Patents

Literature

3527 results about "Torch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A torch is a stick with combustible material at one end, which is ignited and used as a light source. Torches have been used throughout history, and are still used in processions, symbolic and religious events, and in juggling entertainment. In some countries "torch" in modern usage is the term for a battery-operated portable light.

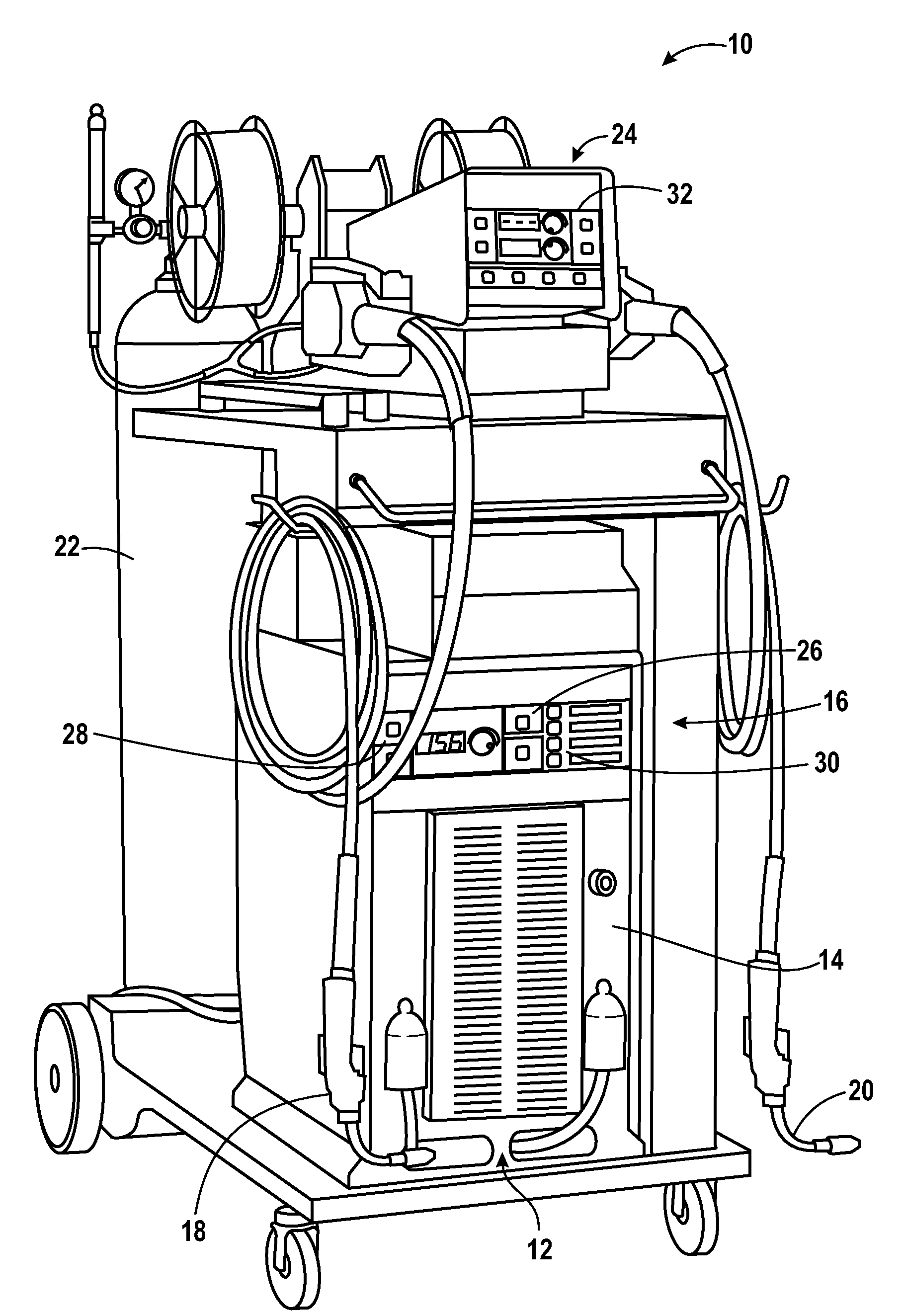

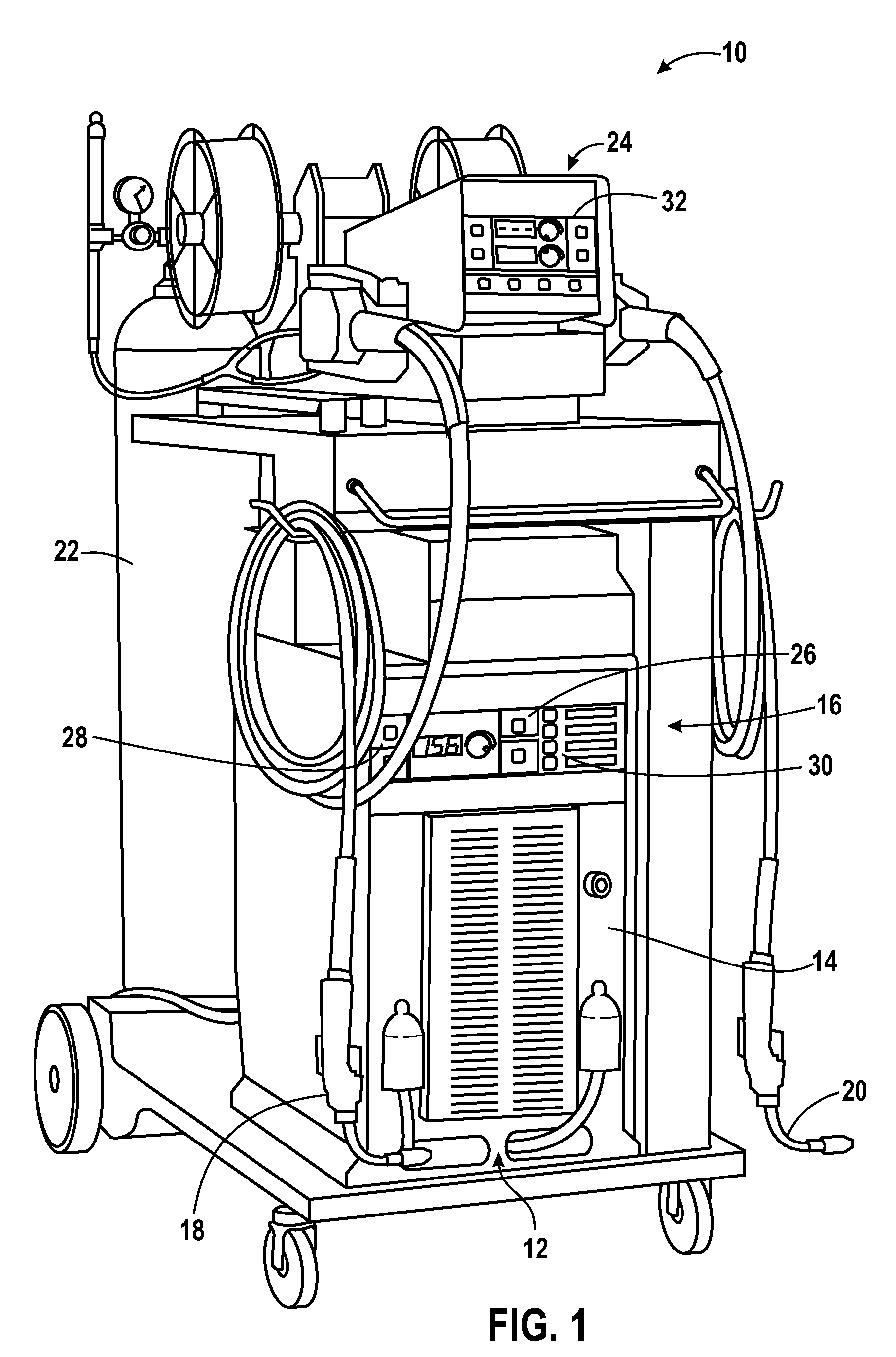

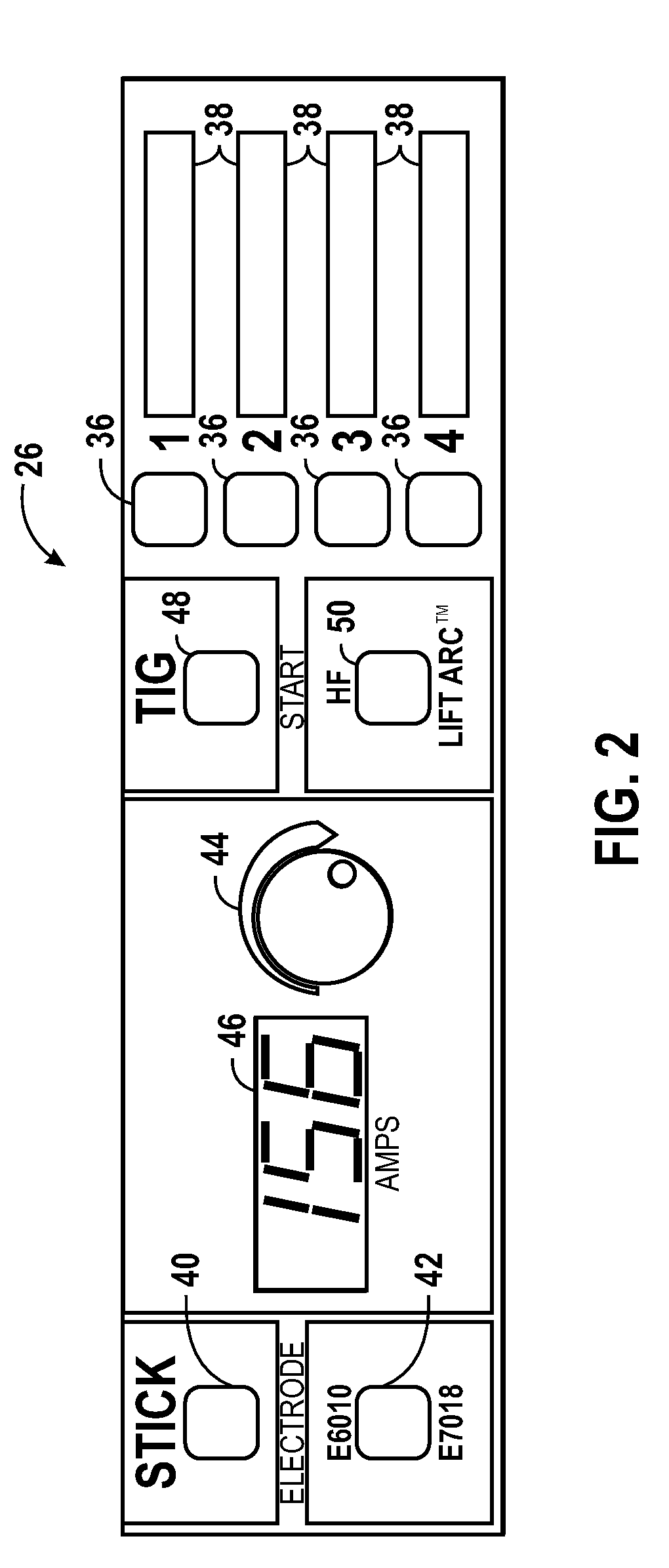

Personalized interface for torch system and method

There is provided a system and method for quick identification and selection of torch processes based on a profile scheme. In an illustrated embodiment, a profile selectable via a one-click process may define operational parameters for one or more torch processes. Multiple profiles may be identified by corresponding labels that are visible on the face of the system. Furthermore, in an illustrated embodiment, the profiles and associated torch processes may be automatically stored in the system upon user configuration of the operational parameters. For example, in one embodiment, the user may select a profile and configure a welding process. Upon changing an operational parameter, it may be automatically saved to the selected profile and process. Reselection of that profile may recall the last used process and its associated parameters. The operational parameters of other configured processes may then be retrieved by selecting the desired process within the selected profile.

Owner:ILLINOIS TOOL WORKS INC

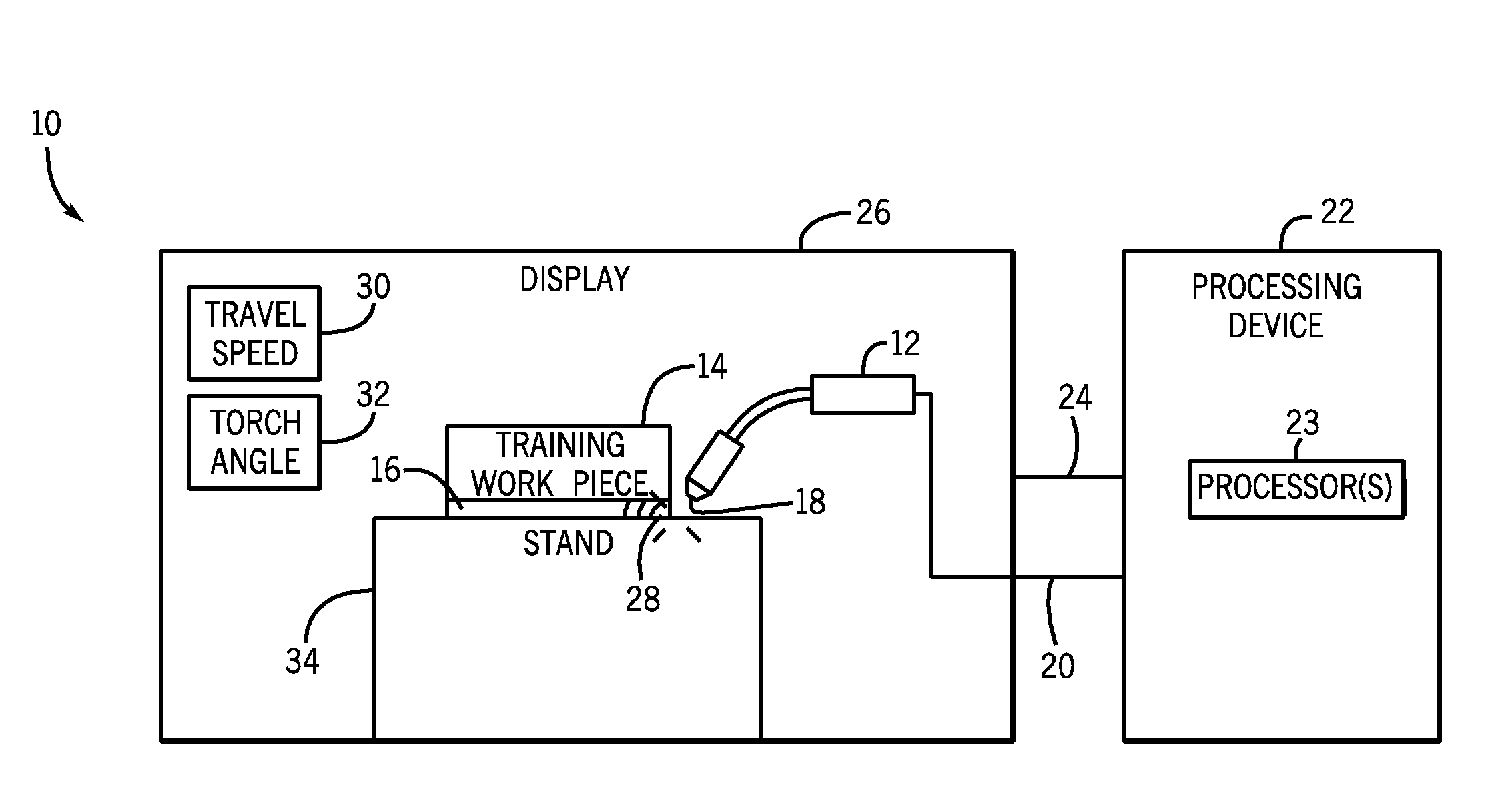

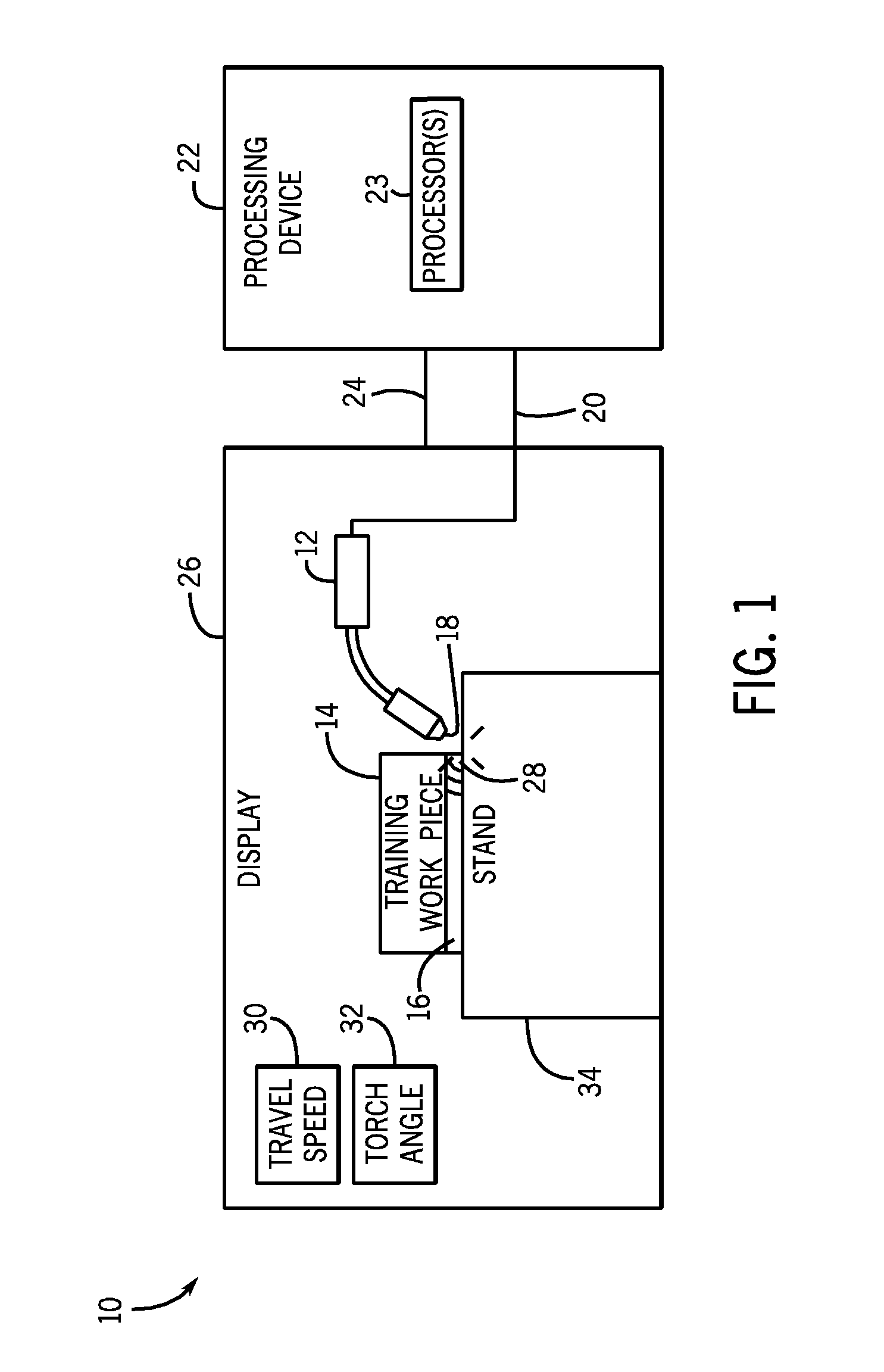

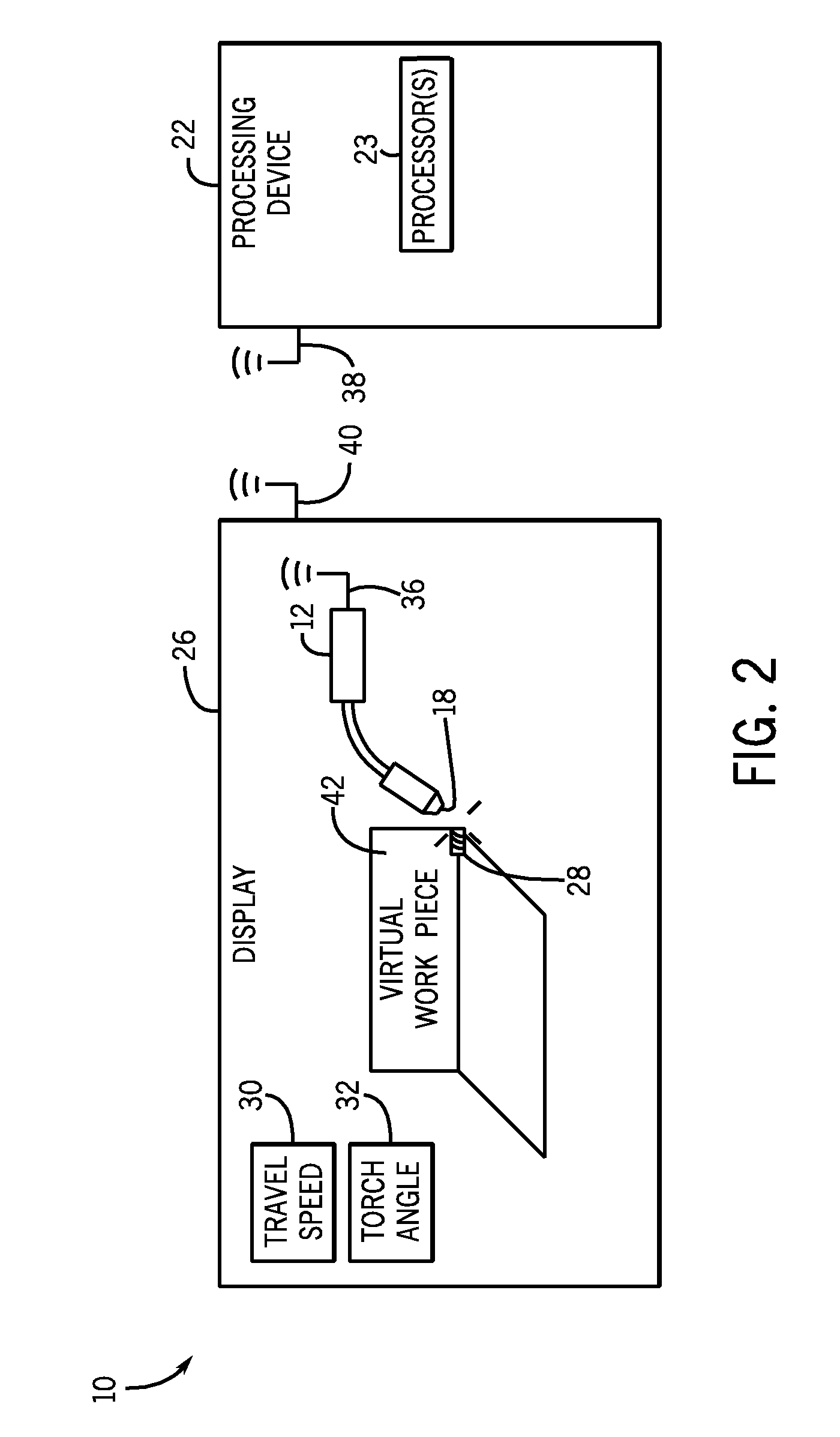

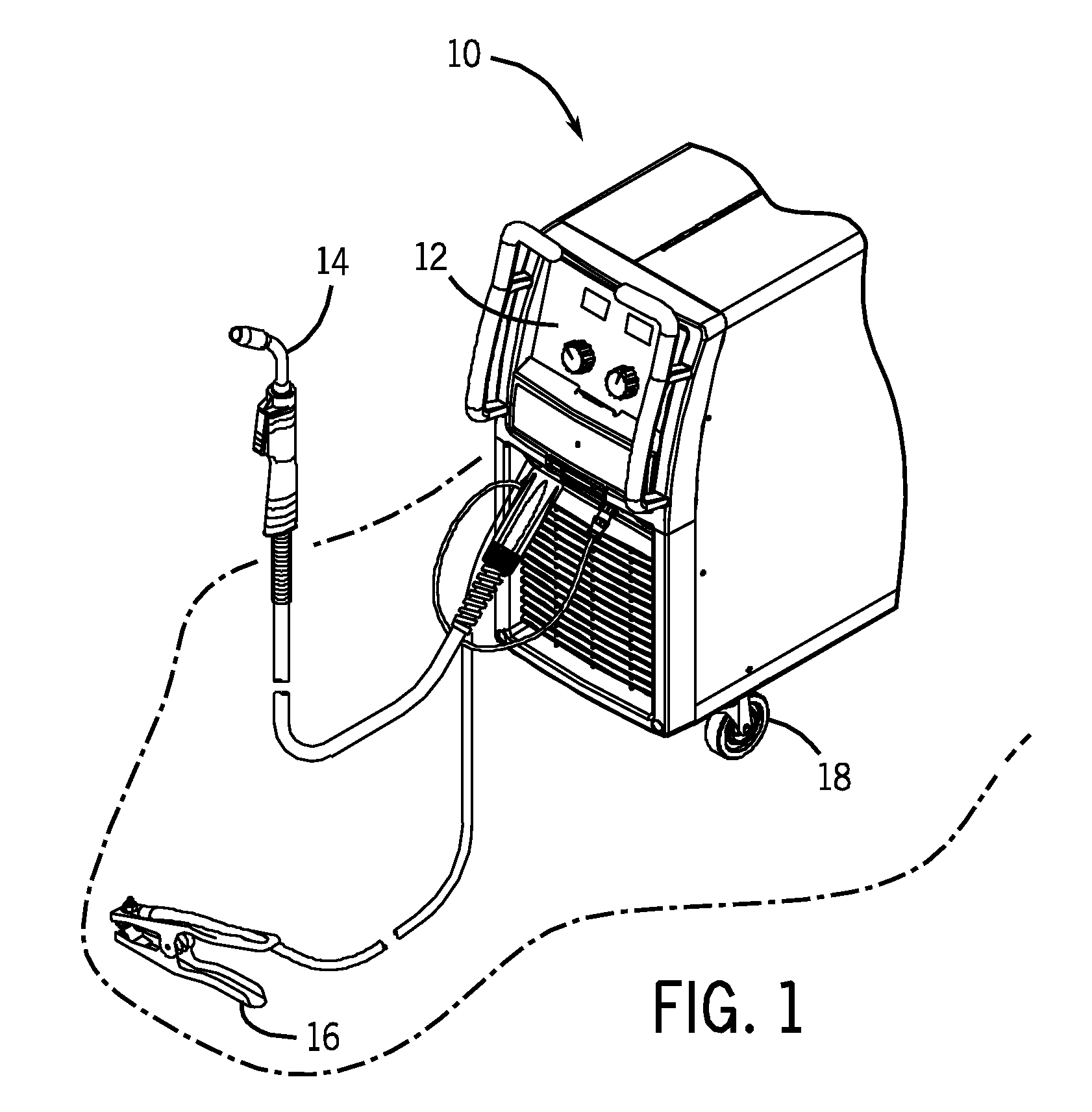

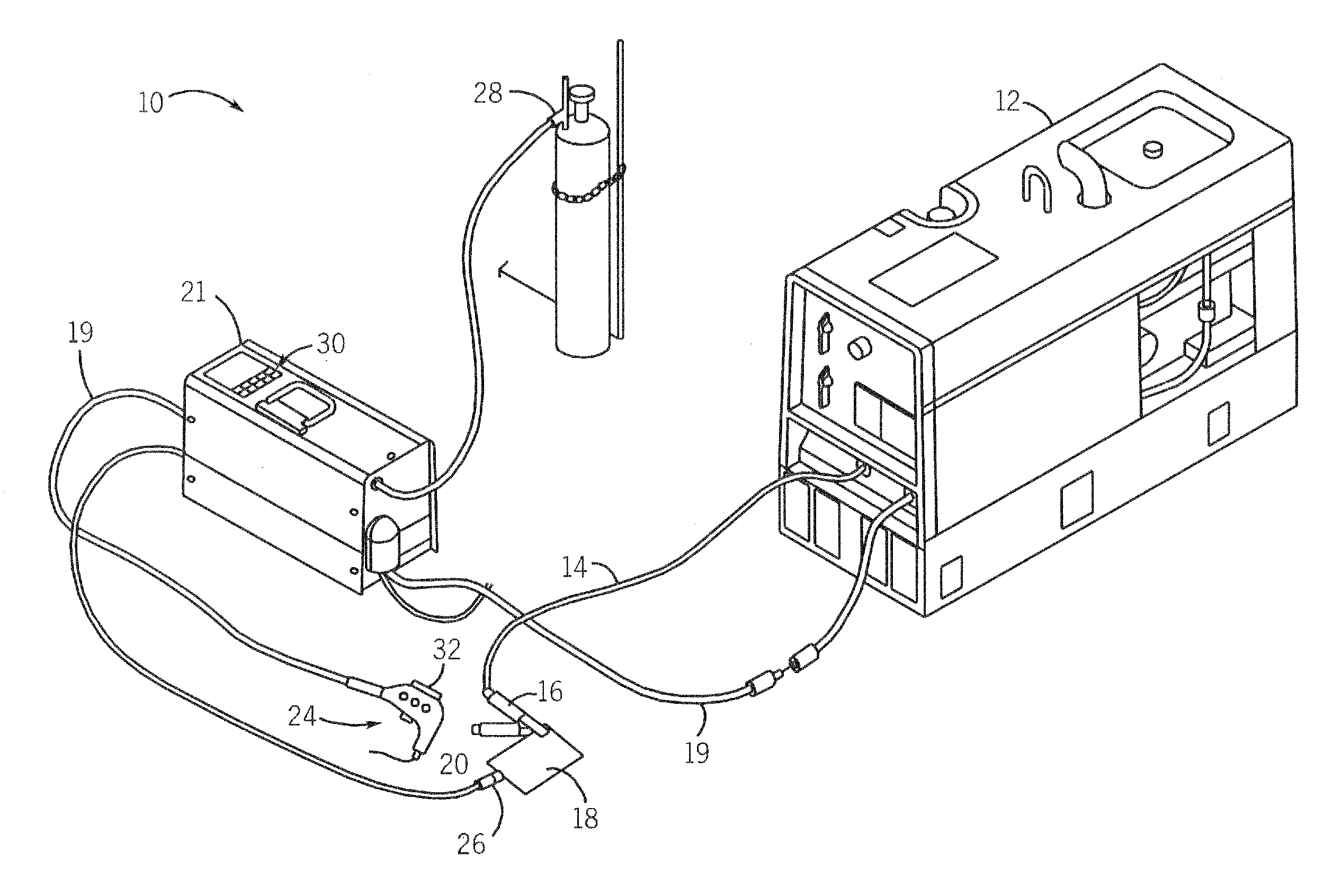

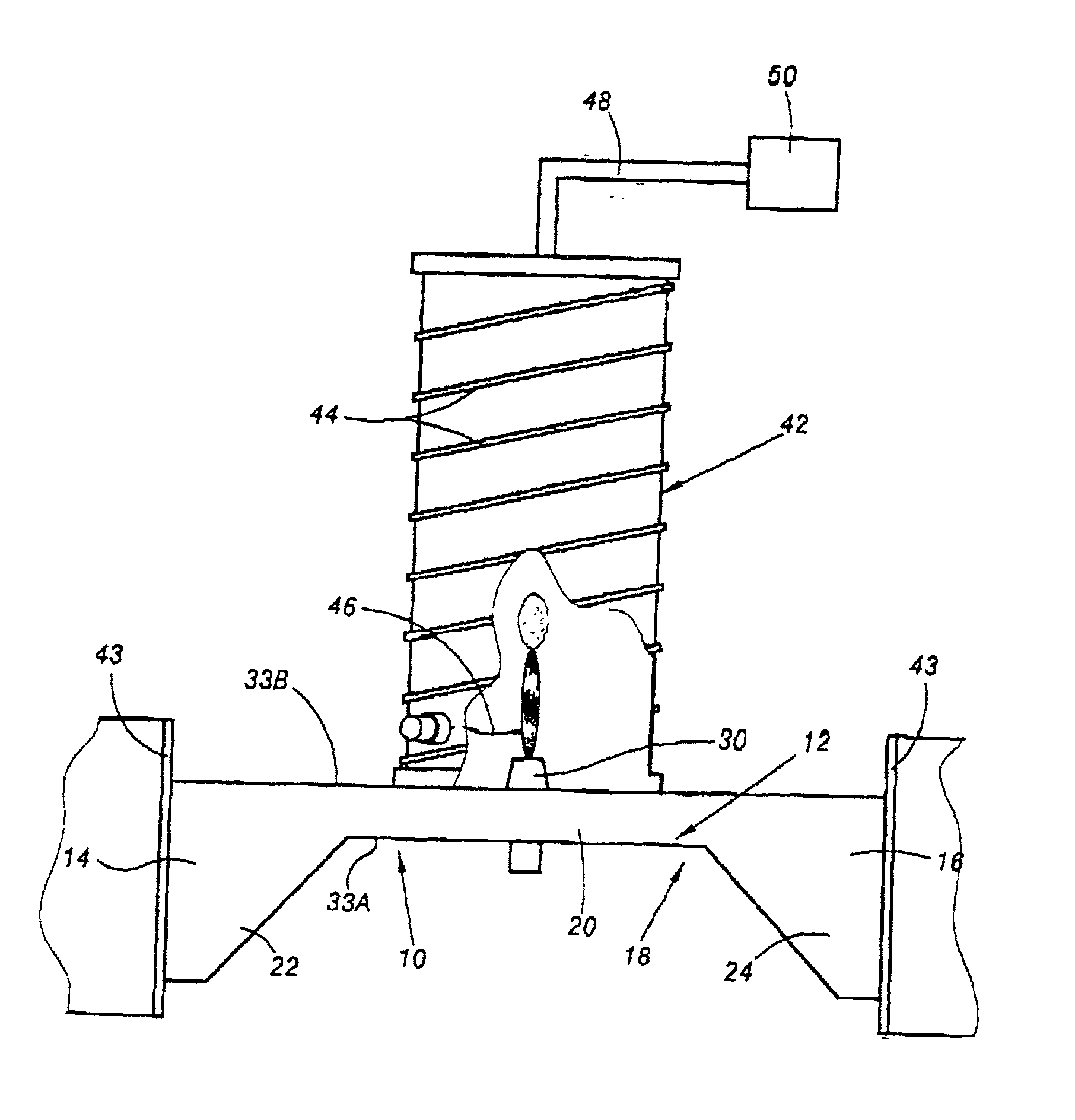

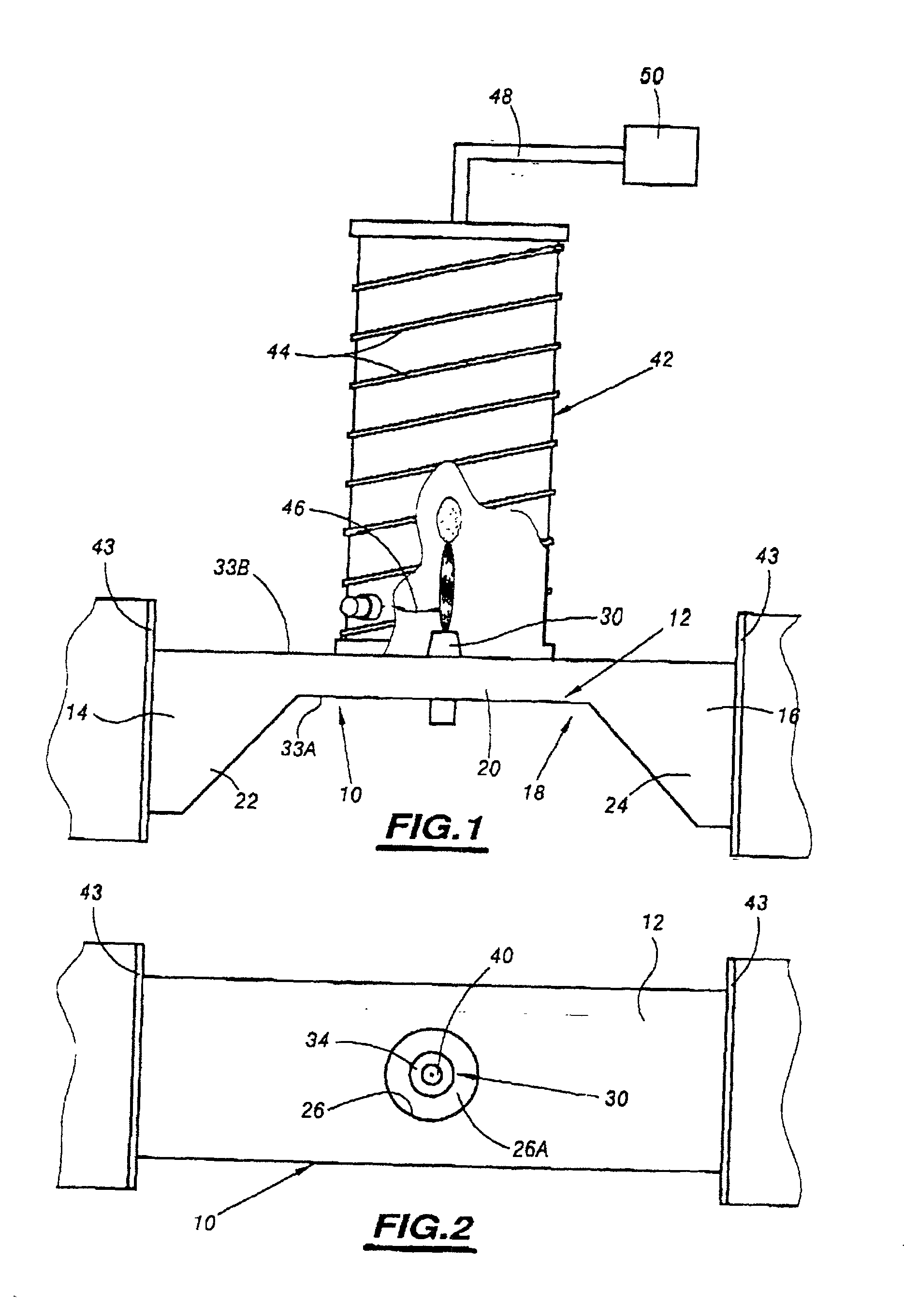

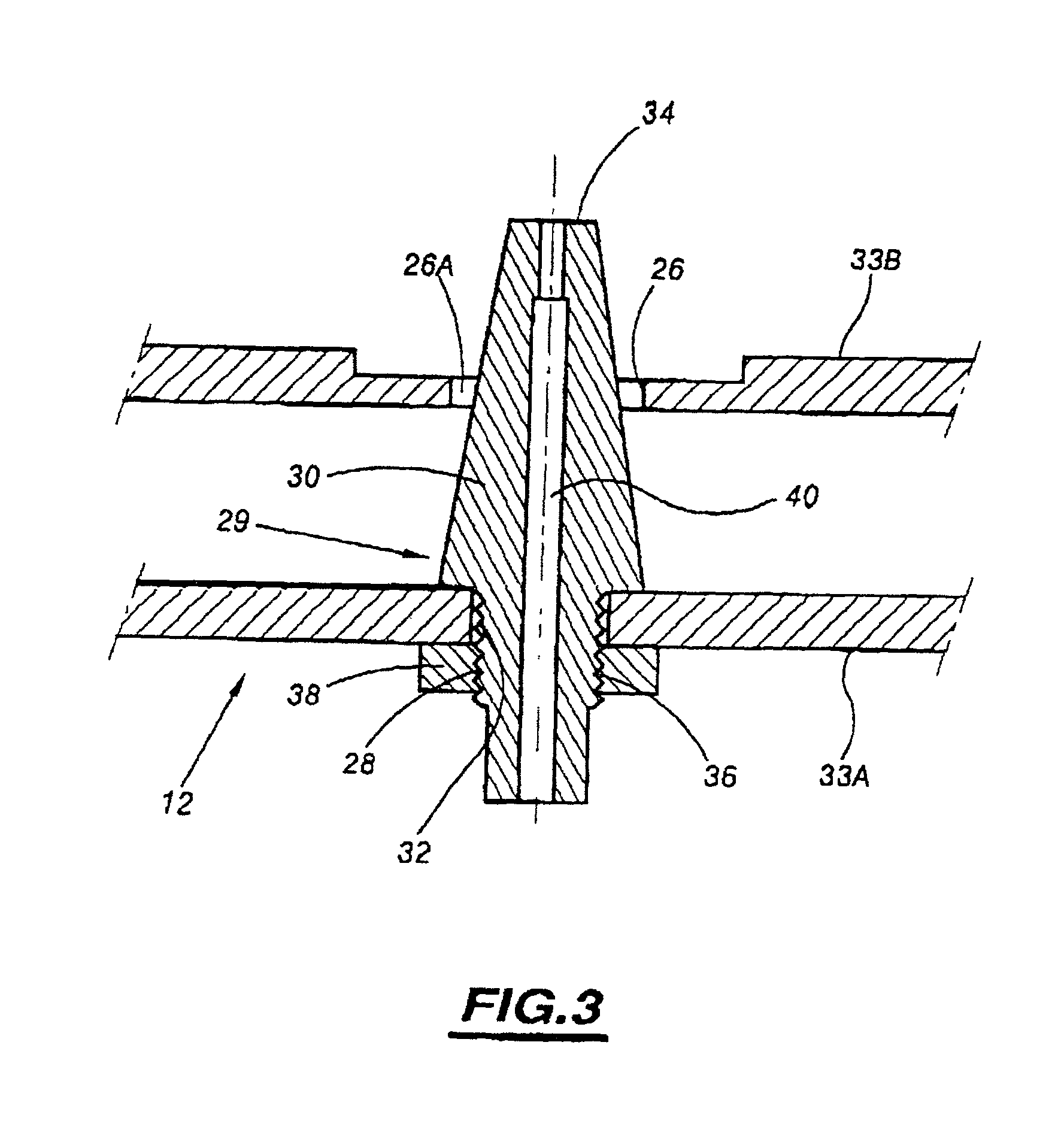

System and device for welding training

A system and device for welding training. In one example, a welding training system includes a display configured to show welding features related to a training welding operation. The system also includes a training workpiece having a substantially transparent weld joint configured to be placed adjacent to the display during the training welding operation. The system includes a processing device coupled to the display and configured to provide welding data relating to the training welding operation to the display. The system also includes a training torch comprising an optical sensor. The training torch is coupled to the processing device and configured to provide the processing device with data from the optical sensor corresponding to a position of the training torch relative to the training workpiece.

