Patents

Literature

15404results about How to "Improve stress resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hesperaloe tissue having improved cross-machine direction properties

ActiveUS10337148B2Satisfactory softness and strength and bulkNegatively effecting tissue product strength and stiffness and bulkPaper/cardboardTissue/absorbent paperFiberMedicine

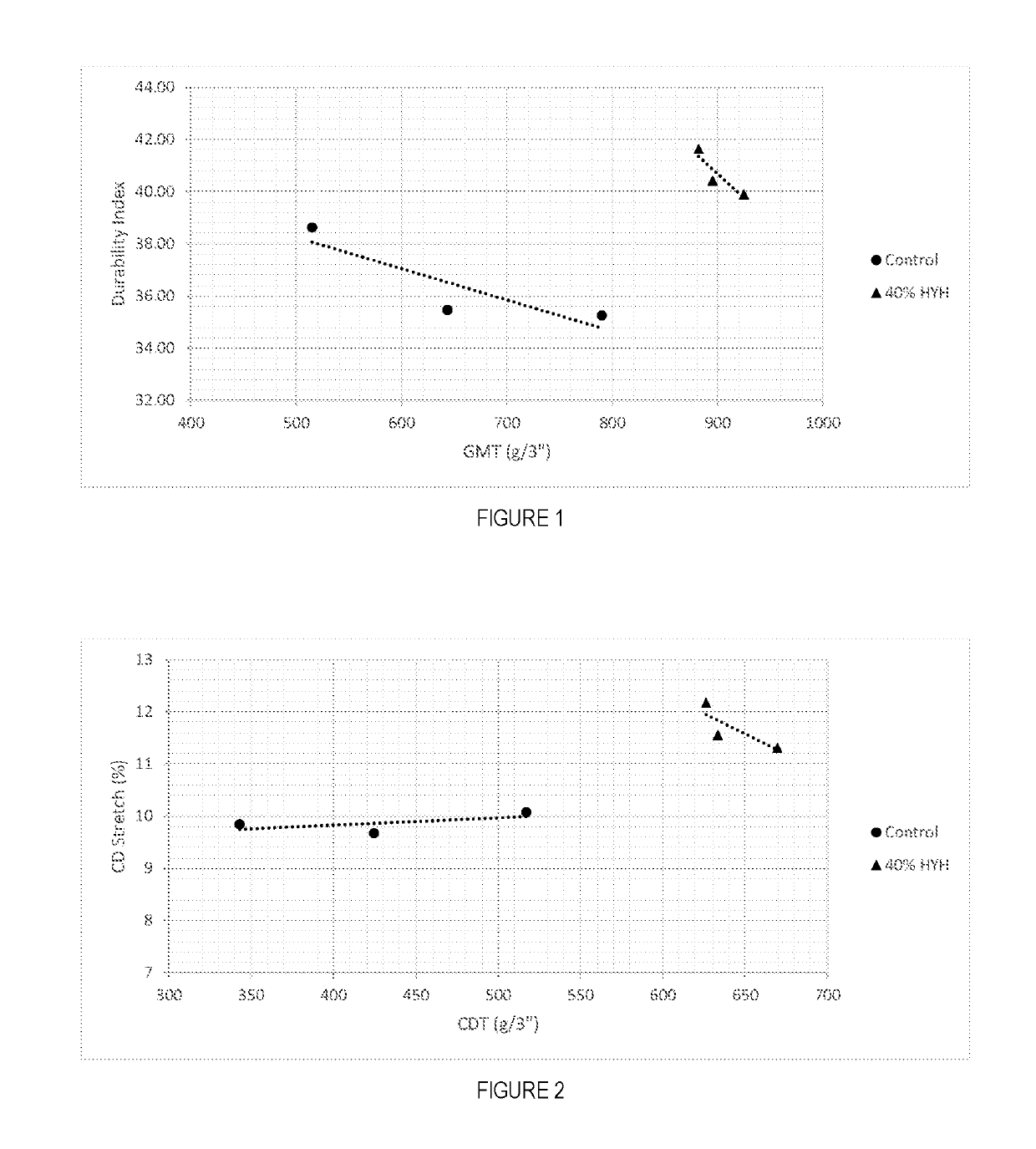

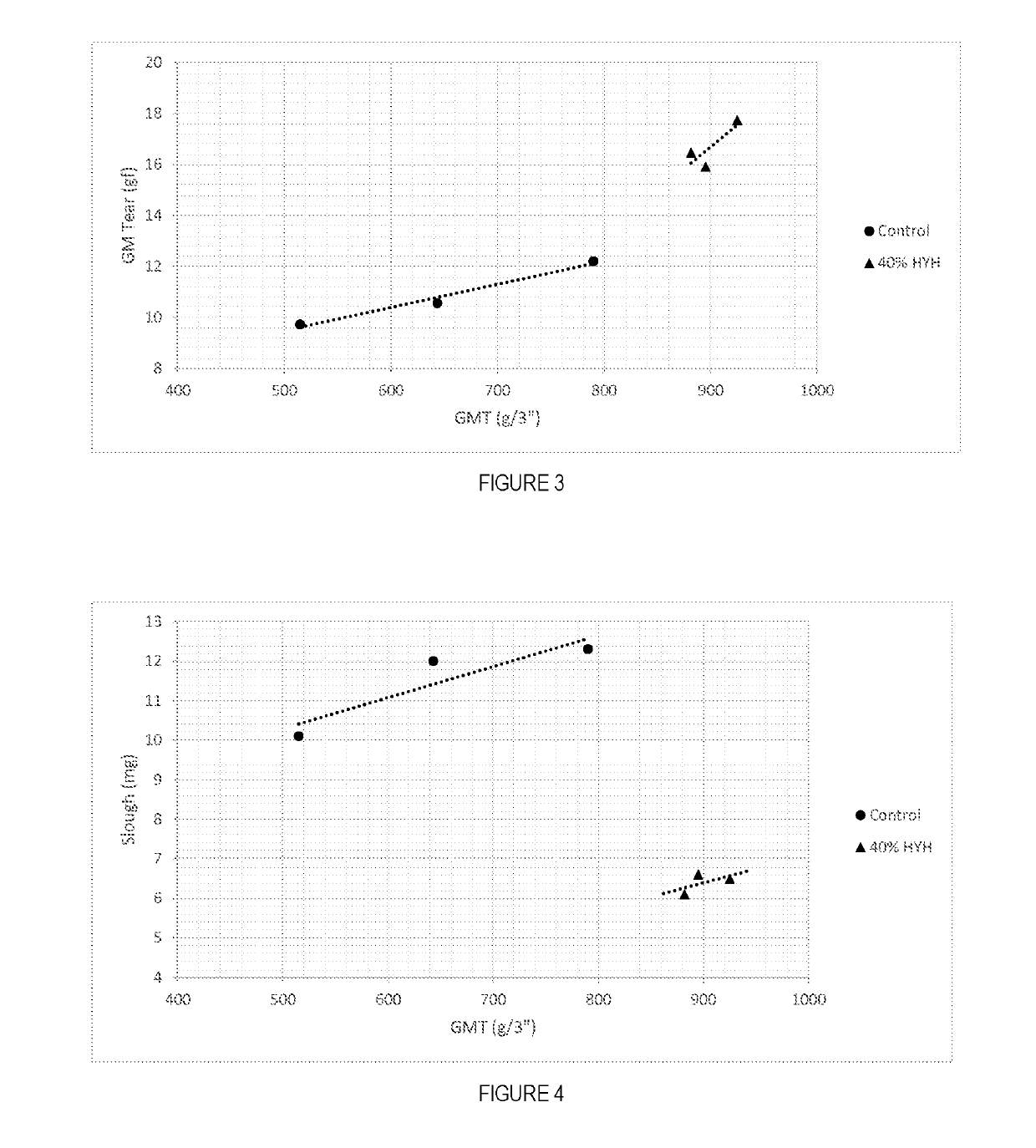

Soft, durable and bulky tissue products comprising non-wood fibers and more particularly high yield hesperaloe pulp fibers are disclosed. The tissue products preferably comprise at least about 5 percent, by weight of the product, high yield hesperaloe pulp fiber and have relatively modest tensile strengths, such as a geometric mean tensile (GMT) less than about 1,000 g / 3″, and improved durability and cross-machine direction (CD) properties, such as a CD Stretch greater than about 10 percent. Additionally, at the foregoing tensile strengths the products are not overly stiff. For example the tissue products may have a Stiffness Index less than about 10.0.

Owner:KIMBERLY-CLARK WORLDWIDE INC

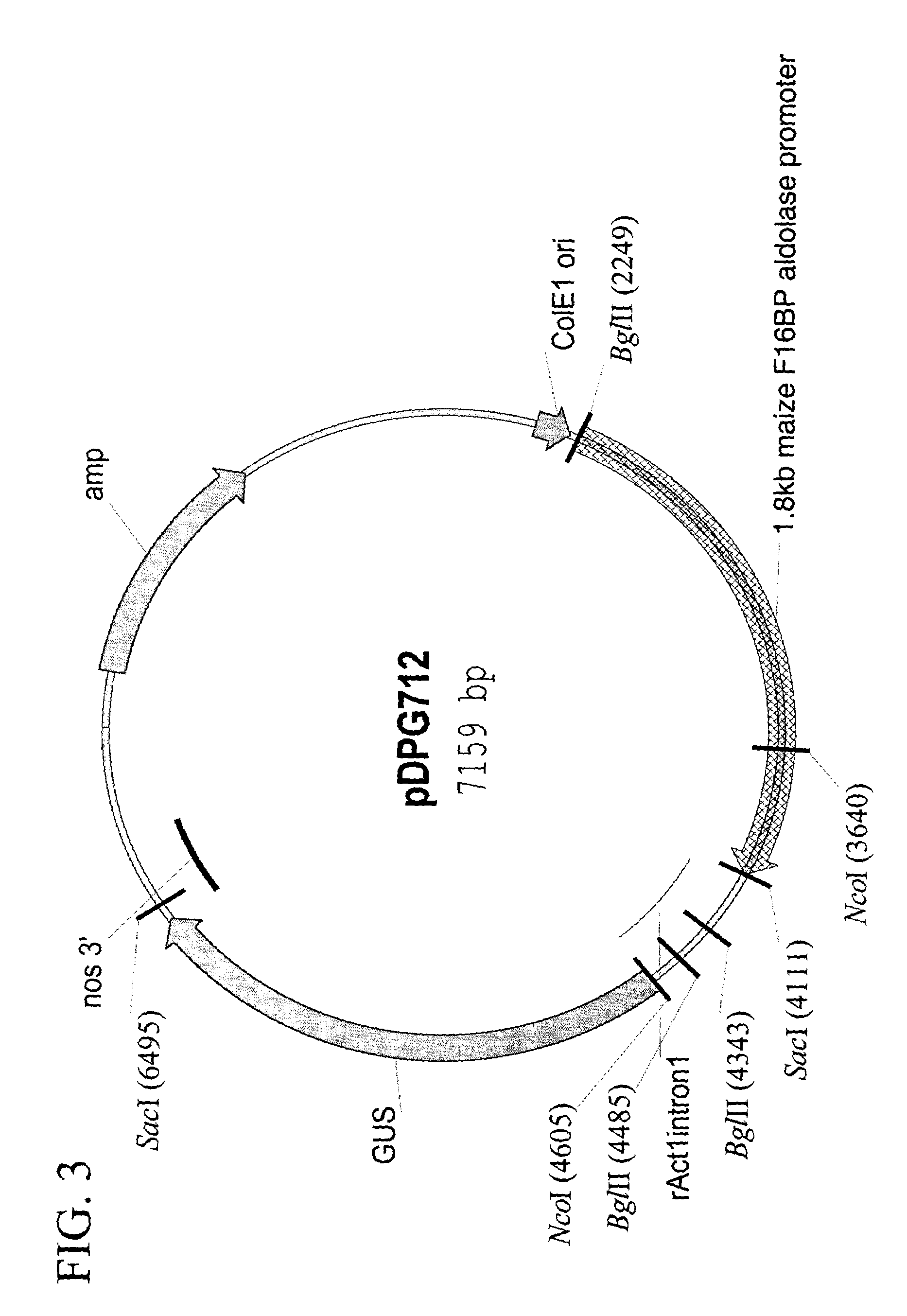

Maize chloroplast aldolase promoter compositions and methods for use thereof

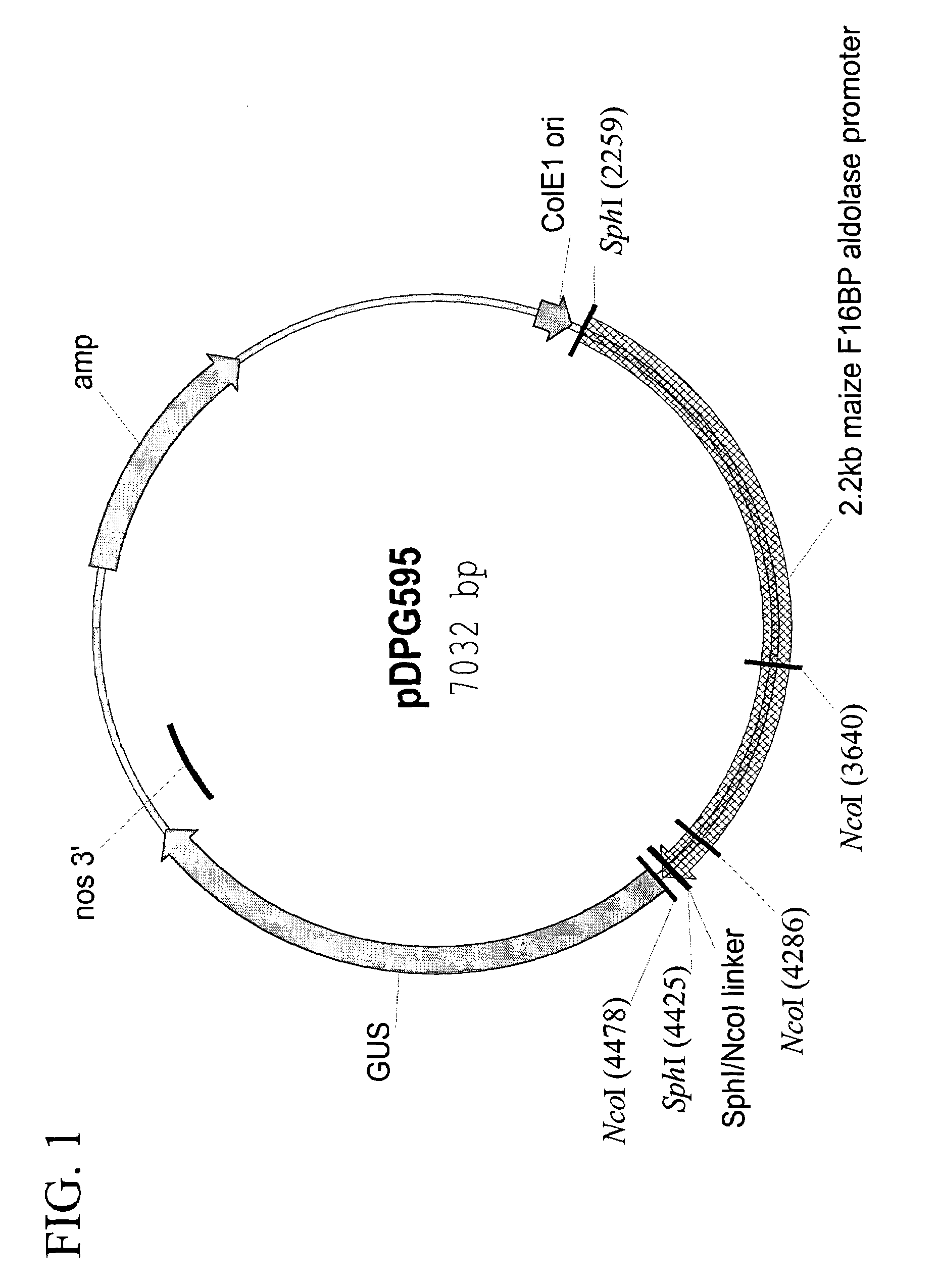

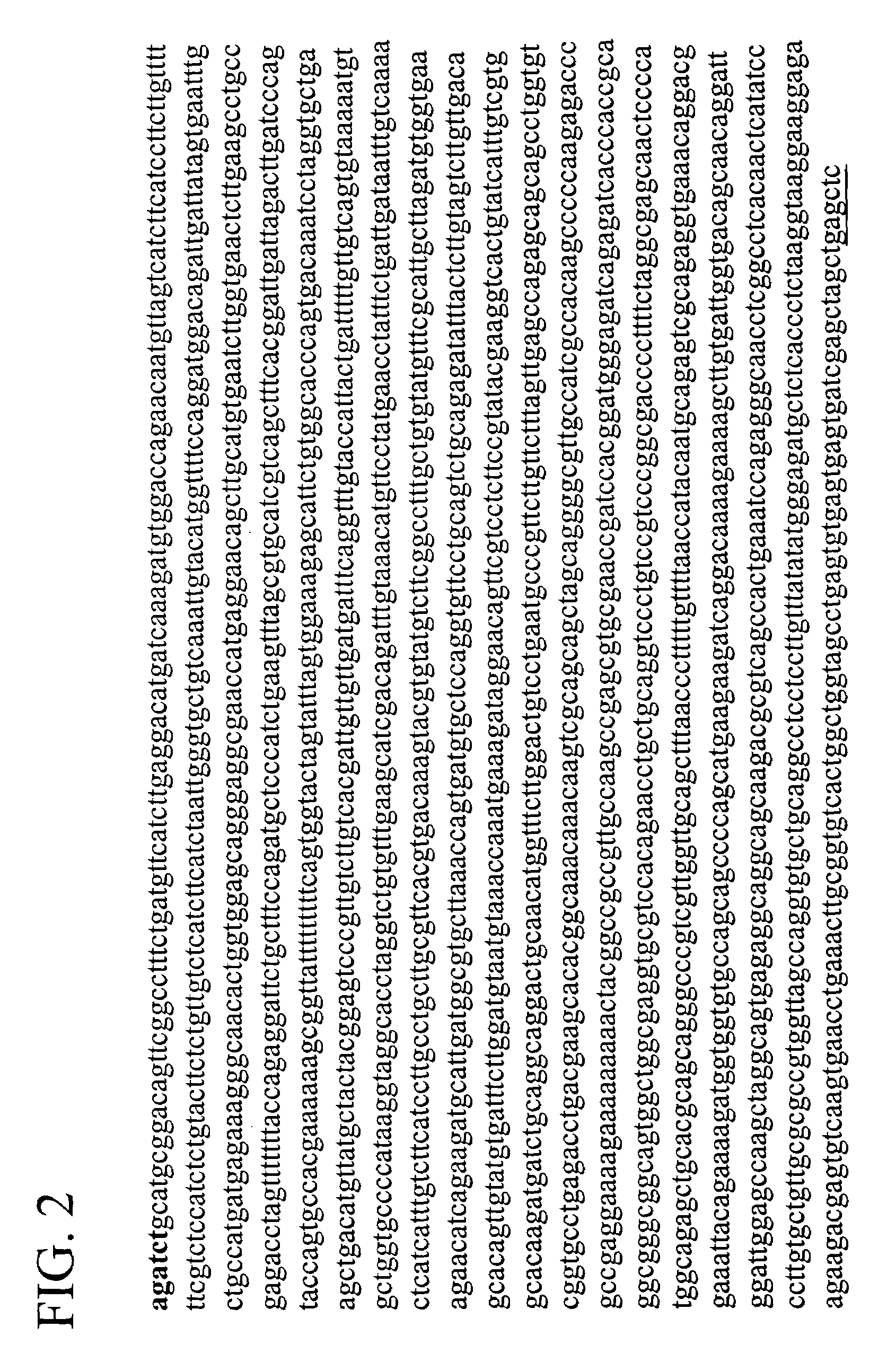

ActiveUS7151204B2Simple compositionQuality improvementSugar derivativesOther foreign material introduction processesFructoseTransgene

The current invention provides the promoter of the Zea mays nuclear gene encoding chloroplast-localized fructose-1,6-bisphosphate (F16BP) aldolase. Compositions comprising this sequence are described, as are plants transformed with such compositions. Further provided are methods for the expression of transgenes in plants comprising the use of these sequences. The methods of the invention include the direct creation of transgenic plants with the chloroplastic F16BP aldolase promoter by genetic transformation, as well as by plant breeding methods. The sequences of the invention represent a valuable new tool for the creation of transgenic plants, preferably having one or more added beneficial characteristics.

