Patents

Literature

1157 results about "Copper electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

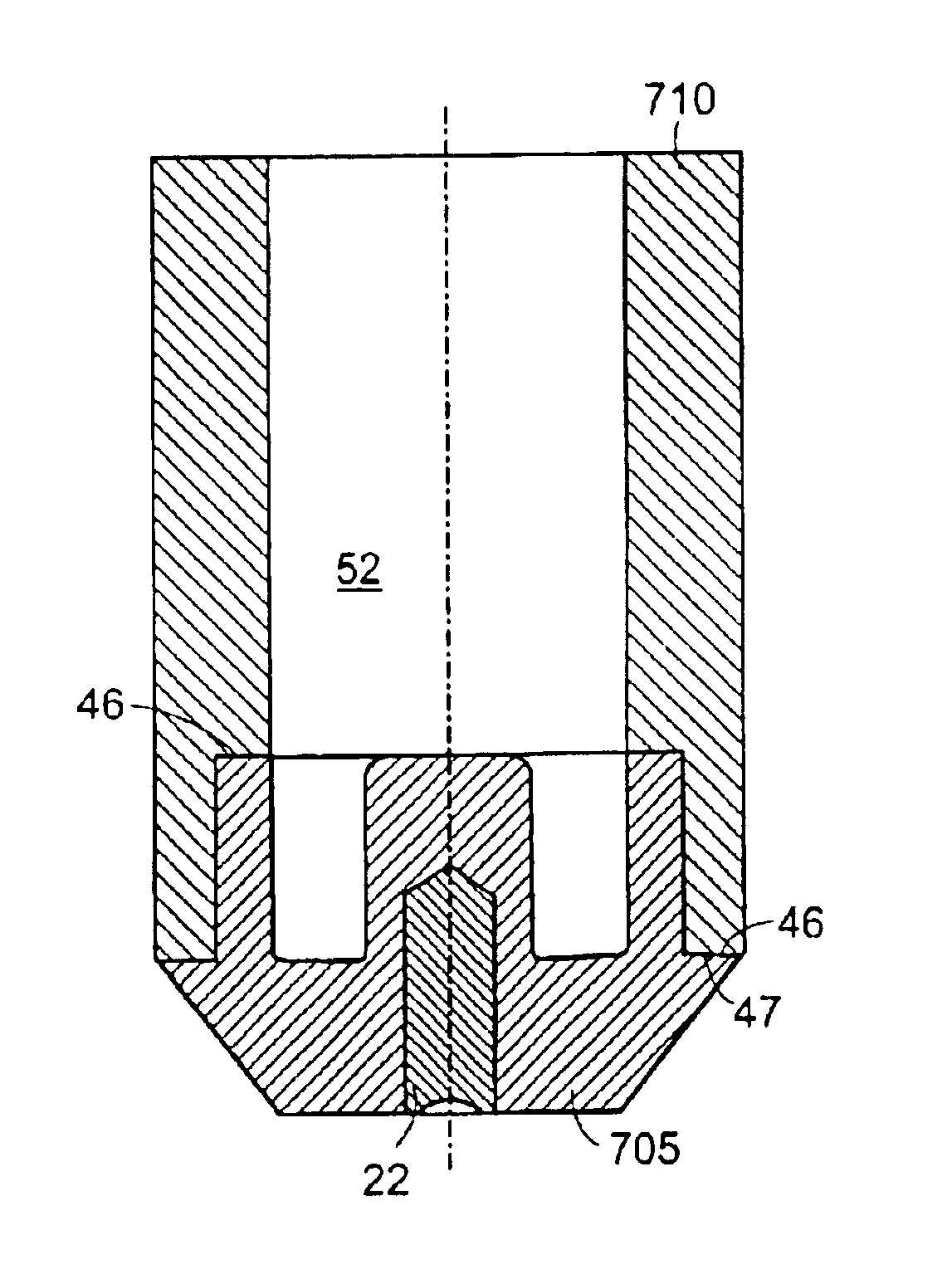

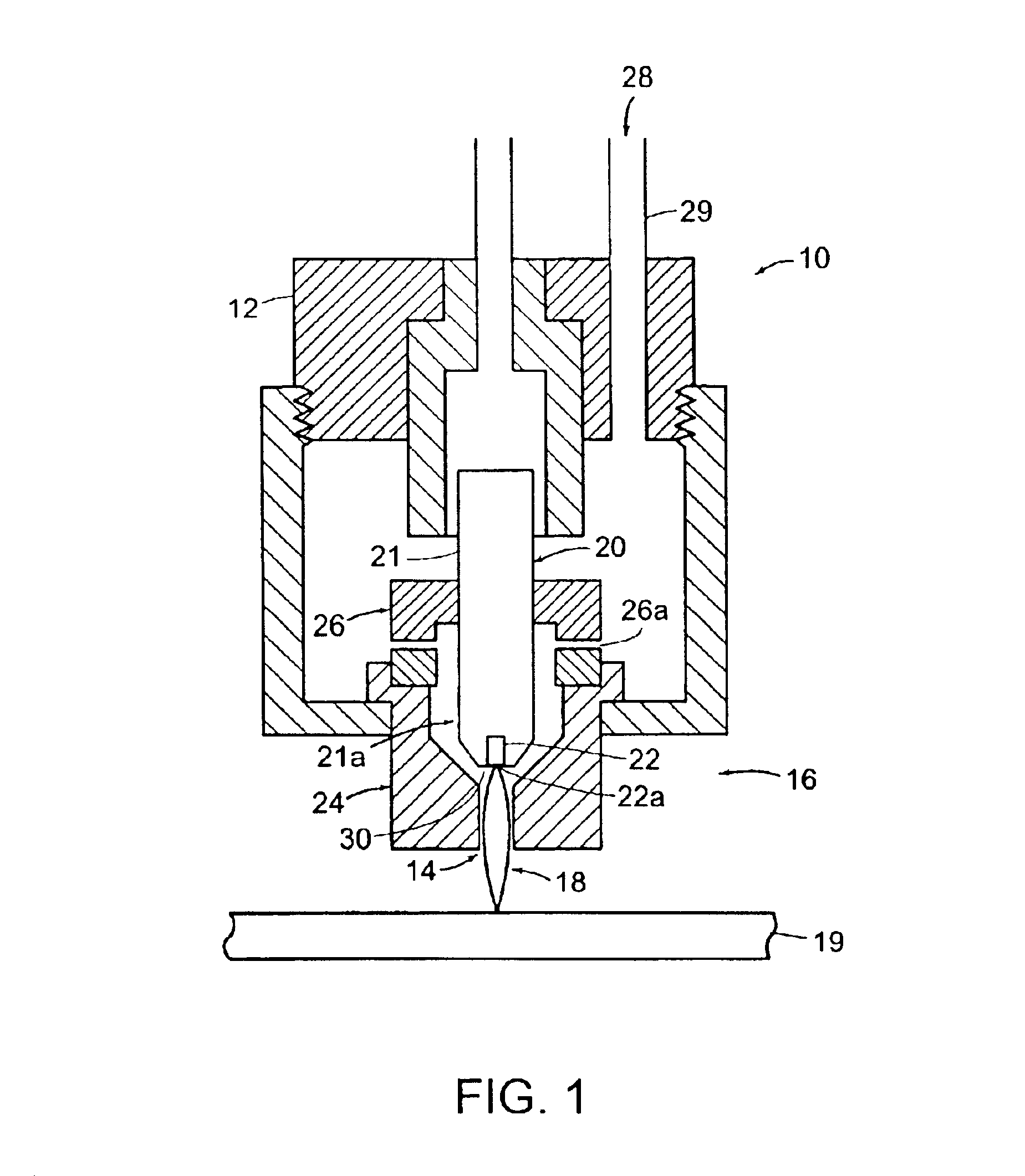

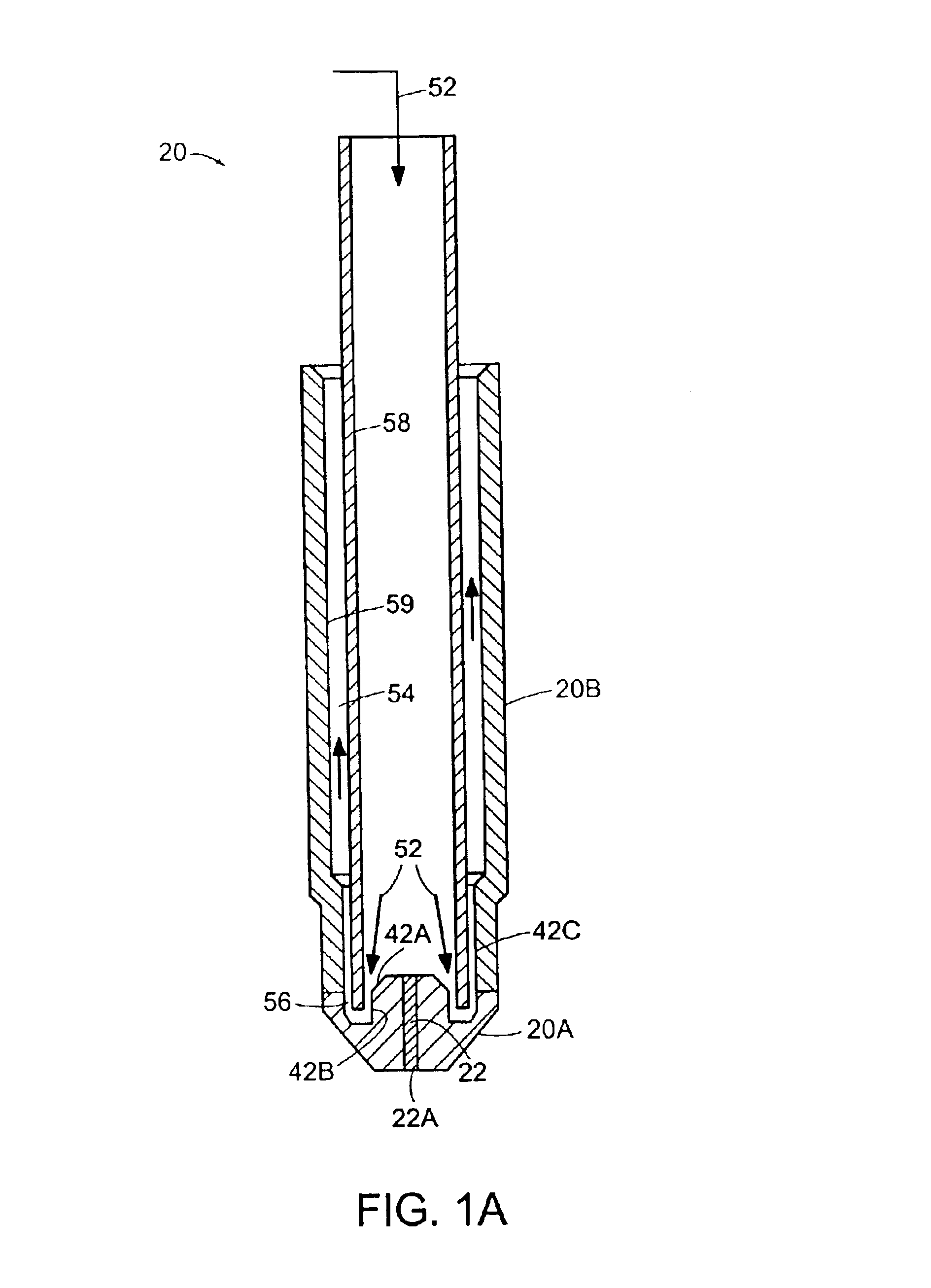

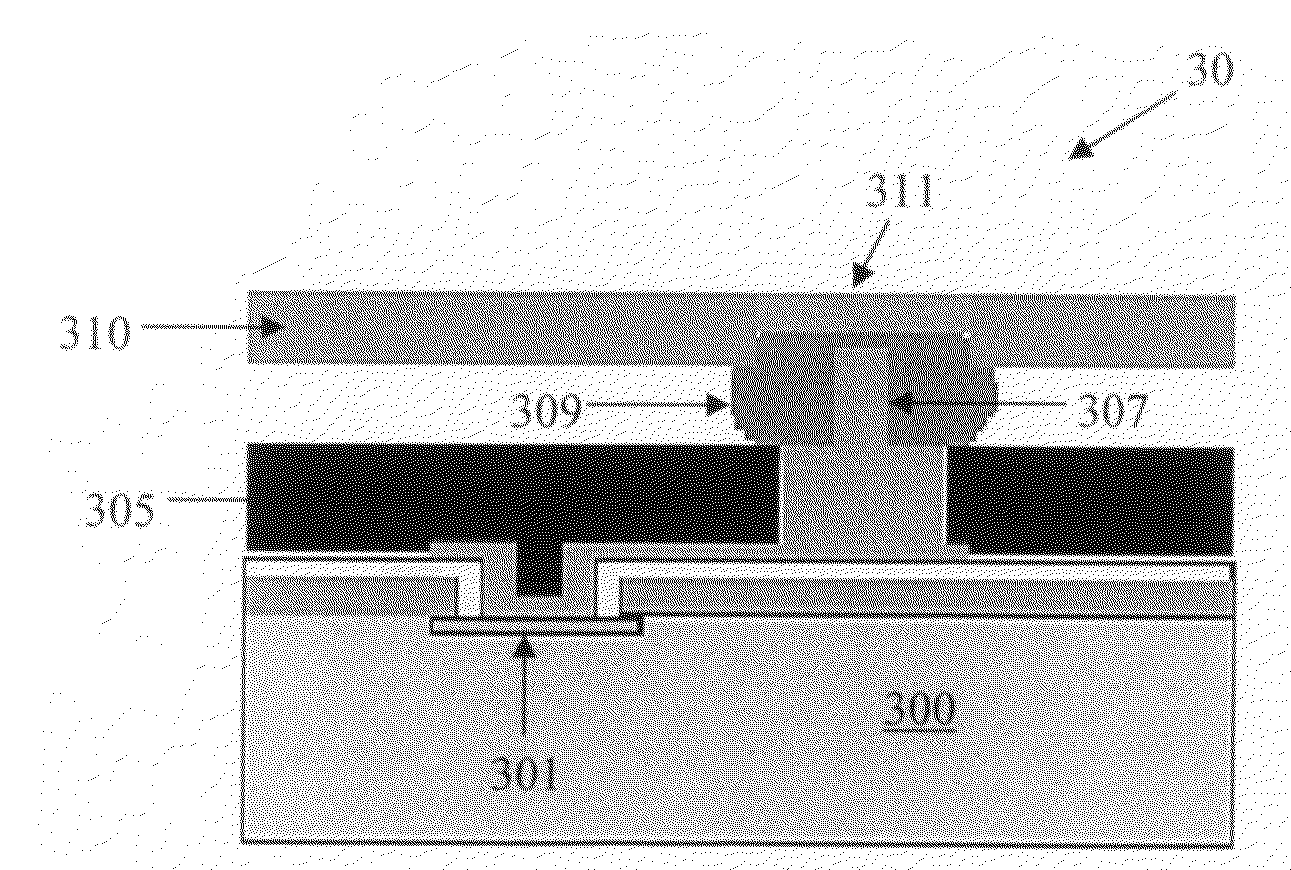

Composite electrode for a plasma arc torch

InactiveUS6841754B2Improve heat transfer performanceImprove thermal conductivityElectric discharge heatingArc welding apparatusMetallic materialsCopper electrode

A plasma arc torch that includes a torch body having a nozzle mounted relative to a composite electrode in the body to define a plasma chamber. The torch body includes a plasma flow path for directing a plasma gas to the plasma chamber in which a plasma arc is formed. The nozzle includes a hollow, body portion and a substantially solid, head portion defining an exit orifice. The composite electrode can be made of a metallic material (e.g., silver) with high thermal conductivity in the forward portion electrode body adjacent the emitting surface, and the aft portion of the electrode body is made of a second low cost, metallic material with good thermal and electrical conductivity. This composite electrode configuration produces an electrode with reduced electrode wear or pitting comparable to a silver electrode, for a price comparable to that of a copper electrode.

Owner:HYPERTHERM INC

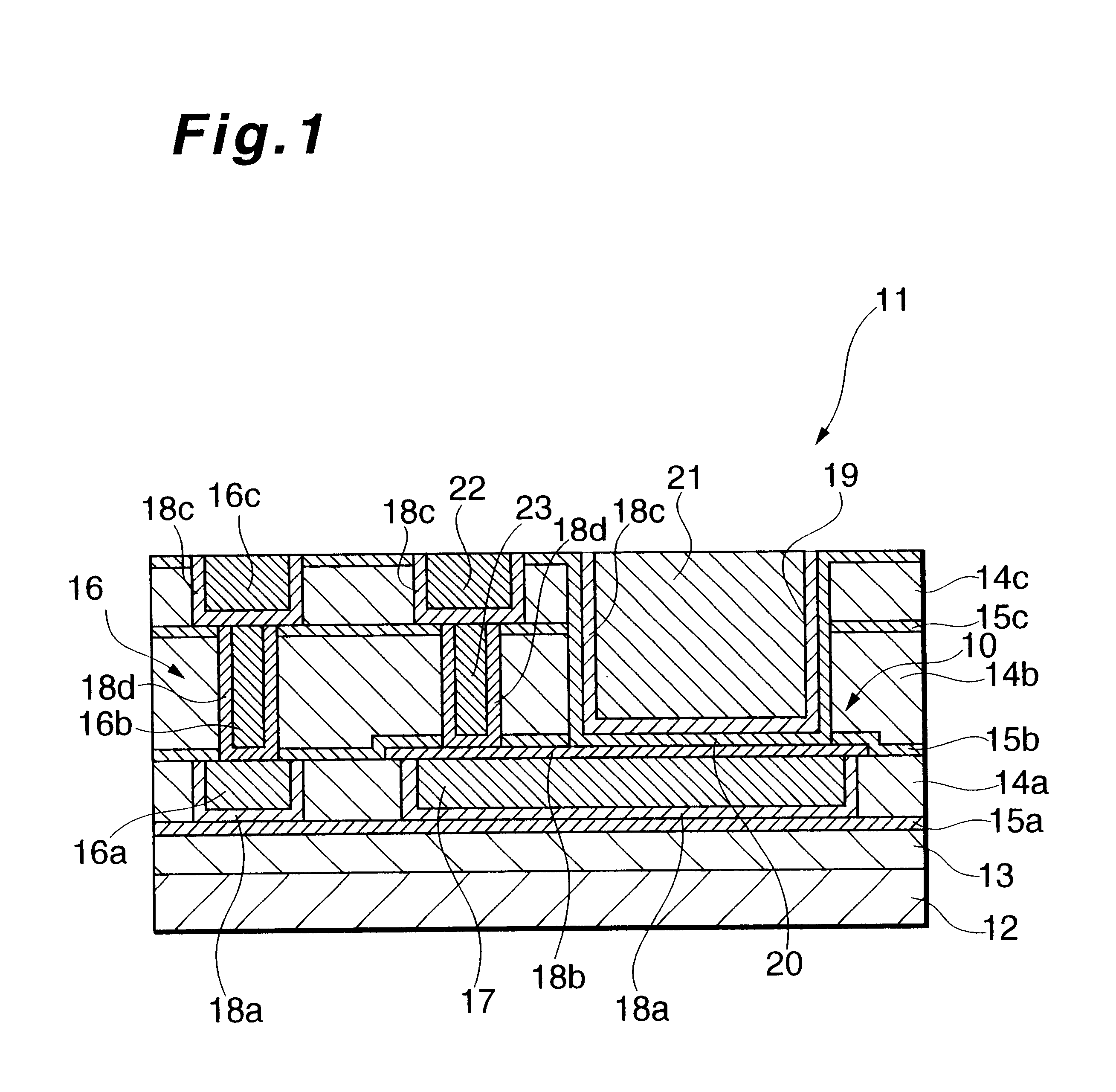

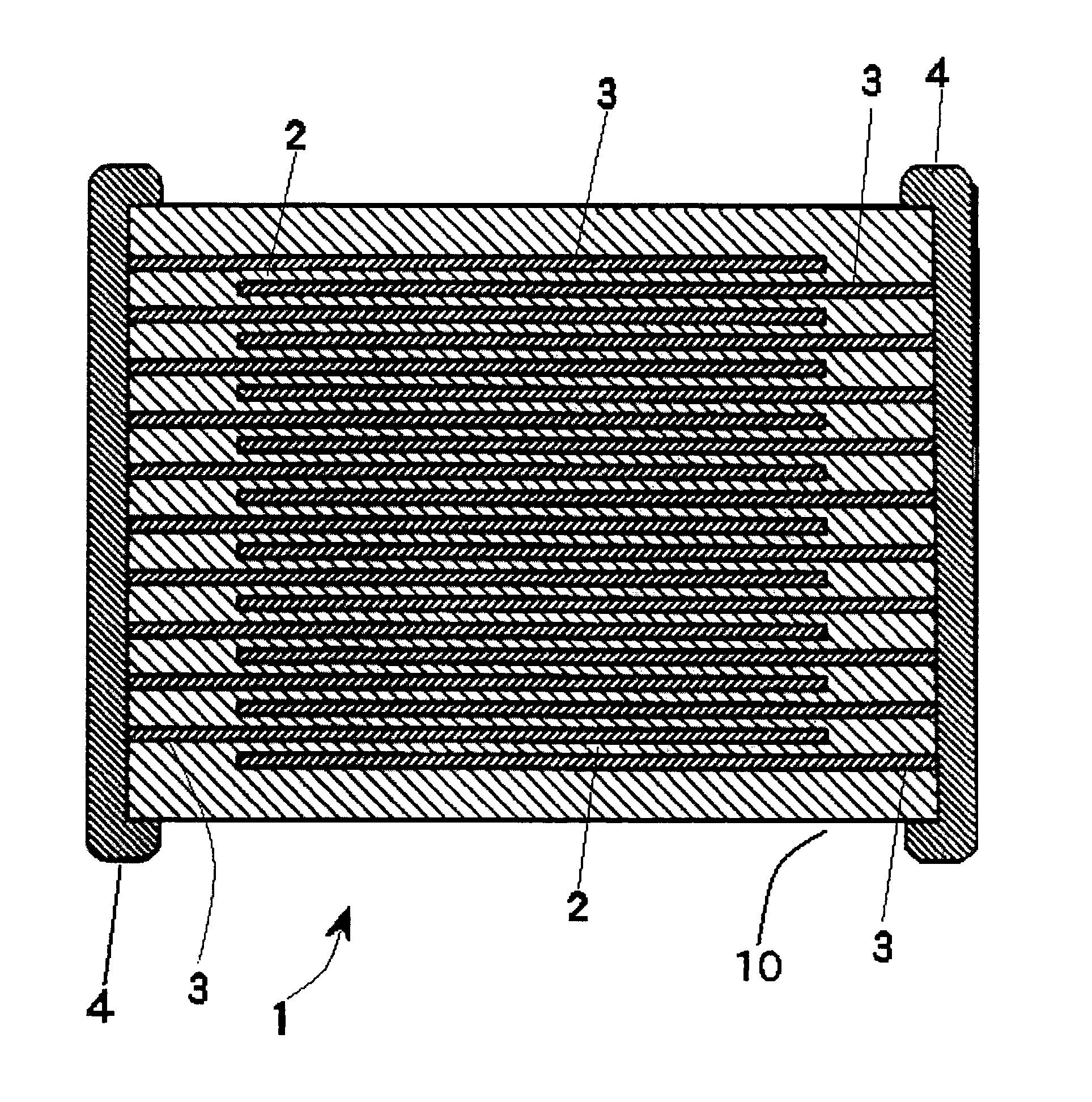

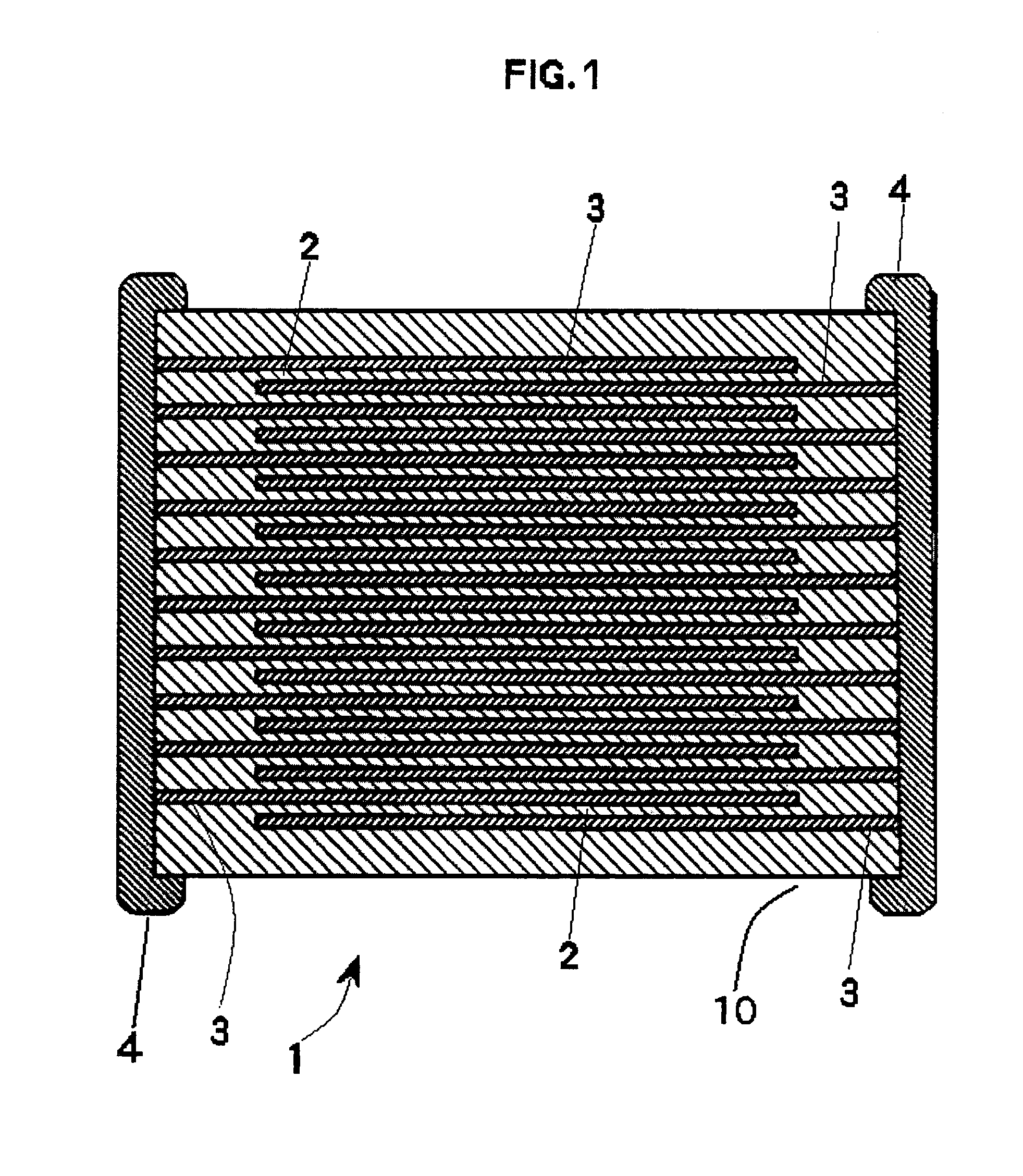

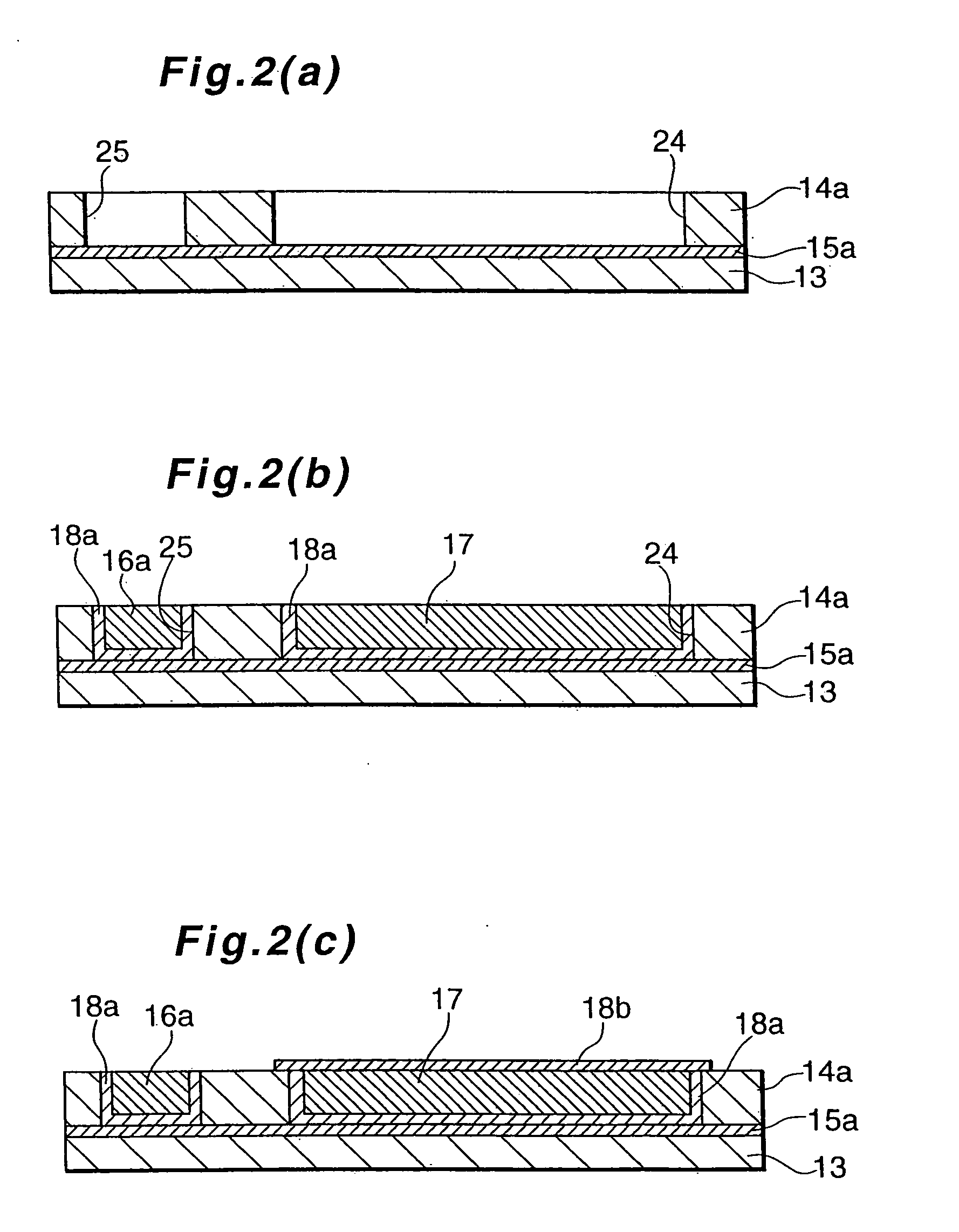

Capacitor and a manufacturing process therefor

A capacitor has a coupled of electrodes with a dielectric placed therebetween. At least one of the electrodes is made of copper, and barriers for preventing the diffusion of copper into the dielectric are provided between the dielectric and the copper electrodes, respectively.

