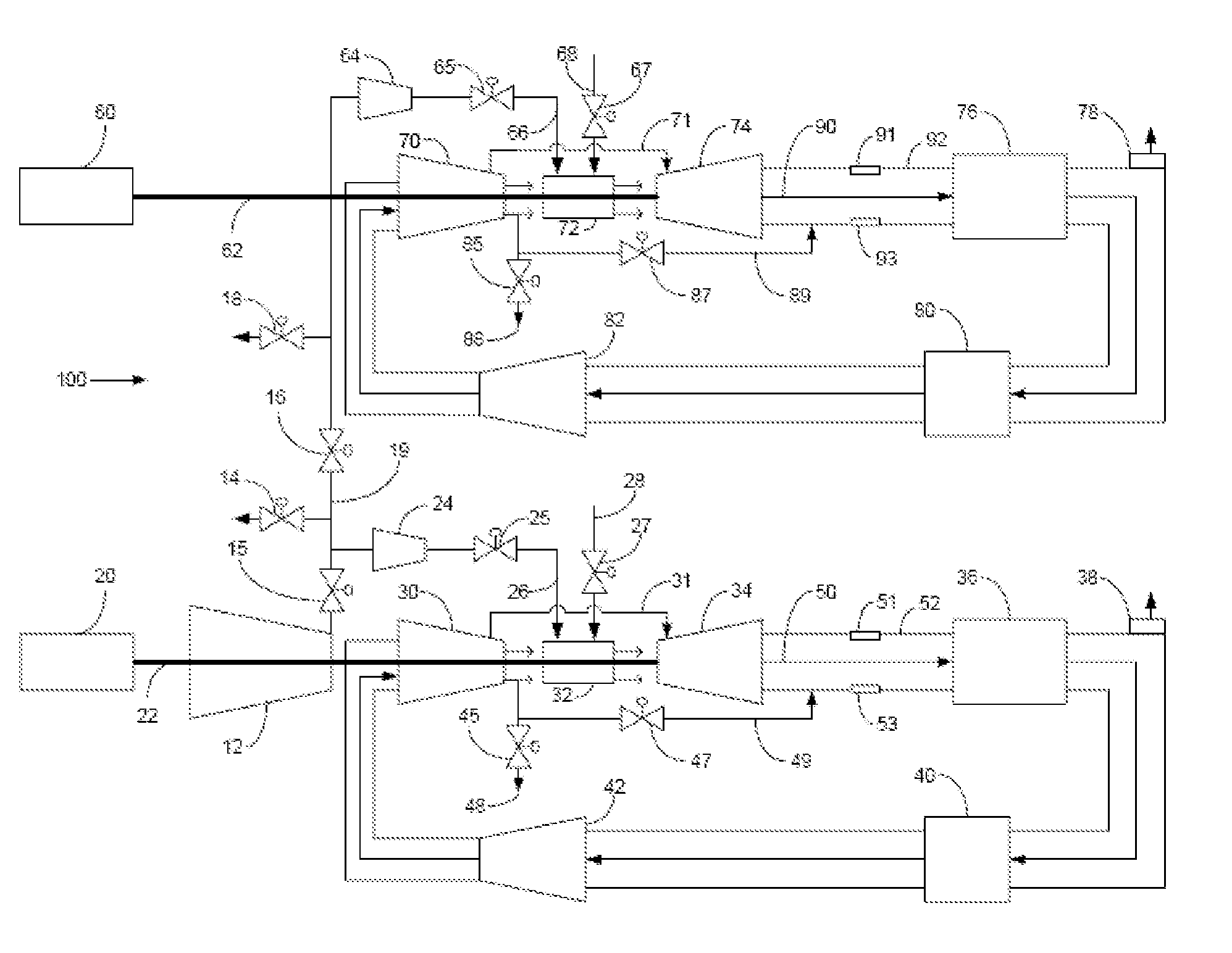

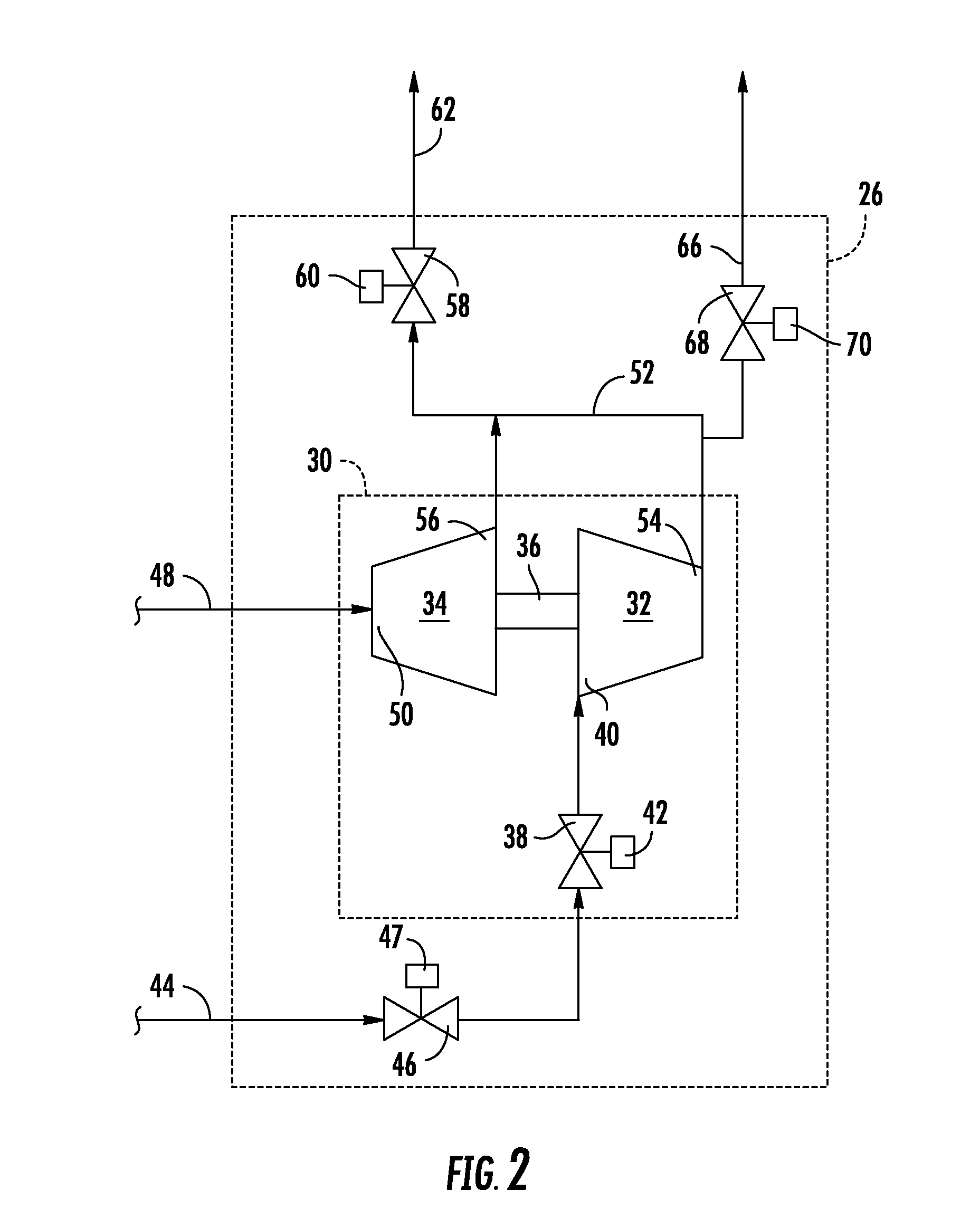

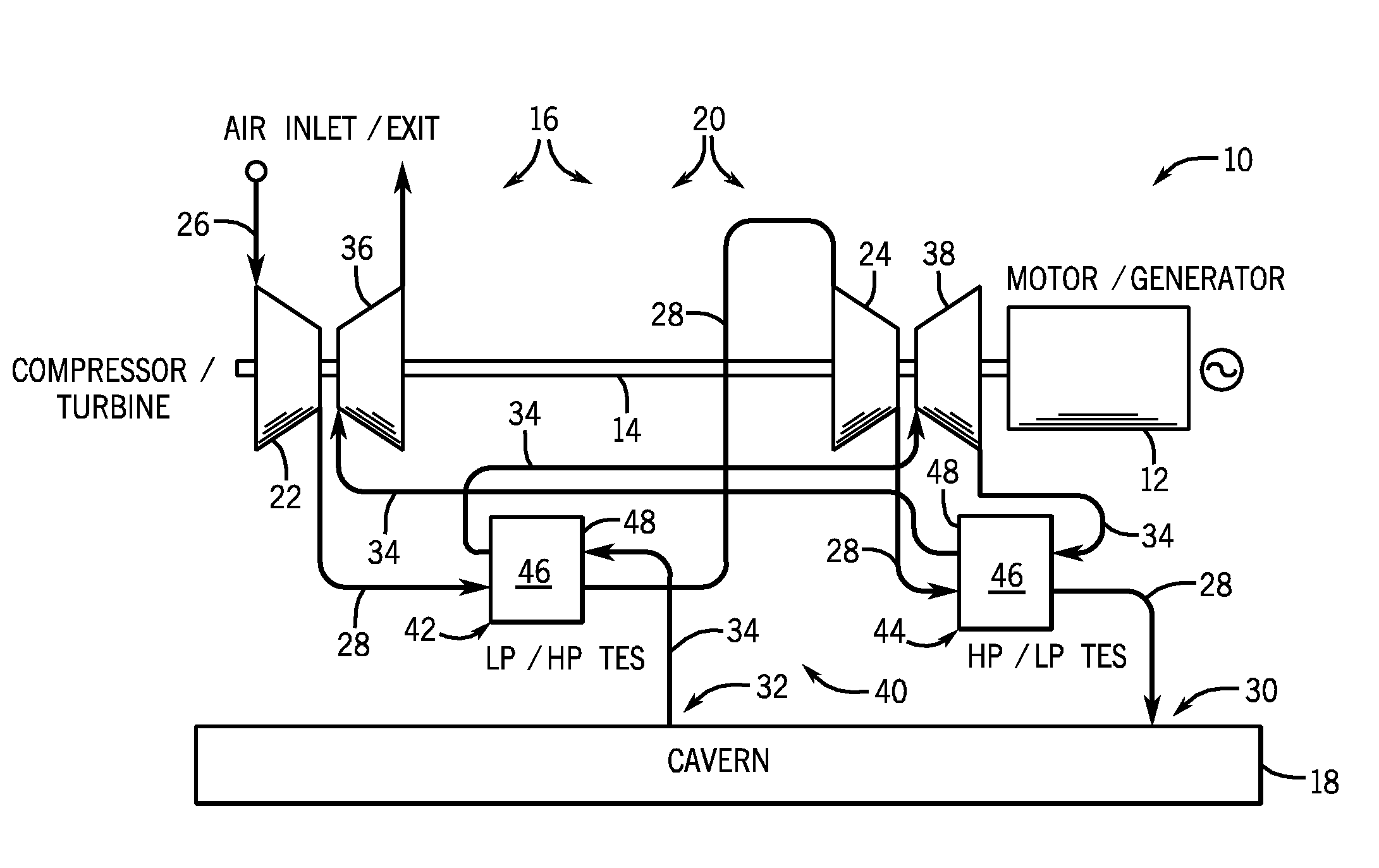

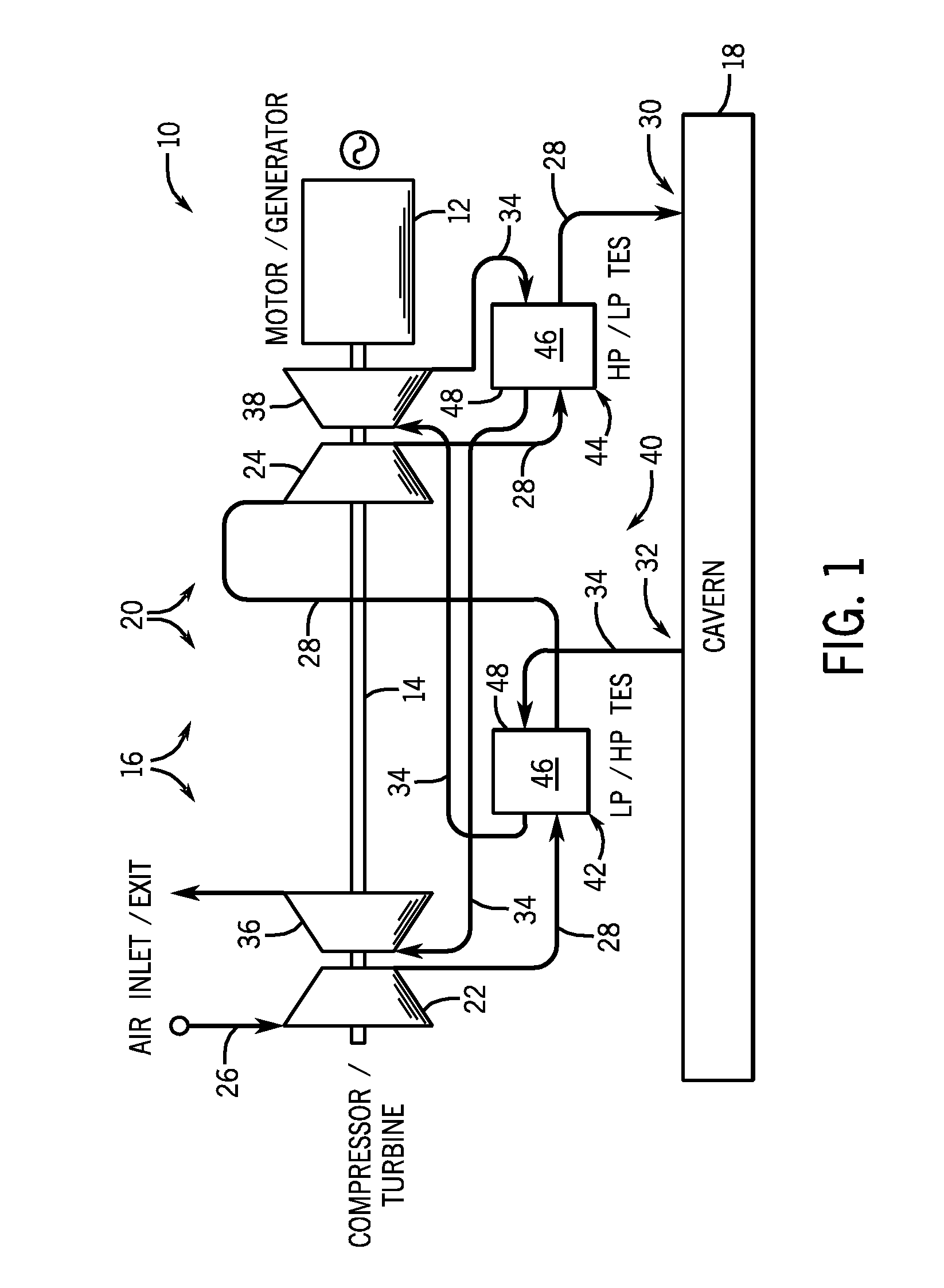

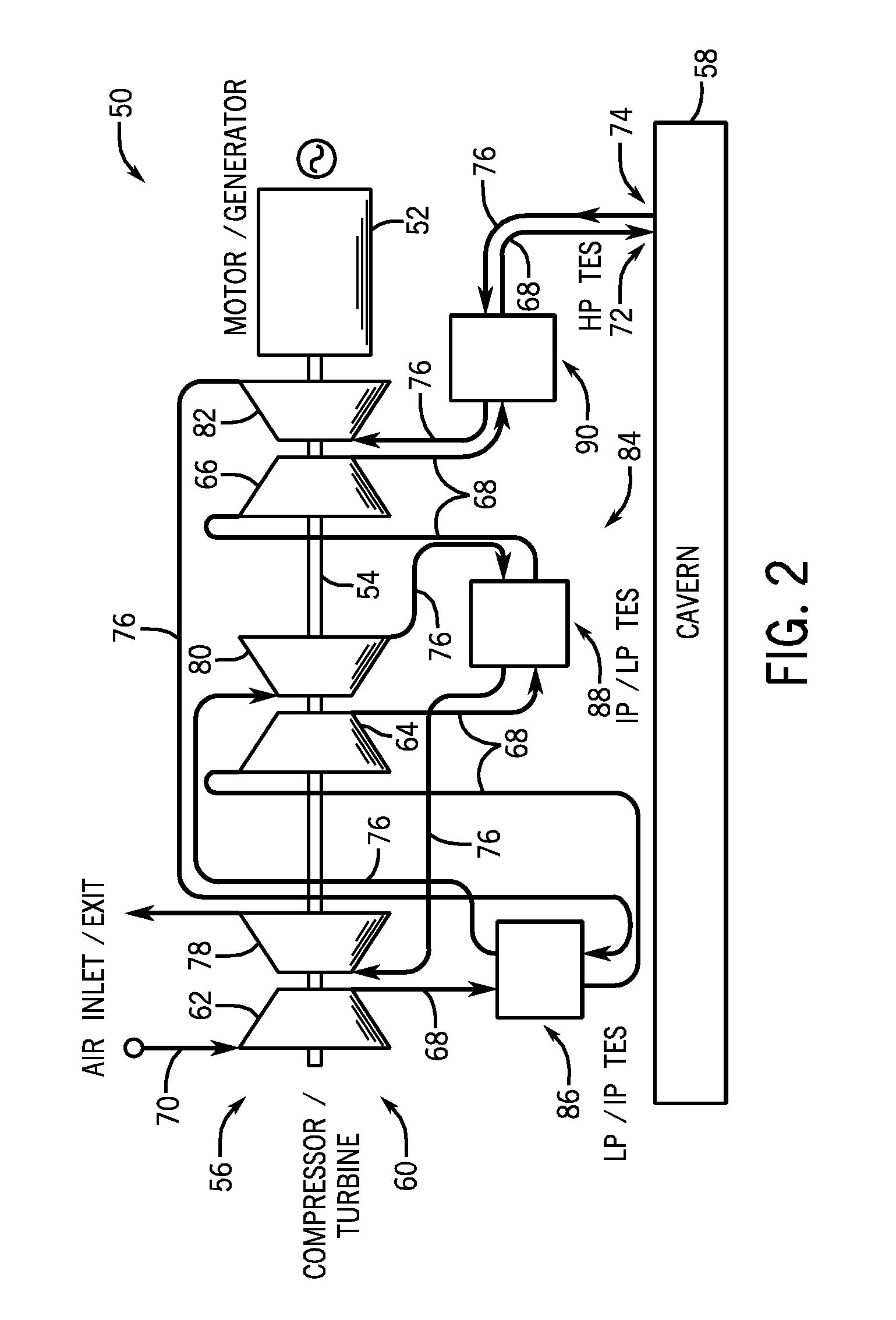

Adiabatic compressed air energy storage system with multi-stage thermal energy storage

An ACAES system operable in a compression mode and an expansion mode of operation is disclosed and includes a compressor system configured to compress air supplied thereto and a turbine system configured to expand compressed air supplied thereto, with the compressor system including a compressor conduit and the turbine system including a turbine conduit. The ACAES system also includes a plurality of thermal energy storage (TES) units positioned on the compressor and turbine conduits and configured to remove thermal energy from compressed air passing through the compressor conduit and return thermal energy to air passing through the turbine conduit. The compressor conduit and the turbine conduit are arranged such that at least a portion of the plurality of TES units operate at a first pressure state during the compression mode of operation and at a second pressure state different from the first pressure state during the expansion mode of operation.