Owner:MONSANTO TECH LLC

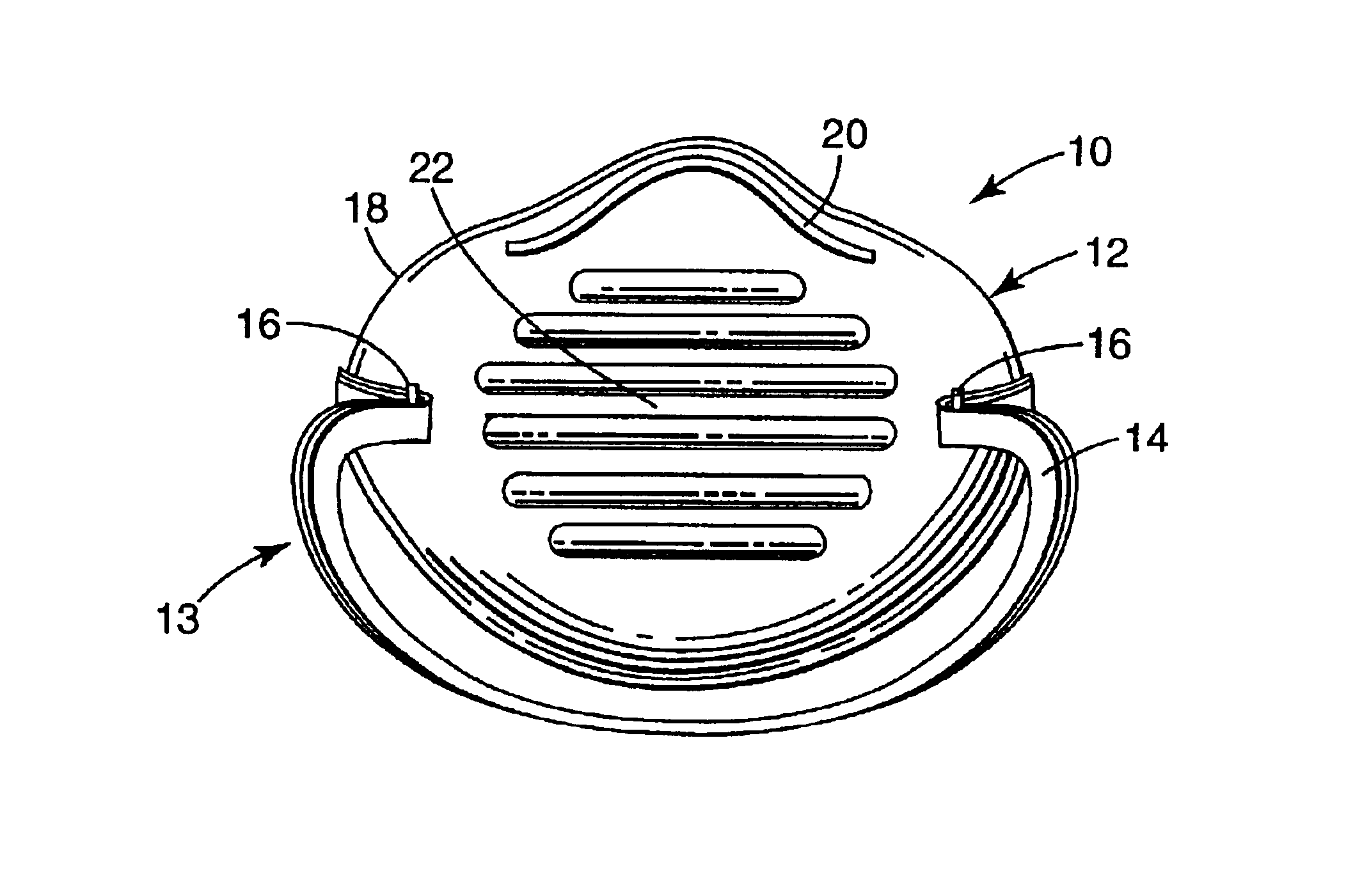

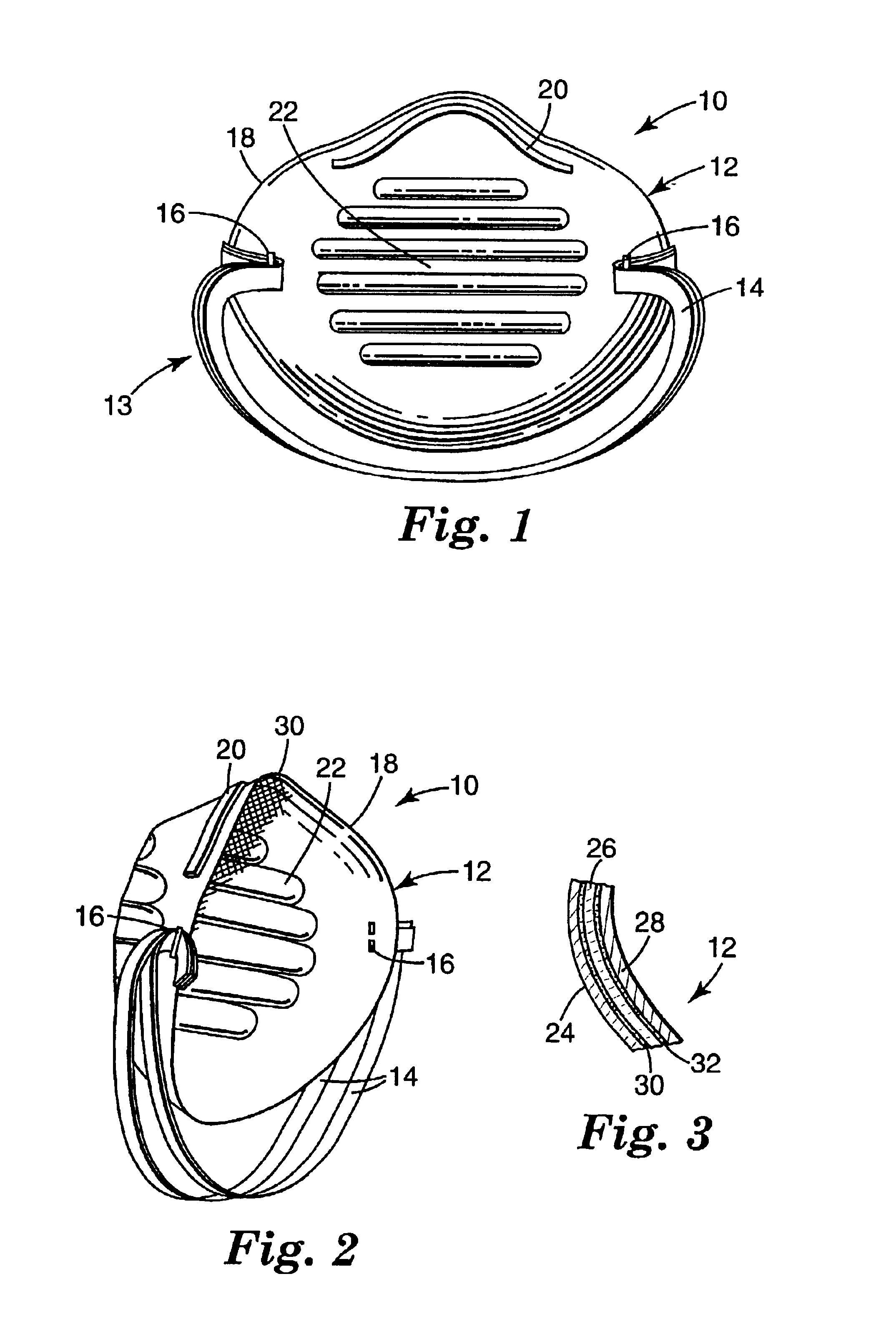

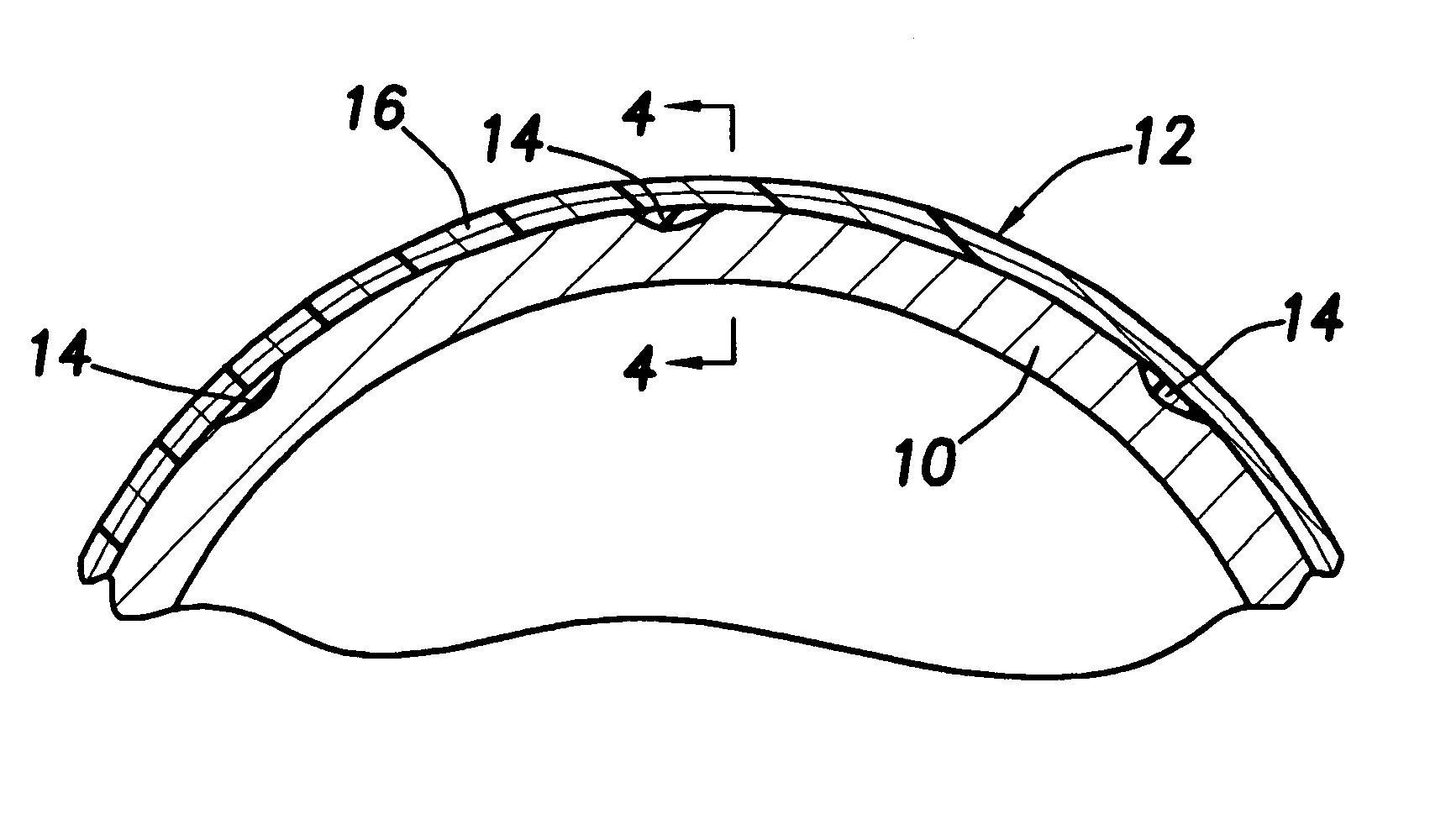

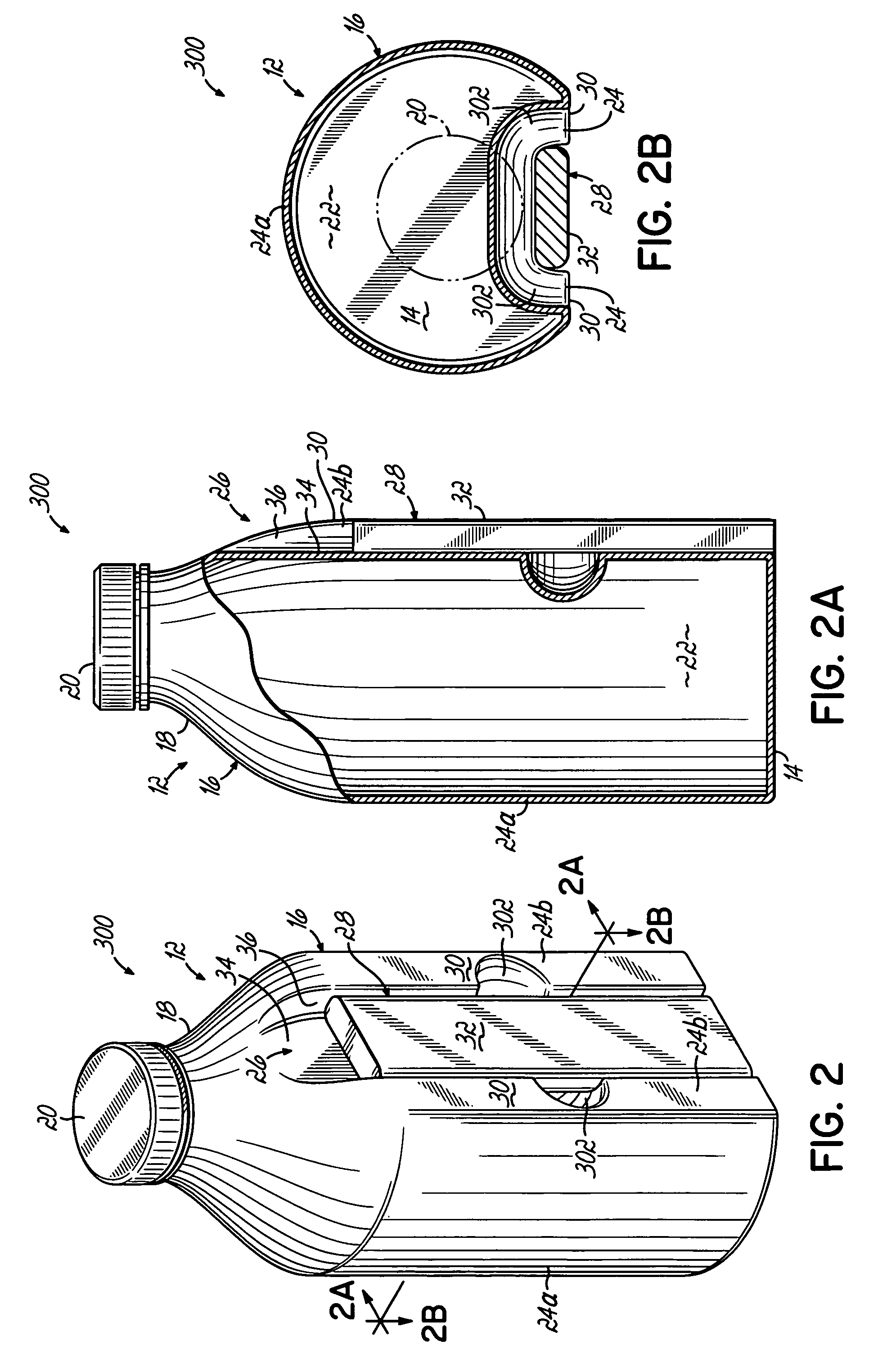

Crush resistant filtering face mask

InactiveUS6923182B2Reduce the possibilityImprove securityBreathing filtersBreathing masksFiltrationNose

A filtering face mask that includes a mask body that is adapted to fit over the nose and mouth of a person and a harness that is attached to the mask body. The mask body comprises i) a first shaping layer that has been molded; ii) a second shaping layer that has been molded; iii) a filtration layer that is disposed between the first and second shaping layers; iv) a first adhesive layer that adheres the first shaping layer to the filtration layer; and v) a second adhesive layer that adheres the second shaping layer to the filtration layer.

Owner:3M INNOVATIVE PROPERTIES CO

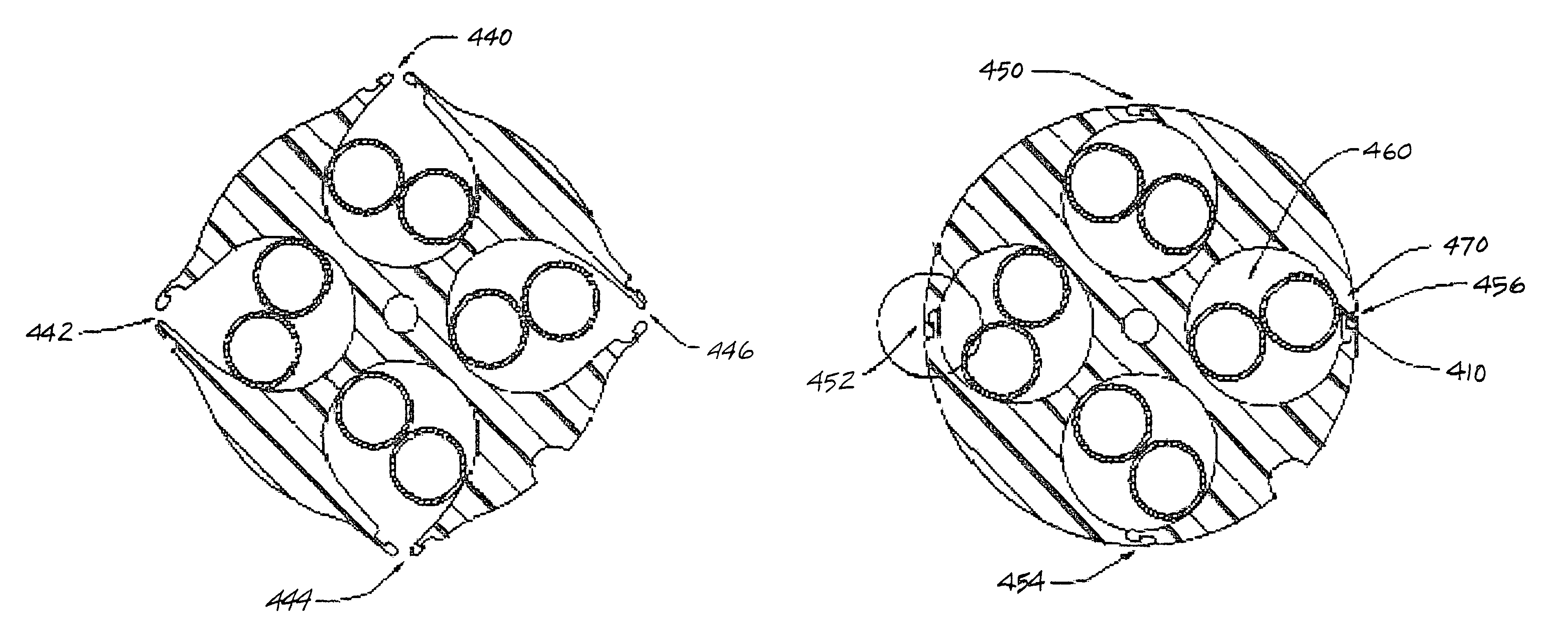

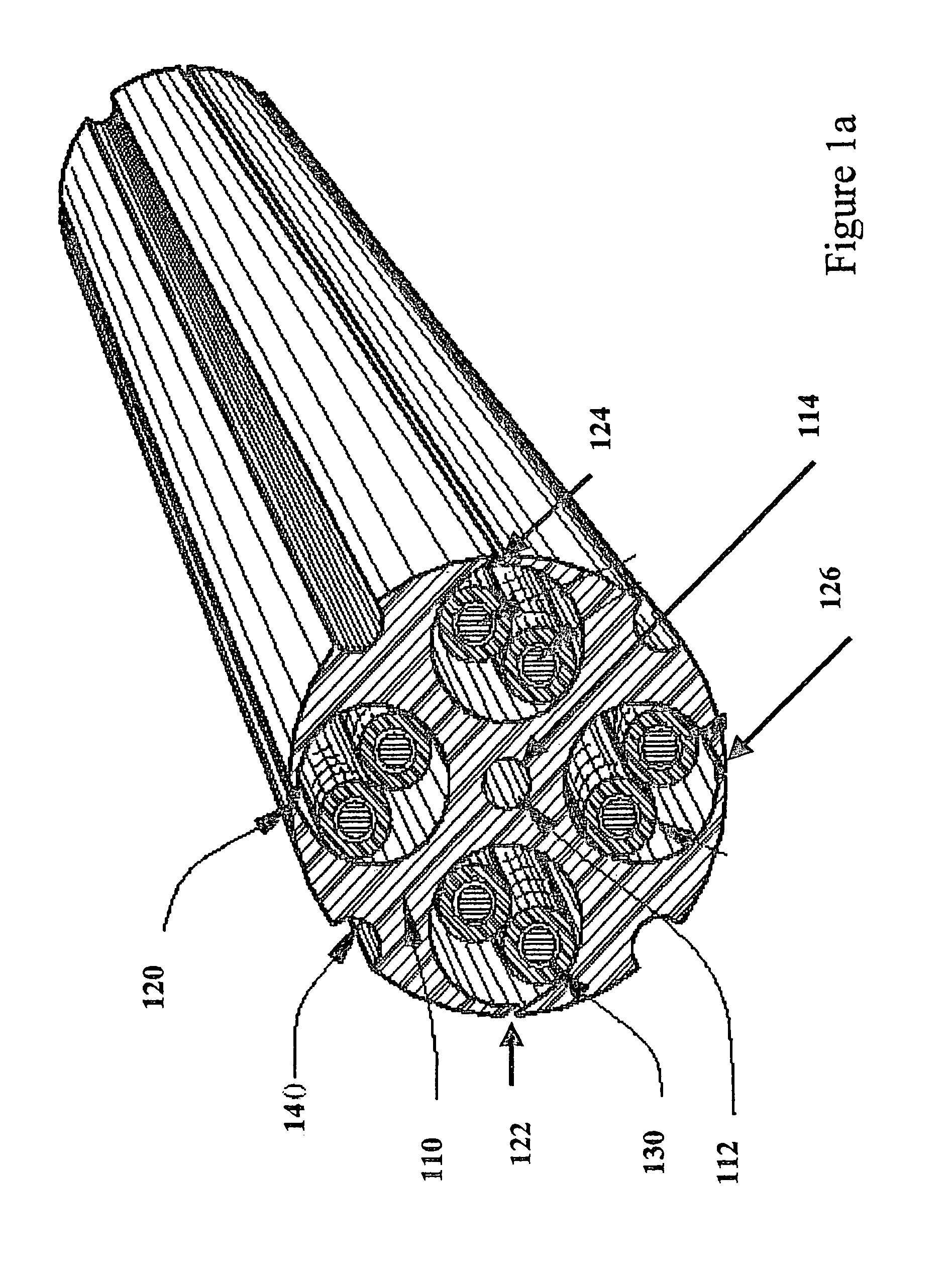

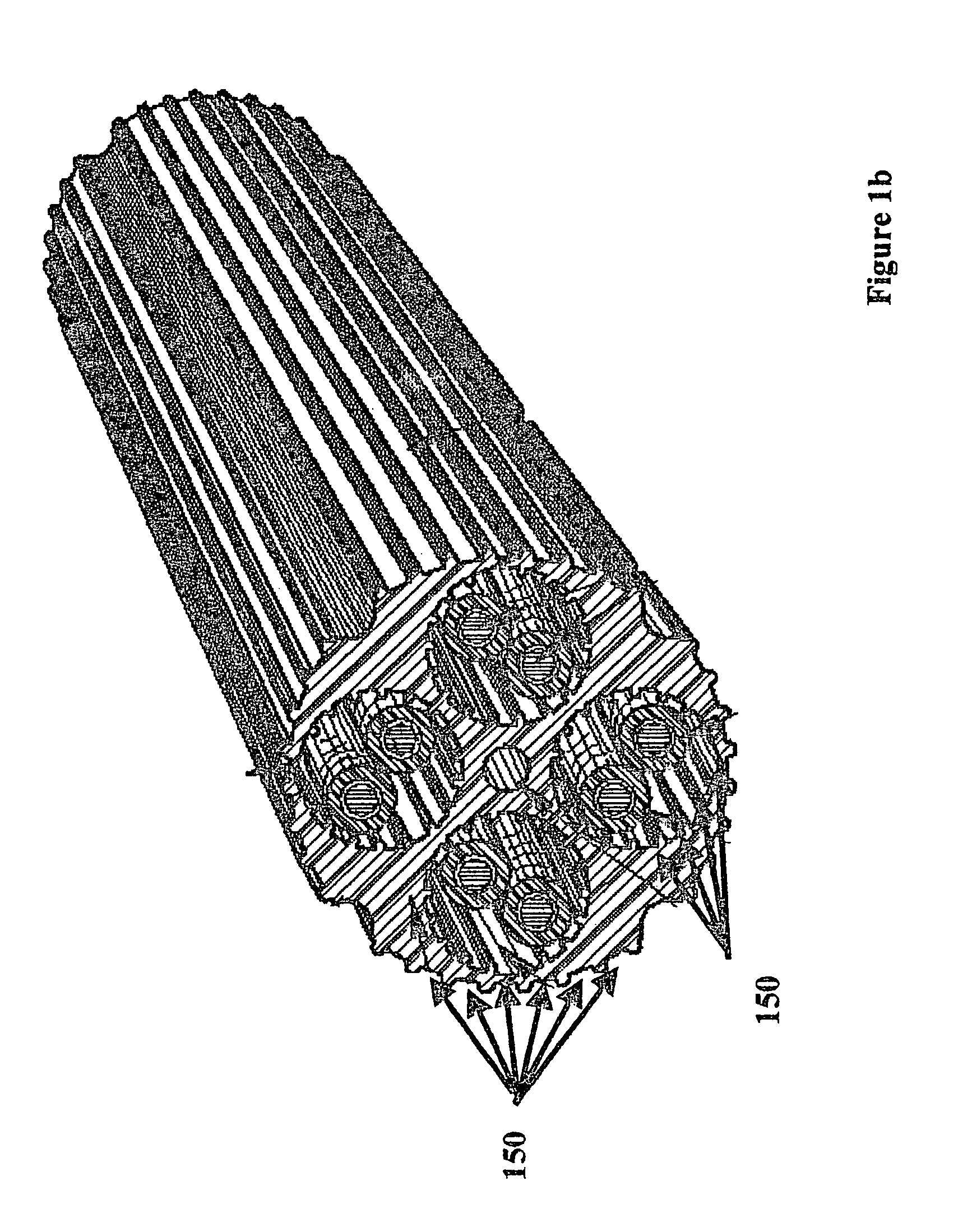

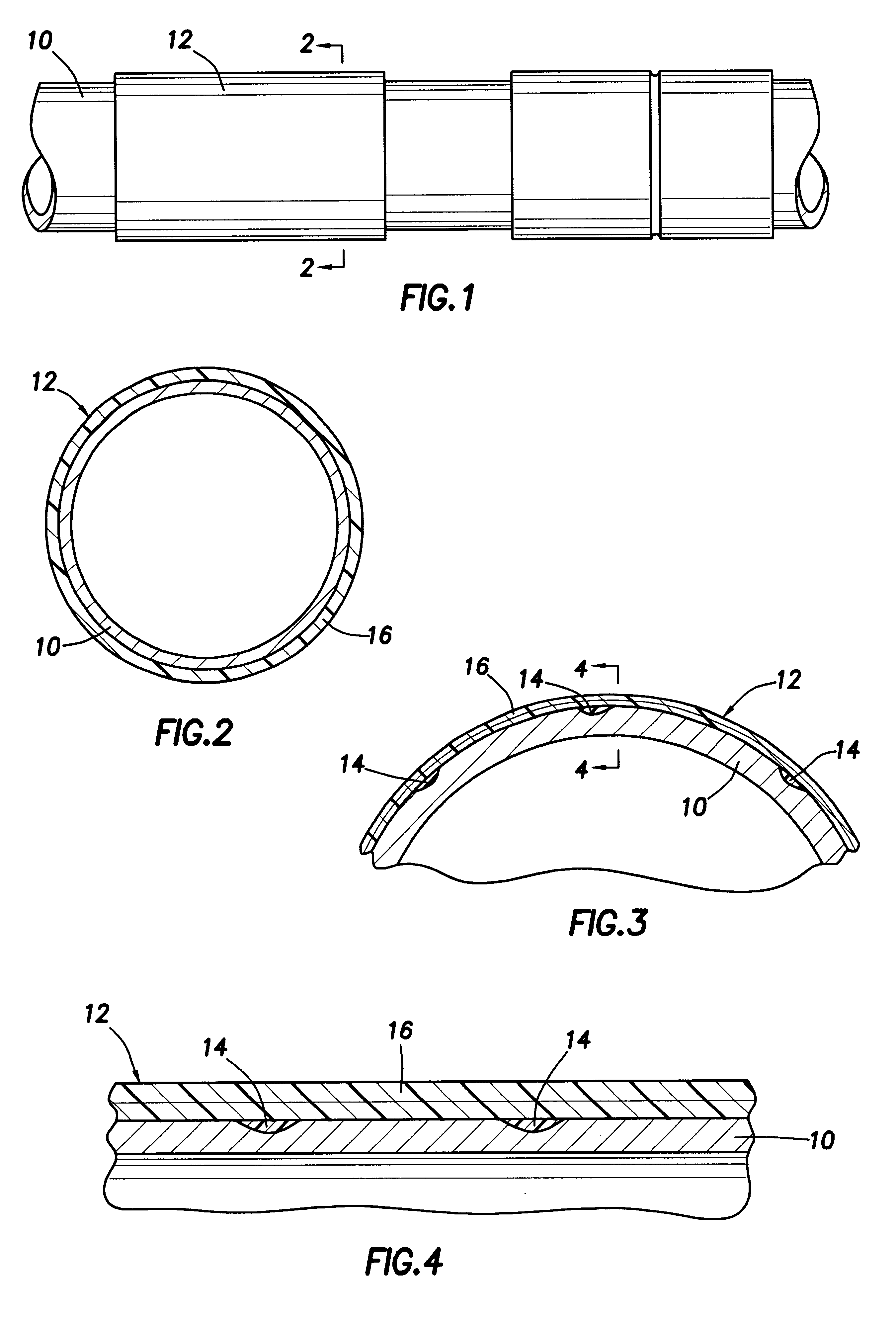

High performance support-separator for communications cables

InactiveUS7098405B2Improve NEXT controlReduce needInsulated cablesOptical light guidesElectrical conductorHigh performance communication

The present invention includes a high performance communications cable for transmission media that includes core support-separators which define clearance channels to maintain spacing between transmission media or transmission media pairs. The core support-separator can be either interior to a cable jacket or be employed singularly without the benefit of a jacket and extends along the longitudinal length of the communications cable. The core support-separator has a central region that may include flap-tops along the radial edge that are available for partial or complete sealing of the clearance channels during manufacturing operations. The central region may also include a hollow center portion and include various geometric shapes to provide proper spacing between conductors. Each of the defined clearance channels allow for disposal therein of metal conductors and / or optical fibers.

