Patents

Literature

6571 results about "Energy absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

External power source, charger and system for an implantable medical device having thermal characteristics and method therefore

Owner:MEDTRONIC INC

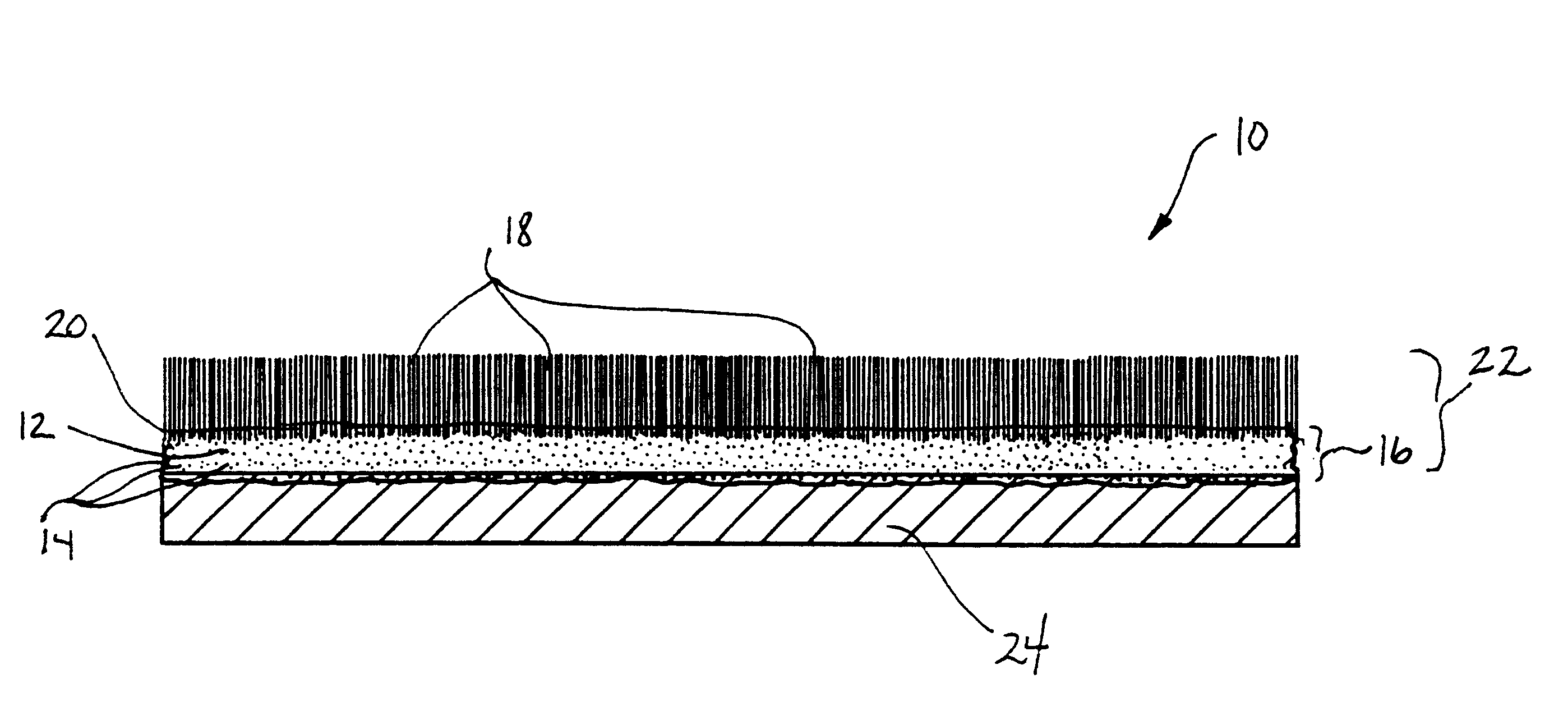

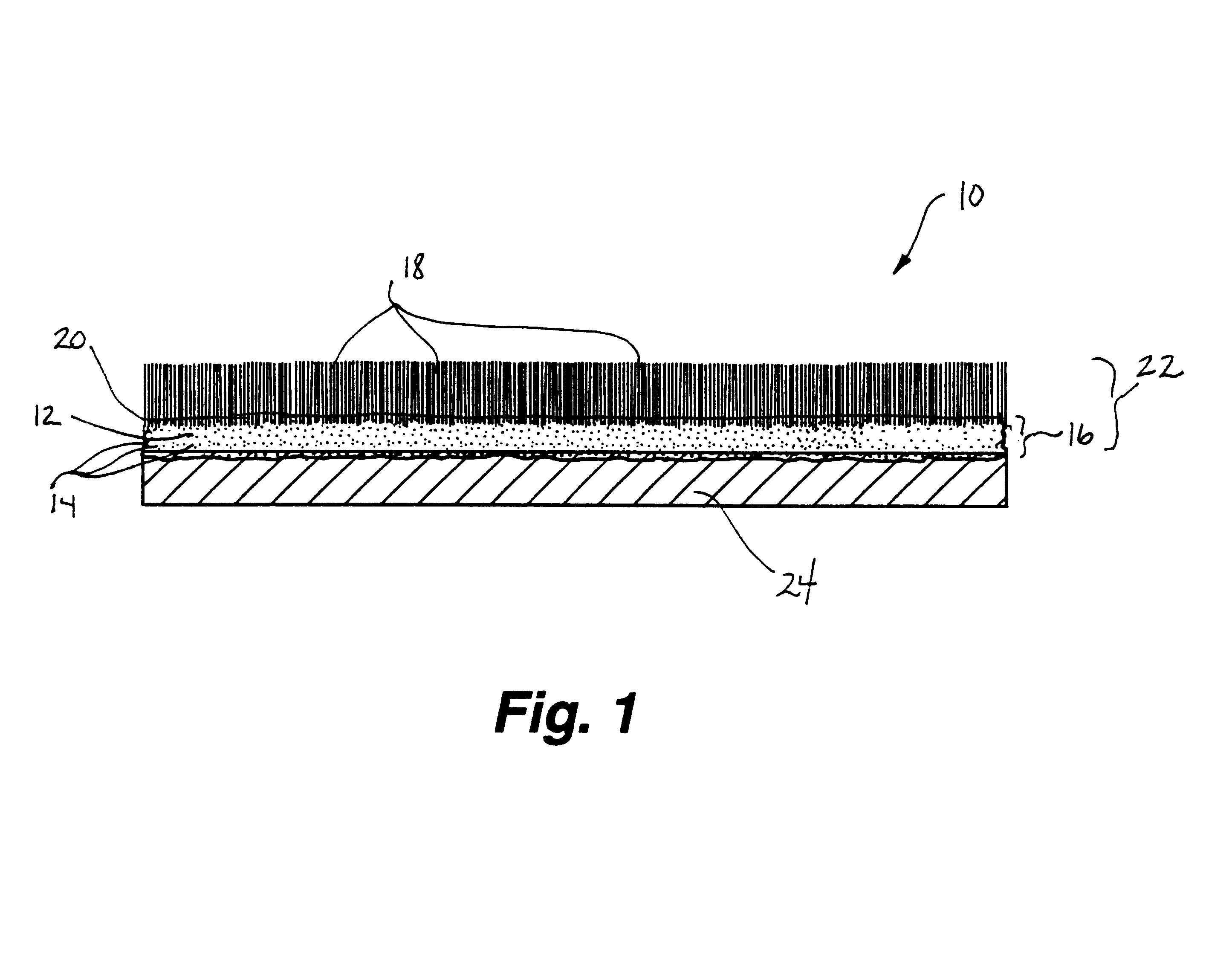

Fabric coating composition containing energy absorbing phase change material

InactiveUS6207738B1Solve the lack of densityReduce and eliminate heat transferHeat storage plantsFibre treatmentMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric.

Owner:OUTLAST TECH LLC

Fabric coating containing energy absorbing phase change material and method of manufacturing same

InactiveUS6514362B1Evenly dispersedEqually distributedDecorative surface effectsHeat storage plantsMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric. In an alternative embodiment, an extensible fabric is coated with an extensible binder containing microencapsulated phase change material to form an extensible, coated fabric. The coated fabric is optionally flocked. The coated fabrics are manufactured using transfer techniques.

Owner:OUTLAST TECH LLC

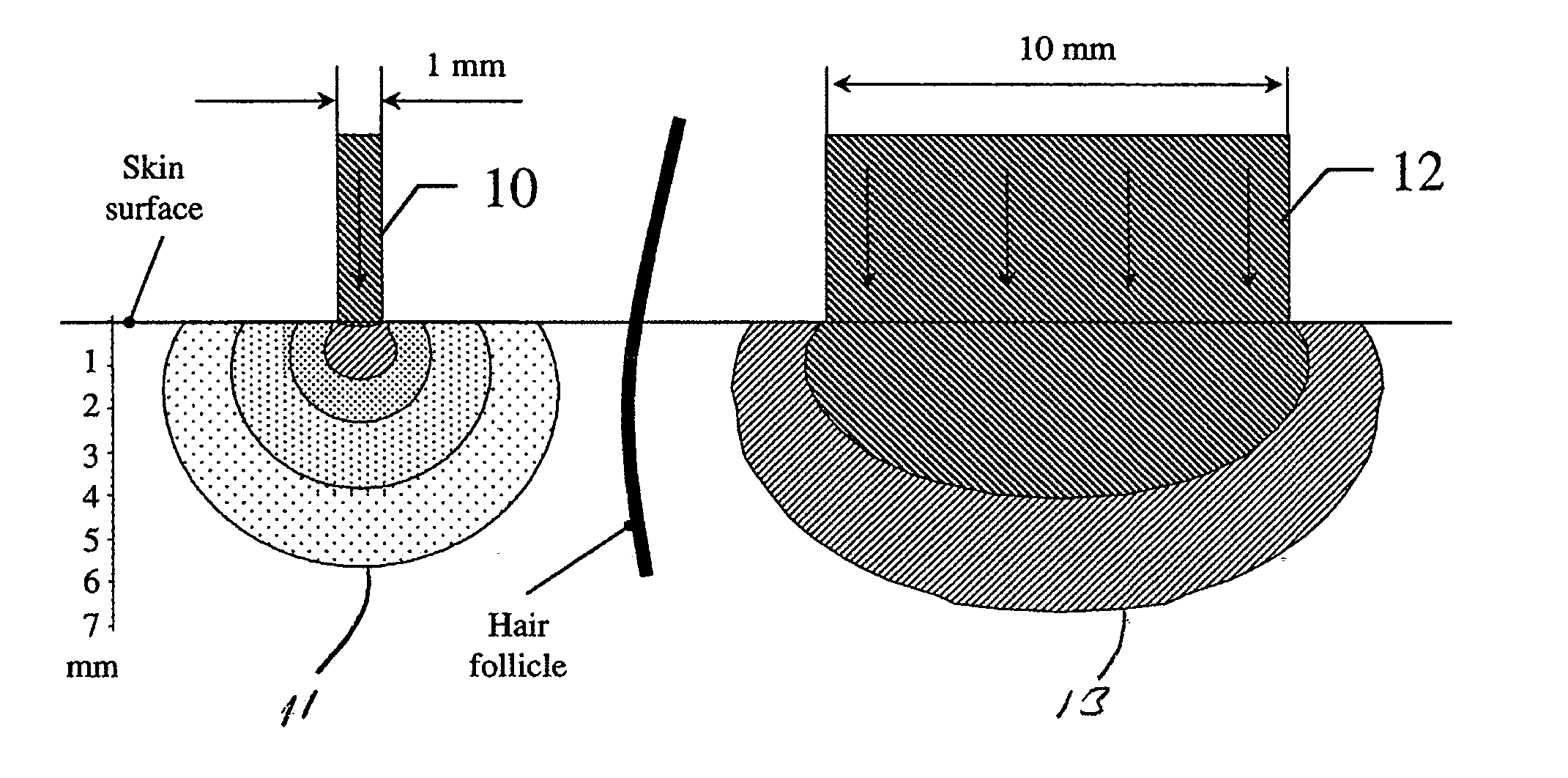

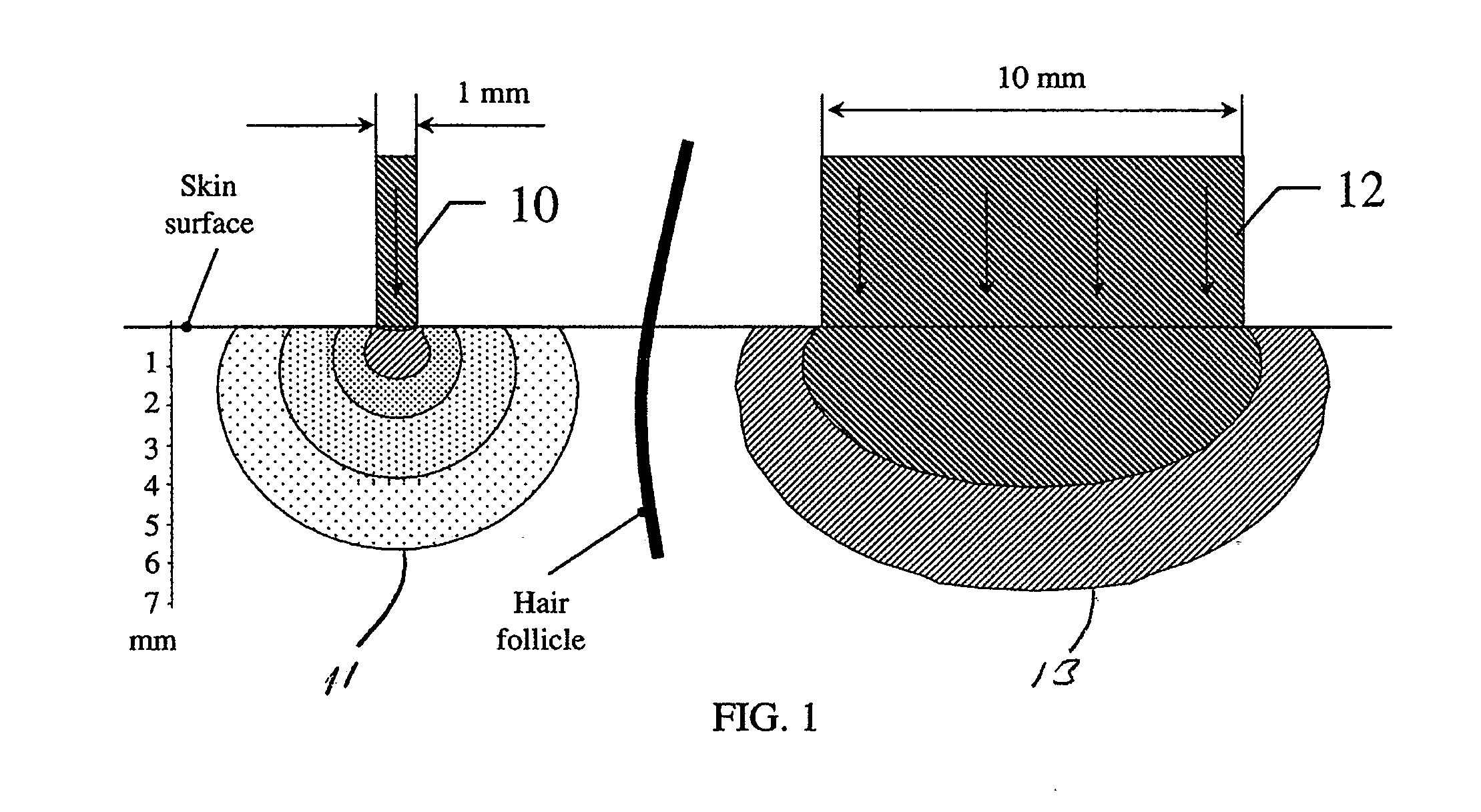

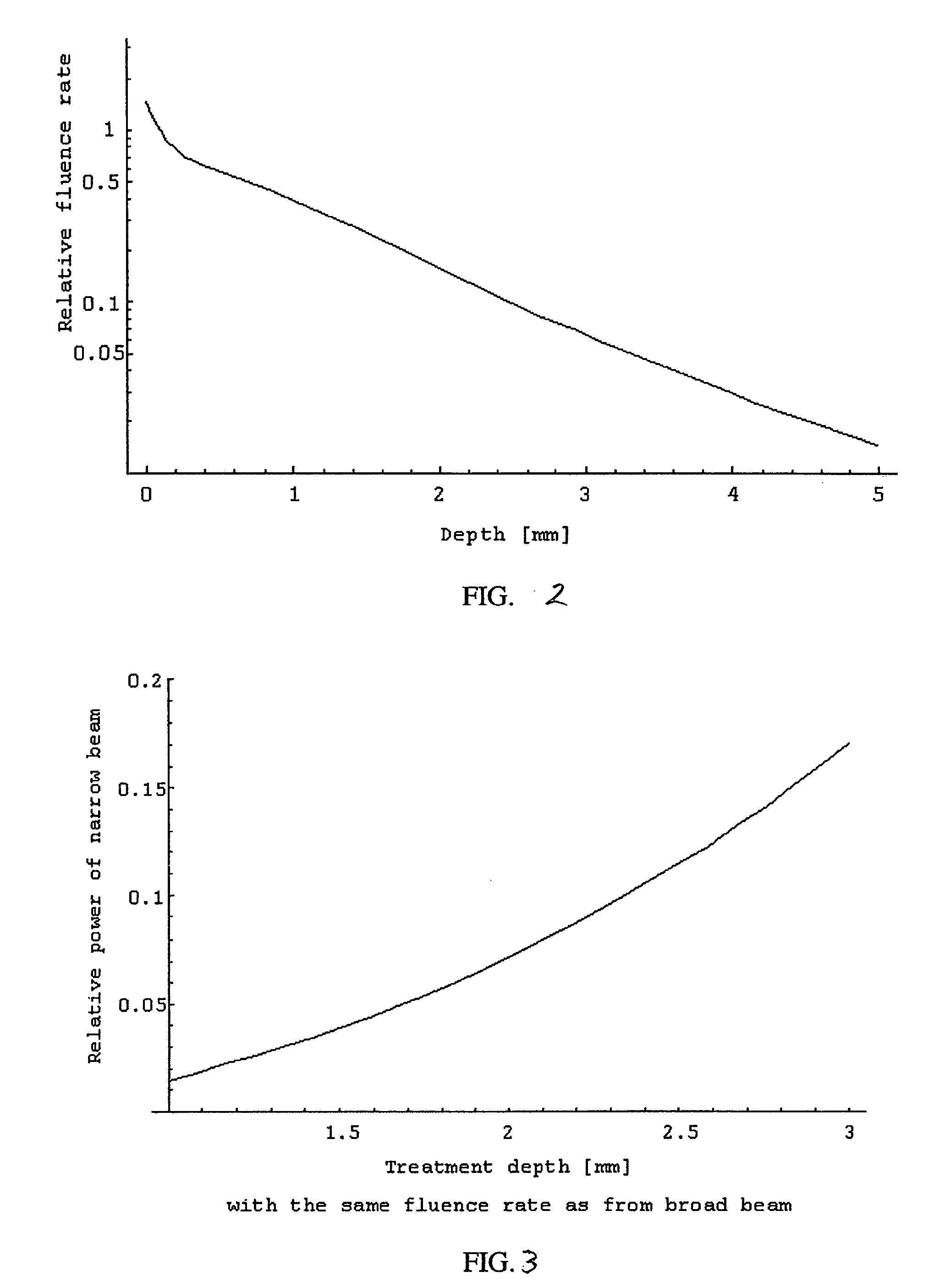

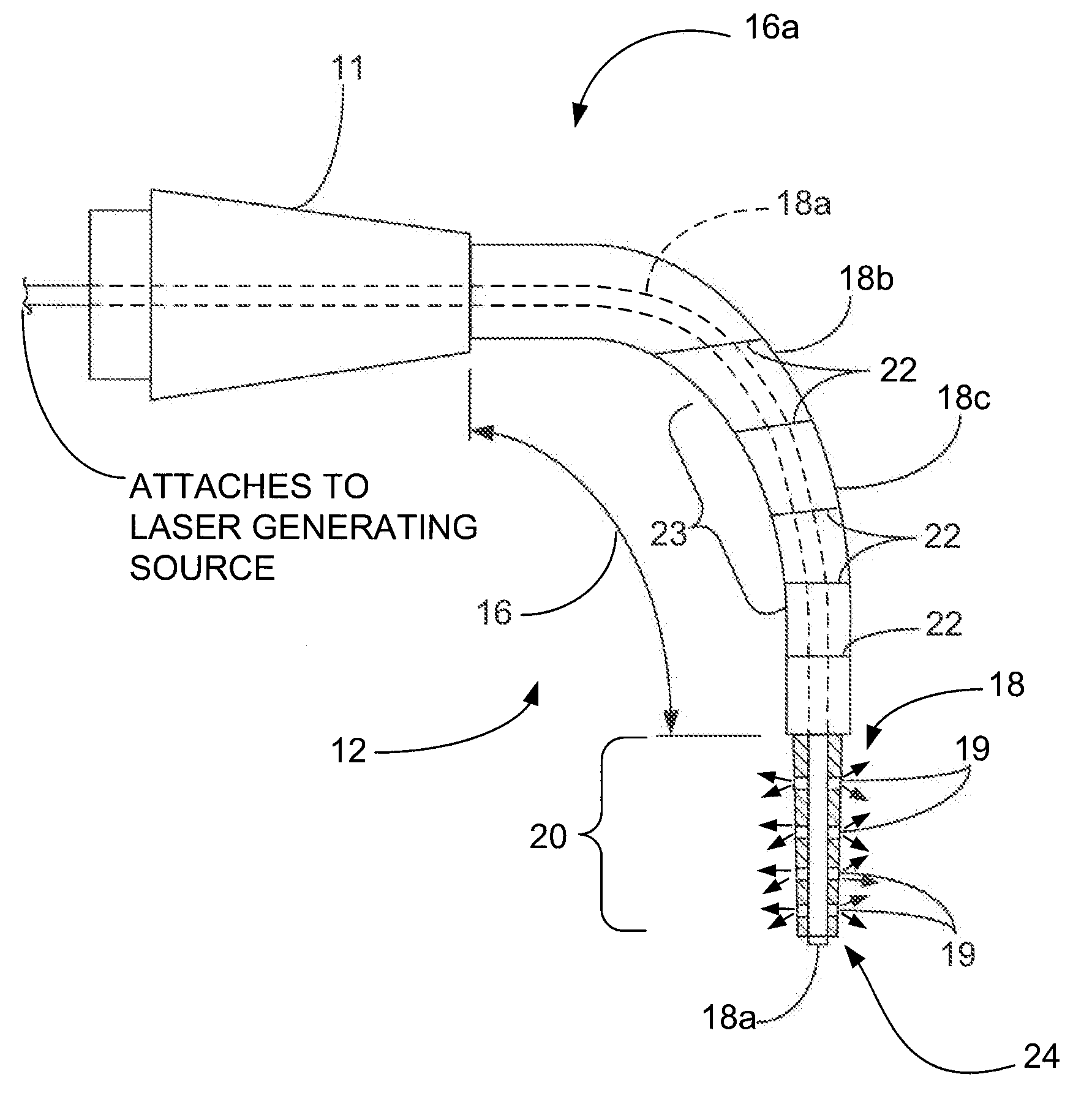

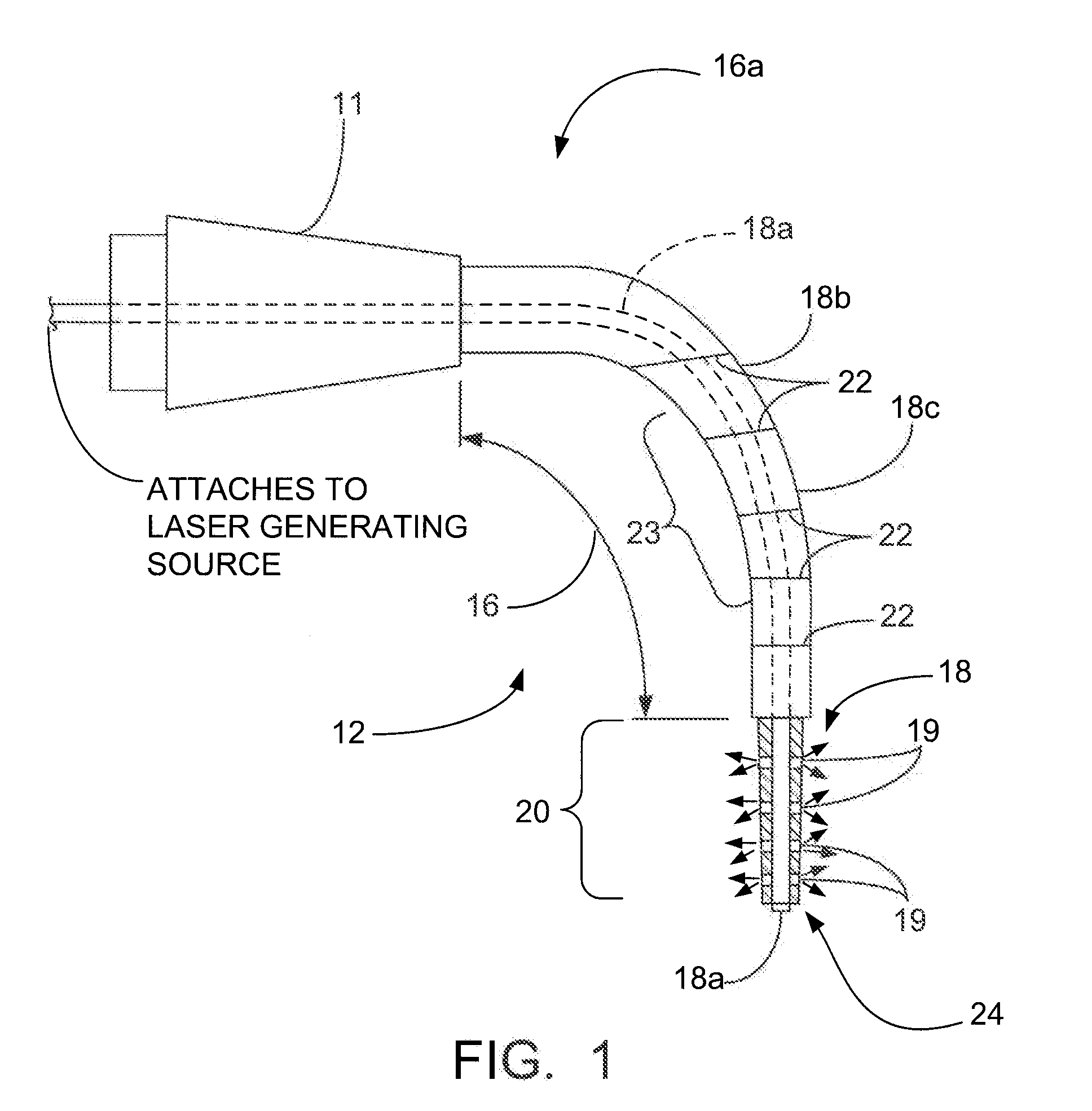

Method and apparatus of treating tissue

InactiveUS20060020260A1Reduce laser powerSurgical instrument detailsLight therapyEnergy absorptionFacula

A method for the treatment of skin including the steps of determining the skin depth for energy absorption necessary for treatment; and generating a spot size for energy impinging on the skin to provide a desired amount of energy to the desired depth for treatment. In one embodiment the selected spot size has a small diameter. In another embodiment the spot diameter is narrower than the spacing between adjacent hairs on the skin. In another aspect the invention relates to an apparatus for the treatment of skin including a source of energy; and a means for selecting a spot size for energy from the source impinging on the skin to provide a desired amount of energy to a desired depth for treatment. In another embodiment the apparatus includes an interlock to prevent the laser from producing light unless the source is positioned to irradiate only the skin.

