Patents

Literature

7835 results about "Phase-change material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

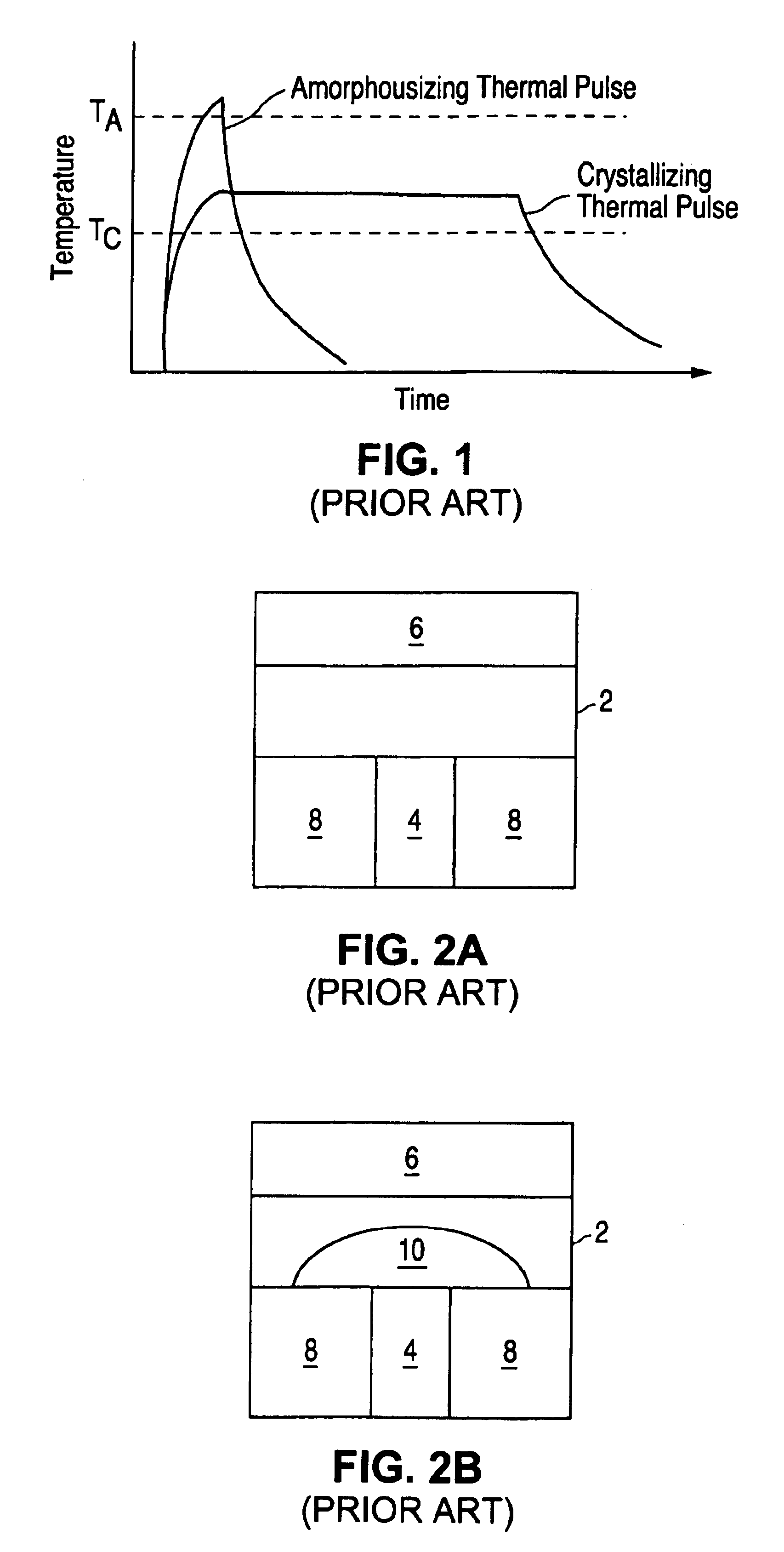

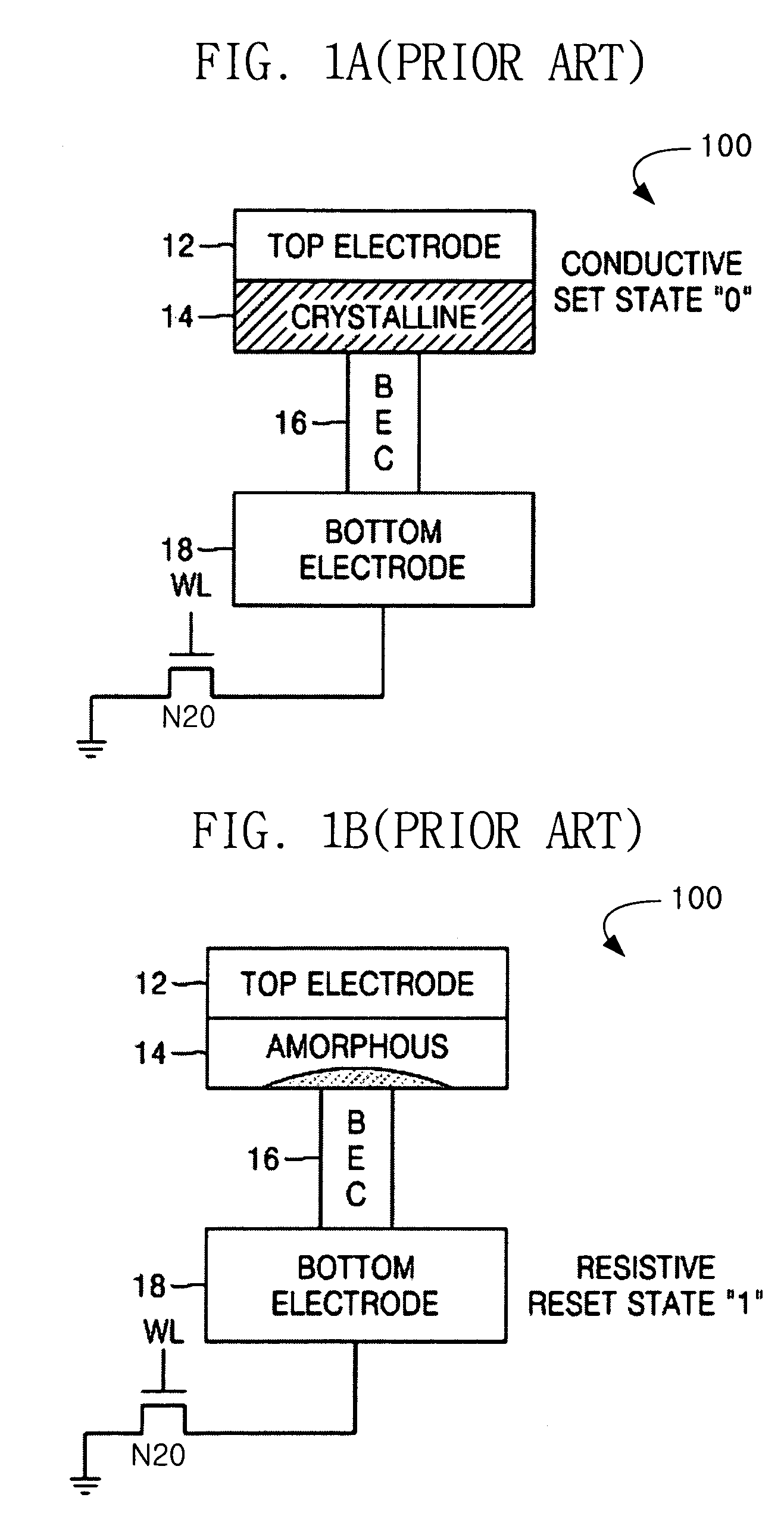

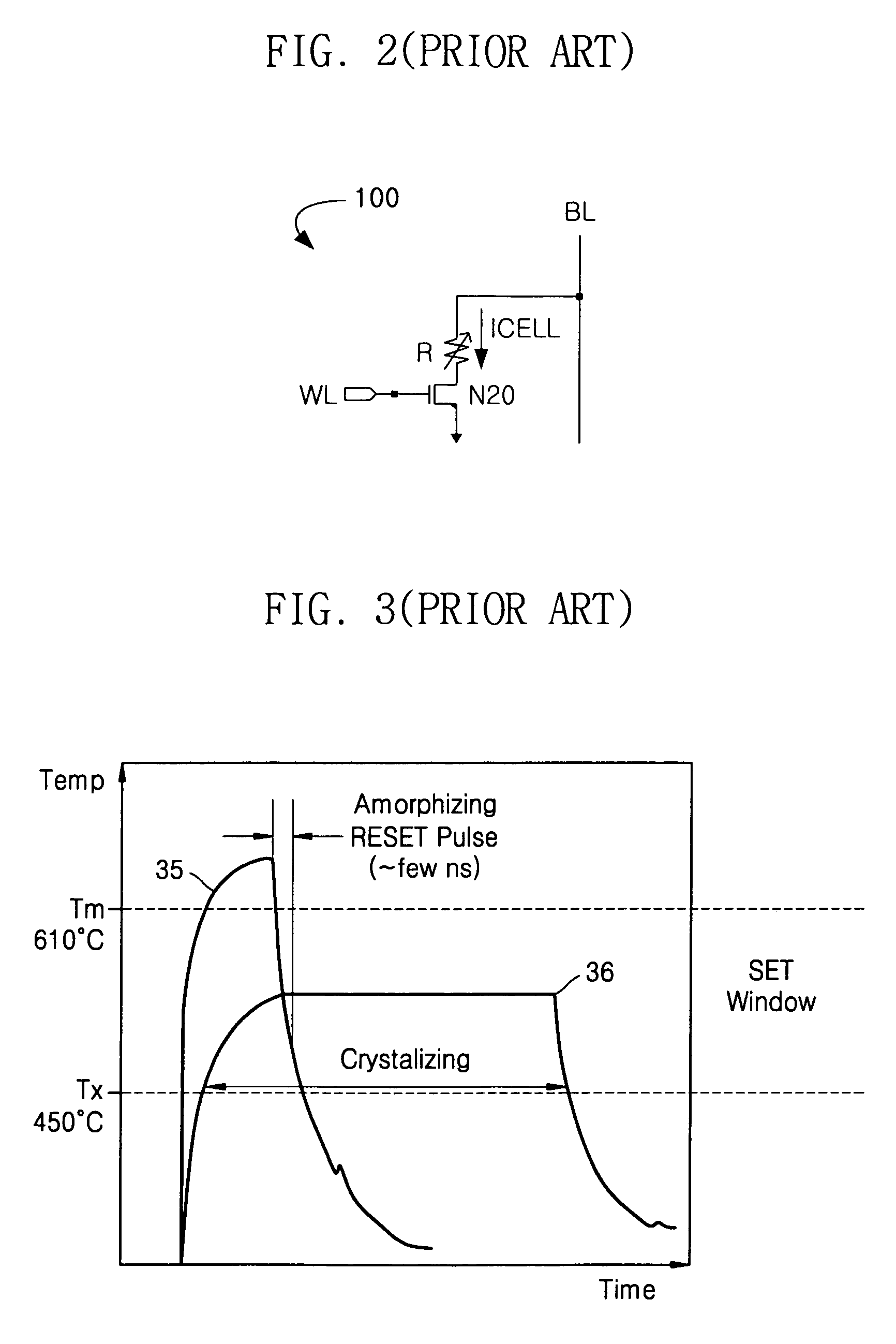

A phase change material (PCM) is a substance which releases/absorbs sufficient energy at phase transition to provide useful heat/coolth. Generally the transition will be from one of the first two fundamental states of matter - solid and liquid - to the other. The phase transition may also be between non-classical states of matter, such as the conformity of crystals, where the material goes from conforming to one crystalline structure to conforming to another, which may be a higher or lower energy state.

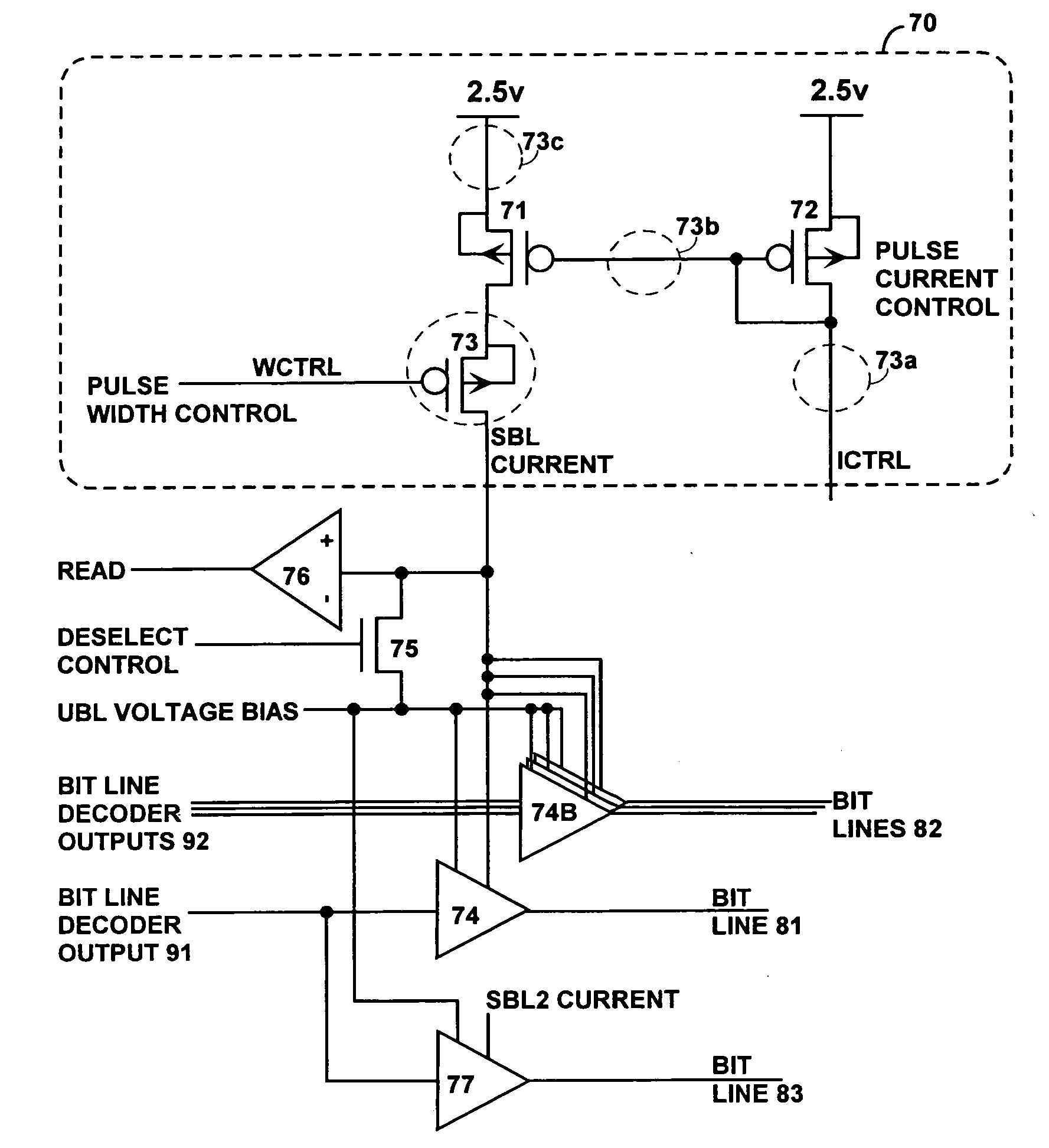

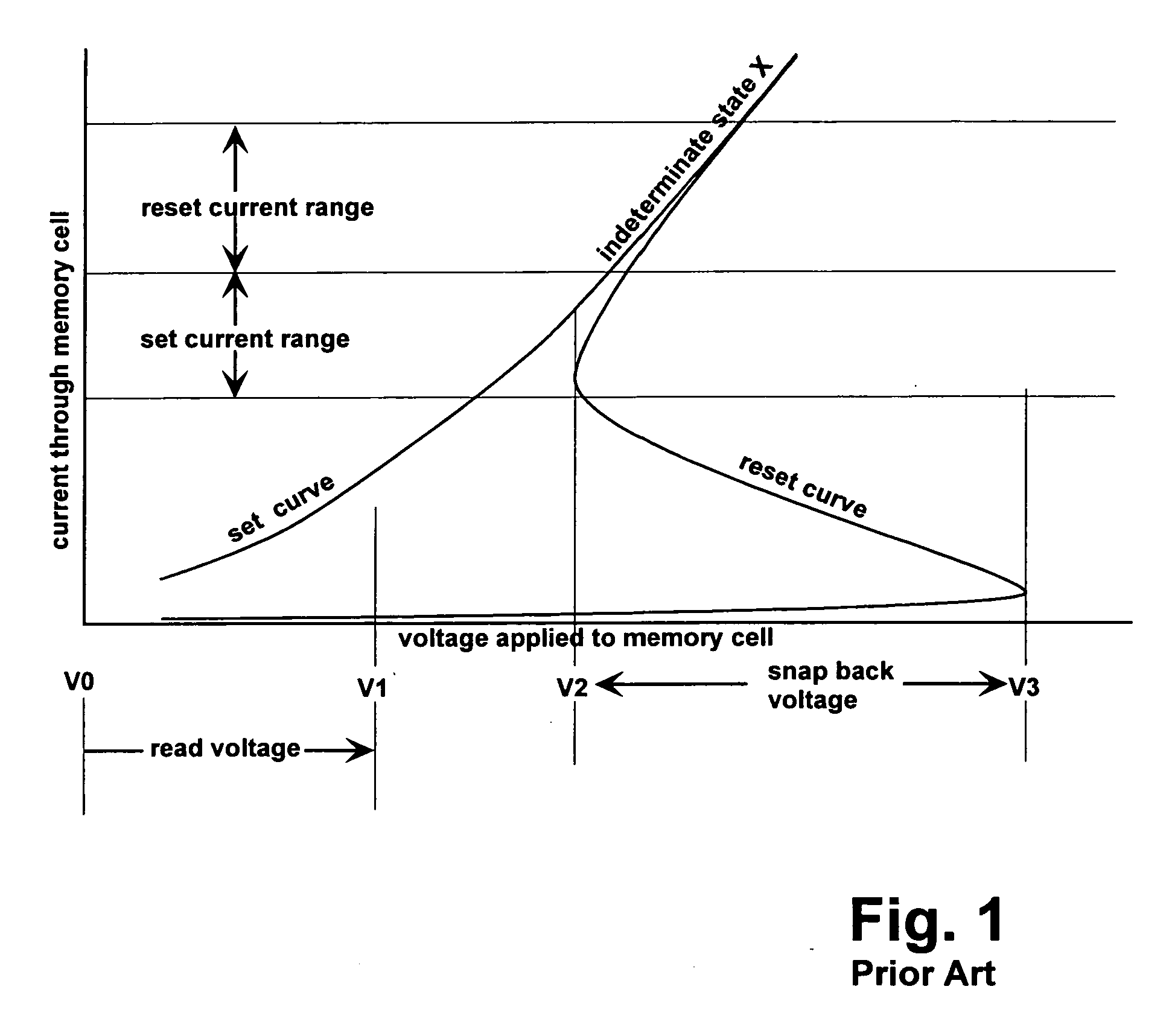

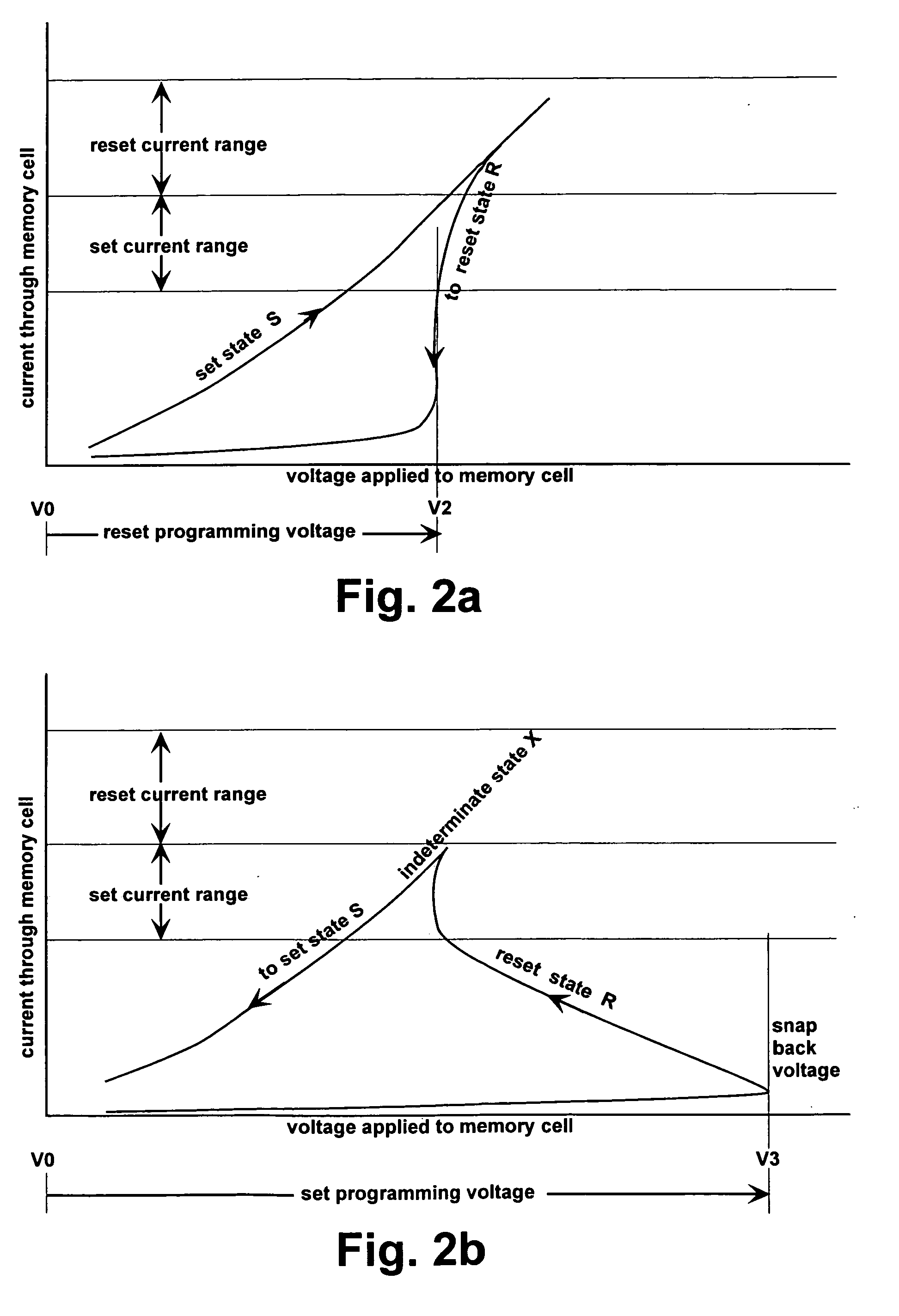

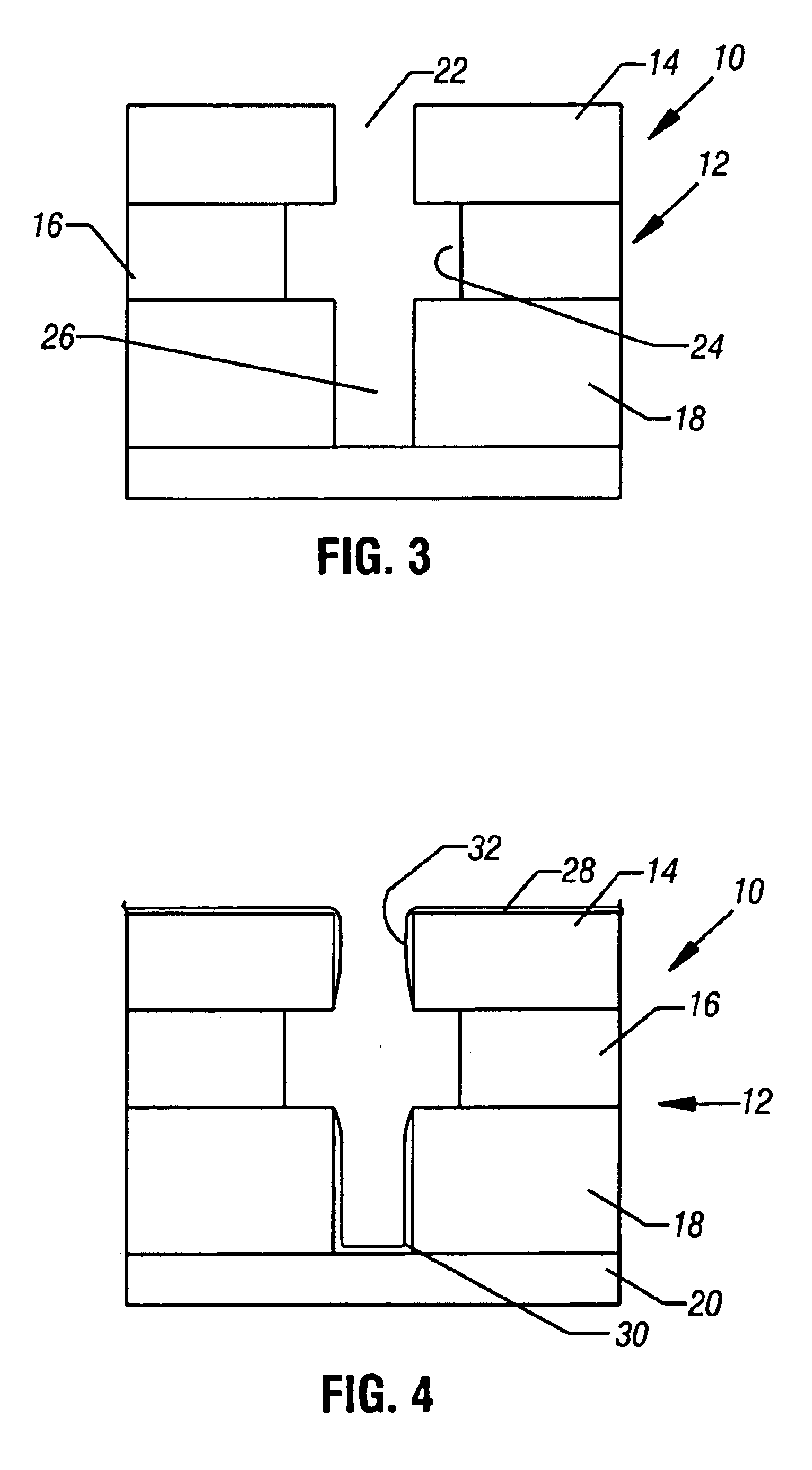

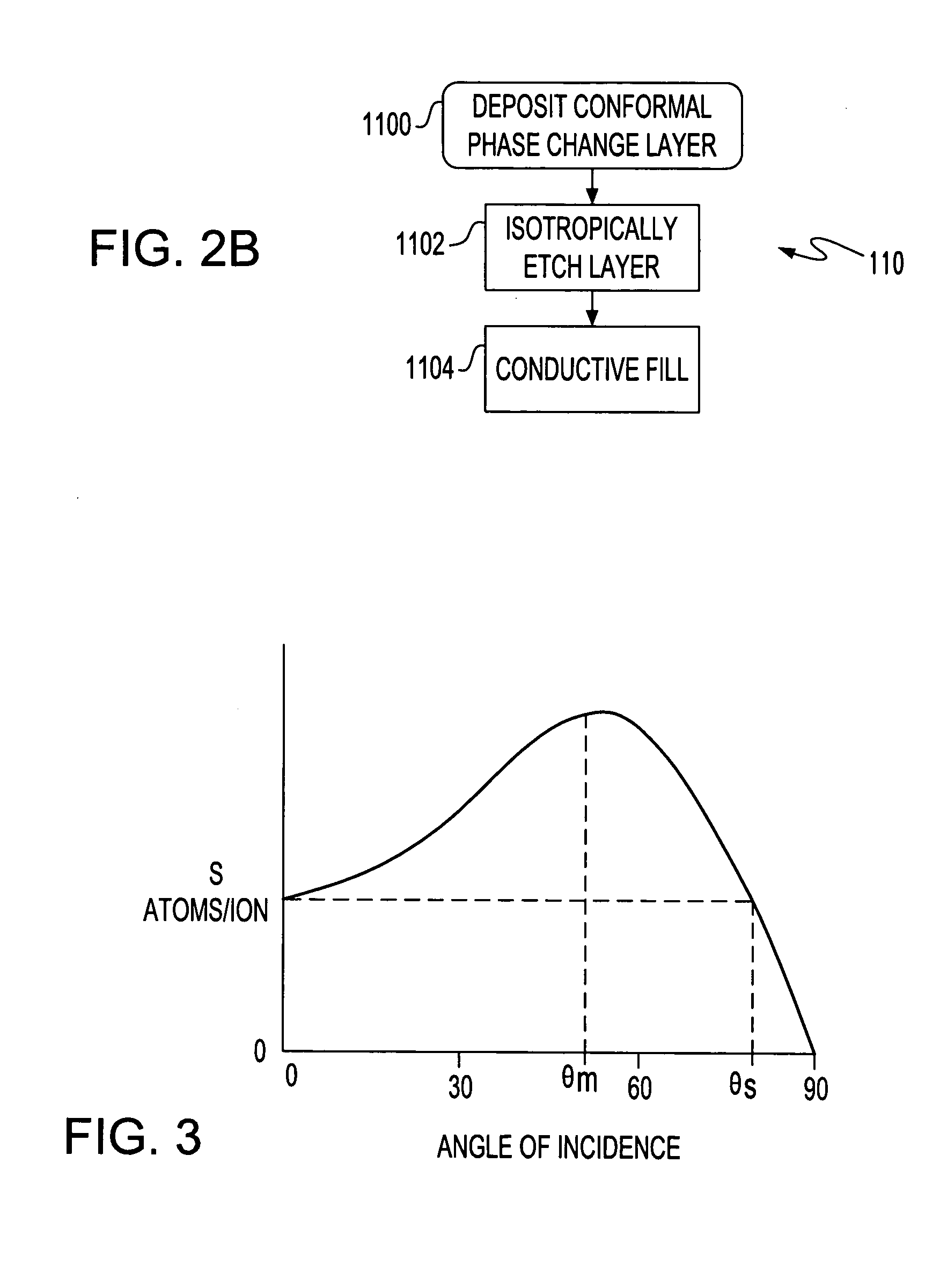

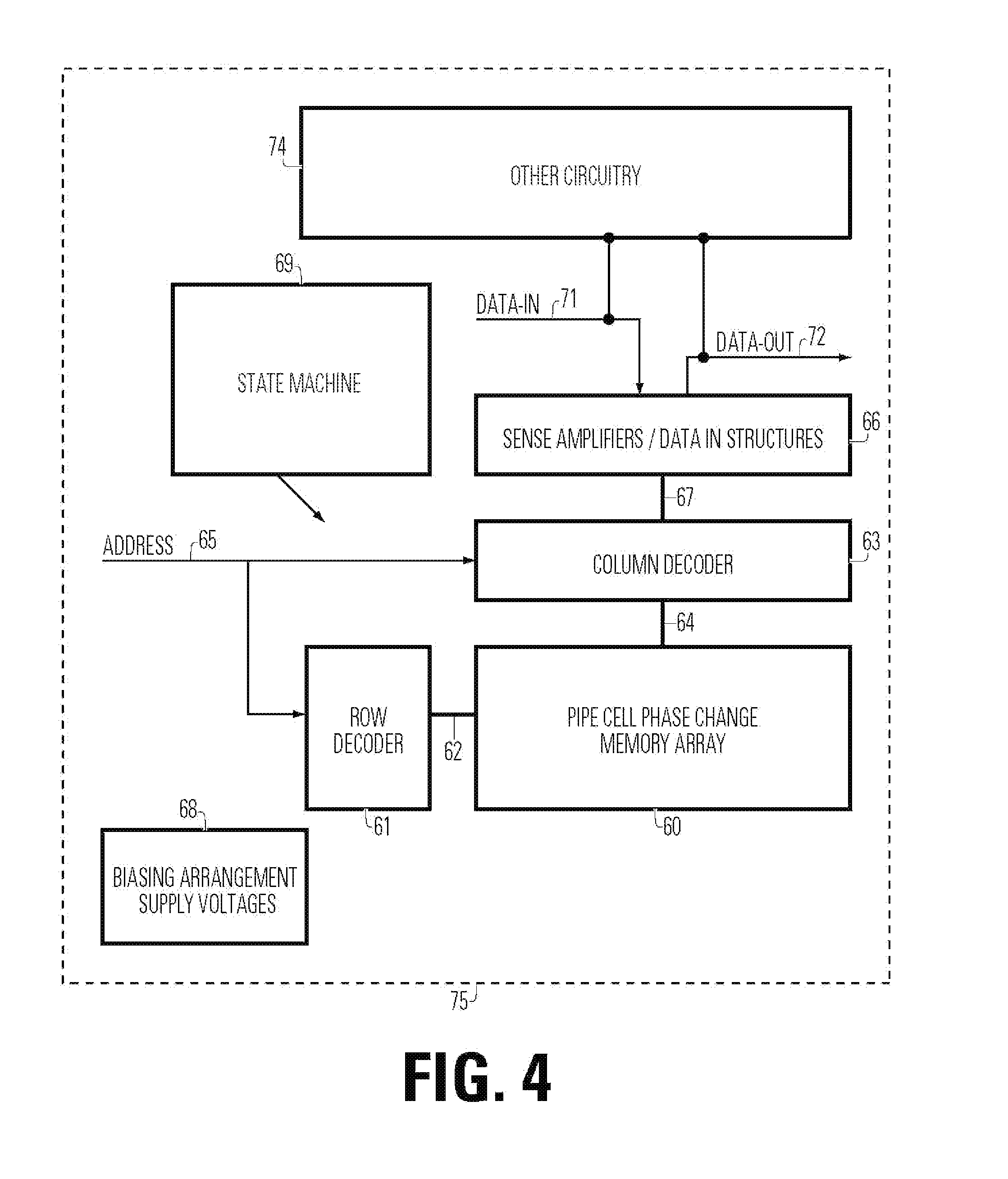

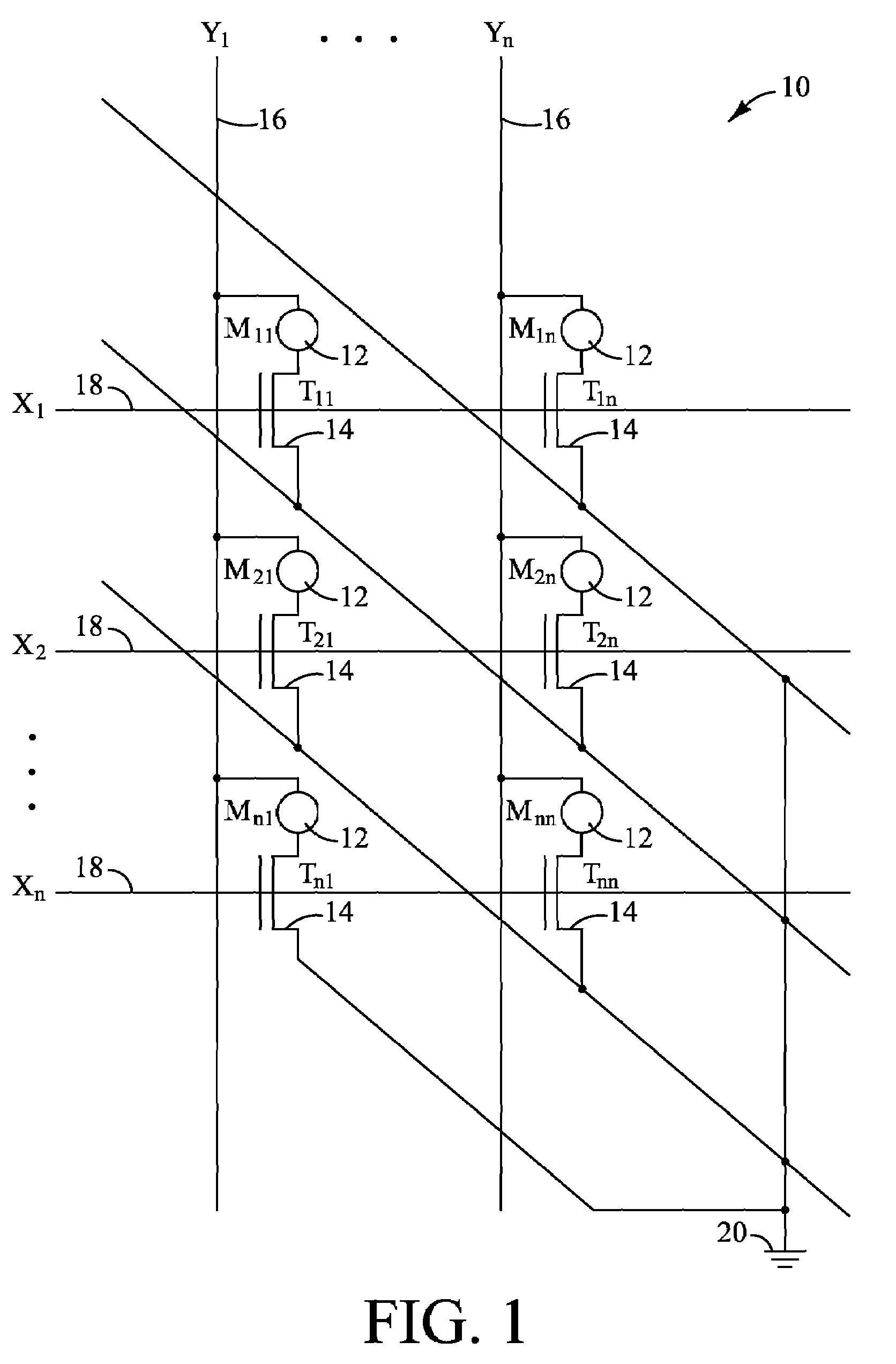

Structure and method for biasing phase change memory array for reliable writing

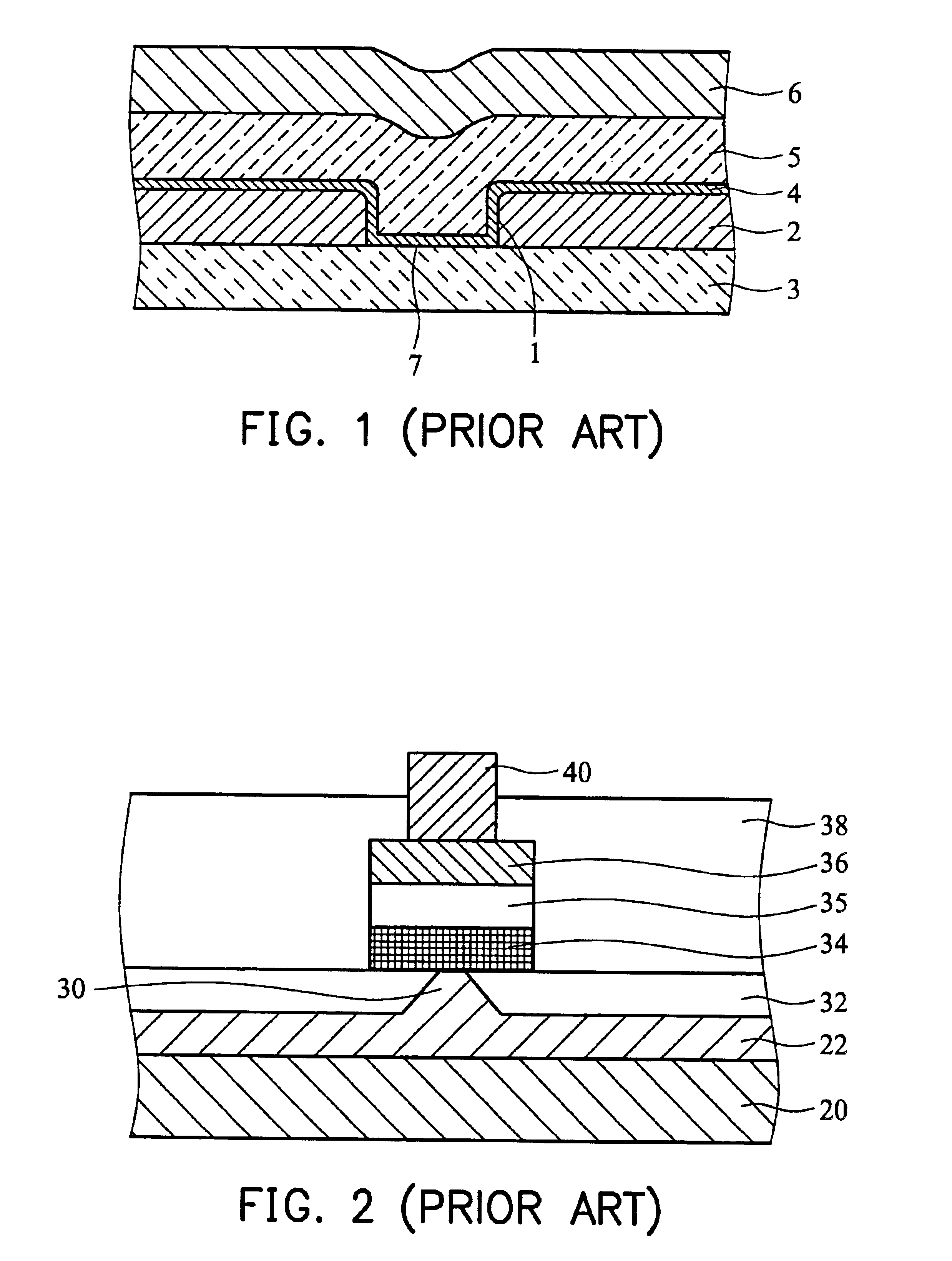

ActiveUS20060157679A1Minimize leakage currentReduce the possibilitySolid-state devicesDigital storageBit linePhase-change memory

A memory array having memory cells comprising a diode and a phase change material is reliably programmed by maintaining all unselected memory cells in a reverse biased state. Thus leakage is low and assurance is high that no unselected memory cells are disturbed. In order to avoid disturbing unselected memory cells during sequential writing, previously selected word and bit lines are brought to their unselected voltages before new bit lines and word lines are selected. A modified current mirror structure controls state switching of the phase change material.