Owner:CABLE COMPONENTS GROUP

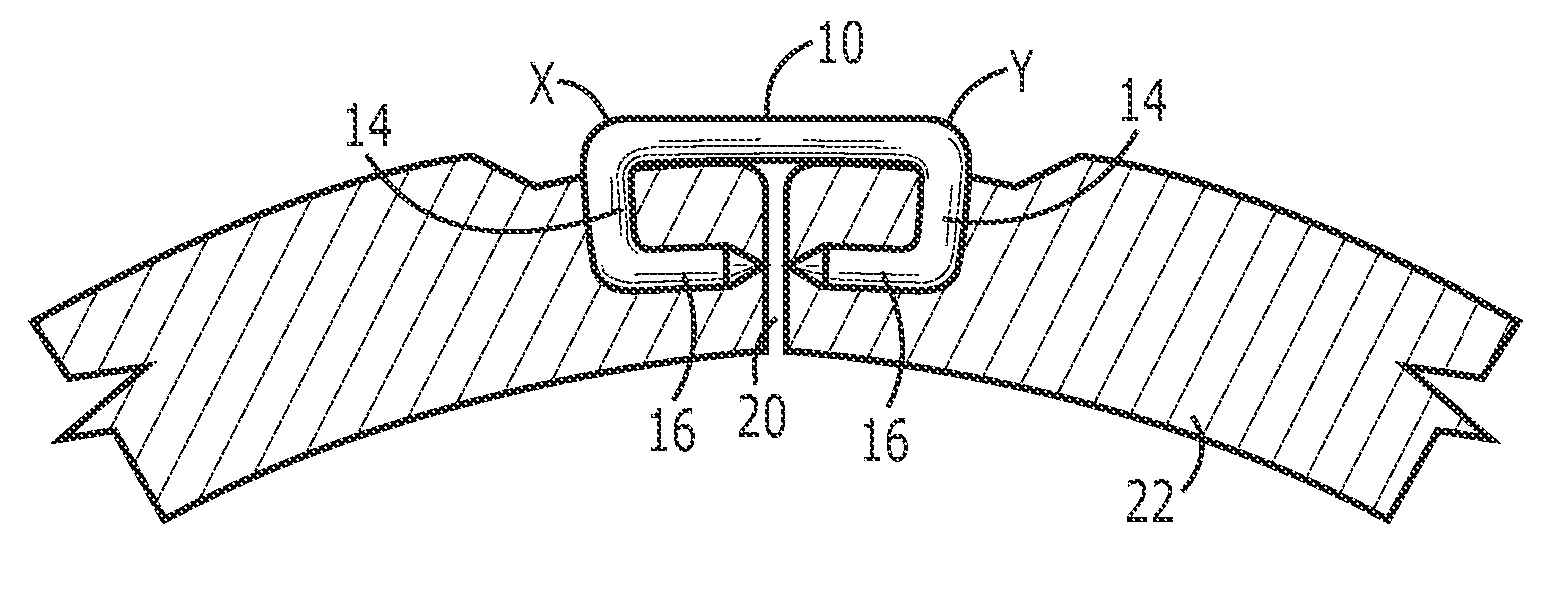

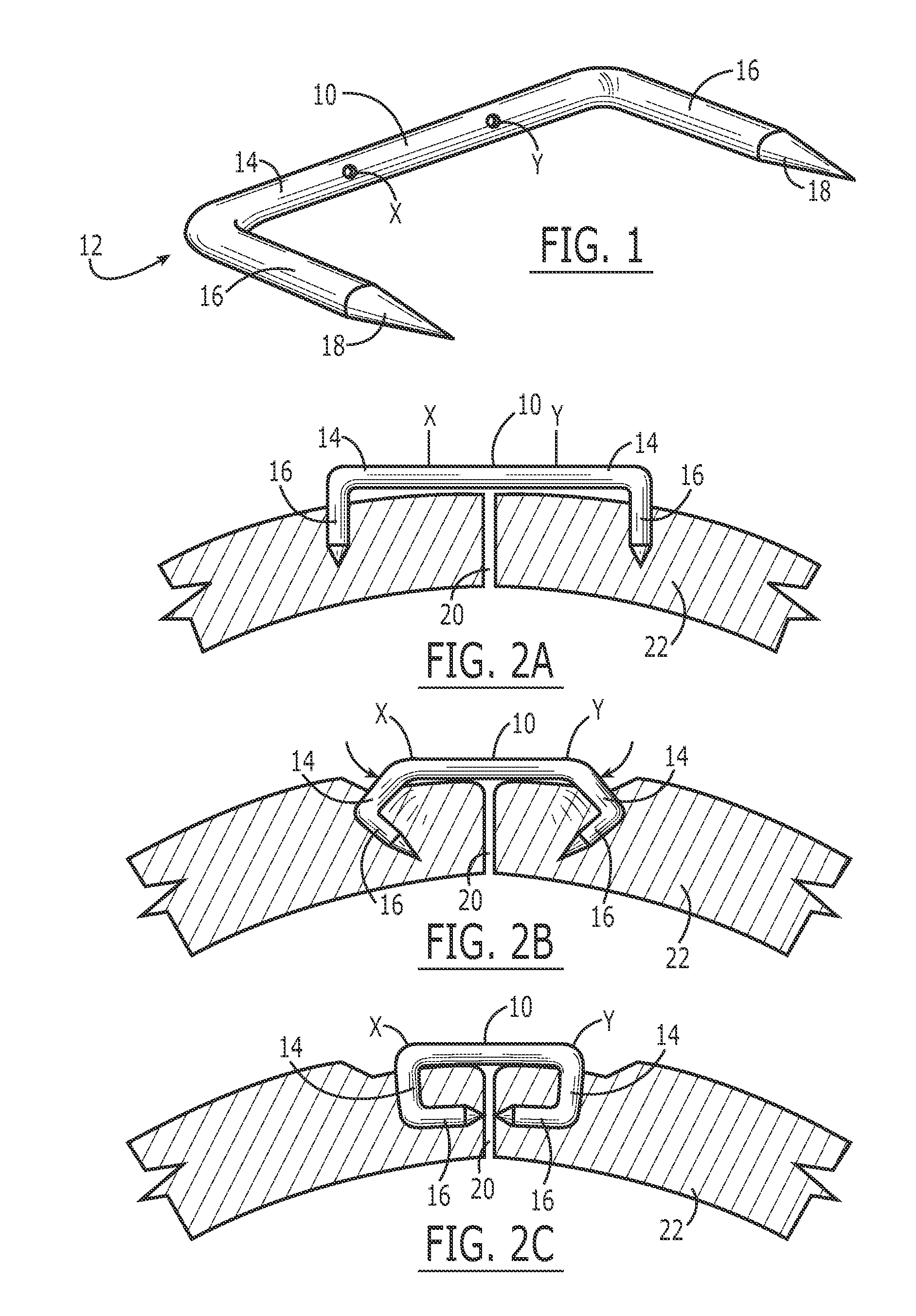

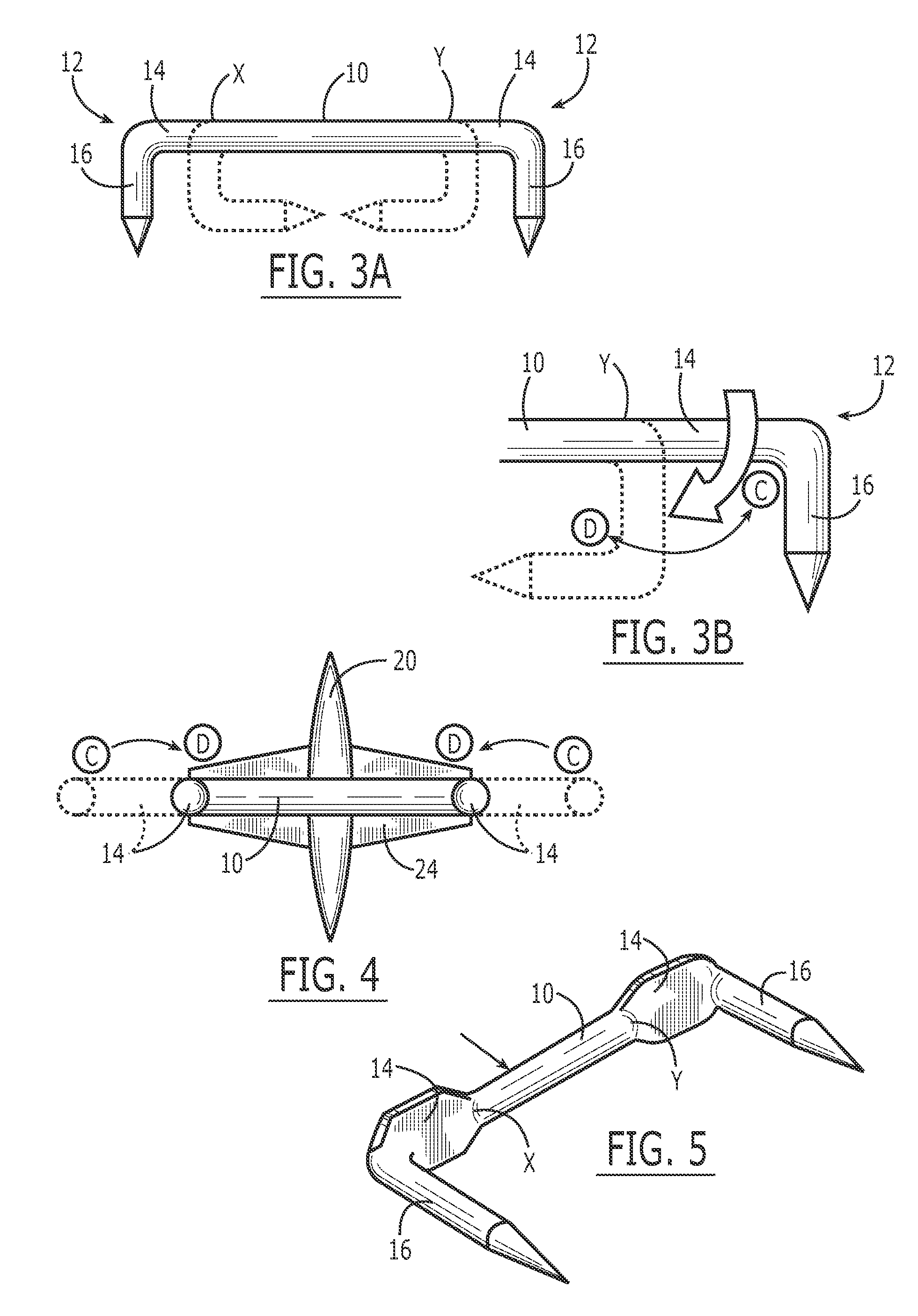

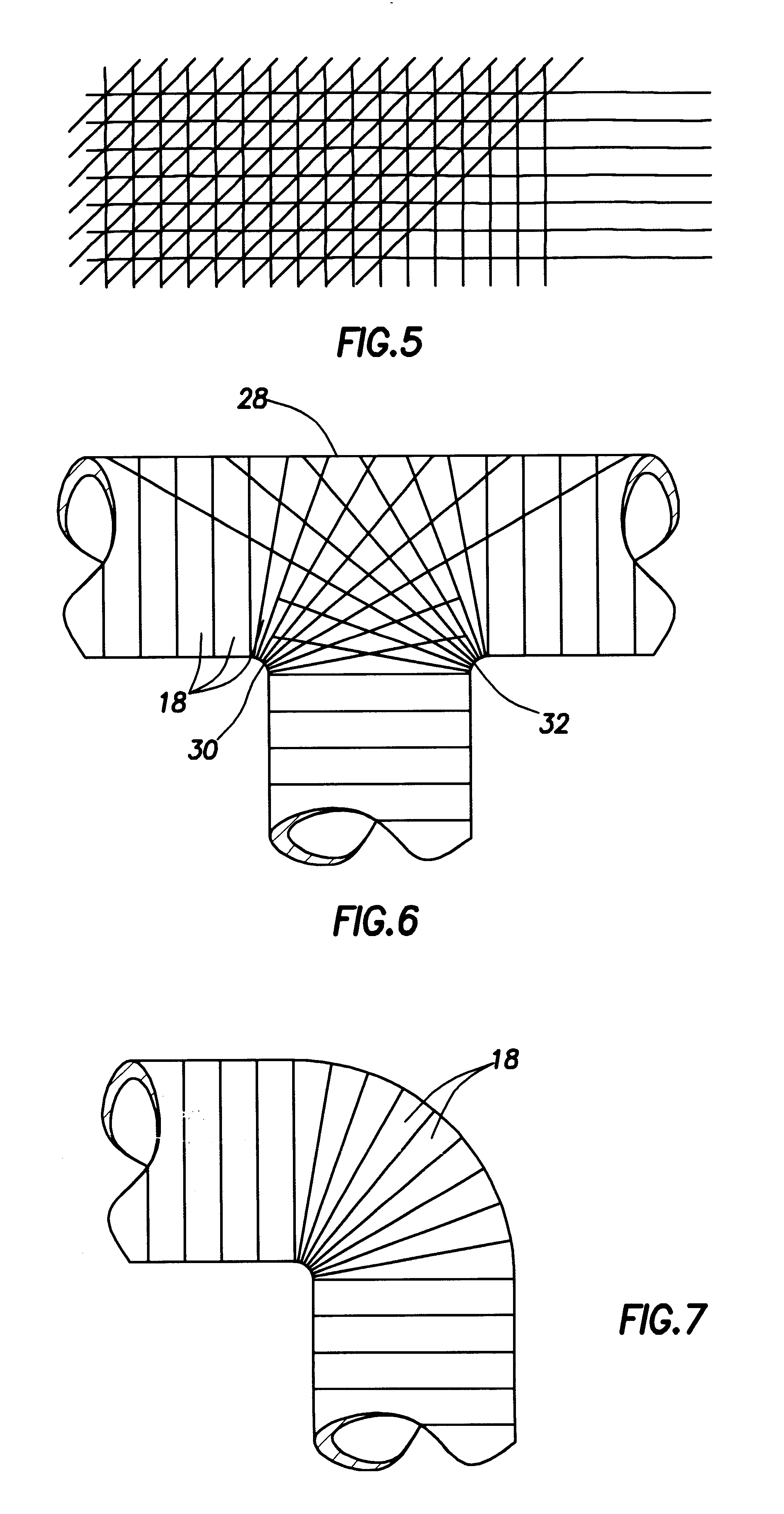

Surgical Staple

InactiveUS20070010854A1Increased area of compressionIncrease the areaStaplesNailsSurgical stapleEngineering

A generally U-shaped surgical staple comprises a base 10 and a pair of generally “L”-shaped legs 12 extending substantially perpendicularly from opposite ends of the base respectively. The legs 12 in use of the staple are bent through approximately 90° relative to the base. To effect a greater compression of the stapled tissue the legs include a penetrative portion 16 adjacent the tip and a compressive structure 30 which, due to its increased height relative to that of the penetrative portion, spreads the compressive forces of the staple further along the length of the incision being closed. The compressive portion also provides a depth stop to avoid the tip penetrating too deeply into the tissue in which it is deployed.

