Lithium iron phosphate-carbon nanotube composite material, preparation method, and application thereof

A technology of lithium iron phosphate and carbon nanotubes, which is applied in the preparation of lithium iron phosphate-carbon nanotube composite materials, in the field of lithium iron phosphate-carbon nanotube composite materials, to achieve the effect of improving dispersion and good crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

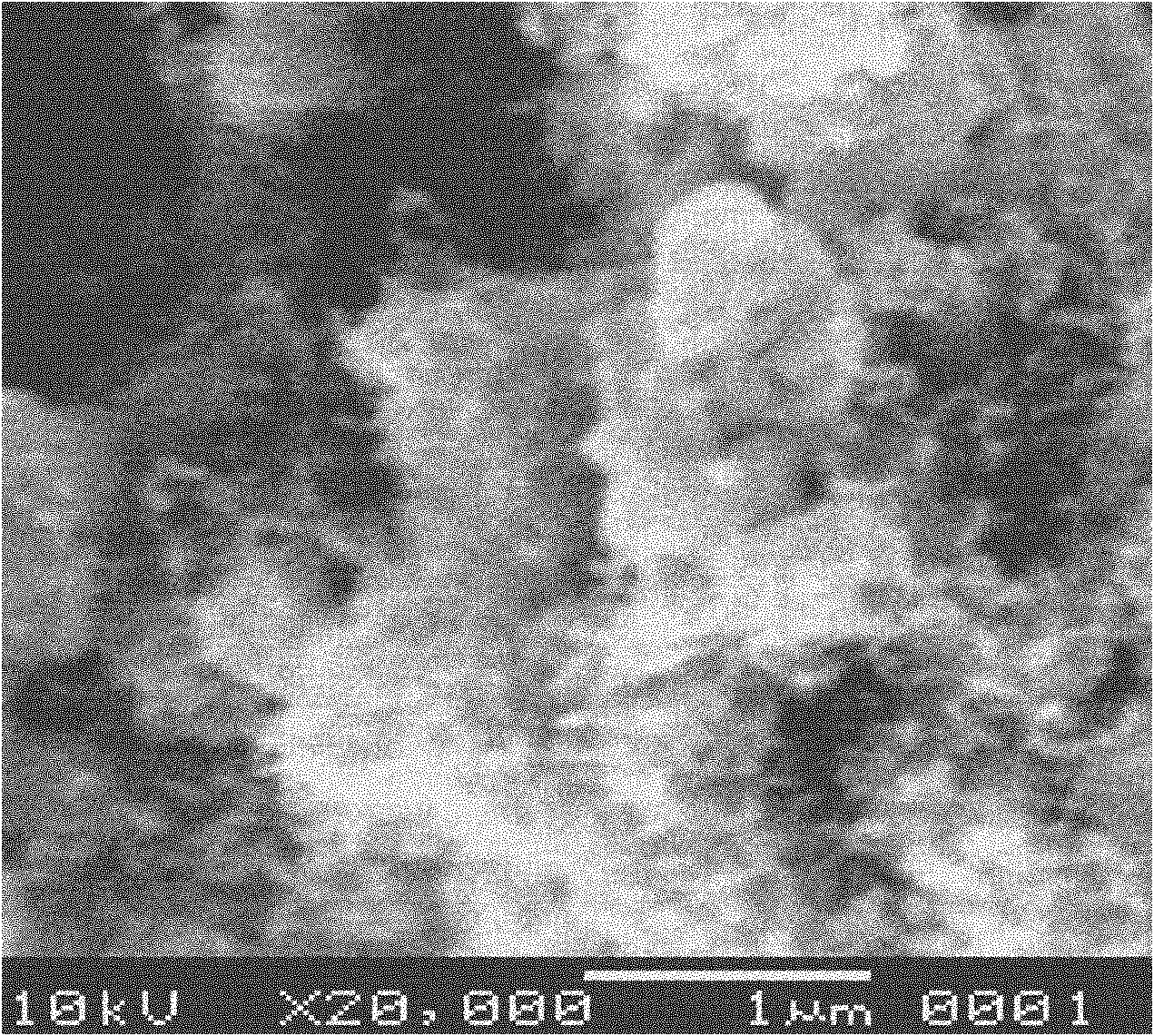

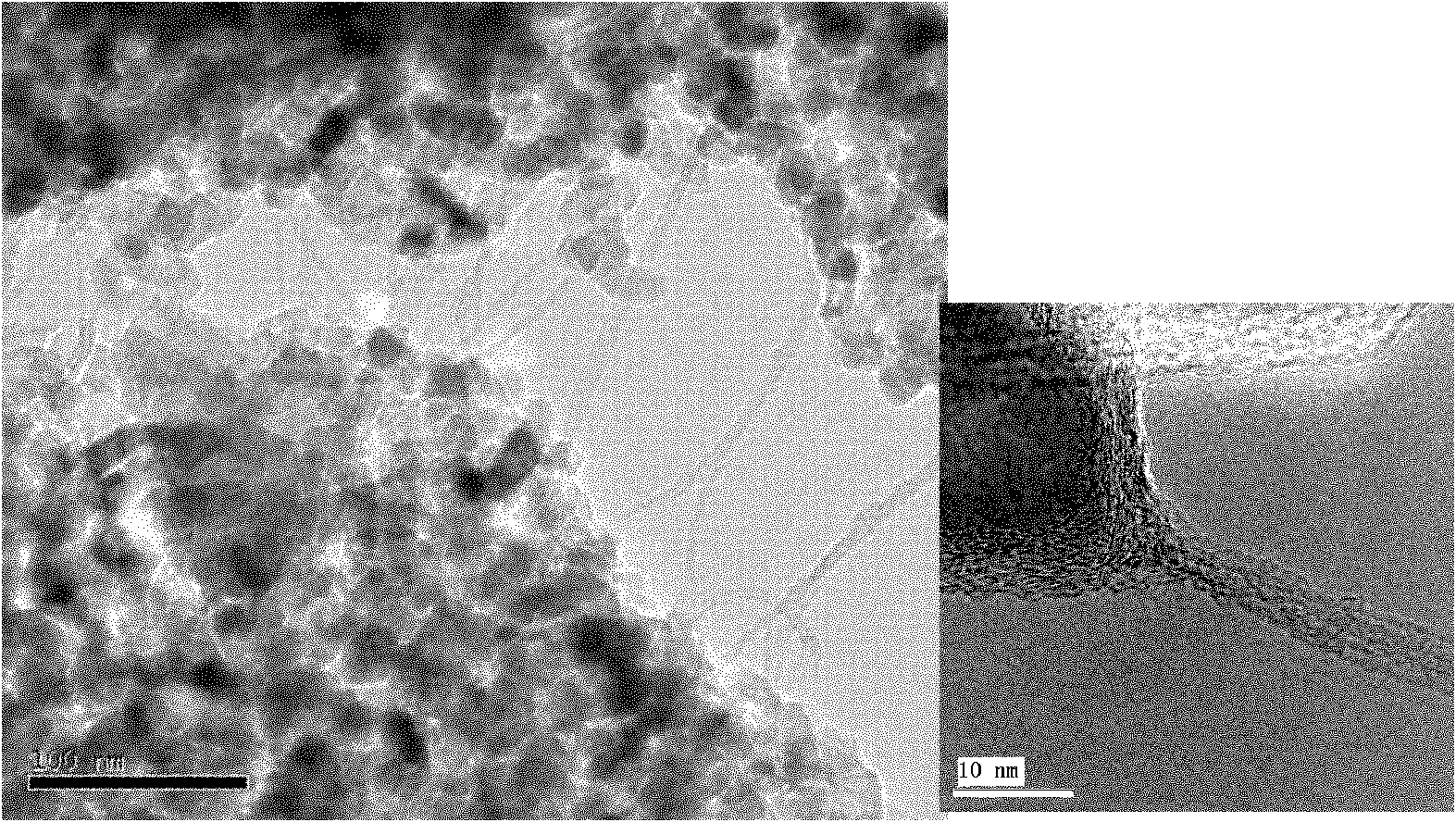

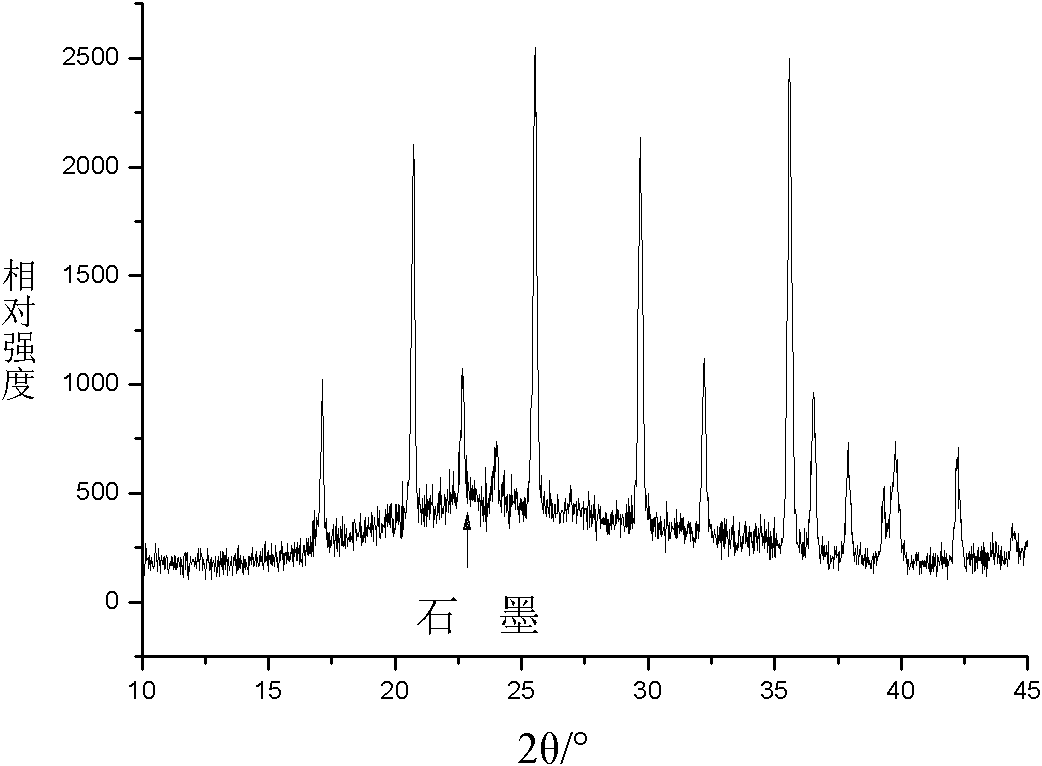

Embodiment 1

[0047] with Fe 3 (PO 4 ) 2 ·8H 2 O. Li 3 PO 4 As a raw material, with absolute ethanol as a dispersant, the ratio of lithium source, iron source, and phosphorus source is weighed according to Li:Fe:P=1:1:1 (molar ratio), and the Fe 3 (PO 4 ) 2 ·8H 2 O 5kg, weighing Li 3 PO 4 1.2kg, adding 6L of absolute ethanol, mechanical ball milling for 8 hours and then drying to obtain the precursor powder. The catalyst components are 1g of nickel sulfate, 0.5g of ammonium heptamolybdate, and 10g of magnesium sulfate. The solution is prepared with 3kg of propanol, and the precursor powder is added and stirred evenly. The pH is adjusted to 8 with ammonia water. 