Patents

Literature

1909 results about "Proportional control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

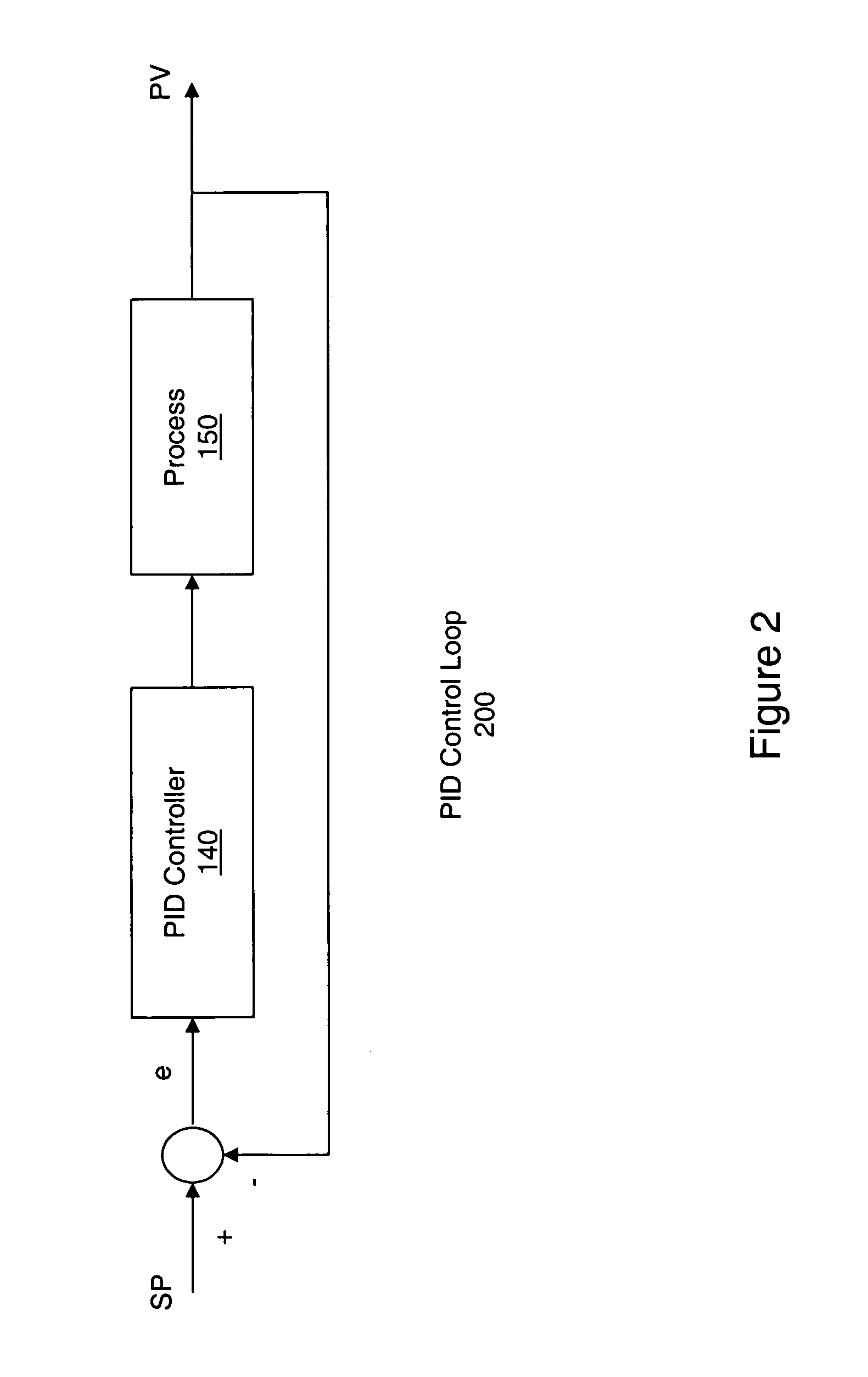

Proportional control, in engineering and process control, is a type of linear feedback control system in which a correction is applied to the controlled variable which is proportional to the difference between the desired value (set point, SP) and the measured value (process value, PV). Two classic mechanical examples are the toilet bowl float proportioning valve and the fly-ball governor.

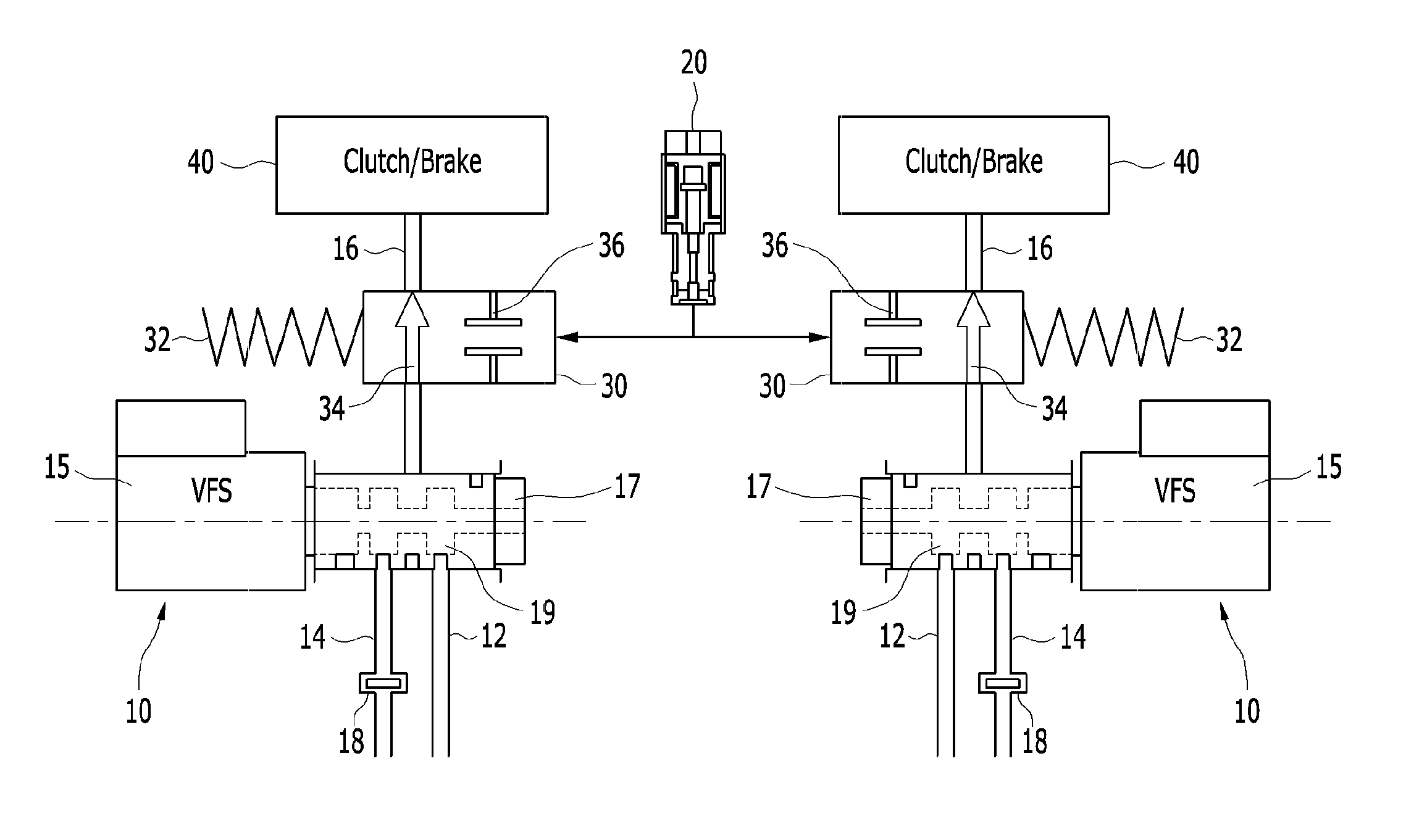

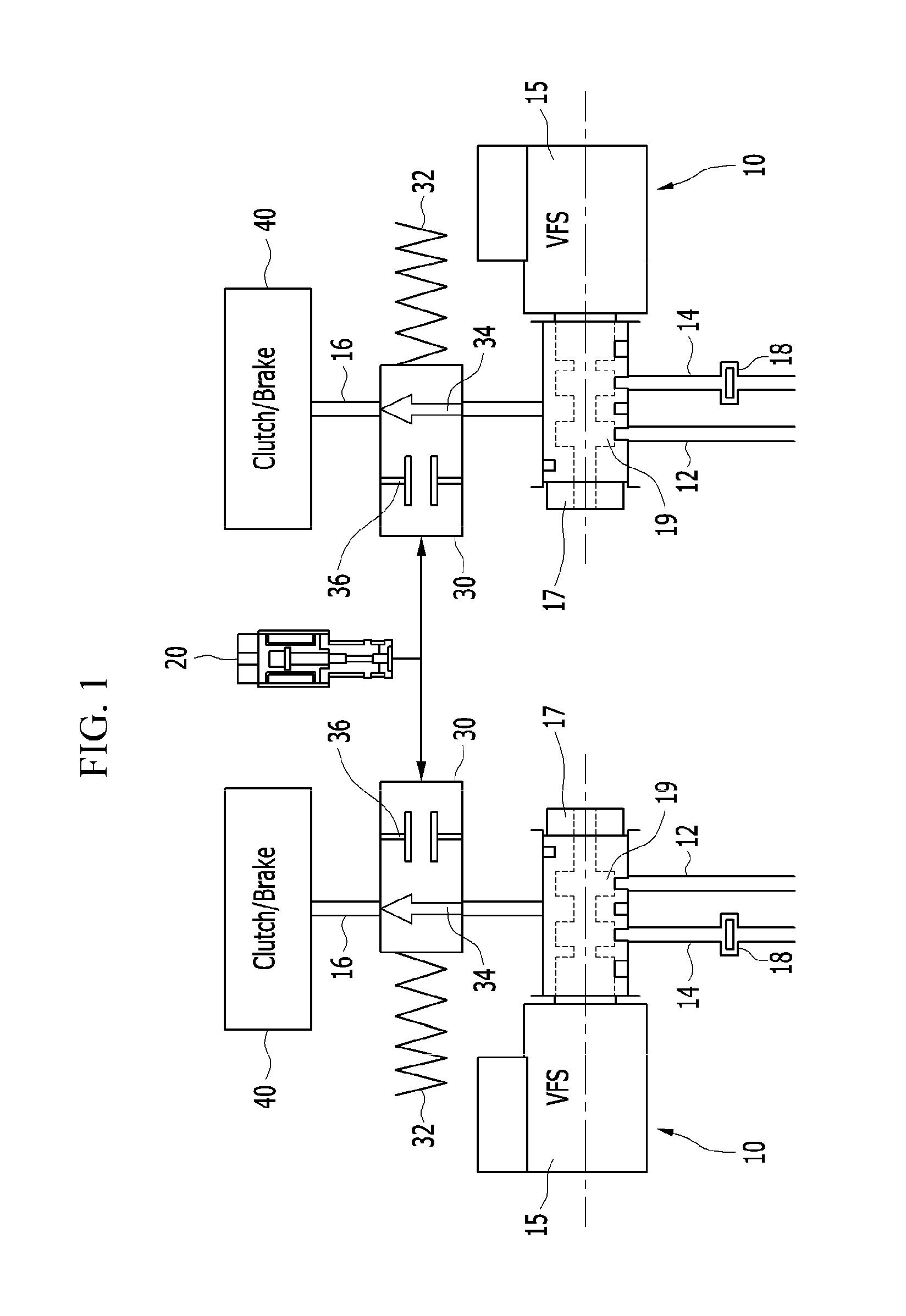

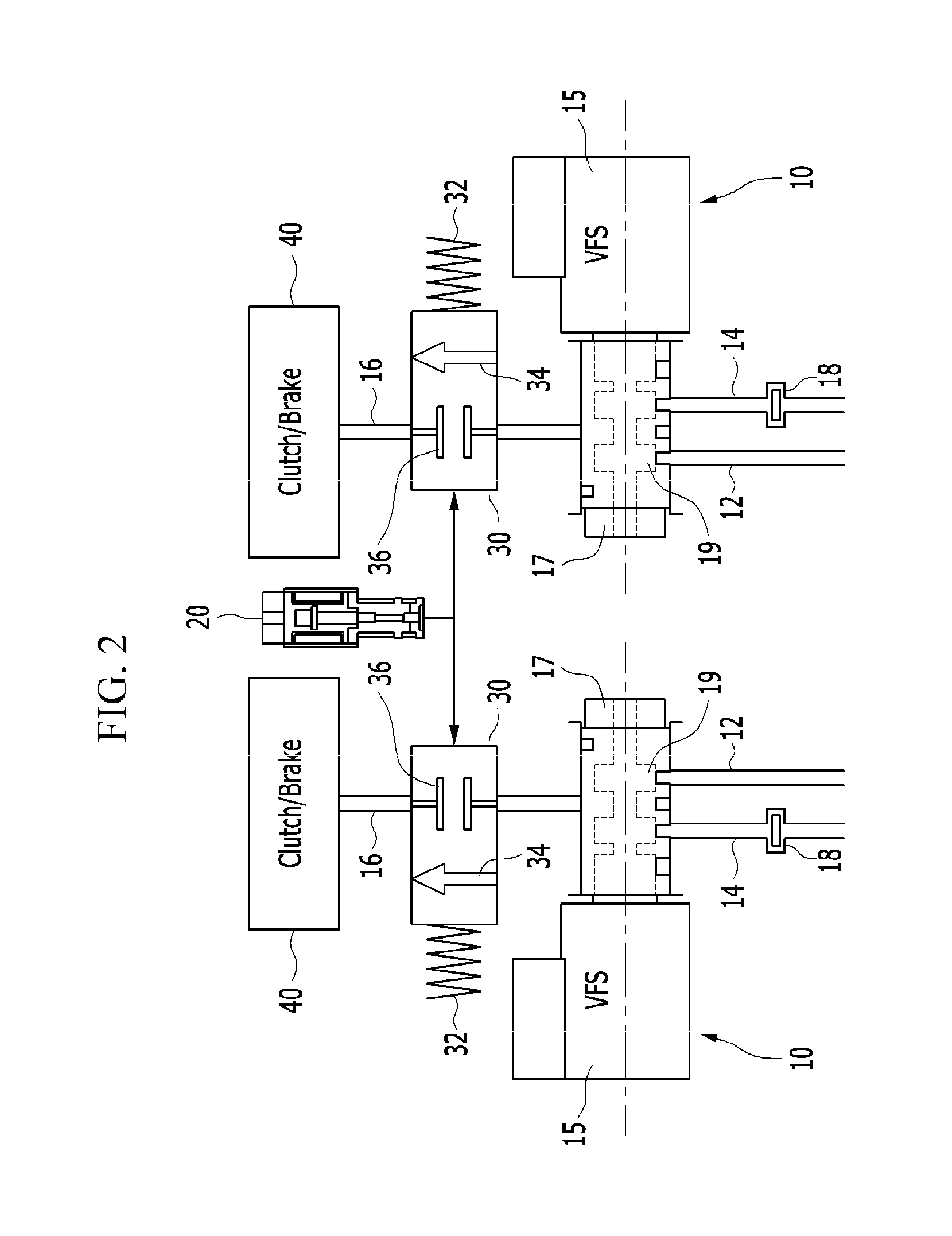

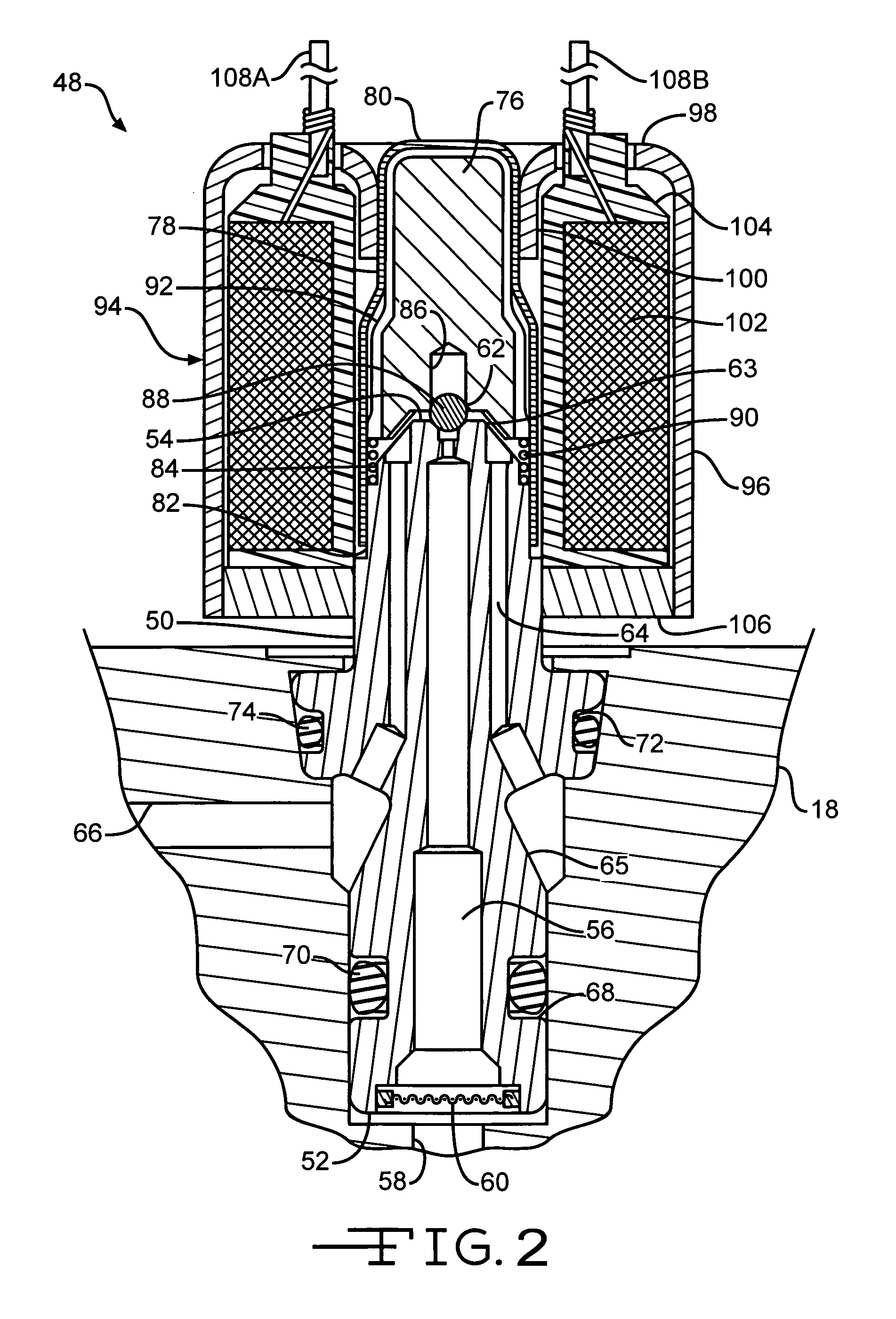

Hydraulic circuit for automatic transmission

ActiveUS9488197B2Rapidly and effectively removing foreign materialFluid-pressure actuator safetyClutchesProportional controlAutomatic transmission

A hydraulic circuit may include a proportional control solenoid valve controlling hydraulic pressure such that an operating hydraulic pressure required by the friction member is supplied to the friction member; a supply hydraulic path connecting the proportional control solenoid valve with the friction member, and adapted to supply hydraulic pressure controlled by the proportional control solenoid valve to the friction member; and a switch valve disposed in the supply hydraulic path so as to selectively open / close the supply hydraulic path.

Owner:HYUNDAI MOTOR CO LTD

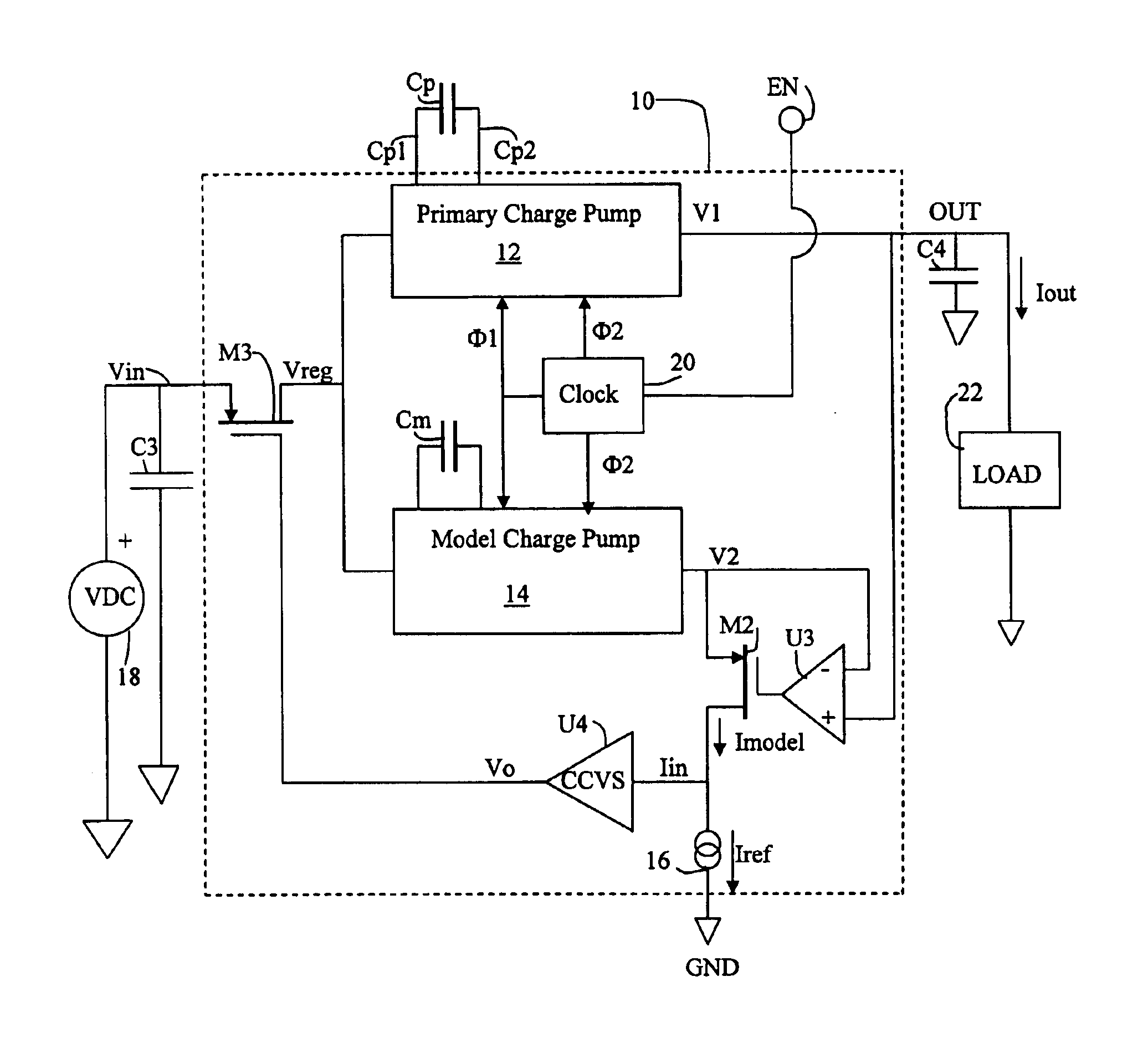

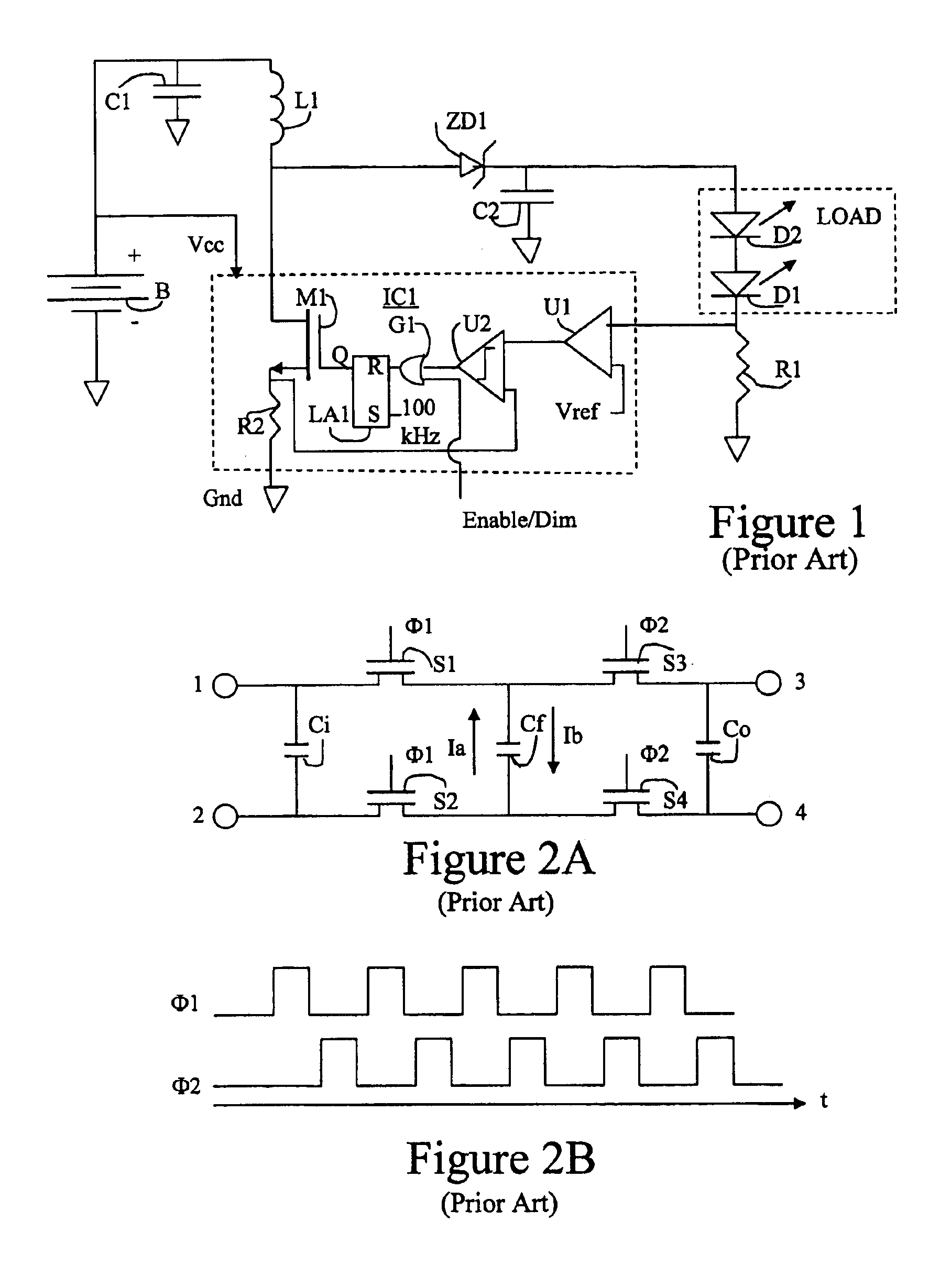

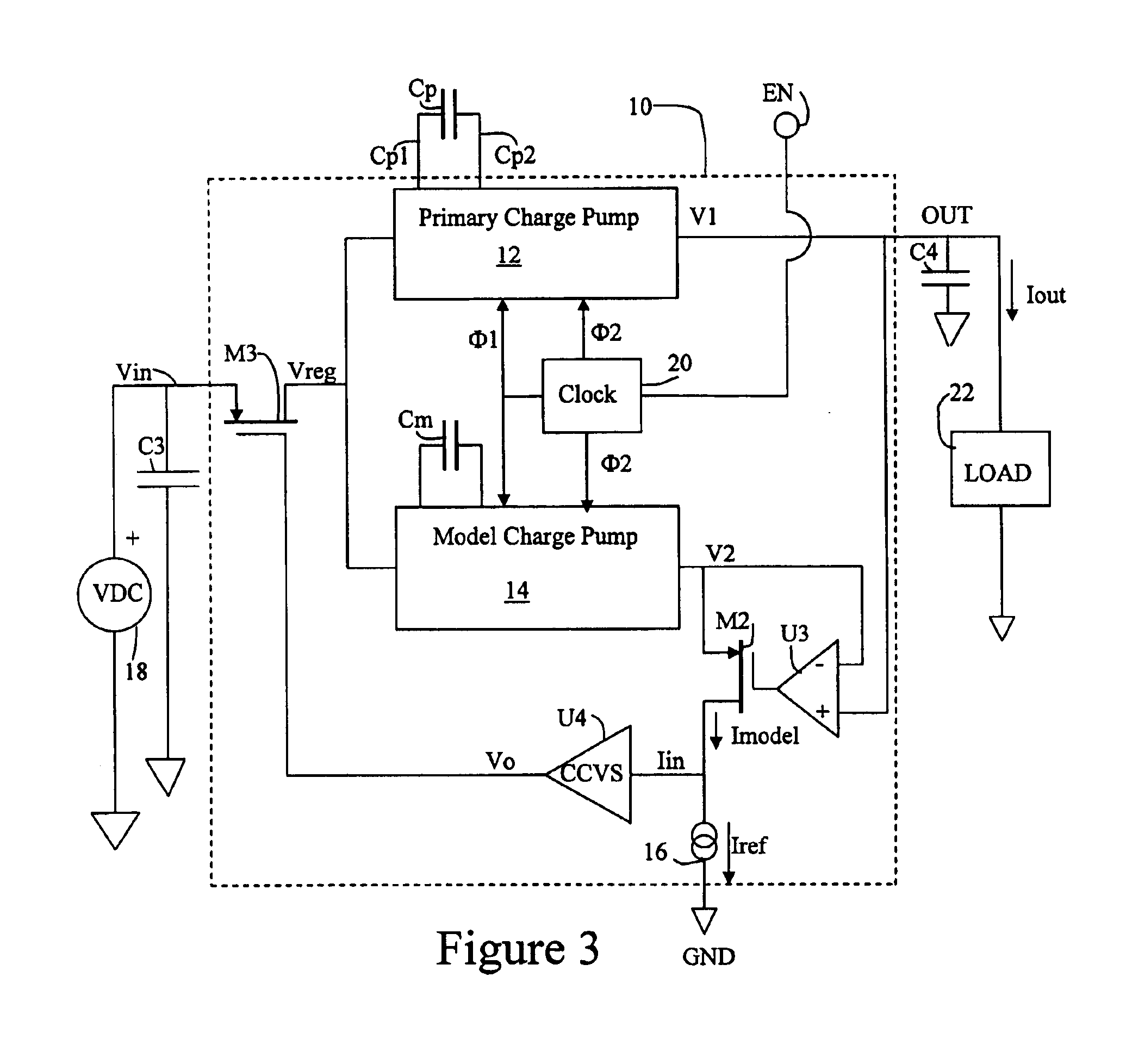

Integrated device providing current-regulated charge pump driver with capacitor-proportional current

InactiveUS6873203B1Low costApparatus without intermediate ac conversionElectric variable regulationCapacitanceProportional control

An integrated circuit regulates current flowing from a battery to a load without requiring an external current sense resistor. The IC includes a primary charge pump; a model charge pump; a current sense circuit, a first control circuit to force a voltage level at the output of the model charge pump to be equal to a voltage level at the output of the primary charge pump; and, a second control circuit to force a model current put out by the model charge pump to be equal to a reference current. Current passing through the primary charge pump is regulated at a level established by the capacitance value of an external flying capacitor irrespective of input voltage variation of the battery power source.

Owner:LAPIS SEMICON CO LTD

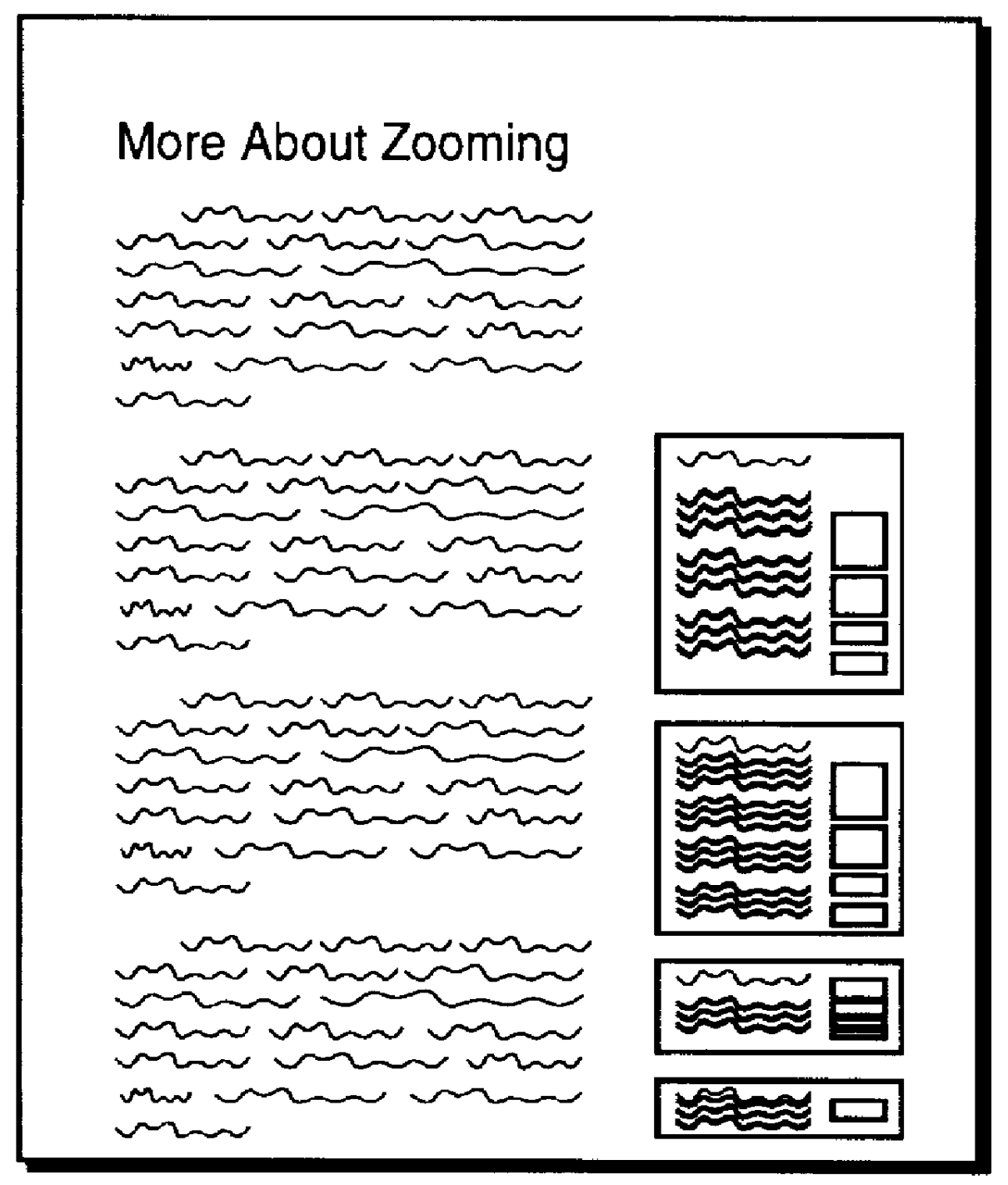

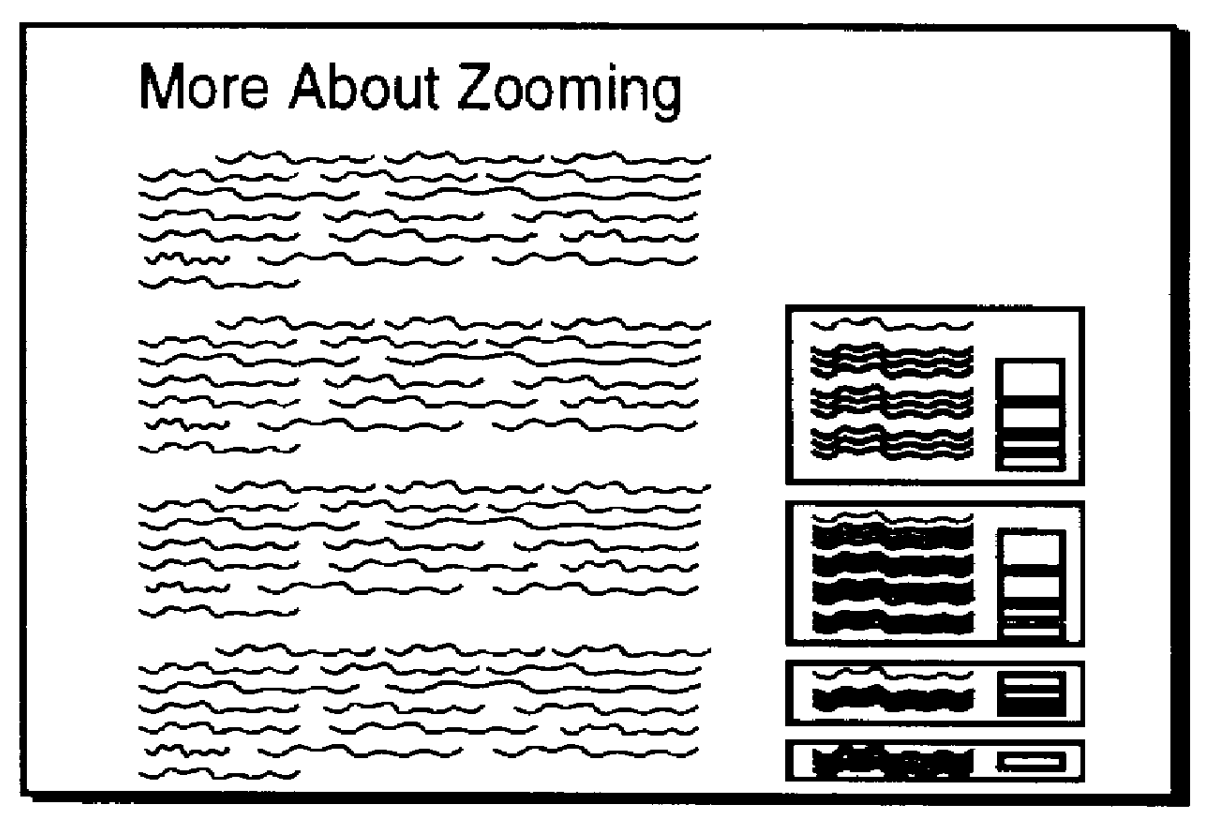

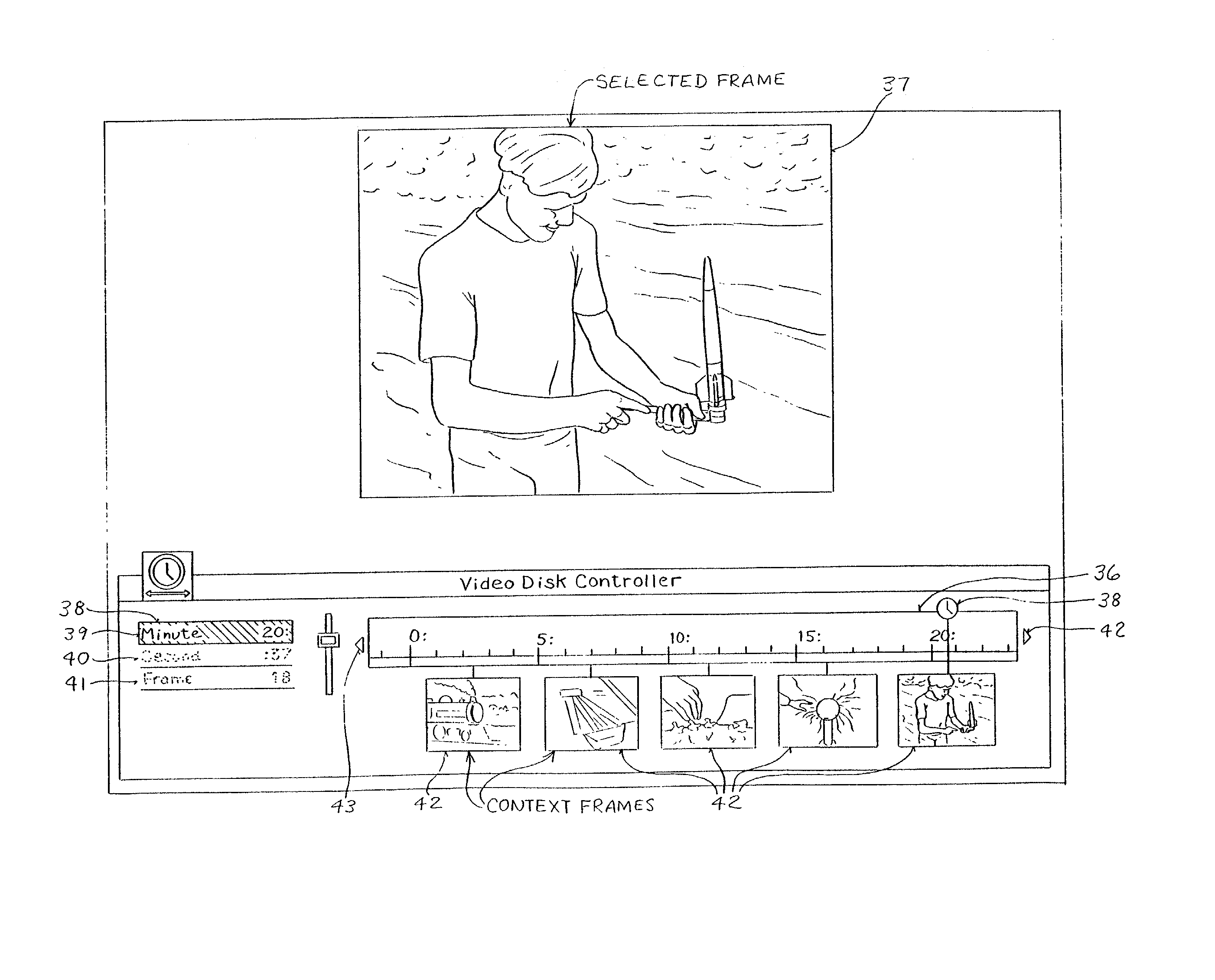

Zooming controller

InactiveUS6061062ACost effectiveIncrease speedInput/output processes for data processingProportional controlImage resolution

A method and device for accessing a broad data field having a fine resolution. The user selects a scale which can be varied. The scale controls a range within the data field. By moving the range to encompass different portions of the data field, the user can scan that portion of the data field. The present invention allows the user to simultaneously select the scale while moving the range over different portions of the data field. Thus, the user can "zoom in" and "zoom out" of different portions of the data field. In one embodiment of the present invention, a particular piece of data within the broad data field can be accessed. First, the scale is selectively varied, thereby controlling a range within the data field. Then, the range is moved to encompass portions of the data field in which the piece of data resides. Next, the scale is successively decreased while, simultaneously, points successively closer to the location are kept with the range. The scale is decreased (i.e., increasing the range's resolution) and the range is moved in this manner until the piece of data is actually accessed.