Owner:ABBOTT CARDIOVASCULAR

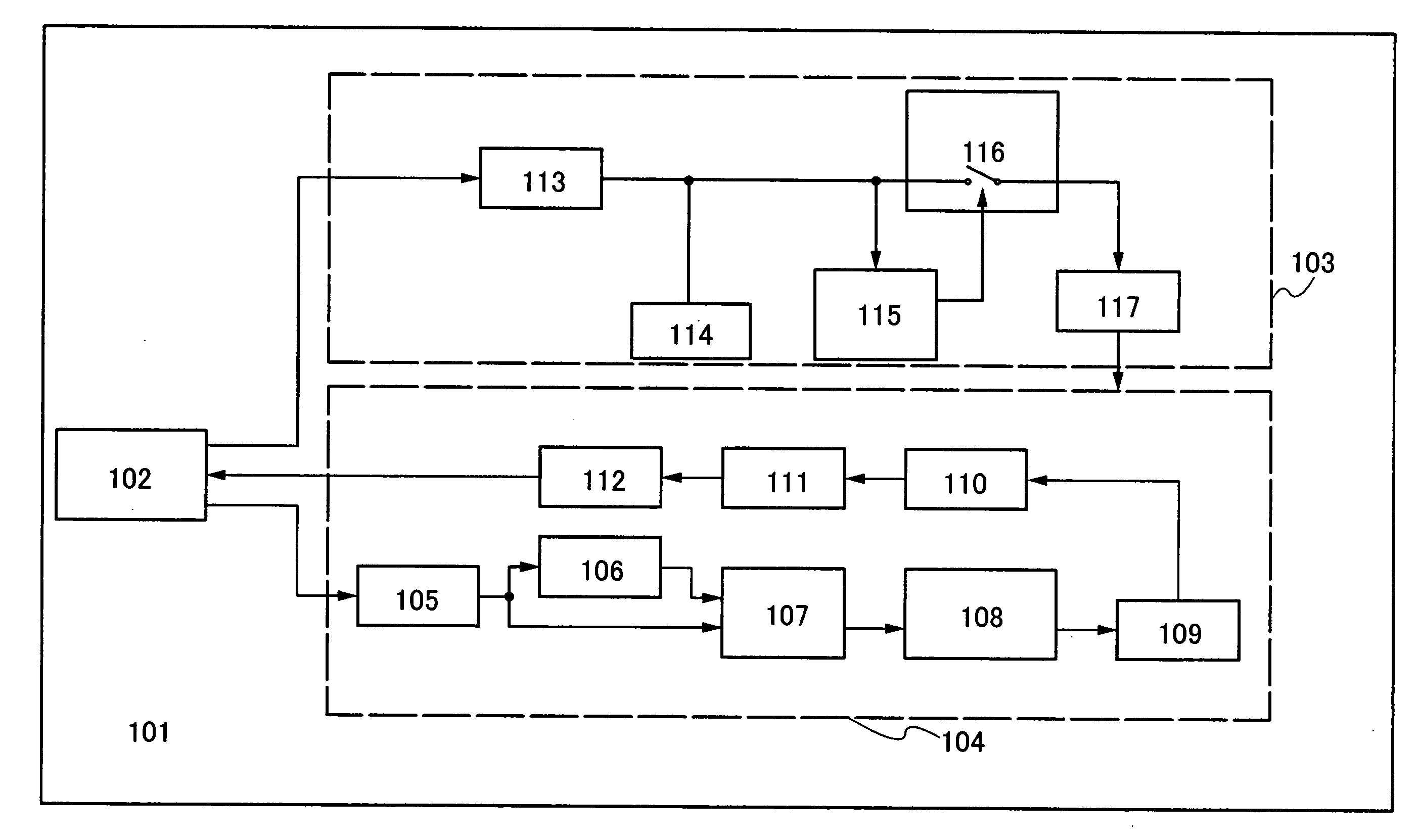

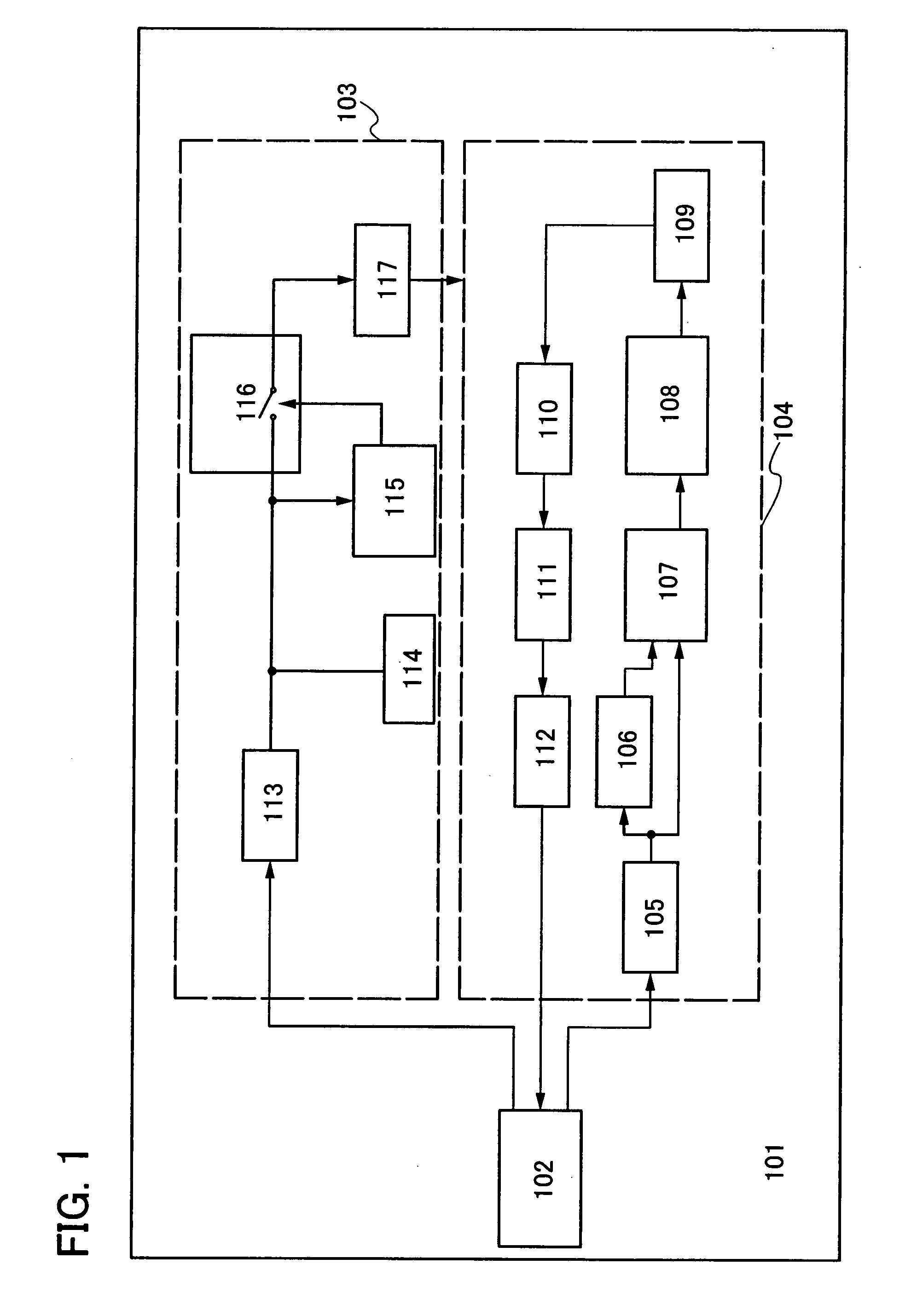

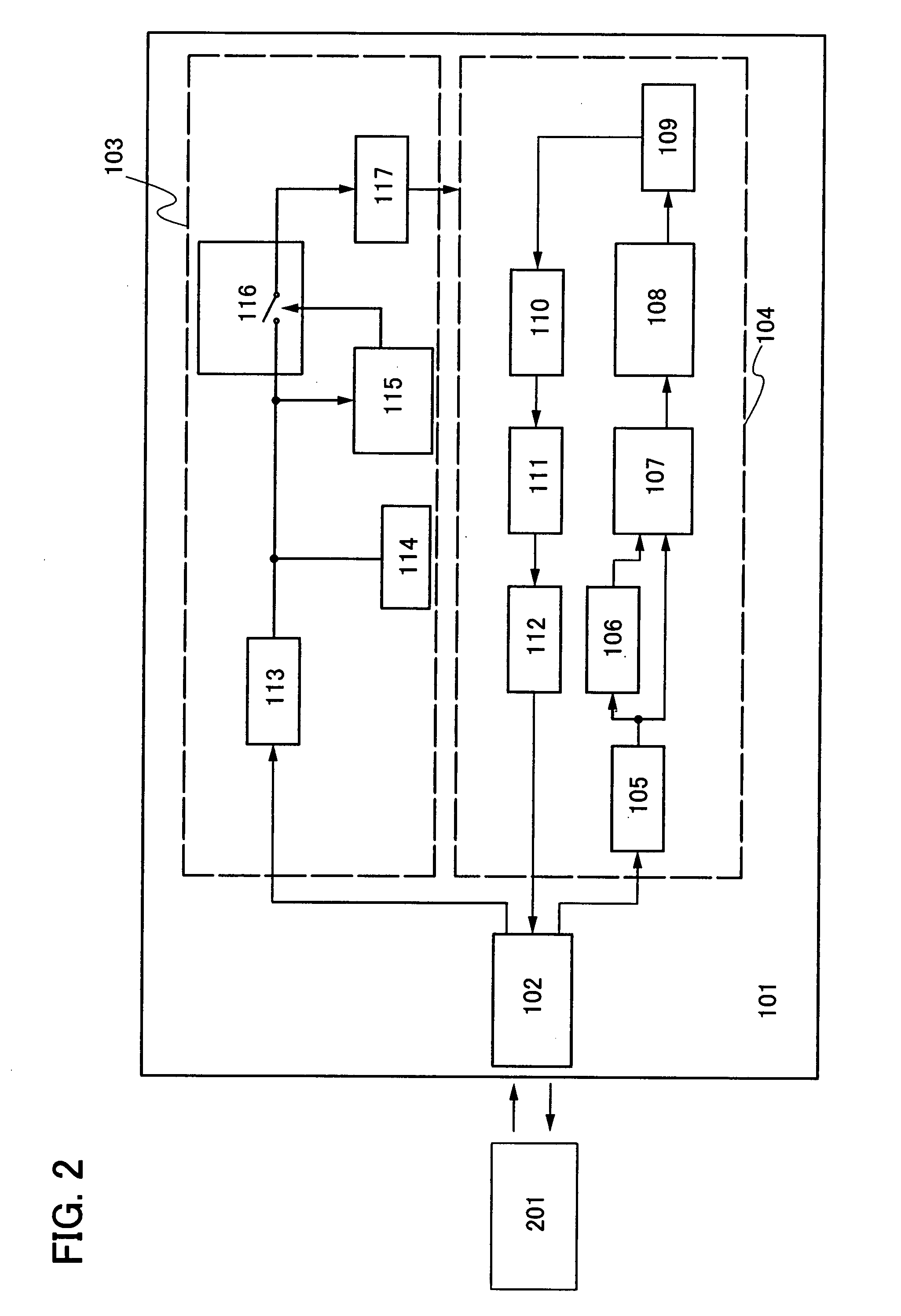

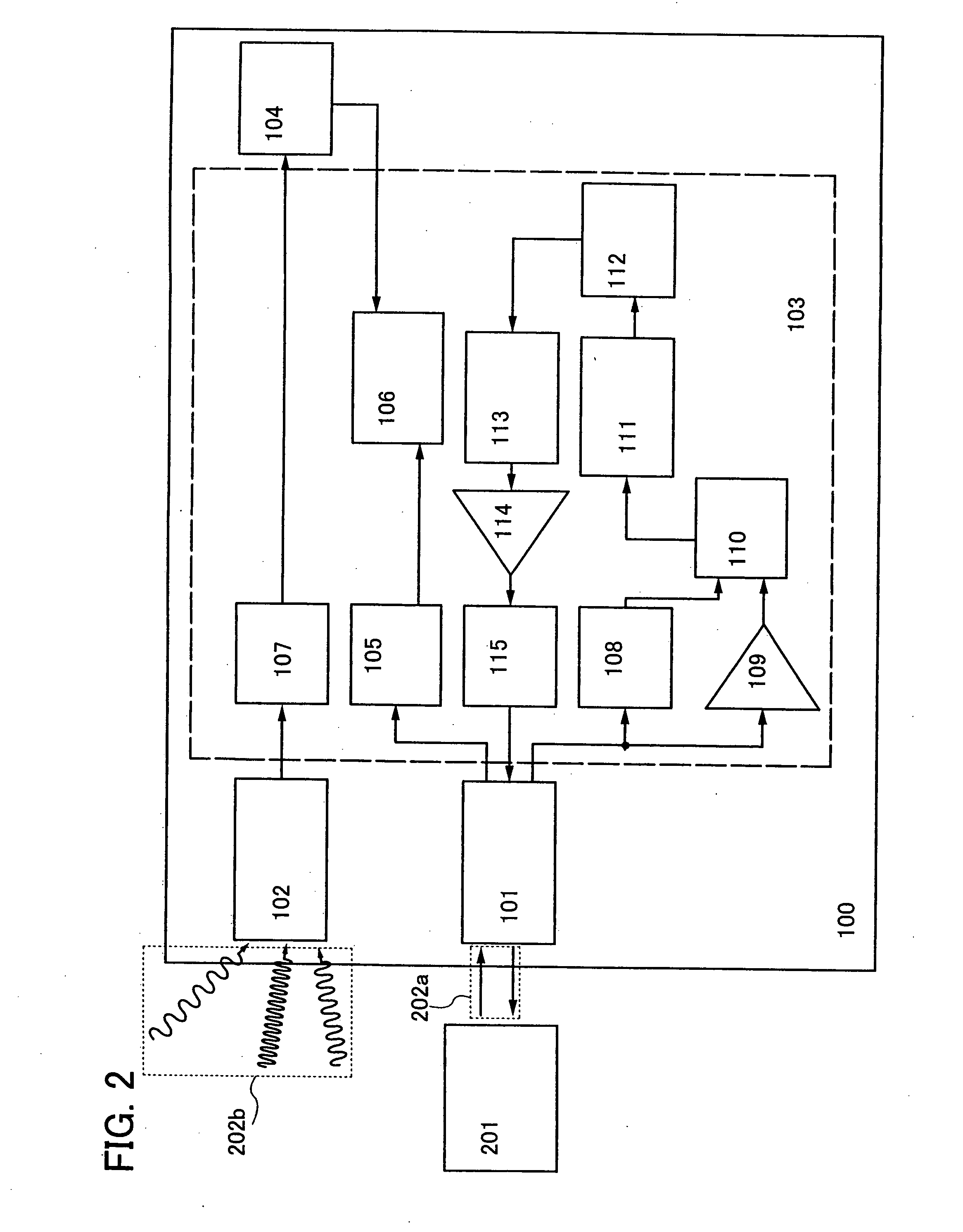

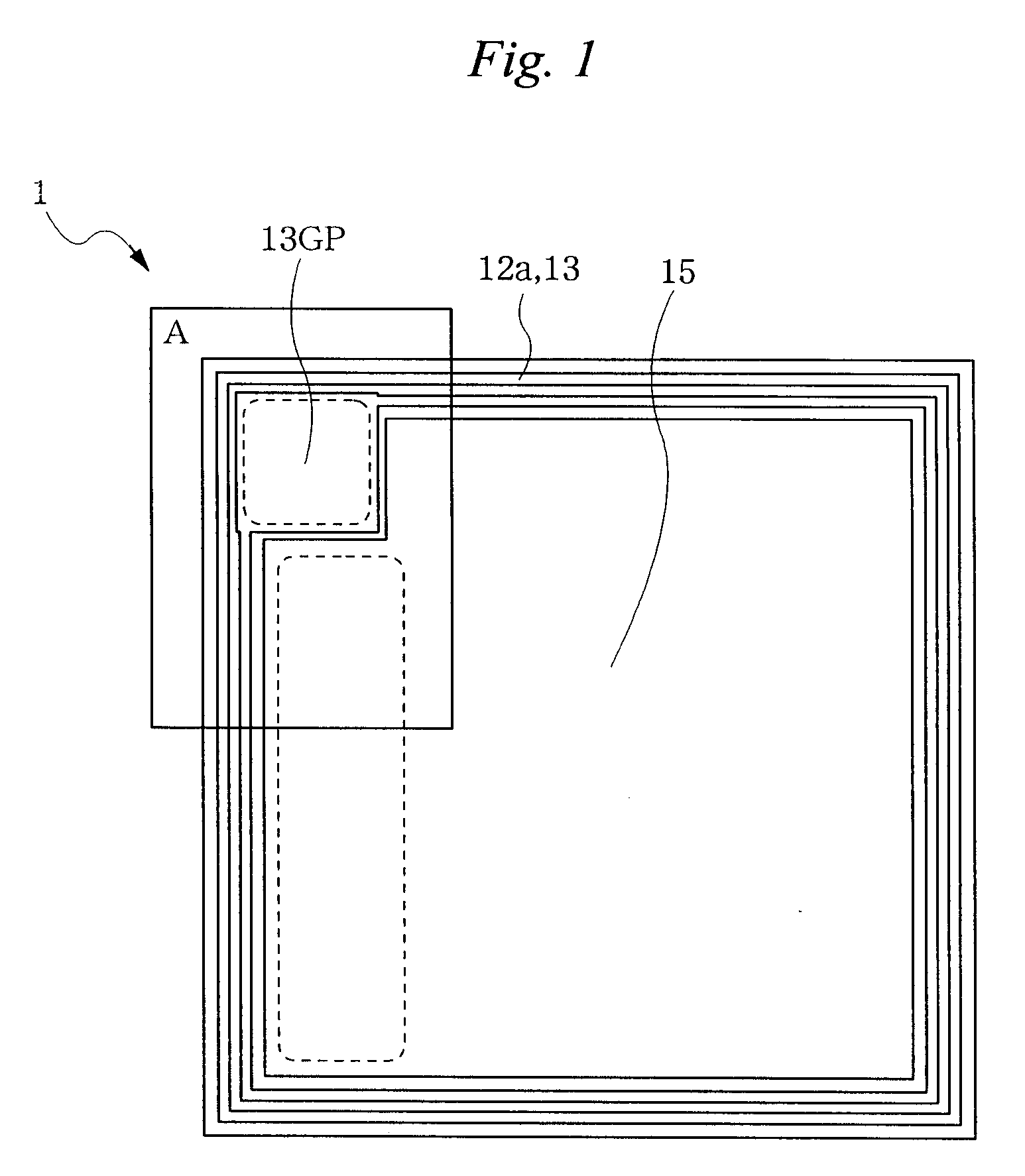

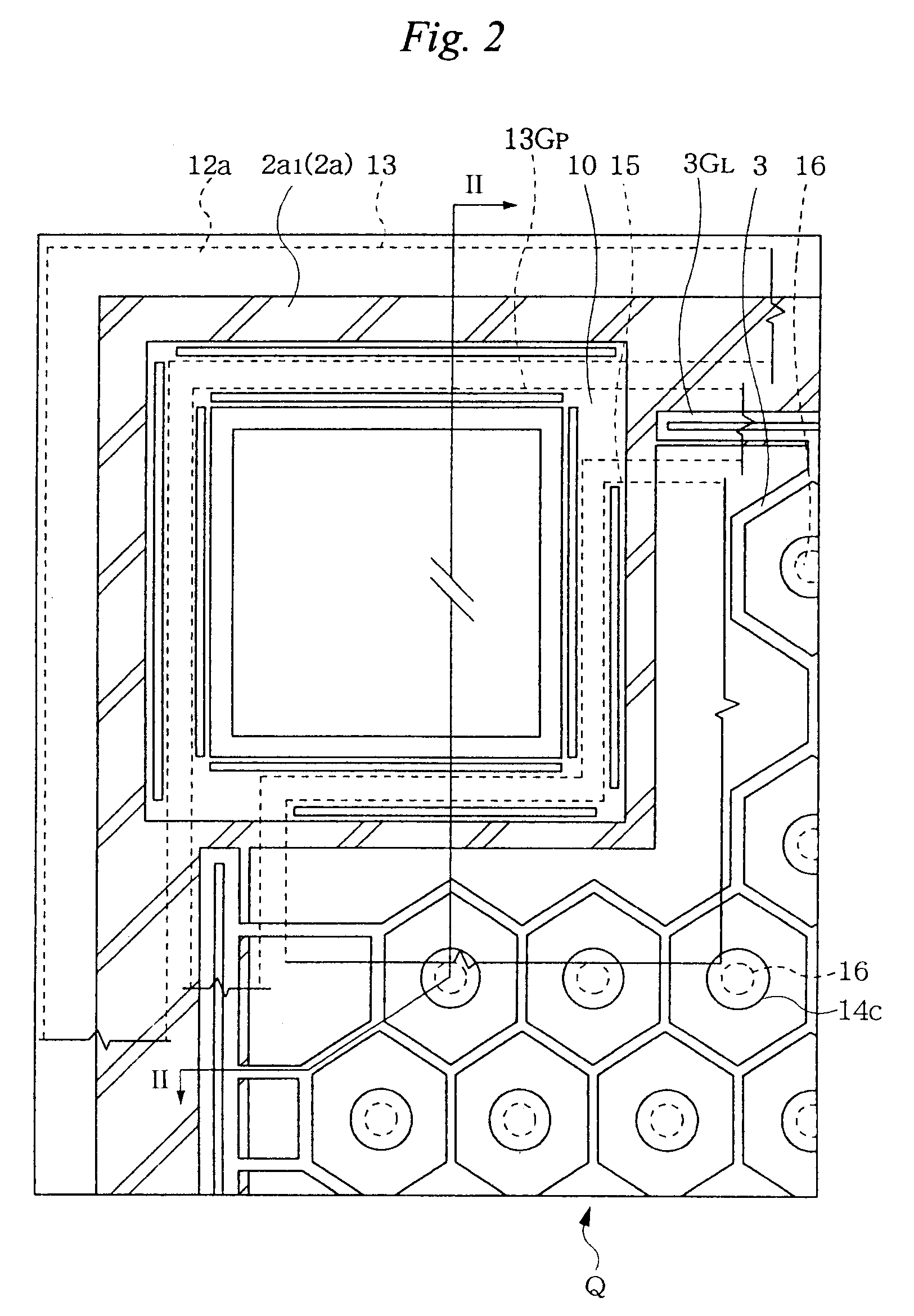

Semiconductor device and IC label, IC tag, and IC card having the same

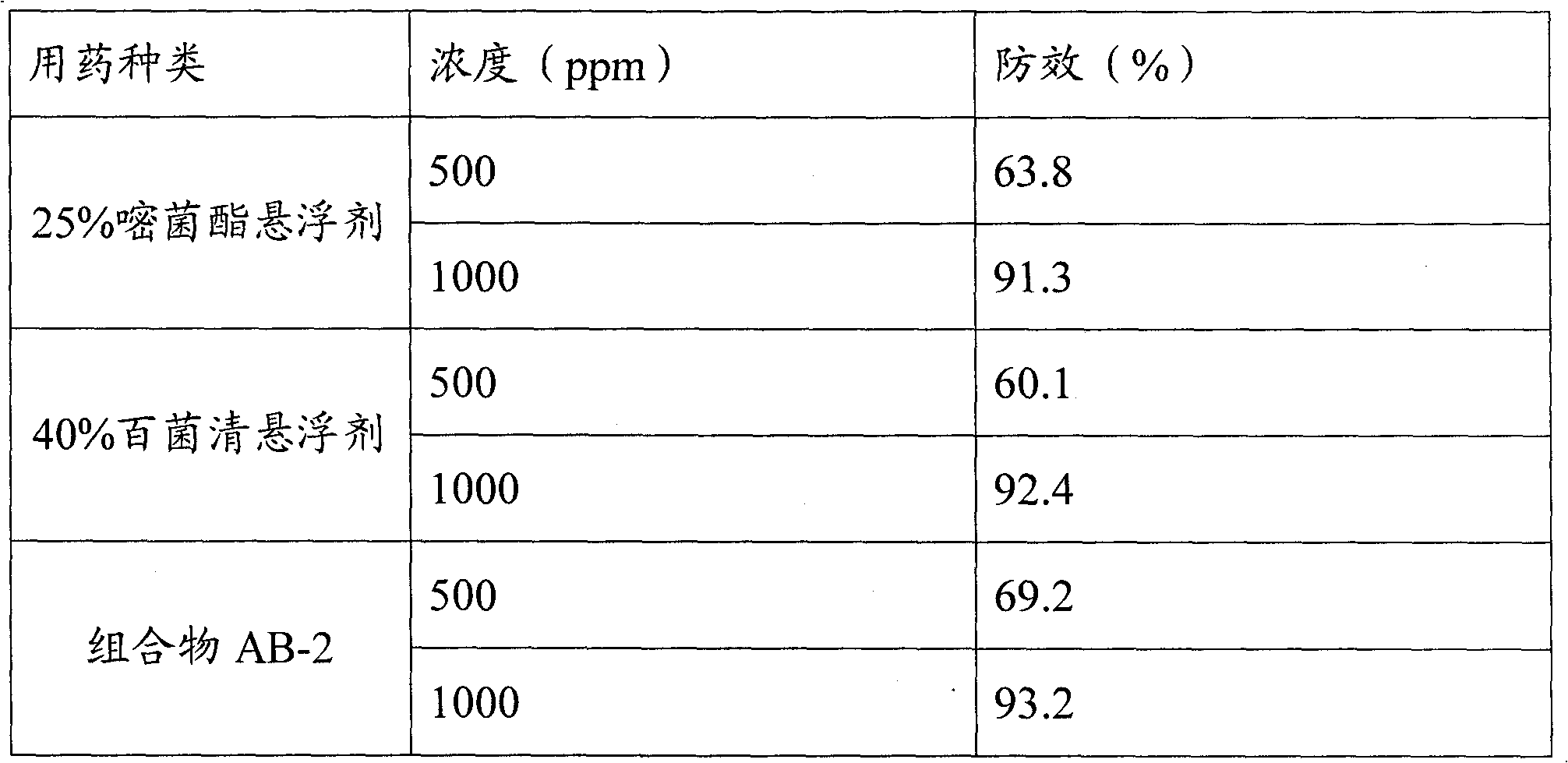

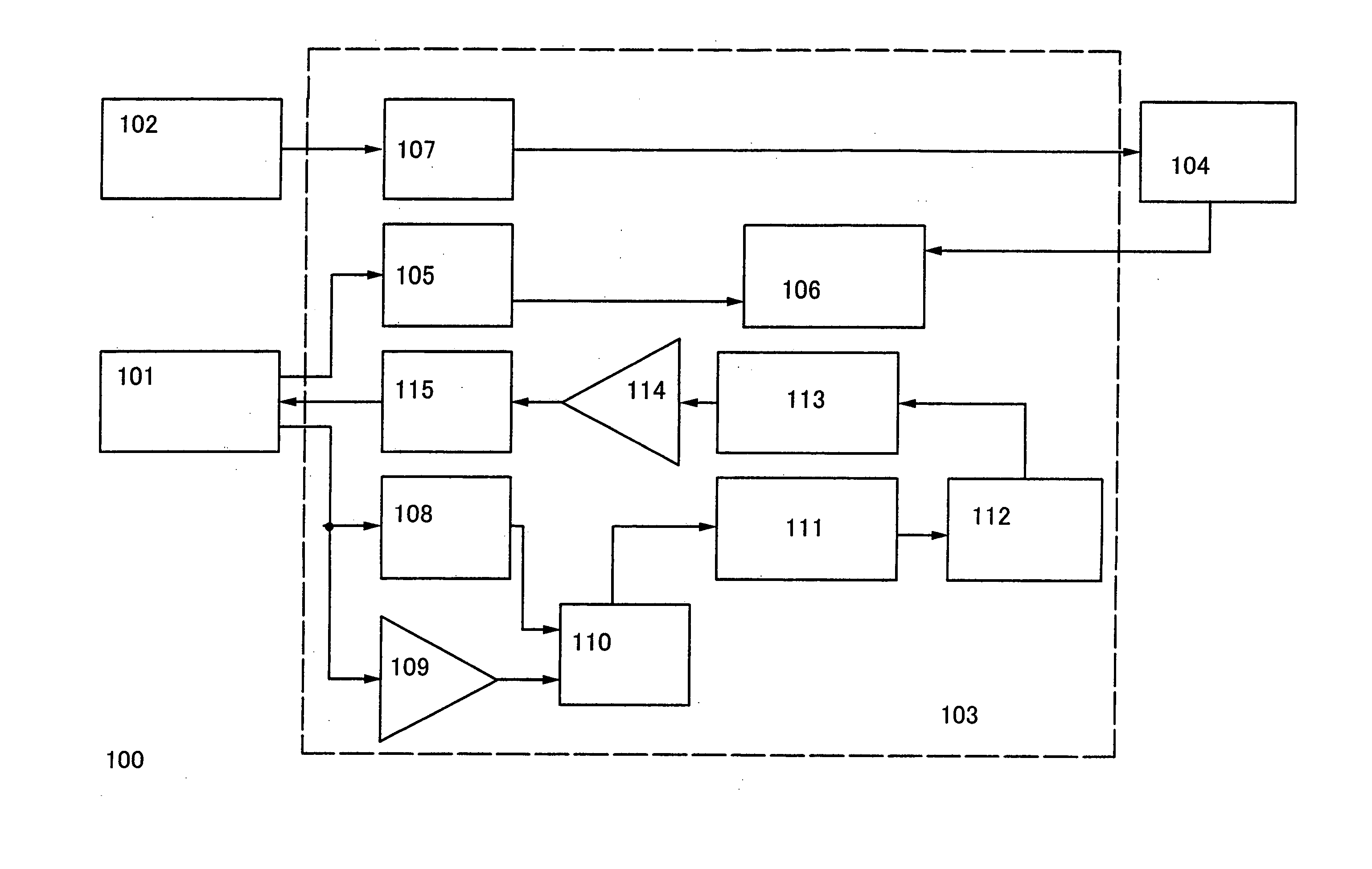

ActiveUS20070285246A1Power shortageDeterioration over time of battery can be preventedNear-field transmissionBatteries circuit arrangementsEngineeringPower circuits

The present invention provides a power supply circuit provided with a battery as a power source for supplying power to an RFID, and the battery of the power supply circuit is charged with a wireless signal. Then, a switching circuit is provided in the power supply circuit that supplies power to a signal control circuit which transmits and receives individual information to and from the outside to intermittently control supply of power to the signal control circuit by a signal from a low-frequency signal generation circuit.

Owner:SEMICON ENERGY LAB CO LTD

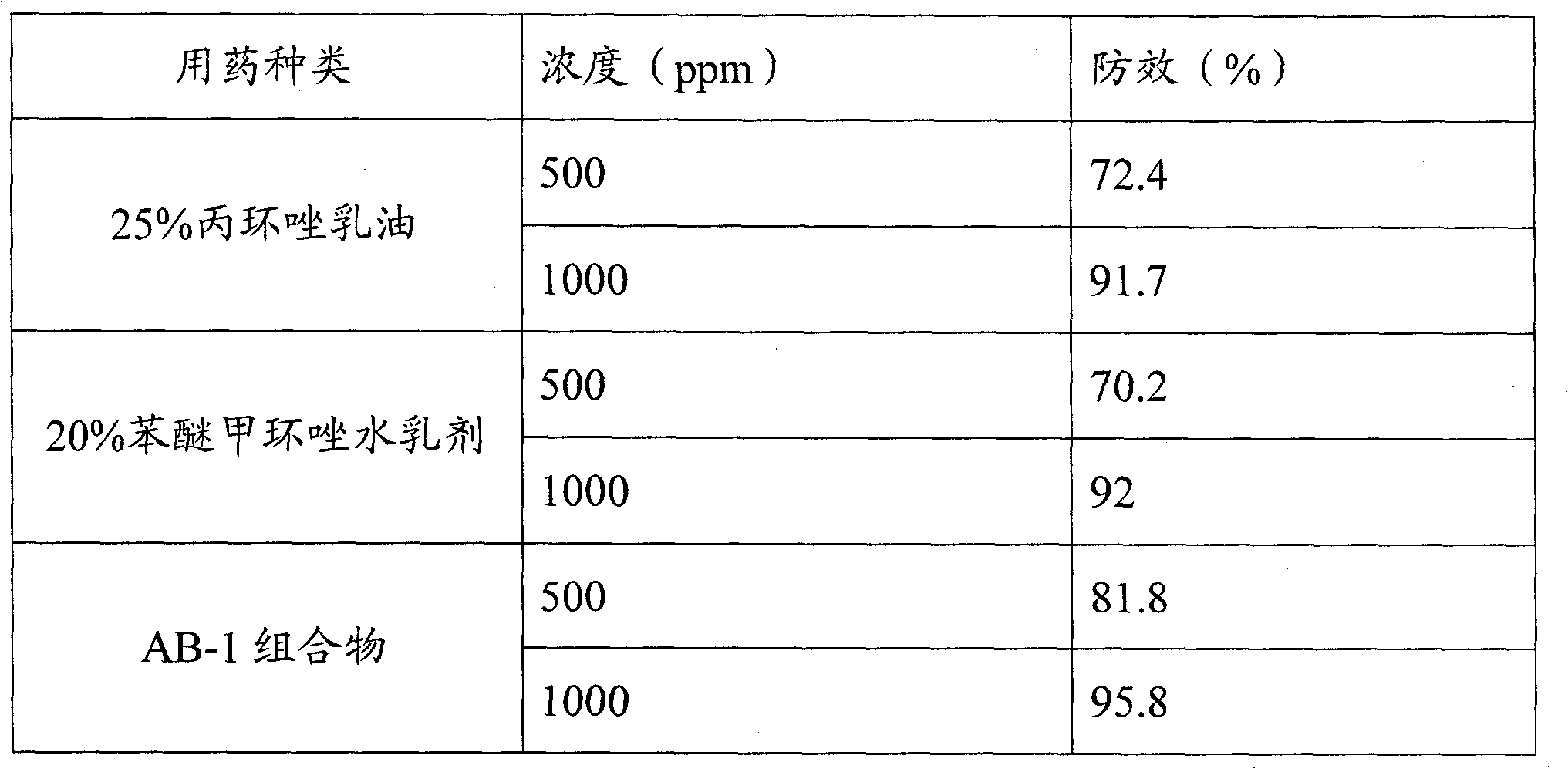

Bactericide pesticide composite containing oligochitosan

InactiveCN101816305AEnhanced application safetyReduce dosageBiocideFungicidesEcological environmentDrug resistance

The invention discloses a bactericide pesticide composite containing oligochitosan, which comprises a component A and a component B, wherein the component A is oligochitosan or a derivative of the oligochitosan; and the component B is one or several of active compounds. The pesticide composition can produce a synergistic action, reduce the dosage of a chemically synthetic bactericide, prevent or delay the medicament resistance of the bactericide, improve crop stress resistance and yield, regulate metabolic balance in plant bodies and improve quality of agricultural products, improve the application safety of the bactericide and is more safe to ecological environmental and human bodies.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

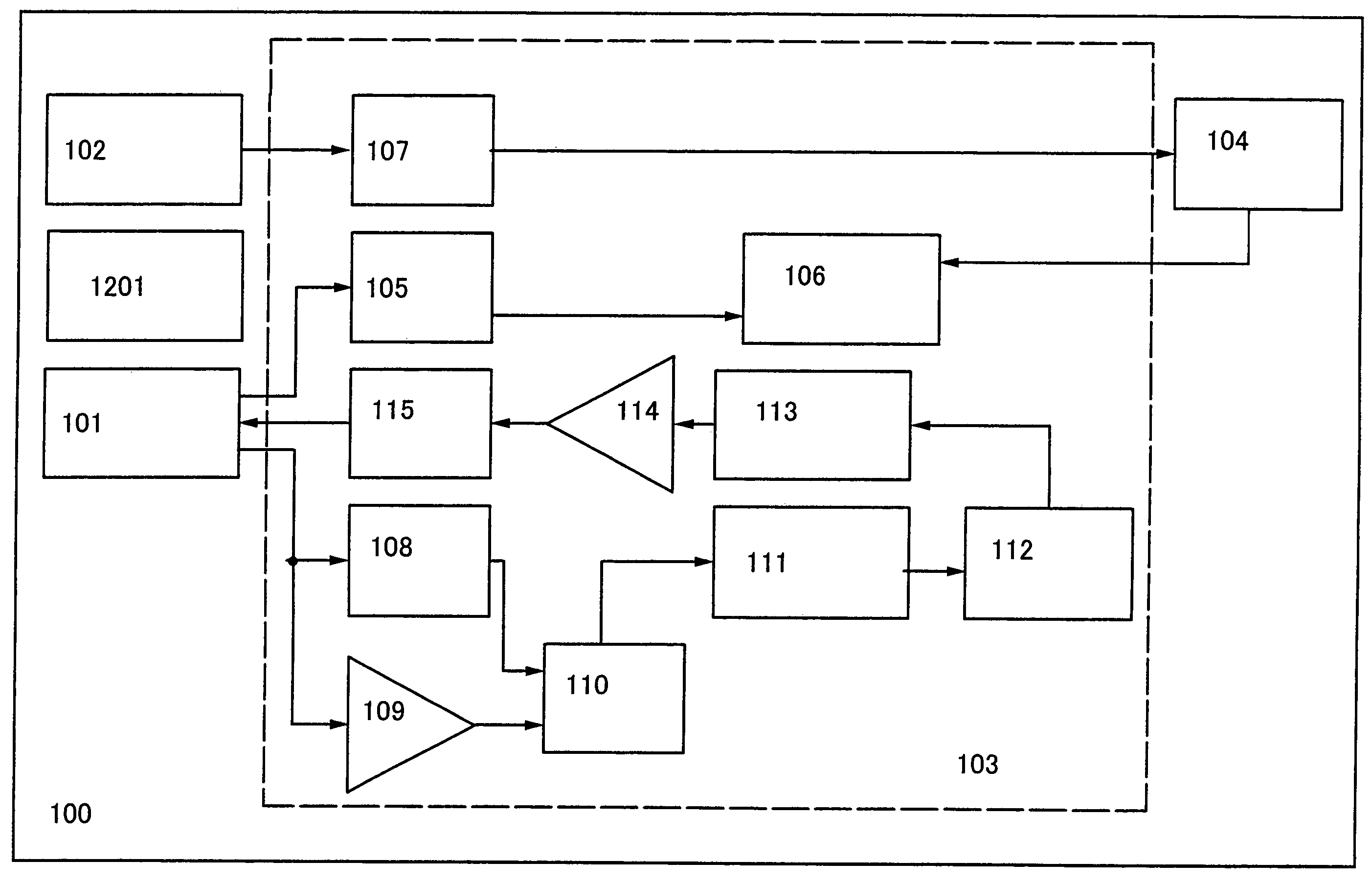

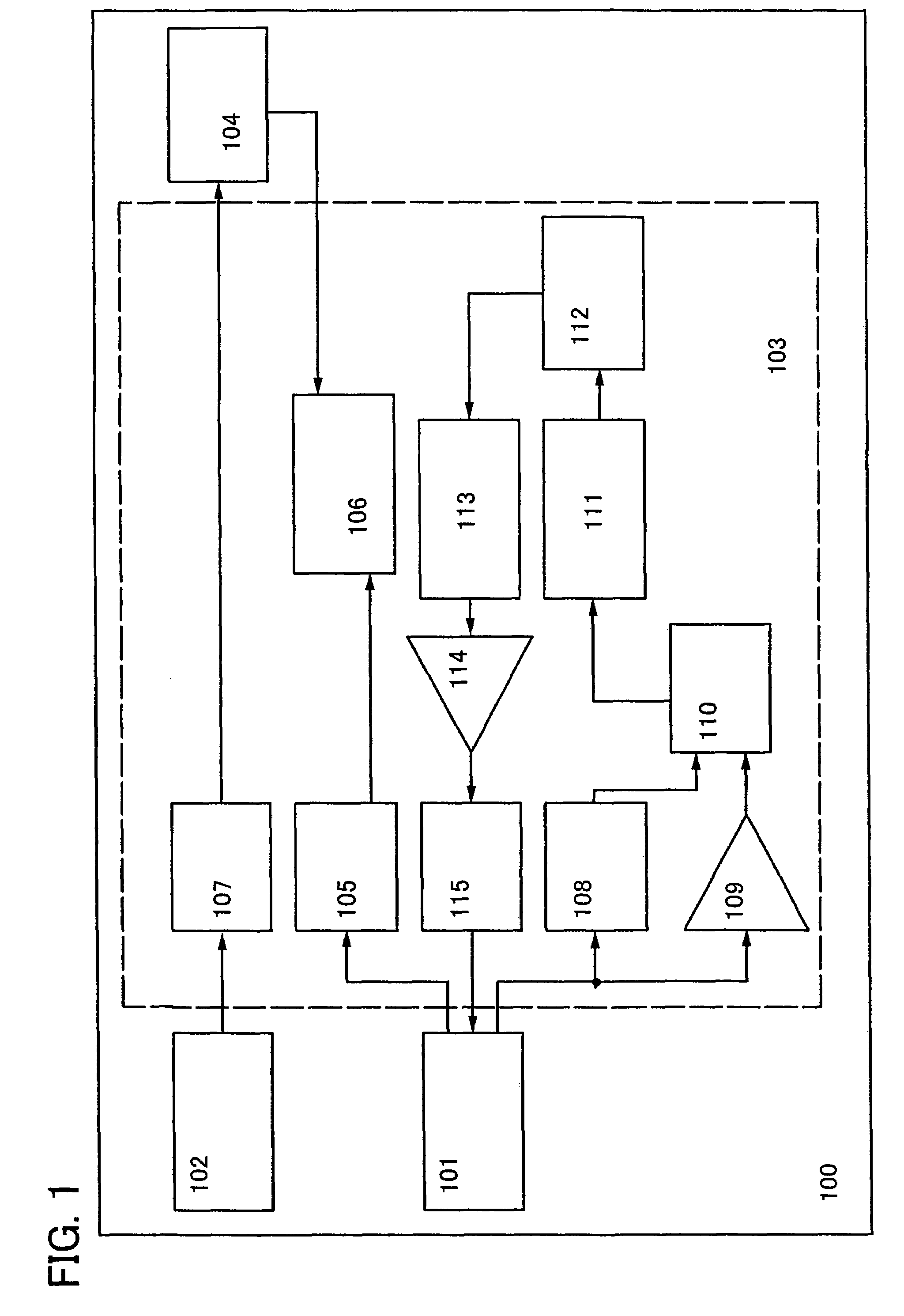

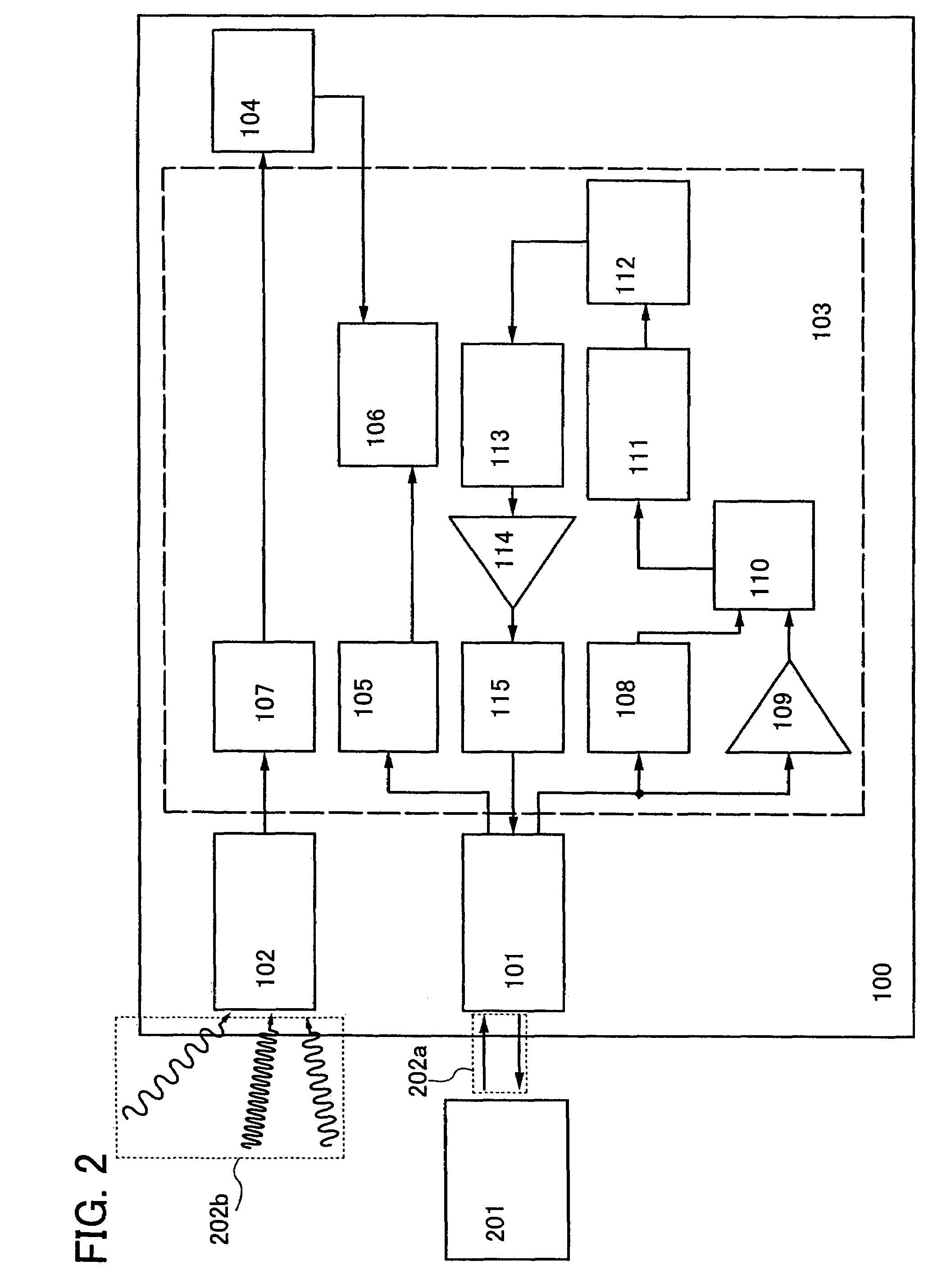

Semiconductor device

InactiveUS20070229281A1Sufficient powerImprove communication distanceBatteries circuit arrangementsSemiconductor/solid-state device detailsSignal processing circuitsEngineering

An object is to provide a semiconductor device including an RFID which can transmit / receive individual information without a change of a battery accompanied by deterioration over time of the battery as a drive power source, and to which driving power can be supplied to keep a favorable transmission / reception state of the individual information even when an external electromagnetic wave is not sufficient. The semiconductor device includes a signal processing circuit, a first antenna circuit and a second antenna circuit operationally connected to the signal processing circuit, and a battery operationally connected to the signal processing circuit, in which the first antenna circuit transmits / receives a signal for transmitting data stored in the signal processing circuit; the second antenna circuit receives a signal for charging the battery; and a signal received by the first antenna circuit and a signal received by the second antenna circuit have different wavelengths.