Owner:SANDISK TECH LLC

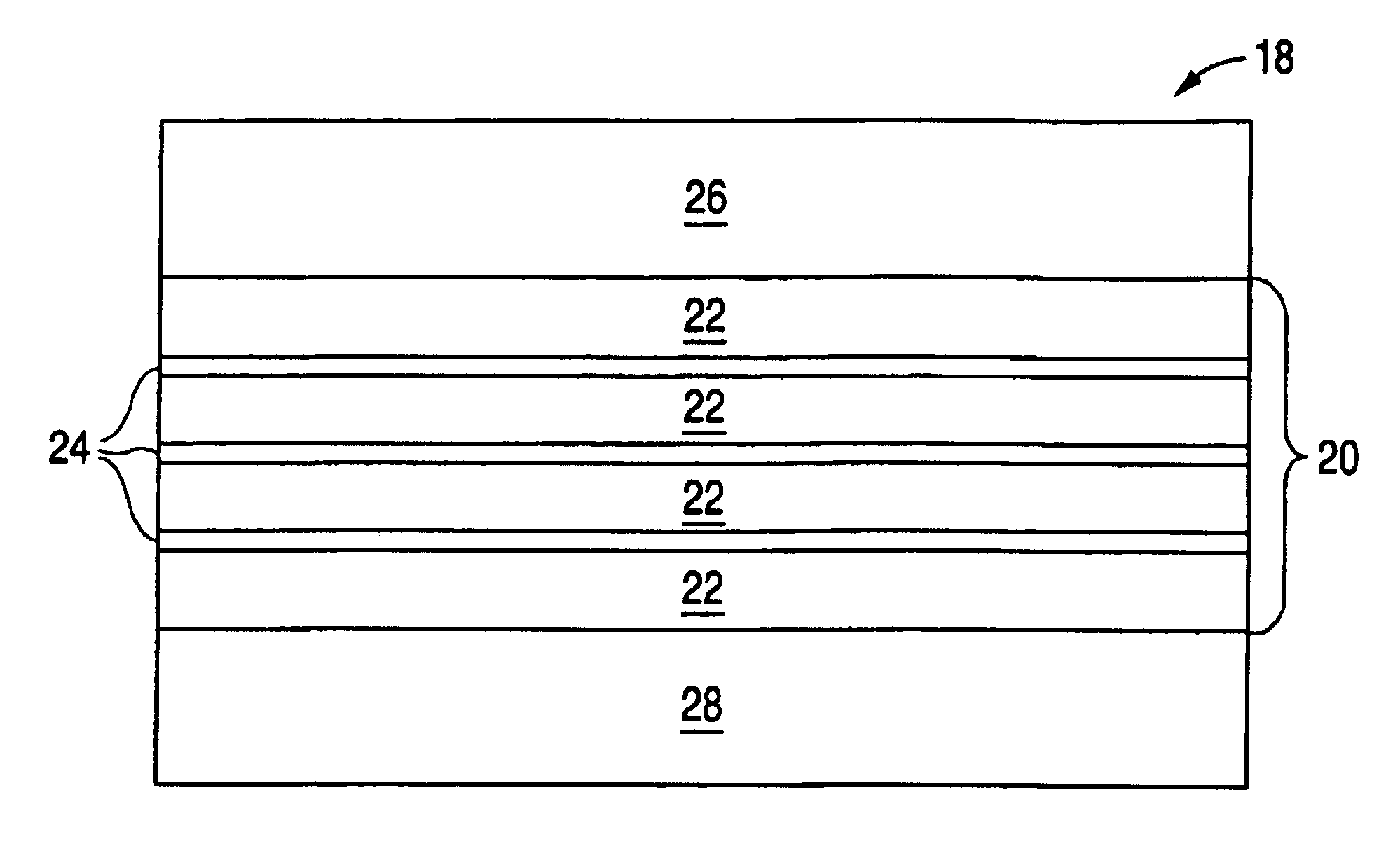

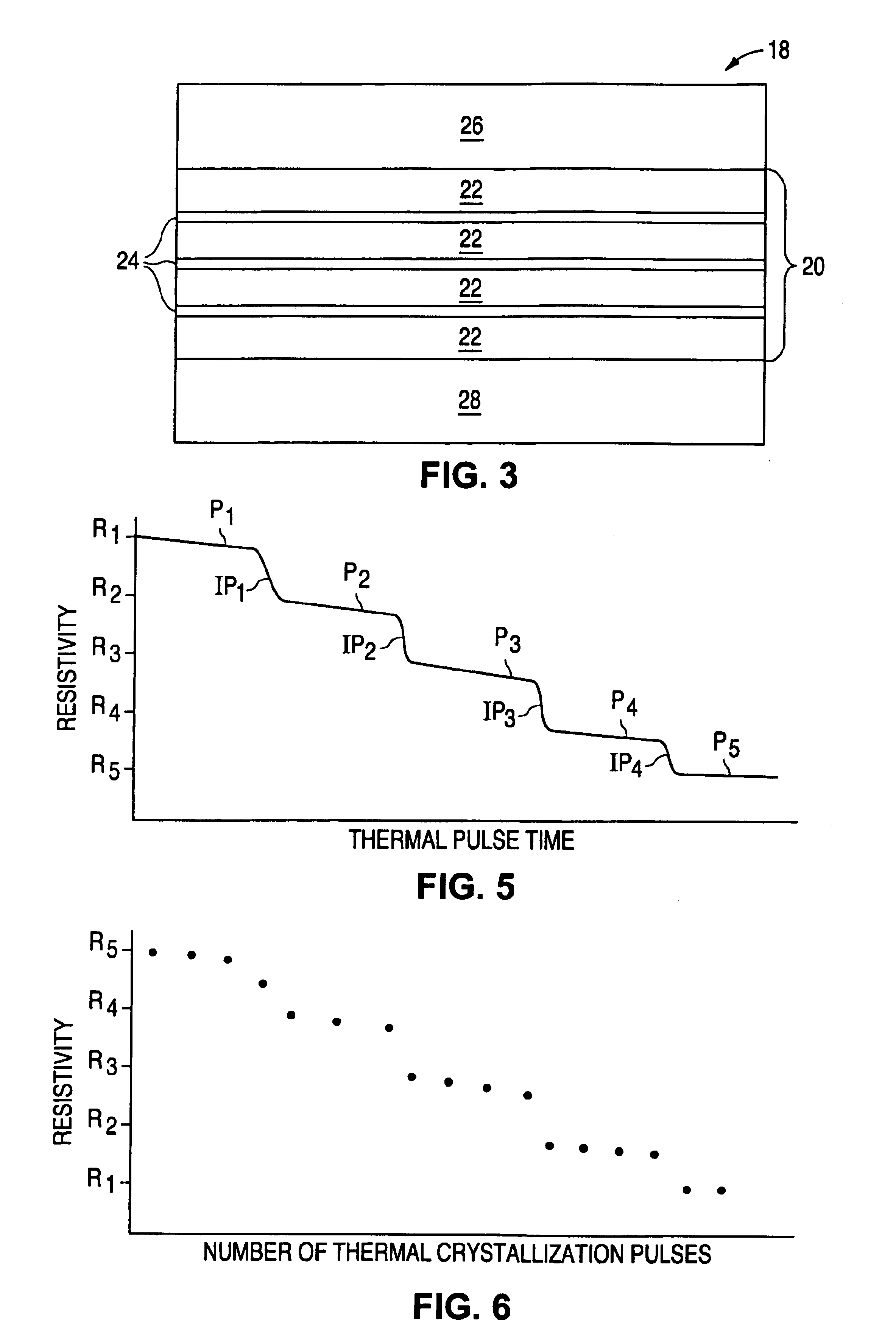

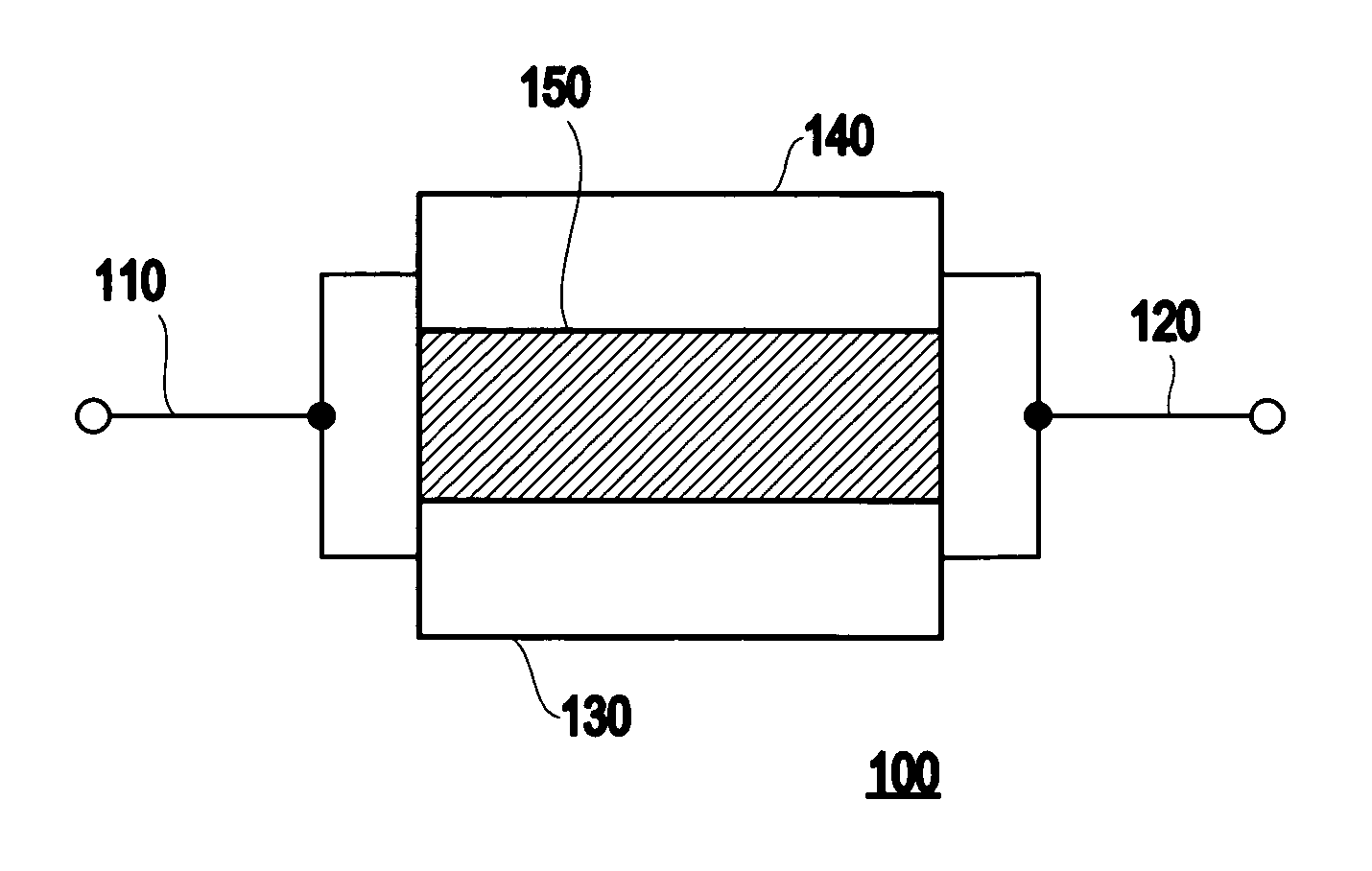

Memory device with discrete layers of phase change memory material

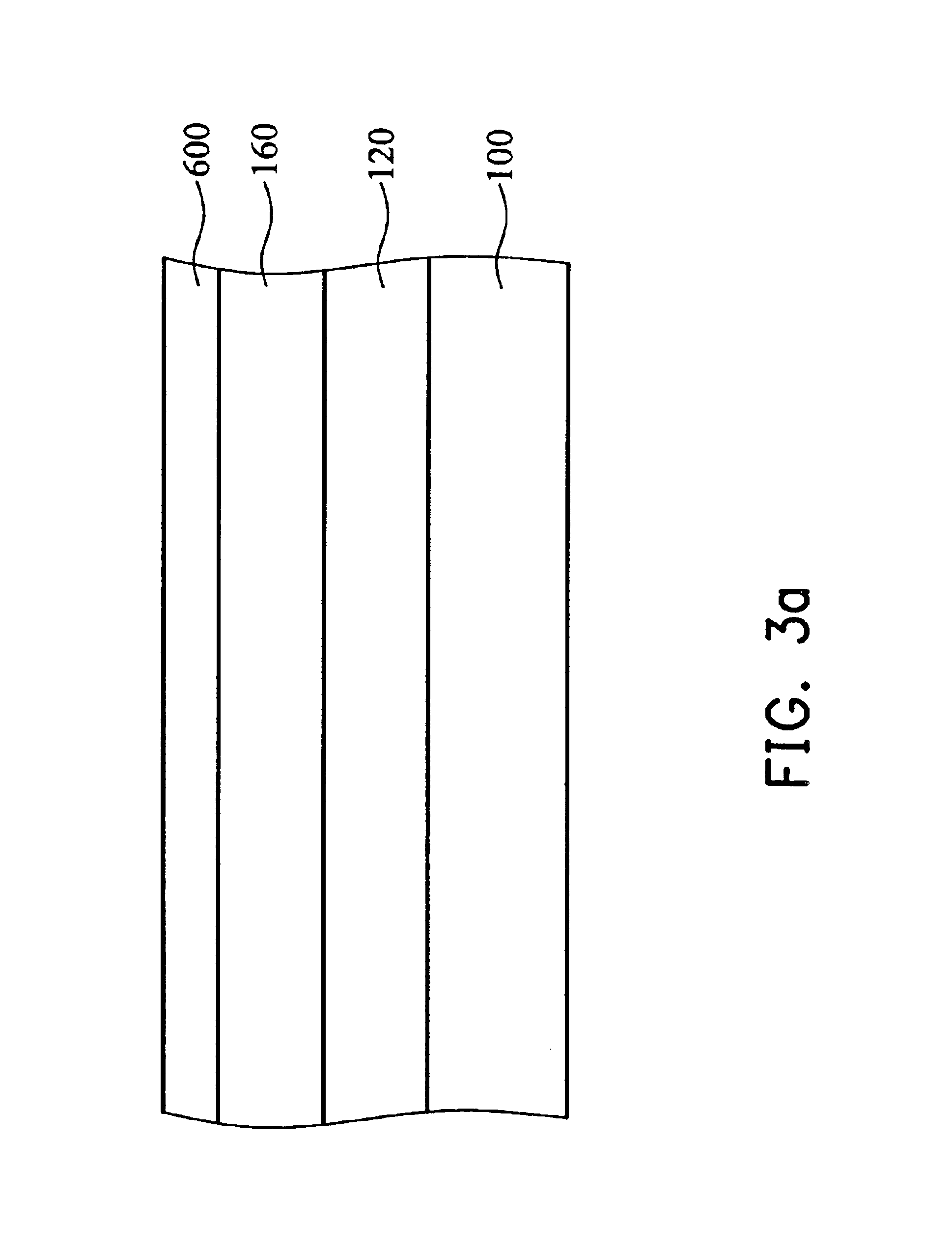

InactiveUS6927410B2Reliably and more repeatedly programmableSemiconductor/solid-state device detailsSolid-state devicesPhase-change memoryInterface layer

A phase changing memory device, and method of making the same, that includes programmable memory material disposed between a pair of electrodes. The programmable memory material includes discrete layers of phase change material, separated by conductive interface layers, that exhibits relatively stable resistivity values over discrete ranges of crystallizing and amorphousizing thermal pulses applied thereto, for multi-bit storage. The memory material and one of the electrodes can be disposed along spacer material surfaces to form an electrical current path that narrows in width as the current path approaches the other electrode, such that electrical current passing through the current path generates heat for heating the memory material disposed between the electrodes.

Owner:SILICON STORAGE TECHNOLOGY

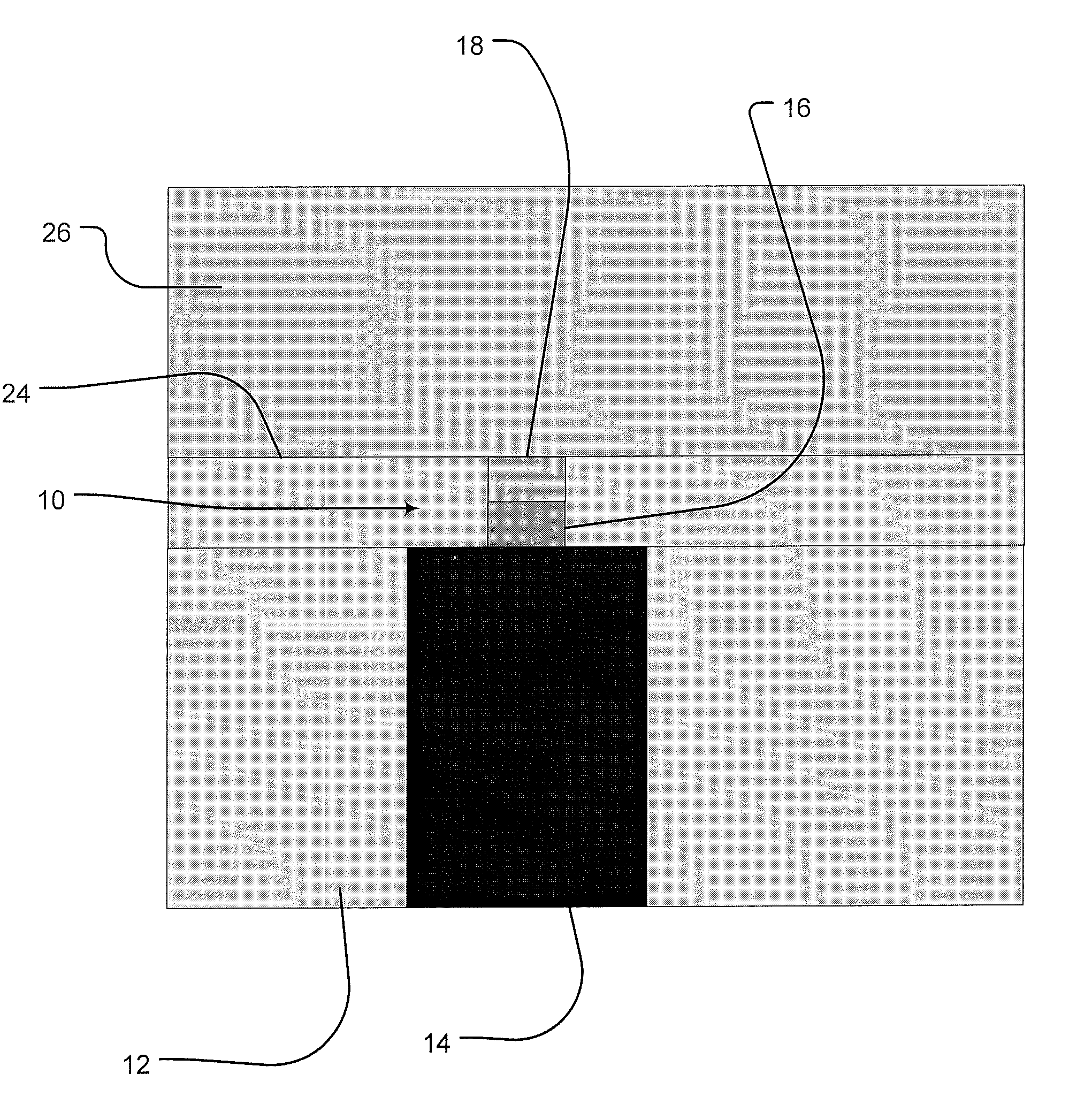

Reducing shunts in memories with phase-change material

A memory cell may include a phase-change material. Adhesion between the phase-change material and a dielectric or other substrate may be enhanced by using an adhesion enhancing interfacial layer. Conduction past the phase-change material through the interfacial layer may be reduced by providing a discontinuity or other feature that reduces or prevents conduction along said interfacial layer.

Owner:MICRON TECH INC

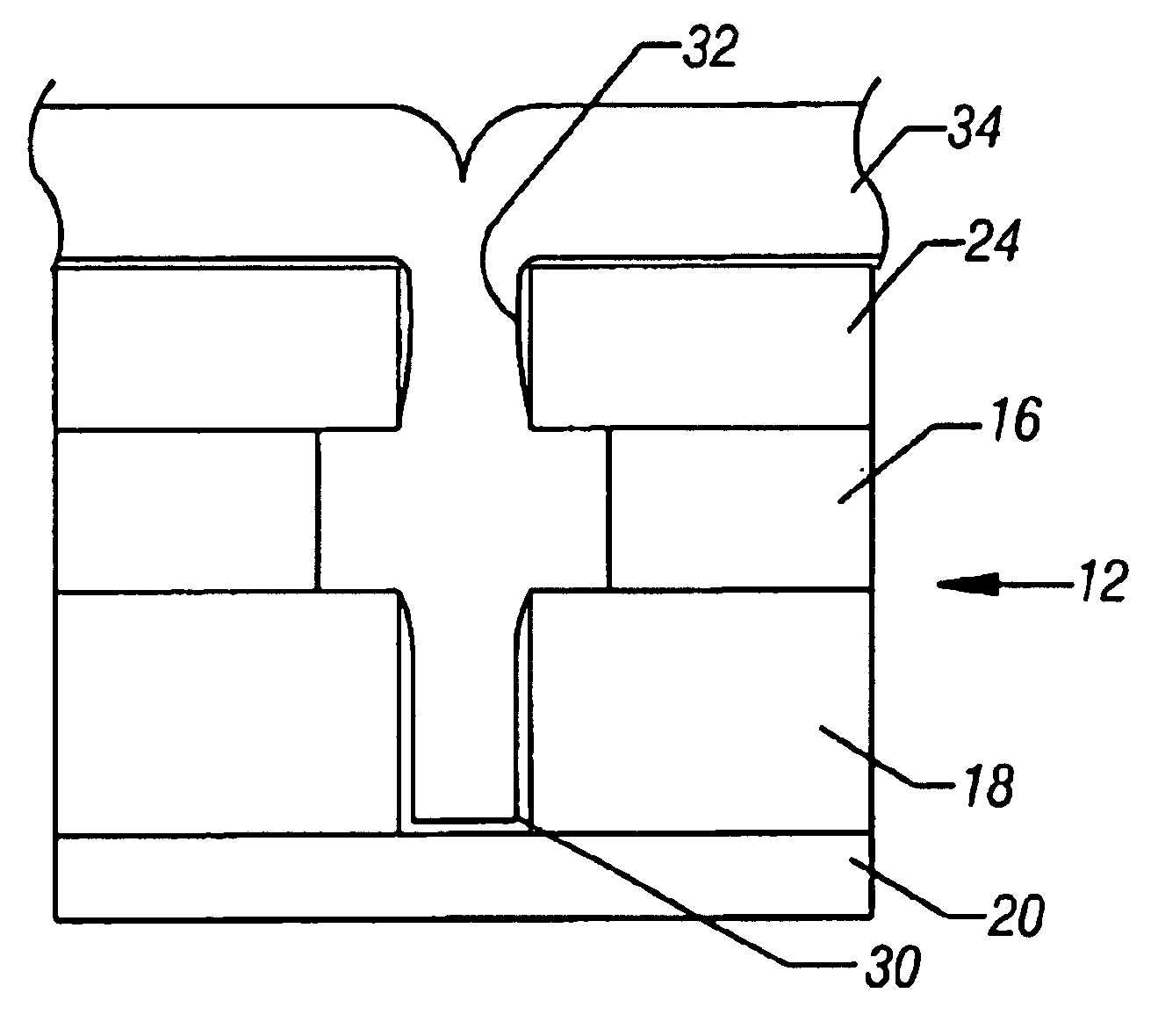

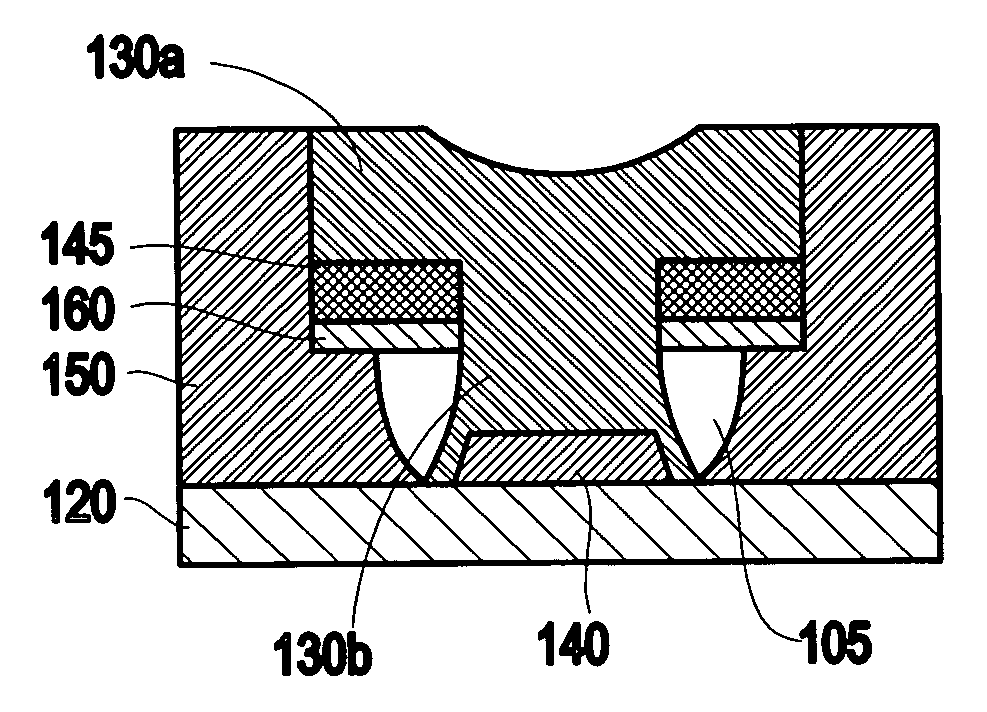

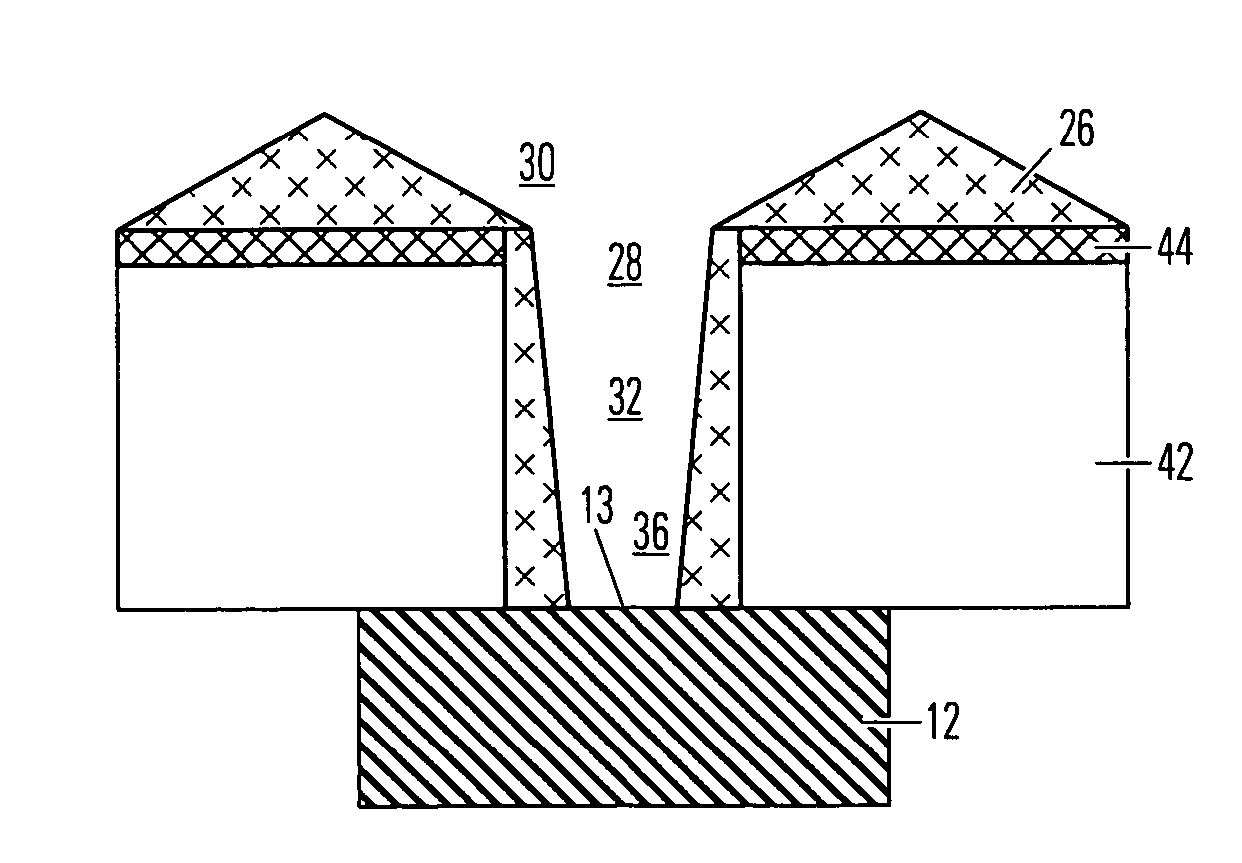

Structure for confining the switching current in phase memory (PCM) cells

InactiveUS20060226409A1Heat dissipation is limitedHigh densityBulk negative resistance effect devicesSemiconductor devicesPhase-change memorySwitched current

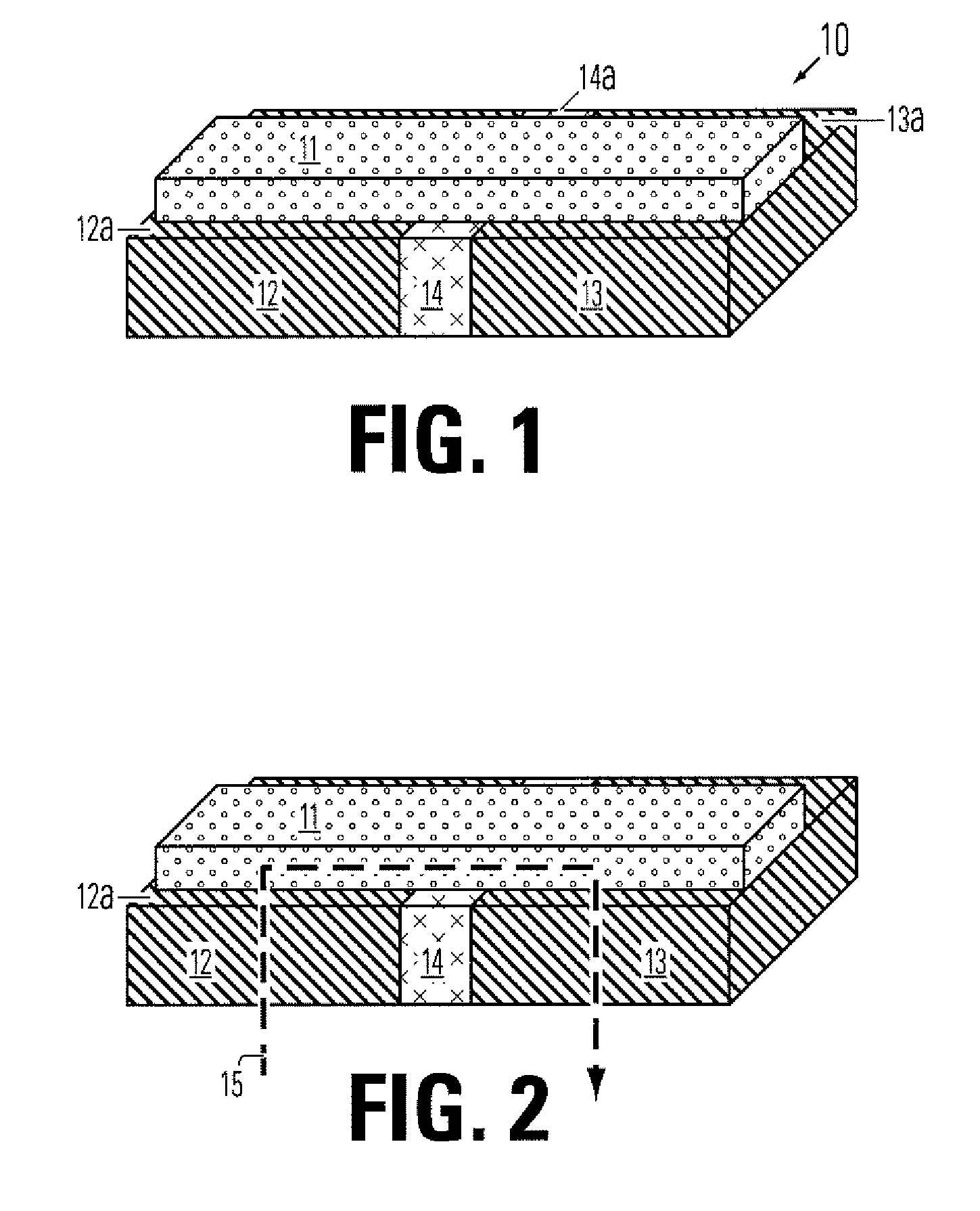

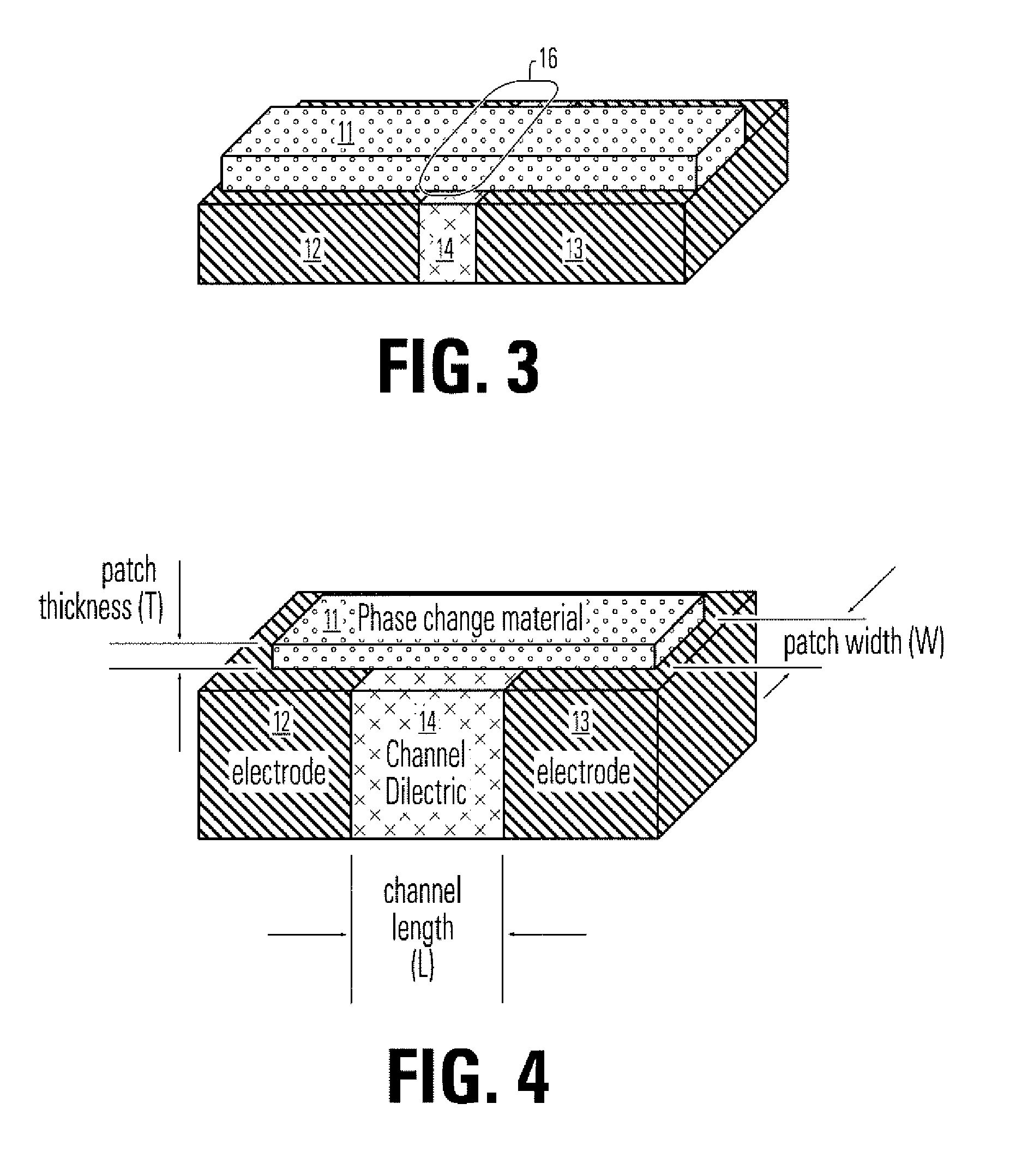

Disclosed are a phase change memory cell and a method of forming the memory cell. The memory cell comprises a main body of phase change material connected directly to a bottom contact and via a narrow channel of phase change material to a top contact. The channel is tapered from the top contact towards the main body. A minimum width of the channel has a less than minimum lithographic dimension and is narrower than a width of the main body. Therefore, the channel provides a confined region for the switching current path and restricts phase changing to within the channel. In addition an embodiment of the memory cell isolates the main body of phase change material by providing a space between the phase change material and the cell walls. The space allows the phase change material to expand and contract and also limits heat dissipation.

Owner:IBM CORP

Phase-change memory cell and method of fabricating the phase-change memory cell

InactiveUS6936840B2Improve reliabilityHigh yieldTransistorSolid-state devicesPhase-change memoryEngineering

A memory cell and method of fabricating the memory cell includes an insulating layer formed on a first electrode layer, the insulating layer having a first opening, a stencil layer formed on the insulating layer, and having a second opening formed in an area of the first opening, a phase-change material layer formed on a surface of the first electrode layer in the first opening, and an electrically conductive layer including a first portion formed on the stencil layer and defining a second electrode layer and a second portion formed on the phase-change material layer.