Owner:APPLE INC

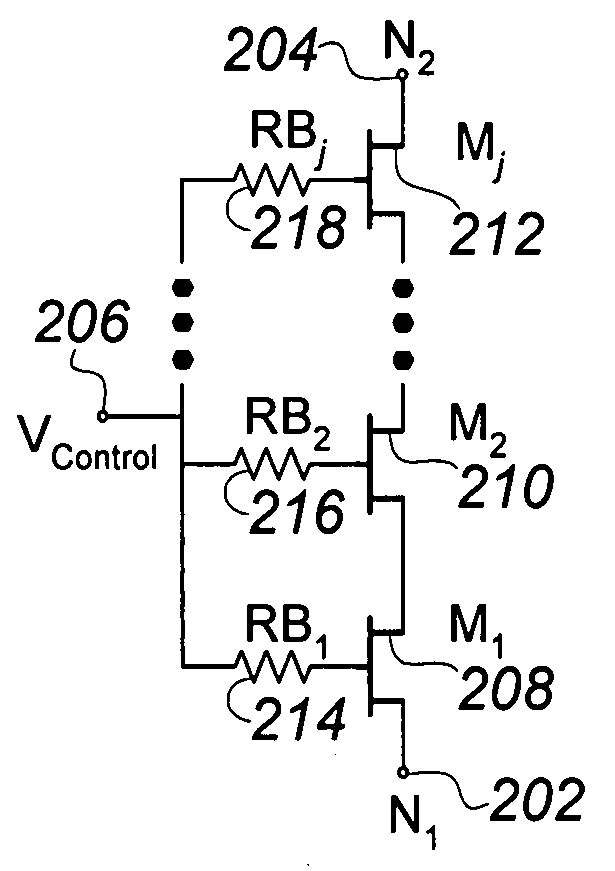

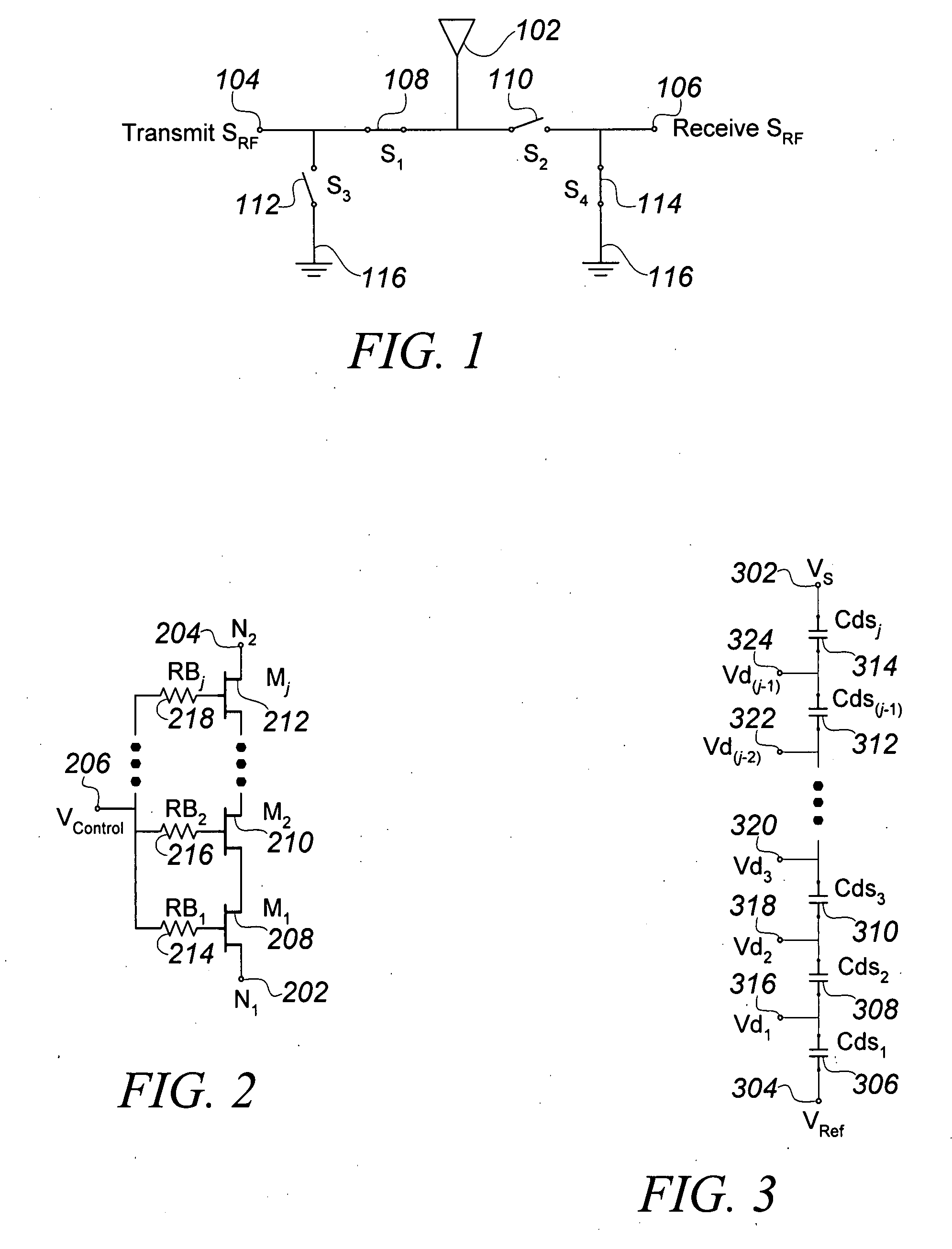

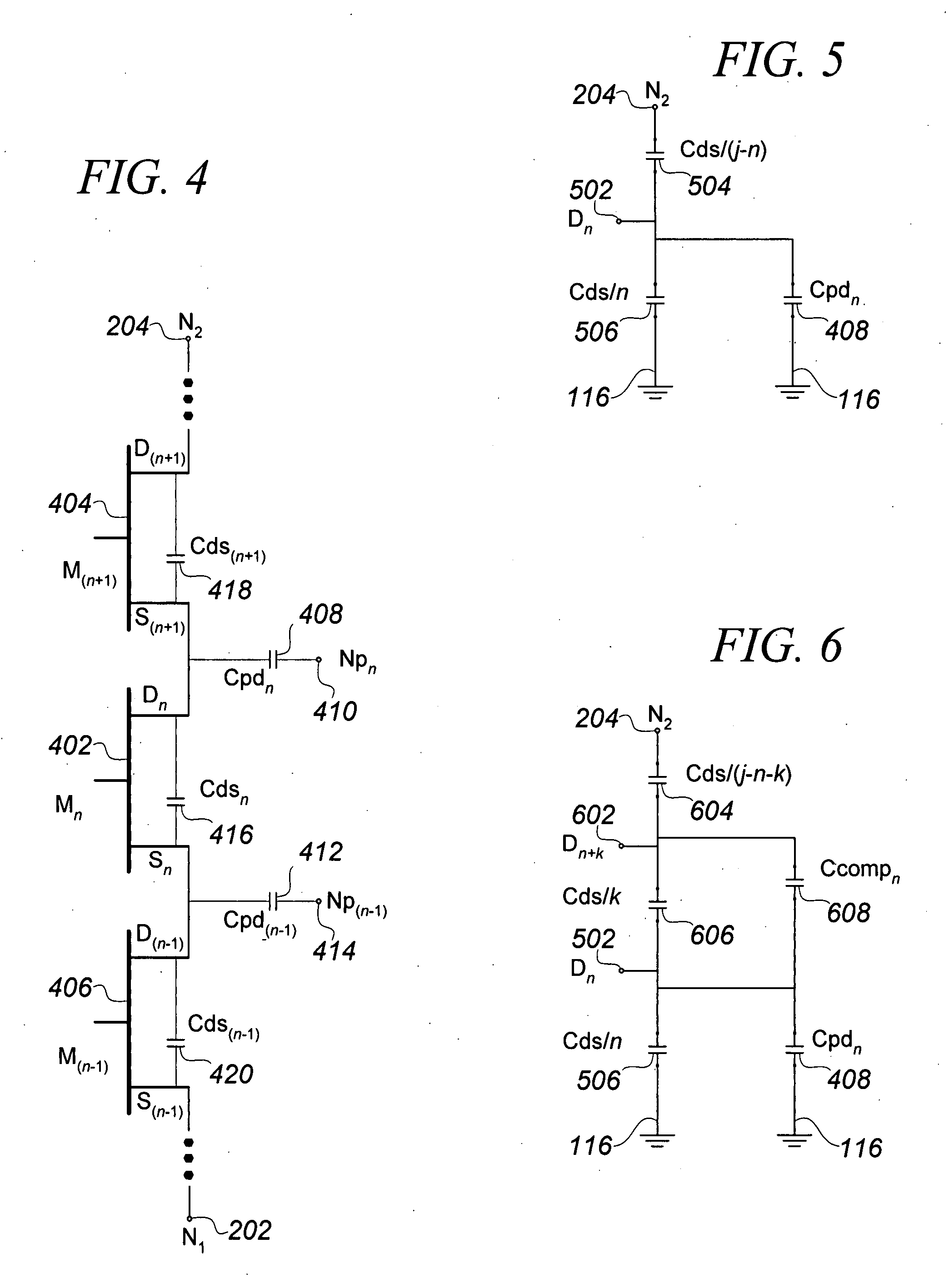

Tuning capacitance to enhance FET stack voltage withstand

An RF switch to controllably withstand an applied RF voltage Vsw, or a method of fabricating such a switch, which includes a string of series-connected constituent FETs with a node of the string between each pair of adjacent FETs. The method includes controlling capacitances between different nodes of the string to effectively tune the string capacitively, which will reduce the variance in the RF switch voltage distributed across each constituent FET, thereby enhancing switch breakdown voltage. Capacitances are controlled, for example, by disposing capacitive features between nodes of the string, and / or by varying design parameters of different constituent FETs. For each node, a sum of products of each significant capacitor by a proportion of Vsw appearing across it may be controlled to approximately zero.

