Automatic gas control for a plasma arc torch

a plasma arc torch and automatic control technology, applied in plasma welding apparatus, plasma technique, manufacturing tools, etc., can solve the problems of increasing control difficulties, tedious empirical determinations of different torches, wear and replacement of consumable parts, etc., to prolong the life of the electrode, increase the cut duration, and increase the cut duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

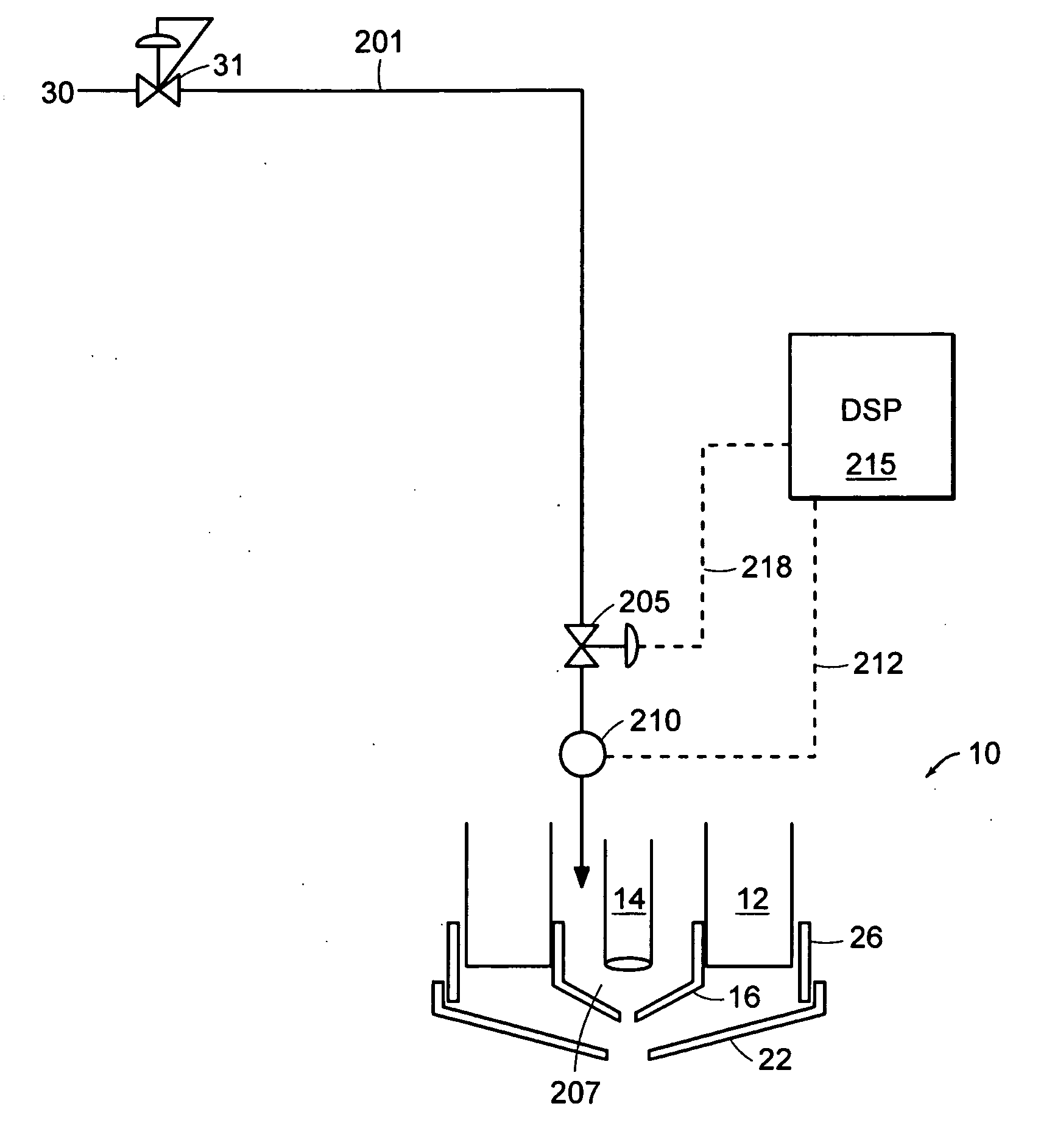

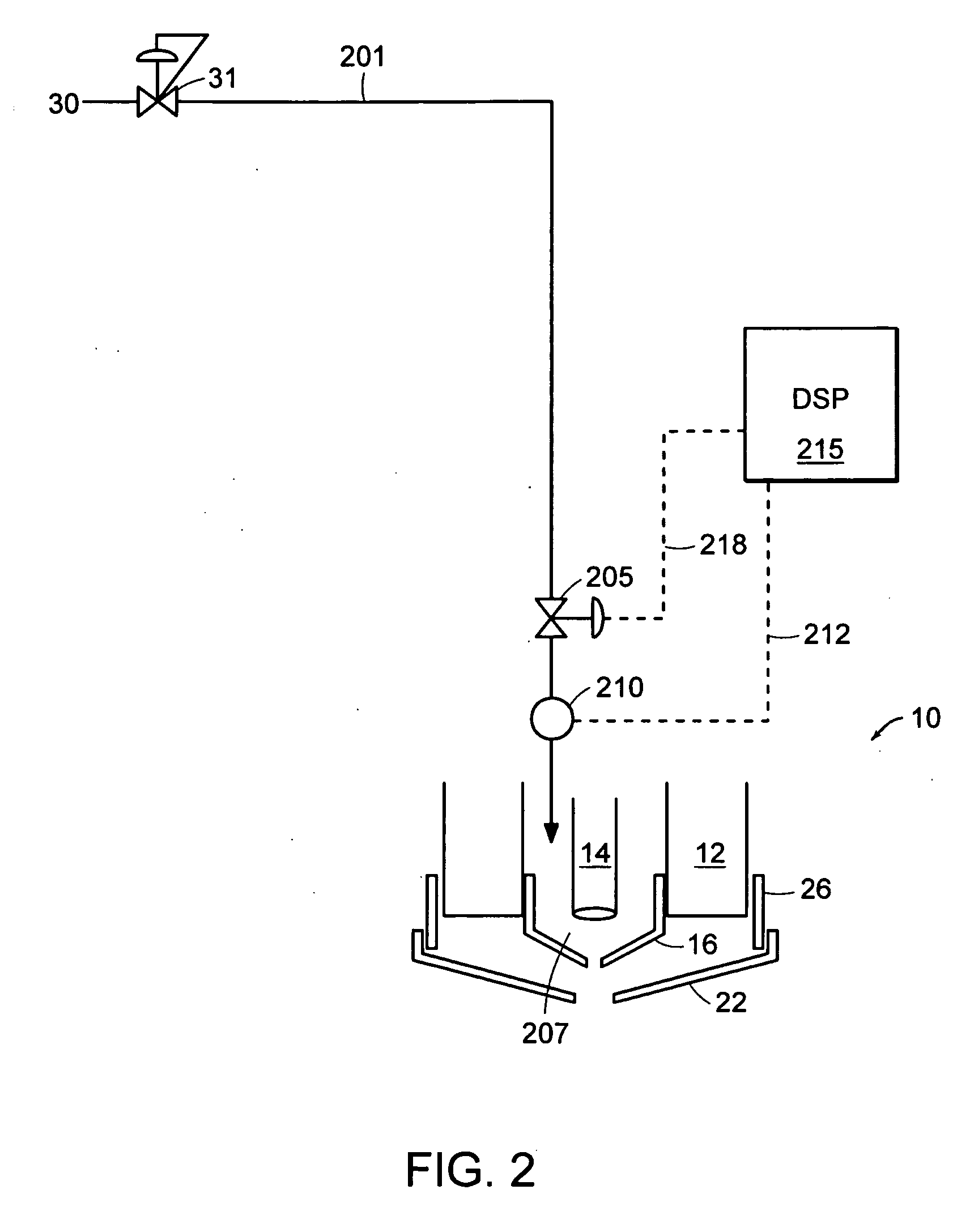

[0039]FIG. 2 is a schematic representation of a plasma gas supply system to a plasma arc torch incorporating features of the invention. A plasma gas, e.g., including oxygen, nitrogen, and / or argon flows from a plasma gas supply 30 to a plasma gas supply line 201. This first gas supply line channels plasma gas to the plasma torch 10 through a programmable control valve 205 such as a proportional solenoid control valve. The plasma gas flows to a plasma chamber 207 of the torch, and can pass through a sensor 210, such as a flow sensor or a pressure sensor. In some embodiments a signal 212 from the plasma gas sensor 210 can pass to a digital signal processor (DSP) 215 (e.g., a microprocessor, computer, computerized numeric controller (CNC), or PLC), which in turn can manipulate an output 218 to the programmable control valve 205 based on the signal 212. However, the sensor 210 is optional and embodiments include a plasma gas supply line 201 with no sensor 210, and manipulation of the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com