Owner:LAPIS SEMICON CO LTD

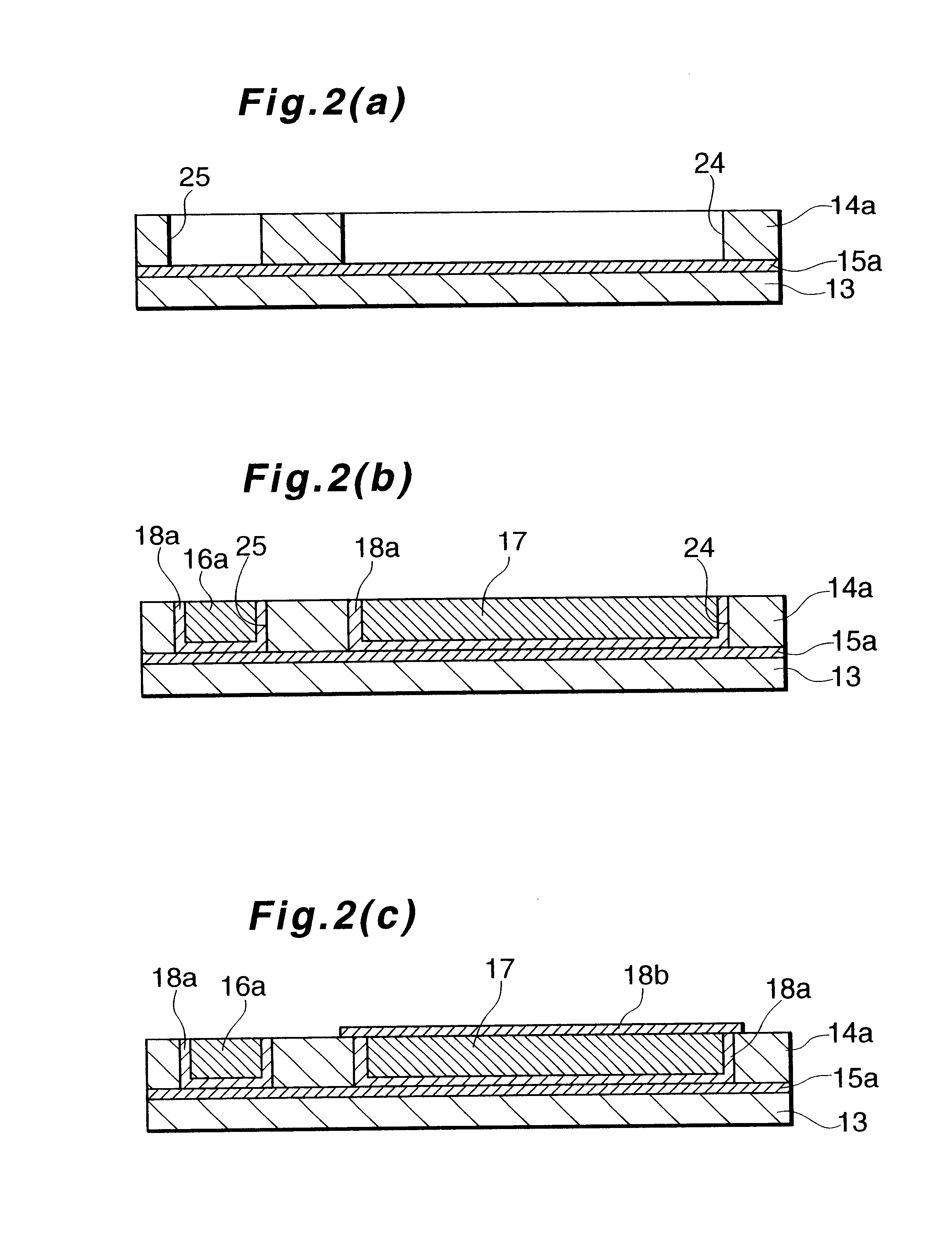

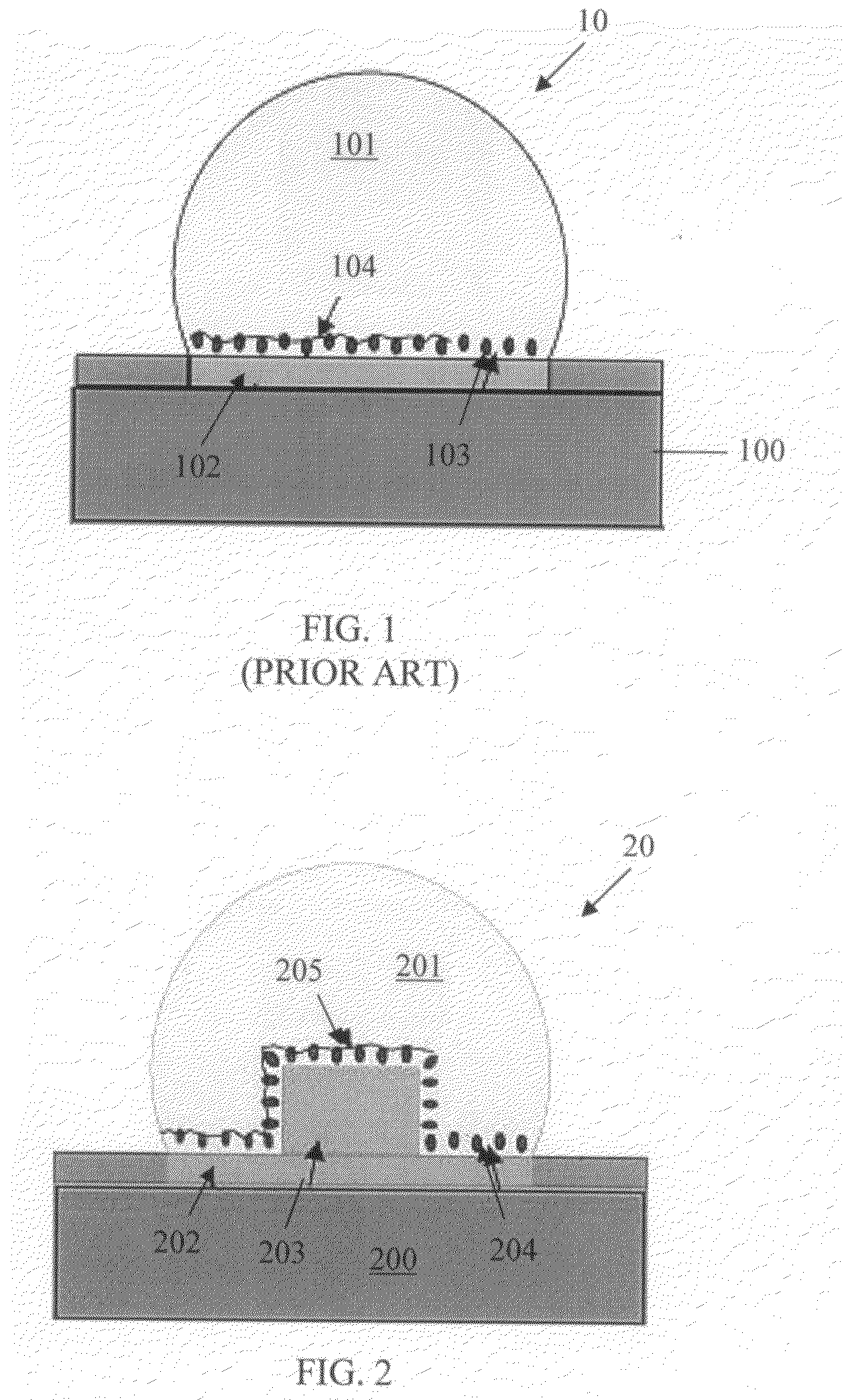

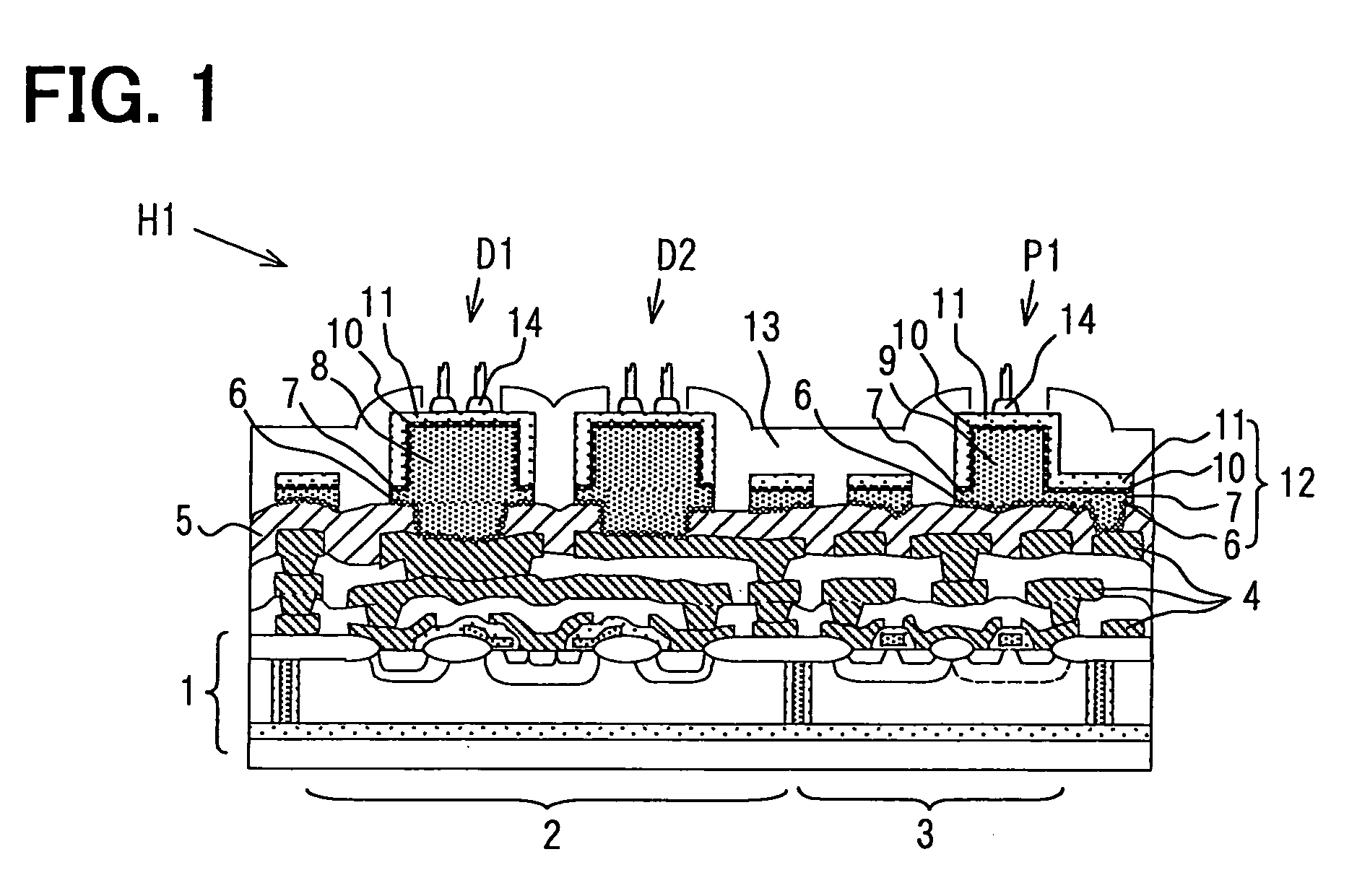

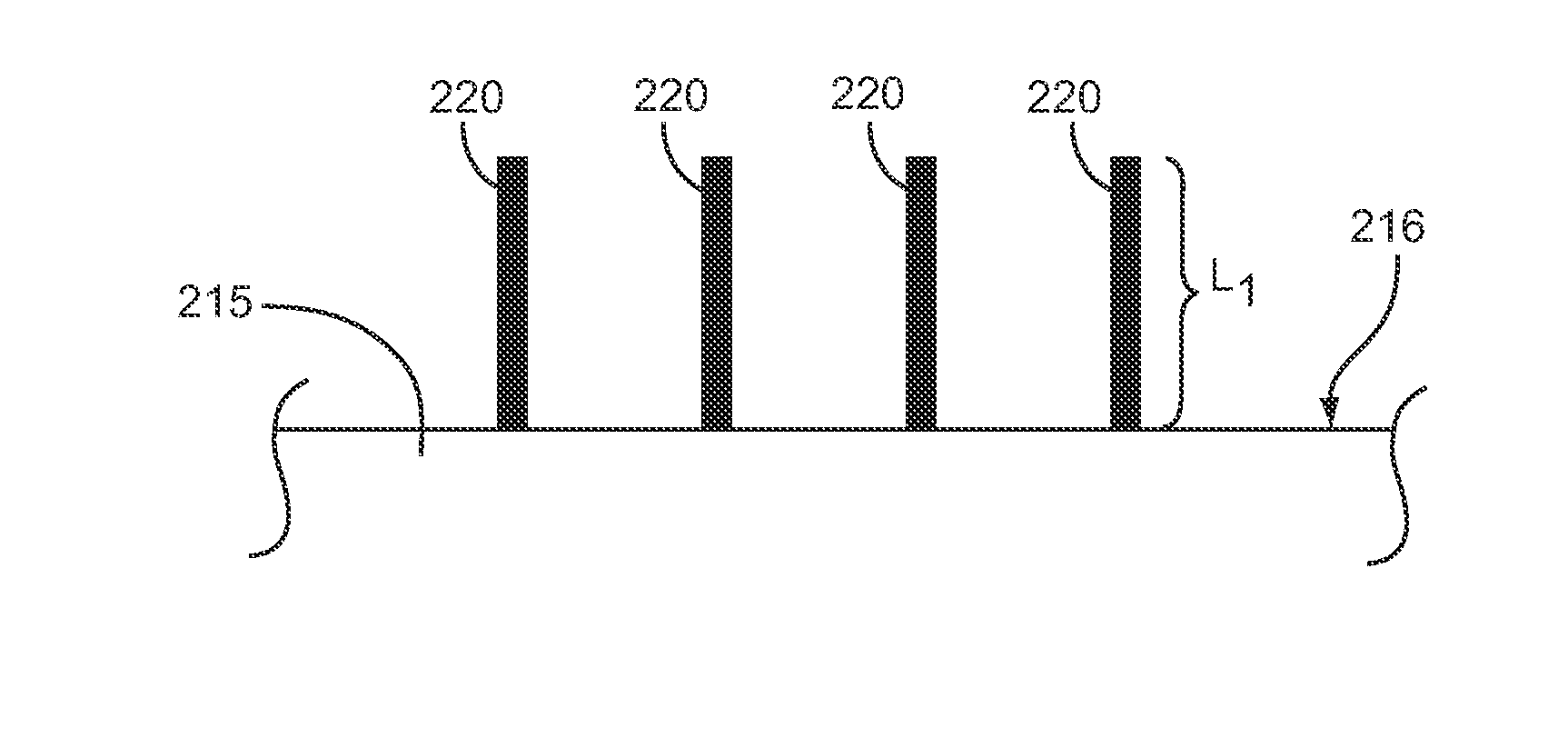

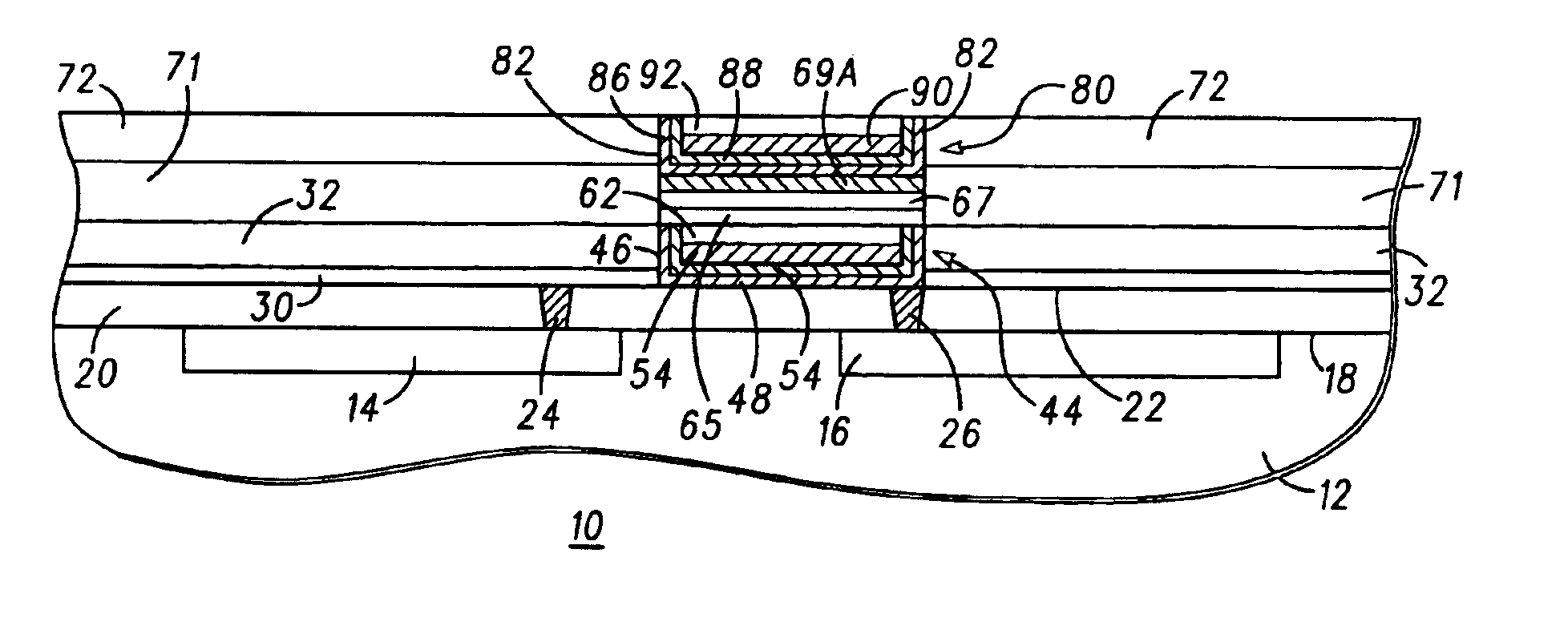

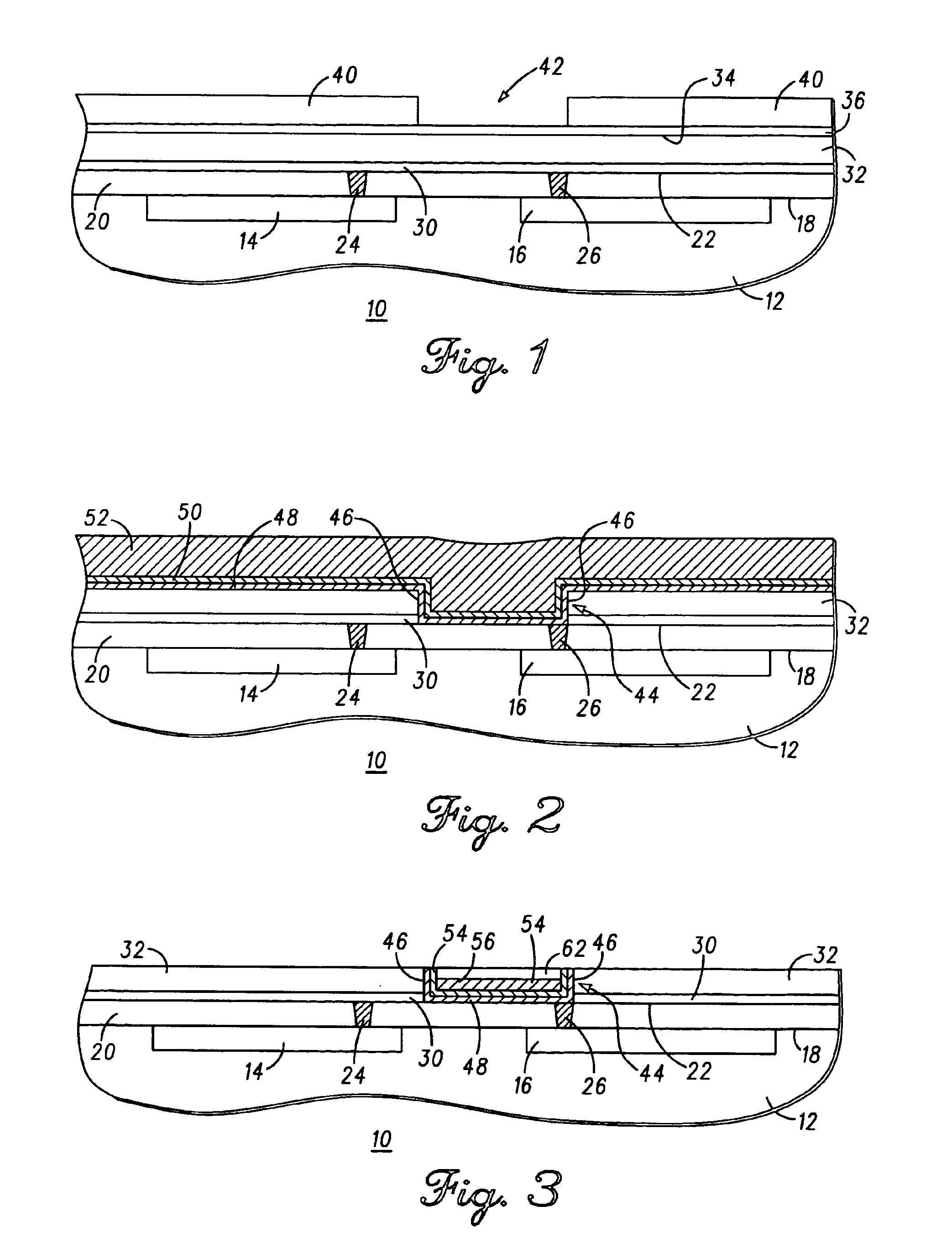

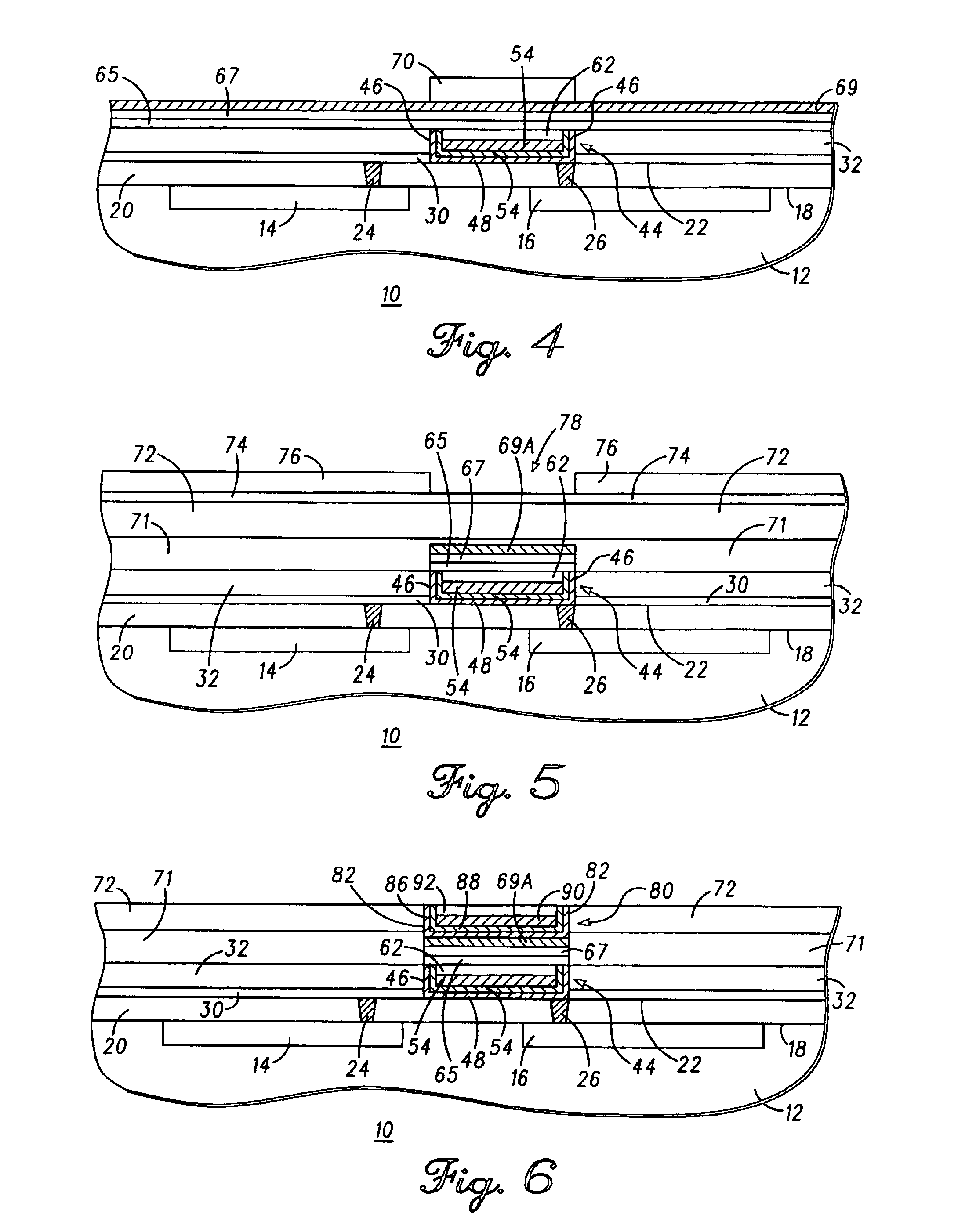

Enhanced copper posts for wafer level chip scale packaging

ActiveUS20080296764A1Increased shear strengthImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesElectrical connectionCopper electrode

An enhanced wafer level chip scale packaging (WLCSP) copper electrode post is described having one or more pins that protrude from the top of the electrode post. When the solder ball is soldered onto the post, the pins are encapsulated within the solder material. The pins not only add shear strength to the soldered joint between the solder ball and the electrode post but also create a more reliable electrical connection due to the increased surface area between the electrode post / pin combination and the solder ball. Moreover, creating an irregularly shaped solder joint retards the propagation of cracks that may form in the intermetal compounds (IMC) layer formed at the solder joint.