Owner:ILLINOIS TOOL WORKS INC

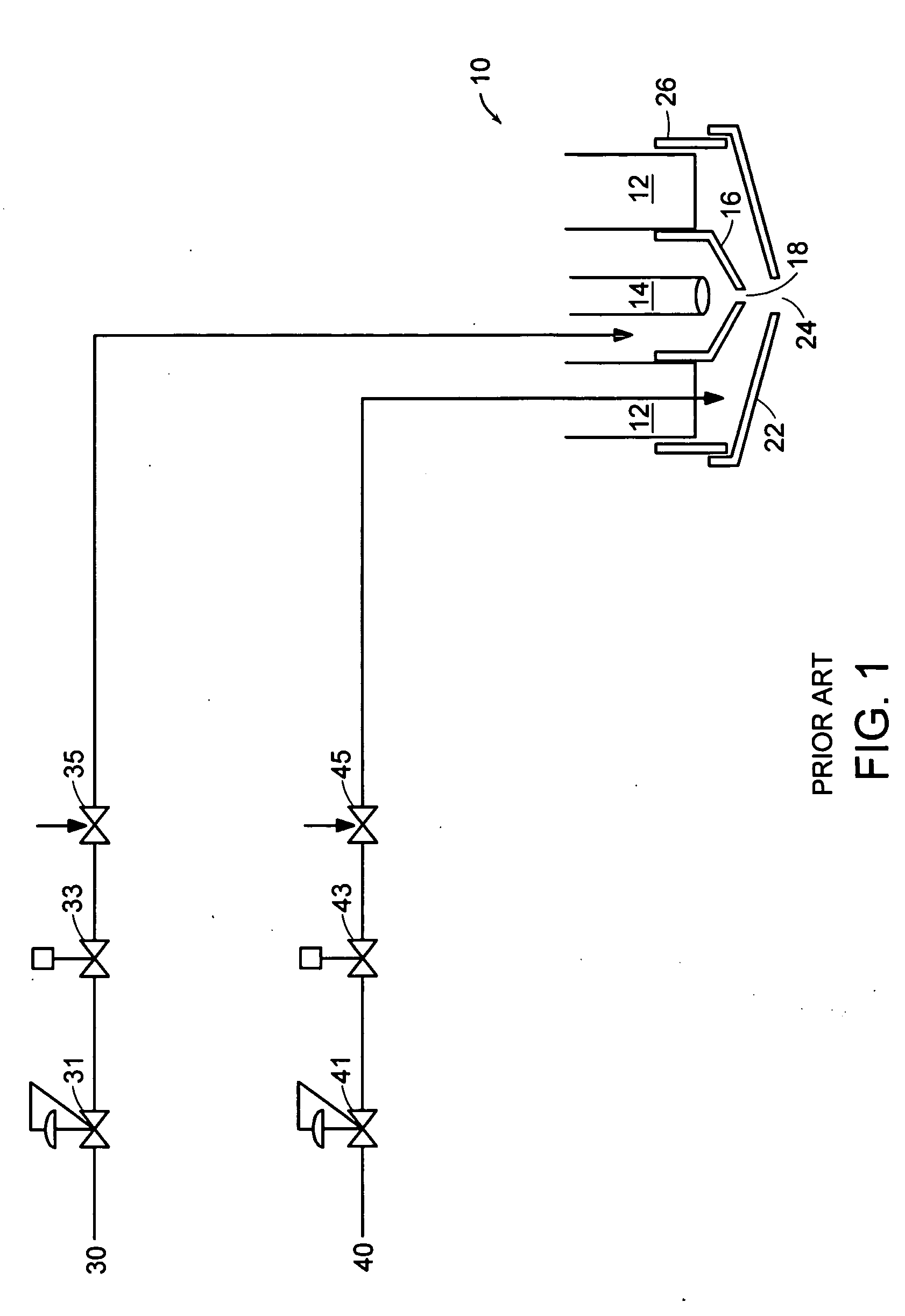

Method of operating a combustion system for increased turndown capability

ActiveUS7137256B1Emission reductionStable combustionContinuous combustion chamberGas turbine plantsCombustion systemLow load

A method of operating a gas turbine engine combustion system at lower load conditions while maintaining required emissions levels is disclosed. The present invention includes multiple embodiments of axial, radial, and circumferential fuel staging within a can-type combustor having alternate ignition techniques of spark ignition or torch ignition.

Owner:ANSALDO ENERGIA SWITZERLAND AG

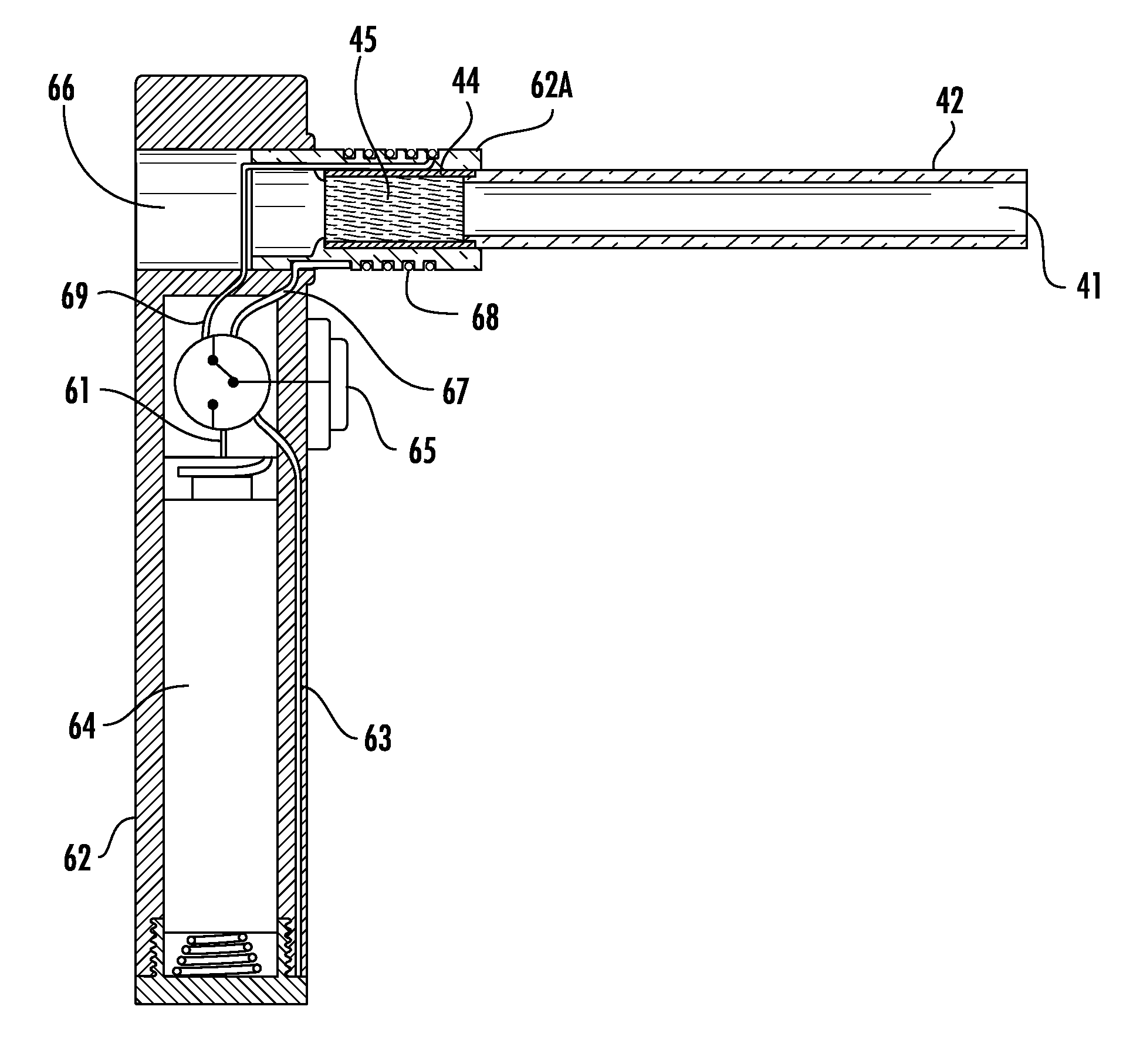

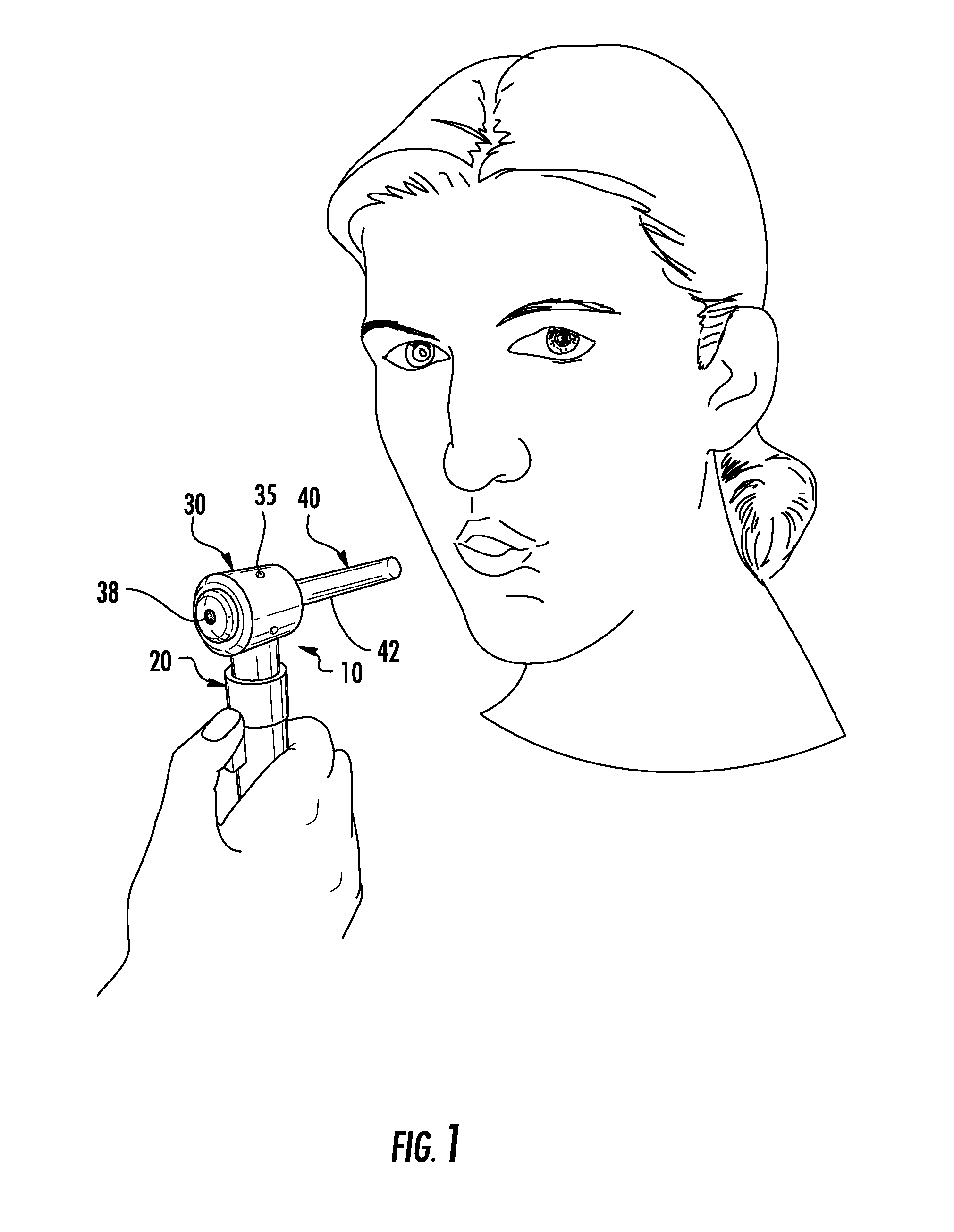

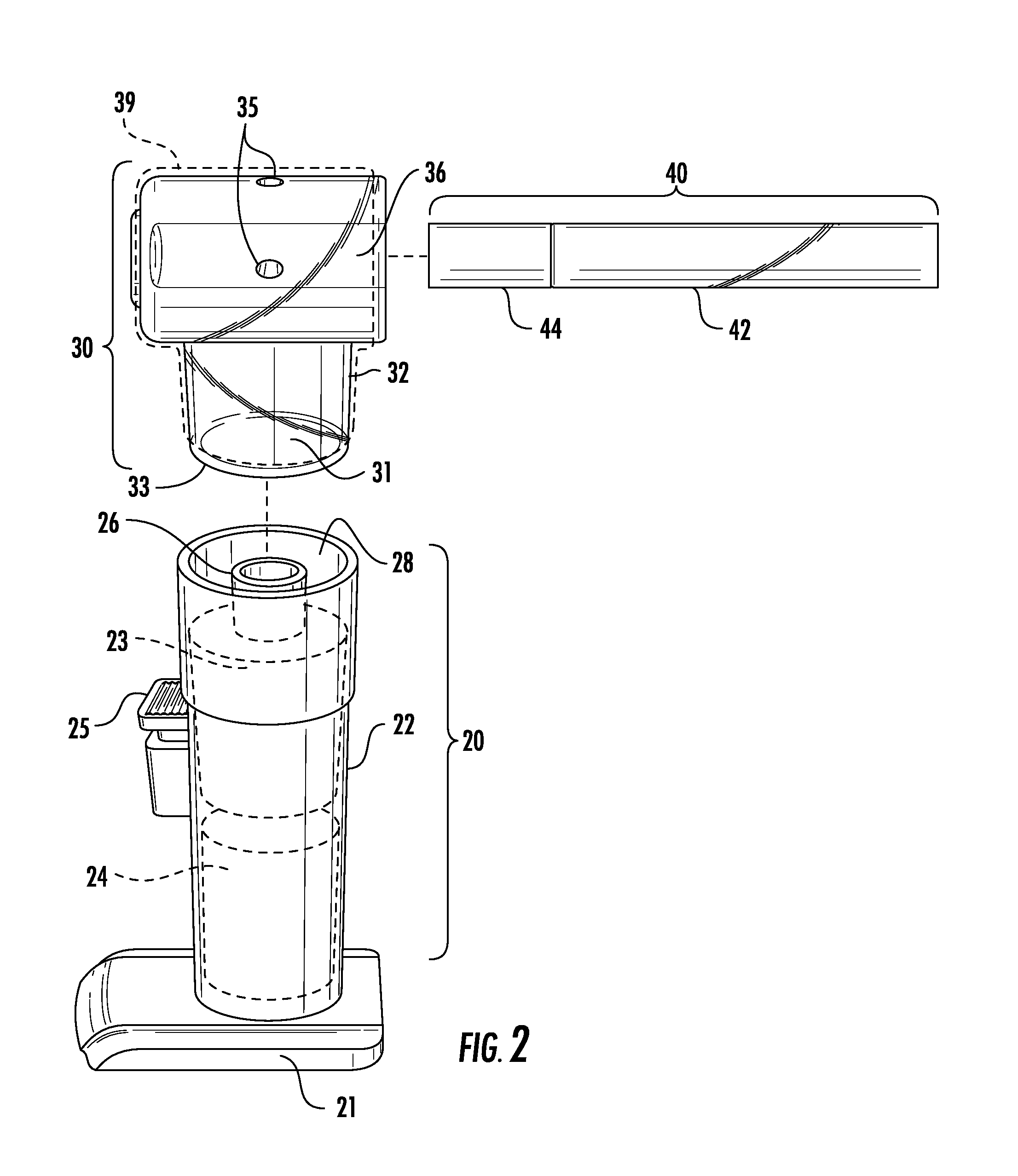

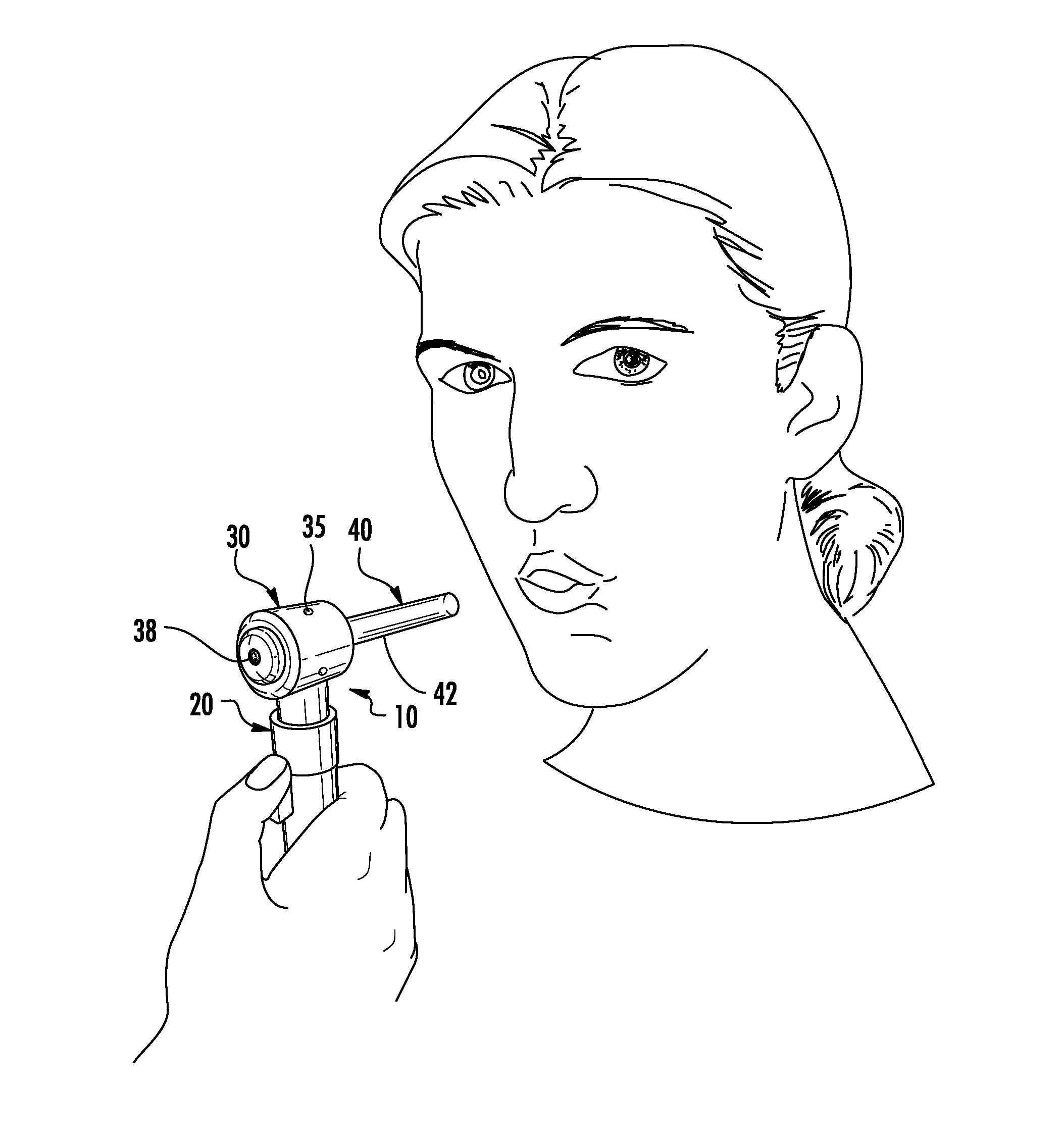

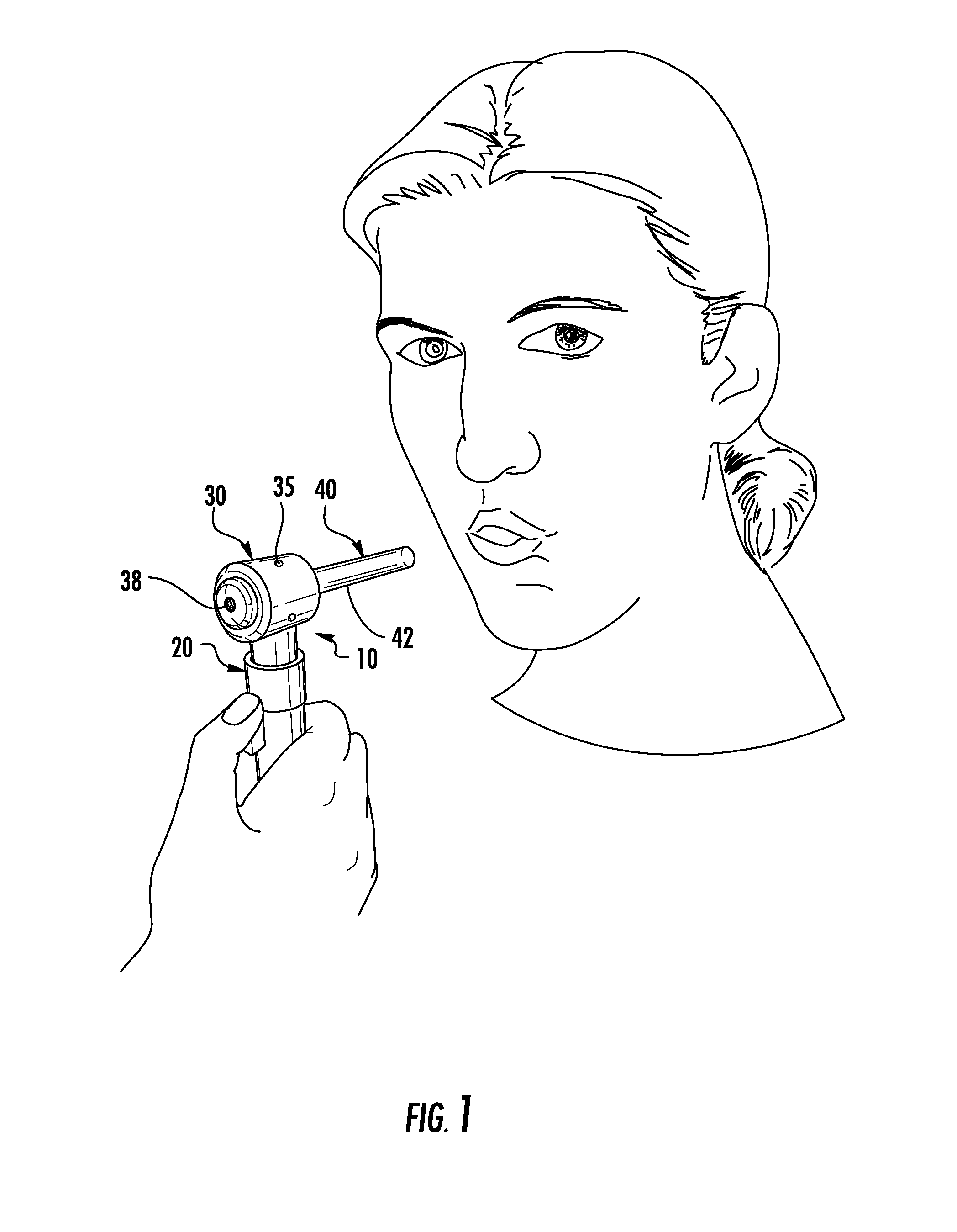

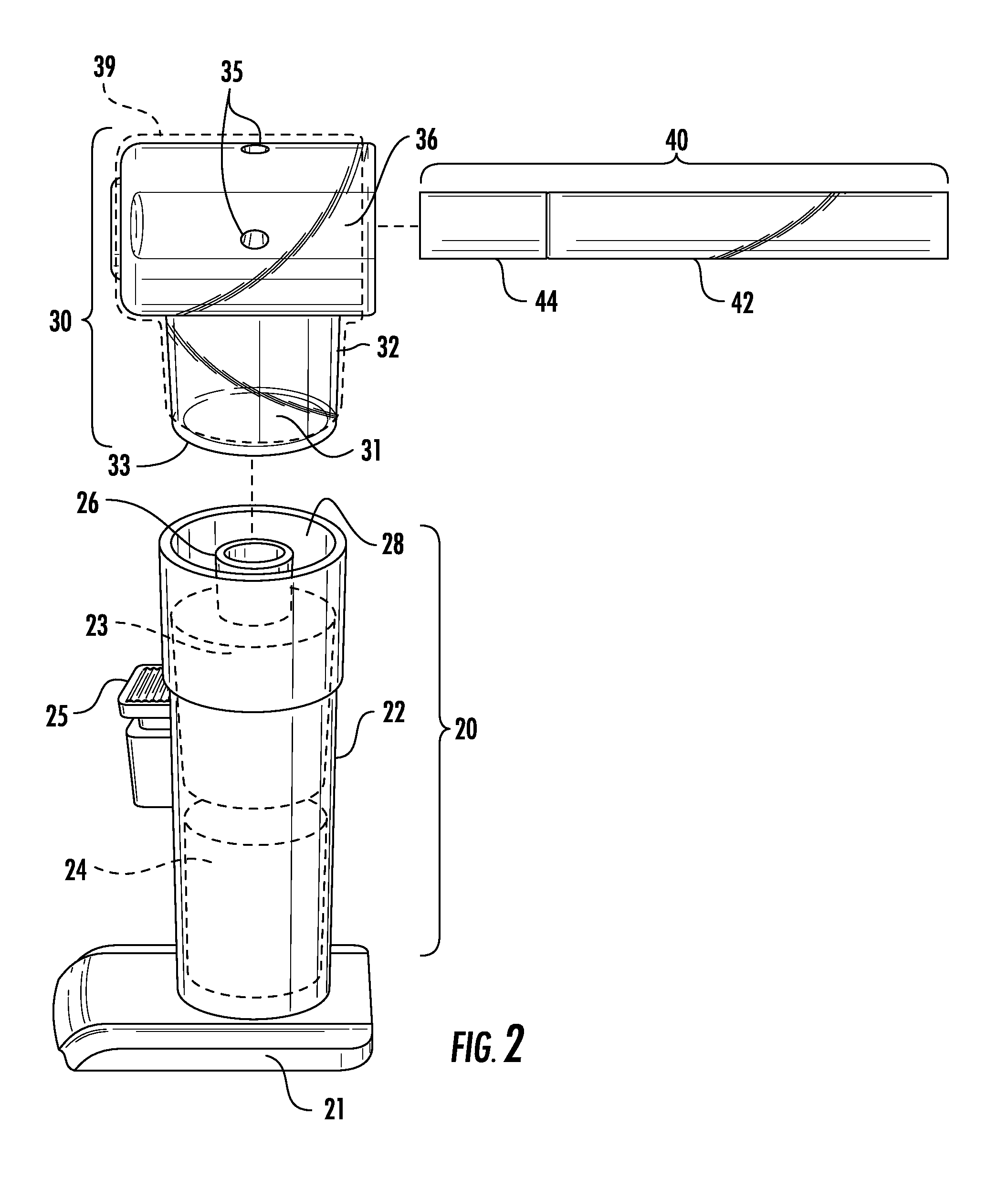

Devices for vaporizing and delivering an aerosol agent

ActiveUS20150101606A1Effective and convenient and easy to useRespiratorsMedical devicesElectricityElectrical conductor

A device for vaporizing and delivering an aerosol agent includes a heat generator, a heat conductor in fluid (airflow) communication with the heat generator, and a substrate holder in heat conducting relation with the heat conductor. The heat generator is a handheld, portable torch and the heat conductor defines an annular heat conducting chamber surrounding a substrate disposed within the substrate holder that supports the aerosol agent and an aerosol forming agent. Another device is a handheld, battery-powered heat generator including a heating element in heat conducting relation with a substrate holder. The heating element is a nichrome heating coil wound about the substrate disposed within the substrate holder and electrically coupled to the battery. Another device further includes an auxiliary heat generator having an auxiliary heating element formed by a finely woven wire mesh positioned adjacent the substrate and electrically coupled to the battery.