Owner:GENERAL ELECTRIC CO

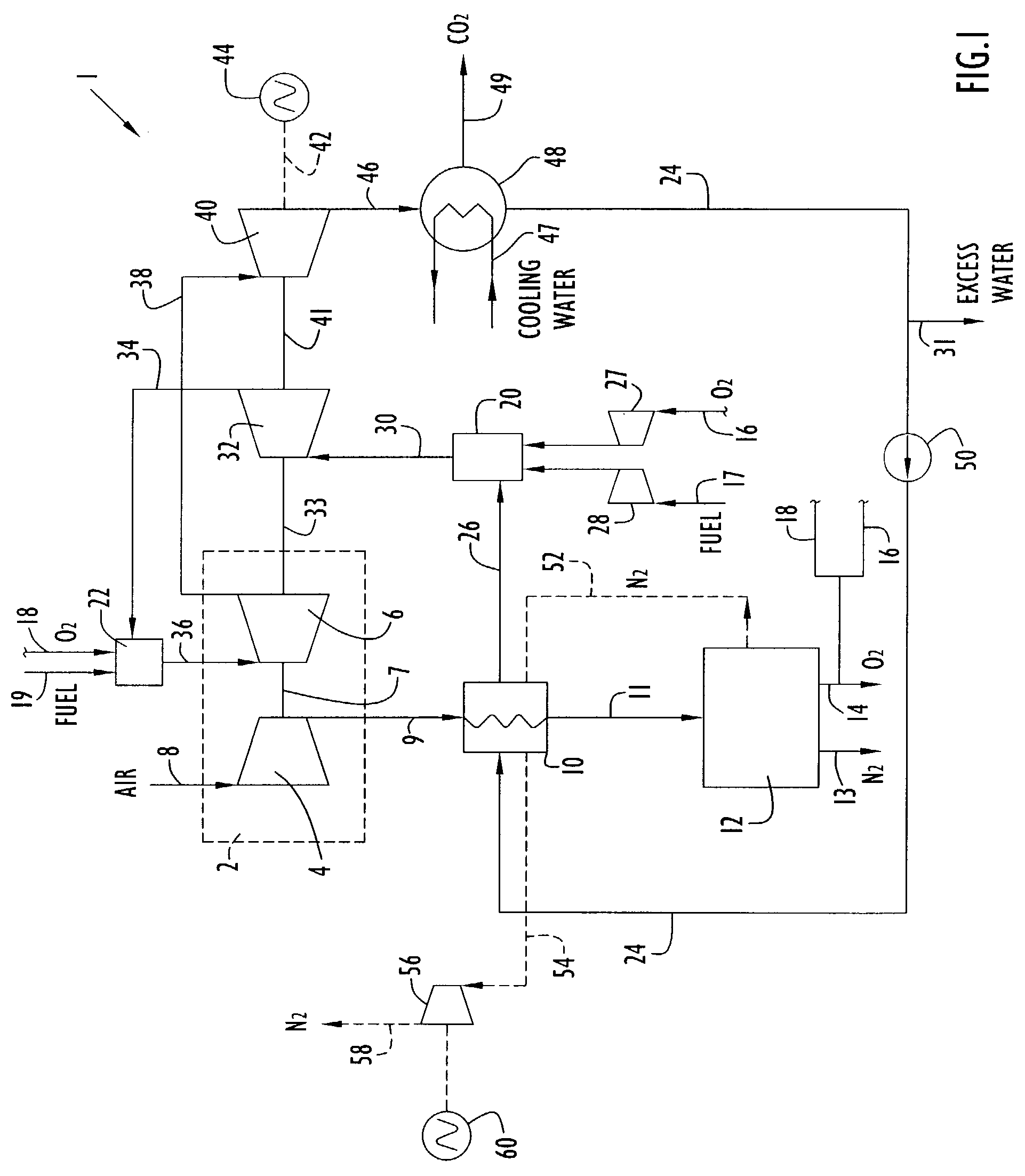

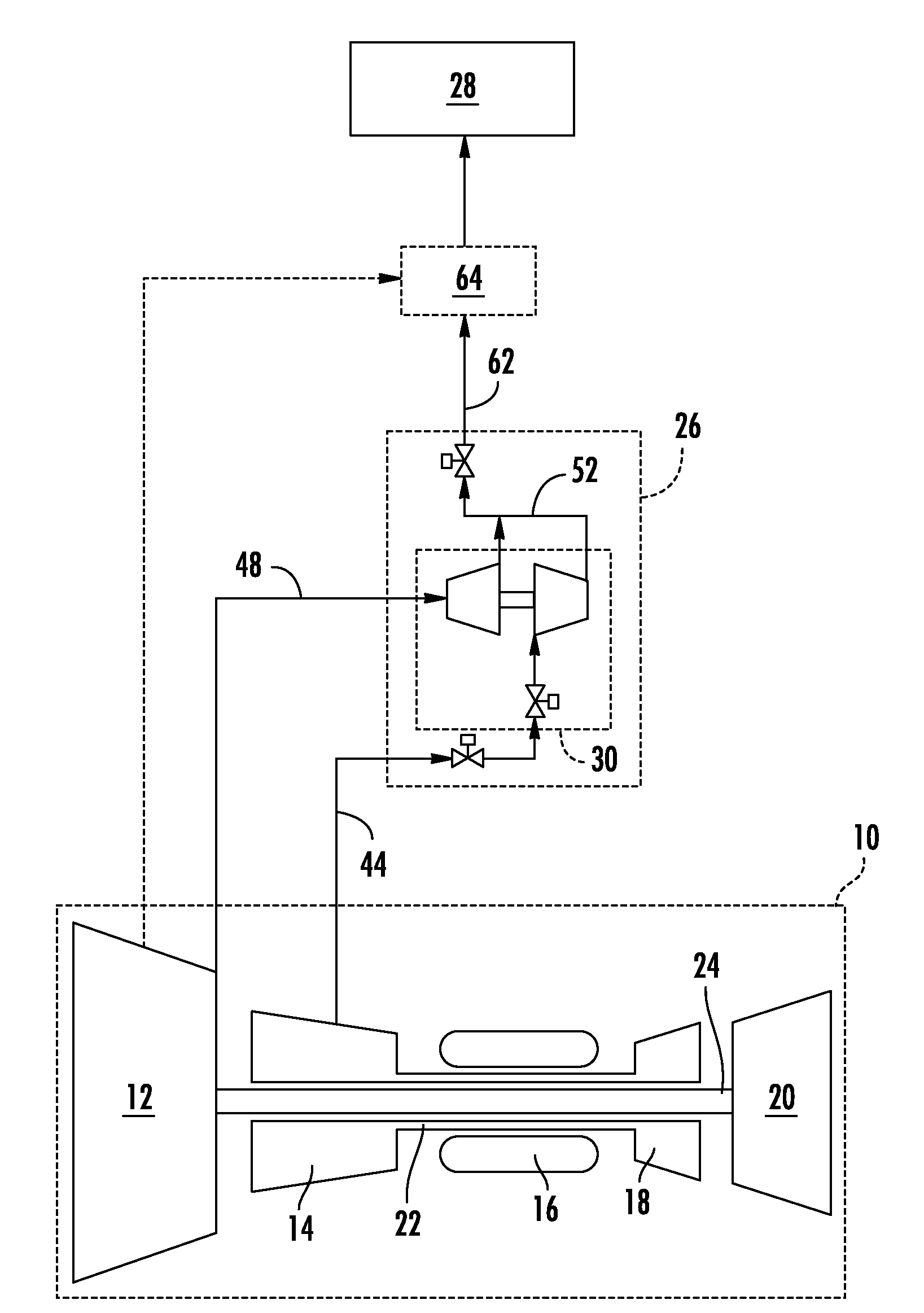

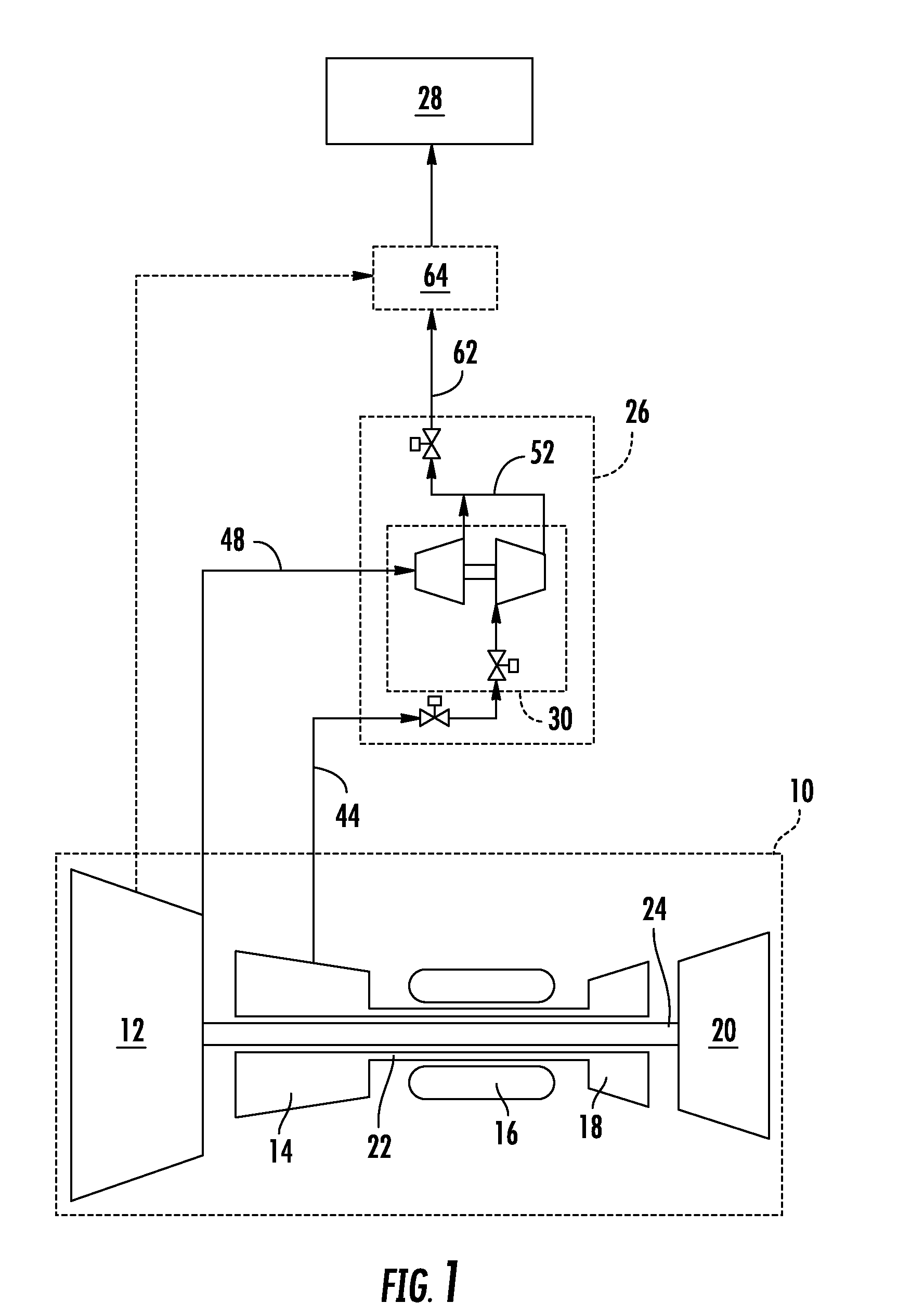

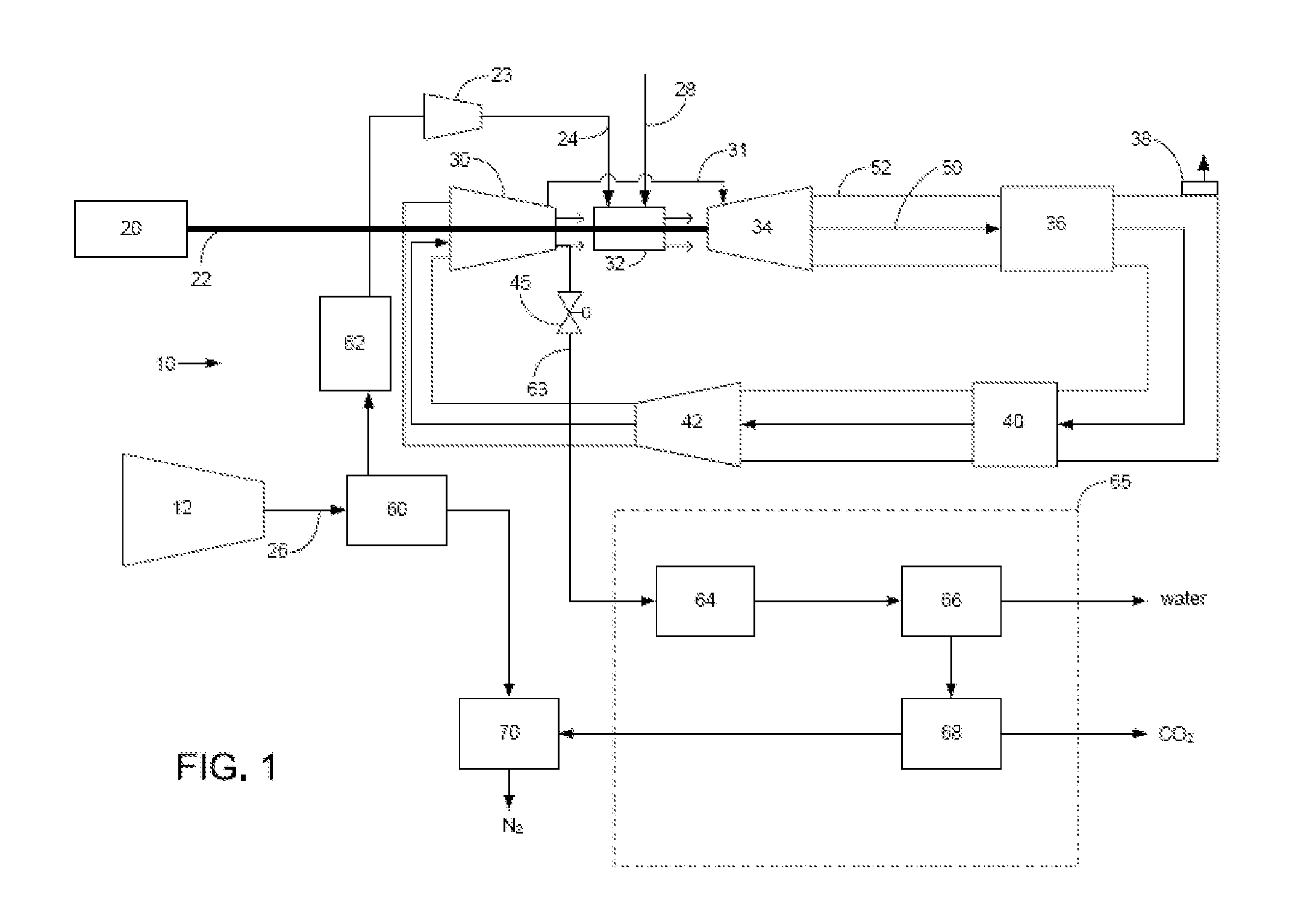

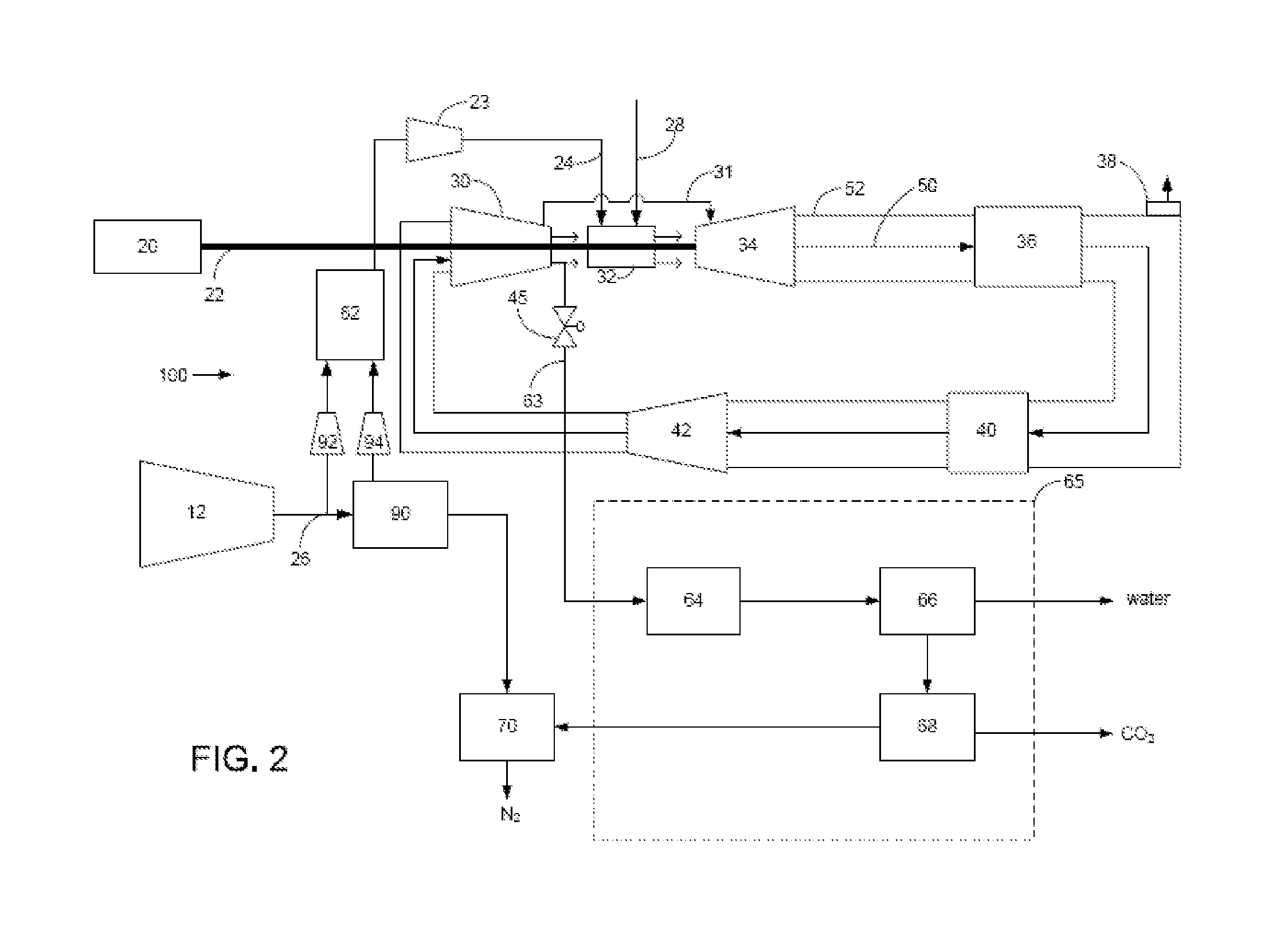

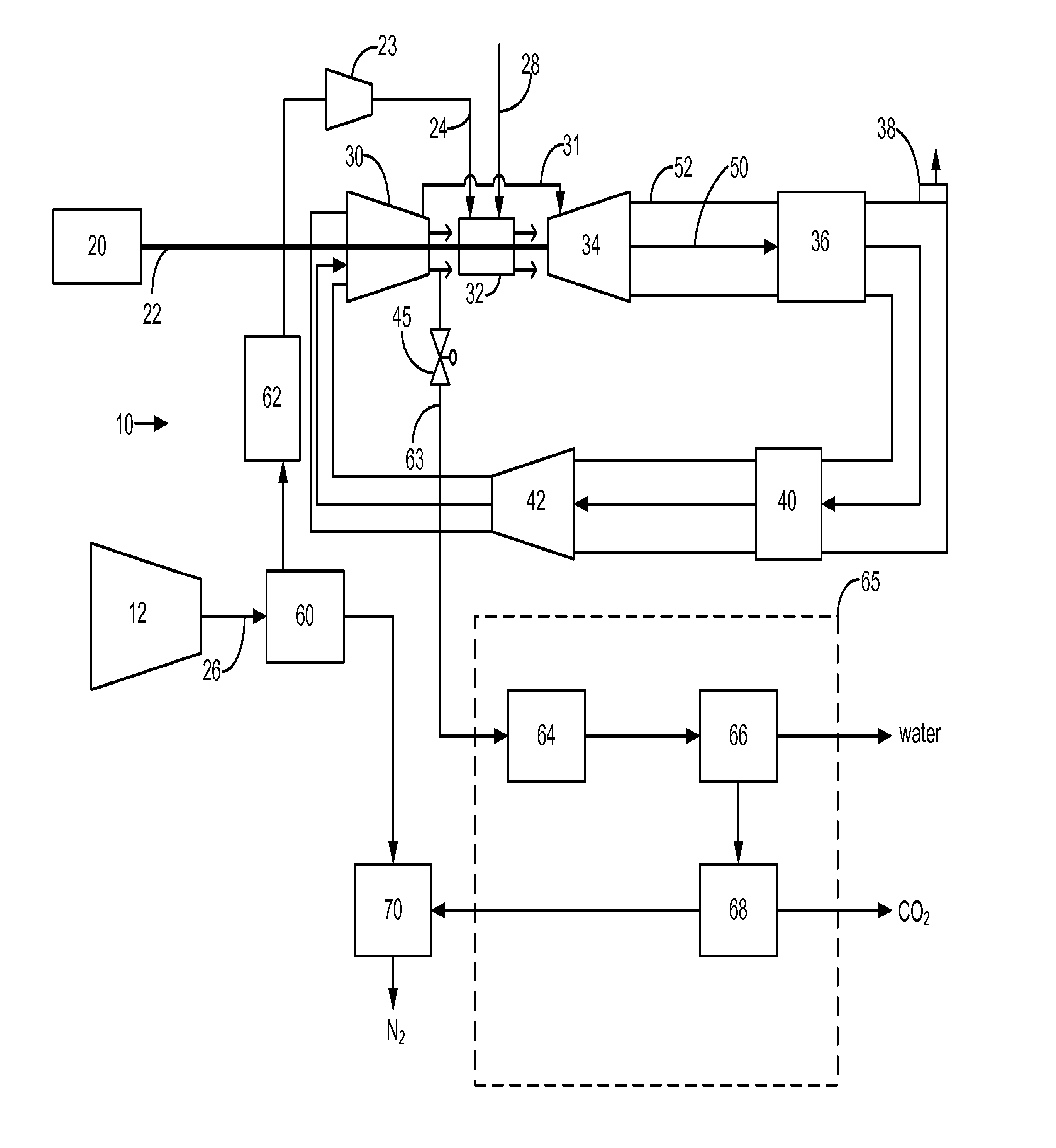

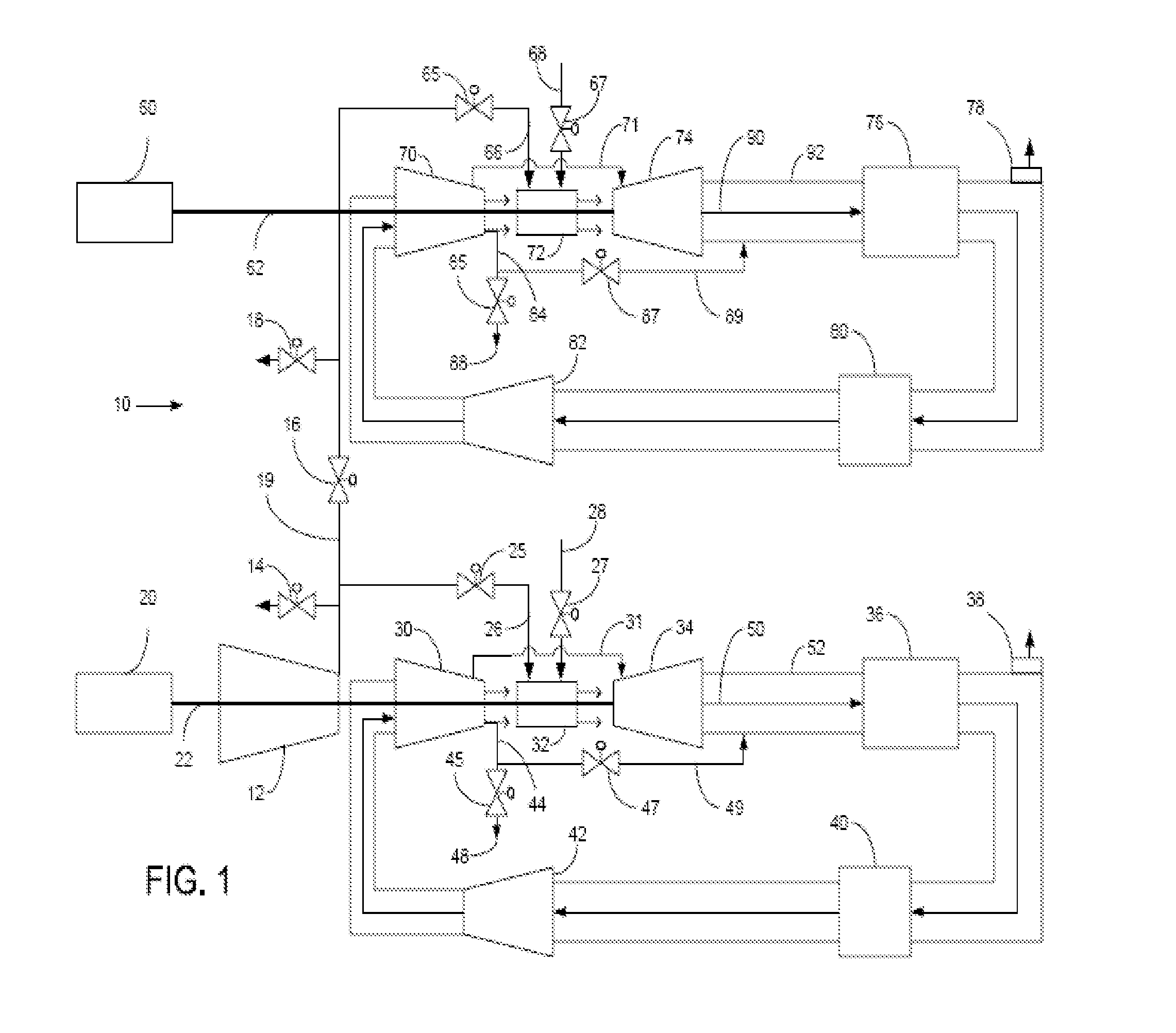

Power plant and method of operation

A power plant and method of operation is provided. The power plant comprises at least one main air compressor, an oxidizer unit configured to deliver a compressed oxygen-rich gas flow to at least one gas turbine assembly. Each assembly comprises a turbine combustor for mixing the compressed oxygen-rich gas flow with a recirculated gas flow and a fuel stream to burn a combustible mixture and form the recirculated gas flow. The assembly also comprises a recirculation loop for recirculating the recirculated gas flow from a turbine to a turbine compressor. The assembly further comprises a recirculated gas flow extraction path for extracting a portion of the recirculated gas flow from the assembly and delivering this to a gas separation system. The gas separation system separates the portion of the recirculated gas flow into a nitrogen portion and a carbon dioxide portion.

Owner:GENERAL ELECTRIC CO

Engine-Driven Air Compressor/Generator Load Priority Control System and Method

A system, in one embodiment, may include a portable unit having an engine, a generator coupled to the engine, a compressor coupled to the engine, and a priority load controller. The controller may be configured to adjust various loads on the engine, the generator, or the compressor, or a combination thereof, in response to sensor feedback and a priority control scheme. A computer-implemented method, in another embodiment, may include adjusting power output to various loads on an engine, a welding generator coupled to the engine, or an air compressor coupled to the engine, or a combination thereof, in a portable welding unit in response to sensor feedback and a priority control scheme.