Owner:ADVANCED MFG INNOVATIONS INC

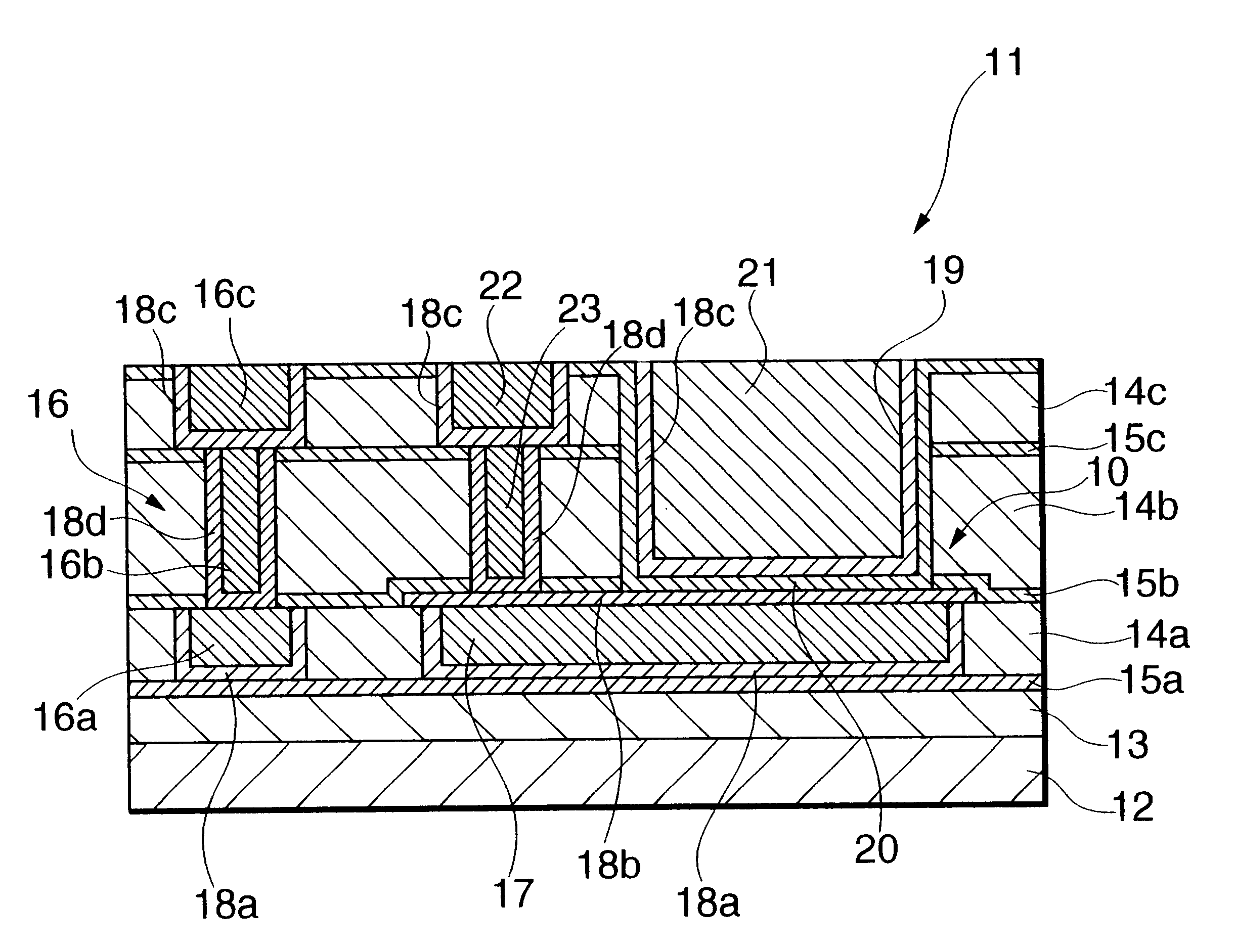

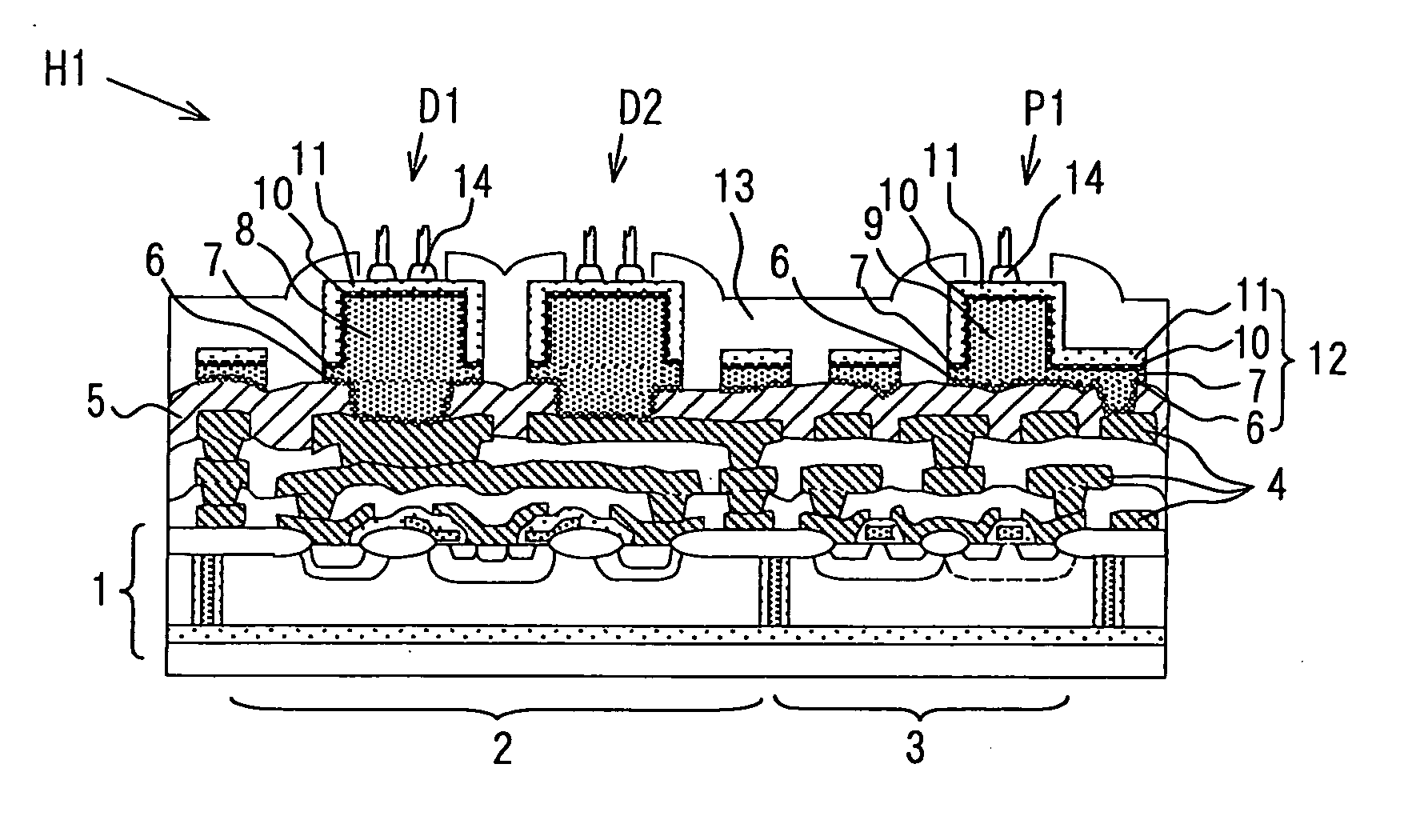

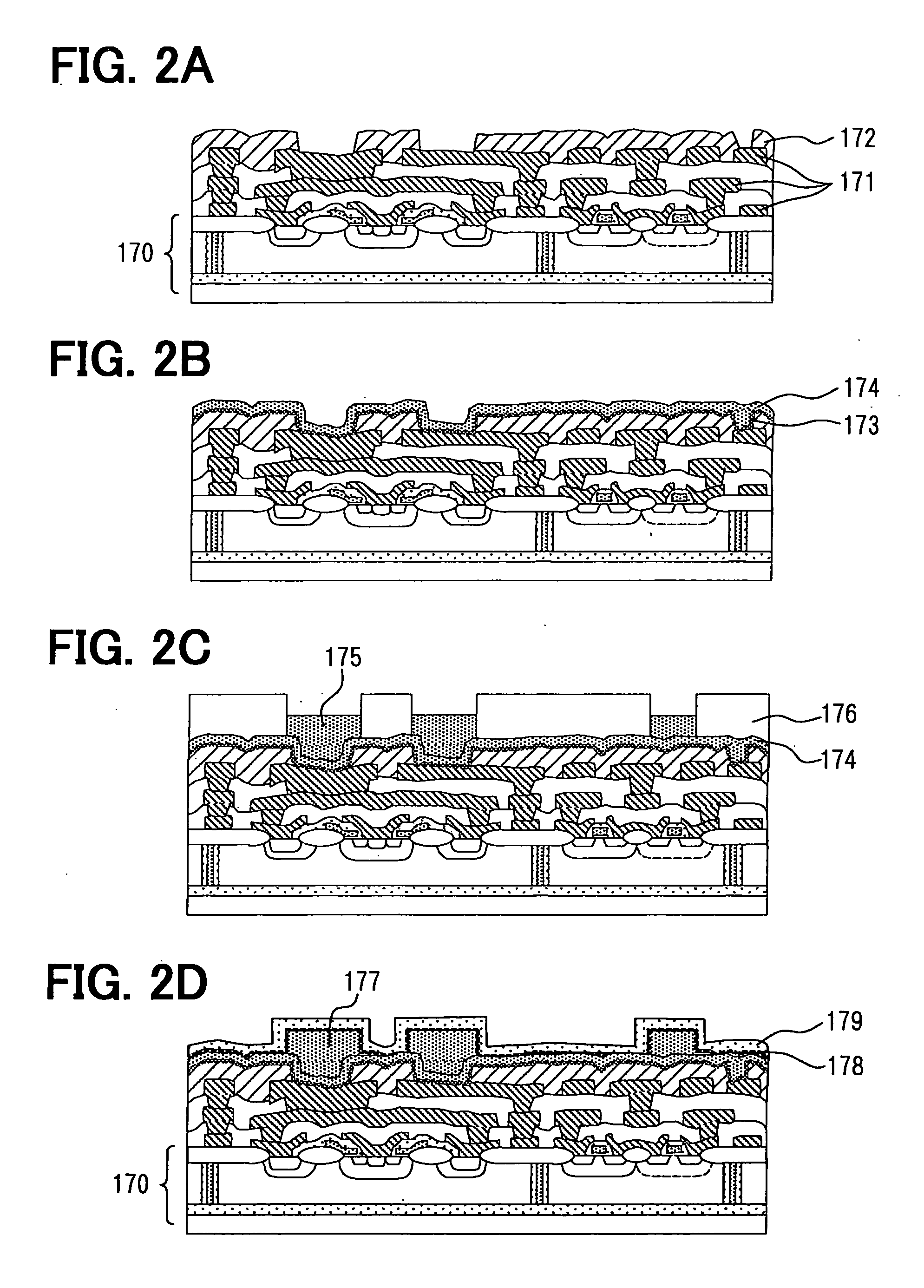

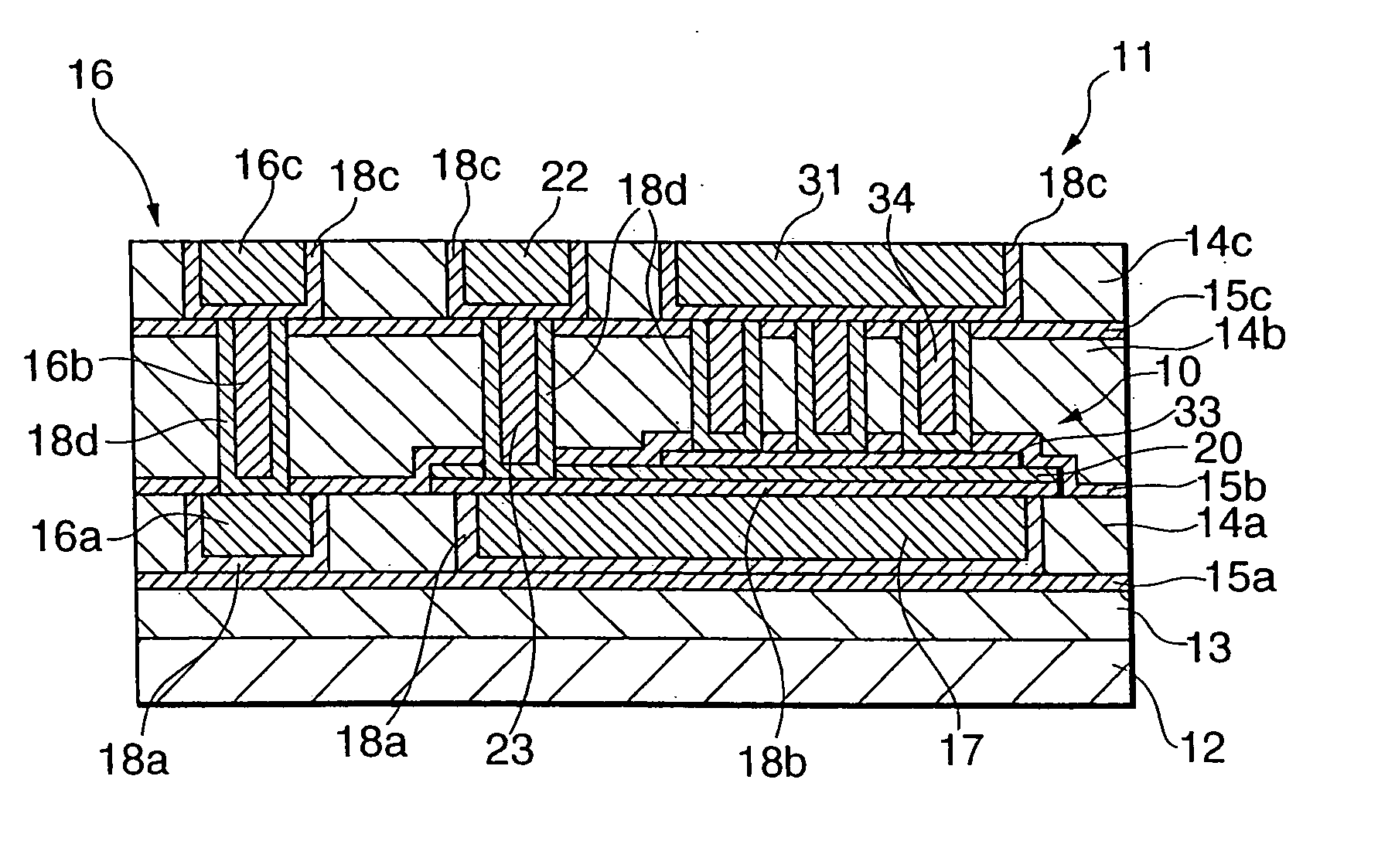

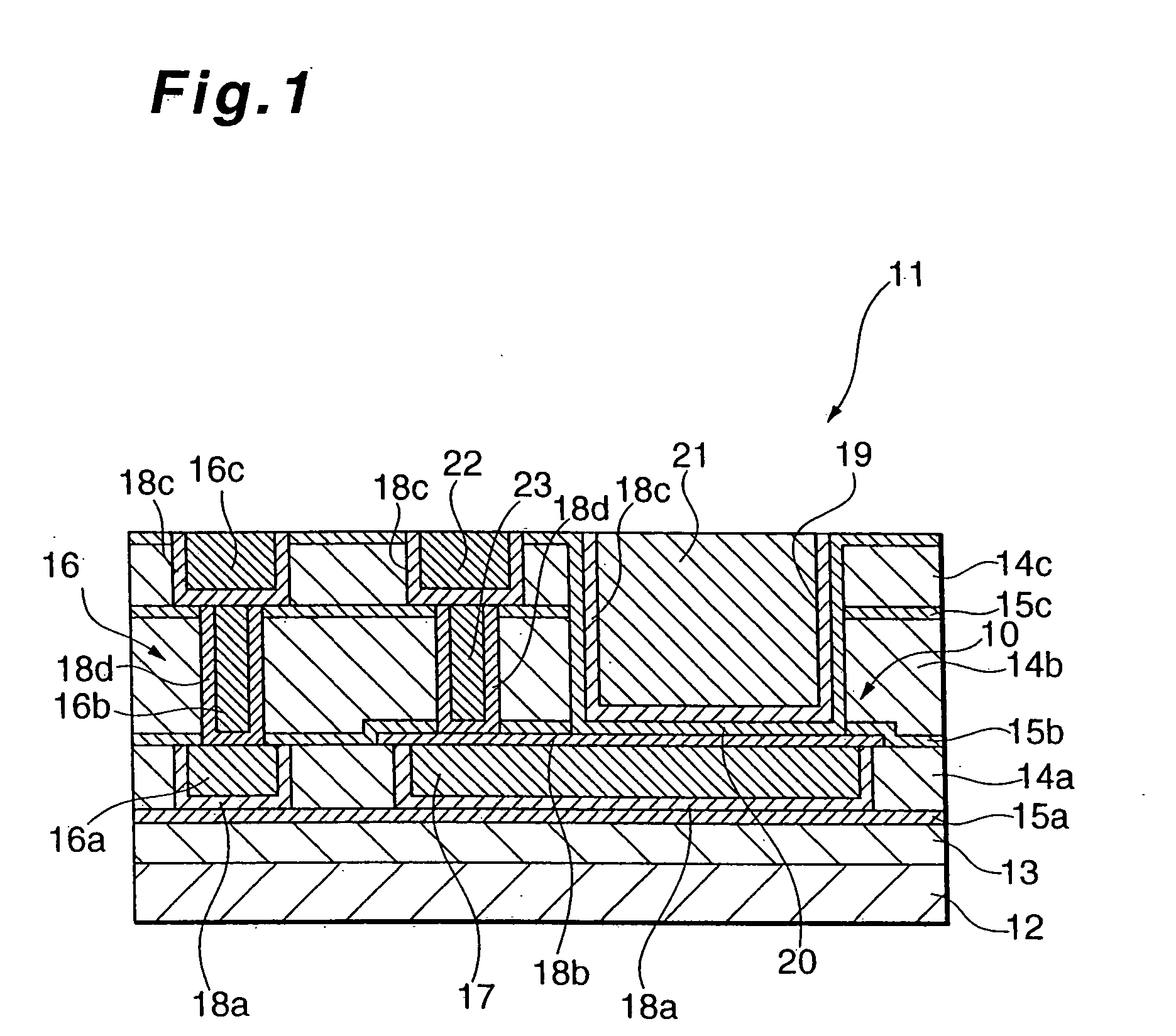

Power composite integrated semiconductor device and manufacturing method thereof

ActiveUS20050258484A1Lower on-resistanceFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesLead bondingDevice material

A high-reliability power composite integrated semiconductor device uses thick copper electrodes as current collecting electrodes of a power device portion to resist wire resistance needed for reducing ON-resistance. Furthermore, wire bonding connection of the copper electrodes is secured, and also the time-lapse degradation under high temperature which causes diffusion of copper and corrosion of copper is suppressed. Still furthermore, direct bonding connection can be established to current collecting electrodes in the power device portion, and also established to a bonding pad formed on the control circuit portion in the control circuit portion. A pad area at the device peripheral portion which has been hitherto needed is reduced, so that the area of the device is saved, and the manufacturing cost is reduced.

Owner:DENSO CORP

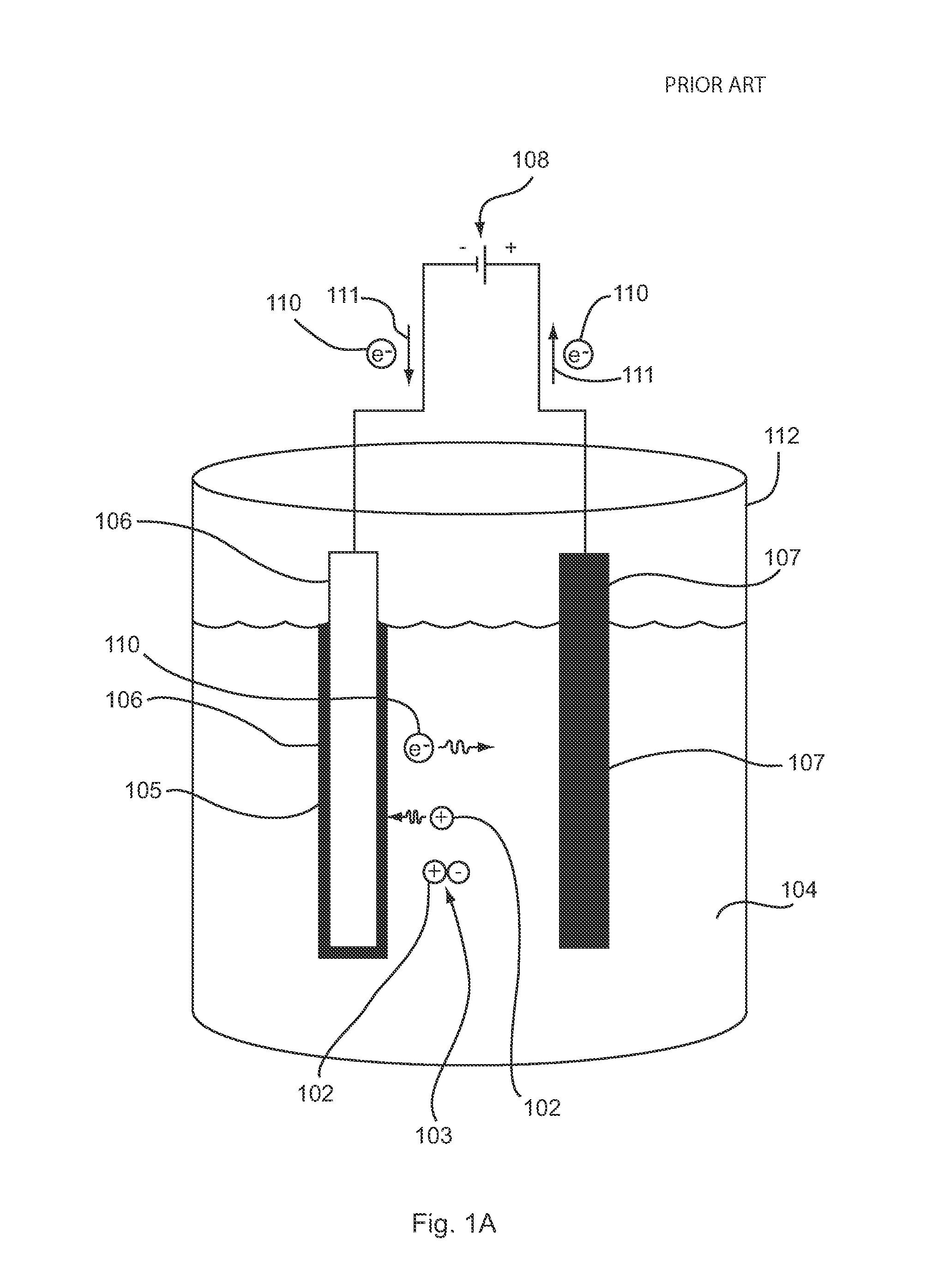

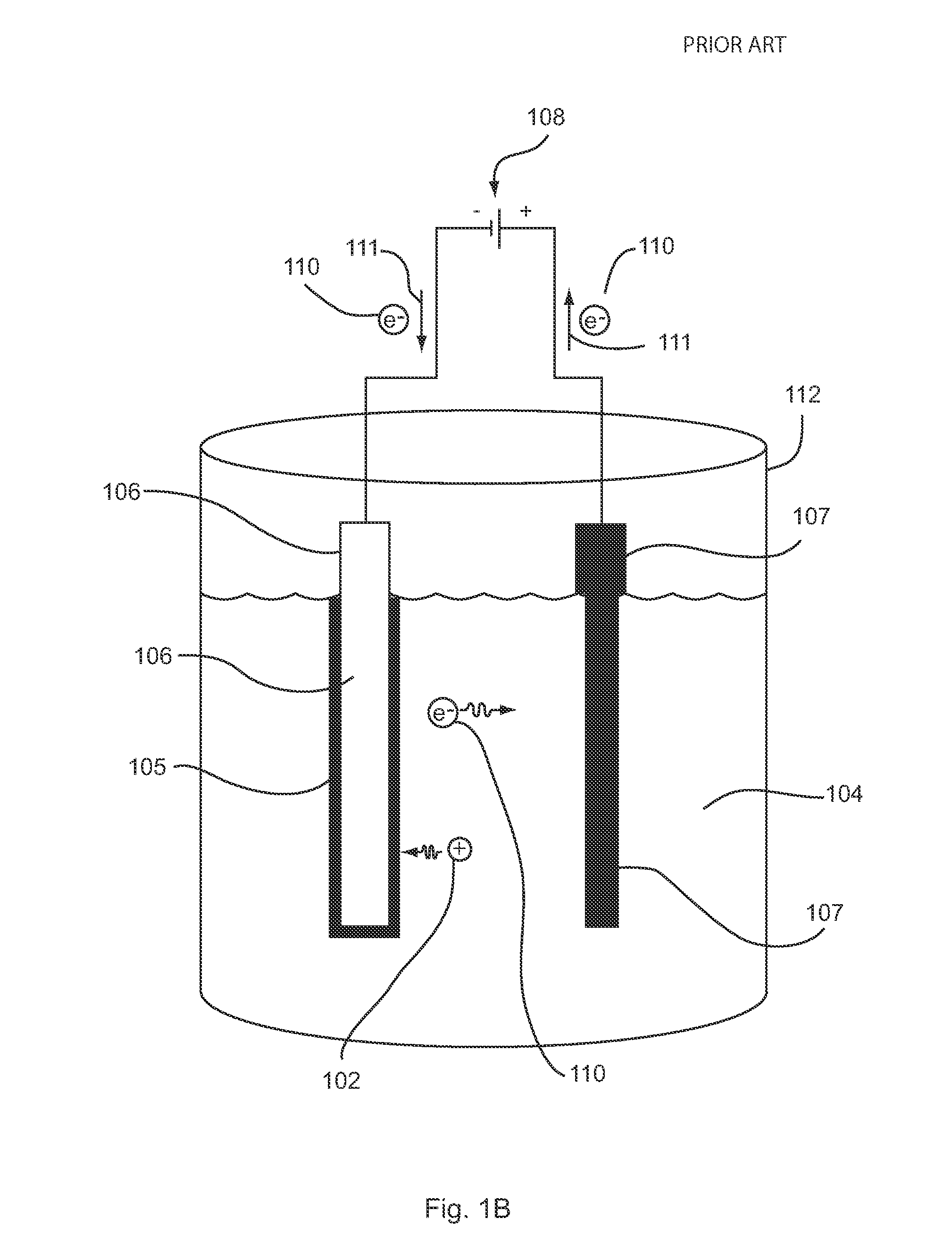

Silicon Nanostructure Active Materials for Lithium Ion Batteries and Processes, Compositions, Components and Devices Related Thereto

ActiveUS20140248543A1Highly controllableAvoid irreversibleElectrochemical processing of electrodesElectrode carriers/collectorsCopper electrodeGraphite particle

The present invention relates to nanostructured materials for use in rechargeable energy storage devices such as lithium batteries, particularly rechargeable secondary lithium batteries, or lithium-ion batteries (LIBs). The present invention includes materials, components, and devices, including nanostructured materials for use as battery active materials, and lithium ion battery (LIB) electrodes comprising such nanostructured materials, as well as manufacturing methods related thereto. Exemplary nanostructured materials include silicon-based nanostructures such as silicon nanowires and coated silicon nanowires, nanostructures disposed on substrates comprising active materials or current collectors such as silicon nanowires disposed on graphite particles or copper electrode plates, and LIB anode composites comprising high-capacity active material nanostructures formed on a porous copper and / or graphite powder substrate.

Owner:ONED MATERIAL INC

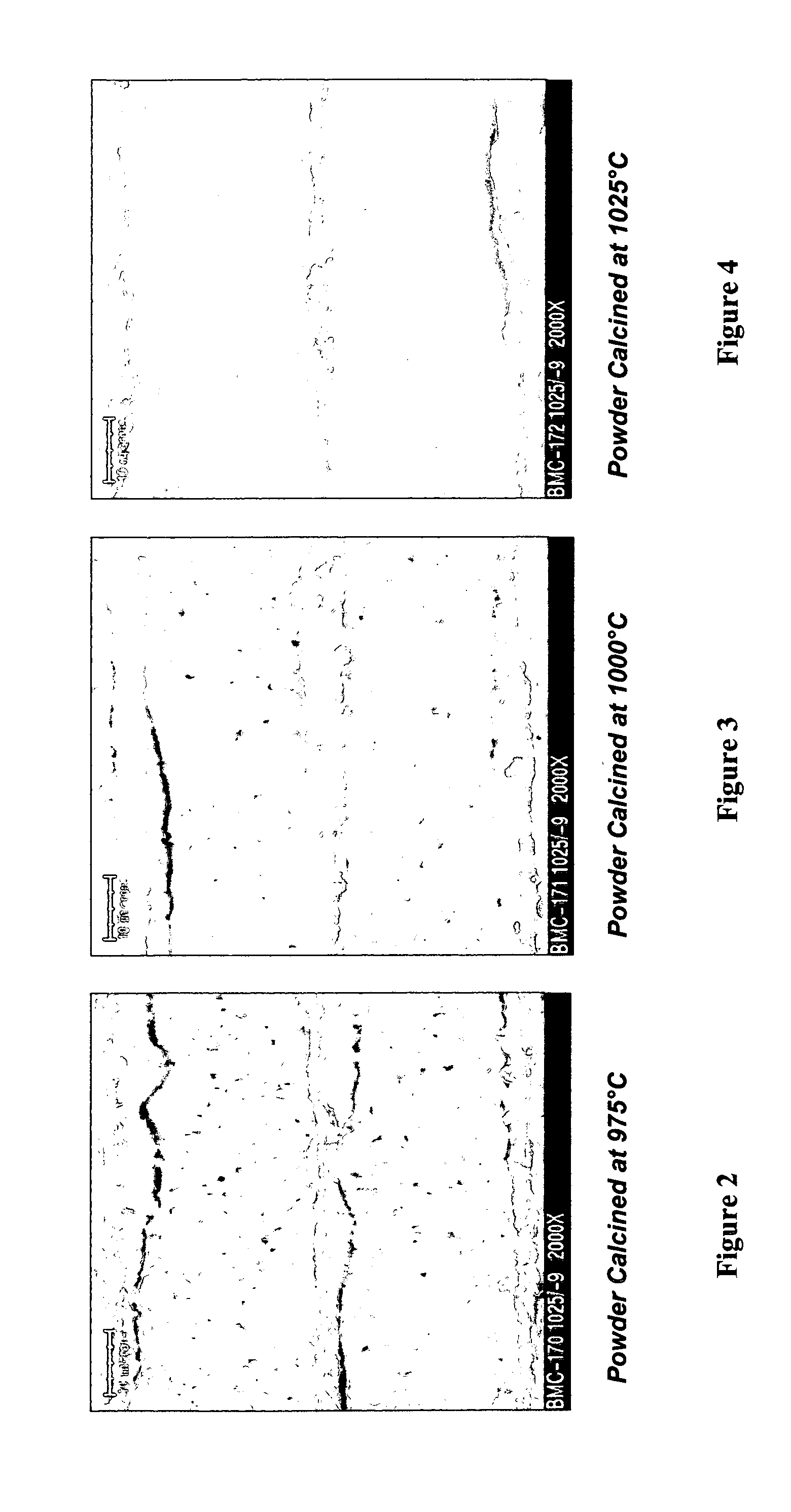

COG dielectric composition for use with copper electrodes

ActiveUS7161795B1Small dielectric lossImprove reliabilityFixed capacitor dielectricStacked capacitorsLow dissipationBarium titanate

Multilayer ceramic chip capacitors which satisfy COG requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as copper and copper alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise a composite oxide formed by calcining rare earth titanates, barium titanate, together with other metal oxides such as MgO, CaO, ZnO, MnO2, ZrO2, SiO2, Ga2O3, Nd2O3, Nb2O5, and Y2O3.

Owner:FERRO CORP

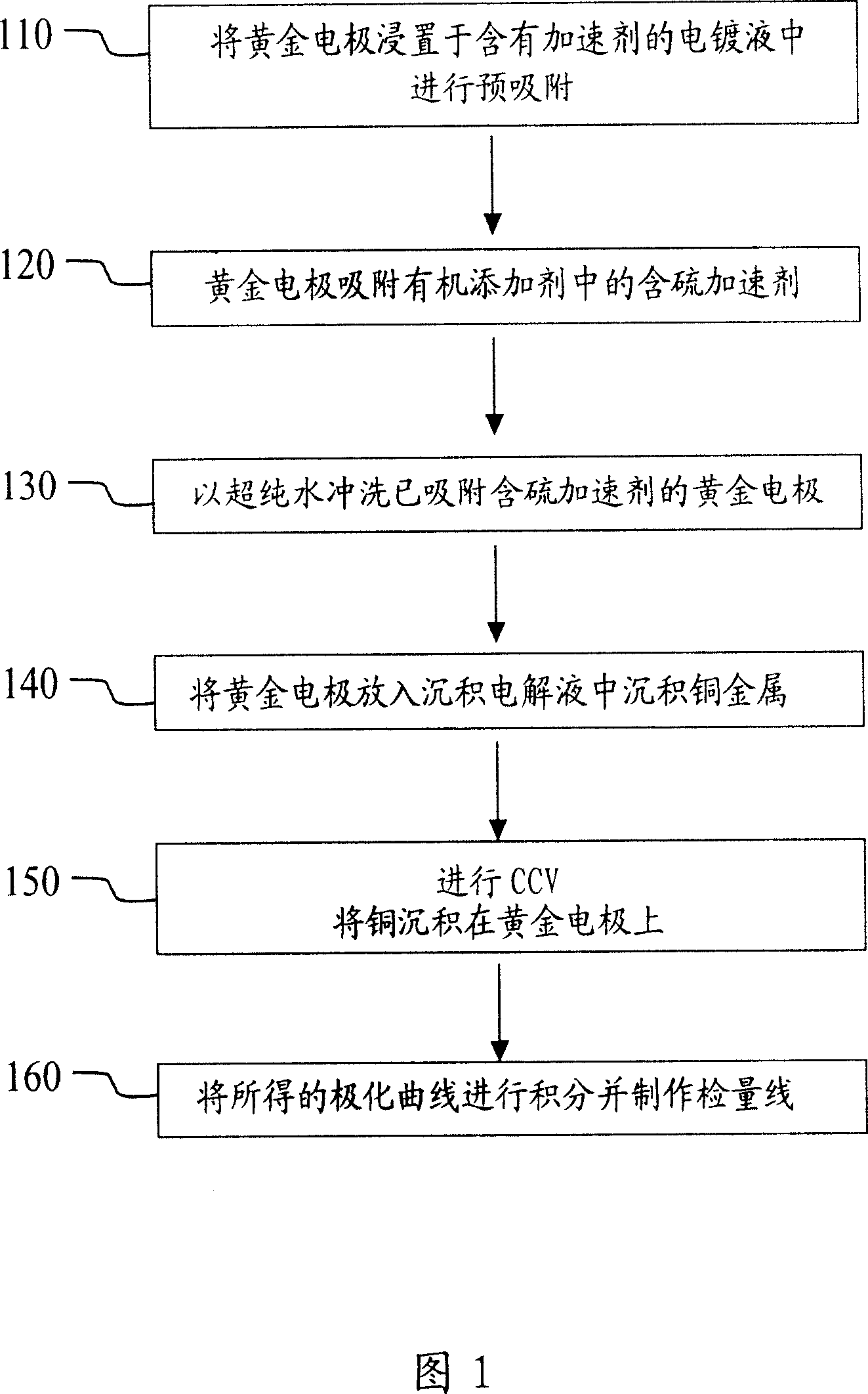

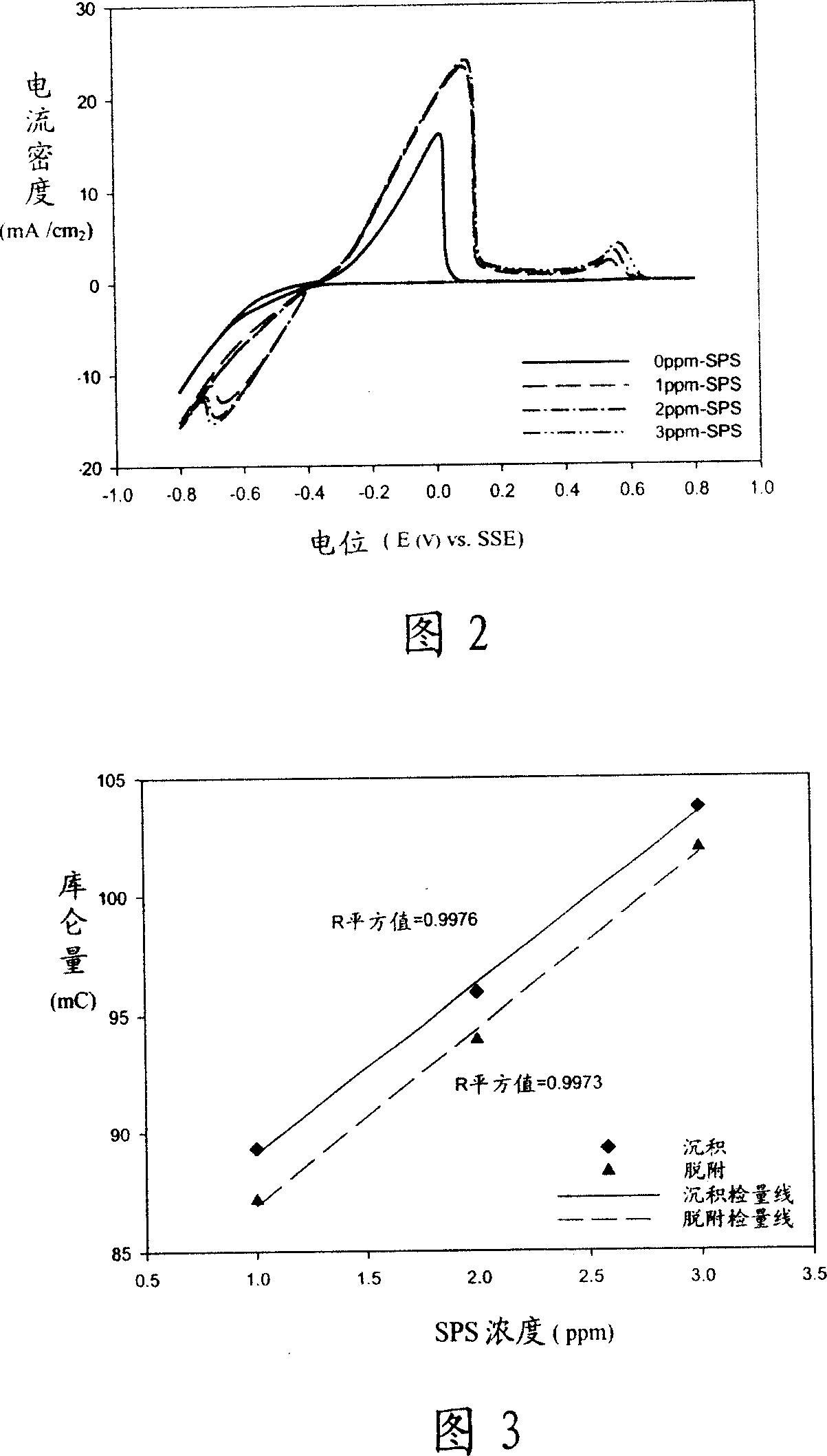

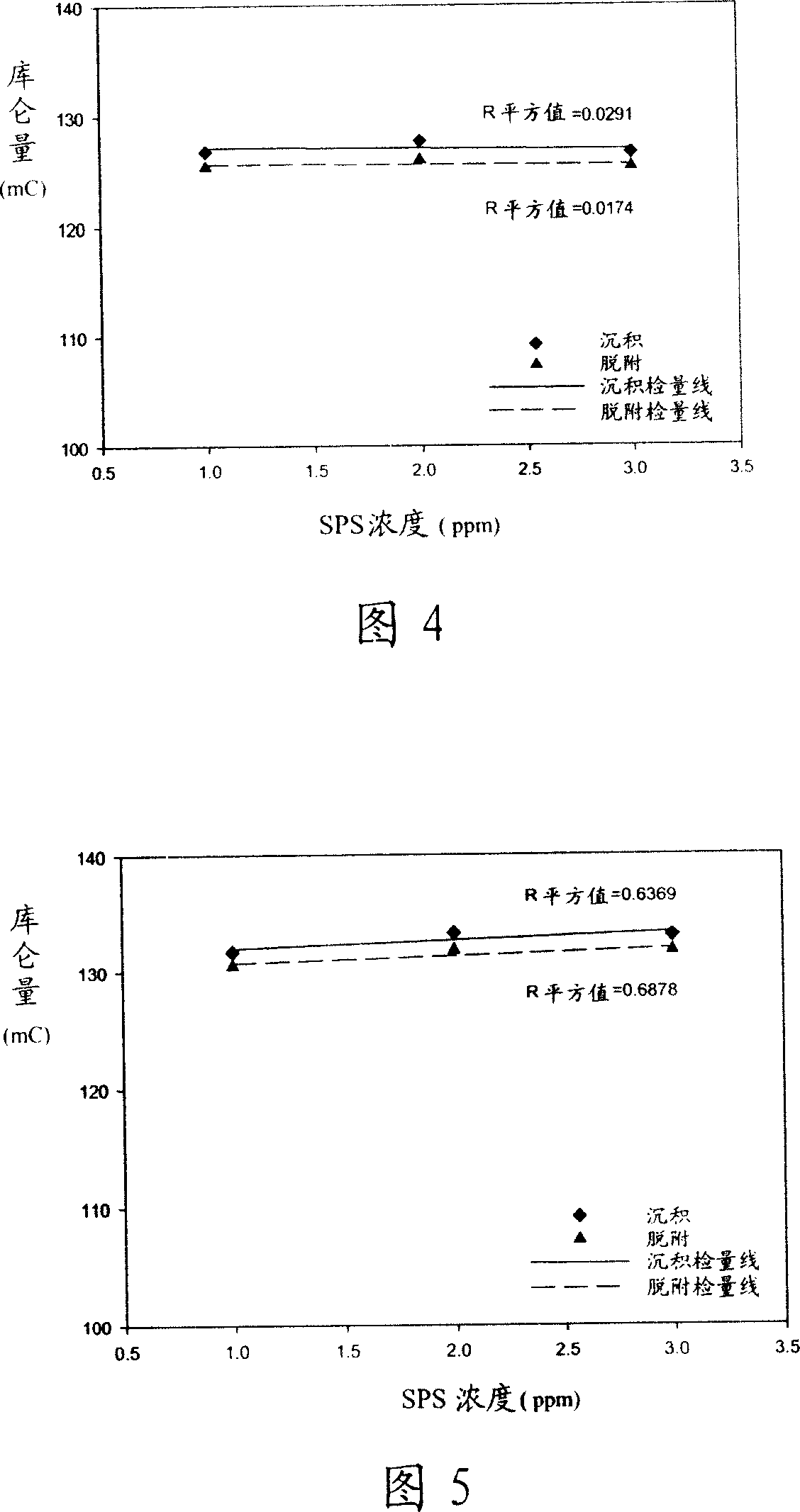

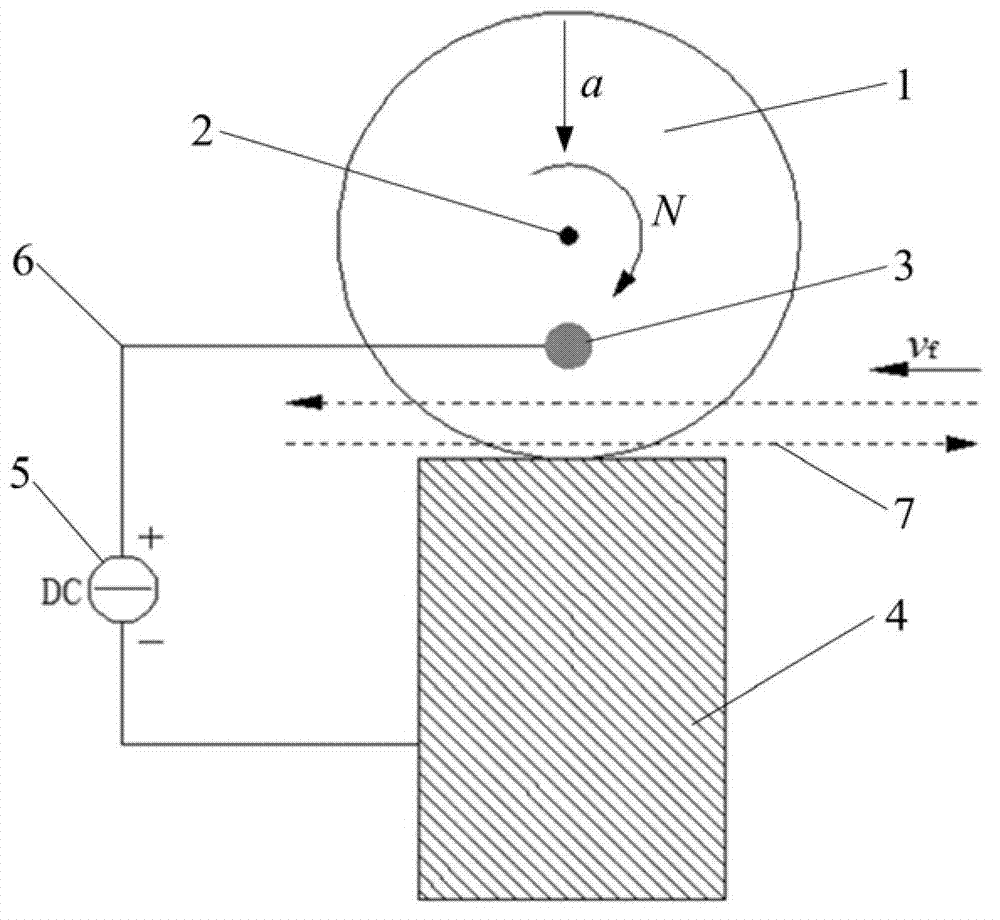

Method for analyzing accelerating agent of electro coppering, and deposited electrolyte

InactiveCN101004401ARelatively small errorAccurate concentration calibration lineCellsMaterial electrochemical variablesElectrolytic agentPolyethylene glycol

A method for analyzing accelerant of electroplated copper includes placing copper electrode in electrolyte containing organic additives to let copper electrode absorb accelerant containing sulphur, using pure water to wash copper electrode absorbed with sulphur compound then placing copper electrode into deposit-electrolyte containing polyethylene glycol and chlorine ion and carrying out cathode circulation VA scan to deposit down copper metal, carrying out integration on obtained polarization curve to prepare out detection line. The deposit-electrolyte used in said method is also disclosed.