Owner:SEMICON ENERGY LAB CO LTD

High nutrient compound selenium fertilizer and preparation method thereof

InactiveCN102320879AGood compatibilityPromote degradationFertilizer mixturesTrace element compositionInorganic materials

The invention discloses a high nutrient compound selenium fertilizer comprising selenium, nuisanceless organic material-inorganic material and medium and trace elements, and a preparation method thereof. The high nutrient compound selenium fertilizer comprises 45-60 wt% of organic material, 55-35 wt% of inorganic material, 1-6 wt% of medium and trace elements, and 0.011-0.025 wt% of purified selenium. The fertilizer disclosed in the invention can increase yield efficiently, and allow the applied plant to contain selenium element which has health care effect to human body. The fertilizer adopts a plurality of internal adsorptions to protect selenium to let the selenium in the selenium fertilizer be effective, has good intermiscibility and degradability, keeps selenium from fix, and obviously improves the biological absorption utilization rate of selenium of plants (including tea).

Owner:李子先 +1

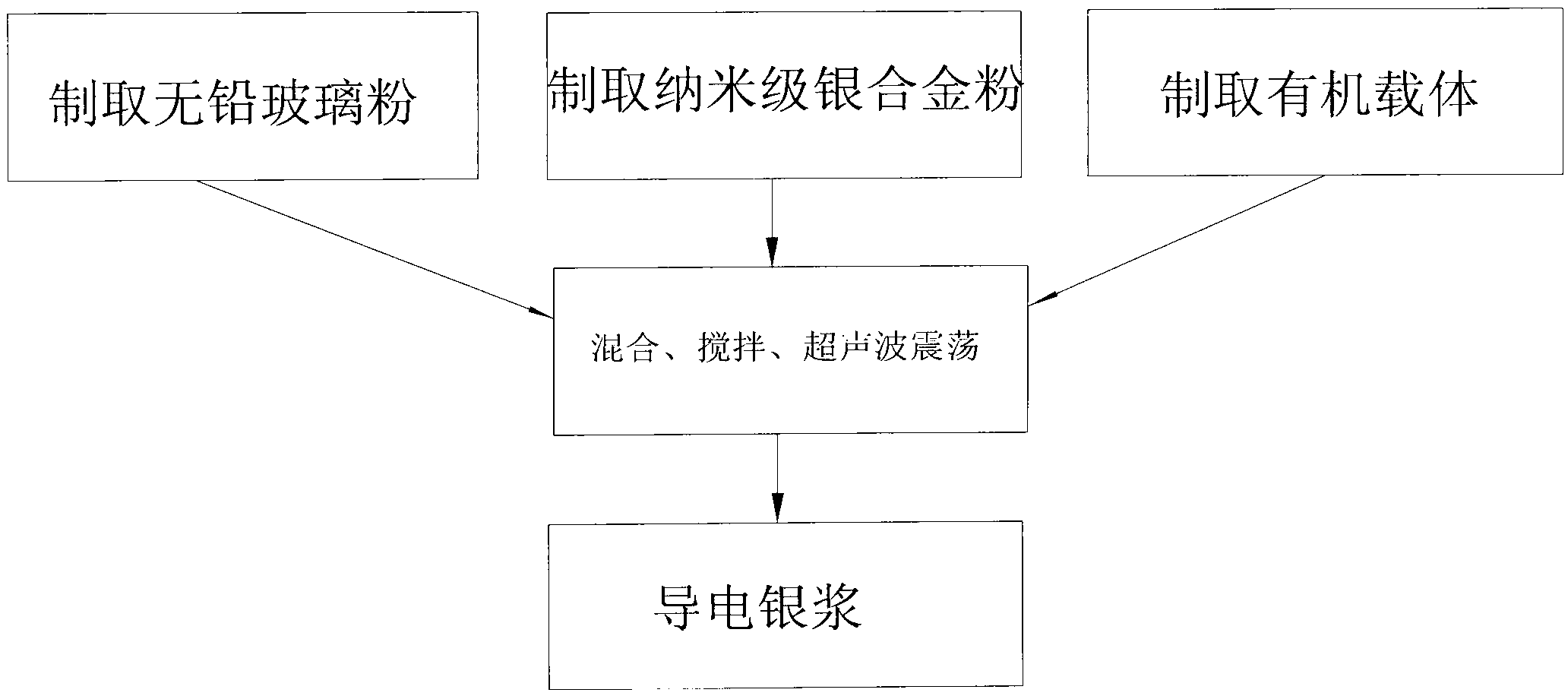

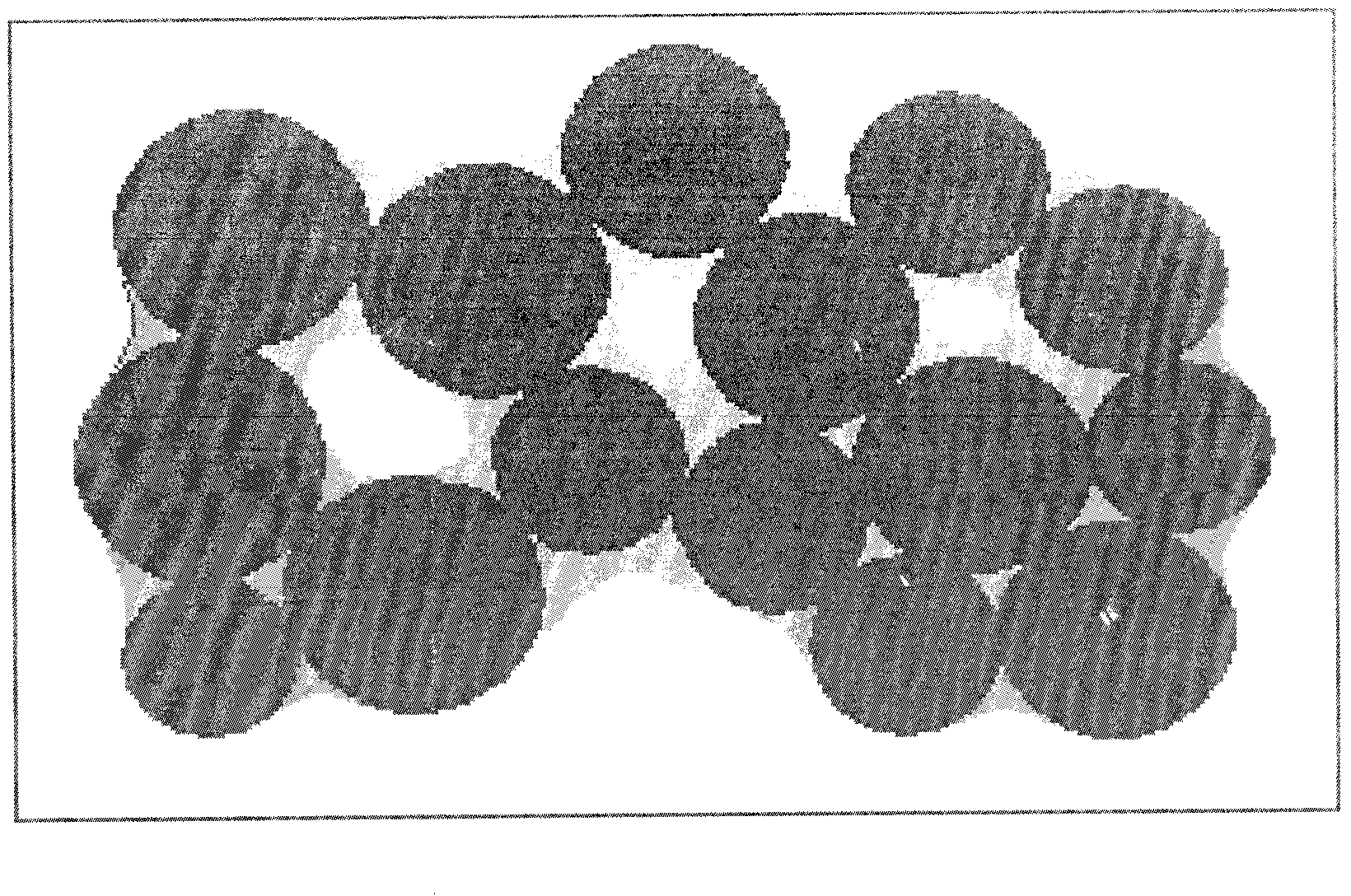

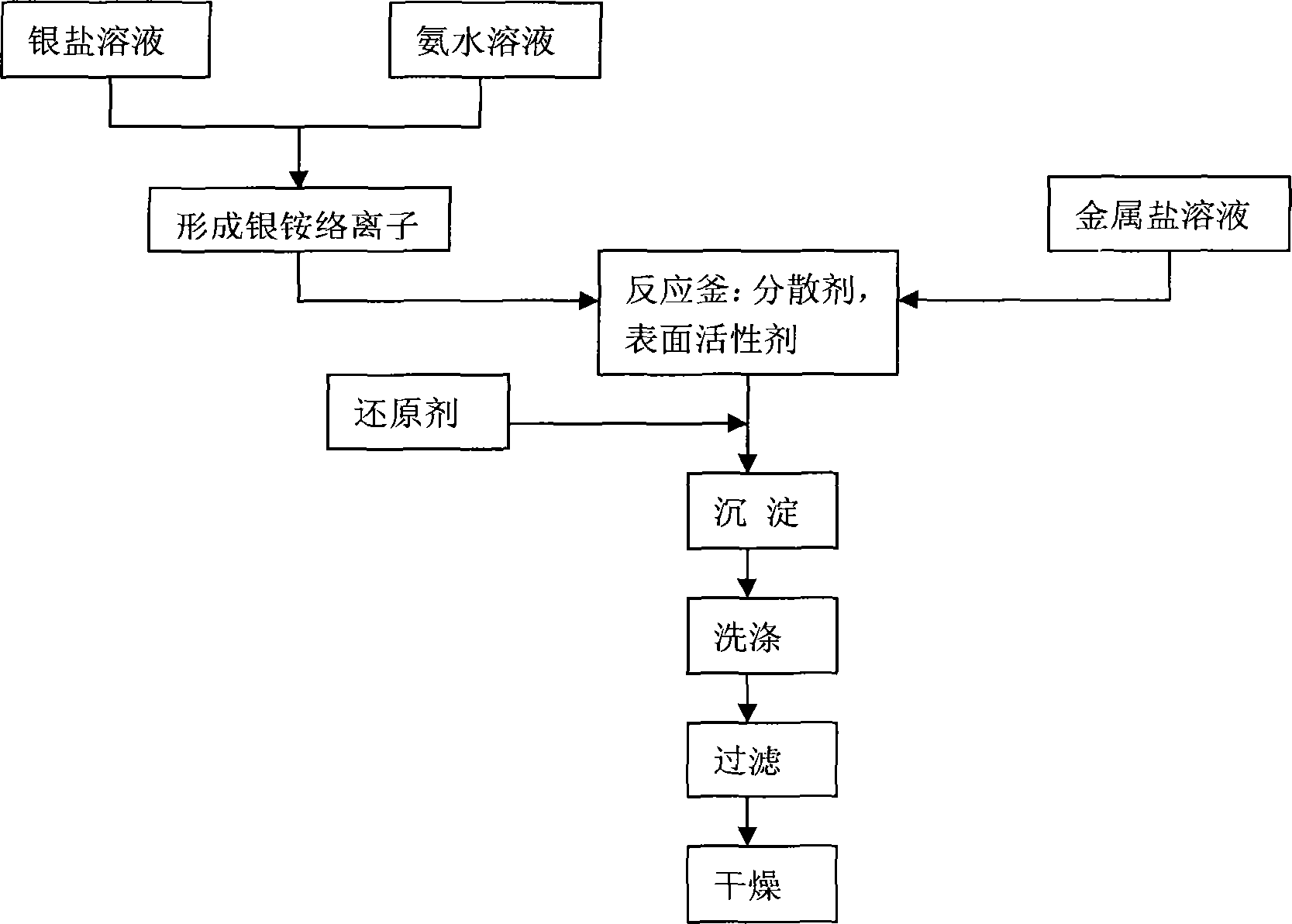

Electric conductive silver paste and manufacturing method thereof

ActiveCN103258584AEnhanced interconnectionIncrease contact areaNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetal alloy

The invention discloses electric conductive silver paste and a manufacturing method of the electric conductive silver paste. The electric conductive silver paste comprises, by mass percentage, 35 - 65 % of micron-sized silver powder, 1-10 % of nanometer-sized silver powder of or 1-20 % of nanometer-sized silver and other metal alloy powder, and 1-10 % of an organic carrier; for ceramics, solar cell silver paste comprises 2-15 % of unleaded glass powder, each component is manufactured in parts, weighed, mixed and stirred or mixed and rapidly scattered, and ultrasonic-vibrated or fine adjusted of viscosity of solvent, and therefore the electric conductive silver paste is obtained. Due to the fact that the nanometer-sized silver powder or the nanometer-sized silver alloy powder is mixed with the micron-sized silver powder, intensity of conductivity and a circuit is improved, adhesive force of crushing resistance and a base plate is improved, at the same time unleaded slurry good in thixotropy, low in contacting resistance and low in piece-needed slurry amount replaces lead slurry materials, the electric conductive silver paste is used for manufacturing crystalline silicon solar cells, improves photoelectric conversion efficiency, accords with environmental-protection ideas, and can be produced in large scales continuously.

Owner:SHENZHEN CHENGGONG CHEM

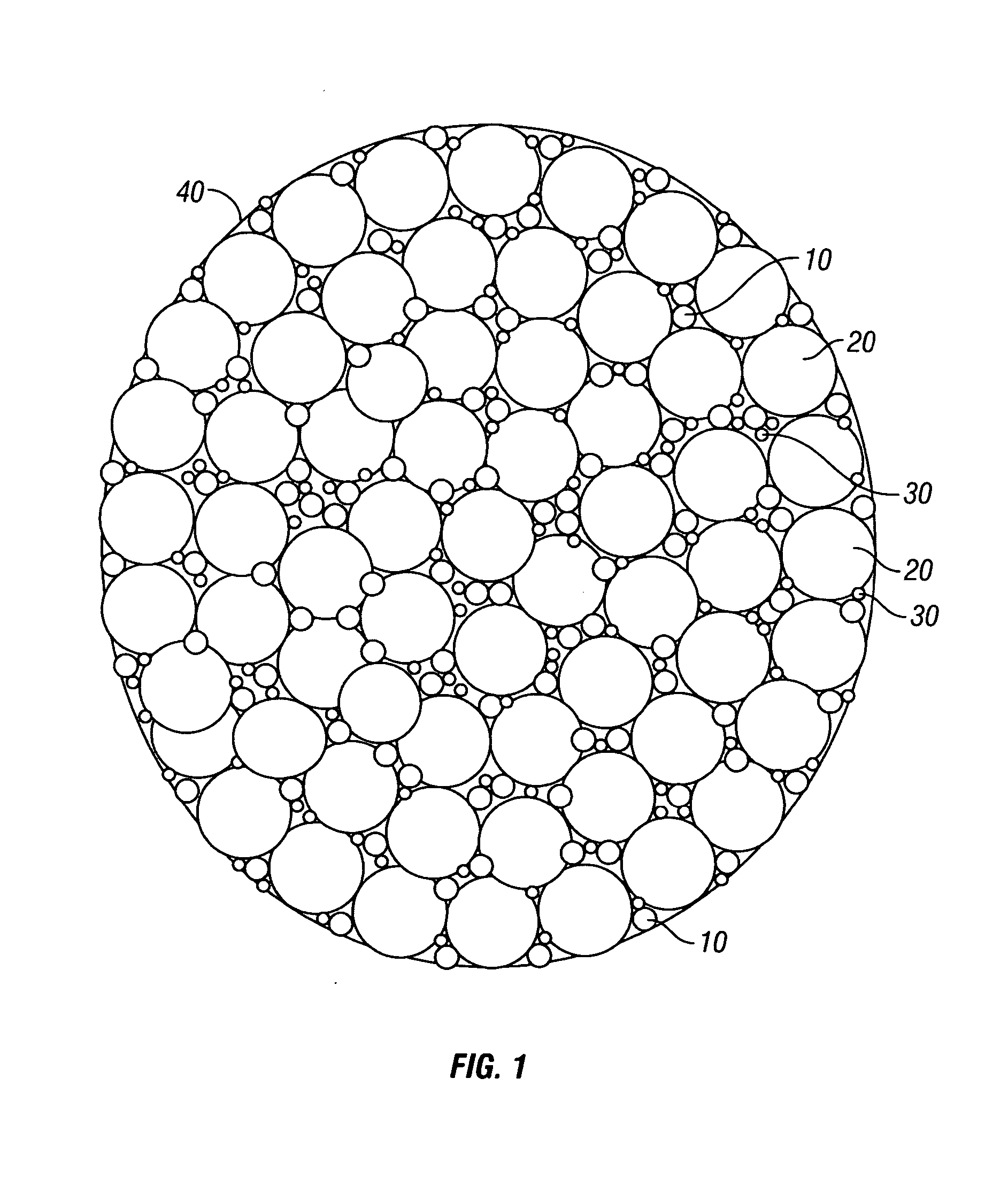

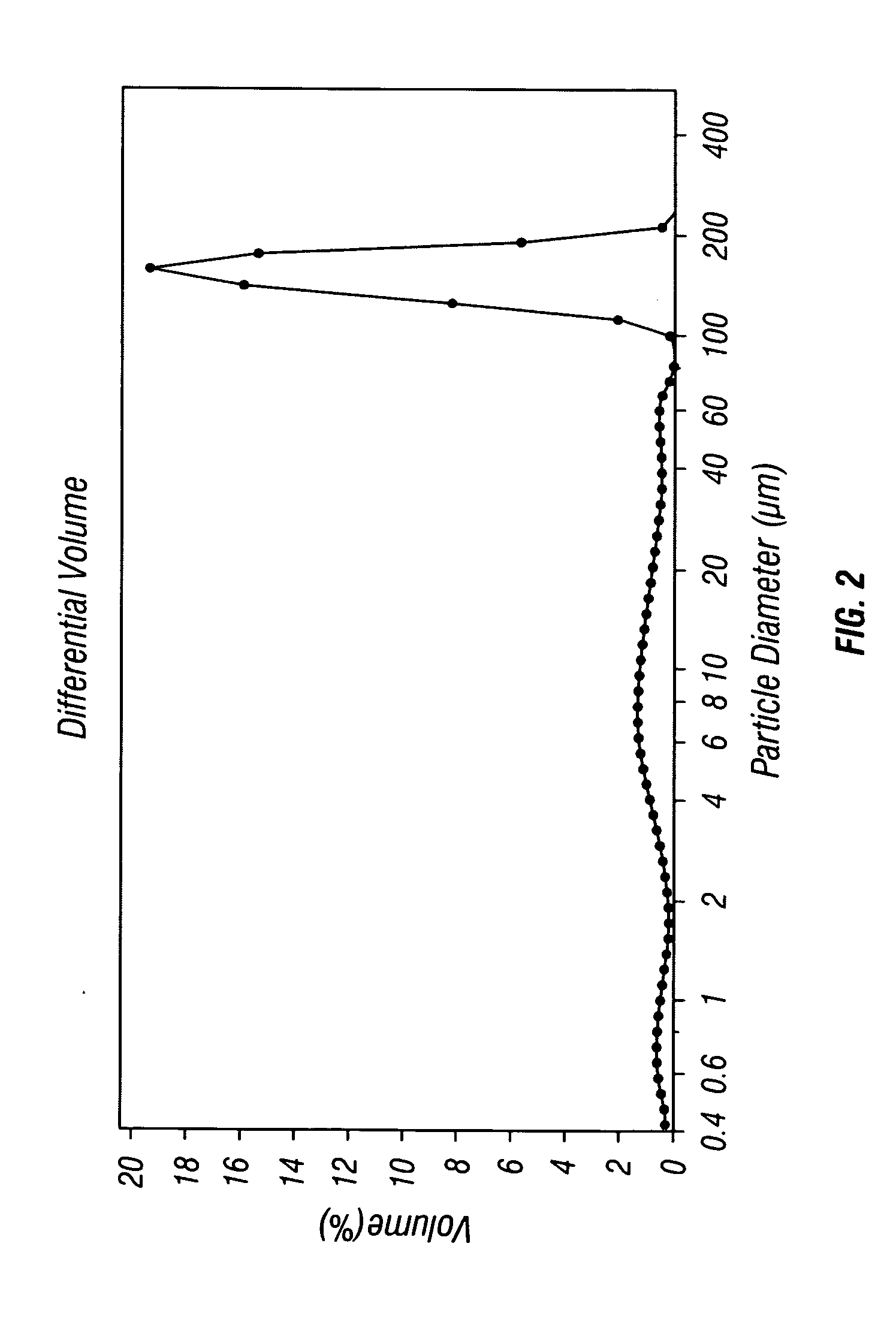

Structured composite compositions for treatment of subterranean wells

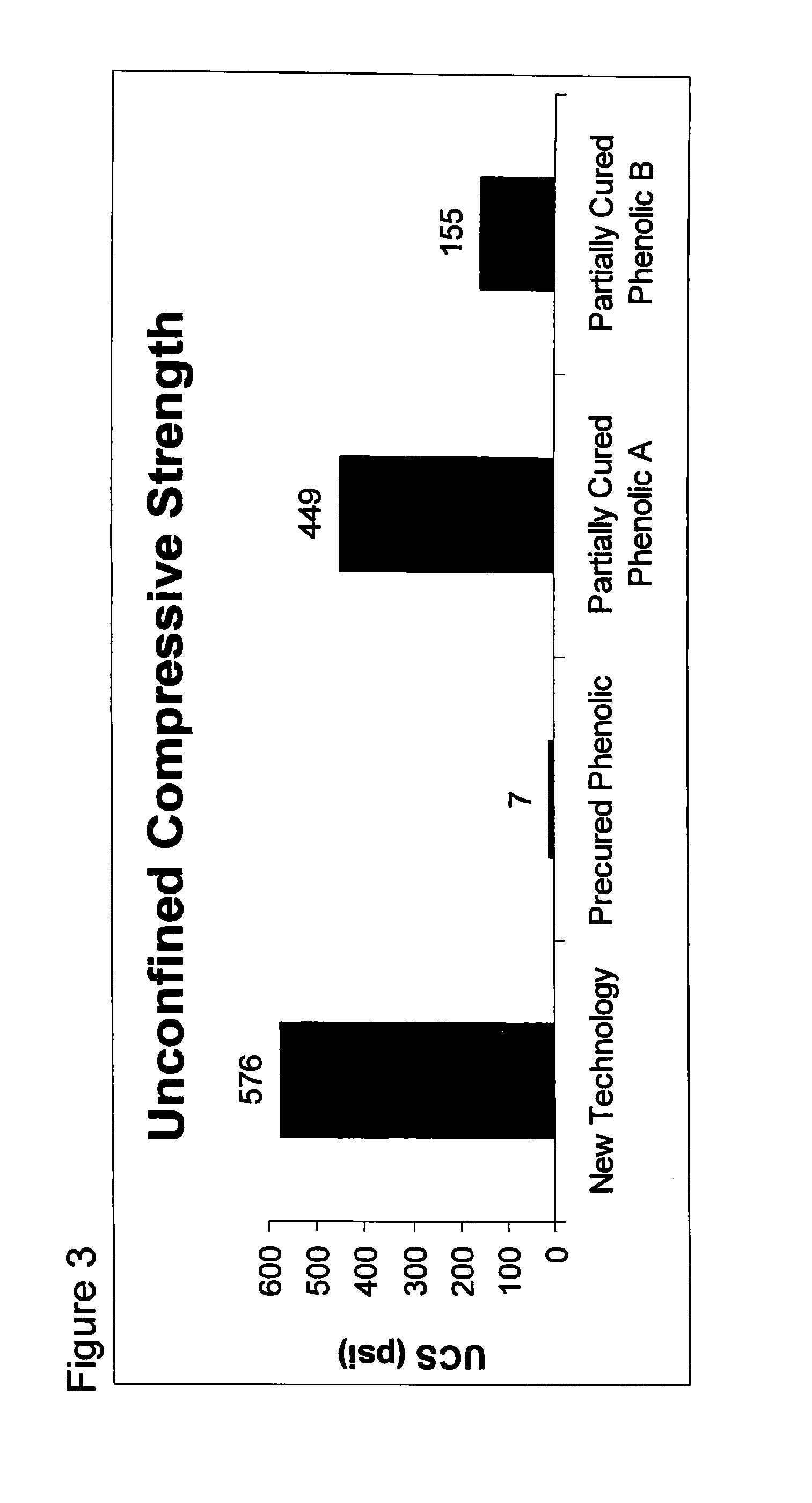

ActiveUS20060258546A1Reinforce strength (or modulus)Improve stress resistancePretreated surfacesFlushingParticulatesBi modal

A structured composite is comprised of particulates having particle size distribution of at least two modes and a binder. The particle size distribution is preferably bi-modal or tri-modal. The composite may further contain a density-modifying agent for modifying the density of the composite. The particulates are preferably substantially spherical and may be ultra lightweight (ULW) materials. The resulting composites exhibit the requisite strength to survive downhole imposed stresses and temperatures.