Owner:ILLINOIS TOOL WORKS INC

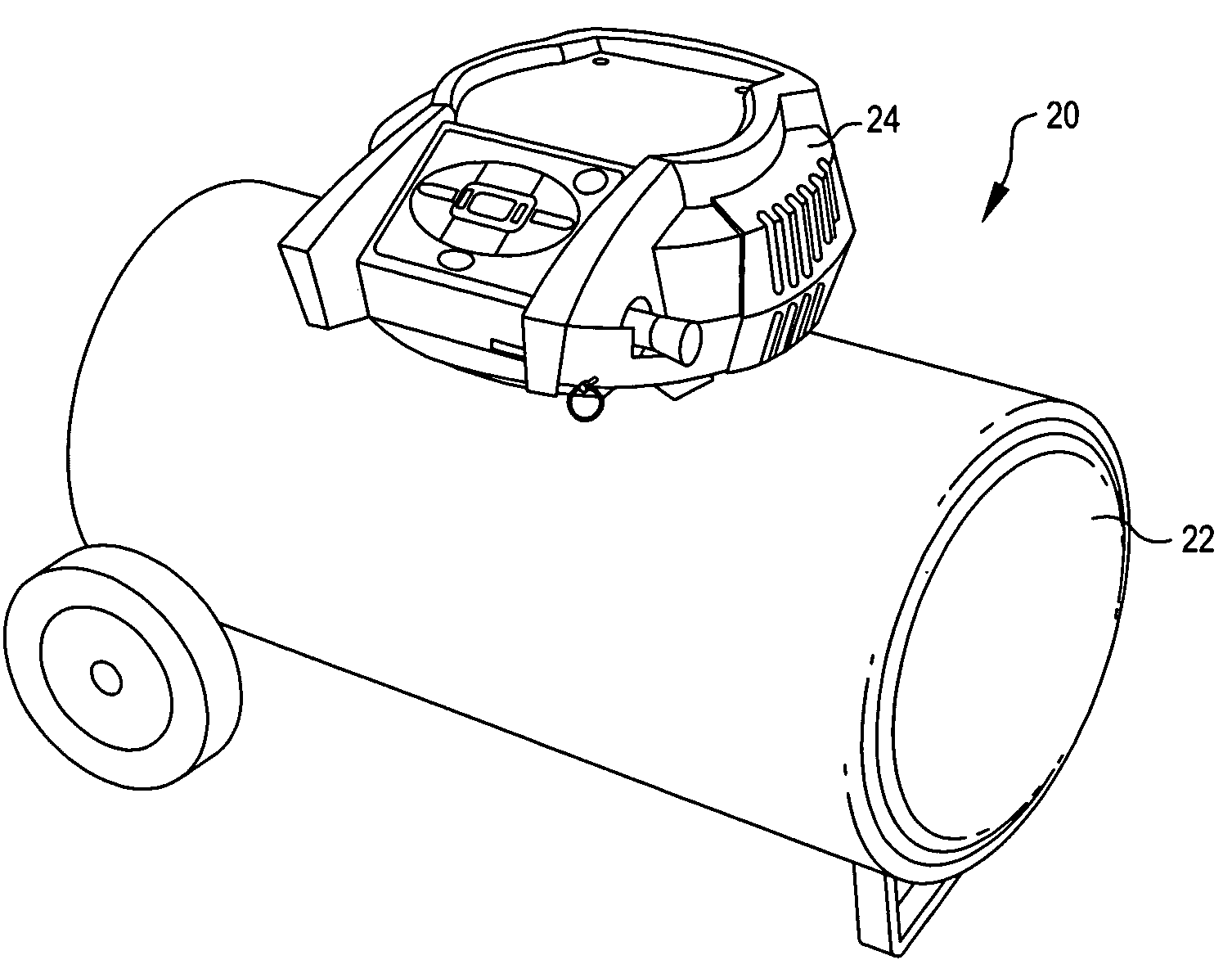

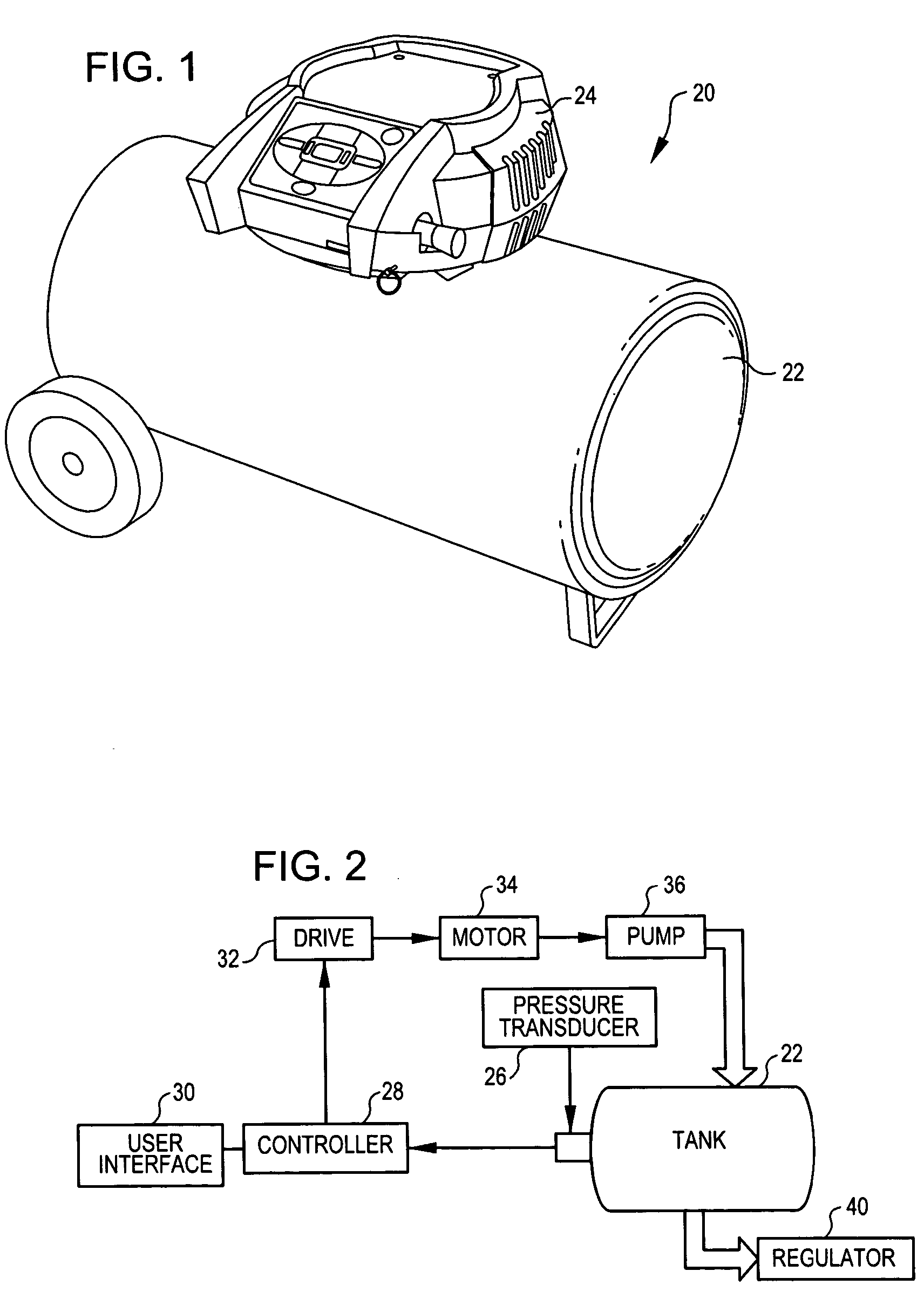

Air compressor with variable speed motor

InactiveUS20060045751A1Resistance may varyEliminate confusionMotor parameterPump controlMotor speedControl system

An air compressor utilizing an electronic control system. A pneumatically controlled regulator is provided for controlling output pressure for an air compressor. Digital gauges are provided on the air compressor to replace conventional mechanical gauges. A variable speed motor is used, which in turn varies the speed of the pump. Tools are provided for an air compressor that are capable of transmitting a signal to the air compressor indicating a desired pressure and / or motor speed at which the air compressor is to operate.

Owner:DEVILBISS AIR POWER COMPANY

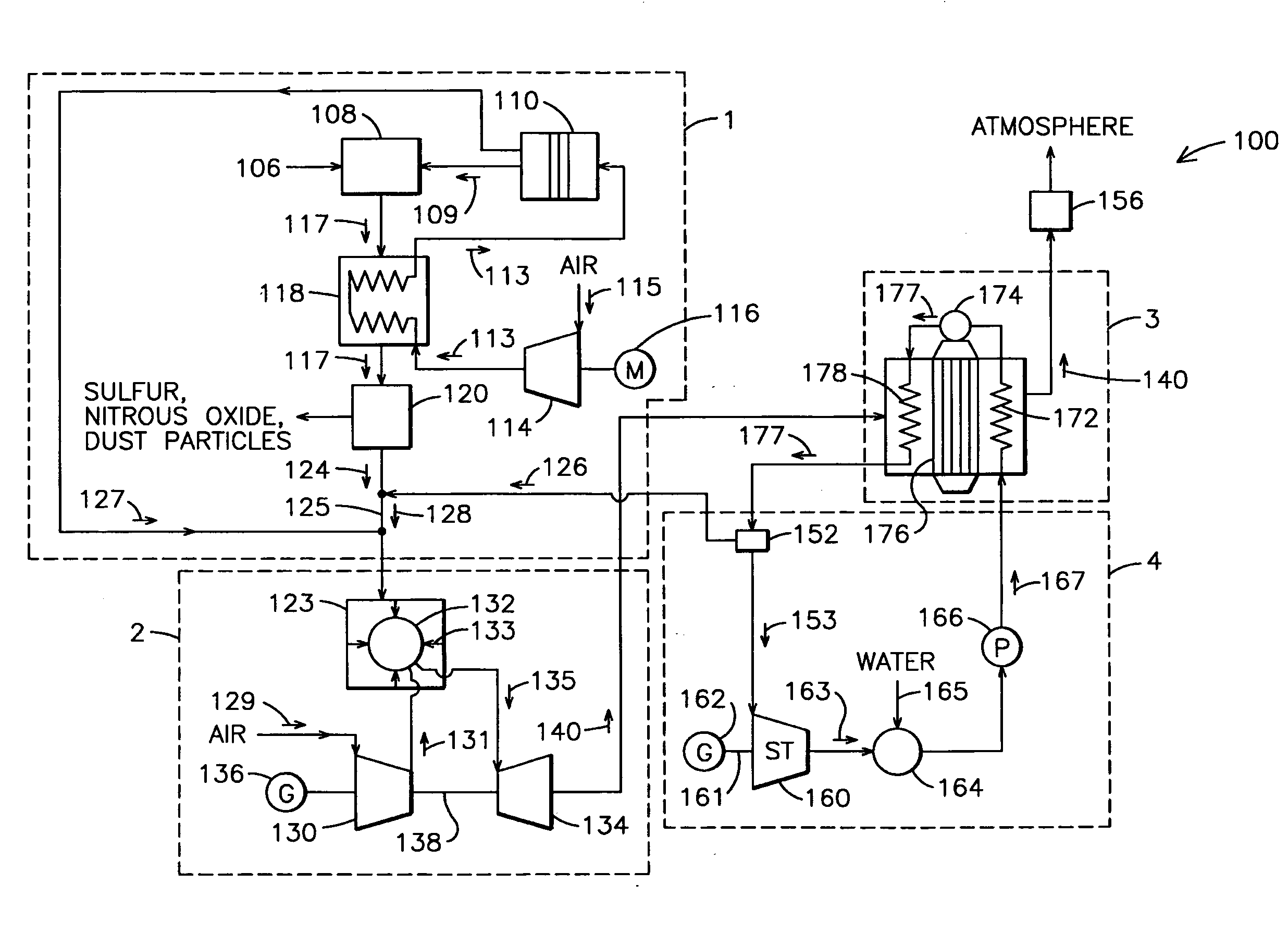

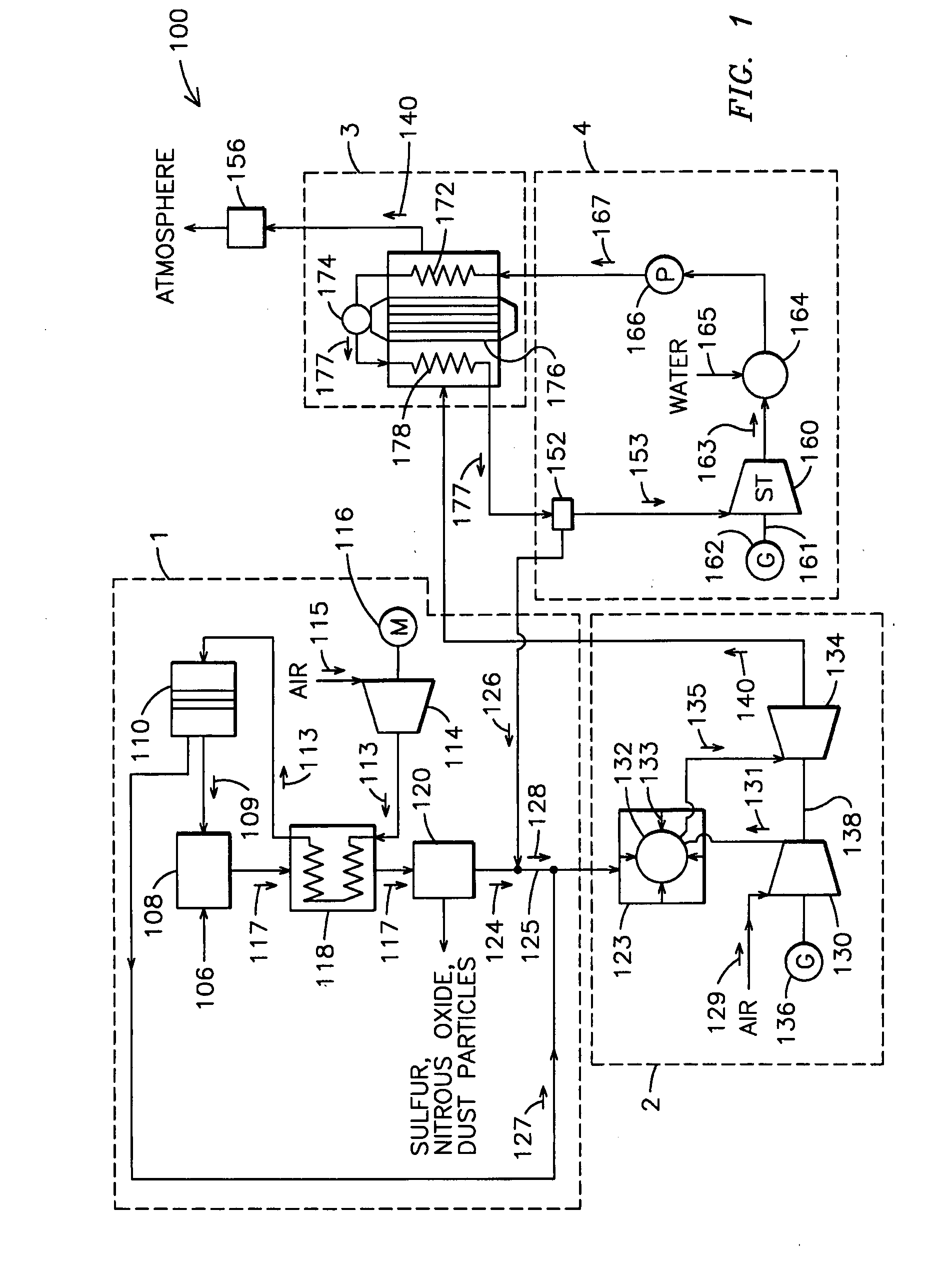

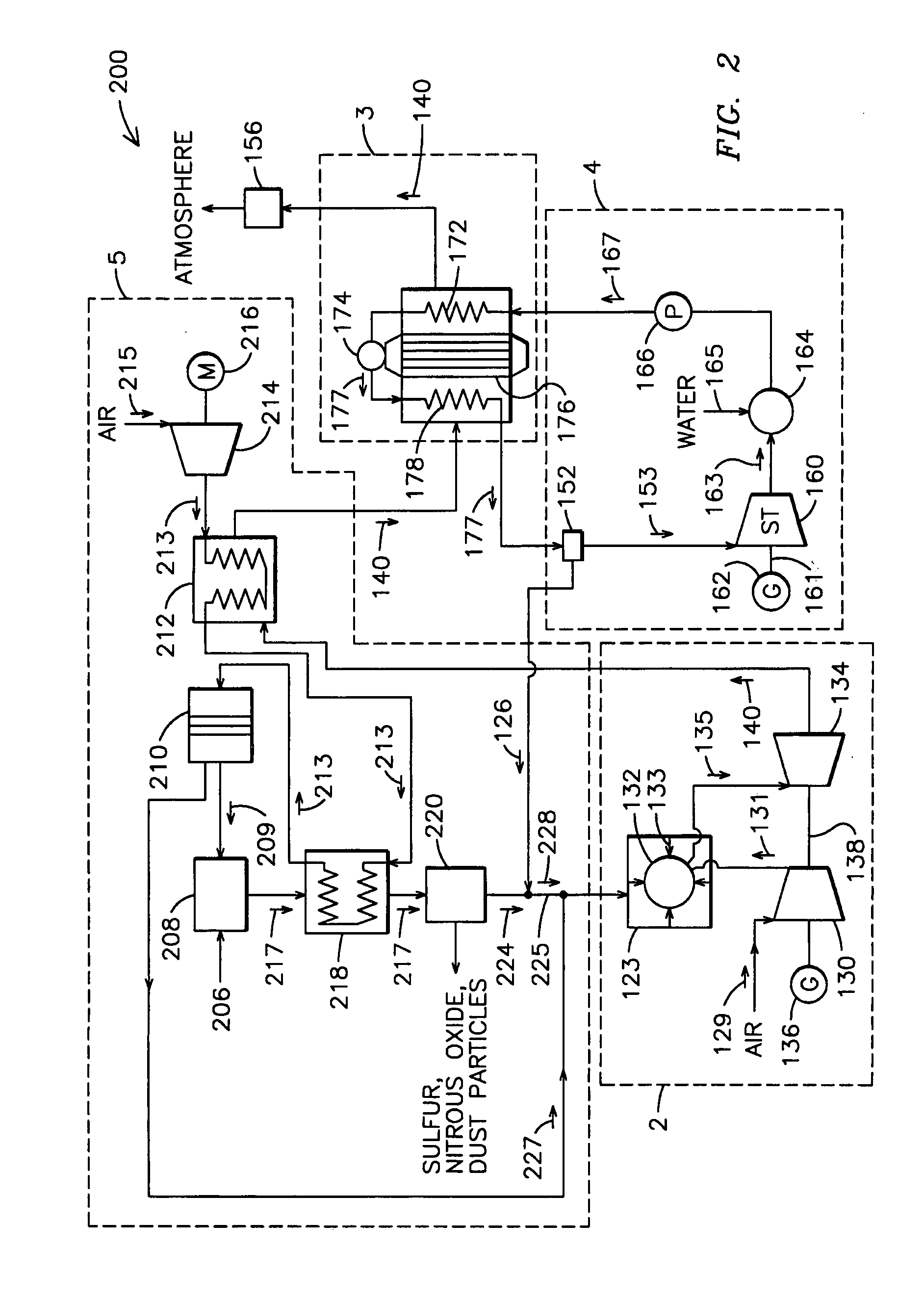

System and method for oxygen separation in an integrated gasification combined cycle system

An integrated gasification combined cycle power generation system (100). In one embodiment, shown in FIG. 1, a gasifier (108) is configured to generate synthetic gas (117) from a carbonaceous material (106) and an oxygen supply (109) with a cleaning stage (120) positioned to receive synthetic gas (117) from the gasifier (108) and remove impurities therefrom. A gas turbine combustion system (2) including a turbine (123) is configured to receive fuel (128) from the gasifier (108) and a first air supply (131) from a first air compressor (130). A steam turbine system (4) is configured to generate power with heat recovered from exhaust (140) generated by the gas turbine system (2) and an ion transport membrane air separation unit (110) includes a second air compressor (114) for generating a second air supply (113). A first heat exchanger (118) is configured to cool the synthetic gas (117) prior to removal of impurities in the cleaning stage (120) by flowing the second air supply (113) through the first heat exchanger (118) so that the second air supply (113) receives heat from the synthetic gas (117).