Owner:欧恩吉亚洲股份有限公司

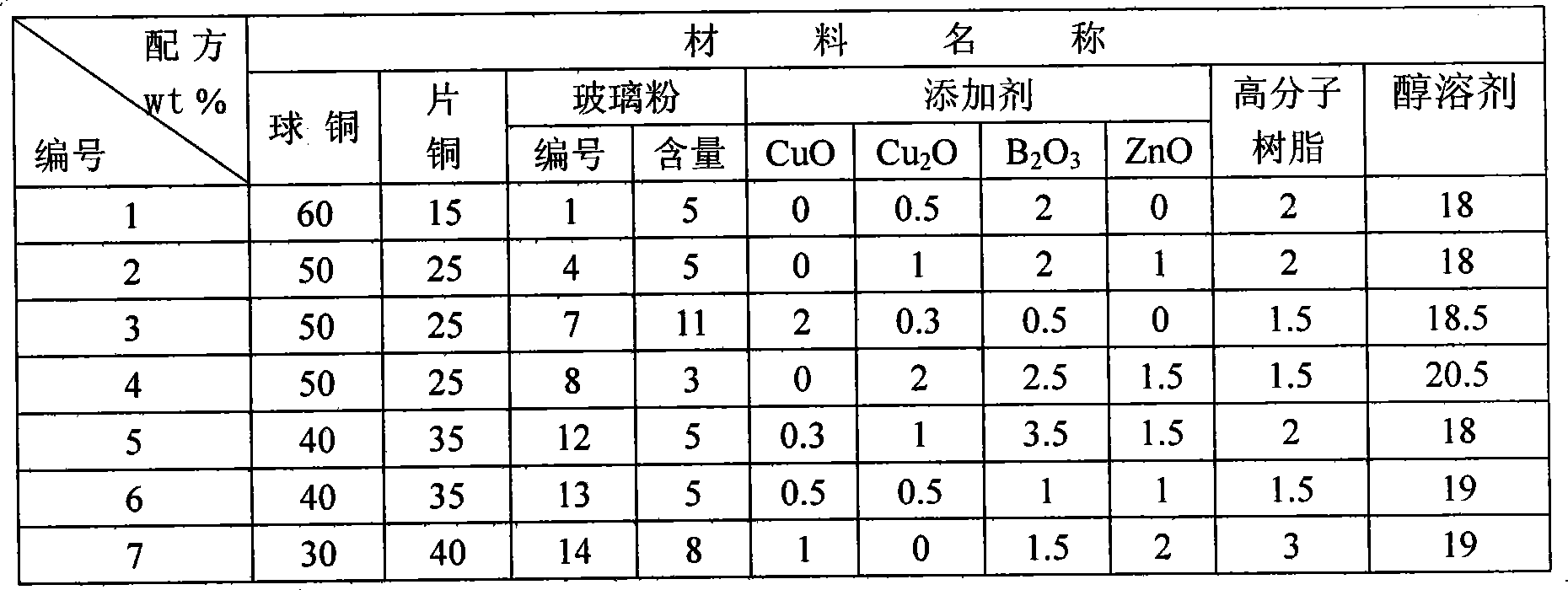

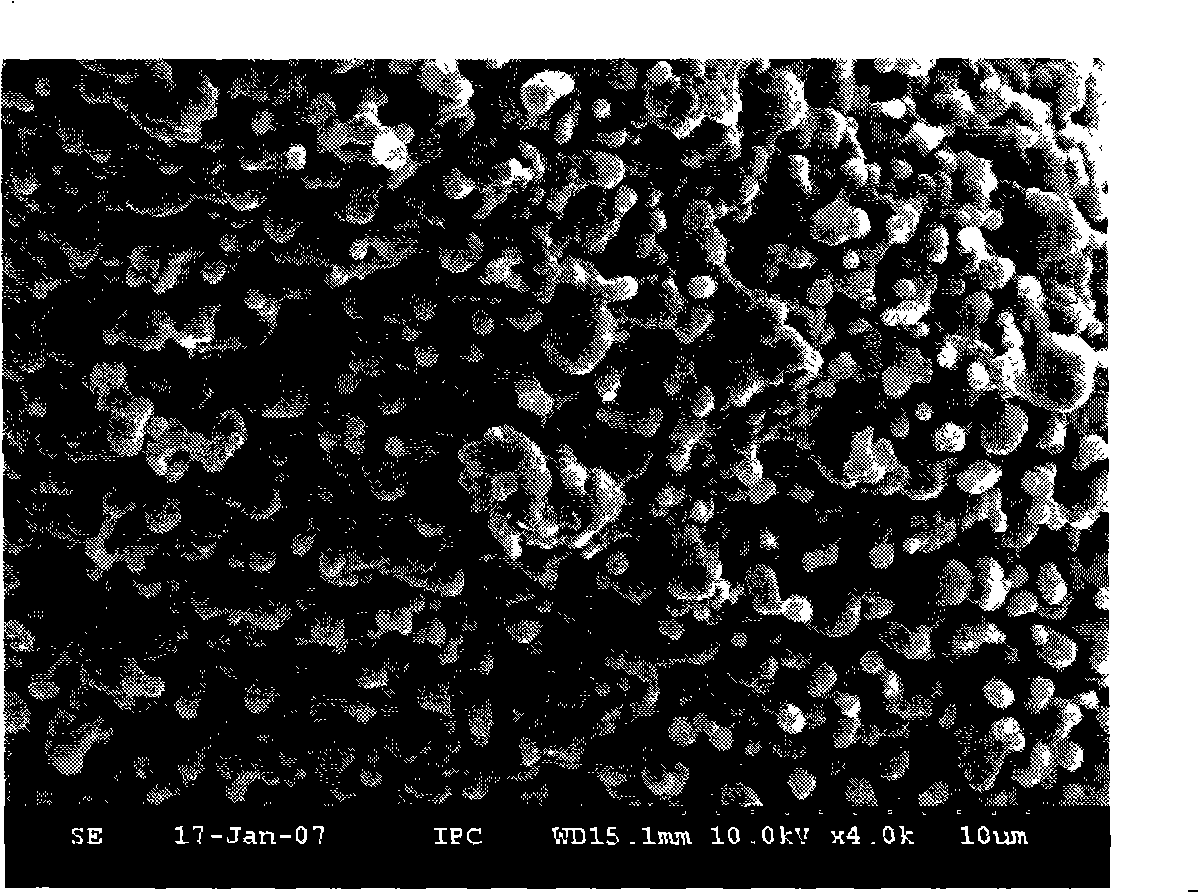

Copper electrode slurry material and manufacturing method thereof

ActiveCN101136261AAvoid performance degradationLow priceFixed capacitor electrodesElectrolytic capacitorsSilver electrodeHazardous substance

This invention discloses a kind of slurry of copper electrodes and a manufacturing method, in which, the weight percentage of the slurry includes: Ball copper: 25-64%, sheet copper: 10-40%, glass powder: 2-8%, macromolecular resin: 0.5-6% and solvent: 16-26%, in which, the slurry does not contain harmful materials of Pb, Cd and hexavalent Cr and meets the needs of environment protection, first of all, organic carrier is prepared and then the glass powder is put into the carrier to be mixed and form precursor dispersed mixture, then the balls and sheets are put into the mixture to form copper electrode slurry used in piezoelectric resistors, the sintered copper electrode is good in weld, the anti-welding performance is better than silver electrode and has better adherence than porcelain.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

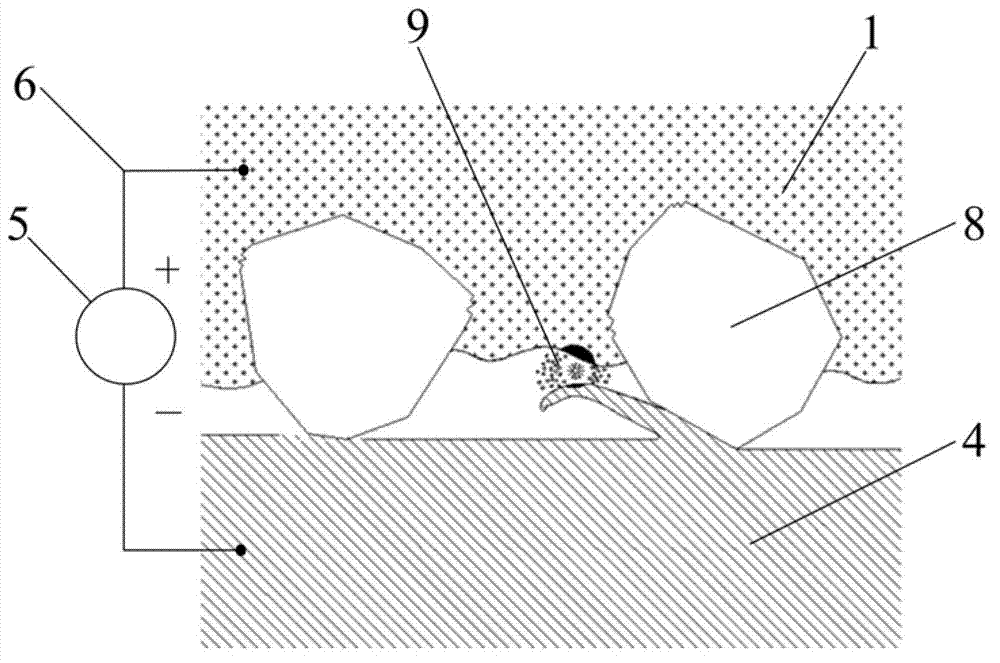

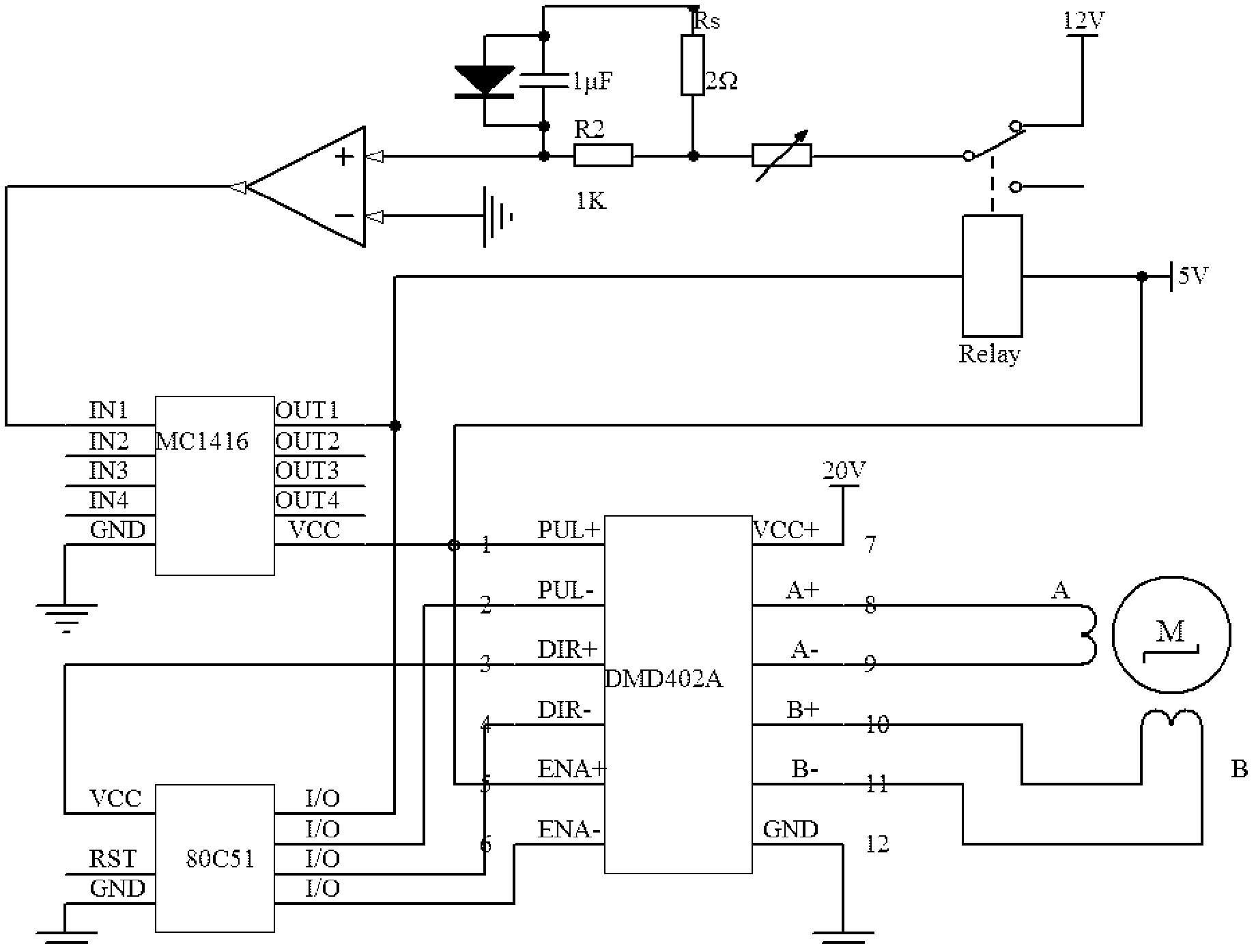

In-gas discharge dressing and truing method for large-particle diamond grinding wheel

ActiveCN103395002AWon't burnAvoid arcingAbrasive surface conditioning devicesWear particleCopper electrode

The invention discloses an in-gas discharge dressing and truing method for a large-particle diamond grinding wheel. The method includes: fixing the diamond grinding wheel on a grinding wheel shaft, and fixing a conducting electrode on the horizontal plane; connecting the diamond grinding wheel, the electrode, a graphite brush, a power source and a wire to form a discharge circuit; connecting a positive pole of the power source to the grinding wheel, and connecting a negative pole of the power source to the electrode. When rotating, the diamond grinding wheel linearly reciprocates on the surface of the electrode; metal bond is removed by pulse sparks generated between the electrode and the metal bond of the grinding wheel, so that diamond abrasive particles are edged from the surface of the grinding wheel; spark discharge occurs between the metal bond and whirling conducting chips generated when the edged diamond abrasive particles cut the copper electrode, generated instant high temperature is transmitted to cutting edges of the diamond abrasive particles in contact cutting through the chips, the tips of the cutting edges are pneumatically dressed, and accordingly micro edging, dressing and truing of the grinding wheel are achieved, more effective abrasive particles are generated and efficient grinding of smooth mirrors is achieved.