Owner:BJ SERVICES CO

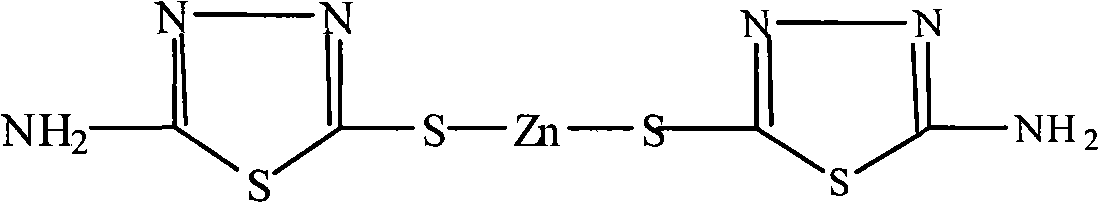

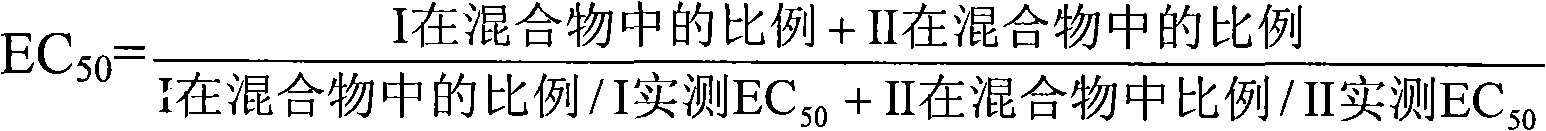

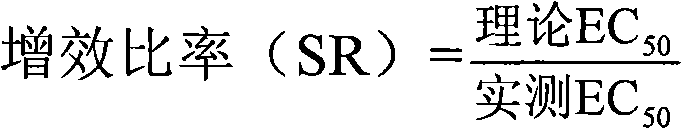

Zinc thiazole-containing bactericidal composition

ActiveCN101953346ASignificant synergyImprove protectionBiocidePlant growth regulatorsTriazole antifungalsKetone

The invention provides a zinc thiazole-containing bactericidal composition, which contains an active compound I and a bactericidally active compound II, wherein the active compound I is zinc thiazole; the bactericidally active compound II may be any one of a methoxyacrylate bactericide, a triazole bactericide, an amide bactericide, an iminazole bactericide, a dicarboxylic imide bactericide, a carbamic acid ester bactericide, an antibiotic bactericide, an oxazole bactericide, a morpholine bactericide, a pyrimidine bactericide, a quinazolone bactericide, a dithiocarbamate bactericide or other given bactericides.

Owner:ZHEJIANG XINNONG CHEM CO LTD

Birds feed additive

InactiveCN1471836ANo cross resistanceImprove immunityAnimal feeding stuffAccessory food factorsFowlFishery

An additive for fowl's feed is prepared from more Chinese-medicinal materials, and can serve to improve immunity, promote appetite and absorption, and relieve inflammation. Its advantages are high effect and low cost.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

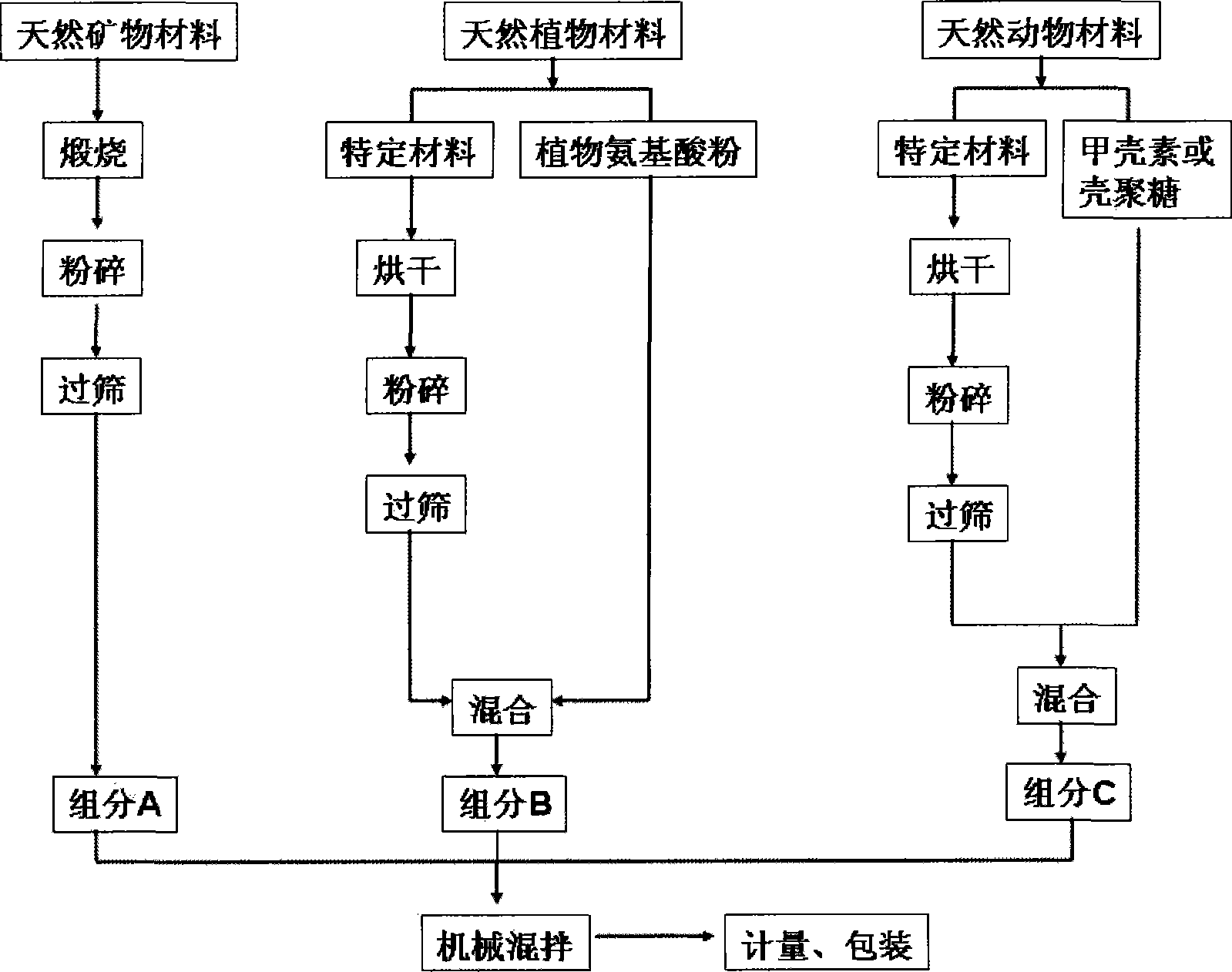

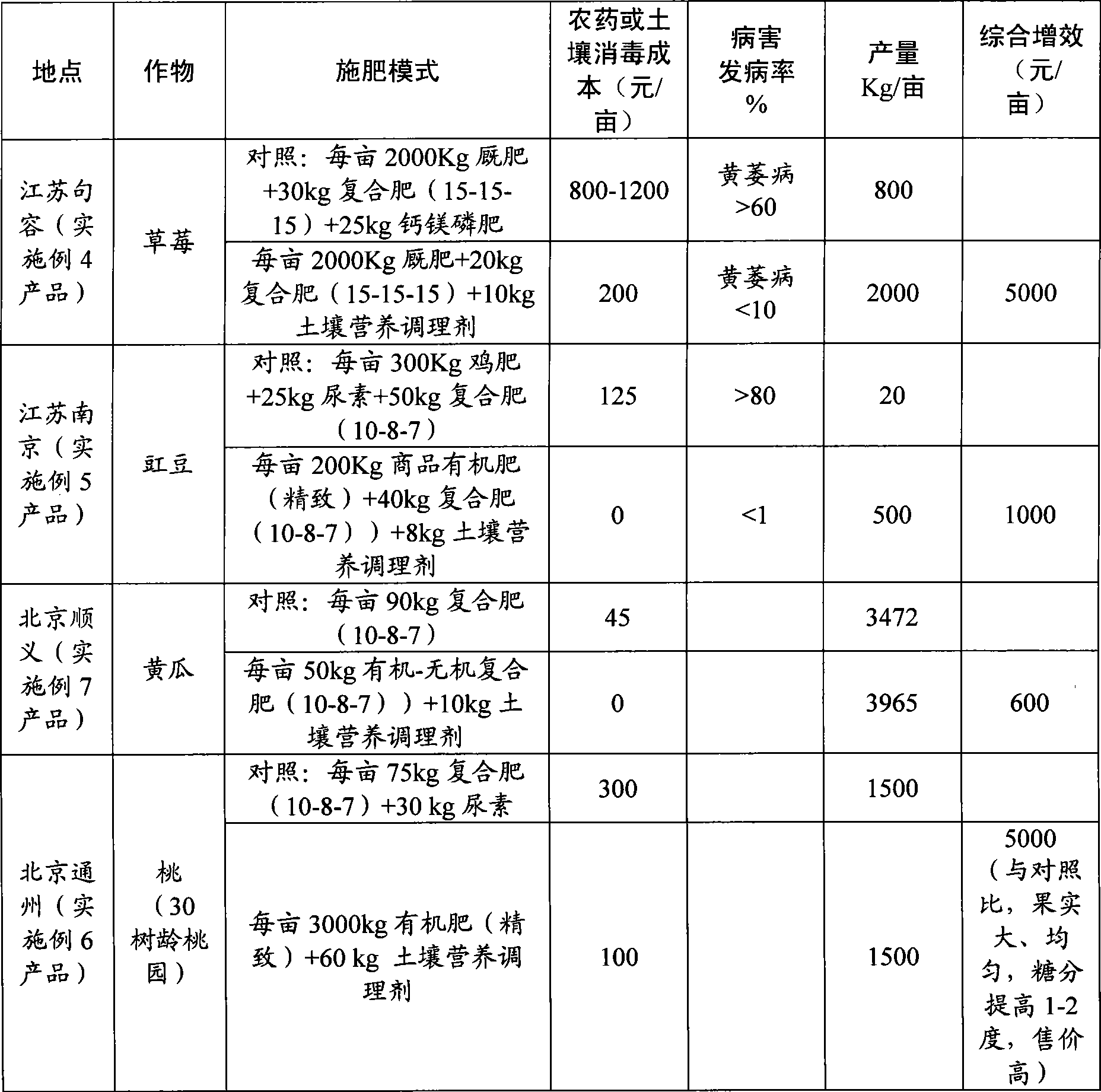

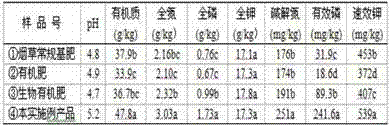

Soil fertility amendment and preparation method thereof

The invention provides a multifunctional soil nutrient conditioner formula with low cost, practicality and effectiveness and a preparation method thereof aiming at the technical problems. The production technology is simple, the production cost is low, and no harmful gas and sewage are generated during production. The product can effectively provide dozens of nutritive elements required for plant growth, is applied by being combined with a common fertilizer and an organic fertilizer, and can obviously improve the utilization rate of the fertilizer, so as to reduce the fertilizer input; and simultaneously the product can obviously stimulate action of beneficial floras of the soil, inhibit action of causal organisms, and increase the disease suppression of the soil and the resistance of plants, and then can effectively control generation of physiological diseases and soil-borne diseases, so as to reduce the pesticide input. The fertilizer input and the pesticide input can be reduced by more than 15 to 30 percent, and the yield can be increased by more than 15 to 30 percent, and simultaneously the product quality is obviously improved and cost conservation and synergism are obvious. Moreover, the soil improvement effect is obvious, and the sustainable utilization capacity can be obviously enhanced.

Owner:仲元(北京)绿色生物技术开发有限公司 +1

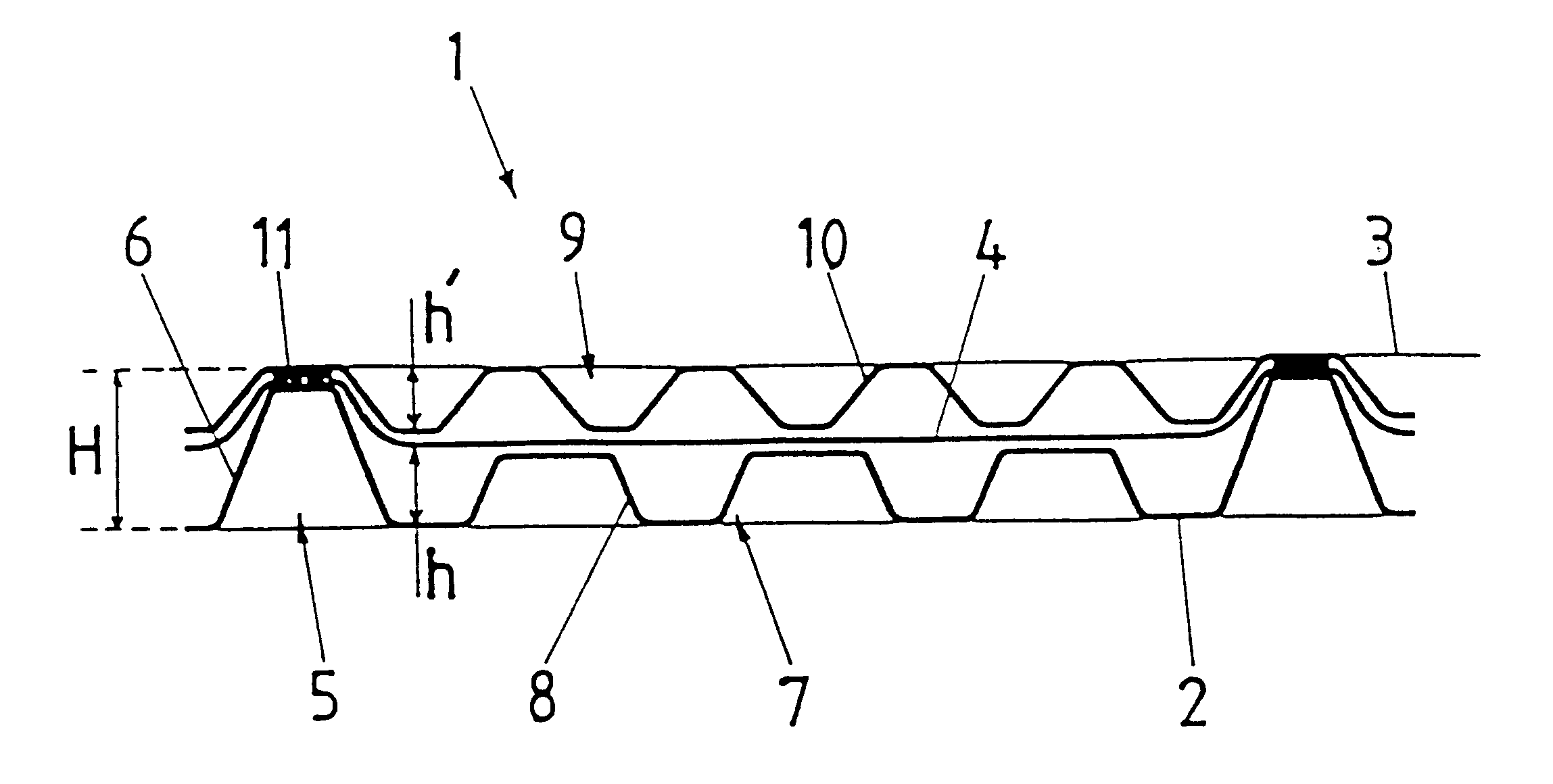

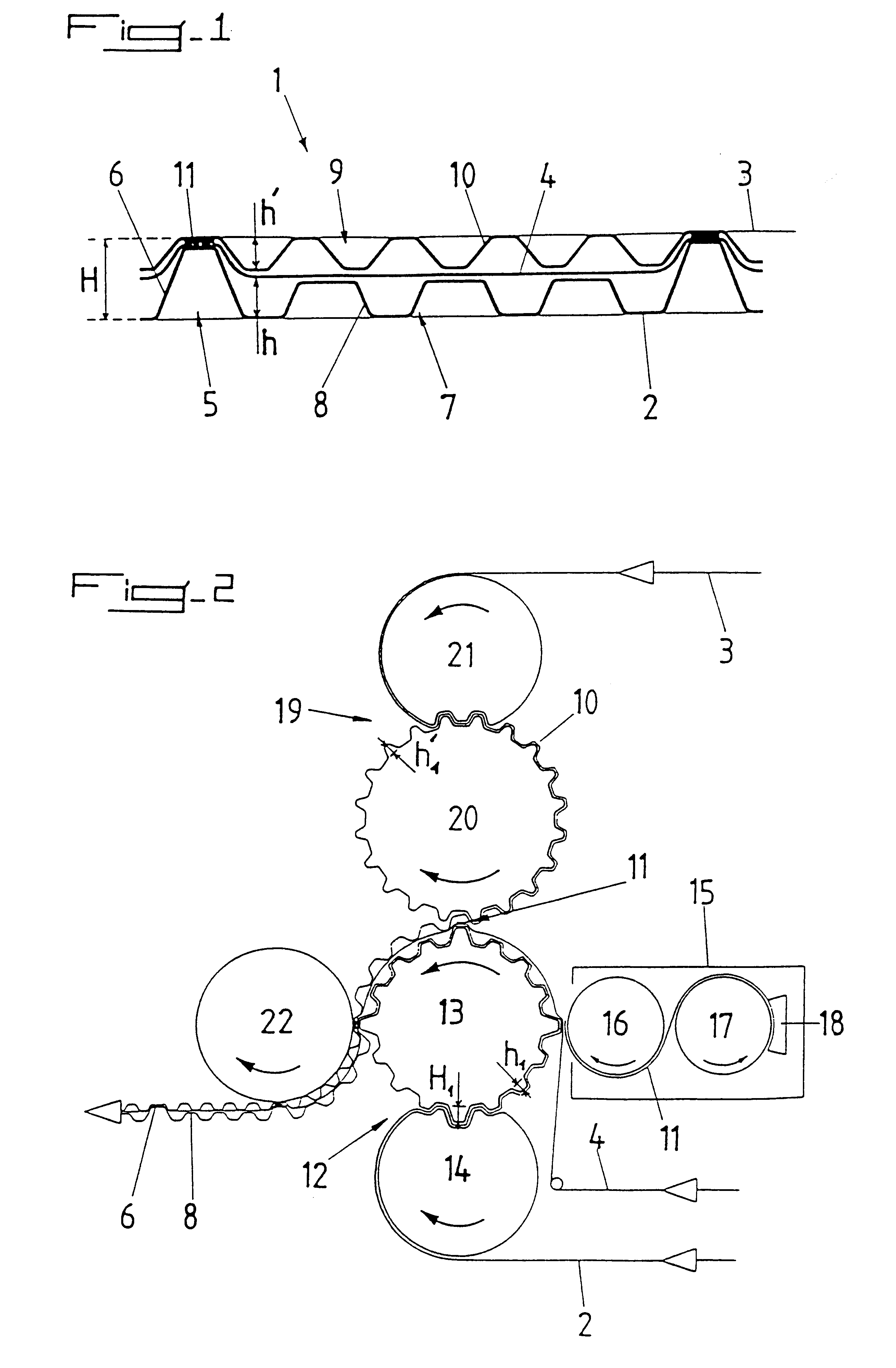

Absorbent paper product of at least three plies and method of manufacture

InactiveUS6551691B1Feel goodResist crushingNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringVolumetric Mass Density

Owner:ESSITY OPERATIONS FRANCE

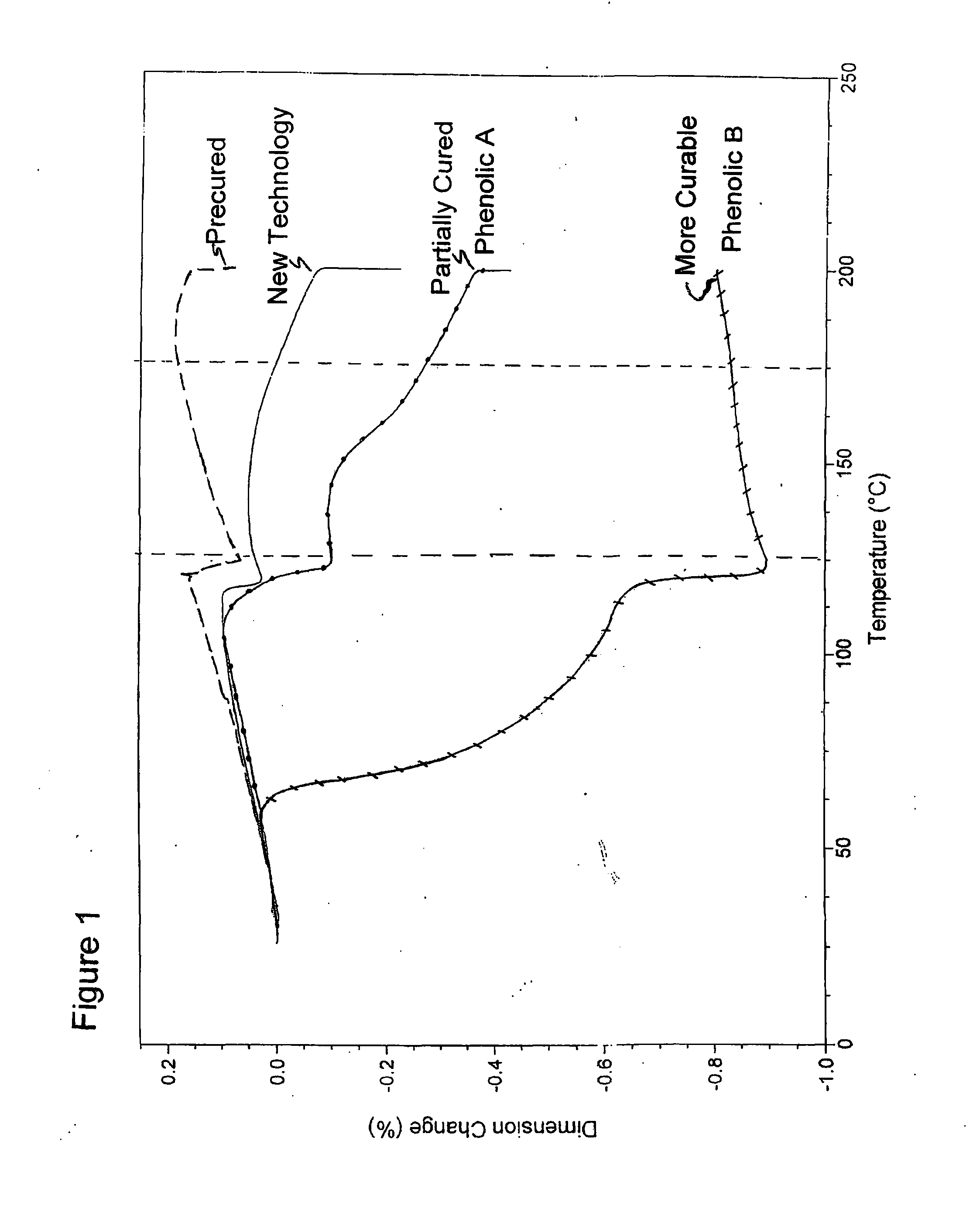

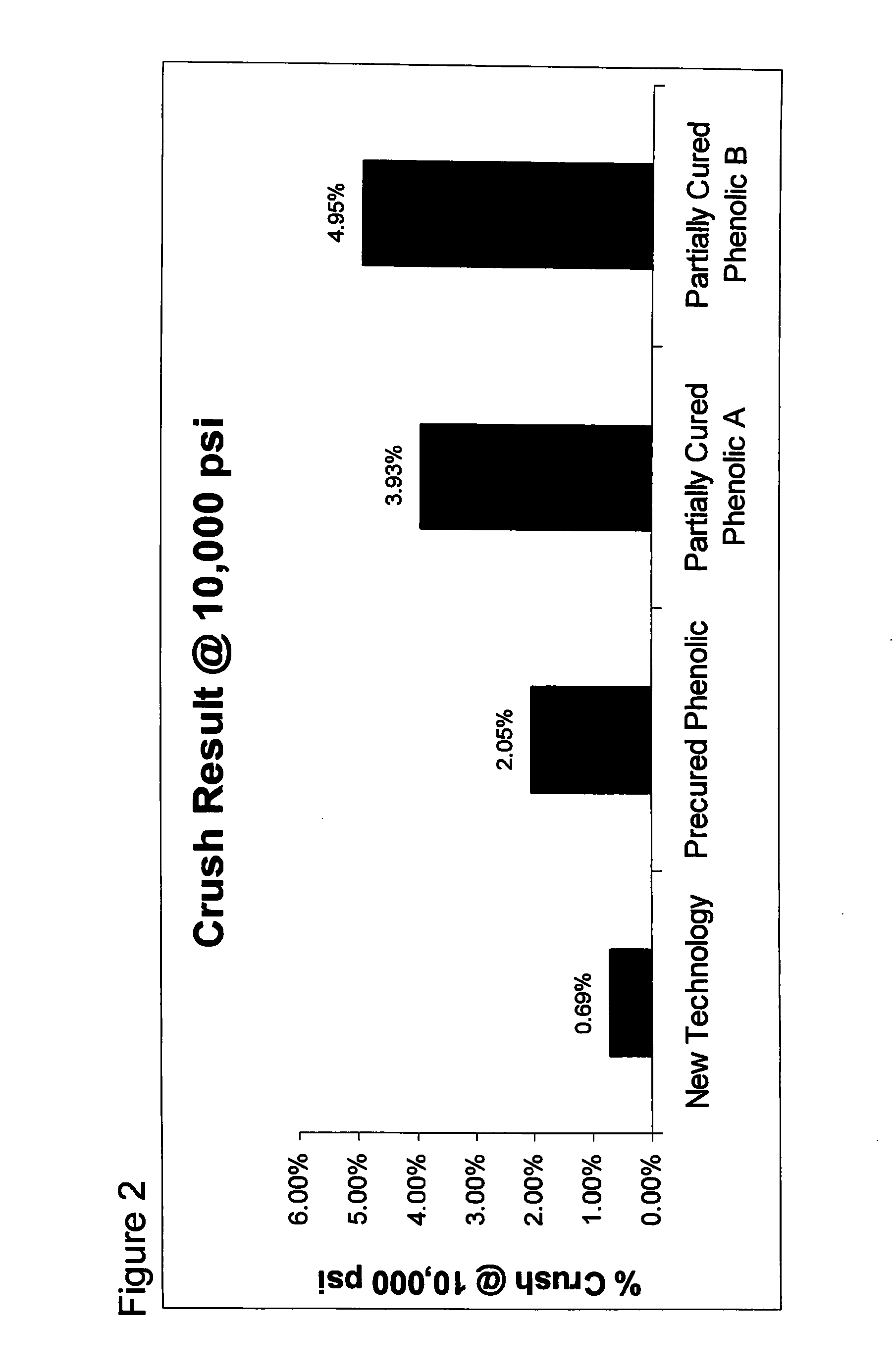

Coated and cured proppants

ActiveUS20130065800A1Improve crush resistanceGood fracture conductivityPretreated surfacesFluid removalAlcoholFirming agent