Owner:PSEMI CORP

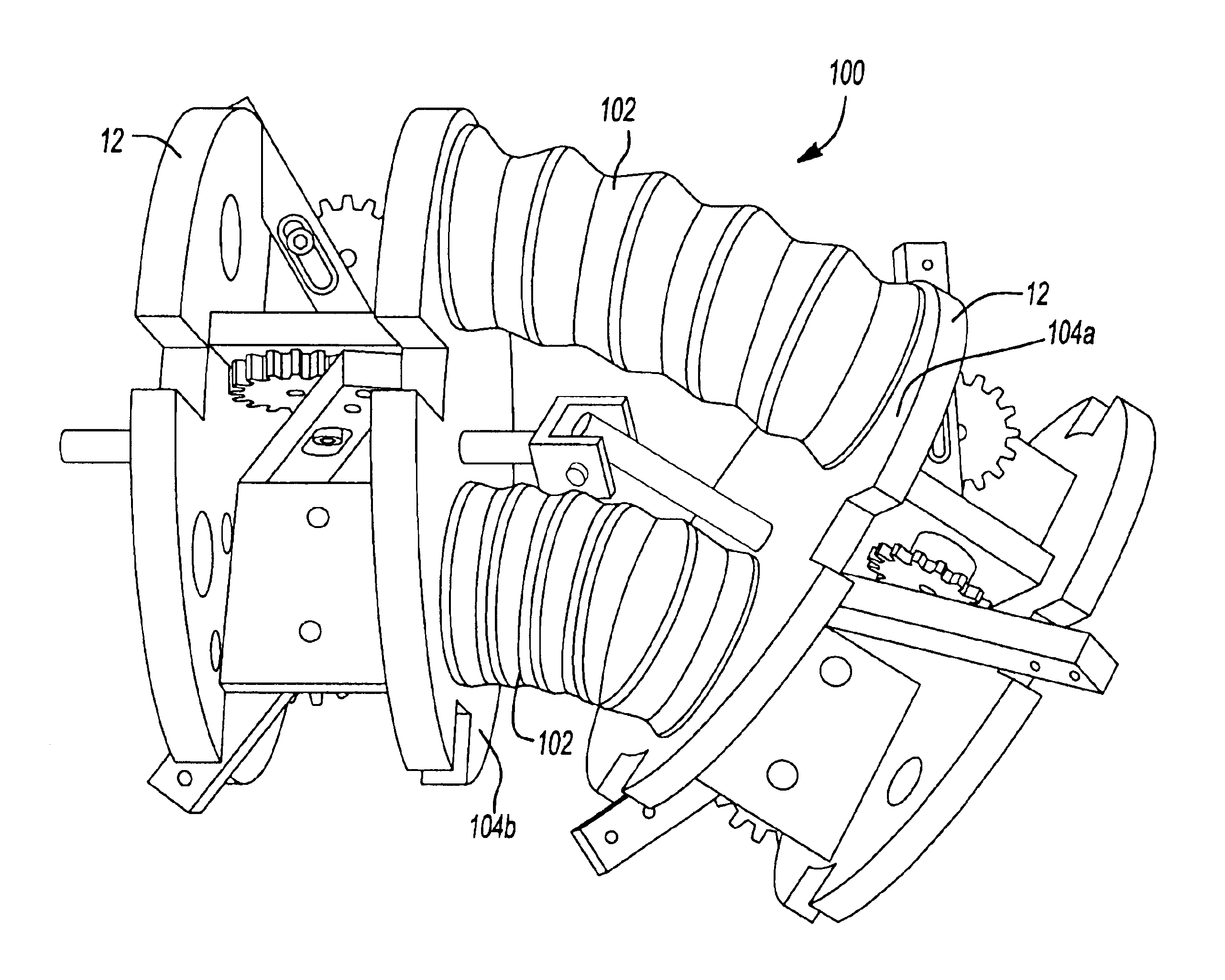

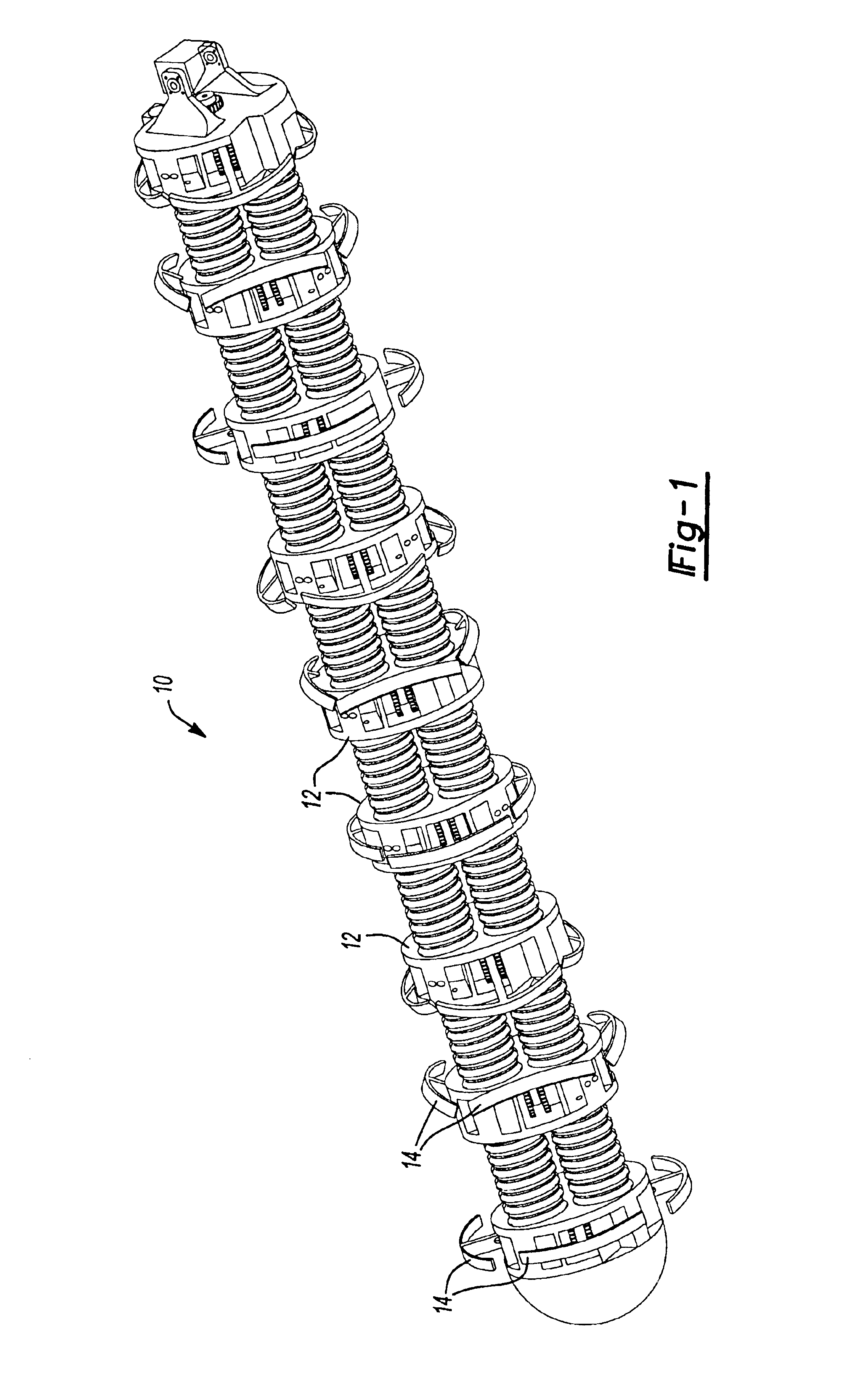

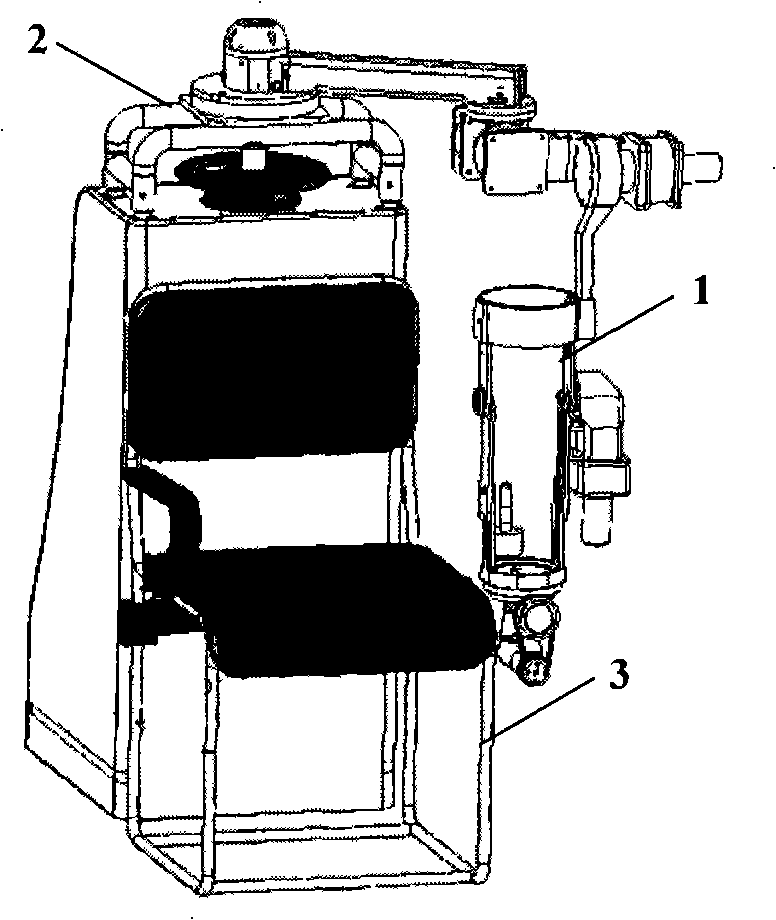

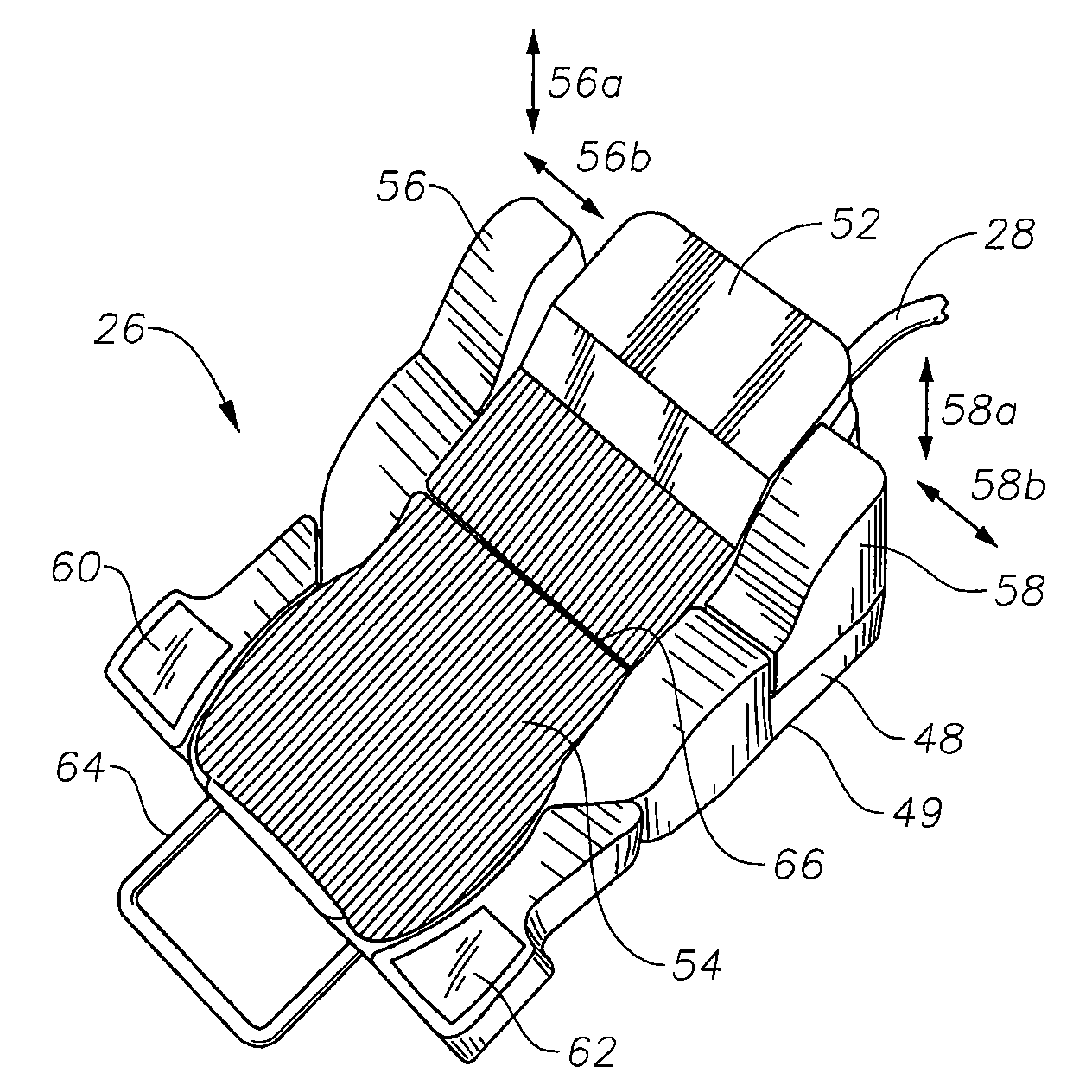

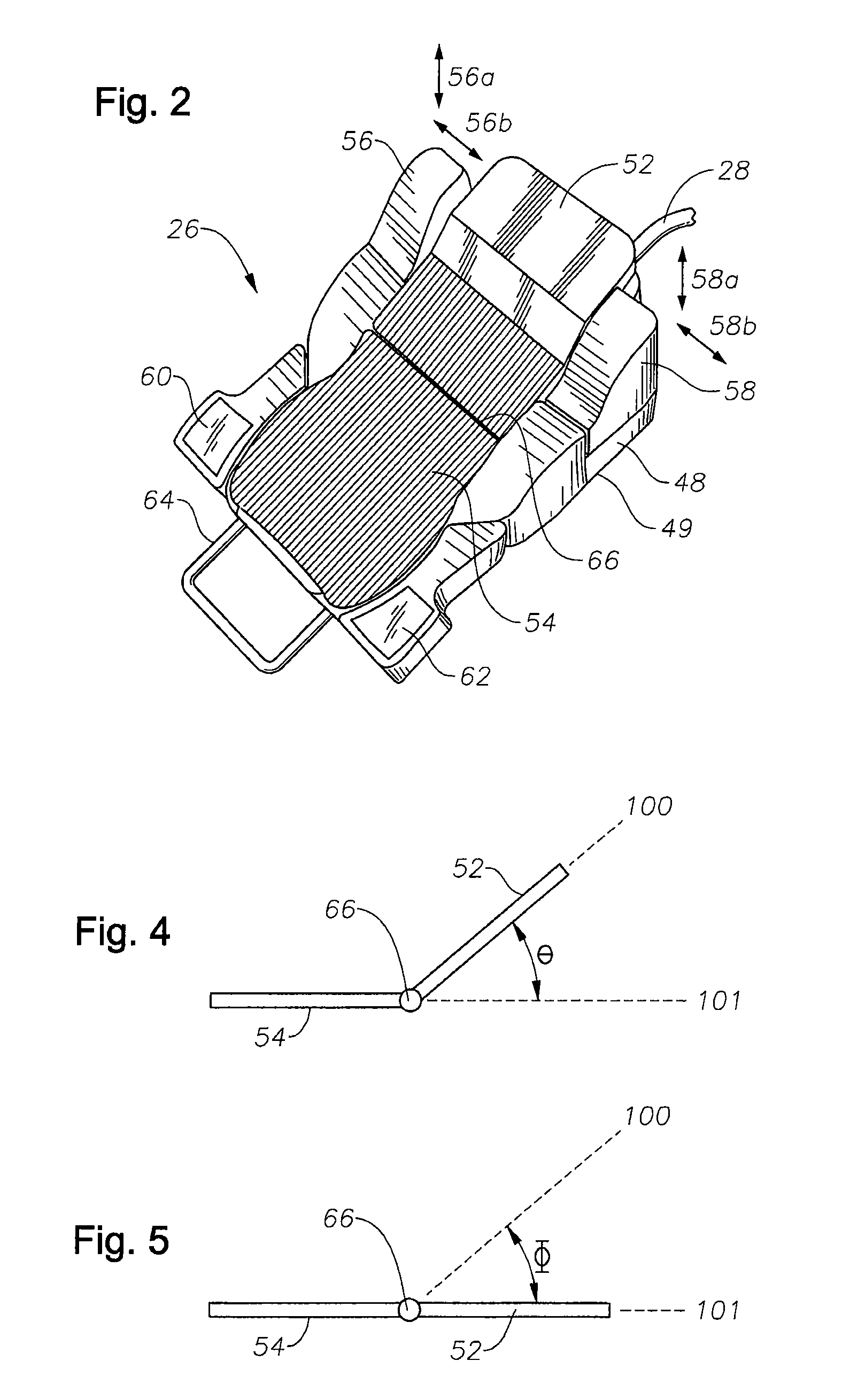

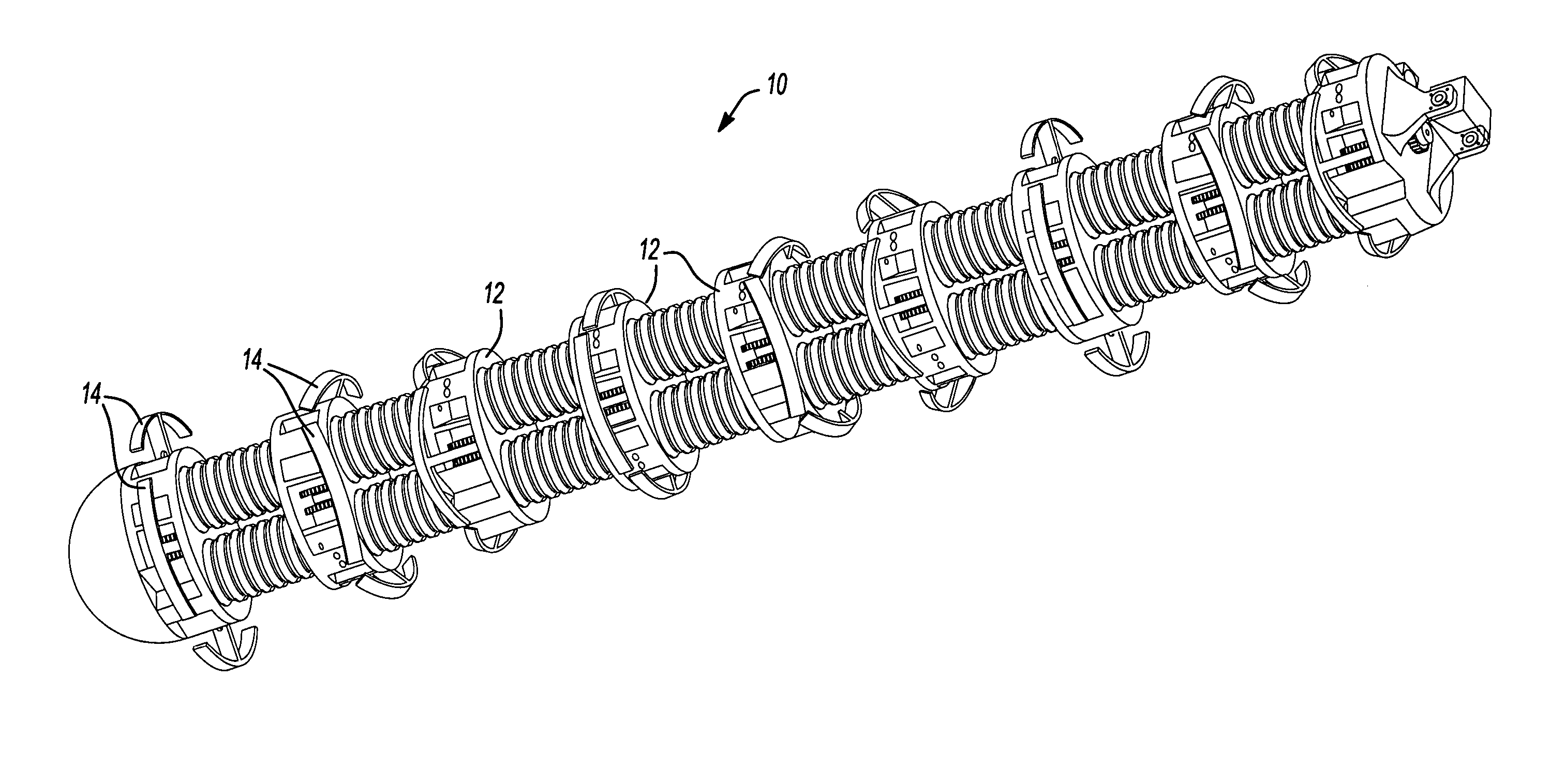

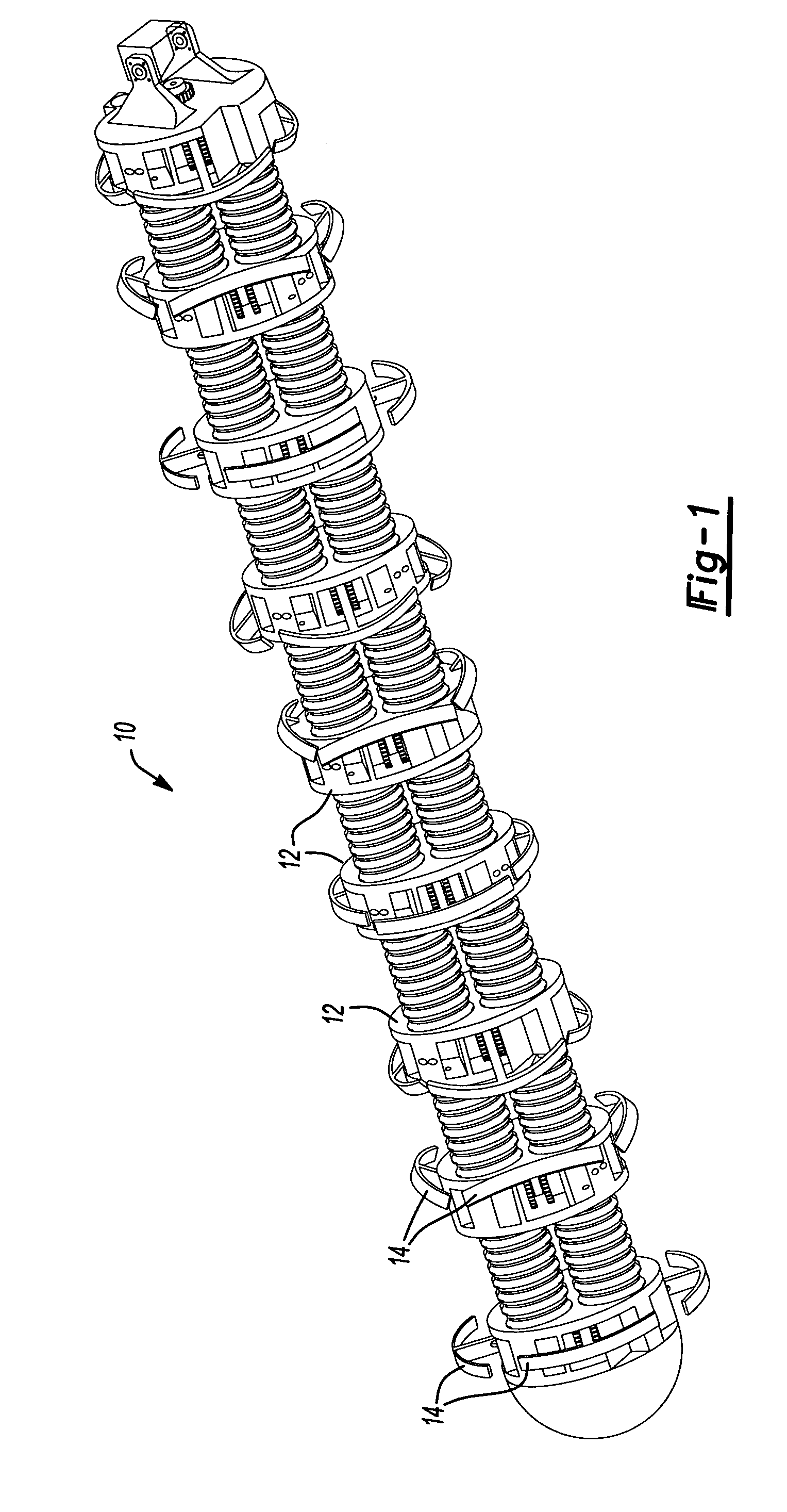

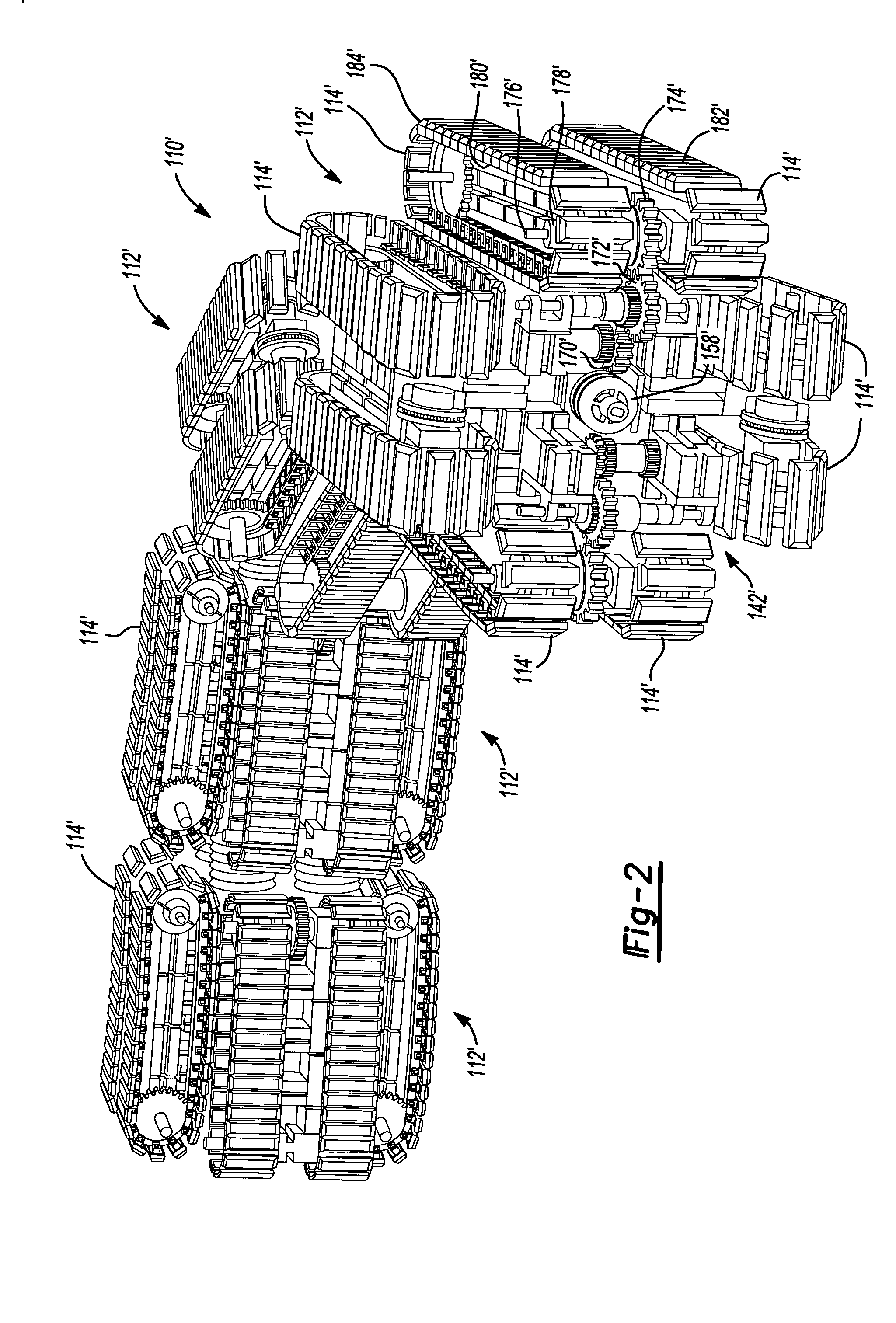

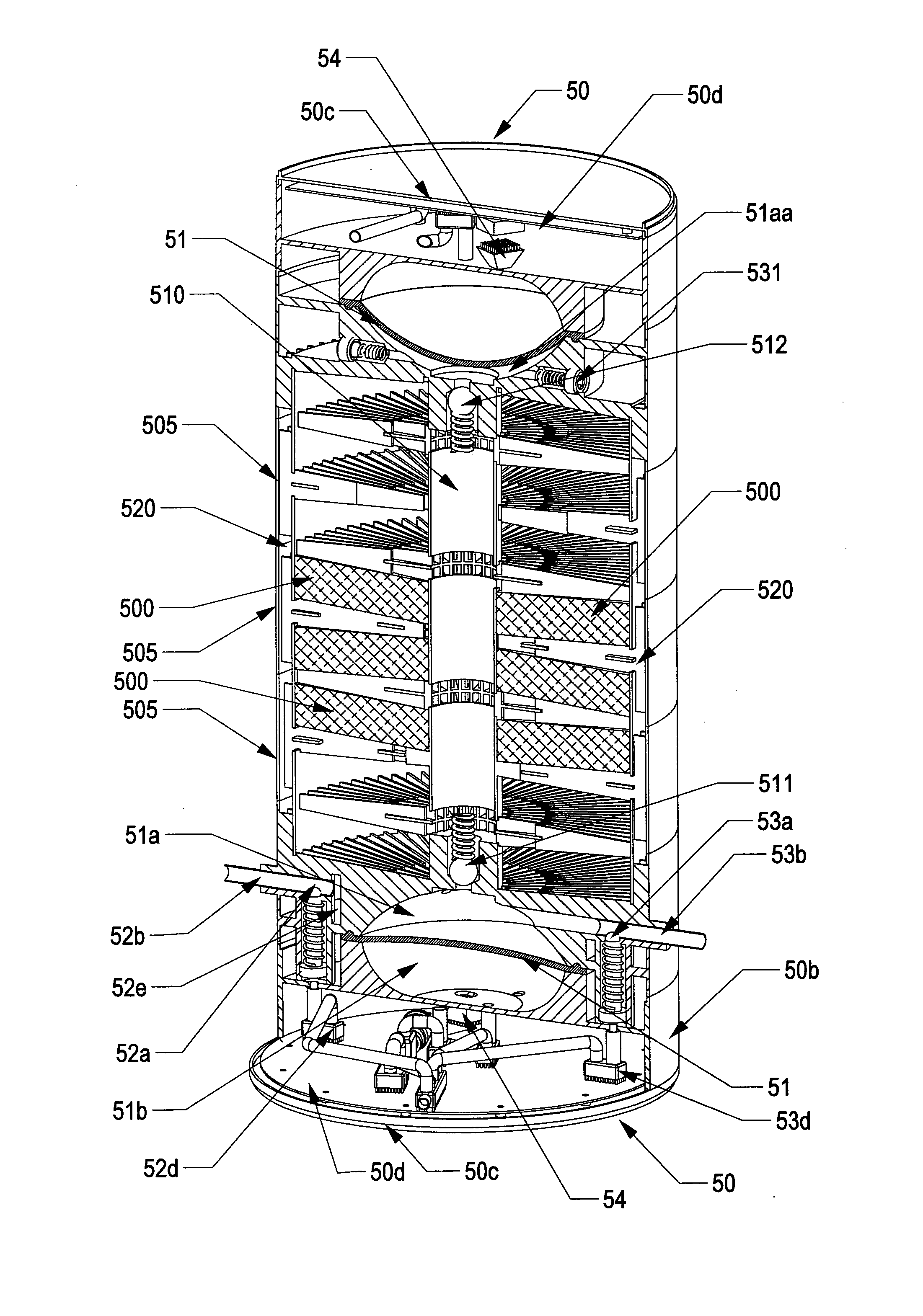

Integrated, proportionally controlled, and naturally compliant universal joint actuator with controllable stiffness

InactiveUS6870343B2Limited stiffnessMinimize airflowProgramme-controlled manipulatorComputer controlProportional controlUniversal joint

An apparatus for traversing obstacles having an elongated, round, flexible body that includes a plurality of segments interconnected by an integrated joint actuator assembly. The integrated joint actuator assembly includes a plurality of bellows-type actuators individually coupling adjacent segments to permit pivotal actuation of the apparatus therebetween. A controller is employed to maintain proper positional control and stiffness control while minimize air flow.

Owner:RGT UNIV OF MICHIGAN

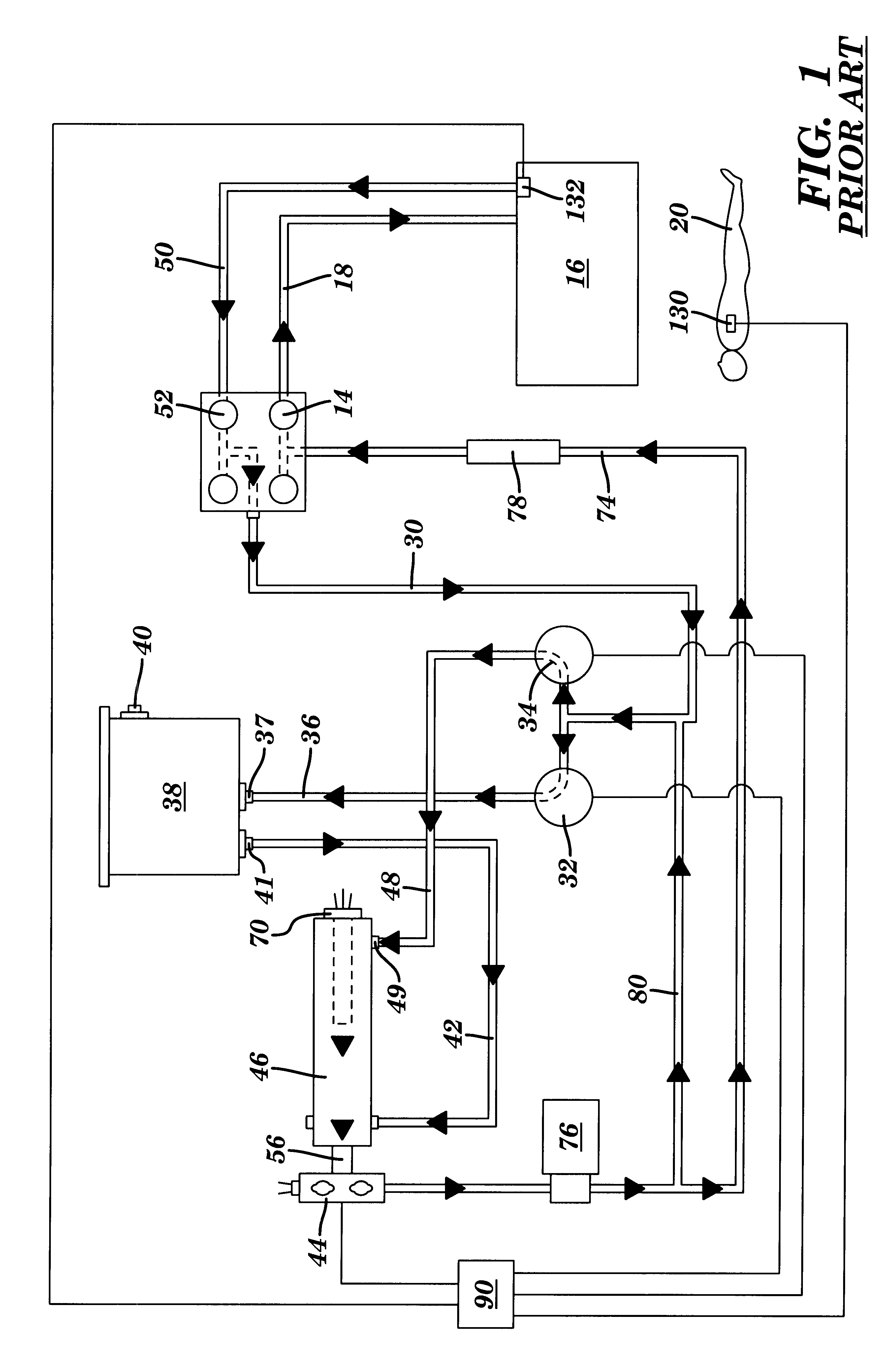

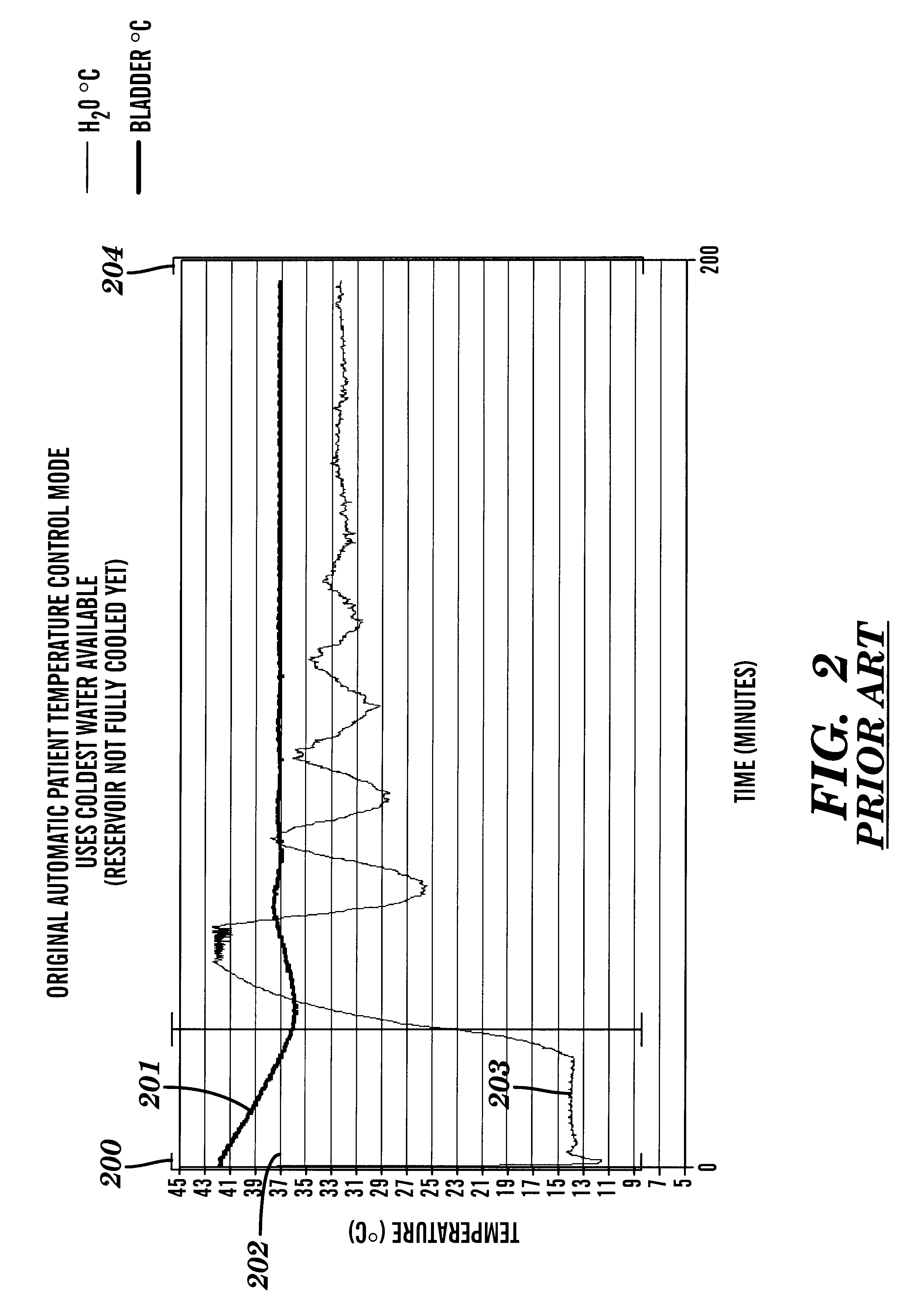

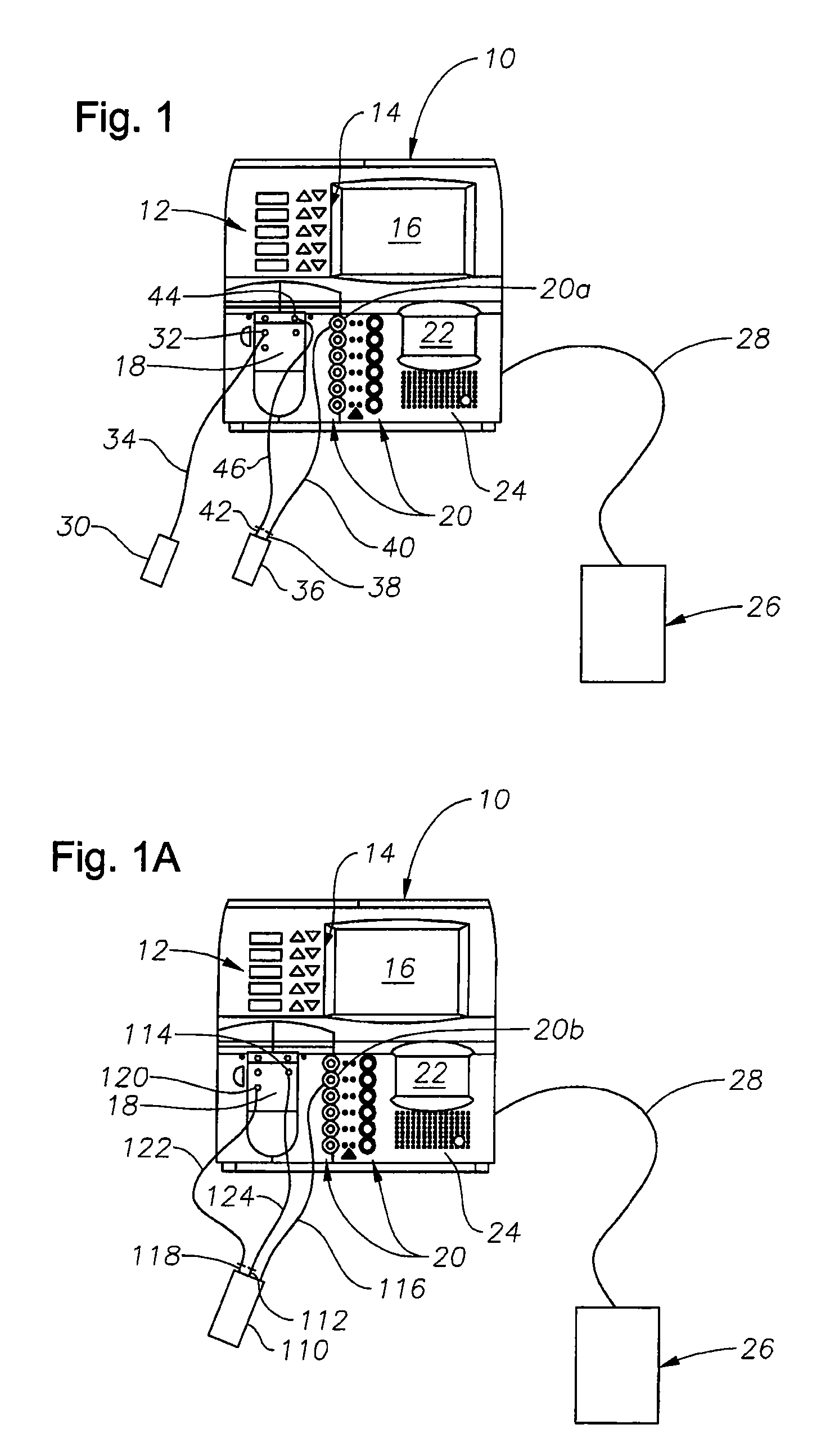

Automatic patient control device

InactiveUS6517510B1Reduce chancePressure pumpsMedical devicesProportional controlHigh body temperature

The present invention relates to regulating the temperature of a desired medium that is applied to the exterior surface of a mammal. These devices have been used in the past but not with the ability to control the temperature of the desired medium in a predetermined ratio to the temperature of the mammal. With such control, the present invention decreases the change of discomforting the patient when the patient's temperature is being brought to a set point temperature body temperature.