Owner:SOUTH CHINA UNIV OF TECH

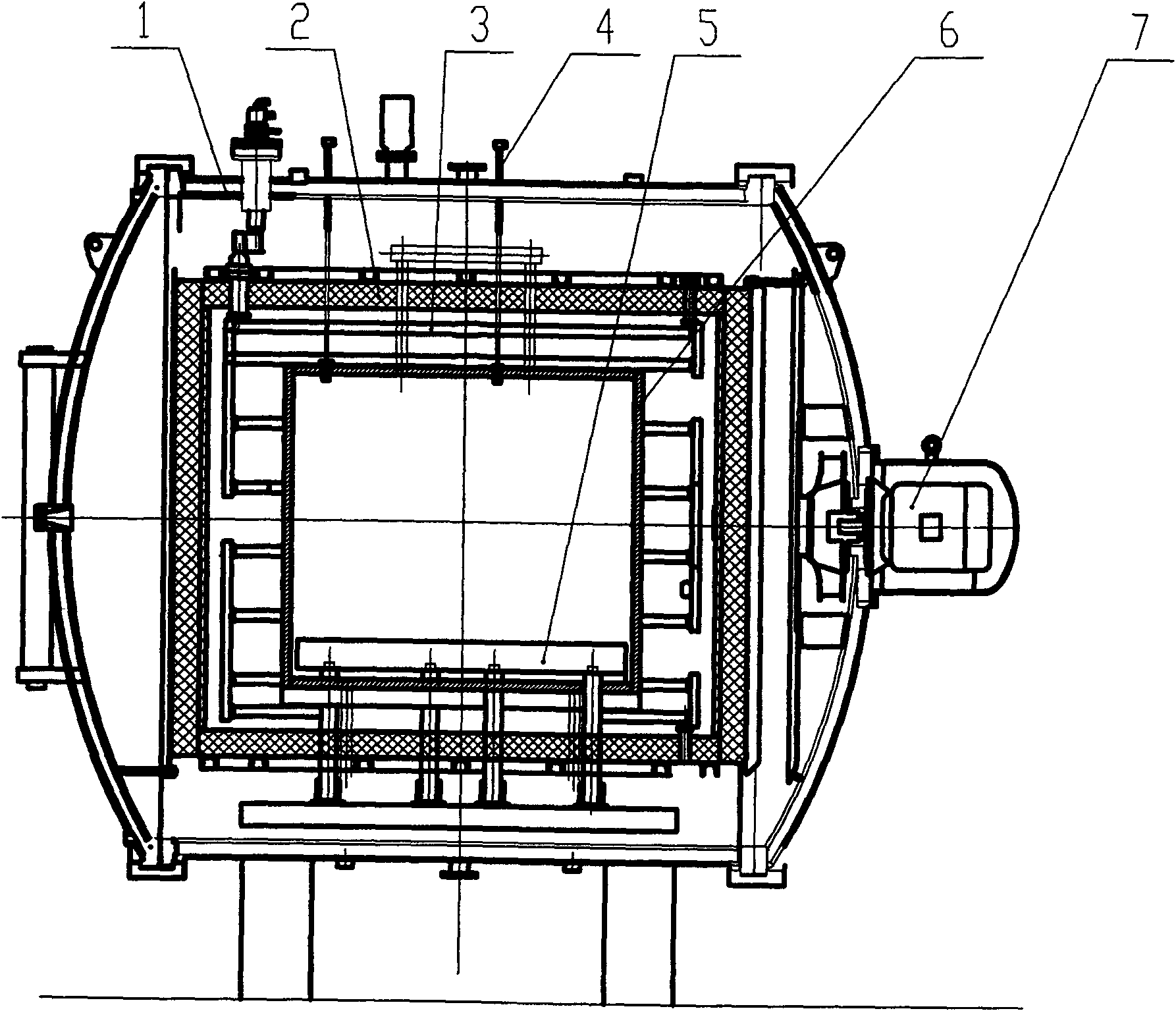

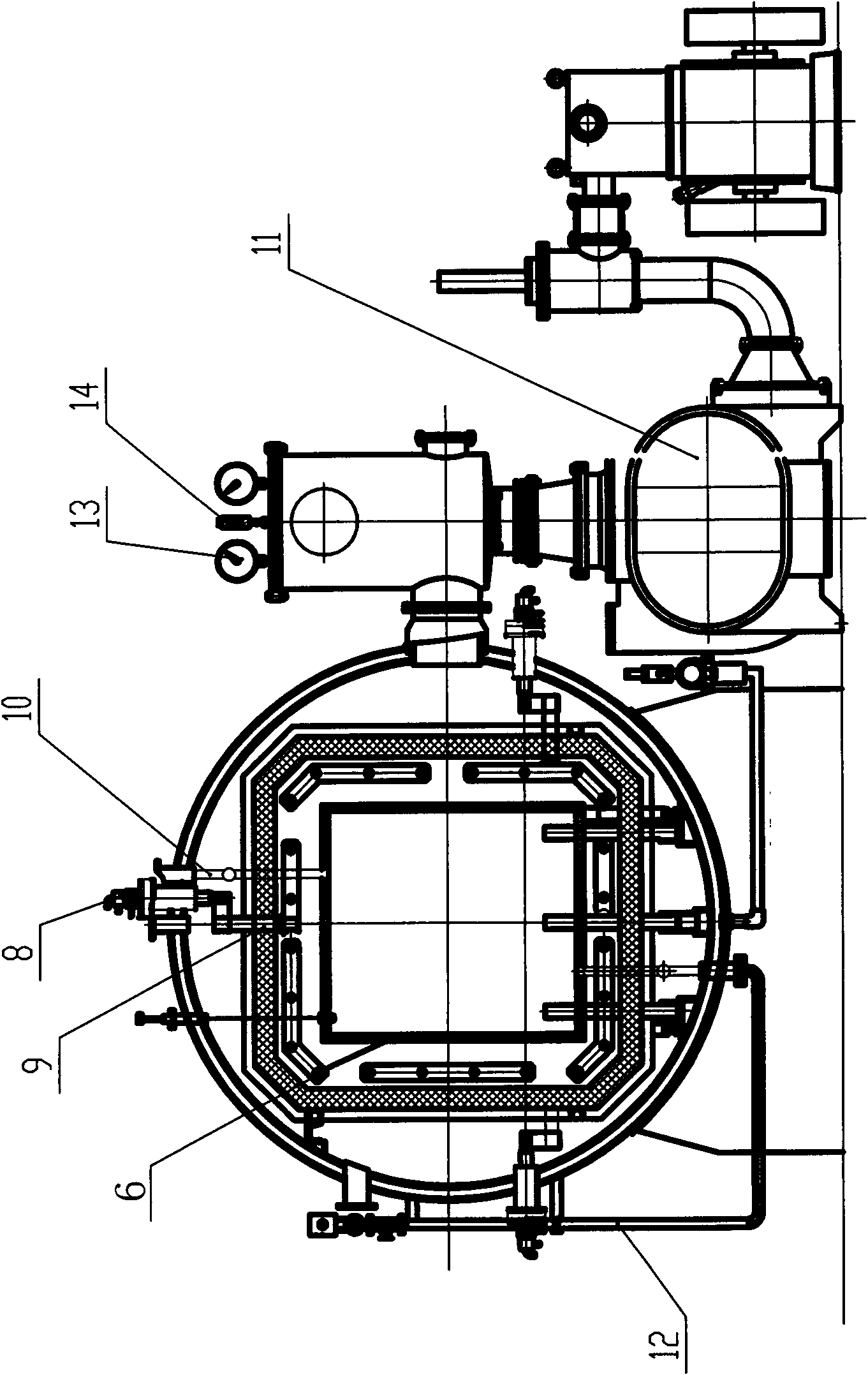

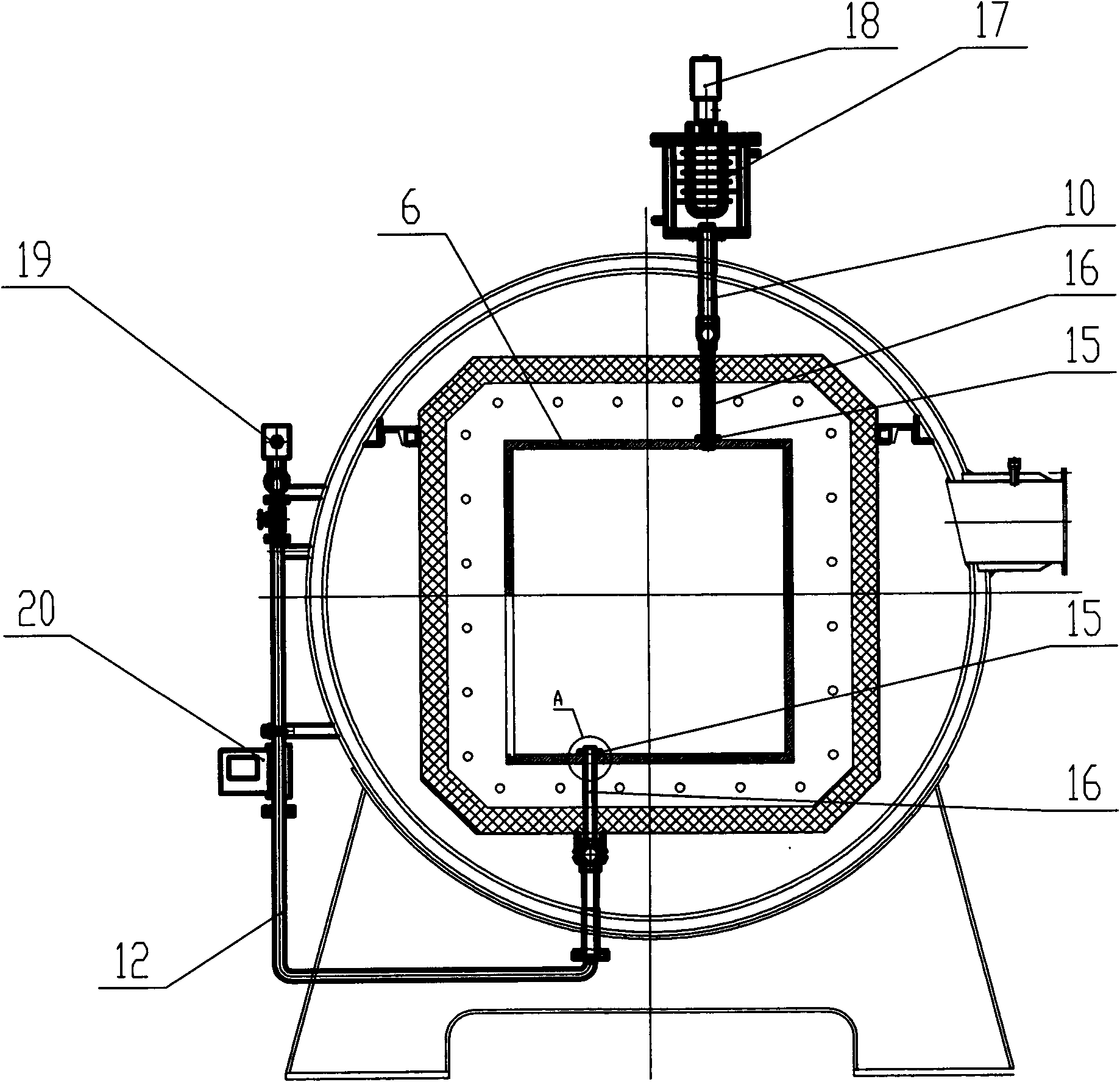

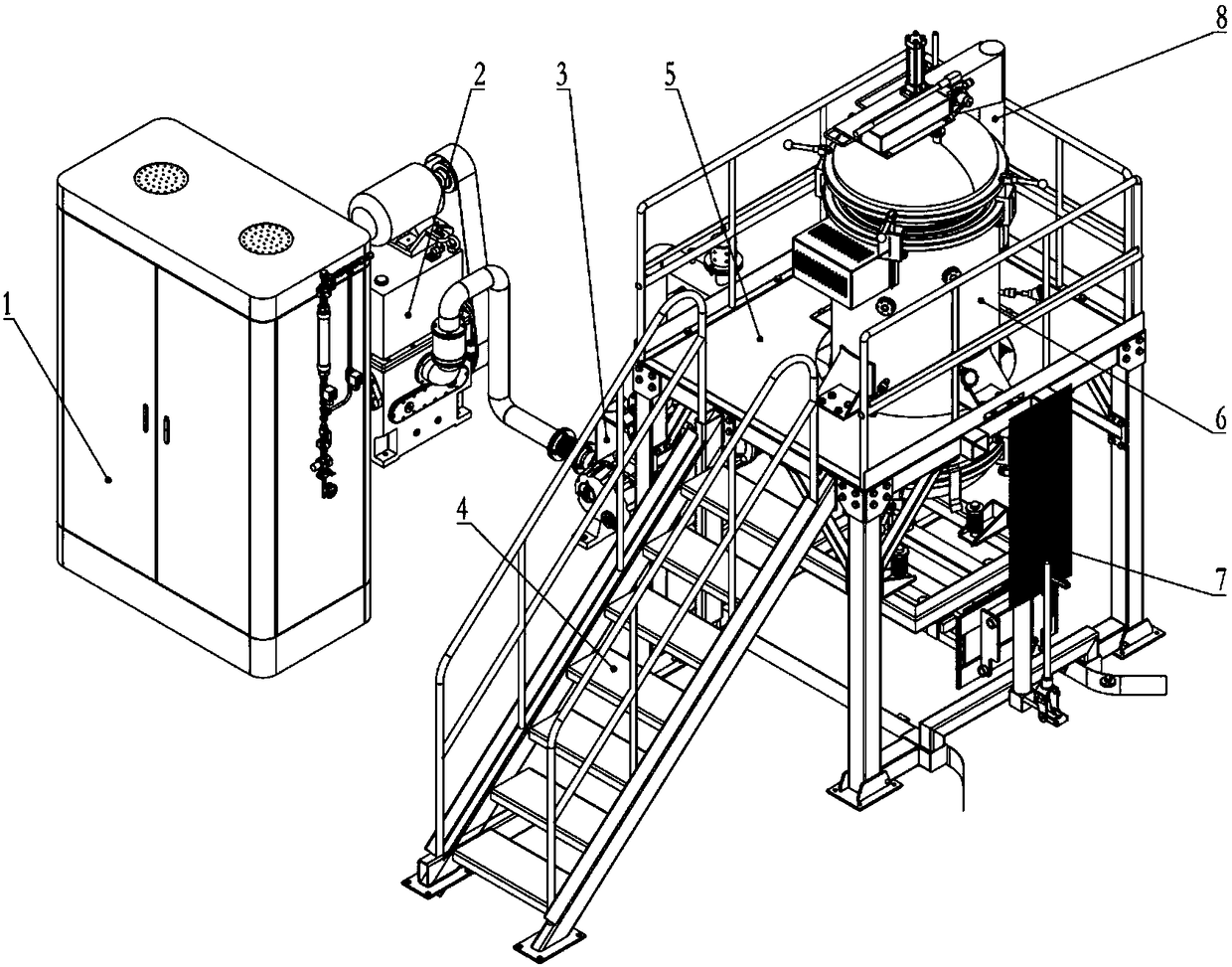

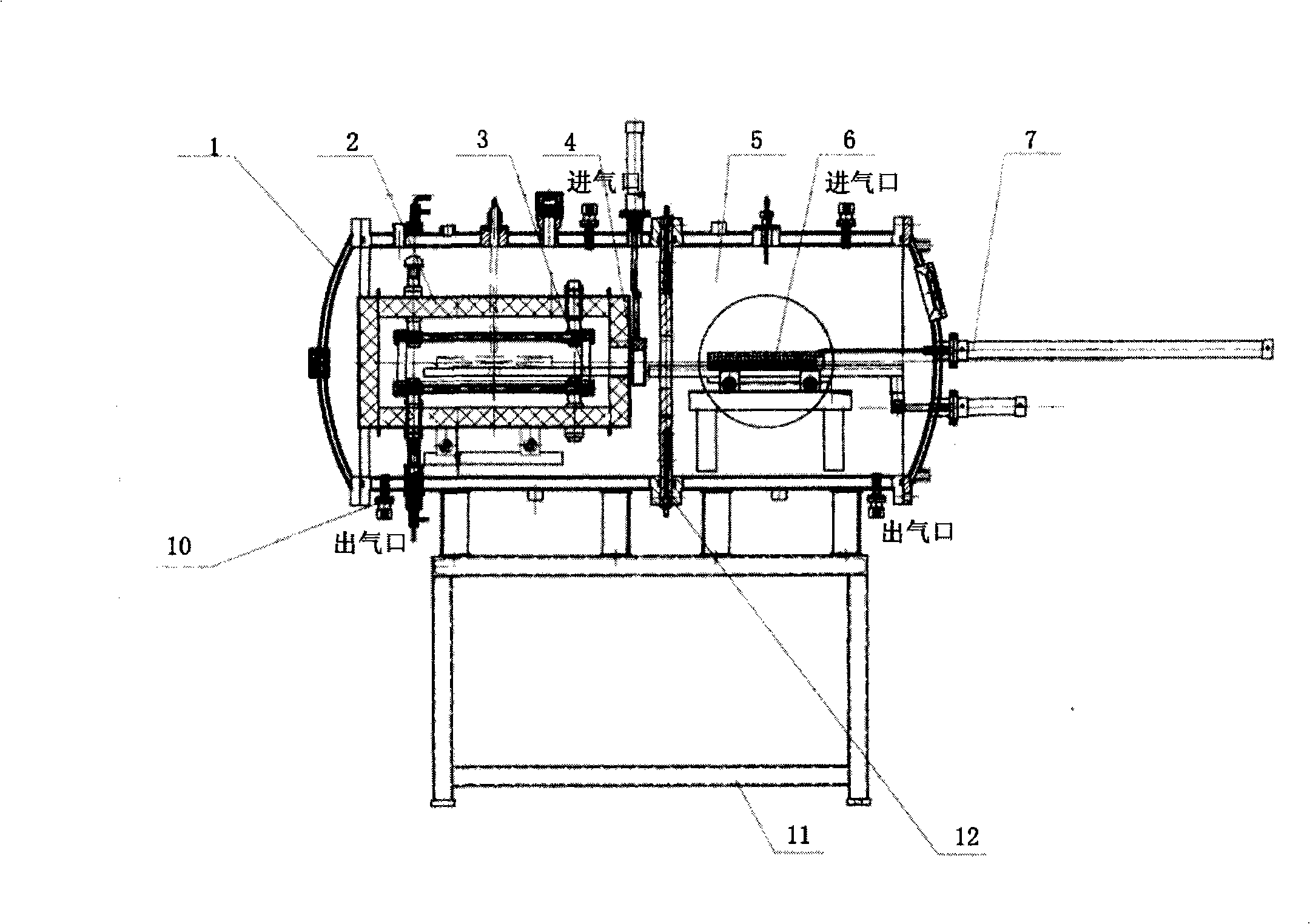

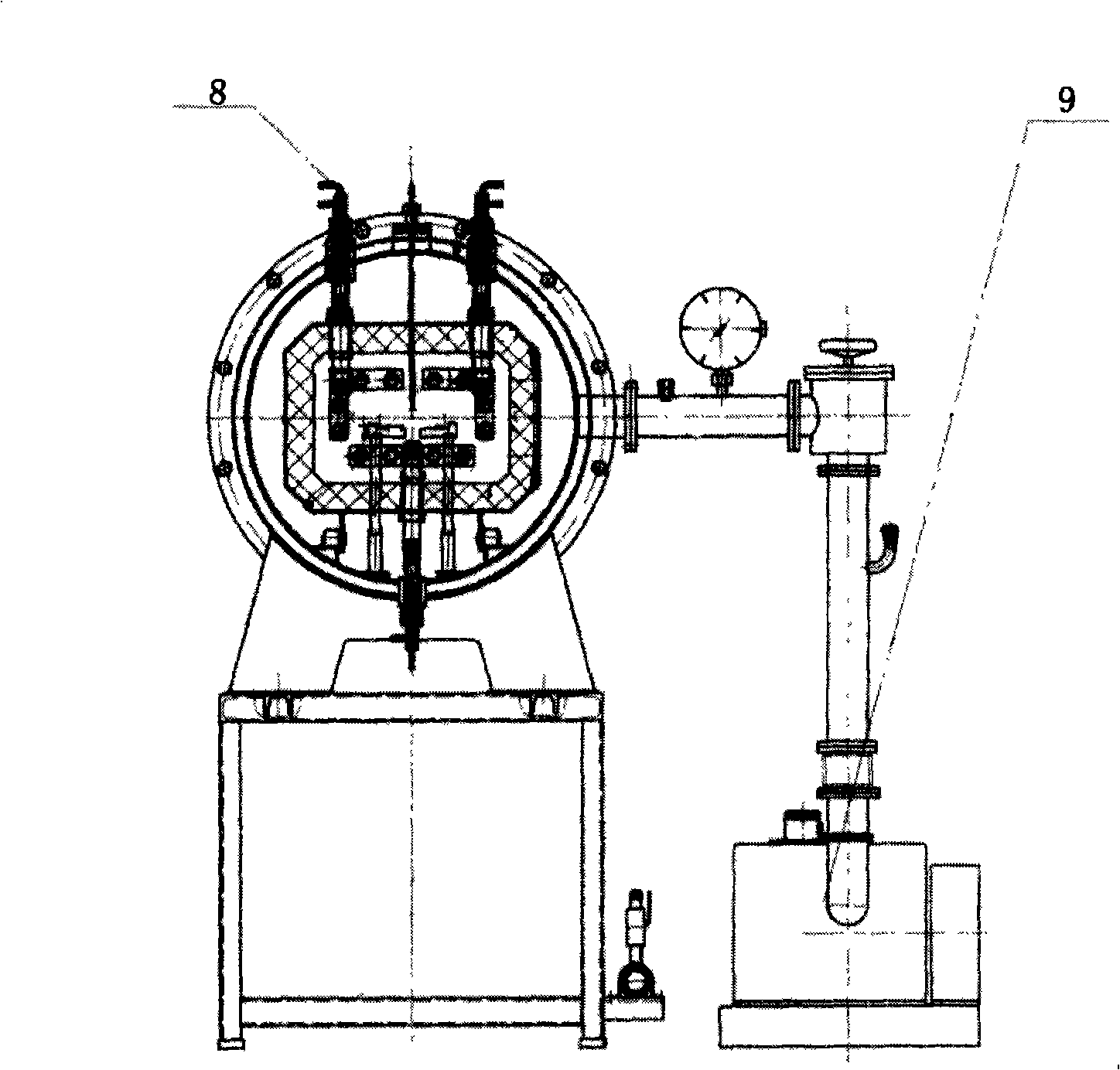

Protective atmosphere vacuum sintering furnace with high temperature of 1800 DEG C

InactiveCN101655310ASolve insulation problemsSolve the sealing problemMuffle furnacesRetort furnacesGraphite electrodeControl system

The invention discloses a protective atmosphere vacuum sintering furnace with high temperature of 1800 DEG C. A control system is connected with an electronically-controlled execution component arranged in an apparatus, a graphite sealing box is arranged in a heating chamber, an air inlet pipeline and an exhaust pipeline of a high-temperature vacuum sintering furnace are connected with the graphite sealing box. The protective atmosphere vacuum sintering furnace is characterized in that the furnace has two techniques of atmosphere sintering and vacuum sintering, and a function conversion measurement is actualized by a control program; a furnace shell is provided with a thermoelectric couple and a copper electrode; the part of a shell column body is provided with a pipe joint communicated with an evacuation unit of a vacuum system; and a square heating chamber is arranged in the furnace shell, heaters are fixed on four walls in the heating chamber, and the heater is internally provided with a sealing box and a support material frame; and the air inlet pipeline and the exhaust pipeline communicated with the sealing box passes through an upper wall and a lower wall of the heating chamber and the sealing box through a graphite pipe to communicate with the inside of the sealing box, one end of the furnace shell is provided with a gas circulating cooling blower, an inner wall of the sealing box is provided with the thermoelectric couple and the copper electrode, and the copper electrode is connected with the heater through a graphite electrode. A volatile substance sealed in the sealing box can not disperse during vacuum sintering, thereby effectively preventing the volatile substance from polluting and damaging the heater, and simultaneously achieving the effect of enabling the protective gas to take the volatile substance away to protect furnace materials, and improving the utilization ratio of the protective gas.

Owner:SHENYANG HENGJIN VACUUM TECH

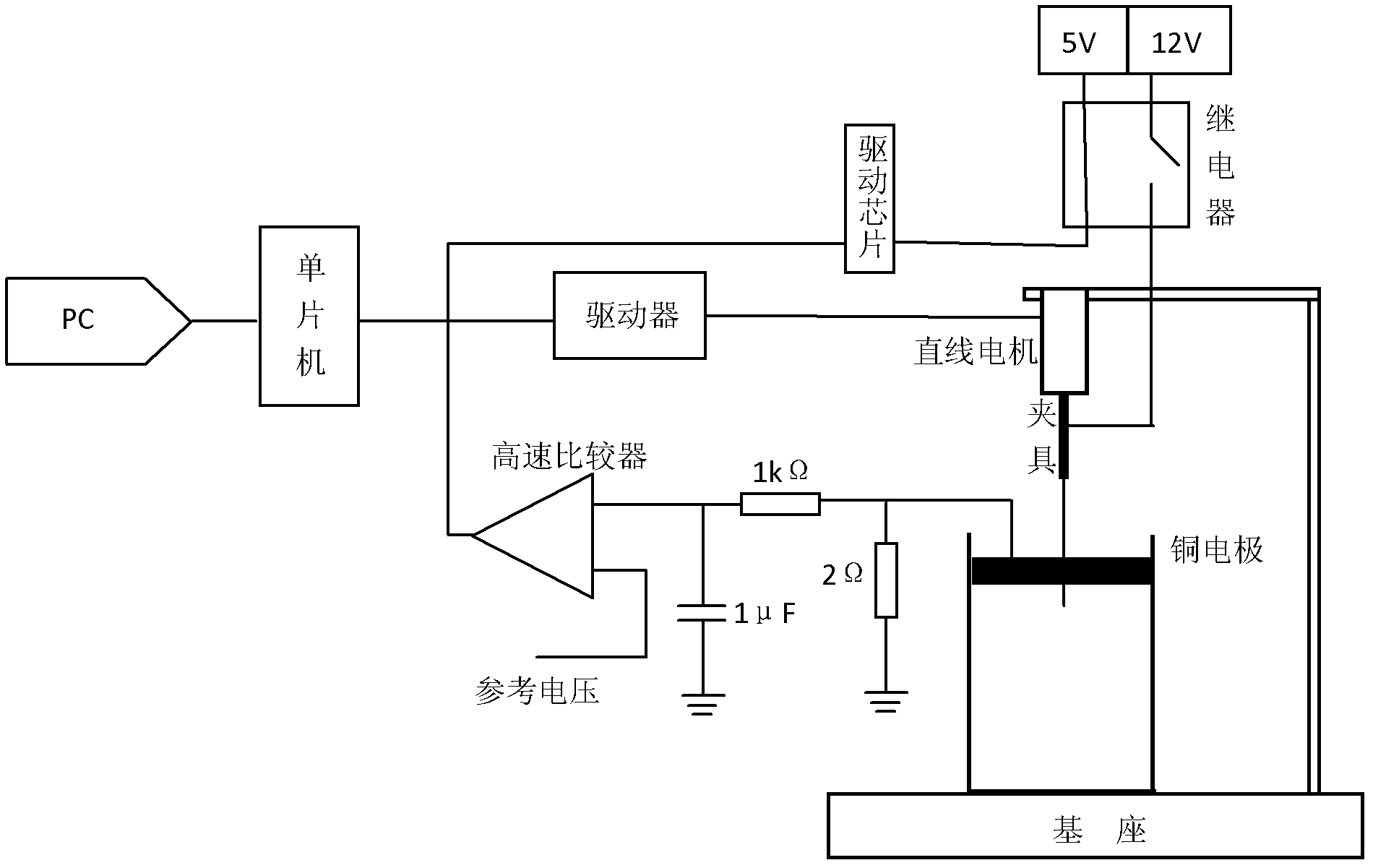

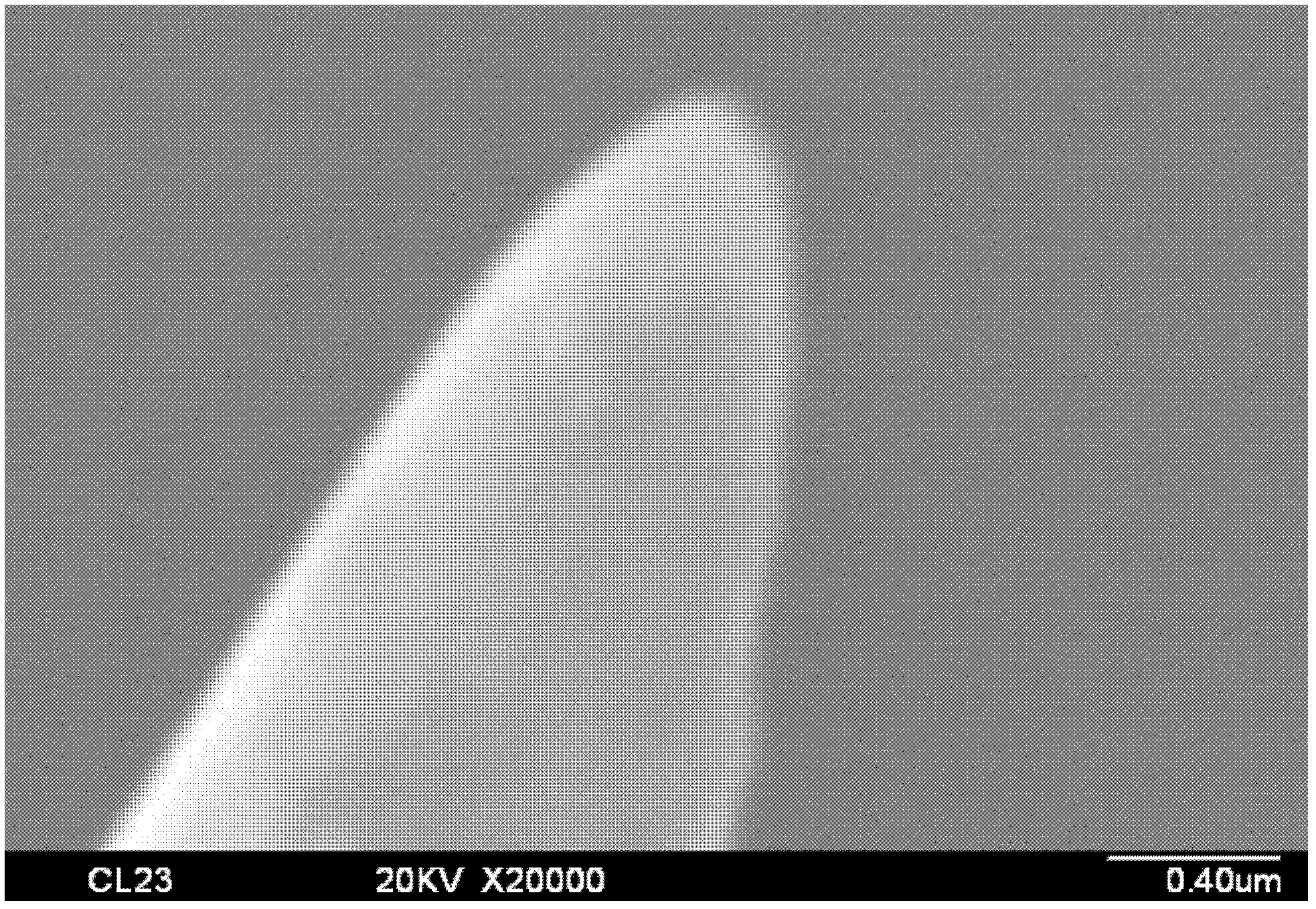

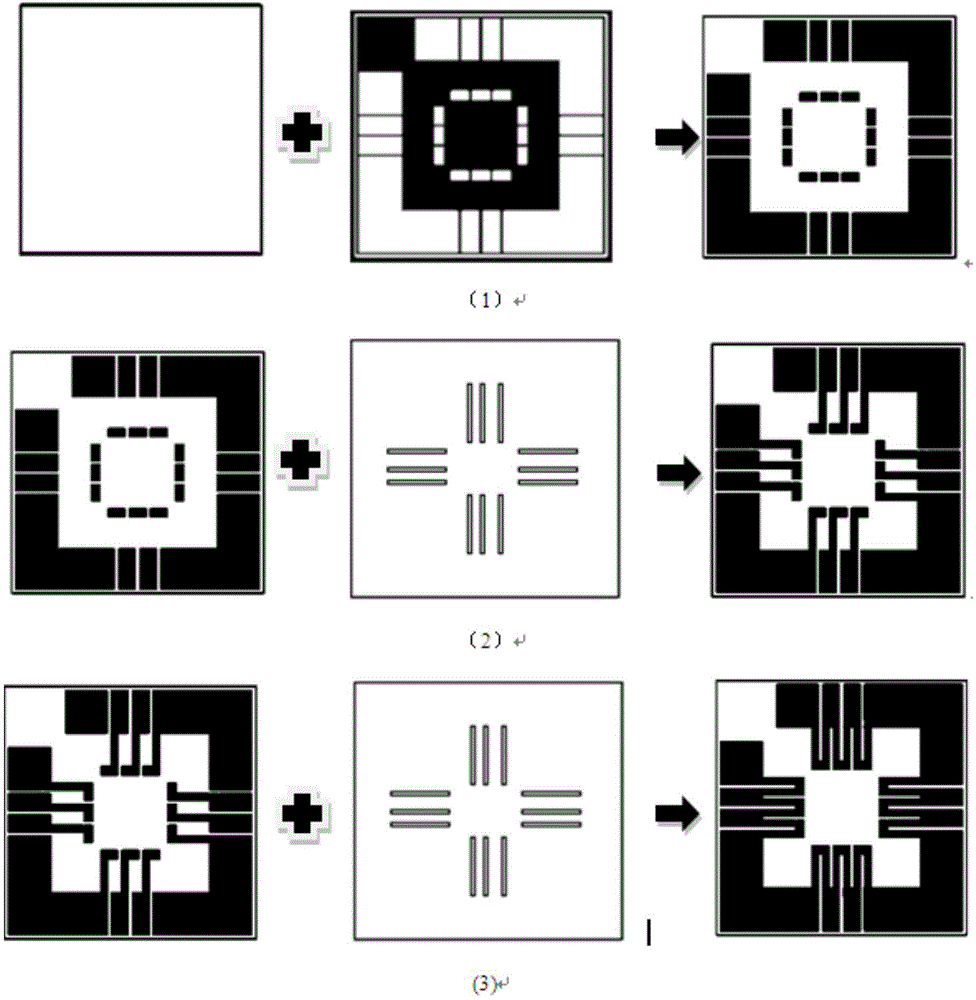

High-efficiency automatic tungsten needle manufacturing device and method

ActiveCN102586854AImprove corrosion efficiencyReduce corrosion costsElectrolysis componentsNanotechnologyElectrochemical responseElectrolysis

The invention discloses an automation high-efficiency direct-current-controlled dynamic manufacturing device and method of tungsten needles. In the device, an electrochemical reaction principle is adopted, a tungsten wire is driven by a linear motor to move up and down in NaOH corrosion liquid in a reciprocating manner so that a reaction is carried out between an anode tungsten wire and a cathode annular copper electrode, and the change of current in a circuit is monitored by utilizing a sampling resistor, a low-pass filter circuit, a voltage follower and a high-speed comparer; when the tungsten wire is corroded to be broken in an electrolyte solution, the sudden change of the current in the circuit causes an output signal of the comparer to change, a voltage applying circuit is switched off and a whole electrolytic corrosion process is finished; and furthermore, the conical degree and the tip radius of the tungsten needle can be adjusted by utilizing the change of motion speed of the linear motor. The device and the method, disclosed by the invention, have the characteristics of high automation degree of tungsten needle preparation, good repeatability and high efficiency.

Owner:咸阳瞪羚谷新材料科技有限公司

Flexible pyroelectric thin film device

InactiveCN104701449AReliable depositionImprove bindingThermoelectric device manufacture/treatmentThermoelectric device detailsIn planeCopper electrode

The invention discloses a flexible pyroelectric thin film device. The device comprises a polyimide flexible substrate, a copper electrode thin film, a nickel transition layer and pyroelectric thin films, the particles of the pyroelectric thin film are arranged in a gradient mode on particle diameter, the pyroelectric thin films comprise a P type pyroelectric thin film and an N type pyroelectric thin film, the P type pyroelectric thin film and the N type pyroelectric thin film are connected through the copper electrode thin film, the p-n thermoelectric couple pairs arranged in an array mode and serially connected are formed on the flexible substrate for forming the flexible pyroelectric thin film device having in-plane structure. The sputtering parameter and the heat treatment process are adjusted and controlled for optimizing microcosmic interfacial structure of the thin film material, the inorganic thin film can be reliably deposited on the flexible substrate and the reliable flexible pyroelectric thin film device with high performance is prepared.

Owner:STATE GRID CORP OF CHINA +2

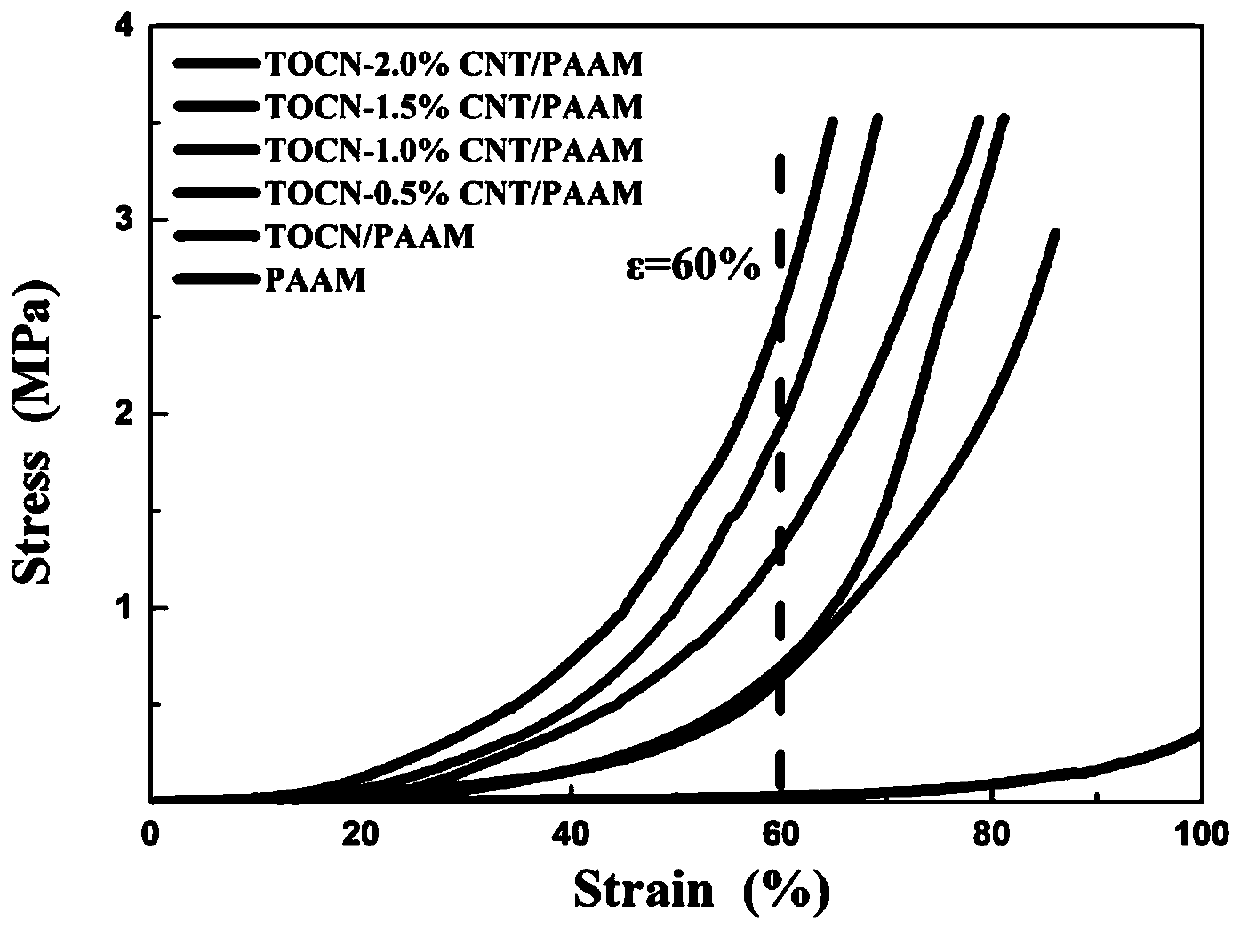

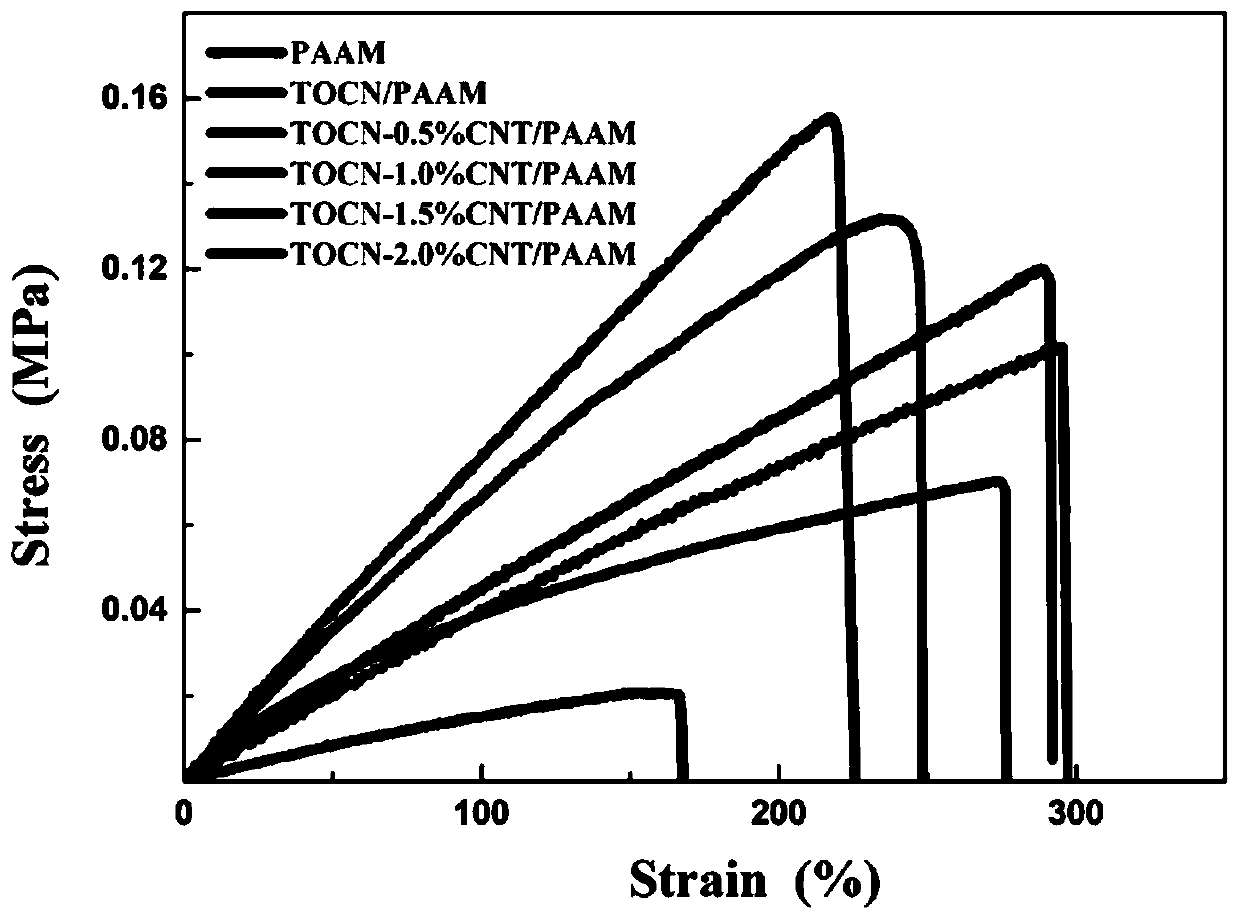

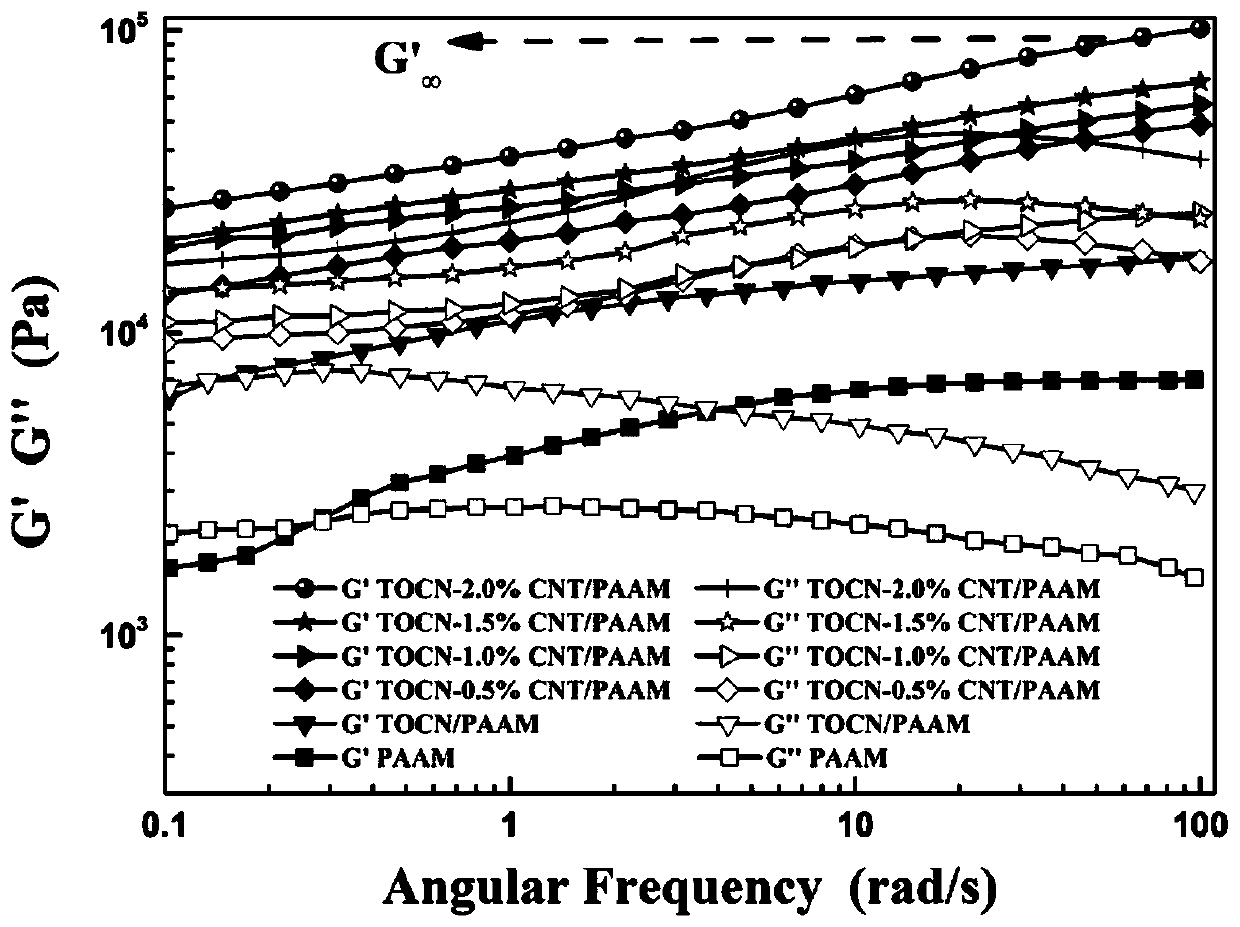

Preparation method of flexible strain sensor based on nanocellulose-carbon nanotube/polyacrylamide conductive hydrogel

ActiveCN110183688AAchieve autonomous self-healingHigh strengthElectrical/magnetic solid deformation measurementCarbon nanotubeCopper electrode

The invention discloses a flexible strain sensor based on nanocellulose-carbon nanotube / polyacrylamide conductive hydrogel. The preparation method of the flexible strain sensor comprises the followingsteps: (1) preparing a TEMPO nanocellulose suspension; (2) preparing a carbon nanotube dispersion; (3) preparing TEMPO nanocellulose-carbon nanotube / polyacrylamide conductive hydrogel; and (4) attaching two separate copper electrodes to both sides of the hydrogel so as to obtain the flexible strain sensor based on the nanocellulose-carbon nanotube / polyacrylamide conductive hydrogel. The sensor has high flexibility, stretchability, high mechanical properties, high electrical conductivity and strain sensitivity.

Owner:NANJING FORESTRY UNIV

Method for performing spot welding on Al-Zn hot-coated steel plate

InactiveCN101961814ASolder joint appearance is goodQuality improvementWelding/cutting media/materialsWelding/soldering/cutting articlesPlanar electrodePower flow

The invention provides a method for performing spot welding on an Al-Zn hot-coated steel plate. In the method, a foil belt is arranged between a copper electrode and an Al-Zn hot-coated steel plate workpiece; a step type large-contact planar electrode is adopted, a two-section welding current mode is adopted; and the two-section welding current adopts a constant current control mode, so that the foil belt is not adhered to the workpiece and the electrode and each welding spot has fine appearance and stable quality. The copper electrode is only contacted with a non-tinplated surface of the foil plate, so the method solves the problem that the electrode is alloyed by a zinc aluminium coating fundamentally, prolongs the service life and improves the welding spot quality of a spot-welding electrode of the zinc aluminium plated steel plate, prolongs the service life of the electrode and has favorable popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Thin film transistor and manufacturing method thereof and array substrate and display device

ActiveCN103219389AImprove adhesionImprove performanceTransistorSolid-state devicesInsulation layerDisplay device

The invention discloses a thin film transistor, a manufacturing method of the thin film transistor, an array substrate and a display device which are used for improving performance of the thin film transistor (TFT) and quality of an image. The thin film transistor comprises a substrate, a grid electrode formed on the substrate, a source electrode, a drain electrode, a semiconductor layer, a grid electrode insulation layer located between the grid electrode and the semiconductor layer or among the grid electrode, the source electrode and the drain electrode, an etching barrier layer located among the semiconductor layer, the source electrode and the drain electrode and provided with a source electrode contact hole and a drain electrode contact hole, a source electrode buffer layer located between the source electrode and the semiconductor layer and a drain electrode buffer layer located between the drain electrode and the semiconductor layer. The source electrode and the drain electrode are metallic copper electrodes. The buffer layers are made of copper alloy.