Owner:SHASER

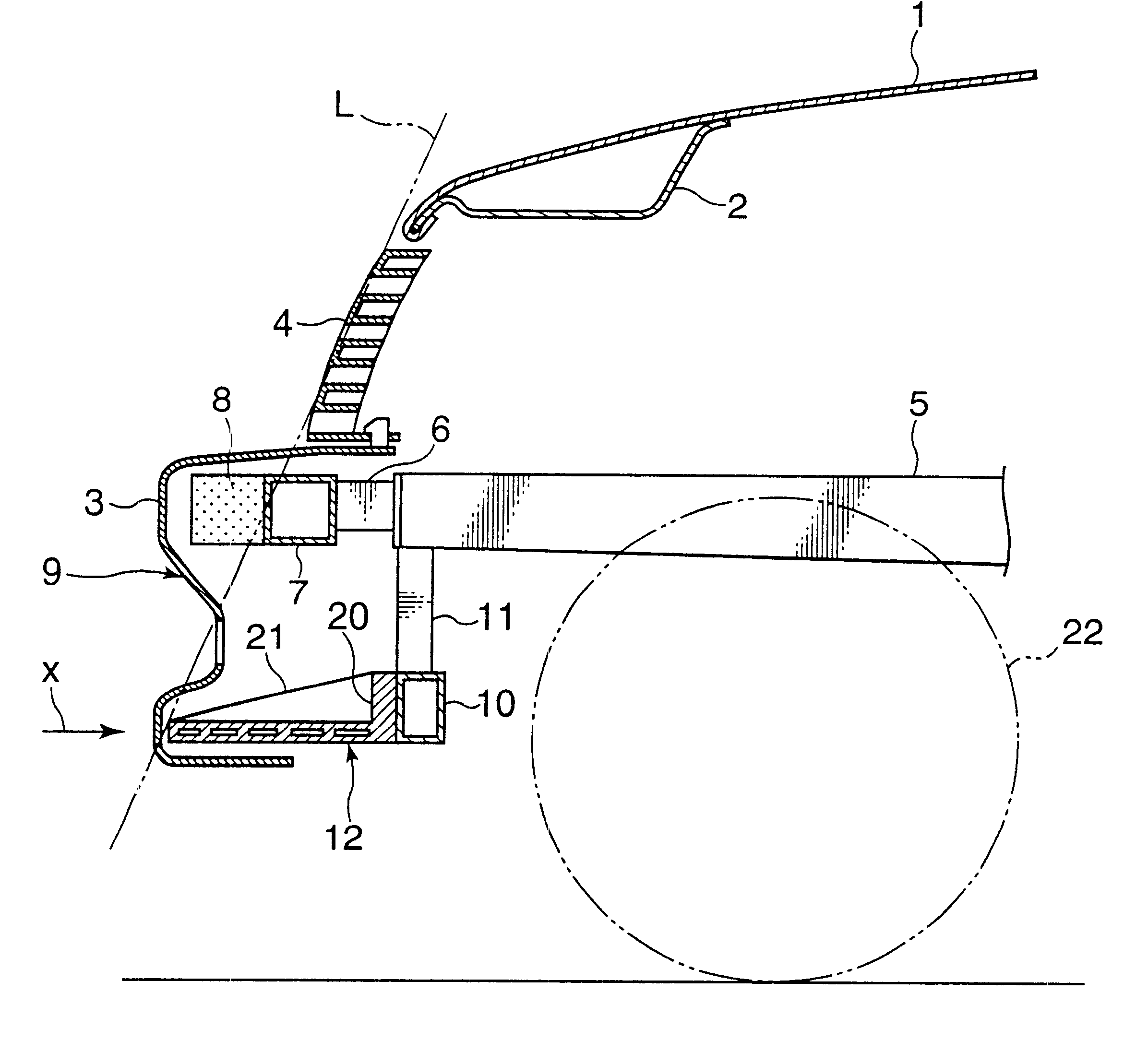

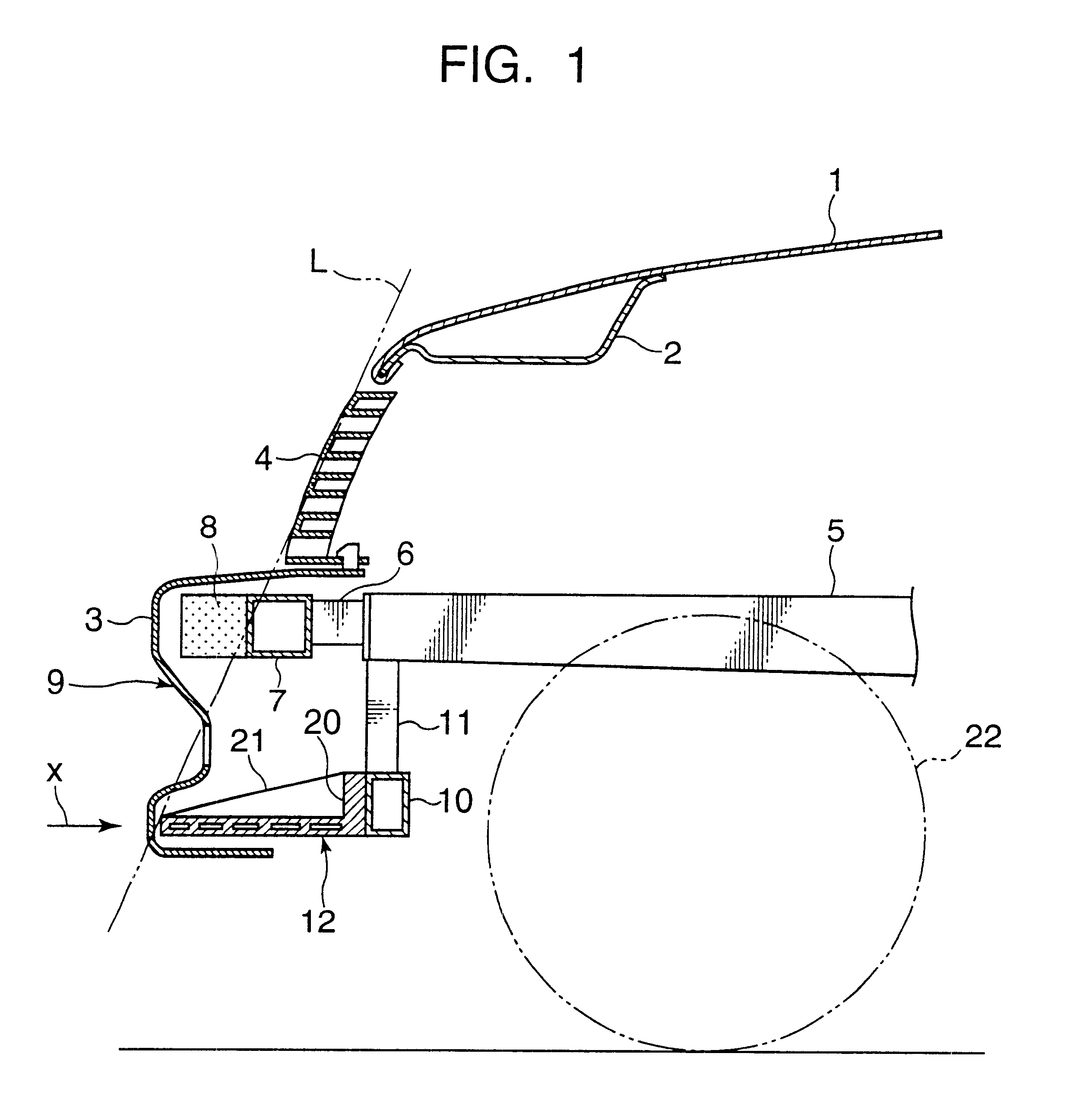

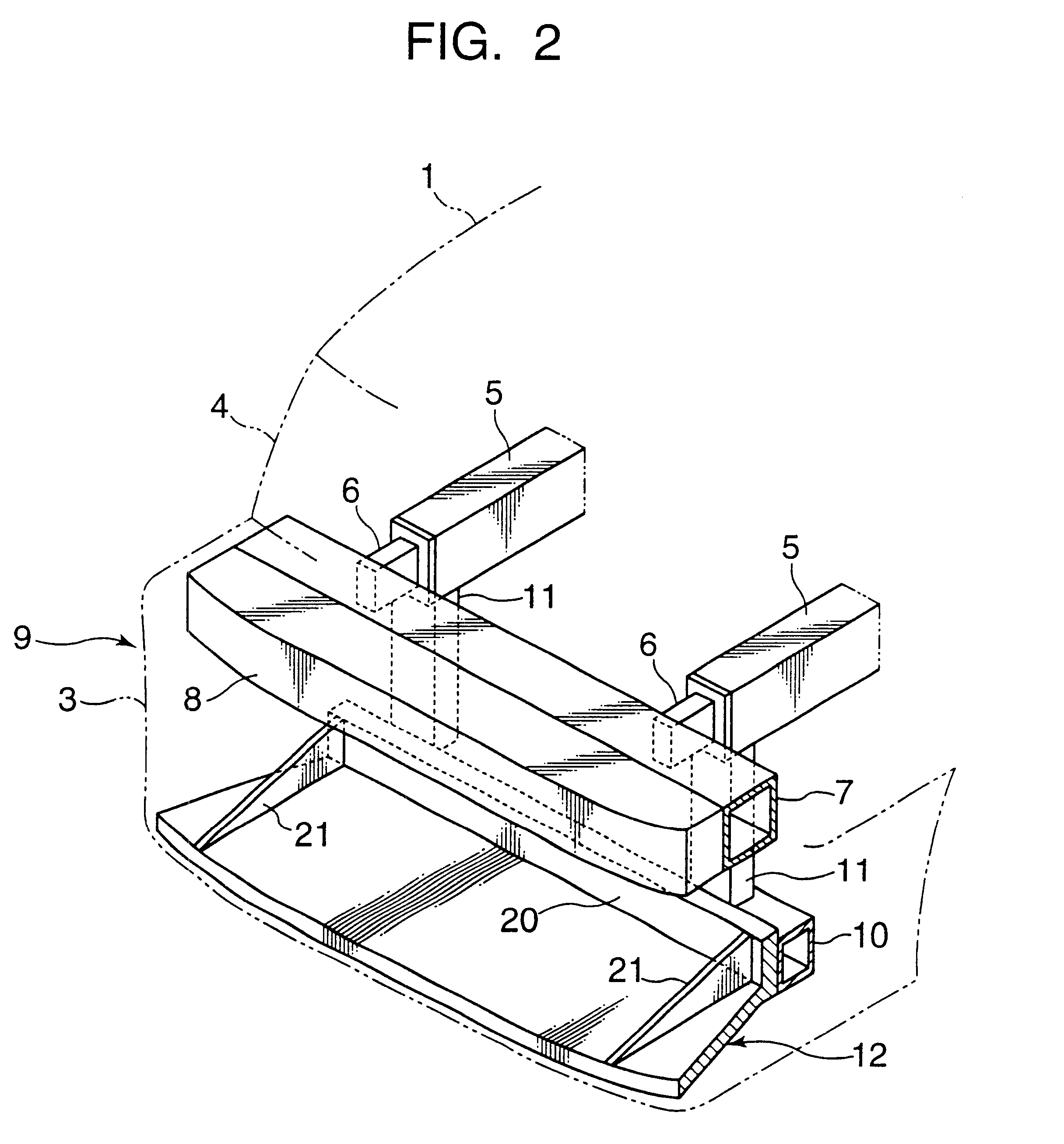

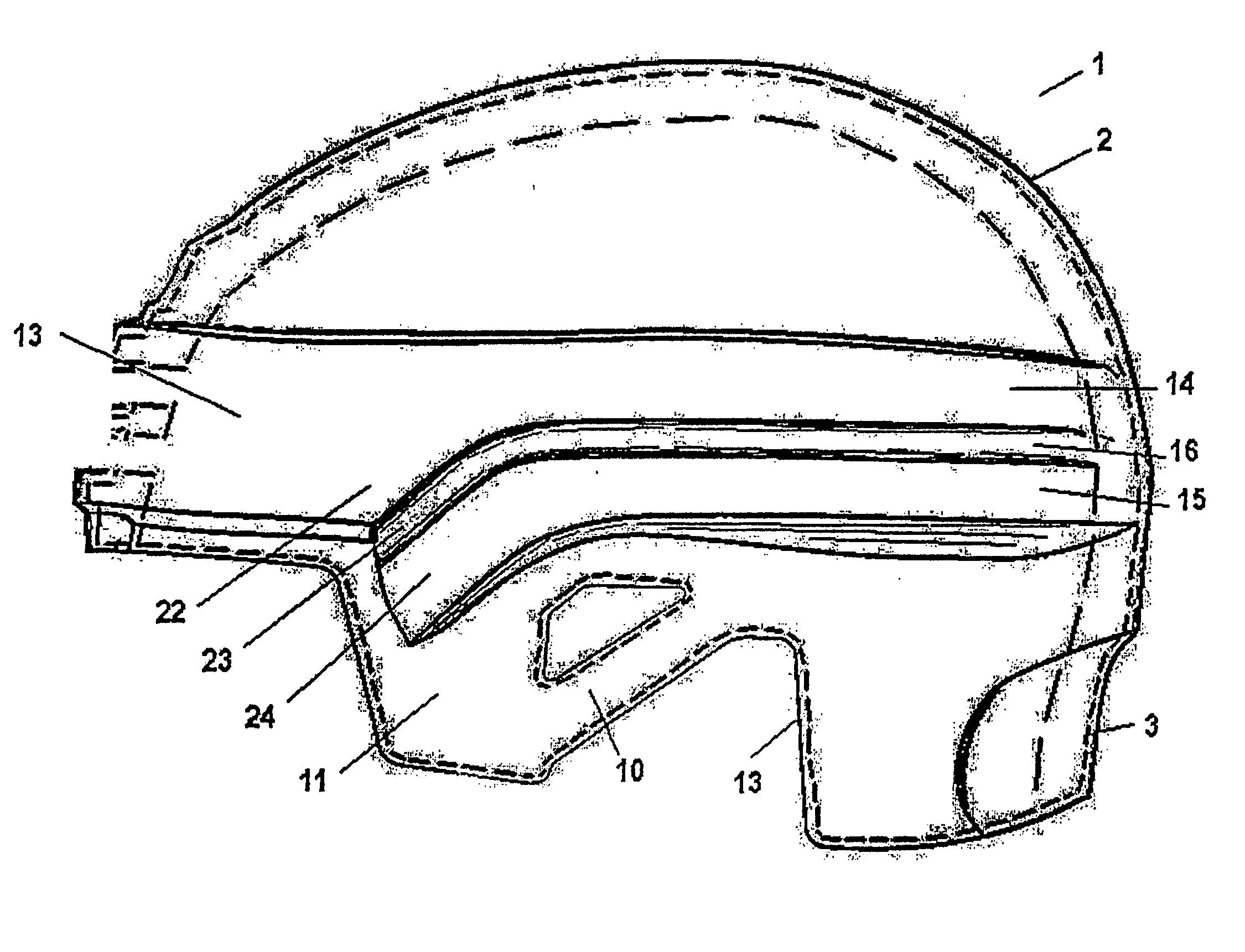

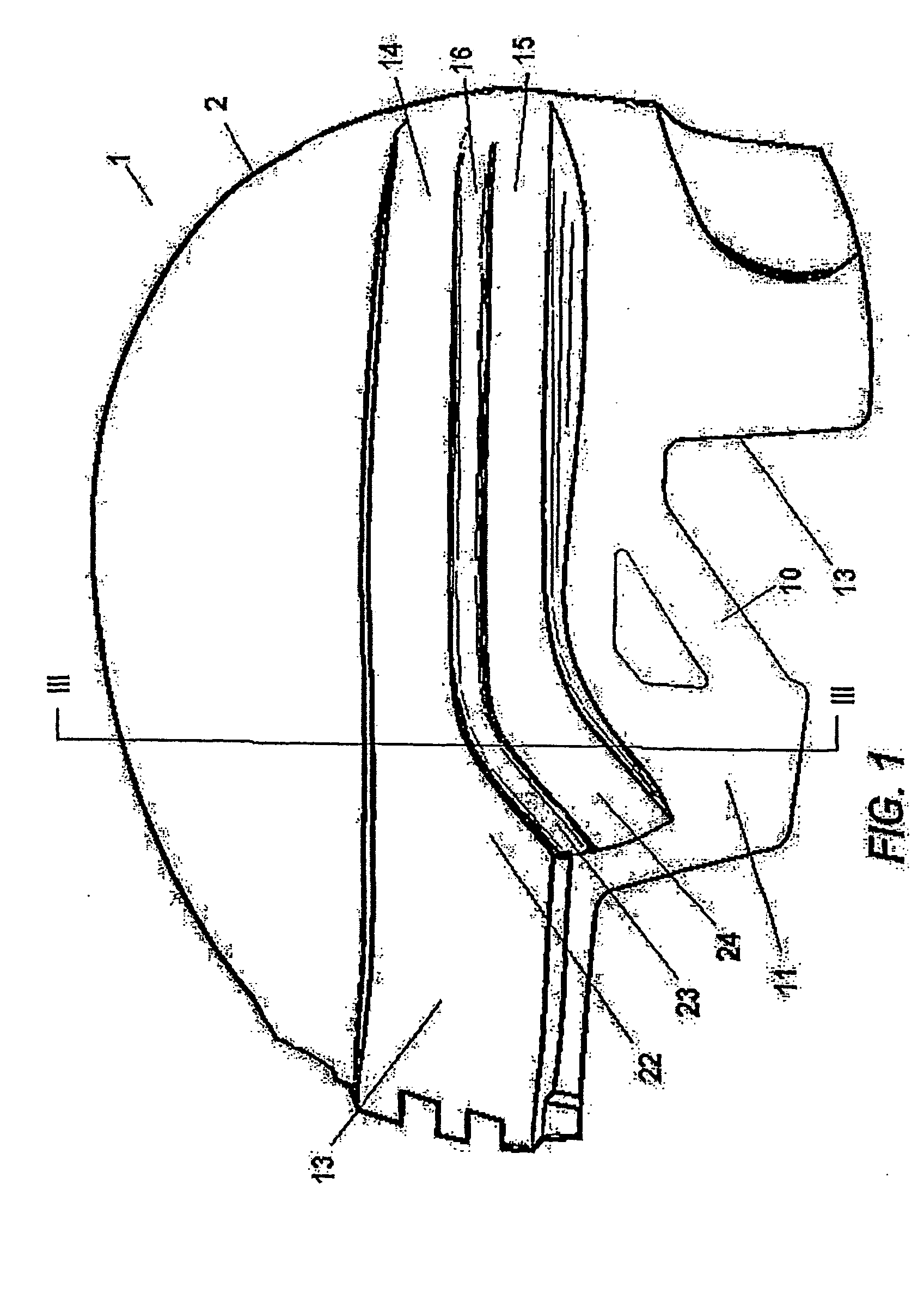

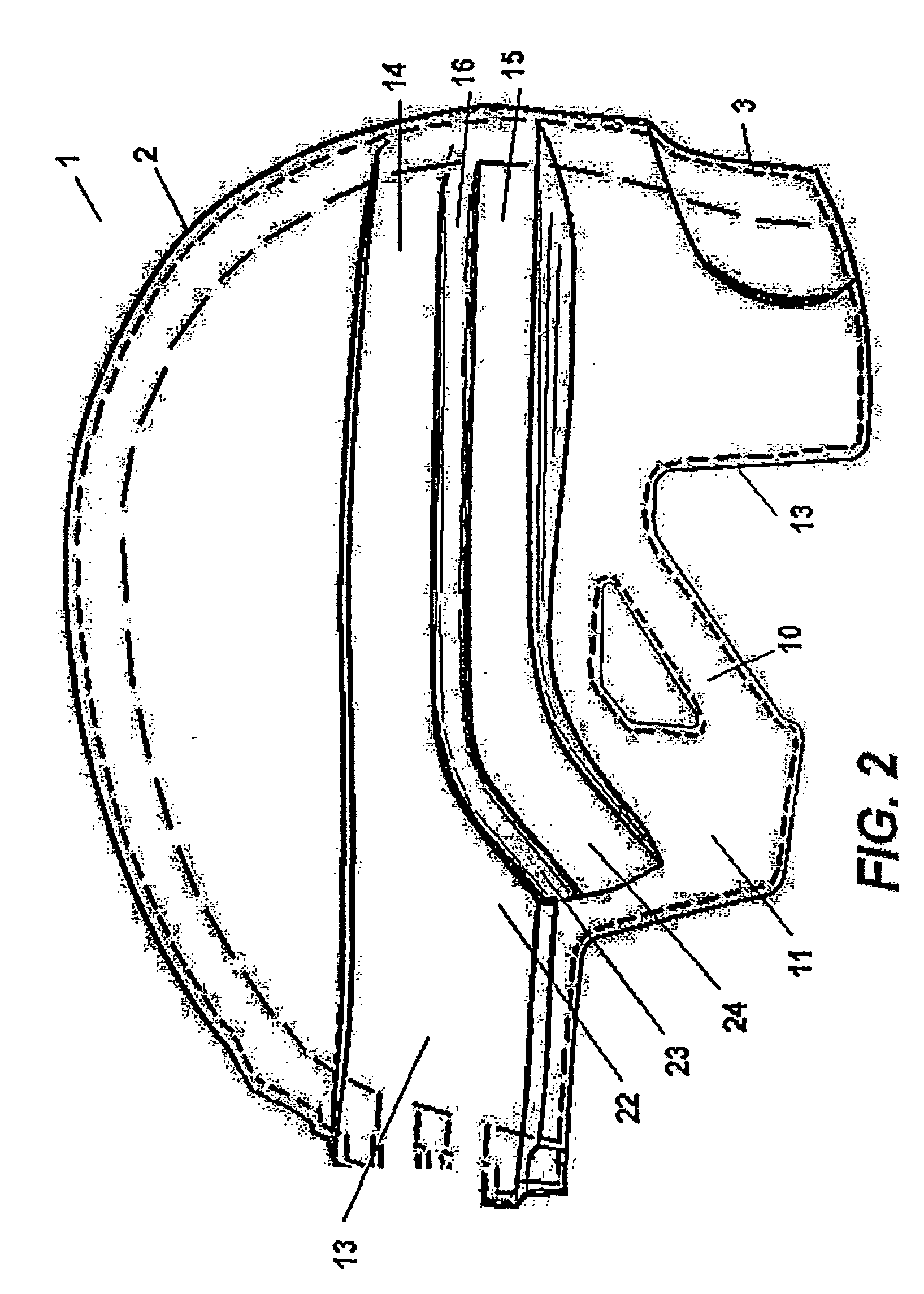

Structure of the front of a vehicle body

InactiveUS6540275B1Pedestrian/occupant safety arrangementRailway wheel guards/bumpersEnergy absorptionEngineering

The invention provides a structure of a front part of a vehicle body that is simple and free from the risk of maloperation. In the event of a collision between the vehicle and a pedestrian, a projecting part sweeps the pedestrian by parts of his or her legs lower than the knees in the event of a collision between the vehicle and the pedestrian, causing the pedestrian to be thrown over toward the vehicle, and after an energy-absorbing member has absorbed impact energy exerted on the legs, the pedestrian is caused to drop onto the top of a hood and protected from secondary damage. In one specific example, a structure of a front part of a vehicle body in which a bumper (9) is provided at a lower front position of a hood (1) of the vehicle comprises a lateral supporting member (7) provided in the front part of the vehicle body and extending in the direction of vehicle width, an energy-absorbing member (8) provided ahead of the lateral supporting member (7), and a projecting part (12) provided at a lower part of the bumper 9 in such a manner that a forward end of the projecting part (12) juts out more frontward than the lateral supporting member (7).

Owner:MAZDA MOTOR CORP

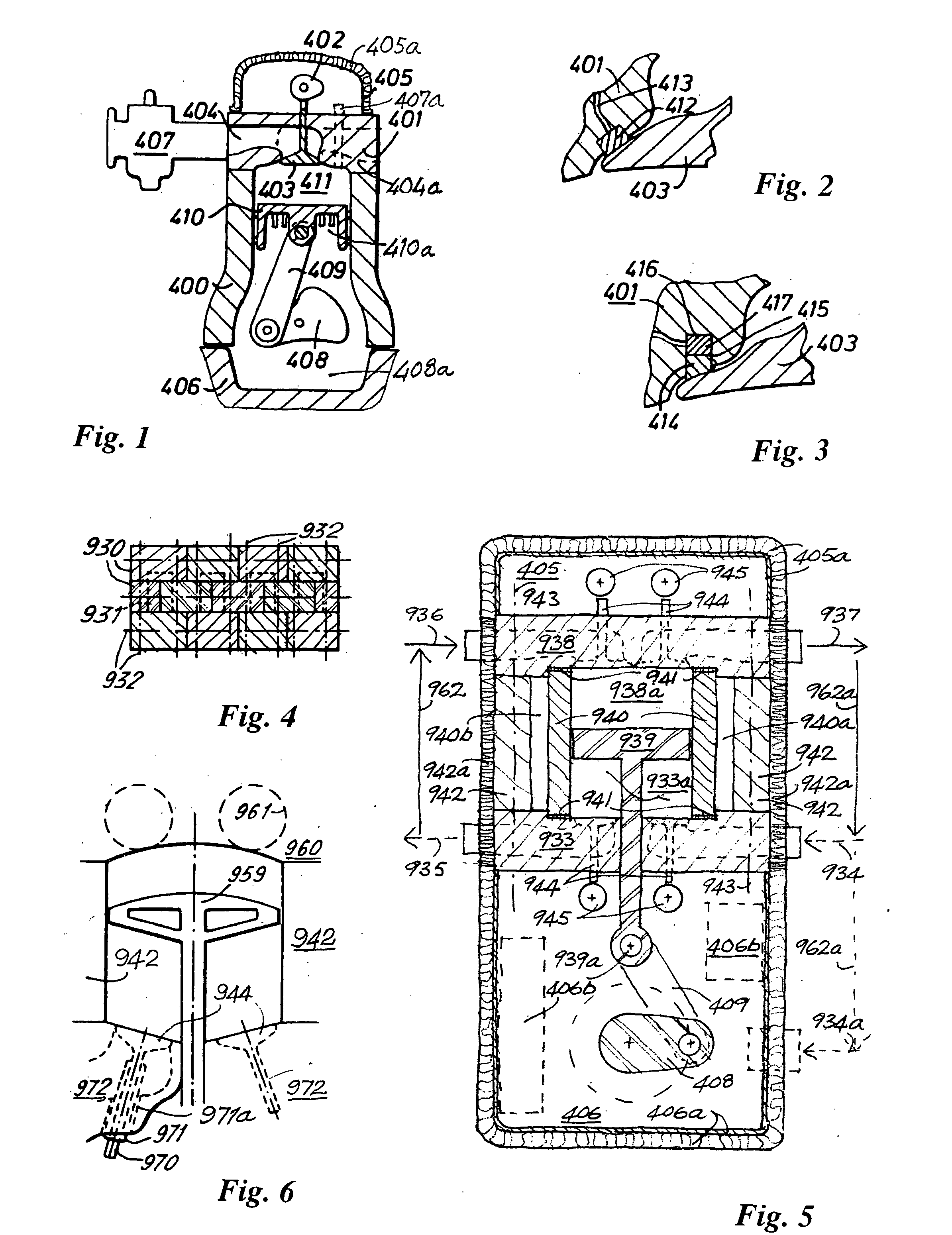

Reciprocating devices

ActiveUS20080141921A1Improve power densityImprove efficiencyHybrid vehiclesInternal combustion piston enginesExternal combustion engineEnergy absorption

The disclosure relates to fluid working devices including reciprocating internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in reciprocating internal combustion IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, pistons reciprocating between pairs of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Compound engines having the new engines as a reciprocating stage are described. Improved vehicles, aircraft, marine craft and transmissions adapted to receive or be linked to the improved IV engines are also disclosed.

Owner:HINDERKS MITJA VICTOR

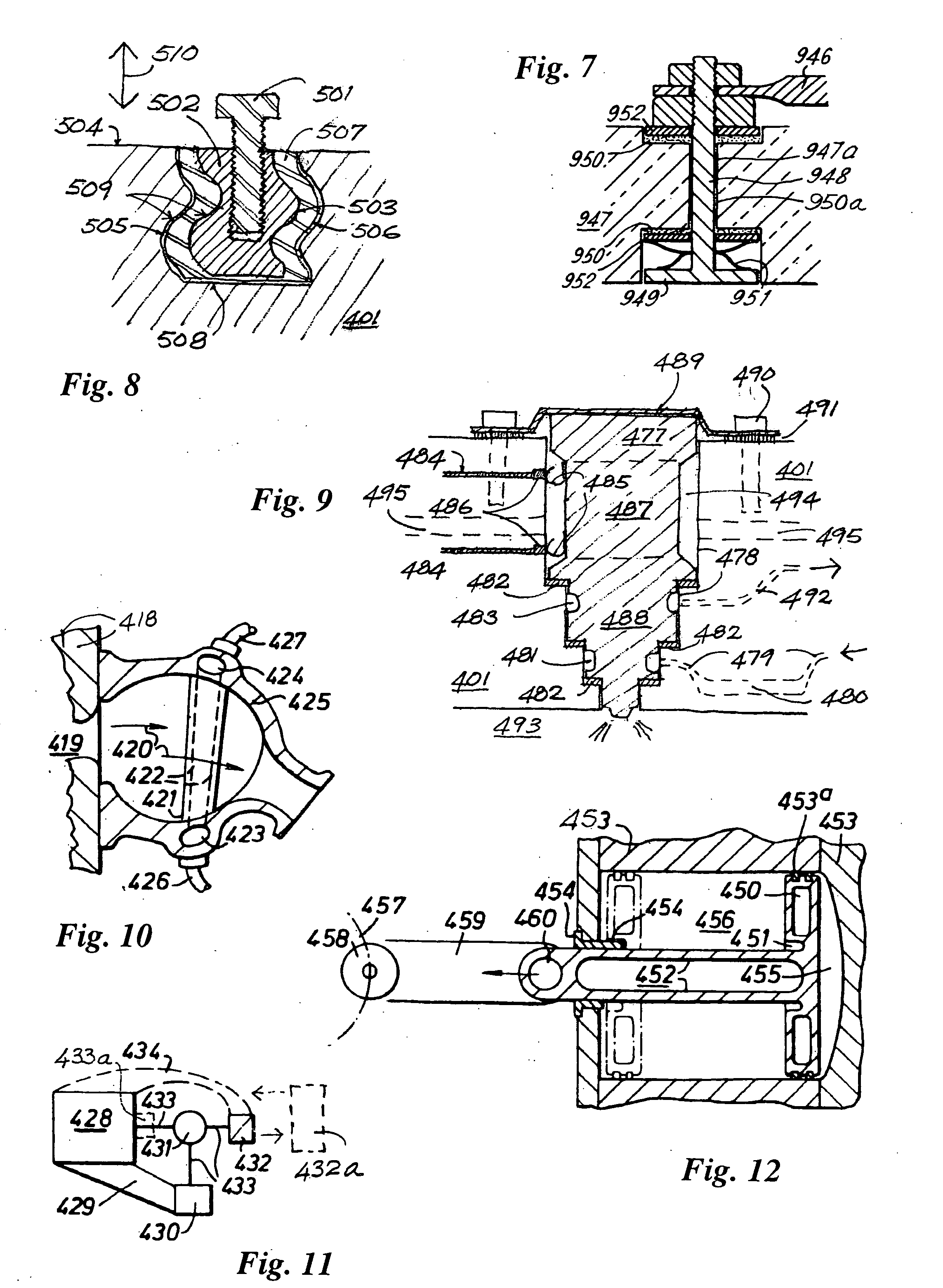

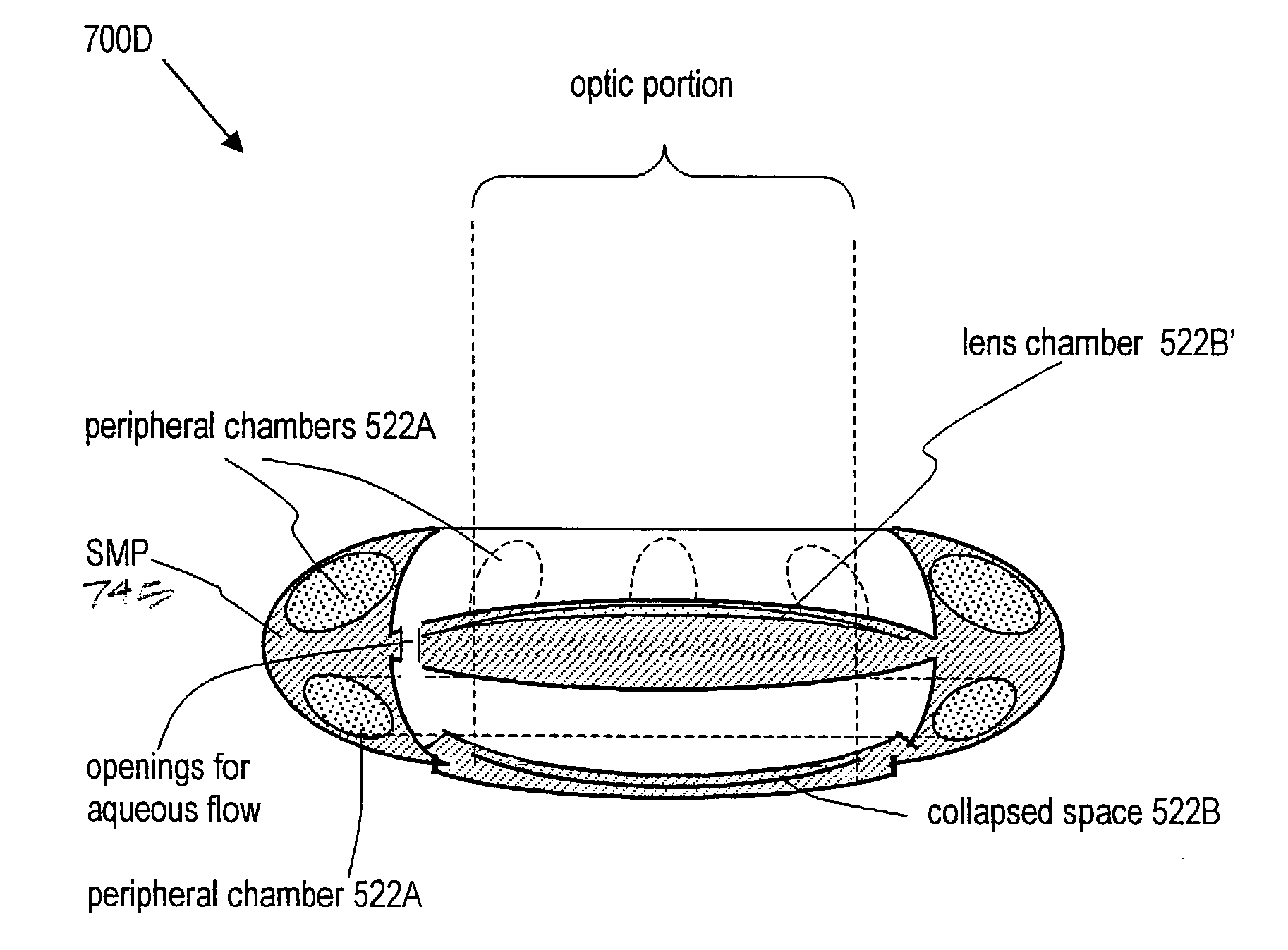

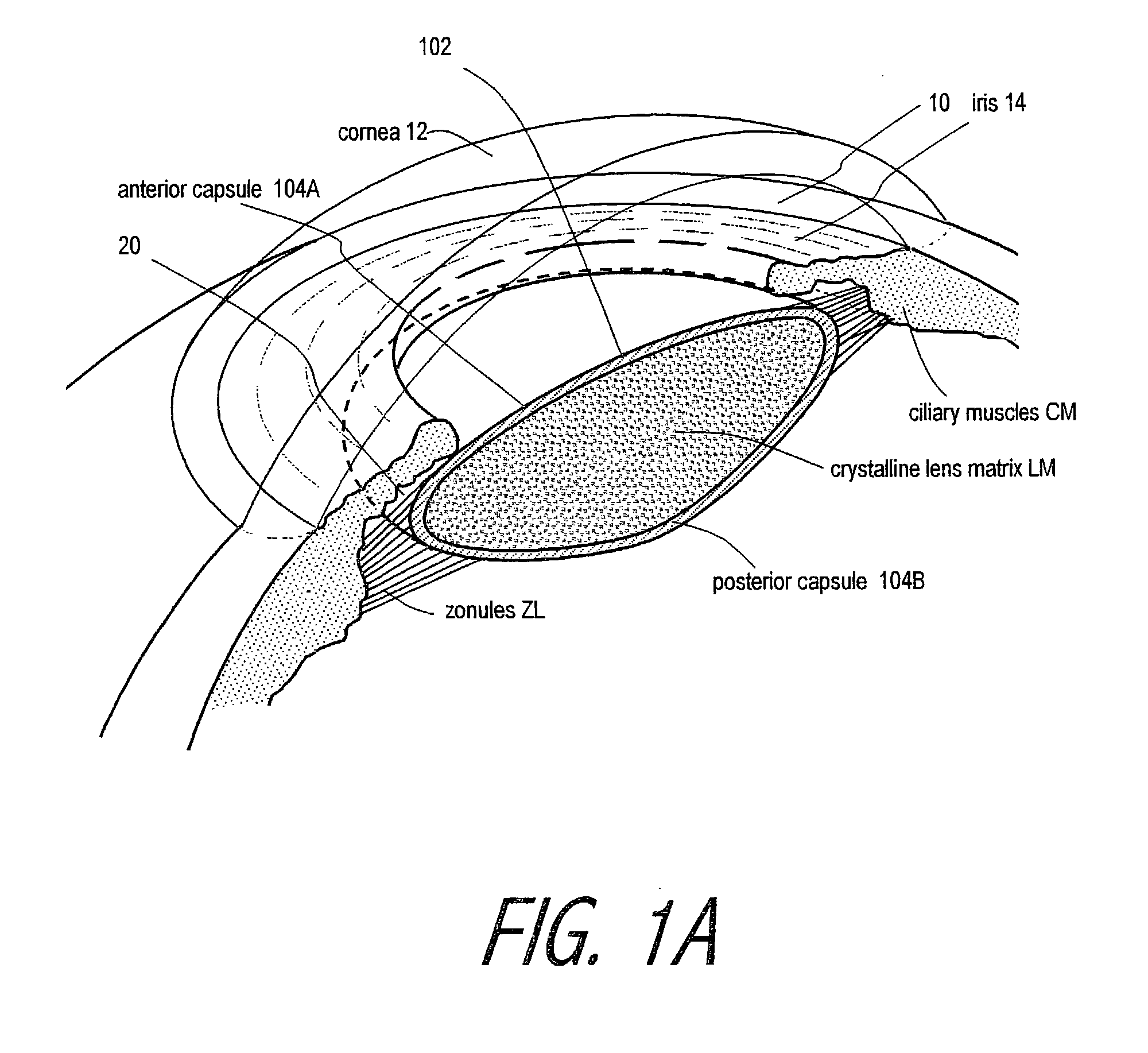

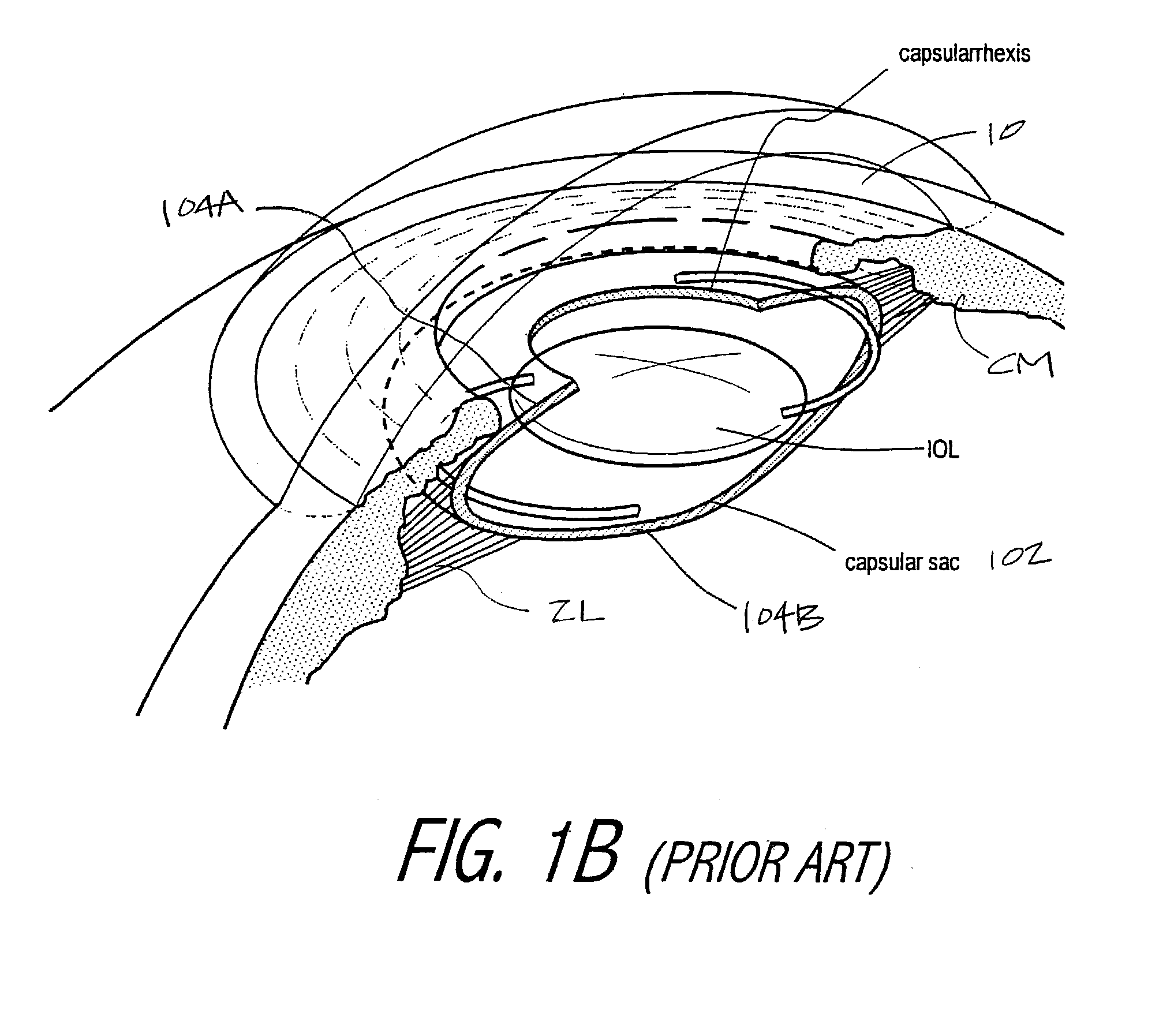

Intraocular implant devices

A deformable intracapsular implant device for shaping an enucleated lens capsule sac for use in cataract procedures and refractive lensectomy procedures. In one embodiment, the intraocular implant devices rely on thin film shape memory alloys and combine with the post-phaco capsular sac to provide a biomimetic complex that can mimic the energy-absorbing and energy-releasing characteristics of a young accommodative lens capsule. In another embodiment, the capsular shaping body is combined with an adaptive optic. The peripheral capsular shaping body carries at least one fluid-filled interior chamber that communicates with a space in a adaptive optic portion that has a deformable lens surface. The flexing of the peripheral shaping body in response to zonular tensioning and de-tensioning provides an inventive adaptive optics mechanism wherein fluid media flows between the respective chambers “adapts” the optic to increase and decrease the power thereof. In one embodiment, the capsular shaping body carries a posterior negative power adaptive optic that can be altered in power during accommodation to cooperate with an independent drop-in exchangeable intraocular lens.

Owner:ALCON INC

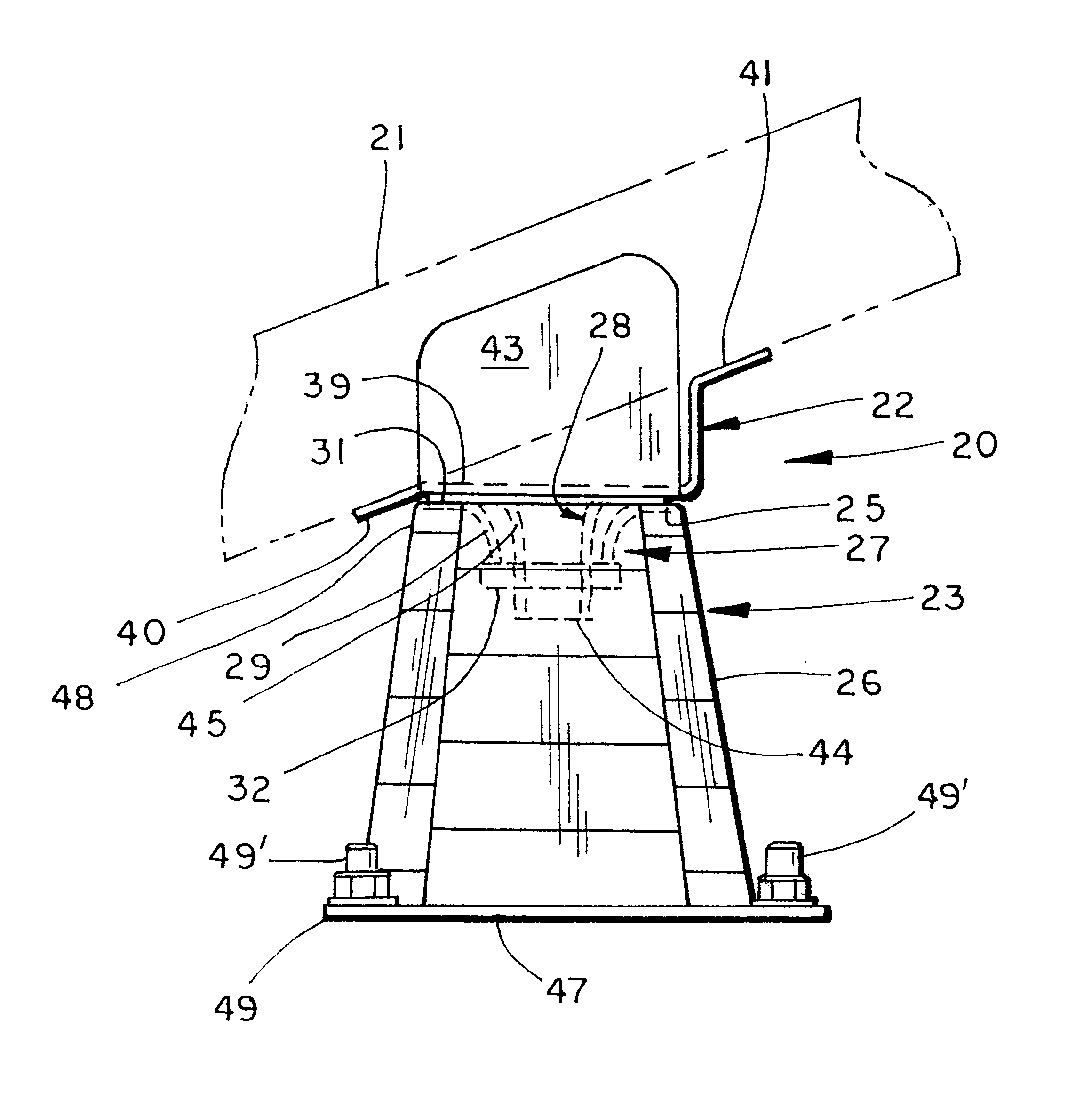

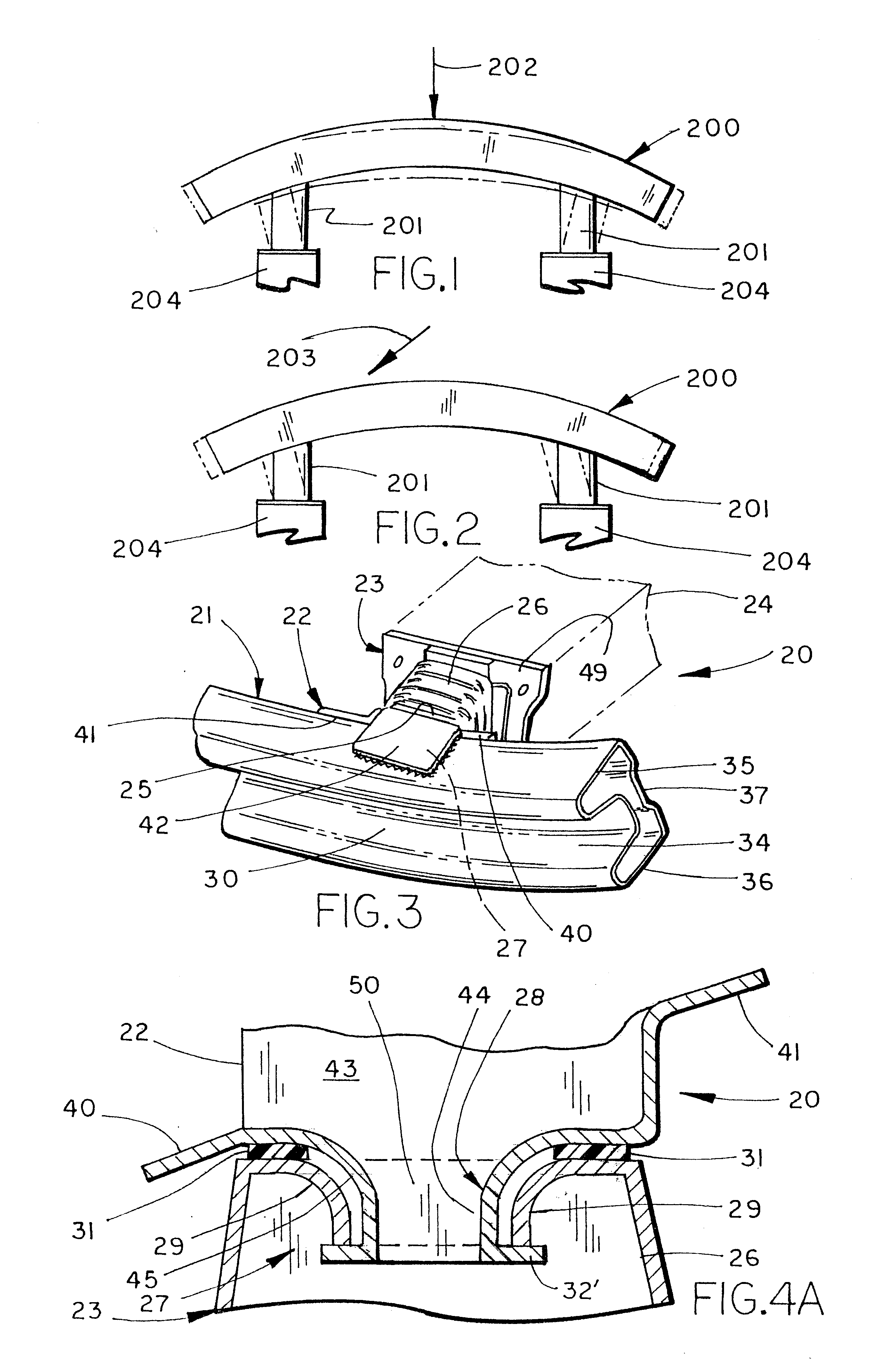

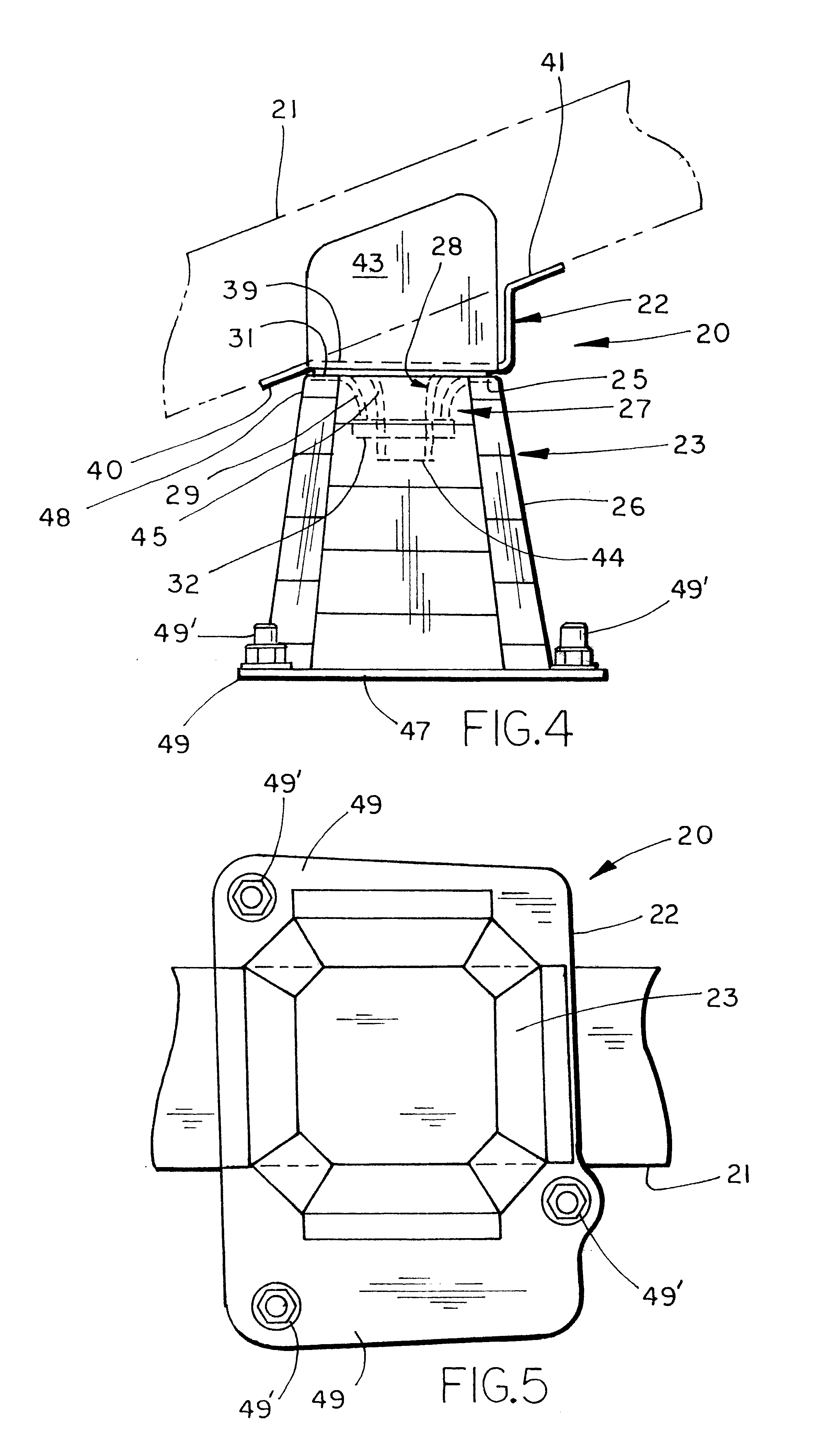

Bumper construction including self-orienting support towers providing consistent energy absorption on impact

InactiveUS6174009B1Pedestrian/occupant safety arrangementElastic dampersEnergy absorptionHigh energy

A bumper construction for a vehicle includes a swept tubular bumper beam having a pair of spaced-apart brackets and a pair of towers configured to attach to the brackets and support the bumper beam on a vehicle. The towers each include a platform configured for attachment to one of the brackets, and further include an elongated portion configured for connection to the vehicle. A swivel connection connects the tower to the bumper beam. The connection includes a protruding section on one of the bracket and the tower, and a socket receiving the protruding section on the other of the bracket and the tower. The protruding section and the socket are configured to draw the tower toward an impacting force during a catastrophic impact, such that the tower is more likely to crush with a high-energy absorbing, accordion-like collapse (as opposed to a low-energy absorbing parallelogram-like collapse).