Owner:GAYMAR IND

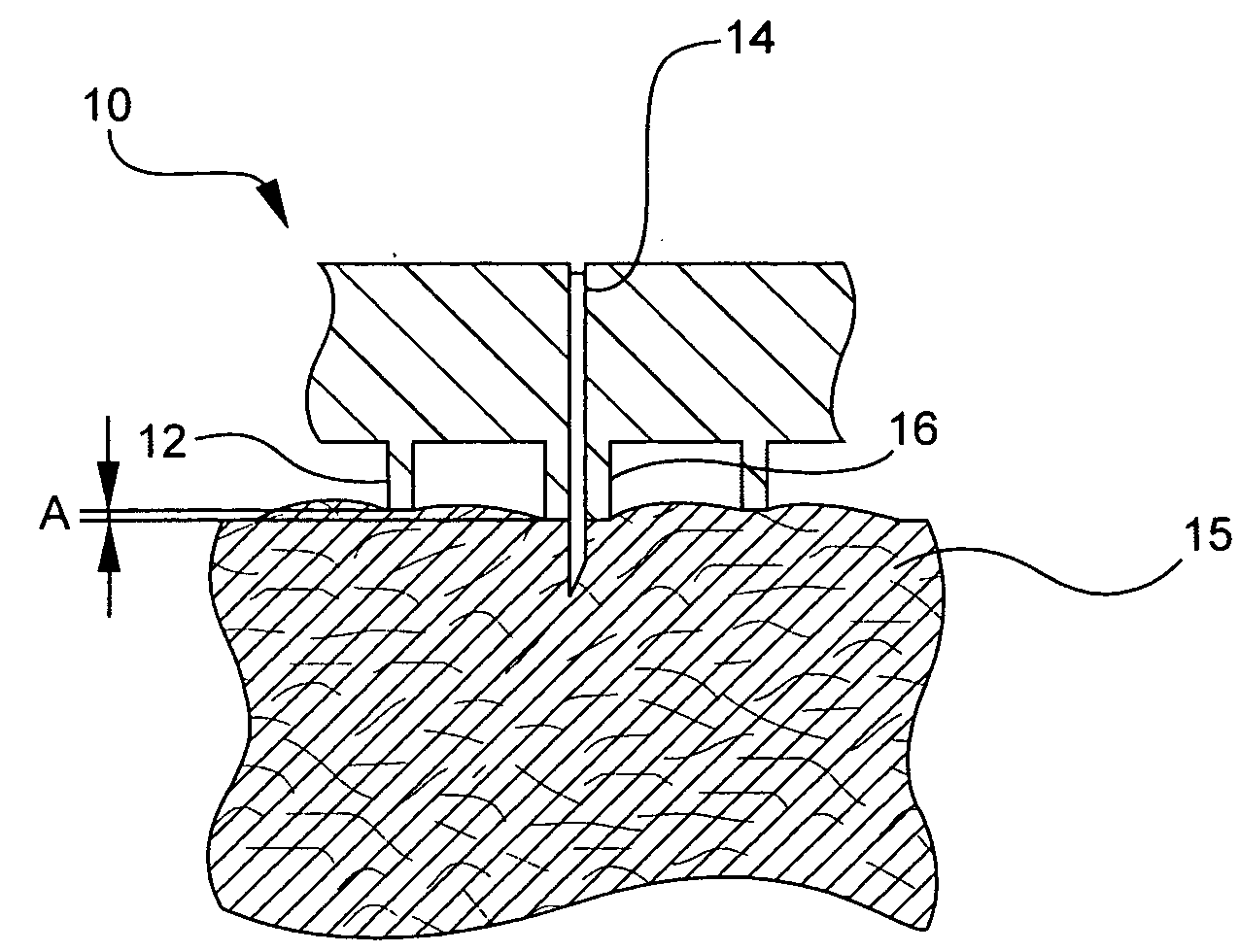

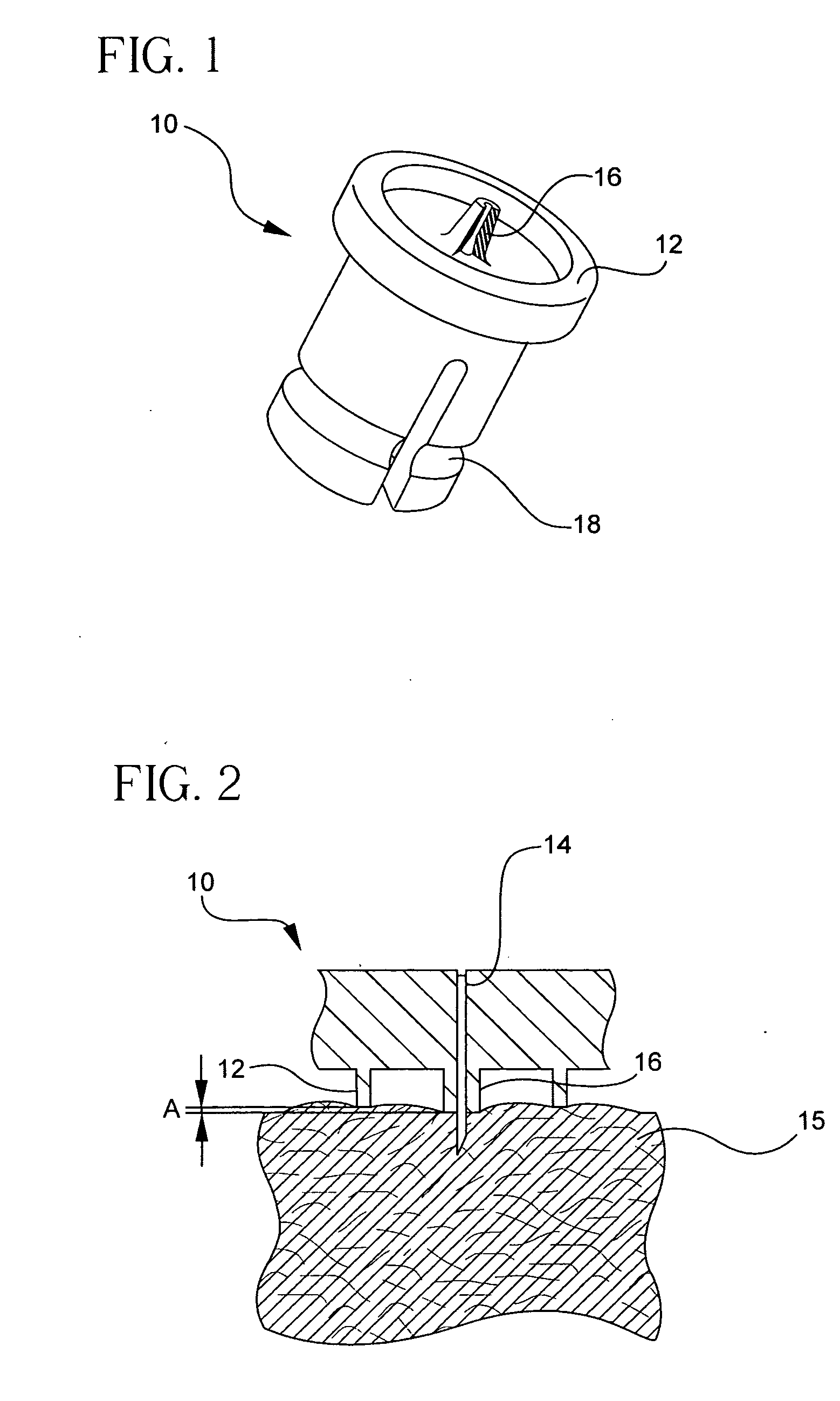

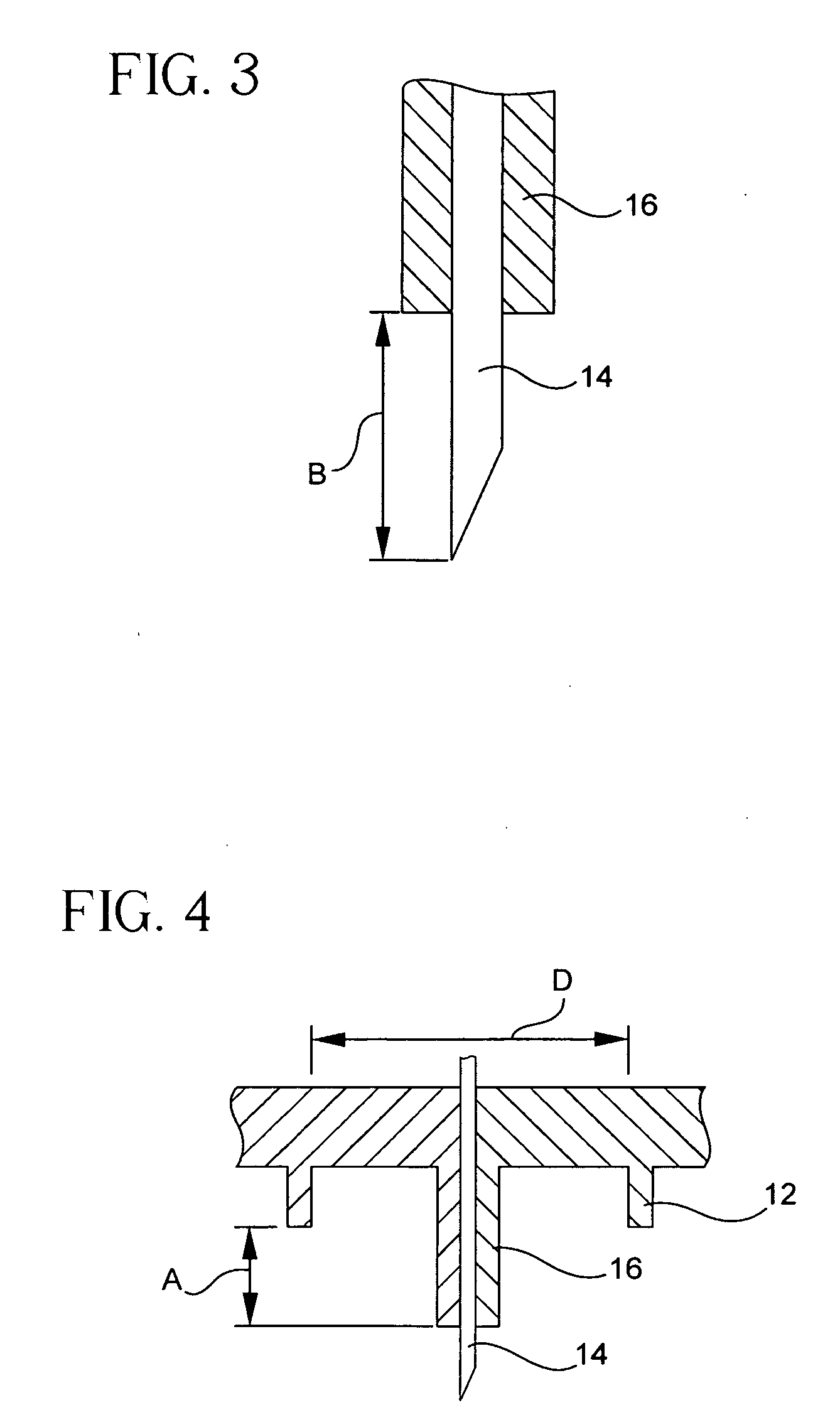

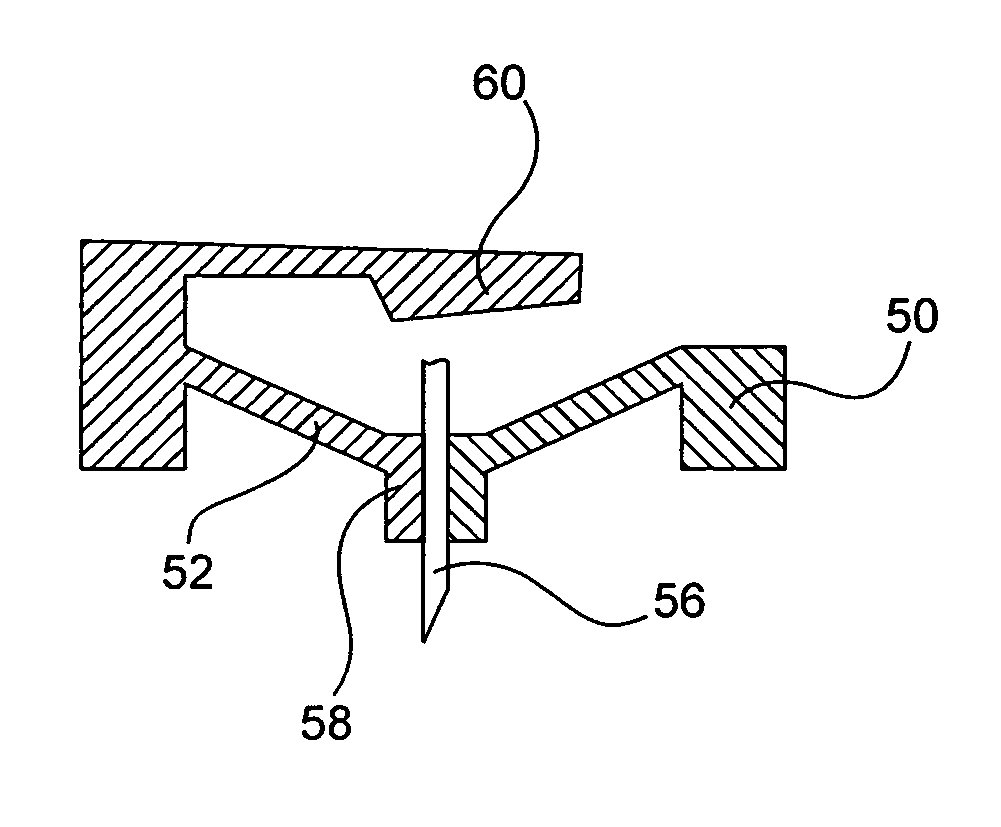

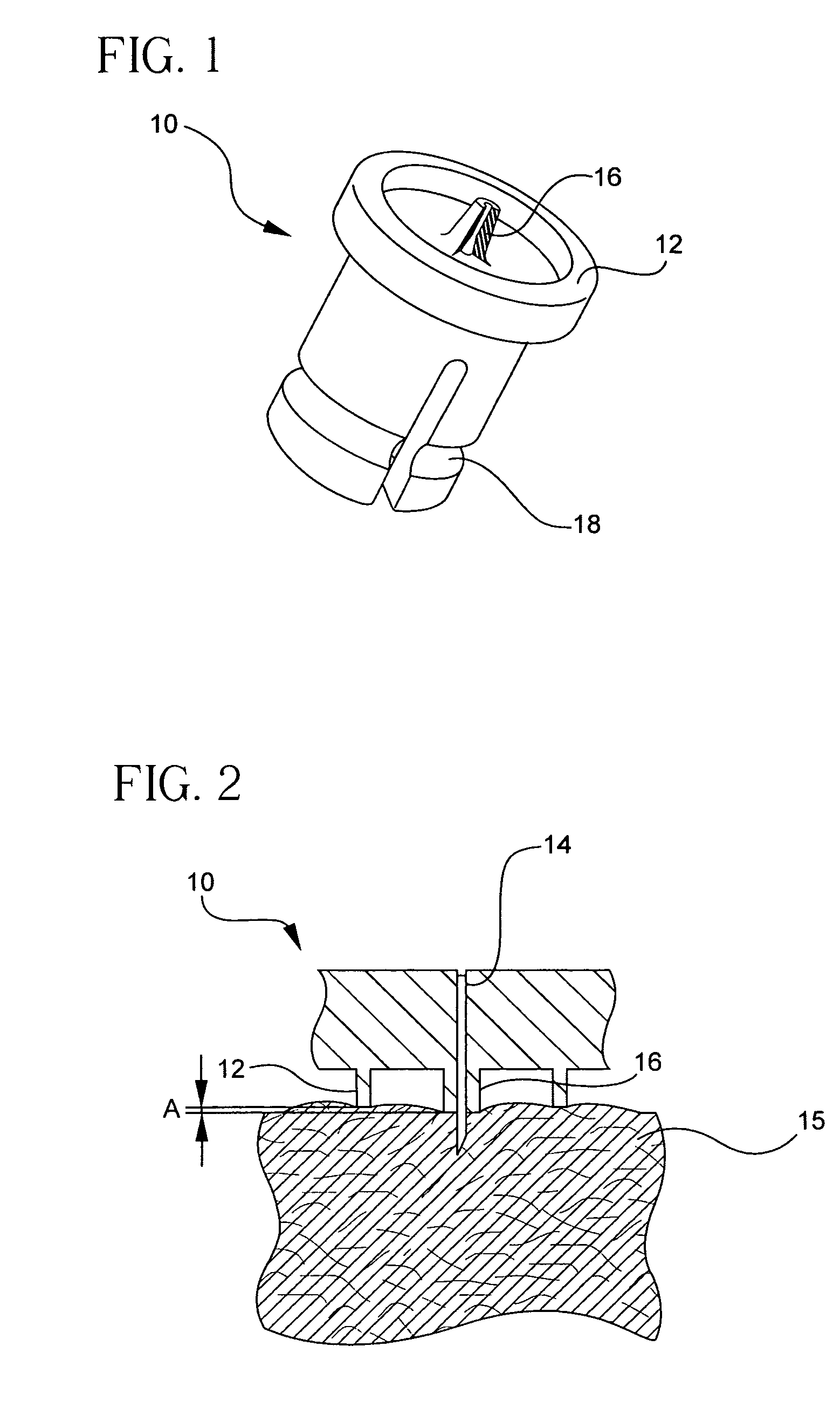

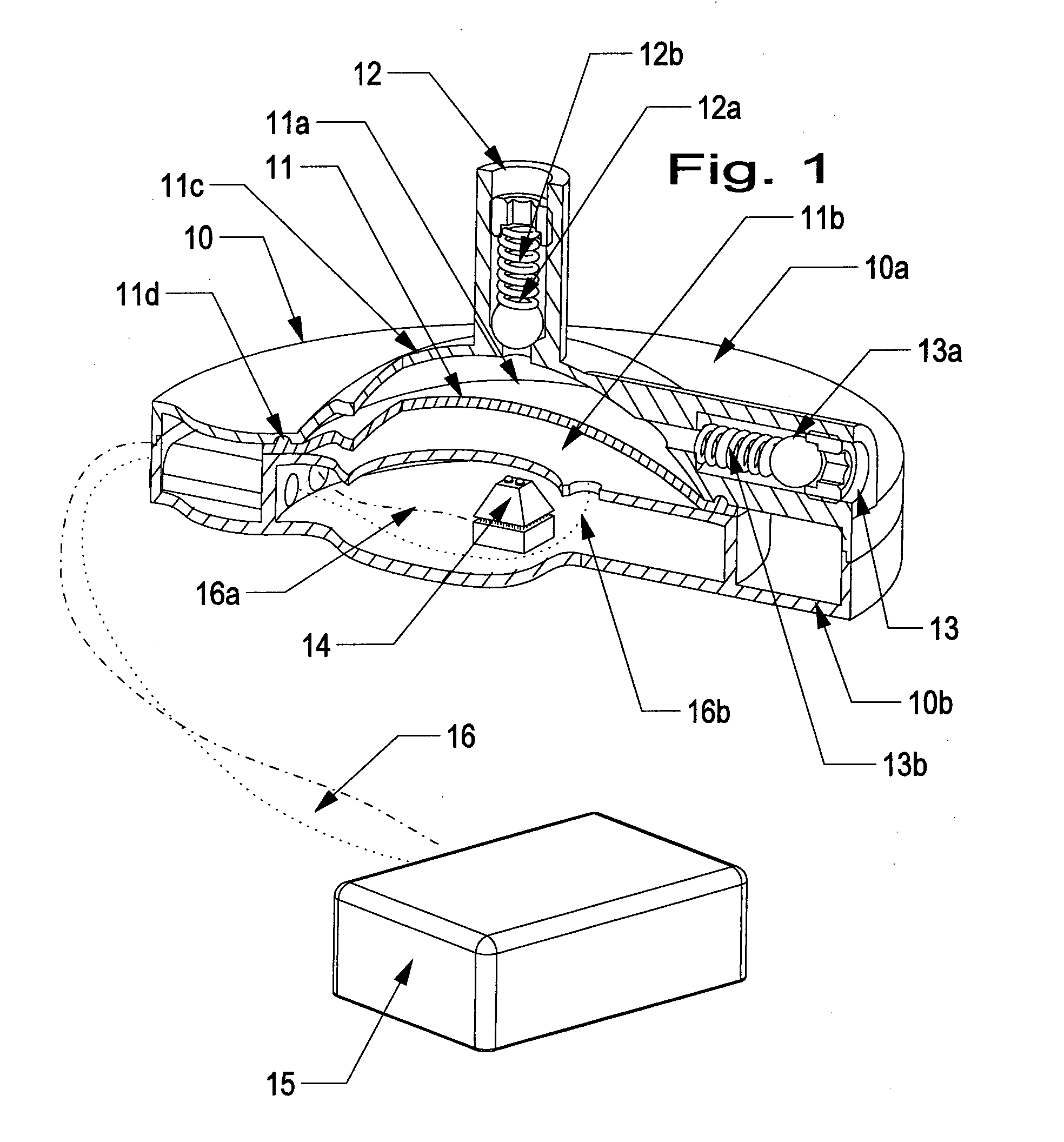

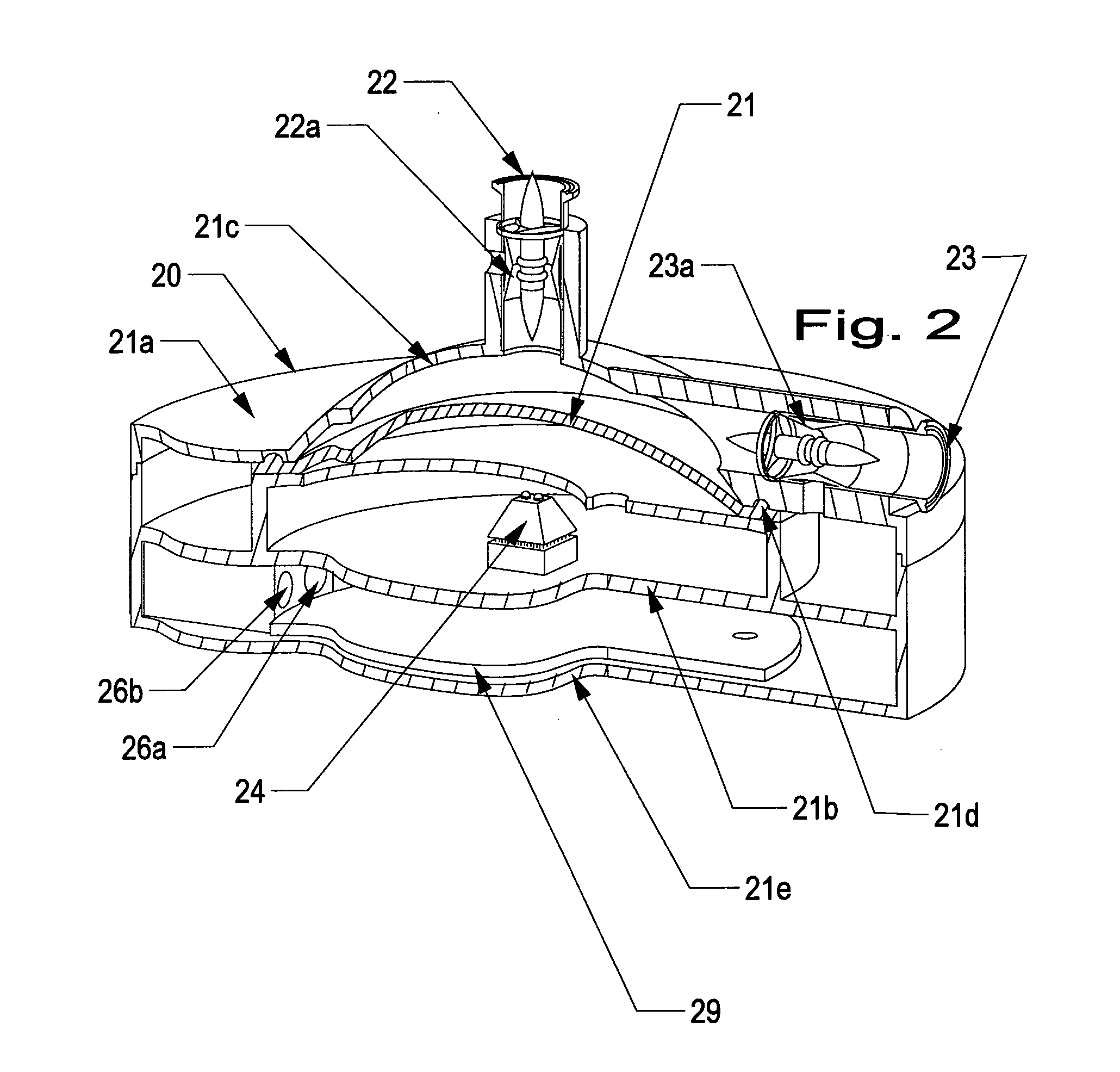

Intradermal delivery device

ActiveUS20070118077A1Minimal leakageReduce pressureCatheterInfusion needlesProportional controlInsertion depth

A system and method is provided for an injectable substance delivery device comprising a limiter, shoulder or post, that controls how deep the needle is inserted into the tissue. The limiter is sized in proportions that control the maximum insertion depth of the needle into the tissue without excessively restricting the complete insertion of the needle. The system and method further comprises an normalization or stabilizer ring that prevents distortion of the tissue in the vicinity of the infusion, so that the needle length is the major determining factor as to how deep the infusion is delivered.

Owner:BECTON DICKINSON & CO

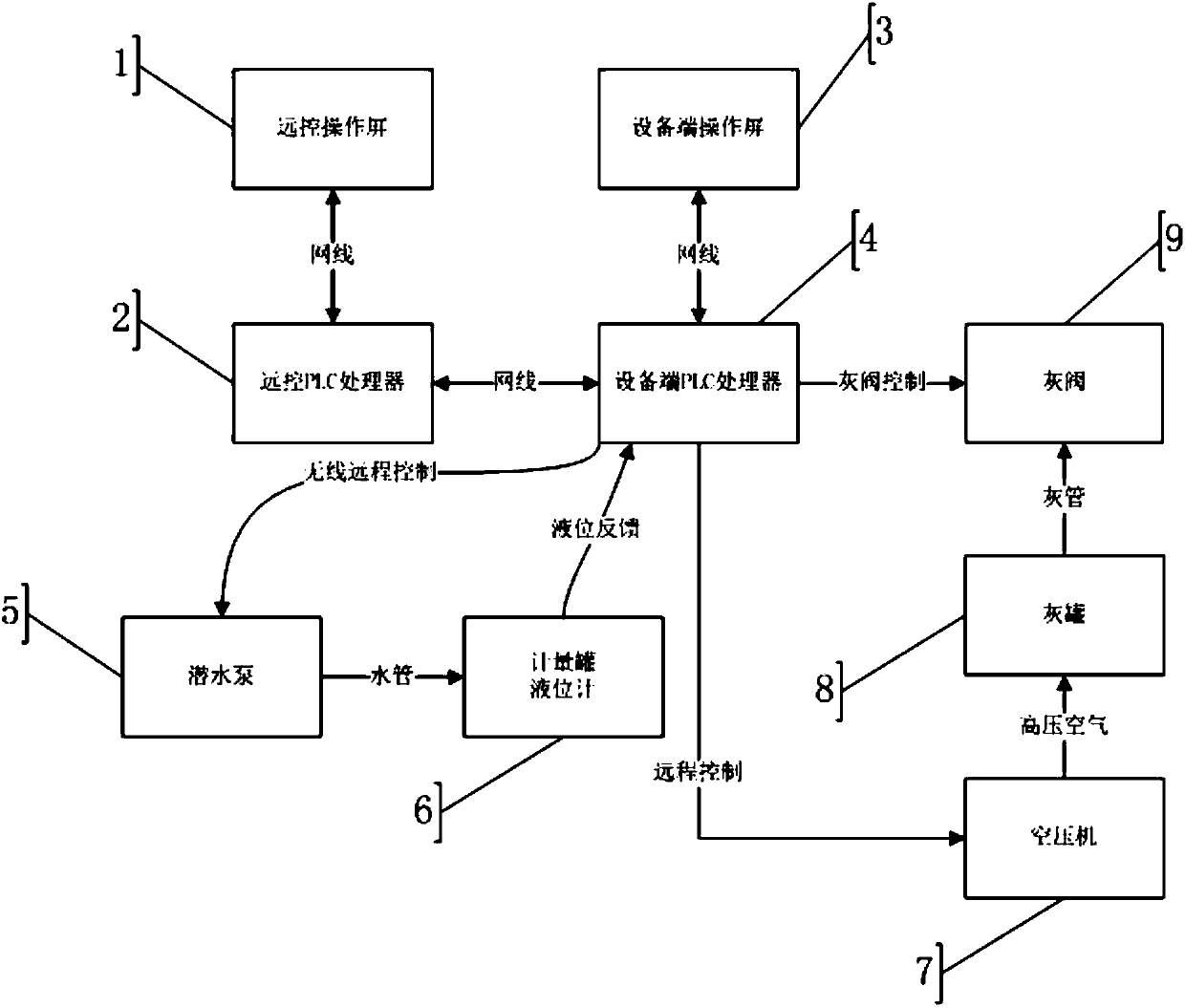

Remote automatic cement supplying control system

PendingCN107656499ARealize remote automatic centralized controlRealize the centralized control of the whole processProgramme control in sequence/logic controllersProportional controlRemote control

The invention belongs to the field of petroleum equipment, and particularly relates to full-automatic intelligent remote controlled well solidifying equipment, and to a remote automatic cement supplying control system for well solidifying equipment. The remote automatic cement supplying control system comprises a control unit, an air compressor, a cement tank and a cement valve. The remote automatic cement supplying control system is characterized in that the control unit comprises an equipment end operating screen, an equipment end PLC processor, a remote control operating screen and a remotecontrol PLC processor; the equipment end operating screen, the equipment end PLC processor, the remote control operating screen and the remote control PLC processor are connected through netting twines; the equipment end PLC processor can remotely control a remote control module for starting and stopping the air compressor, thereby controlling the air compressor through the remote control module;after the air compressor is started, high-pressure air is discharged to the cement tank; the equipment end PLC processor automatically calculates a required cement supplying amount through a preset density of the well solidifying equipment; through comparing the calculated cement supplying amount with a current acquired cement supplying amount, proportion controlling and adjustment of the cementvalve are performed; and furthermore the cement supplying amount of the equipment is controlled.

Owner:CNPC DRILLING RES INST +2

Zooming controller

InactiveUS20020080151A1Cost effectiveIncrease speedCathode-ray tube indicatorsInput/output processes for data processingProportional controlImage resolution

A method and device for accessing a broad data field having a fine resolution. The user selects a scale which can be varied. The scale controls a range within the data field. By moving the range to encompass different portions of the data field, the user can scan that portion of the data field. The present invention allows the user to simultaneously select the scale while moving the range over different portions of the data field. Thus, the user can "zoom in" and "zoom out" of different portions of the data field. In one embodiment of the present invention, a particular piece of data within the broad data field can be accessed. First, the scale is selectively varied, thereby controlling a range within the data field. Then, the range is moved to encompass portions of the data field in which the piece of data resides. Next, the scale is successively decreased while, simultaneously, points successively closer to the location are kept with the range. The scale is decreased (i.e., increasing the range's resolution) and the range is moved in this manner until the piece of data is actually accessed.

Owner:APPLE INC

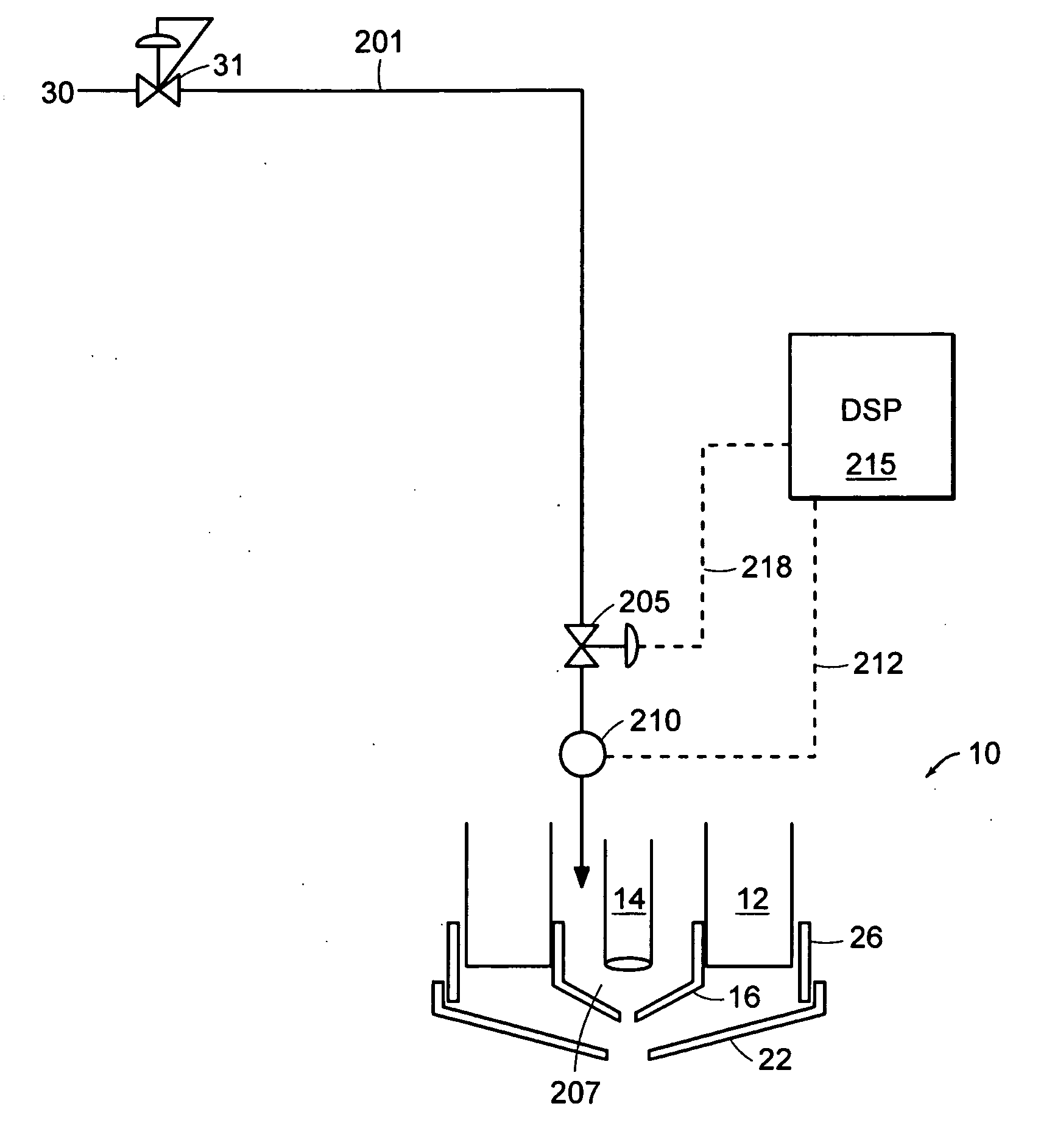

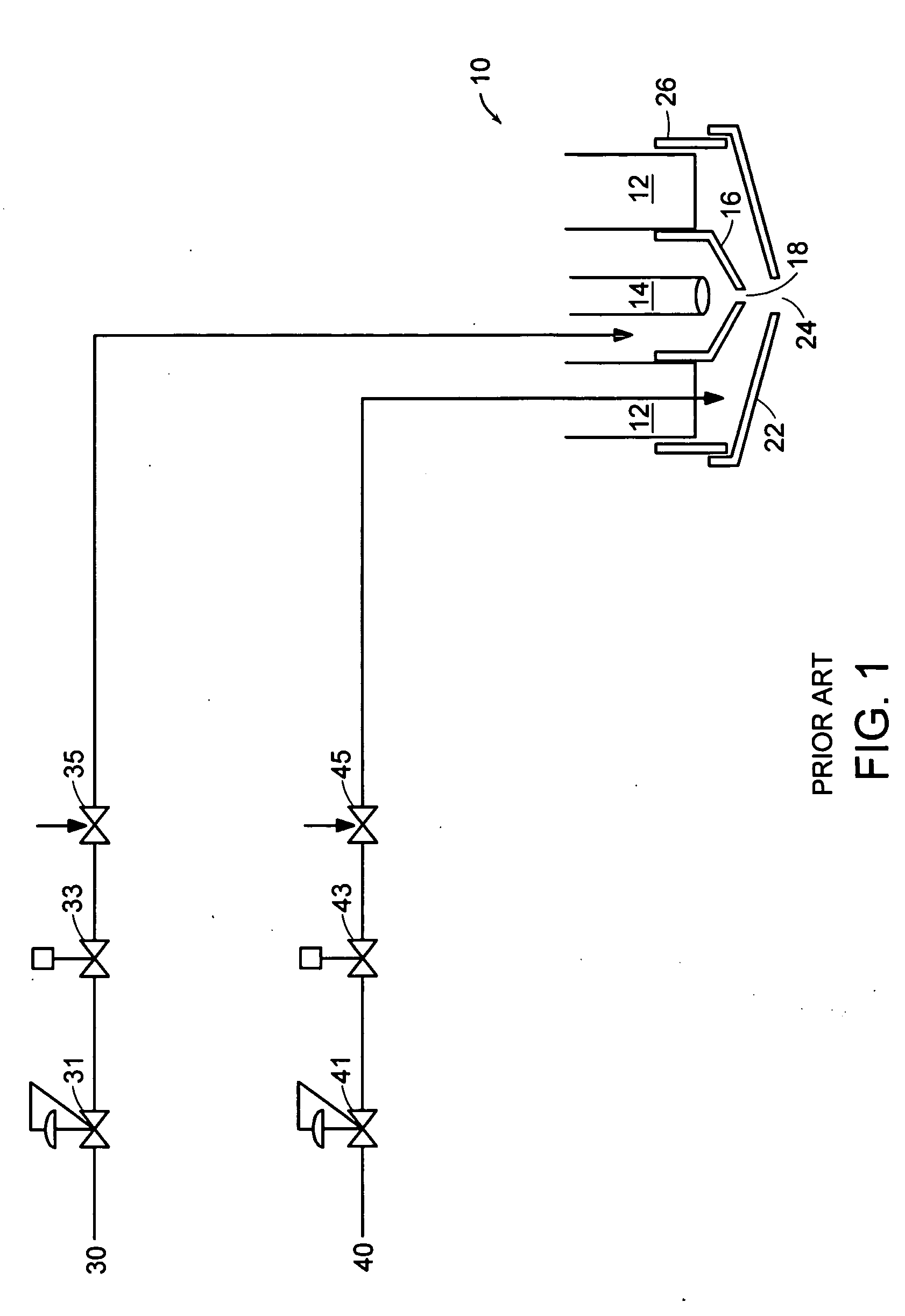

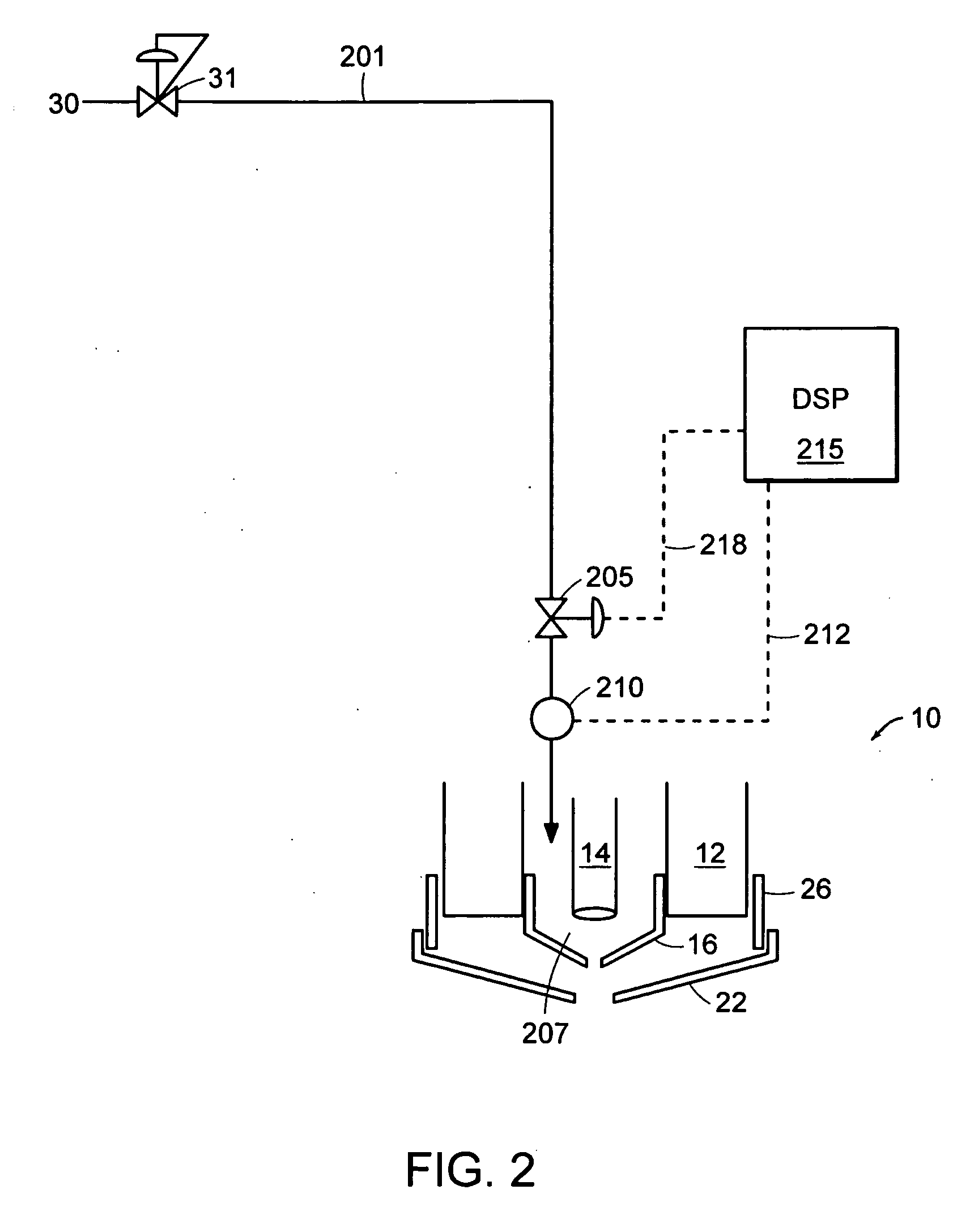

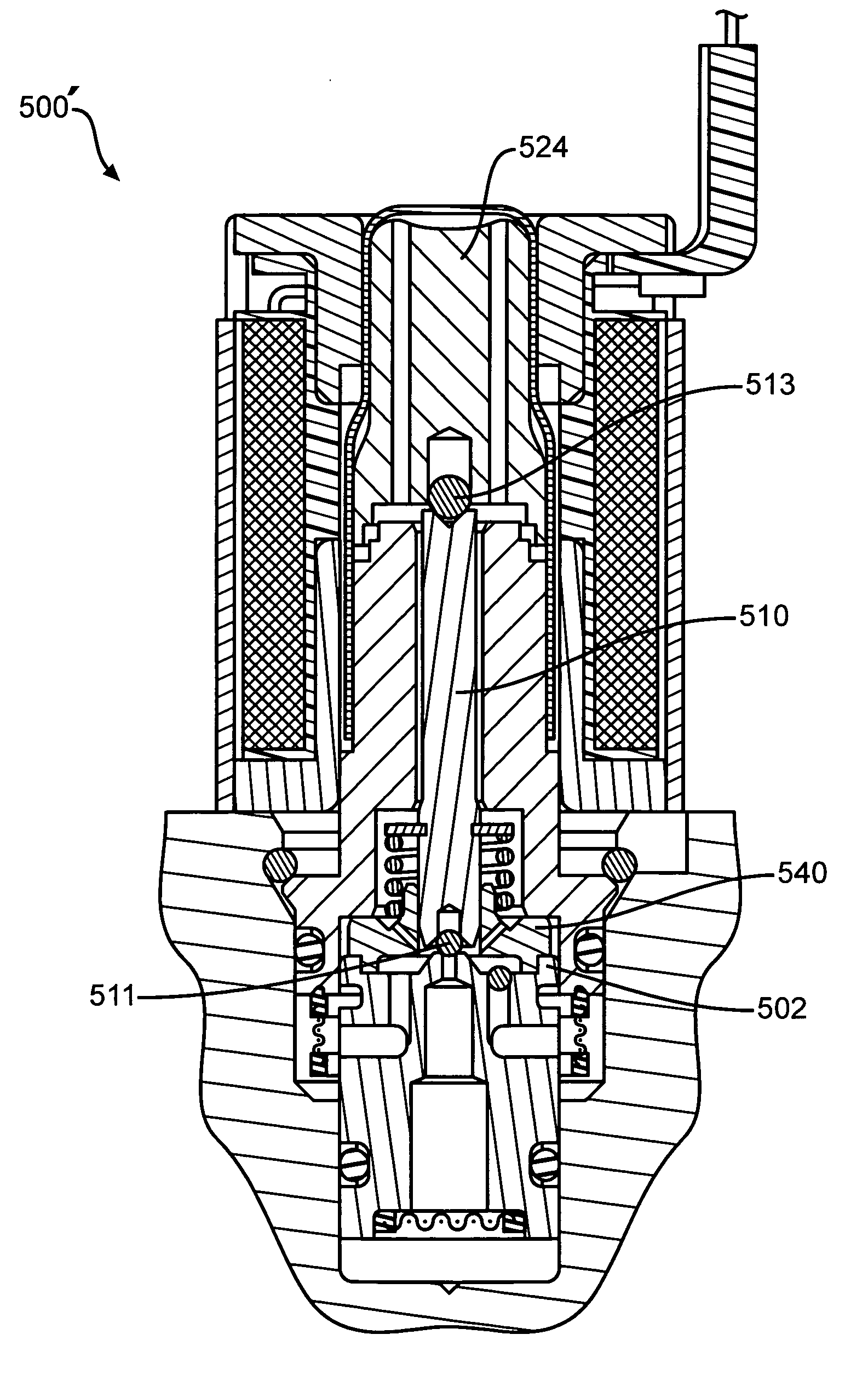

Automatic gas control for a plasma arc torch

InactiveUS20060163216A1Prolong lifeHigh operating current levelArc welding apparatusPlasma welding apparatusProportional controlSolenoid valve

A method and apparatus for controlling a gas supply to a plasma arc torch uses a proportional control solenoid valve positioned adjacent the torch to manipulate the gas flow to the torch, thereby extending electrode life during arc transfer and shutdown. Swirl ring design can be simplified and gas supply and distribution systems become less complicated. The invention also allows manipulation of shield gas flow to reduce divot formation when making interior cuts. The system can be controlled with a digital signal processor utilizing a feedback loop from a sensor.

Owner:HYPERTHERM INC

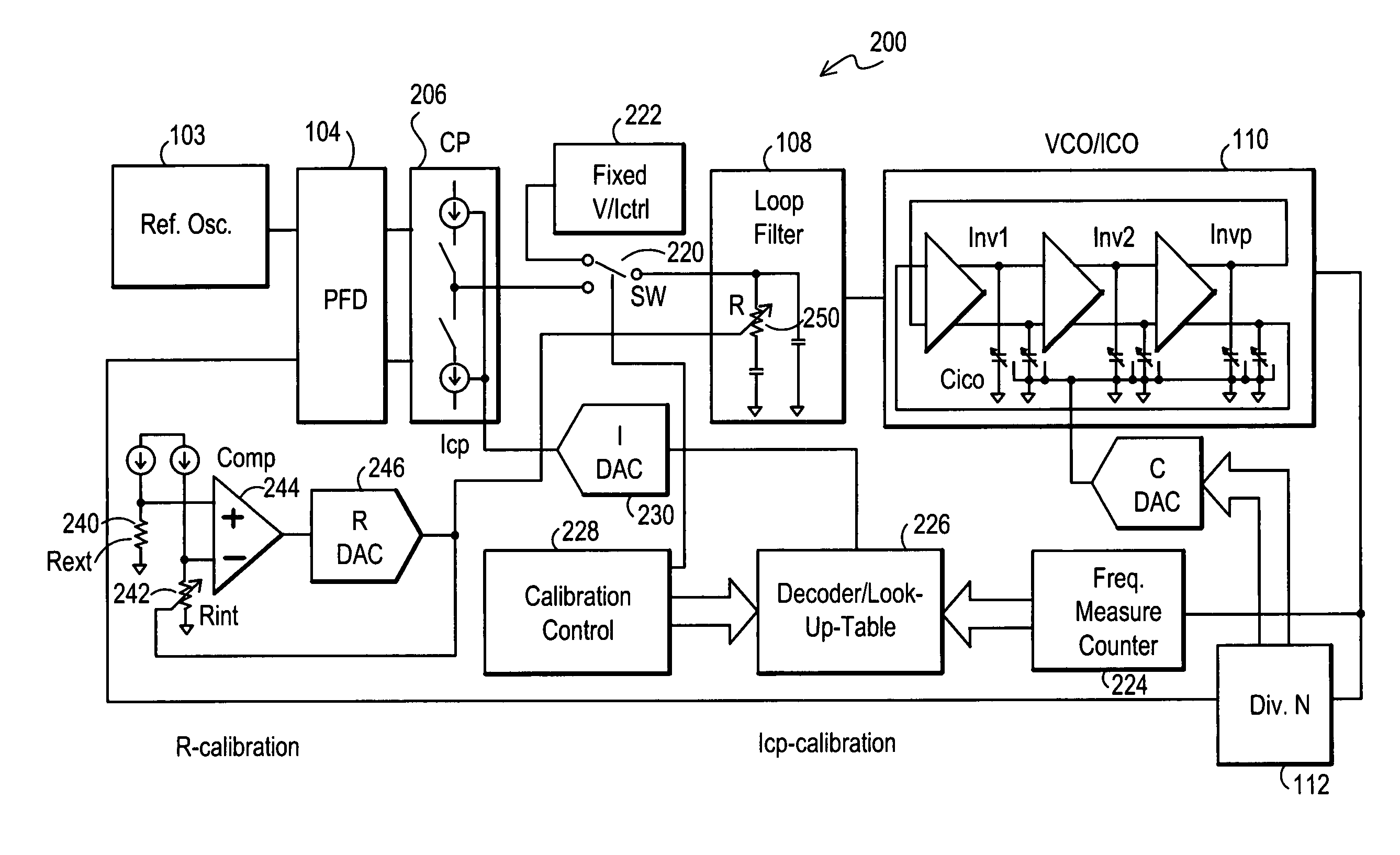

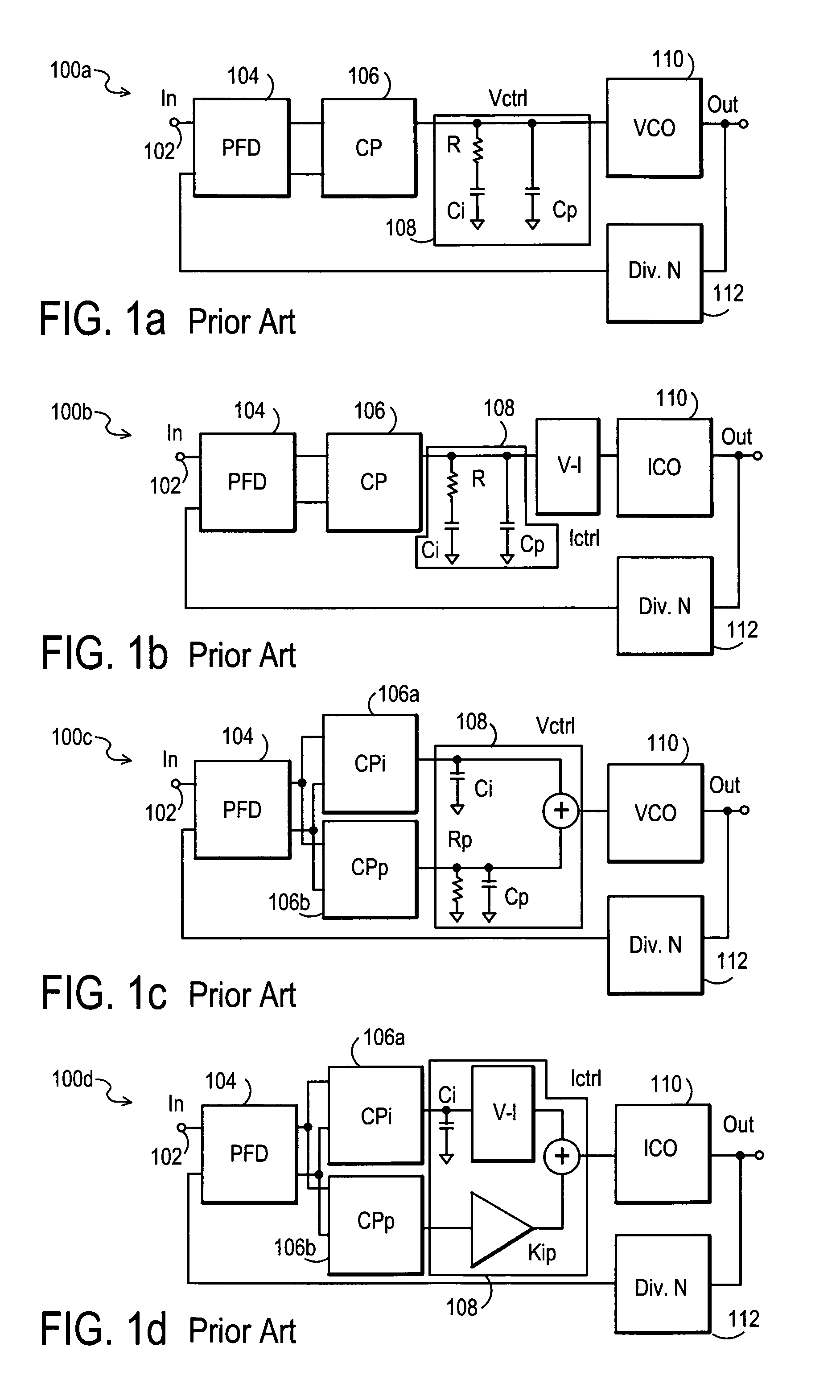

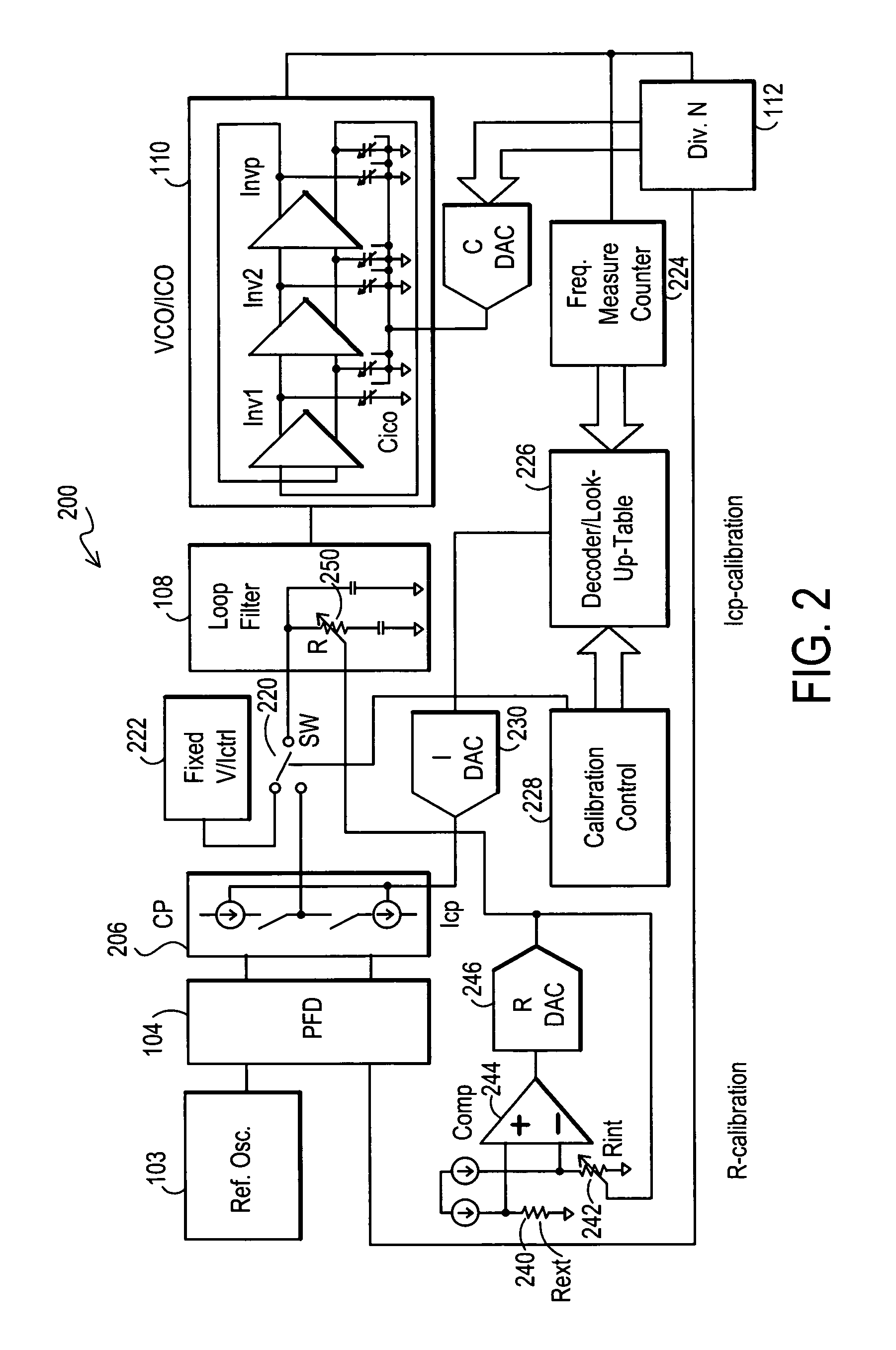

Method and apparatus to achieve a process, temperature and divider modulus independent PLL loop bandwidth and damping factor using open-loop calibration techniques