Owner:GLOBALFOUNDRIES INC

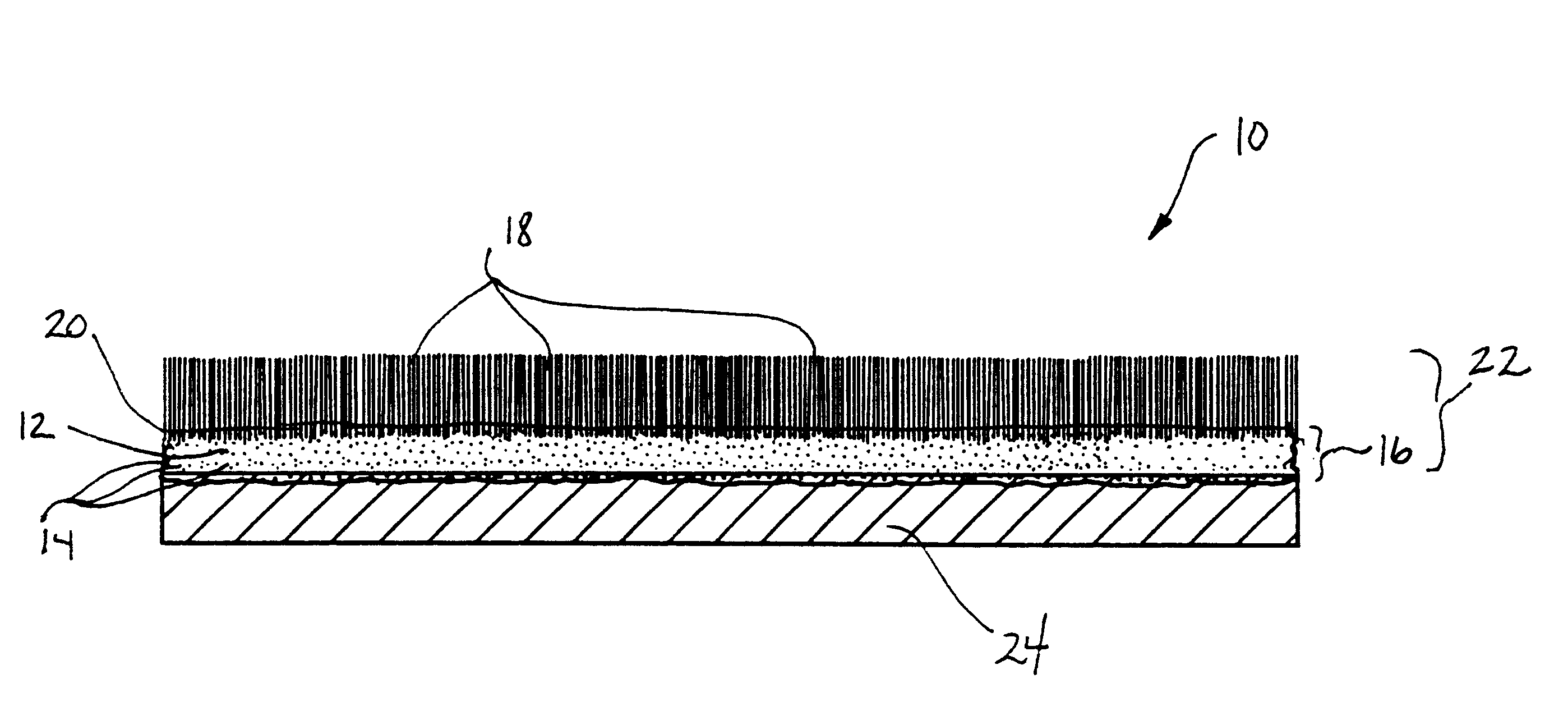

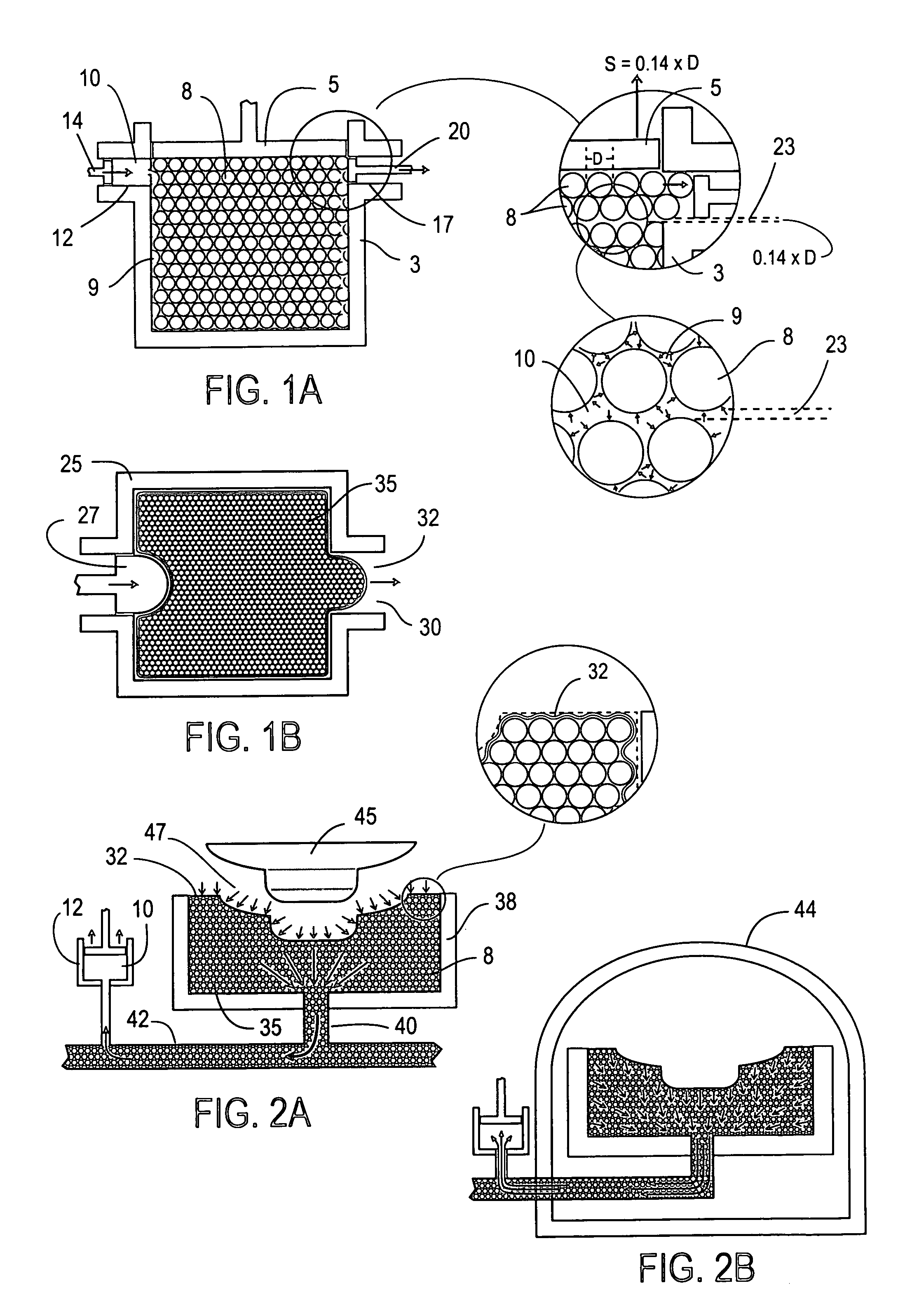

Fabric coating composition containing energy absorbing phase change material

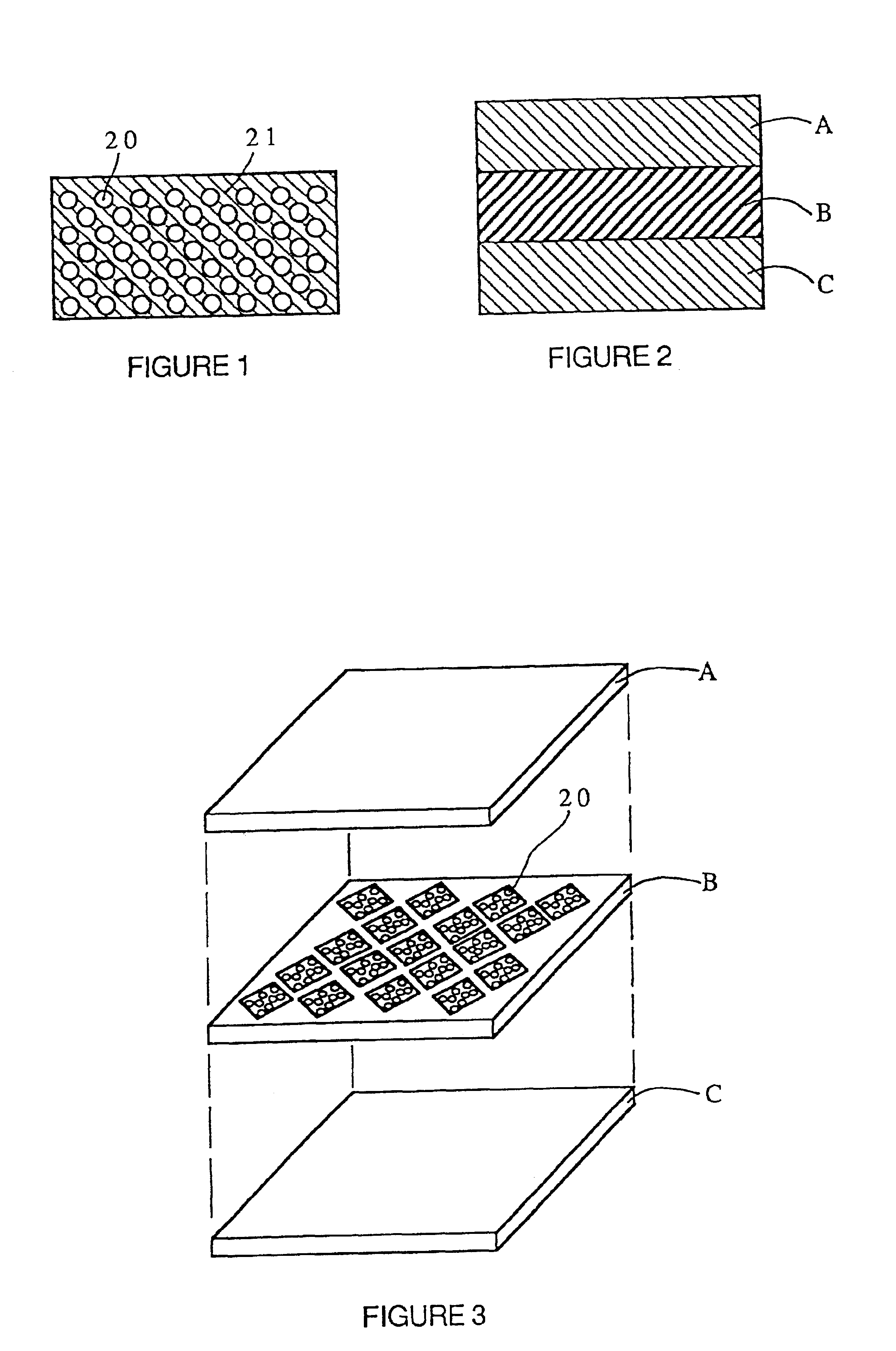

InactiveUS6207738B1Solve the lack of densityReduce and eliminate heat transferHeat storage plantsFibre treatmentMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric.

Owner:OUTLAST TECH LLC

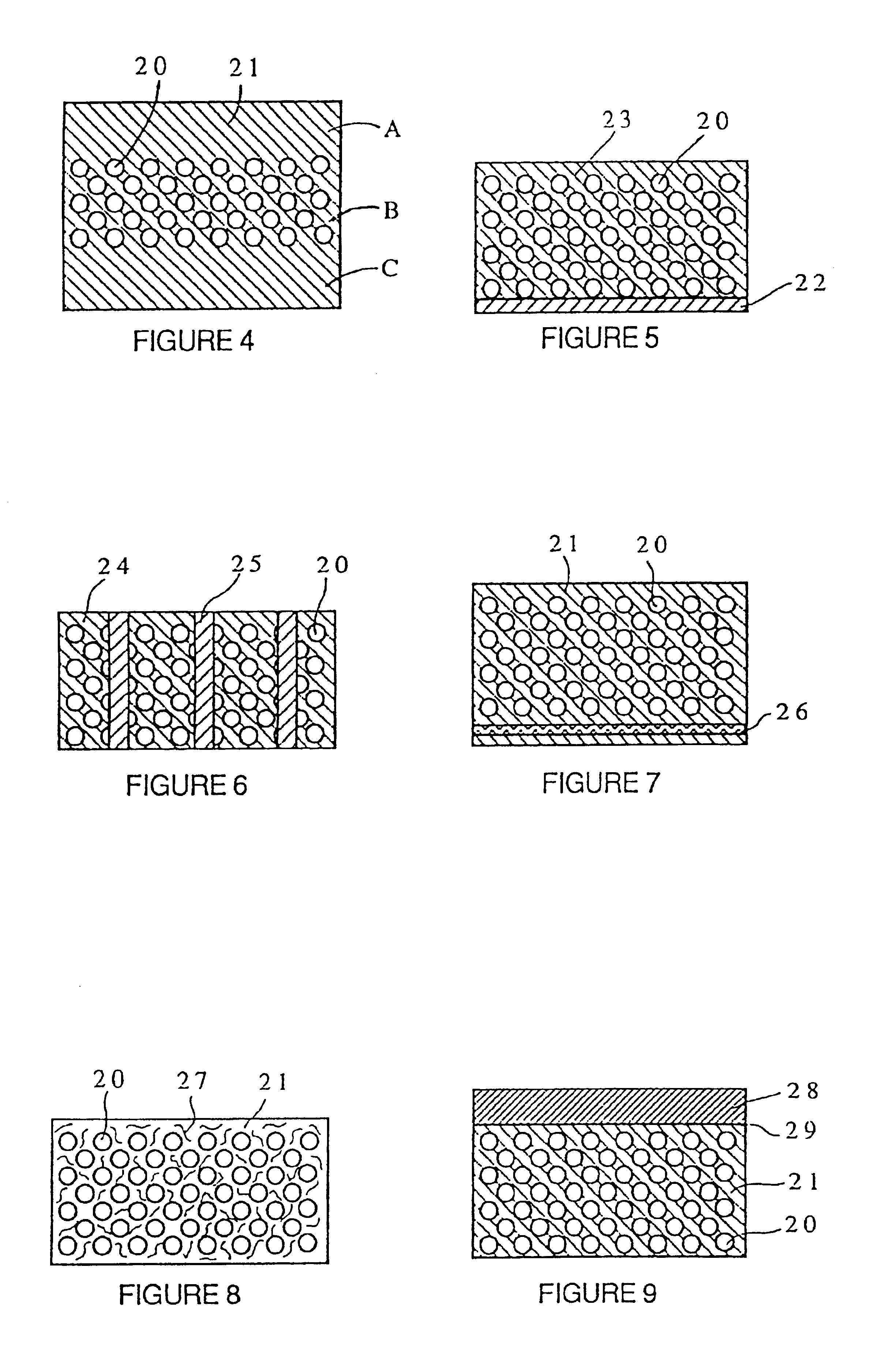

Phase change material thermal capacitor clothing

InactiveUS6855410B2Good thermal controlFast regenerationExothermal chemical reaction heat productionNatural cellulose pulp/paperSOCKSThermal insulation

An apparatus and method for metabolic cooling and insulation of a user in a cold environment. In its preferred embodiment the apparatus is a highly flexible composite material having a flexible matrix containing a phase change thermal storage material. The apparatus can be made to heat or cool the body or to act as a thermal buffer to protect the wearer from changing environmental conditions. The apparatus may also include an external thermal insulation layer and / or an internal thermal control layer to regulate the rate of heat exchange between the composite and the skin of the wearer. Other embodiments of the apparatus also provide 1) a path for evaporation or direct absorption of perspiration from the skin of the wearer for improved comfort and thermal control, 2) heat conductive pathways within the material for thermal equalization, 3) surface treatments for improved absorption or rejection of heat by the material, and 4) means for quickly regenerating the thermal storage capacity for reuse of the material. Applications of the composite materials are also described which take advantage of the composite's thermal characteristics. The examples described include a diver's wet suit, ski boot liners, thermal socks, gloves and a face mask for cold weather activities, and a metabolic heating or cooling blanket useful for treating hypothermia or fever patients in a medical setting and therapeutic heating or cooling orthopedic joint supports.

Owner:BUCKLEY THERESA M

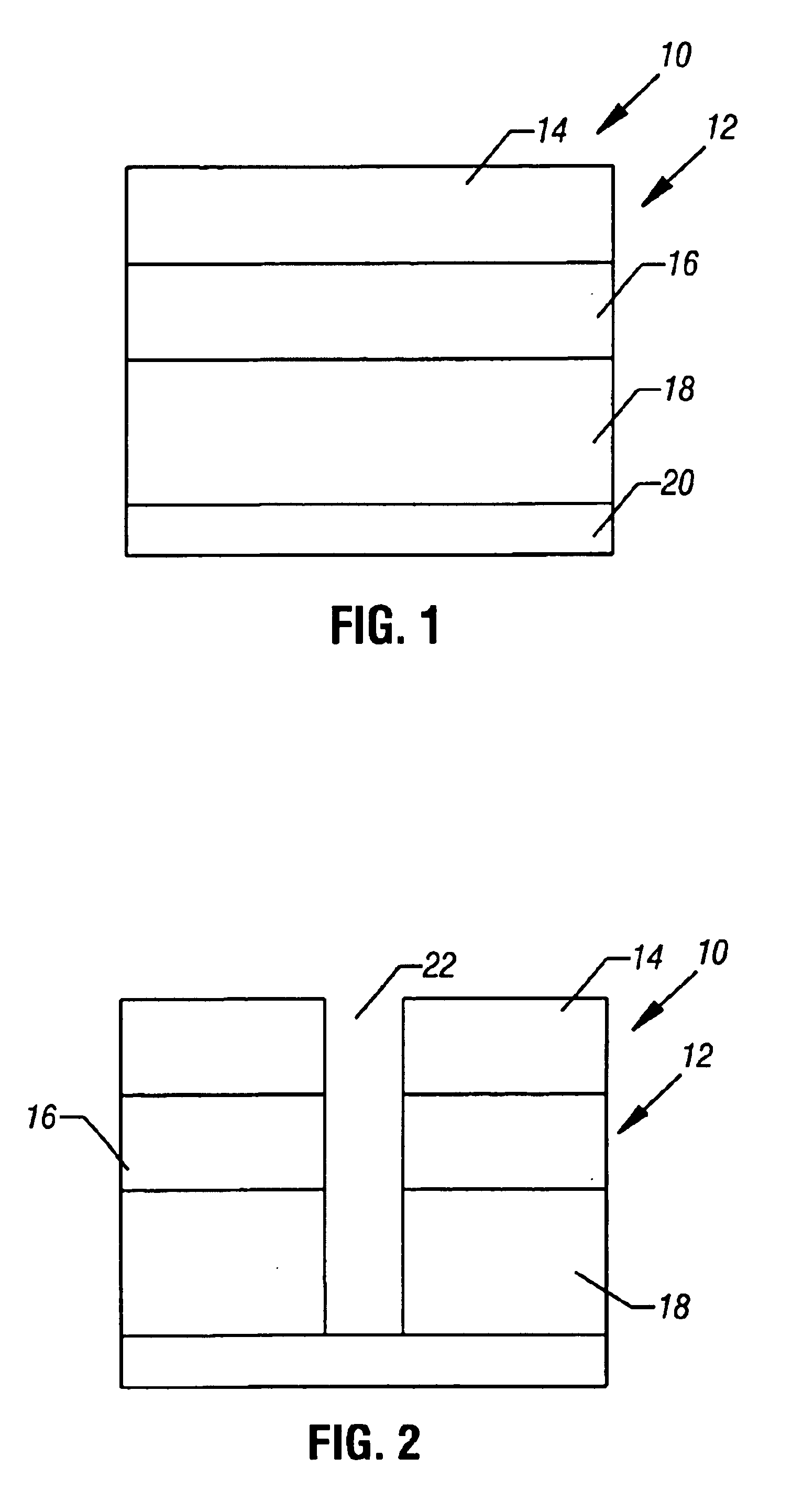

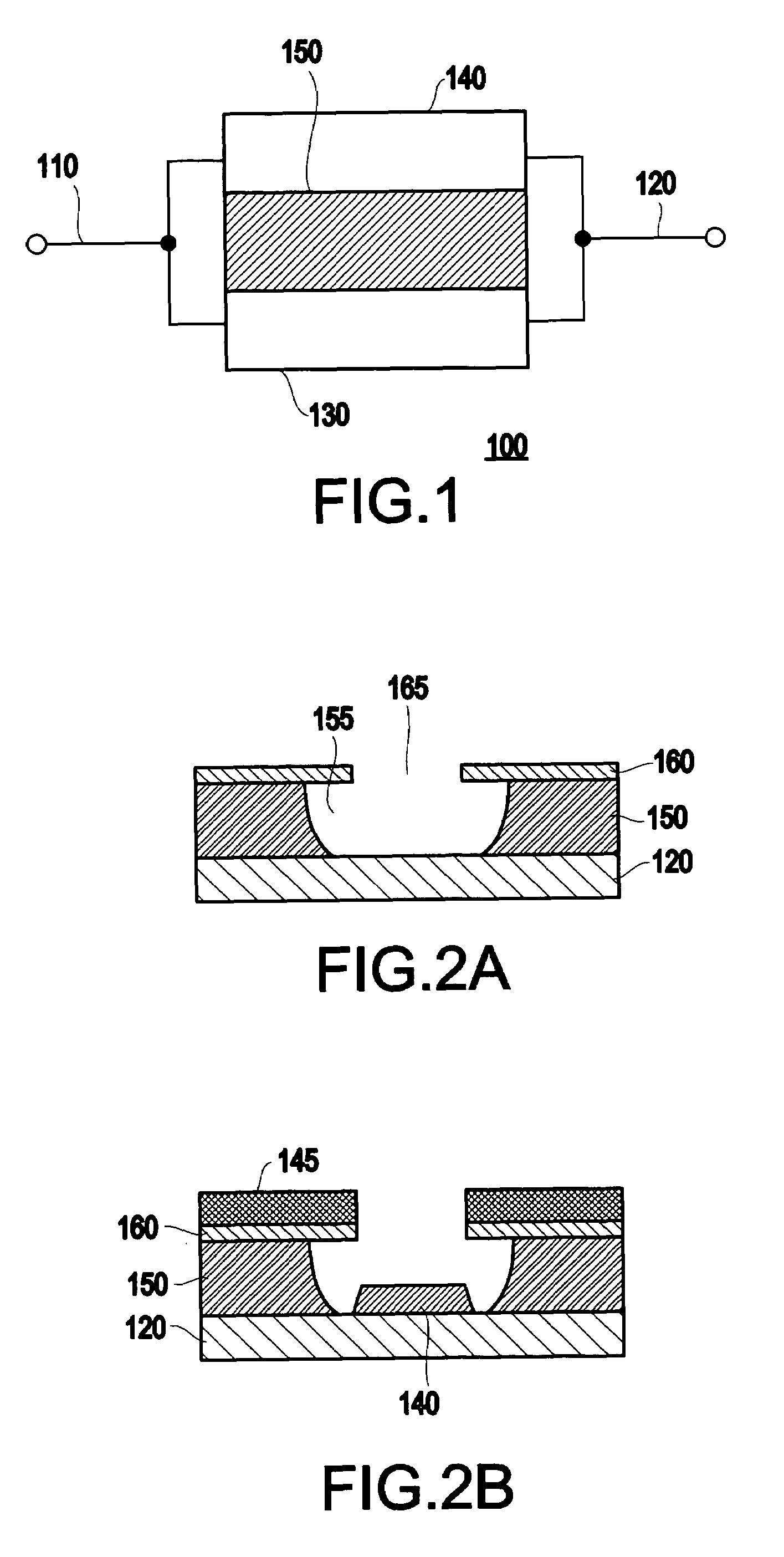

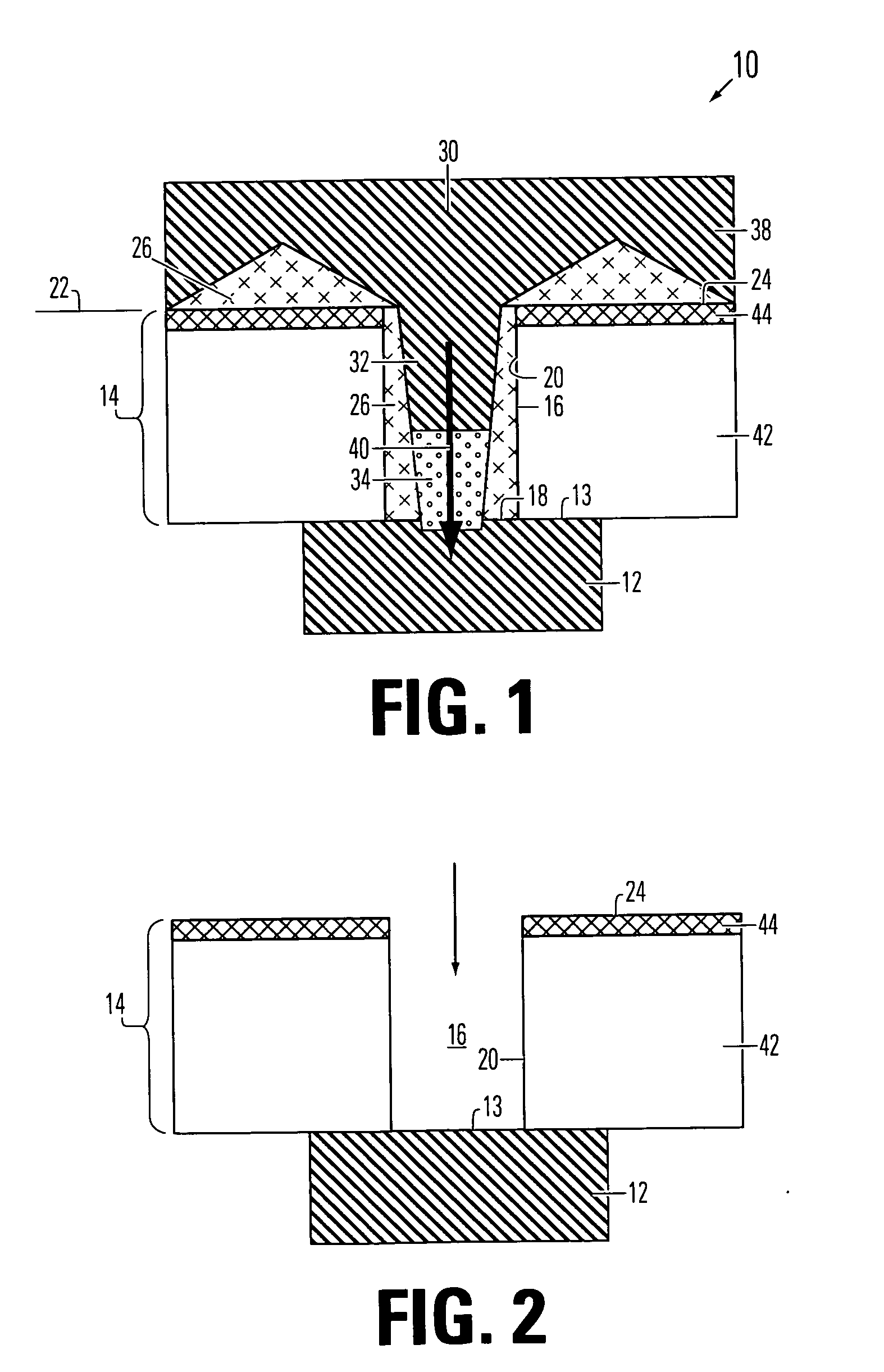

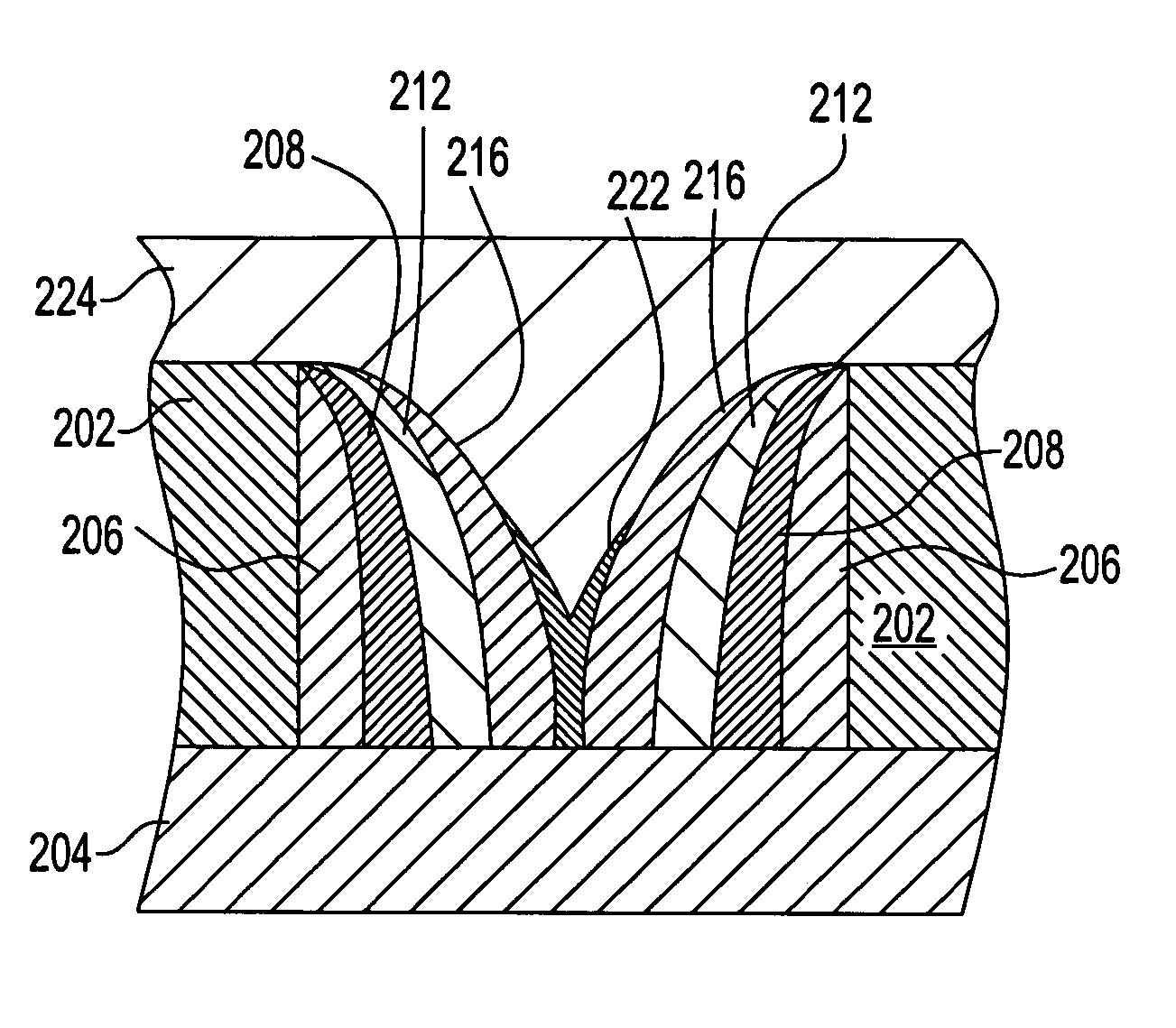

Memory cell device and manufacturing method

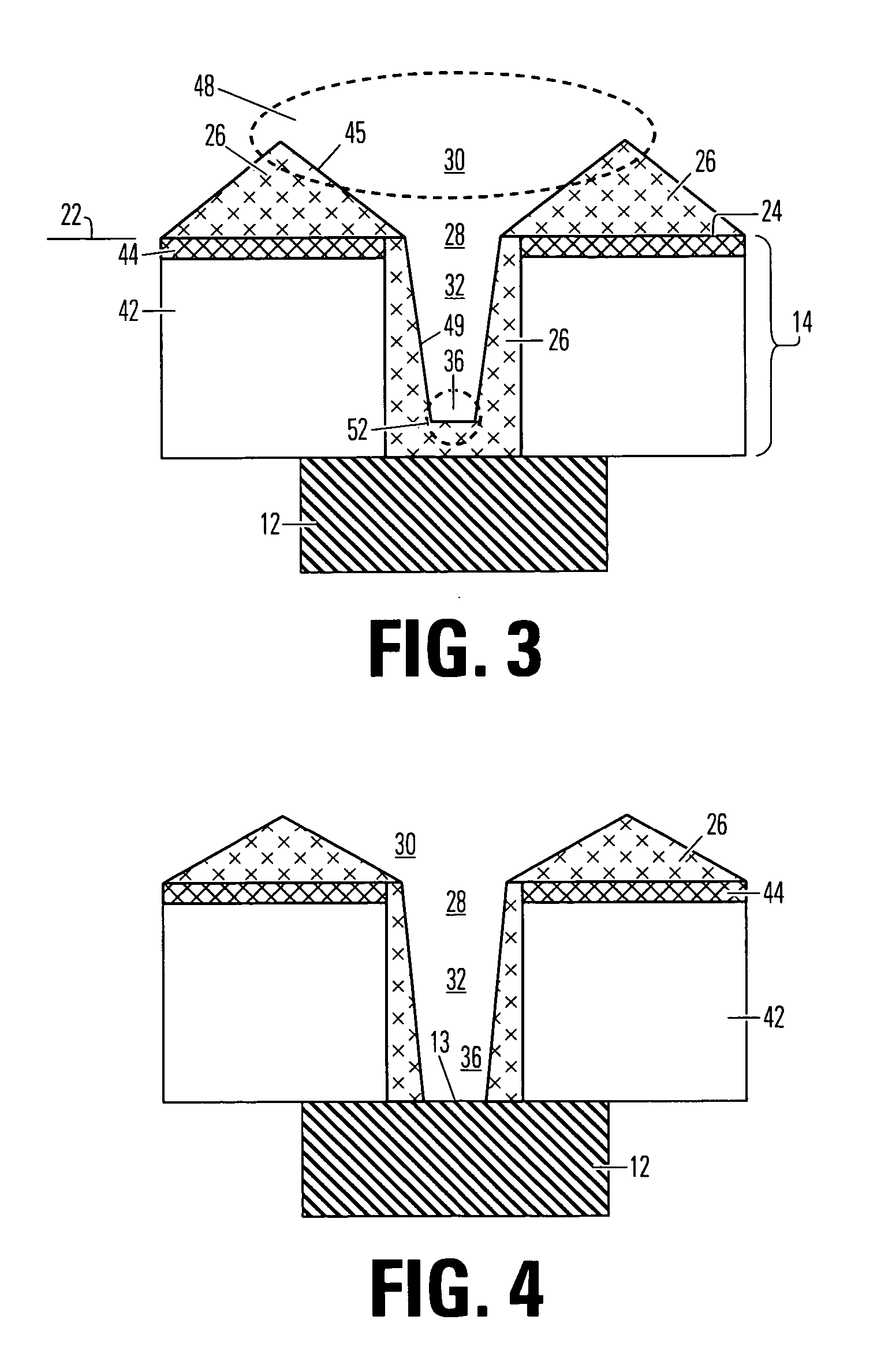

ActiveUS20070117315A1Facilitate changing electrical property stateTransistorSolid-state devicesHigh densityPhase-change material

A memory cell device, having a memory material switchable between electrical property states by the application of energy, comprises an electrode, a separation layer against an electrode surface, a hole in the separation layer, a second material in the hole defining a void having a downwardly and inwardly tapering void region. A memory material is in the void region in electrical contact with the electrode surface. A second electrode is in electrical contact with the memory material. Energy passing between the first and second electrodes is concentrated within the memory material so to facilitate changing an electrical property state of the memory material. The memory material may comprise a phase change material. The second material may comprise a high density plasma-deposited material. A method for making a memory cell device is also disclosed.

Owner:MACRONIX INT CO LTD

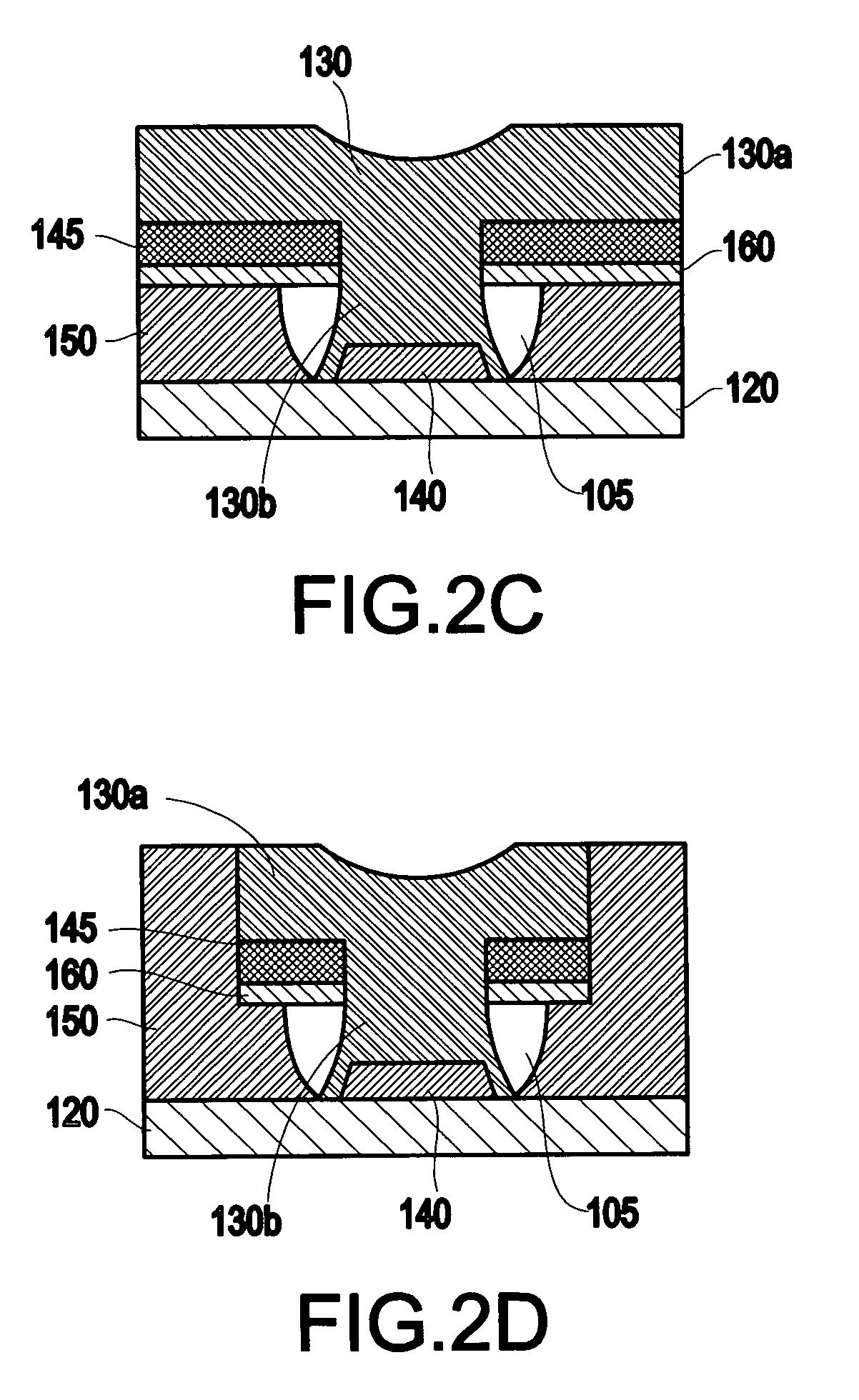

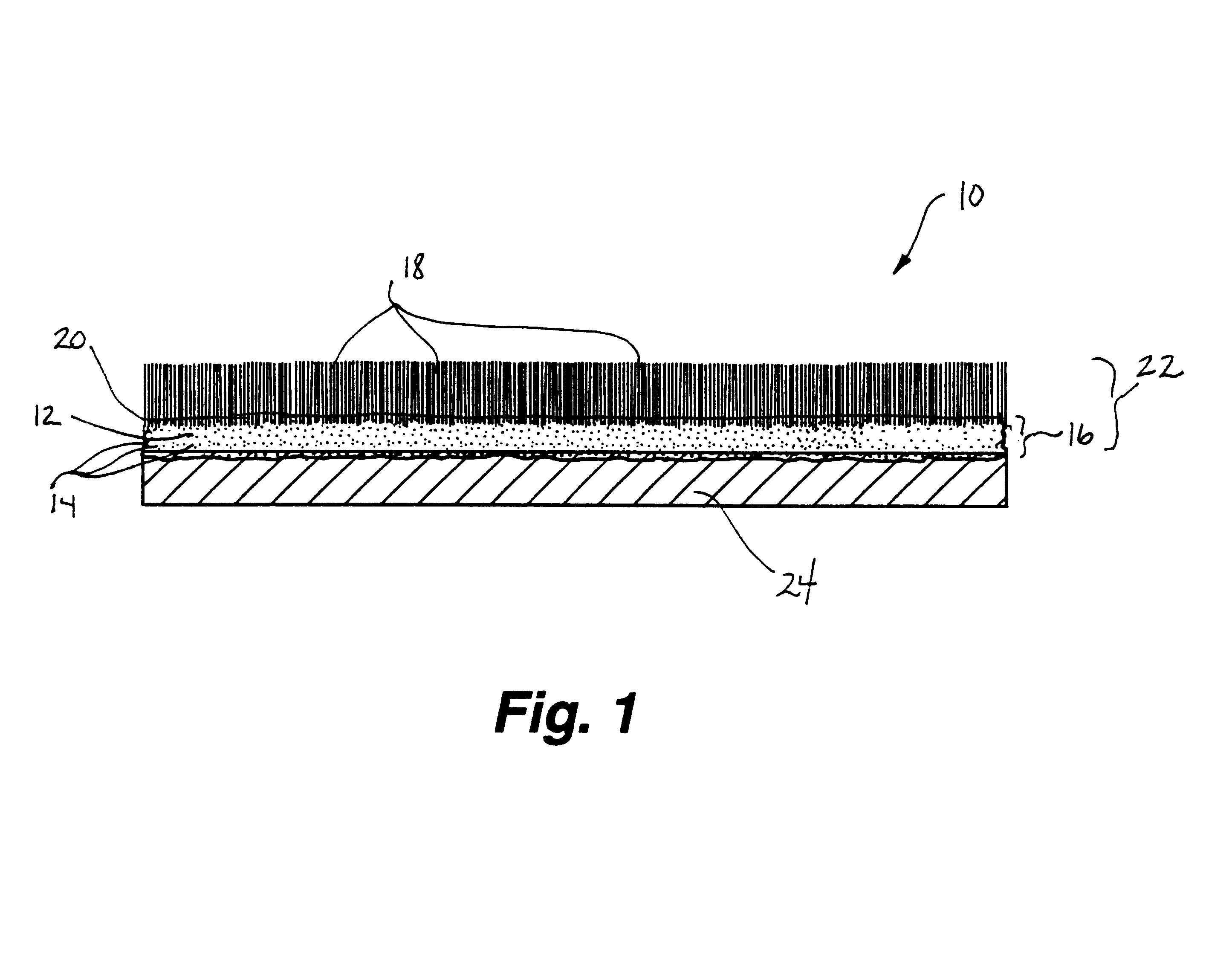

Phase changeable memory cells and methods of forming the same

InactiveUS20060118913A1Solid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryPhase-change material

A phase changeable memory cell is provided. The phase changeable memory cell includes a lower interlayer dielectric layer formed on a semiconductor substrate and a lower conductive plug passing through the lower interlayer dielectric layer. The lower conductive plug is in contact with a phase change material pattern disposed on the lower interlayer dielectric layer. The phase change material pattern and the lower interlayer dielectric layer are covered with an upper interlayer dielectric layer. The phase change material pattern is in direct contact with a conductive layer pattern, which is disposed in a plate line contact hole passing through the upper interlayer dielectric layer. Methods of fabricating the phase changeable memory cell is also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