Owner:PATHFINDER INNOVATIONS LLC

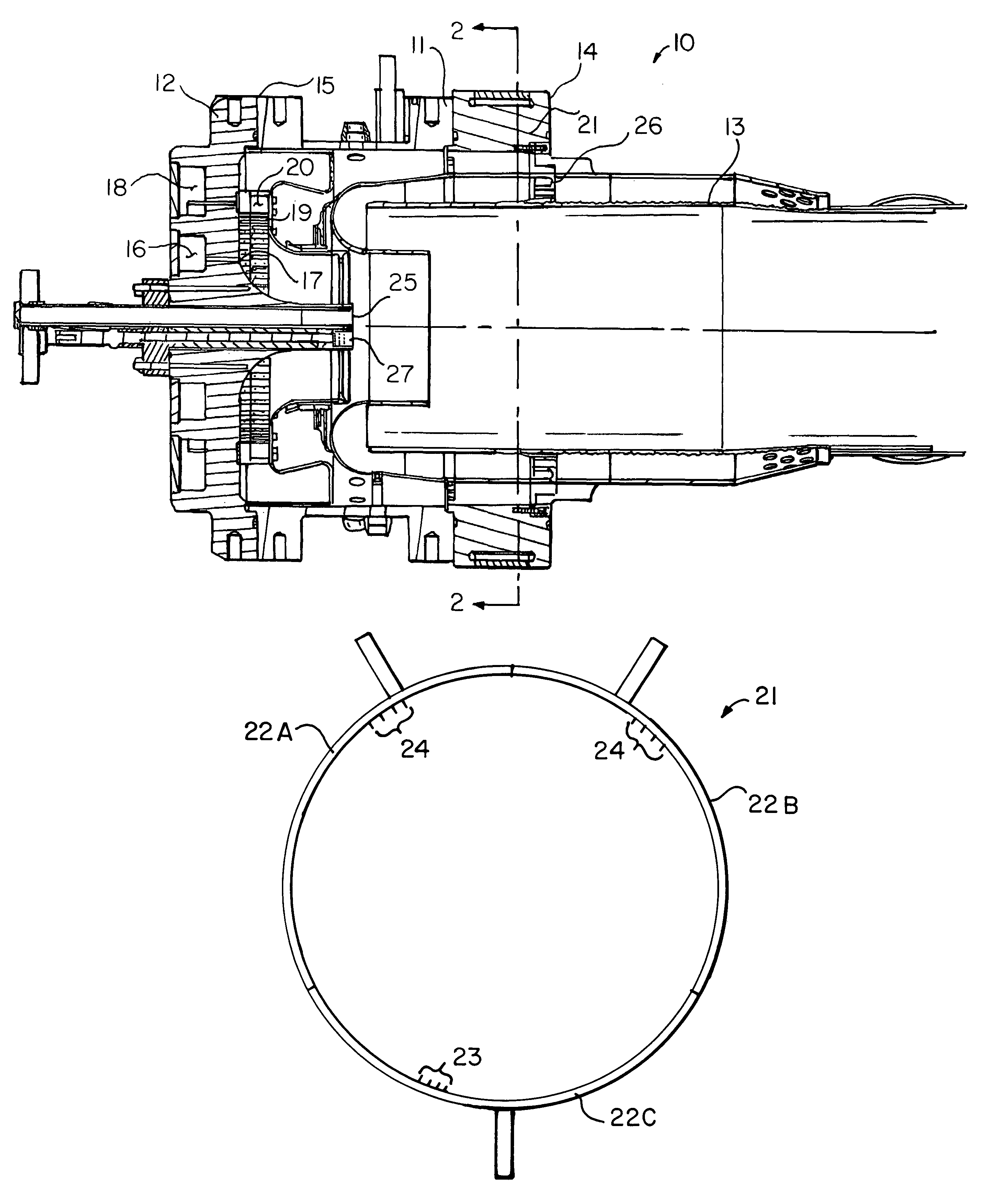

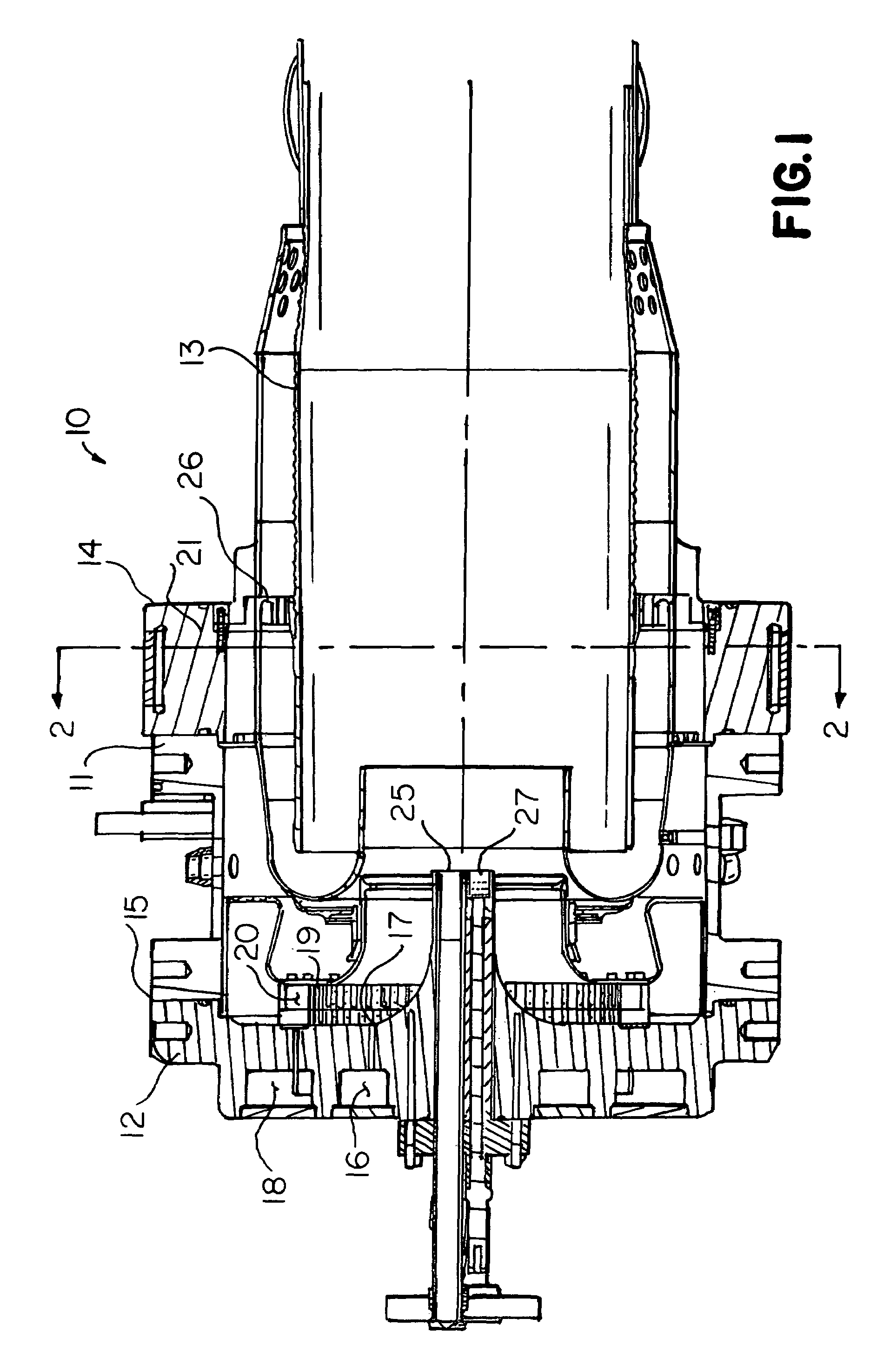

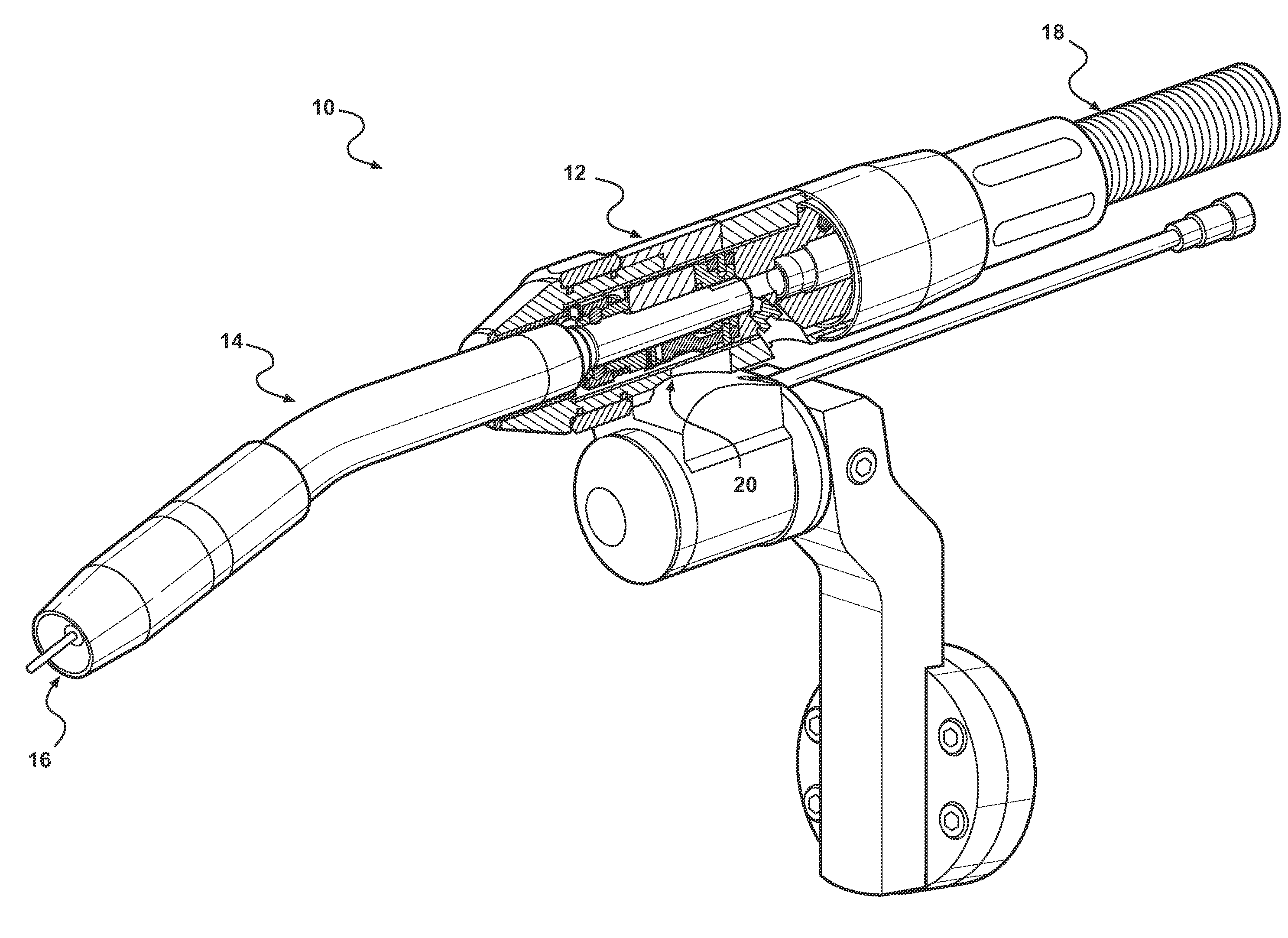

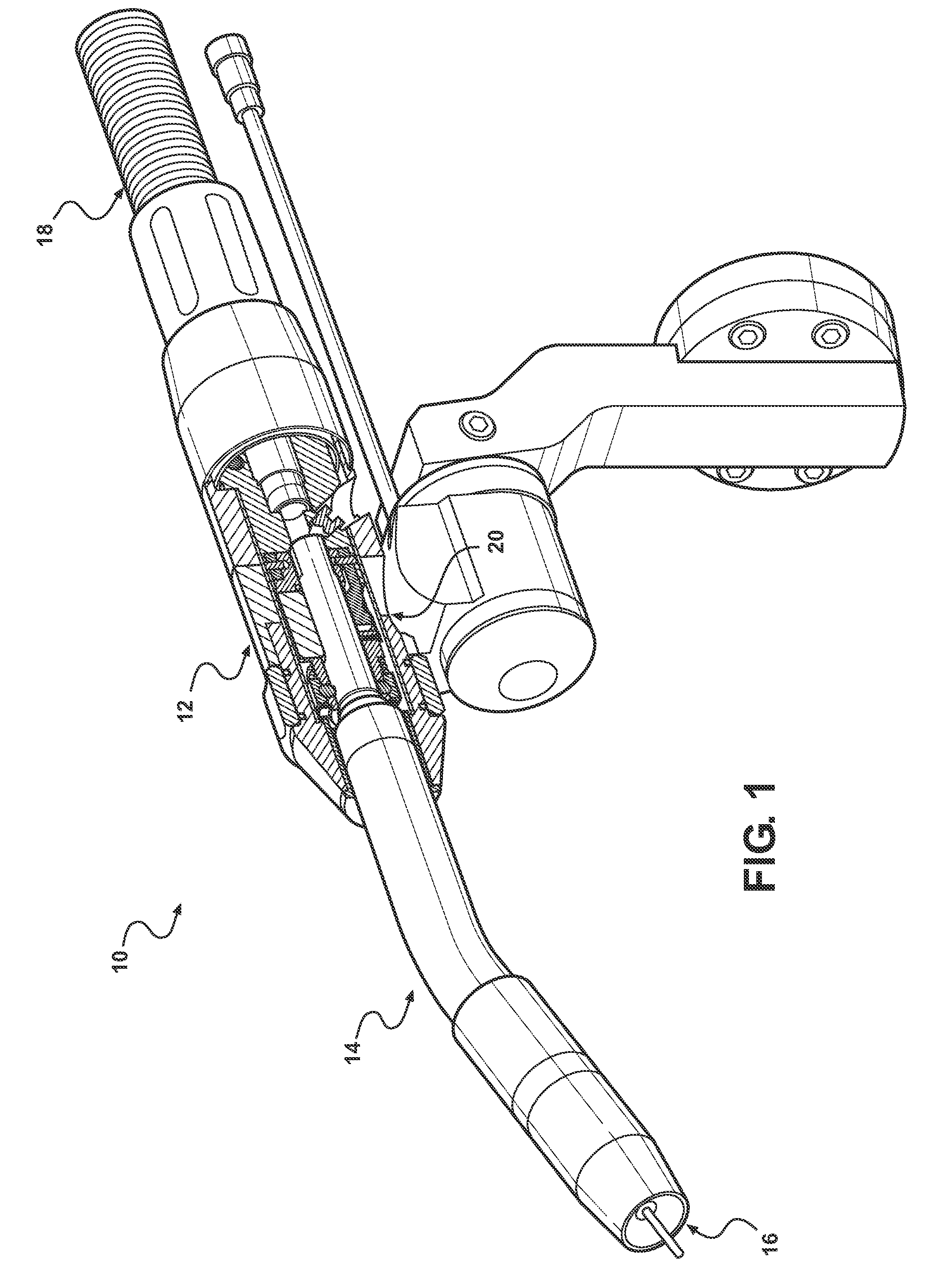

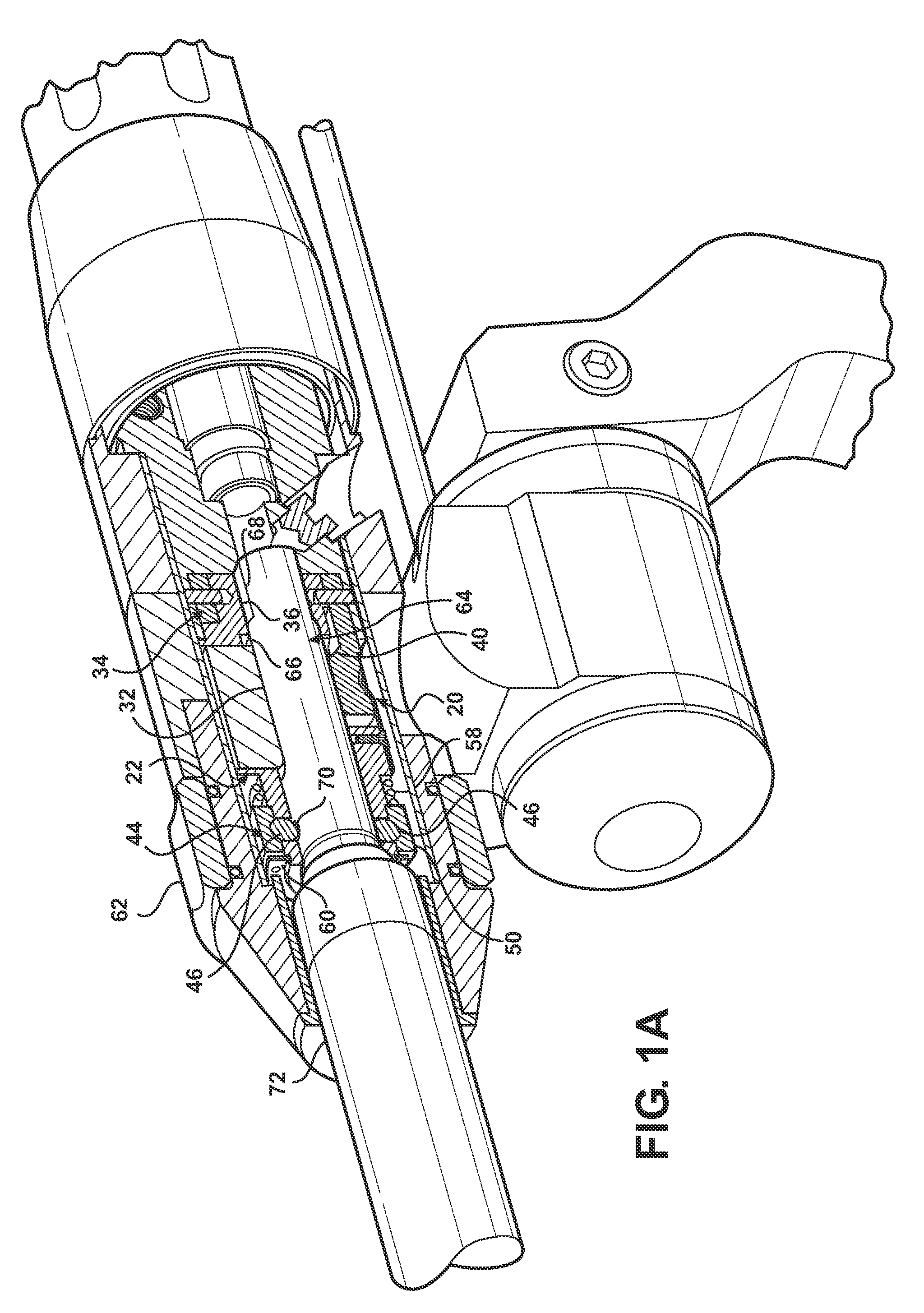

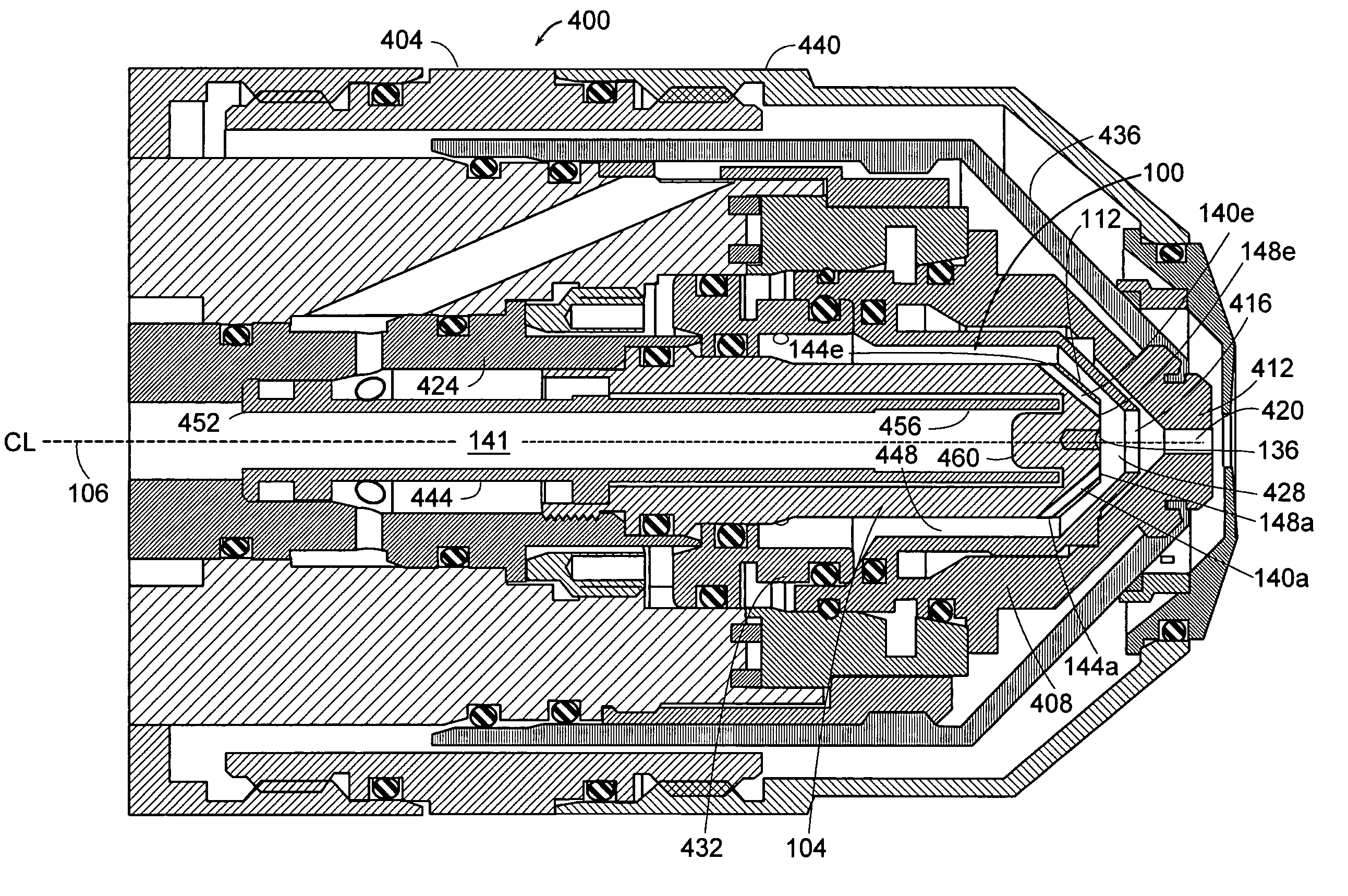

Robotic gmaw torch with quick release gooseneck locking mechanism, dual alignment features, and multiple electrical contacts

InactiveUS20100012637A1Increased durabilityImprove consistencyShielding gas supply/evacuation devicesSupport devices with shieldingLocking mechanismDetent

A gooseneck locking mechanism for a robotic GMAW torch having a torch body and a gooseneck includes a connector receiver disposed in the torch body. The connector receiver includes longitudinal ends and a passageway extending between the longitudinal ends. An indexing feature is disposed in the passageway. An elongated connector is mountable on a proximal end of the gooseneck. The connector includes a cooperable indexing feature. The locking mechanism further includes a detent for joining the connector receiver and the elongated connector. The indexing features align the gooseneck relative to the torch body, and the detent secures the connector in the connector receiver for quick release. The locking mechanism may include a plurality of electrical contacts in the connector receiver that are engageable with the connector to provide flow of electrical current through the connector receiver to the gooseneck.

Owner:ILLINOIS TOOL WORKS INC

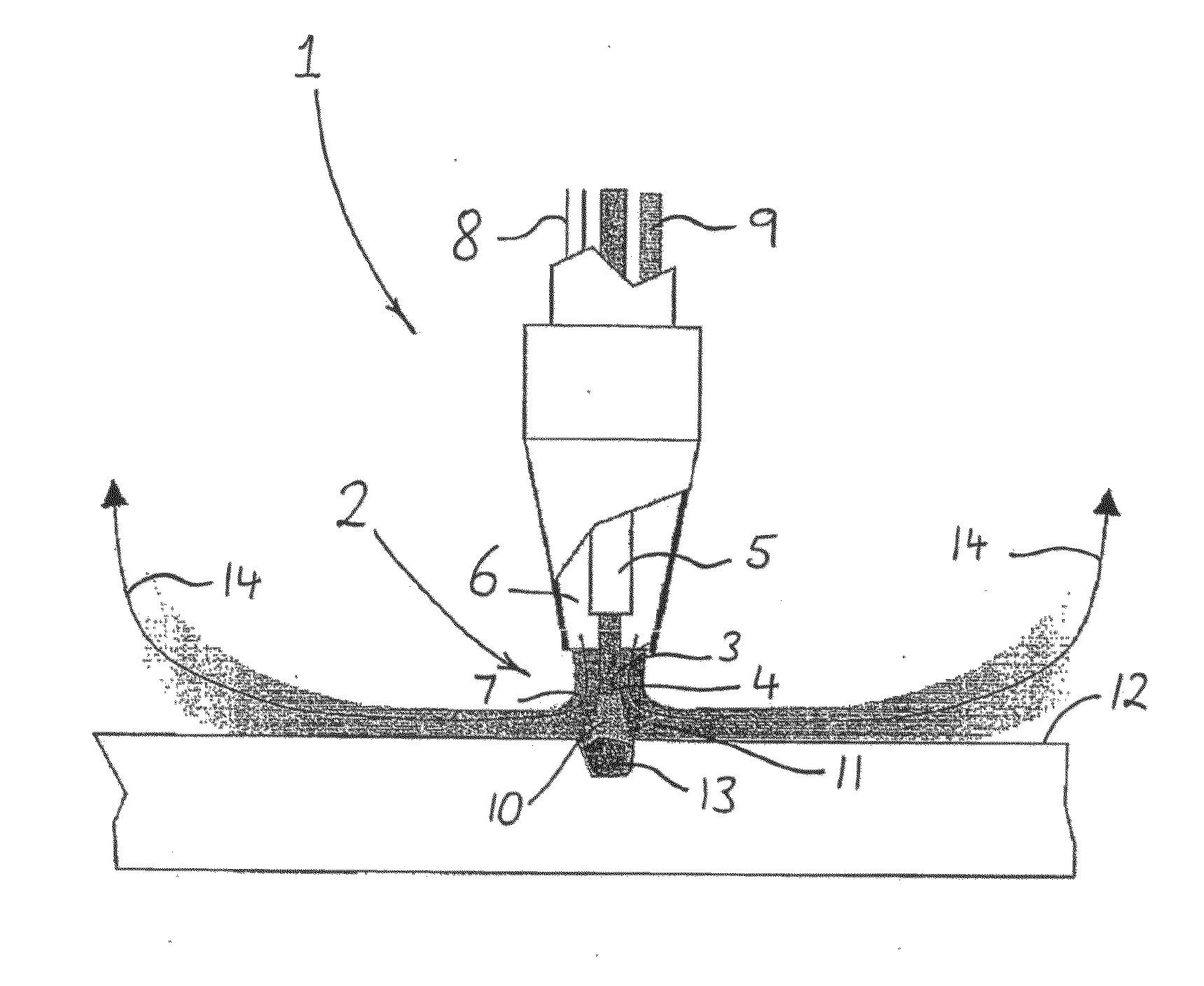

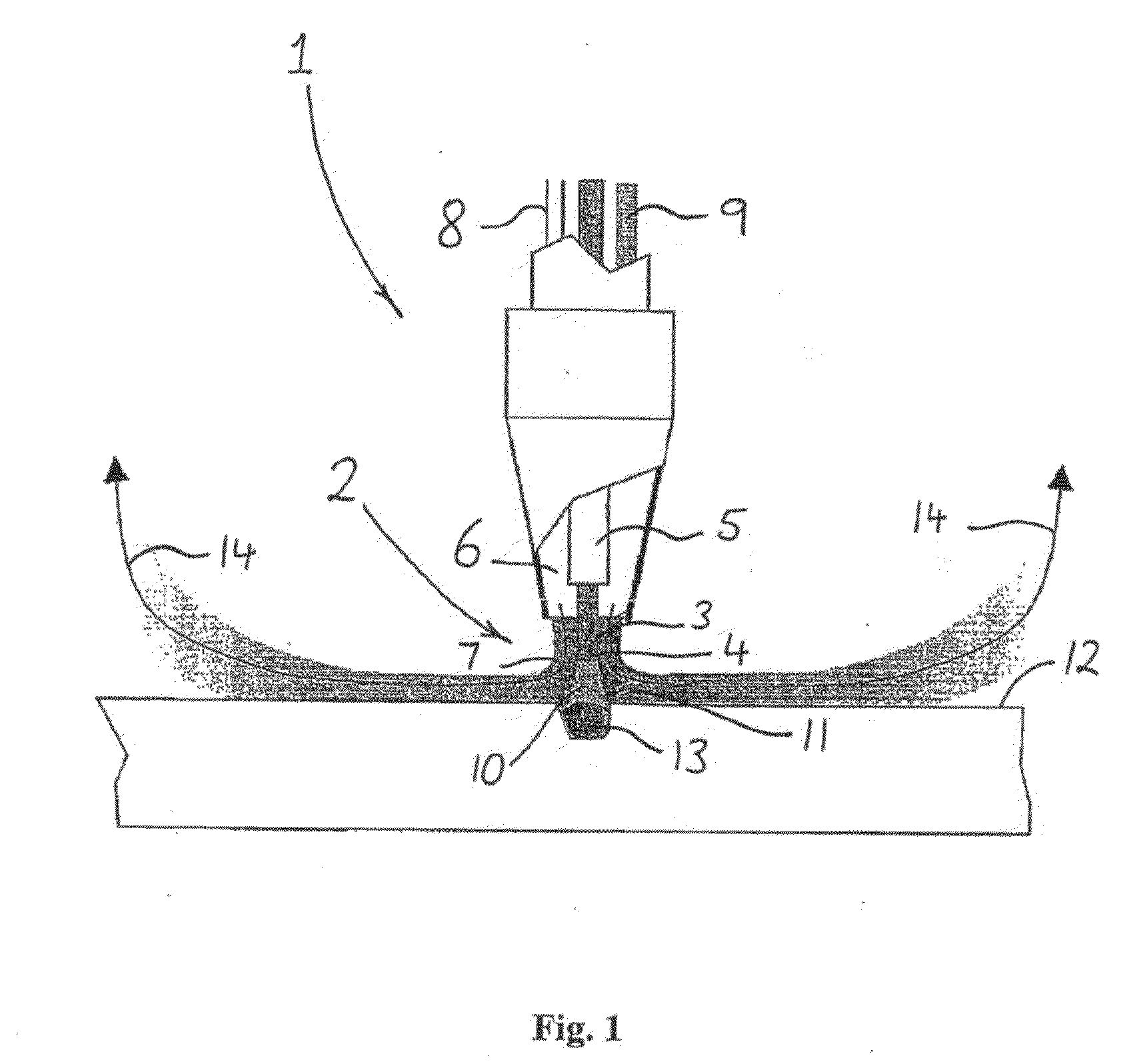

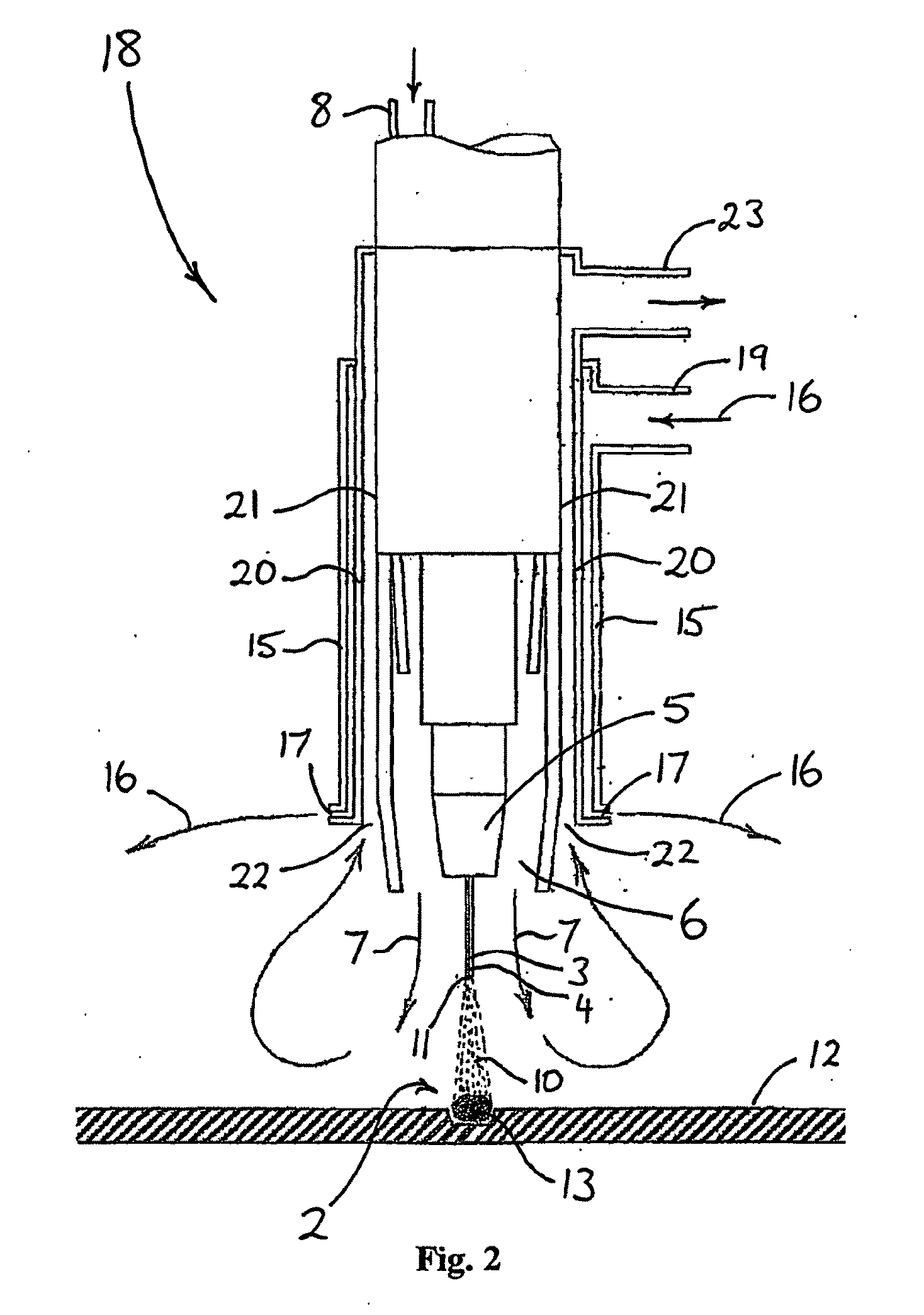

Apparatus and method for welding

InactiveUS20100276396A1Improve smoke extraction efficiencyFine-tune fume extraction efficiencyShielding gas supply/evacuation devicesDirt cleaningShielding gasCarbon Dioxide / Helium

The present invention relates to arc welding torch and a method of extracting fume gas from a welding site. The torch comprises a metal electrode and at least one shield gas port adapted to direct a shield gas curtain around the metal electrode and a welding site. At least one shroud gas port is spaced radially outward from the shield gas port and adapted to impart to an exiting shroud gas a radially outward component of velocity. Fume gas is preferably extracted from a position radially intermediate the shield gas curtain and the shroud gas curtain.

Owner:COOPER PAUL +2

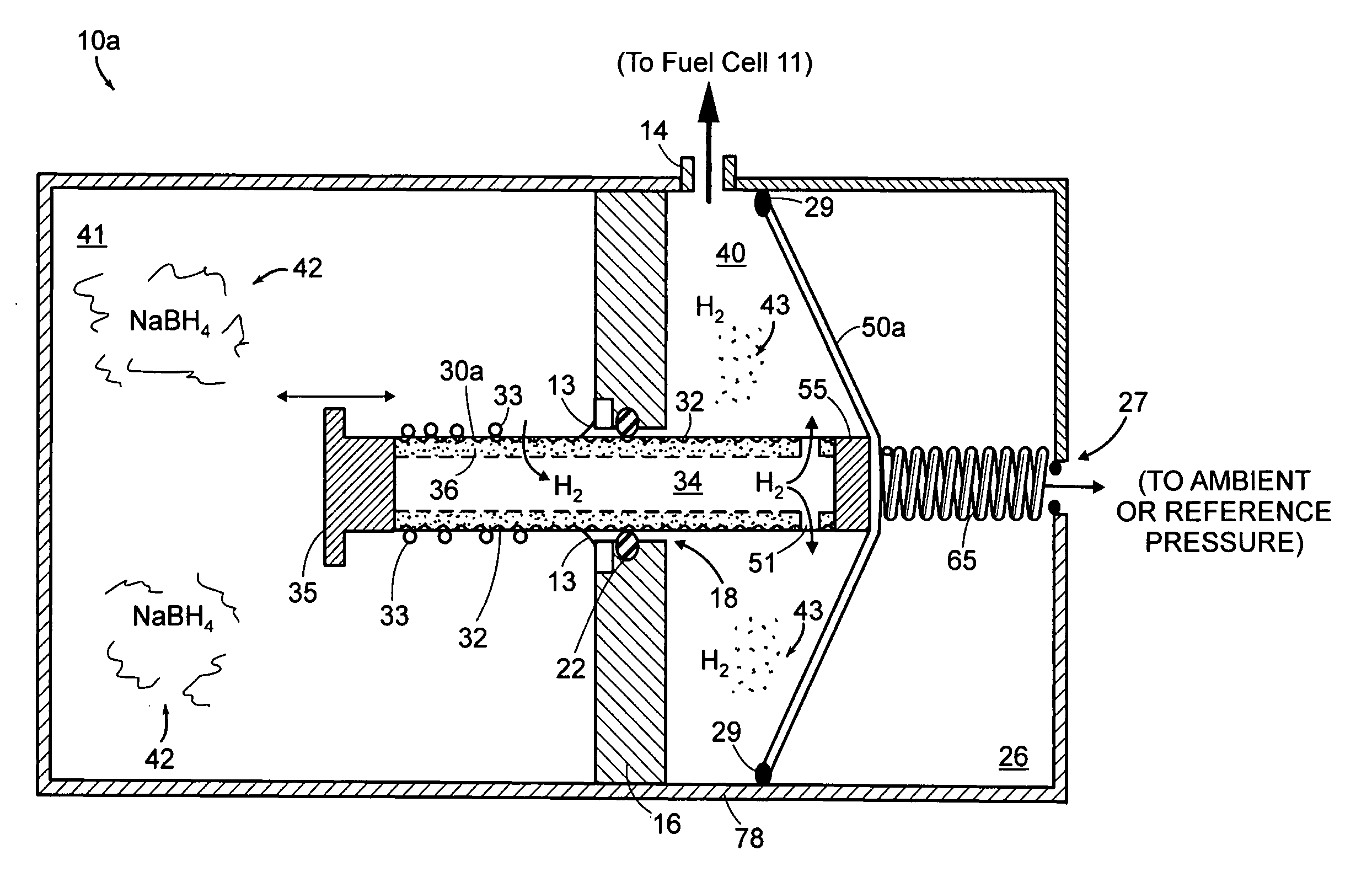

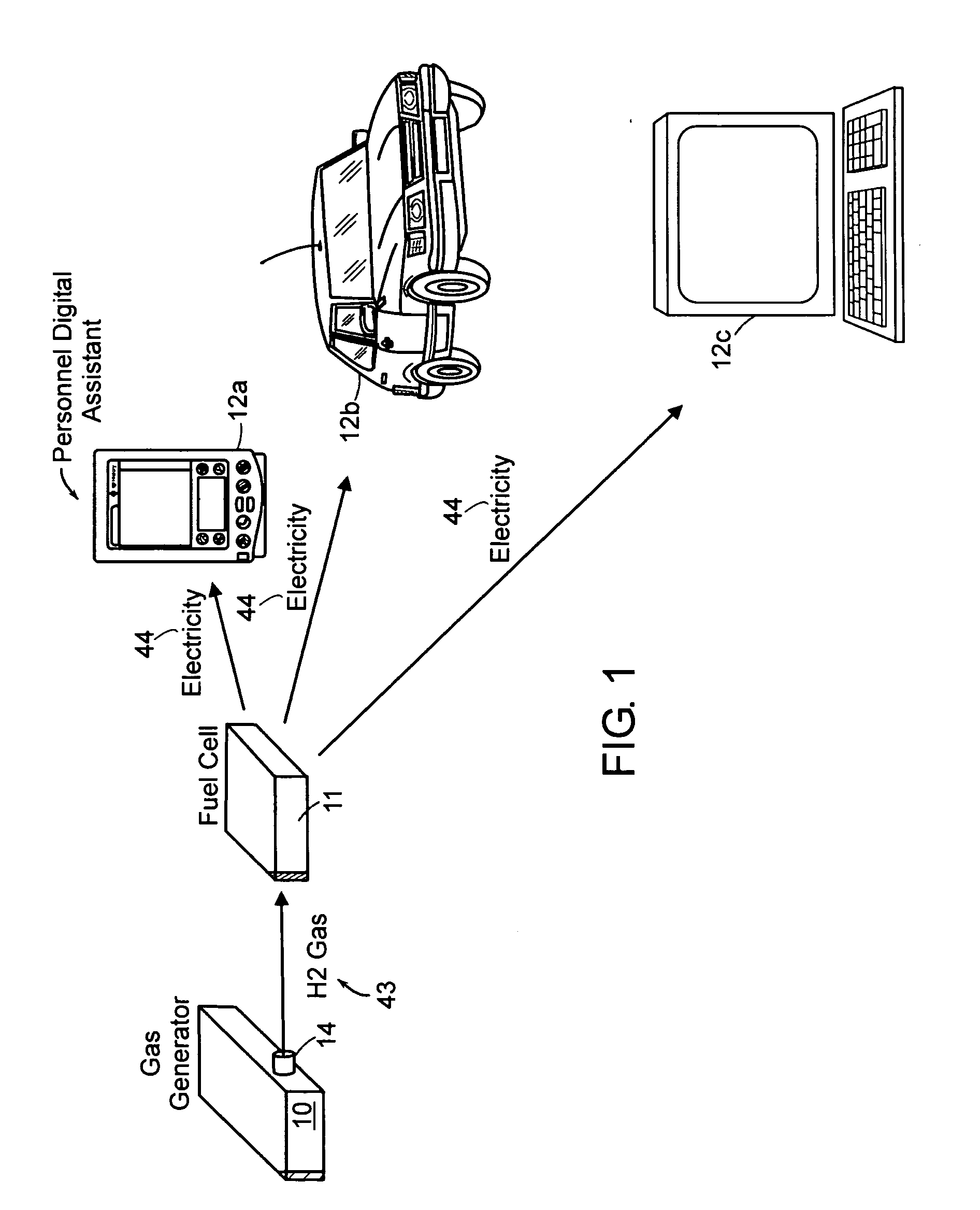

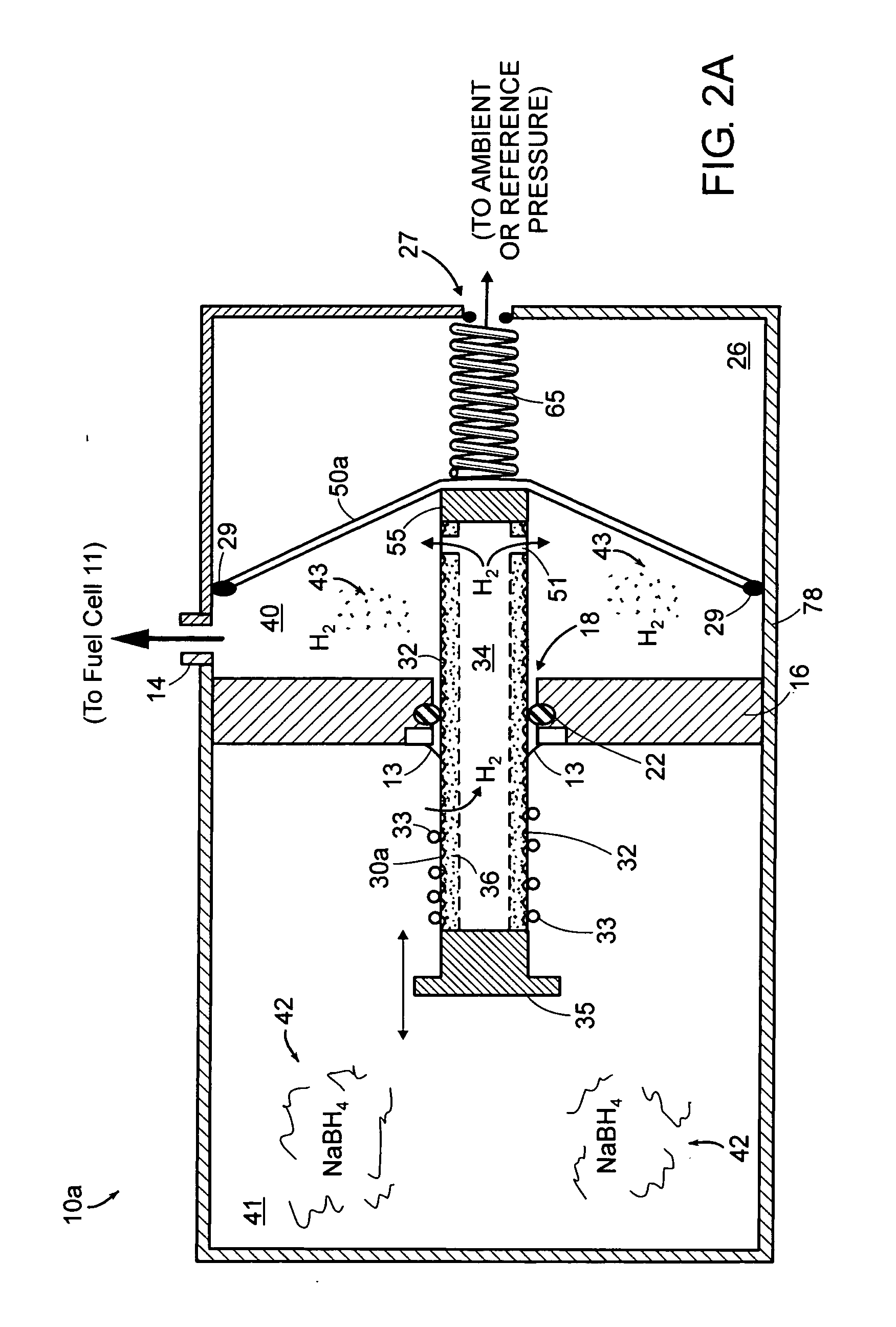

Self-regulating gas generator and method

ActiveUS20050158595A1Increase and decreases gas production rateExtend your lifeReactant parameters controlMultiple metal hydridesHydrogenFuel cells

A self-regulating gas generator that, in response to gas demand, supplies and automatically adjusts the amount of gas (e.g., hydrogen or oxygen) catalytically generated in a chemical supply chamber from an appropriate chemical supply, such as a chemical solution, gas dissolved in liquid, or mixture. The gas generator may employ a piston, rotating rod, or other element(s) to expose the chemical supply to the catalyst in controlled amounts. The gas generator may be used to provide gas for various gas consuming devices, such as a fuel cell, torch, or oxygen respiratory devices.

Owner:ENCITE LLC

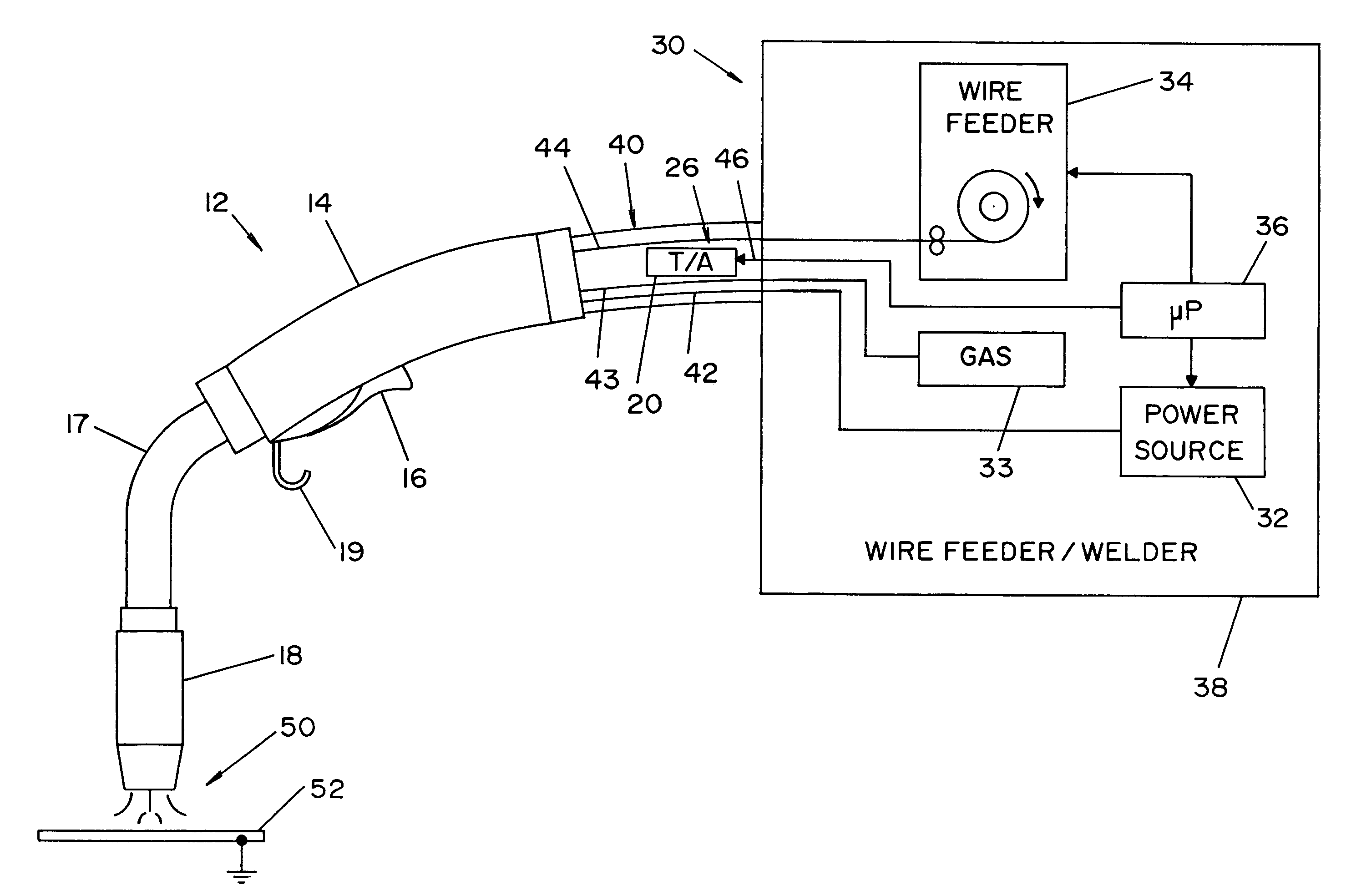

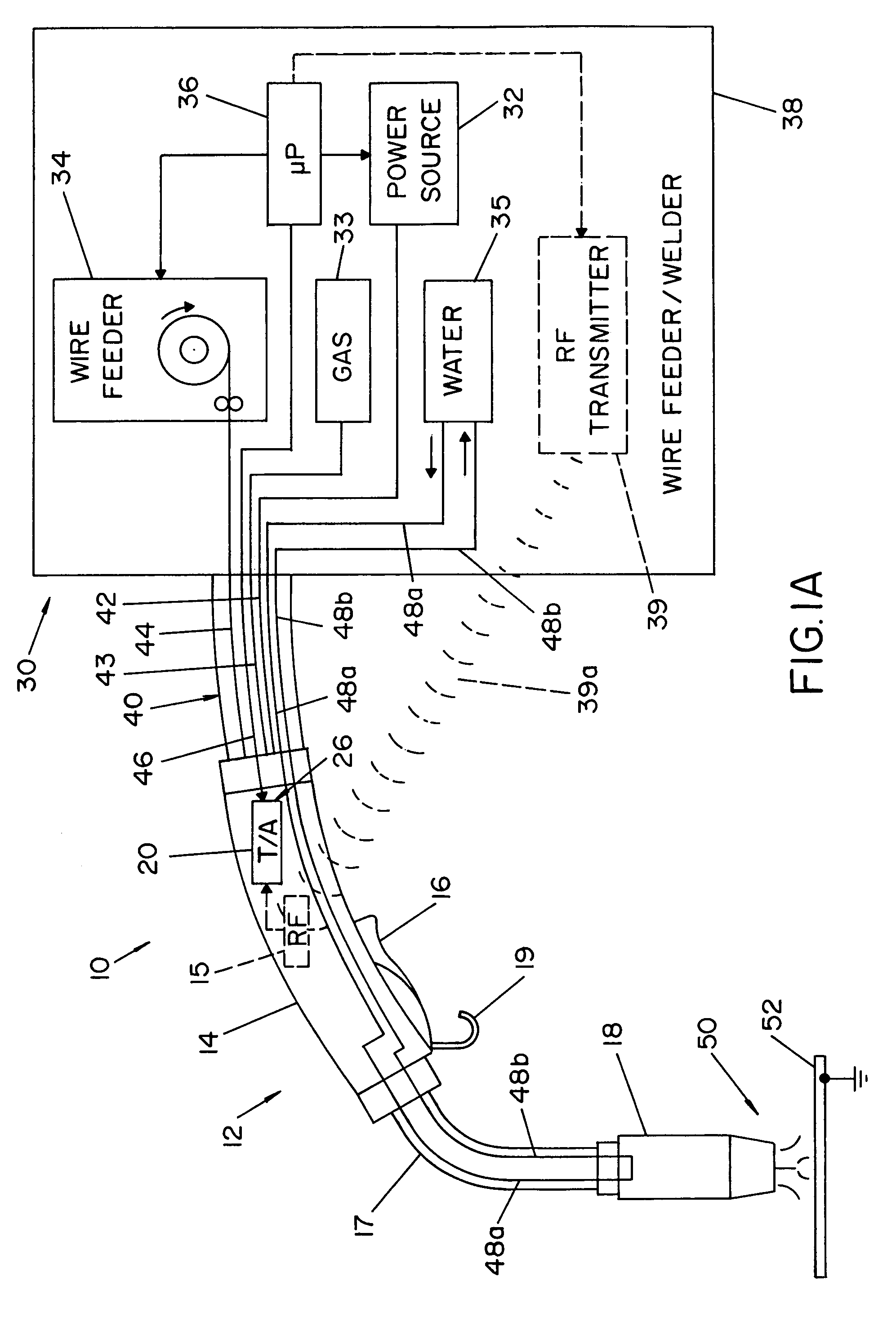

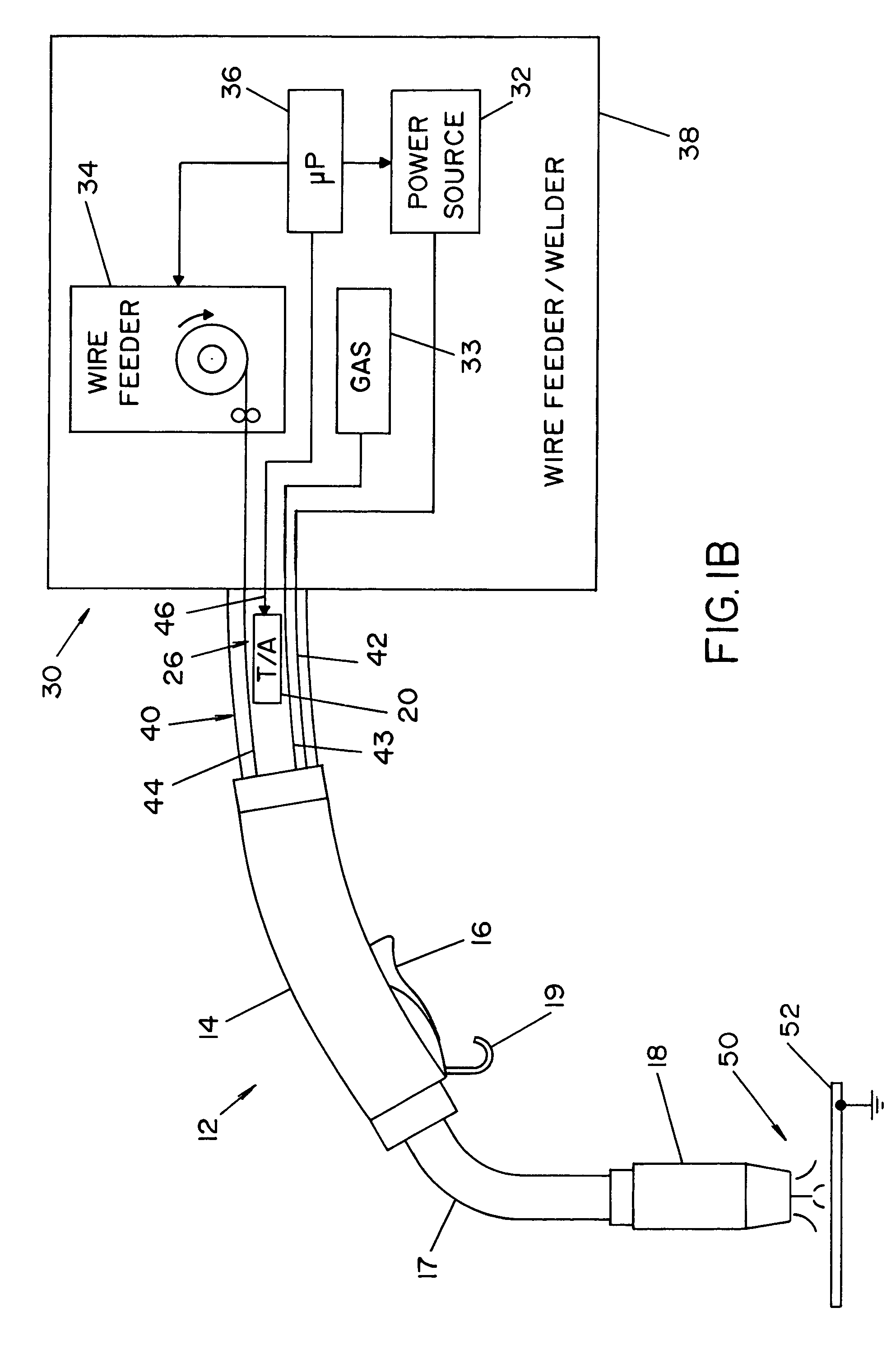

Methods and apparatus for tactile communication in an arc processing system

ActiveUS7358458B2Facilitate communicationReduce eliminateArc welding apparatusTactile deviceTactile communication

Systems and methods are presented for tactile communication with an operator in an arc processing system, in which a tactile device is mechanically coupled with a handheld torch to provide tactile messages to the operator according to information related to the system or to an arc processing operation being performed.