InactiveUS7095287B2Reduce complexityImprove accuracyPulse automatic controlFrequency analysisDamping factorProportional control

Several open-loop calibration techniques for phase-locked-loop circuits (PLL) that provide a process, temperature and divider modulus independence for the loop bandwidth and damping factor are disclosed. Two categories of open-loop techniques are presented. The first method uses only a single measurement of the output frequency from the oscillator and adjusts a single PLL loop element that performs a simultaneous calibration of both the loop bandwidth and damping factor. The output frequency is measured for a given value of the oscillator control signal and the charge-pump current is adjusted such that it cancels the process variation of the oscillator gain. The second method uses two separate and orthogonal calibration steps, both of them based on the measurement of the output frequency from the oscillator when a known excitation is applied to the open loop signal path. In the first step the loop bandwidth is calibrated by adjusting the charge-pump current based on the measurement of the forward path gain when applying a constant phase shift between the two clocks that go to the phase frequency detector, while the integral path is hold to a constant value. During the second step the damping factor is calibrated by adjusting the value of the integral loop filter capacitor based on the measurement of the oscillator output frequency when excited with a voltage proportional with the integral capacitor value, while the proportional control component is zeroed-out.

Owner:SILICON LAB INC

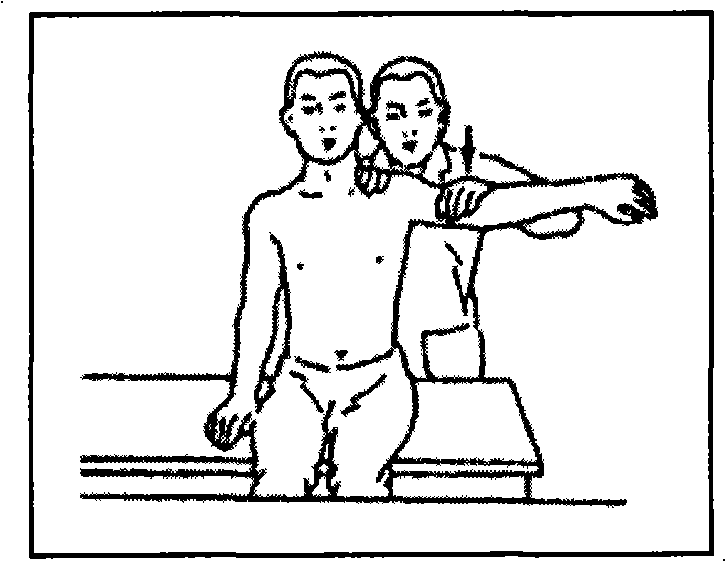

Five-freedom degree dermaskeleton type upper limb rehabilitation robot interactive rehabilitation training control policy

InactiveCN101301250AReduce quality problemsIncrease initiativeGymnastic exercisingChiropractic devicesProportional controlRecovery period

The invention provides a five-degree of freedom exoskeleton-type upper limb recovery robot interactive recovery training control strategy. The strategy comprises two training patterns corresponding to the different recovery period of a patient, i.e. a passive interactive recovery training control strategy and an active-auxiliary interactive recovery training control strategy; during passive movement, a surface myoelectric signal of relevant muscles on a healthy upper limb of a patient is picked up and taken as the movement intention of the patient, thereby controlling a robot to drive a diseased side to realize movement passive training; during active movement, the movement intention of an upper limb of a human body is judged through acquiring in real time the arthrosis force moment generated by a diseased limb acting on the robot during movement, and an applied force is converted into the velocity quantity of the tail end of a mechanical arm by means of a proportional controller, thereby driving the robot to follow the intention so as to carry out recovery active-auxiliary training of the diseased limb. The five-degree of freedom exoskeleton-type upper limb recovery robot interactive recovery training control strategy can provide all-around recovery training movement for a clinic hemiplegia patient, thereby increasing the activeness of the patient in recovery training and the confidence of the patient in recovery; meanwhile, the recovery training control strategy also increases the attractiveness of a recovery process and promotes recovery efficacy.

Owner:HARBIN INST OF TECH

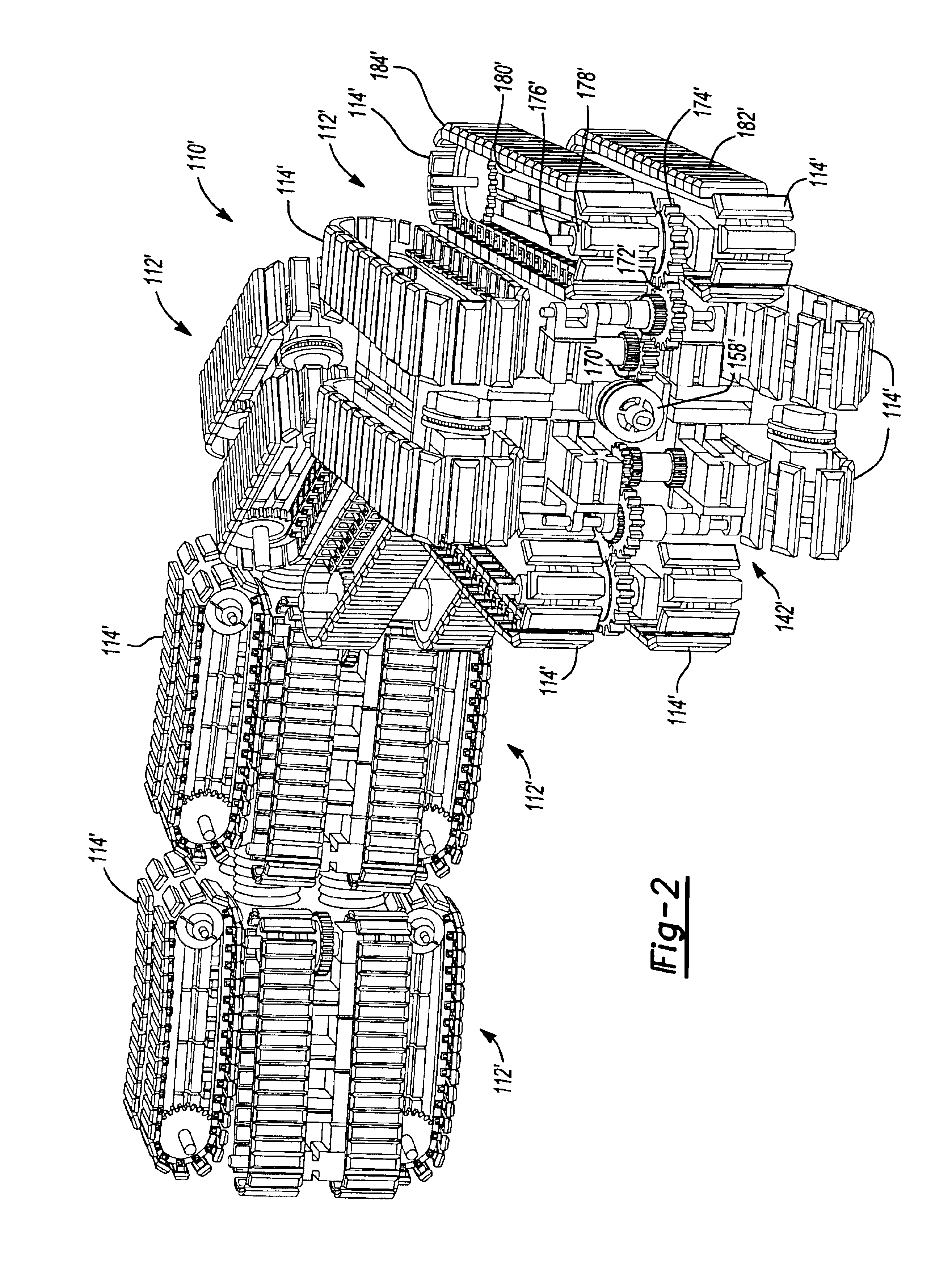

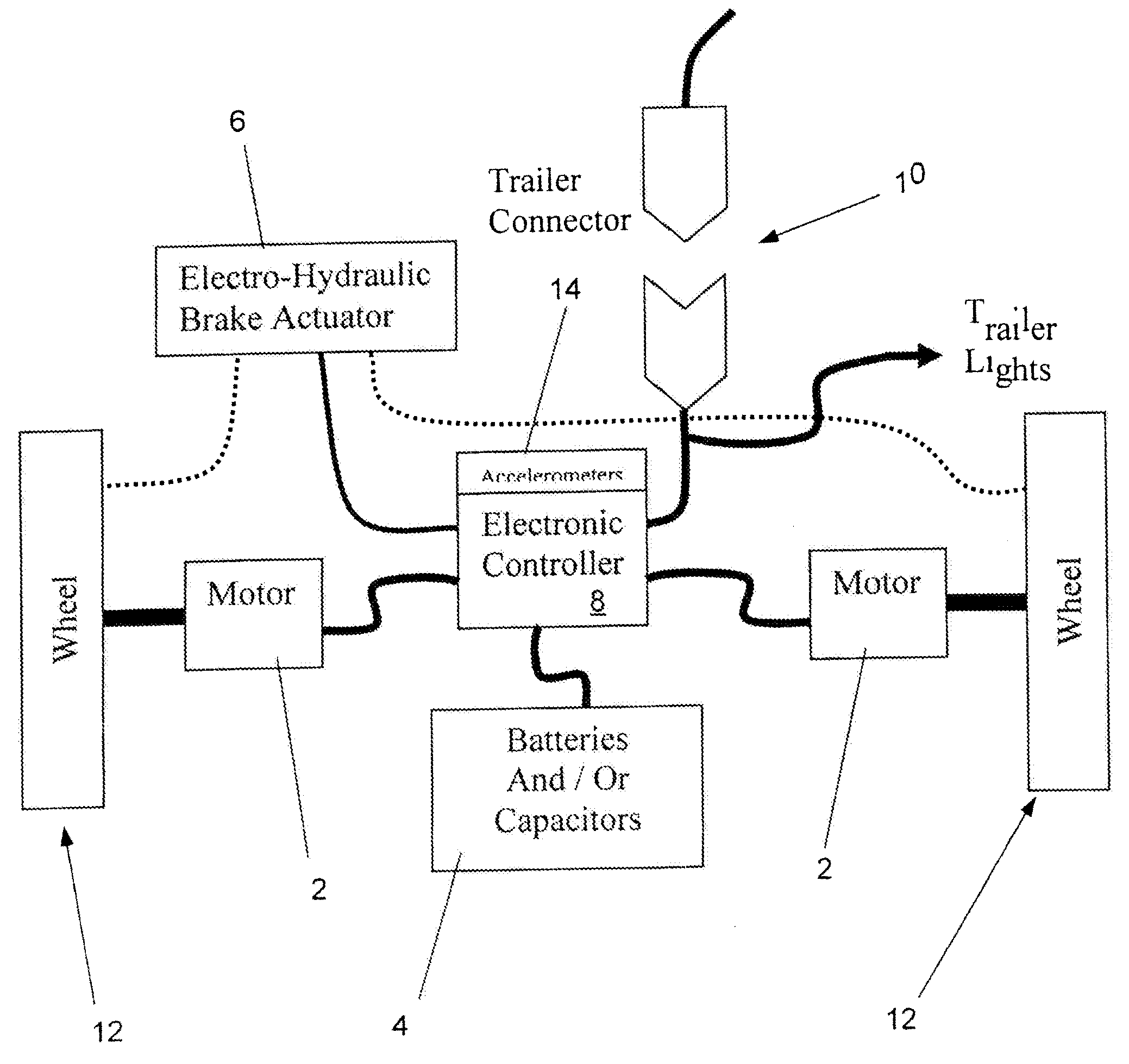

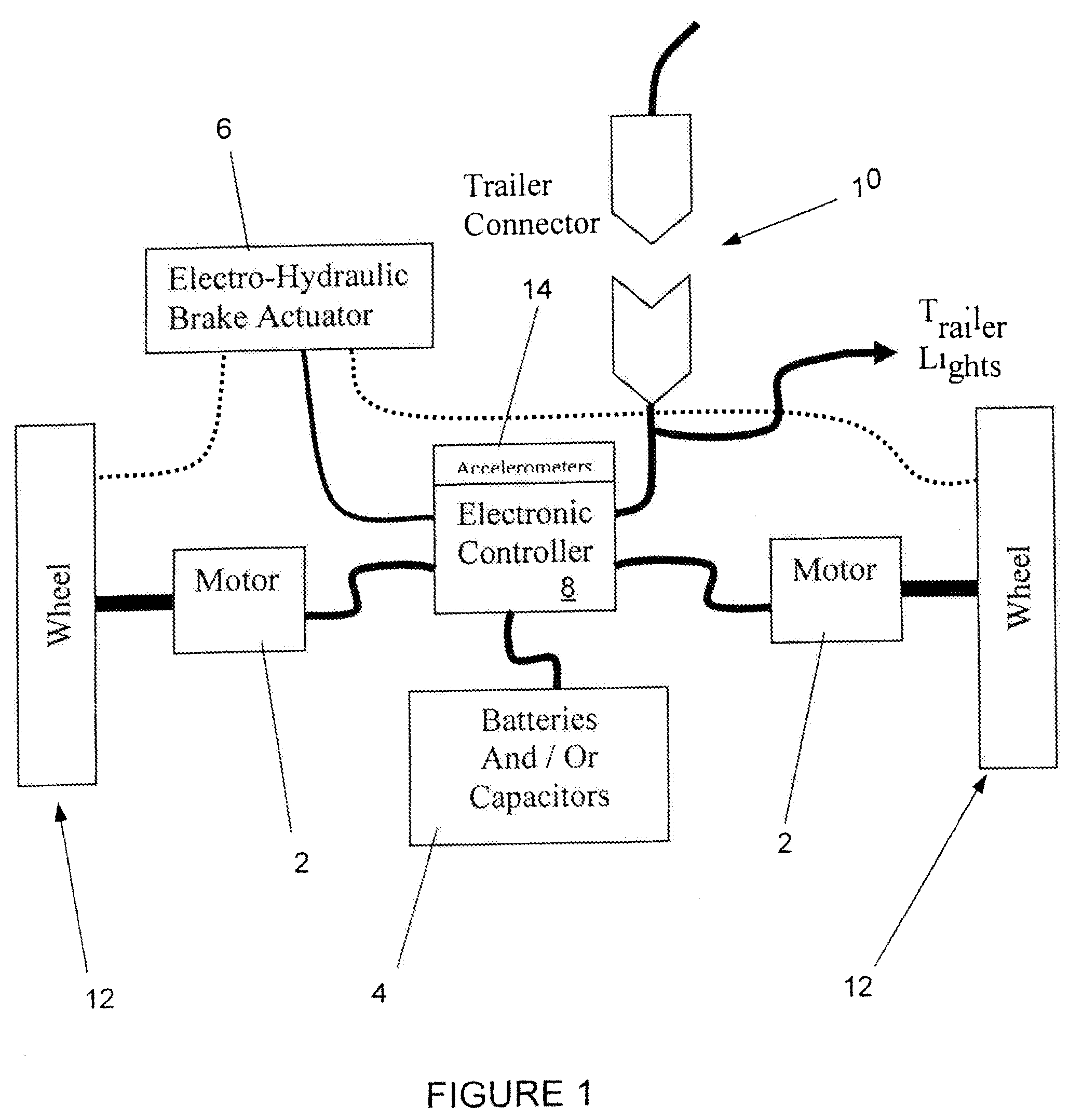

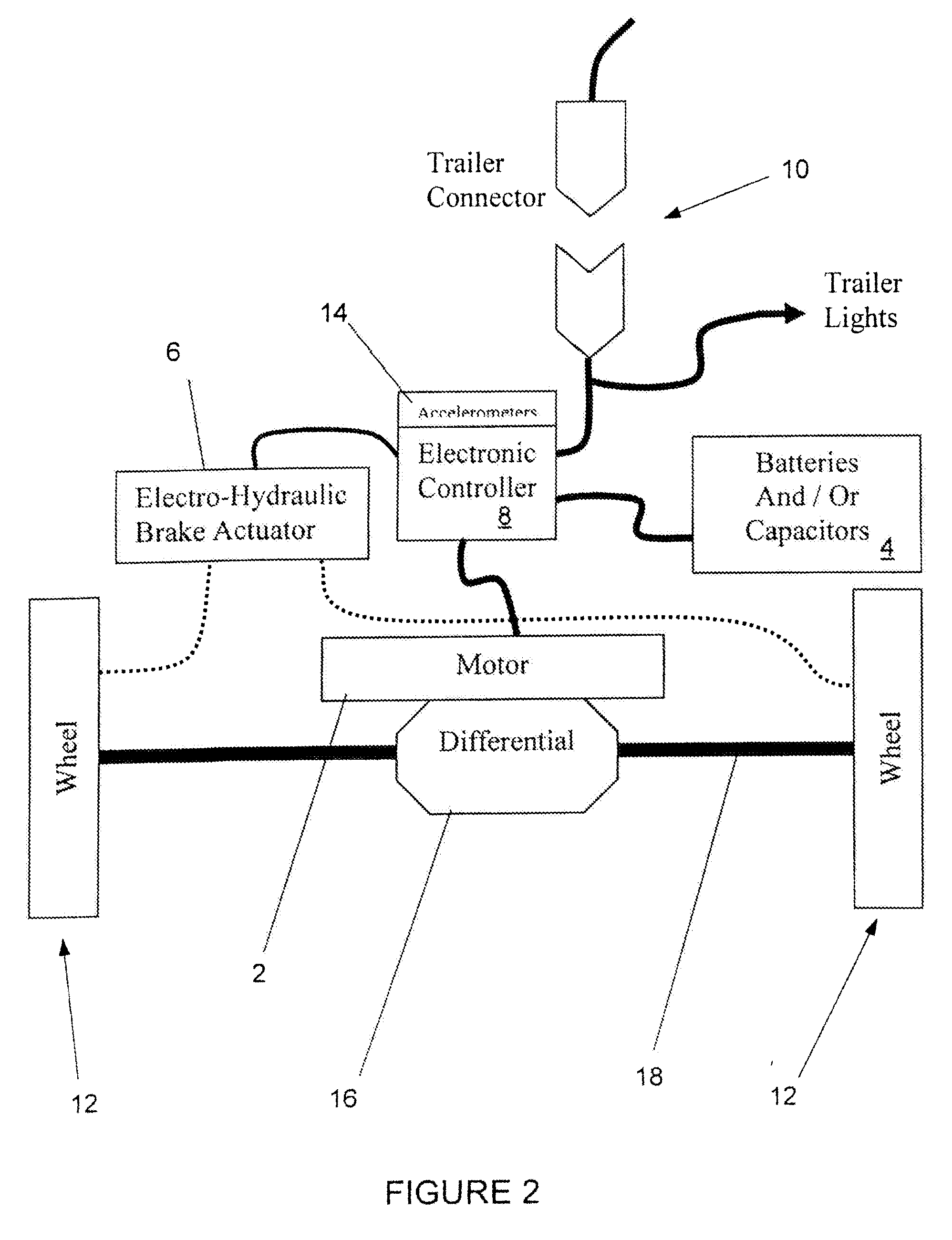

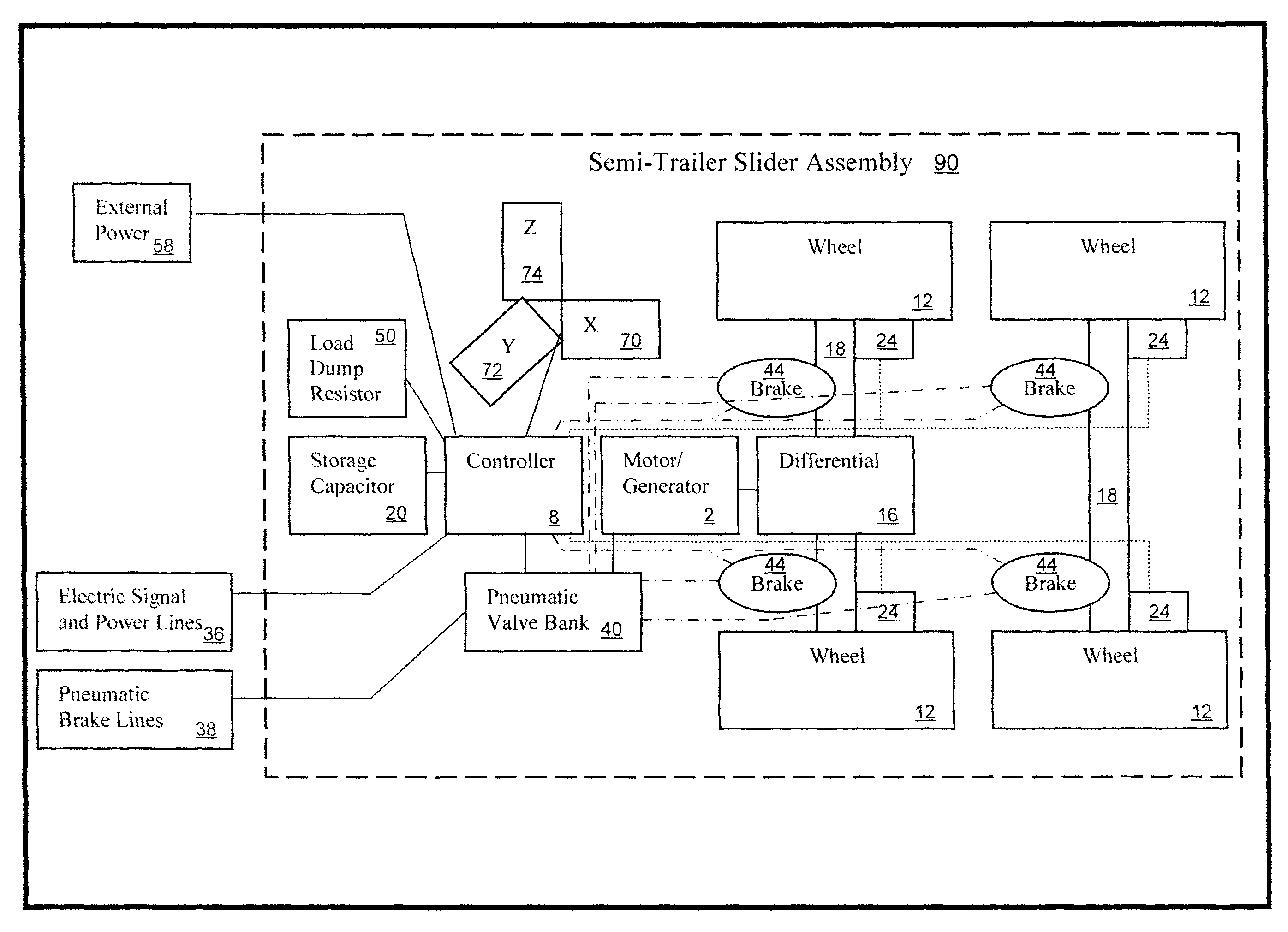

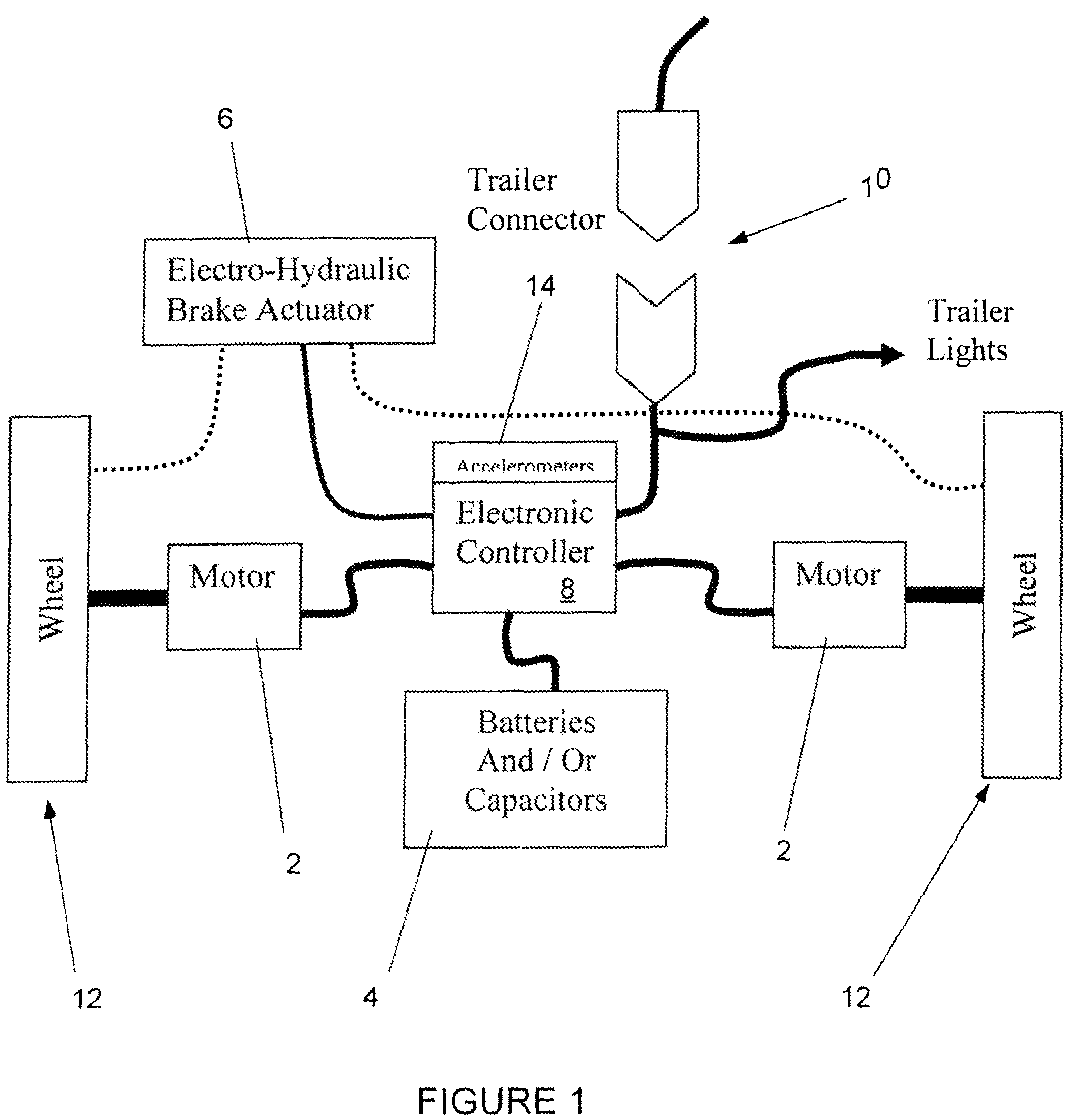

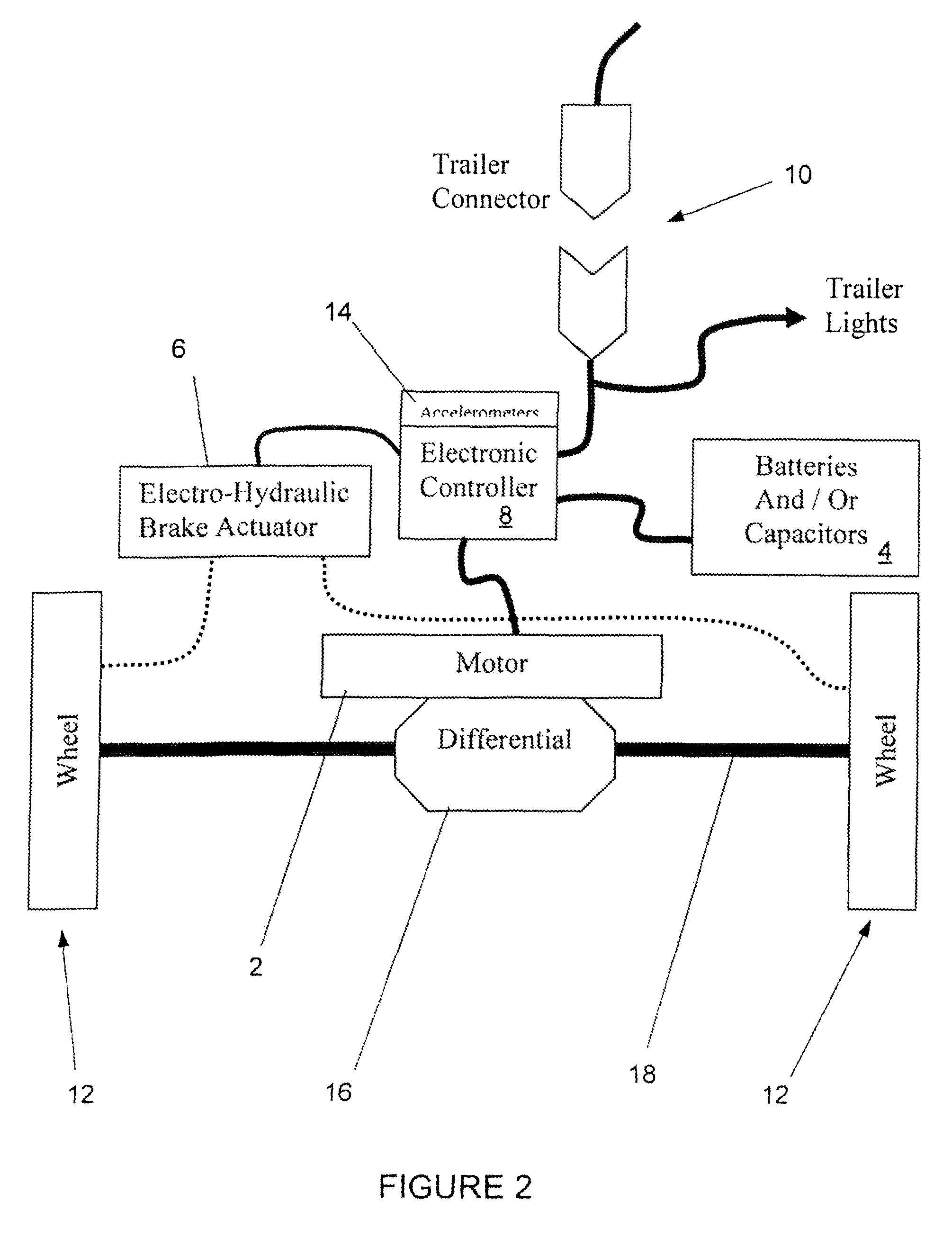

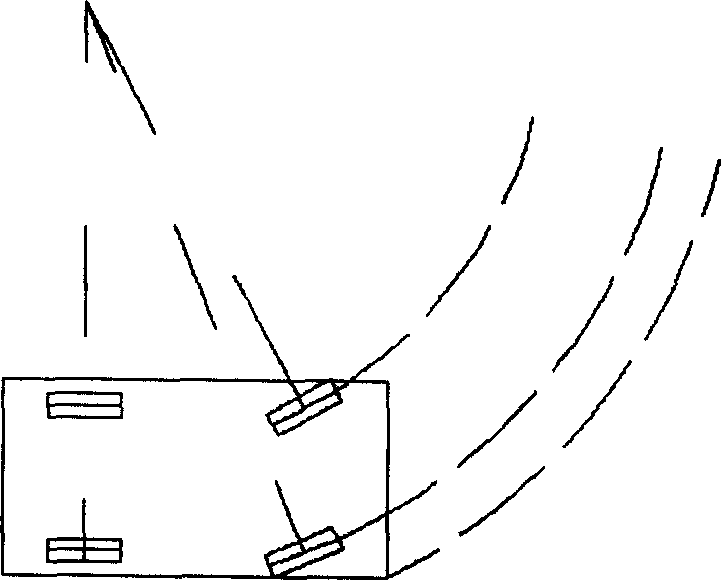

Hybrid trailer system

InactiveUS20080169144A1Easily retrofit into new and used trailerReduce maintenanceAuxillary drivesConvertible cyclesCapacitanceCapacitive storage

A system and related method for a regenerative braking system on a towed vehicle, such as a trailer or semi-trailer. The system provides power and braking to the respective trailer wheels, as needed, to help stabilize the trailer. Power is regenerated during braking. While batteries may be used to store the energy, the system also may use capacitive storage units, which charge and discharge large amounts of energy at a fast rate. A multiple-axis sensor system in conjunction with wheel sensors, load sensors, and proportional control of the brakes and motor power to the axles and wheels, is used to achieve superior load stabilization. The invention can be easily retrofit into new or used trailers, and is self-contained with low maintenance.