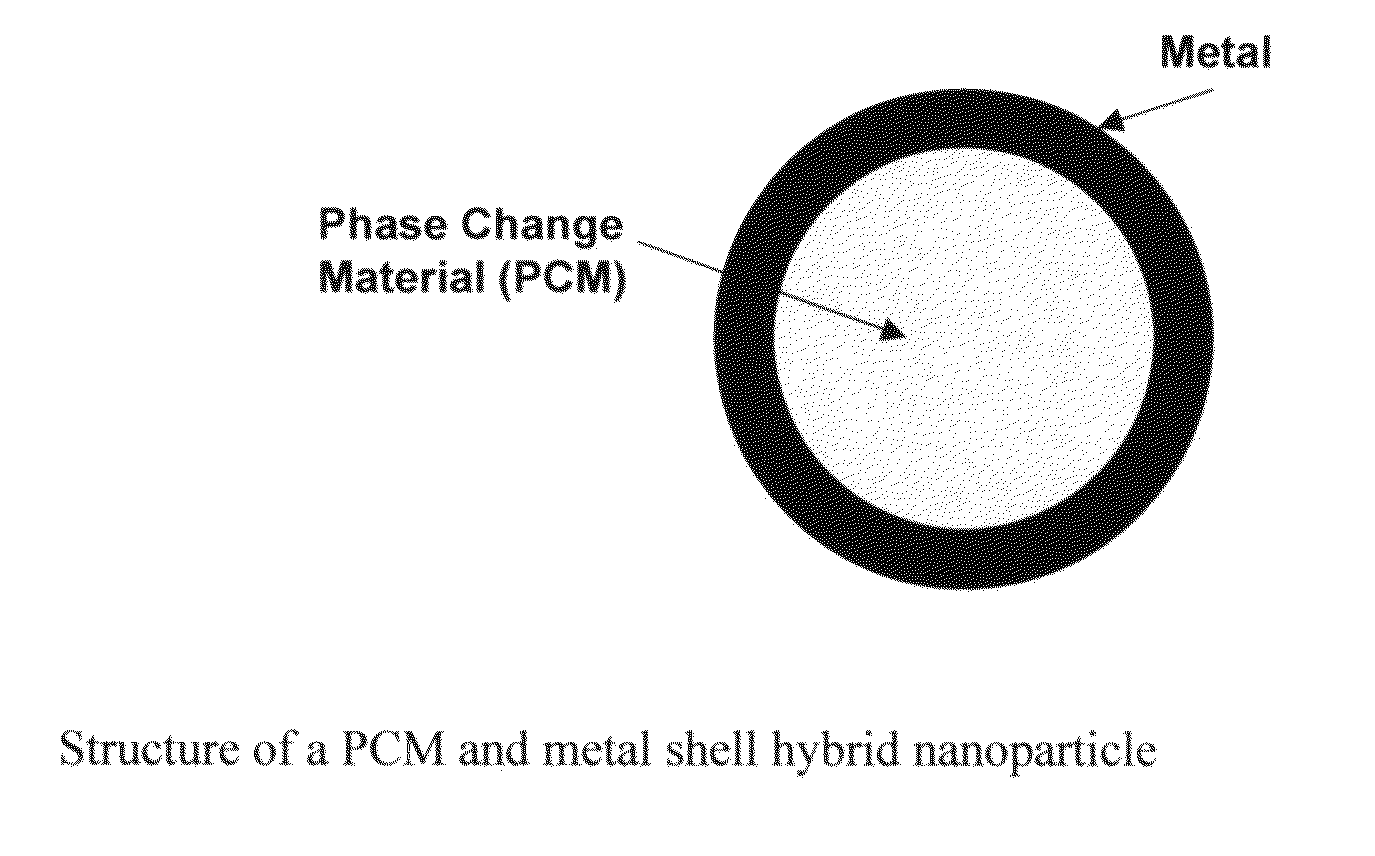

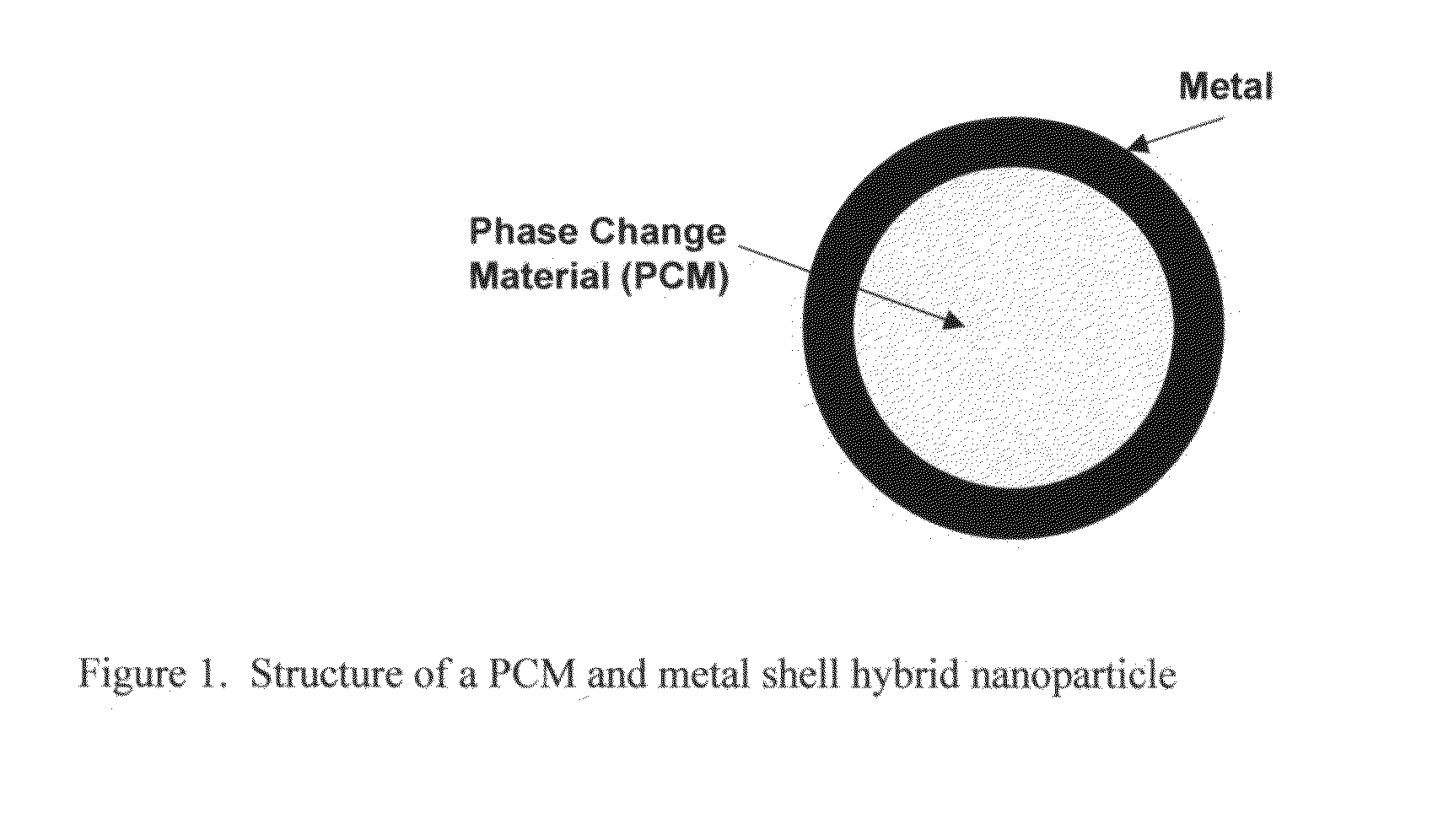

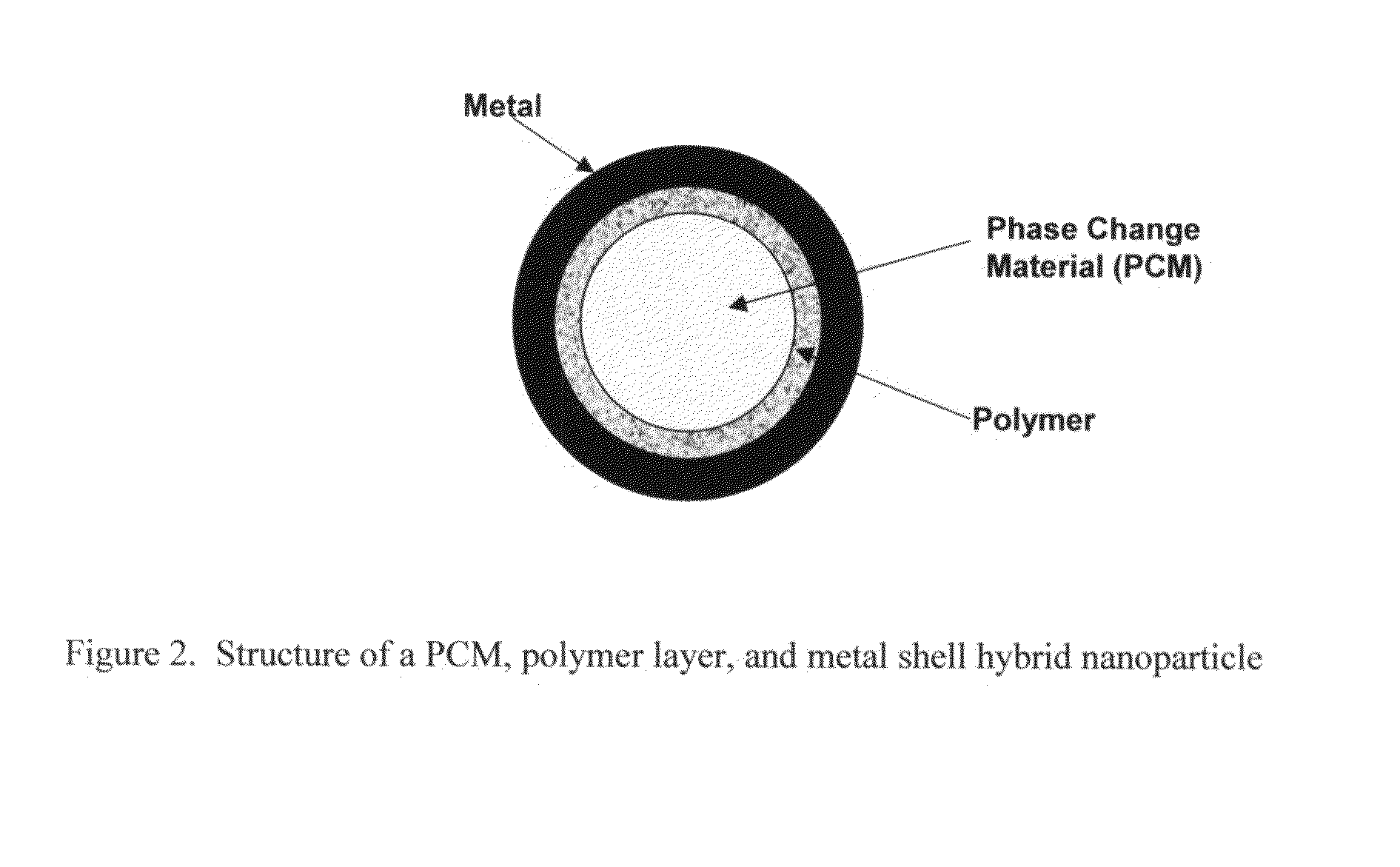

Hybrid nanoparticles

A method and composition for making hybrid nanoparticles and use of such nanoparticles are disclosed herein. In one embodiment of the invention, the hybrid nanoparticles comprise a phase change material (PCM) and a metal layer encapsulating the phase change material. In another embodiment of the invention, the hybrid nanoparticles comprise a phase change material, a polymer layer encapsulating the phase change material, and an outer metal layer encapsulating the polymer layer. In another embodiment of the invention, the hybrid nanoparticles comprise an inner core of a PCM encapsulated by a polymer shell containing embedded nanoparticles that have a high thermal conductivity.

Owner:MOHAPATRA SATISH C +6

Self-aligned, embedded phase change ram and manufacturing method

ActiveUS20060284158A1Simple structureReduce power consumptionSolid-state devicesDigital storageElectrical conductorEngineering

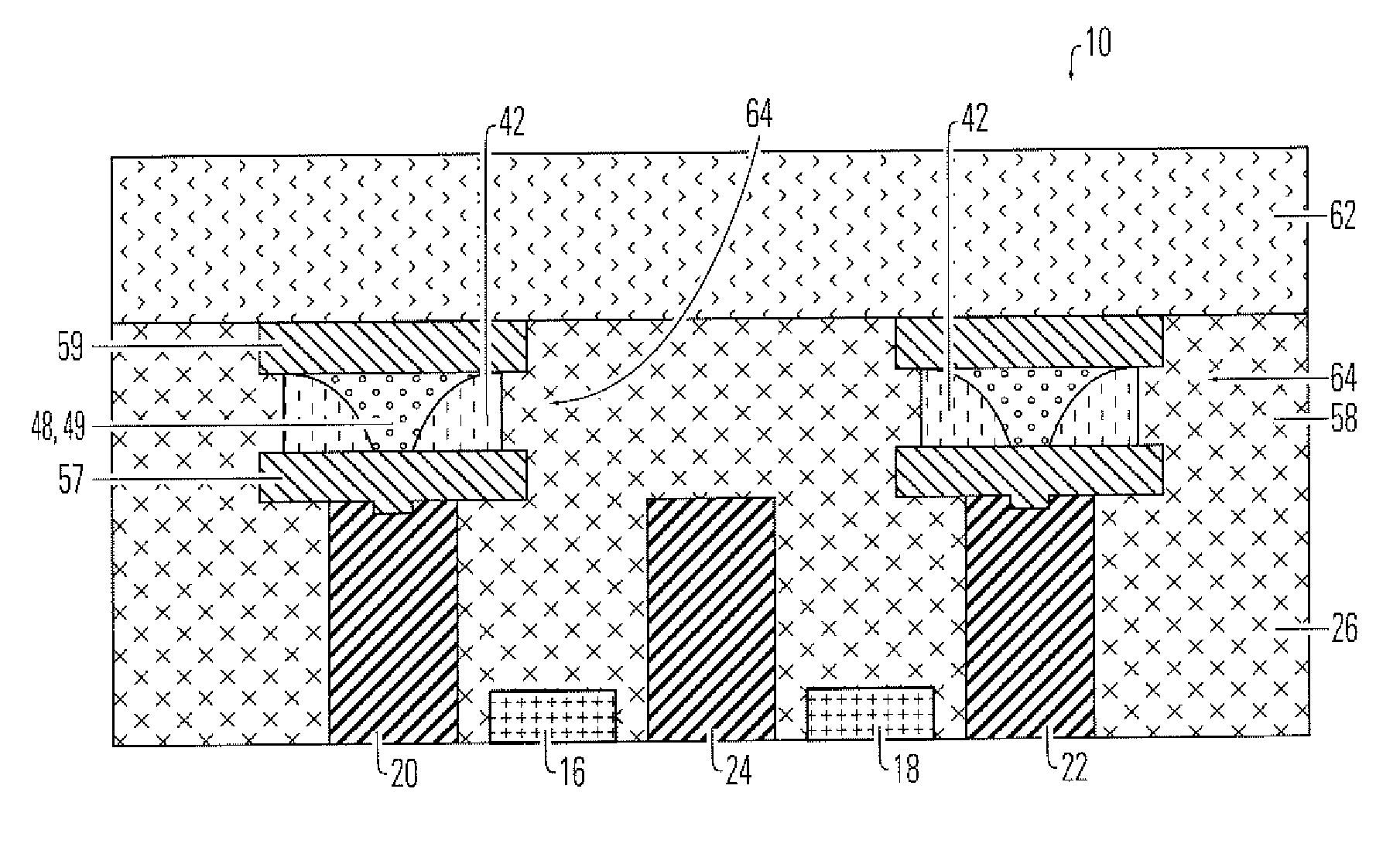

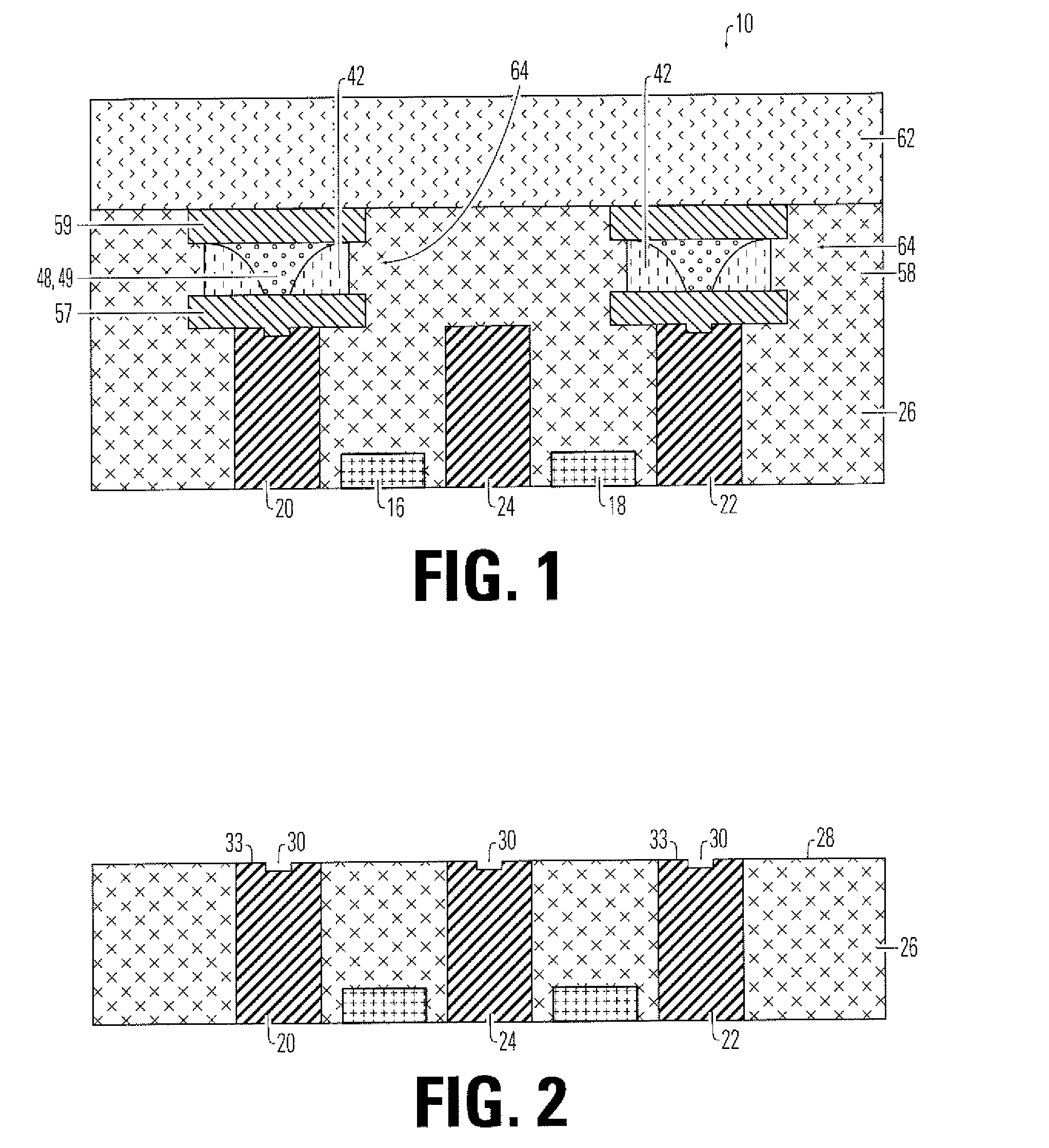

An integrated circuit with an embedded memory comprises a substrate and a plurality of conductor layers arranged for interconnecting components of the integrated circuit. An intermediate layer in the plurality of conductor layers includes a first electrode having a top surface, a second electrode having a top surface, an insulating member between the first electrode and the second electrode. A bridge overlies the intermediate layer between the first and second electrodes across the insulating member, wherein the bridge comprises a programmable resistive memory material, such as a phase change material. A conductor in at least one layer in the plurality of conductor layers over said intermediate layer is connected to said bridge.

Owner:MACRONIX INT CO LTD

Thermally insulated phase change memory device and manufacturing method

ActiveUS20070109836A1Reduce the required powerImprove flatnessSolid-state devicesDigital storagePhase-change memoryEngineering

A thermally insulated memory device comprises a memory cell, the memory cell having electrodes with a via extending therebetween, a thermal insulator within the via and defining a void extending between the electrode surfaces. A memory material, such as a phase change material, is within the void and electrically couples the electrodes to create a memory material element. The thermal insulator helps to reduce the power required to operate the memory material element. An electrode may contact the outer surface of a plug to accommodate any imperfections, such as the void-type imperfections, at the plug surface. Methods for making the device and accommodating plug surface imperfections are also disclosed.

