Base metal copper electrode paste and preparation of obtained capacitor

A copper electrode, base metal technology, used in capacitors, fixed capacitors, fixed capacitor electrodes, etc., can solve problems such as uneven appearance and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

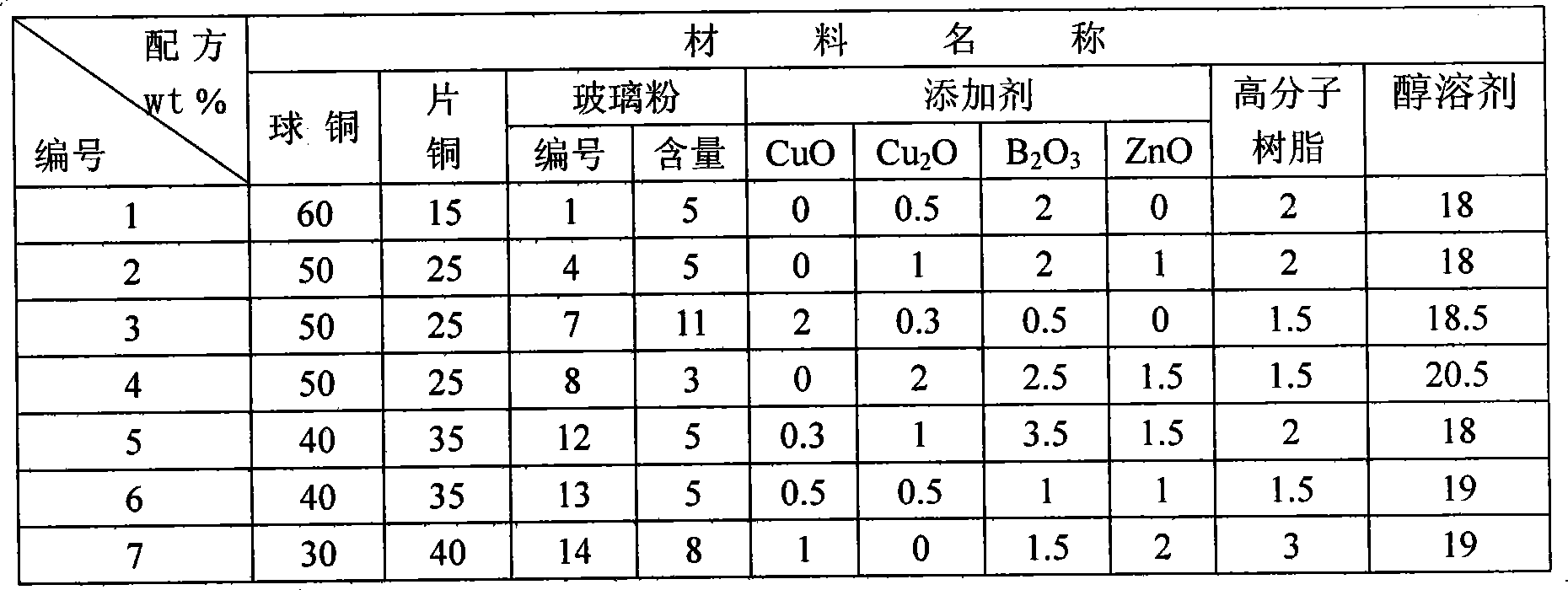

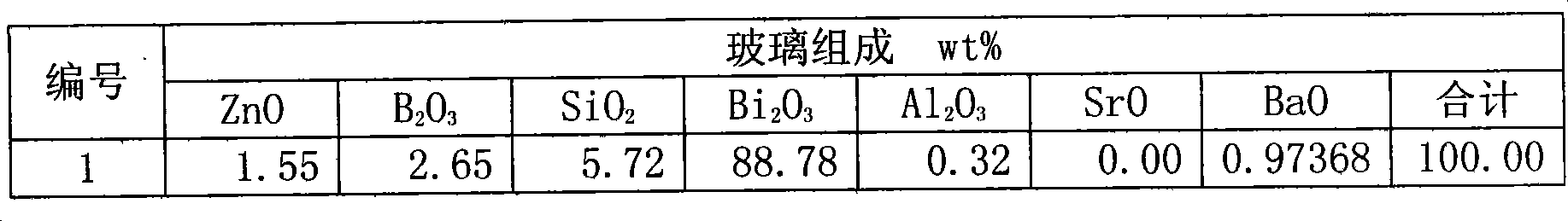

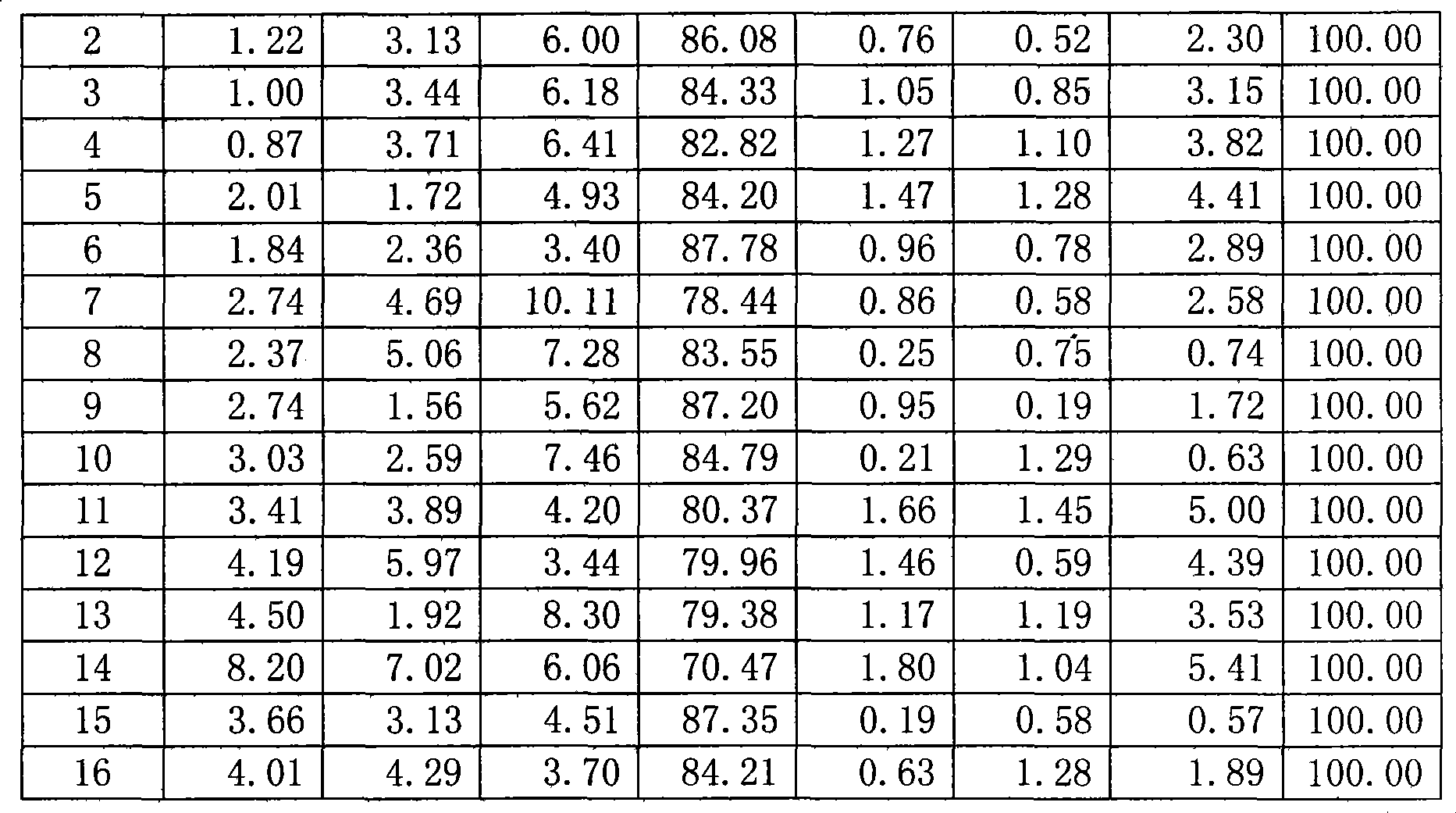

[0011] According to the No. 1-7 slurry formulas in Table 1, the glass powder in the formula is any one of the glass powder 1-16 formulas in Table 2, and the polymer resin is ethyl cellulose, hydrogenated rosin resin, polymer One or several kinds of ethylene and polyurethane resins are fully mixed and then fully ground and rolled by a three-roller grinder. After reaching a certain fineness and viscosity, a base metal copper electrode slurry is formed, and then the base metal copper electrode slurry is formed by a conventional method. The ceramic disc capacitor Y5P252-4830-102K500V specification is produced, and its sintering temperature is 600-800°C. After sintering, the copper electrode paste becomes a copper electrode. The obtained capacitor performance test parameters are the test parameters corresponding to No. 1-7 material formulations in Table 3.

[0012] Table 1: The best embodiment formula components of copper electrode slurry of the present invention are as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com