Owner:LINCOLN GLOBAL INC

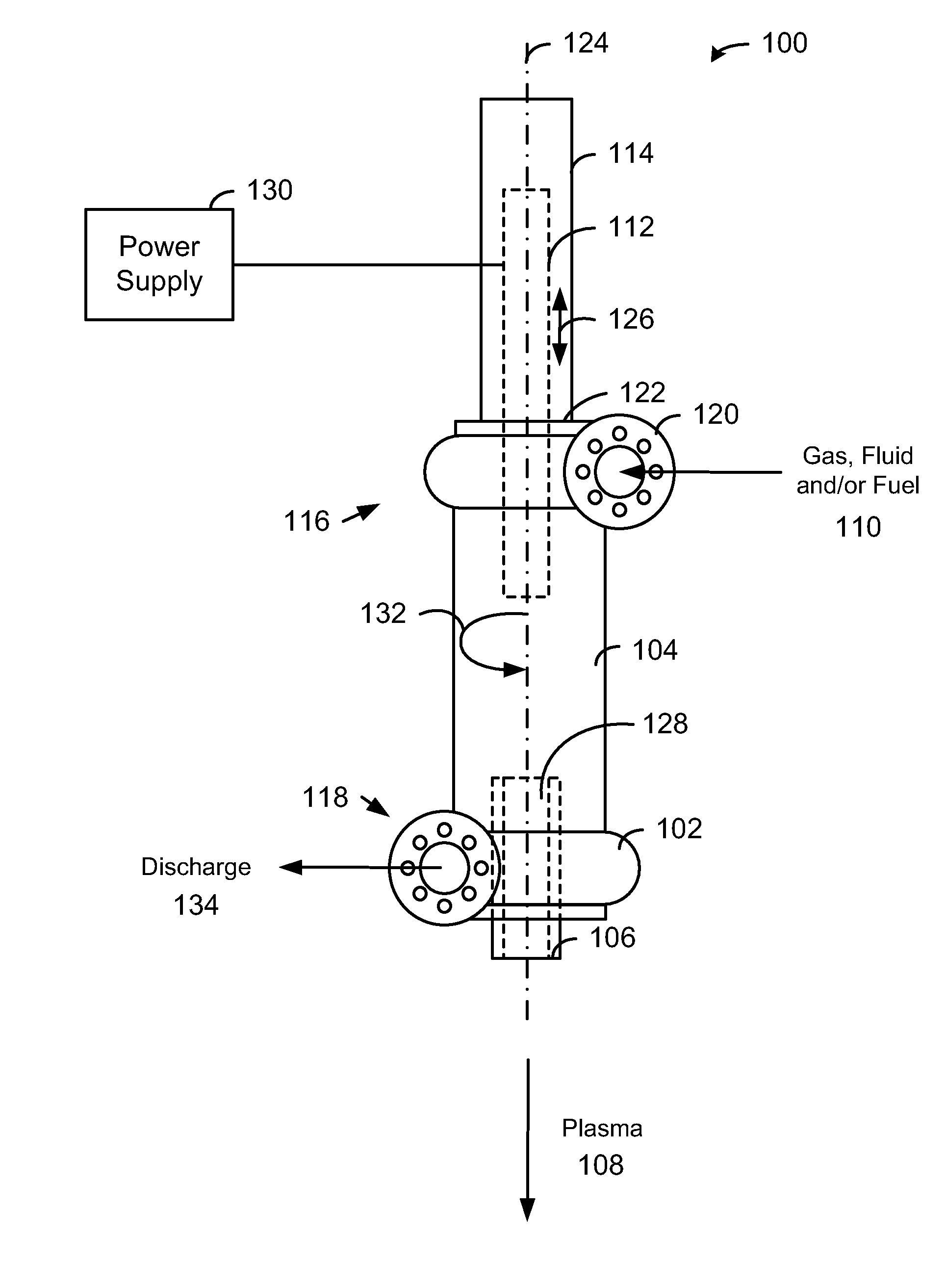

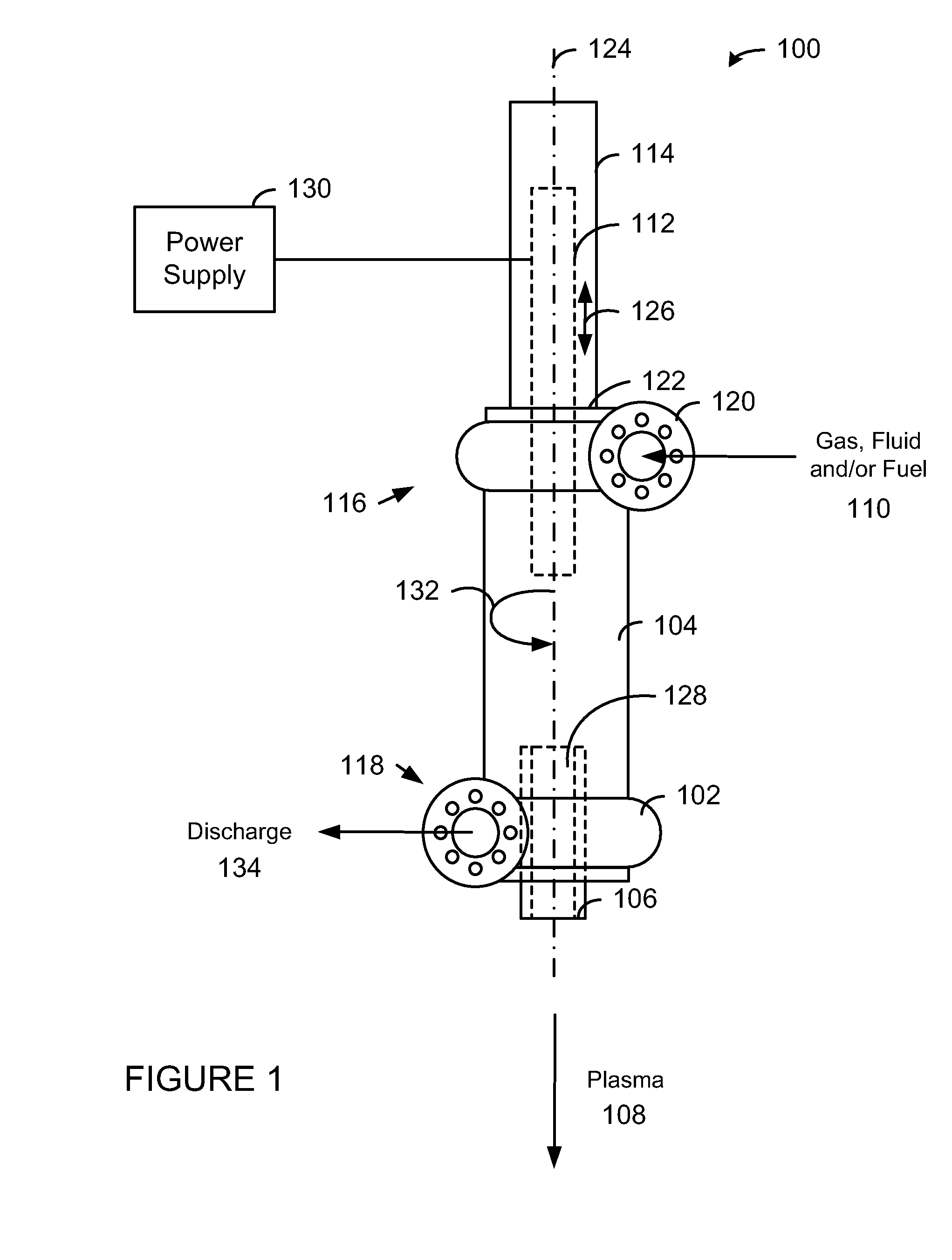

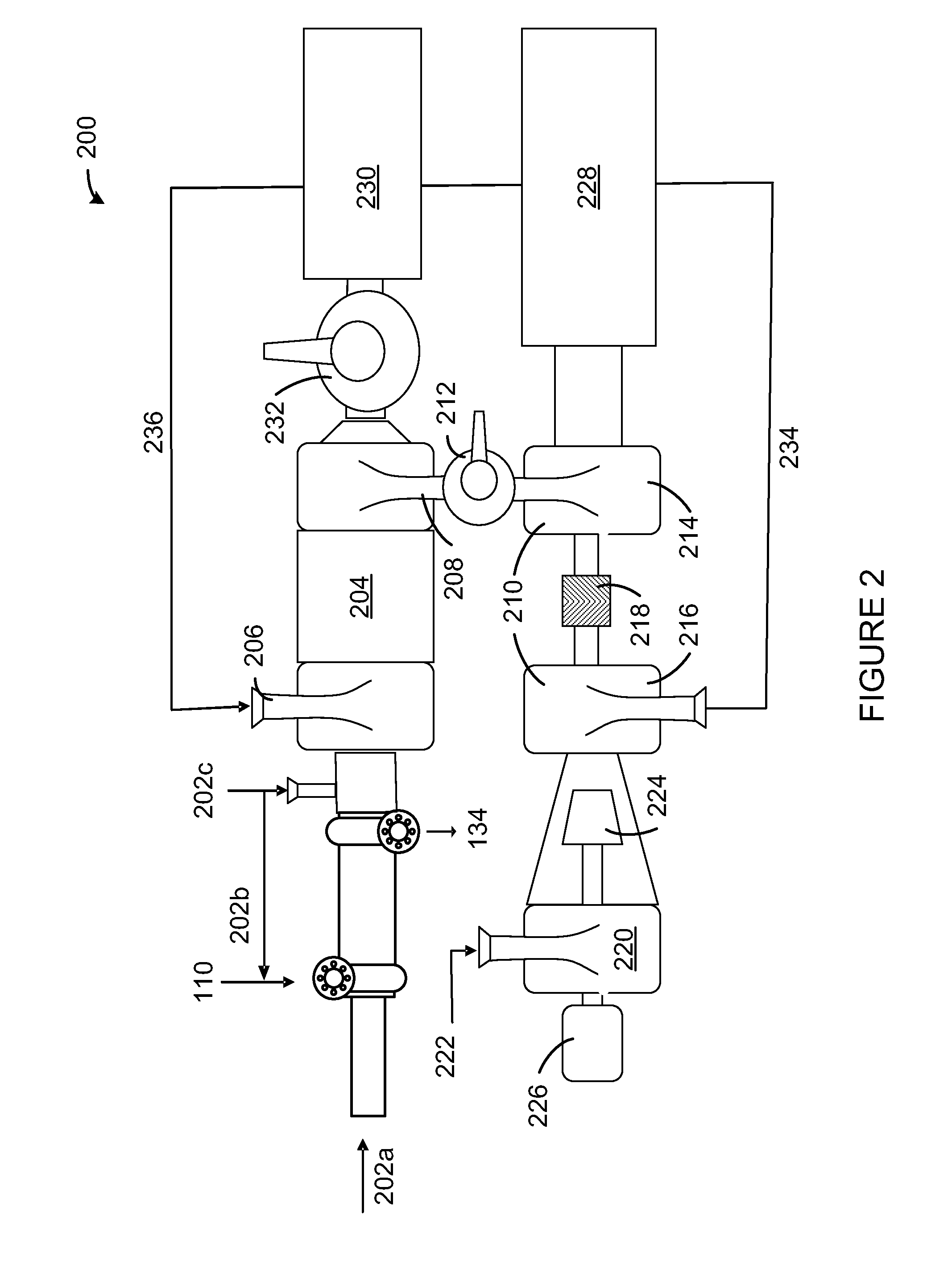

System, method and apparatus for lean combustion with plasma from an electrical arc

The present invention provides a plasma arc torch that can be used for lean combustion. The plasma arc torch includes a cylindrical vessel, an electrode housing connected to the first end of the cylindrical vessel such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, (b) extends into the cylindrical vessel, and (c) can be moved along the longitudinal axis, a linear actuator connected to the first electrode to adjust a position of the first electrode, a hollow electrode nozzle connected to the second end of the cylindrical vessel such that the center line of the hollow electrode nozzle is aligned with the longitudinal axis of the cylindrical vessel, and wherein the tangential inlet and the tangential outlet create a vortex within the cylindrical vessel, and the first electrode and the hollow electrode nozzle crate a plasma the discharges through the hollow electrode nozzle.

Owner:FORET PLASMA LABS

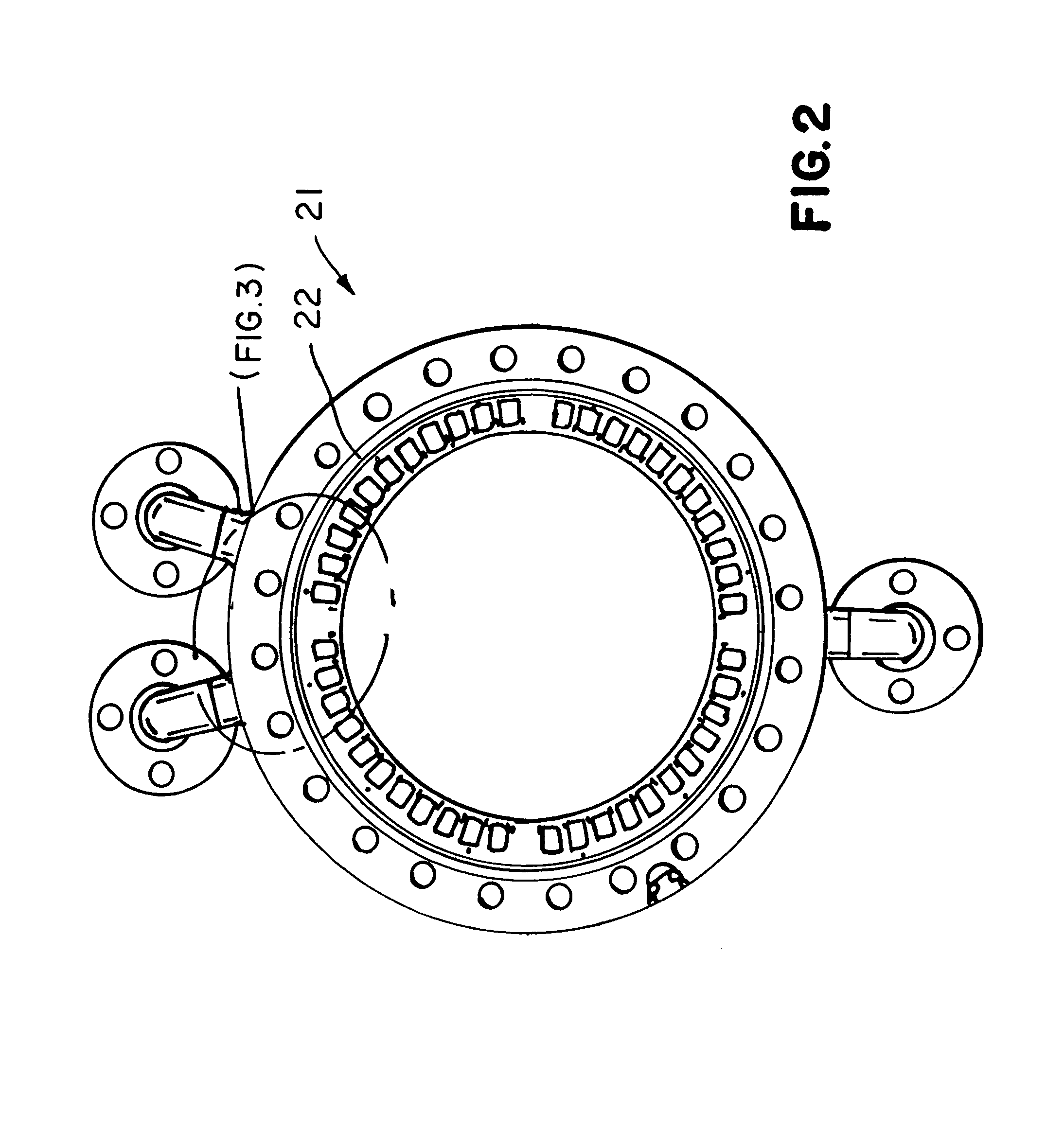

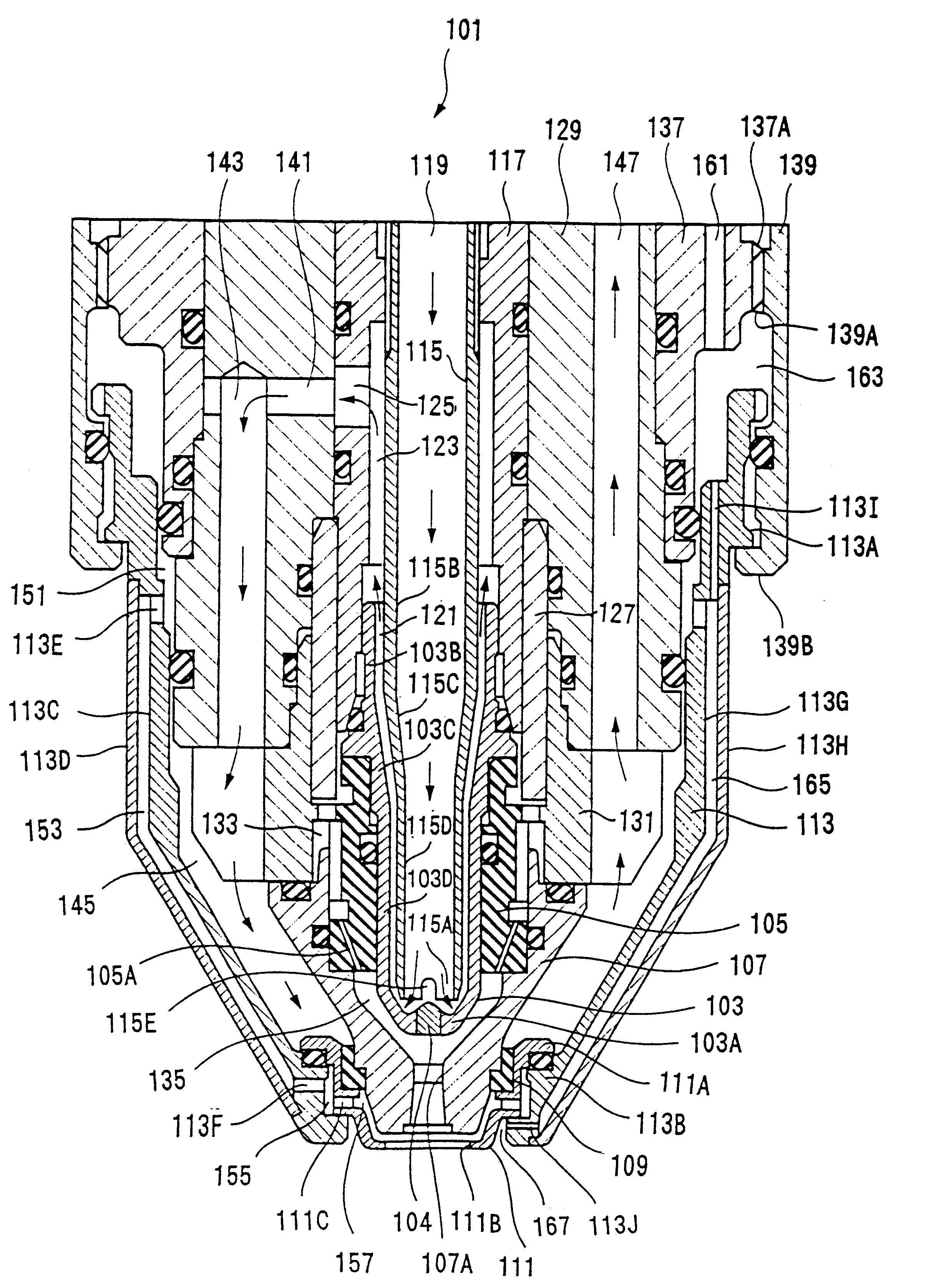

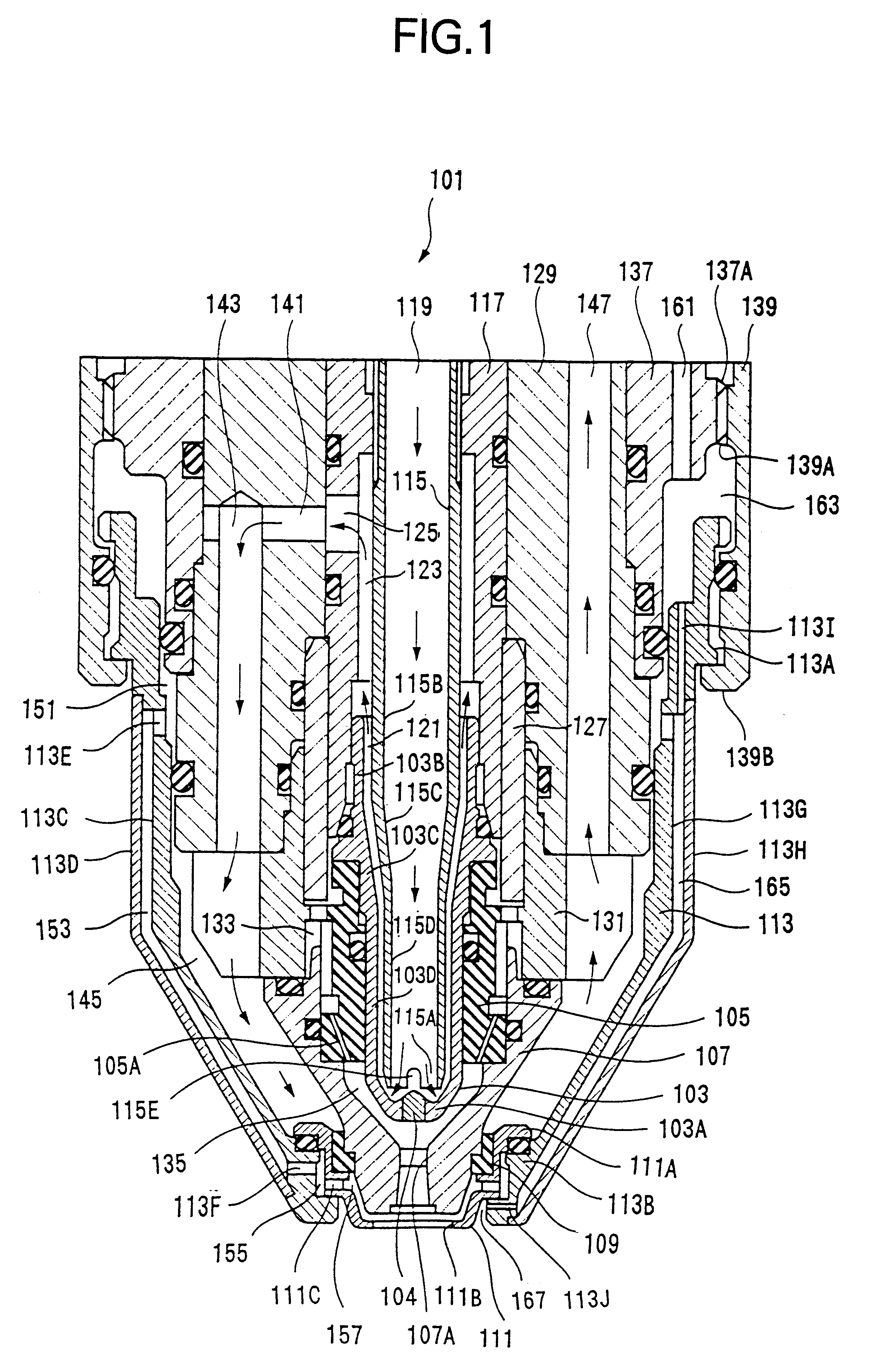

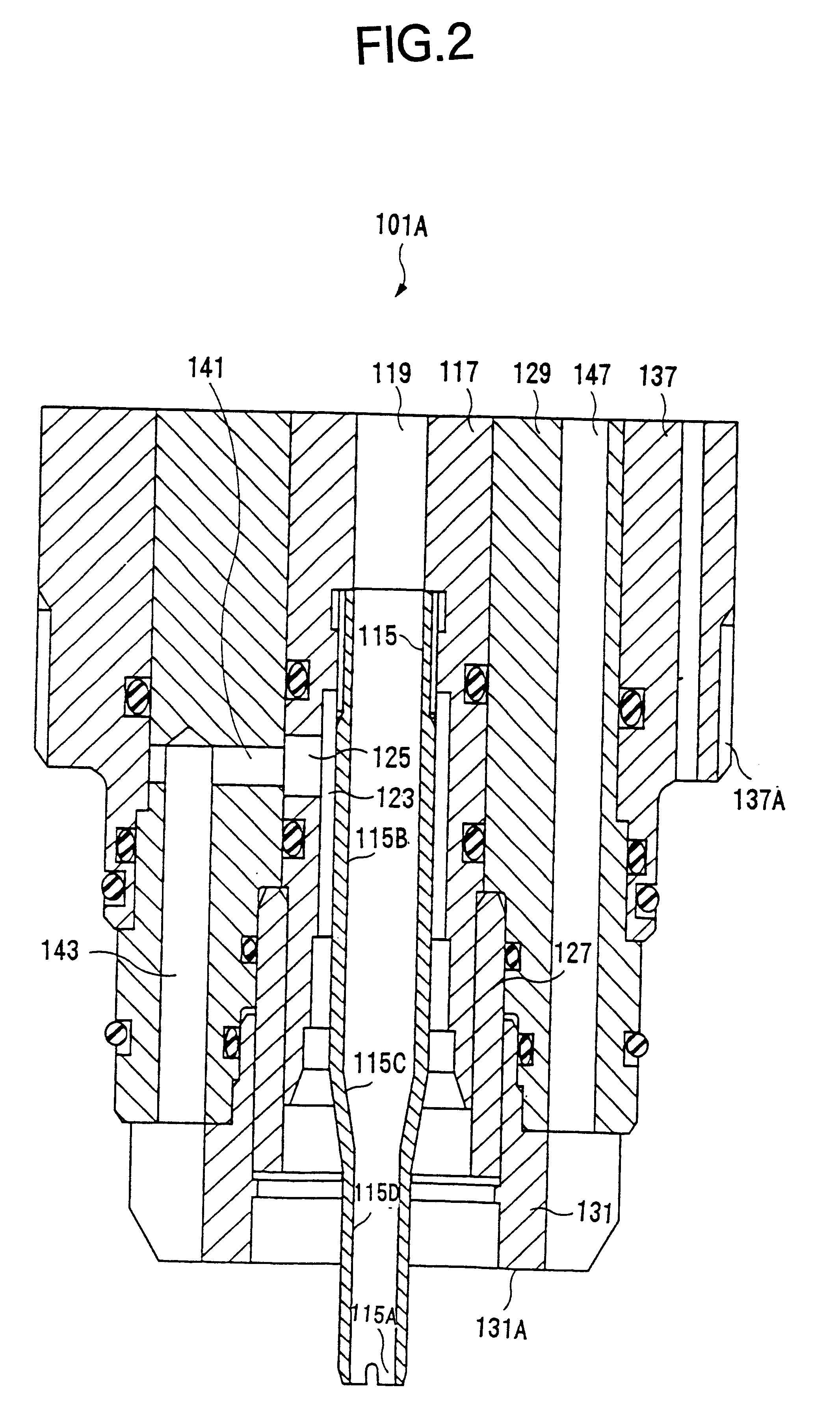

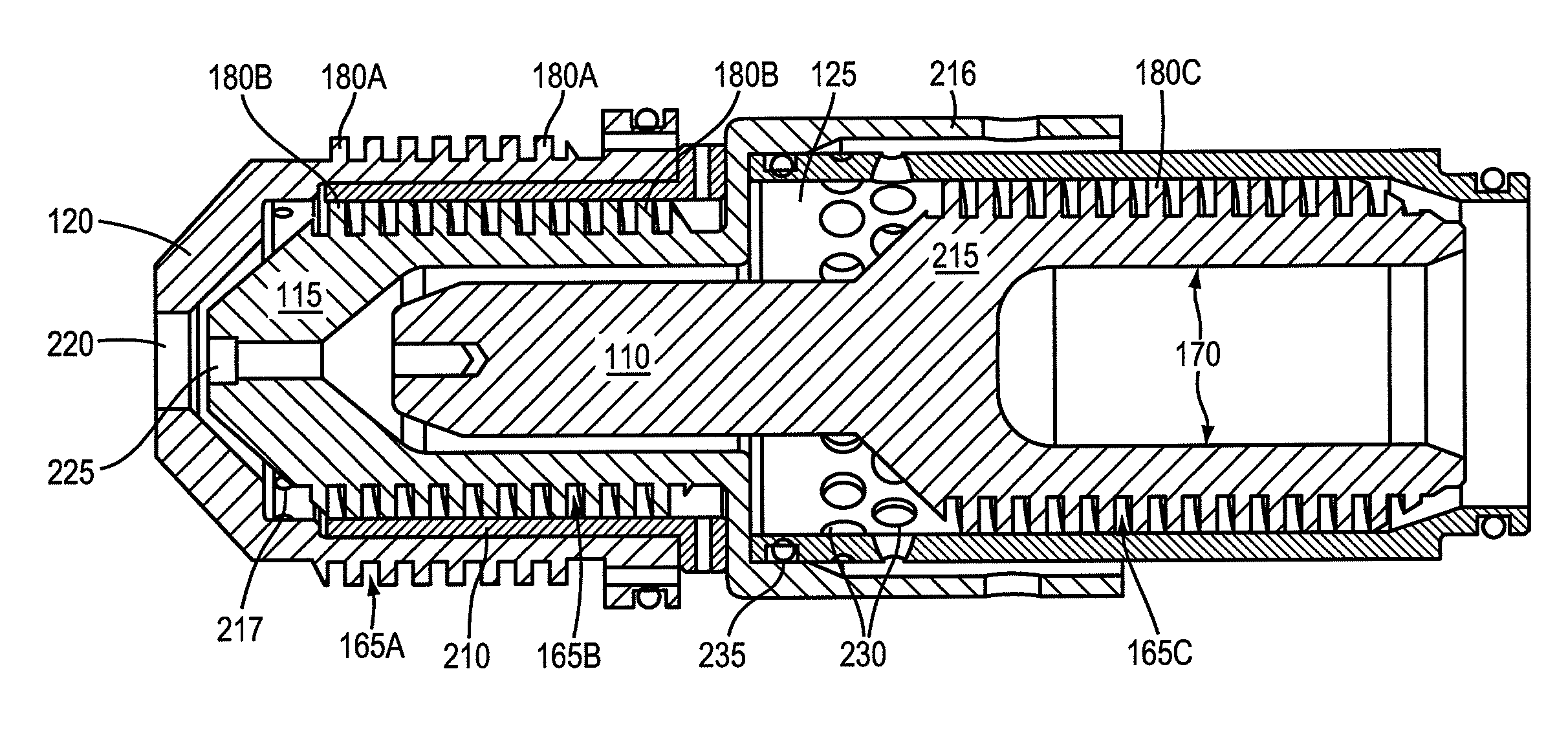

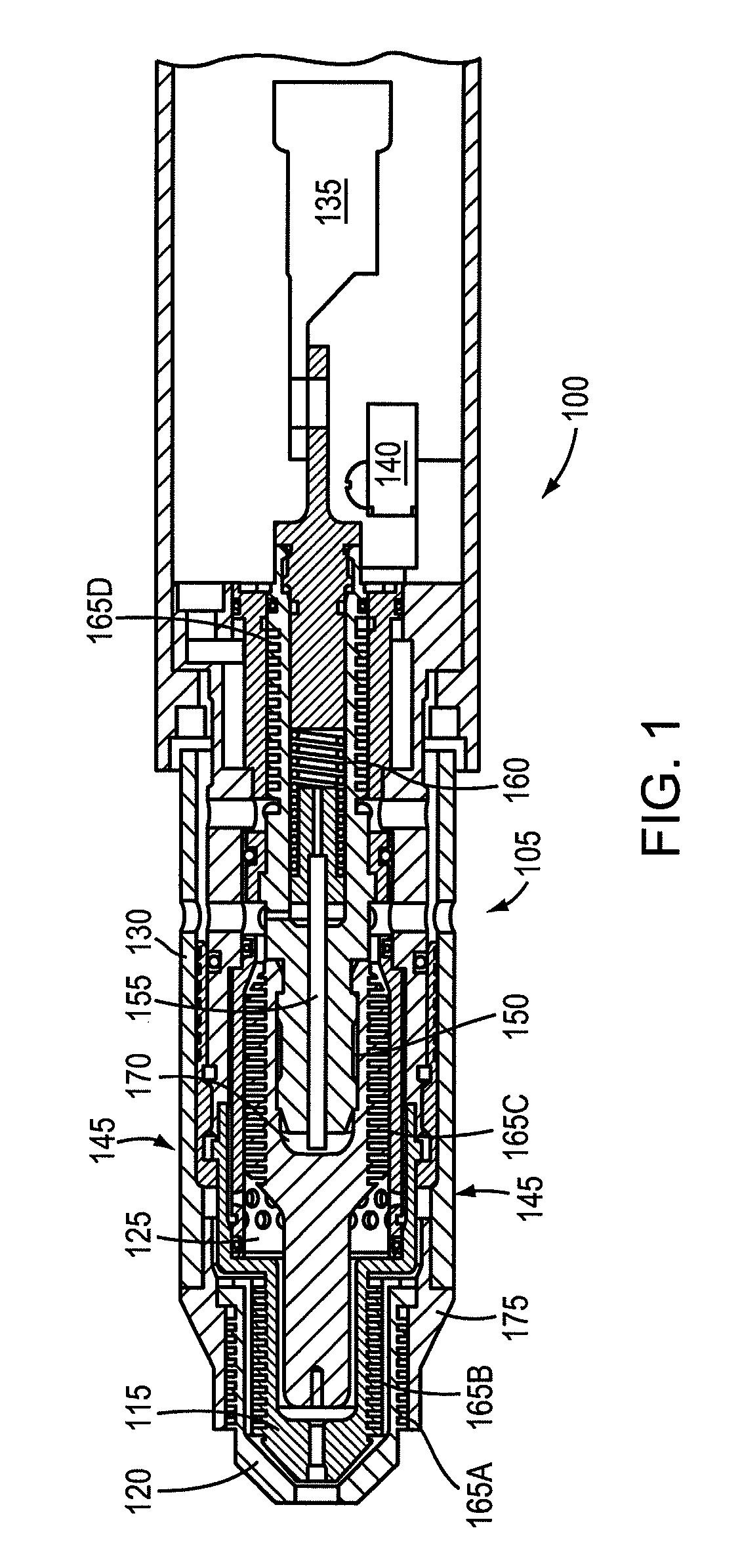

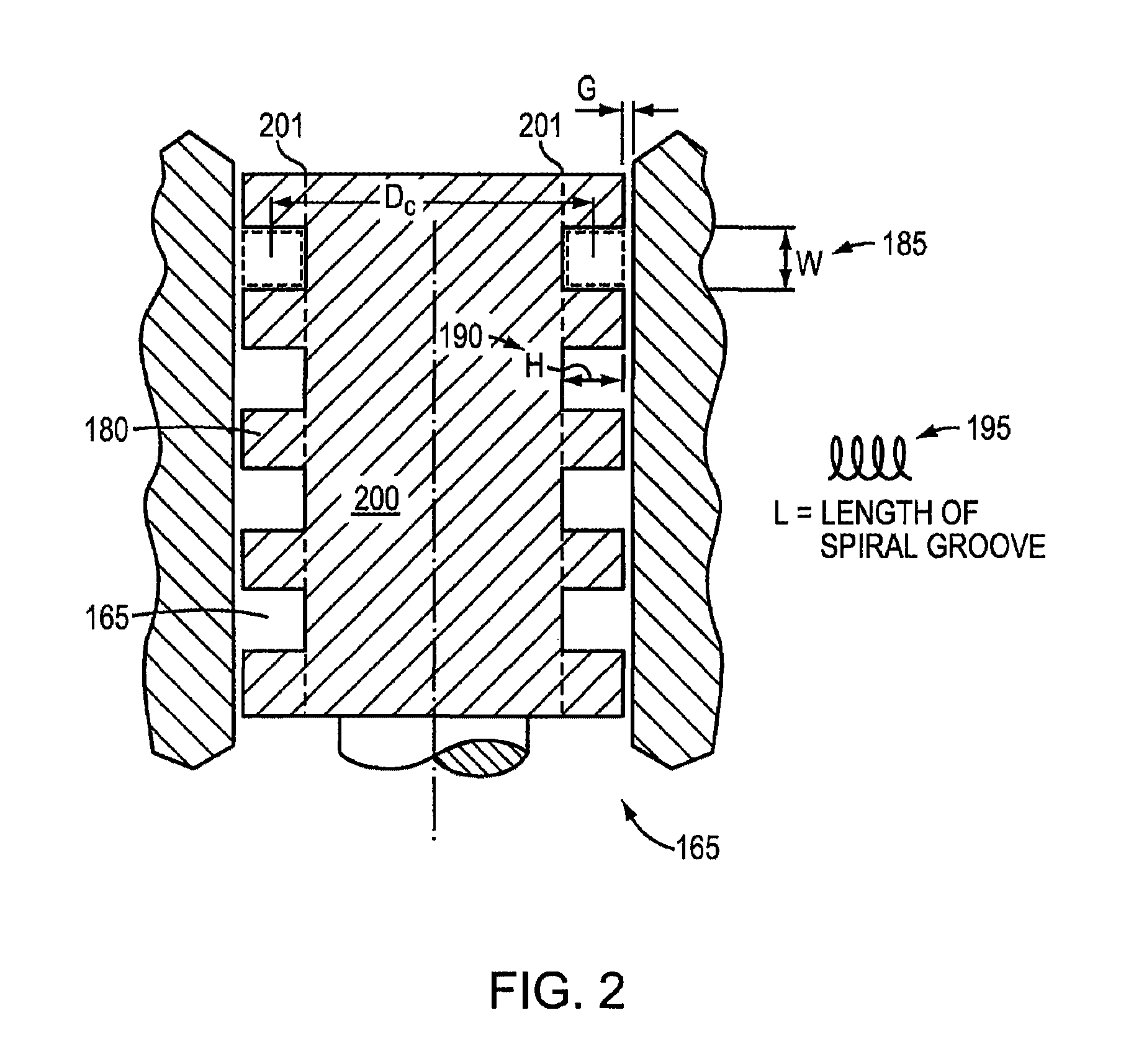

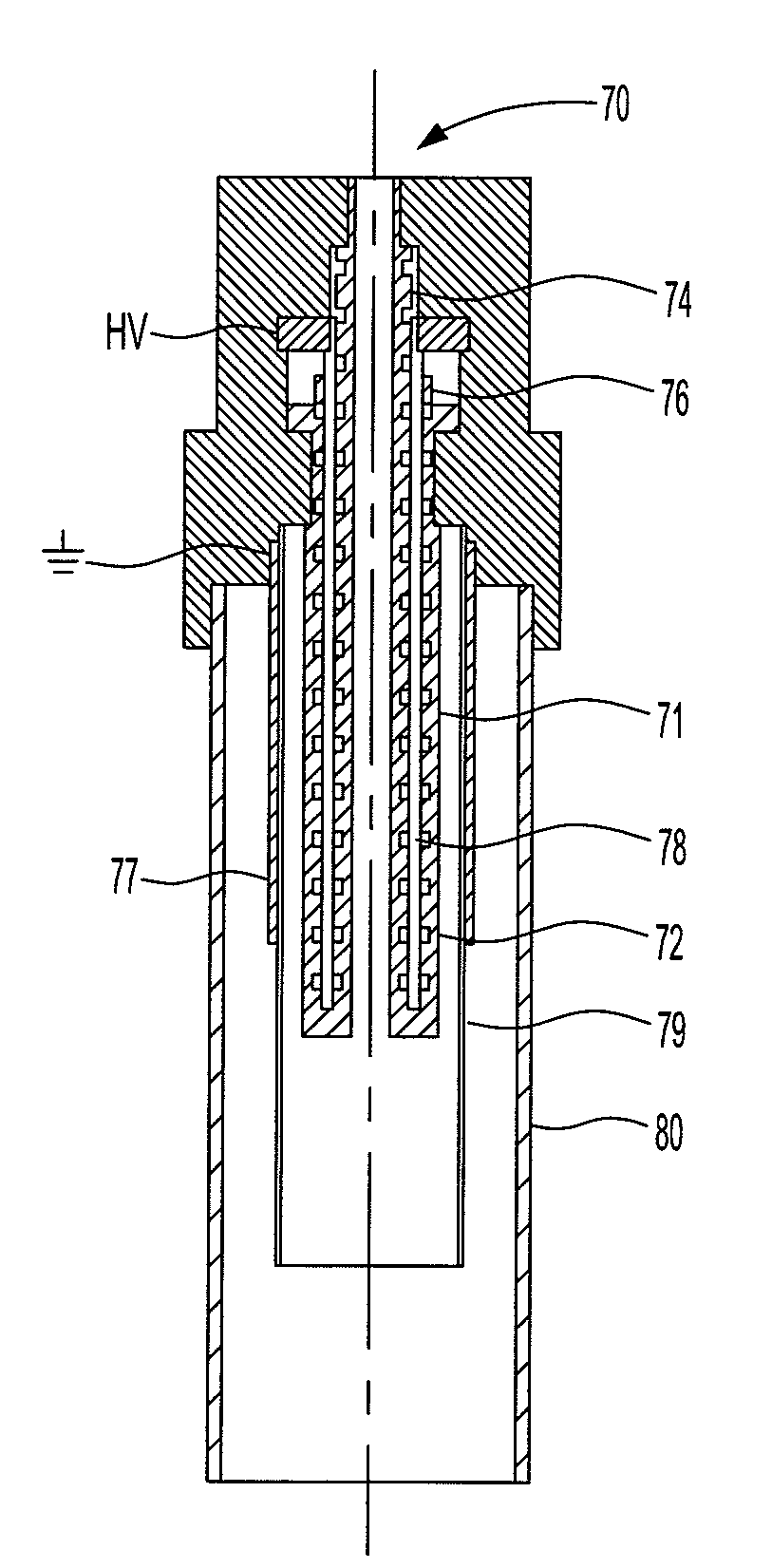

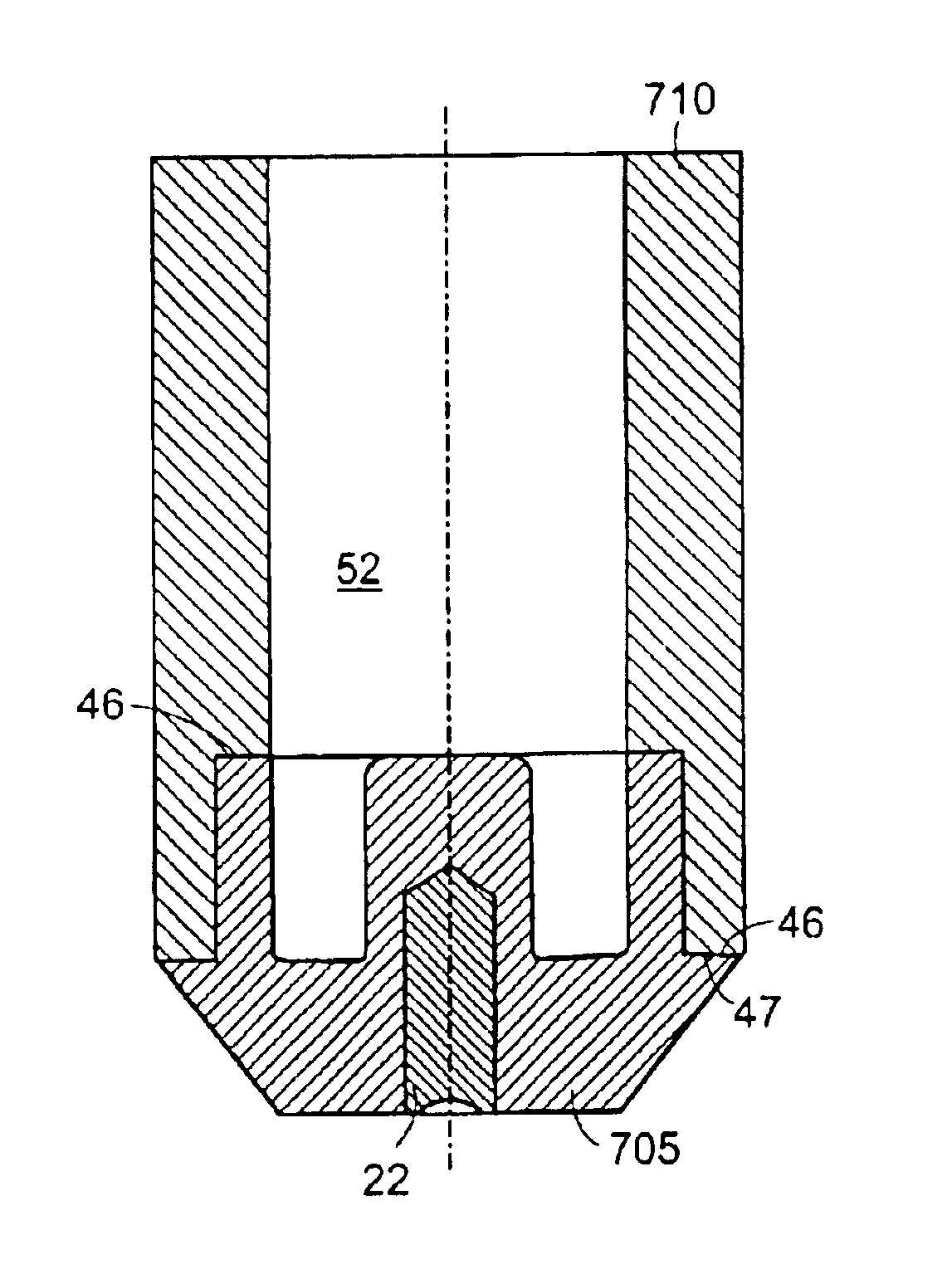

Plasma processing device, plasma torch and method for replacing components of same

InactiveUS6320156B1Simplifies taskAvoid connection failurePlasma welding apparatusWelding/cutting media/materialsCouplingTorch

The object is to facilitate replacement of consumable parts, such as the electrode, nozzle, or the like, in a plasma torch, whilst suppressing any increase in structural complexity or cost. An electrode 103, insulating guide 105 and nozzle 107 are fit together installed in a retainer cap 113. By means of O-rings 193, 195, 197, the electrode 103, insulating guide 105, nozzle 107 and retainer cap 113 are coupled together by a coupling force which allows the components to be pulled apart and separated manually. By attaching the retainer cap 113 to the torch main unit and detaching the retainer cap 113 from same, the electrode 103, insulating guide 105 and nozzle 107 can be attached and detached to and from the torch main unit, simultaneously.