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

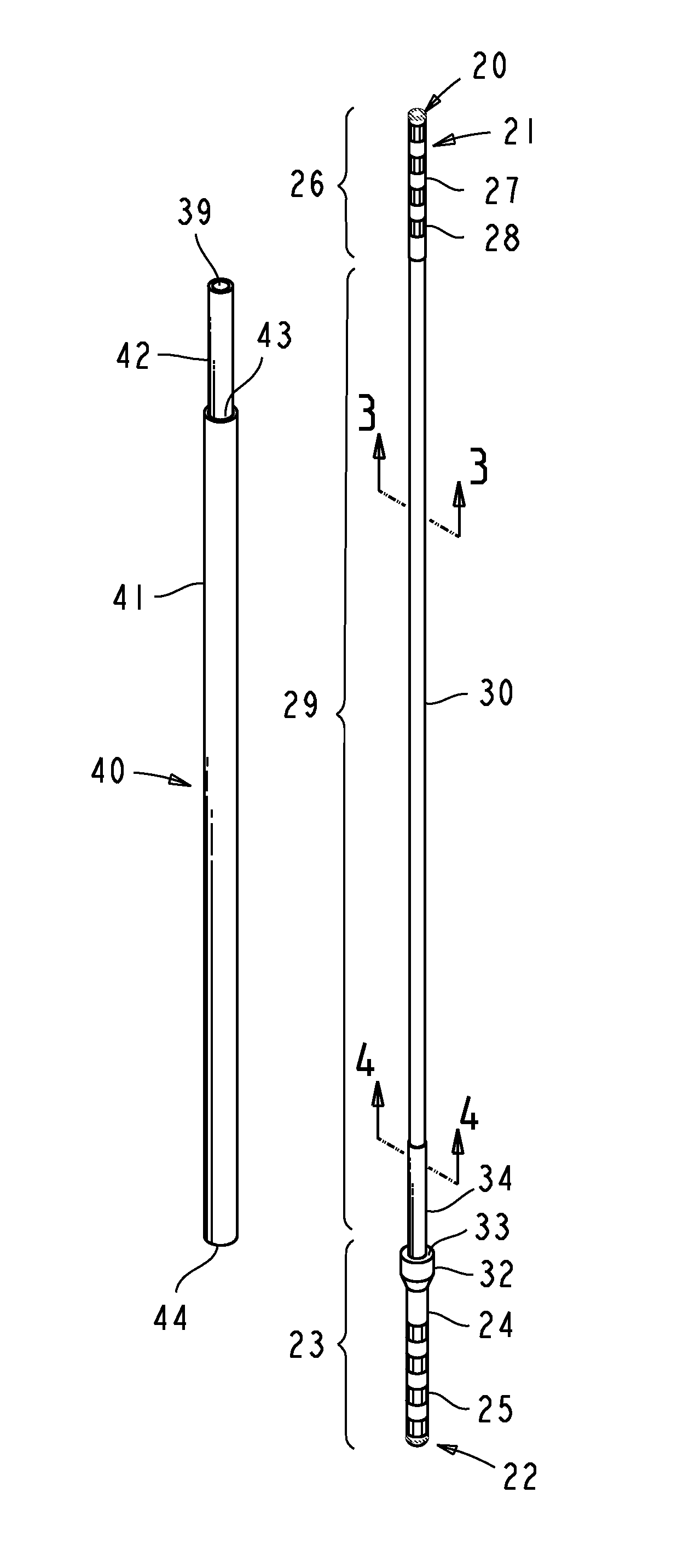

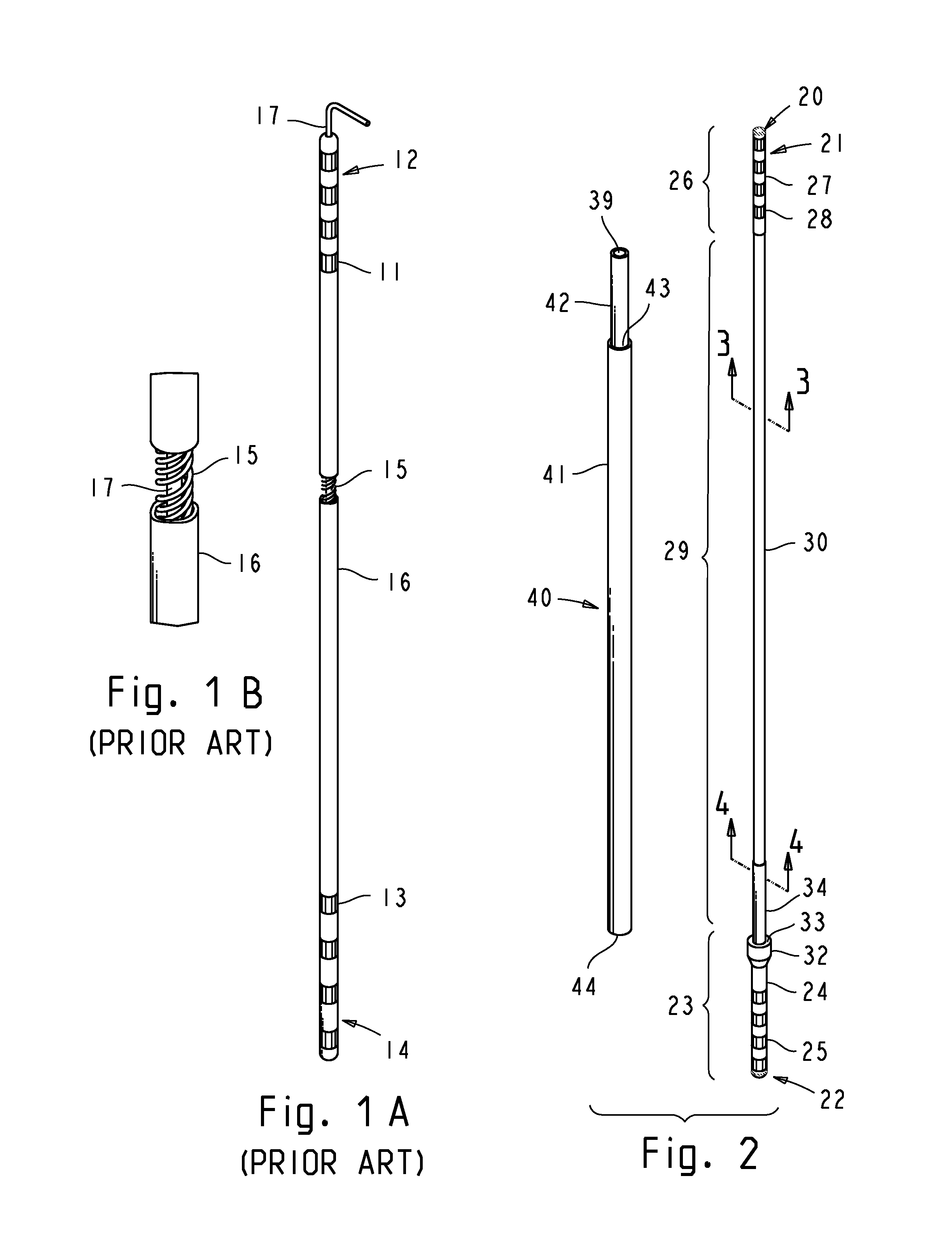

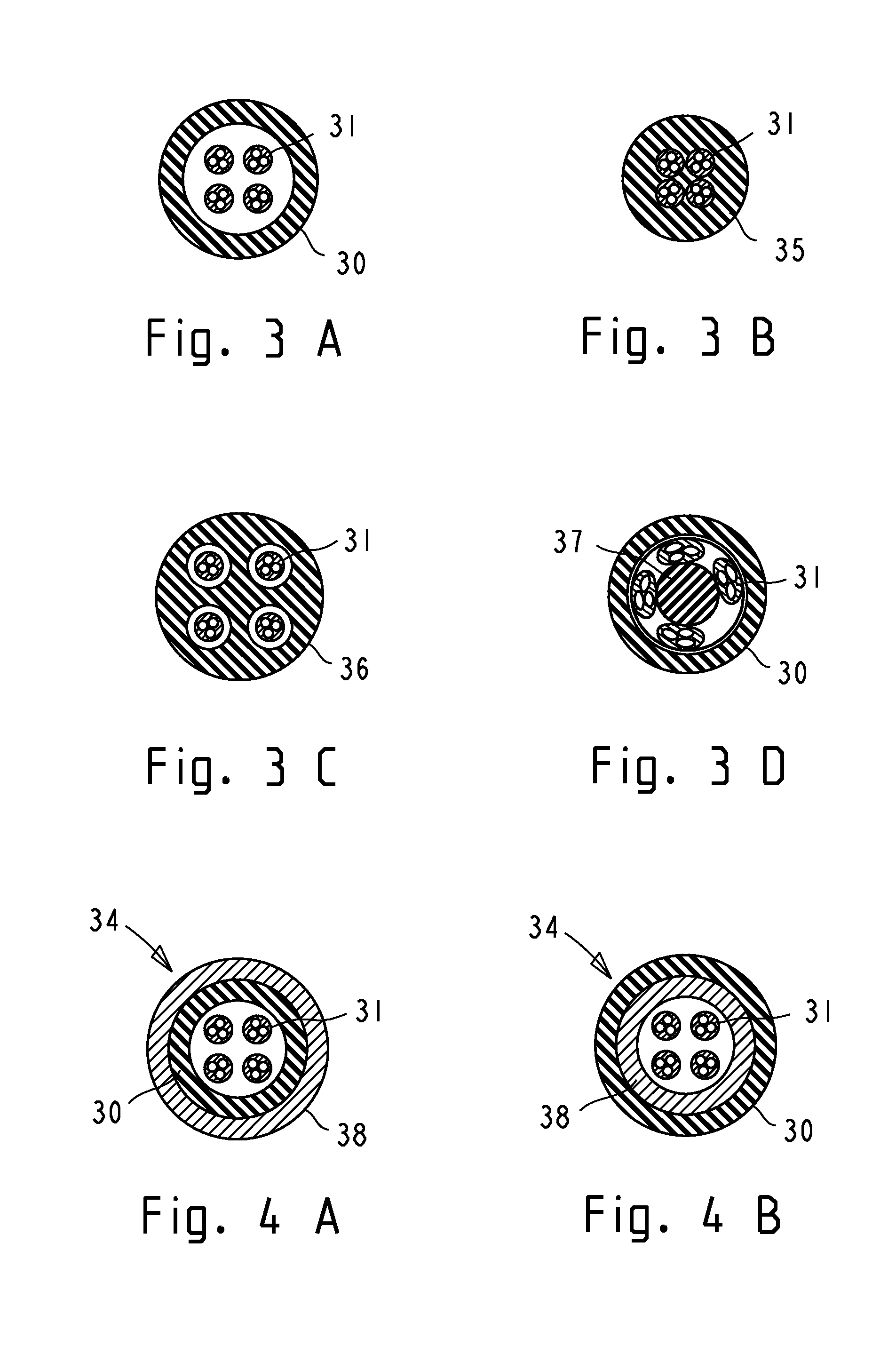

Implantable lead and surgical accessories

InactiveUS8968331B1Improve stress resistanceEliminate useHead electrodesDiagnosticsImplantable rodElectrical conductor

Leads for chronic implantation in the brain or other anatomical targets utilize tubular stylet means which are external to the lead. The lead comprises a distal electrode terminal, a proximal connector terminal, and a conductor cable having a reinforced distal portion and a stepped outside diameter providing a shoulder which cooperates with the distal end of the external stylet means. The substantial stiffness of the external stylet allows implantation of the lead without a brain-entering cannula. A tubular stylet spacer is employed to minimize lead dislodgement due to disassembly and removal of the lead introduction tools. Externalized stylet allows the conductor cable to have a small outside diameter and a desirably short length. A method of terminating conductors to electrodes using inserts is suitable for very fine wires and stranded conductors. A reinforced electrode terminal construction enables robust small-dimensioned terminal and high localization accuracy when introduced with external stylet means.

Owner:SOCHOR JERZY ROMAN

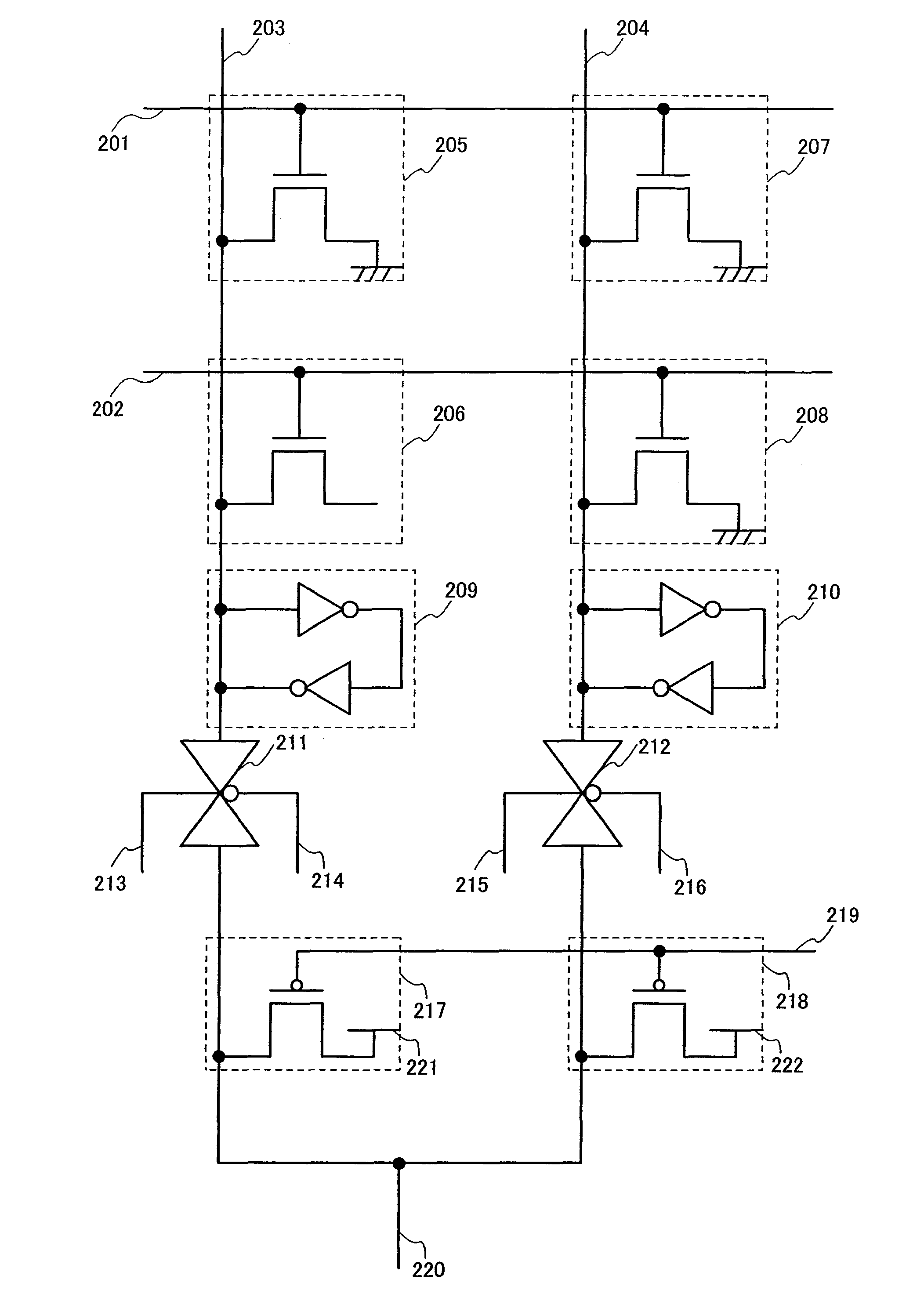

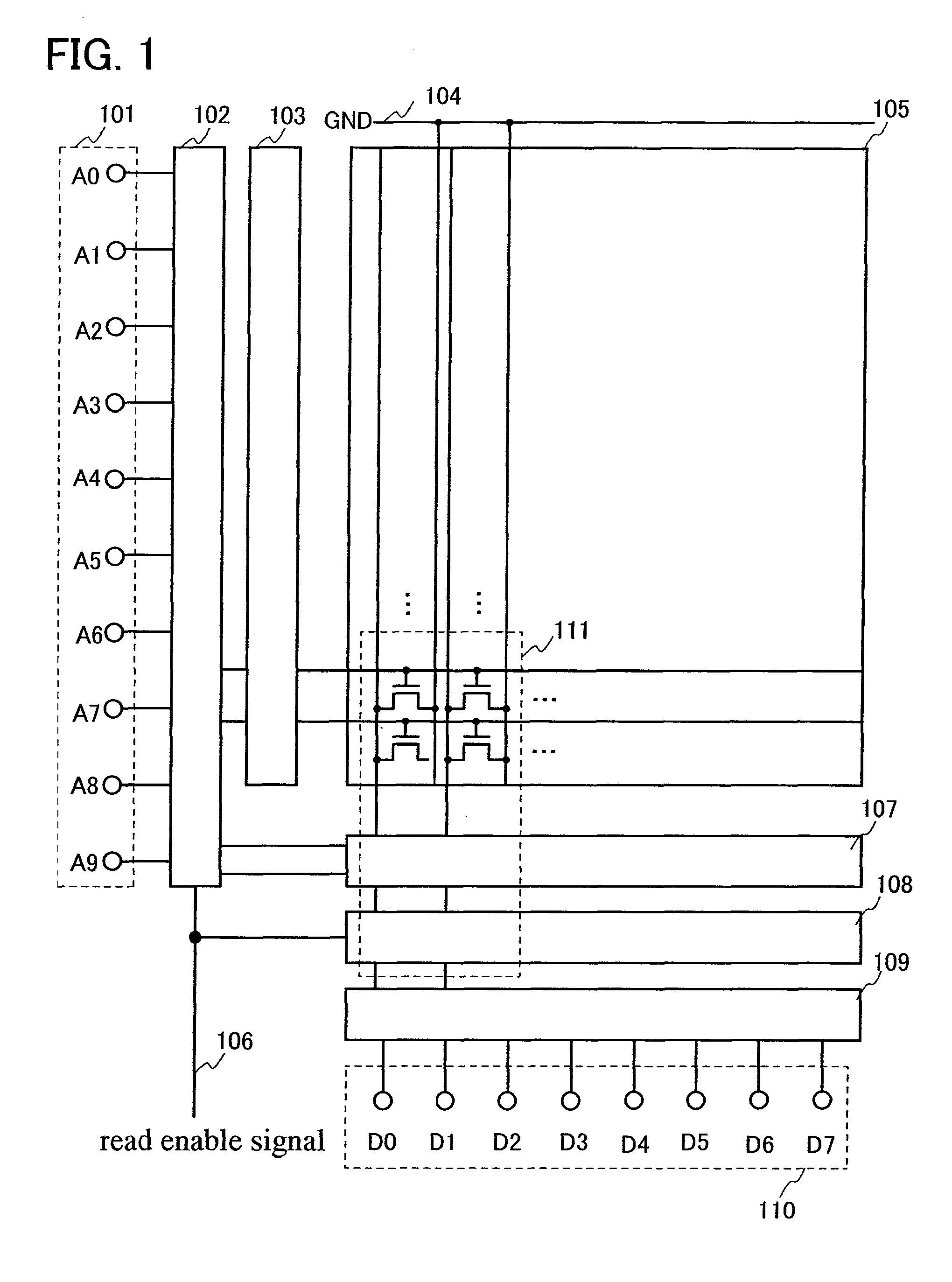

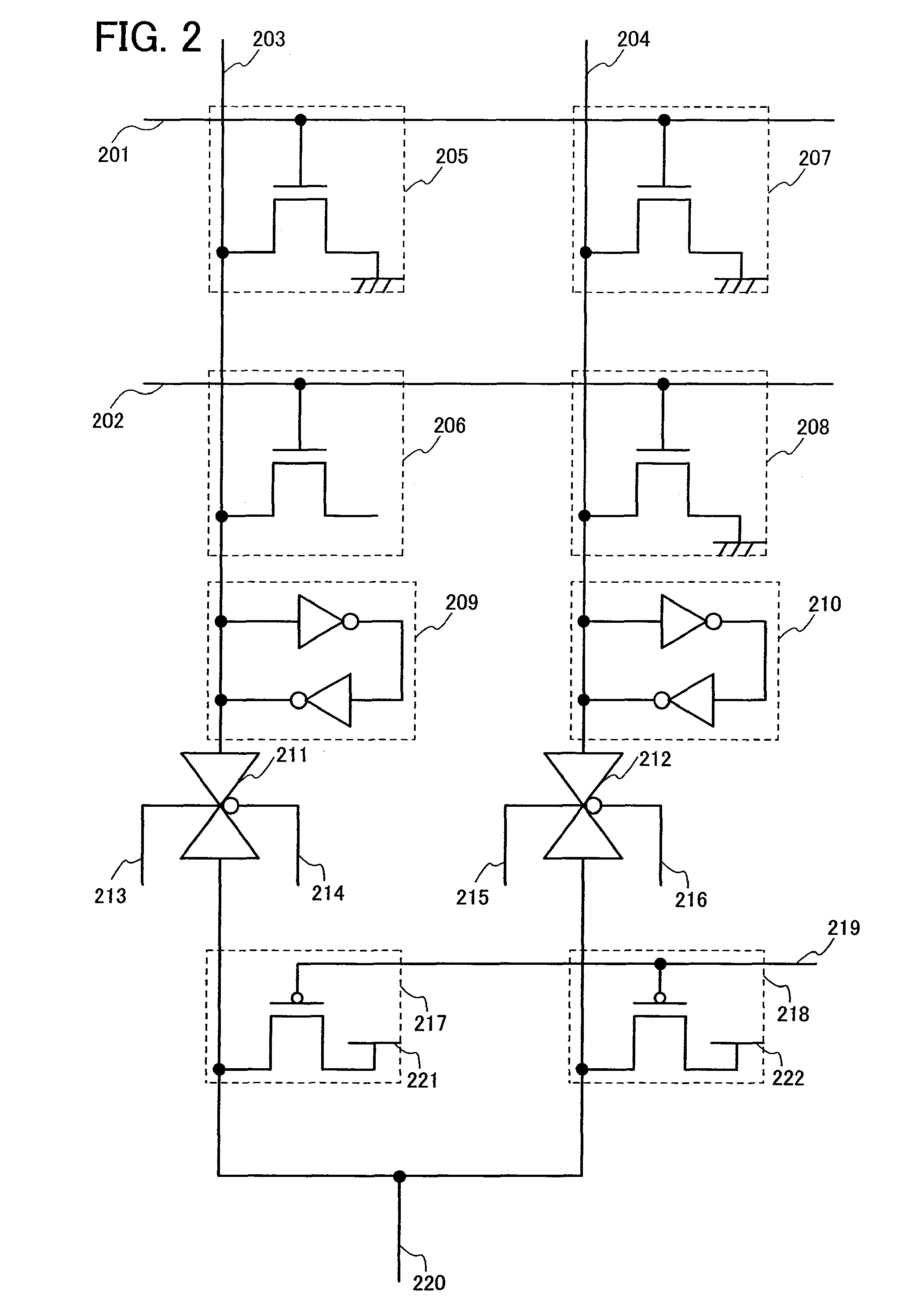

Semiconductor device and electronic device

InactiveUS7742351B2Increase valueAppropriate performanceSolid-state devicesSemiconductor/solid-state device manufacturingBit lineHemt circuits

In relation to reading of data in a memory, it is an object to provide a semiconductor device mounted with a low power consumption memory. A semiconductor device including a word line, a bit line, and a memory cell electrically connected to the word line and the bit line, further includes a precharge circuit for making the bit line have an electric potential for reading data stored in the memory cell. The precharge circuit is provided for each bit line and connected to the bit line. Further, the precharge circuit is capable of making each bit line have an electric potential for reading the data stored in the memory cell for each bit line.

Owner:SEMICON ENERGY LAB CO LTD

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

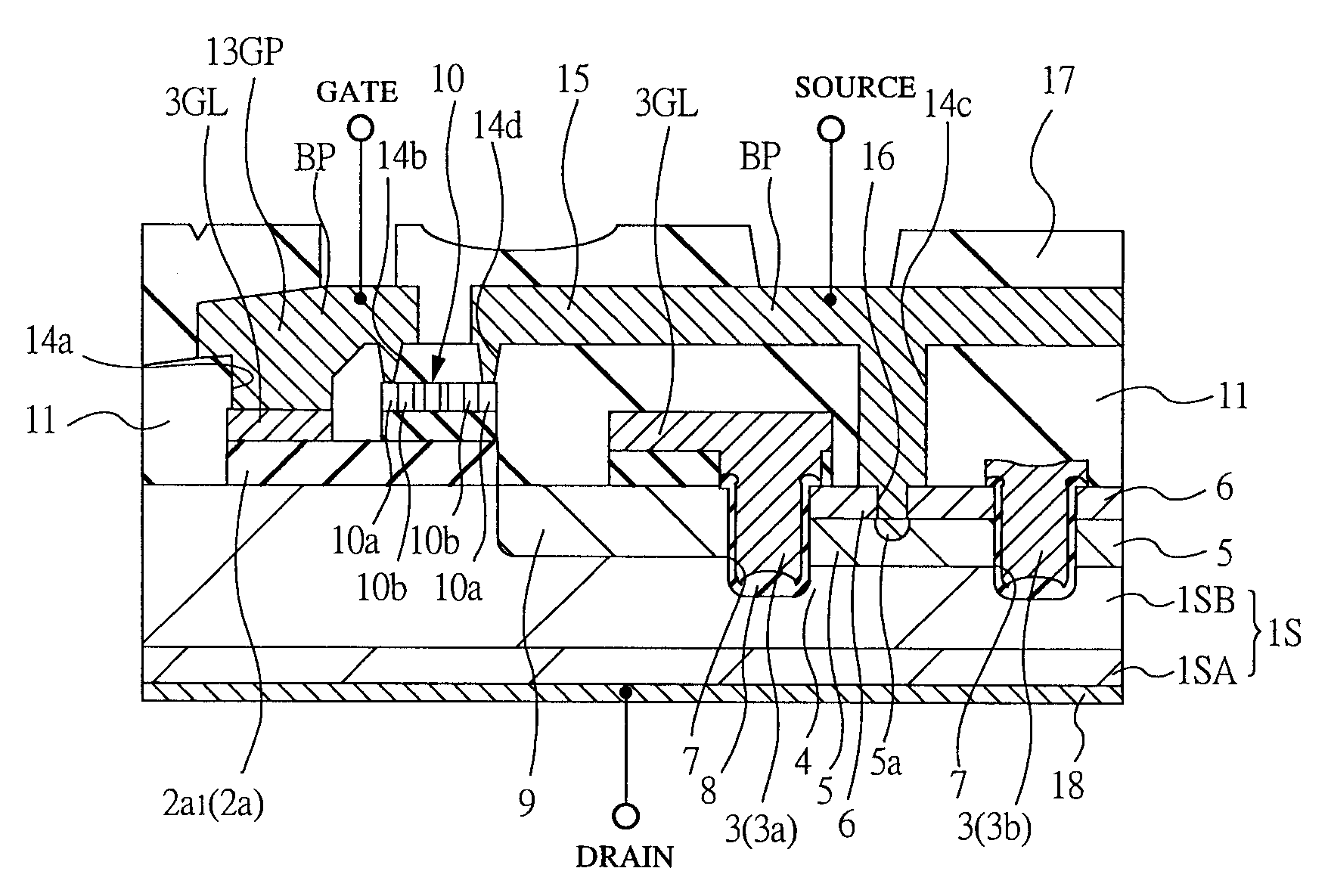

Method of manufacturing a trench gate power transistor with a thick bottom insulator

InactiveUS6455378B1Reduce capacityImprove rendering capabilitiesSemiconductor/solid-state device manufacturingDiodeGate insulatorEngineering physics

There are formed a gate insulator 8 and a gate 3 of a power transistor Q having a trench-gate structure. There are then formed a channel region 5 and a source region 6 of the power transistor Q.