Owner:DEGRAVE KEN +1

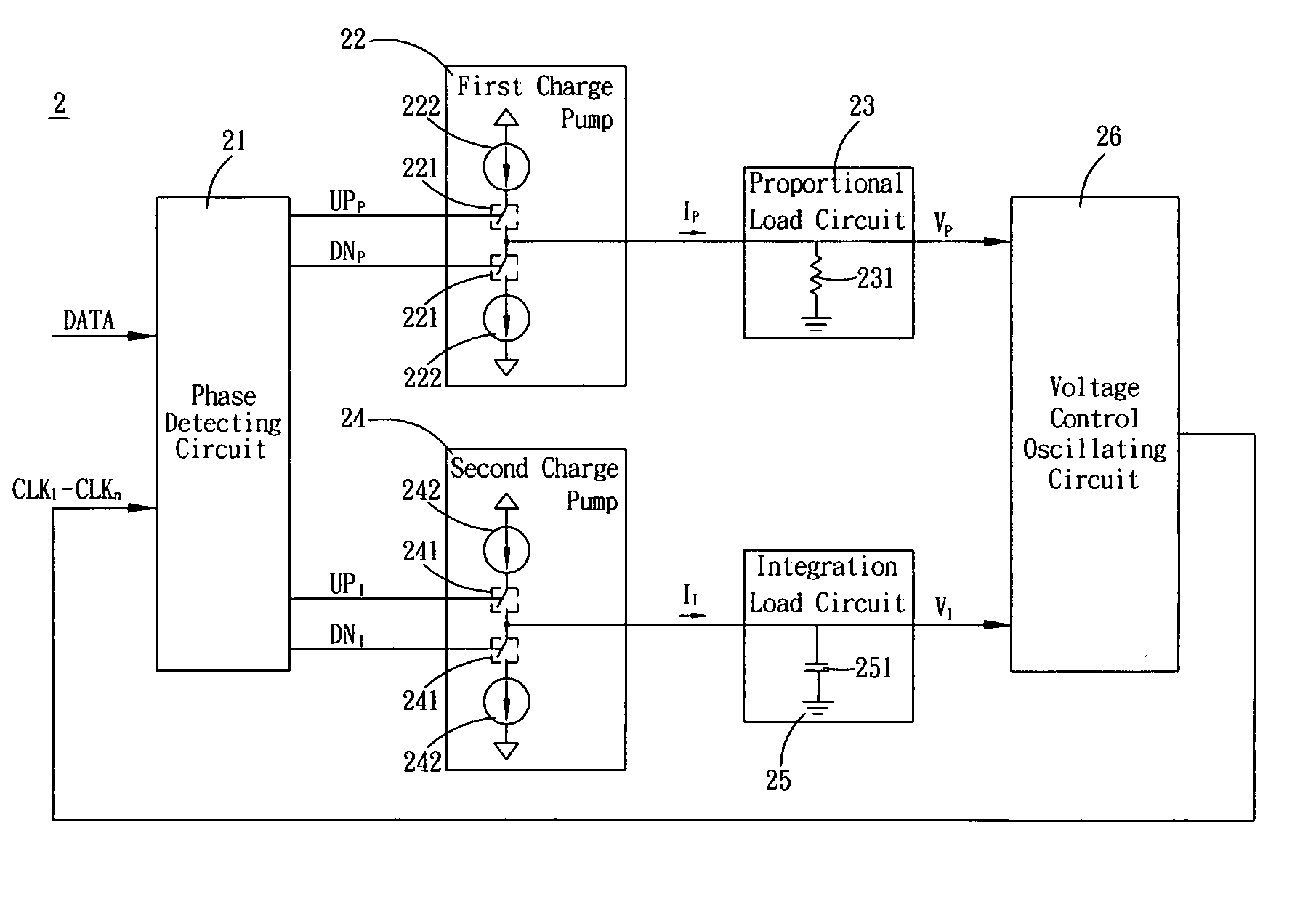

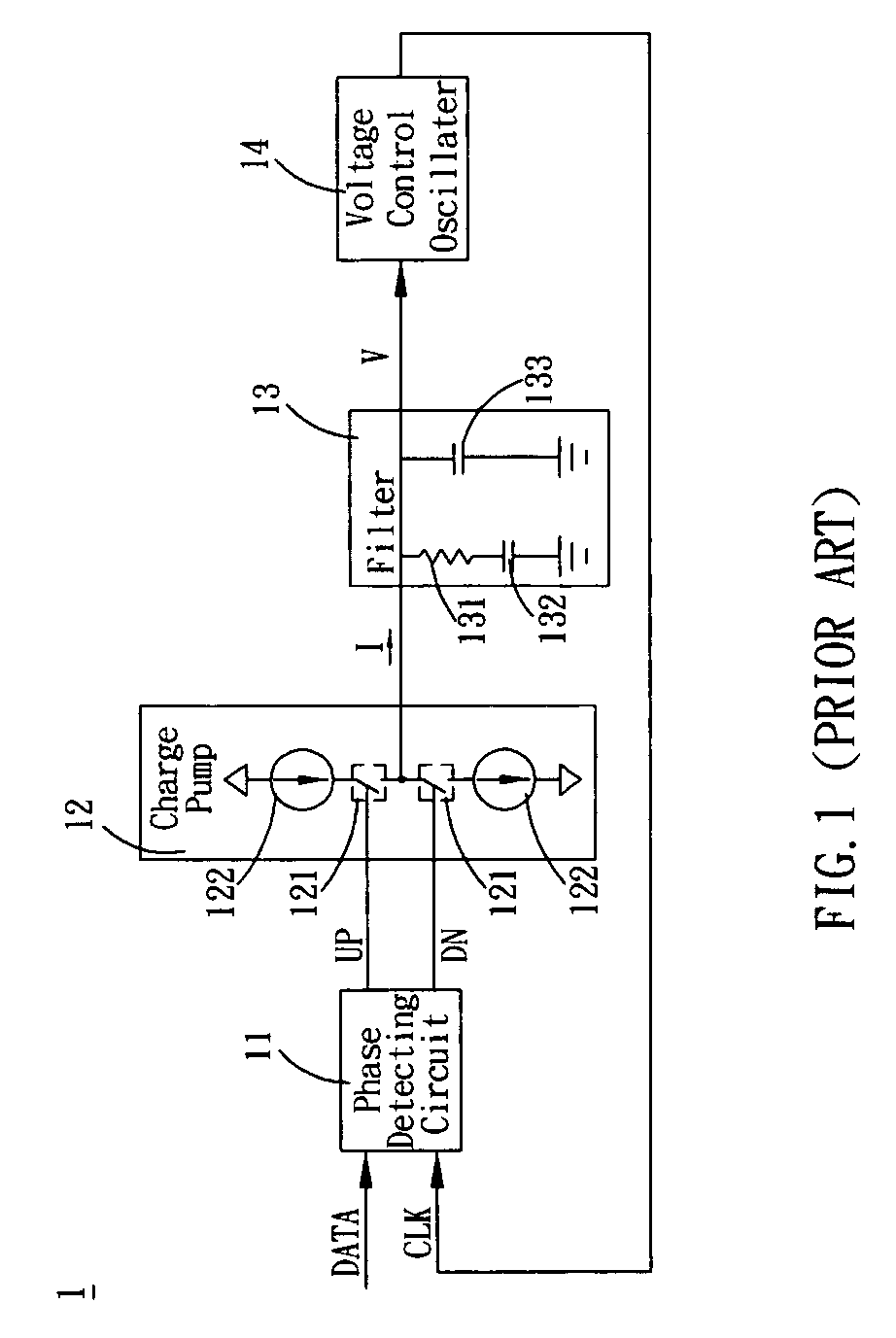

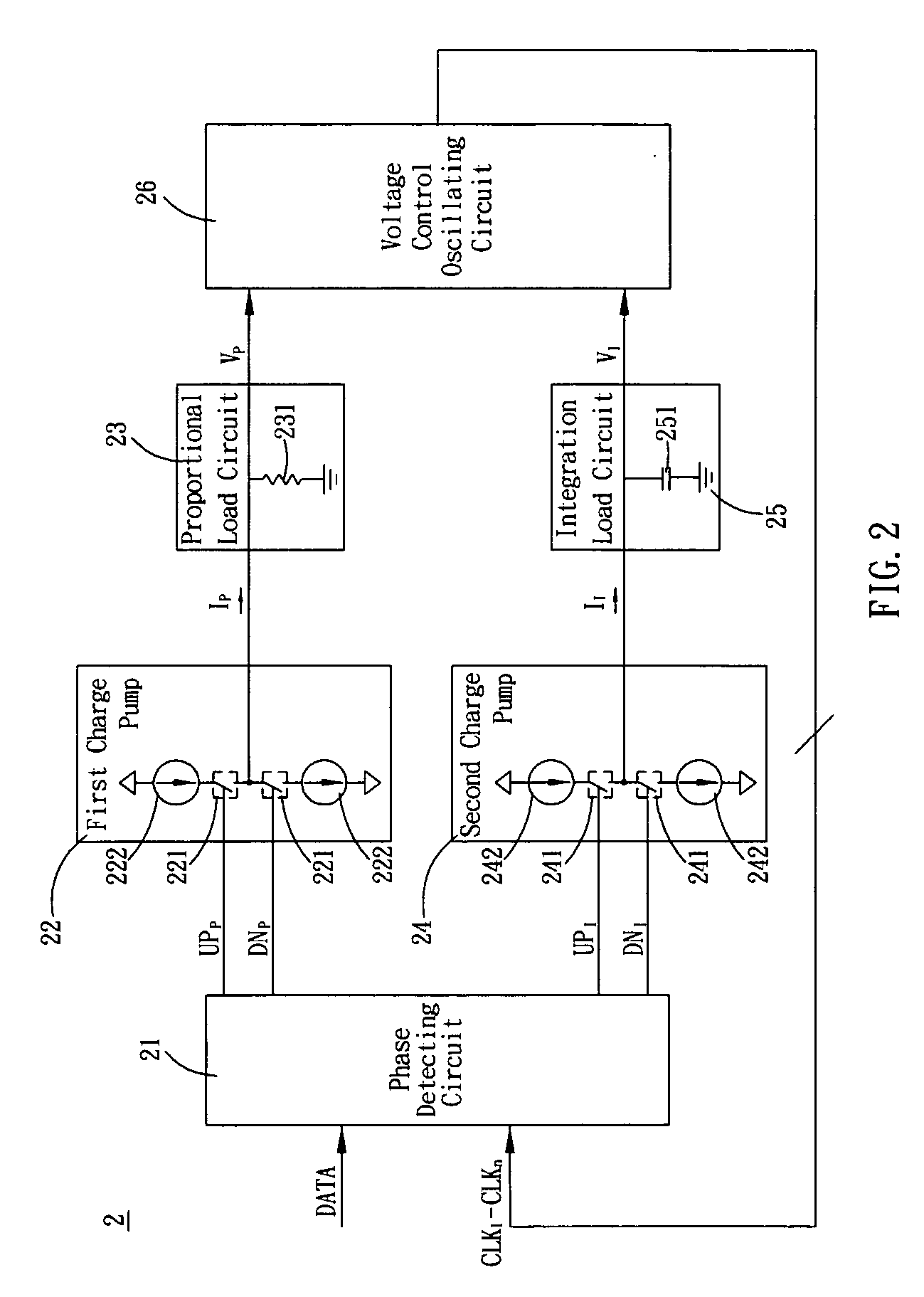

Clock and data recovery circuit and method thereof

ActiveUS20070001723A1Easy to optimizeEasy to regulatePulse automatic controlSynchronising arrangementLoad circuitProportional control

A clock and data recovery circuit having parallel dual path is disclosed, which includes a phase detecting circuit, a first charge pump, a proportional load circuit, a second charge pump, an integration load circuit, and a voltage control oscillating circuit. The phase detecting circuit respectively compares a phase difference between a data signal and a plurality of clock signals to generate two proportional control signal and two integration control signal for respectively controlling the first charge pump and the second charge pump to generate a first current and a second current. The proportional load circuit and the integration load circuit respectively receive the first current and the second current to output a proportional voltage and an integration voltage. The voltage control oscillating circuit adjusts the phase and frequency of the plurality of clock signals in response to the proportional voltage and the integration voltage.

Owner:VIA TECH INC

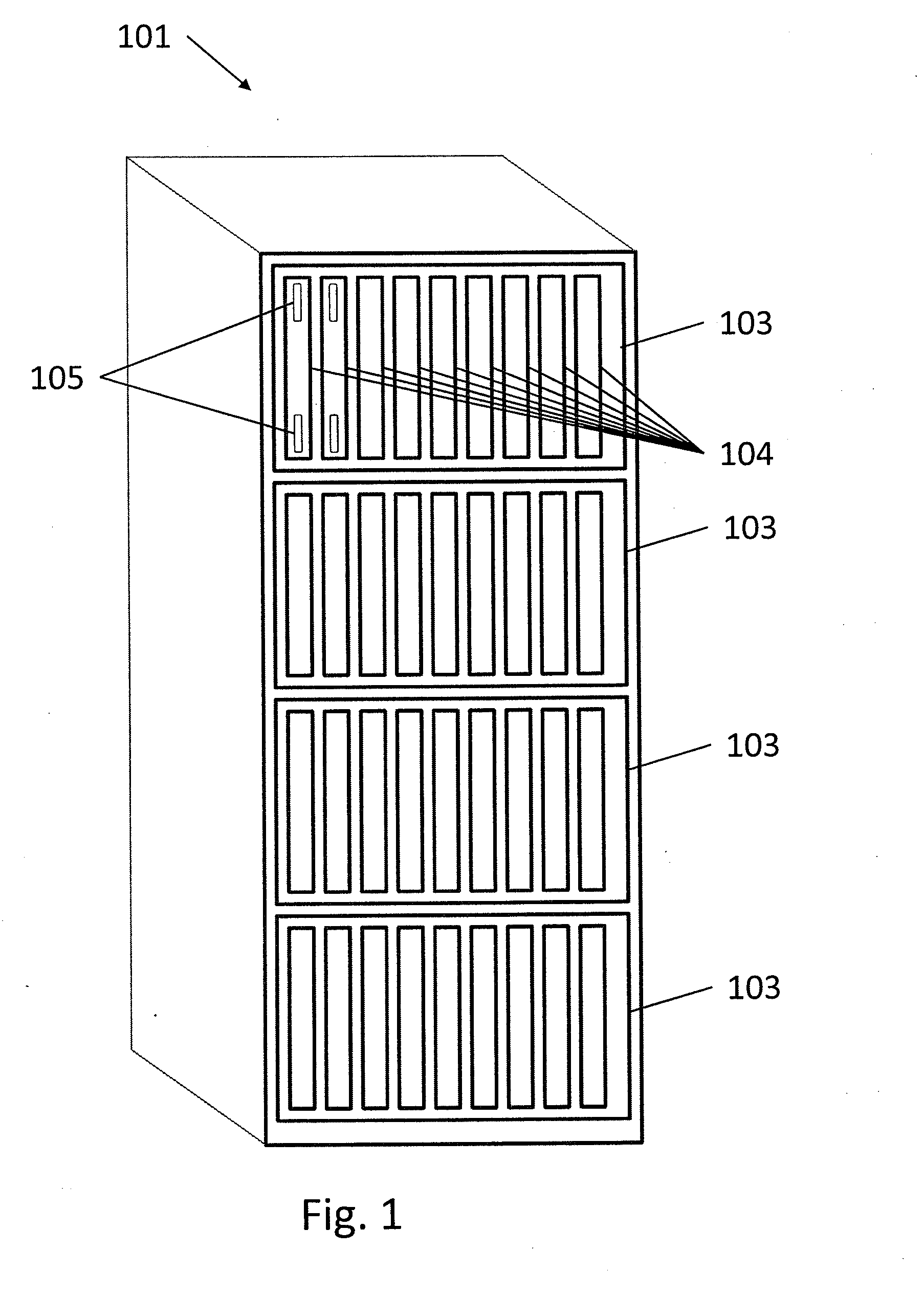

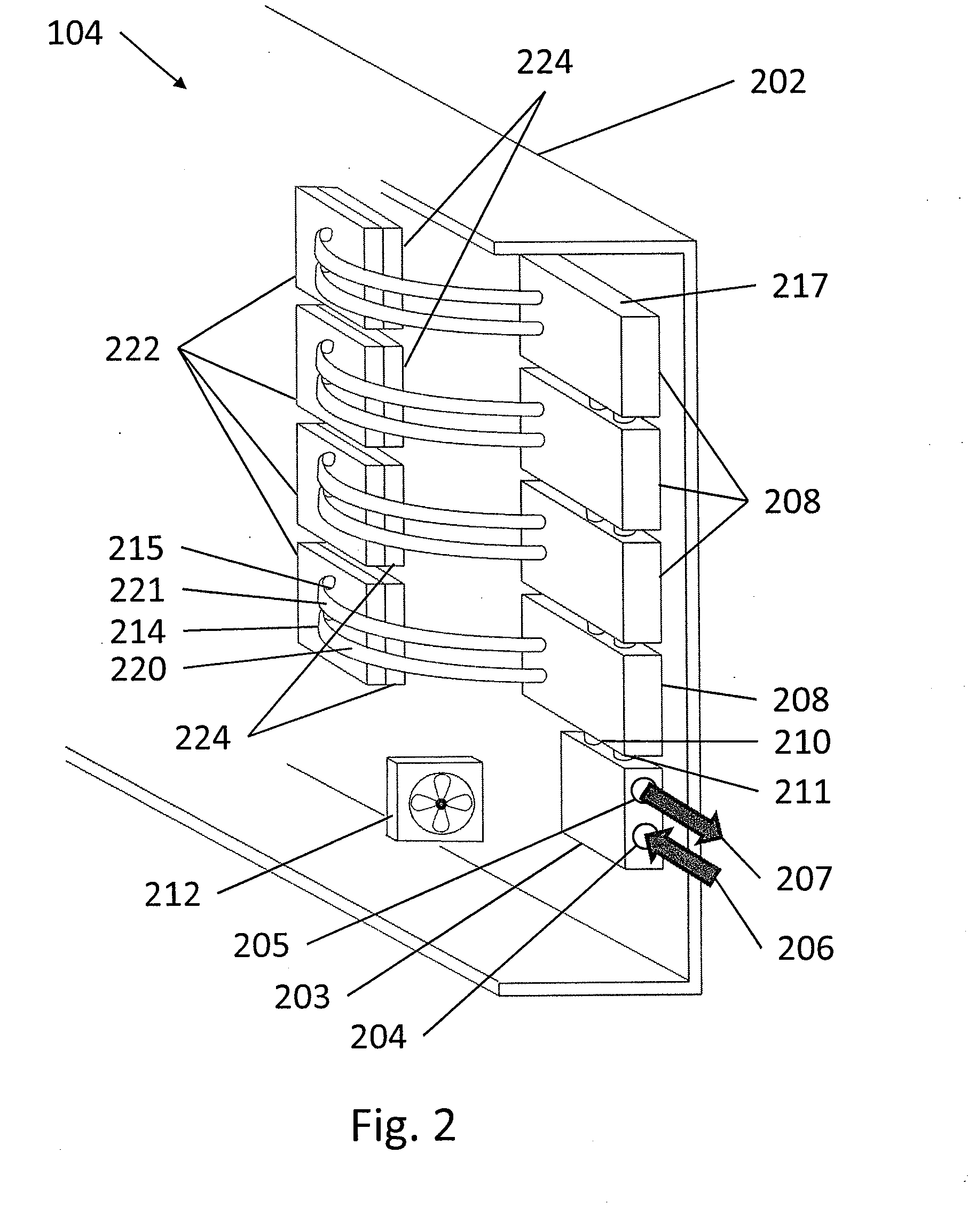

Liquid-Based Cooling System For Data Centers Having Proportional Flow Control Device

InactiveUS20110240281A1Efficient use ofMaximize engine efficiencyTemperature control using digital meansDigital data processing detailsProportional controlAdsorption chiller

A liquid-based cooling system provides a method of supplying a heated coolant fluid at a relatively constant temperature and pressure to one or more heat driven engines, such as adsorption chillers or heat pumps, by utilizing a proportional flow control device in association with each of a plurality of heat-producing electronic components to optimize the output of a plurality of liquid-cooled cold plates operatively mounted on such plurality of heat-producing electronic components. The proportional flow control devices may be electro-mechanical or solid state proportional control valves for water flow control. The proportion flow control devices are operatively connected to be actuated based upon the electrical signals typically generated to control the variable cooling fans of the electronic components.

Owner:INDAL IDEA PARTNERS

Integrated, proportionally controlled, and naturally compliant universal joint actuator with controllable stiffness

InactiveUS20050007055A1Minimize airflowLimited stiffnessProgramme-controlled manipulatorComputer controlProportional controlUniversal joint

An apparatus for traversing obstacles having an elongated, round, flexible body that includes a plurality of segments interconnected by an integrated joint actuator assembly. The integrated joint actuator assembly includes a plurality of bellows-type actuators individually coupling adjacent segments to permit pivotal actuation of the apparatus therebetween. A controller is employed to maintain proper positional control and stiffness control while minimize air flow.

Owner:RGT UNIV OF MICHIGAN

Hybrid trailer system

InactiveUS8215436B2Easily retrofit into new and used trailerReduce maintenanceAuxillary drivesConvertible cyclesCapacitanceCapacitive storage

A system and related method for a regenerative braking system on a towed vehicle, such as a trailer or semi-trailer. The system provides power and braking to the respective trailer wheels, as needed, to help stabilize the trailer. Power is regenerated during braking. While batteries may be used to store the energy, the system also may use capacitive storage units, which charge and discharge large amounts of energy at a fast rate. A multiple-axis sensor system in conjunction with wheel sensors, load sensors, and proportional control of the brakes and motor power to the axles and wheels, is used to achieve superior load stabilization. The invention can be easily retrofit into new or used trailers, and is self-contained with low maintenance.

Owner:DEGRAVE KEN +1

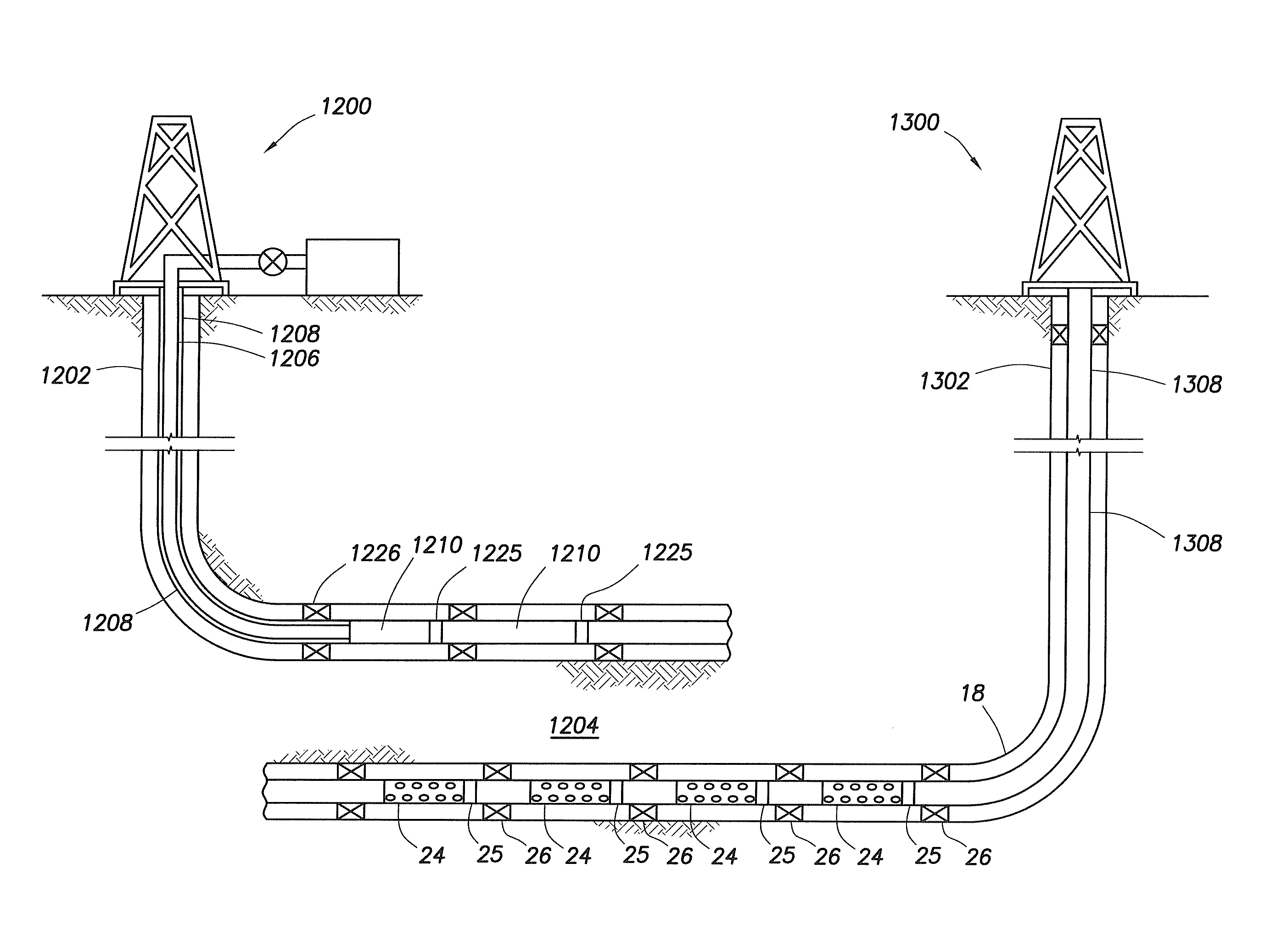

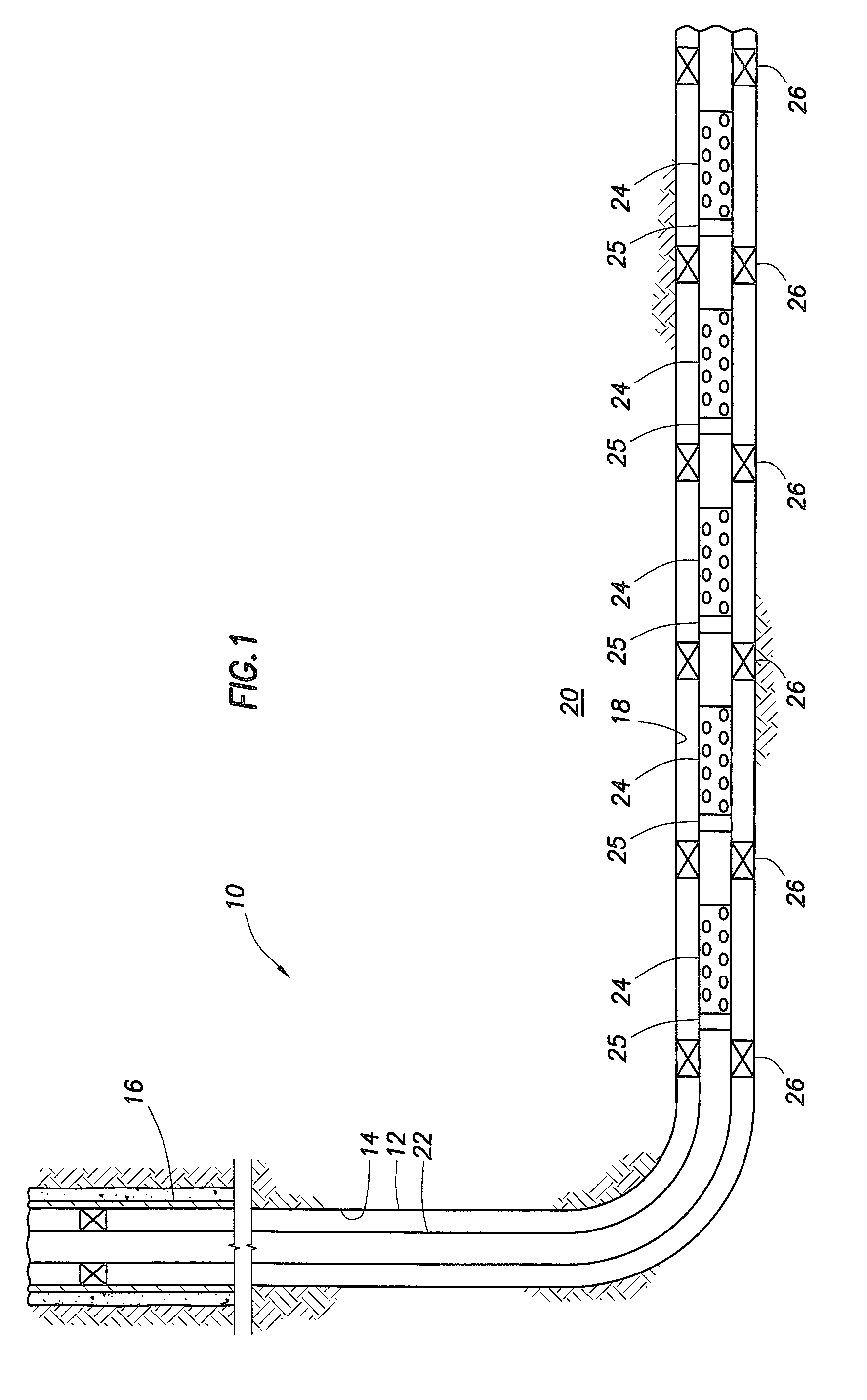

Method and apparatus for autonomous downhole fluid selection with pathway dependent resistance system

An apparatus is described for controlling flow of fluid in a tubular positioned in a wellbore extending through a subterranean formation. A flow control system is placed in fluid communication with a main tubular. The flow control system has a flow ratio control system and a pathway dependent resistance system. The flow ratio control system has a first and second passageway, the production fluid flowing into the passageways with the ratio of fluid flow through the passageways related to the characteristic of the fluid flow. The pathway dependent resistance system includes a vortex chamber with a first and second inlet and an outlet, the first inlet of the pathway dependent resistance system in fluid communication with the first passageway of the fluid ratio control system and the second inlet in fluid communication with the second passageway of the fluid ratio control system. The first inlet is positioned to direct fluid into the vortex chamber such that it flows primarily tangentially into the vortex chamber, and the second inlet is positioned to direct fluid such that it flows primarily radially into the vortex chamber. Undesired fluids, such as natural gas or water, in an oil well, are directed, based on their relative characteristic, into the vortex primarily tangentially, thereby restricting fluid flow when the undesired fluid is present as a component of the production fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

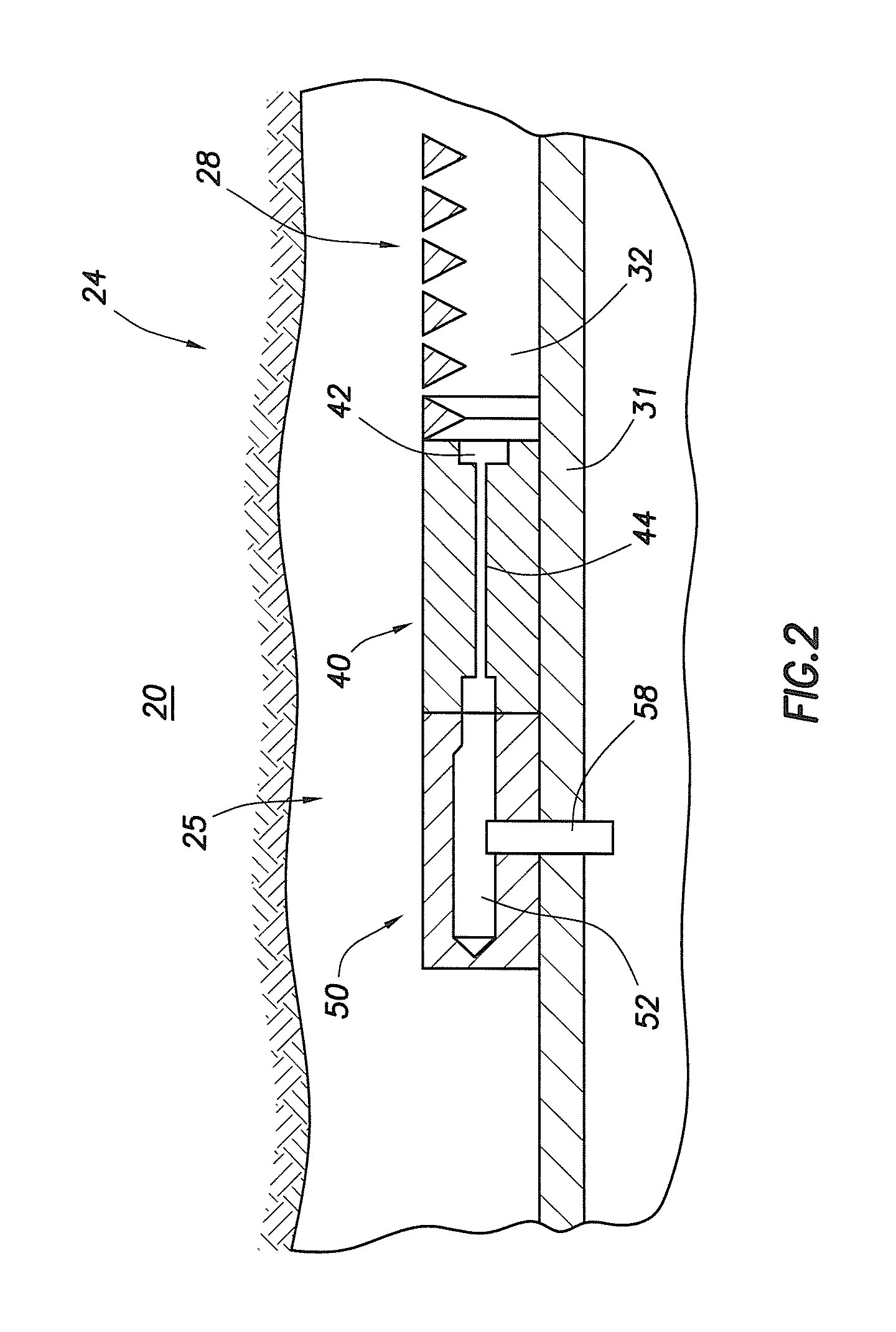

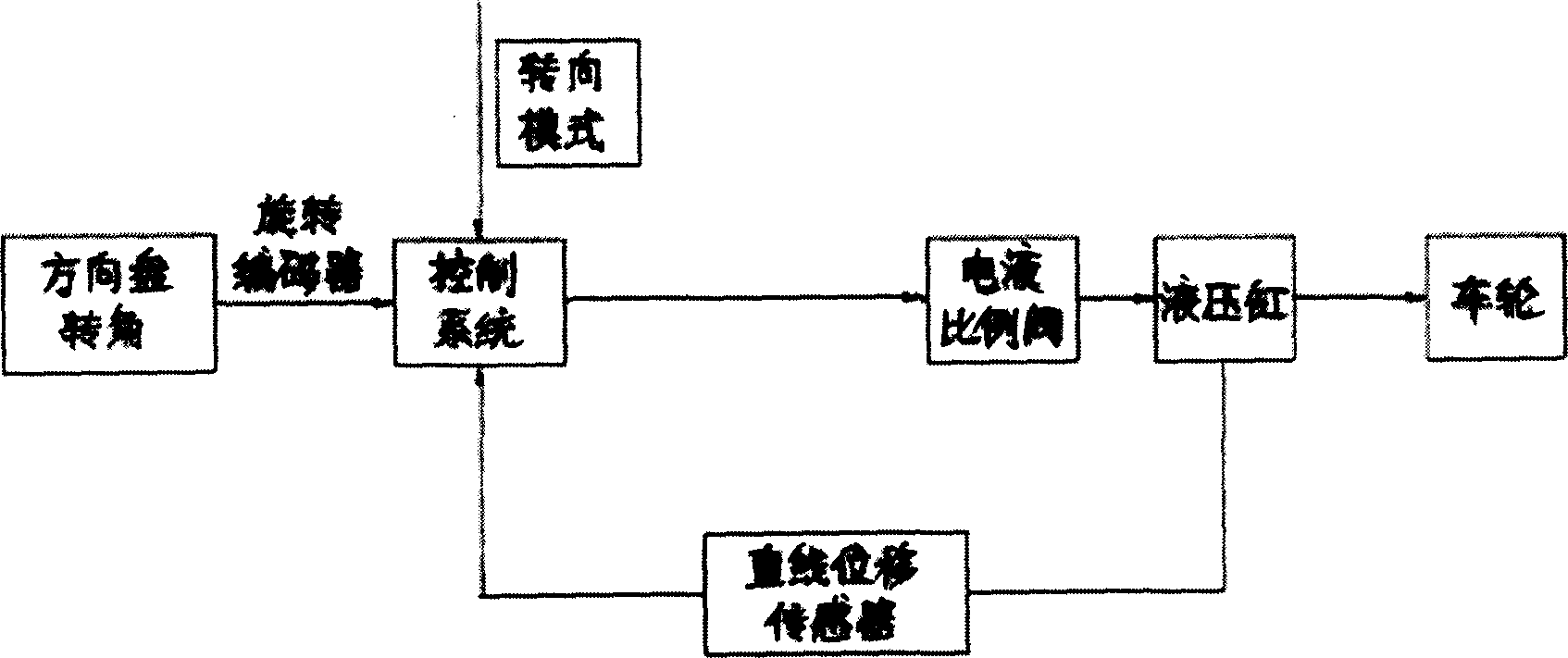

Separated steering device for vehicular four wheels and its control method

The invention relates to domain of special purpose vehicle and especially to a separate four-wheel steering device of vehicle and controlling means, which is mainly used in steering system of special purpose vehicle to guarantee steering behavior. The device comprises steering knuckle arm, steering hydraulic cylinder, electro-hydraulic proportional control valves, and accumulator, easing valve, hydraulic pump, clarifier and electronic control system. The invention is characterized in that every wheel is controlled by independent oil-hydraulic cylinder, electronic control system comprises steering emulator, signal processor and measuring apparatus of displacement line and hydraulic pump driven by engine in steering hydraulic system controls hydraulic cylinder of steering system via electro-hydraulic proportional control valves of steering system. Hydraulic cylinder connects with linear movement pickup to feed variable of displacement line of hydraulic cylinder back to CPU. System adopts closed-loop control. Control circuit equips system failure diagnosis element to realize alarm when system steering error occurs and steering mode switching control unit to complete steering mode switching of vehicle.