Owner:KOMATSU LTD

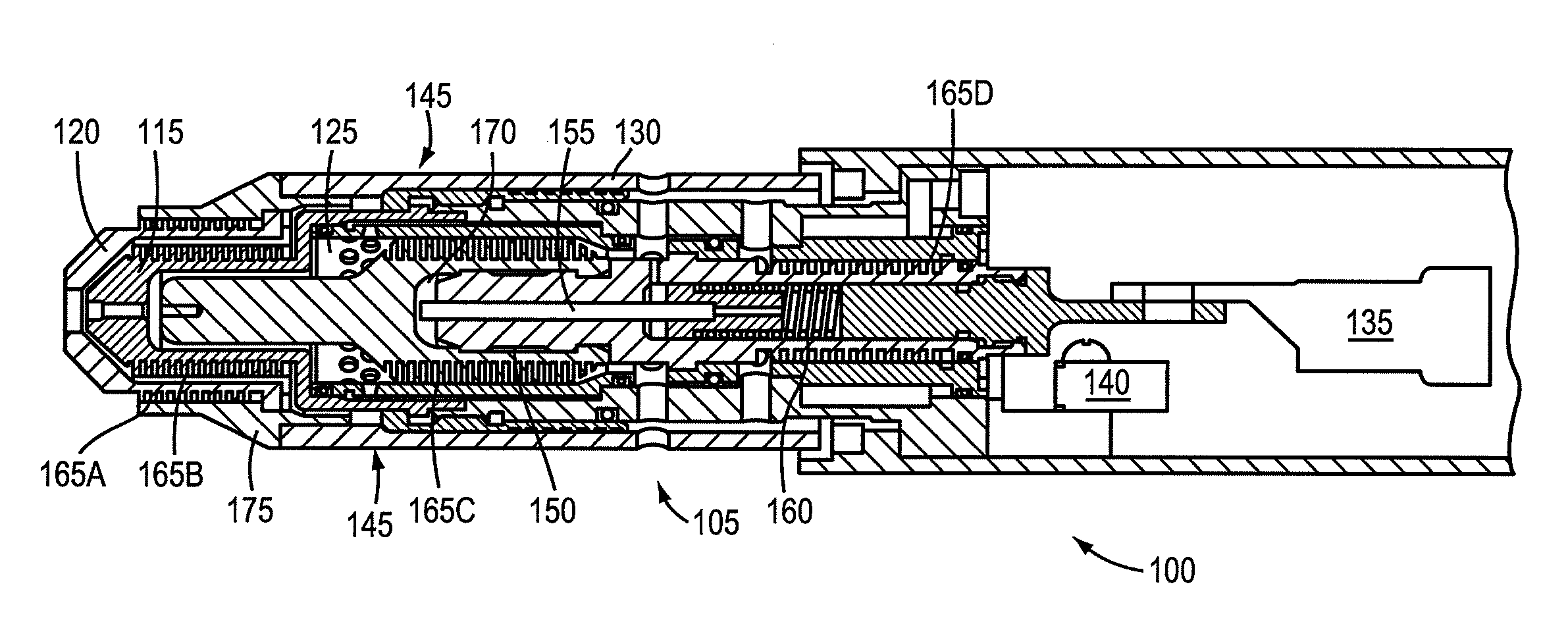

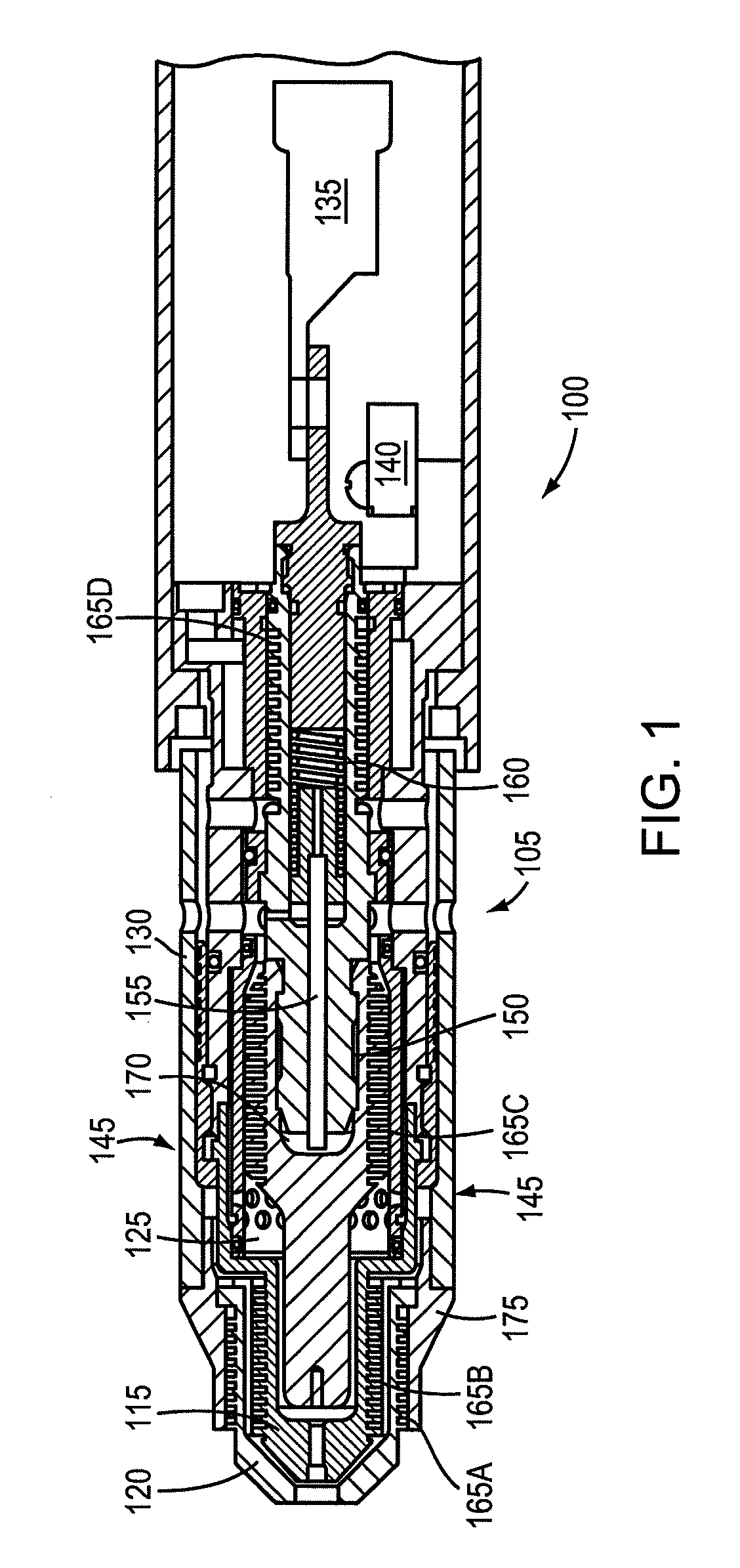

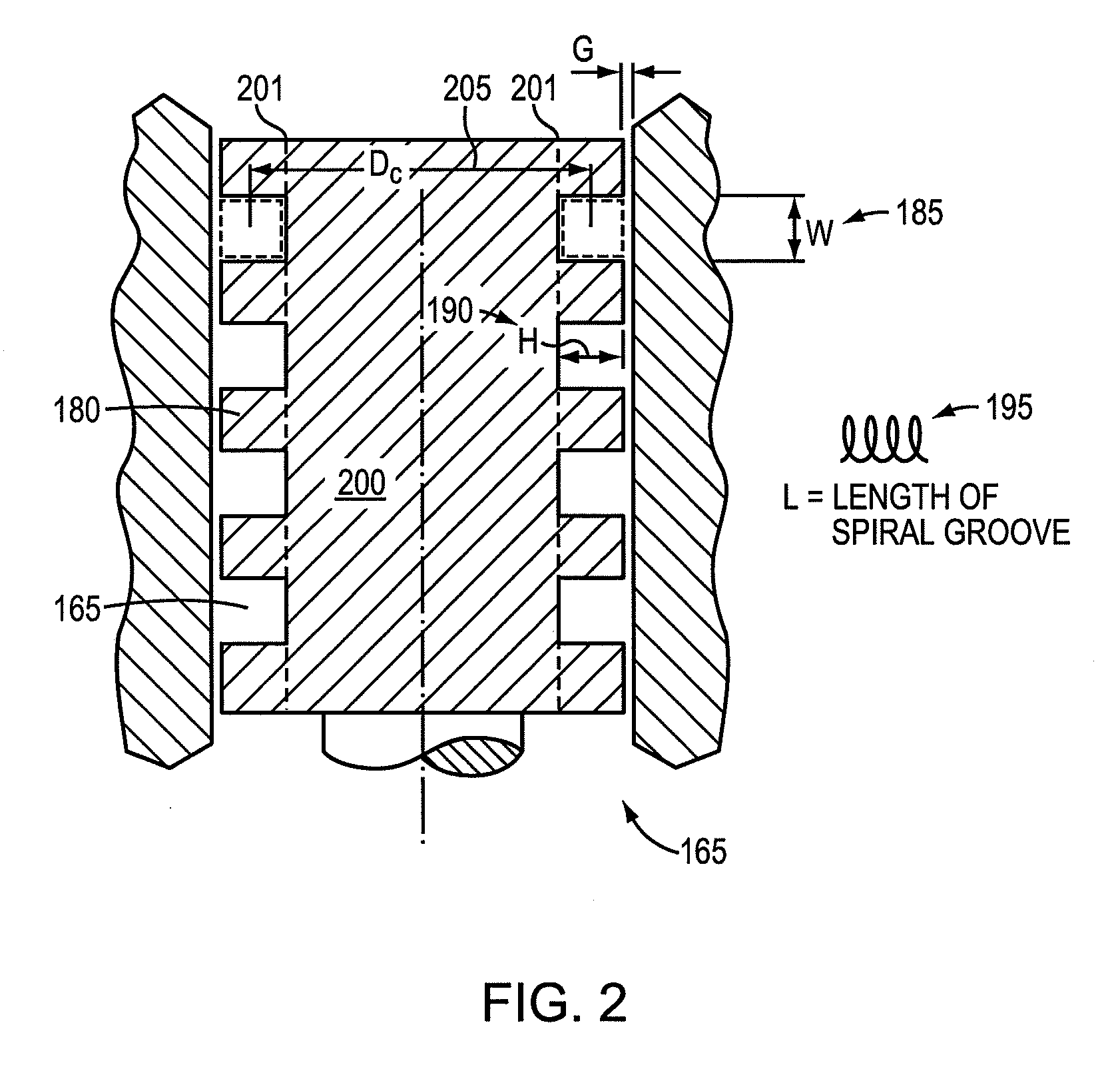

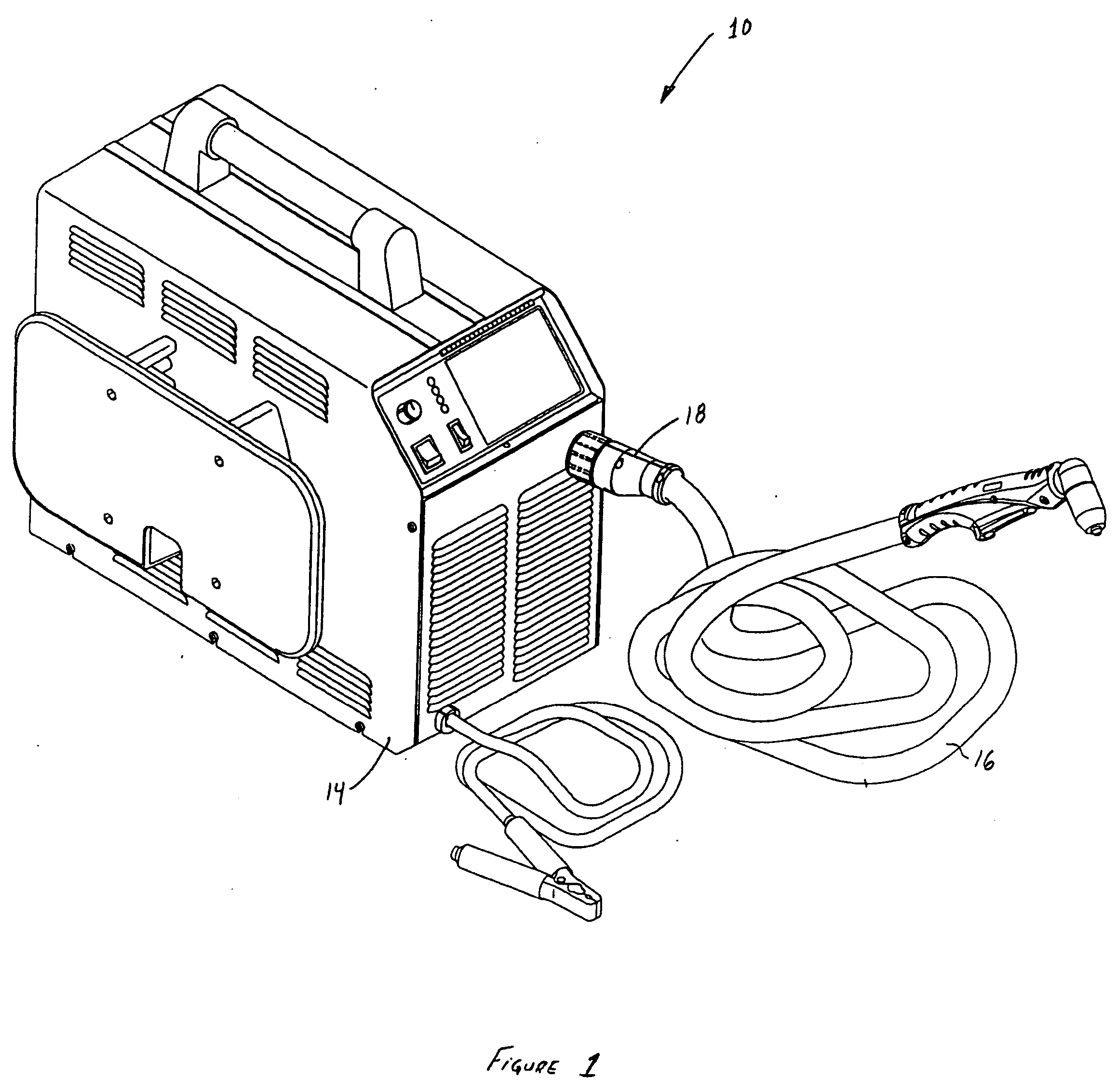

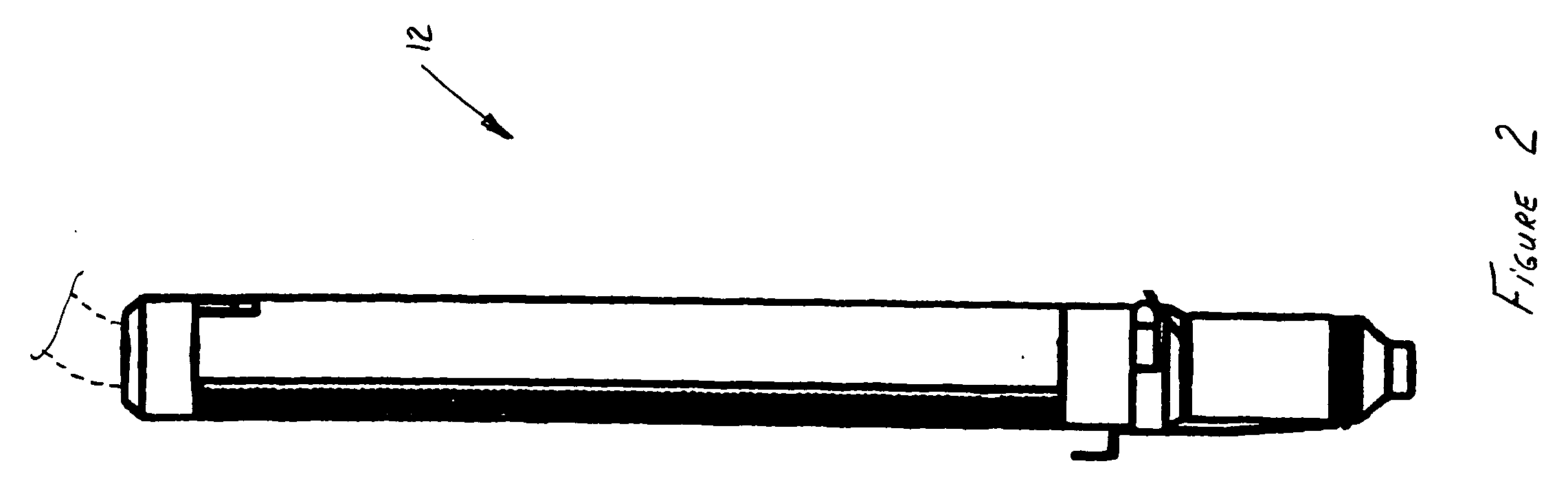

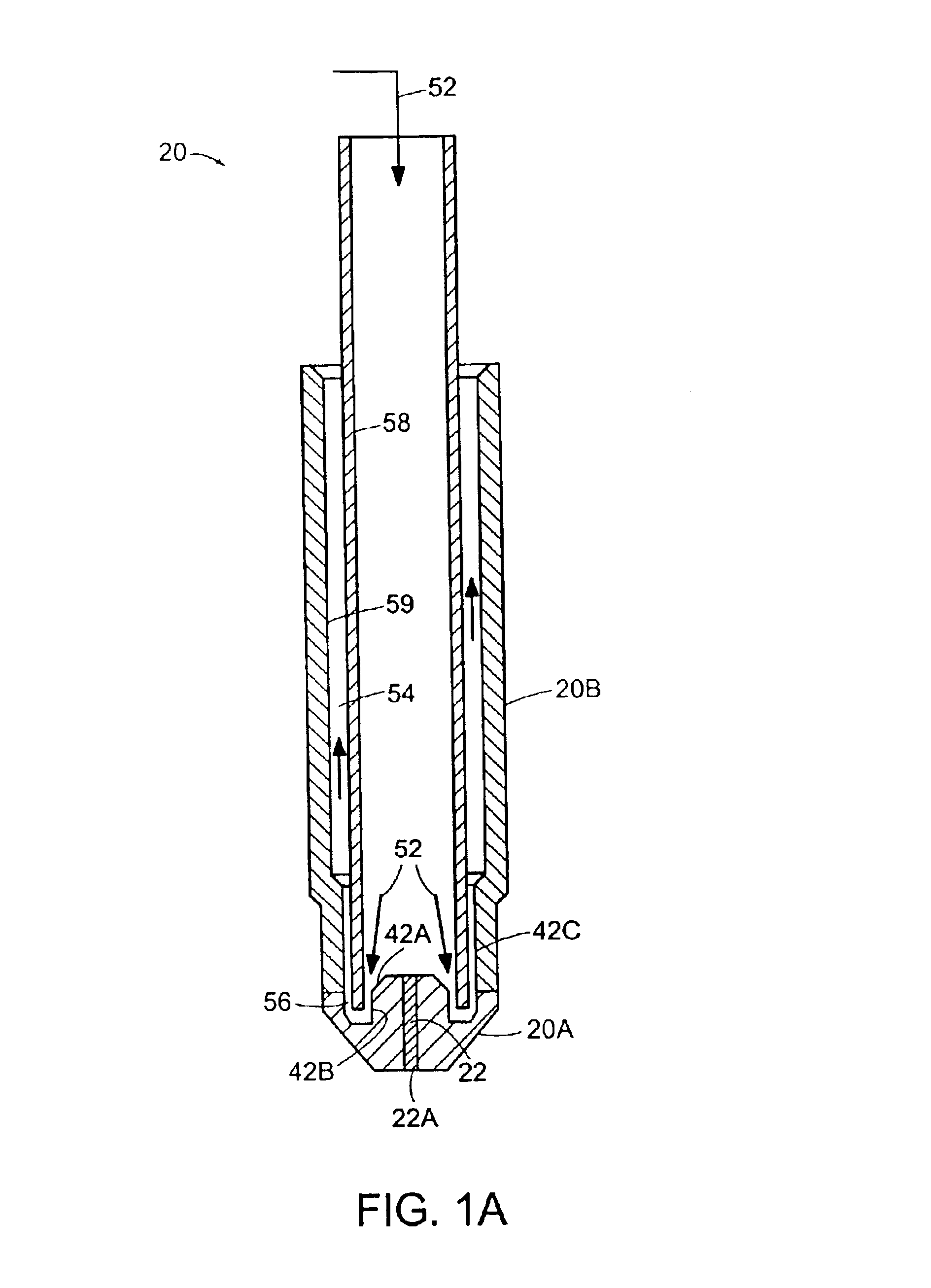

Gas-Cooled Plasma Arc Cutting Torch

ActiveUS20080217305A1Dampening motionPlasma welding apparatusWelding/cutting media/materialsTorchEngineering

A method and apparatus for a gas-cooled plasma arc torch. Components of the torch can include an electrode, nozzle and a shield, each of which can be gas-cooled. The nozzle can be disposed relative to the electrode and can include a generally hollow conductive body and a cooling gas flow channel defined by at least one fin disposed about an exterior surface of the body, the body providing a thermal conductive path that transfers heat between the nozzle to the cooling gas flow channel during operation of the torch. The shield can be disposed relative to the nozzle and can include a generally hollow conductive body and a cooling gas flow channel defined by at least one fin disposed about an exterior surface of the body, the body providing a thermal conductive path that transfers heat between the shield to the cooling gas flow channel during operation of the torch.

Owner:HYPERTHERM INC

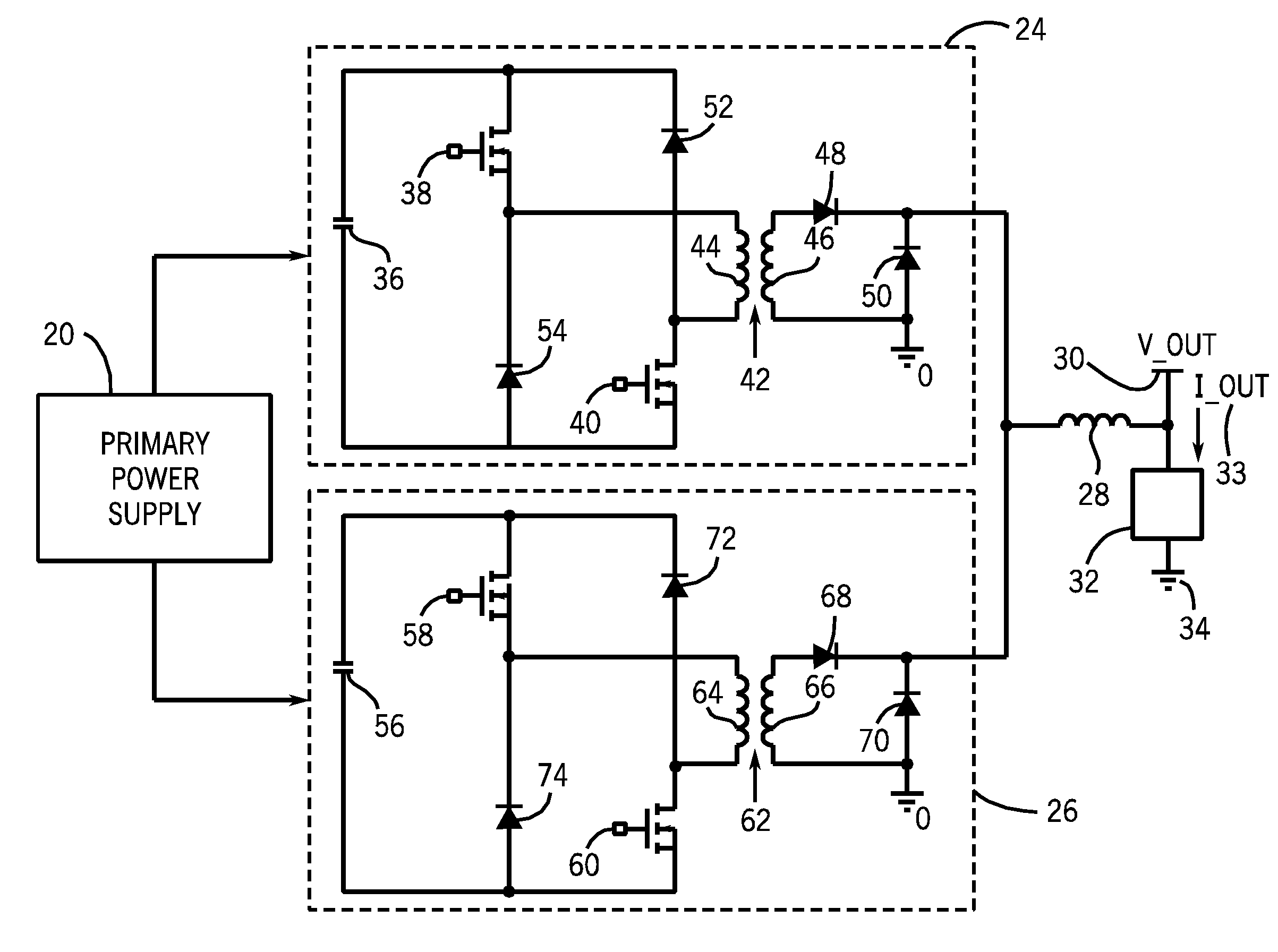

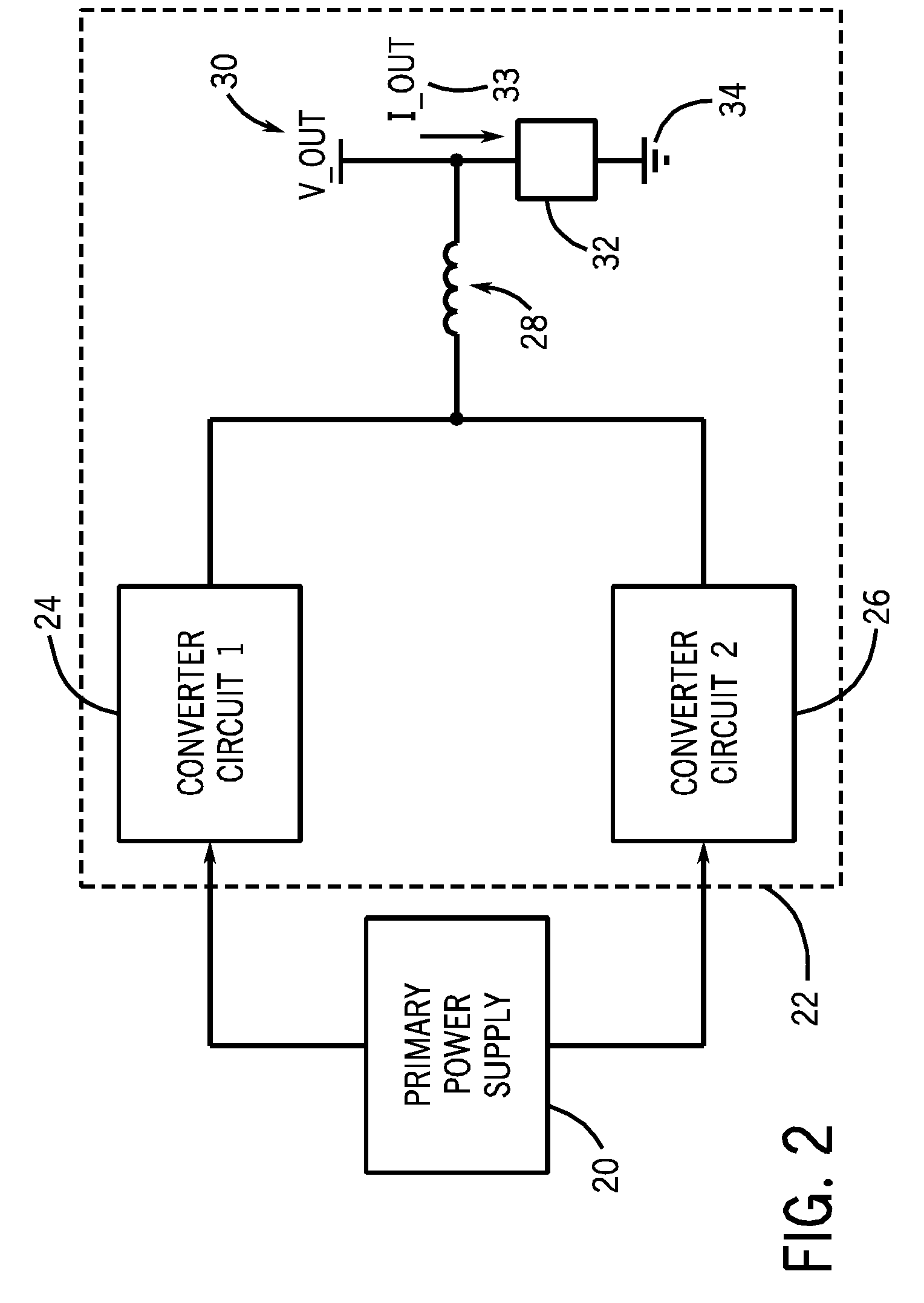

Welding or cutting power supply using phase shift double forward converter circuit (PSDF)

A technique for dynamically adjusting an output voltage for a welding or cutting operation is provided. The technique allows for varying output voltage at the welding or cutting torch by manipulating the duty cycles of two forward converter circuits. The present disclosure provides methods and systems for increasing synchronized duty cycles in a pair of forward converter circuits in response to increasing output voltage demand then changing a phase shift between the duty cycles in response to further increases in output voltage demand. The present disclosure provides a controller designed to receive input signals and generate output pulse width modulation signals that control the duty cycle width and phase shift of the outputs of the forward converter circuits in response to these signals. Methods of accommodating for the time needed for the transformer core to reset via leading edge or lagging edge compensation are provided.

Owner:ILLINOIS TOOL WORKS INC

Plasma torch with corrosive protected collimator

ActiveUS20070084834A1Welding/cutting media/materialsWelding electrode featuresTorchPlasma arc welding

To protect the collimator of a transferred plasma arc torch from premature failure due to corrosion, an anti-corrosive covering is applied on the exposed face surface and a portion of the inner exit bore of the collimator. The specification describes several methods for producing the collimator for a plasma torch having an anti-corrosive coating or cladding on the exposed surfaces thereof, including electroplating, electroless plating, flame spraying, plasma spraying, plasma transferred arc, hot isostatic pressing and explosive cladding.