Owner:MACRONIX INT CO LTD

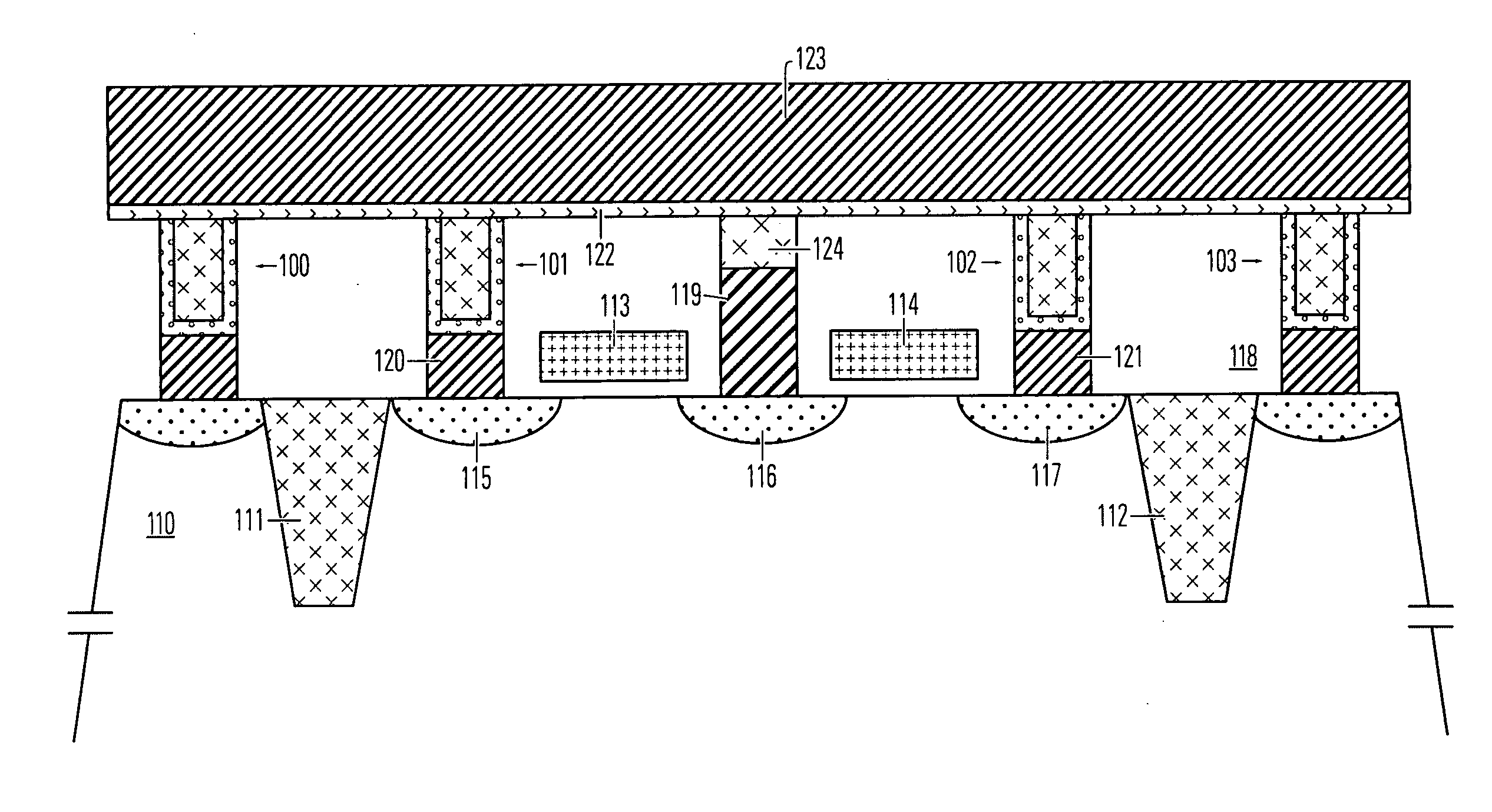

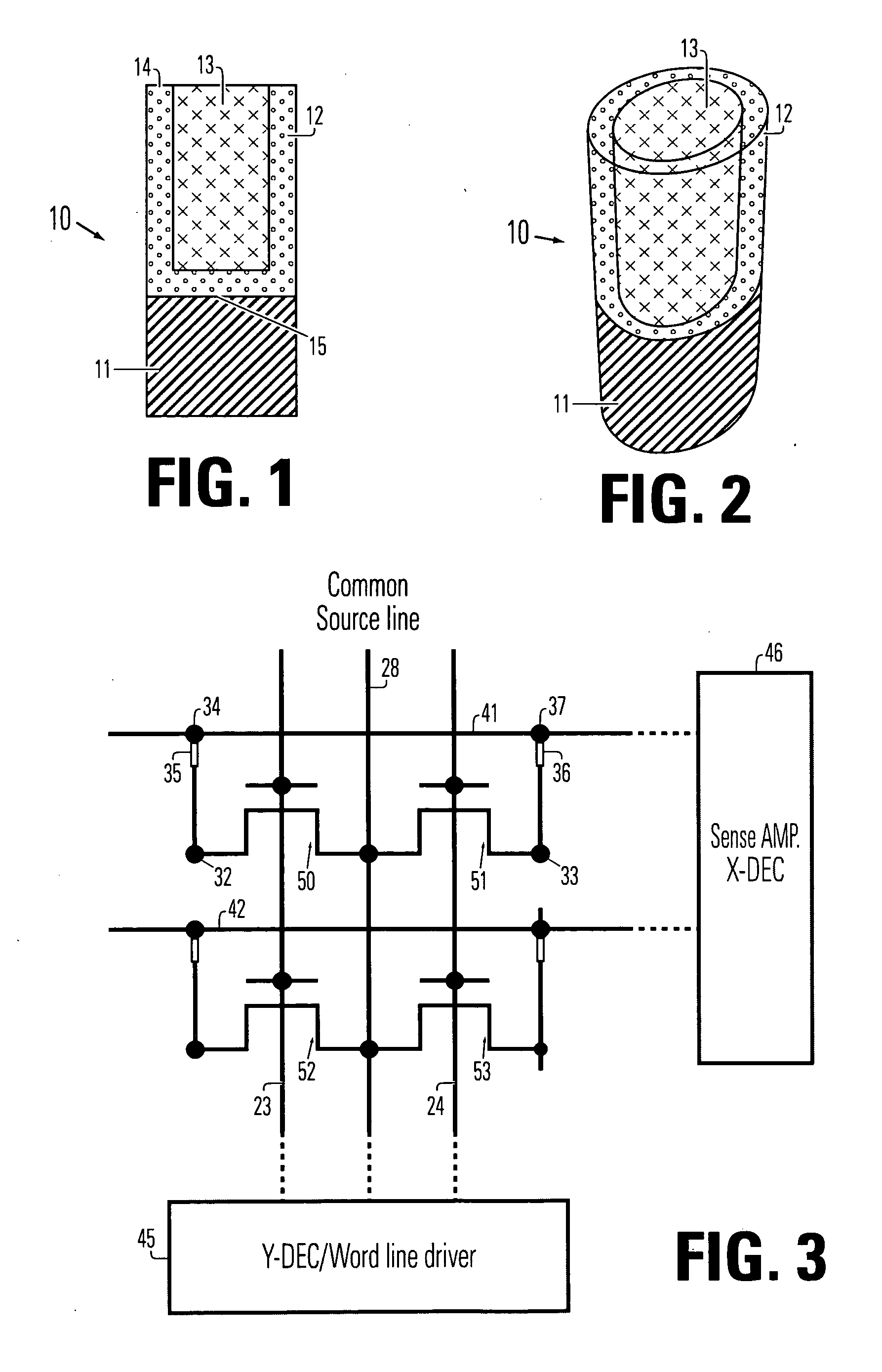

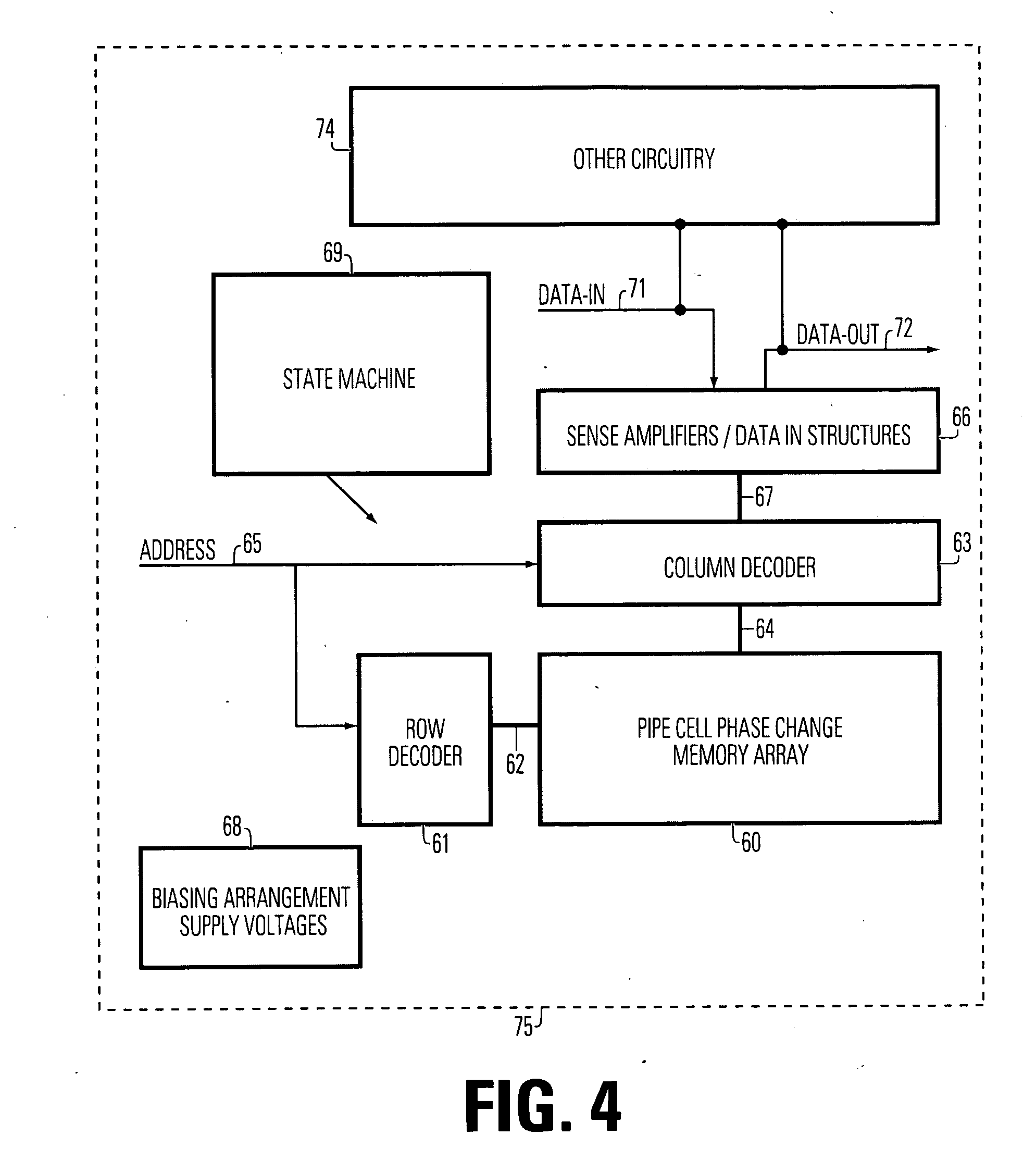

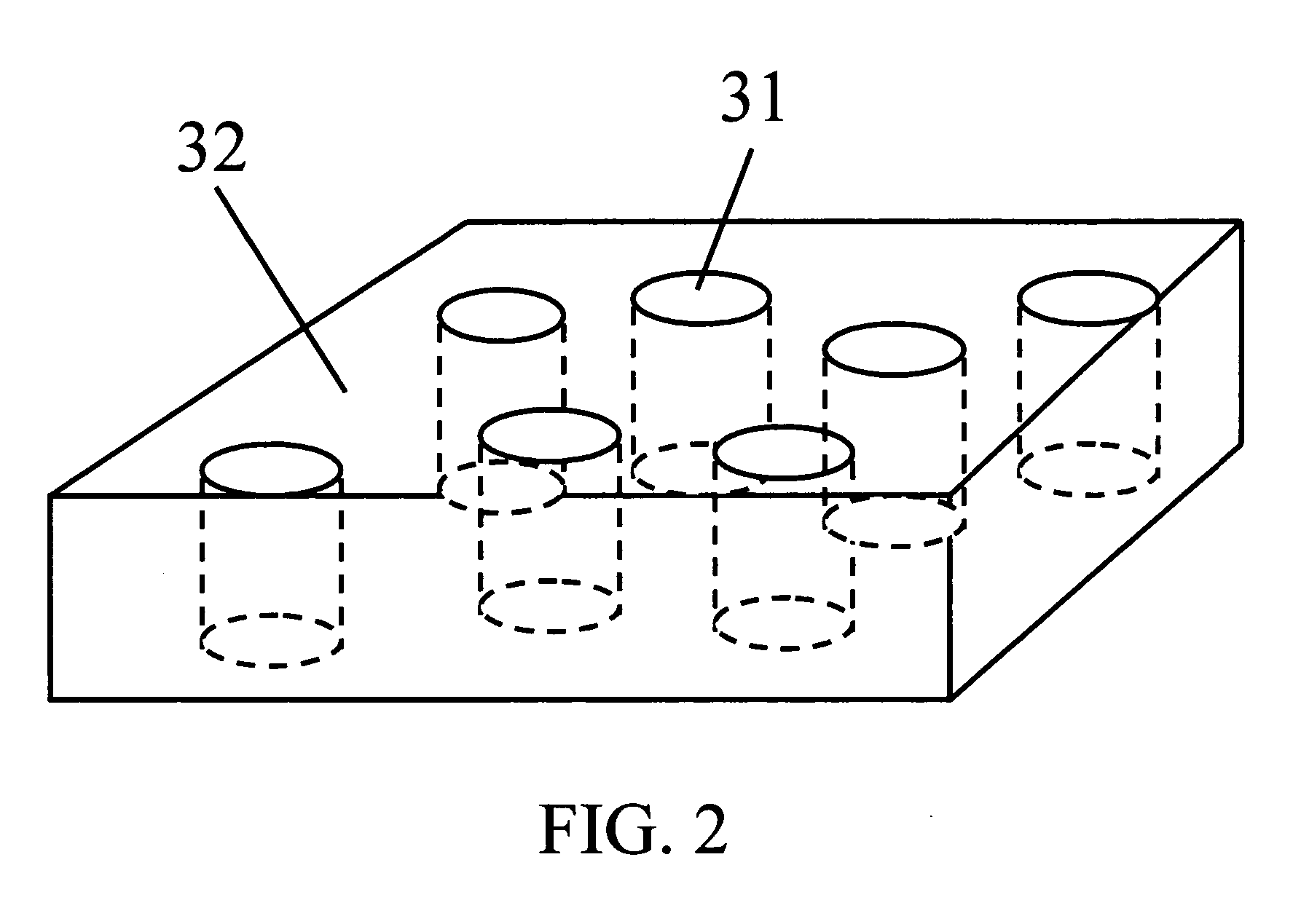

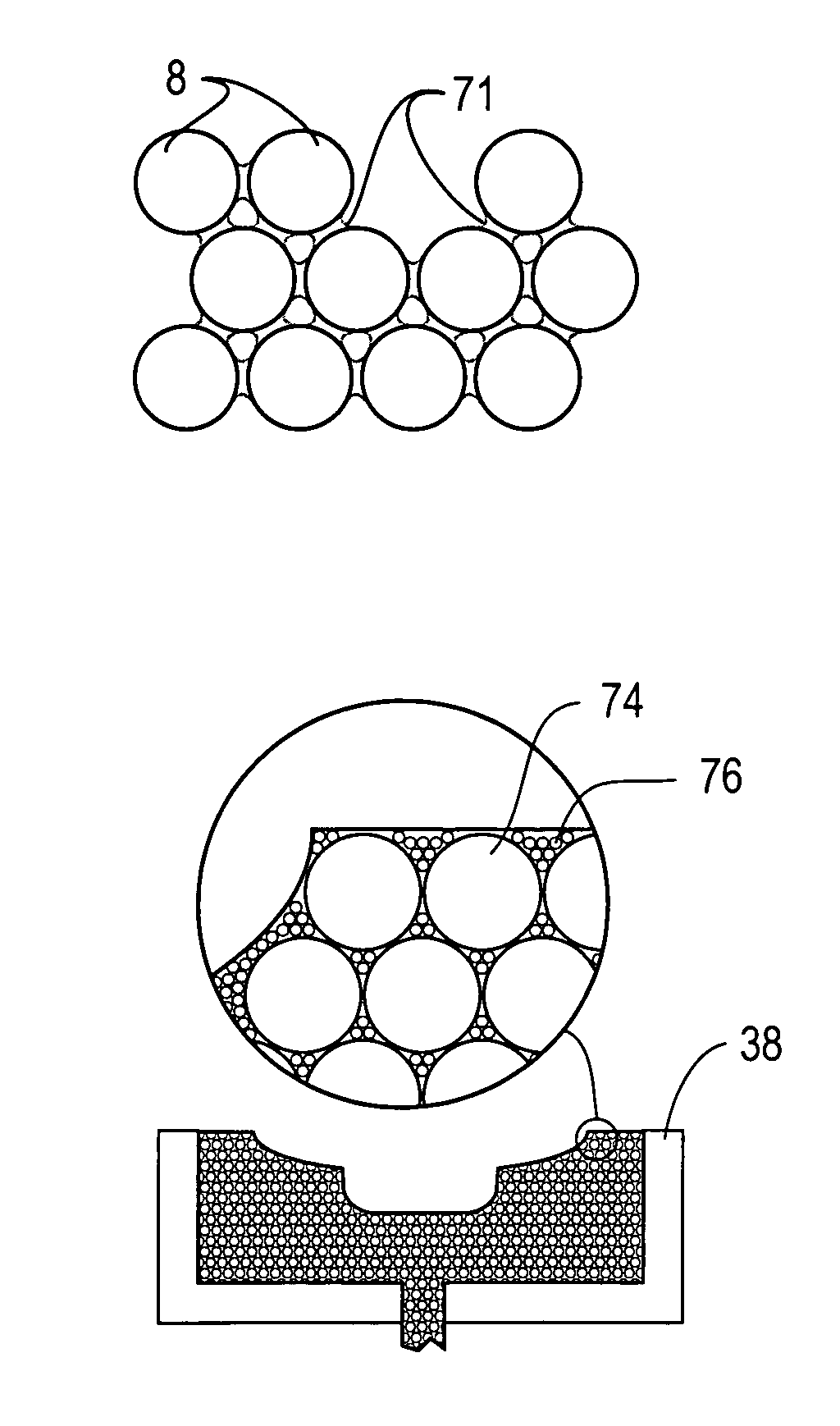

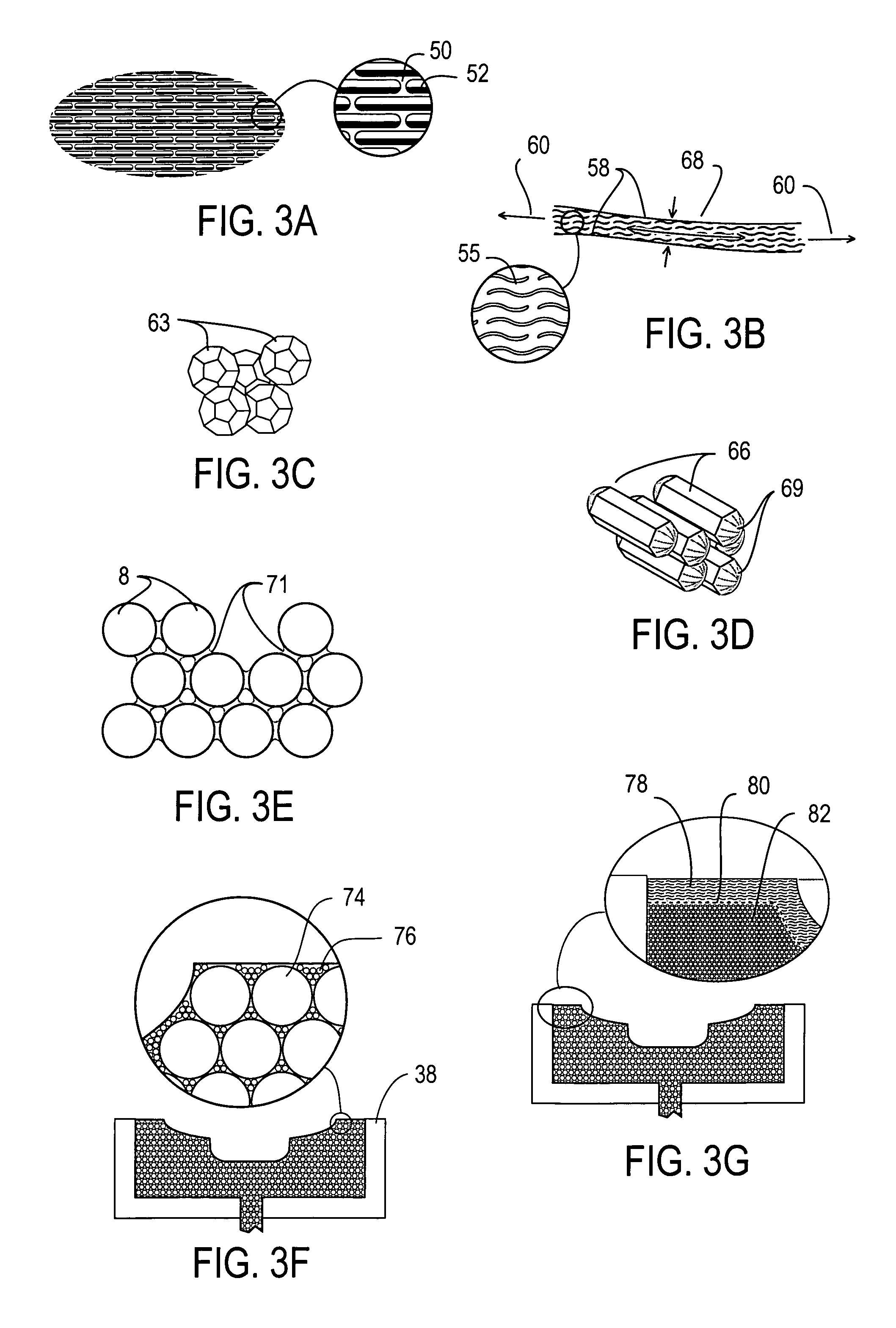

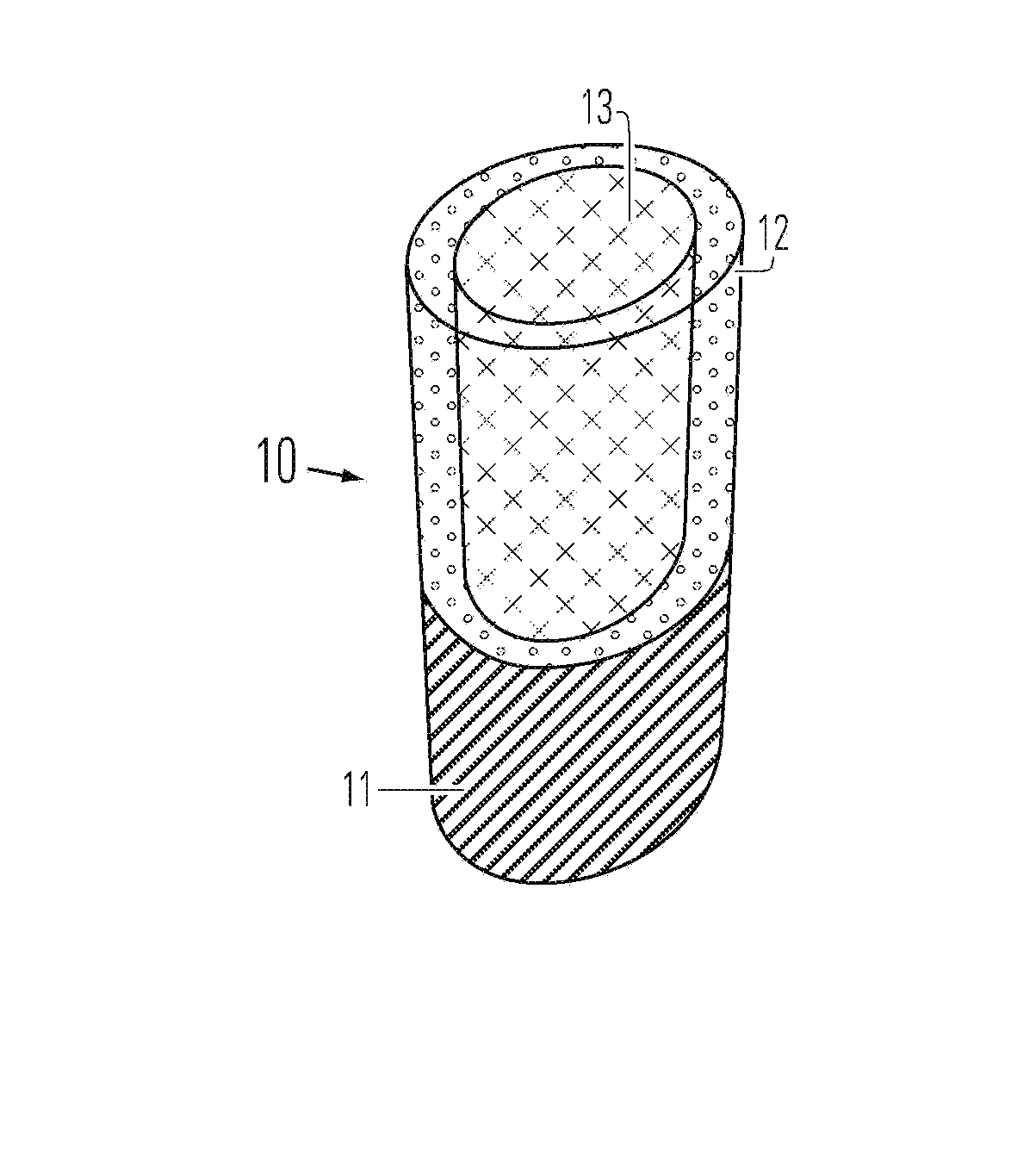

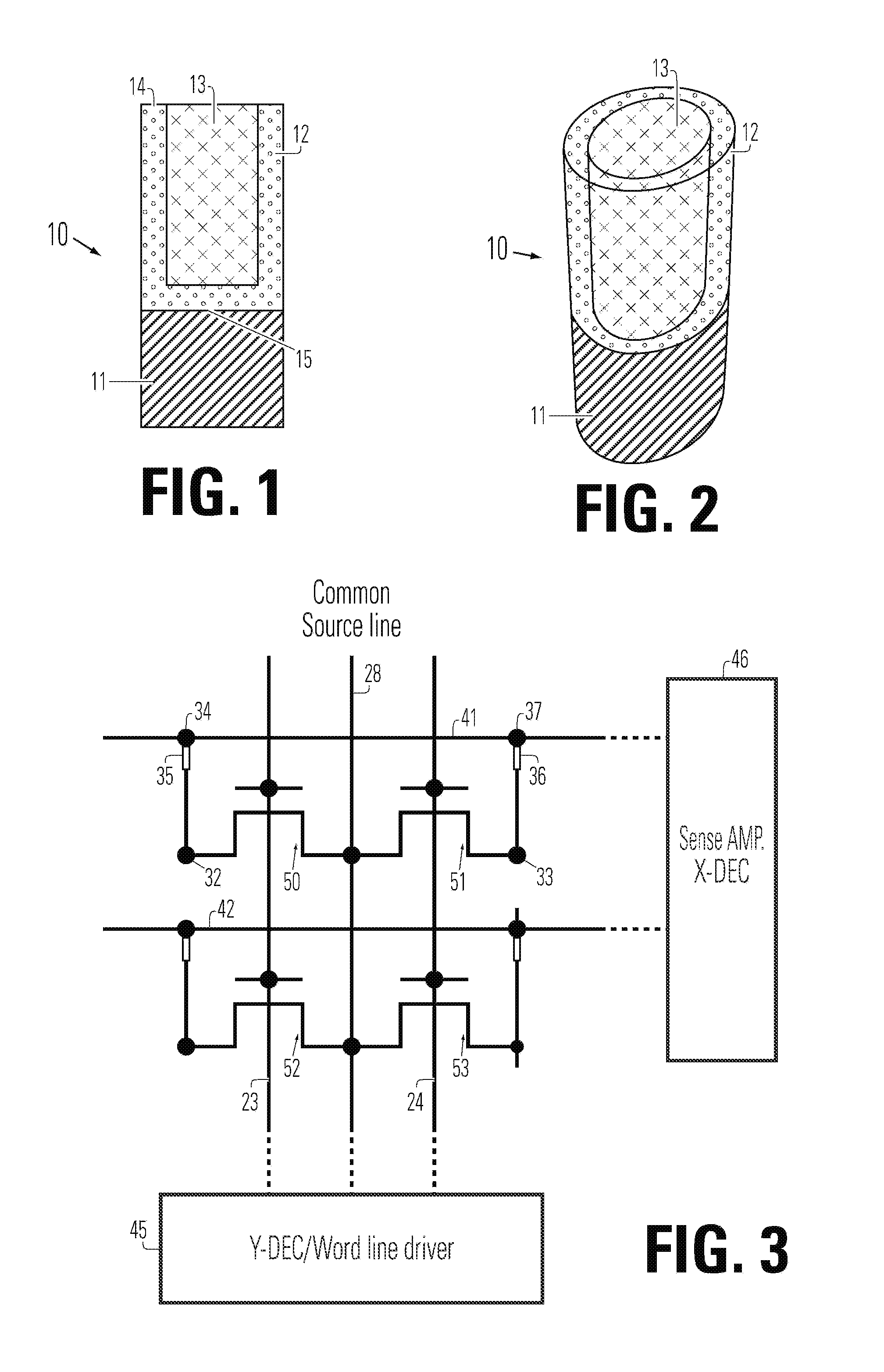

Pipe shaped phase change memory

ActiveUS20070108429A1High resistivityLow thermal conductivitySolid-state devicesBulk negative resistance effect devicesPhase-change memoryEngineering

A memory cell device includes a bottom electrode, pipe shaped member comprising phase change material and a top electrode in contact with the pipe-shaped member. An electrically and thermally insulating material is inside the pipe-shaped member. An integrated circuit including an array of pipe-shaped phase change memory cells is described.

Owner:MACRONIX INT CO LTD

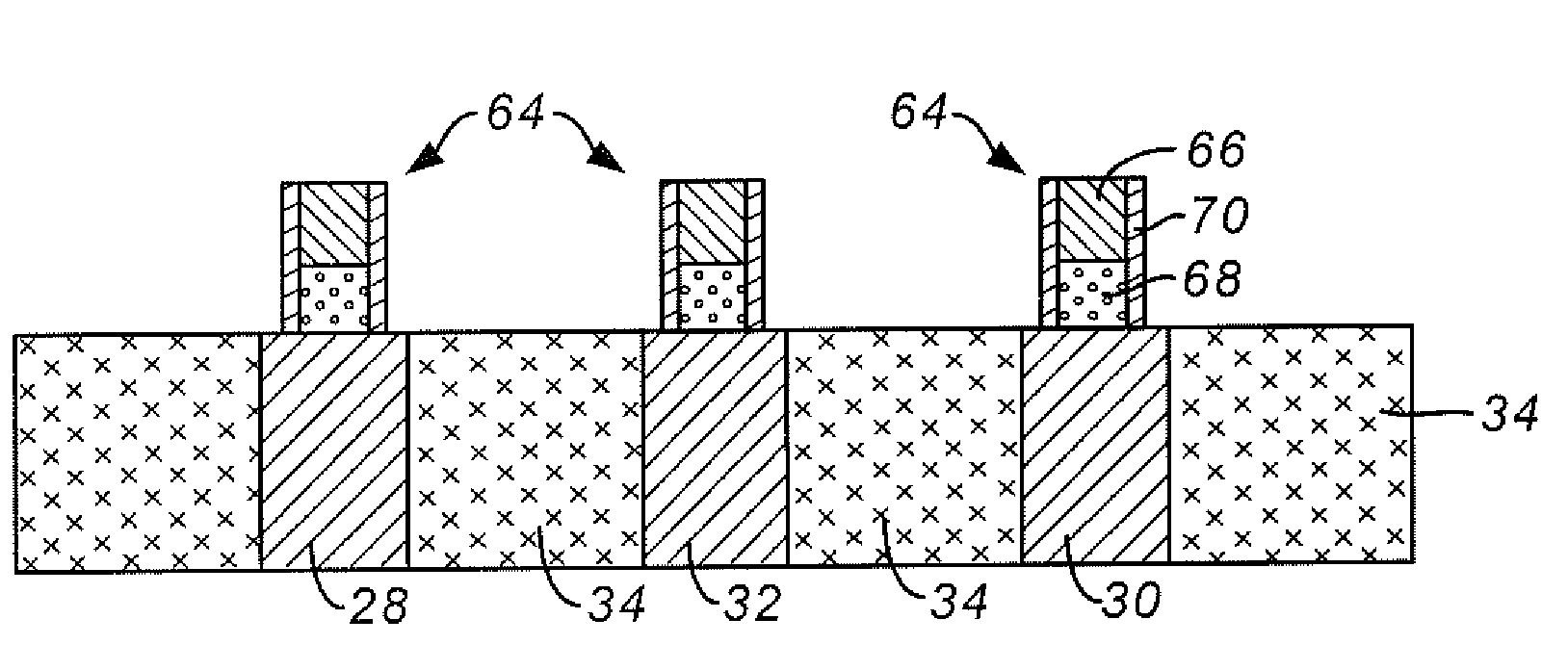

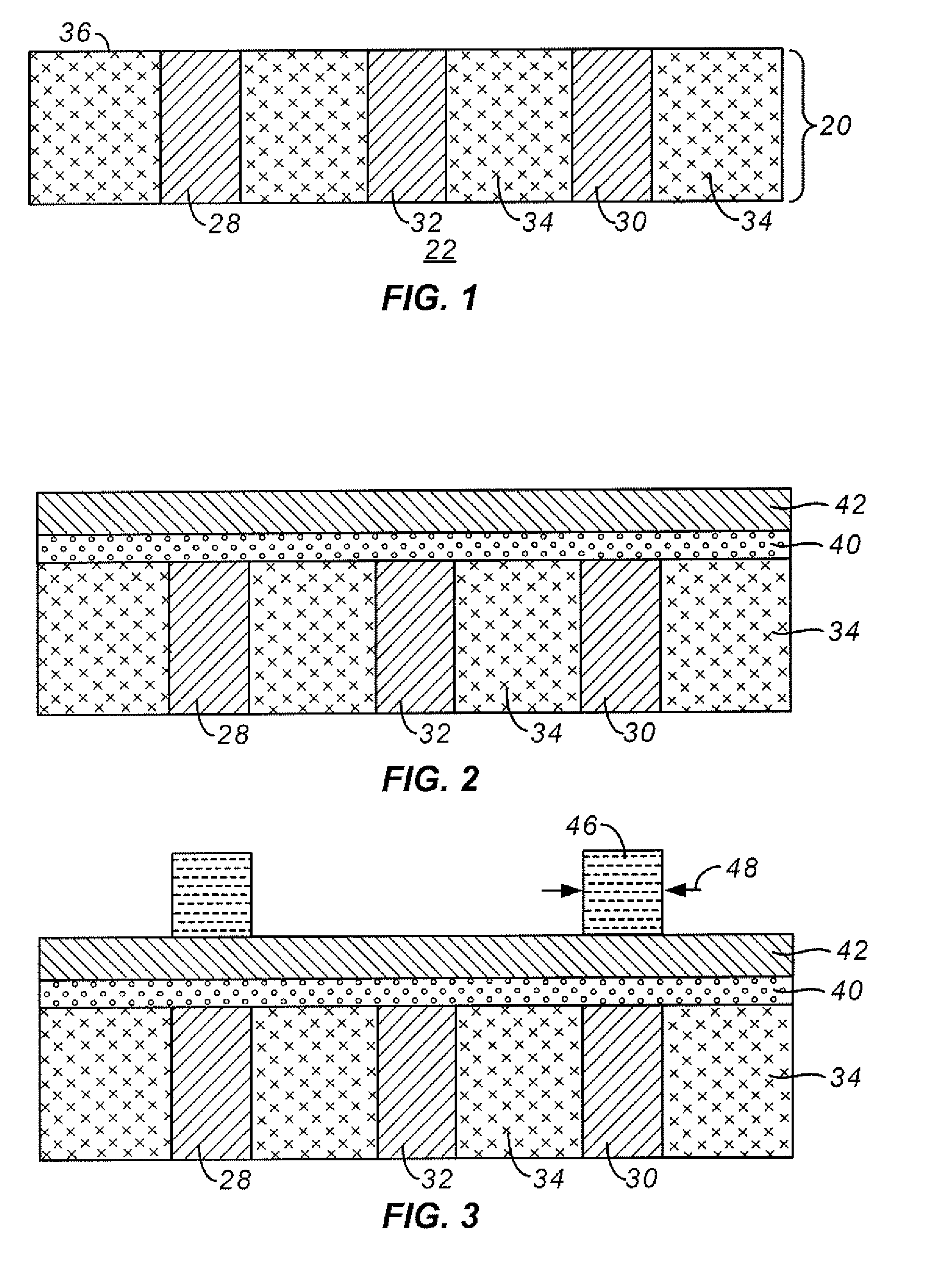

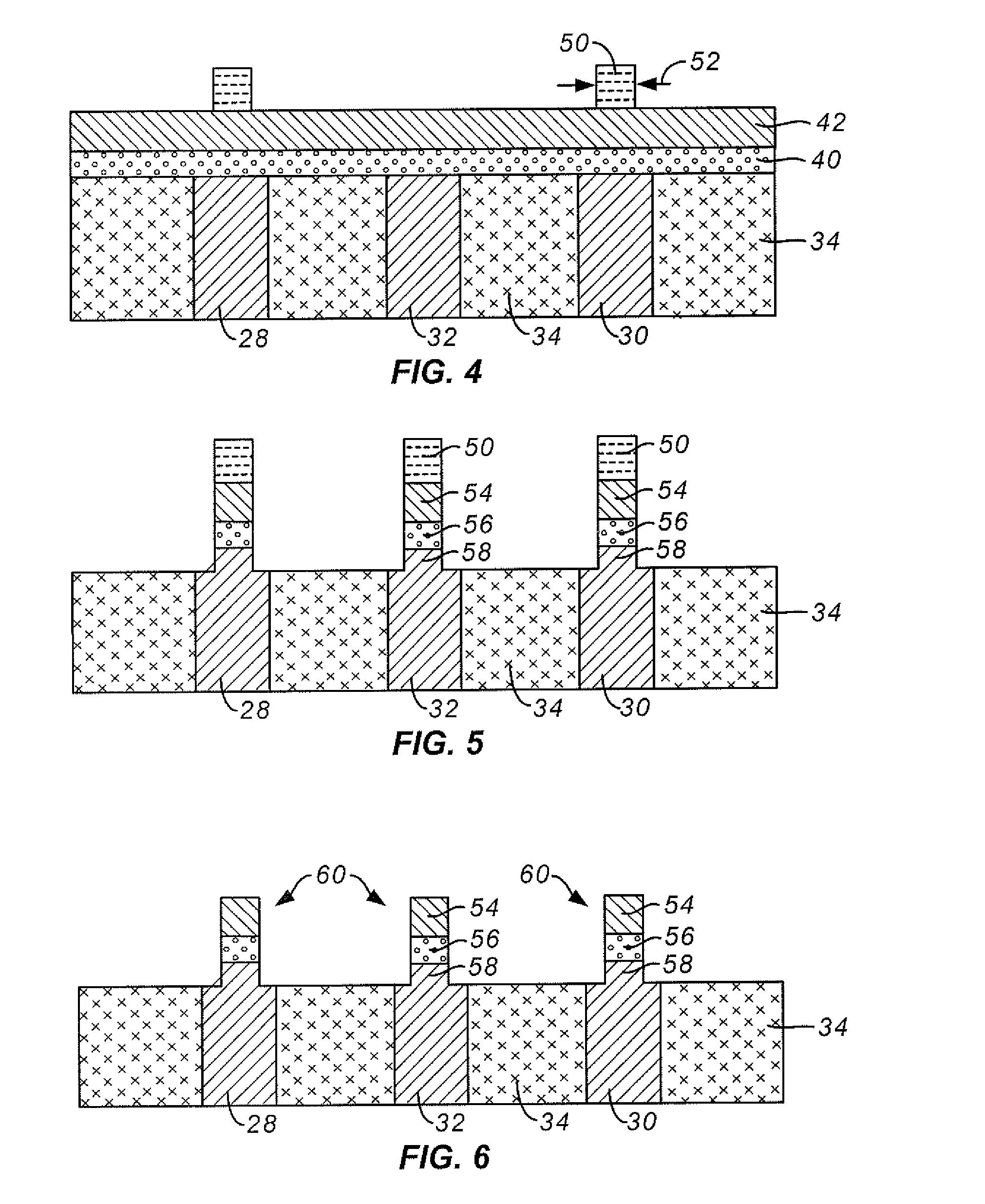

Method for Fabricating a Pillar-Shaped Phase Change Memory Element

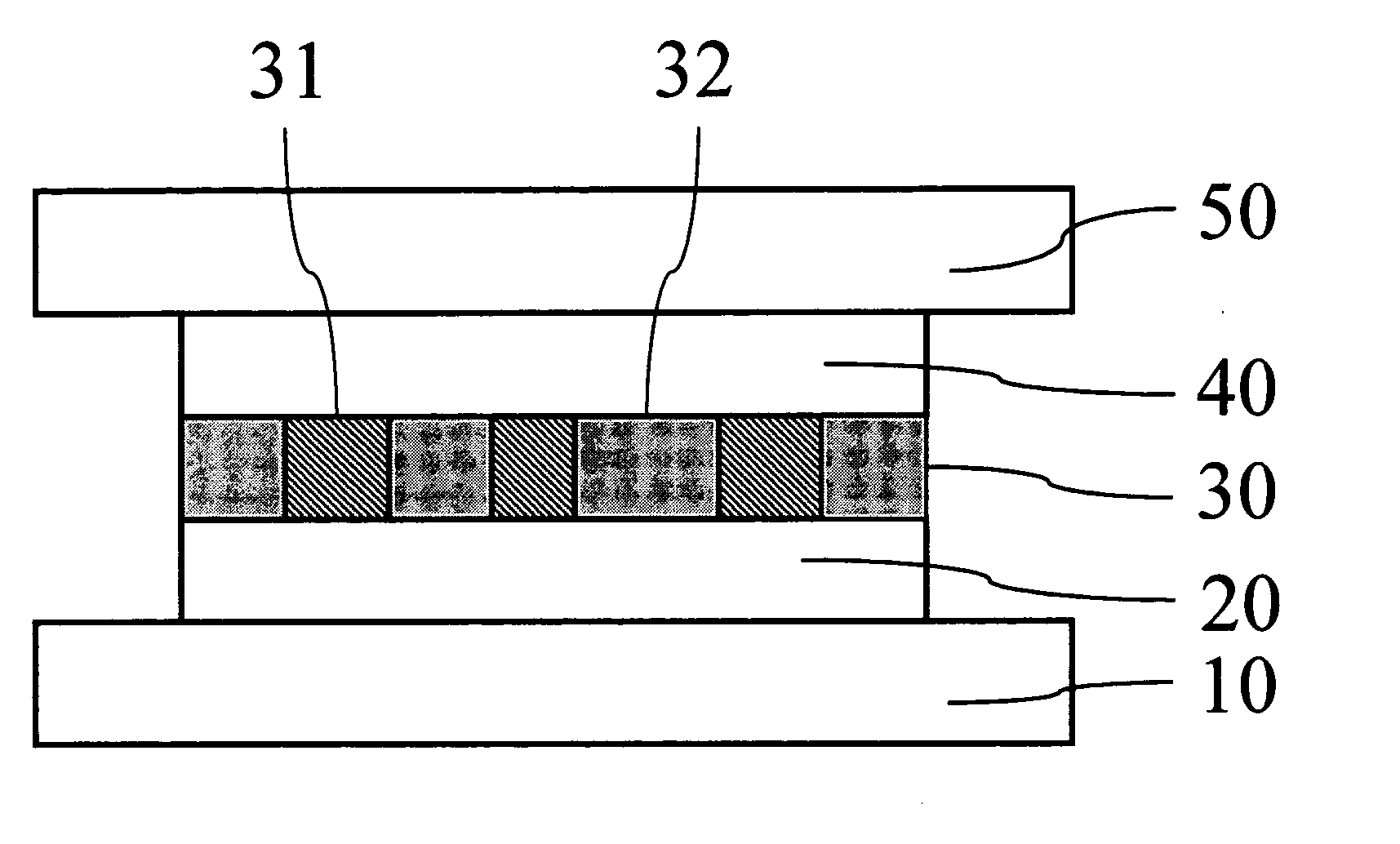

InactiveUS20070158632A1Photomechanical apparatusSemiconductor/solid-state device manufacturingPhase-change memoryPhase-change material

A method of fabricating a sub-feature size pillar structure on an integrated circuit. The process first provides a substrate having formed thereon a phase change layer, an electrode layer and a hard-mask layer. Then there is formed a feature-size hard-mask, by lithographically patterning, etching and stripping a photoresist layer, followed by trimming the hard-mask to a selected sub-feature size, wherein the trimming step is highly selective between the electrode and phase change material layers and the hard-mask. The final steps are trimming the electrode and phase change layers to the size of the hard-mask and removing the hard-mask.

Owner:MACRONIX INT CO LTD

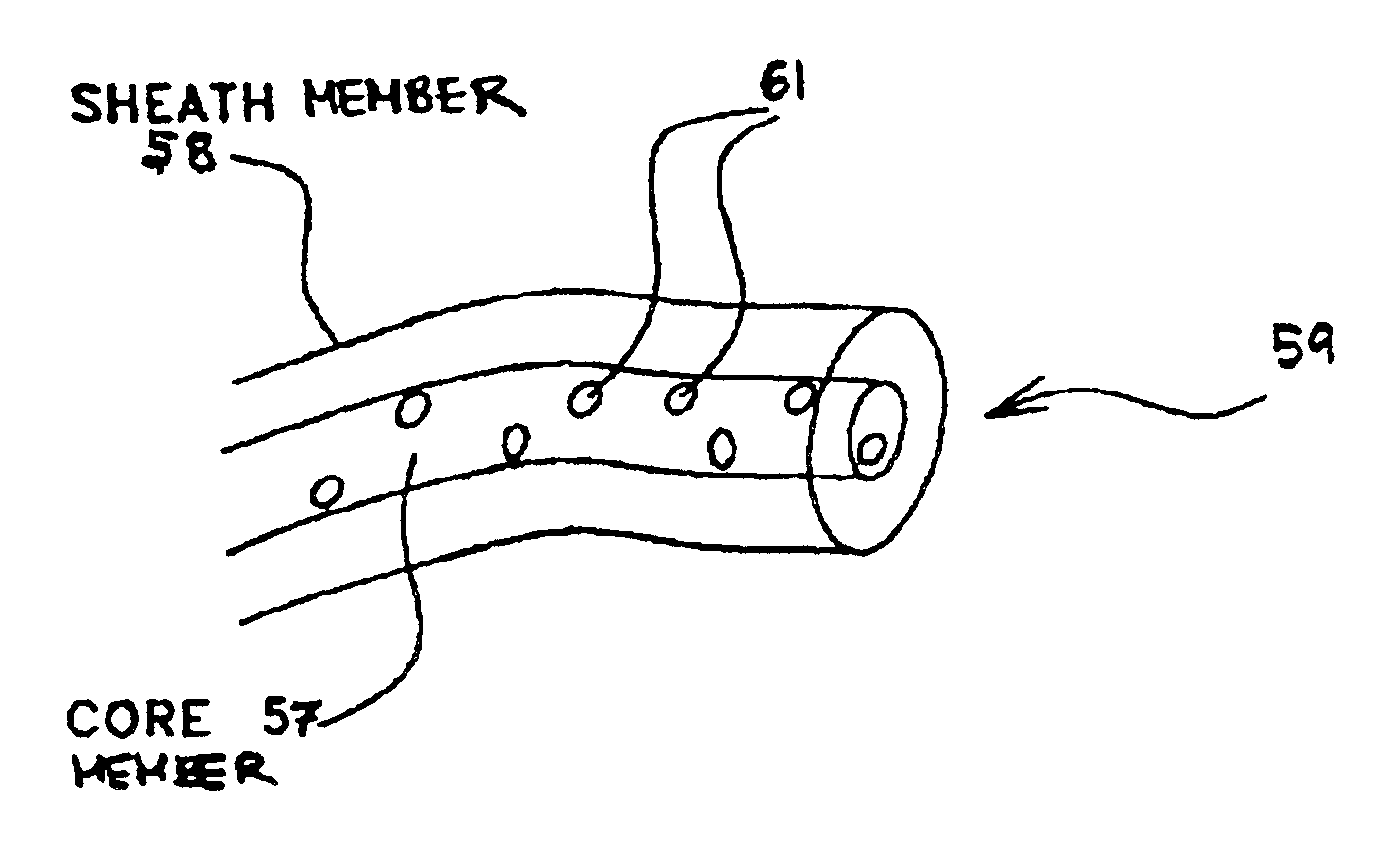

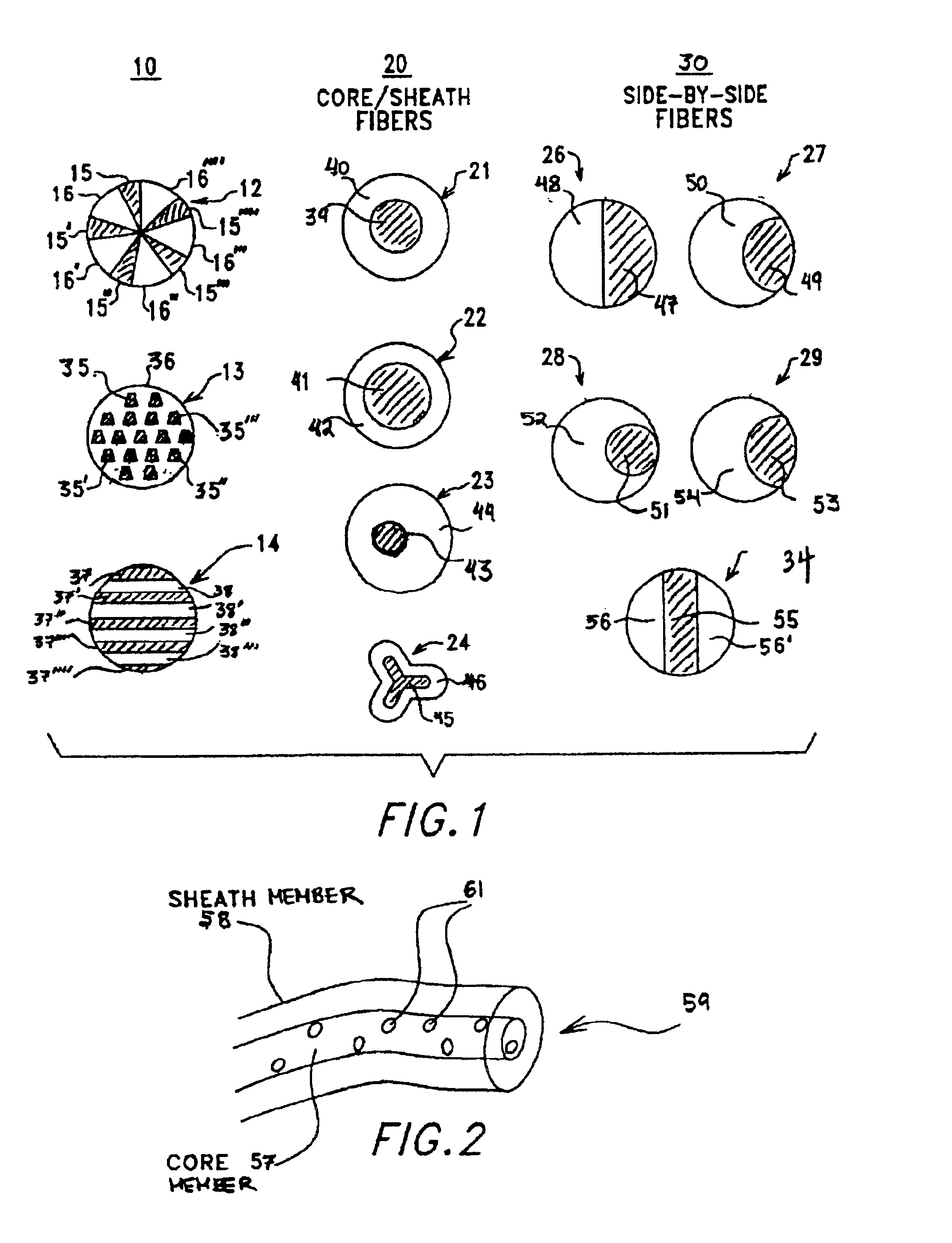

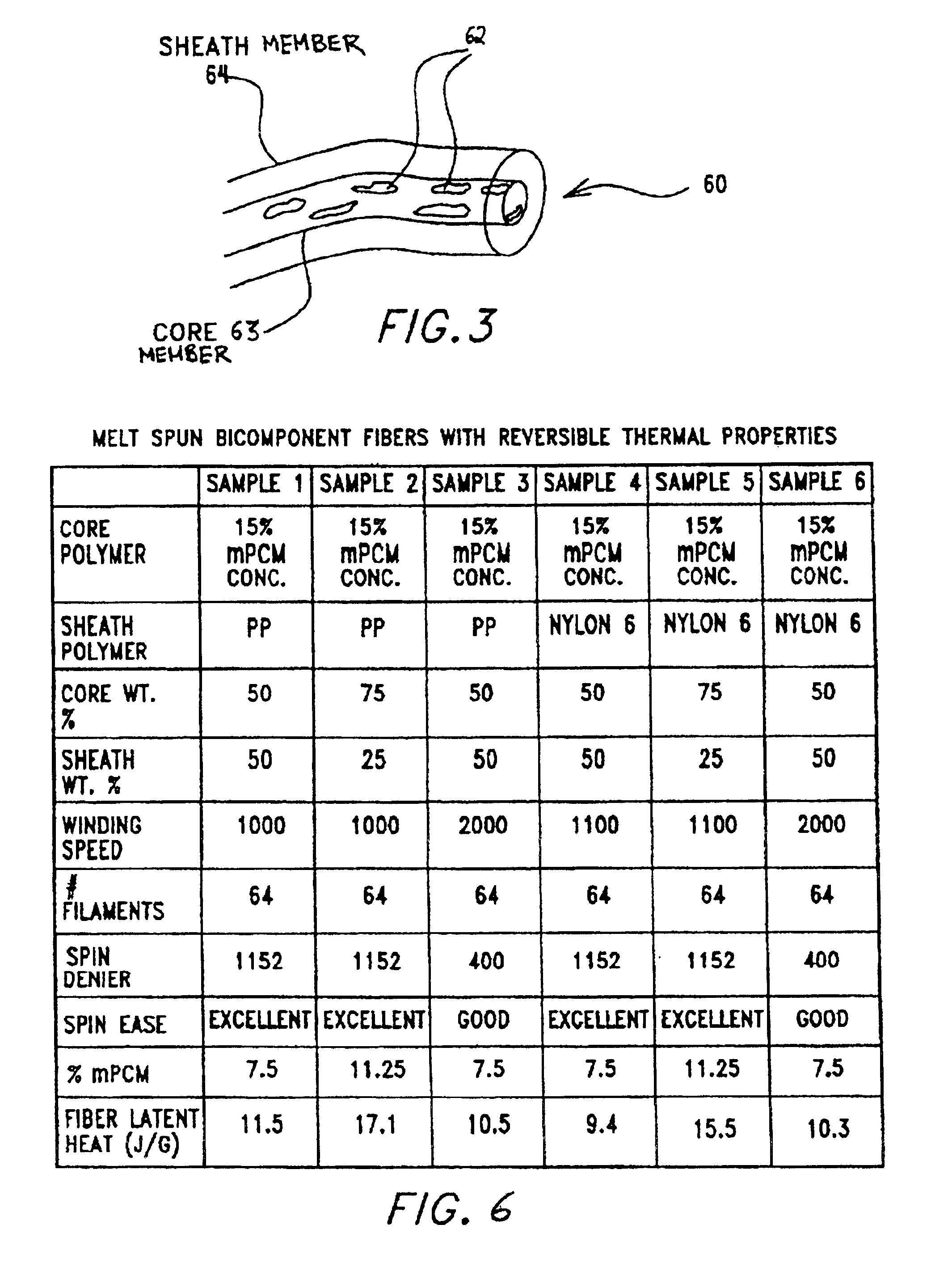

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof

InactiveUS6855422B2Easy to processImprove propertiesHeat storage plantsWarp knittingMedical productPhase-change material

The invention relates to a multi-component fiber having enhanced reversible thermal properties and methods of manufacturing thereof. The multi-component fiber comprises a fiber body formed from a plurality of elongated members, at least one of the elongated members comprising a temperature regulating material dispersed therein. The temperature regulating material comprises a phase change material. The multi-component fiber may be formed via a melt spinning process or a solution spinning process and may be used or incorporated in various products where a thermal regulating property is desired. For example, the multi-component fiber may be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:HILLS CO