Owner:SIEMENS ENERGY INC

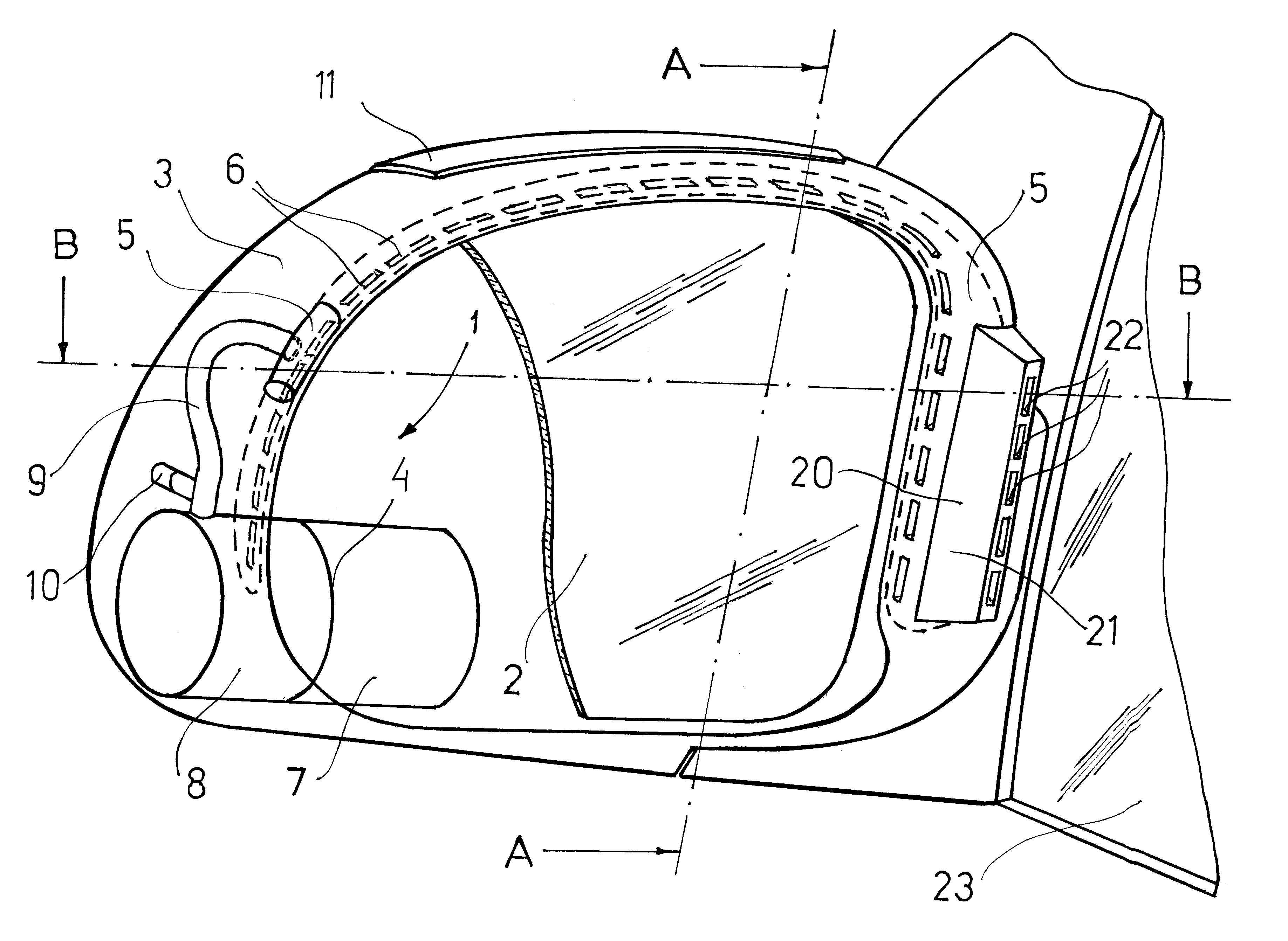

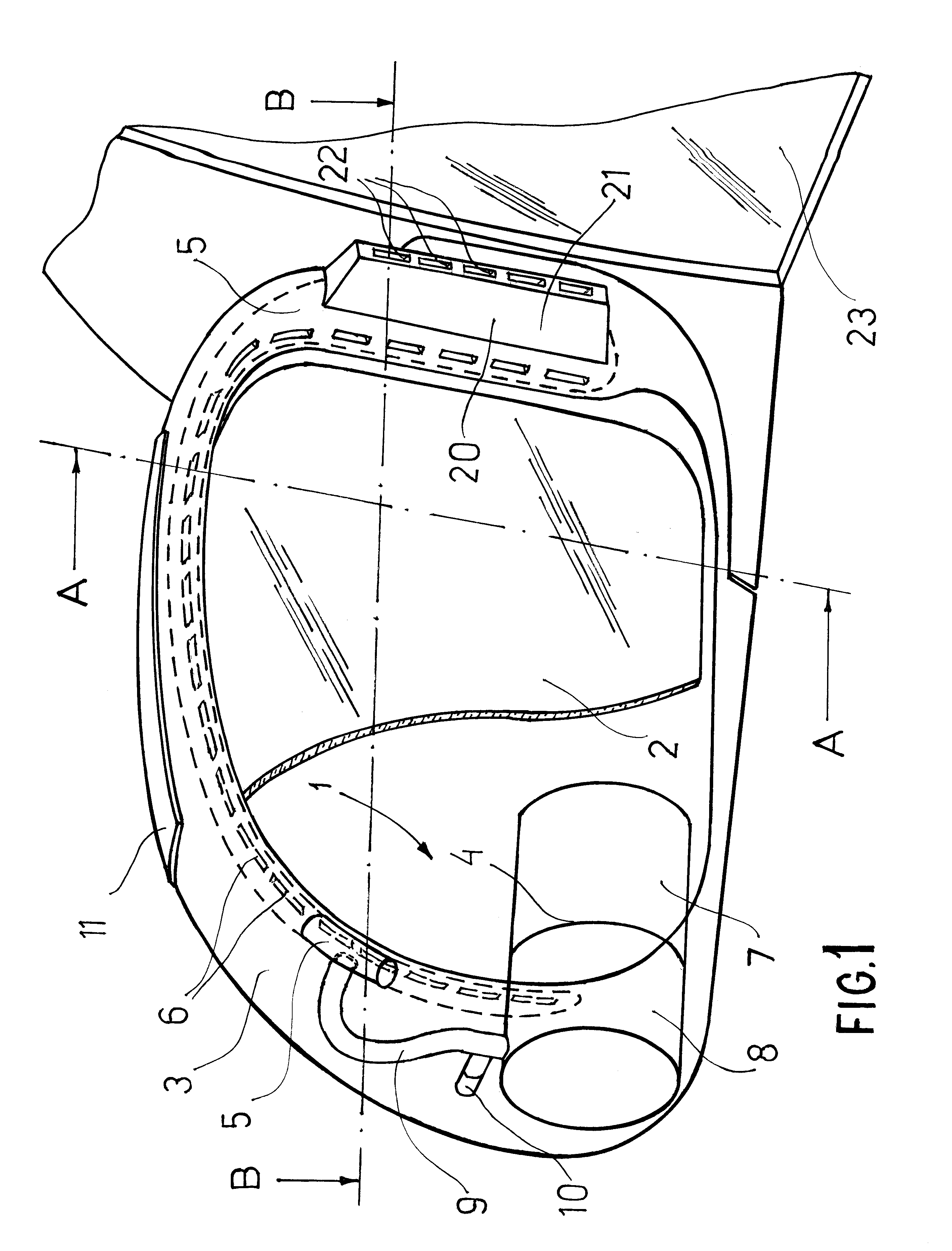

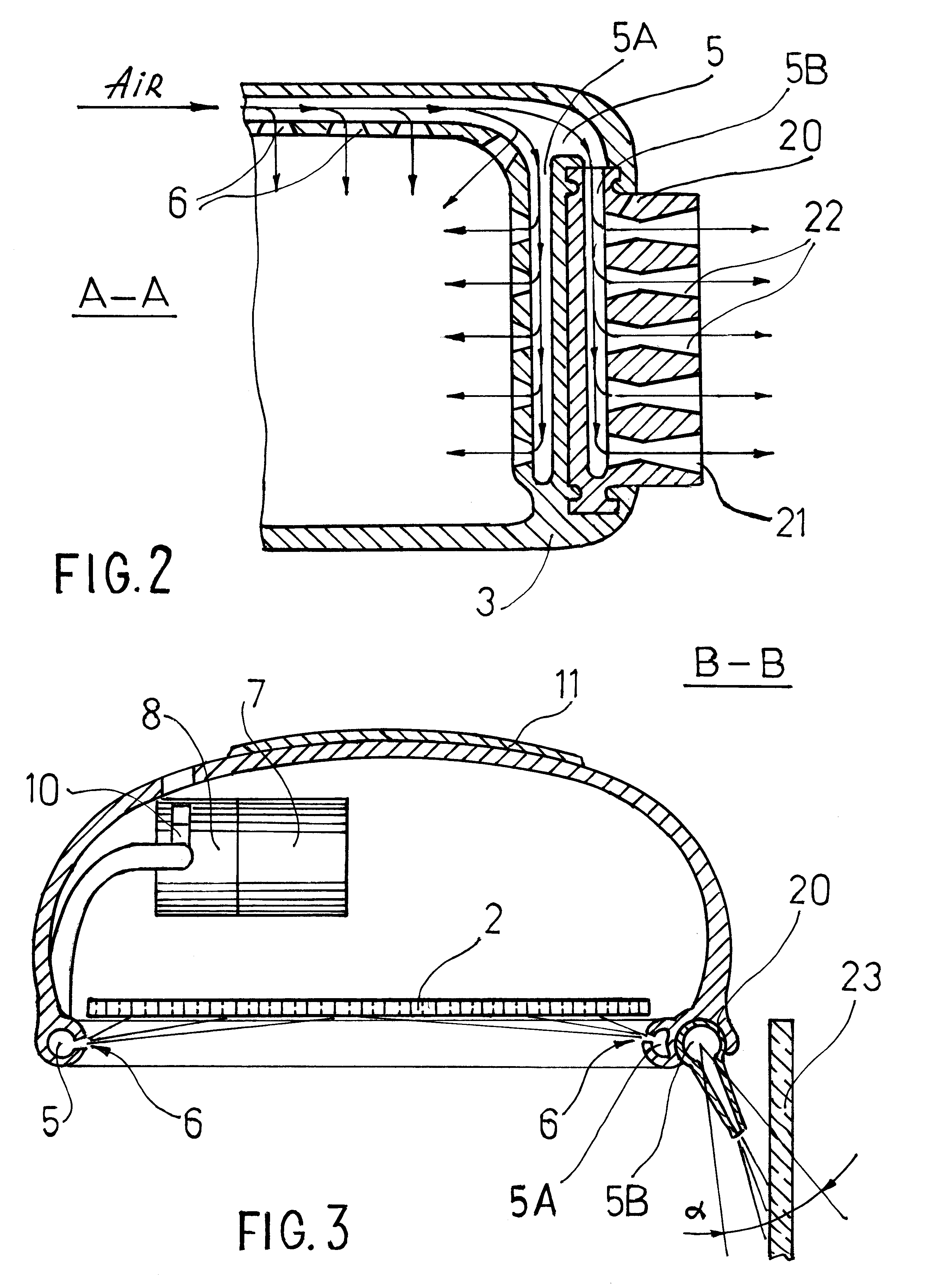

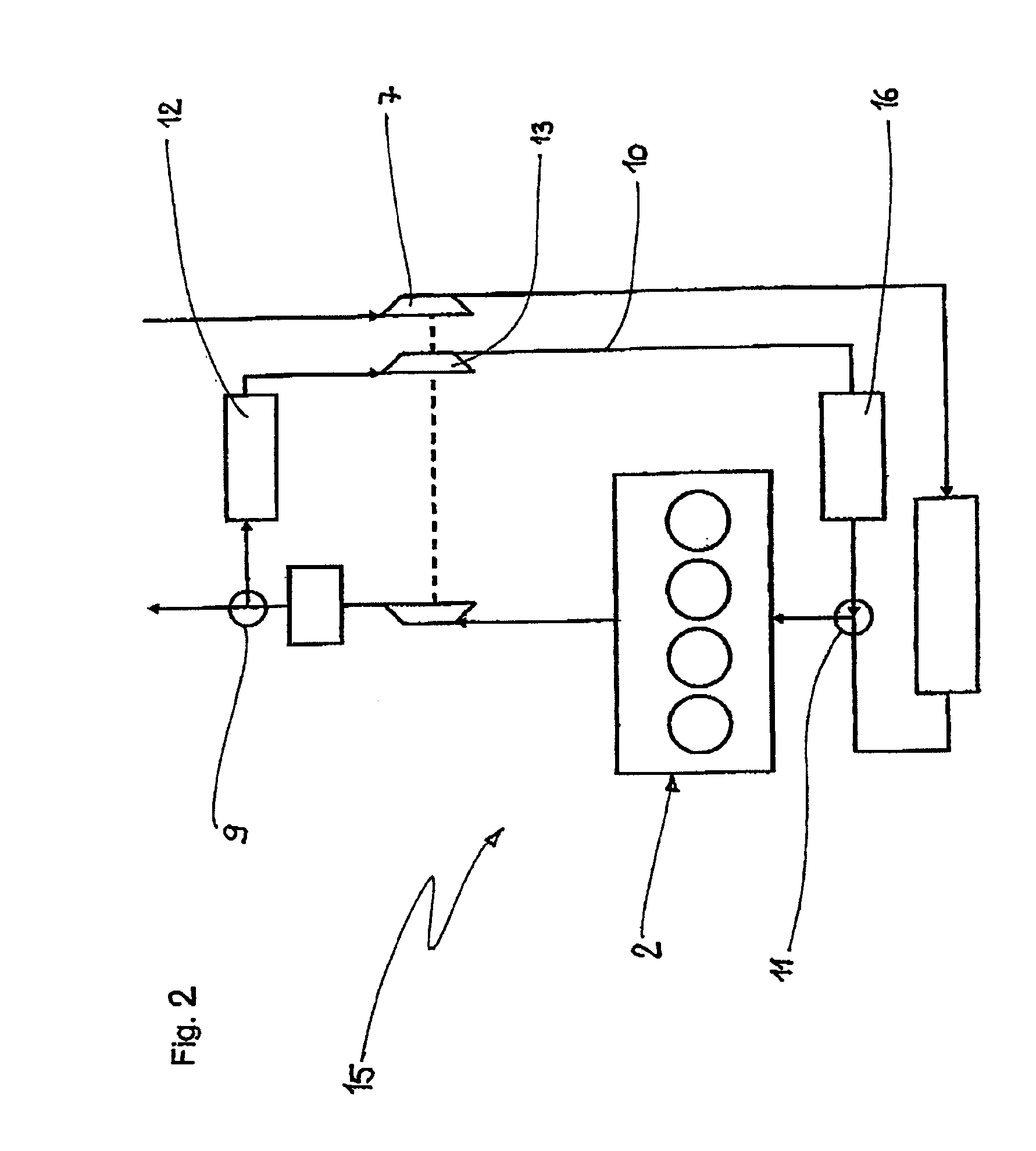

Universal clearing air system for windows and external mirrors of a vehicle

A clearing system for external mirrors and side windows of a vehicle provides a flow of compressed warm air to an air distribution unit equipped with a number of openings to direct the flow of air towards the surface of the mirror or a side window. In one embodiment, the air compressor, the air heater and an optional air filter are located in the housing of the external mirror. In another embodiment, a supplemental air distribution unit is provided to be mounted along the door of the vehicle to increase the coverage area of the side window. In a further embodiment of the invention, the system is made adjustable for allowing the most appropriate angle for the air openings towards the mirror and the side window. Provisions are also made to use the system for newly designed vehicles and incorporate the elements of the system into the design of the vehicle door. Alternately, an add-on elements are described to allow existing vehicles to benefit from the system. Additional supplemental air disbribution units may be attached to the main system to improve visibility throughout the vehicle.

Owner:BERZIN LEONID

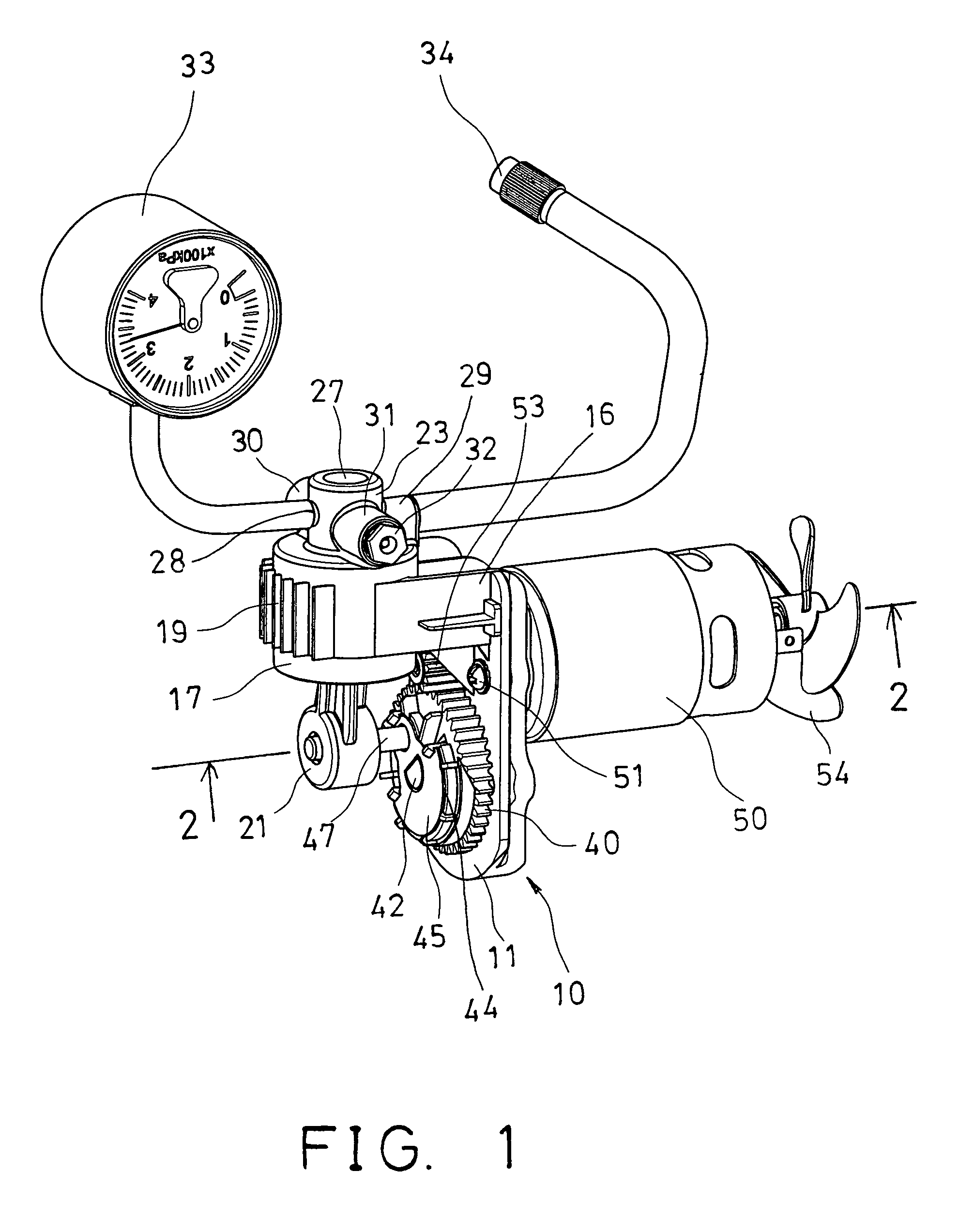

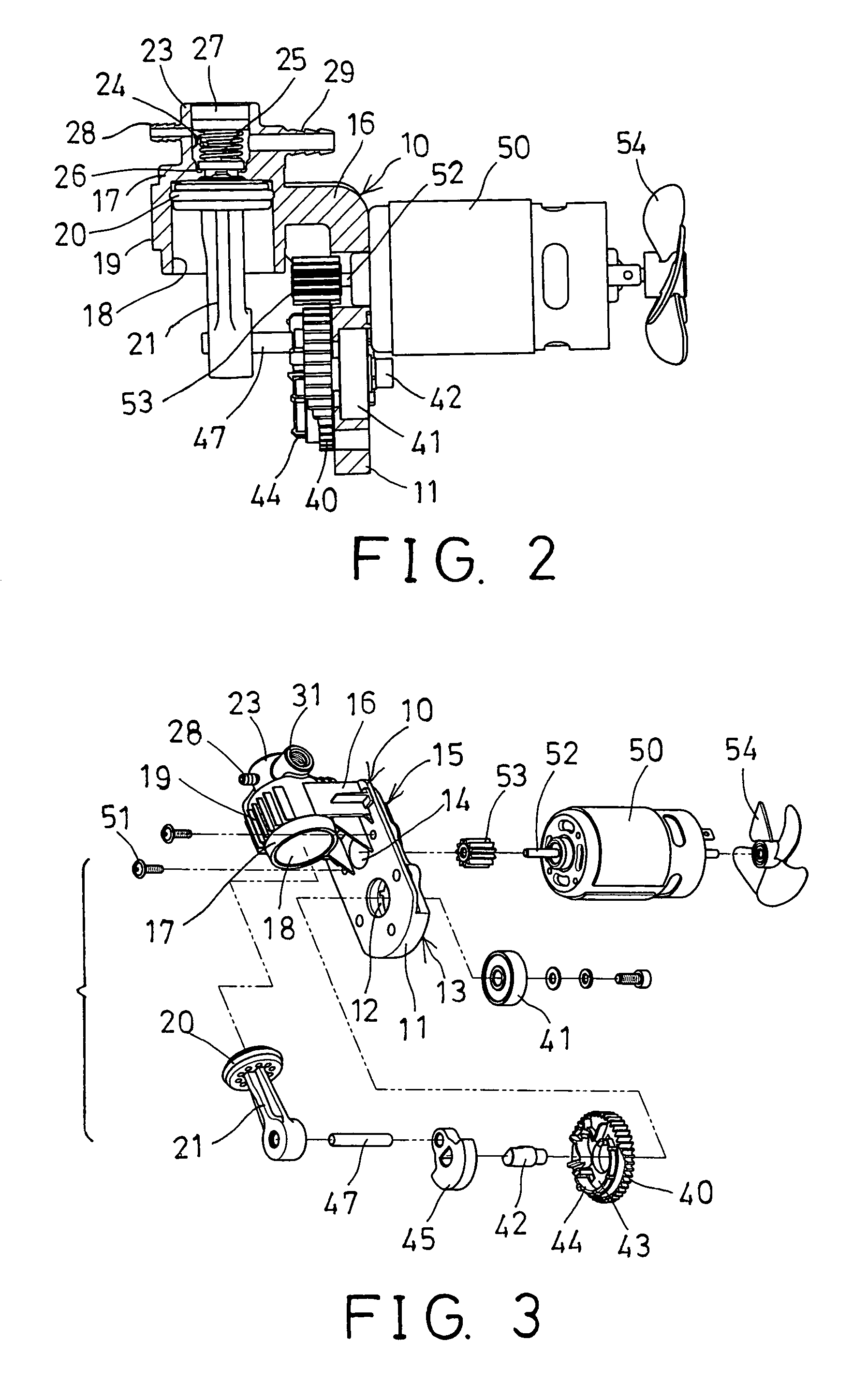

Air compressor having stable configuration

InactiveUS7462018B2StablySmoothly coupled togetherPositive displacement pump componentsPump controlEngineeringAir compressor

An air compressor includes a supporting base having an arm extended from a plate, and a cylinder housing formed integral with the arm and the plate and having an outlet tube. The cylinder housing includes three or more ducts extended outwardly from the outlet tube and communicating with the outlet tube, for attaching a pressure gauge, a nozzle or other devices. A piston is slidably received in the cylinder housing. A motor is attached to the plate, and includes a spindle extendible through either the lower or the upper portion of the plate, and coupled to the piston with an eccentric member, to move the piston to the cylinder housing in a reciprocating action, in order to generate pressurized air.

Owner:CHOU WEN SAN

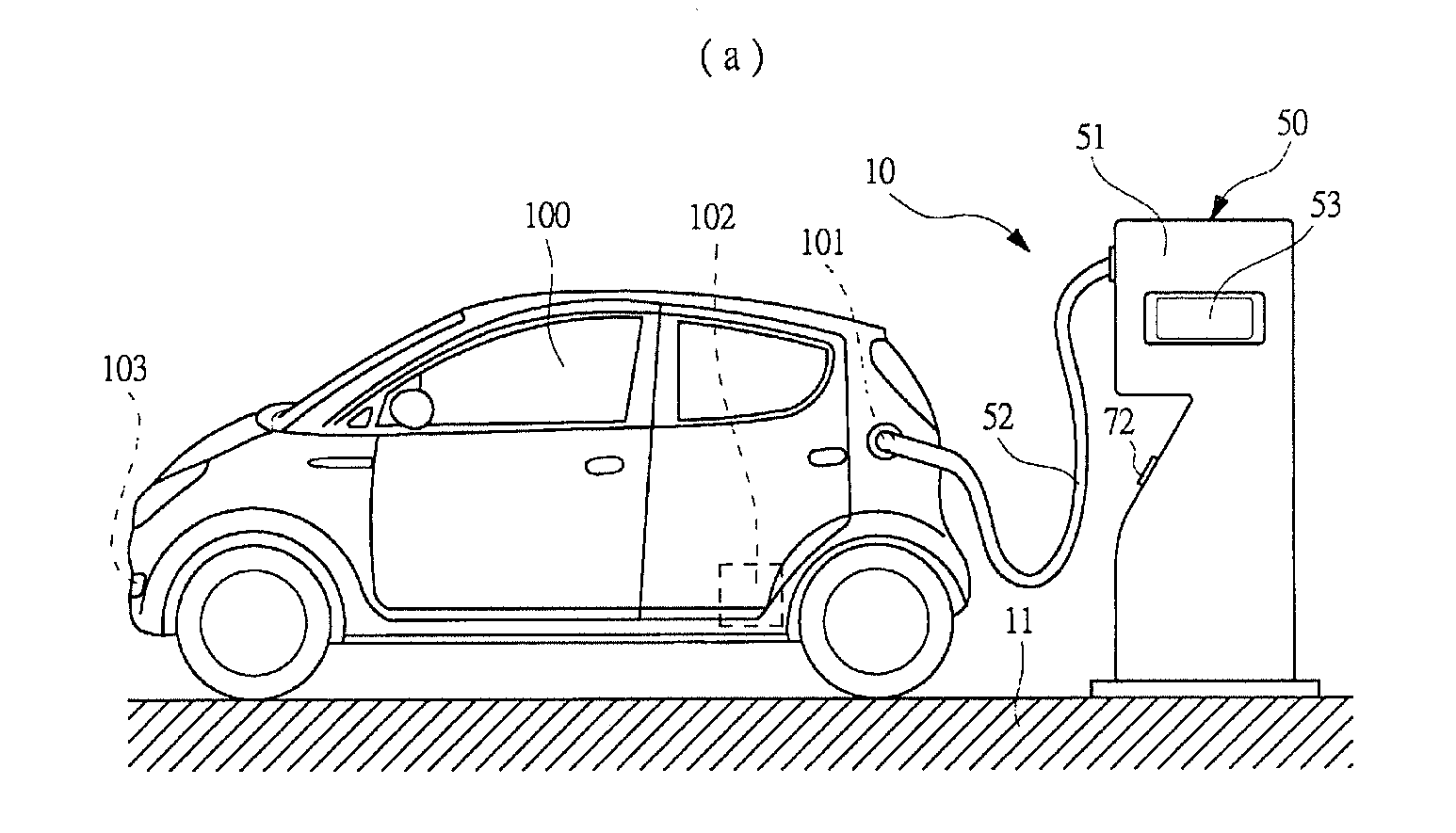

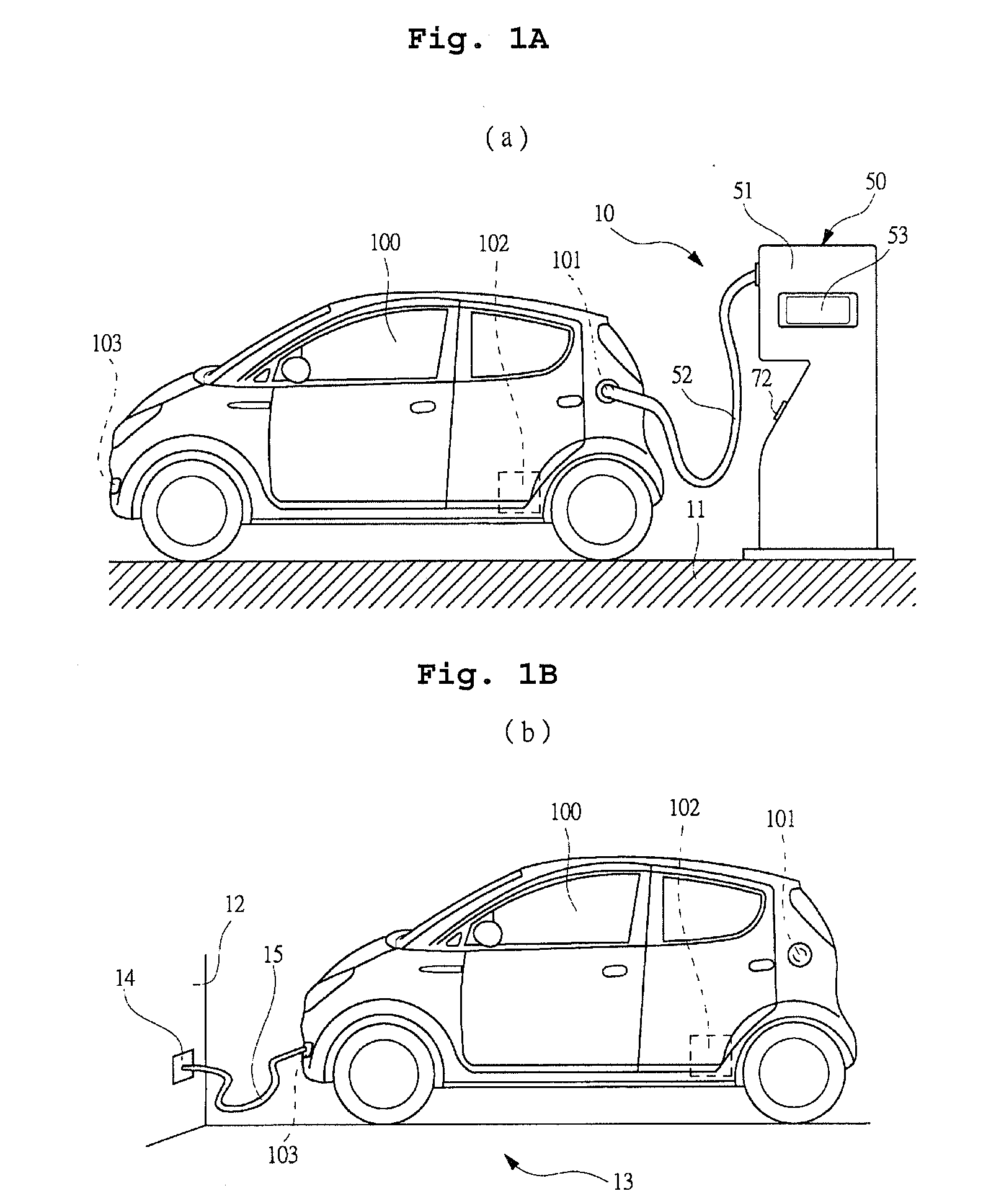

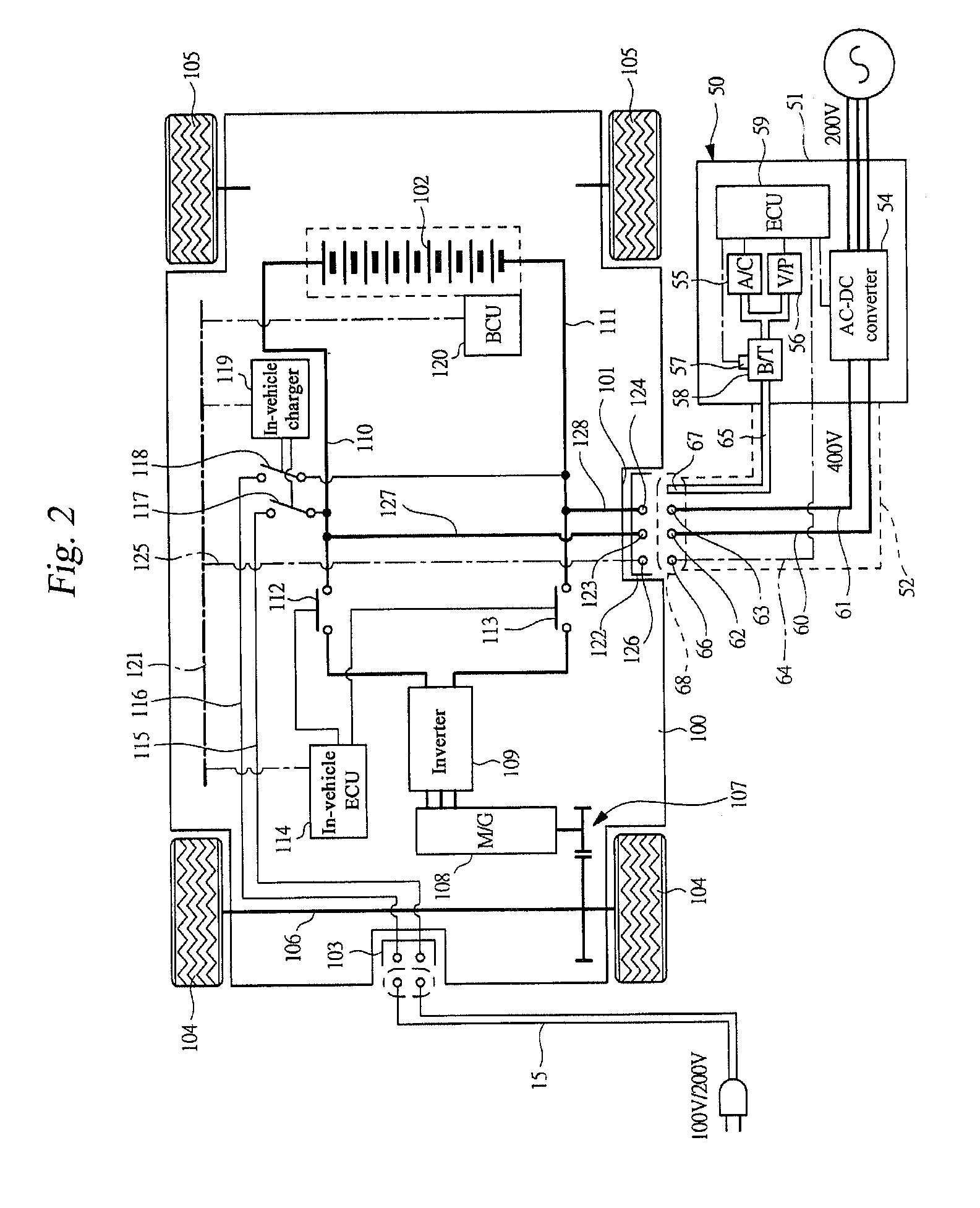

Charging device and charging structure

ActiveUS20100315040A1Avoid problemsReliable preventionBatteries circuit arrangementsCharging stationsElectricityEngineering

A charging device includes an air nozzle that prevents power-feeding-side terminals from becoming wet by blasting air, fitting switches operated when a power feeding connector is removed from a connector holding portion, and an ECU that activates an air compressor and a vacuum pump on the basis of operations of the fitting switches. The power-feeding-side terminals can be prevented from becoming wet while the power feeding connector is attached to a power receiving connector of an electric vehicle after being removed from the connector holding portion.

