Reinforced aerogel composite material and preparation method thereof

A composite material and airgel technology, which is applied in the fields of explosion-proof, sound insulation, shock absorption and energy-absorbing materials, heat preservation, light weight, and fire prevention. , pollute the operating environment and other issues, and achieve the effect of excellent flexural resistance, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

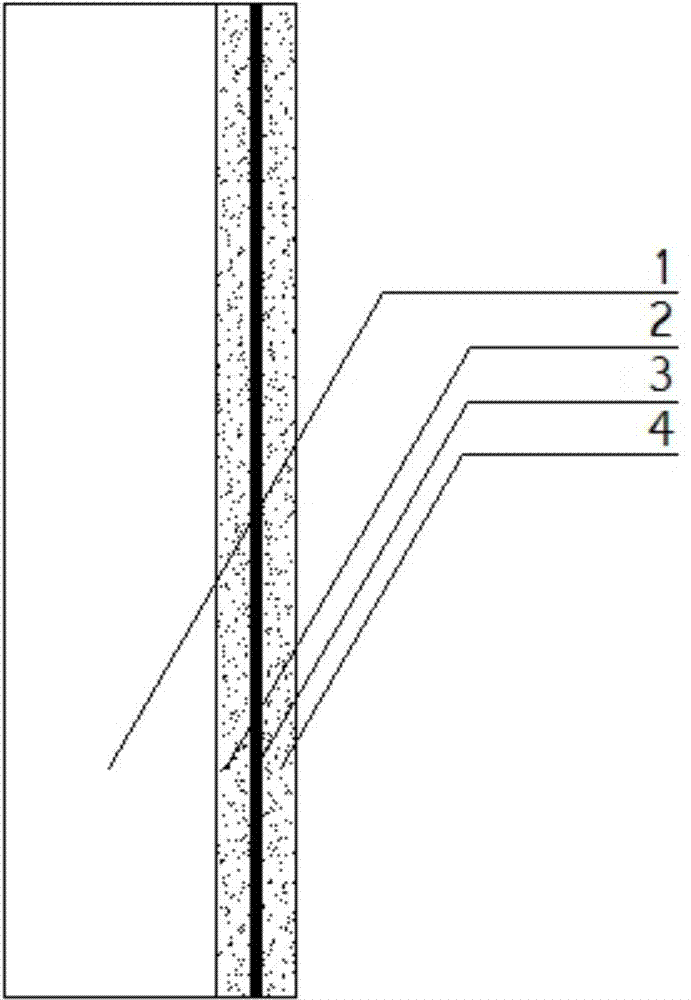

[0022] Such as figure 1 As shown, a reinforced airgel composite material of this embodiment is composed of a single or multiple silica airgel blocks 1, and between the surface of the airgel or the interface of the blocks, the fiber net The water-based adhesive reinforced by grid cloth 3 is coated or bonded into one. The water-based adhesive is one or more mixtures of water-based inorganic adhesives and water-based organic adhesives. The water-based inorganic adhesive is selected from From the group consisting of cement, gypsum, limestone, water glass, copper oxide-phosphate glue, the water-based organic adhesive is selected from water-based acrylic resin, water-based polyurethane resin, water-based epoxy resin, water-based silicone resin, water-based fluorocarbon resin, acetic acid A group consisting of ethylene-ethylene polymer glue and polyvinyl acetal glue, the fiber mesh cloth is selected from alkali-resistant glass fiber mesh cloth, polyvinyl alcohol fiber mesh cloth, pol...

Embodiment 2

[0024] The preparation method of the enhanced airgel composite material of embodiment 1 comprises the following steps: (1) surface modification of silica airgel block: under the condition of 200 ℃, use hexamethyldisilazane and iso Propanol (molar ratio: 3:1) was used to gas-phase modify silica airgel blocks for 4 hours; then the modified airgel was heat-treated at 450°C for 3 hours in an air atmosphere, and then used for later use. .

[0025] (2) Use 525 ordinary Portland cement as the water-based adhesive and alkali-resistant glass fiber mesh cloth (3×3mm, 80g / m2) to evenly cover the surface of the silica airgel block or two pieces of silica airgel. Between the silica airgel blocks, the thickness of the water-based adhesive is 1-5mm.

[0026] (3) According to the cement curing standard, the airgel composite material was prepared after curing for 28 days under certain temperature and humidity conditions.

Embodiment 3

[0028] The preparation method of the reinforced airgel composite material in this example is to change the water-based adhesive in Example 2 to 901 glue.

[0029] (1) Surface modification of silica airgel blocks: at 200°C, use hexamethyldisilazane and isopropanol (molar ratio 3:1) to modify the surface of silica airgel blocks Carry out gas phase modification, and the modification time is 4 hours; then heat-treat the modified airgel in an air atmosphere environment at 450°C for 3 hours, and set aside.

[0030] (2) Using 901 glue as the water-based adhesive, alkali-resistant glass fiber mesh cloth (3×3mm, 80g / m2) is evenly coated on the surface of the silica airgel block or two silica airgel Between the blocks, the thickness of the water-based adhesive is 1-5mm.

[0031] (3) Stand still in the air atmosphere for 48 hours, and prepare the airgel composite material after the 901 glue is completely cured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com