Owner:BOE TECH GRP CO LTD

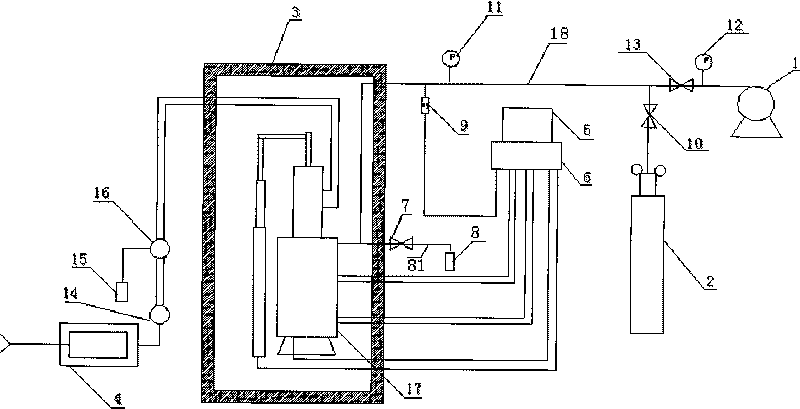

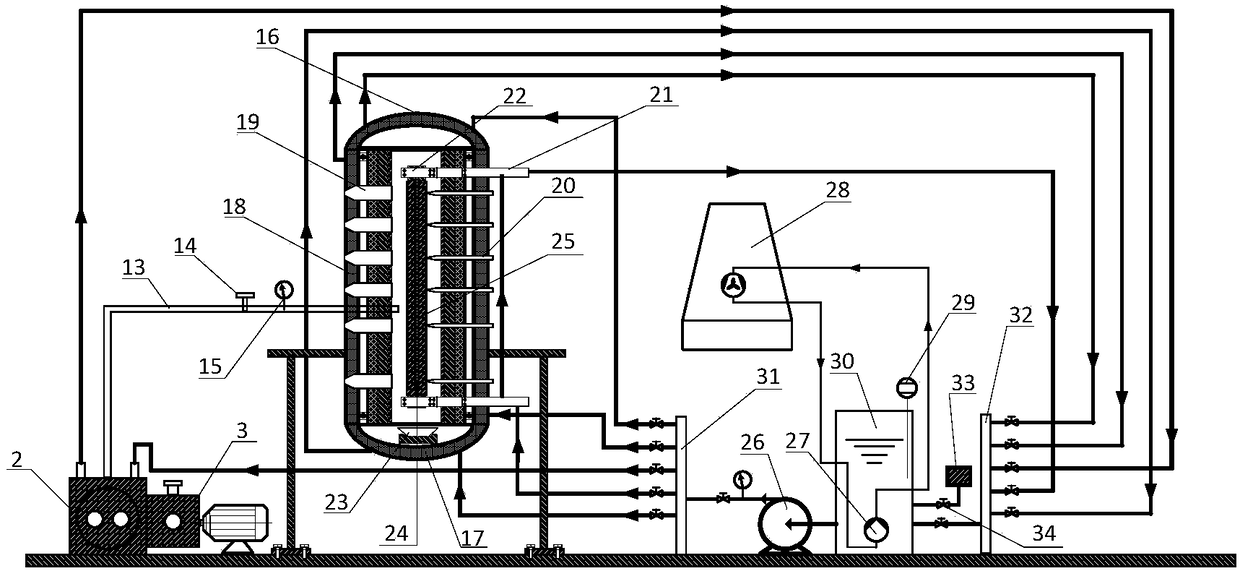

Method and device for measuring the resistivity of gas hydrate and hydrate-containing sediment in situ

The invention discloses a method and a device for measuring the resistivity of gas hydrates and hydrate-containing sediments in situ. The device comprises a hydrate reaction kettle, a temperature control system, an air supplying system, a water supplying system, a measurement and control collection system and a displacement sensor, wherein the temperature control system is arranged on the periphery of the hydrate reaction kettle and provides constant temperature for the hydrate reaction kettle; the air supplying system and the water supplying system are respectively connected with the hydrate reaction kettle; the measurement and control collection system is used for measuring the respectively physical property of the hydrates or the hydrate-containing sediments, one end of the measurement and control collection system is connected between the hydrate reaction kettle and the air supplying system, and the other end of the measurement and control collection system is connected with the hydrate reaction kettle; the output of the hydrate reaction kettle is connected with a hydraulic transmission system used for providing gas reaction pressure; the displacement sensor is arranged on the hydrate reaction kettle, and a measuring bar of the displacement sensor is inserted into the hydrate reaction kettle; and the top and the bottom inside the hydrate reaction kettle are respectively provided with a first copper electrode and a second copper electrode which are connected with the measurement and control collection system. The invention adopts integral optimized design and has compact structure.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

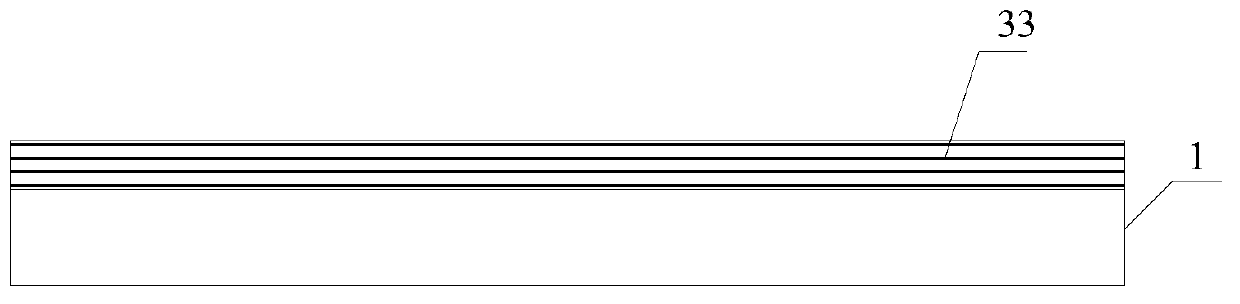

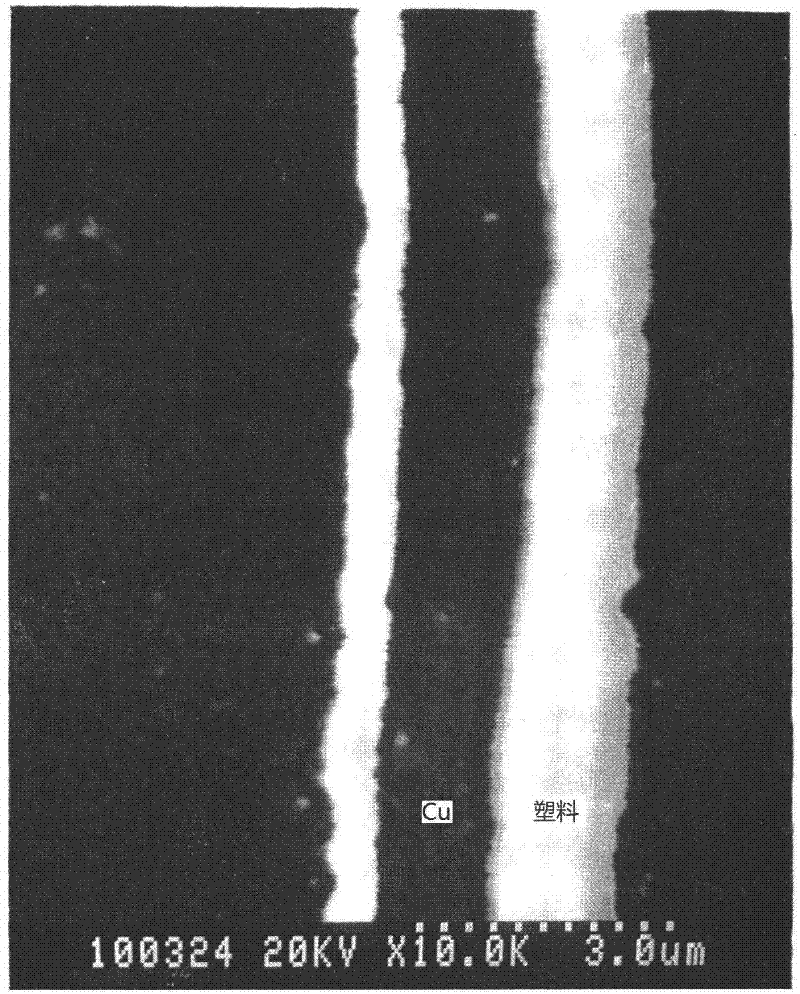

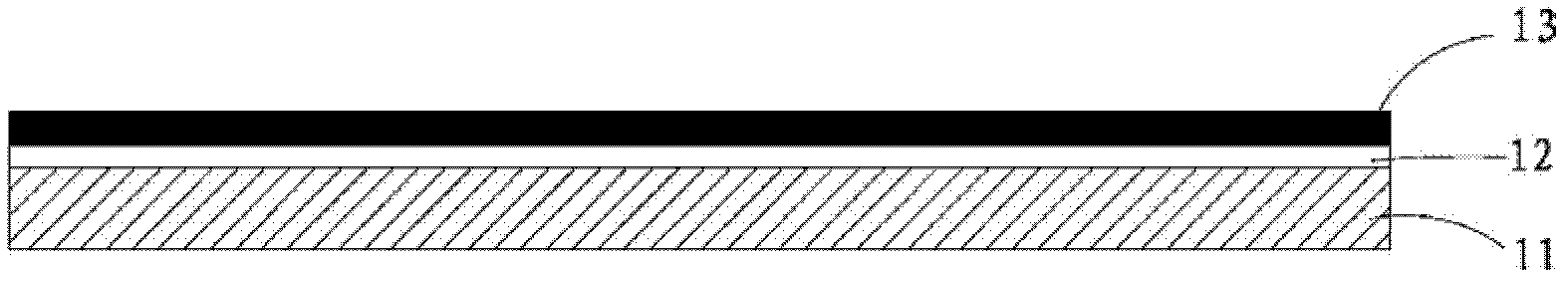

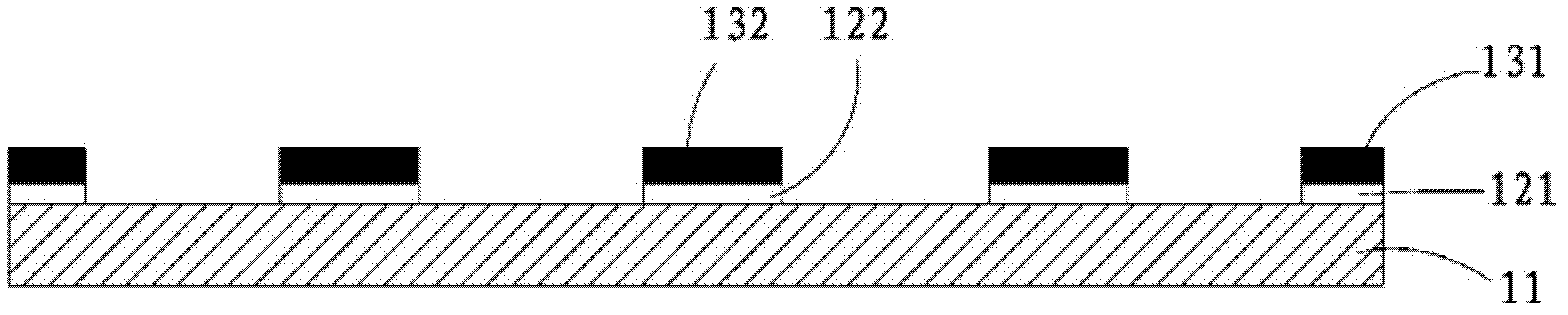

Preparation method of flexible copper electrode pattern in micron level wire width

InactiveCN102400115AImprove conductivityGood adhesionLiquid/solution decomposition chemical coatingCopper platingCopper electrode

The invention belongs to the field of microelectronic material, and relates to a preparation method of a flexible copper electrode pattern in a micron level wire width. The preparation method provided by the invention is a ''whole addition'' method, which means that metal copper only precipitates on a predetermined position on a plastic substrate. A specific process comprises steps of plastic substrate cleaning, drying, surface modification, ultraviolet irradiation under a photomask and chemical coppering, etc. The flexible copper electrode pattern prepared by the invention has the following advantages that (1) precision of the electrode pattern is determined by the photomask to reach a micron level wire width; (2) most of the process is carried out in solution, so the process does not require large-scale apparatus equipment and rigorous environment of anultraclean chamber and is suitable for low cost and large scale production; (3) the electrode pattern and the plastic substrate are firmly bonded, can stand repeat folding and have long service life and high reliability; (4) the electrode pattern has good conductivity and is beneficial for reducing energy consumption during usage. The flexible copper electrode pattern prepared by the invention can be widely applied to industrial fields of flexible transistor, flexible solar cell and flexible luminescent device, etc.

Owner:FUDAN UNIV

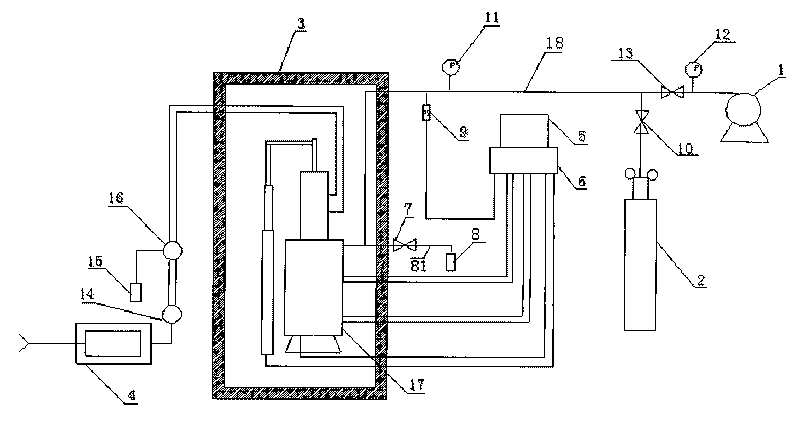

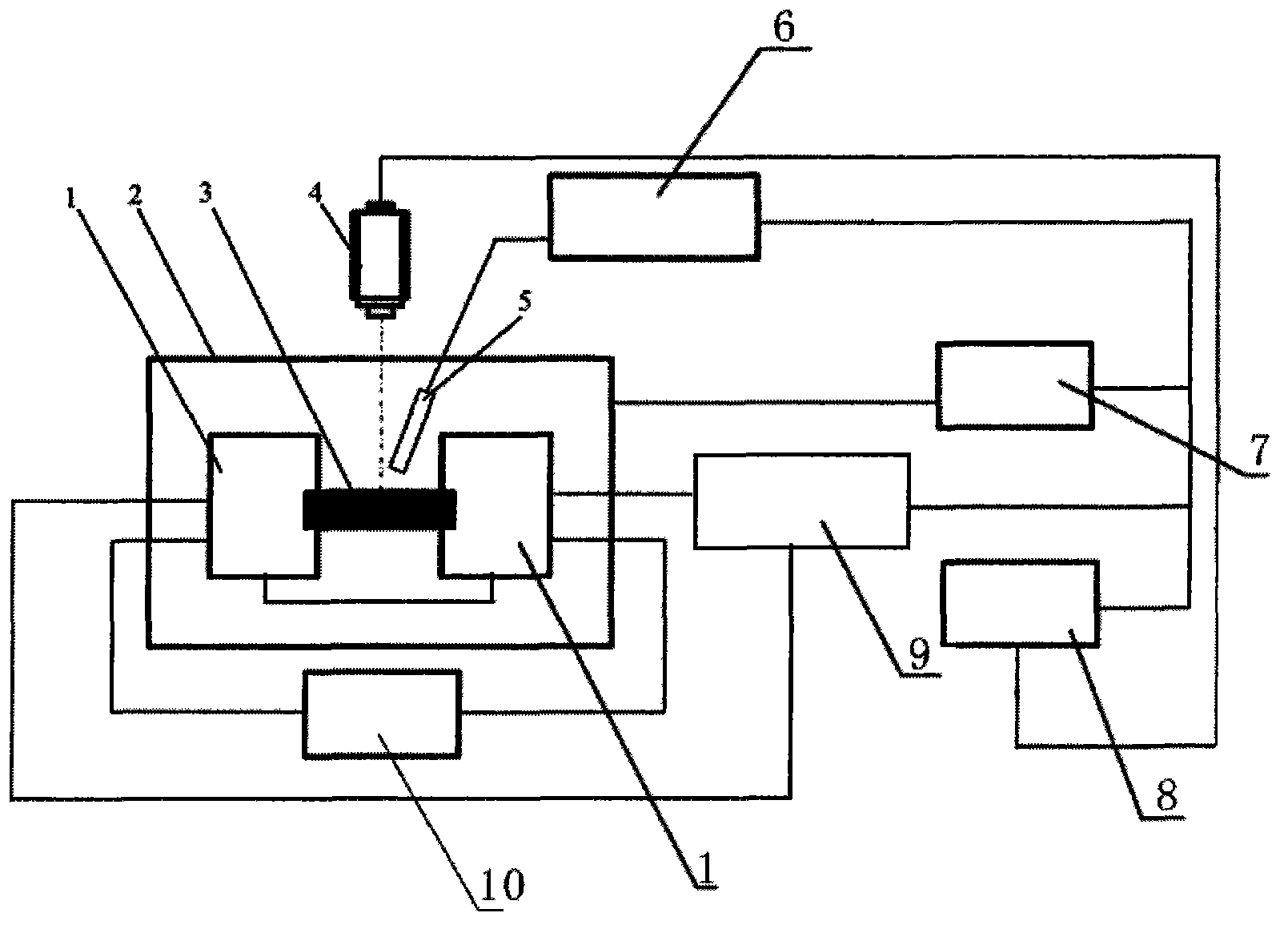

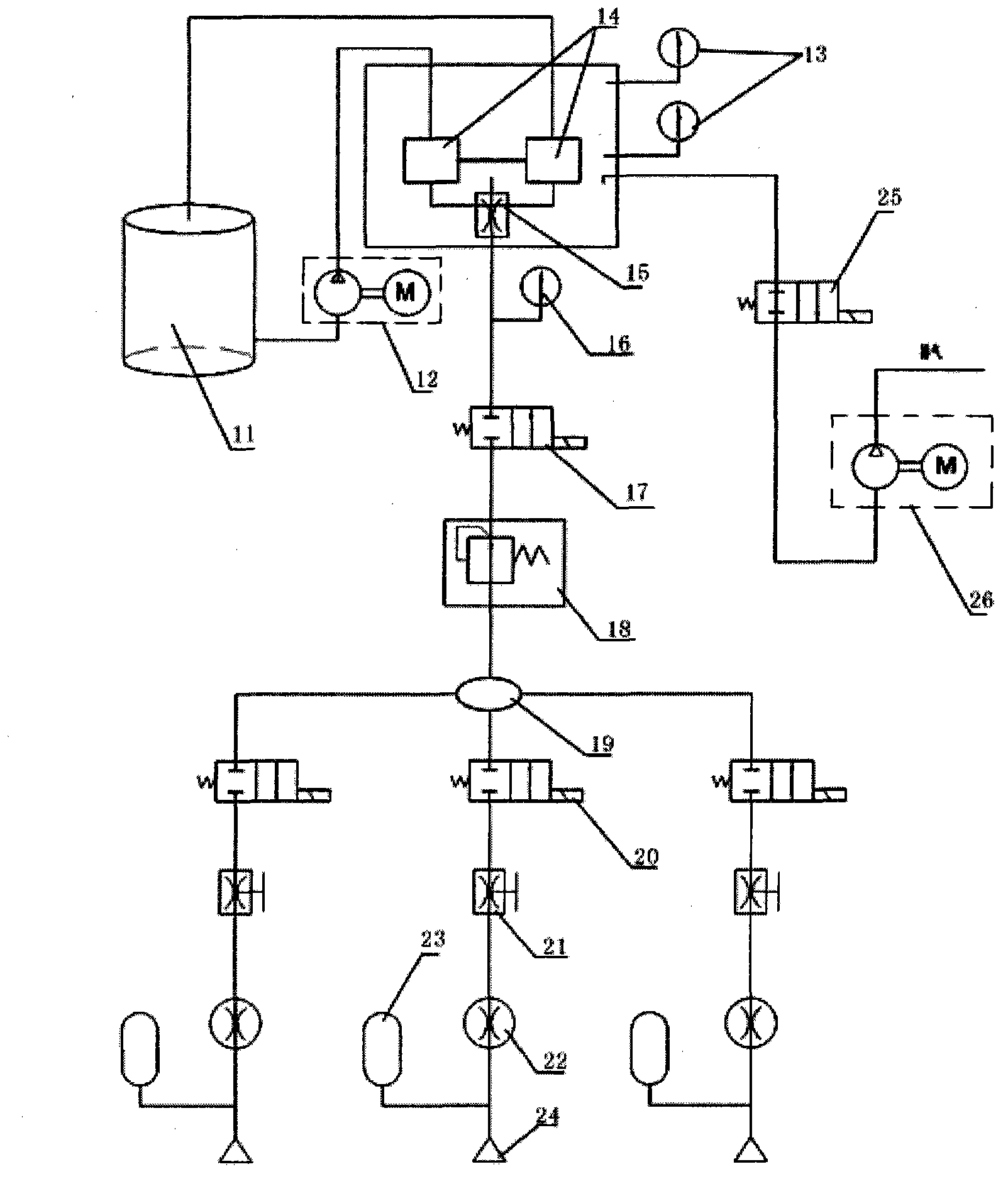

Pneumatic thermal loading simulation test device for thermal shielding materials

ActiveCN102841111AImplement decoupled testingEasy to operateMaterial heat developmentVacuum extractionSprayer

A pneumatic thermal loading simulation test device for thermal shielding materials comprises a stainless steel environmental chamber, two heating copper electrodes, a single / double colored infrared thermometer, a power supply secondary system, a gas supply secondary system, a vacuum extraction secondary system, a cooling cycle secondary system and a programmable logic controller (PLC) system. The stainless steel environmental chamber is fixed on the ground through supports and insulated from the ground. Three observation windows are arranged on the stainless steel environmental chamber, and the two heating copper electrodes are connected with the power supply secondary system through cables. A gas sprayer is arranged above thermal shielding material samples, and the vacuum extraction secondary system adjusts pressure in the stainless steel environmental chamber. The power supply secondary system is connected with an industrial power wire net. The heating copper electrodes are hollow and connected with the cooling cycle secondary system for cooling in water-cooling mode. The thermal shielding material samples are fixed between the two heating copper electrodes through a copper fixture. The single / double colored infrared thermometer is connected with the PLC system in electric signals mode. The pneumatic thermal loading simulation test device is simple to operate, wide in adjustment range, low in cost, and can be applied to principle researches of pneumatic thermal loading of the thermal shielding materials.

Owner:HARBIN INST OF TECH

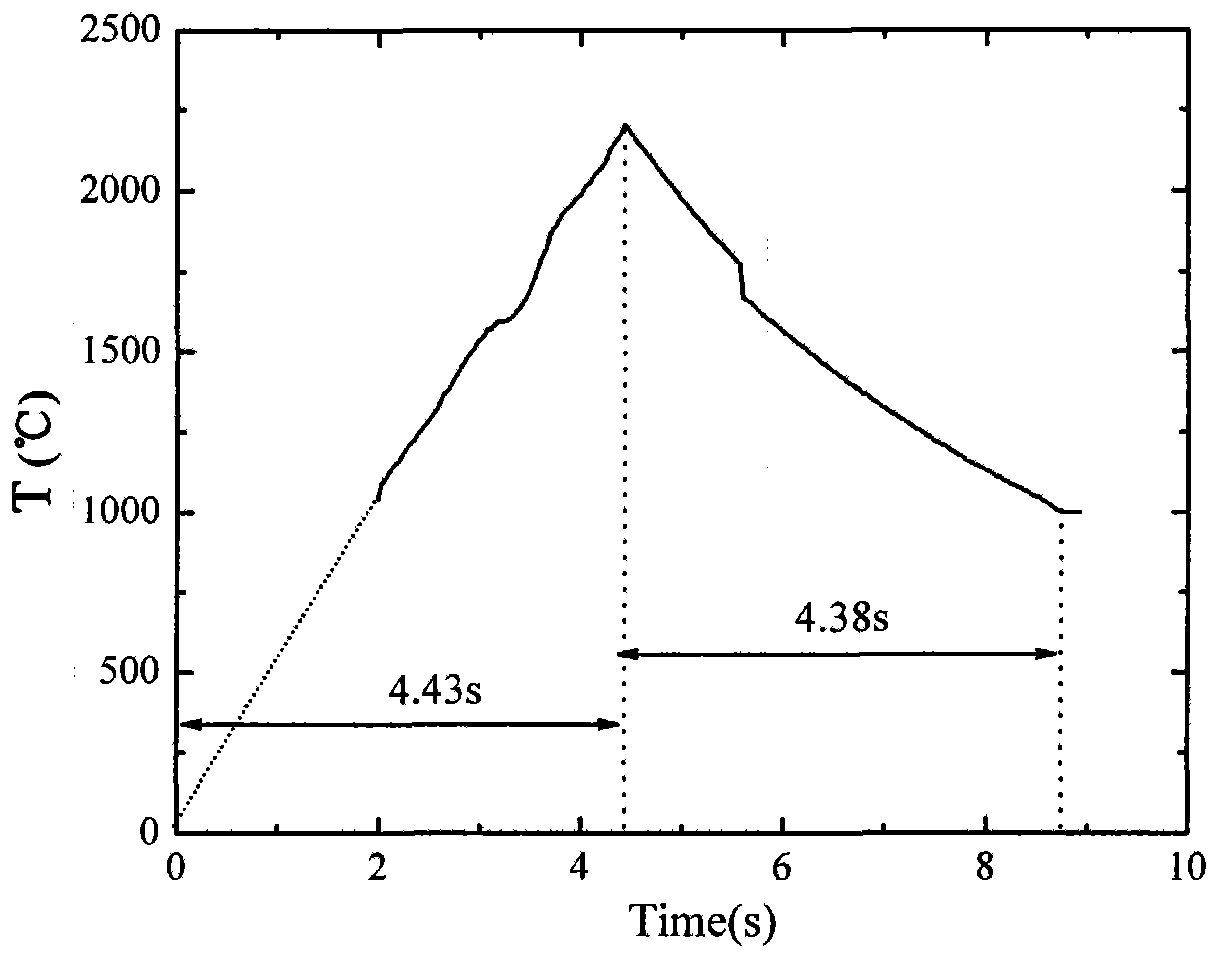

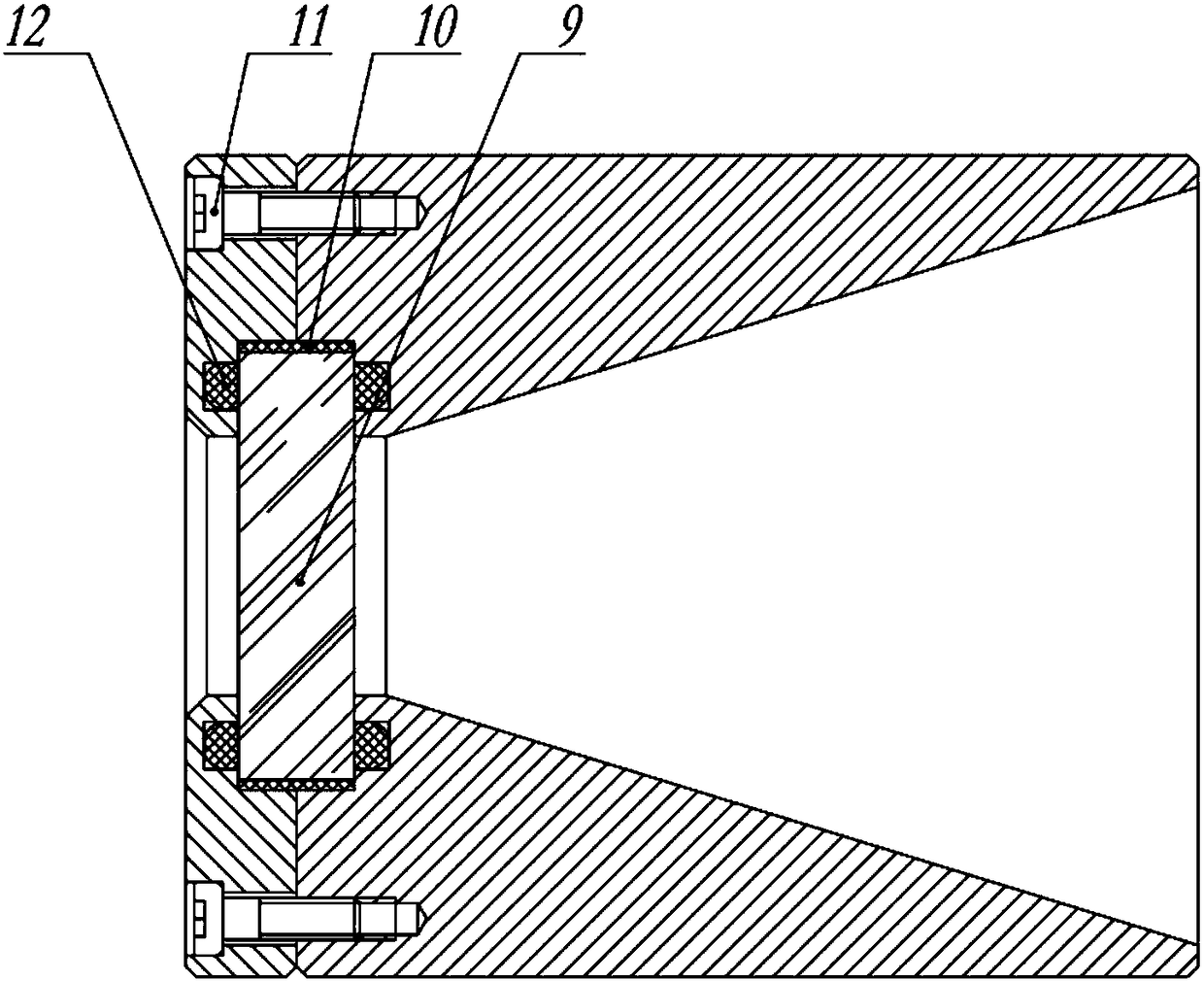

Visual experiment device for melting of nuclear reactor fuel rod and method

ActiveCN108447573ASimple structureOvercoming the inability to observe the exact process of fuel rod meltingNuclear energy generationNuclear monitoringNuclear reactorTest article

The invention provides a visual experiment device for melting of a nuclear reactor fuel rod and a method. The visual experiment device comprises a high-temperature melting furnace provided with a plurality of transparent windows, wherein a test article is vertically arranged in the high-temperature melting furnace; rhenium-molybdenum electrodes are arranged at the upper end and the lower end of the test article respectively and connected with copper electrodes penetrating the side wall of the high-temperature melting furnace; the test article comprises the fuel rod; a tungsten-rhenium heatingrod is arranged in the fuel rod; a cooling water circulation system used for cooling the high-temperature melting furnace is arranged outside the high-temperature melting furnace. By means of the cooling water circulation system for the high-temperature melting furnace, the temperature of the outer side of the furnace body is kept in safe limits, an external high-speed camera can work normally, and a core melting process under a severe accident of a reactor can be simulated realistically. Obtained experiment data can provide verification for the traditional numerical simulation method, and uncertainty of the existing severe accident analyzing procedure is reduced.

Owner:XI AN JIAOTONG UNIV

Novel electrode lead capacitive screen manufacturing method and its product and touch screen terminal

ActiveCN102279684AThere will be no disconnectionPrecise thickness controlInput/output processes for data processingPolyesterCapacitance

The invention is applicable to the technical field of touch screen production and provides a method for manufacturing a novel electrode lead capacitive screen, the novel electrode lead capacitive screen and a touch screen terminal. The method comprises the following steps of: (1) preparing an indium tin oxide (ITO) conductive film on a polyester (PET) base film; (2) preparing a copper film on the ITO conductive film by using a magnetically-controlled splutter coating method; (3) manufacturing ITO patterns, and forming an edge copper electrode lead at one time; (4) selectively etching the copper film on the middle ITO pattern, and reserving the ITO pattern to obtain PET thin film structures; and (5) sequentially adhering two PET thin film structures which are obtained in the step (4) and a piece of panel glass by using an optical adhesive to obtain the novel electrode lead capacitive screen. In the method for manufacturing the novel electrode lead capacitive screen provided by the invention, the magnetically-controlled splutter coating method is adopted to replace a silk-screening silver paste process to manufacture an electrode lead of a capacitive screen with mature technical means; and by the method, the good rate for manufacturing the capacitive screen having a film-film structure can be greatly improved, so that the manufacturing cost of the capacitive screen is saved.