Owner:SUBARU CORP

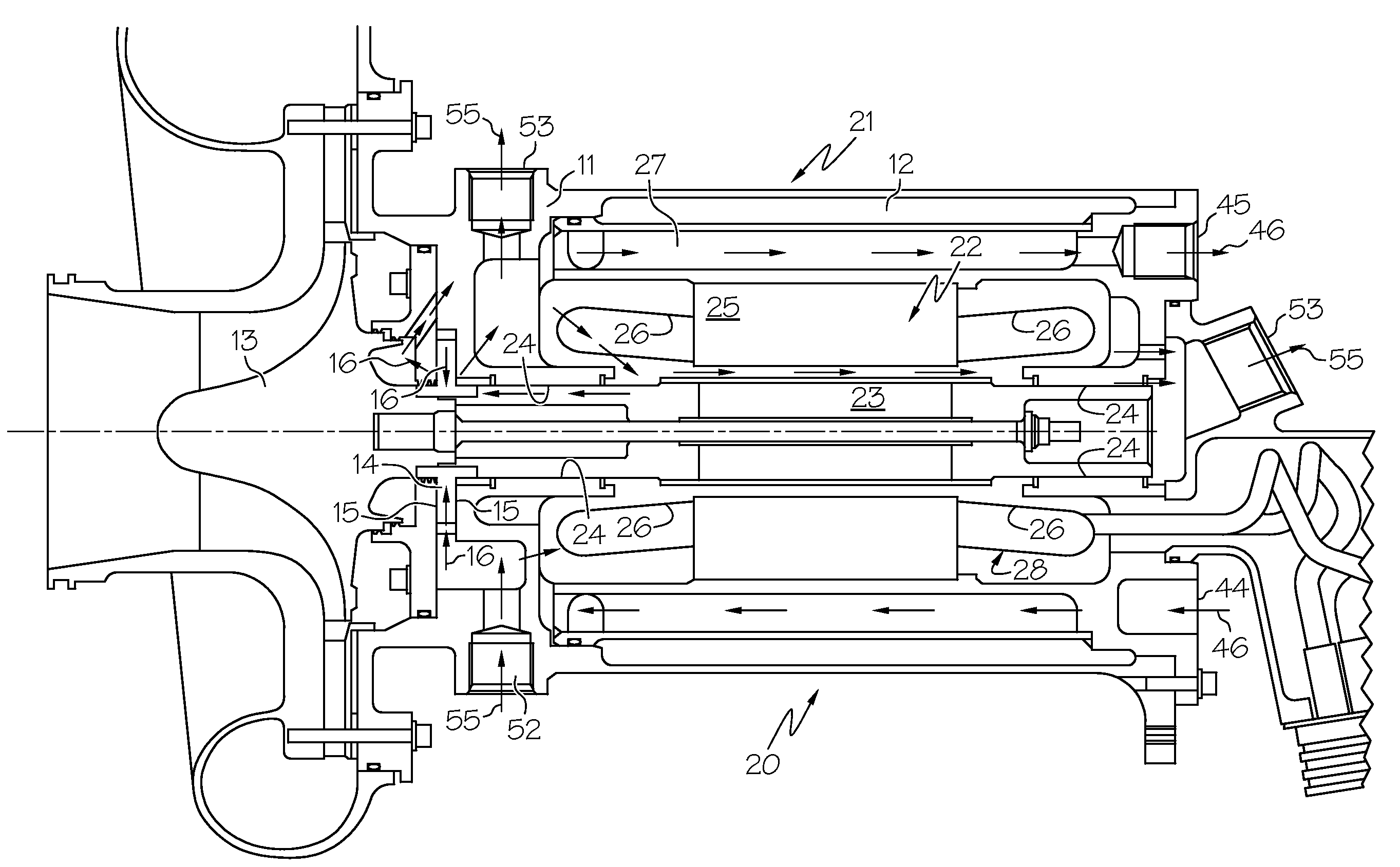

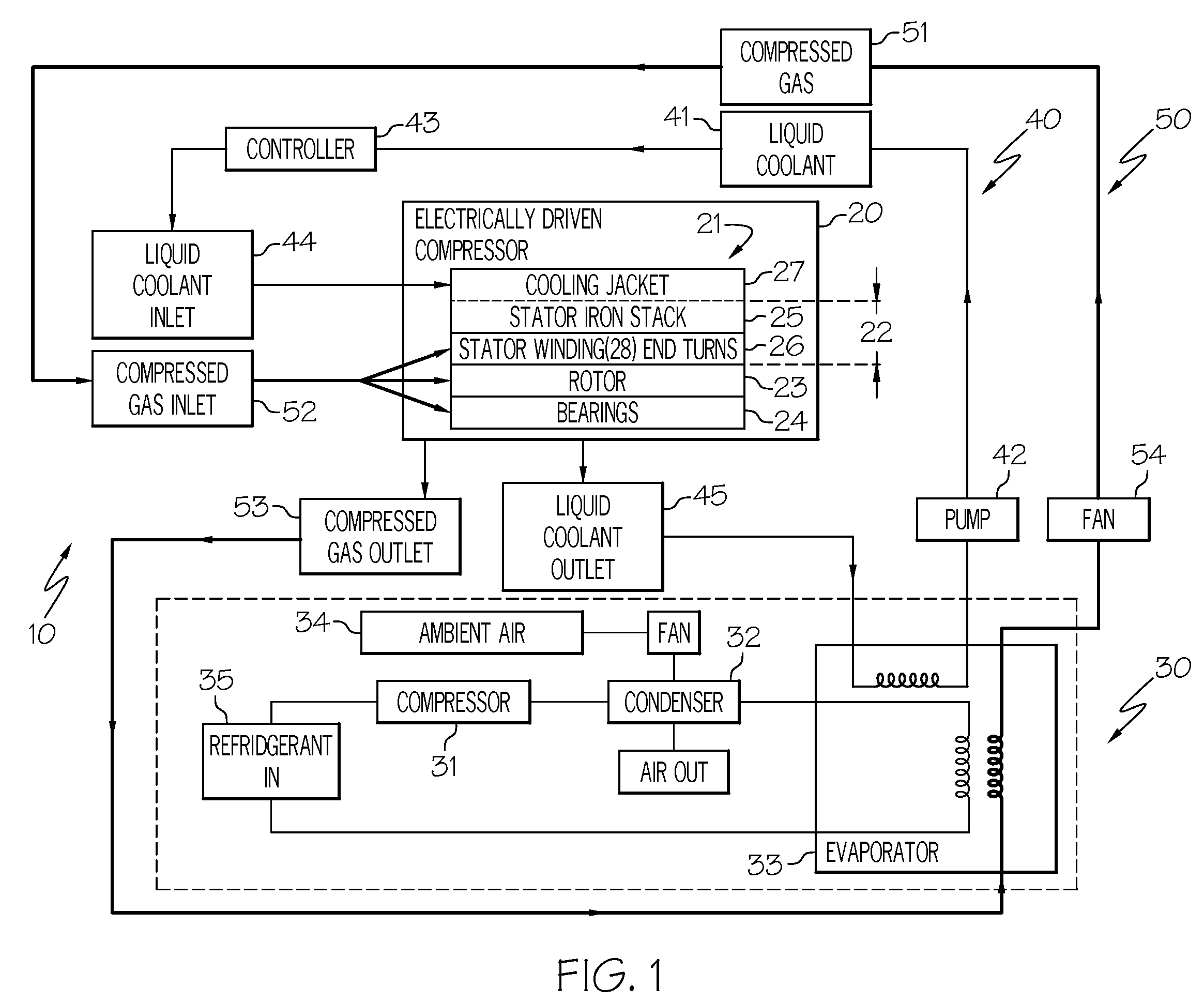

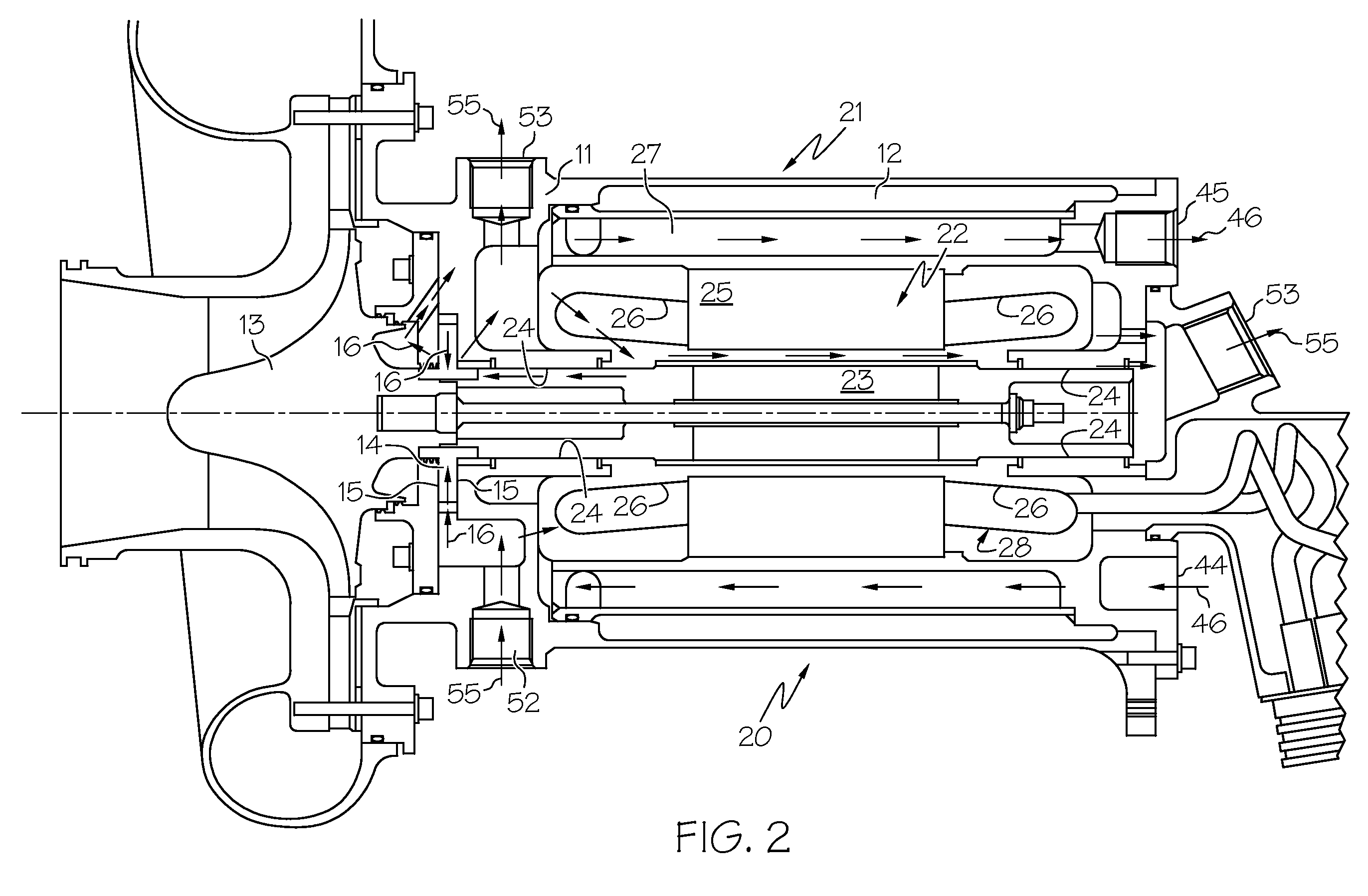

Thermal and secondary flow management of electrically driven compressors

Owner:HONEYWELL INT INC

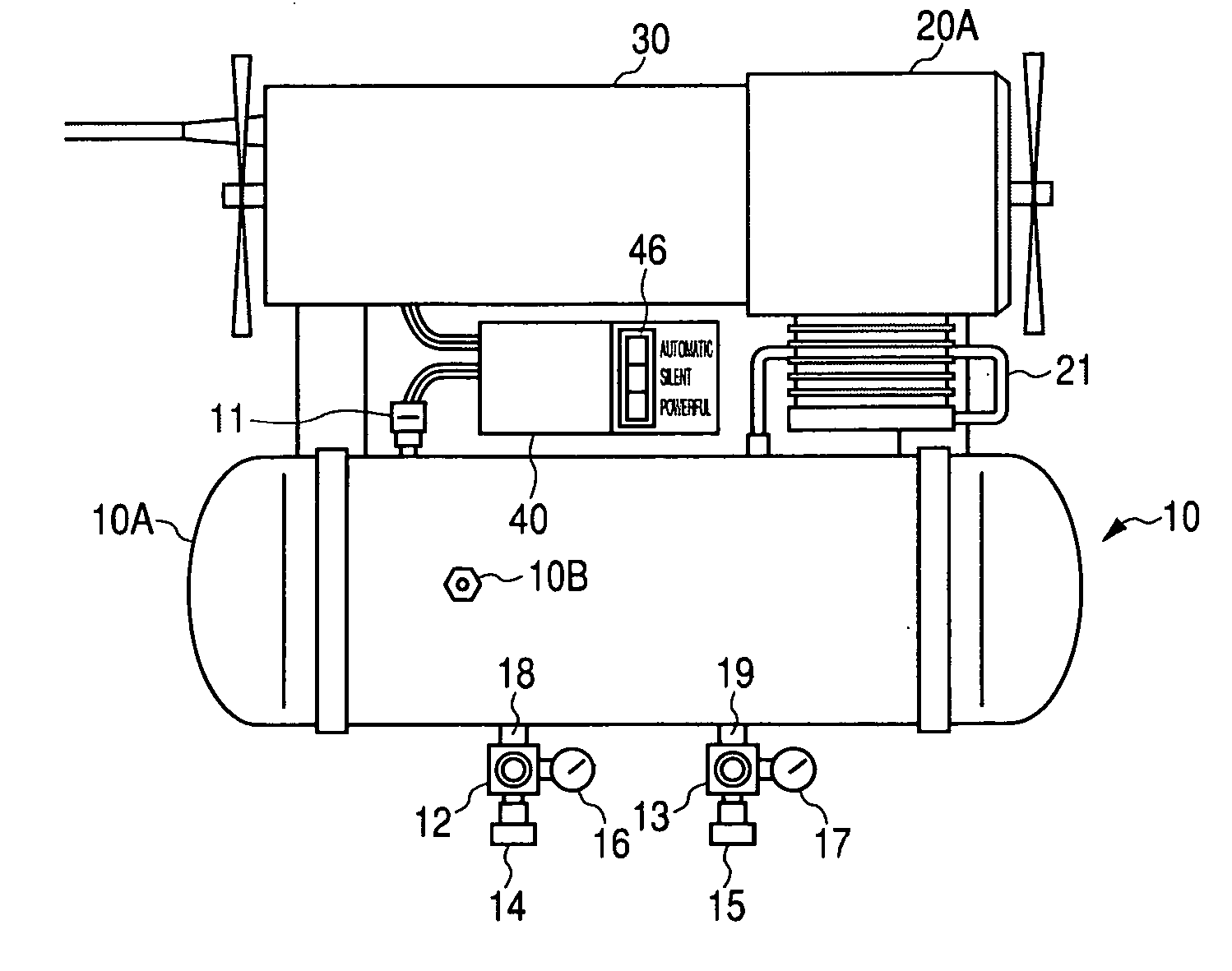

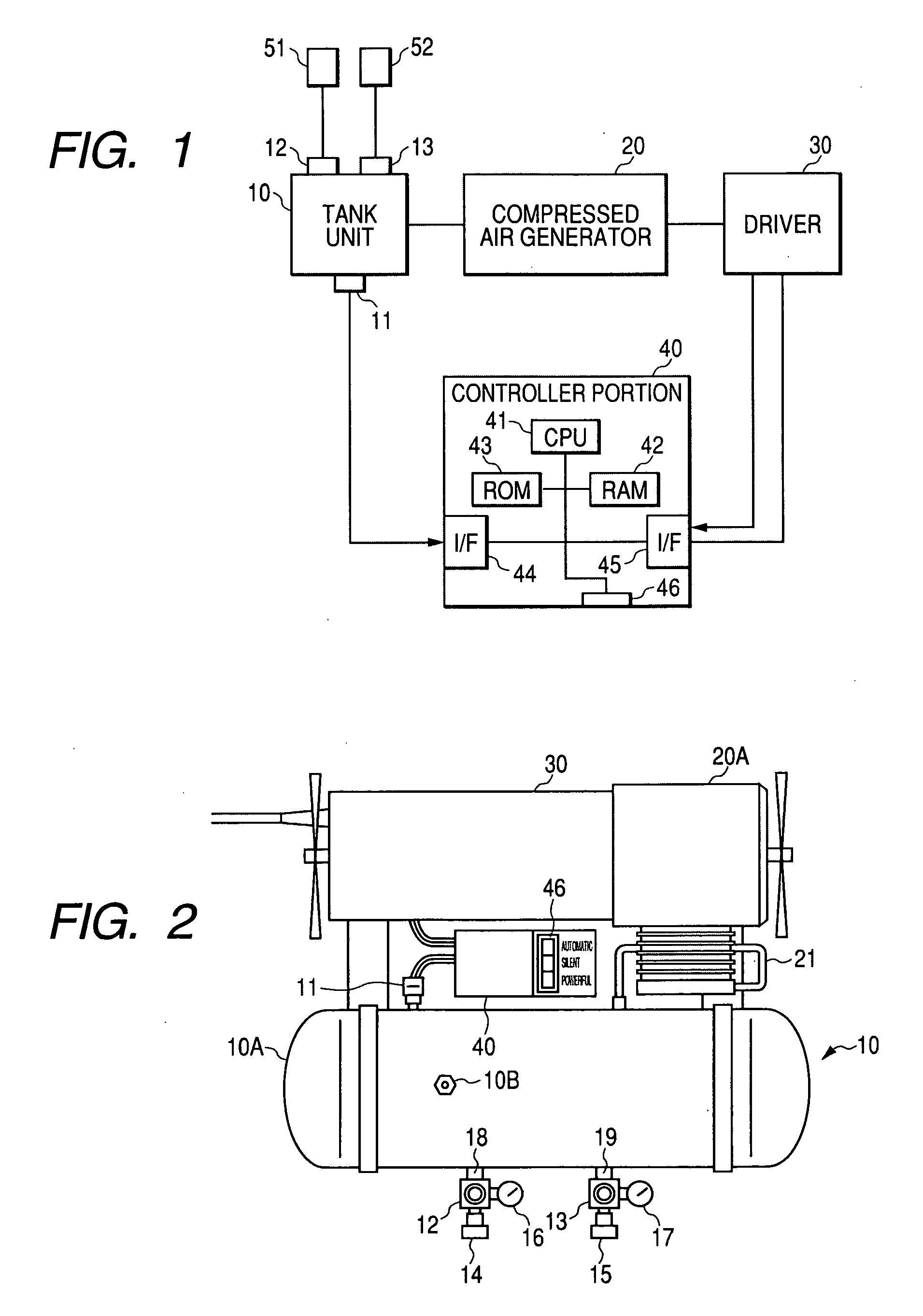

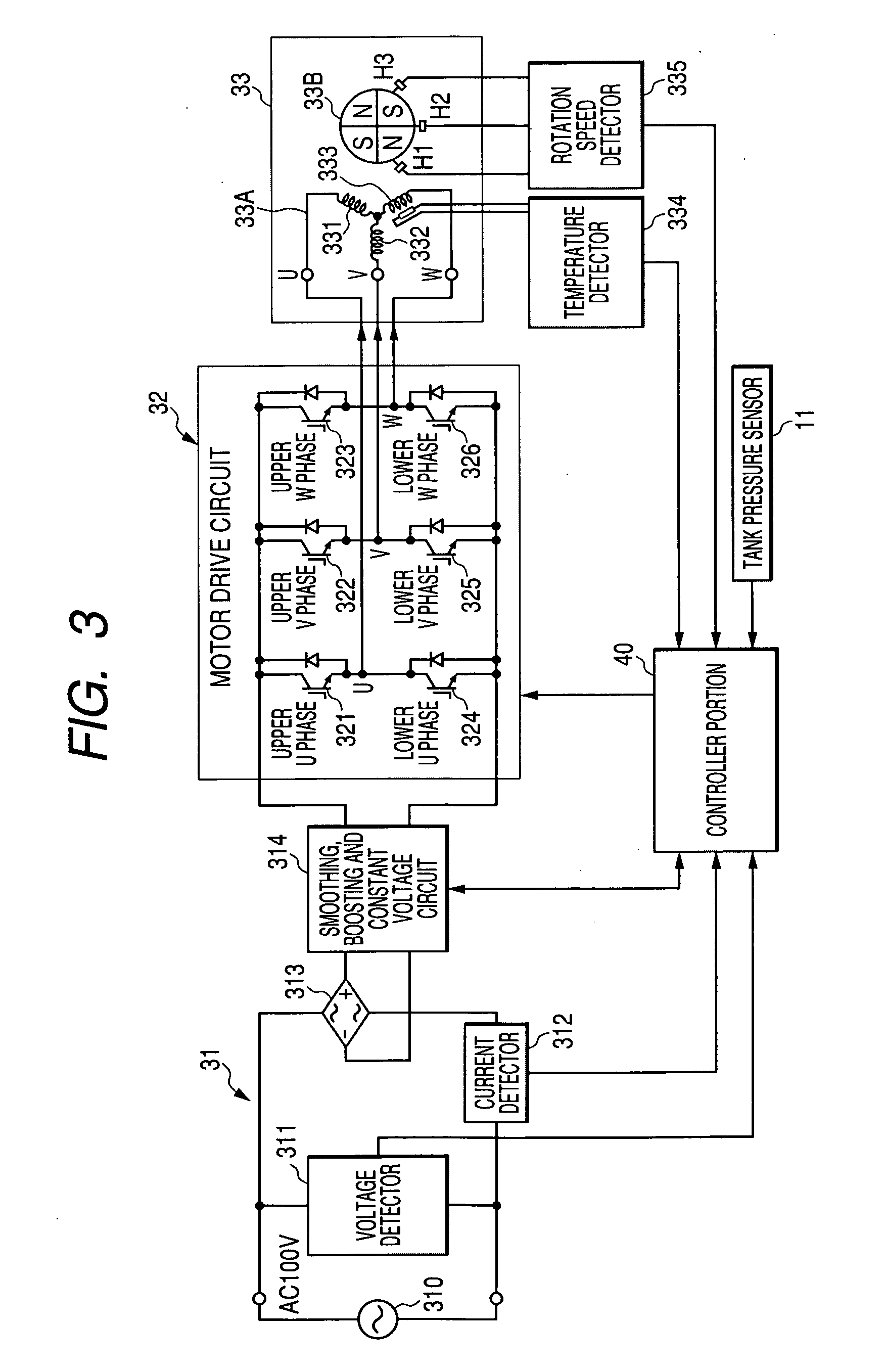

Air compressor and control method therefor

InactiveUS20040265134A1Reduce noiseLow powerFlexible member pumpsPump controlLow speedAir compressor

For a motor that drives a compressed air generator, three operating modes which includes a powerful mode for rotating a motor in a high speed range, a silent mode for rotating the motor in a low speed range, and an automatic mode for automatically changing the rotation speed of the motor from the low speed to the high speed in accordance with a setup condition are prepared. A user can designate a desired operating mode by using an operating mode selection switch.