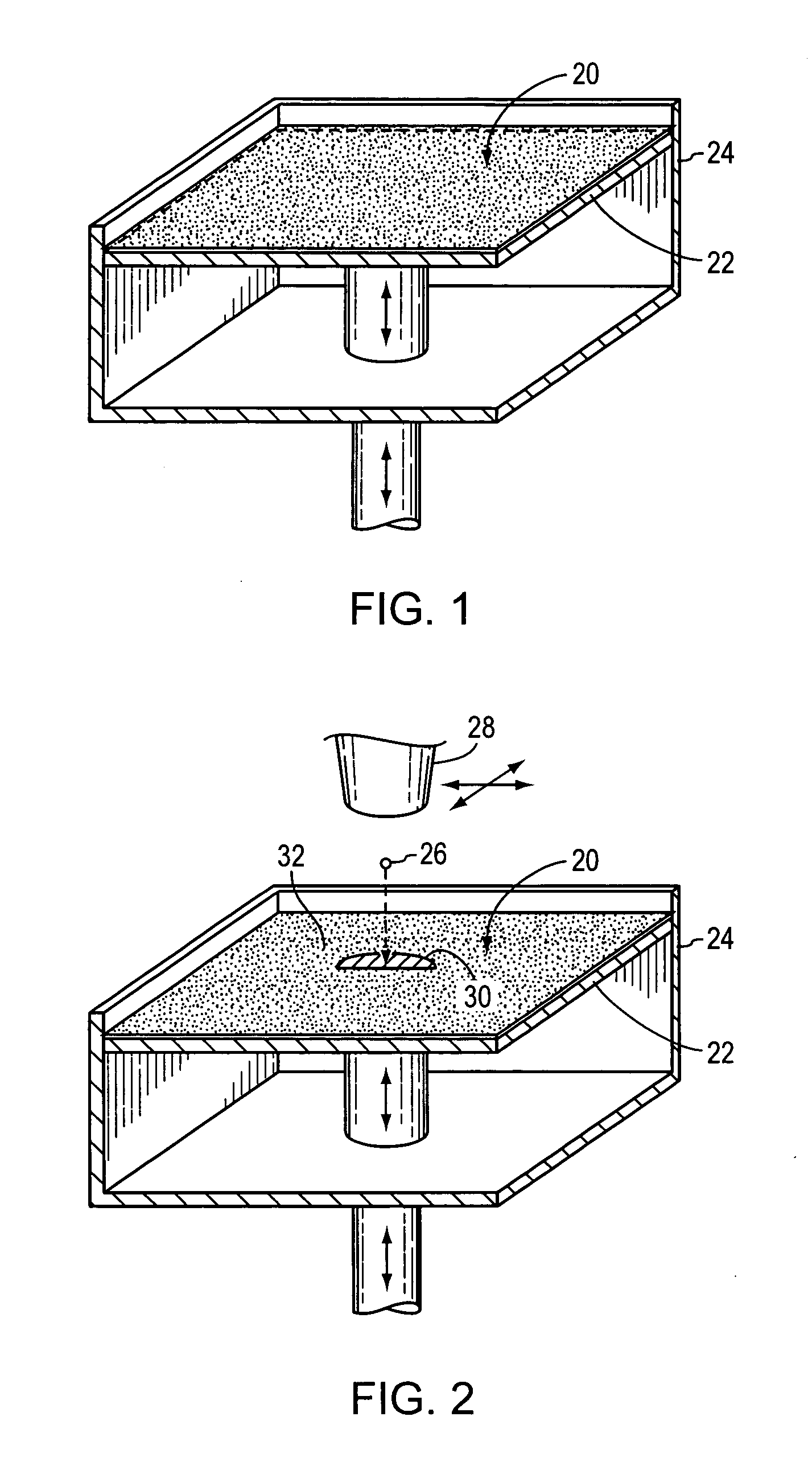

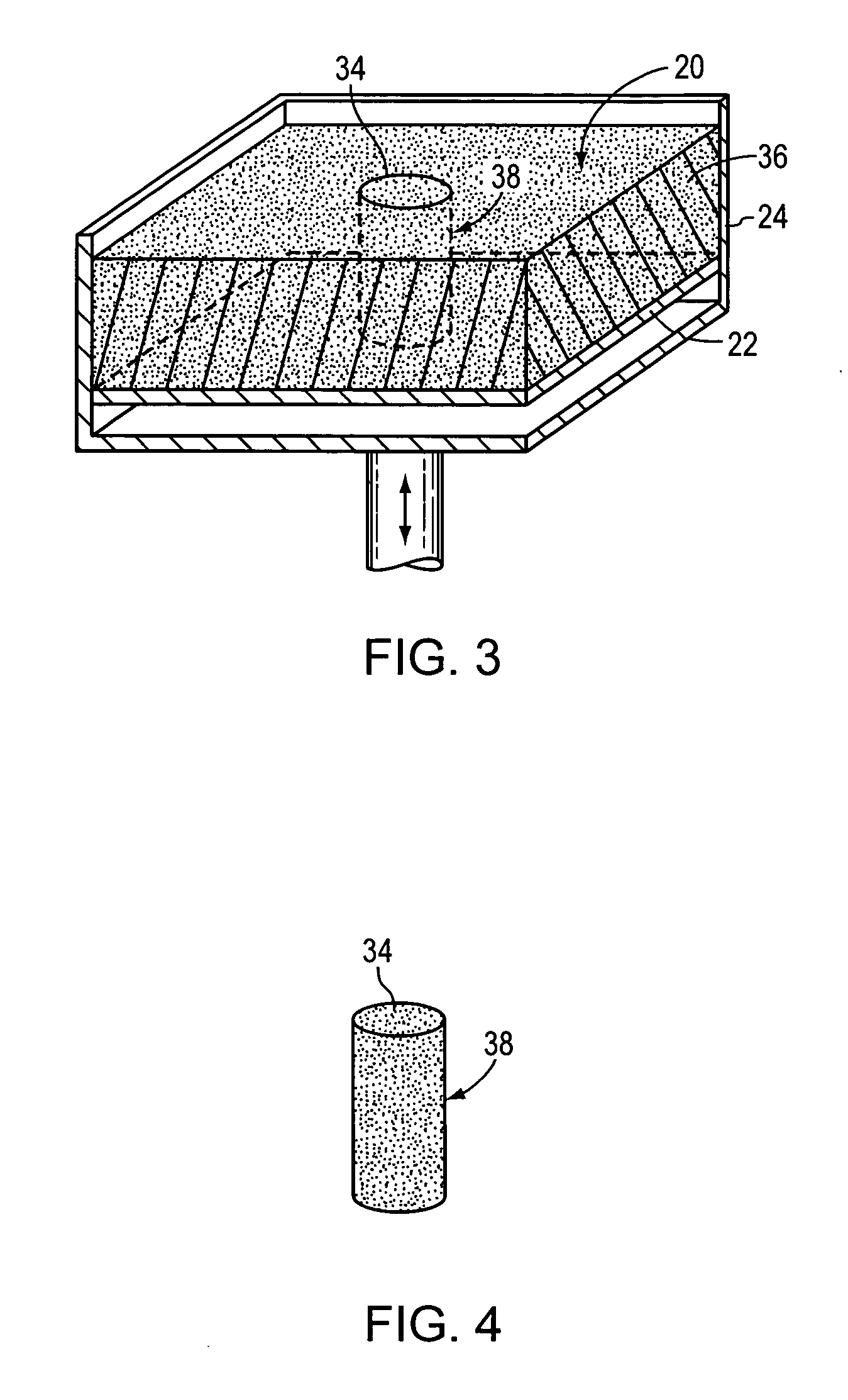

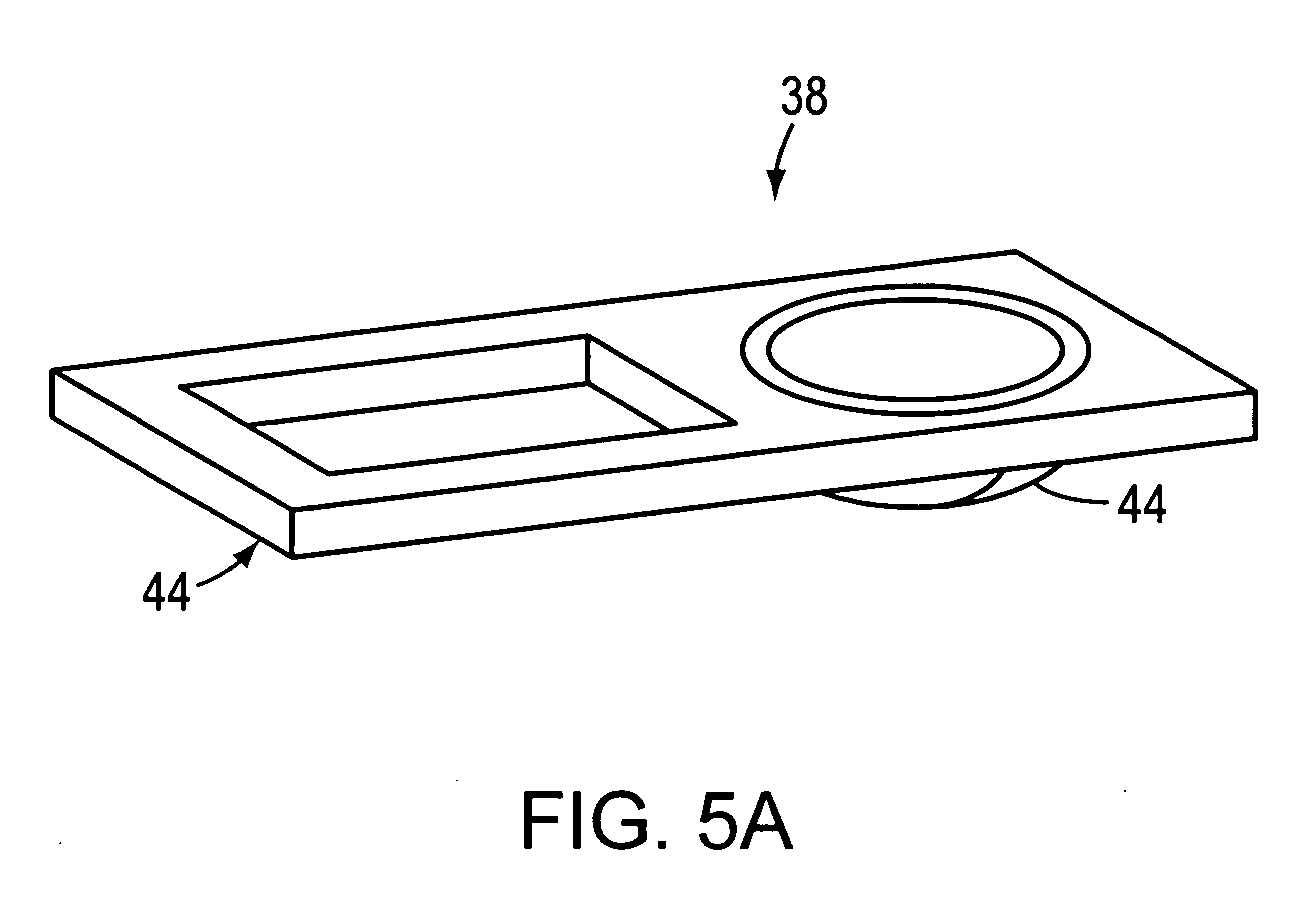

Absorbent fillers for three-dimensional printing

InactiveUS20050059757A1Quick and reliable and safe and inexpensiveSmooth surface finishPigmenting treatmentAdditive manufacturing apparatusParticulatesEngineering

A materials system and methods are provided to enable the formation of articles by three-dimensional printing. The materials system includes an absorbent particulate filler that facilitates absorption of infiltrants, thereby allowing the accurate definition of articles with enhanced mechanical and structural characteristics. The methods include the use of phase-change materials to bind a powder, as well as the formation of support structures to improve the control of the shape of the articles.

Owner:Z CORPORATION

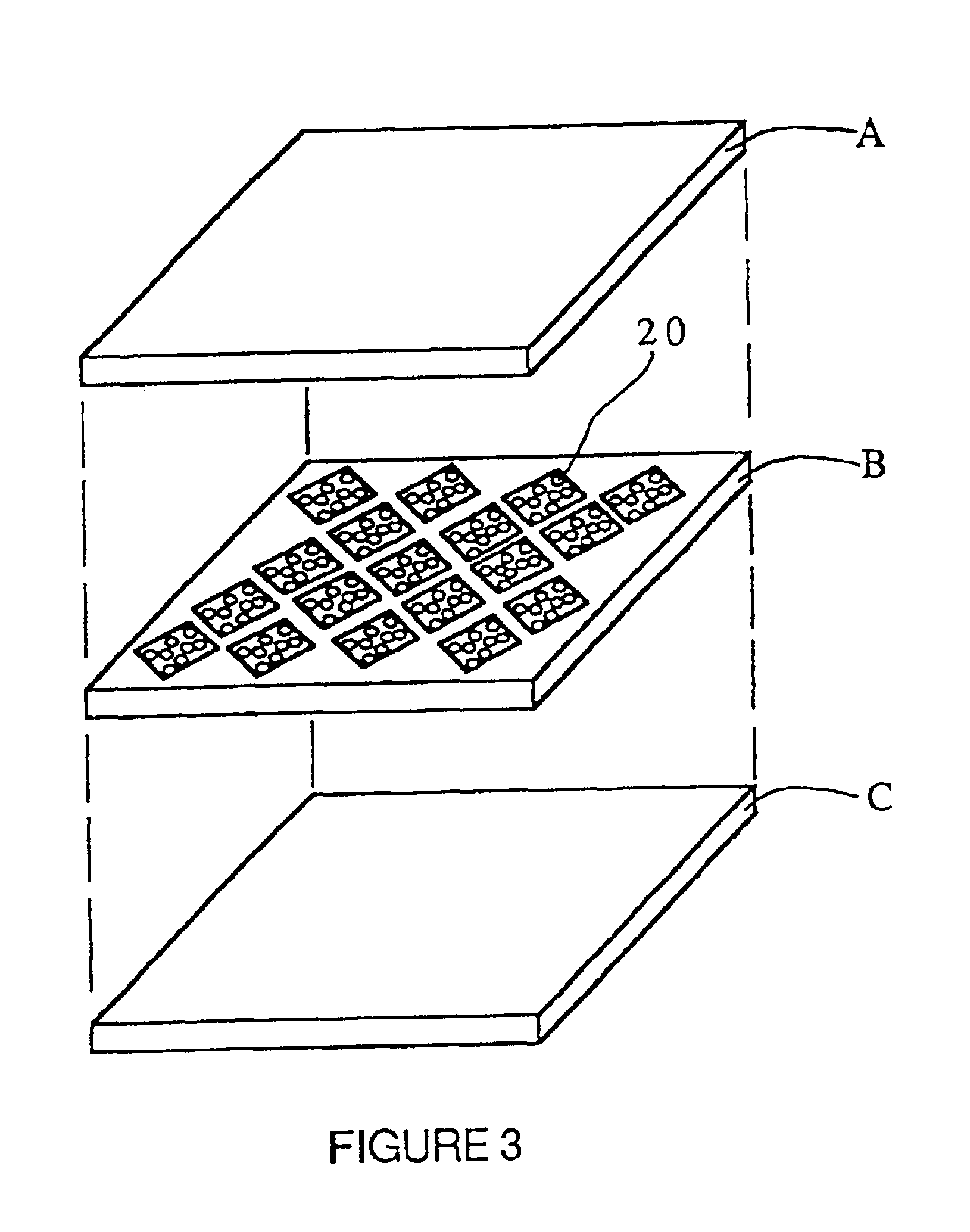

Fabric coating containing energy absorbing phase change material and method of manufacturing same

InactiveUS6514362B1Evenly dispersedEqually distributedDecorative surface effectsHeat storage plantsMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric. In an alternative embodiment, an extensible fabric is coated with an extensible binder containing microencapsulated phase change material to form an extensible, coated fabric. The coated fabric is optionally flocked. The coated fabrics are manufactured using transfer techniques.

Owner:OUTLAST TECH LLC

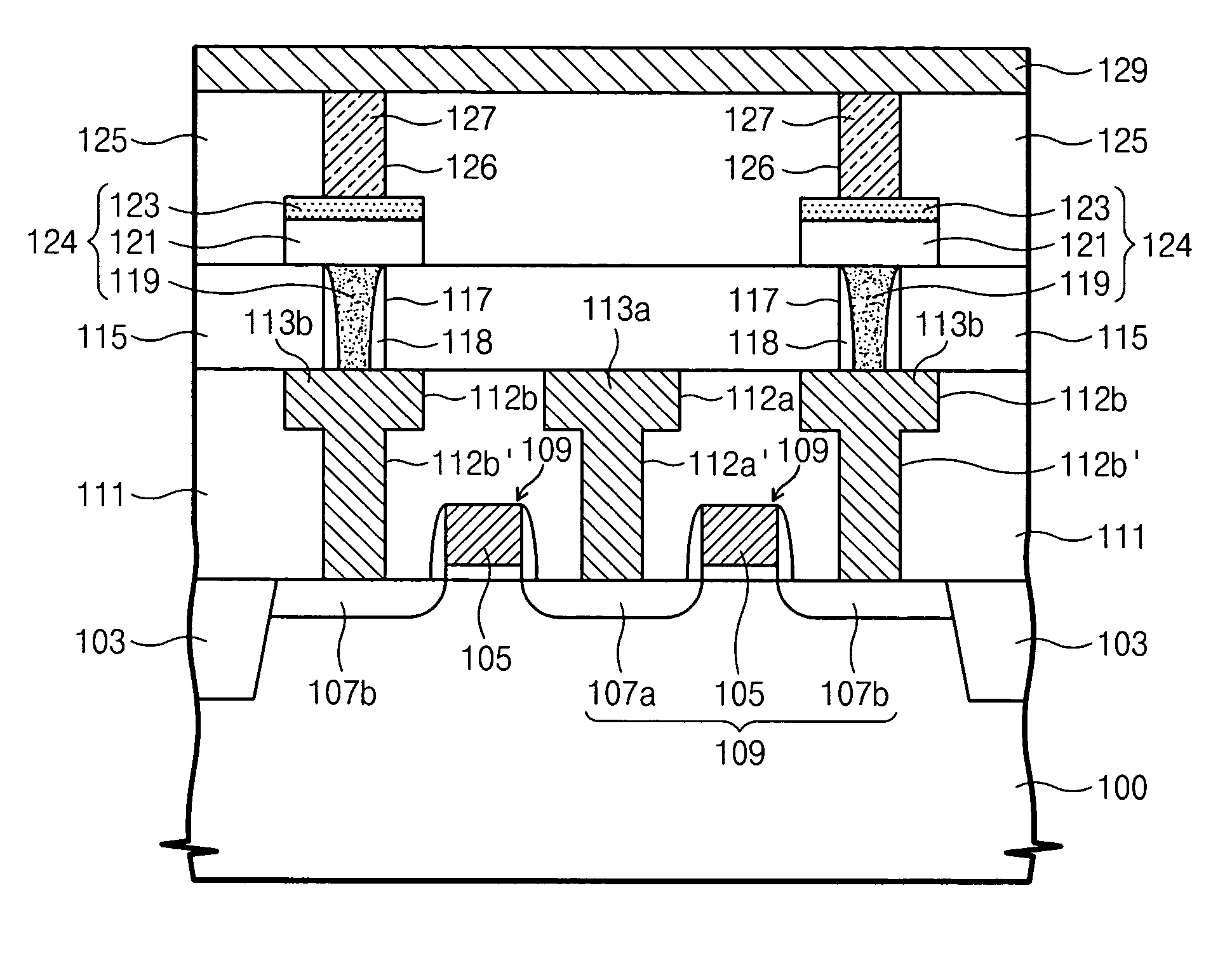

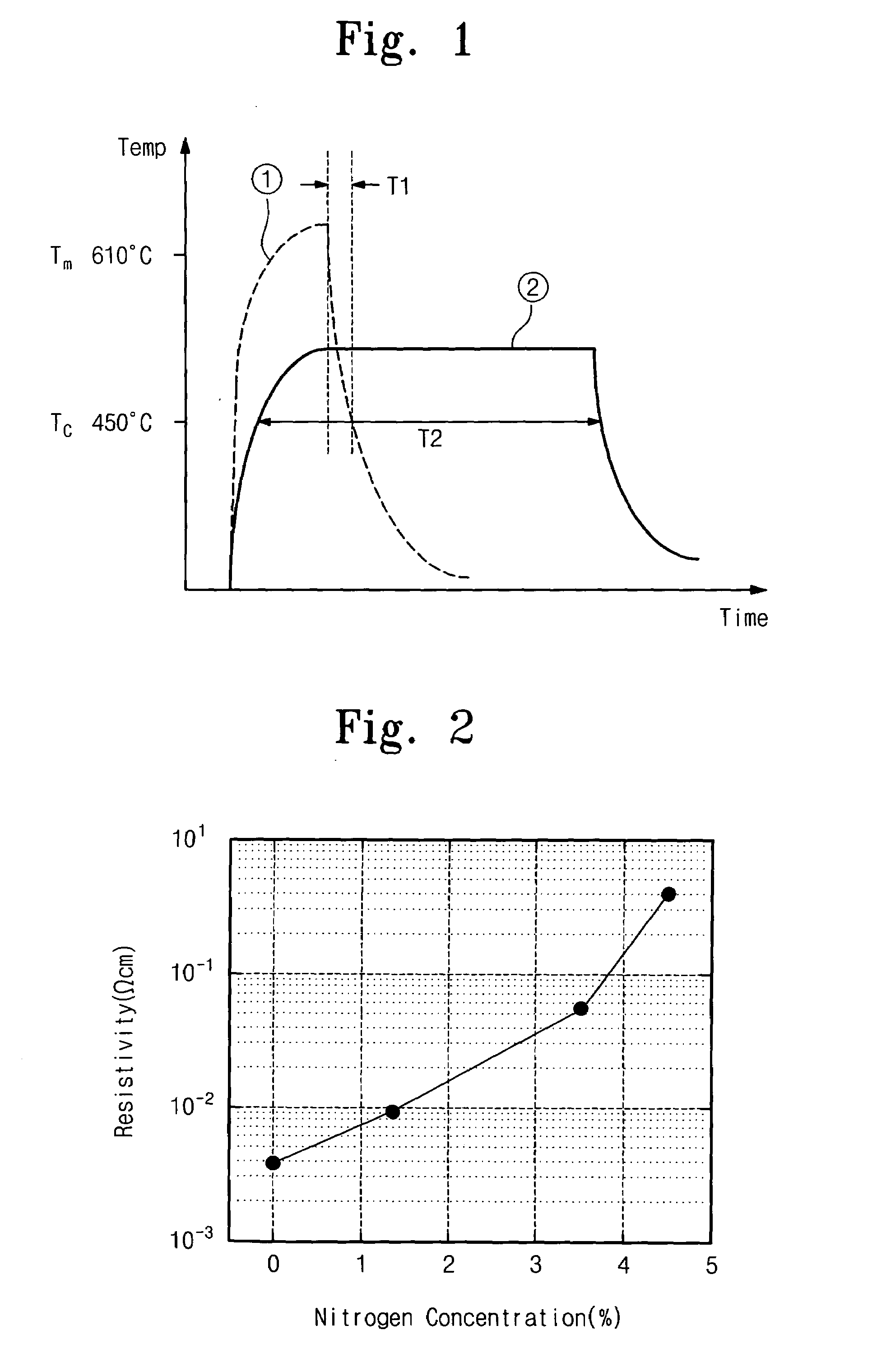

Phase changeable memory devices

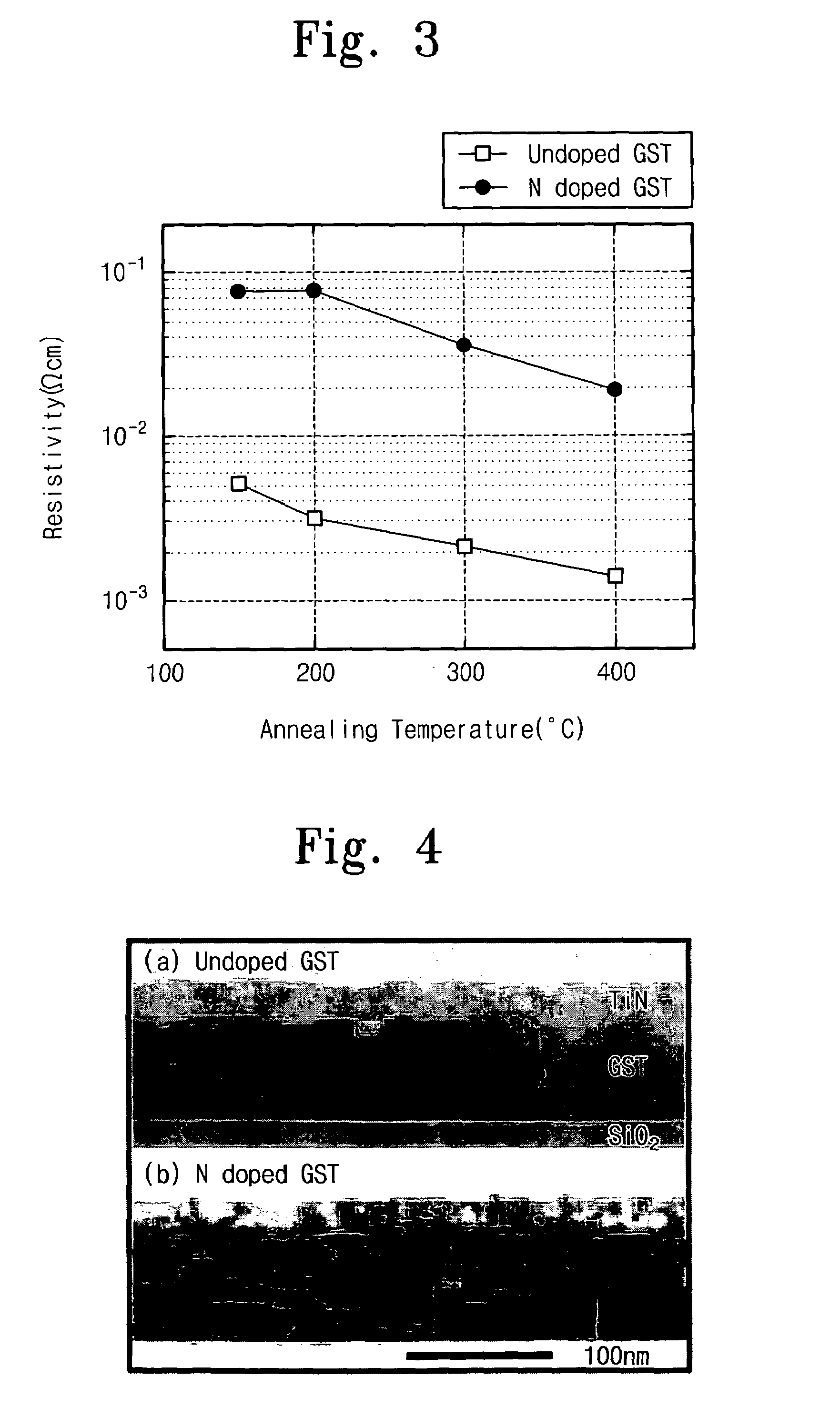

Phase-changeable memory devices and method of fabricating phase-changeable memory devices are provided that include a phase-changeable material pattern of a phase-changeable material that includes nitrogen atoms. First and second electrodes are electrically connected to the phase-changeable material pattern and provide an electrical signal thereto. The phase-changeable material pattern may have a polycrystalline structure.

Owner:SAMSUNG ELECTRONICS CO LTD

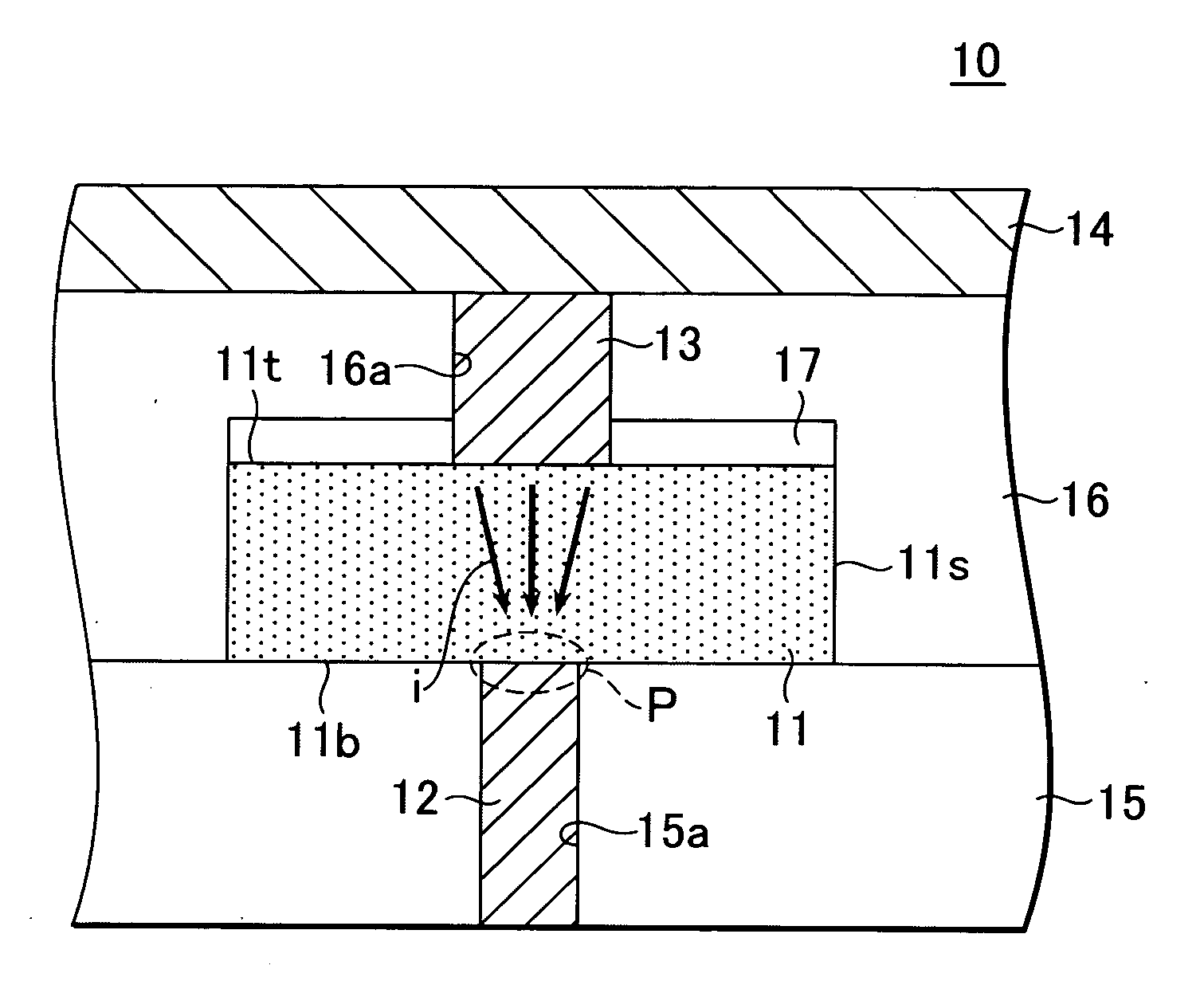

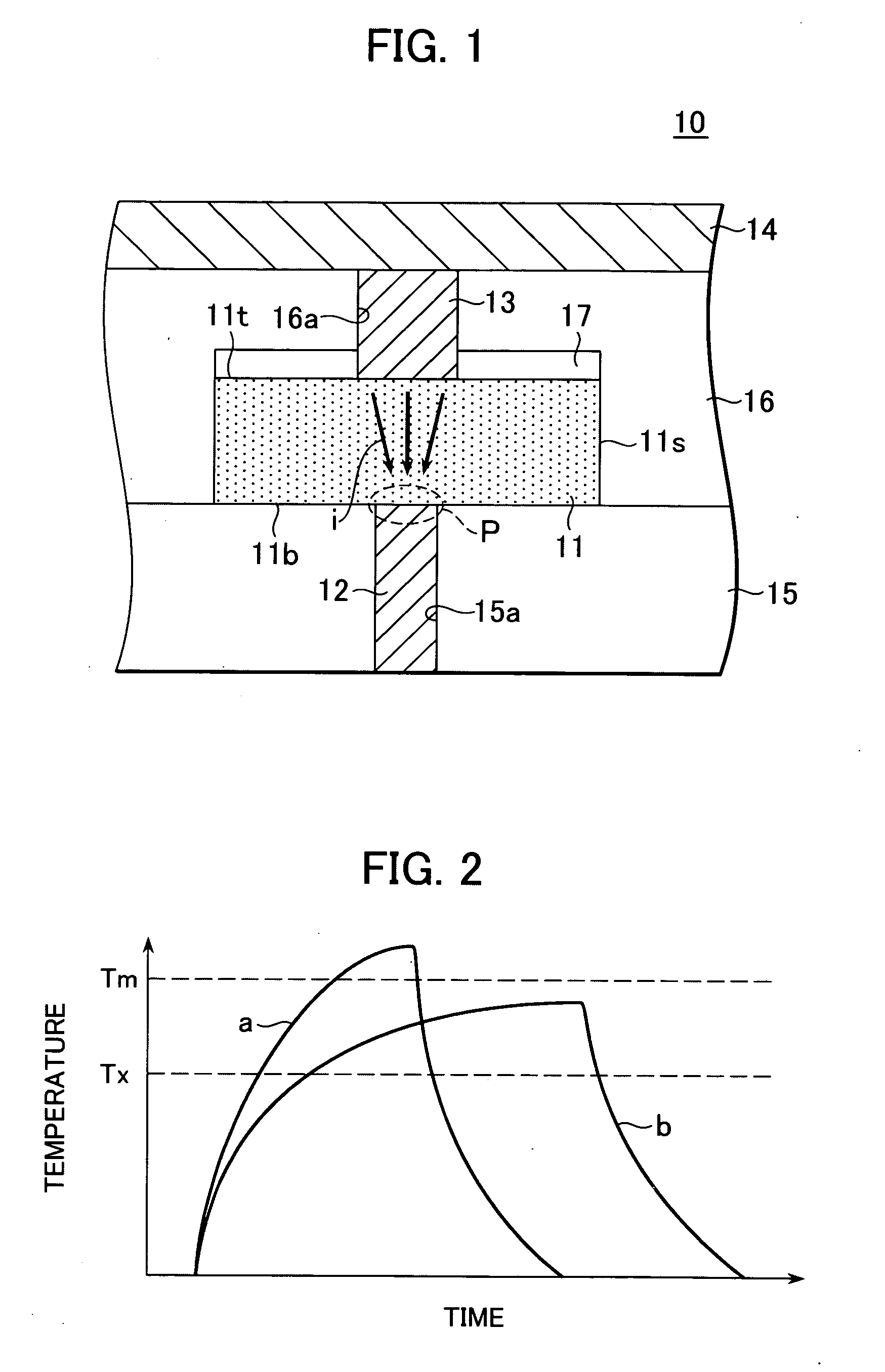

Electrically rewritable non-volatile memory element and method of manufacturing the same

InactiveUS20070063180A1Minimizing damageImprove thermal efficiencySolid-state devicesBulk negative resistance effect devicesEngineeringRecording layer

A non-volatile memory element includes a recording layer that includes a phase change material, a lower electrode provided in contact with the recording layer, an upper electrode provided in contact with a portion of the upper surface of the recording layer, a protective insulation film provided in contact with the other portion of the upper surface of the recording layer, and an interlayer insulation film provided on the protective insulation film. High thermal efficiency can thereby be obtained because the size of the area of contact between the recording layer and the upper electrode is reduced. Providing the protective insulation film between the interlayer insulation film and the upper surface of the recording layer makes it possible to reduce damage sustained by the recording layer during patterning of the recording layer or during formation of the through-hole for exposing a portion of the recording layer.

Owner:ELPIDA MEMORY INC

Method for Making a Pillar-Type Phase Change Memory Element

ActiveUS20080014676A1Semiconductor/solid-state device manufacturingPhase-change materialPhase-change memory

A pillar-type phase change memory element comprises first and second electrode elements and a phase change element therebetween. A second electrode material and a chlorine-sensitive phase change material are selected. A first electrode element is formed. The phase change material is deposited on the first electrode element and the second electrode material is deposited on the phase change material. The second electrode material and the phase change material are etched without the use of chlorine to form a second electrode element and a phase change element. The second electrode material selecting step, the phase change material selecting step and the etching procedure selecting step are carried out so that the phase change element is not undercut relative to the second electrode element during etching.

Owner:MACRONIX INT CO LTD

Chalcogenide memory device with multiple bits per cell

InactiveUS6838692B1Reduce energy inputSave energySolid-state devicesDigital storagePhase-change materialSemiconductor

A memory device with multiple bits per-cell. The memory device includes a side electrode; a doped semiconductor region disposed laterally in contact with a sidewall of the side electrode, such that the doped semiconductor region forms a diode, or the junction between the side electrode and the doped semiconductor region forms a diode; a layer of phase-changing material disposed laterally in contact with a sidewall of the doped semiconductor region, such that the doped semiconductor region is disposed between the layer of phase-changing material and the side electrode; and an upper electrode disposed on the layer of phase-changing material. Many storage regions can be stacked vertically, and multiple bits can be stored in one cell. Also, the contact area is reduced to a minimum dimension below the photolithographic limit.

Owner:MACRONIX INT CO LTD

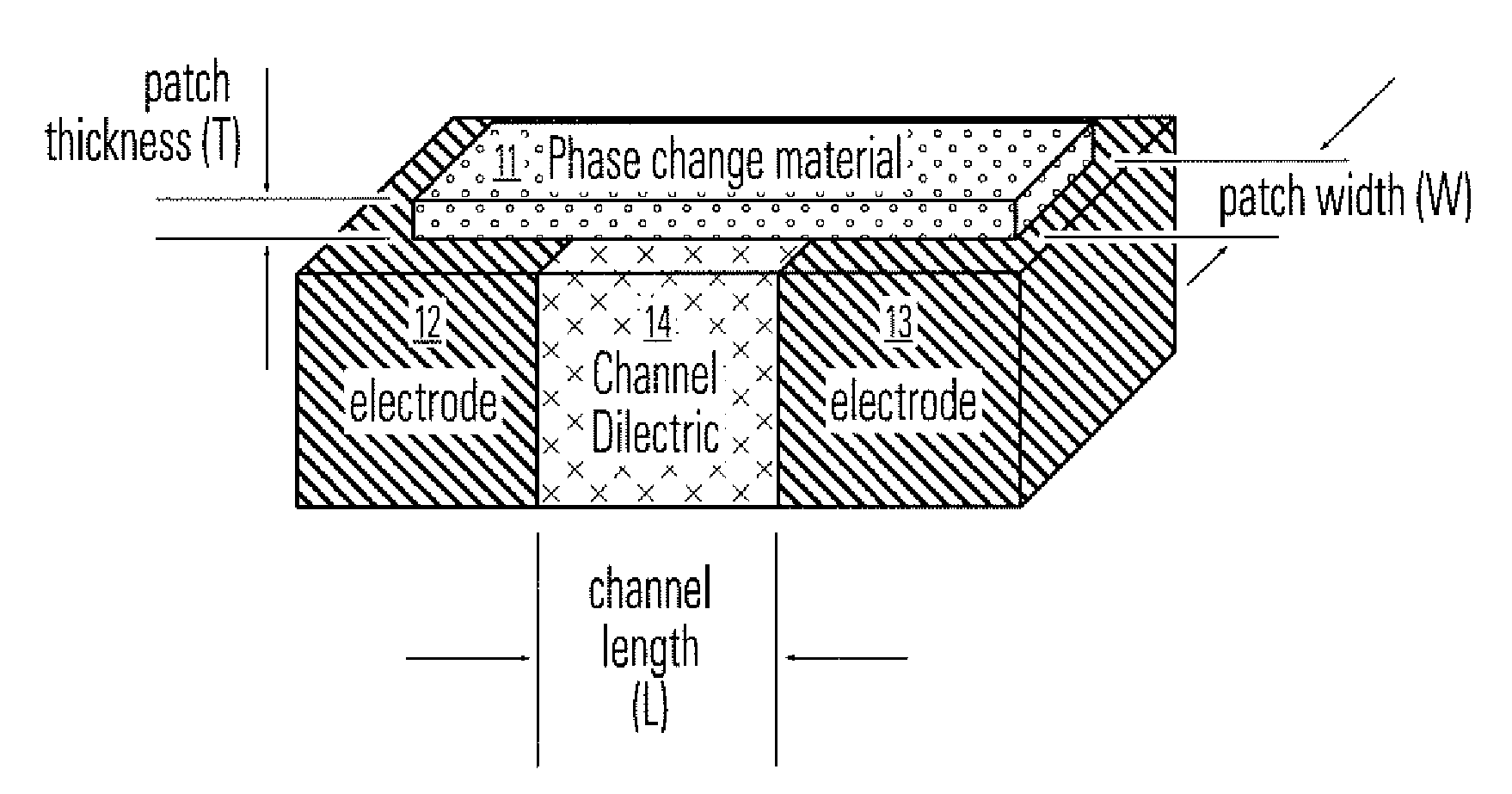

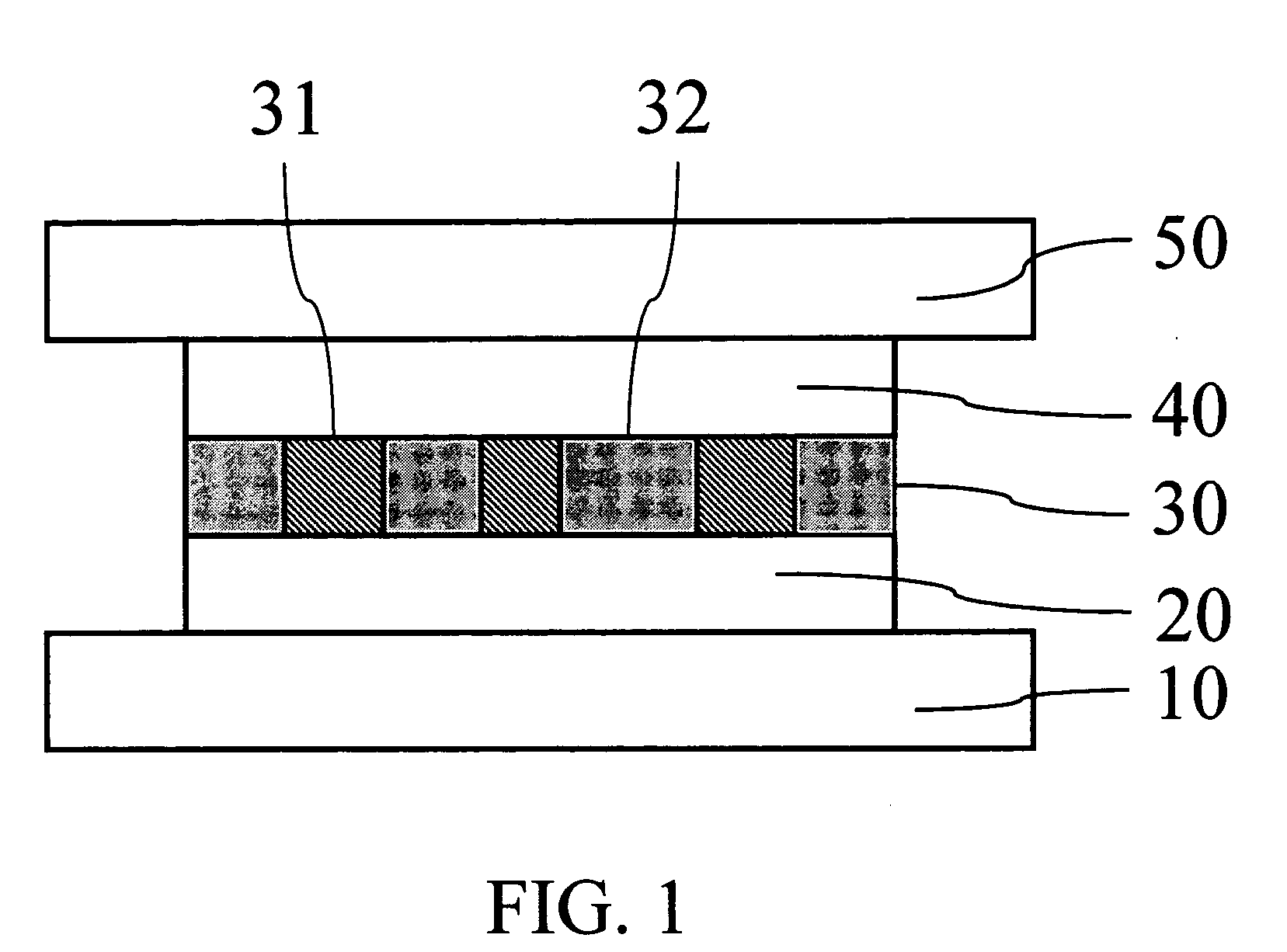

Phase change memory with extra-small resistors

InactiveUS20060006472A1SmallImprove good performanceSemiconductor/solid-state device detailsSolid-state devicesNano sizePhase-change memory

A phase change memory cell comprises of multiple resistors. In one design, the resistor layer is a layer with a plurality of resistors embedded in an insulator layer which is sandwiched between the electrodes. In the other design, a combination of a heater layer with a plurality of heaters and a layer of phase change material constitutes the resistor sandwiched a pair of electrodes. The resistor or heater can be easily made in nano-size.