Owner:HITACHI LTD +1

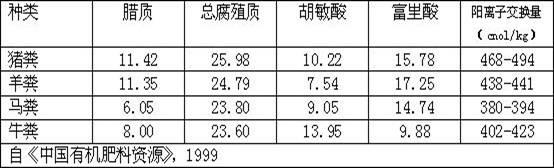

Tobacco composite microbial fertilizer and its preparation method

ActiveCN102515951AImprove qualityTo achieve a long-term mechanismFertilizer mixturesPotassiumRapeseed

Disclosed are a tobacco composite microbial fertilizer and its preparation method. The tobacco composite microbial fertilizer contains an active functional bacteria ingredient, an organic fertilizer ingredient and an inorganic composite fertilizer ingredient, wherein the active functional bacteria ingredient contains phosphate solubilizing bacteria-Bacillus megaterium powder, potassium bacteria-Bacillus mucilaginosus powder, tobacco growth-promoting rhizobacteria-Bacillus amyloliquefaciens powder and tobacco endophytic antagonistic bacteria-Brevibacillus laterosporus powder; and the organic fertilizer ingredient contains decomposed manure, a rapeseed cake fertilizer and straws. The invention also relates to a preparation method of the tobacco composite microbial fertilizer. The fertilizerprovided by the invention has advantages of an organic fertilizer, an inorganic fertilizer and a microbial fertilizer. According to the invention, utilization rate of the fertilizer can be raised, soil organic matters can be increased, tobacco plant rhizosphere microbial proliferation can be promoted, soil physical and chemical property and biological activity can be improved, comprehensive and balanced nutrients can be provided for the early growth of tobacco seedling, the occurrence of soil borne disease can be decreased, and flue-cured tobacco output and quality can be substantially improved.

Owner:湖南润邦生物工程有限公司

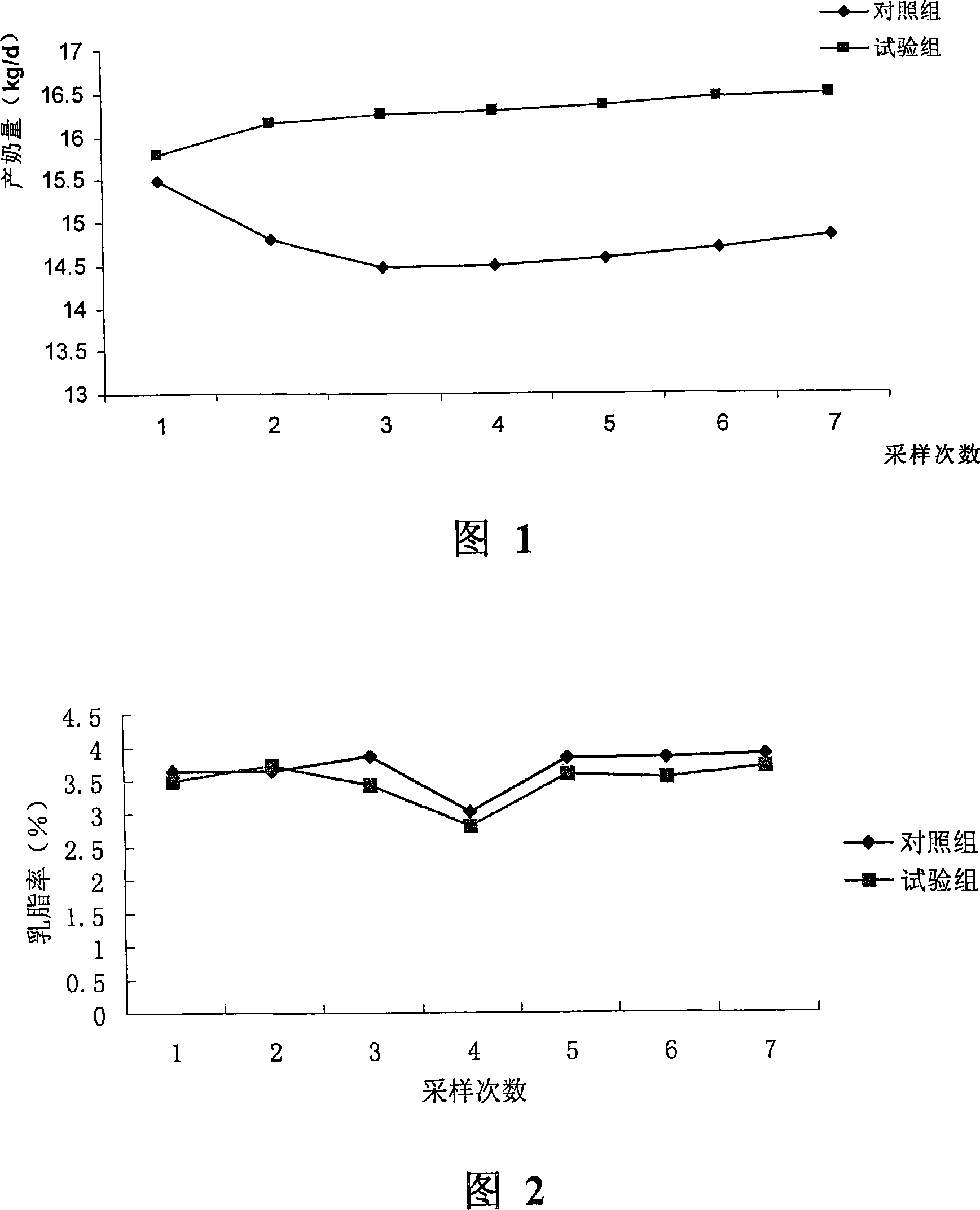

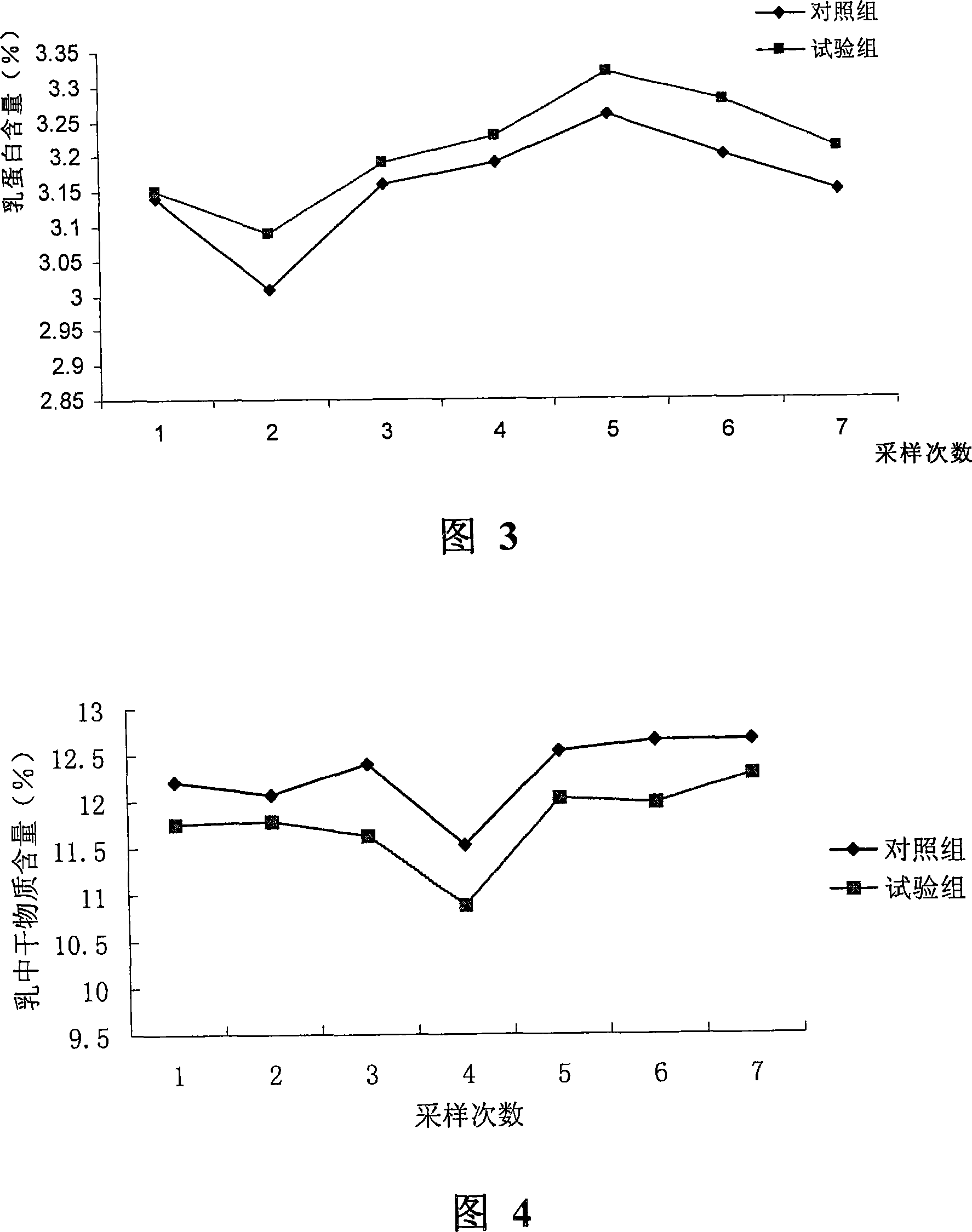

Functional feedstuff composition for feeding heavy milk producing cows

ActiveCN101112225AImprove body conditionReasonable formulaFood processingAnimal feeding stuffDiseaseAnti stress

The invention provides a cow feedstuff combination, in particular to a functional feedstuff combination to feed high production cow. The invention endows fatty acid with function of rumen passing by adding strong alkali week acid salt fatty acid salt, to act as energy supplement agent for cow; the combination is matched with other protein feedstuff, energy feedstuff, mineral, Vitamin and so on to acquire a fine mixture, which can meet the special requirement of such components as energy, protein, Vitamin and mineral and so on of cow, in particular to high production cow 100 days after delivery, and release the energy balance, improve the body condition, milk quality and anti-stress, and prevent the occurrence of nutrition metabolization diseases.

Owner:INNER MONGOLIA YOURAN ANIMAL HUSBANDRY CO LTD

Methods and compositions to enhance plant breeding

InactiveUS20060282911A1Enhanced agronomicEnhanced transgenic traitBiocideDead animal preservationGermplasmHaplotype

Owner:MONSANTO TECH LLC

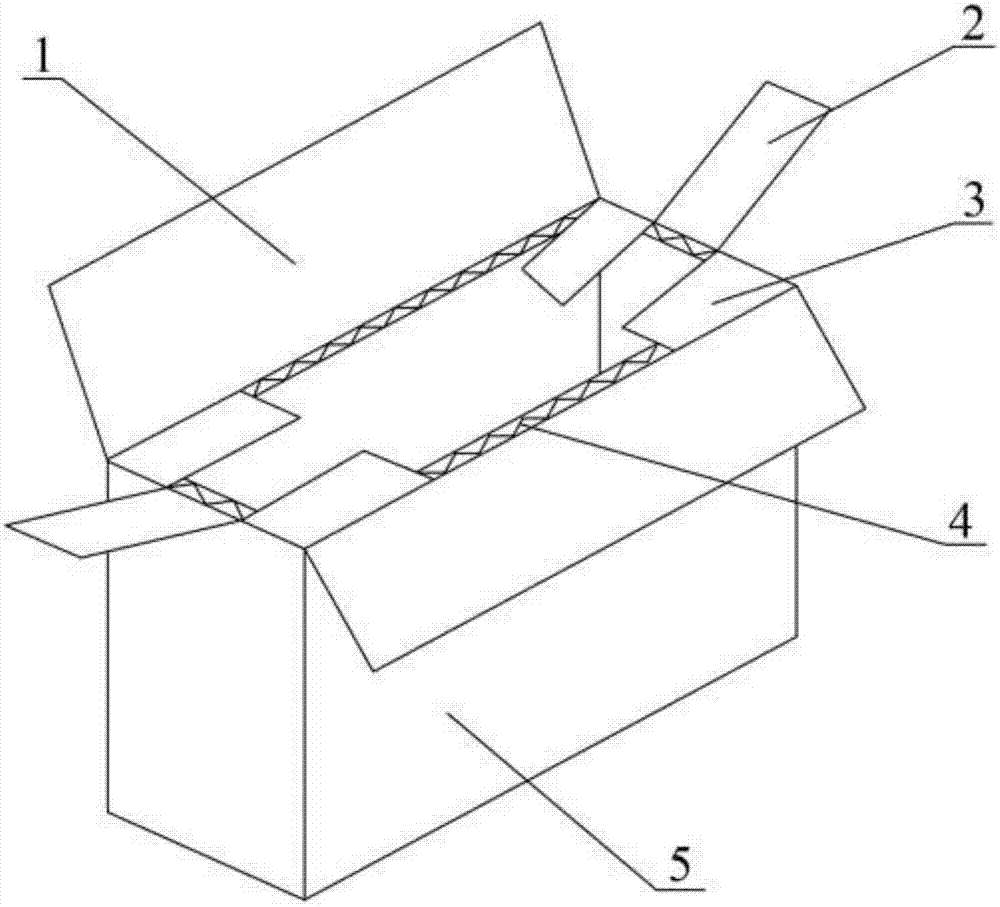

Double-layered packaging paper box

The invention relates to the technical field of paper boxes, and provides a double-layered packaging paper box. The double-layered packaging paper box comprises box covers, cover strips, flaps, reinforcing plates and a box body outer layer, wherein the reinforcing plates are arranged in the box body outer layer; the cover strips are arranged on the left surface and the right surface of the upper part of the box body outer layer; the flaps are arranged on the front surfaces and the rear surfaces of the cover strips; the box covers are arranged on the front surface and the rear surface of the upper part of the box body outer layer; and each reinforcing plate comprises a reinforcing plate main body, reinforcing ribs and connecting ribs. By arrangement of the cover strips and the flaps, good paper box packaging operation can be realized favorably, the box packaging speed is increased, the production efficiency is improved, and huge economic benefits can be brought for users; and by arrangement of the reinforcing ribs, impact resistance and compression resistance of the paper box are enhanced favorably, the using effect of the paper box is improved, the impact resistance and the compression resistance of the paper box are high, huge economic benefits are brought for the users, and characteristics of impact resistance and extrusion resistance are realized.

Owner:慈溪市奇超科技有限公司

Semiconductor device

InactiveUS7710270B2Favorable transmission/reception stateAvoid chargingBatteries circuit arrangementsSemiconductor/solid-state device detailsSignal processing circuitsLength wave

An object is to provide a semiconductor device including an RFID which can transmit / receive individual information without a change of a battery accompanied by deterioration over time of the battery as a drive power source, and to which driving power can be supplied to keep a favorable transmission / reception state of the individual information even when an external electromagnetic wave is not sufficient. The semiconductor device includes a signal processing circuit, a first antenna circuit and a second antenna circuit operationally connected to the signal processing circuit, and a battery operationally connected to the signal processing circuit, in which the first antenna circuit transmits / receives a signal for transmitting data stored in the signal processing circuit; the second antenna circuit receives a signal for charging the battery; and a signal received by the first antenna circuit and a signal received by the second antenna circuit have different wavelengths.

Owner:SEMICON ENERGY LAB CO LTD

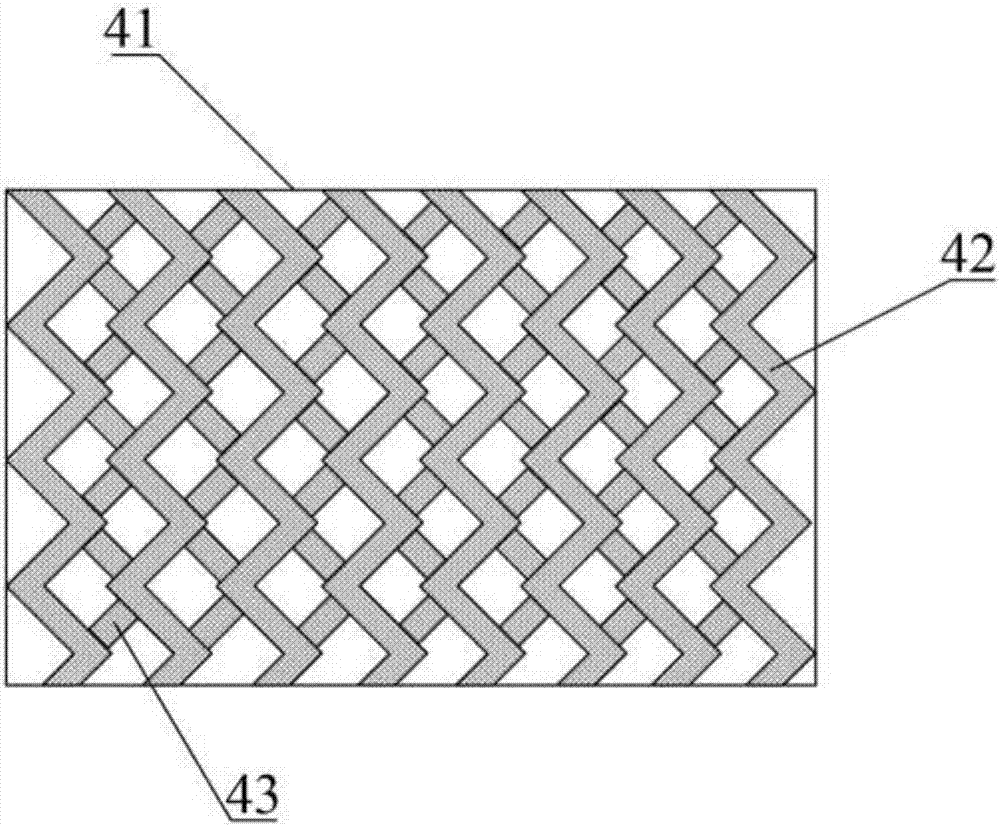

High temperature composite pipe wrapping system

InactiveUS6276401B1Improve stress resistanceMinimize dimensional changeLayered productsLaminationUnderlaySolvent

A method and apparatus for providing metal or non-metal vessels, including straight and curved pipes and various pipe connections, such as T's, elbows, swages, etc., and pressure containing vessels such as tanks, with an external composite lining of a webbing of biaxial or triaxial weave preferably composed of fiberglass which is pre-impregnated with a high temperature heat curable polymer composition capable of being heat cured at a temperature range of from about 275° F. to about 375° F. The vessel is prepared for bonding by abrasive cleaning and by solvent cleaning. Metal imperfections are then filled with an epoxy. A small amount a quick setting epoxy is employed to attach one end of the web to the external surface of the vessel in oriented position for wrapping of the web in intimate surface-to-surface contact with the vessel. During wrapping only enough tension is applied to the pre-impregnated webbing to eliminate any wrinkles. The number of layers of the impregnated webbing will be determined by the safe pressure containing capability of the pipe or vessel and its composite lining. An external heating element is then placed about the wrapping of pre-impregnated webbing material so as to be in substantially intimate relation therewith and is energized to apply sufficient heat for a sufficient period of time to completely cure the epoxy surface filler and to cure the polymer resin components of the pre-impregnated woven wrappings of webbing.

Owner:WILSON FRED D

Water soluble humic acid multi-element solid fertilizer and production method thereof

InactiveCN101570456ADissolve fastNot easy to agglomerateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceWater soluble

The invention discloses a water soluble fertilizer and a production method thereof, in particular to a water soluble humic acid multi-element solid fertilizer and a production method thereof. The water soluble humic acid multi-element solid fertilizer is made by mixing water soluble humic acid, water soluble nitrogenous fertilizer, water soluble phosphorous fertilizer, water soluble potassic fertilizer and water soluble complex trace elements. Compared with the prior art, the water soluble humic acid multi-element solid fertilizer can reduce the transporting and packing cost, can be rapidly dissolved without agglomeration when in use, is applied along with water, and has the advantages of strong points, high nutrient content, complete nutrition, good water-solubility, combination of organic and inorganic matters as well as high effect of fertilizer and utilization rate. The utilization rate of product nitrogen reaches 60%, the utilization rate of phosphorus is 30-35%, and the utilization rate of potassium is 60-70%, so that the fertilizer application utilization rate is increased by more than 10% compared with the conventional fertilizer.

Owner:新疆三赢农业科技发展有限公司

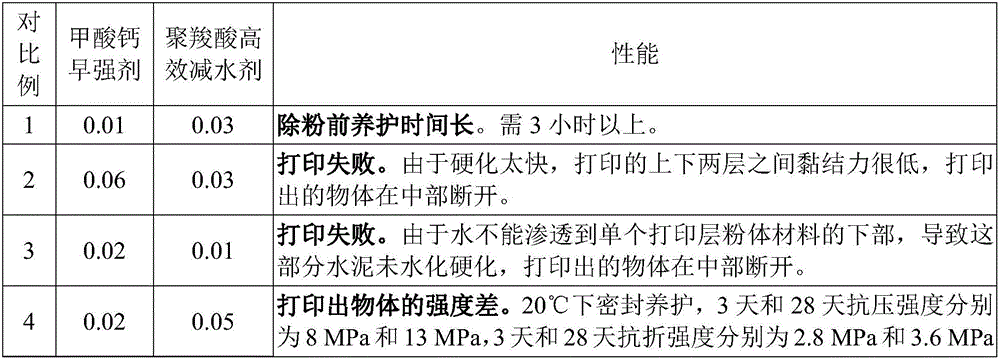

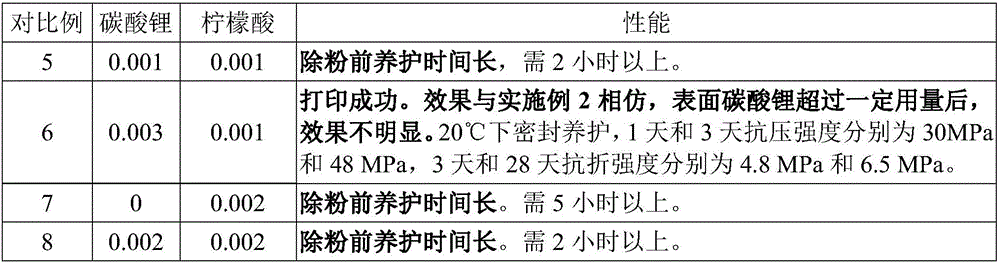

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

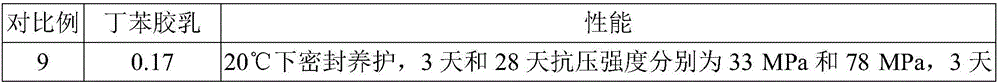

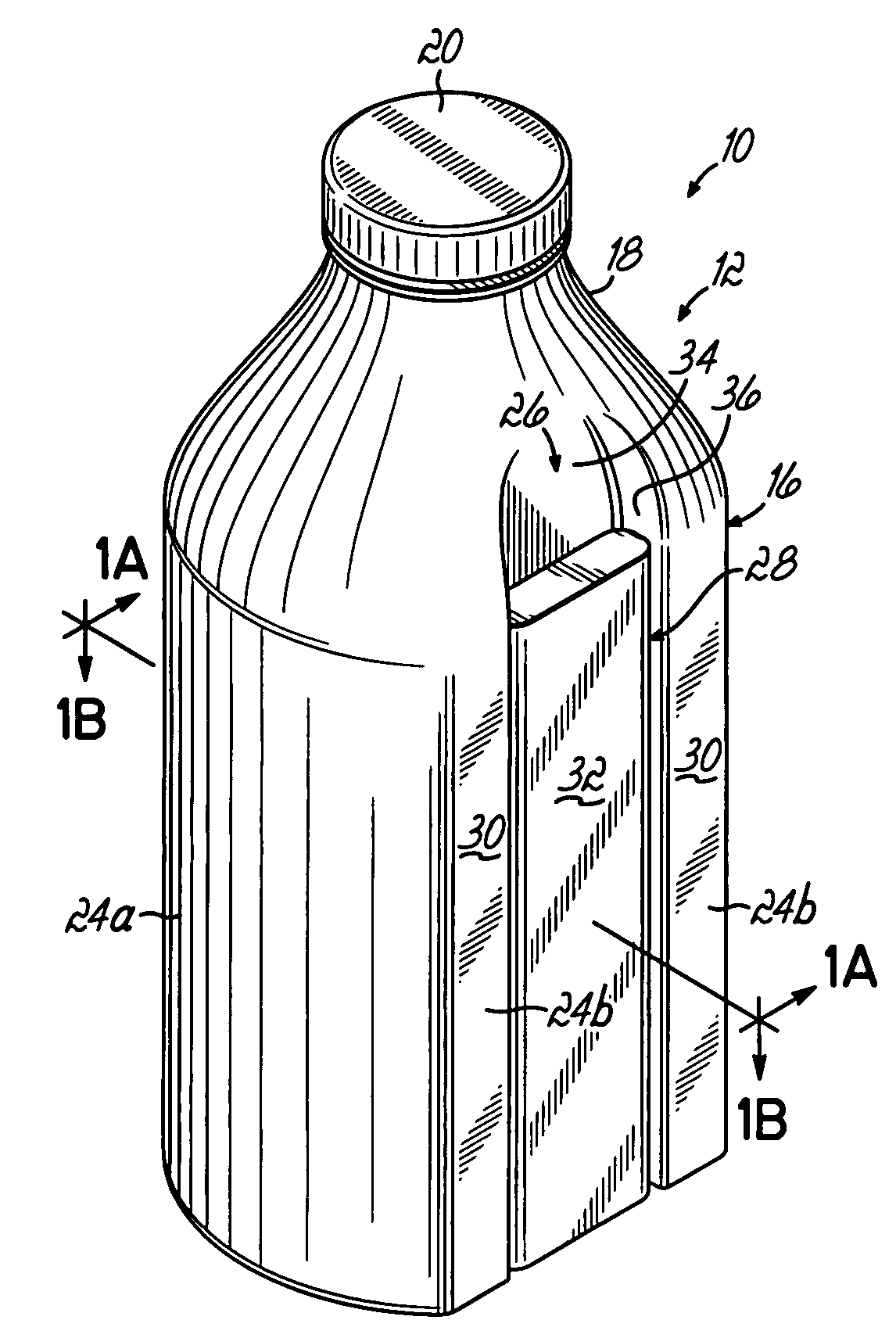

Package system

InactiveUS7225937B2Easy to graspEasy to removeFlexible coversWrappersEngineeringElectrical and Electronics engineering

A package system which combines an article and a container in an integrated package with the article secured in nested relationship within a recess of the container. The recess has sufficient depth such that portions of the side walls of the container extend outwardly effectively beyond an exposed surface of the article so as to protect the article against damage. Alternatively, the package system includes a pair of spaced columns which are integrally formed with the side wall of the container and which extend outwardly from the side wall. A recess is formed between the column members which is configured to receive an article in nested relationship within the recess. Methods for securing the article in nested relationship within the recess of the container are also disclosed.

Owner:SCHROEDER MICHAEL D

Fertilizer coating composite, its making method and multicomponent coated granular fertilizer

InactiveCN1535939AIncrease profitExtend the fertilizer periodFertilizer mixturesOrganic acidAdjuvant

The present invention relates to a coating composite for making coated granular fertilizer and its production method, and the fertilizer made up by using said coating composite. The coating composite is formed from coating agent, solidfying agent, nitrogen synergist, inorganic acid or organic acid, surfactant and adjuvant. As compared with non-coated fertilizer the nitrogen utilization rate of fertilizer produced by adopting said invention can be raised by 6%-10%, the fertilizer can be saved by 15-45%, and its fertilizer efficiency time can be obviously prolonged, and can be reached to 60-120 days.

Owner:陈大顺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com