Owner:HITACHI KOKI CO LTD

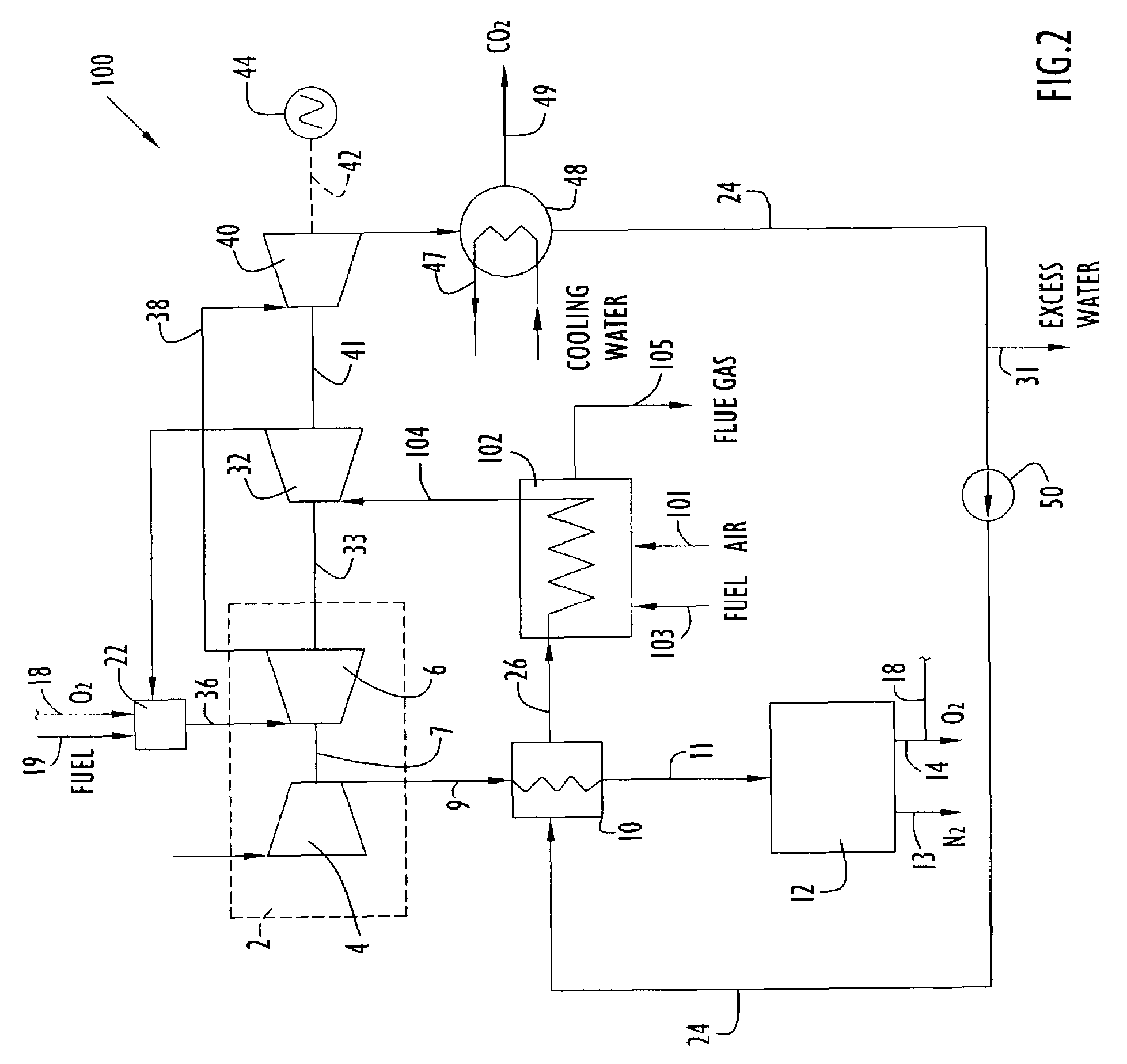

Power plant and method of operation

A power plant and method of operation that comprises at least one main air compressor and at least one gas turbine assembly. The assembly comprises a turbine combustor for mixing compressed ambient gas with a recirculated low oxygen content gas flow and a fuel stream to form a combustible mixture and for burning the combustible mixture and forming the recirculated low oxygen content flow. The assembly comprises a recirculation loop for recirculating the recirculated low oxygen content gas flow from the turbine to the turbine compressor. The assembly comprises an integrated inlet bleed heat conduit that fluidly connects the at least one gas turbine assembly to an input of the at least one main air compressor and delivers at least a portion of the recirculating low oxygen content gas flow from the at least one gas turbine assembly to the input of the at least one main air compressor.

Owner:GENERAL ELECTRIC CO

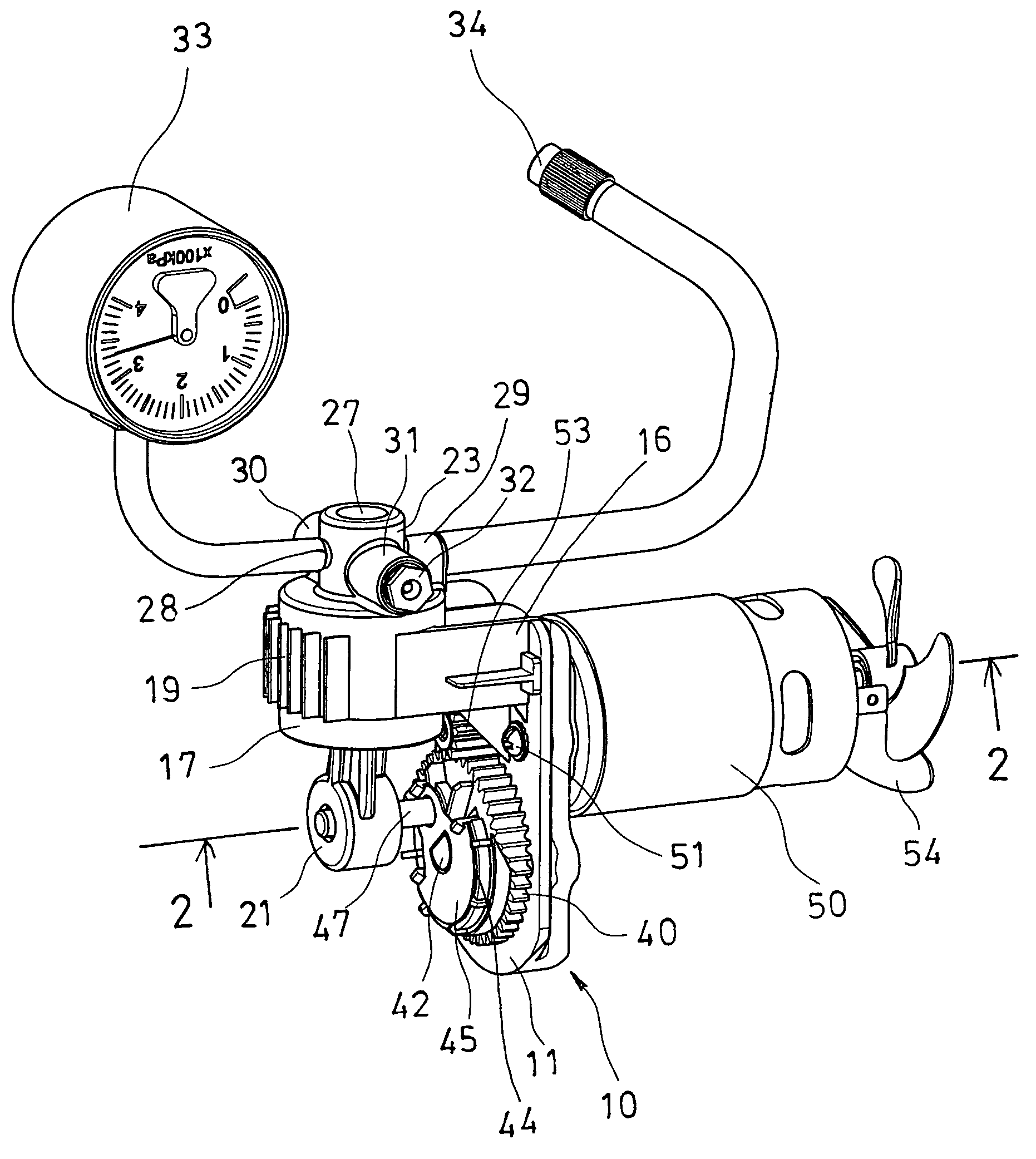

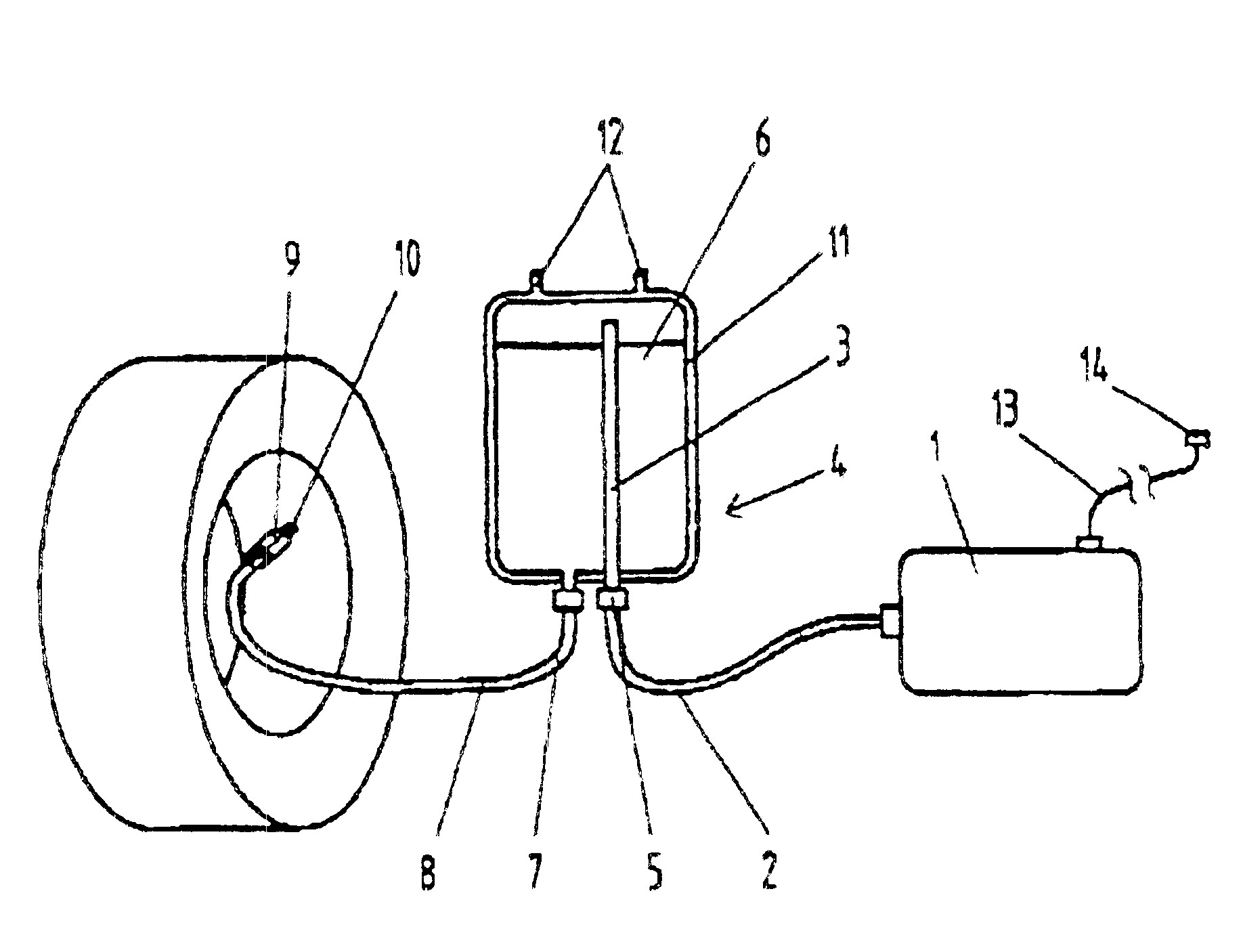

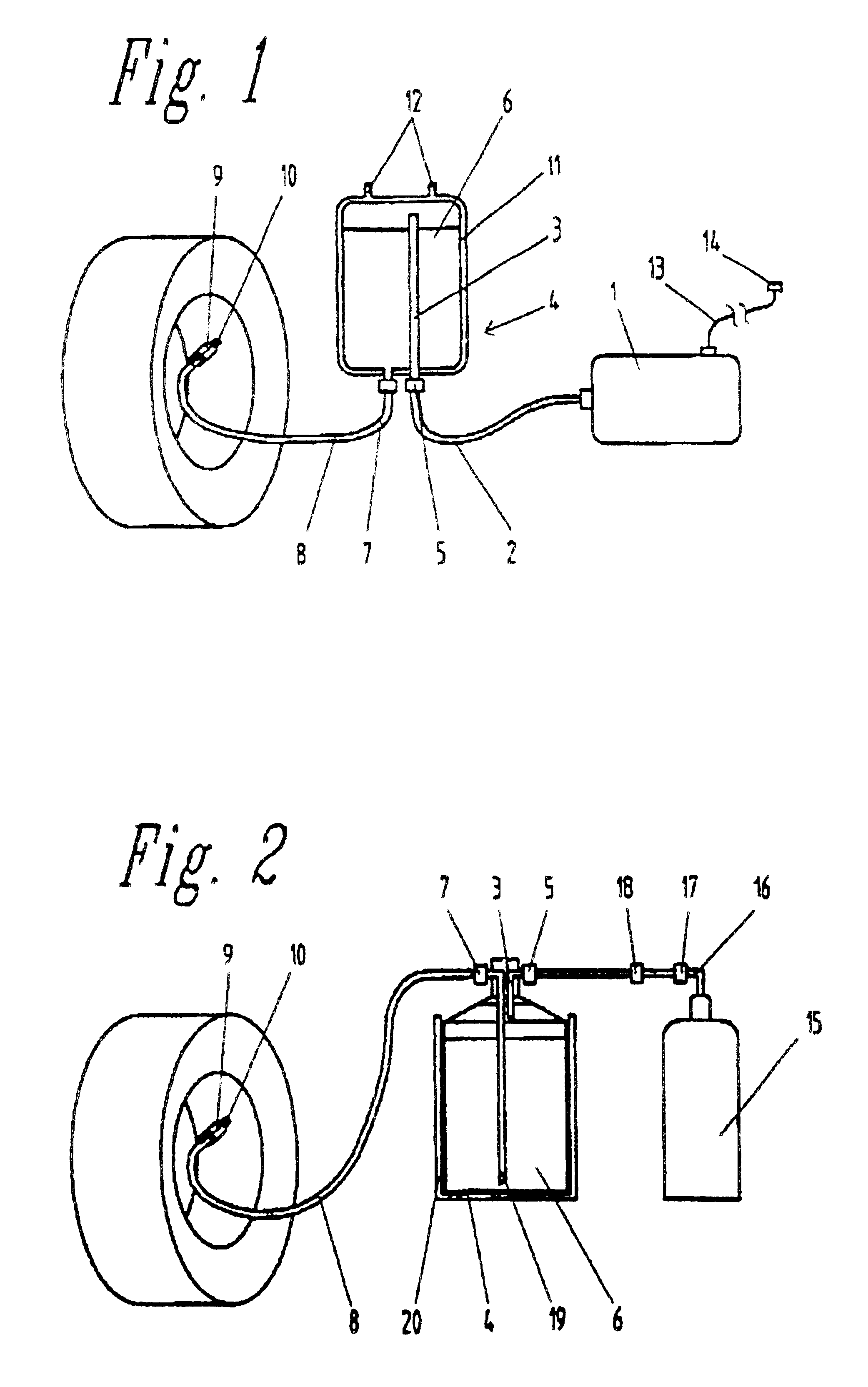

Preparation for sealing punctured tires and apparatus for the sealing and pumping up of tires

InactiveUS6889723B2Avoid easy removalImprove sealingLiquid surface applicatorsTyresSulfur hexafluorideEngineering

A sealing preparation for tire problems is proposed which seals in wet conditions, at low and high temperatures and with defects at the transition between the tread and the side wall of the tire. The sealing preparation contains natural rubber latex or a combination of rubber latex and compatible adhesive resin. Furthermore, various devices are proposed for introducing the sealing preparation into the tire and for the pumping up. An air compressor, or liquefied dinitrogenoxide, or sulphur hexafluoride are preferably used with these devices as a pressure source.

Owner:SUMITOMO RUBBER IND LTD

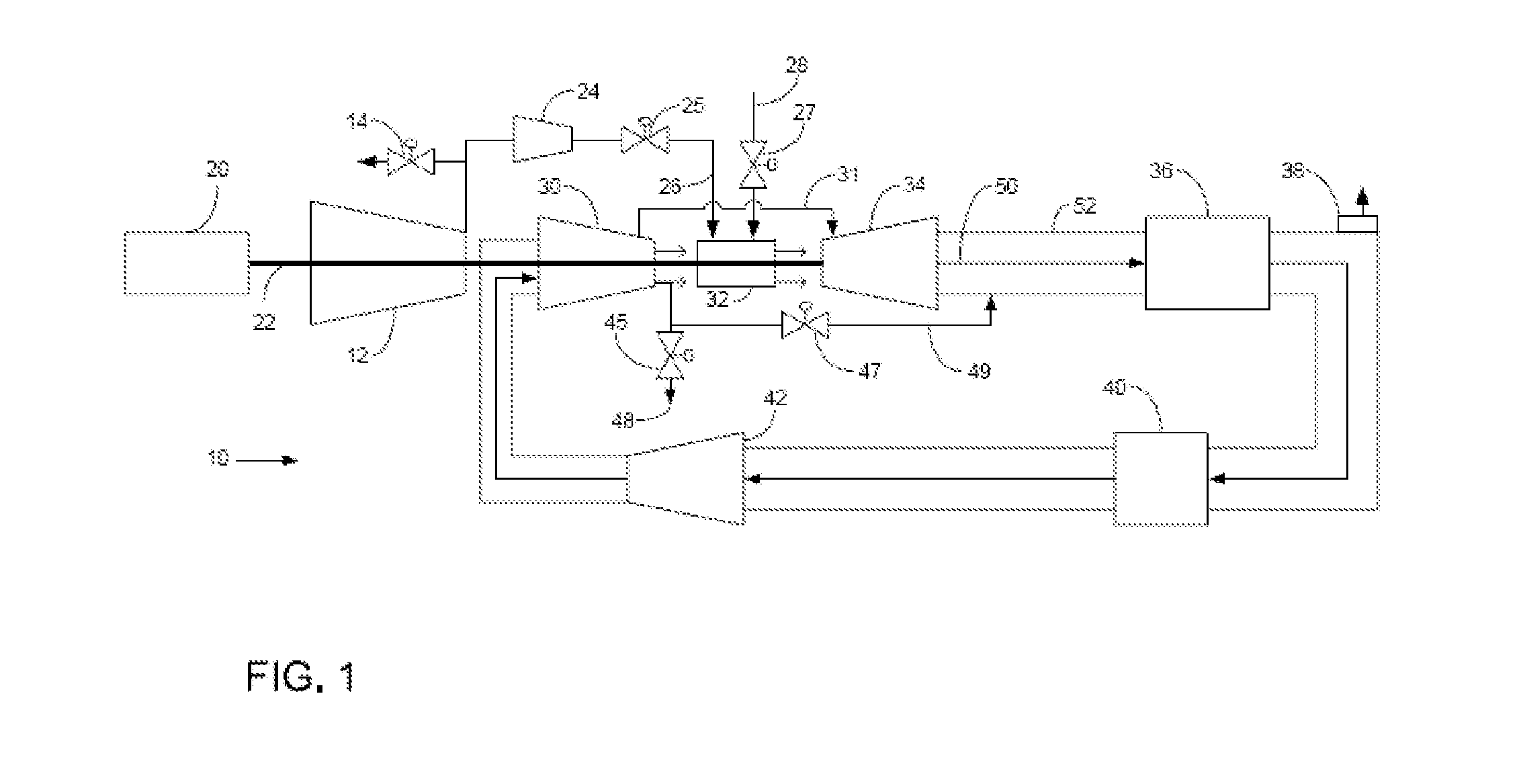

Power plant and control method

Ambient air is compressed into a compressed ambient gas flow with a main air compressor. The compressed ambient gas flow having a compressed ambient gas flow rate is delivered to a turbine combustor and mixed with a fuel stream having a fuel stream flow rate and a portion of a recirculated low oxygen content gas flow to form a combustible mixture. The combustible mixture is burned and forms the recirculated low oxygen content gas flow that drives a turbine. A portion of the recirculated low oxygen content gas flow is recirculated from the turbine to the turbine compressor using a recirculation loop. The compressed ambient gas flow rate and the fuel stream flow rate are adjusted to achieve substantially stoichiometric combustion. An excess portion, if any, of the compressed ambient gas flow is vented. A portion of the recirculated low oxygen content gas flow is extracted using an extraction conduit.