Owner:SHAPE CORP

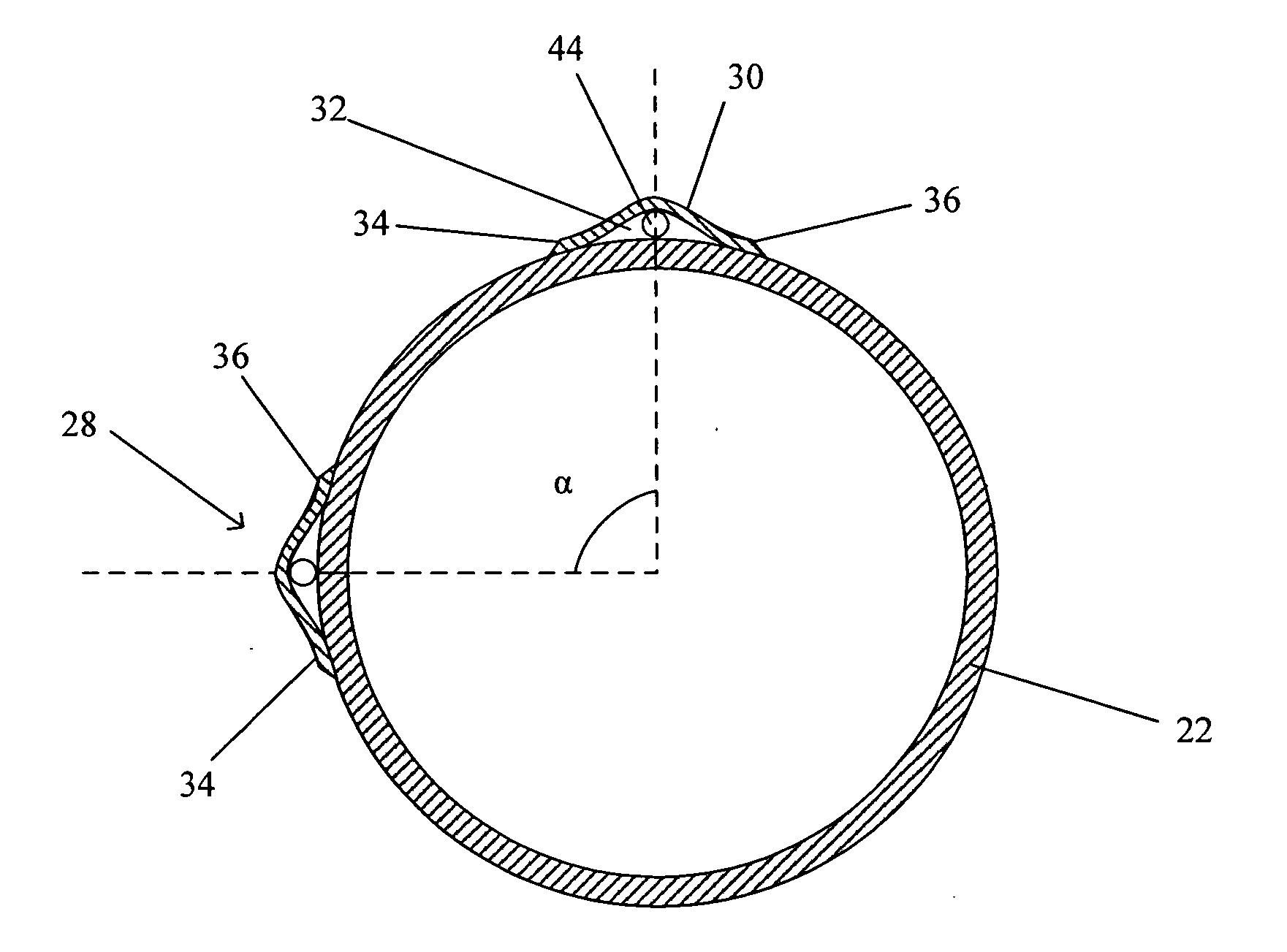

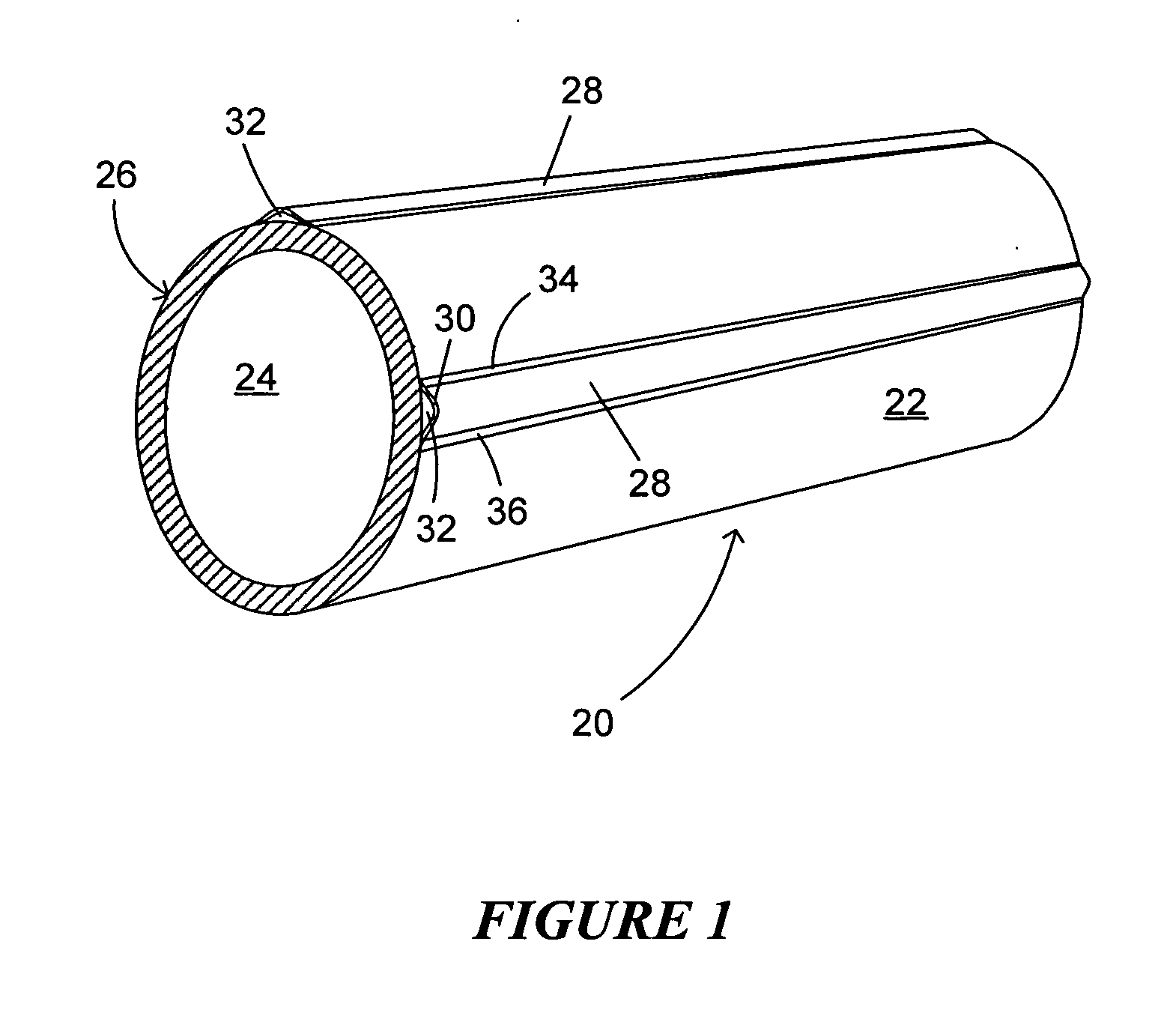

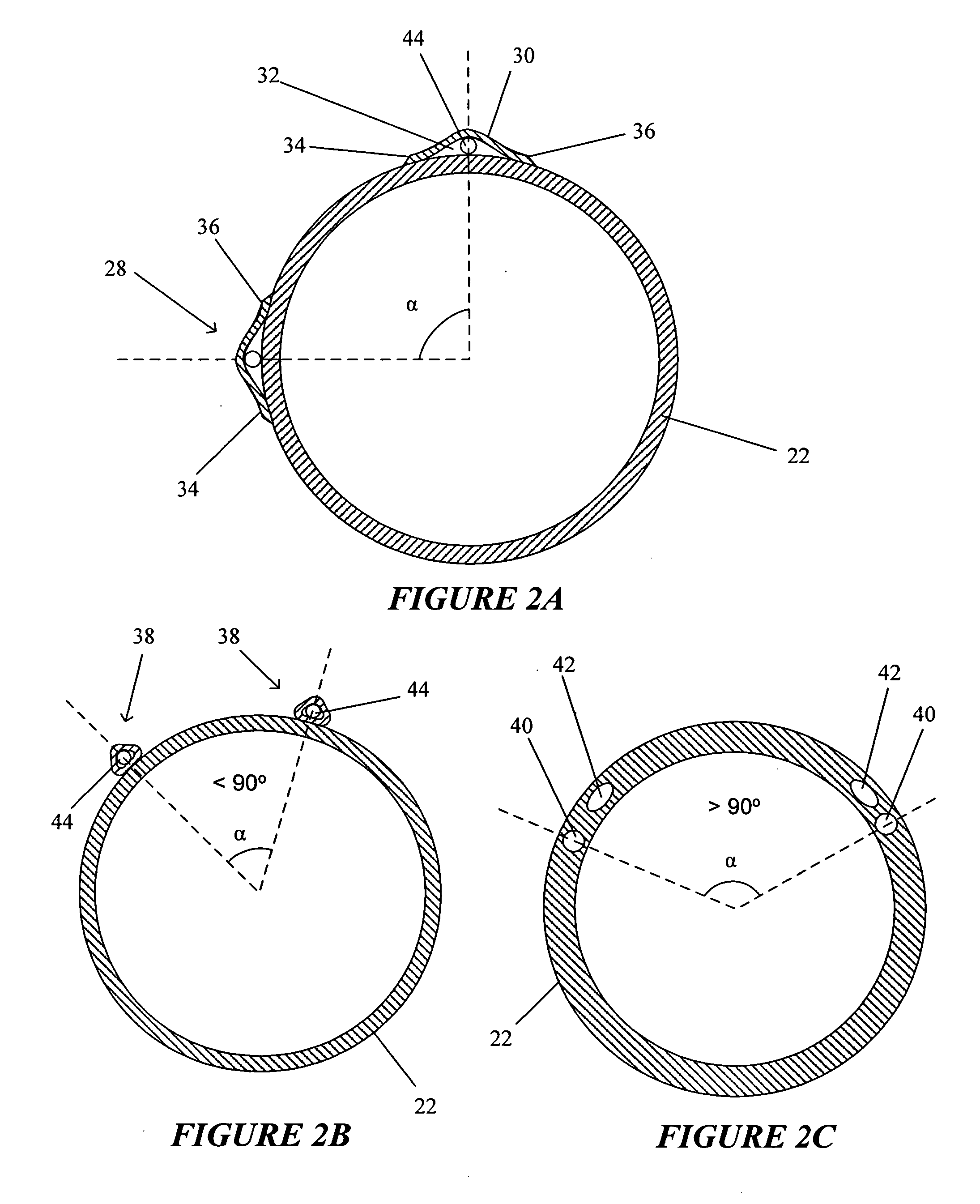

Catheters having stiffening mechanisms

InactiveUS20060264907A1Solve the lack of flexibilitySufficient pushabilityCatheterVariable stiffnessShape change

Catheters having selectively insertable or selectively activatable and releasable stiffening mechanisms are provided. In general, the catheter is inserted, navigated and withdrawn from a subject in a relaxed, flexible condition and stiffening mechanisms are deployed to prevent the catheter from shifting during placement or operation of an accessory device or tool through the catheter. Stiffening members(s) may be inserted into and removed from one or more longitudinal channel(s) provided in proximity to the catheter wall and generally coaxial with the primary catheter lumen to change the stiffness properties of the catheter. The properties, configuration and size of the stiffening members and channels may be varied to vary the stiffness properties of the catheter and stiffening members may be constructed from materials having shape change properties or materials that change conformation or stiffness with application of heat, current or electrical field. Stiffening mechanisms may also employ energy absorbing and viscoelastic polymer materials having variable stiffness properties depending on ambient conditions.

Owner:PULSAR VASCULAR

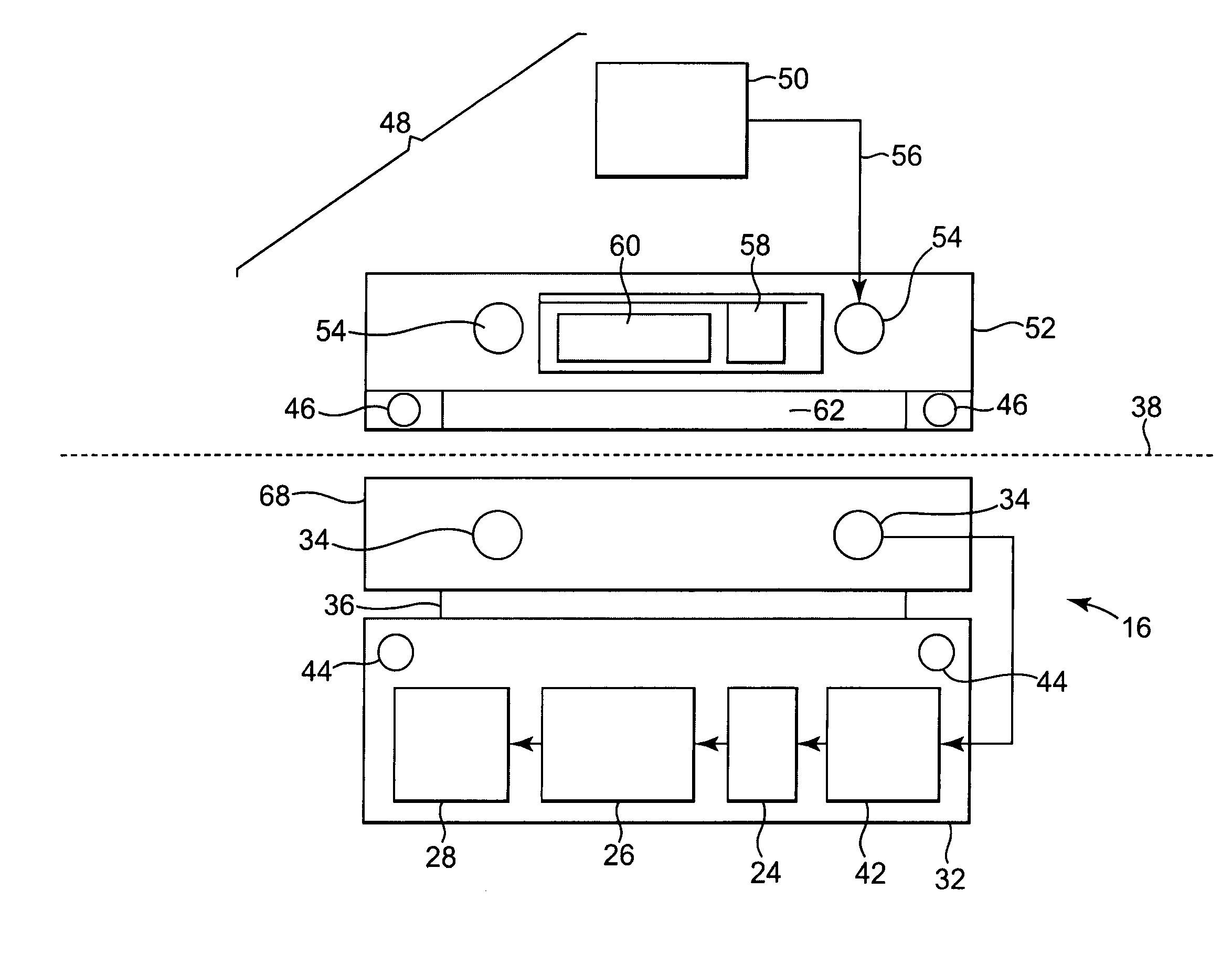

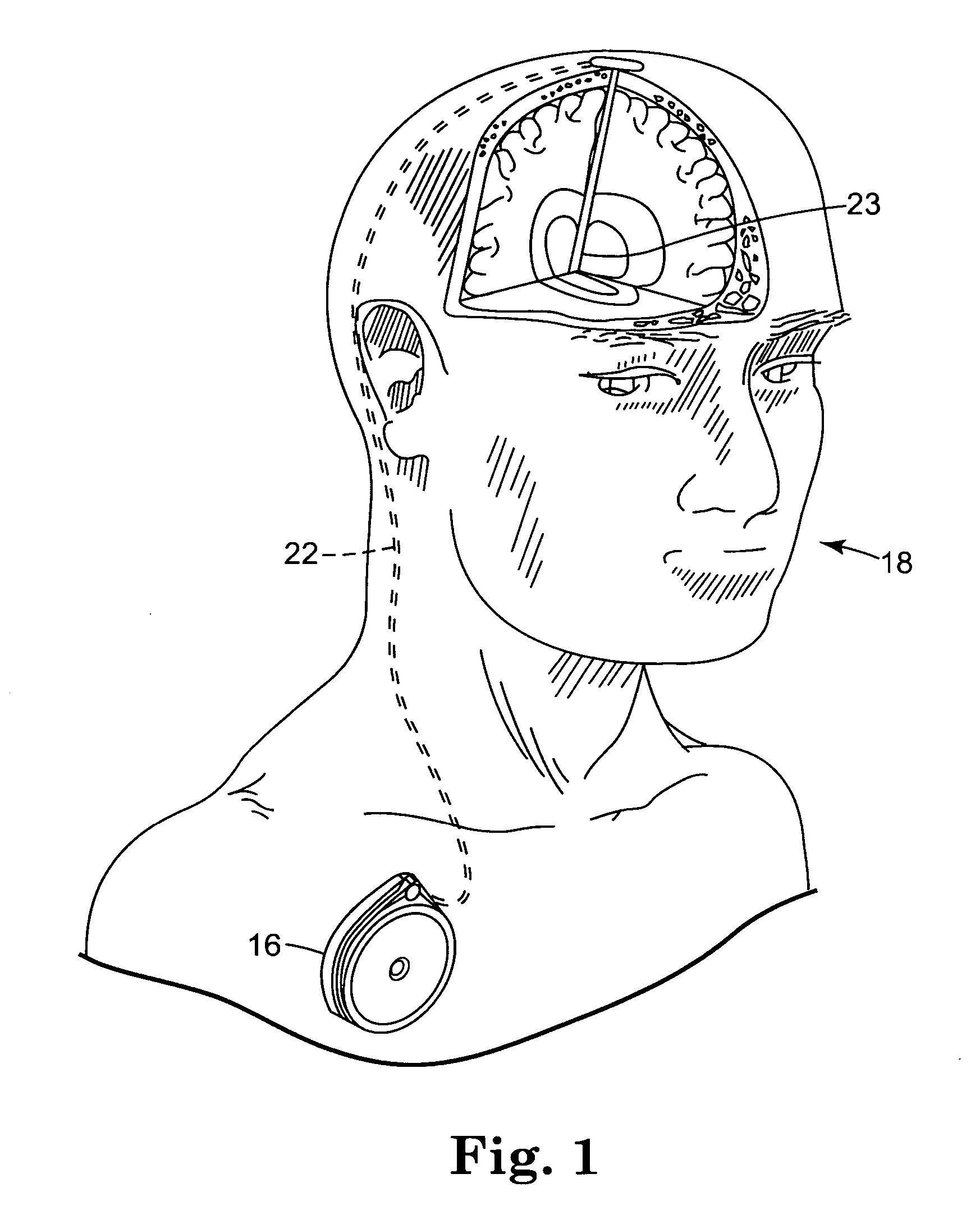

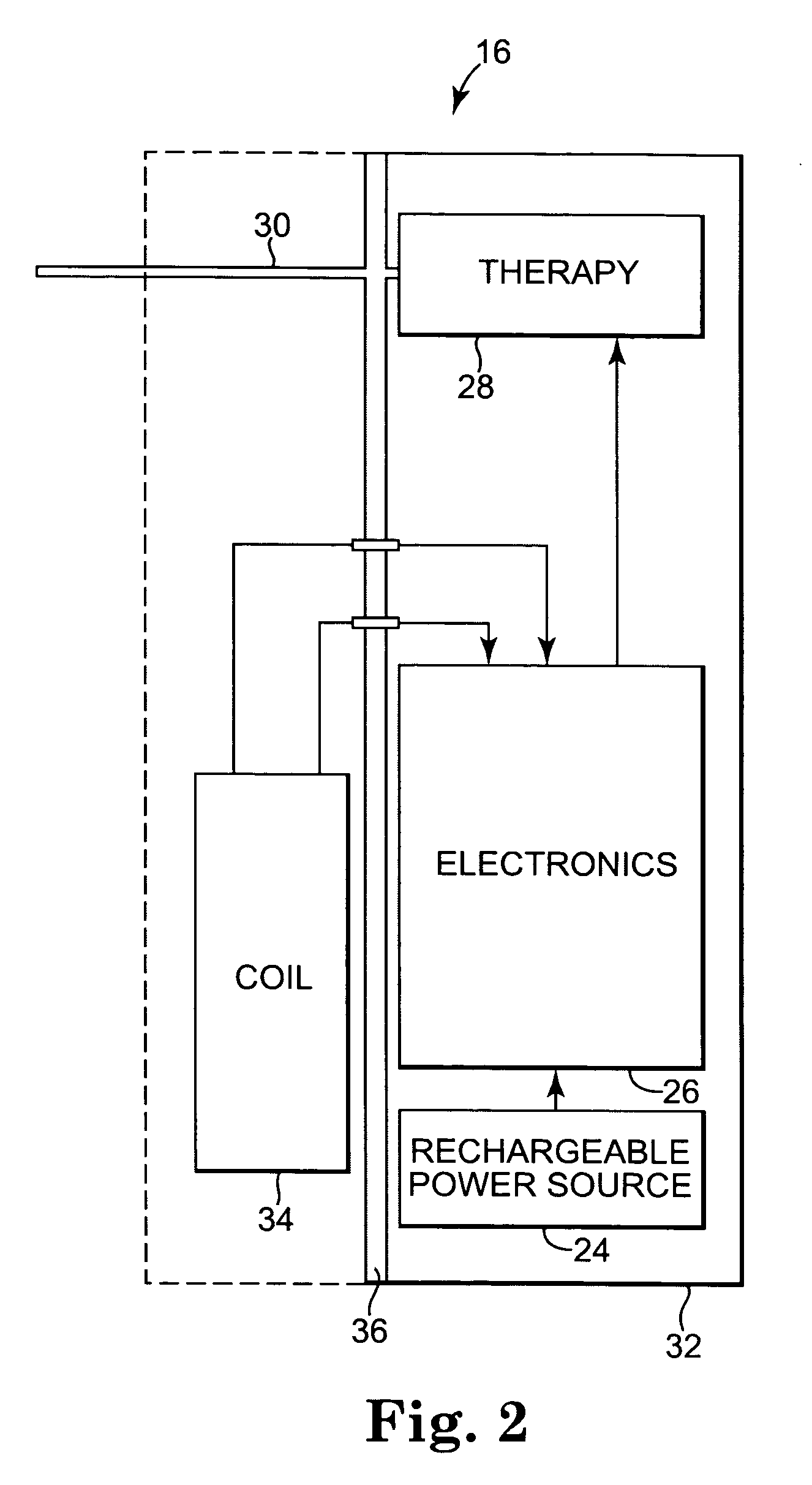

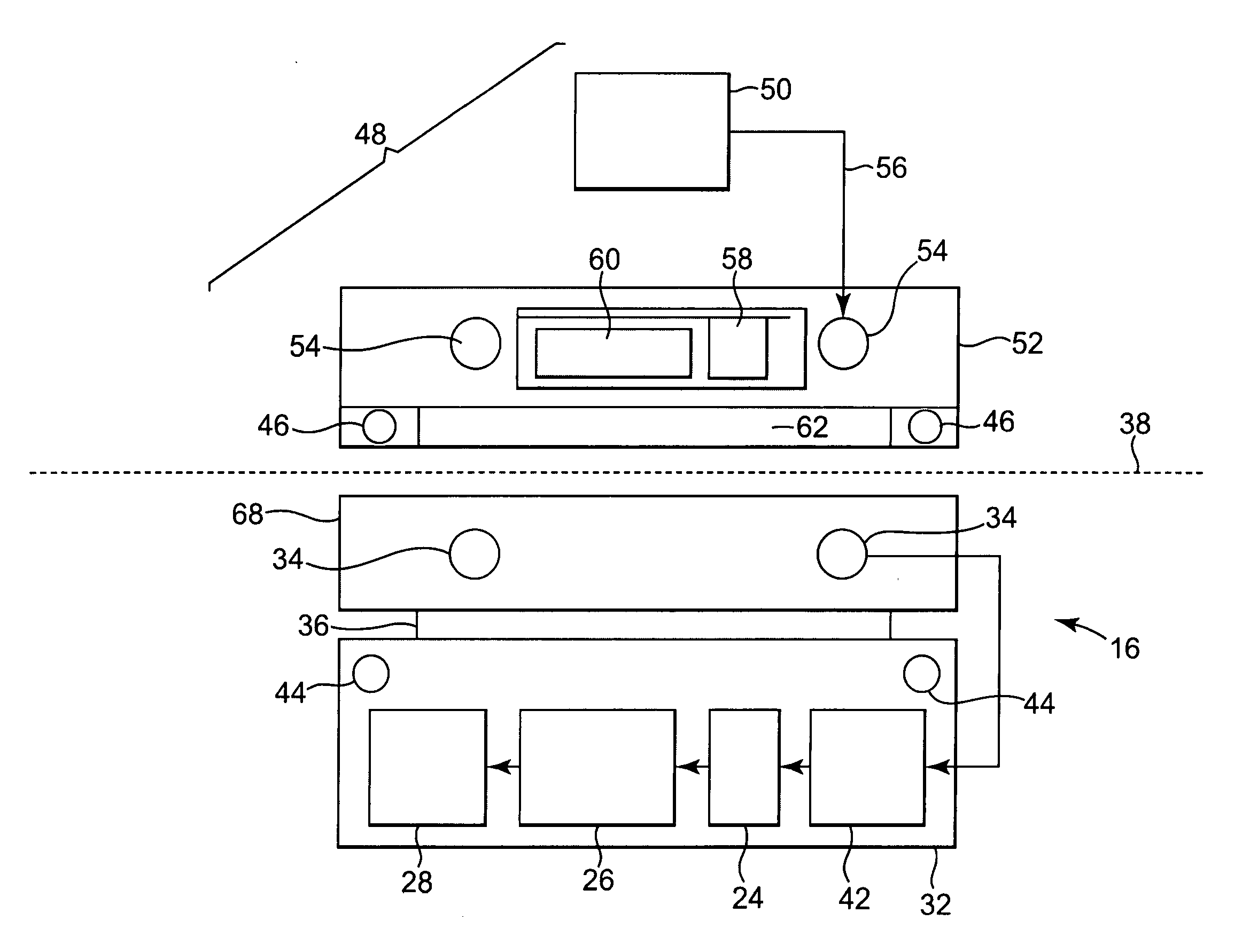

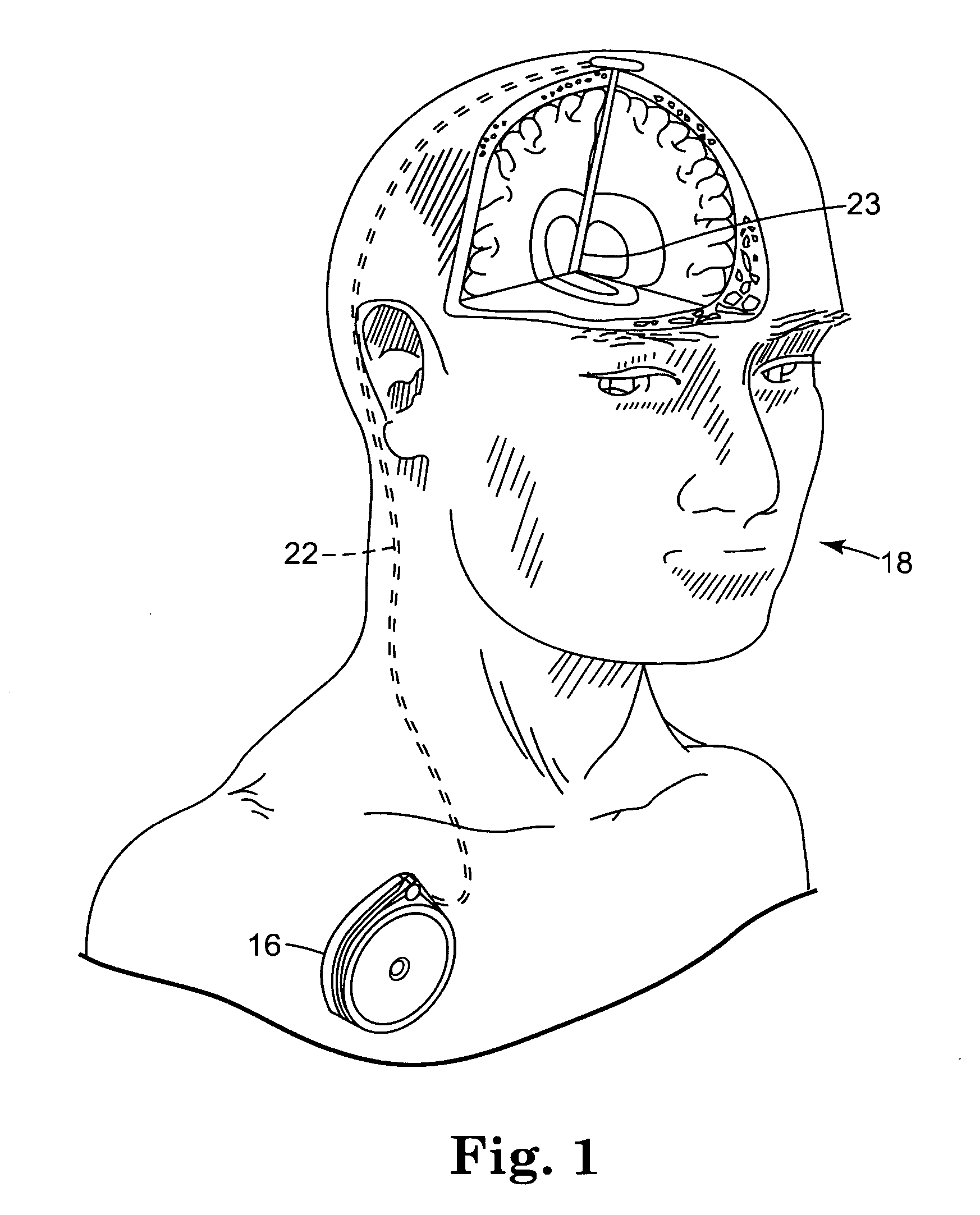

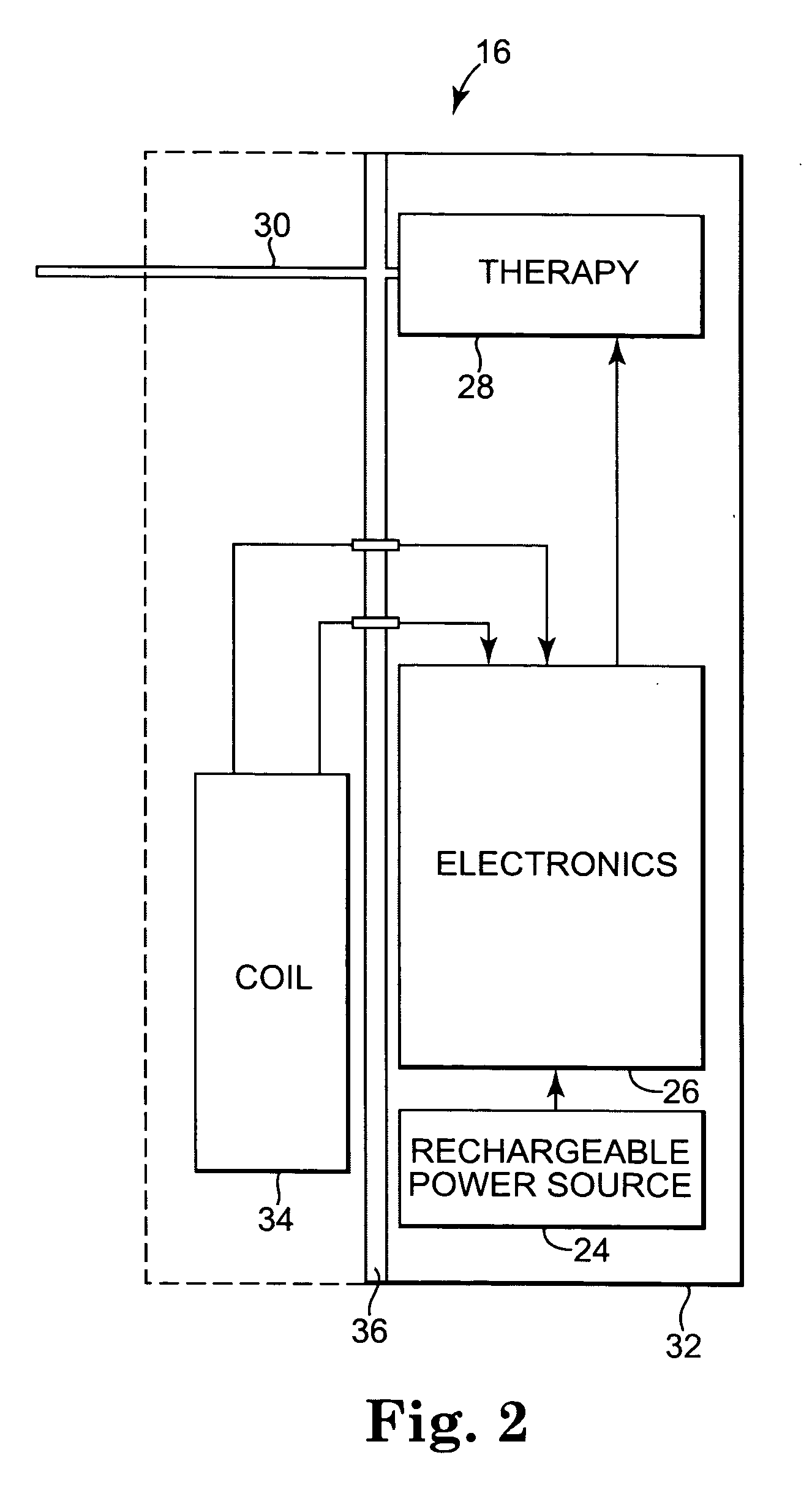

External power source, charger and system for an implantable medical device having thermal characteristics and method therefore

External power source, charger, system and method for transcutaneous energy transfer. An implantable medical device has a first housing having operational componentry for providing the therapeutic output. A secondary housing is mechanically coupled to the first housing having a secondary coil operatively coupled to the componentry, the secondary coil capable of receiving energy from the external source. A magnetically shielding material is positioned between the secondary coil and the first housing. An external power source has an external housing. A primary coil carried in the external housing, the primary coil being capable of inductively energizing the secondary coil when the housing is externally placed in proximity of the secondary coil with a first surface of the housing positioned closest to the secondary coil, the first surface of the housing being thermally conductive surface. An energy absorptive material carried within the external housing.