Owner:深圳豪威显示科技有限公司

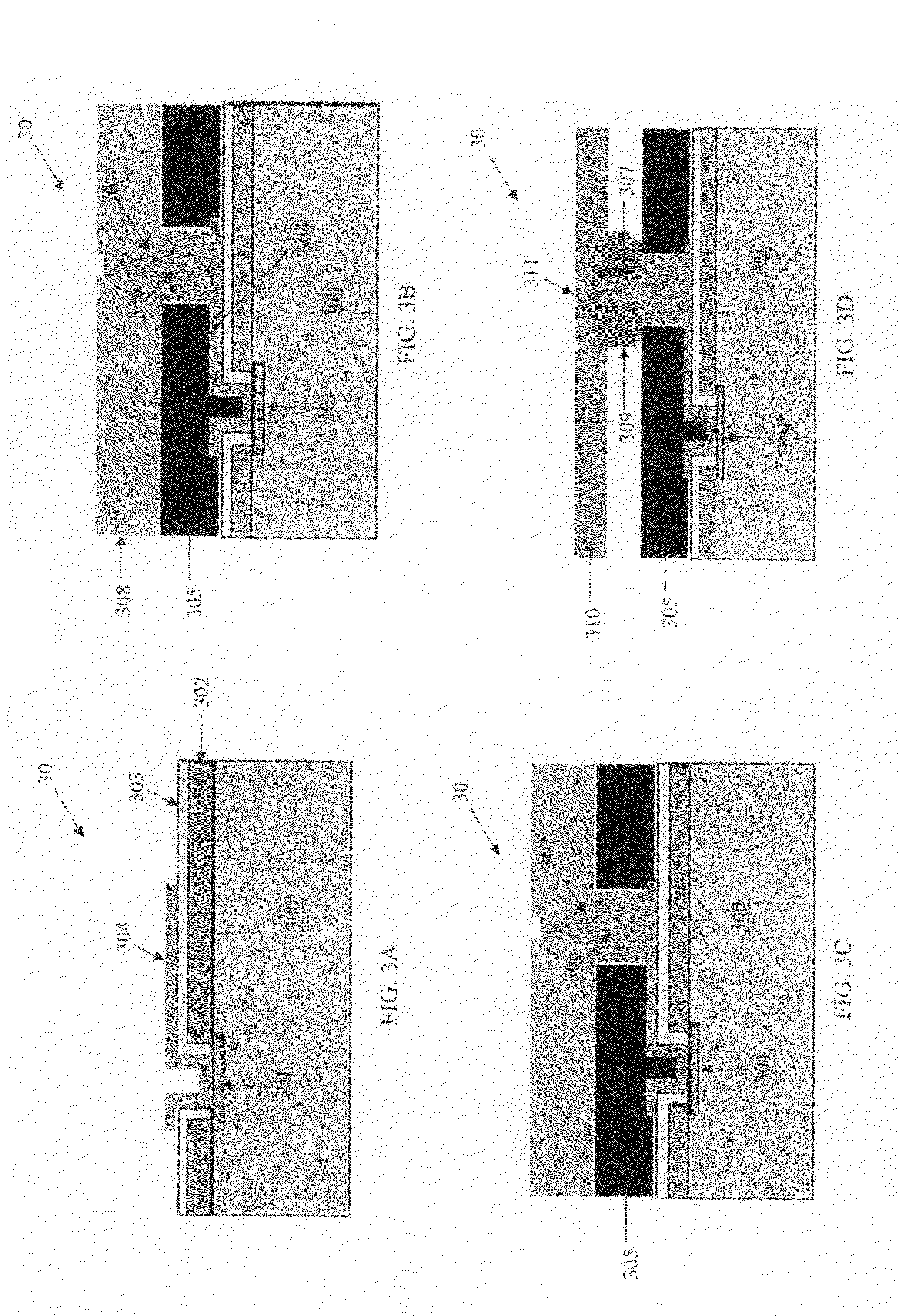

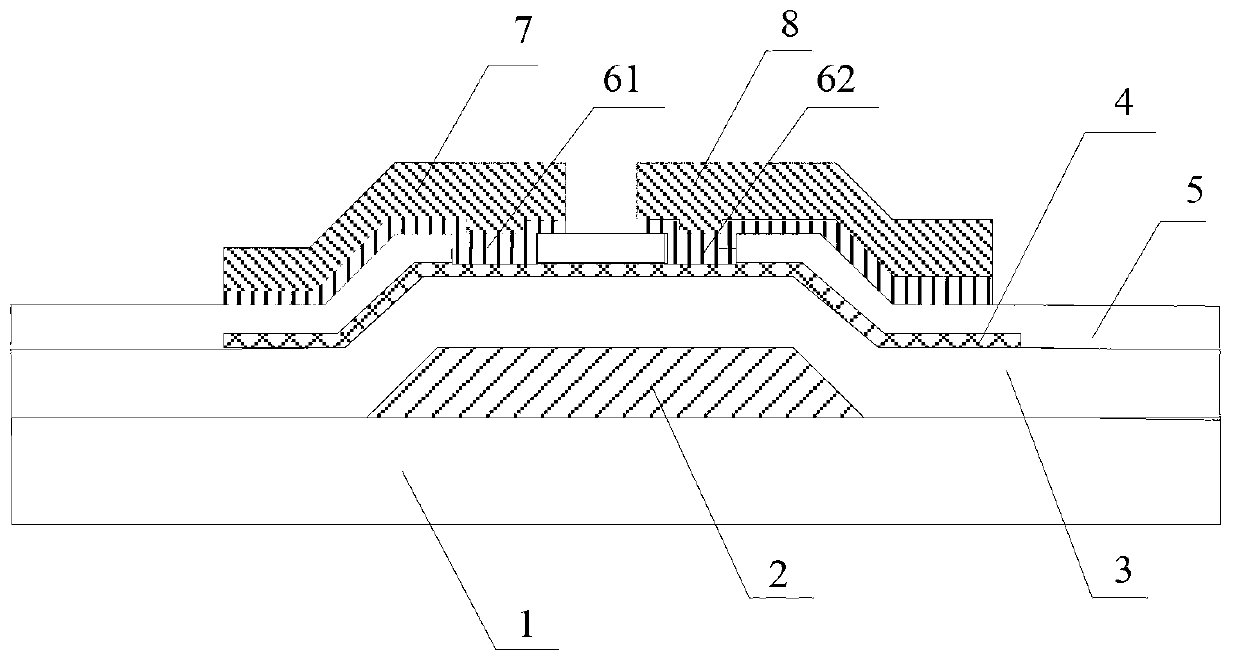

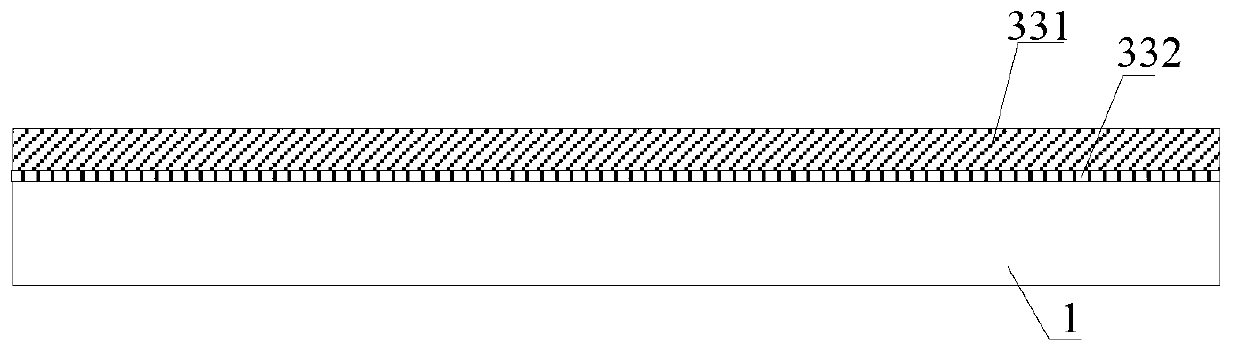

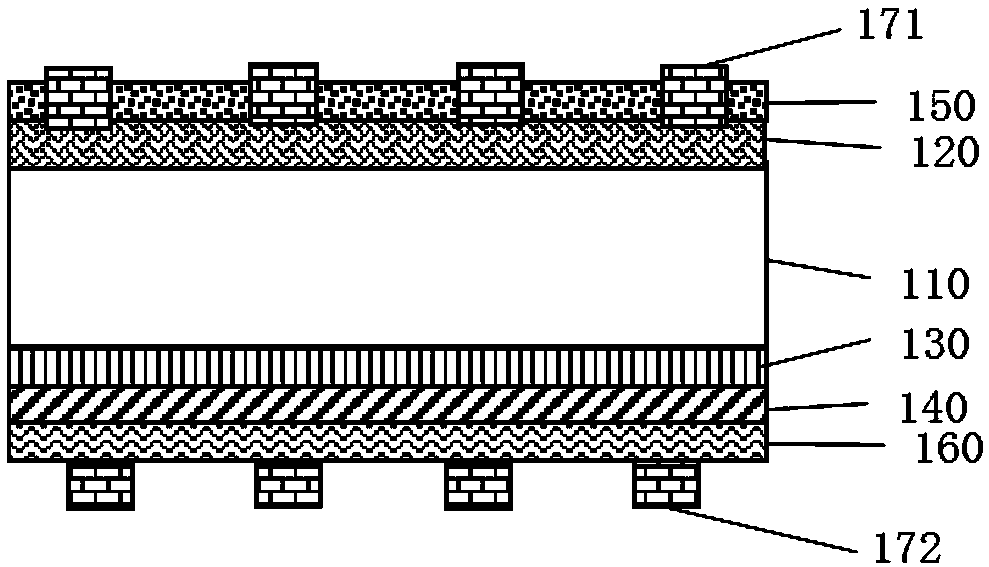

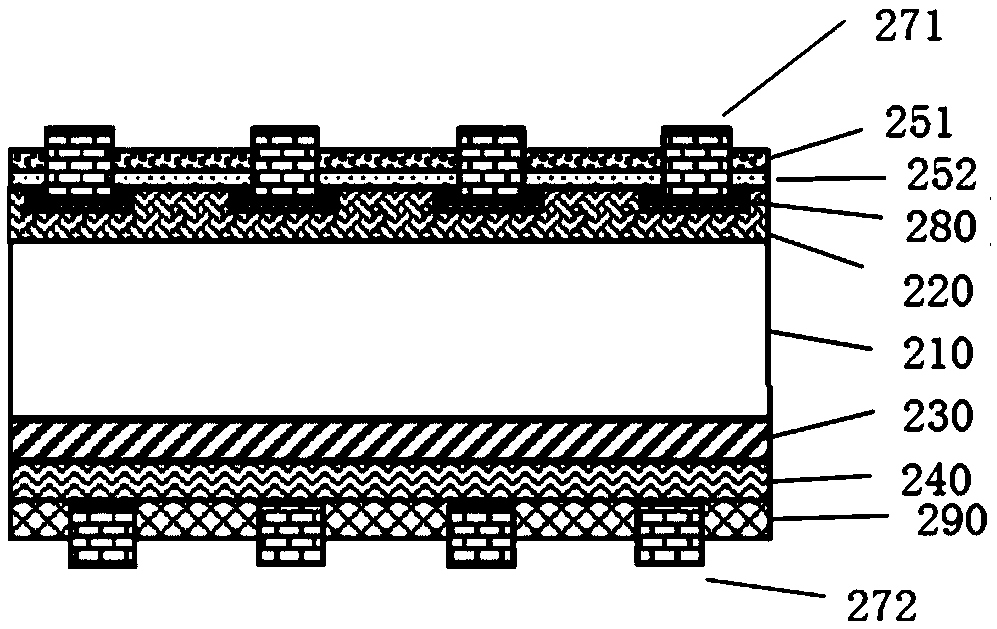

Passivation contact electrode structure and applicable solar cell and manufacturing method thereof

PendingCN108807565ALow priceImprove conductivityFinal product manufacturePhotovoltaic energy generationCopper electrodeMicrocrystalline silicon

The invention discloses a passivation contact electrode structure and an applicable solar cell and a manufacturing method thereof. The electrode structure comprises a doped semiconductor layer and a copper electrode, wherein the doped semiconductor layer is deposited on a crystalline silicon substrate, the copper electrode is arranged on the doped semiconductor layer, the doped semiconductor is any one of polycrystalline silicon, microcrystalline silicon or microcrystalline silicon carbon alloy, and the thickness of the doped semiconductor is 5 to 100 nm. In an implementation process, the applicable solar cell is arranged on the back side or the two sides of the crystalline silicon substrate and comprises the passivation contact electrode structure. The invention further discloses a manufacturing of the solar cell with the passivation contact electrode structure. According to the passivation contact electrode structure disclosed by the invention, a surface composite efficiency of photo-induced carriers is reduced by passivating contact among all the metal electrodes, and a more complete passivation effect is achieved; meanwhile, compared with an existing technological method, massproduction of the passivation contact electrode structure disclosed by the invention is achieved; furthermore, electroplated copper is utilized as a conducting layer to replace silver, so that cell production cost is reduced.

Owner:SUZHOU SUNWELL NEW ENERGY CO LTD

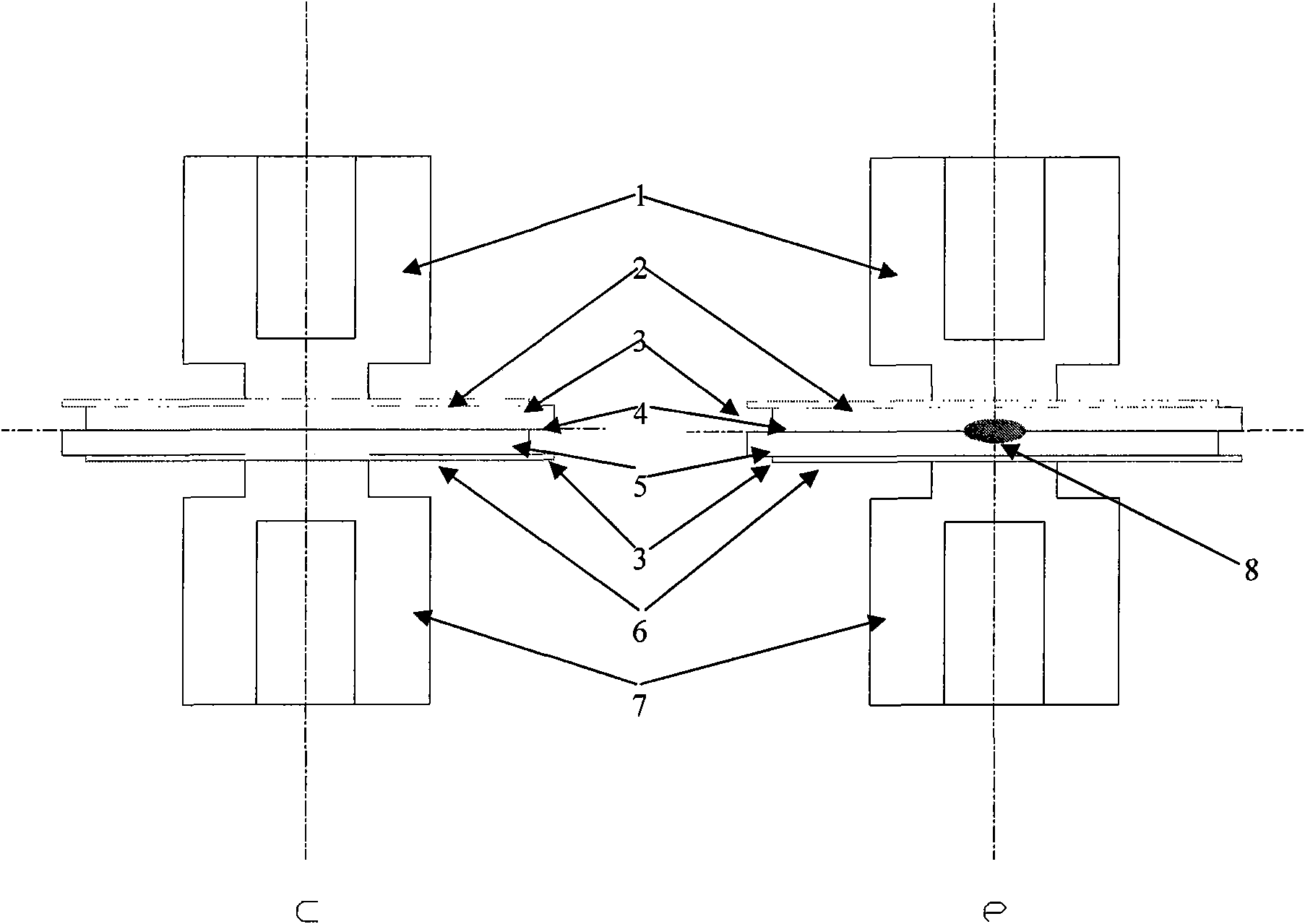

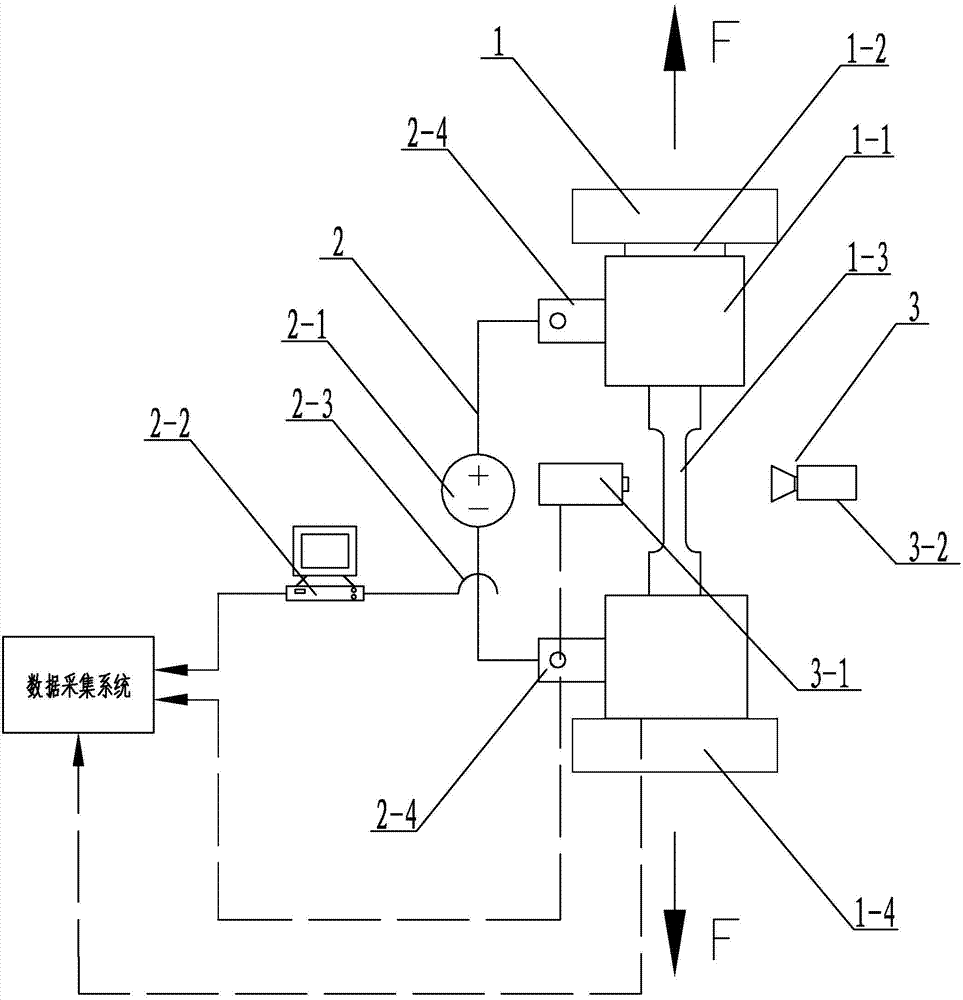

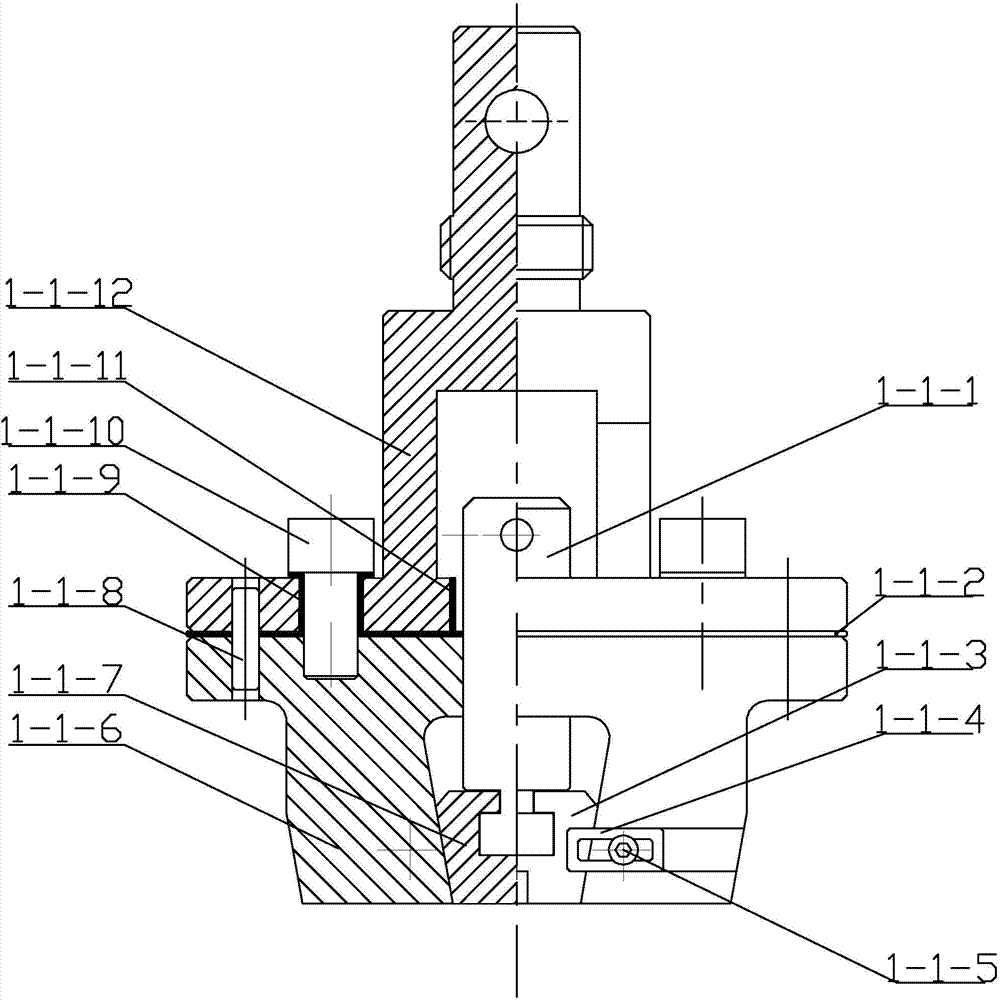

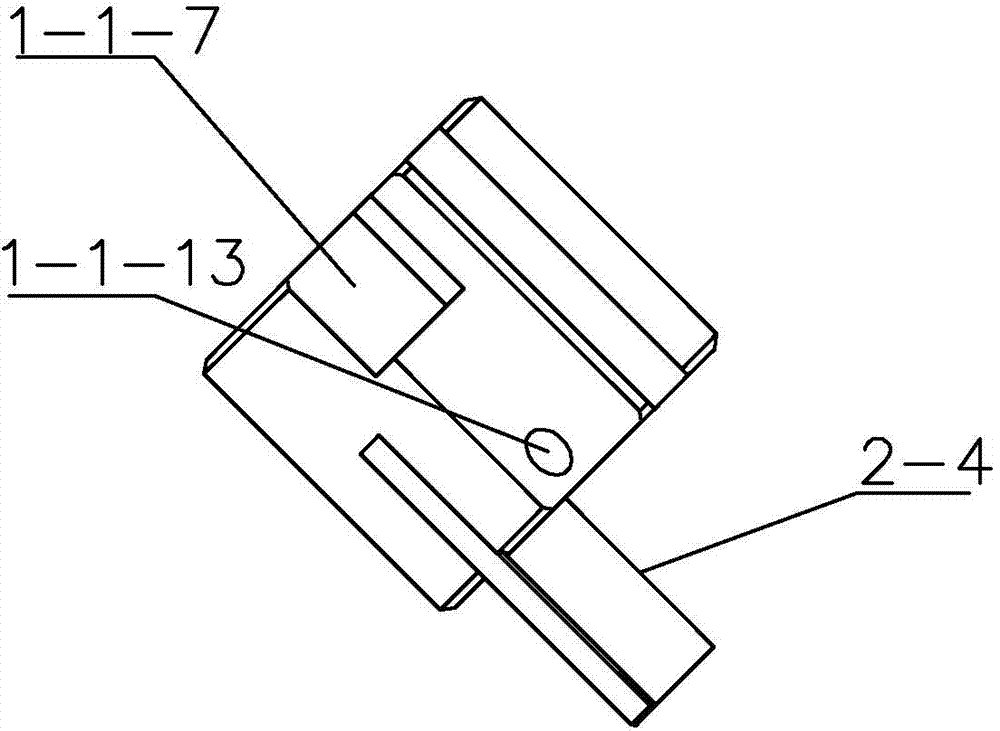

Testing device for current auxiliary type micro-stretching mechanical property of metal thin plate

ActiveCN104502203AImprove insulation performanceHigh withstand voltage breakdown indexMaterial strength using tensile/compressive forcesThin slabCopper electrode

The invention provides a testing device for a current auxiliary type micro-stretching mechanical property of a metal thin plate and relates to a mechanical property testing device. As no relative information can be referred at home and abroad at present, the problems of electrification and insulation of a micro-stretching clamp, a clamping form of a micro-test sample, control and acquisition of the temperature of the test sample, and current parameter acquisition are required to be solved. A force sensor is mounted at the lower part of a movable transverse beam of an all-purpose material testing machine; two sets of clamp bodies are symmetrically mounted on the all-purpose material testing machine; a micro-stretching test sample is mounted between the two sets of clamp bodies; the two ends of a pulse power supply are connected with the two sets of clamp bodies by purple copper electrodes; a digital storage type oscilloscope is connected with the pulse power supply through a Hall current probe; a loop is formed by the pulse power supply, the two purple copper electrodes, the two sets of clamp bodies and the micro-stretching test sample; and a thermal infrared imager and an industrial air blower are mounted on the two sides of the all-purpose material testing machine by brackets. The testing device is used for current auxiliary type micro-stretching mechanical property testing.

Owner:HARBIN INST OF TECH

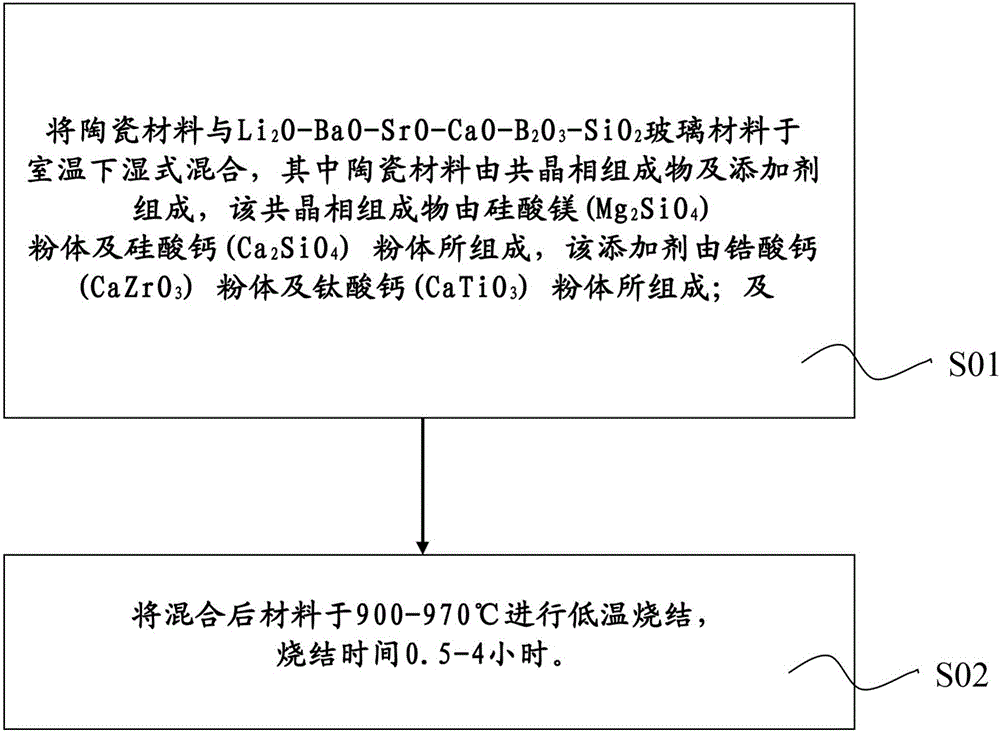

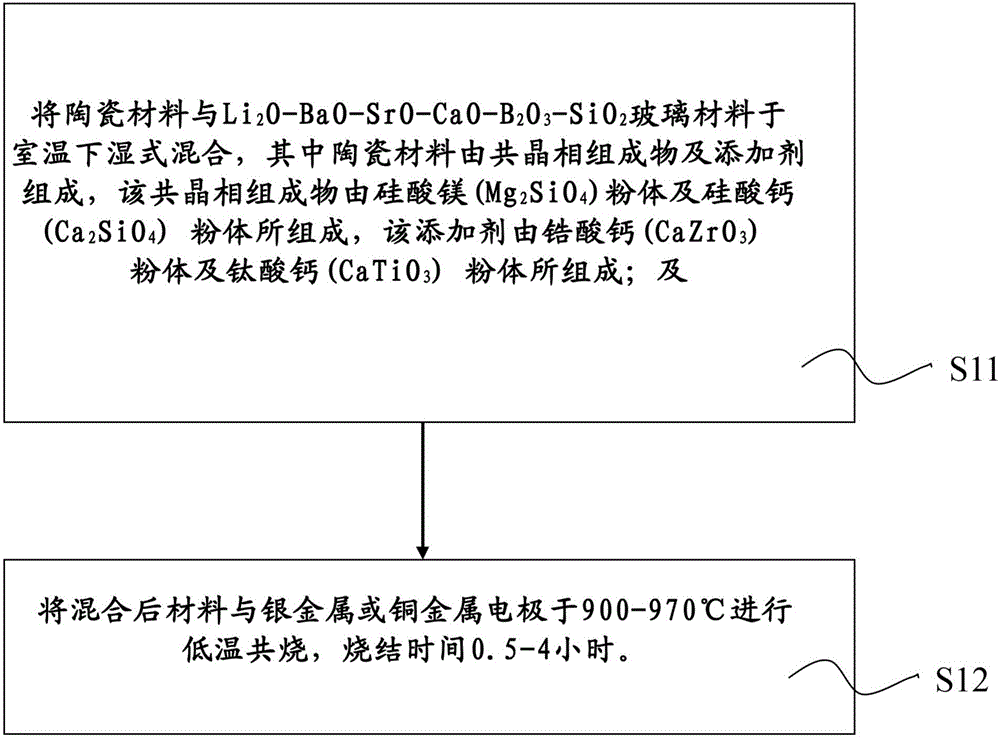

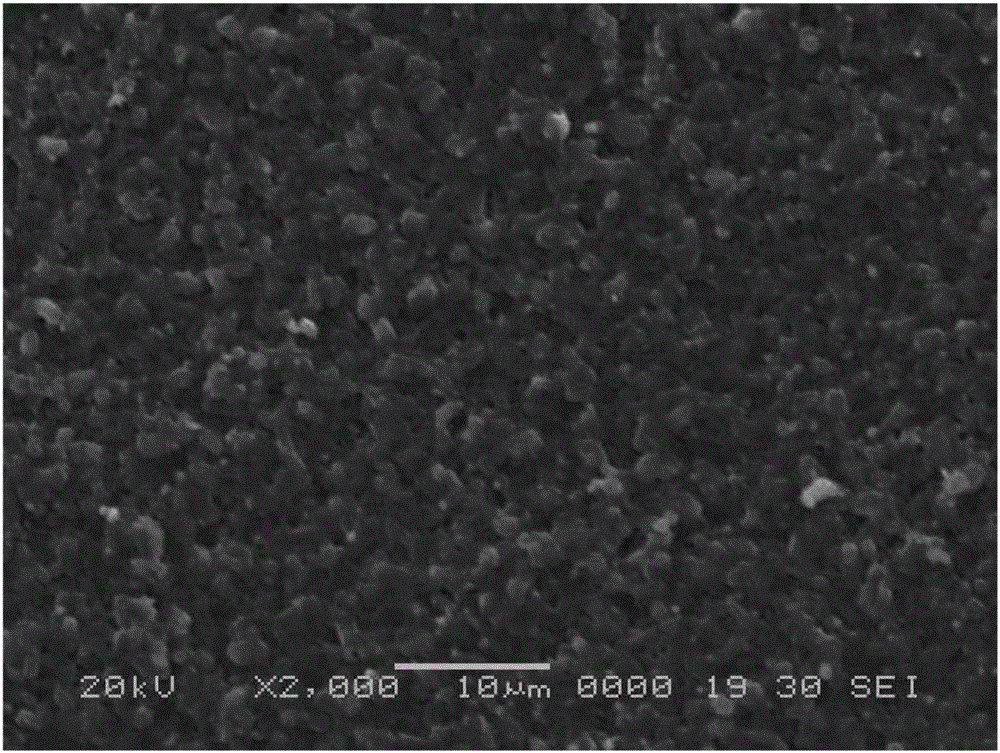

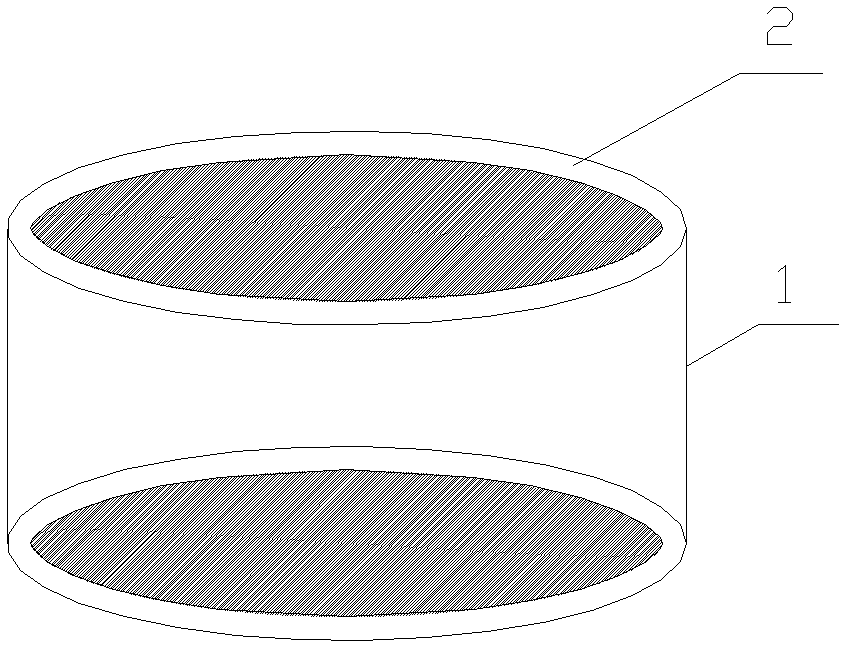

Low-temperature co-fired microwave dielectric ceramic material and preparation method thereof

The invention provides a microwave dielectric ceramic material which can be cofired with a silver or copper electrode at a low temperature and a preparation method thereof. The microwave dielectric ceramic material is prepared from a microwave dielectric ceramic material 1-y-z[(1-x)Mg2SiO4-xCa2SiO4]-yCaTiO3-zCaZrO3, and mixed with a multicomponent glass material Li2O-BaO-SrO-CaO-B2O3-SiO2, wherein x is more than or equal to 0.2 and is less than or equal to 0.7, y is more than or equal to 0.05 and is less than or equal to 0.3, and z is more than or equal to 0.02 and is less than or equal to 0.15. The low-temperature co-fired microwave dielectric ceramic material can be co-fired with silver or copper and other conductive metals at 900-970 DEG C at an atmosphere and inert gas environment. The material has excellent characteristics of low dielectric consumption, high quality factor, low temperature capacitance and the like, and is applicable to multilayer ceramic component manufacture procedure and processing after being fired.