Owner:GENERAL ELECTRIC CO

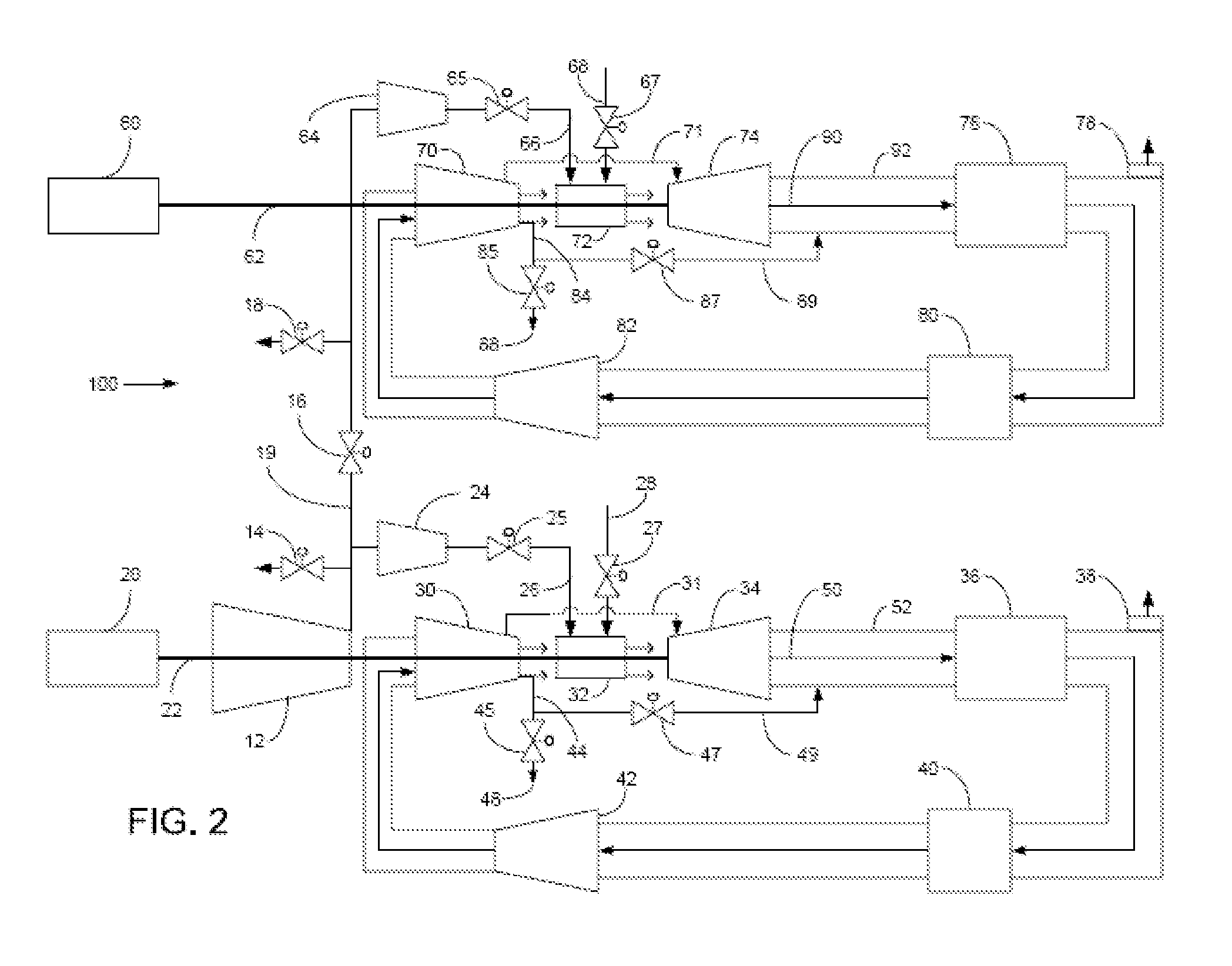

Power plant and method of operation

A power plant and method of operation is provided. The power plant comprises at least one main air compressor, an oxidizer unit configured to deliver a compressed oxygen-rich gas flow to at least one gas turbine assembly. Each assembly comprises a turbine combustor for mixing the compressed oxygen-rich gas flow with a recirculated gas flow and a fuel stream to burn a combustible mixture and form the recirculated gas flow. The assembly also comprises a recirculation loop for recirculating the recirculated gas flow from a turbine to a turbine compressor. The assembly further comprises a recirculated gas flow extraction path for extracting a portion of the recirculated gas flow from the assembly and delivering this to a gas separation system. The gas separation system separates the portion of the recirculated gas flow into a nitrogen portion and a carbon dioxide portion.

Owner:GENERAL ELECTRIC CO

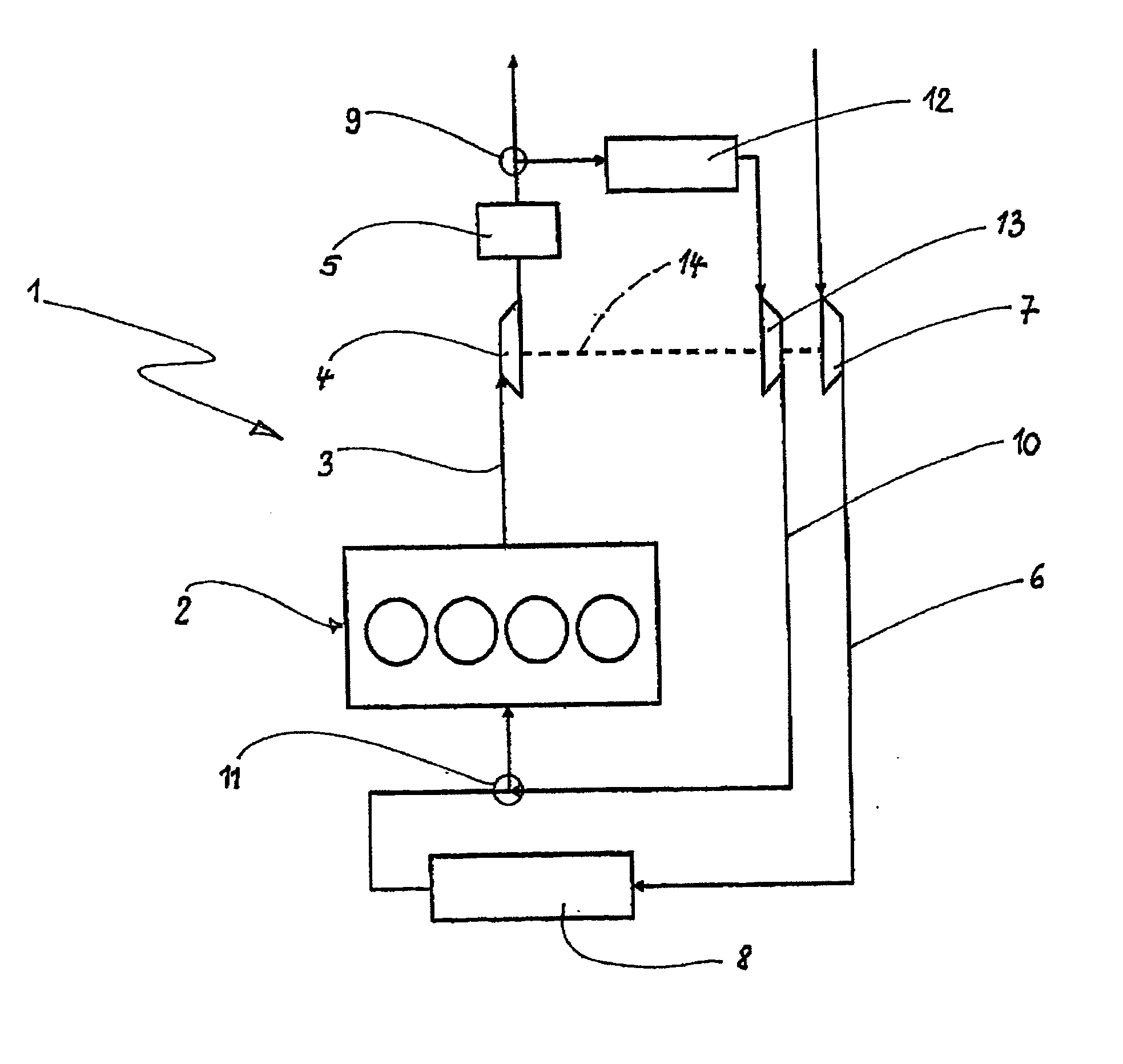

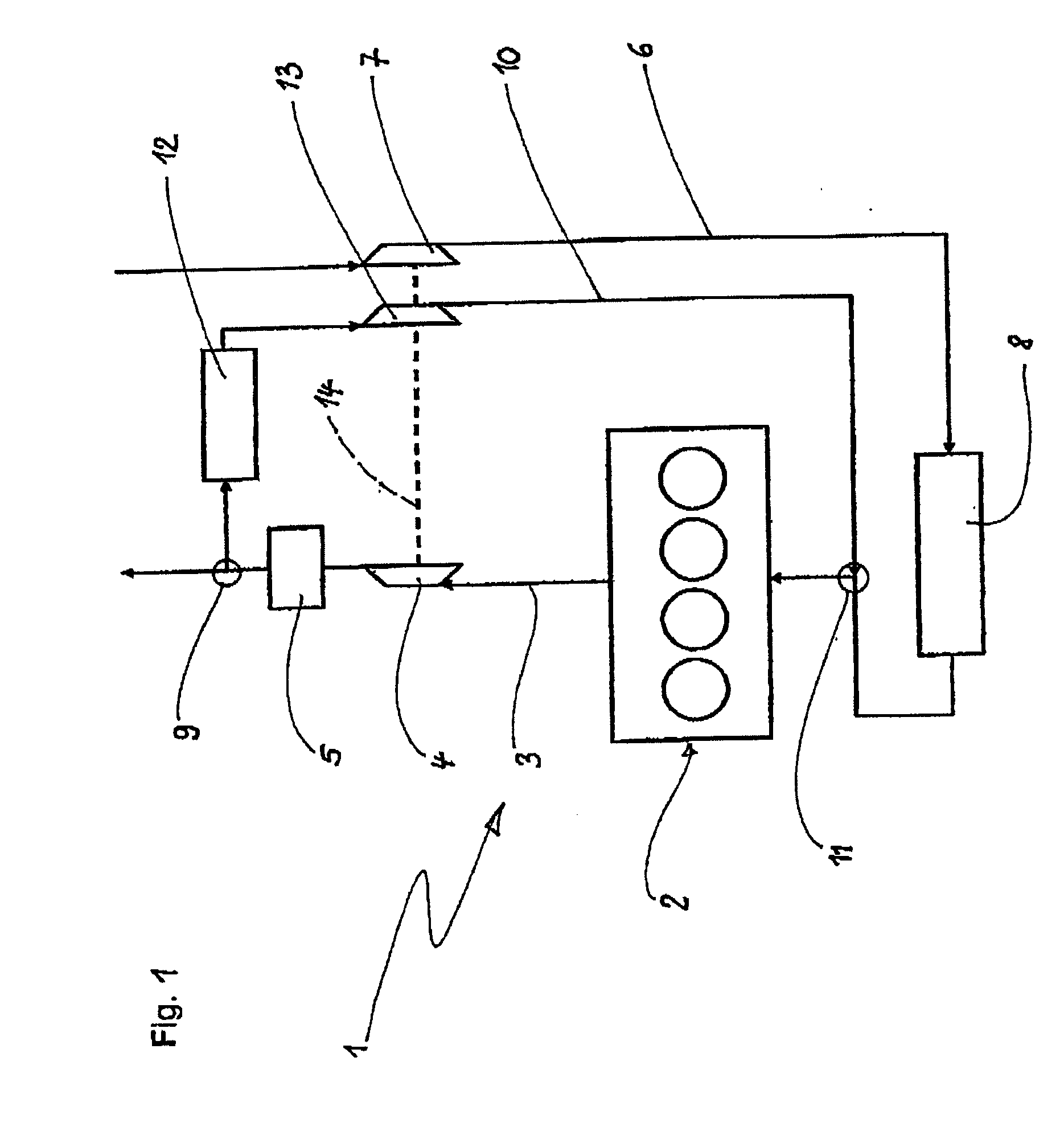

System for exhaust gas recirculation in a motor vehicle

InactiveUS20060248888A1Reduce corrosion damageInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesAir compressor

A system for recirculation of cooled exhaust gas from a vehicle internal combustion engine includes an internal combustion engine (2) having an intake system (6) and an exhaust gas system (3), an exhaust gas recirculation (EGR) line (10) that contains an exhaust gas cooler (12), an exhaust gas turbine (4) arranged in the exhaust gas system, (3) and a charge air compressor (7) and a charge air cooler (8) arranged in the intake system (6). The exhaust gas stream is extracted at the low pressure side (9) of the exhaust gas turbine (4). An exhaust gas compressor (13) is arranged in the EGR line (10), and the recirculated exhaust gas stream can be fed to the intake system downstream of the charge air cooler (8).

Owner:BEHR GMBH & CO KG

Method of operating a stoichiometric exhaust gas recirculation power plant

At least one main air compressor makes a compressed ambient gas flow. The compressed ambient gas flow is delivered to a turbine combustor at a pressure that is greater than or substantially equal to an output pressure delivered to the turbine combustor from a turbine compressor as at least a first portion of a recirculated gas flow. A fuel stream is delivered to the turbine combustor, and a combustible mixture is formed and burned, forming the recirculated gas flow. A turbine power is produced that is substantially equal to at least a power required to rotate the turbine compressor. At least a portion of the recirculated gas flow is recirculated through a recirculation loop. An excess portion of the recirculated gas flow is vented or a portion of the recirculated gas flow bypasses the turbine combustor or both.