Owner:MEDTRONIC INC

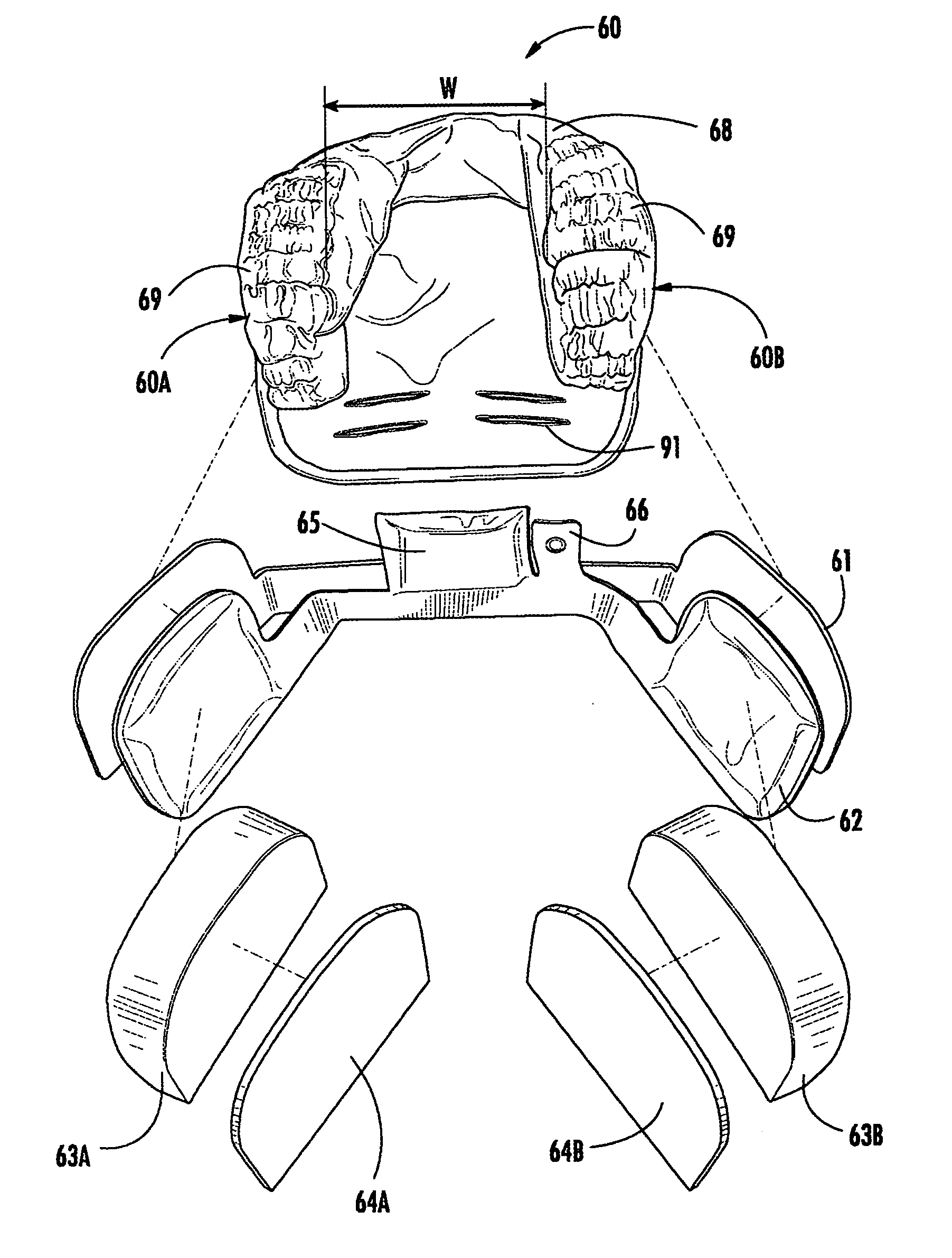

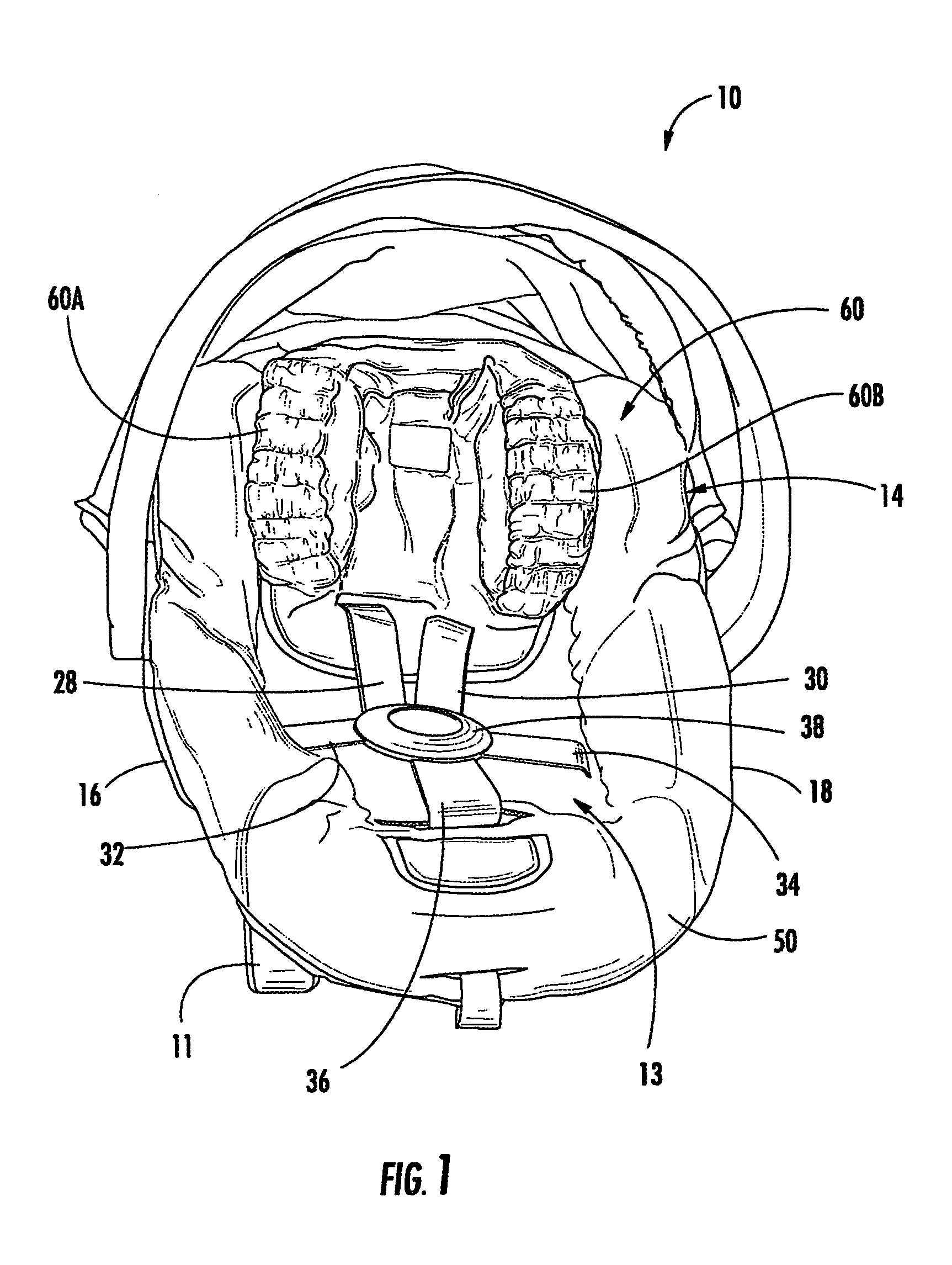

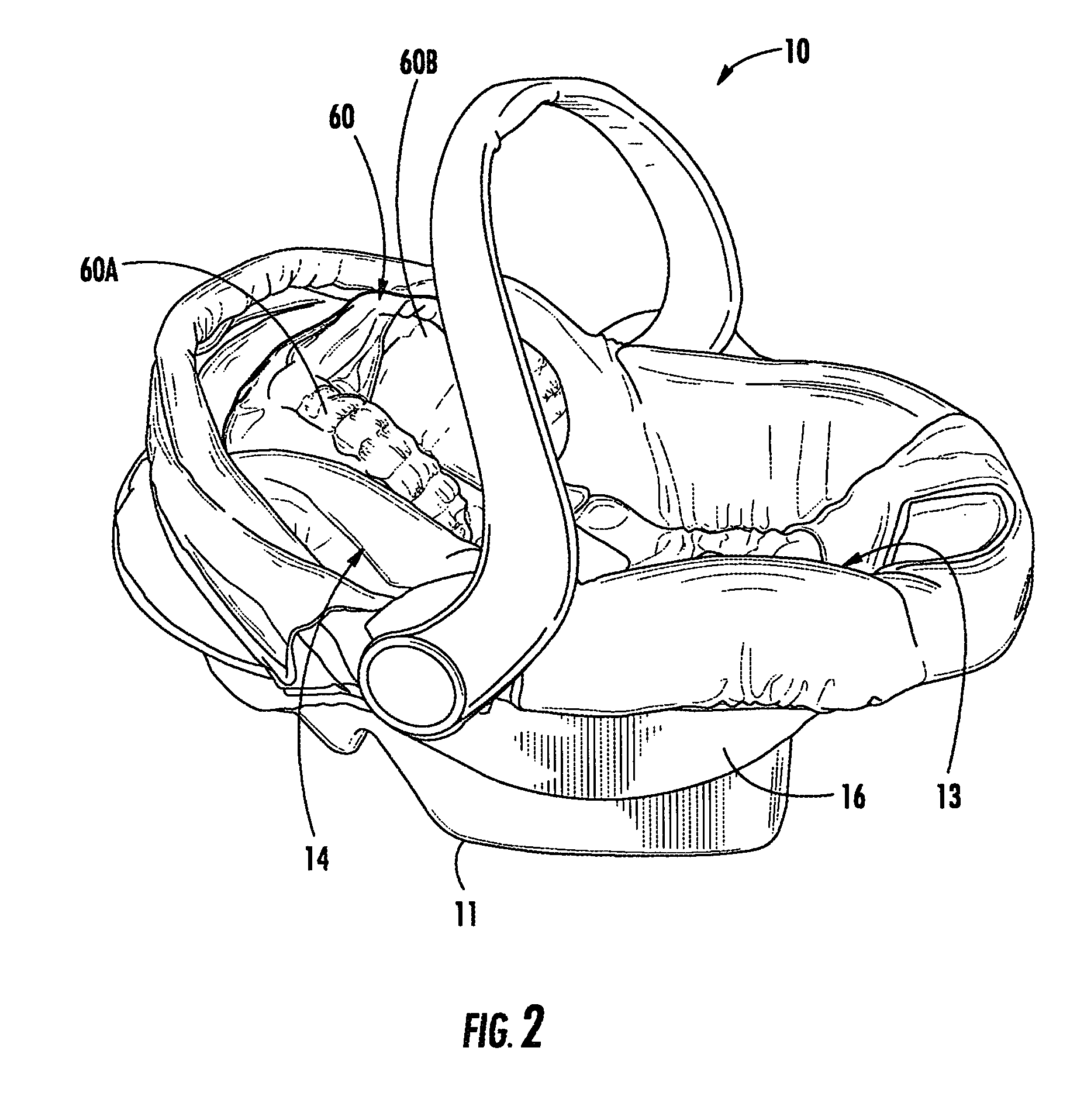

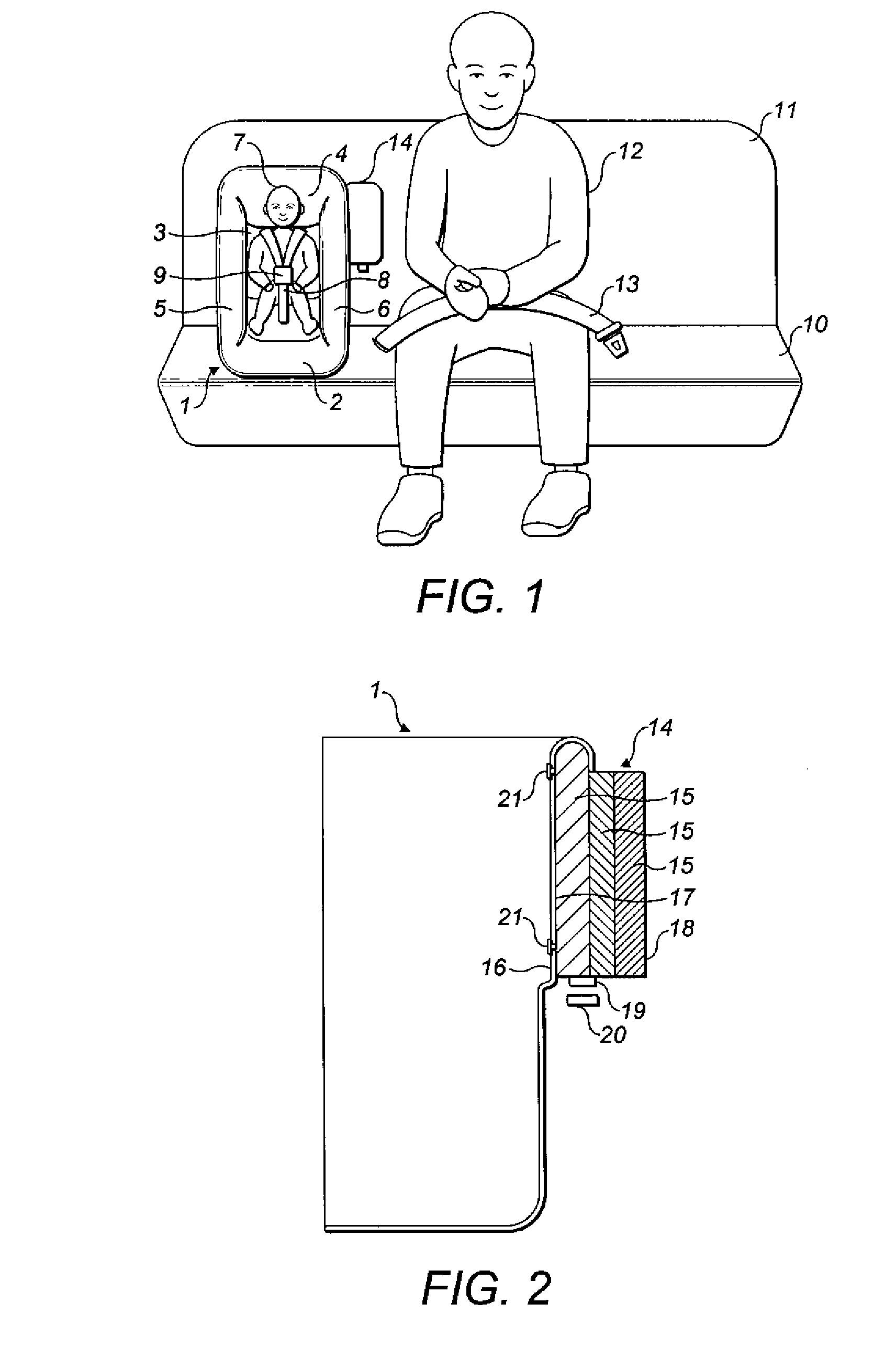

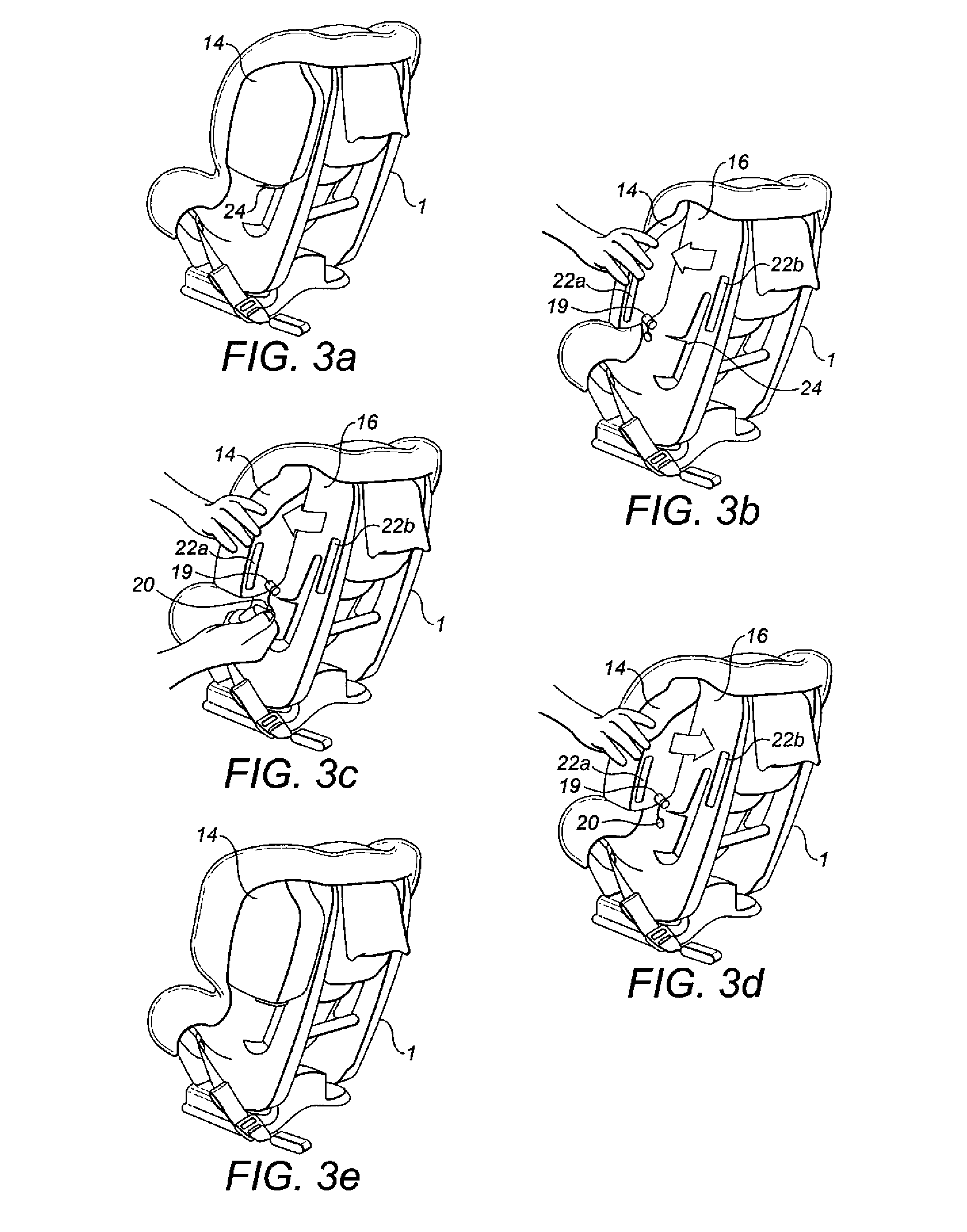

Child safety seat with adjustable head restraint

ActiveUS7234771B2Improve protectionIncrease or decrease thicknessOperating chairsSofasEnergy absorptionEngineering

A side-protective head restraint pad, pad assembly and safety seat. The restraint pad includes an air bladder with a pump for selectively inflating the air bladder and a release valve for selectively deflating the air bladder, an energy-absorbing component and a comfort component. A flexible enclosure is provided within which the air bladder, energy-absorbing component and comfort component are positioned in overlaid configuration to define a unit. The head restraint pad is adapted for being placed in a seat in lateral alignment with one side of the head of an occupant and inflatable or deflatable as appropriate to restrain the head against injurious lateral movement caused by a side impact relative to the seat.

Owner:BRITAX CHILD SAFETY

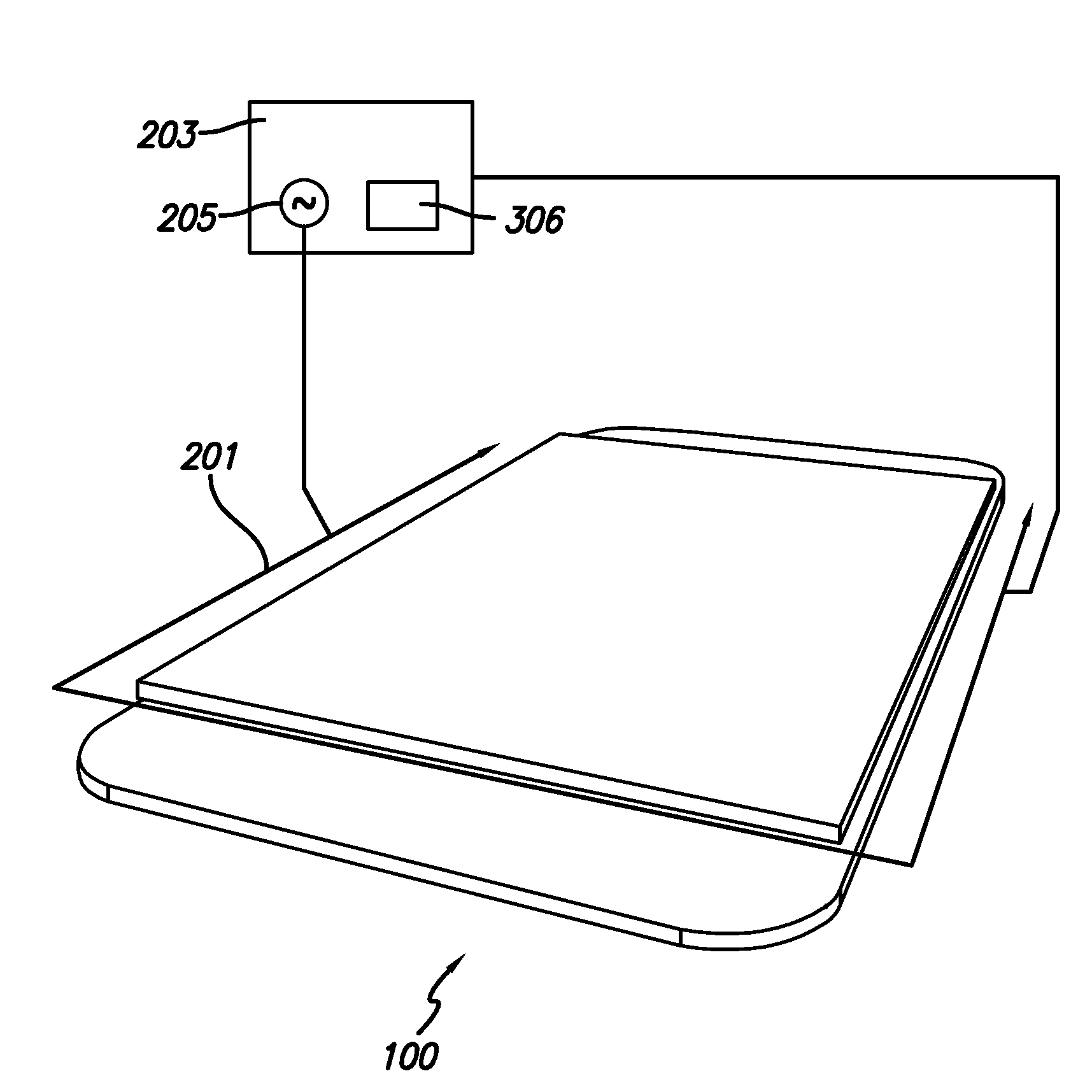

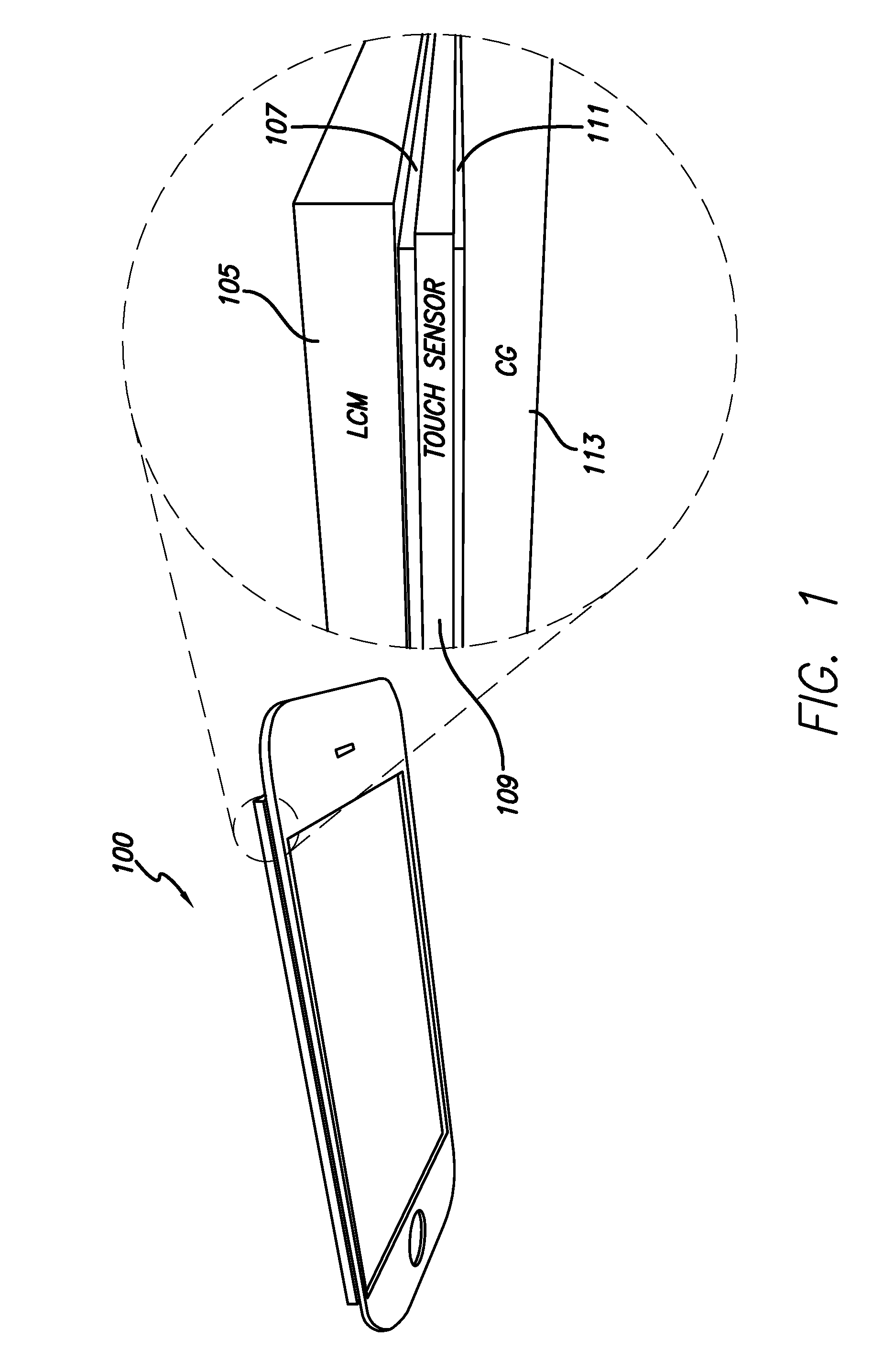

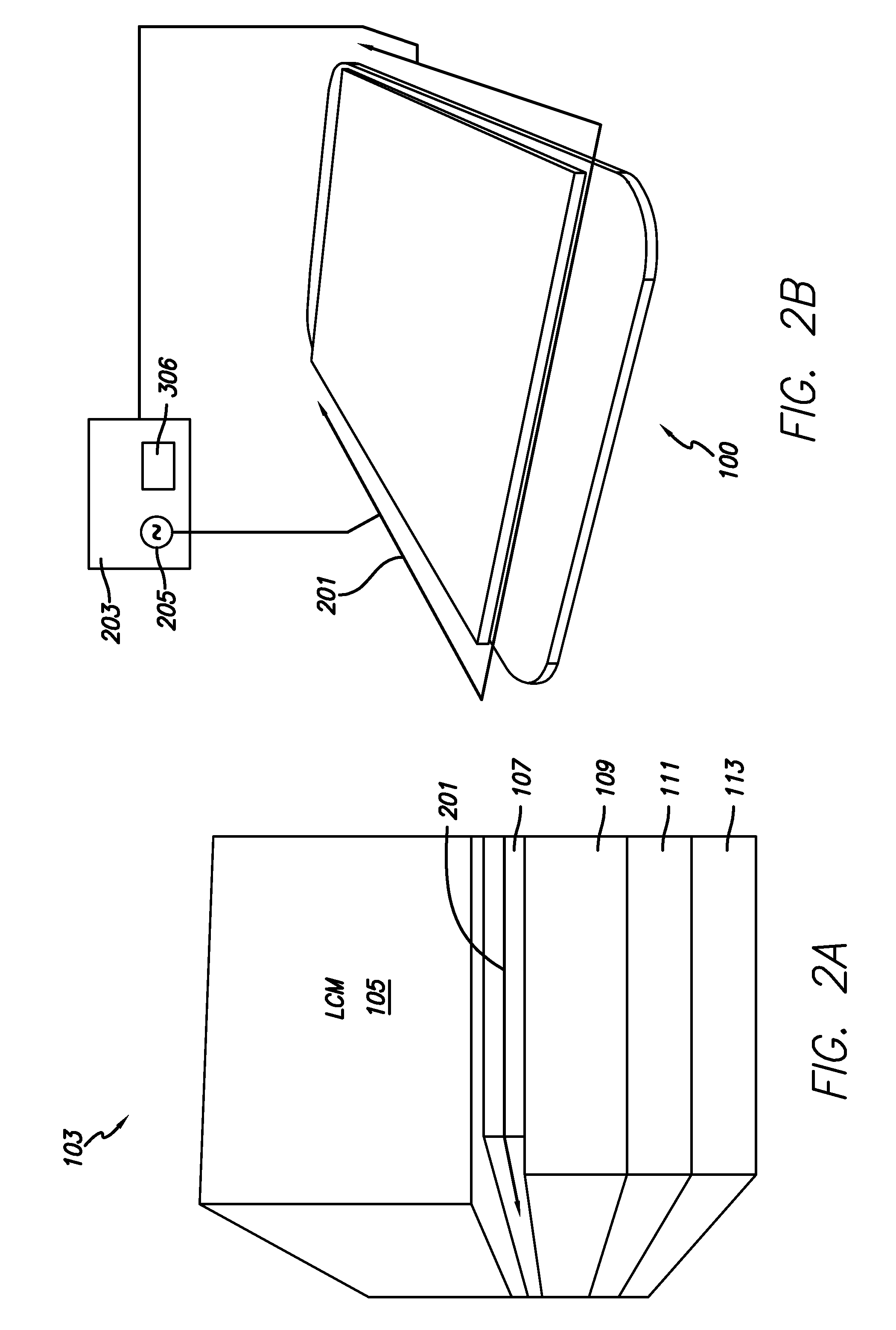

Layer-Specific Energy Distribution Delamination

InactiveUS20100154992A1Faster and efficient delamination processReduce and eliminate damageLamination ancillary operationsLayered product treatmentEnergy transferMicrowave

Delamination of a laminated multilayer stack is provided by generating a layer-specific energy distribution in the stack during delamination. A localized energy transferrer can generate localized heating, cooling heating, cooling, or other form of energy absorption or transmission, in a bonding layer of a multilayer stack. Localized energy transfer can include thermal energy transfer, such as heating and / or cooling, acoustic energy transfer, such as applying ultrasonic energy, electromagnetic energy transfer, such as applying laser light, directed microwaves, etc. Localized energy transfer can generate a layer-specific energy distribution that can weaken the bonding layer while reducing damage to other layers of the stack.