Owner:WALSIN TECHNOLOGY CORPORATION

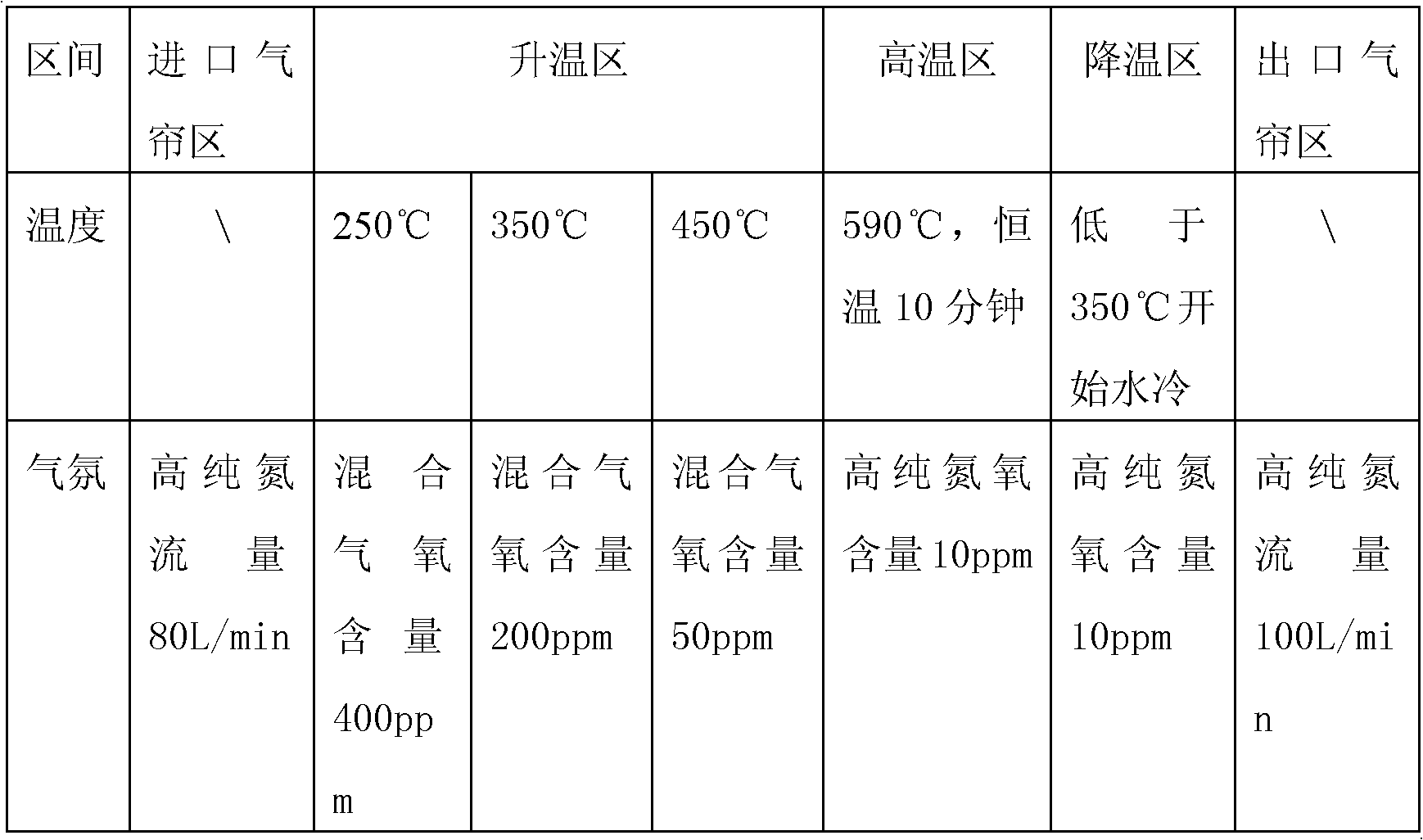

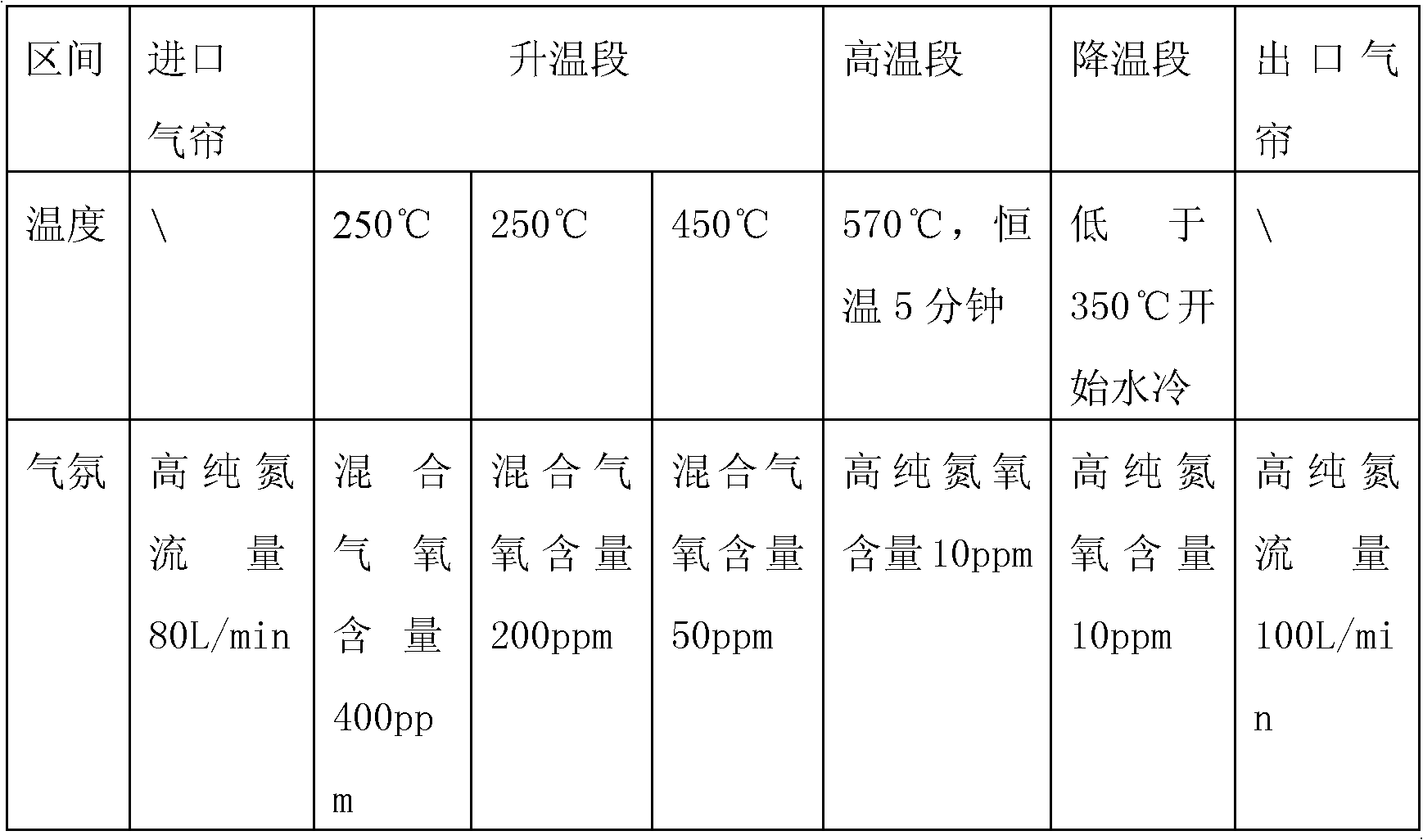

Copper-electrode zinc-oxide voltage-sensitive resistor and preparation method thereof

ActiveCN102324290AReduce manufacturing costSuitable for mass productionResistors adapted for applying terminalsResistor detailsCopper electrodeSlurry

The invention discloses a preparation method of a copper-electrode zinc-oxide voltage-sensitive resistor, which comprises the following steps of: voltage-sensitive ceramic-body manufacture, copper-electrode slurry printing, copper-electrode drying and copper-electrode sintering and permeation, wherein the copper-electrode sintering and permeation are carried out under an oxygen-free atmosphere environment by adopting a chain-belt type tunnel electric furnace as production equipment. In the invention, the copper-electrode zinc-oxide voltage-sensitive resistor with qualified performances is manufactured by replacing noble-metal silver with base-metal copper as an electrode material and using special electrode sintering and permeating processes, so that the production cost is greatly saved. The preparation method has the following advantages that: 1. the process technology is suitable for the mass production of the copper-electrode zinc-oxide voltage-sensitive resistors; 2. all the electrical performances (comprising voltage nonlinear coefficient, leakage current, through-current capacity, energy tolerance and the like) of a product produced through the process technology can reach the level equivalent to a silver-electrode product, and the requirements of clients are met; and 3. the cost of the product is much lower than that of the silver-electrode product in the same specification.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Method of manufacturing a capacitor with copper electrodes and diffusion barriers

A method of manufacturing a capacitor having a couple of electrodes with a dielectric placed therebetween. At least one of the electrodes is made of copper, and barriers for preventing the diffusion of copper into the dielectric are provided between the dielectric and the copper electrode respectively.

Owner:LAPIS SEMICON CO LTD

Method for manufacturing a memory element

A method for manufacturing the memory device by plasma decomposition of sulfur dioxide. A first copper electrode having a surface is provided. The surface of the first copper electrode may be made amorphous. A copper sulfide layer, CuxS, where 1≦x≦2, is disposed on the copper surface by decomposing sulfur dioxide in an ambient containing excess hydrogen. The copper sulfide layer may be is cuprous sulfide or cupric sulfide. A second copper electrode is coupled to the copper sulfide layer.

Owner:GLOBALFOUNDRIES INC

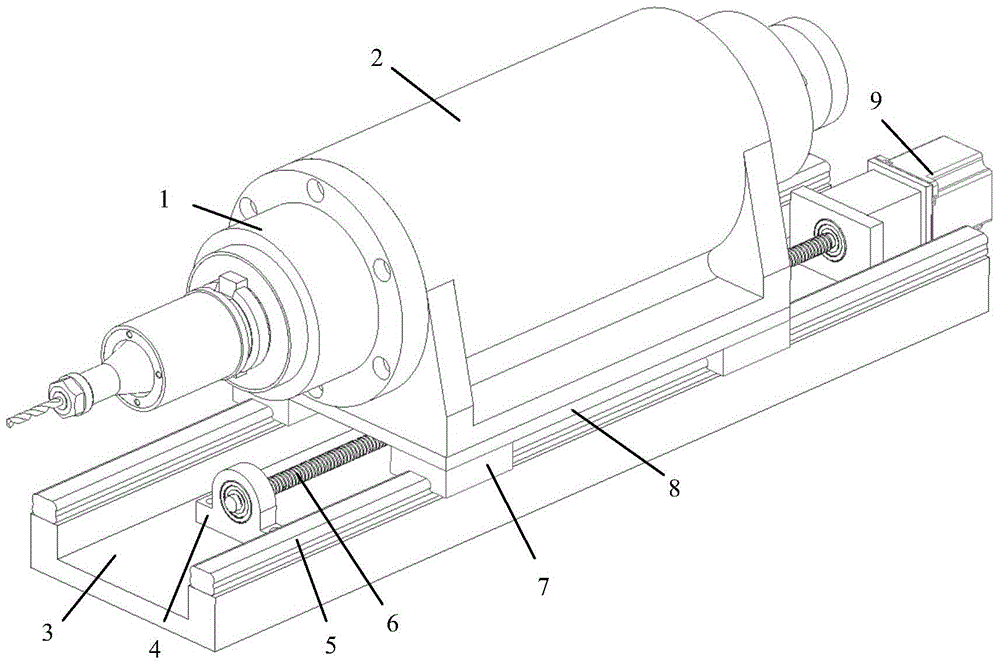

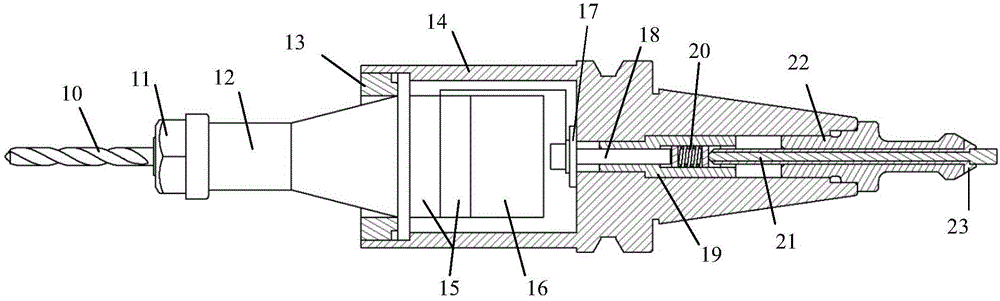

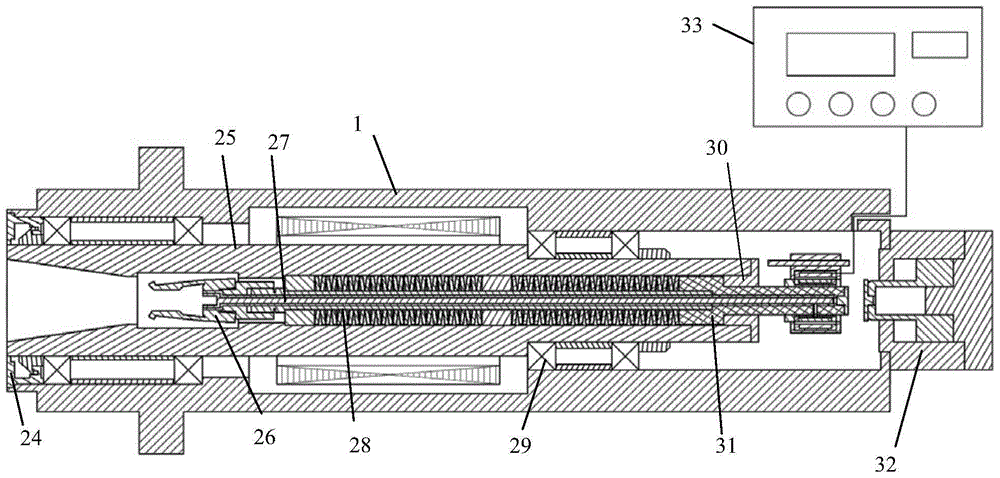

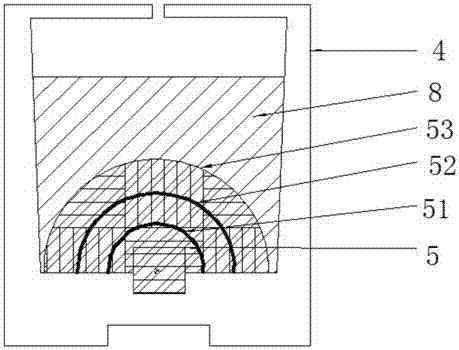

Ultrasonic vibration drill hole tail end actuator

The invention discloses an ultrasonic vibration drill hole tail end actuator which comprises a main shaft unit, an ultrasonic knife handle unit and a feeding unit. The ultrasonic vibration drill hole tail end actuator overcomes the defects of a traditional drilling technique, an ultrasonic vibration drilling technique is utilized for conducting drilling on aluminum alloy, titanium alloy, carbon fiber composite materials and other materials difficult to process through robots, especially for conducting drilling on small holes with the diameter being less than 6 mm, and the machining quality and efficiency are improved. A radial wireless transmission mode is adopted for the tail end of a rotor to transmit ultrasonic signals, interference with oil cylinder cutter movement and spindle rotation does not occur, a copper electrode penetrates through a spring rod inner hole to be connected with a knife handle inner copper electrode in cooperation with an elastic pin shaft in the knife assembling process so as to transmit ultrasonic signals, a carbon brush does not need to be replaced, device durability is improved, all power transmission devices are arranged in a main shaft, and a robot can achieve multi-angle drilling. Multiple ultrasonic knife handles can be replaced quickly, and machining efficiency is improved.

Owner:DALIAN UNIV OF TECH

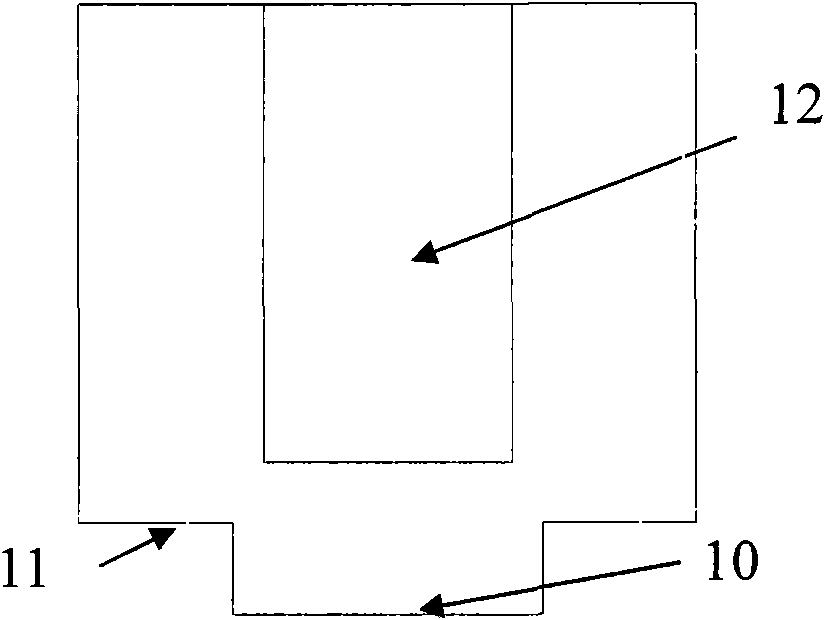

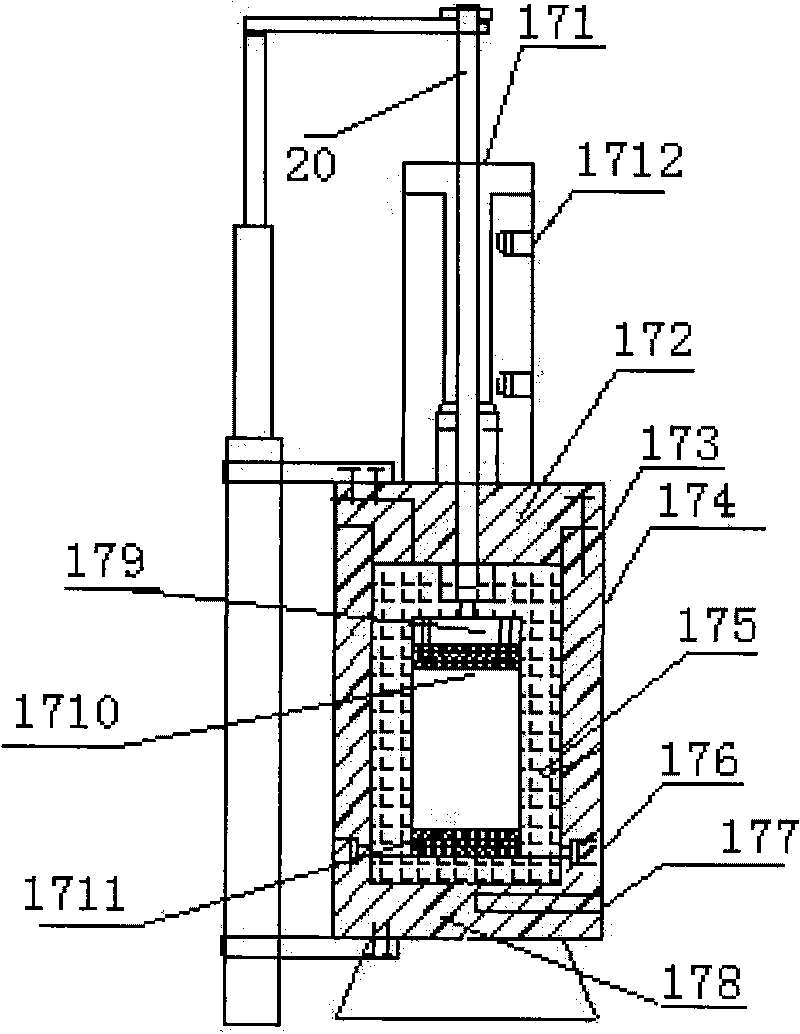

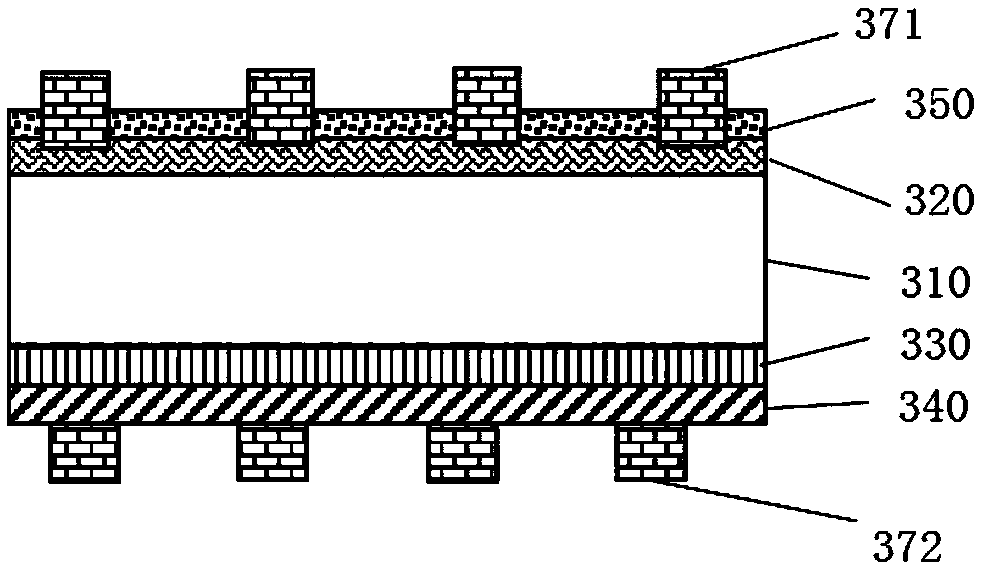

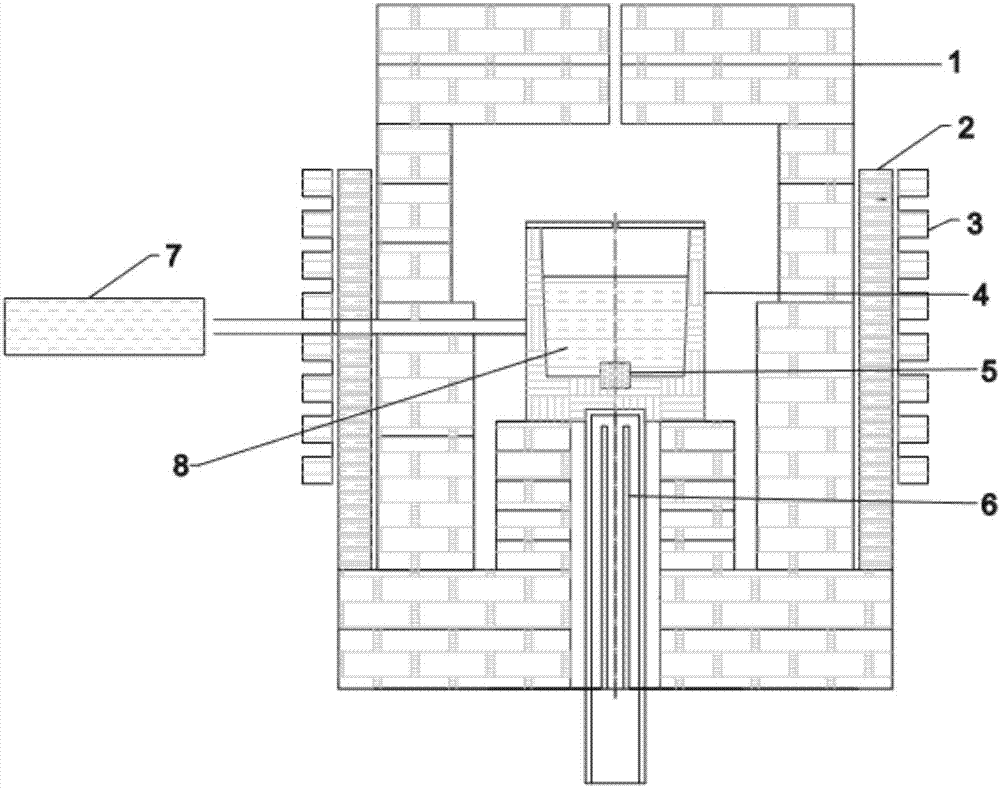

Growth equipment and growth method for large-size gallium oxide monocrystalline

InactiveCN107541776AReduce volatilityReduce decompositionPolycrystalline material growthUnder a protective fluidBrickCopper electrode

The invention relates to a piece of growth equipment and a growth method for large-size gallium oxide monocrystalline. The equipment comprises the following components: a zirconia insulating brick (1), a quartz cylinder (2), a water cooling copper electrode (3), an iraurita crucible (4), a heat exchanger (6), and an infrared thermometer (7). The method comprises the following steps: the iraurita crucible (4) is placed in the crystal growth furnace cavity formed by the zirconia insulating brick (1), the outside of the zirconia insulating brick (1) is provided with the quartz cylinder (2) and the water cooling copper electrode (3) in order, the heat exchanger (6) is placed at the bottom of the iraurita crucible (4), the infrared thermometer (7) is connected to the iraurita crucible (4), andthe iraurita crucible (4) contains a gallium oxide solution (8) and seed crystal (5). Compared with the prior art, heat exchange method is used for growing crystal, the efficiency is improved, and production cost is reduced; at the same time, grown crystal has the advantages of excellent quality, little stress, low dislocation density, good crystal perfection and optical homogeneity, improved utilization rate of the gallium oxide material, and simplified processing operation.

Owner:TONGJI UNIV

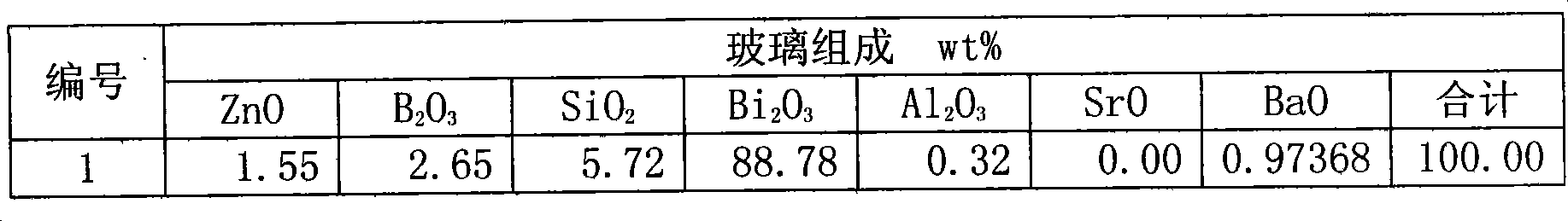

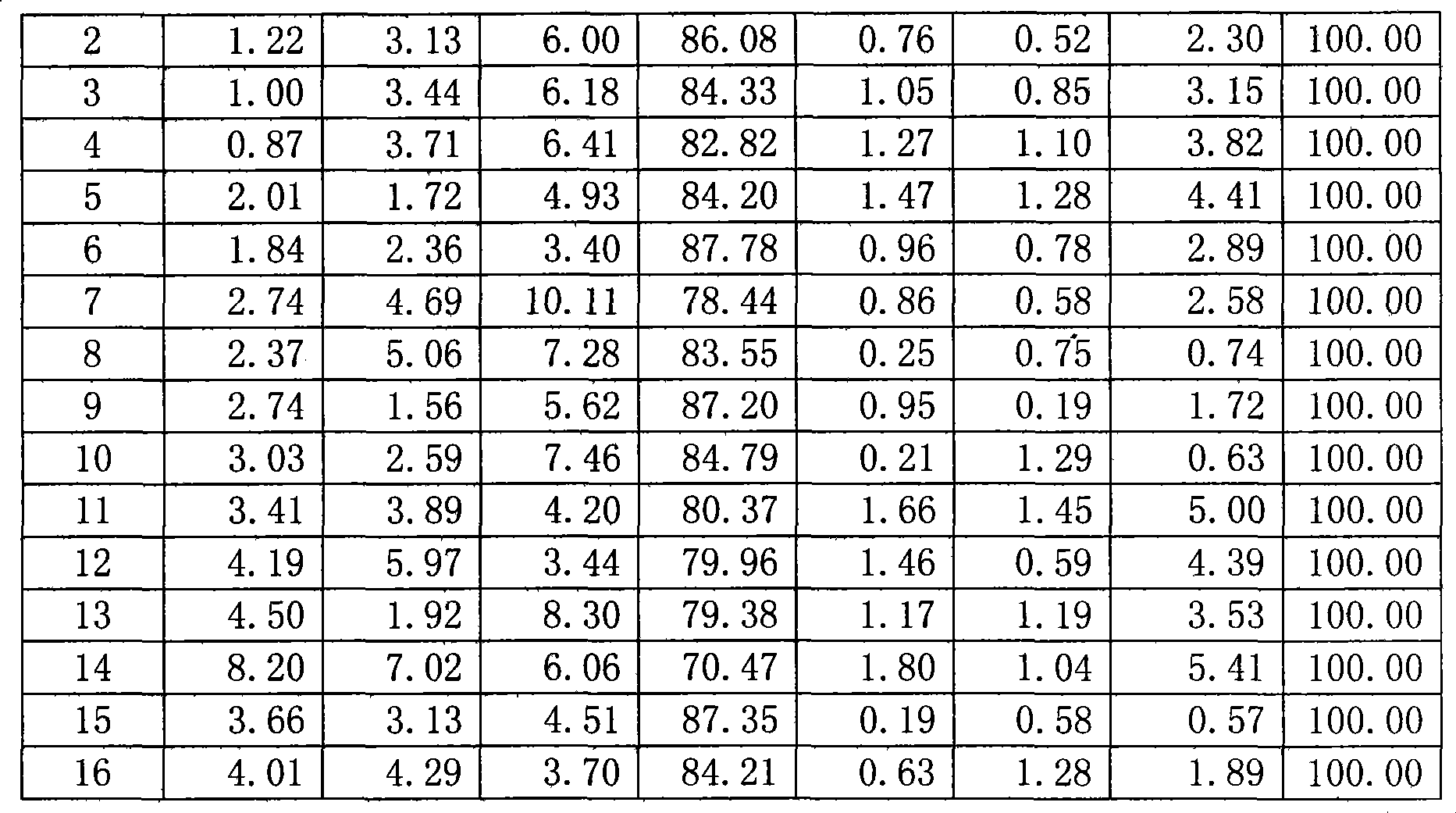

Base metal copper electrode paste and preparation of obtained capacitor

ActiveCN101364455APromote crystallizationImprove uniformityFixed capacitor electrodesConductive materialPolymer resinCopper electrode

The invention relates to base metal copper electrode slurry and a preparation method of a capacitor from the same. The base metal copper electrode slurry comprises the following components (wt%): 30-65 wt% of spherical copper, 10-30 wt% of sheet copper, 1.52-10 wt% of glass powder, 2-15 wt% of inorganic non-metallic additive, and 10.5-24 wt% of organic carrier, wherein the glass powder is a ZnO-B2O3-SiO2-Bi2O3 glass system; the inorganic non-metallic additive is one or more selected from CuO, Cu2O, ZnO and B2O3; and the organic carrier is polymer resin and a solvent. The base metal copper electrode slurry can be used in a ceramic disc capacitor and a semiconductor disc ceramic capacitor chip, the sintering temperature is 600-800 DEG C, and after sintering, the copper electrode slurry is converted to a copper electrode. The base metal copper electrode slurry has the characteristics of low cost, uniform material, uniform particle size distribution, high dispersibility, good forming process, and environmental friendliness.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Quick reaction synthesis type high temperature atmosphere stove and method for synthesizing ceramic powder

The invention relates to a method to synthesize high-temperature atmosphere furnace and ceramic powder in the way of rapid reaction. A water-cooled flange provided with a water-cooled intermediate separator board at the middle part divides an atmosphere furnace into a high temperature atmosphere furnace and a cold chamber furnace. The high temperature atmosphere furnace is provided with a horizontal heating chamber which is installed on the hearth and which consists of insulation material and heating elements. The heating elements are uniformly distributed on the upper and lower surfaces of the internal walls of the insulation material and connected with the copper electrode installed on the high temperature atmosphere furnace through leads; a heat insulation valve is mounted on the surface of the horizontal heating chamber facing the cold chamber furnace, wherein a fixed track is mounted in the heat insulation valve; the movable track in the cold chamber furnace is connected with the lower push rod in the push rod mechanism, wherein the movable track is provided with a hopper onside, and the hopper is connected with the upper push rod of the push rod mechanism; every furnace is provided with an air inlet and an air outlet with a valve, a vacuum hole and a thermocouple, etc. The invention not only realizes the rapid heating of the materials and the rapid synthesis of the atmosphere, but also realizes the rapid cooling of the products and the even growth of the crystal.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com