Owner:JIANGSU UNIV

EHB proportional solenoid valve with stepped gap armature

InactiveUS6994406B1Operating means/releasing devices for valvesMagnetsMagnetic tension forceElectricity

A control valve includes a magnetic pole member. An armature is slidably supported relative to the magnetic pole member for movement between a fully open position and a closed position. A biasing spring is disposed between the magnetic pole member and the armature for forcing the armature away from the magnetic pole member. A coil is placed about the magnetic pole member and the armature for inducing a magnetic field for moving the armature toward the magnetic pole member. One of either of the magnetic pole member or the armature has a recess for non-contactingly receiving the other when the armature moves between the fully open and closed positions. The control valve can be embodied as a normally open valve or a normally closed valve. The use of dual lateral poles and triple lateral poles create a flat magnetic force versus travel curve thereby allowing for greater proportional control of the valve. Additionally, the use of double lateral gaps and triple lateral gaps respectively results in force increases of 21% and 12% respectively. Compounding the force increases results in a net additional force of 36%.

Owner:KELSEY HAYES CO

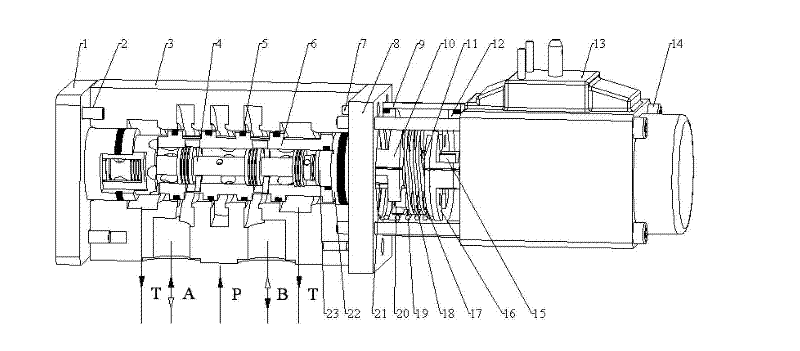

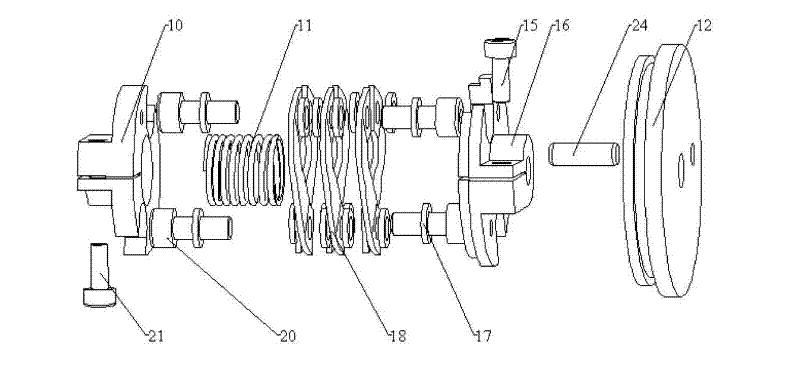

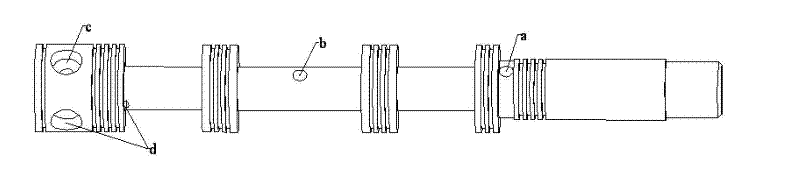

2D hydraulic-power-assisted electro-hydraulic proportional reversing valve

ActiveCN102650305AHigh precisionReduce adverse effectsServomotor componentsElectricityProportional control

The invention provides a 2D (2-dimensional) hydraulic-power-assisted electro-hydraulic proportional reversing valve, which comprises a valve body, a valve core, a valve sleeve, a linear electro-mechanical converter and a compressive-torsional coupling, wherein the valve core, the compressive-torsional coupling and the linear electro-mechanical converter are coaxially connected; an output shaft of the linear electro-mechanical converter is fixedly connected with an input end of the compressive-torsional coupling; an output end of the compressive-torsional coupling is fixedly connected with the right end of the valve core; a sensitive cavity is formed by the left end of the valve core, the valve sleeve and a left cover plate; a pair of axisymmetric high pressure holes and a pair of axisymmetric low pressure holes are respectively formed on the surfaces of shoulders of the valve core in the sensitive cavity; a pair of axisymmetric sensing channels are arranged on the inner surface of the valve sleeve outside the sensitive cavity; and one end of each receptive channel is communicated with the sensitive cavity, and the other ends of the receptive channels cover areas between adjacent high pressure holes and low pressure holes. The 2D hydraulic-power-assisted electro-hydraulic proportional reversing valve not only has the characteristics of high flow rate, high working pressure, and the like of an ordinary pilot-control type electro-hydraulic proportional valve, but also fulfils a proportional control function like a direct-actuated proportional valve under the circumstance of zero pressure (pressure loss).

Owner:ZHEJIANG UNIV OF TECH

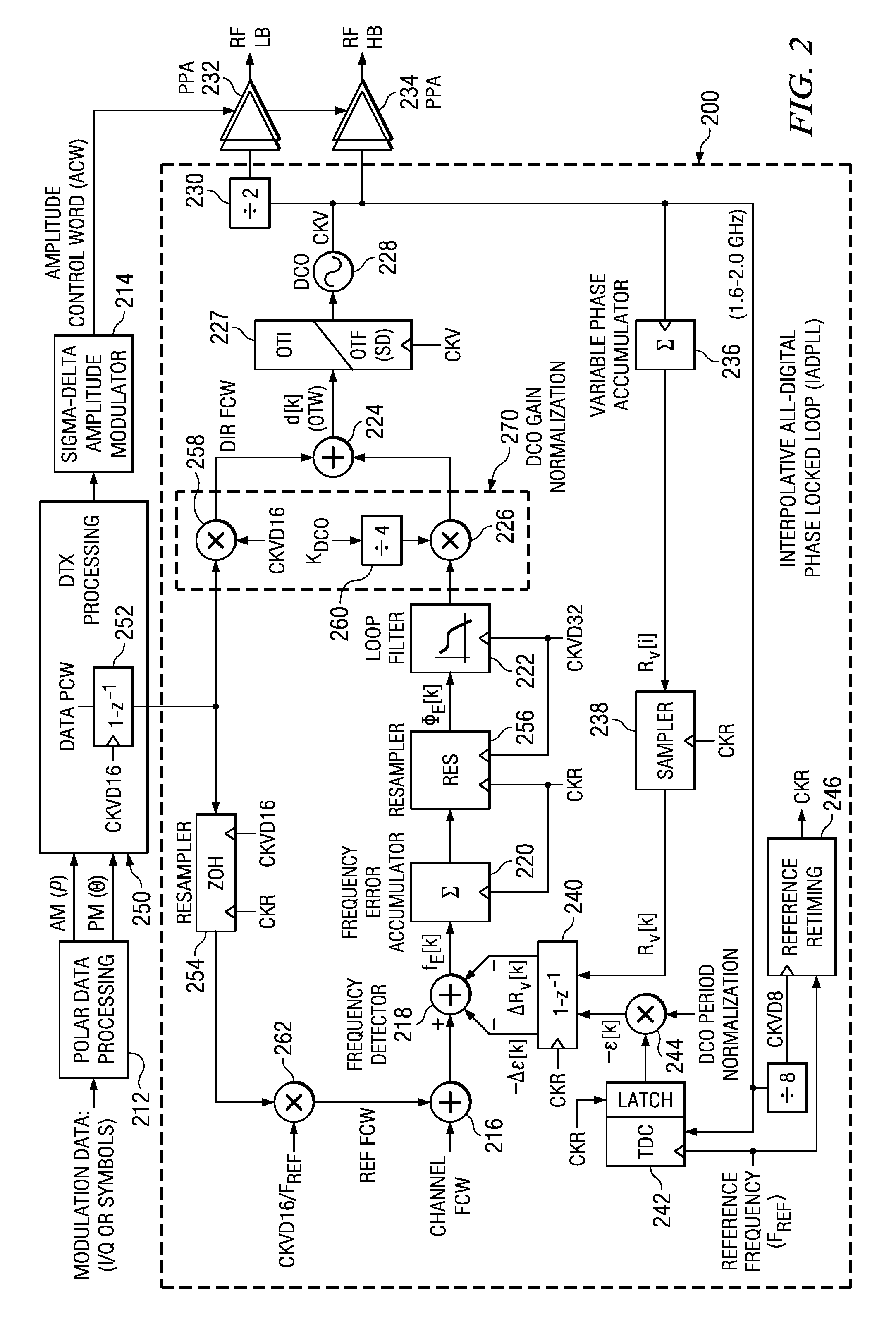

Digital Phase Locked Loop with Gear Shifting

ActiveUS20080315960A1Pulse automatic controlTransmission path divisionProportional controlPhase difference

An embodiment of the present invention provides a phase locked loop that operates on clock signals derived from an RF clock signal generated by the phase locked loop. A frequency reference input provides a reference clock. A controllable oscillator generates the RF clock signal. A phase detection circuit operates on the reference clock to provide digital phase error samples indicative of a phase difference between the reference clock and the RF clock. A programmable filter is connected to receive the phase error samples and connected to provide a filtered output having a gain and a phase margin to the controllable oscillator. The programmable filter includes a proportional loop gain control having a programmable loop gain coefficient (alpha-α) and an integral loop gain control having a programmable loop gain coefficient (rho-ρ). Alpha and rho are configured to be programmatically changed simultaneously and are selected such that the gain is changed and the phase margin remains substantially unchanged

Owner:TEXAS INSTR INC

Intradermal delivery device

Owner:BECTON DICKINSON & CO

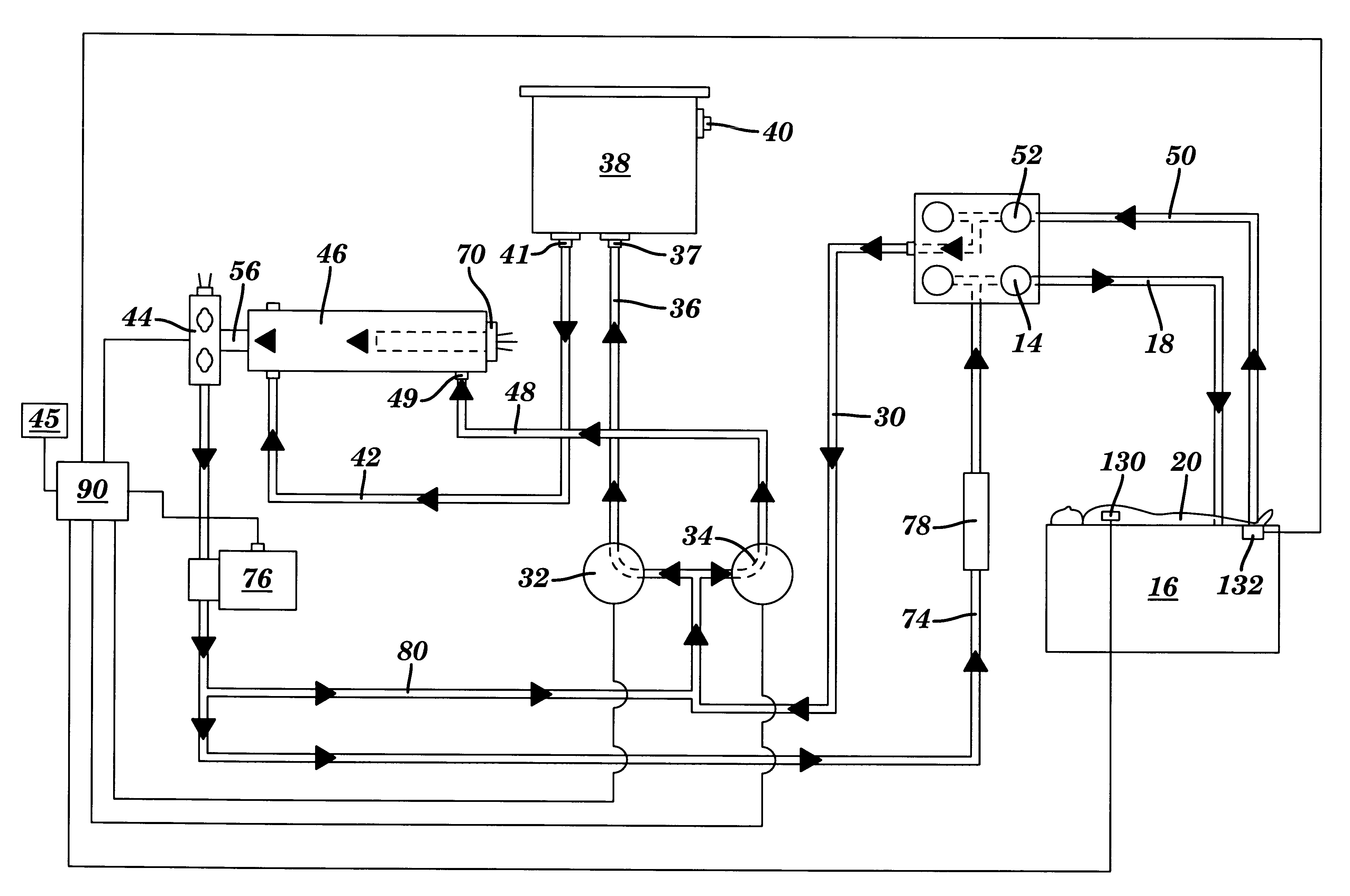

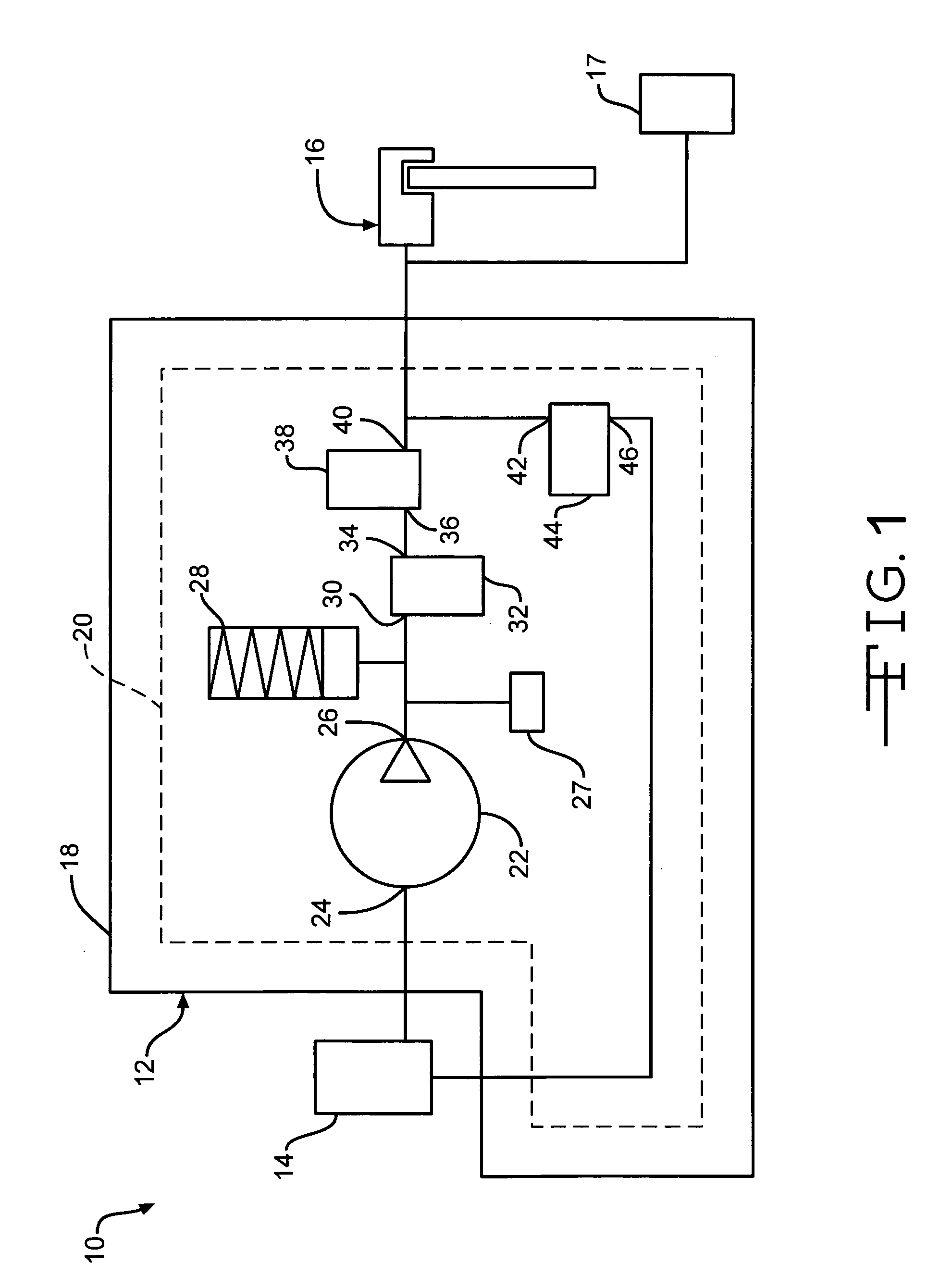

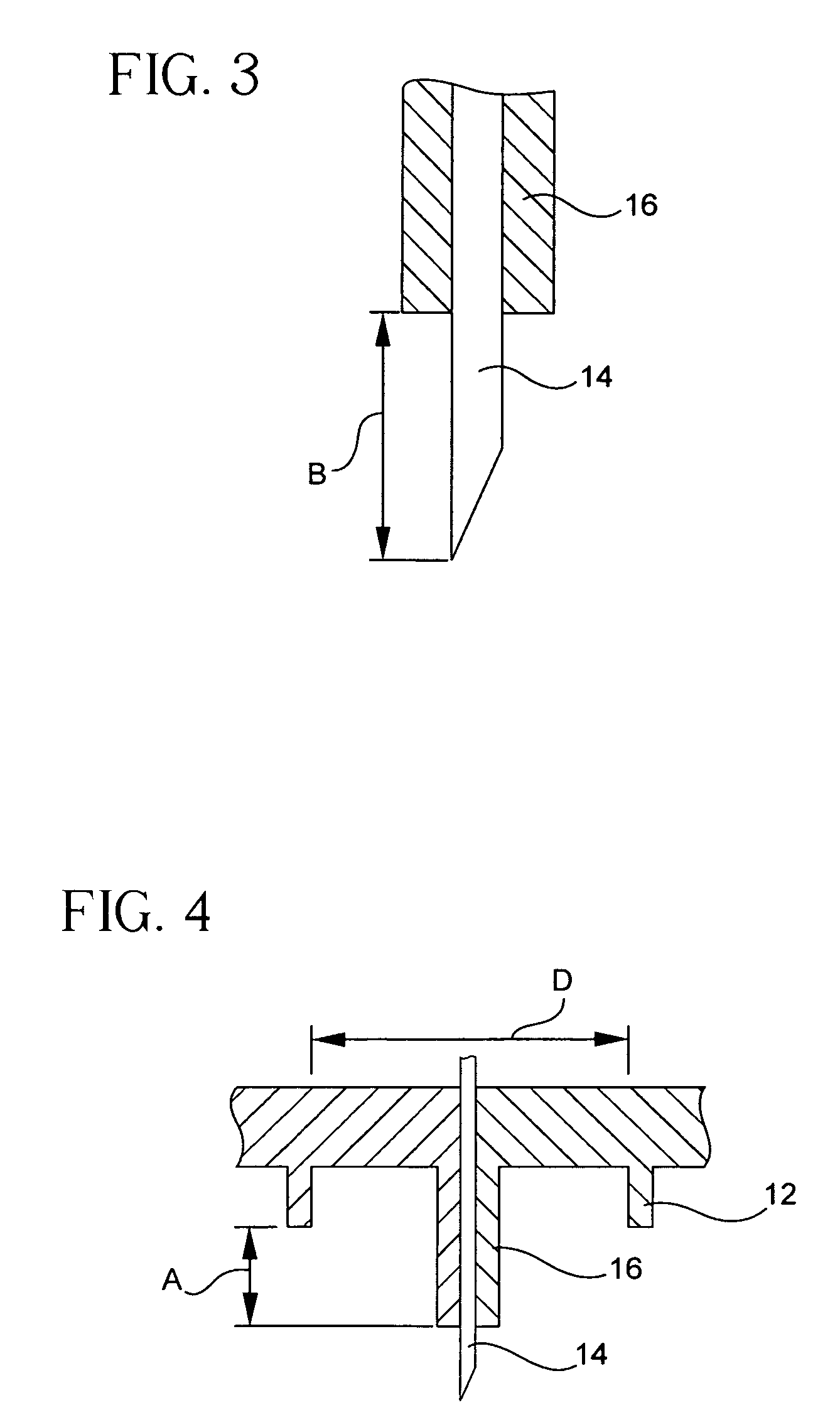

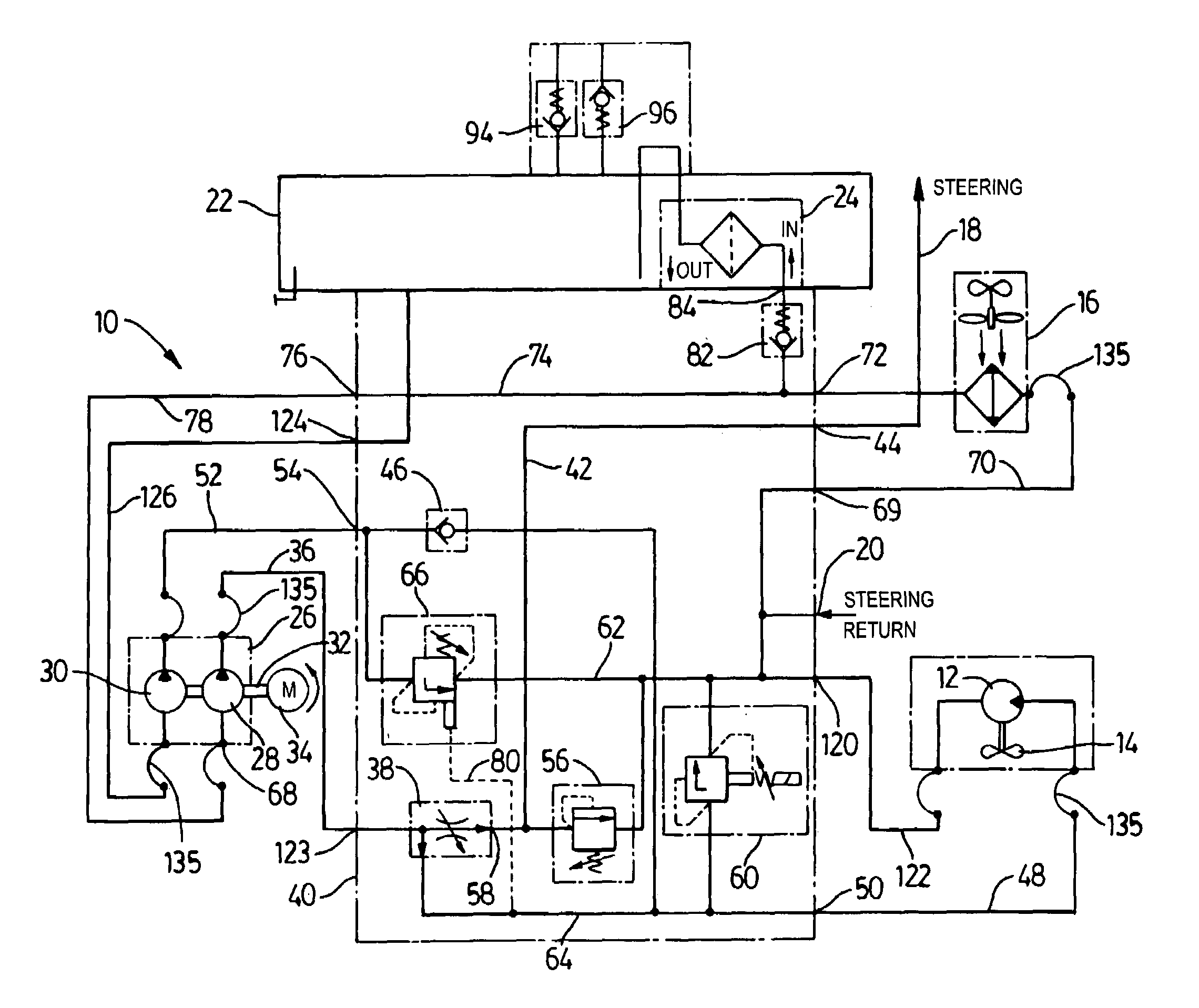

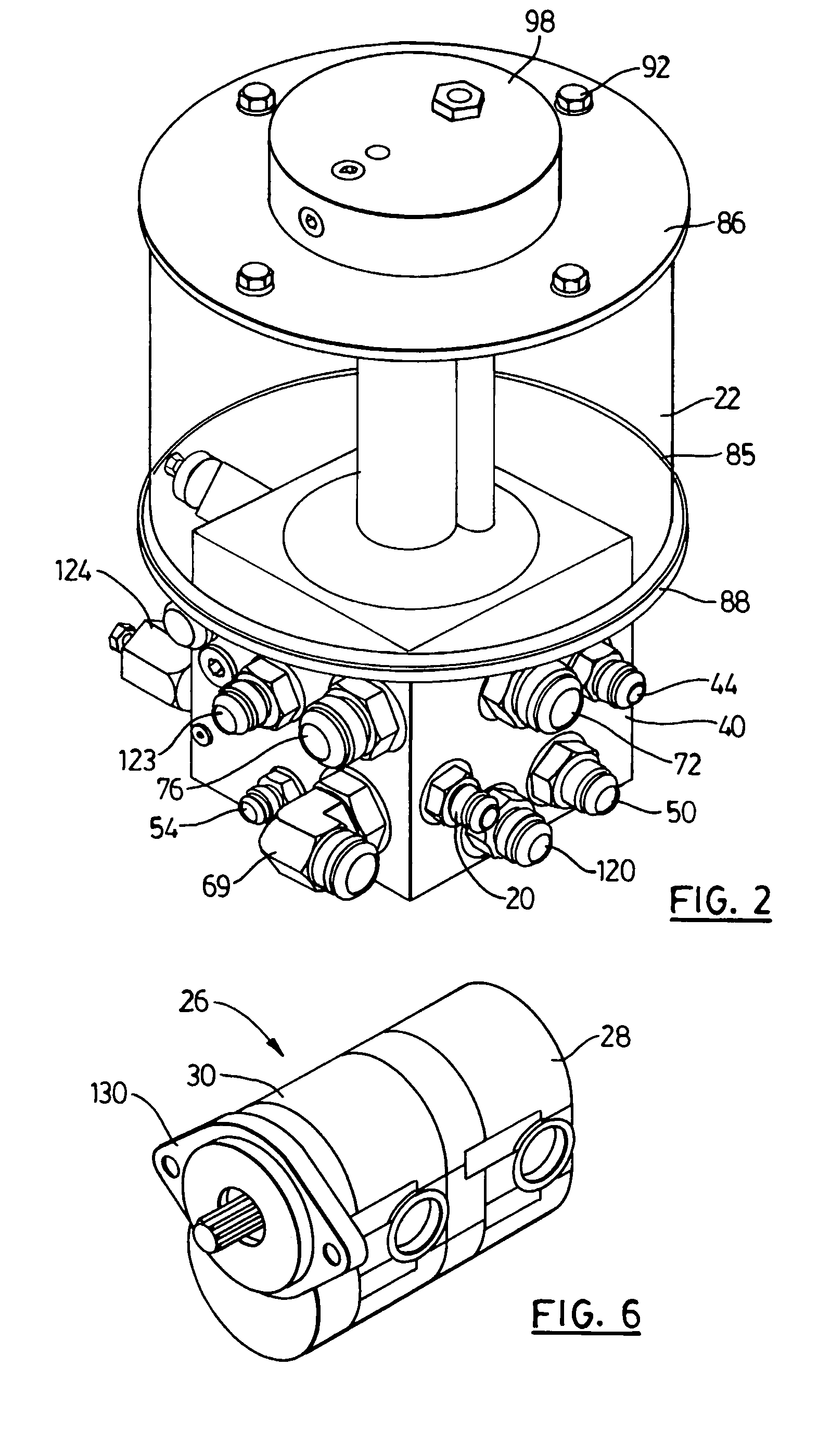

Electro-hydraulic fan drive cooling and steering system for vehicle

An electro-hydraulic system for operating a cooling fan and providing hydraulic fluid to a power steering system of the vehicle includes a hydraulic pump unit including first and second fixed displacement pumps and a common drive shaft for these pumps. A hydraulic fluid reservoir is connected to the inlet of each of the pumps. A priority valve is operatively connected to the outlet of the first pump and has an outlet connectible to the power steering system. This valve also has a second outlet connectible to a hydraulic motor for the cooling fan. This valve is arranged to provide a constant flow of hydraulic fluid to the power steering system. A hydraulic line connects an outlet of the second pump to the hydraulic motor. Hydraulic fluid flow through this line is combined with hydraulic fluid flow from the first pump to drive the motor. An electro-hydraulic proportional control valve has an inlet connected to the aforementioned line and an outlet connectible to the reservoir inlet and this control valve controls and limits the rotational speed of the motor. An electronic control device electrically operates and controls the control valve during use of the system.

Owner:HYDRA FAB FLUID POWER

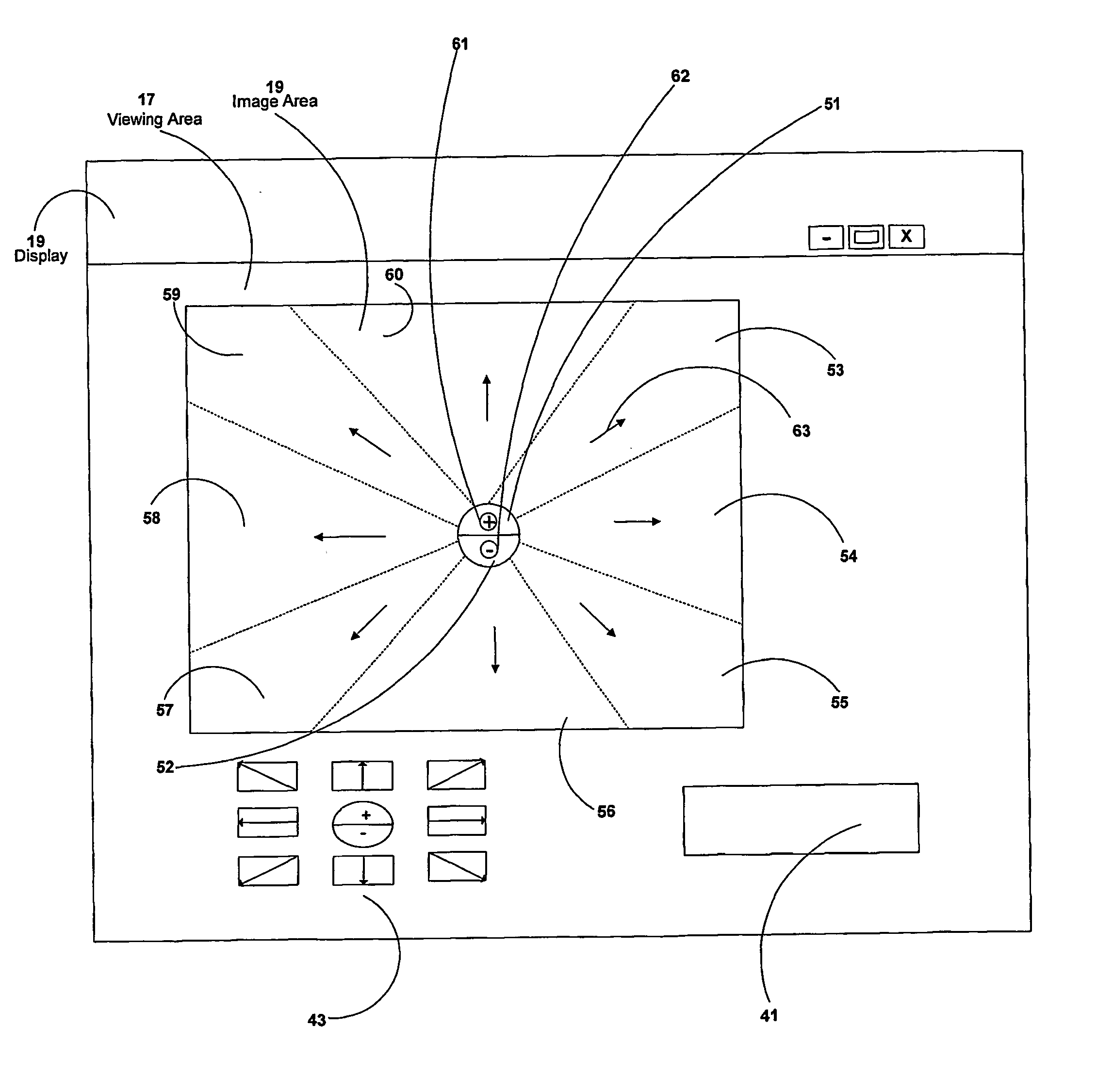

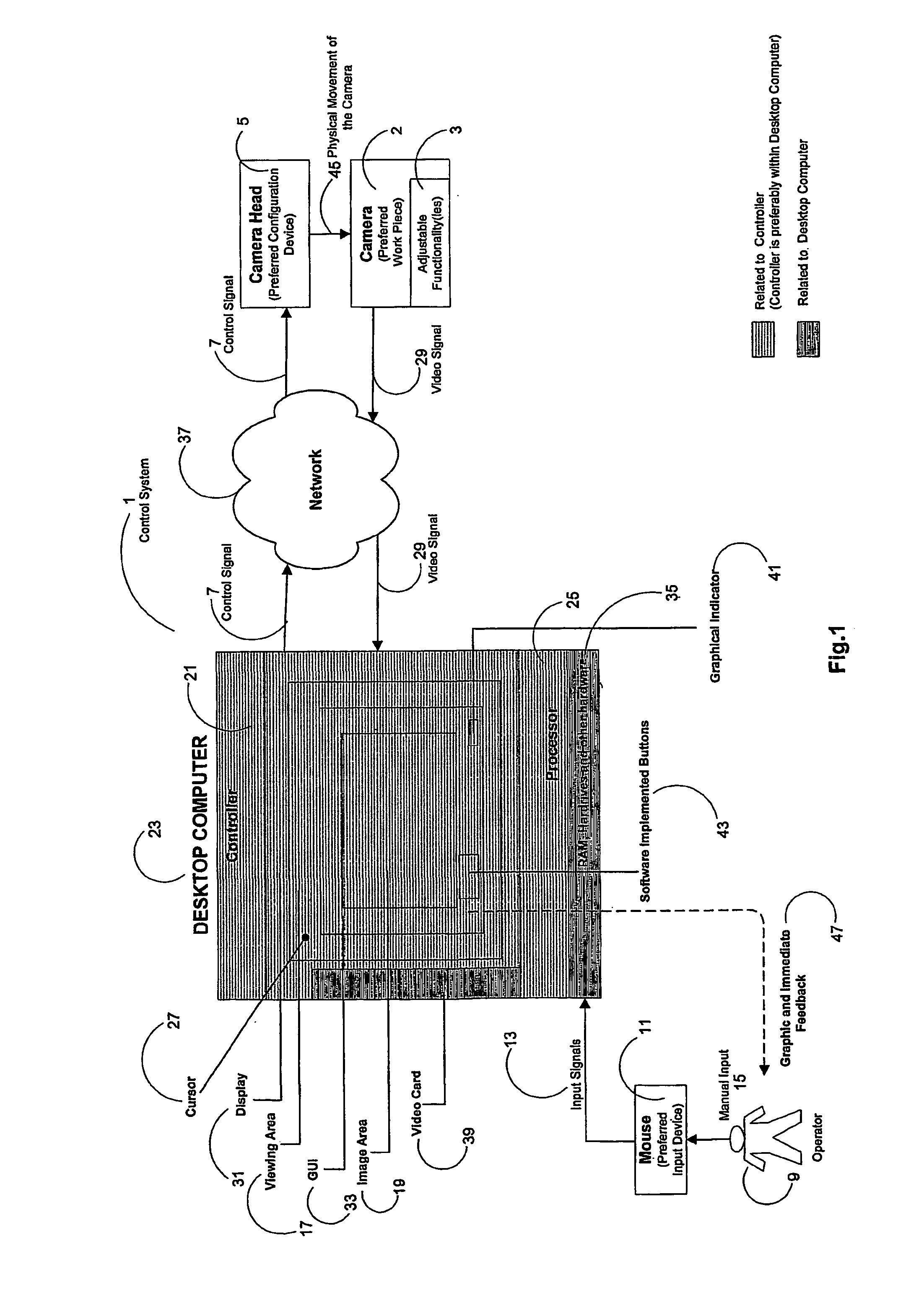

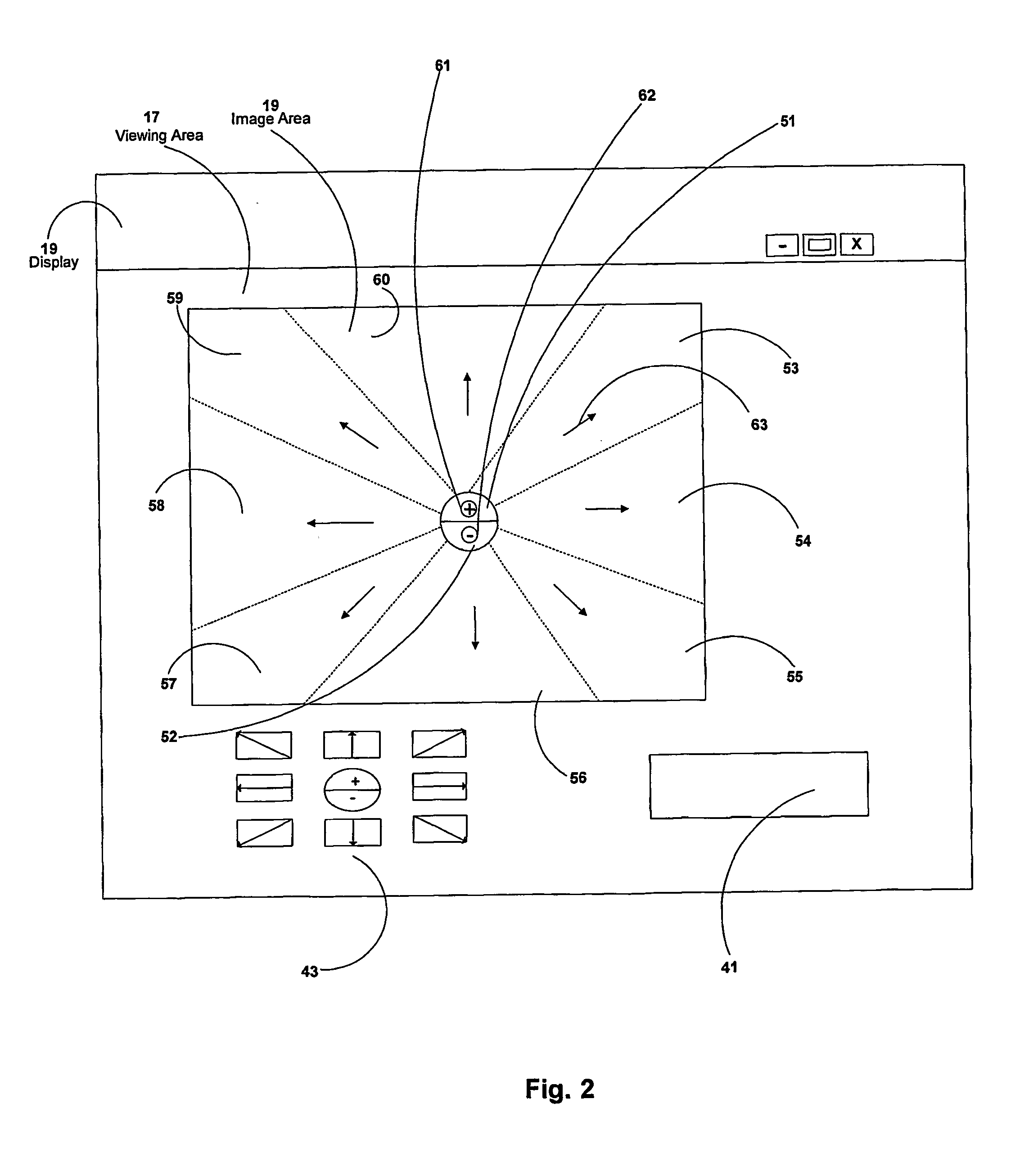

Control system for allowing an operator to proportionally control a work piece

InactiveUS20040189802A1Television system detailsColor television detailsProportional controlControl signal

A control system (1) includes a work piece, such as a camera (2), having an adjustable functionality (3). A configuration device is associated with the work piece and is responsive to one or more control signals (7), the configuration device affects one or more selective adjustments to the adjustable functionality (3). Further included is an input device, such as a mouse (11), for generating one or more input signals (13) in response to one or more predetermined manual inputs (15) from an operator (9). Also a controller (21) is included for providing the control signals (7), the controller (21) being implemented in a graphical user environment and being responsive to the impute signals (13) such that the selective adjustments made to the adjustable functionality (3) are substantially proportional.