Owner:APPLE INC

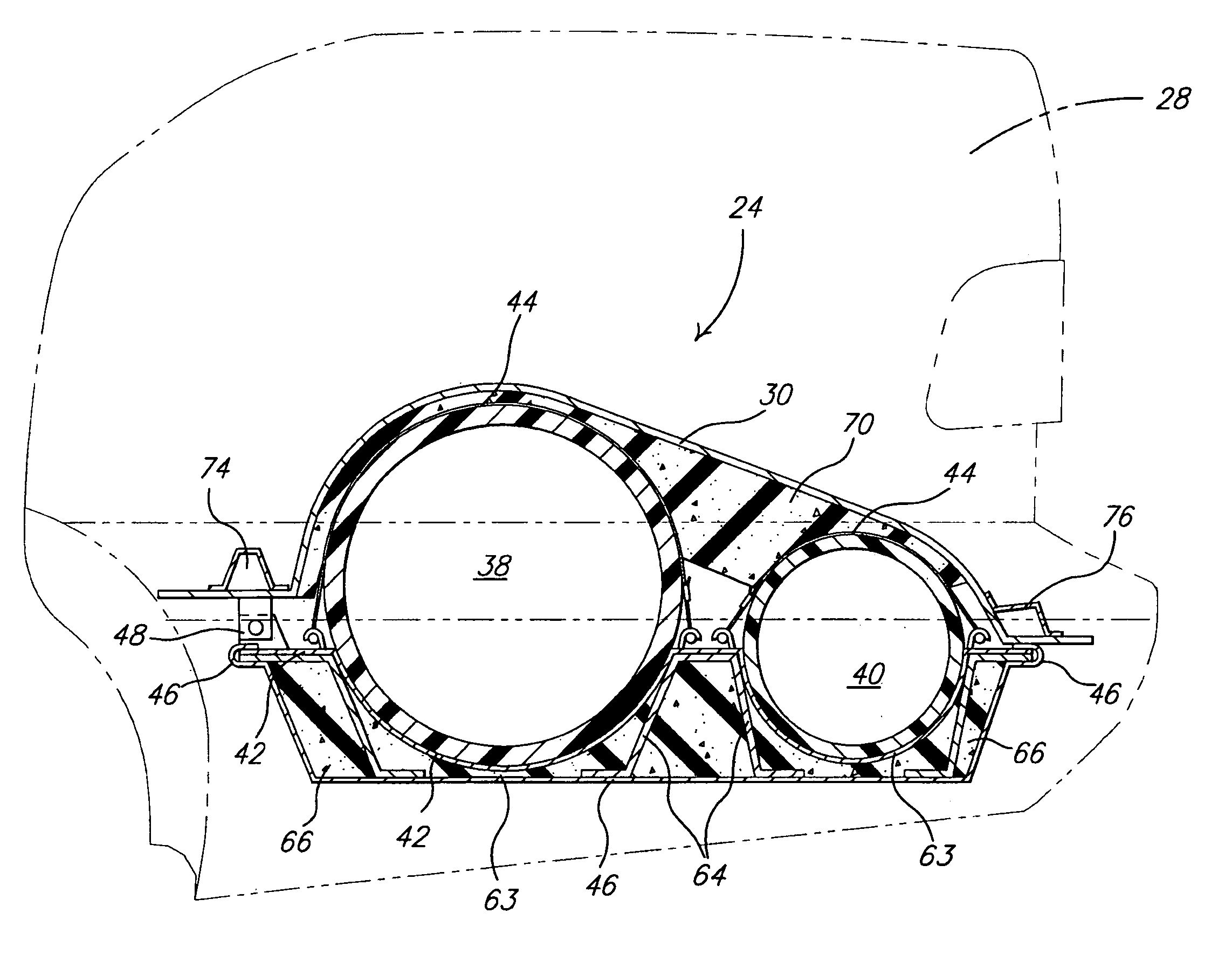

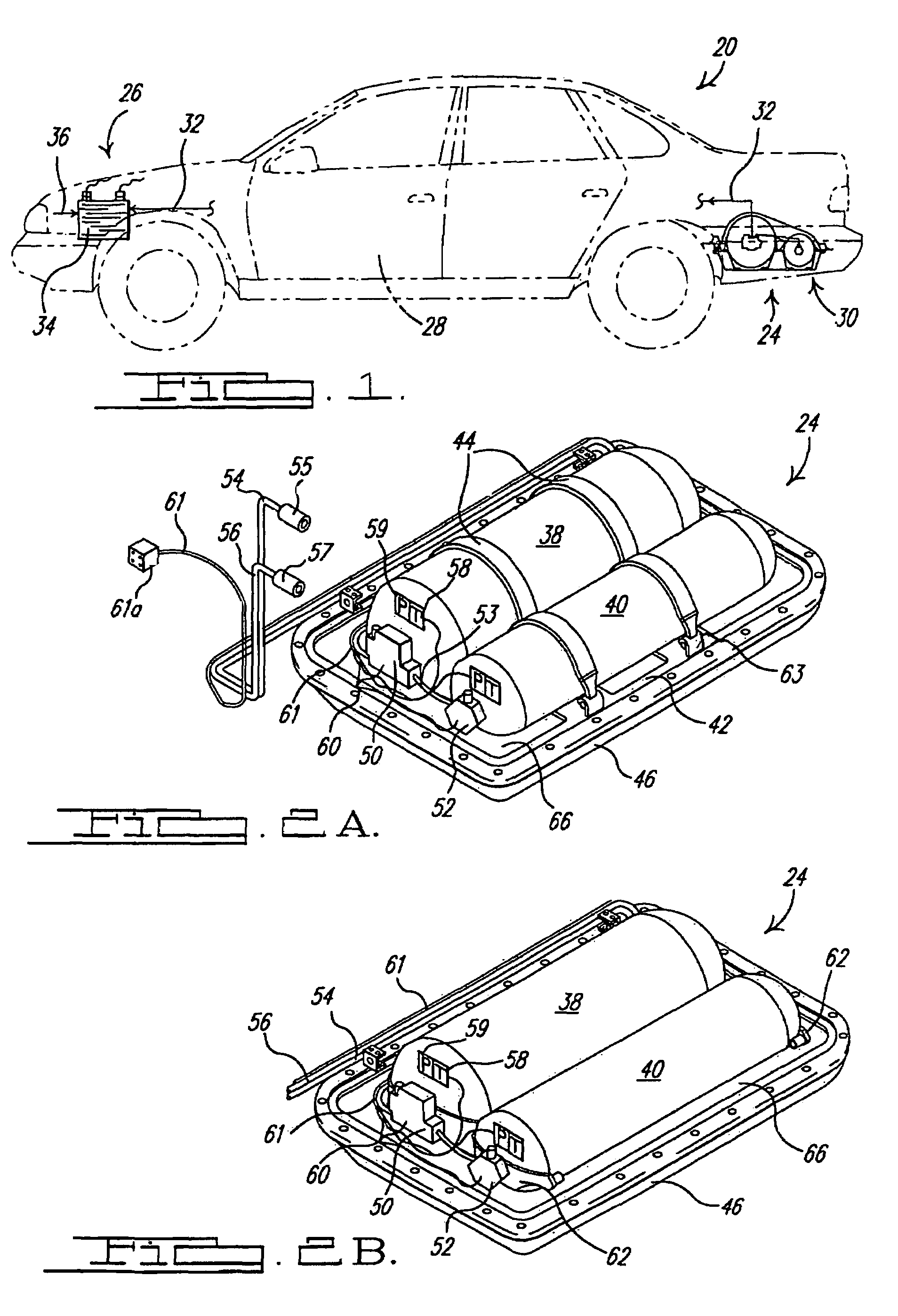

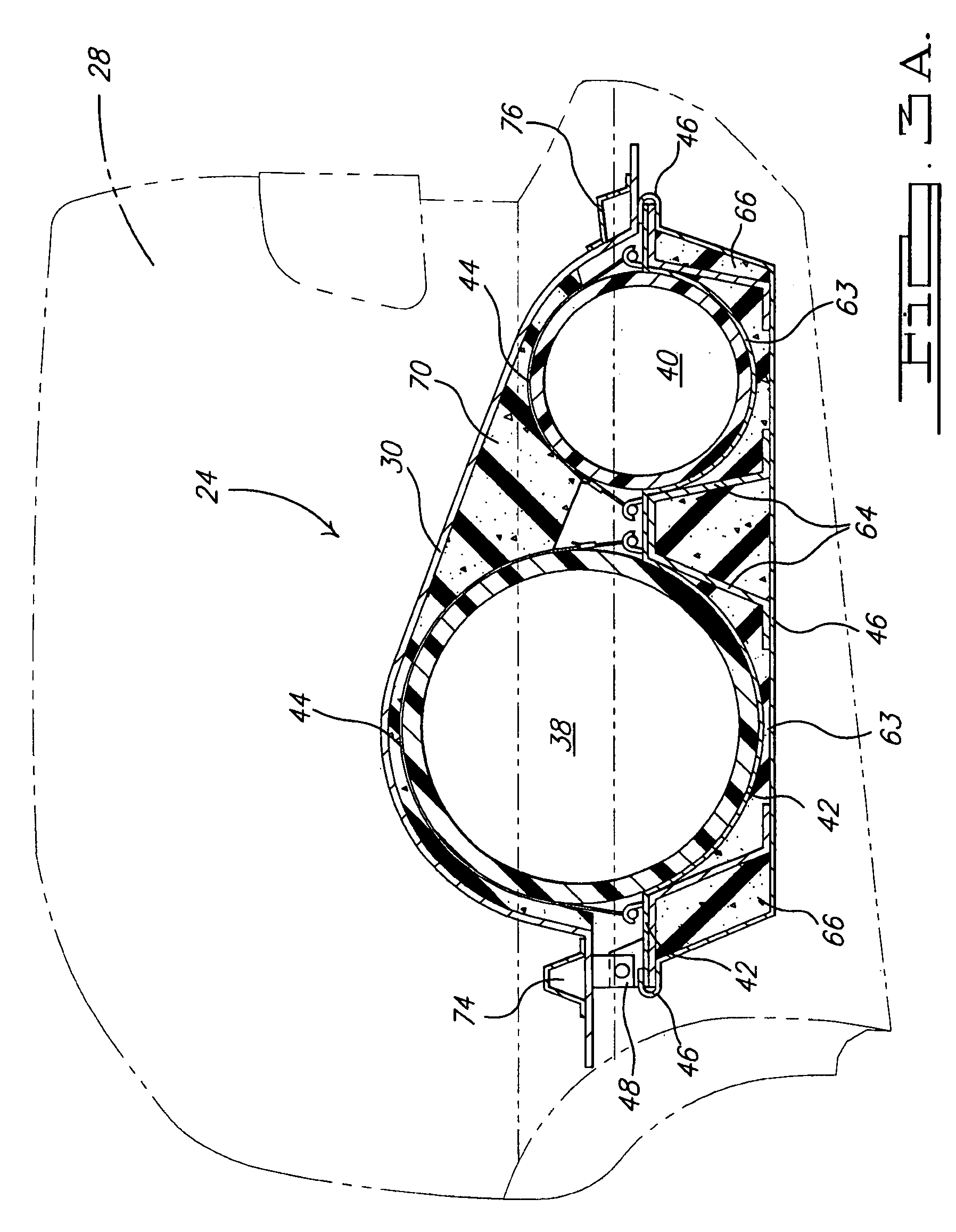

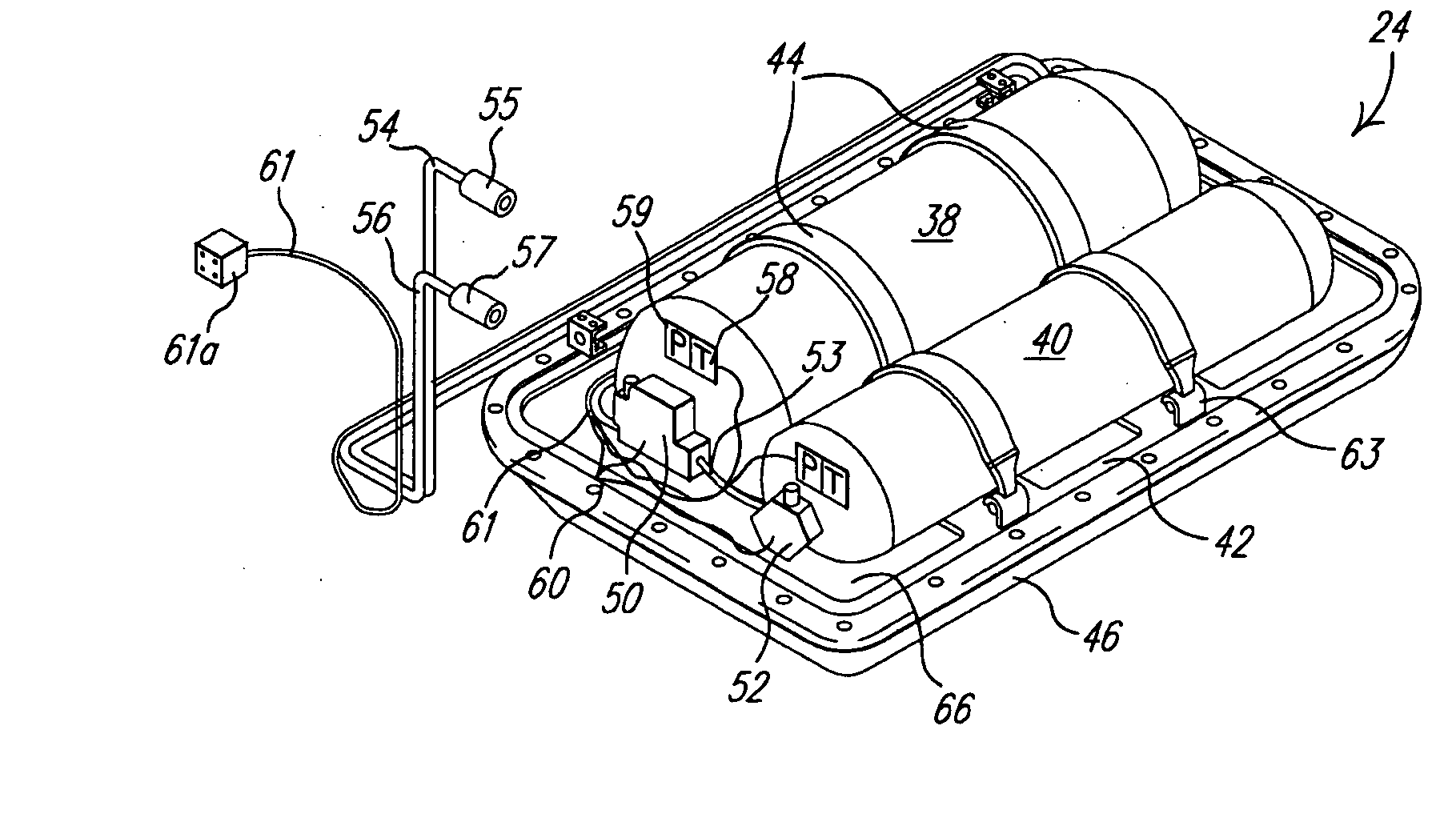

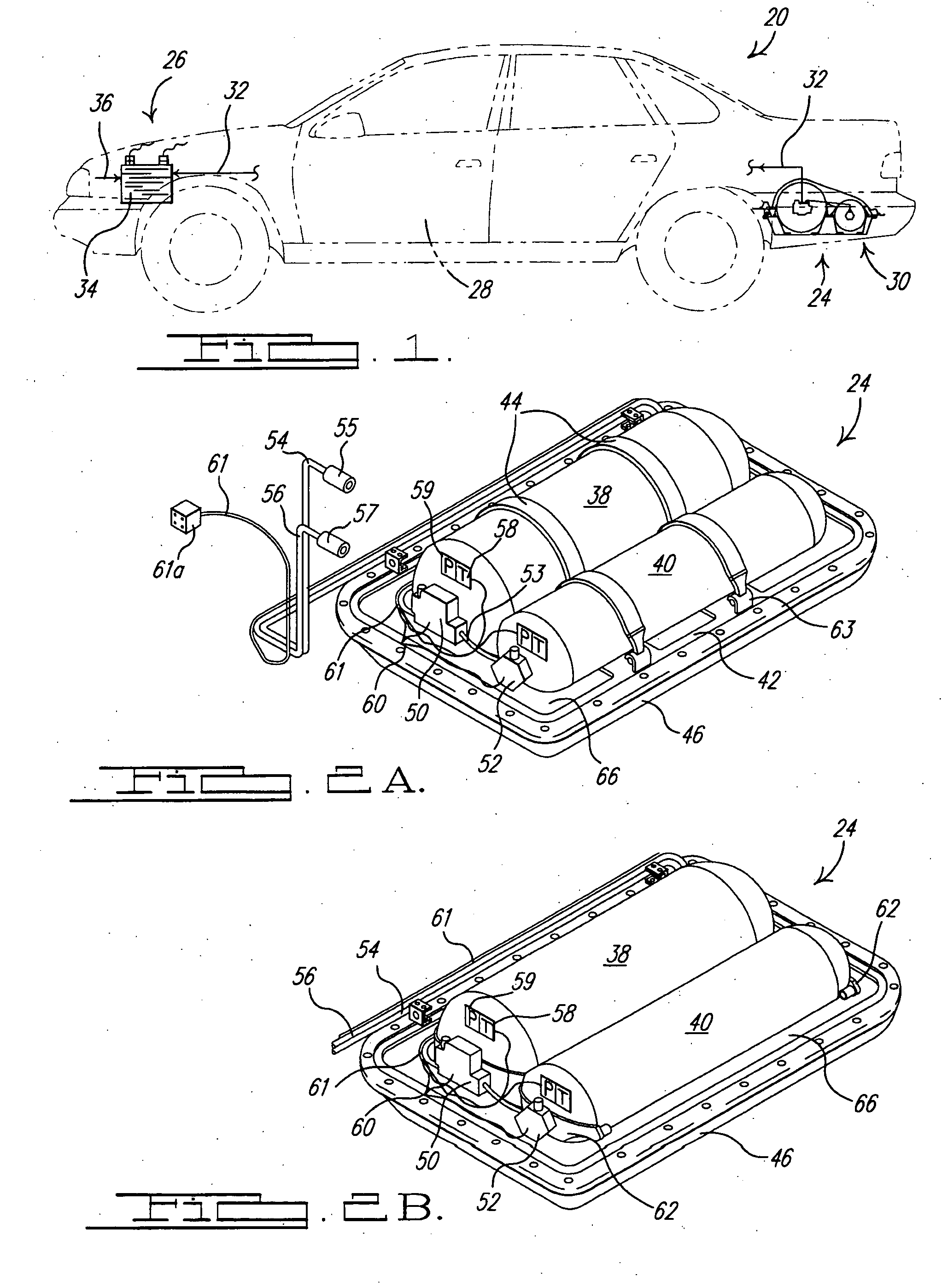

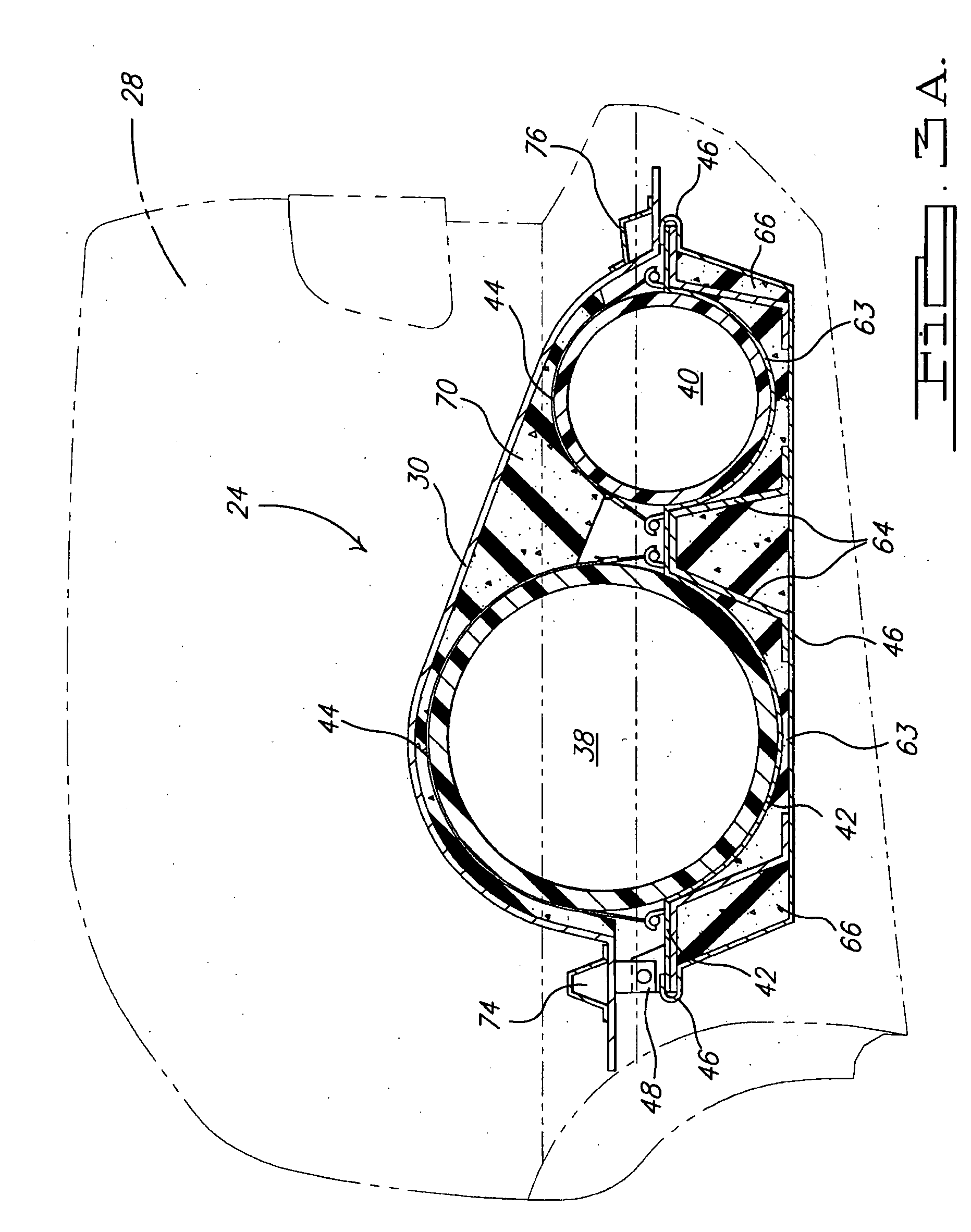

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

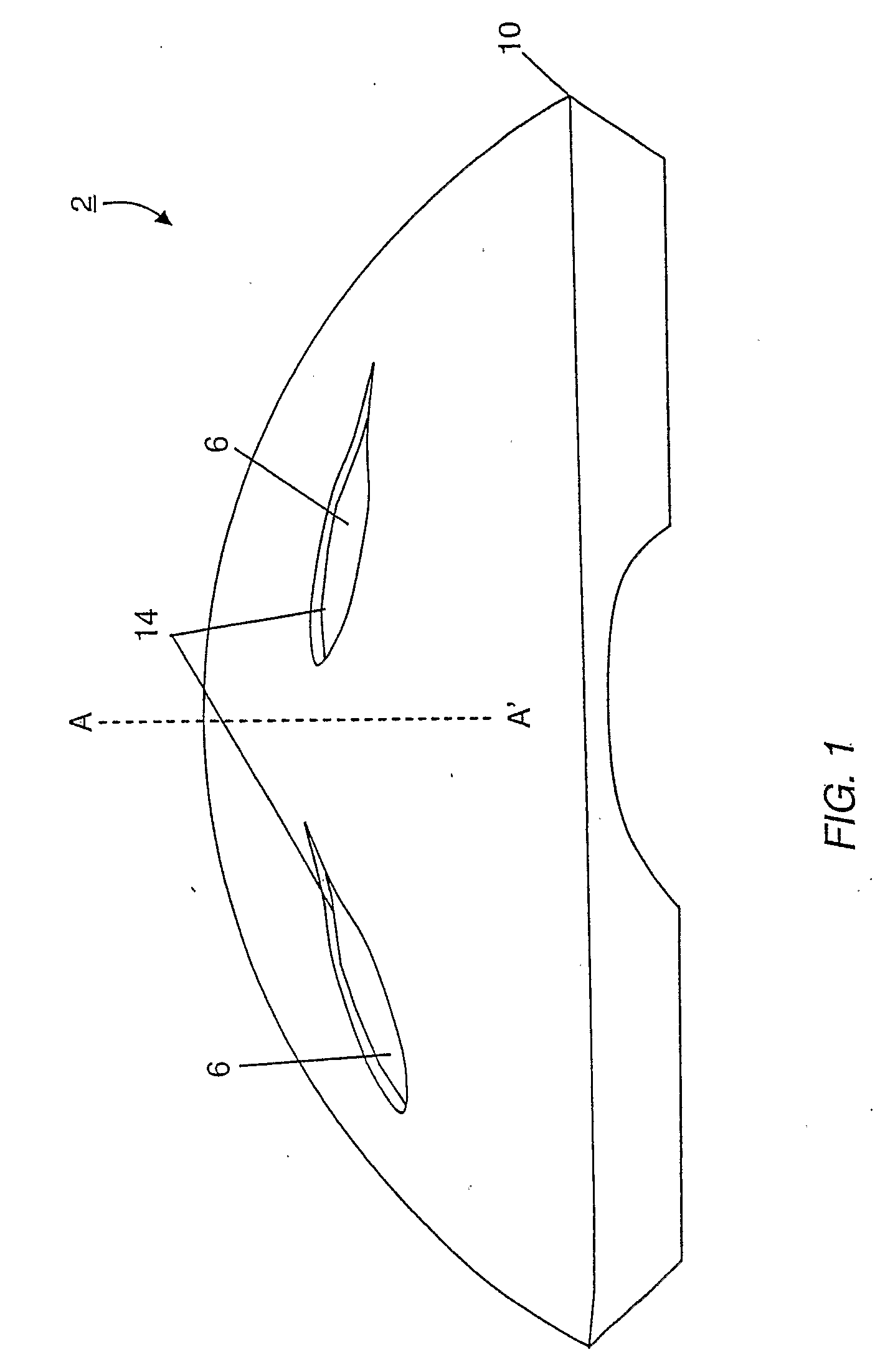

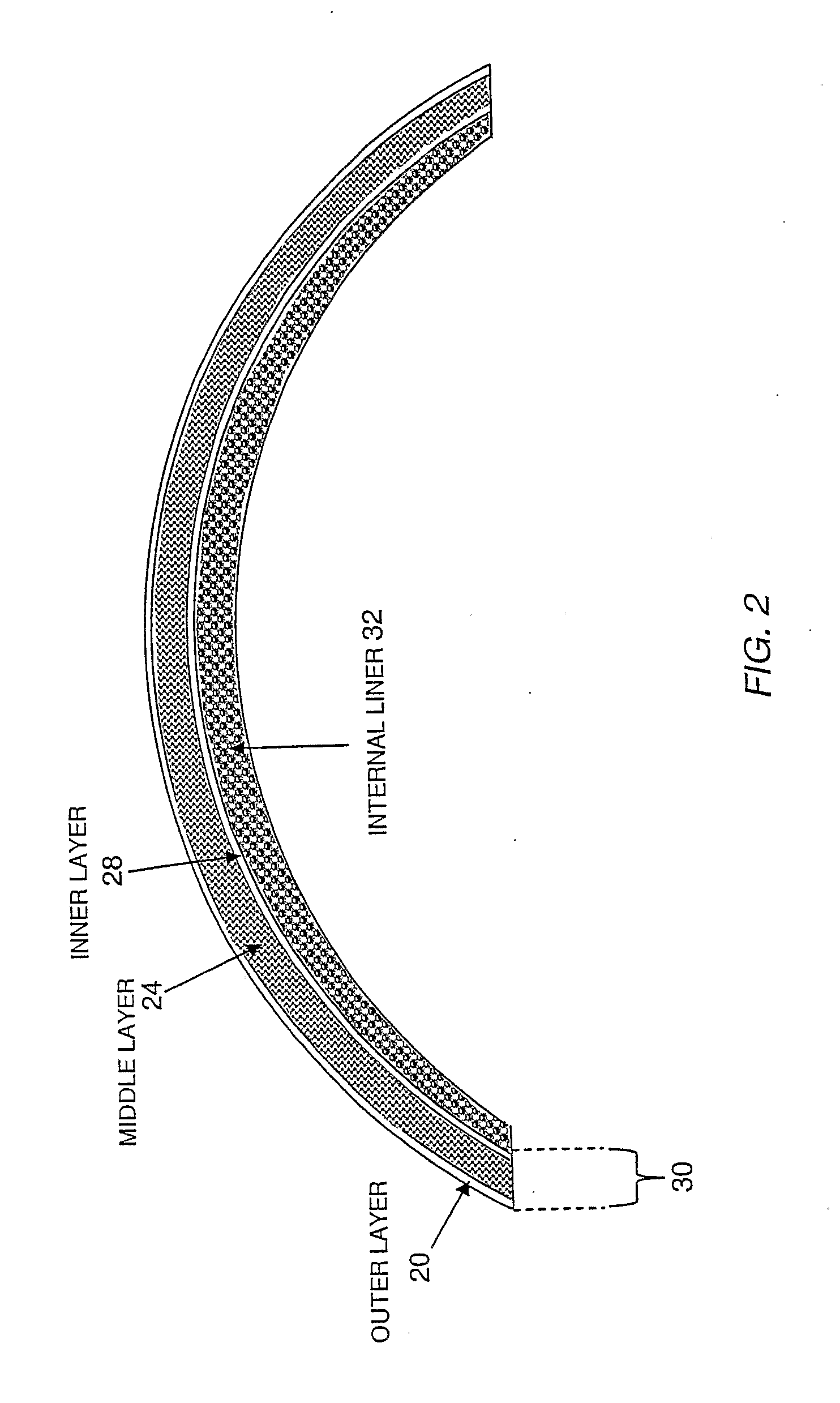

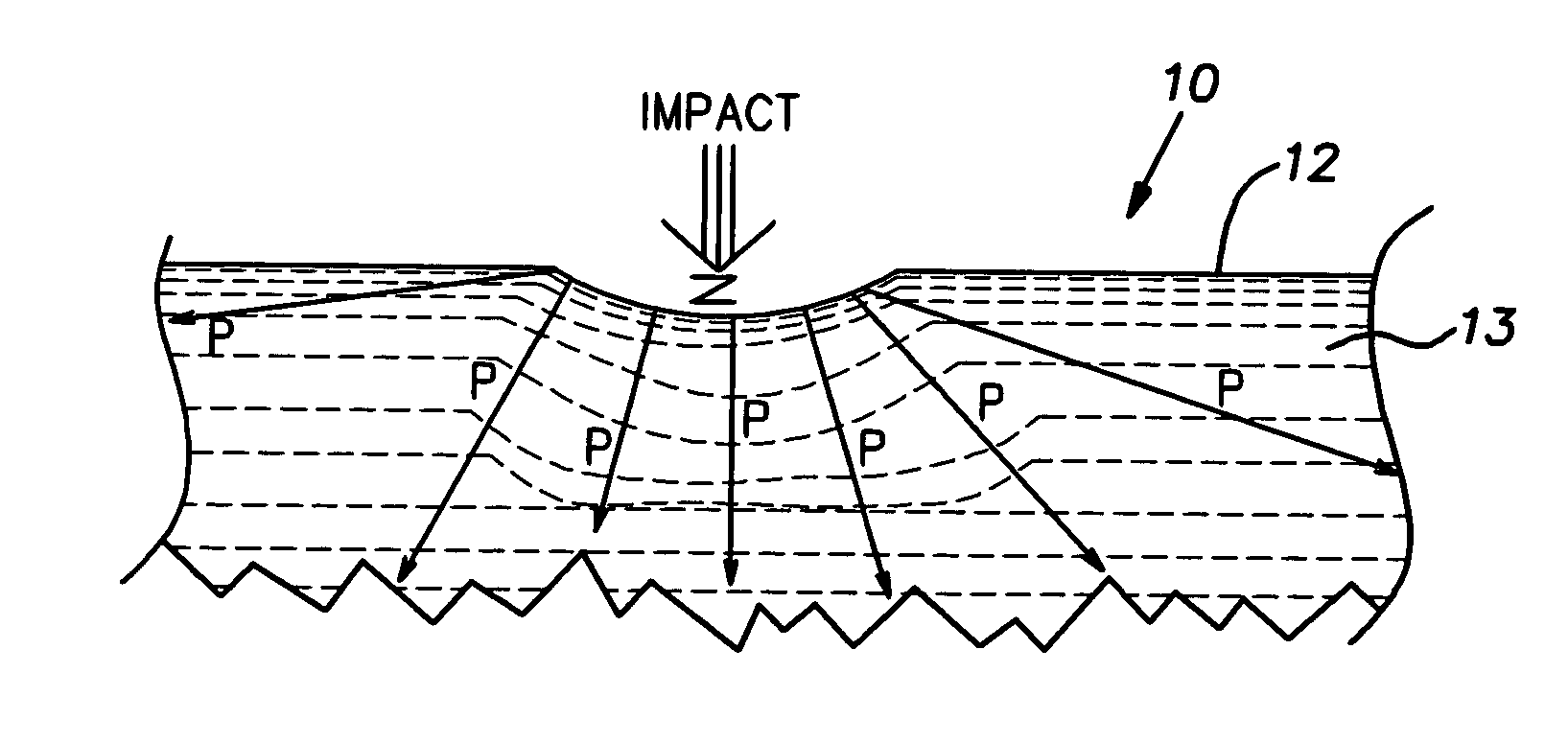

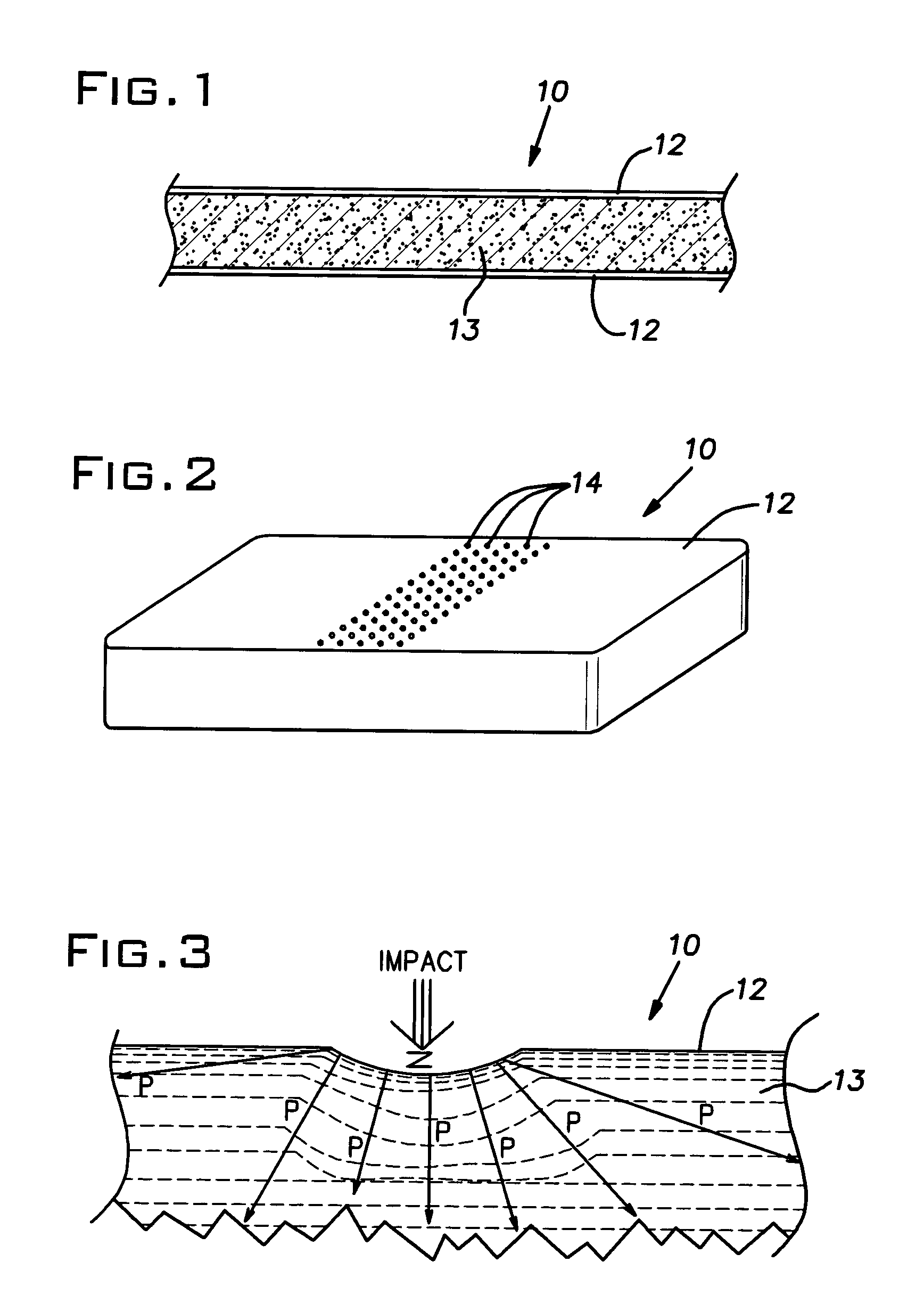

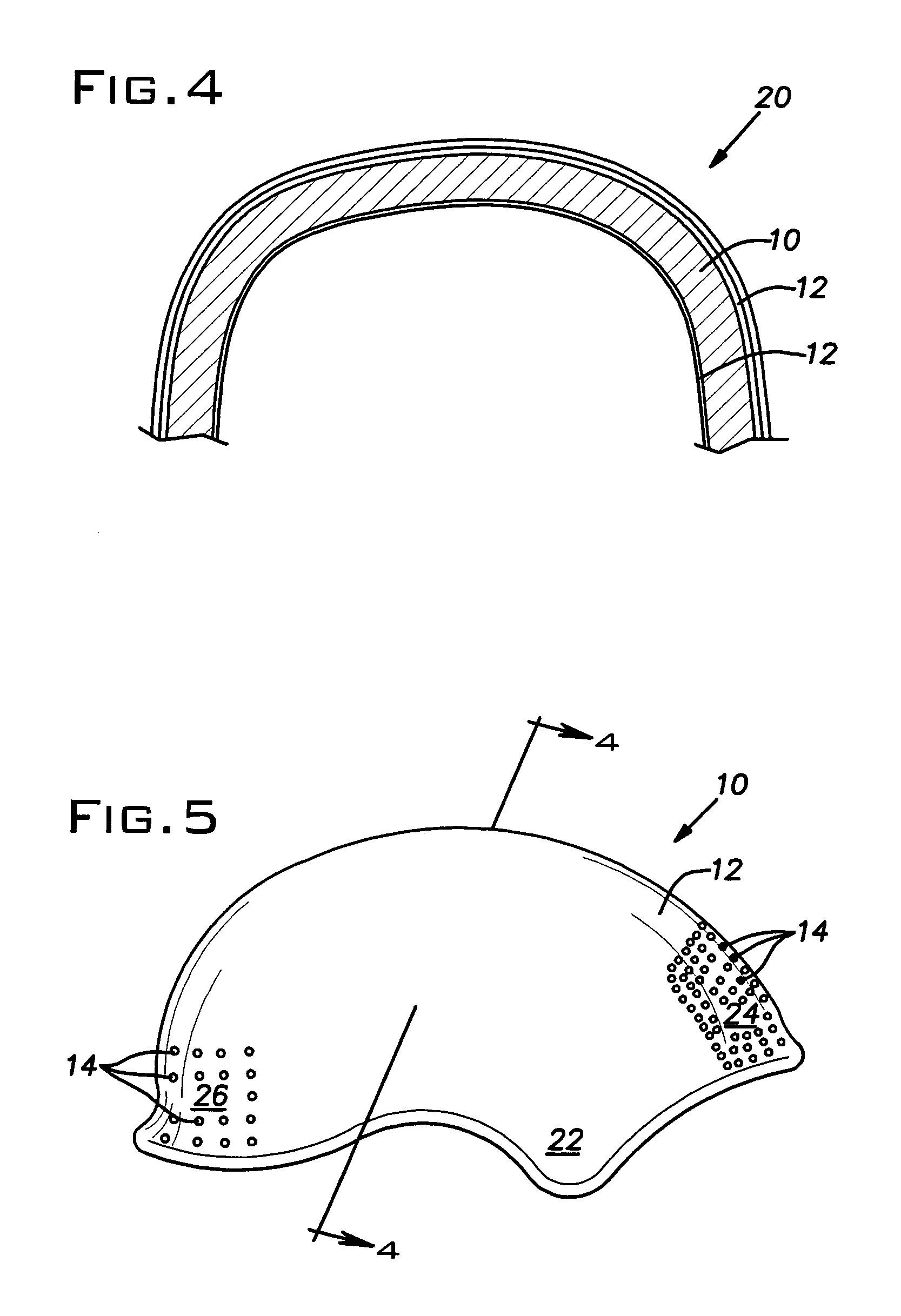

Energy-Absorbing Liners and Shape Conforming Layers for Use with Pro-Tective Headgear

InactiveUS20080155735A1Weight increaseEnhance user fit and comfortBiocideAnimal repellantsProtective headgearEnergy absorption

A multilayer shell for use in the construction of protective headgear, the shell including an outer layer, an inner layer, a middle layer disposed between the outer and inner layer which resiliently compresses in response to an impact to the outer layer, and an internal liner disposed inwardly of the inner layer. The middle layer includes a plurality of compressible members, which resiliently compress to absorb the energy of a direct impact to the outer layer and resiliently shear with respect to the inner layer in response to a tangential impact to the outer layer. The inner layer includes an open configuration, which reduces the weight of the shell, provides for greater heat ventilation from the head of the user, and permits for visualization of the compressible elements. The internal liner is formed from contourable materials which enhance user fit and comfort and reduce the weight of the protective headgear without compromising user safety.

Owner:XENITH

Protective foam with skin

A protective foam layer is provided. The protective layer has a foam substrate that is at least partially enclosed by a formed skin adjacent the outer surface of the foam substrate. The formed skin is substantially non-porous. The combination of the foam substrate with the formed skin results in a protective layer that is effective to absorb and / or dissipate impact force for both high- and low-speed impacts that can be experienced during a sporting event such as cycling. The formed skin can also be provided with a plurality of protective zones having vent holes through the formed skin to regulate the degree of energy absorption in the respective zones. In this manner, a single continuous protective foam layer can be provided having multiple protective zones having distinct energy absorption characteristics instead of providing discrete protective layers that must be joined or meet at a seam. According to the invention, by providing such a continuous protective layer with no such seams, a known failure mode in protective equipment is eliminated.

Owner:TEAM WENDY

Energy absorbing assembly and methods for operating the same

An energy absorbing assembly includes a covering; and a shape memory material in operative communication with the covering, wherein the shape memory material has a first shape attached to an underside of the covering and is operative to change to a second shape in response to an activation signal. The second shape of the shape memory material can cause the covering to expand or expand and detach from a surrounding surface medium. The energy absorbing assembly is used to absorb kinetic energy of an object impacting the assembly. Methods of operating the assembly are also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and Apparatus for Disinfecting or Sterilizing a Root Canal System Using Lasers Targeting Water

InactiveUS20090130622A1Sufficient deliveryEnhanced light absorptionSurgical instrument detailsDental toolsDiseaseEnergy absorption

Method and apparatus for disinfecting and / or sterilizing a root canal system by targeting the water content of disease and debris in the canals. The laser technique of employs a frequency of the wavelength emissions between about 930 to about 1065 nanometers with an optimum of 980 nm. This range of wavelengths targets the water content of tissue cells and pathogens as well as any residual organic debris in water within the root canal system after its preparation while being poorly absorbed by the surrounding dentin. The selection of the optimum wavelength produces significant effects generating and advancing treatment to the targeted aqueous environments. This is due to the rapid energy absorption by the water and the subsequent creation of gas bubbles, liberation of heat and subsequent propulsion of waves of heat and gas that impact along the canal walls and ramifications resulting in an enhanced bacterial kill and cleaning of the canal walls and ramifications. No dyes or other additives are necessary to enhance the effectiveness of the laser kill of bacteria, etc.

Owner:BOLLINGER JAMES EDWIN +2

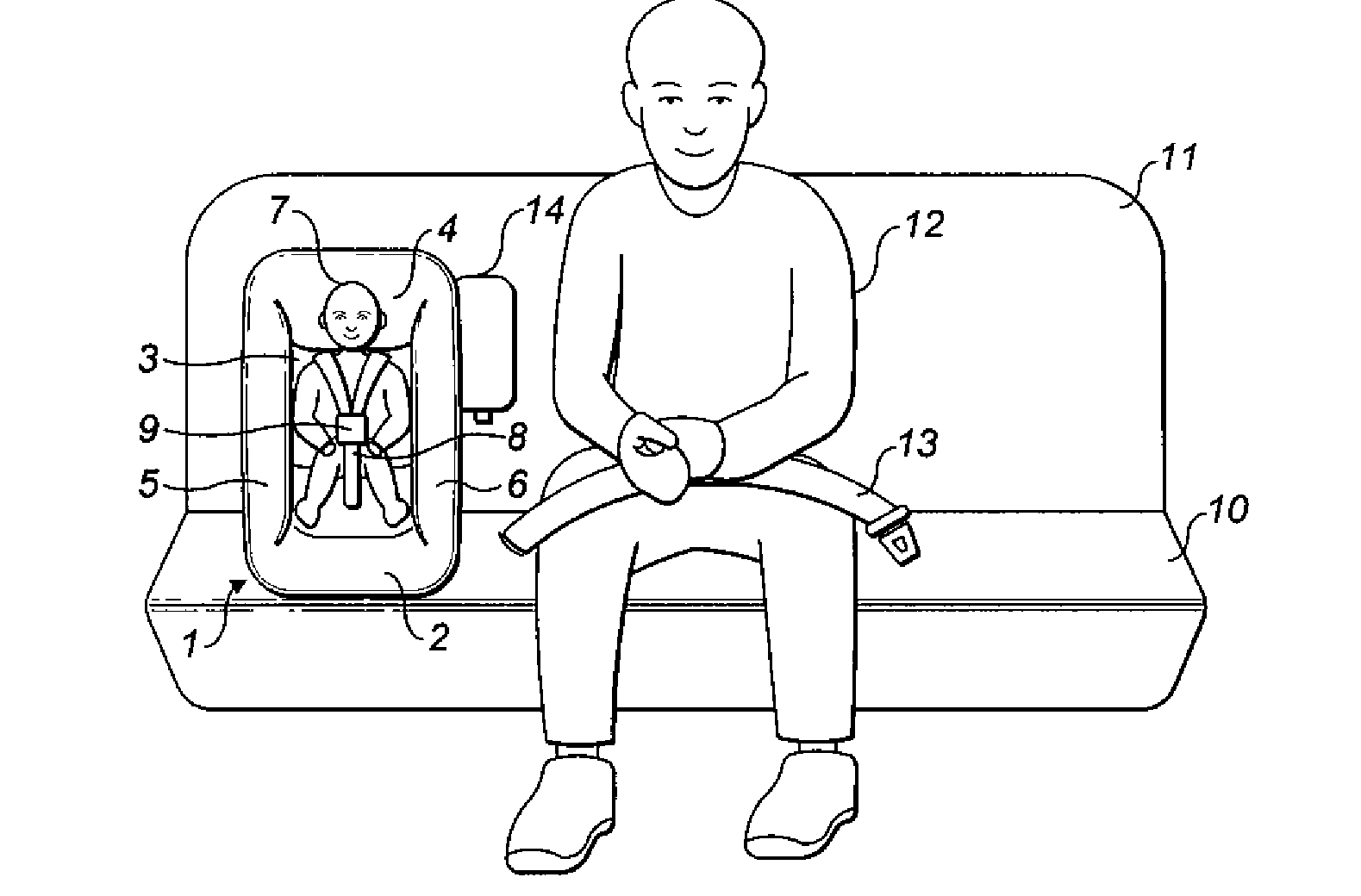

Child restraint apparatus for vehicle

ActiveUS20090152913A1Reduce the likelihood of injuryCushion the impactVehicle seatsPedestrian/occupant safety arrangementEnergy absorptionEngineering

A child restraint apparatus relates to holding a child within a vehicle interior. The apparatus has a body with an internal area for receiving a child. An energy absorbing member extends in use over at least part of an external surface of the body. This energy absorbing member faces away from the internal area.