Owner:PHOENIX SOLUTIONS CO

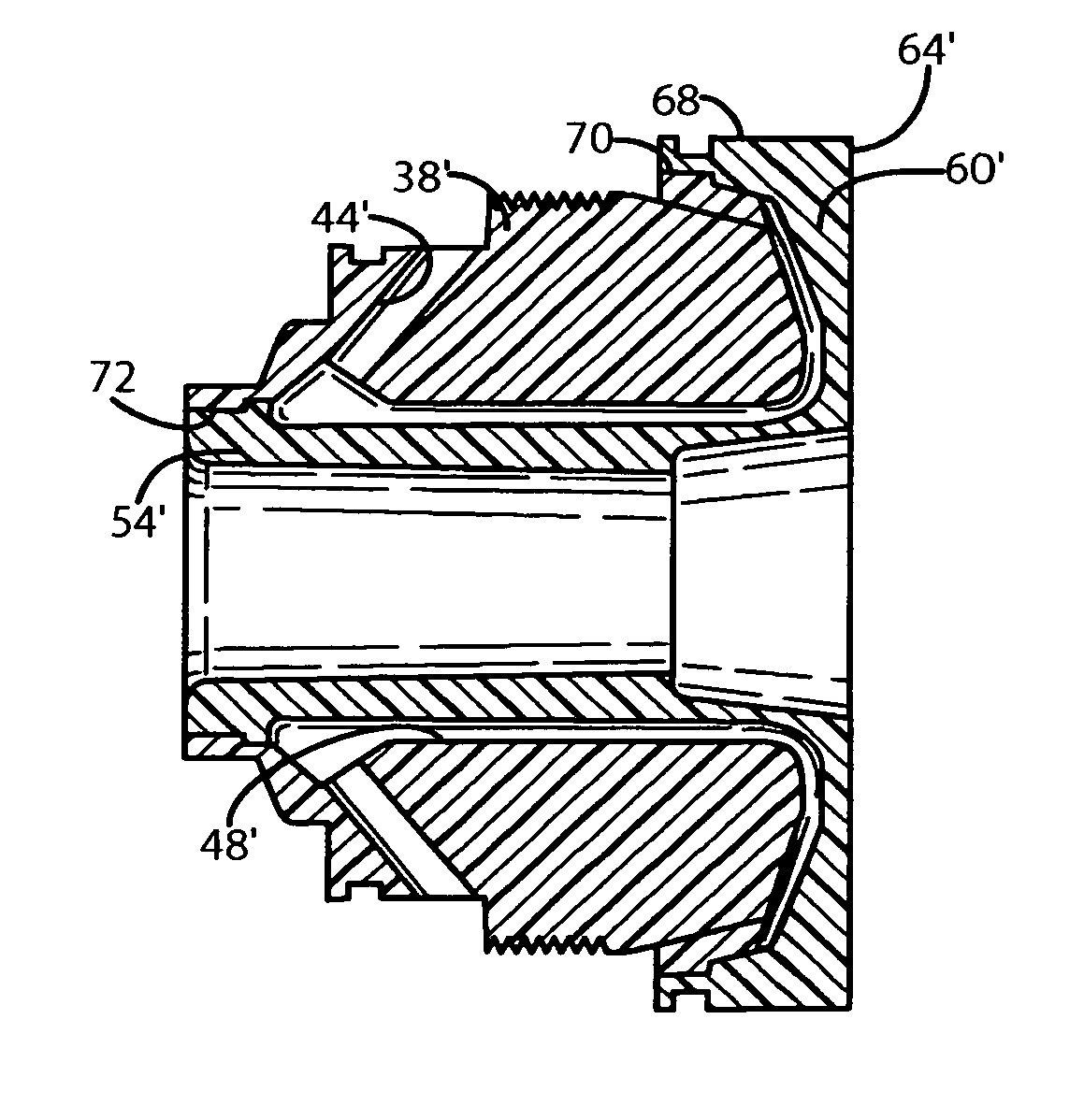

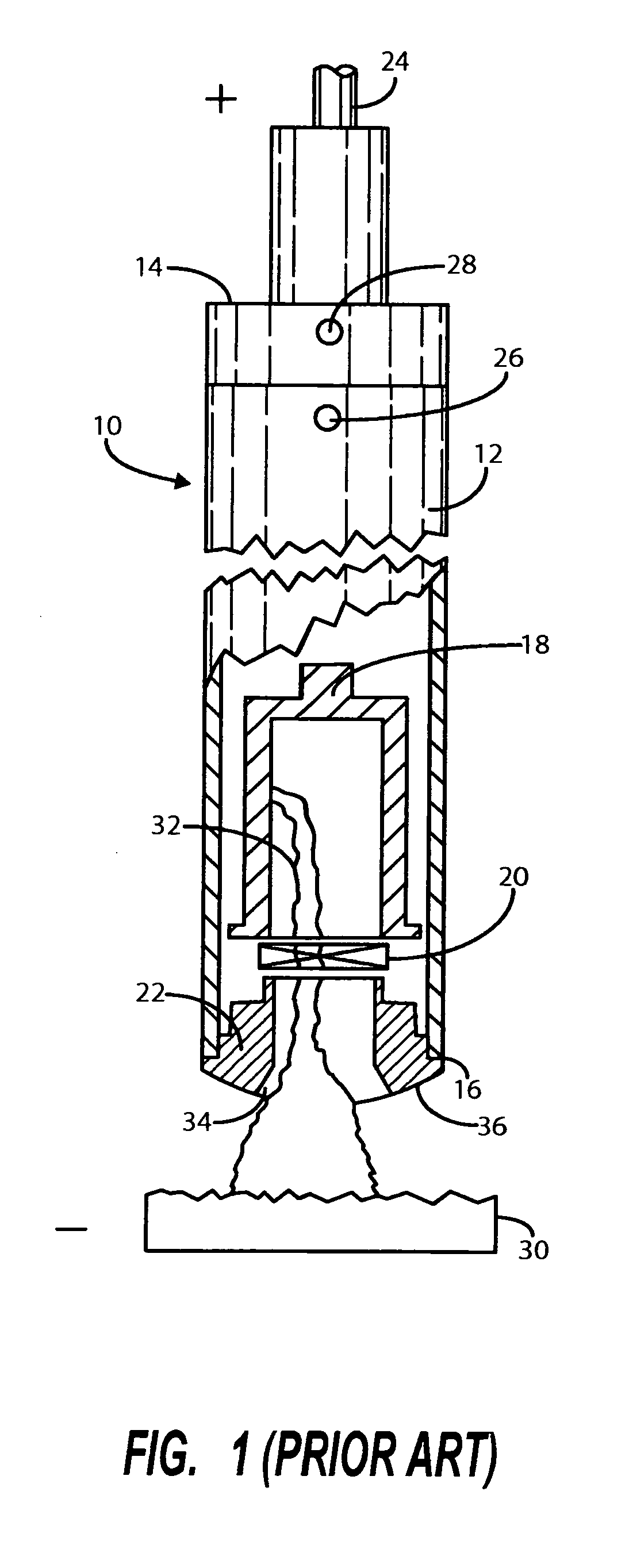

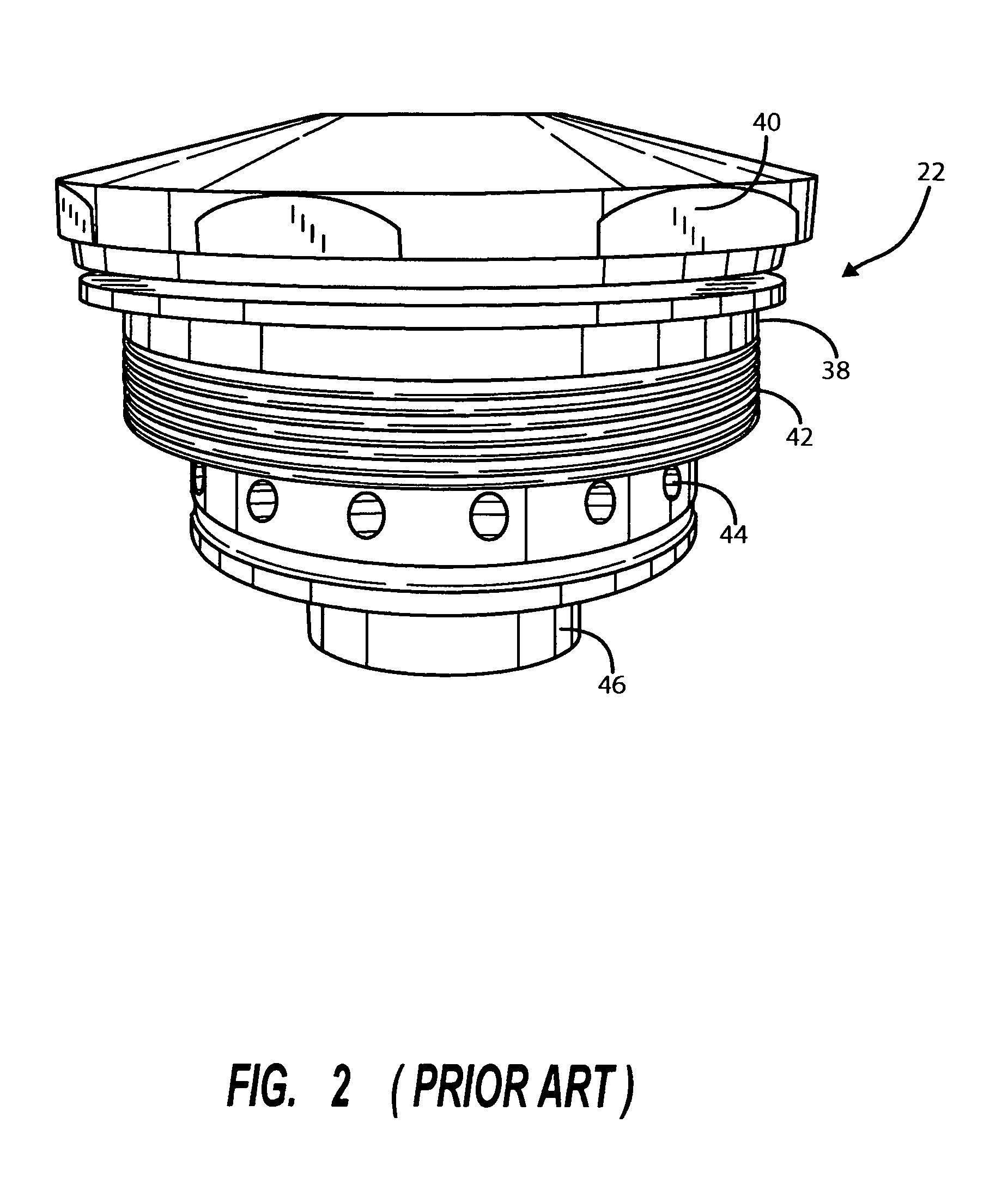

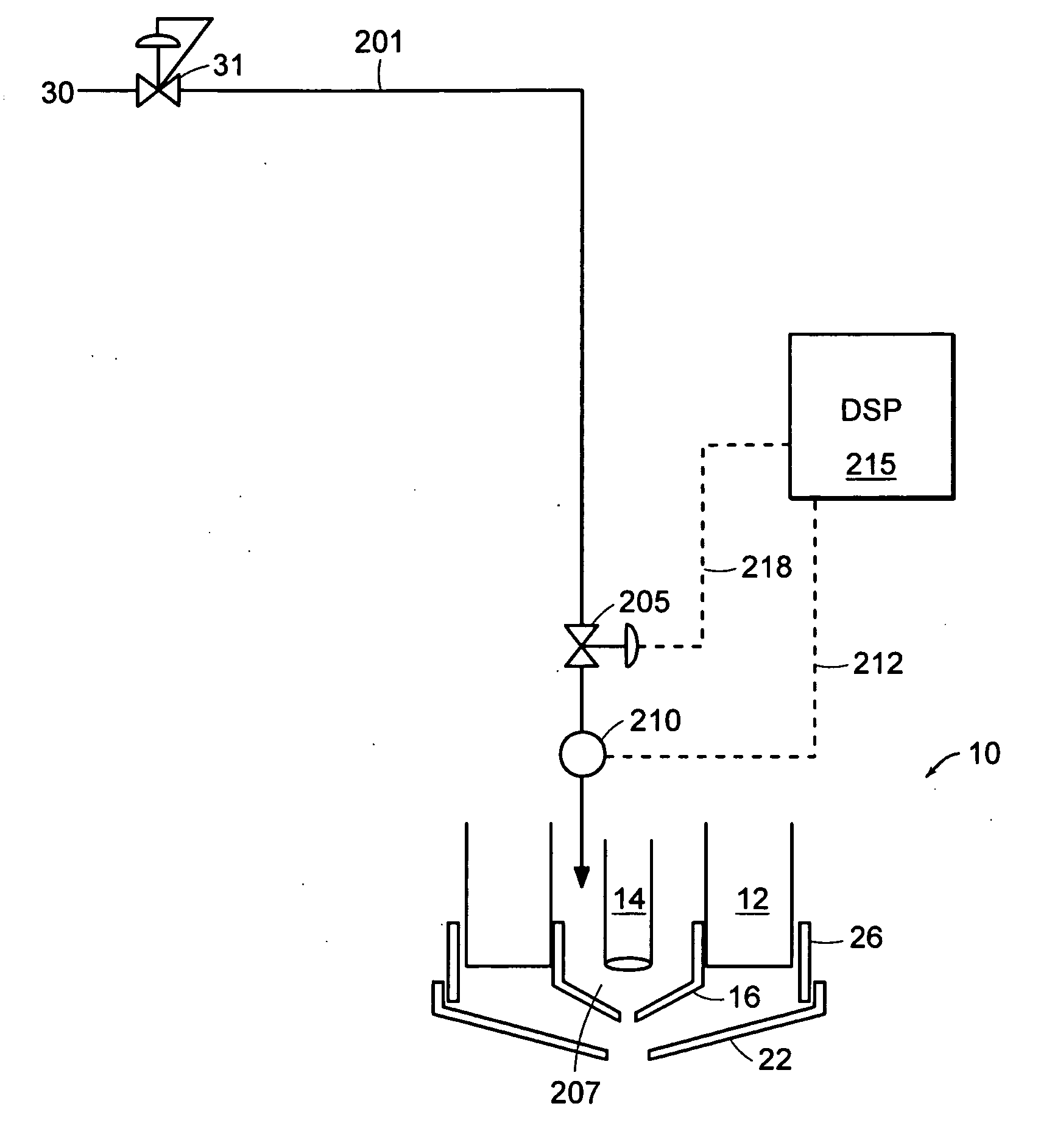

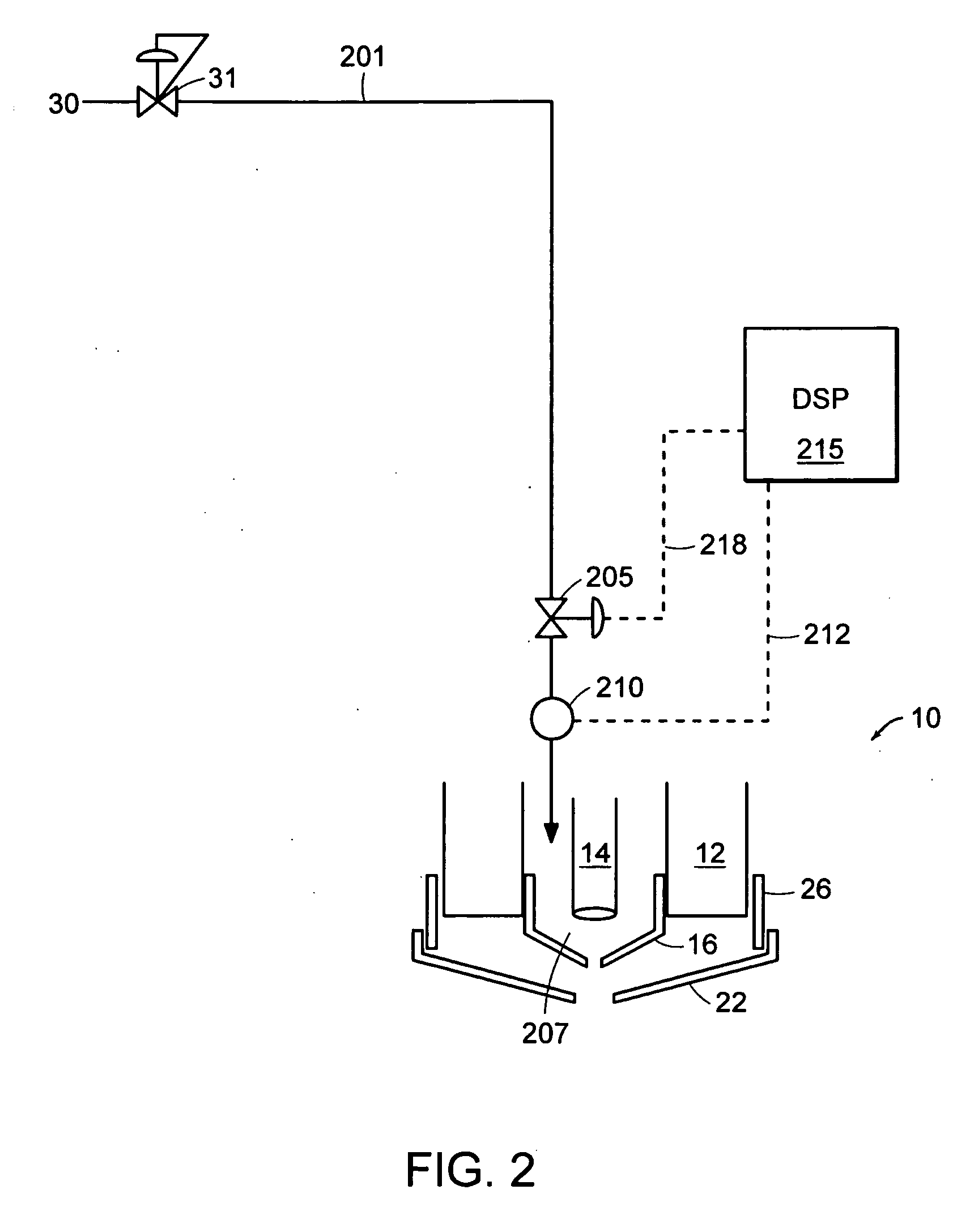

Automatic gas control for a plasma arc torch

InactiveUS20060163216A1Prolong lifeHigh operating current levelArc welding apparatusPlasma welding apparatusProportional controlSolenoid valve

A method and apparatus for controlling a gas supply to a plasma arc torch uses a proportional control solenoid valve positioned adjacent the torch to manipulate the gas flow to the torch, thereby extending electrode life during arc transfer and shutdown. Swirl ring design can be simplified and gas supply and distribution systems become less complicated. The invention also allows manipulation of shield gas flow to reduce divot formation when making interior cuts. The system can be controlled with a digital signal processor utilizing a feedback loop from a sensor.

Owner:HYPERTHERM INC

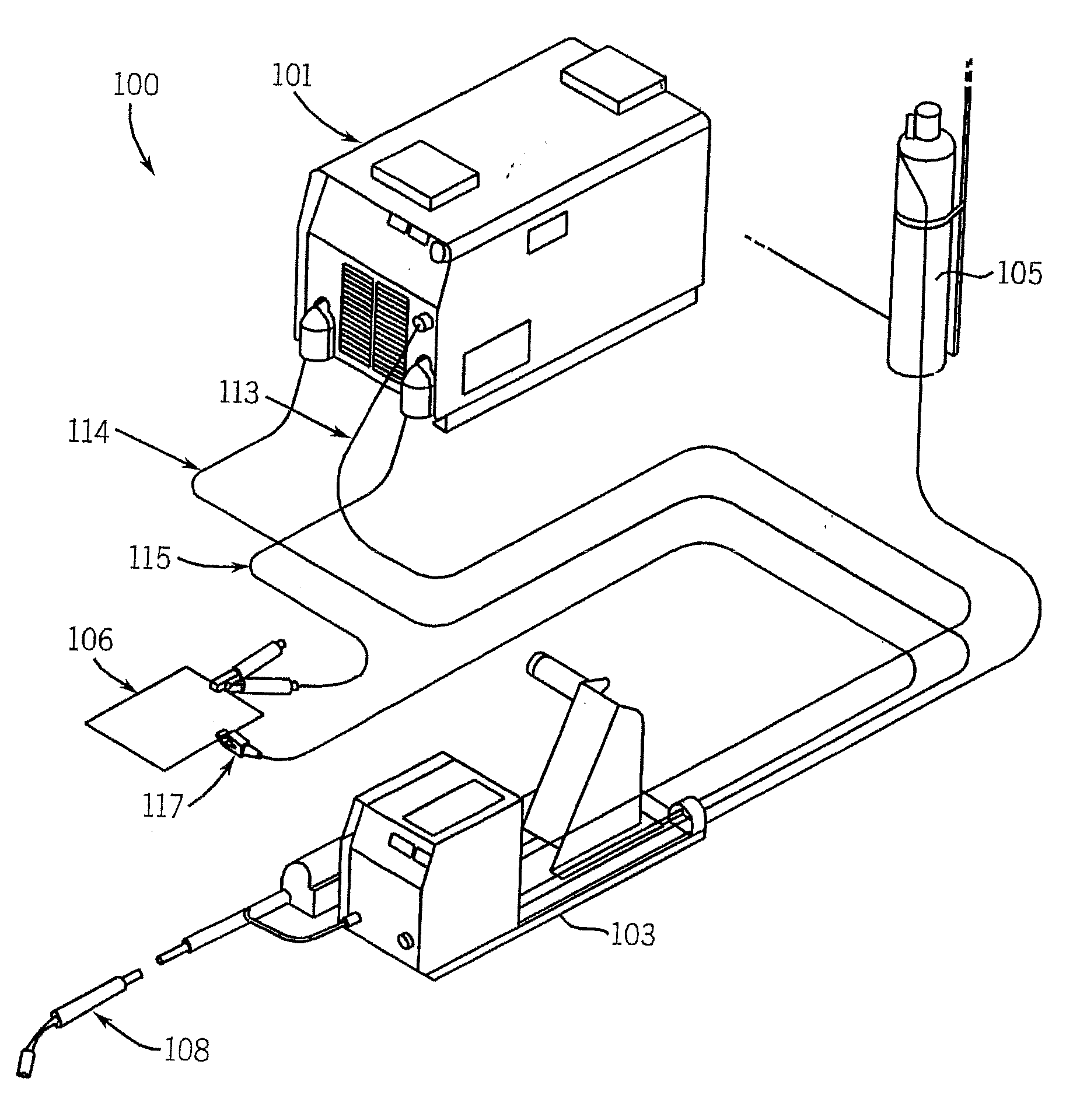

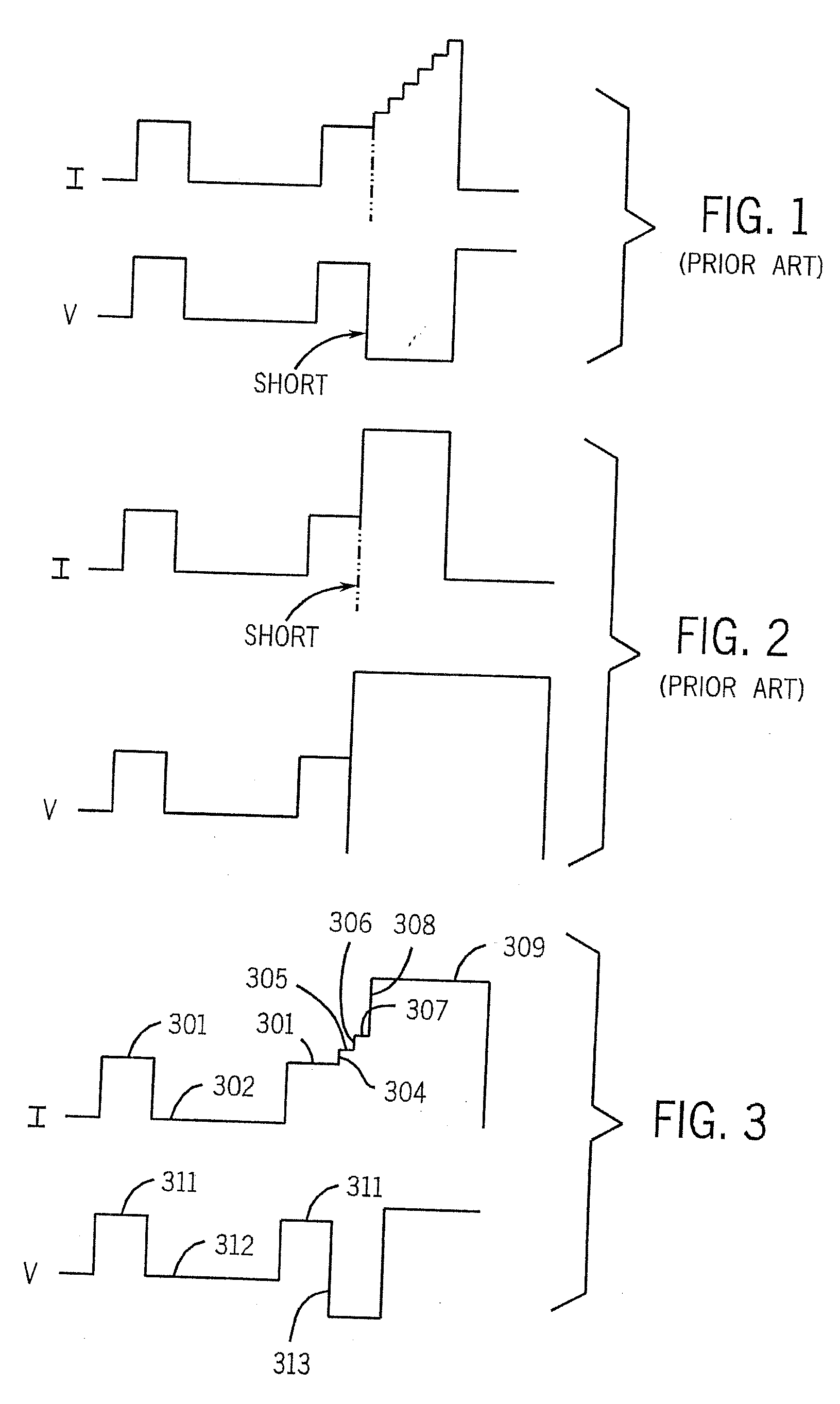

Method and Apparatus For Feeding Wire to a Welding Arc

A method and apparatus for feeding wire in a welding system include one or more motors disposed adjacent the wire to drive it. A wire feed motor is also disposed along the wire path, and is closer to the source of wire than the torch, and closer to the source than the one or more motors. The motors may be a pair motors disposed on opposite sides of the wire and move the wire to and away from an arc end of a torch. They preferably reversing the direction of the wire within one process cycle. The or more motors may be a stepper motor, a servo motor, a zero backlash motor, a gearless motor, a planetary drive motor, or a linear actuator (such as a piston), in various embodiments.

Owner:ILLINOIS TOOL WORKS INC

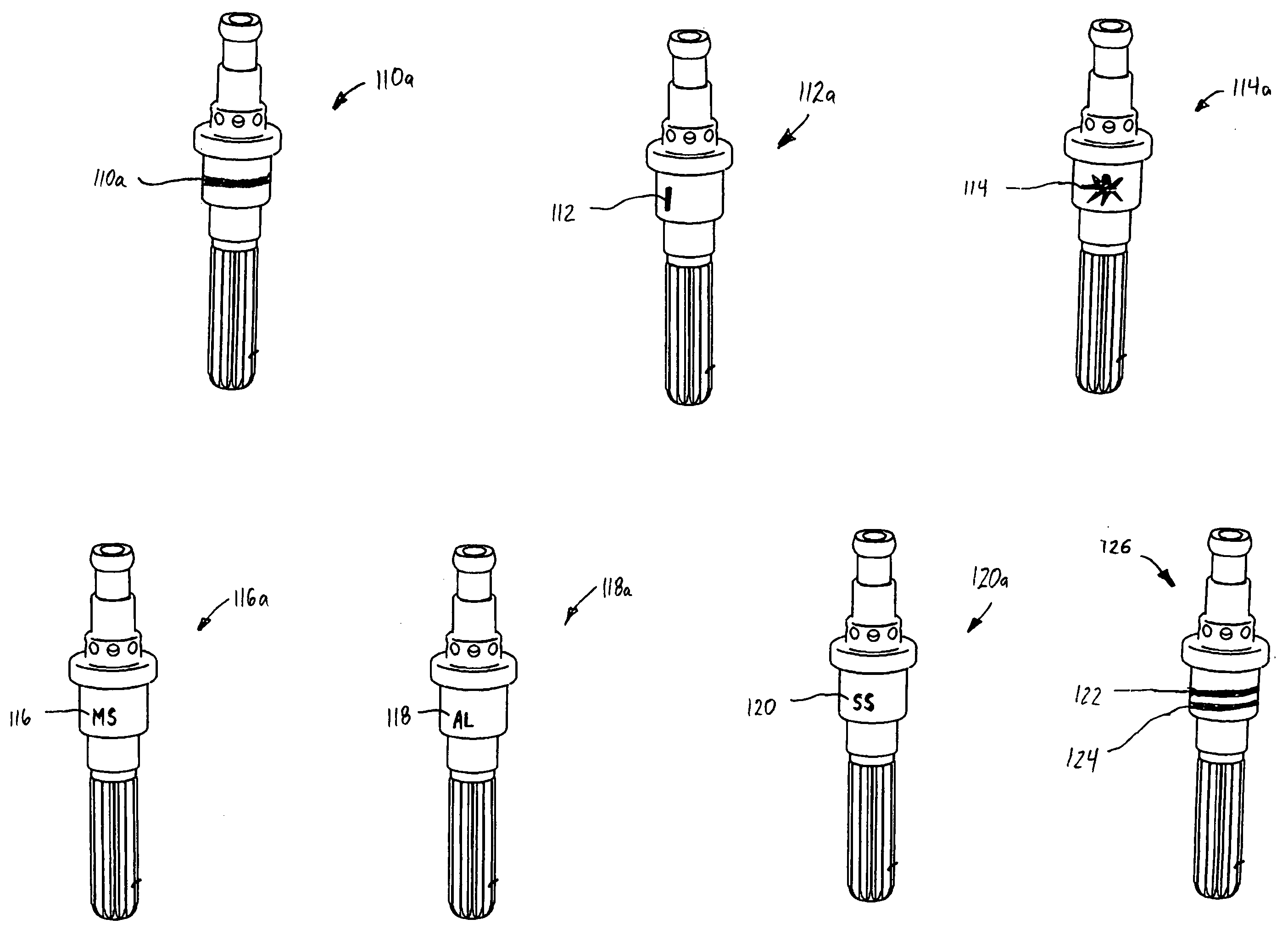

Color coding of plasma arc torch parts and part sets

A series of replacement parts for use in a plasma arc torch is provided, wherein the parts have a color indicia and are adapted for use at different operating parameter values. Each part in the series has a color indicia formed on the part with a different color identifying the particular value of the operating parameter at which the part is adapted to operate. In another form, each part in the series is packaged in a package with a different color indicia identifying the particular value of the operating parameter at which the part is adapted to operate. Additionally, methods of packaging, applying the color indicia, selecting a package or part, and specifying a package or part are provided by the present invention.

Owner:THERMAL DYNAMICS

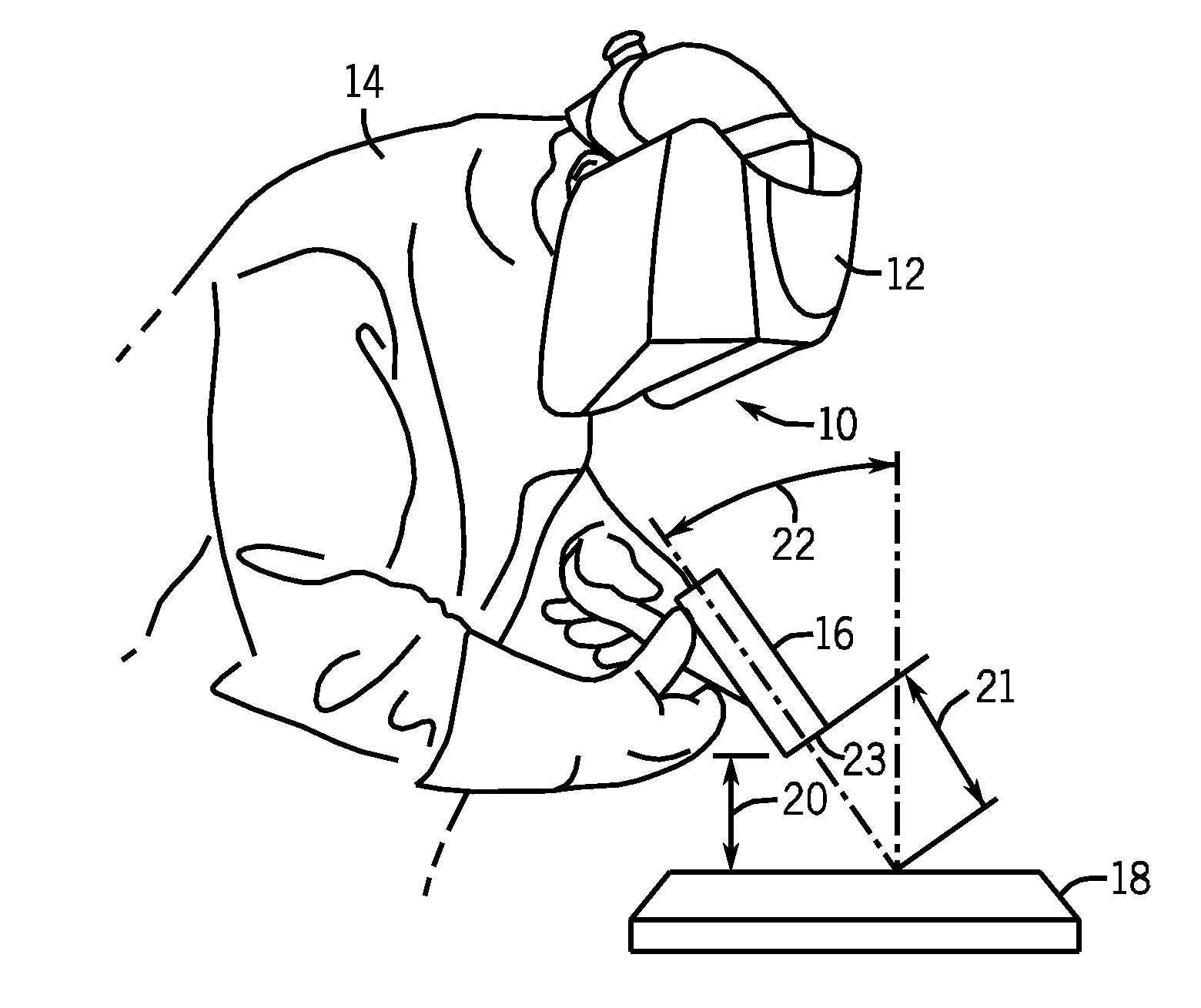

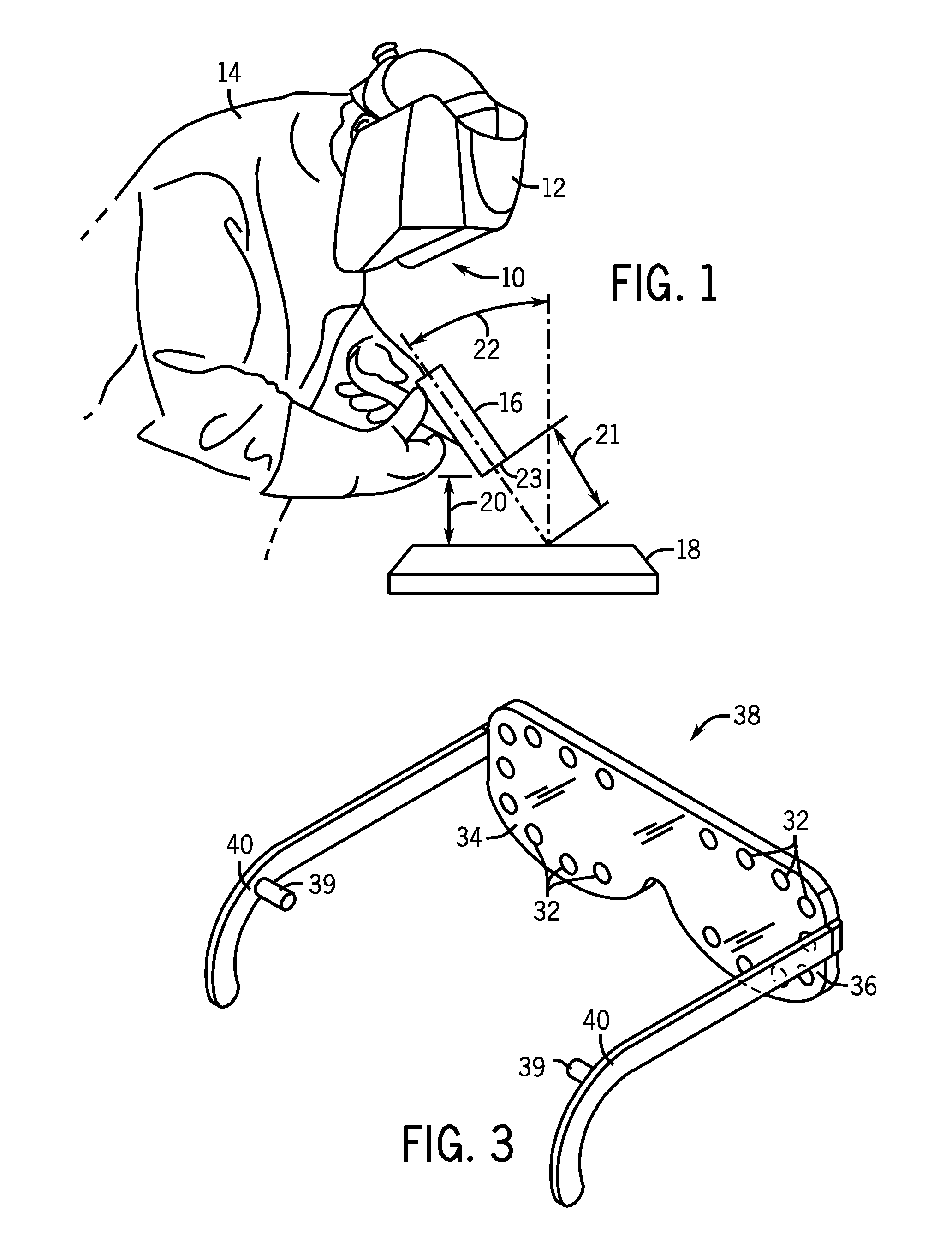

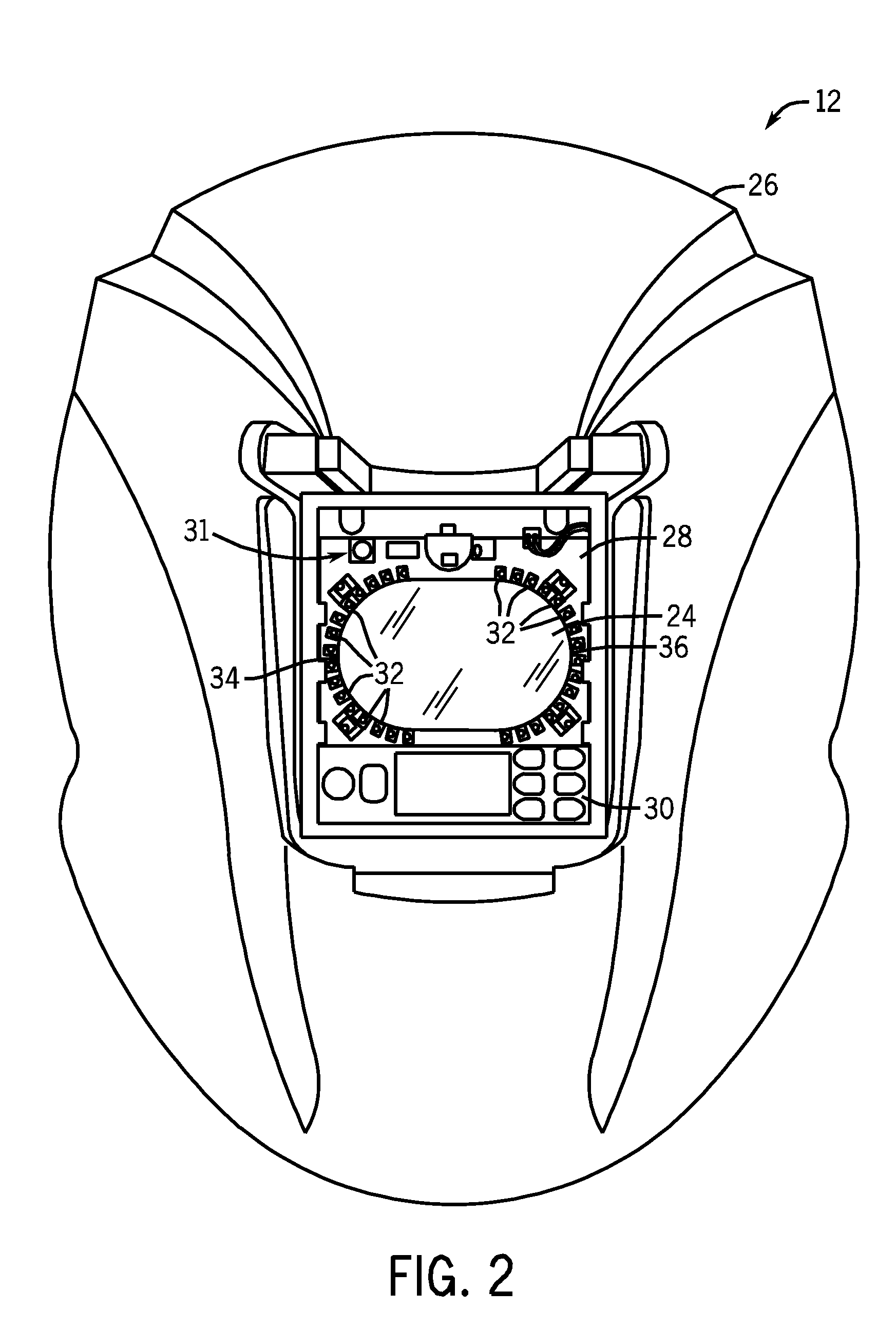

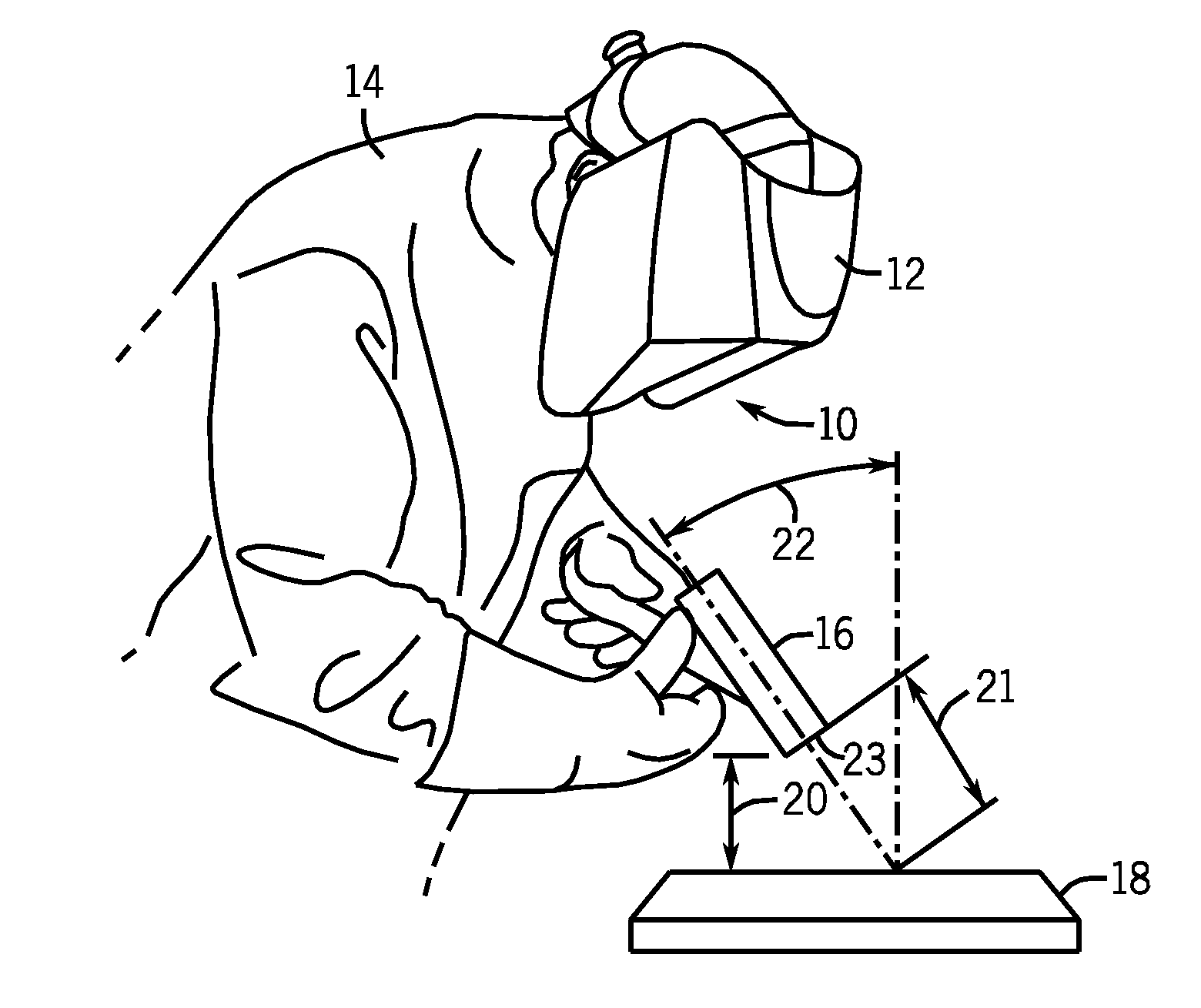

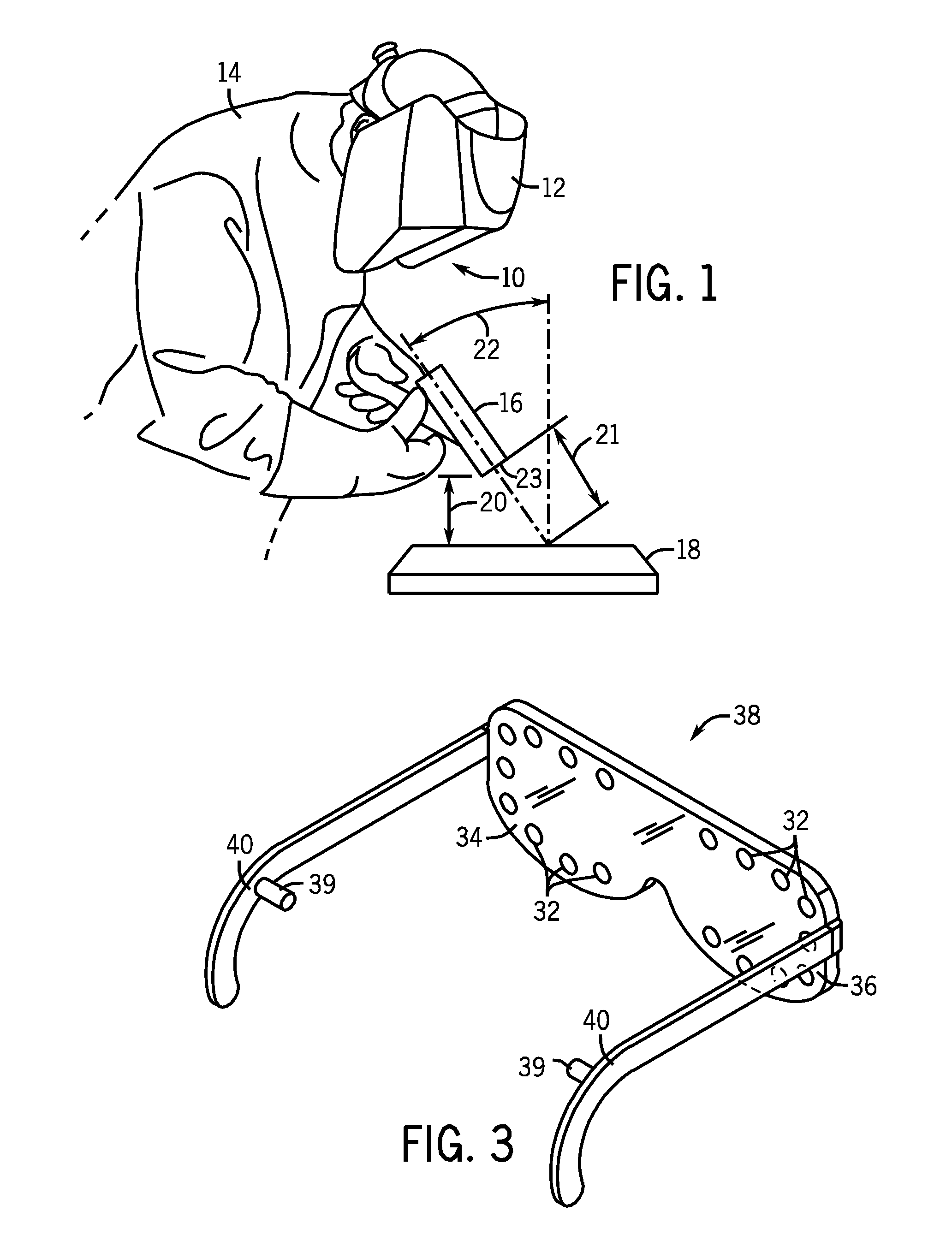

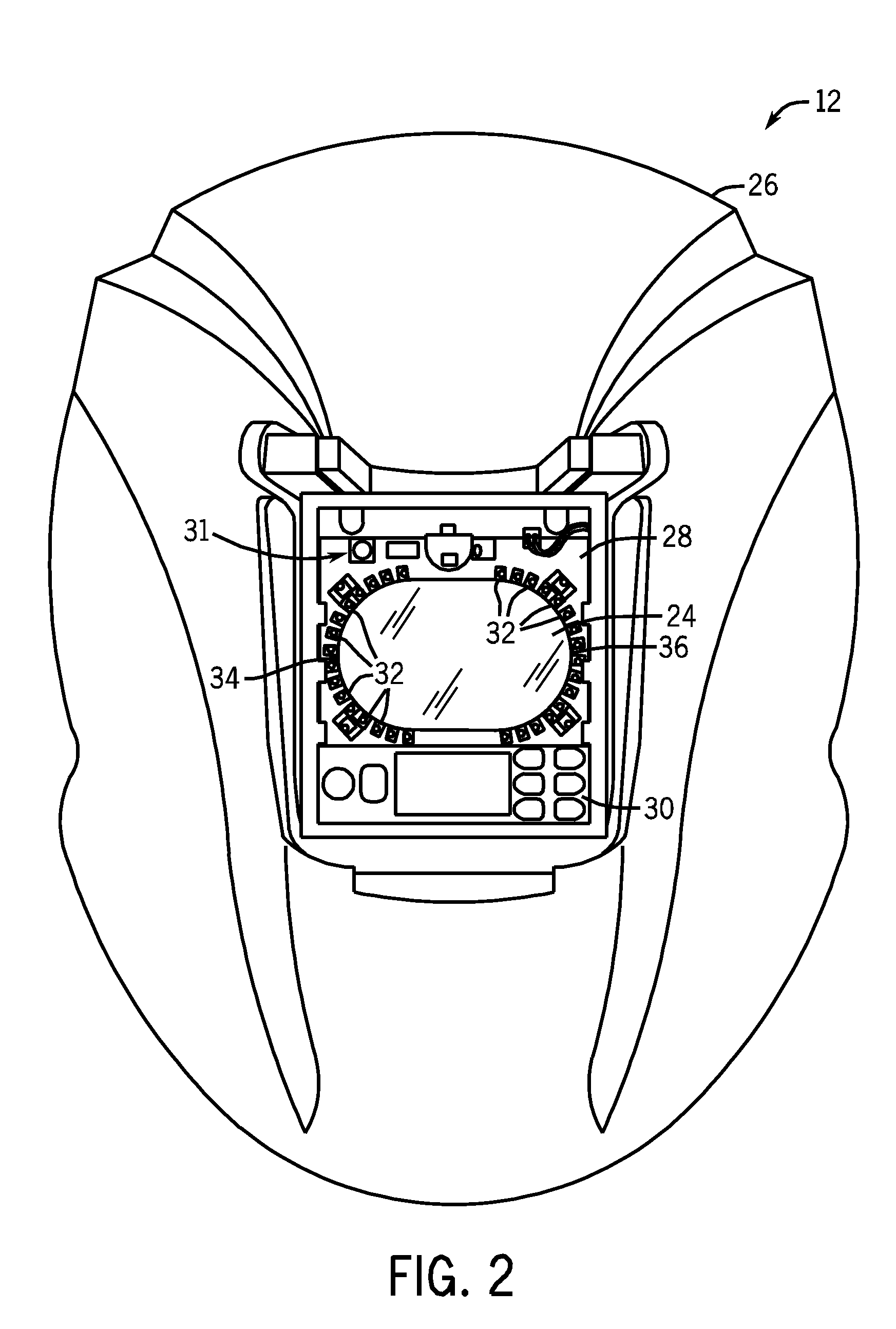

Weld characteristic communication system for a welding mask

Methods and systems for transmitting a torch angle and / or a torch-to-workpiece distance error to a welding operator when these parameters are outside of a preset optimal range via real time visual and / or audio cues are provided. One embodiment of the present disclosure relates to weld characteristic communication via intuitive arrays of visual indicators located on the periphery of a lens, which indicate to the welding operator the direction and severity of the torch angle error. In one embodiment, audio cues, such as pulsed or continuous tones may be used to communicate torch-to-workpiece distance to the welding operator. In certain embodiments, vertical visual indicator arrays may be used to indicate additional weld or auxiliary information, such as battery charge state, torch speed and so forth, to the welding operator. All the components of the communication system may be located in or on the welding helmet or the components may be split between the helmet and a belt pack.