Owner:JIANG HAI

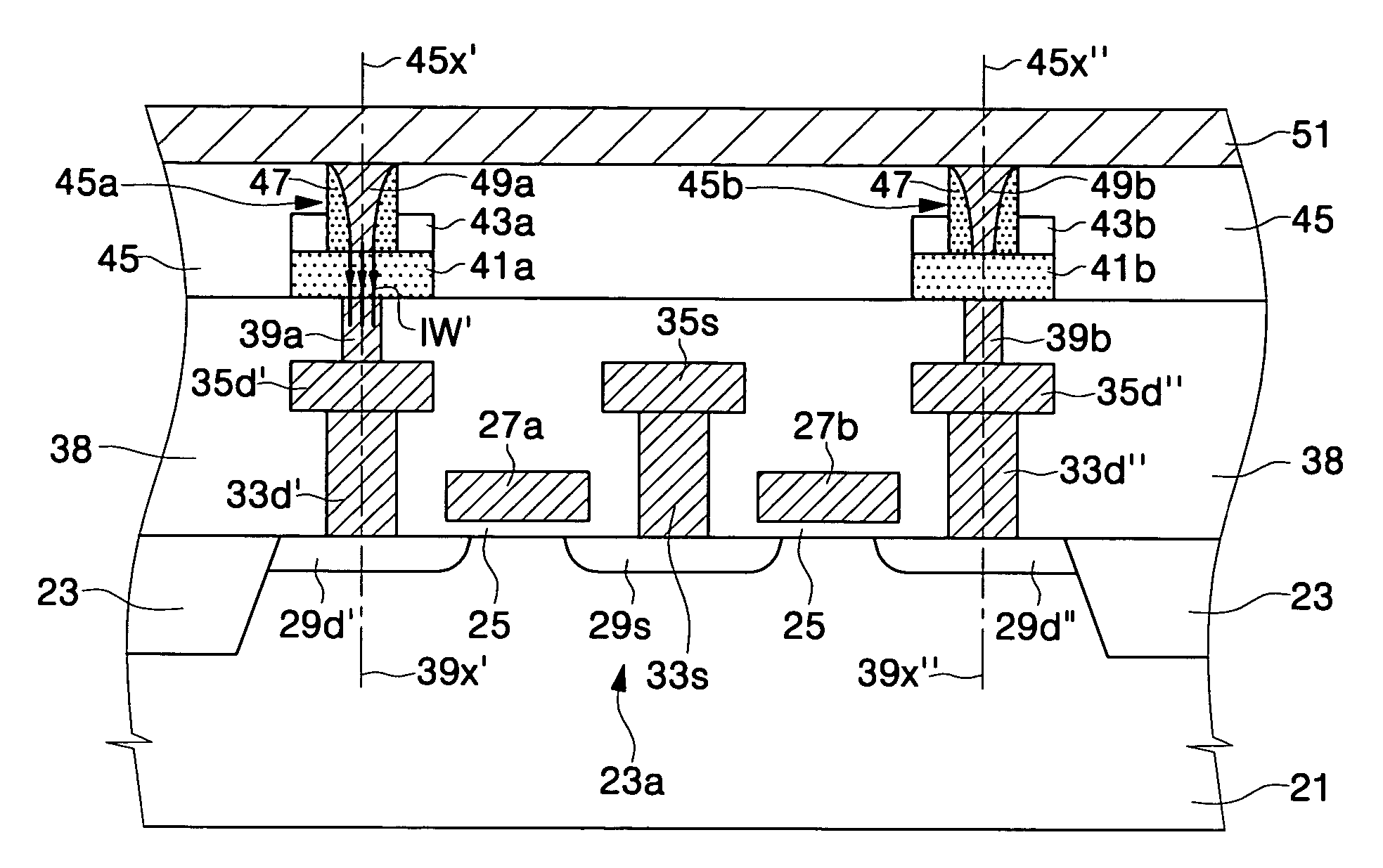

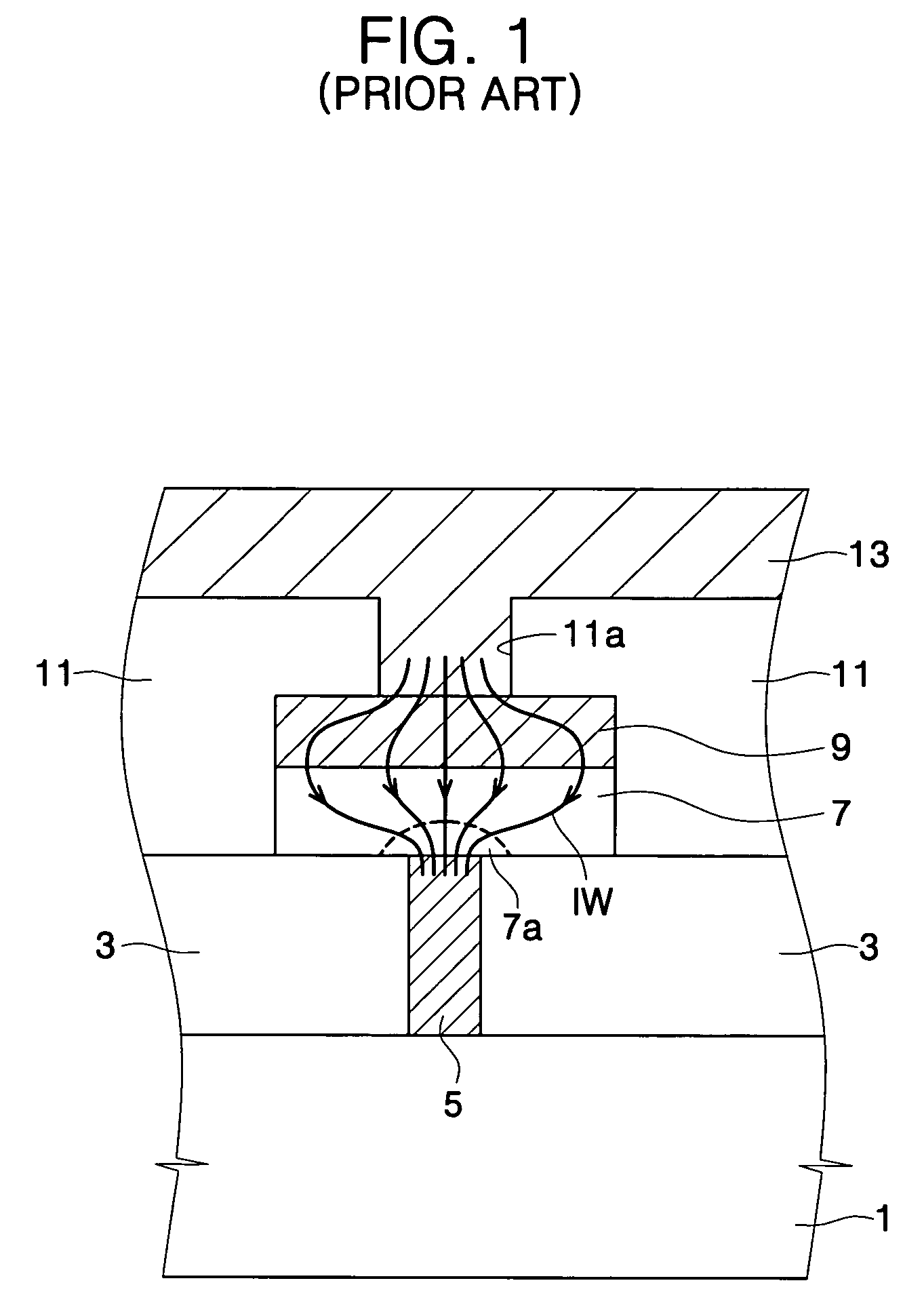

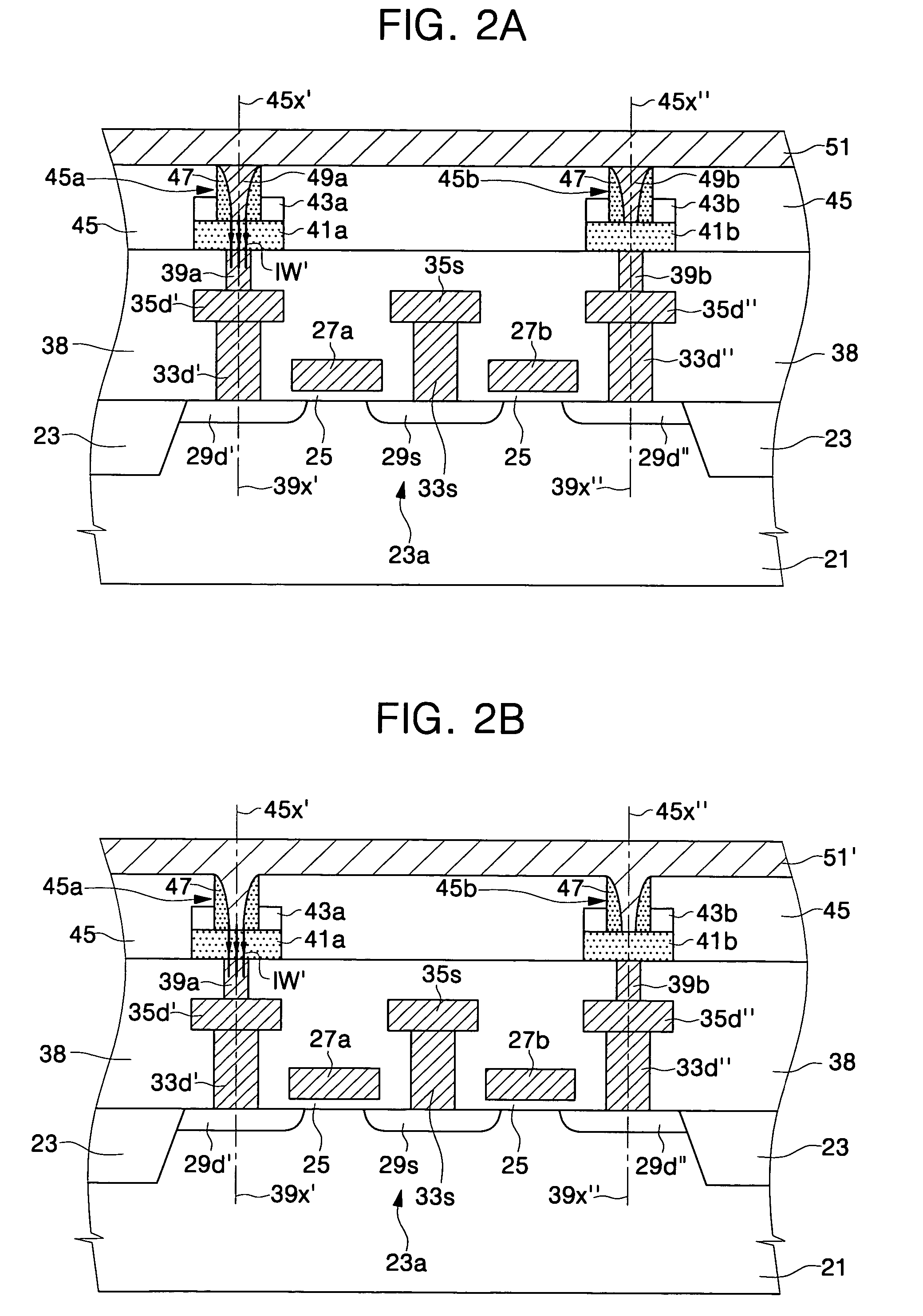

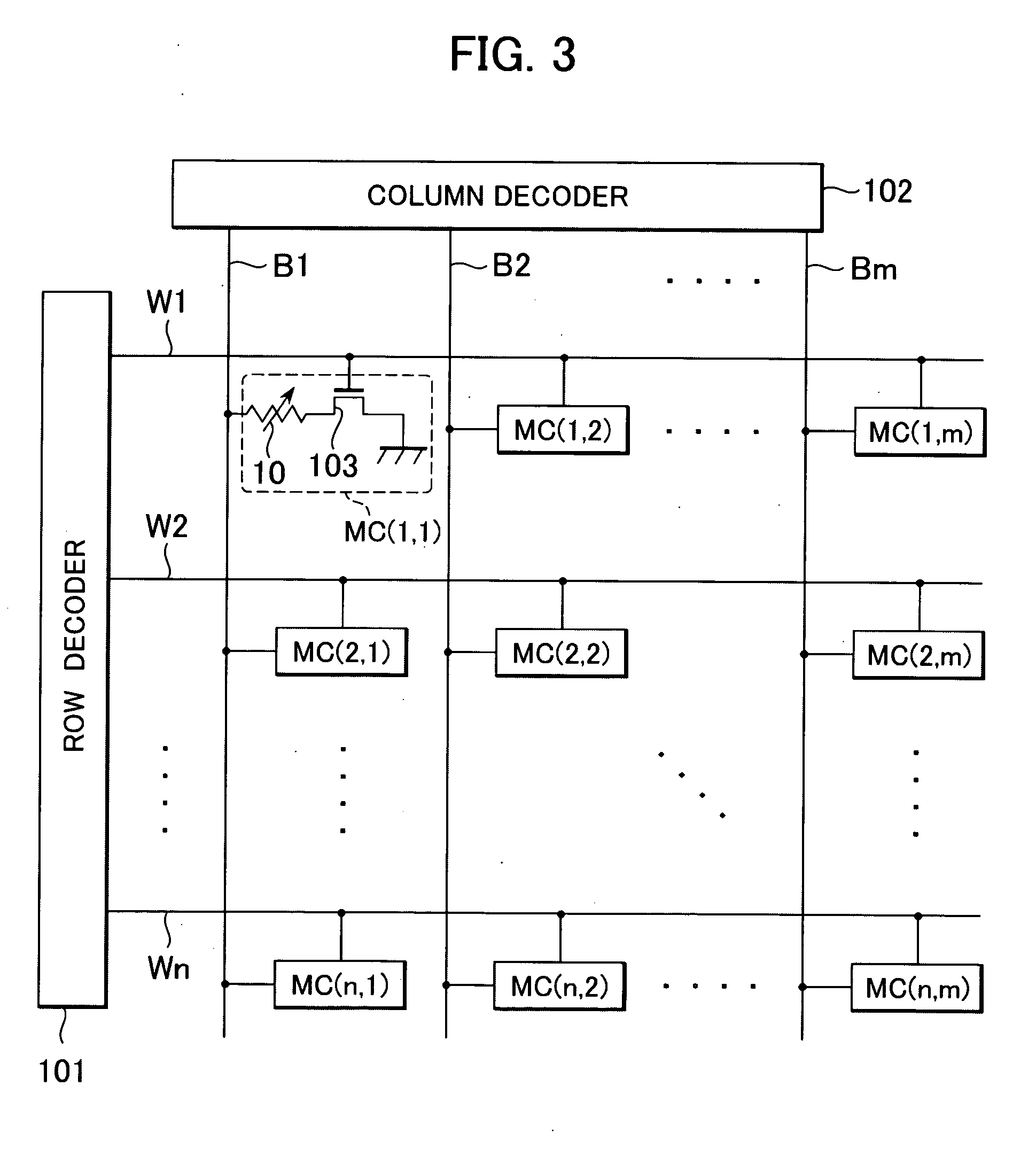

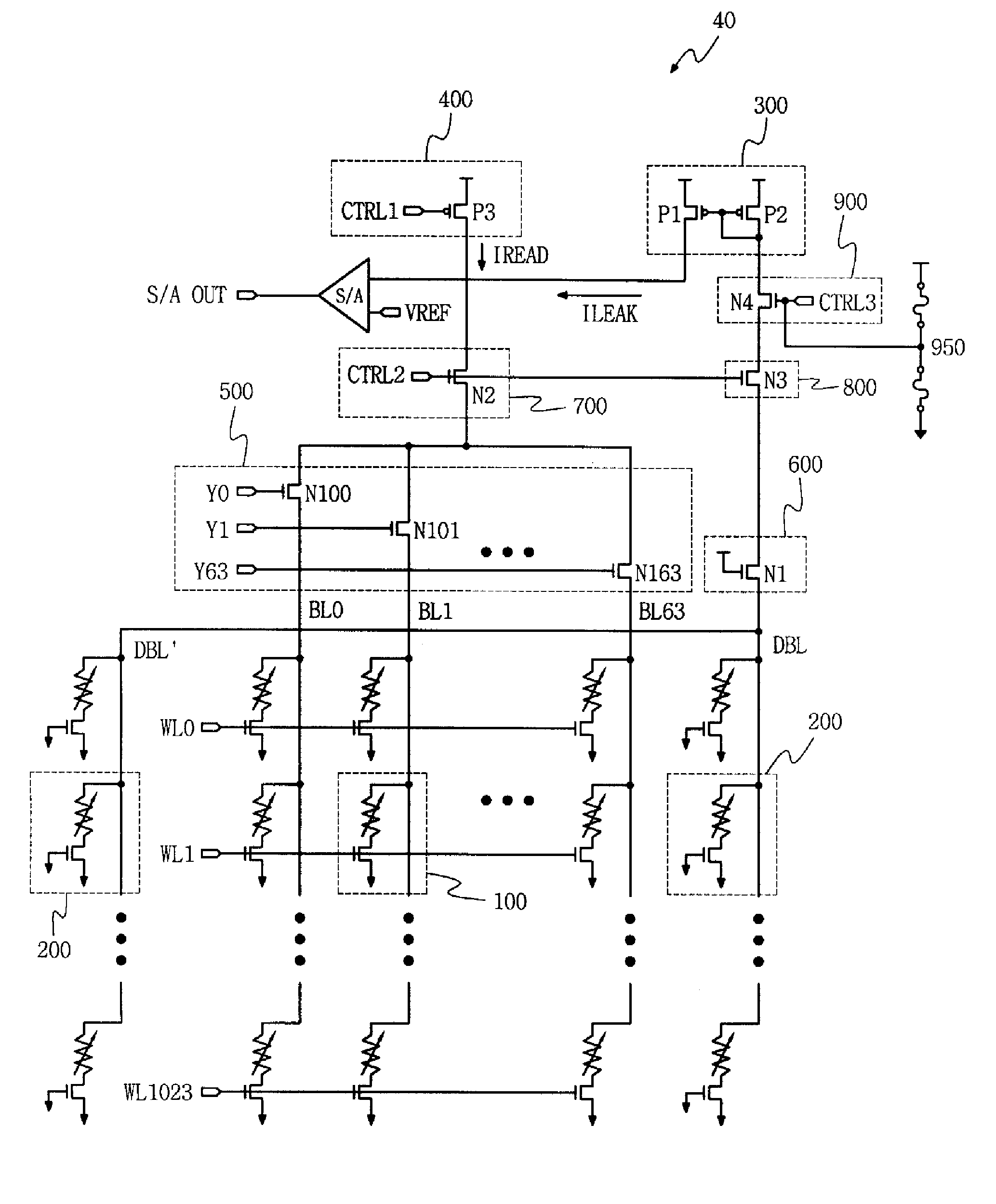

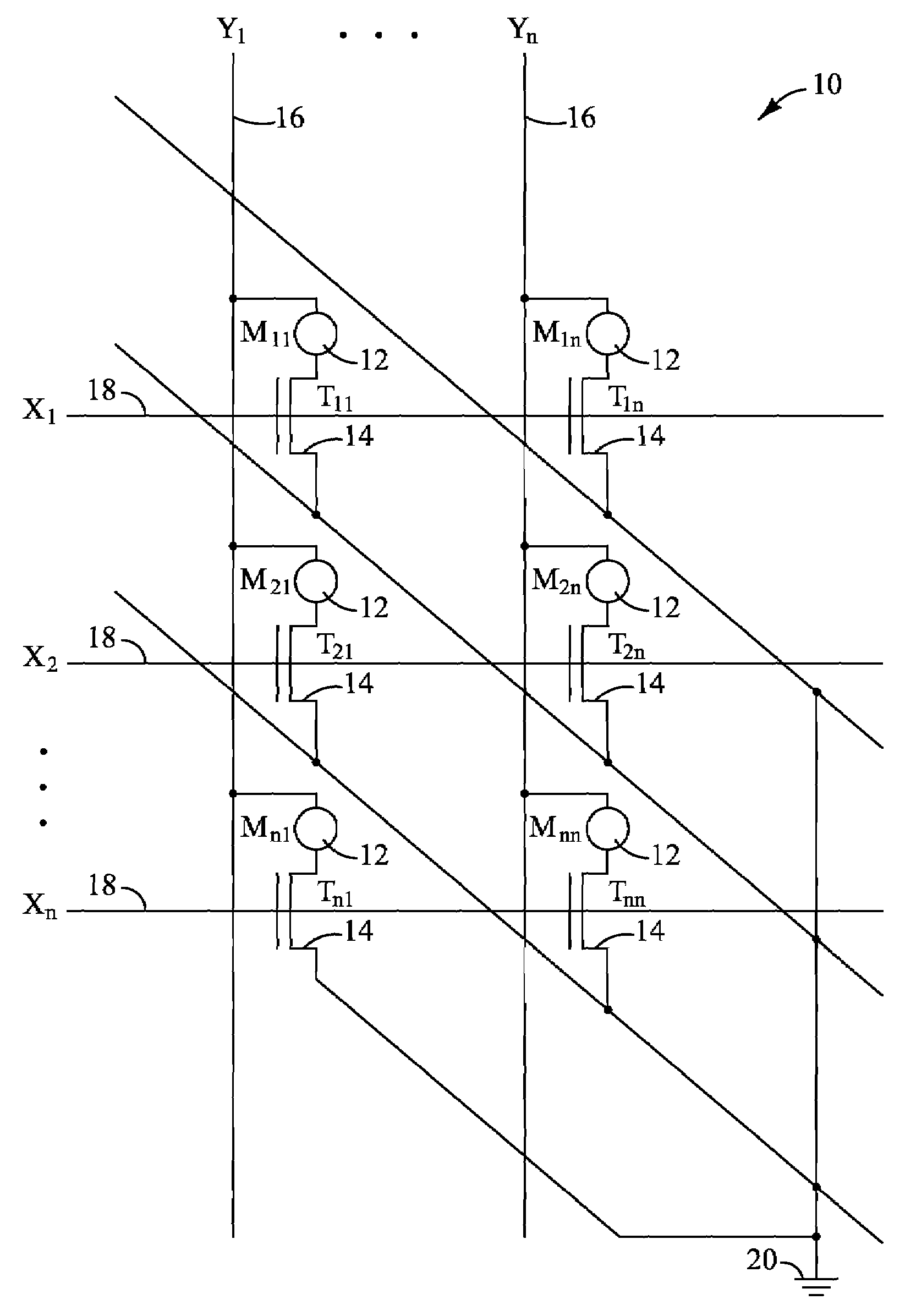

Semiconductor memory device capable of compensating for leakage current

ActiveUS7248494B2Convenient and highly integratedReduce power consumptionDigital storageBit linePhase-change memory

A semiconductor memory device compensates leakage current. A plurality of memory cells is disposed at intersections of word lines and bit lines. A plurality of dummy cells is connected to at least one dummy bit line. A leakage compensation circuit is connected to the at least one dummy bit line that outputs a leakage compensation current to at least one of the bit lines. A read current supply circuit outputs a read current necessary for a read operation to at least one of the bit lines in response to a first control signal. The memory device is a phase-change memory device containing phase-change material. The semiconductor memory device compensates leakage current in a read operation and supplies the leakage compensation current to a selected bit line, thereby suppressing error operation occurrence caused by leakage current.