Owner:BRITAX CHILD SAFETY

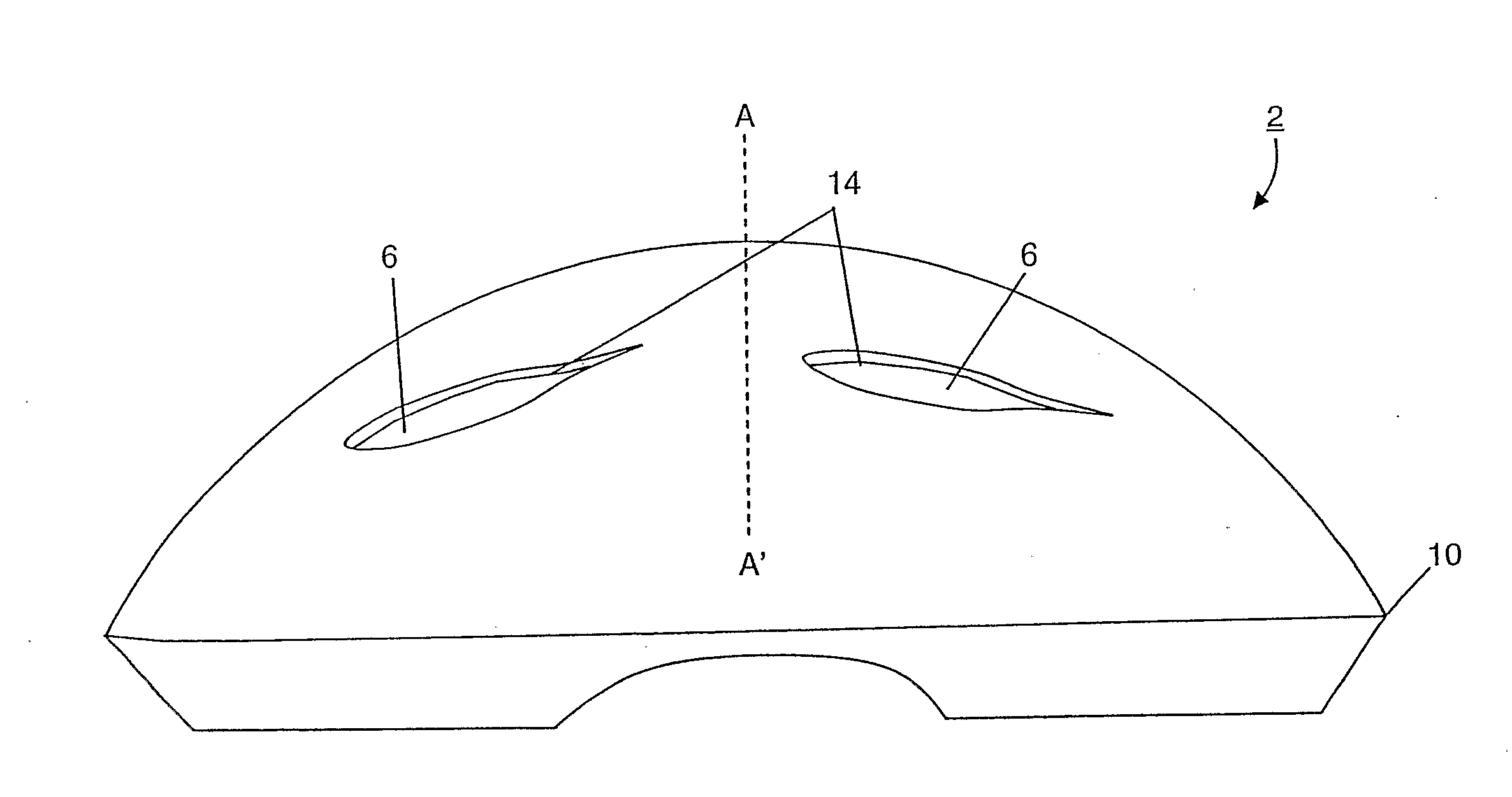

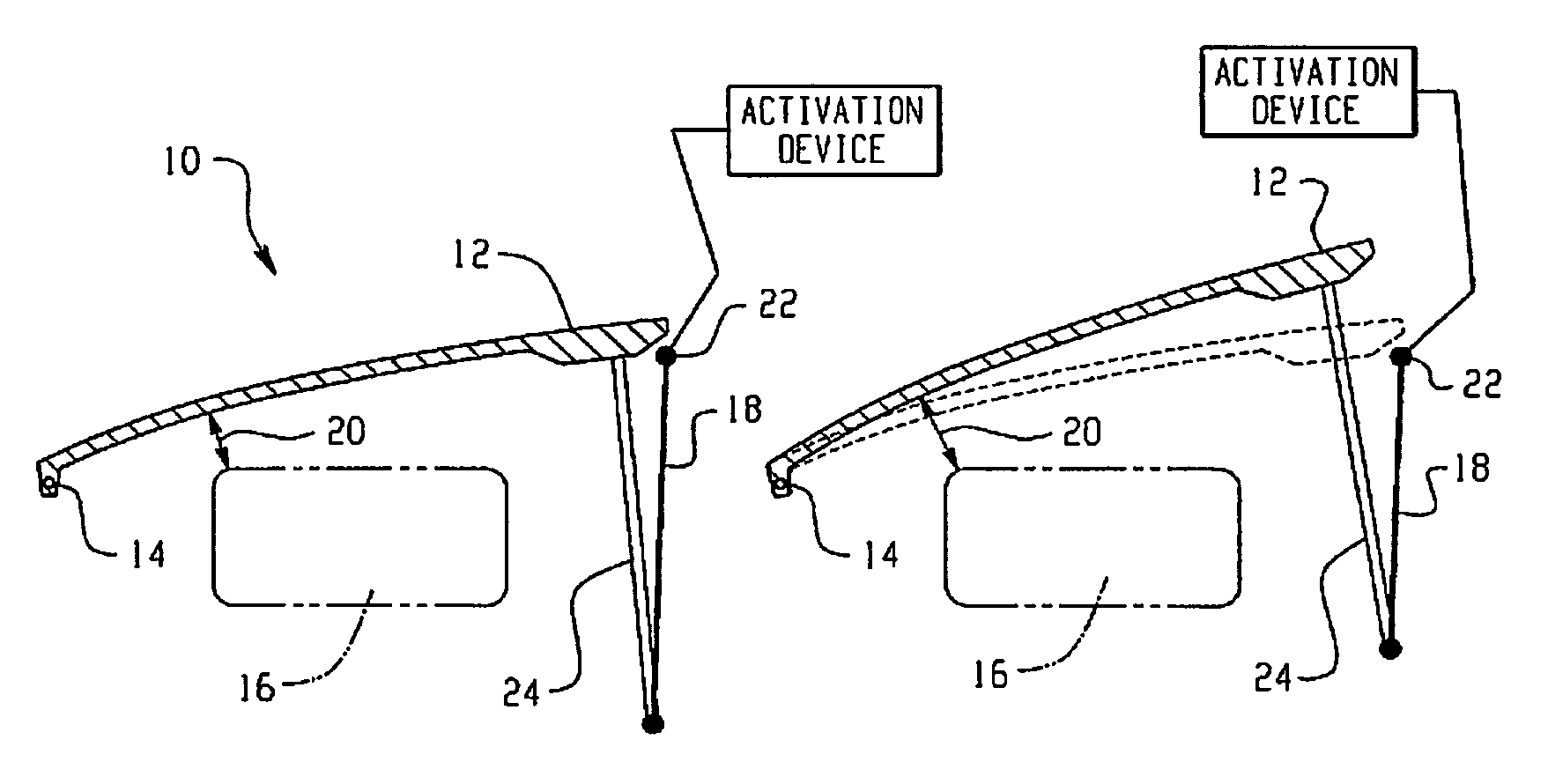

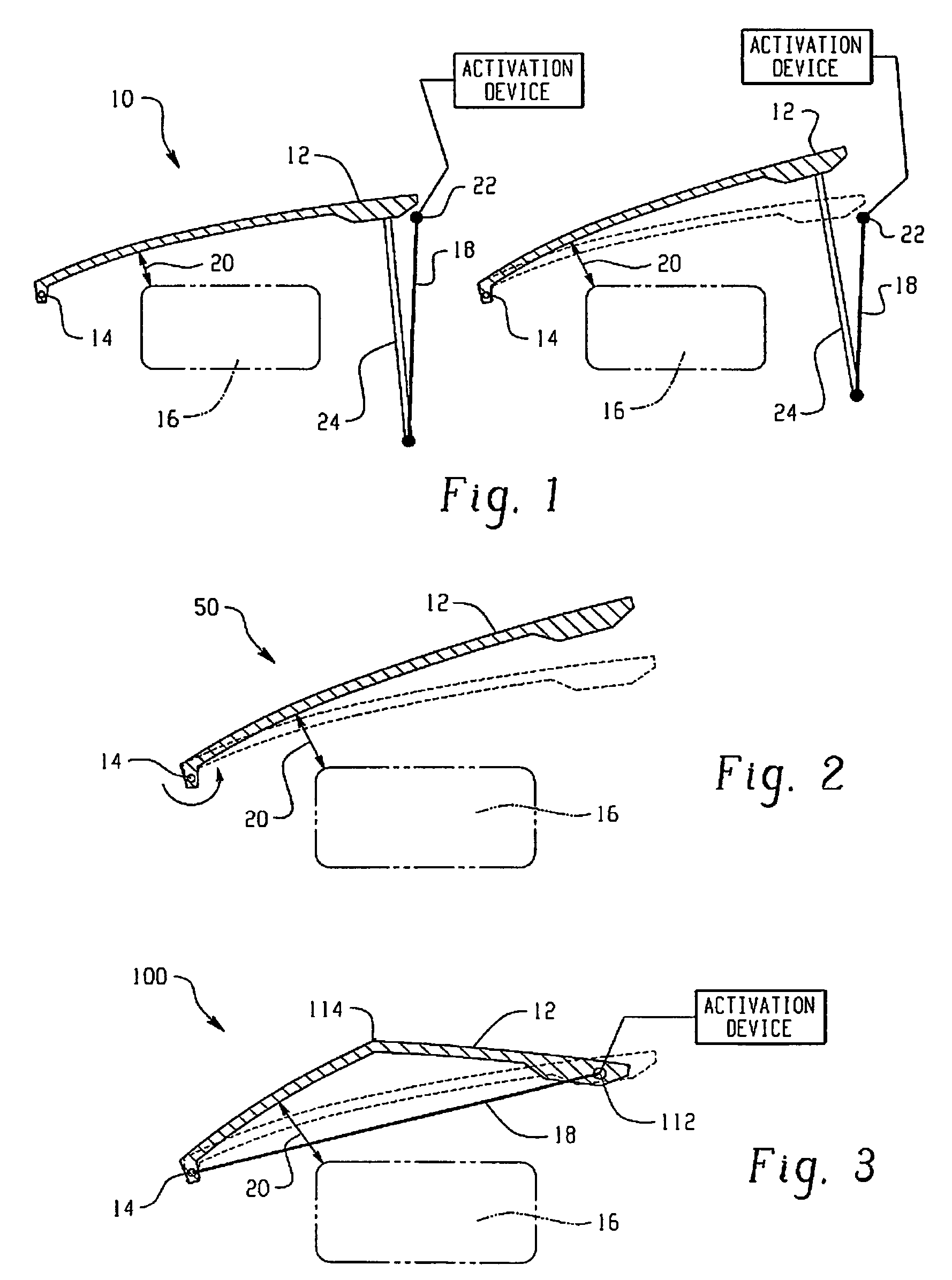

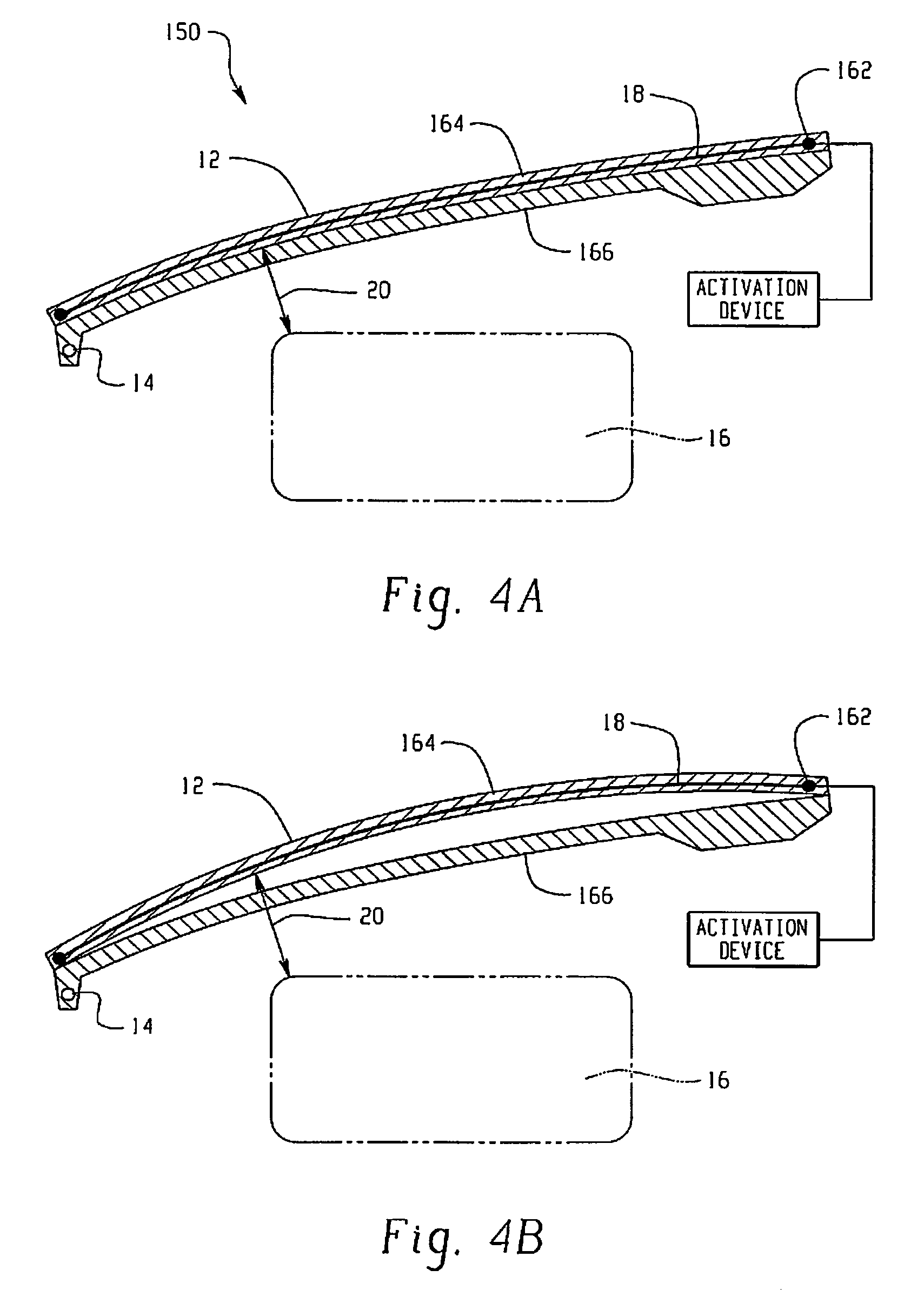

Hood lift mechanisms utilizing active materials and methods of use

InactiveUS7063377B2Clearance distanceIncrease distanceVehicle seatsSuperstructure subunitsIonic polymer–metal compositesEnergy absorption

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for preparation of metallic and ceramic foam products and products made

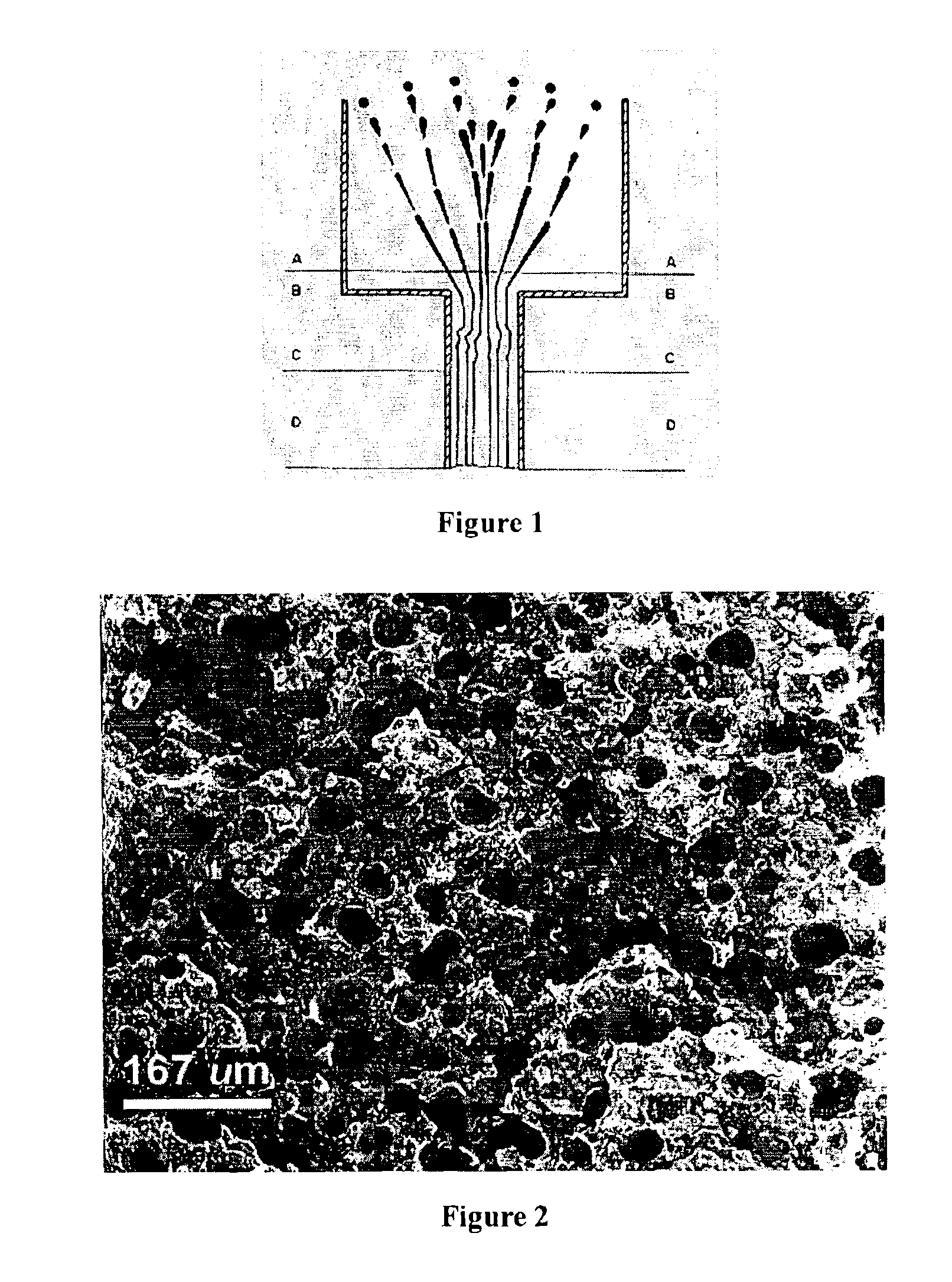

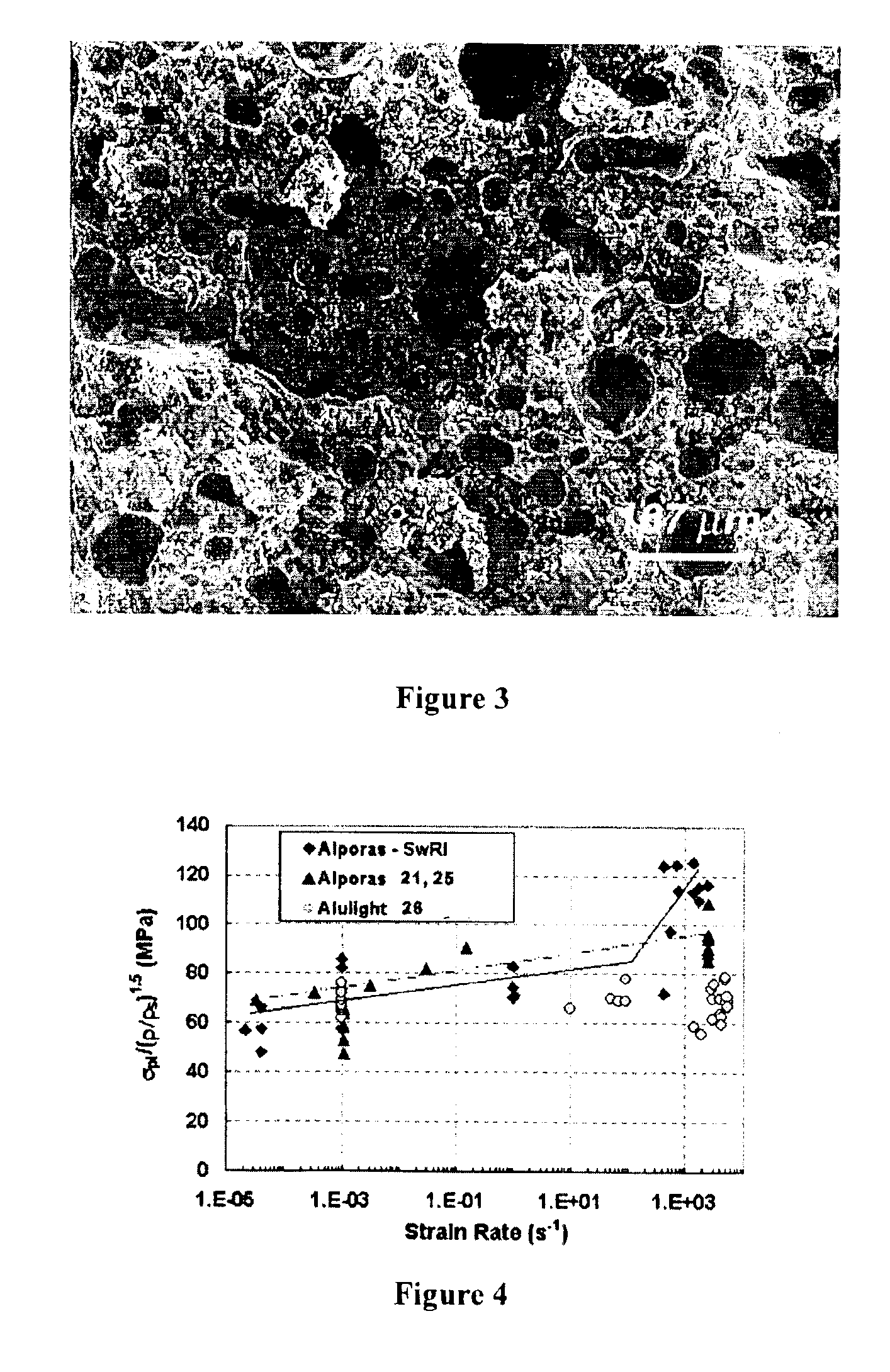

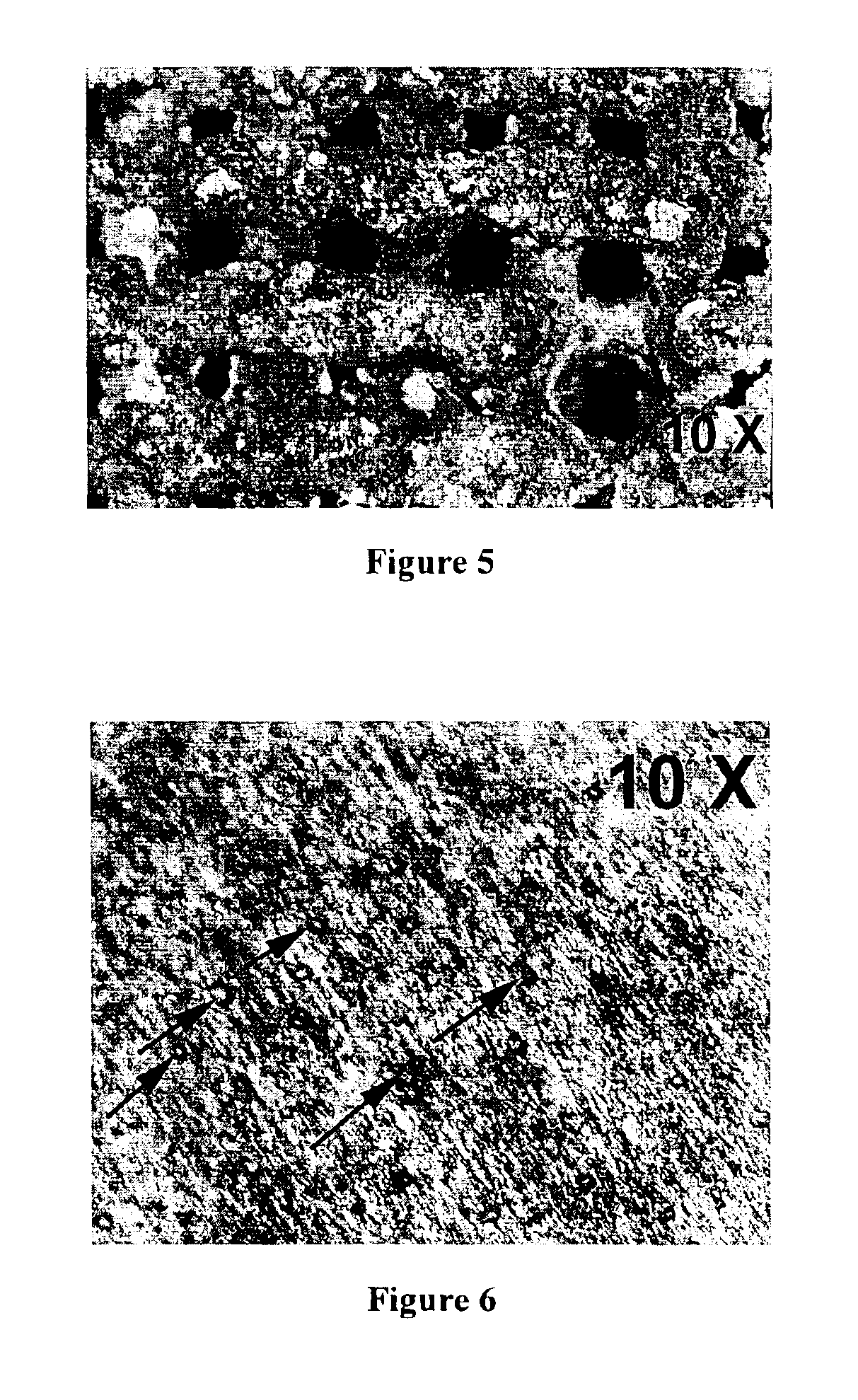

InactiveUS6852272B2Efficient and cost-effectiveImprove mechanical propertiesAdditive manufacturing apparatusTransportation and packagingEnergy absorptionMechanical property

The present invention relates to the fabrication of low cost, in situ, porous metallic, ceramic and cermet foam structures having improved mechanical properties such as energy absorption and specific stiffness. Methods of fabricating the structures from compositions including ceramic and / or metallic powders are provided. The flowable compositions also include an immiscible phase that results in pores within the final structure. Furthermore, the structures may be shaped to have external porosity, such as with mesh-like structures.

Owner:ADVANCED CERAMICS

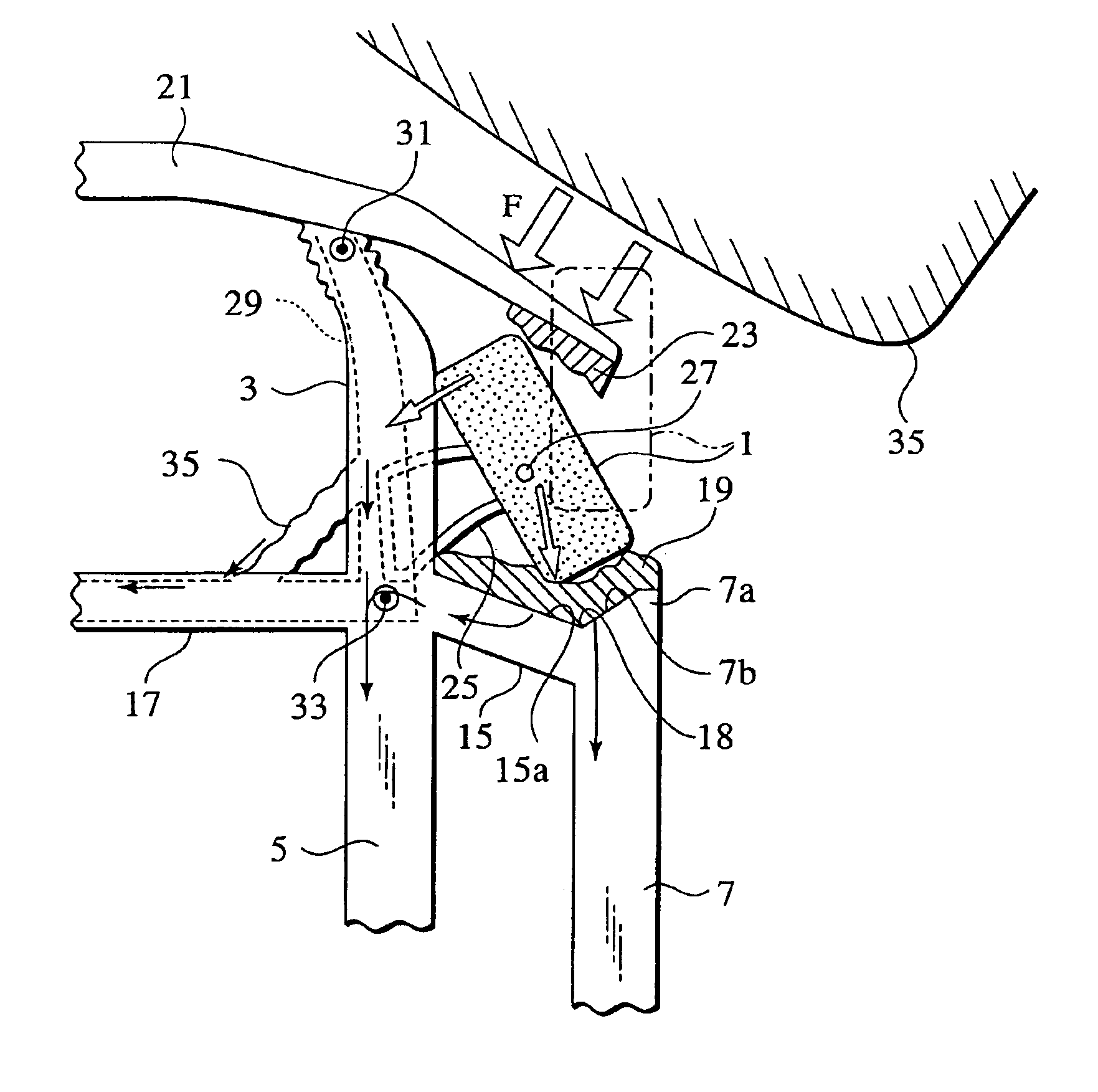

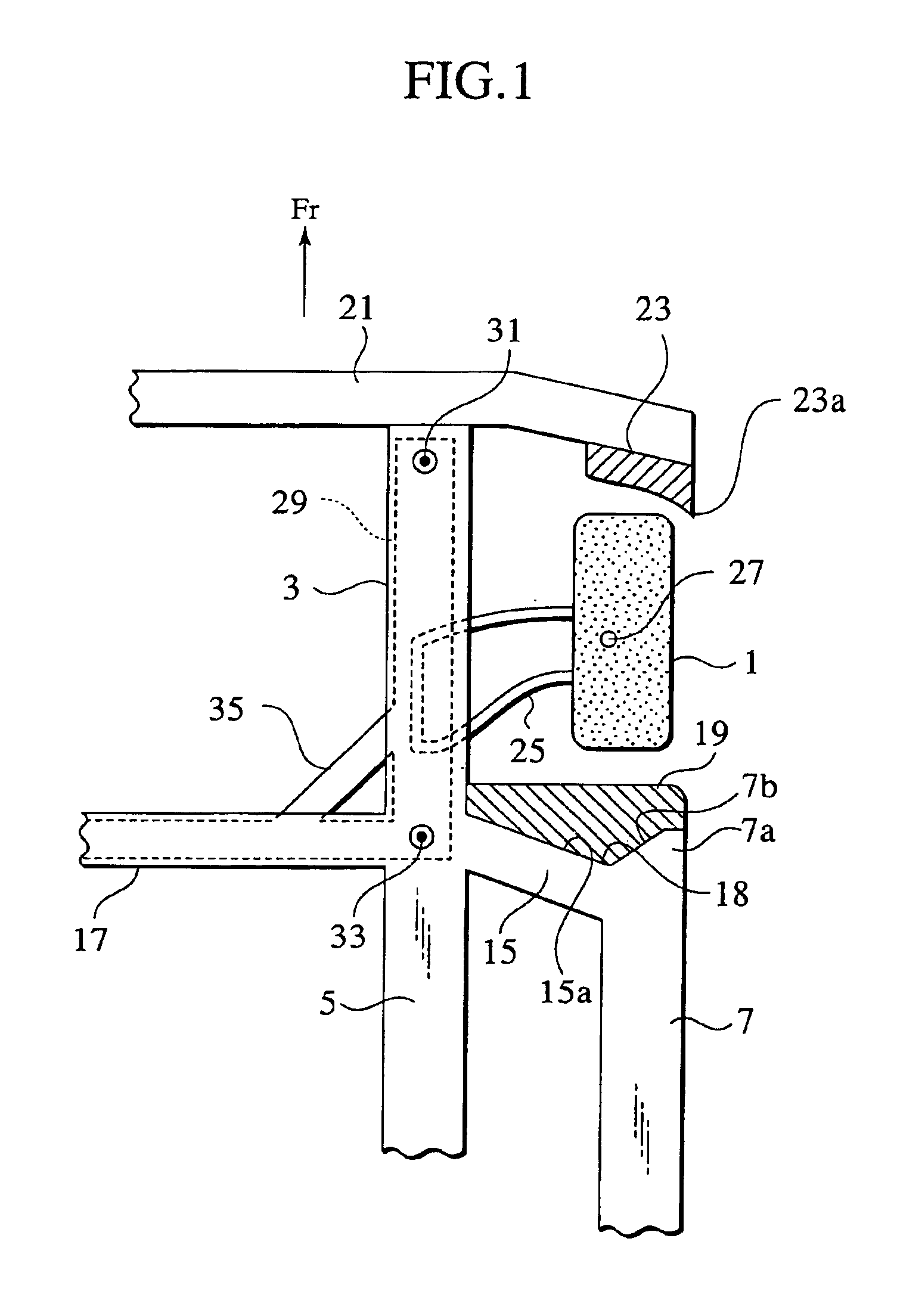

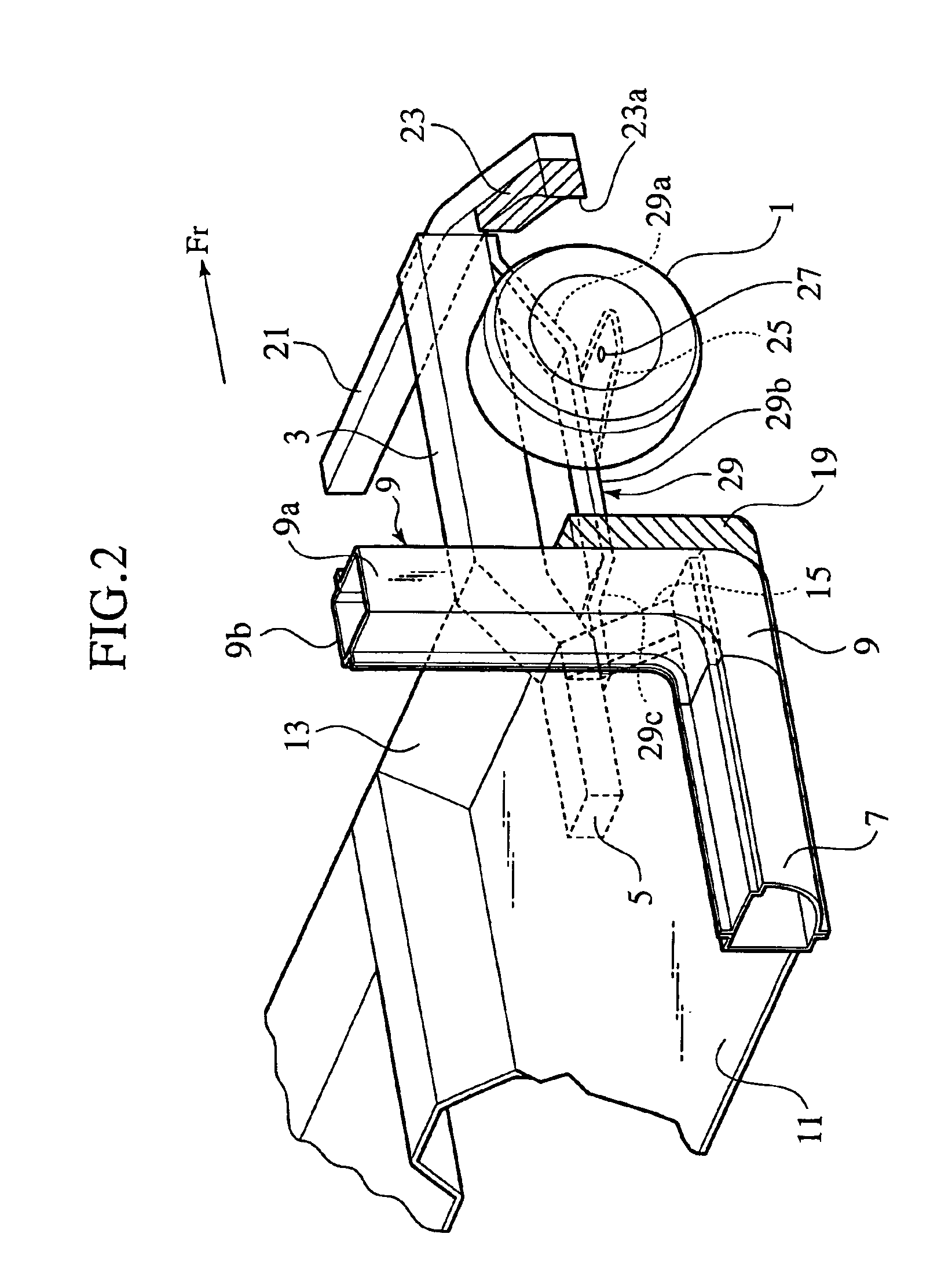

Front body structure for vehicle

A front body structure is provided to restrain a collision load, which has been applied on a front wheel by a vehicle front collision, to be concentrated on a front end of a side sill excessively. In the structure, a front energy absorbing member 23 is attached to a back face of a lateral end of a bumper 21. A recess 18 is formed by a front end of the side sill 7 and a front face of an outrigger 15. A rear energy absorbing member 19 is attached into the recess 18. The outrigger 15 connects the side sill 7 with a front side member extension 5 joined to the rear end of a front side member 3. At the vehicle front collision, the front energy absorbing member 23 interferes with the right-and-front part of the front wheel 1 to allow the left-and-front part of the front wheel 1 to interfere with the side face of the front side member 3 and also allow the rear part of the wheel 1 to interfere with the rear energy absorbing member 19.