Owner:ILLINOIS TOOL WORKS INC

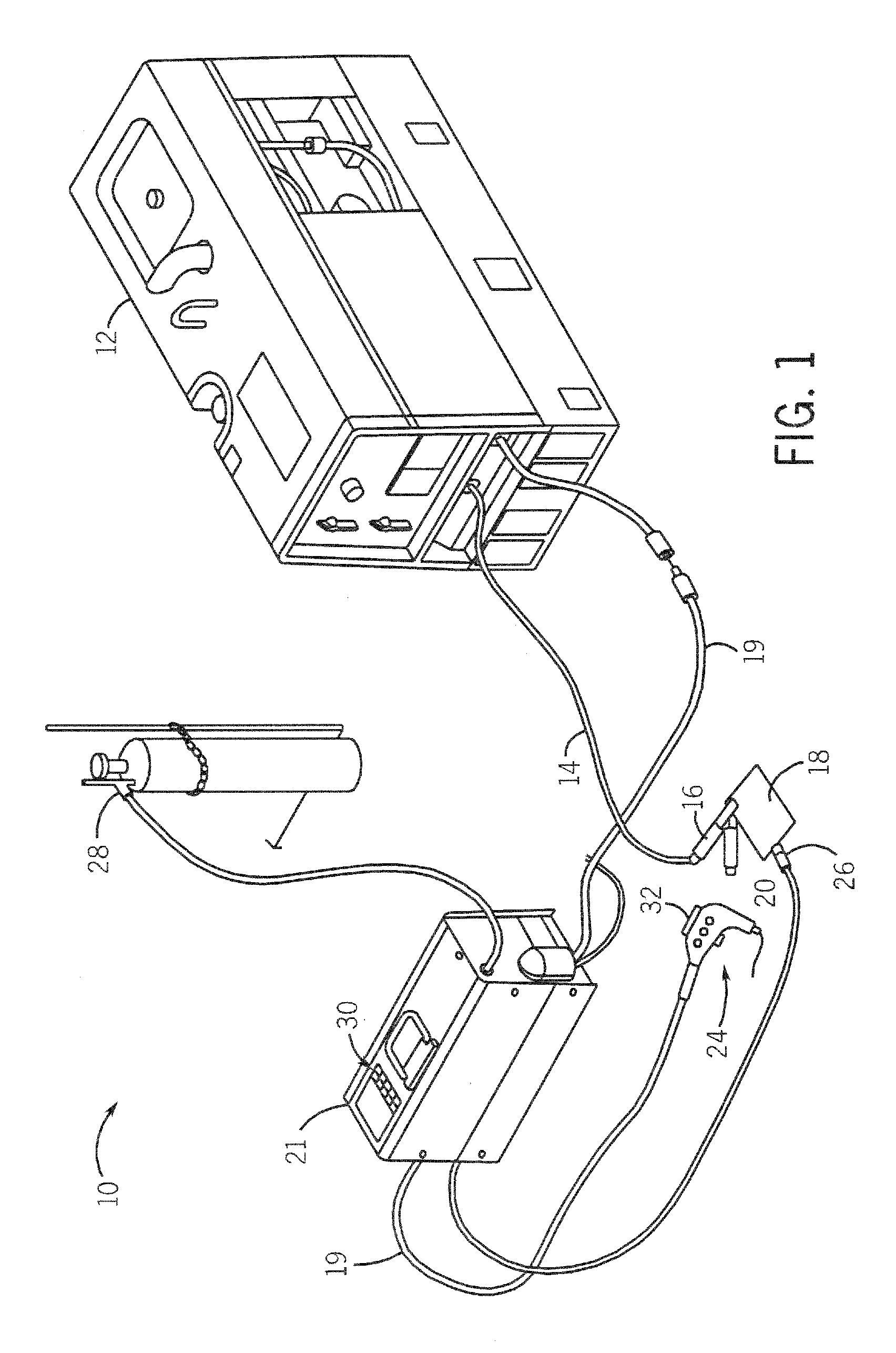

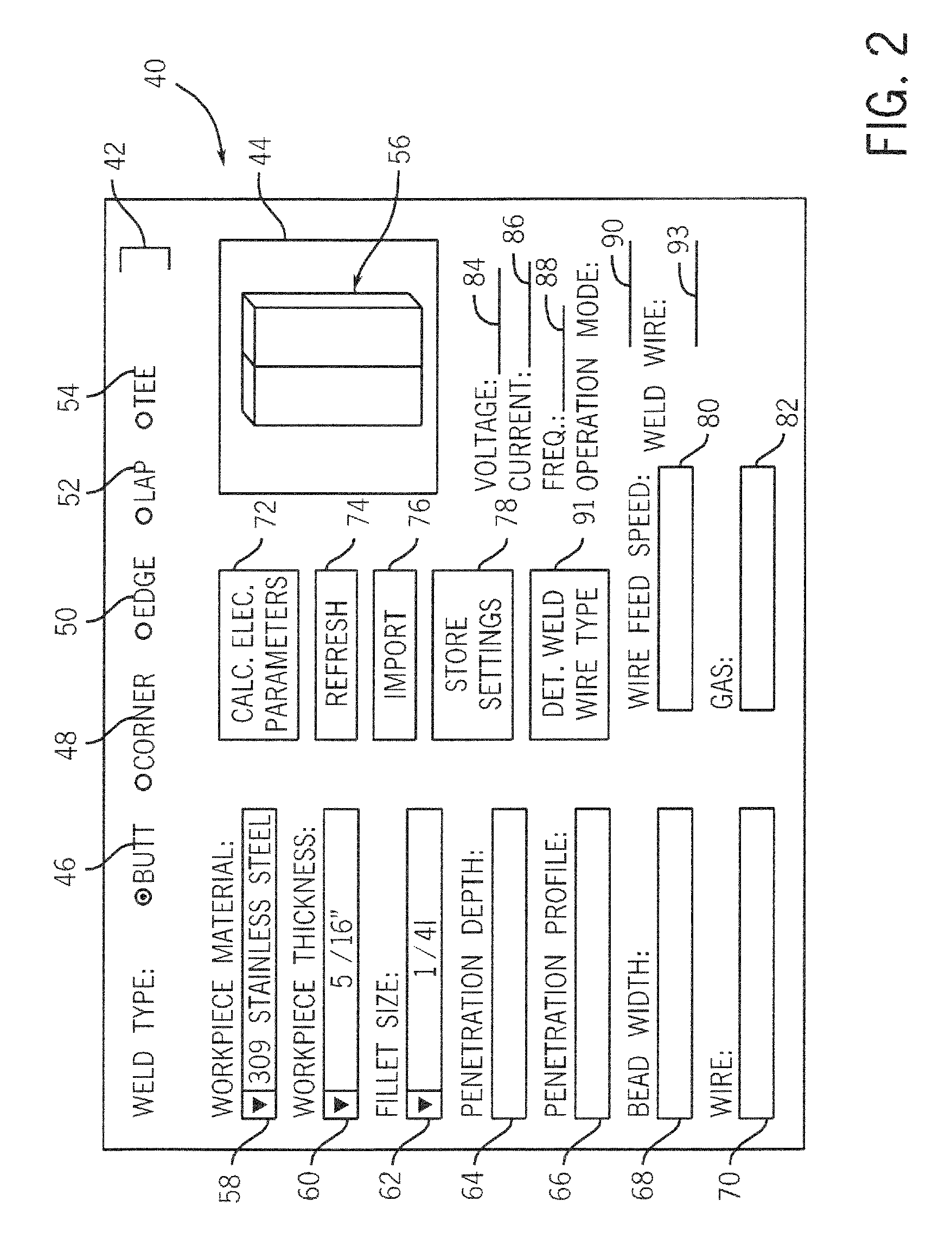

Weld parameter interface

ActiveUS20100108654A1Improve simplicityOvercomes drawbackElectric discharge heatingArc welding apparatusElectricityEngineering

A system and method for determining settings or parameters for a welding-type power source are provided. By presenting an operator with an interface that is positioned along the path of a weld cable and configured to input weld characteristics, an operator is not required to determine electrical parameters for setting a welding-type power source output at the power source. The interface is presented to the operator at a remote welding-type device, such as a wire feeder, a weld robot, a torch, or the like. From the operator-specified weld characteristics, the system and method determine appropriate settings for the power source. In some embodiments, the system and method may automatically set the power source accordingly.

Owner:ILLINOIS TOOL WORKS INC

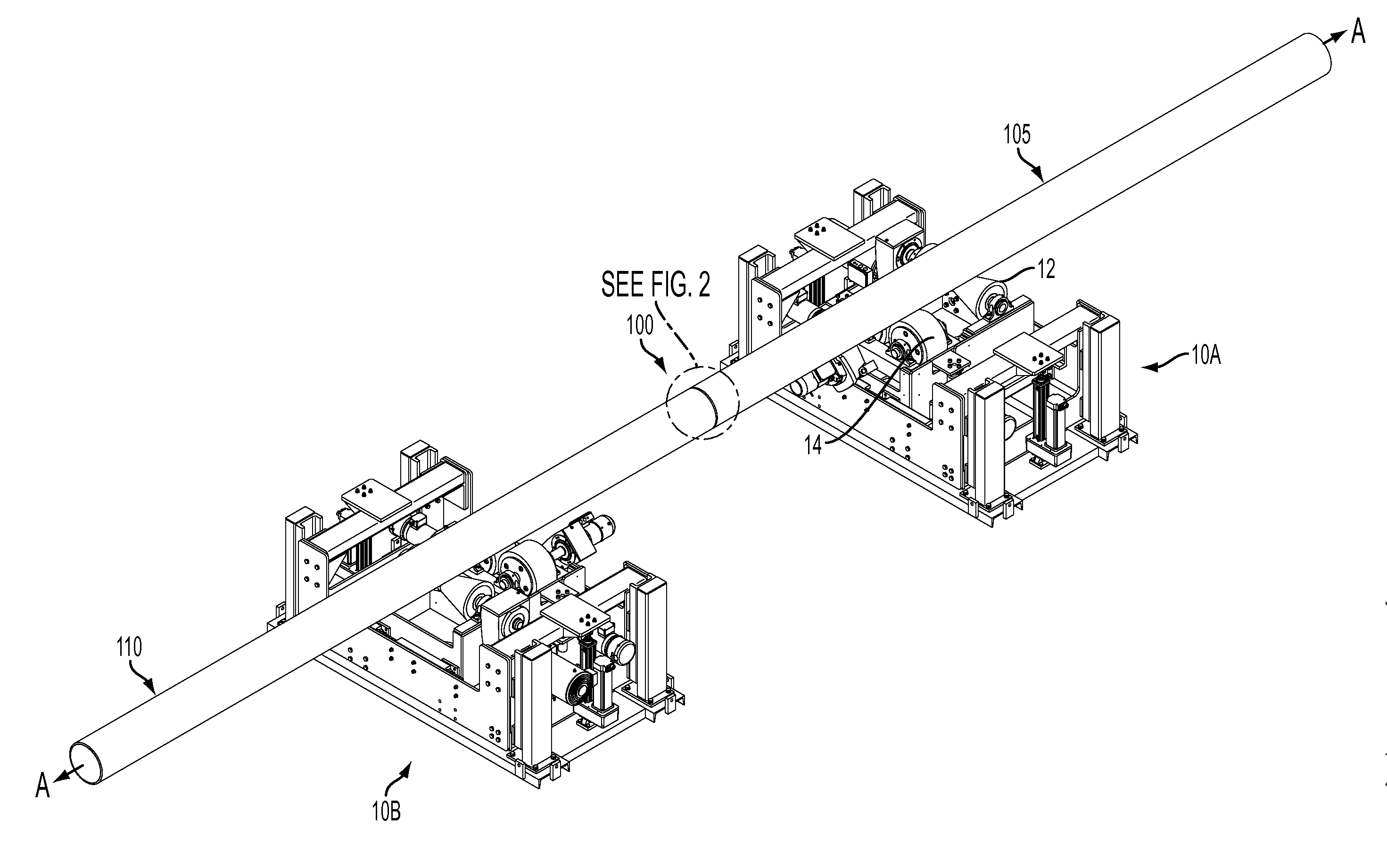

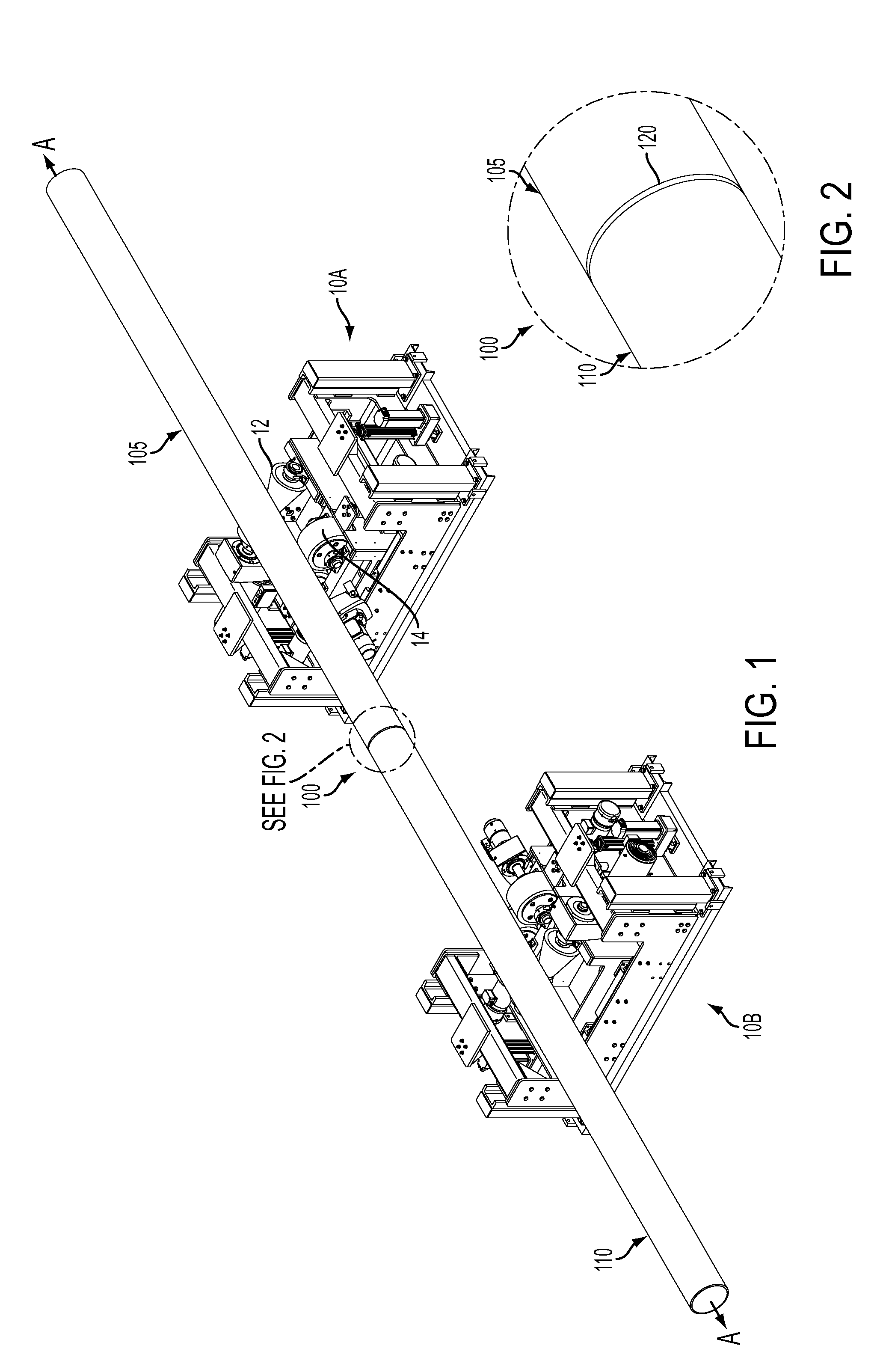

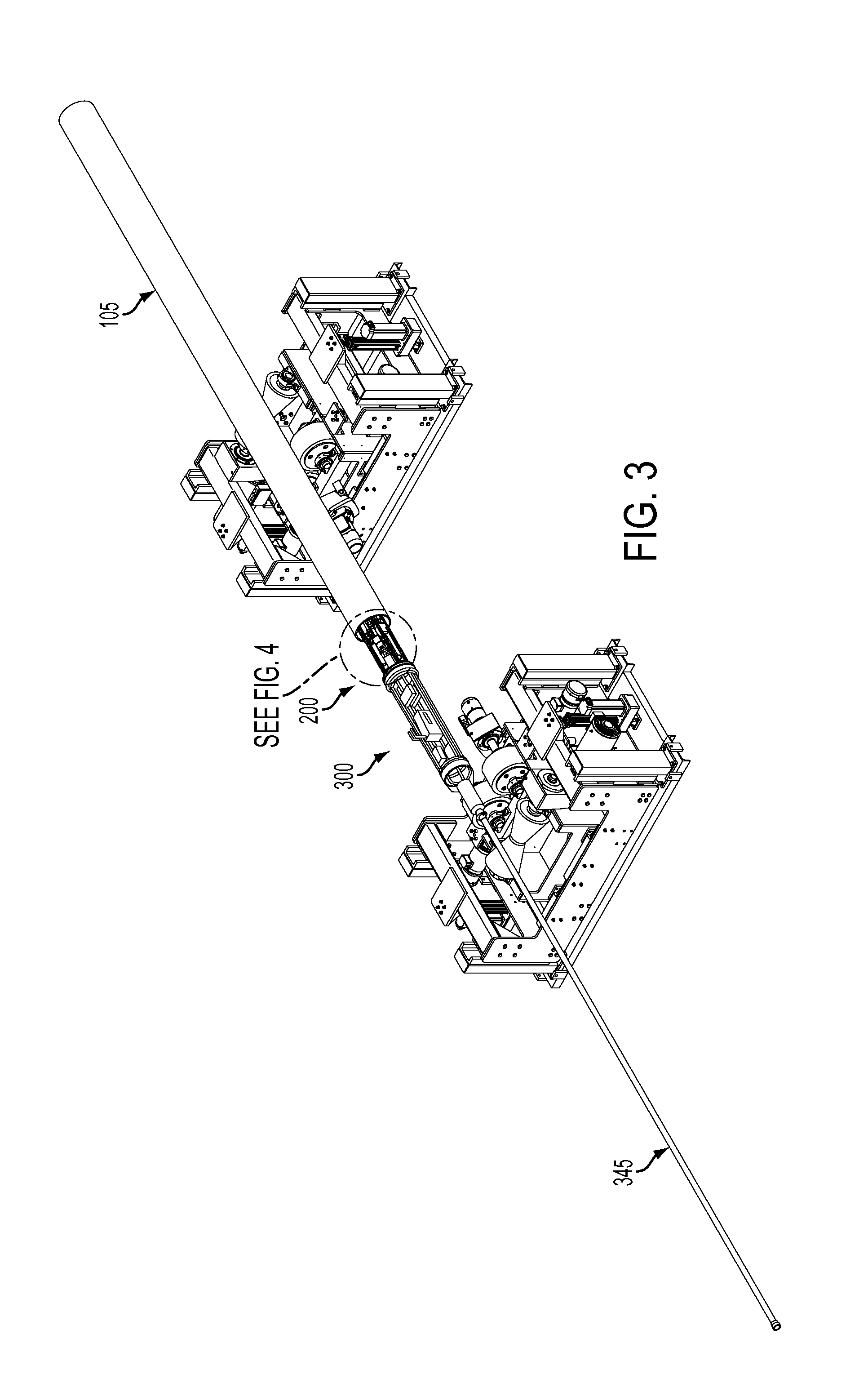

Laser controlled internal welding machine for a pipeline

ActiveUS20140346163A1Effective and efficient in fillingWelding/cutting auxillary devicesPipeline systemsEngineeringTorch

The present invention is directed to a system for welding together segments of a pipeline. The system includes an external alignment mechanism for externally supporting and manipulating the orientation of pipe segments in order to align relative segments. The system also includes an internal welding mechanism for applying a weld to an interior face joint of the two abutted pipe segments. The internal welding mechanism including a torch for applying a weld, a laser for tracking the weld profile and guiding an articulating head of the torch, and a camera for visually inspecting the weld after the weld is applied.

Owner:CRC EVANS PIPELINE INT INC

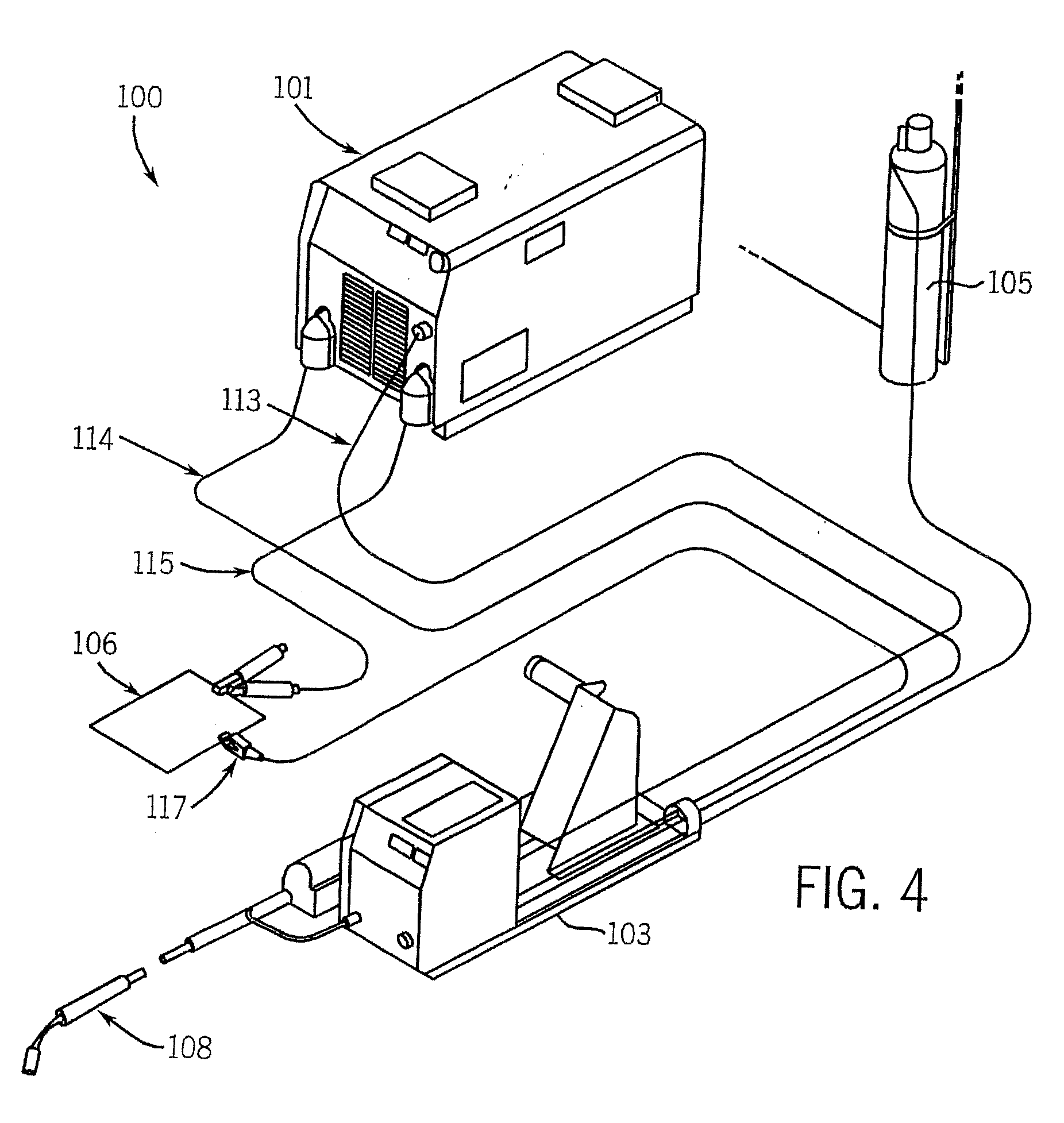

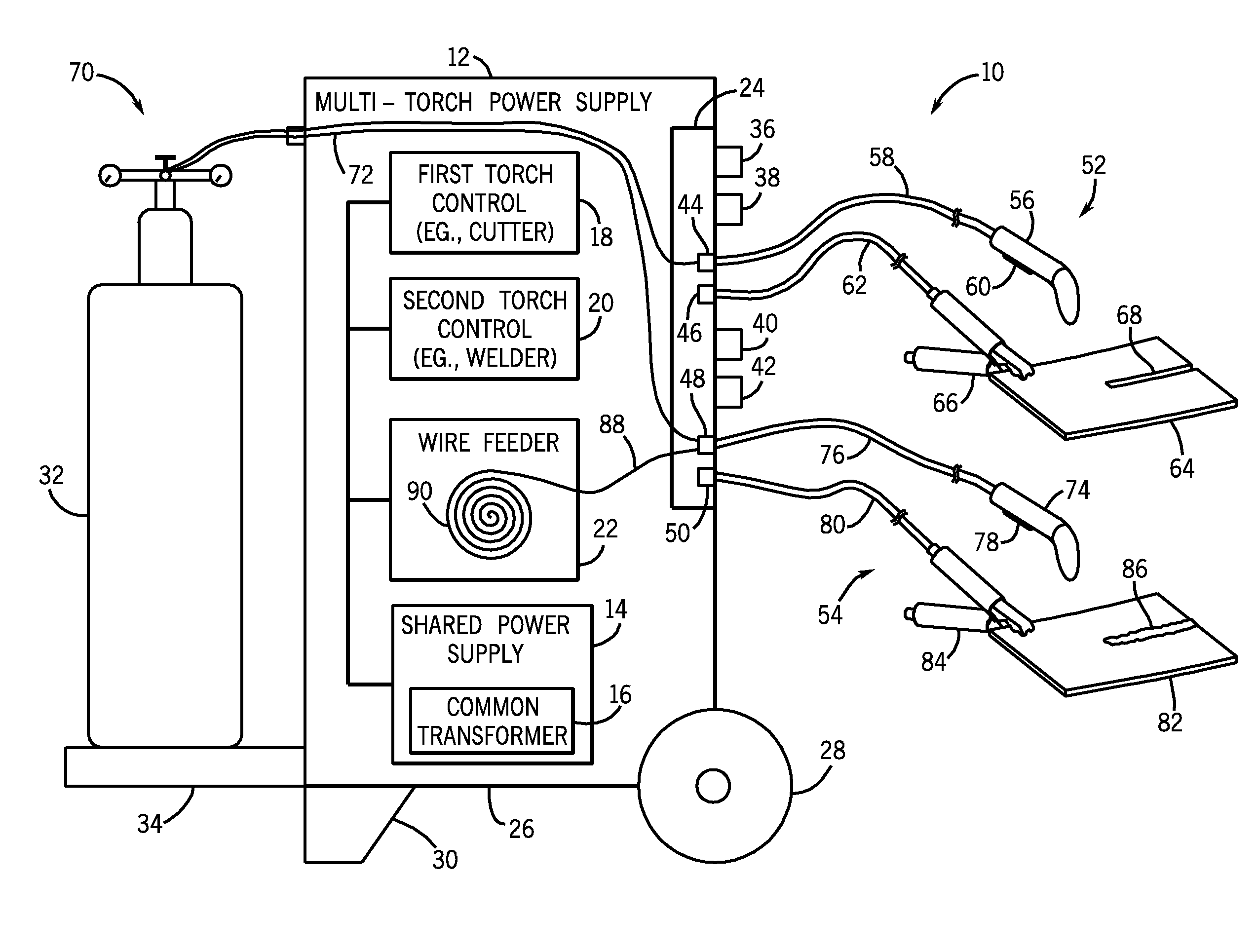

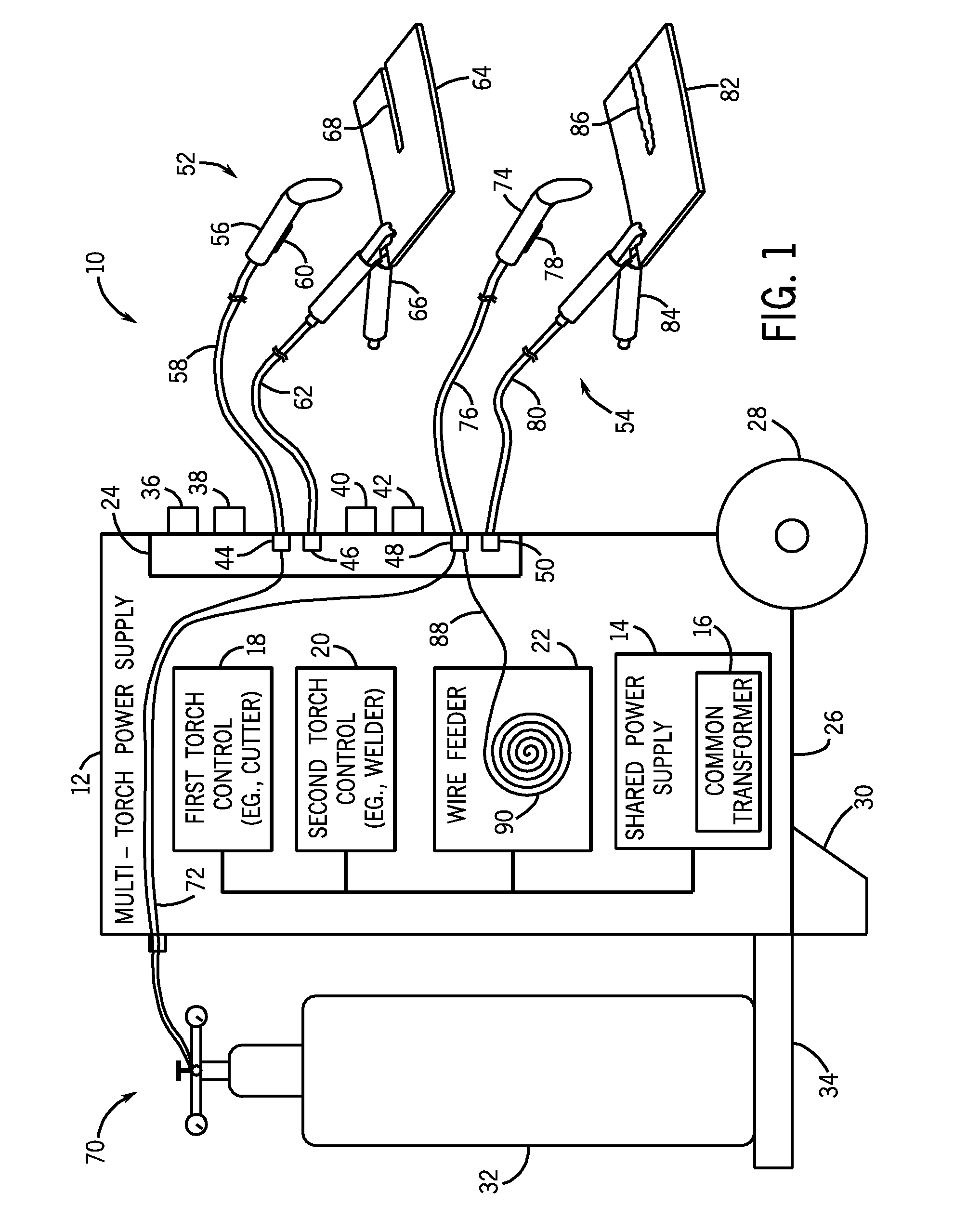

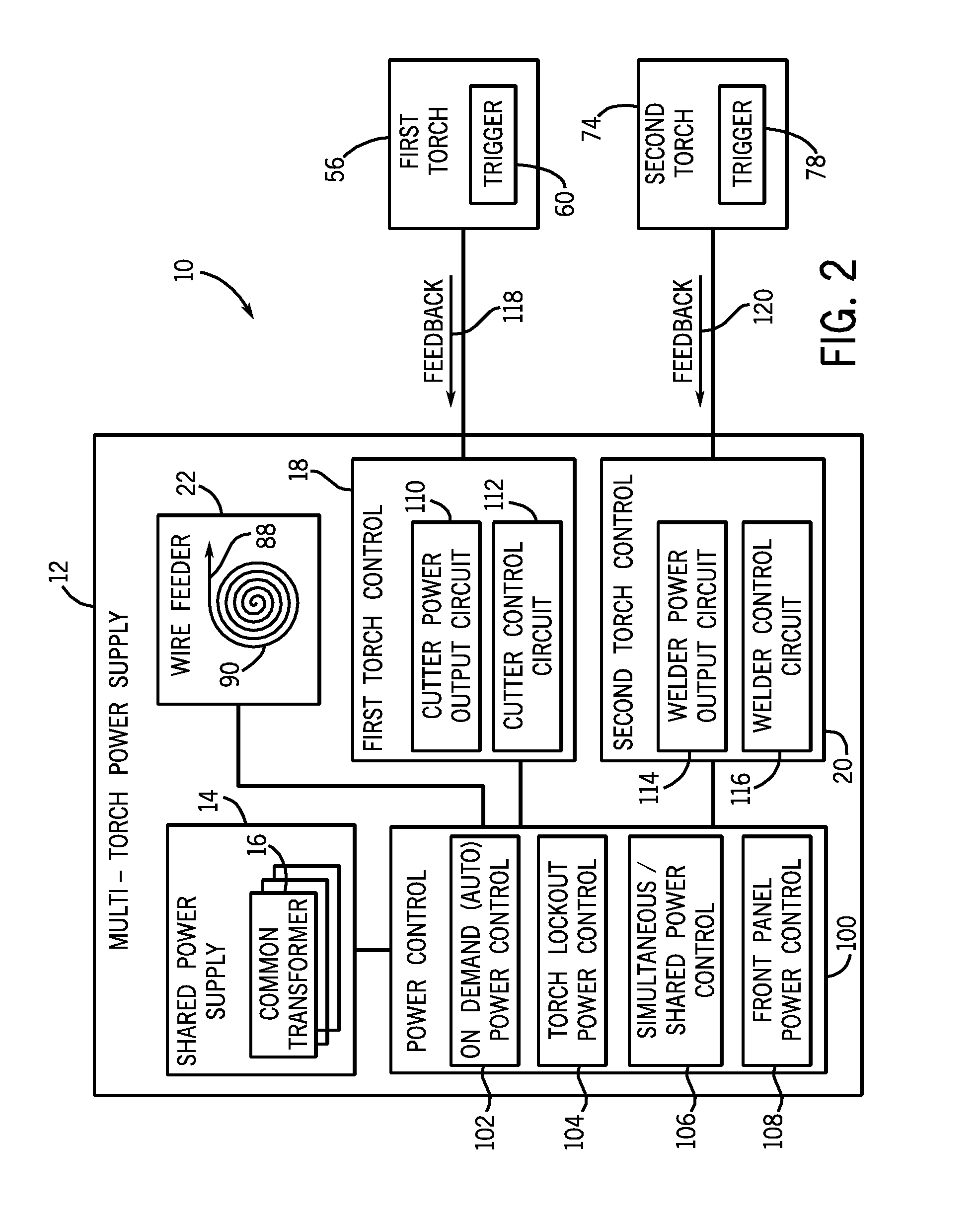

Welding and plasma cutting method and system

A system, in some embodiments, includes a multi-torch power supply. The power supply has a first circuit configured to control output to a first electrical torch, and a second circuit configured to control output to a second electrical torch. The power supply also has a power source configured to supply power to the first and second circuits to enable both independent and simultaneous operation of the first and second electrical torches.

Owner:ILLINOIS TOOL WORKS INC

Gas-cooled plasma arc cutting torch

ActiveUS8089025B2Dampening motionPlasma welding apparatusWelding/cutting media/materialsSpray nozzleTorch

A method and apparatus for a gas-cooled plasma arc torch. Components of the torch can include an electrode, nozzle and a shield, each of which can be gas-cooled. The nozzle can be disposed relative to the electrode and can include a generally hollow conductive body and a cooling gas flow channel defined by at least one fin disposed about an exterior surface of the body, the body providing a thermal conductive path that transfers heat between the nozzle to the cooling gas flow channel during operation of the torch. The shield can be disposed relative to the nozzle and can include a generally hollow conductive body and a cooling gas flow channel defined by at least one fin disposed about an exterior surface of the body, the body providing a thermal conductive path that transfers heat between the shield to the cooling gas flow channel during operation of the torch.

Owner:HYPERTHERM INC

Devices for vaporizing and delivering an aerosol agent

ActiveUS9016274B1Effective and convenient and easy to useRespiratorsLiquid surface applicatorsElectricityElectrical conductor

A device for vaporizing and delivering an aerosol agent includes a heat generator, a heat conductor in fluid (airflow) communication with the heat generator, and a substrate holder in heat conducting relation with the heat conductor. The heat generator is a handheld, portable torch and the heat conductor defines an annular heat conducting chamber surrounding a substrate disposed within the substrate holder that supports the aerosol agent and an aerosol forming agent. Another device is a handheld, battery-powered heat generator including a heating element in heat conducting relation with a substrate holder. The heating element is a nichrome heating coil wound about the substrate disposed within the substrate holder and electrically coupled to the battery. Another device further includes an auxiliary heat generator having an auxiliary heating element formed by a finely woven wire mesh positioned adjacent the substrate and electrically coupled to the battery.