Owner:HONEYWELL INC

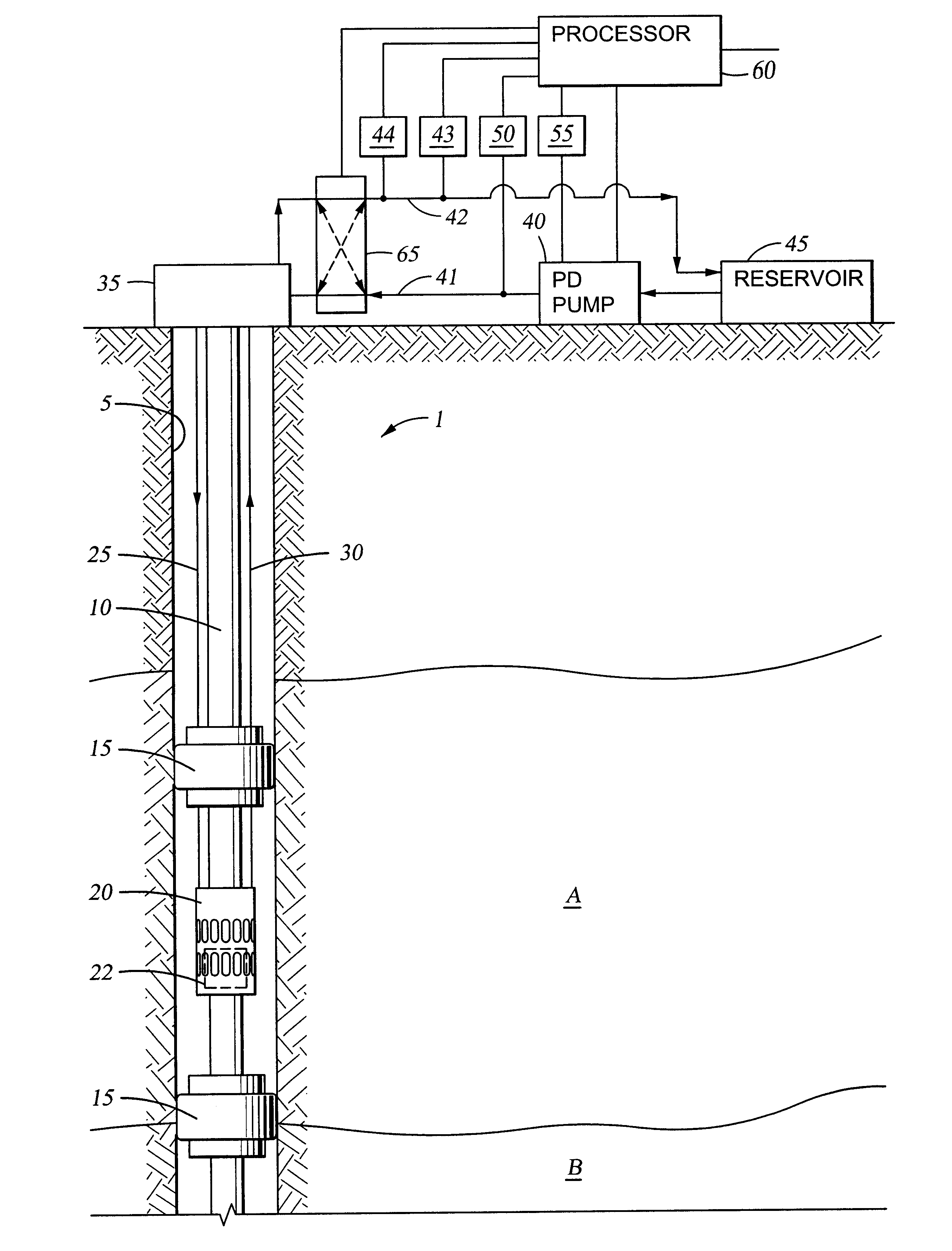

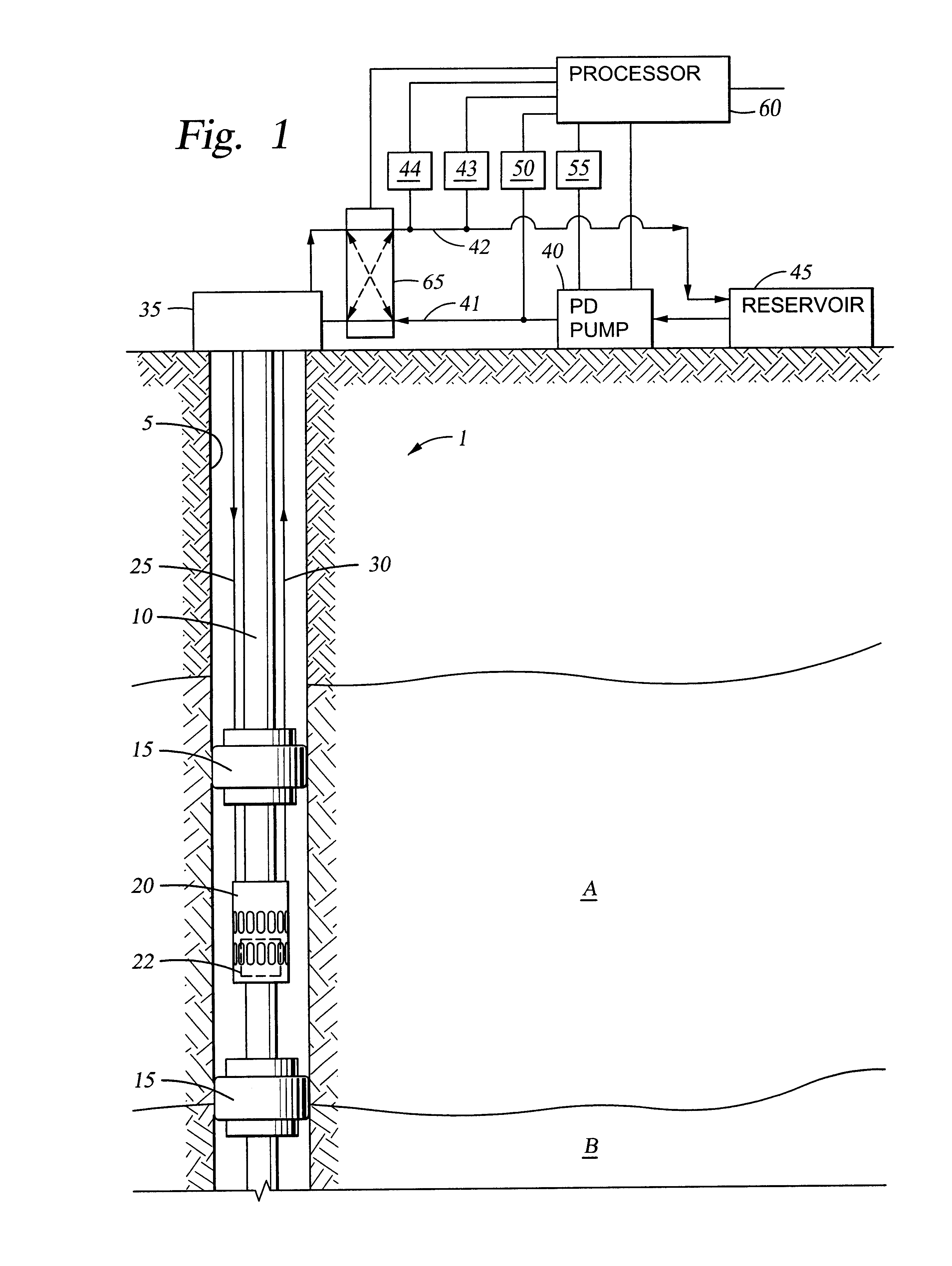

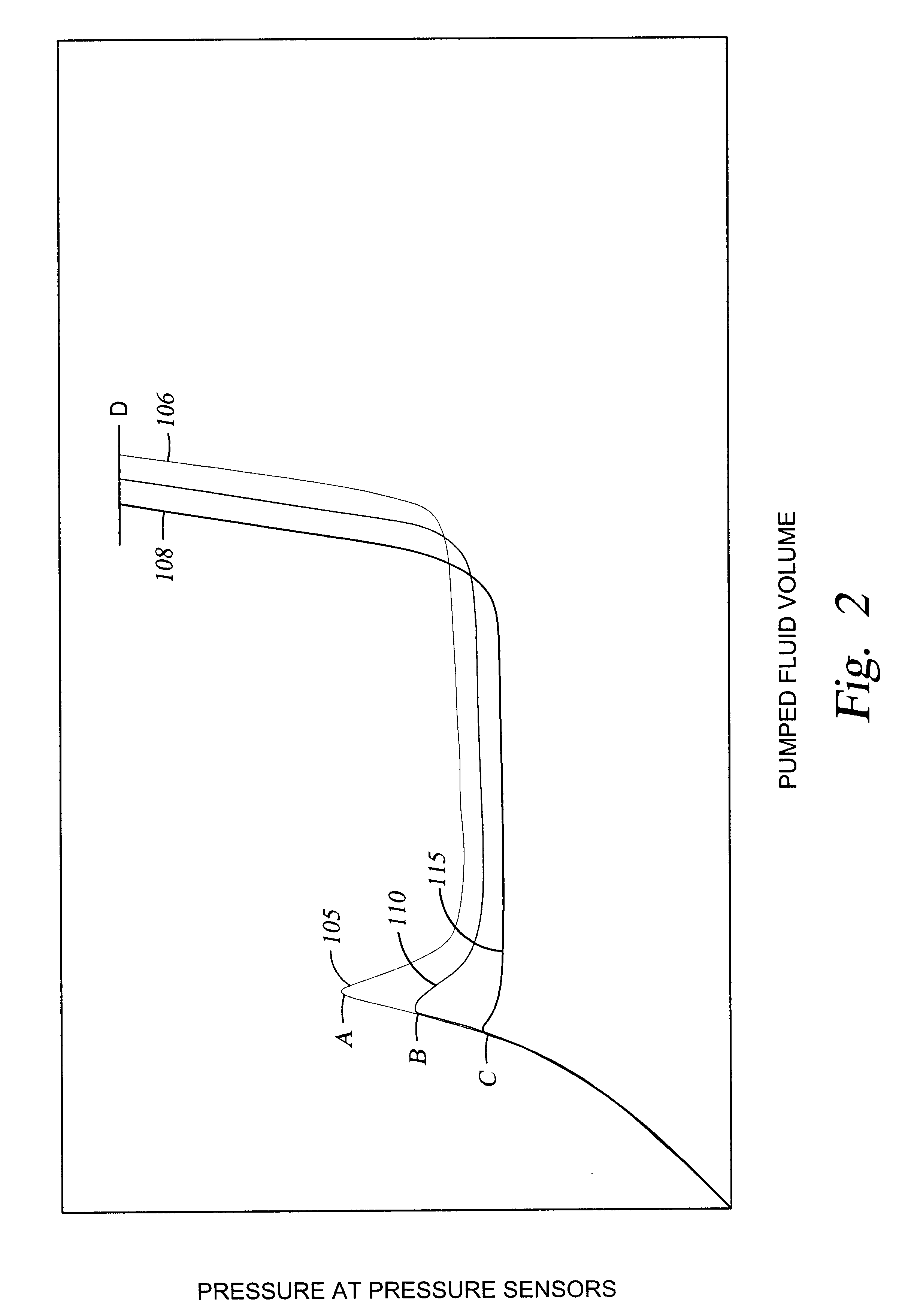

Method and system for controlling a downhole flow control device using derived feedback control

A system and methods for proportionally controlling hydraulically actuated downhole flow control devices using derived feedback control. The system comprises a downhole flow control device with a moveable element in a stationary housing. The moveable element is actuated by a balanced hydraulic piston. Hydraulic lines are fed to either side of the piston to effect actuation in either direction. A processor controlled, surface mounted hydraulic system supplies fluid to the piston. A pressure sensor measures supply pressure to the piston and a cycle counter indicates pump cycles and both sensors generate outputs to the processor. The downhole moveable element is cycled between end stops until successive moveable element breakout pressures are within a predetermined value as measured by the surface pressure sensor. A relationship is then derived between moveable element movement and pumped fluid volume and the relationship is used to move the moveable element to a predetermined position to control flow.

Owner:BAKER HUGHES HLDG LLC

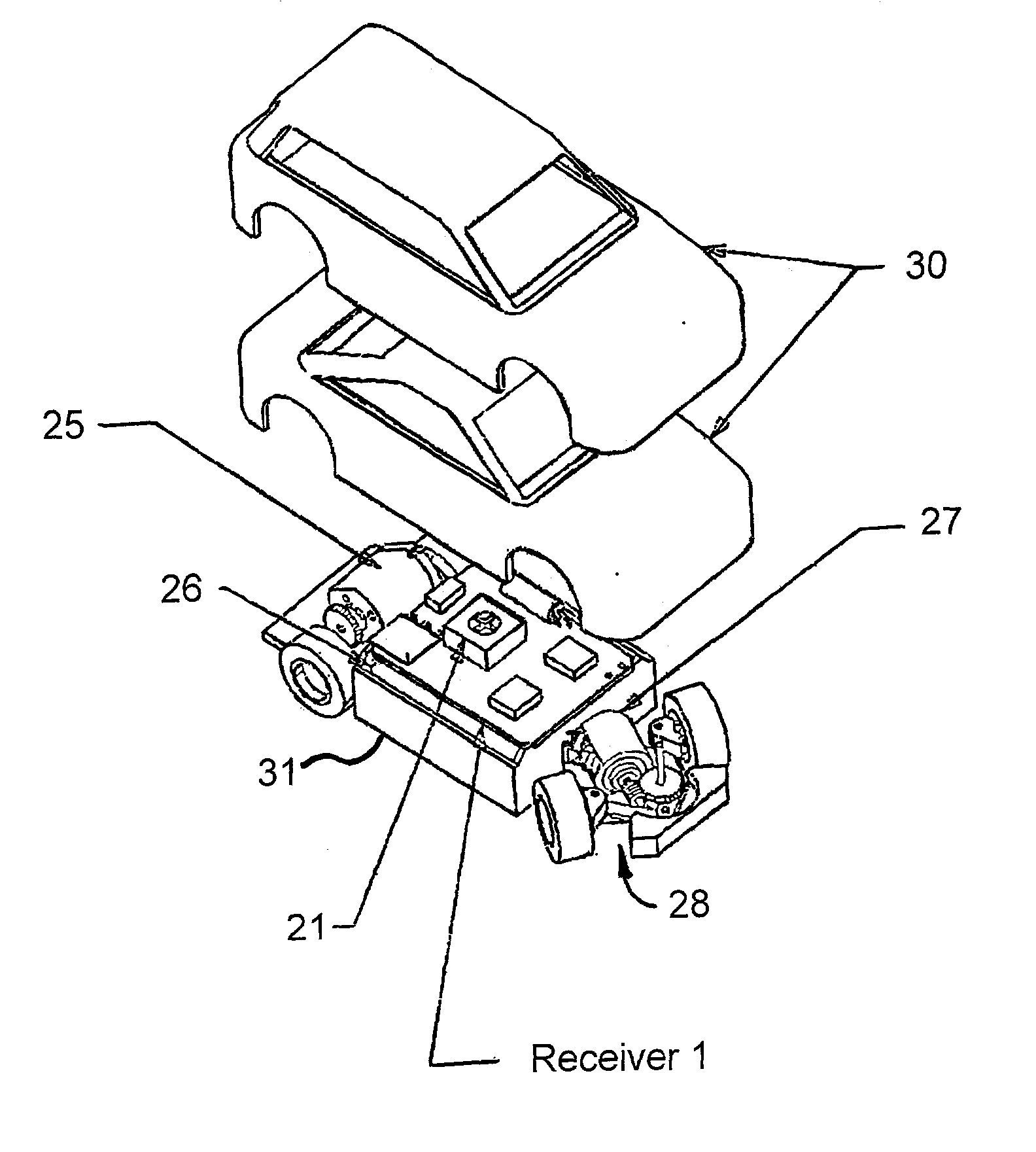

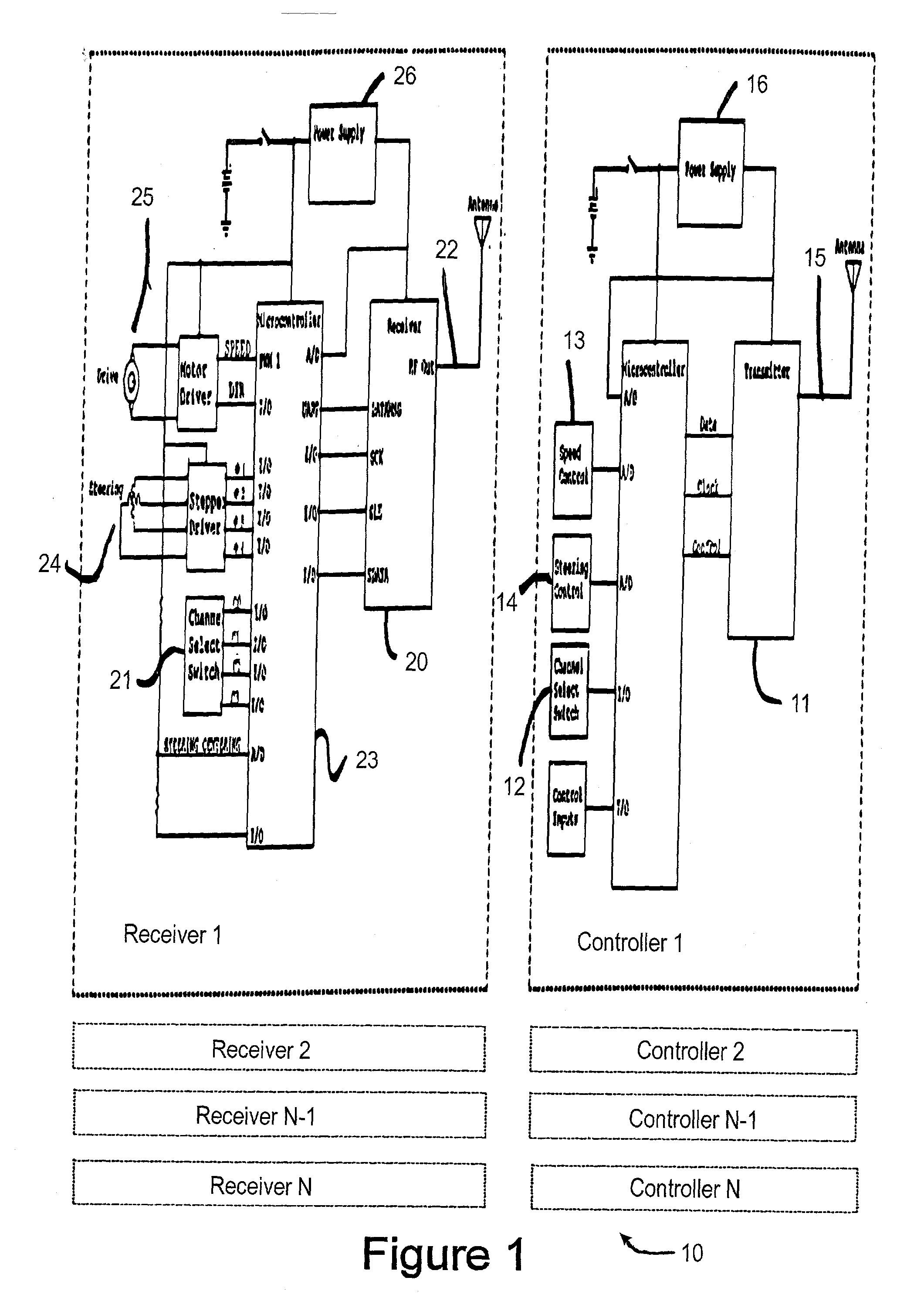

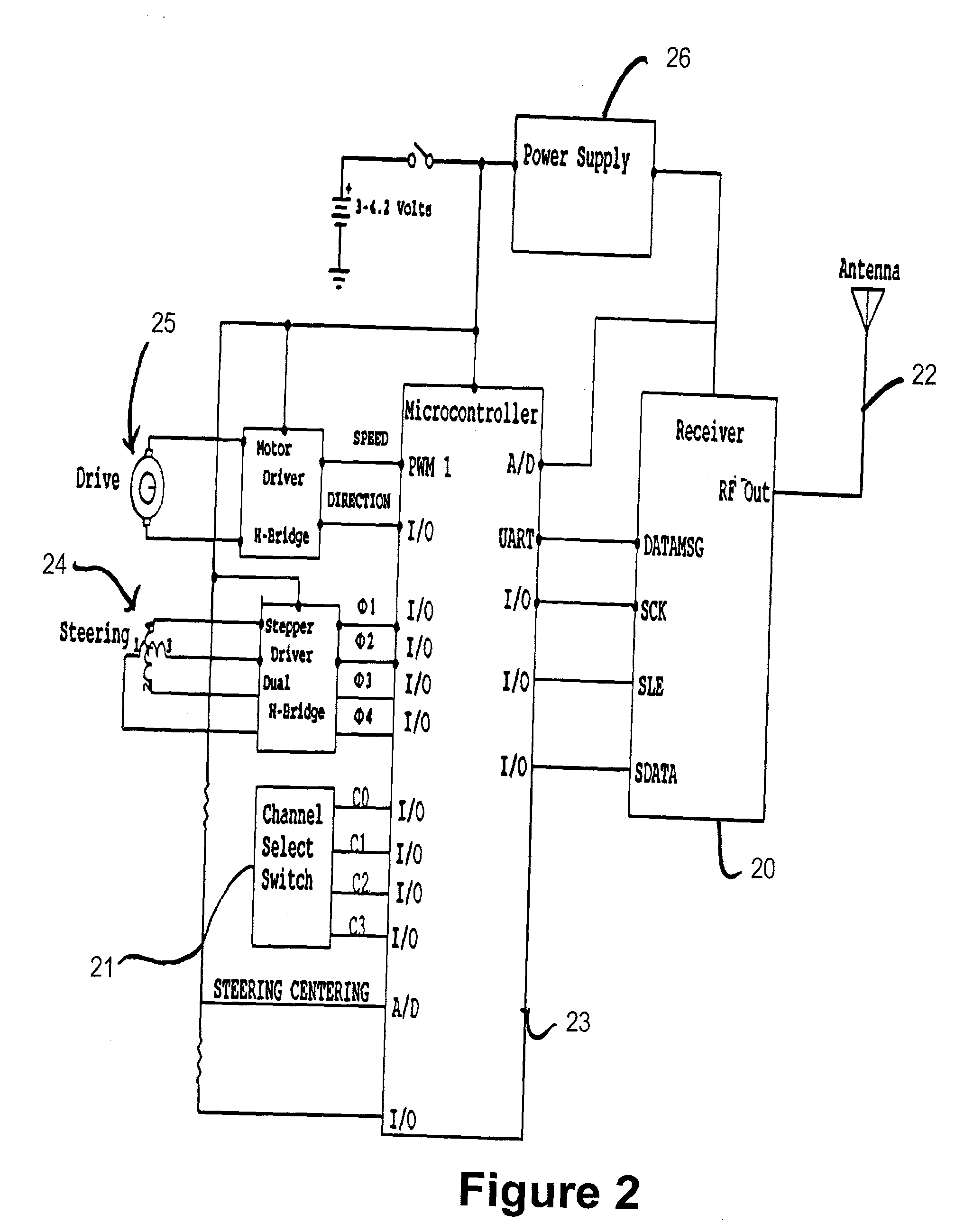

Systems and methods for radio control and operation of a miniature toy vehicle including interchangeable bodies

InactiveUS20030148703A1Easy to set upSolve excessive overheadRemote-control toysError checkingProportional control

A radio control system for a single or multi-controller, single or multi-receiver independently controlled system providing digital and proportional control without mutual interference, especially suited for a miniature toy vehicle. The controller may operate on multiple frequencies (channels) selected by the user. The receivers may receive on multiple frequencies (channels) selected by the user. When the receiver is first turned on, it reads the channel select switch and sets its receiver accordingly then normal remote control signals may be received such as speed, steering and digital commands. Commands are sent in bursts with an error checking protocol implemented. Commands are not executed by the receiver unless they are received error free. If the receiver fails to receive error-free command bursts within a short period of time (less than one second), it shuts off all motors and controls and go into a dormant state awaiting an error-free command burst. If error-free command bursts are not received within an extended period of time such as two minutes, the receiver completely shuts off thereby conserving battery power. The receiver includes a long-life rechargeable battery system that lasts for the normal lifetime of the car. The vehicle includes a simplified steering system that provides full proportional control without requiring position feedback.

Owner:XXAP DESIGN

Electronically controlled diaphragm pump

InactiveUS20110223581A1Microbiological testing/measurementFlexible member pumpsDiaphragm pumpProportional control

An electronically controlled diaphragm pump system is provided. The pump systems comprises a pump housing with a drive gas chamber and a fluid chamber separated by a diaphragm. The drive gas chamber is connected to one or more gas ports for injecting and / or sucking a gas into and out of the gas chamber. The fluid chamber is connected to a least one port for fluid inlet and at least one port for fluid outlet, where the inlet port has a valve adapted to open for fluid inlet when gas is sucked out of the gas chamber and the outlet port has a valve adapted to open for fluid outlet when gas is injected into the gas chamber. The pump system further has gas pressure means connected to a gas inlet port for providing a drive gas pressure in response to a control signal, and gas under-pressure means connected to a gas outlet port for providing a gas under-pressure or sucking of gas in response to a control signal. Furthermore, the pump system has a displacement sensor for detecting displacement or position of the diaphragm, and control circuitry connected to the displacement sensor for determining the displacement or position of the diaphragm and adapted for supplying the control signals to the gas pressure means and the gas under-pressure means. It is preferred that the means for providing a drive gas pressure comprises a gas-pressure proportional control valve being connected to the gas port and the control circuitry, whereby the drive gas pressure is varied as a function of the control signal supplied by the control circuitry. Also the means for providing a gas under-pressure may comprise a gas-under proportional control valve for controlling the gas under-pressure as a function of the control signal supplied by the control circuitry.

Owner:STOBBE TECH

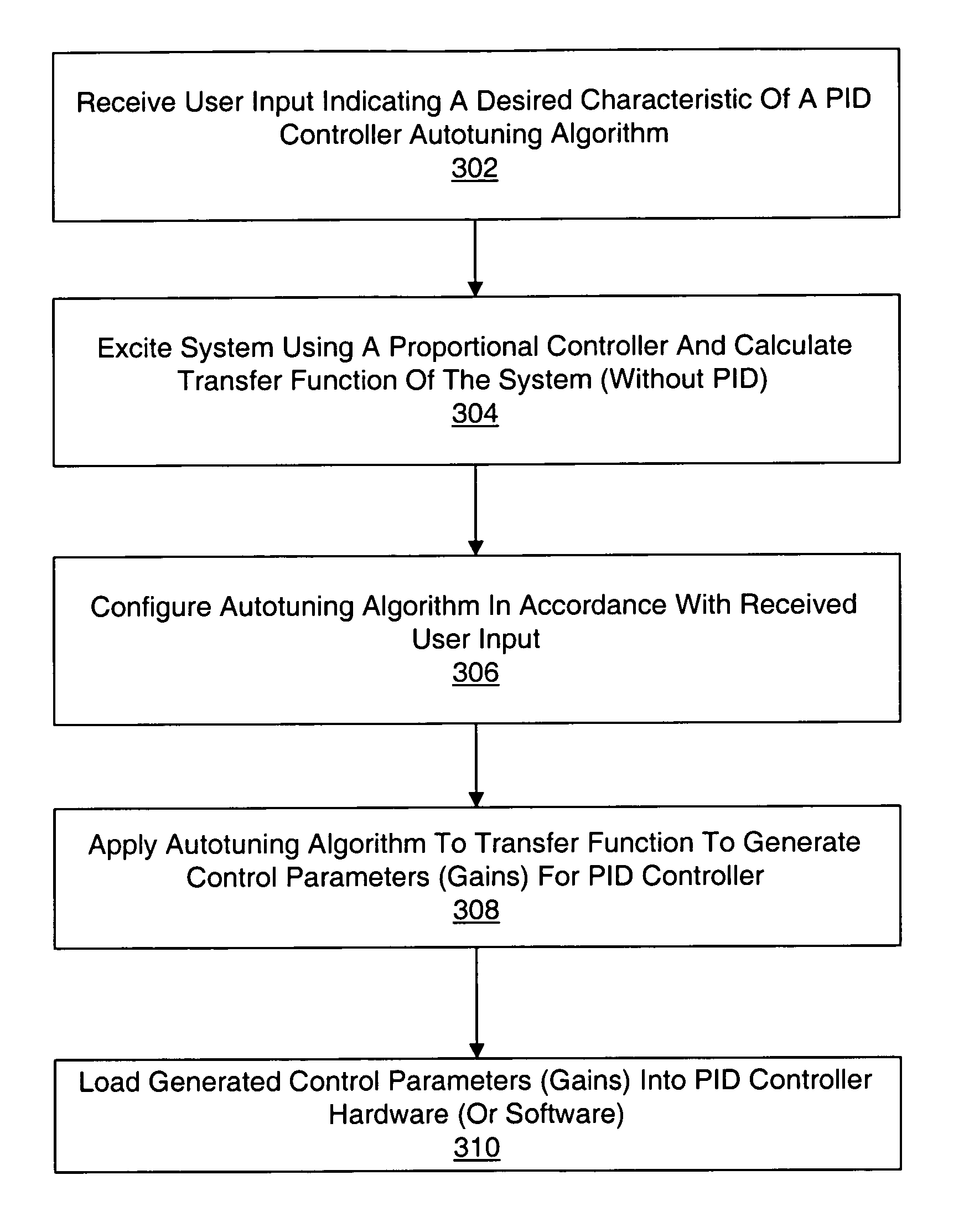

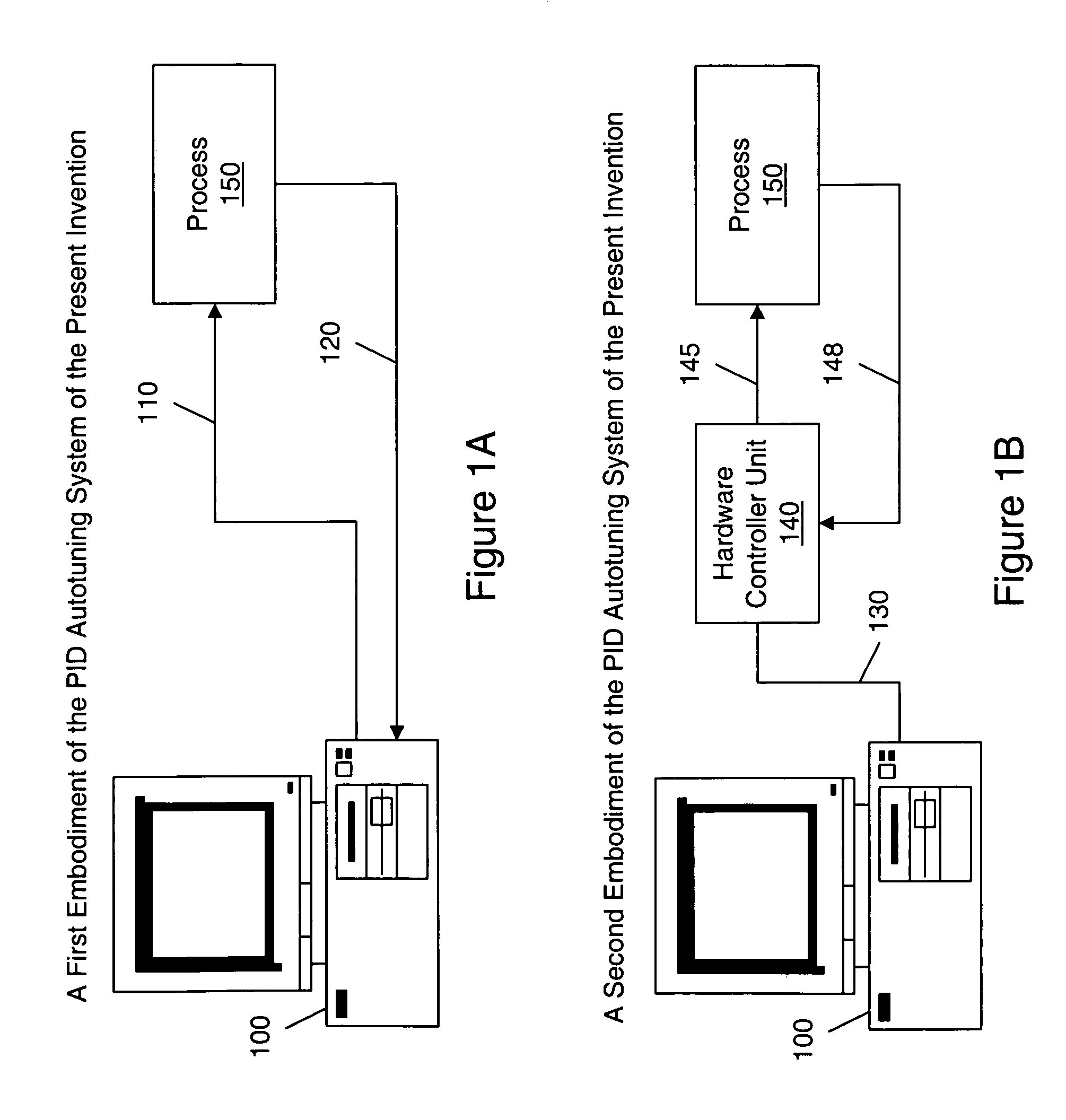

System and method for user controllable PID autotuning and associated graphical user interface

InactiveUS6980869B1Programme-controlled manipulatorComputer controlProportional controlPid autotuning

A system and method for user configuration of an autotuning algorithm for a PID controller. User input is received via a Graphical User Interface (GUI) indicating a desired characteristic of a PID controller, such as stiffness or response time. The system is excited via a proportional controller to characterize the intrinsic behavior of the system, i.e., to calculate a system transfer function. An autotuning algorithm is configured in accordance with the user input. The configured autotuning algorithm is applied to the transfer function to generate gain values for the PID controller resulting in the PID controller characteristic specified by the user. The PID controller gains are loaded into the PID controller hardware or software, thereby configuring the PID controller to operate according to the desired characteristic specified by the user. The user may trigger and view a step response of the system to review the results of the tuning process.

Owner:NATIONAL INSTRUMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com