Owner:NISSAN MOTOR CO LTD

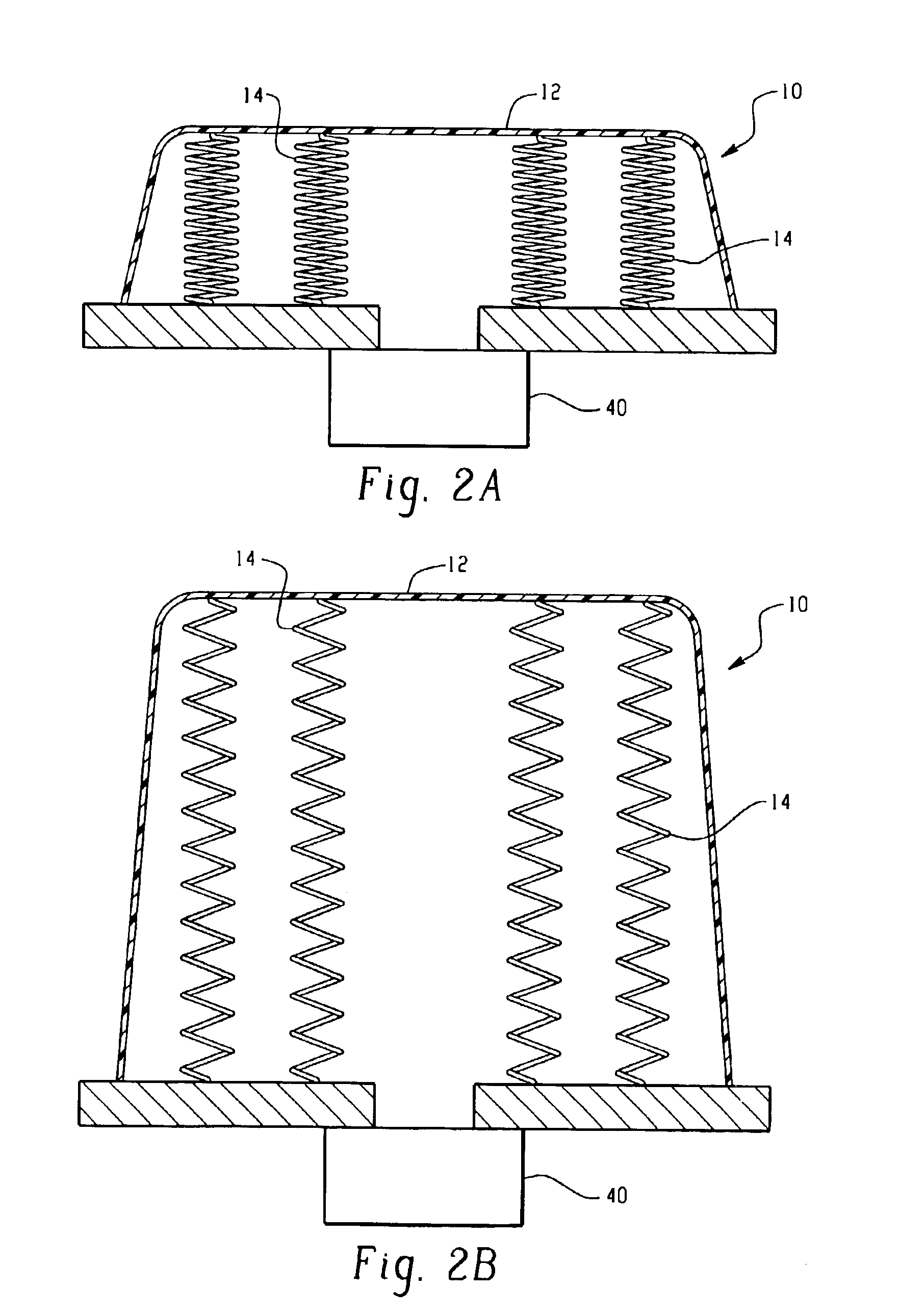

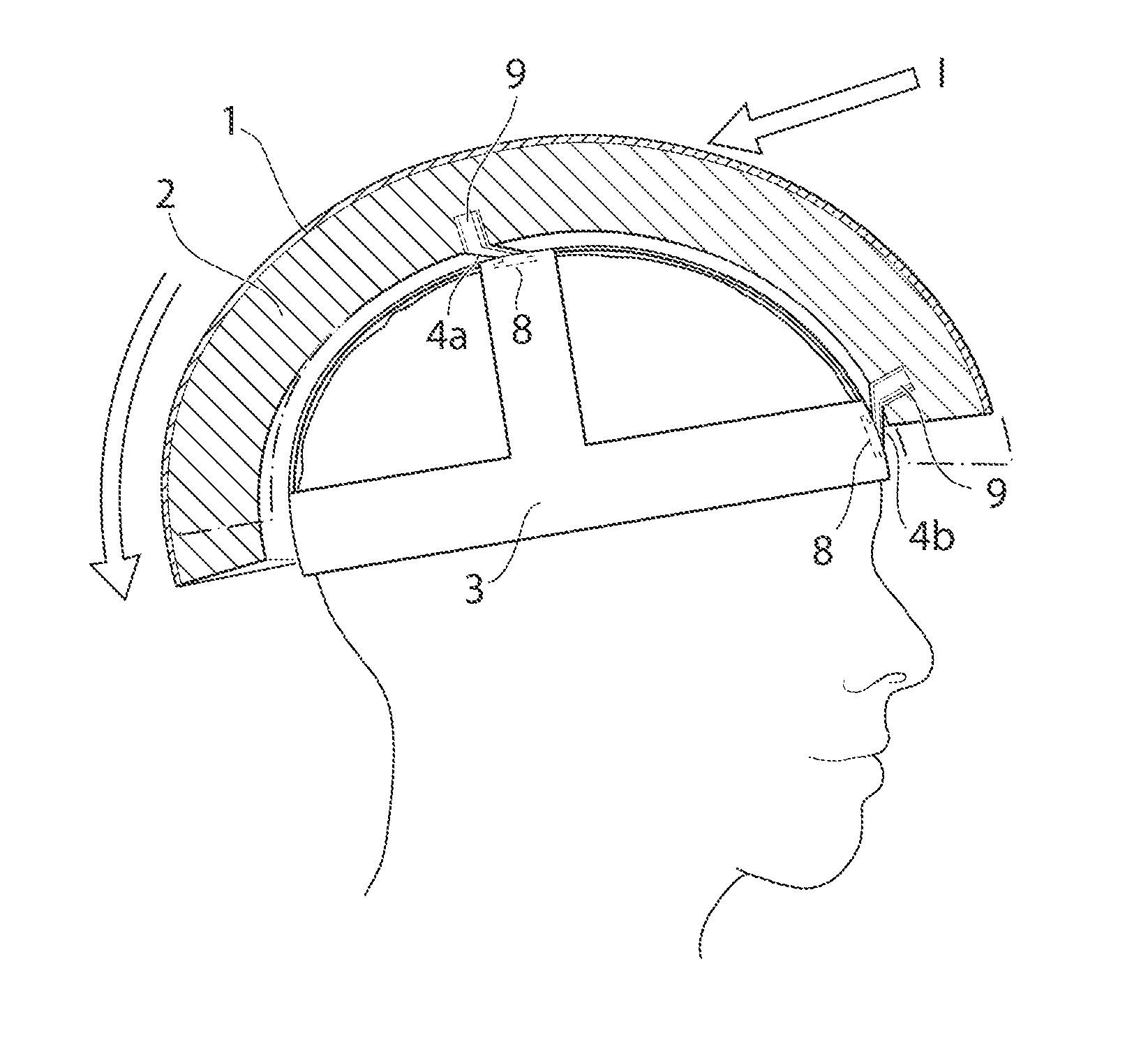

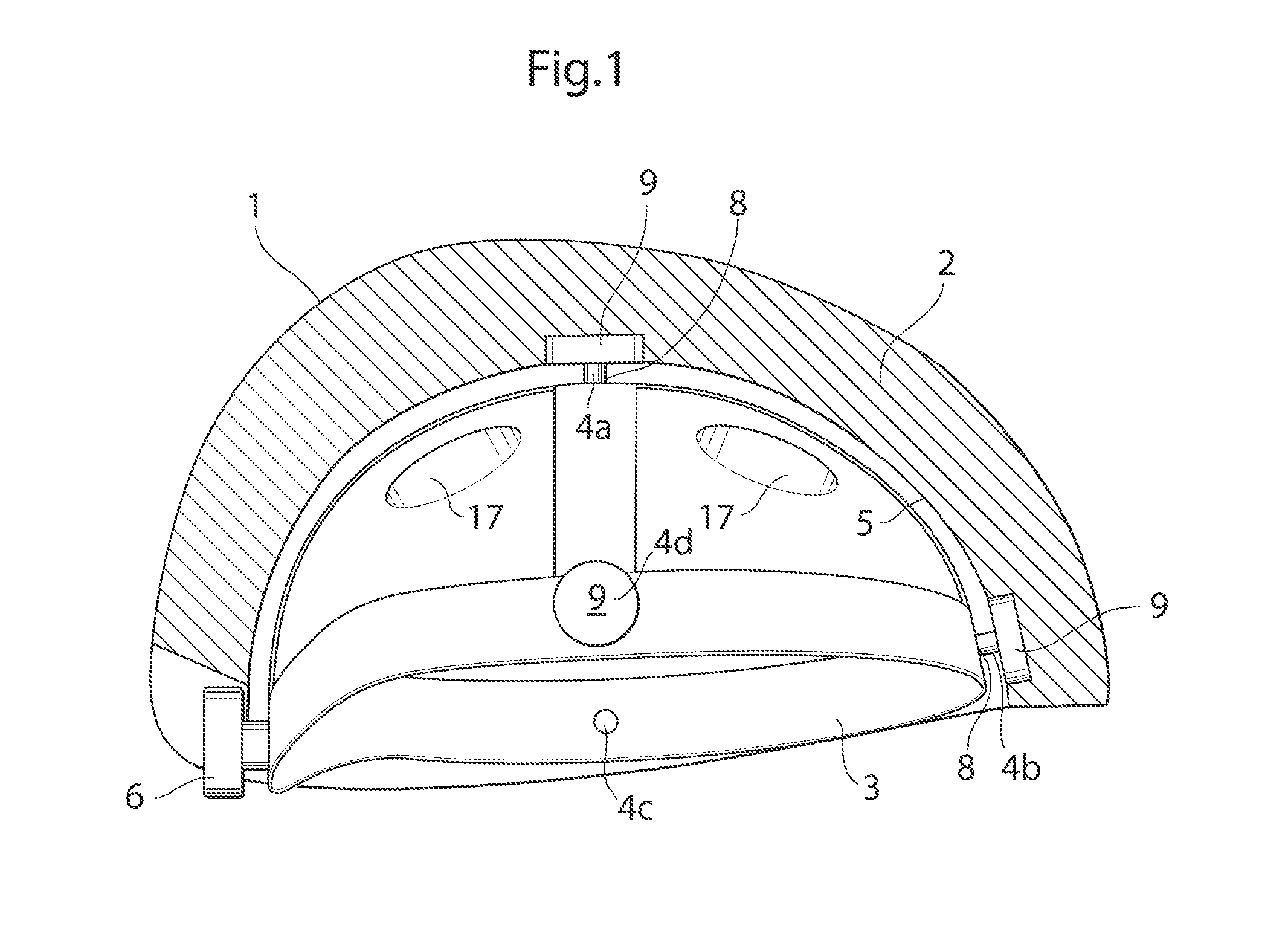

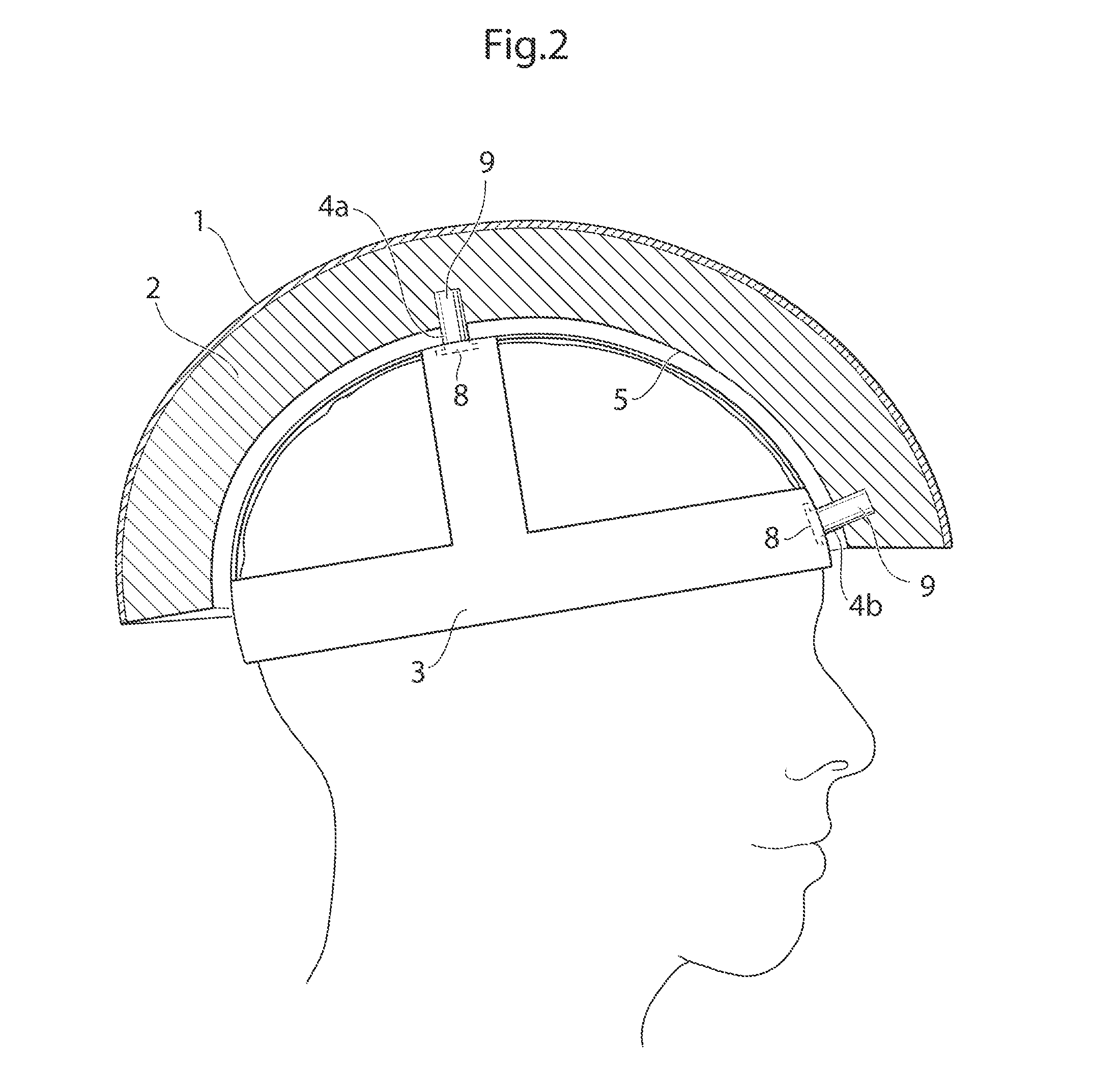

Helmet

ActiveUS8578520B2Reduce the amount requiredReduce rotationSport apparatusHelmetsEnergy absorptionEngineering

The present application provides a helmet. The helmet includes an energy absorbing layer (2) and a sliding facilitator (5). The sliding facilitator is provided on an inside surface of the energy absorbing layer (2). A method of manufacturing the helmet is further provided. The method includes the steps of: providing an energy absorbing layer in the mold, and providing a sliding facilitator contacting an inside surface of the energy absorbing layer.

Owner:MIPS

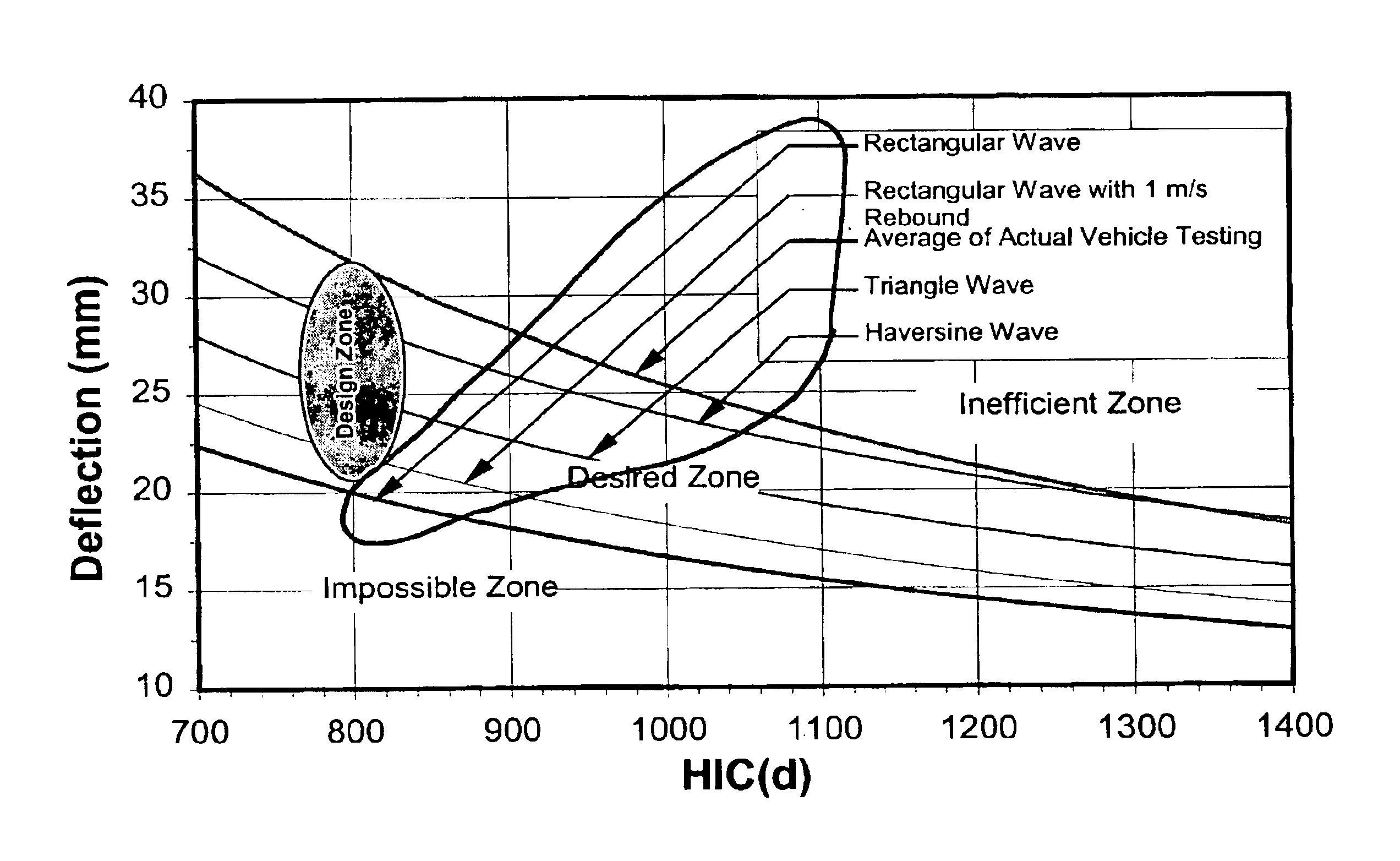

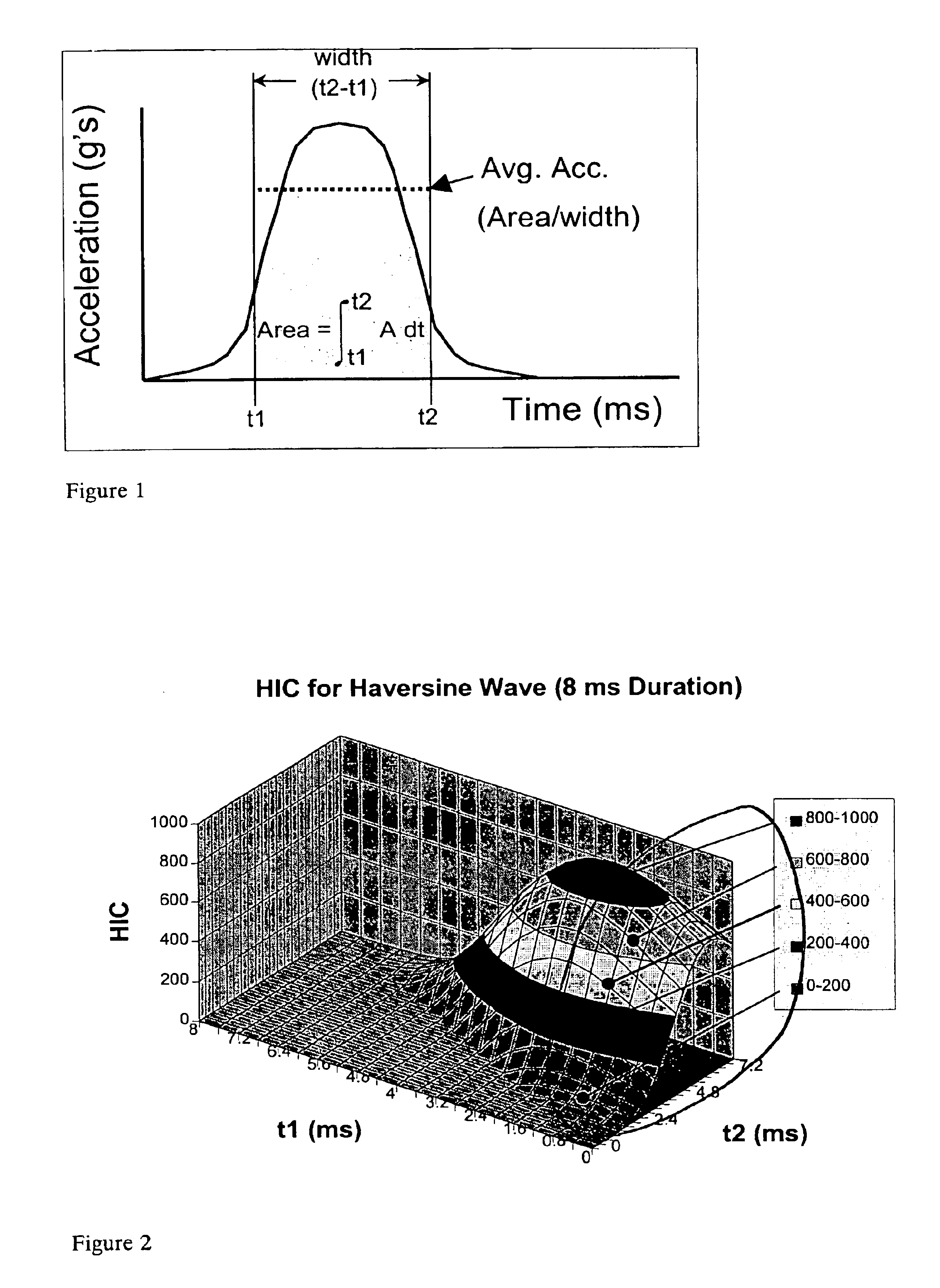

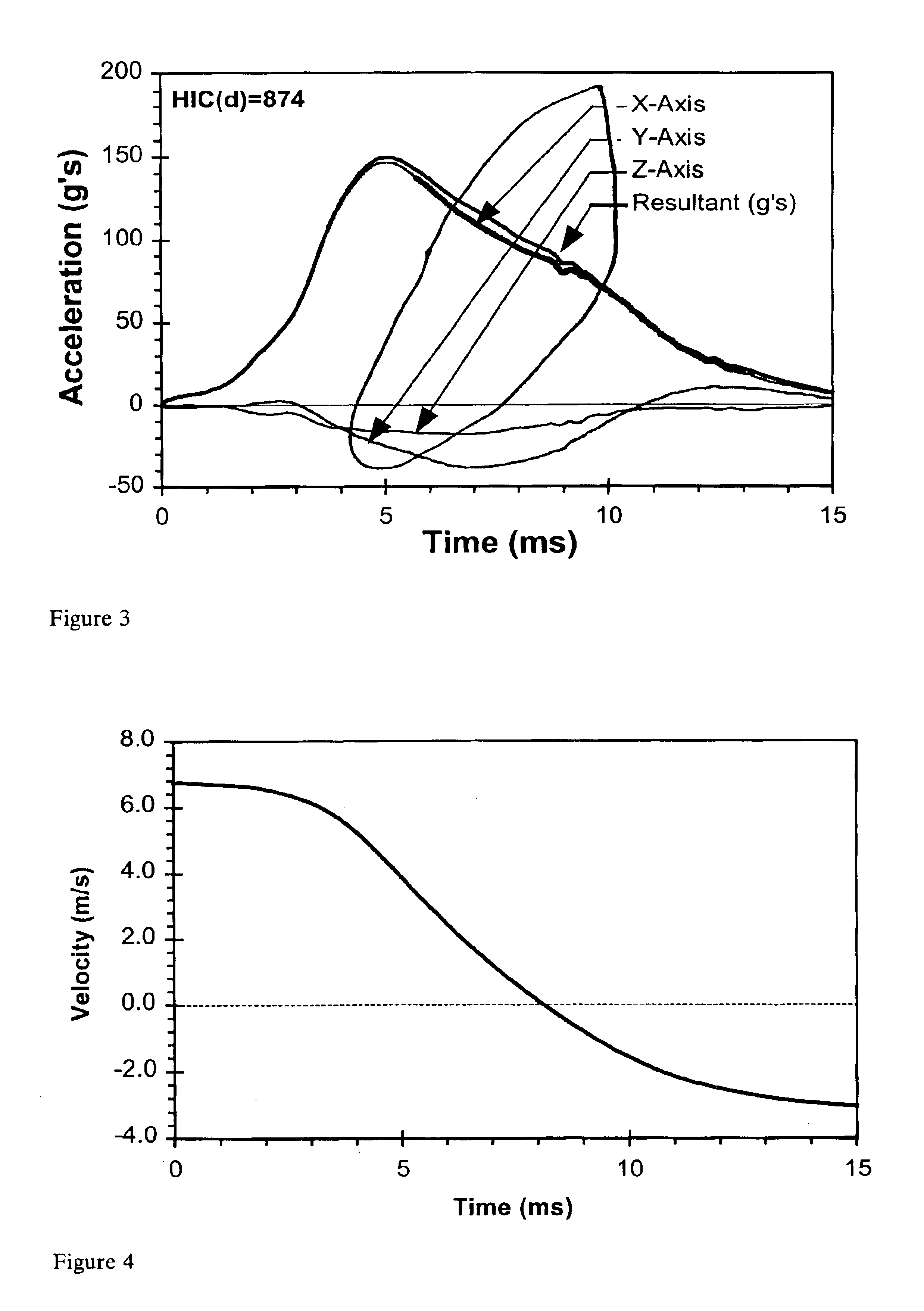

Method for improving the energy absorbing characteristics of automobile components

InactiveUS6907391B2Effective evaluationImprove countermeasure designVehicle seatsPedestrian/occupant safety arrangementEnergy absorptionMinimum deviation

A method is disclosed for designing an energy-absorbing impact zone for a vehicle interior, including acquiring test data representative of an occupant, determining a force versus deflection curve for the vehicle impact zone, analyzing the force versus deflection curve, and utilizing the analysis to adjust the stiffness of the energy-absorbing impact zone and to shape the force versus deflection curve so that a constant area under the force versus deflection curve has the minimum deflection possible without exceeding a certain force limit and a certain head impact criterion.

Owner:JOHNSON CONTROLS TECH CO

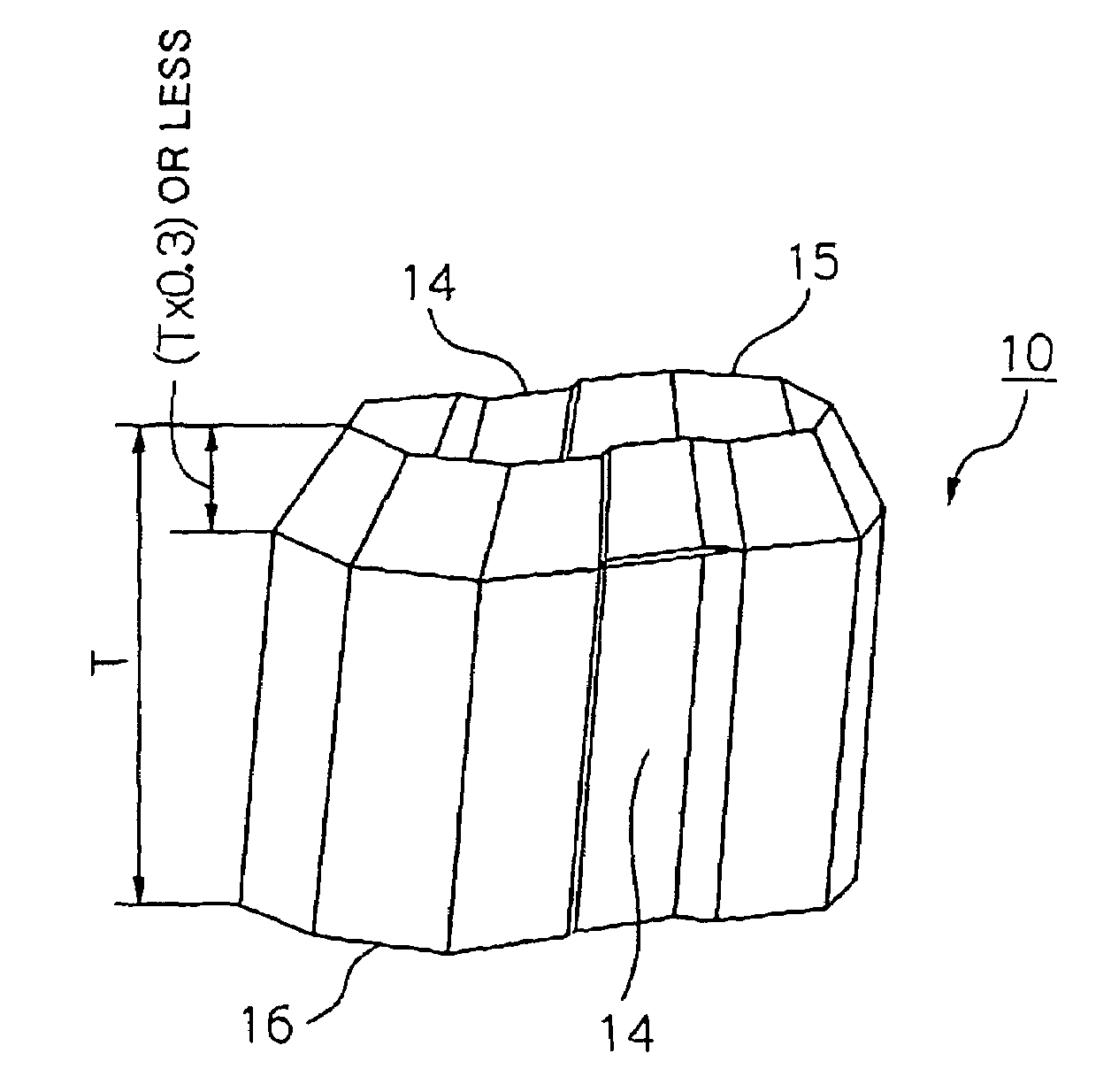

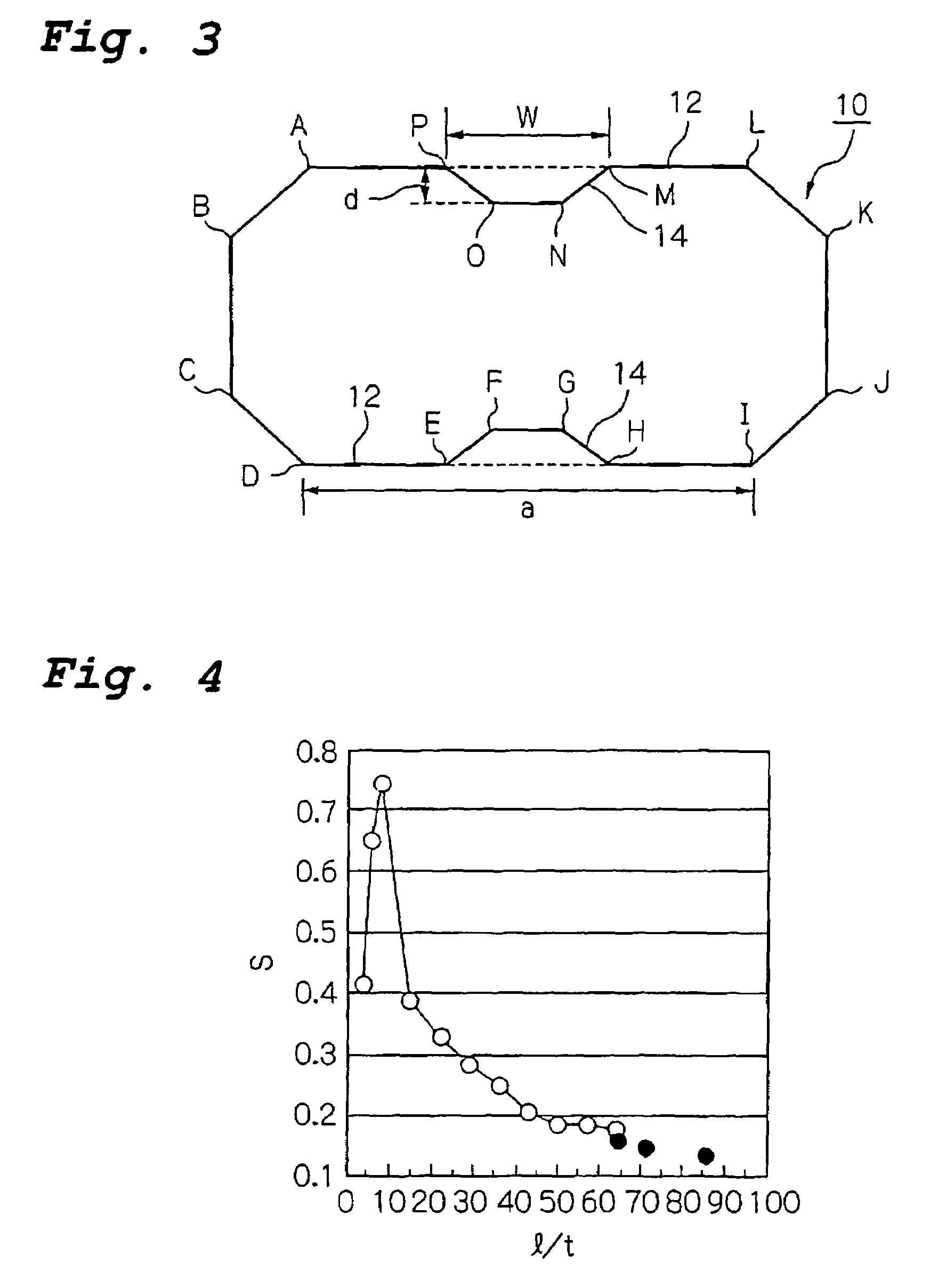

Crash energy absorption member

Owner:NIPPON STEEL CORP +1

Energy absorbing sports helmet

Slow recovery viscoelastic polyurethane foam with a surface impregnation of silicone, coupled with a rigid helmet shell, is used for athletic headgear. The helmet shell should have a rigid construct to provide dispersion of impact energy, absorbing at least thirty percent of the impact energy delivered to the helmet shell. The slow recovery viscoelastic polyurethane foam has unique characteristics making it suitable for use as an energy absorbing liner for athletic headgear. The energy absorbing liner can be made with varying thickness and size, so retail establishments can custom fit a helmet to a particular customer.