Owner:PATHFINDER INNOVATIONS LLC

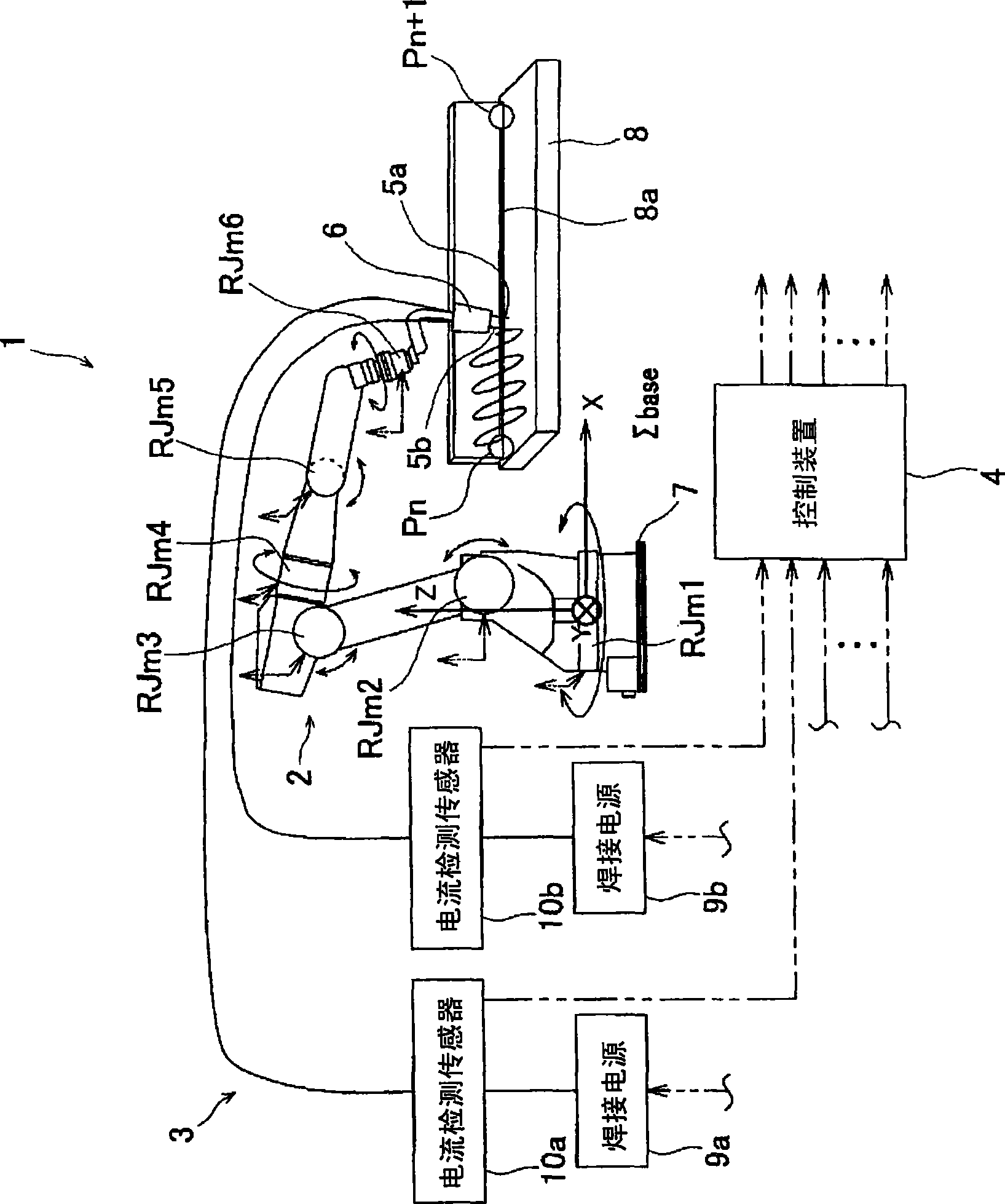

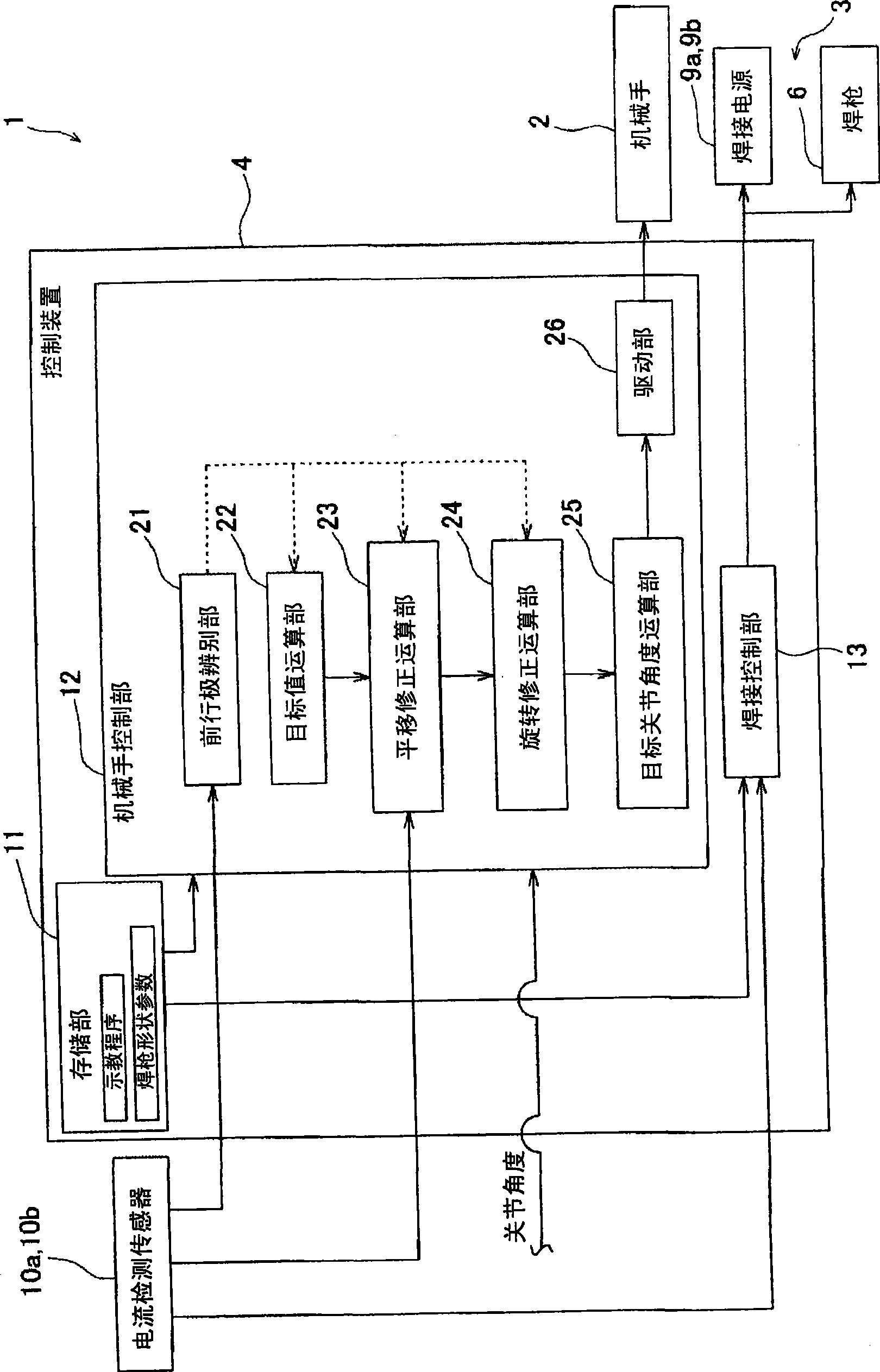

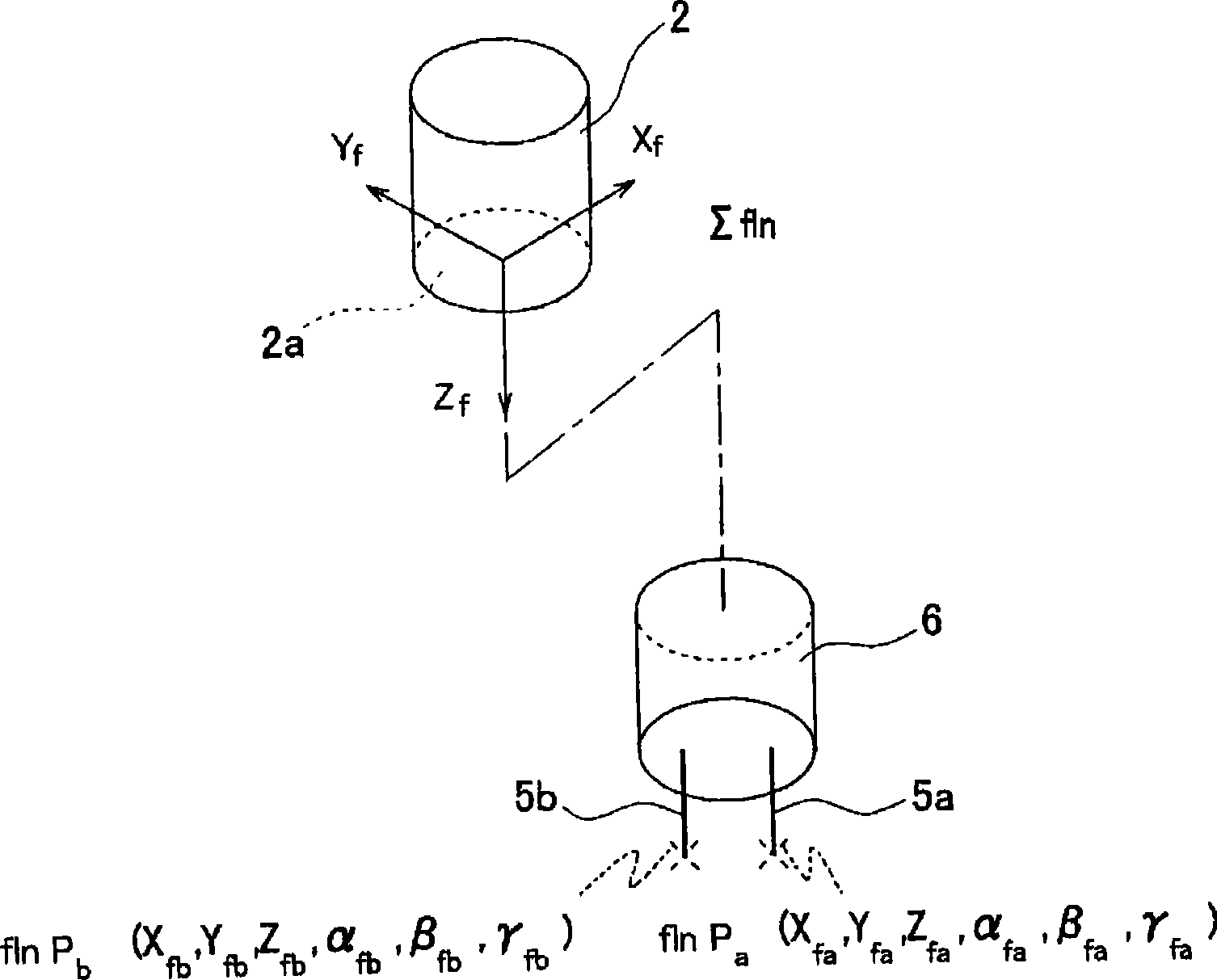

Welding robot

ActiveCN101486123AQuality improvementEfficient Tracking and TracingProgramme-controlled manipulatorArc welding apparatusEngineeringTorch

The invention provides a welding robot which makes it possible to, in a seam tracking operation during tandem welding, realize a high tracking ability, not only for a leading electrode, but also for a trailed electrode. A translational correction calculating unit (23) corrects a target value Plead(t) of the leading electrode (5a) using a translational correction amount Delta P(t) in a base coordinate system Sigmabase for a next time position of the leading electrode (5a), to obtain a primary correction target value Plead(t)'. A rotational correction calculating unit (24) calculates a rotation correction amount Delta theta(t) for correcting displacement of an orientation of a torch (6) around the leading electrode (5a) with respect to a actual weld line Lre generated because of the translational correction amount Delta P(t), and calculates a secondary correction target value Plead(t)'' resulting from correcting the primary correction target value Plead(t)' so that the torch (6) rotates around the leading electrode (5a) by the rotation correction amount Delta theta(t). A manipulator (2) is driven on the basis of the secondary correction target value Plead(t)''.

Owner:KOBE STEEL LTD

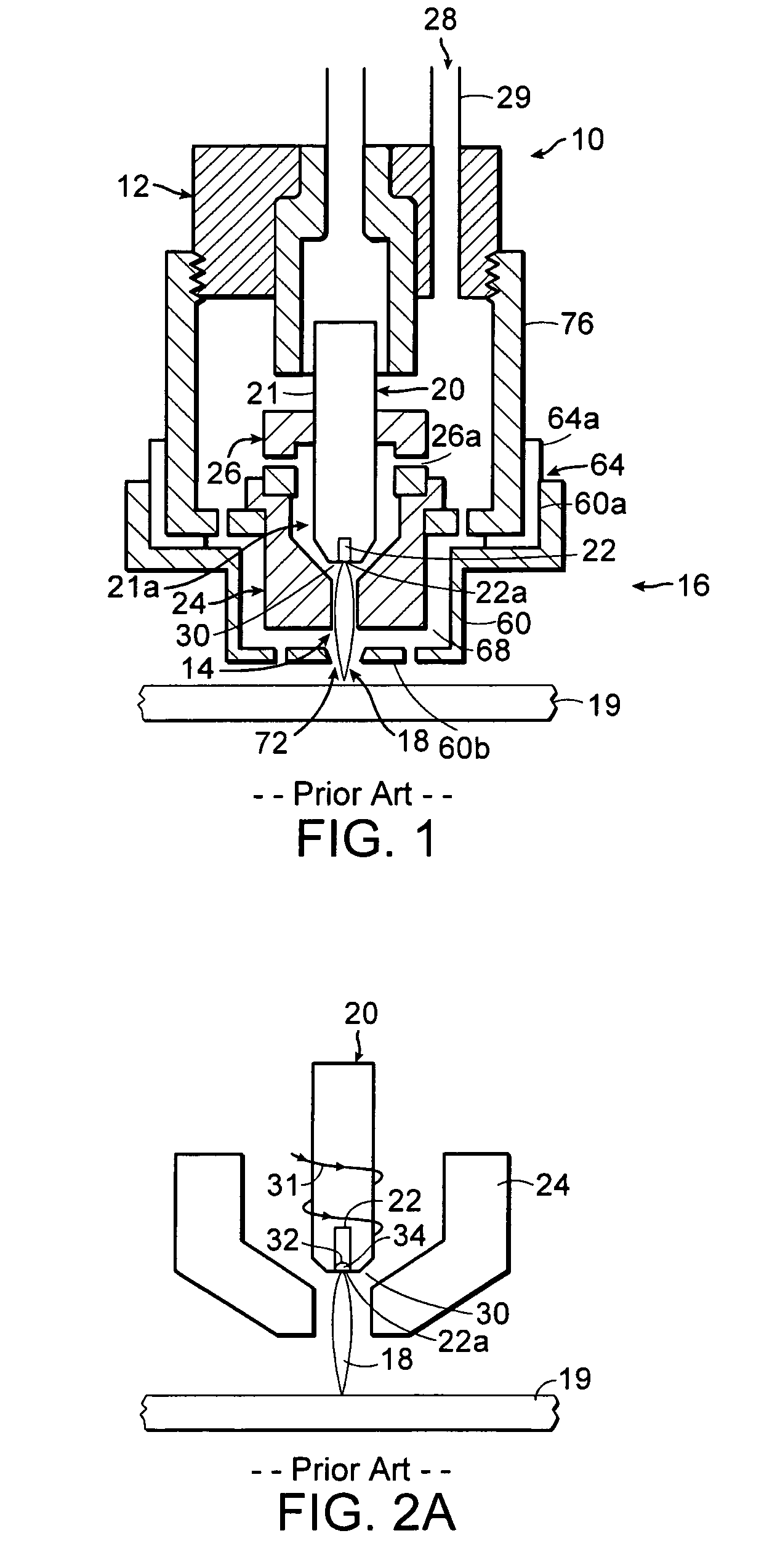

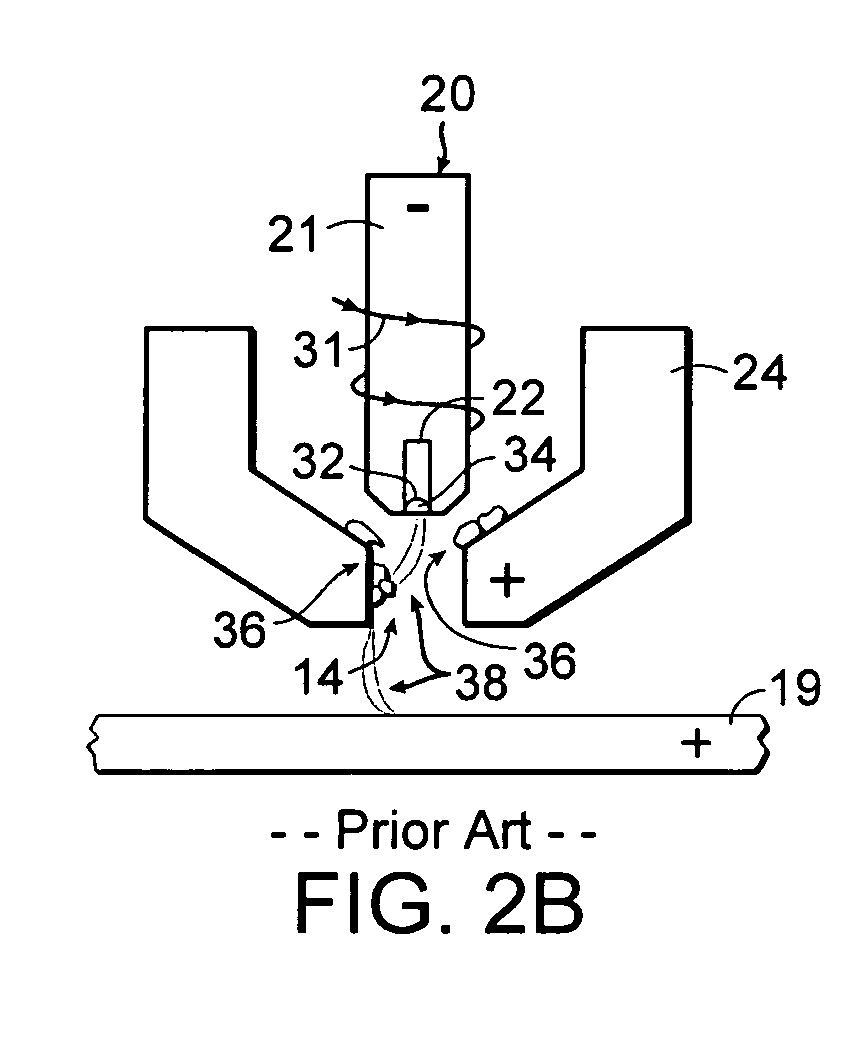

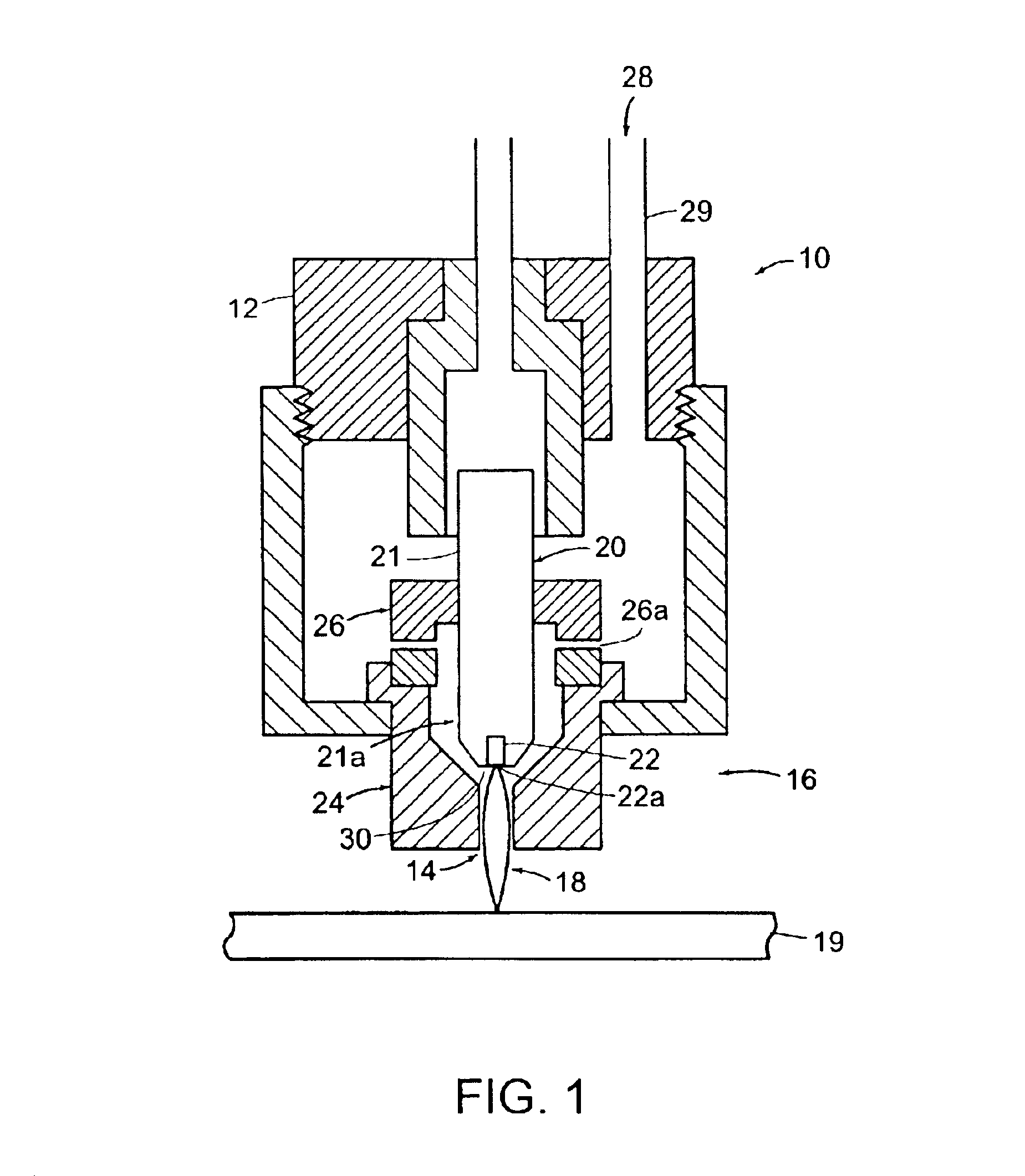

Plasma arc torch having an electrode with internal passages

InactiveUS7375302B2Reduce wearHigh emissivityArc welding apparatusPlasma welding apparatusEmissivityTorch

An electrode for a plasma arc cutting torch which minimizes the deposition of high emissivity material on the nozzle, reduces electrode wear, and improves cut quality. The electrode has a body having a first end, a second end in a spaced relationship relative to the first end, and an outer surface extending from the first end to the second end. The body has an end face disposed at the second end. The electrode also includes at least one passage extending from a first opening in the body to a second opening in the end face.

Owner:HYPERTHERM INC

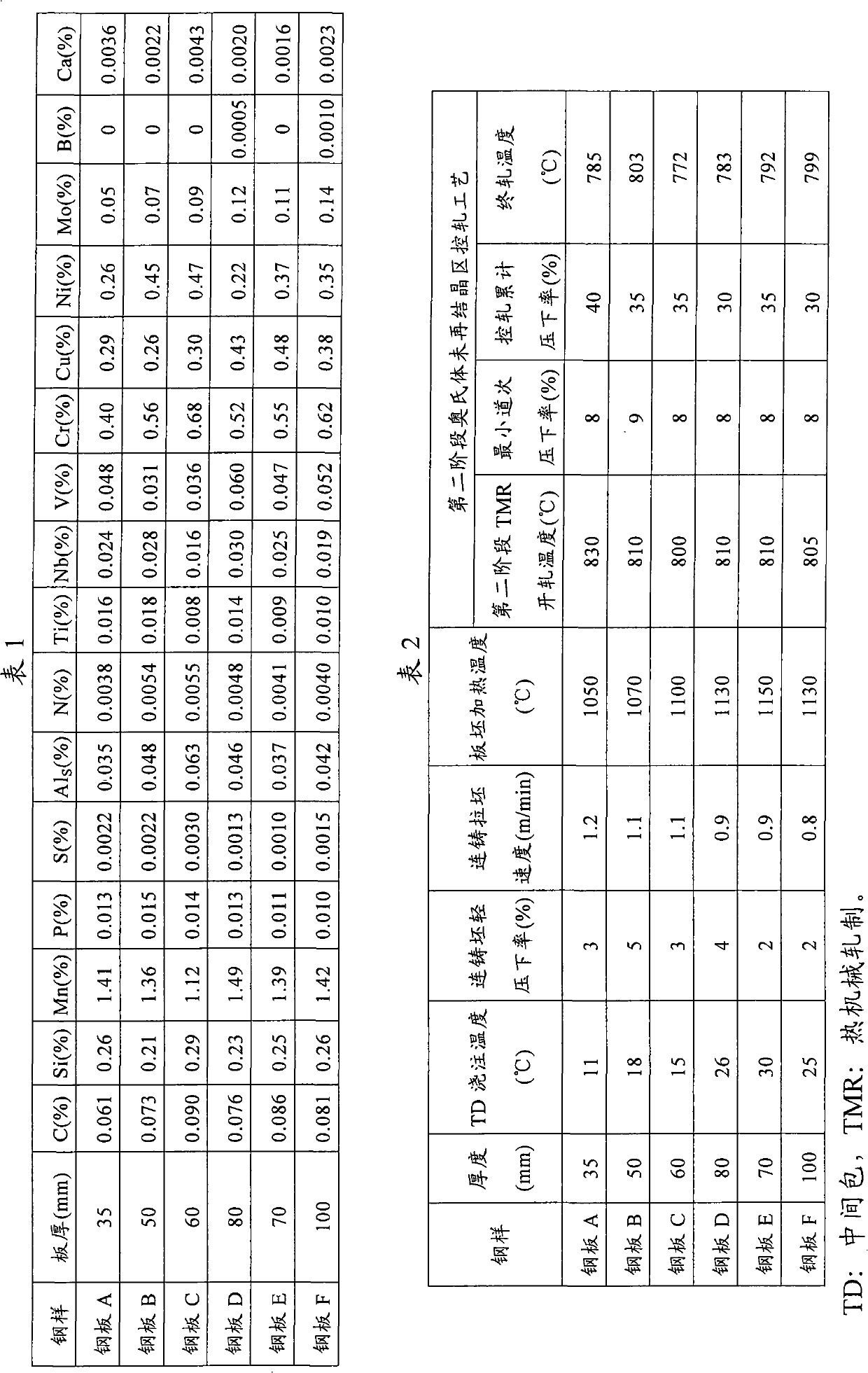

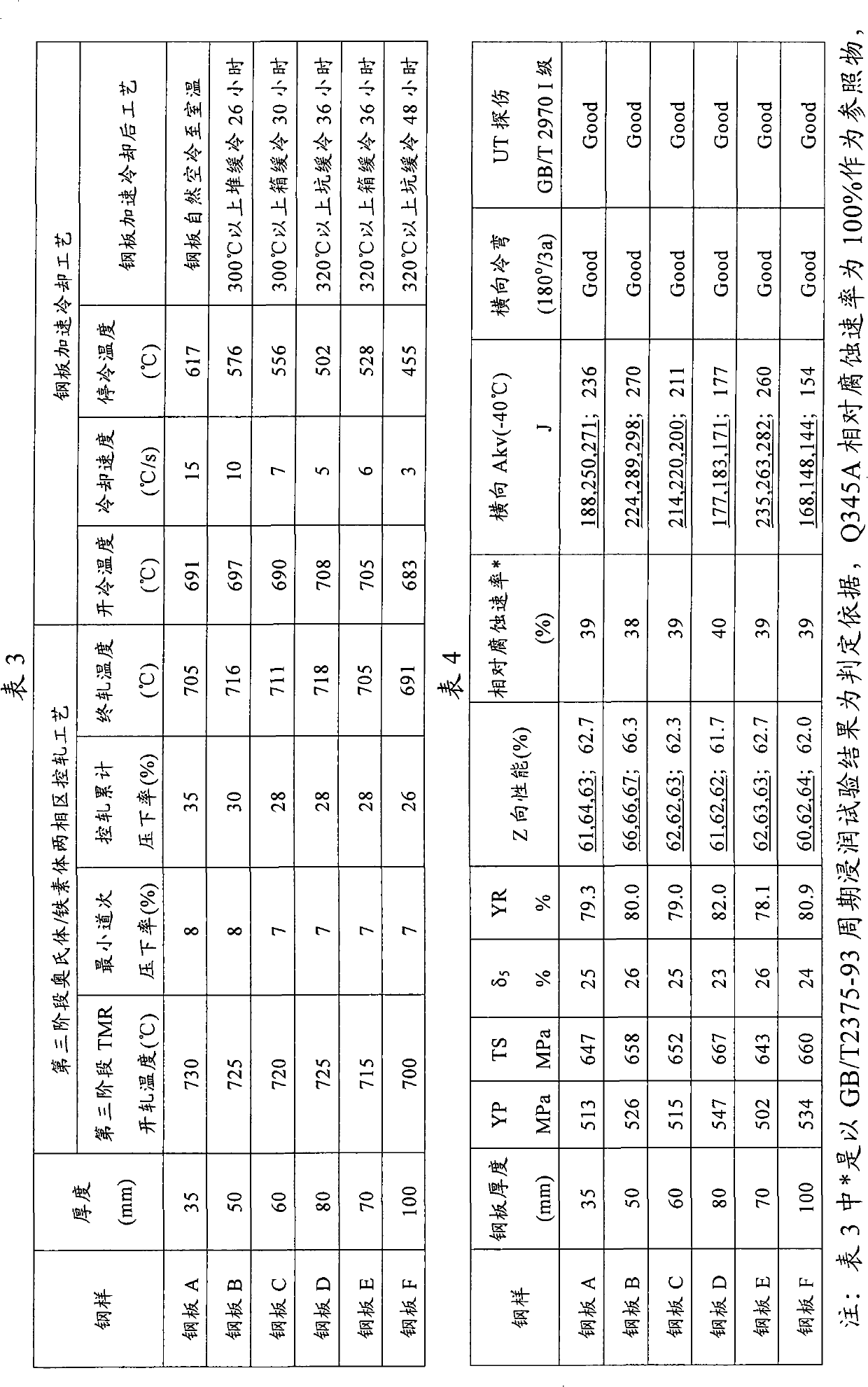

Weather resistant thick steel plate and manufacturing method thereof

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

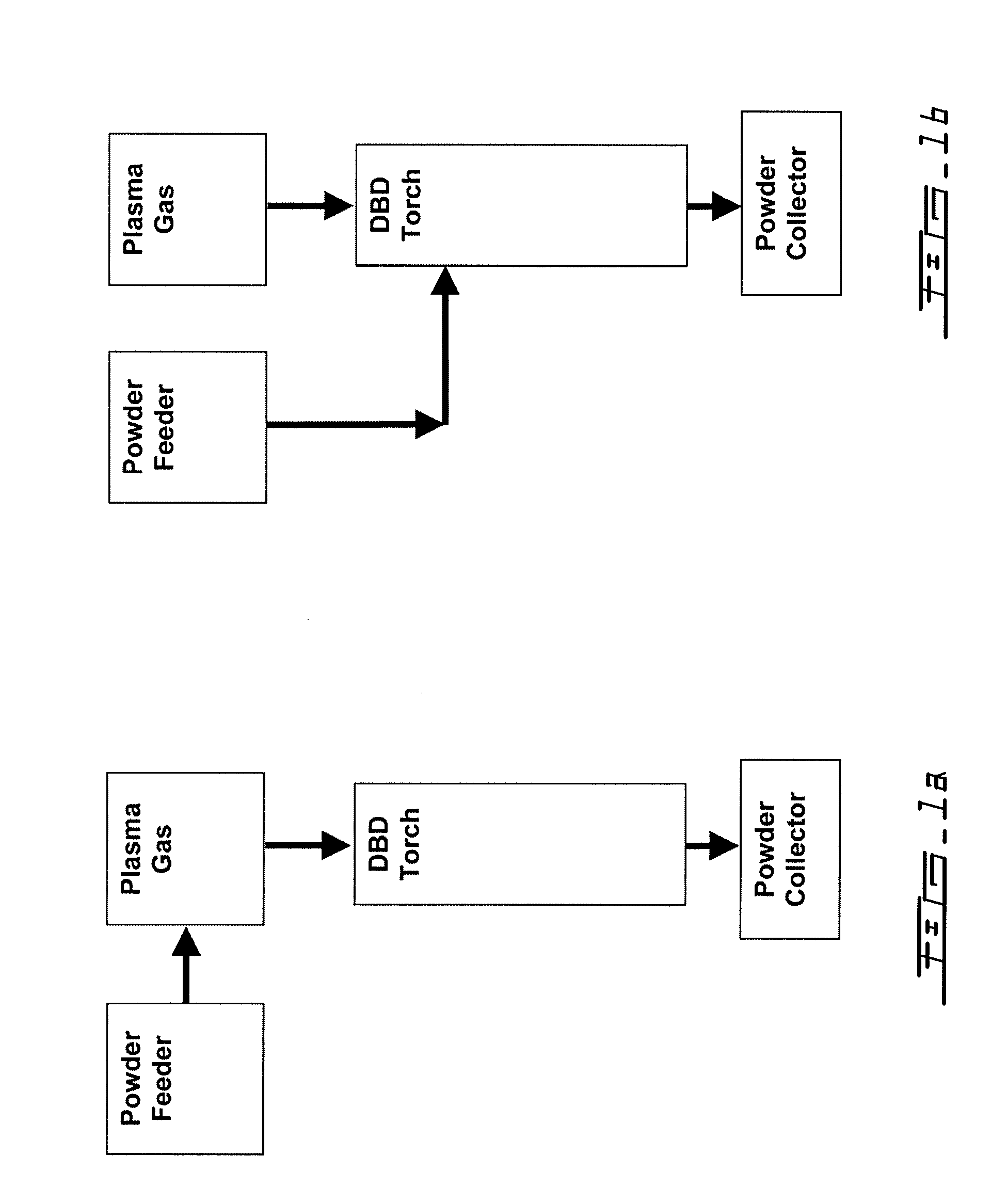

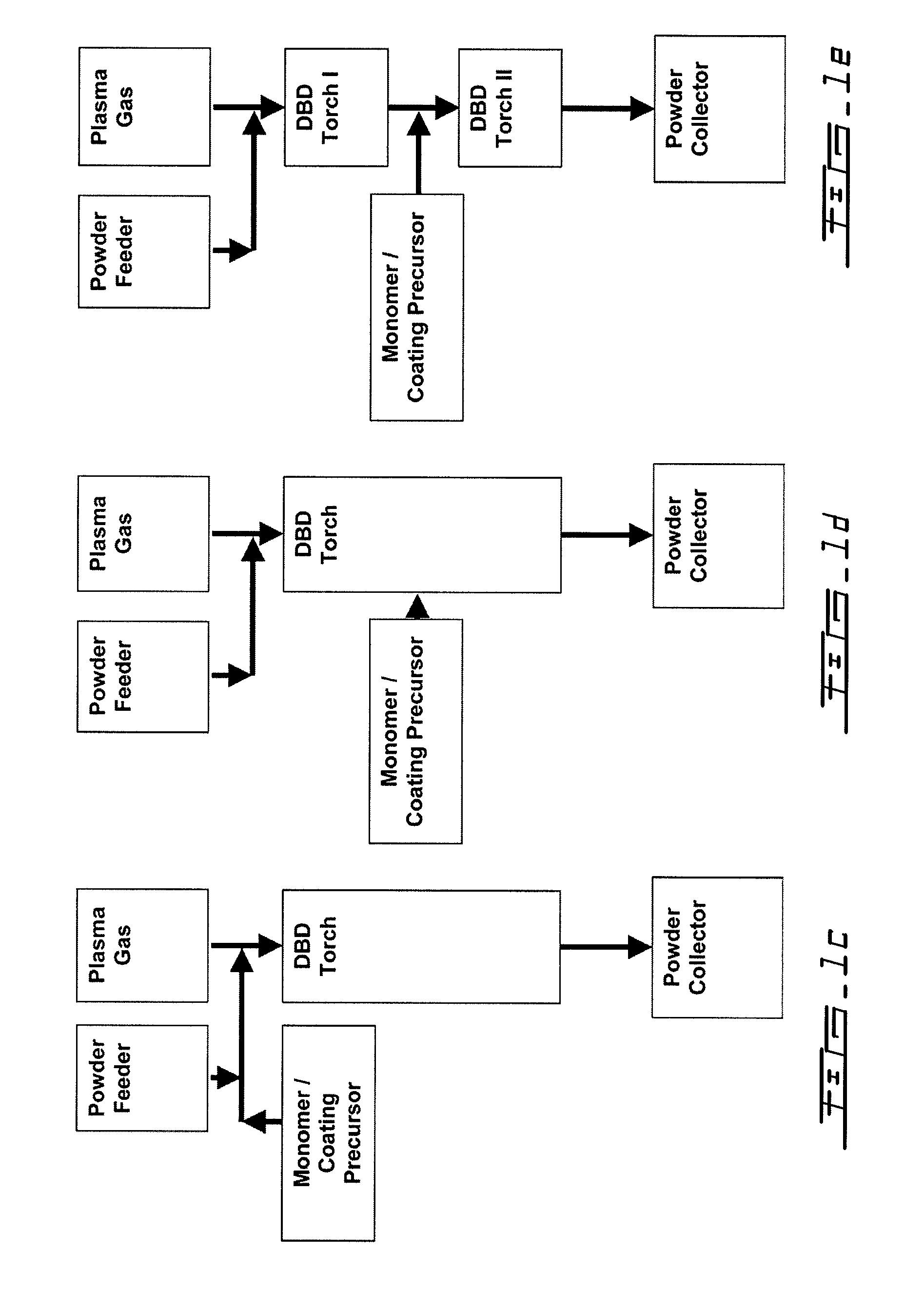

Plasma surface treatment using dielectric barrier discharges

A process for the in-flight surface treatment of powders using a Dielectric Barrier Discharge Torch operating at atmospheric pressures or soft vacuum conditions is described herein. The process comprising feeding a powder material into the Dielectric Barrier Discharge Torch yielding powder particles exhibiting a reduced powder agglomeration feature; in-flight modifying the surface properties of the particles; and collecting coated powder particles. An apparatus for surface treating micro- and nanoparticles comprising a Dielectric Barrier Discharge Torch operating at atmospheric pressure or soft vacuum conditions is also described herein.

Owner:TEKNA PLASMA SYST INC

Weld characteristic communication system for a welding mask

Methods and systems for transmitting a torch angle and / or a torch-to-workpiece distance error to a welding operator when these parameters are outside of a preset optimal range via real time visual and / or audio cues are provided. One embodiment of the present disclosure relates to weld characteristic communication via intuitive arrays of visual indicators located on the periphery of a lens, which indicate to the welding operator the direction and severity of the torch angle error. In one embodiment, audio cues, such as pulsed or continuous tones may be used to communicate torch-to-workpiece distance to the welding operator. In certain embodiments, vertical visual indicator arrays may be used to indicate additional weld or auxiliary information, such as battery charge state, torch speed and so forth, to the welding operator. All the components of the communication system may be located in or on the welding helmet or the components may be split between the helmet and a belt pack.

Owner:ILLINOIS TOOL WORKS INC

Device for the plasma treatment of gases

Provided is a device for the microwave-sustained plasma treatment of gases, which comprises a hollow structure forming a waveguide intended to be connected to a microwave generator, and means for making the gas to be treated flow through the said structure in a region in which the amplitude of the electric field associated with the incident wave is high. The means for making the gas flow comprise a plasma torch for producing a plasma in the gas. The torch comprises an injector made of an electrically conducting material mounted on a first large face of the said structure and extending so as to project through an orifice made in a second large face opposite the said first large face. A gap for passage of the incident waves lies around the injector.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Composite electrode for a plasma arc torch

InactiveUS6841754B2Improve heat transfer performanceImprove thermal conductivityElectric discharge heatingArc welding apparatusMetallic materialsCopper electrode

A plasma arc torch that includes a torch body having a nozzle mounted relative to a composite electrode in the body to define a plasma chamber. The torch body includes a plasma flow path for directing a plasma gas to the plasma chamber in which a plasma arc is formed. The nozzle includes a hollow, body portion and a substantially solid, head portion defining an exit orifice. The composite electrode can be made of a metallic material (e.g., silver) with high thermal conductivity in the forward portion electrode body adjacent the emitting surface, and the aft portion of the electrode body is made of a second low cost, metallic material with good thermal and electrical conductivity. This composite electrode configuration produces an electrode with reduced electrode wear or pitting comparable to a silver electrode, for a price comparable to that of a copper electrode.

Owner:HYPERTHERM INC

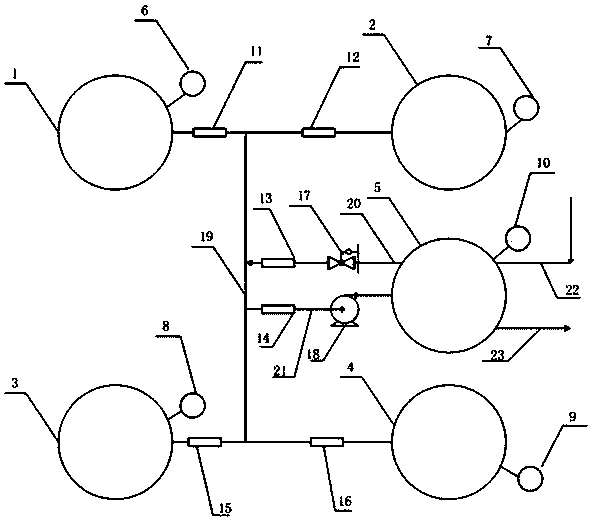

Safe and environment-friendly method for protecting storage tanks

InactiveCN104370000AShort processReduce dosageLarge containersEnvironmental resistancePositive pressure

The invention relates to a safe and environment-friendly method for protecting storage tanks to mainly solve the problems that in the prior art, the gas consumption of nitrogen protection is excessively large, cost is high, and sulfur-containing gas and other peculiar smell gas are hard to treat. According to the safe and environment-friendly method for protecting the storage tanks, the gas produced by liquid in the storage tanks enters a compressor (18) through a main gas pipe (19) and an inflation pipe (21), the gas is pressurized by the compressor (18) and stored in a buffering tank (5) to serve as one part of positive-pressure protection gas, when the gas stored in the buffering tank (5) cannot meet the positive-pressure protection of all storage tanks, the nitrogen from a nitrogen inlet pipeline (22) is used for performing supplementation, and when the pressure stored in the buffering tank (5) exceeds the designed pressure, the residual gas is sent to a torch or combustion furnace through a torch or combustion furnace leading pipeline (22), the problems are well solved through the technical scheme, and the method can be used in storage tank protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com