30% slurry. Adjust the parameters of the spraying equipment, spray the above slurry into the rotary furnace at a uniform speed, the inert atmosphere is 3000 SCCM positive high-purity nitrogen, and the furnace temperature is stabilized at 700°C and kept warm. The feeding time lasts for 20 minutes. After the end, the high-...

Embodiment 2

[0050] FePO 4 2H 2 O. Li 2 CO 3 As the main raw material, weigh the raw material according to the mol ratio of 2:1, FePO 4 2H 2 O3.7kg, Li 2 CO 3 0.7kg, a total of 4kg, the dispersant is acetone 3L, mechanical ball milling for 3 hours and then drying to obtain the precursor powder. The catalyst is 2g of iron nitrate, 20g of magnesium nitrate, and 2kg of absolute ethanol, which are mixed with the precursor powder and fed with ammonia gas to adjust the pH value to 8 to make a slurry. Adjust the parameters of the spray equipment, spray the above slurry into the rotary furnace at a uniform speed, the inert atmosphere is 3000 sccm positive high-purity argon, and the furnace temperature is stable at 800°C. The feeding time lasts for 10 minutes. After the end, the high-pressure nitrogen flow will bring the powder into the rear section of the reaction furnace for deposition. After the nitrogen gas is kept at normal pressure for 6 hours, it is cooled and sampled to obtain LiFeP...

Embodiment 3

[0052] Weigh 2LiOH·H at a ratio of 1:2mol 2 O, FePO 4 2H 2 O is 2kg in total, using 2L of isopropanol as a dispersant to mix evenly, then blending with a solution of 2g of magnesium nitrate, 1g of nickel nitrate, and 0.4g of ammonium heptamolybdate dissolved in 50g of absolute ethanol, and adjusting the pH value to the catalyst group by using ammonia water After the sub-precipitation is complete, continue to add 8 kg of absolute ethanol to adjust the overall solid content of the slurry to 20%, and stir at a high speed to prepare a stable precursor slurry. Adjust the parameters of the spray equipment, spray the above slurry into the rotary furnace at a uniform speed, and the inert atmosphere is 2000 sccm forward high-purity argon. The feed reaction time was controlled to 12 minutes, and the floating CVD temperature was 700°C for the reaction; the composite precursor was kept at 730°C for 2 hours in the sintering section, and then cooled and sampled to obtain LFP-CNTs with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com