Owner:SCHNEIDER MARC S

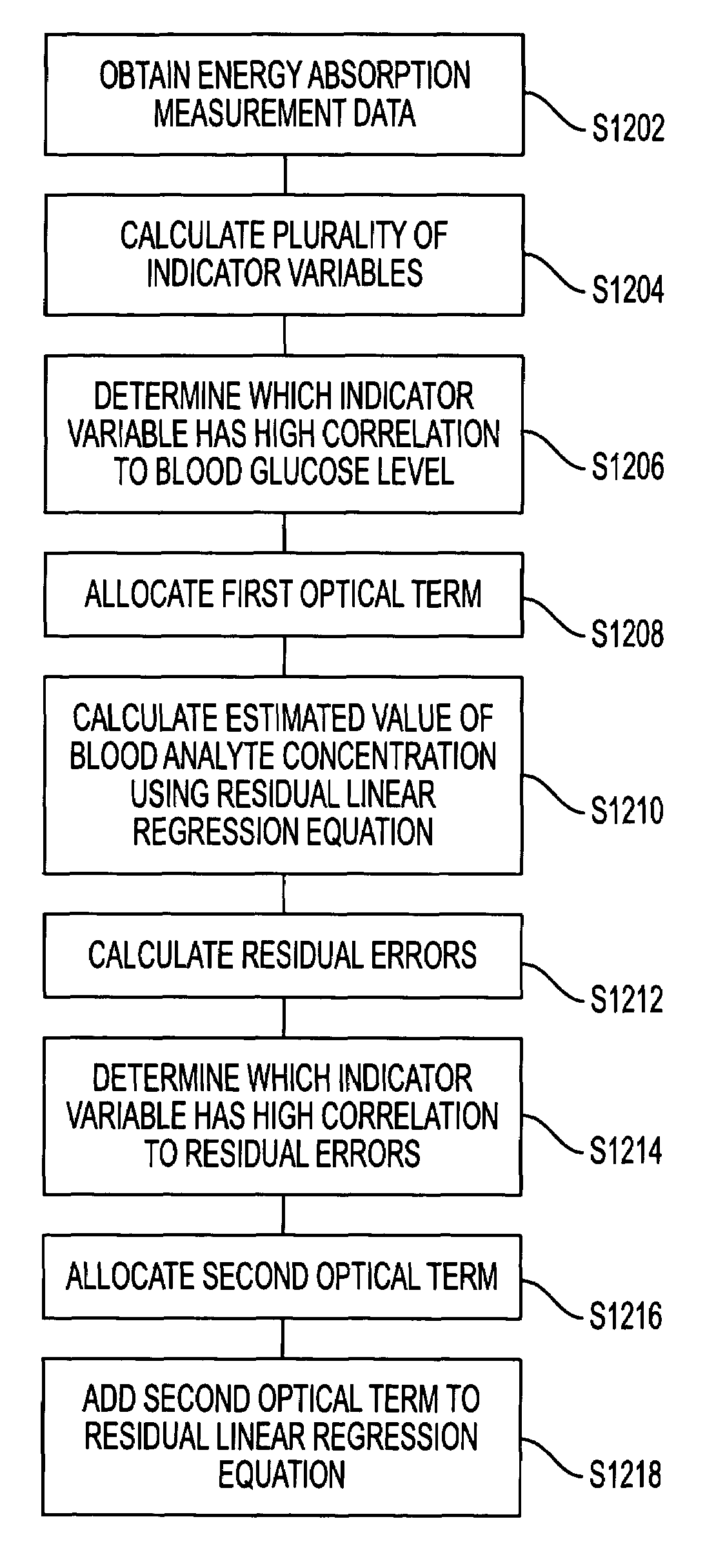

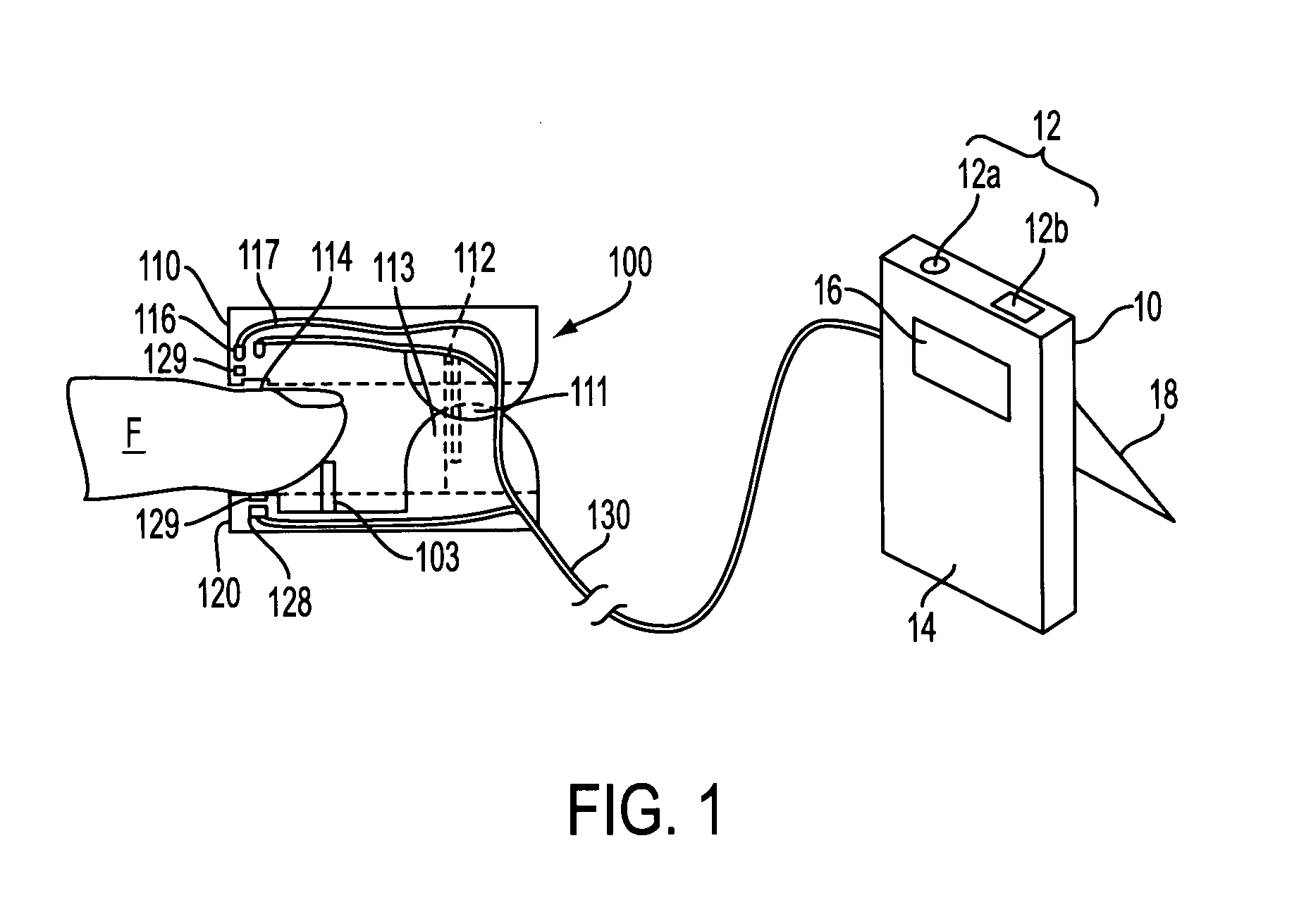

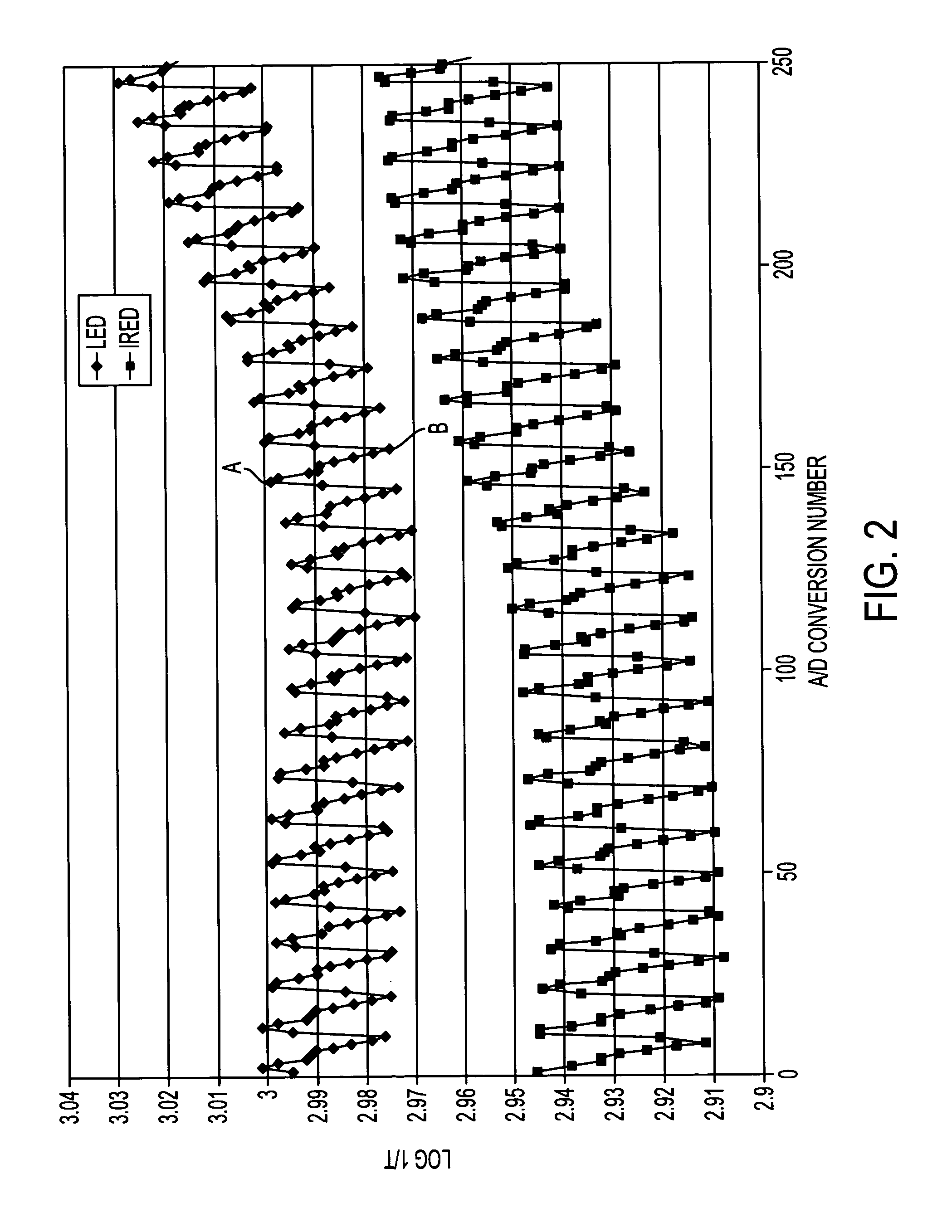

Low-cost method and apparatus for non-invasively measuring blood glucose levels

A method and apparatus for measuring a blood analyte concentration using an inexpensive, low precision sensor device is provided. One embodiment of the method includes obtaining energy absorption measurement data through a body part of an individual. A plurality of indicator variables are subsequently calculated from the energy absorption measurement data. An indicator variable from the plurality of indicator variables having the highest correlation to blood glucose level is determined, and a first optical term based on the indicator variable with the highest correlation to blood glucose level is allocated to form a regression analysis equation. An estimated value of the blood analyte concentration using the regression analysis equation is calculated.

Owner:FUTREX

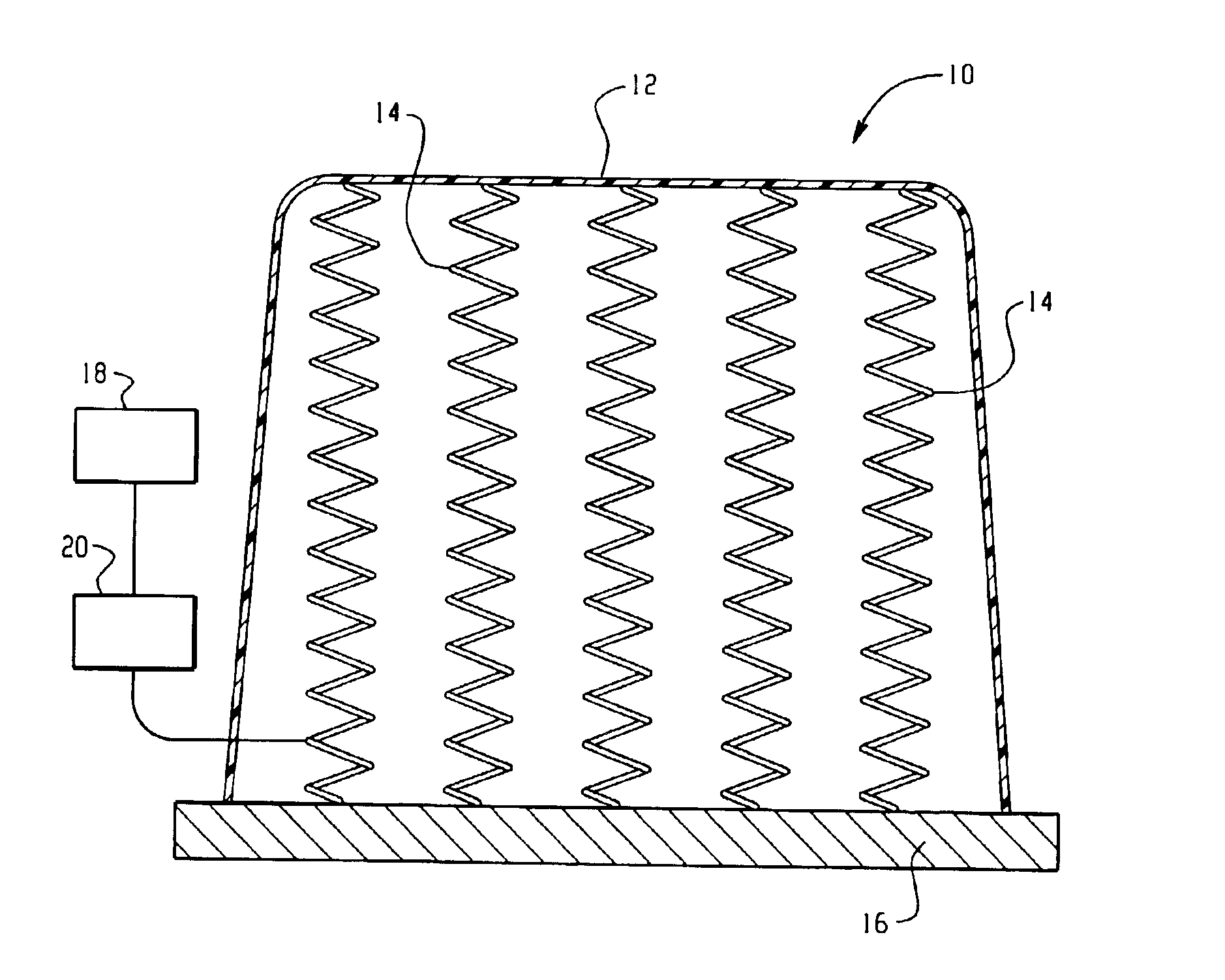

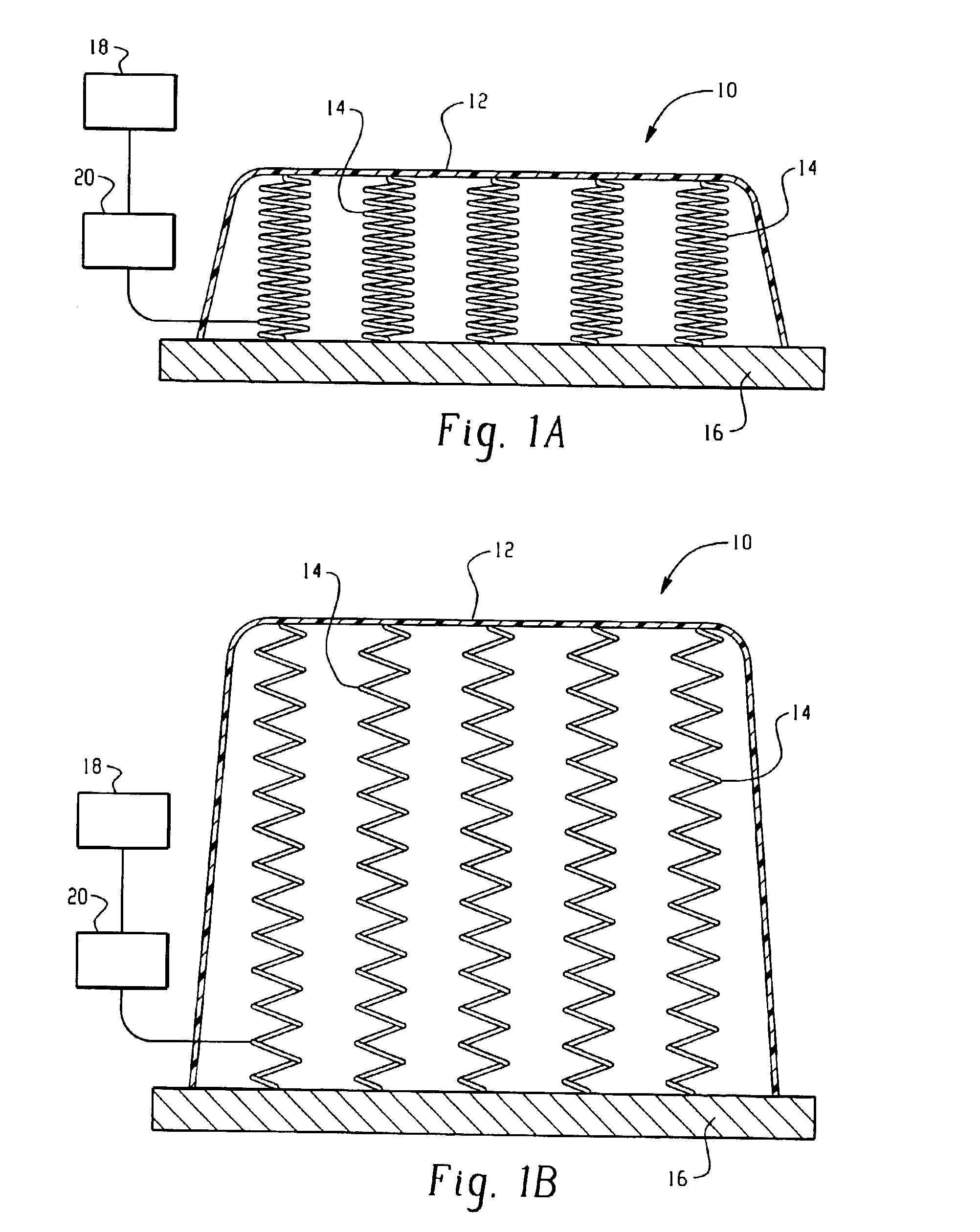

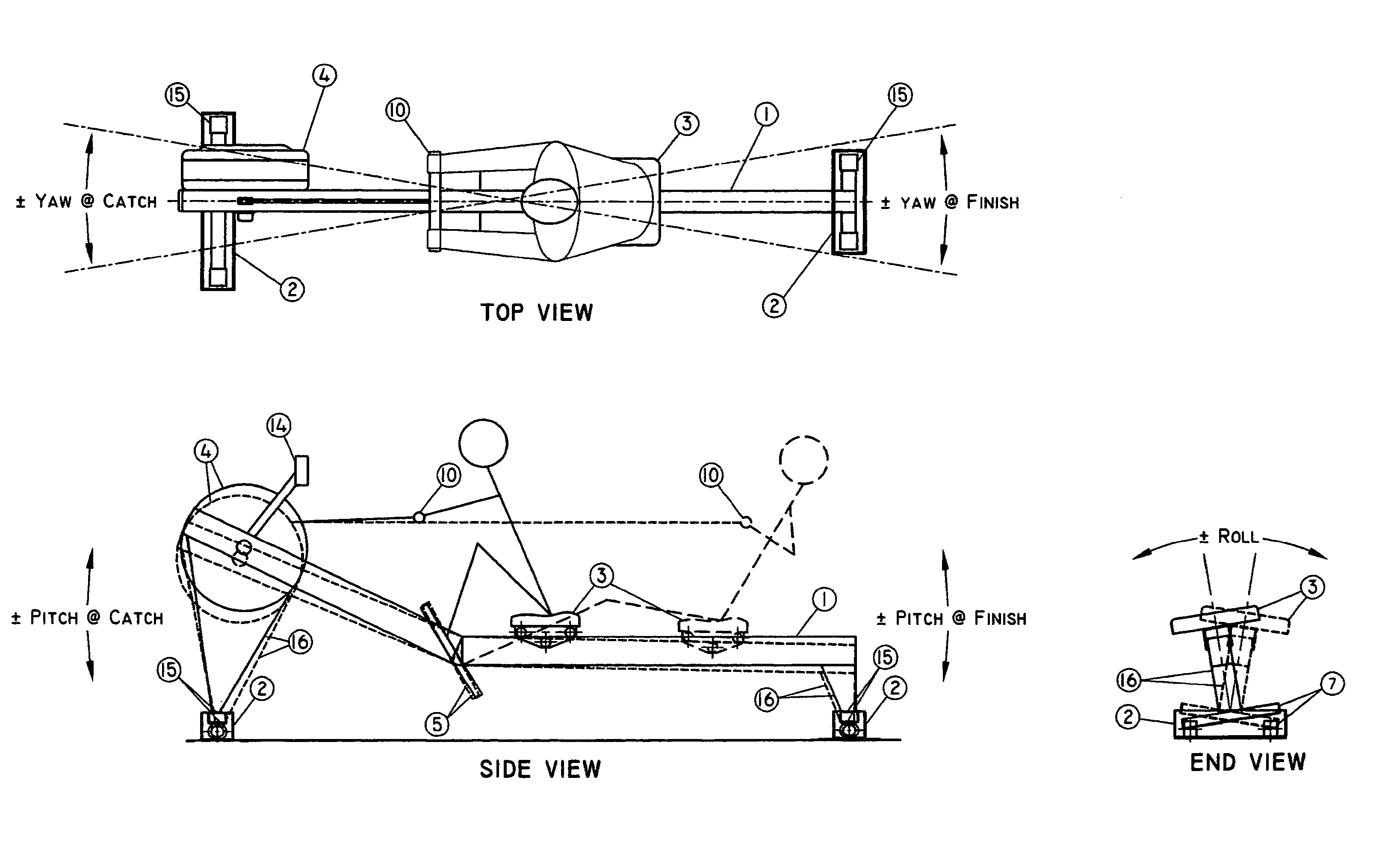

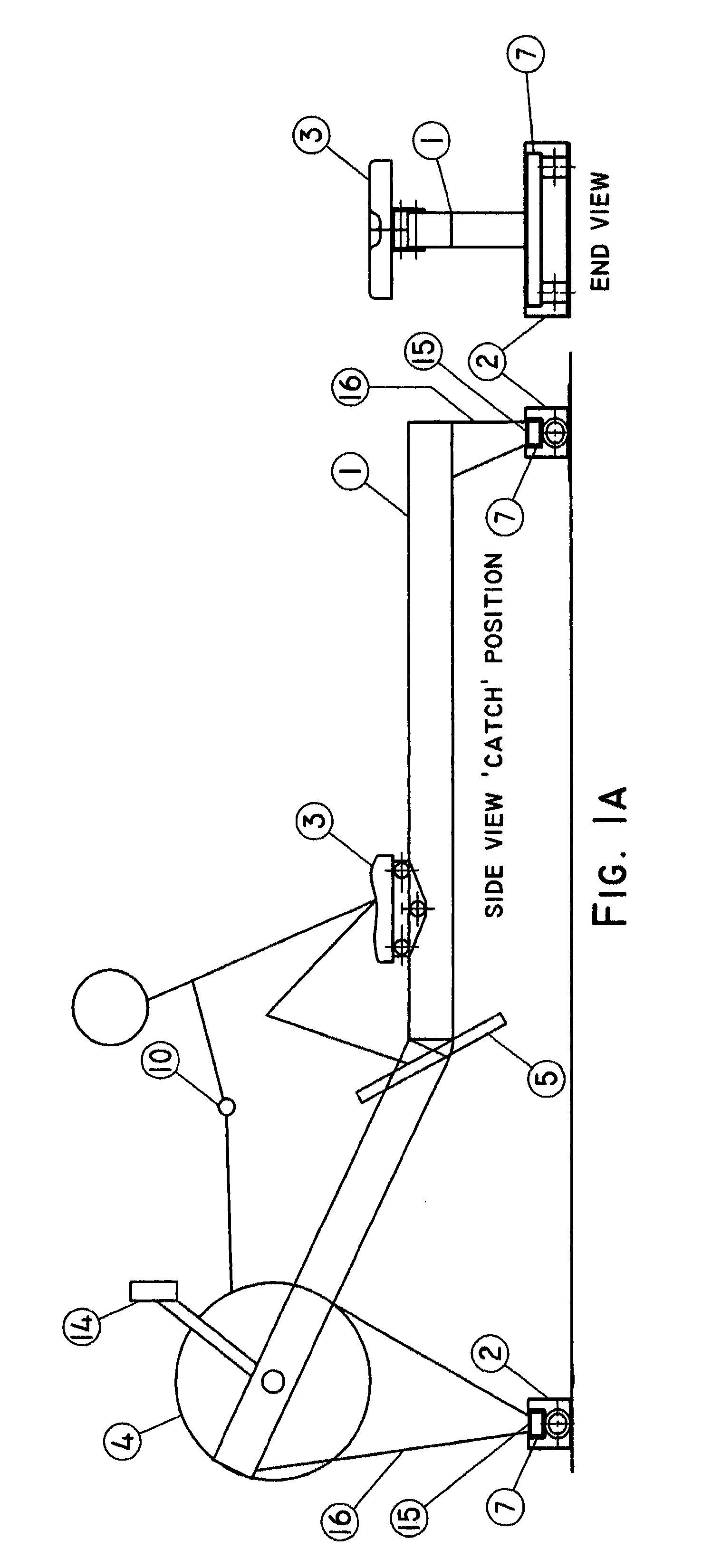

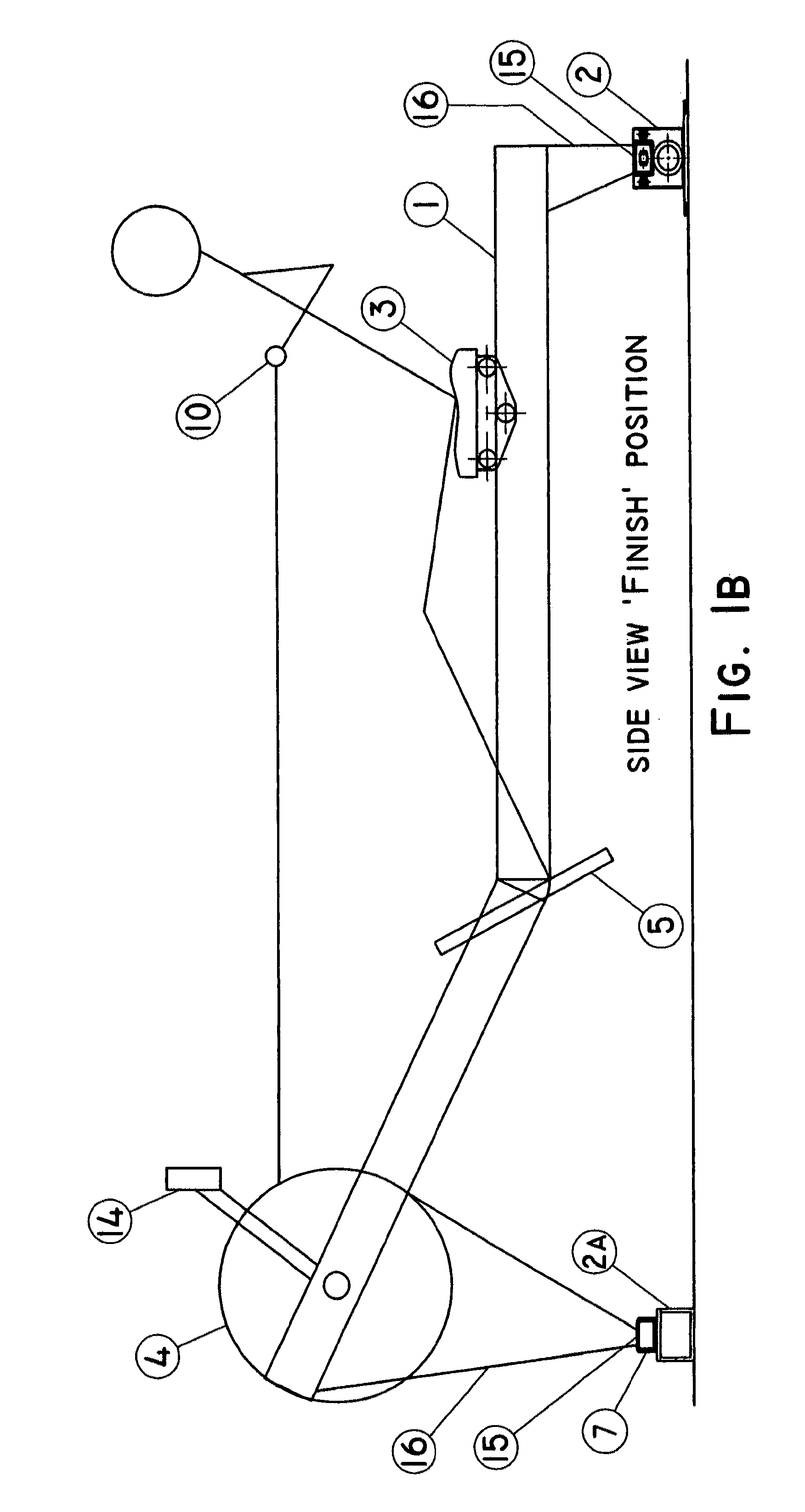

Energy absorbing suspension equipment (EASE) for rowing machines

A rowing machine or rowing machine attachment with an energy absorbing component configured to add responsive and compliant roll, pitch, and yaw motions to the rowing machine. The energy absorbing component is also configured to change shape so as to absorb energy in response to a compressive force by the user. Said energy absorption component returns substantially to its first shape in response to the removal of the compressive force. The energy-absorbing apparatus is configured to reduce a reaction force exerted on the user of the rowing machine.

Owner:SMITH LAURIE A +1

Reinforced aerogel composite material and preparation method thereof

The invention provides a reinforced aerogel composite material and a preparation method thereof. The reinforced aerogel composite material comprises single aerogel or two aerogels or more than two aerogels, the surfaces or block interfaces of the block aerogel are coated or bound into a whole by virtue of fiber mesh fabric-reinforced waterborne adhesive. The preparation method of the reinforced aerogel composite material comprises the following steps: (1) carrying out hydrophobic modification treatment on the surfaces; (2) carrying out hydrophilic / hydrophobic modification treatment on the surfaces; and (3) preparing the reinforced aerogel composite material: uniformly coating the surface of the block aerogel or the interface of two aerogels with waterborne adhesive and fiber mesh fabric and curing to obtain the reinforced aerogel composite material. The reinforced aerogel composite material provided by the invention has the characteristics of excellent thermal-insulation property, heat preservation property, sound insulation property, fireproof property, explosion resistance, shock absorption, energy absorption, light weight, better mechanical properties, the preparation process of the material is simple and practical and the material has wide range of applications.

Owner:NANJING WEICAI NEW ENERGY TECH

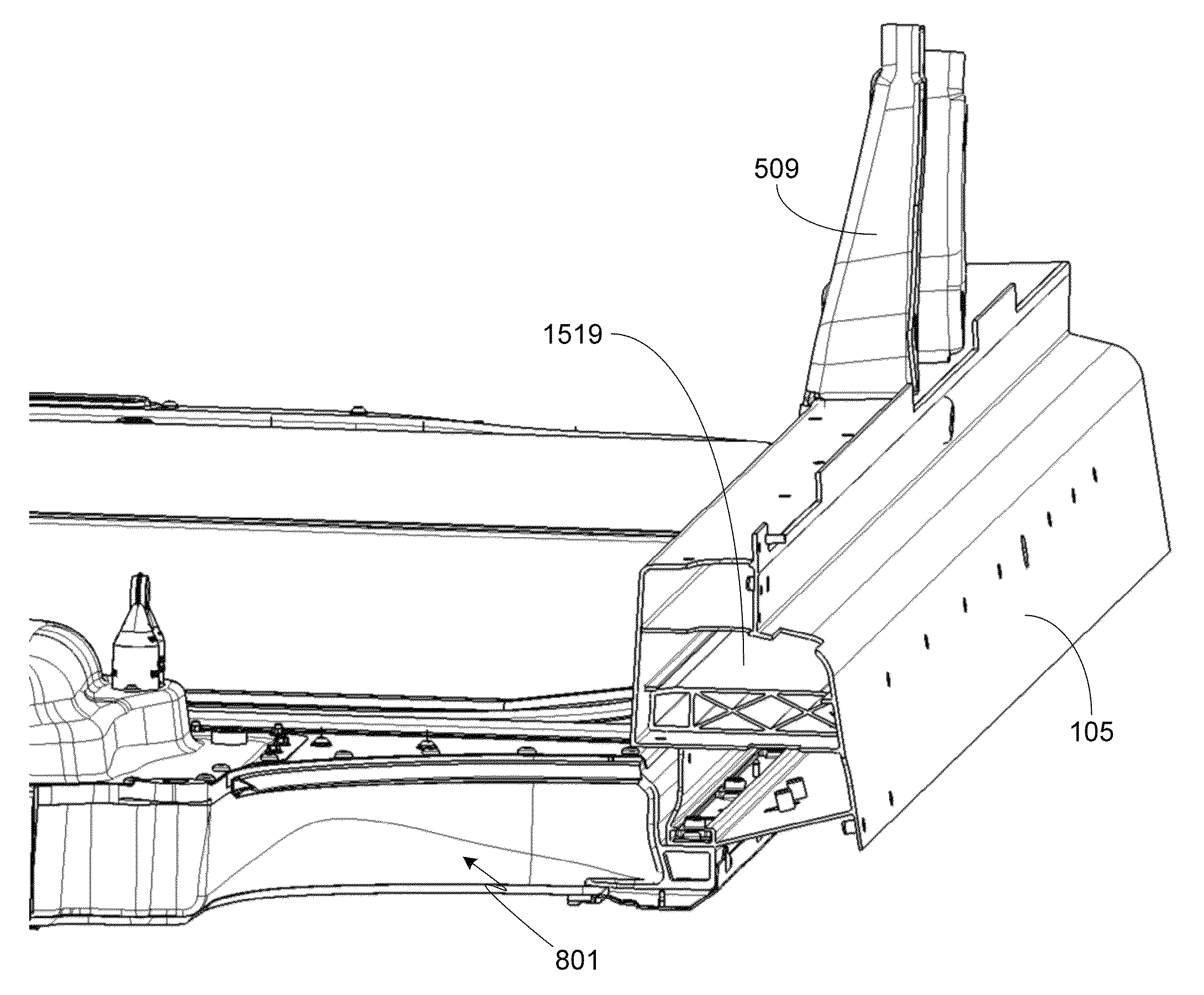

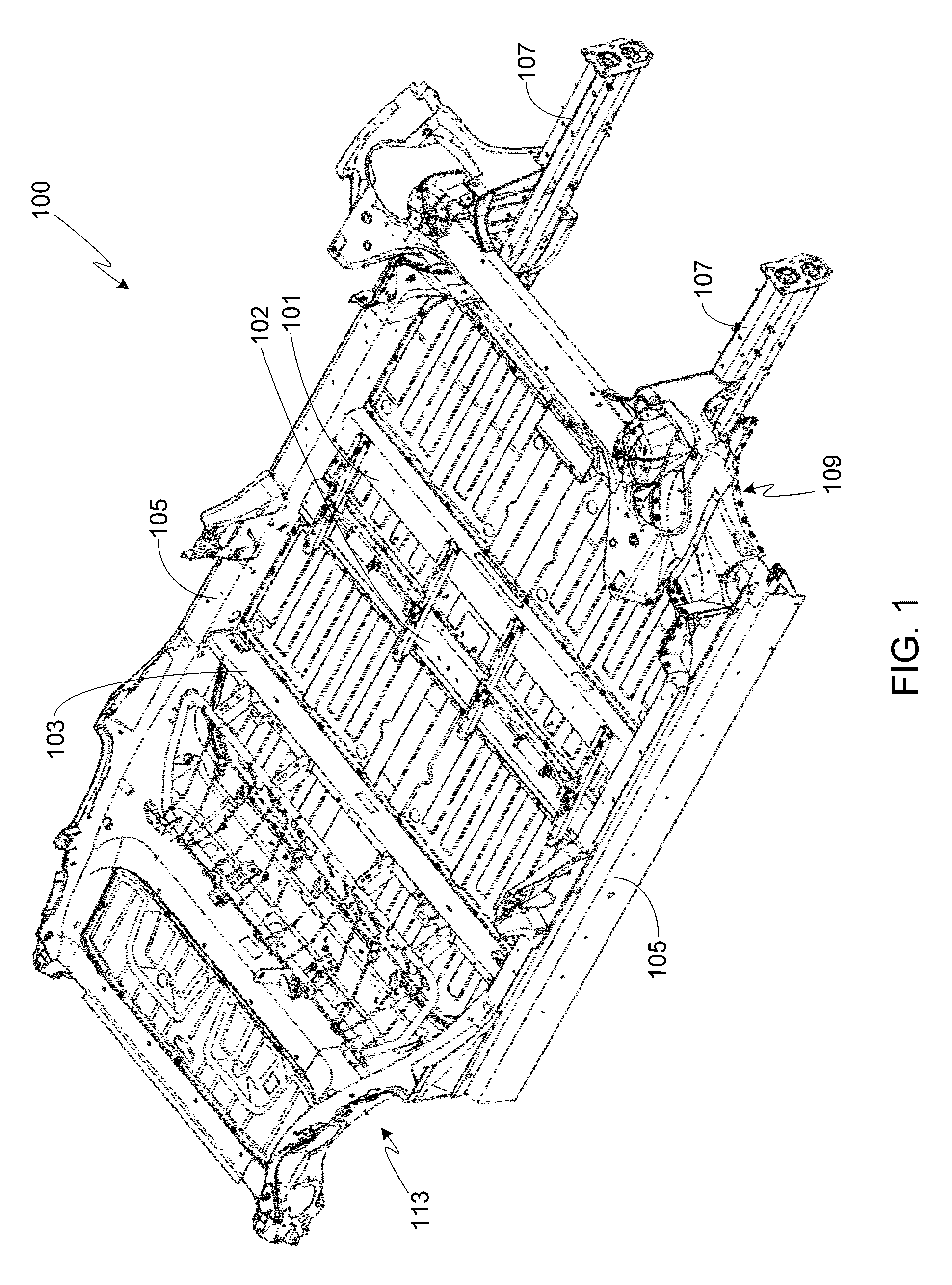

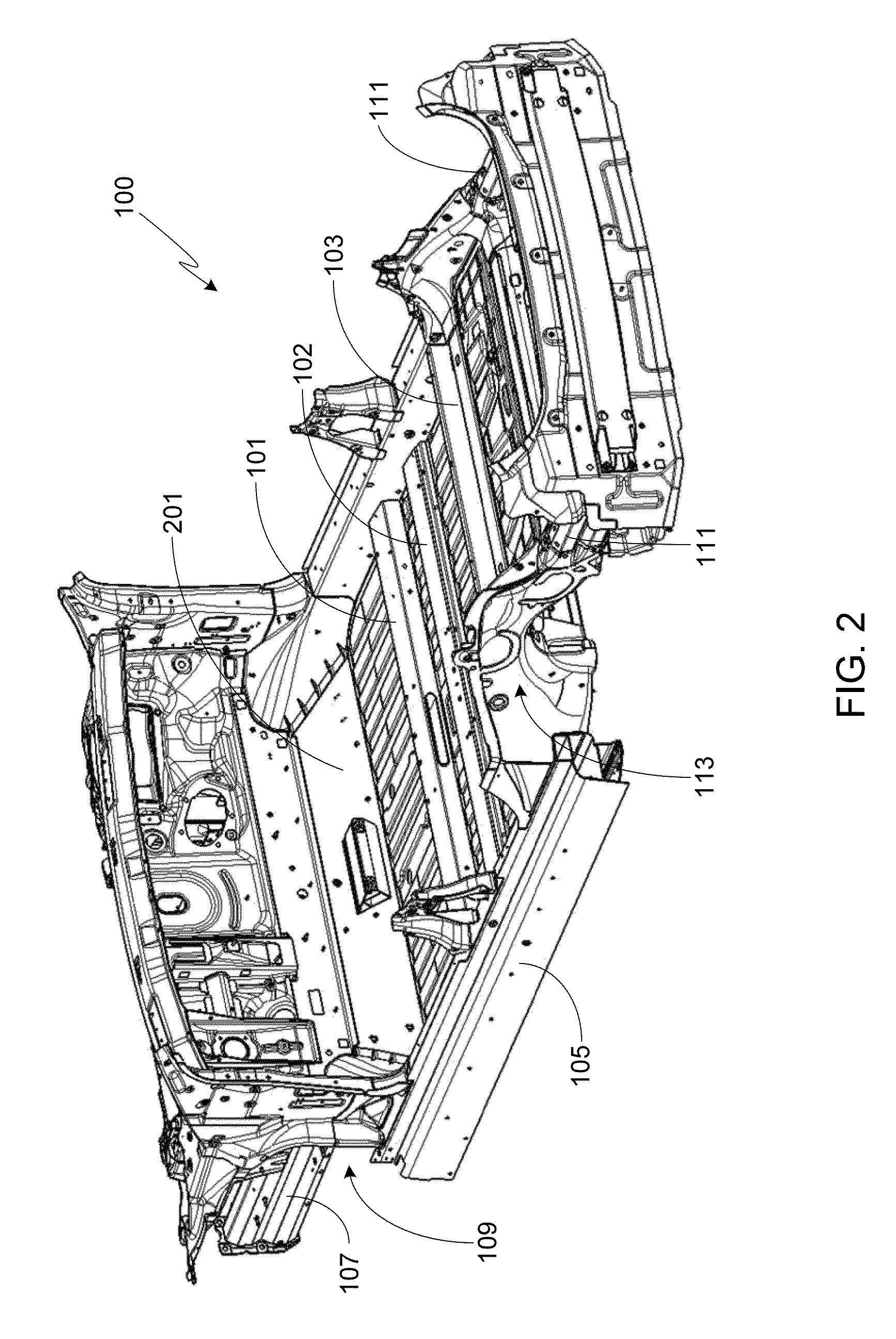

System for absorbing and distributing side impact energy utilizing a side sill assembly with a collapsible sill insert

An energy absorbing and distributing side impact system for use with a vehicle is provided, the system utilizing a collapsible side sill assembly along with multiple vehicle cross-members to achieve the desired level of vehicle side impact resistance, the combination of these elements absorbing and distributing the impact load throughout the vehicle structure. The collapsible side sill assembly includes a side sill insert, the insert divided into a collapsible portion designed to absorb impact energy and a reacting portion designed to distribute the impact energy to the vehicle cross-members.

Owner:TESLA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com