Owner:GENERAL ELECTRIC CO

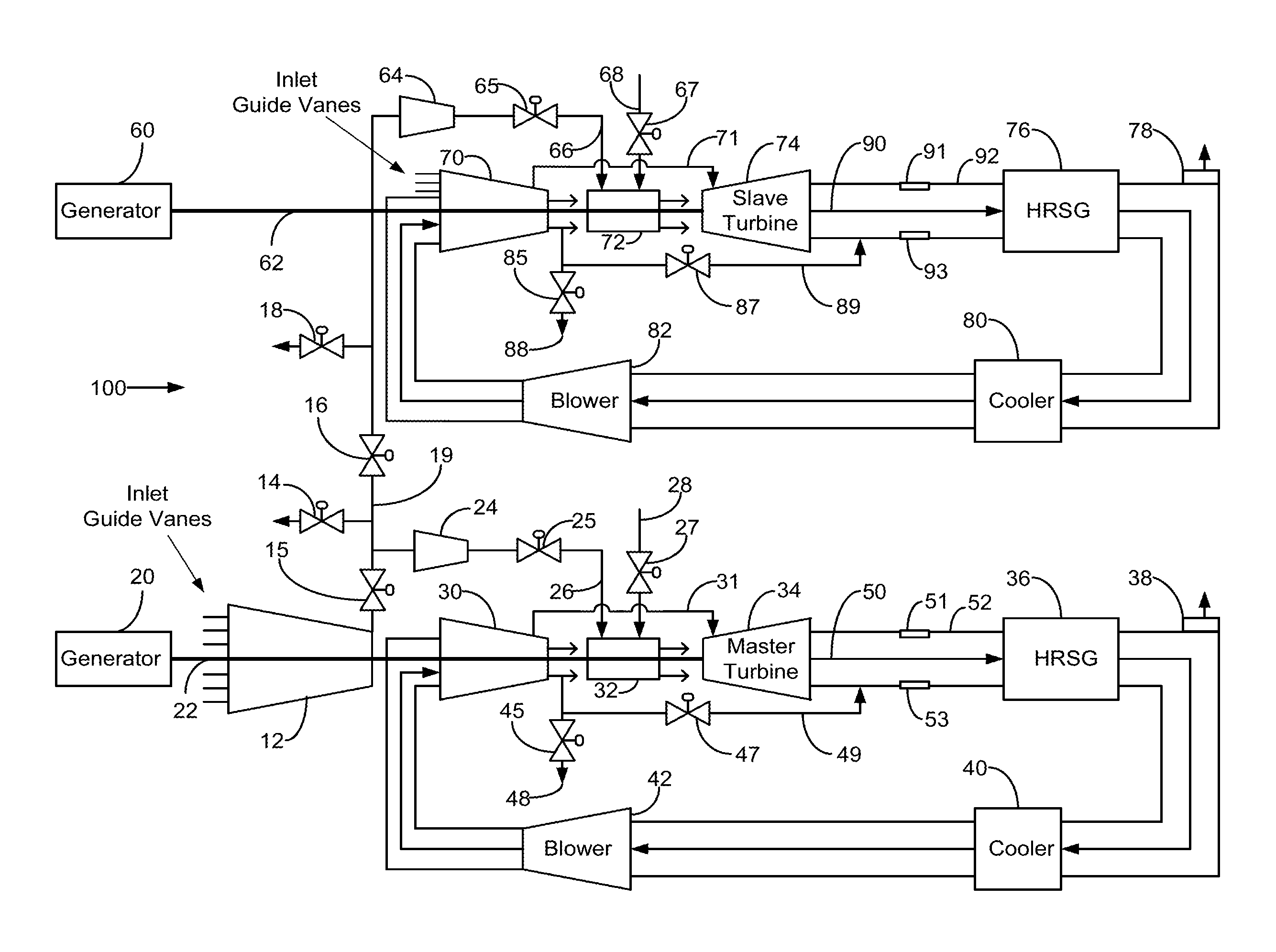

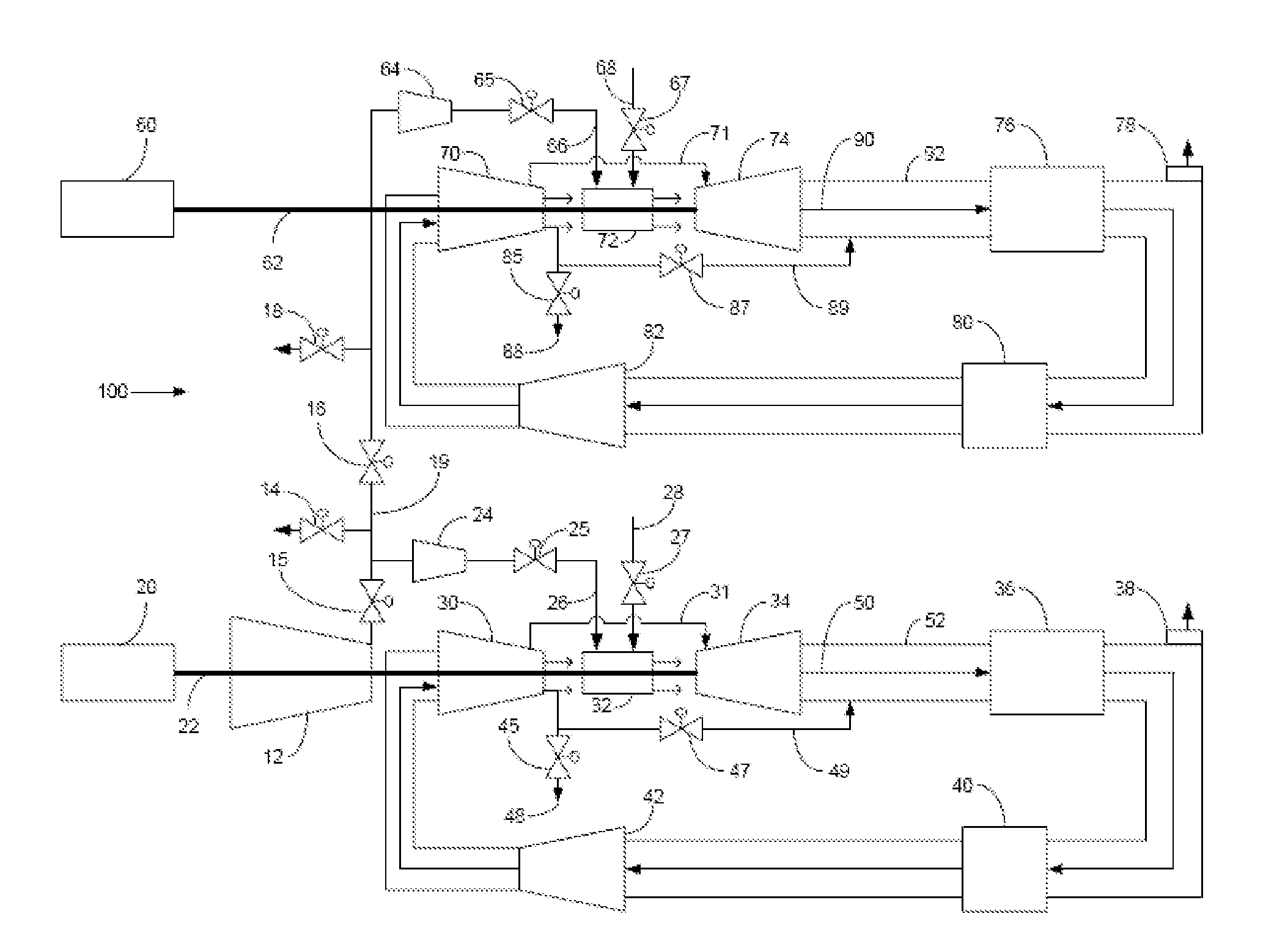

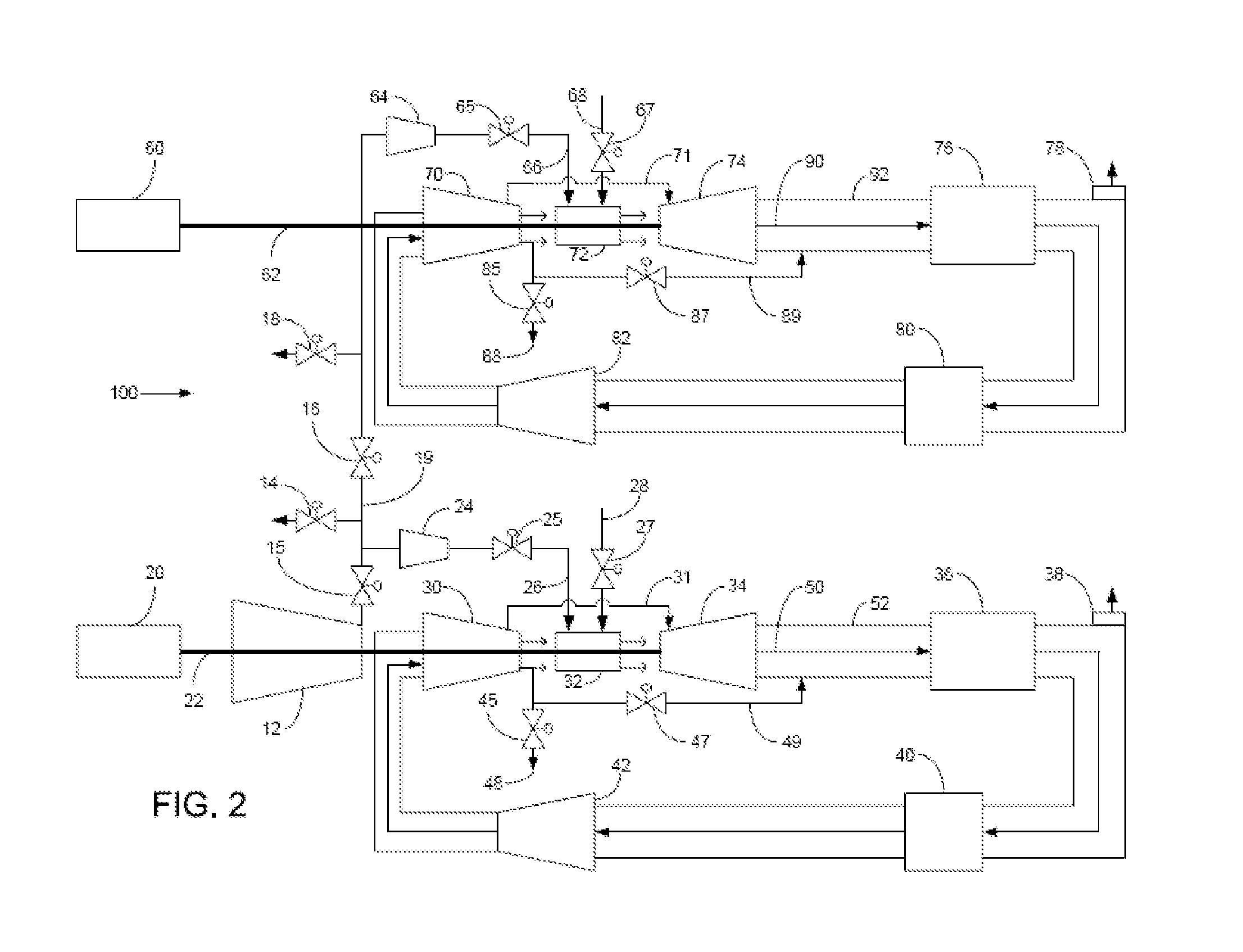

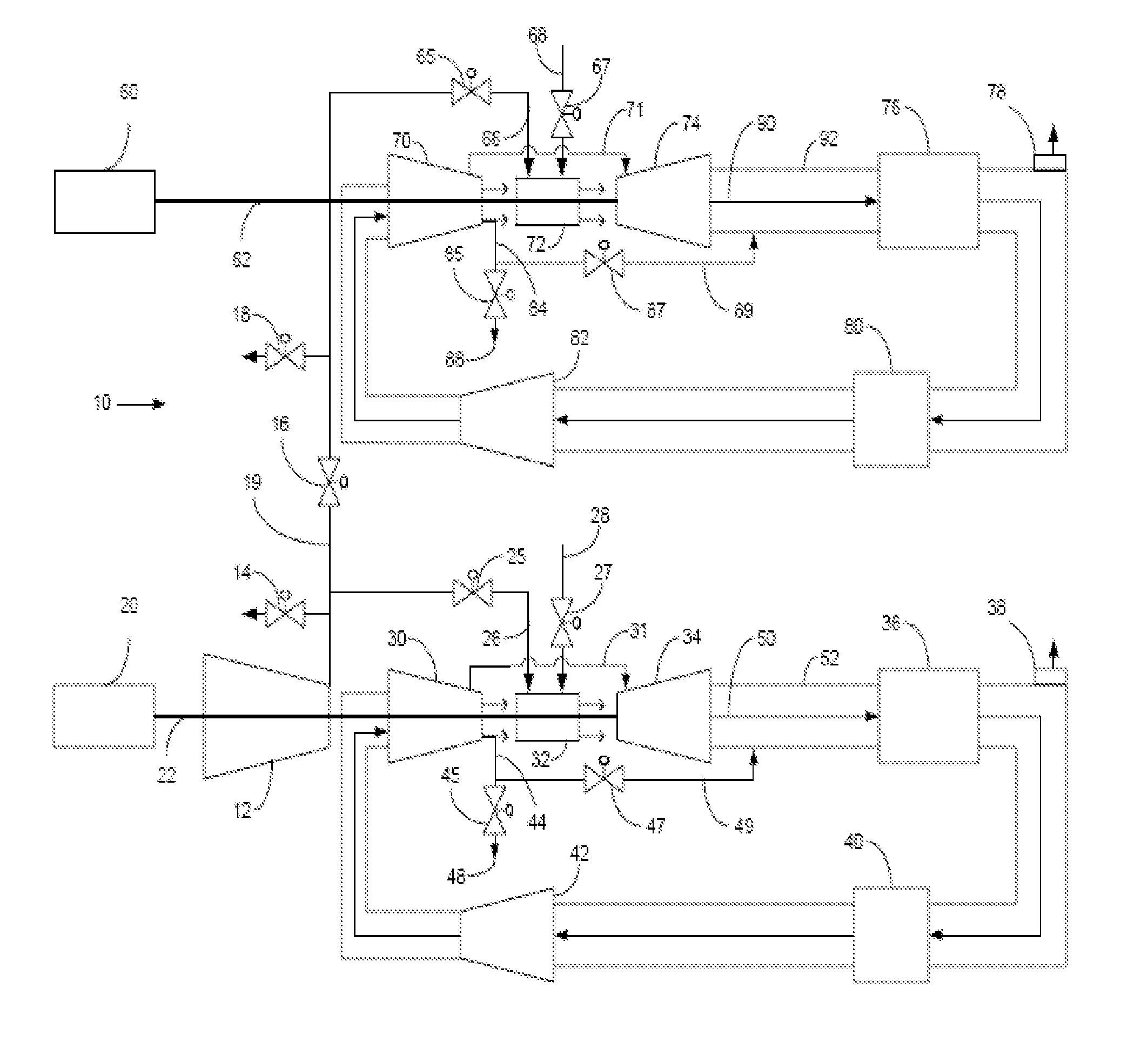

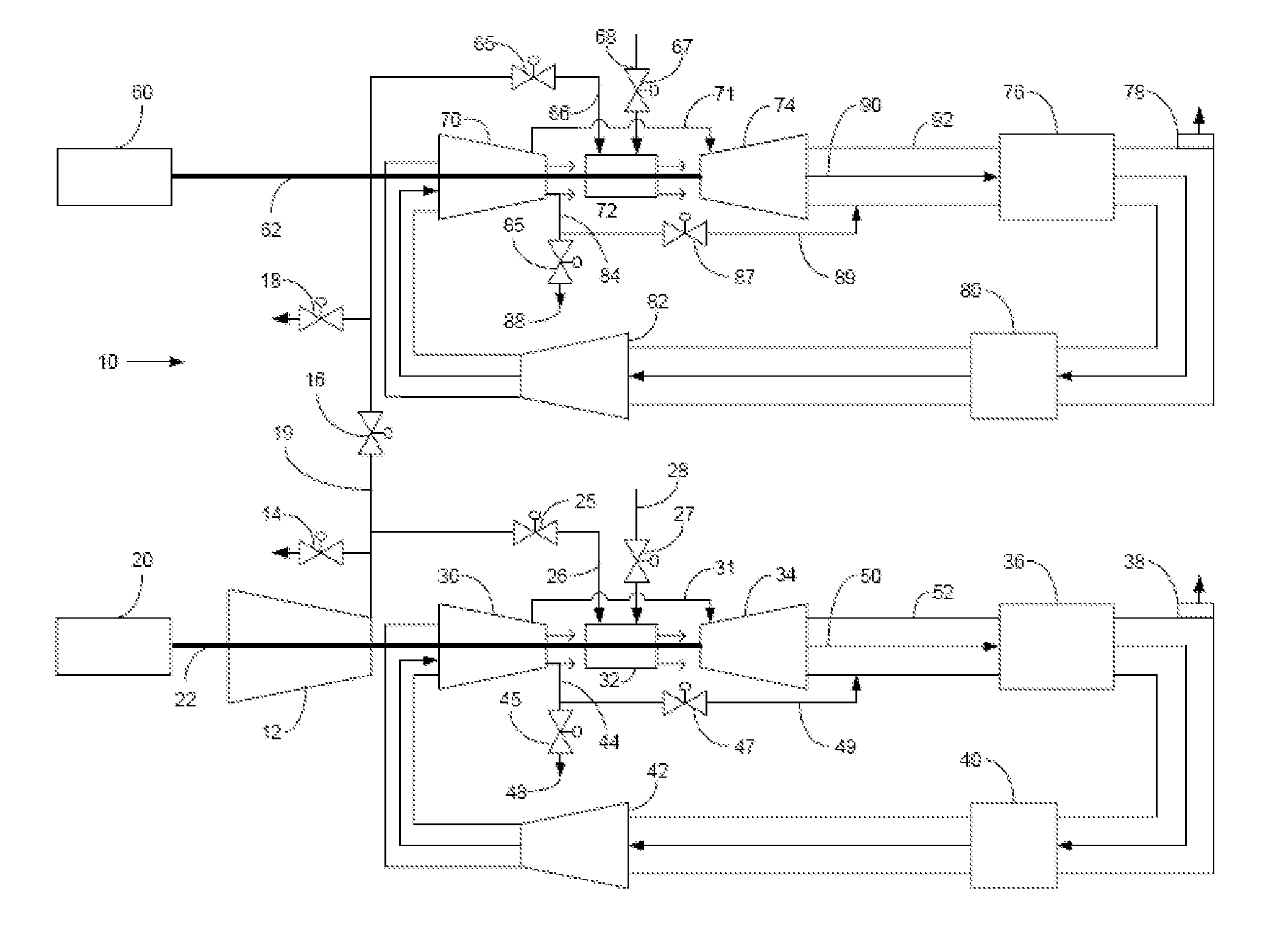

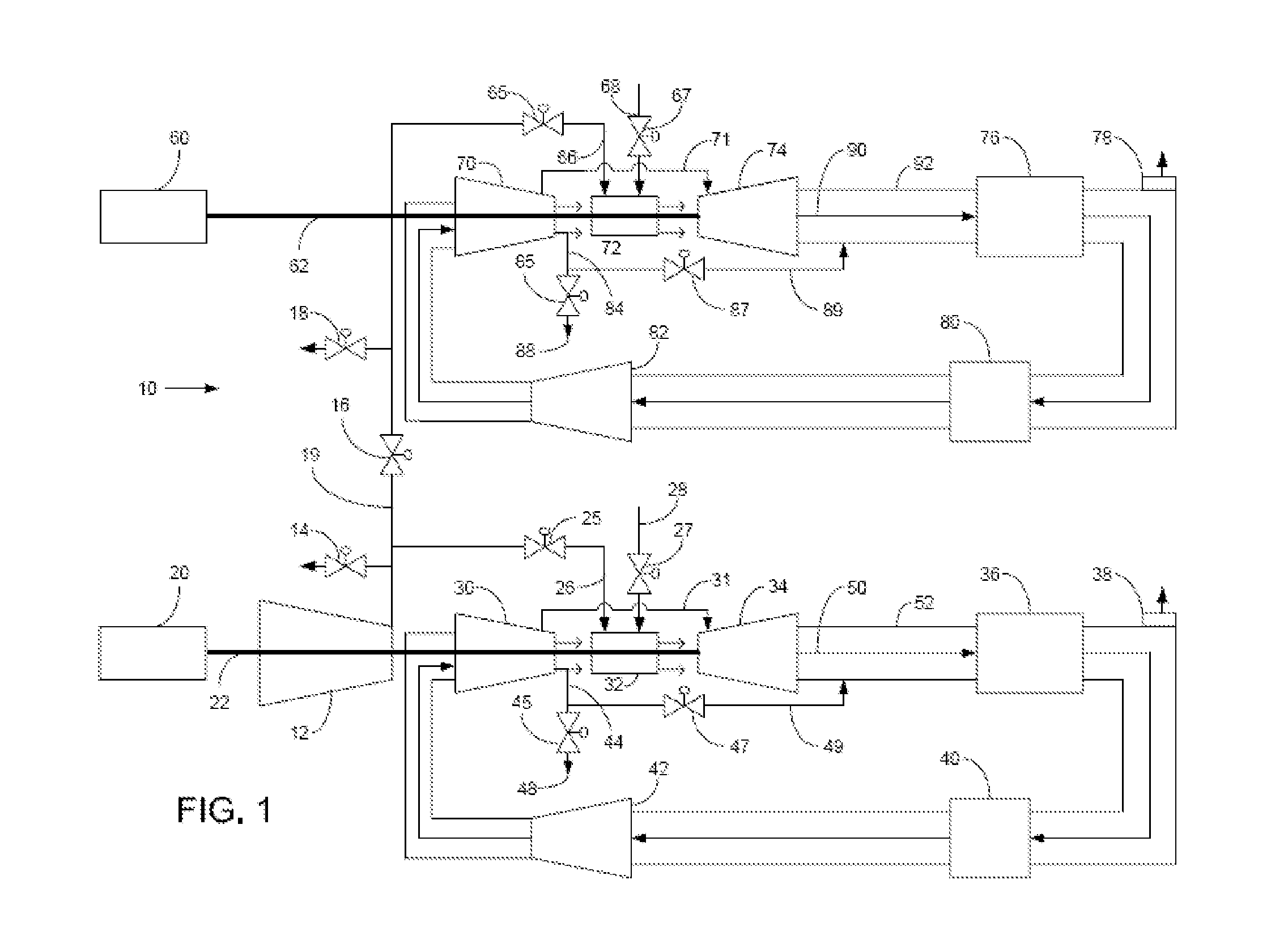

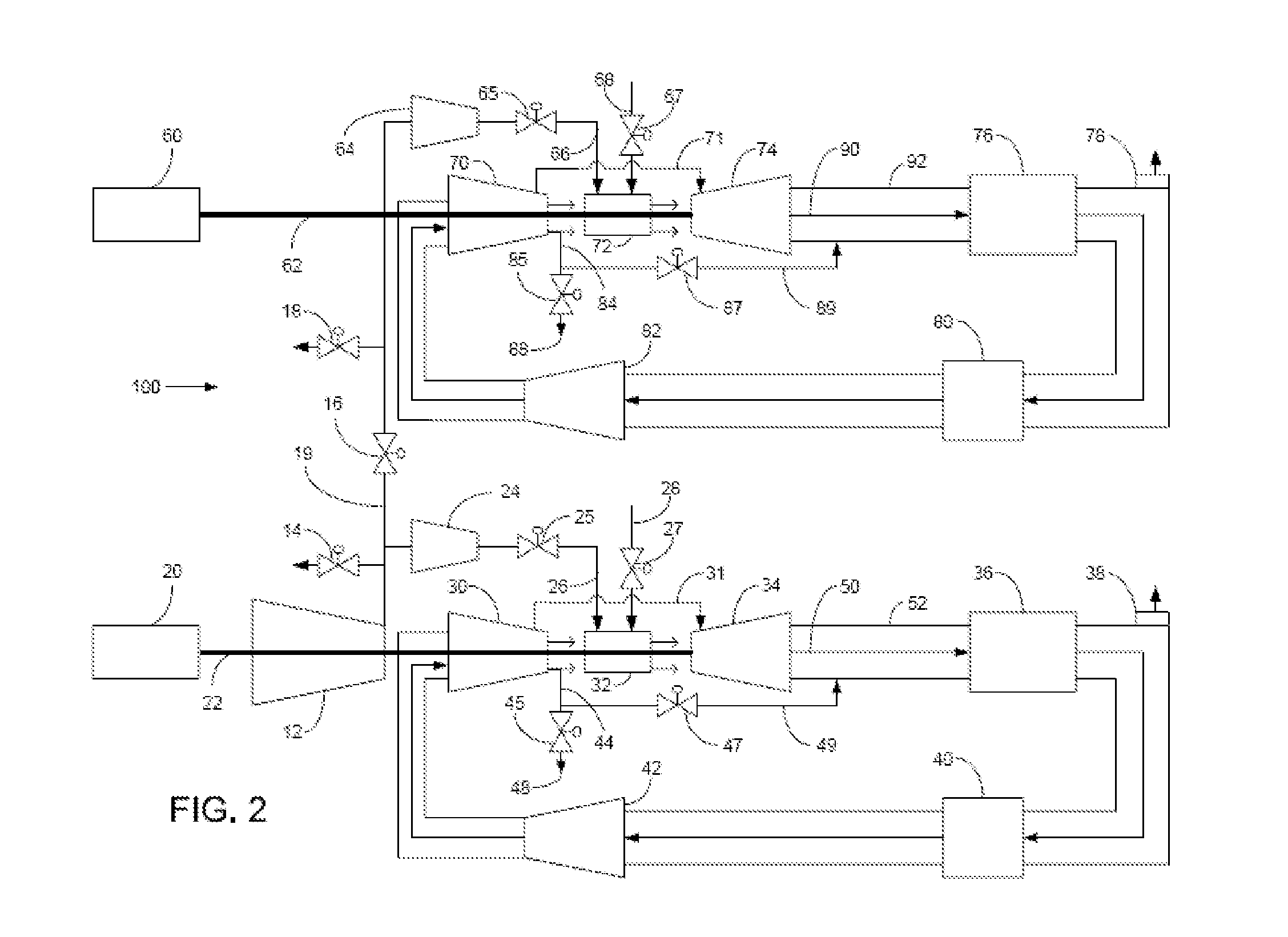

Power plant and method of operation

At least one main air compressor makes a compressed ambient gas flow. The compressed ambient gas flow is delivered to both master and slave turbine combustors at a pressure that is greater than or substantially equal to an output pressure delivered to each turbine combustor from each turbine compressor as at least a first portion of a recirculated gas flow. A fuel stream is delivered to each turbine combustor, and combustible mixtures are formed and burned, forming the recirculated gas flows. A master and slave turbine power are produced, and each is substantially equal to at least a power required to rotate each turbine compressor. At least a portion of the recirculated gas flow is recirculated through recirculation loops. At least a second portion of the recirculated gas flow bypasses the combustors or an excess portion of each recirculated gas flow is vented or both.

Owner:GENERAL ELECTRIC CO

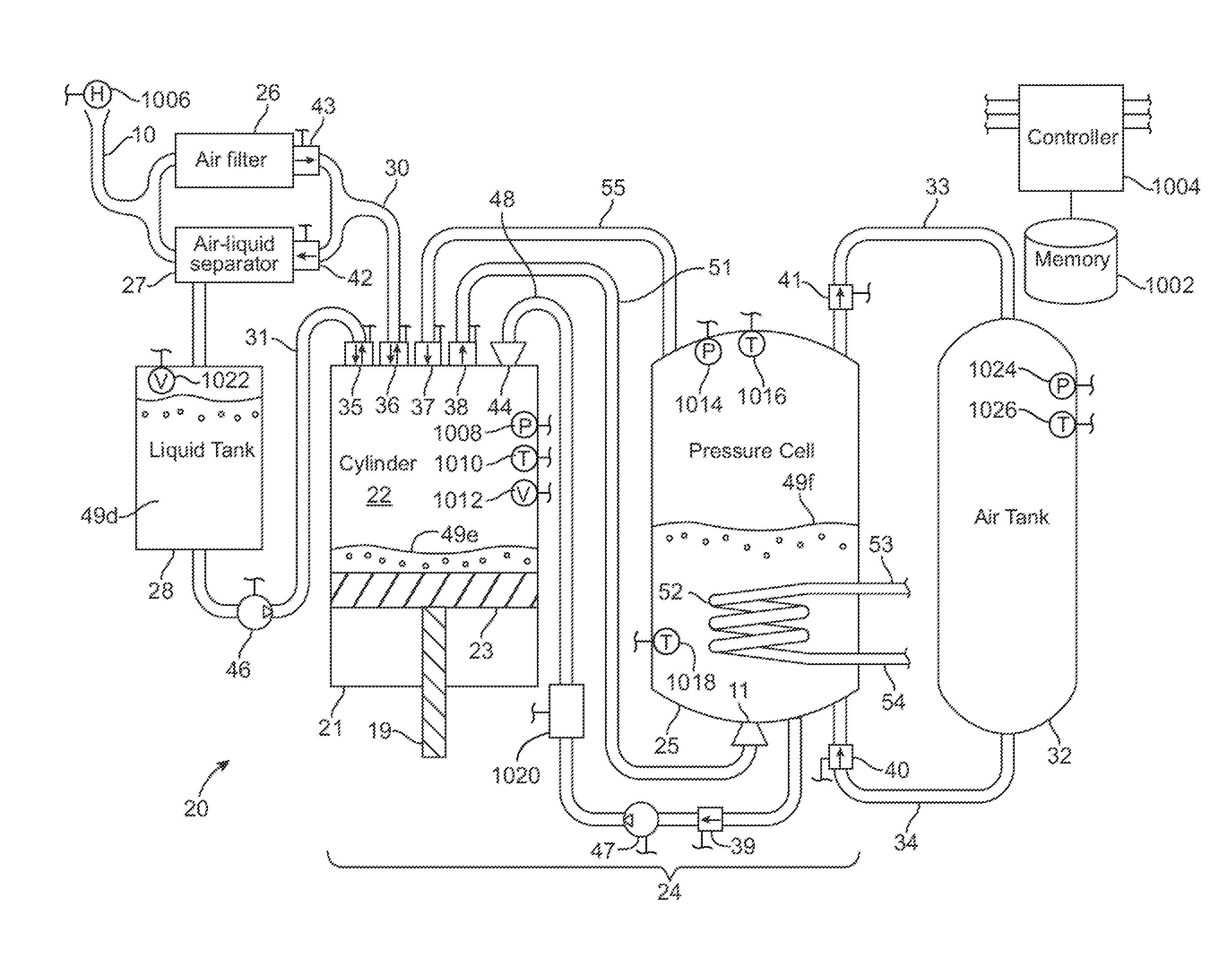

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326062A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

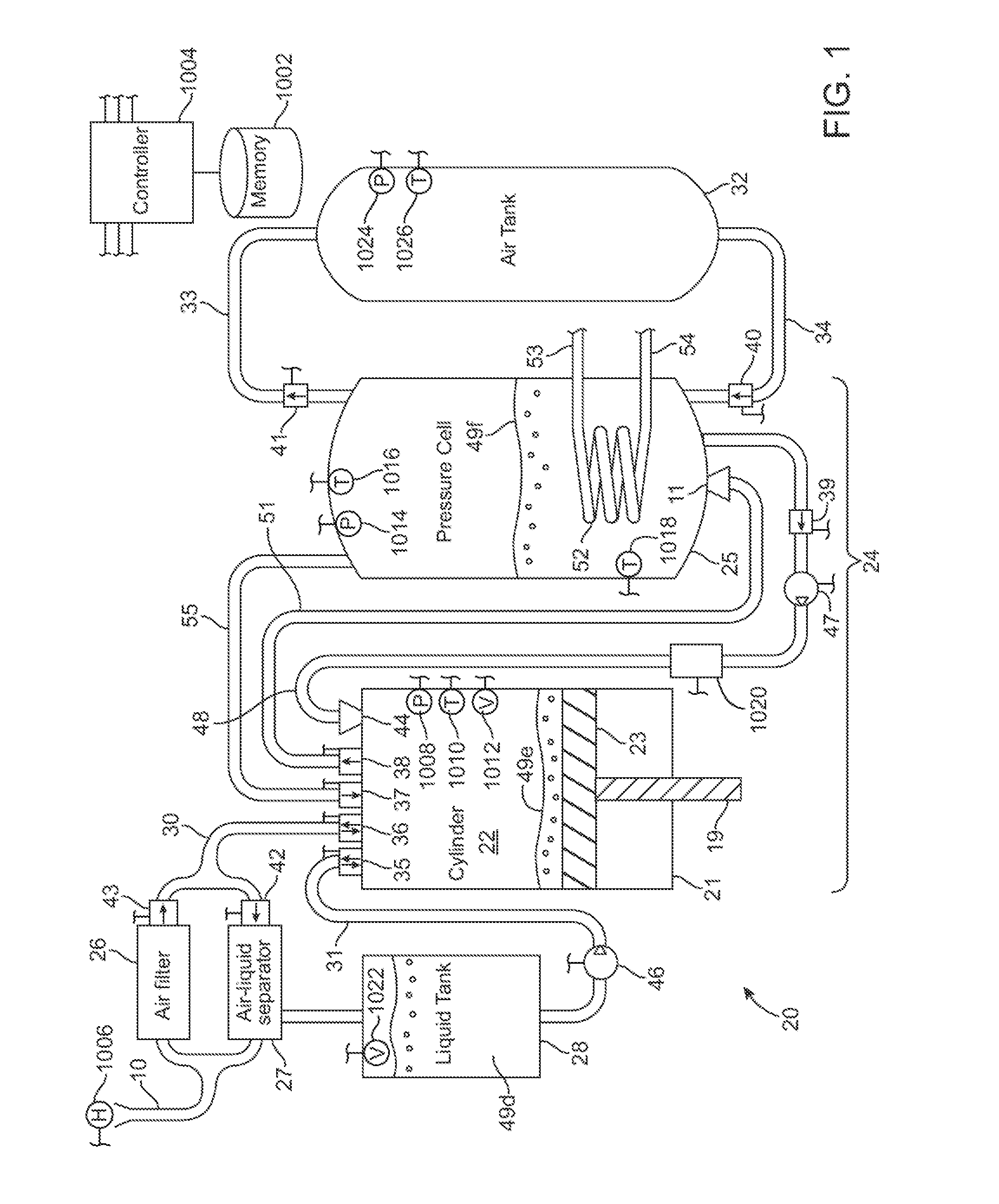

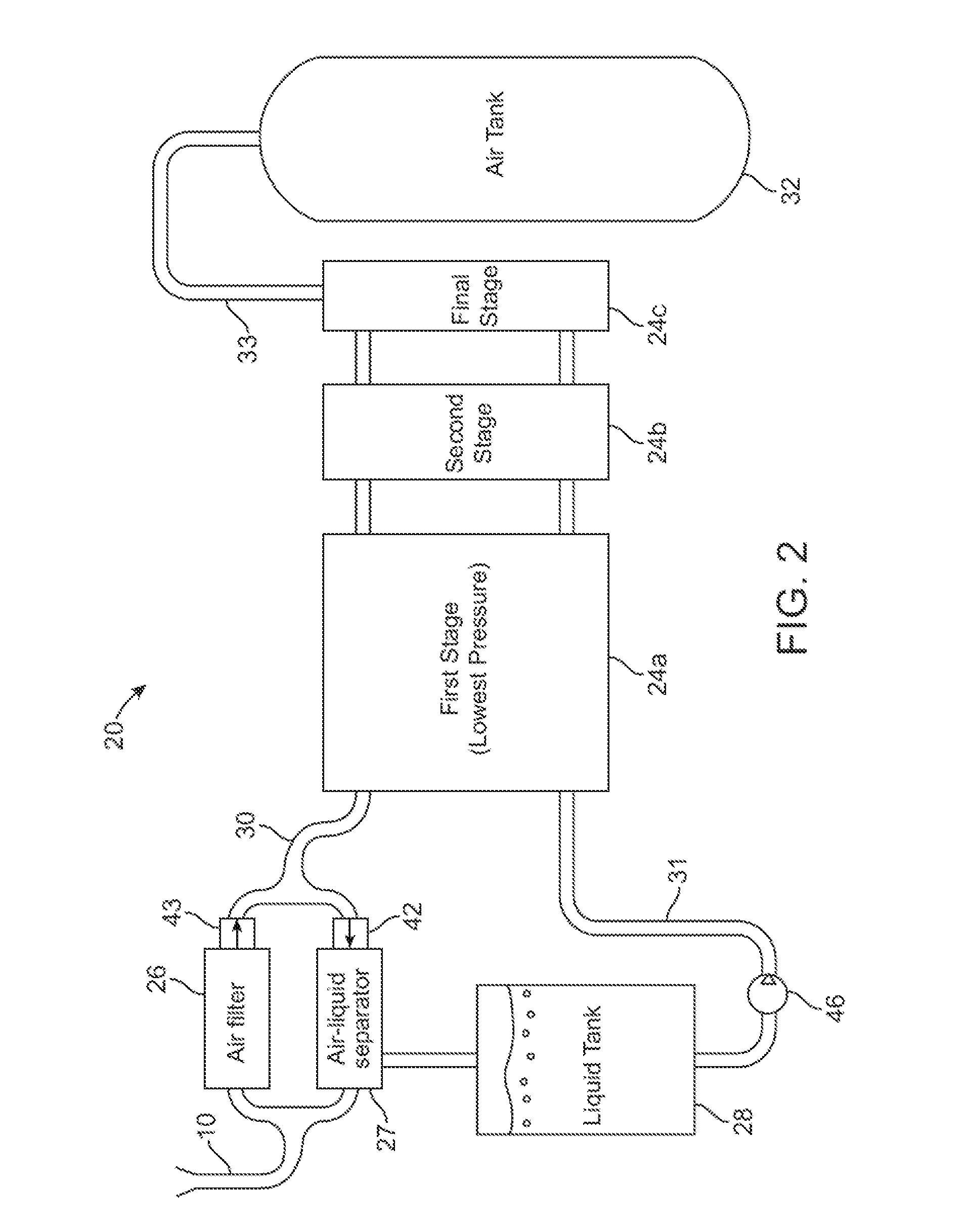

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com