Owner:SAMSUNG ELECTRONICS CO LTD

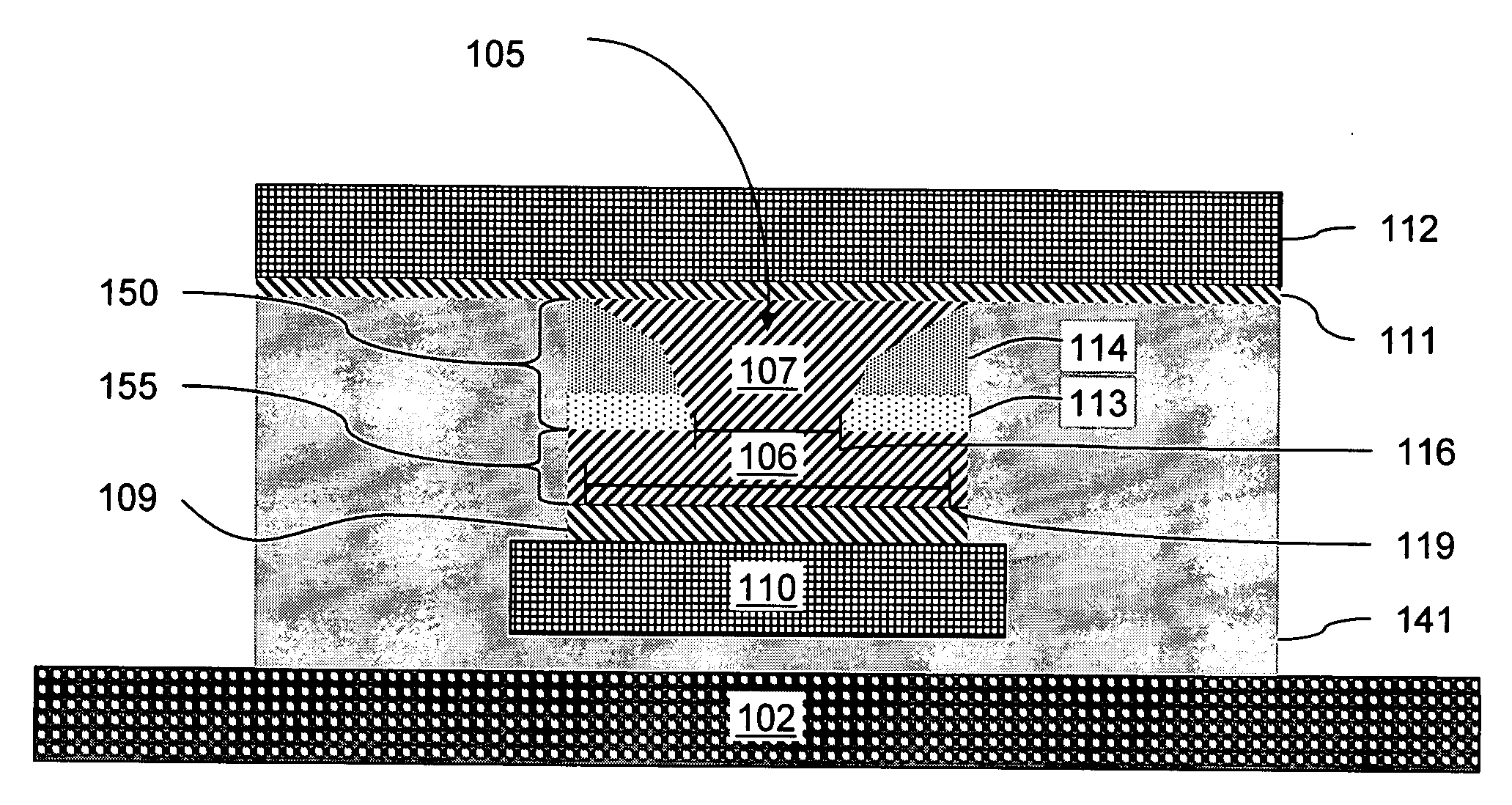

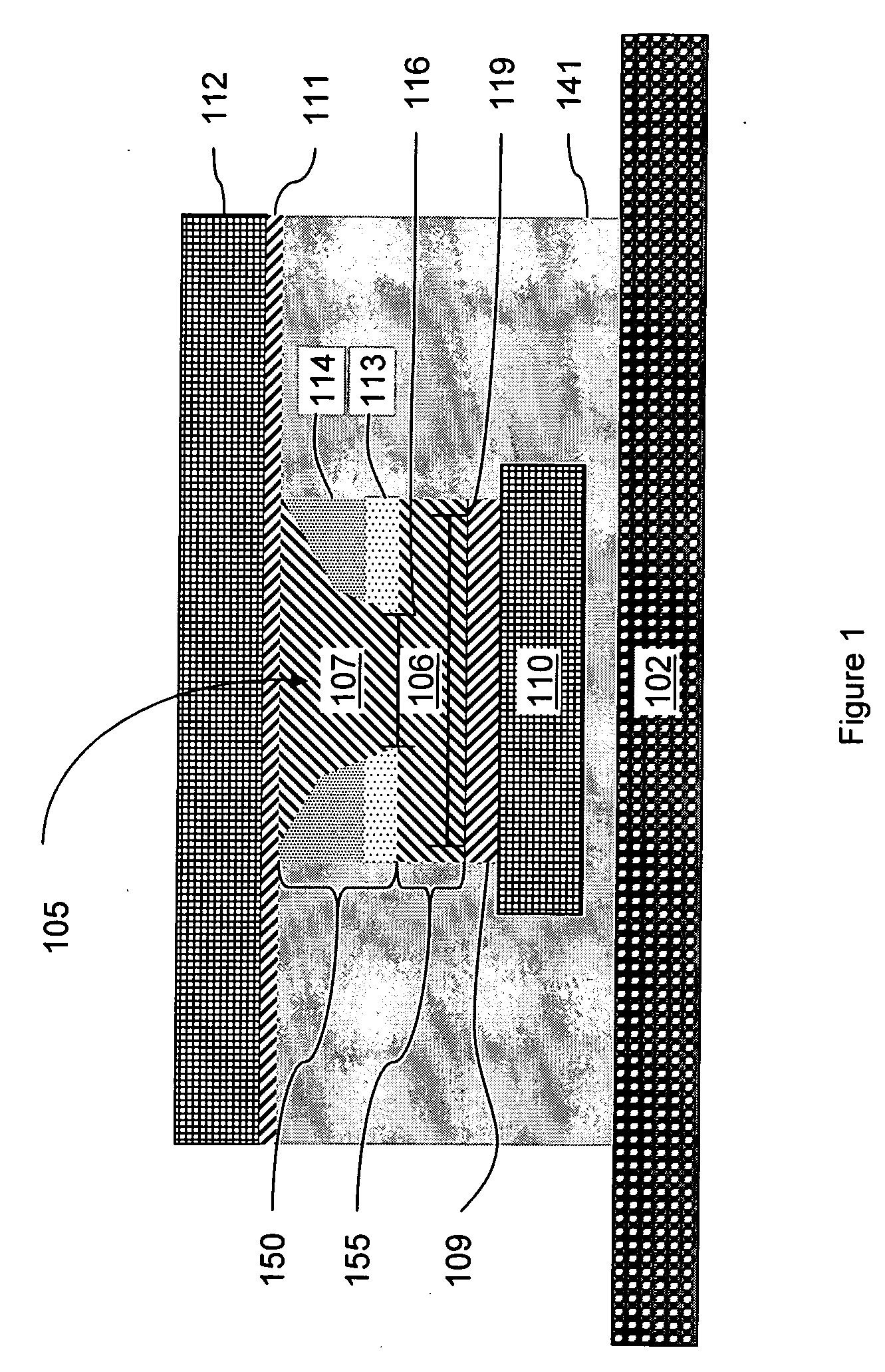

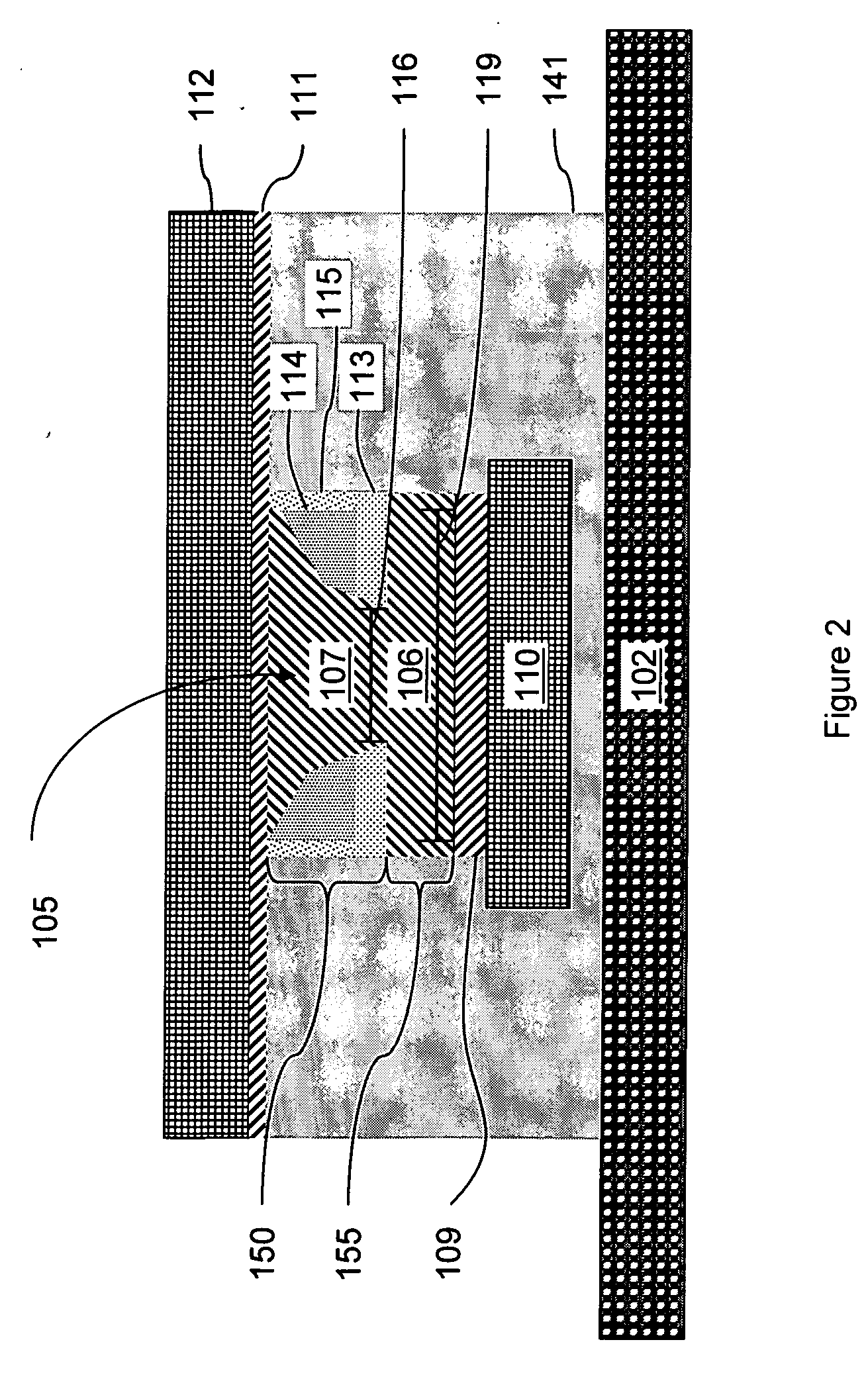

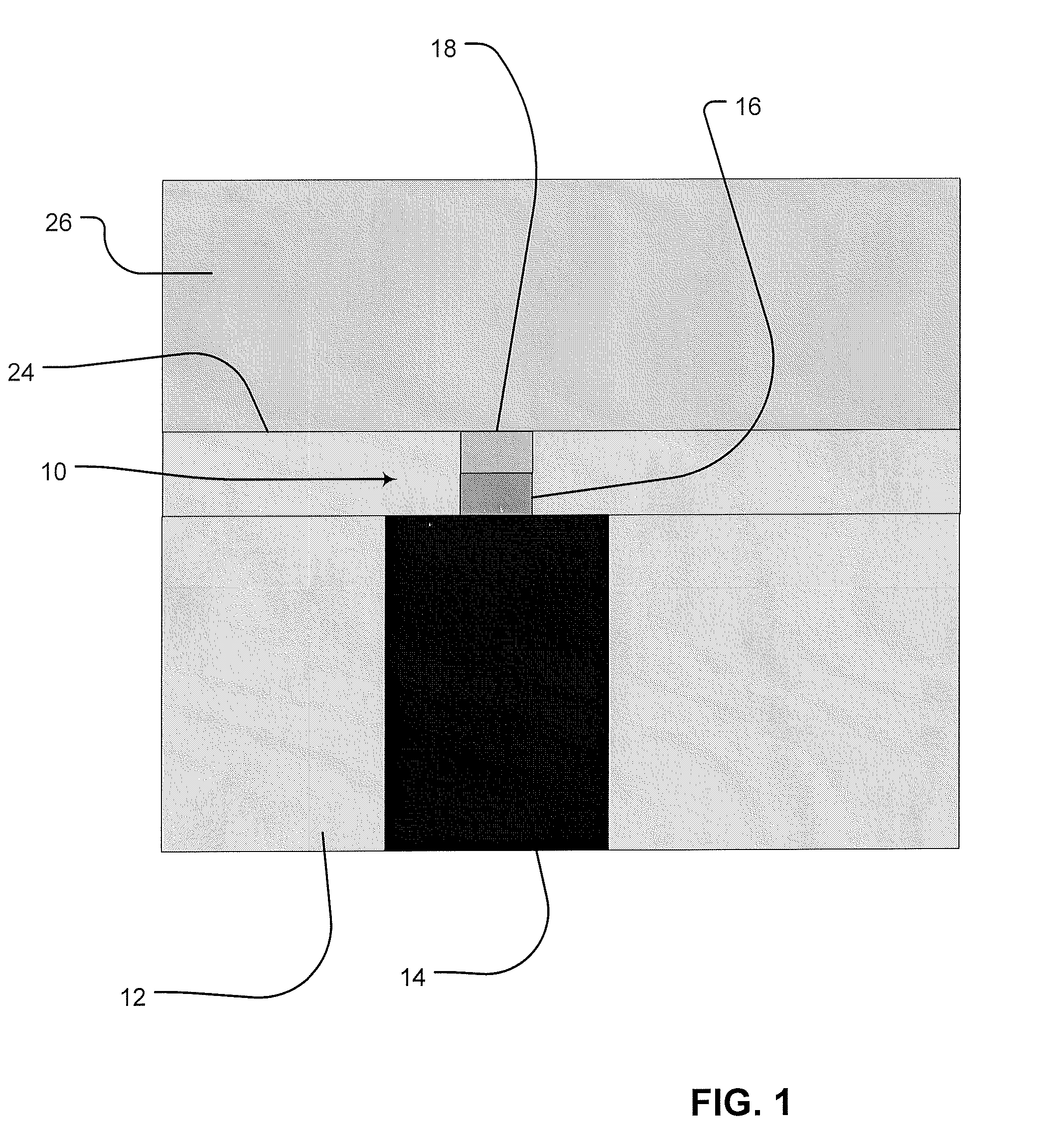

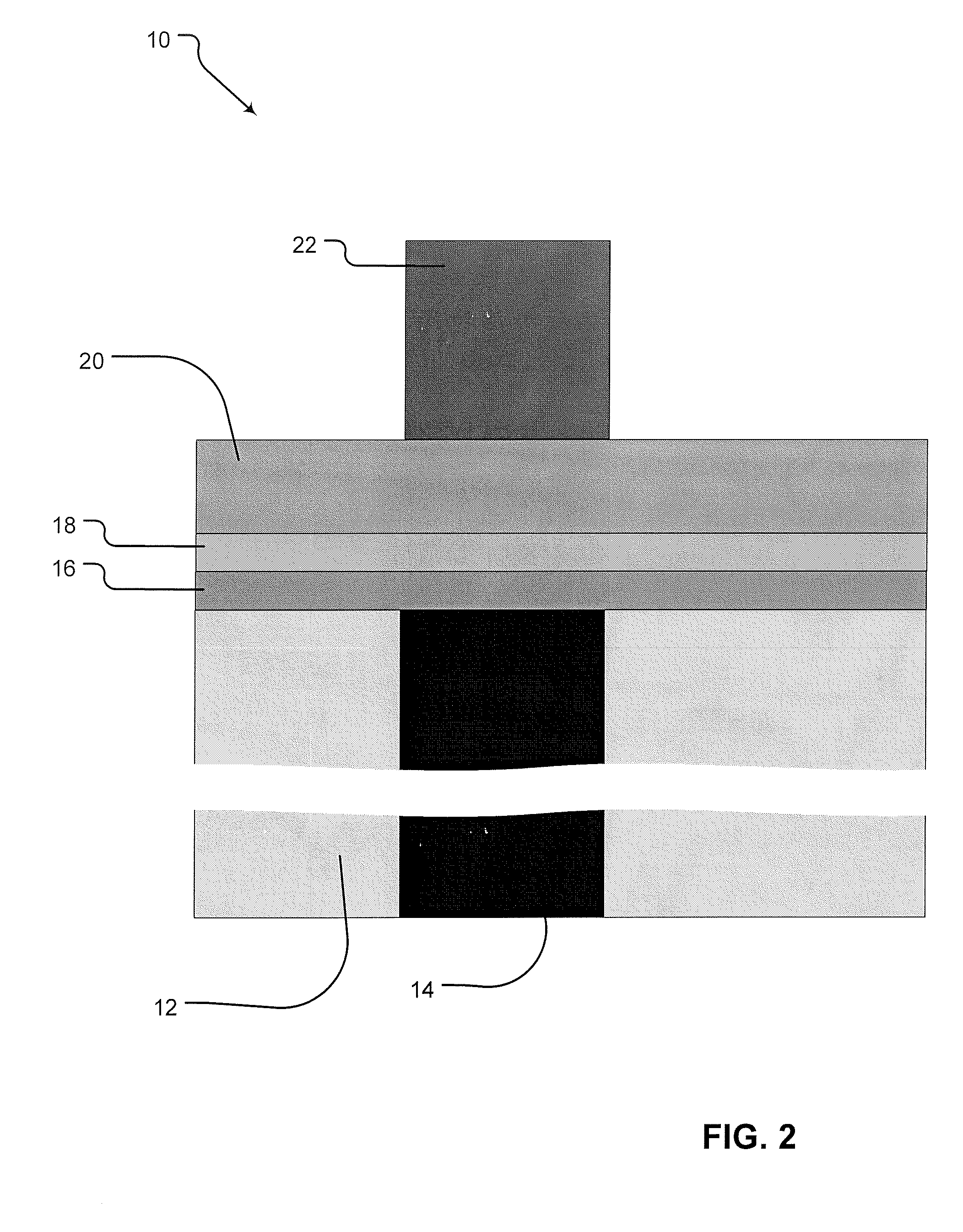

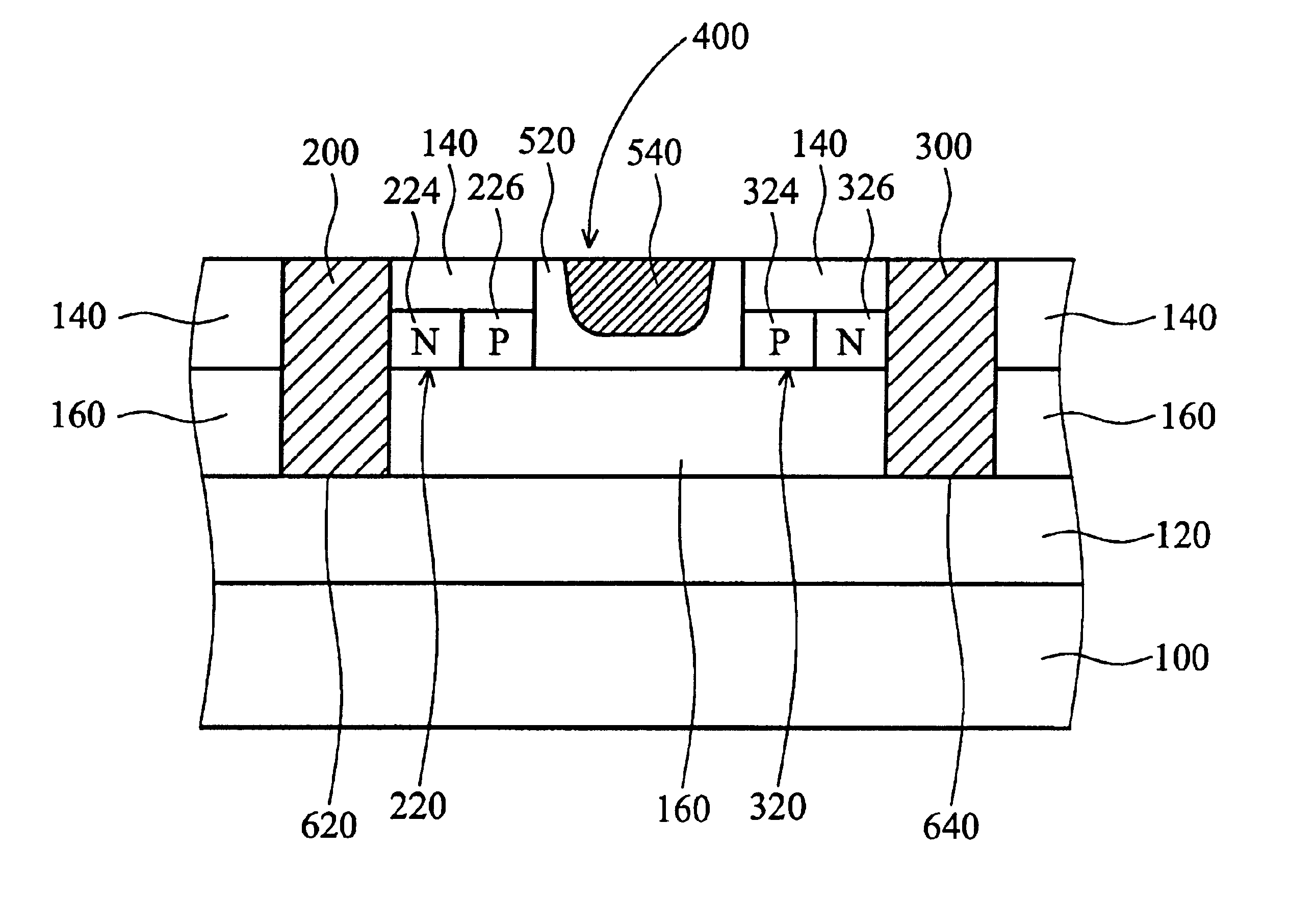

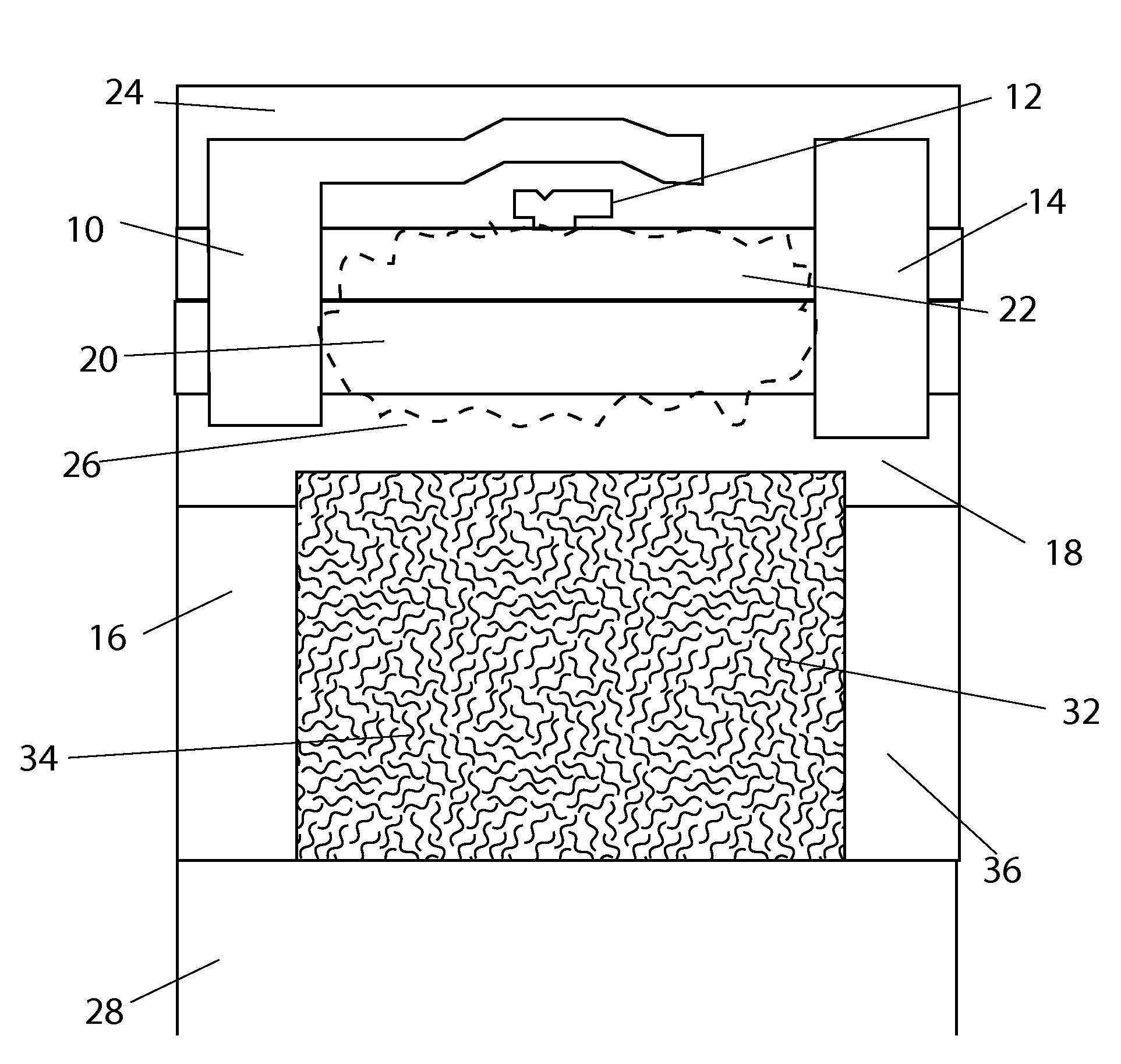

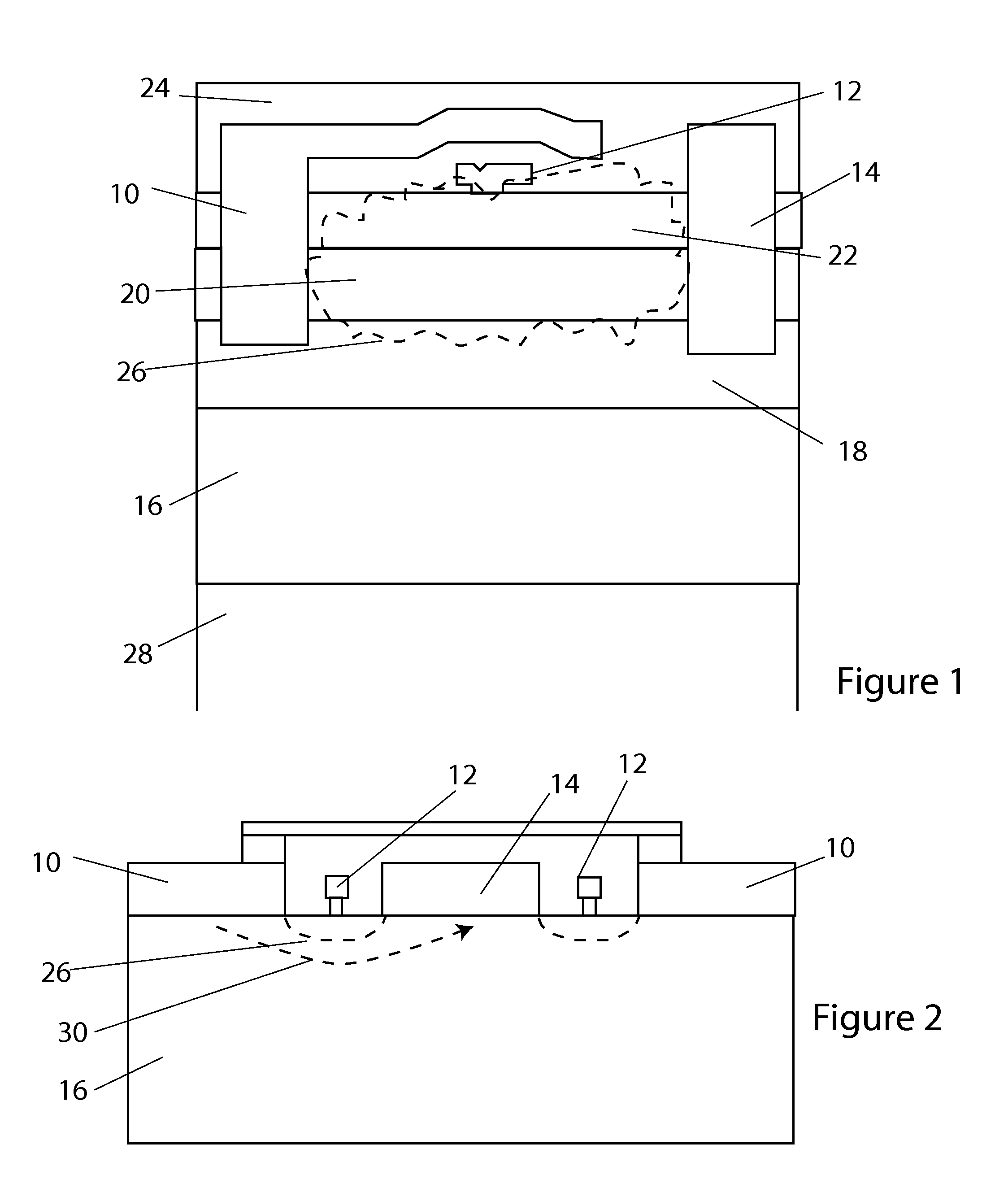

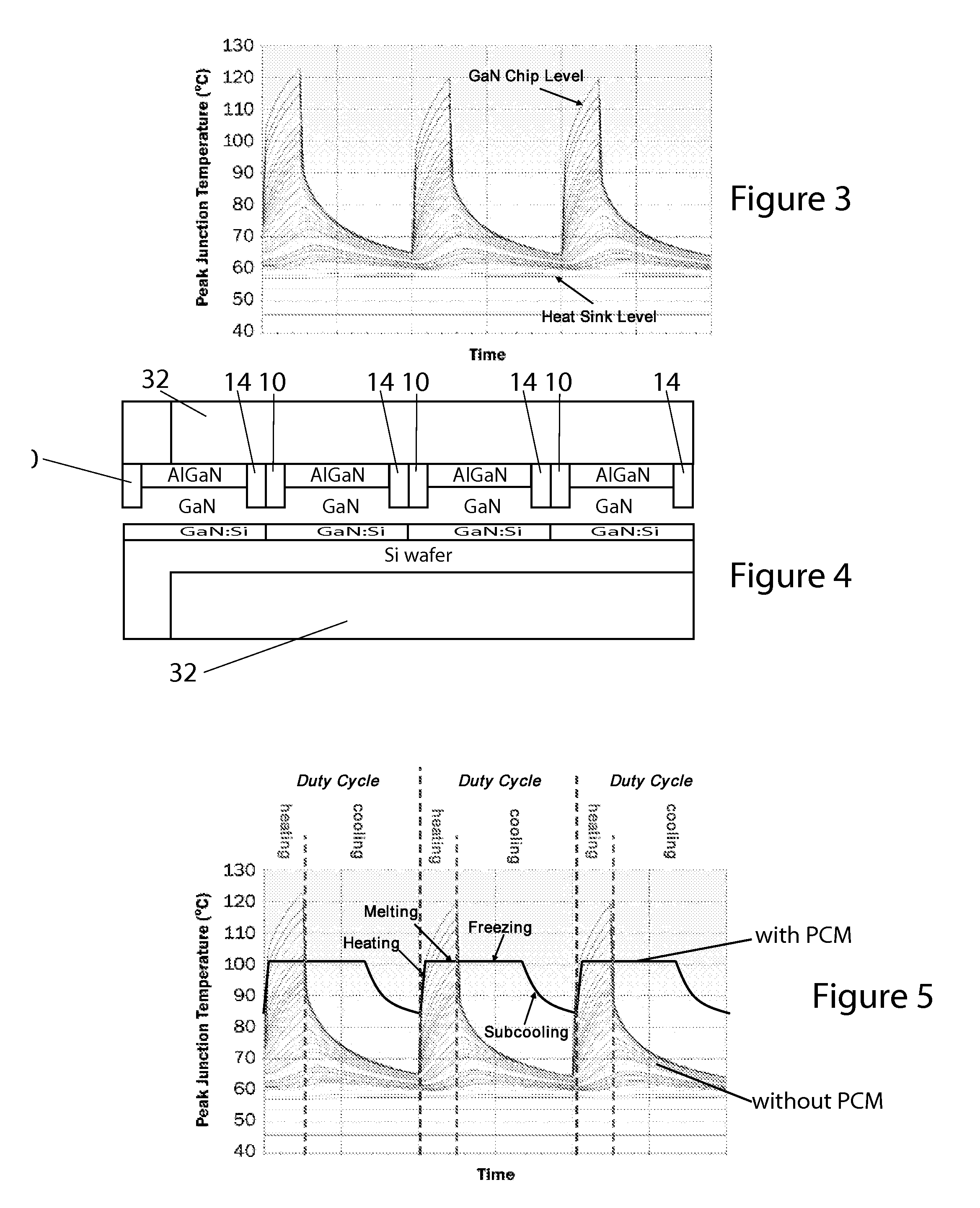

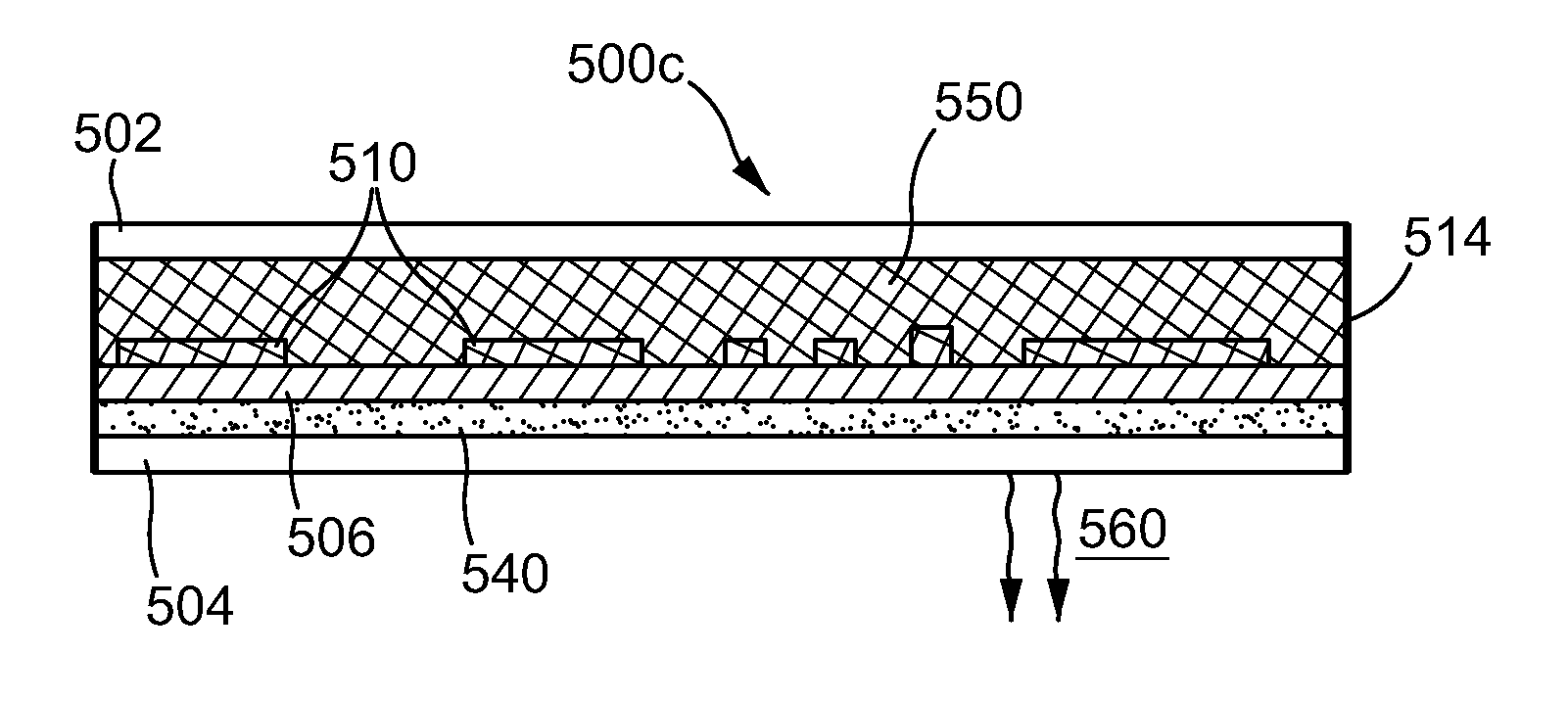

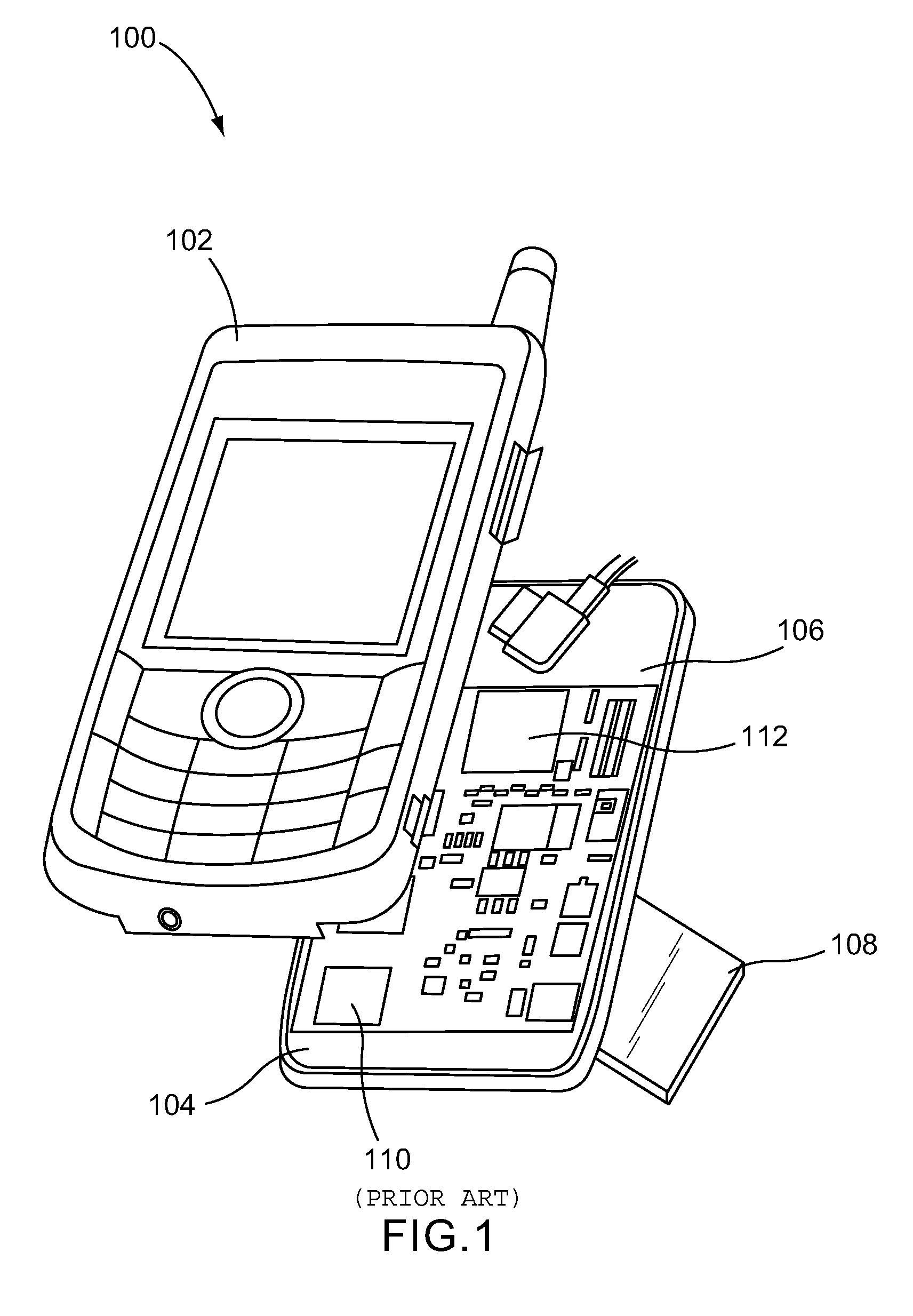

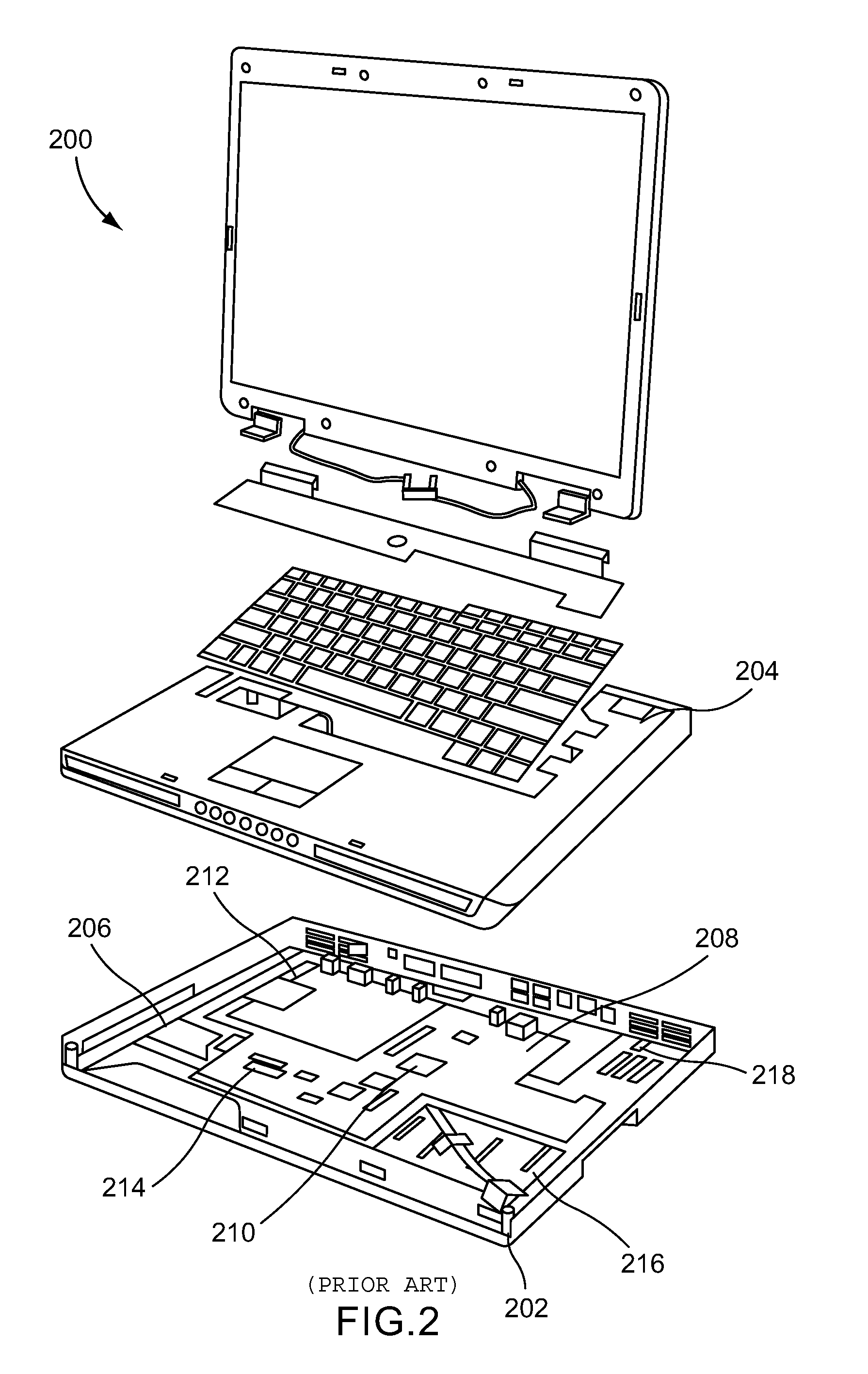

Semiconductor having integrally-formed enhanced thermal management

InactiveUS20130147050A1Increase heating capacityImproved thermal managementSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureElectron flow

A semiconductor structure and method of manufacturing that has integrally-formed enhanced thermal management. During operation of a semiconductor device, electron flow between the source and the drain creates localized heat generation. A containment gap is formed by selectively removing a portion of the back side of the semiconductor device substrate directly adjacent to a localized heat generation area. A thermal management material is filled in the containment gap. This thermal management material enhances the thermal management of the semiconductor device by thermally coupling the localized heat generation area to a heat sink. The thermal management material may be a Phase Change Material (PCM) having a heat of fusion effective for absorbing heat generated in the localized heat generation area by the operation of the semiconductor device for reducing a peak operating temperature of the semiconductor device.

Owner:ADVANCED COOLING TECH

Phase-change memory cell and method of fabricating the phase-change memory cell

InactiveUS20050167656A1Improve reliabilityHigh yieldTransistorDigital storagePhase-change memoryEngineering

A memory cell and method of fabricating the memory cell includes an insulating layer formed on a first electrode layer, the insulating layer having a first opening, a stencil layer formed on the insulating layer, and having a second opening formed in an area of the first opening, a phase-change material layer formed on a surface of the first electrode layer in the first opening, and an electrically conductive layer including a first portion formed on the stencil layer and defining a second electrode layer and a second portion formed on the phase-change material layer.

Owner:GLOBALFOUNDRIES INC

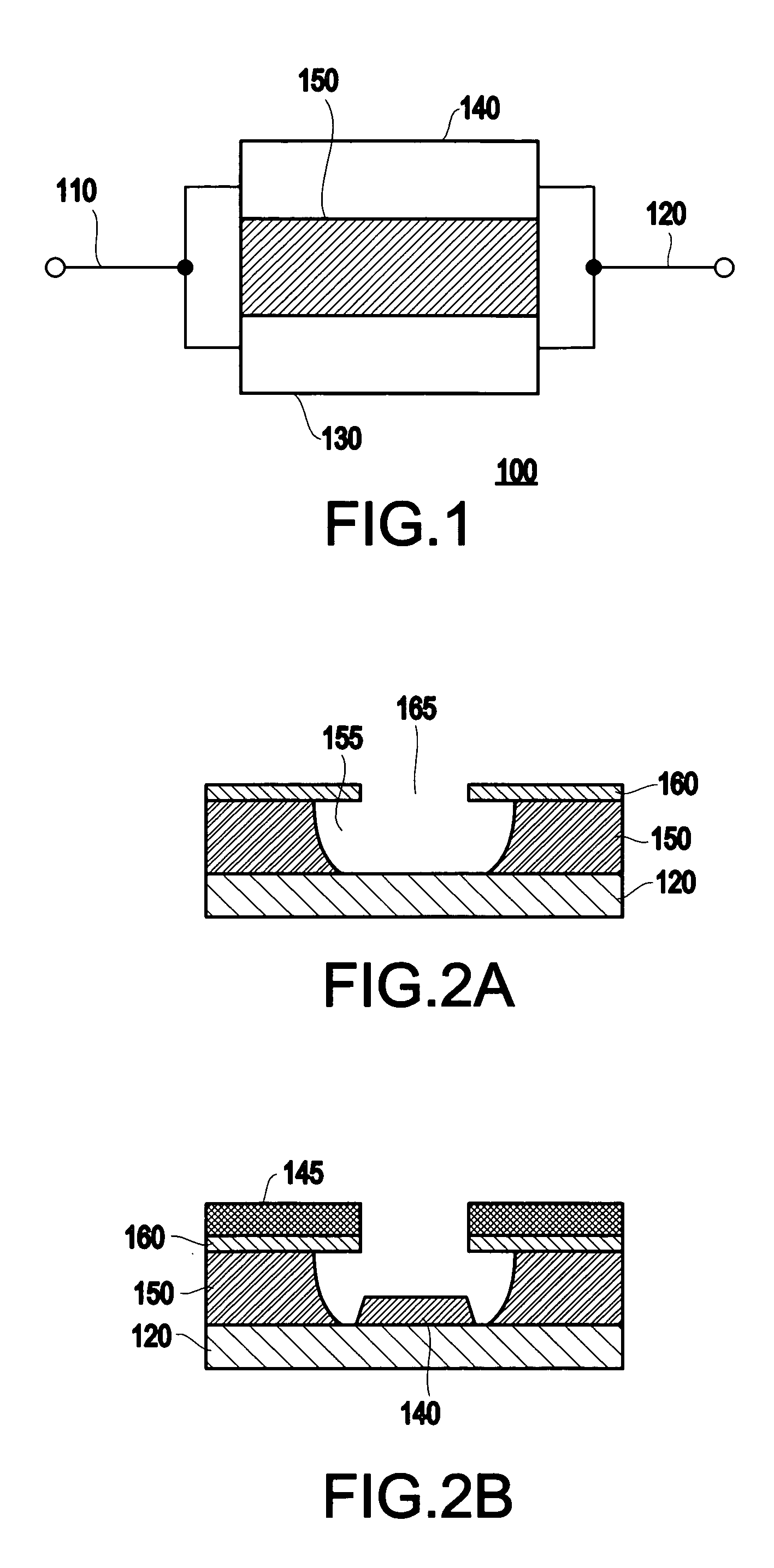

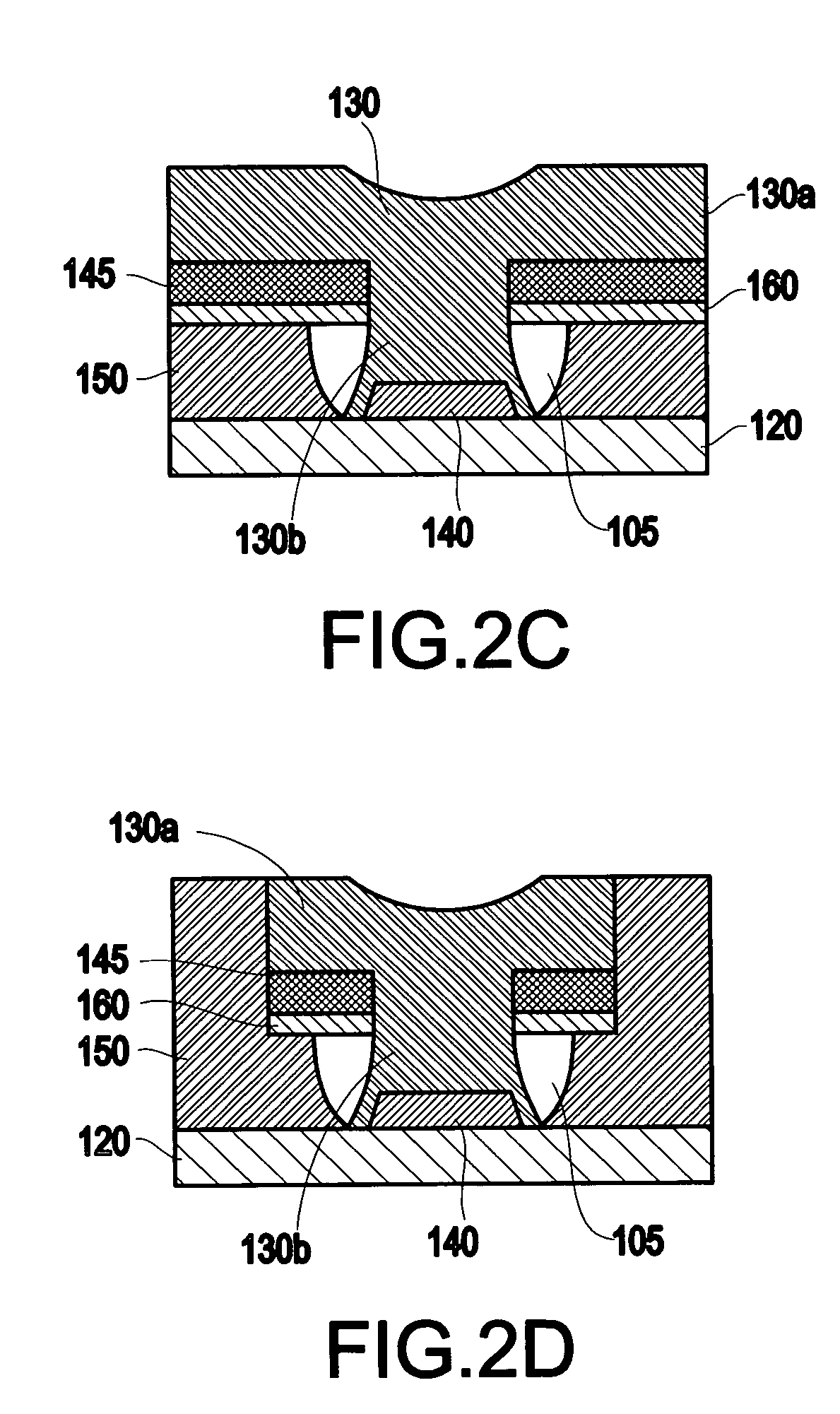

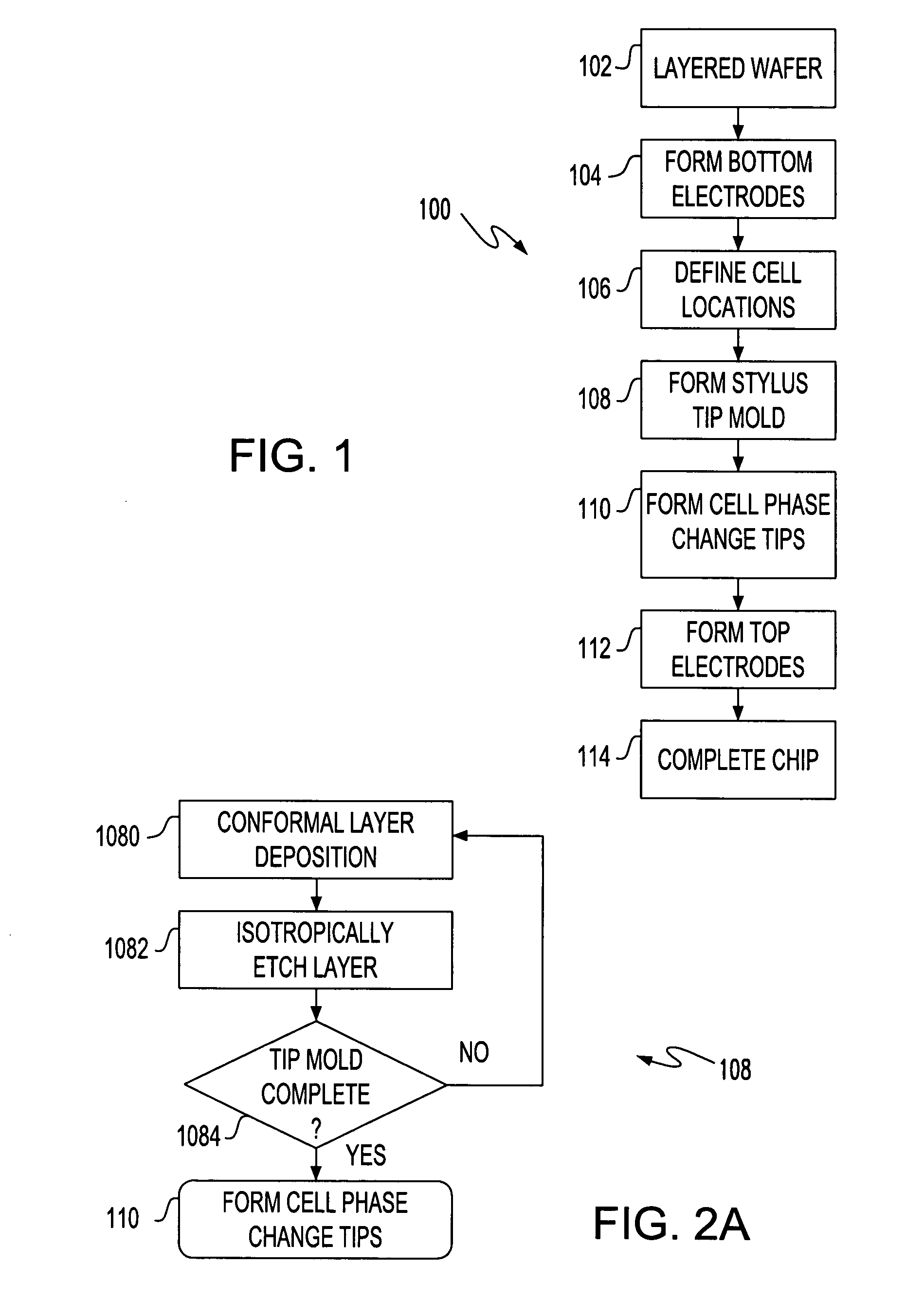

Phase change tip storage cell

ActiveUS20050127349A1Reduce the required powerSolid-state devicesDigital storageTitanium nitrideTe element

A storage cell, integrated circuit (IC) chip with one or more storage cells that may be in an array of the storage cells and a method of forming the storage cell and IC. Each storage cell includes a stylus, the tip of which is phase change material. The phase change tip may be sandwiched between an electrode and conductive material, e.g., titanium nitride (TiN), tantalum nitride (TaN) or n-type semiconductor. The phase change layer may be a chalcogenide and in particular a germanium (Ge), antimony (Sb), tellurium (Te) (GST) layer.

Owner:GLOBALFOUNDRIES US INC

Use of state-change materials in reformable shapes, templates or tooling

Techniques for generating a stable, force-resisting positive or negative representation of a shape. A state-changeable mixture includes uniform, generally ordered, closely-spaced solid bodies and a liquid carrier medium, with the liquid filling any voids or interstices between the bodies and excluding air or gas bubbles from the mixture. Within the mixture, the solid bodies can be caused to transition from a near-liquid or fluent condition of mobility to a stable, force-resisting condition. To create mobility, a small excess quantity or transition liquid is introduced to create a fluent condition by providing a slight clearance between the bodies which permits the gently-forced introduction of at least two simultaneous slip planes between ordered bulk masses of the bodies at any point in the mixture. Transition to the stable condition is caused by extraction of the transition liquid, removing the clearance between bodies and causing them to make stable, consolidated contact.

Owner:TRAN BAO

Pipe shaped phase change memory

ActiveUS7397060B2Lower average currentSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryEngineering

A memory cell device includes a bottom electrode, pipe shaped member comprising phase change material and a top electrode in contact with the pipe-shaped member. An electrically and thermally insulating material is inside the pipe-shaped member. An integrated circuit including an array of pipe-shaped phase change memory cells is described.

Owner:MACRONIX INT CO LTD

Systems structures and materials for electronic device cooling

An electronic device having one or more components that generate heat during operation includes a structure for temperature management and heat dissipation. The structure for temperature management and heat dissipation comprises a heat transfer substrate having a surface that is in thermal communication with the ambient environment and a temperature management material in physical contact with at least a portion of the one or more components of the electronic device and at least a portion of the heat transfer substrate. The temperature management material comprises a polymeric phase change material having a latent heat of at least 5 Joules per gram and a transition temperature between 0° C. and 100° C., and a thermal conductive filler.

Owner:LATENT HEAT SOLUTIONS LLC

Sequential and video access for non-volatile memory arrays

An array of non-volatile memory cells arranged in logical columns and logical rows, and associated circuitry to enable reading or writing one or more memory cells on a row in parallel. In some embodiments, the array of memory cells may include a phase change material. In some embodiments, the circuitry may include a write driver, a read driver, a sense amplifier, and circuitry to isolate the memory cells from the sense amplifier with extended refresh. In some embodiments, the circuitry may further include shift registers and one or more arithmetic logic units to provide a video memory.

Owner:OVONYX MEMORY TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com